Ballastless track board lifting support

A ballastless track and track slab technology, applied in tracks, track laying, track maintenance, etc., can solve problems such as increasing construction difficulty, local track slab crack damage, and insufficient temporary support stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

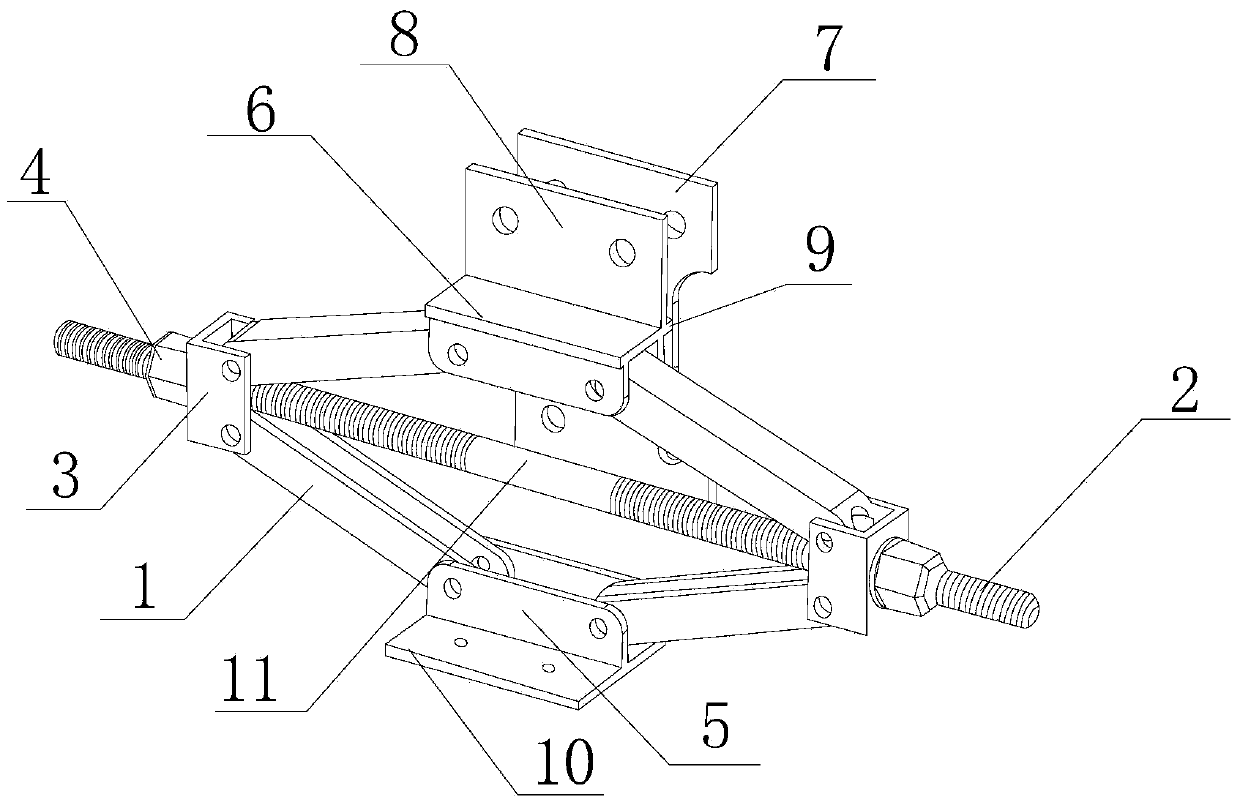

[0020] Embodiment 1: as figure 1 as shown,

[0021] A lifting bracket for a ballastless track slab, comprising: a threaded rod 2, a plurality of buckles, two fixing nuts 4 matched with the threaded rod 2, and four support rods 1 made of channel steel;

[0022] The ends of the two adjacent support rods 1 are all connected to one of the buckles in rotation, and the four support rods 1 are connected end to end in turn to form a quadrilateral support frame; the two adjacent support rods in the support frame The lengths of the support rods 1 are equal;

[0023] On the support frame, a set of symmetrical buckles is provided with a through hole for the threaded rod 2 to pass through, and the threaded rod 2 passes through the two through holes and the buckle at the same time. Socketing, the two fixing nuts 4 are arranged at both ends of the threaded rod 2 for positioning the two buckles;

[0024] In another set of vertices, one of the vertices is fixed on the base plate through the...

