Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1876 results about "Repair processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process of repair in living tissue depends upon an inherent power possessed by vital cells of reacting to the irritation caused by injury or disease. The cells of the damaged tissues, under the influence of this irritation, undergo certain proliferative changes, which are designed to restore the normal structure and configuration of the part.

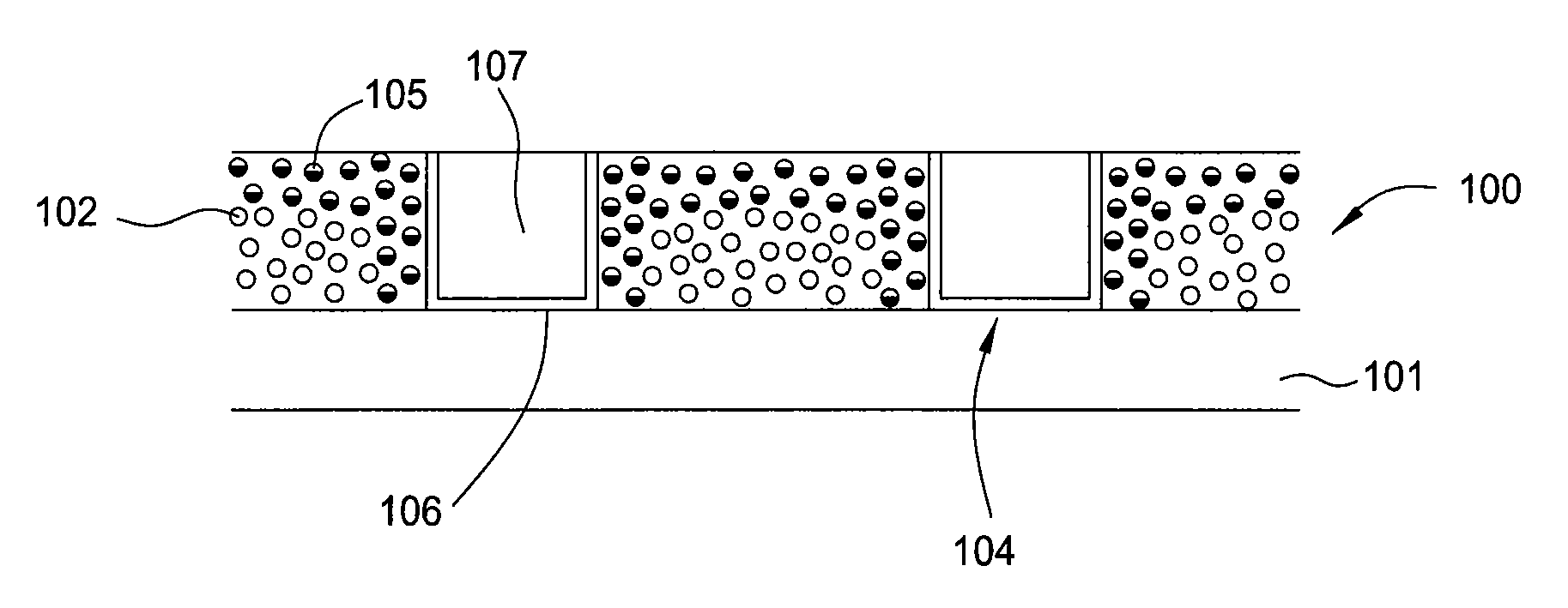

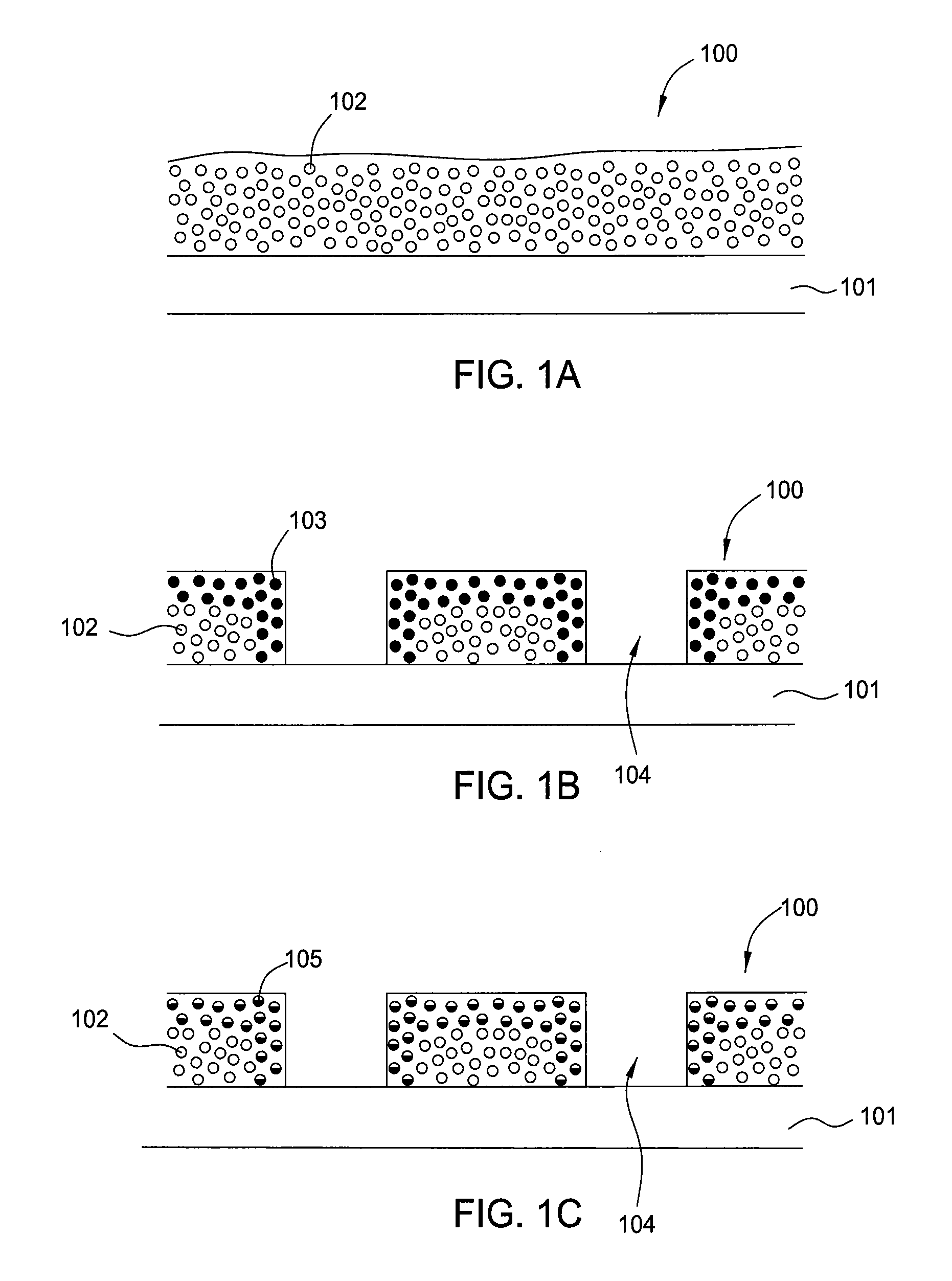

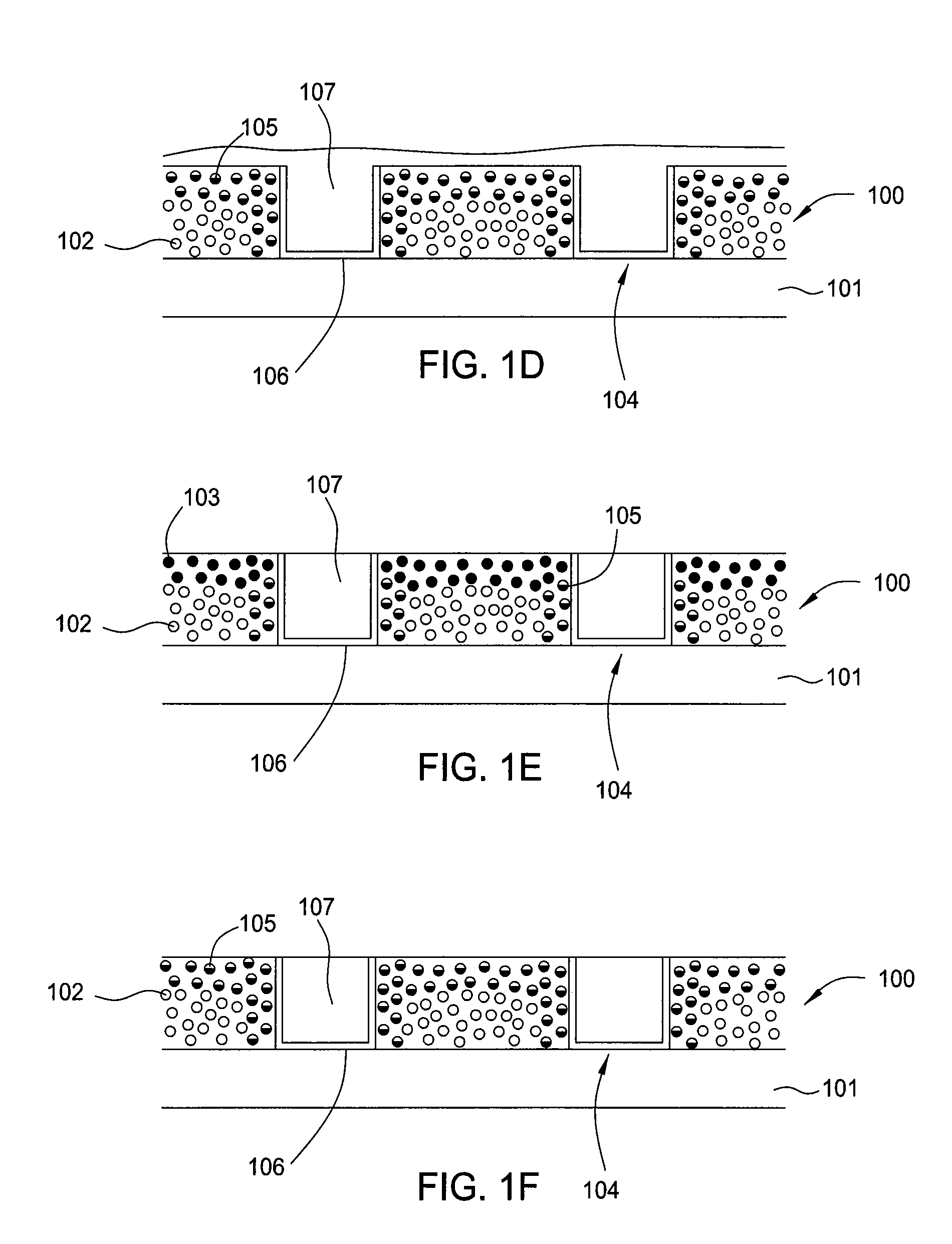

UV assisted silylation for recovery and pore sealing of damaged low K films

Methods for the repair of damaged low k films are provided. Damage to the low k films occurs during processing of the film such as during etching, ashing, and planarization. The processing of the low k film causes water to store in the pores of the film and further causes hydrophilic compounds to form in the low k film structure. Repair processes incorporating ultraviolet (UV) radiation and silylation compounds remove the water from the pores and further remove the hydrophilic compounds from the low k film structure.

Owner:APPLIED MATERIALS INC

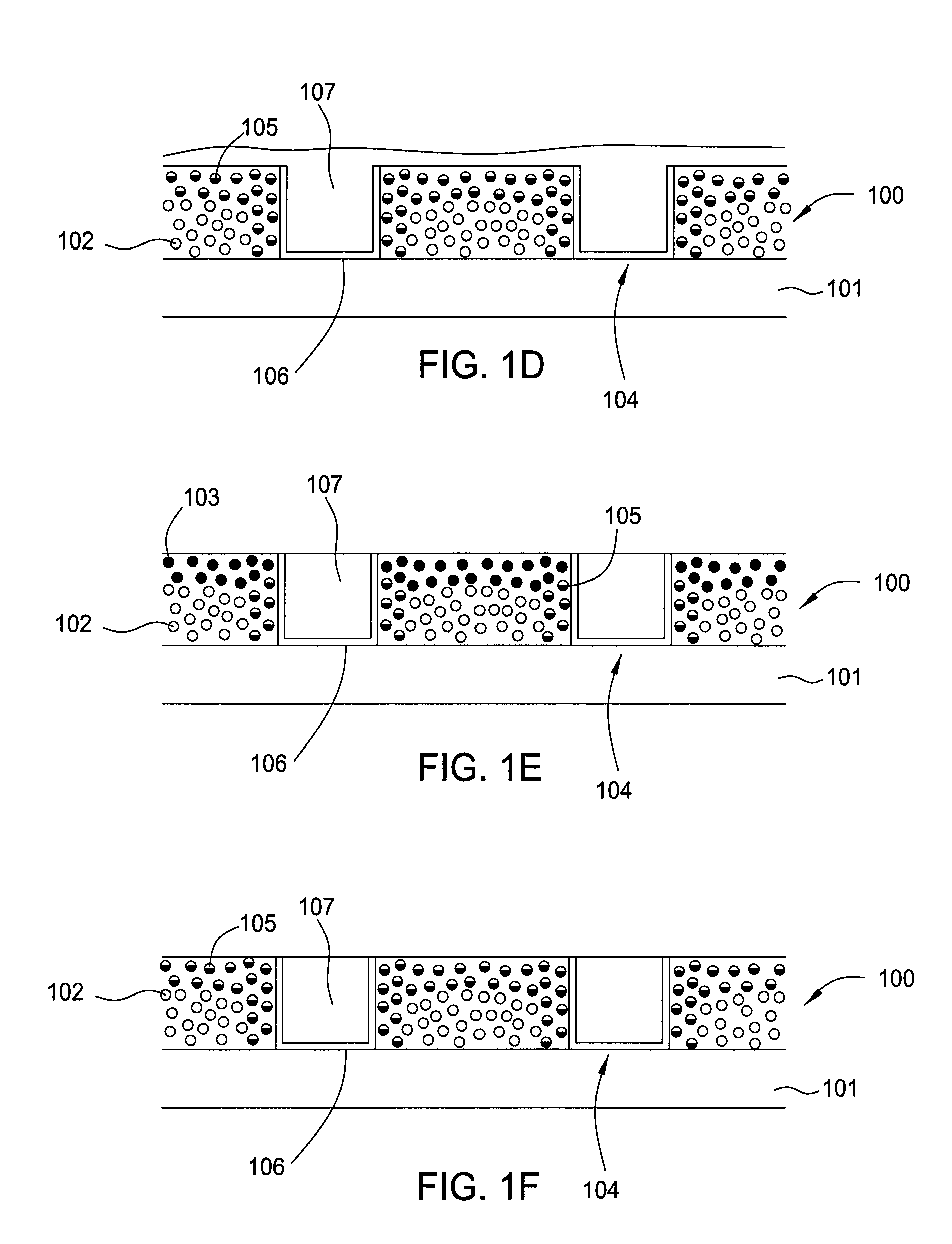

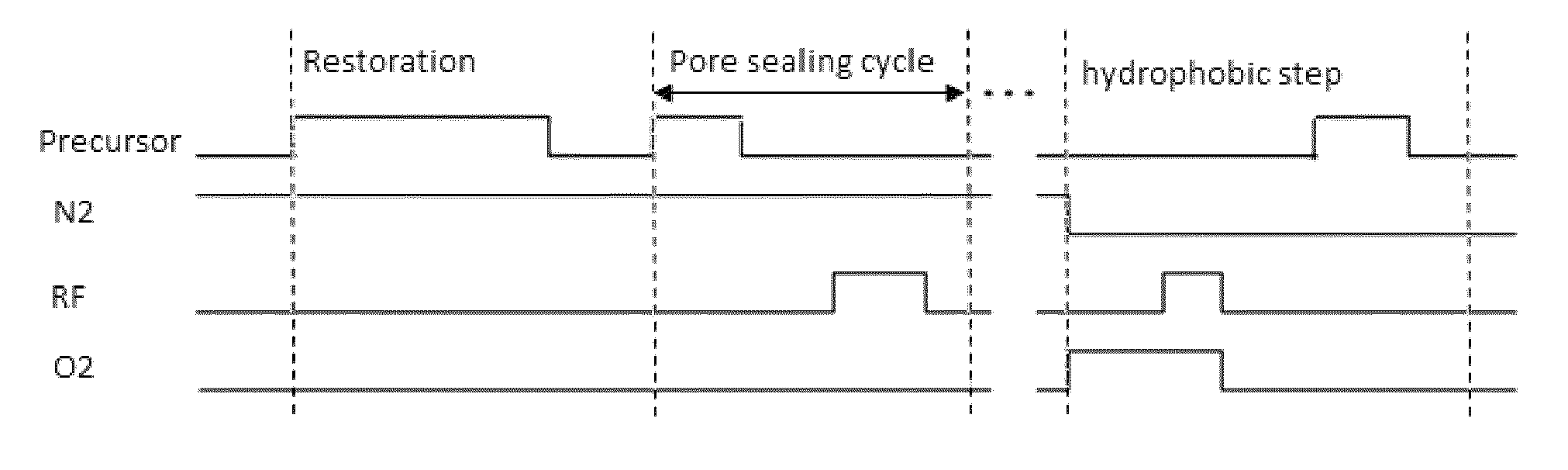

Method for repairing damage of dielectric film by cyclic processes

ActiveUS8785215B2Enhanced barrier functionPlasma-enhanced atomic layerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCyclic processSilicon

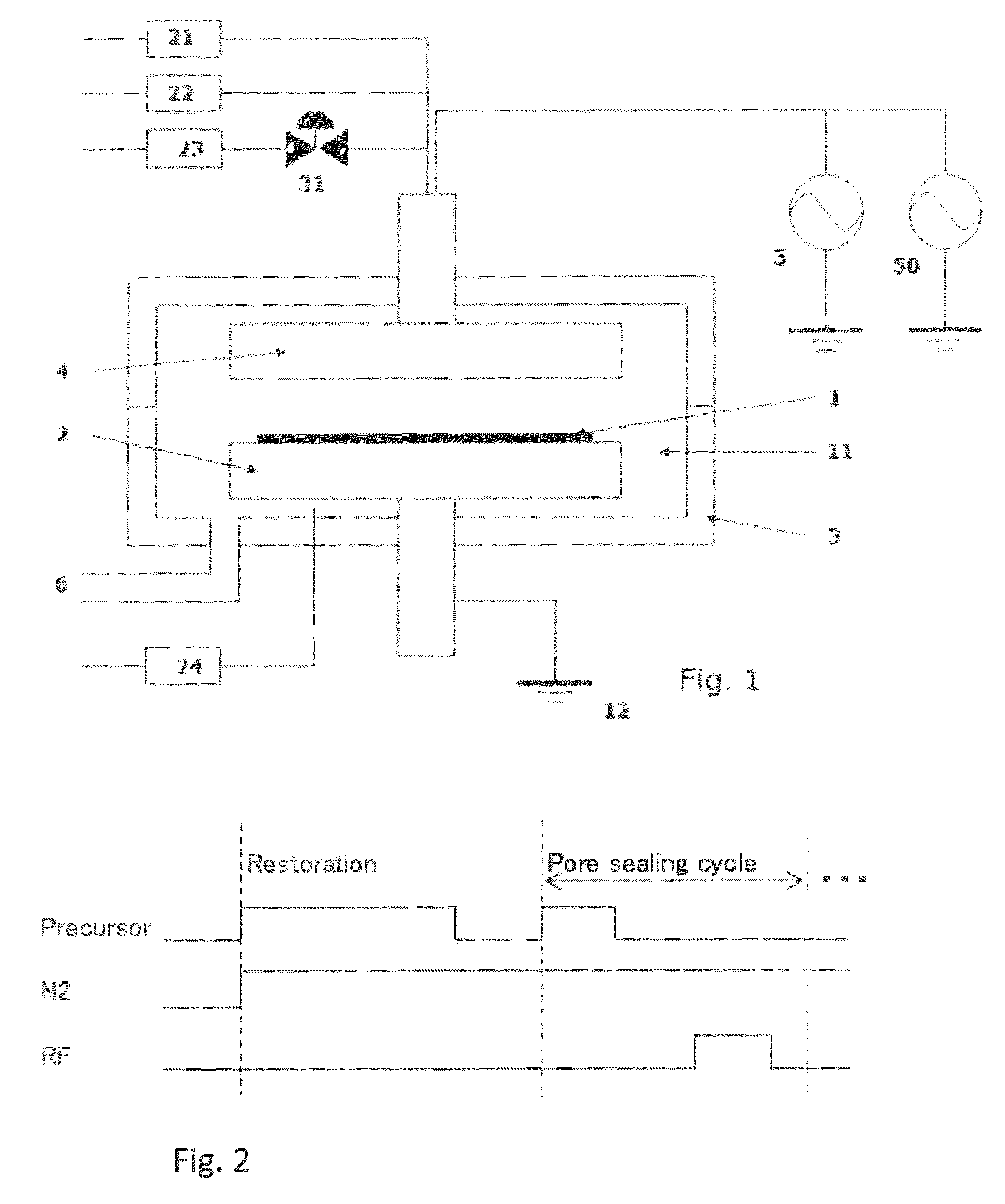

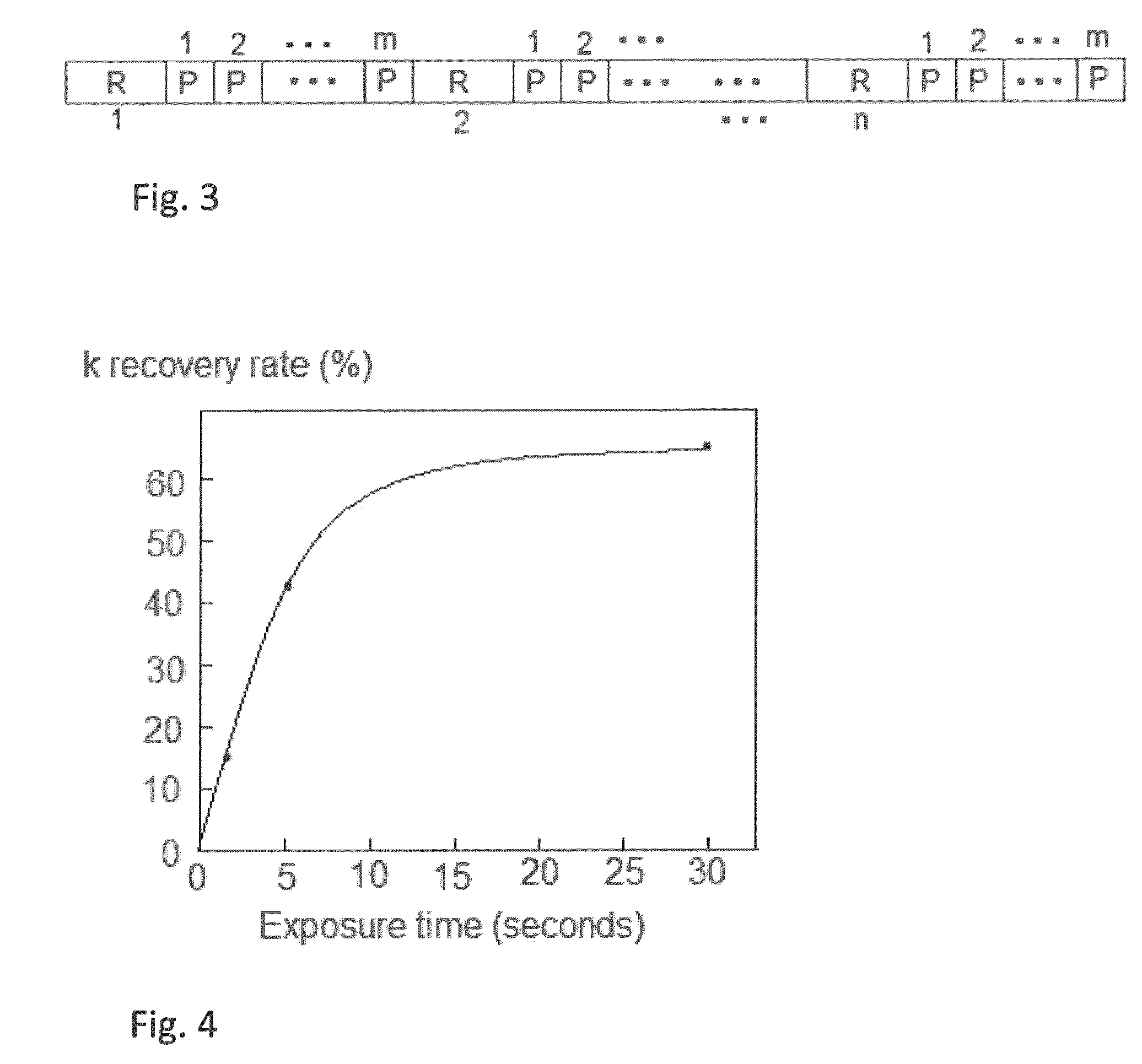

A method for repairing process-related damage of a dielectric film includes: (i) adsorbing a first gas containing silicon on a surface of the damaged dielectric film without depositing a film in the absence of reactive species, (ii) adsorbing a second gas containing silicon on a surface of the dielectric film, followed by applying reactive species to the surface of the dielectric film, to form a monolayer film thereon, and (iii) repeating step (ii). The duration of exposing the surface to the first gas in step (i) is longer than the duration of exposing the surface to the second gas in step (ii).

Owner:ASM IP HLDG BV

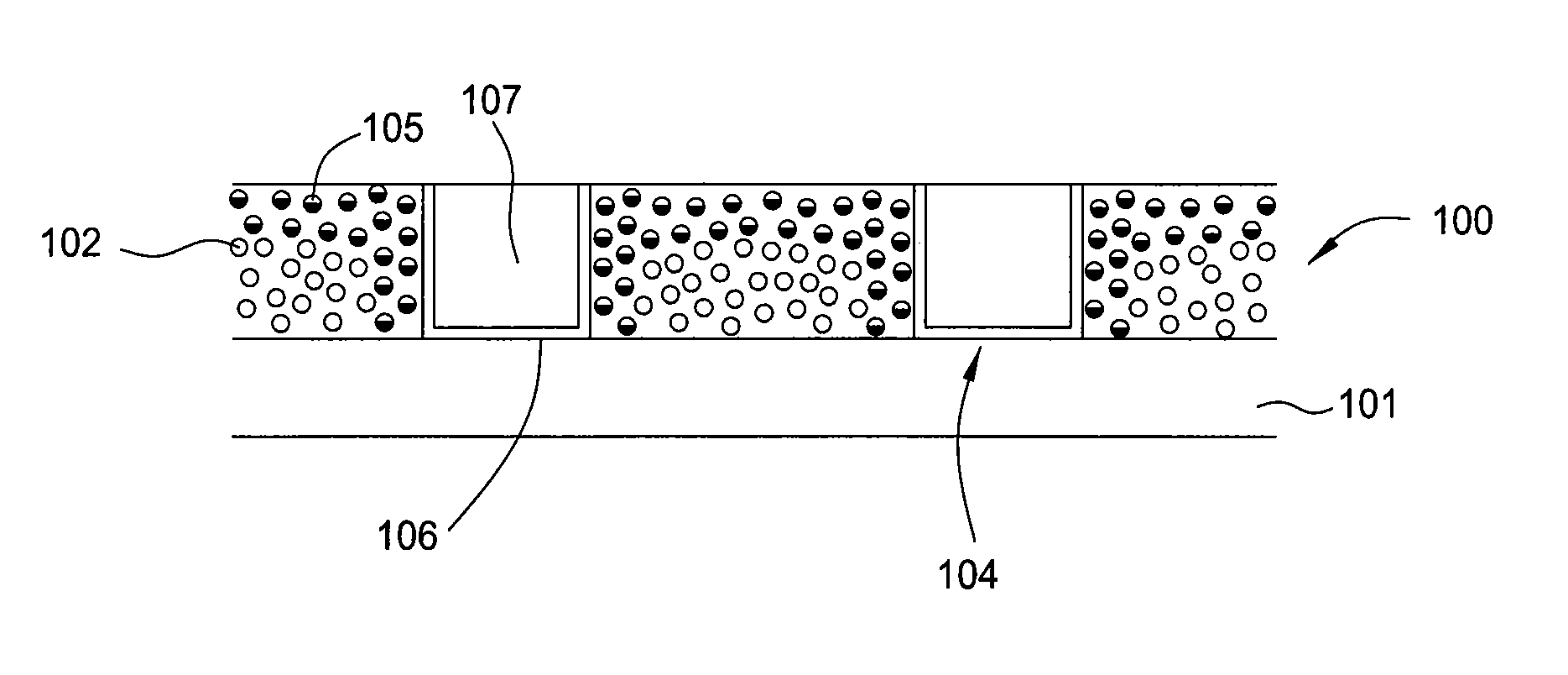

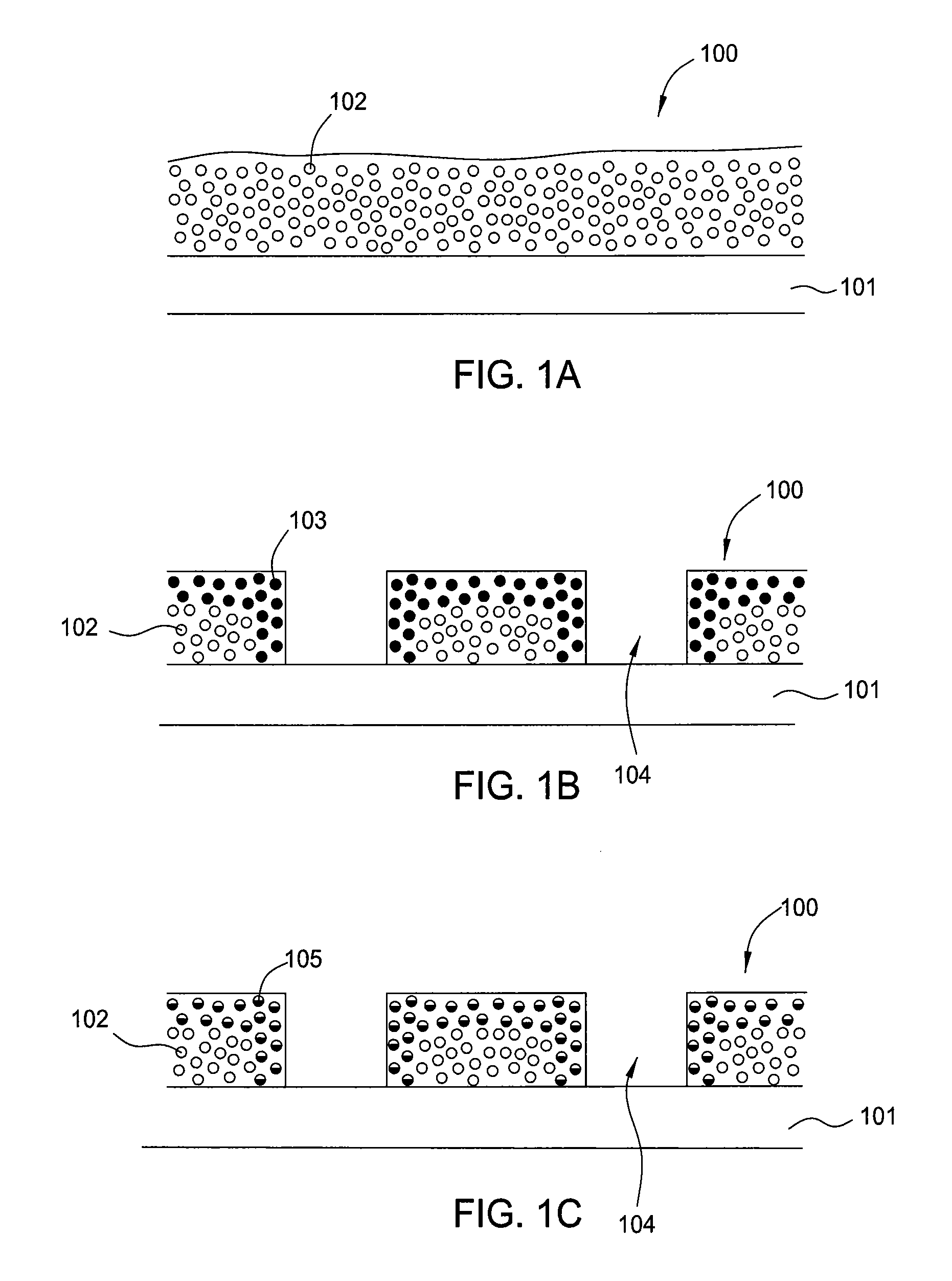

UV assisted silylation for recovery and pore sealing of damaged low k films

ActiveUS20120270339A1Dielectric constant be lowerSemiconductor/solid-state device manufacturingUltravioletSilylation

Methods for the repair of damaged low k films are provided. Damage to the low k films occurs during processing of the film such as during etching, ashing, and planarization. The processing of the low k film causes water to store in the pores of the film and further causes hydrophilic compounds to form in the low k film structure. Repair processes incorporating ultraviolet (UV) radiation and silylation compounds remove the water from the pores and further remove the hydrophilic compounds from the low k film structure.

