Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10292results about How to "Prevent splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

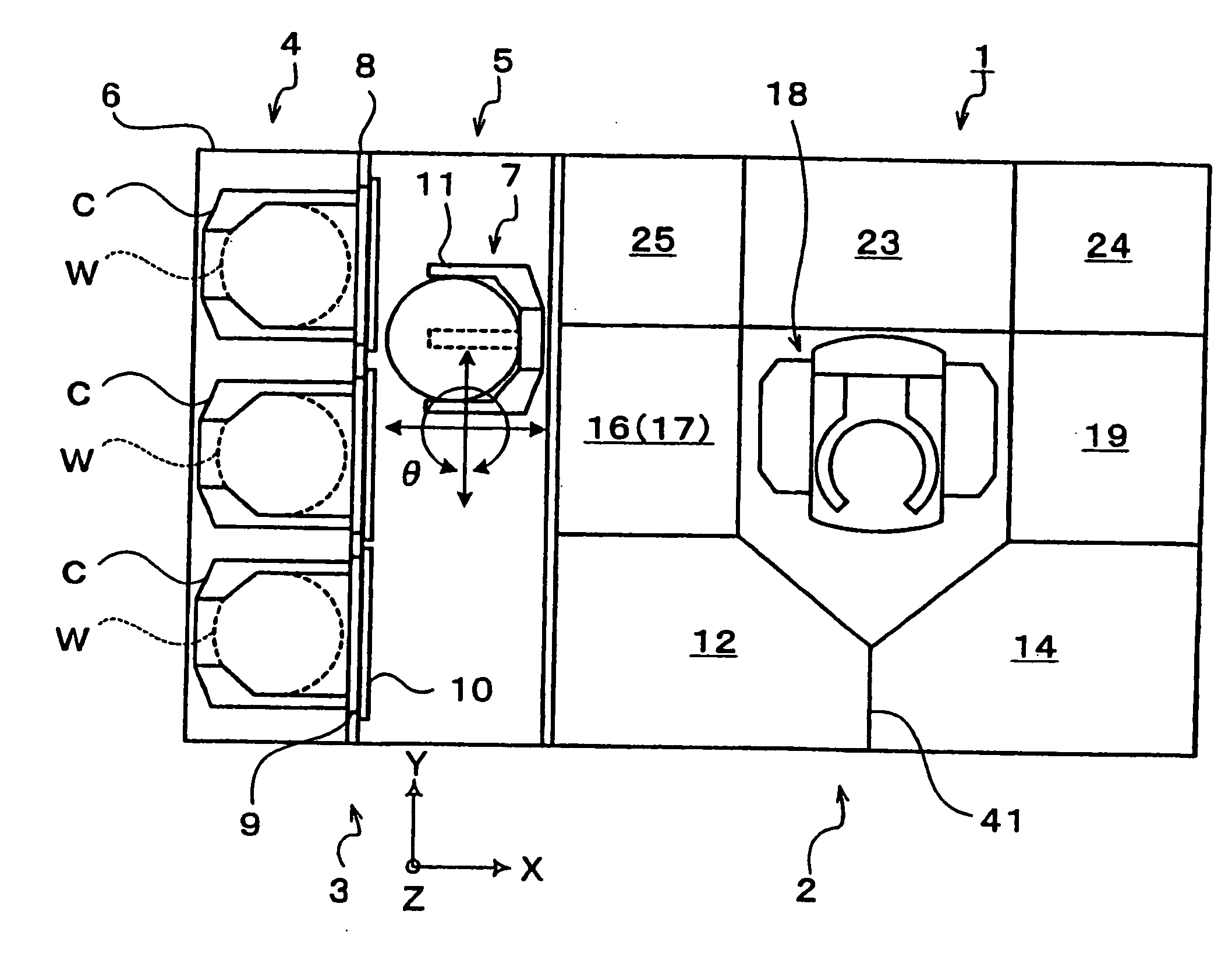

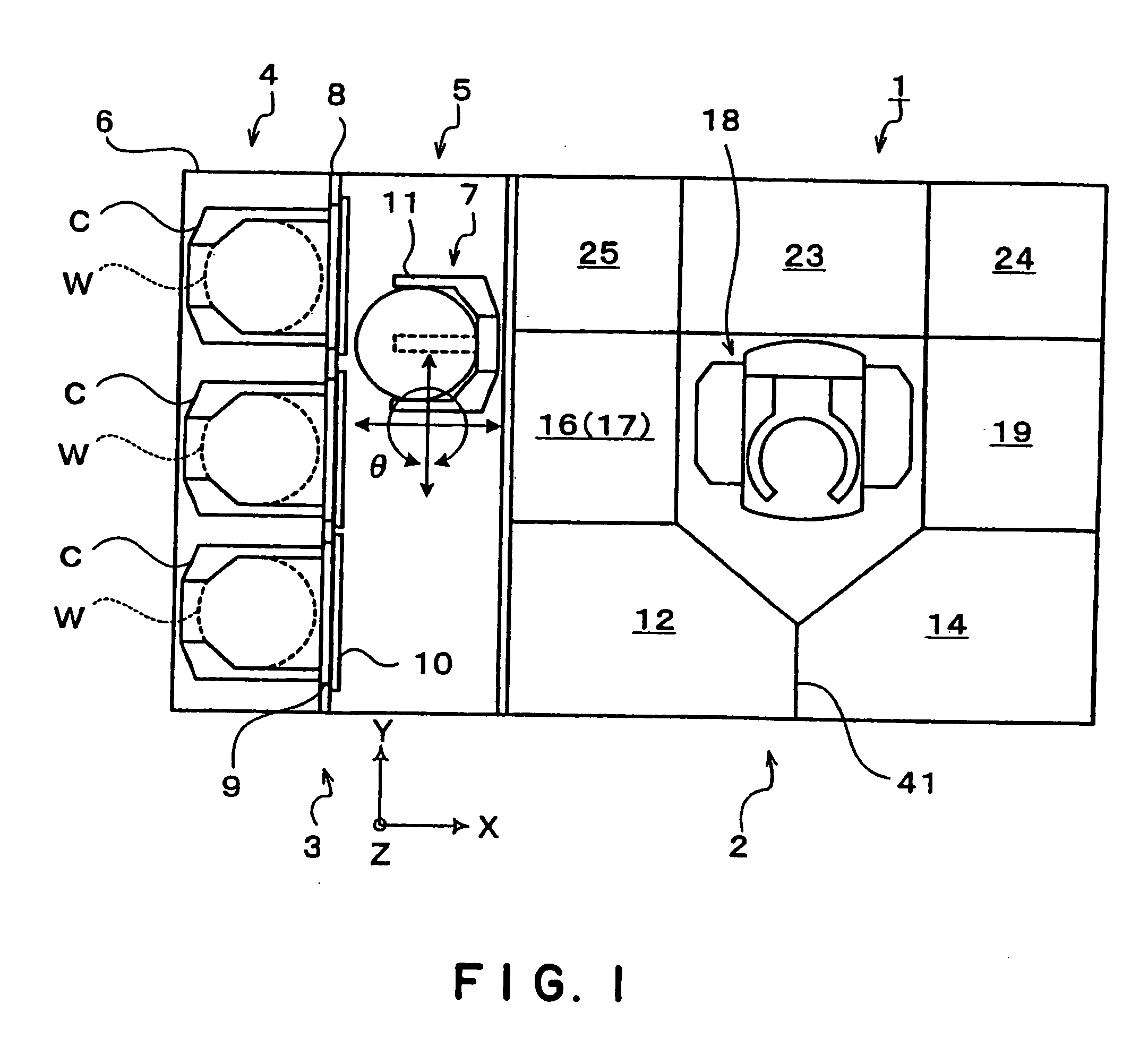

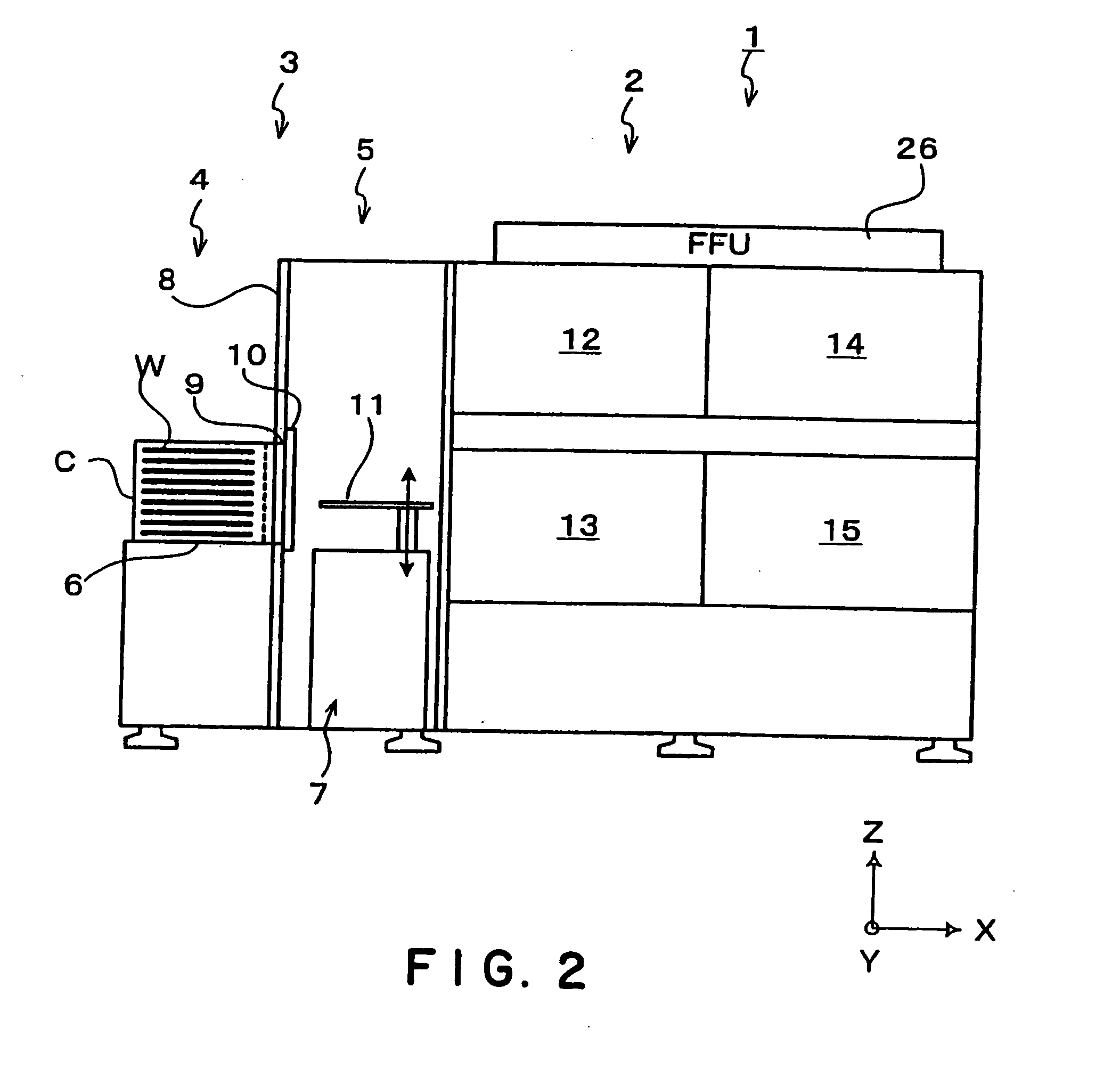

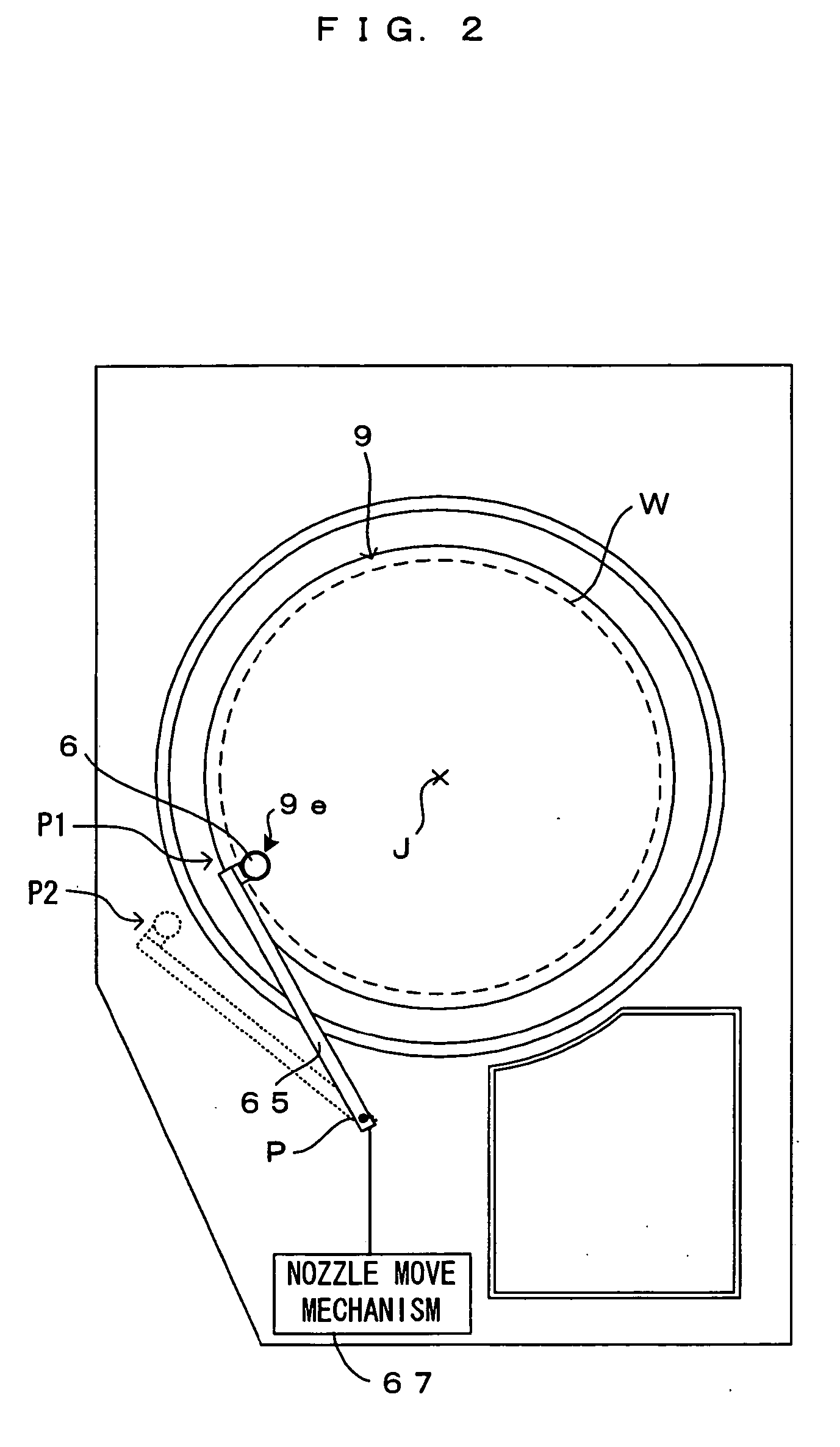

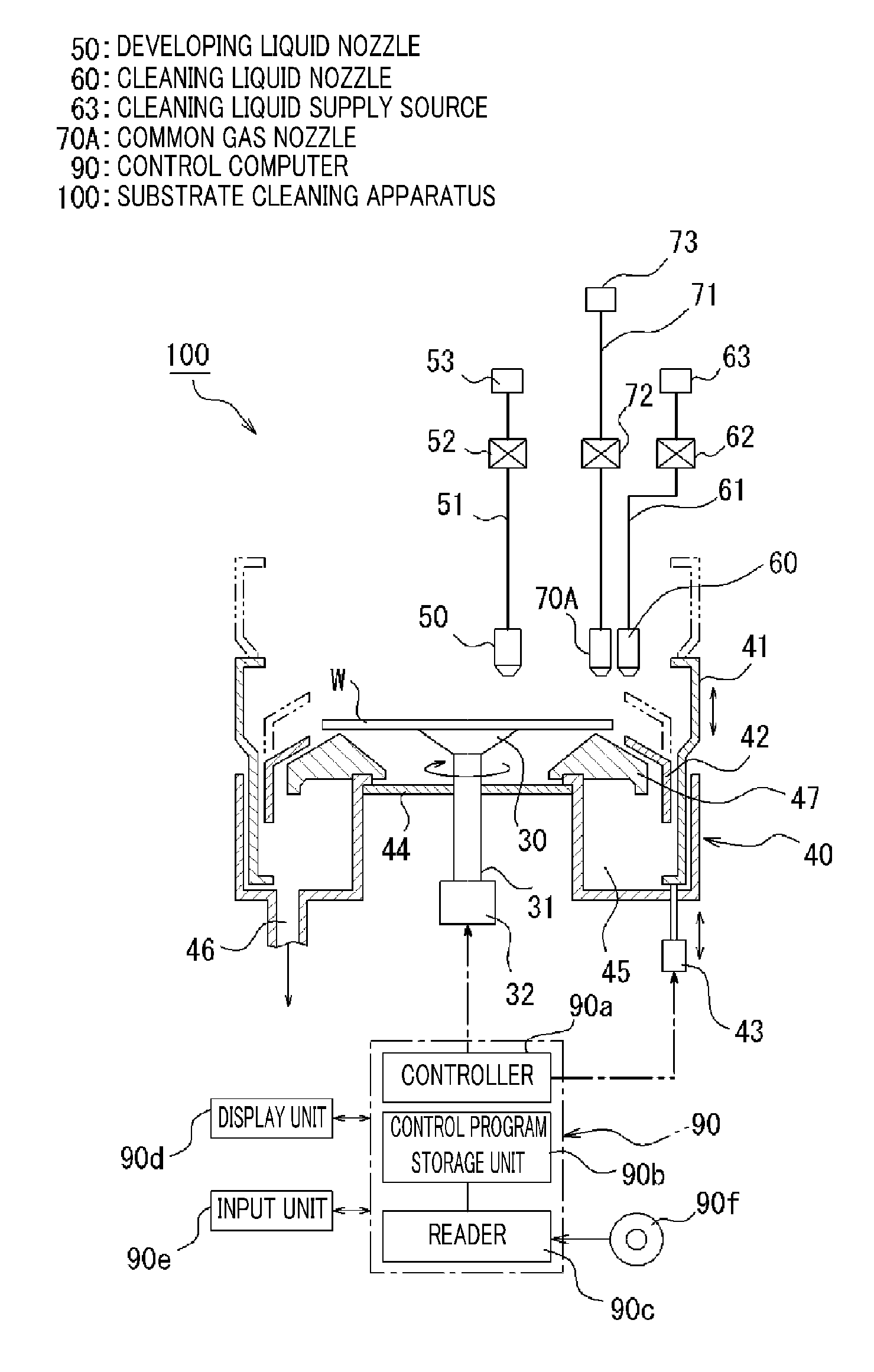

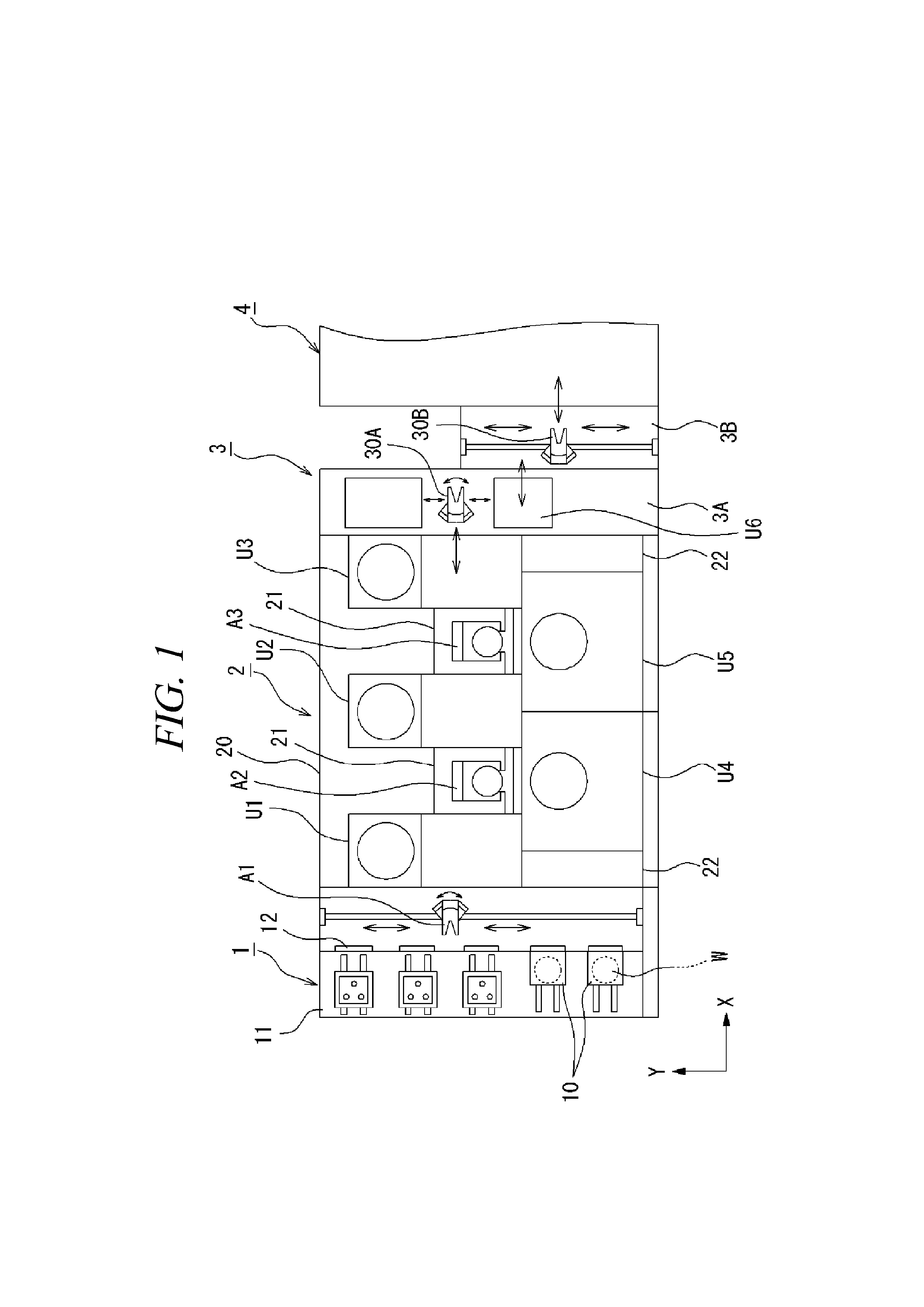

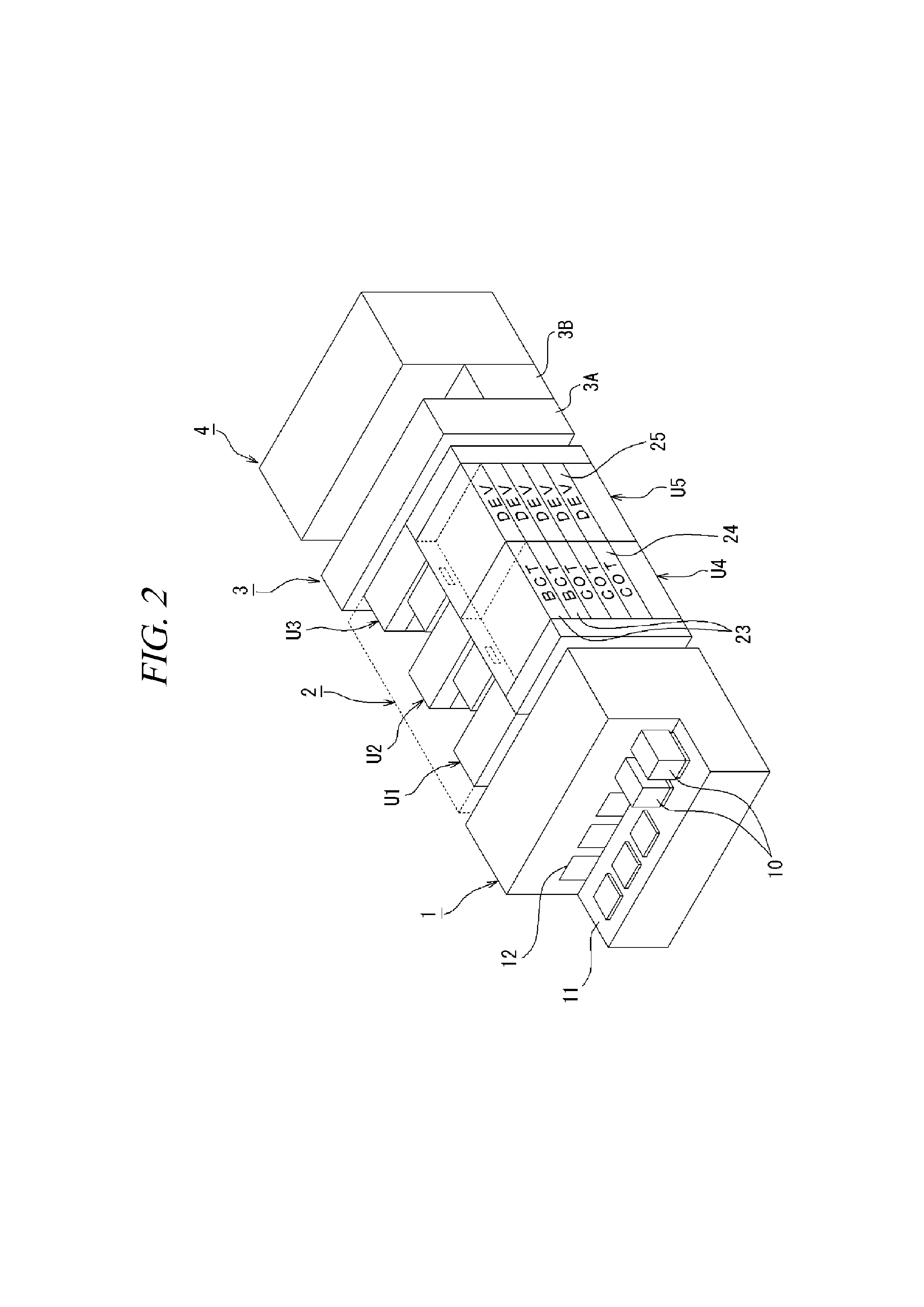

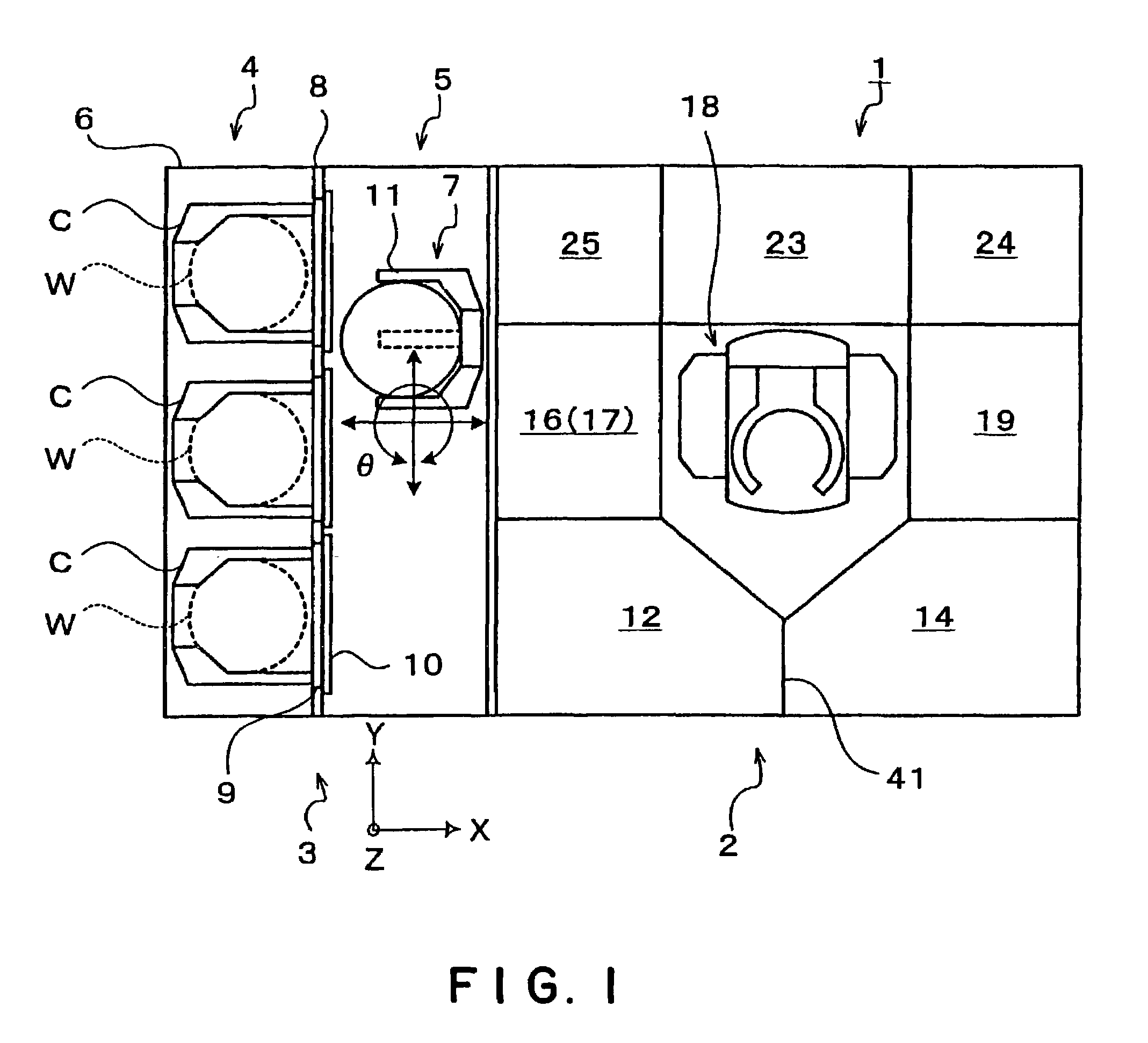

Substrate processing apparatus

InactiveUS20080210278A1Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

A substrate processing apparatus is provided. The apparatus includes a plurality of fluid suppliers 61, 61, 63 for supplying different processing fluids. In processing a wafer W, the substrate processing apparatus moves the fluid suppliers 61, 62, 63 along the peripheral part of the wafer W relatively. The fluid suppliers 61, 62, 63 are arranged in a direction extending from the circumference of the wafer W to its inside. With the arrangement, the apparatus is capable of stable processing of the wafer W in spite of rotating the wafer W at a low speed. Further, it is possible to improve a throughput of the apparatus in resist processing.

Owner:TOKYO ELECTRON LTD

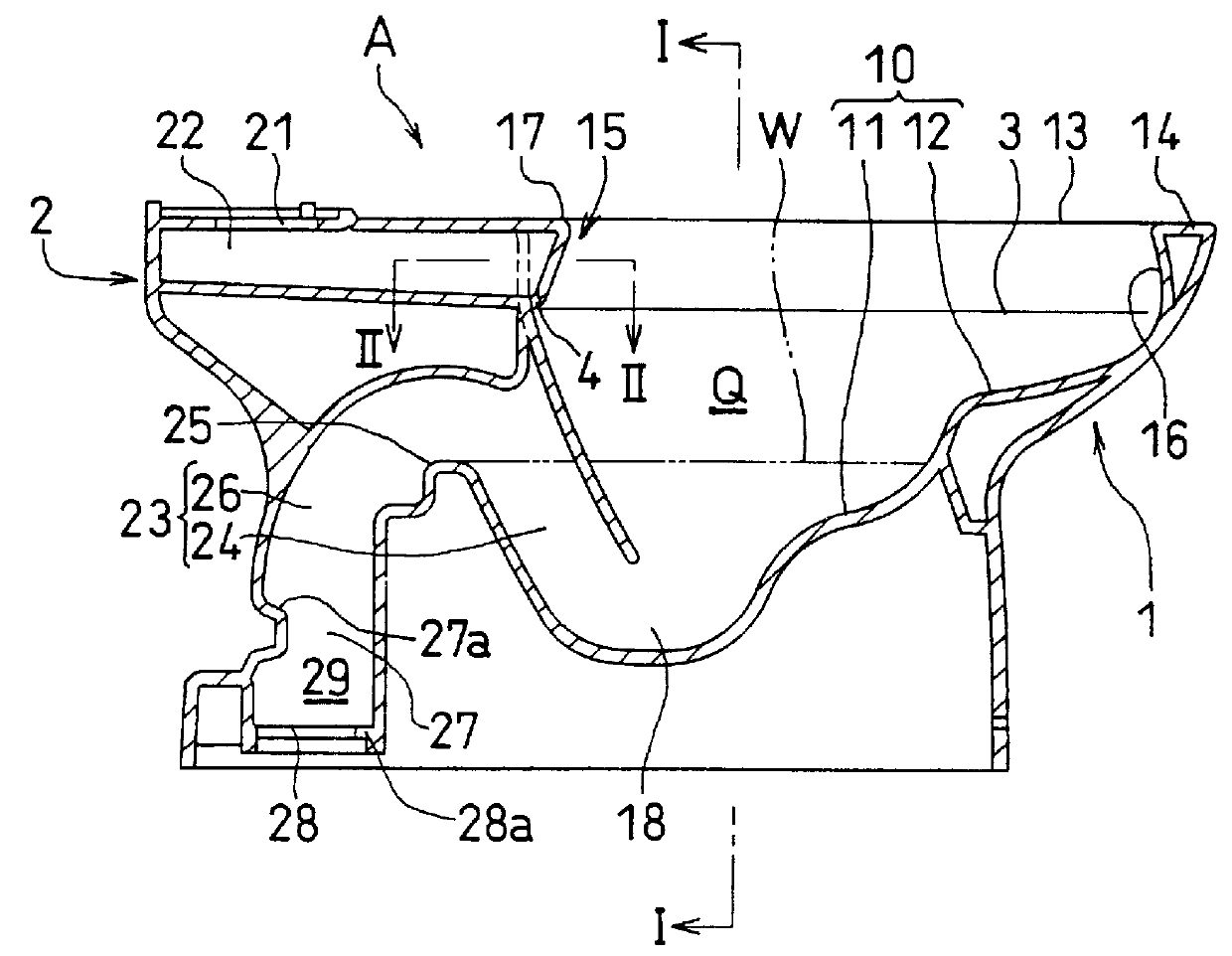

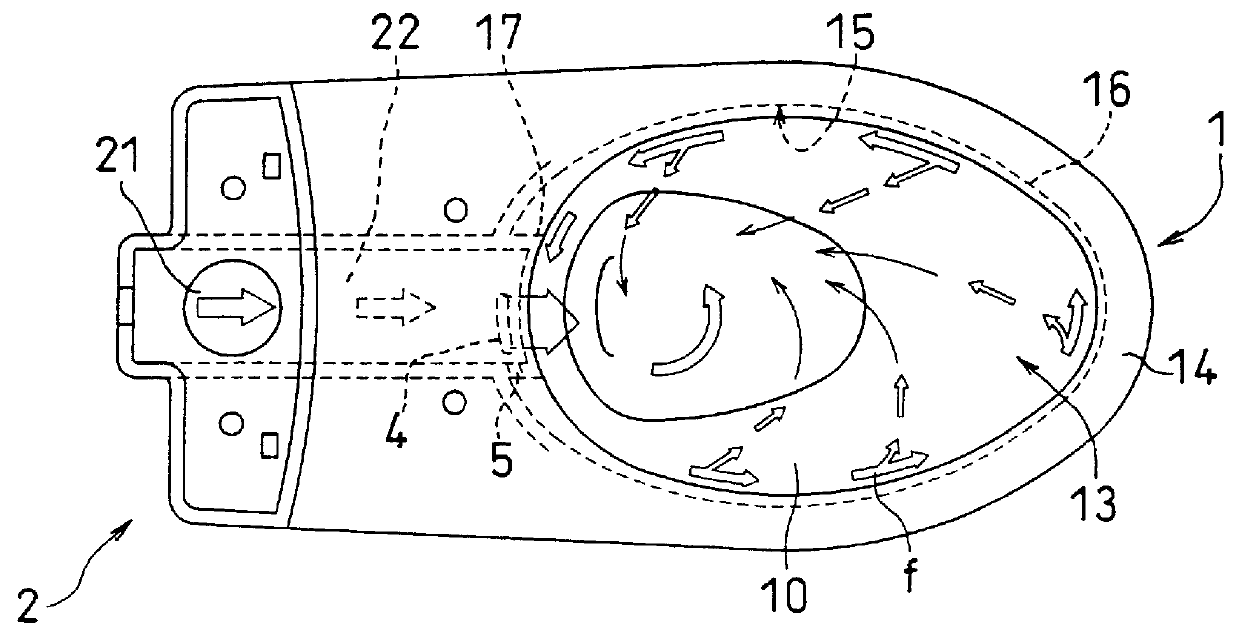

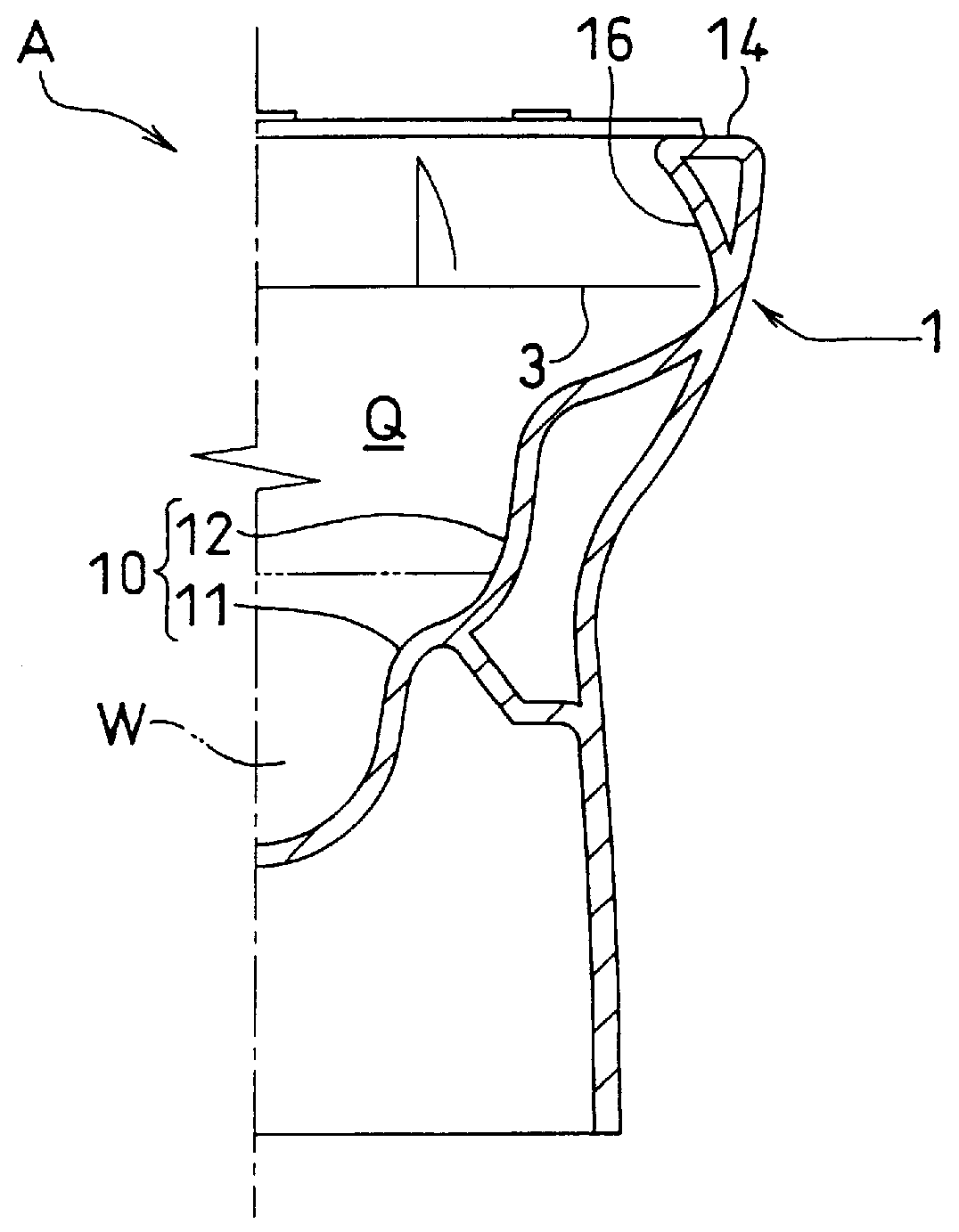

Flush toilet

