Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1775results about "Coverings/external coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

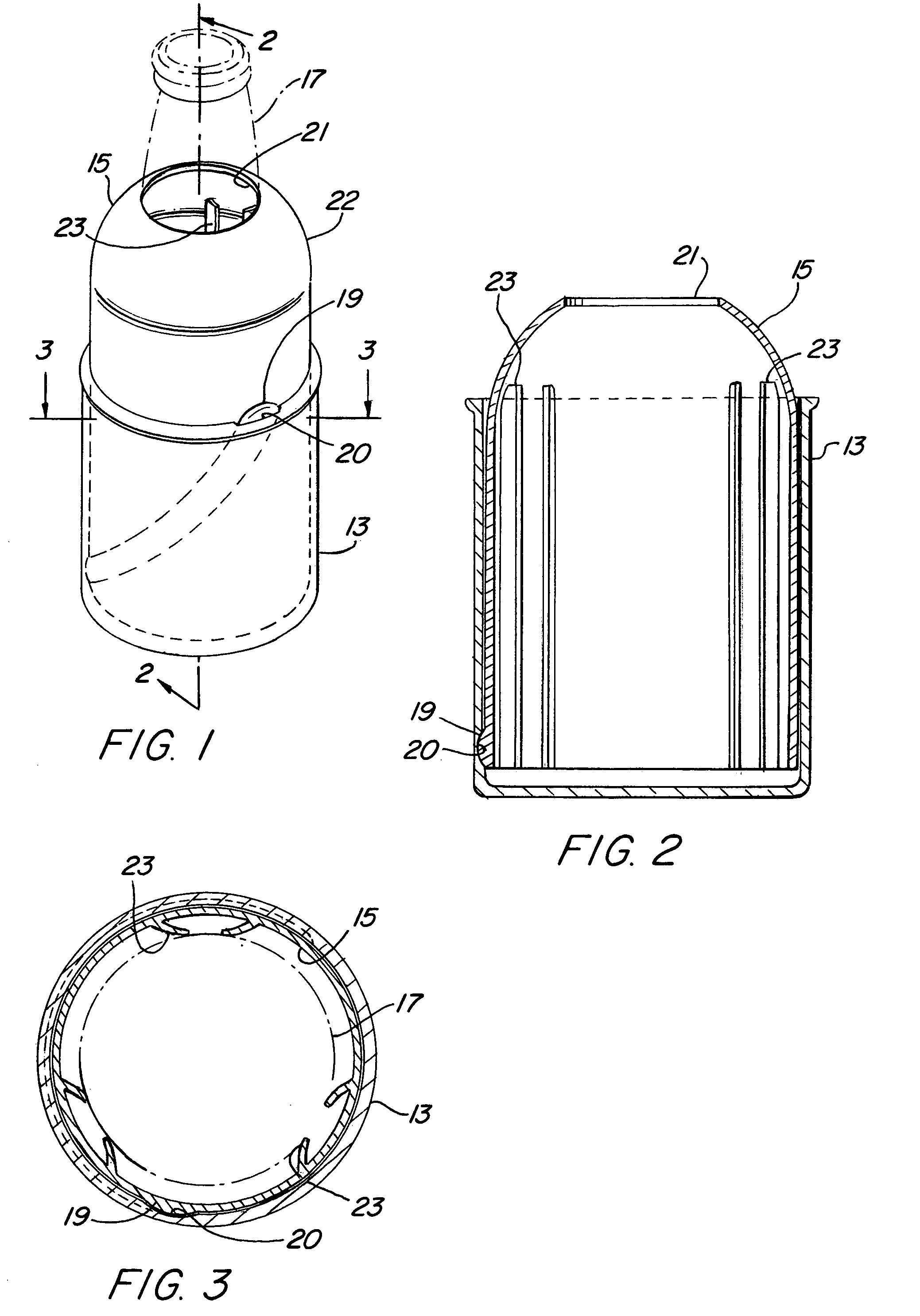

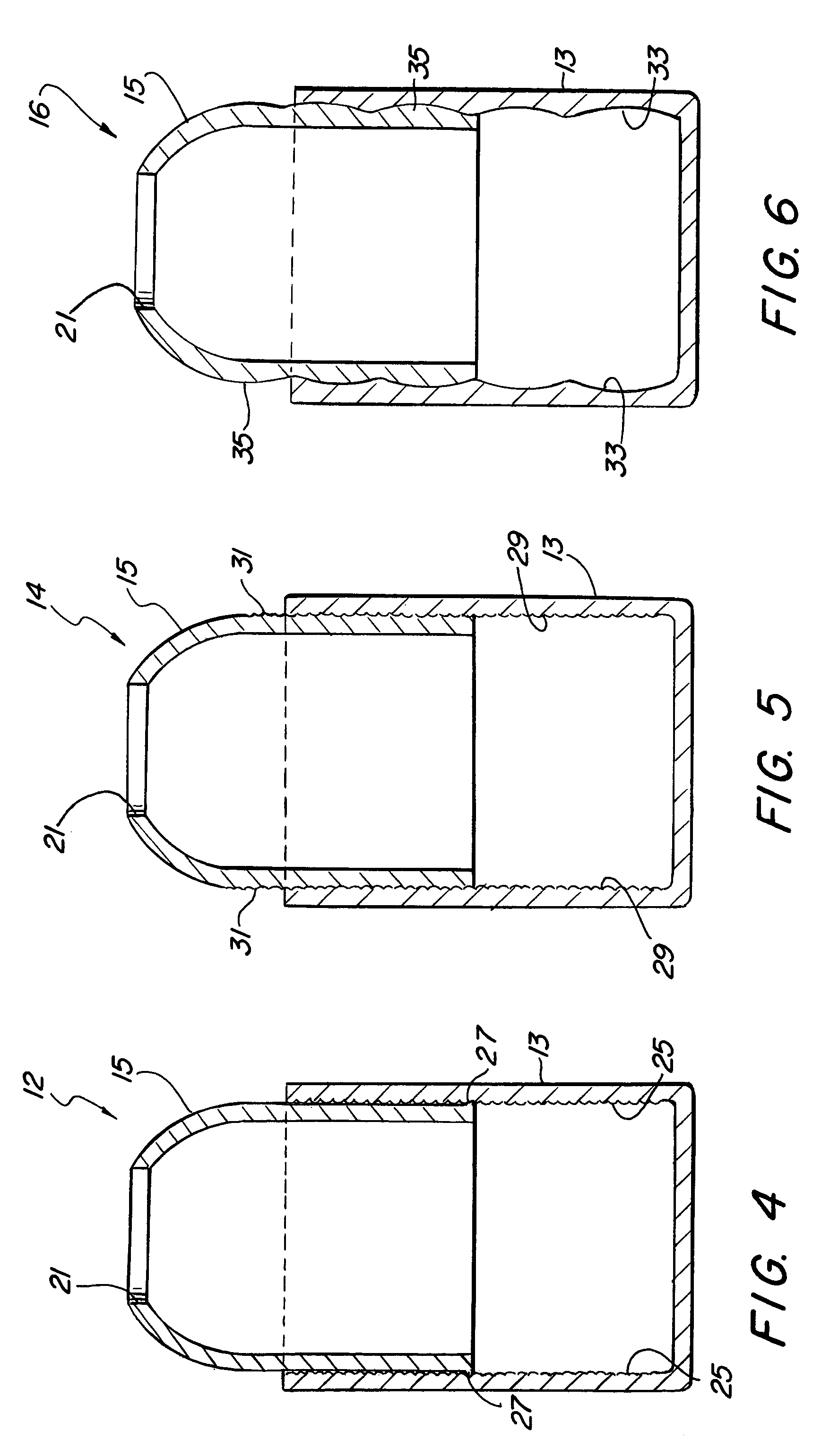

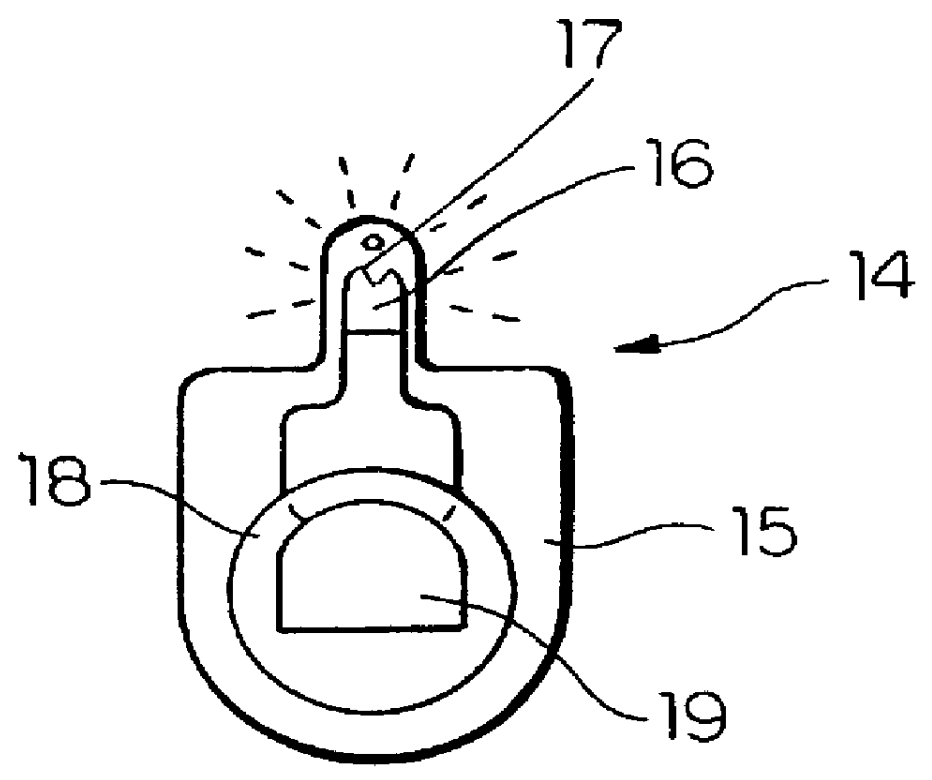

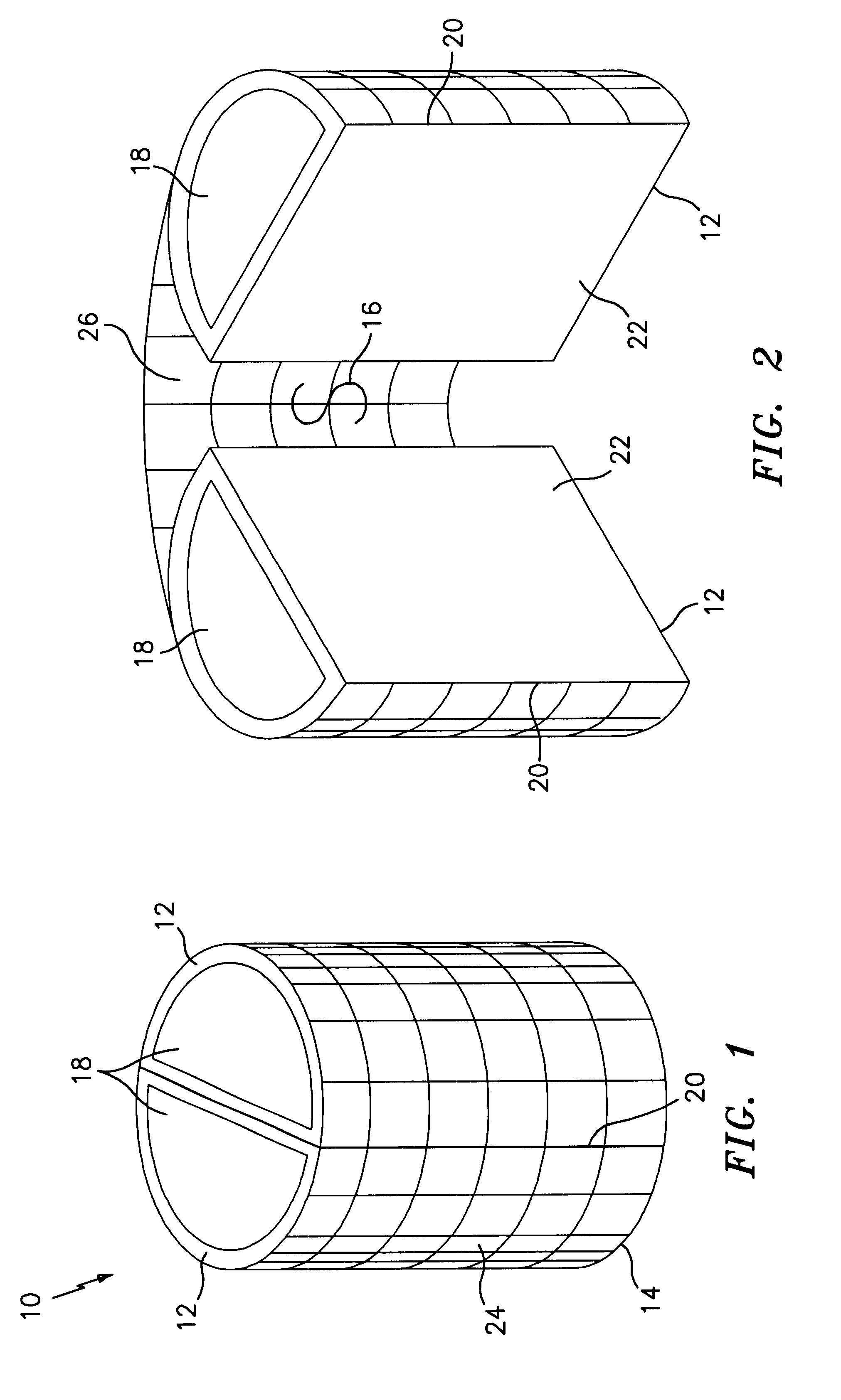

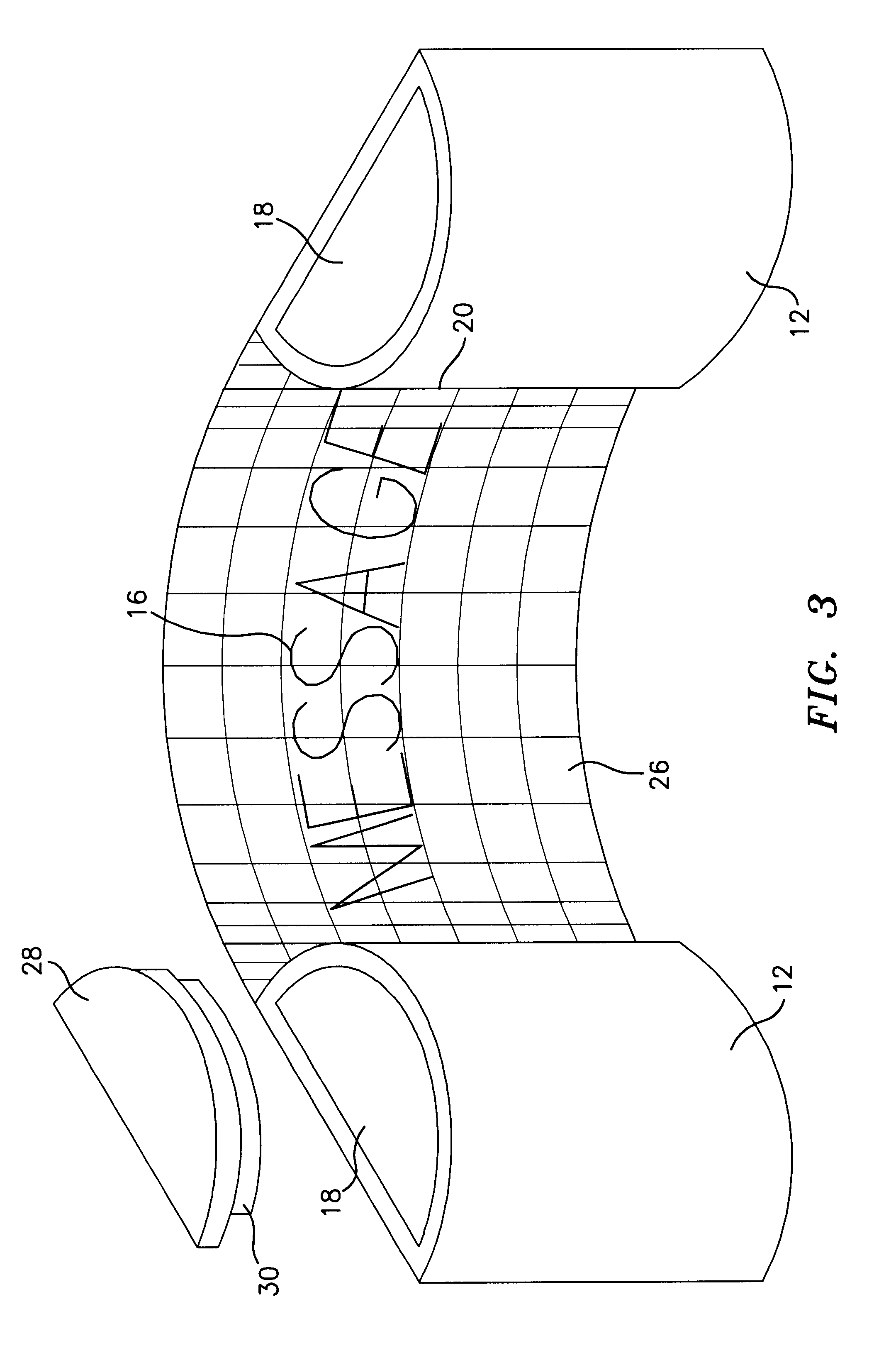

Dual function insulating holder for bottle or can

An insulating holder for holding a beverage in a bottle or a can having a lower cylindrical enclosure which receives an upper enclosure having a dome-shaped upper end. The upper and lower enclosures are provided with mating threads or other mating devices to hold the upper and lower enclosures in place when enjoyed. The upper enclosure is adapted to cover the top portion of a bottle inserted into the lower enclosure and to snuggly receive a can when inverted and inserted into the lower enclosure.

