Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Reliably conveyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

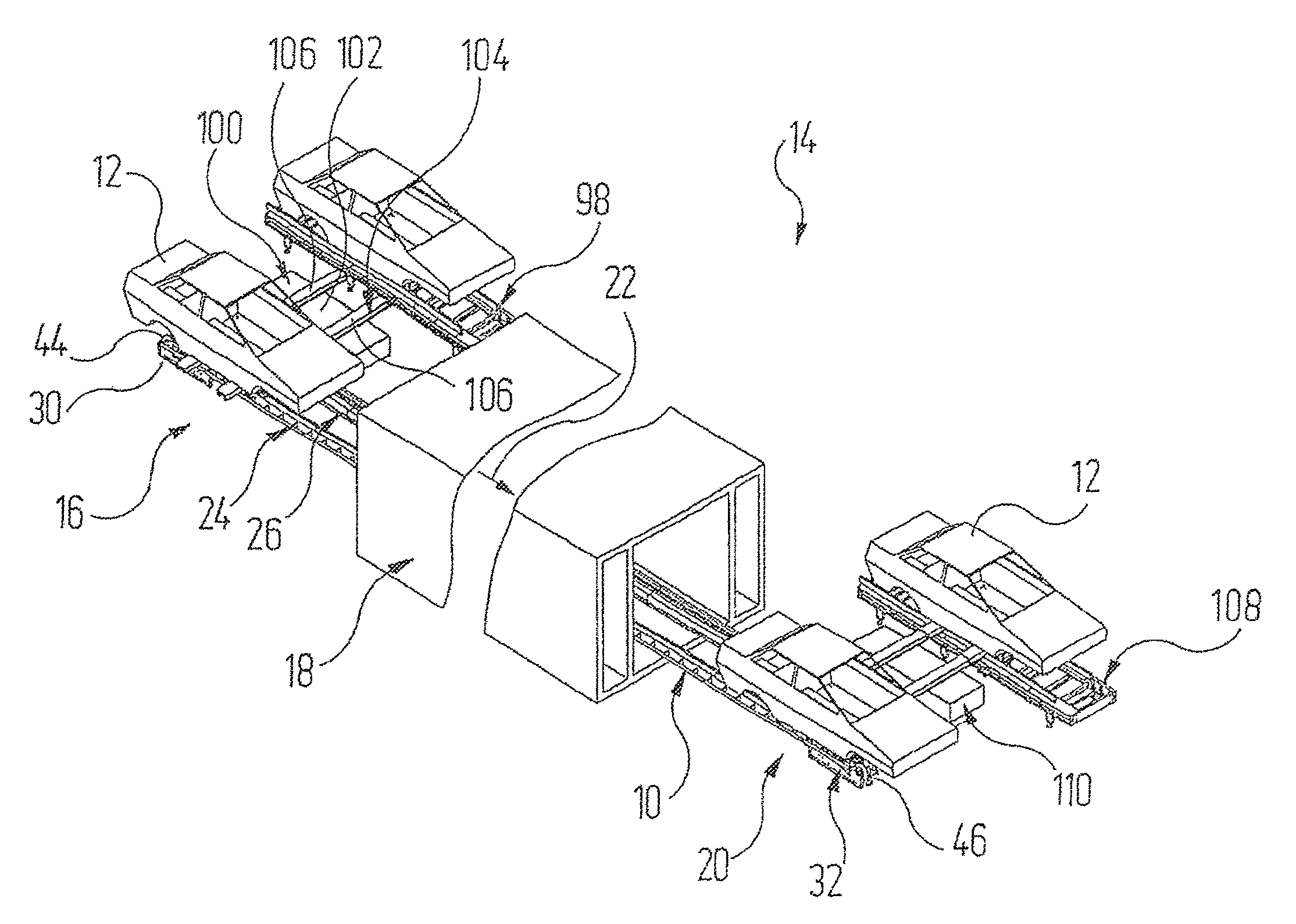

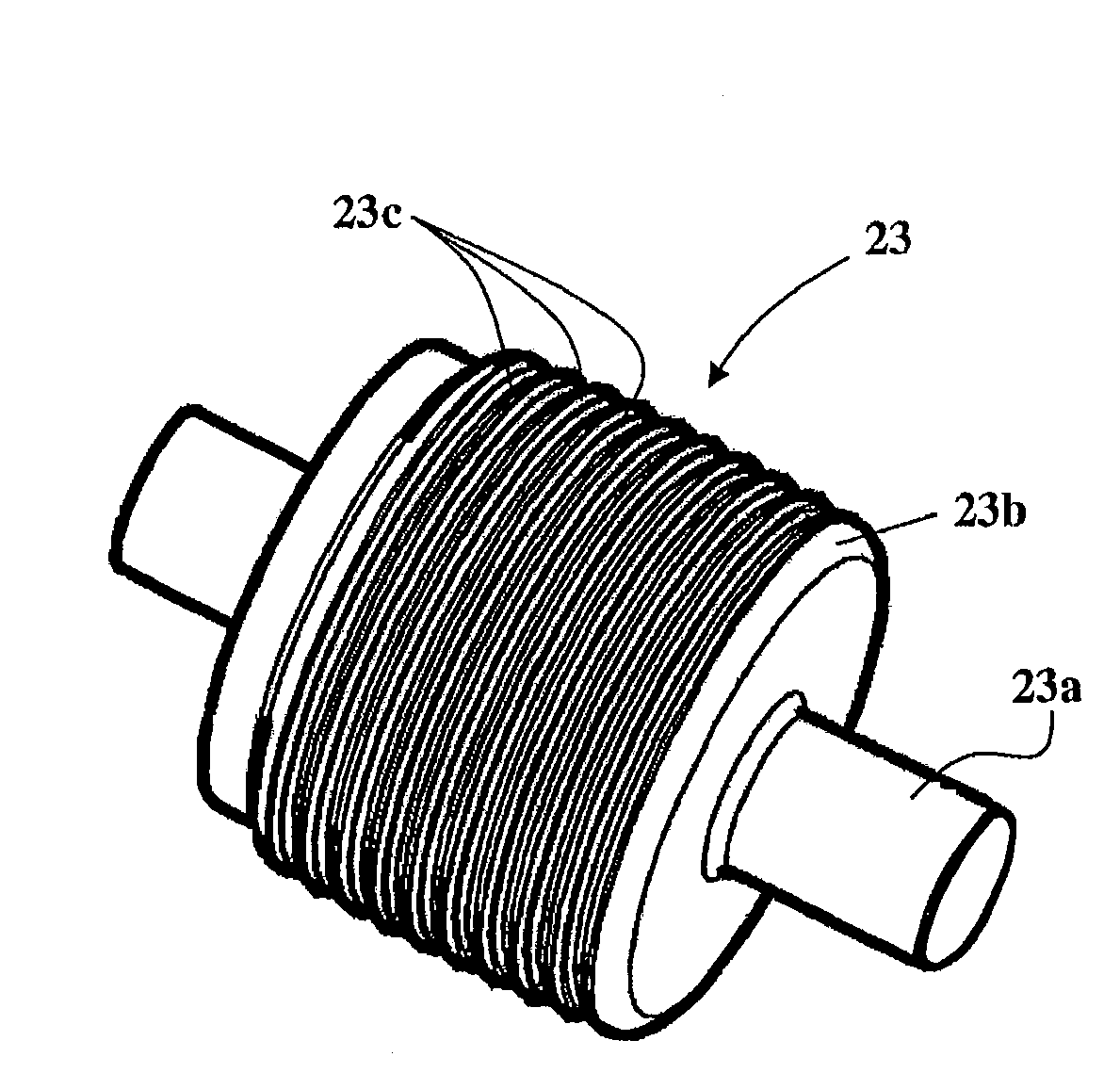

Ejector, fine solid piece recovery apparatus and fluid conveyor

InactiveUS6974279B2Long distanceReduce distanceBulk conveyorsEngineeringPressure controlled ventilation

An ejector is configured to generate a high negative pressure capable of sucking and conveying fine metal pieces or chips, such as machinings or cuttings, for example, when using the ejector as a driving source for a fluid conveyor. The ejector includes a convergent-divergent nozzle having a throat formed between a suction port and a discharge port. Jet blowing holes are formed in the convergent-divergent nozzle to direct a jet stream from upstream of the throat to downstream of the throat, thereby forming a negative pressure. Pressure control holes open to the downstream of the jet blowing holes and are configured to communicate with a pressure space at a pressure level higher than a negative pressure formed by the jet stream and lower than a static pressure of the jet stream and the inside of the convergent-divergent nozzle.

Owner:TRINITY IND CORP

Ejector, fine solid piece recovery apparatus and fluid conveyor

InactiveUS20050074303A1Long distanceReduce distanceBulk conveyorsEngineeringPressure controlled ventilation

An ejector capable of generating a high negative pressure capable of sucking and conveying fine metal pieces such as cuttings, for example, in a case of using the ejector as a driving source for a fluid conveyor, comprising a convergent-divergent nozzle having a throat formed between a suction port and a discharge port in which jet blowing holes are formed in the convergent-divergent nozzle for jetting a jet stream from the upstream to the downstream of the throat thereby forming a negative pressure, wherein pressure control holes are formed being opened to the downstream of the jet blowing holes for communicating a pressure space at a level higher than a negative pressure formed by the jet stream and lower than a static pressure of the jet stream and the inside of the convergent-divergent nozzle.

Owner:TRINITY IND CORP

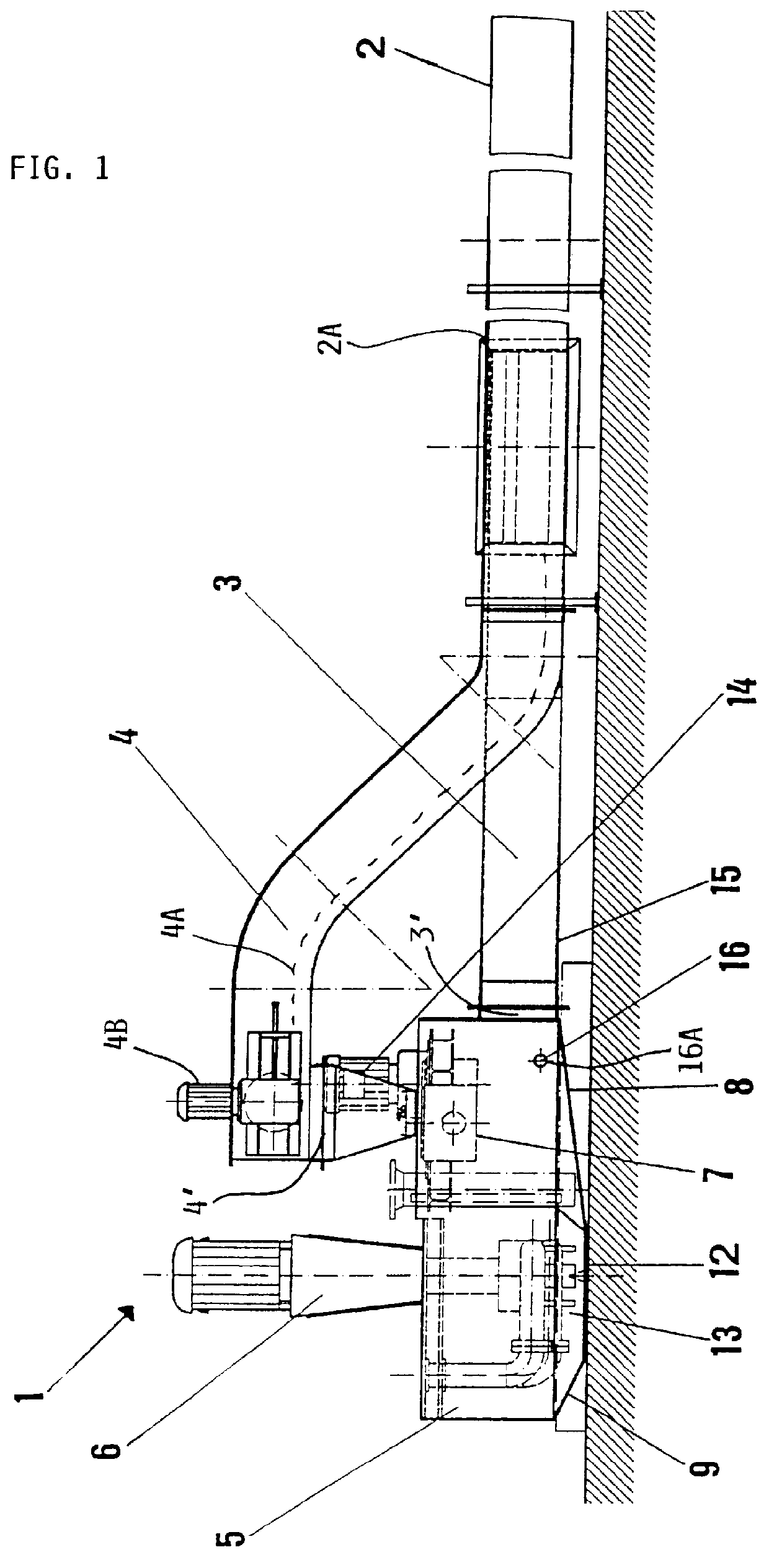

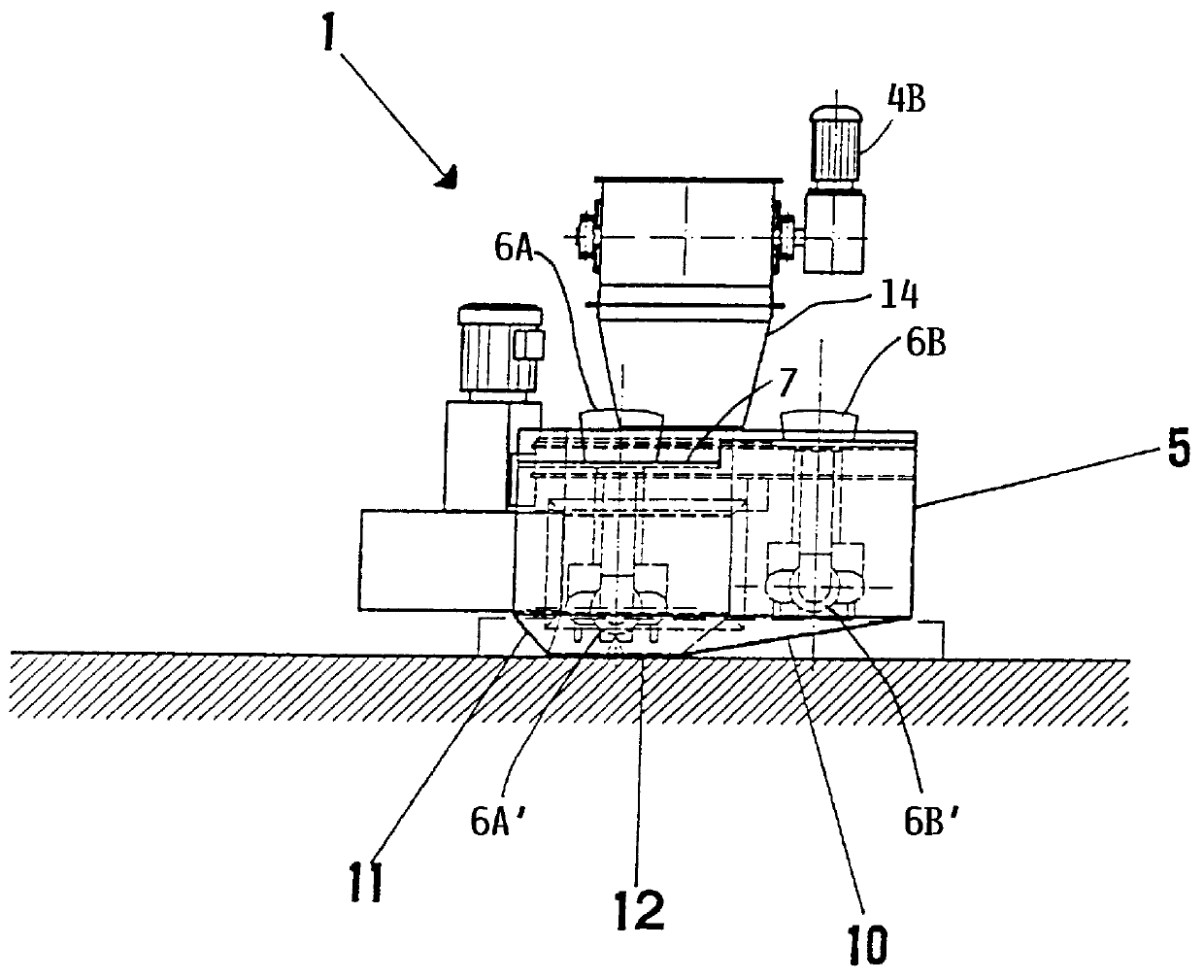

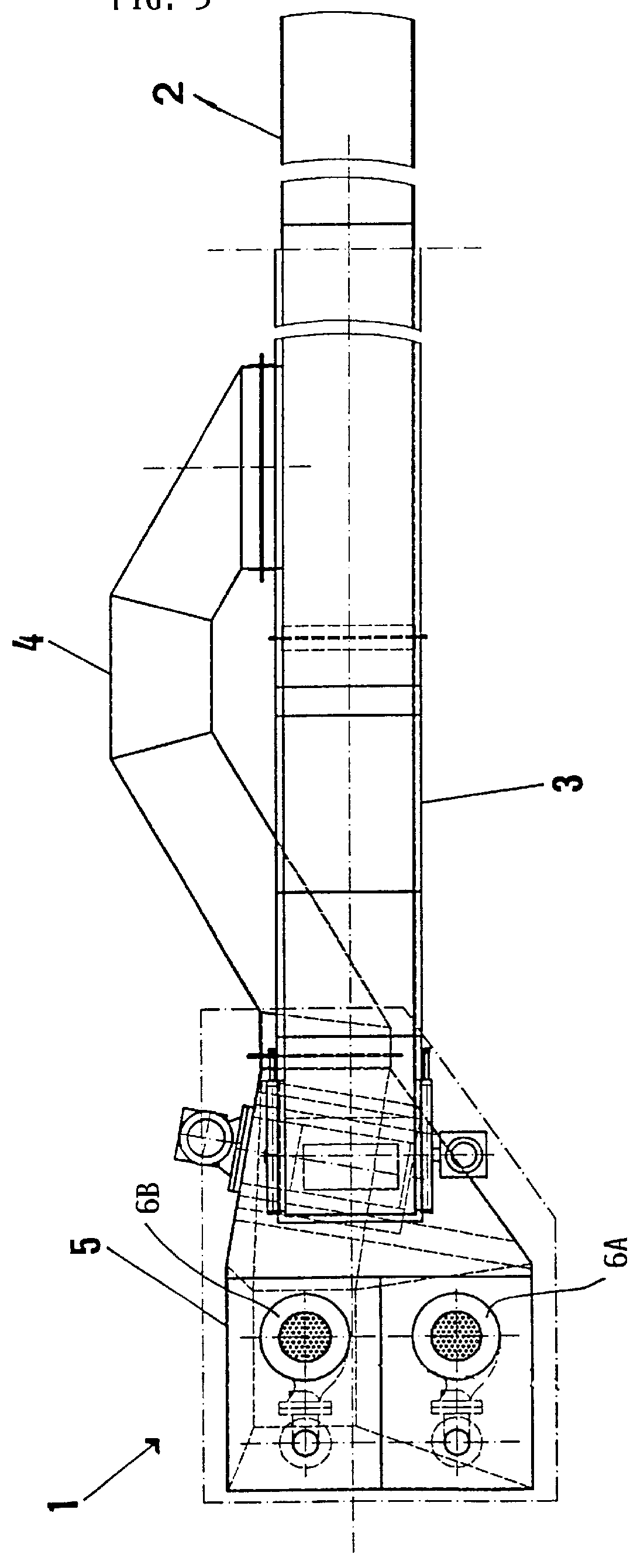

Pumping station for a cooling and lubricating fluid containing particulate matter

A pumping station for pumping a cooling and lubricating fluid containing particulate matter such as machining chips has a compact structure with a relatively low total structural height, while still assuring that the chips are conveyed with the fluid to the pump suction inlet, without settling-out or accumulating in the apparatus. The pumping station (1) includes a collecting container (5) with at least one pump (6) arranged therein, a chip breaker (7) and a supply conduit arrangement. The supply conduit arrangement includes a supply line (2) through which the cooling and lubricating fluid containing the machining chips is received from a machining tool or transfer station. Furthermore, two branch lines (3) and (4) are interposed and connected between the supply line (2) and the collecting container (5). A first branch line (3) conveys the fluid, from which the chips have been removed, with a slight downward slope toward the collecting container (5). The second branch line (4) conveys the chips that have been removed from the fluid flow. A scraper conveyor or the like conveys the chips upward through the second branch line (4), and the outlet end of the branch line (4) is arranged directly above the chip breaker (7), which in turn is arranged above the outlet end of the fluid conveying branch line (3). The comminuted chips thus fall from the breaker (7) directly into the flow of fluid, in which the chips are then entrained and carried along into the sump (13) of the collecting container (5), where the chips and fluid are sucked and pumped away by the pump (6).

Owner:MANN HUMMEL GMBH +1

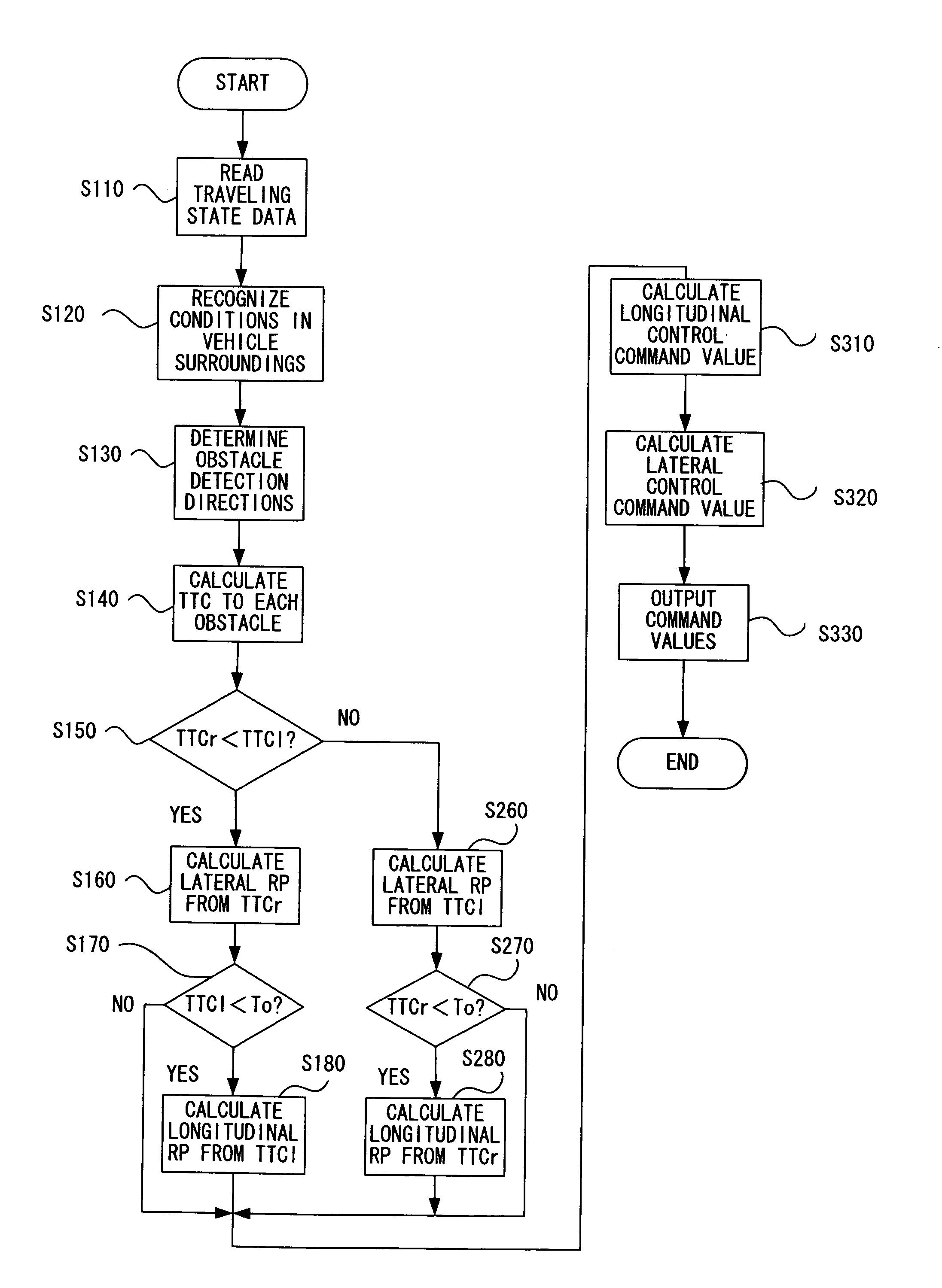

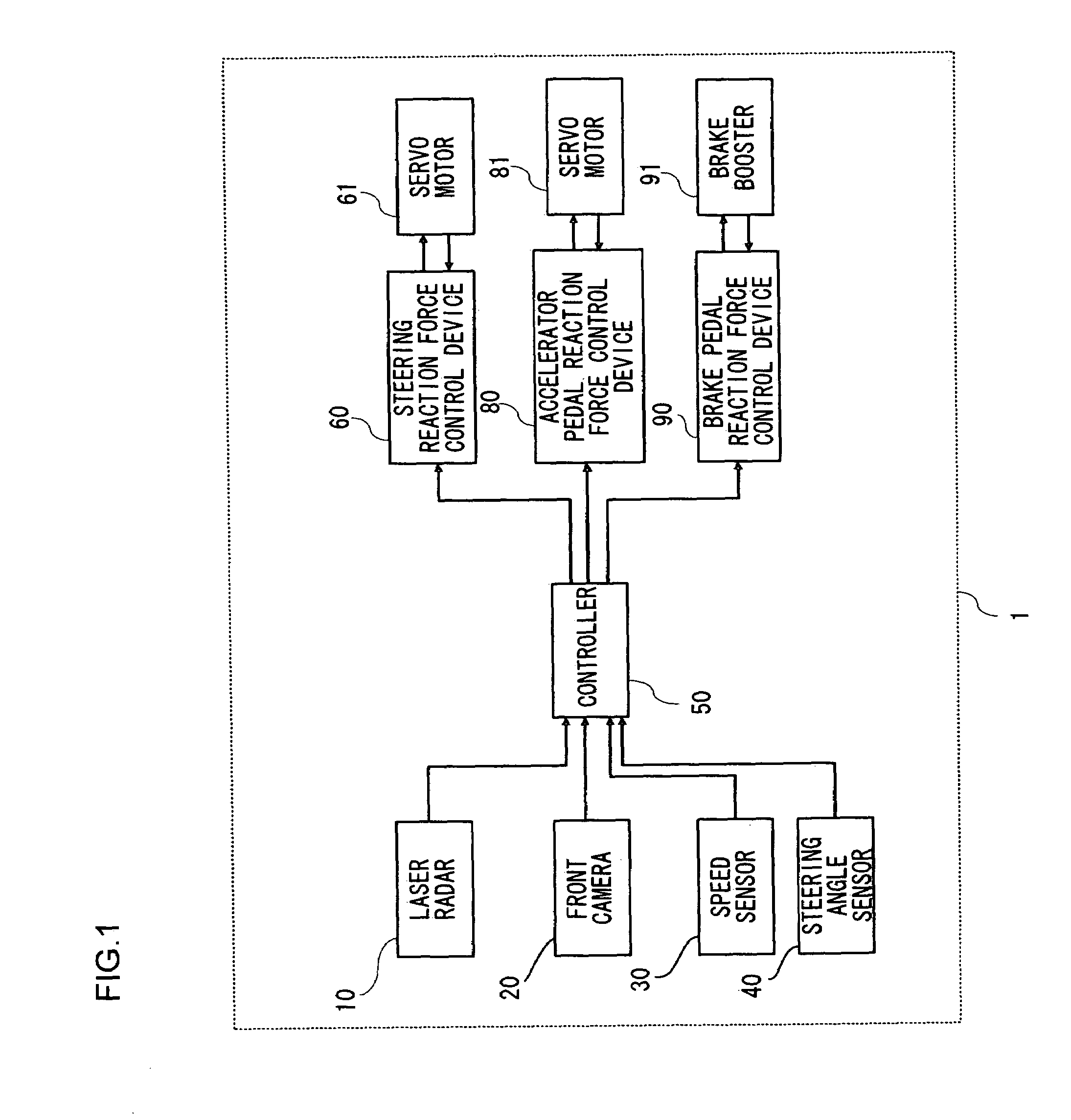

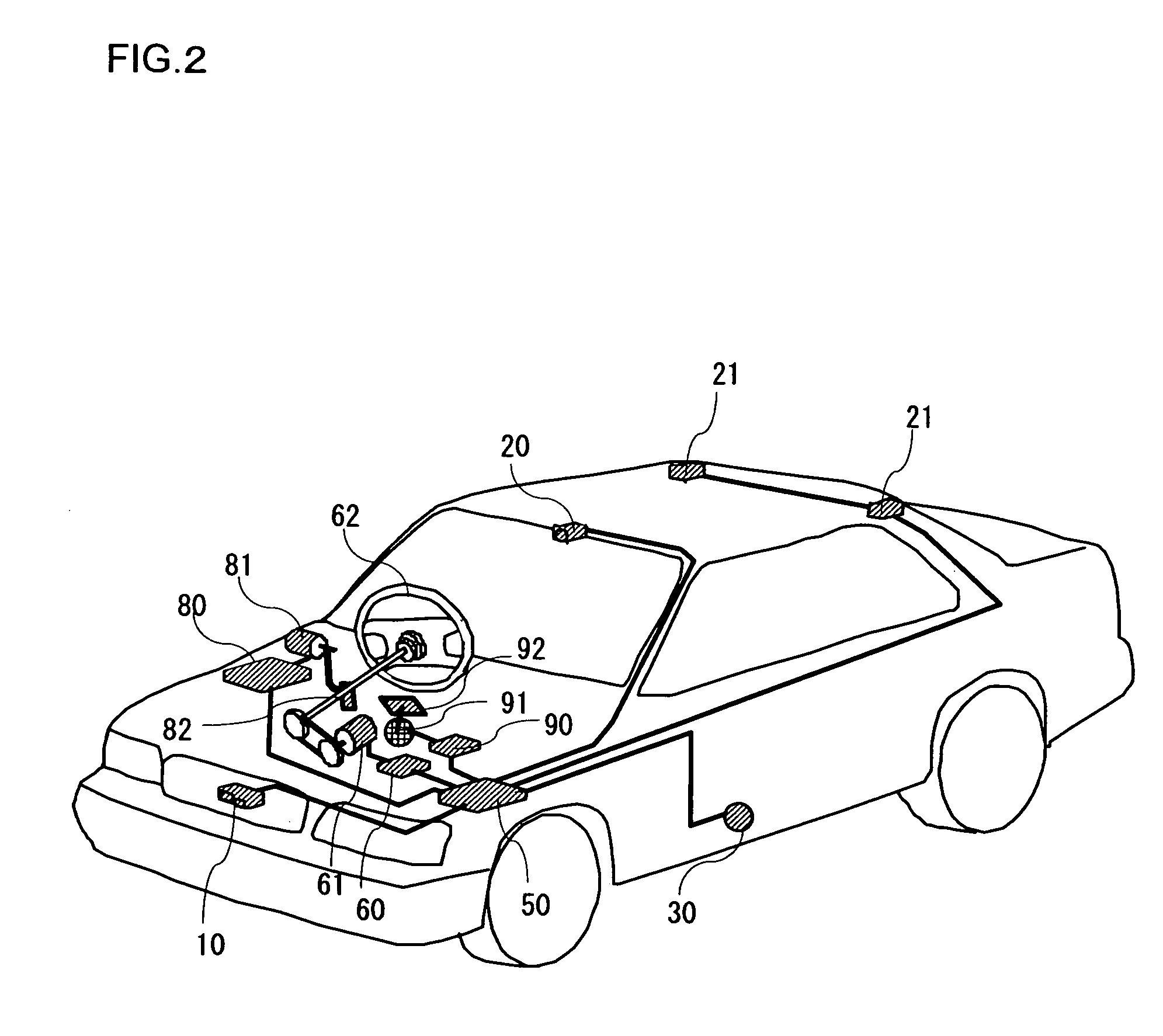

Driving assist system for vehicle

InactiveUS7136755B2Easily understoodEasy to understandVehicle fittingsDirection finders using radio wavesEngineeringVehicle driving

In a vehicle driving assist system, an obstacle detection device detects an obstacle present in each of two obstacle detection directions with respect to a subject vehicle; and a TTC calculation device calculates a TTC between the subject vehicle and each of obstacles based on detection results of the obstacle detection device. A lateral reaction force control device controls a reaction force generated at a vehicle operation equipment for drive operation in a lateral direction of the subject vehicle based on a first TTC which is smaller in the TTCs calculated in the TTC calculation device; and a longitudinal reaction force control device controls a reaction force generated at a vehicle operation equipment for drive operation in a longitudinal direction based on a second TTC which is larger in the TTCs.

