Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce plasma damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

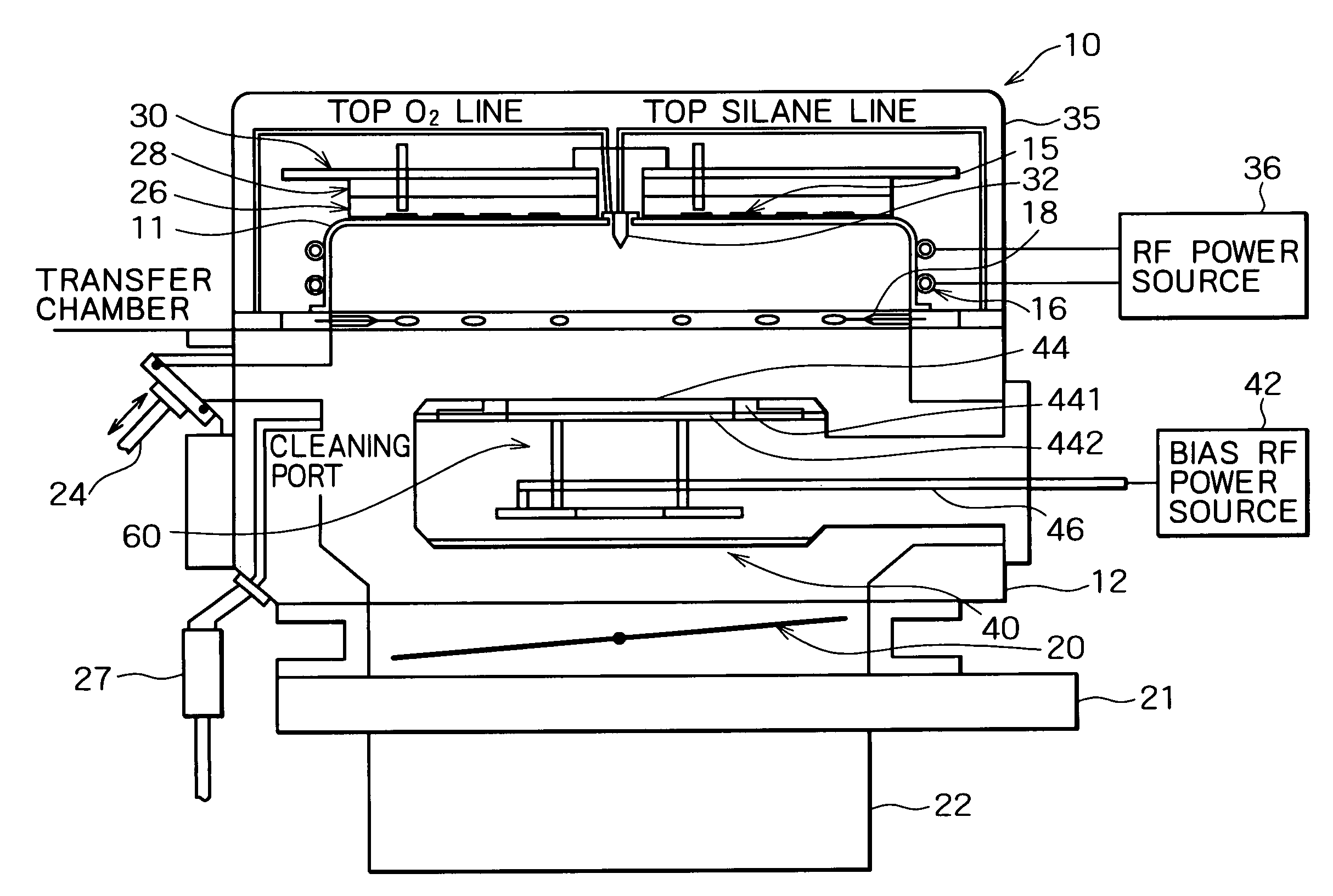

Film deposition apparatus, film deposition method and storage medium

ActiveUS20130059415A1Reduce plasma damageAvoid passingLiquid surface applicatorsElectric discharge tubesEngineeringPlasma Gases

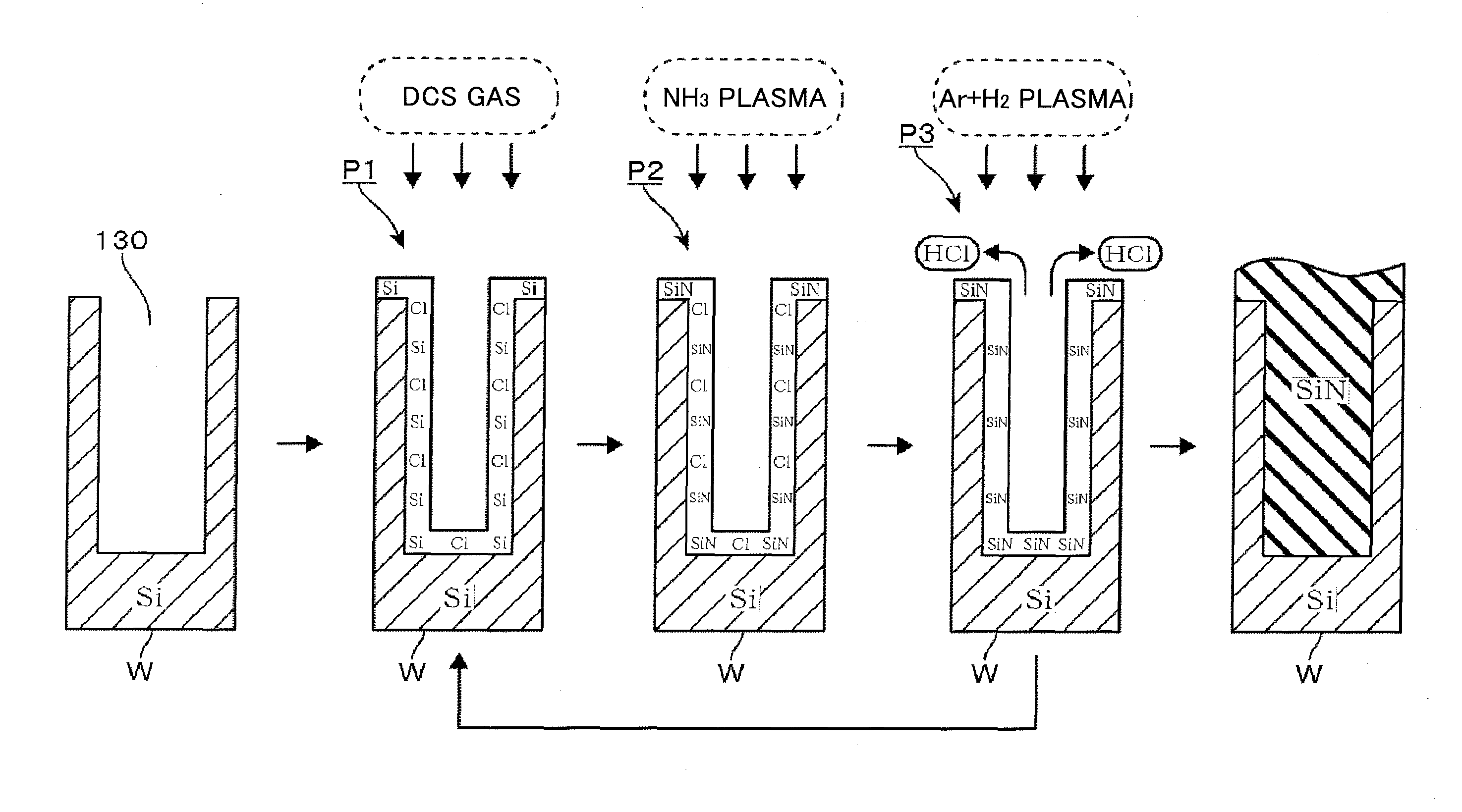

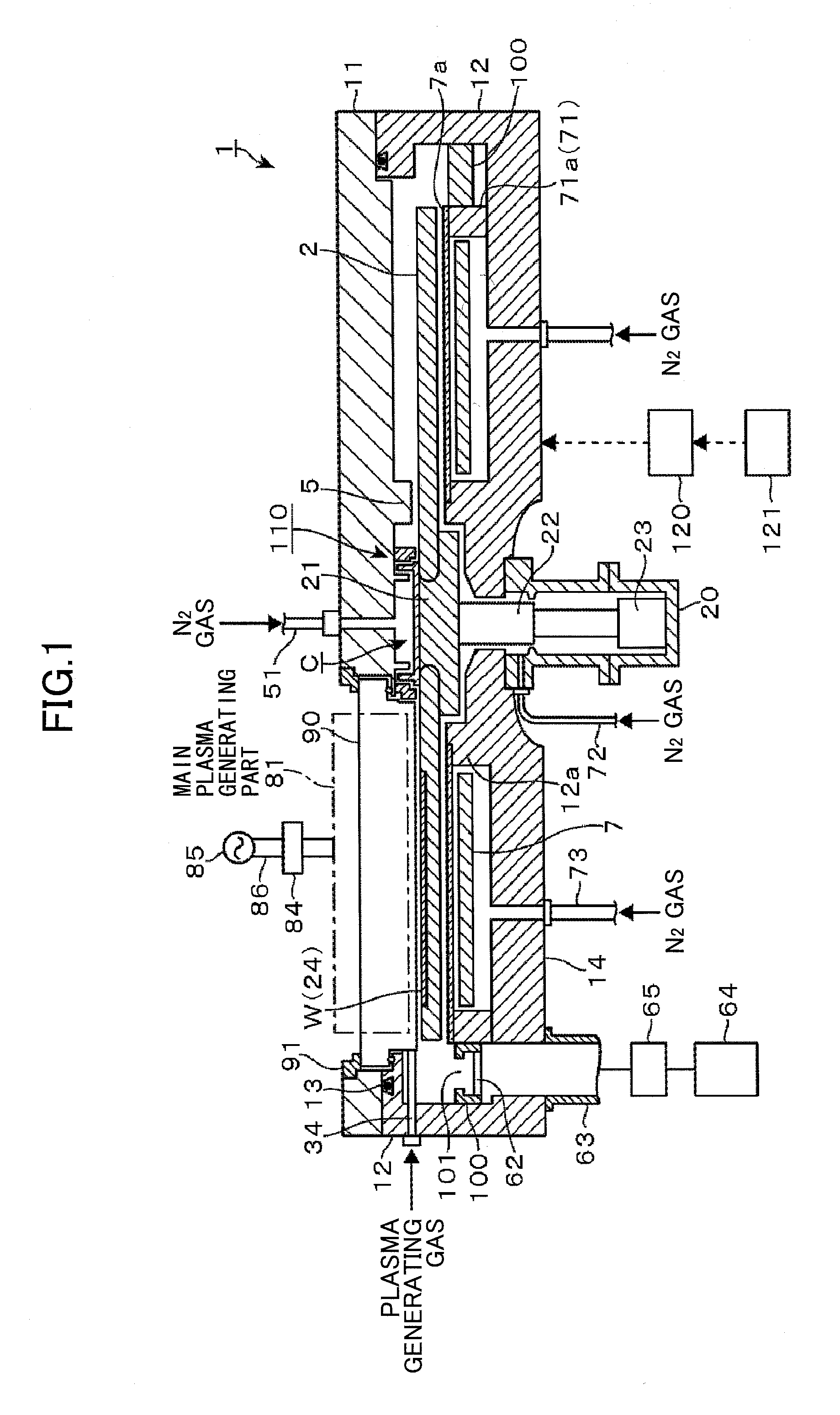

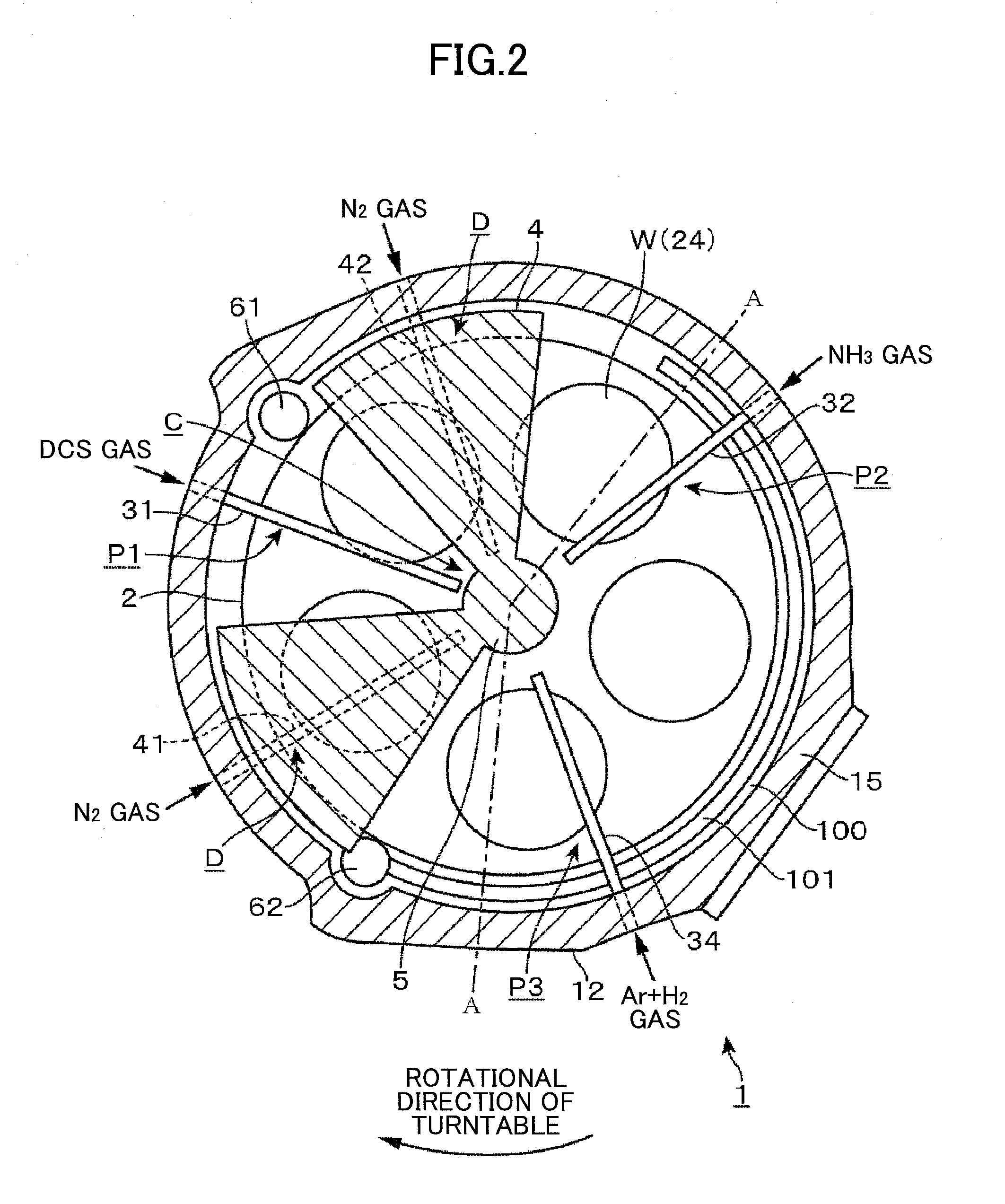

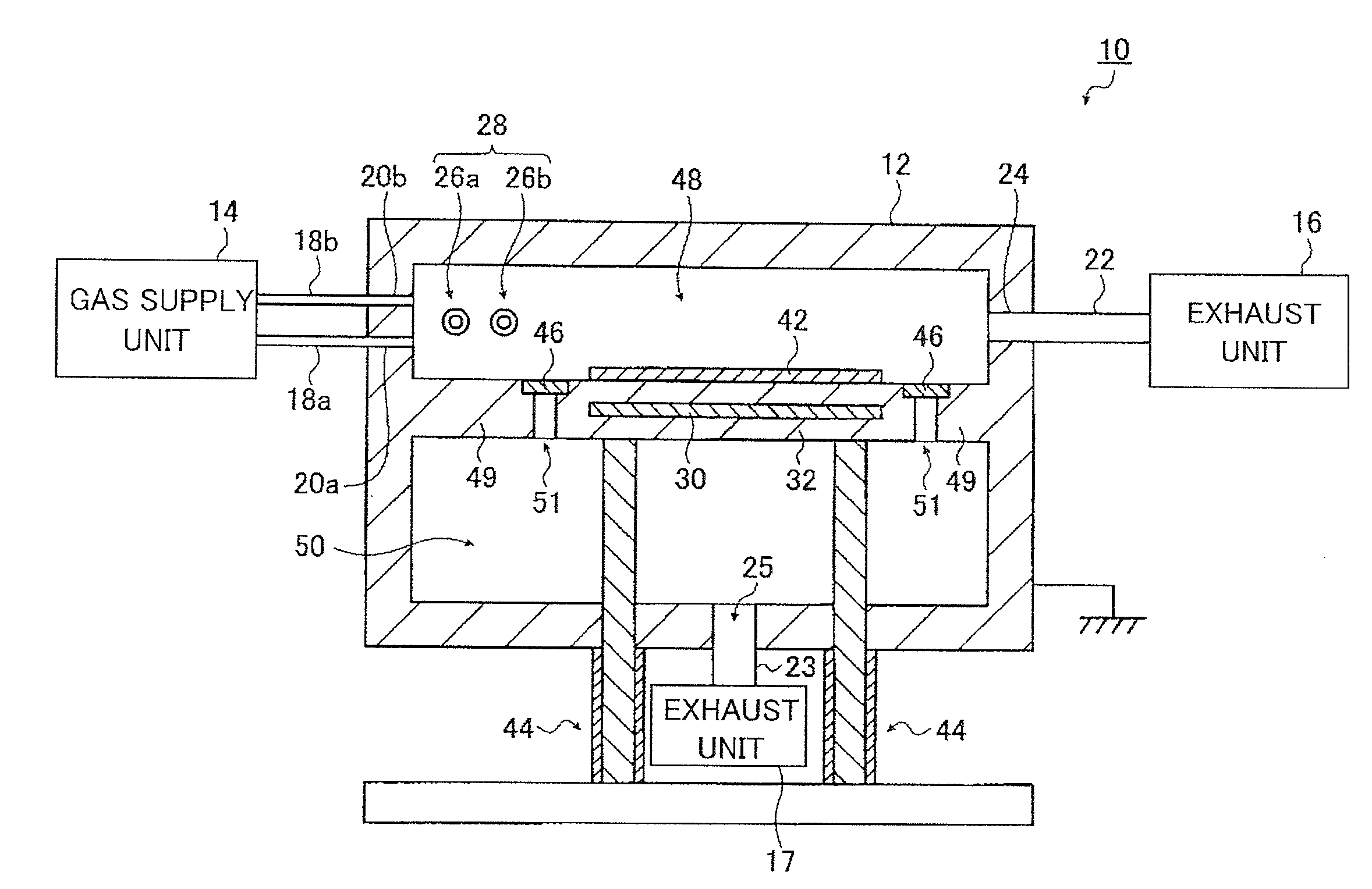

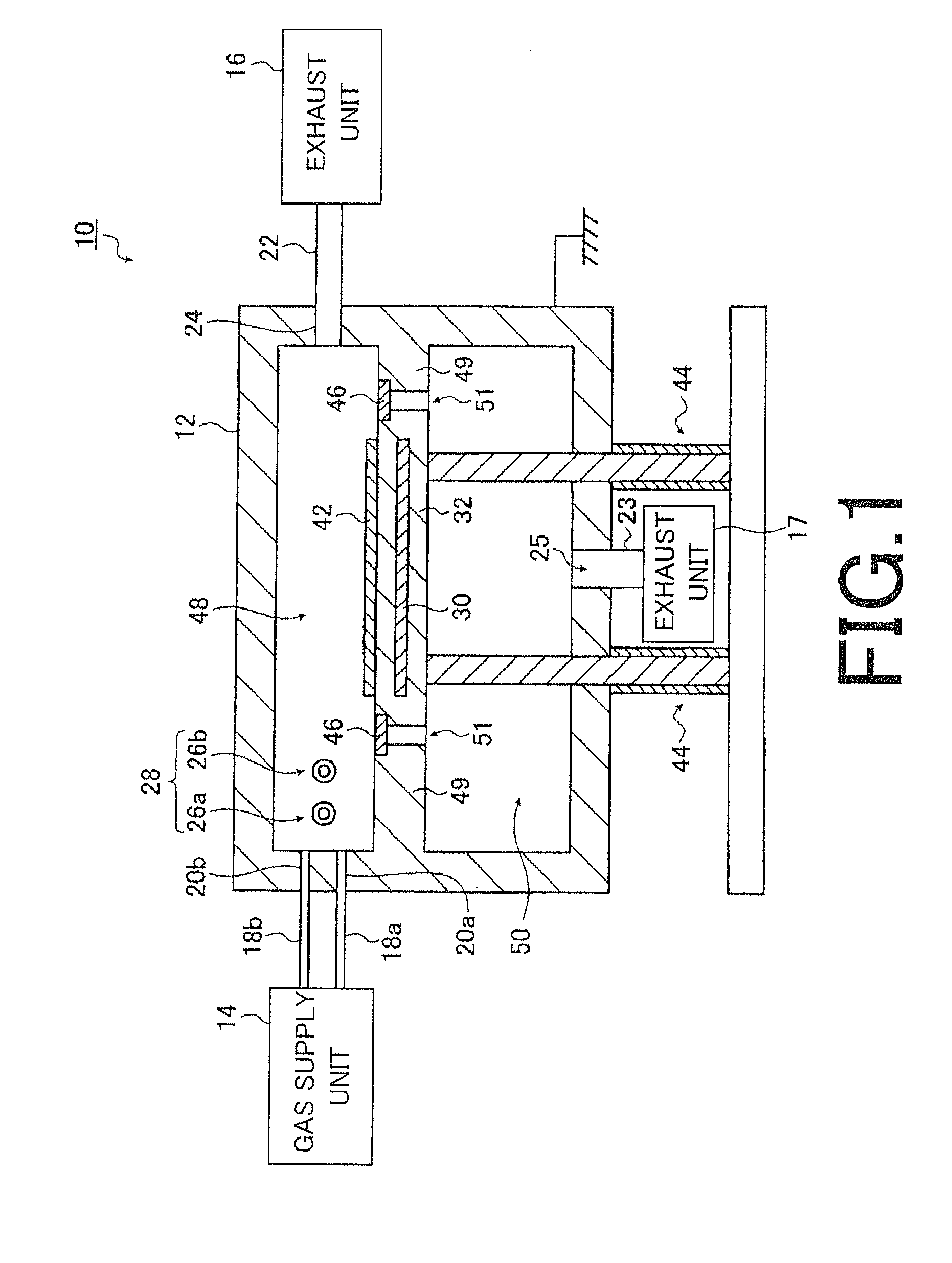

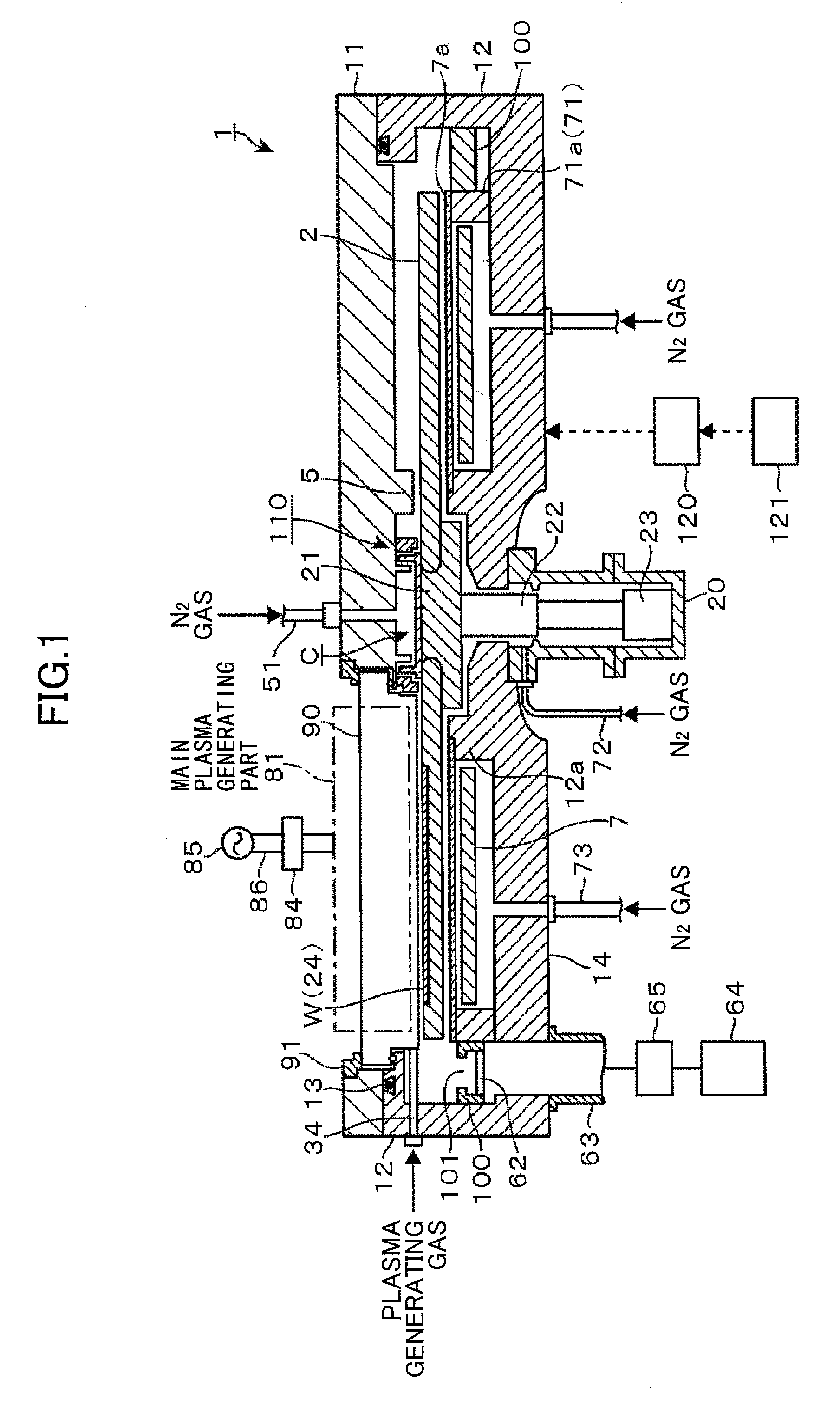

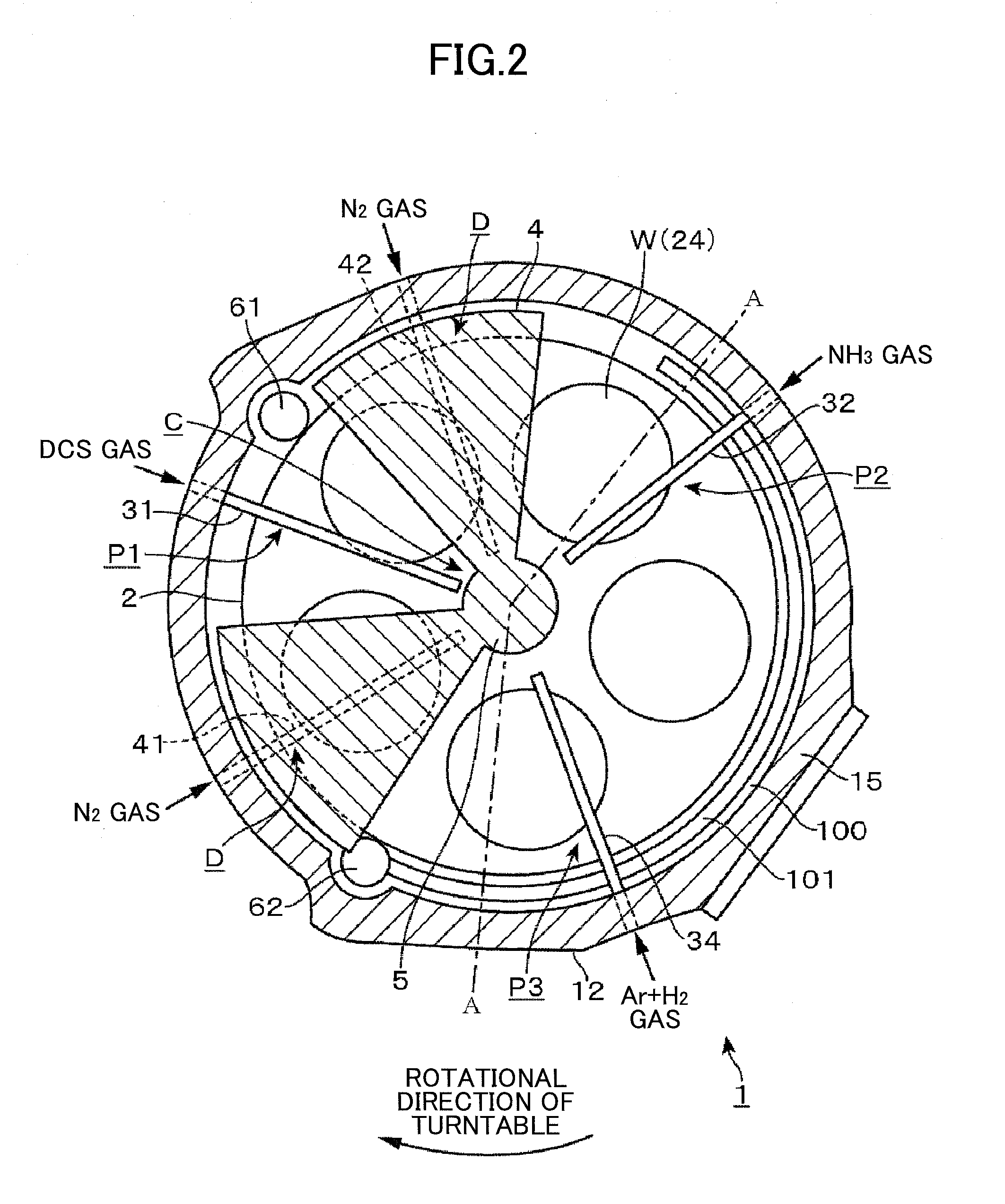

A film deposition apparatus includes a turntable having a substrate mounting area, a first plasma gas supplying part, a second plasma supplying part, a first plasma gas generating part to convert the first plasma generating gas to first plasma, and a second plasma generating part provided away from the first plasma generating part in a circumferential direction and to convert the second plasma generating gas to second plasma. The first plasma generating part includes an antenna facing the turntable so as to convert the first plasma generating gas to the first plasma, and a grounded Faraday shield between the antenna and an area where a plasma process is performed, and to include plural slits respectively extending in directions perpendicular to the antenna and arranged along an antenna extending direction to prevent an electric field from passing toward the substrate and to pass a magnetic field toward the substrate.