Owner:APPLIED MATERIALS INC

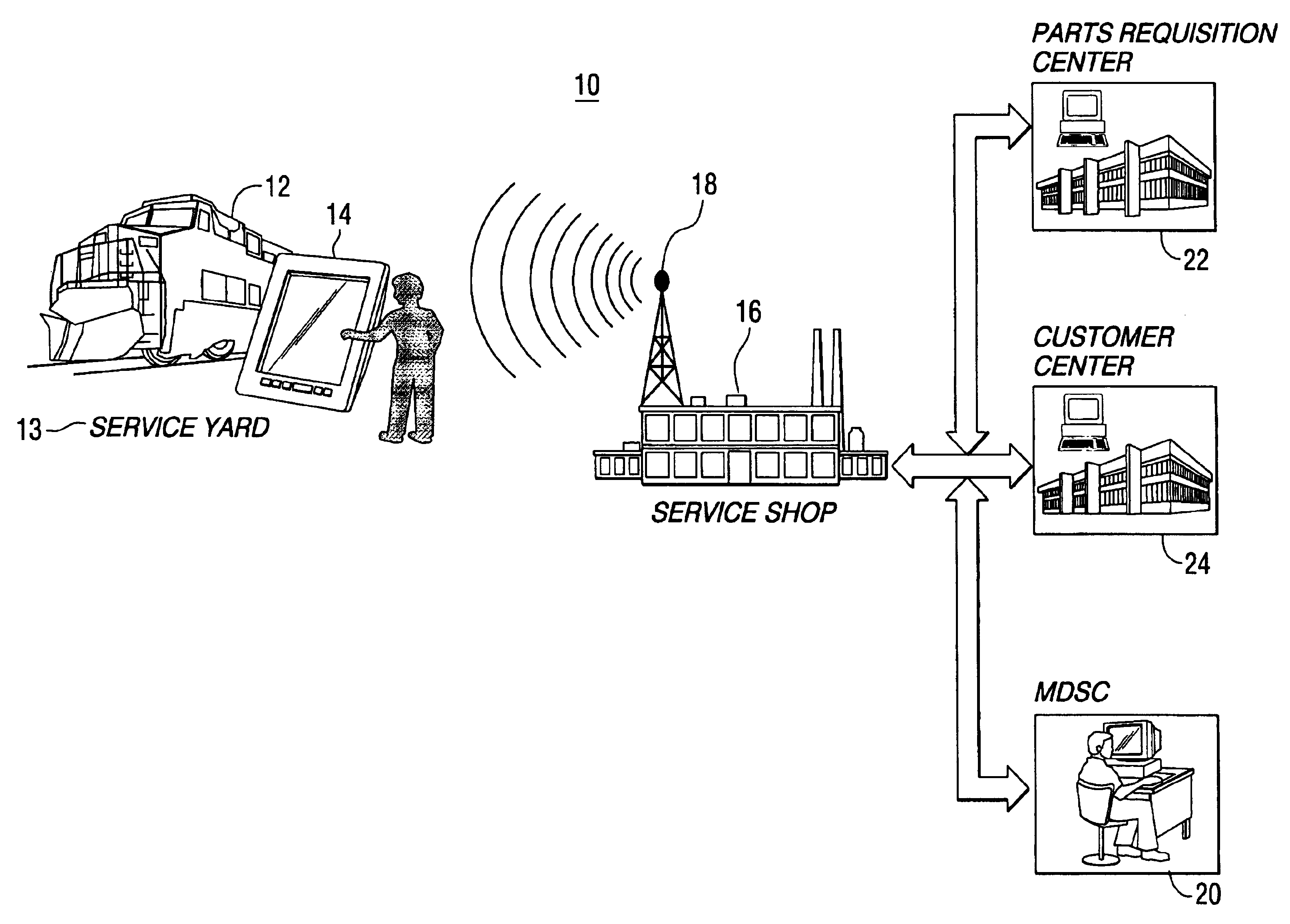

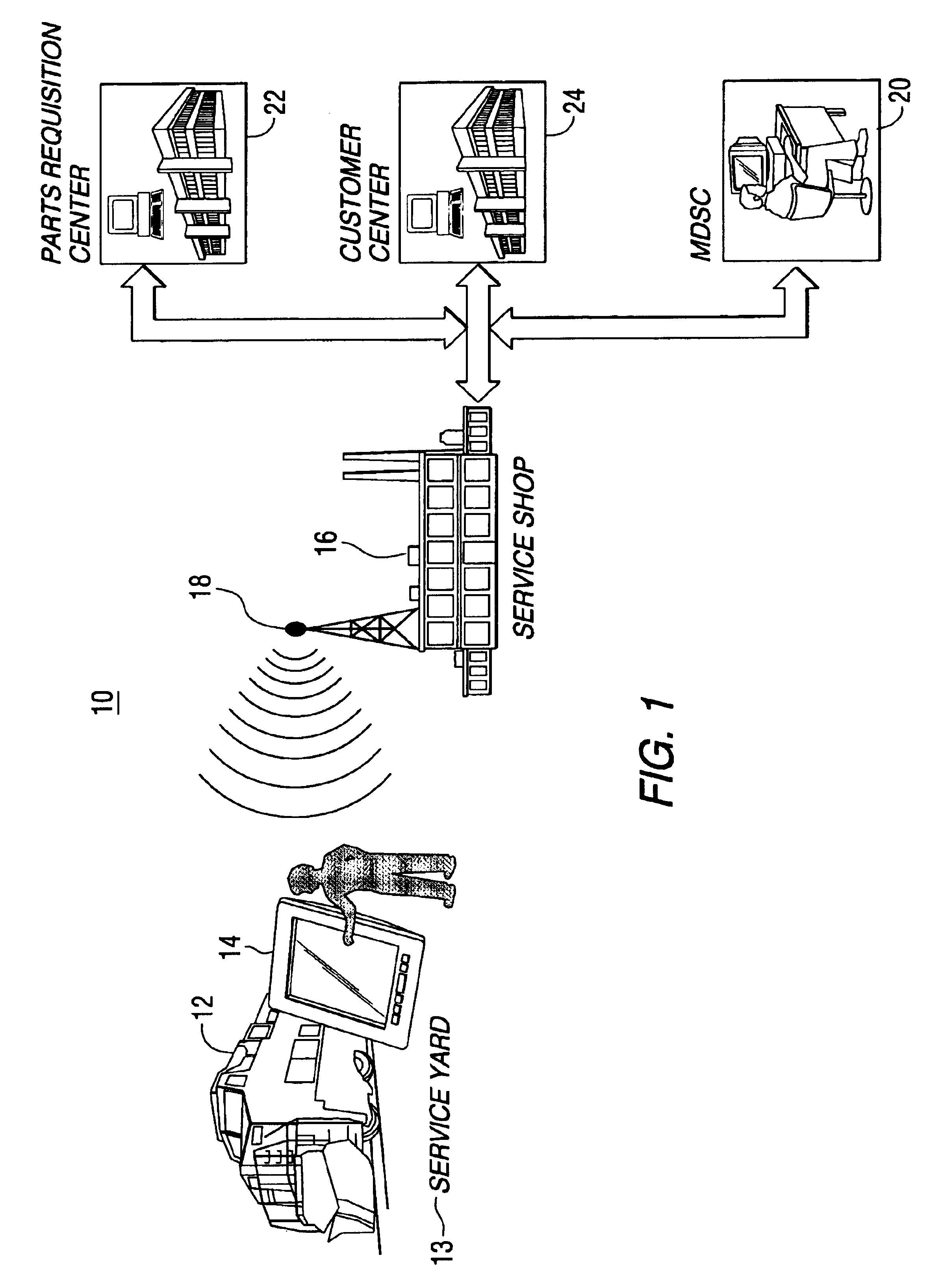

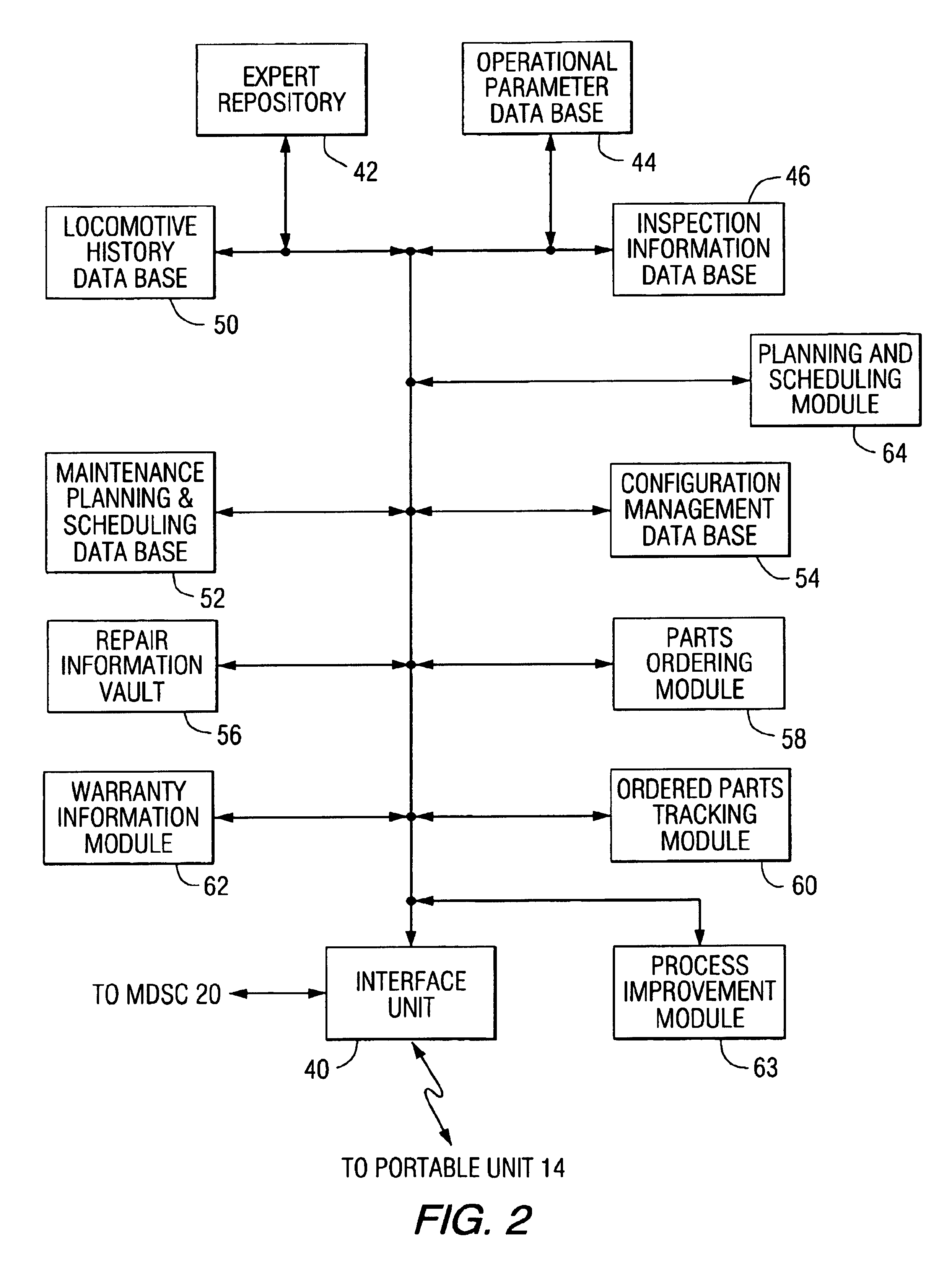

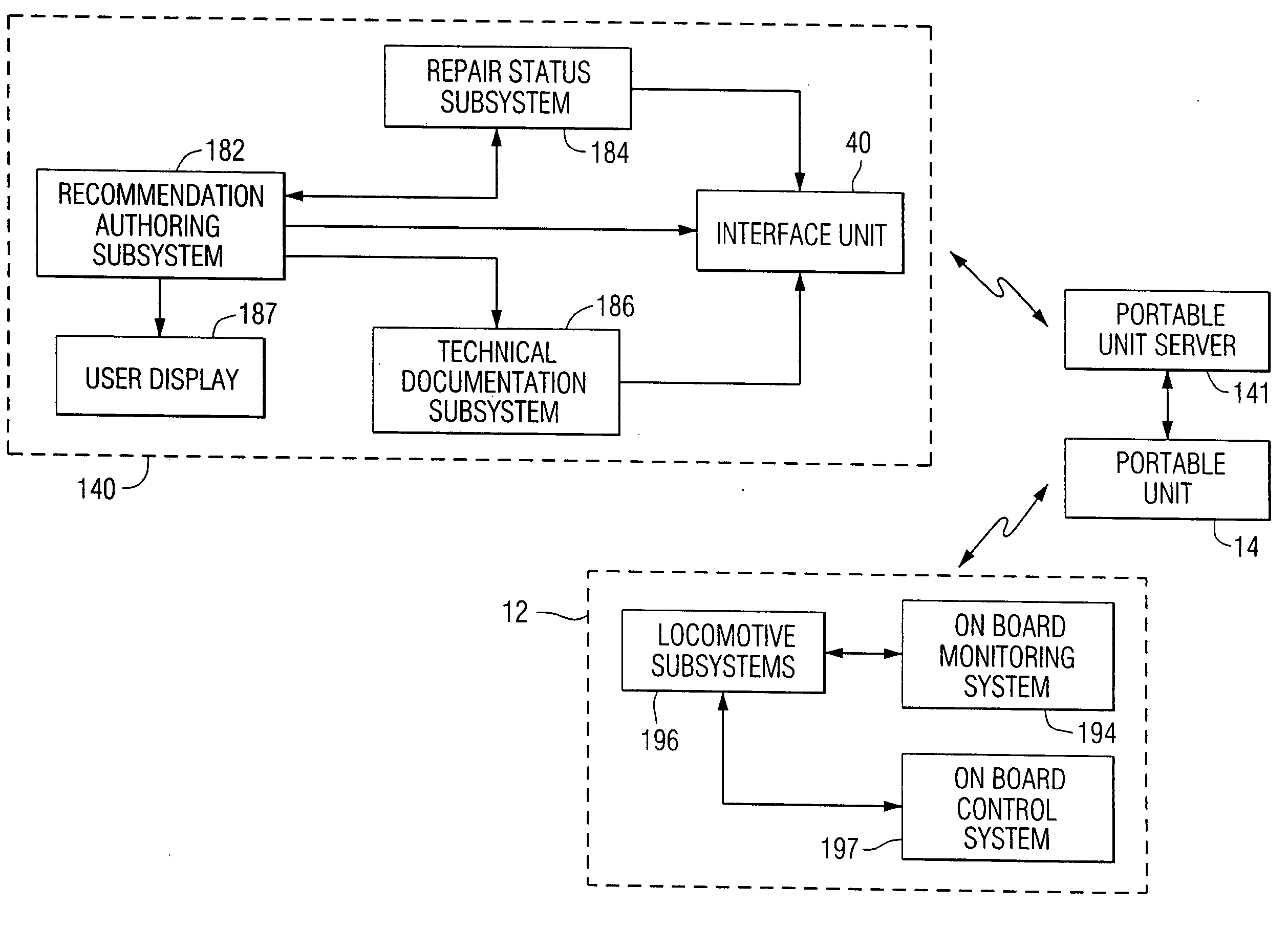

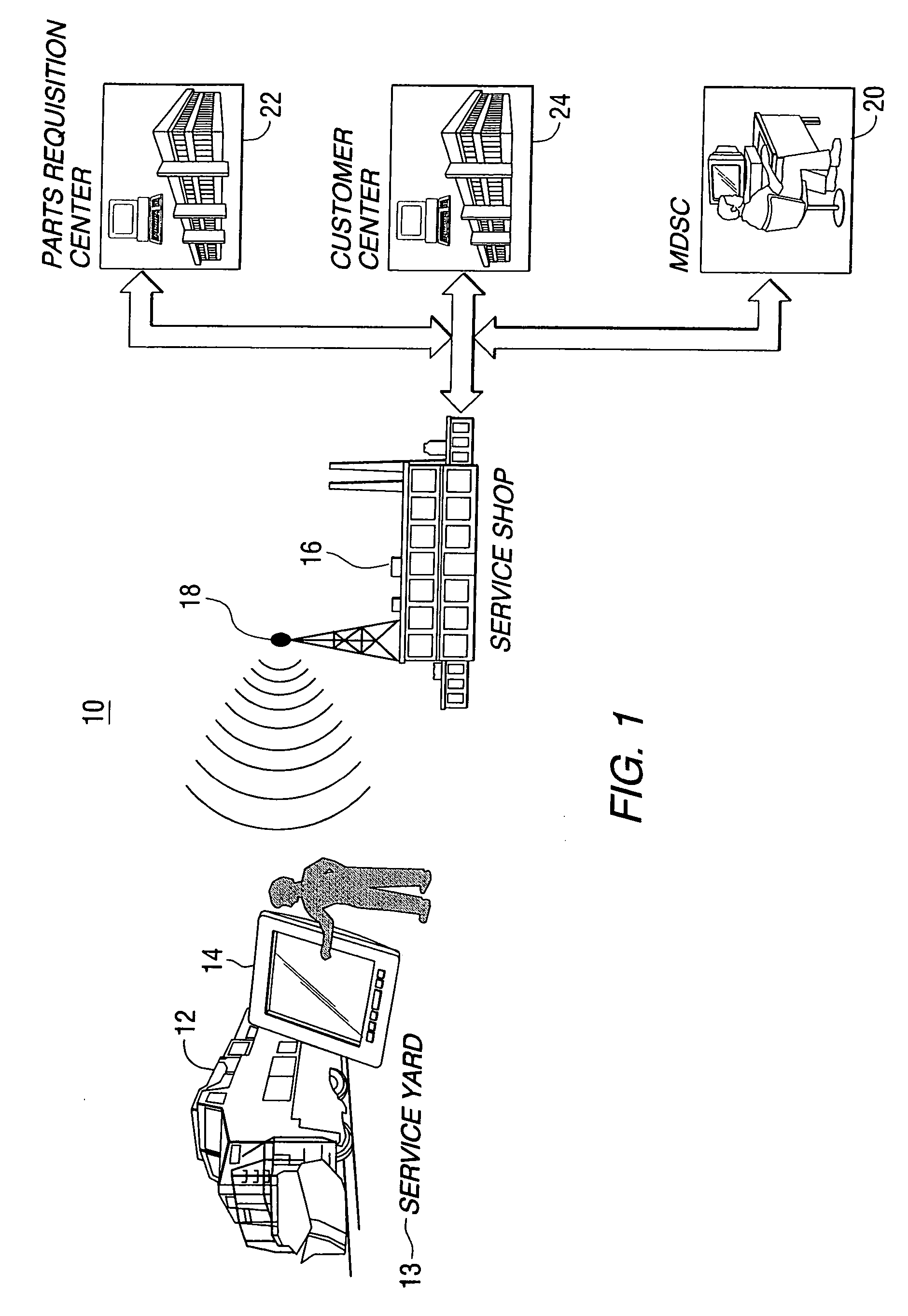

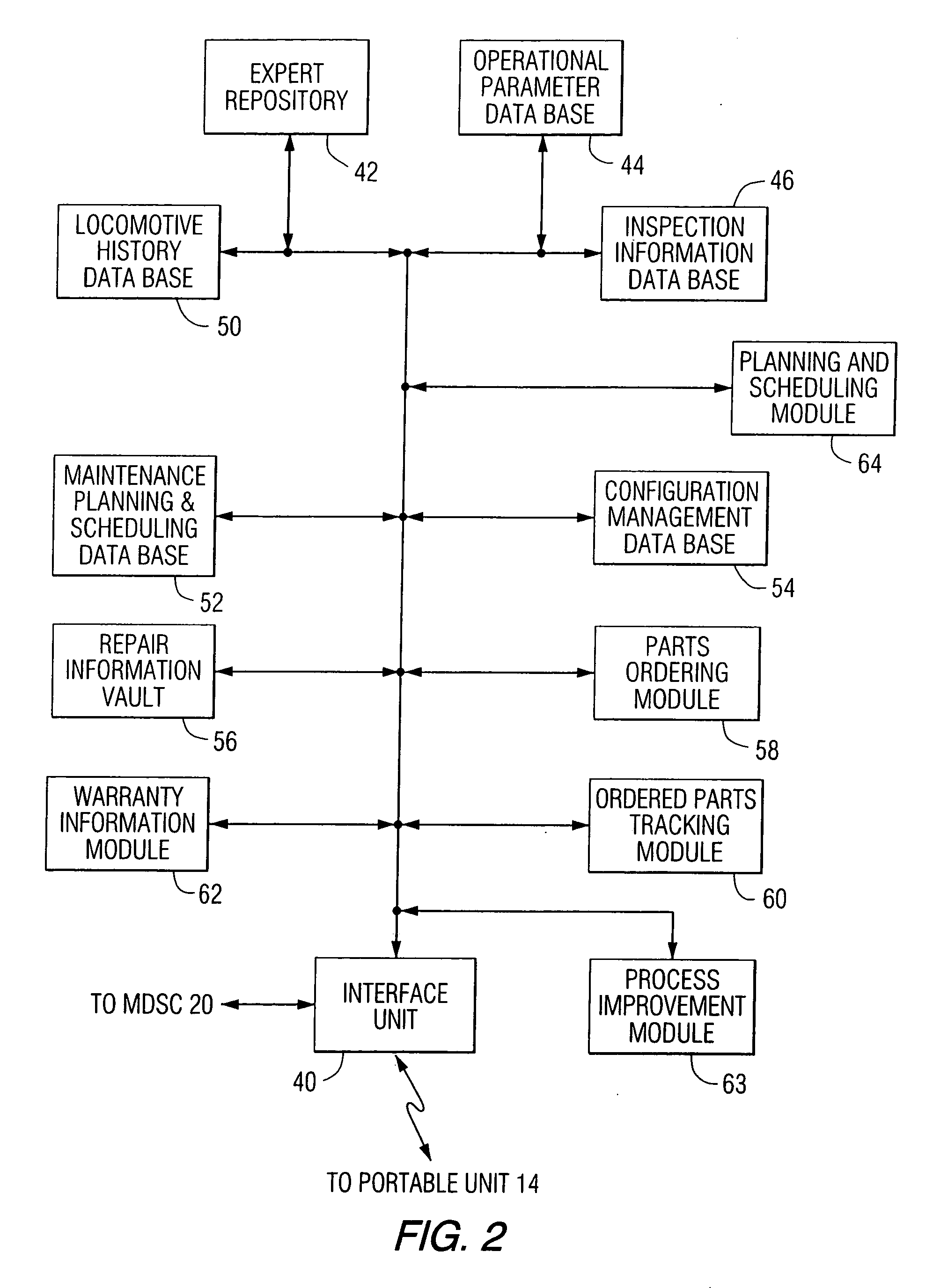

Diagnosis and repair system and method

InactiveUS6959235B1The process is fast and accurateSignificant costVehicle testingRegistering/indicating working of vehiclesDocumentation procedureSystem usage

A diagnosis and repair recommendation system for a railroad locomotive is disclosed. The system uses generalized repair recommendations and instantiates them to a specific repair process for a unique road number locomotive. In addition to repair steps to be executed by the technician, the method and system remotely provides supporting documentation specifically tailored for each step in the repair process. As the repair is being conducted, feedback information is entered by the technician. The repair recommendations and the supporting documents are available to the technician via a remote unit, thereby allowing the technician to access the repair steps and supporting documentation while the repair is in progress.

Owner:GE GLOBAL SOURCING LLC

Diagnosis and repair system and method

InactiveUS20050171661A1The process is fast and accurateReduction in locomotive failureVehicle testingRegistering/indicating working of vehiclesDocumentation procedureSystem usage

A diagnosis and repair recommendation system for a railroad locomotive is disclosed. The system uses generalized repair recommendations and instantiates them to a specific repair process for a unique road number locomotive. In addition to repair steps to be executed by the technician, the method and system remotely provides supporting documentation specifically tailored for each step in the repair process. As the repair is being conducted, feedback information is entered by the technician. The repair recommendations and the supporting documents are available to the technician via a remote unit, thereby allowing the technician to access the repair steps and supporting documentation while the repair is in progress.