PCT No. PCT / JP97 / 03706 Sec. 371 Date Apr. 14, 1999 Sec. 102(e) Date Apr. 14, 1999 PCT Filed Oct. 14, 1997 PCT Pub. No. WO98 / 16696 PCT Pub. Date Apr. 23, 1998The flush toilet has a waste receipt surface section (10) of a bowl section (1) formed continuously integrally with an inner rim wall surface section (15) of the rim portion disposed at a peripheral edge of an upper opening (13) of the bowl section (1) as a curved surface; and the inner rim wall surface section (15) of the rim portion acts as a flush water passage (16) of the bowl section. The flush water passage (16) of the bowl section is further configured such that the inner rim wall surface section (15) of the rim portion is shaped in an overhanging form inclining so as to hang over inside of the bowl section (1). The flush toilet of this configuration can be cleaned with ease and kept clean in sanitation.

Owner:TOTO LTD

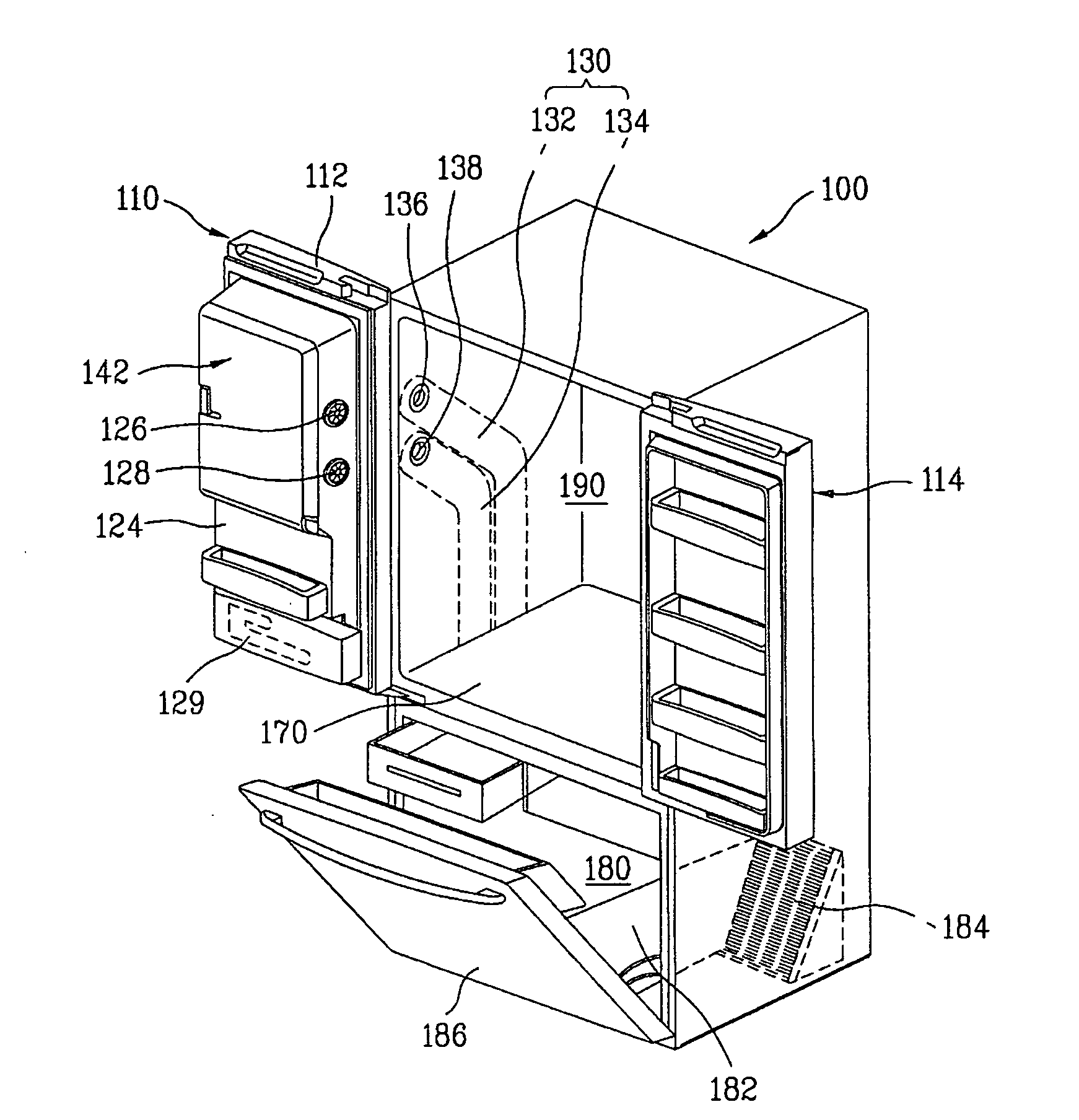

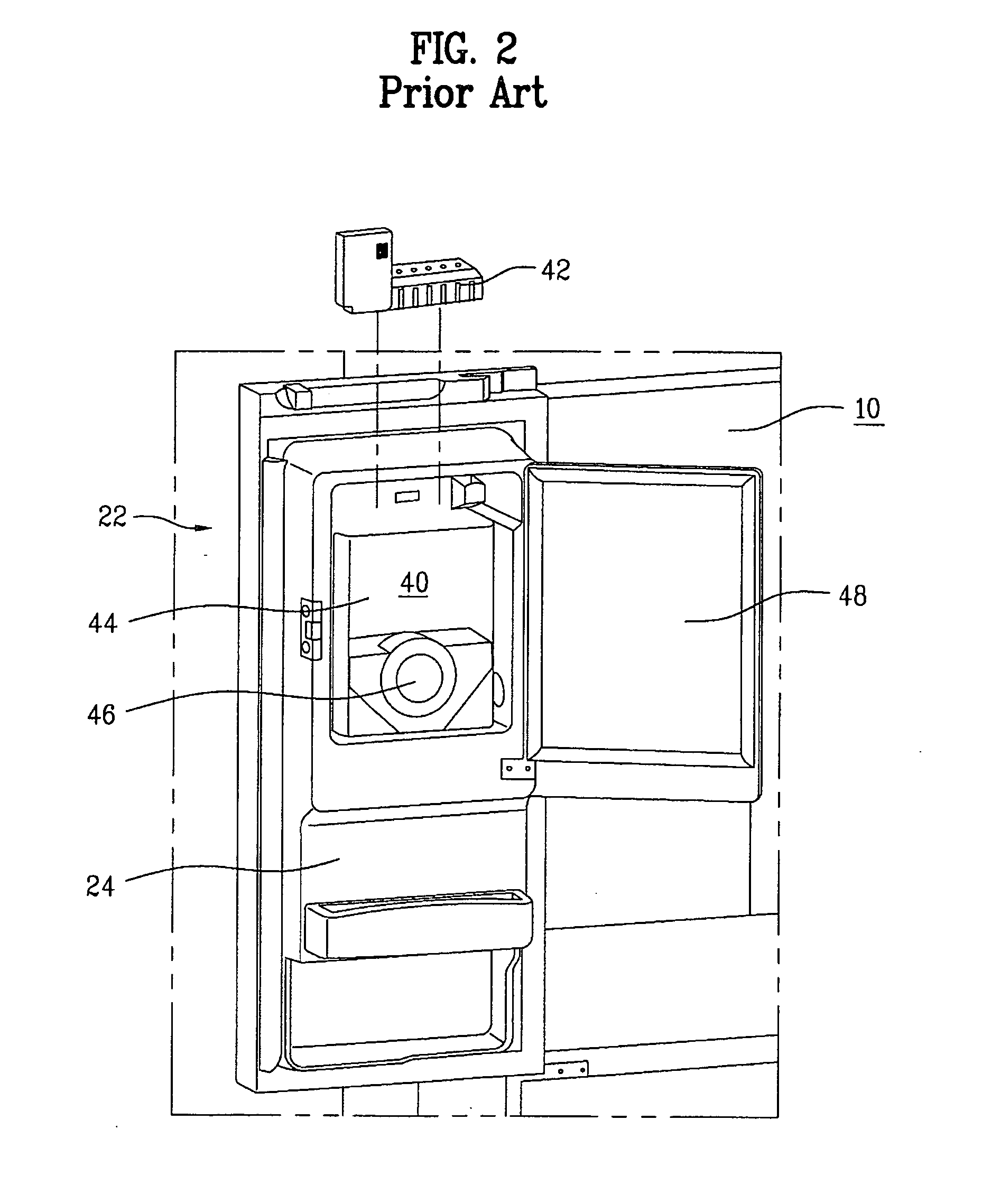

Refrigerator door

ActiveUS20070074527A1FillAvoid breakingLighting and heating apparatusIce productionMechanical engineeringRefrigerated temperature

A refrigerator door is provided. The refrigerator door has an outer case forming a shape of the refrigerator door, an inner case provided within the outer case to configure a backside of the refrigerator door wherein a space between the inner case and the outer case is charged with a foaming liquid, an ice making unit provided to one side of the inner case to make ice, a fixing unit provided to the space charged with the foaming liquid between the inner case and the outer case and fixing the ice making unit to the refrigerator door, and a dispenser provided to one side of the outer case to discharge the ice supplied by the ice making unit.