Owner:TOKYO ELECTRON LTD

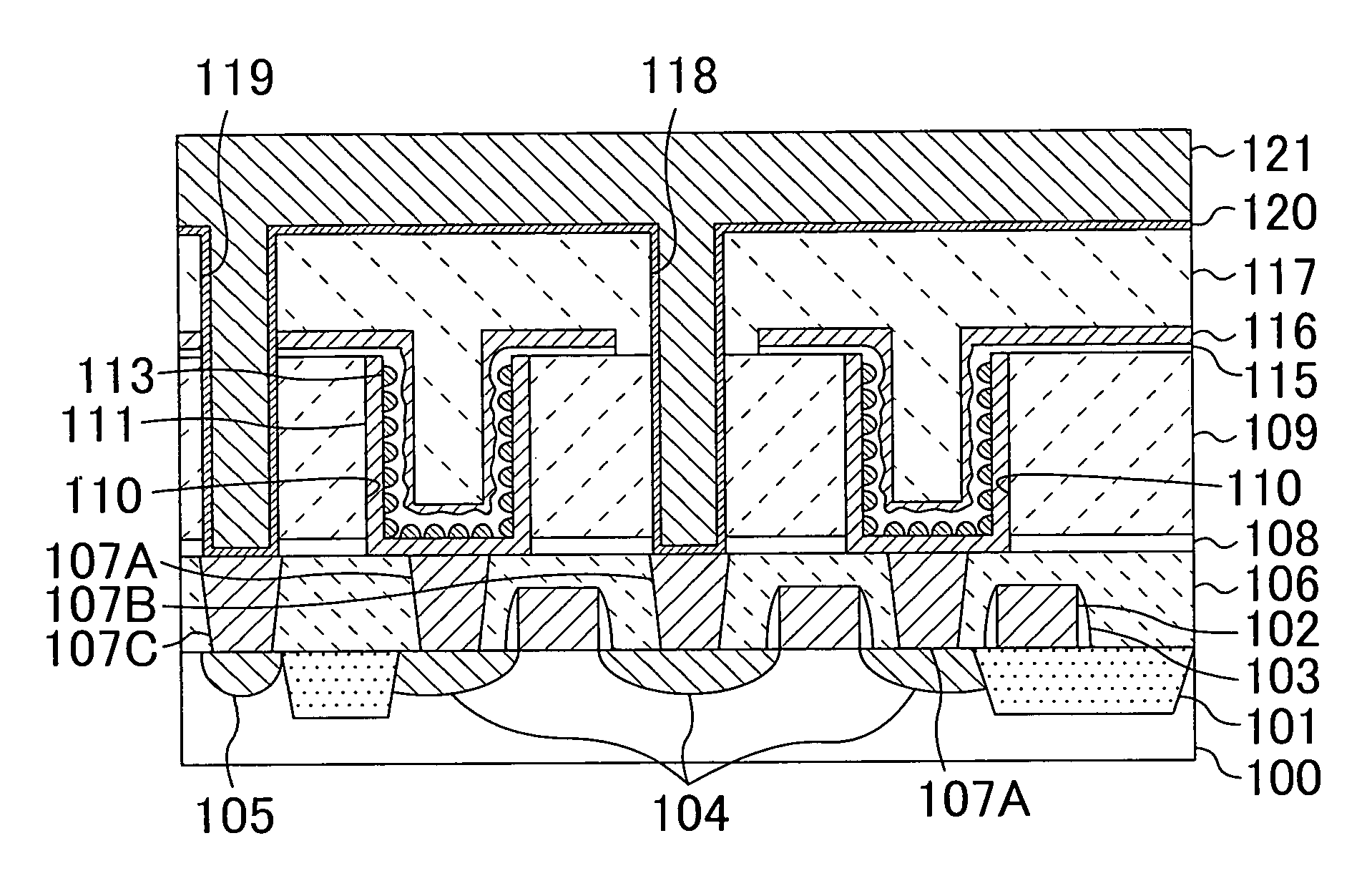

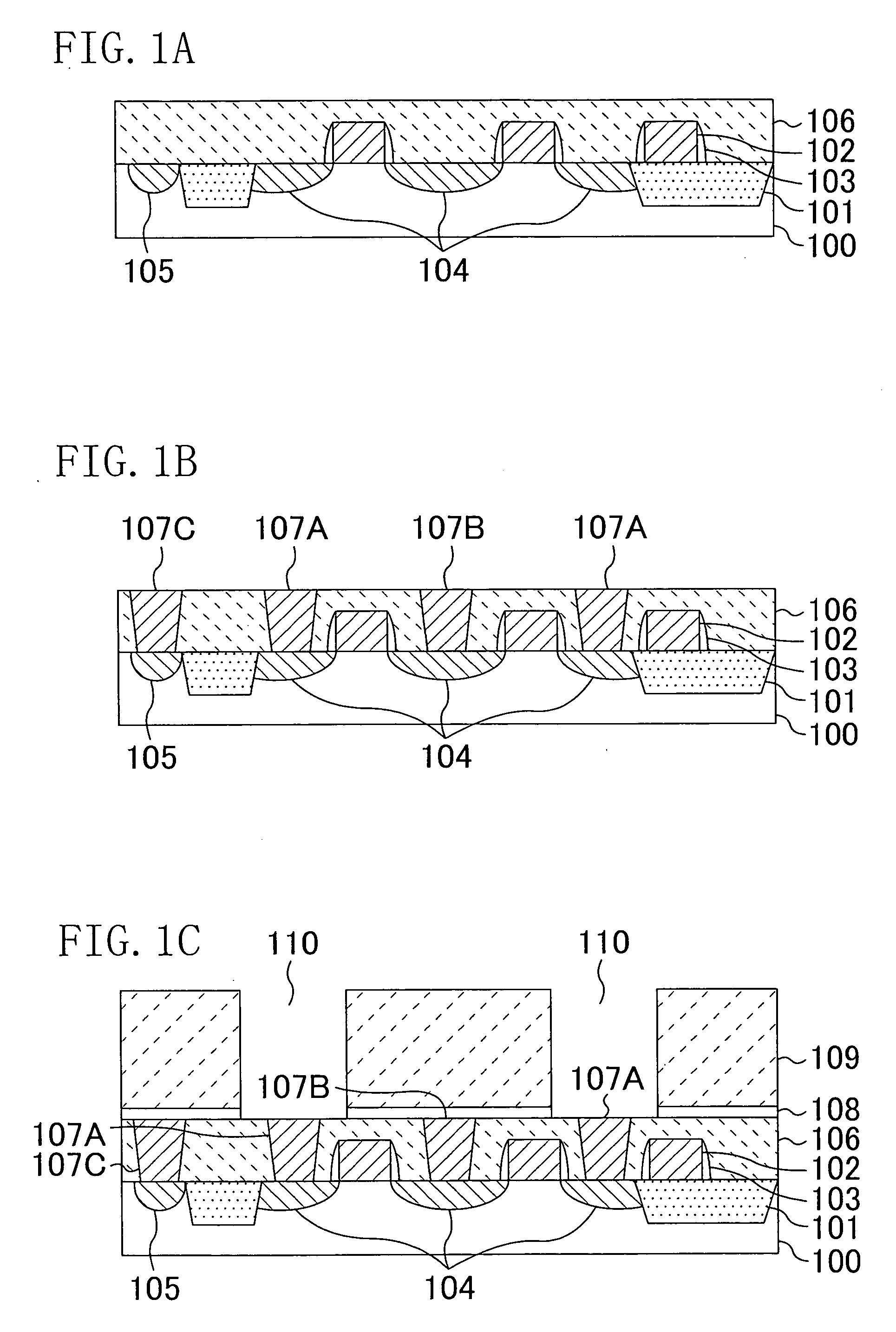

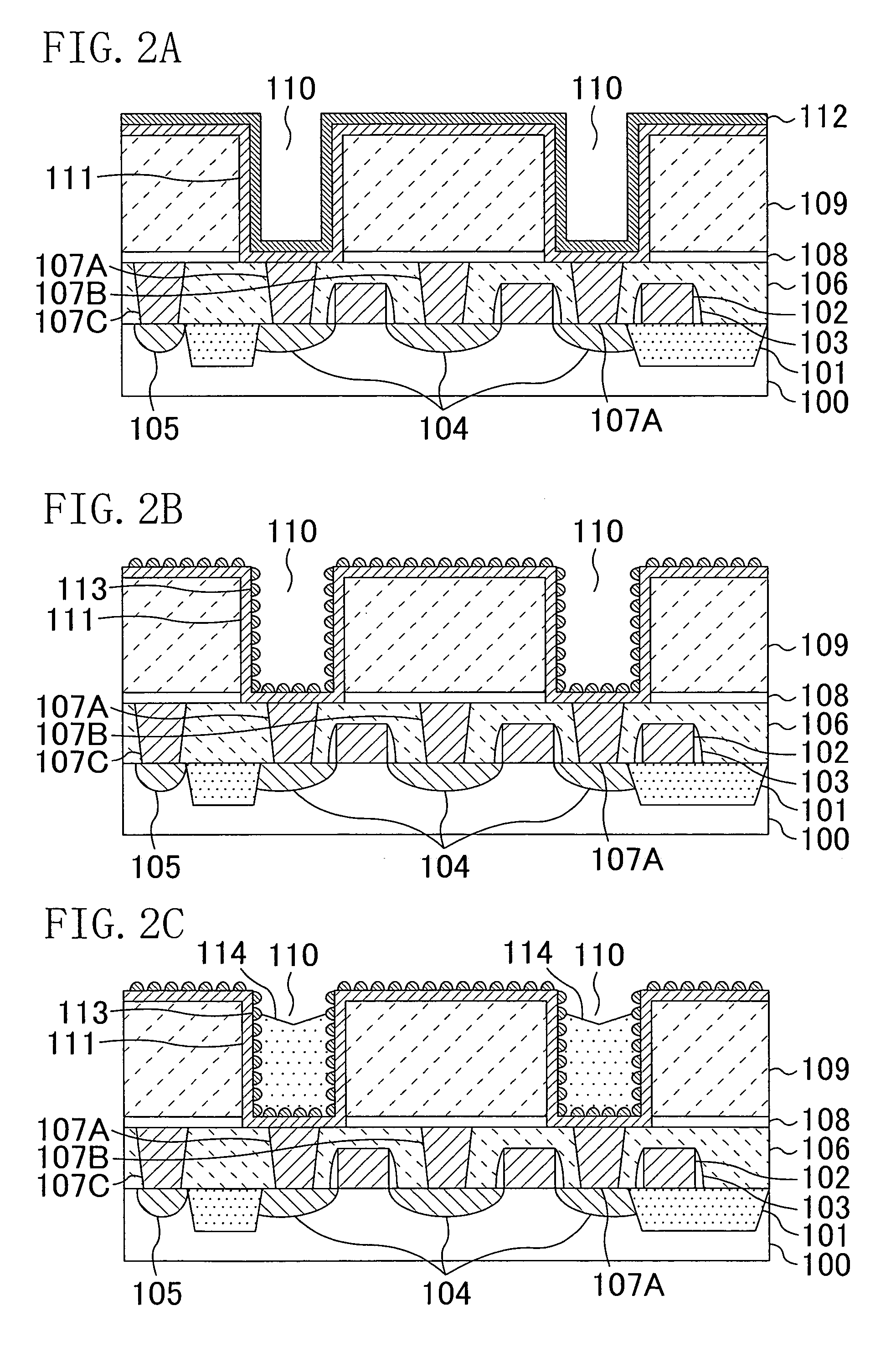

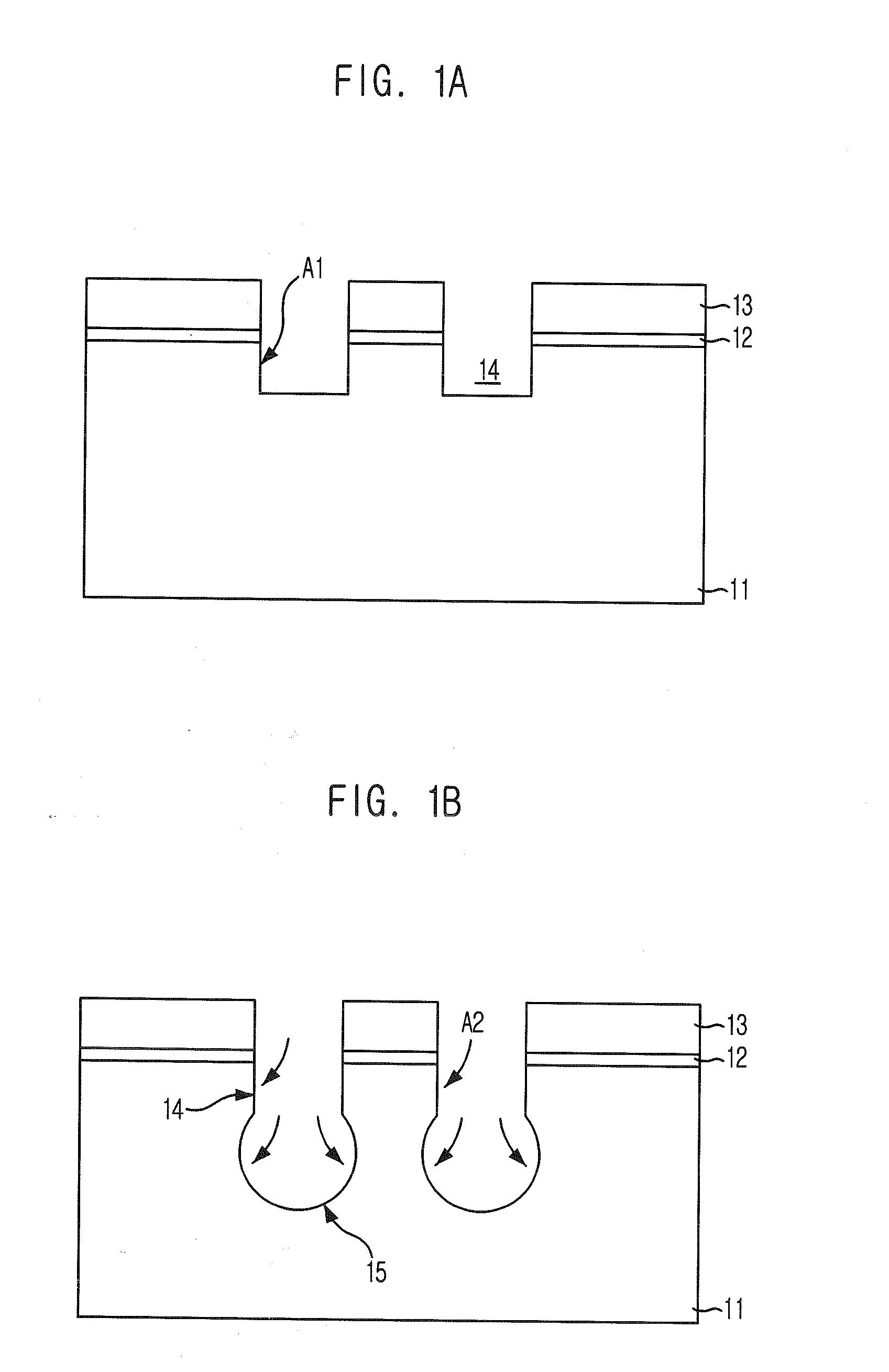

Method for manufacturing semiconductor device including etching process of silicon nitride film

InactiveUS20080293198A1Increase productivityImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDry etchingSemiconductor

A manufacturing method of a semiconductor device includes the step for forming a silicon nitride film having a first part where arsenic is included and a second part where less amount of or substantially no arsenic is included, the step for removing at least a portion of the first part by dry etching, and the step for removing at least a portion of the second part by wet etching. Since arsenic in the silicon nitride film is removed by dry etching, arsenic is never eluted into the wet etching liquid from the silicon nitride film during subsequent wet etching. Therefore, one can prevent the wet etching from being contaminated. Etching of the silicon nitride film is performed by a combination of dry etching and wet etching. Therefore, compared with the case where etching is performed only by dry etching, plasma damage to the region exposed in the plasma atmosphere except for the silicon nitride film can be decreased.

Owner:NEC ELECTRONICS CORP

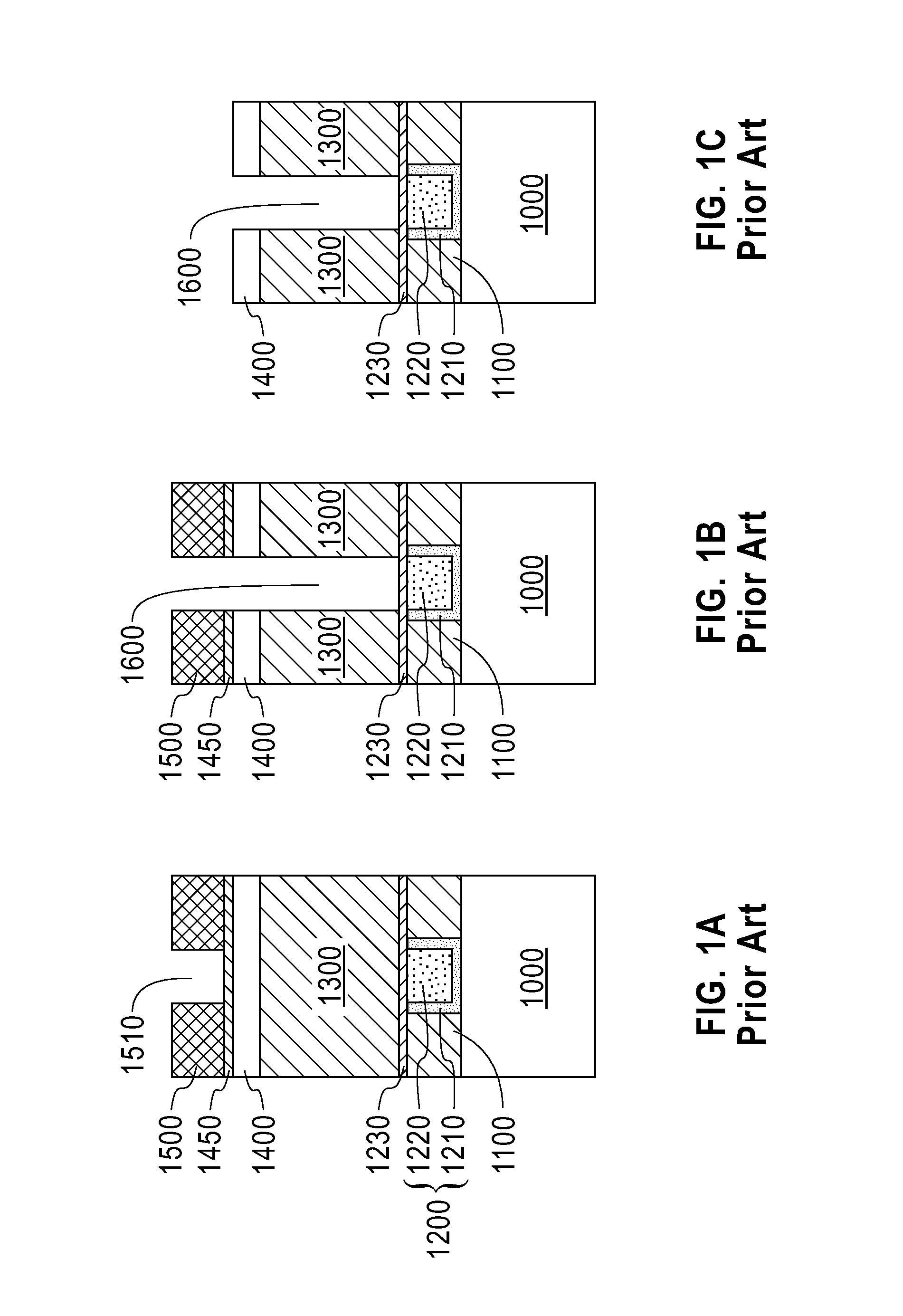

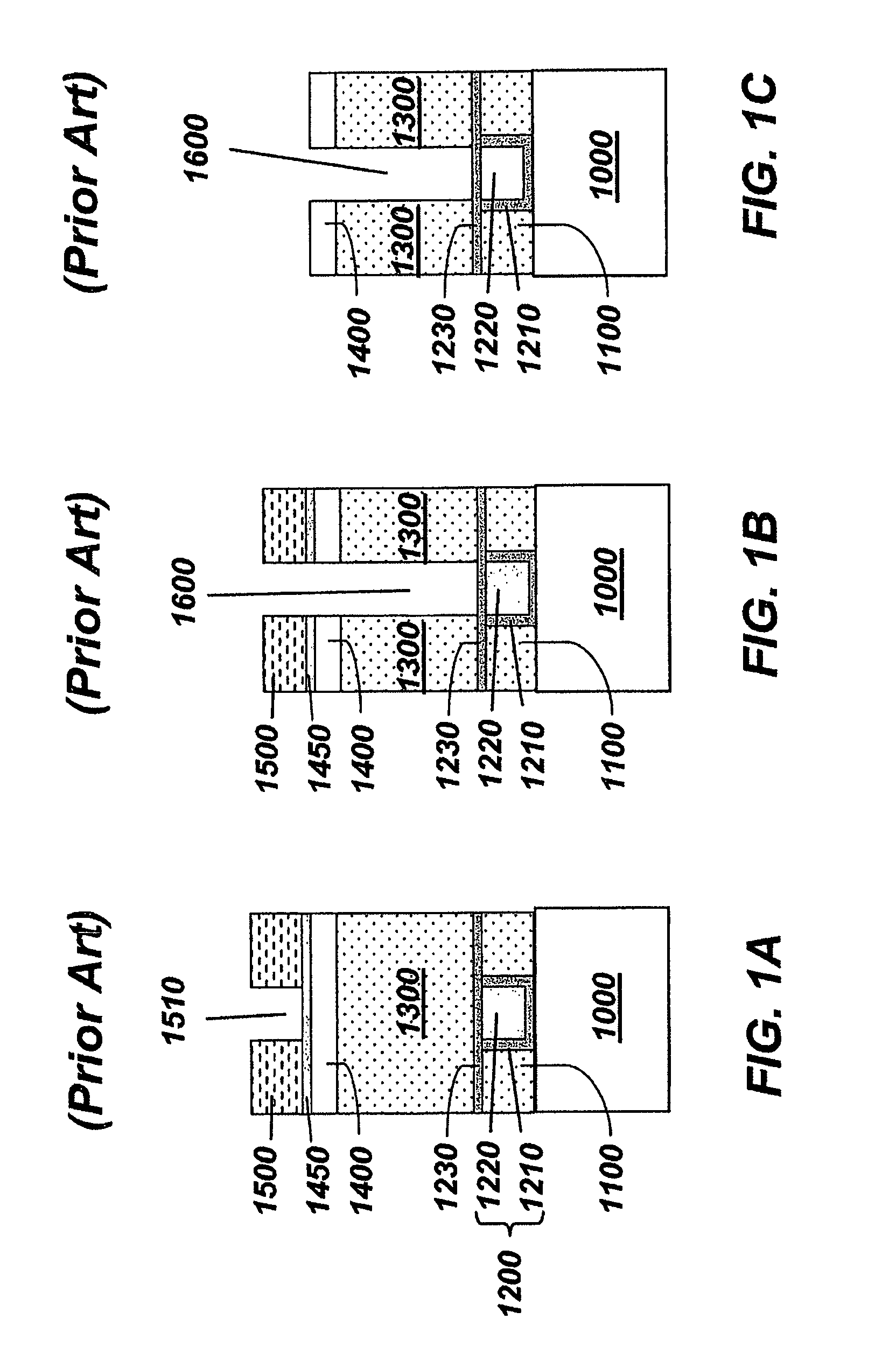

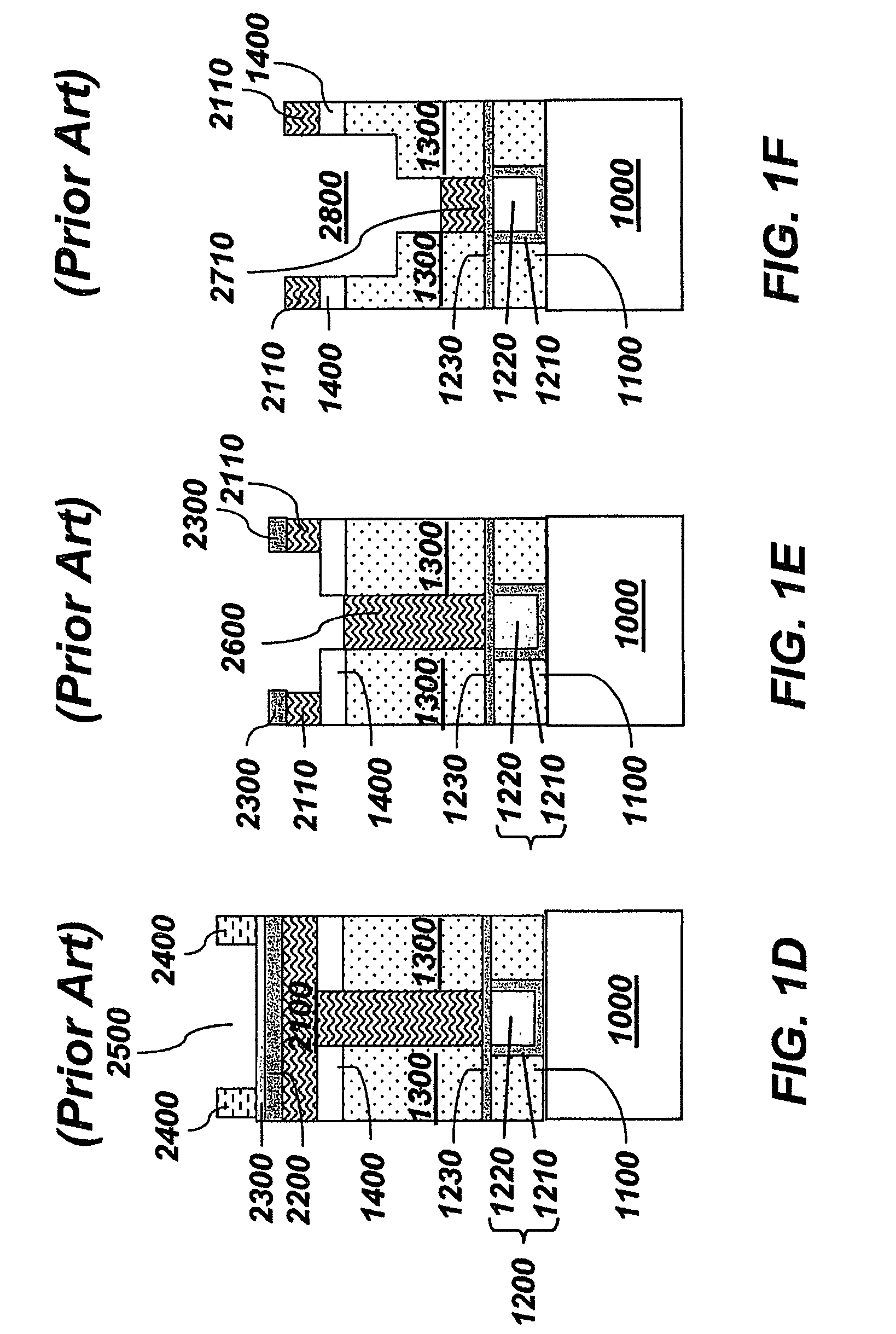

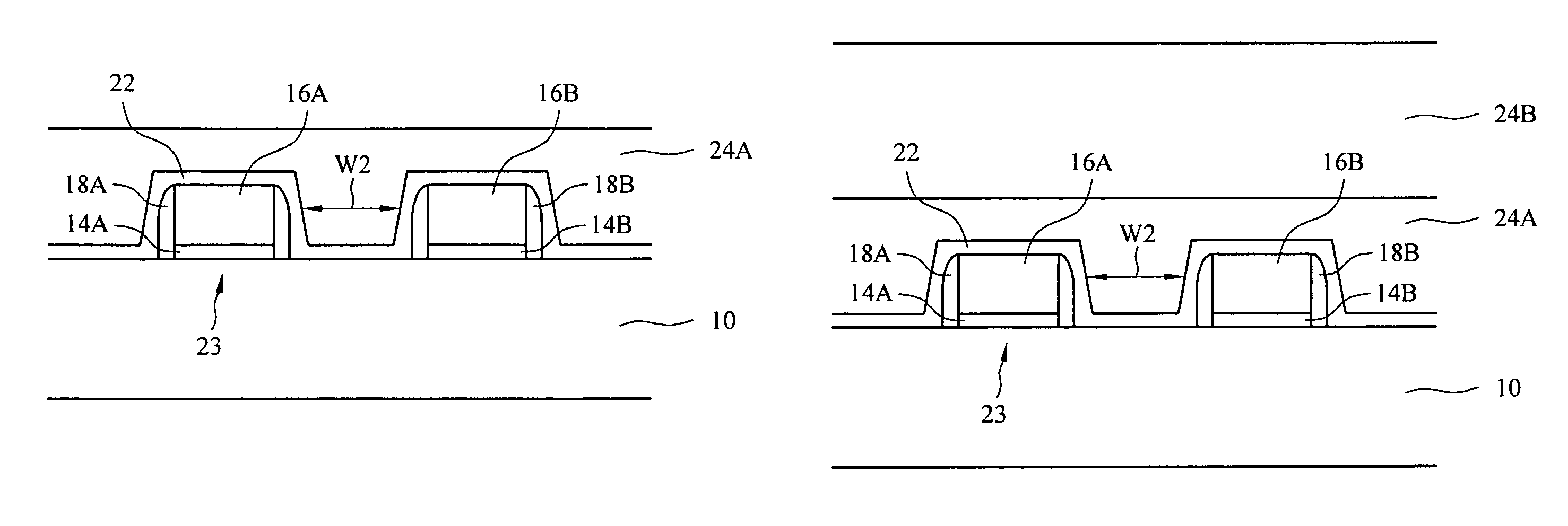

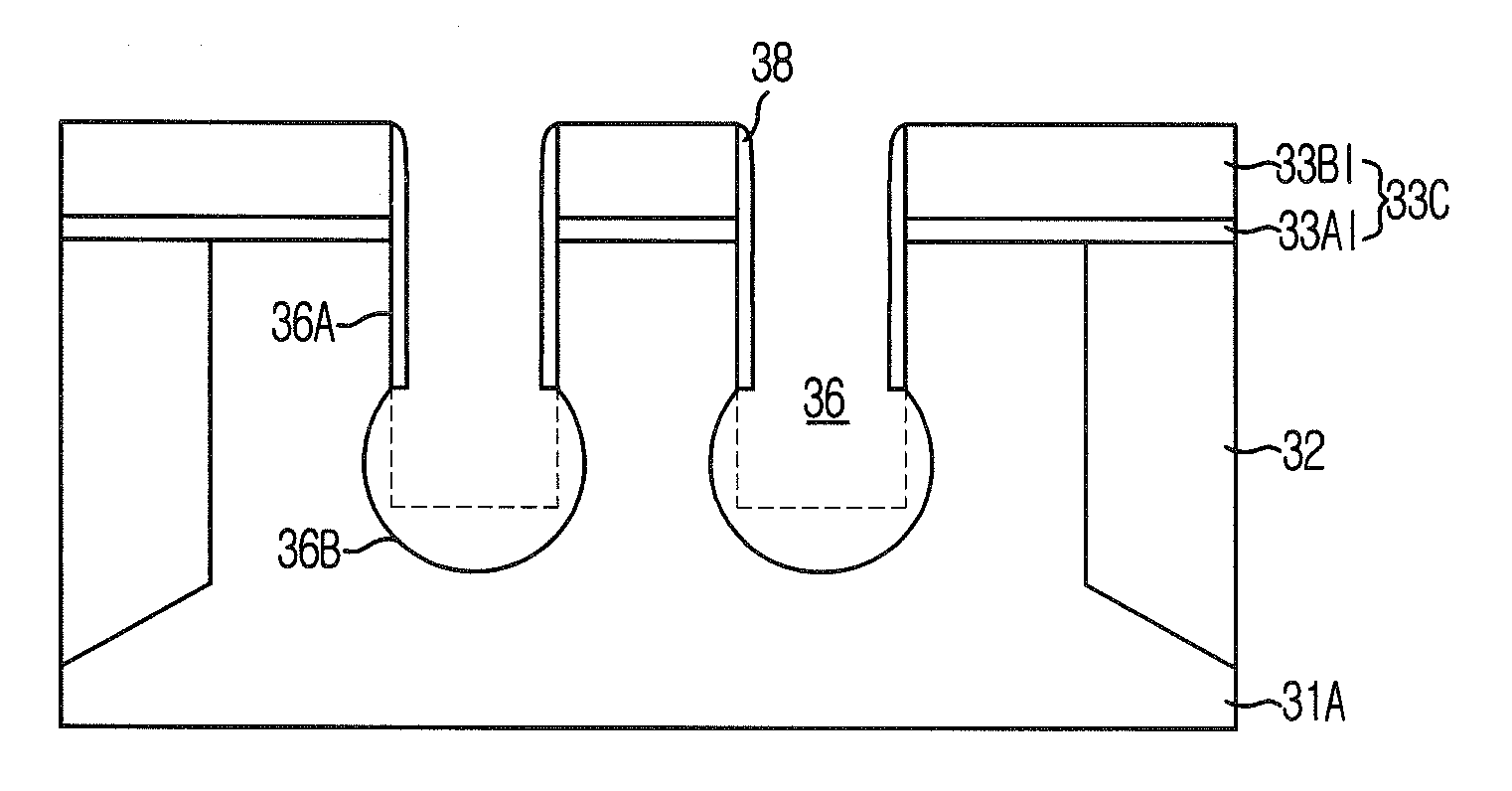

Methods to mitigate plasma damage in organosilicate dielectrics

InactiveUS20090075472A1High yieldMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingMetal interconnectLine width

Methods of minimizing or eliminating plasma damage to low k and ultra low k organosilicate intermetal dielectric layers are provided. The reduction of the plasma damage is effected by interrupting the etch and strip process flow at a suitable point to add an inventive treatment which protects the intermetal dielectric layer from plasma damage during the plasma strip process. Reduction or elimination of a plasma damaged region in this manner also enables reduction of the line bias between a line pattern in a photoresist and a metal line formed therefrom, and changes in the line width of the line trench due to a wet clean after the reactive ion etch employed for formation of the line trench and a via cavity. The reduced line bias has a beneficial effect on electrical yields of a metal interconnect structure.