Owner:NISSAN MOTOR CO LTD

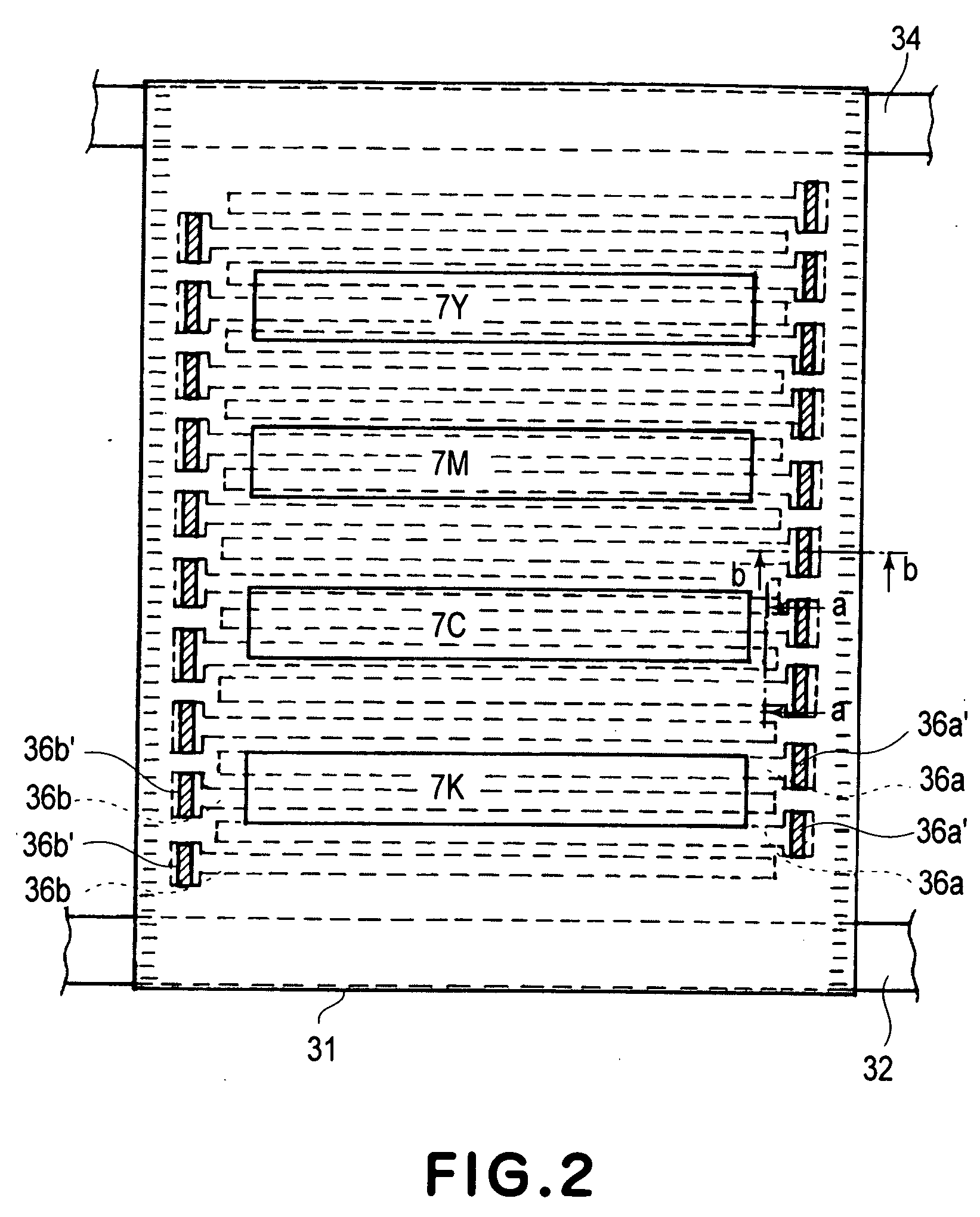

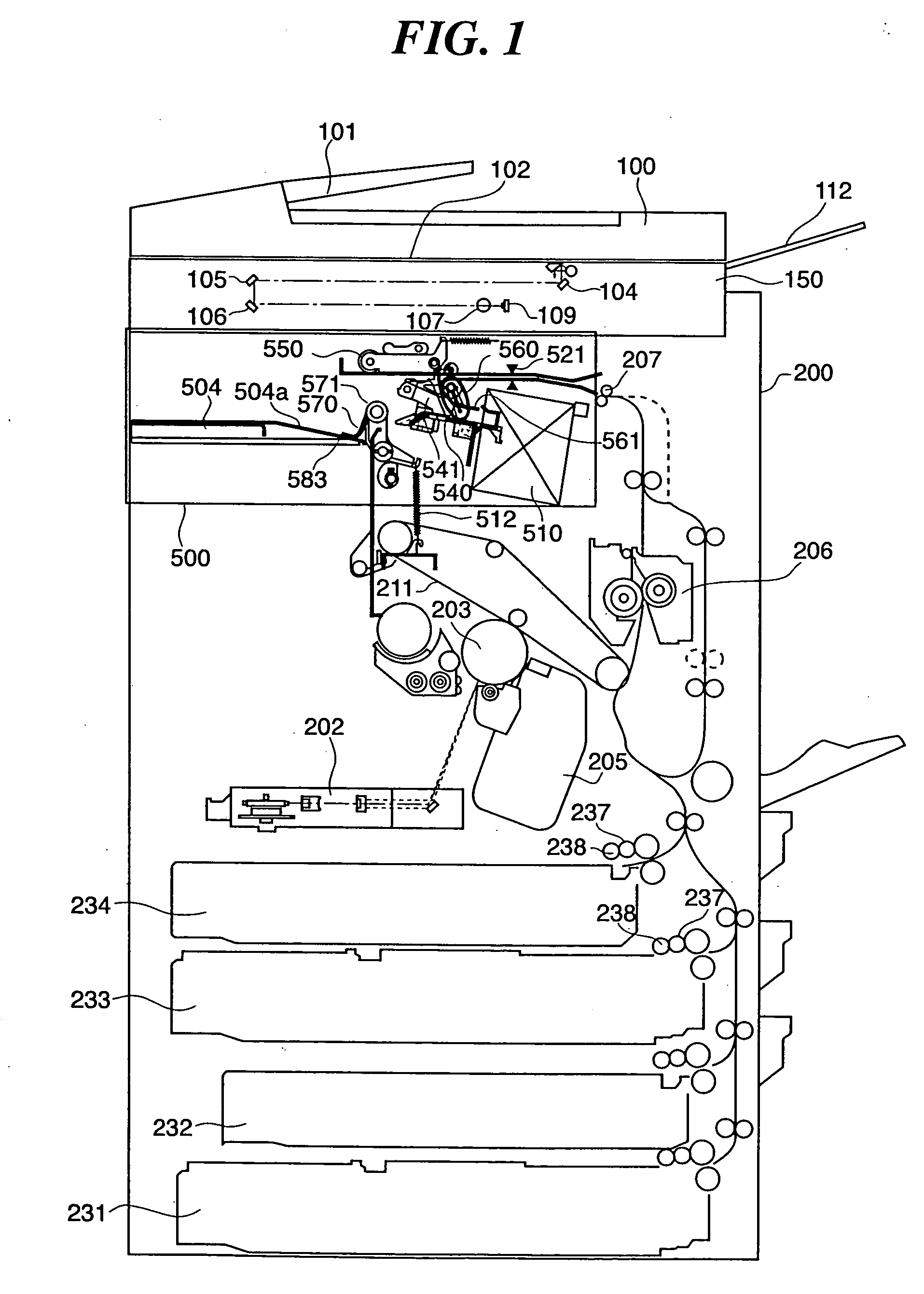

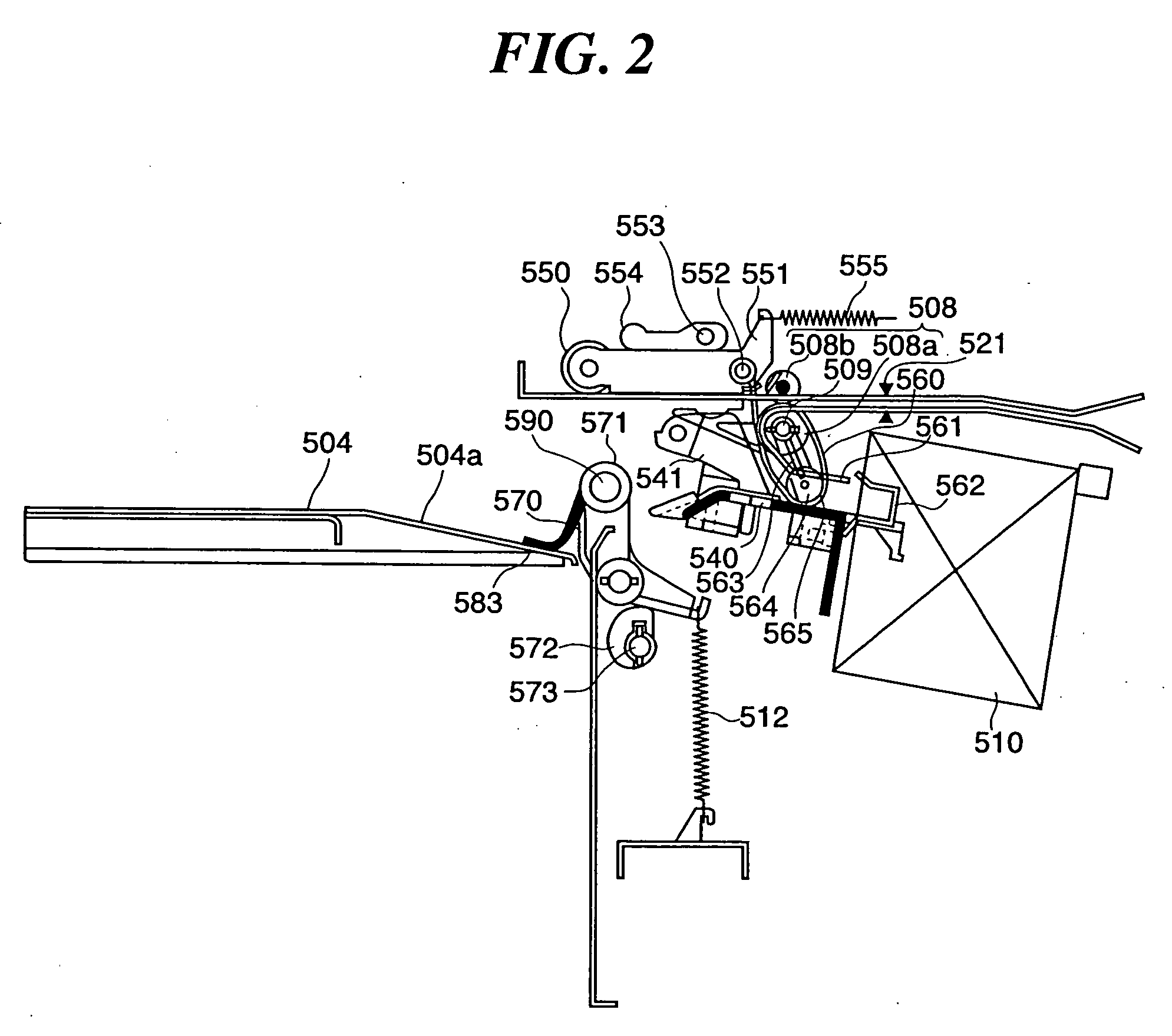

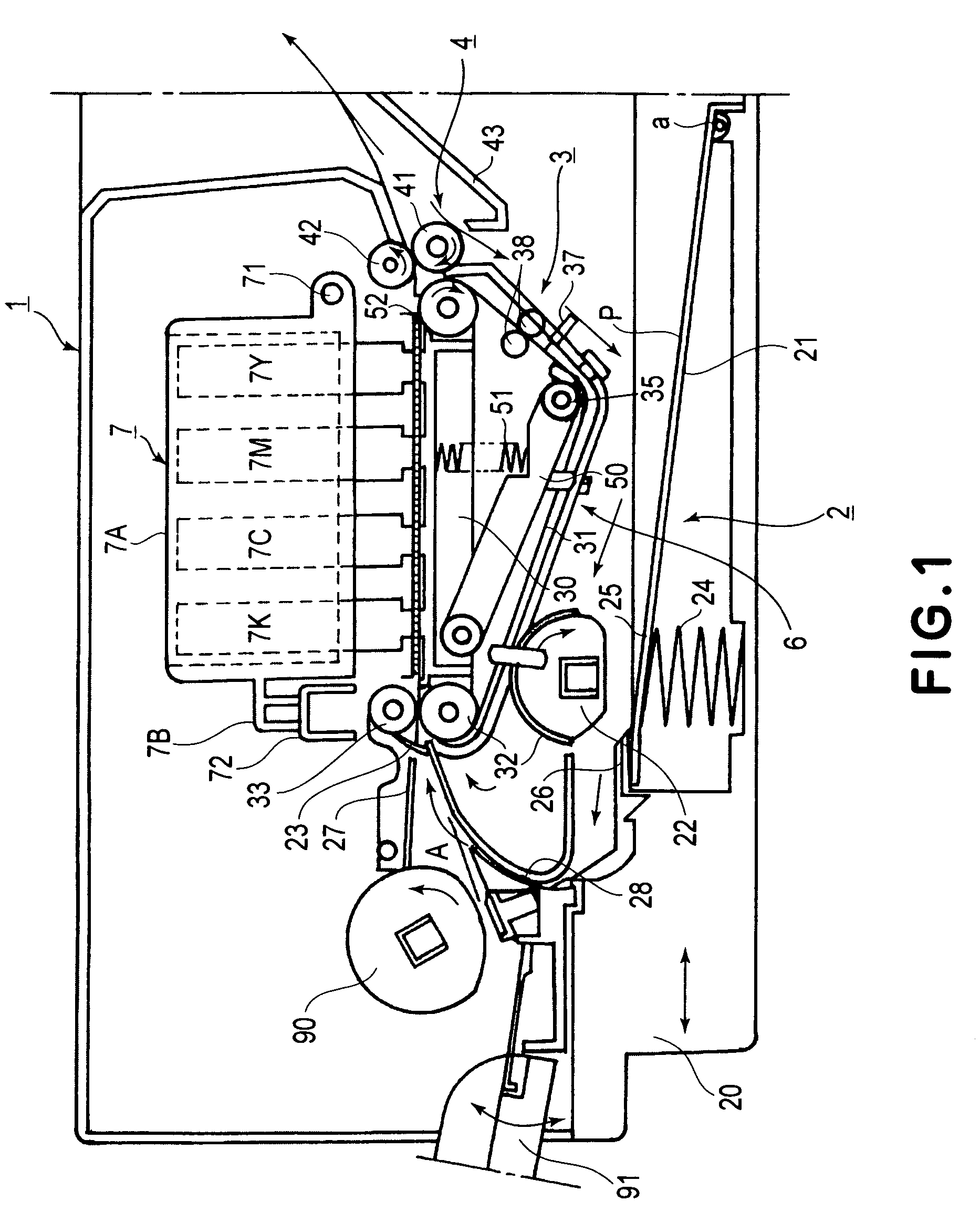

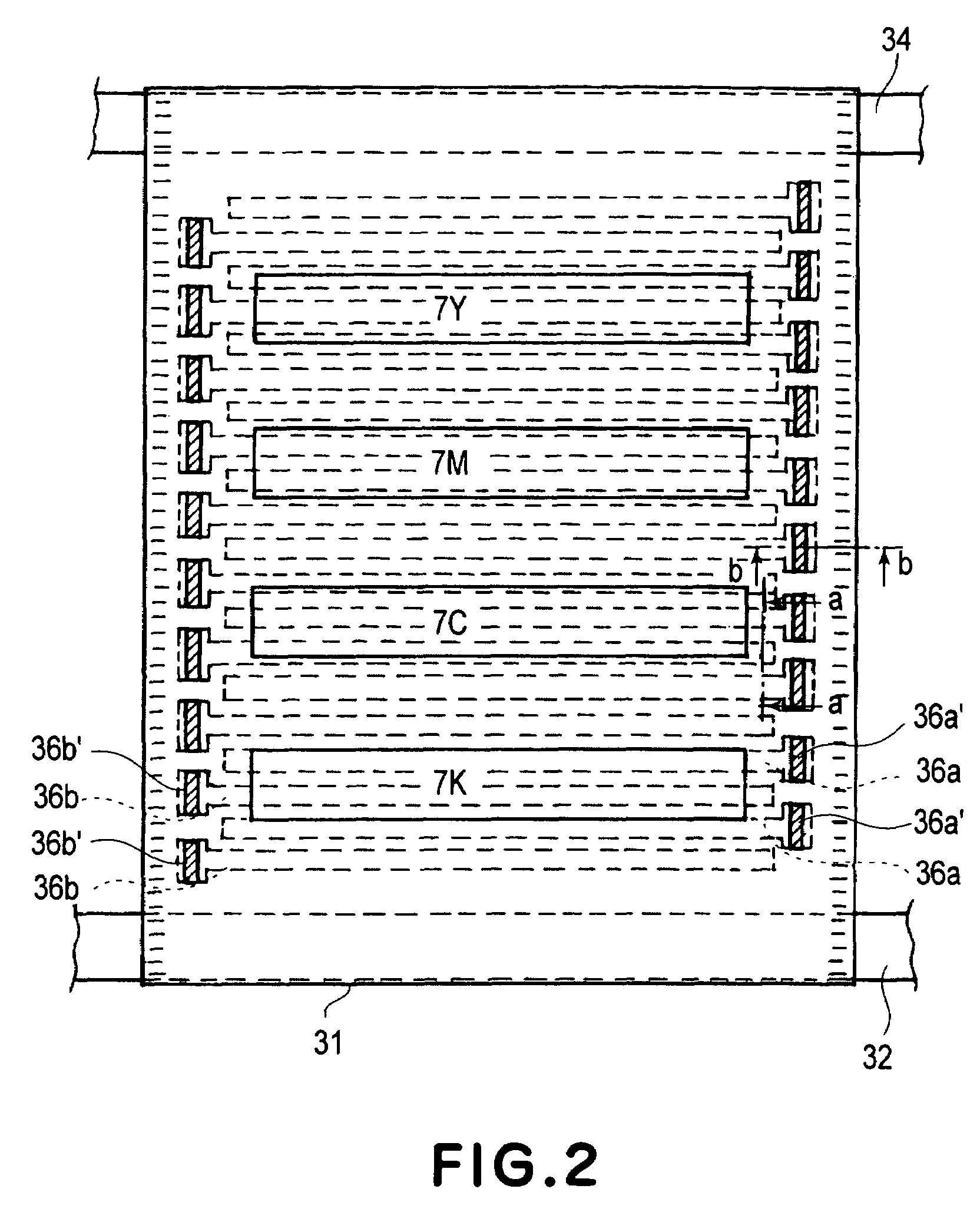

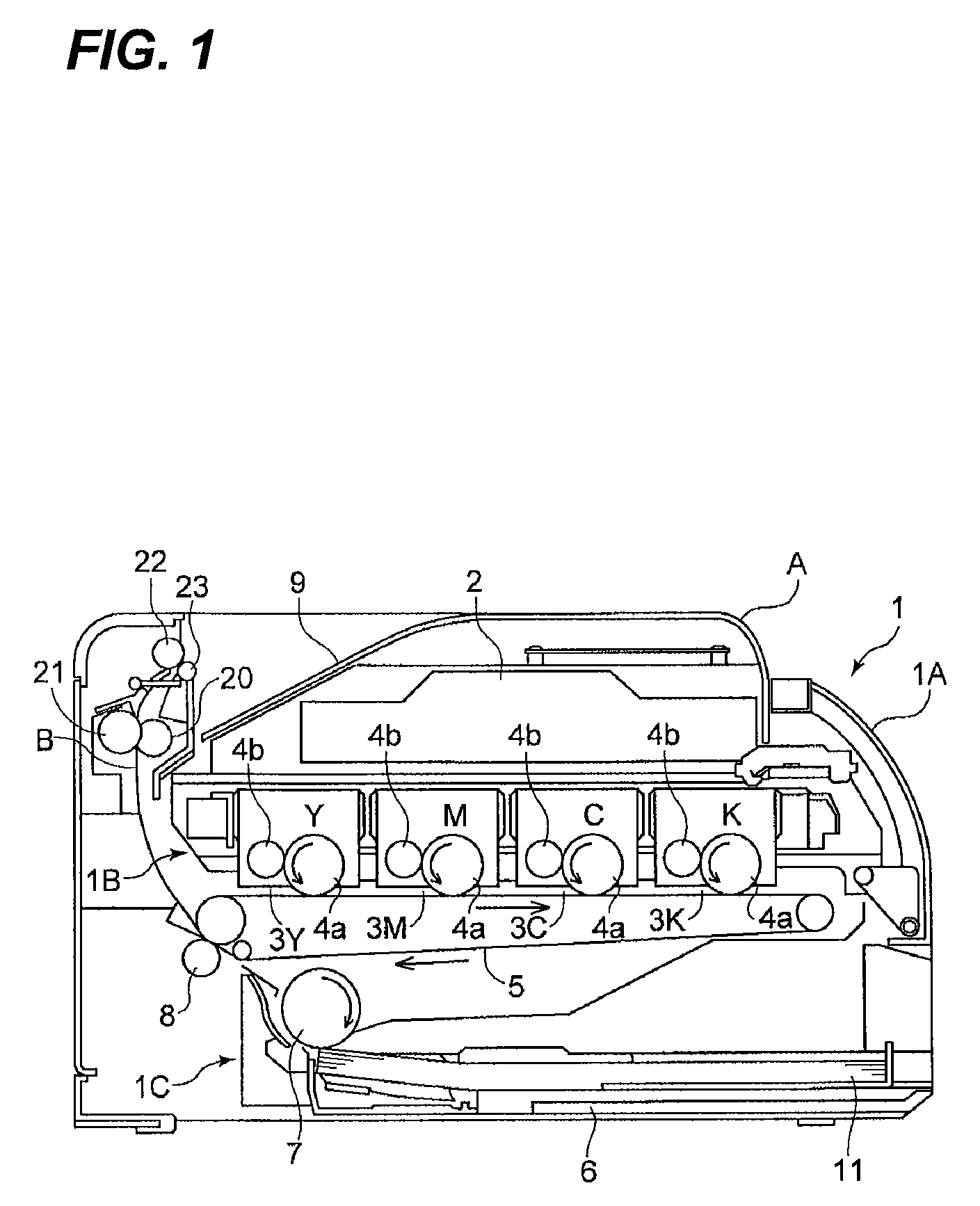

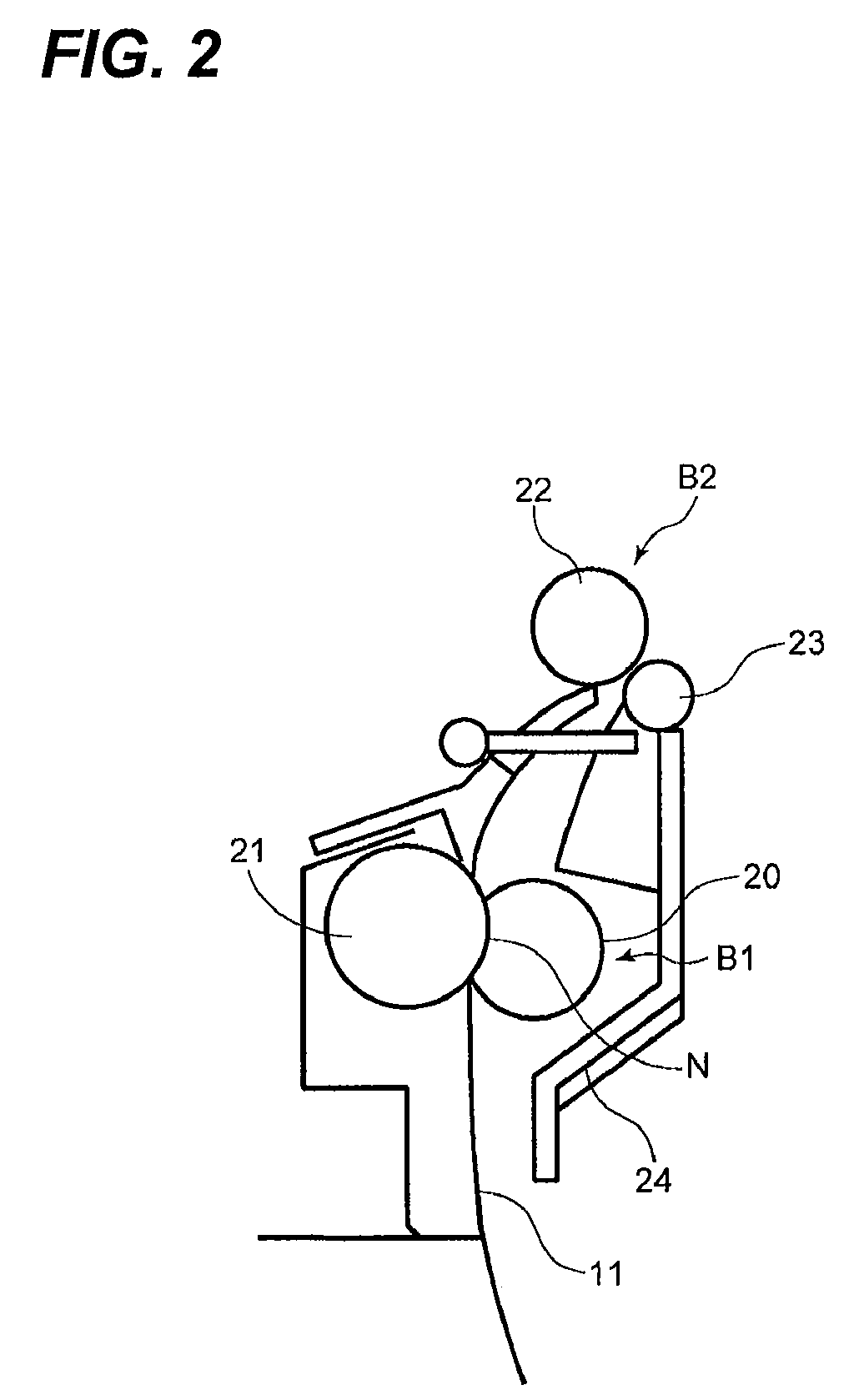

Conveying apparatus and recording apparatus

InactiveUS20050195264A1Reliably conveyedPreventing recording medium from fluttering and/or floatingOther printing apparatusArticle feedersElectrical resistance and conductanceSurface layer

A feeding device includes a conveying member for conveying a recording material; and an electrode, disposed in the conveying member, for generating an electrostatic attraction force for electrostatic attraction of the recording material on the conveying member and for controlling a temperature of a surface layer of the conveying member to provide a substantially constant resistance value of the surface layer of the conveying member.

Owner:CANON KK

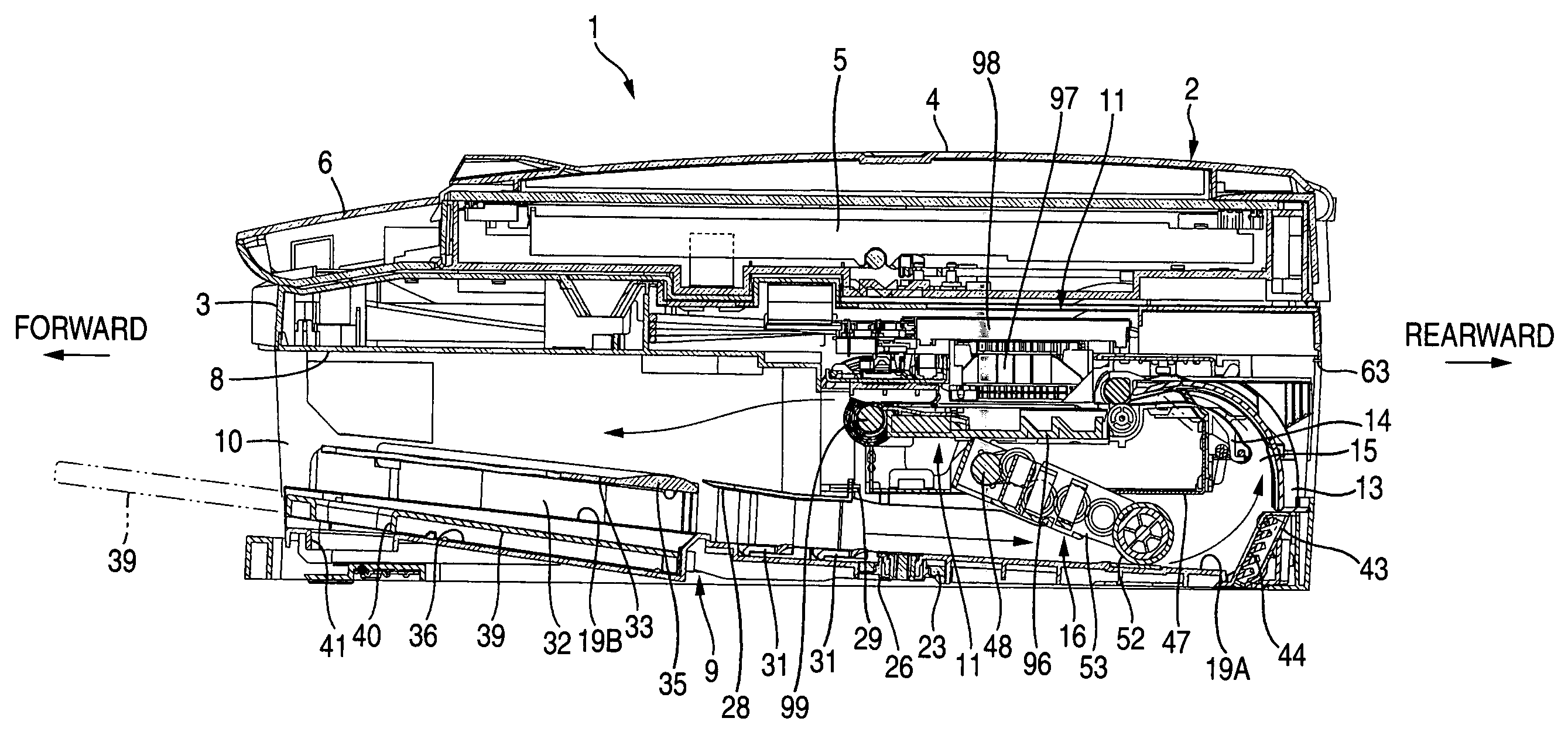

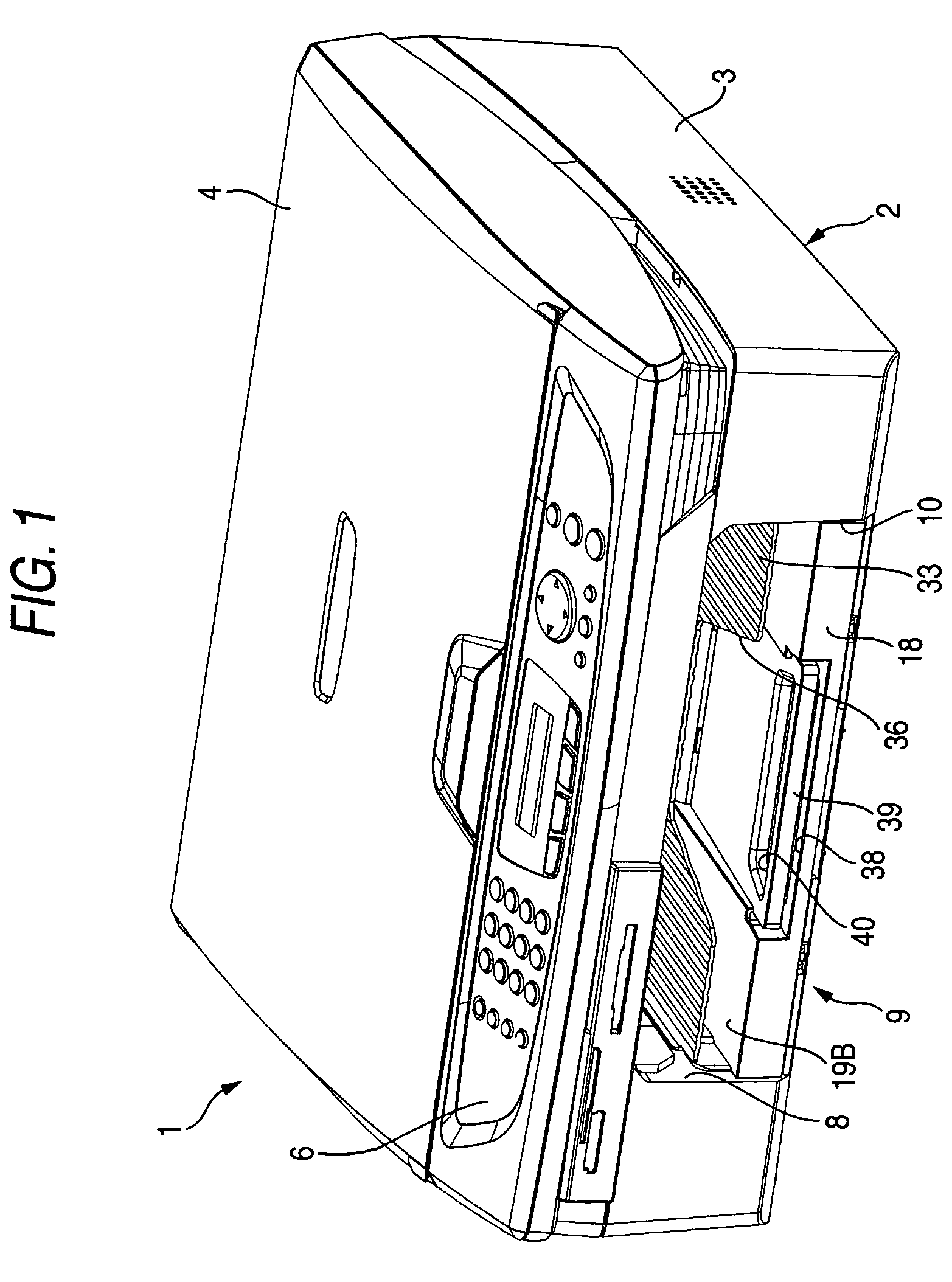

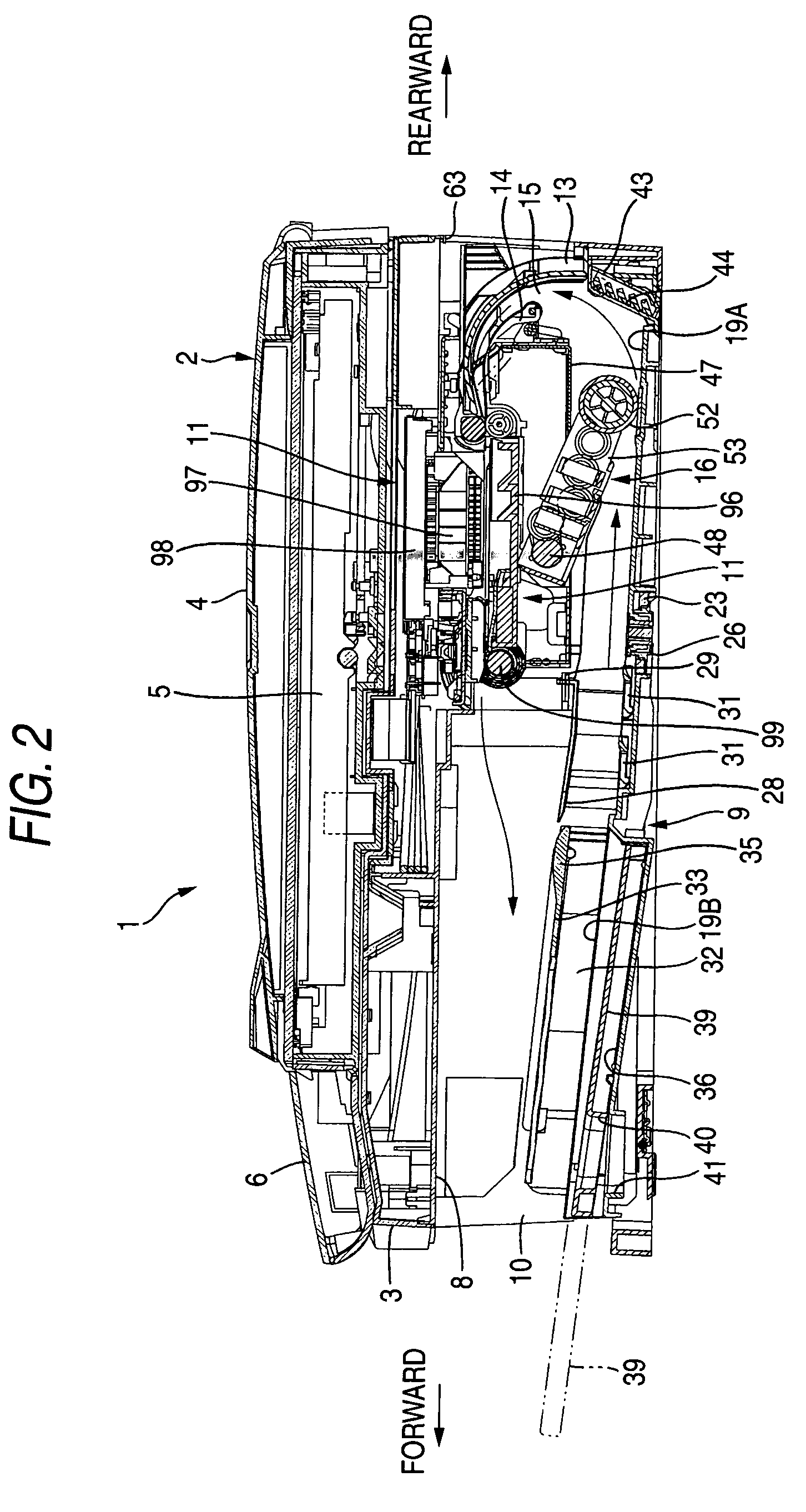

Image recording apparatus

ActiveUS7435025B2Reliably convey recording mediumReliably conveyedOther printing apparatusArticle feedersImage recordingEngineering