Owner:LG ELECTRONICS INC

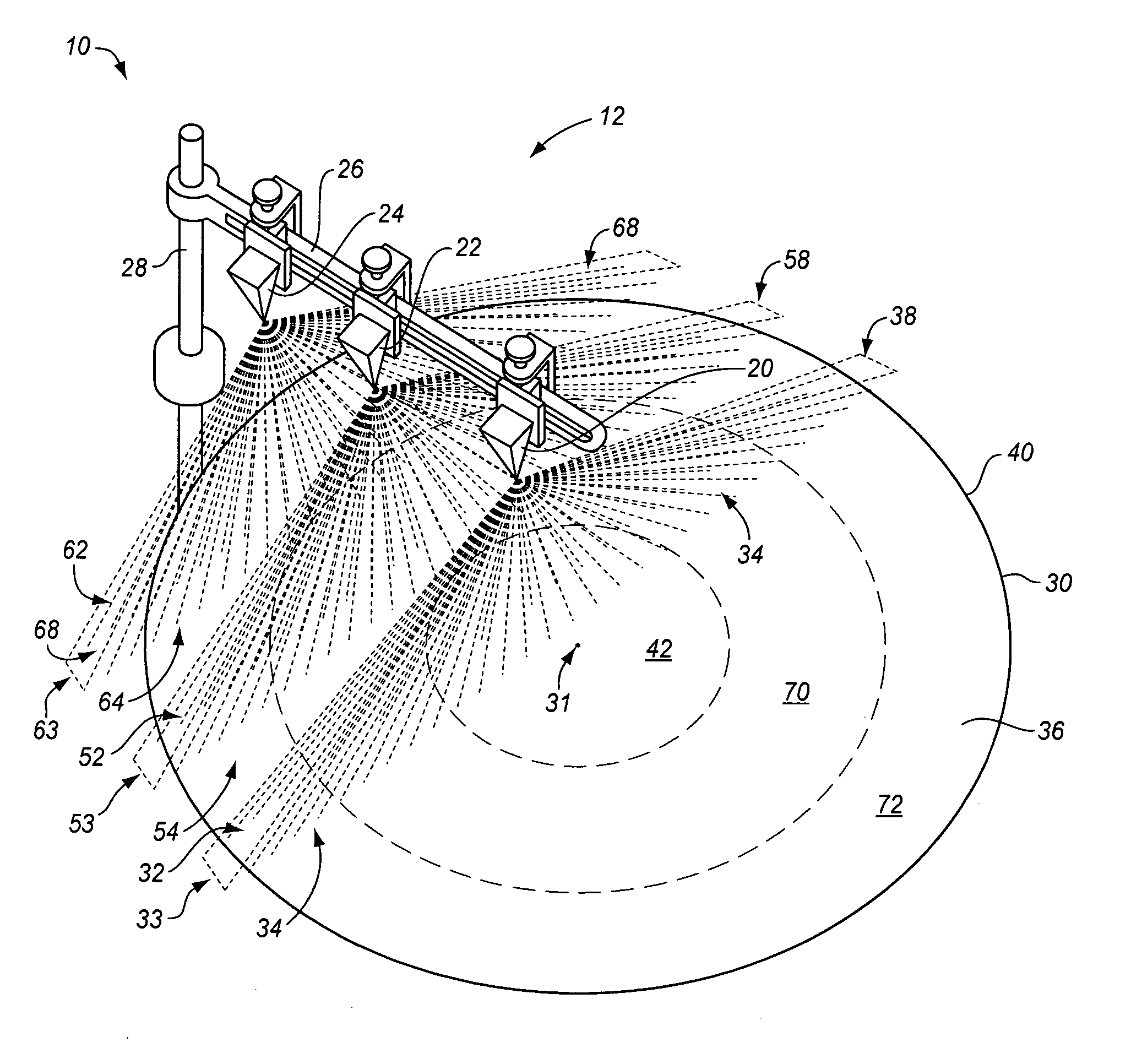

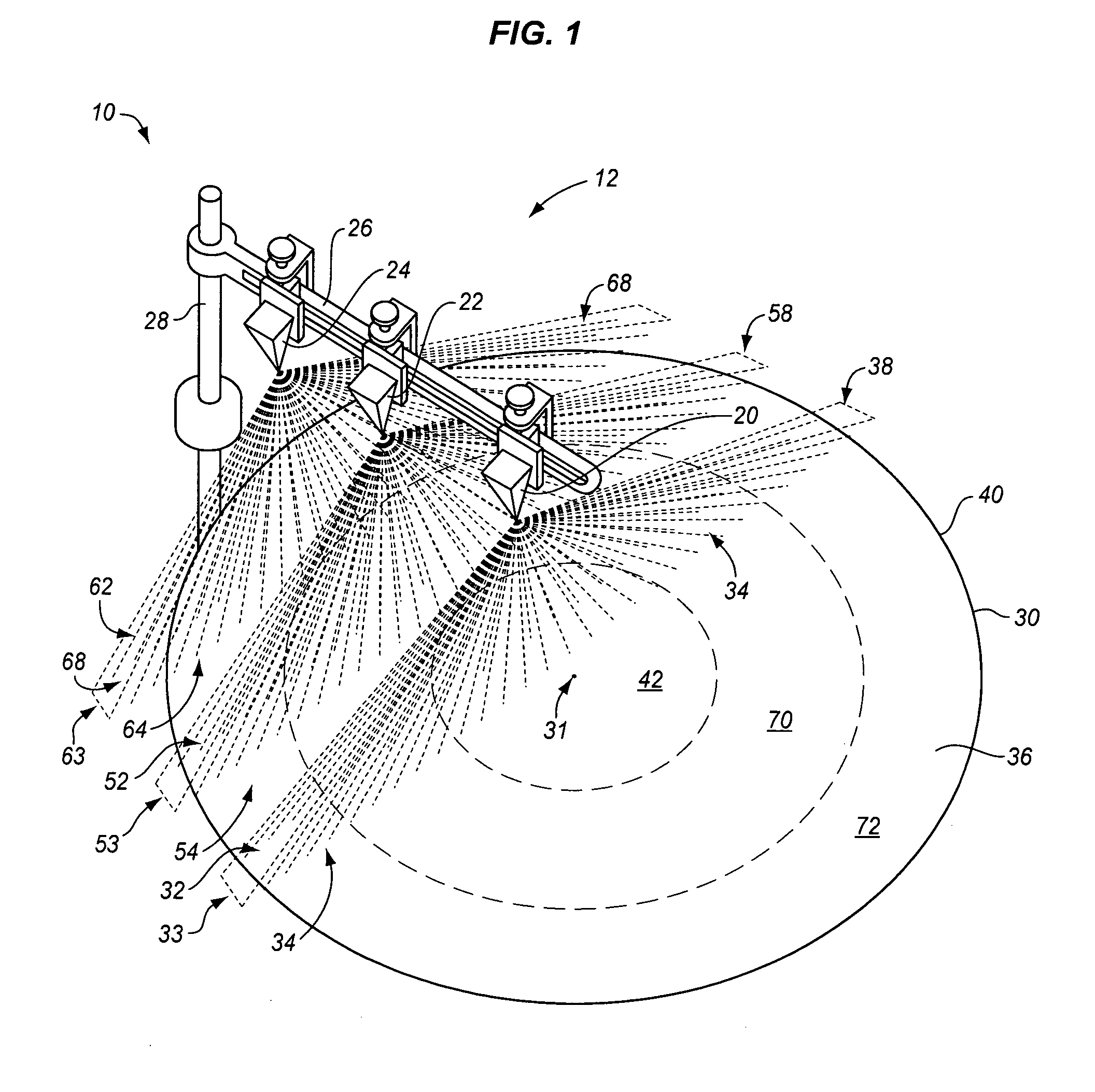

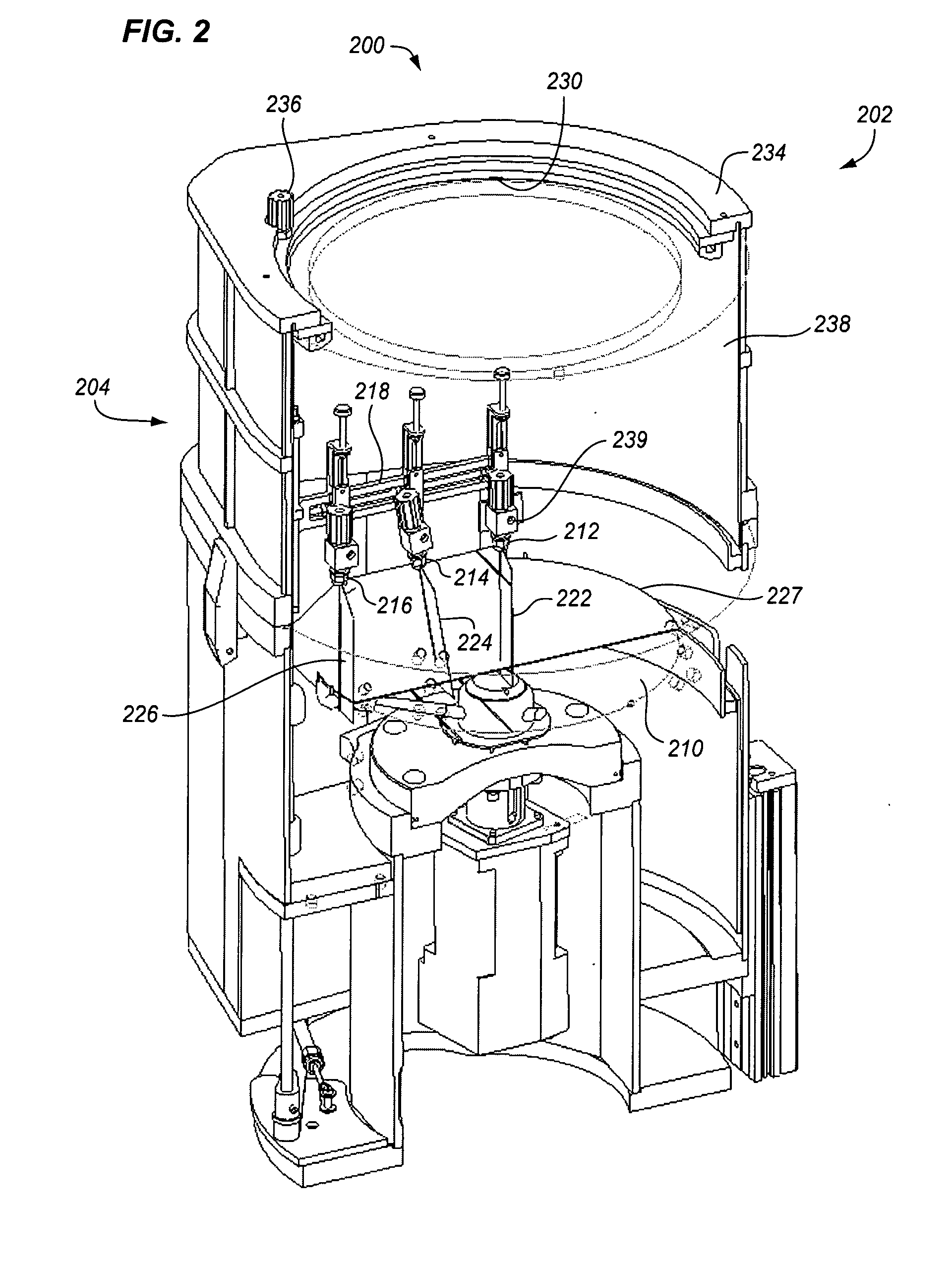

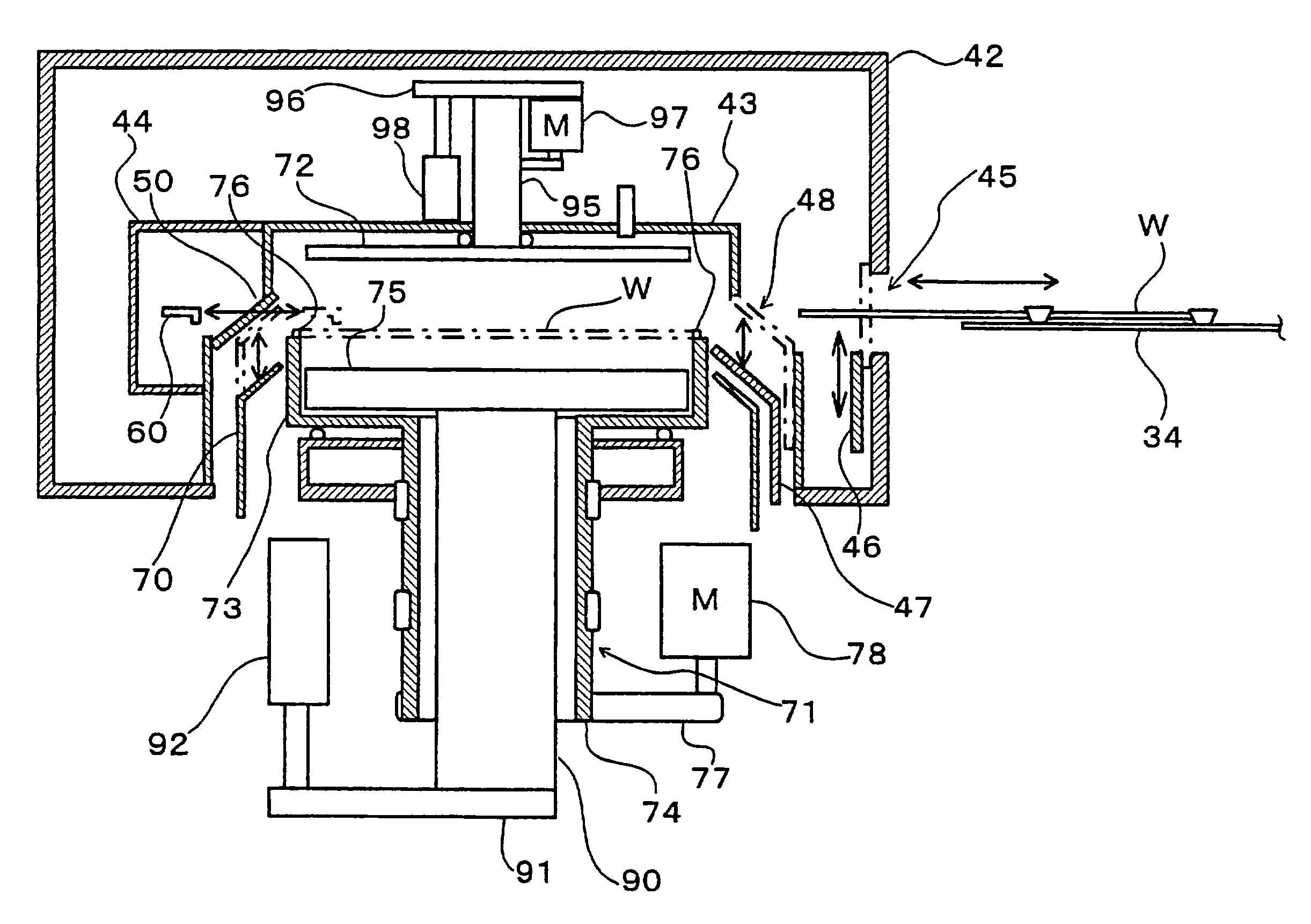

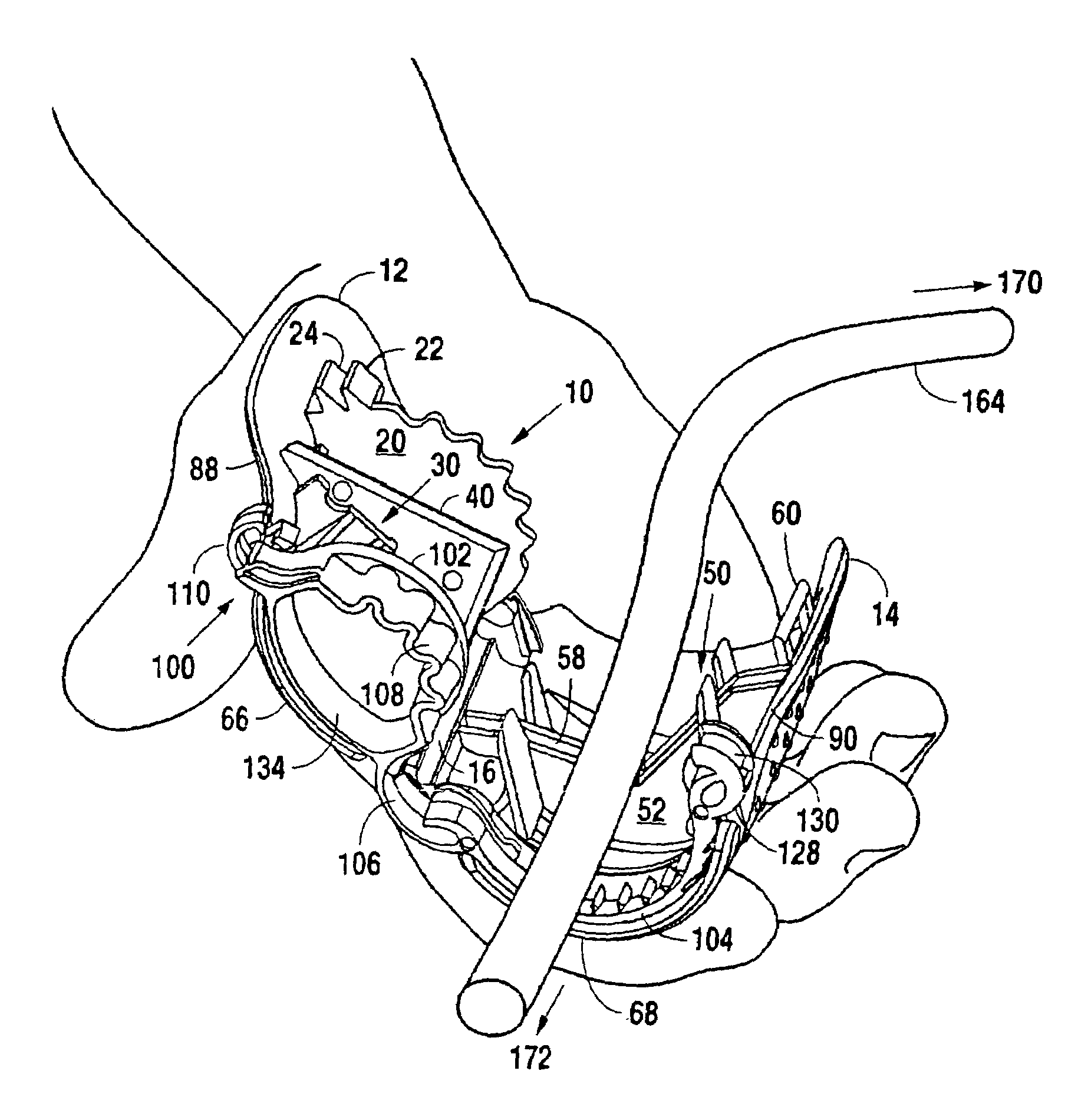

Modulated metal removal using localized wet etching

ActiveUS20100029088A1Prevent splashQuantity maximizationDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceBand shape

An apparatus for wet etching metal from a semiconductor wafer comprises a wafer holder for rotating a wafer and a plurality of nozzles for applying separate flow patterns of etching liquid to the surface of the wafer. The flow patterns impact the wafer in distinct band-like impact zones. The flow pattern of etching liquid from at least one nozzle is modulated during a total etching time control the cumulative etching rate in one local etch region relative to the cumulative etching rate in one or more other local etch regions. Some embodiments include a lower etch chamber and an upper rinse chamber separated by a horizontal splash shield. Some embodiments include a retractable vertical splash shield used to prevent splashing of etching liquid onto the inside walls of a treatment container. An etch-liquid delivery system includes a plurality of nozzle flow paths having corresponding nozzle flow resistances, and a plurality of drain flow paths having corresponding drain flow resistances. Nozzle flow resistances and drain flow resistances are matched so that switching the flow from a nozzle to a corresponding drain flow path does not change the flow rate of etching liquid through other nozzles. A non-wafer-contacting measuring device measures a metal thickness on a rotating semiconductor wafer during metal wet etching by immersing a plurality of electrodes in etching liquid in close proximity to the wafer surface of the rotating wafer and determining electrical resistance between a plurality of electrodes.