Owner:ADVANCED MICRO DEVICES INC +1

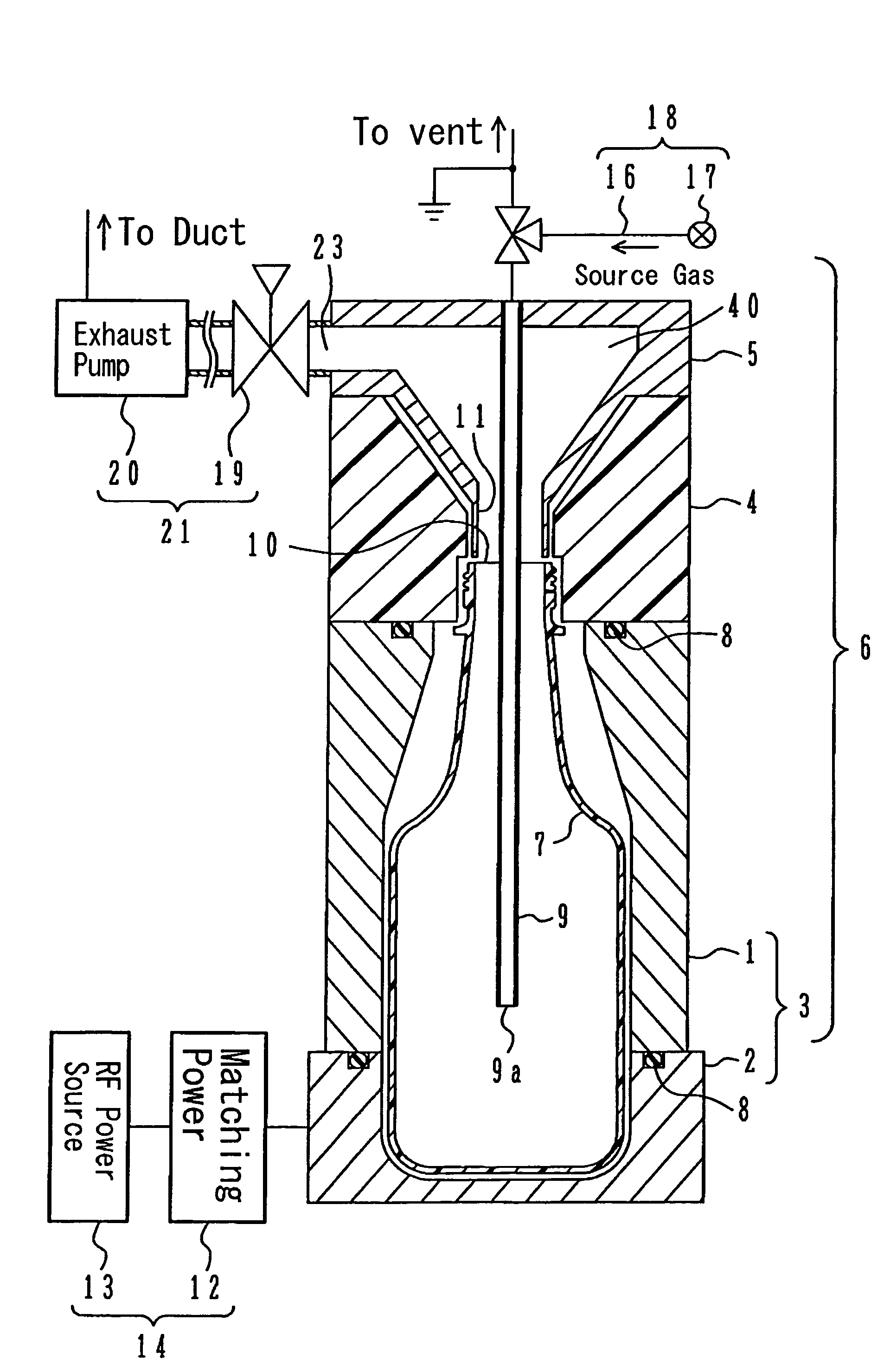

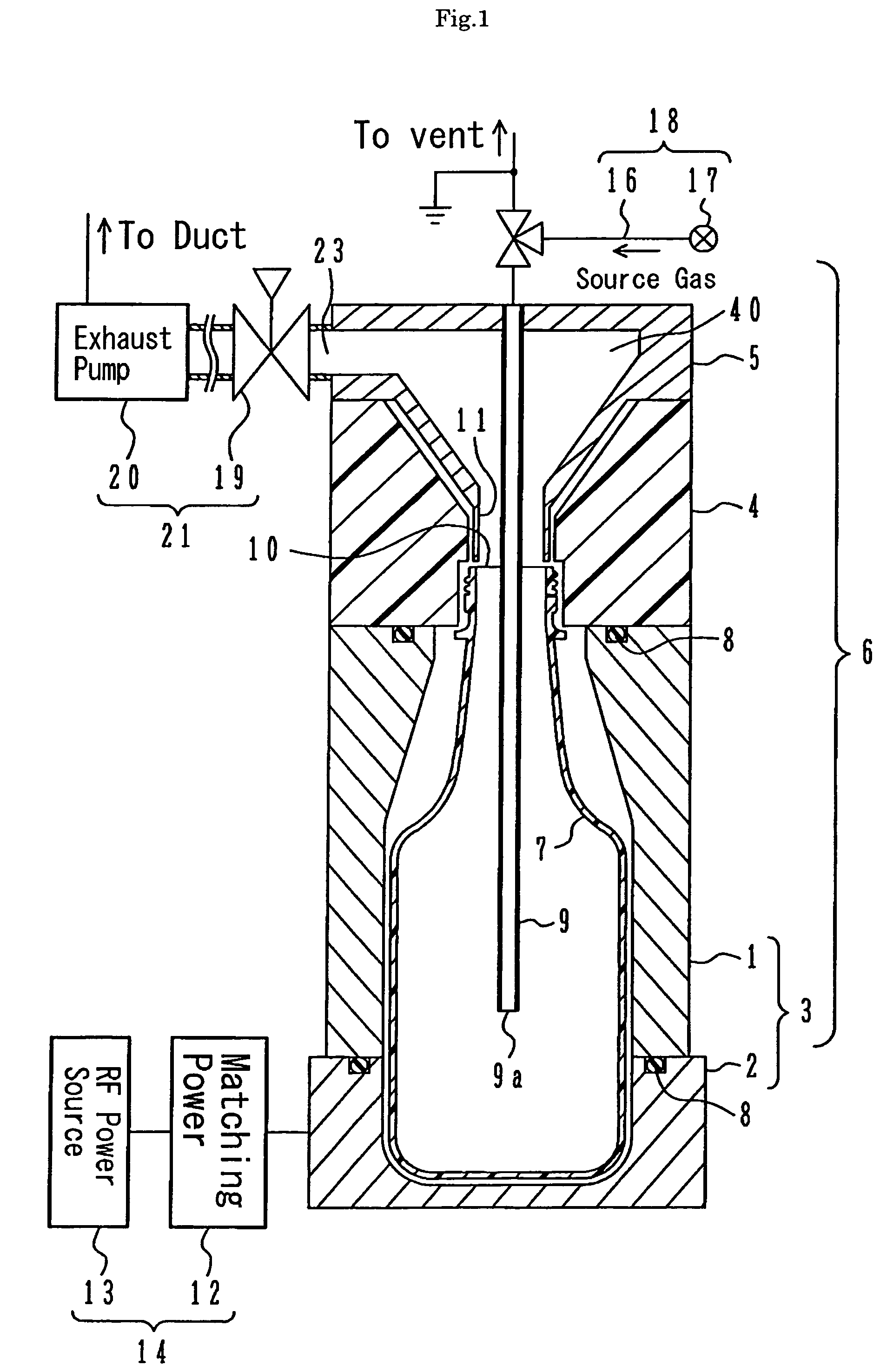

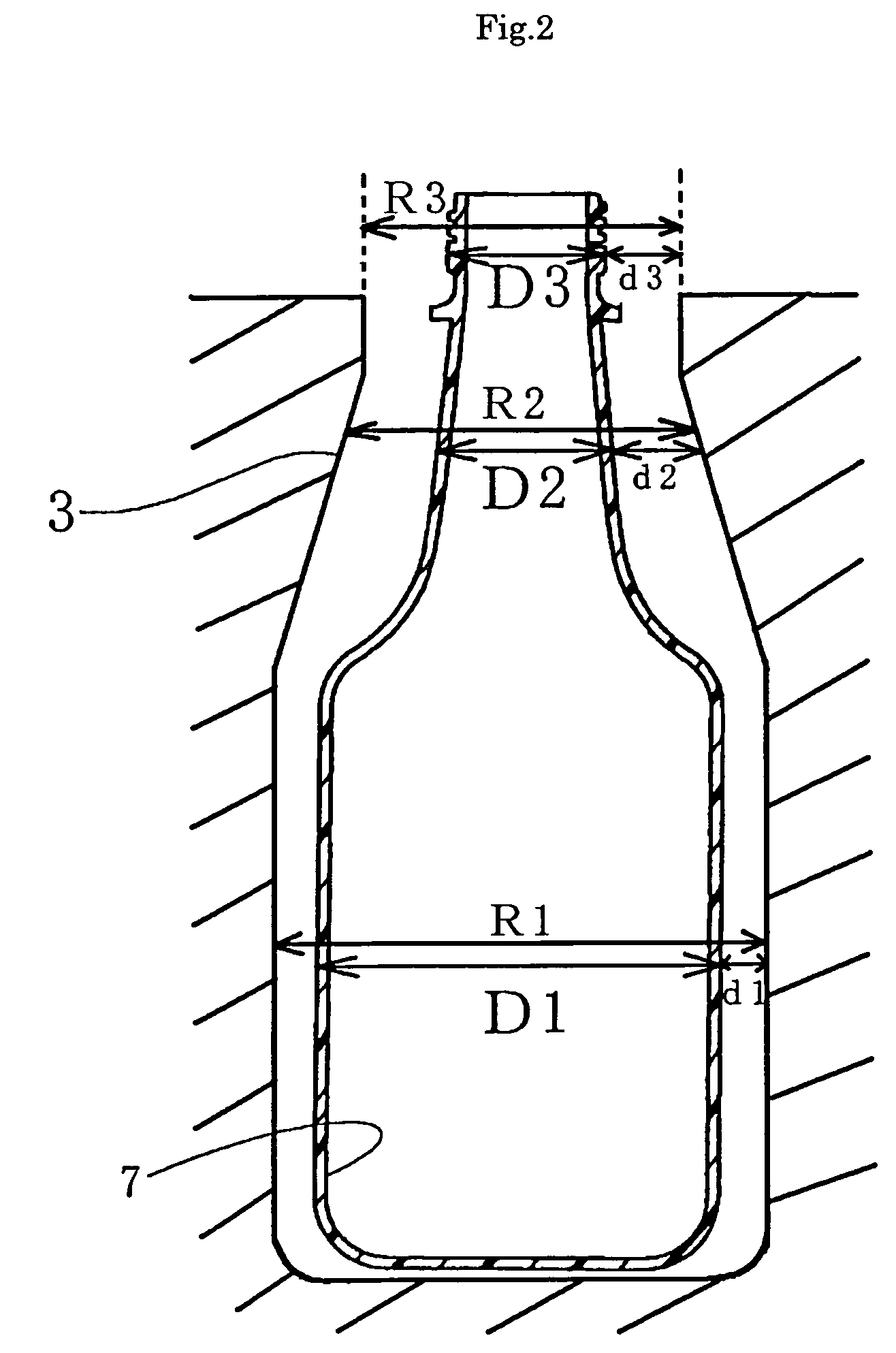

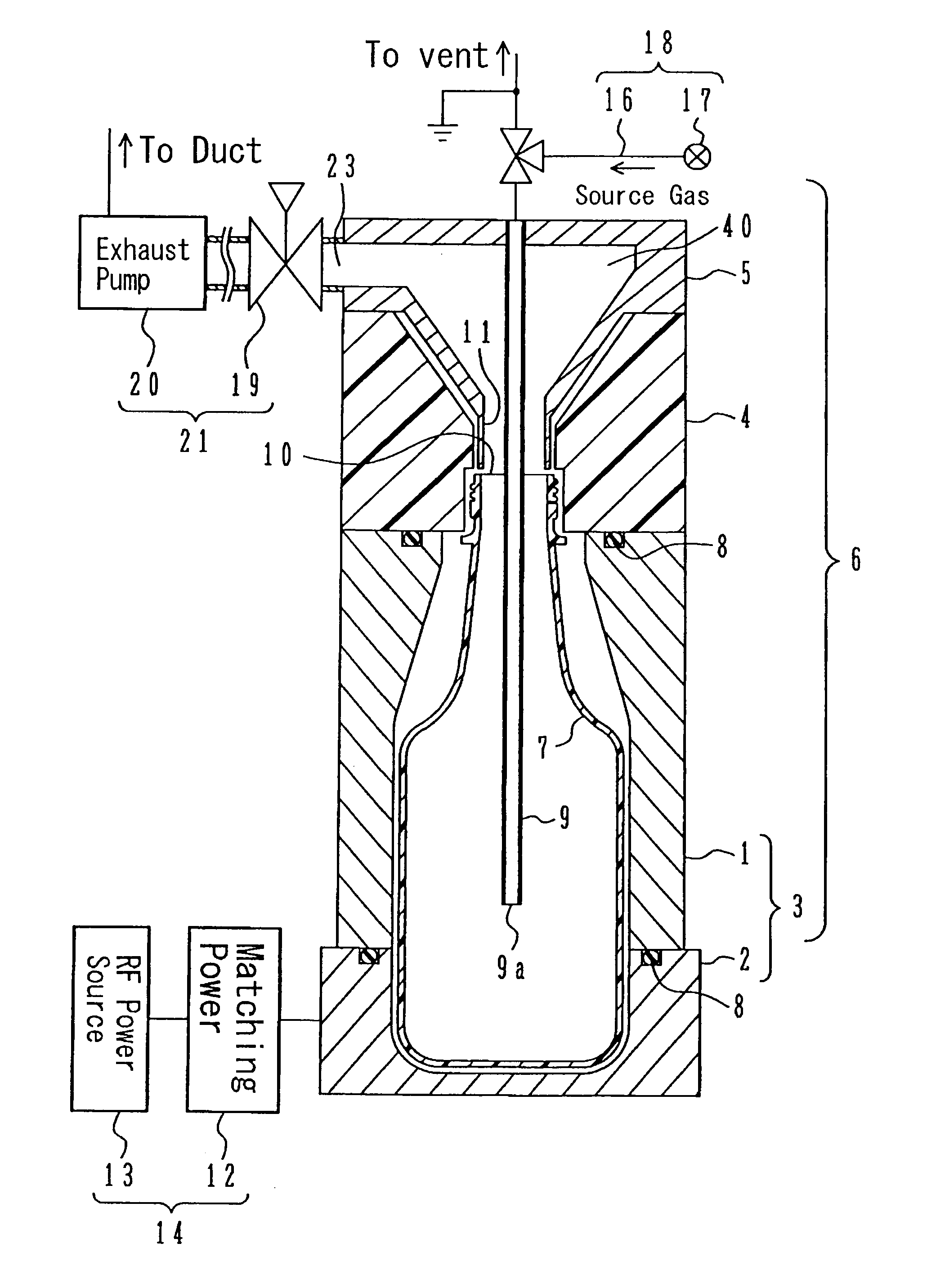

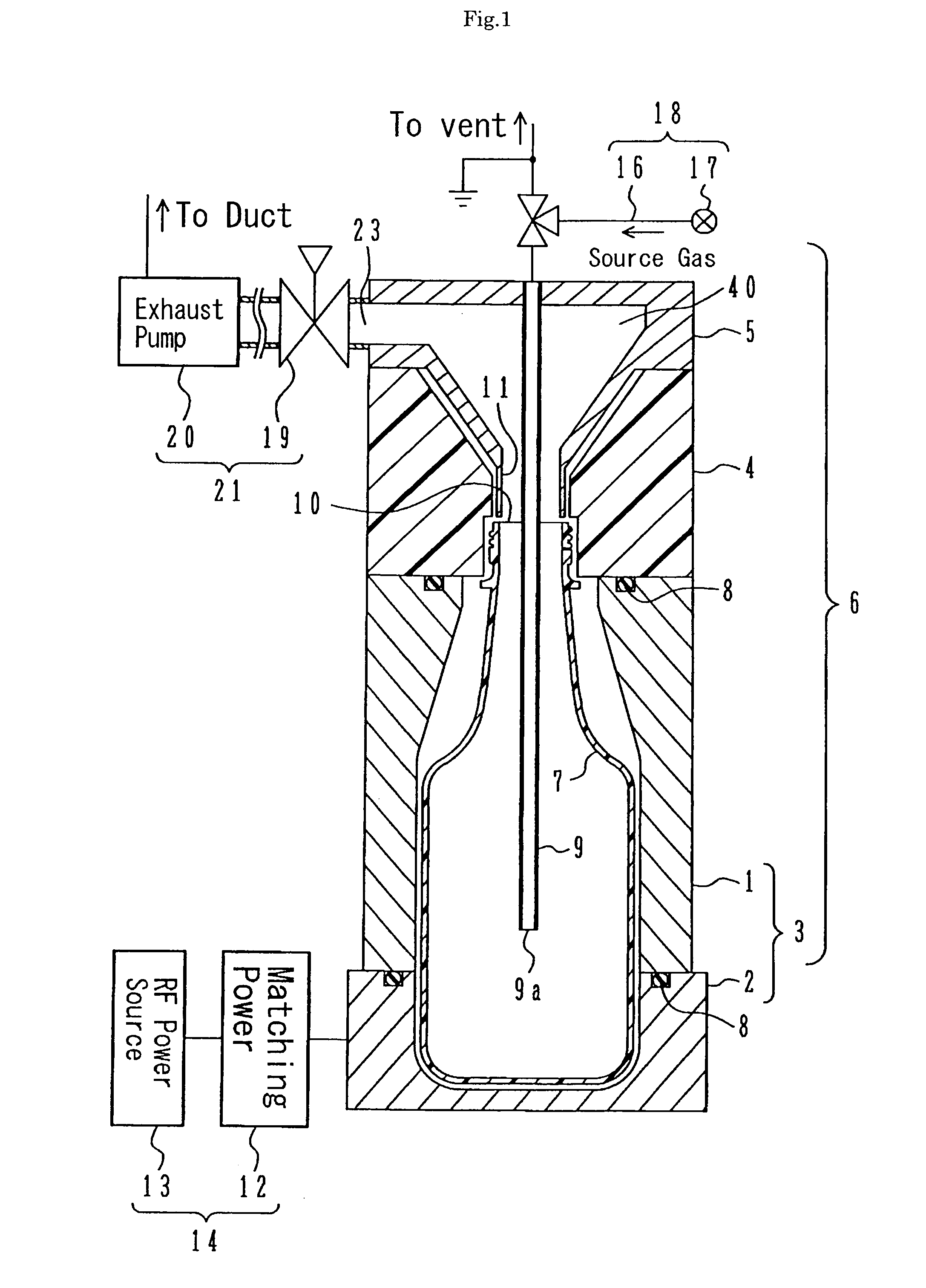

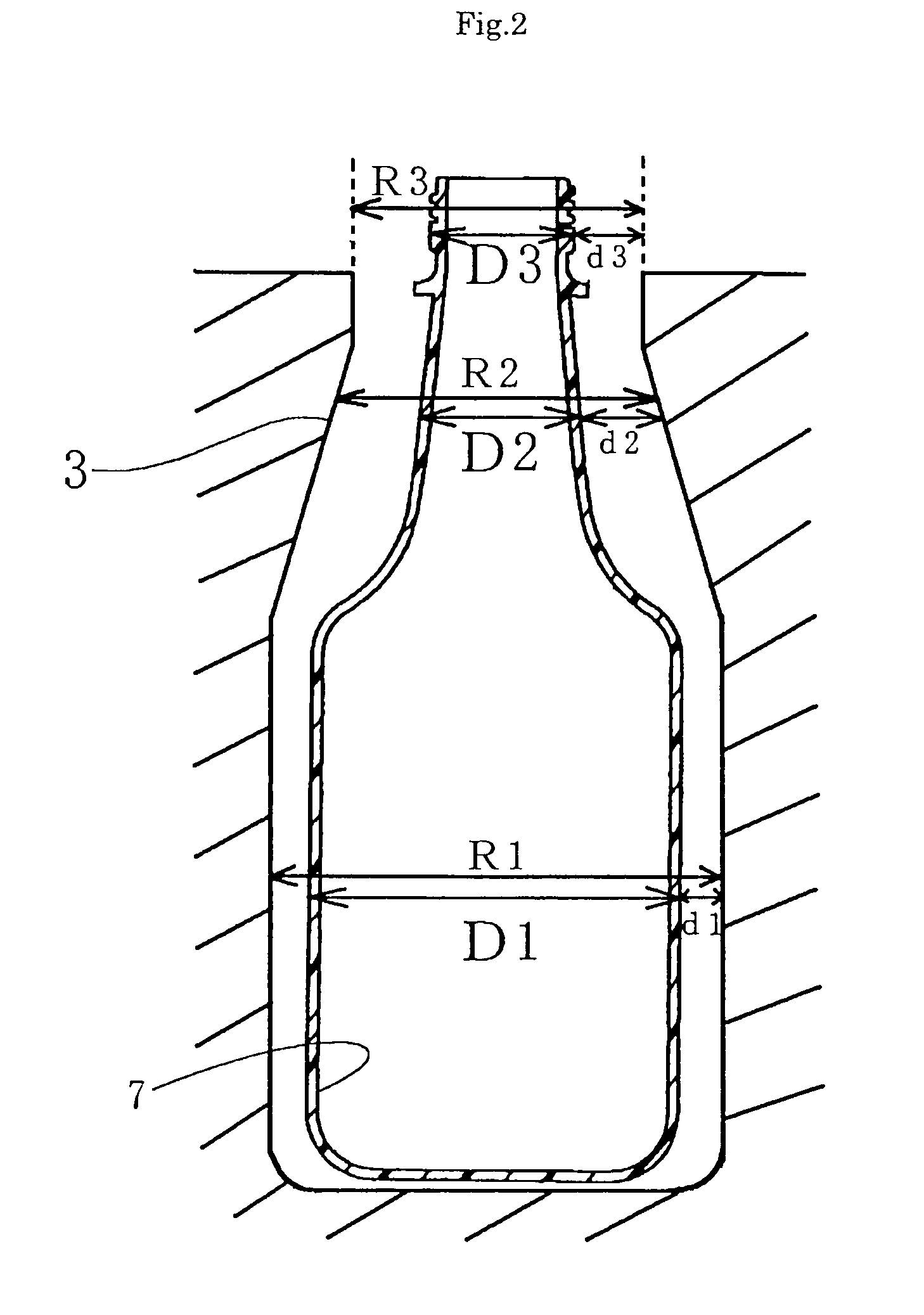

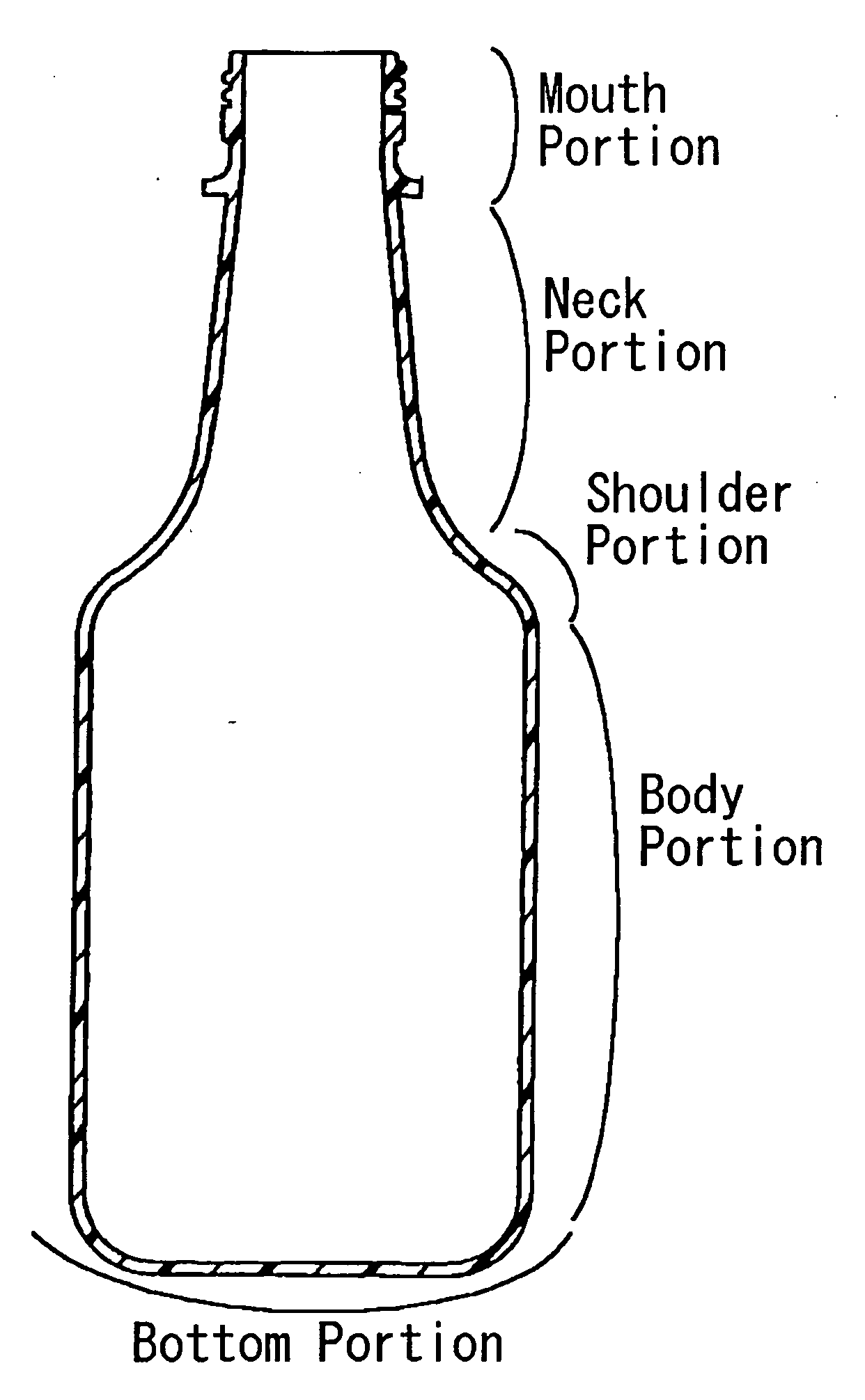

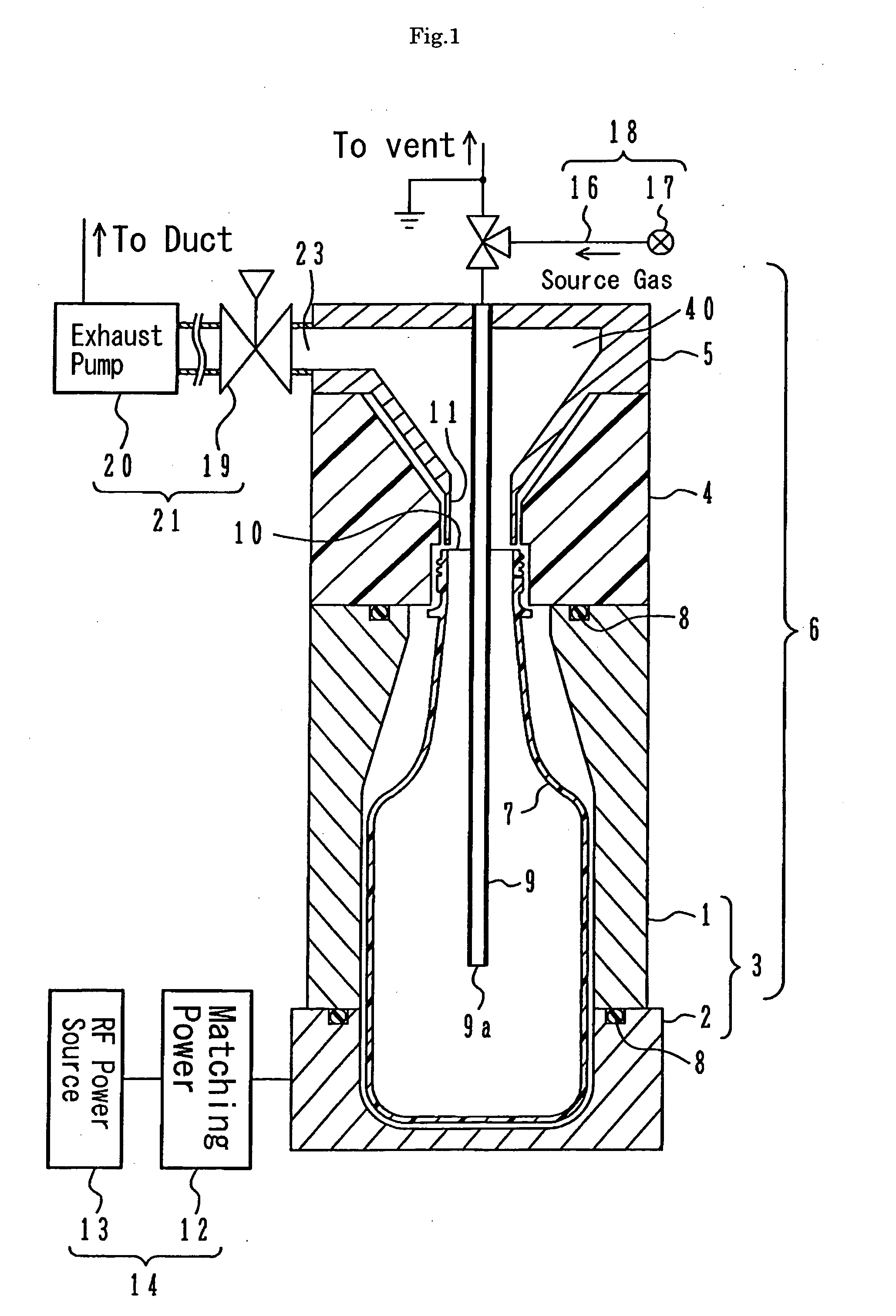

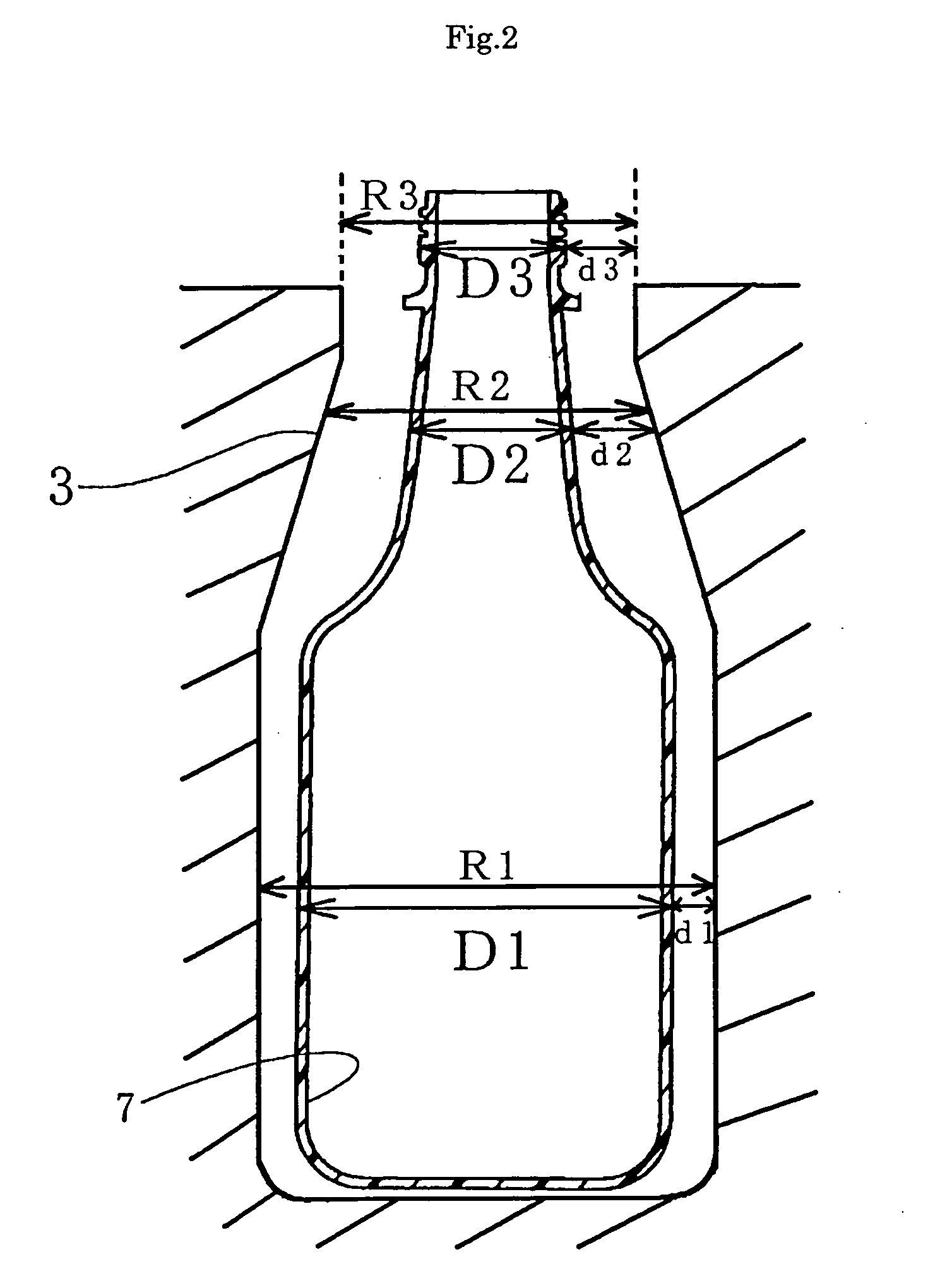

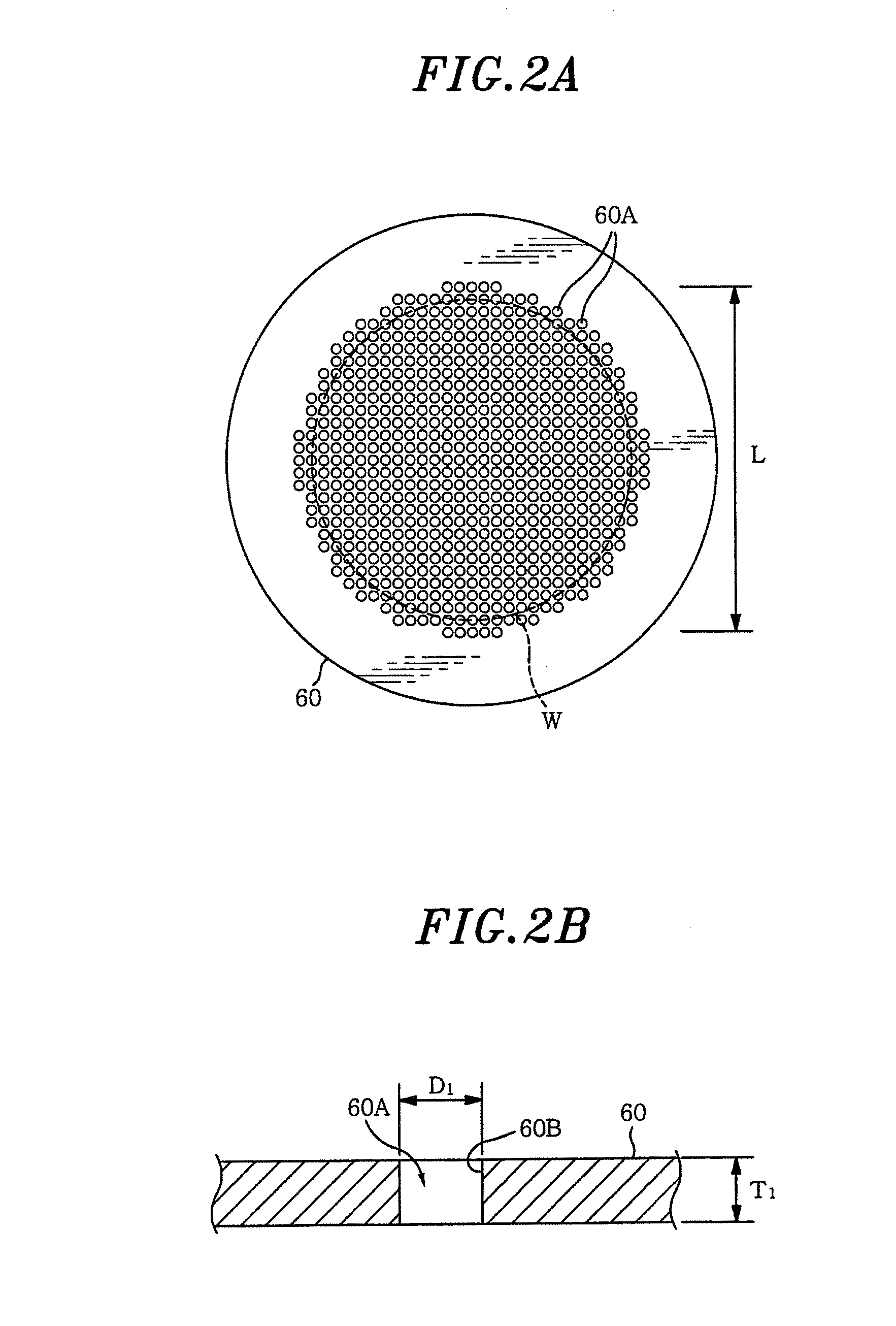

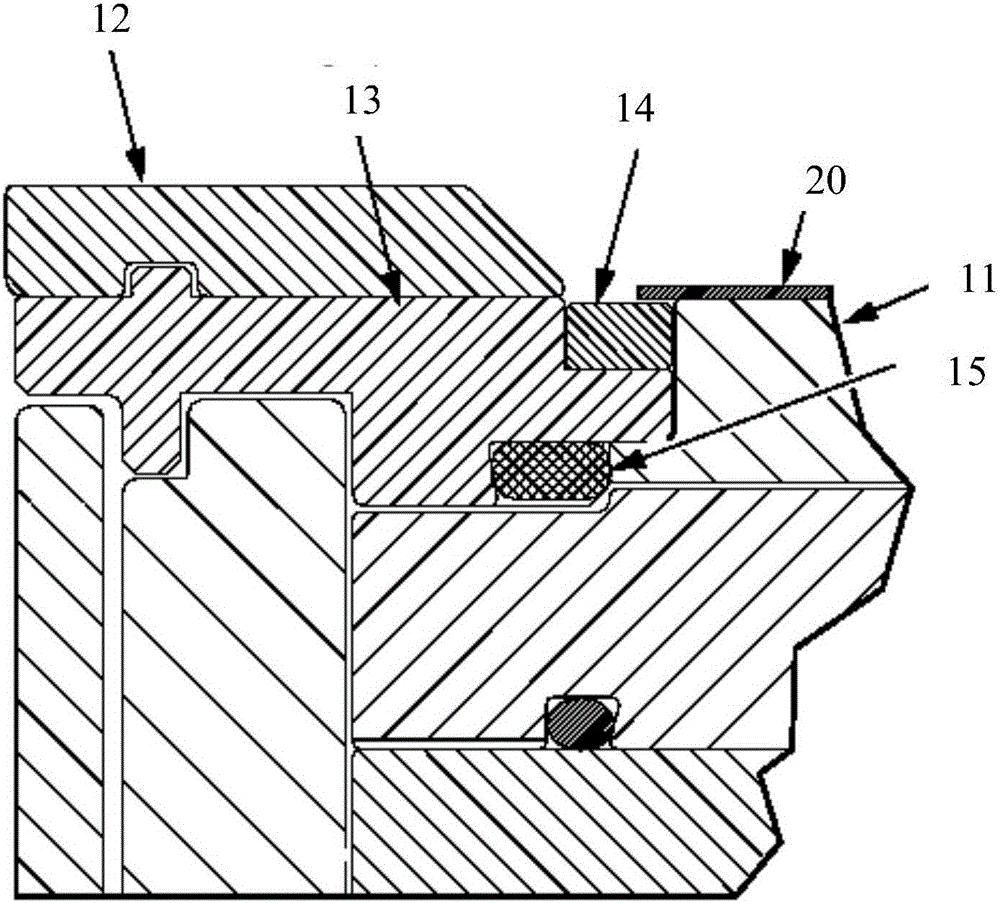

DLC film coated plastic container, and device and method for manufacturing the plastic container

InactiveUS7754302B2Inhibit coloringReduce plasma damageLiquid surface applicatorsSynthetic resin layered productsGraphiteEngineering

The present invention provides a plastic container or bottle having an inner wall surface coated with a DLC film which has the same level of oxygen barrier property as prior art DLC coated containers while at the same time preventing the coloration of the neck portion found in the containers of the prior art. The DLC film formed on the neck portion of the inventive bottle has a lower graphite mixing proportion than the DLC film formed on body portion, and the oxygen permeability of the container is less than or equal to 0.0050 ml / container (500 ml PET container) / day. The apparatus and the method of producing such a bottle are also described.