Owner:BEGGINS HLDG LLC

Totes for bottles

Owner:LIFETIME BRANDS

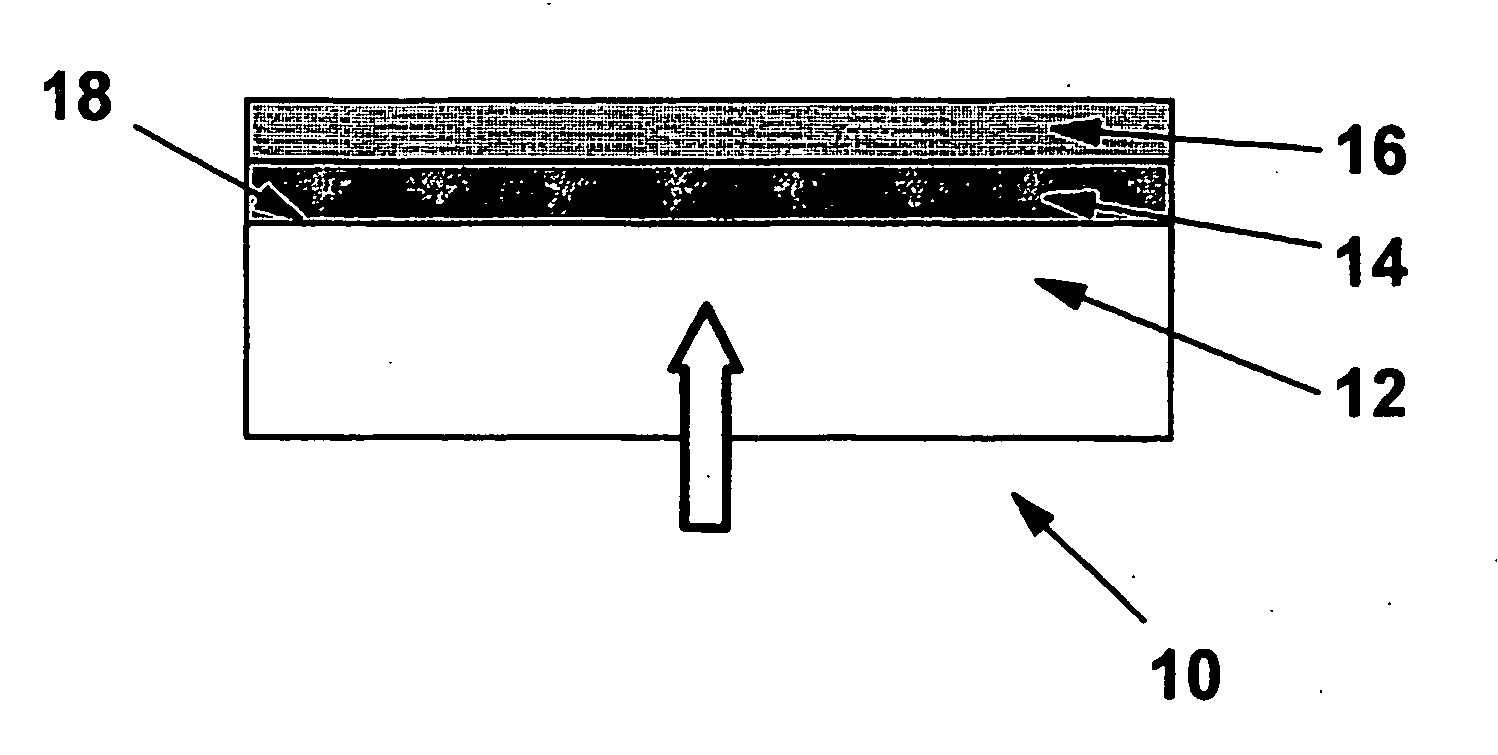

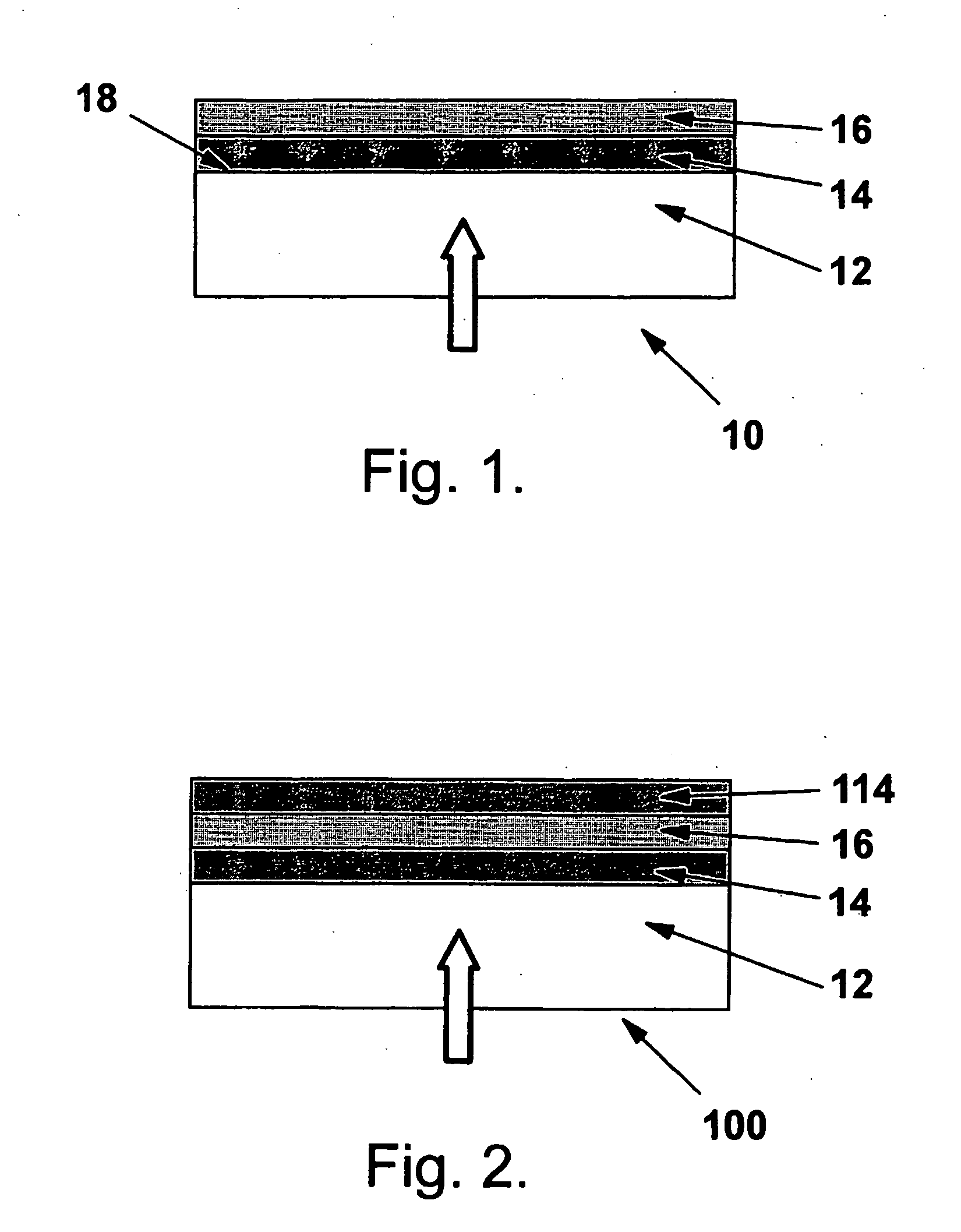

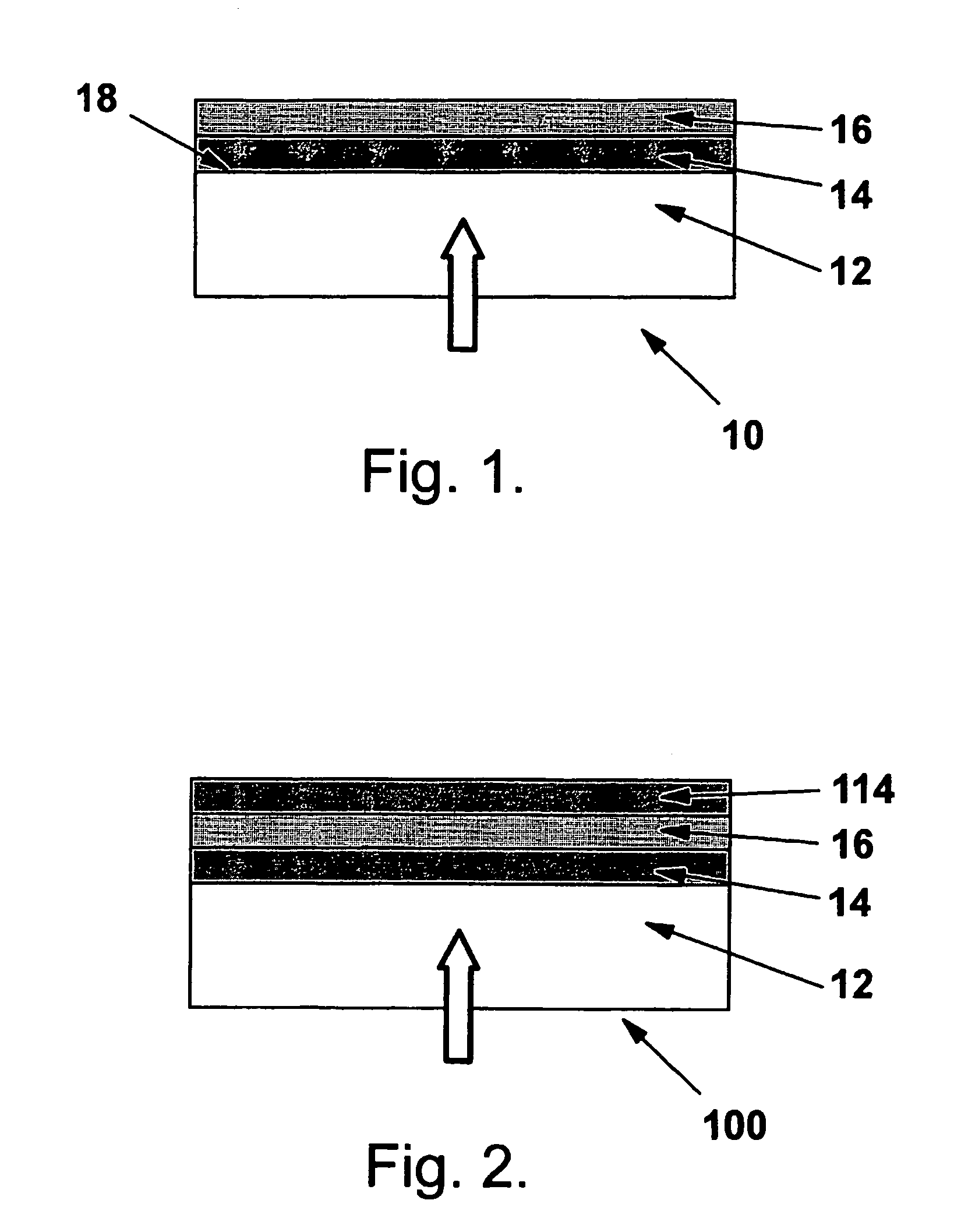

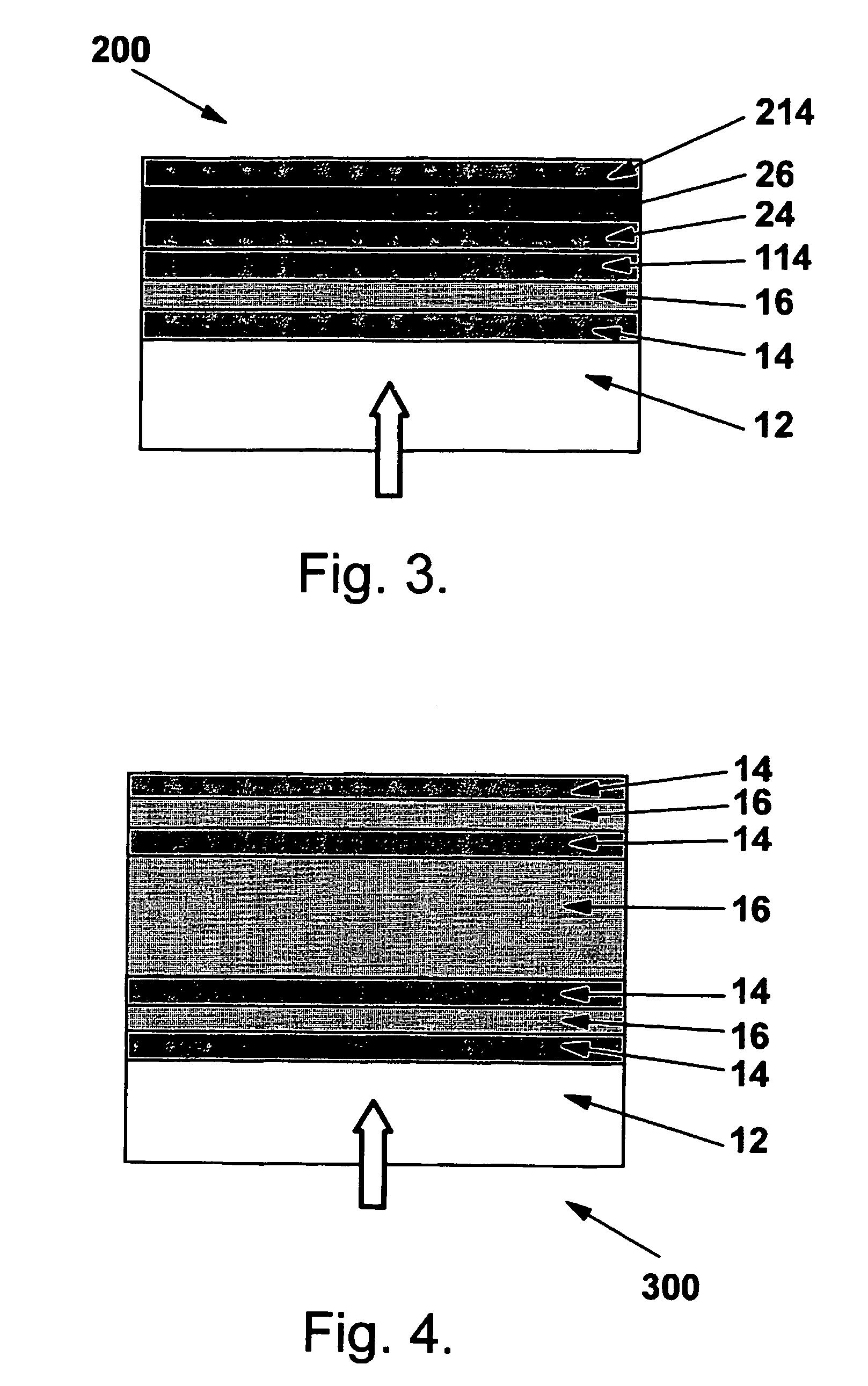

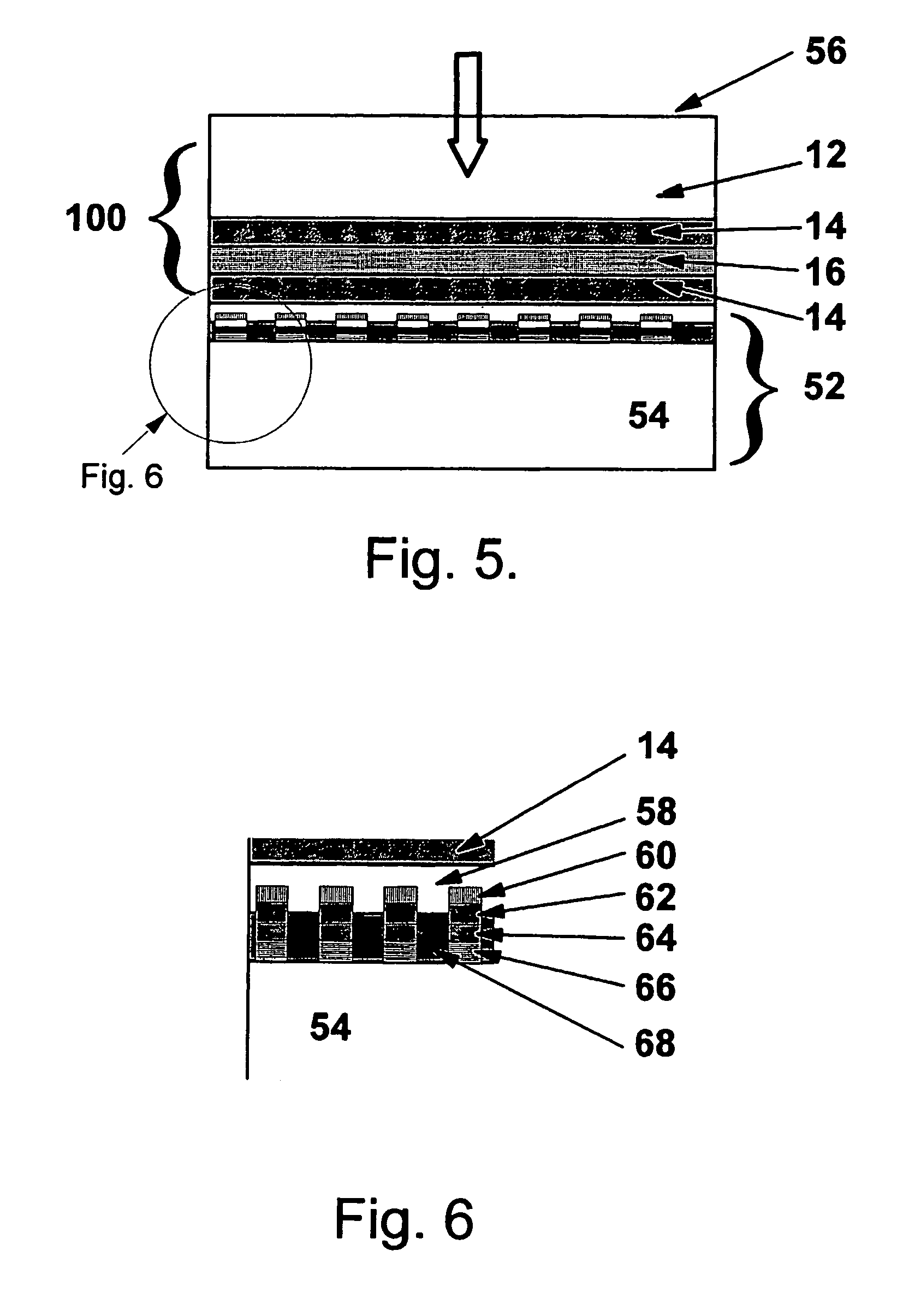

Coatings with low permeation of gases and vapors

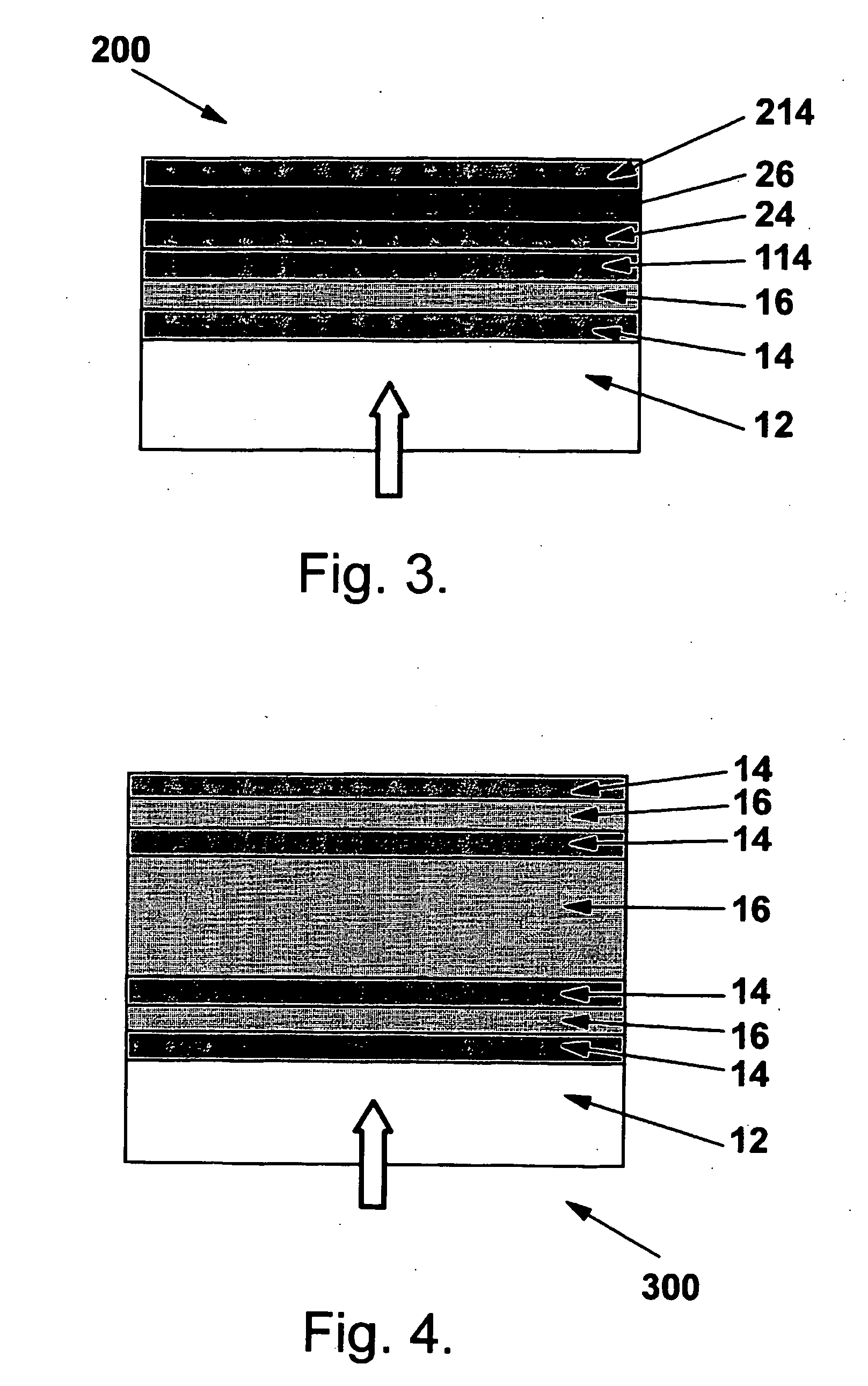

A multilayer structure has barrier properties for gases and vapors, for example oxygen and water vapor; the structure comprises: an organic substrate layer, and a multilayer permeation barrier thereon; the barrier comprises: a) a first inorganic coating contacting a surface of the substrate layer, and b) a first organic coating contacting a surface of the inorganic coating; the structure may be employed in a variety of articles where barrier properties are important especially in electronic articles such as organic light emitting diode devices where superior barrier characteristics over the life of the device are required.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

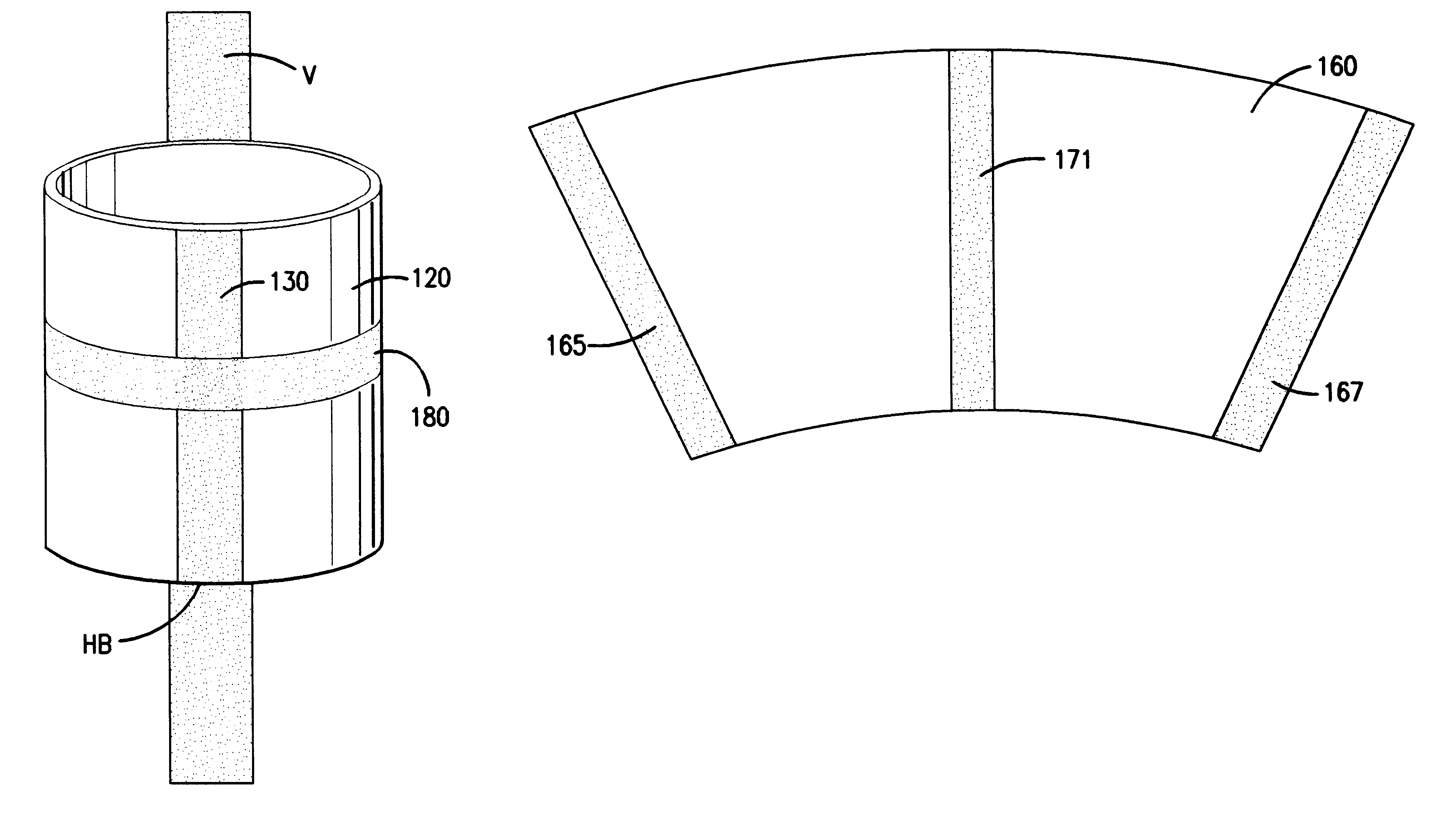

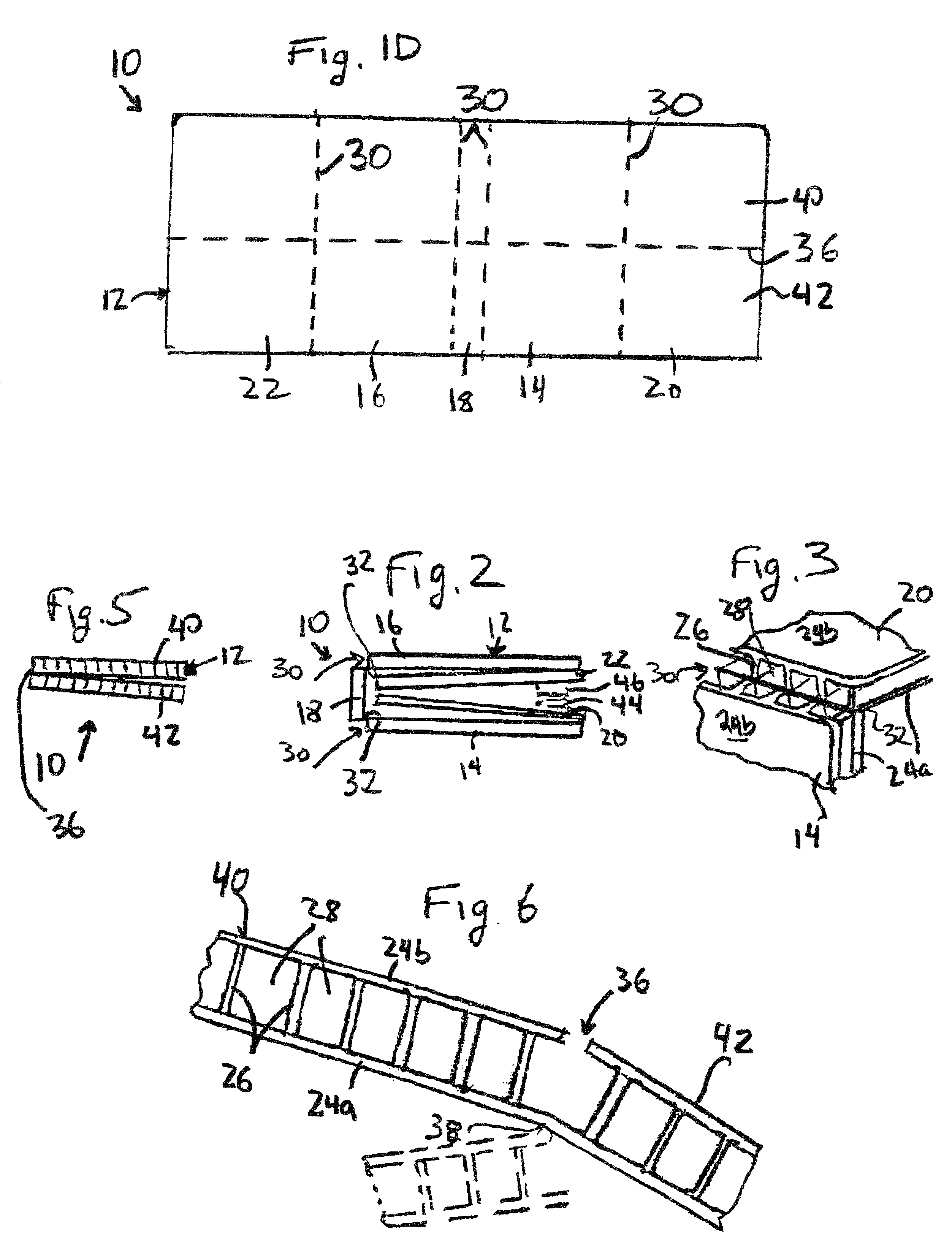

Insulating sleeve for grasping container and manufacturing method

InactiveUS6814253B2Easy to masterEasy to useSynthetic resin layered productsRefuse receptaclesPlastic materialsVolumetric Mass Density

Owner:DOUBLE TEAM

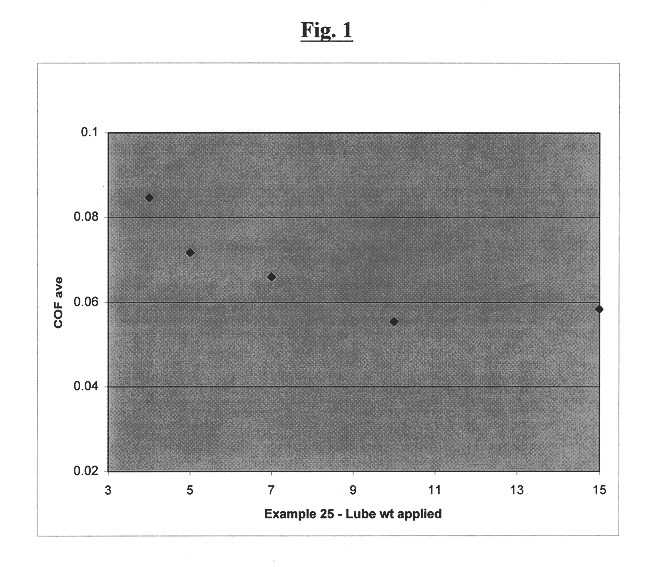

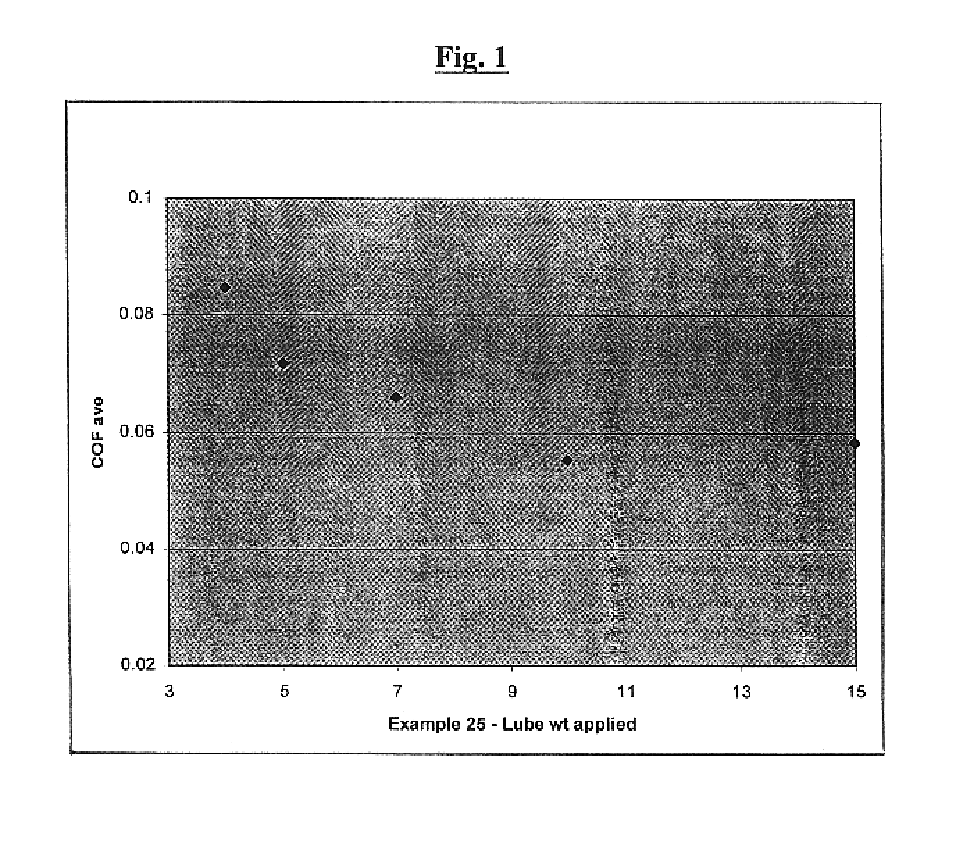

Container, such as a food or beverage container, lubrication method

A process for lubricating a container, such as a beverage container, or a conveyor for containers, by applying to the container or conveyor, a thin continuous, substantially non-dripping layer of a liquid lubricant. The process provides many advantages compared to the use of a conventional dilute aqueous lubricant.