Owner:NOVELLUS SYSTEMS

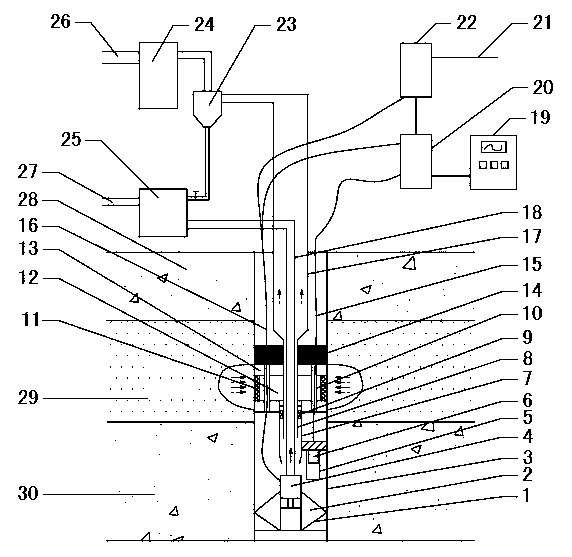

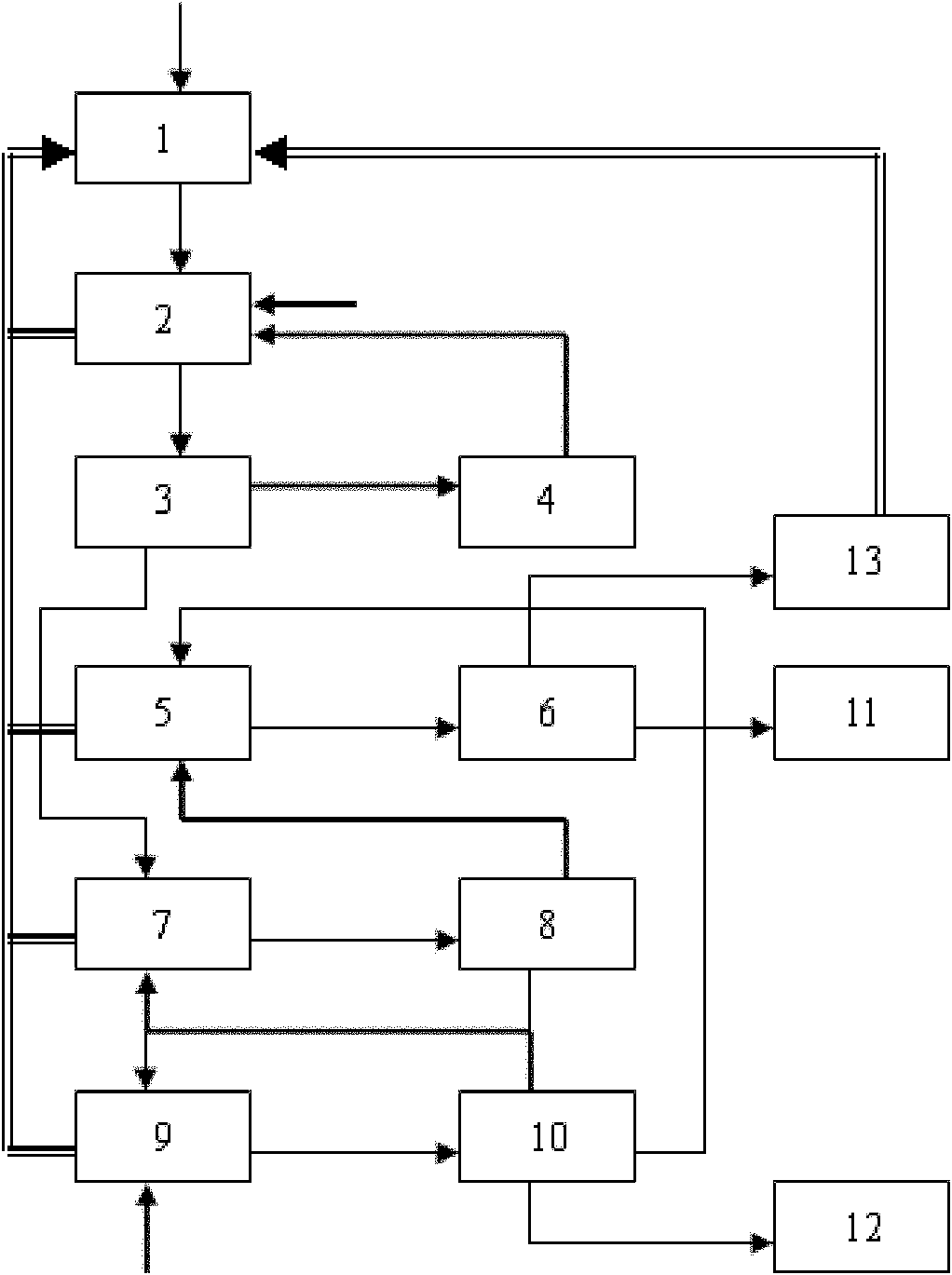

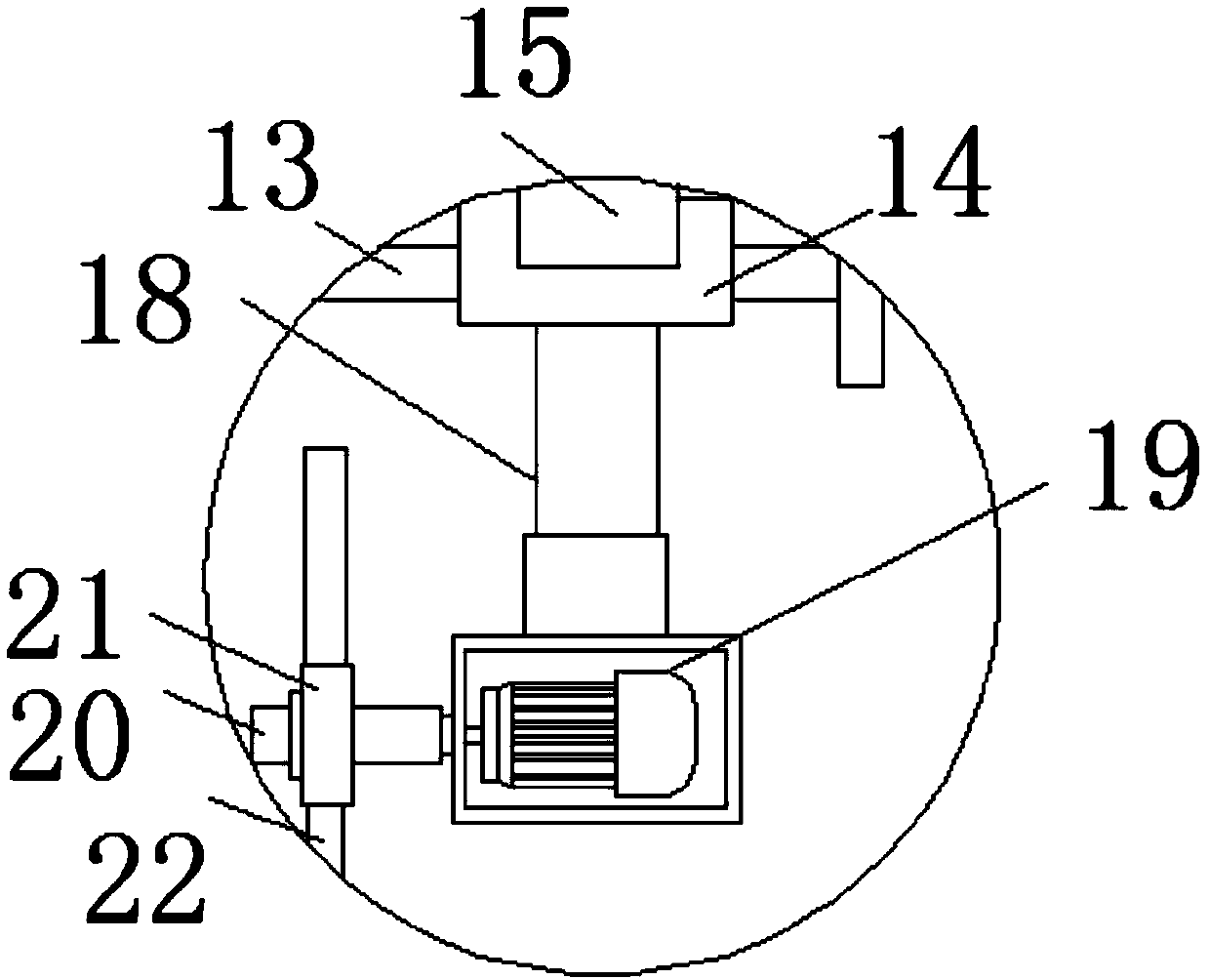

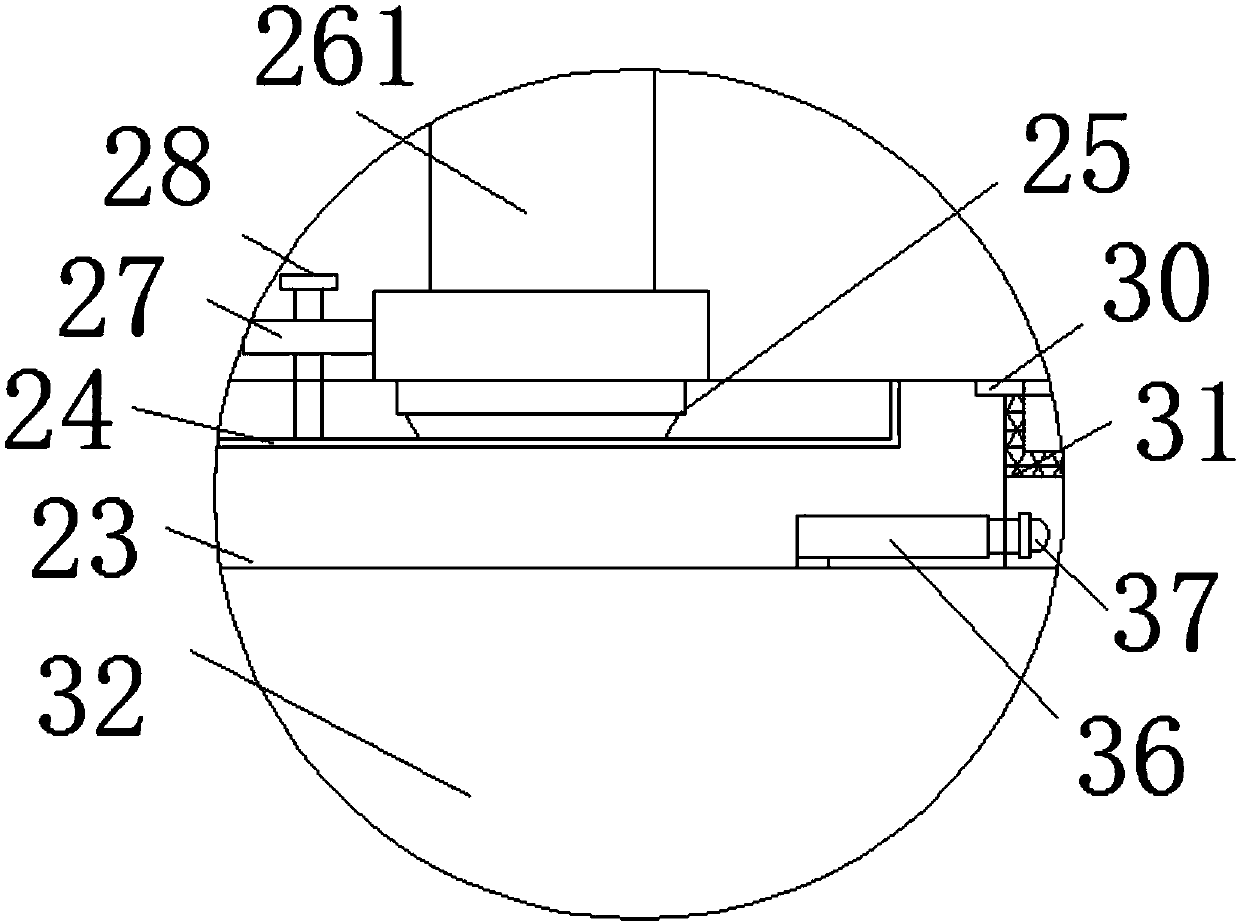

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

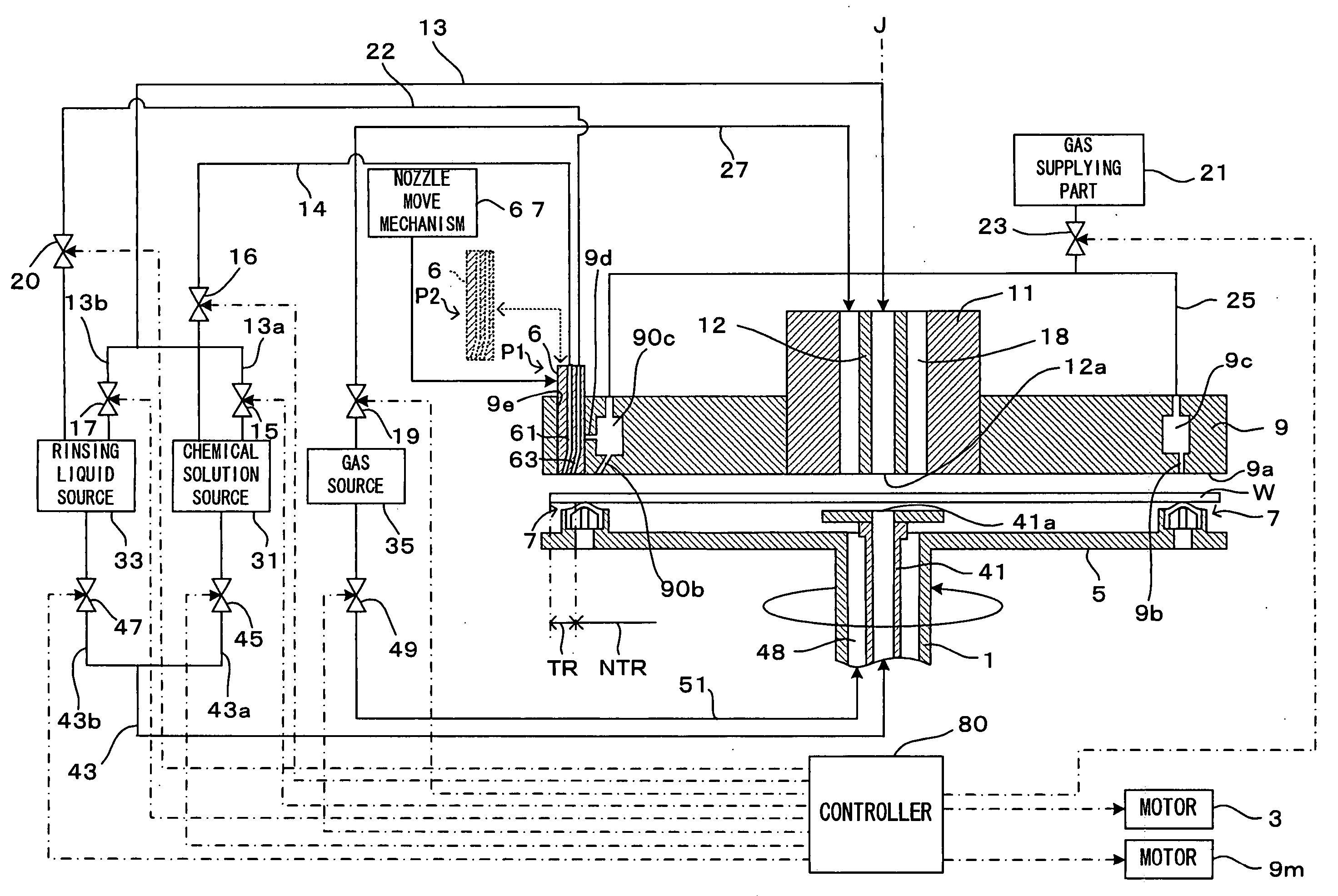

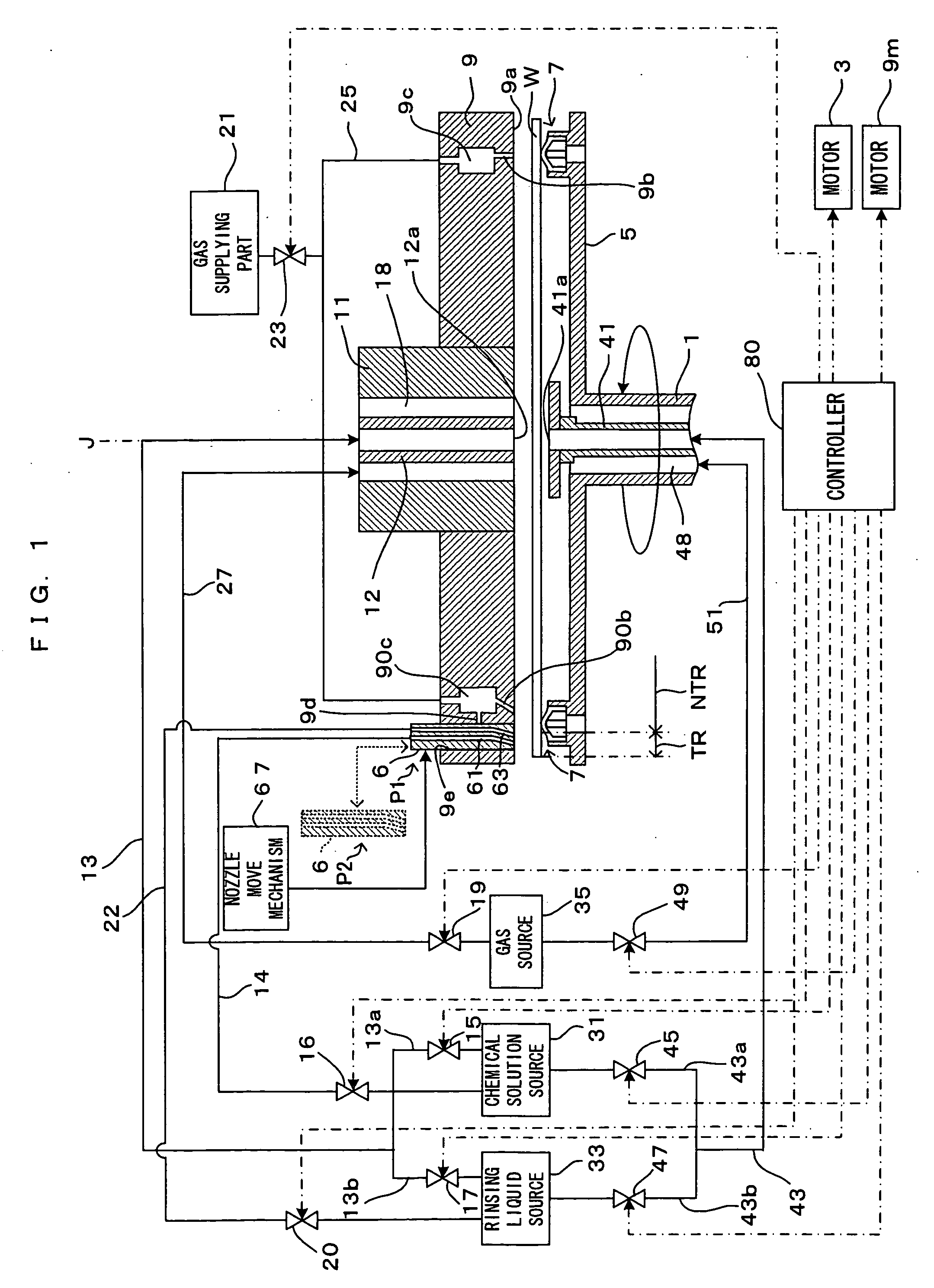

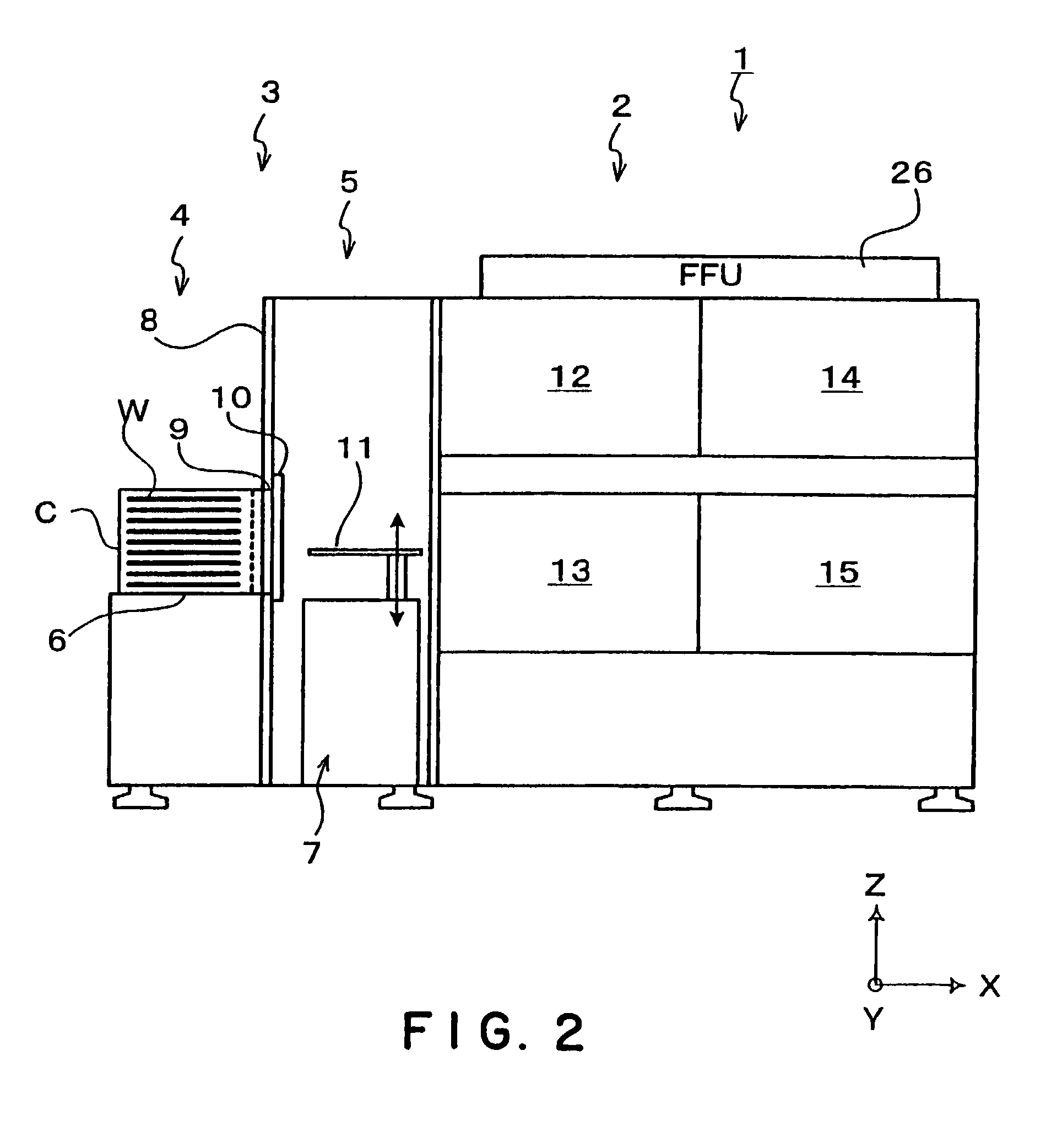

Apparatus for and method of processing a substrate with processing liquid

InactiveUS20060021636A1Reduce widthEasy to makeSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringMechanical engineering

On the top surface of a substrate, an atmosphere blocker plate, of which plan size is equal or larger than the substrate size, is disposed opposing to the top surface of the substrate. In the rim portion of the atmosphere blocker plate, a vertical through hole is formed so that a nozzle can be inserted into the hole. Nozzle move mechanism moves the nozzle to insert the nozzle to the through hole and position it to the opposing position that is opposed to the top rim portion of the substrate and to the retract position that is away from the atmosphere blocker plate. Processing liquid is supplied from the nozzle, which is positioned to the opposing position, to the top rim portion of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