Owner:KIRIN BREWERY CO LTD

Dlc film coated plastic container, and device and method for manufacturing the plastic container

InactiveUS20100275847A1Inhibit coloringReduce plasma damageLinings/internal coatingsCoverings/external coatingsManufactured apparatusThin membrane

Owner:KIRIN BREWERY CO LTD

Methods to mitigate plasma damage in organosilicate dielectrics

InactiveUS20120329269A1High yieldMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingMetal interconnectLine width

Methods of minimizing or eliminating plasma damage to low k and ultra low k organosilicate intermetal dielectric layers are provided. The reduction of the plasma damage is effected by interrupting the etch and strip process flow at a suitable point to add an inventive treatment which protects the intermetal dielectric layer from plasma damage during the plasma strip process. Reduction or elimination of a plasma damaged region in this manner also enables reduction of the line bias between a line pattern in a photoresist and a metal line formed therefrom, and changes in the line width of the line trench due to a wet clean after the reactive ion etch employed for formation of the line trench and a via cavity. The reduced line bias has a beneficial effect on electrical yields of a metal interconnect structure.

Owner:GLOBALFOUNDRIES INC

DLC film coated plastic container, and device and method for manufacturing the plastic container

InactiveUS20060051539A1Inhibit coloringReduce plasma damageLiquid surface applicatorsSynthetic resin layered productsOxygen barrierGas supply

The present invention provides a plastic container having a inner wall surface coated with DLC film which has same level of oxygen barrier property as prior art and can prevent a coloring of the DLC film formed on a neck portion of the container, manufacturing apparatus therefor and manufacturign method thereof. The apparatus for manufacturing the DLC film coated plastic container, comprising: a container side electrode which forms one portion of a pressure-reducing chamber which houses a container formed from plastic, a facing electrode which faces said container side electrode and is arranged inside said container or above said opening, wherein said container side electrode and said facing electrode are made to face each other via an insulating body which forms a portion of said pressure-reducing chamber, source gas supply means which includes a supply gas inlet pipe, exhaust means, and high frequency supply means; wherein said container side electrode is formed so that the average inner hole diameter of the inner wall surrounding said neck portion when the container is housed becomes smaller than the average inner hole diameter of the inner wall surrounding said body portion, and the average distance between the outer wall of said container and the inner wall of said container side electrode in a horizontal cross section with respect to the vertical direction of said container at said neck portion becomes longer than the average distance between the outer wall of said container and the inner wall of said container side electrode in a horizontal cross section with respect to the vertical direction of said container at said body portion.

Owner:KIRIN BREWERY CO LTD

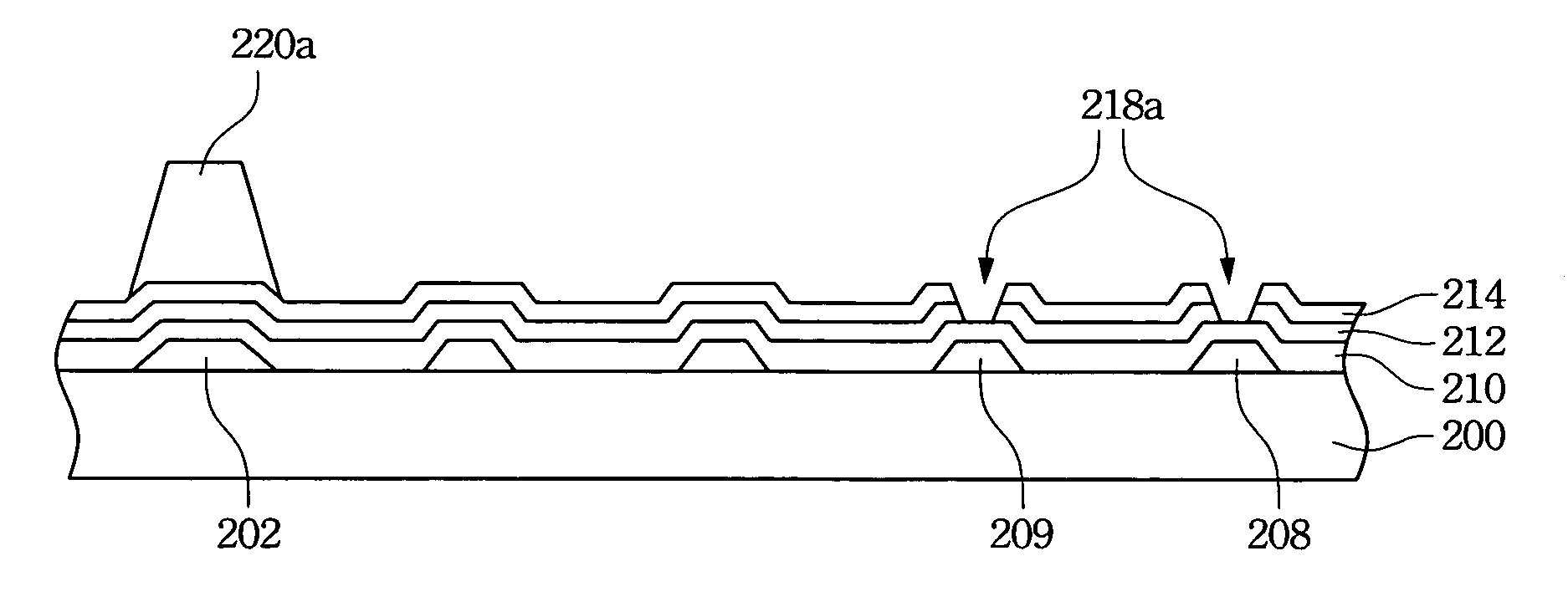

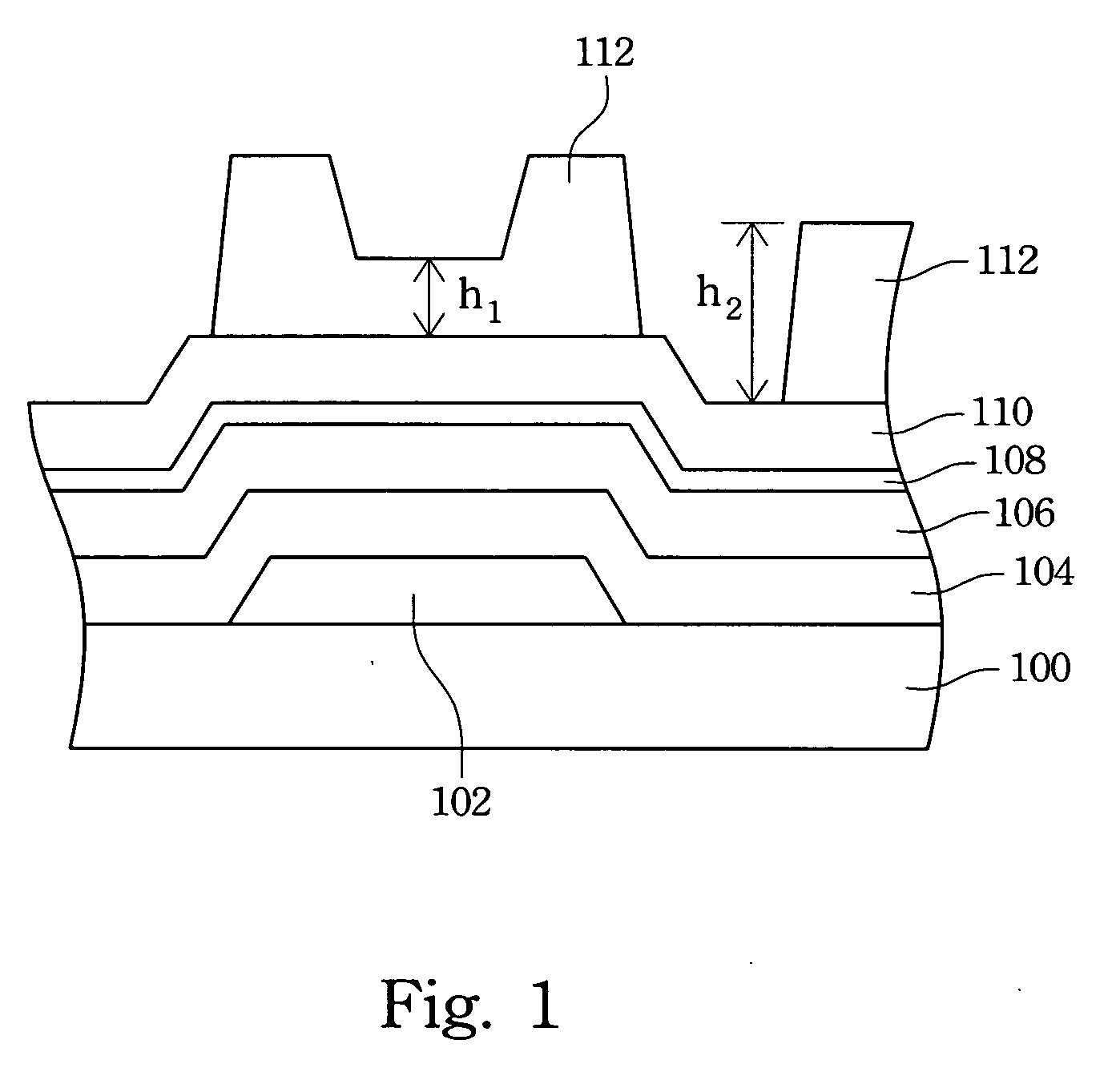

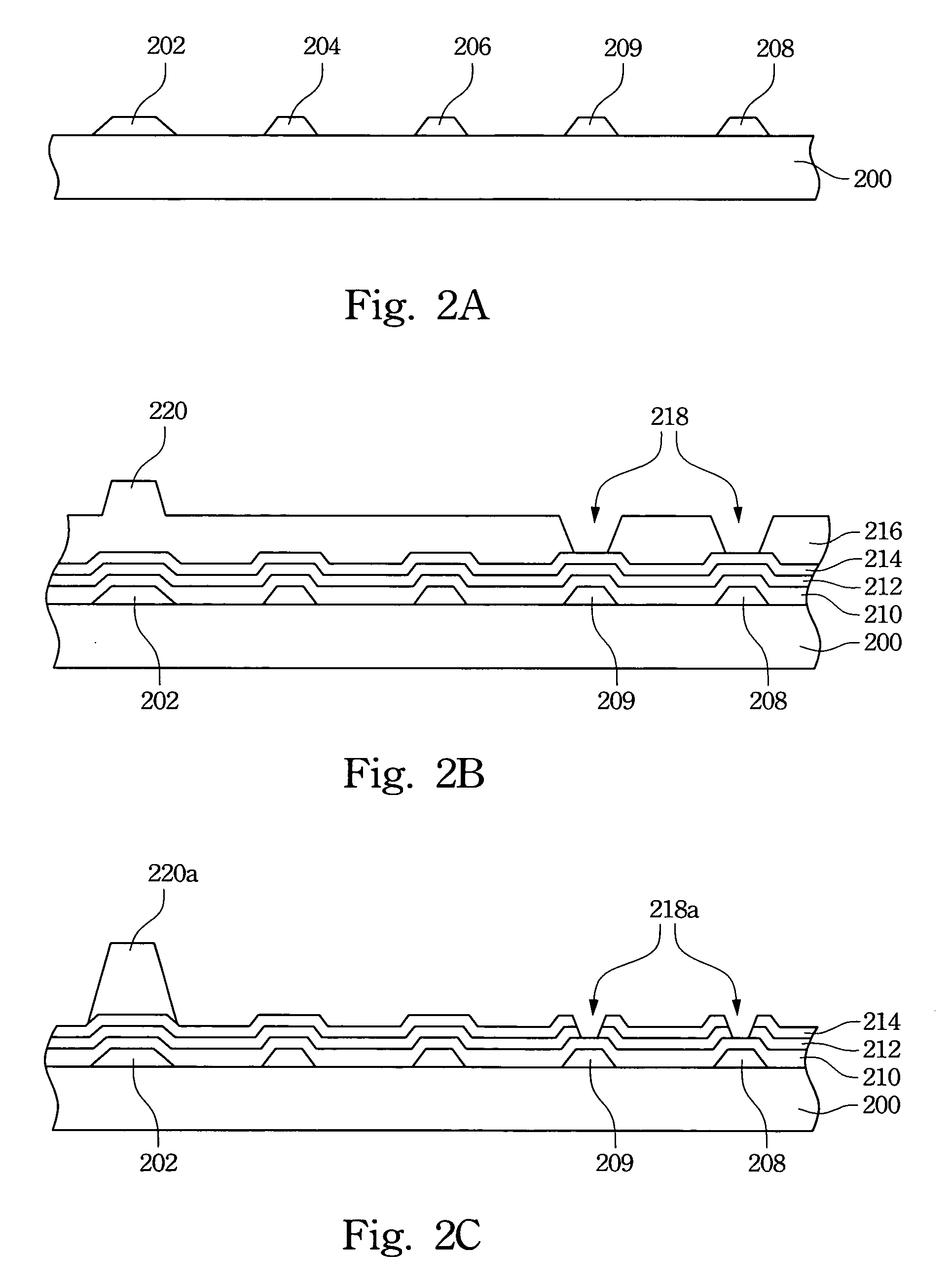

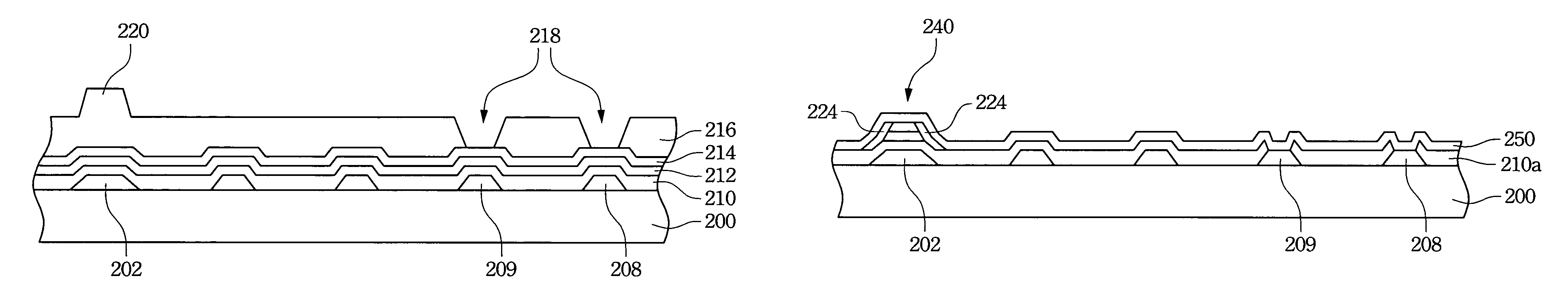

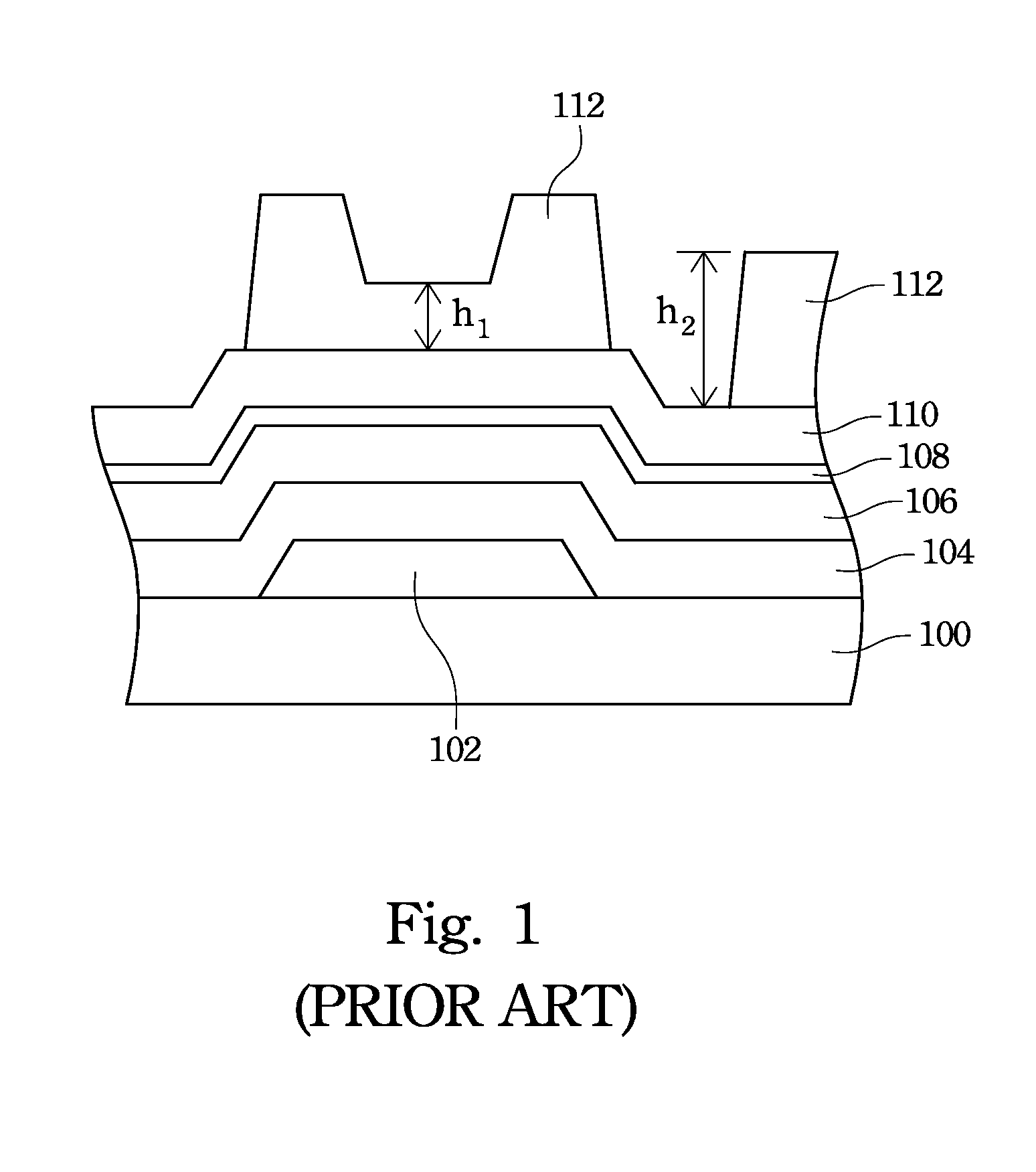

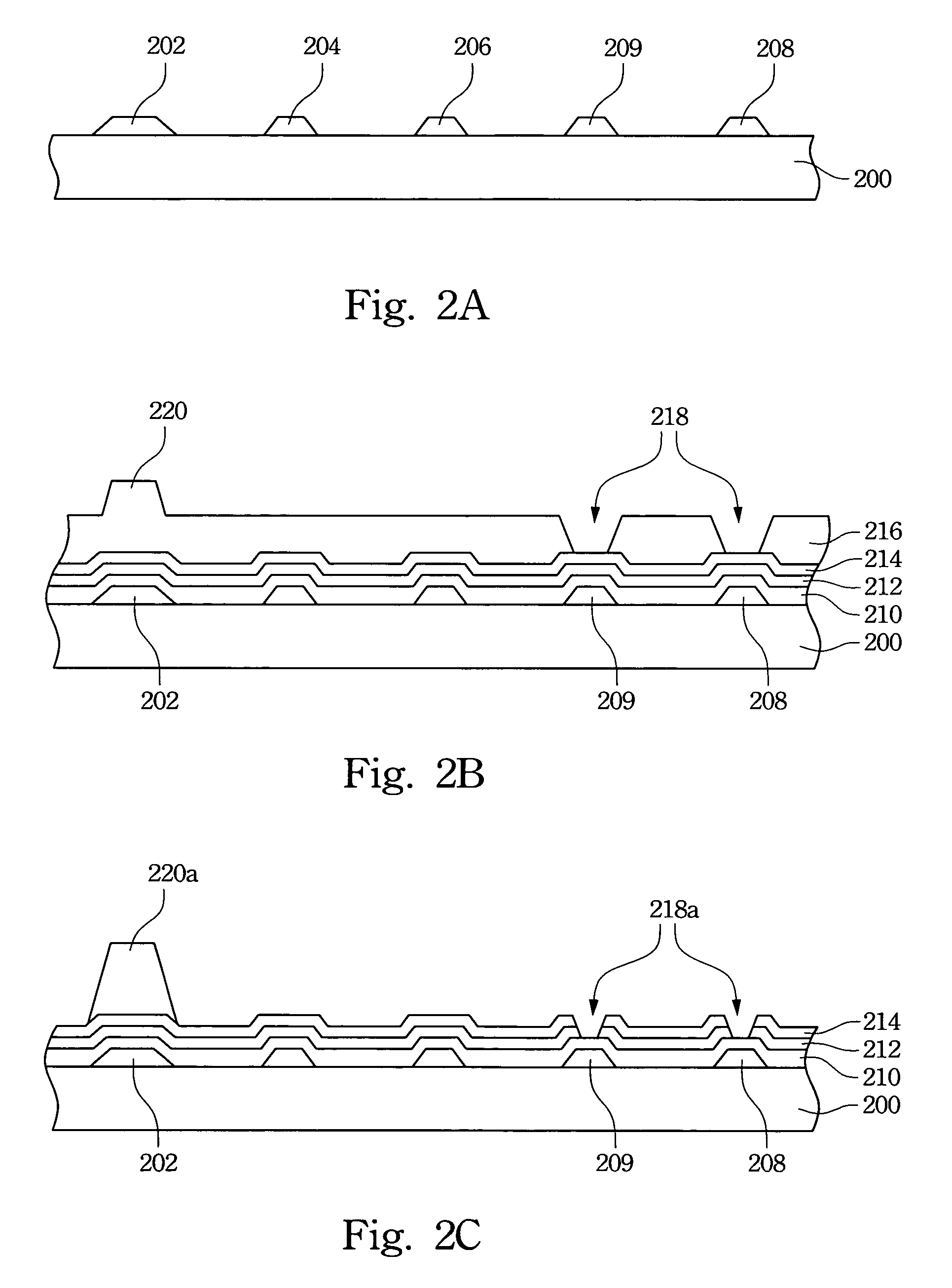

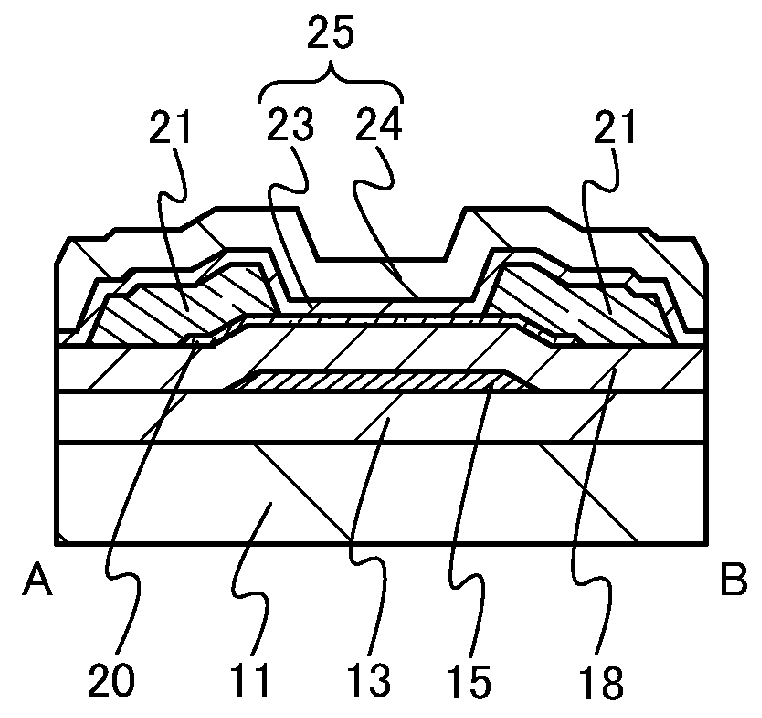

Method of manufacturing a thin film transistor matrix substrate

ActiveUS20070042537A1Reduce numberReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringTransistor

A method of manufacturing a thin film transistor matrix substrate is provided. The first photo-mask process is used to define a gate electrode and a signal electrode. The second photo-mask process is used to obtain different thickness of a PR layer in different regions for forming a channel, gate electrode through holes, signal electrode through holes and conductive pads. The third photo-mask process is used to define a source, a drain, an upper signal electrode, a pixel electrode, gate electrode pads and signal electrode pads.

Owner:AU OPTRONICS CORP

Atomic layer growing apparatus and thin film forming method

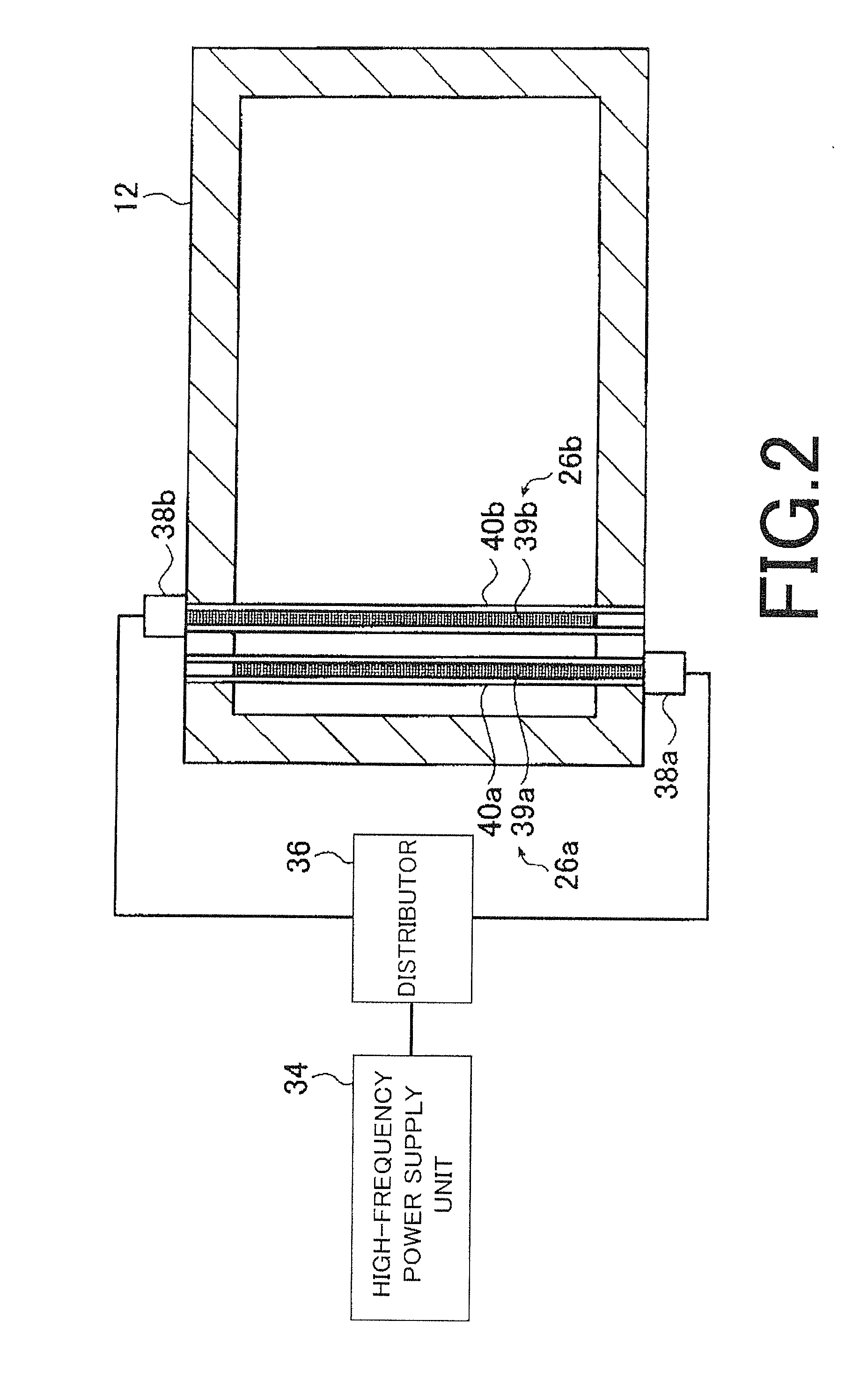

InactiveUS20110008550A1High reactivityReduce plasma damageElectric discharge tubesSemiconductor/solid-state device manufacturingPhysics

An atomic layer growing apparatus includes a deposition container, a gas supply unit, and an exhaust unit. In the deposition container, an antenna array and a substrate stage are provided. The antenna array is formed by disposing a plurality of antenna elements in parallel, each of the antenna elements being configured by coating a rod-shaped antenna body with a dielectric material. The antenna array generates plasma using one of an oxidizing gas and a nitriding gas. The substrate is placed on the substrate stage. The gas supply unit alternately supplies the source gas and the oxidizing gas toward the substrate stage from a supply hole made in a sidewall of the deposition container when a film is formed on the substrate. The exhaust unit exhausts the source gas and one of the oxidizing gas and the nitriding gas, which are alternately supplied into the deposition container.