Embodiment 2

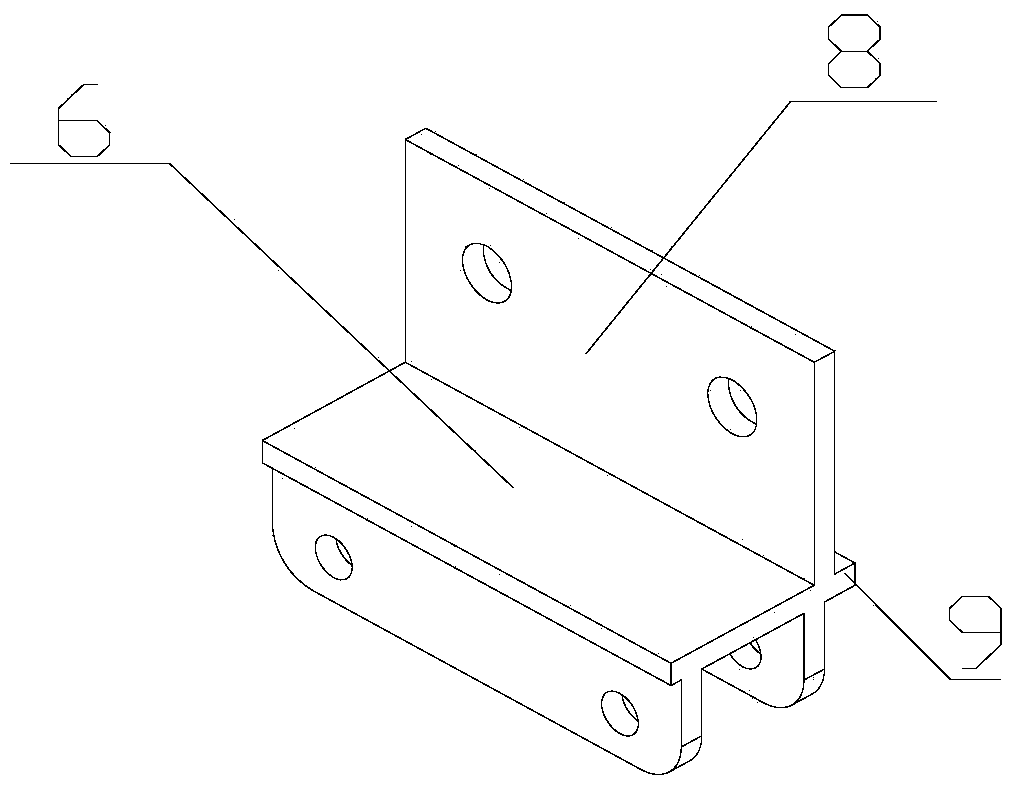

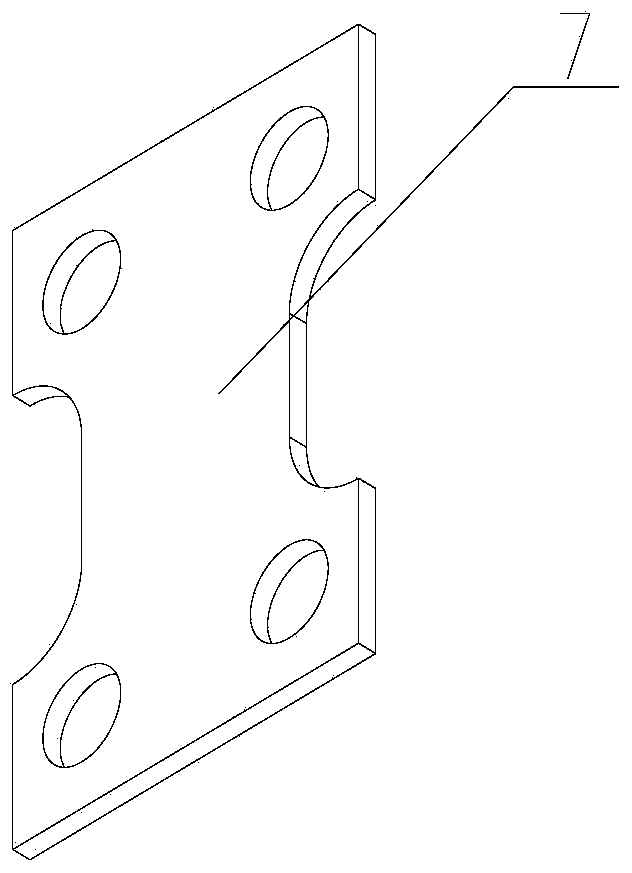

[0026] Embodiment 2: as Figure 2 to Figure 6 as shown,

[0027] A lifting bracket for a ballastless track slab, comprising: a threaded rod 2, a plurality of buckles, two fixing nuts 4 matched with the threaded rod 2, and four support rods 1 made of channel steel;

[0028] The ends of the two adjacent support rods 1 are all connected to one of the buckles in rotation, and the four support rods 1 are connected end to end in turn to form a quadrilateral support frame; the two adjacent support rods in the support frame The lengths of the support rods 1 are equal;

[0029] On the support frame, a set of symmetrical buckles is provided with a through hole for the threaded rod 2 to pass through, and the threaded rod 2 passes through the two through holes and the buckle at the same time. Socketing, the two fixing nuts 4 are arranged at both ends of the threaded rod 2 for positioning the two buckles;

[0030] In another set of vertices, one of the vertices is fixed on the base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com