Owner:BROTHER KOGYO KK

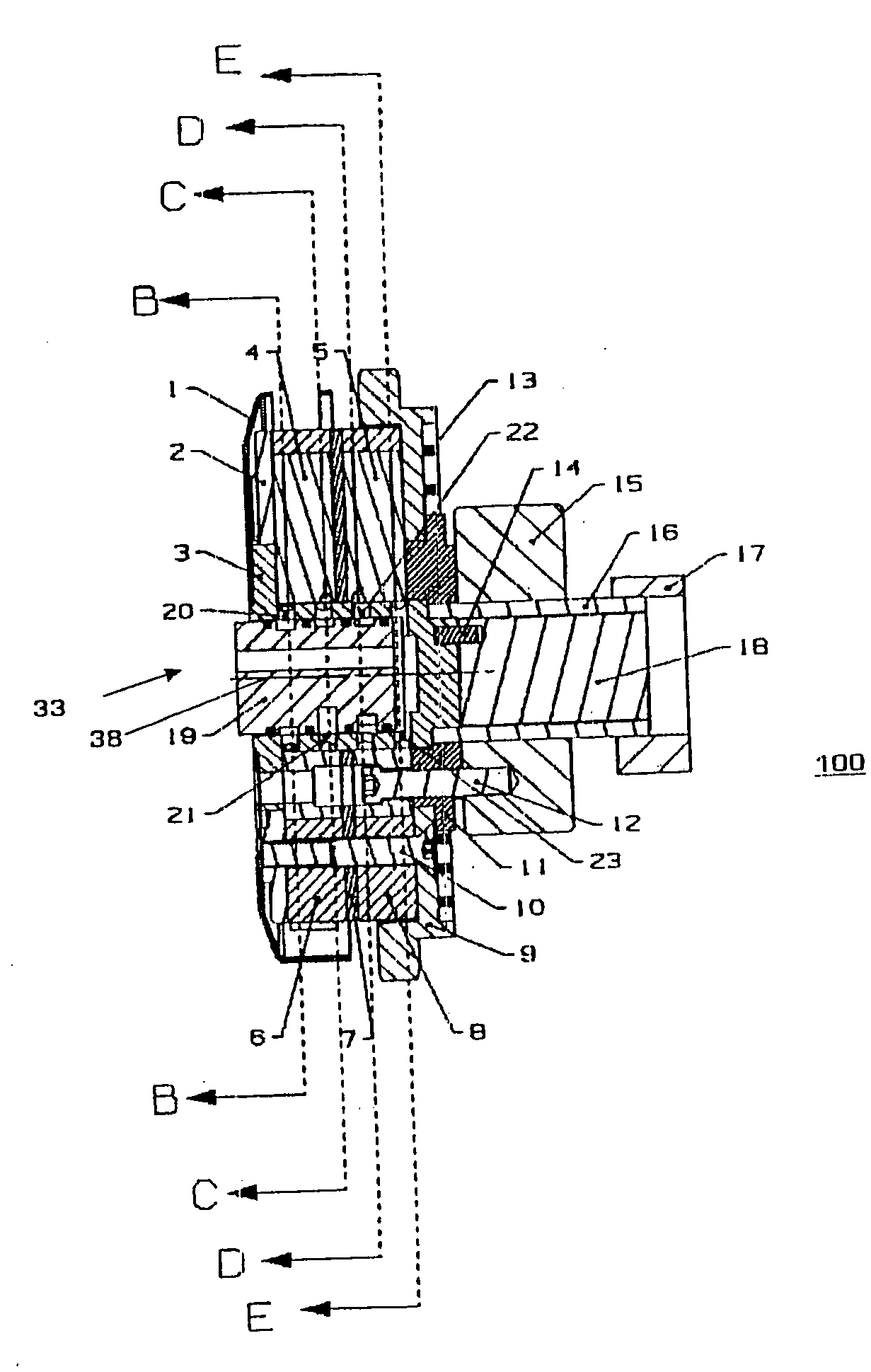

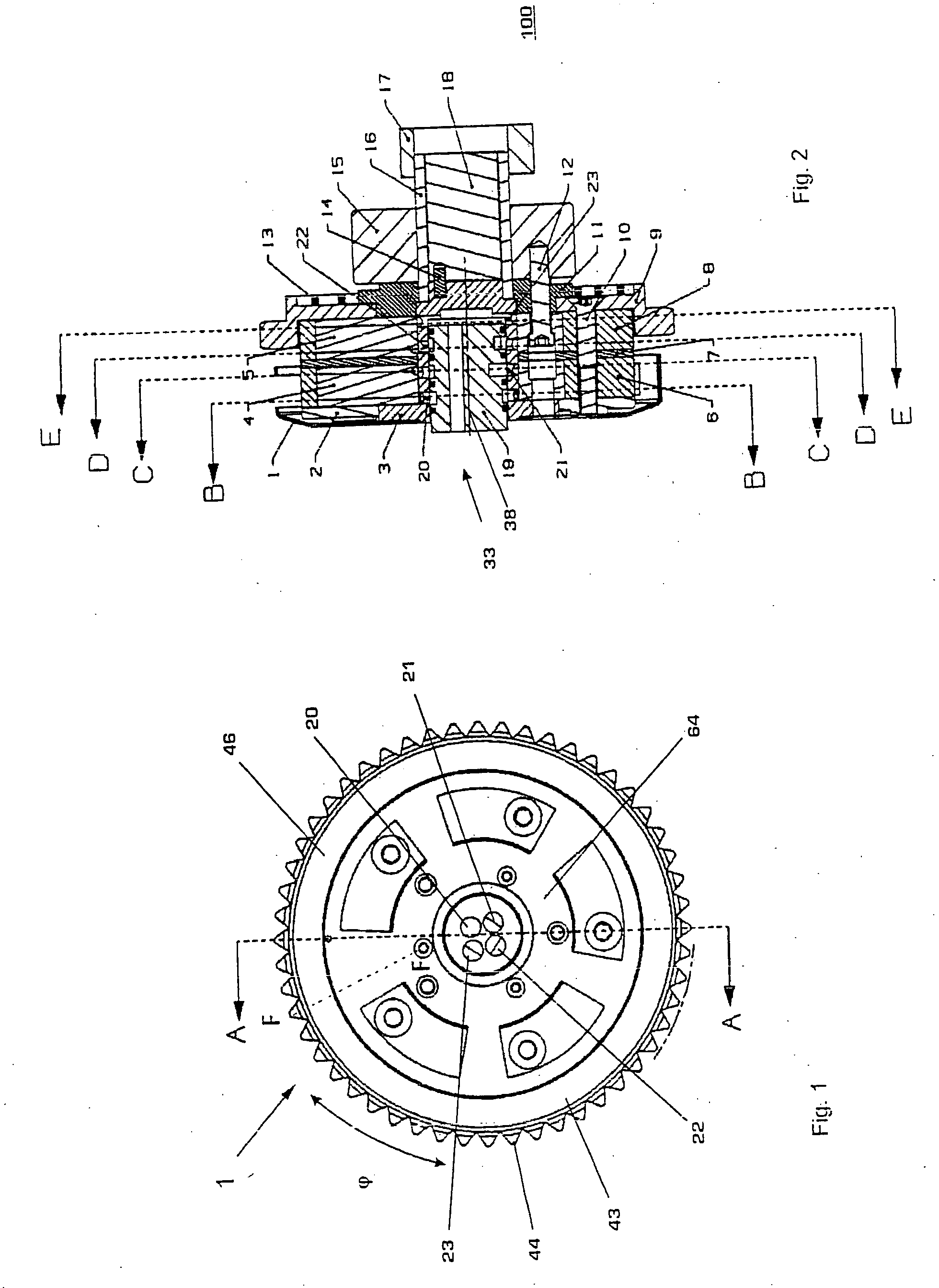

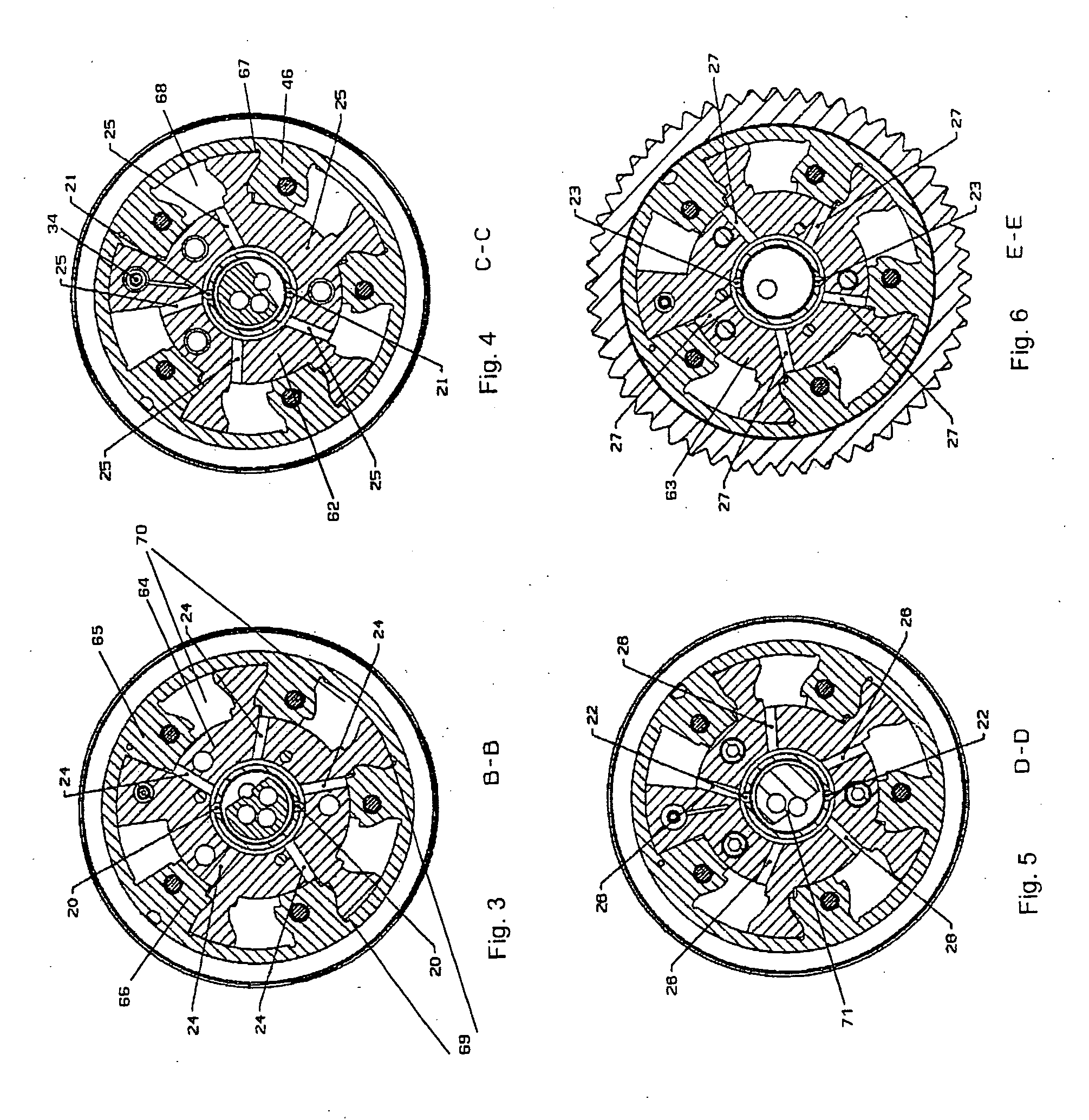

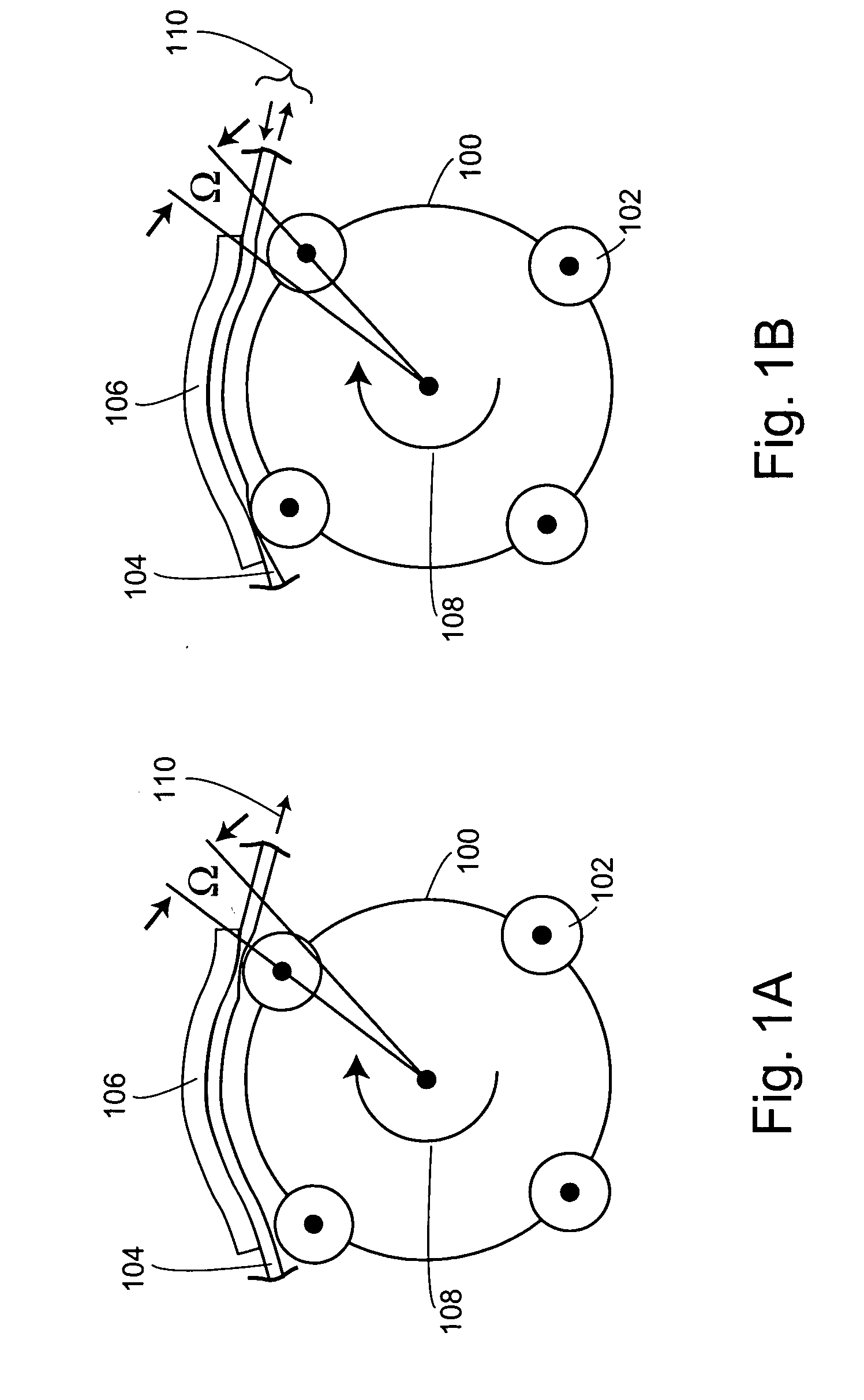

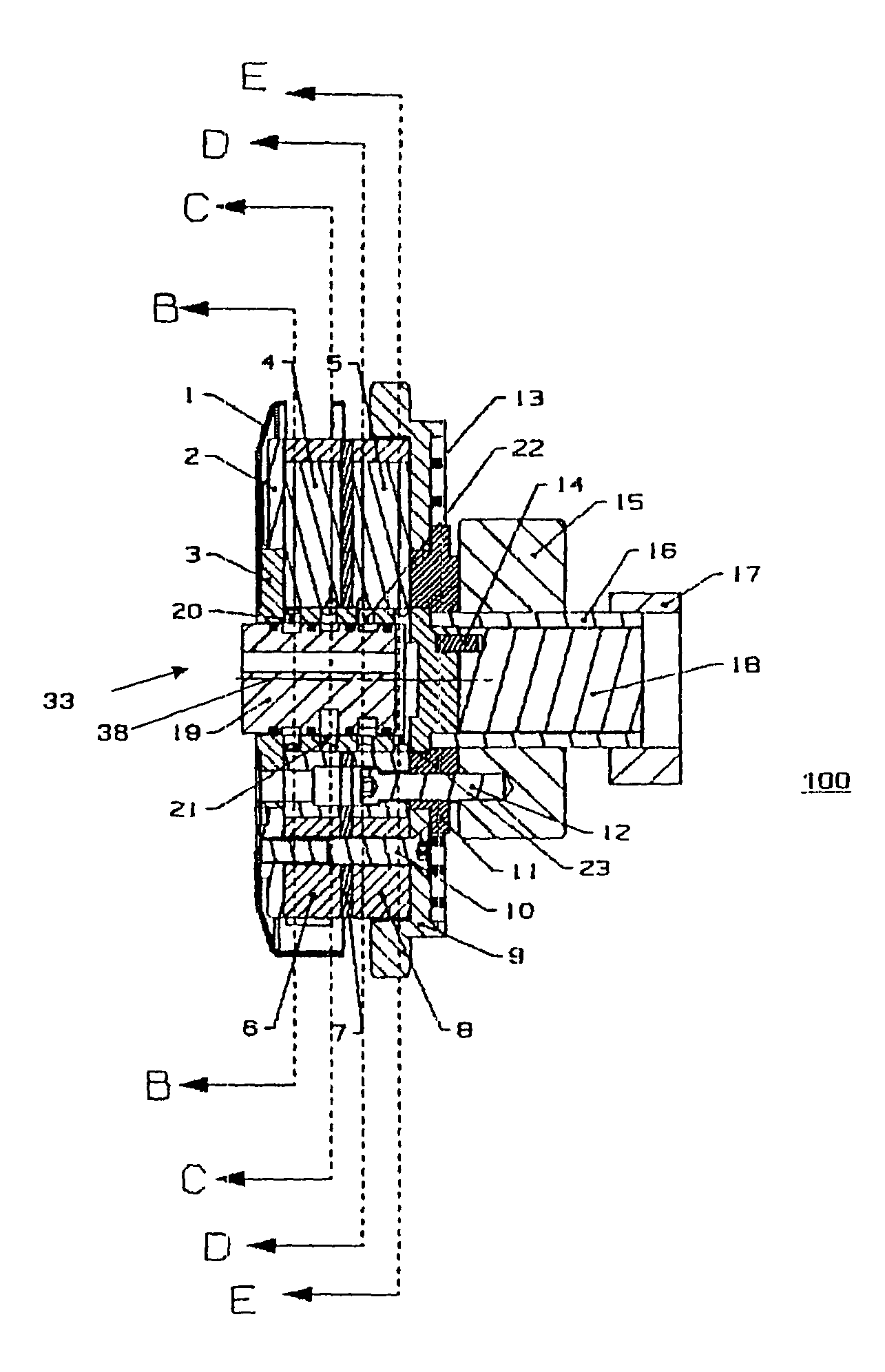

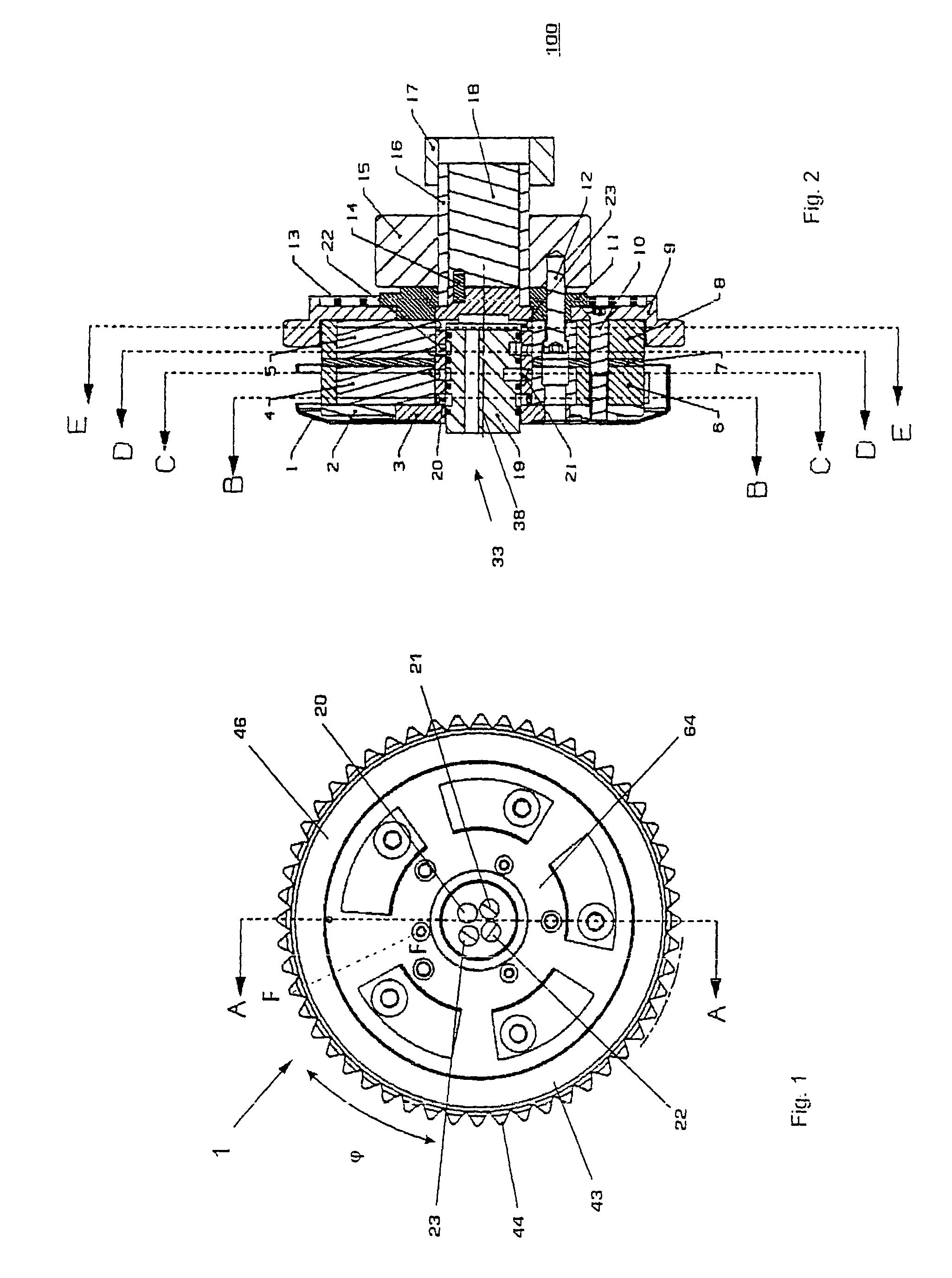

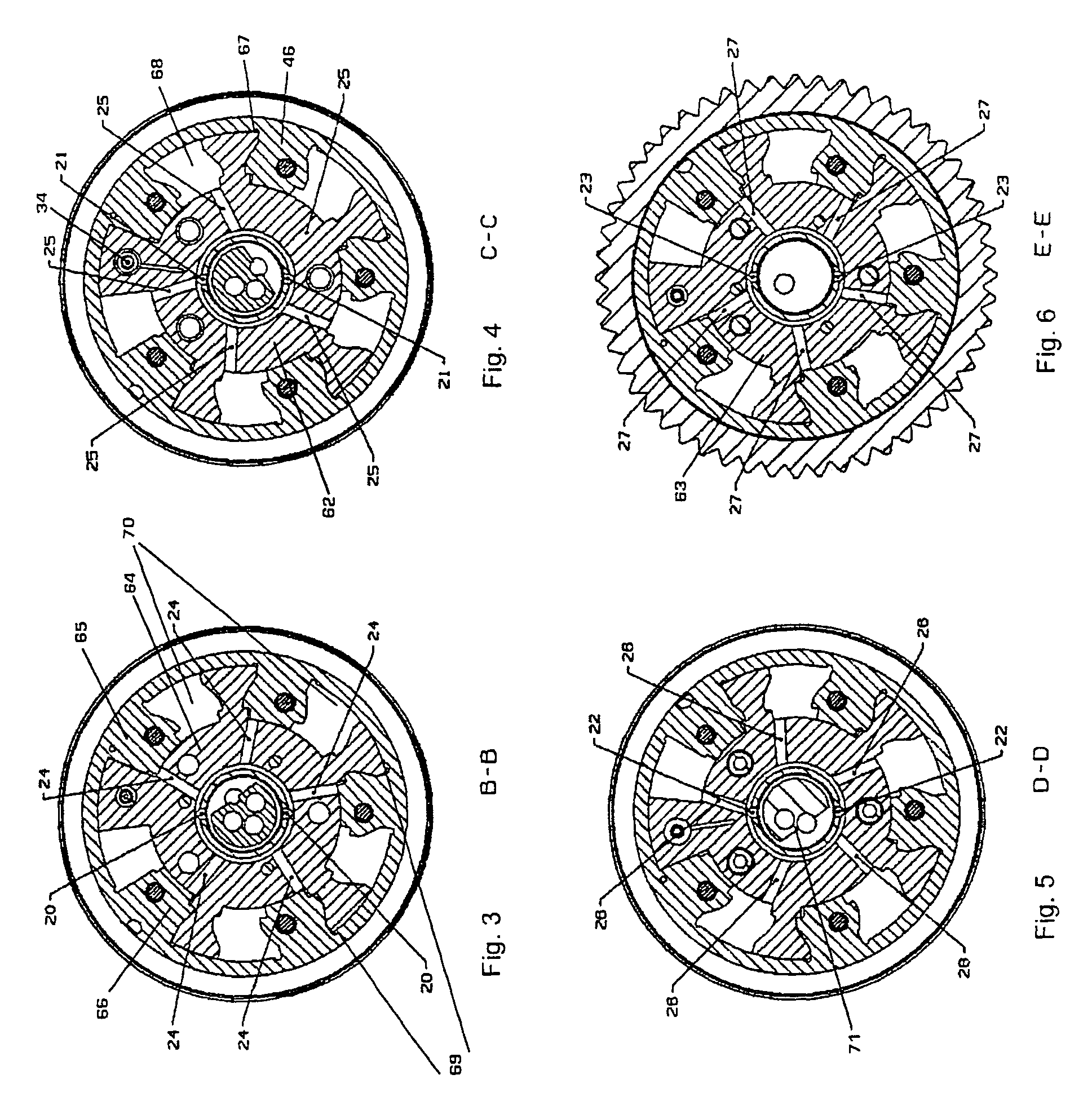

Doubled cam shaft adjuster in layered construction

InactiveUS20090183702A1Avoids tilting and deflectionSpace minimizationValve arrangementsYielding couplingCam

The present invention provides a cam shaft adjuster, which is designed for controlling a double cam shaft, which has a layered construction. The cam shaft adjuster is equipped with a first rotor-type output body and a second rotor-type output body which are arranged parallel to each other with their rotary vane body parts.

Owner:HILITE GERMANY

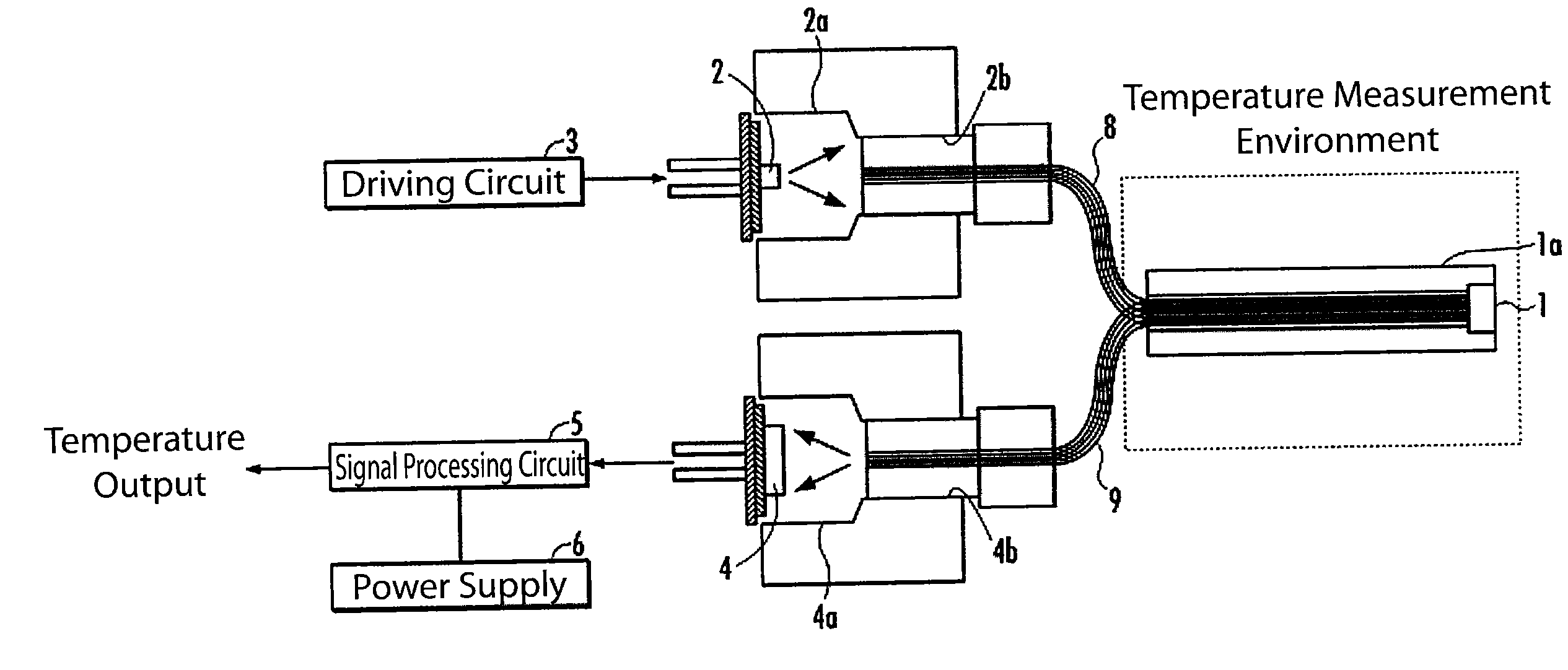

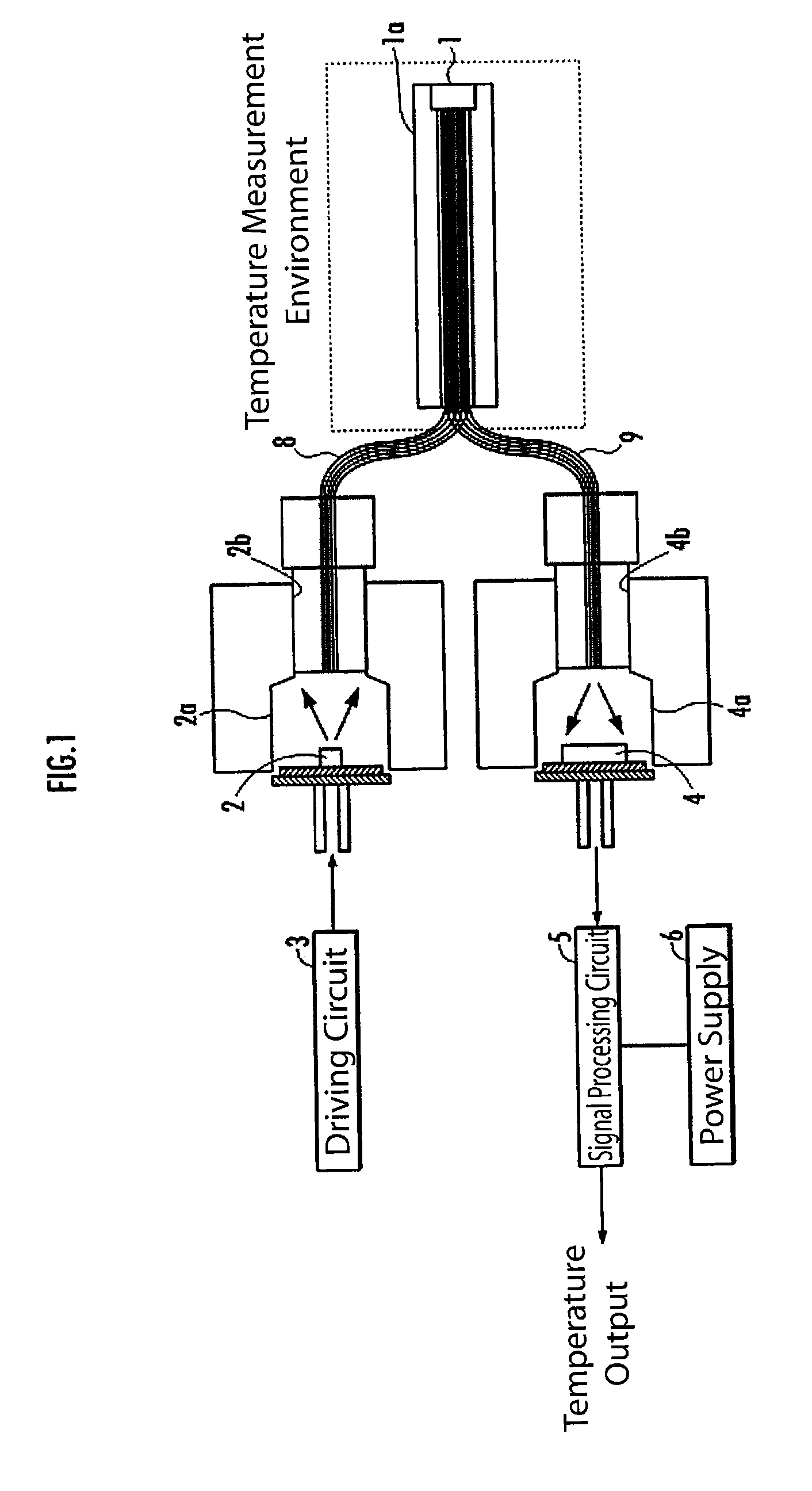

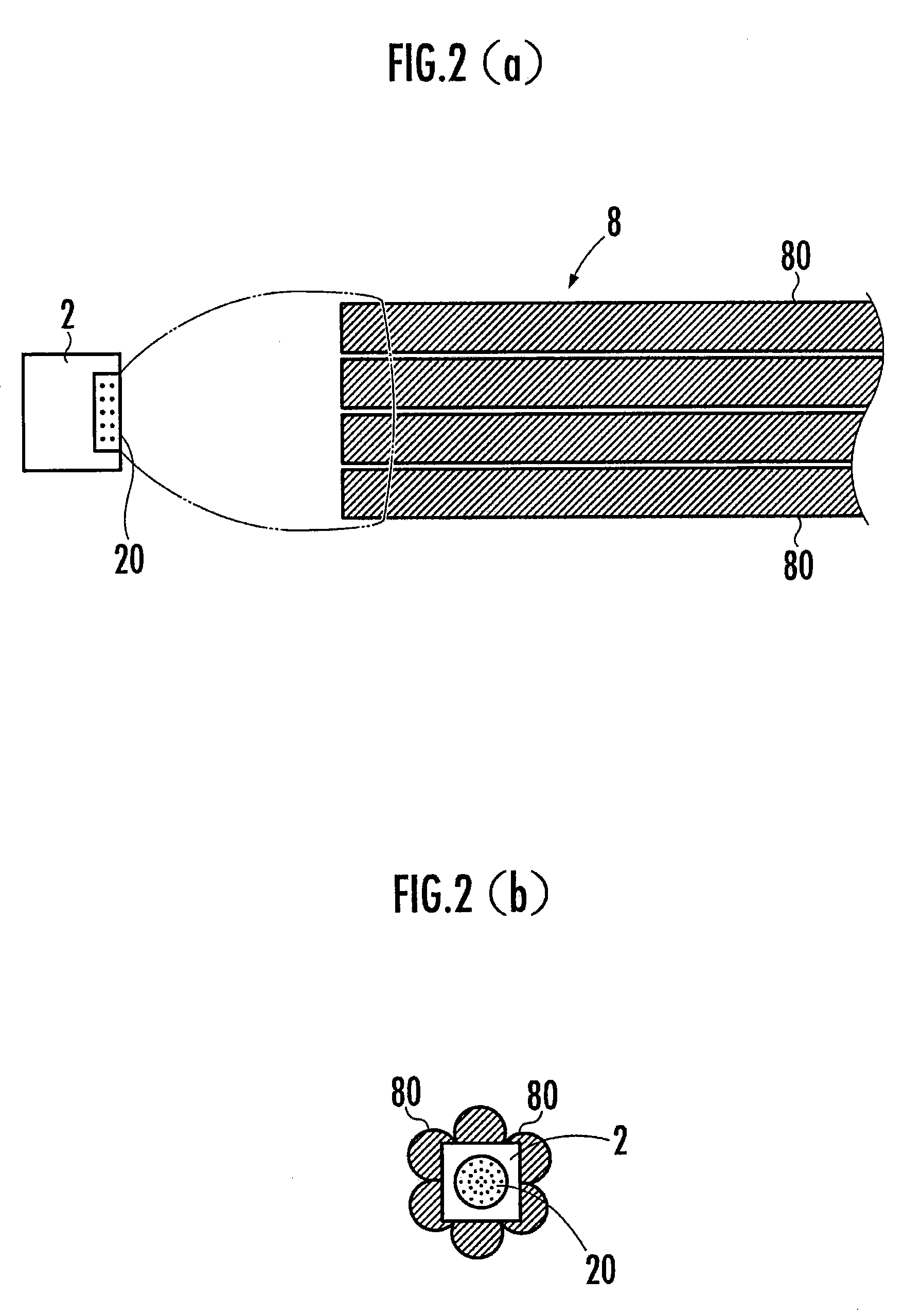

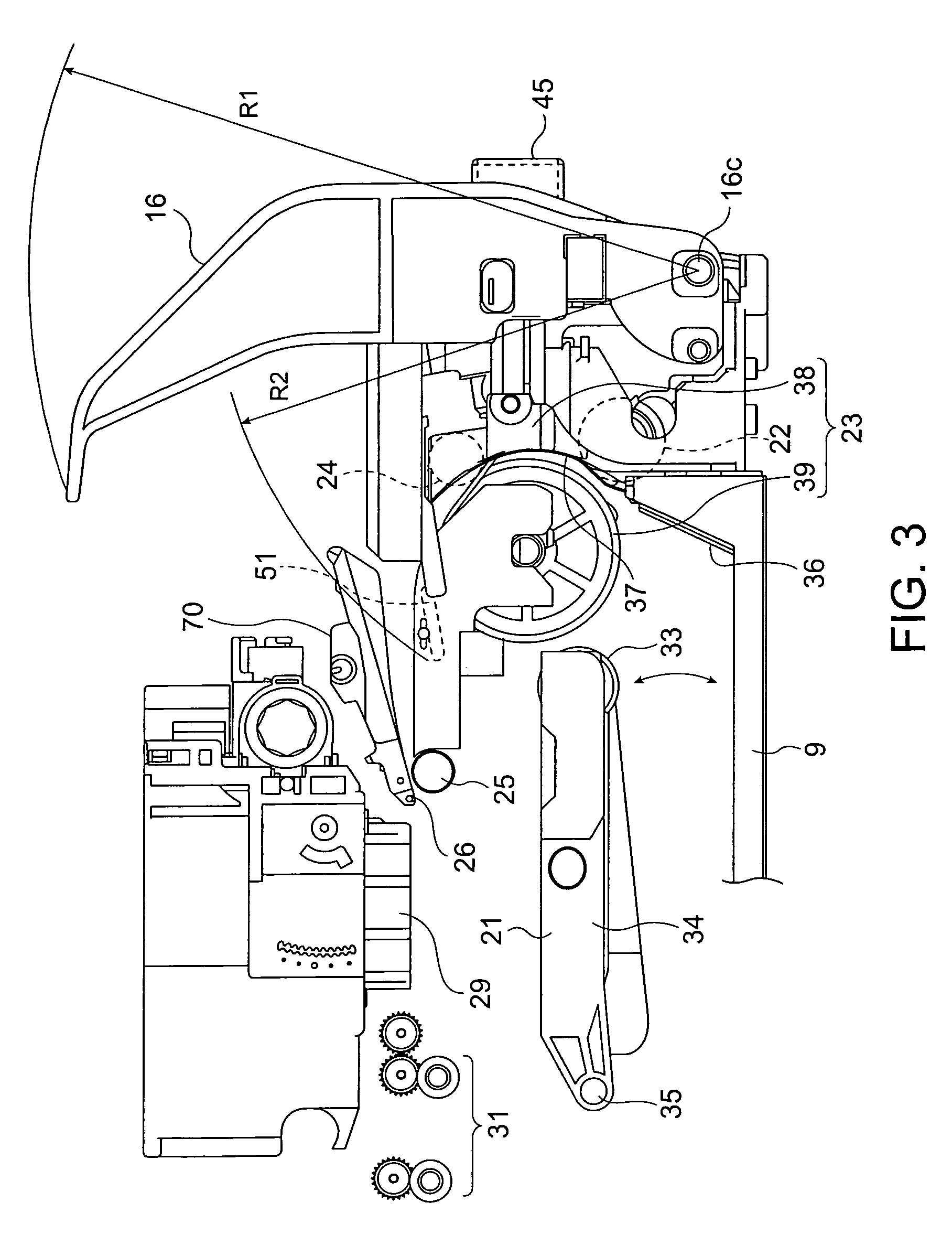

Fluorescent temperature sensor

InactiveUS20090296778A1Stable temperature measurementReliably conveyedThermometers using physical/chemical changesSignal processing circuitsFluorescent light

To use a simple structure to provide a fluorescent temperature sensor with increased accuracy through increasing the fluorescent light intensity of the fluorescent materials. A fluorescent temperature sensor for producing a temperature signal from a fluorescent light of a fluorescent material that is optically stimulated is provided with an LED for projecting light onto the fluorescent material, a photodiode for receiving the fluorescent light that is emitted by the fluorescent material, and a signal processing circuit for generating the temperature signal from the output of the photodiode. Optical fibers for the projected light, for conveying the light from the LED to the fluorescent material, and optical fibers for the received light, for conveying the light from the fluorescent material to the photodiode, are separated and independent from each other on one end side thereof, facing the respective elements, and on the other end side, which faces the fluorescent material, are bundled so as to be mixed together.

Owner:YAMATAKE HONEYWELL CO LTD

Material conveying systems, computer program products, and methods

InactiveUS20050163637A1Minimizes shearing effectMinimise carryoverFlexible member pumpsPump controlProviding materialDelivery system

This invention provides material conveying systems that are configured to convey substantially uniform quantities of material to and / or from the material sites and to minimize periodic variation among the conveyed quantities of material. Related computer program products and methods are also provided.