Owner:MITSUI ENG & SHIPBUILD CO LTD

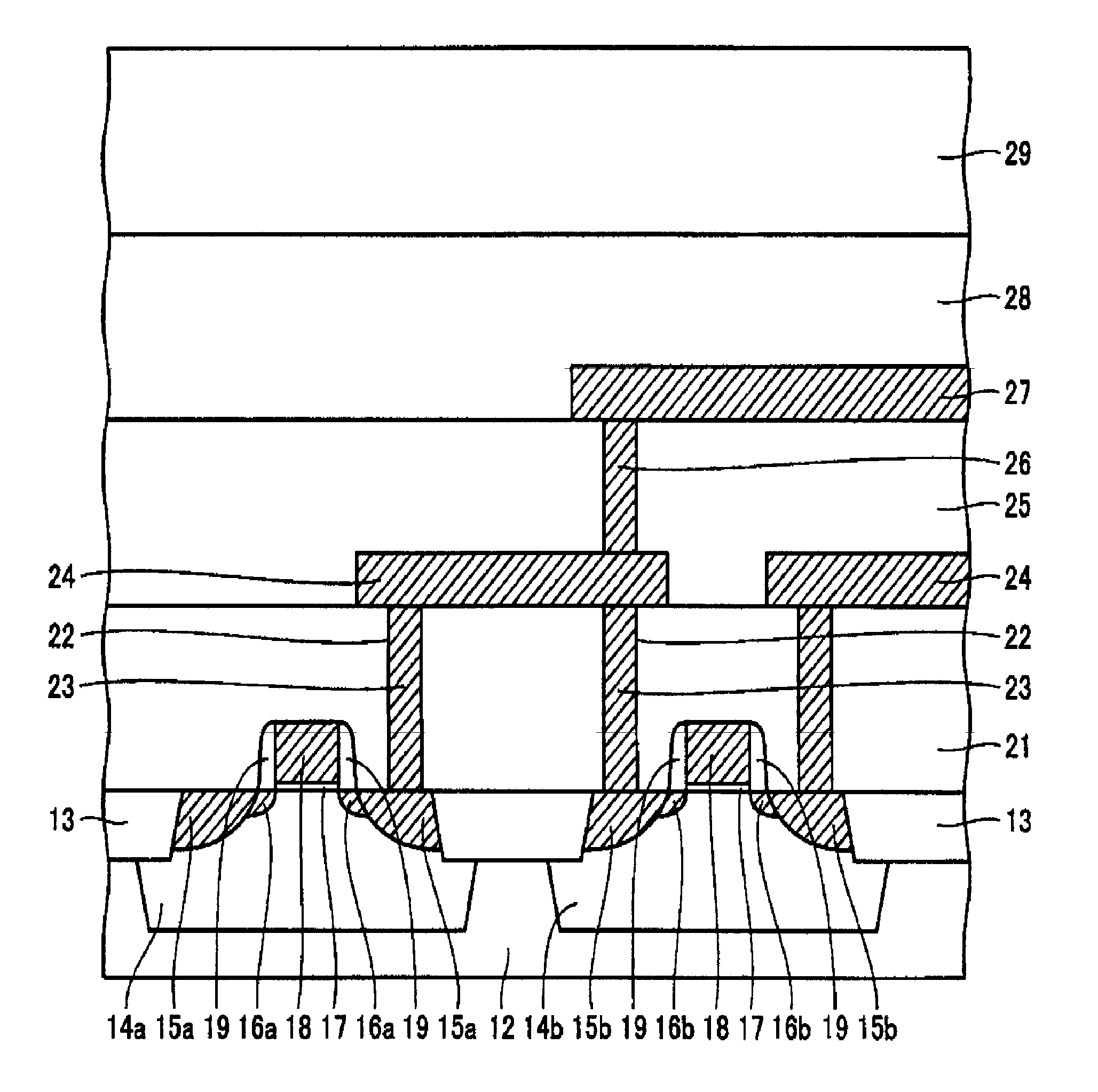

Semiconductor element and method for manufacturing the same

InactiveUS20070117406A1Total current dropLeakage currentElectric discharge tubesSolid-state devicesElectron temperatureEngineering

A method by which generation of leak current can be suppressed and also a fine element can be formed by performing element isolation at a temperature at which a glass substrate can be used is provided. The method includes a first step of forming a base film over a glass substrate; a second step of forming a semiconductor film over the base film; a third step of forming, over the semiconductor film, a film preventing oxidation or nitridation of the semiconductor film into a predetermined pattern; and a fourth step of performing element isolation by radical oxidation or radical nitridation of a region of the semiconductor film, which is not covered with the predetermined pattern, at a temperature of the glass substrate lower than a strain point thereof by 100° C. or more, where radical oxidation or radical nitridation is performed over a semiconductor film placed apart from a plasma generation region, in a plasma treatment chamber with an electron temperature within the range of 0.5 to 1.5 eV, preferably less than or equal to 1.0 eV, and an electron density within the range of 1×1011cm−3 to 1×1013cm−3.

Owner:SEMICON ENERGY LAB CO LTD

Methods to mitigate plasma damage in organosilicate dielectrics using a protective sidewall spacer

InactiveUS7781332B2Reduce plasma damageIncrease widthSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectEngineering

Plasma damage in ultra low k dielectric materials during formation of a dual damascene metal interconnect structure is reduced by providing a protective spacer on sidewalls of a line trench. A densified trench bottom region may be additionally formed directly beneath an exposed horizontal surface of the line trench. The protective spacer and / or the densified trench bottom region protects an ultra low k intermetal dielectric layer from plasma damage during a plasma strip process that is used to remove a disposable via fill plug employed in the dual damascene metal interconnect structure.

Owner:GLOBALFOUNDRIES INC

Method for nitriding substrate and method for forming insulating film

InactiveUS20090269940A1Improve film qualityImprove concentrationElectric discharge tubesSolid-state devicesNitrogen plasmaPotential difference

In a substrate nitriding method for nitriding a target substrate by allowing a nitrogen-containing plasma to act on silicon on a surface of the substrate in a processing chamber of a plasma processing apparatus, the nitridation by the nitrogen-containing plasma is performed by controlling a sheath voltage Vdc around the substrate to be less than or equal to about 3.5 eV. The sheath voltage Vdc is a potential difference Vp−Vf between a plasma potential Vp in a plasma generating region and a floating potential Vf of the substrate.

Owner:TOKYO ELECTRON LTD

Semiconductor device and method for fabricating the same

InactiveUS20060163638A1Prevent increase of capacitor leakage currentAvoid flowTransistorSolid-state devicesEngineeringDielectric

A semiconductor device includes a first insulating film formed on a semiconductor substrate; a second insulating film formed on the first insulating film and having a recess corresponding to a capacitor region; a lower electrode formed in the recess; a capacitor dielectric film formed on the lower electrode; and an upper electrode formed on the capacitor dielectric film. The semiconductor device further includes a conductive portion formed in the first insulating film and the second insulating film for electrically connecting the semiconductor substrate to the upper electrode.

Owner:PANASONIC CORP

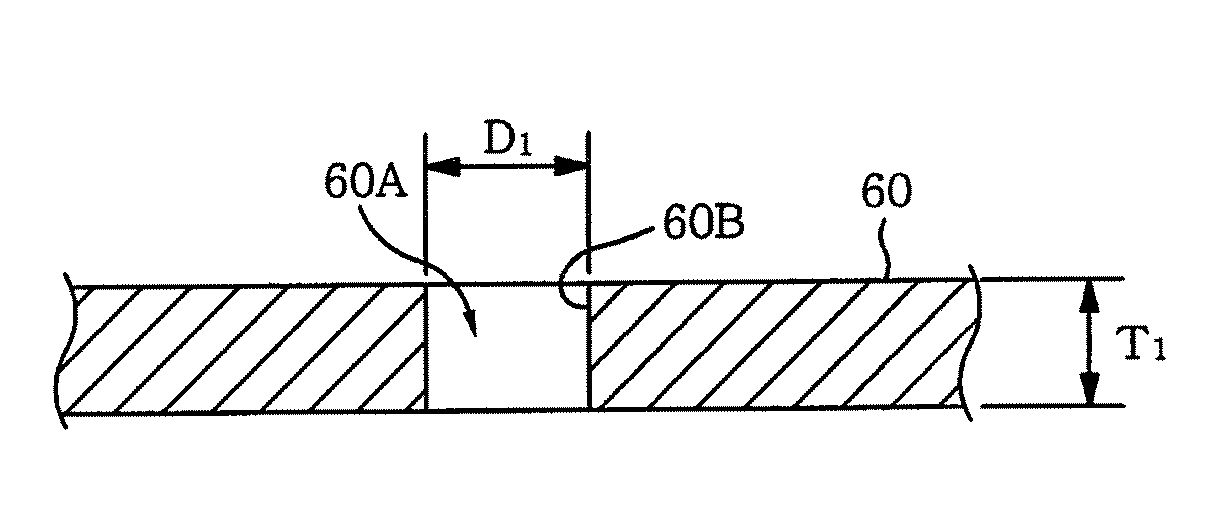

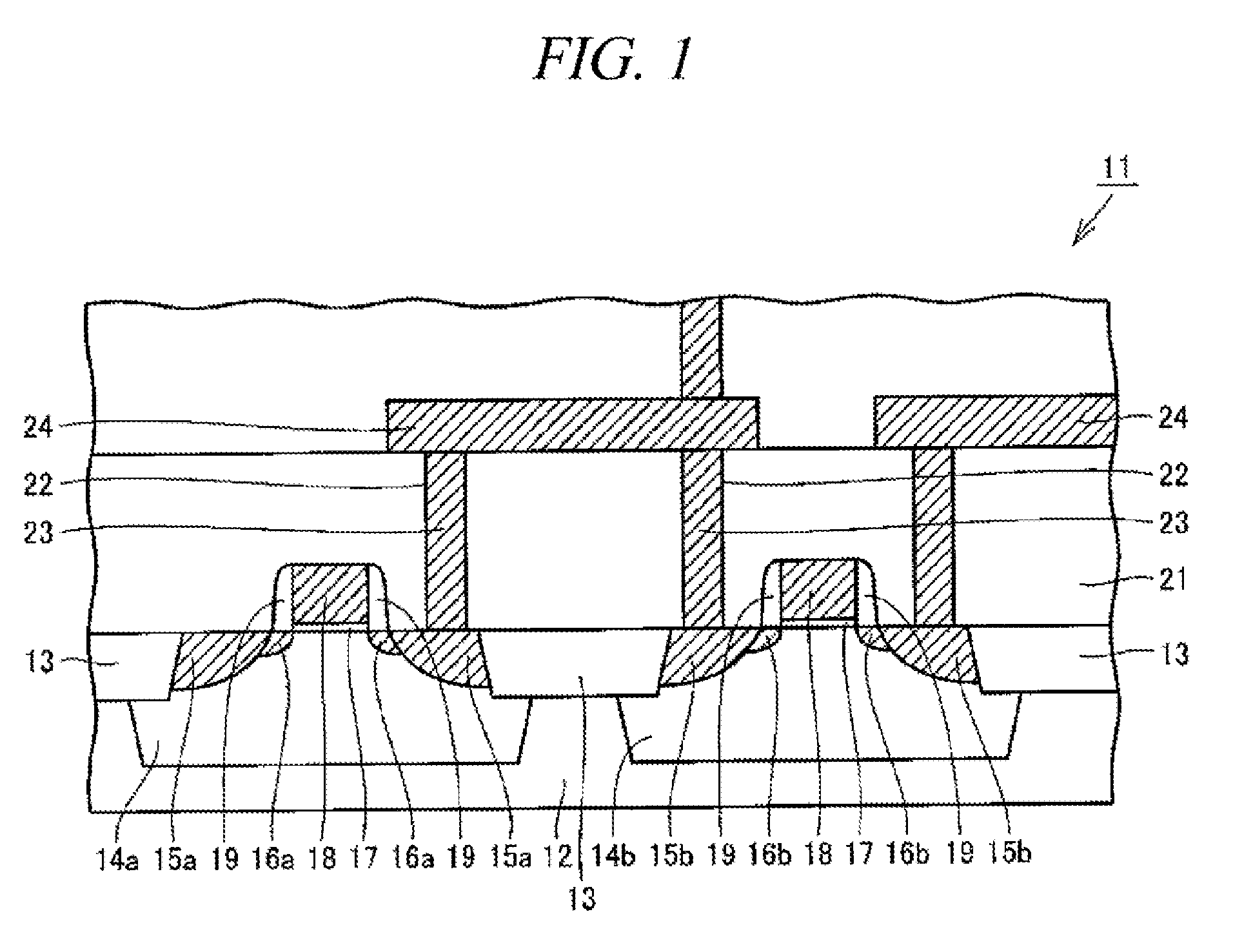

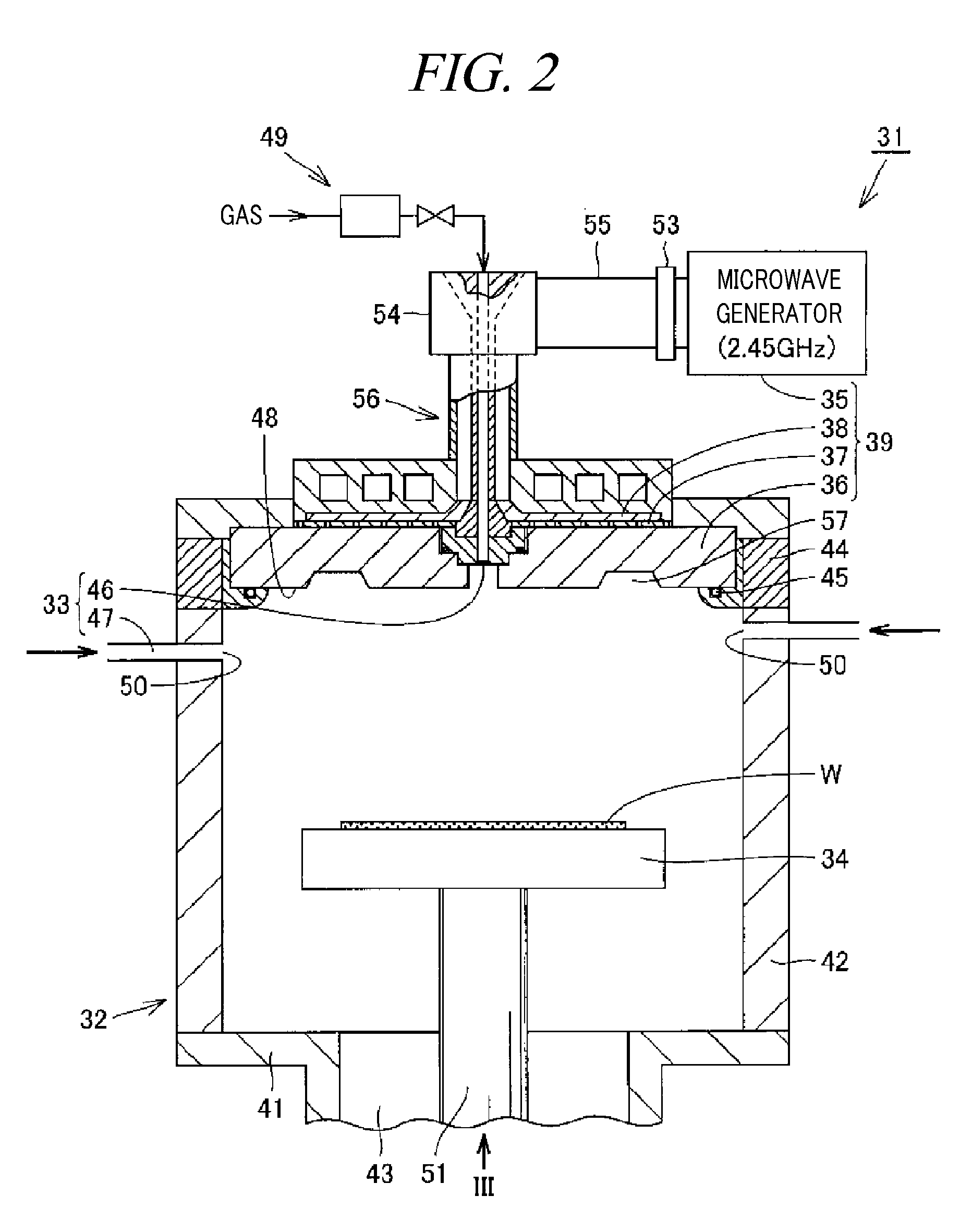

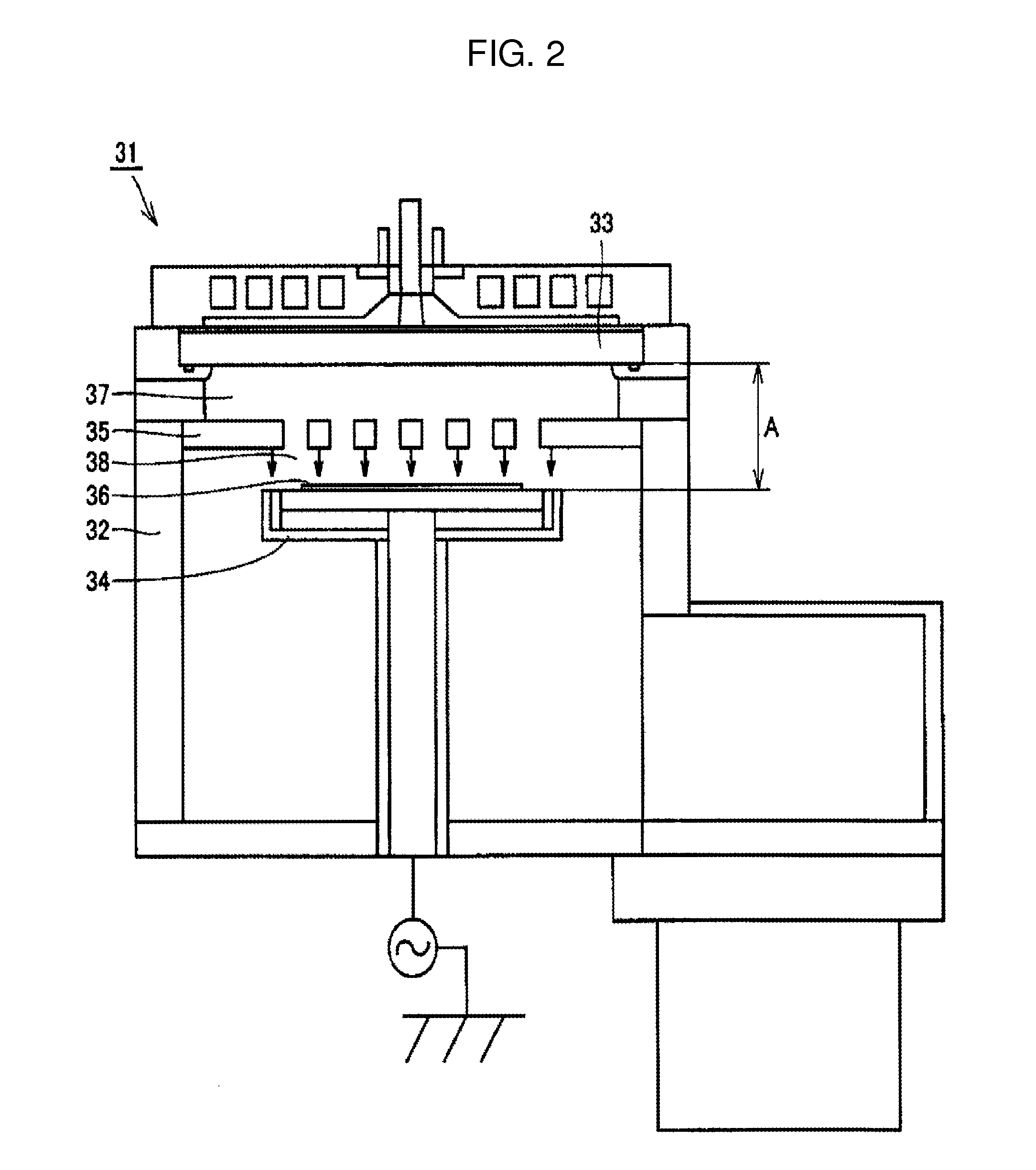

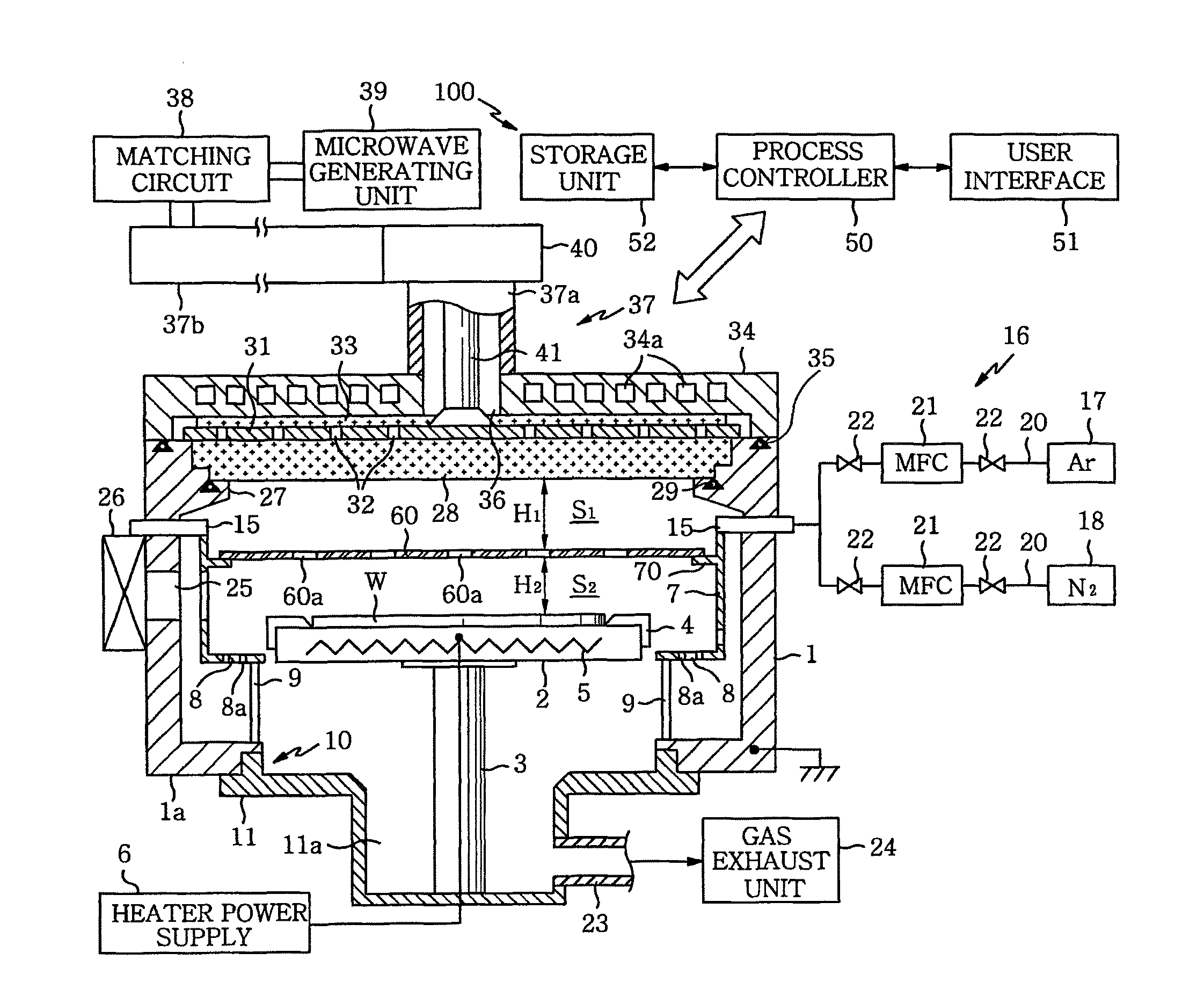

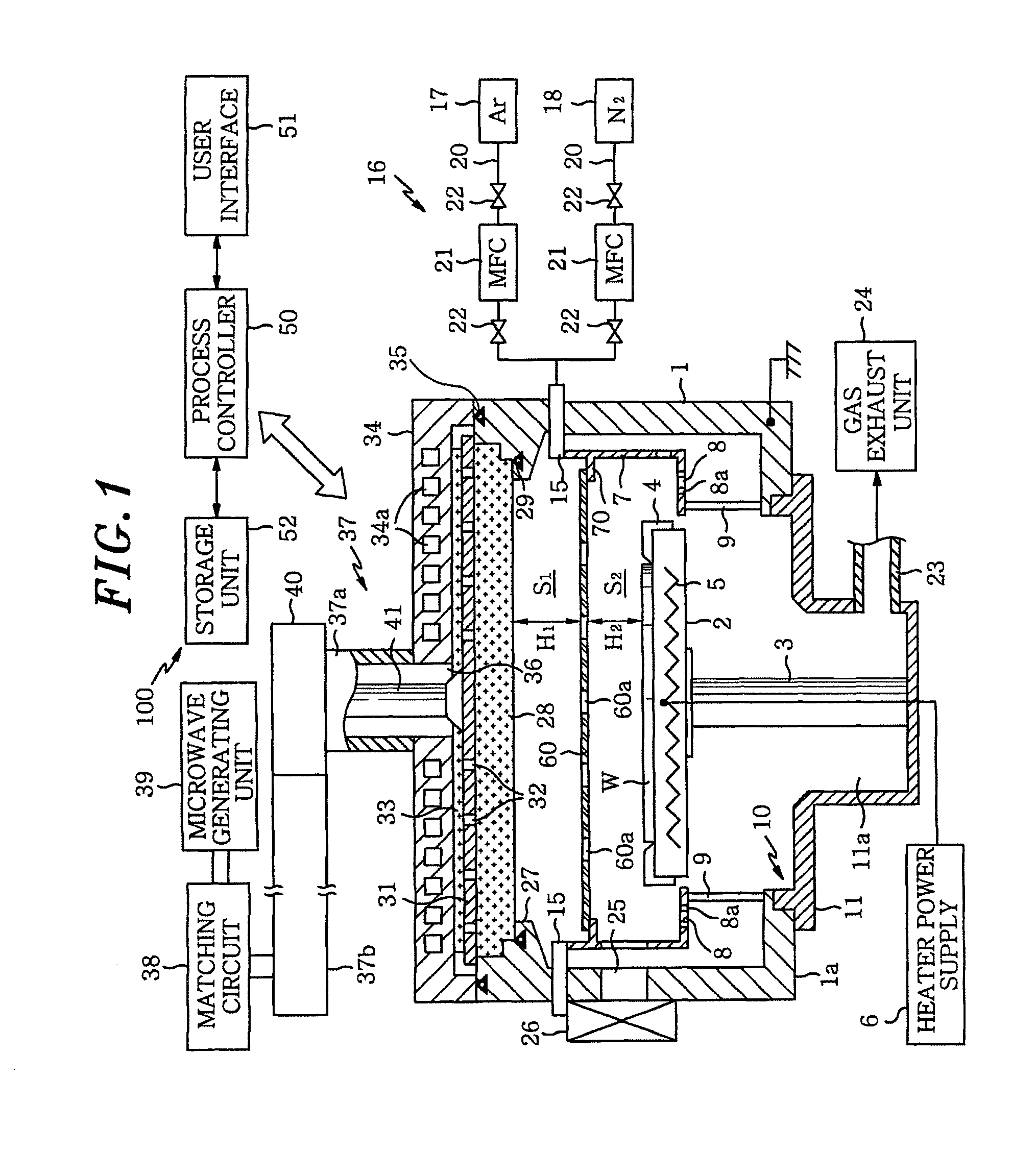

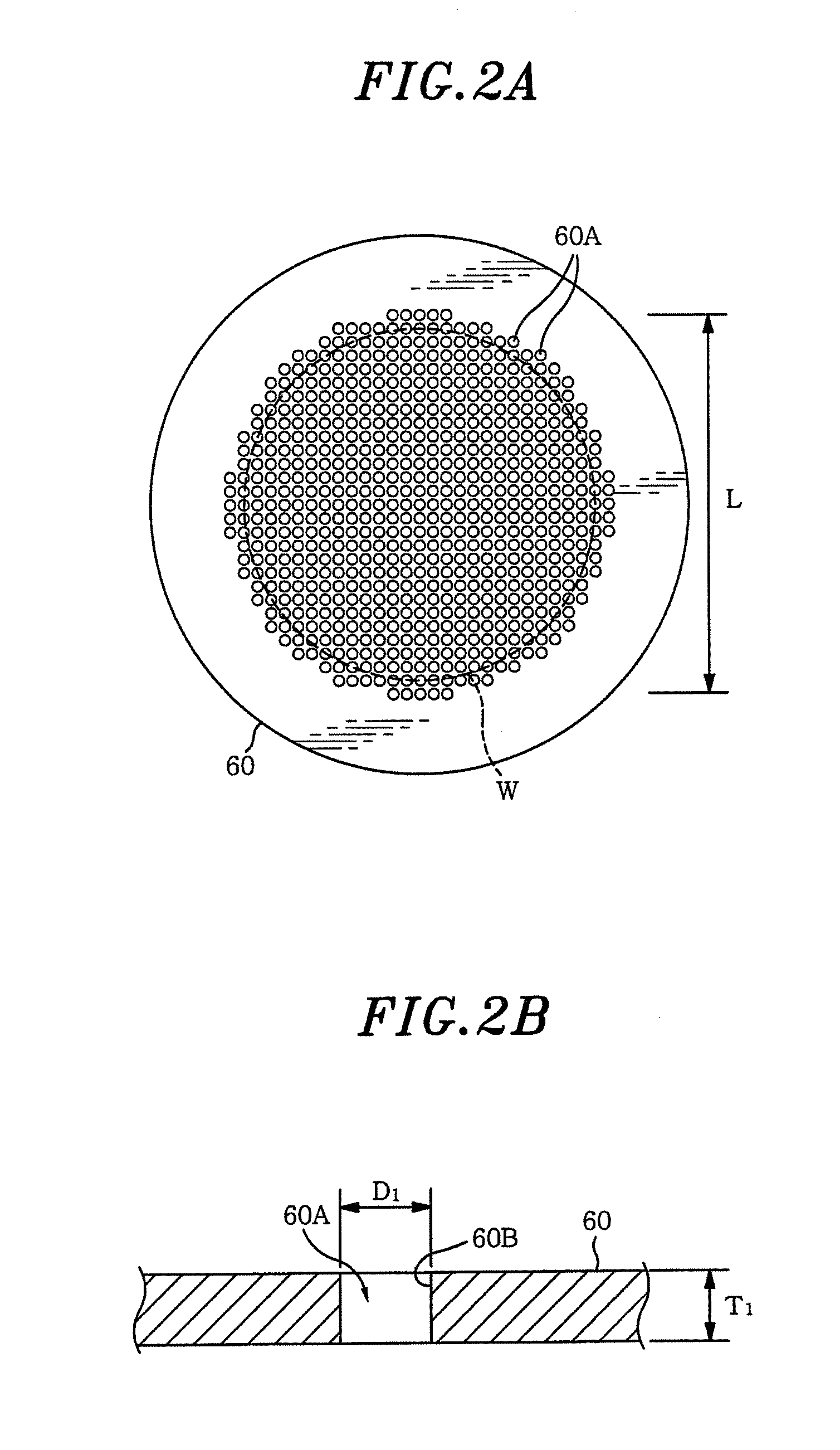

Film forming method, semiconductor device manufacturing method, insulating film and semiconductor device

InactiveUS20120190211A1High-quality filmReduce plasma damageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasPower semiconductor device

In a film forming method, firstly, a processing target substrate W as a base of a semiconductor device is held on a mounting table 34 by an electrostatic chuck. Then, a film forming gas is adsorbed onto the processing target substrate W (a gas adsorption process) ((A) of FIG. 6). Thereafter, the inside of the processing chamber 32 is evacuated in order to remove residues of the film forming gas ((B) of FIG. 6). Upon the completion of the first exhaust process, a plasma process using microwave is performed ((C) of FIG. 6). Upon the completion of the plasma process, the inside of the processing chamber 32 is evacuated in order to remove an unreacted reactant gas and the like ((D) of FIG. 6). These series of steps (A) to (D) are repeated in this sequence until a desired film thickness is obtained.

Owner:TOKYO ELECTRON LTD

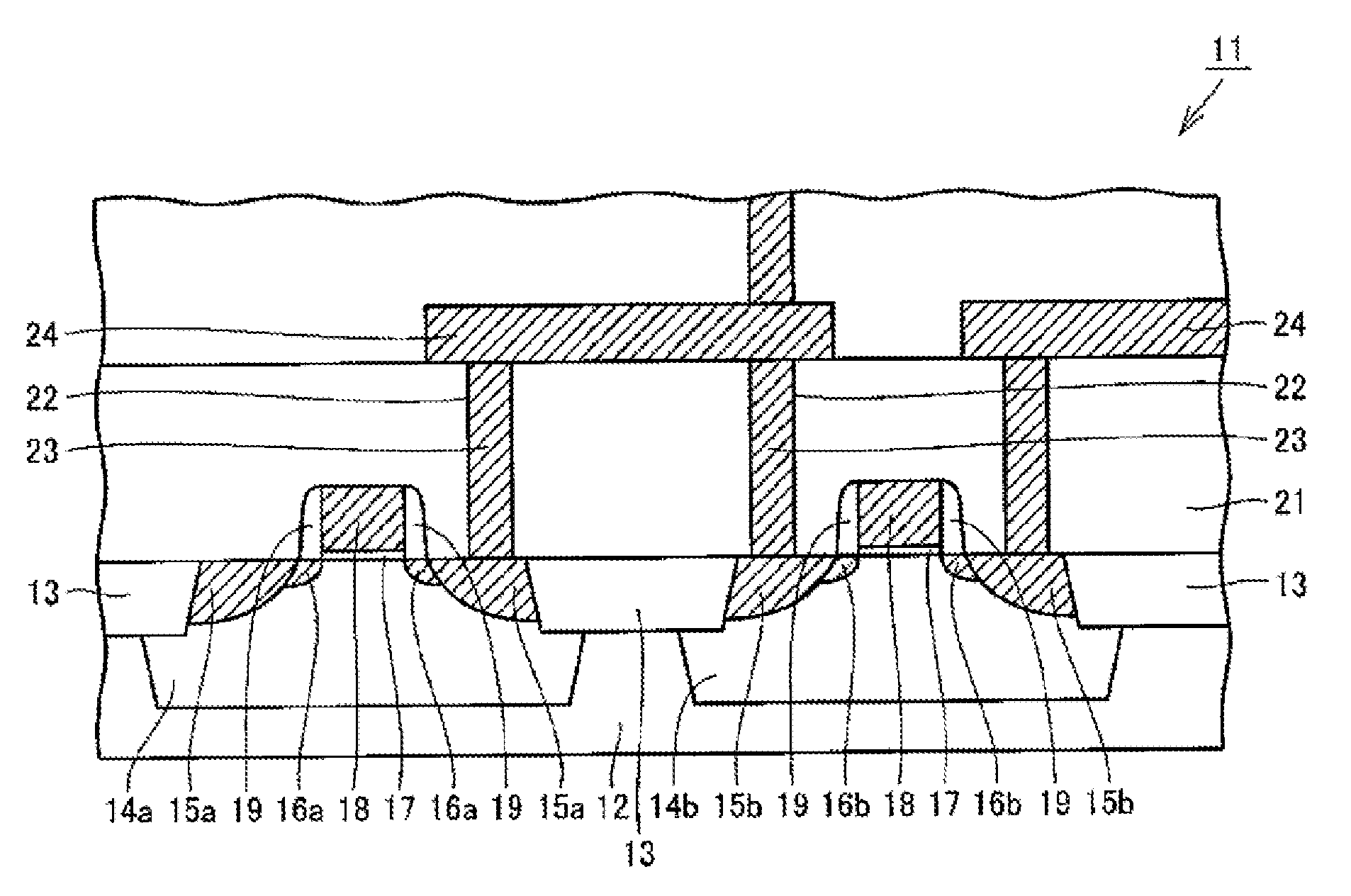

Semiconductor device manufacturing method

ActiveUS20100216300A1Reduce the impactReduce plasma damageElectric discharge tubesSemiconductor/solid-state device manufacturingElectron temperatureMicrowave

A semiconductor device manufacturing method, the method including: forming a semiconductor element on a semiconductor substrate; and by using microwaves as a plasma source, forming an insulation film on the semiconductor element by performing a CVD process using microwave plasma having an electron temperature of plasma lower than 1.5 eV and an electron density of plasma higher than 1×1011 cm−3 near a surface of the semiconductor substrate.

