Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5197results about "Cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

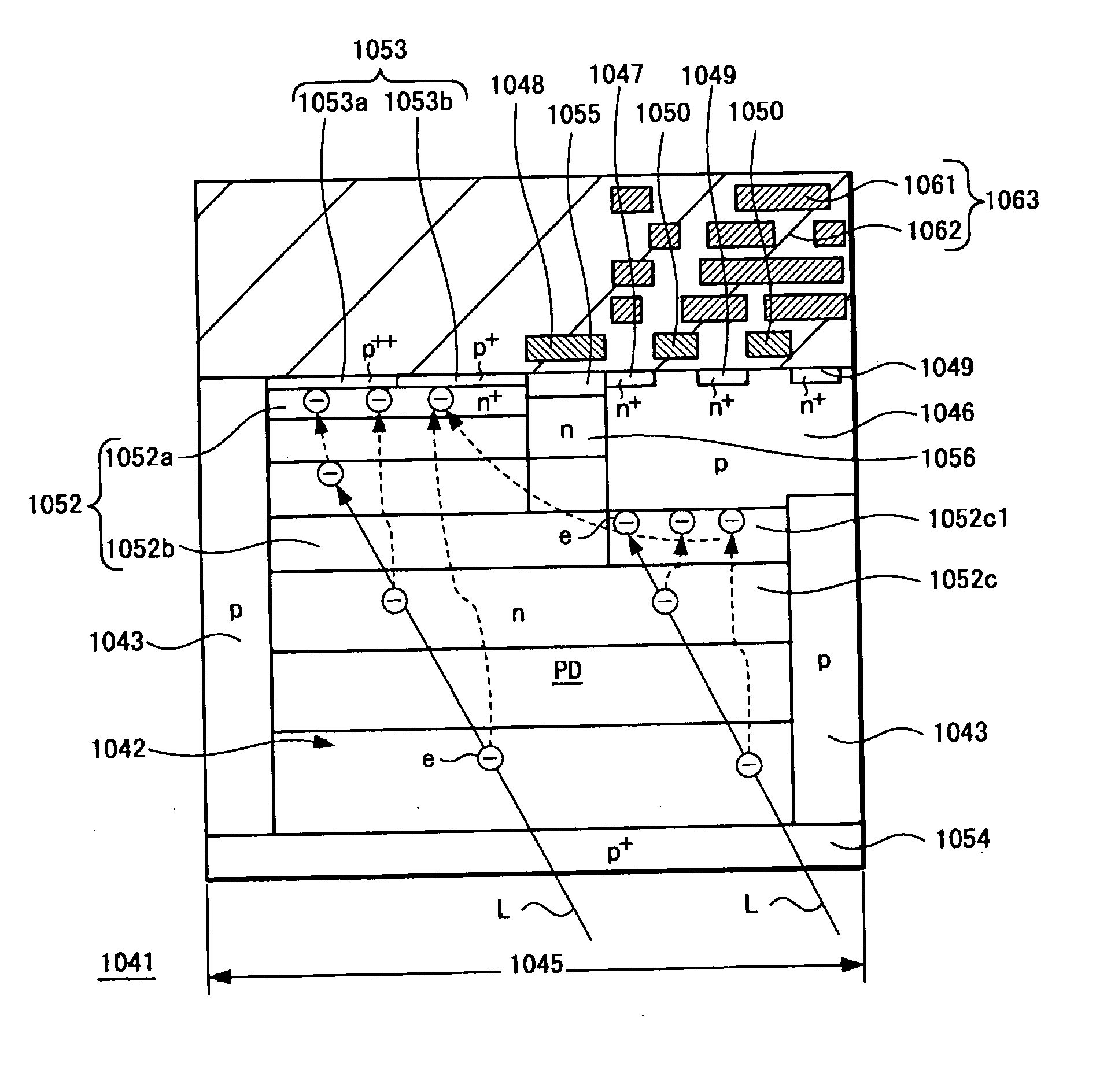

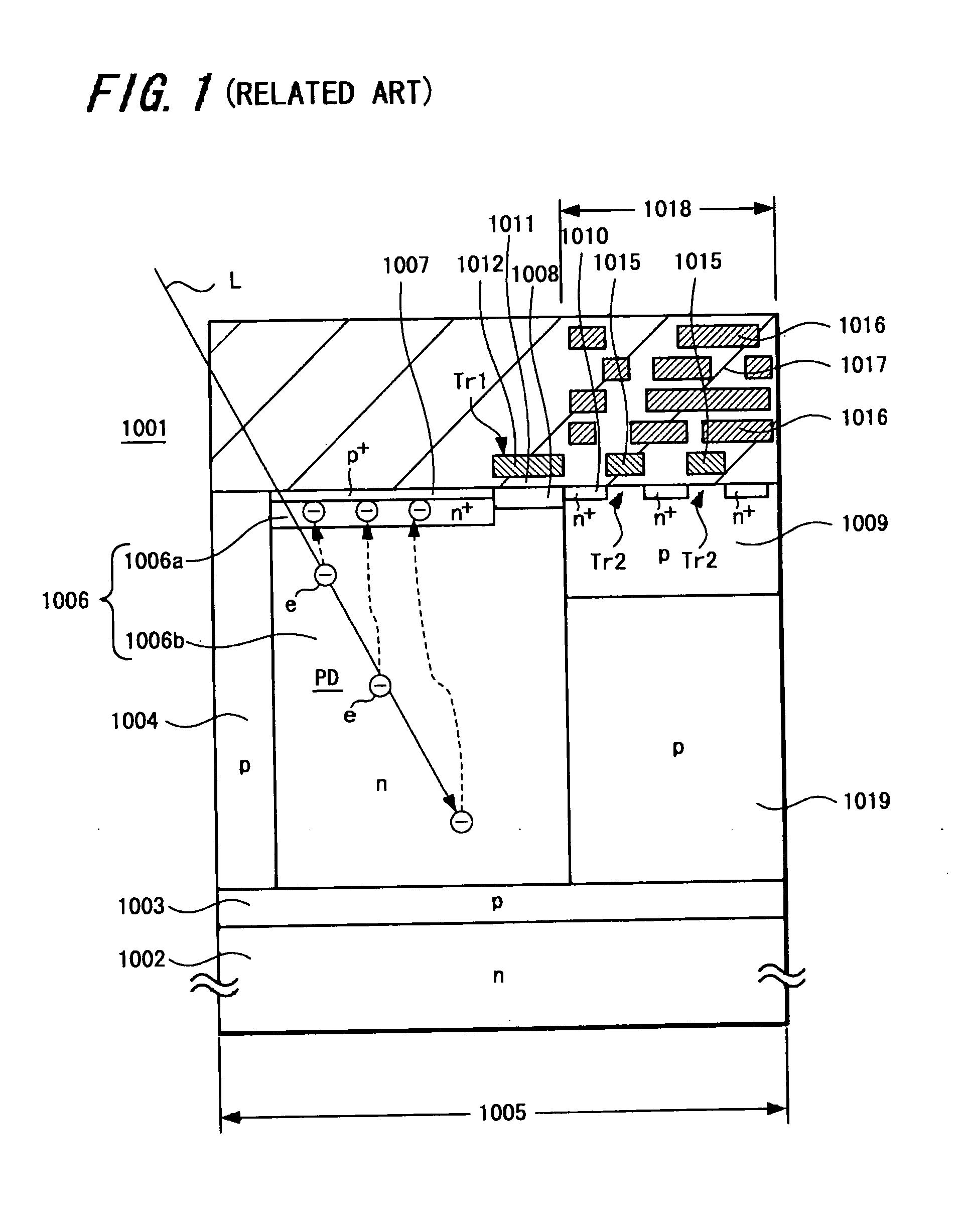

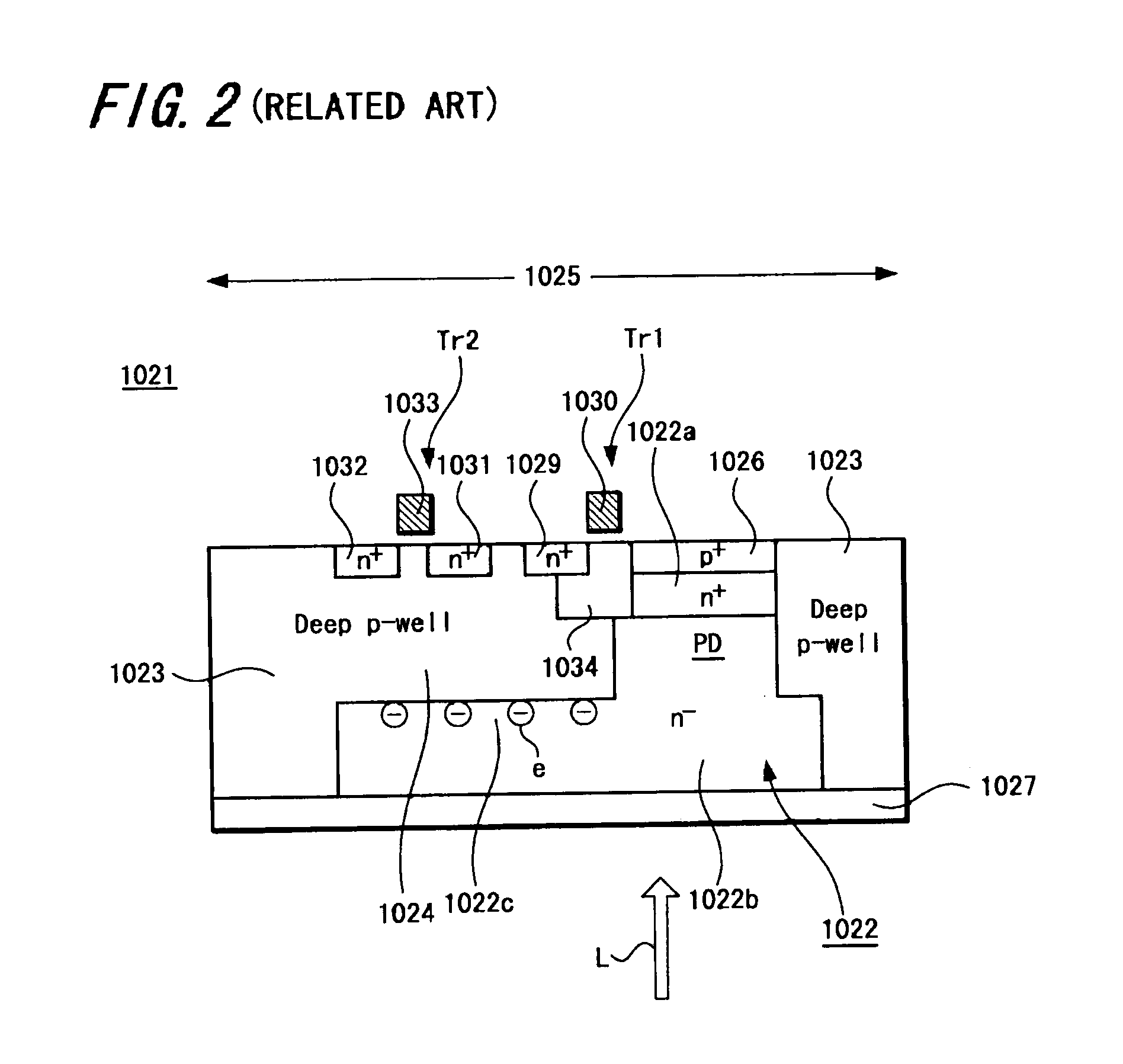

Solid-state image pickup device, electronic apparatus using such solid-state image pickup device and method of manufacturing solid-state image pickup device

ActiveUS20060197007A1Reduce the amount requiredReduce sensitivityConveyorsCleaningEngineeringElectron

A back-illuminated type solid-state image pickup device (1041) includes read circuits (Tr1, Tr2) formed on one surface of a semiconductor substrate (1042) to read a signal from a photo-electric conversion element (PD) formed on the semiconductor substrate (1042), in which electric charges (e) generated in a photo-electric conversion region (1052c1) formed under at least one portion of the read circuits (Tr1, Tr2) are collected to an electric charge accumulation region (1052a) formed on one surface side of the semiconductor substrate (1042) of the photo-electric conversion element (PD) by electric field formed within the photo-electric conversion element (PD). Thus, the solid-state image pickup device and the camera are able to make the size of pixel become very small without lowering a saturation electric charge amount (Qs) and sensitivity.

Owner:SONY CORP

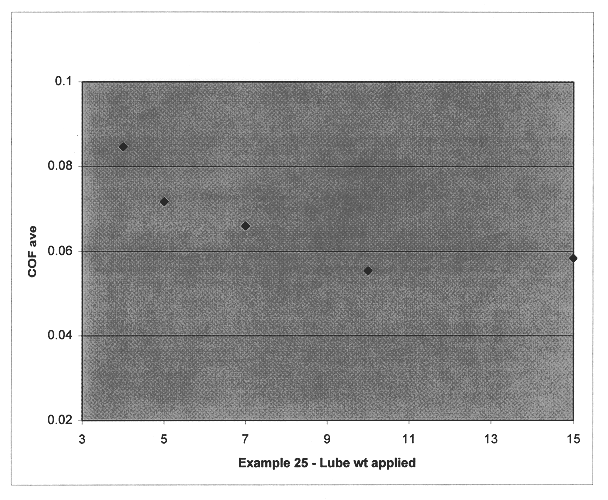

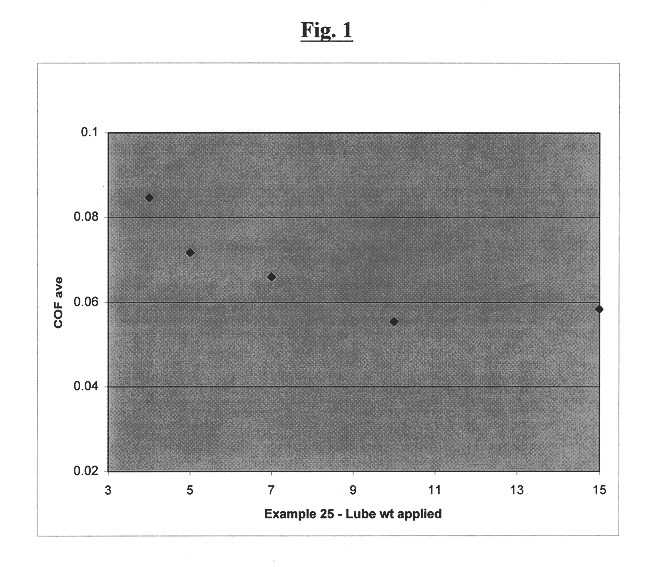

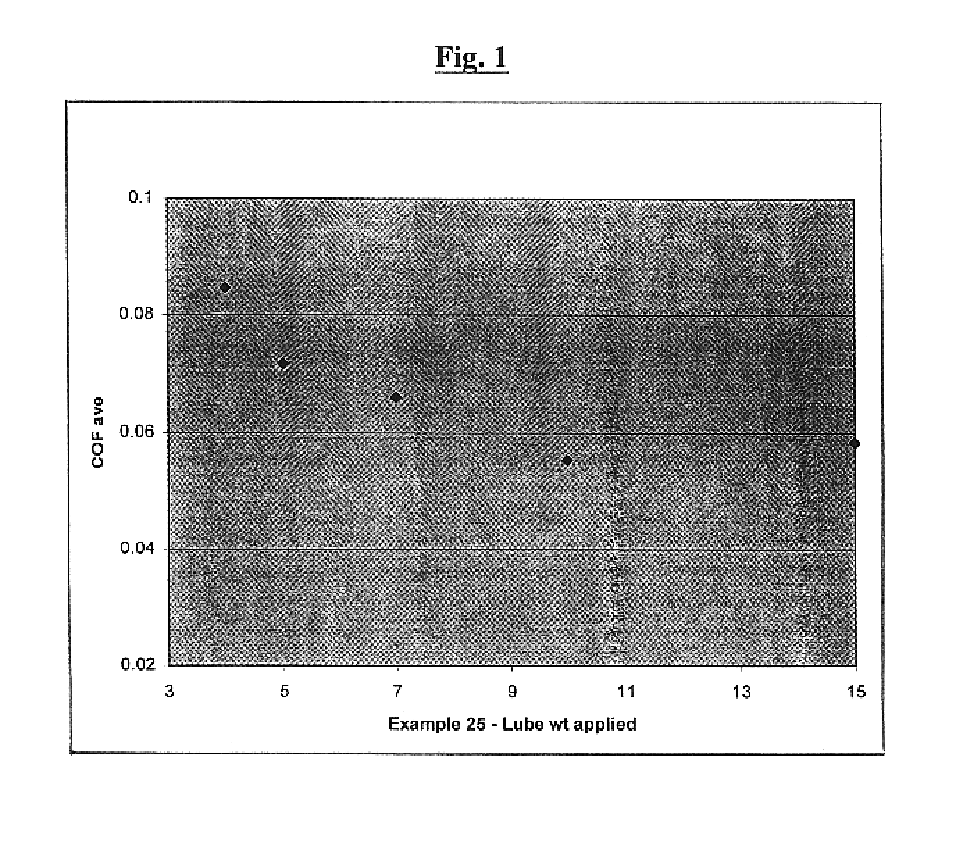

Container, such as a food or beverage container, lubrication method

A process for lubricating a container, such as a beverage container, or a conveyor for containers, by applying to the container or conveyor, a thin continuous, substantially non-dripping layer of a liquid lubricant. The process provides many advantages compared to the use of a conventional dilute aqueous lubricant.

Owner:ECOLAB USA INC

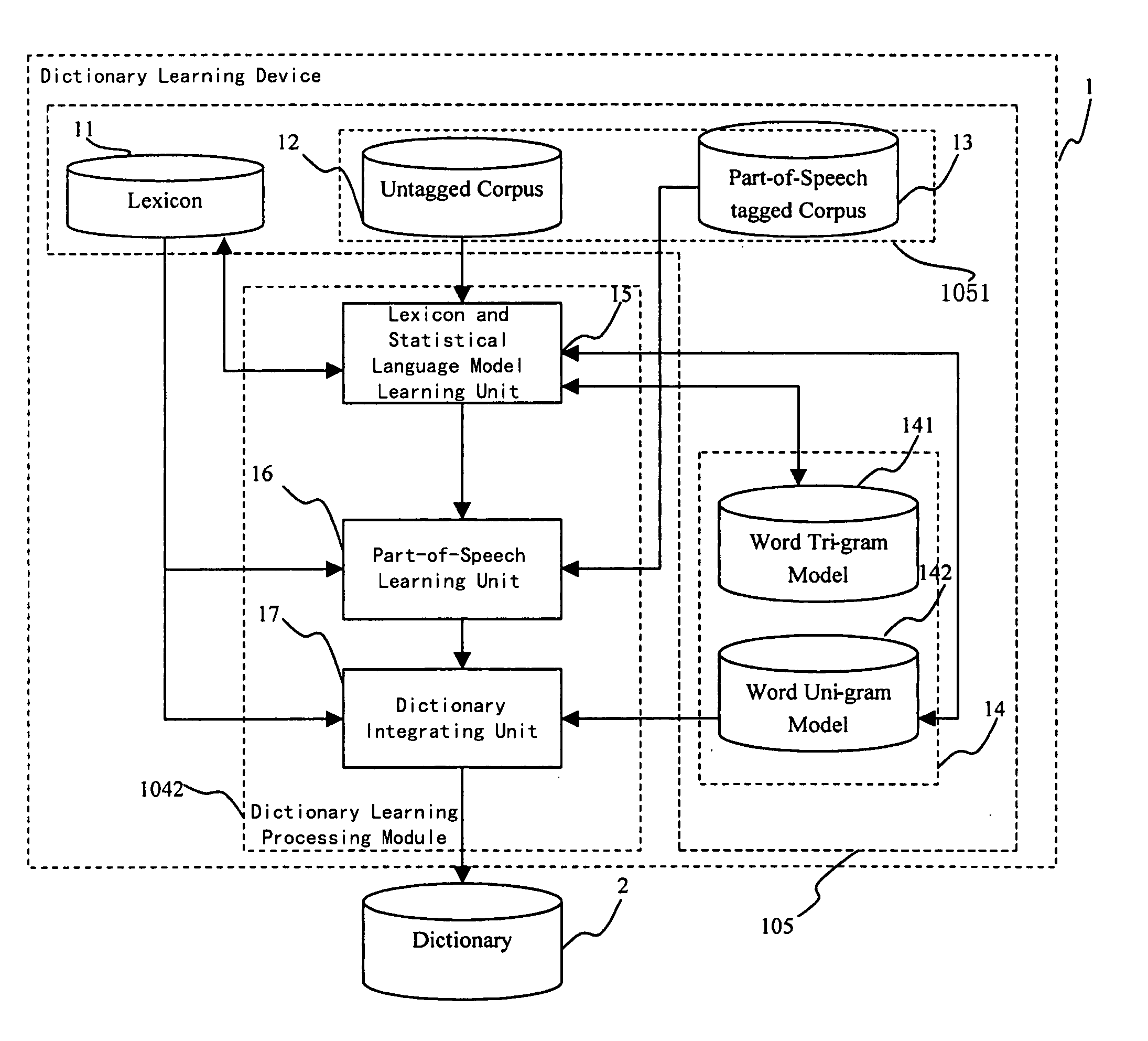

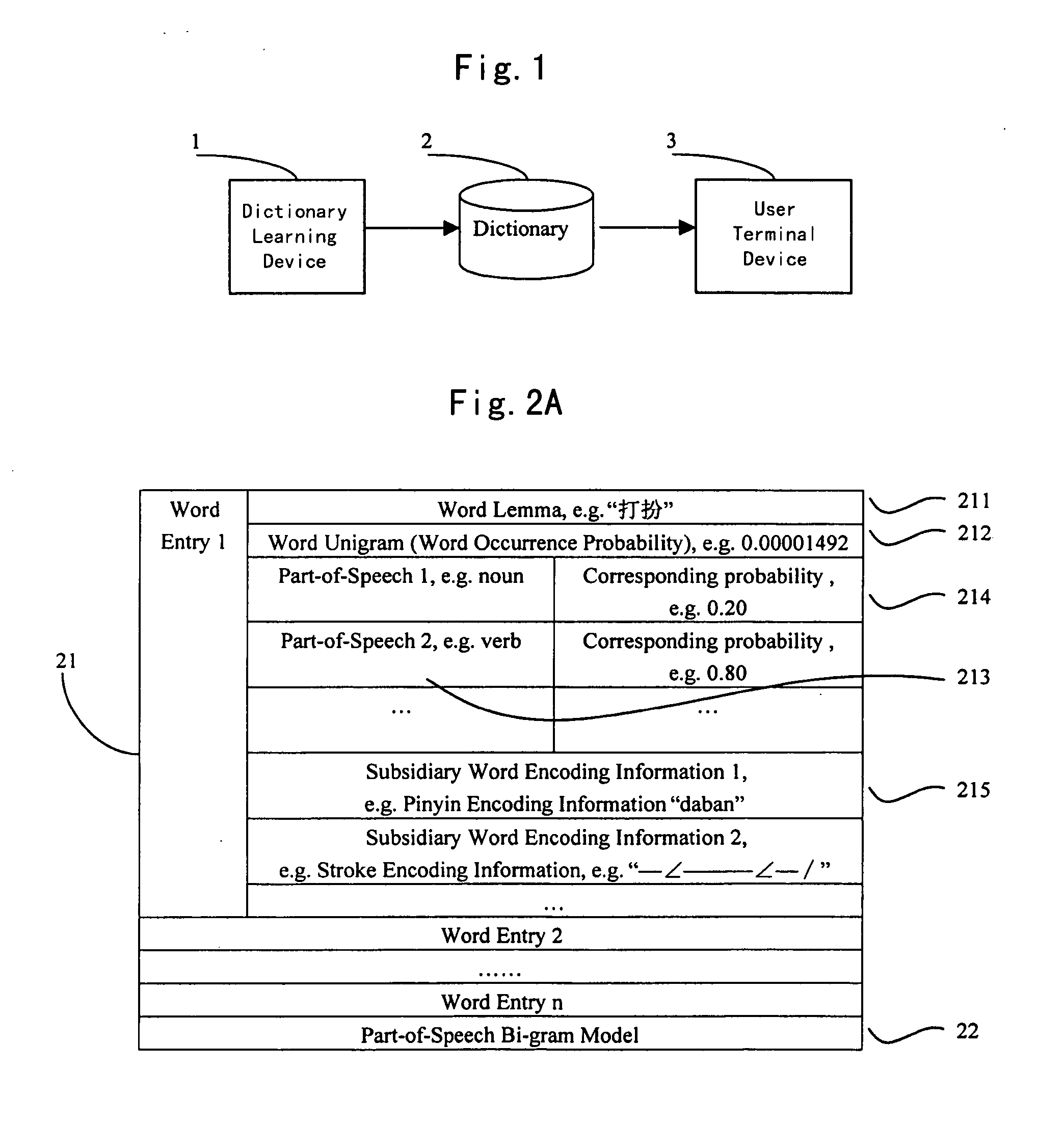

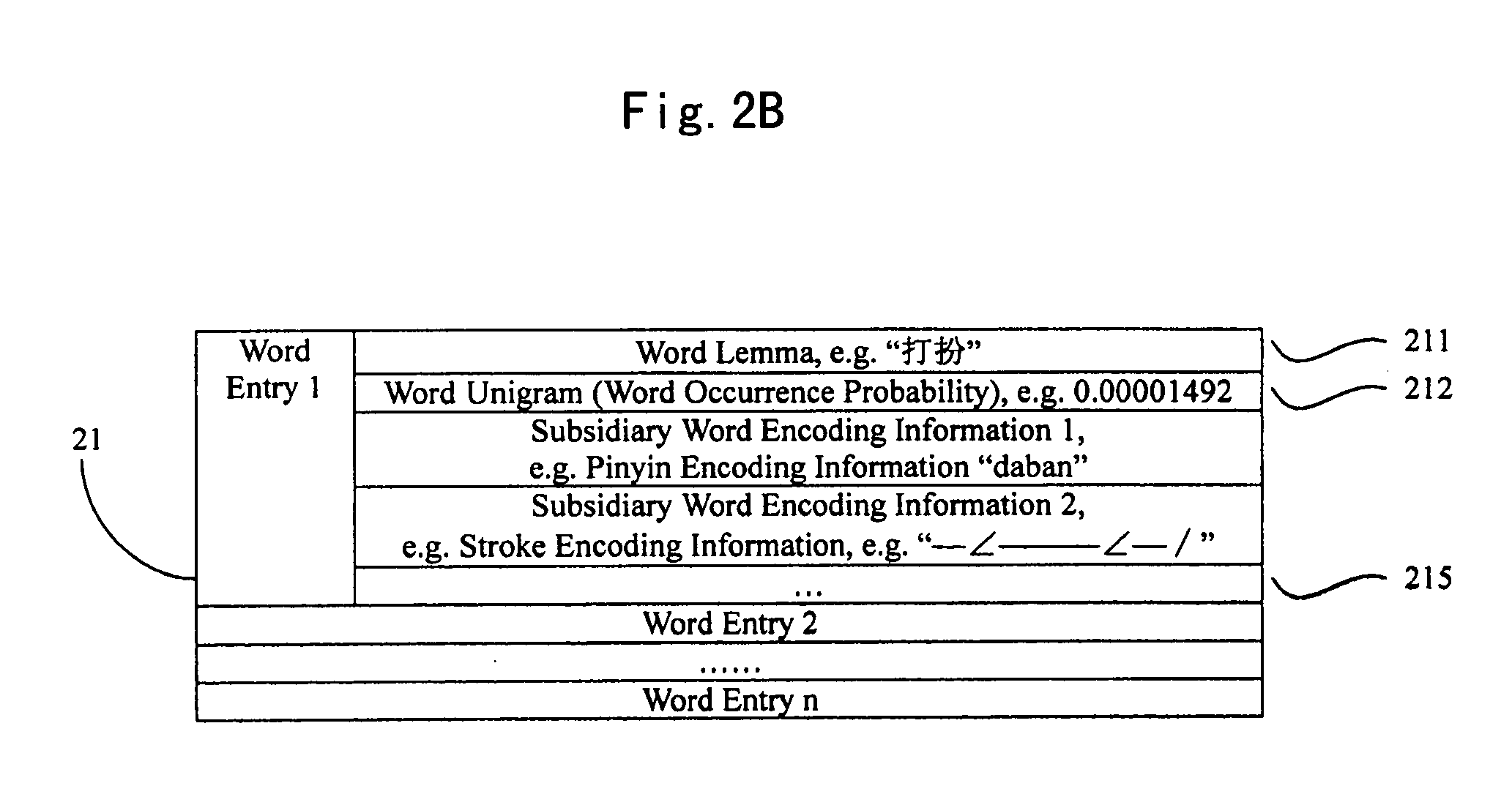

Dictionary learning method and device using the same, input method and user terminal device using the same

InactiveUS20060206313A1Increase typing speedSmall sizeConveyorsCleaningDictionary learningPart of speech

This invention provides a dictionary learning method, said method comprising the steps of: learning a lexicon and a Statistical Language Model from an untagged corpus; integrating the lexicon, the Statistical Language Mode and subsidiary word encoding information into a small size dictionary. And this invention also provides an input method on a user terminal device using the dictionary with Part-of-Speech information and a Part-of-Speech Bi-gram Model added, and a user terminal device using the same. Therefore, sentence level prediction and word level prediction can be given by the user terminal device and the input is speeded up by using the dictionary which is searched by a Patricia Tree index of a dictionary index.