Owner:IRM

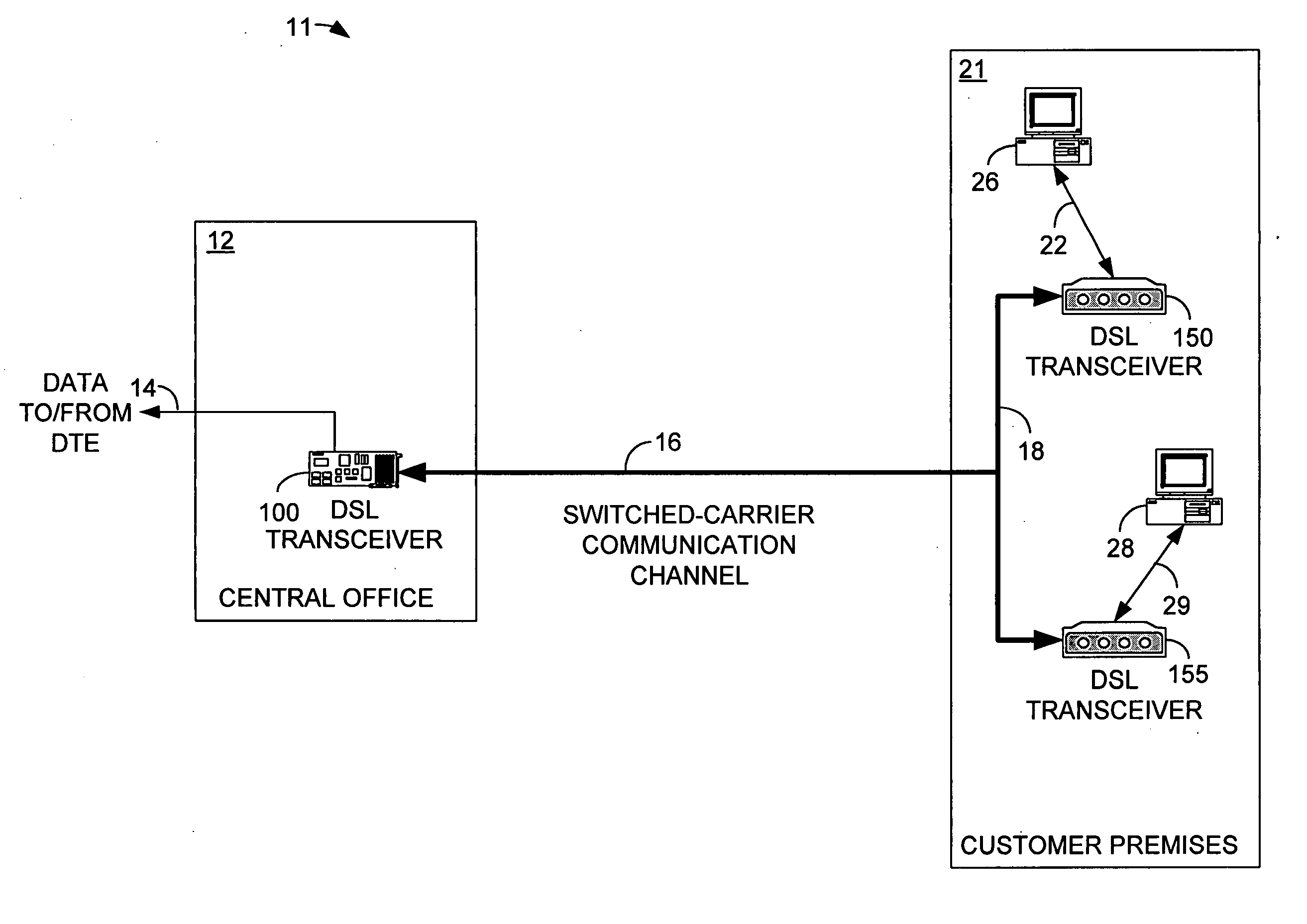

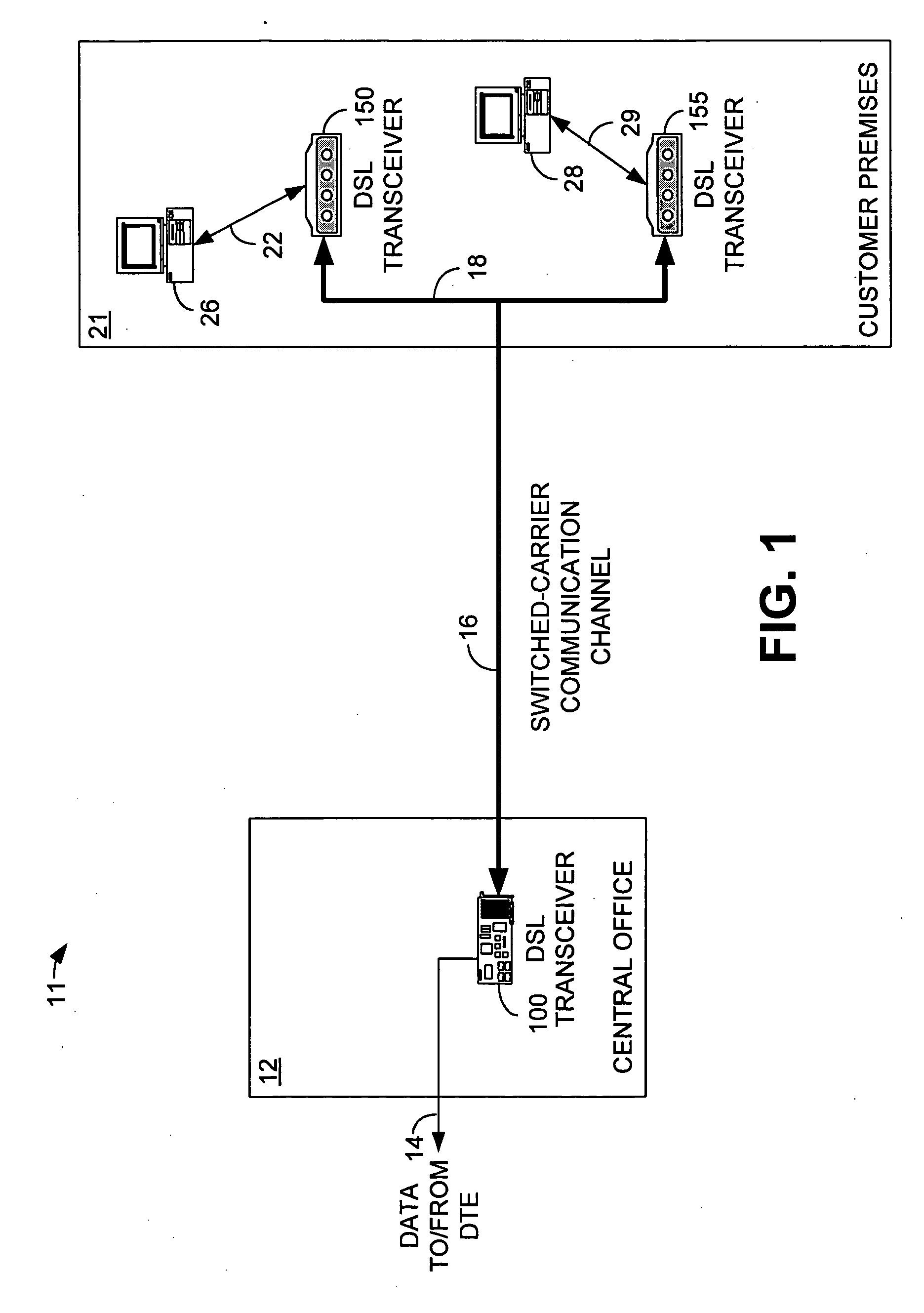

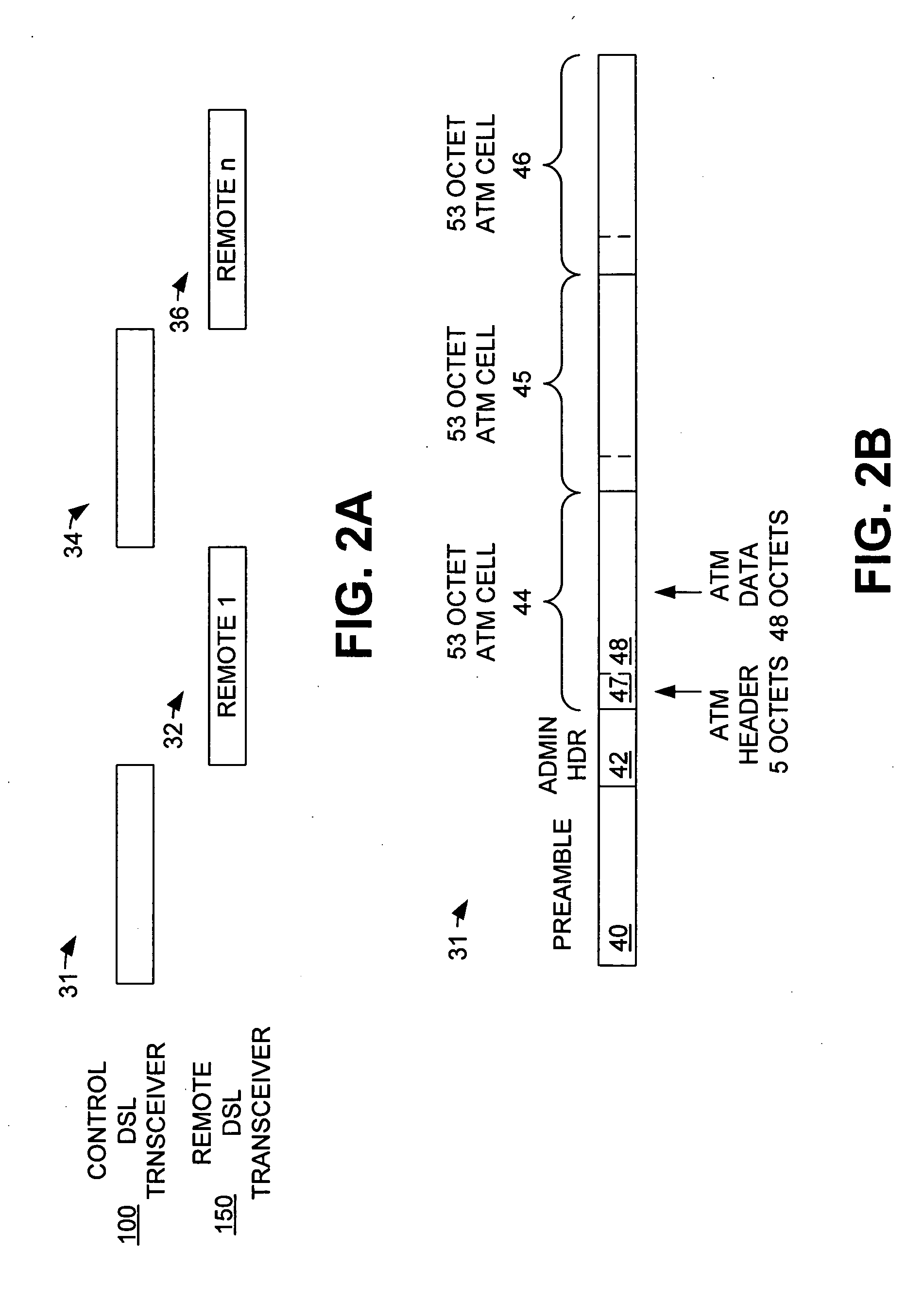

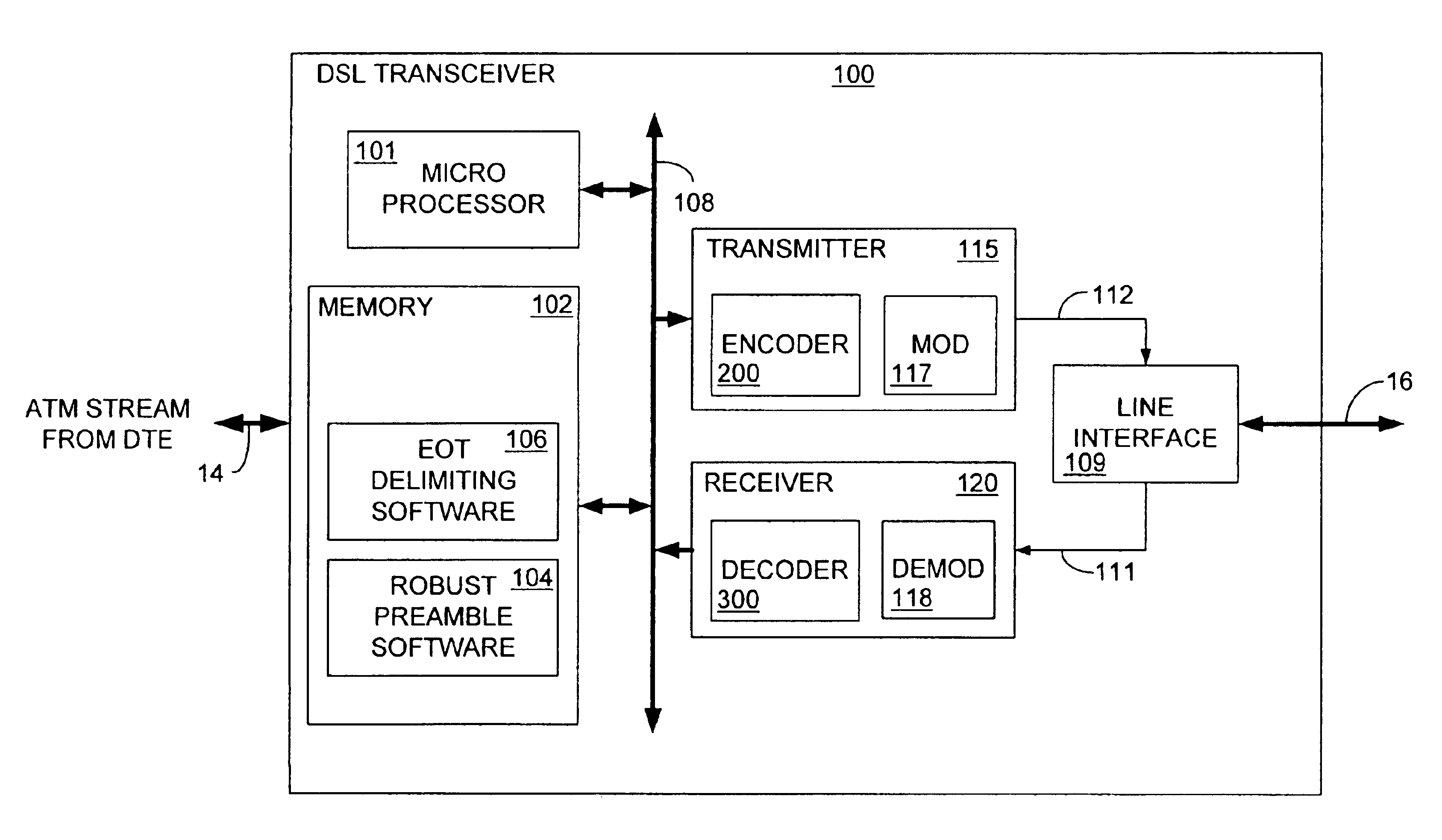

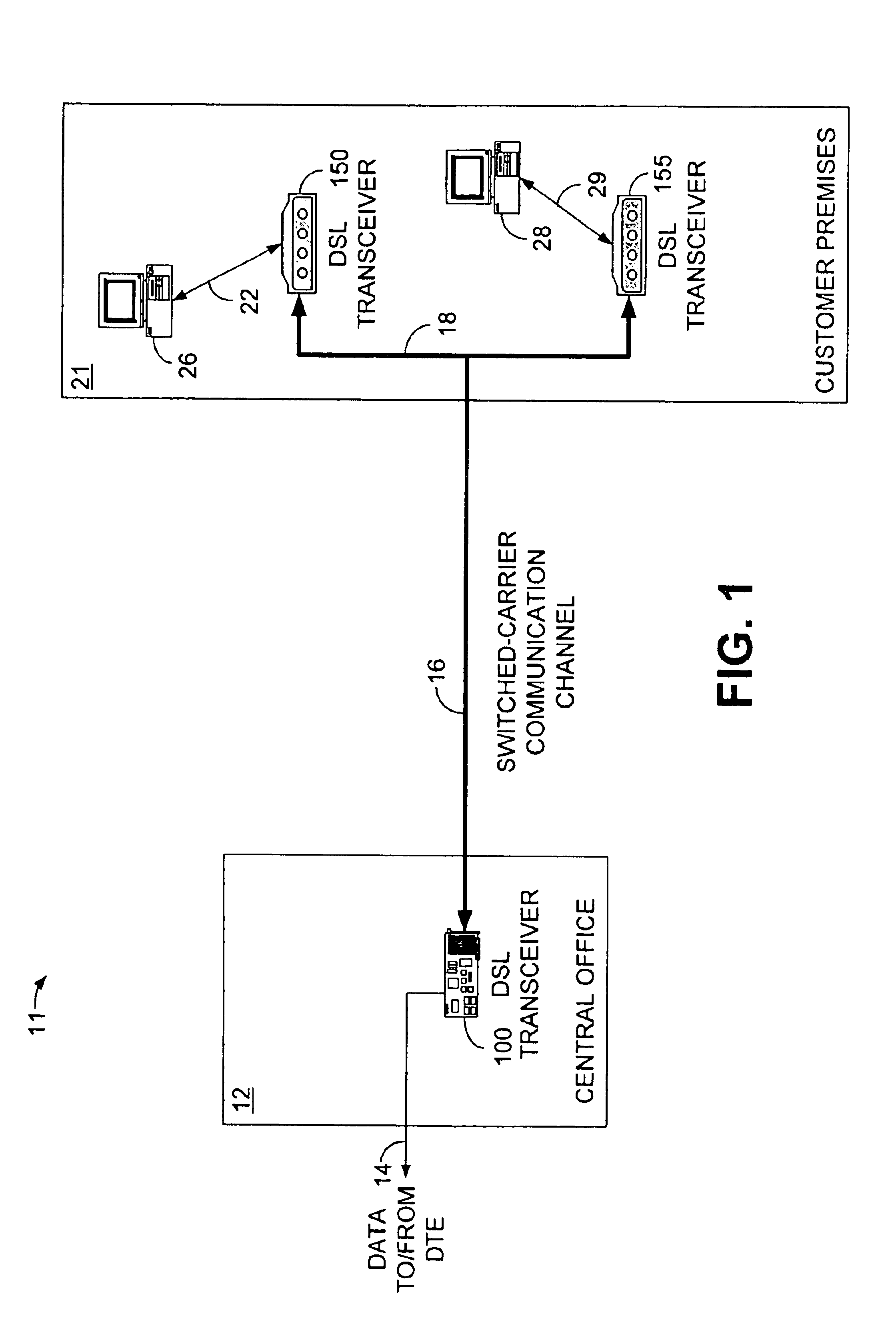

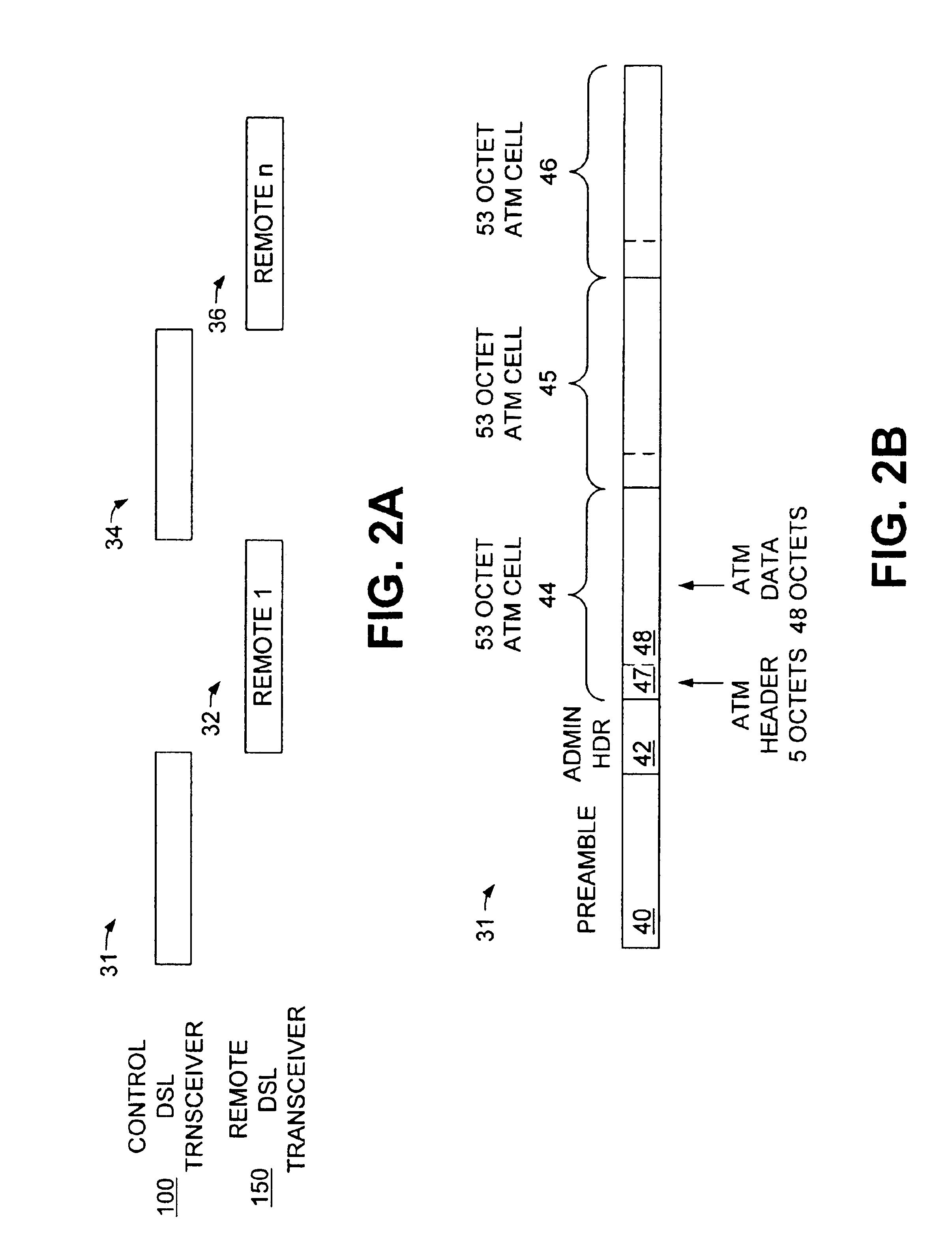

System and method for a robust preamble and transmission delimiting in a switched-carrier transceiver

InactiveUS20050152404A1Robustly delimitingReliably conveyedFrequency-division multiplexSignalling characterisationCarrier signalTelecommunications

A method and system for robust delimiting of messages in switched-carrier operation in which a preamble precedes each message. The preamble comprises symbols transmitted at a rate lower than that of the following data. The lower rate significantly increases the probability that decoding of the preamble symbols will be error-free. Communication line control information can be included in the preamble, thereby ensuring that line control information is reliably transferred over the channel. The preamble's first symbol can be transmitted at the lower symbol rate and at an increased power level, thereby reliably delimiting the beginning of a transmission. The end of the message can be reliably delimited by sending the first symbol which contains only bits from a next cell of information at a lower symbol rate, and including an extra bit in that symbol. The extra bfit can indicate to a receiver when the last cell of information begins.