Owner:ECOLAB USA INC

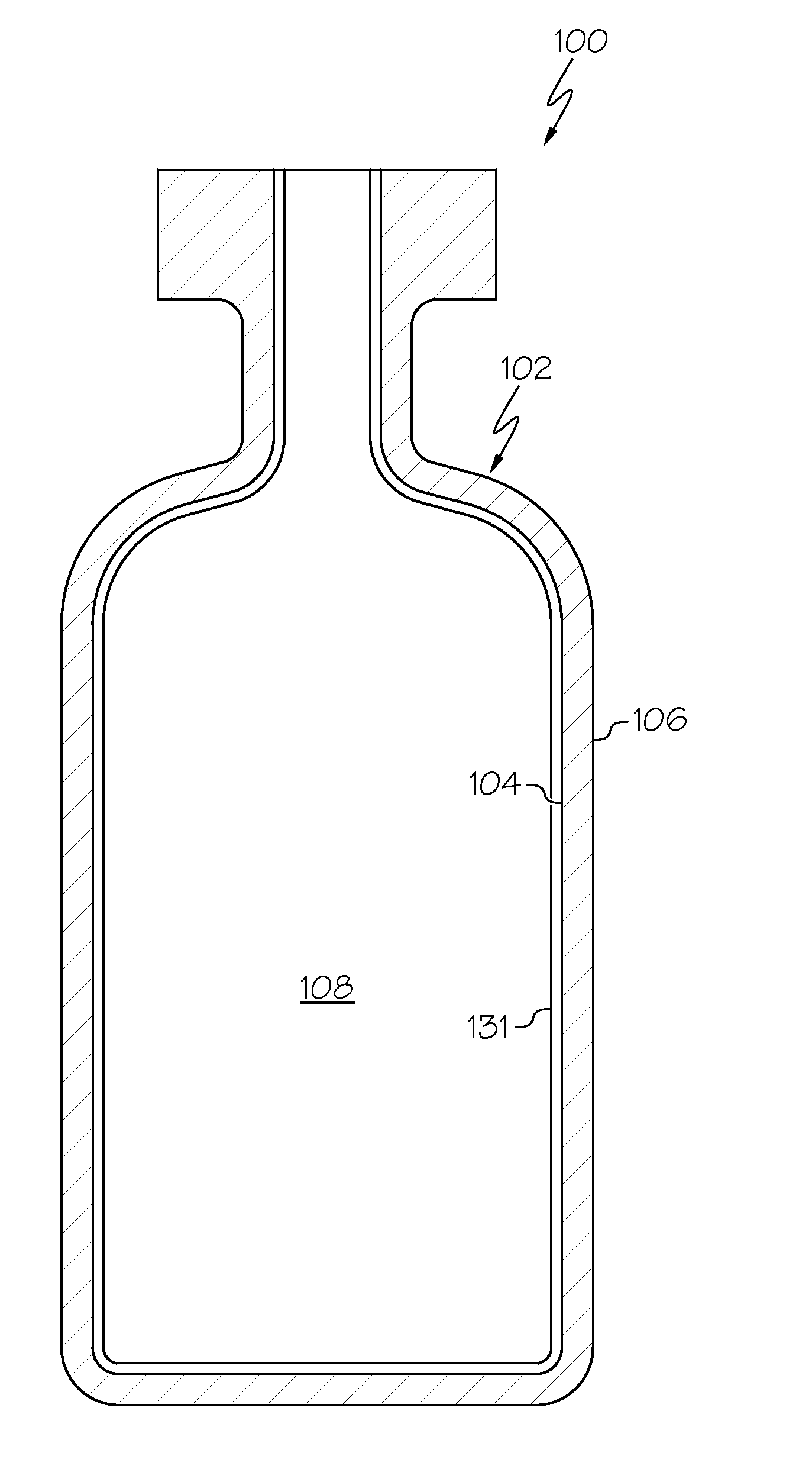

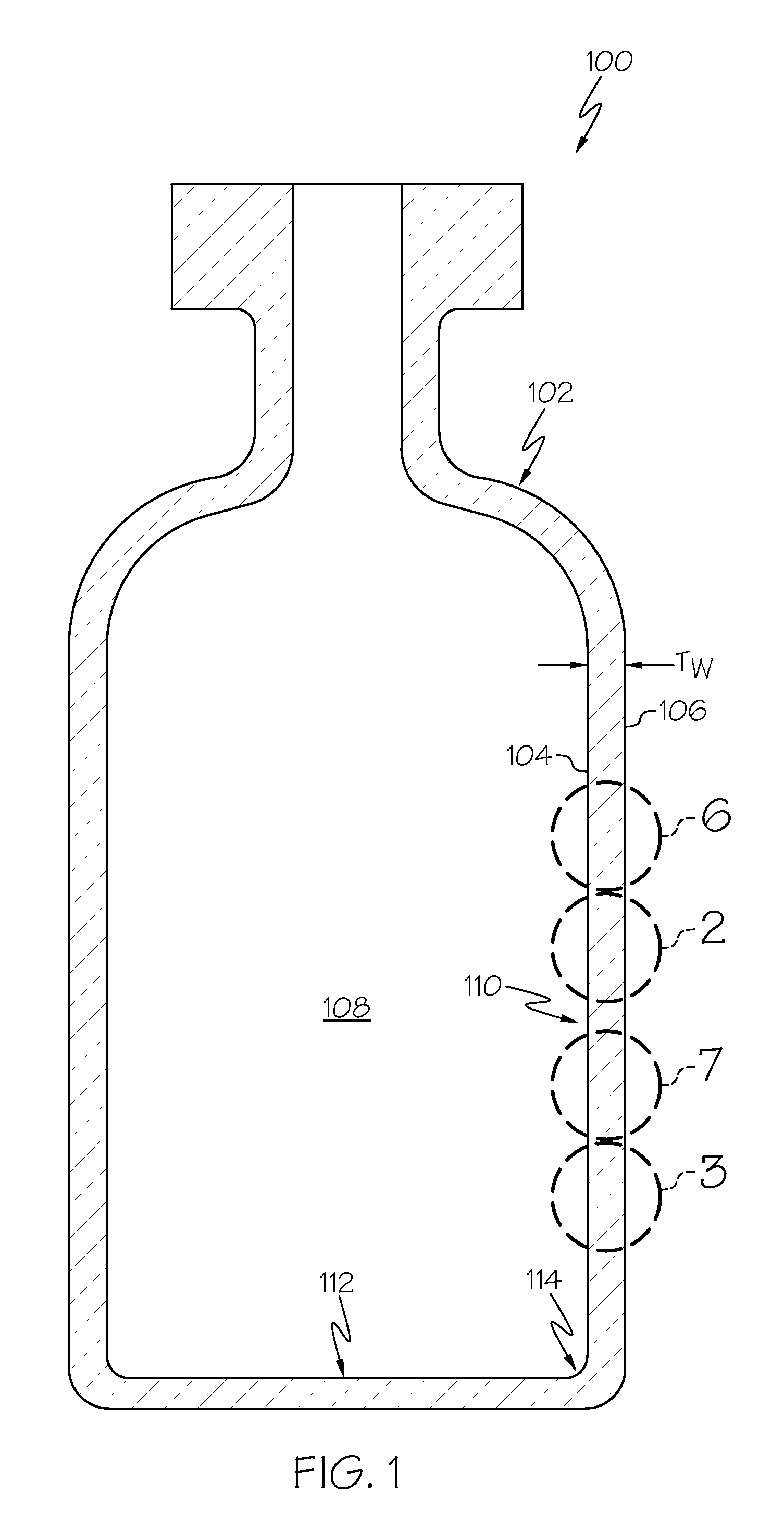

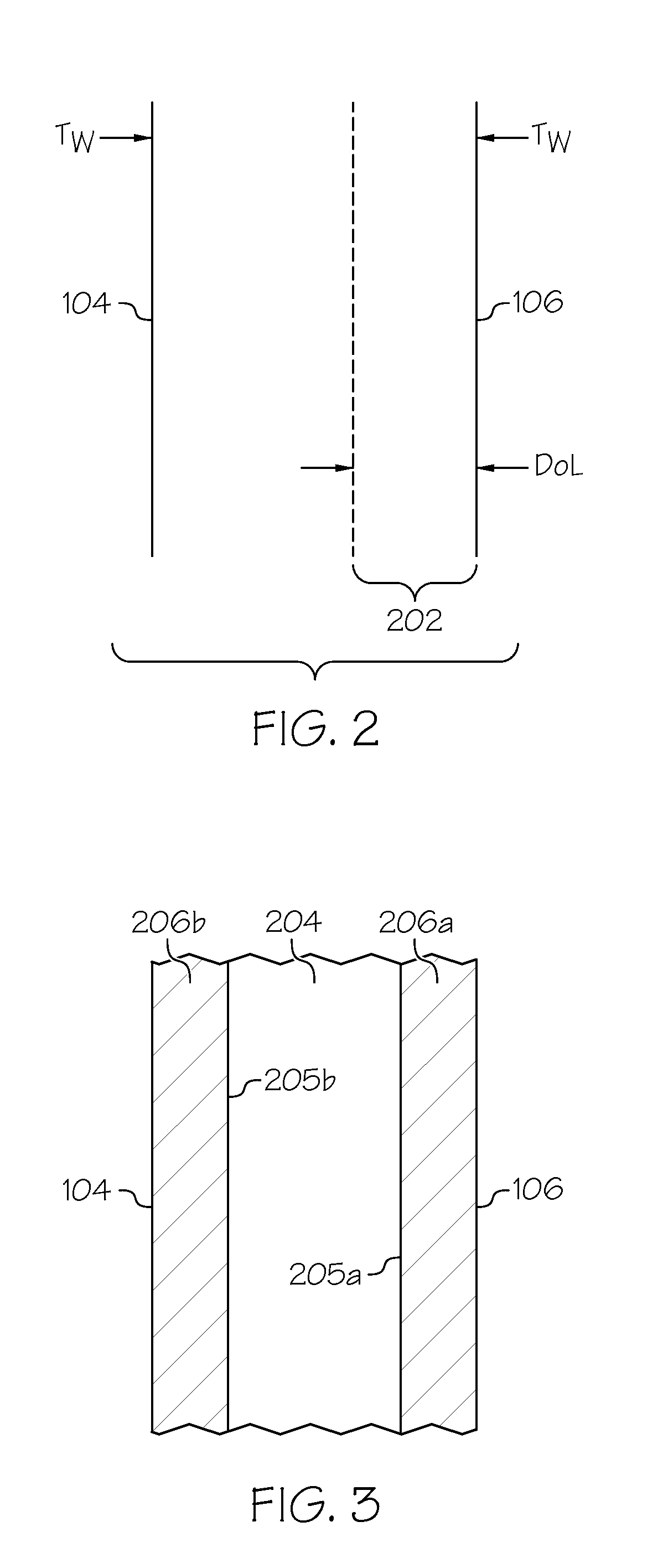

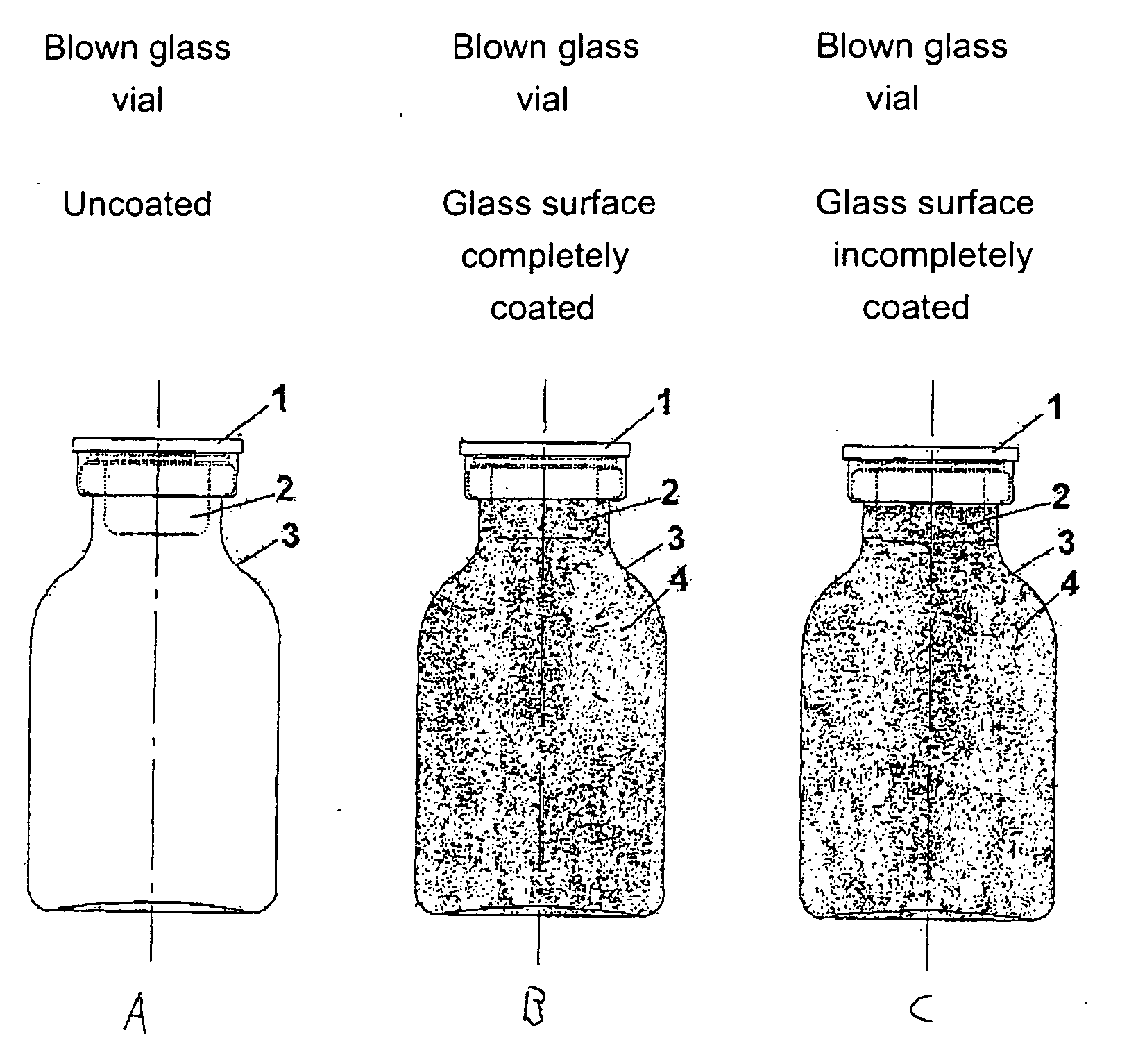

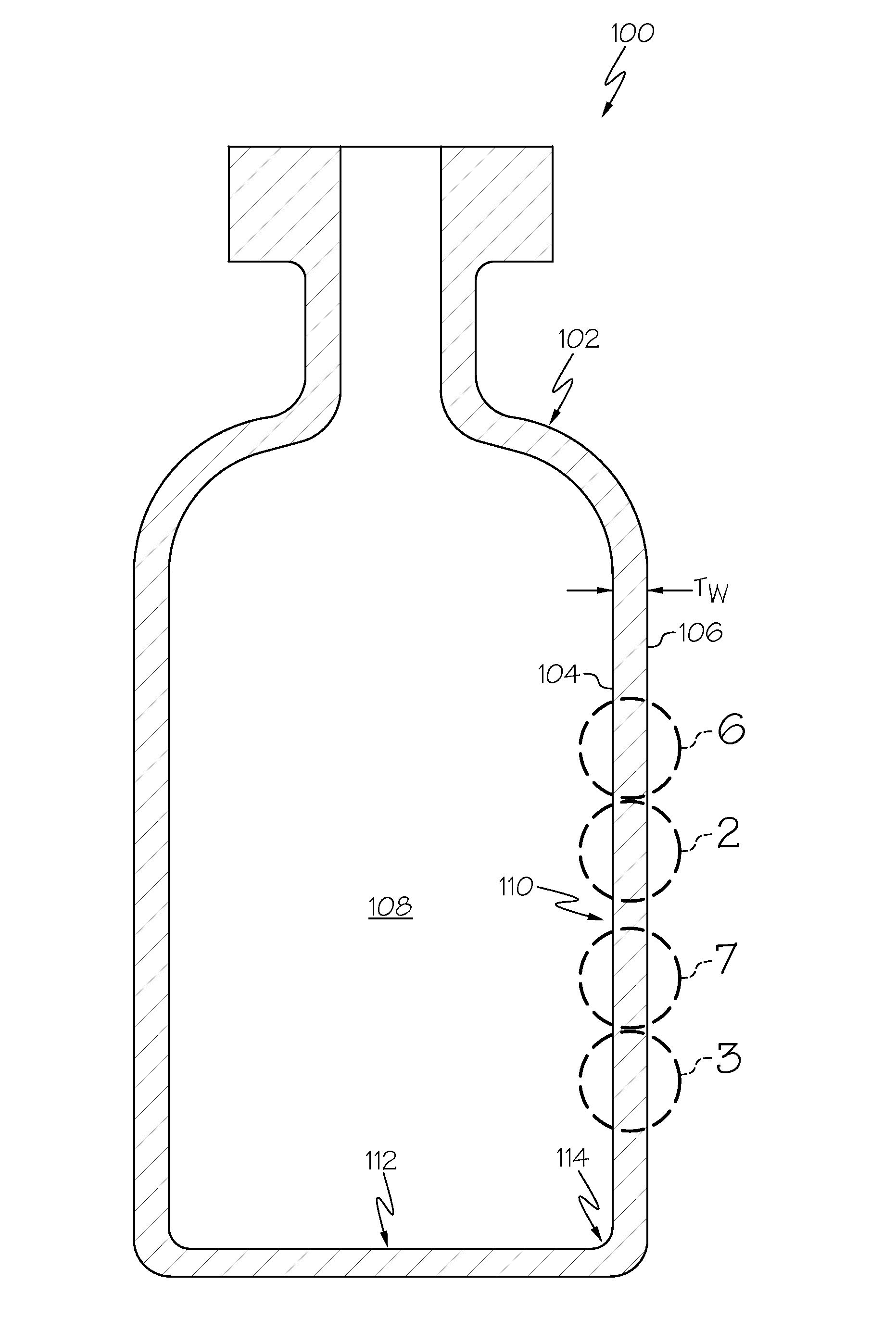

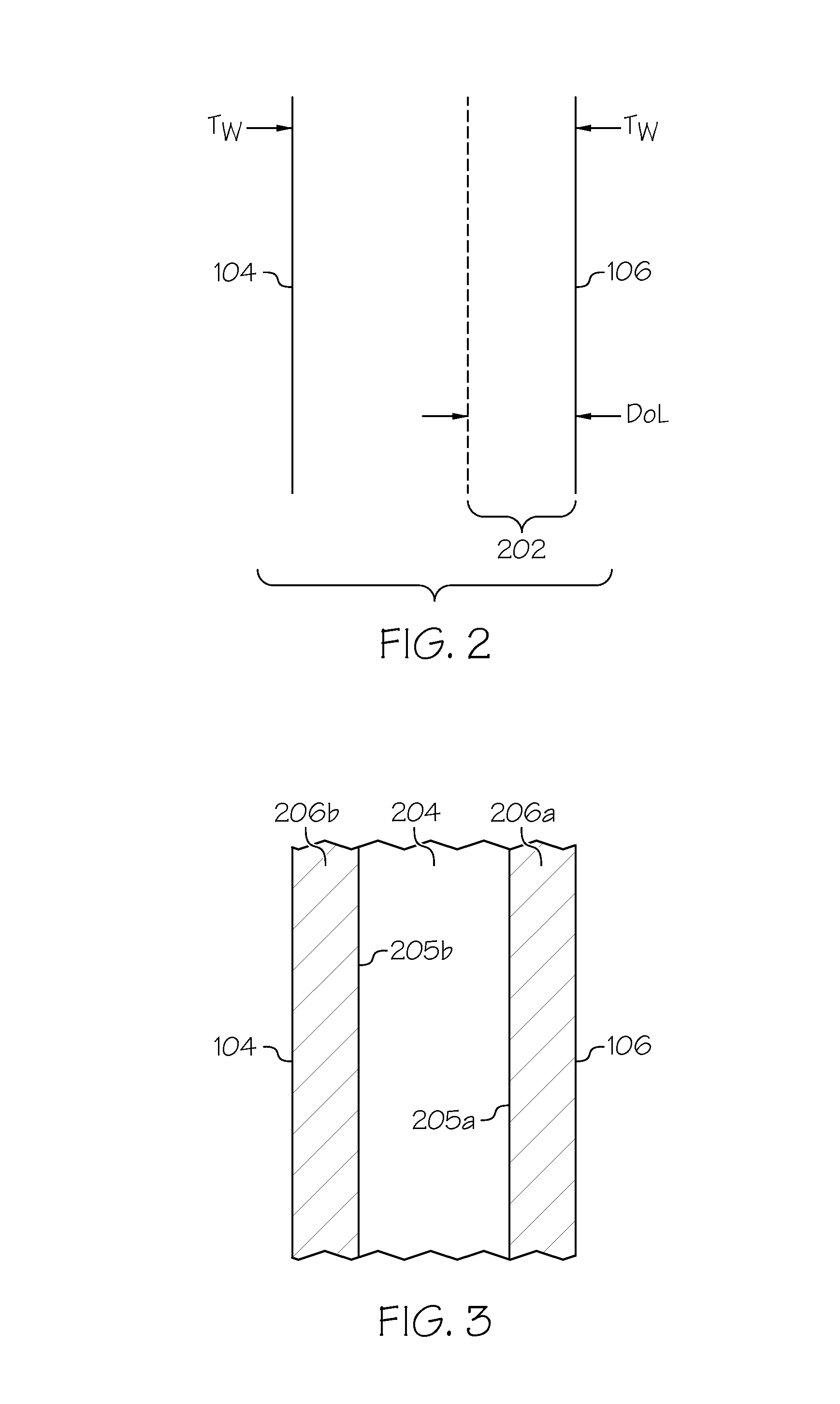

Strengthened glass containers resistant to delamination and damage

ActiveUS20140151370A1Pharmaceutical containersLarge containersUltimate tensile strengthMaterials science

The glass containers described herein are resistant to delamination, have improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The body may also have a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa. A lubricous coating may be positioned around at least a portion of the outer surface of the body, such that the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

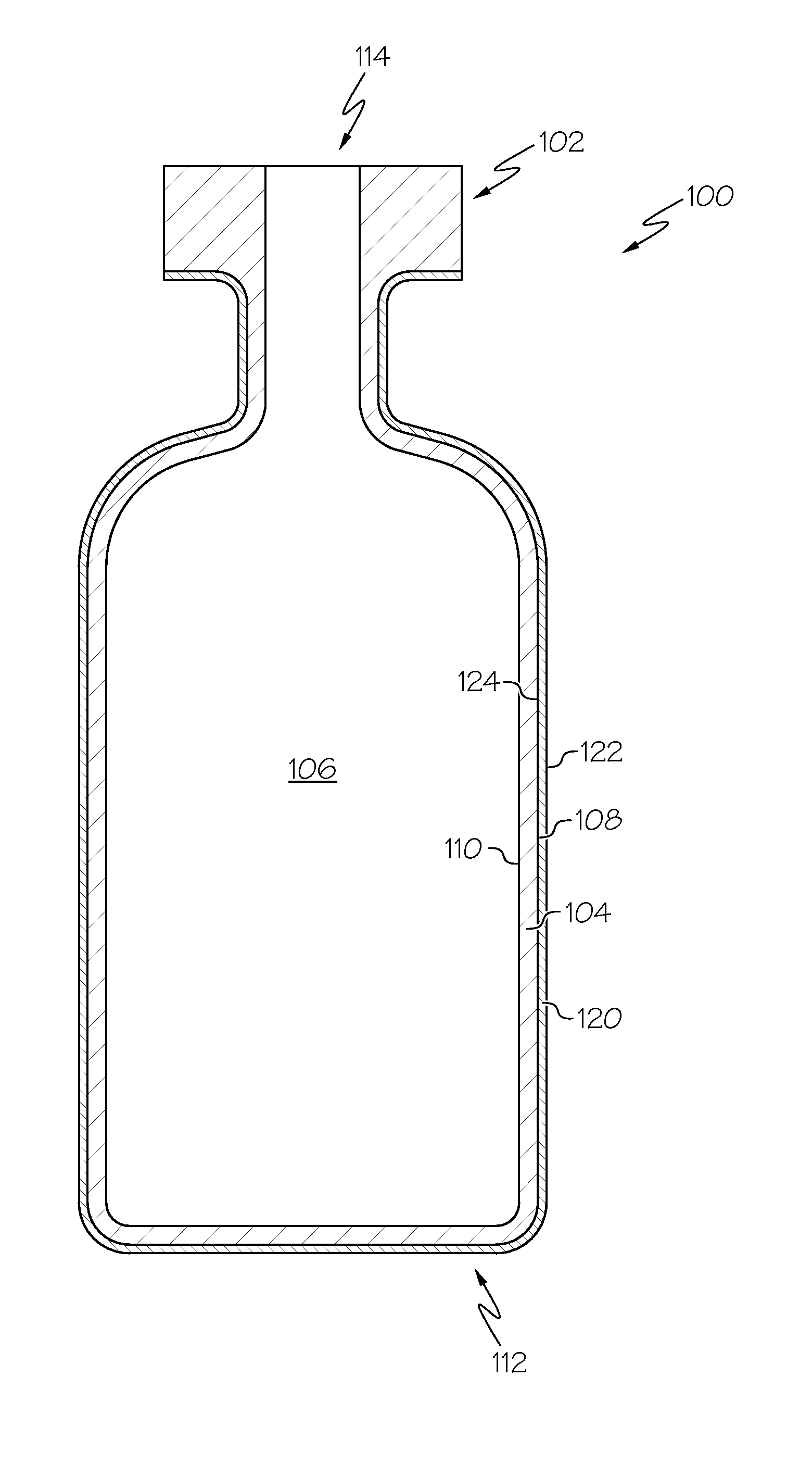

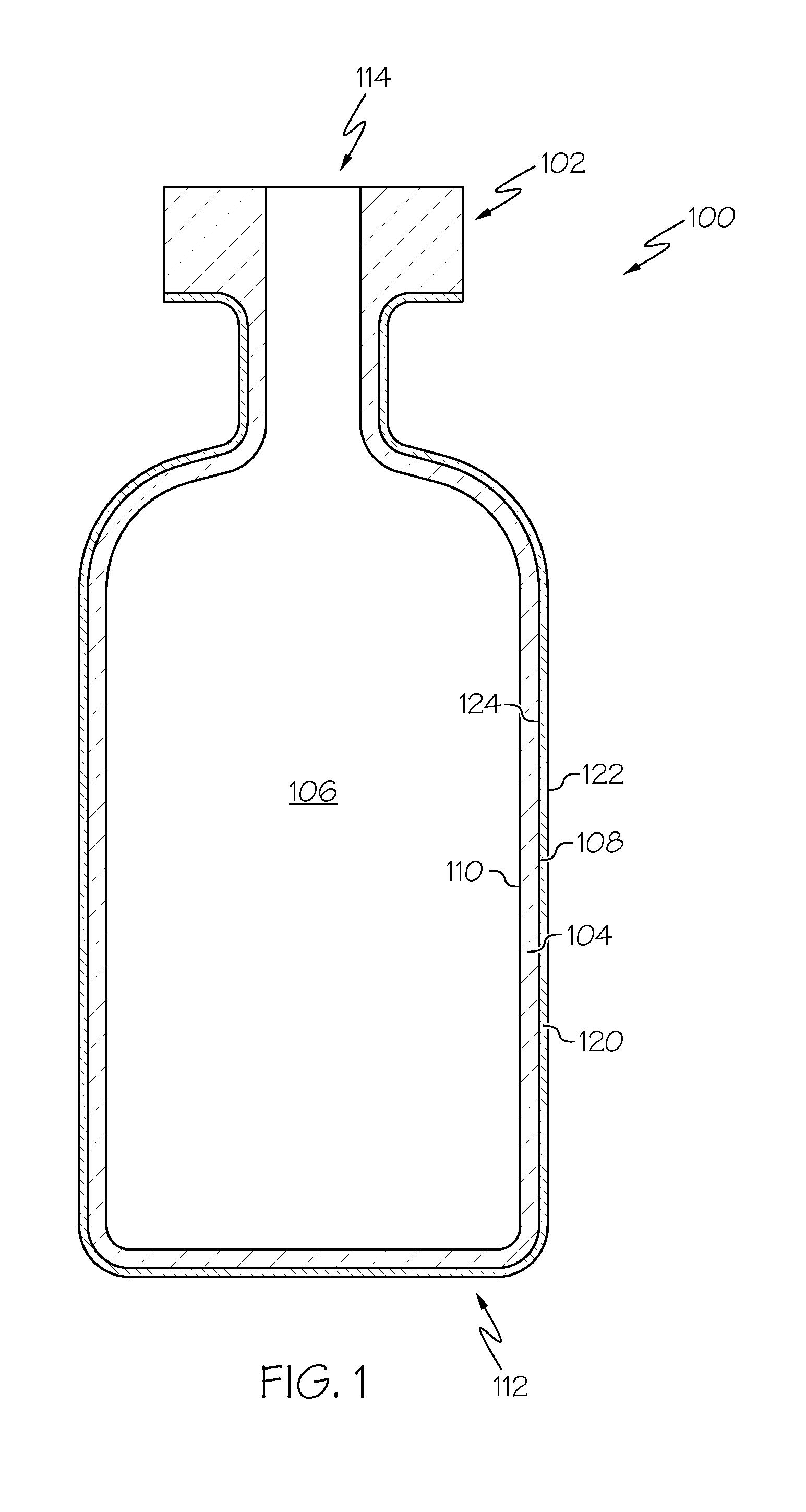

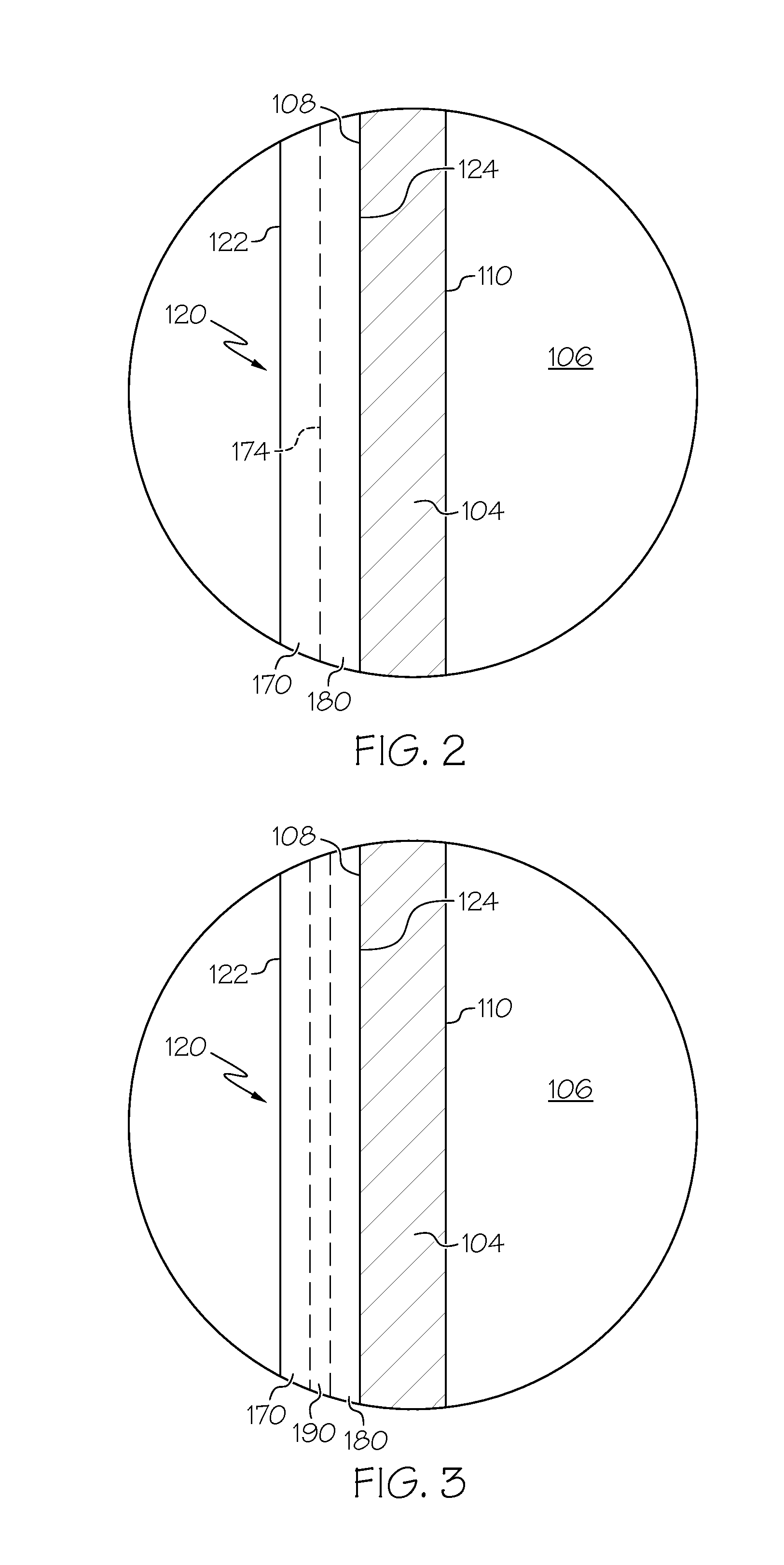

Glass Articles With Low-Friction Coatings

ActiveUS20130171456A1Thermally stablePharmaceutical containersMedical packagingChemical compositionLength wave

Low-friction coatings and glass articles with low-friction coatings are disclosed. According to one embodiment, a coated glass article may include a glass body comprising a first surface and a low-friction coating positioned on at least a portion of the first surface of the glass body. The low-friction coating may include a polymer chemical composition. The coated glass article may be thermally stable at a temperature of at least about 260° C. for 30 minutes. A light transmission through the coated glass article may be greater than or equal to about 55% of a light transmission through an uncoated glass article for wavelengths from about 400 nm to about 700 nm. The low-friction coating may have a mass loss of less than about 5% of its mass when heated from a temperature of 150° C. to 350° C. at a ramp rate of about 10° C. / minute.