Owner:NEC (CHINA) CO LTD

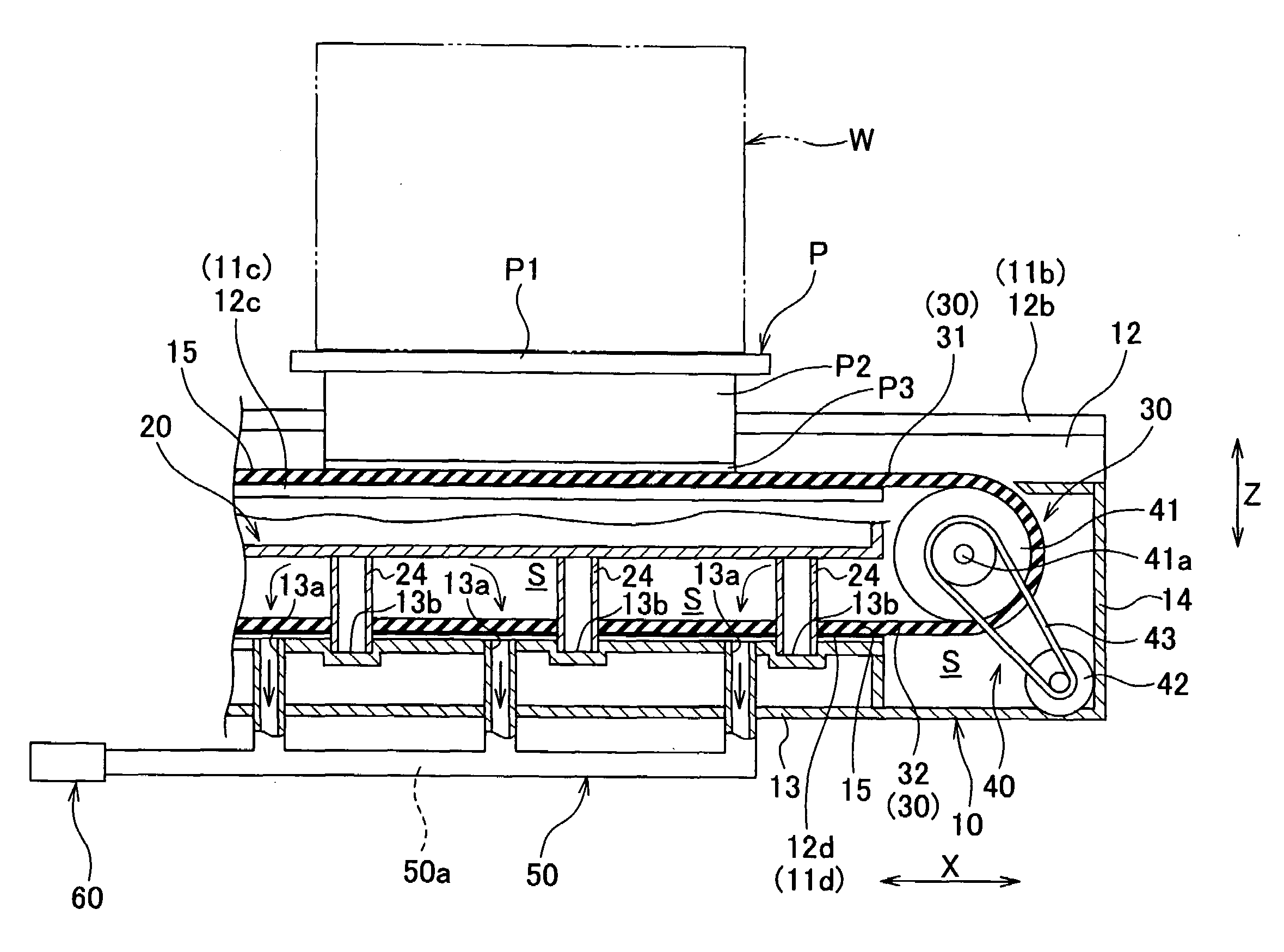

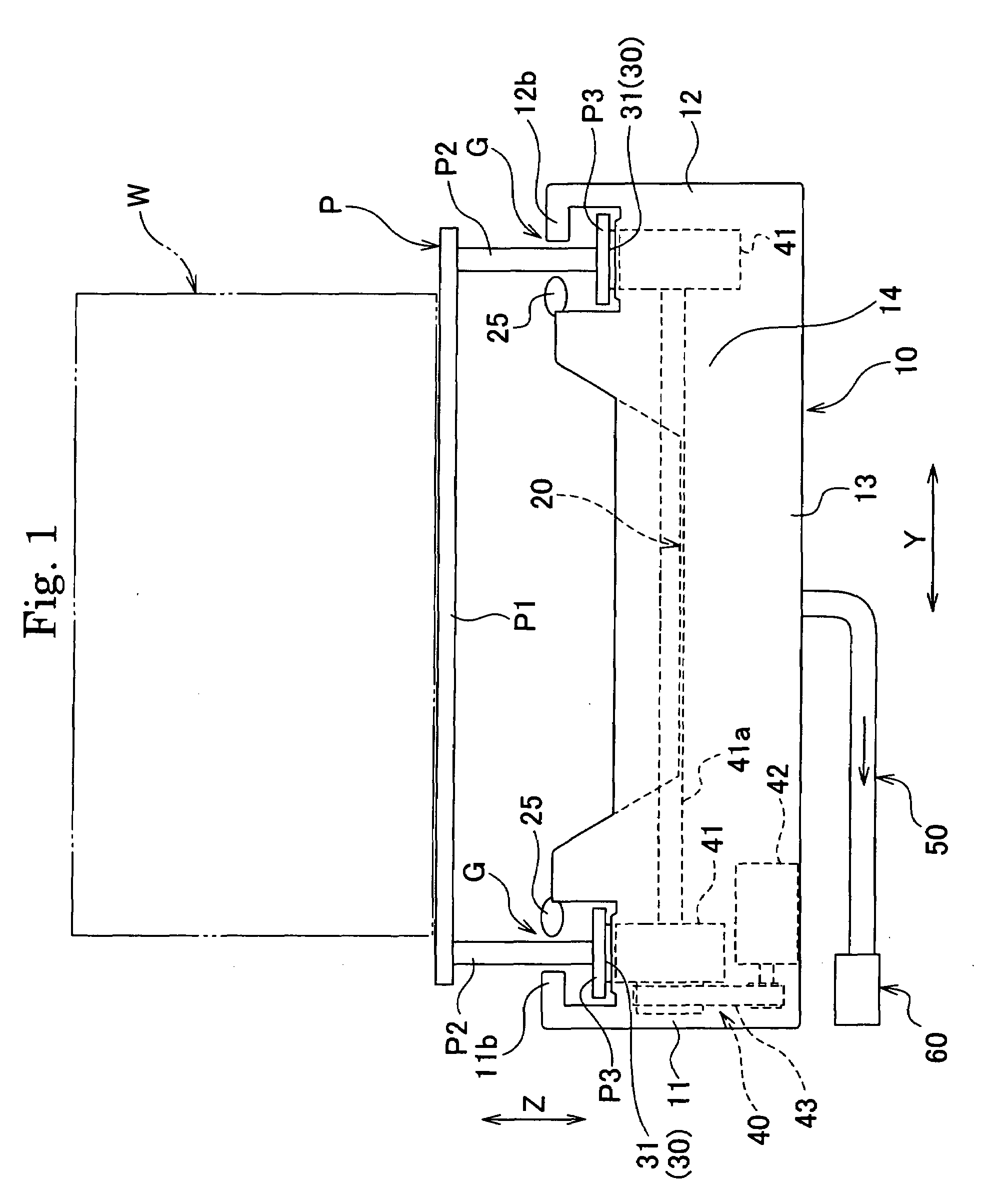

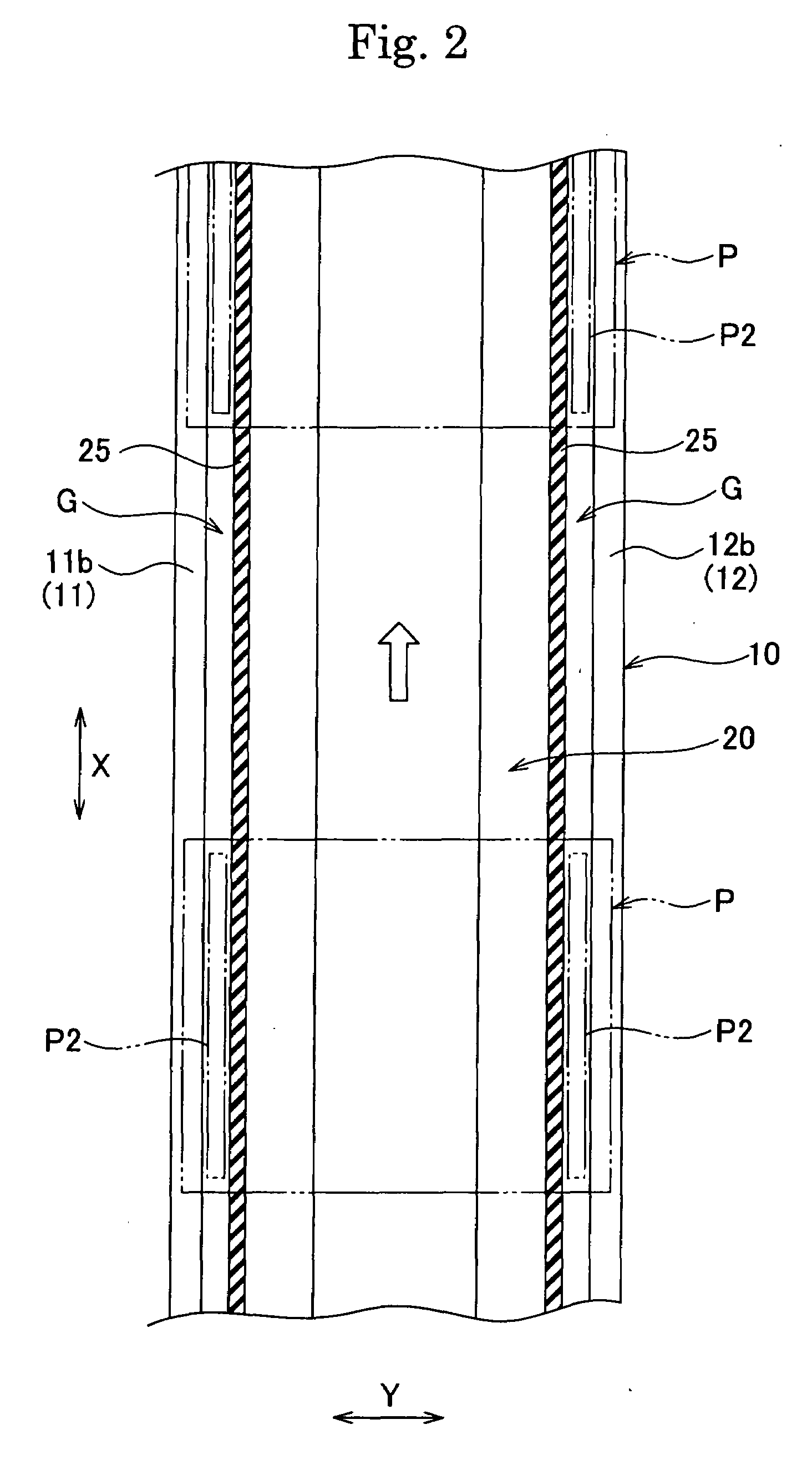

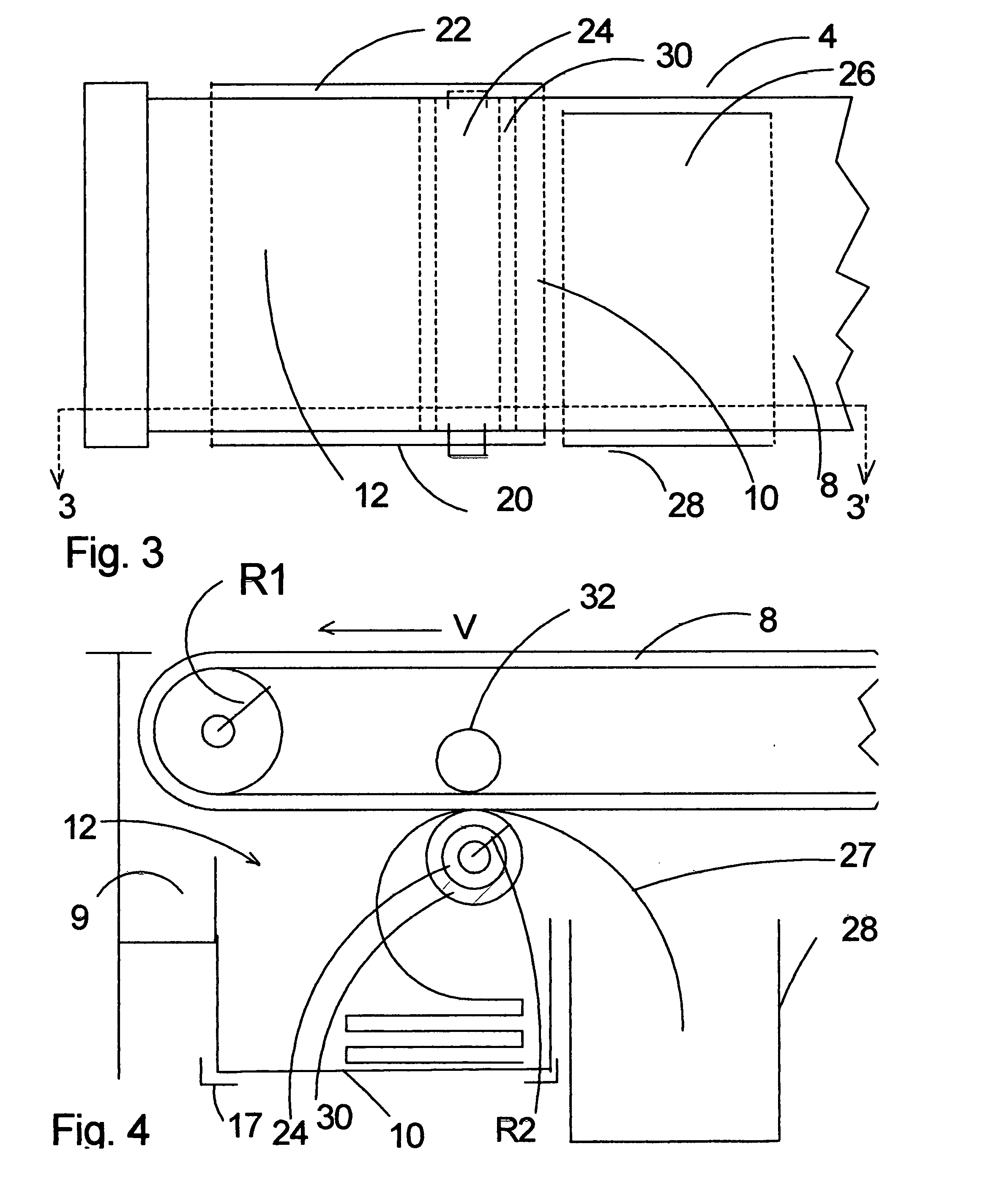

Conveyer apparatus

A conveyer apparatus according to the present invention includes a case that defines a pair of right and left gap portions each of which has a predetermined width and extends in a conveying direction of a conveyance object, a conveyer that is arranged near or in a region adjacent to each of the pair of right and left gap portions and supported by the case to support and convey the conveyance object, a driving mechanism that is arranged in an internal space of the case to drive each conveyer, and sucking means for sucking air in the internal space. According to this configuration, when the sucking means sucks air in the internal space in the case, an air current flowing into the internal space from the outside through each gap portion is produced, and an abrasion powder or dust generated near, e.g., each conveyer arranged near under each gap portion flows with this air current to be sucked, thus avoiding scattering toward the outside.

Owner:HIRATA & CO LTD

Conveyor lubricants including emulsion of a lipophilic compound and an emulsifier and/or an anionic surfactant and methods employing them

The present invention relates to conveyor lubricant compositions including an emulsion of a lipophilic compound and also including an emulsifier and / or an anionic surfactant. The present invention also relates to methods employing such lubricant compositions. In an embodiment, the method includes applying the present lubricant composition to a conveyor with a non-energized nozzle.

Owner:ECOLAB USA INC

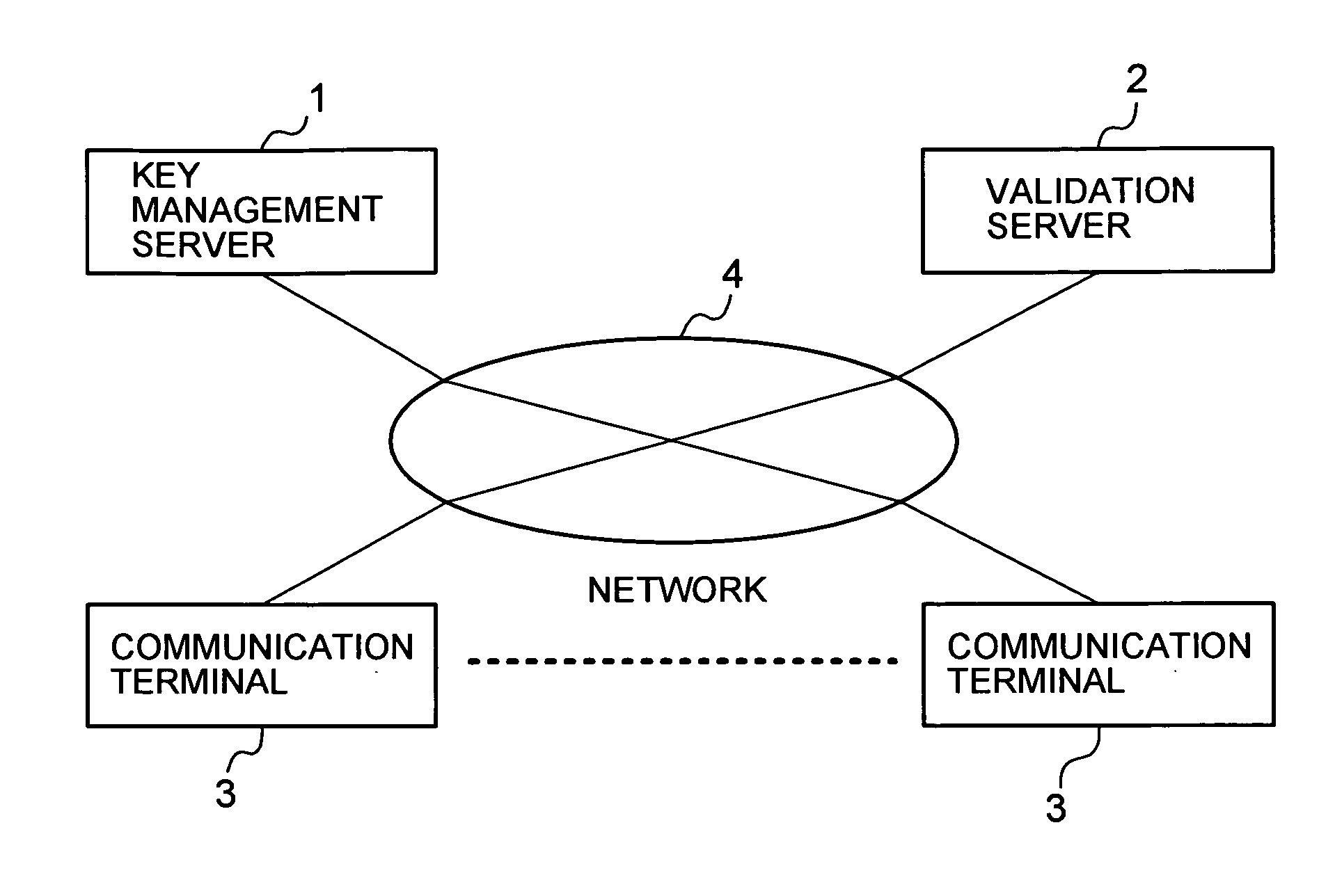

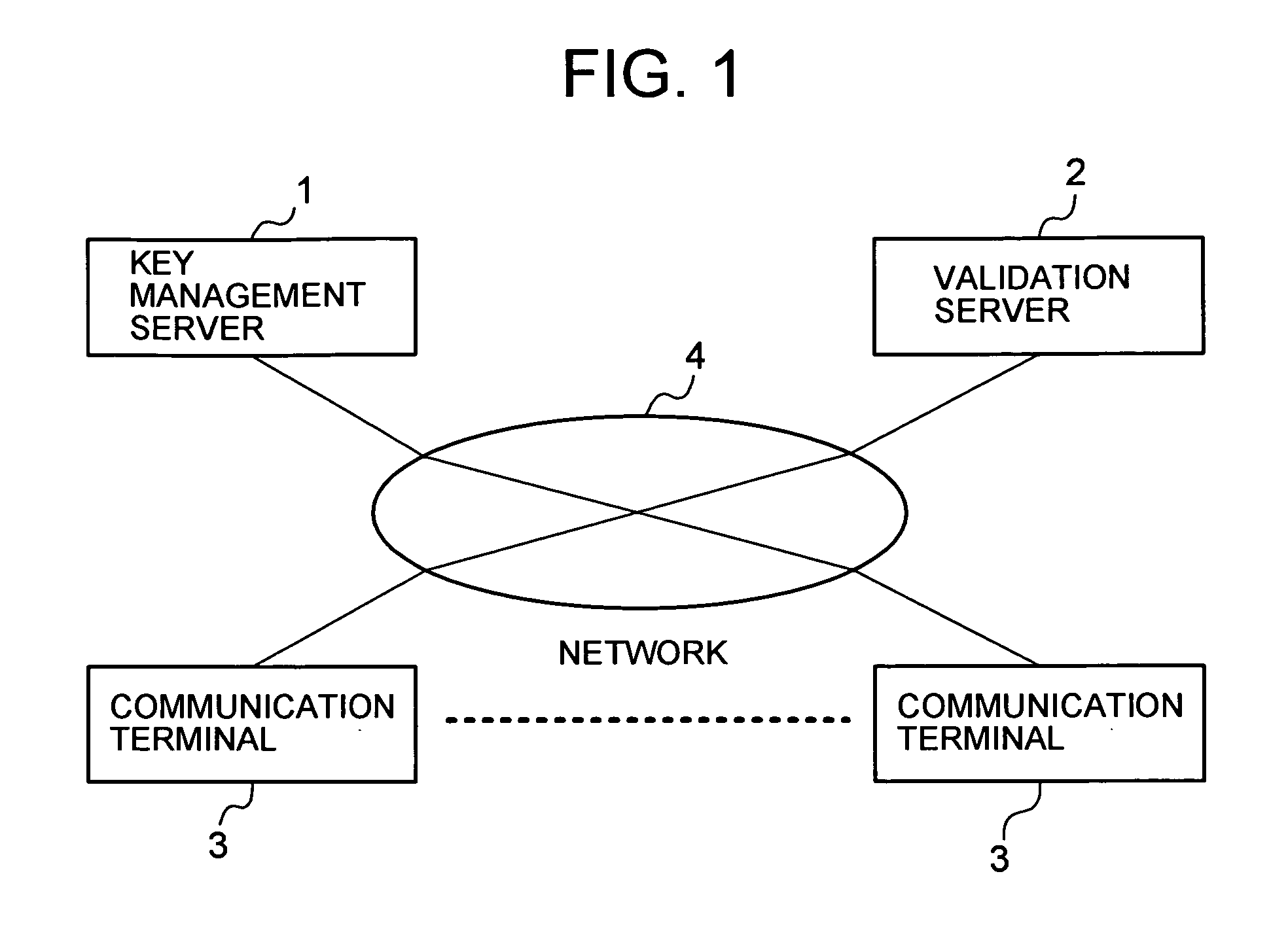

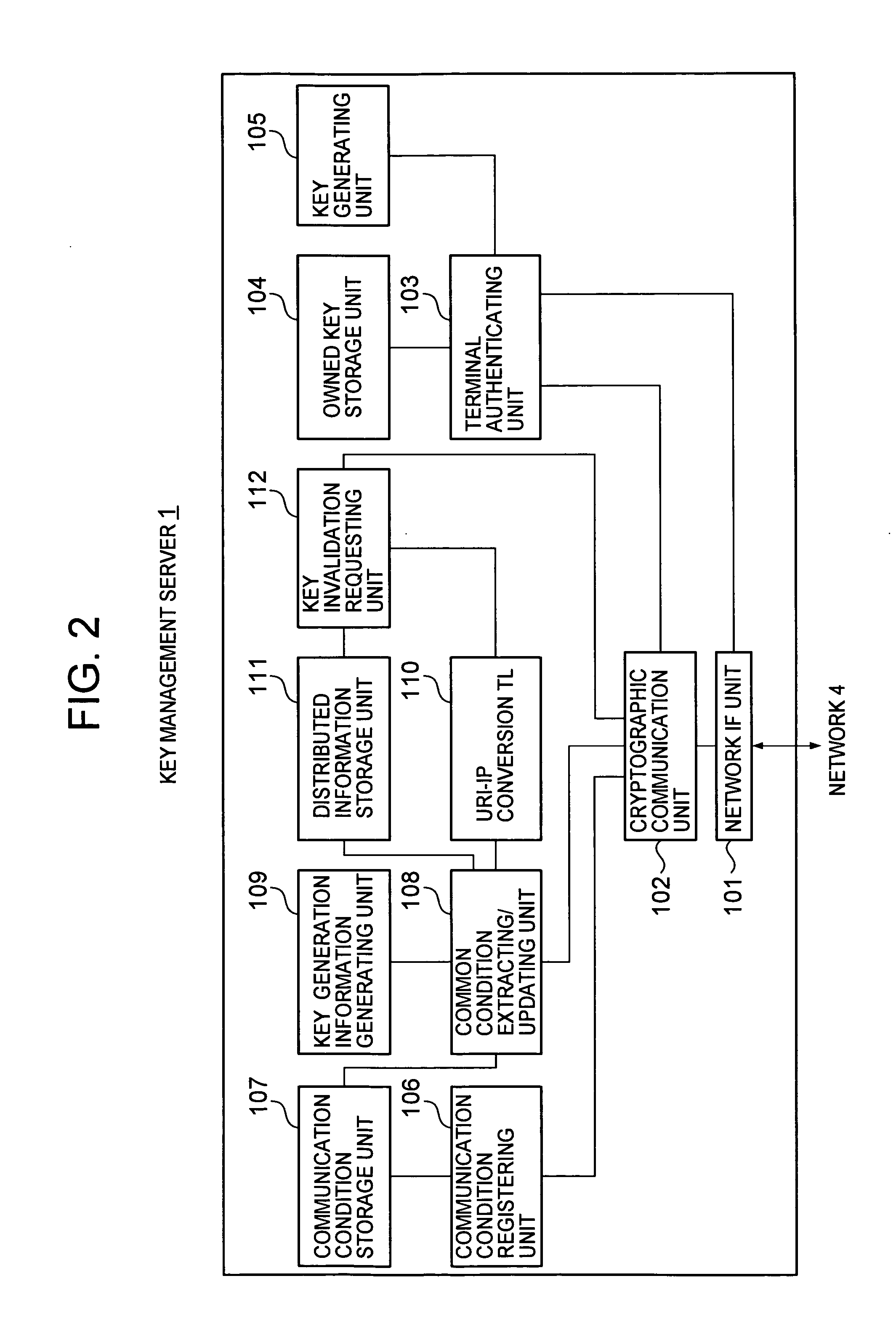

Cryptographic communication system and method

InactiveUS20060204003A1Reduce processing overheadAchieve communicationConveyorsMultiple keys/algorithms usageComputer hardwareCommunications system

Cryptographic communication between communication terminals can be realized even when a plurality of cryptographic algorithms are present, and secure cryptographic communication for a longer time is realized without increasing a processing overhead at each of the communication terminals. A key management server manages cryptographic algorithms that can be used by each of the communication terminal, and searches for a cryptographic algorithm common to the communication terminals, and notifies each of the communication terminals of the cryptographic algorithm found by the search together with plural key generation informations, each piece containing a key to be used in the cryptographic algorithm or a key type for generating the key. Each of the communication terminals sequentially switches the plural key generation informations notified from the key management server, and performs the cryptographic communication with a communication counterpart in accordance with the cryptographic algorithm notified from the key management server.