Owner:TOKYO ELECTRON LTD +1

Method of manufacturing a thin film transistor matrix substrate

ActiveUS7678619B2More competitive pricingLow production costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

A method of manufacturing a thin film transistor matrix substrate is provided. The first photo-mask process is used to define a gate electrode and a signal electrode. The second photo-mask process is used to obtain different thickness of a PR layer in different regions for forming a channel, gate electrode through holes, signal electrode through holes and conductive pads. The third photo-mask process is used to define a source, a drain, an upper signal electrode, a pixel electrode, gate electrode pads and signal electrode pads.

Owner:AU OPTRONICS CORP

Method of forming plasma and method of forming a layer using the same

InactiveUS20070042132A1Lower ionization energyReduce harmDecorative surface effectsSemiconductor/solid-state device manufacturingDevice materialEngineering

A method of forming plasma used in a process of manufacturing a semiconductor device and a method of forming a layer for a semiconductor device using the plasma are disclosed. The plasma forming method includes forming a plasma region in a sealed space by supplying a plasma source gas into the sealed space at a first flow rate and maintaining the plasma region by supplying a plasma maintenance gas into the sealed space at a second flow rate higher than the first flow rate. The plasma source gas includes a first gas having a first atomic weight, and the plasma maintenance gas includes a second gas having a second atomic weight lower than the first atomic weight. The plasma source gas includes argon and the plasma maintenance gas includes helium. The method may further include forming the layer on a wafer by supplying a source gas into the sealed space.

Owner:SAMSUNG ELECTRONICS CO LTD

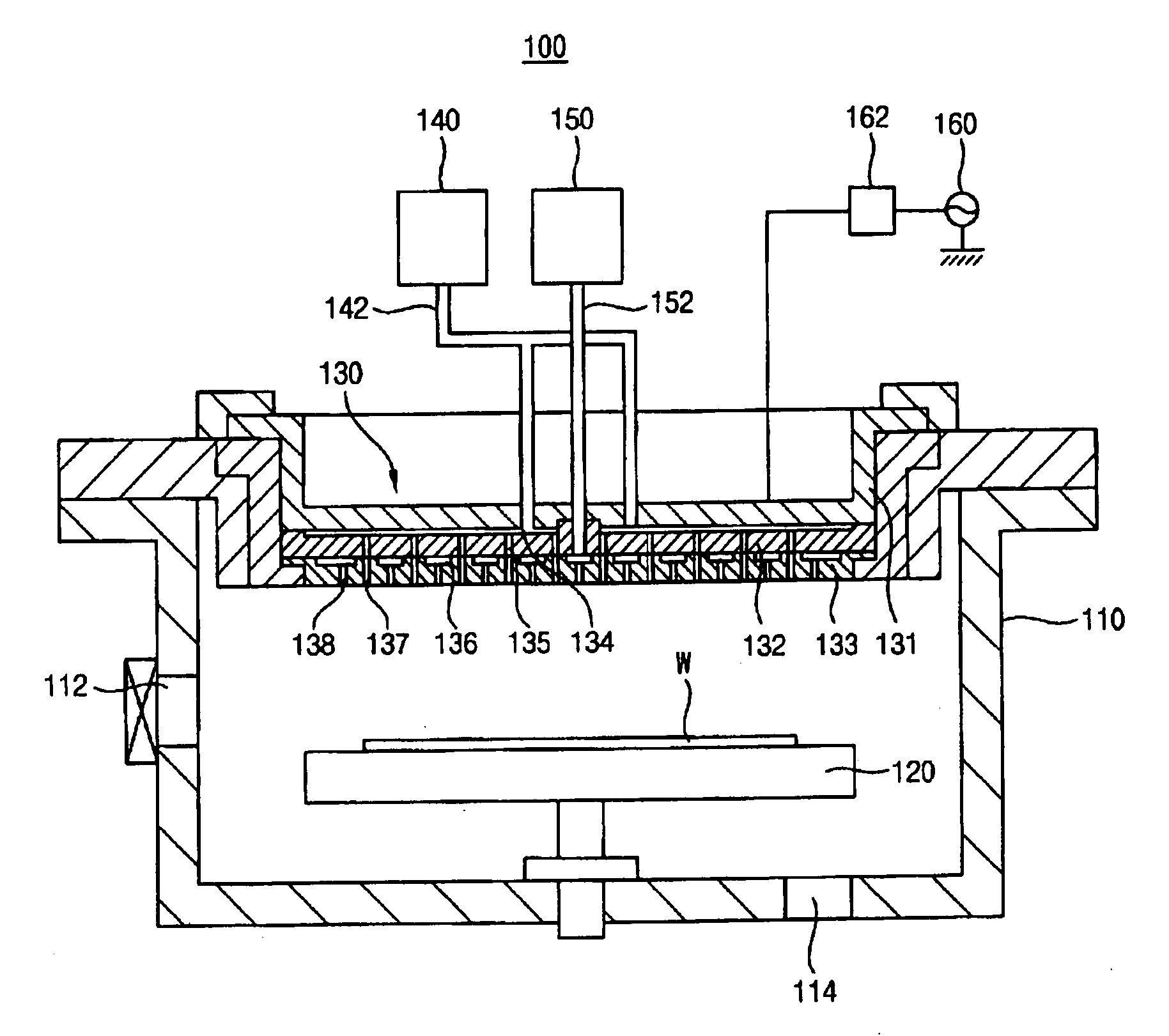

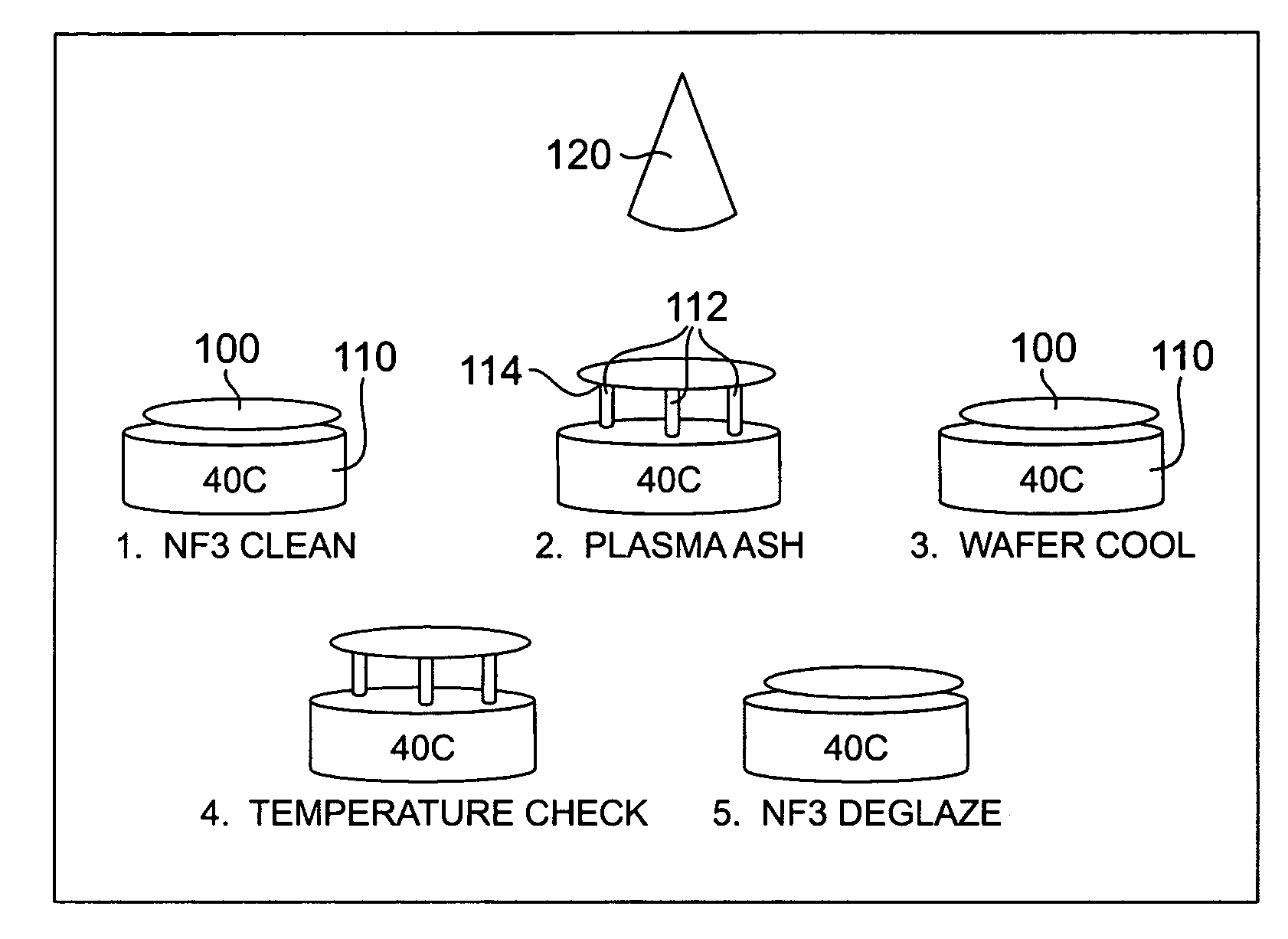

Methods of downstream microwave photoresist removal and via clean, particularly following Stop-On TiN etching

InactiveUS20060043062A1Improve product qualityReduce plasma damageBioreactor/fermenter combinationsBiological substance pretreatmentsEtchingMicrowave

A process for photoresist layer removal from a semiconductor wafer comprises exposing at relatively high temperature the wafer to an RIE-free microwave-energy-generated plasma of a primary gas mixture, the exposing causing photoresist removal such as by ashing. The method also comprises determining an endpoint to the removal by a determined change in the visible light emanating from a chamber containing the wafer. A multi-step process of the present invention comprises the above method and a preliminary RIE-free microwave-energy-generated plasma that solubilizes polymer on walls of vias of the wafer. This multi-step process also comprises, following the exposing step, a cooling step, a cooling step with a temperature check, and a deglazing step. The deglazing step also uses an RIE-free microwave-energy-generated plasma. Specific gas mixtures for the respective plasmas are exemplified. Other embodiments of methods of the present invention are comprised of less steps, or a consolidation of such steps.

Owner:BELL SEMICON LLC

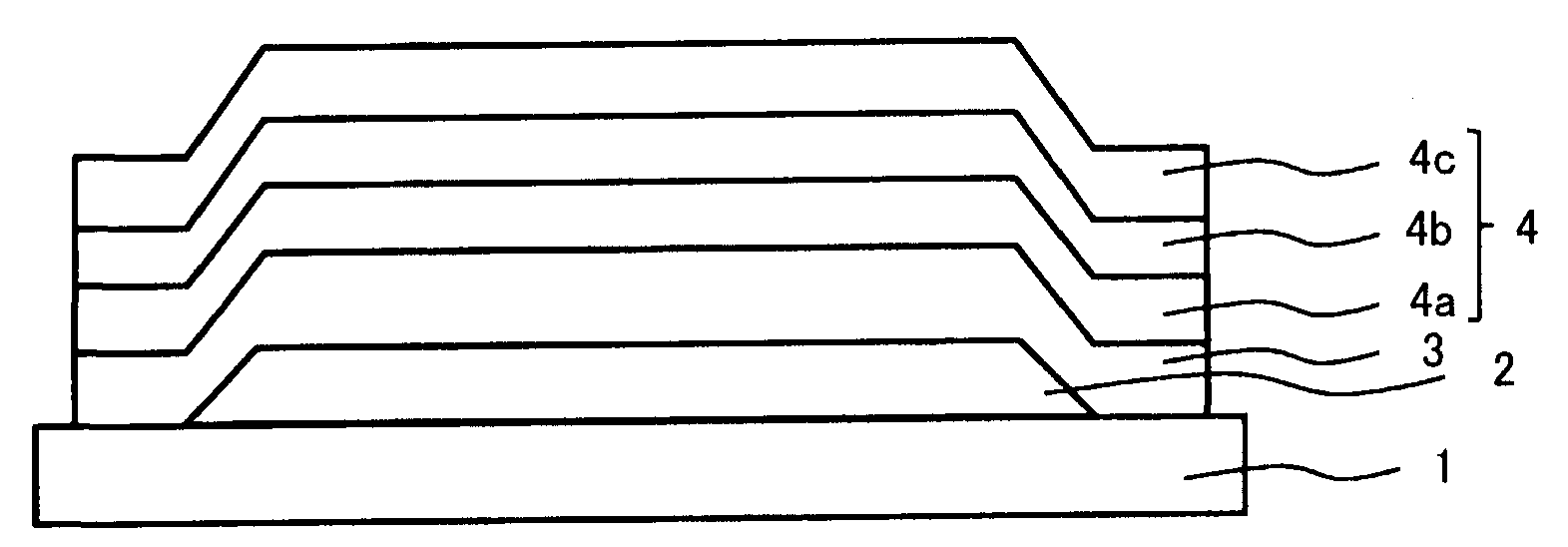

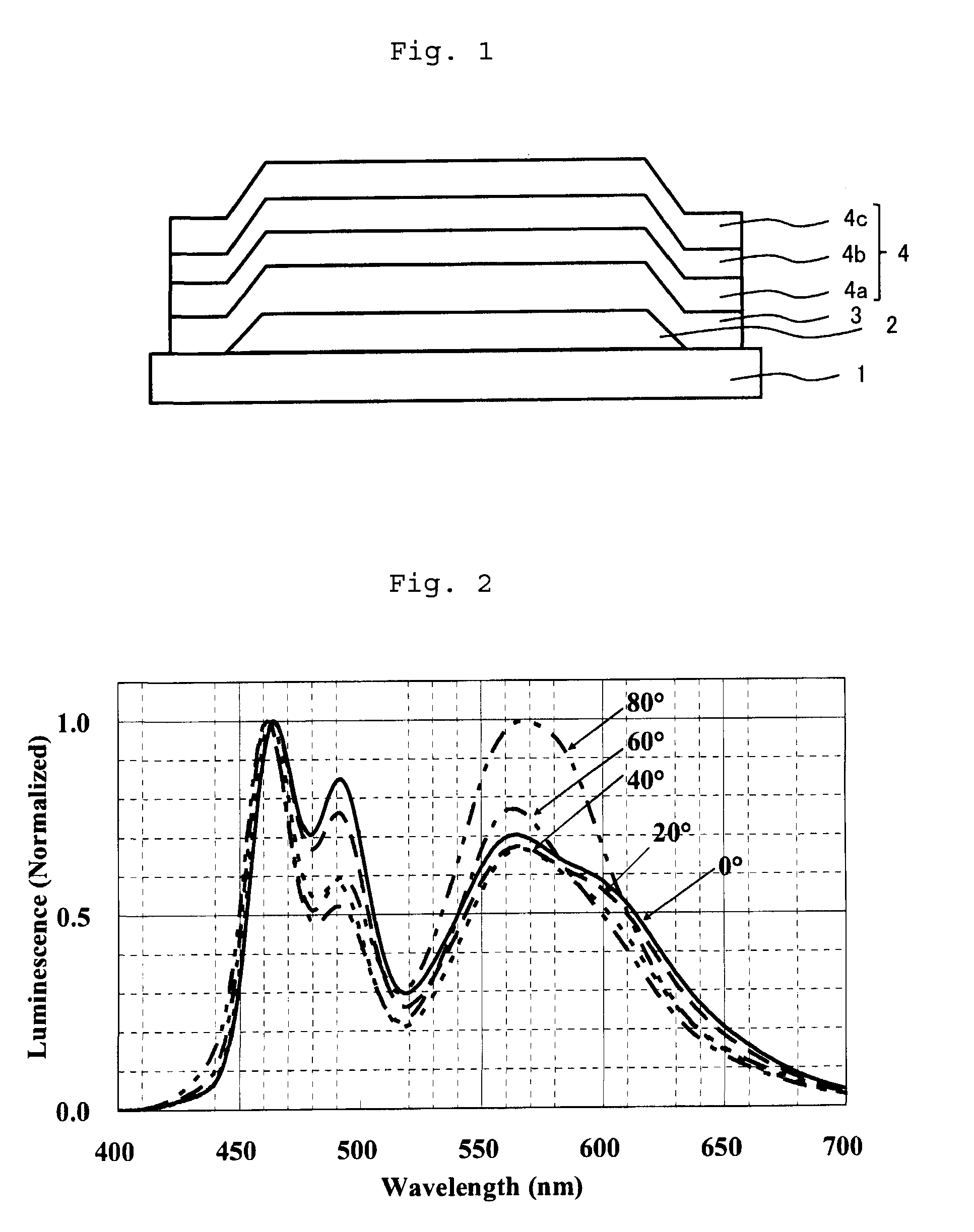

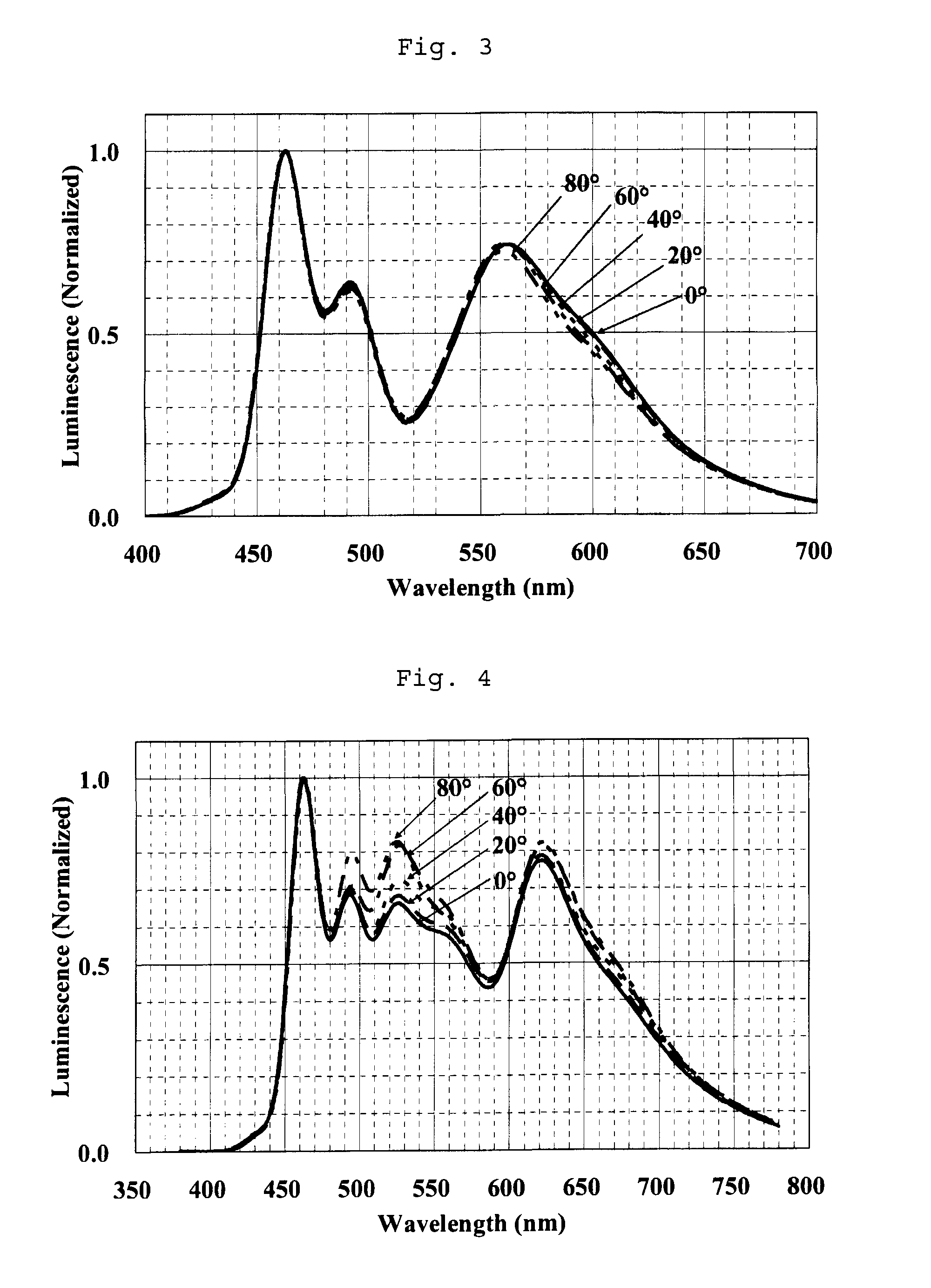

Organic electroluminescence element and method of manufacturing the same

InactiveUS20100052525A1Reduce plasma damageImprove extraction efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceVoltage

The present invention provides an organic electroluminescence element in which an anode layer 2, a light emitting unit 3, and a cathode layer 4 which each have optical permeability are stacked on a transparent substrate 1, the cathode layer 4 including a first charge generation layer 4a and a cathode 4c. The cathode 4c is formed by way of a facing target sputtering method. Even in the case where a cathode material which has optical permeability is used, the organic electroluminescence element is driven at a low applied voltage, has no angle dependability of an emission spectrum, and has high luminous efficiency.

Owner:YAMAGATA PROMOTIONAL ORG FOR INDAL TECH

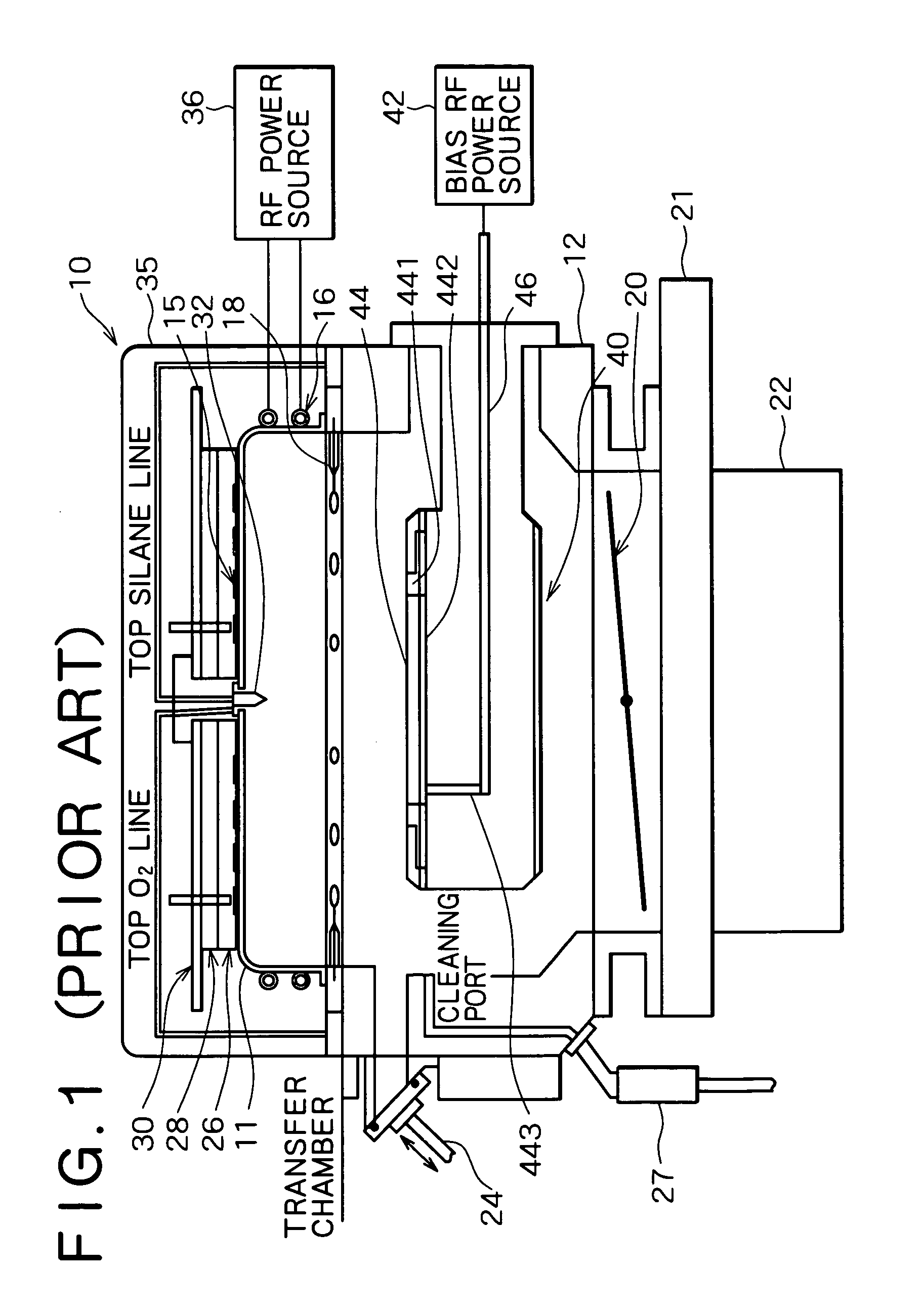

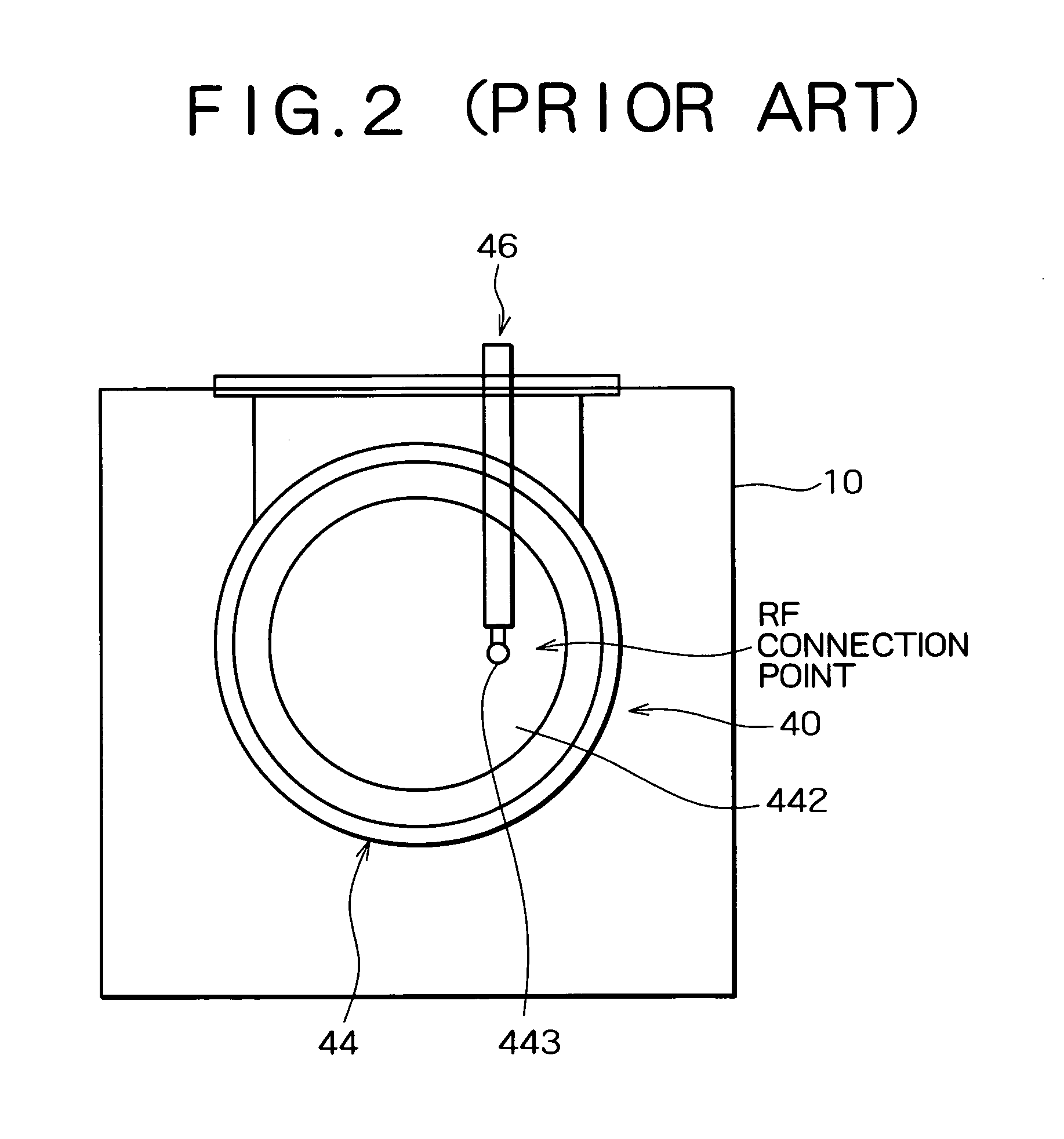

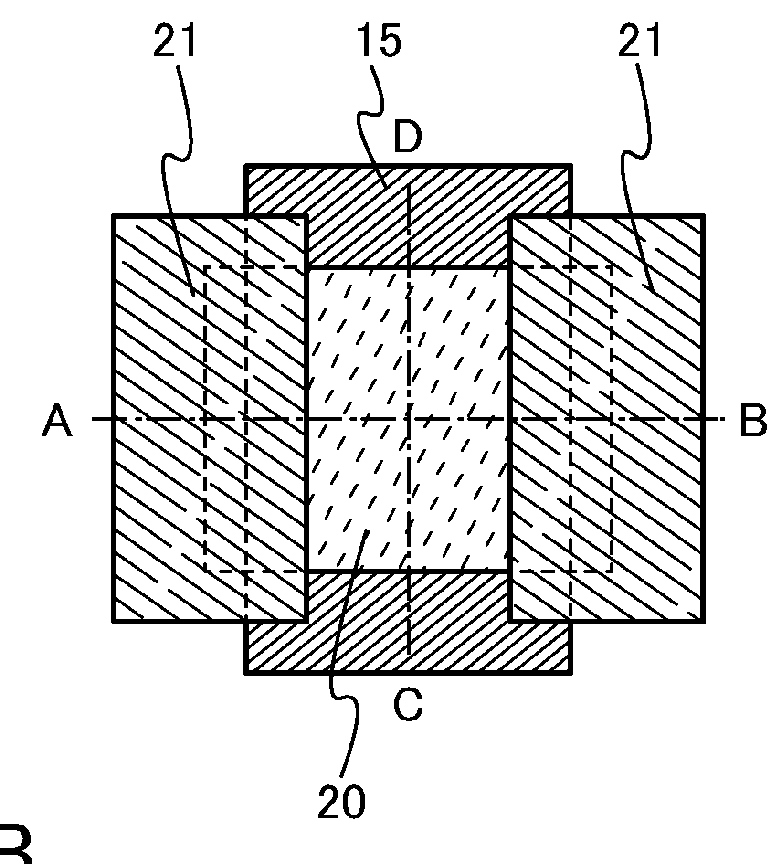

Plasma processing apparatus, semiconductor manufacturing apparatus and electrostatic chucking unit used thereof

InactiveUS7393433B2Improve device yieldReduce plasma damageSleeve/socket jointsElectric discharge tubesManufactured apparatusSemiconductor

A wiring member which becomes substantially symmetrical on the plane of an electrostatic chuck unit is connected to the tip end of an RF introduction rod between the RF introduction rod and the electrostatic chuck unit in order to make uniform generation of an electric field due to bias RF which becomes a cause of plasma damage. The connection point between the electrostatic chuck unit and the wiring member may be single or plural.