Owner:GE GLOBAL SOURCING LLC

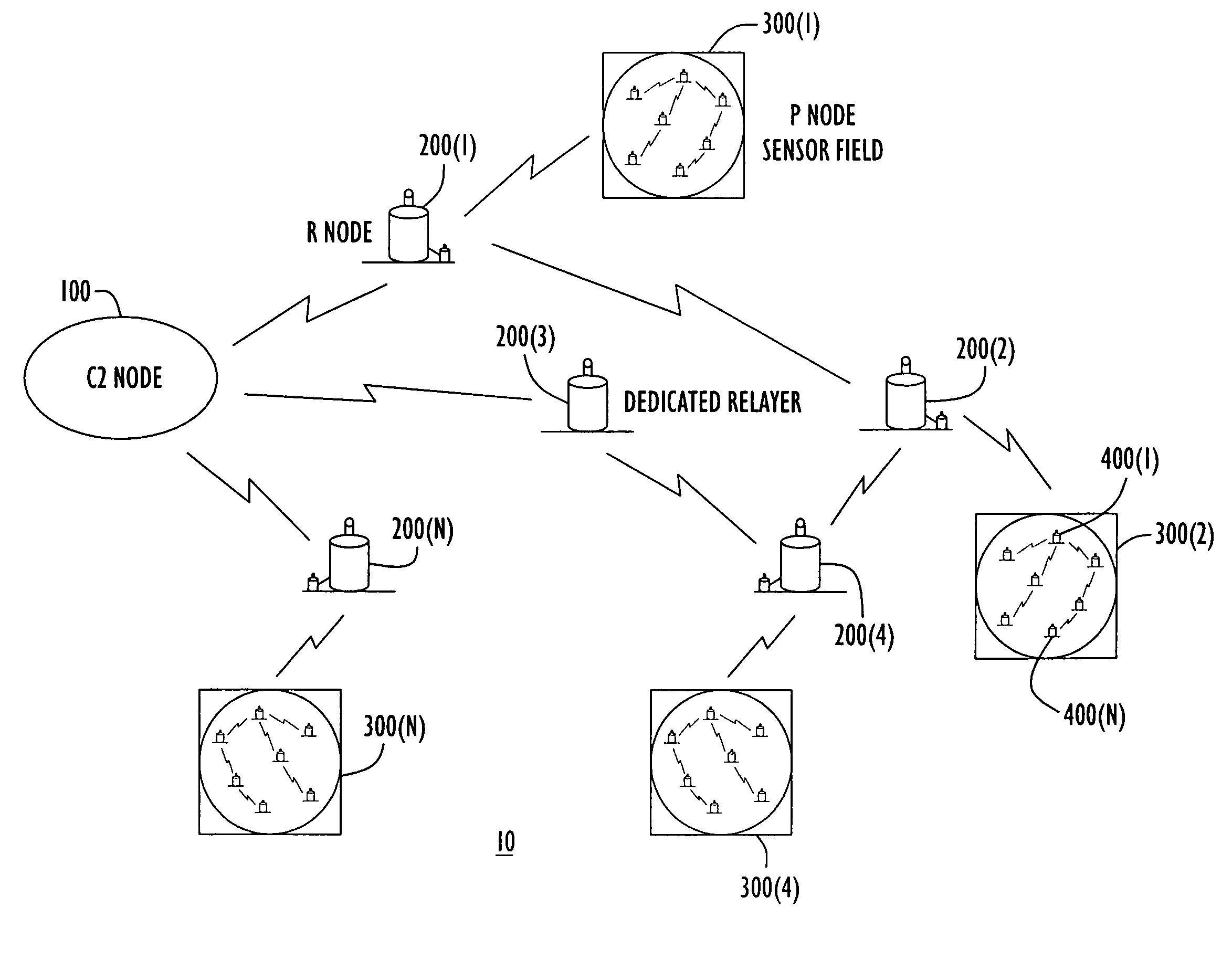

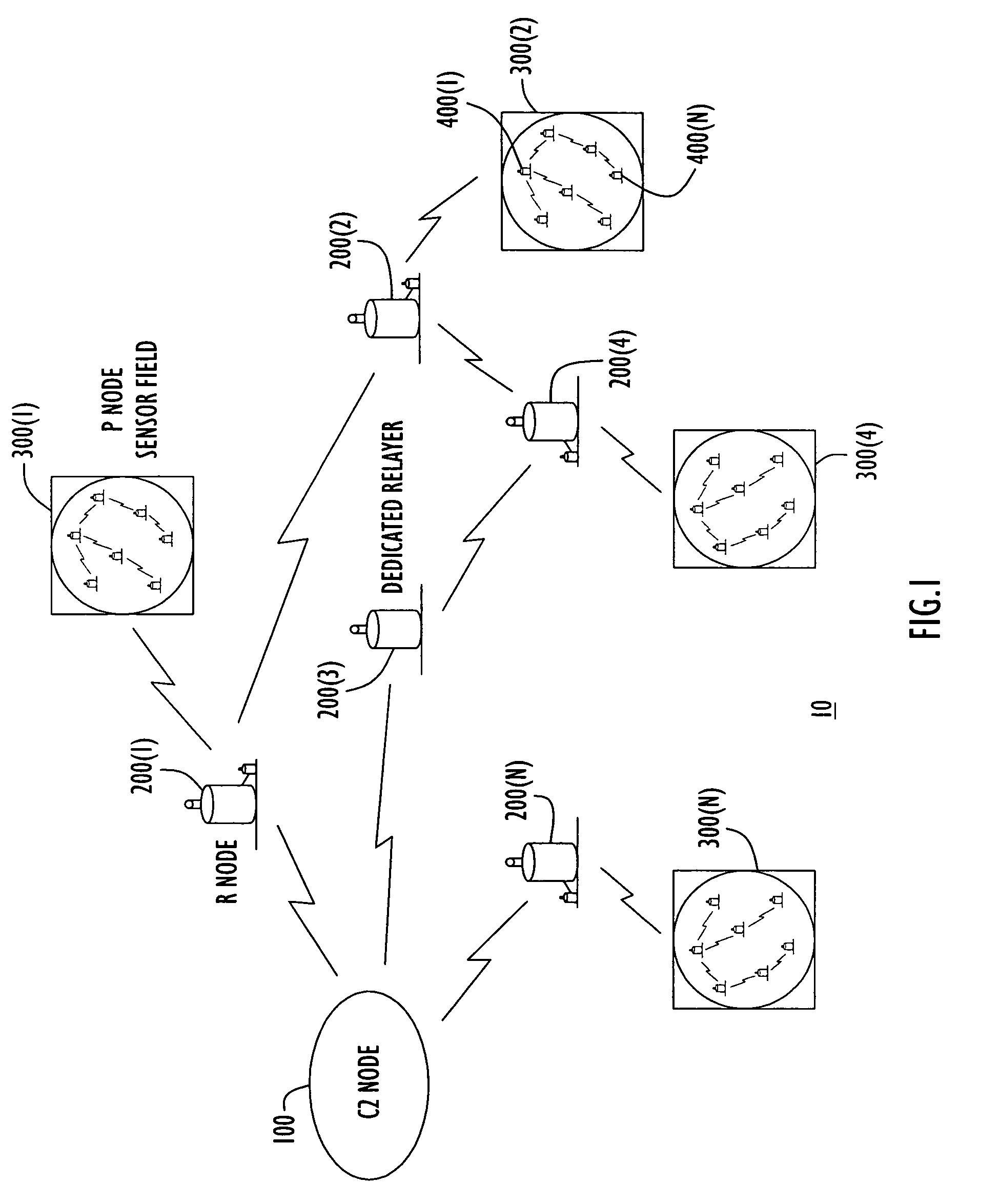

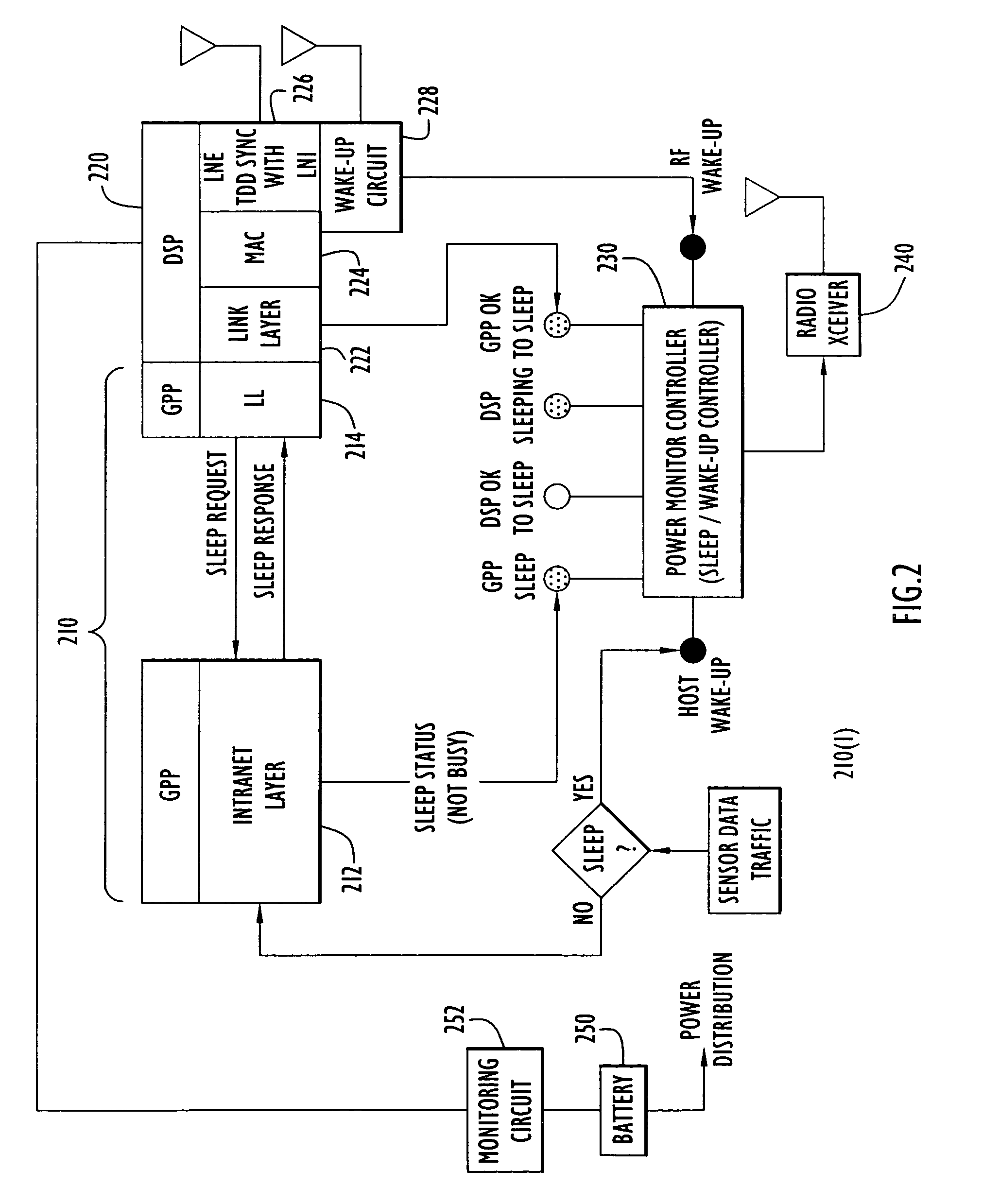

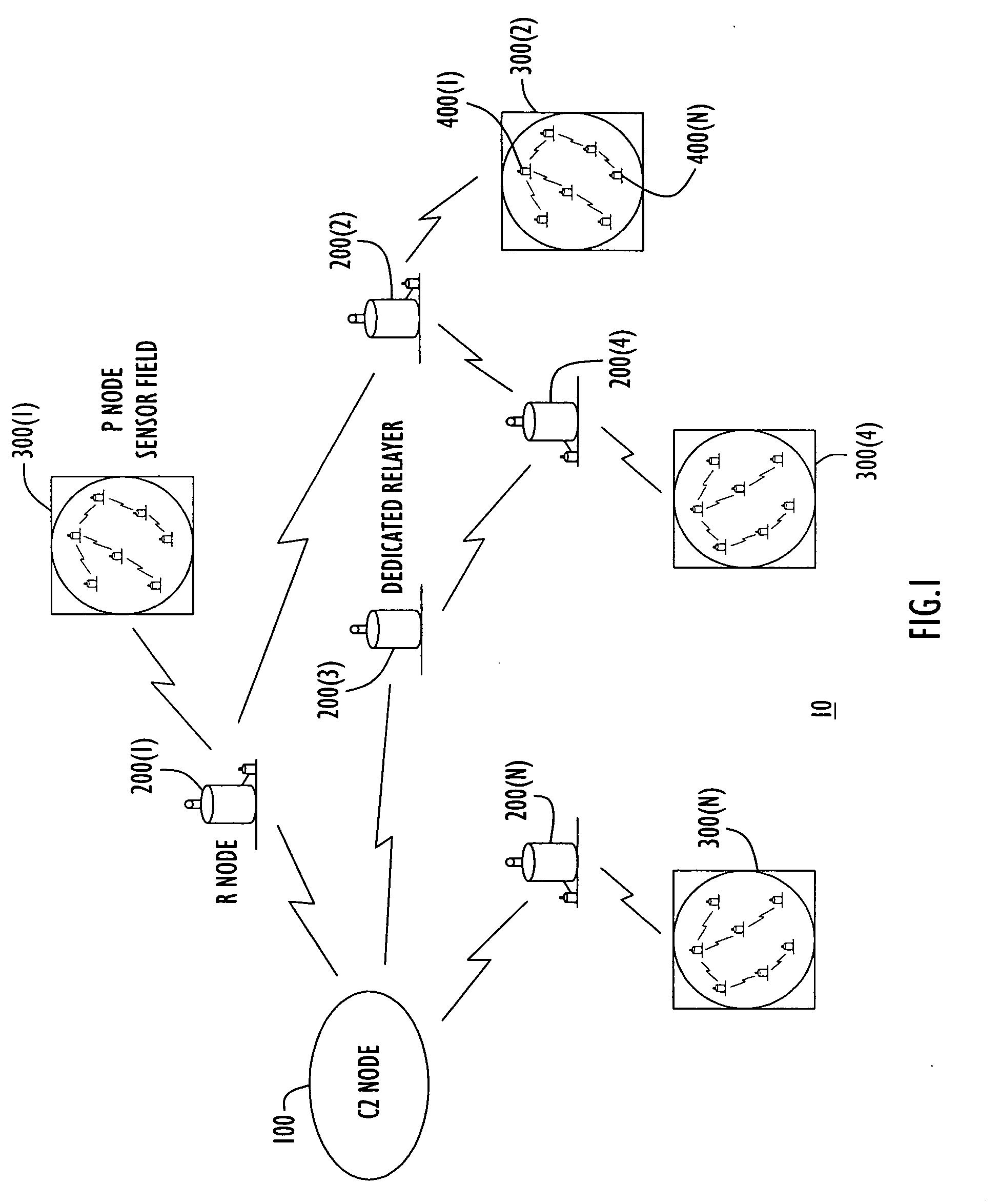

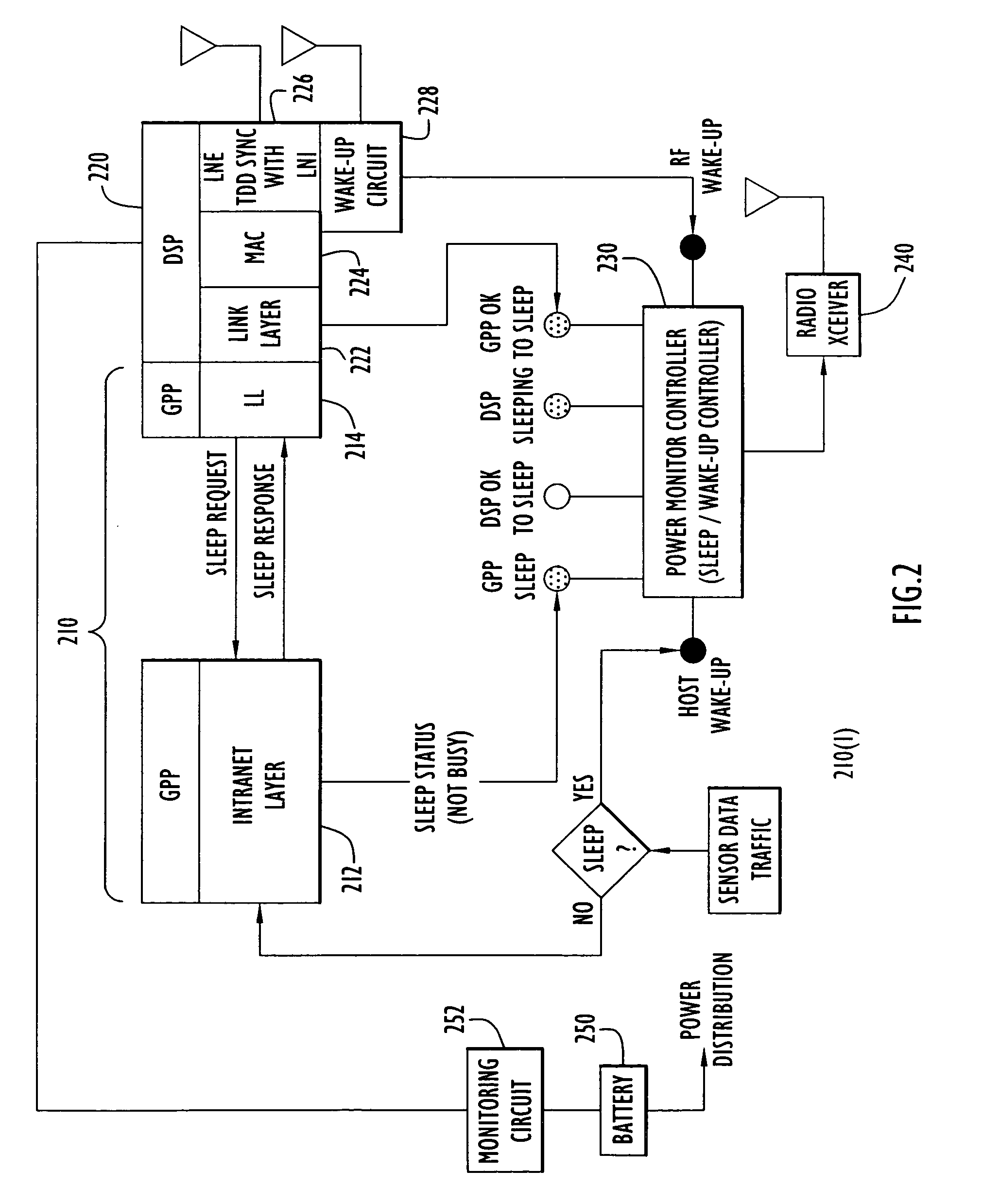

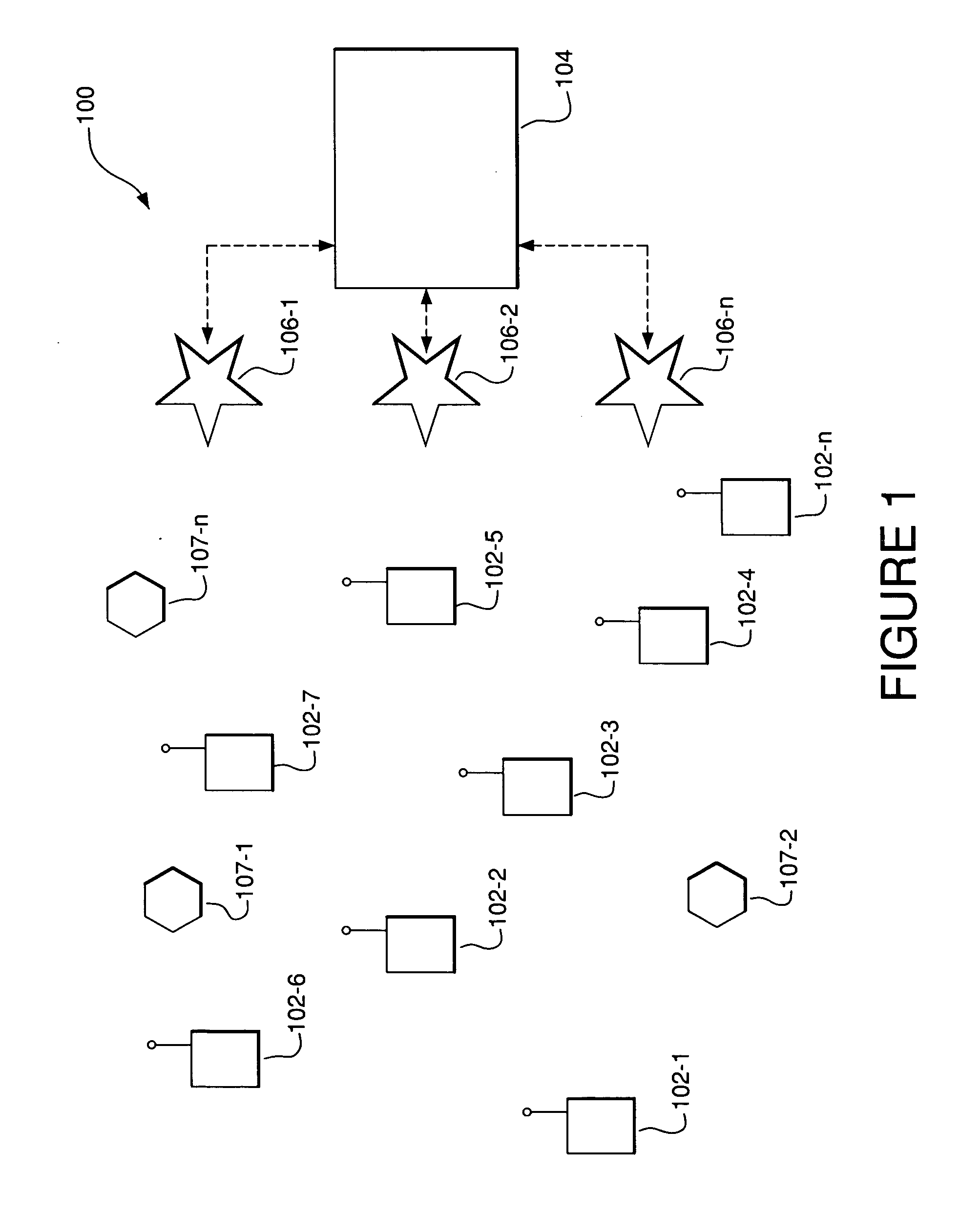

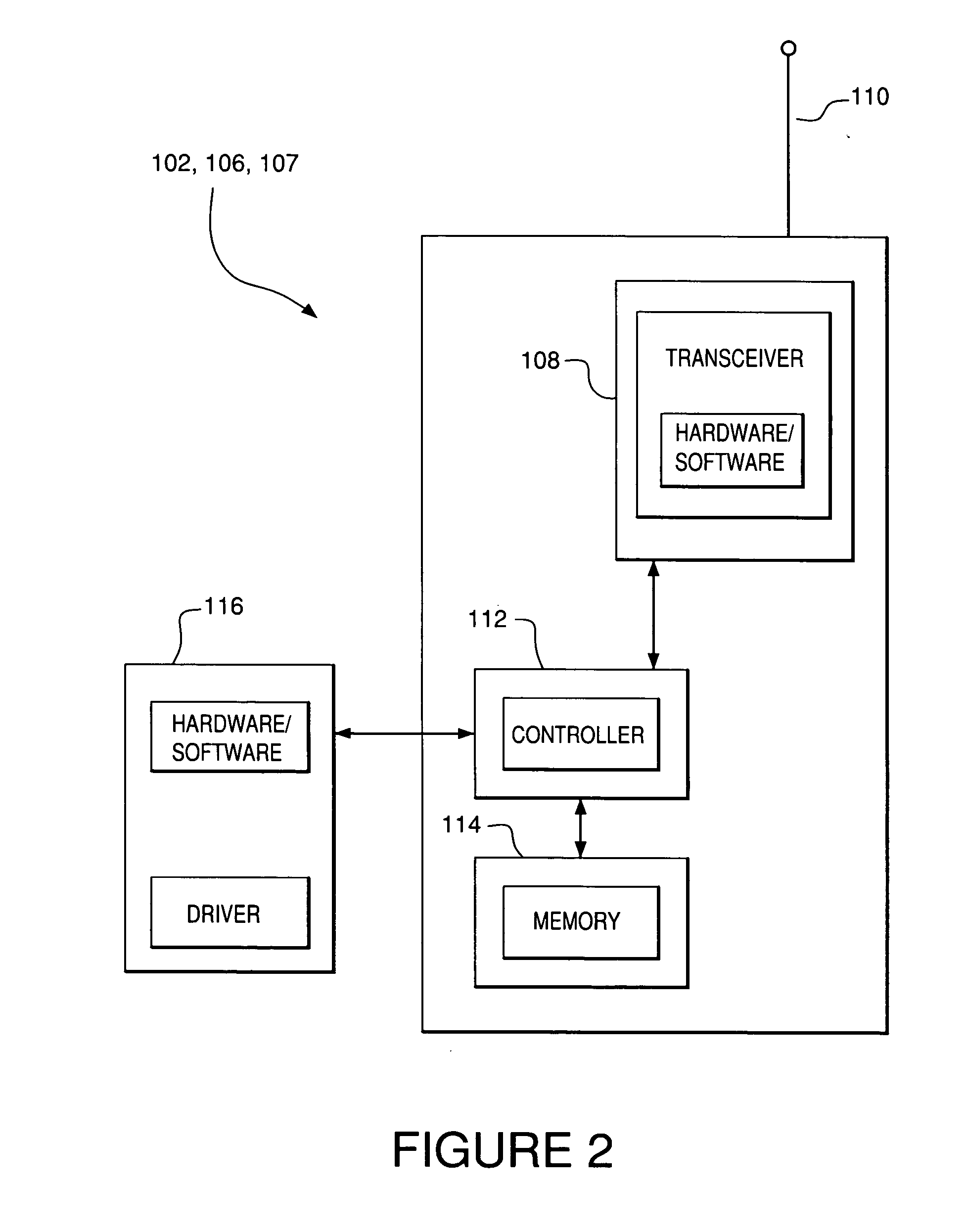

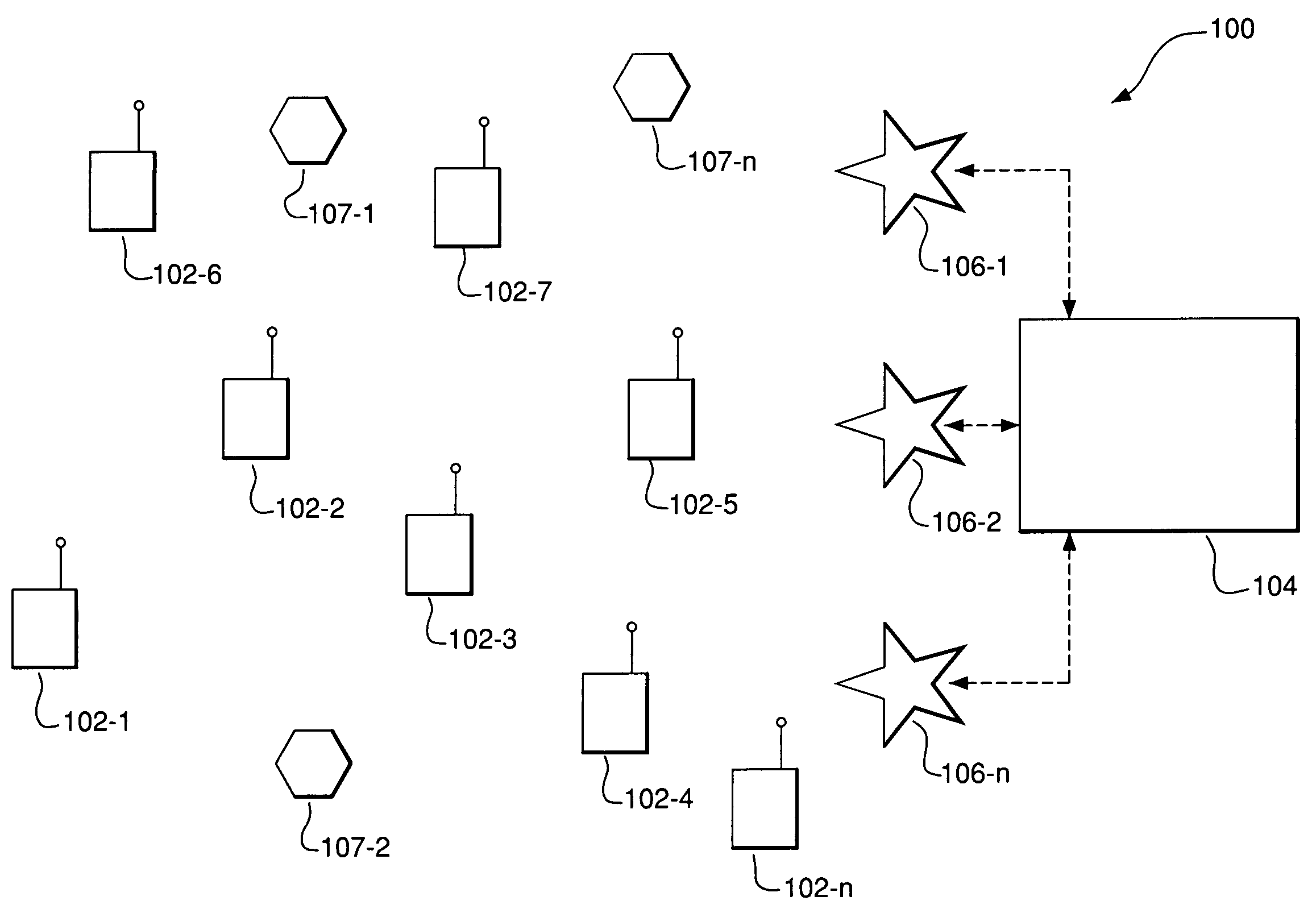

Energy-efficient network protocol and node device for sensor networks

ActiveUS7729285B2Balanced energy consumptionEnergy efficiencyPower managementEnergy efficient ICTComputer scienceEnergy consumption

Owner:OLLNOVA TECH LTD

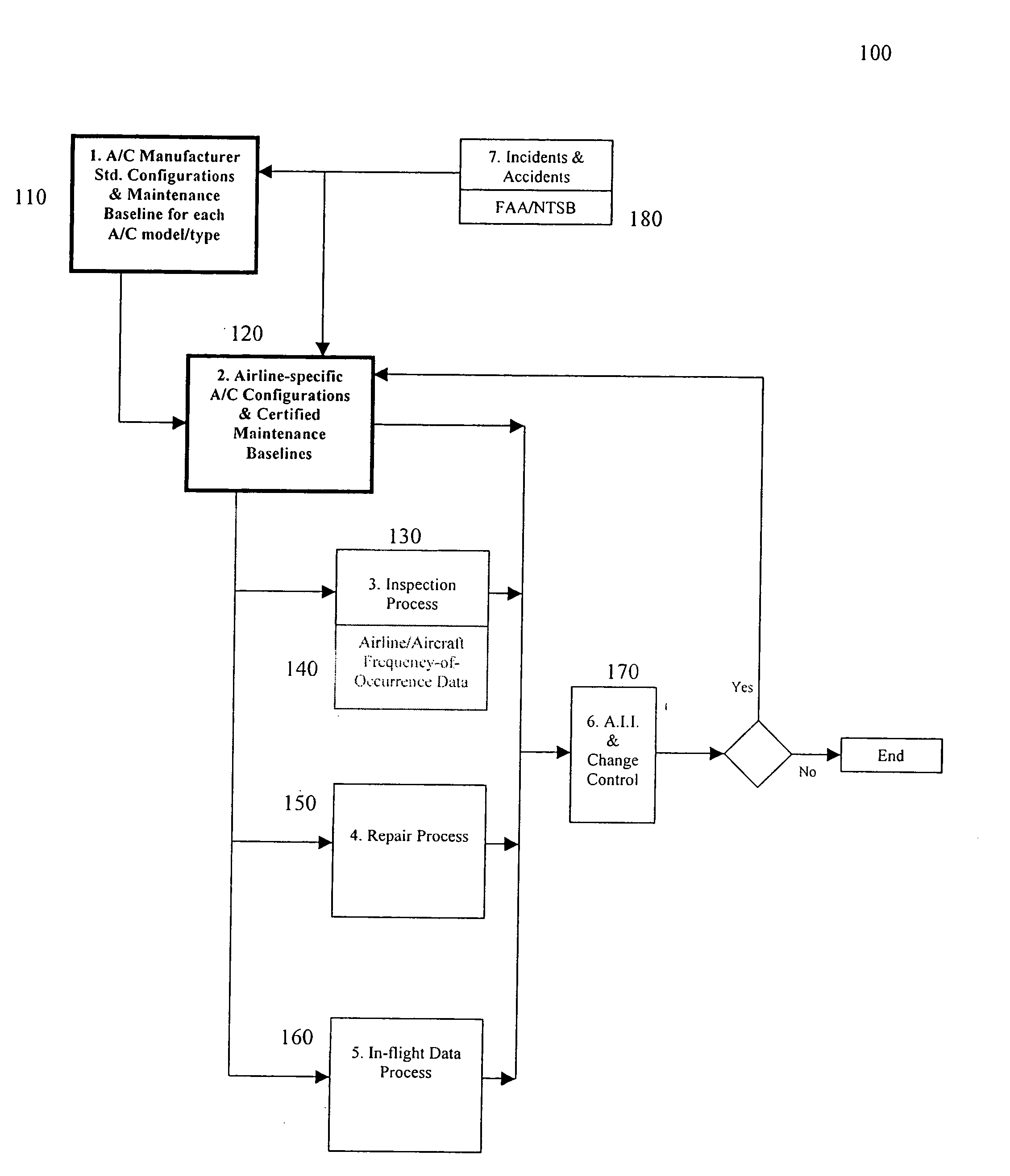

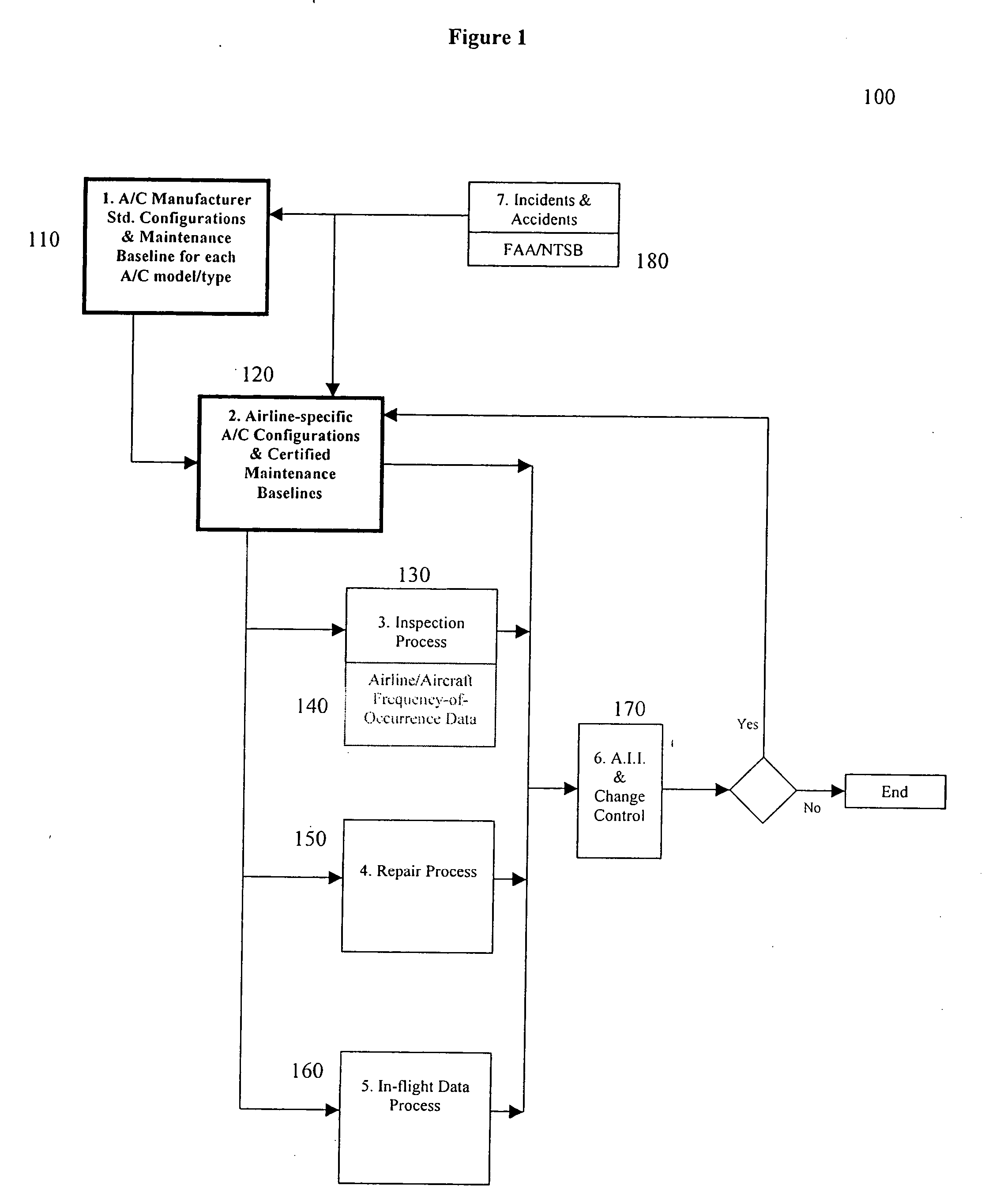

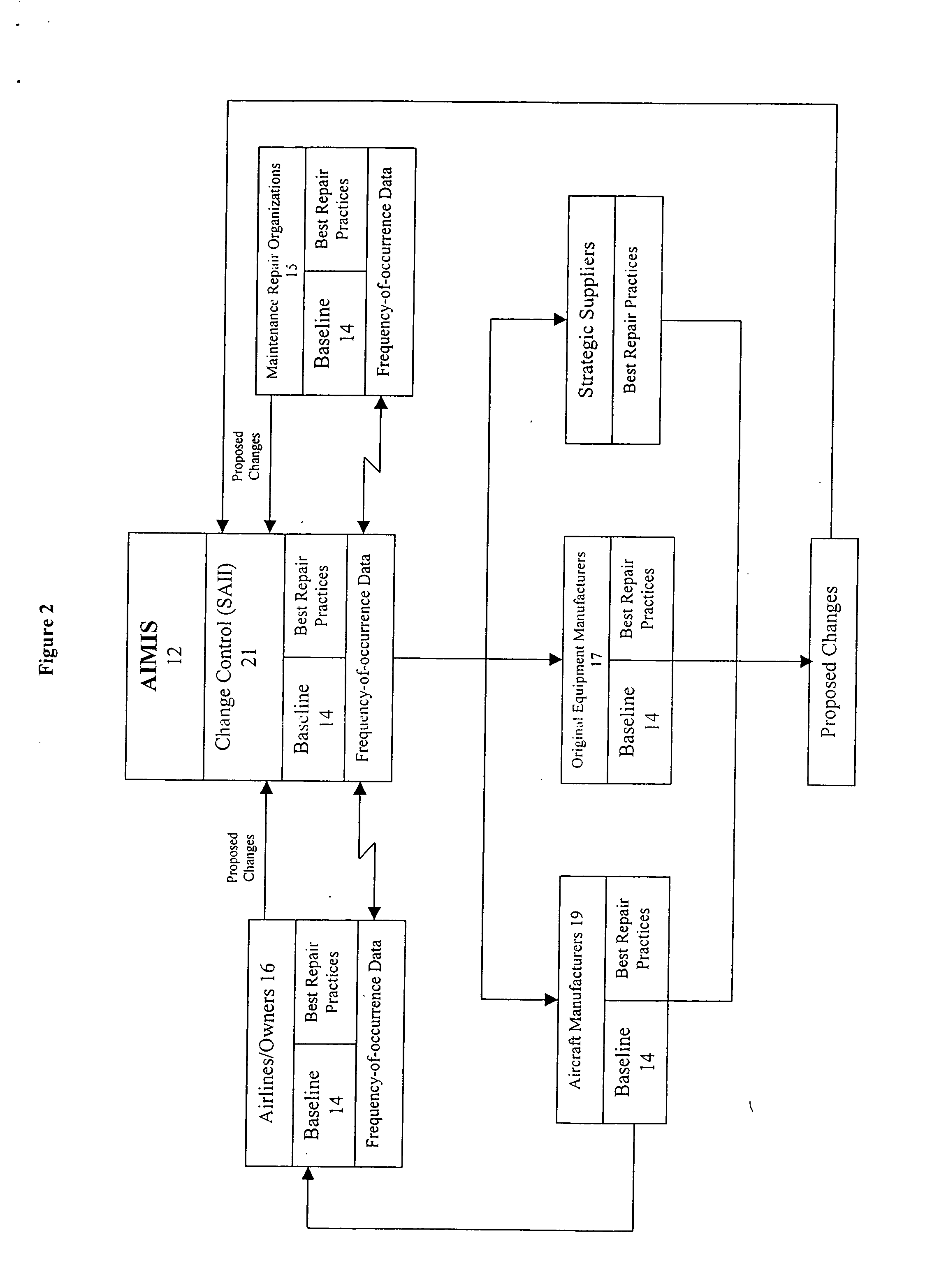

System and method for coordinating product inspection, repair and product maintenance

InactiveUS20050065842A1Economic impactEconomic securityTechnology managementResourcesProduct inspectionOriginal equipment manufacturer

A system and method for coordinating product inspection, repair and product maintenance features a proactive, data-driven process where industry-wide maintenance baselines, problems, frequency-of-occurrence data and best-in-class repair processes are identified in a central, secure, structured database environment and thereby where the safety and operational and economic impact of a problem can be evaluated and acted upon. Using industry-wide data provided by users, the present system and method will link repair and inspection finds (non-routines), reason codes and severity data related to potential safety, reliability, cycle time and cost implications with the root cause analysis and certified best inspection / repair / preventative process instructions, materials, tools and / or equipment. This information, combined with a maintenance provider's, manufacturer's and OEM's information, will greatly improve safety, reliability, cycle time and budget performance on repair, maintenance and inspection of equipment utilizing the present system and method.