Owner:HITACHI LTD

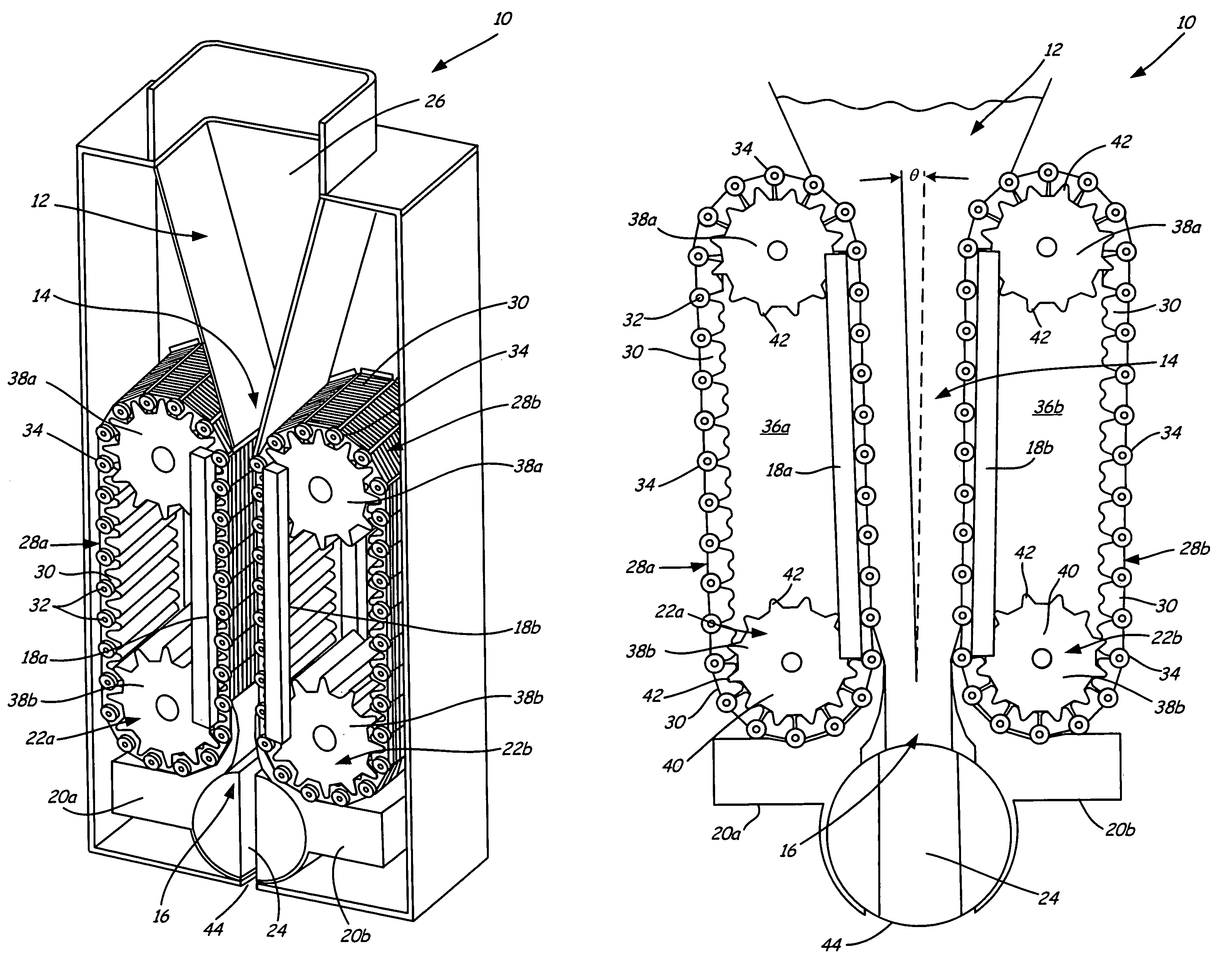

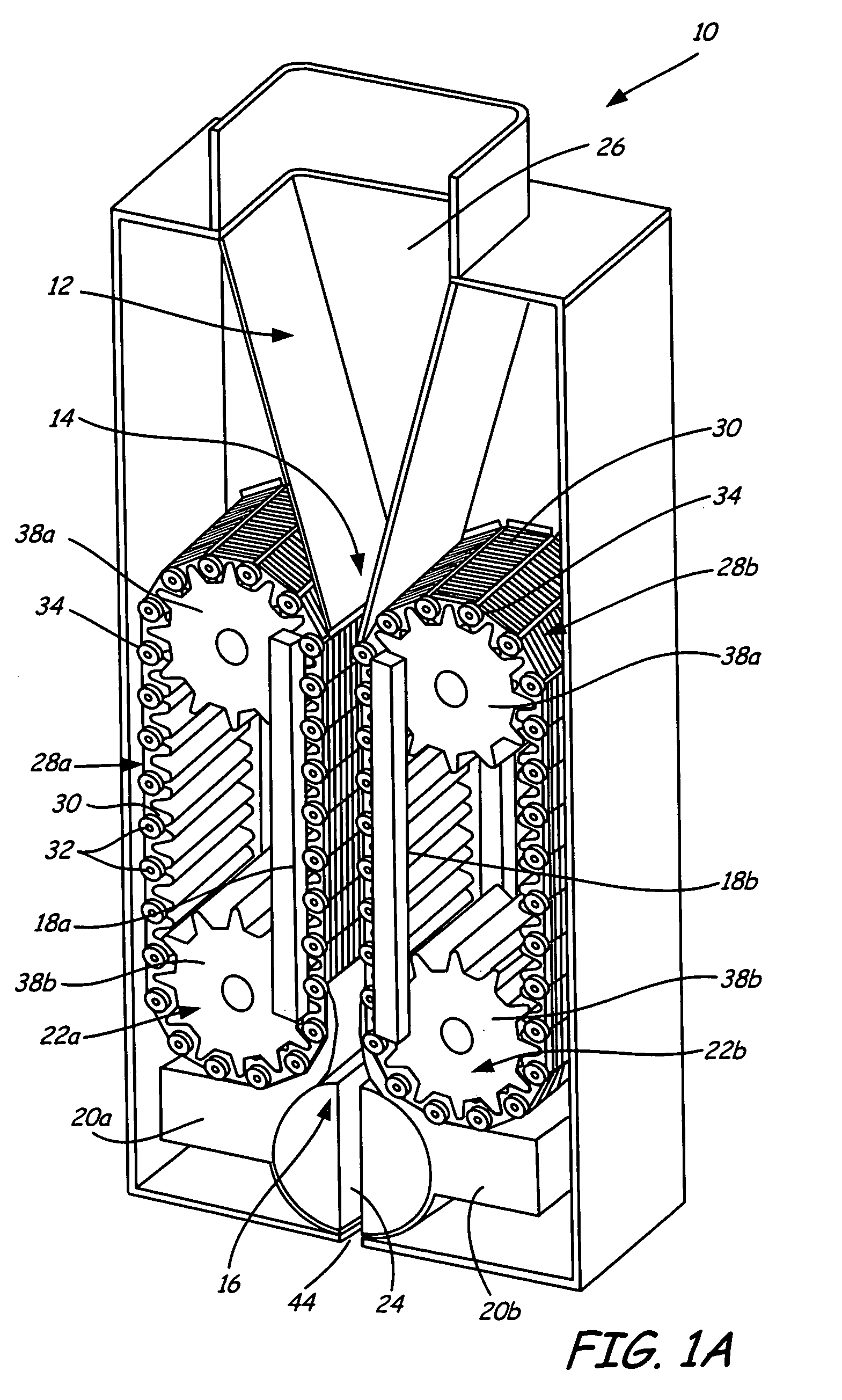

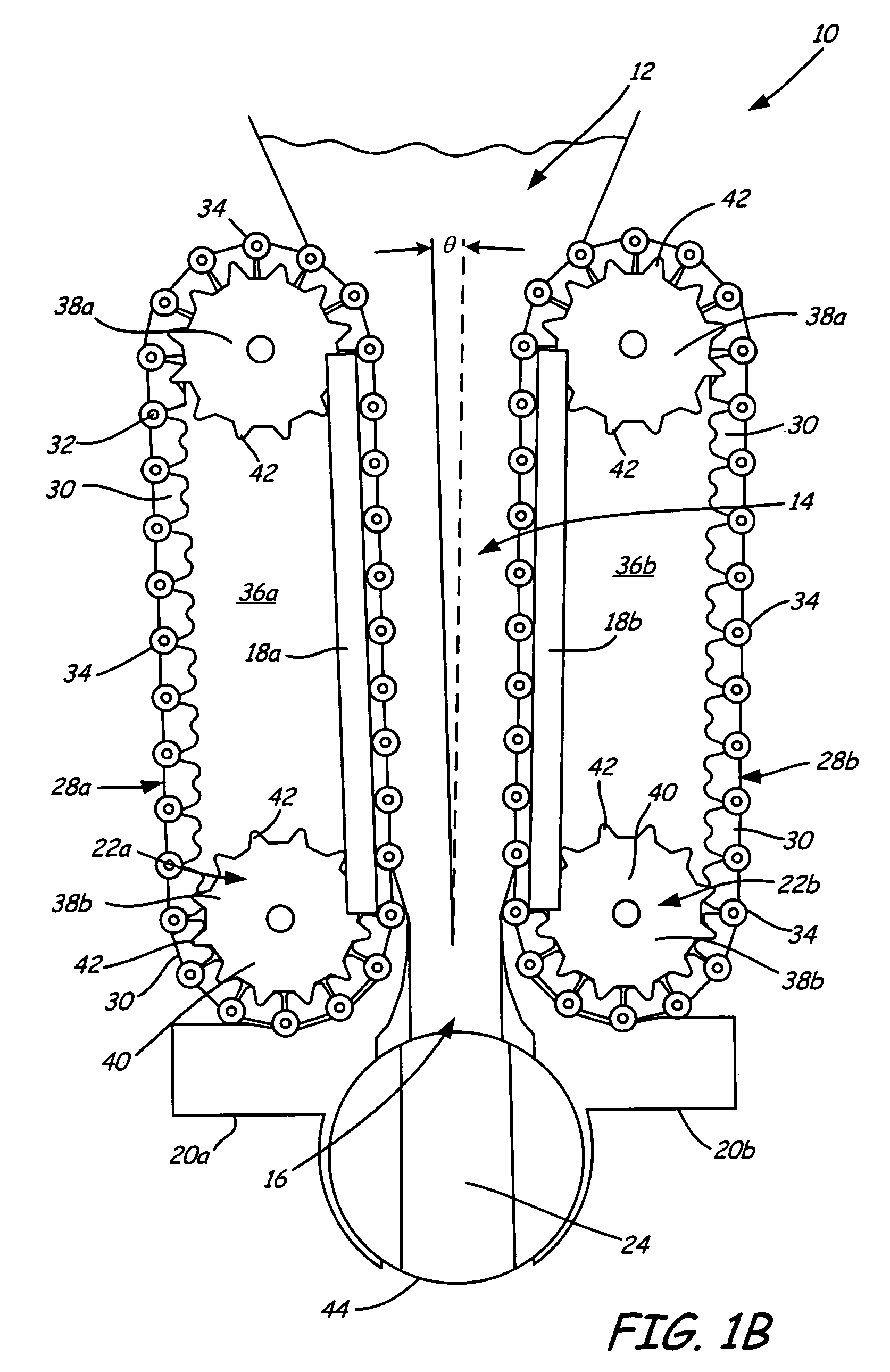

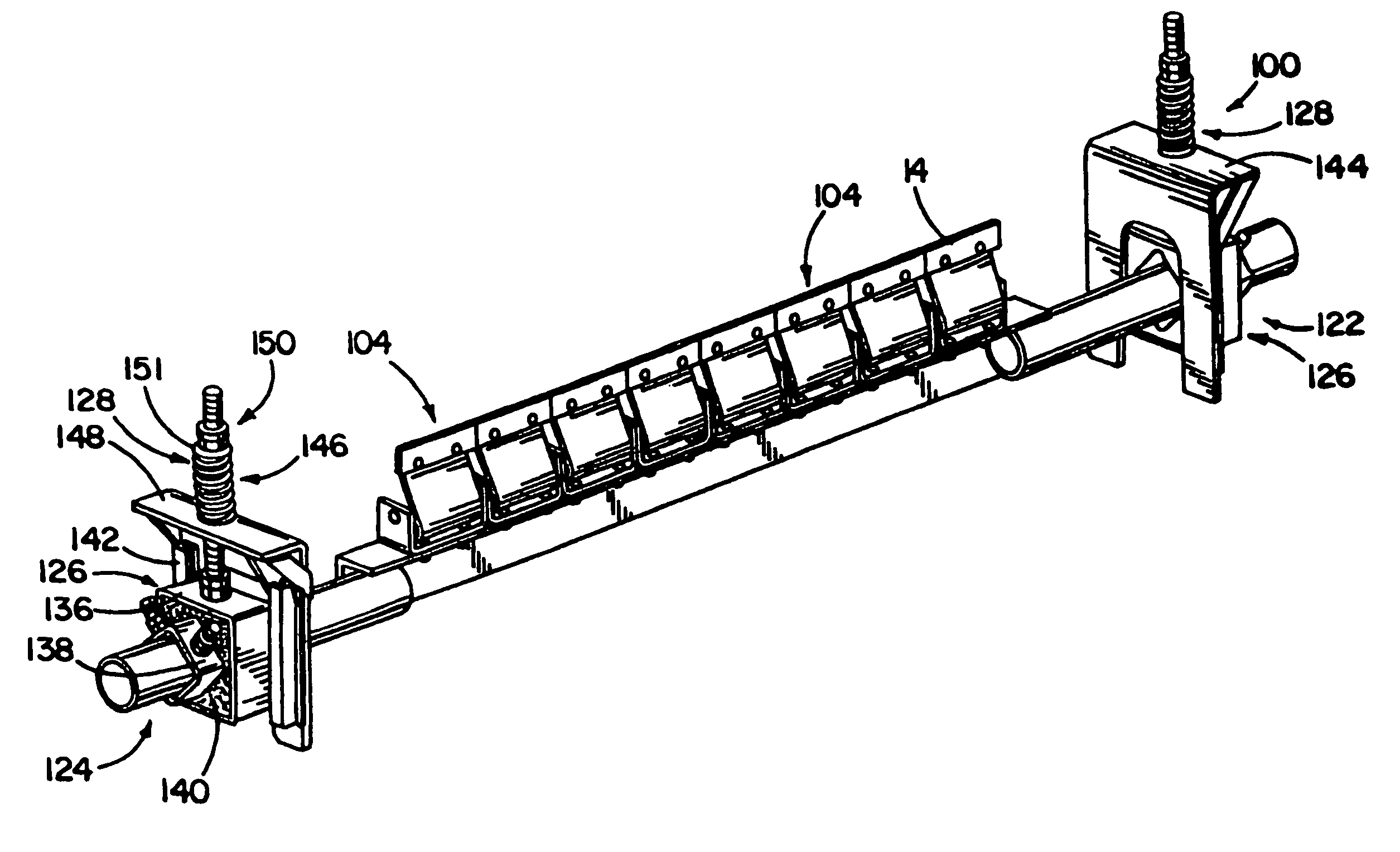

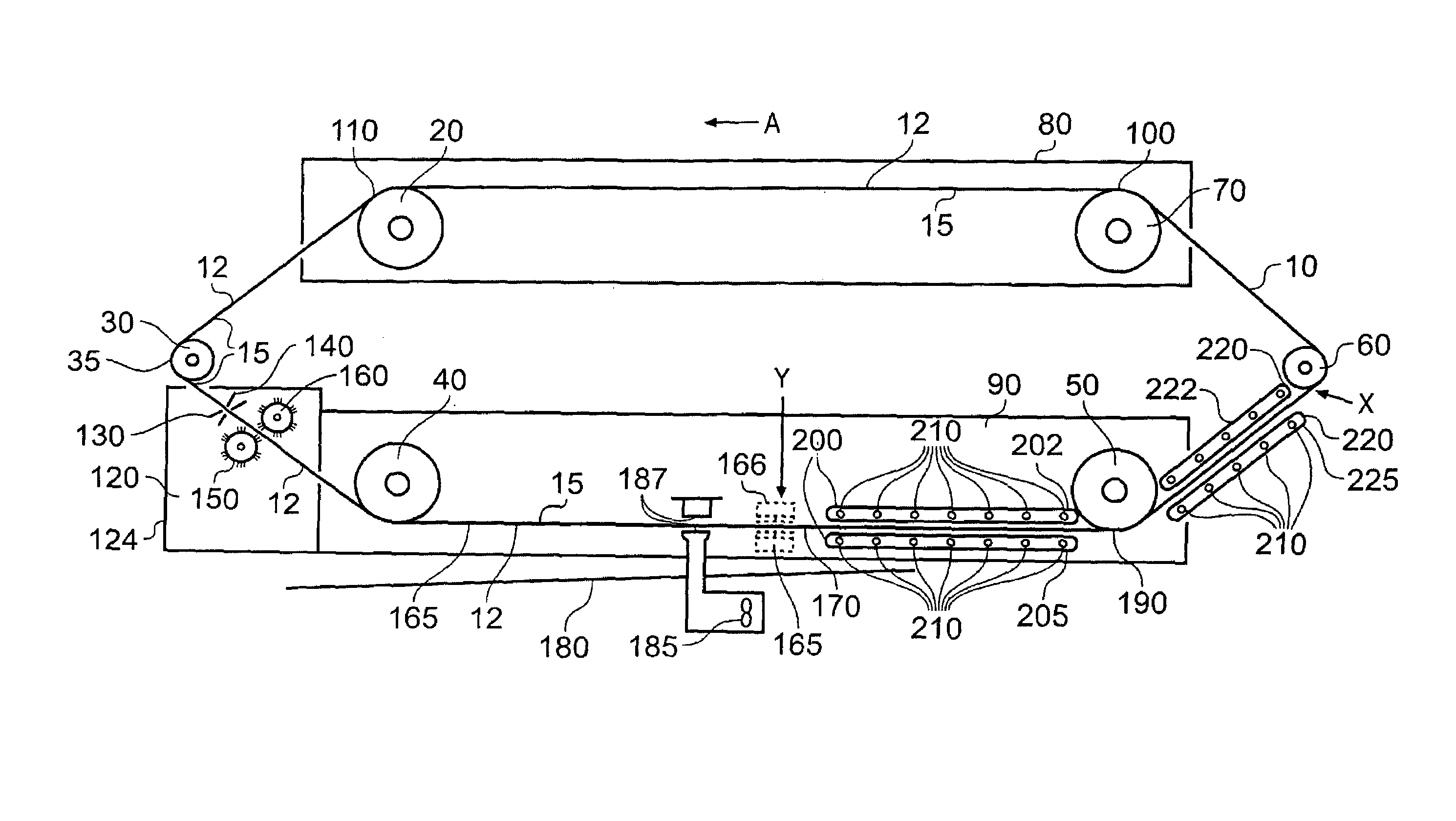

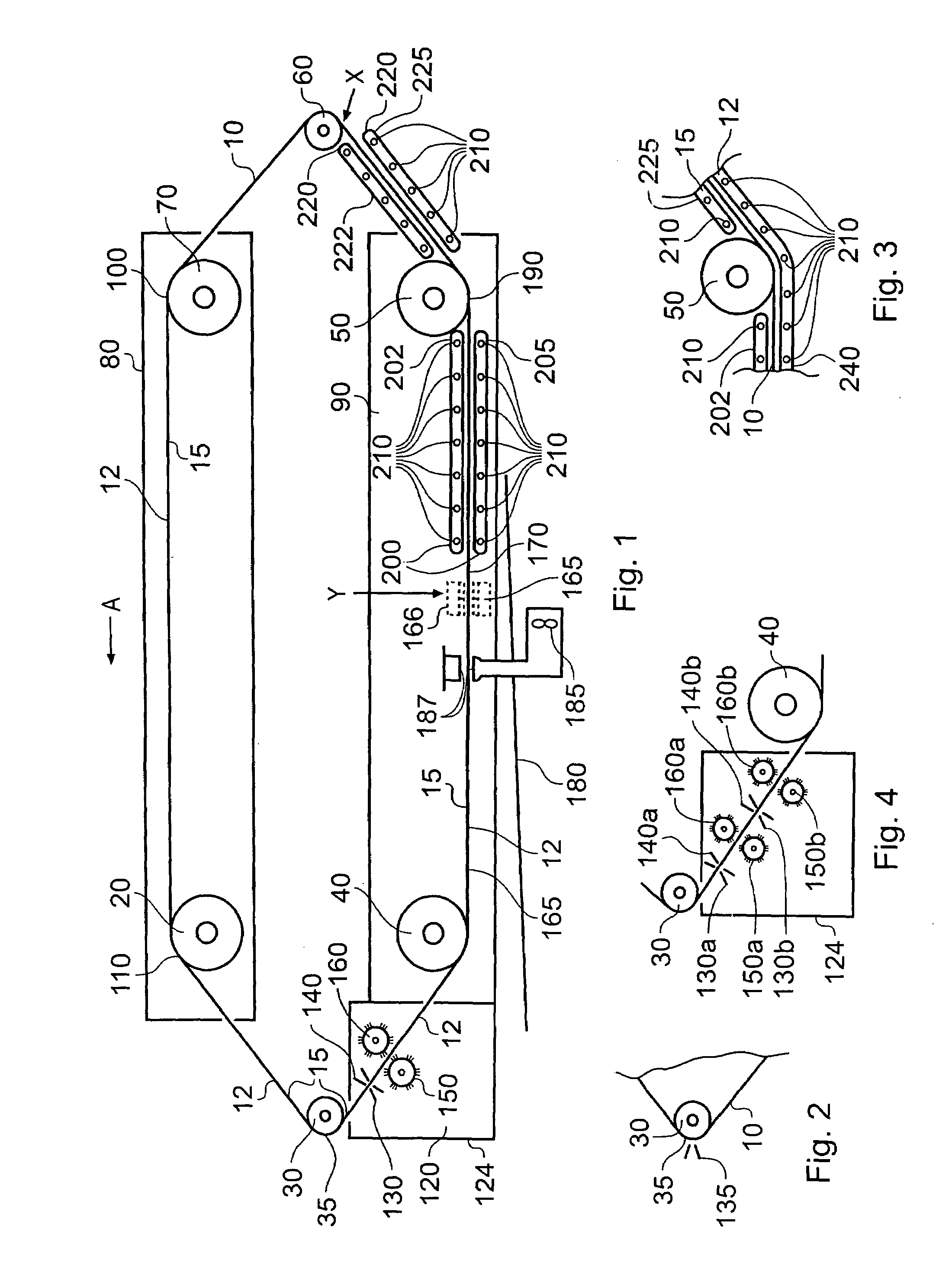

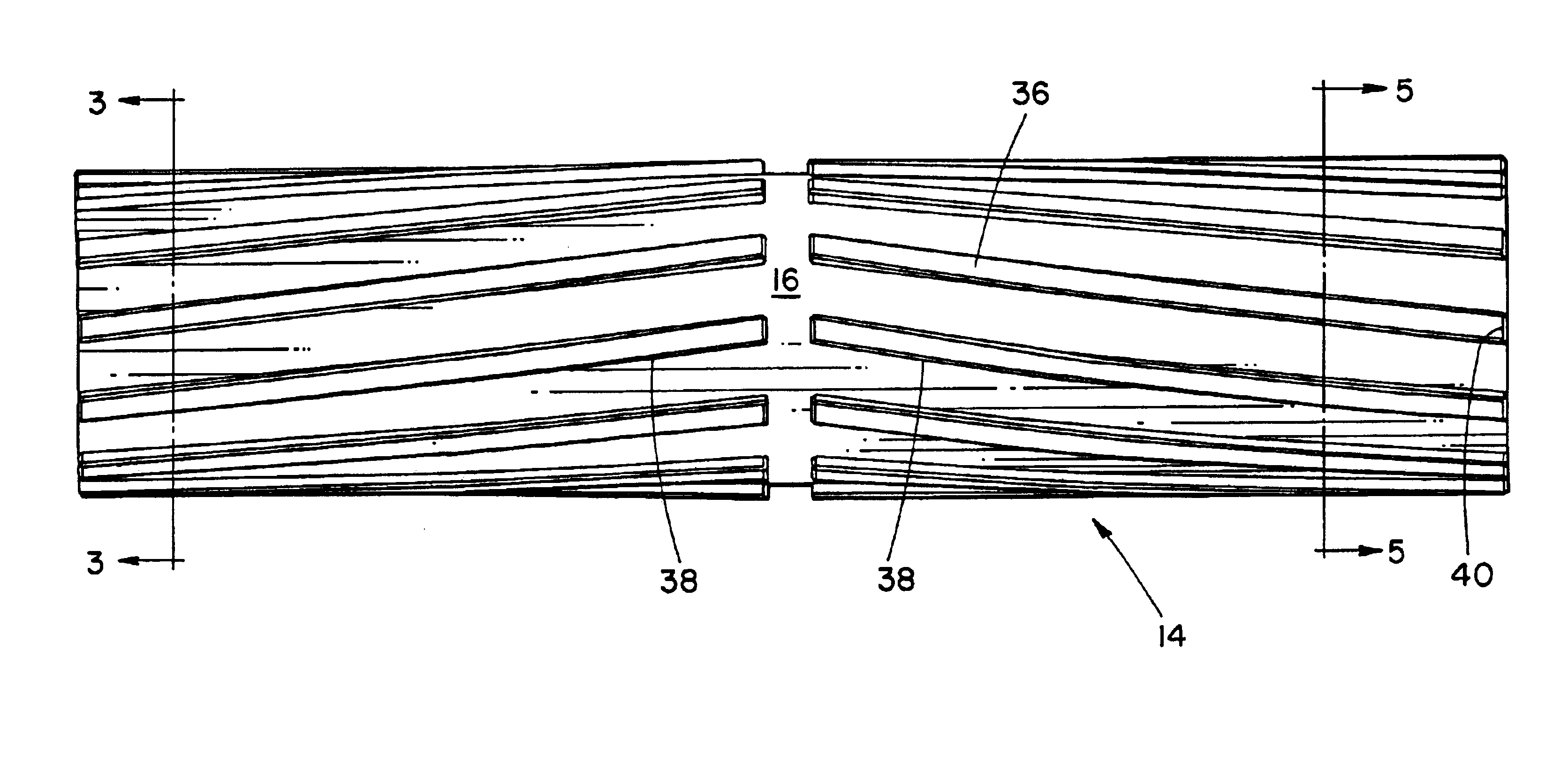

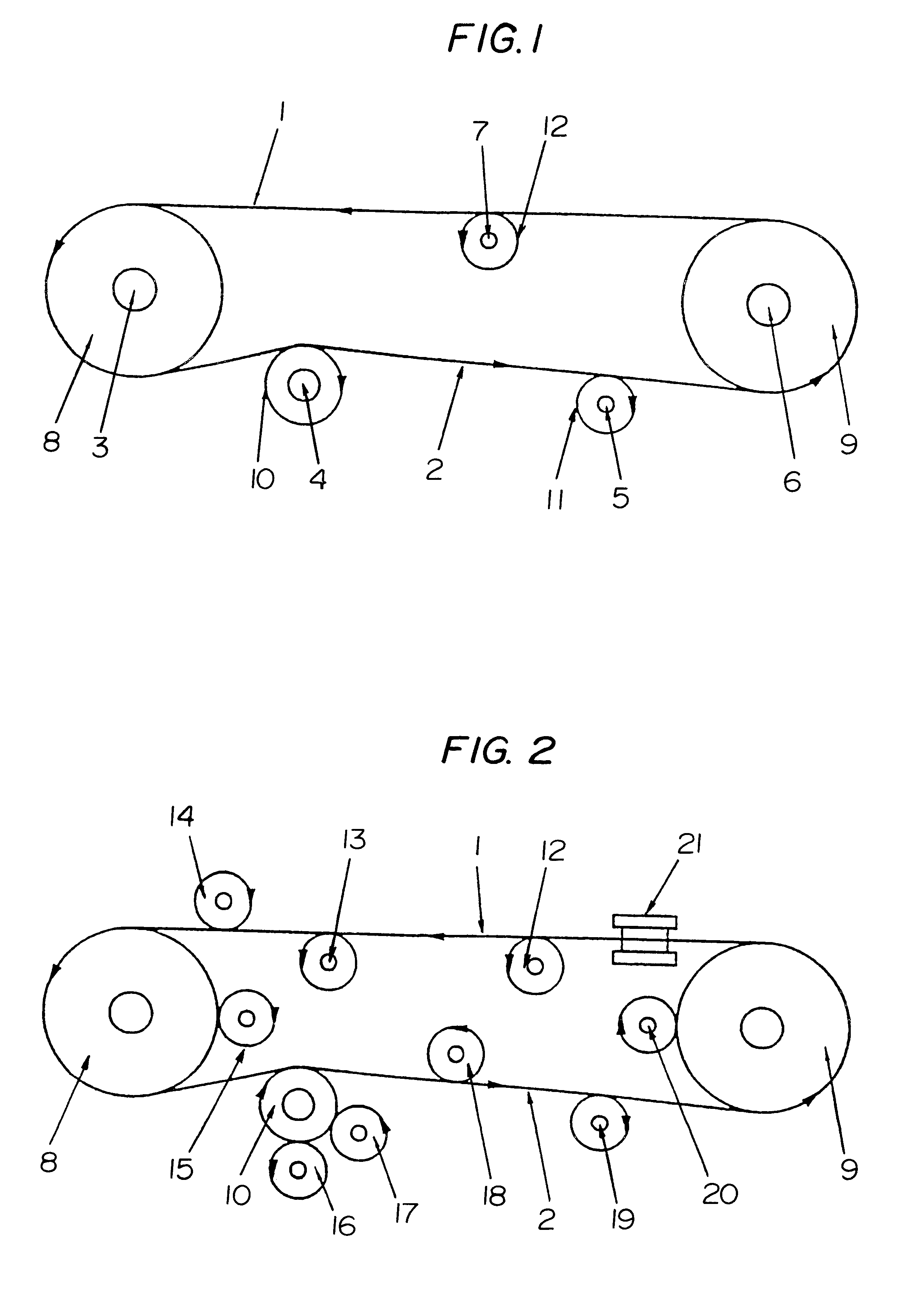

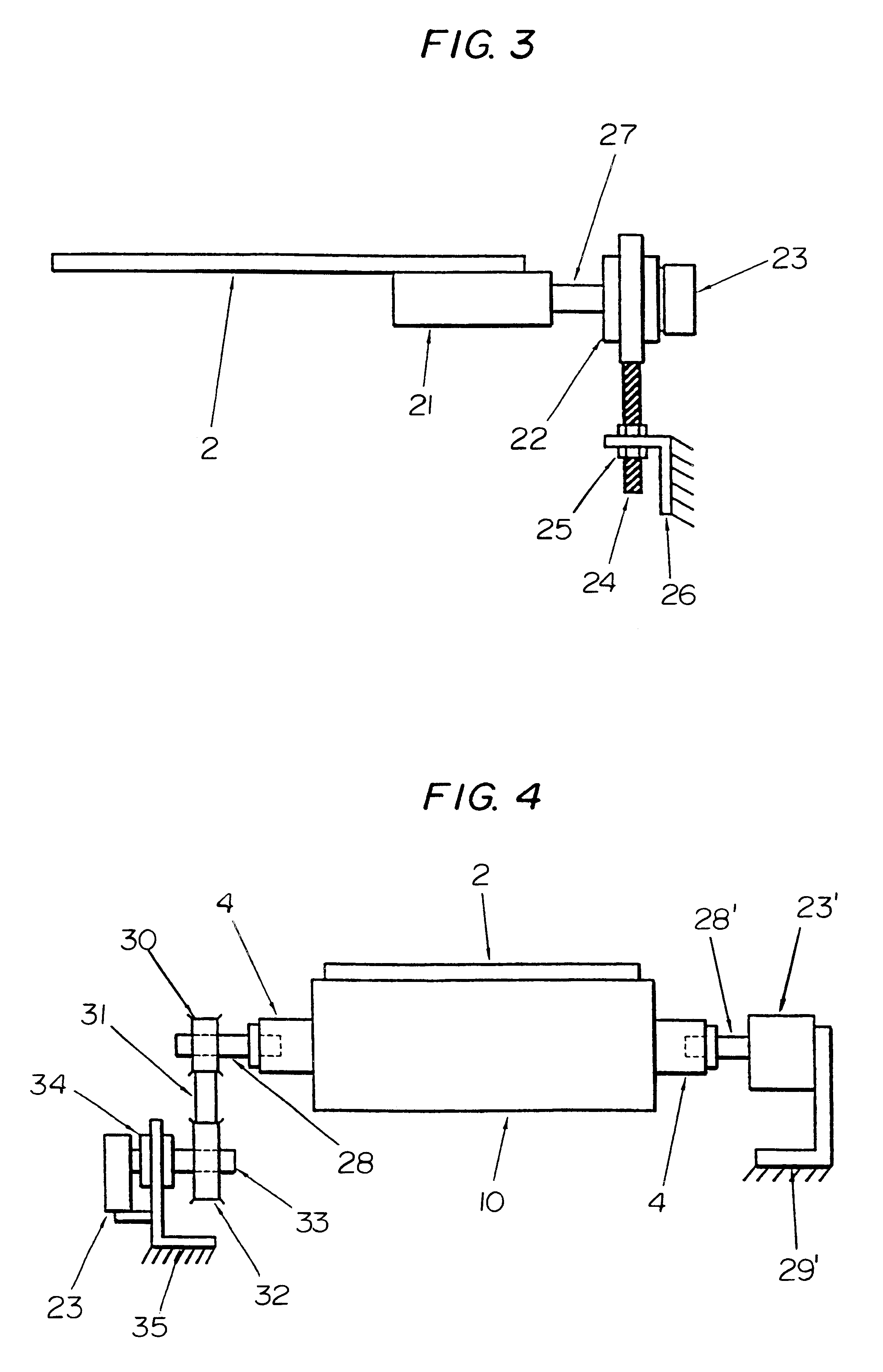

Linear tractor dry coal extrusion pump

A pump for transporting particulate material includes an inlet, an outlet, a passageway, a first and second load beam, a first and second scraper seal, and a first and second drive assembly. The inlet introduces the particulate material into the passageway and the outlet expels the particulate material from the passageway. The passageway is defined by a first belt assembly and a second belt assembly that are opposed to each other. The first and second load beams are positioned within the first belt assembly and the second belt assembly, respectively. The first scraper seal and a second scraper seal are positioned proximate the passageway and the outlet. The first drive assembly is positioned within an interior section of the first belt assembly and drives the first belt assembly and the second drive assembly is positioned within an interior section of the second belt assembly and drives the second belt assembly.