Owner:RENESAS ELECTRONICS CORP

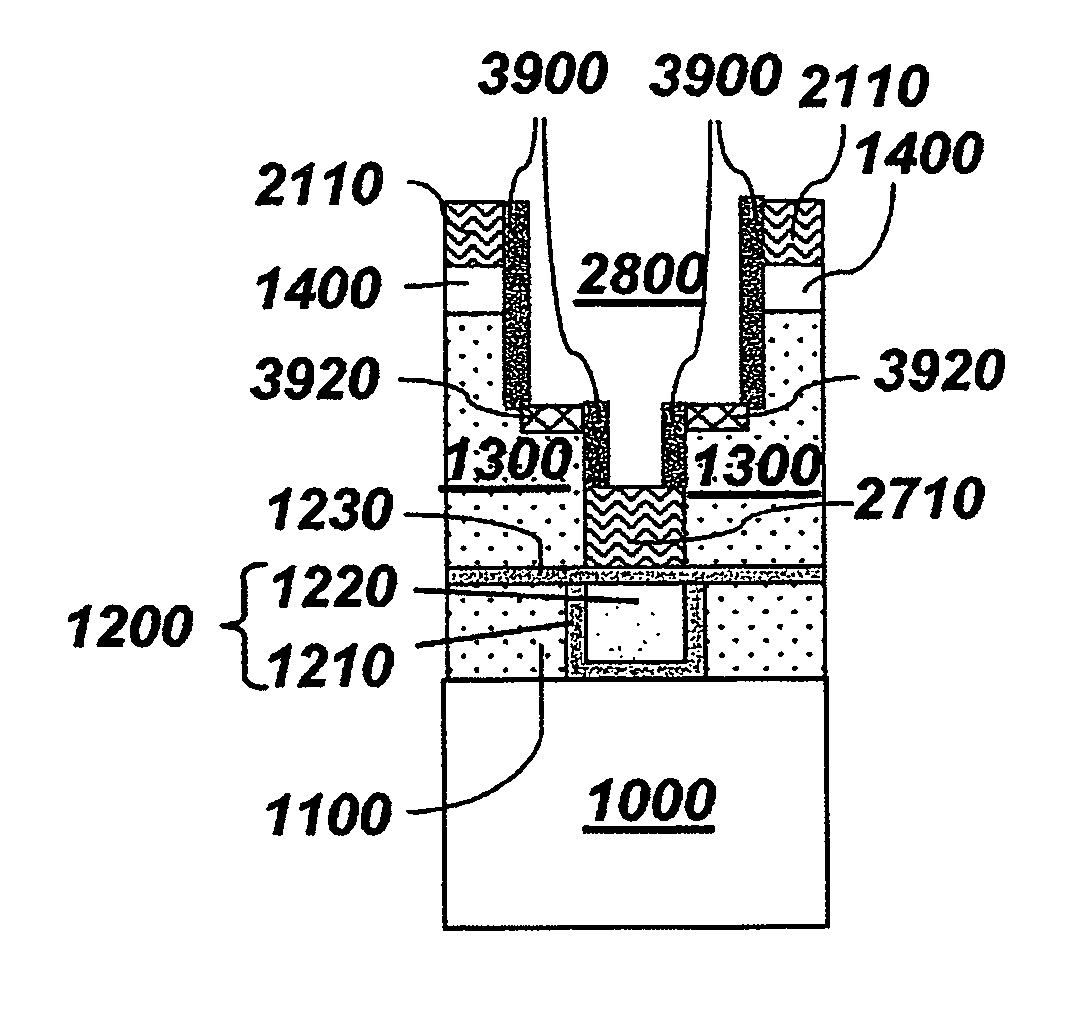

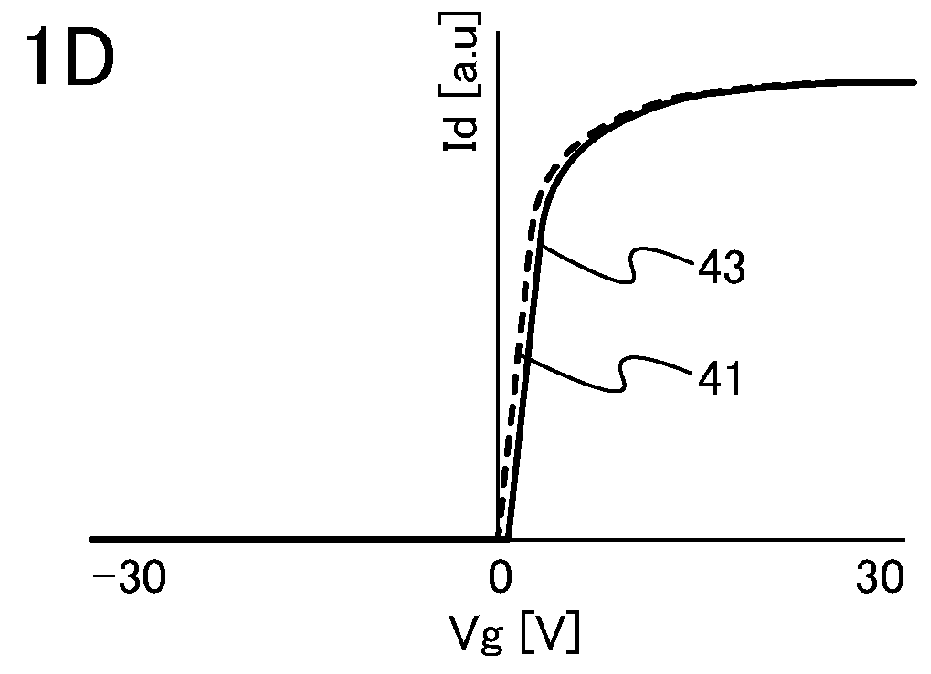

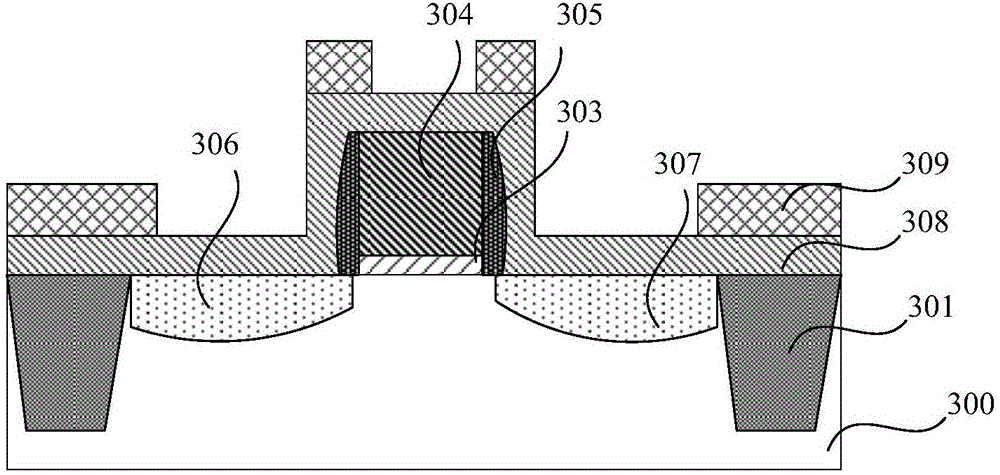

Semiconductor device and method for manufacturing semiconductor device

ActiveUS9337342B2Reduce amount of oxygen vacancyImprove featuresTransistorSolid-state devicesHydrofluoric acidOxygen vacancy

In a semiconductor device including an oxide semiconductor, the amount of oxygen vacancies is reduced. Moreover, electrical characteristics of a semiconductor device including an oxide semiconductor are improved. The semiconductor device includes a transistor including a gate electrode over a substrate, a gate insulating film covering the gate electrode, an oxide semiconductor film overlapping with the gate electrode with the gate insulating film provided therebetween, and a pair of electrodes in contact with the oxide semiconductor film; and over the transistor, a first insulating film covering the gate insulating film, the oxide semiconductor film, and the pair of electrodes; and a second insulating film covering the first insulating film. An etching rate of the first insulating film is lower than or equal to 10 nm / min and lower than an etching rate of the second insulating film when etching is performed at 25° C. with 0.5 weight % of hydrofluoric acid.

Owner:SEMICON ENERGY LAB CO LTD

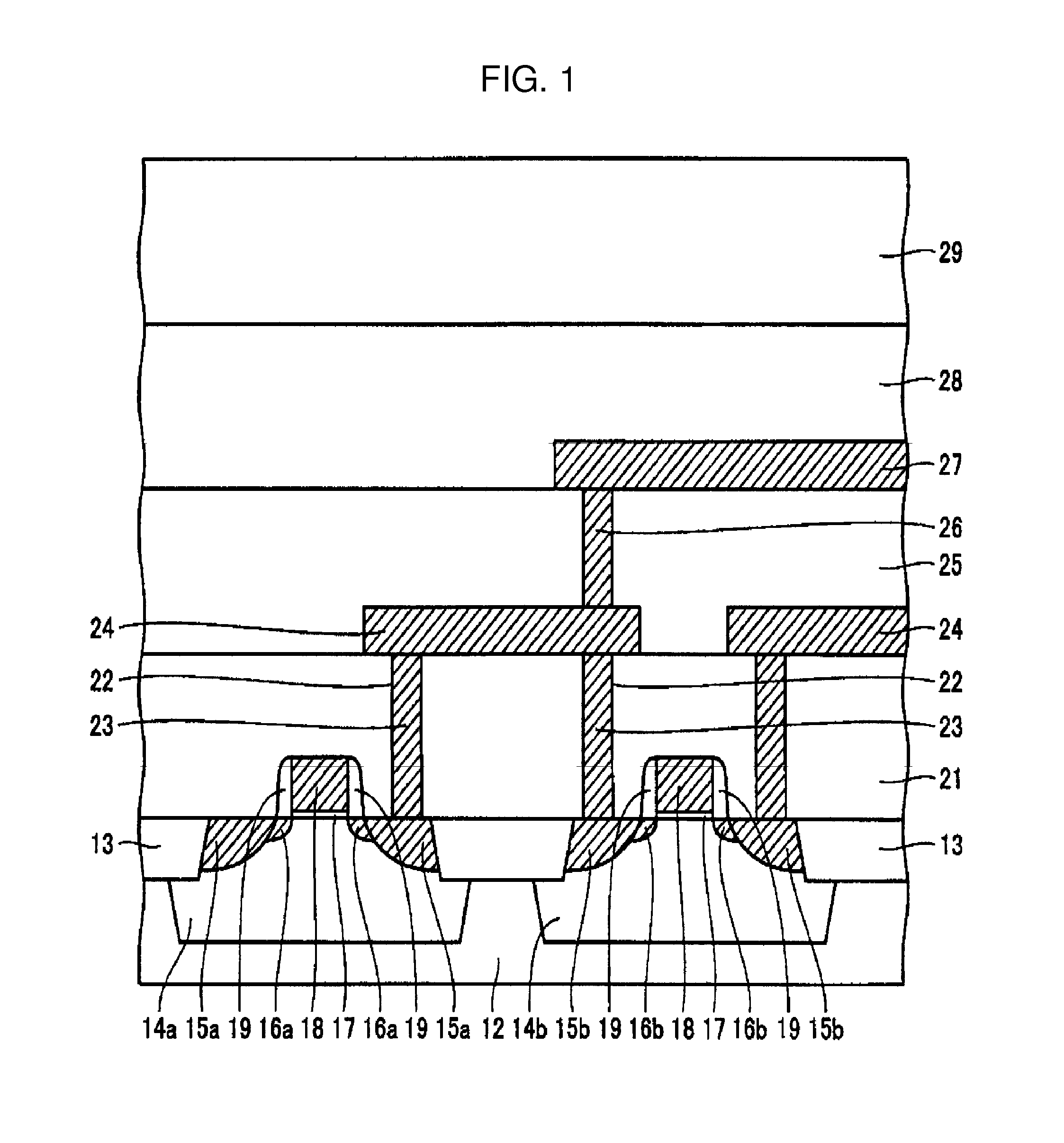

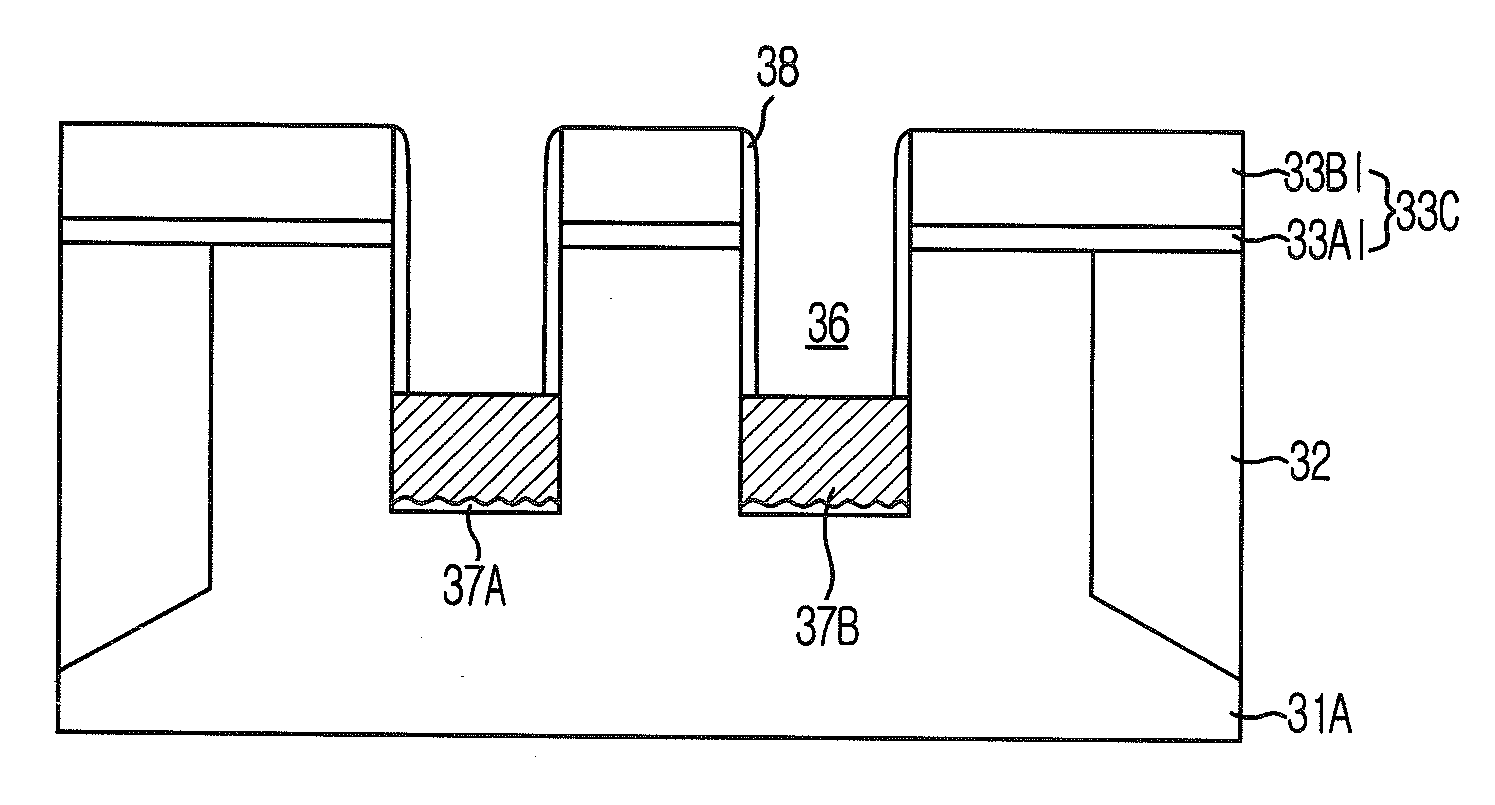

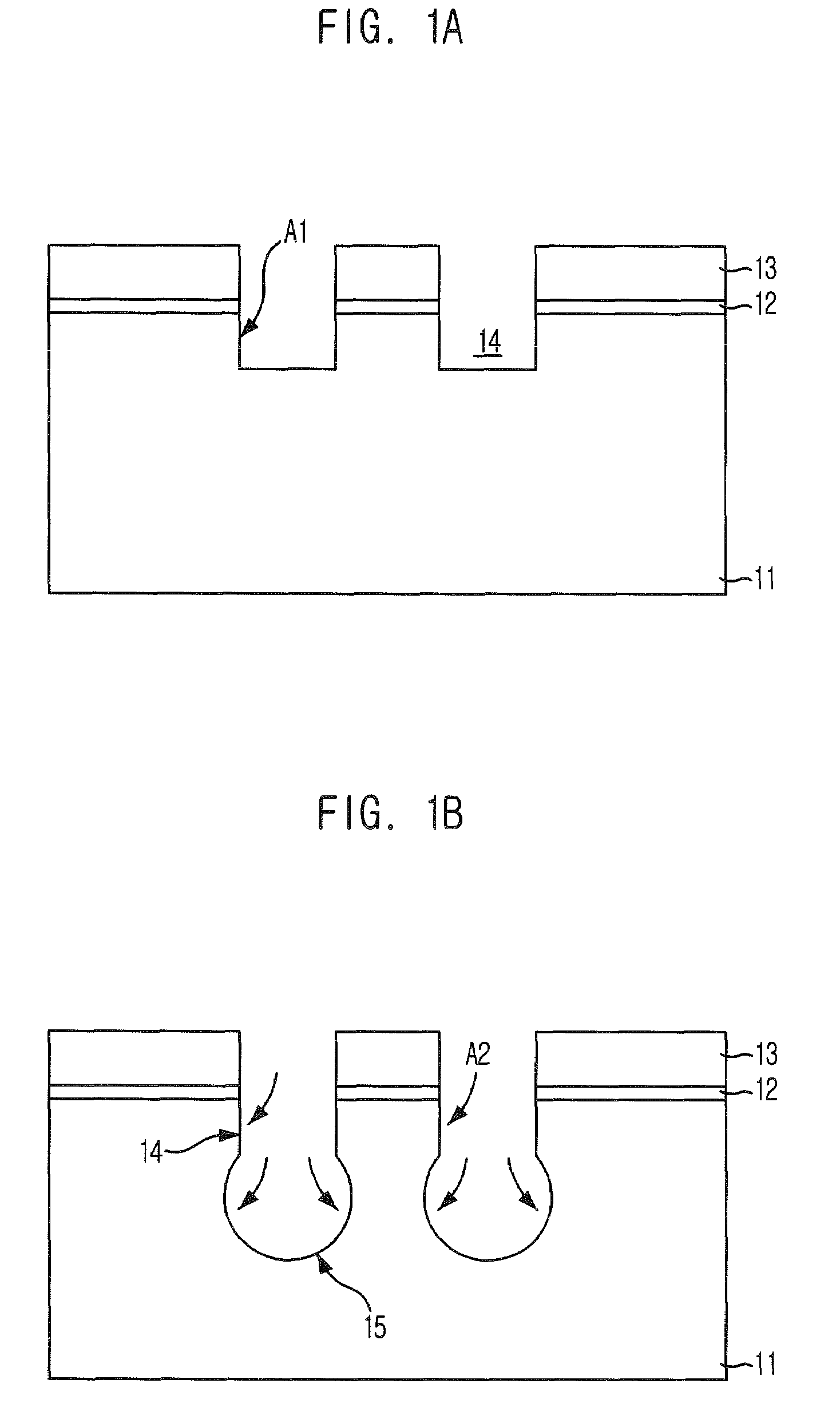

Method for fabricating semiconductor device having bulb-shaped recess gate

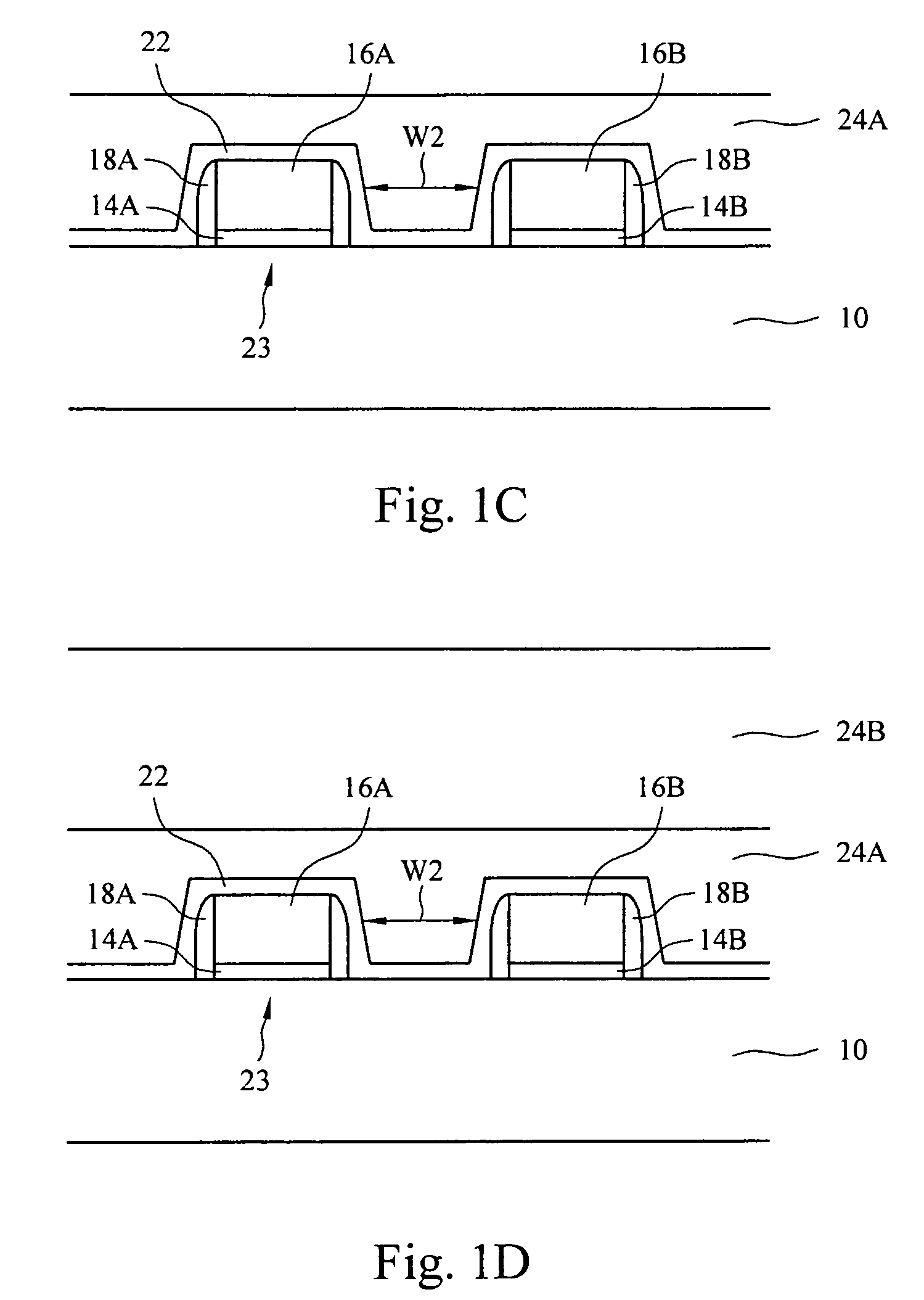

InactiveUS20070232042A1Avoid etchingReduce plasma damageSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A method for fabricating a semiconductor device includes etching a portion of a substrate to form a recess. A polymer layer fills a lower portion of the recess. Sidewall spacers are formed over the recess above the lower portion of the recess. The polymer layer is removed. The lower portion of the recess is isotropically etching to form a bulb-shaped recess.

Owner:SK HYNIX INC

Method for nitriding substrate and method for forming insulating film

InactiveUS7820557B2Suppressing plasma damageImprove film qualityElectric discharge tubesSolid-state devicesNitrogen plasmaFloating potential

In a substrate nitriding method for nitriding a target substrate by allowing a nitrogen-containing plasma to act on silicon on a surface of the substrate in a processing chamber of a plasma processing apparatus, the nitridation by the nitrogen-containing plasma is performed by controlling a sheath voltage Vdc around the substrate to be less than or equal to about 3.5 eV. The sheath voltage Vdc is a potential difference Vp−Vf between a plasma potential Vp in a plasma generating region and a floating potential Vf of the substrate.

Owner:TOKYO ELECTRON LTD

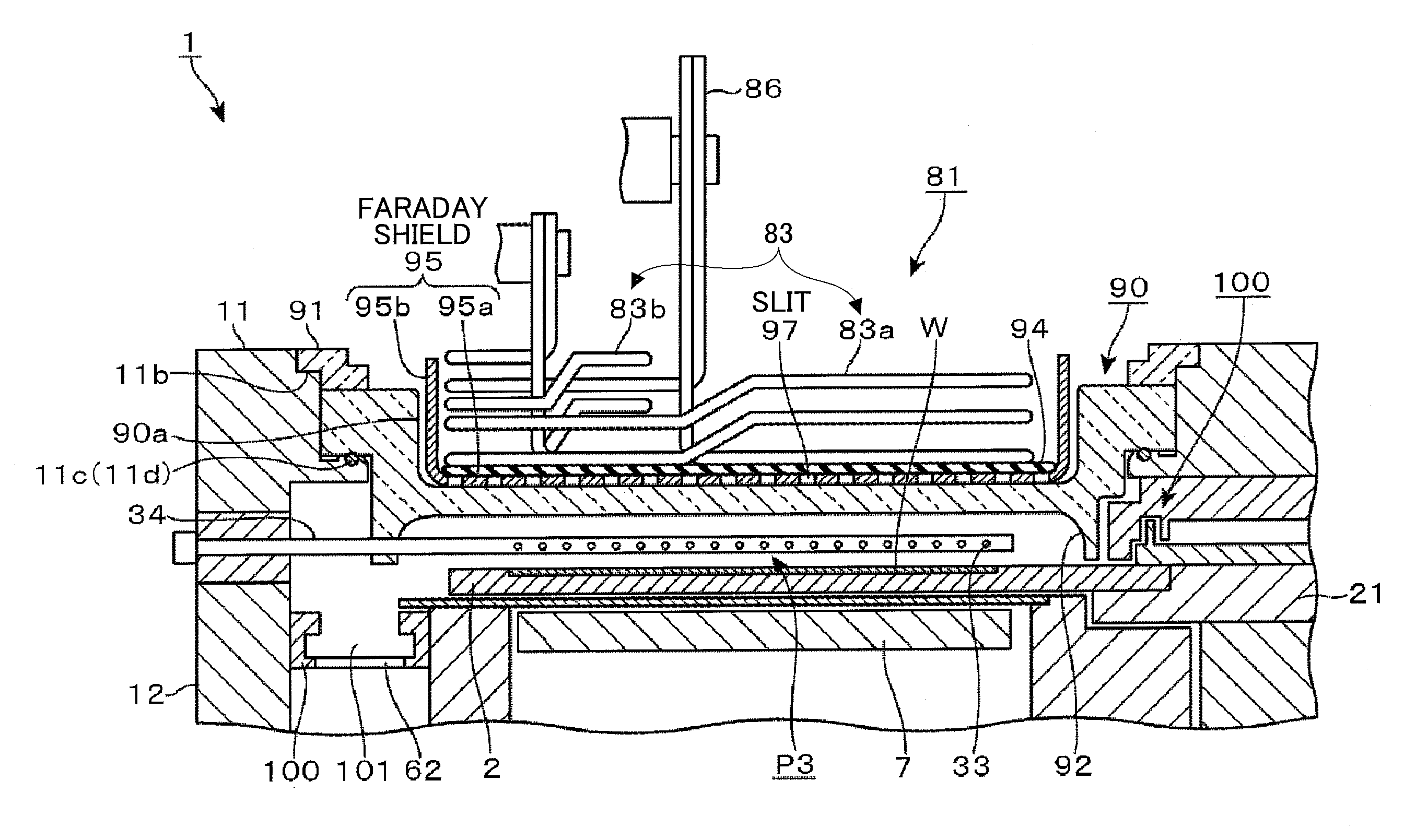

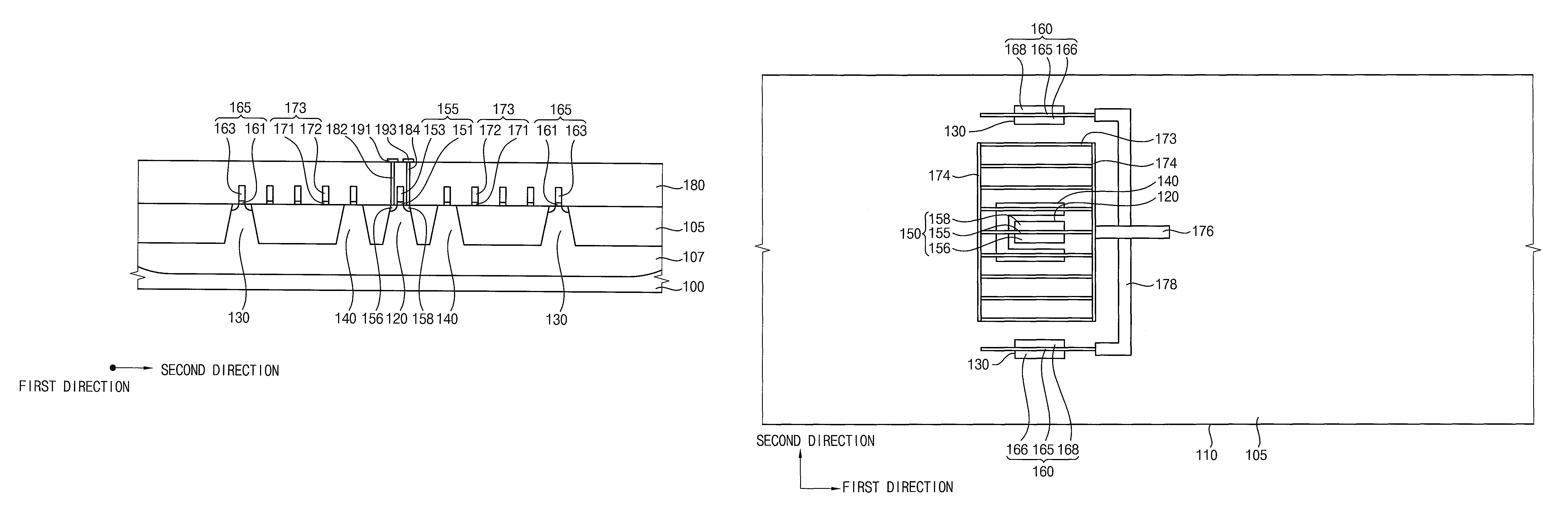

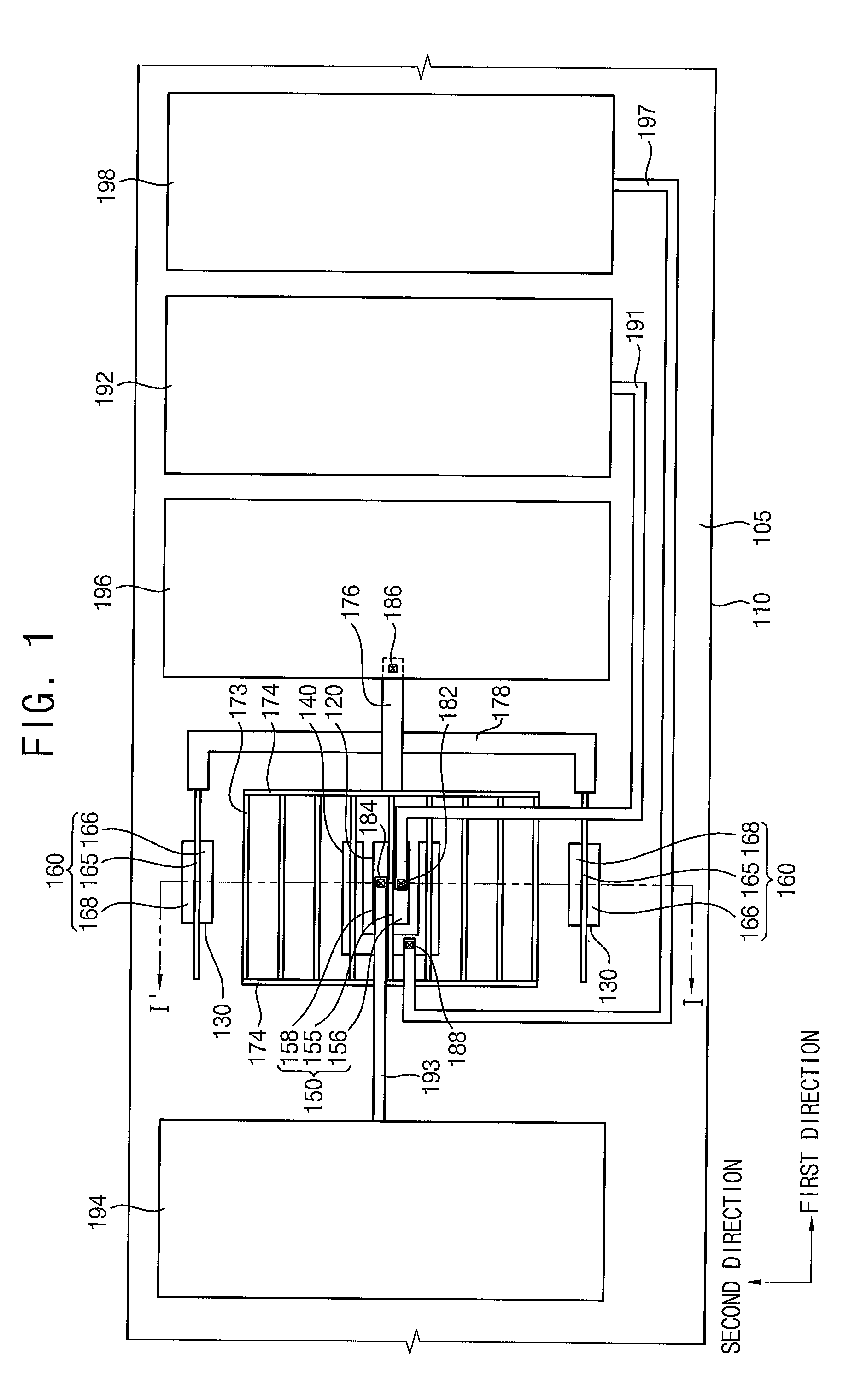

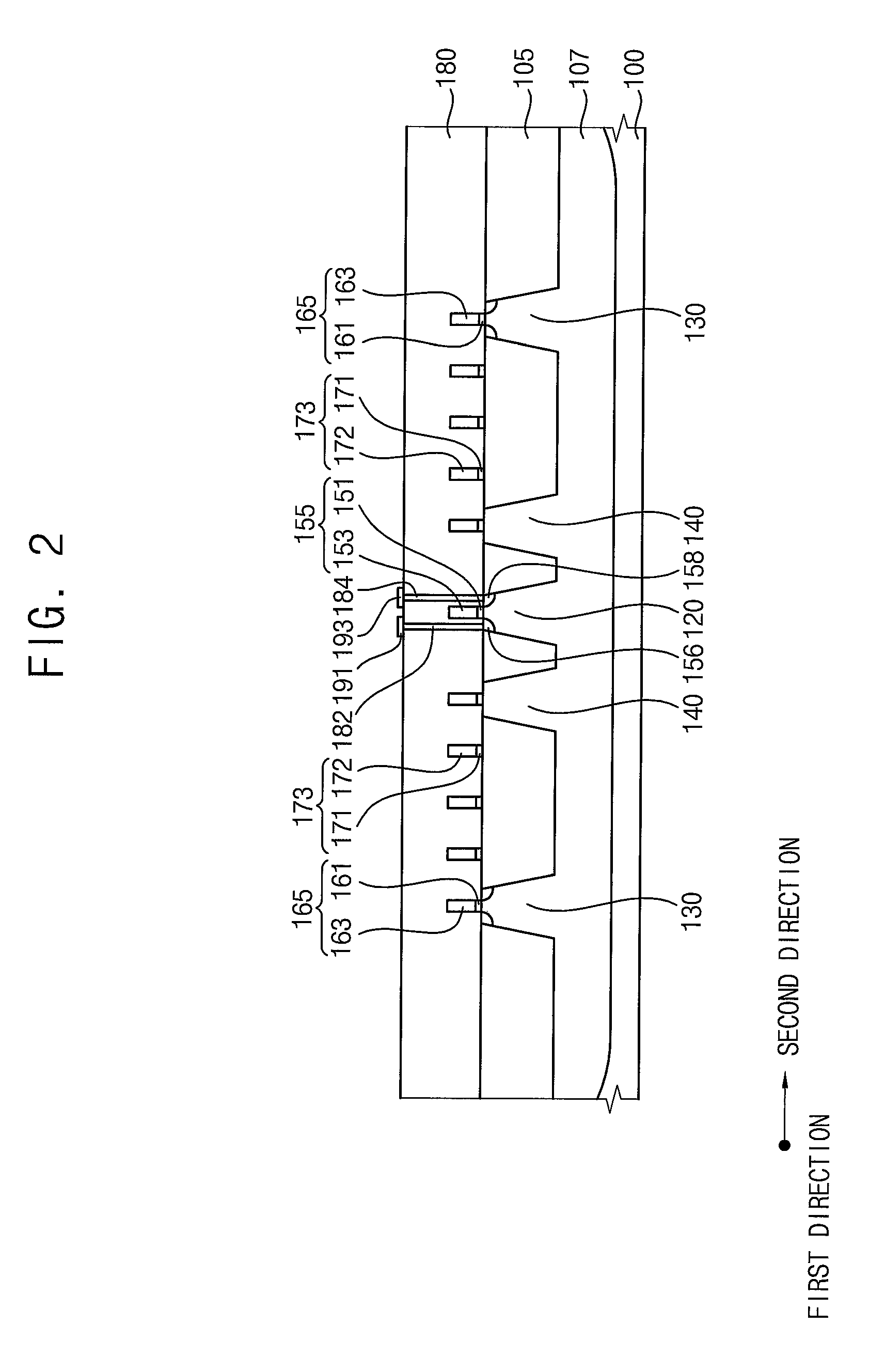

Film deposition apparatus, film deposition method and storage medium

ActiveUS9453280B2Reduce plasma damageAvoid passingLiquid surface applicatorsElectric discharge tubesEngineeringPlasma Gases

A film deposition apparatus includes a turntable having a substrate mounting area, a first plasma gas supplying part, a second plasma supplying part, a first plasma gas generating part to convert the first plasma generating gas to first plasma, and a second plasma generating part provided away from the first plasma generating part in a circumferential direction and to convert the second plasma generating gas to second plasma. The first plasma generating part includes an antenna facing the turntable so as to convert the first plasma generating gas to the first plasma, and a grounded Faraday shield between the antenna and an area where a plasma process is performed, and to include plural slits respectively extending in directions perpendicular to the antenna and arranged along an antenna extending direction to prevent an electric field from passing toward the substrate and to pass a magnetic field toward the substrate.