Owner:THE SUMMERS GRP

Energy-efficient network protocol and node device for sensor networks

ActiveUS20060215588A1Balanced energy consumptionEnergy efficiencyEnergy efficient ICTPower managementComputer scienceEnergy consumption

An “on-demand” approach for a routing protocol for a wireless network that achieves balanced energy consumption among all participating nodes in the network. Synchronization messages transmitted by nodes associated with an upstream node include local node information (LNI) that a node can use to repair or bypass a lost upstream node in a real or virtual (temporary) manner depending upon the local node's battery level. Only if a repair process fails will a global re-organization (Re-Org) be initiated. The LNI also allows for nodes having lower power availability (battery level) not to transmit the LNI so that unaffiliated node(s) can select an upstream node having more power availability thereby extending network life.

Owner:OLLNOVA TECH LTD

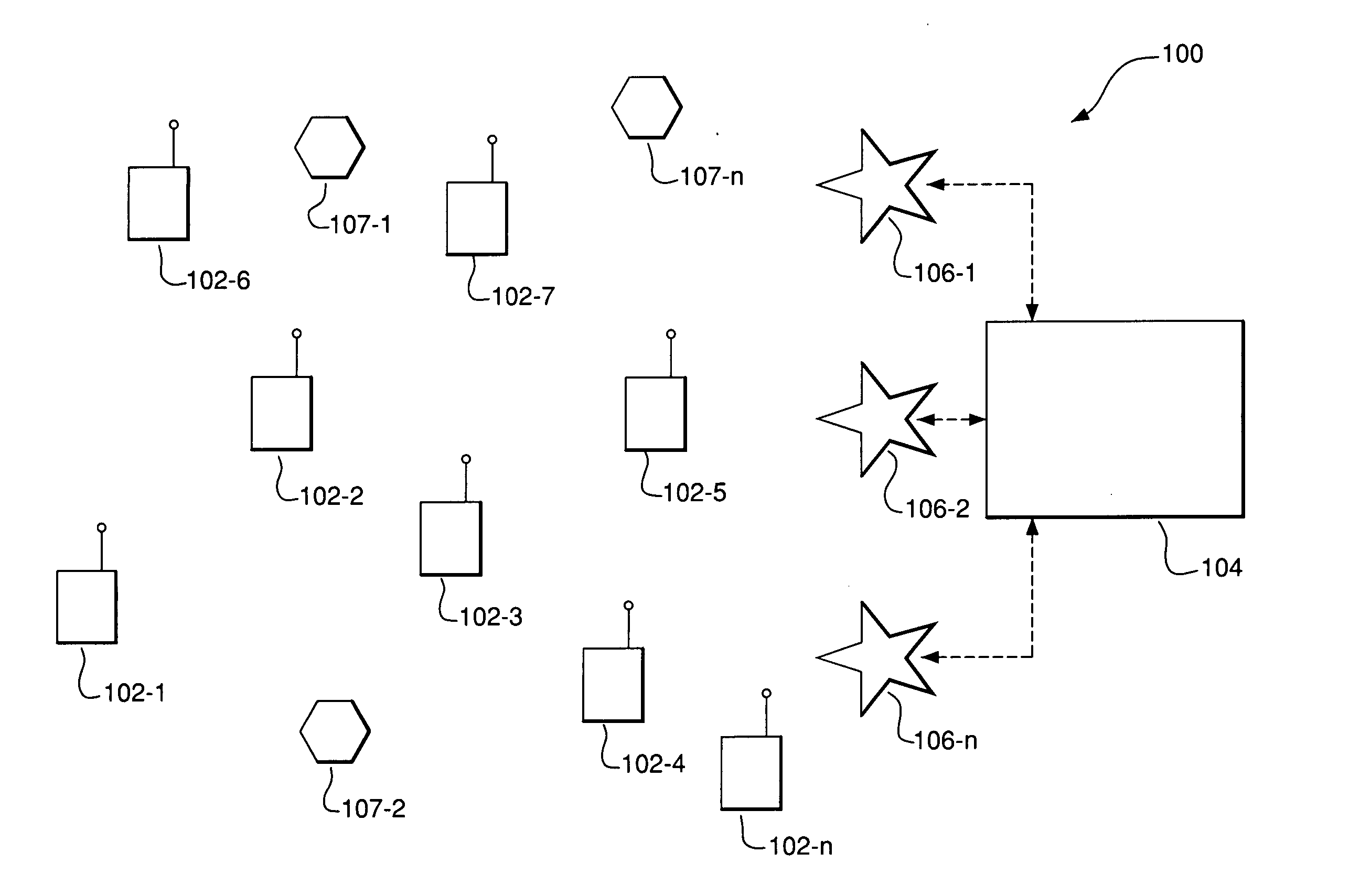

Method to support multicast routing in multi-hop wireless networks

ActiveUS20060250999A1Network topologiesBroadcast transmission systemsExtensibilityWireless ad hoc network

A system and method for supporting multicast in highly dynamic wireless multi-hop networks, such as ad-hoc networks, with good scalability. The system and method provide a multicast routing algorithm to work in wireless ad-hoc networks without any fixed infrastructure nodes present. In doing so, the system and method provide a technique to build a multicast source specific tree on demand, while using a core source node to limit routing overhead. The system and method further provide a repair process to reduce the latency of discovery of topology change, employ a node sequence number mechanism to differentiate between upstream nodes and downstream nodes on the multicast tree in the repair process, and provide an active joining process to reduce the latency of discovery of membership change.

Owner:ARRIS ENTERPRISES LLC

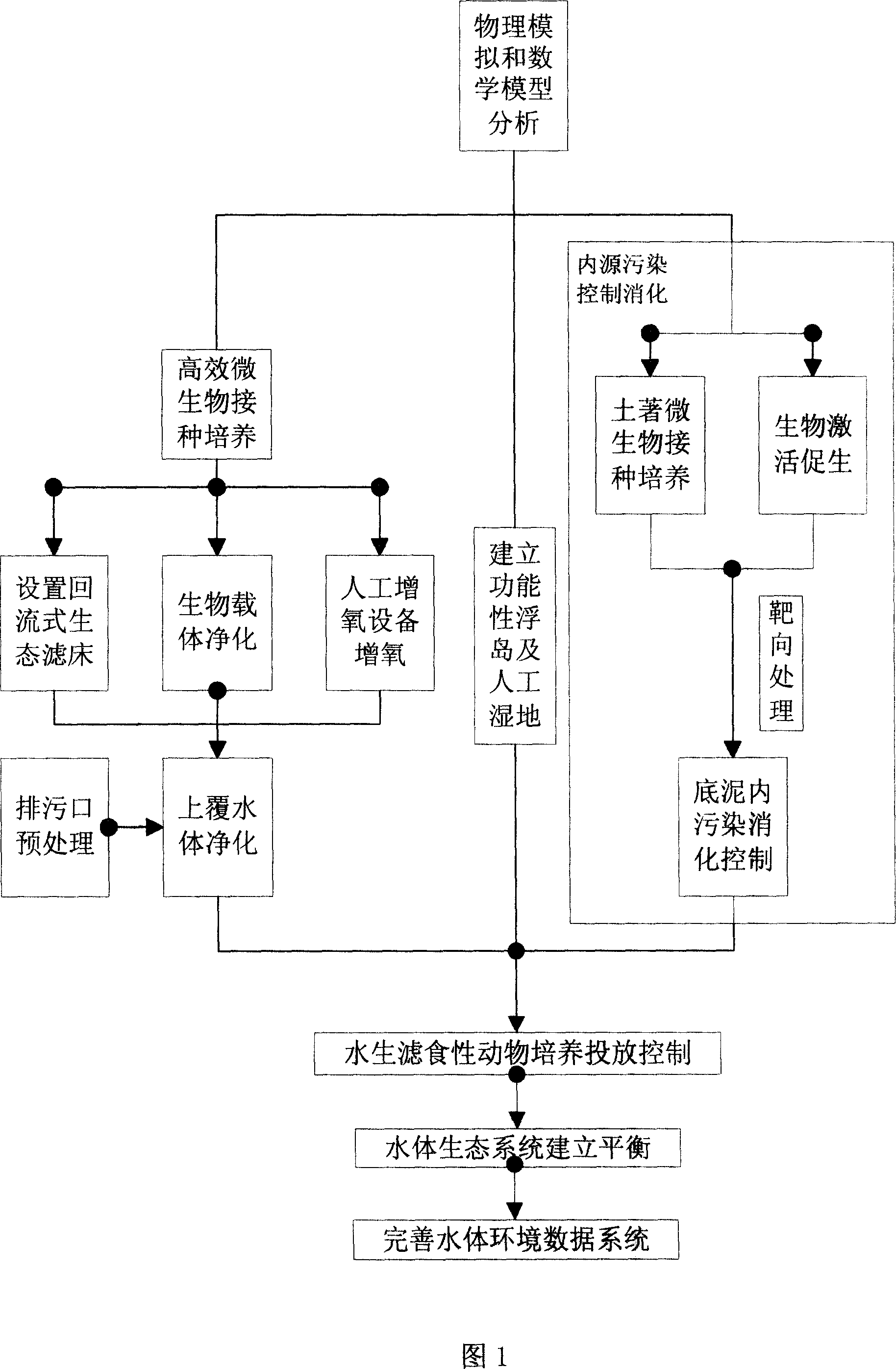

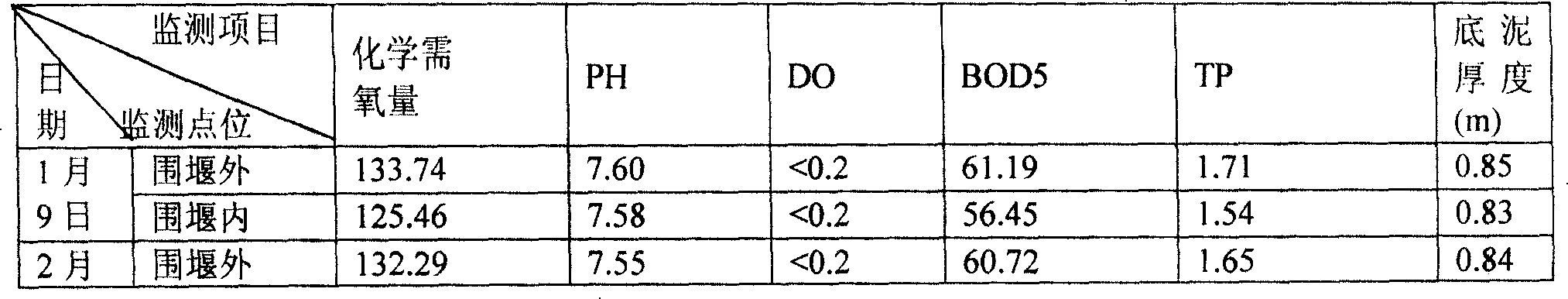

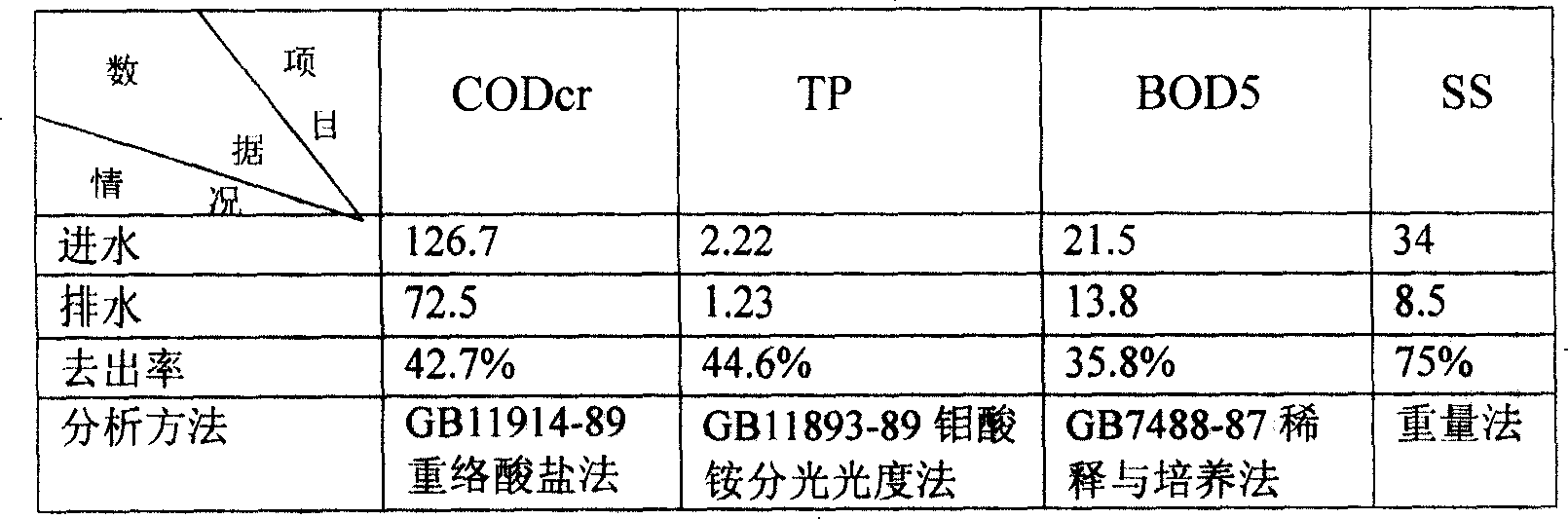

Stereo in-situ ecological urban water system repairing process

InactiveCN101021062AControl survivalPurify waterEnergy based wastewater treatmentHydraulic engineering apparatusMicrobial inoculationConstructed wetland

The stereo in-situ ecological urban water system repairing process tackles polluted water via the quantitative analysis on the water. The technological scheme includes physical simulation and mathematic model analysis, microbe inoculation and culture, constituting refluxing ecological filter bed, purification with biocarrier, artificial aeration, purifying upper water, pre-treatment in the blow down port, establishing water ecological system balance, perfecting water environment data, etc. The present invention realizes the comprehensive tackling of urban water system.

Owner:上海中渠生态环保科技有限公司

Method to support multicast routing in multi-hop wireless networks

A system and method for supporting multicast in highly dynamic wireless multi-hop networks, such as ad-hoc networks, with good scalability. The system and method provide a multicast routing algorithm to work in wireless ad-hoc networks without any fixed infrastructure nodes present. In doing so, the system and method provide a technique to build a multicast source specific tree on demand, while using a core source node to limit routing overhead. The system and method further provide a repair process to reduce the latency of discovery of topology change, employ a node sequence number mechanism to differentiate between upstream nodes and downstream nodes on the multicast tree in the repair process, and provide an active joining process to reduce the latency of discovery of membership change.

Owner:ARRIS ENTERPRISES LLC

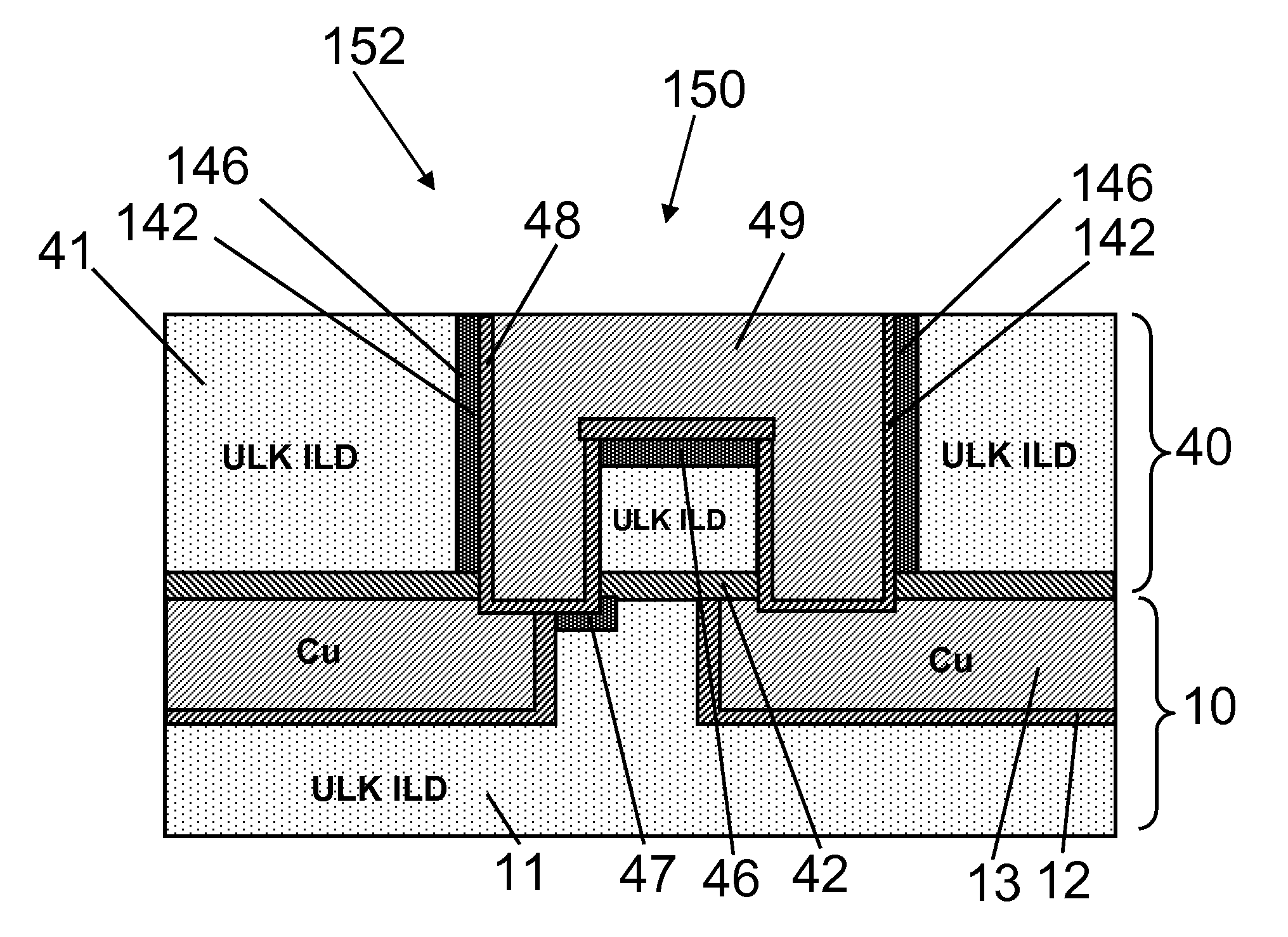

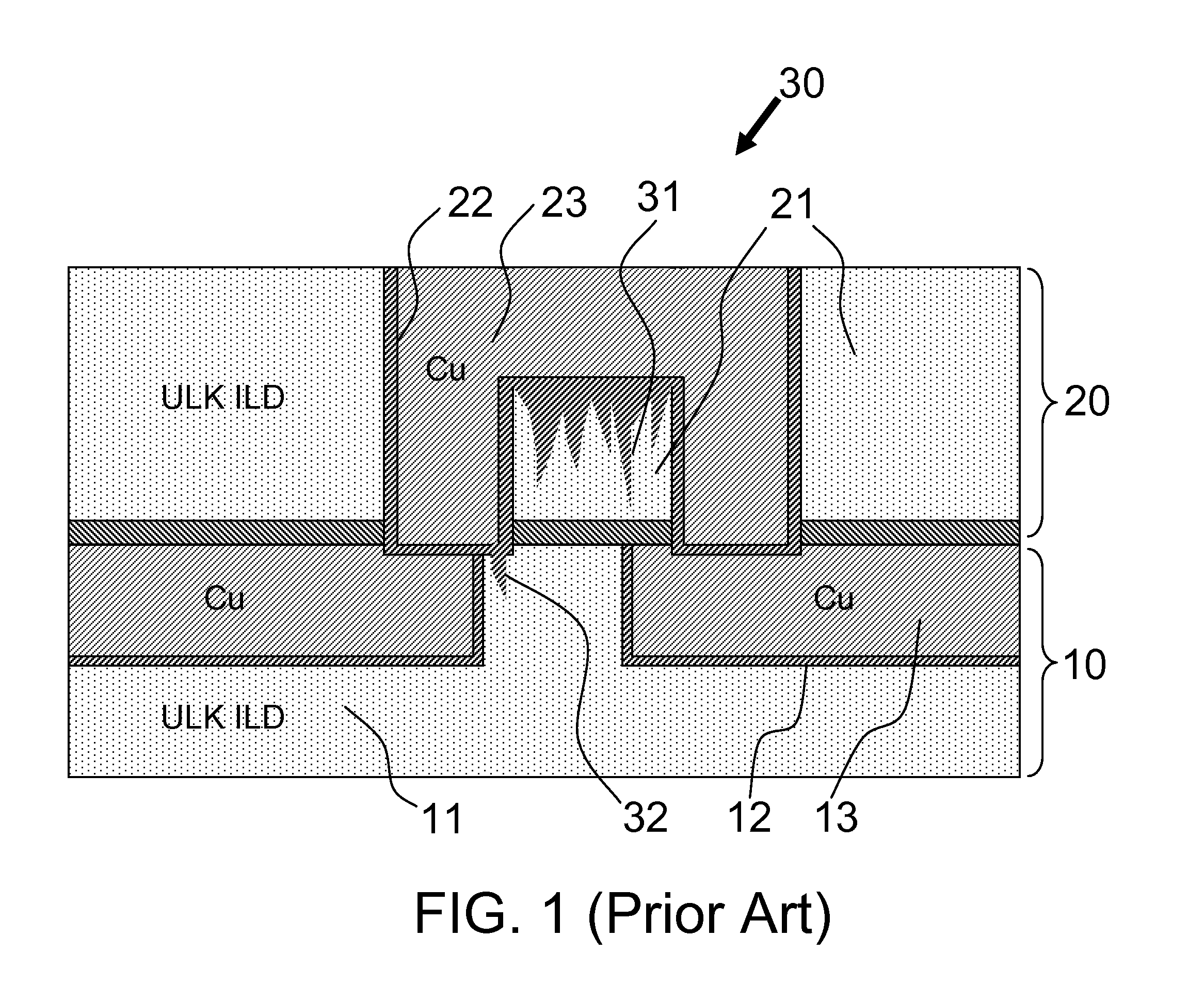

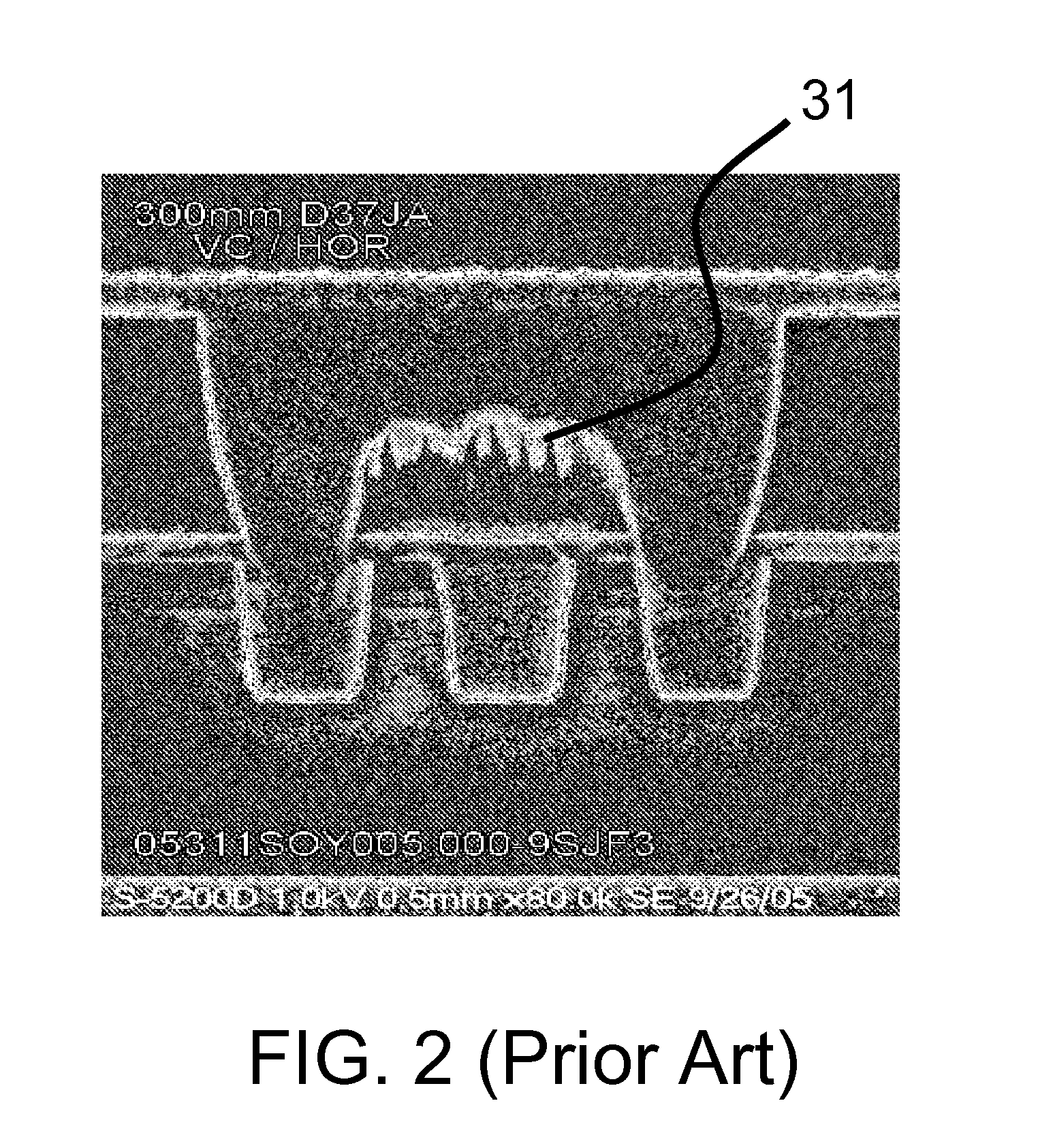

Method of repairing process induced dielectric damage by the use of gcib surface treatment using gas clusters of organic molecular species

When an interconnect structure is built on porous ultra low k (ULK) material, the bottom and / or sidewall of the trench and / or via is usually damaged by a following metallization or cleaning process which may be suitable for dense higher dielectric materials. Embodiments of the present invention may provide a method of repairing process induced dielectric damage from forming an interconnect structure on an inter-layer dielectric (ILD) material. The method includes treating an exposed area of the ILD material to create a carbon-rich area, and metallizing the carbon-rich area. One embodiment includes providing treatment to an exposed sidewall area of the ILD material to create a carbon-rich area by irradiating the exposed area using a gas cluster ion beam (GCIB) generated through a gas including a straight chain or branched, aliphatic or aromatic hydrocarbon, and metallizing the carbon-rich area.