Owner:ROCKETDYNE

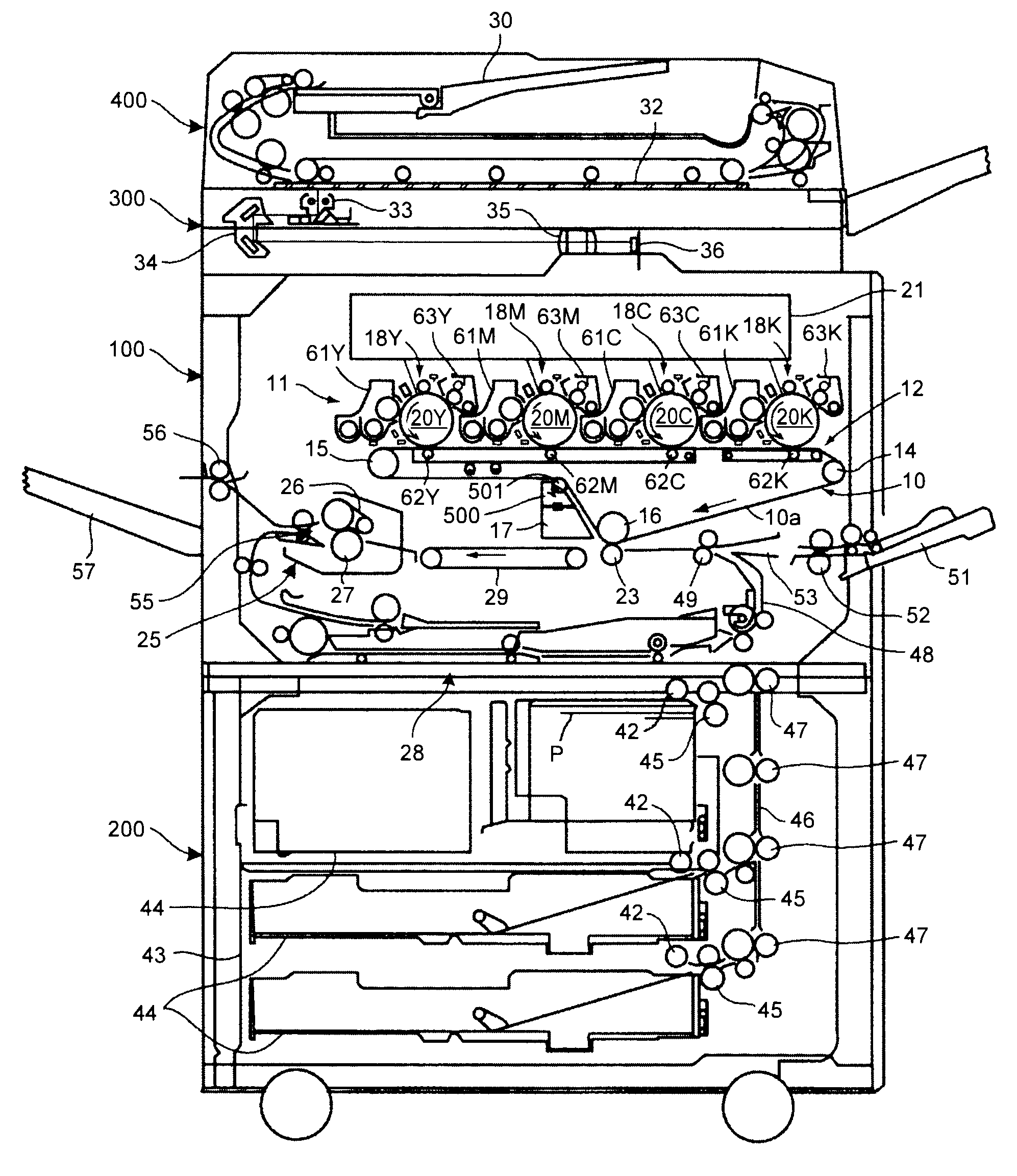

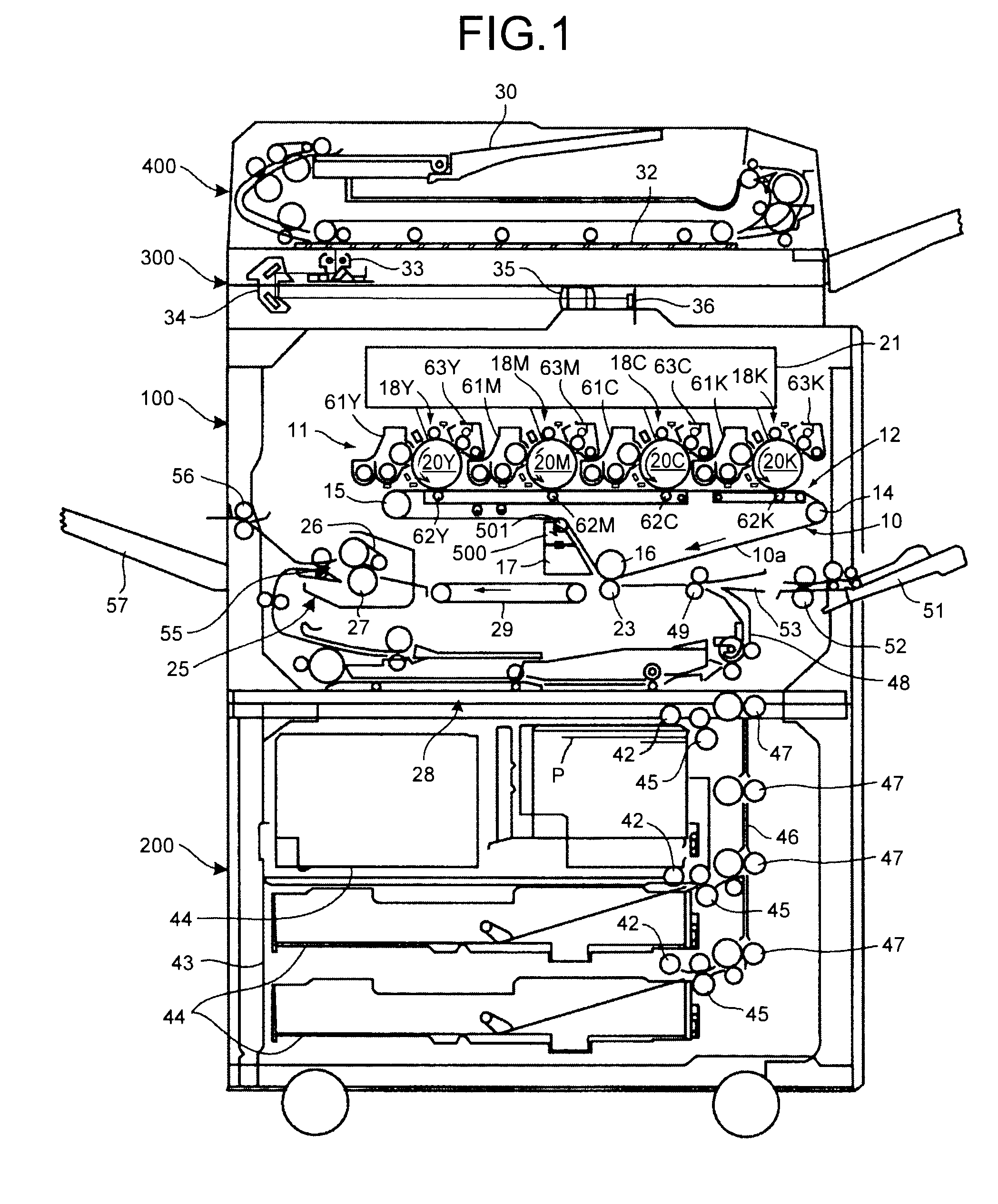

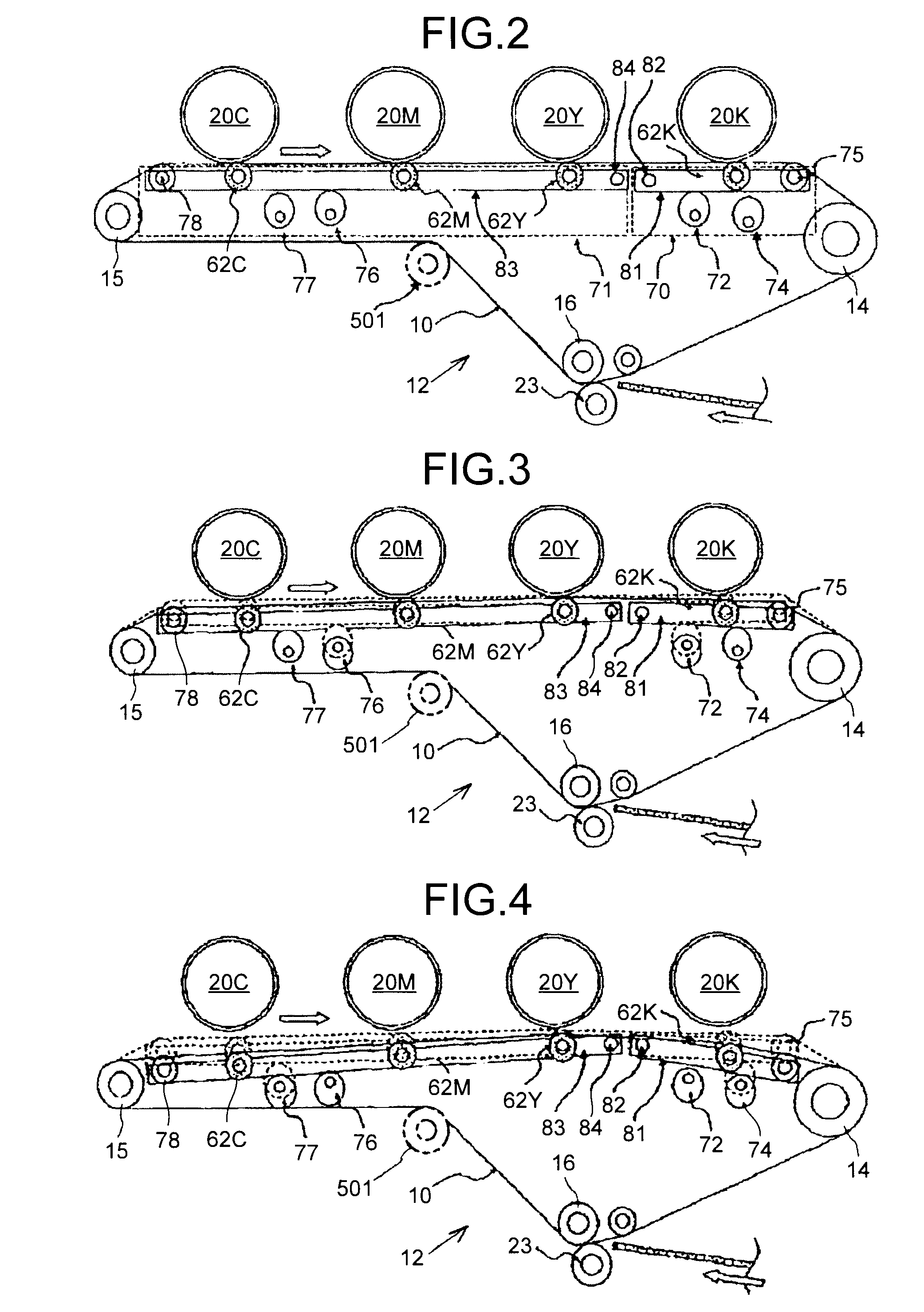

Image forming apparatus and belt tensioning unit

Owner:RICOH KK

Lubricant composition

Use of a liquid composition for lubricating conveyor belts is provided, said liquid composition being suitable for producing a “dry” lubricant film on a surface by discontinuous application thereof, wherein the liquid composition can also be used for continuous application to a conveyor belt surface, with or without further dilution with water, to remove incidental spillages of extraneous material from the conveyor belt surface without loss of the required lubricity.This liquid composition was found to exhibit remarkably good durability.

Owner:JOHNSONDIVERSEY INC

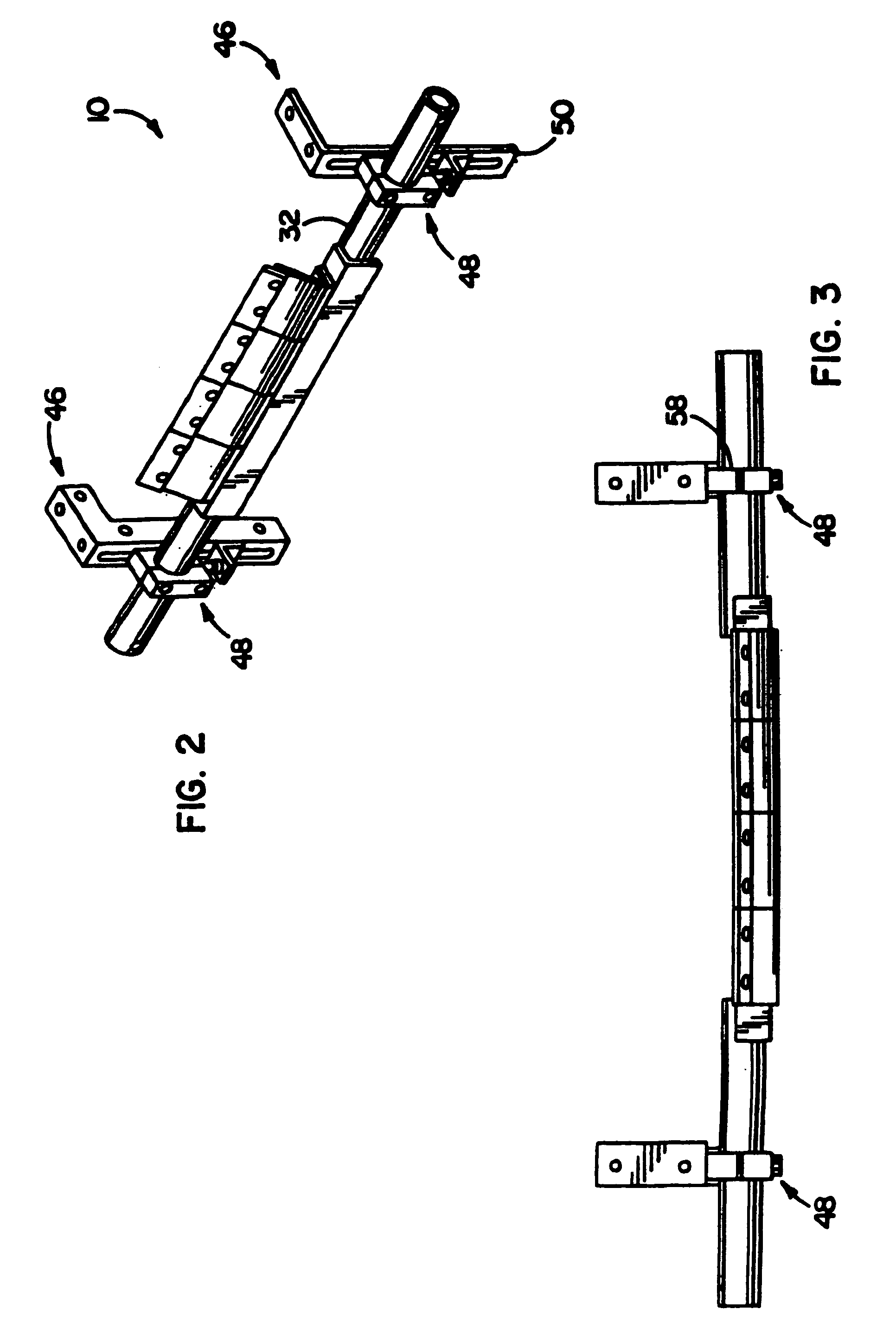

Mountable cleaning apparatus for commercial conveyors

A first embodiment of this invention is a cleaning apparatus for a commercial conveyor belt that is mounted on a conveyor table. The cleaning apparatus is a housing that includes a spraying tube for dispensing a cleaning solution and a novel wiping device. The wiping device is constructed to apply a disposable towel, such as a paper towel, to the conveyor belt to remove the solvent including any contaminants while the conveyor belt is in motion. The used disposable towels are deposited into a waste container thereby requiring very little cleaning maintenance. By a second embodiment the spraying tube is eliminated and the disposable paper towels include a solvent (wet wipes) for removing the contaminants. The cleaning apparatus is preferably mounted on the underside of the conveyor belt next to a crumb tray so that the cashier can easily operate the cleaning apparatus.

Owner:KELLY CAROL LYNN +1

Container, such as a food or beverage container, lubrication method

A process for lubricating a container, such as a beverage container, or a conveyor for containers, by applying to the container or conveyor, a thin continuous, substantially non-dripping layer of a liquid lubricant. The process provides many advantages compared to the use of a conventional dilute aqueous lubricant.

Owner:ECOLAB USA INC

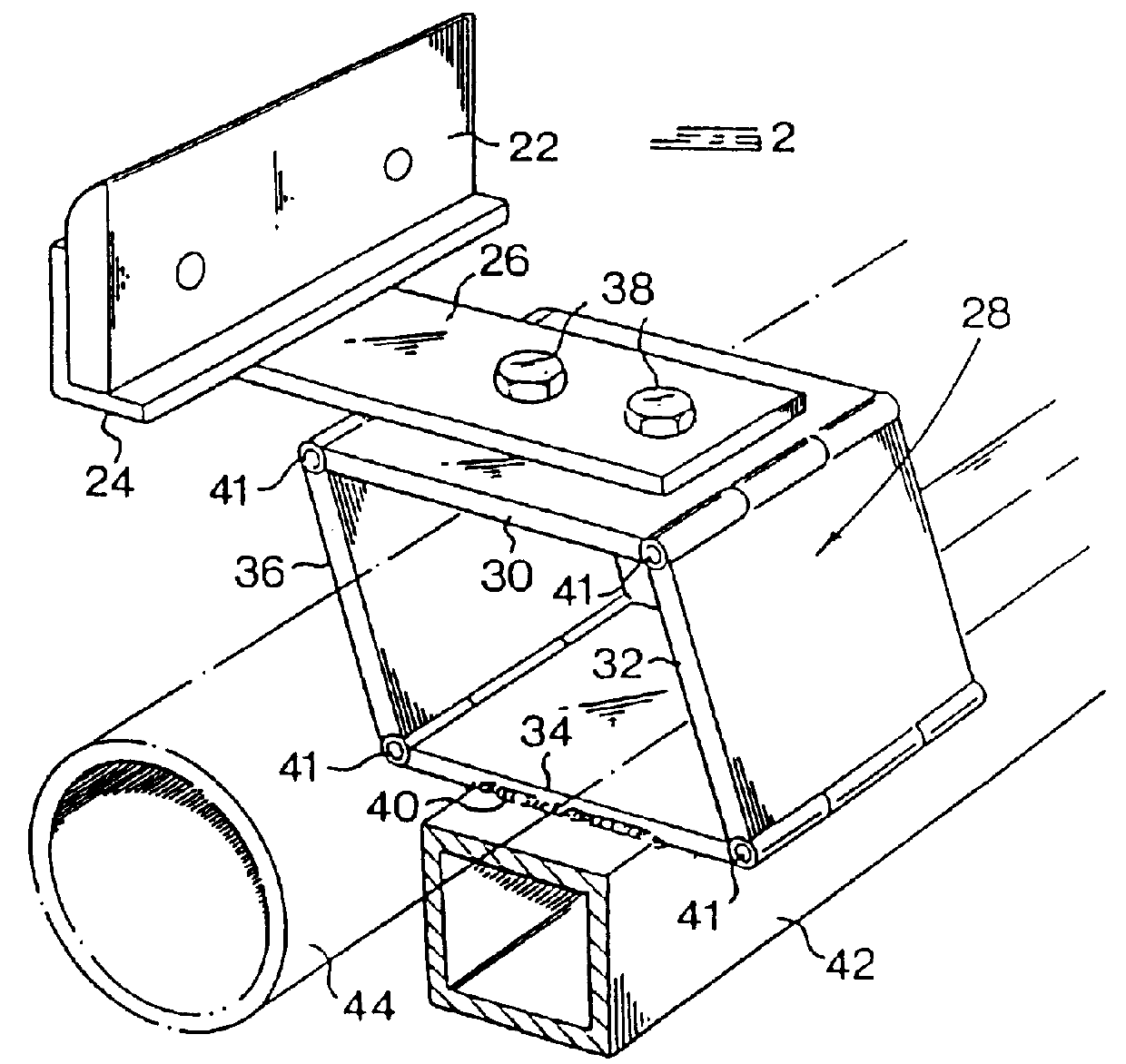

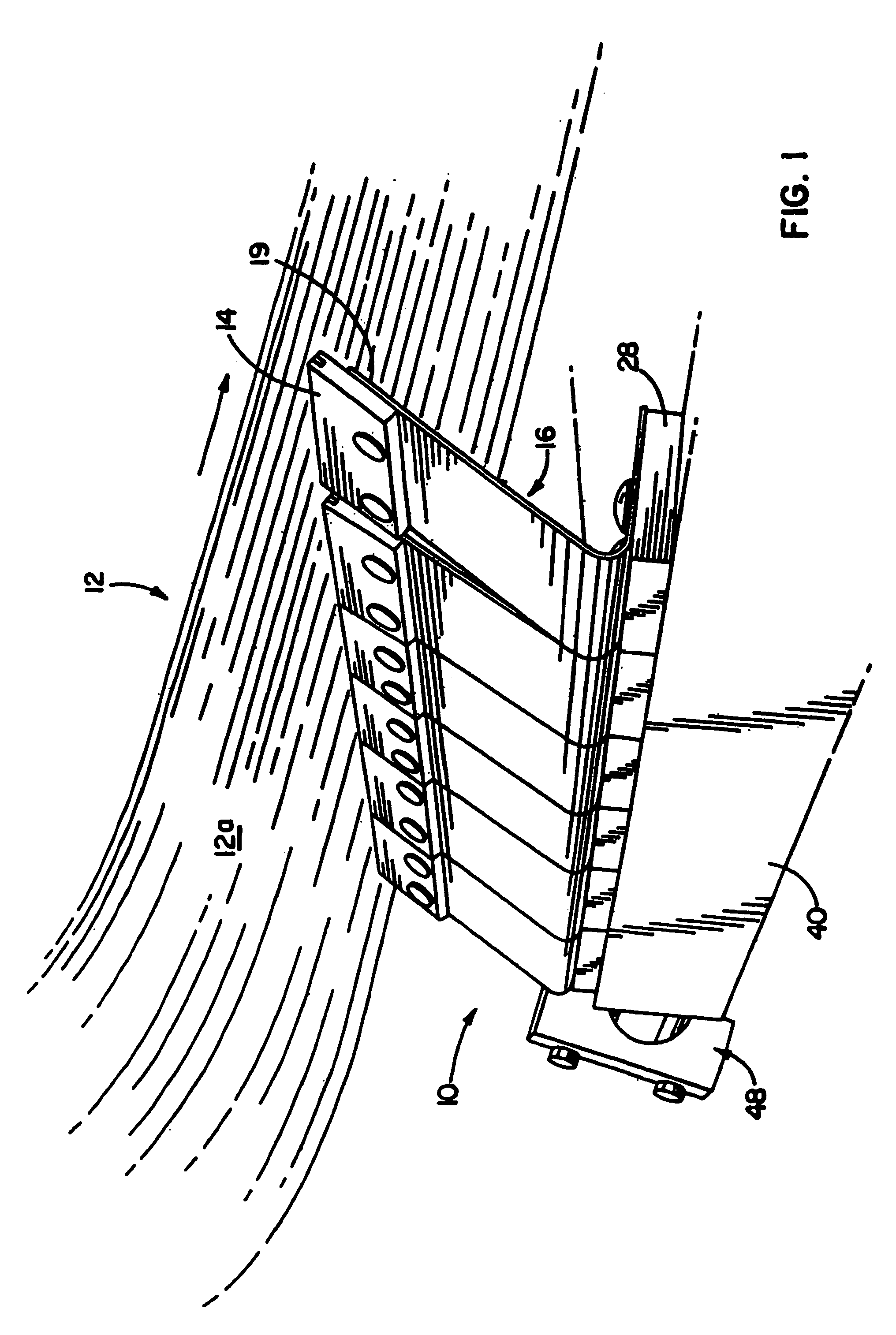

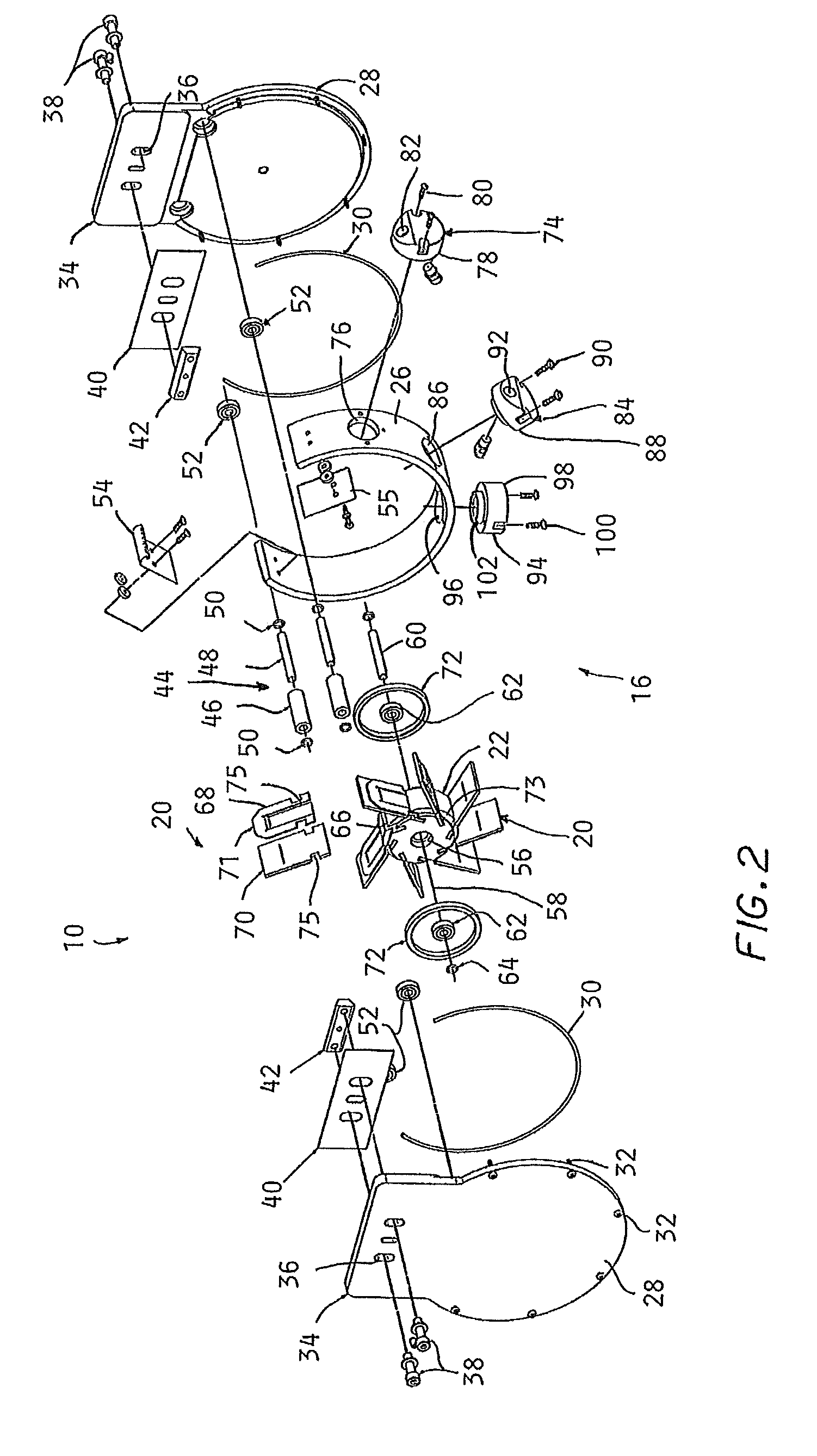

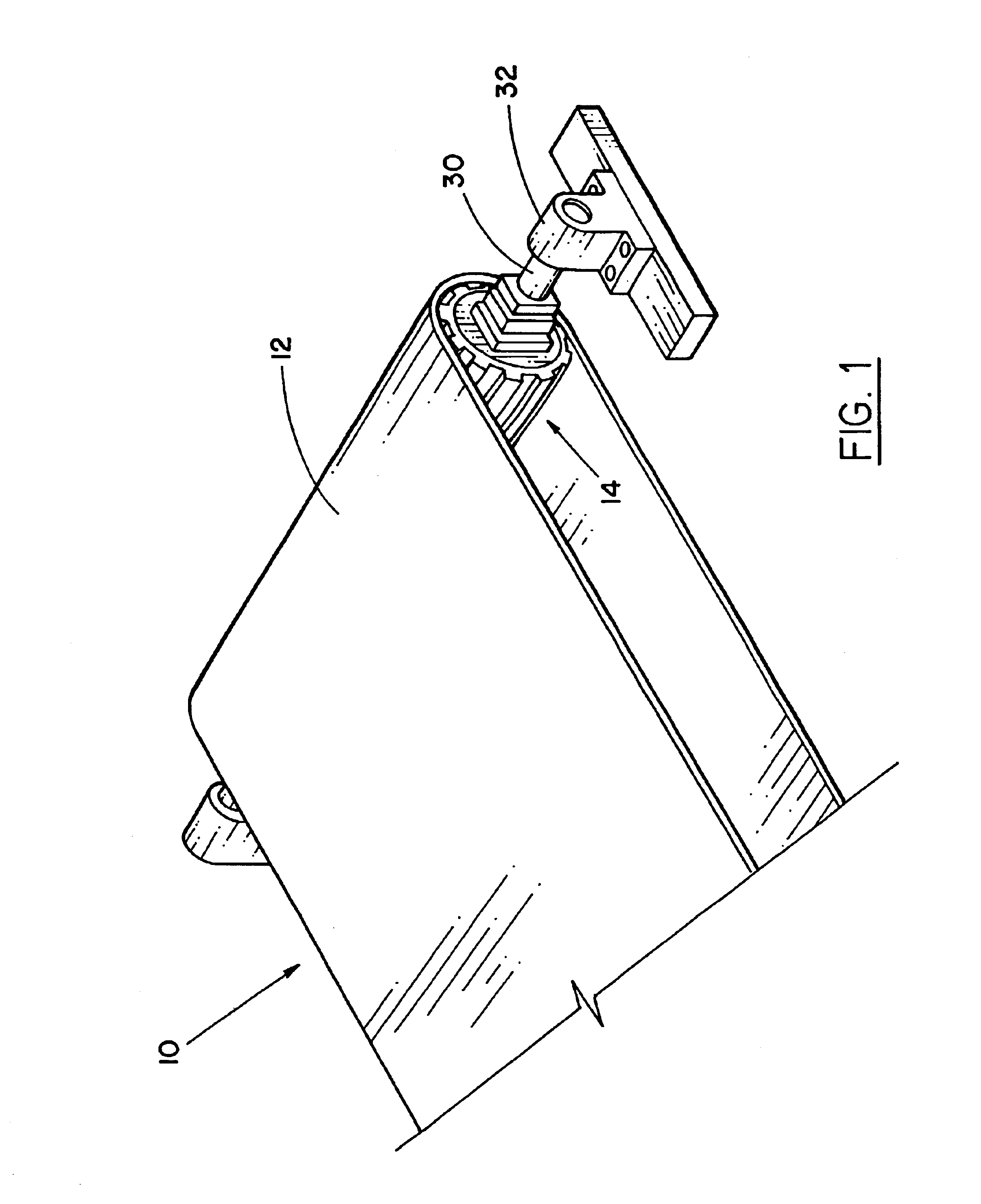

Conveyor belt scrapers

PCT No. PCT / EP96 / 04228 Sec. 371 Date Feb. 20, 1998 Sec. 102(e) Date Feb. 20, 1998 PCT Filed Sep. 27, 1996 PCT Pub. No. WO97 / 14635 PCT Pub. Date Apr. 24, 1997The invention concerns a conveyor belt scraper used to scrape debris from the surface of a conveyor belt (10). The scraper incorporates a segmented scraper blade which includes individual blade segments (22) arranged side by side with one another such that in use each blade segment scrapes a portion of the width of the belt surface. For blade segment there is a blade segment support (28) on which the associated blade segment (22) is supported. Each blade segment support (28) includes pivotally interconnected links (30, 32, 34, 36) forming a closed parallelogram linkage. A support structure (42, 82) is provided to support the parallelogram linkages in side by side relationship adjacent the belt surface. Gas-inflatable biasing means (44, 58) act on the parallelogram linkages such that inflation thereof causes the linkages to deform in a manner to displace the blade segments (22) in a direction lengthwise of the belt (10) and towards the belt surface. During such displacement, each blade segment (22) moves parallel to itself and maintains a constant inclination to the vertical.

Owner:MAT GHISLAIN JUSTIN MARIE

Conveyor belt cleaning system

A conveyor belt cleaner is provided that is particularly well-suited for high temperature applications. The cleaner includes a blade mount that has a layback arm mounting the cleaning blade and which can simultaneously deflect horizontally and vertically via changes in the radius of curvature of a lower arcuate portion connected thereto so as to minimize stress on the blade mount. The layback arm extends toward the conveyor belt at an acute layback angle relative to the immediately upstream belt surface. In another aspect, a belt cleaning system is provided including a plurality of resilient blade mounts that absorb the energy of impacts with the cleaning blade so as to allow for controlled release of the impact energy upon bringing the blade quickly back into scraping engagement with the belt. Preferably, two of these resilient mounts are associated with each blade in the belt scraping area and the others at ends of an elongate support laterally spaced from the scraping area.