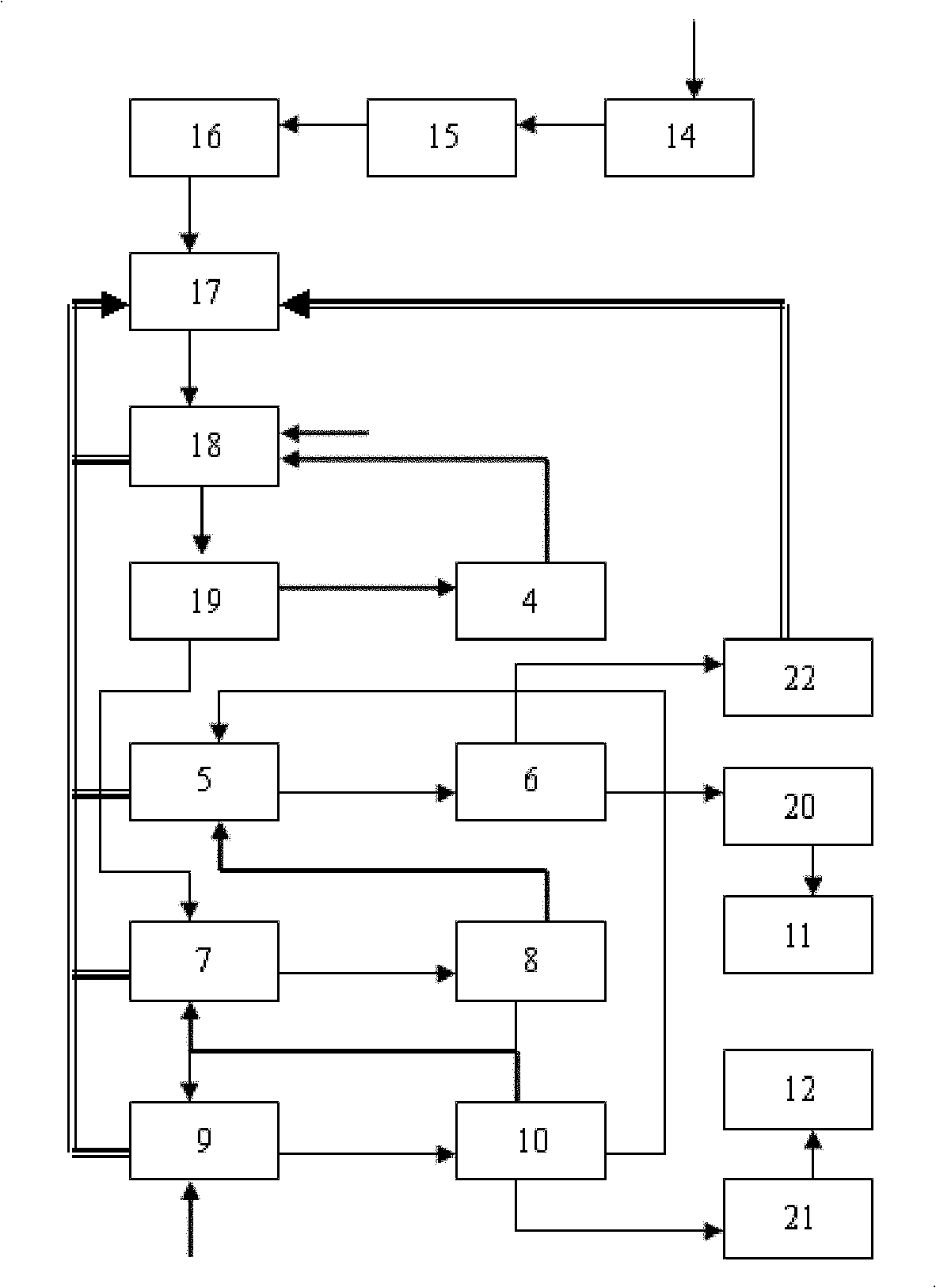

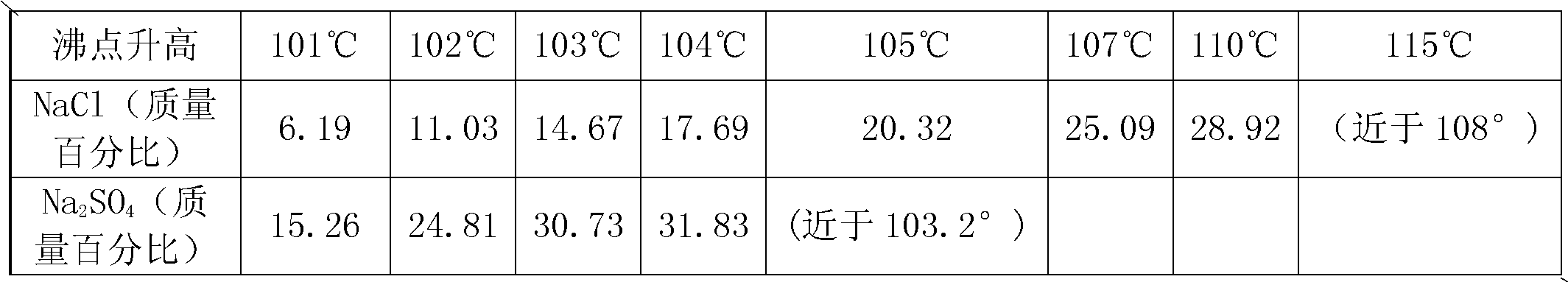

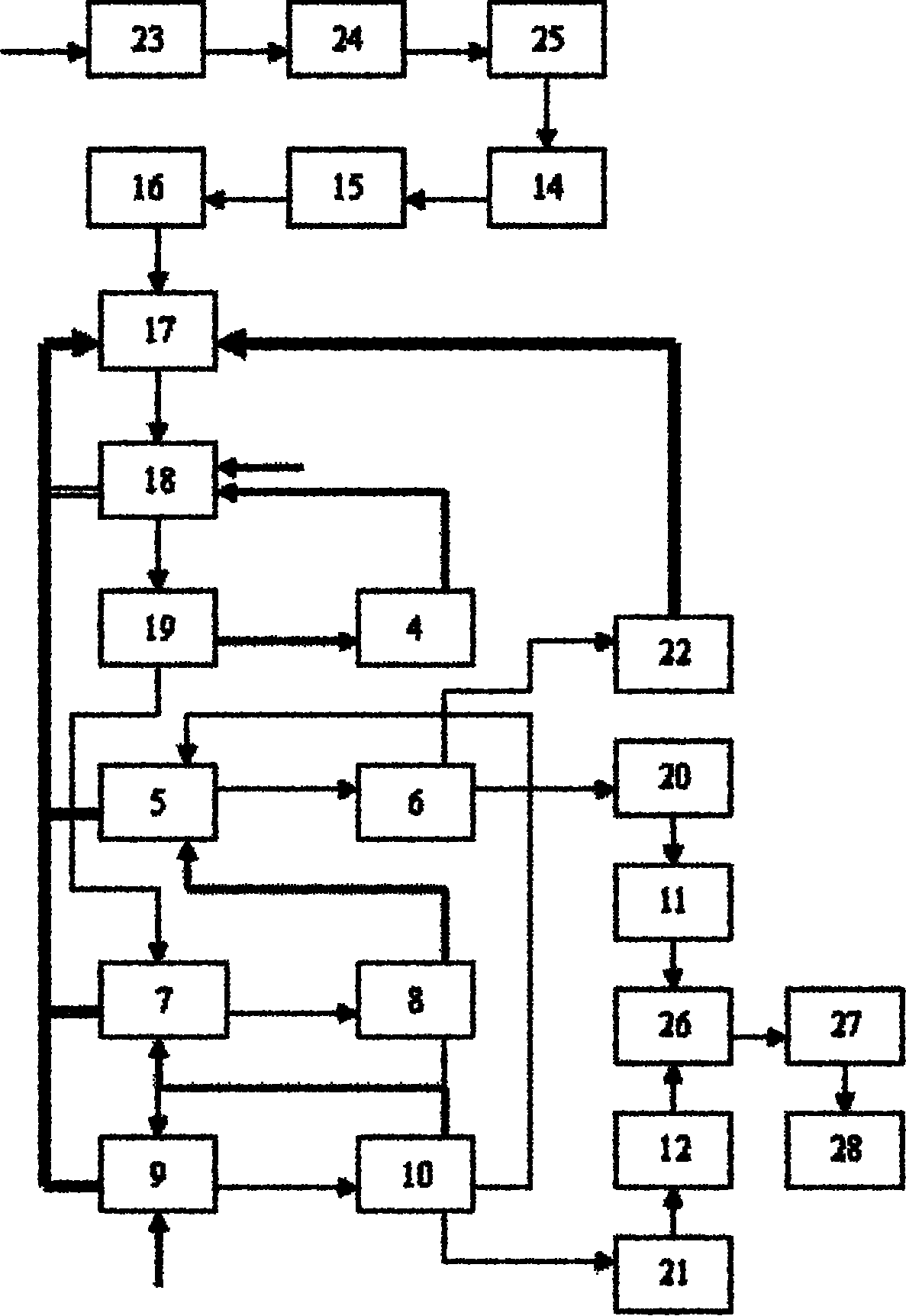

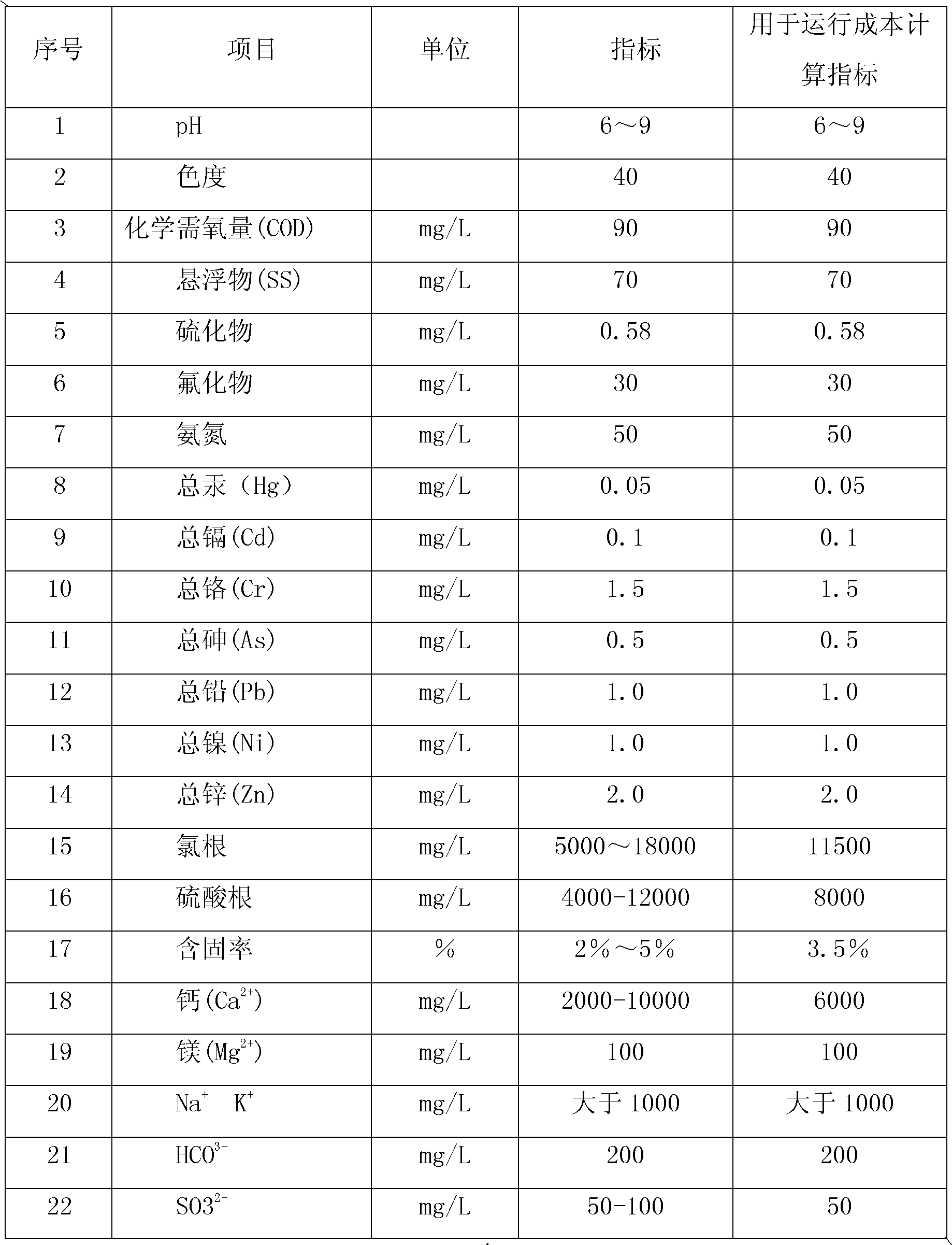

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

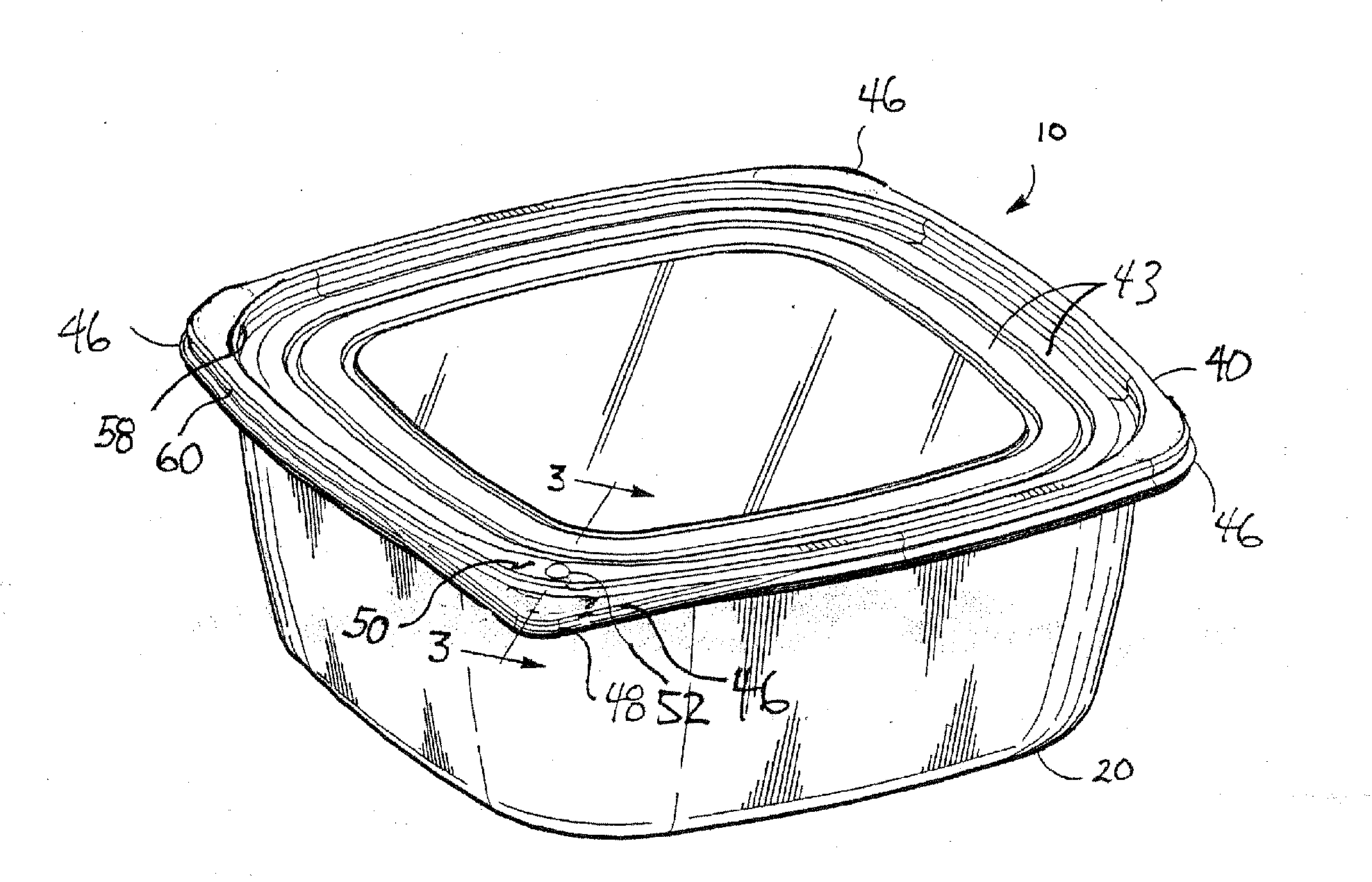

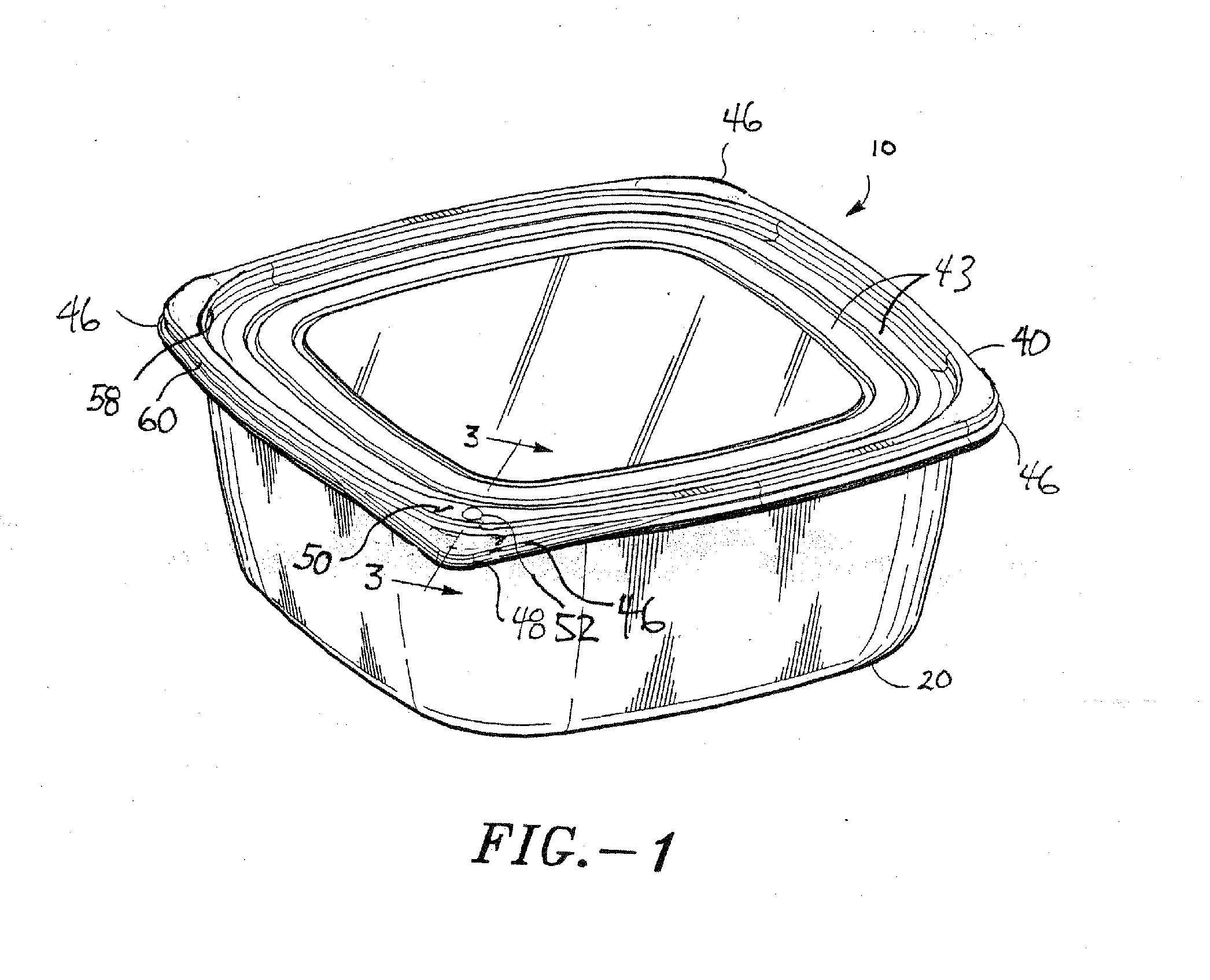

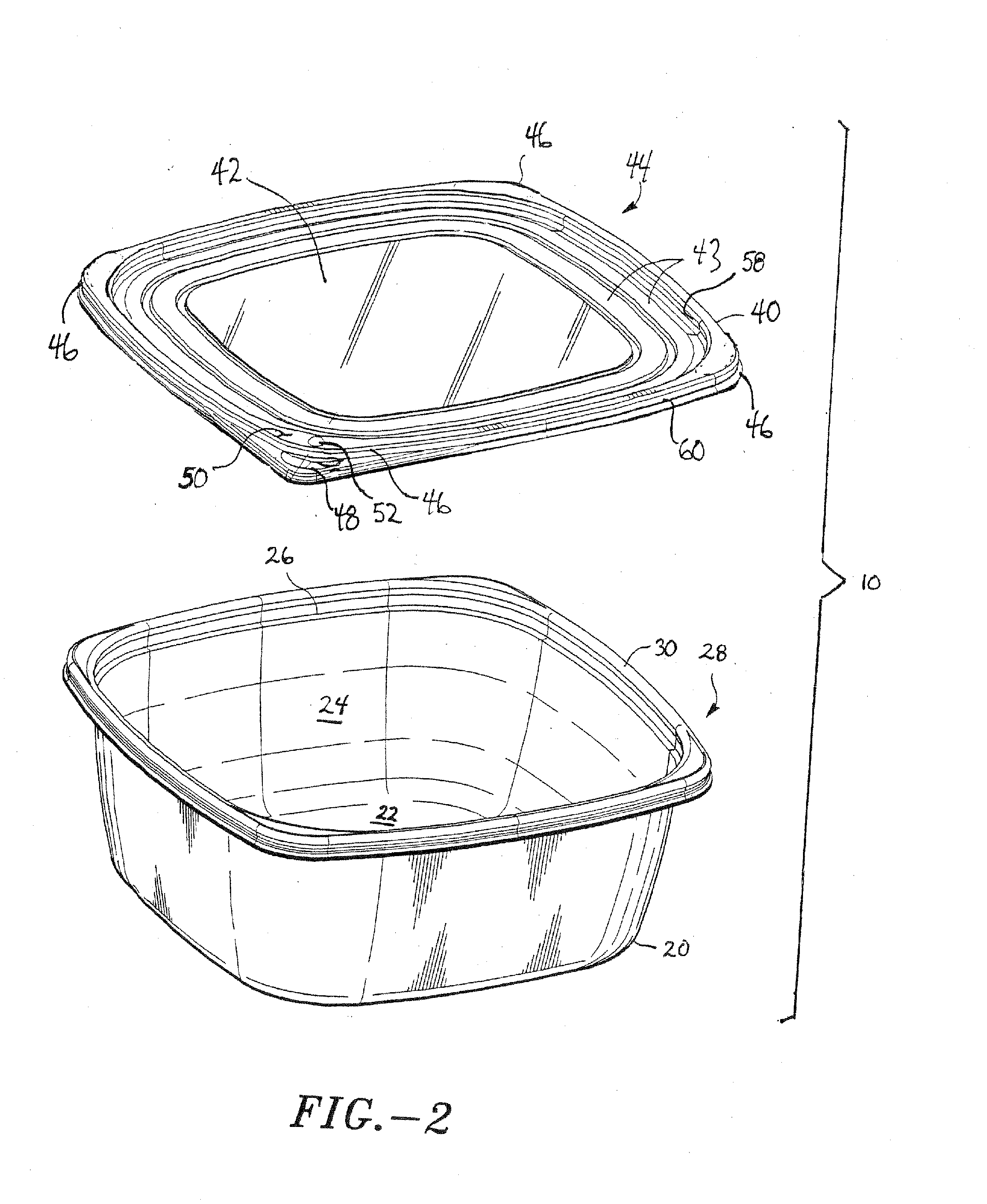

Venting container

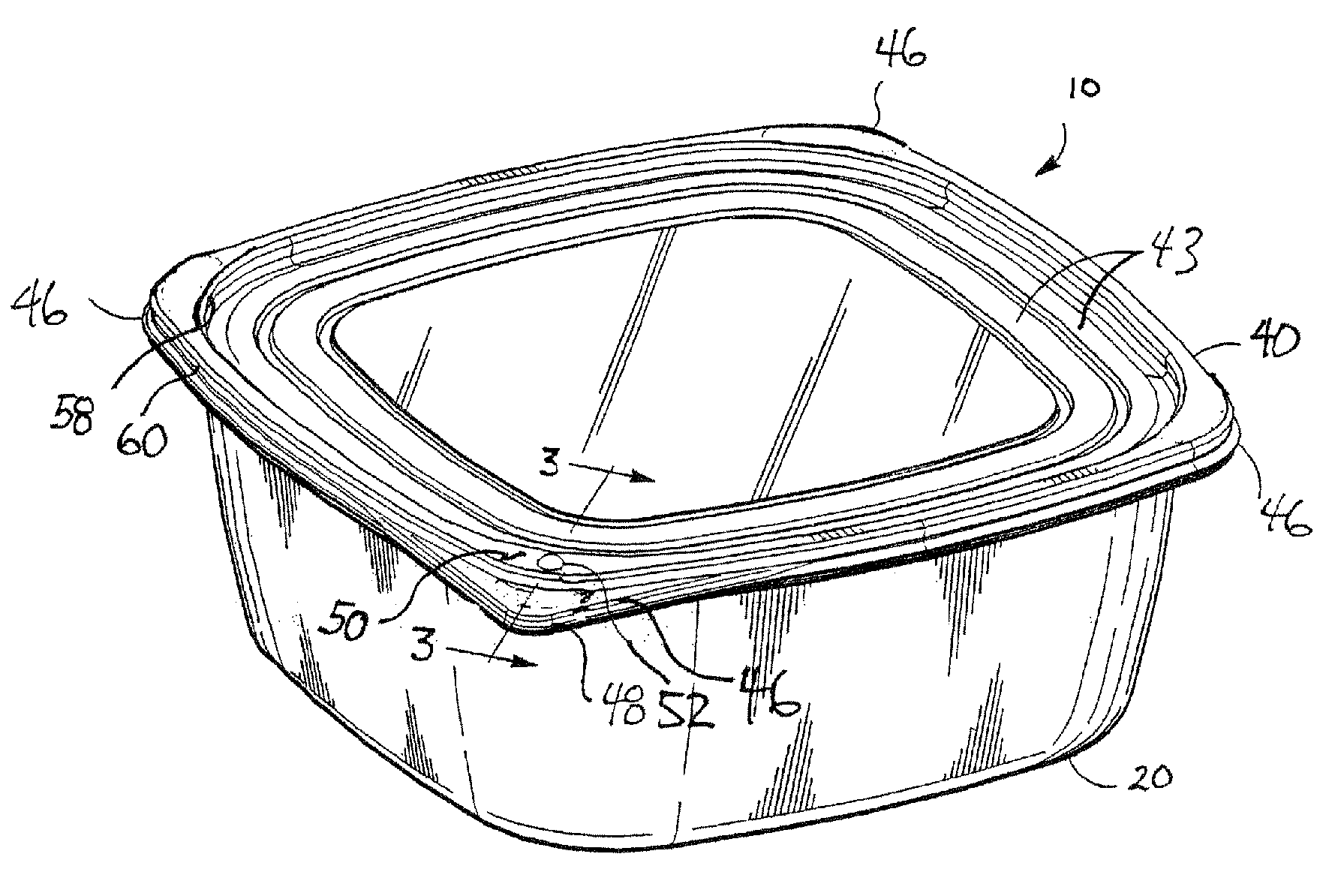

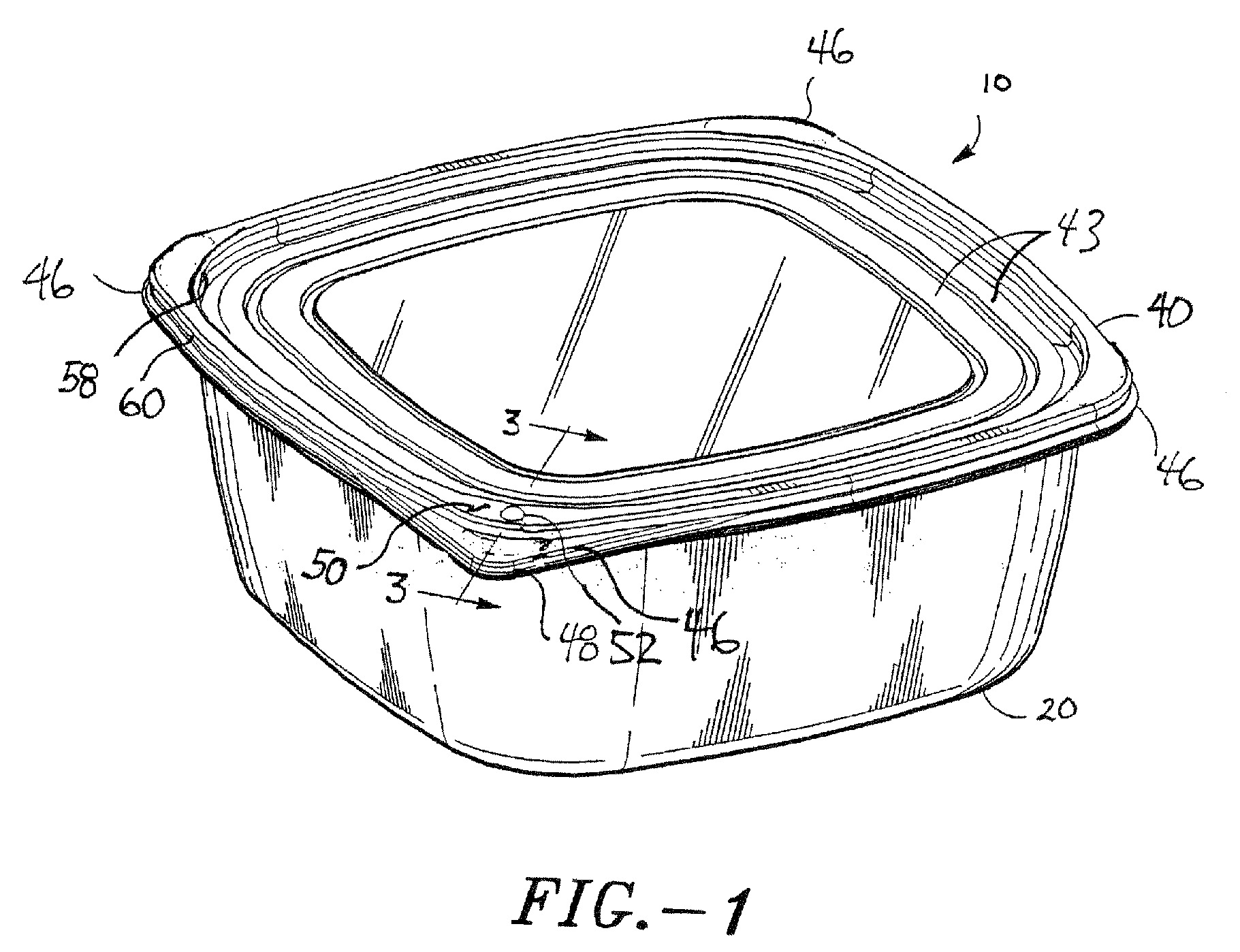

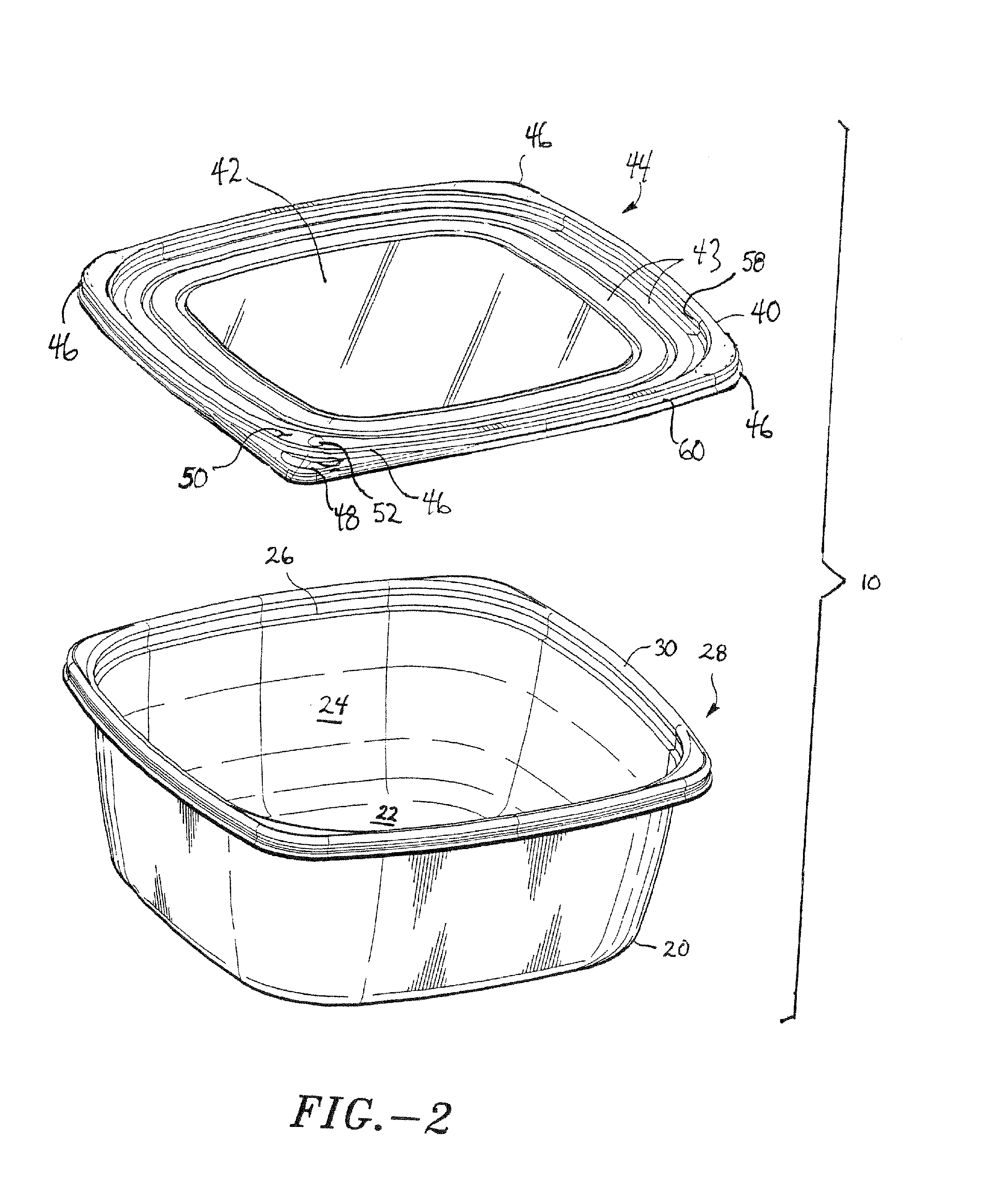

ActiveUS7866502B2Increase volumeReduces and eliminates disadvantage and drawbackCapsClosure capsEngineeringMechanical engineering

A venting container including a lid and base having an inner cavity and a side wall that terminates in a rim, the lid including a central panel and a peripheral sealing lip that surrounds the panel, the peripheral sealing lip having a generally inverted U-shaped cross section that defines a lid channel into which the container rim fits, the sealing lip including at least one venting feature in the form of a flexible venting button that is adapted to transition from a first position to a second position upon application of an actuation force, the venting button being further adapted and positioned whereby when the container rim is positioned in the lid channel and the venting button is in the first position, sealed engagement of the lid to the container is effectuated and when the venting button is in the second position a venting air passage is provided from the container cavity to the container surroundings. In a second embodiment, the venting feature is in the form of a downwardly protruding venting boss provided to the lid closure and a boss seat formed in the base closure whereby the venting boss is received with the boss seat when the lid is oriented in a first non venting attachment position and the venting boss abuts against a surface of the base closure to provide a vent passage between the lid and base upon removal and repositioning of the lid to a second venting attachment position.

Owner:THE GLAD PROD CO

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

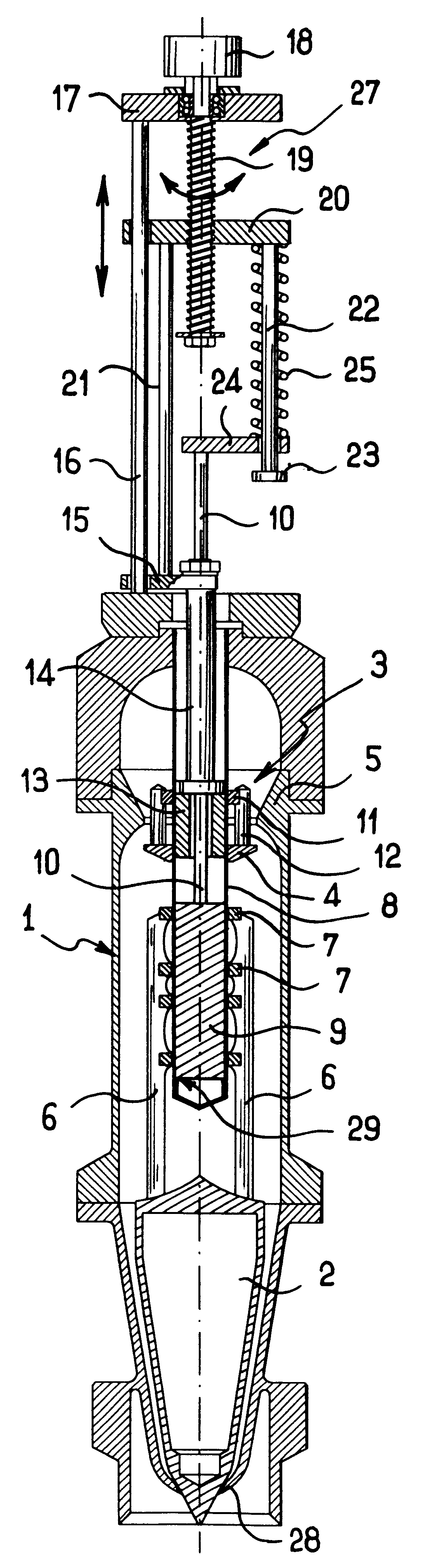