Owner:GLOBALFOUNDRIES INC

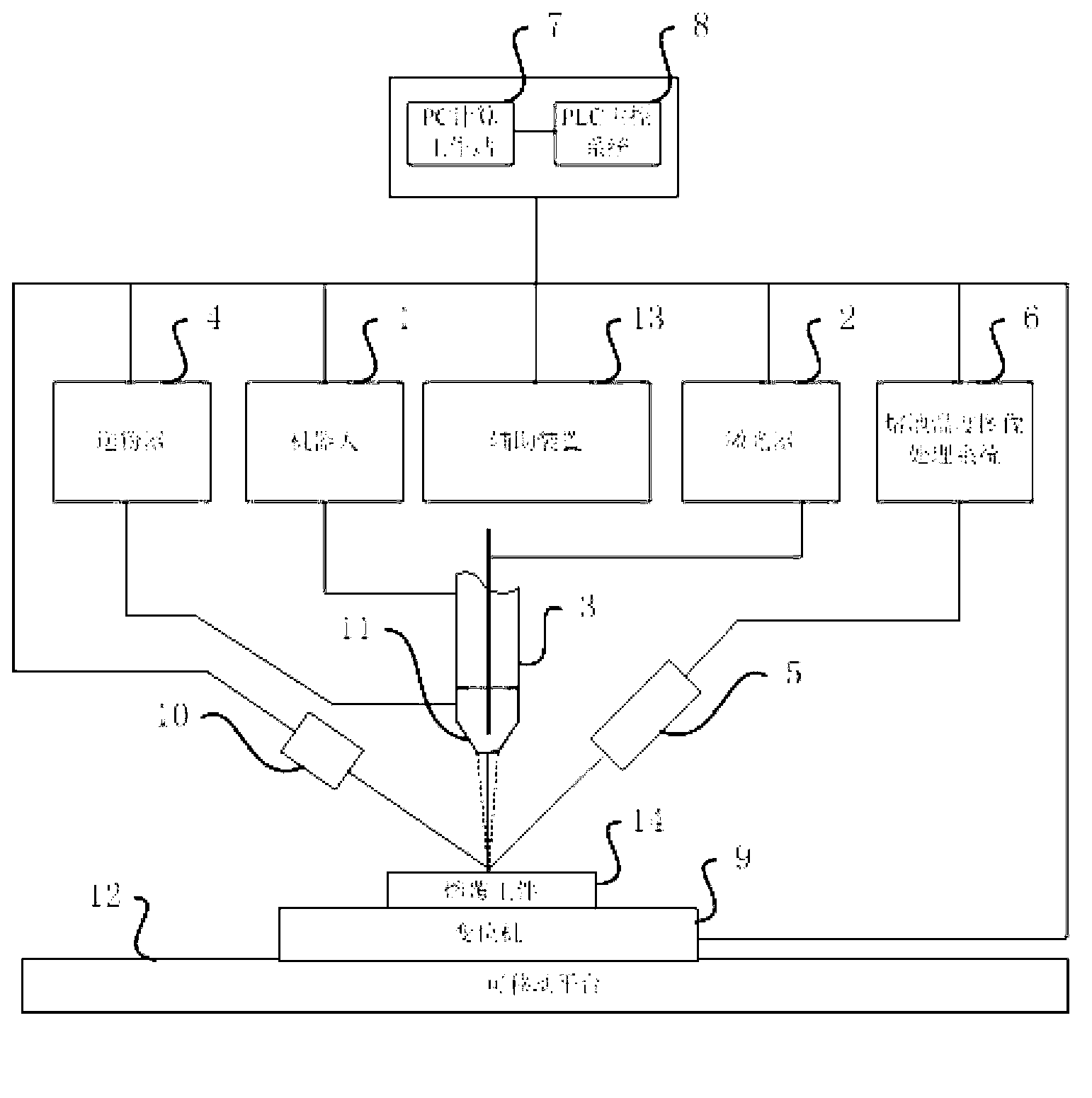

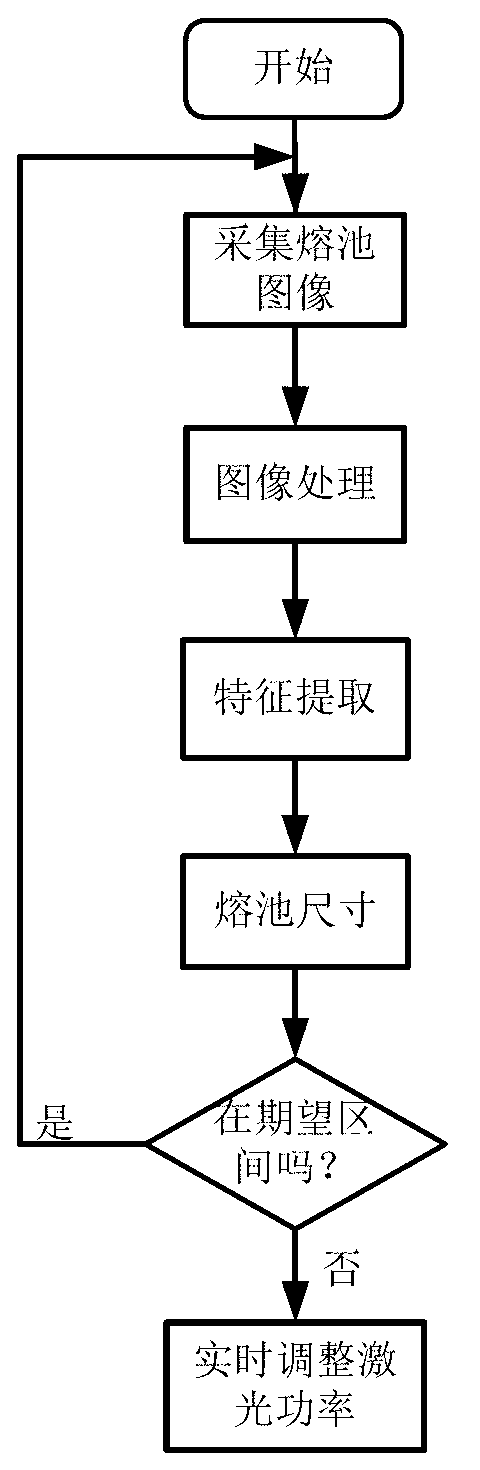

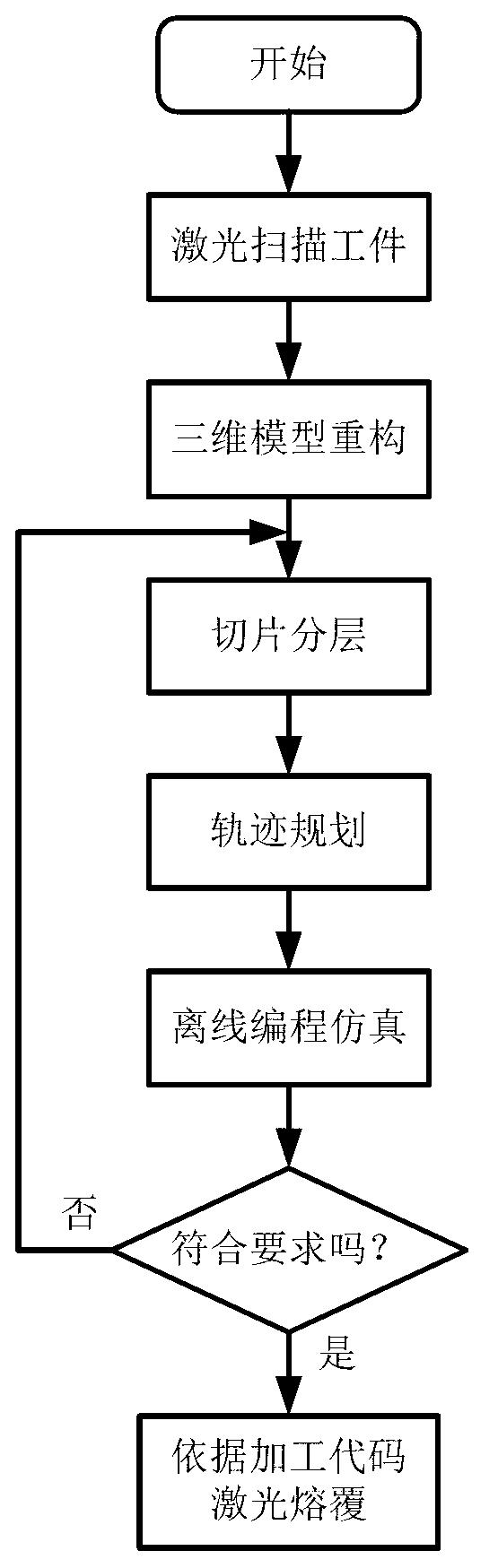

Movable laser cladding and repairing system

ActiveCN103074625AAchieve claddingAchieve fixMetallic material coating processesLaser scanningLaser sensor

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

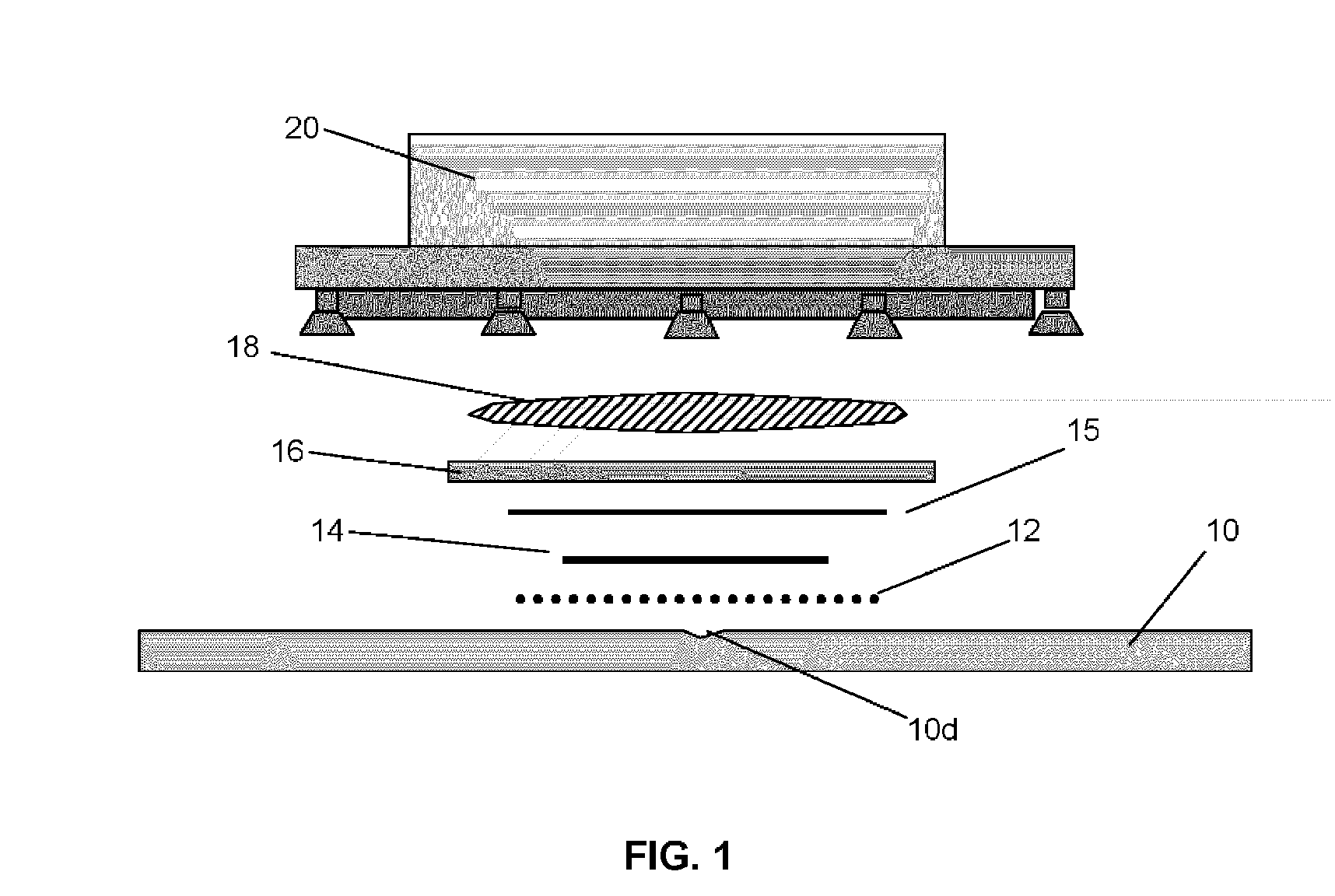

Fast line maintenance repair method and system for composite structures

InactiveUS20070095457A1Minimum skillQuick fixLighting and heating apparatusLayered productsAdhesiveRepair material

A fast line maintenance repair process for damaged composite structures includes the application of a pre-cured patch that uses a quick curing paste adhesive to bond the patch to the structure. The adhesive is cured at relatively low elevated temperatures provided by a chemical heat pack. The low temperature cure eliminates the need to dry out the part and permits the application of the repair in a hazardous environment. In a typical commercial airline application, airline maintenance personnel can install the repair at the flight gate. The repair is intended to restore the structure to a desired load capability in approximately one hour. The repair can be removed if need be with less overall damage than would occur upon removal of typical mechanically fastened repairs. All or some of the repair materials and tools can be provided in a portable kit.

Owner:THE BOEING CO

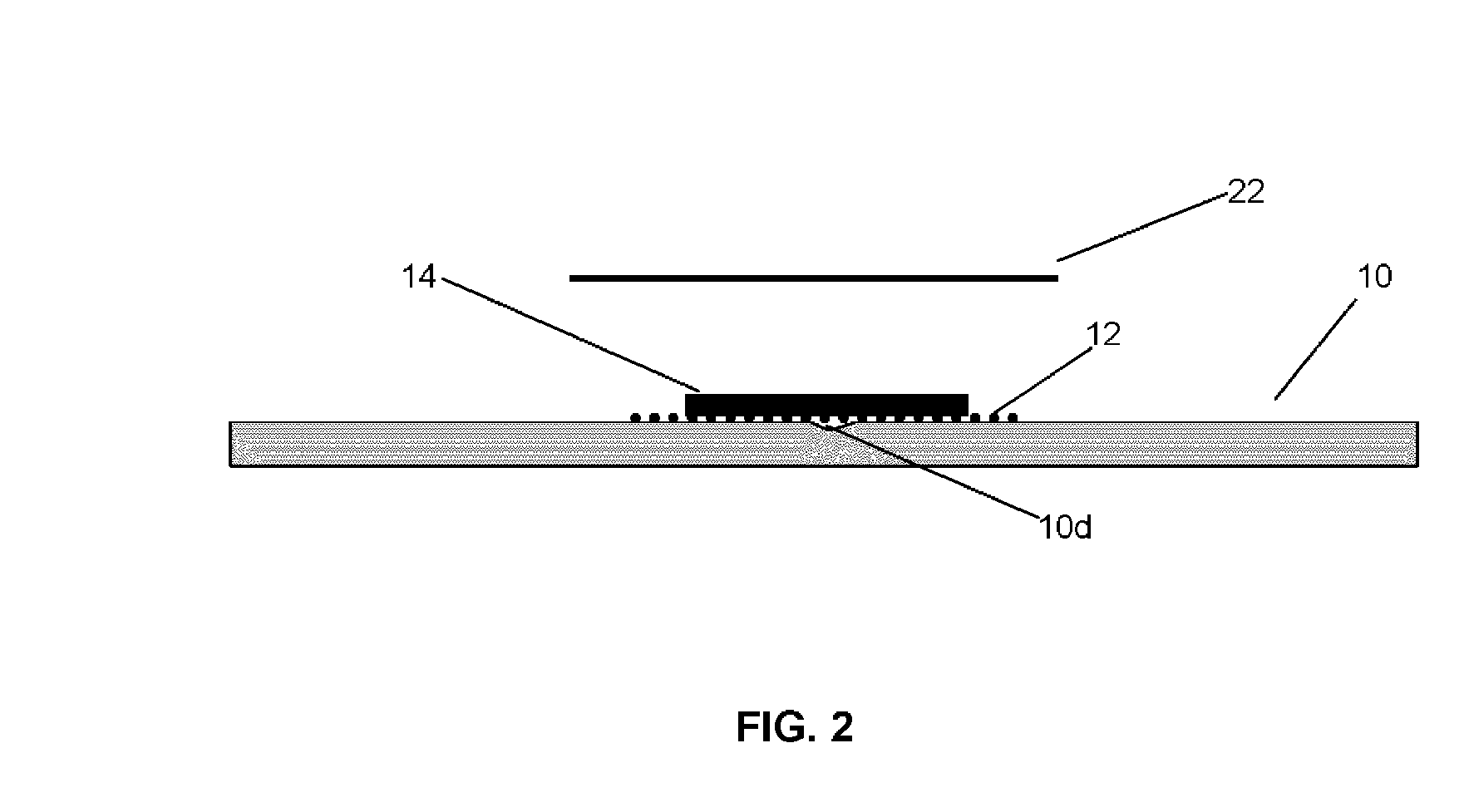

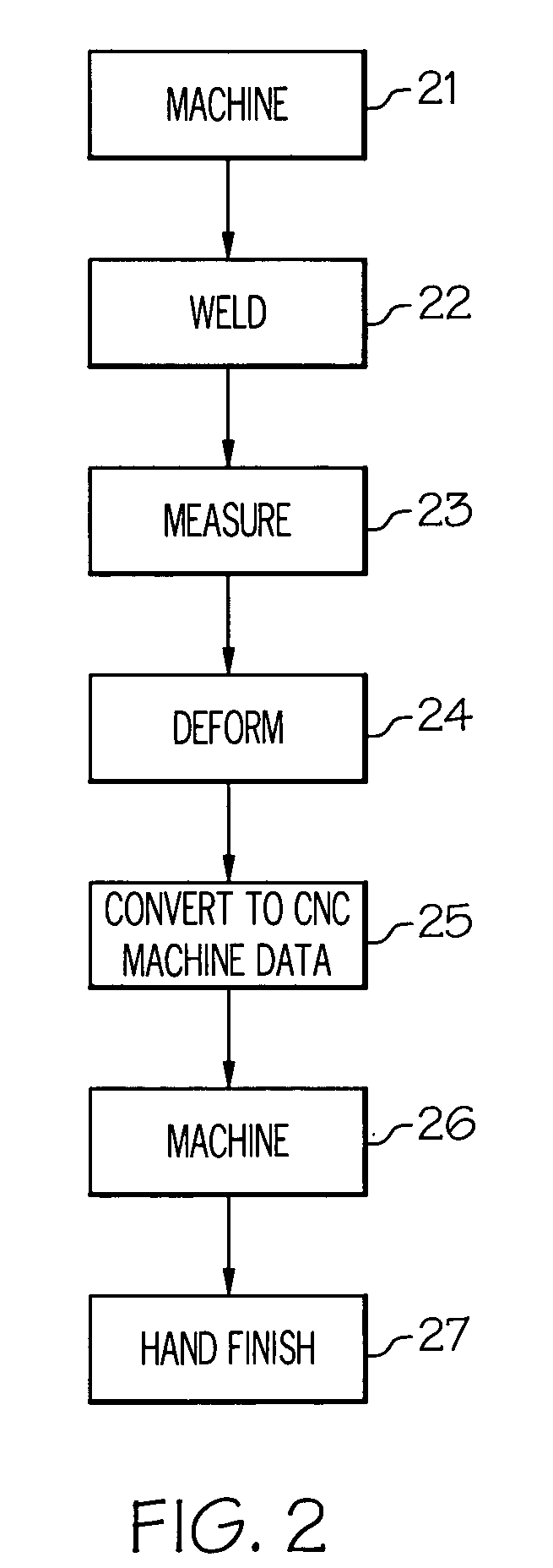

Adaptive machining and weld repair process

ActiveUS20060090336A1Blade accessoriesEfficient propulsion technologiesLeading edgeFilling materials

The present invention provides an apparatus and method for an adaptive machining and weld repair process useful for repairing airfoils, particularly damage to an airfoil leading edge and tip. The process first machines away damaged portions of an airfoil. Filler material is then added to the machined area through a process such as laser welding. At this point, the actual profile of the welded airfoil is measured using a Coordinate Measuring Machine. This data is then used to generate a “deformation” profile, an airfoil profile that approximates the ideal shape of the airfoil. The airfoil is then machined using the date of the deformation profile to produce that shape. The adaptive technology minimizes the amount of stock on material that needs to be removed by hand. The technique thereby significantly reduces costly manual processing.

Owner:HONEYWELL INT INC

Repair process for aluminum nitride substrates

A method to repair Aluminum Nitride (AlN) substrates is disclosed wherein a frequency doubled Q-switched Nd:YAG laser is used to remove unwanted metallurgy. The substrate is place in a liquid filled work chamber which acts to prevent metallic species of AlN from forming. The repair site can be sealed with a novel polymer coating to prevent contamination or corrosion. Repairs can be made to buried or surface metallurgy.

Owner:IBM CORP

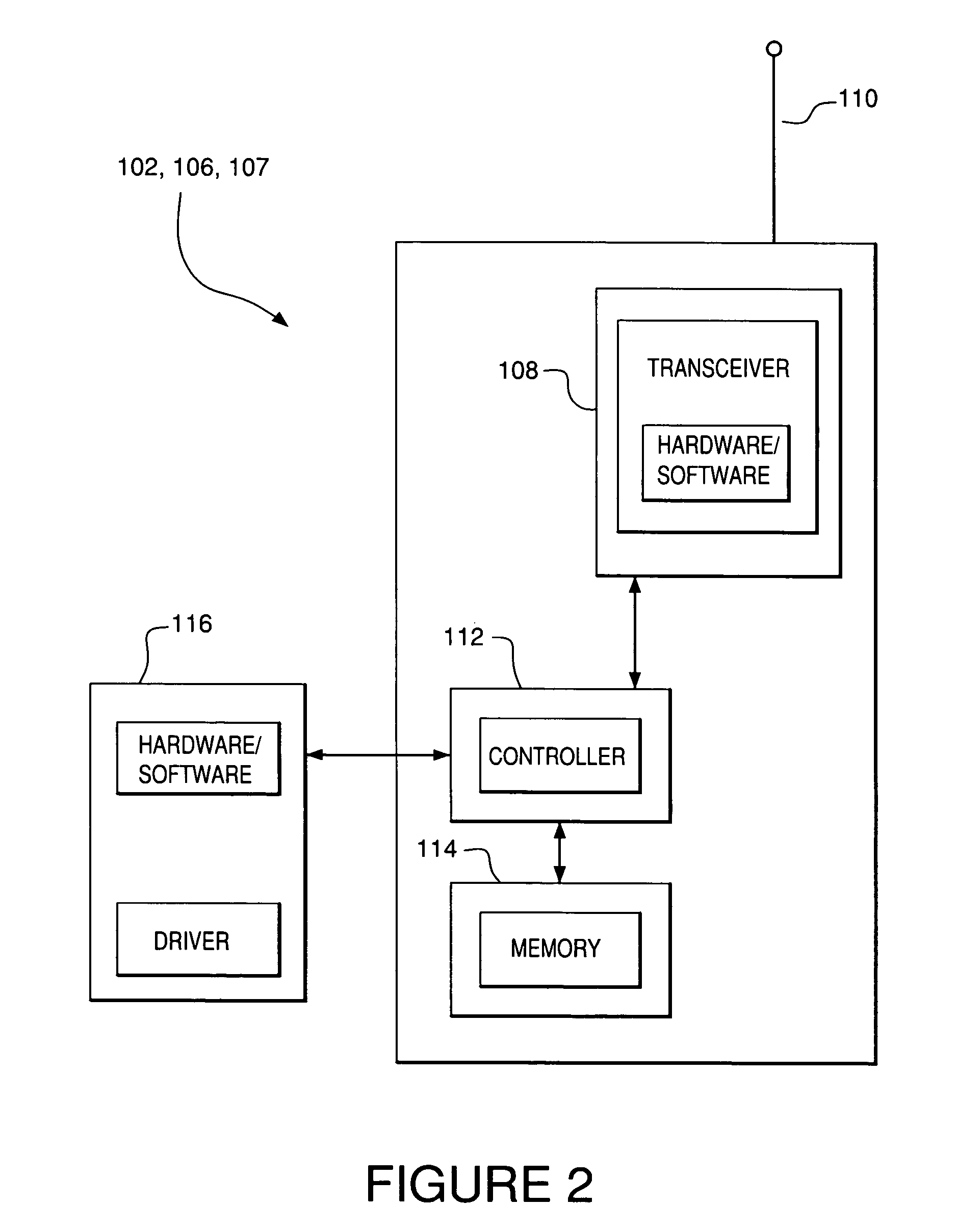

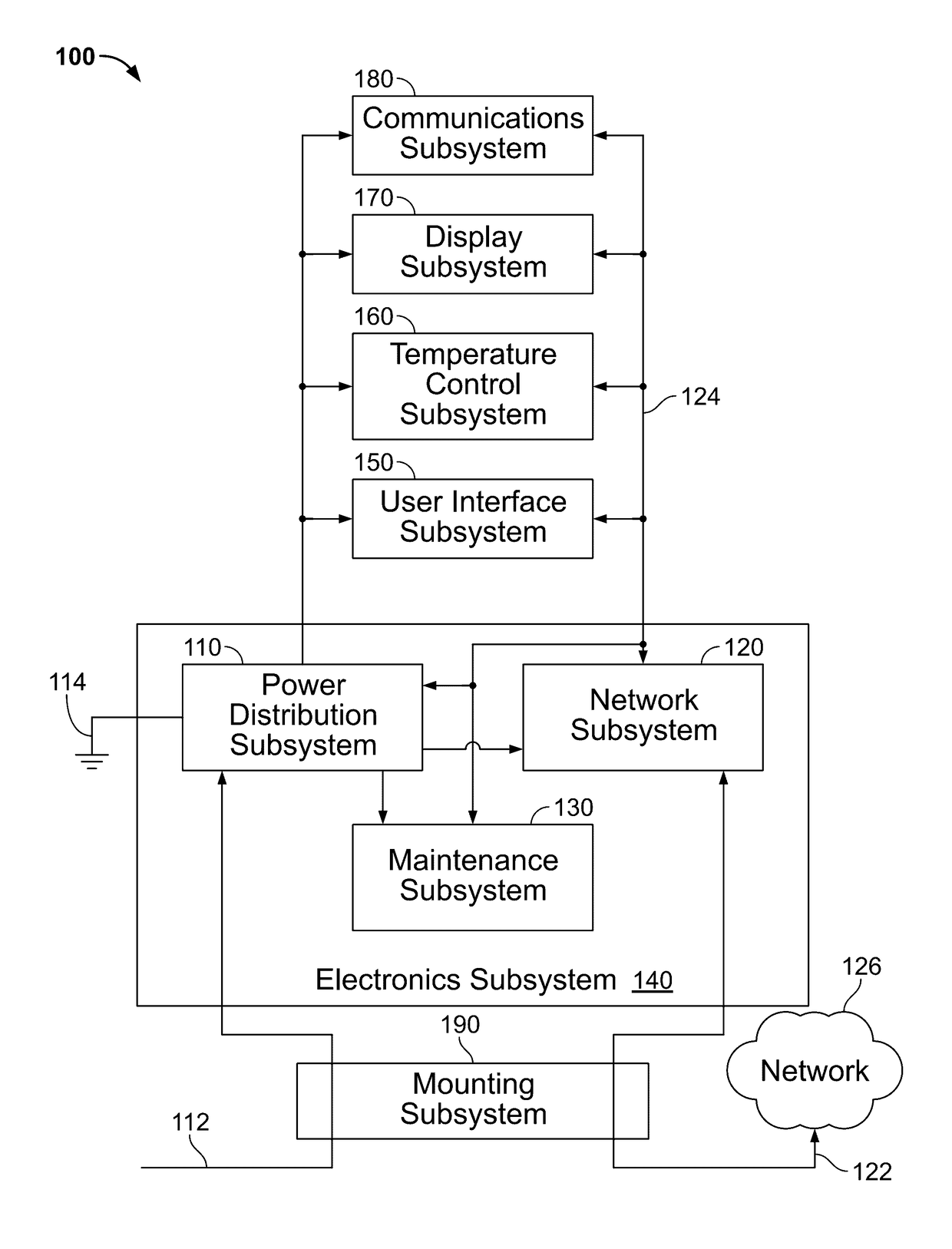

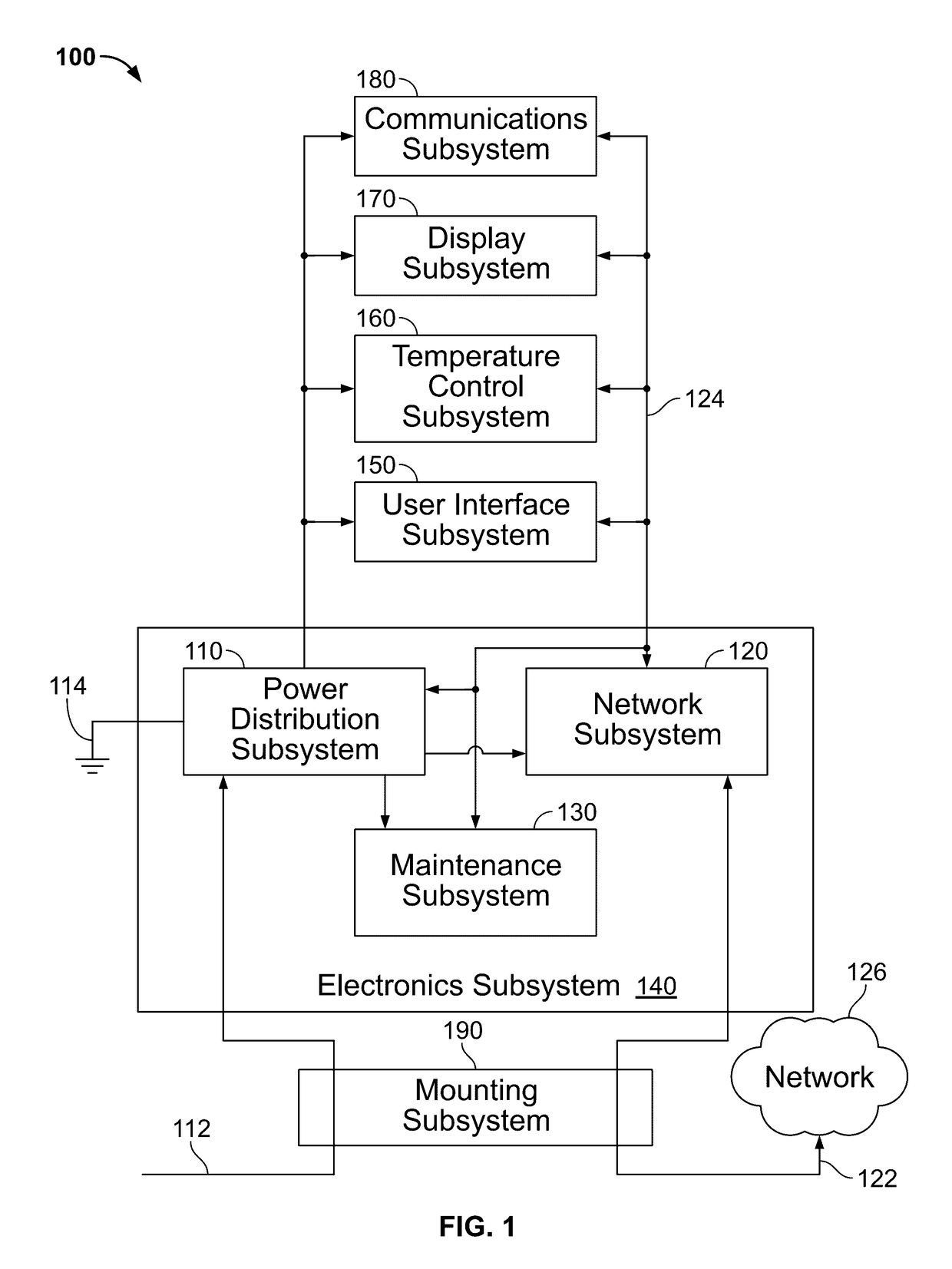

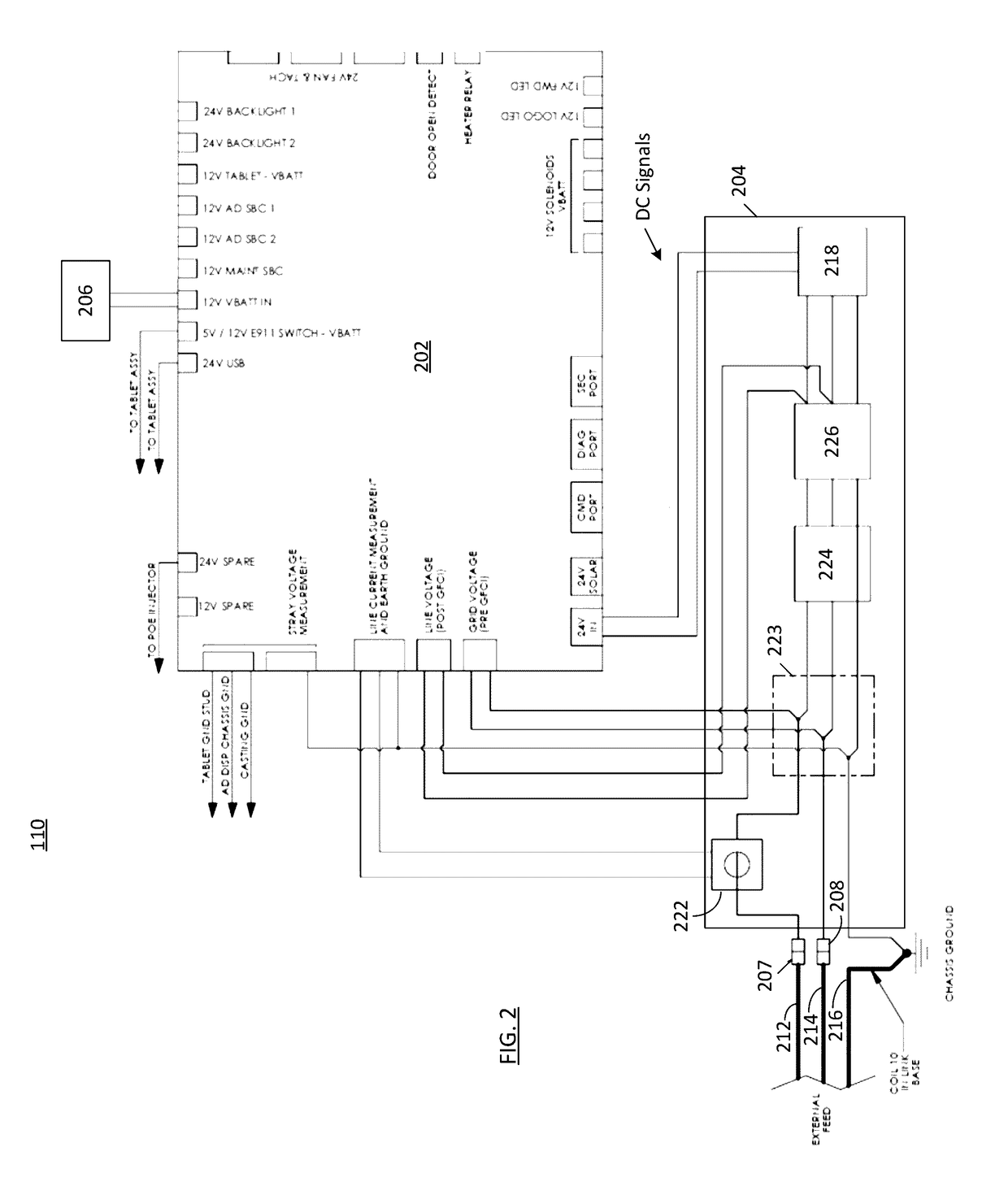

Techniques and systems for servicing a personal communication structure (PCS)

InactiveUS20170163519A1Easy accessExpand accessNetwork topologiesIndividual entry/exit registersService controlField service

Techniques and systems for servicing a personal communication structure (PCS) are described. The PCS may include a servicing controller that schedules, initiates, and / or otherwise controls testing of the PCS components. The PCS may transmit the results of the tests to a remote entity. Based on the test results, the remote entity may detect faulty components and / or allocate servicing resources (e.g., technicians, replacement parts, etc.) to the PCS as part of a field service repair process. The tests may be initiated by the servicing controller or by a remote entity.