Owner:FLEXIBLE STEEL LACING

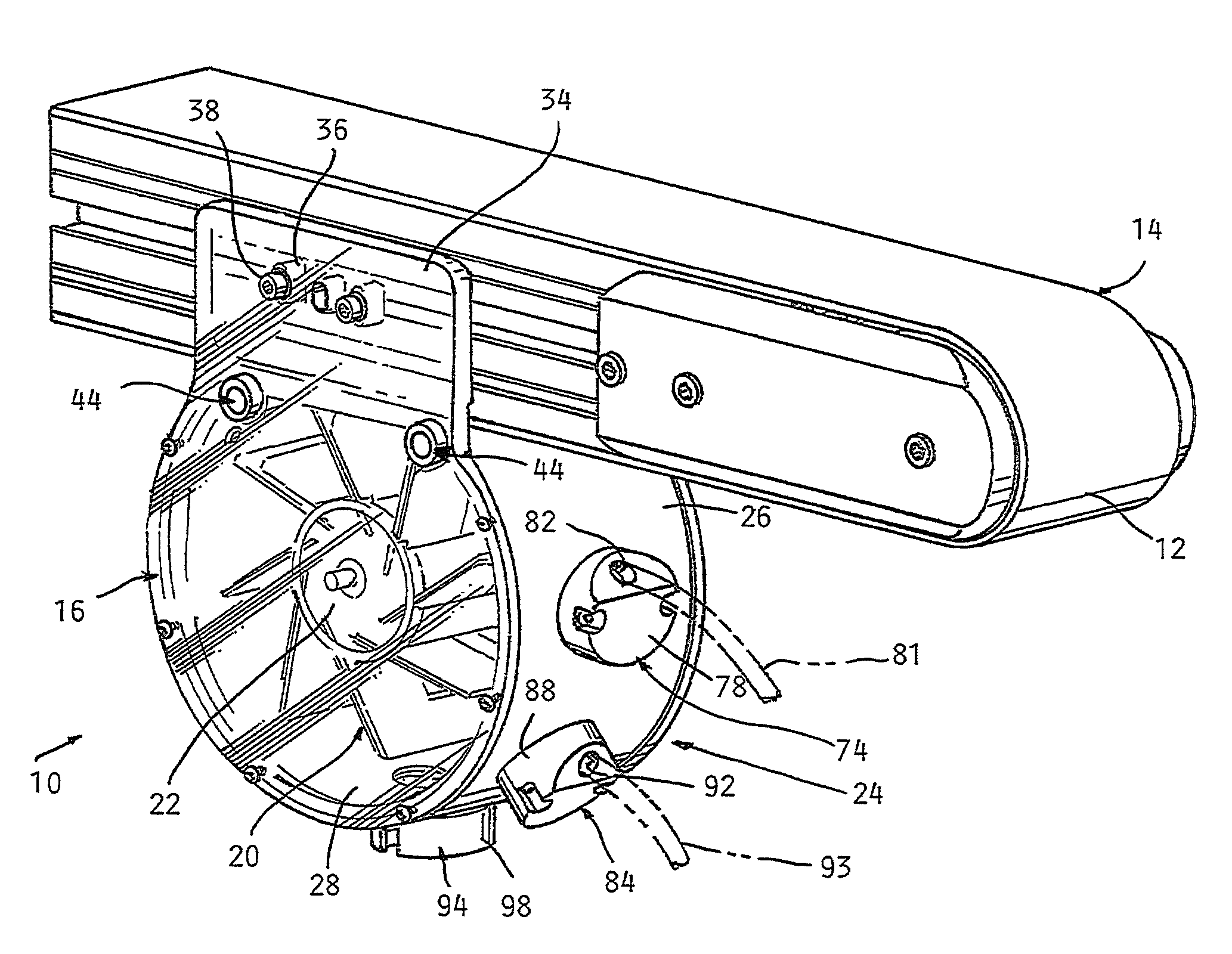

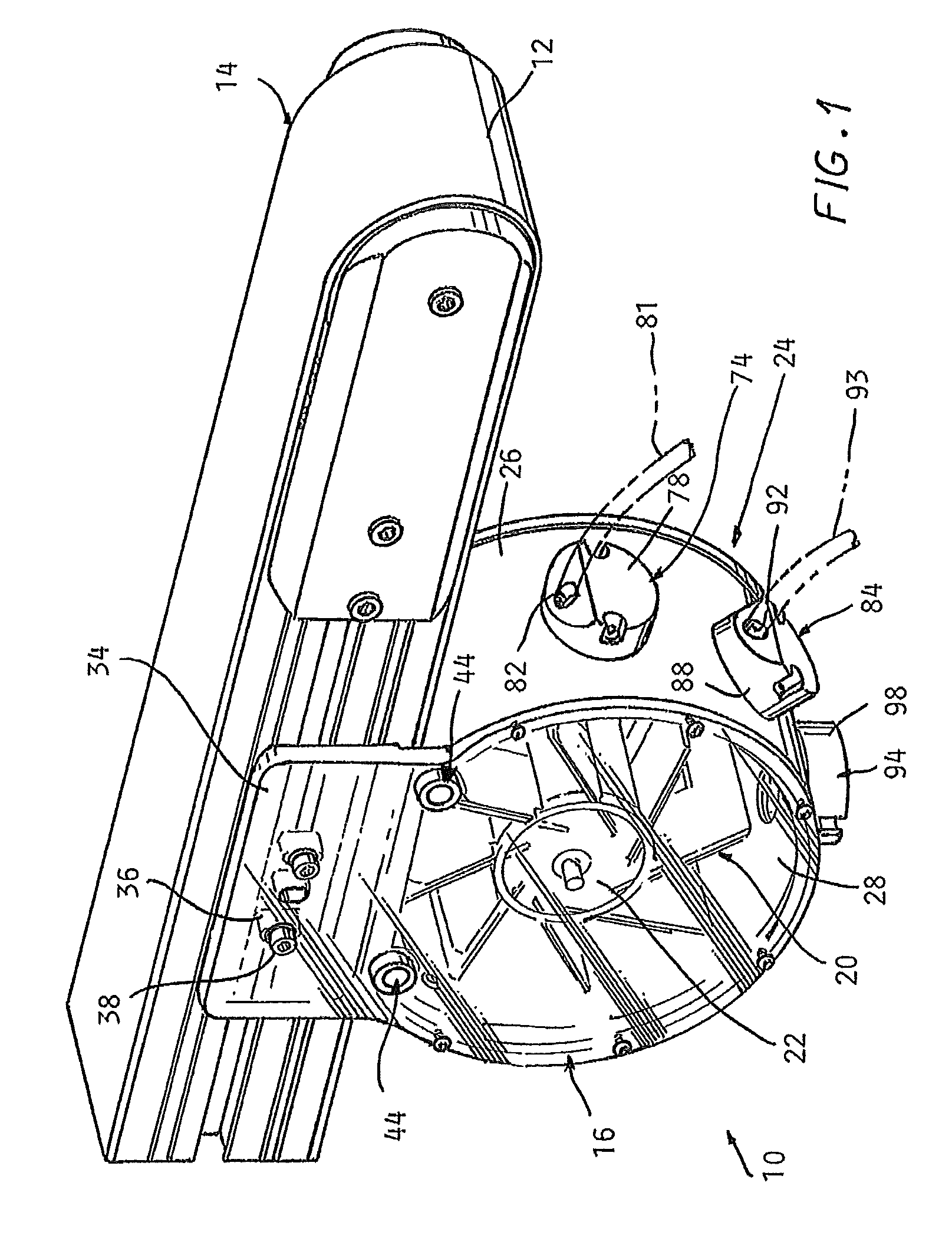

Apparatus for cleaning a conveyor belt

An apparatus for cleaning a moving conveyor belt of a conveyor belt assembly. The apparatus includes an enclosed housing connectable to the conveyor belt assembly, wherein the housing has an open portion adjacent to the moving conveyor belt. A hub is rotatably connected to and within the enclosed housing, and a plurality of wipers are releasably connected to and extend outward from the hub. A driving means rotates the hub and the wipers such that the plurality of wipers at least partially engage and wipe the conveyor belt clean, as the wipers rotate through the open portion of the housing.

Owner:AUTOMATIC FEED

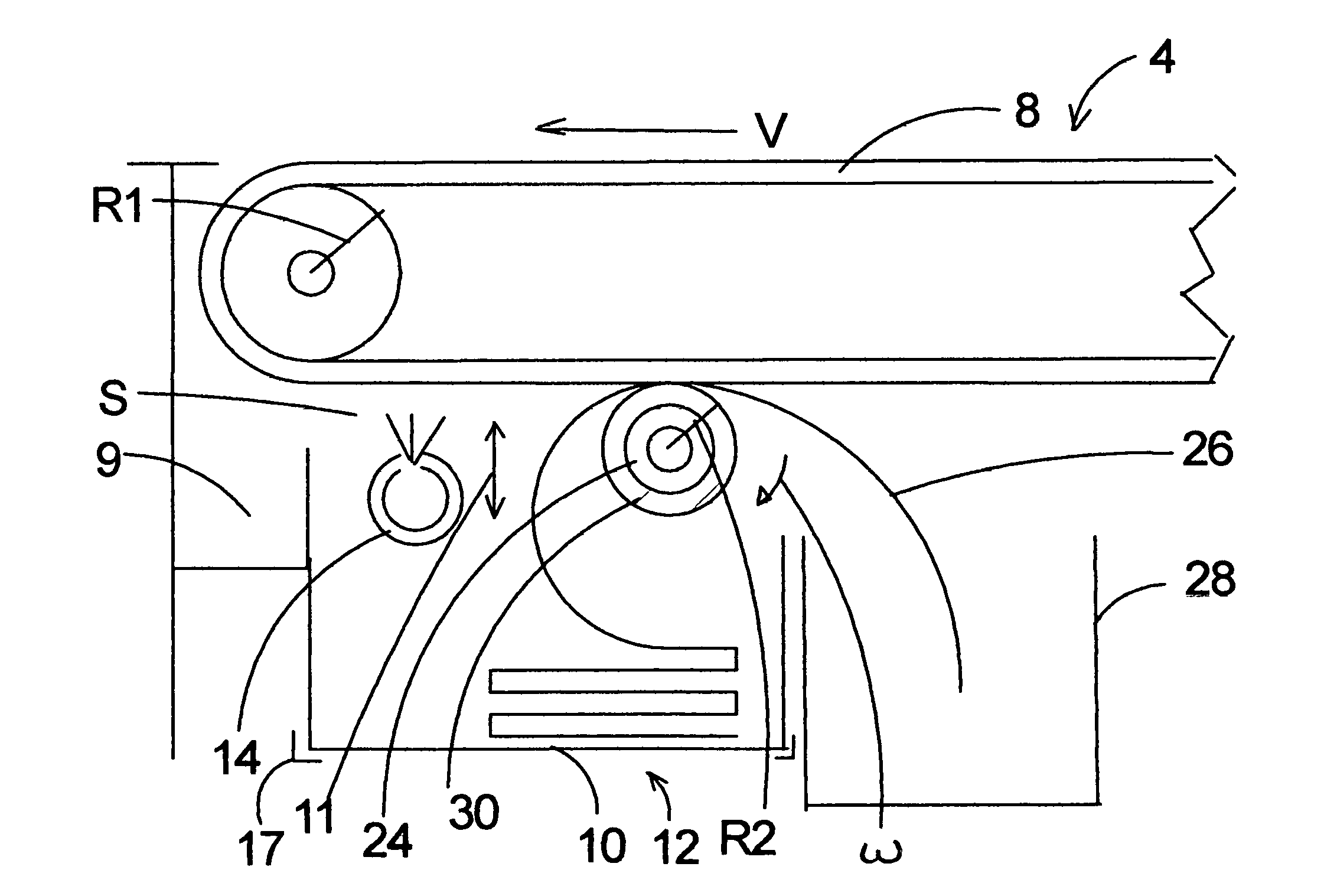

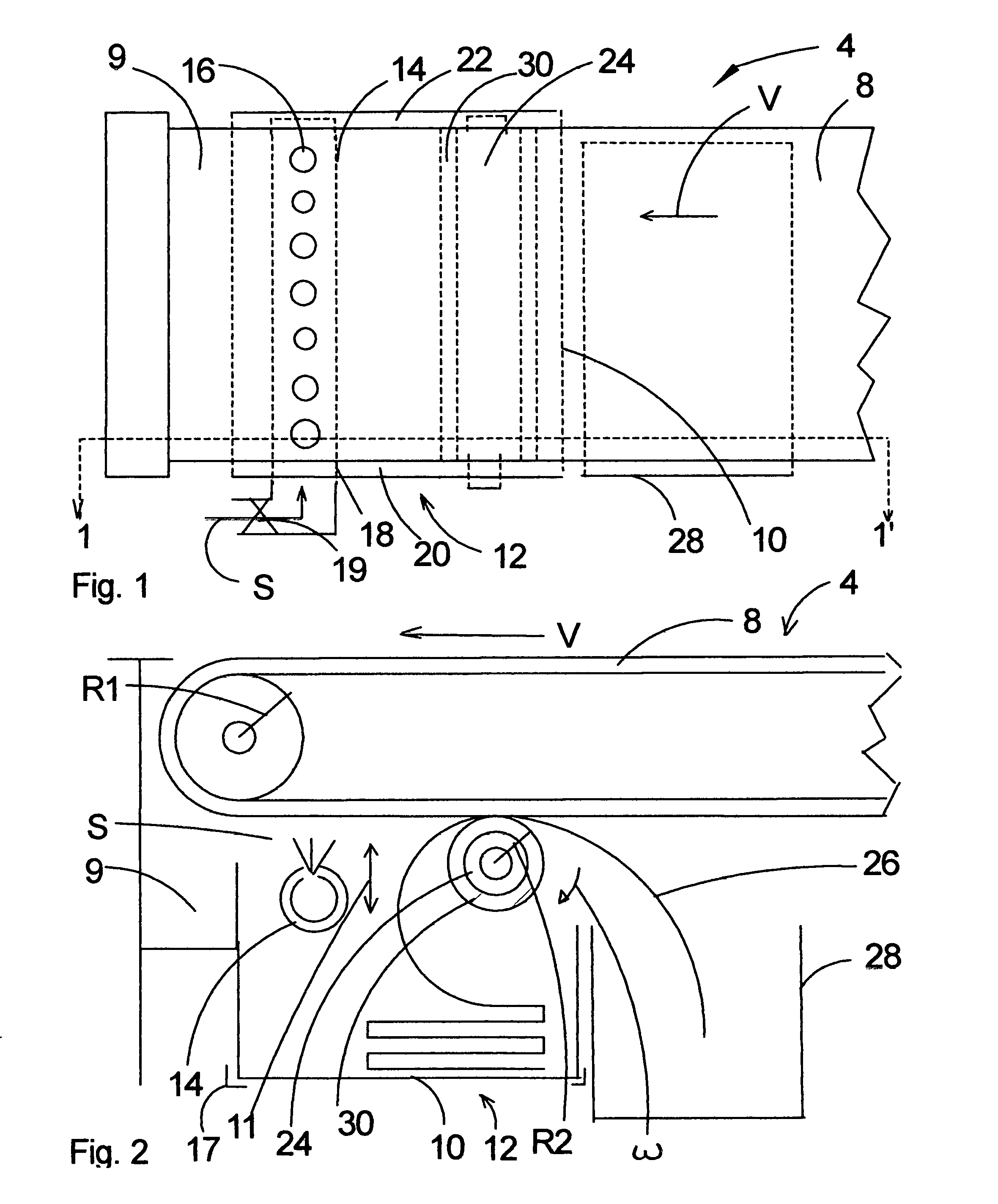

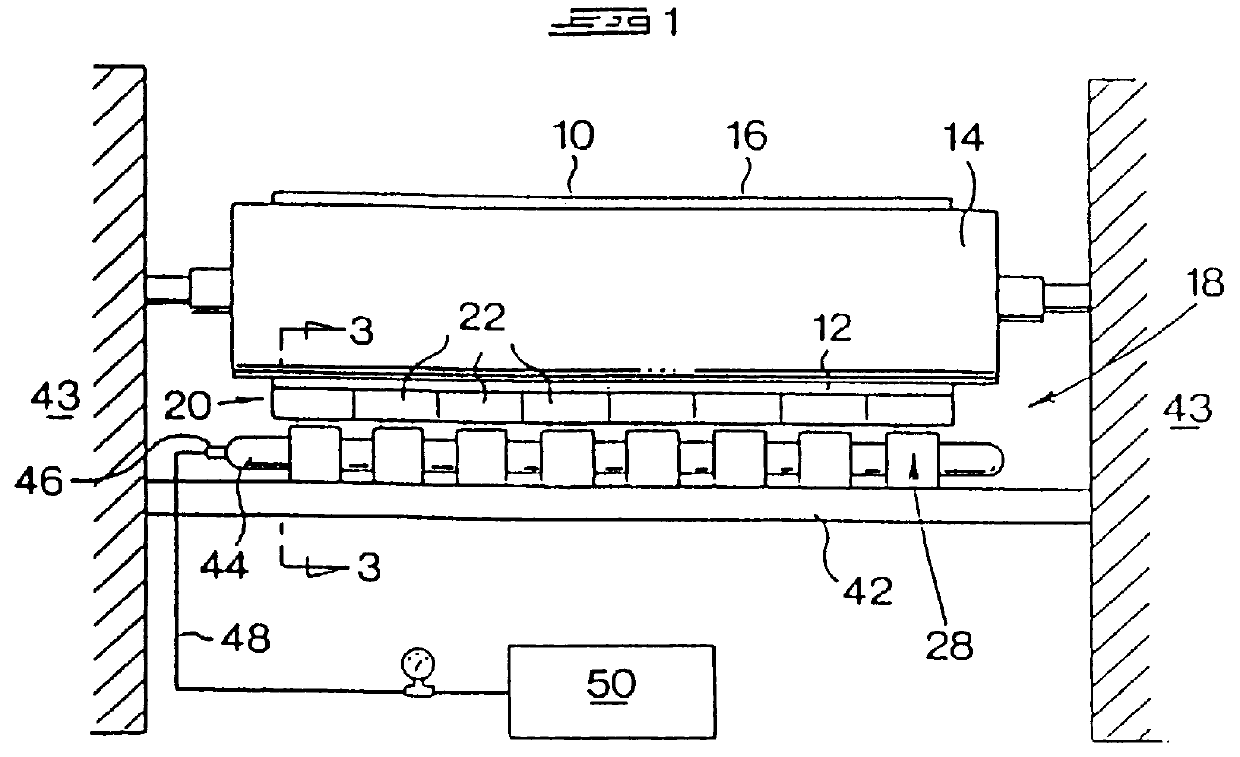

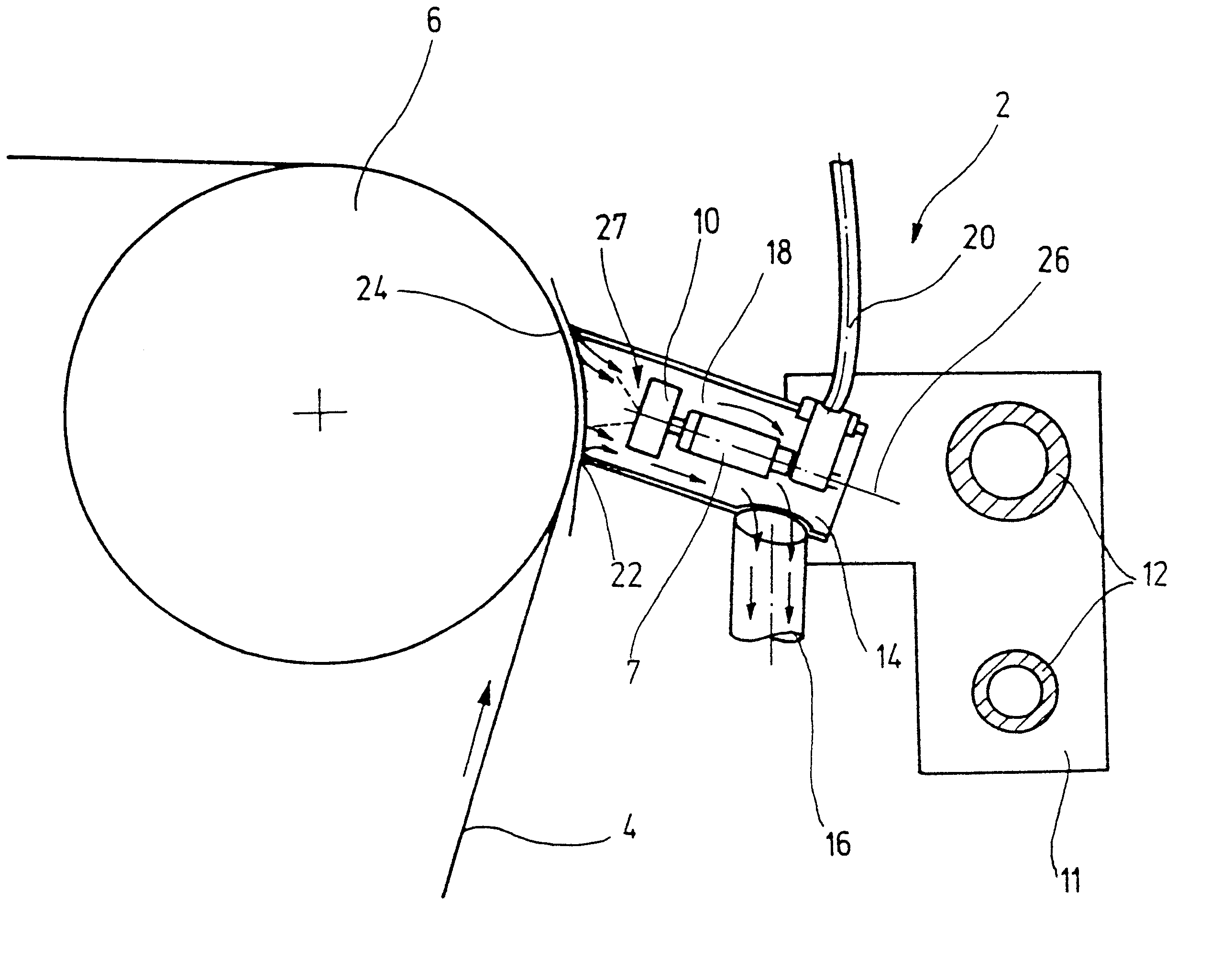

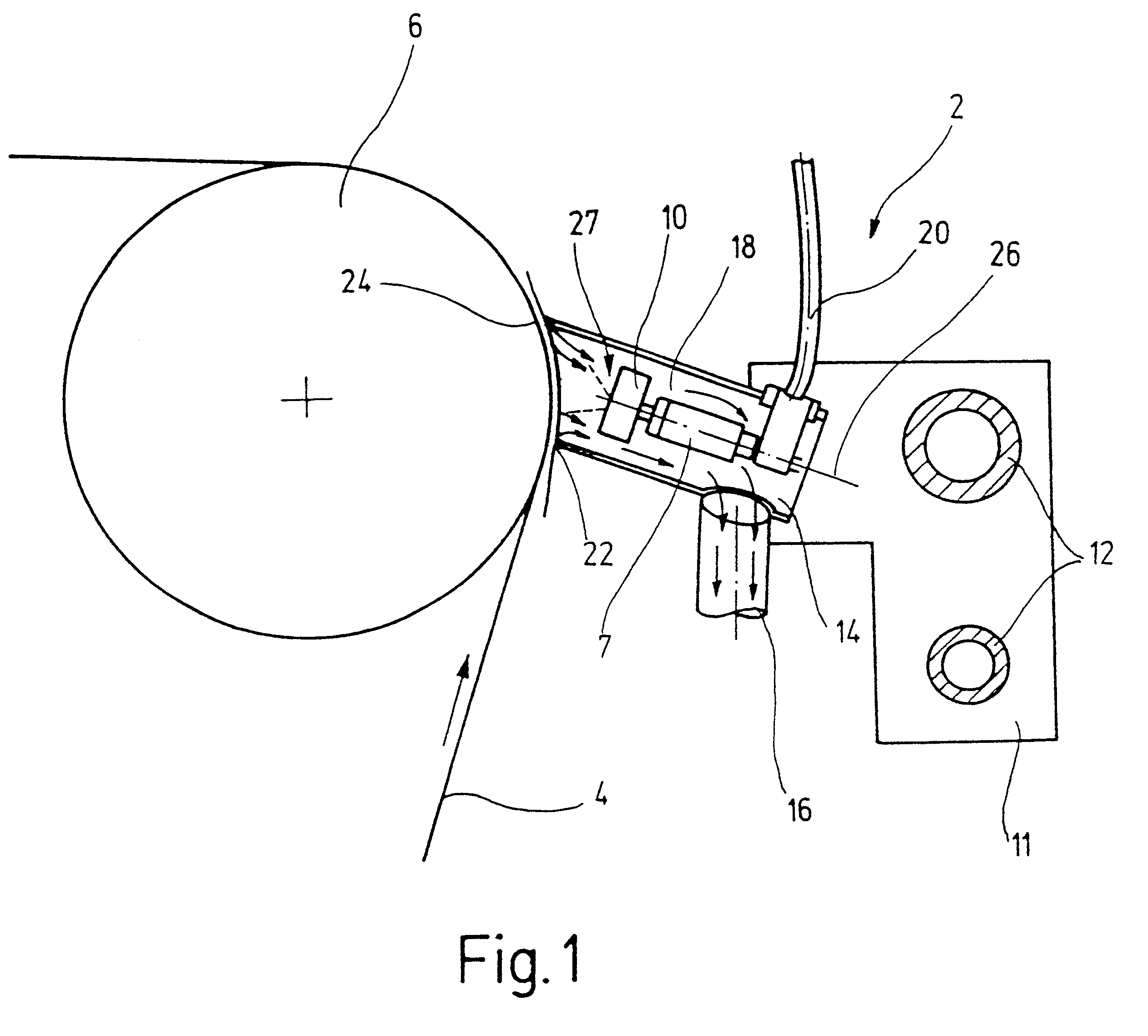

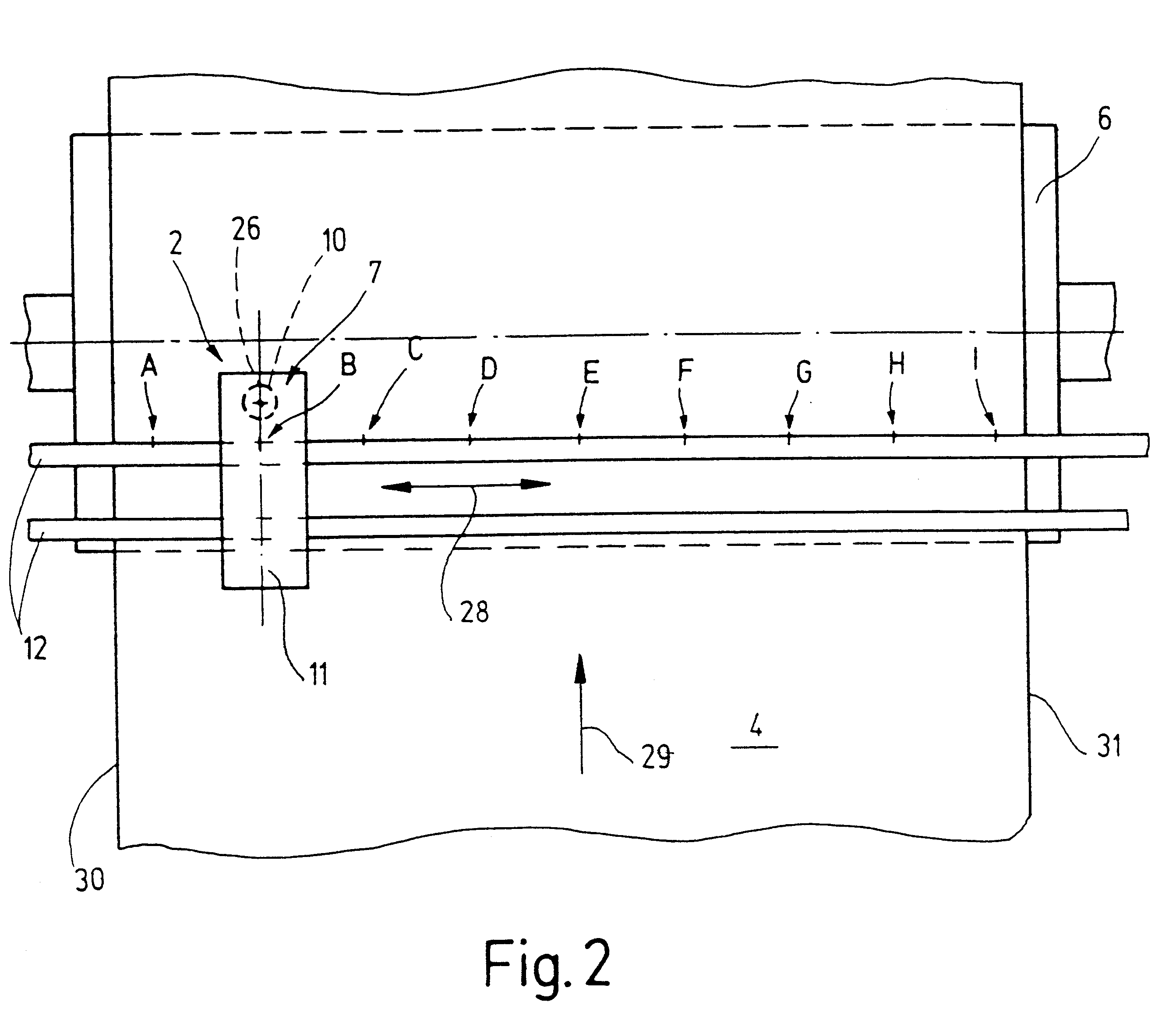

Process for cleaning a transport belt

InactiveUS6364959B1Reduce movement speedUniform and intense and cleaningCleaningWork treatment devicesEngineeringNozzle

A process and apparatus for cleaning a transport belt of a machine for the production or processing a web. The apparatus includes at least one nozzle device composed of a rotatable nozzle head having at least one cleaning nozzle, a transport device including a crosspiece extending substantially crosswise to a transport belt travel direction, in which the at least one nozzle device is coupled to the transport device and adapted for displacement along the crosspiece. A traversing speed of the nozzle device is very low and falls within a range of between approximately 1 mm / min and 10 mm / min. Alternatively, the at least one nozzle is positionable in a plurality of cleaning positions that are successively arranged crosswise to the transport belt, and the at least one nozzle is held stationary in each respective cleaning position for a predefined time period. The process includes displacing the at least one cleaning nozzle at a very slow traversing speed within a range of between approximately 1 mm / min and 10 mm / min. Alternatively, the process includes discontinuously moving the at least one cleaning nozzle to a plurality of cleaning positions successively arranged in a transport belt travel direction, positioning the at least one nozzle to remain in the cleaning positions for a predefined period of time, and rapidly displacing the at least one nozzle between adjacent cleaning positions.