Owner:REMBRANDT COMM LP

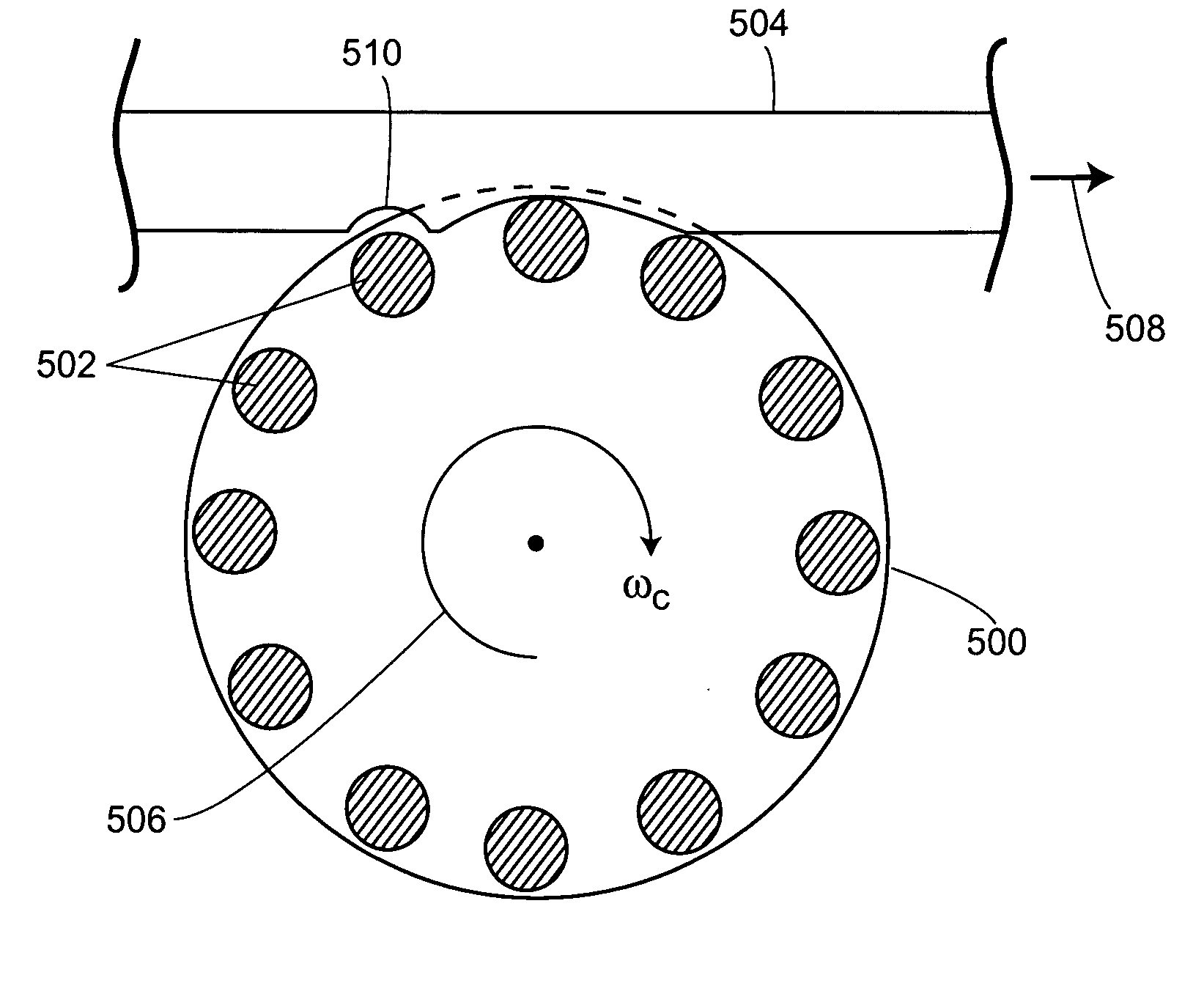

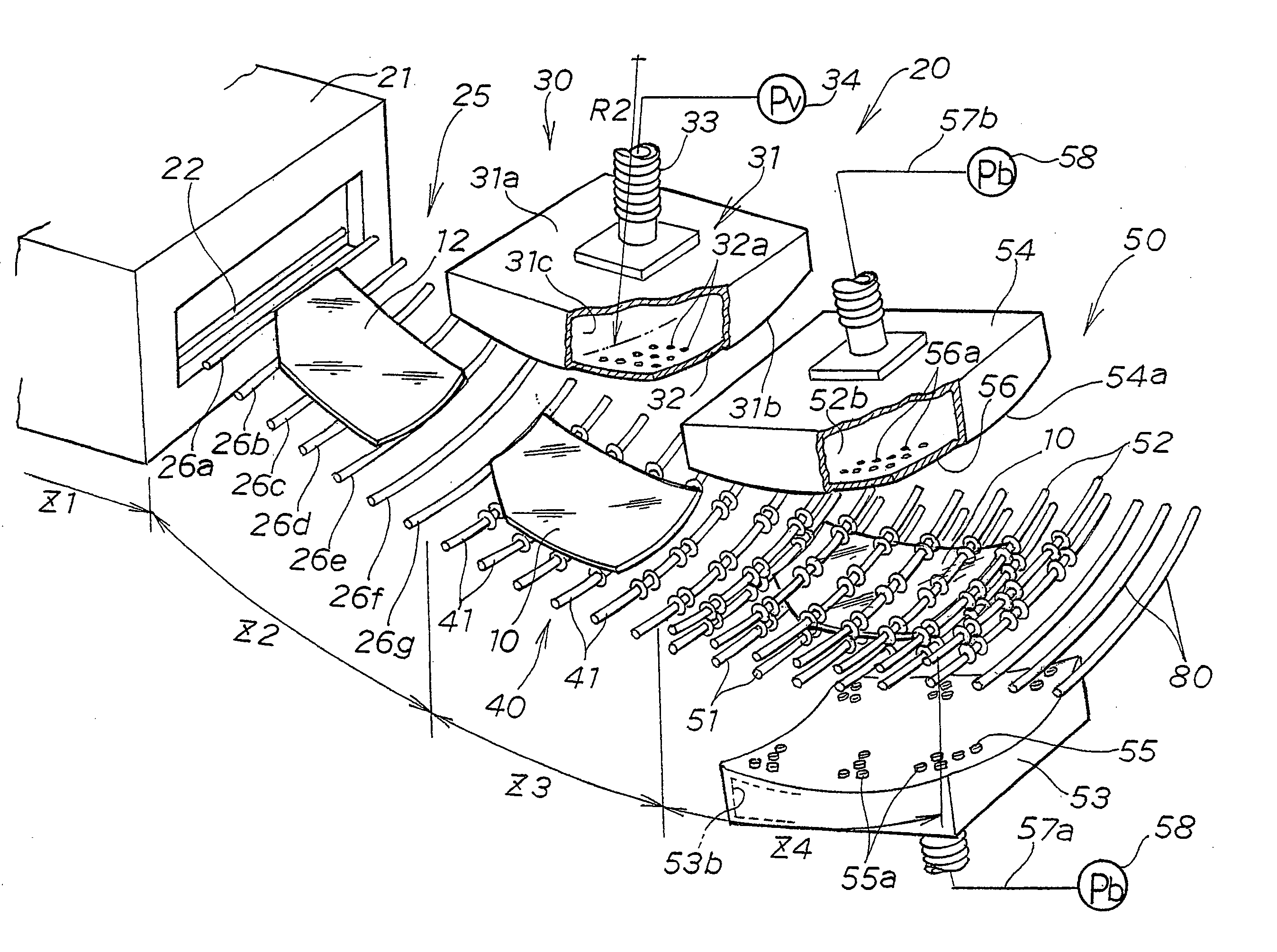

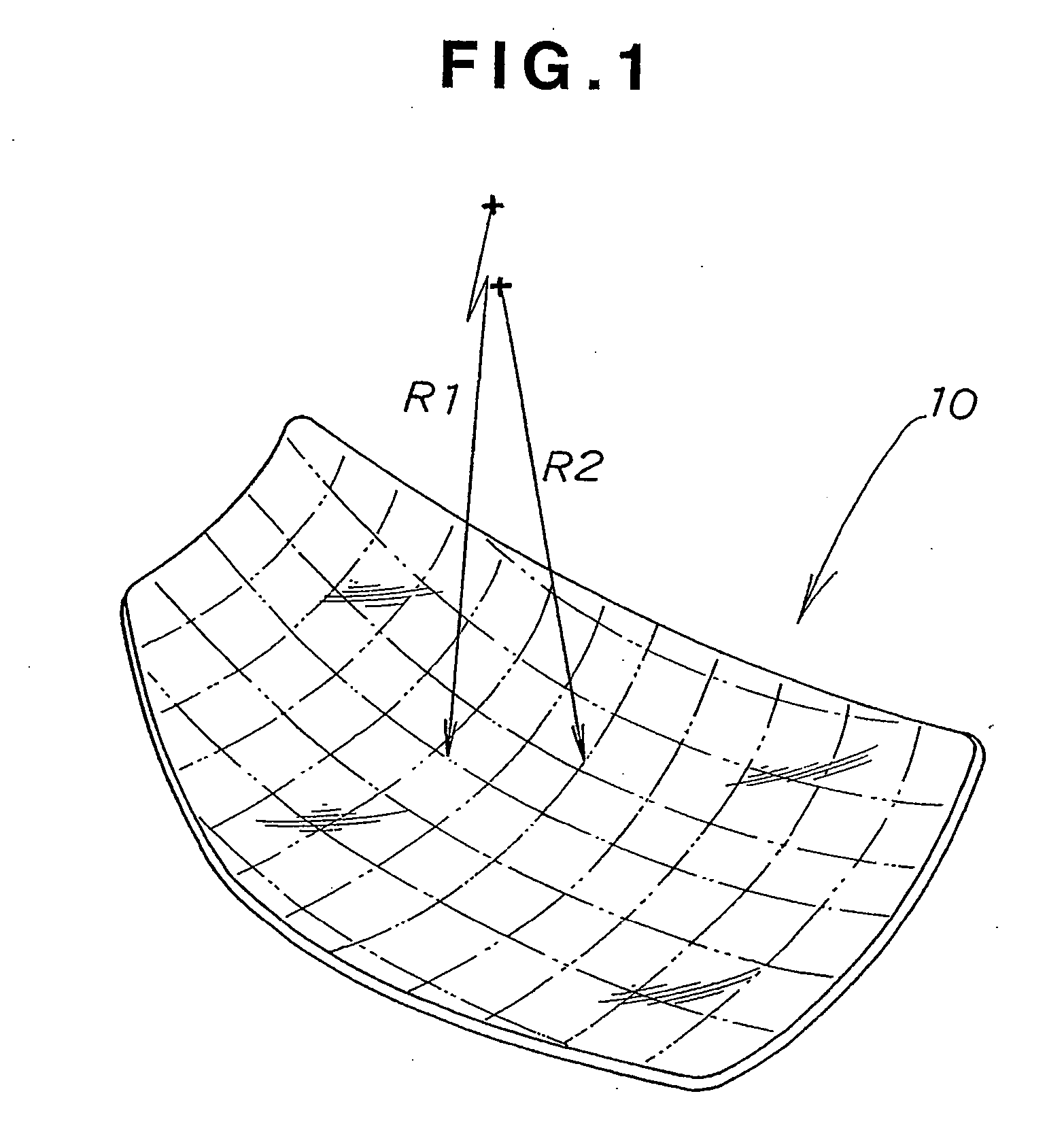

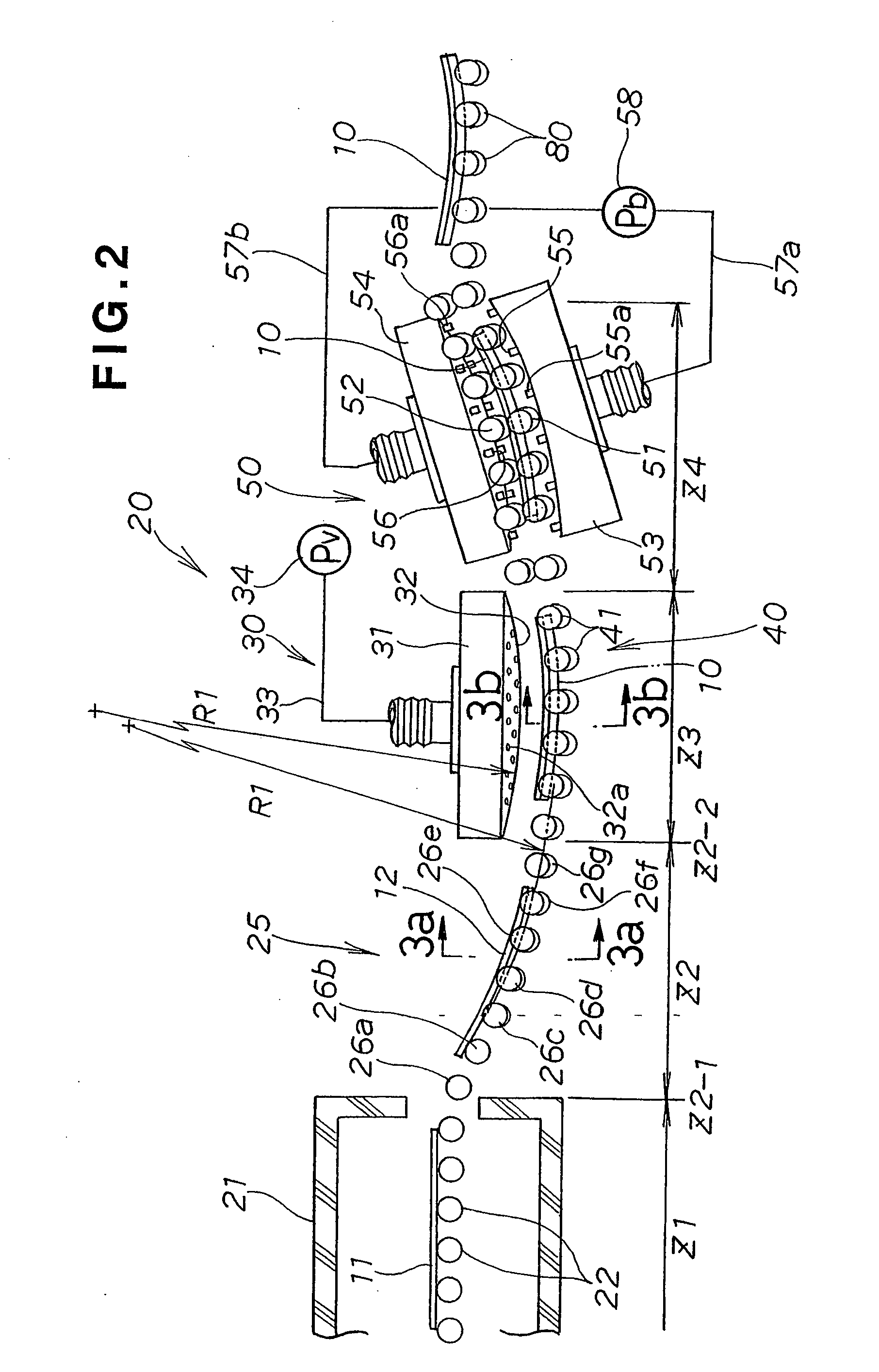

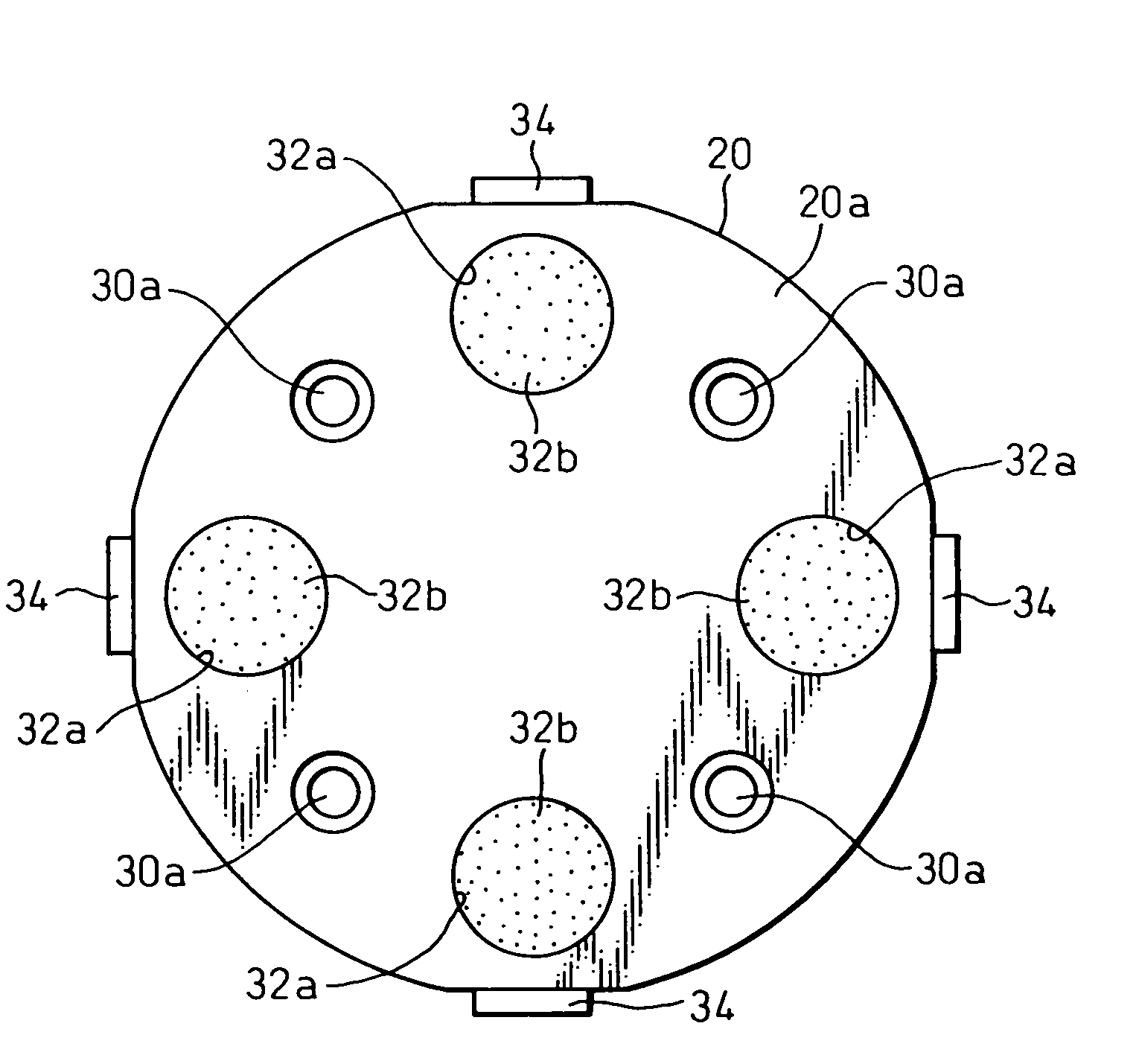

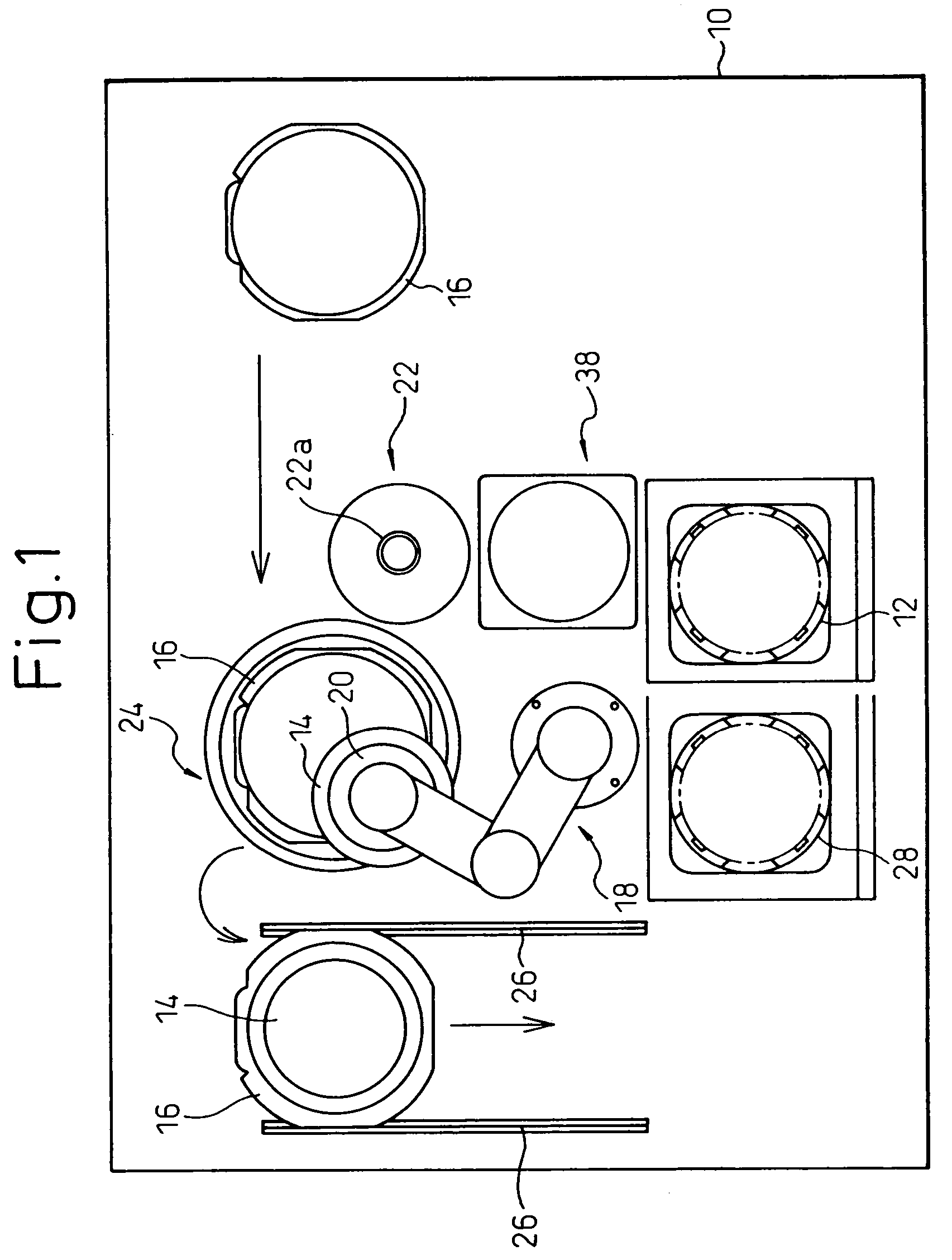

Apparatus and method for producing a bent glass sheet

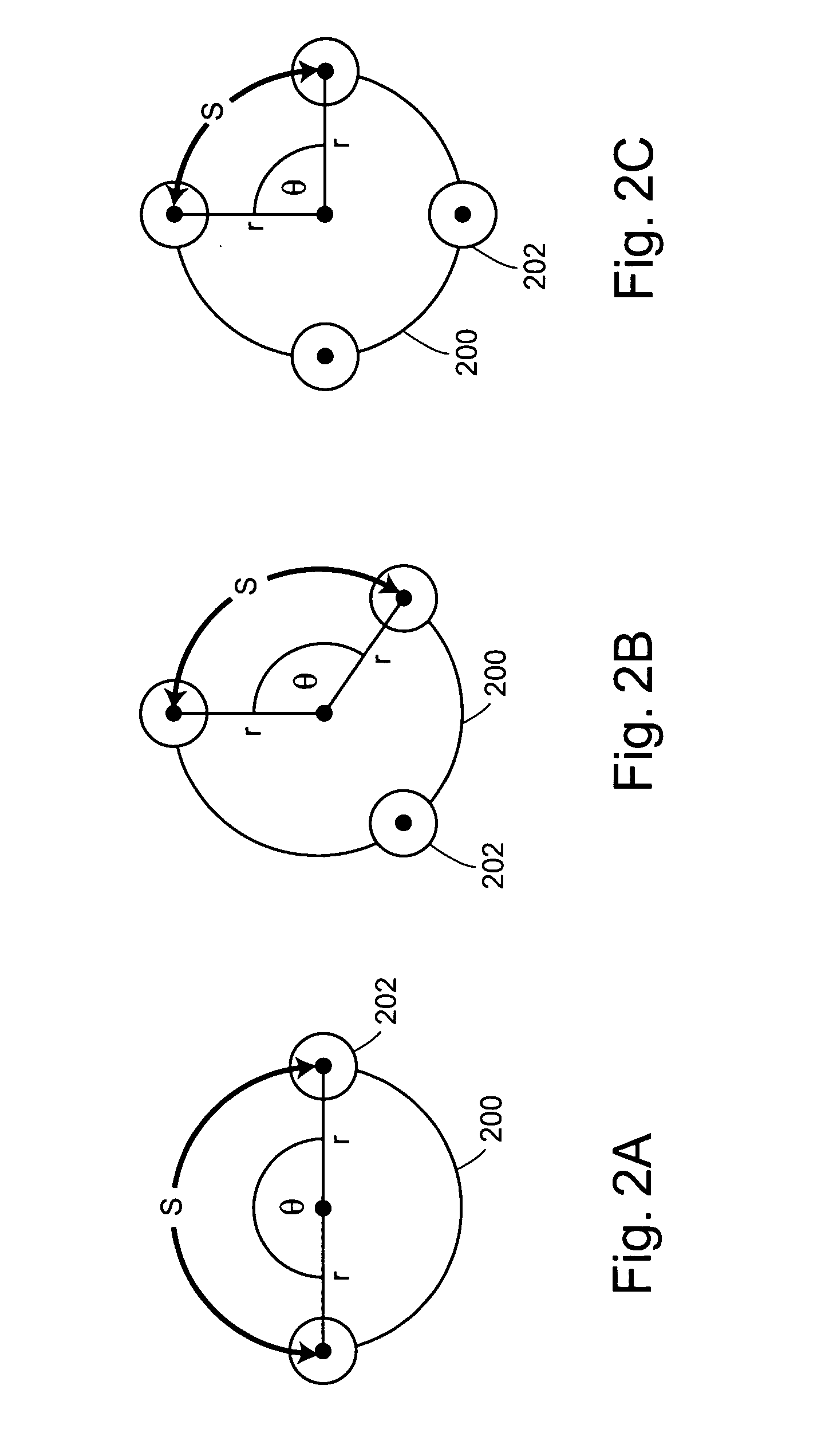

InactiveUS20050000247A1Precise supportReliably conveyedGlass transportation apparatusGlass rolling apparatusArcuate shapeHeating furnace

An bent glass sheet producing apparatus (20) has a heating furnace (21) in a heating zone (Z1), a preliminary forming mechanism (25) in a preliminary forming zone (Z2) downstream of the heating zone (Z1), a two-directional bending mechanism (30) and a conveyor roller mechanism (40) in a forming zone (Z3) downstream of the preliminary forming zone (Z2), and a cooling mechanism (50) in a cooling zone (Z4) downstream of the forming zone (Z3). For a purpose of conveying a two-directionally bent glass sheet formed by the two-directional bending mechanism, the conveyor roller mechanism (40) includes a plurality of conveyor rollers (41) having an arcuate shape of a radius (R2) in a direction perpendicular to the conveyance direction of the glass sheet, the conveyor rollers (41) being arranged on an arcuate line having a radius in the conveyance direction.

Owner:NIPPON SHEET GLASS CO LTD

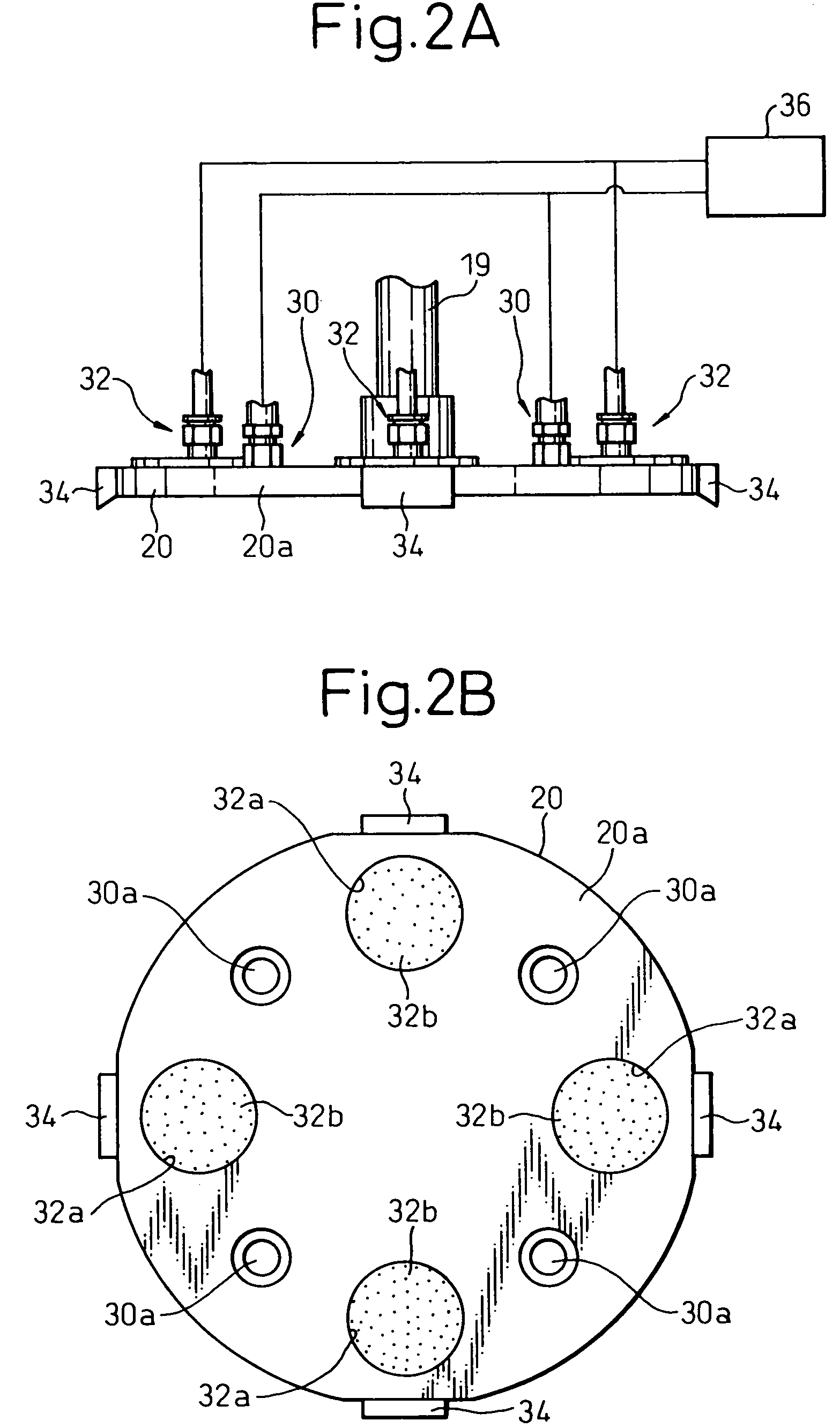

Conveyor system

InactiveUS7063499B2Achieve safe transportationPrecise positioningGripping headsSemiconductor/solid-state device manufacturingEngineeringDelivery system

A conveyor system able to safety convey a workpiece having a thickness of less than 100 μm and easily position the workpiece, provided with a plate-shaped member provided movably and swivelably and a moving and swiveling means moving and swiveling the plate-shaped member, the plate-shaped member being provided together with a lifting means for uniformly lifting in its entirety a workpiece carried at the carrying location and a holding means for holding a workpiece lifted by the lifting means by chucking its entirety on a workpiece chucking surface of the plate-shaped member, and a plurality of Verneuil nozzles serving as the lifting means and a plurality of vacuum chucking nozzles serving as the holding means being formed in the workpiece chucking surface near an outer periphery of the plate-shaped member along the outer periphery.

Owner:SHINKO ELECTRIC IND CO LTD

Doubled cam shaft adjuster in layered construction

InactiveUS8201528B2Avoids jamming and deflectionSpace minimizationValve arrangementsYielding couplingEngineeringCam

The present invention provides a cam shaft adjuster, which is designed for controlling a double cam shaft, which has a layered construction. The cam shaft adjuster is equipped with a first rotor-type output body and a second rotor-type output body which are arranged parallel to each other with their rotary vane body parts.

Owner:HILITE GERMANY

Roller and sheet delivery unit

InactiveUS6962333B2Increase flexibilityImprove wear resistanceShaft and bearingsPortable power-driven toolsElastomerPliability

The invention provides a roller having excellent flexibility and wear resistance. The invention also provides a sheet delivery unit equipped with this roller. The unit is prevented from being clogged up with sheets due to rigidities of the sheets. Also, simultaneous delivery of plural sheets is suppressed. The allowable range of rigidities of paper currencies and the allowable range of their widths can be extended. The roller has a central portion extending along an axis, an outer peripheral portion formed around the central portion and made of a resilient body, and plural helical ribs connecting together the central portion and the outer peripheral portion. Each rib consists of a resilient body. Each rib is so shaped as to thicken gradually from the central portion toward the outer peripheral portion.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

System and method for a robust preamble and transmission delimiting in a switched-carrier transceiver

InactiveUS6950444B1Robustly delimitingRobust transmissionTime-division multiplexSignalling characterisationTelecommunicationsCarrier signal

Owner:REMBRANDT TECH LP

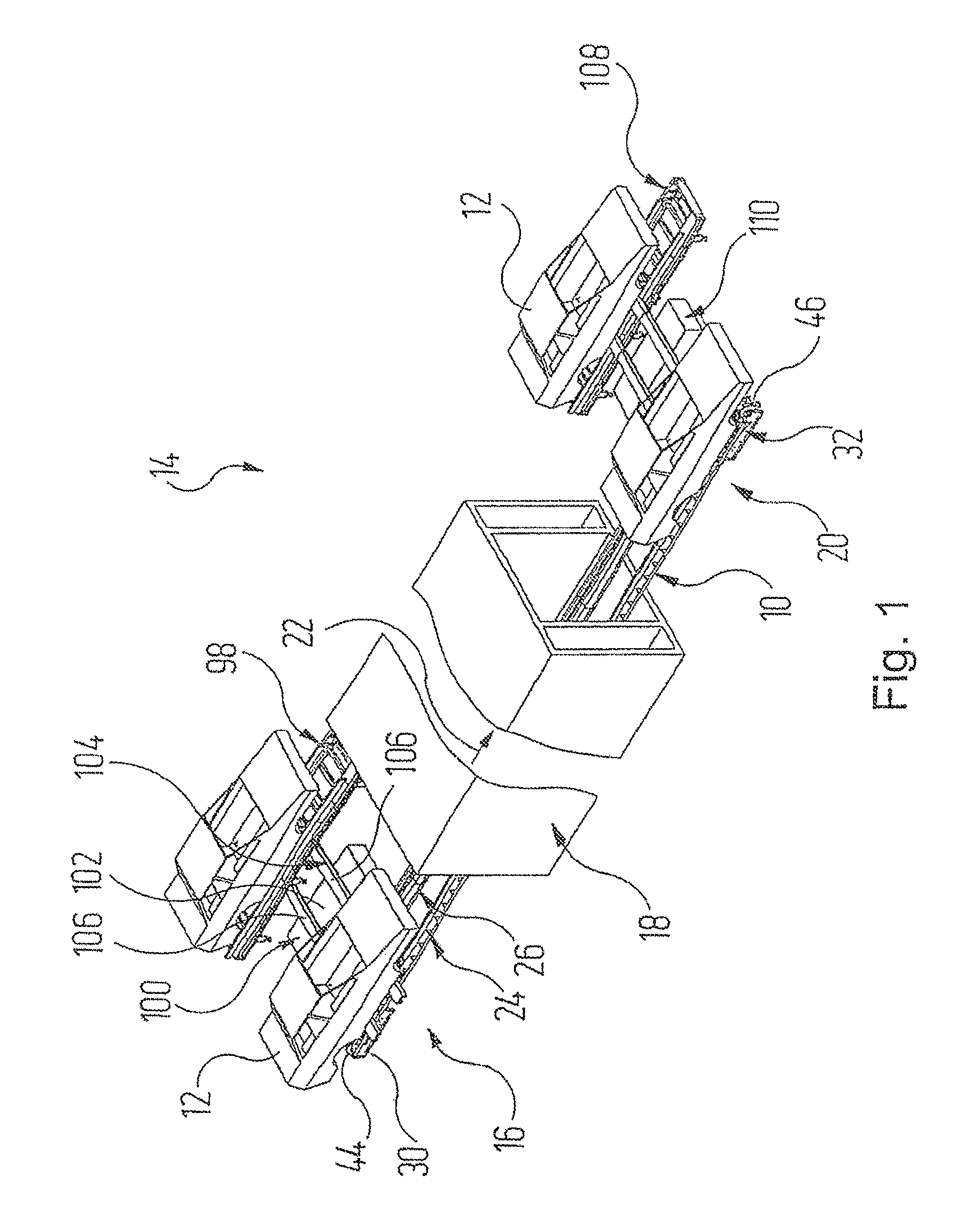

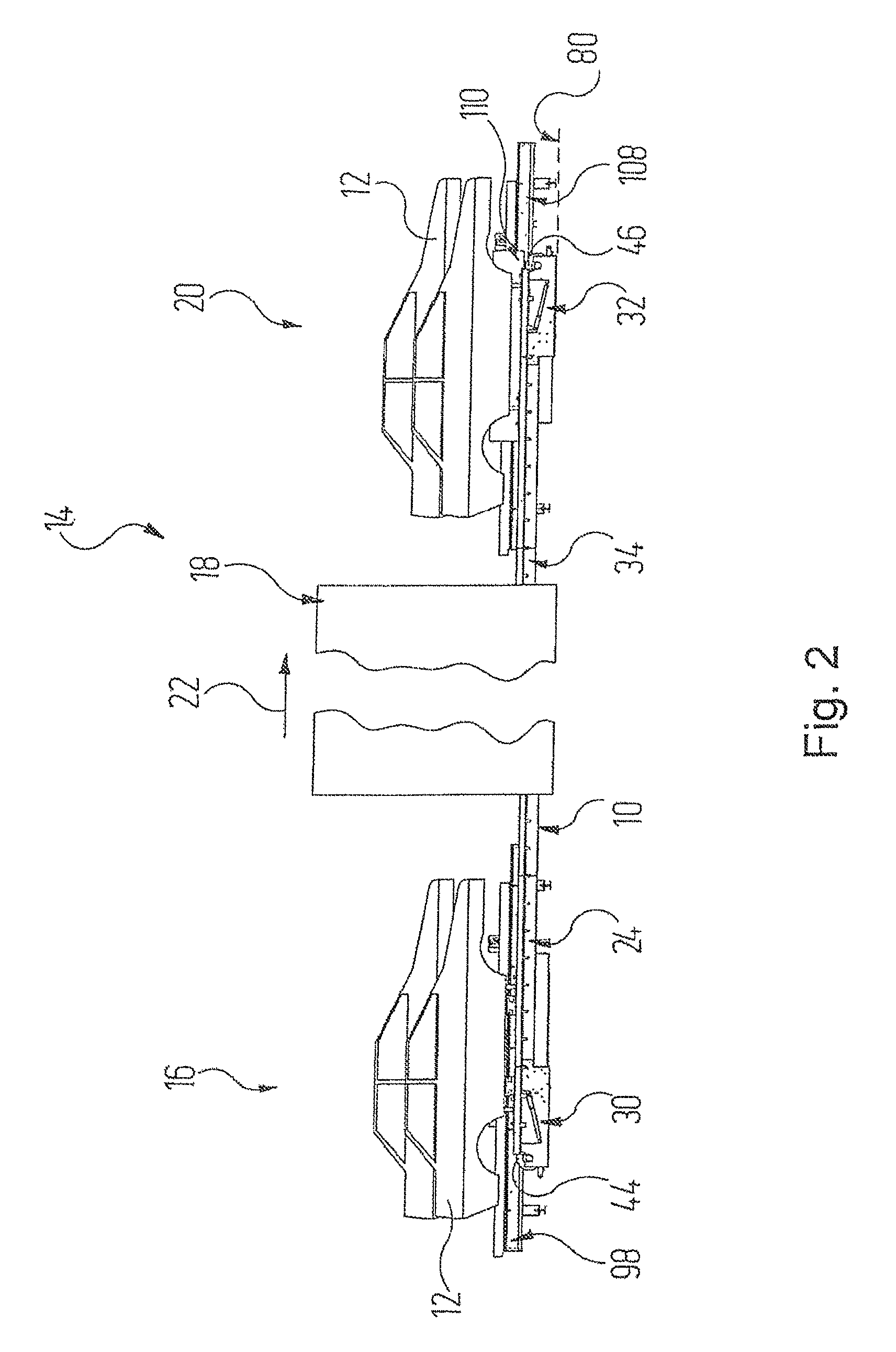

Apparatus for conveying and plant for surface-treating articles

ActiveUS9394110B2Easy constructionReliably conveyedPackagingConveyor partsEngineeringSurface finishing

An apparatus for conveying articles, in which at least one endless drive train forms a load-bearing strand and a return strand and specifies a conveying direction. A guide device for the at least one endless drive train includes a first deflecting element and at least one second deflecting element, over which the at least one endless drive train circulates. The at least one endless drive train carries along a plurality of supporting members which are arranged and configured such that they interact with supporting structures to which at least one article can be fastened. Furthermore, the at least one endless drive train carries along a plurality of coupling members which are arranged and configured such that they interact with standardized holding components of vehicle bodies. Also, a surface treatment plant having such a conveying apparatus.

Owner:EISENMANN AG

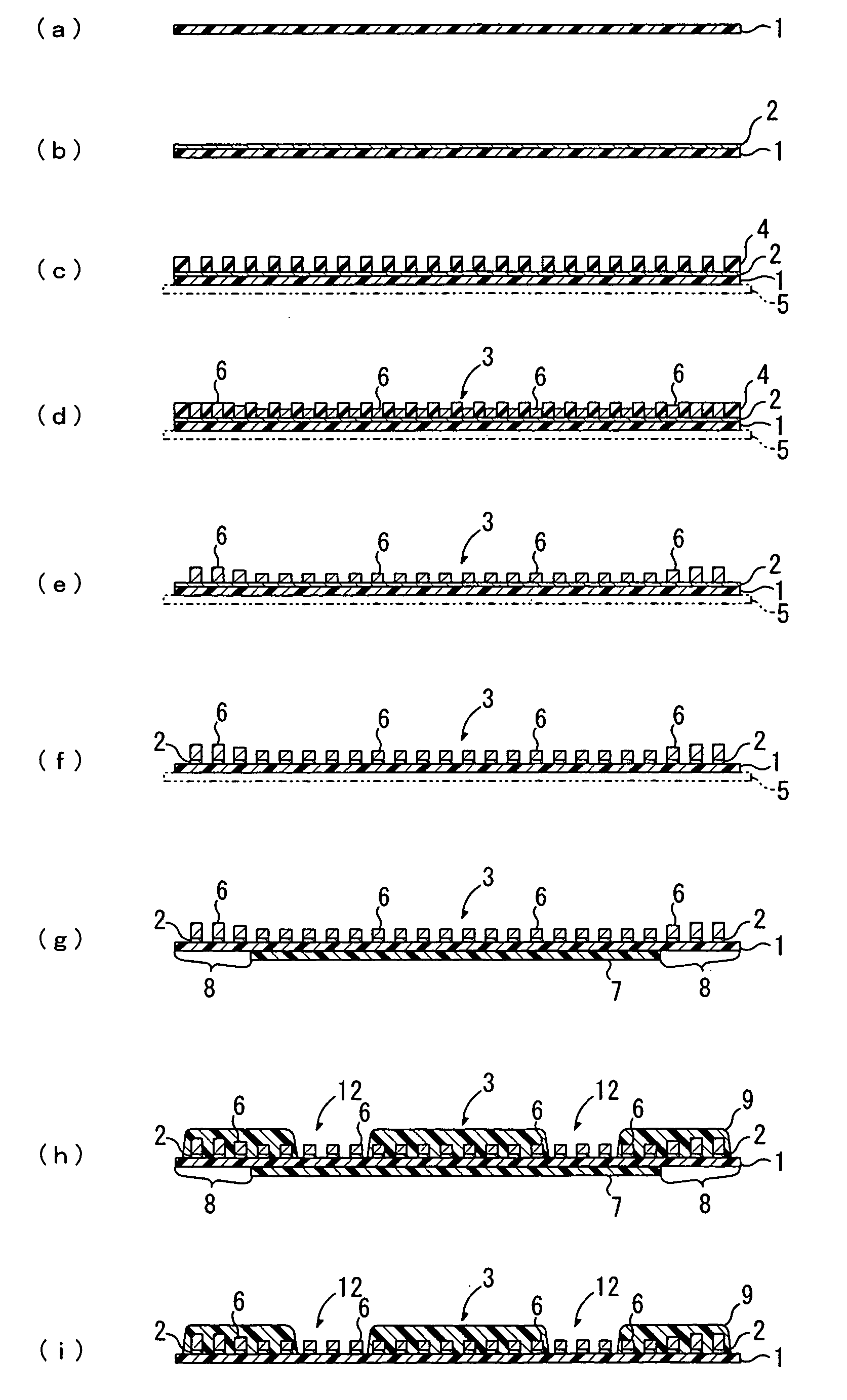

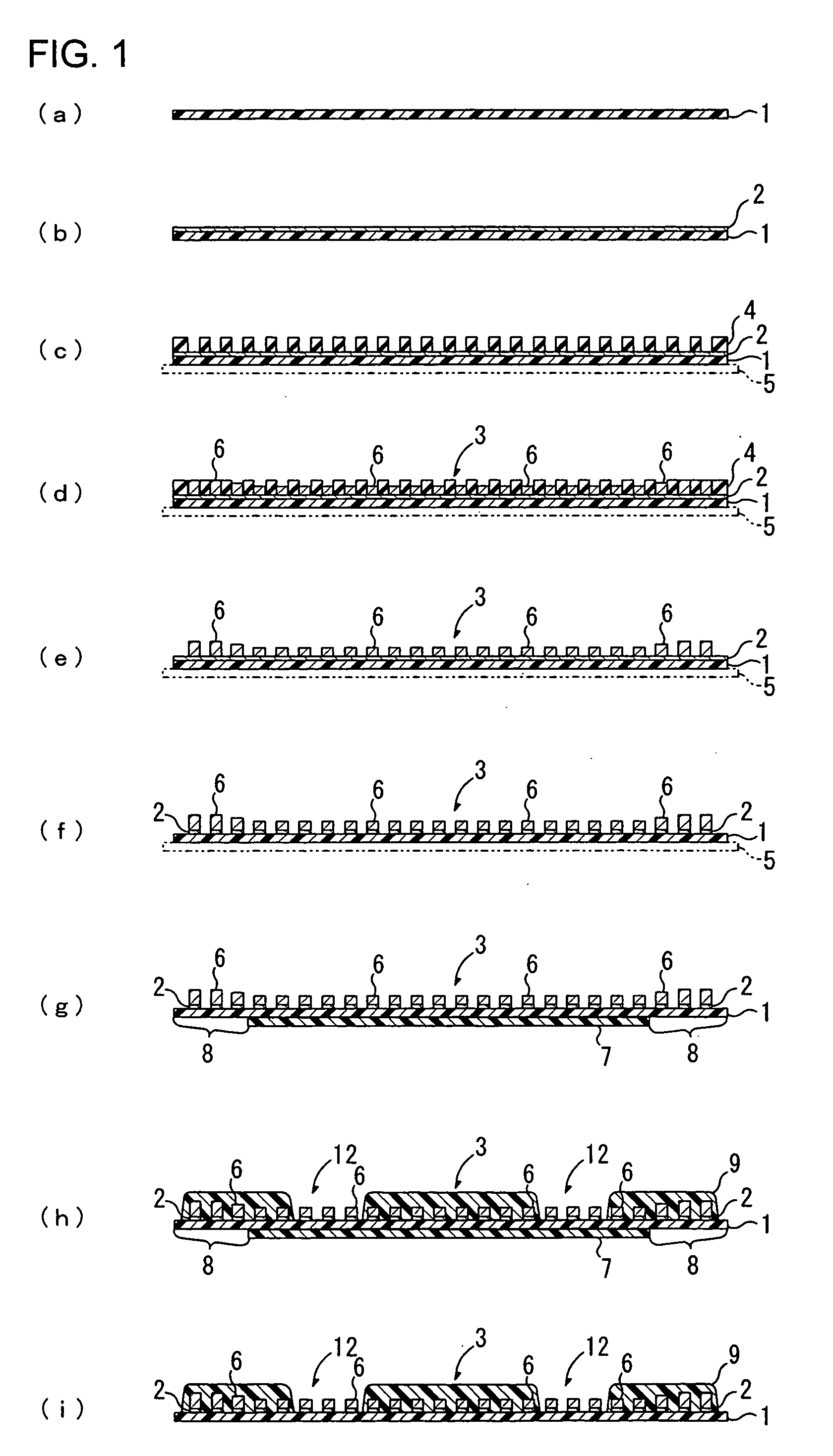

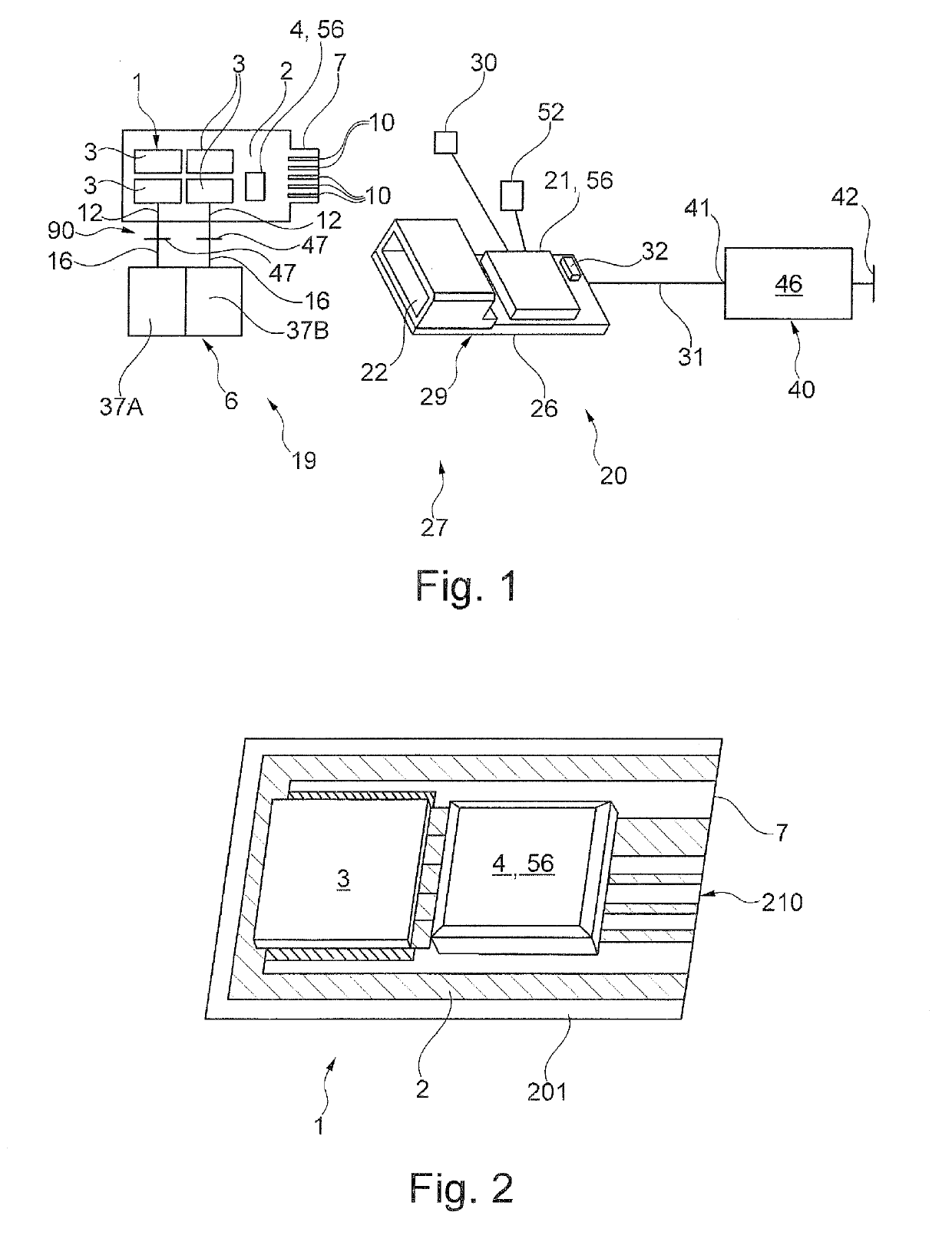

Producing method of wired circuit board

InactiveUS20060076242A1Uniform pressureAvoid enteringPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistEngineering

A producing method of a wired circuit board that can prevent meandering of the elongate base material conveyed with the rolls and also prevent entry of air bubbles in between a light-transparency protecting film and a photosensitive solder resist layer when the light-transparency protecting film is laminated on the photosensitive solder resist layer. After a conductive pattern 3 is formed on the front side of the elongate base material 1 by the additive process, a narrow stiffener sheet 7 smaller in width than the elongate base material 1 is provided on the back side of the elongate base material 1. Then, after the photosensitive solder resist layer 10 is formed on the front side of the elongate base material 1 to cover the conductive pattern 3, the light-transparency protecting film 11 is laminated on the front side of the photosensitive solder resist layer 10. Thereafter, the photosensitive solder resist layer 10 is exposed to light through the light-transparency protecting film 11. Then, after the light-transparency protecting film 11 is stripped off from the photosensitive solder resist layer 10, the photosensitive solder resist layer 10 was developed and then cured by heating. Thereafter, the narrow stiffener sheet 7 is stripped off from the elongate base material. The flexible wired circuit board is produced in the manner described above.

Owner:NITTO DENKO CORP

Sheet stacking apparatus

ActiveUS20050263957A1Reliably sandwiching and catchingReliably conveyedFunction indicatorsPile receiversEngineeringElectrical and Electronics engineering

A sheet stacking apparatus which is capable of reliably sandwiching or catching sheets, and also capable of providing control so as to ensure reliable conveyance of succeeding sheets during the catching operation. A stack tray is provided downstream of a processing tray that stacks sheets. A position on the stacking surface of the stack tray at which the leading end of a sheet having its trailing end passing a discharging section, which discharges sheets toward the processing tray, contacts the stacking surface is lower in level than the highest portion of the processing tray. A swinging arm that discharges the sheets stacked on the processing tray to the stack tray is capable of selectively assuming a catching state in which a sheet discharged to the processing tray is caught by the swinging arm, and a non-catching state in which a sheet discharged to the processing tray is not caught by the swinging arm. The swinging arm is controlled to assume the non-catching state when the discharging section starts discharging a sheet, and switch to the catching state before the trailing end of the sheet discharged by the discharging section passes the swinging arm.