Owner:CIVIQ SMARTSCAPES LLC

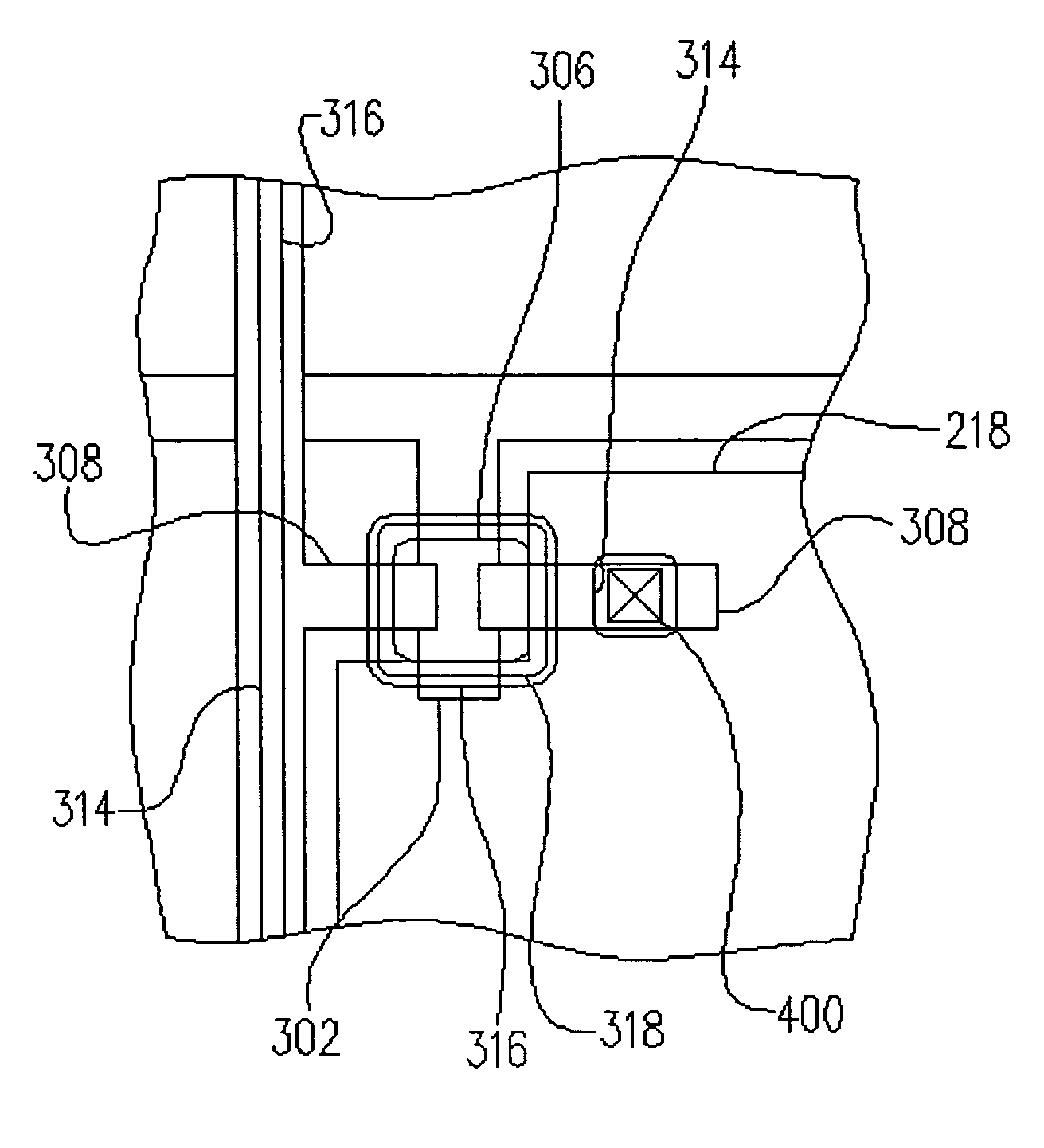

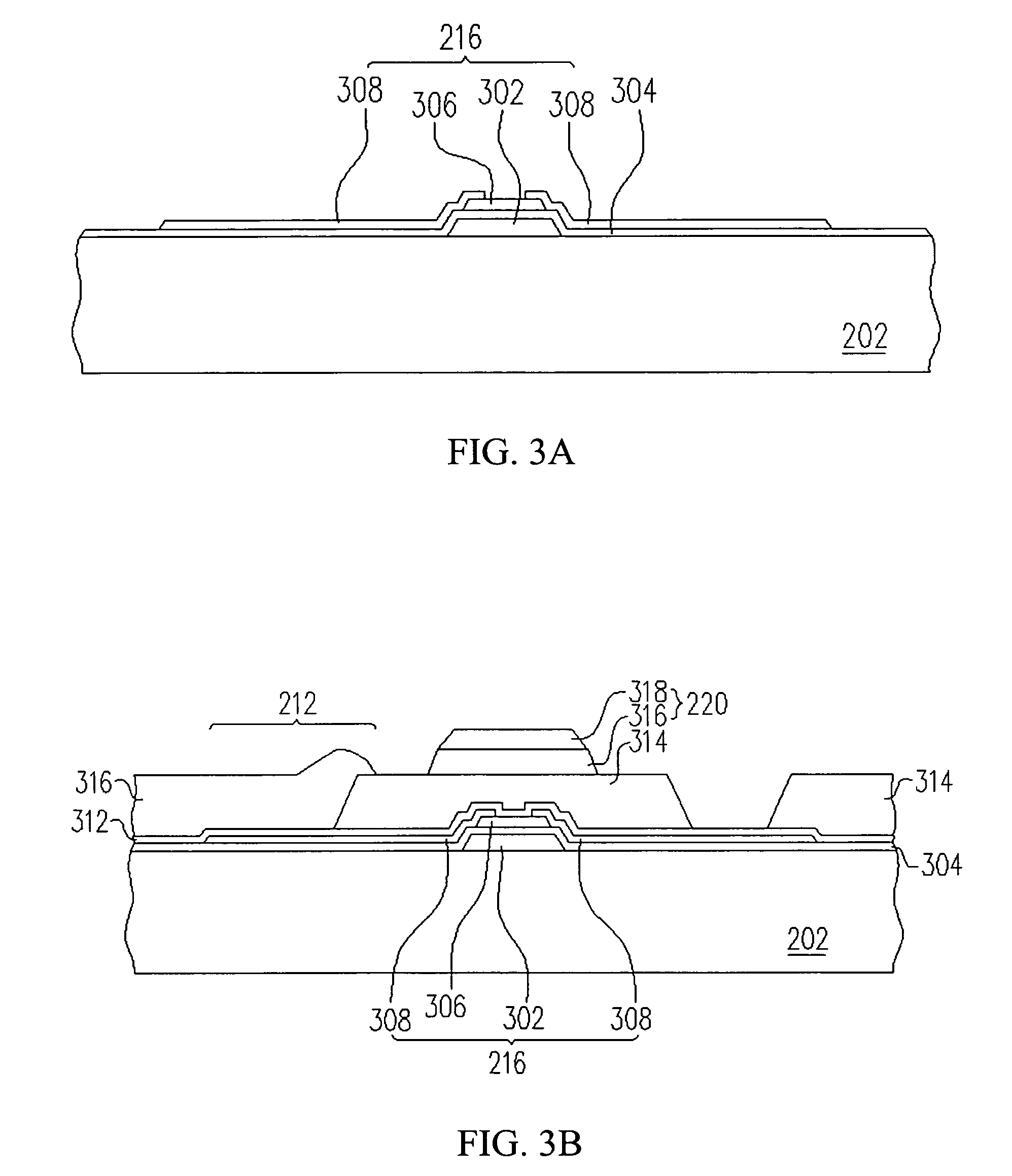

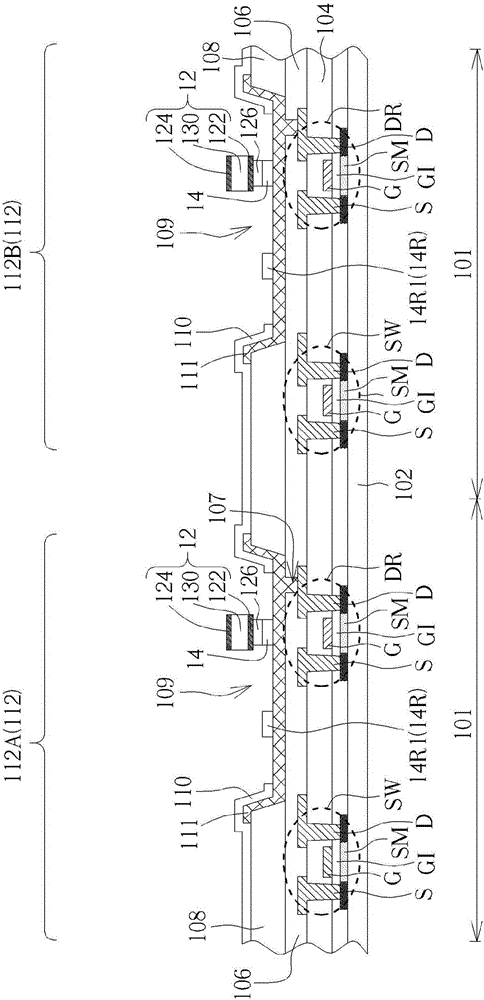

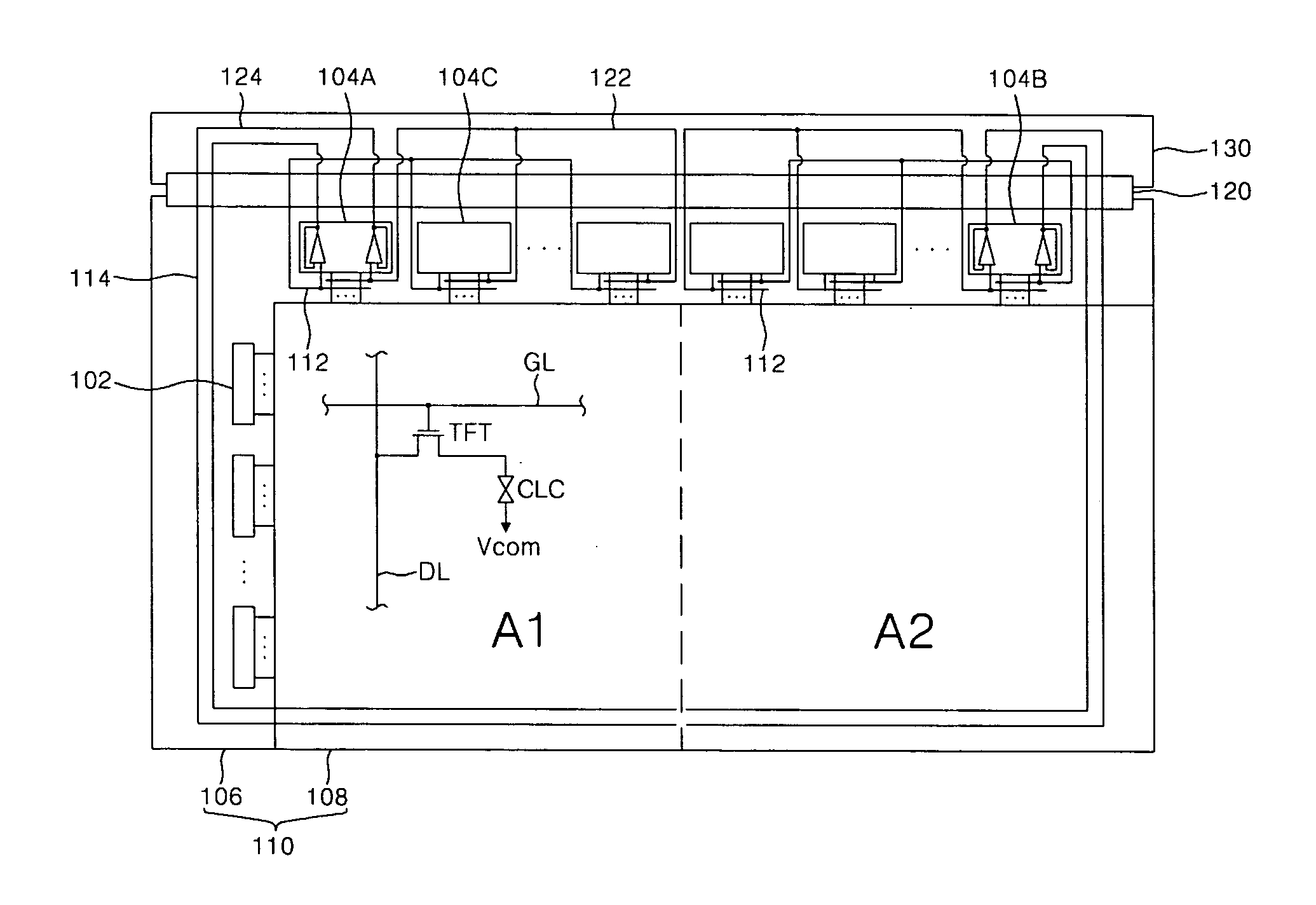

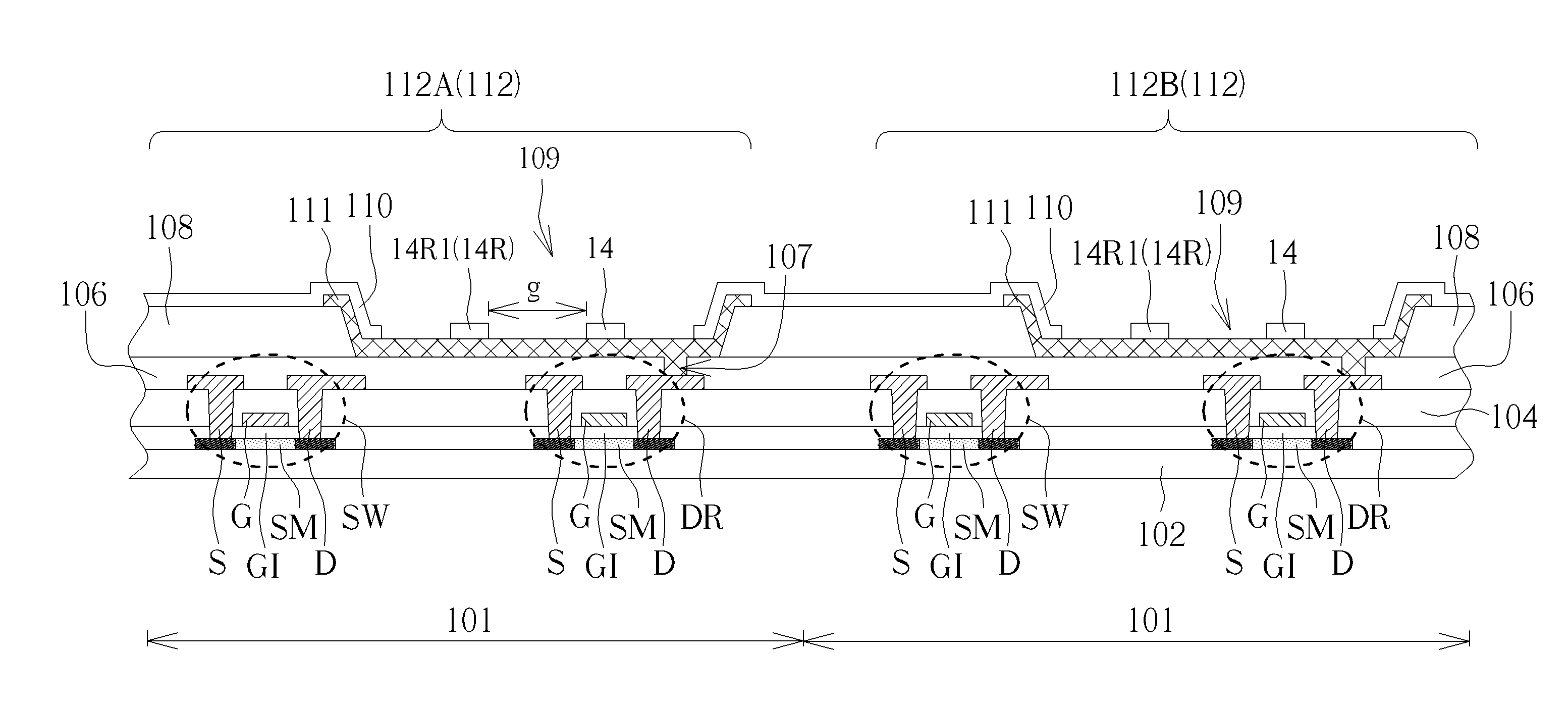

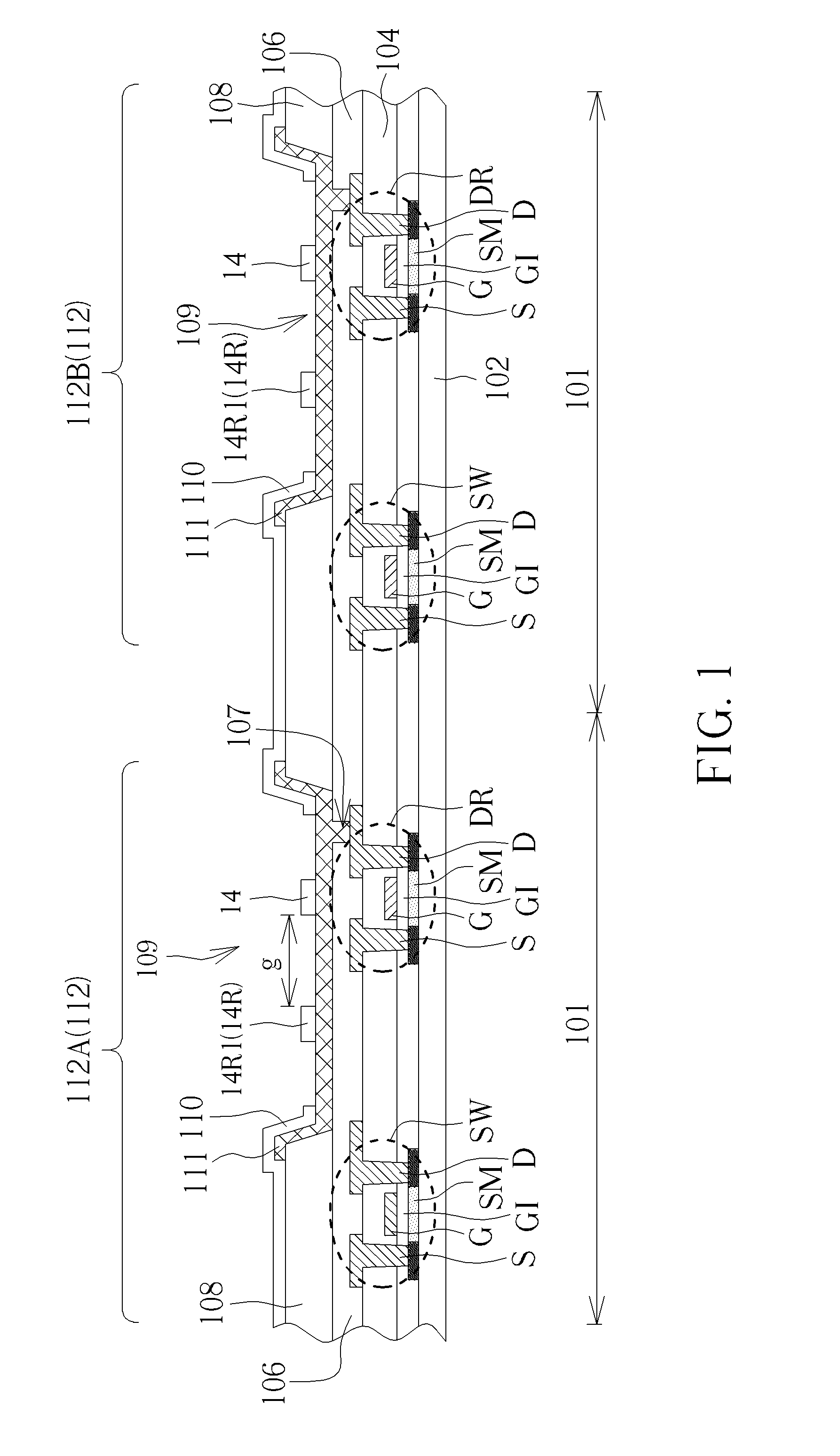

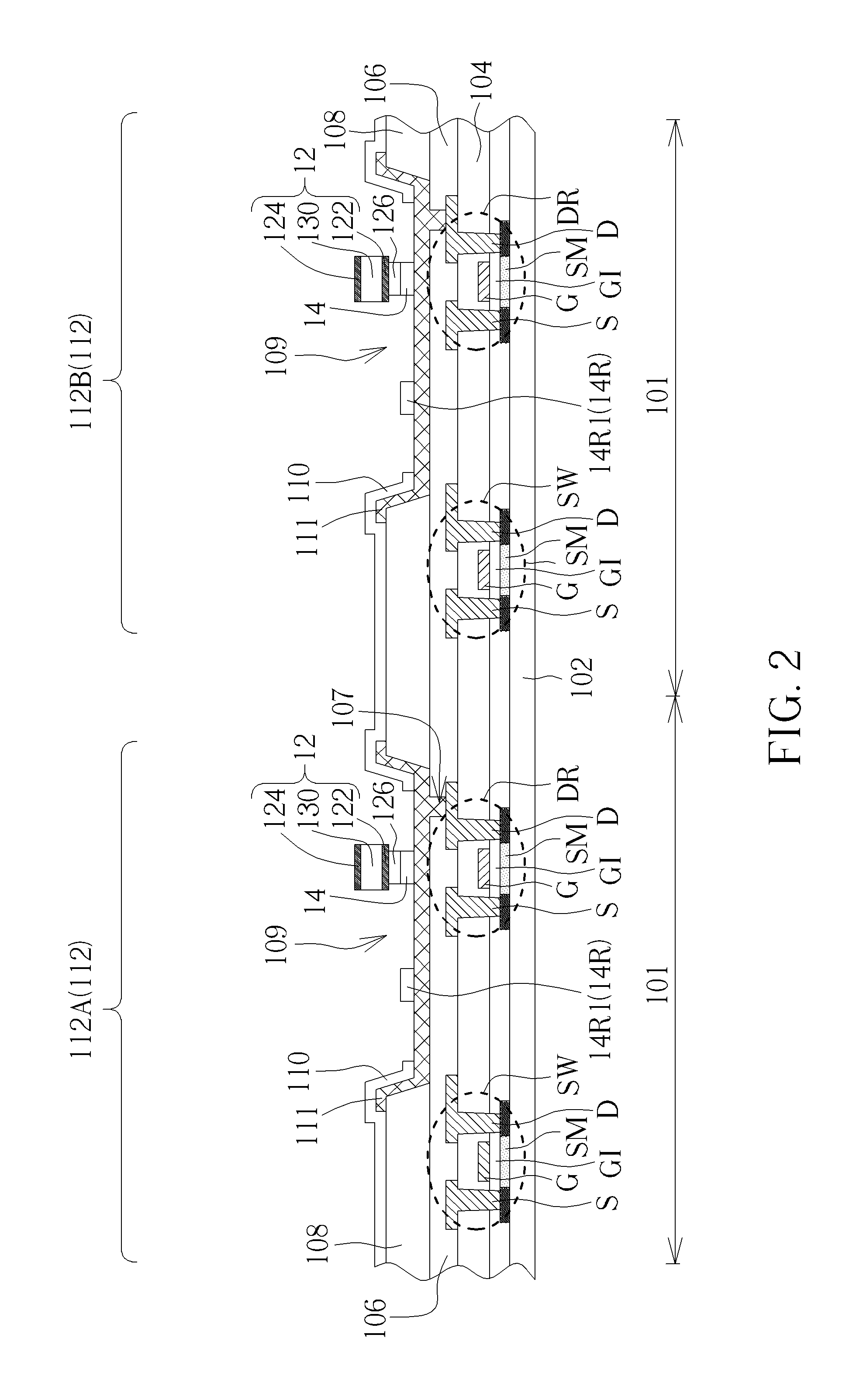

Thin film transistor liquid crystal display

A thin film transistor (TFT) liquid crystal display (LCD) panel, its array substrate, and its manufacturing method. Color filters are integrated on the TFT array, and color filter stacks are formed on the thin film transistors to replace a black matrix, thereby reducing manufacturing time and costs. The color filter stacks can be placed at the border of the display area of the panel to reduce light leakage. The border of the display area has a liquid crystal injection hole. To allow the size of the liquid crystal injection hole to be increased, and to reduce the light leakage at the hole, color filter blocks and overlapping metal layers can be used at the border of the display area. The color filter stacks and other dielectric layers need to be away from the welding points of repair structures to prevent dielectric layer bursts during a repair process. Storage capacitors can use the feature described above so that the color filters are positioned away from the overlapping portions. Welding is used to improve the electrical contact between the metal layers and the pixel electrode.

Owner:INNOLUX CORP

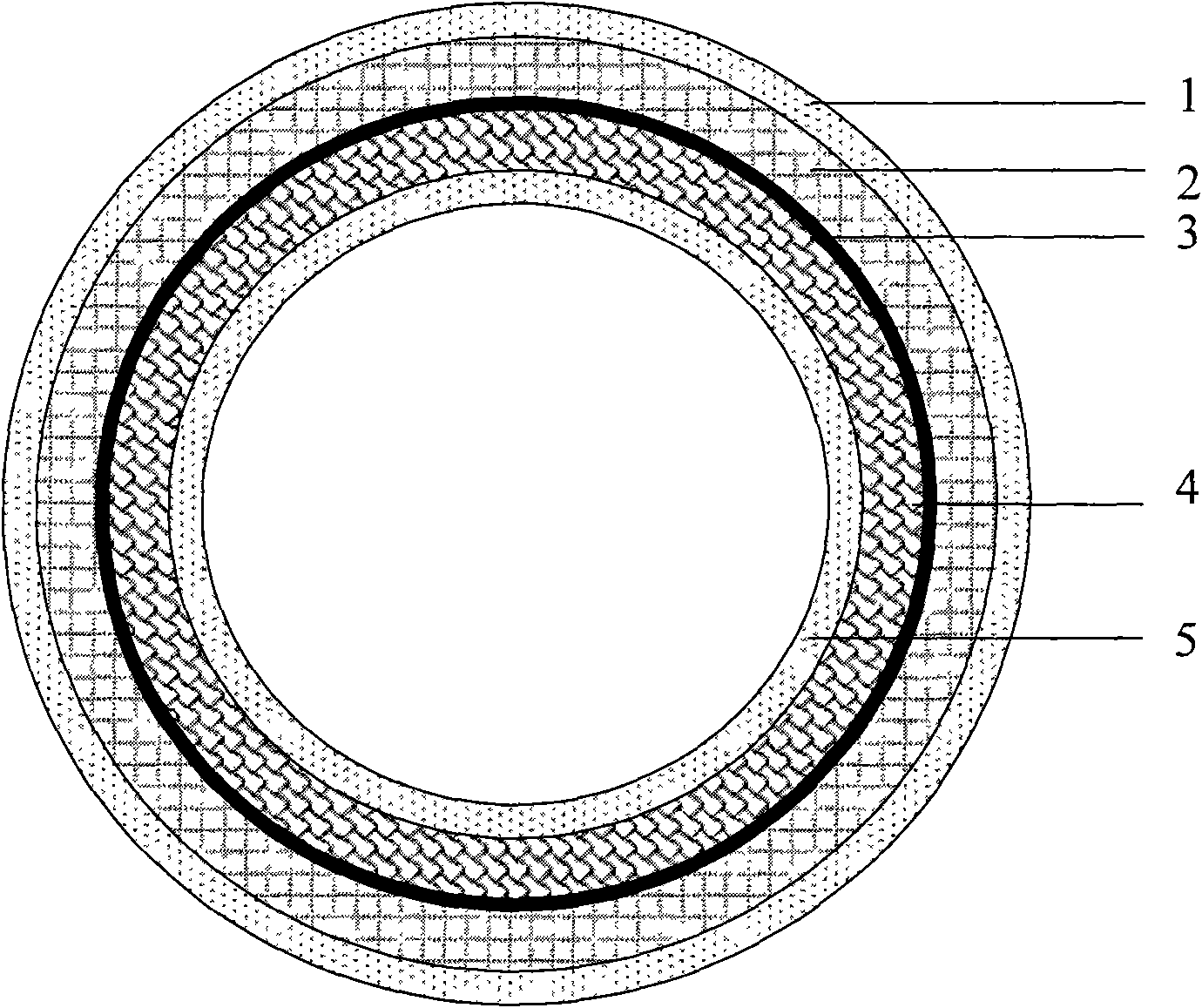

Regeneration type artificial blood vessel based on in-situ self stem cell technology and preparation method thereof

The present invention discloses a regeneration type artificial blood vessel based on an in-situ self stem cell technology and a preparation method thereof. The artificial blood vessel is a structure composed of at least three connected bionic support layers, wherein the bionic support layer is prepared by nanometer bionic supports and hydrosol attached to the nanometer bionic supports; the structure is a concentric circle loop and has an inner layer, an insulating layer and an outer layer outwards; the hydrosol of the inner layer and the outer layer are packaged with one or more specificity antibodies and / or cytokines and / or adhered short peptides and / or medicaments. The preparation method includes preparing the inner layer by an electrostatic spinning; preparing the insulating layer on an external surface of the inner layer; preparing the outer layer on an external surface of the insulating layer. The artificial blood vessel of the invention may be degraded safely and automatically during a wound surface repair process, and defect blood vessel is repaired completely during the degradation process, thus a regenerative process and a normal differentiation process are identical, and a good repairing effect will be obtained.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Display panel and repairing method thereof

InactiveCN105023522AGuaranteed normal operationStatic indicating devicesSolid-state devicesComputer scienceRepair method

The invention provides a display panel and a repairing method thereof. The repairing method comprising the steps of: a) providing a display panel, which comprises a substrate and a plurality of pixel units. The plurality of pixel units are disposed on the substrate, wherein each pixel unit comprises at least one connection pad, the at least one light-emitting element and at least a first alternate connection pad, the connection pad is provided on the substrate, the light emitting element is disposed on the connection pad and pad electrically connected with the connection, and the first backup connection pad is provided on the substrate and the connection pads electrically connected; 2) a testing process to determine whether the light emitting element is in an abnormal state function; and 3) a repair process, when detecting that the light emitting element of a pixel unit functional abnormality, there is provided a first light emitting element so as to form a first alternate alternate abnormality in the light emitting element having a function of pixel cells connected to the pad. Through the repair method, each pixel unit Jieneng normal operation and emits preset light color.