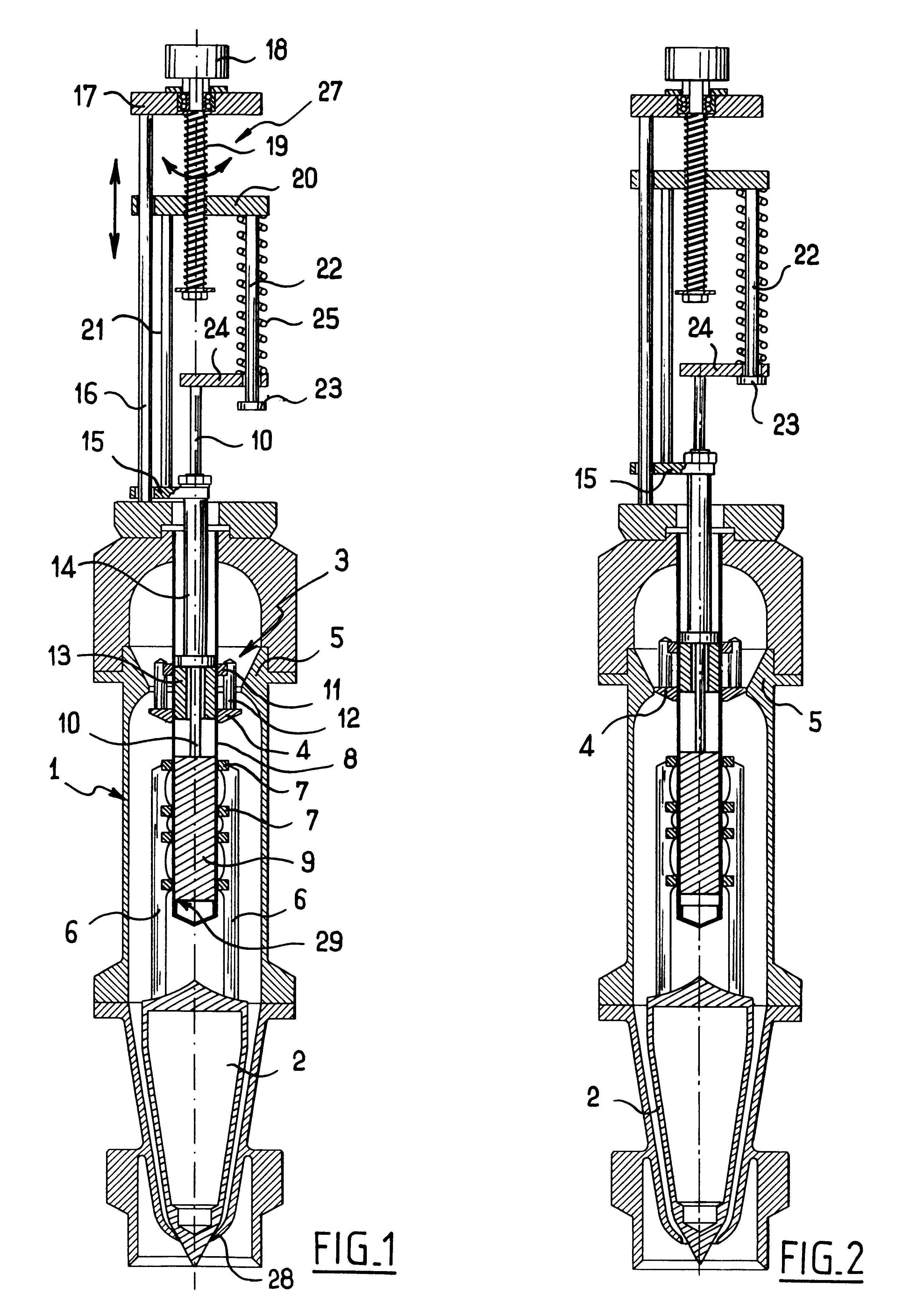

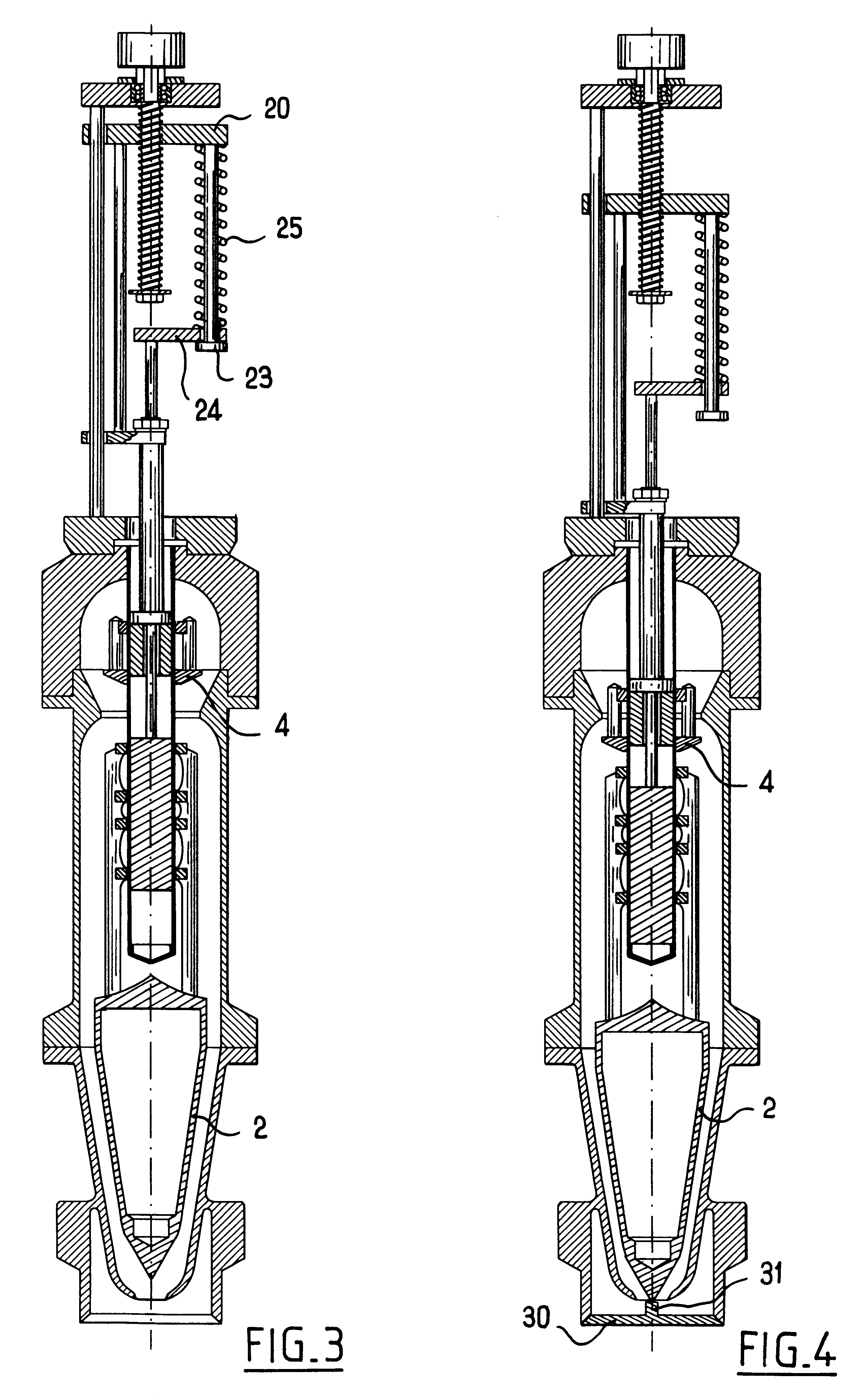

Filling spout whose flow rate can be adjusted by a single actuator device

InactiveUS6375050B1Risk minimizationDeformation MinimizationLiquid fillingOperating means/releasing devices for valvesEngineeringActuator

A filling spout having an adjustable flow rate and comprising a valve body receiving a valve member extending facing a valve seat, and a flow-rate adjustment member disposed upstream from the valve member and extending in register with a constriction in the valve body, the valve member and the flow-rate adjustment member being connected to a single actuator device via means allowing limited axial movement by enabling the adjustment member and the valve member to move axially relative to each other to a limited extent.

Owner:SERAC GROUP

Diamond marking

InactiveUS6391215B1Good resolutionControl depthBranding equipmentCellsElectrically conductiveGemstone

An information mark invisible to the naked eye is applied to the polished facet of a diamond gemstone by coating the diamond gemstone surface with an electrically conductive layer so as to prevent the diamond becoming charged, forming the mark with a focused ion beam, and cleaning the diamond surface with a powerful oxidizing agent to reveal a mark having an appropriate depth, which does not detrimentally affect the clarity or color grade of the diamond.

Owner:DE BEERS UK LTD

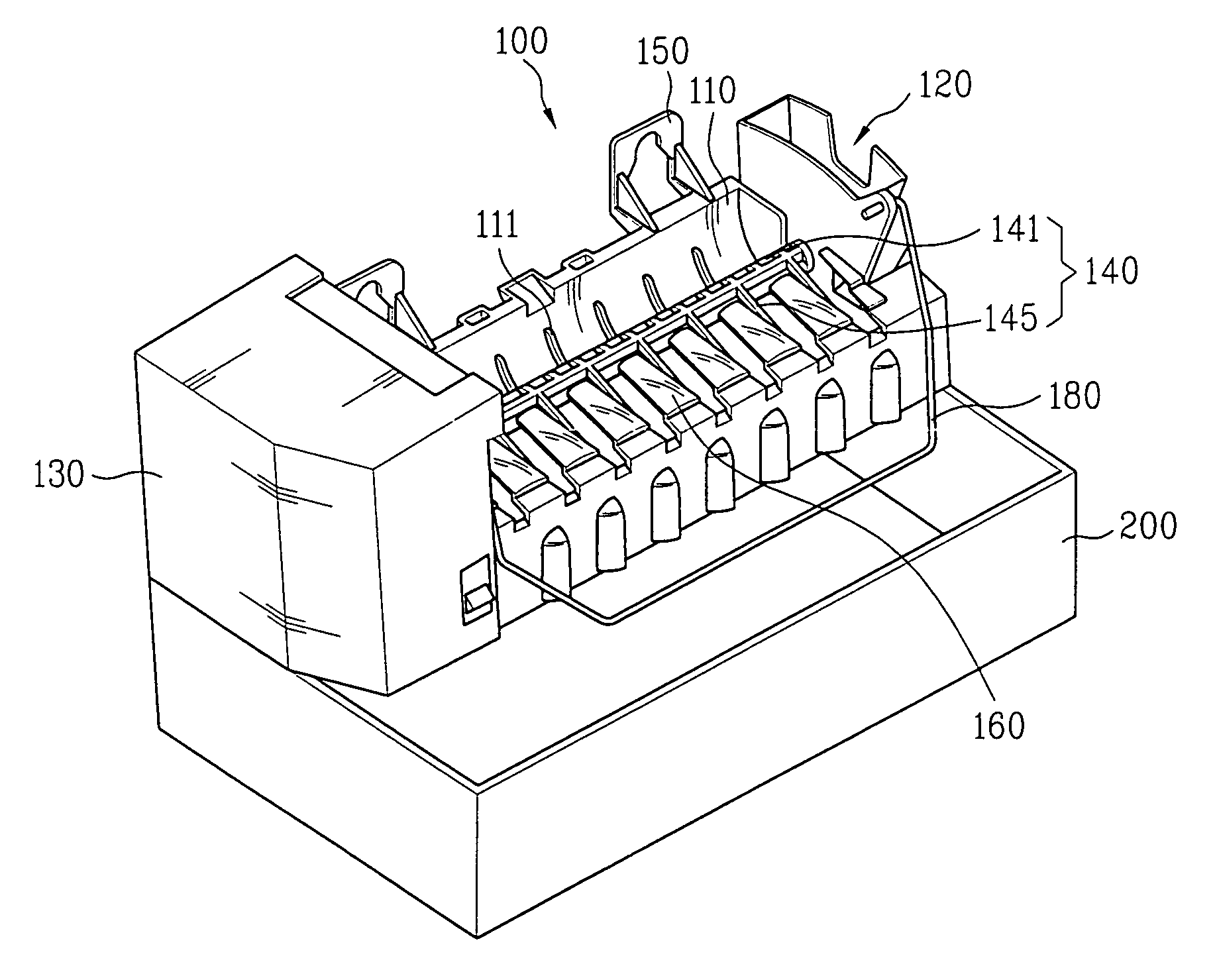

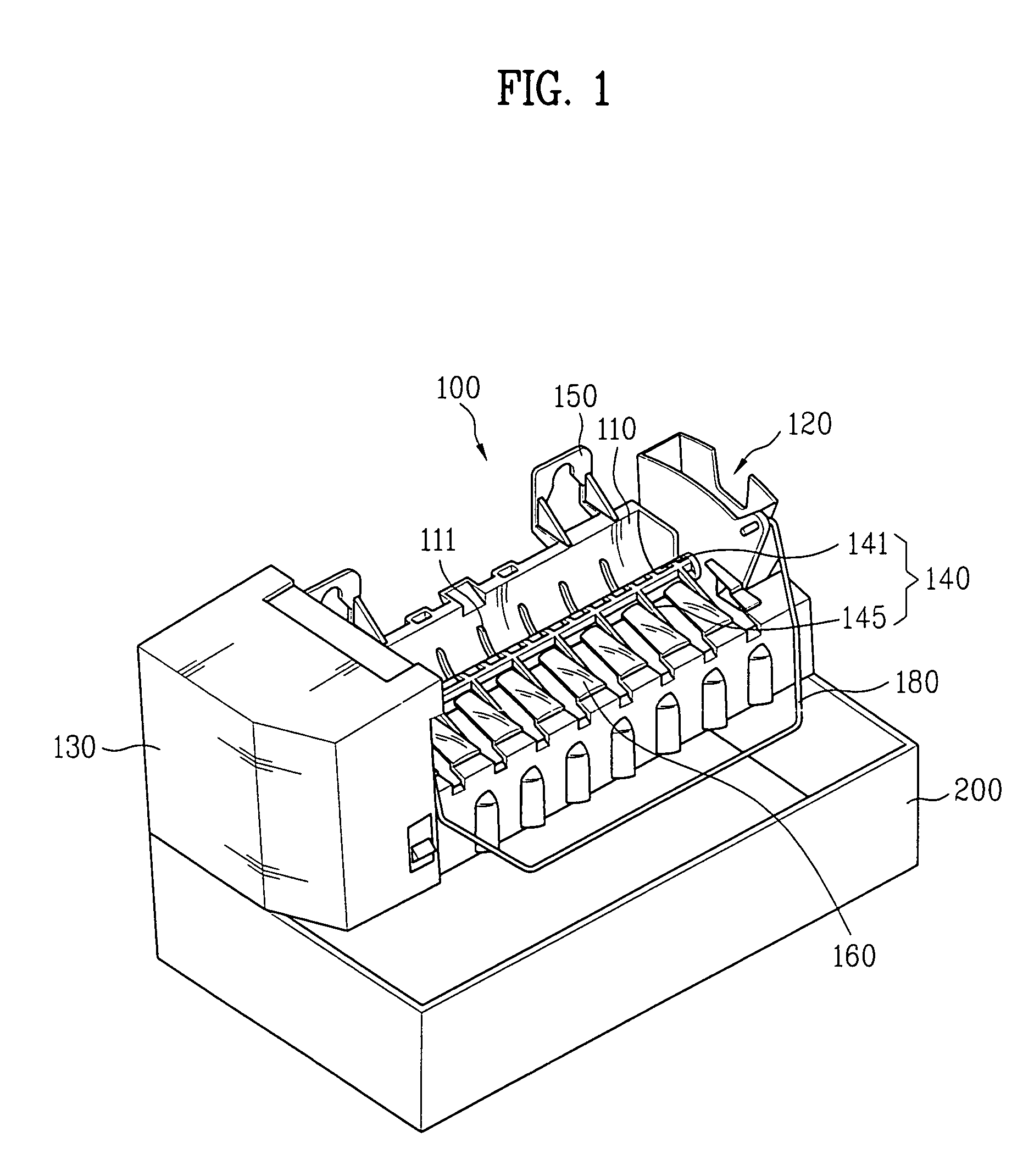

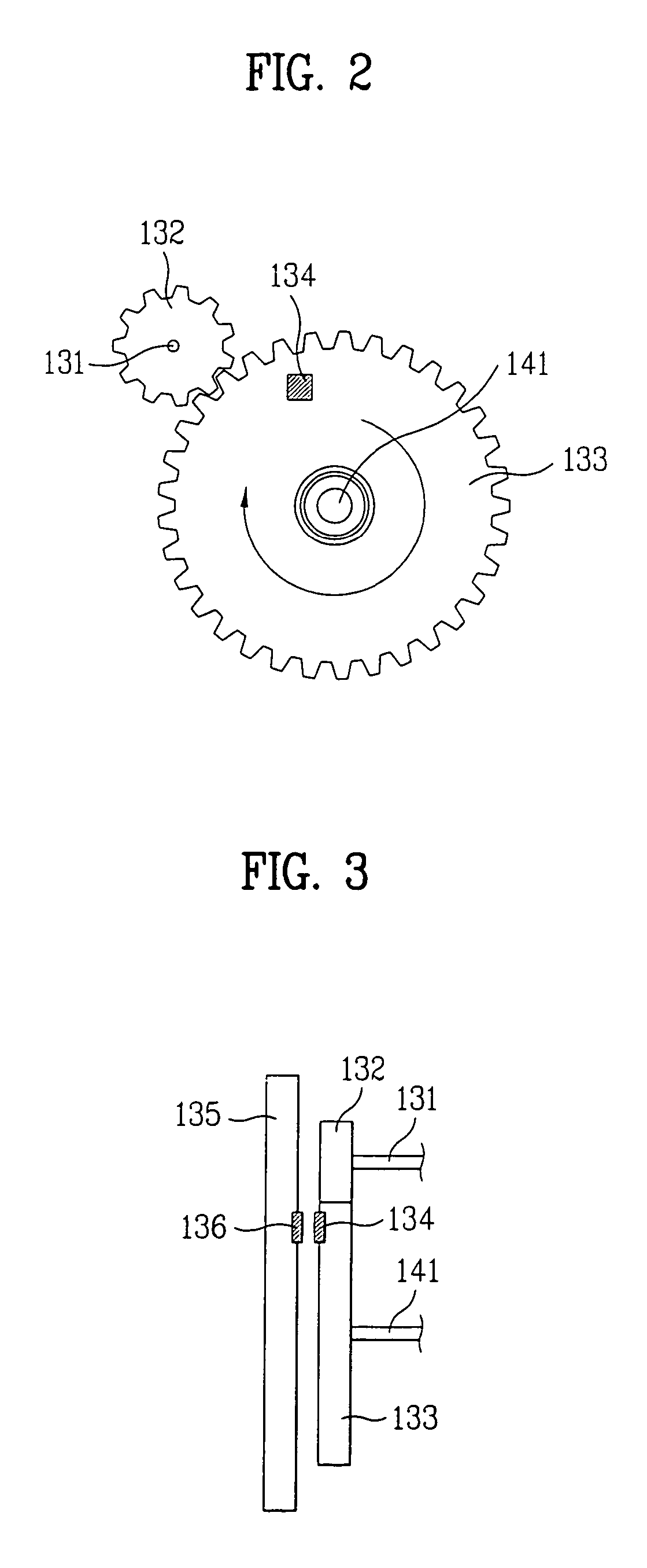

Icemaker in refrigerator

ActiveUS7051541B2Easy to take outSimple structureLighting and heating apparatusIce productionEngineeringRefrigerated temperature

Icemaker in a refrigerator for making ice automatically is disclosed. The icemaker in includes an ice tray provided to a door on the refrigerator for holding water, an ejector fitted adjacent to the ice tray so as to be rotatable by a motor for ejecting ice from the ice tray, means for detecting a rotation angle of the ejector, and a control part for controlling a rotation direction of the ejector based on information detected at the means.