Owner:CANON KK

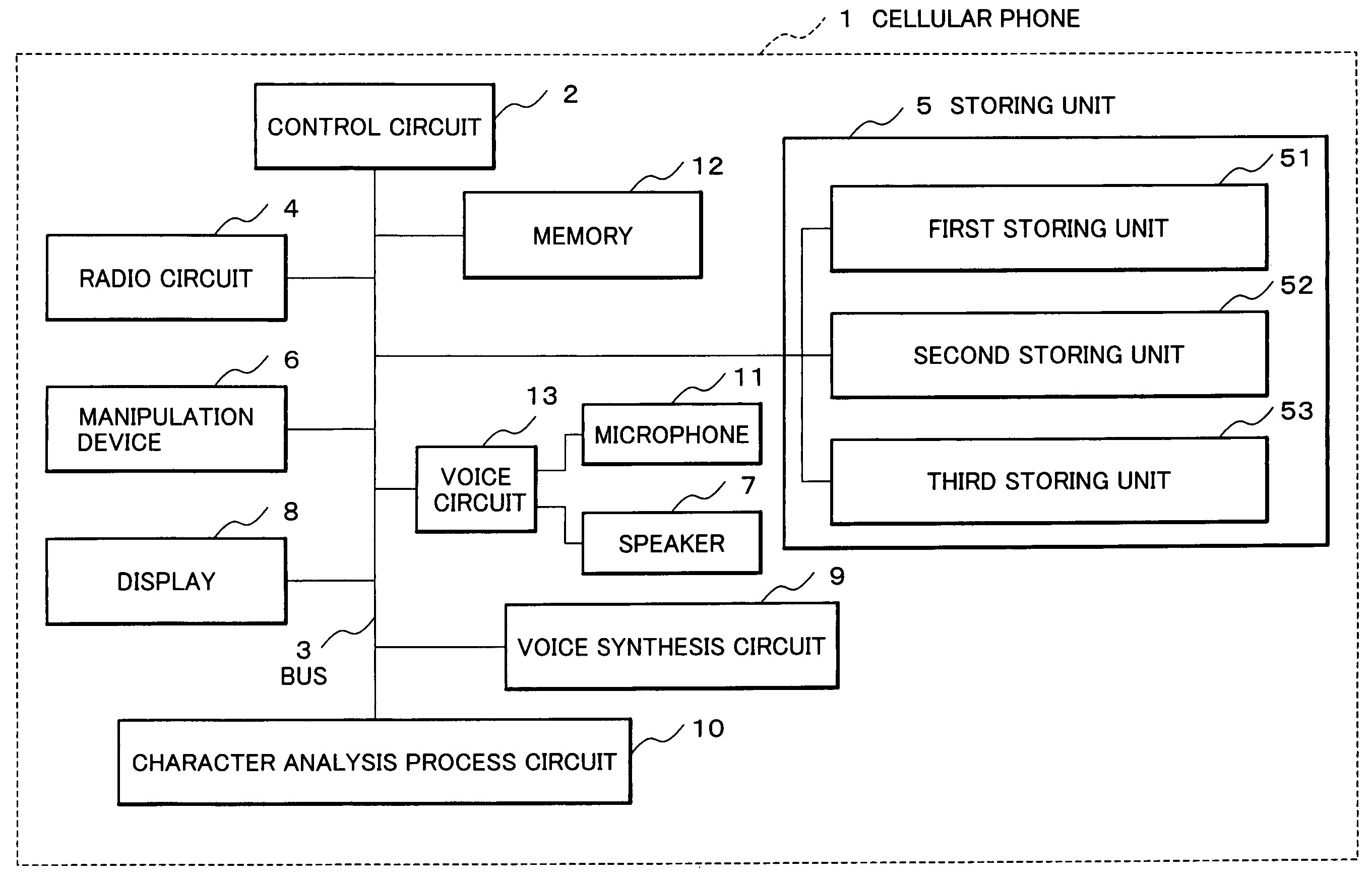

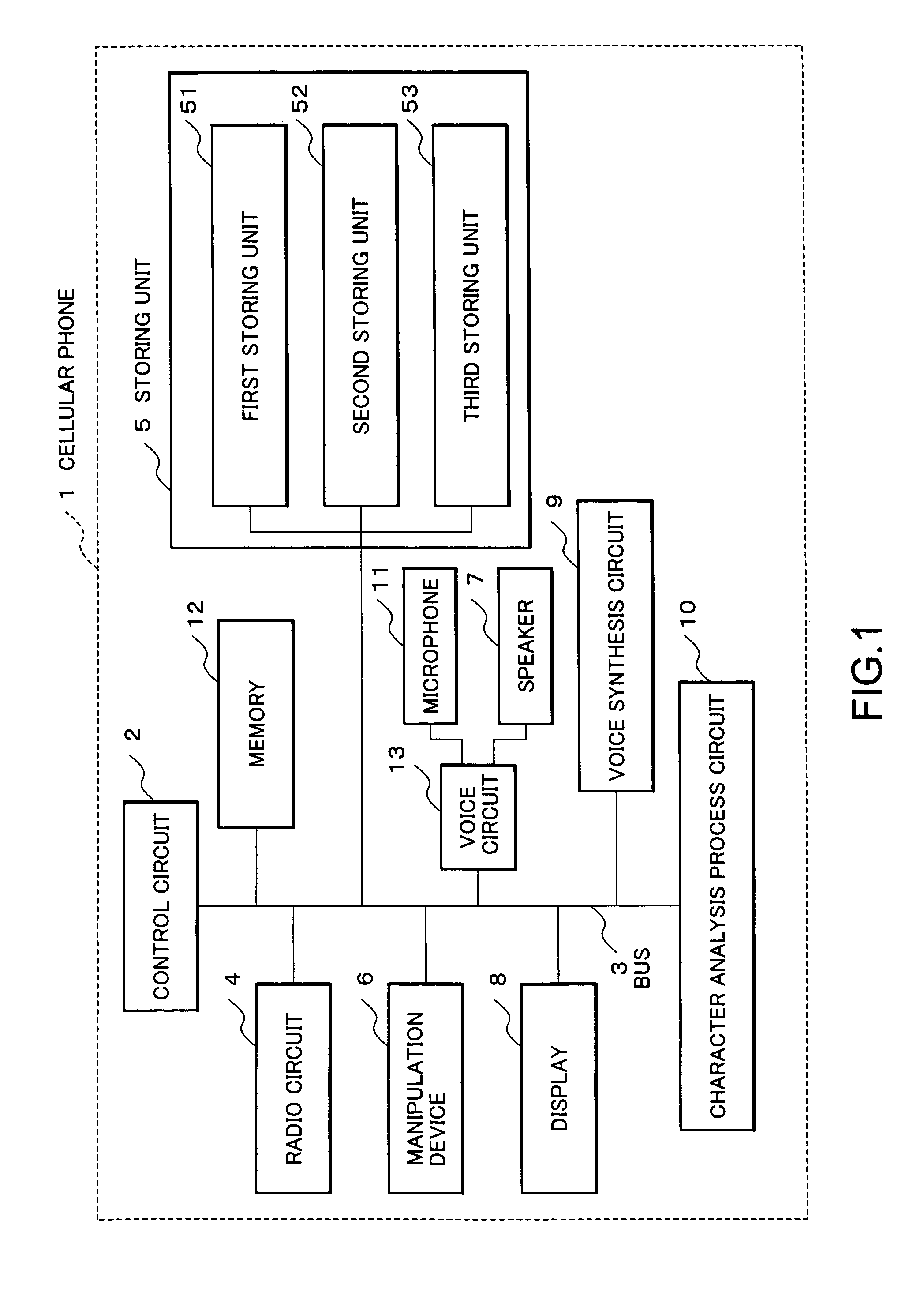

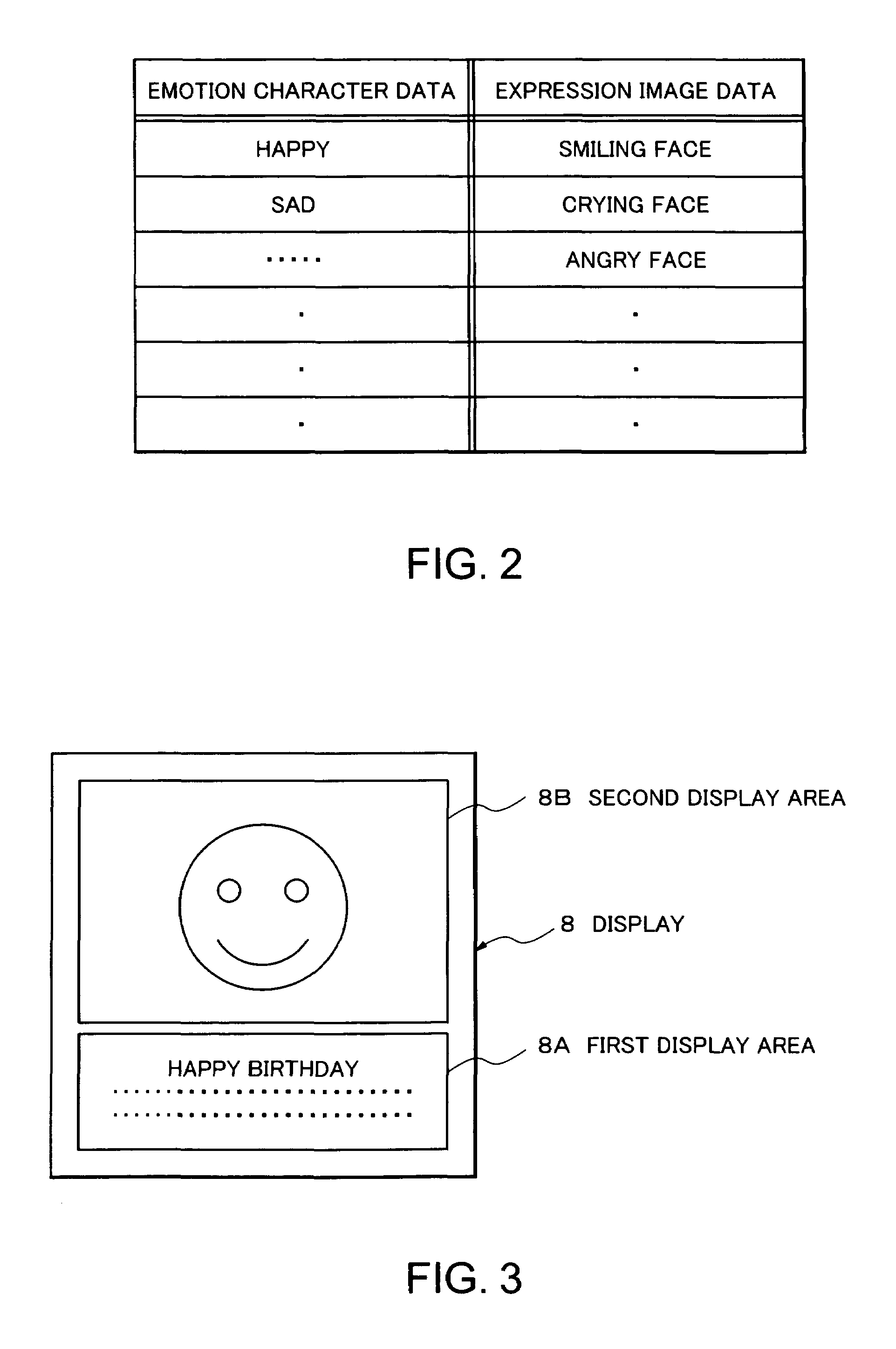

Data processing device, data processing method, and electronic device

InactiveUS7570814B2Reliably conveyedInput/output for user-computer interactionCharacter and pattern recognitionData displayDisplay device

Owner:NEC CORP

Conveying apparatus and recording apparatus

InactiveUS7703912B2Reliably conveyedPreventing recording medium from fluttering and/or floatingOther printing apparatusArticle feedersElectrical resistance and conductanceSurface layer

A feeding device includes a conveying member for conveying a recording material; and an electrode, disposed in the conveying member, for generating an electrostatic attraction force for electrostatic attraction of the recording material on the conveying member and for controlling a temperature of a surface layer of the conveying member to provide a substantially constant resistance value of the surface layer of the conveying member.

Owner:CANON KK

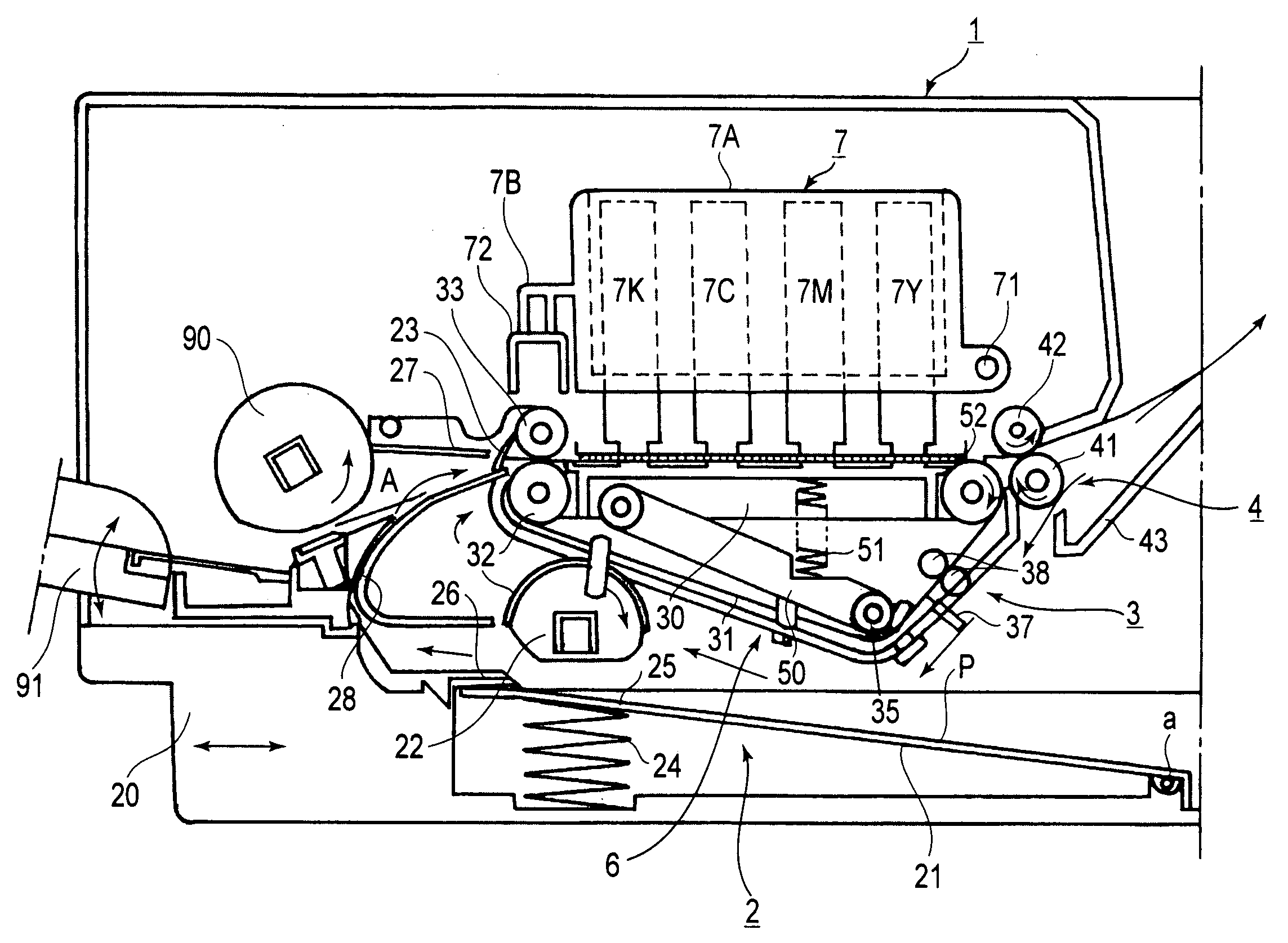

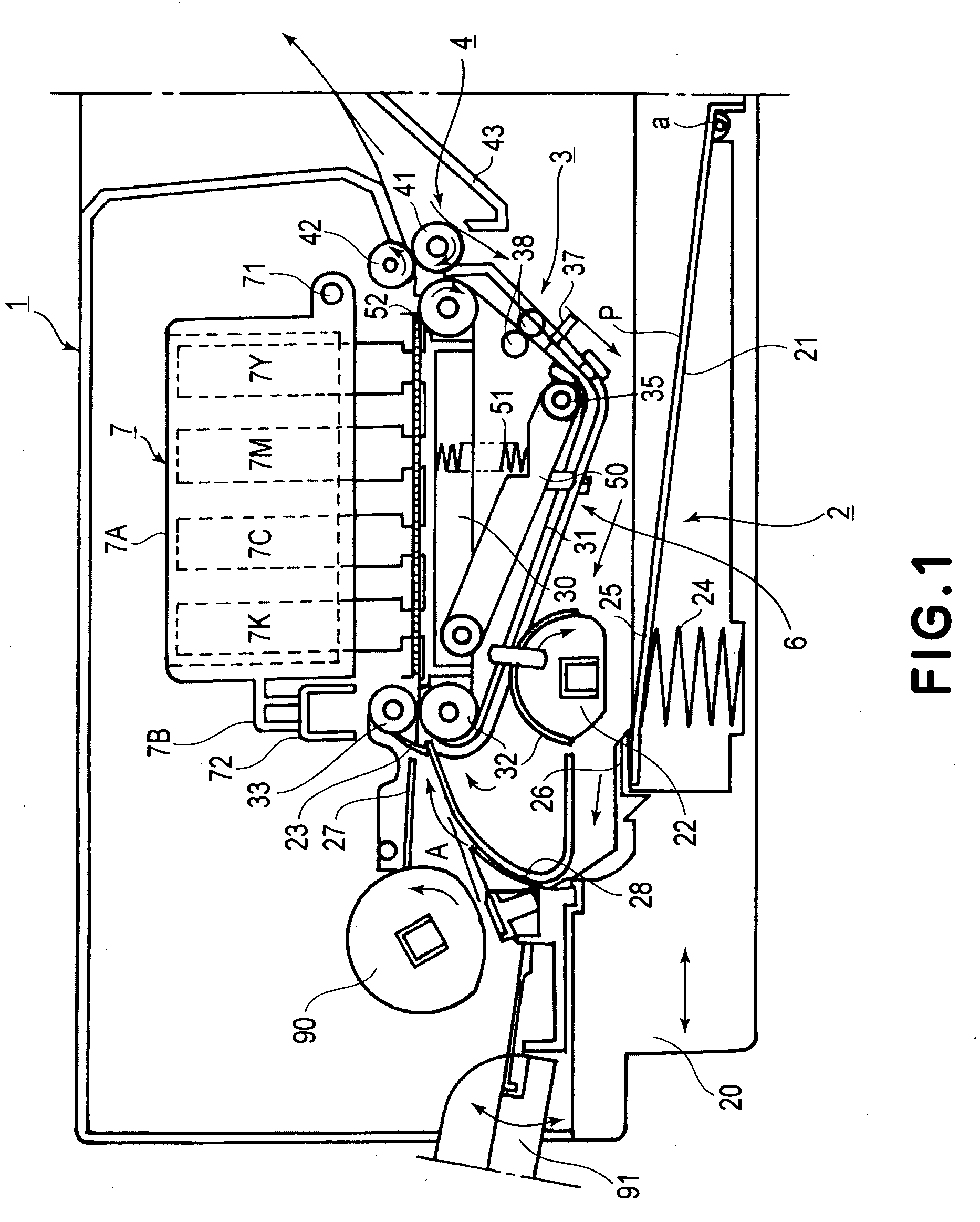

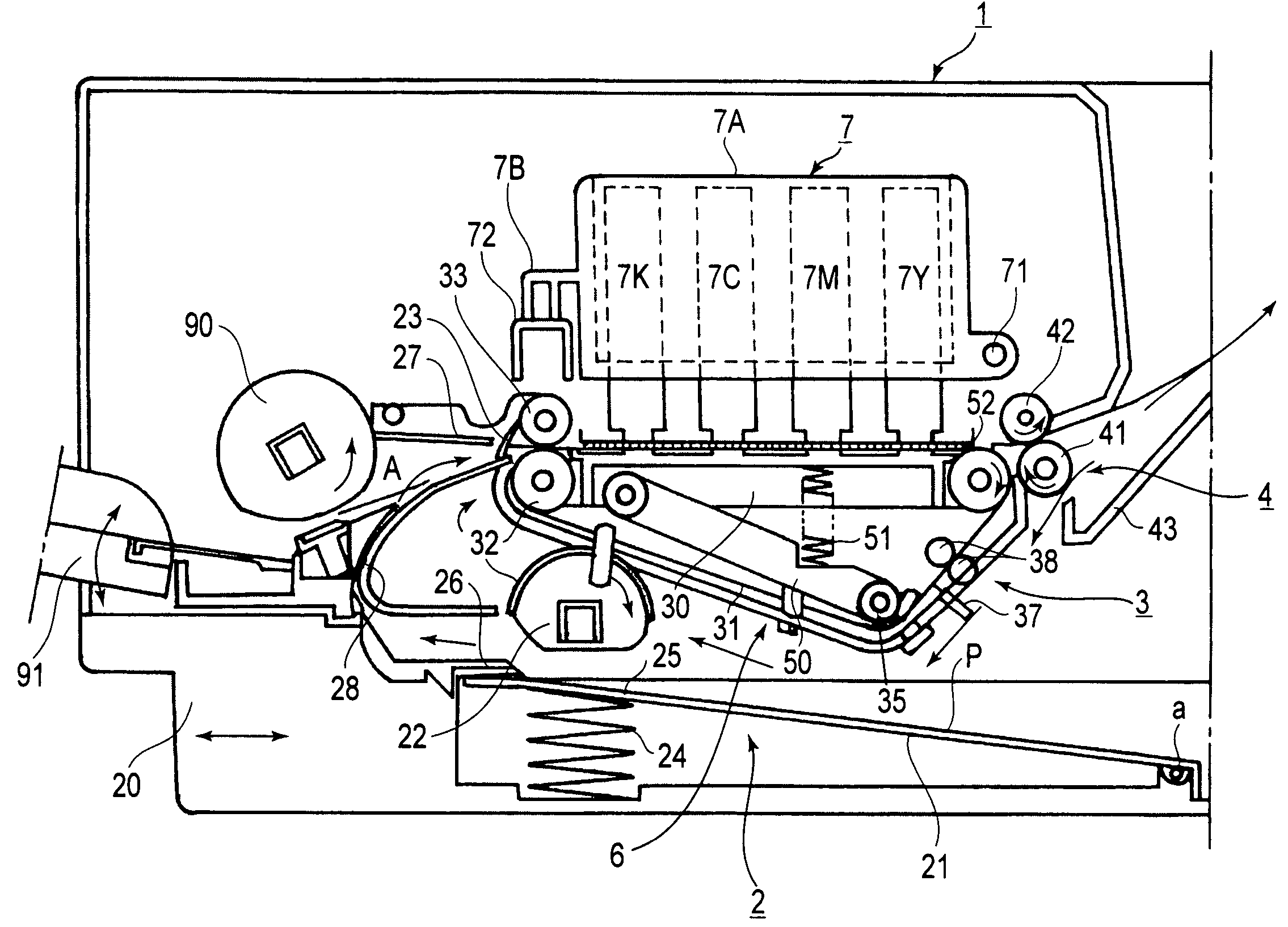

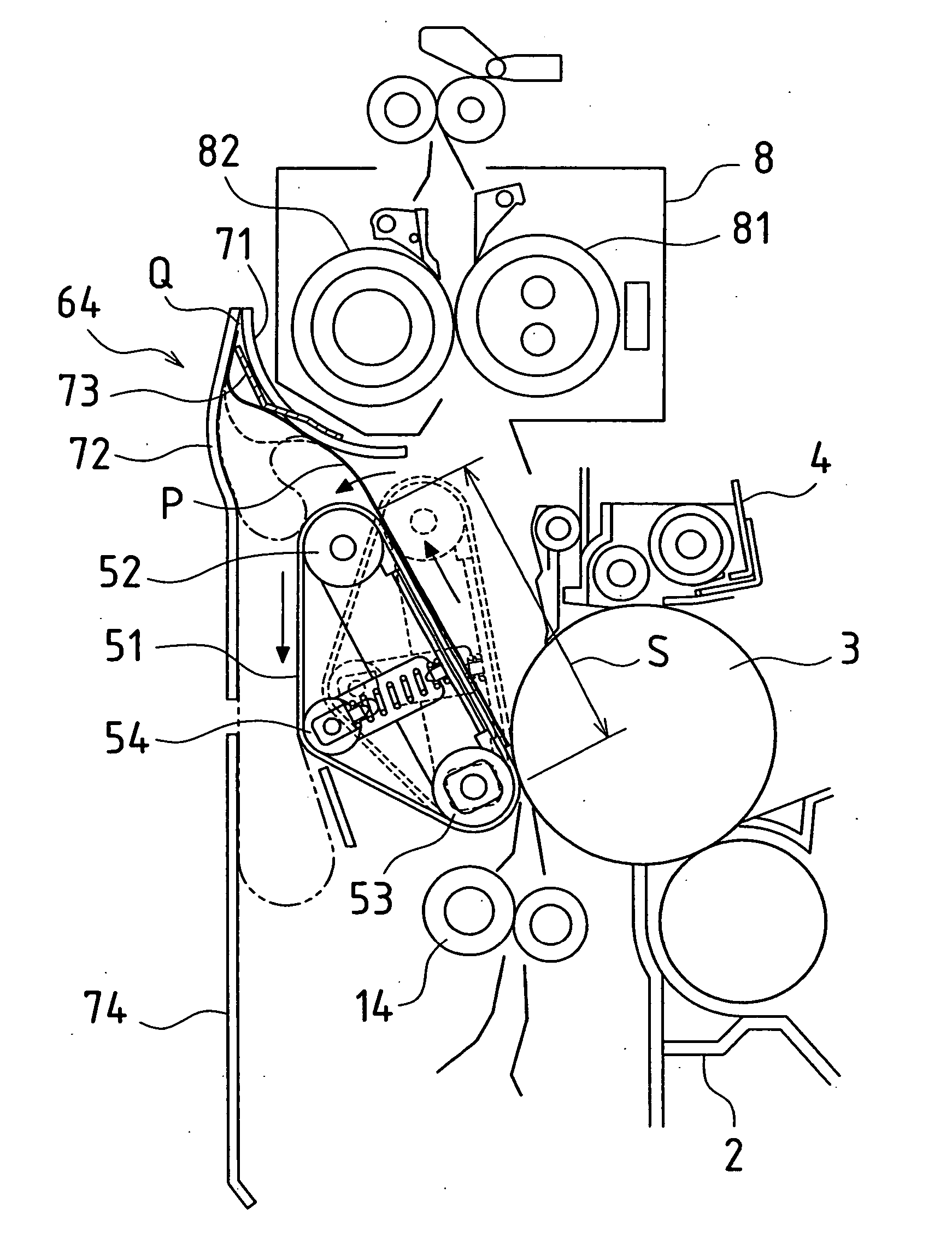

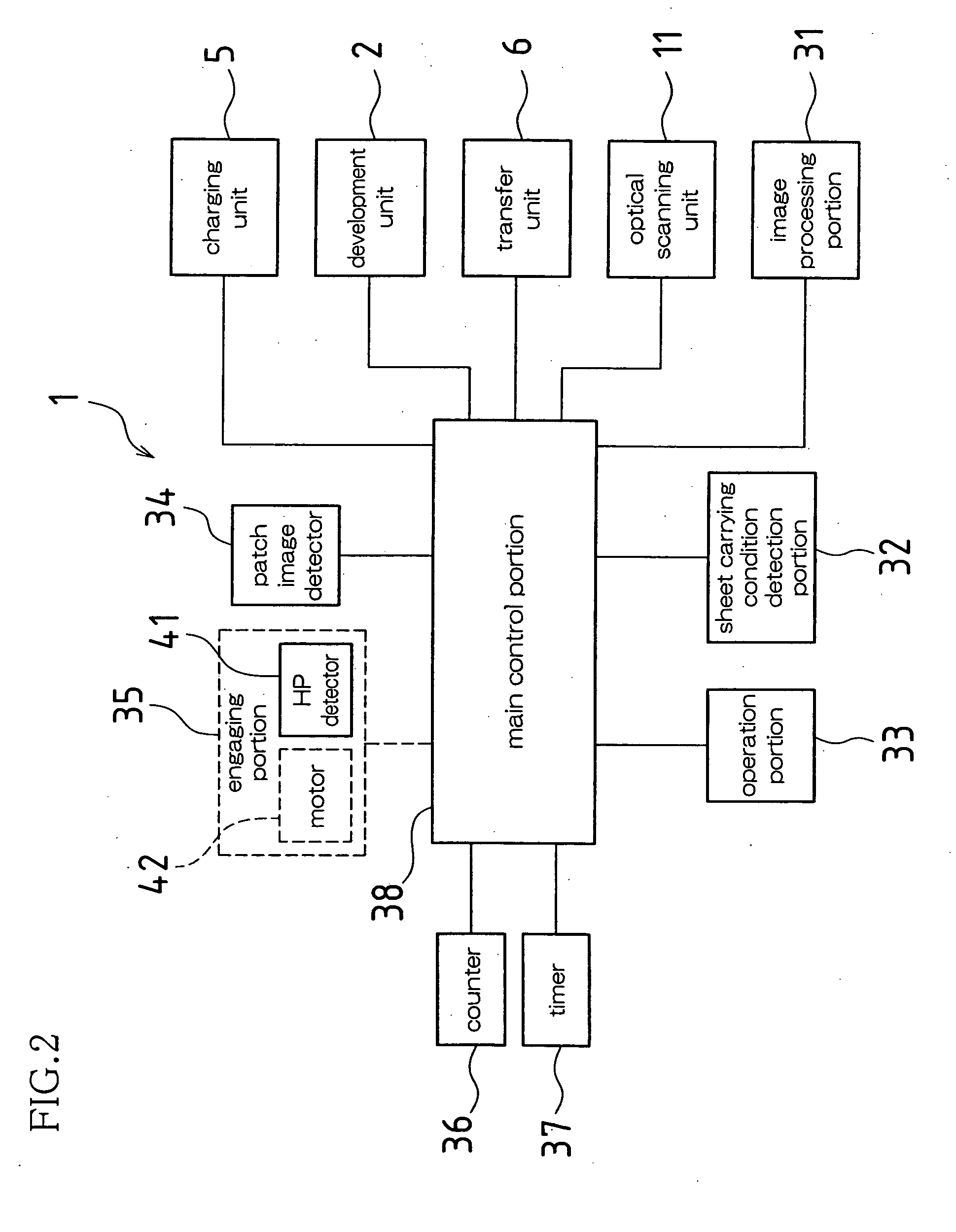

Image forming apparatus

InactiveUS20060045548A1Prevent splashEasy to separateElectrographic process apparatusImage formationEngineering

A sheet P on which an image of a developer is unfixed is recovered from a transfer unit 6 to a sheet recovery portion 64, the sheet P is bent with the surface of the sheet P on which the image of the developer has been transferred facing inward and, while remaining bent, the sheet P drops downward between an outer guide plate 72 and a transfer convey belt 51, then an openable cover 74 is opened to remove the sheet P.