Owner:AU OPTRONICS CORP

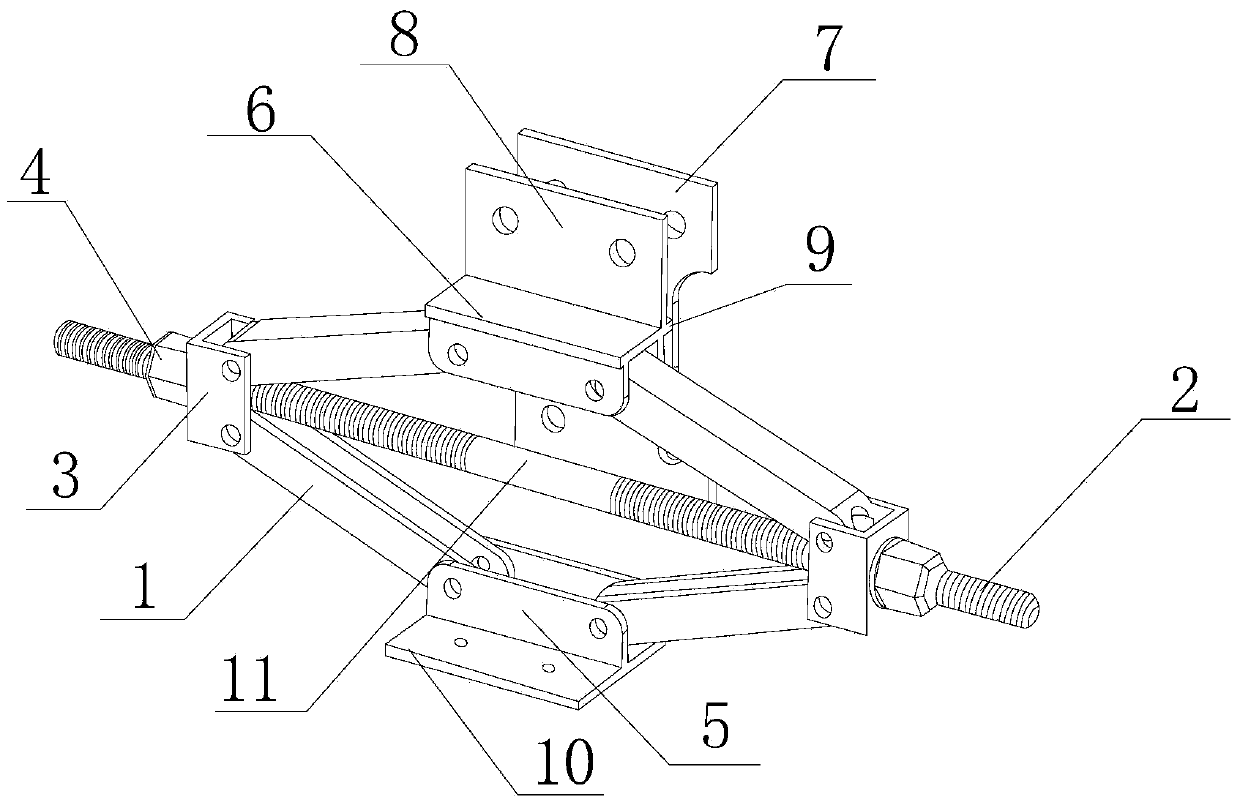

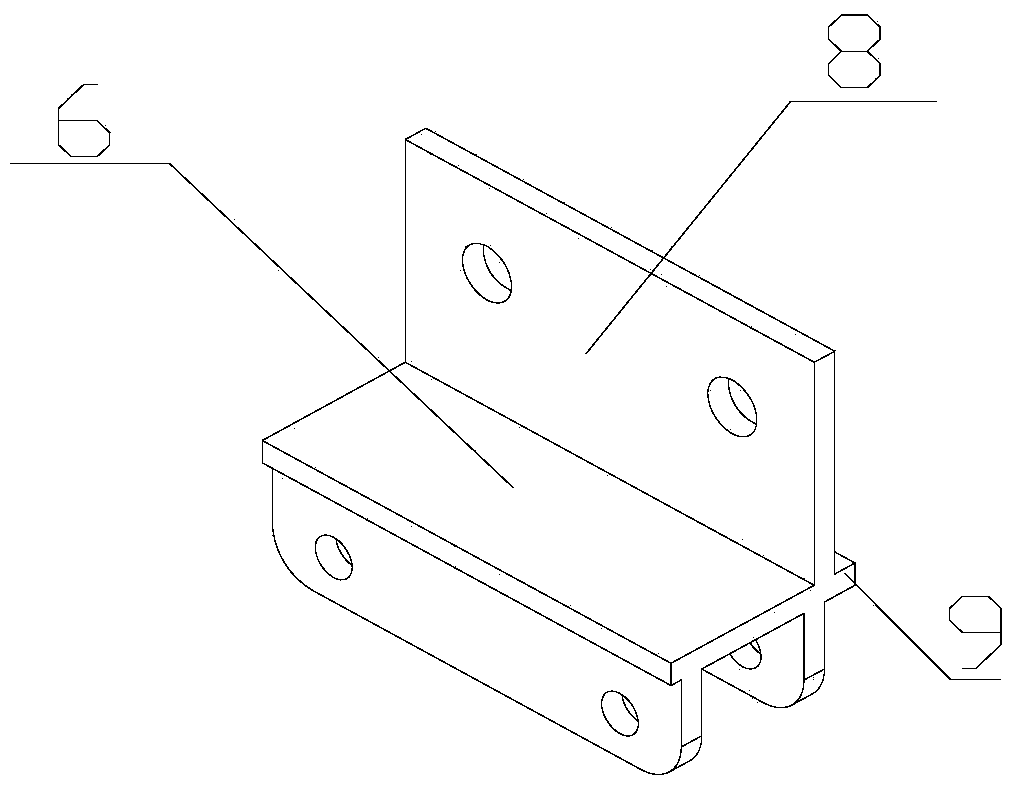

Ballastless track board lifting support

ActiveCN103434970AAvoid damageLower the altitudeLifting devicesRailway track constructionEngineeringTruck

The invention relates to the field of communication and transportation, in particular to a ballastless track board lifting support. The ballastless track board lifting support comprises a threaded rod, a plurality of buckles, two fixing nuts matched with the threaded rod, and four supporting rods made of channel steel; the ends of two adjacent supporting rods are rotationally connected with one buckle, and the four supporting rods are connected end to end in sequence to form a quadrilateral supporting frame; the lengths of two adjacent supporting rods in the supporting frame are the same; the threaded rod penetrates through two through holes in one group of the symmetrical buckles in the support at the same time to be connected with the through holes in a sleeved mode, and the two fixing nuts are arranged at the two ends of the threaded rod to be used for positioning the two buckles; in another group of vertexes, one vertex is fixed onto a base board through one buckle, and the other vertex is fixed onto a truck board through one buckle. According to the ballastless track board lifting support, concentrated stress on the damaged track board in a lifting process is reduced, and therefore the possibility that the track board is damaged in a lifting repair process is further reduced.

Owner:SOUTHWEST JIAOTONG UNIV

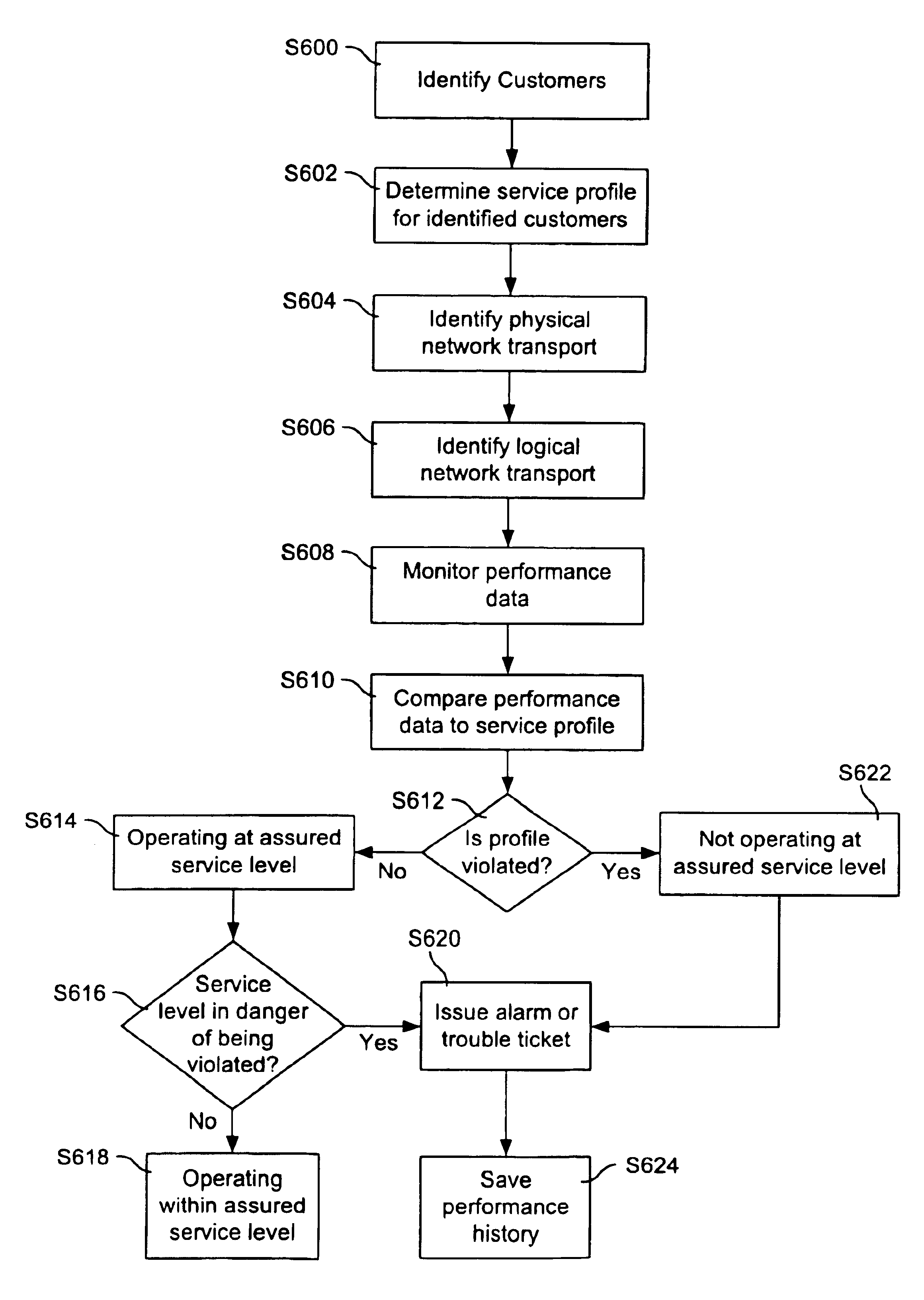

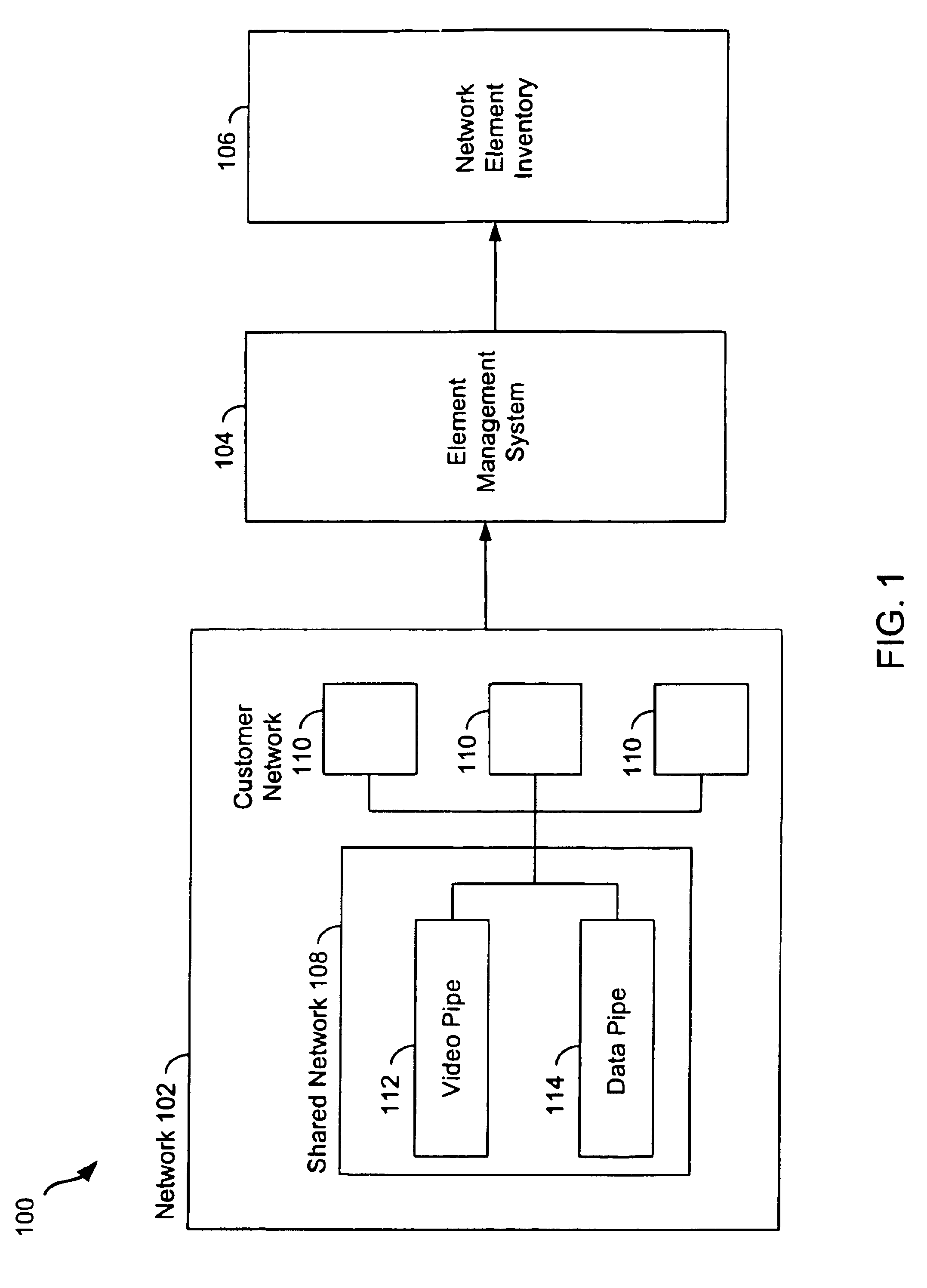

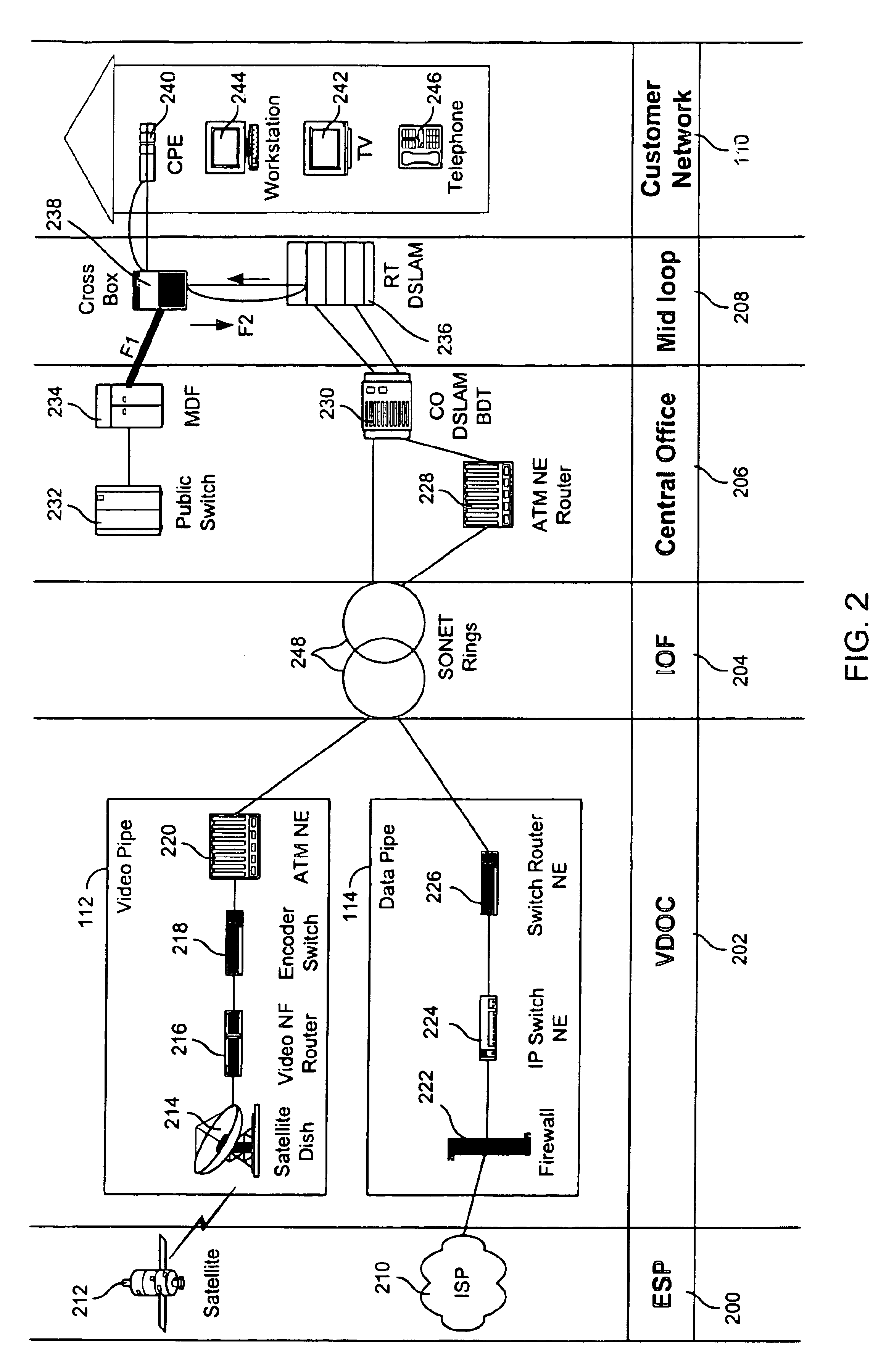

Proactive repair process in the xDSL network (with a VDSL focus)

InactiveUS6901530B2Increase bitrateData processing applicationsError detection/correctionDistributed computingRepair processes

A method for proactively managing a fault in a video and data network is provided. The method includes collecting network correlation data for the fault. Additionally, a physical connectivity test of the video and data network is automatically performed. Physical connectivity data from the physical connectivity test is collected. Also, a virtual connectivity test of the video and data network is automatically performed. Virtual connectivity data from the virtual connectivity test is collected. The network correlation data, physical connectivity data, and virtual connectivity data is then correlated based on the fault. Once the correlation is performed, a defined resolution procedure for resolving the fault using the correlated network correlation data, physical connectivity data, and virtual connectivity data is provided.

Owner:QWEST

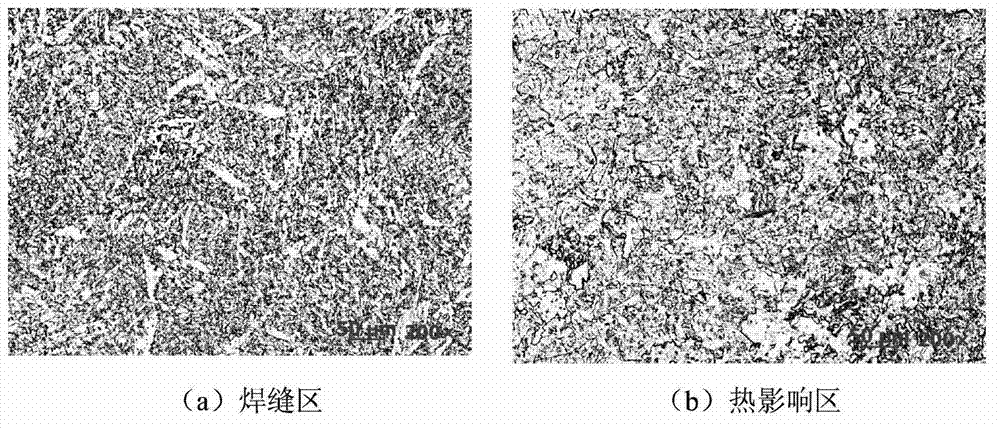

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

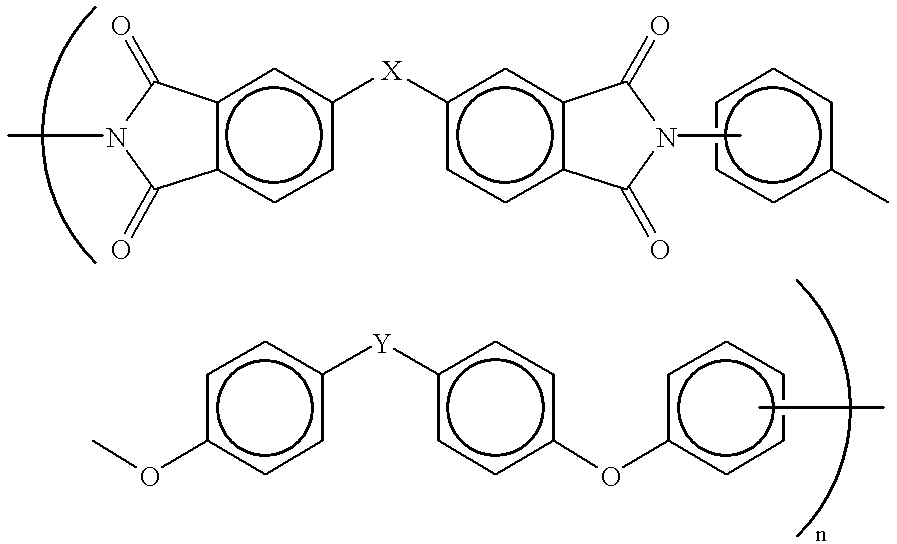

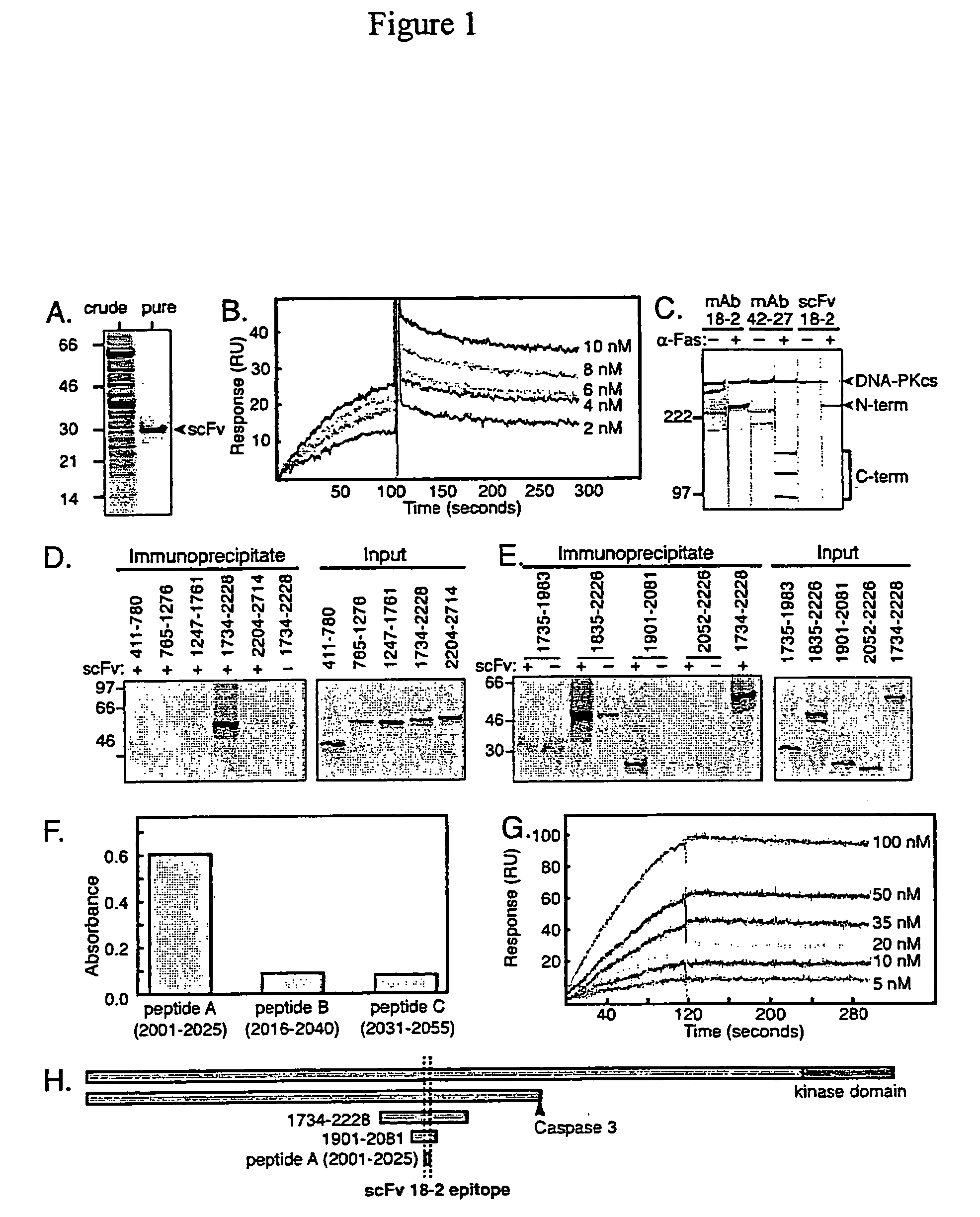

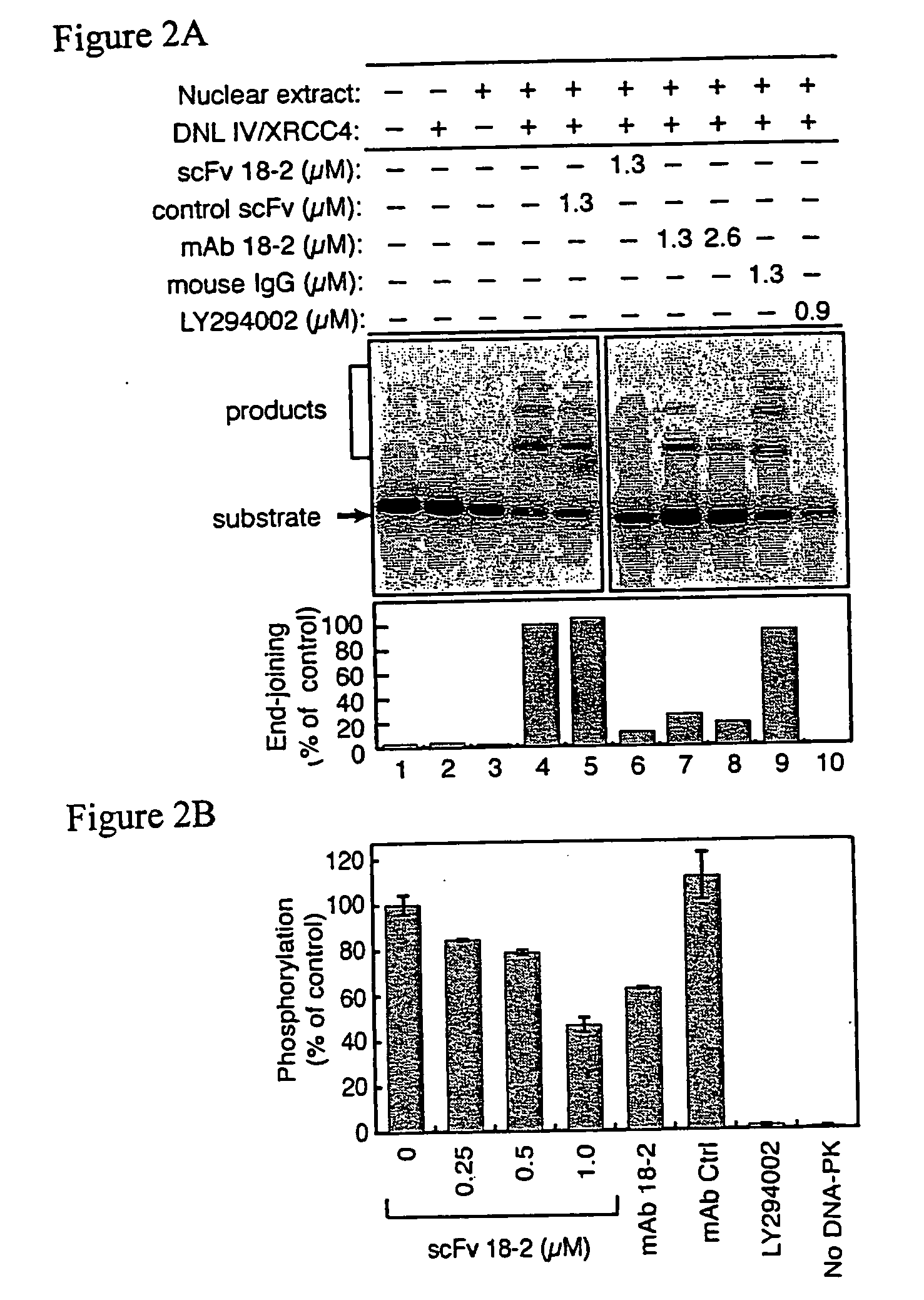

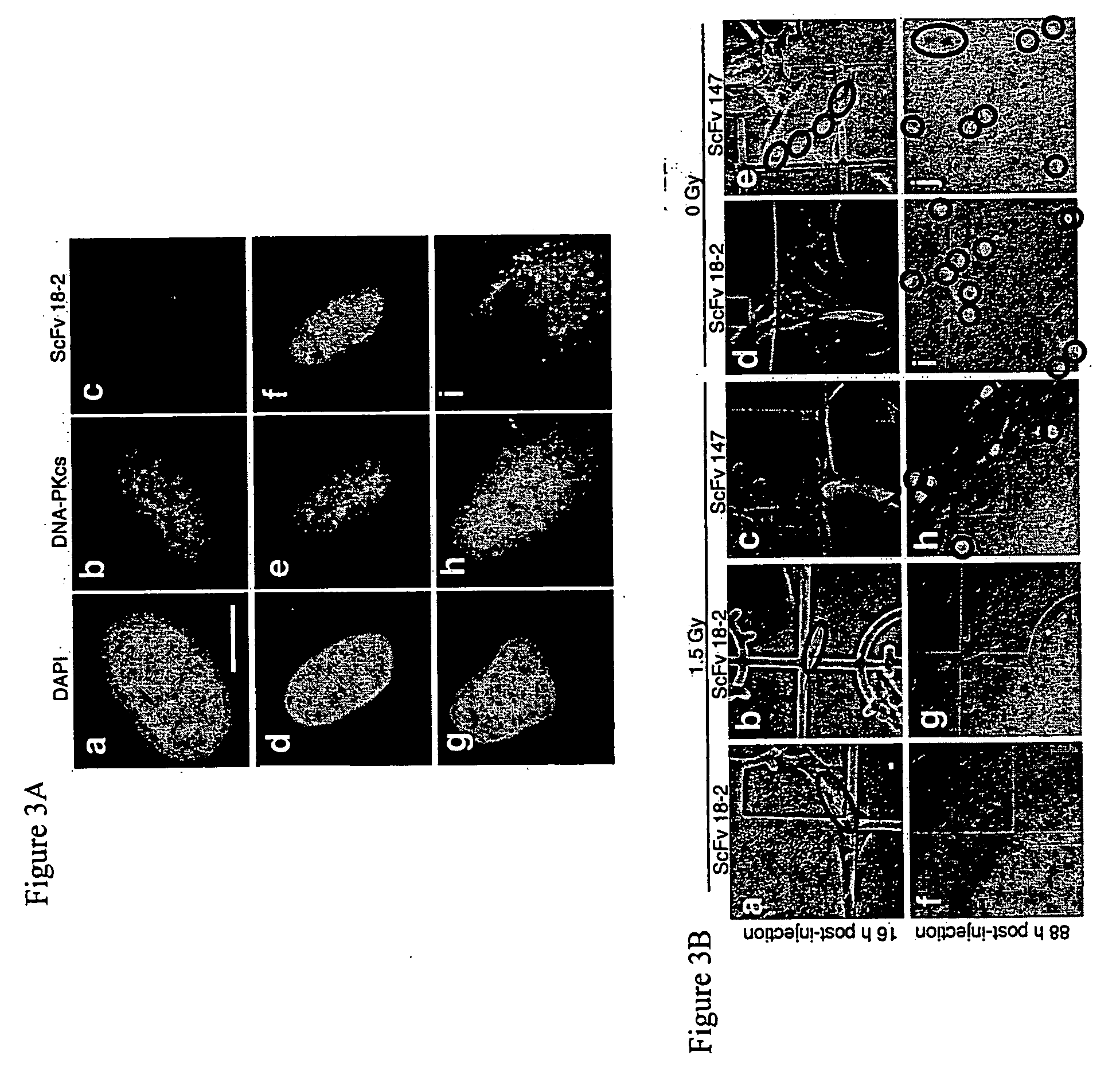

Compositions and methods for modulating DNA repair

InactiveUS20050220796A1Reduce and prevent formationConvenient introductionCompound screeningApoptosis detectionA-DNAIn vivo

Compositions and methods for modulating a DNA repair process in vivo or in vitro are provided. One aspect of the disclosure provides a pharmaceutical composition including a DNA repair modulator. The DNA repair modulator includes, but is not limited to, compositions such as polypeptides, for example antibodies; modified polypeptides; and branched or unbranched aliphatic, cycloaliphatic, substituted aliphatic, aromatic hydrocarbons, or heterocyclic carbon-based compounds that associate with a DNA repair polypeptide, for example, DNA-PKcs.