Owner:LG ELECTRONICS INC

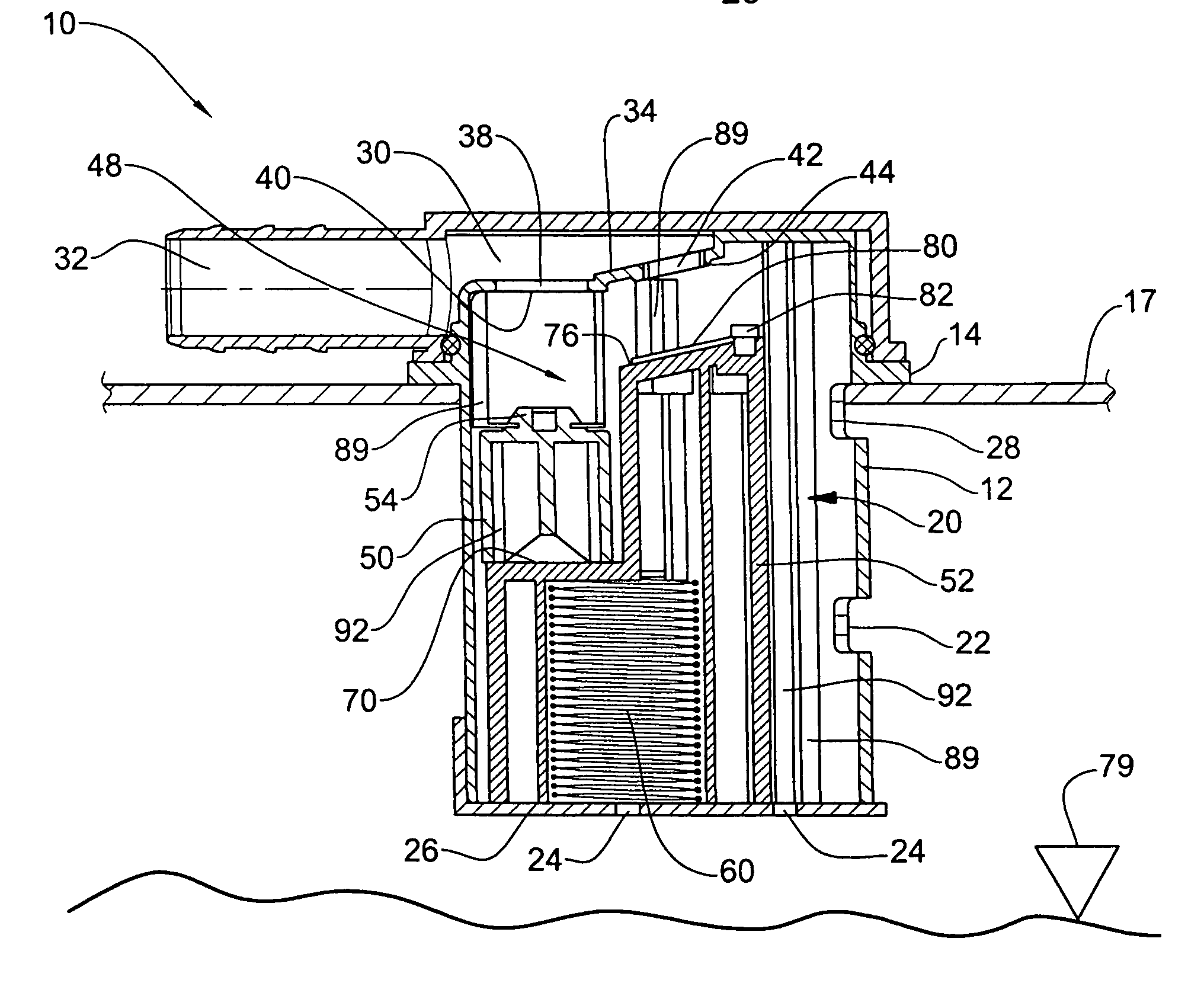

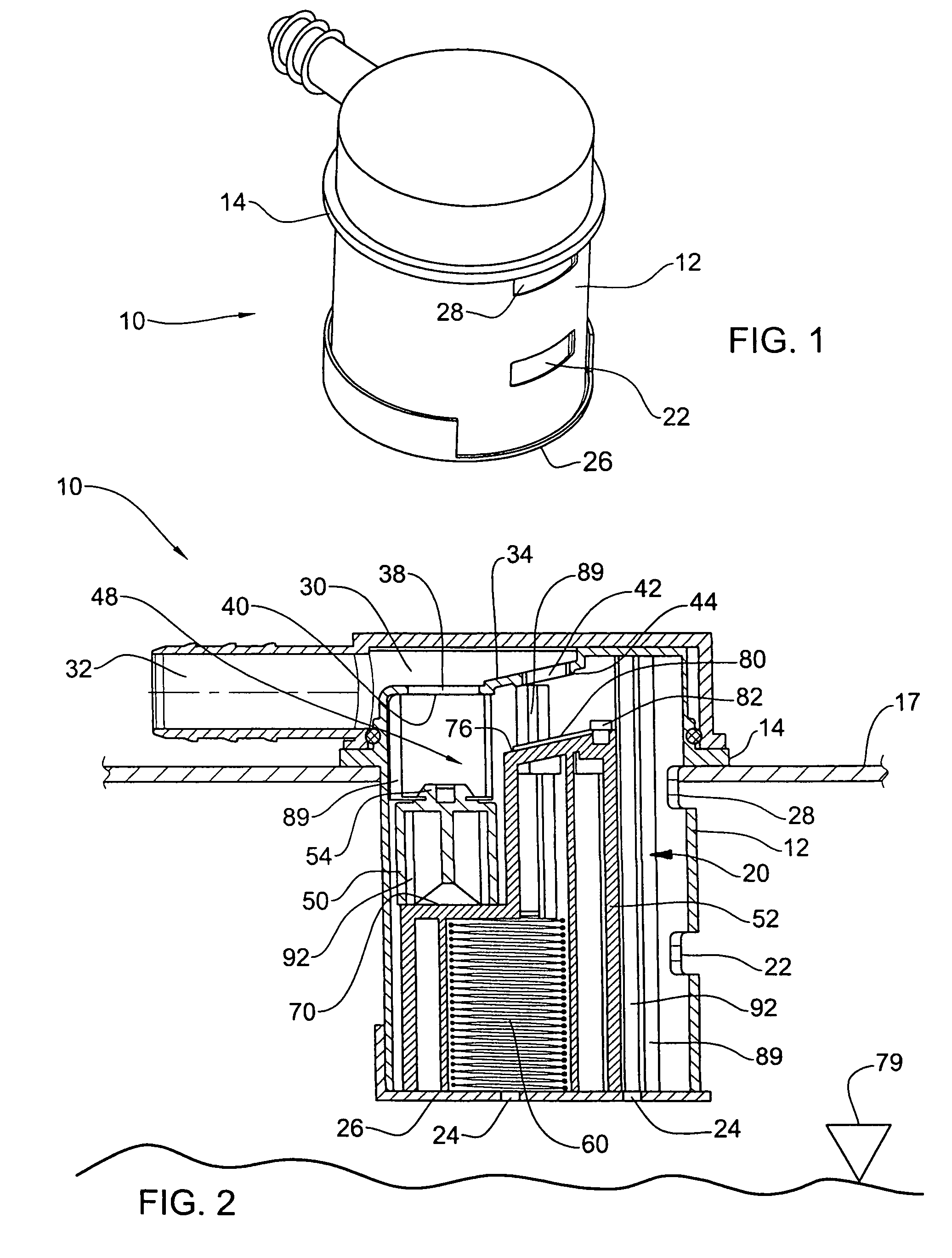

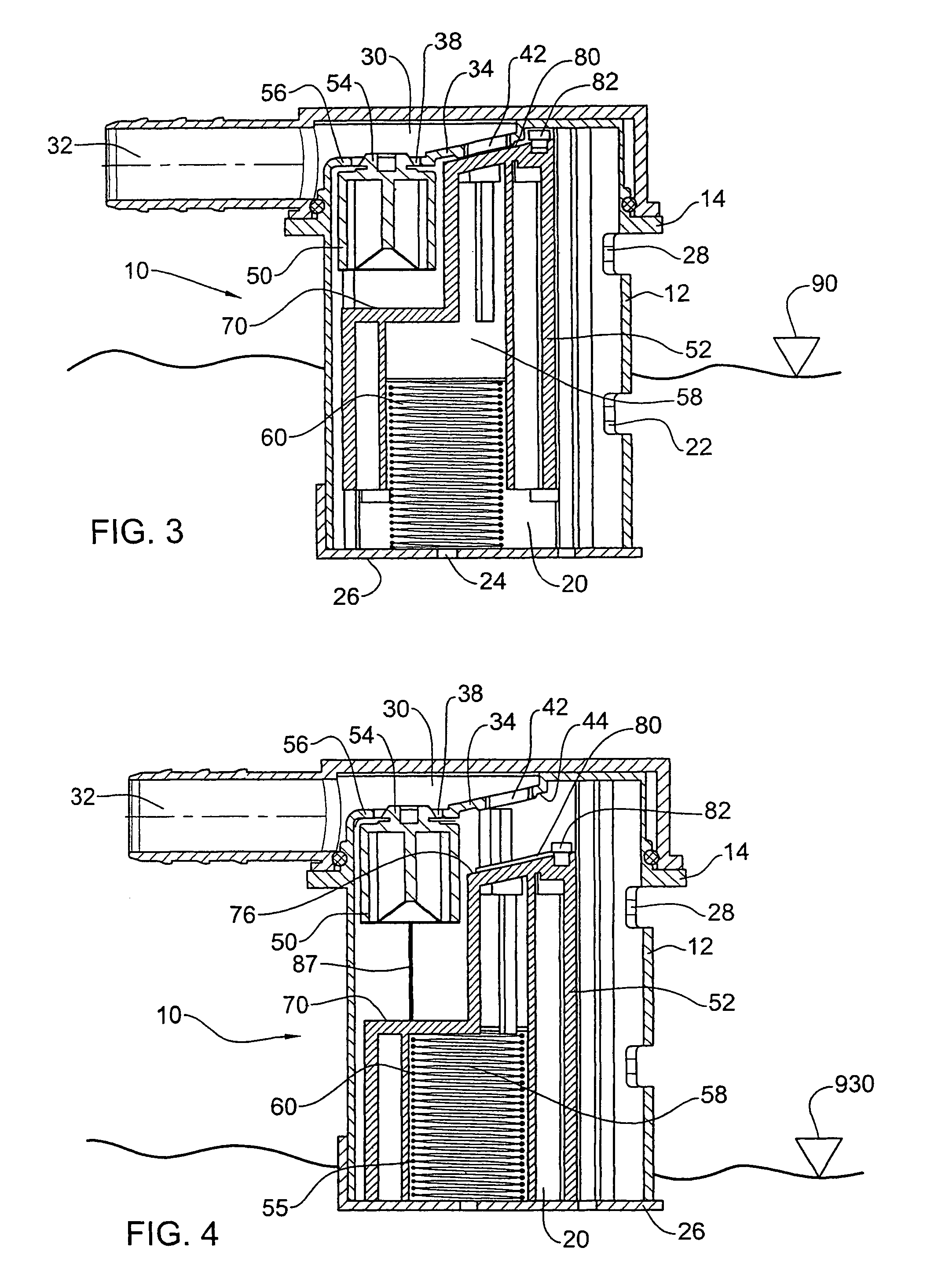

Dual function valve for fuel tank

ActiveUS7207347B2Improve sealingPrevent splashLarge containersEqualizing valvesFuel tankDual function

Owner:RAVAL - AGRI COOP SOCIETIES

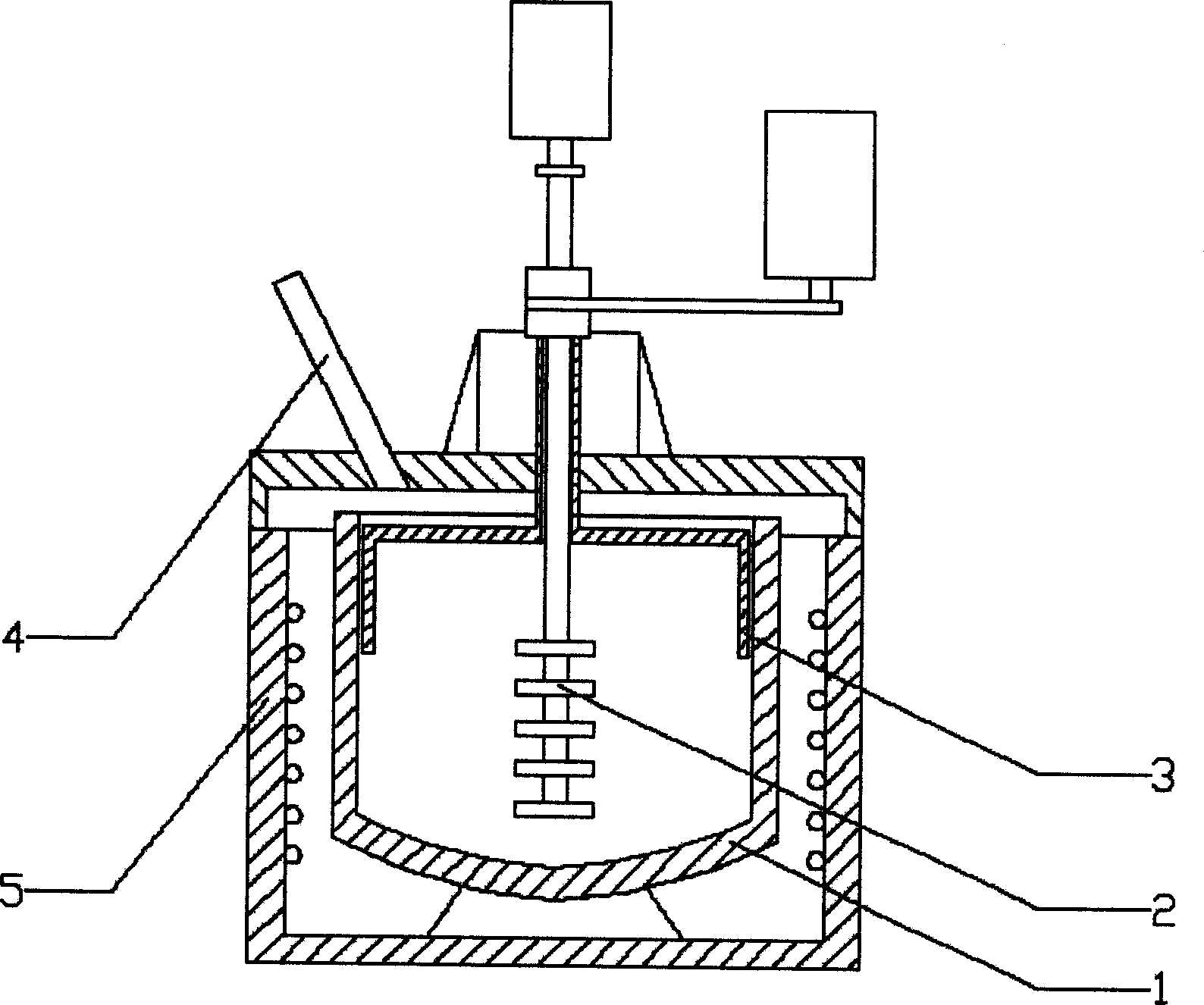

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

The present invention relates to a vacuum mechanical double-stirring casting method for preparing granule reinforced aluminium base composite material. Said method includes the following steps: melting and purifying aluminium material, cooling and deslagging; under the condition of vacuum reverse slowly internal stirring to implement degassing process, adding the pretreated reinforcing granules onto the deslagged aluminium liquid surface, internal and external forward simultaneously stirring, mixing the reinforcing granules into the melt, stoping external stirring, under the condition of retaining stable liquid surface high-speed internal stirring so as to make the reinforcing granules be uniformly distributed in the liquid, heating, internal and external reverse double stirring and slowly rotating to implement degassing; adding alternant and fining agent, internal stirring slowly rotating so as to make them be mixed into melt and uniformly distributed, removing vacuum, tapping and casting to obtain ingot casting.

Owner:BEIJING JIAOTONG UNIV

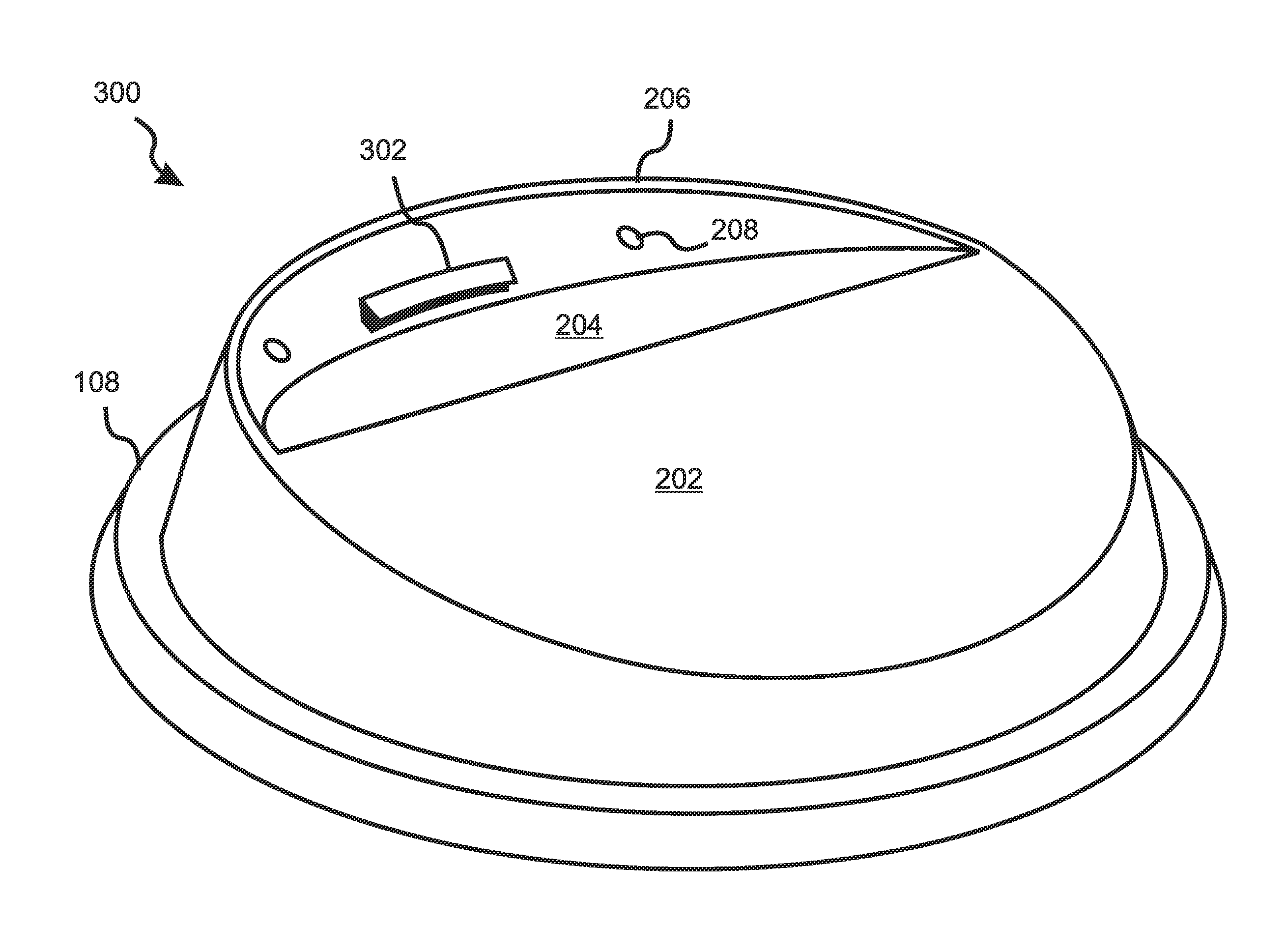

Venting Container

ActiveUS20080197134A1Increase volumeReduces and eliminates disadvantage and drawbackCapsClosure capsEngineeringMechanical engineering

A venting container including a lid and base having an inner cavity and a side wall that terminates in a rim, the lid including a central panel and a peripheral sealing lip that surrounds the panel, the peripheral sealing lip having a generally inverted U-shaped cross section that defines a lid channel into which the container rim fits, the sealing lip including at least one venting feature in the form of a flexible venting button that is adapted to transition from a first position to a second position upon application of an actuation force, the venting button being further adapted and positioned whereby when the container rim is positioned in the lid channel and the venting button is in the first position, sealed engagement of the lid to the container is effectuated and when the venting button is in the second position a venting air passage is provided from the container cavity to the container surroundings. In a second embodiment, the venting feature is in the form of a downwardly protruding venting boss provided to the lid closure and a boss seat formed in the base closure whereby the venting boss is received with the boss seat when the lid is oriented in a first non venting attachment position and the venting boss abuts against a surface of the base closure to provide a vent passage between the lid and base upon removal and repositioning of the lid to a second venting attachment position.