Owner:SHARP KK

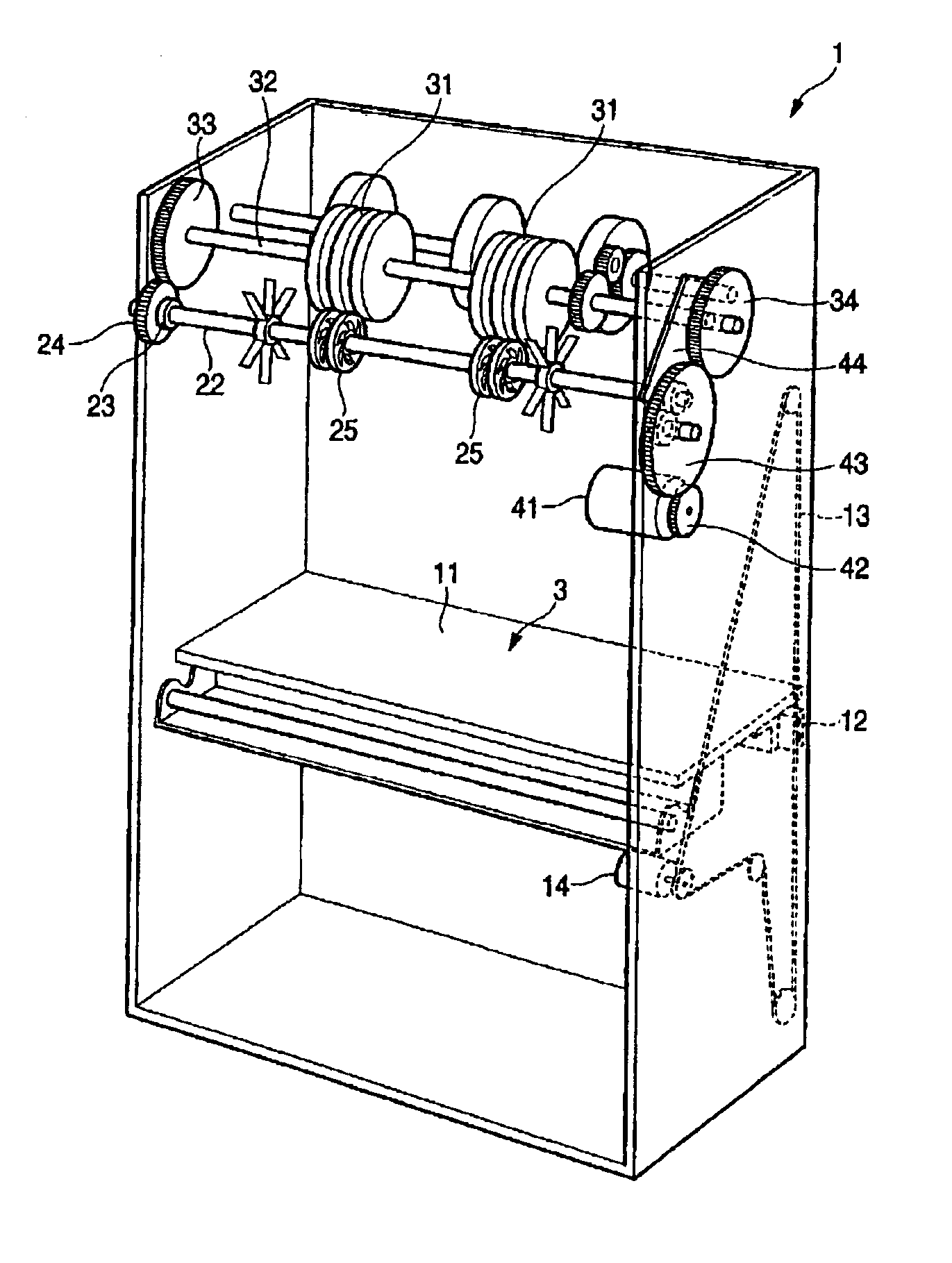

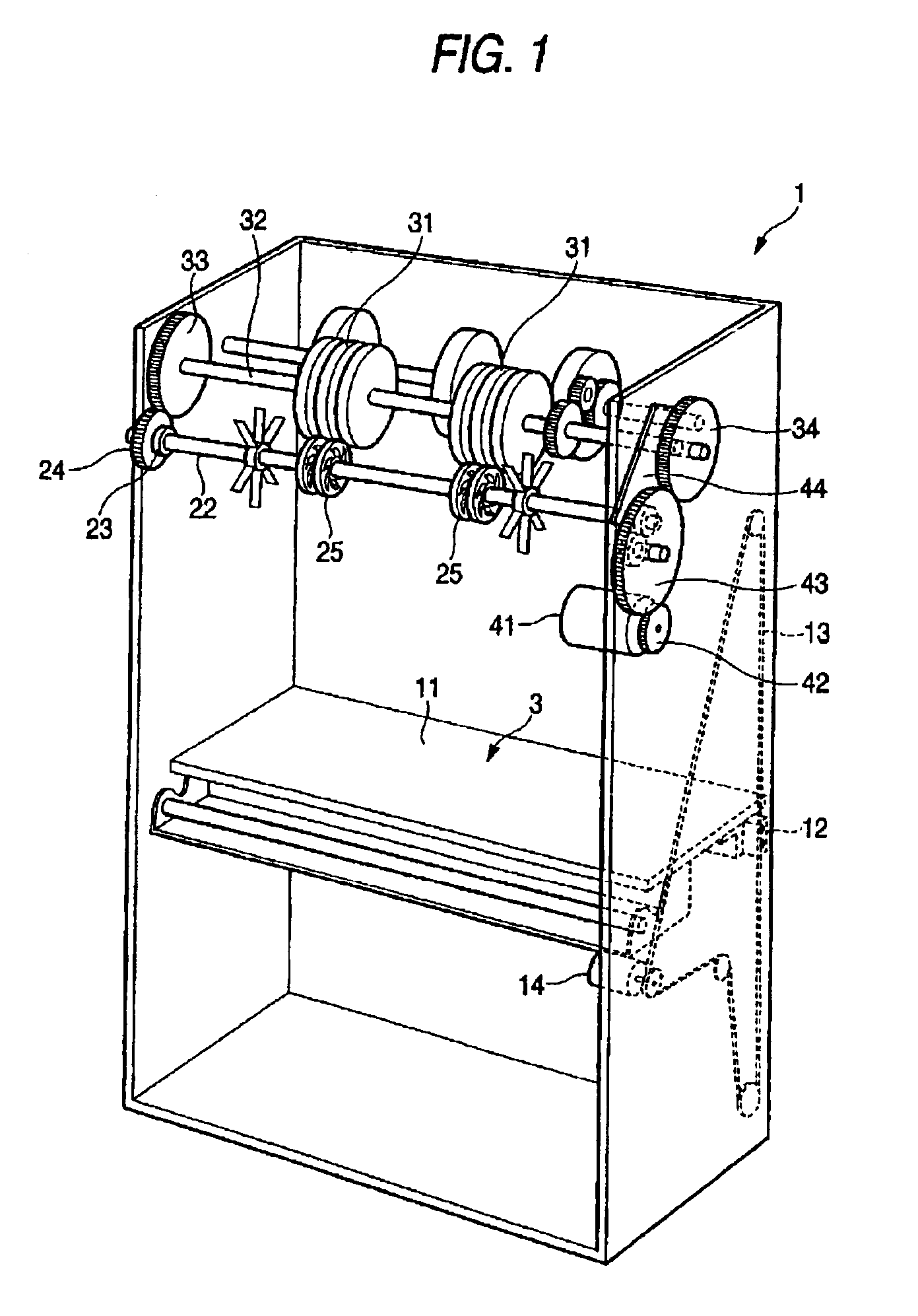

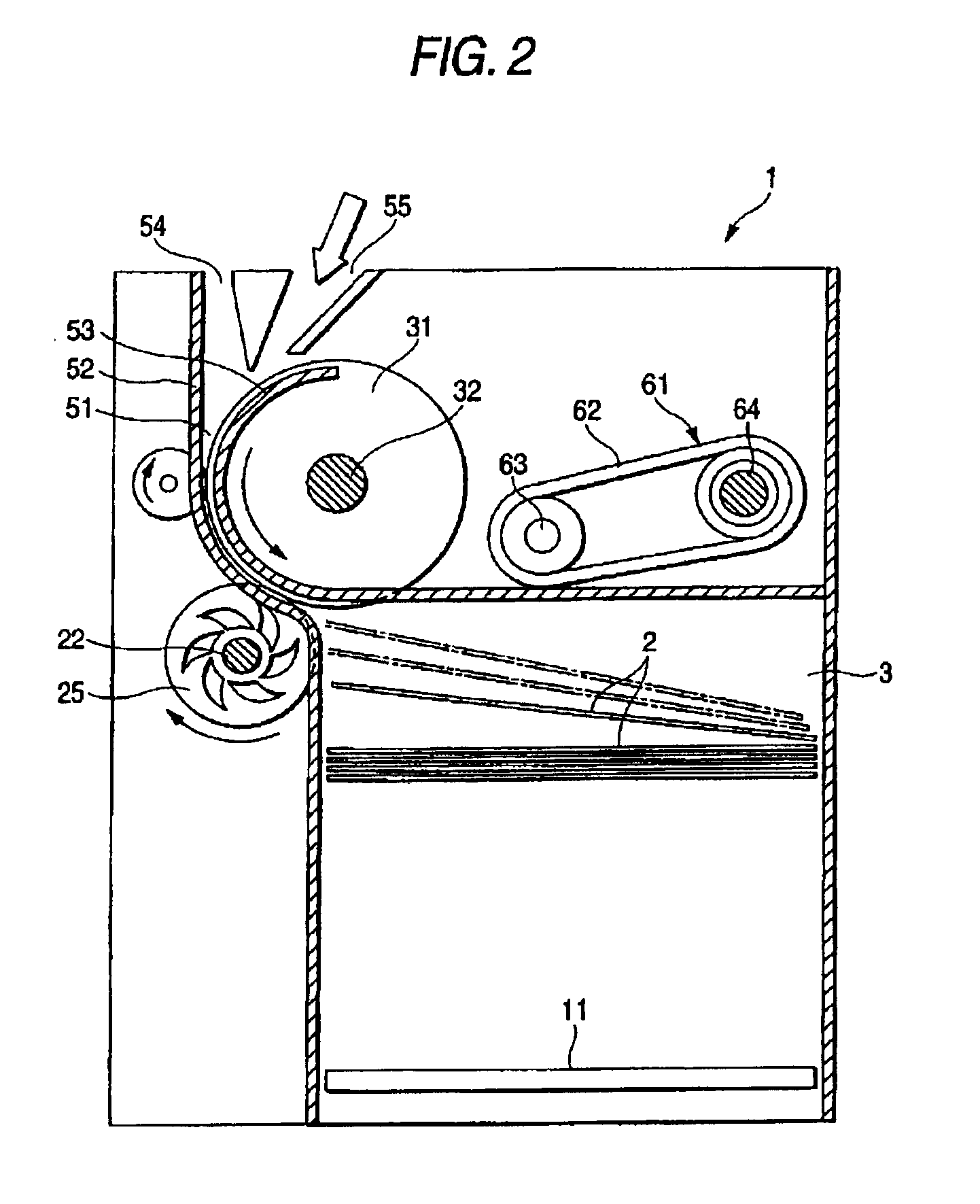

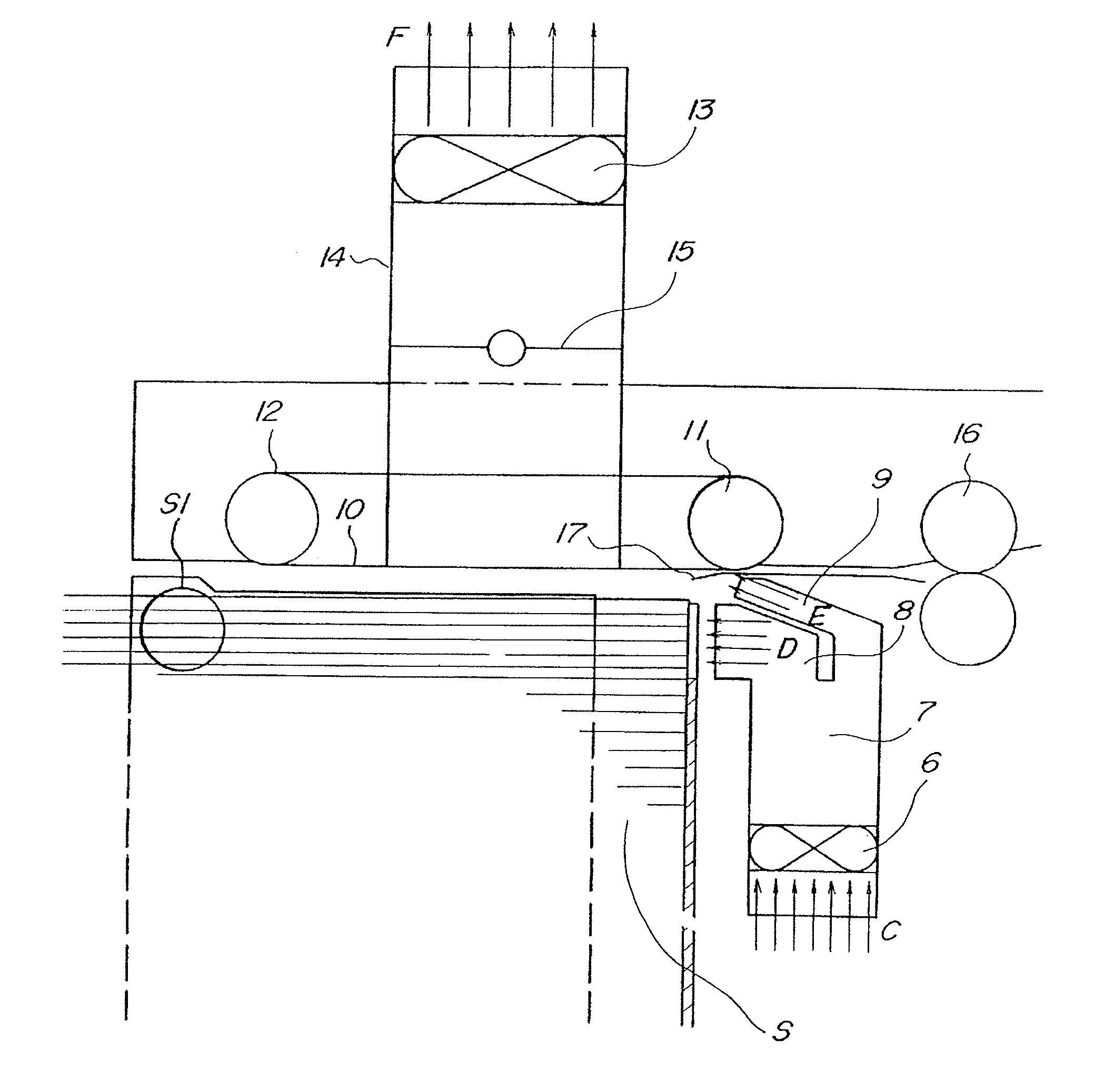

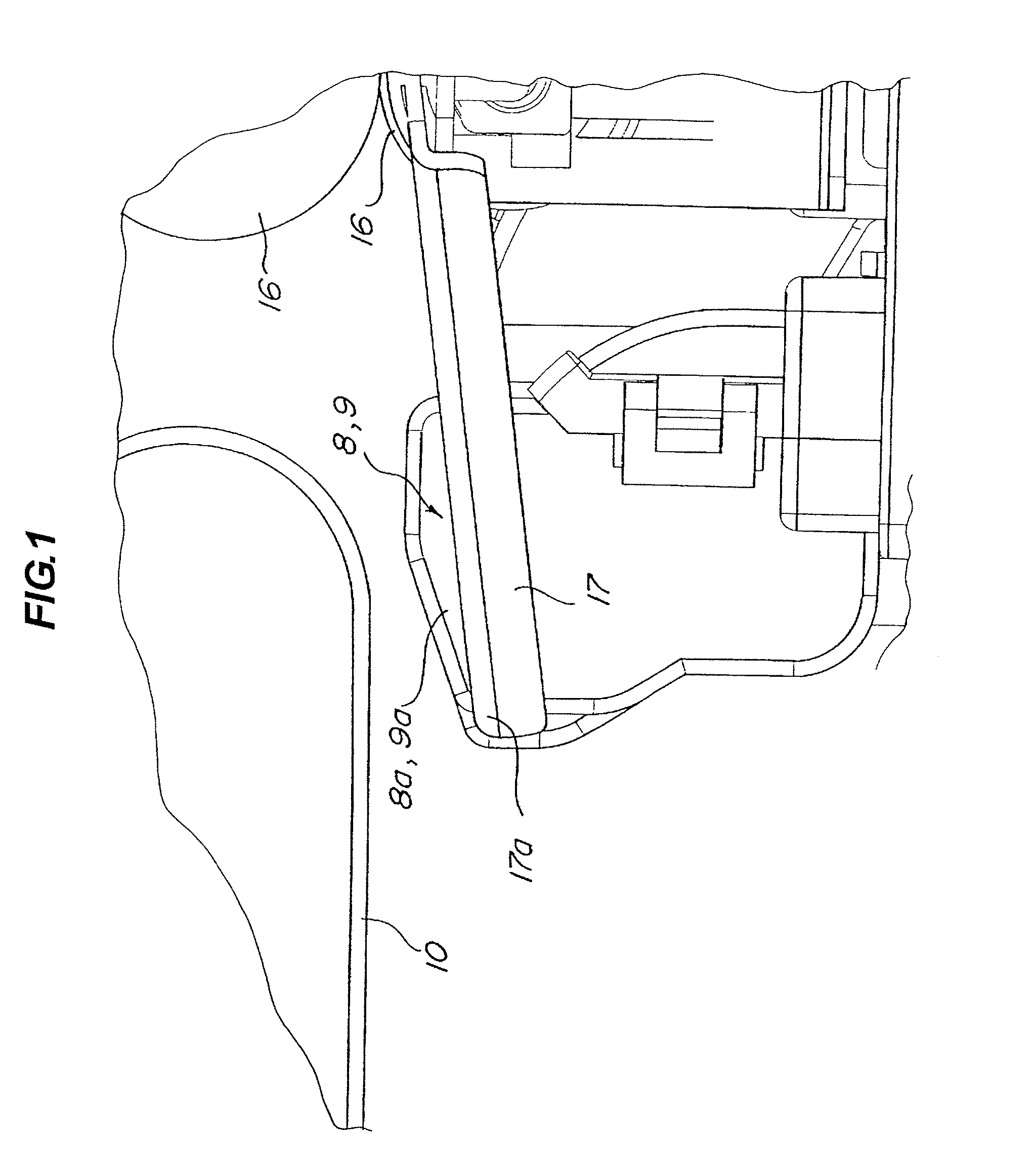

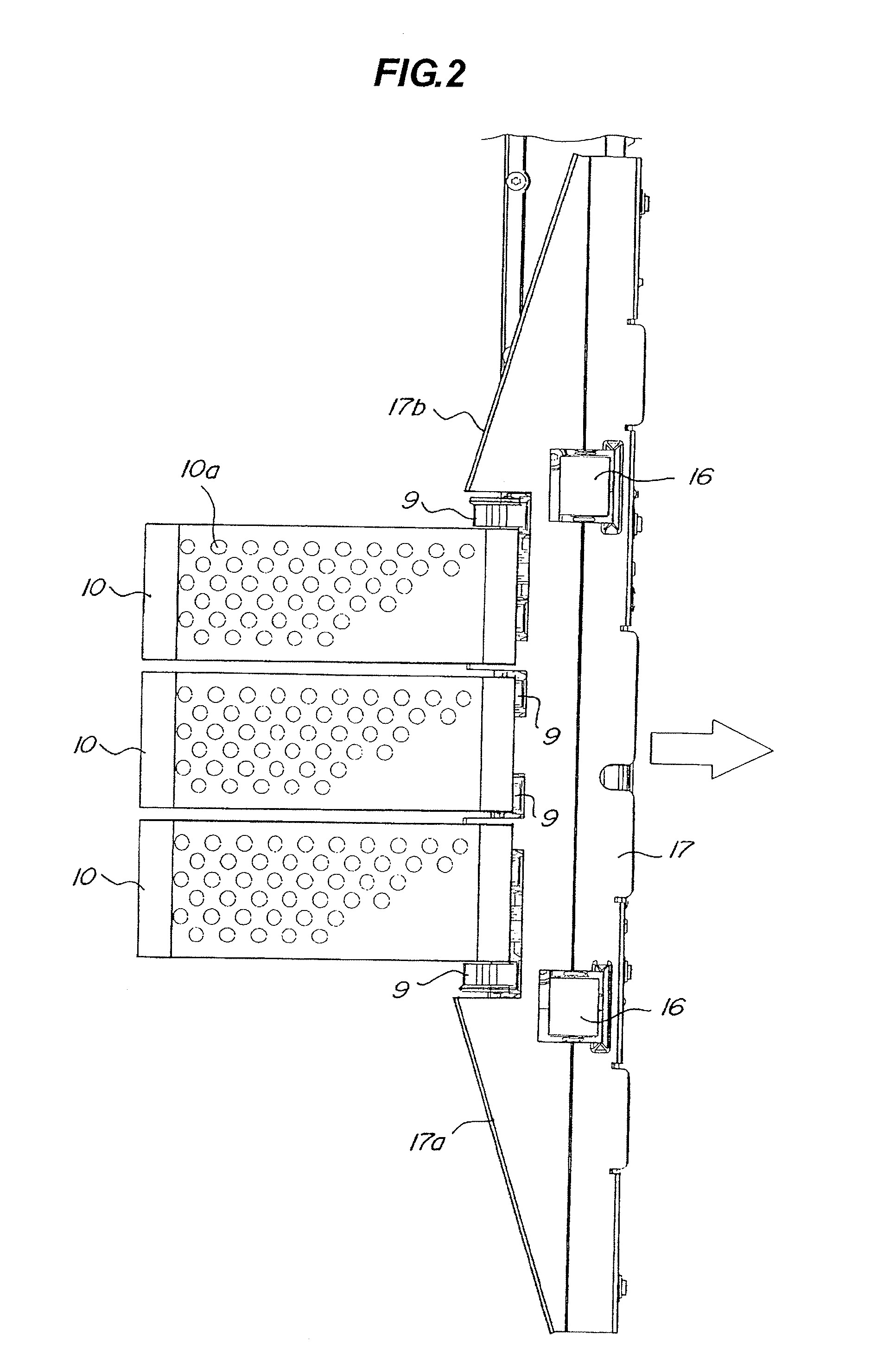

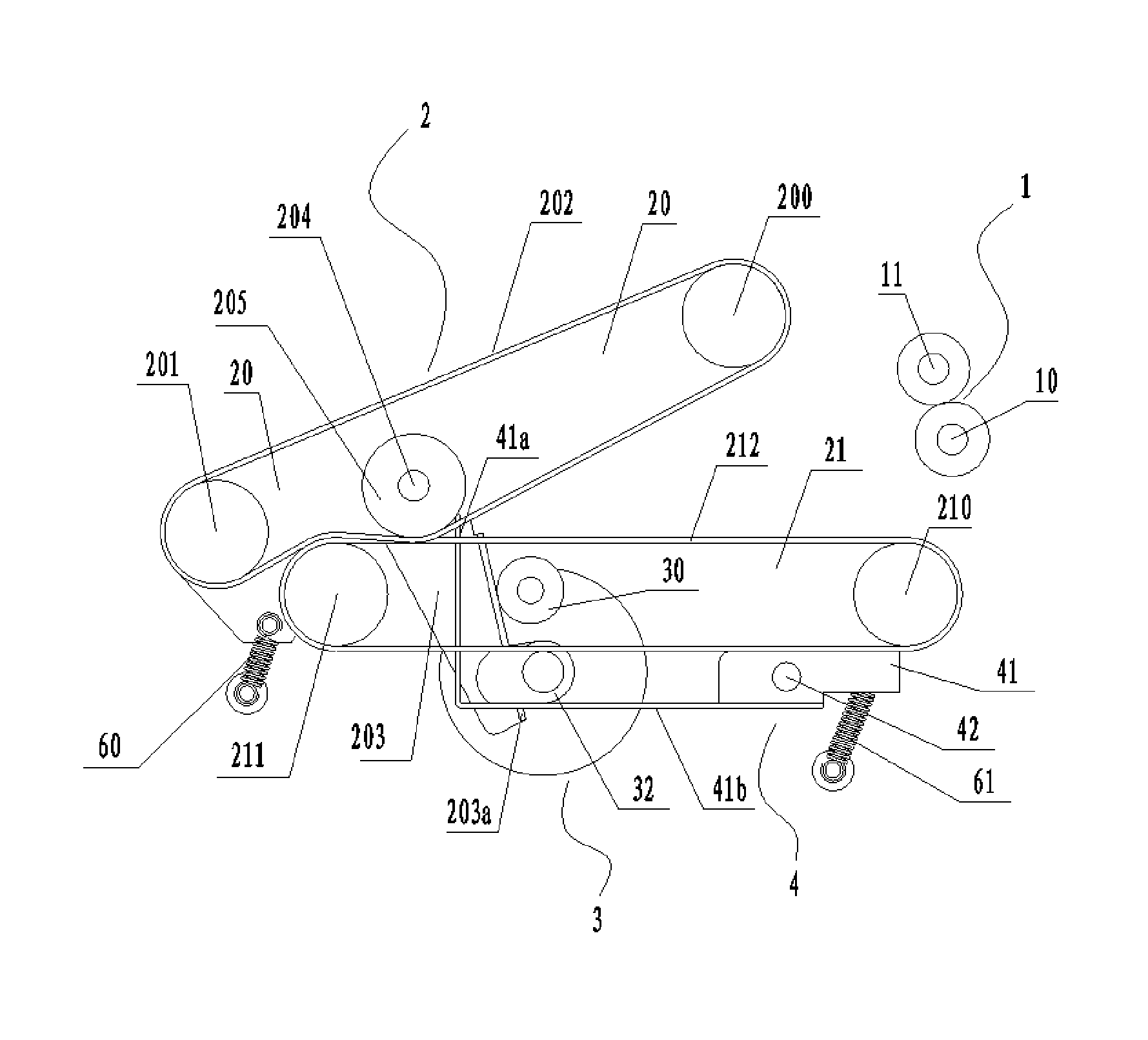

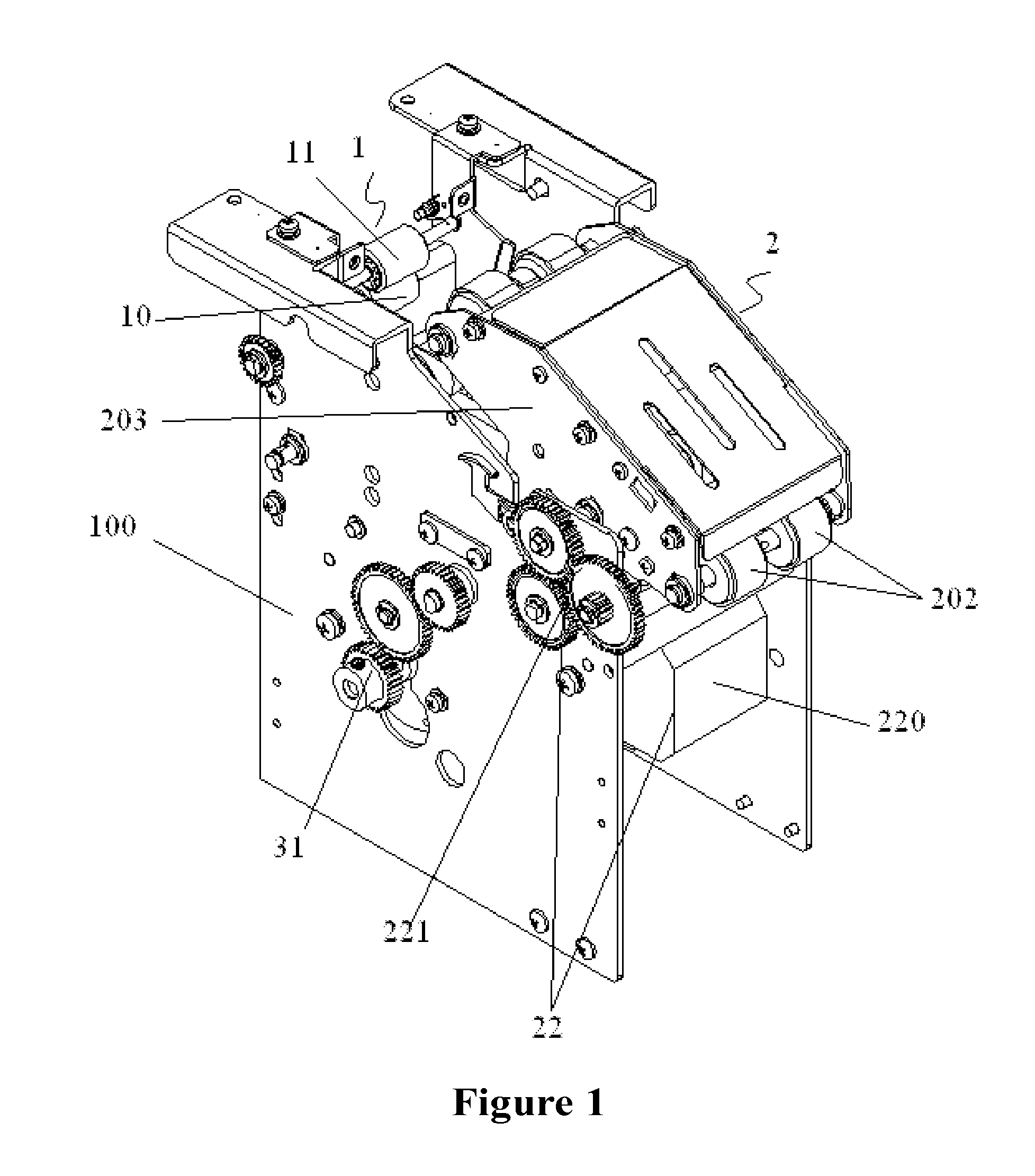

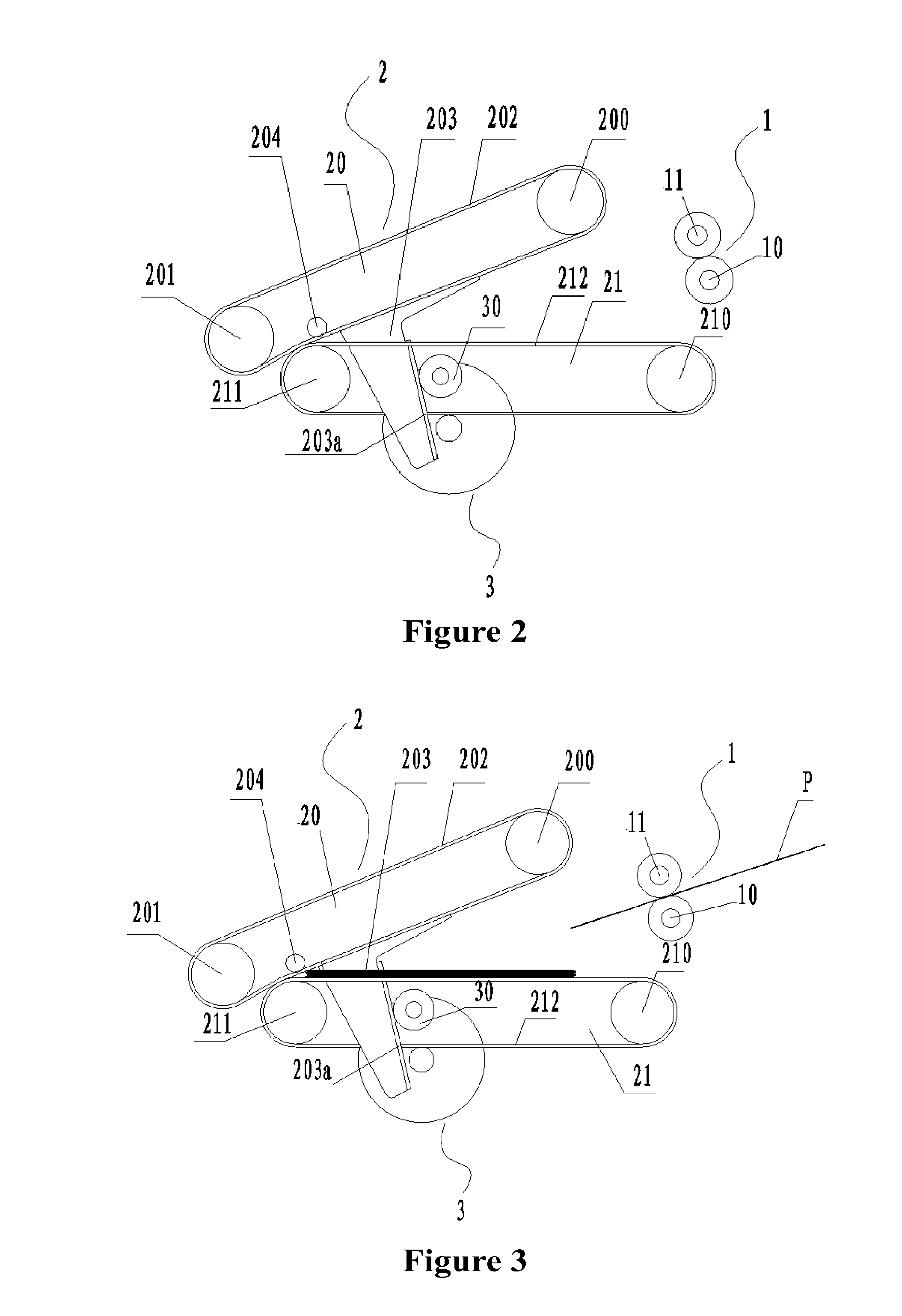

Sheet feeding device and image forming apparatus

The present invention relates to a sheet feeding device includes a sheet tray 2 to place sheets thereon, a nozzle 9 which blows air onto the sheets supported by the sheet tray 2, a conveyance belt 10 to adsorb and convey a sheet floated by blowing air by the nozzle 9, a pulling roller pair 16 which is arranged on a downstream side of the conveyance belt in a sheet conveyance direction and conveys the sheet conveyed by the conveyance belt 10, and a conveyance guide 17 which guides the sheet conveyed from the conveyance belt 10 to the pulling roller pair 16. The conveyance guide 17 has slope portions 17a, 17b which are sloped from an upstream side in the sheet conveyance direction to the downstream side to extend from a central portion in a sheet width direction perpendicular to the sheet conveyance direction to both the end portions.

Owner:CANON KK

Sheet medium processing device

ActiveUS8382103B2Improve adaptabilityReliably conveyedRegistering devicesPile receiversCamSheet material

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

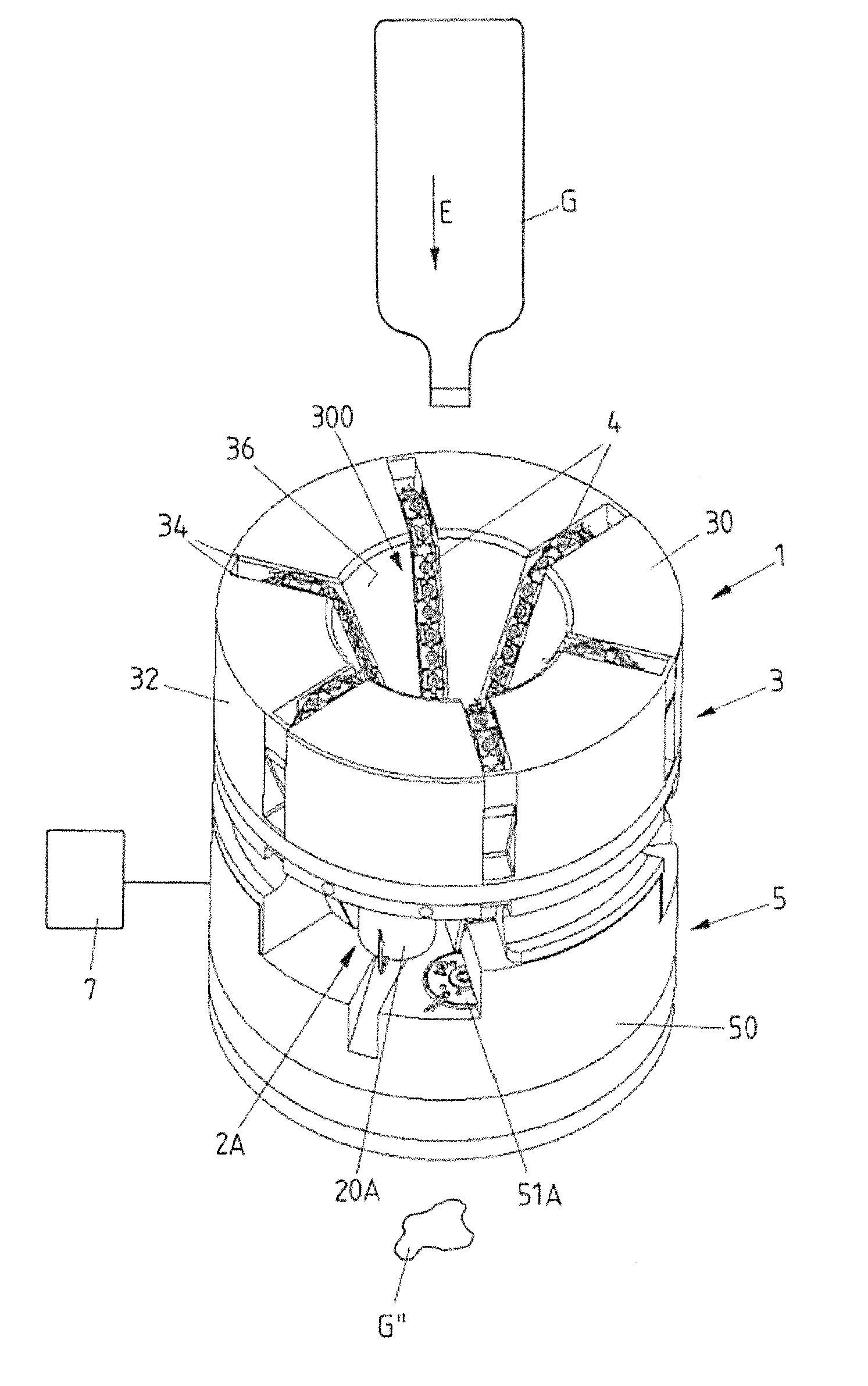

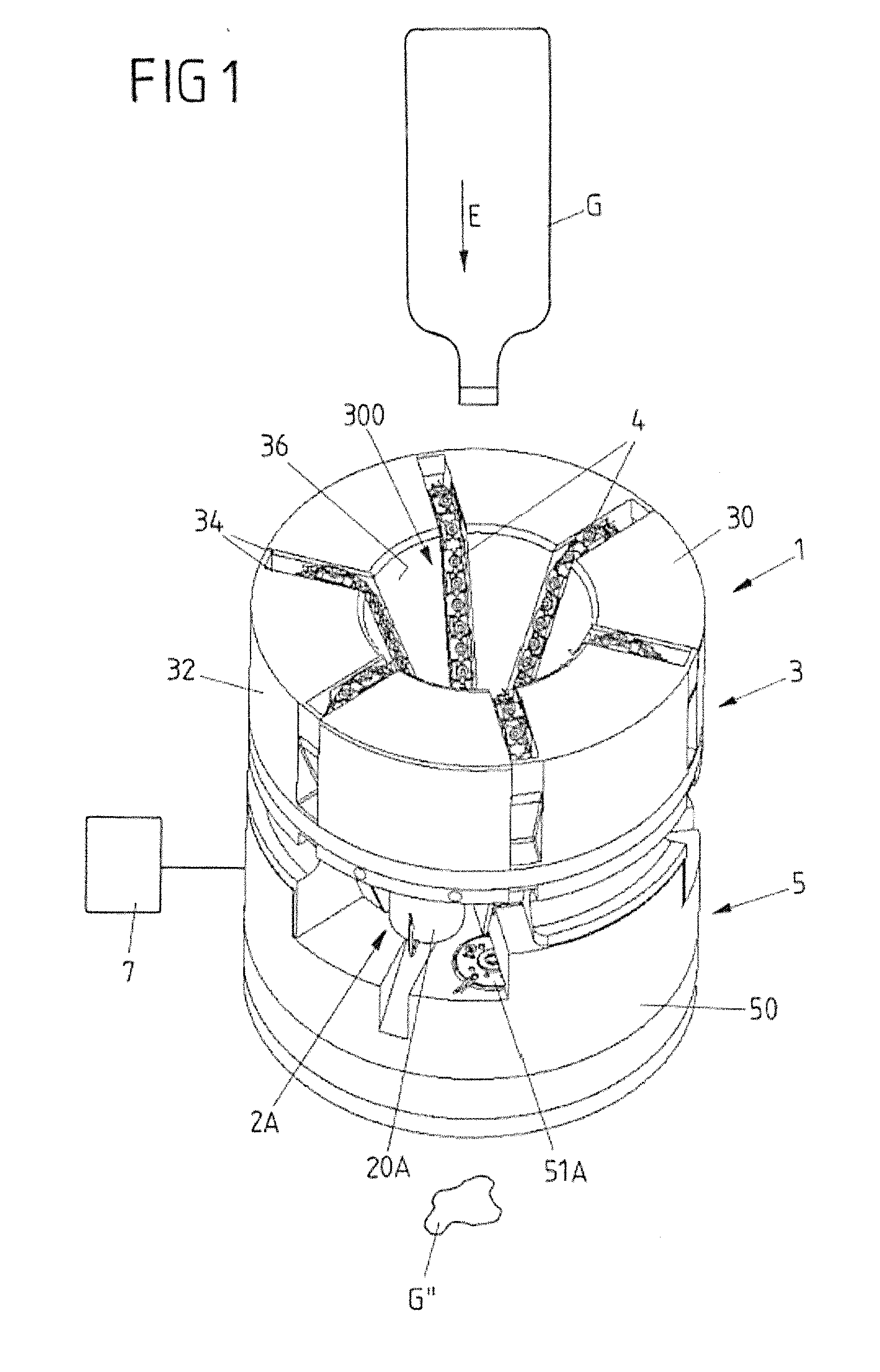

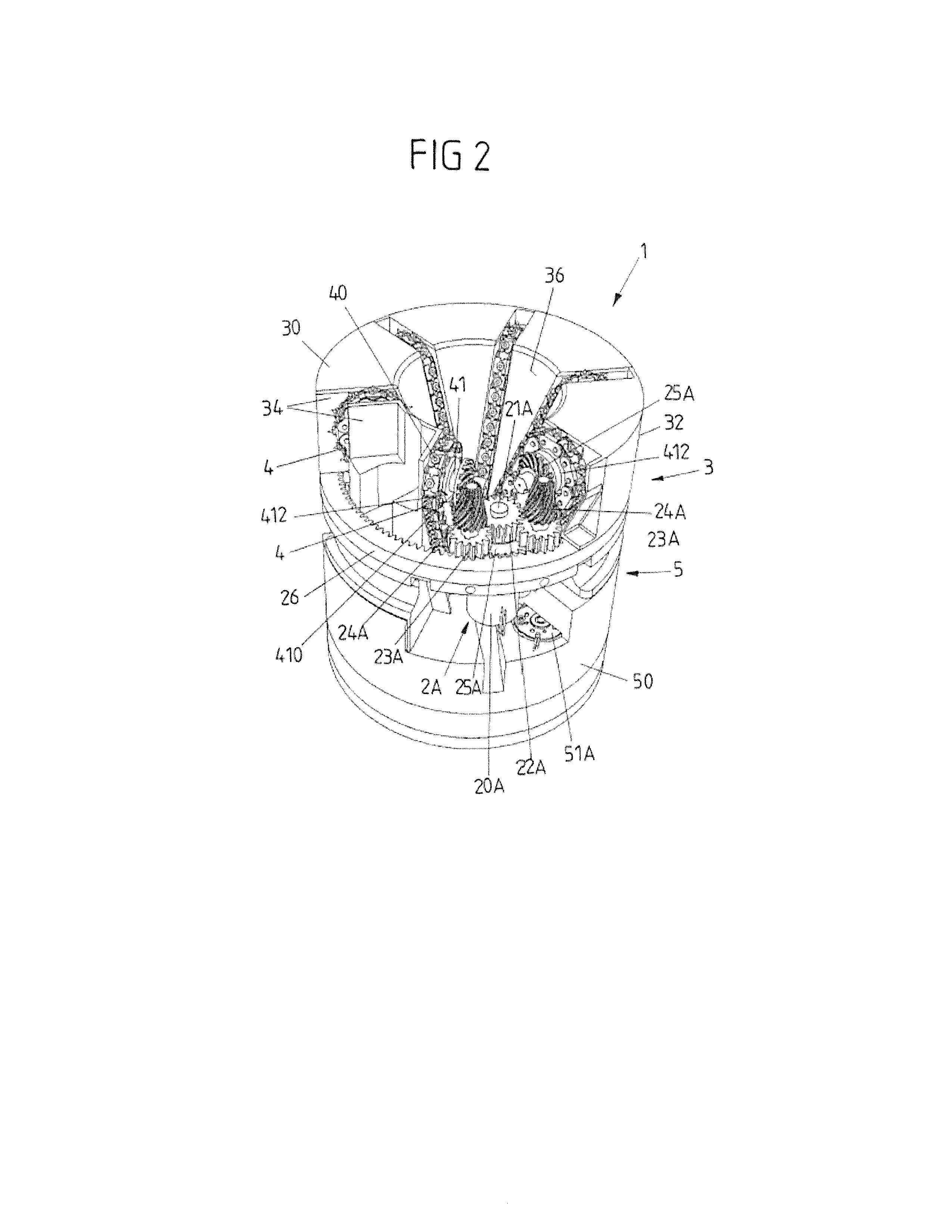

Compacting device for compacting container

ActiveUS20150033961A1Reduce conveying speedRisk of destructionPress ramMechanical engineeringEngineering

A compacting apparatus (1) for compacting receptacles has a compacting unit (3) with at least one first advancing device (4) for transporting at least one receptacle (G) in an insertion direction (E). The compacting unit (3) is configured to compact the receptacle (G) while the receptacle (G) is transported in the insertion direction (E). A post-compacting unit (5) is downstream of the compacting unit (3) in the insertion direction (E) and has at least one second advancing device (6) for transporting the at least one receptacle (G) through the post-compacting unit (5). The post-compacting unit (5) is configured to compact the at least one receptacle (G) further. Positions of the at least one first advancing device (4) of the compacting unit (3) and the at least one second advancing device (6) of the post-compacting unit (5) are changeable with respect to one another in the insertion direction (E).

Owner:WINCOR NIXDORF INT

Device ad method for loading a liquid with a gas

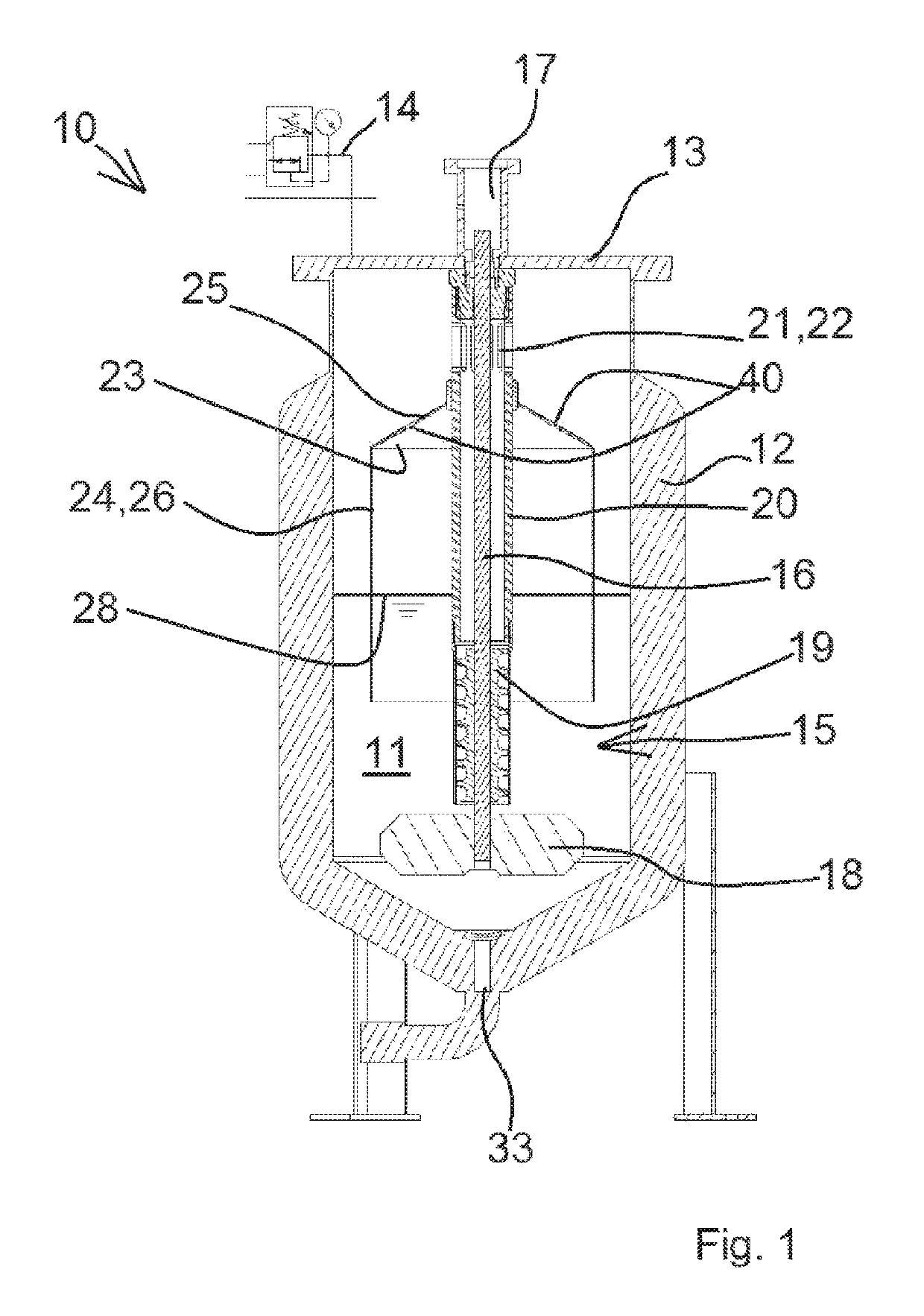

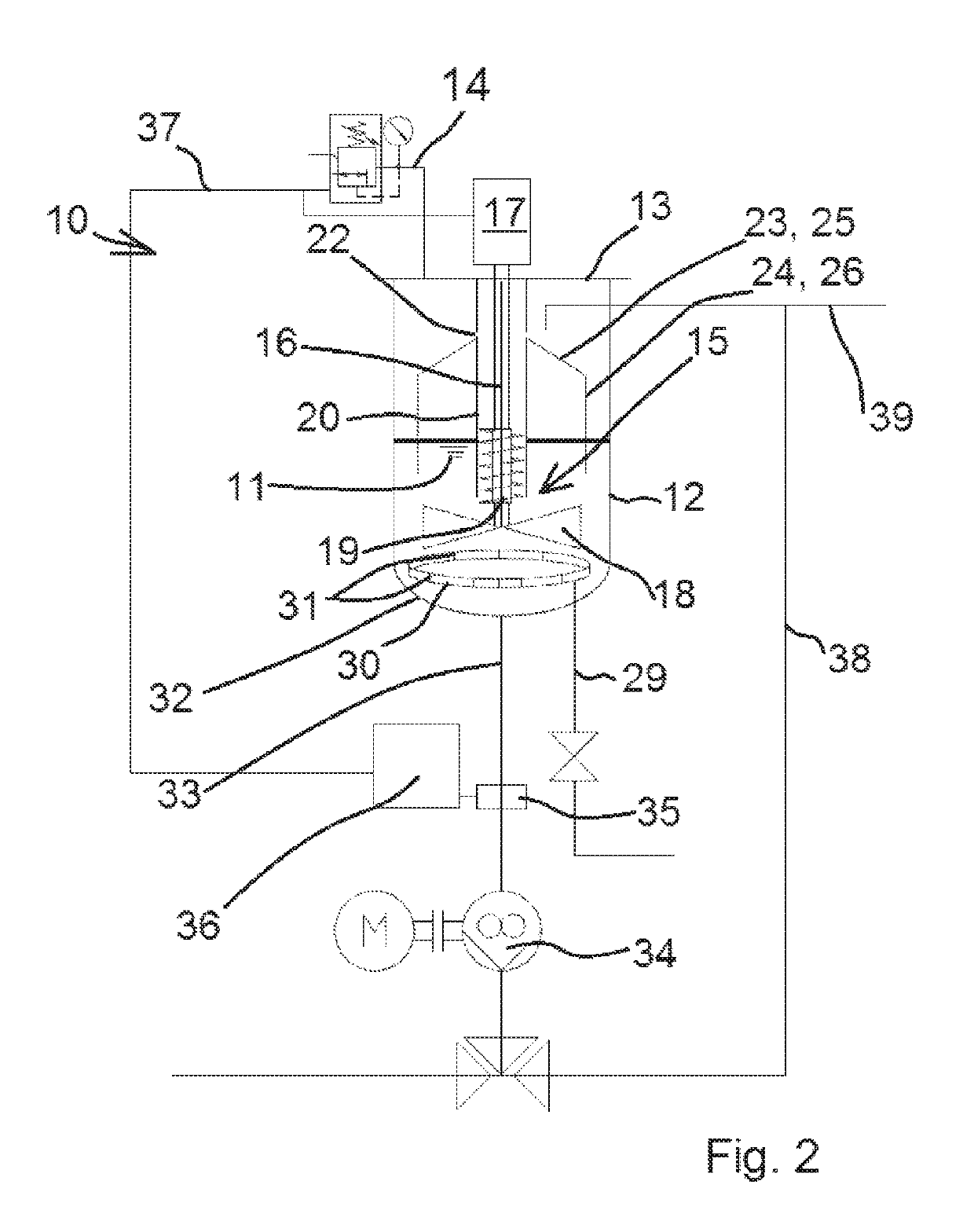

ActiveUS10343123B2Compact designLittle maintenanceTransportation and packagingRotary stirring mixersDrive shaftThin layer

A device for loading an in particular higher-viscosity liquid, such as a silicon resin, for example, with air or another gas. The device has a pressure vessel receiving the liquid and the gas, in which pressure vessel an agitator, having a drive shaft set through the pressure vessel at least in part, is arranged. In order to enable the particularly fast and homogeneous intermixing of the liquid and gas, the drive shaft is arranged in a conveying pipe and drives a conveying organ, in particular a screw conveyor, which transports the liquid through the conveying pipe to at least one outlet, and there is an running-off surface underneath the outlet from the conveying pipe for the liquid flowing out of the outlet. Upon actuation of the agitator, the liquid is thus not only well intermixed together with the air already received therein, but at the same time conveyed through the conveying pipe to the running-off surface, on which it can discharge in a thin layer and has a particularly large exchange area with the gas as a result.