Owner:TOKYO ELECTRON LTD

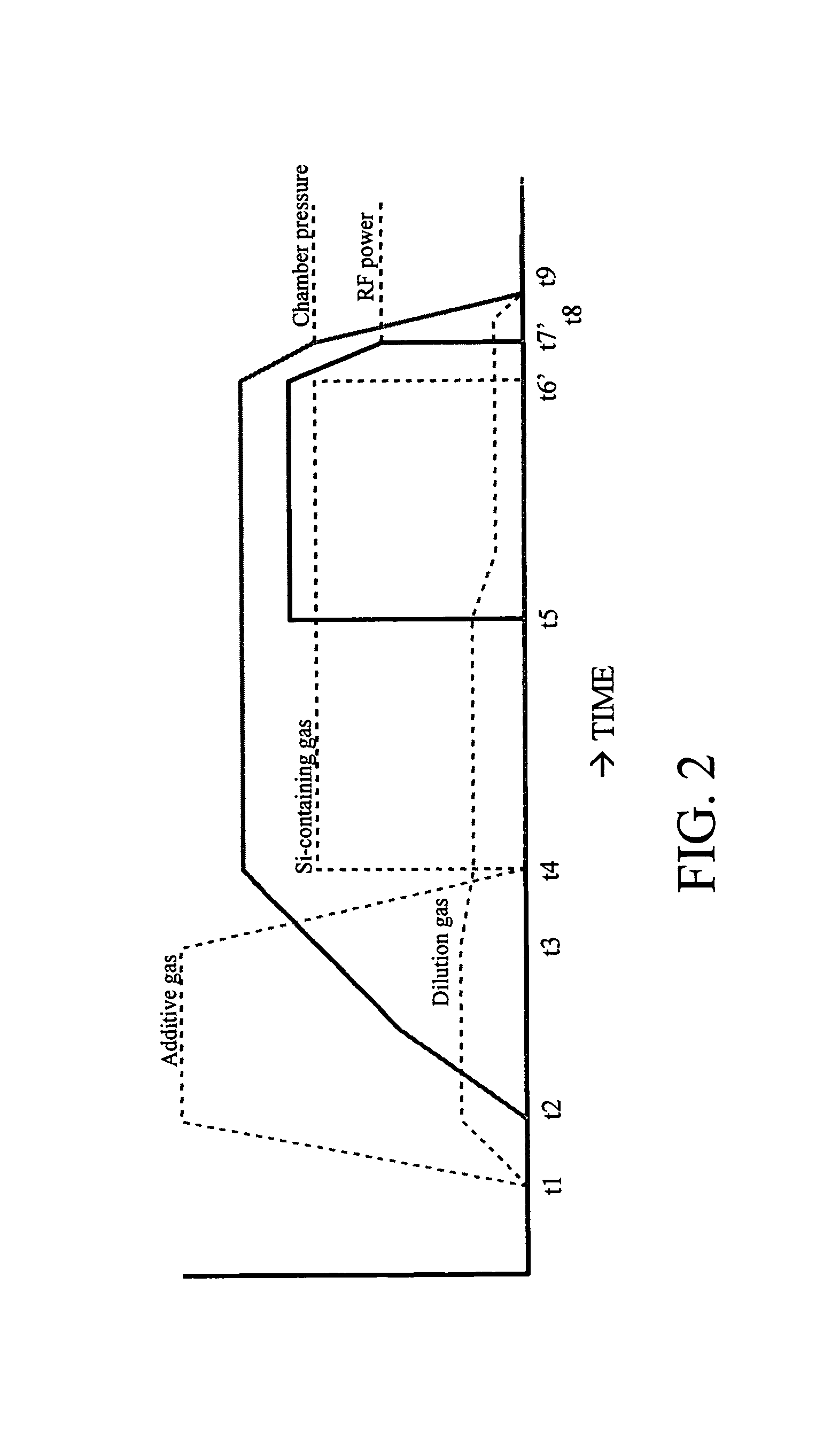

Method of forming a thin film by plasma CVD of a silicon-containing source gas

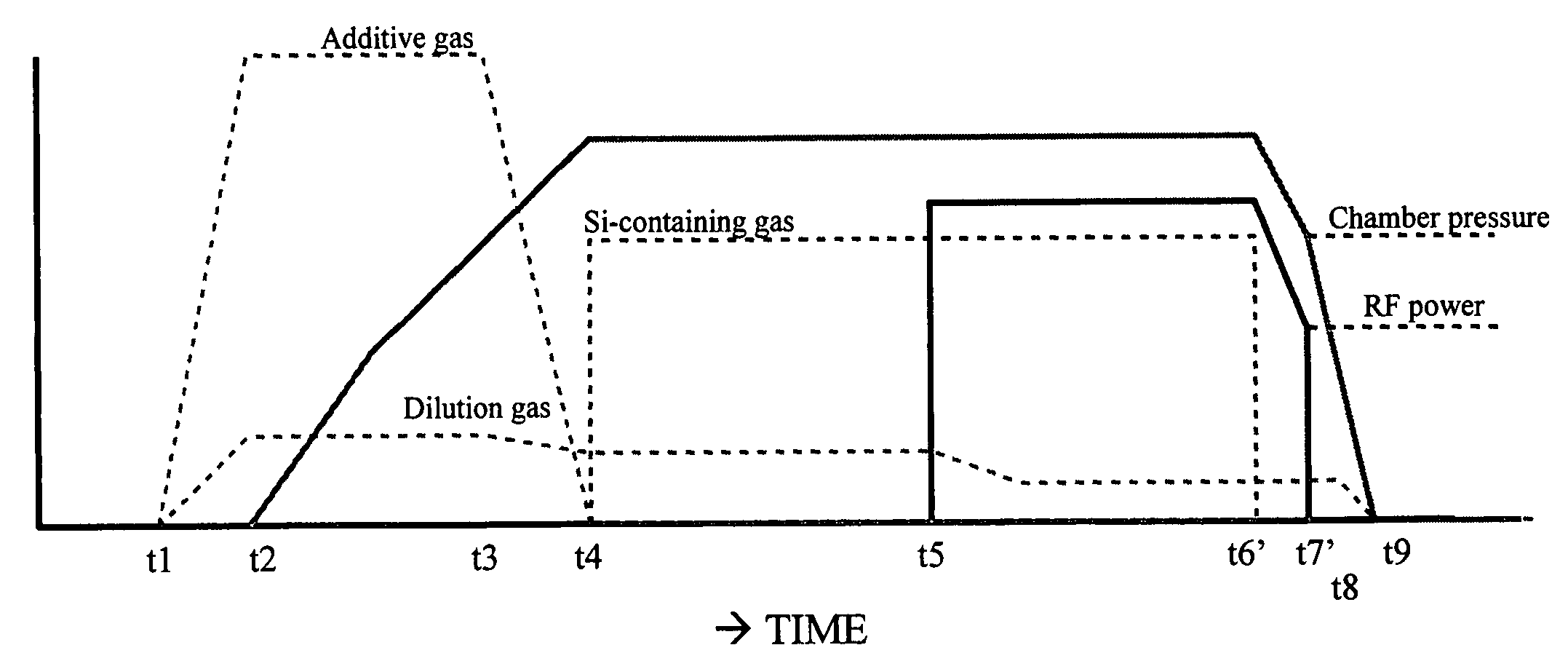

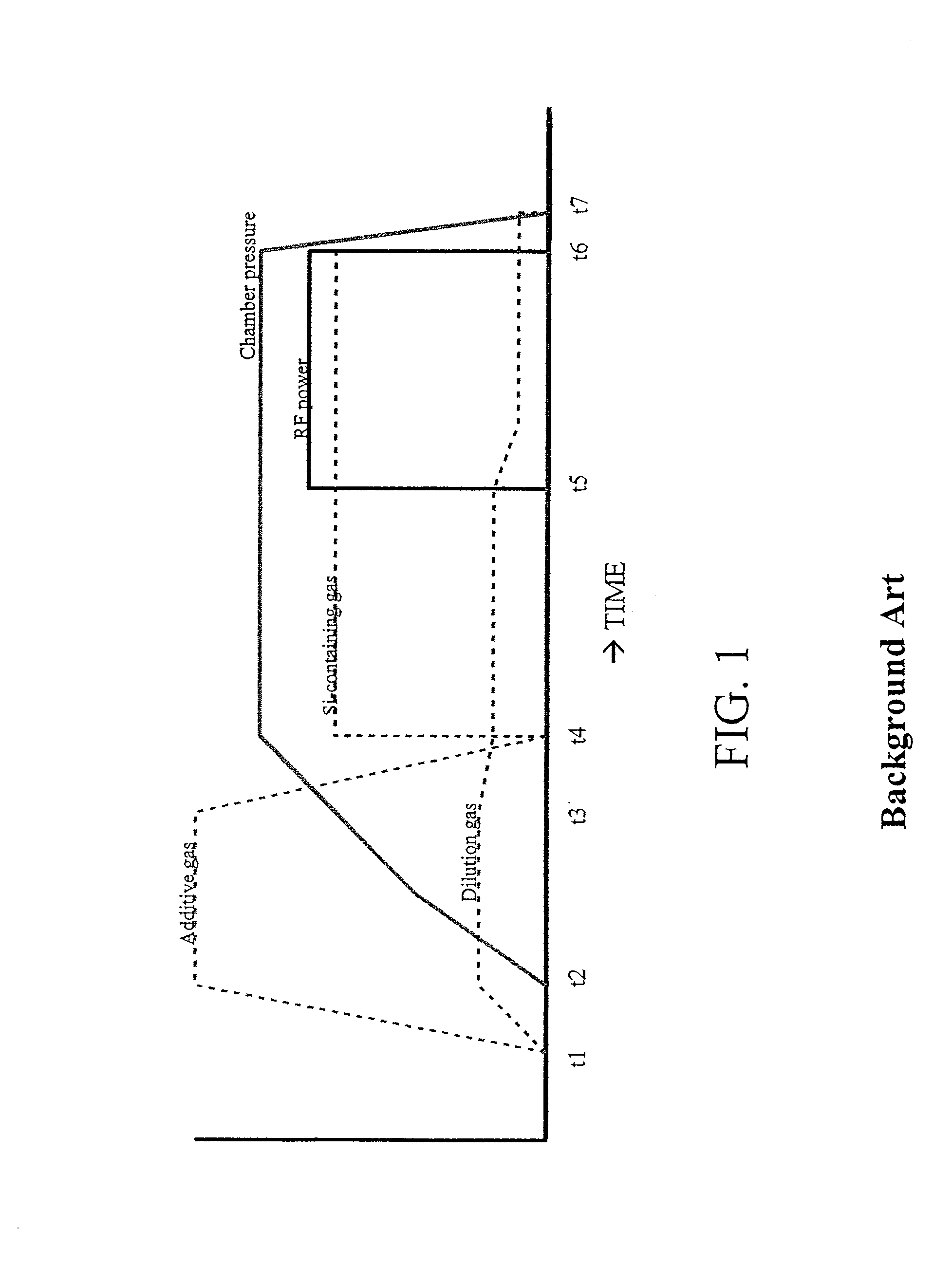

ActiveUS7229935B2Reduce plasma damageImprove adhesionSemiconductor/solid-state device manufacturingSolid state diffusion coatingProduct gasRadio frequency

A method for forming a thin film includes: supplying an additive gas, a dilution gas, and a silicon-containing source gas into a reaction chamber wherein a substrate is placed; forming a thin film on the substrate by plasma CVD under a given pressure with a given intensity of radio-frequency (RF) power from a first point in time to a second point in time; at the second point in time, stopping the supply of the silicon-containing source gas; and at the second point in time, beginning reducing but not stopping the RF power, and beginning reducing the pressure, wherein the reduction of the RF power and the reduction of the pressure are synchronized up to a third point in time.

Owner:ASM JAPAN

Test structure of a semiconductor device and semiconductor device

InactiveUS7851864B2Plasma damage theretoReduce plasma damageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor

A test structure includes a transistor, a dummy transistor and a pad unit. The transistor is formed on a first active region of a substrate. The dummy transistor is formed on a second active region of the substrate and electrically connected to the transistor. The pad unit is electrically connected to the transistor. Plasma damage to the transistor is reduced due to the presence of dummy transistor.

Owner:SAMSUNG ELECTRONICS CO LTD

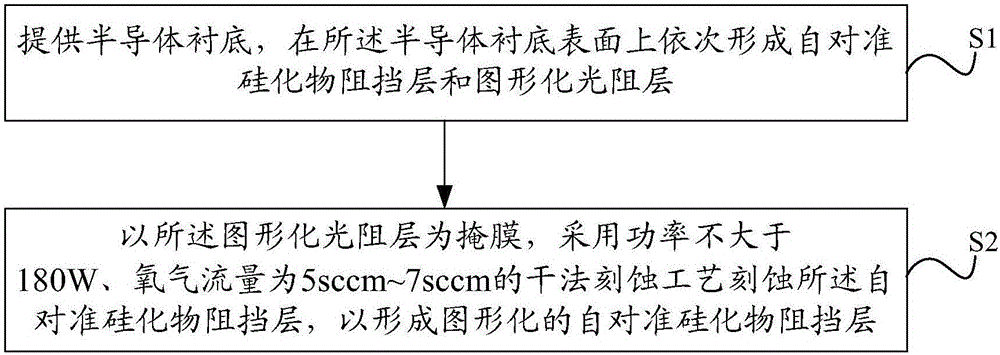

Method for manufacturing self-aligned silicide barrier layer

ActiveCN106024622AReduce plasma damageConsider both etch rate and etch uniformitySemiconductor/solid-state device manufacturingEtching rateMetallurgy

The invention provides a method for manufacturing a self-aligned silicide barrier layer, which is characterized in that dry etching is carried out on the self-aligned silicide barrier layer by adopting the etching power being not greater than 180W and the oxygen flow rate of 5sccm-7sccm, plasma damages in the etching process can be reduced, diffusion of a polymer generated by etching towards the edge of a semiconductor substrate is reduced, and an effect of giving consideration to the etching rate and the etching uniformity is achieved, thereby acquiring a uniform graphical self-aligned silicide barrier layer with excellent performance, avoiding offset of device performance design indicators, and improving the product yield.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

HDP-CVD methodology for forming PMD layer

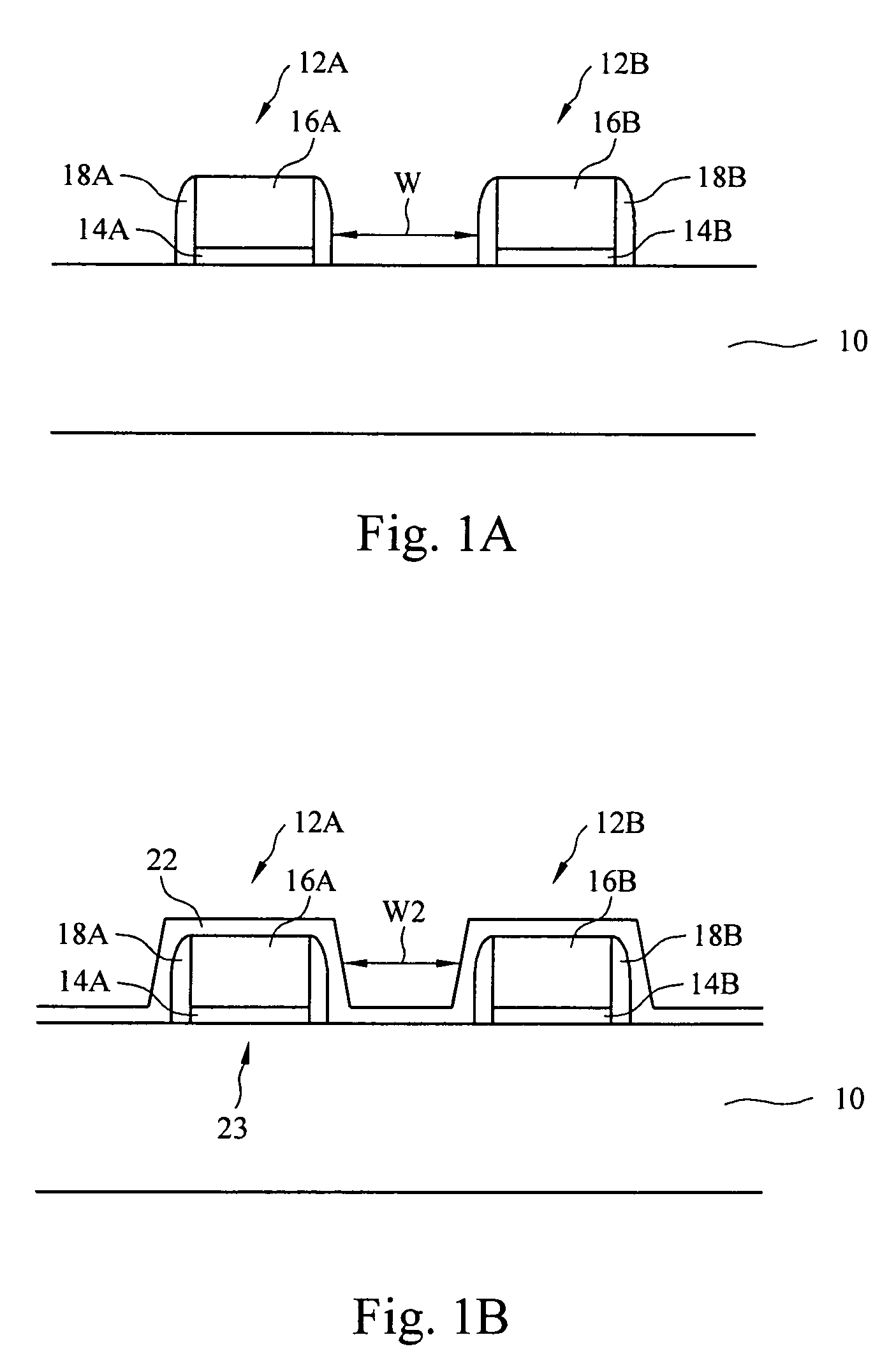

ActiveUS7265009B2Reduce plasma damageReduce the temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricSputtering

A method of forming an HDP-CVD pre-metal dielectric (PMD) layer to reduce plasma damage and / or preferential sputtering at a reduced a thermal budget including providing a semiconductor substrate comprising at least two overlying semiconductor structures separated by a gap; forming a PMD layer according to an HDP-CVD process over the at least two overlying semiconductor structures without applying a chucking bias Voltage to hold the semiconductor substrate.

Owner:TAIWAN SEMICON MFG CO LTD

Method for fabricating semiconductor device having bulb-shaped recess gate

InactiveUS7585727B2Reduce plasma damageAvoid etchingSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A method for fabricating a semiconductor device includes etching a portion of a substrate to form a recess. A polymer layer fills a lower portion of the recess. Sidewall spacers are formed over the recess above the lower portion of the recess. The polymer layer is removed. The lower portion of the recess is isotropically etching to form a bulb-shaped recess.

Owner:SK HYNIX INC

Solar cell and method of fabricating the same

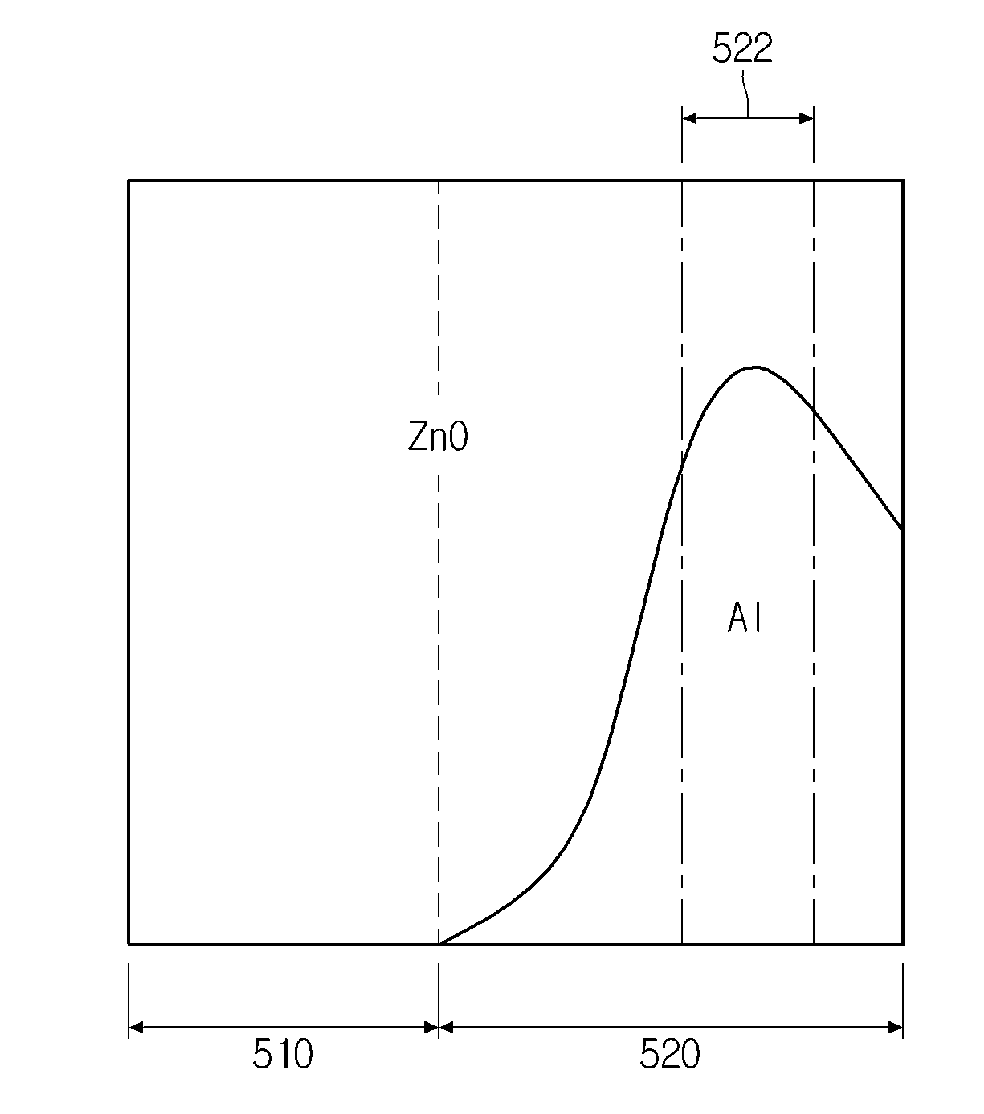

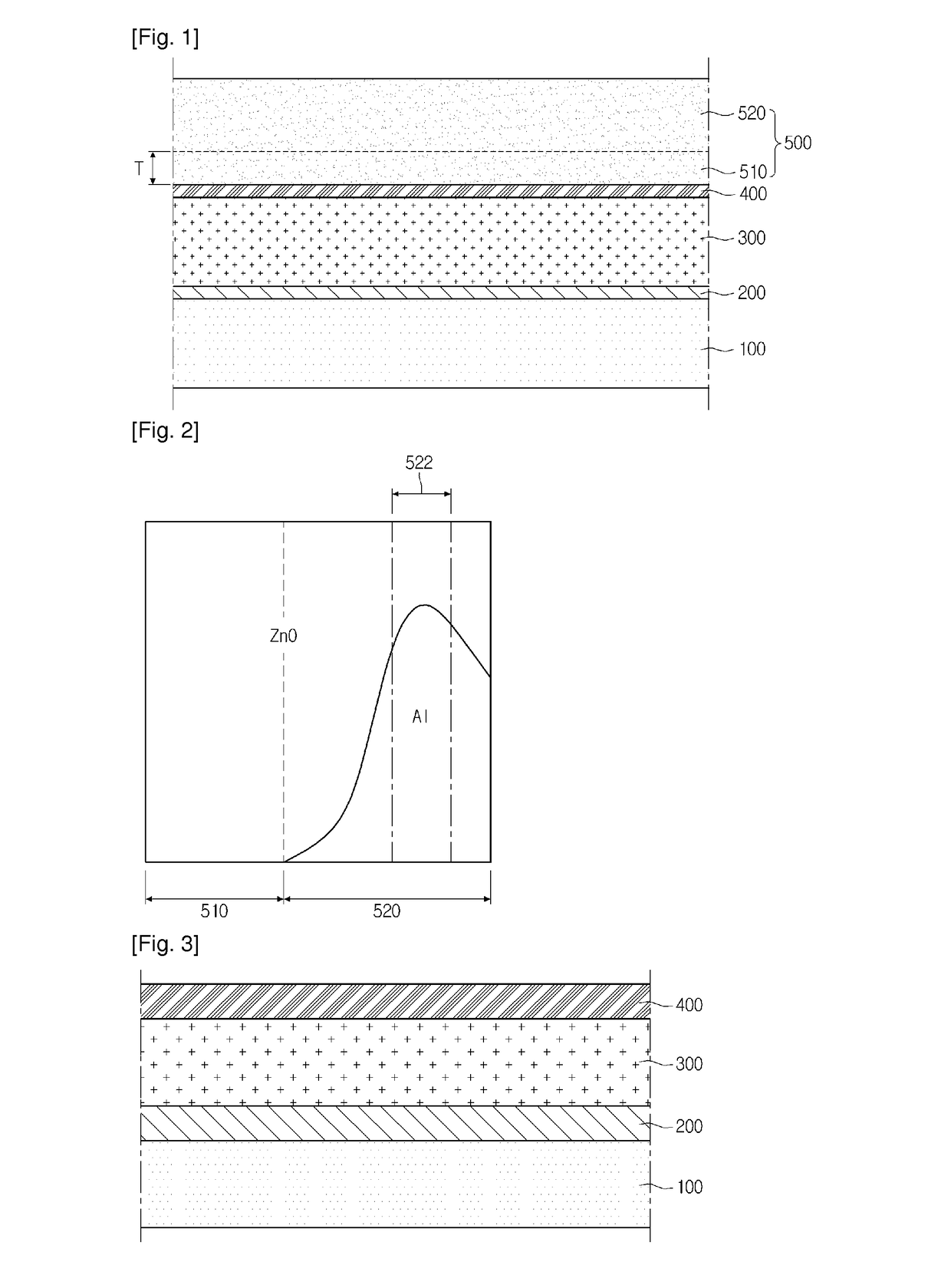

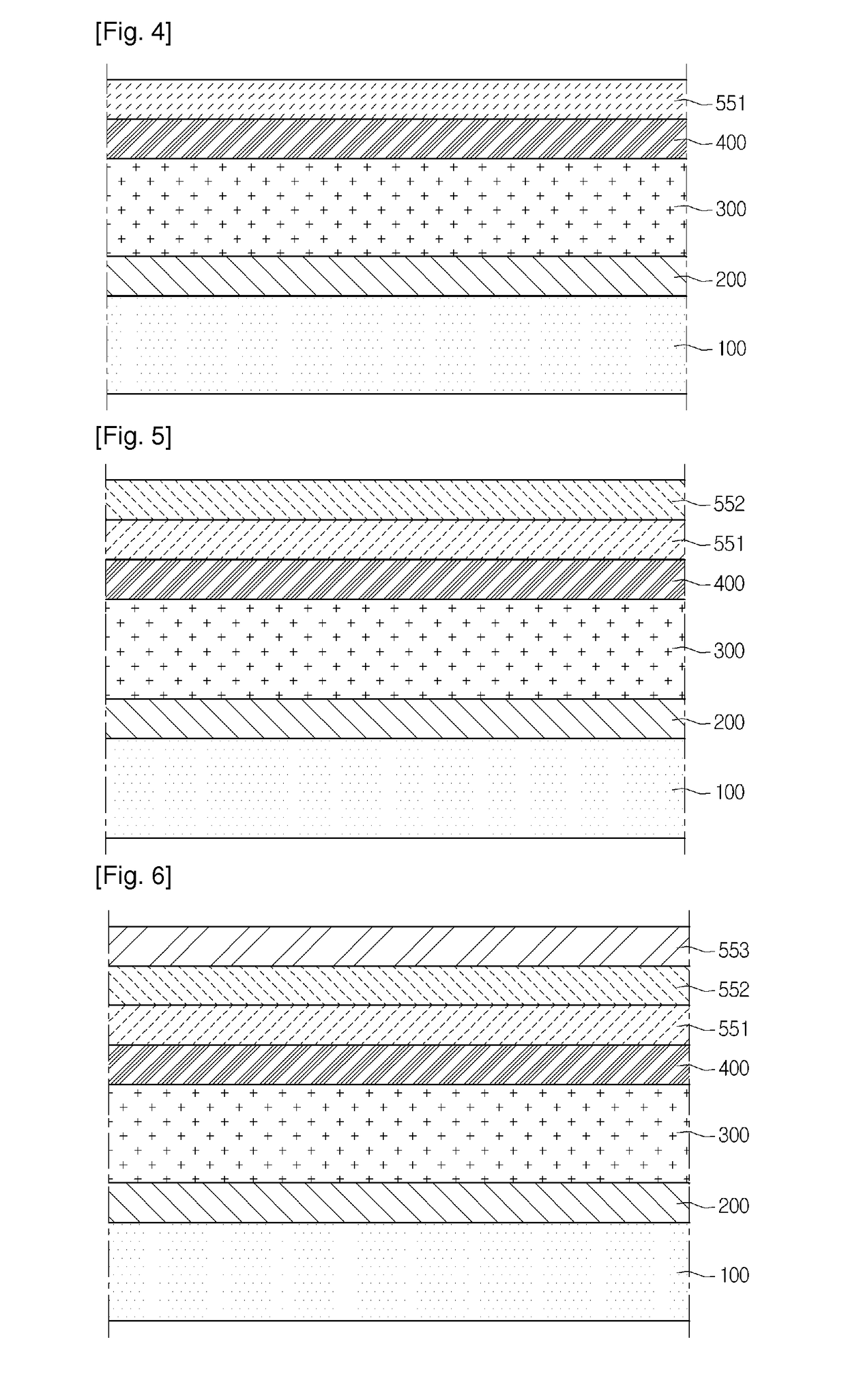

ActiveUS9780237B2Reduce layeringReduce plasma damageFinal product manufactureSemiconductor/solid-state device manufacturingDopantSolar cell

According to the embodiment, there is provided a solar cell including: a back electrode layer; a light absorbing layer on the back electrode layer; a buffer layer on the light absorbing layer; and a front electrode layer on the buffer layer, wherein the front electrode layer comprises an intrinsic region and a doping region having a conductive dopant, and a concentration of the conductive dopant is gradually lowered in upward and downward directions from an excess doping region of the doping region.

Owner:LG INNOTEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com