Owner:CORNING INC

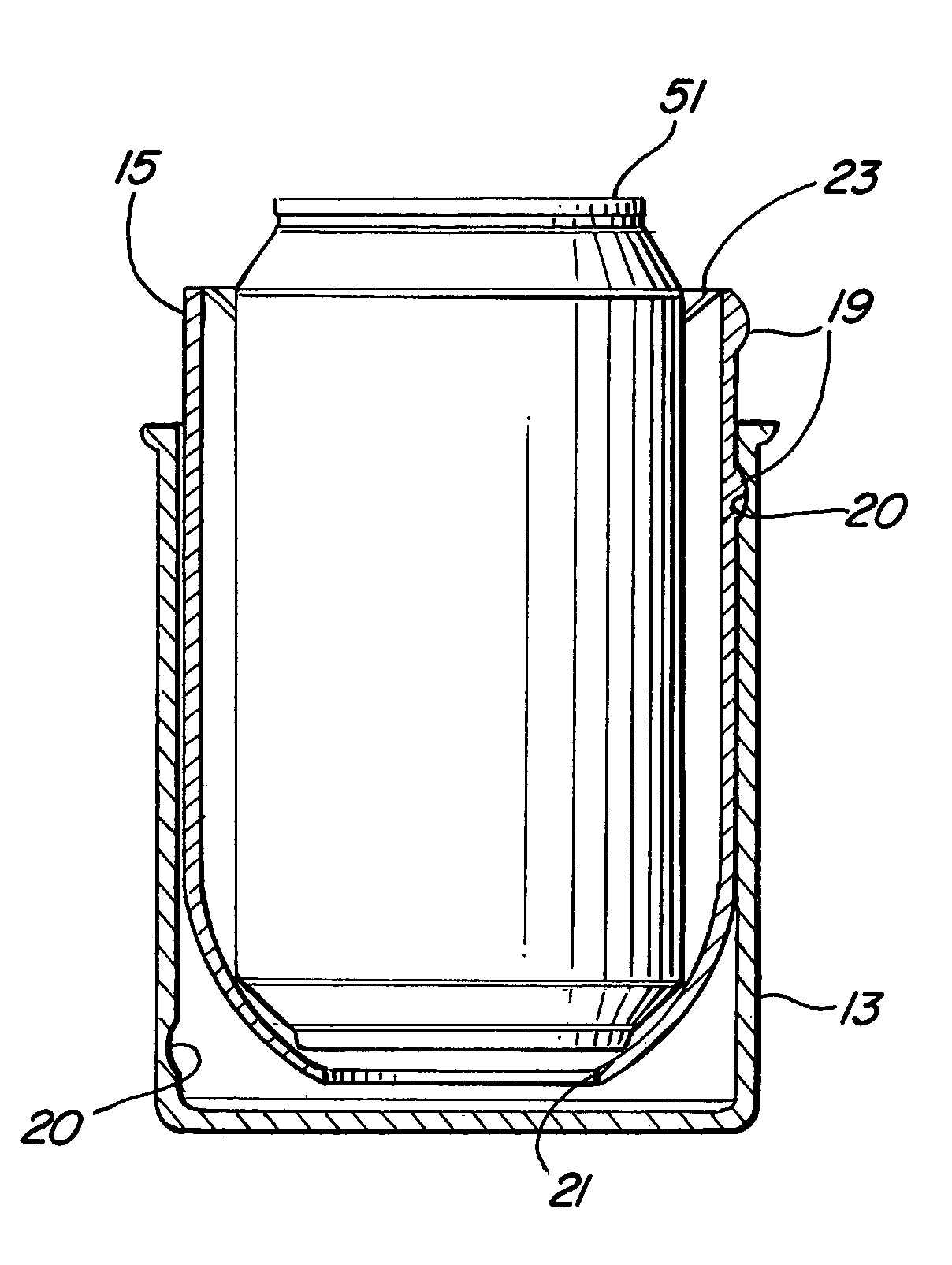

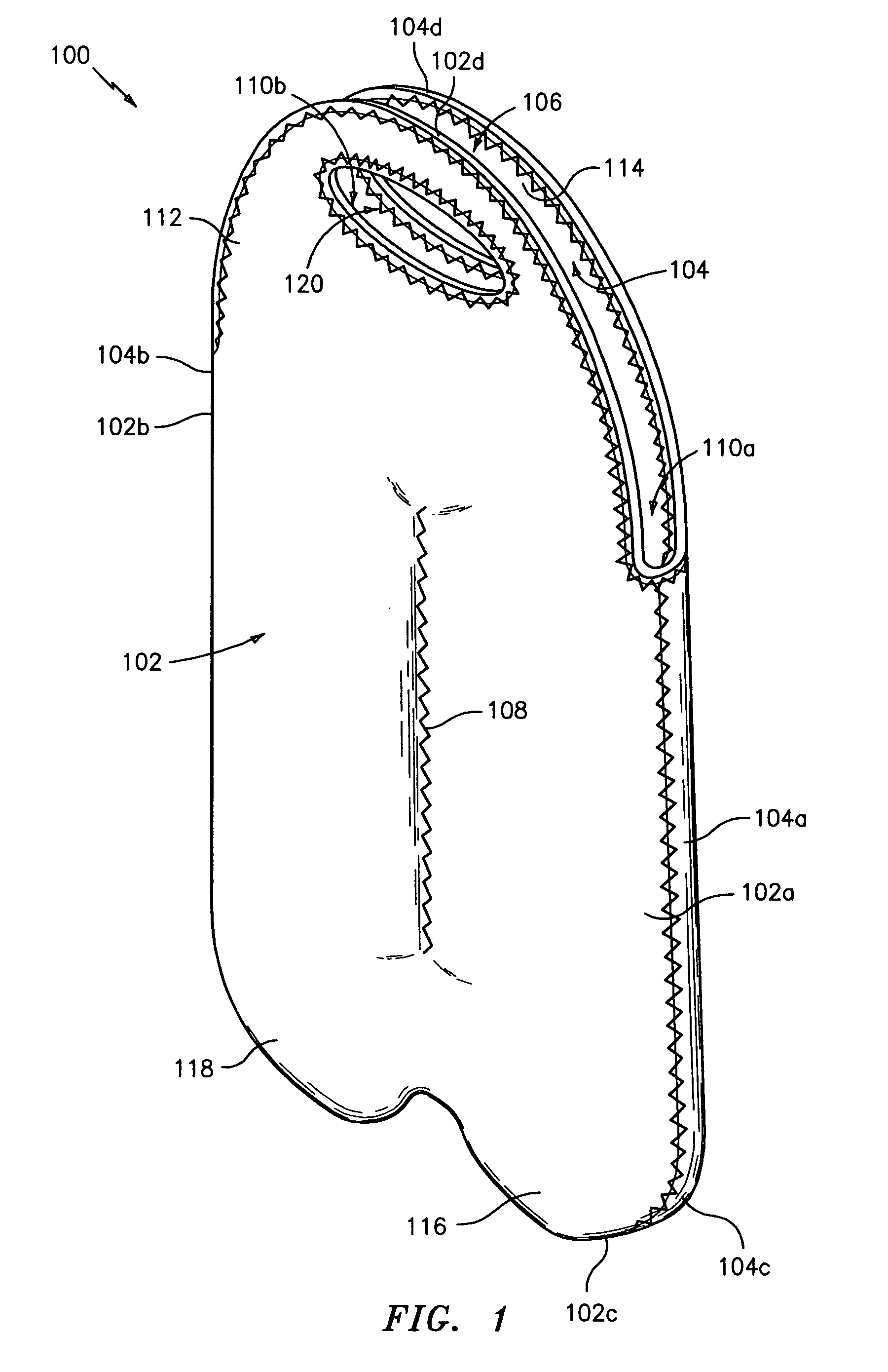

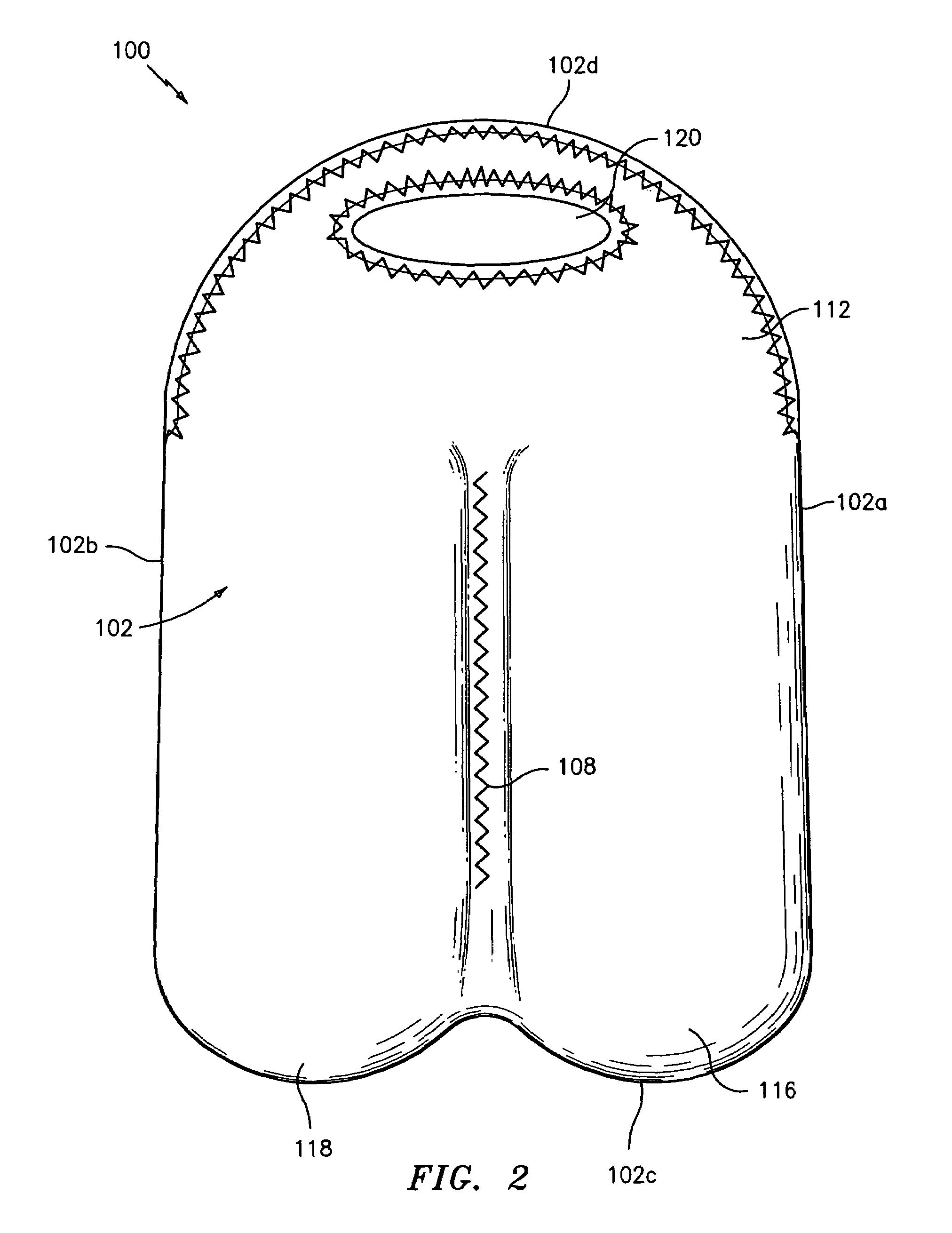

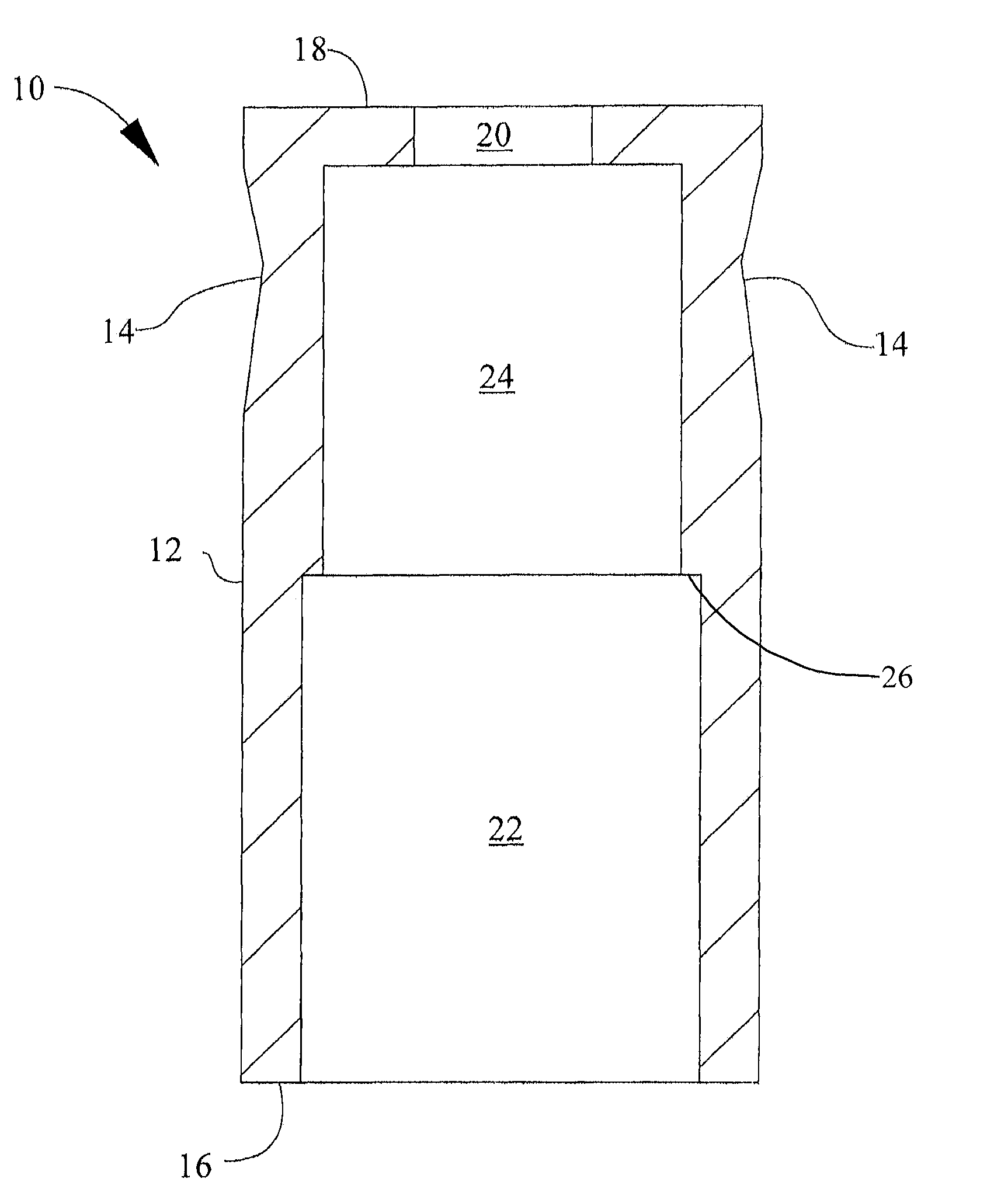

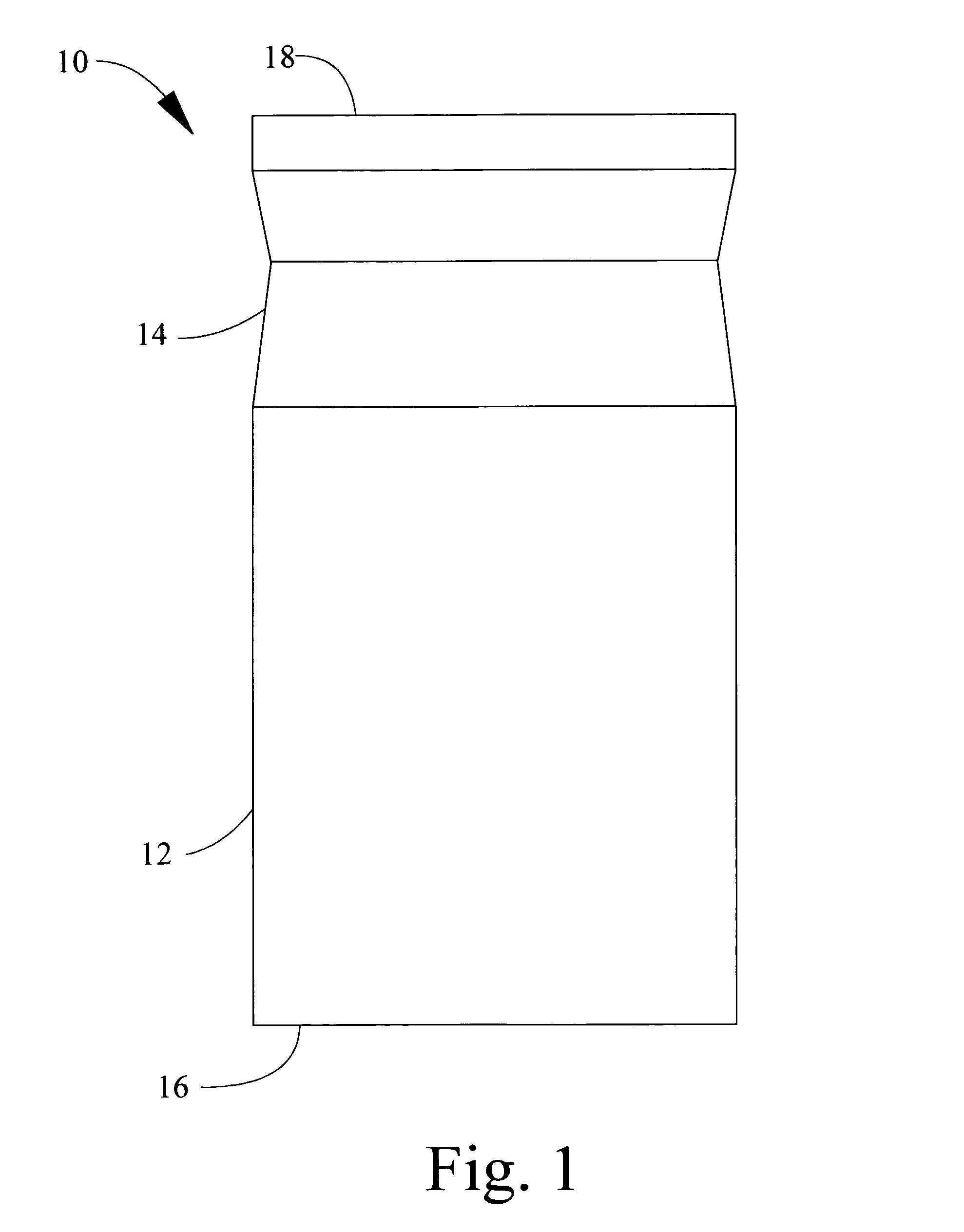

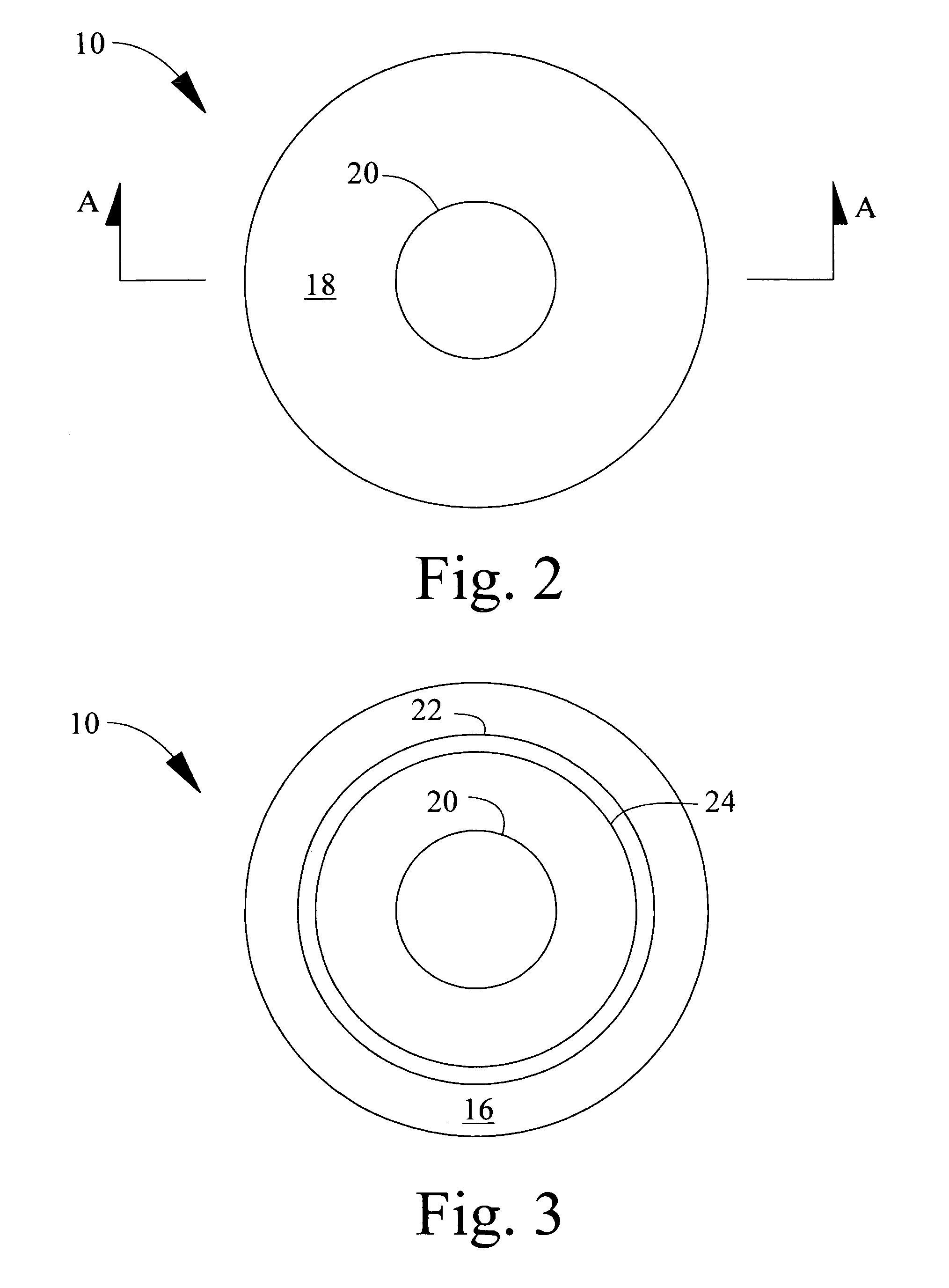

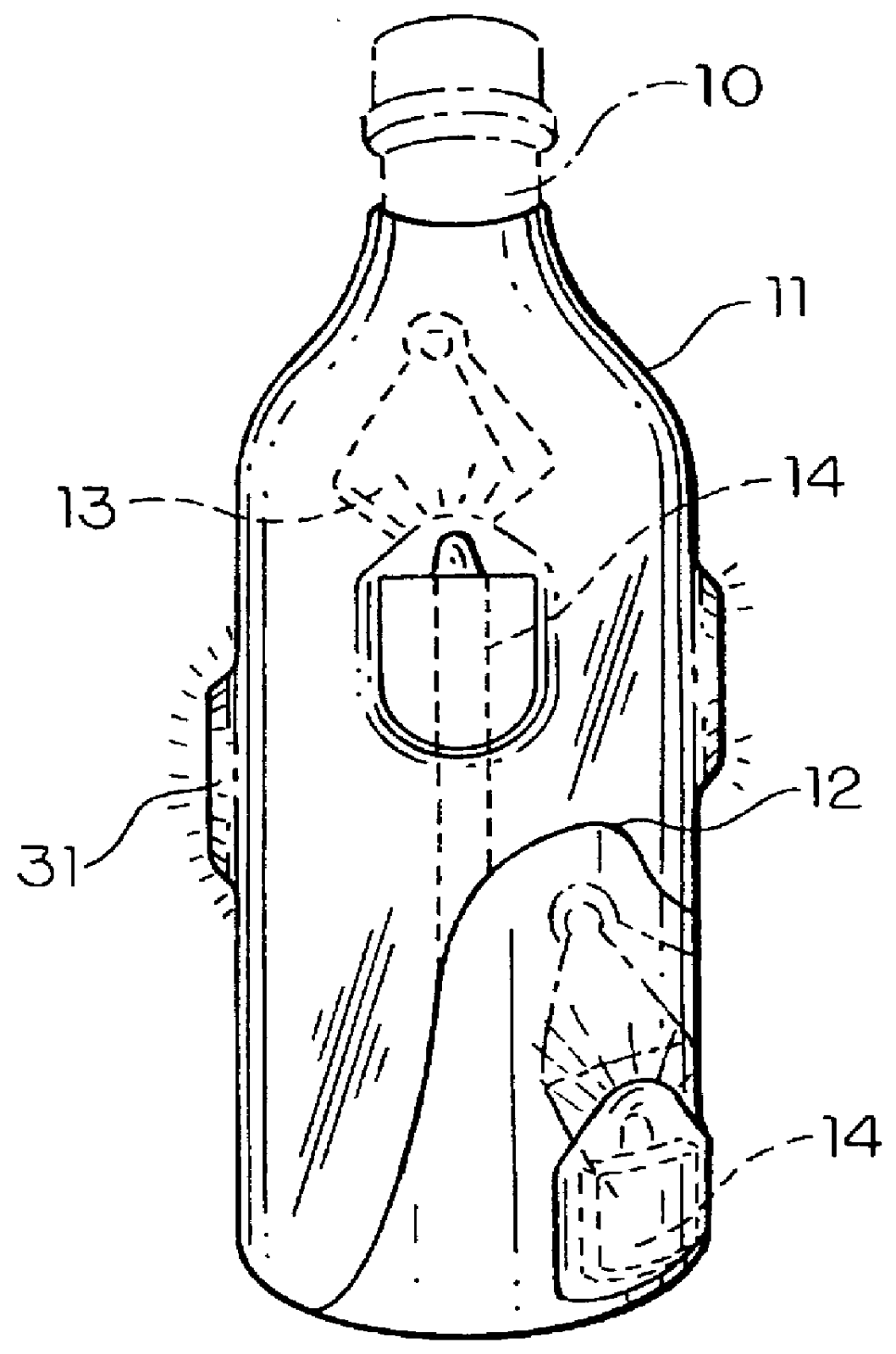

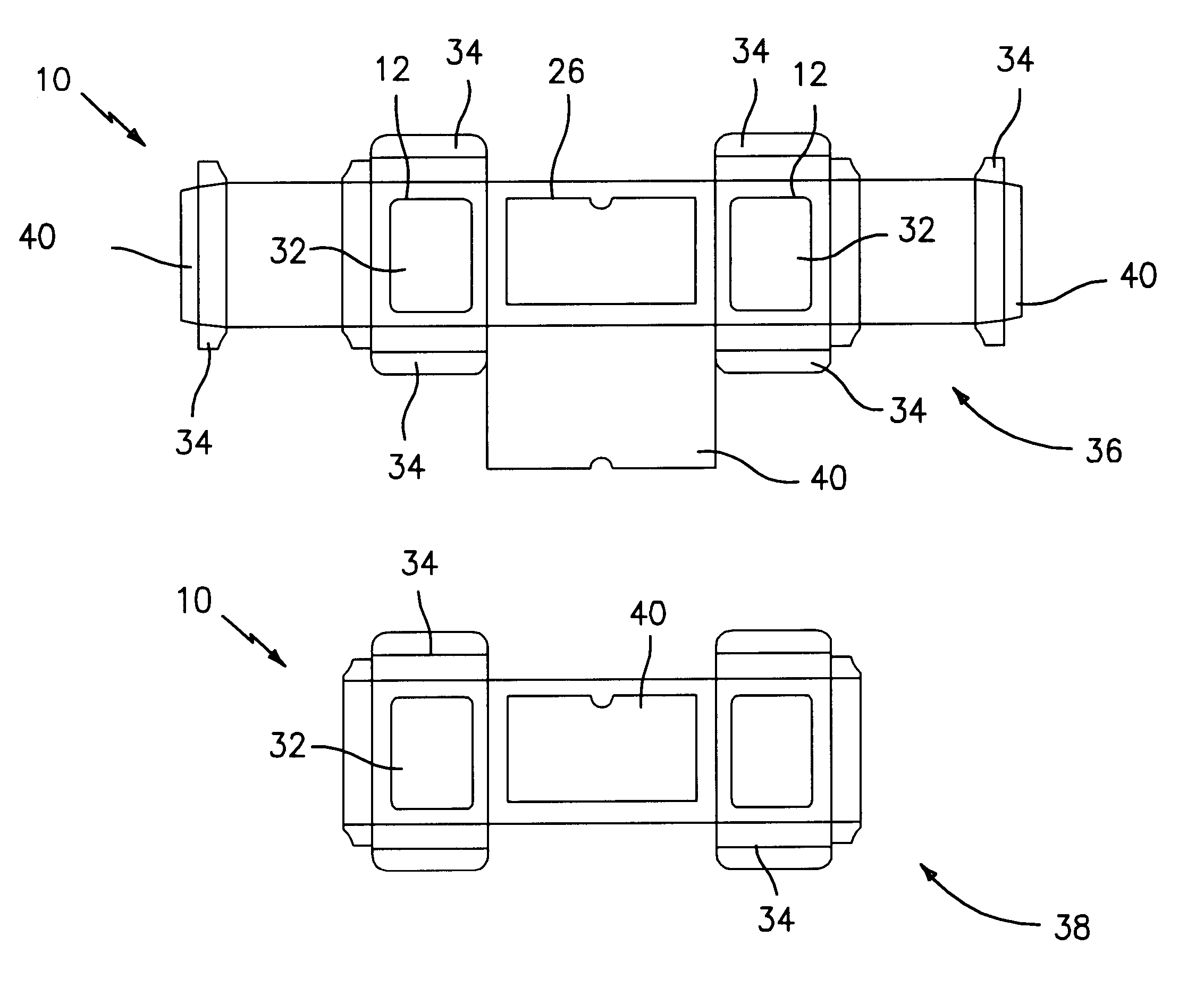

Insulated can and longneck bottle beverage container holder

ActiveUS8544678B1Suitable for useCoverings/external coatingsRigid containersInterference fitAluminum can

An insulating beverage container holder is disclosed that is adapted to receive either longneck beverage bottles or aluminum cans. The insulating beverage holder consists of a substantially cylindrical body having 3 axially aligned apertures therein. One aperture is sized for an interference fit with the cylindrical diameter of an aluminum can beverage container. A second aperture is sized for an interference fit with the neck portion of a longneck beverage container. A third aperture, situated between the first and second apertures, is sized for an interference fit with the larger diameter of a longneck beverage container. Retaining mechanisms are also disclosed that secure longneck beverage containers within the holder to prevent inadvertent removal of the beverage container from within the insulated beverage container holder.

Owner:FLIPZIE INC

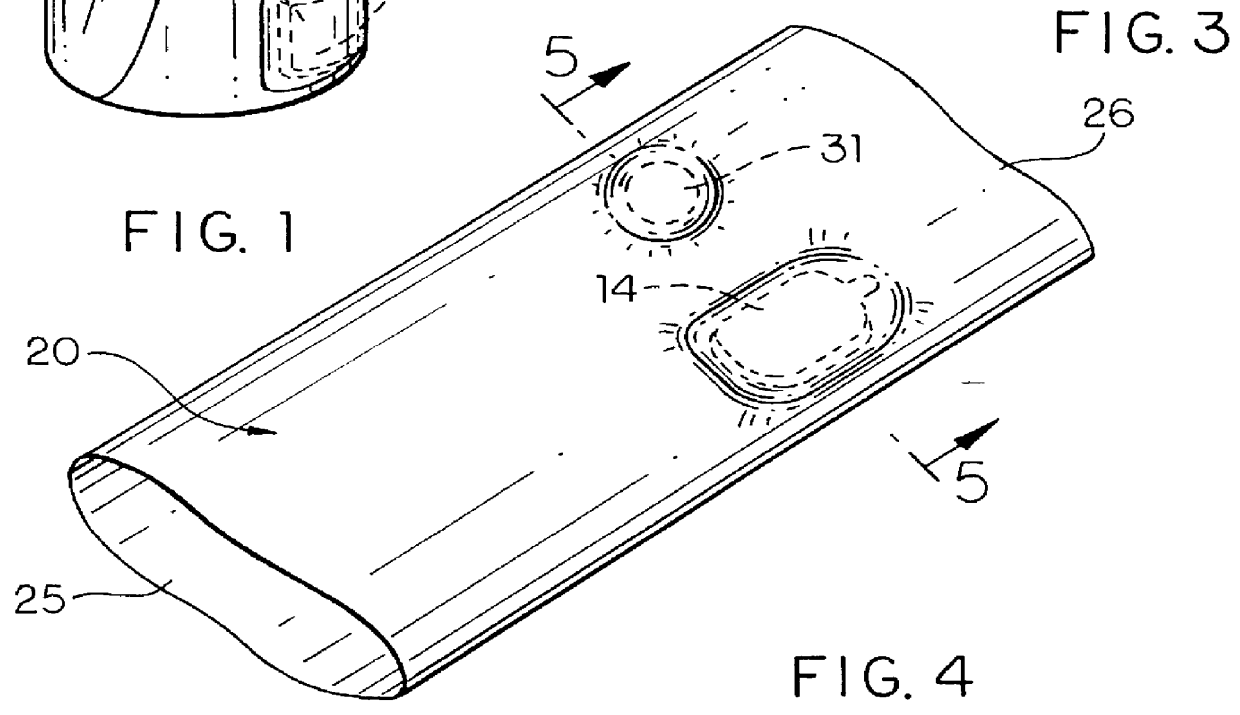

Versatile beverage container holder

Owner:TREASURES UNTOLD

Decorative packaging with special effects

A package wrap for decoratively covering a container having side walls defining an interior space for carrying a product therein, includes a flexible thin sheet of polymeric material adapted to be shrink-wrapped onto the exterior of the container. An illuminating or a sound producing device is positioned between the flexible thin sheet of polymeric material and the exterior of the container so that when the flexible sheet of polymeric material is shrink-wrapped onto the container, the illuminating device or the sound device will be held securely in place. The illuminating device is adapted to be illuminated upon activation by a pressure, motion, or acoustically sensitive switch. The sound device is adapted to produce an audible signal upon activation by a pressure or motion sensitive switch. When the illuminating device is activated, illumination therefrom will be visible through the flexible thin sheet of polymeric material to enhance and highlight a printed pattern on the exterior of the package wrap.

Owner:DECICCO RICHARD J

Coatings with low permeation of gases and vapors

InactiveUS7074501B2Reduce permeationFinal product manufactureVacuum evaporation coatingCoated surfaceLight-emitting diode

A multilayer structure has barrier properties for gases and vapors, for example oxygen and water vapor; the structure comprises: an organic substrate layer, and a multilayer permeation barrier thereon; the barrier comprises: a) a first inorganic coating contacting a surface of the substrate layer, and b) a first organic coating contacting a surface of the inorganic coating; the structure may be employed in a variety of articles where barrier properties are important especially in electronic articles such as organic light emitting diode devices where superior barrier characteristics over the life of the device are required.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