Owner:VOITH PATENT GMBH

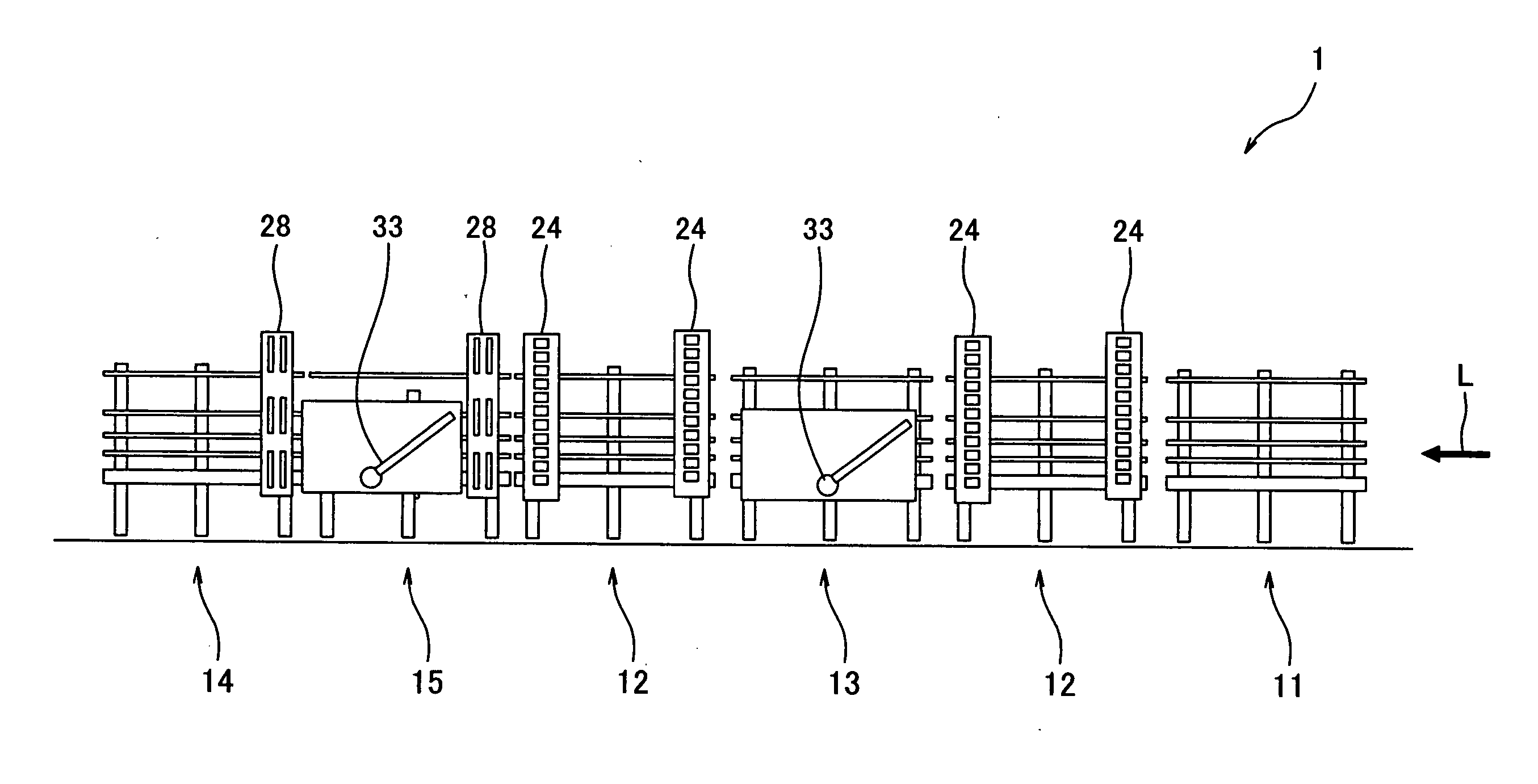

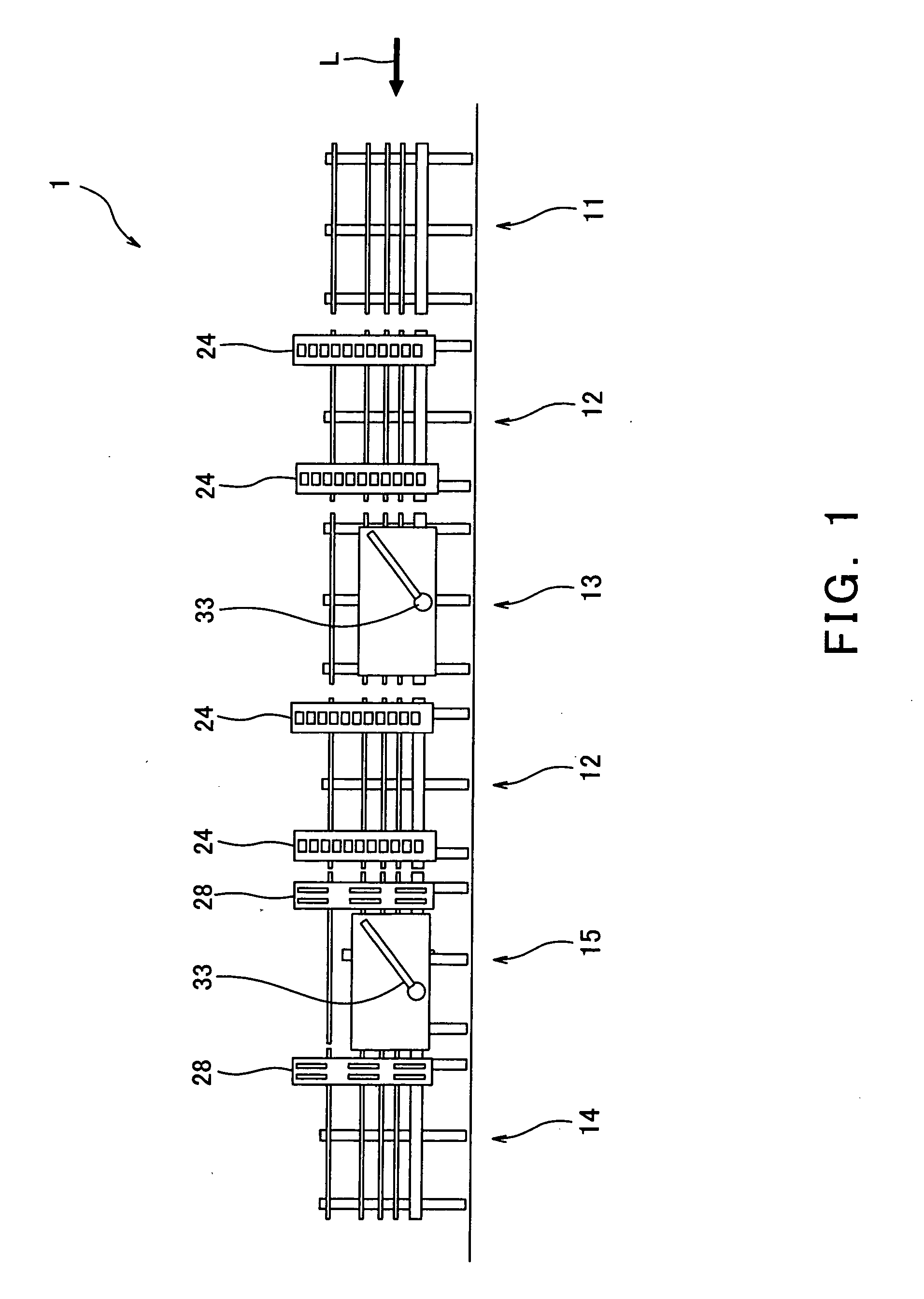

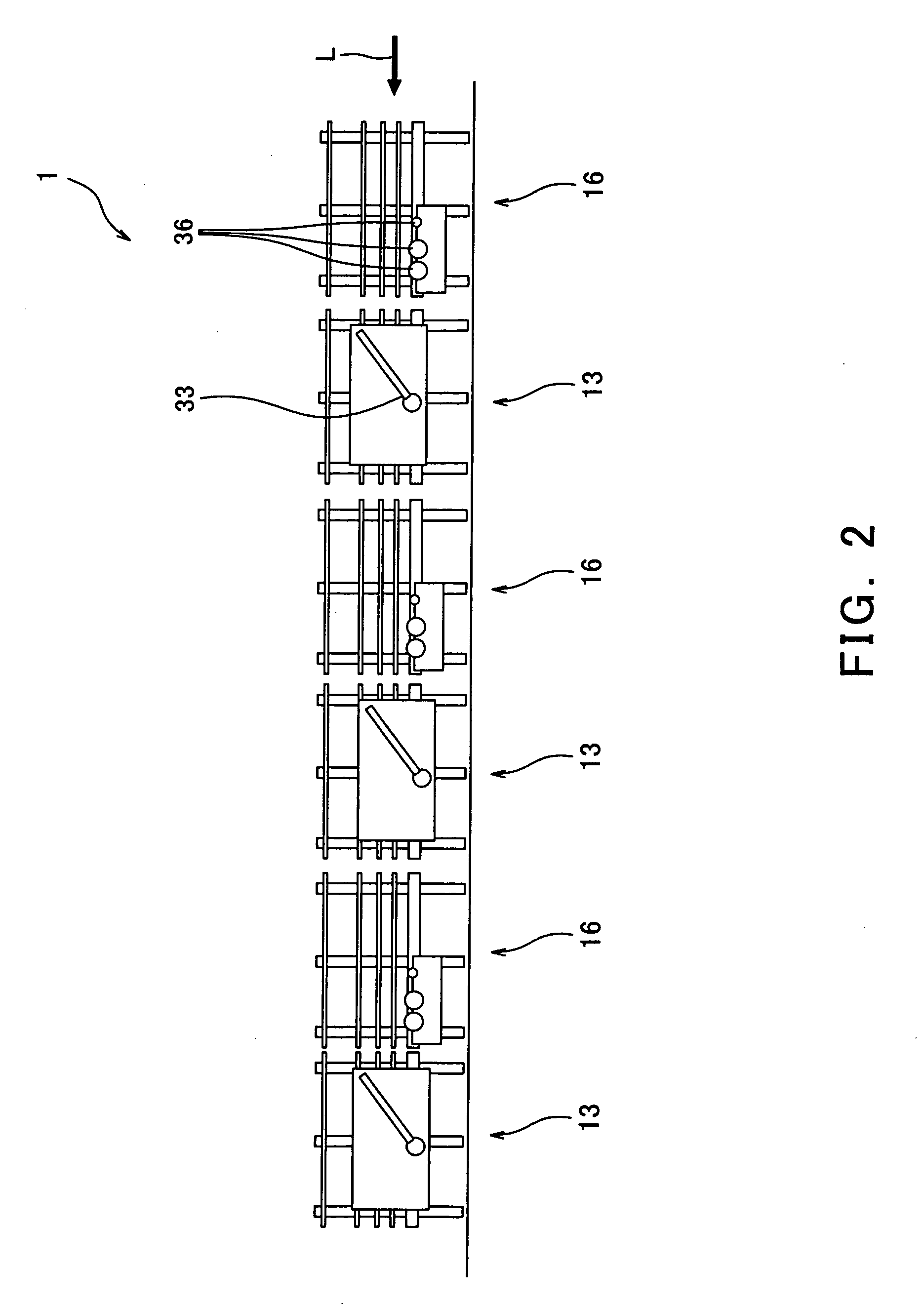

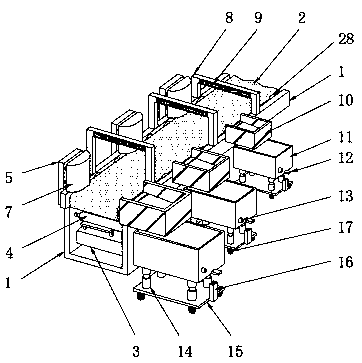

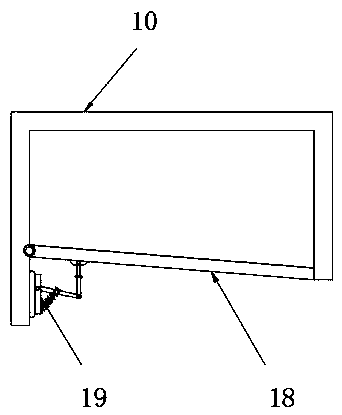

Plate Material Vertical Processing Line

ActiveUS20070271756A1Quality improvementSave installation spaceCharge manipulationSupporting framesHigh pressure waterHigh pressure

A plate material vertical processing line that is capable of subjecting large-sized and thinned glass plates to scribing, venting, etc without degrading their quality, comprises a plurality of processing devices each having a modular structure; wherein each of the processing devices includes a platform; a belt conveyor that is mounted on the platform and is configured to convey a glass plate placed in a substantially upright position while supporting a lower end of the glass plate; and a fluid guide that is mounted on the platform and is configured to apply a fluid pressure to a surface of the glass plate to support the glass plate in the substantially upright position and in a non-contact state; and wherein the processing devices include a combination of at least two processing devices selected from a scribing device, a venting device, a chamfering device, a cleaning agent washing device, a water washing device, a high-pressure water spray device, and a glass plate turn device.

Owner:KAWASAKI HEAVY IND LTD

Light duty belt cleaning system

Owner:ASGCO MFG

Self-cleaning foodstuff conveyors

A conveyor suitable for use, e.g., in food processing apparatus, includes particular procedures and arrangements for decontaminating the surface of the conveyor. The conveyor surface is subject first to a mechanical cleaning, e.g., by spraying of liquid followed by brushing in a rinse / clean unit. This step displaces gross debris from the conveyor surface. In a second step, the surface is subjected to UV irradiation to sterilize the cleaned surface. This UV irradiation may be provided by banks of UV lamps between which the conveyor passes. Detectors for residual organic material may be used to monitor the cleanliness of the surface.

Owner:NEWMAN PAUL BERNARD

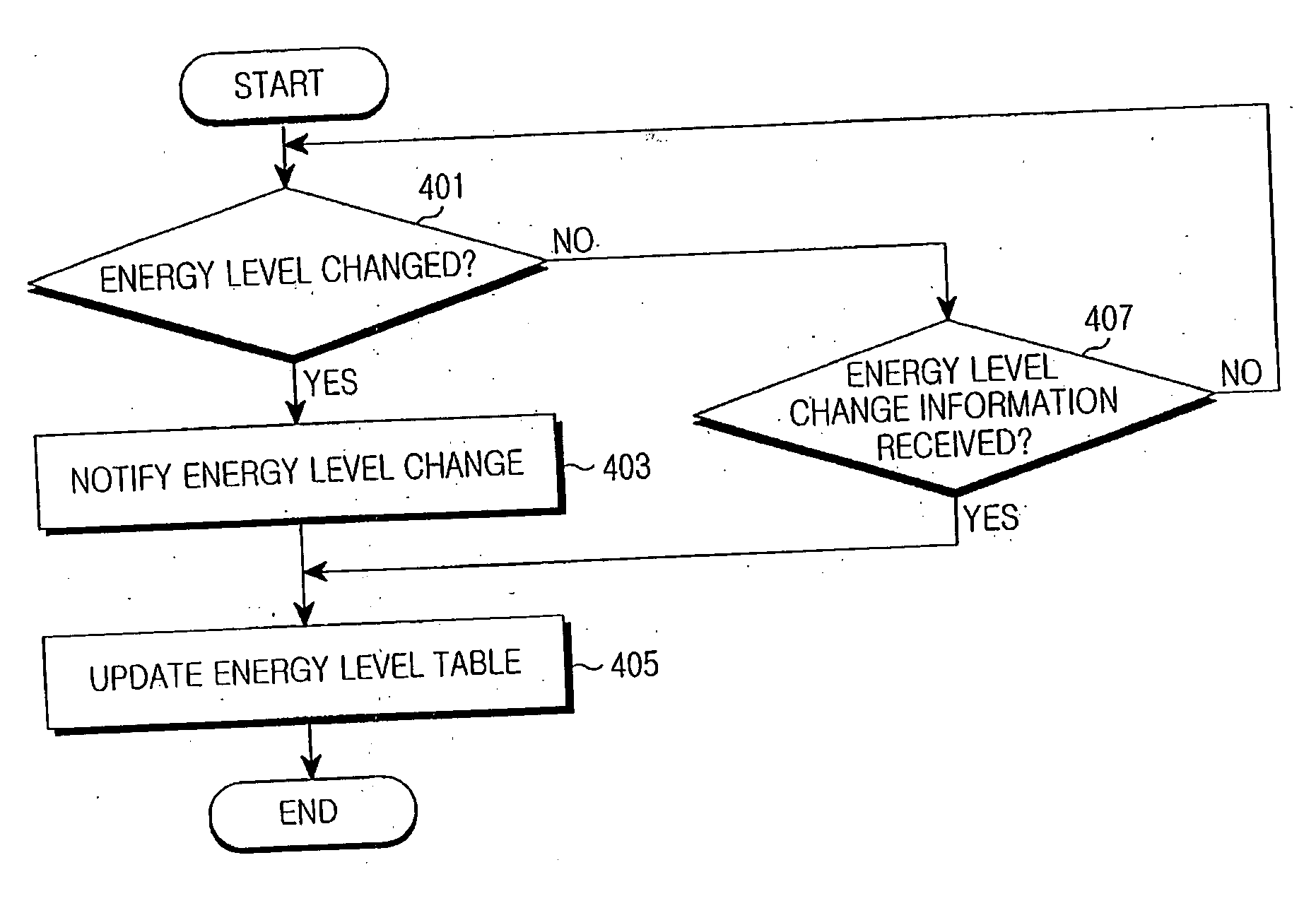

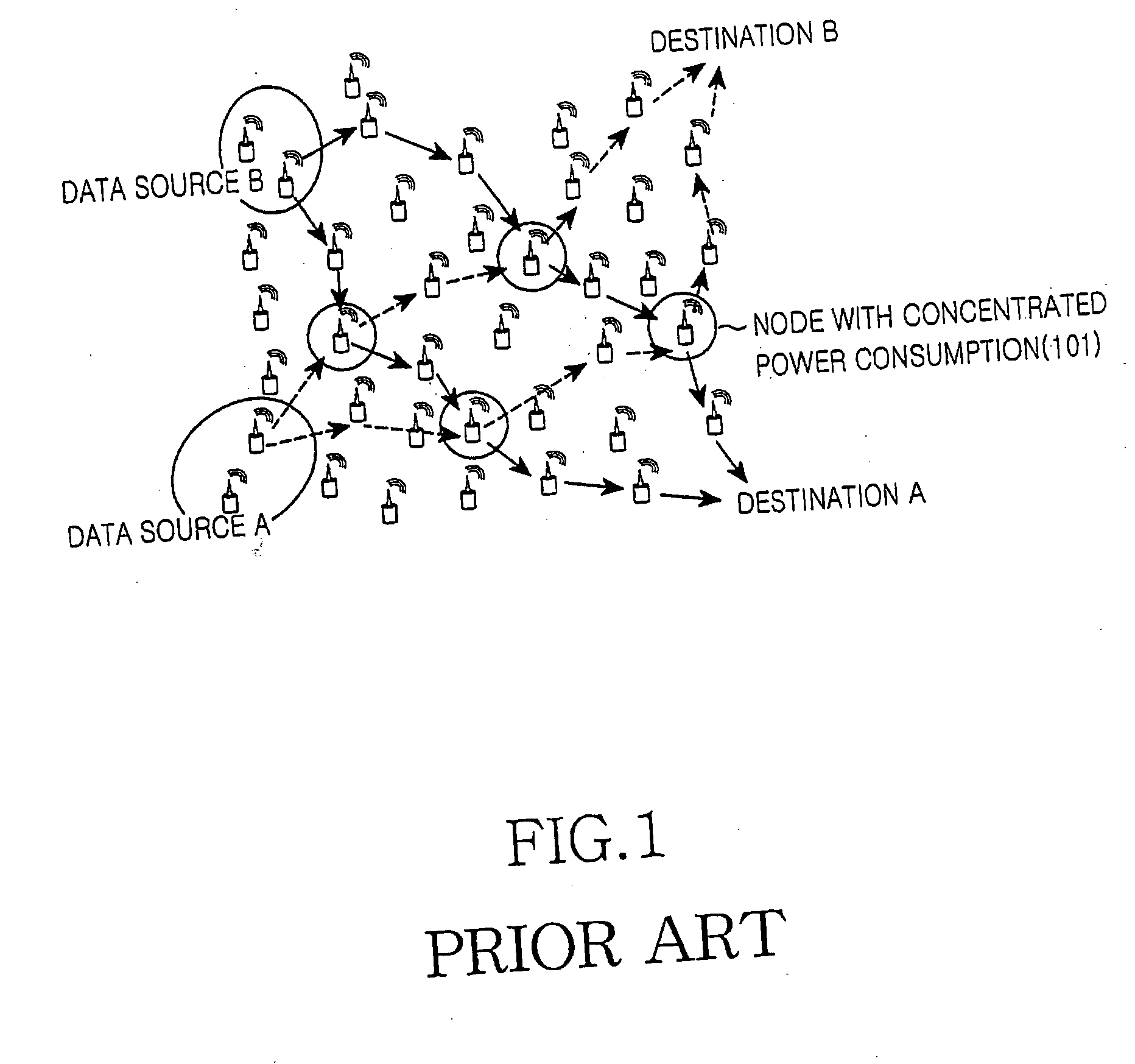

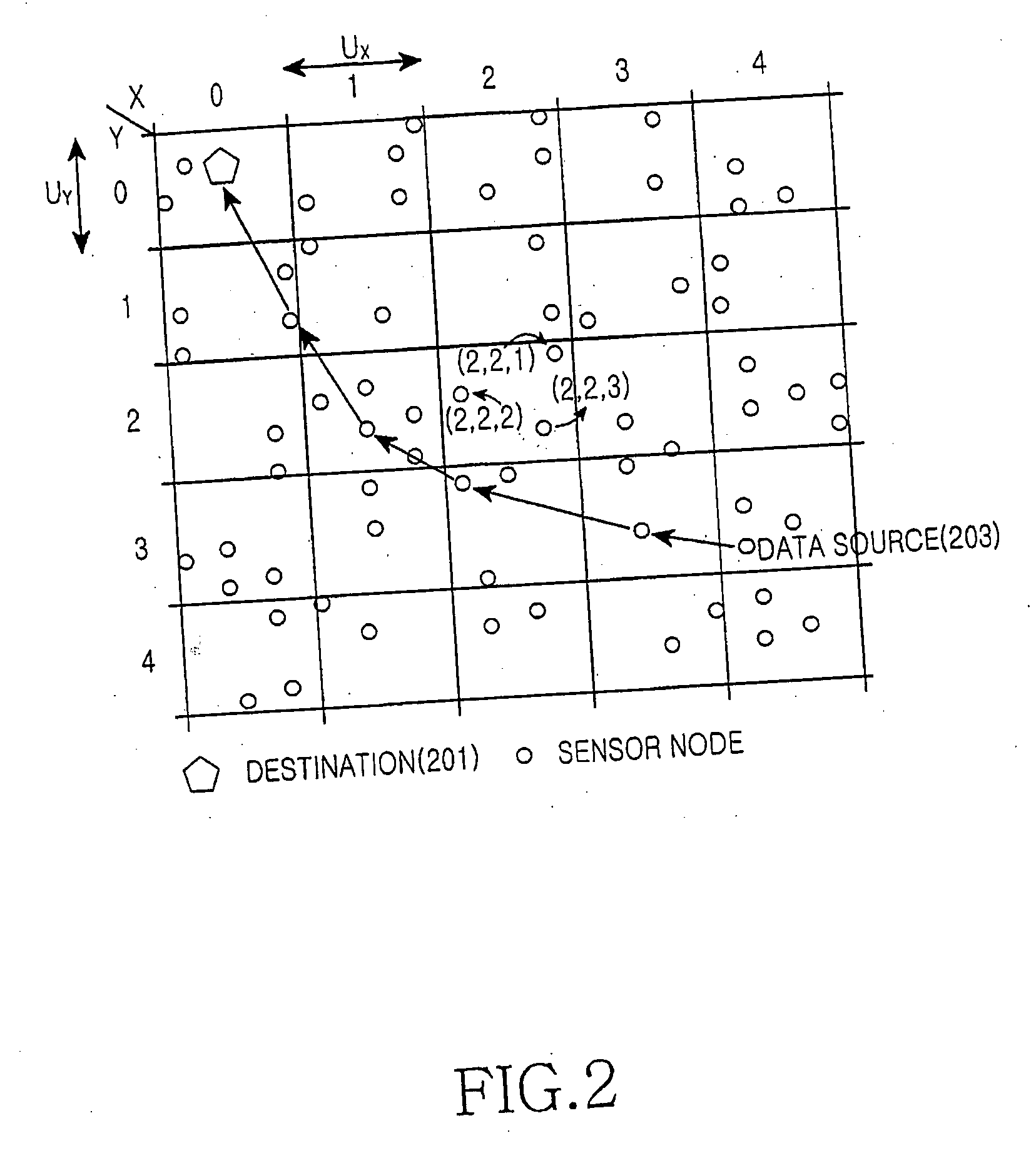

Routing method in a wireless sensor network

InactiveUS20060178156A1Preventing concentrated power consumptionConveyorsCleaningLine sensorWireless sensor networking

A routing method in a wireless sensor network where sensor nodes are grouped into cells is provided. Upon receipt of detected information to be transmitted to a destination, a sensor node determines whether a cell to which the destination belongs is one hop away. If the cell of the destination is not one hop away, the sensor node selects a cell set close to the destination from available neighbor cells to which the detected information can be forwarded, selects a cell from the cell set according to energy densities of the cells in the cell set, and forwards the detected information to a main sensor node of the selected cell.

Owner:SAMSUNG ELECTRONICS CO LTD

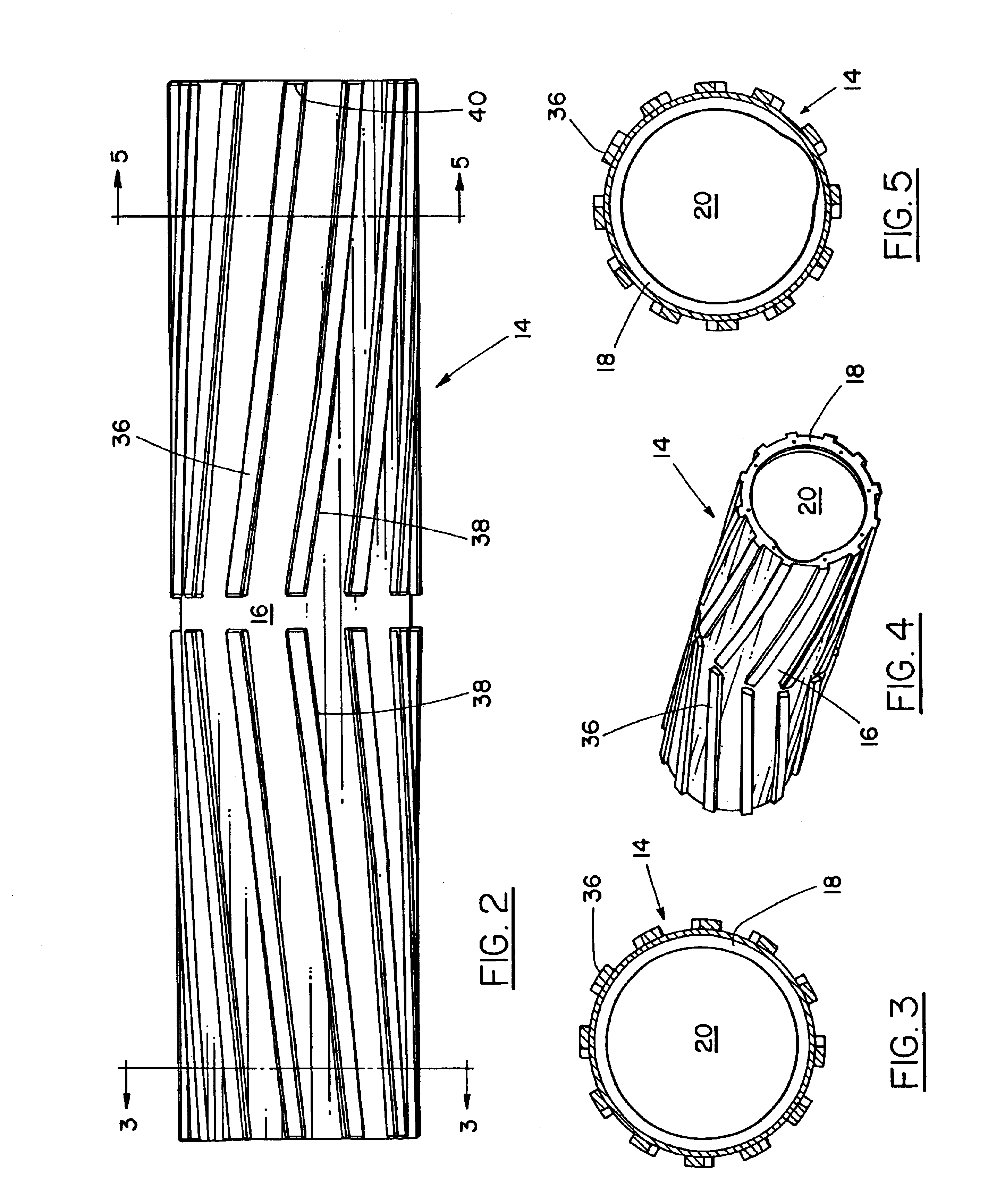

Self-cleaning conveyor roller

A self cleaning conveyor roller for supporting a conveyor media carrying contaminant materials. The conveyor roller consists of a drum defining a support surface, having a generally cylindrical shape, and being adapted to be supported for rotation, for supporting a conveyor media. The conveyor roller has a plurality of abutments on the support surface, raised above the support surface, and defining a series of spaced apart conveyor media support ridges lying on a circular configuration, concentric with the drum. The abutments are arranged in generally chevron shapes, around the drum. During rotation of the conveyor roller the abutments cause any debris or contaminants between the roller and the conveyor media to be guided out of the conveyor system. Also disclosed is a method of cleaning a conveyor roller.

Owner:VAN DER GRAAF

Stripping device for the return run area of conveyor belts

Apparatus for stripping a belt in conveyor belt assemblies includes a stripping element on a system carrier, the stripping element having a stripping lamella on a lamella holder, the stripping lamella contacting the belt in a peeling position, wherein the stripping element has a swivel mount coupled to the lamella holder and a swivel axis parallel to a plane of the belt, a spring for pressing the stripping lamella against the belt such that the lamella holder in the peeling position is swiveled about the horizontal axis, and when obstructions adhering to the belt impact the stripping lamella, the lamella holder deflects and returns a working position, wherein the stripping lamella is swivel mounted at the lamella holder by a swivel mount having an axis parallel to a plane of the belt and is held and spring biased by a top spring is counter to the bottom swivel mount spring.