Owner:HENKEL KGAA

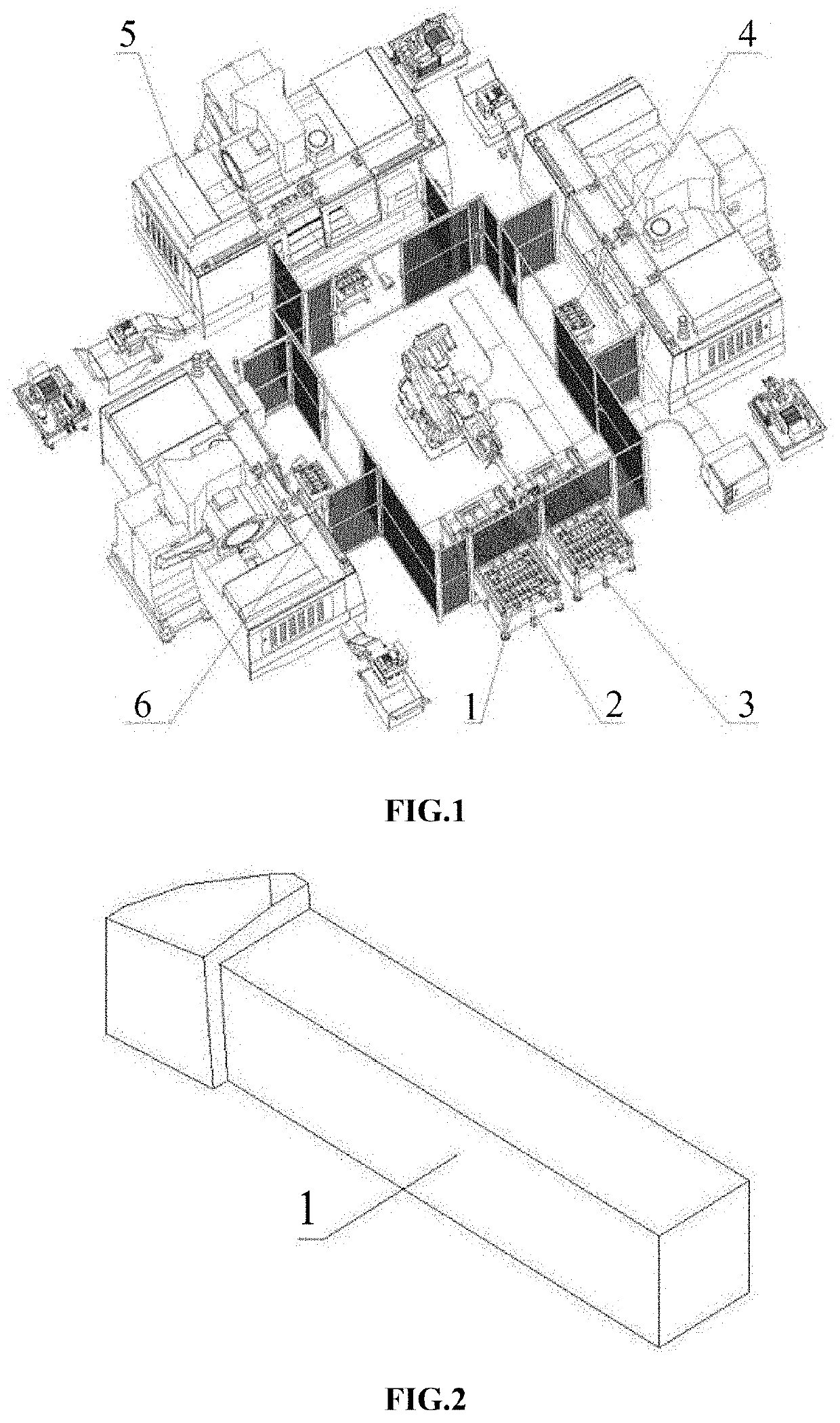

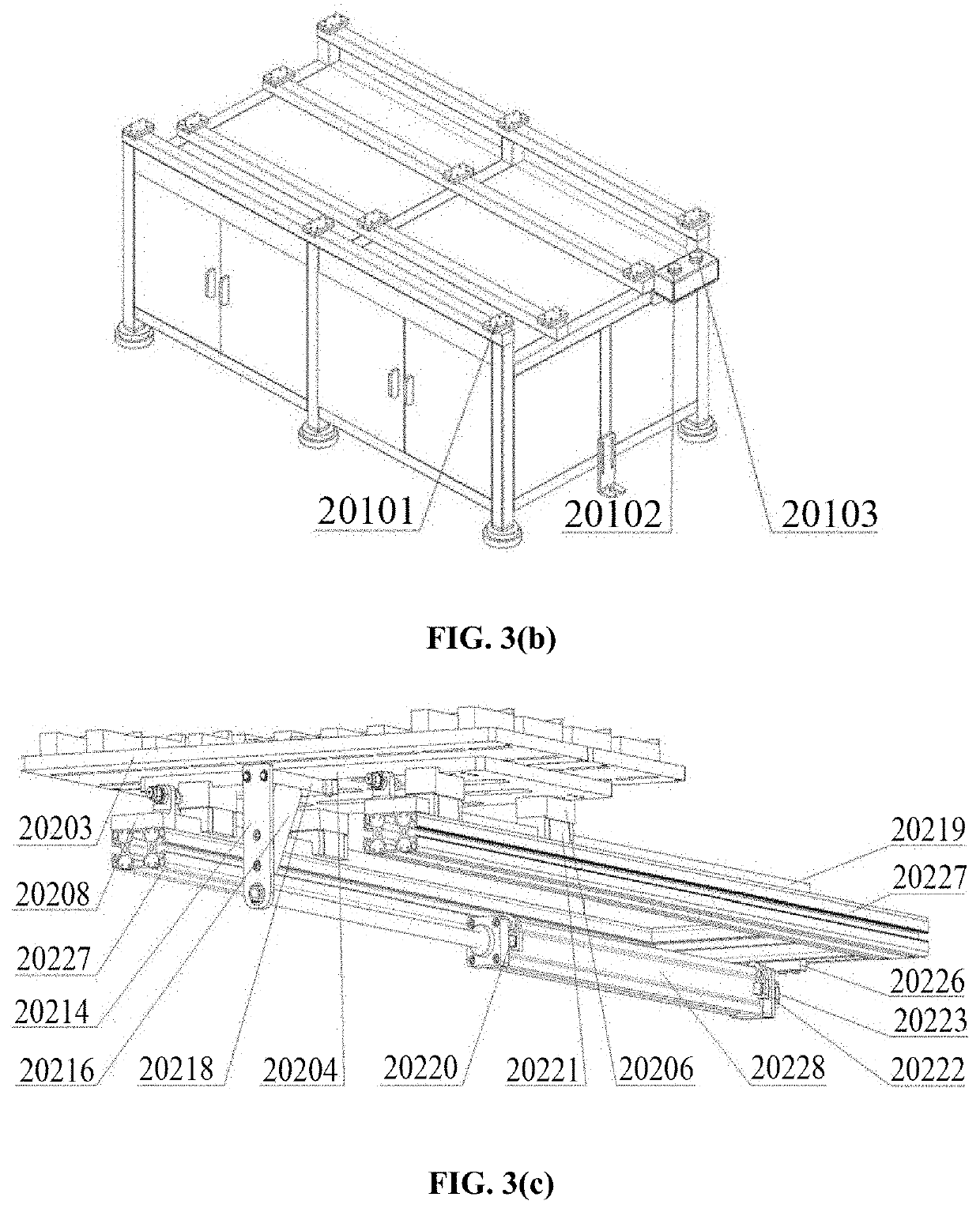

Intelligent production line for turning tool bit cavities and use method thereof

PendingUS20220055164A1Ensure personal safetyCompact structureAutomatic conveying/guiding stockMeasurement/indication equipmentsProduction lineTool bit

An intelligent production line for turning tool bit cavities and an application method are provided, which solve the problem that a production line in the prior art has low working efficiency. The intelligent production line has the beneficial effects of a compact arrangement structure, higher safety and improved working efficiency. The intelligent production line for turning tool bit cavities includes a robot. Material tables and at least one machining center are arranged around the robot. A transfer station used for transferring materials is arranged between the machining center and the robot. A protective fence is arranged between a position above the material tables and the robot, and between the transfer station and the robot. The robot is provided with a mechanical arm including a base plate. The base plate is provided with at least one clamping jaw and fixed with a laser detecting unit for detecting the materials.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

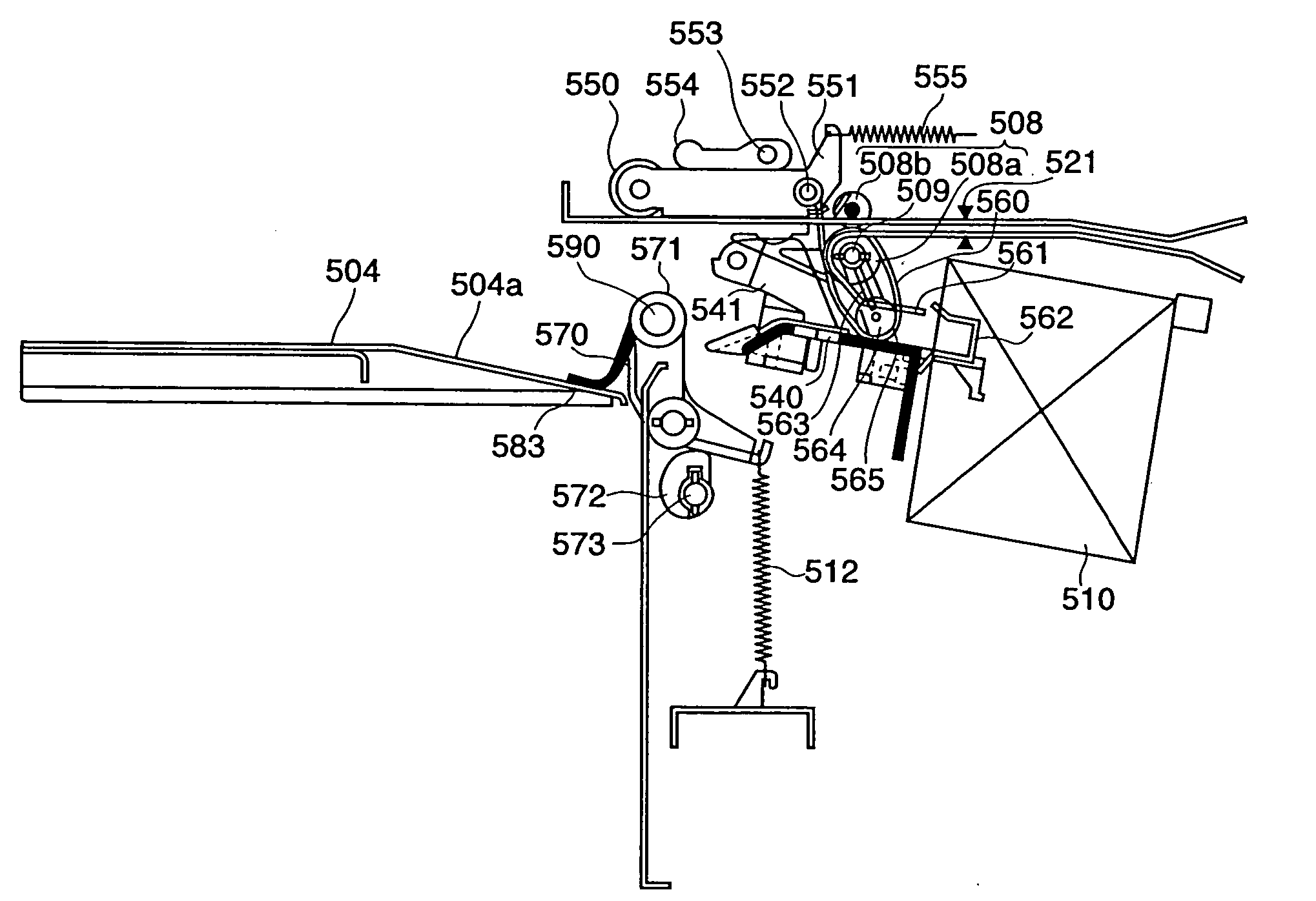

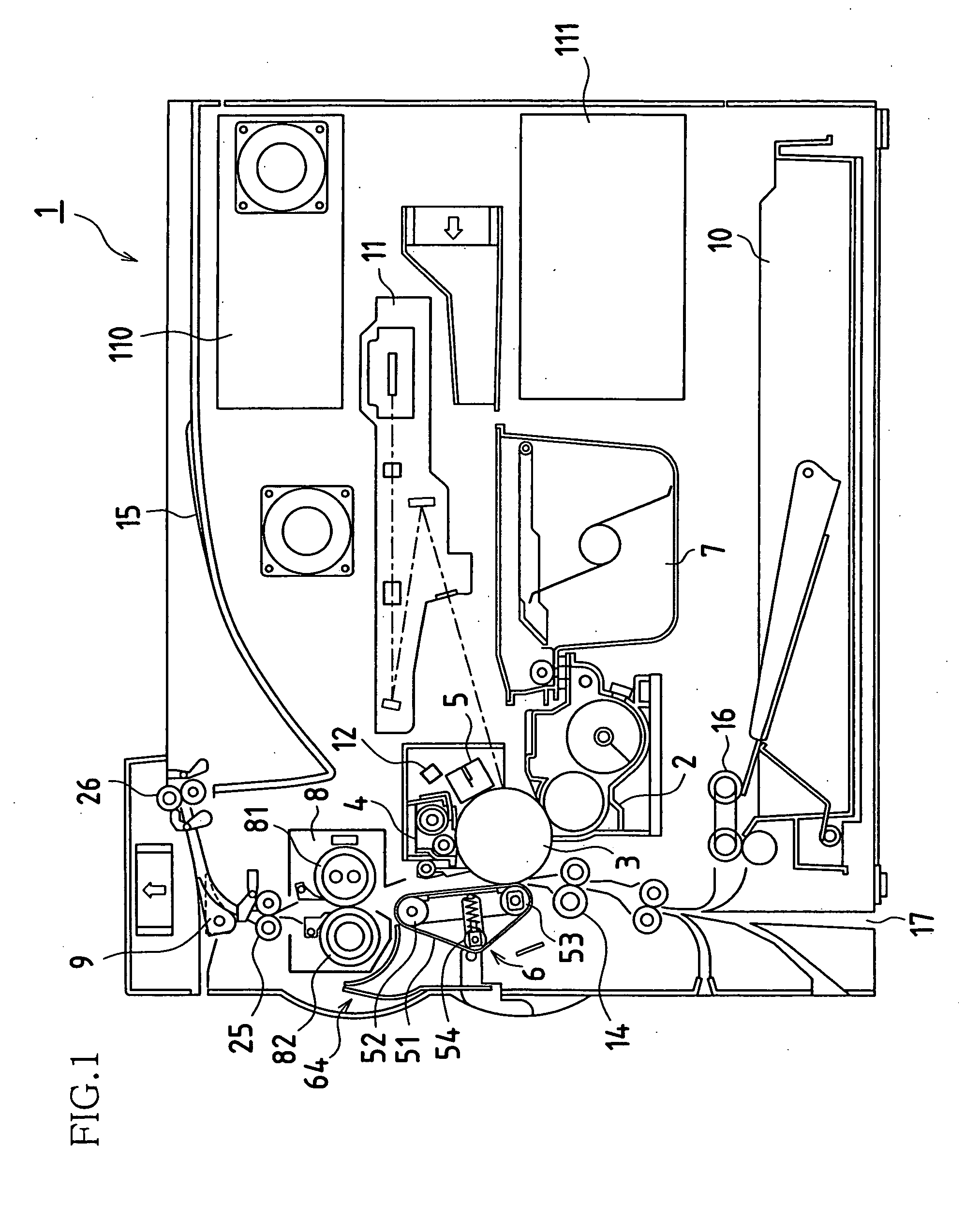

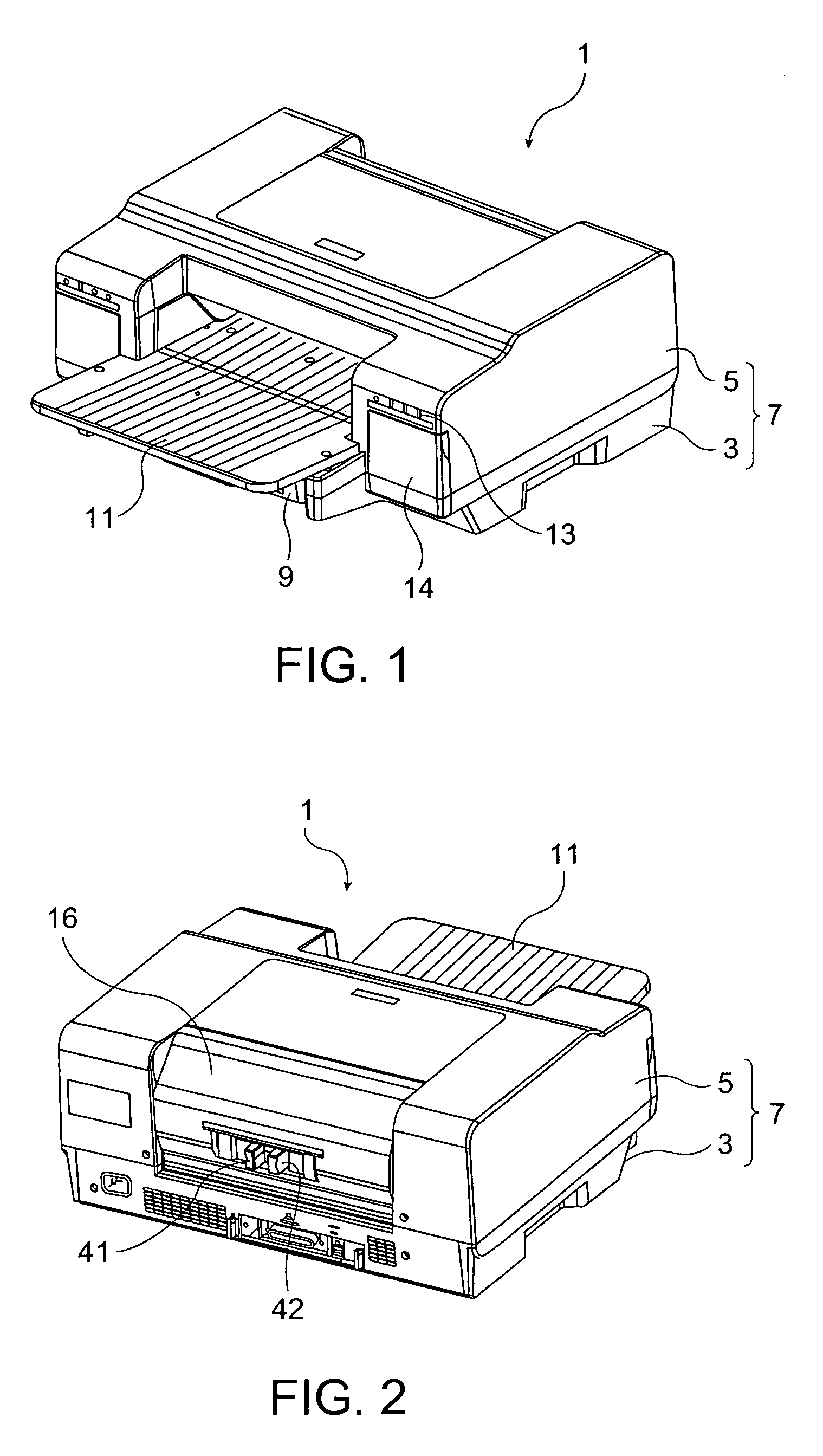

Data processing apparatus

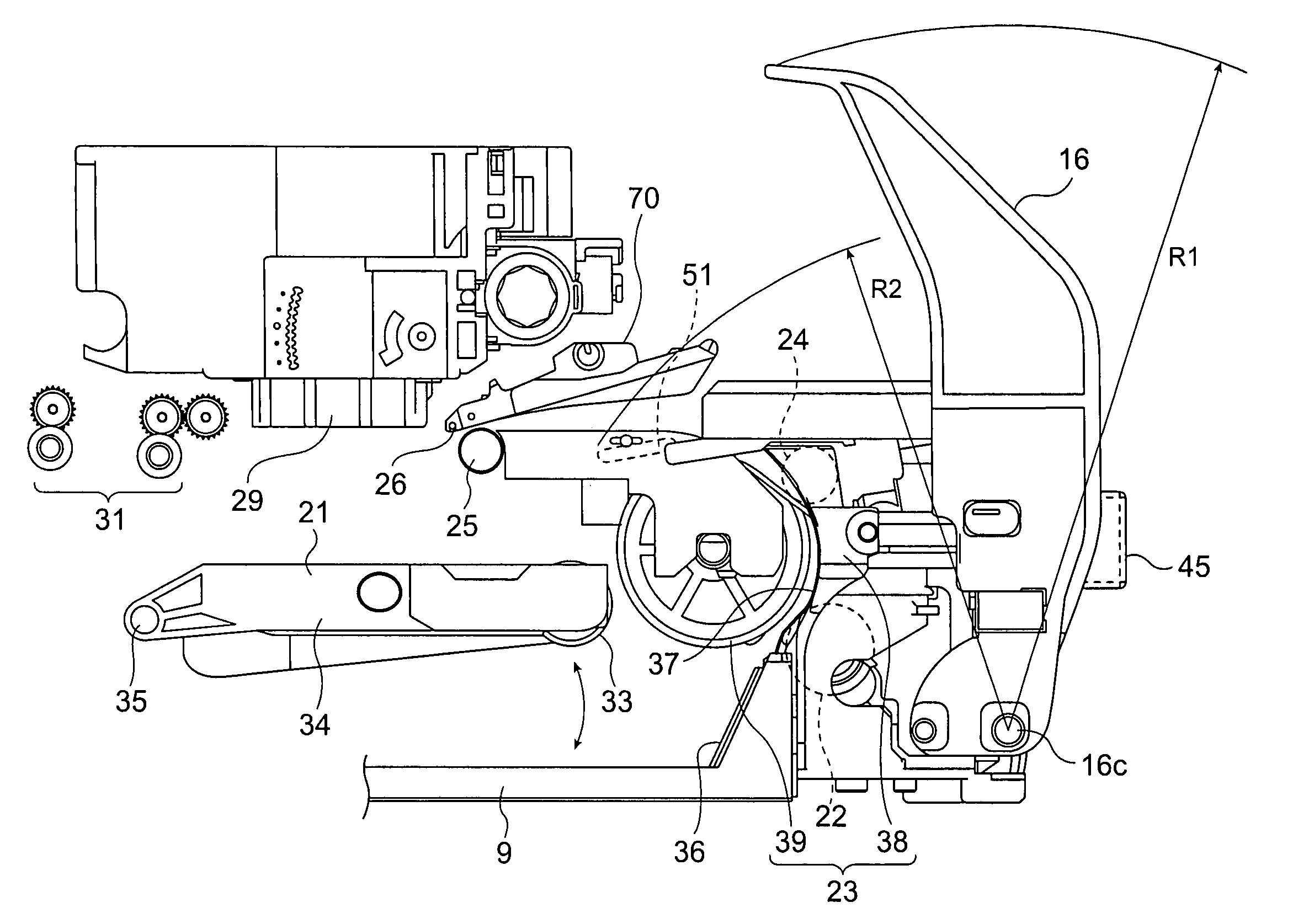

InactiveUS7364156B2Easy to transportReliably conveyedElectrographic process apparatusOther printing apparatusTransport mediumMechanical engineering

A data processing apparatus having a construction for guiding a transported medium conveyed from a curved transportation unit enables opening and closing the guide unit. The data processing apparatus 1 has an intermediate roller 39 and guide portion 38 constituting a curved transportation unit 23 inside the printer case 7, and a paper feed roller pair 25 and 26 for nipping and conveying paper P conveyed from the curved transportation unit 23 disposed a specific distance from the curved transportation unit 23. The guide portion 38 has an auxiliary guide member 51 and can move circularly open and closed in unison with an outside wall unit 16. The auxiliary guide member 51 projects toward the paper feed roller pair 25 and 26 and guides the paper P. An auxiliary guide linking mechanism 53 causes the auxiliary guide member 51 to retract away from the paper feed roller pair 25 and 26 in conjunction with the unlocking operation of opening / closing levers 41 and 42.

Owner:SEIKO EPSON CORP

Vaporizer device for an inhaler, in particular for an electronic cigarette product, and fabrication method

ActiveUS20190183180A1High-quality vaporizationCost effective productionTobacco treatmentTobacco devicesEvaporatorHeating element

A vaporizer device for an inhaler, in particular for an electronic cigarette product, comprises an electrical vaporizer having one or more heating elements for vaporizing liquid supplied by the vaporizer. The vaporizer device is characterized in that a carrier is formed of a layer system with a polymer film and at least one metal film in contact with the polymer film in a planar manner, the polymer film comprises at least one fluid permeable opening, the metal film comprises at least one fluid permeable second opening communicating with the first opening, and the metal film forms the heating elements, wherein the heating elements are arranged delimiting the second opening.

Owner:KÖRBER TECH GMBH

Sheet conveying apparatus and image forming apparatus

ActiveUS8042804B2Reliably conveying a sheetLow costAgricultural rollersRoads maintainenceEngineeringSheet material

Owner:CANON KK

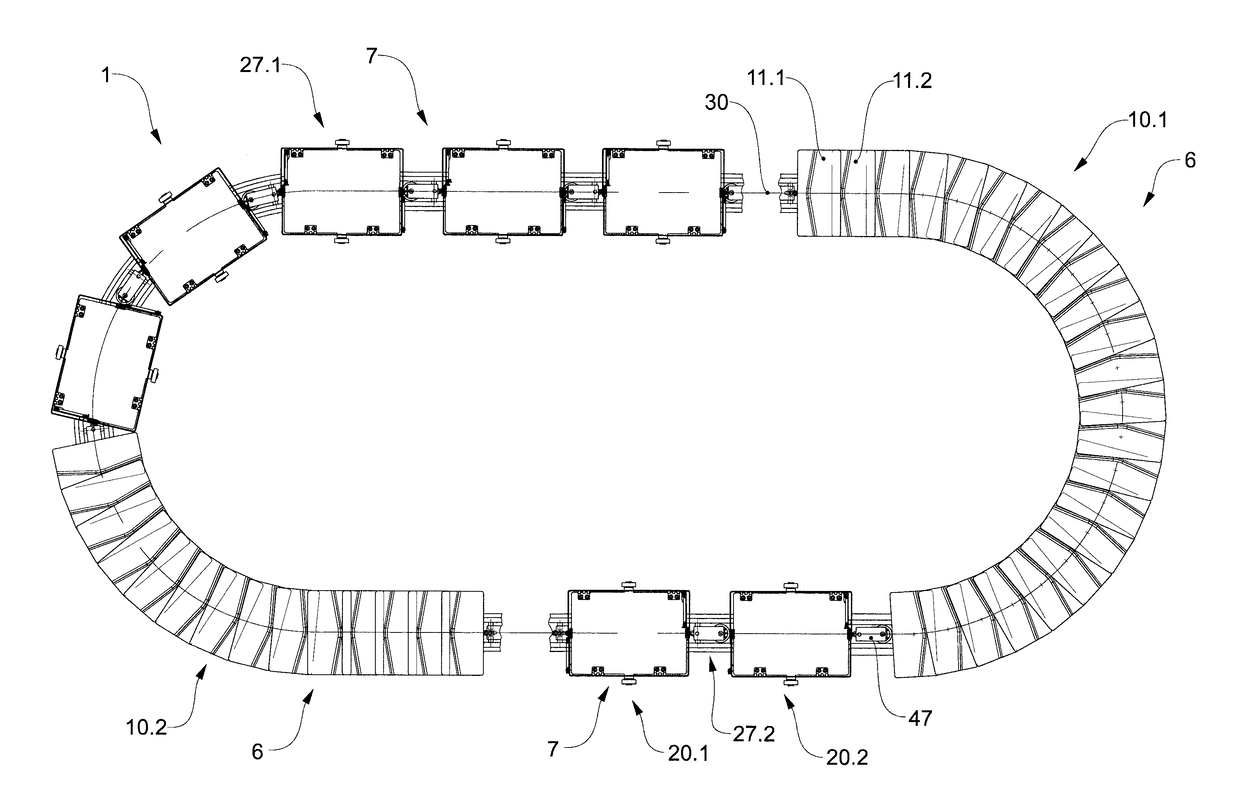

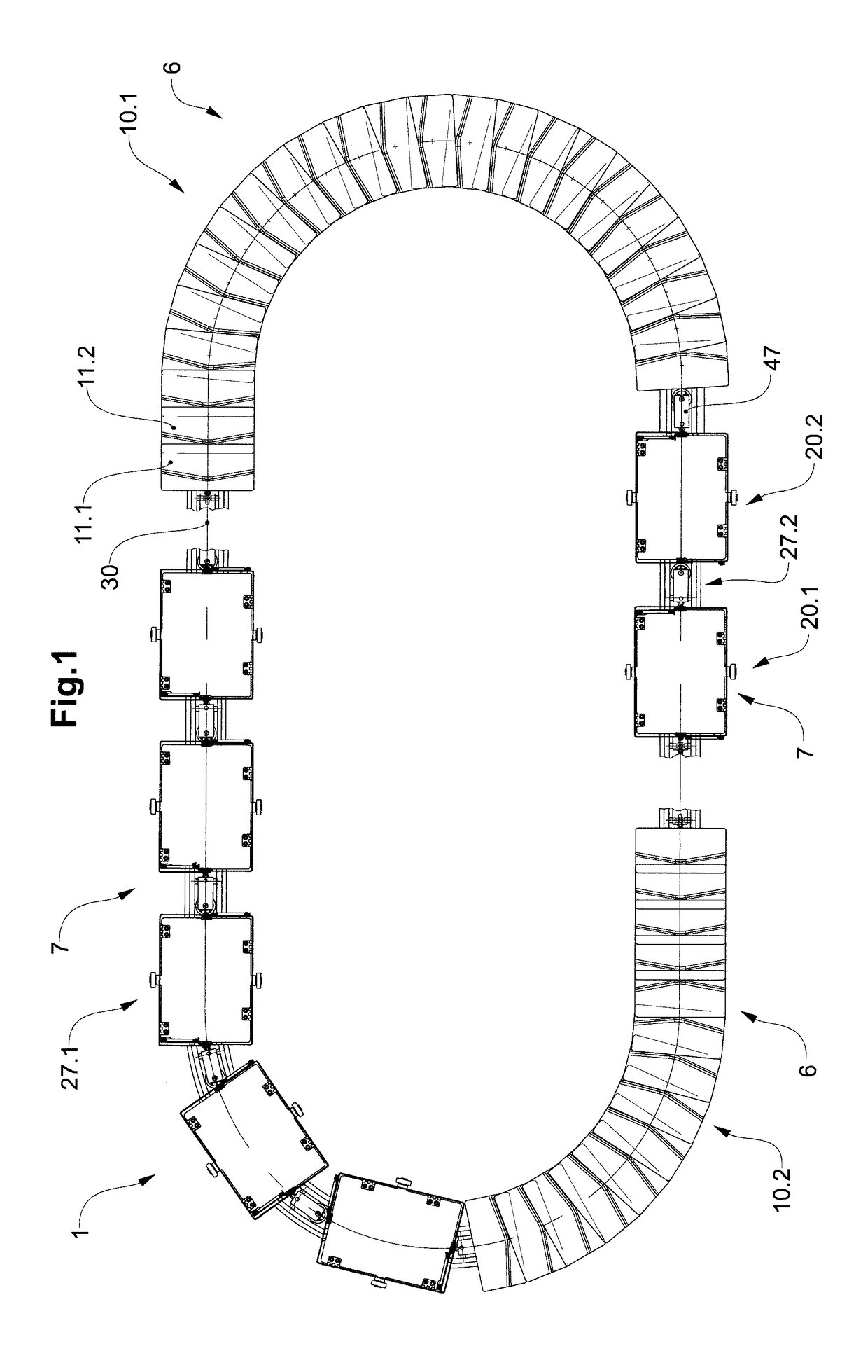

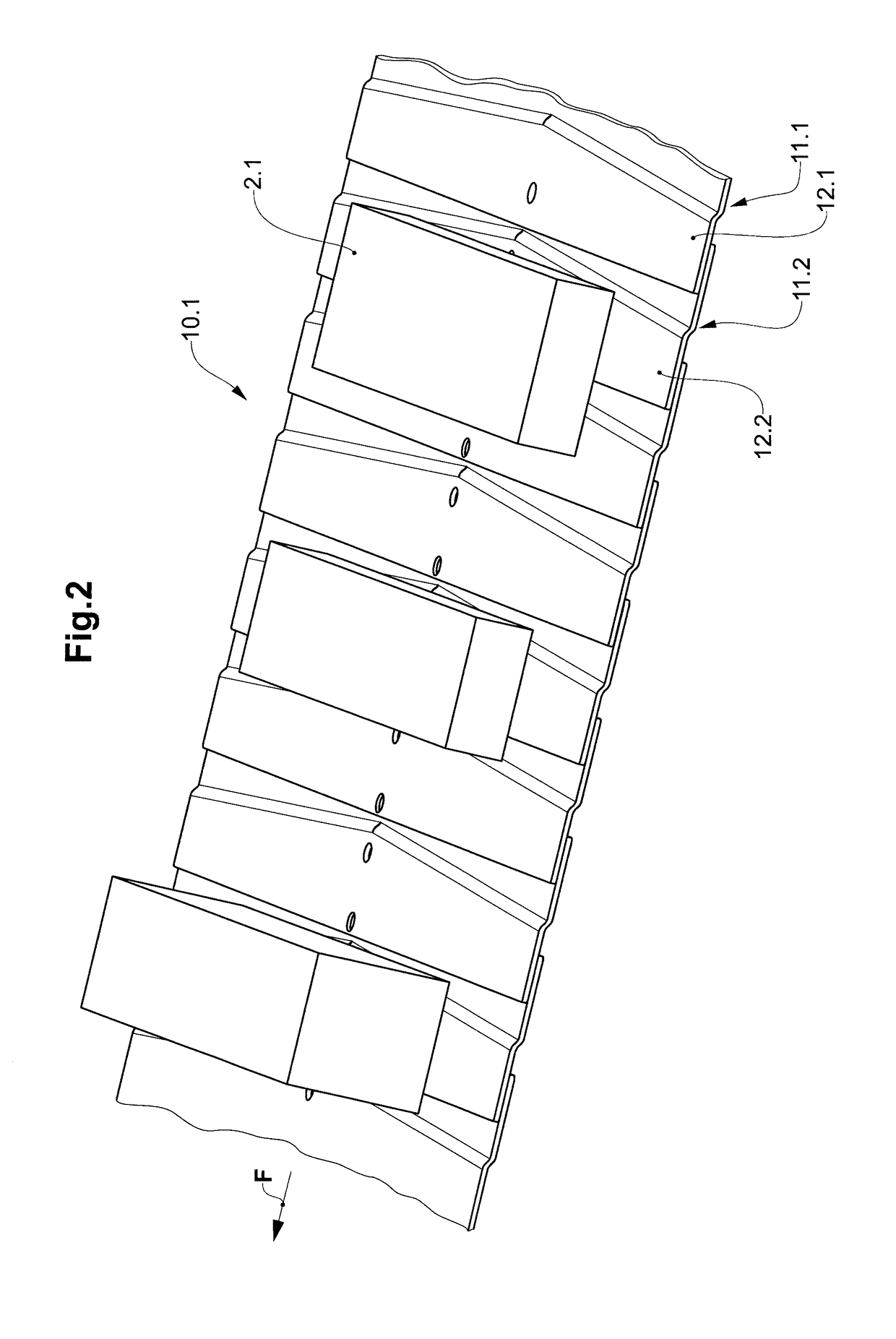

Conveying system

InactiveUS20180327186A1Reliably conveyedAvoid damageConveyorsConveyor partsSoftware engineeringMechanical engineering

The invention relates to a conveying system (1) for conveying items (2.1, 2.2) to be conveyed. The conveying system (1) comprises a conveying path (30) and at least one first conveying means (6) that can move along the conveying path (30) and is designed to convey a first item (2.1) to be conveyed. The conveying system (1) also comprises at least one second conveying means (7) which can move along the conveying path (30) along with the first conveying means (6) and which is designed to convey a second item (2.2) to be conveyed that is of a different type than the first item (2.1).

Owner:WRH WALTER REIST HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com