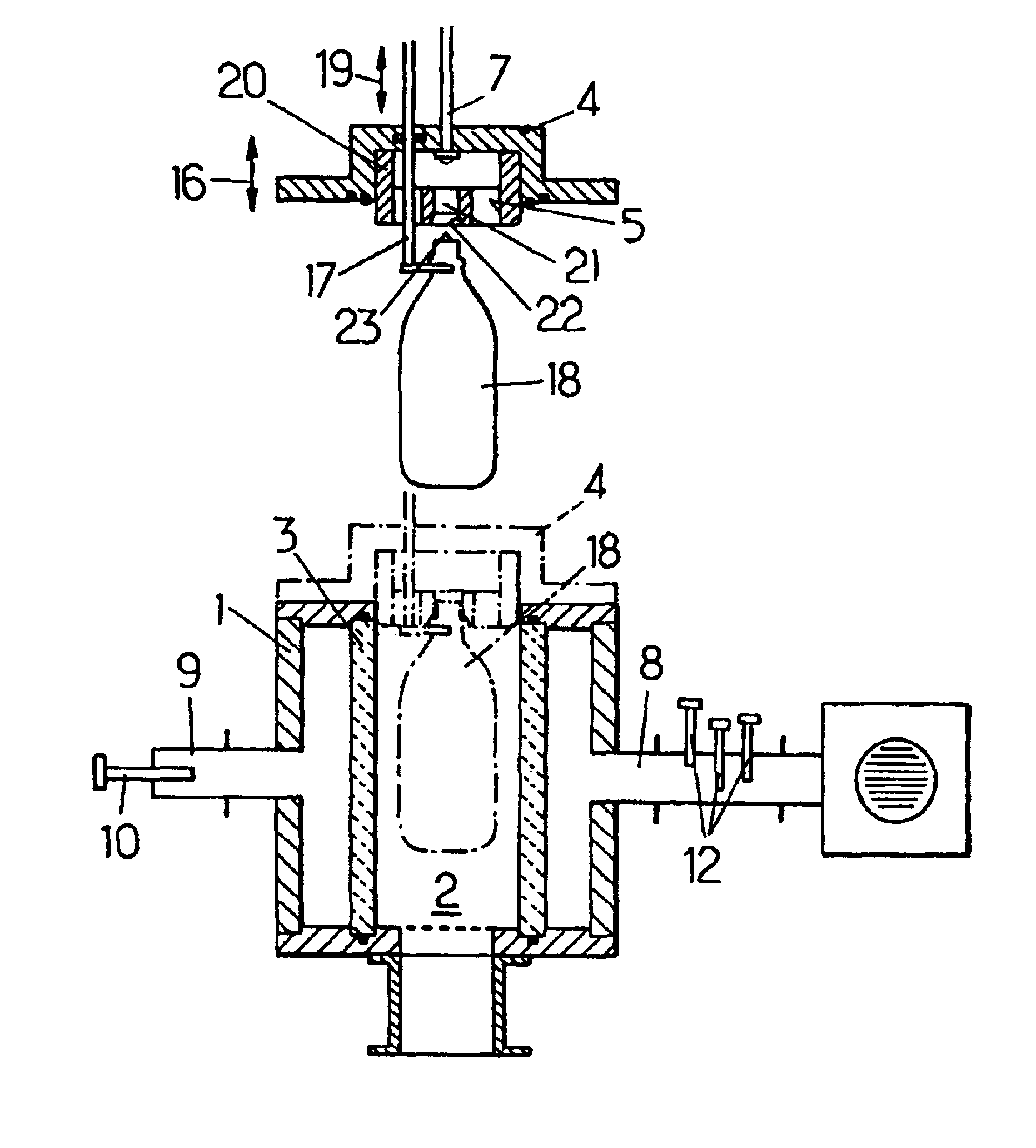

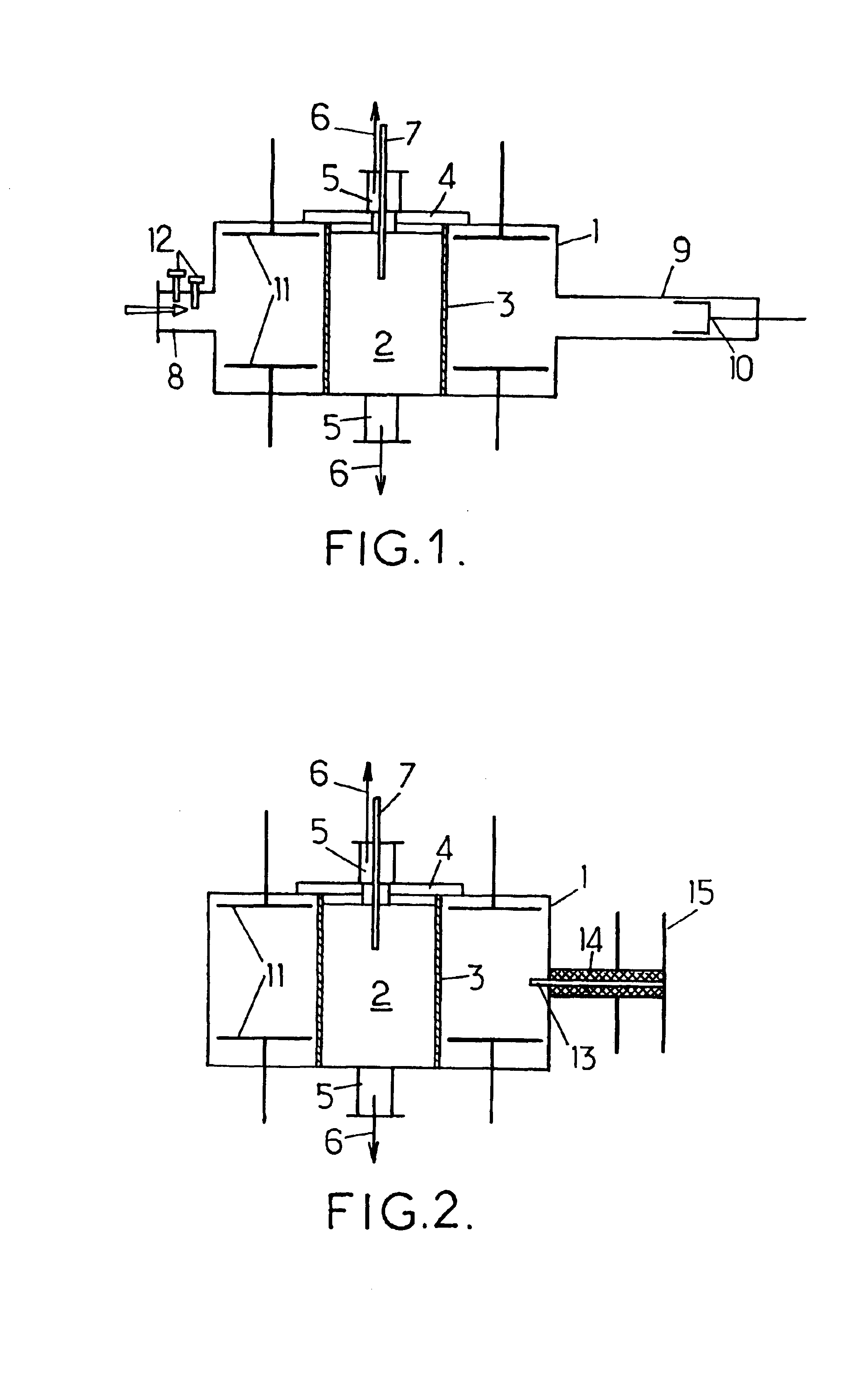

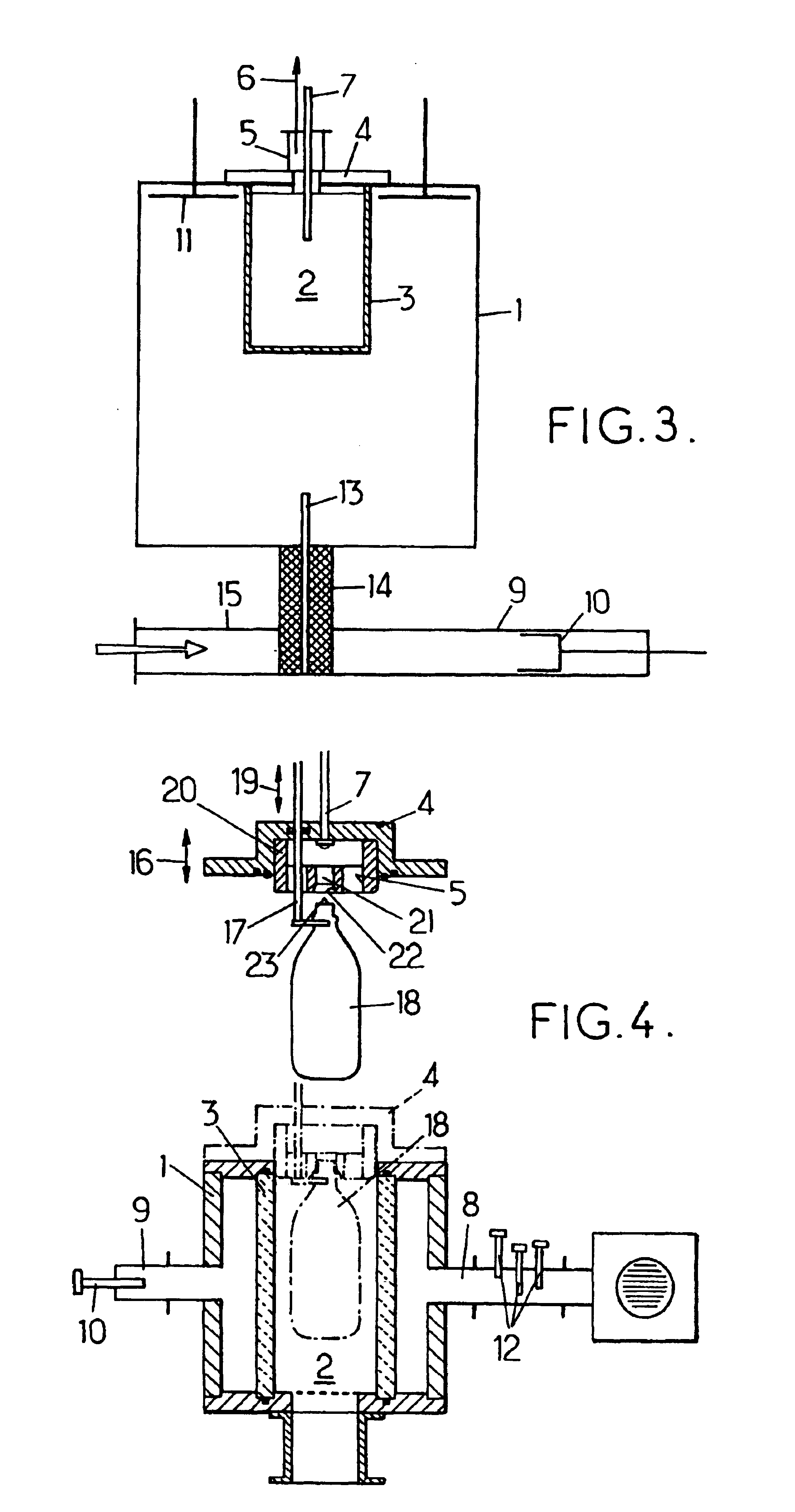

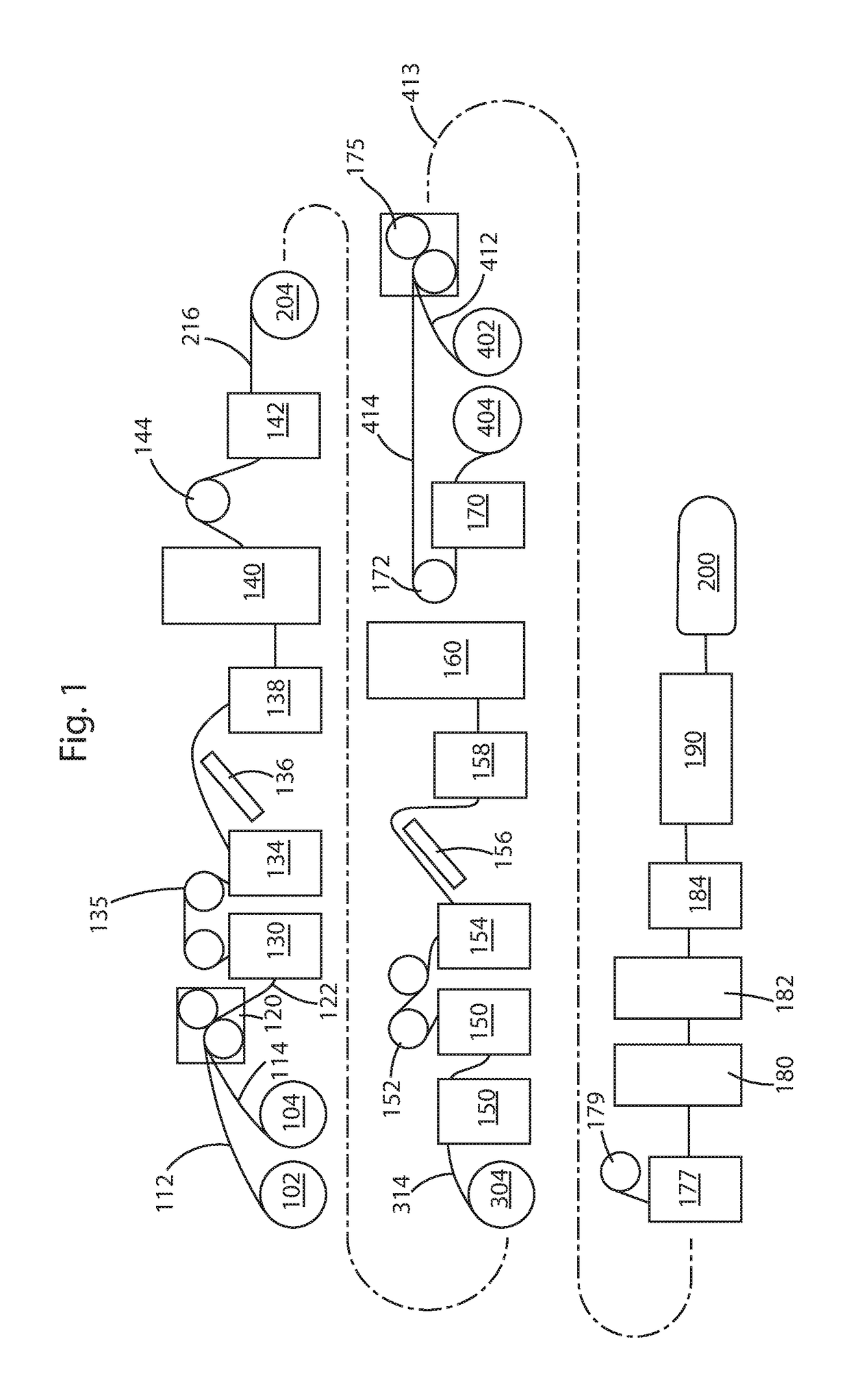

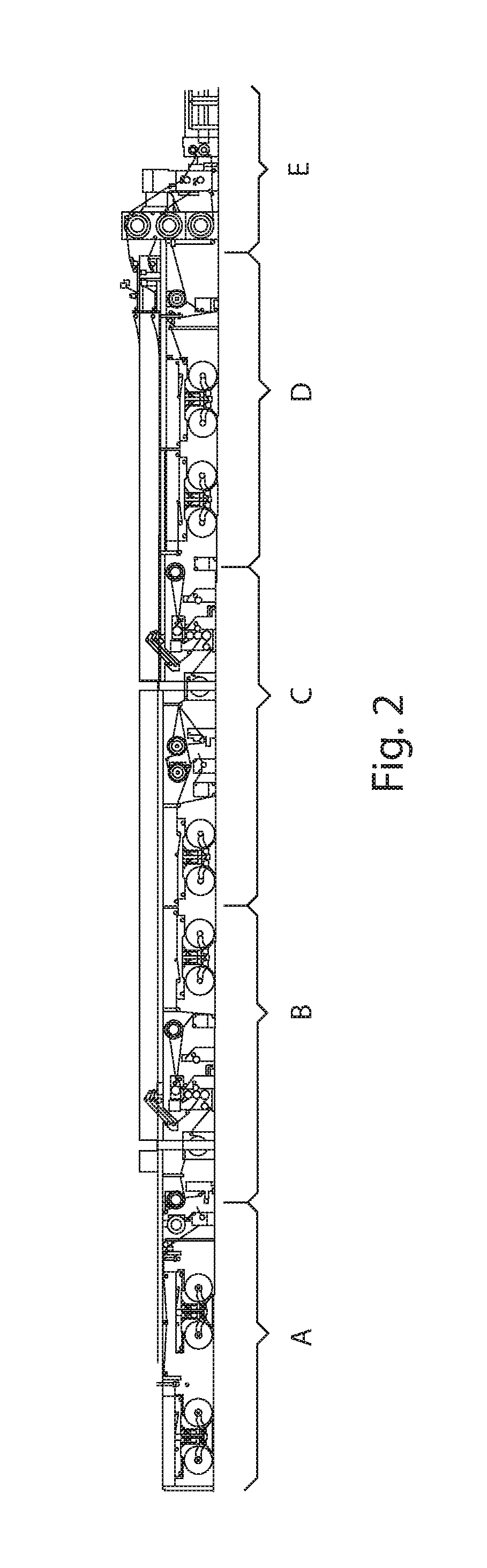

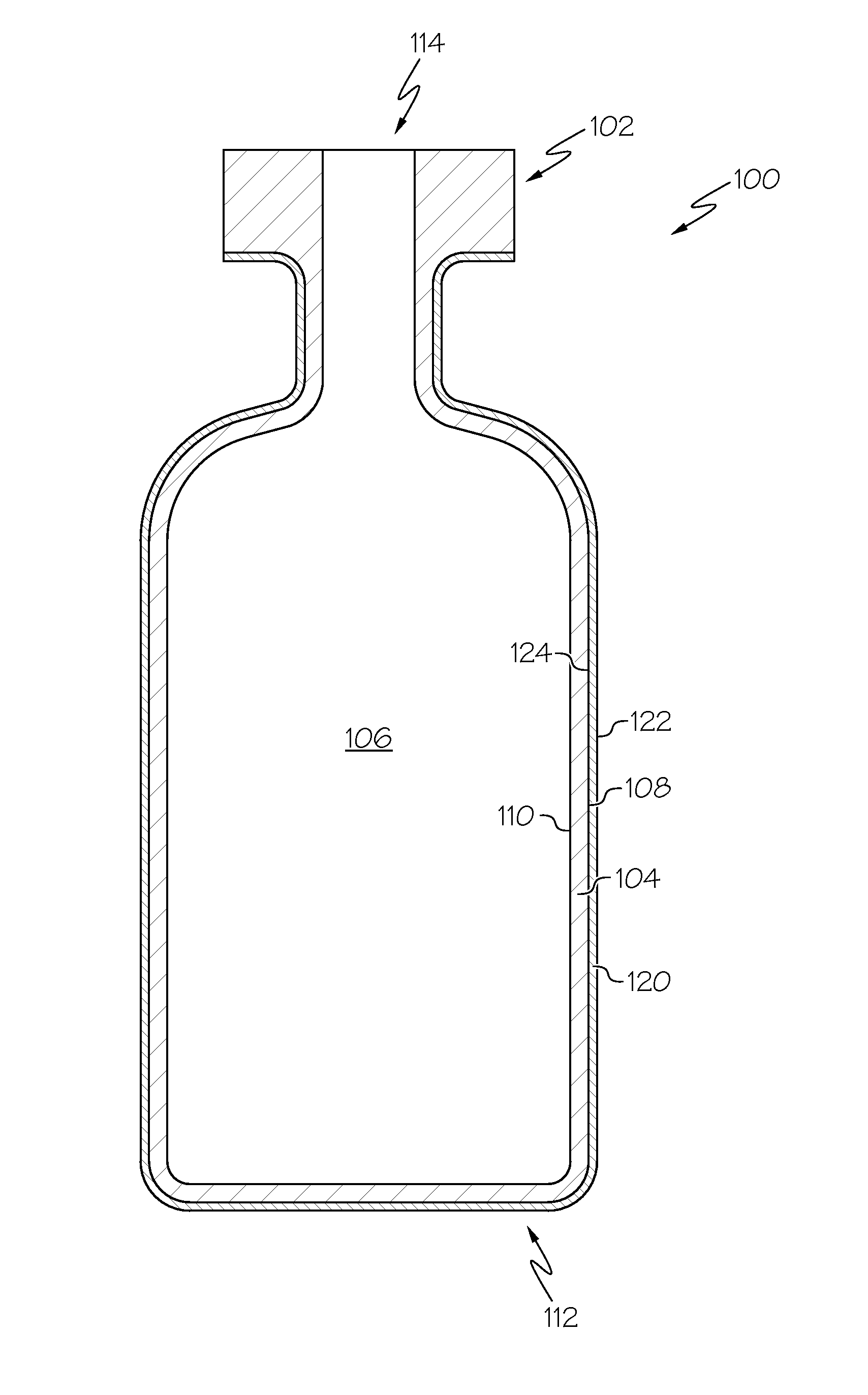

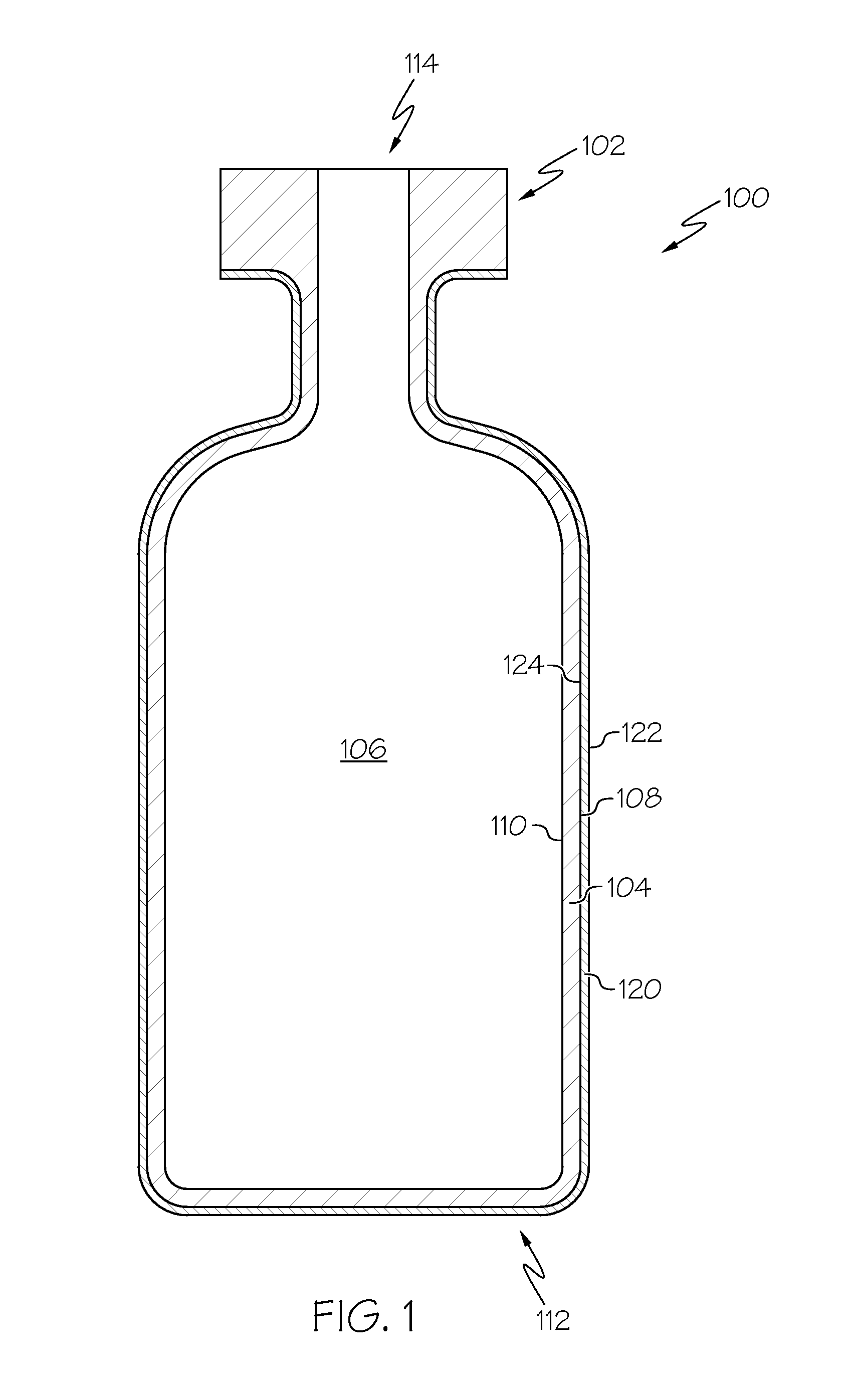

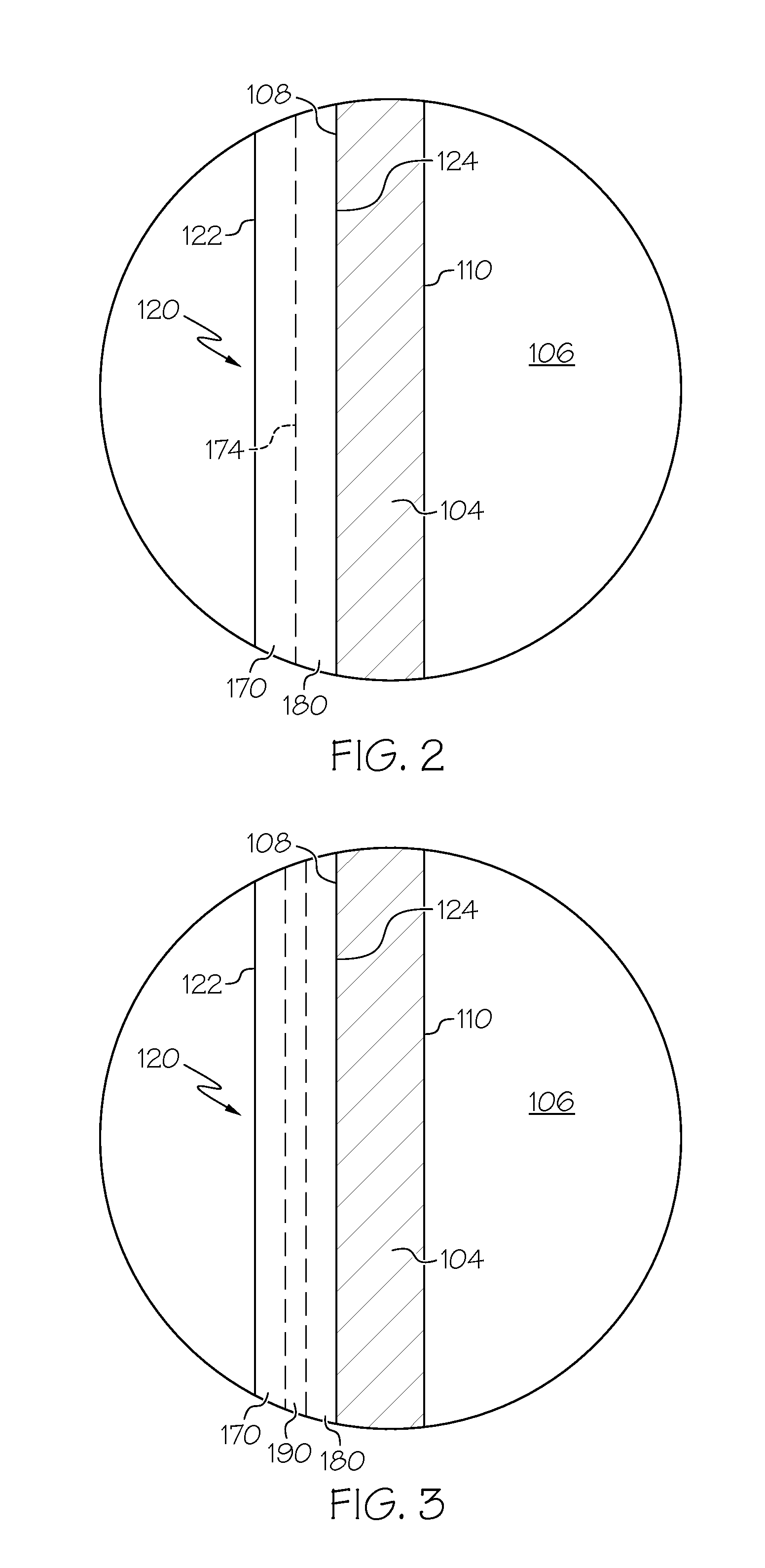

Container with material coating having barrier effect and method and apparatus for making same

InactiveUS6919114B1Easy to manufactureImprove barrier propertiesLiquid surface applicatorsBottlesBarrier effectBottle

The invention provides a container such as a bottle or flask, made heterogeneously from a material with a barrier effect and a polymer material, characterised in that the material with a barrier effect is an amorphous carbon material with a polymer tendency which is applied as a coating on a substrate of polymer material.

Owner:SIDEL PARTICIPATIONS SAS

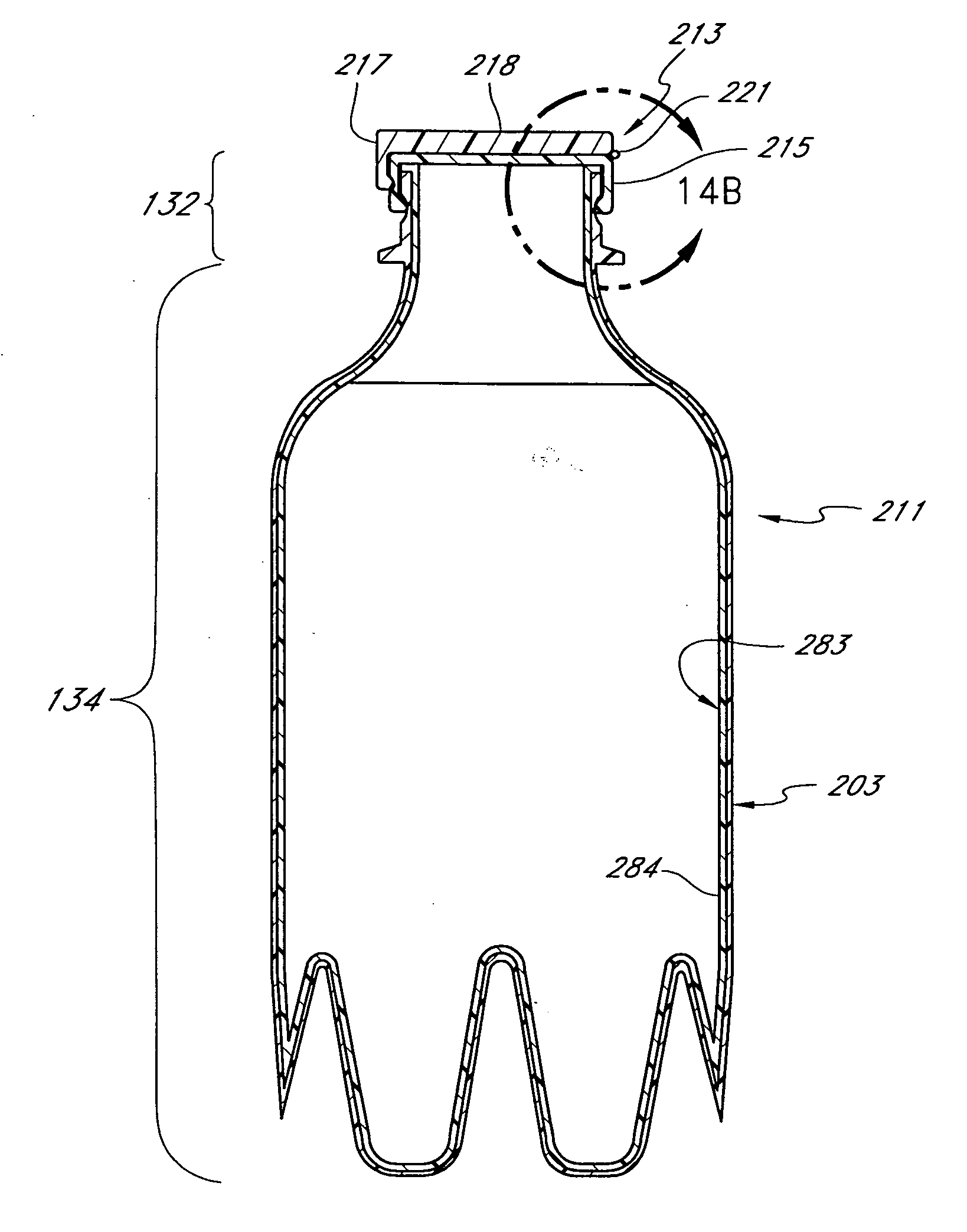

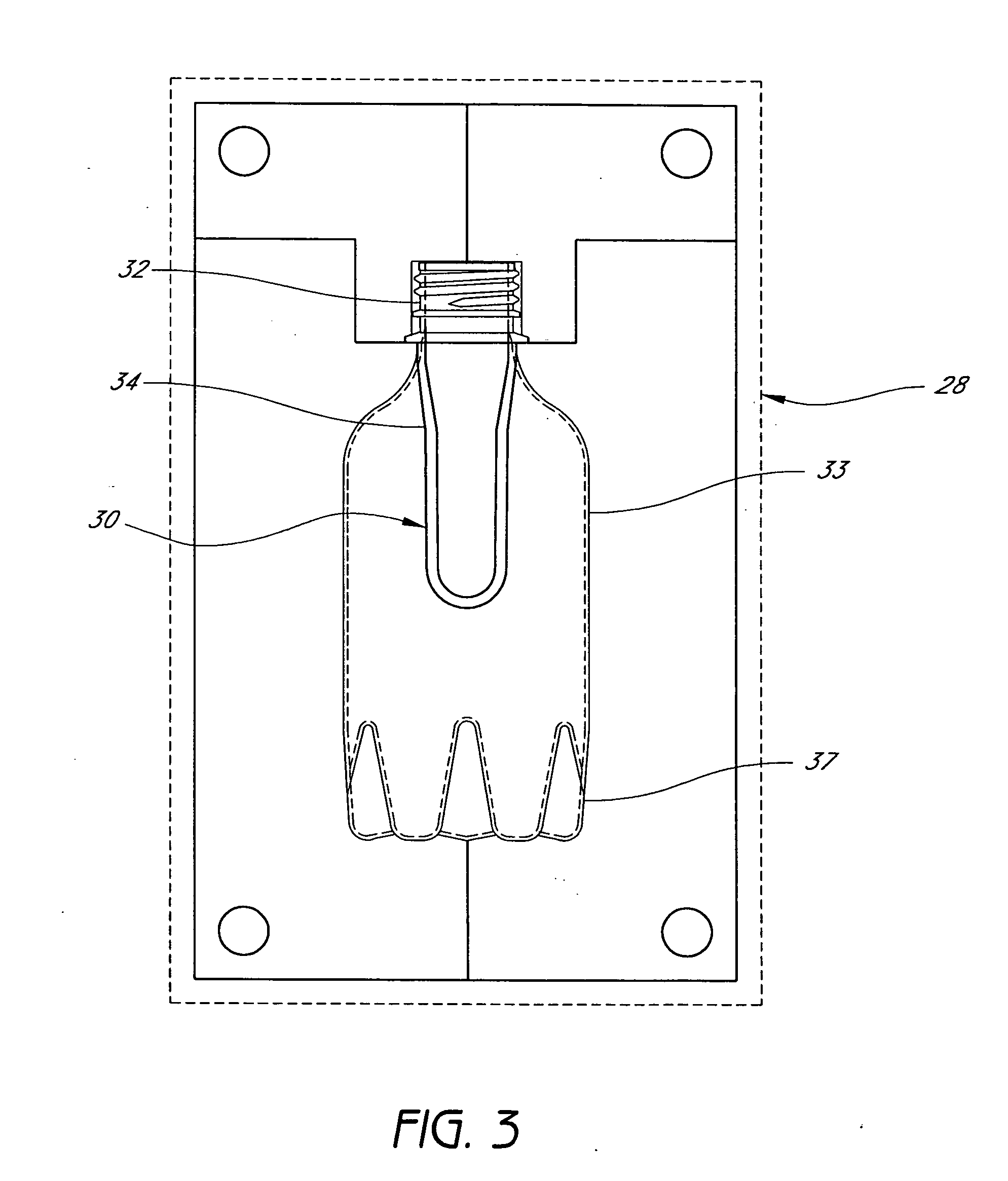

Mono and multi-layer articles and extrusion methods of making the same