Owner:KILL FRECH CORNELIA

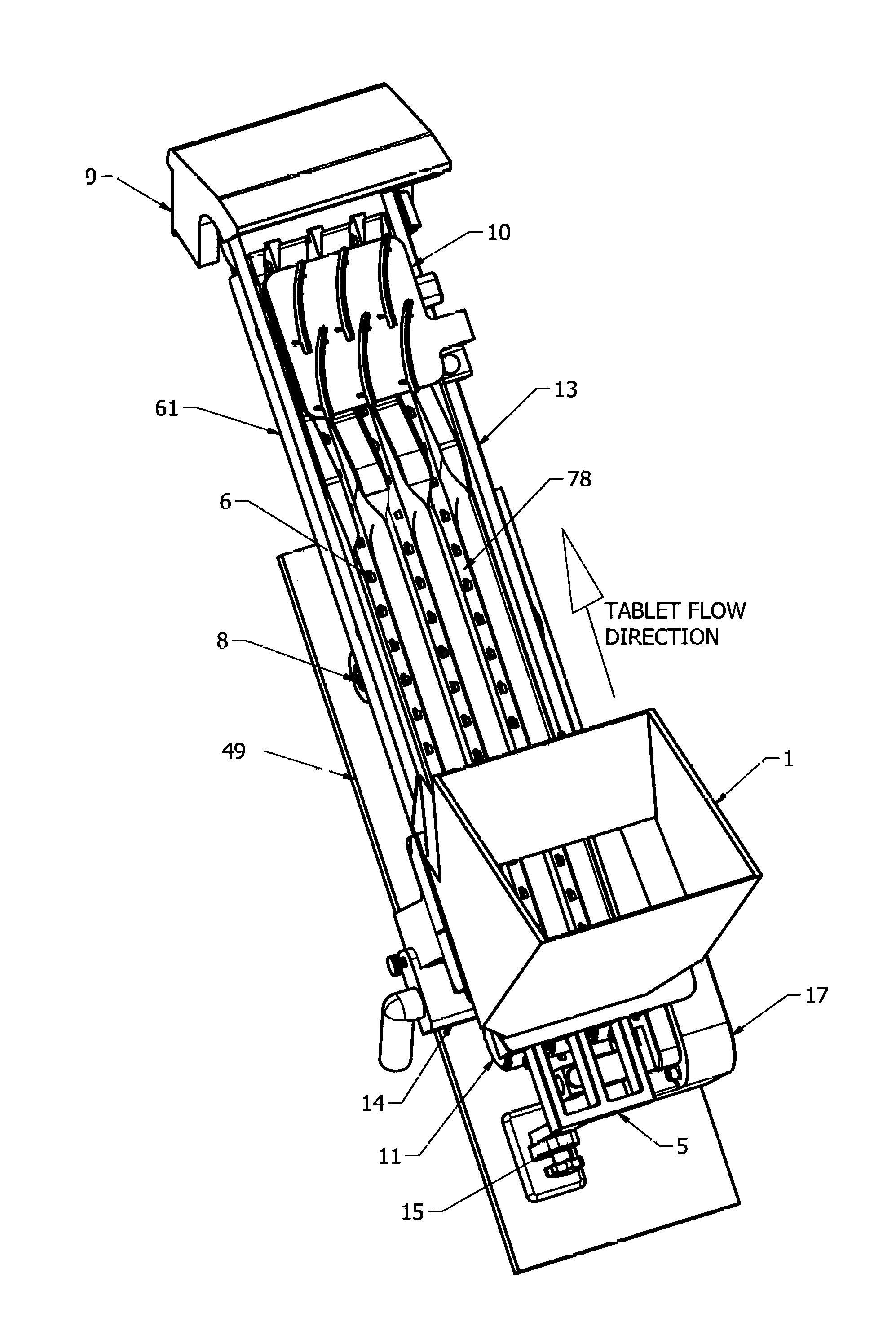

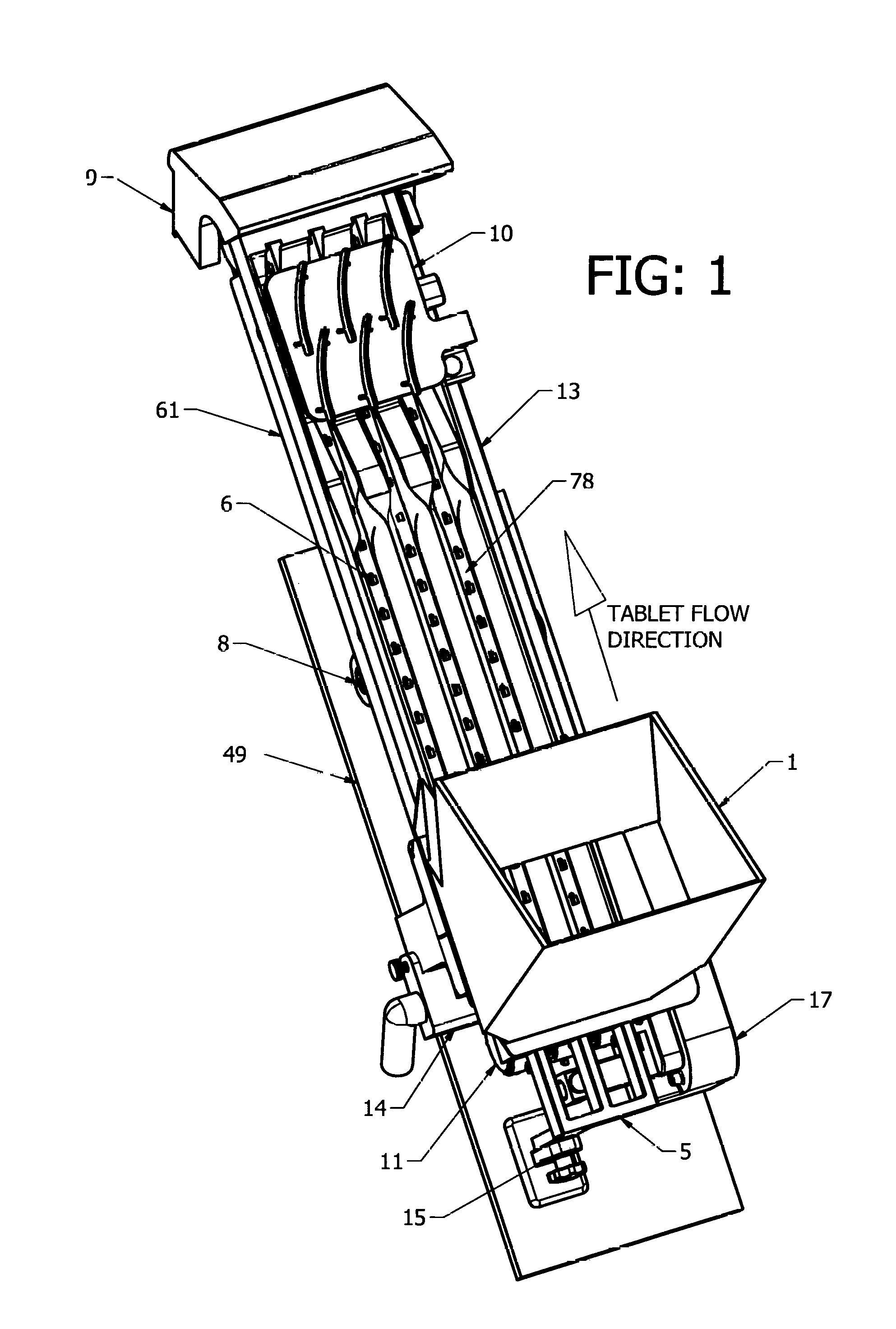

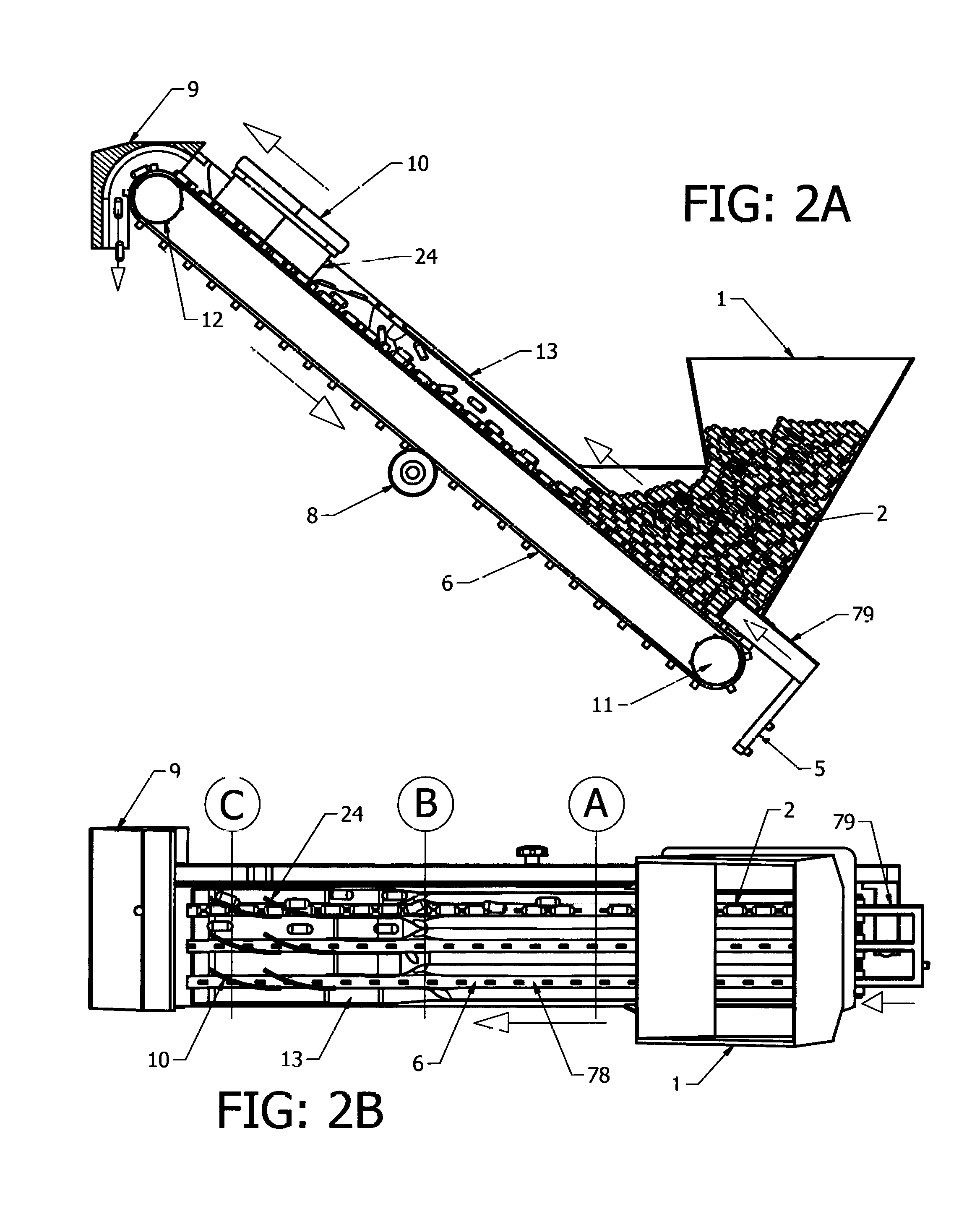

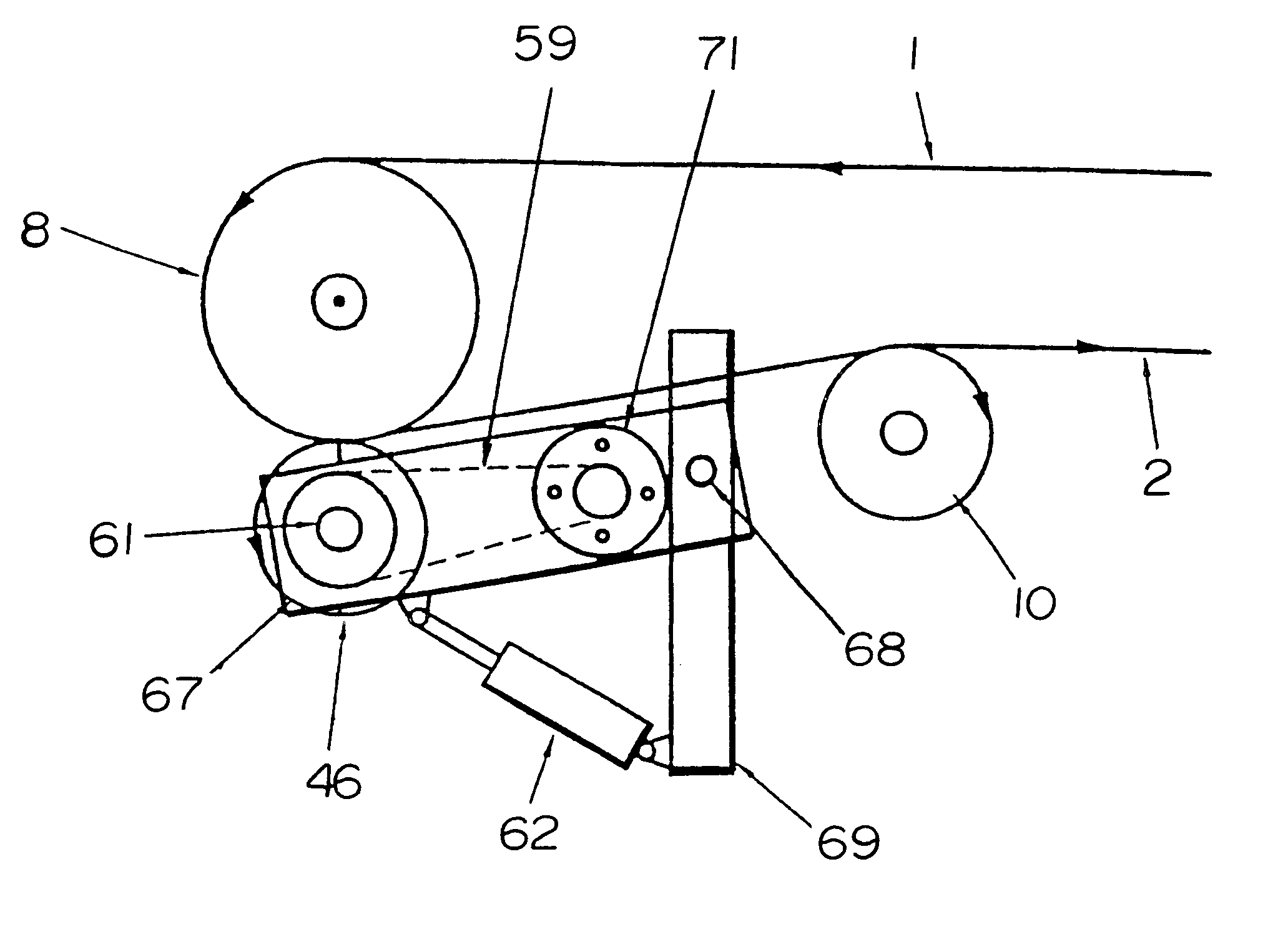

Belt sorting system

InactiveUS20160229575A1Shorten the lengthQuiet and simple and inexpensive to operateConveyorsCleaningEngineeringSpace object

The object counter is provided which includes a conveyor belt having regularly spaced object retaining posts for retaining single objects on the belt in a lane for transport in single file manner from a lower feed end to an upper discharge end. Each lane has lateral guide members for helping objects to settle in the lane between retaining posts during transport on the conveyor belt between the lower feed end and the upper discharge end. A hopper is arranged at the lower feed end of the conveyor belt for providing a quantity of objects to the conveyor belt. A deflector is arranged over the lane before the upper discharge end for removing objects from the lane that settle on top of objects settled in the lane between said retaining posts. An item detector is arranged at the upper discharge end for detecting the passage or discharge of individual objects.

Owner:3605329 CANADA INC

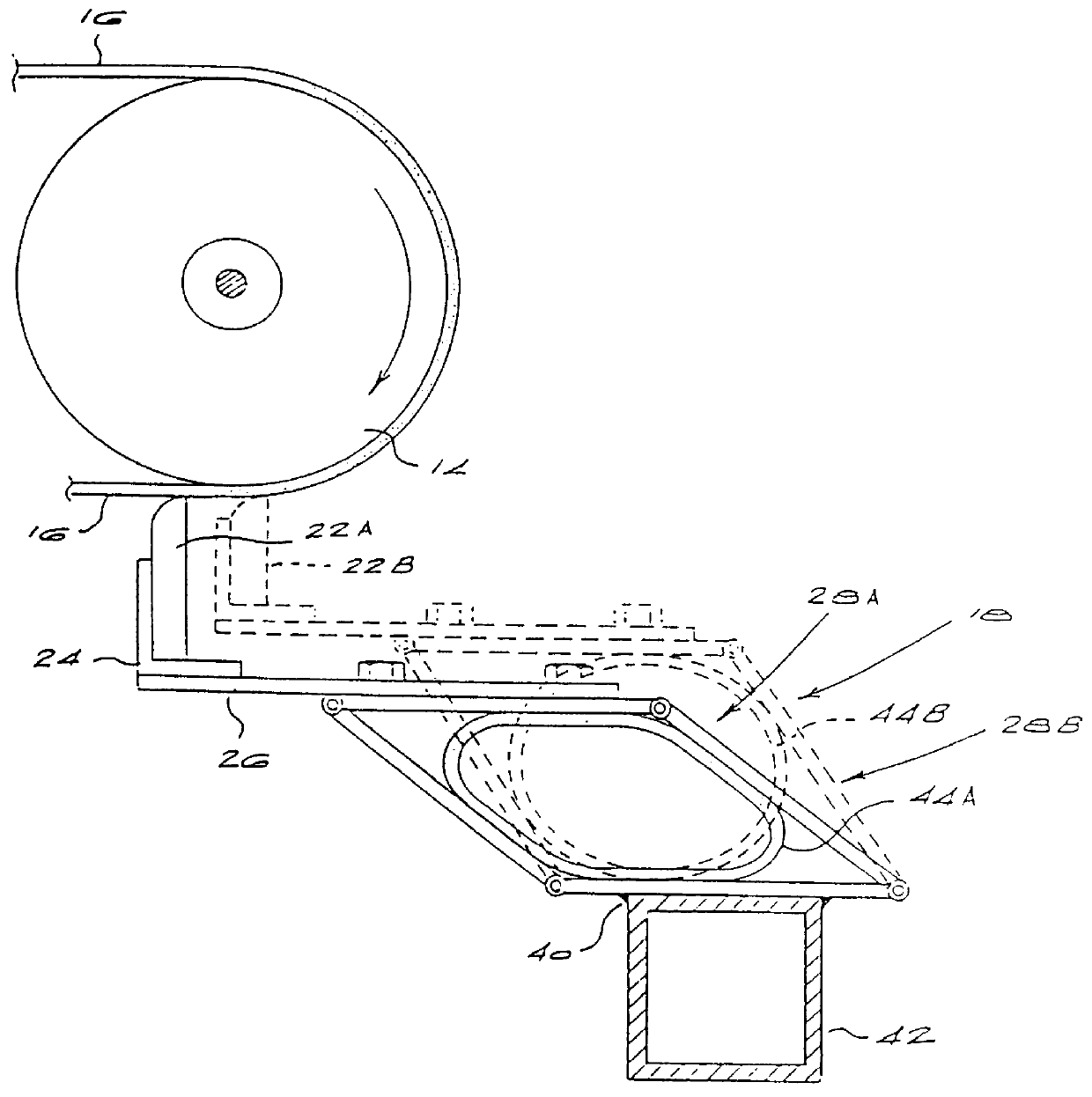

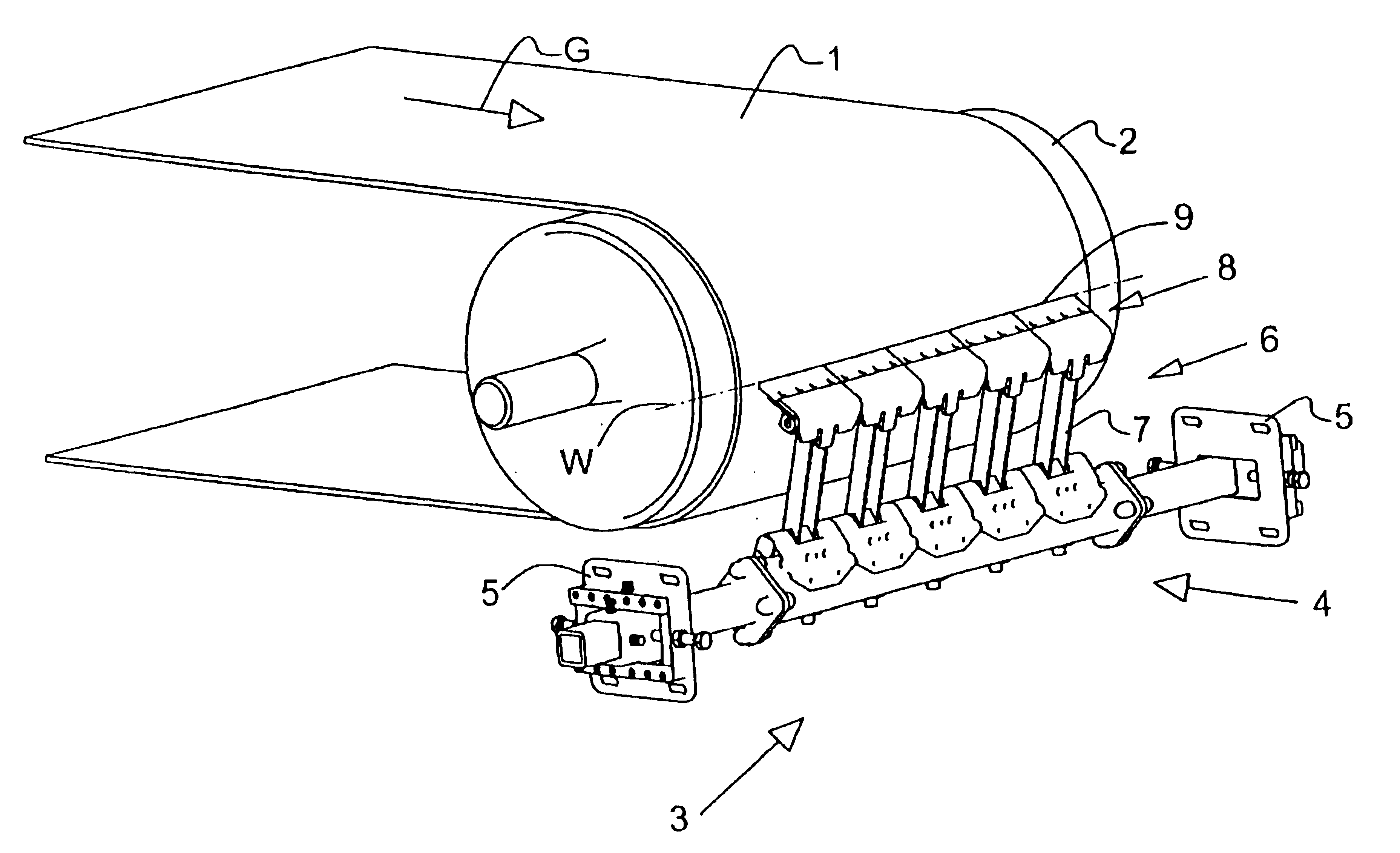

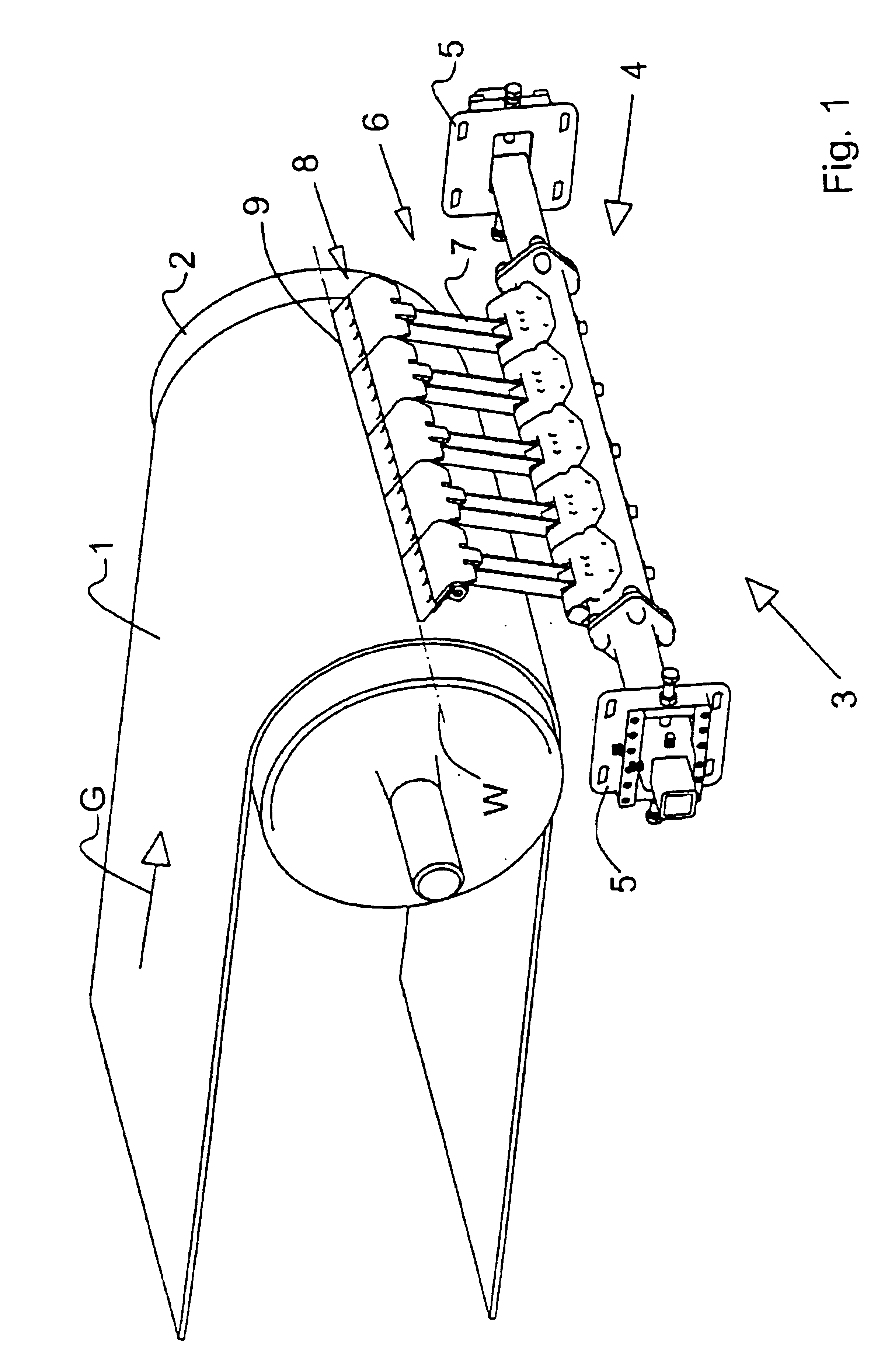

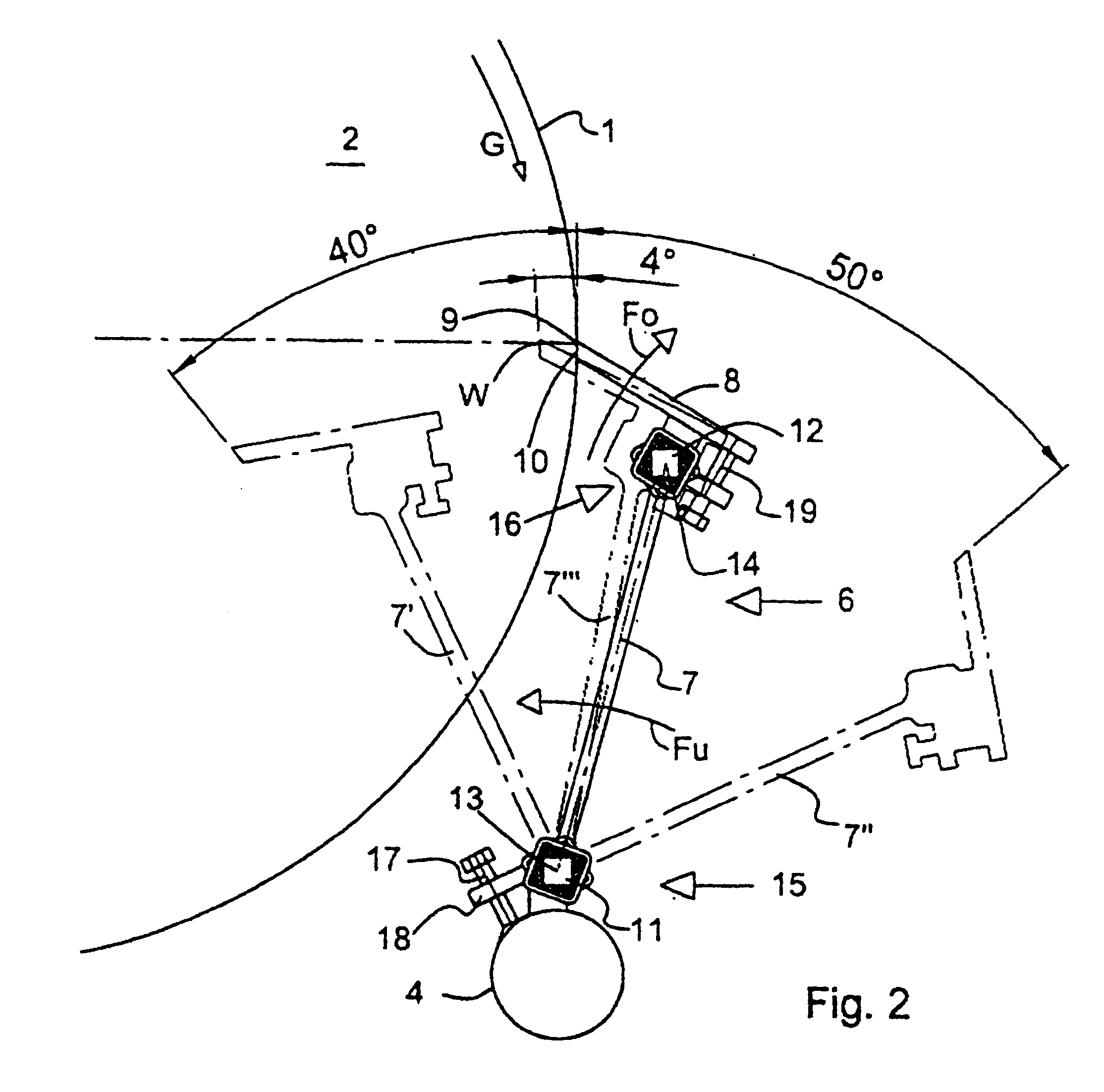

Power take off from an endless conveyor

A hydraulic power take off device for an endless conveyor belt system having an upper material run and a lower return run, said device being arranged to generate hydraulic fluid at pressure to maintain a self adjusting force to belt cleaning equipment, and other equipment that can utilize fluid pressure. The take off device is driven directly or indirectly from the motion of the conveyor belt or from the motion of other components fitted to the endless system. The power take off comprises a hydraulic pump which is rotated by the motion of the endless conveyor and generates fluid at pressure via an adjustable relief valve and maintains a constant self adjusting force of actuators, automatically compensating for wear that takes place on the equipment being operated and providing an automatic and interlocked source of power, generating pressure only when the conveyor belt system operates.

Owner:MARTIN BULK HANDLING SOLUTIONS (PTY) LTD

Sorting device convenient to classify express packages

ActiveCN108657800AEasy to classifyEasy to pack and transportConveyorsCleaningSurface mountingPortal frame

The invention discloses a sorting device convenient to classify express packages. The sorting device comprises a conveyor; a conveying belt is mounted on the upper surface of the conveyor; an arc block is fixedly mounted on the side, near the conveying belt, of the upper surface of the conveyor; an electrostatic generator is embedded in the conveyor; a cleaning roller is embedded in the upper side, near the electrostatic generator, in the conveyor; a fixed plate is fixedly mounted on one side of the conveyor; an express outlet box is fixedly mounted on the other side of the conveyor; and portal frames are fixedly mounted on the side, near the arc block, of the upper surface of the conveyor. Through the portal frames with different heights, the express packages can be classified and sortedaccording to the heights thereof, so that the express packages in the same regions can be conveniently transported; through a push plate and the arc block, the damage problem of the express packages caused by long-time friction with the conveyor can be prevented; and the electrostatic generator and the cleaning roller can clean the conveying belt during working of the conveyor.

Owner:磐安县天诚科技有限公司

Method and apparatus for cleaning and sanitizing conveyor belts

InactiveUS20100243410A1Easy to clean automaticallyEasy to modifyCleaningEngineeringMaterial Perforation

A conveyor belt cleaning and sanitizing apparatus includes a hollow porous roller situated on the obscured or return loop side of the conveyor belt, out of sight of the top or conveying surface of the belt. A perforated rod, positioned within the hollow porous roller, contains a cleaning and sanitizing solution, dispensable through a series of perforations in the rod. The cleaning and sanitizing solution is evenly distributed to the porous roller and dispensed outwardly through the hollow porous roller to remove any debris and bacteria from the conveyor belt without excess solution. The cleaning and sanitizing solution can be inserted in the perforated rod using a pump from a tank reservoir. The pumping system is capable of metering the amount of fluid for application to the belt, based on usage of the belt. A tray can be situated below the hollow porous roller to contain debris and fluids removed from the conveyor belt surface.