Owner:MEDICAL COLLEGE OF GEORGIA RES INST

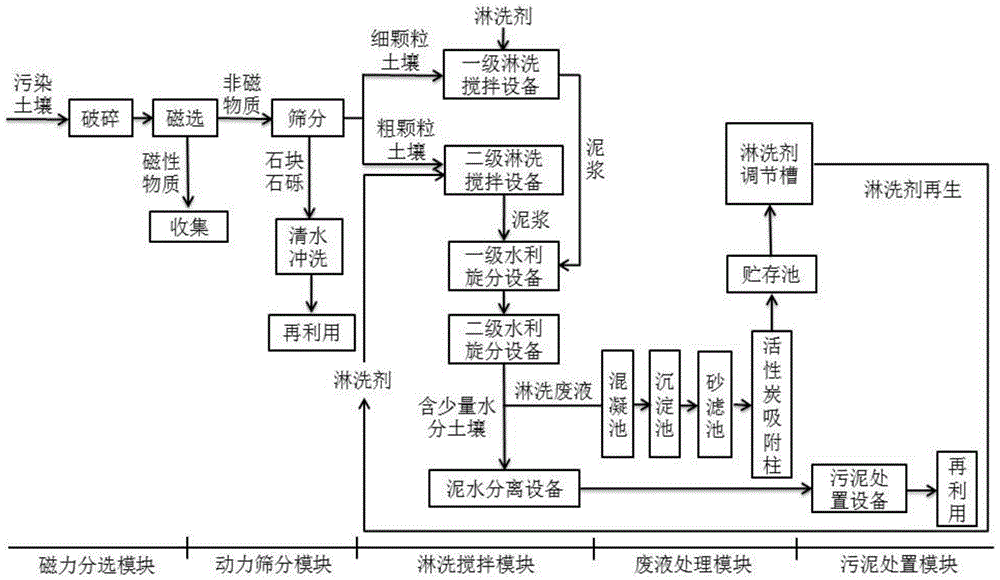

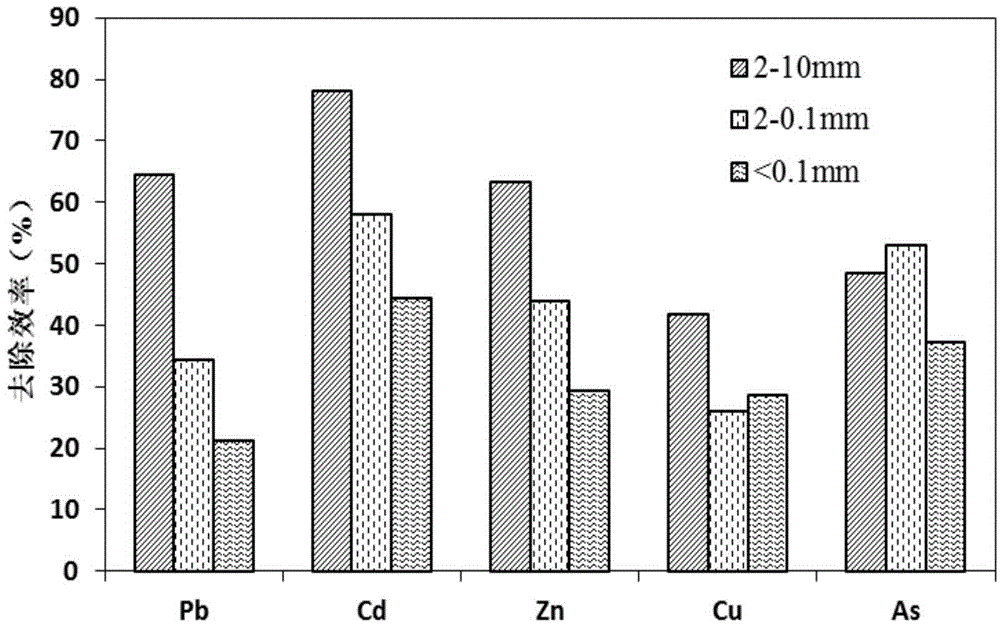

Ectopic classification leaching repair complete process of arsenic and heavy metal contaminated soil

ActiveCN104889149ASolve the regeneration problemSolve the recycling problemContaminated soil reclamationCyclonePrill

The invention discloses an ectopic classification leaching repair complete process of arsenic and heavy metal contaminated soil. The repair process comprises the following steps: the contaminated soil is magnetically separated to extract and recover target metals; a nonmagnetic component is divided into three grades by a vibrating screen after being primarily crushed; stones and boulders are flushed by clear water to directly serve as building materials; thick and fine soil particles obtained through screening respectively enter second-grade leaching mixing equipment for washing; the solid-liquid separation is performed for mud generated by washing through a two-stage hydraulic cyclone device; leaching waste liquid is purified and regenerated for recycling; sludge is added with such repair materials as curing / stabilizing agents for safety treatment after being dehydrated; and after the treatment, the soil particles can be backfilled, or can serve as roadbeds, building materials and the like. Based on the characteristic of large difference of arsenic and heavy metal contents in soils with different particle sizes, the soil leaching treatment according to the particle size is performed, so that the process has such advantages as low repair cost, high treatment efficiency and saving of energy consumption, provides a new method for soil heavy metal pollution abatement, and is broad in application prospect.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS +1

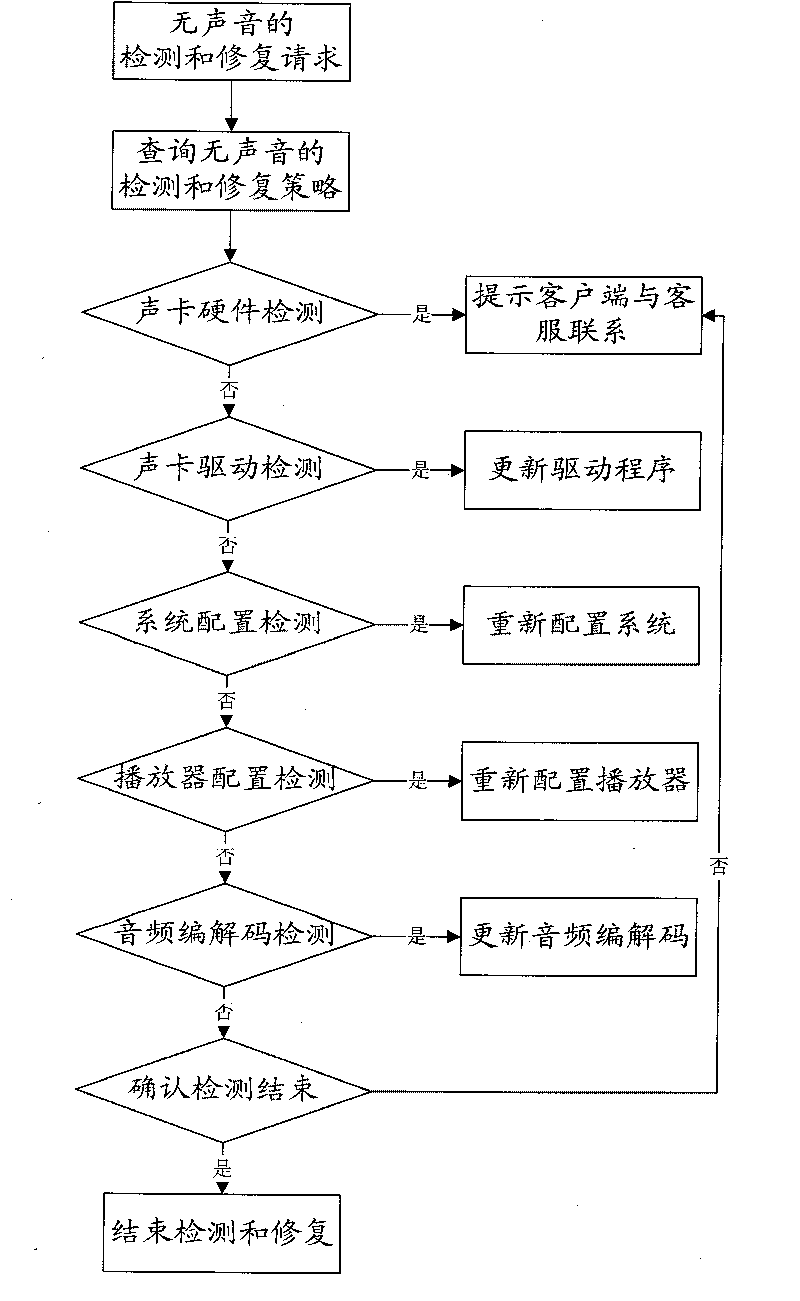

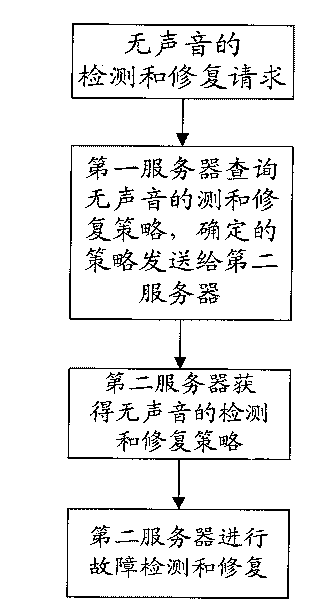

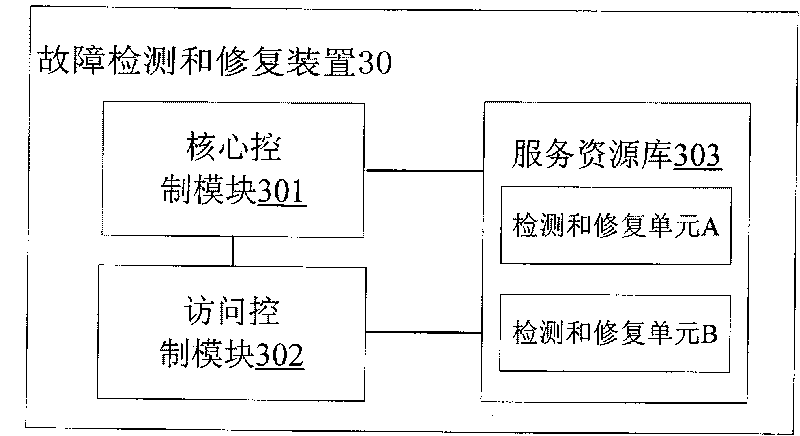

Method and device for fault detection

InactiveCN101719836AReduced phone costsLow costError detection/correctionData switching networksComputer scienceRepair method

The invention discloses a fault detection and repair method, which comprises the following steps: receiving a fault detection and repair request of a client, wherein the fault detection and repair request comprises fault information; correspondingly acquiring a detection and repair strategy according to the fault information; selecting at least one detection and repair unit according to the detection and repair strategy; receiving a detection result which is sent by the client after receiving a detection command and finishing the detection at a local place, wherein the detection command is sent by the detection and repair unit; and receiving the repair result which is sent by the client after receiving a repair command and finishing the repair at the local place, wherein the repair command is sent by the detection and repair unit according to the detection result. Therefore, the automatic and flow detection and repair processes are realized, the personnel cost is reduced, and the user feeling is enhanced.

Owner:LENOVO (BEIJING) CO LTD

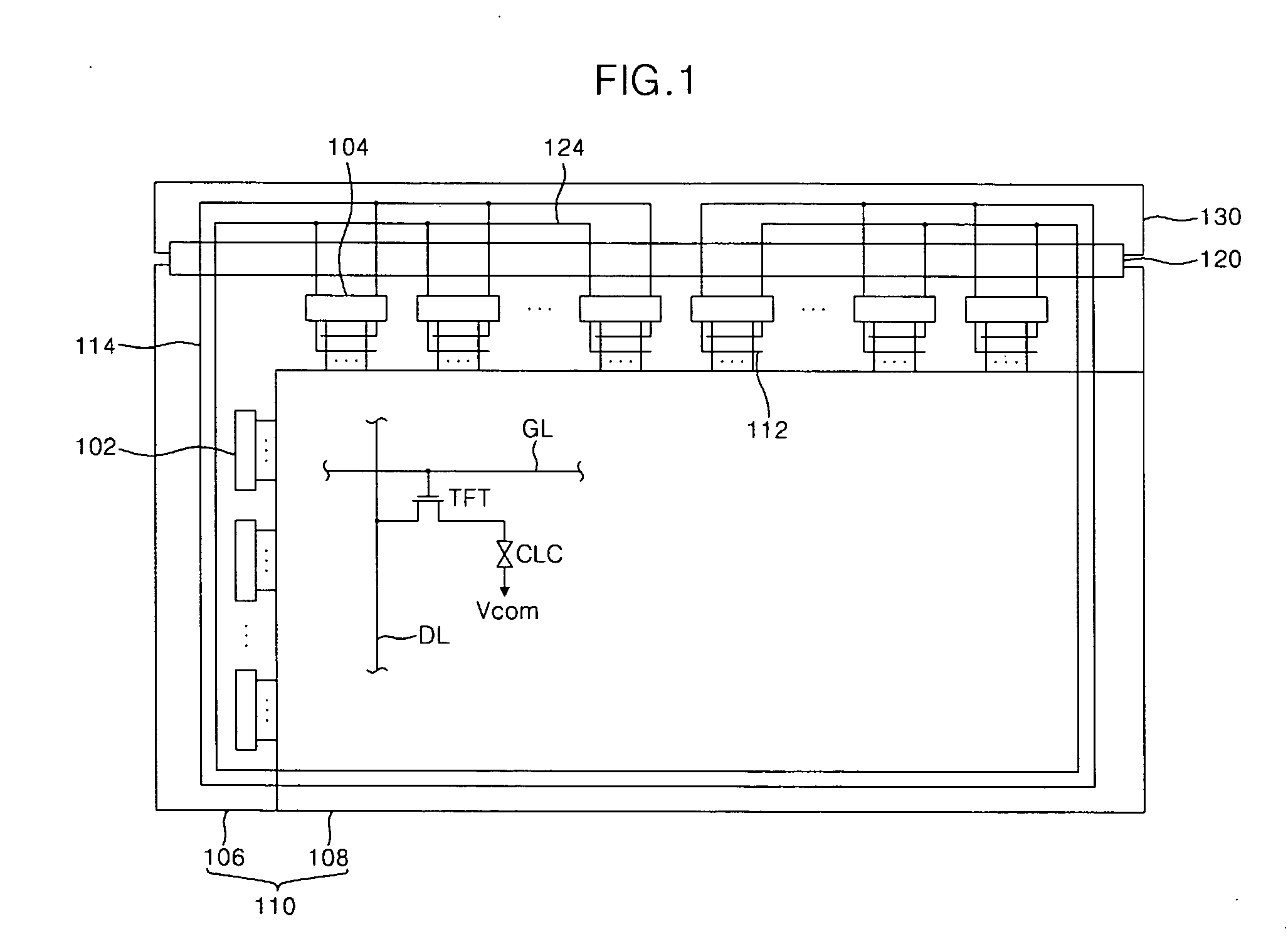

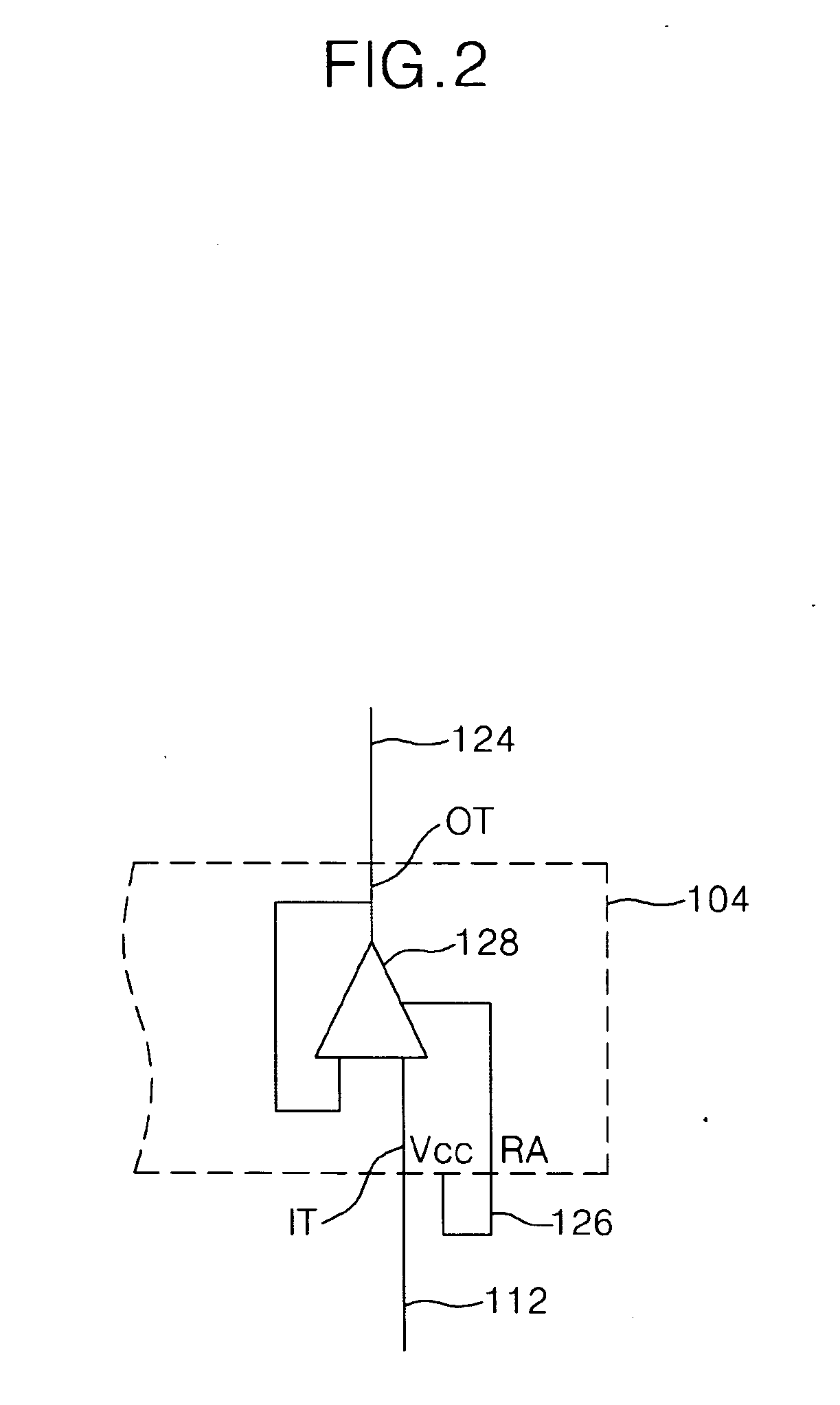

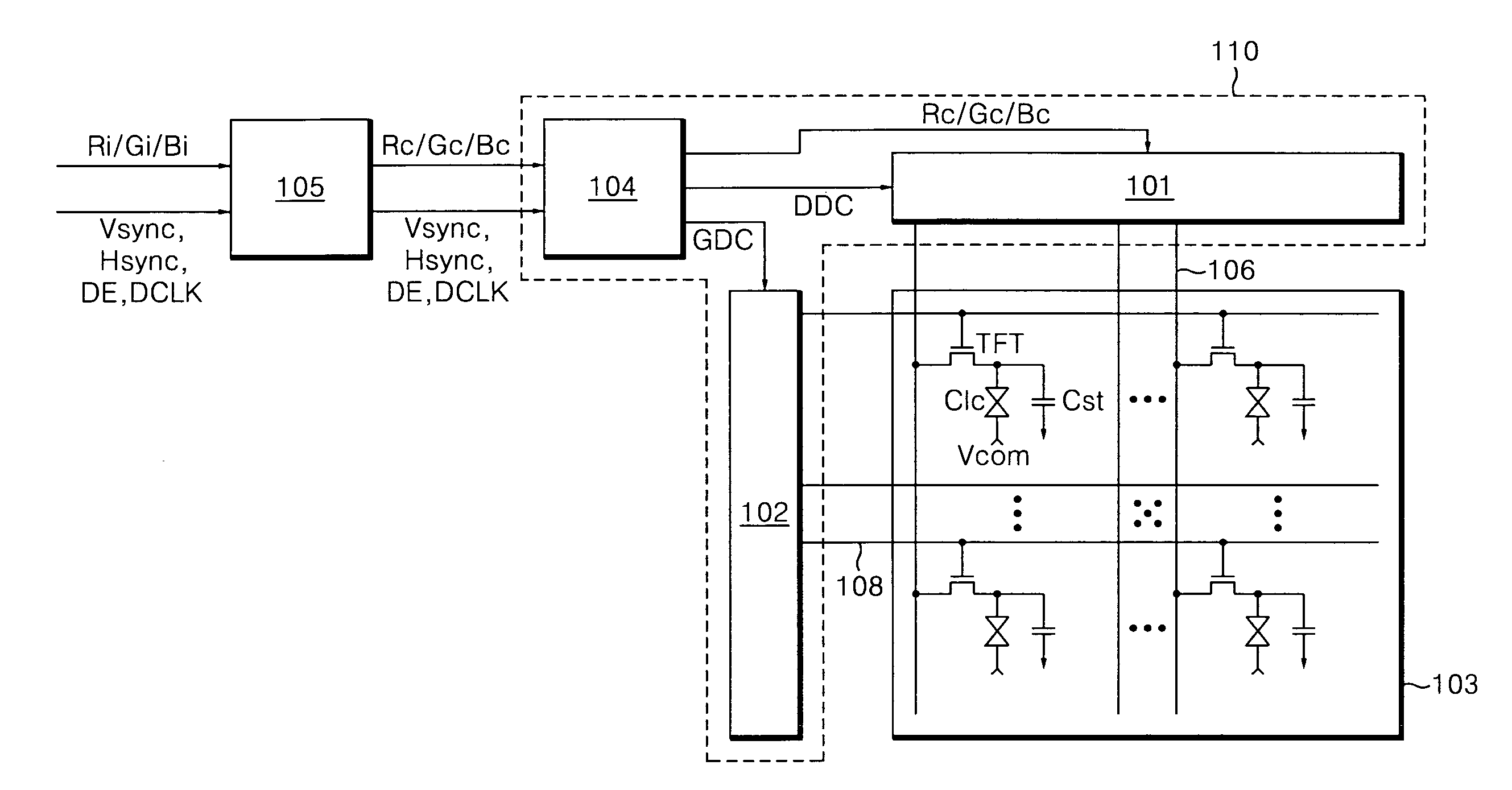

Liquid crystal display device repair system and method thereof

InactiveUS20070040794A1Static indicating devicesNon-linear opticsAudio power amplifierLiquid-crystal display

Disclosed are a liquid crystal display (LCD) device which can minimize power consumption and detect whether a repairing process is successful or not during a testing process, and testing and repairing methods thereof. The LCD device includes gate lines formed on a substrate, data lines formed on the substrate by crossing the gate lines, first and second repair lines for repairing at least one signal line of the data lines and gate lines, amplifiers for amplifying a driving signal supplied to the first repair line and supplying the amplified driving signal to the second repair line, and a first passing line to which input terminals of the amplifiers are commonly connected.

Owner:SAMSUNG ELECTRONICS CO LTD

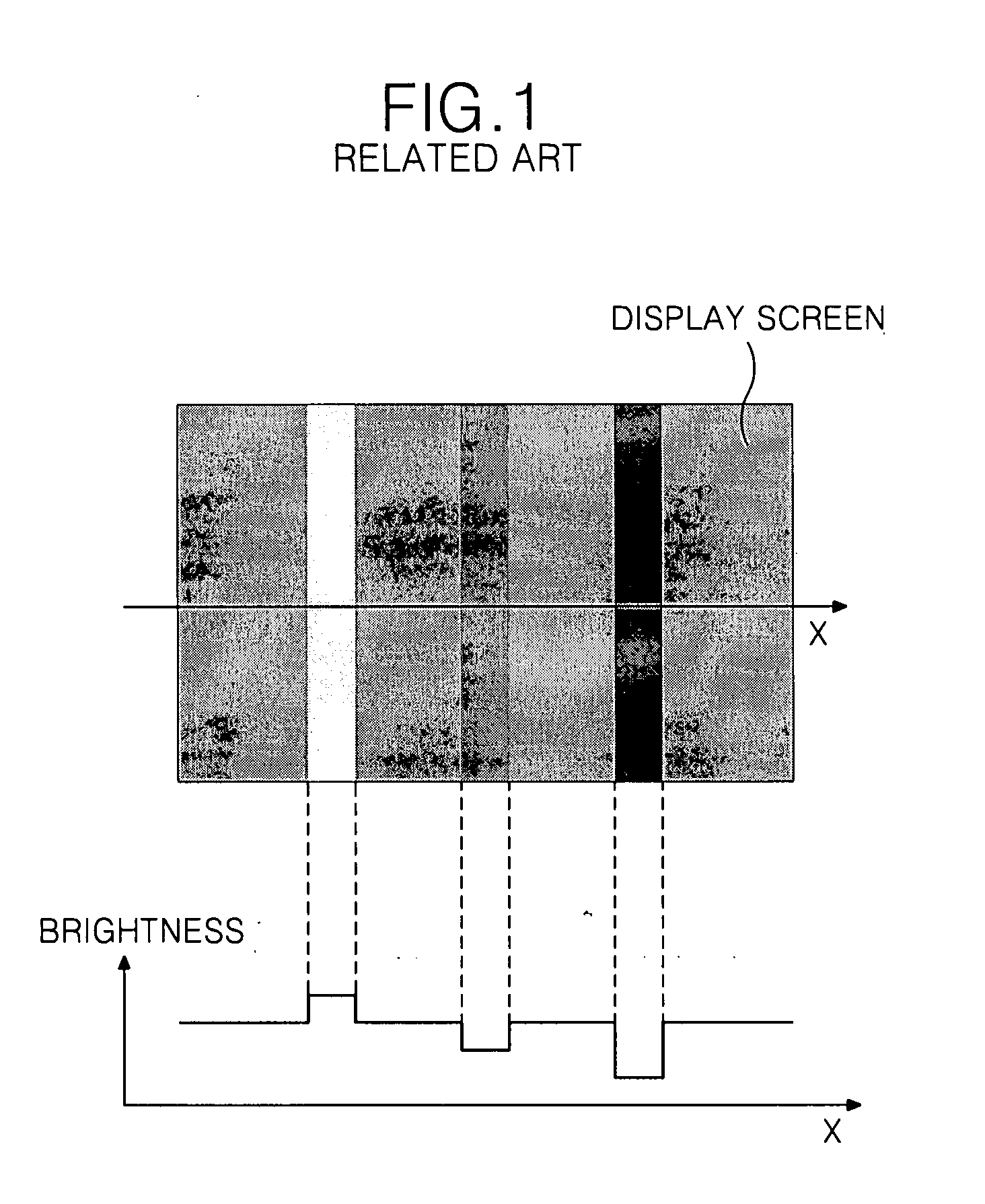

Flat panel display and method of controlling picture quality thereof

ActiveUS20080068324A1Color signal processing circuitsCathode-ray tube indicatorsFlat panel displayImage quality

This invention relates to a flat panel display device that is adaptive for optimizing data, which are to be displayed in a panel defect area, in used of a compensation value of a compensation circuit as well as compensating defect pixels by a repair process, and a method of controlling a picture quality thereof. A flat panel display device according to an embodiment of the present invention includes a display panel; a memory which stores a first compensation data, a second compensation data and a third compensation data; a first compensation part; a second compensation part; a third compensation part; and a driver for driving the display panel in use of the data modulated by the first to third compensation parts.

Owner:LG DISPLAY CO LTD

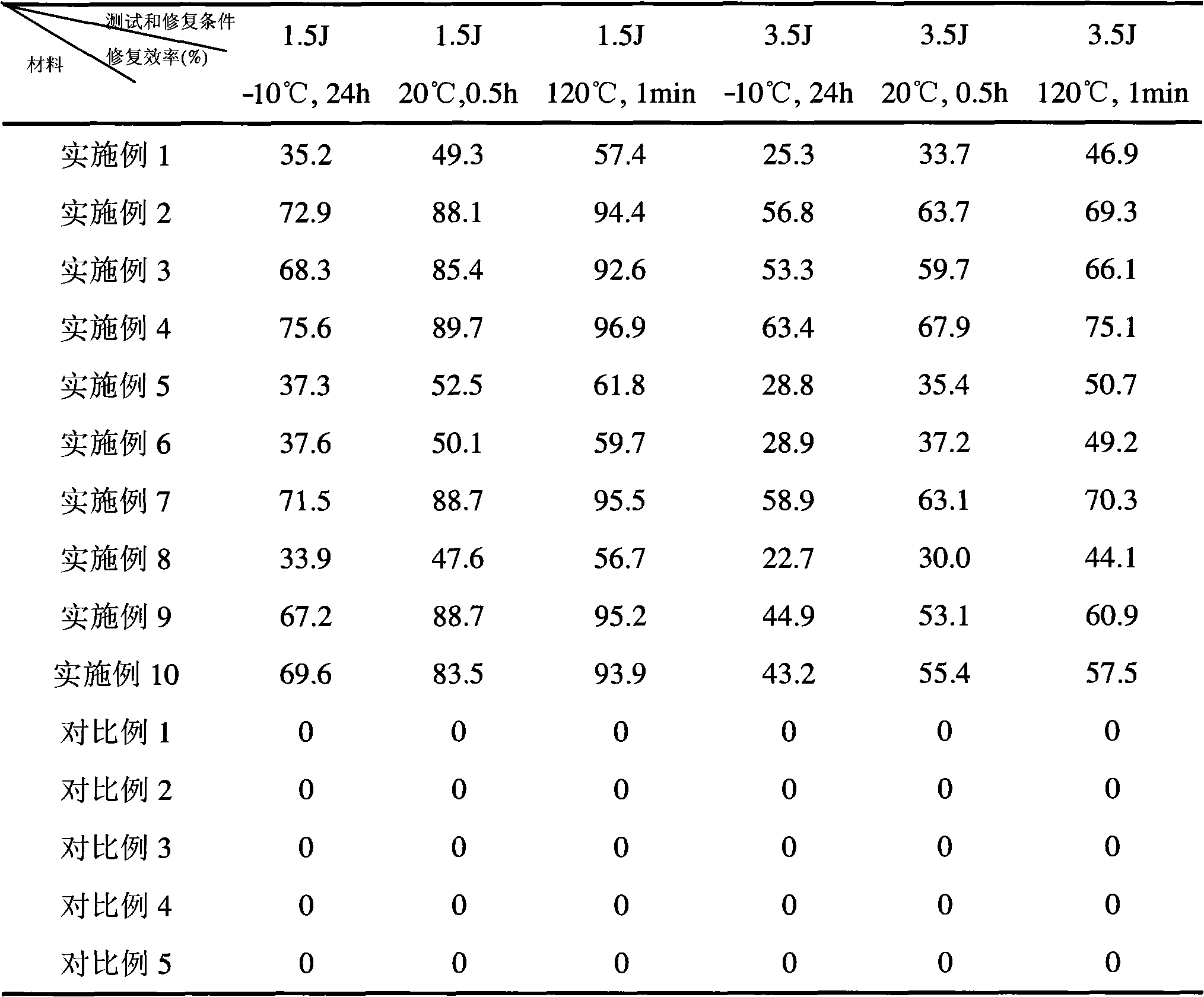

Self-repairing fiber reinforced polymer matrix composite and preparation method thereof

The invention discloses a self-repairing fiber reinforced polymer matrix composite and a preparation method thereof. In the method, a double-capsule repairing system respectively containing epoxy resin prepolymer and curing agent is evenly mixed into a resin matrix, then, the matrix curing agent and catalyst are added to be evenly mixed, the obtained mixture is used for dipping fiber reinforcing material, and at last, the self-repairing fiber reinforced polymer matrix composite is obtained by solidifying and shaping. When the self-repairing composite of the invention generates cracks or fiber unsticking damage owing to heat, force, environment corrosion and the like during processing, storing and using process, cracks pass through a restorative capsule which cracks along with the matrix to release reacting substance and quickly polymerize, thus preventing crack from expanding, repairing crack damage, keeping the mechanical property of the composites and prolonging the service life thereof. The self-repairing composite prepared by the invention can automatically finish repairing cracks at the temperature of negative 50-250 DEG C, and the repairing process totally needs no artificial intervention.

Owner:SUN YAT SEN UNIV

Display panel and repairing method thereof

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com