InactiveUS20060073298A1Easy to processImprove melt strengthBottlesSynthetic resin layered productsThermoplasticPolyester

An extruded blow molded bottle comprises a neck portion and a body portion. The body portion comprises a first inner layer and a second layer. The first inner layer comprises a first material selected from a group consisting of polyester, phenoxy type thermoplastics, phenoxy-polyolefin thermoplastic blends, and combinations thereof. The second layer comprises a second material selected from a group consisting of virgin PET, recycled PET, PETG, foam, polypropylene, polyester, polyolefins, phenoxy type thermoplastic, phenoxy-polyolefin thermoplastic blends, regrind scrap materials, and combinations thereof. The second material is different from the first material.

Owner:PEPSICO INC +1

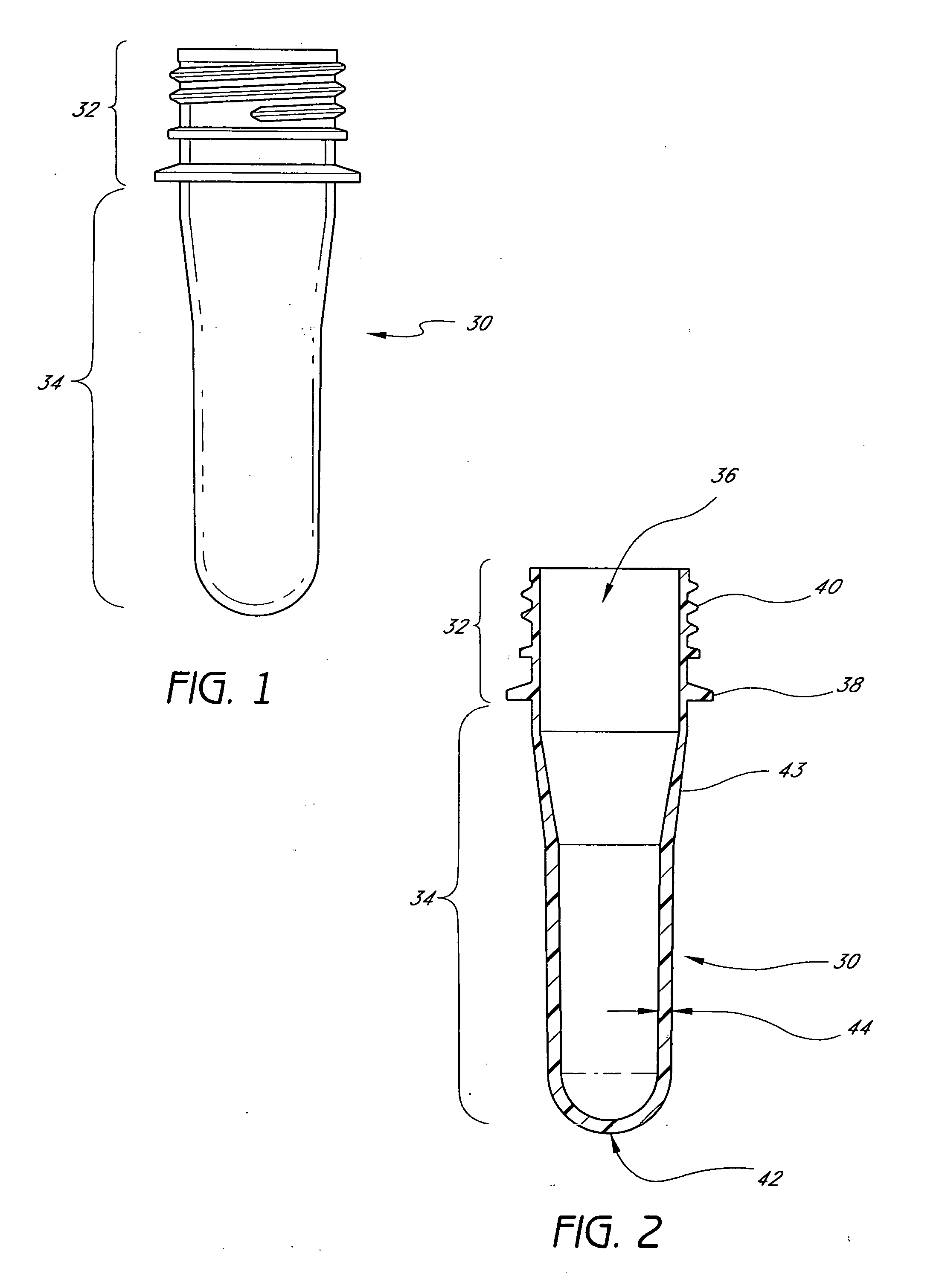

Mono and multi-layer articles and injection molding methods of making the same

ActiveUS20060073294A1Reduce heat transferInhibit transferBottlesSynthetic resin layered productsEngineering