Owner:H & H GREEN

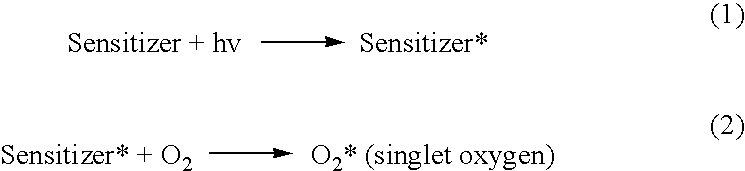

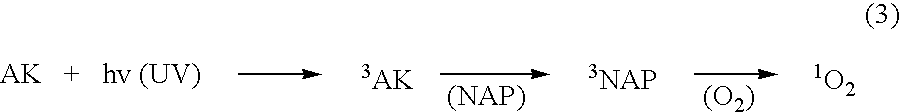

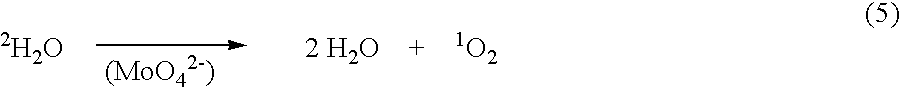

Antimicrobial compositions, methods and articles employing singlet oxygen- generating agent

InactiveUS20030194433A1Long exposureIncrease volumeBiocideCleaningSinglet oxygenGram-positive bacterium

Antimicrobial compositions containing a singlet oxygen-generating agent and a lubricant exhibit very effective antimicrobial activity against a variety of organisms, including Gram-positive bacteria, Gram-negative bacteria, fungi and yeast. The compositions have particular utility as beverage container lubricants. The passage of a container along a conveyor is antimicrobially lubricated by applying a lubricant to at least a portion of the container-contacting surface of the conveyor or to at least a portion of the conveyor-contacting surface of the container and generating singlet oxygen in situ. This method provides effective control of microbes on a beverage conveyor line, at rates comparable to purely chemical biocidal systems.

Owner:ECOLAB USA INC

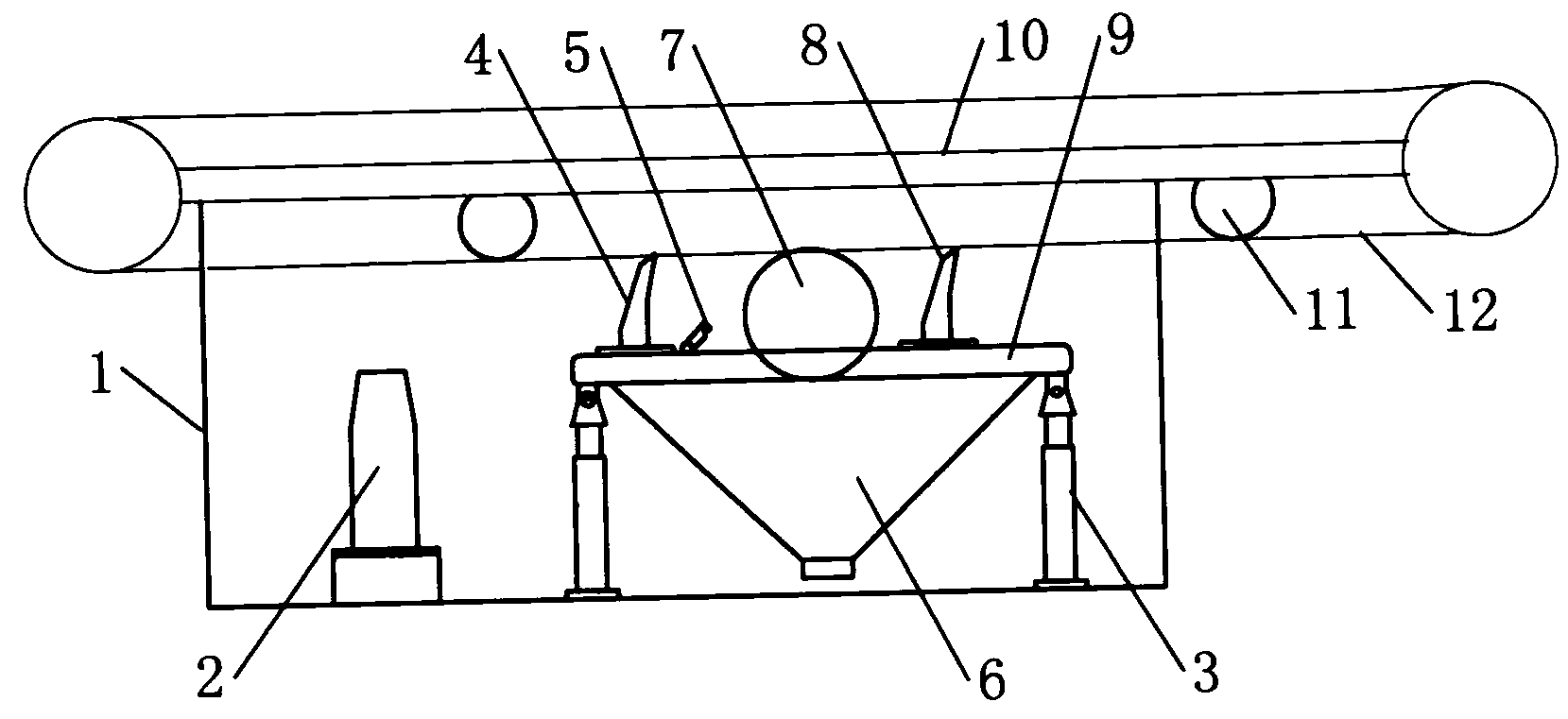

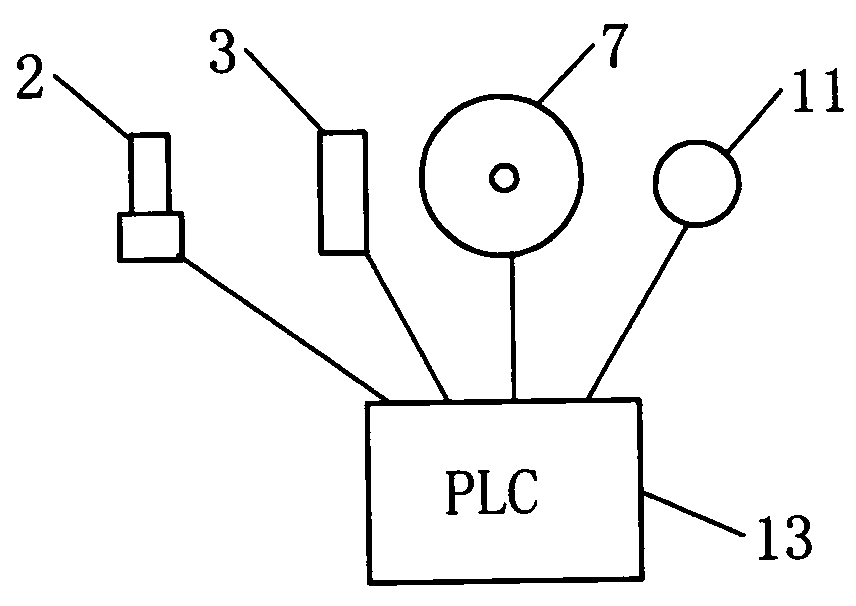

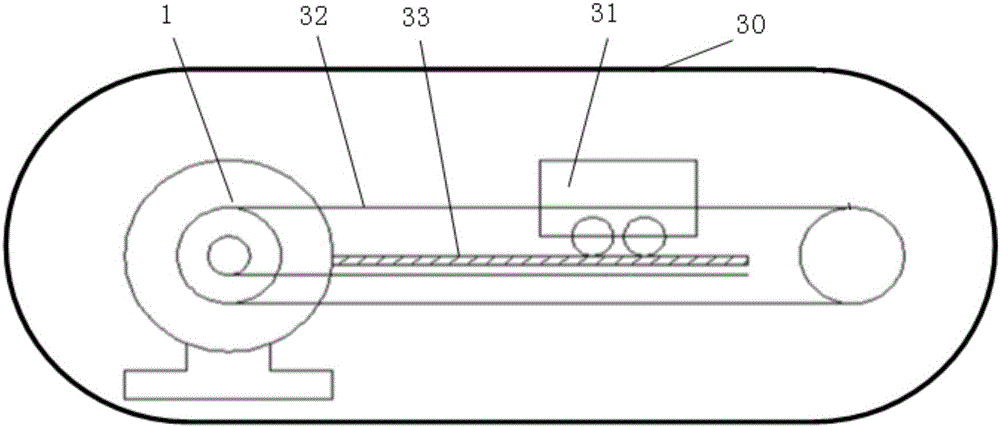

Stain and dust removing device of conveyor belt

InactiveCN103935738AImprove removal efficiencyEasy to controlCleaningEngineeringMechanical engineering

The invention provides a stain and dust removing device of a conveyor belt. The conveyor belt operating in a reciprocating mode is installed on a middle frame of a conveyor. An outer frame is arranged on the lower portion of the middle frame of the conveyor. A blower and a main frame are arranged in the outer frame. The main frame is fixed to the bottom of the outer frame through lifting rods. A first scraper, a second scraper, a water jet and an electric brush roll are installed on the upper portion of the main frame. A stain and dust collecting hopper is arranged between the two lifting rods on the lower portion of the main frame. A compression roll is installed on the middle frame of the conveyor. Gaps are formed between the conveyor belt and the first scraper, between the conveyor belt and the second scraper and between the conveyor belt and the electric brush roll through the lower edge of the compression roll. The blower, the lifting rods, the electric brush roll and the compression roll are connected with a PLC through circuits. The stain and dust removing device hast the advantages that dust and stain which are attached to the conveyor belt can be removed, dust raising is avoided, the dust and stain removing efficiency is high, control is convenient, energy is saved, pollution is controlled, and the stain removing effect is good. The stain and dust removing device is suitable for removing the stain and the dust on the conveyor belt.

Owner:LIAONING JUFENG TECH

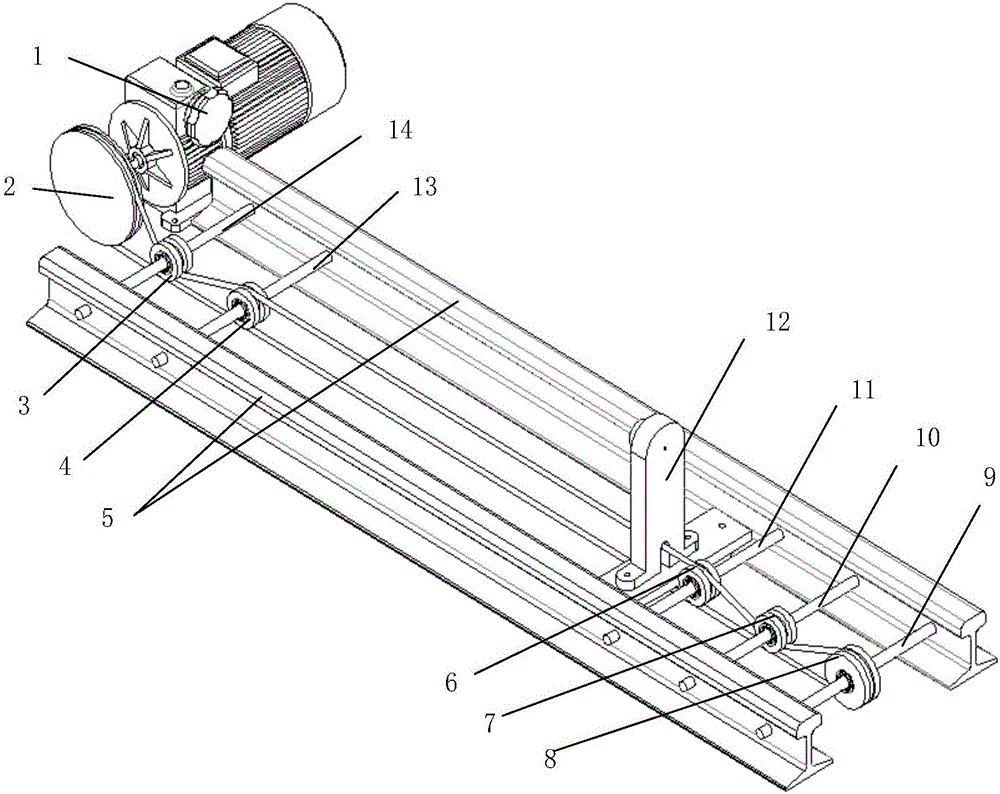

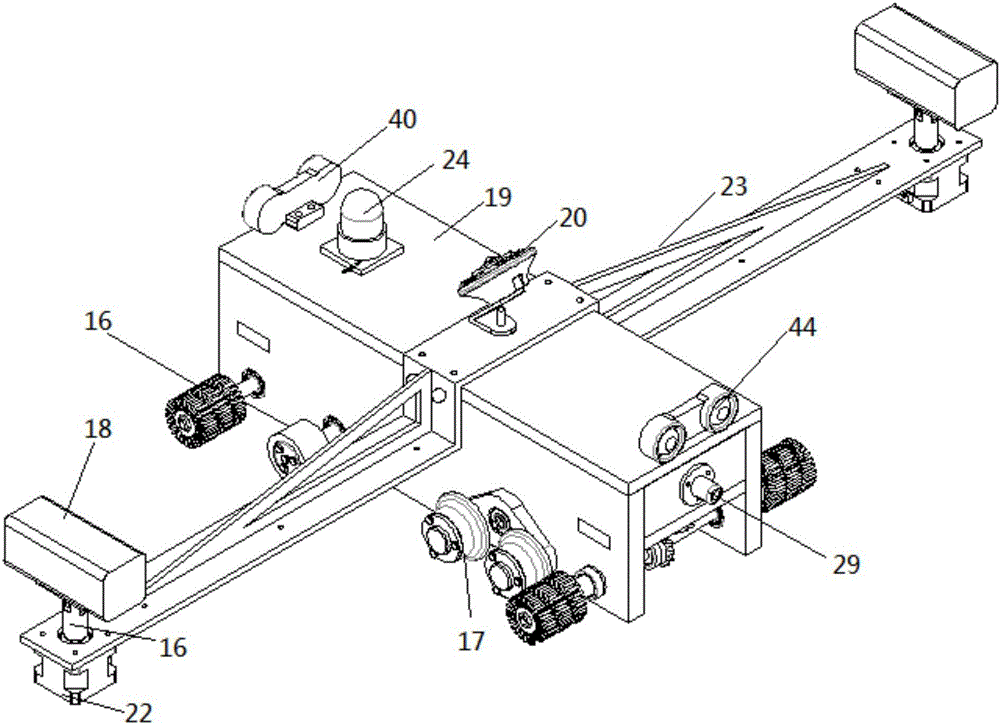

Intelligent patrol robot of belt conveyor

The invention discloses an intelligent patrol robot of a belt conveyor. The patrol robot is mounted in a belt of the belt conveyor, is connected with a driving motor through a steel wire rope, and is towed through driving force of the driving motor to linearly walk on the upper edges of patrol robot wheel rails to realize left-right circular movement in a belt ring, so that the temperature of each key part of the belt conveyor and other abnormal information are detected, maintainers are replaced to detect the temperature of each key part of the belt conveyor and other abnormal information, fixed-point and fixed-time patrol of working states of the belt conveyor can be realized, and personal safety of workers and operation conditions of the belt conveyor are guaranteed; and the patrol robot has the characteristics of compact structure, flexible movement, easiness in control, rust resistance, pressure resistance and fatigue resistance.

Owner:XIAN UNIV OF SCI & TECH

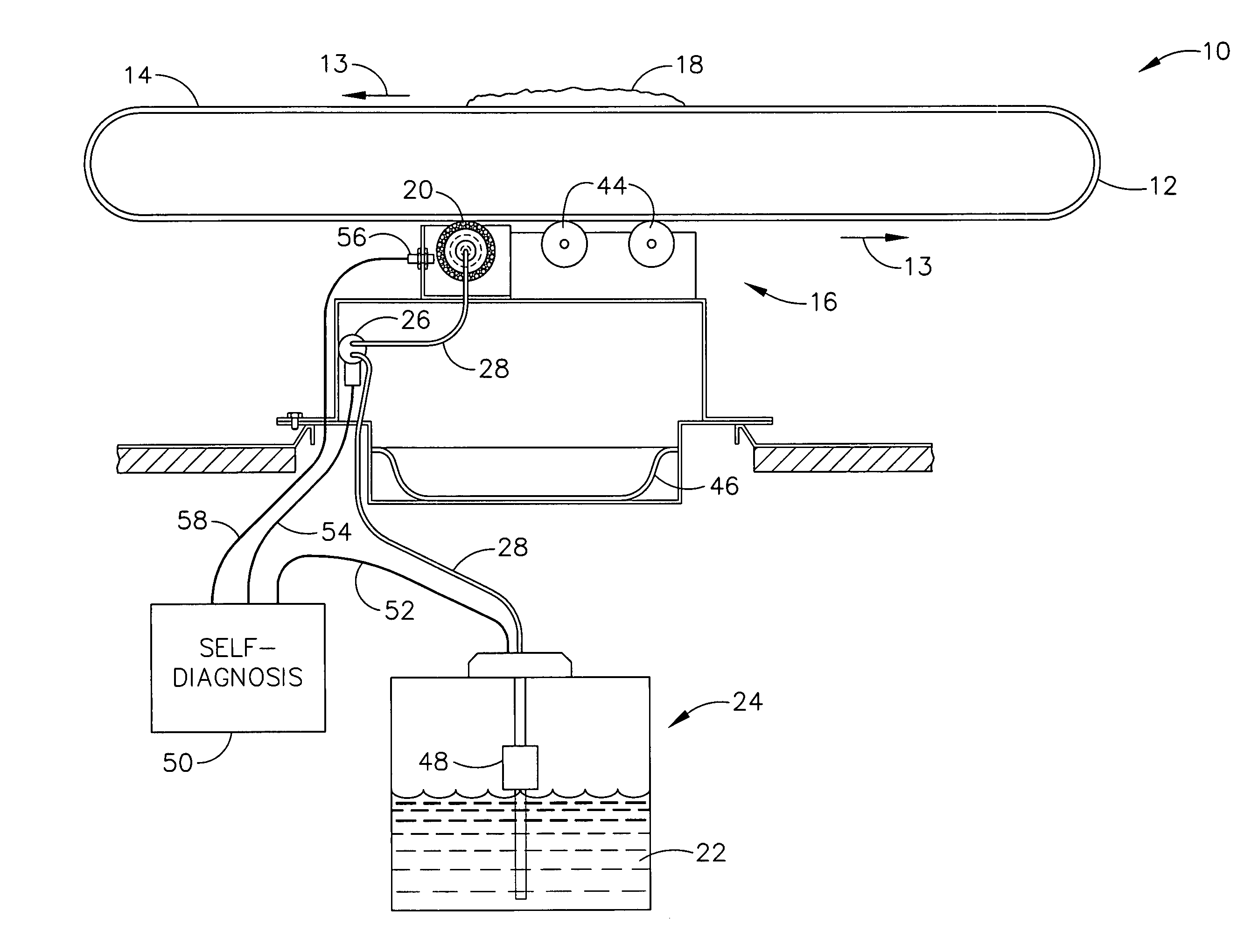

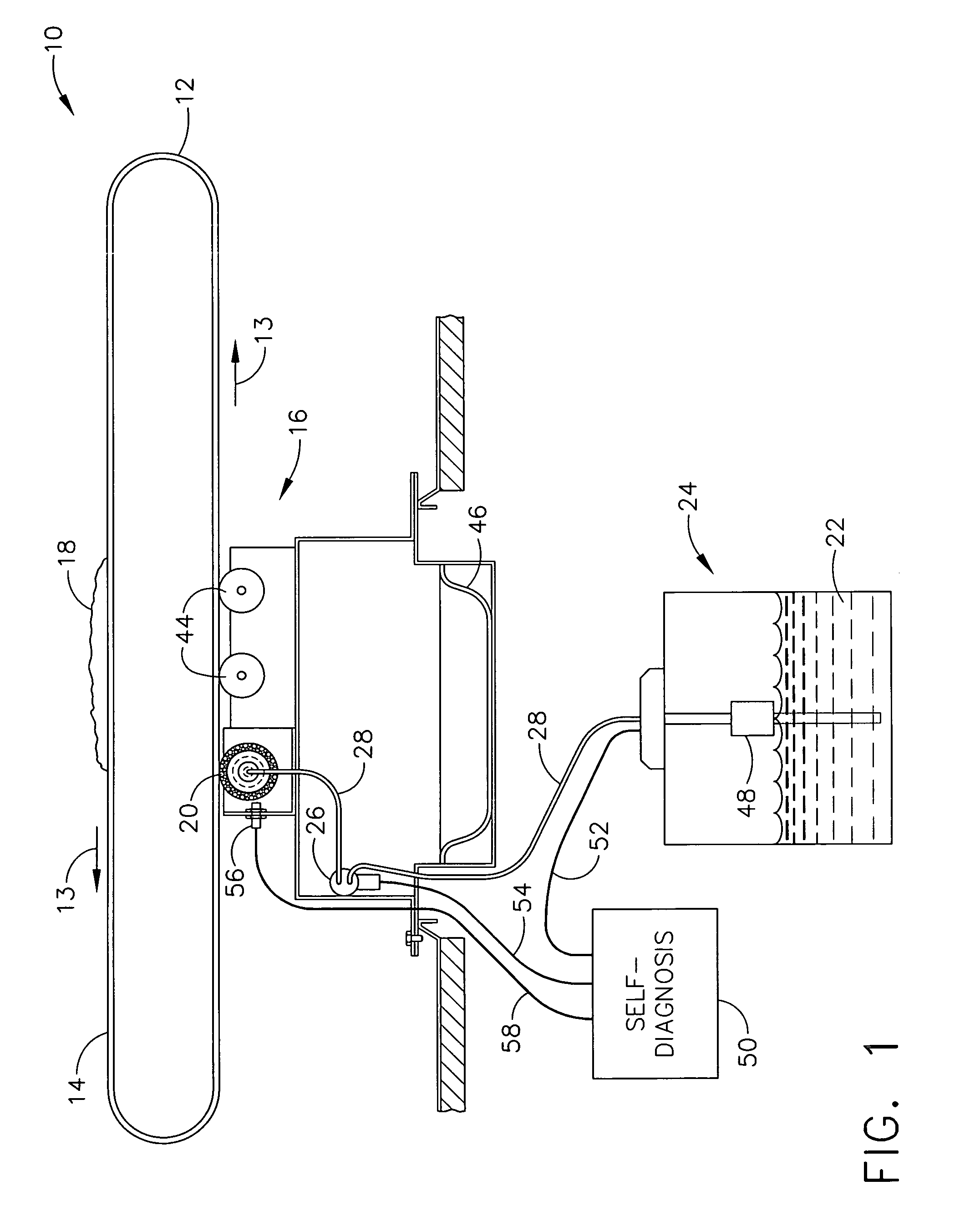

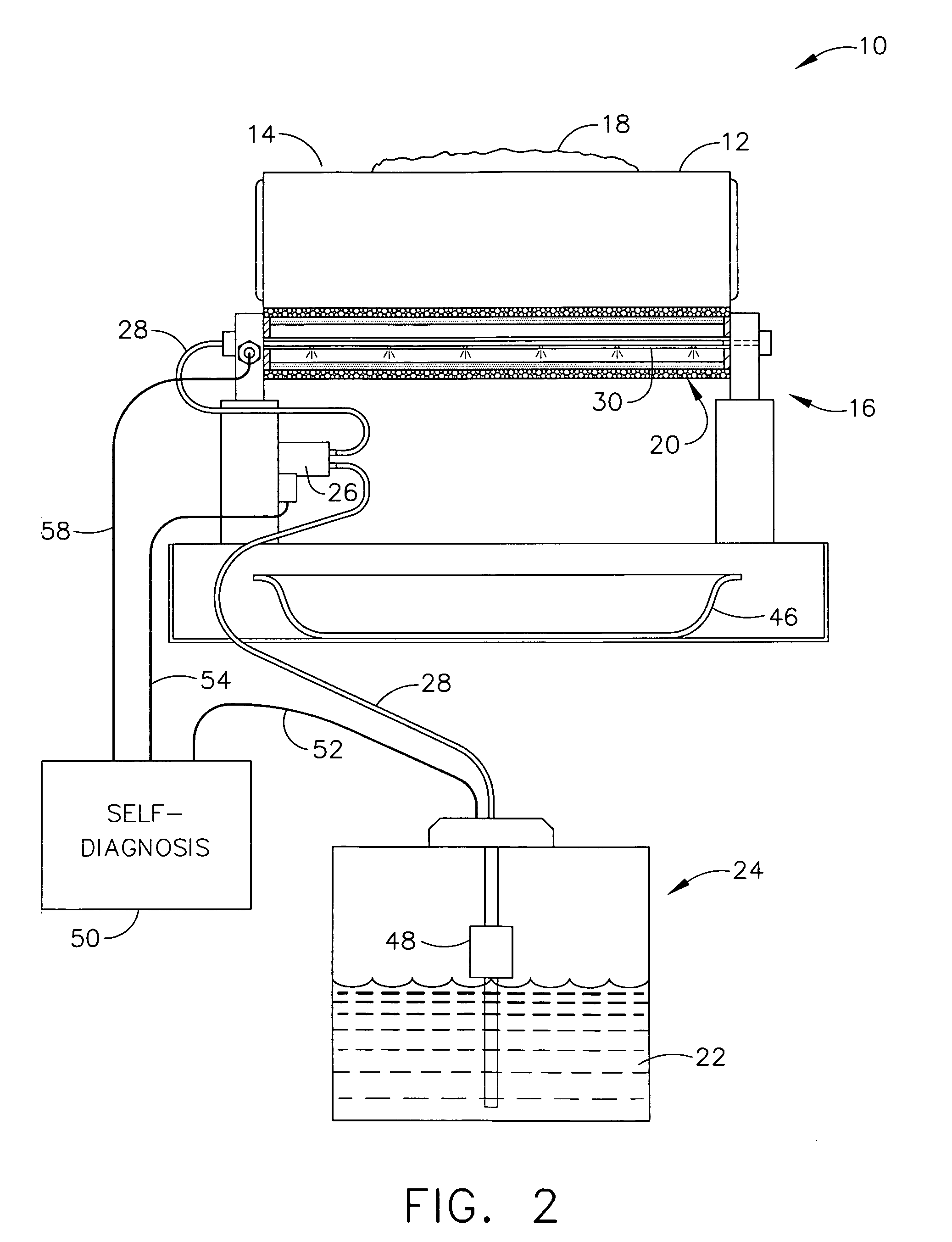

Maintenance cart for remote inspection and cleaning of closed track

InactiveUS6349653B1Improve securityShorten the timeTelevision system detailsPulse modulation television signal transmissionSystem diagnosisTime windows

A maintenance cart in a maintenance system is substituted for a material handling cart in a continuous train of material handling carts circulating on a closed track. The maintenance cart includes both inspection and cleaning functions which may be divided among separate maintenance carts, as desired. Inspection includes location sensing (preferably with a bar-code reader), inspection with one or more television-like cameras and clearance measurements. Cleaning functions include removal of dust and debris from a channel-like track by a vacuum arrangement. The maintenance cart or carts may be continuously left in place or substitute as needed in the train and provide continuous cleaning service and system diagnostics for scheduling repairs prior to failure while in use. The system is particularly advantageous for application to mail sorting systems which are largely unaccessible and which permit only brief time windows during which maintenance, repair and inspection can otherwise be carried out.

Owner:LOCKHEED MARTIN CORP

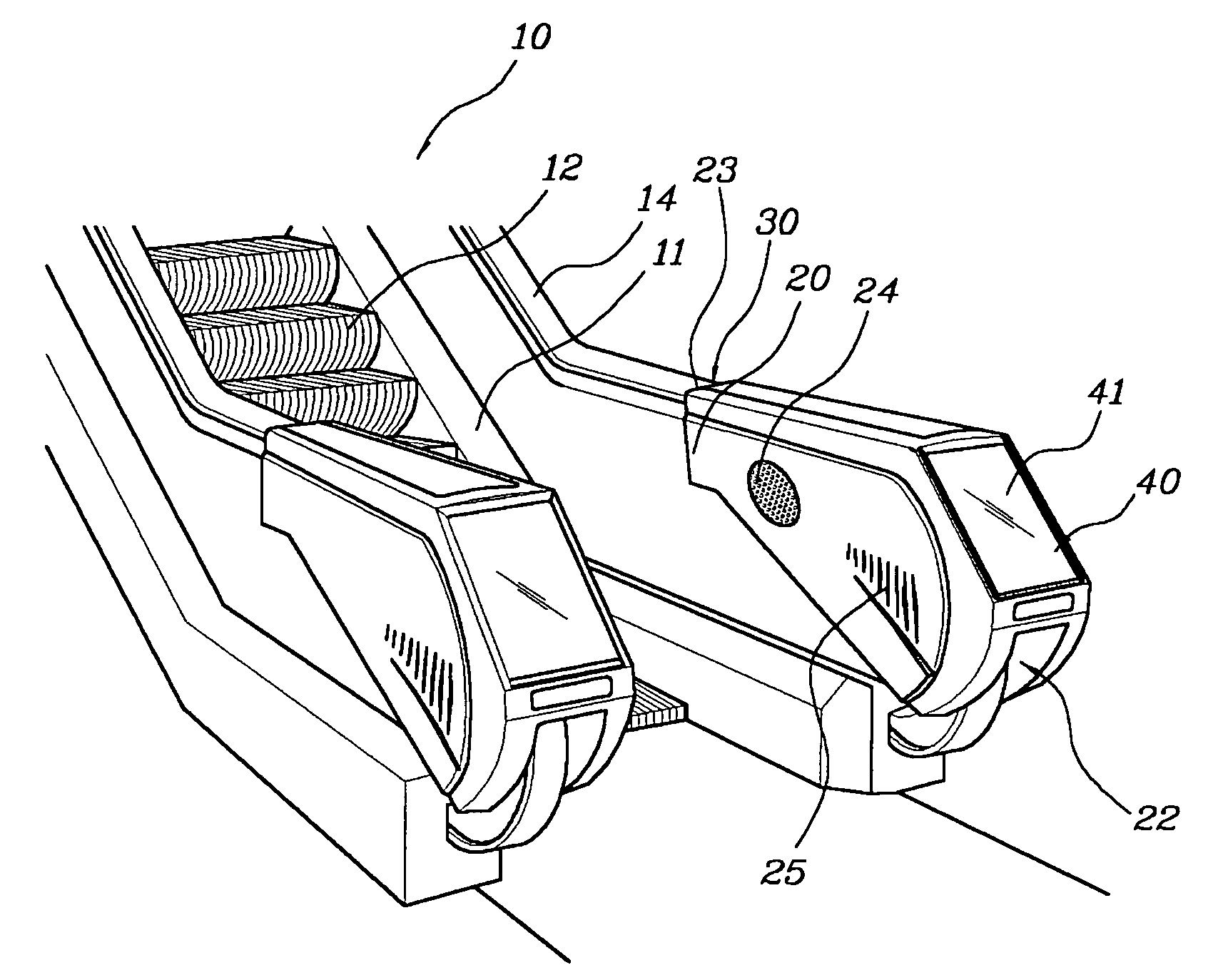

Guard device for escalator handrail

InactiveUS20050217971A1Good advertising effectAvoid infectionConveyorsCleaningAir cleaningDisplay device

A guard device for a handrail in an entry zone of an escalator is disclosed, which assures safety of an entry of the escalator, sanitary maintenance of the handrail by sterilization, efficient advertisement of products and business corporations, and clean maintenance of air in the entry of the escalator. The guard device includes a guide channel at its bottom to receive a part of the handrail. The guard device further includes a sterilization unit to sterilize the handrail, an advertising display provided on a front face thereof, and an air-cleaning unit provided at a side wall thereof.

Owner:I&K INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com