Owner:CONCENTRATE MFG OF IRELAND +1

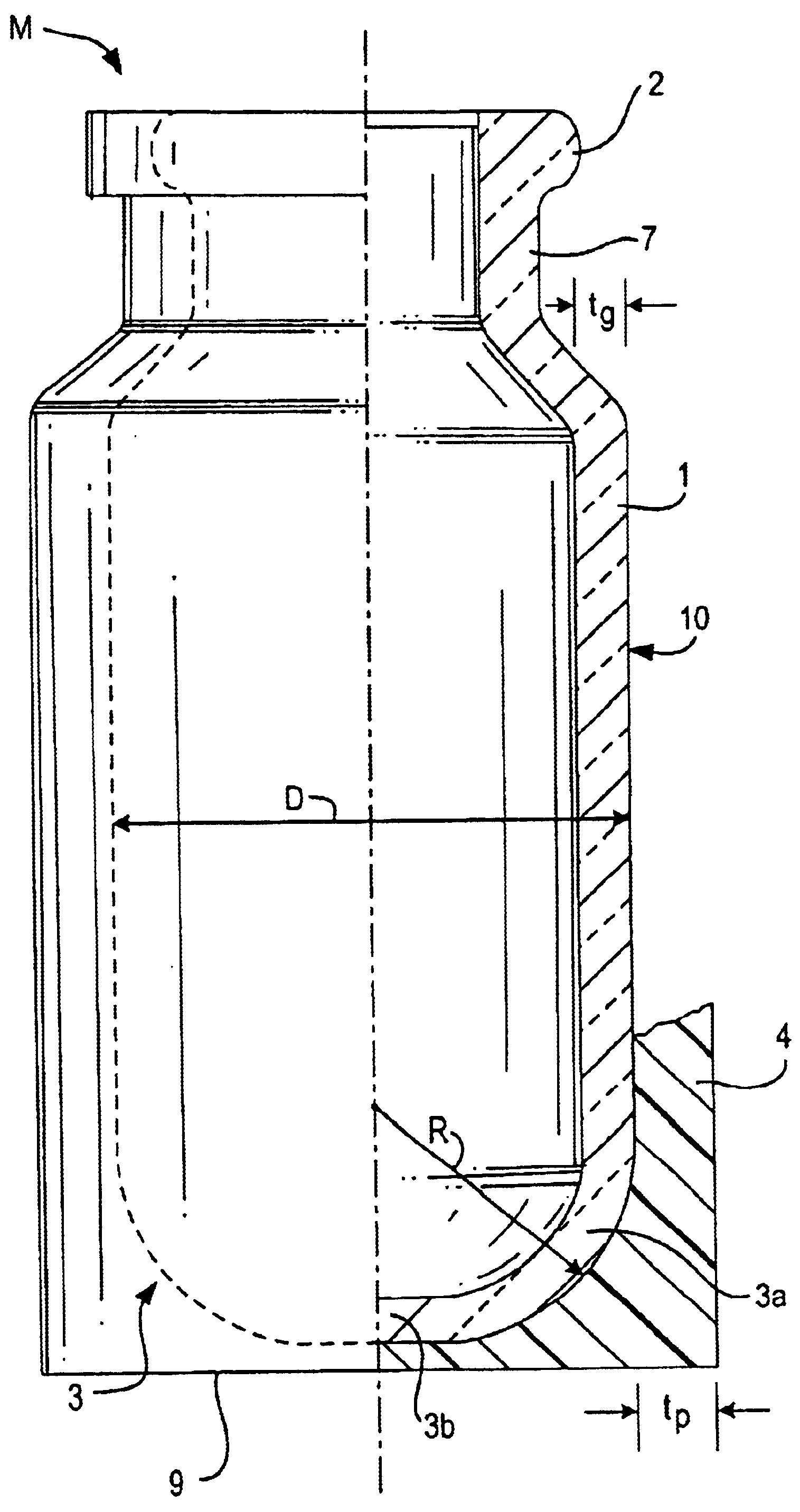

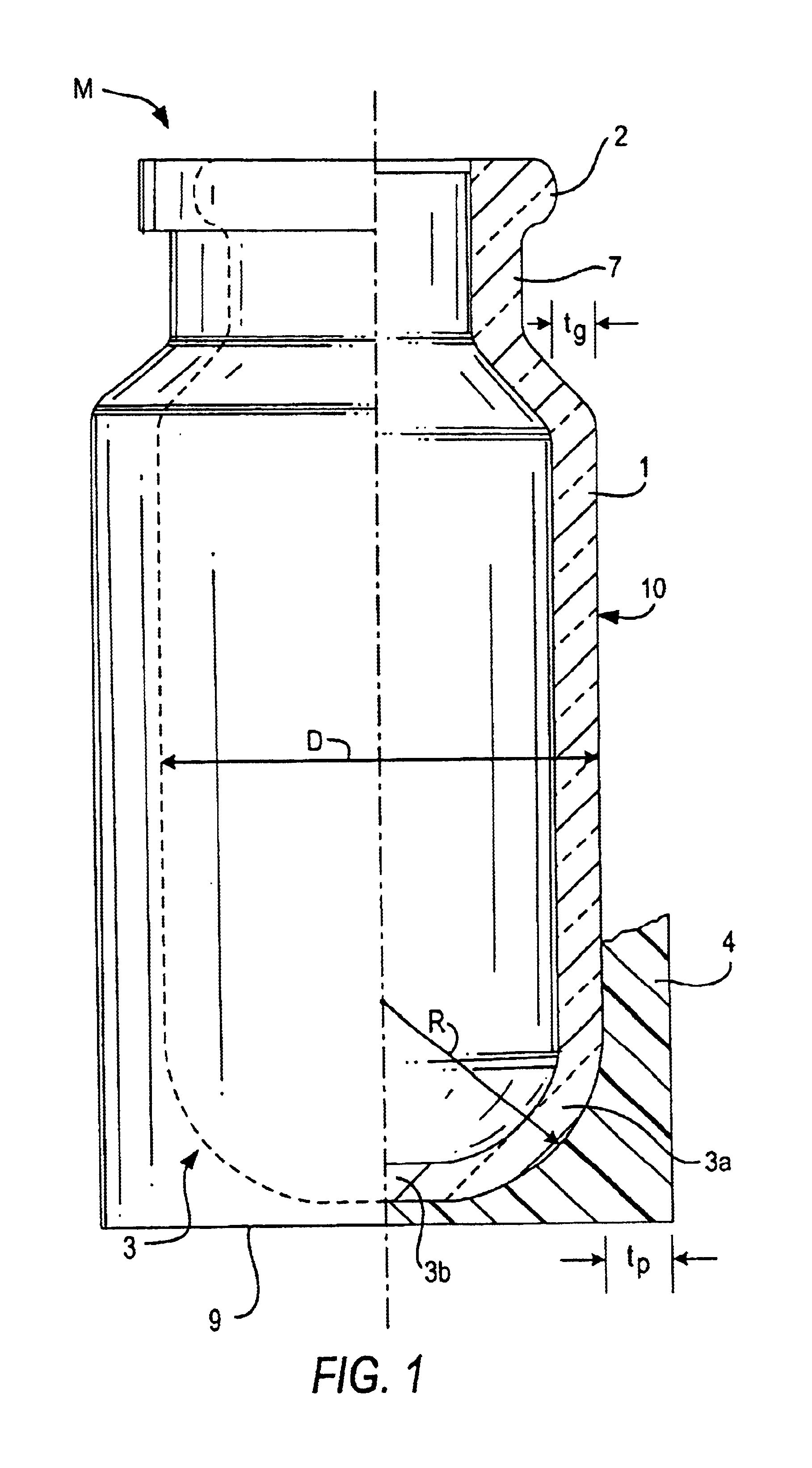

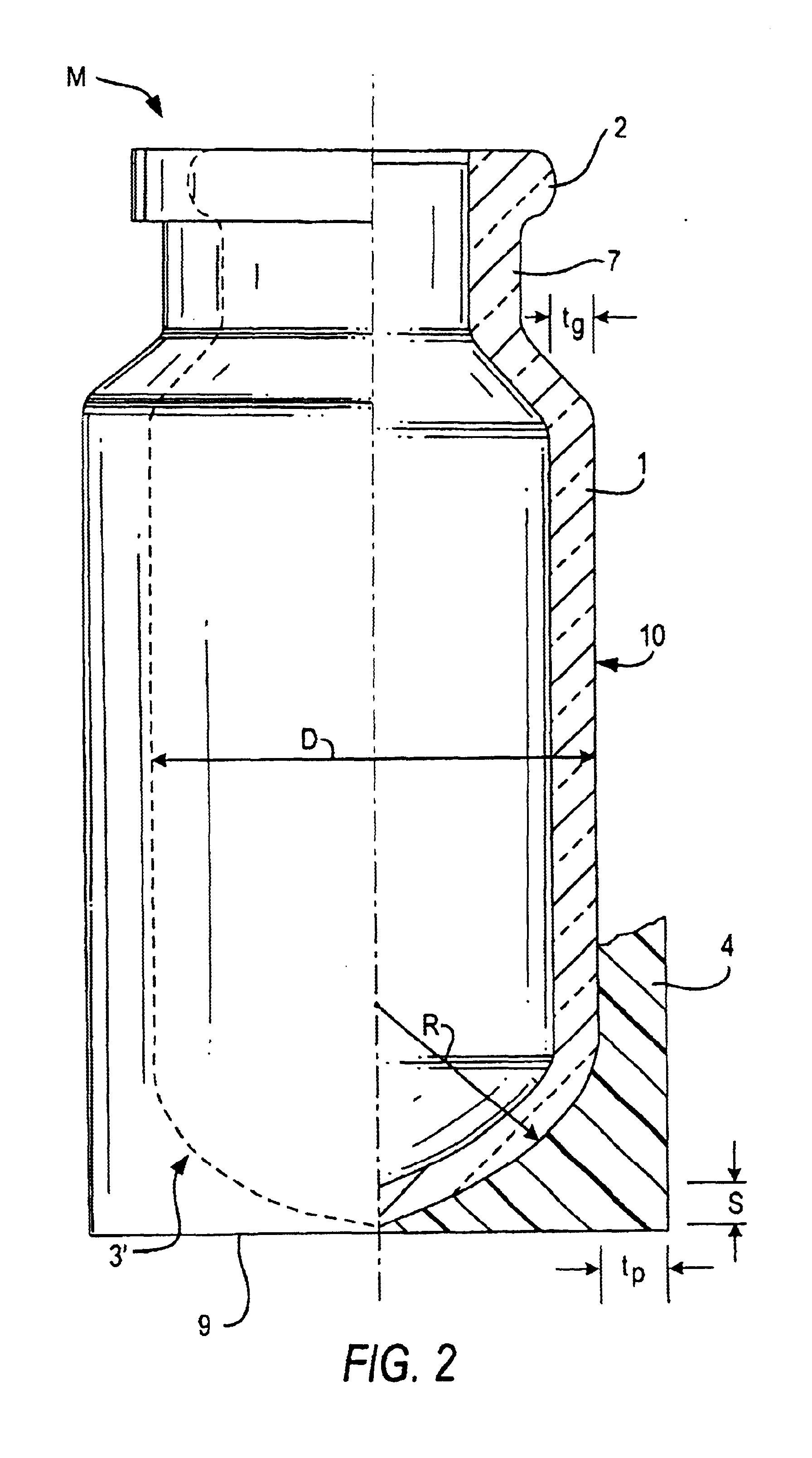

Closeable glass container comprising a plastic coating applied by injection molding and method for the production thereof

InactiveUS6866158B1Reduce wasteProduce some attenuationBottlesNon-pressured vesselsEngineeringBottle

The container is a glass bottle (10) encased with a plastic coating (4) from its base section (3) to a sealing rim (2) around its mouth (M) in order to protect against shattering or explosive failure. The glass bottle, preferably a glass inlet, is fillable under pressure with a sprayable medically active substance and a propellant and provided with a delivery element attached to the sealing rim. To facilitate lower injection molding temperatures and pressures and to permit autoclaving at high temperatures the glass bottle with the plastic coating (4) is made by a method which includes injecting at least one reactively cross-linkable plastic capable of being heat-softened into a mold surrounding the glass bottle and forming the plastic coating (4) by a reaction injection molding (RIM) method.

Owner:SCHOTT AG

Protective bottle enclosure

Owner:BOTTLEKEEPER LLC

Laminated moisture resistant poultry box and process

InactiveUS10226909B2Easily biodegradableEasy to re-pulp and recyclePackage recyclingMechanical working/deformationMechanical engineeringMoisture

A moisture resistant poultry box having a composite structure with a fluted paper medium, a top backing board assembly secured to one side of the fluted medium and a bottom backing board assembly secured to the other side of the fluted medium. The backing board assemblies and the fluted medium are impregnated with a hydrogenated triglyceride, and each backing board assembly has PET film glued thereto covering an outside surface to provide moisture resistant recyclable poultry box so that it has a Cobb value ranging between about 0 to about 1.

Owner:INDEVCO NORTH AMERICA INC

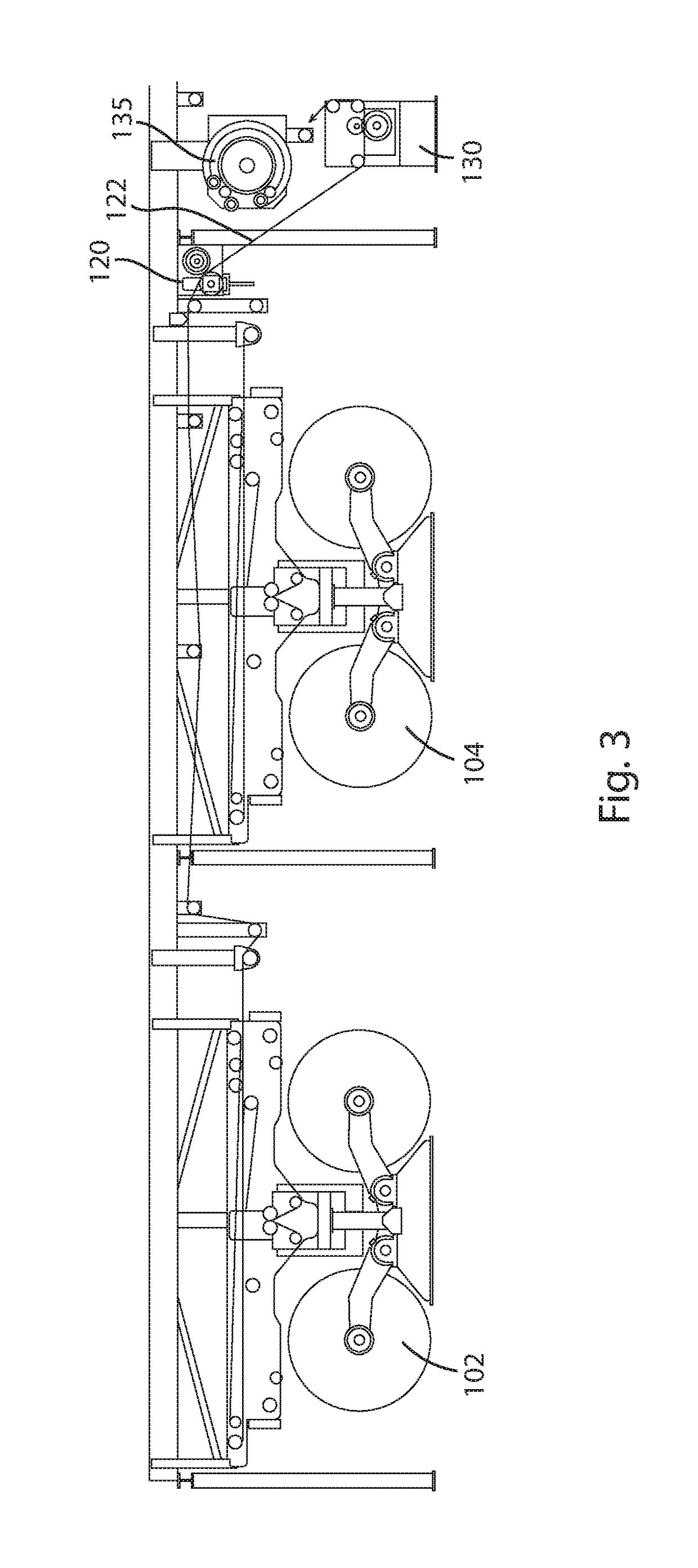

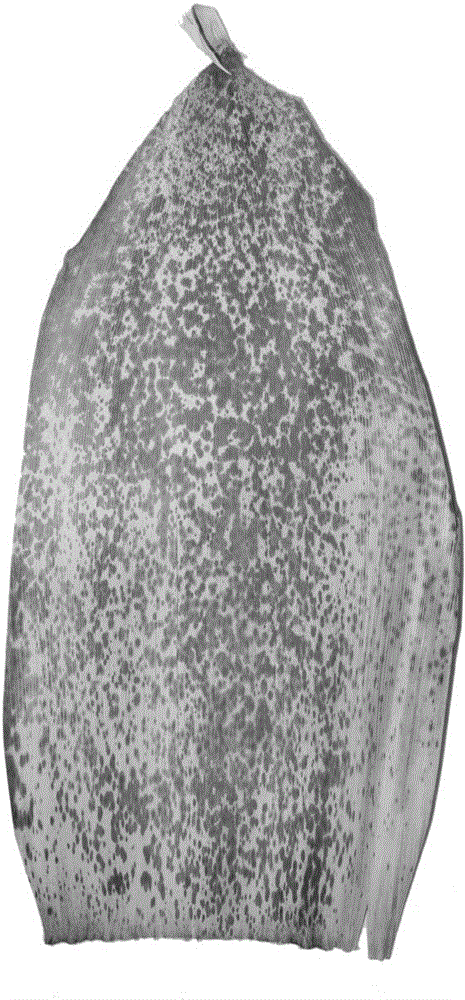

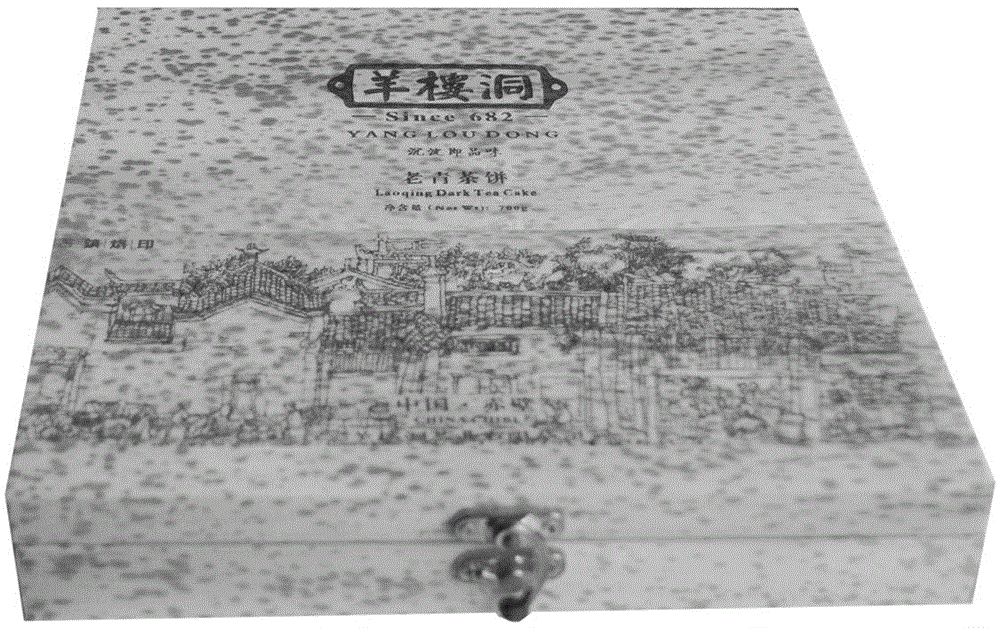

Bamboo shoot clothing packaging box and production process thereof

The invention relates to a packaging box, in particular to a bamboo shoot clothing packaging box which is formed by adopting bamboo shoot clothing (commonly called bamboo shoot shells, bamboo shells and indocalamus shells) made of moso bamboos (phyllostachys pubescens), phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys praecox, fargesia utilis, overlord bamboos and the like as raw materials (give priority to the moso bamboos) and processing through the processes of raw material purchasing and storage, rinsing, harmless treatment (insect control, mildew prevention, fiber softening, color development and mercerization), washing, drying, flattening, cutting, gluing (glue spraying or blanching and gluing), collage (blanching and collage), polishing, laser printing, inspecting, warehousing and the like. The bamboo shoot clothing packaging box has the main characteristics of moisture absorption and mildew prevention, insect control and corrosion resistance, stain repellence and scale prevention, is an ideal preferred package of tea leaves, tobaccos, food, instruments, jewelry and other products and has very extensive purpose; meanwhile, the bamboo shoot clothing packaging box is fashionable and attractive in appearance, realizes low carbon and environmental protection, is durable and fully embodies the change of wastes into valuables; moreover, a new high-quality laying and decoration material and a processing technology can be provided for the packaging industry in China.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

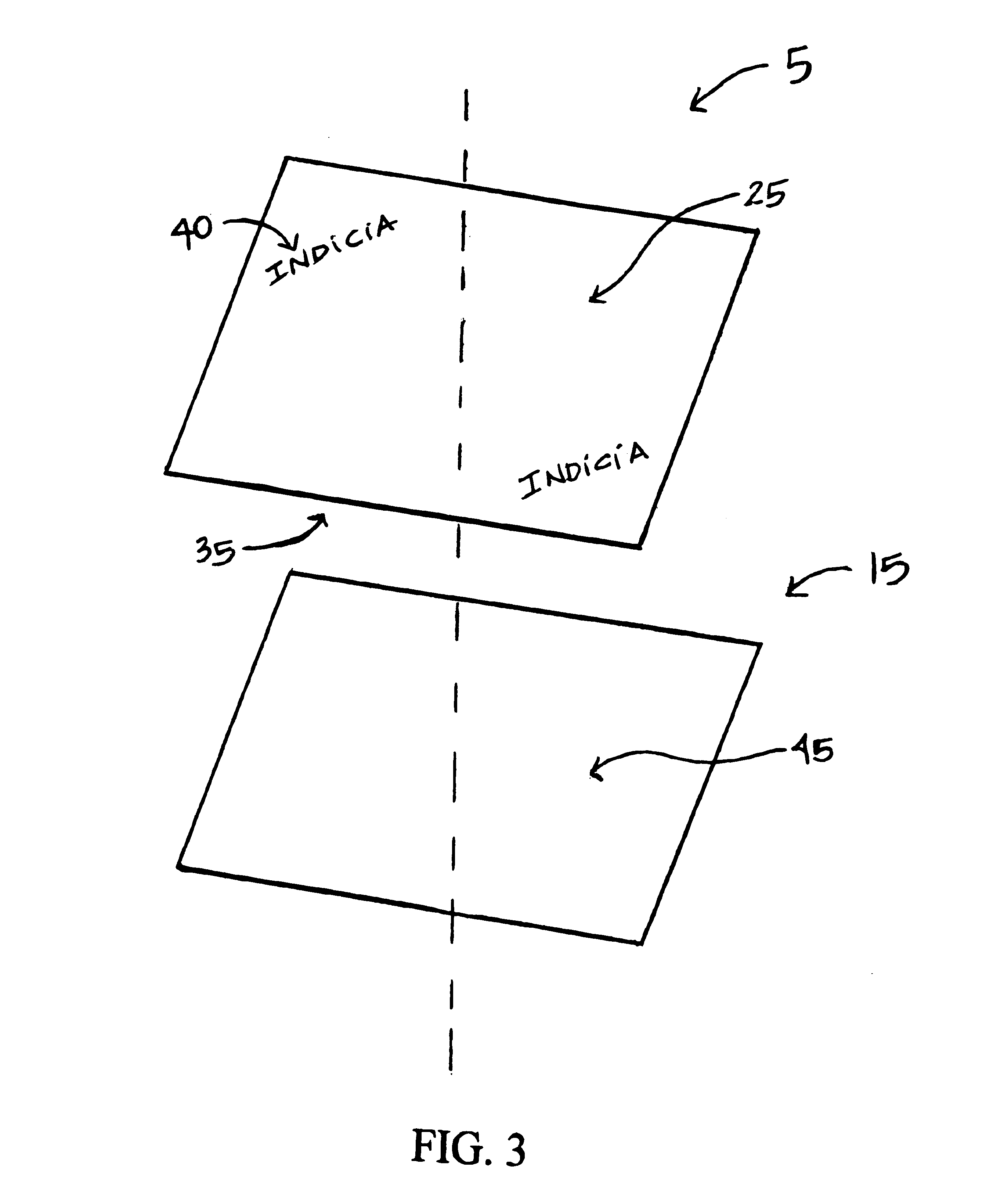

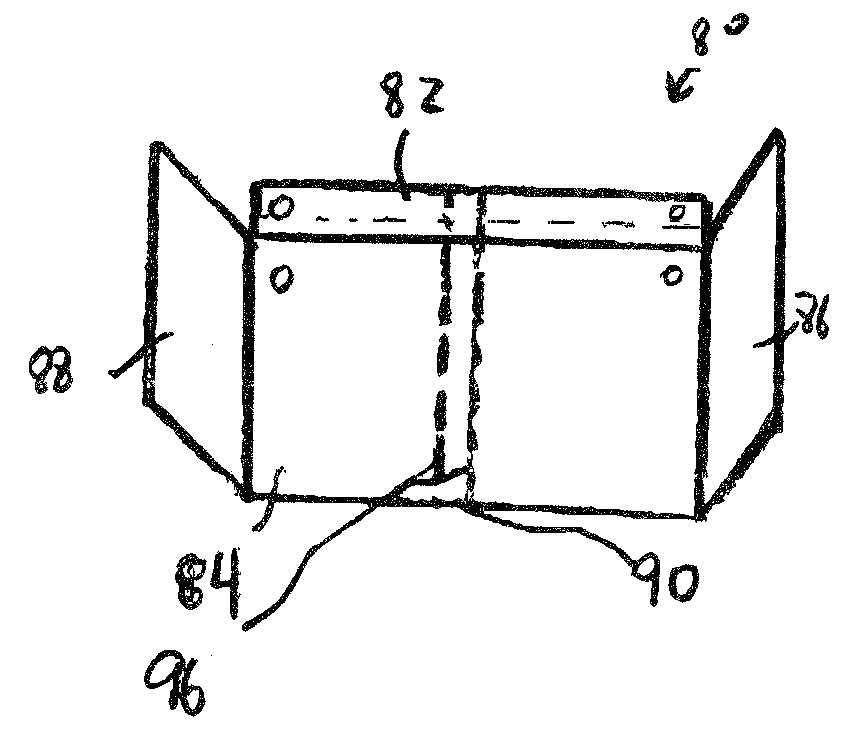

Portable presentation and display boards

ActiveUS7823309B2Easy to carryEasy to collapseWriting boardsFurniture partsDisplay boardDisplay device

Display device including a unitary, rigid sheet defining a left center panel, a right center panel pivotally connected to the left center panels, a left side panel pivotally connected to the left center panel and a right side panel pivotally connected to the right center panel. Vertically extending separation lines are formed on a rear planar layer without penetrating or cutting a front planar layer so that the panels are able to pivot about vertical axes. Fold lines may be formed opposite the separation lines on the front planar layer to facilitate folding the sheet whereby the fold lines define the vertical axes about which the panels pivot. Folding of the sheet provides a compact configuration which enables the display device to be easily carried.

Owner:ALBENDA ABRAHAM

Solvent-containing coating compositions

ActiveUS7198849B2Coating suitableGood chemical resistanceFlexible coversLiquid surface applicatorsEndcappingCopolyester

A solvent-containing coating composition contains at least one hydroxyl-containing saturated copolyester, a phenol-formaldehyde resin, a benzoguanamine-formaldehyde resin and / or a blocked polyisocyanate, a catalyst and at least one solvent, and can further contain aids and additives.

Owner:EVONIK OPERATIONS GMBH

Container, such as a food or beverage container, lubrication method

A process for lubricating a container, such as a beverage container, or a conveyor for containers, by applying to the container or conveyor, a thin continuous, substantially non-dripping layer of a liquid lubricant. The process provides many advantages compared to the use of a conventional dilute aqueous lubricant.

Owner:ECOLAB USA INC

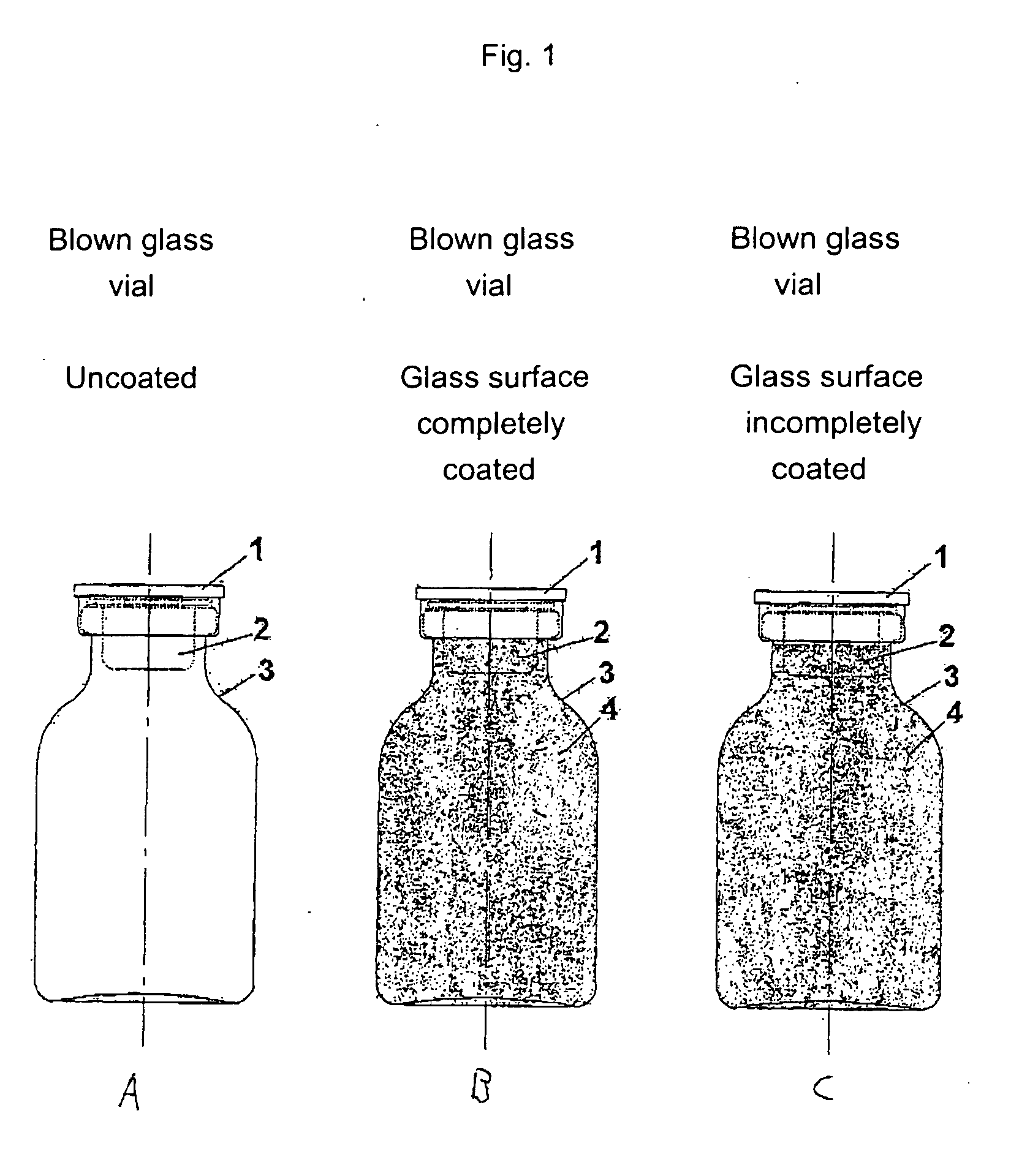

Safety containers for biologically active substances and method for producing said container

InactiveUS20070010700A1Increased and high fracture strengthSimple and rapid to carry-outClosure capsCoverings/external coatingsHigh fractureUltimate tensile strength

The invention relates to safety containers for biologically active substances, in particular cytostatic agents, said container having increased or higher fracture strength and shatterproof qualities, in addition to an uncontaminated exterior. The invention also relates to a method for producing said containers and to the use of a medium containing at least one polymer for decontaminating the exterior of a container that is filled with a biologically active substance, sealed and optionally labelled.

Owner:BAXTER INT INC +1

Glass containers with delamination resistance and improved damage tolerance

The glass containers described herein have at least two performance attributes selected from resistance to delamination, improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. A tenacious inorganic coating may be positioned around at least a portion of the outer surface of the body. The outer surface of the body with the tenacious inorganic coating may have a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Solvent-containing coating compositions

ActiveUS20050014012A1Coating suitableExcellent sterilization stabilityLiquid surface applicatorsFlexible coversCopolyesterSolvent

A solvent-containing coating composition contains at least one hydroxyl-containing saturated copolyester, a phenol-formaldehyde resin, a benzoguanamine-formaldehyde resin and / or a blocked polyisocyanate, a catalyst and at least one solvent, and can further contain aids and additives.

Owner:EVONIK OPERATIONS GMBH

Strengthened borosilicate glass containers with improved damage tolerance

According to one embodiment, a glass container may include a body formed from a Type I, Class B glass composition according to ASTM Standard E438-92. The body may have an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. The body may also include a compressively stressed layer extending into the wall thickness from at least one of the outer surface and the inner surface. A lubricous coating may be positioned on at least a portion of the outer surface of the body, wherein the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Container with a one-piece body

A container body, comprising a single fiber structure molded into the container body having an integral bottom portion and an integral side portion; an open cavity defined by the bottom portion and the side portion; and the side portion being perpendicular to the bottom portion such that a rectangular label is mountable to the side portion without creases.

Owner:U S SMOKELESS TOBACCO COMPANY LLC

Foldable container having flat profile

InactiveUS6491164B1Easy constructionMinimal spaceOther accessoriesCoverings/external coatingsEngineeringMechanical engineering

Owner:VLASSER LLC

Glass Articles With Low-Friction Coatings

ActiveUS20130224407A1Glass/slag layered productsPreformed elementsChemical compositionVitreous Bodies

Low-friction coatings and glass articles with low-friction coatings are disclosed. According to one embodiment, a coated glass article may include a glass body comprising a first surface and a low-friction coating positioned on at least a portion of the first surface of the glass body. The low-friction coating may include a polymer chemical composition. The coated glass article may be thermally stable at a temperature of at least about 260° C. for 30 minutes. A light transmission through the coated glass article may be greater than or equal to about 55% of a light transmission through an uncoated glass article for wavelengths from about 400 nm to about 700 nm. The low-friction coating may have a mass loss of less than about 5% of its mass when heated from a temperature of 150° C. to 350° C. at a ramp rate of about 10° C. / minute.

Owner:CORNING INC

Combination adjustable diameter drinking vessel sleeve and recyclable beverage coaster

Owner:RODRIGUEZ ALBERT

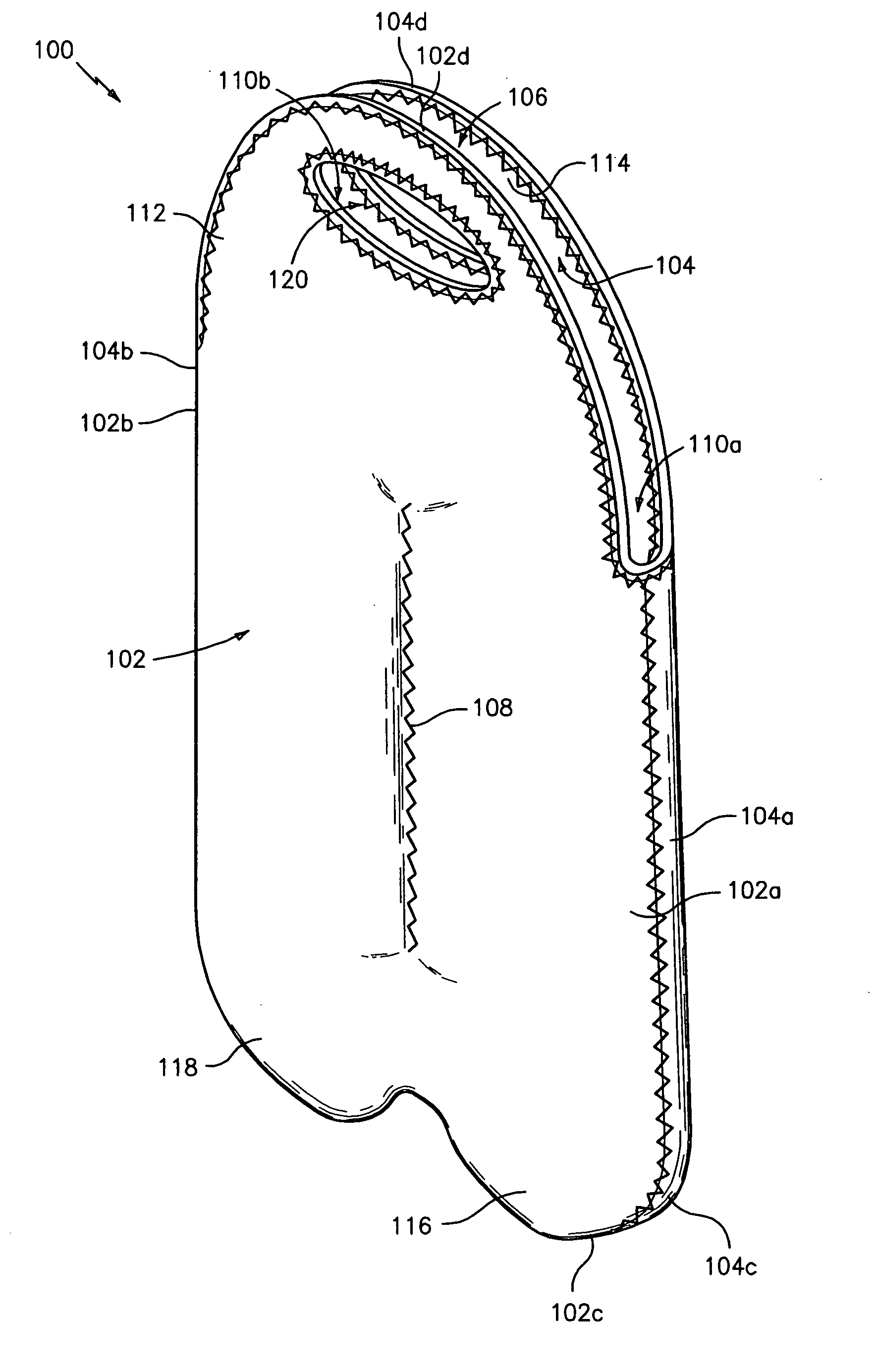

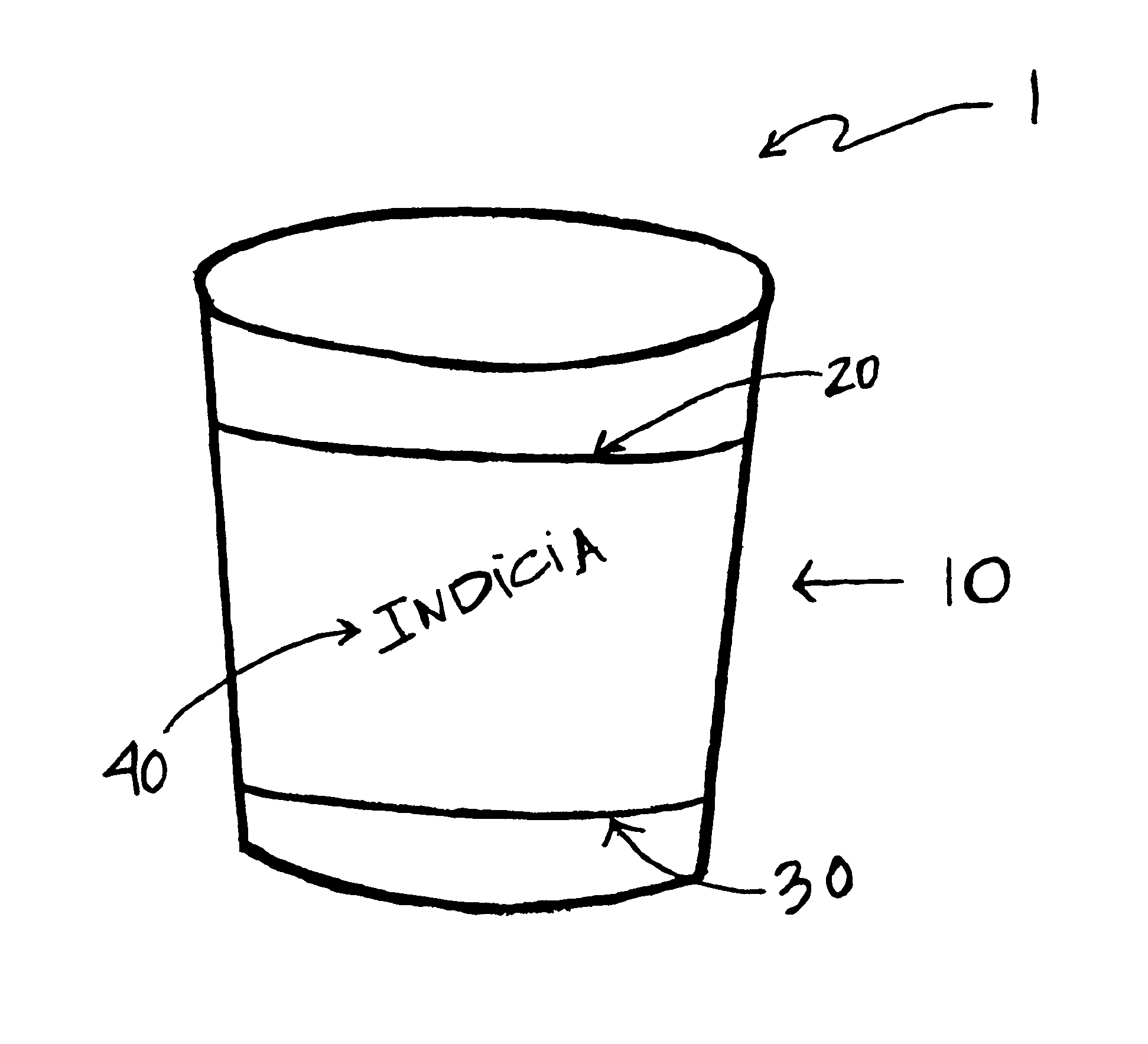

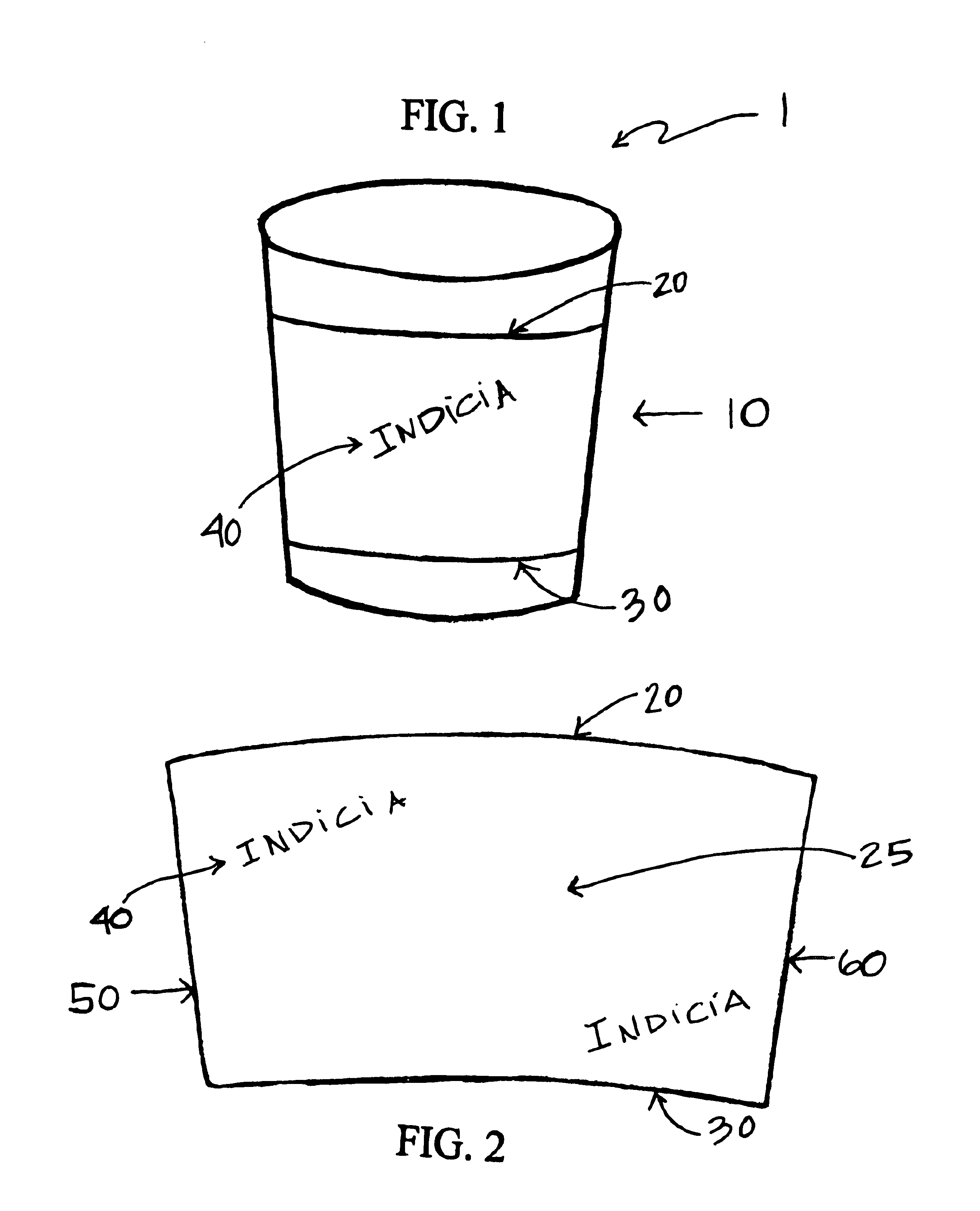

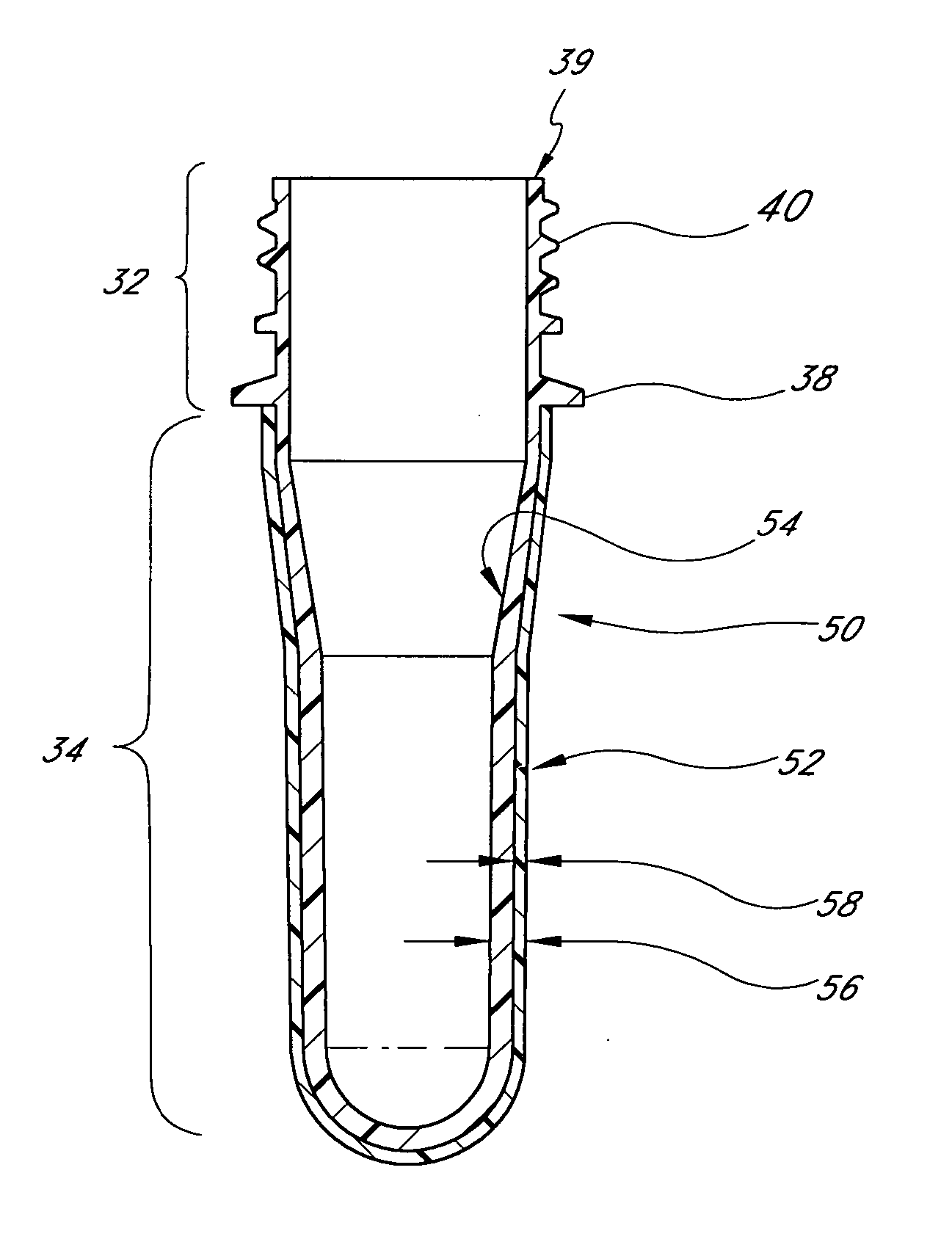

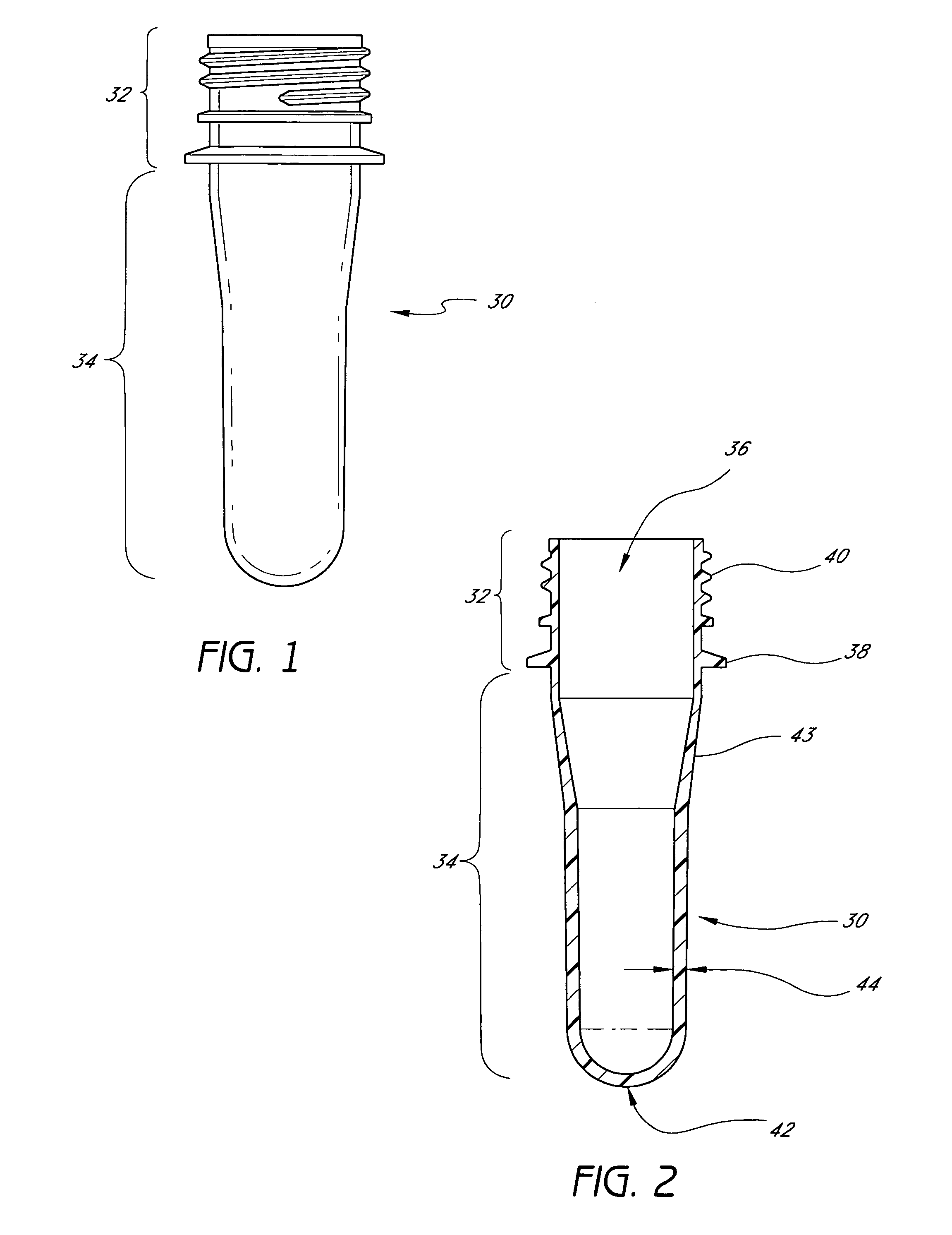

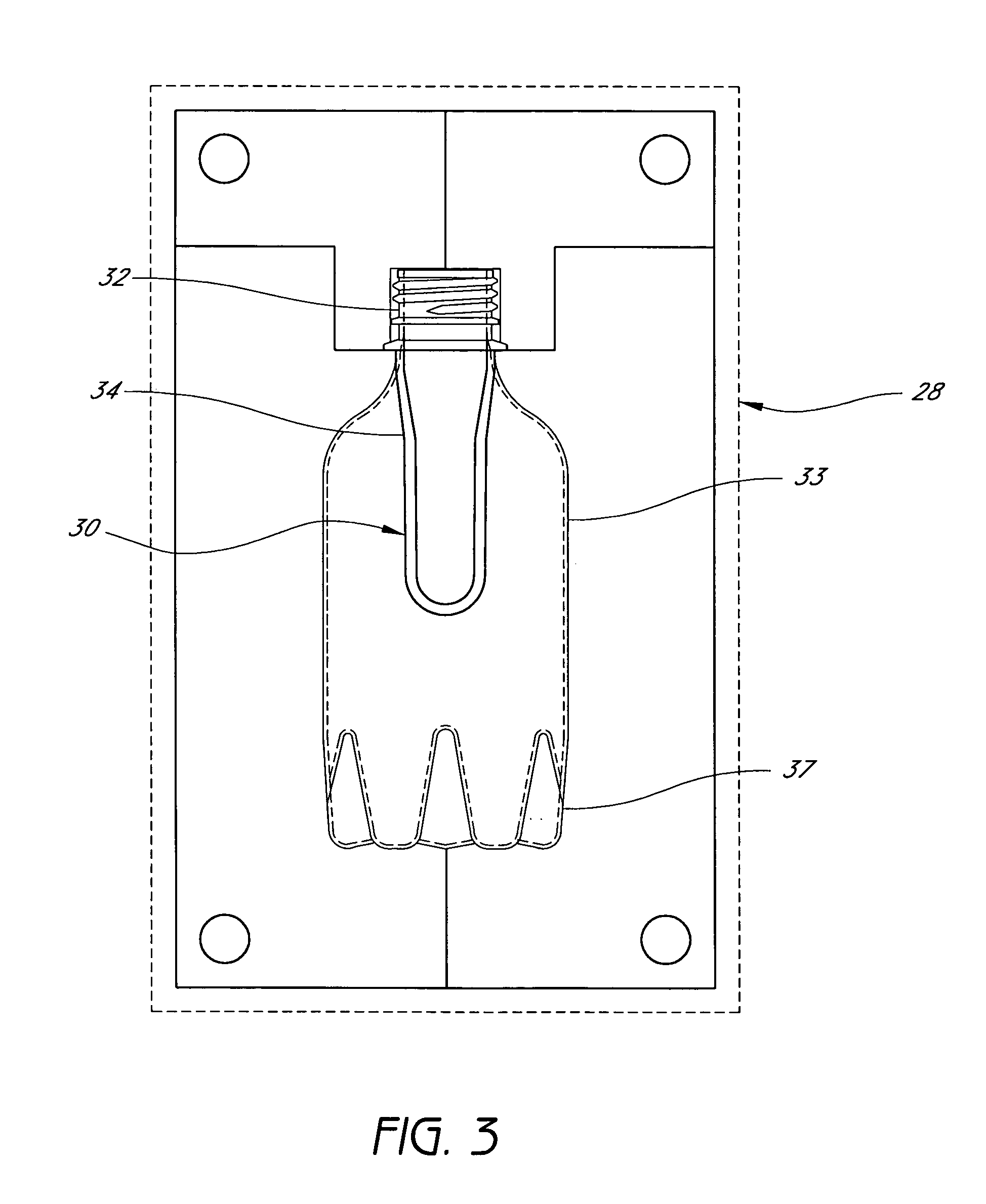

Insulating beverage container holder

InactiveUS7337915B1Maintain temperatureEasy to insertDomestic cooling apparatusLighting and heating apparatusSupport surfaceFlange

A holder for a beverage container wherein the insulating sleeve includes internal ribs proximate to the top and bottom for gripping the container. An inwardly extending flange at the bottom of the sleeve is provided with a plurality of suction cups for stable affixation to a support surface.

Owner:WELDON DANIEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com