Owner:THE GLAD PROD CO

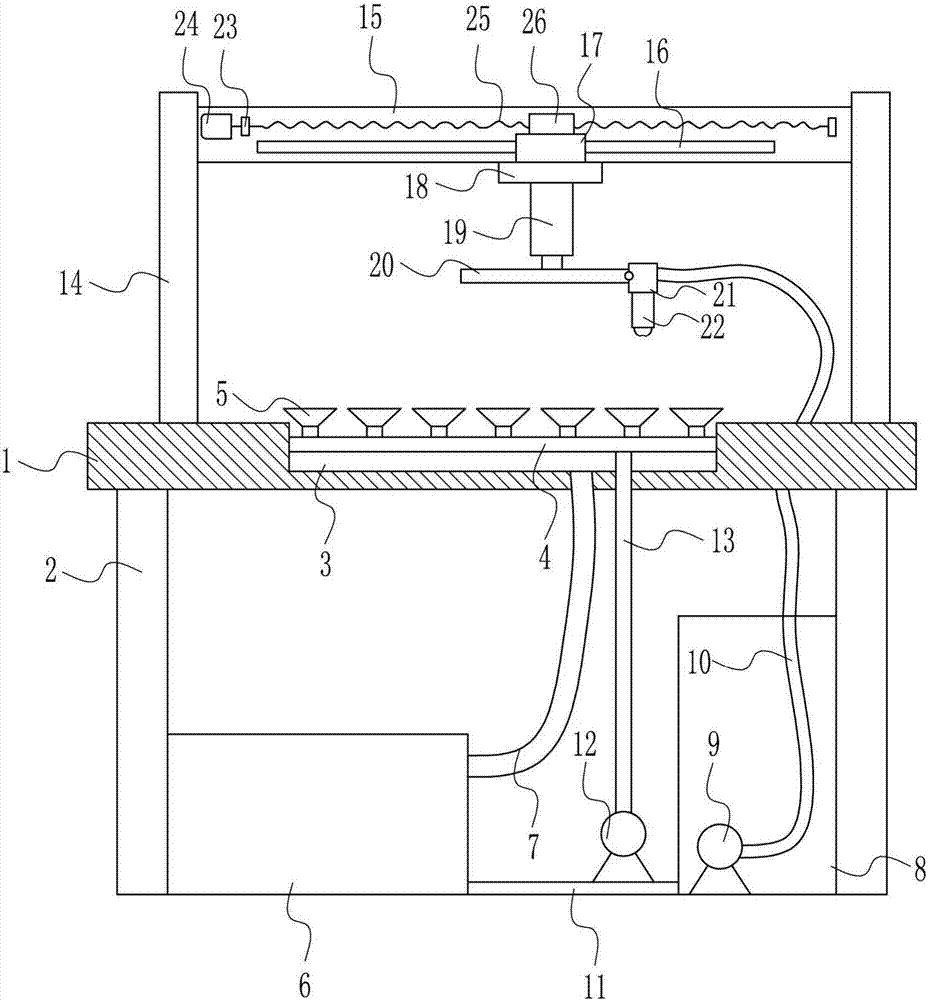

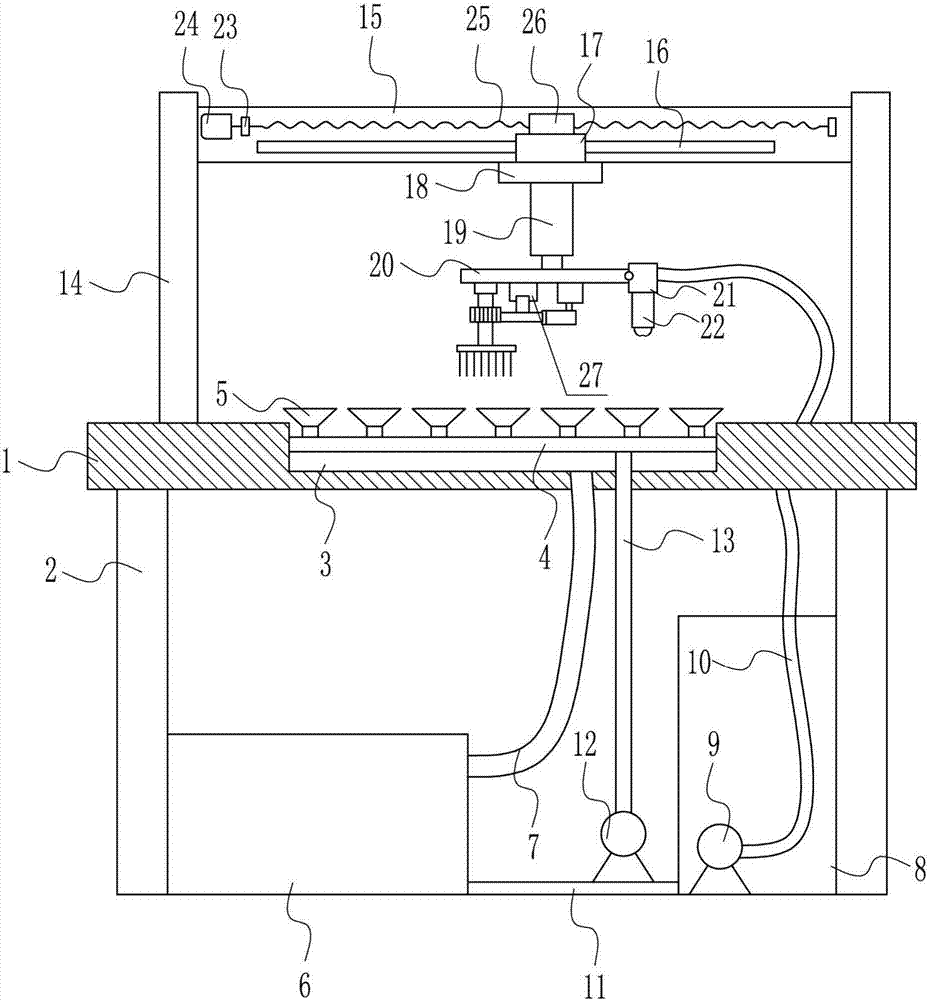

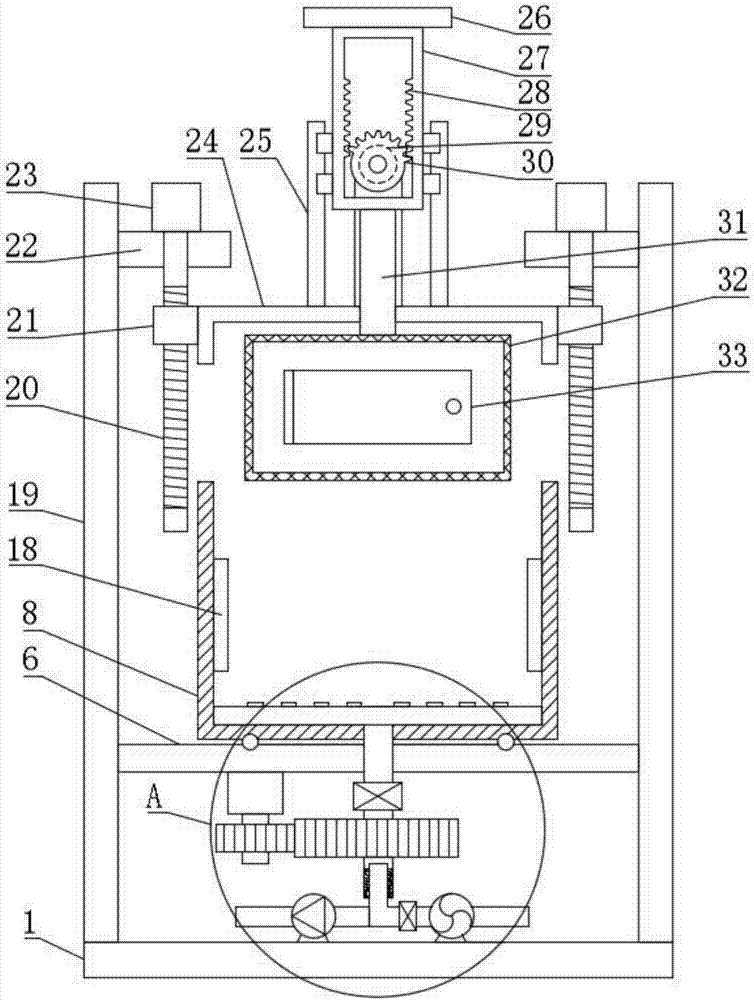

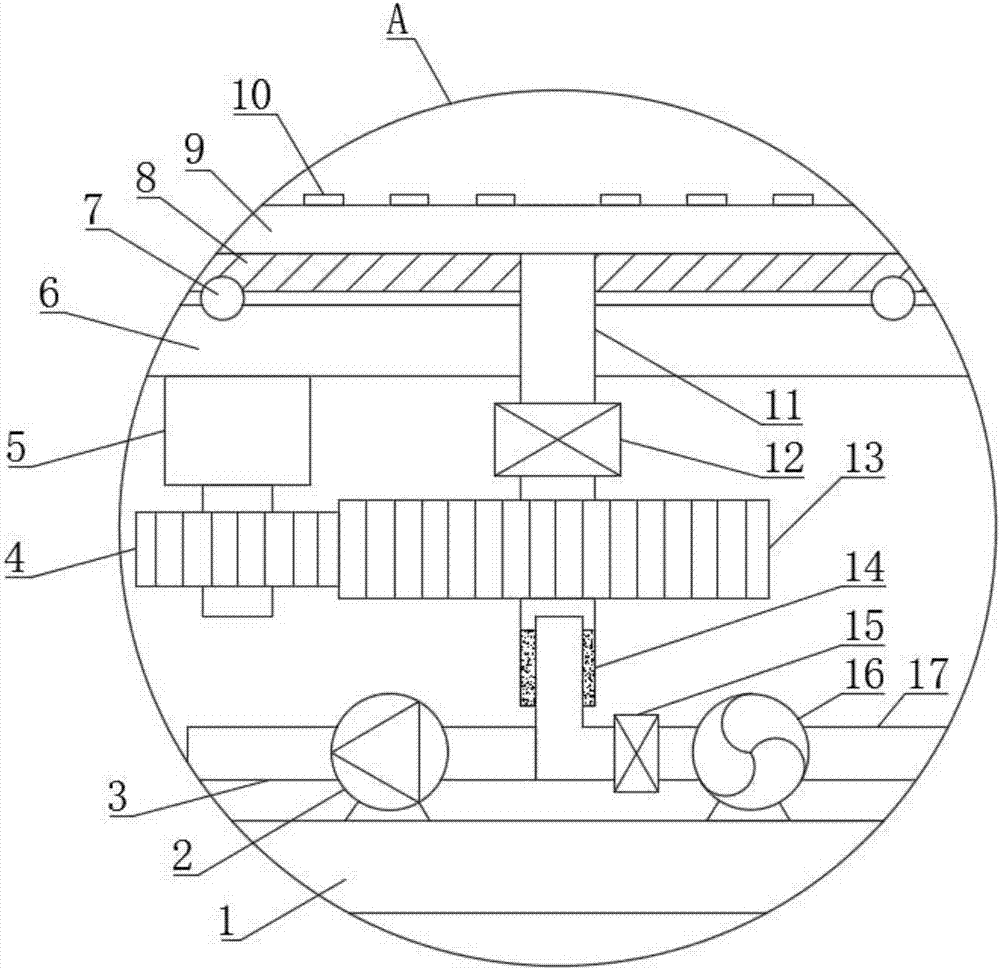

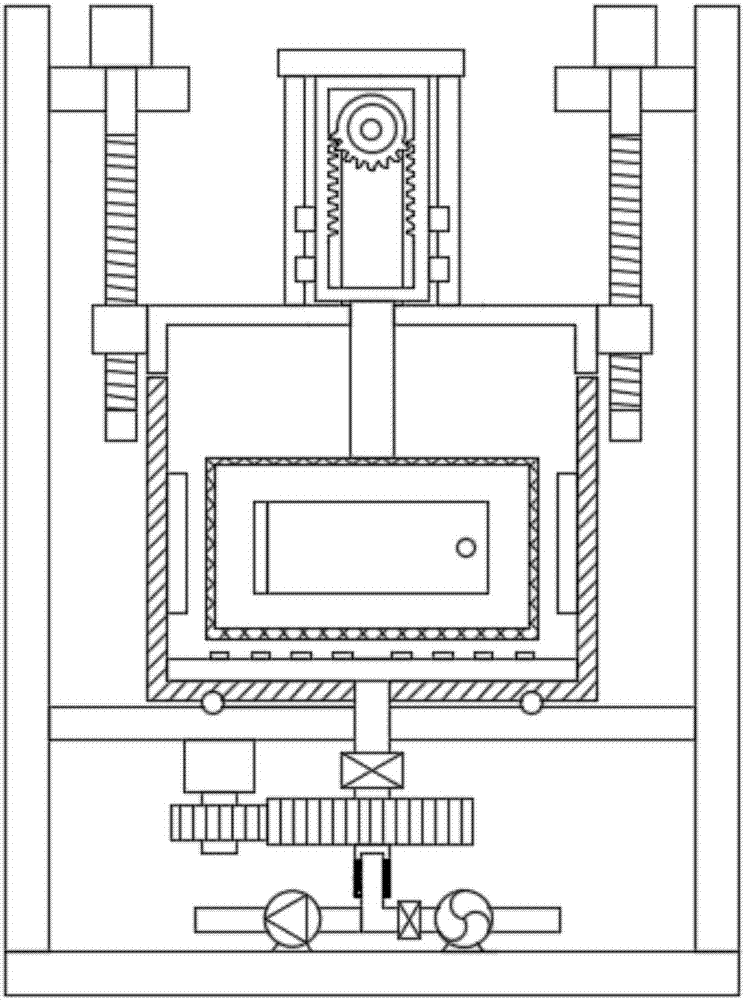

Epitaxial slice cleaning device for LED lamp production

InactiveCN106964588APrevent splashExpand the spraying areaSemiconductor/solid-state device manufacturingCleaning using toolsRefluxEngineering

The invention relates to an LED lamp production device, in particular to an epitaxial slice cleaning device for LED lamp production. The technical problem to be solved by the invention is to provide the epitaxial slice cleaning device for LED lamp production capable of saving both time and labors, improving the cleaning efficiency and protecting the health of workers. In order to solve the technical problem, the invention provides the epitaxial slice cleaning device for LED lamp production. The device comprises a worktable tabletop, support legs, a first air pipe, a vacuum sucker, a recovery water tank, a reflux water pipe, a solution tank, a water pump, a water outlet pipe, a support plate, a vacuum pump and the like; and the support legs are connected to the bottom of the worktable tabletop through a bolt connecting mode. A nozzle sprays out cleaning solution, and moves left and right to once clean more epitaxial slices, so that the effect of saving both time and labors is achieved, and the cleaning efficiency can be improved.

Owner:冯晓栋

Substrate cleaning method, substrate cleaning apparatus and storage medium for cleaning substrate

ActiveUS20130174873A1Avoid circuit damageAvoid damageLighting and heating apparatusSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A substrate cleaning method is capable of preventing a liquid stream on a substrate from being cut and circuit patterns thereon from being damaged. The substrate cleaning method includes a liquid film forming process that forms a liquid film on an entire substrate surface by supplying a cleaning liquid L from a central portion of the substrate W toward a peripheral portion thereof while rotating the substrate; a drying region forming process that discharges a gas G on the substrate surface and removes the cleaning liquid on the substrate surface; and a residual liquid removing process that removes the cleaning liquid remaining between the circuit patterns by discharging a gas G while moving in a diametrical direction of the substrate.

Owner:TOKYO ELECTRON LTD

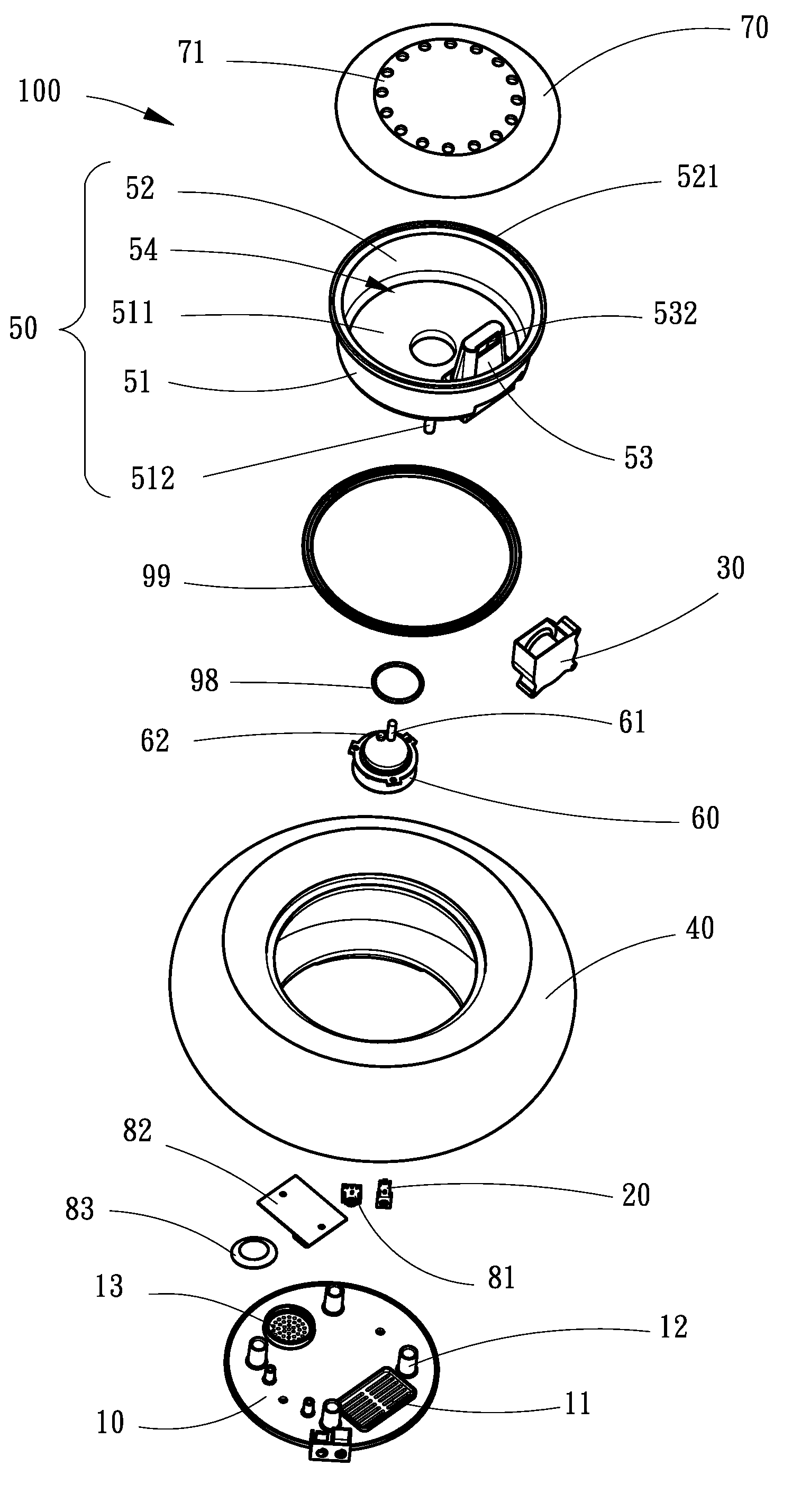

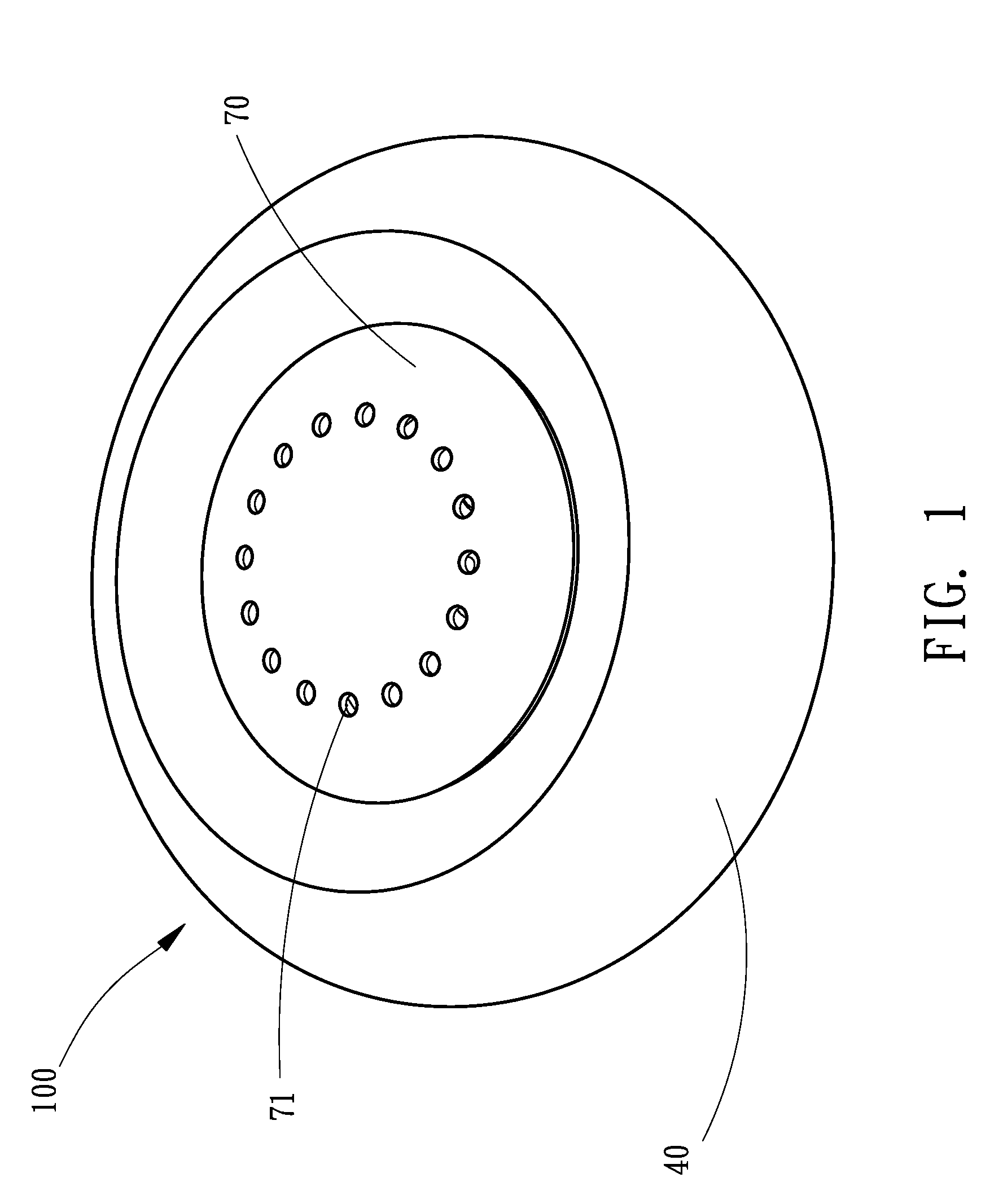

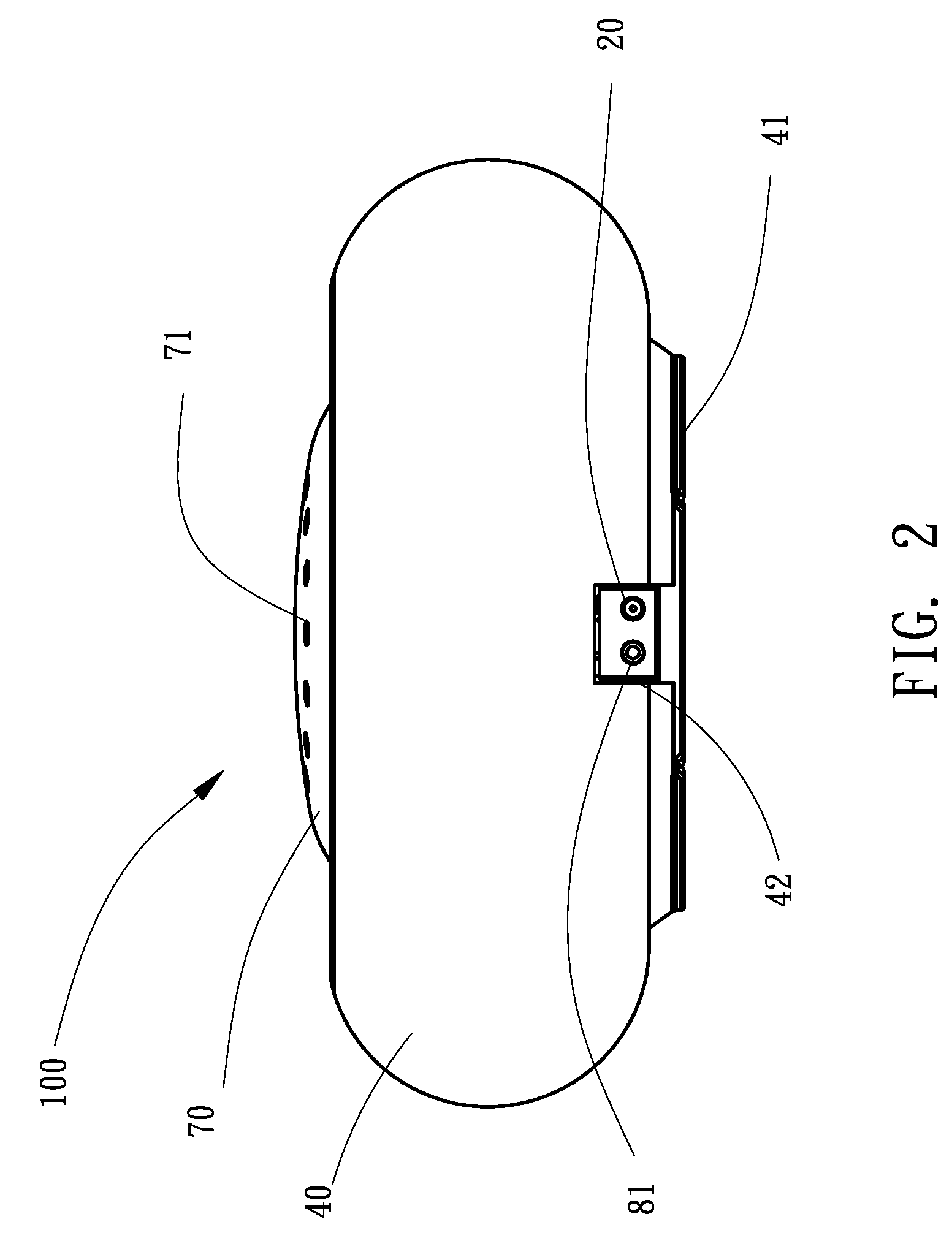

Aromatic nebulizing diffuser

InactiveUS8196903B2Promote atomizationPrevent splashUsing liquid separation agentMixing methodsEngineeringMechanical engineering

Owner:HSIAO MING JEN

Substrate processing apparatus

InactiveUS7332055B2Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

Owner:TOKYO ELECTRON LTD

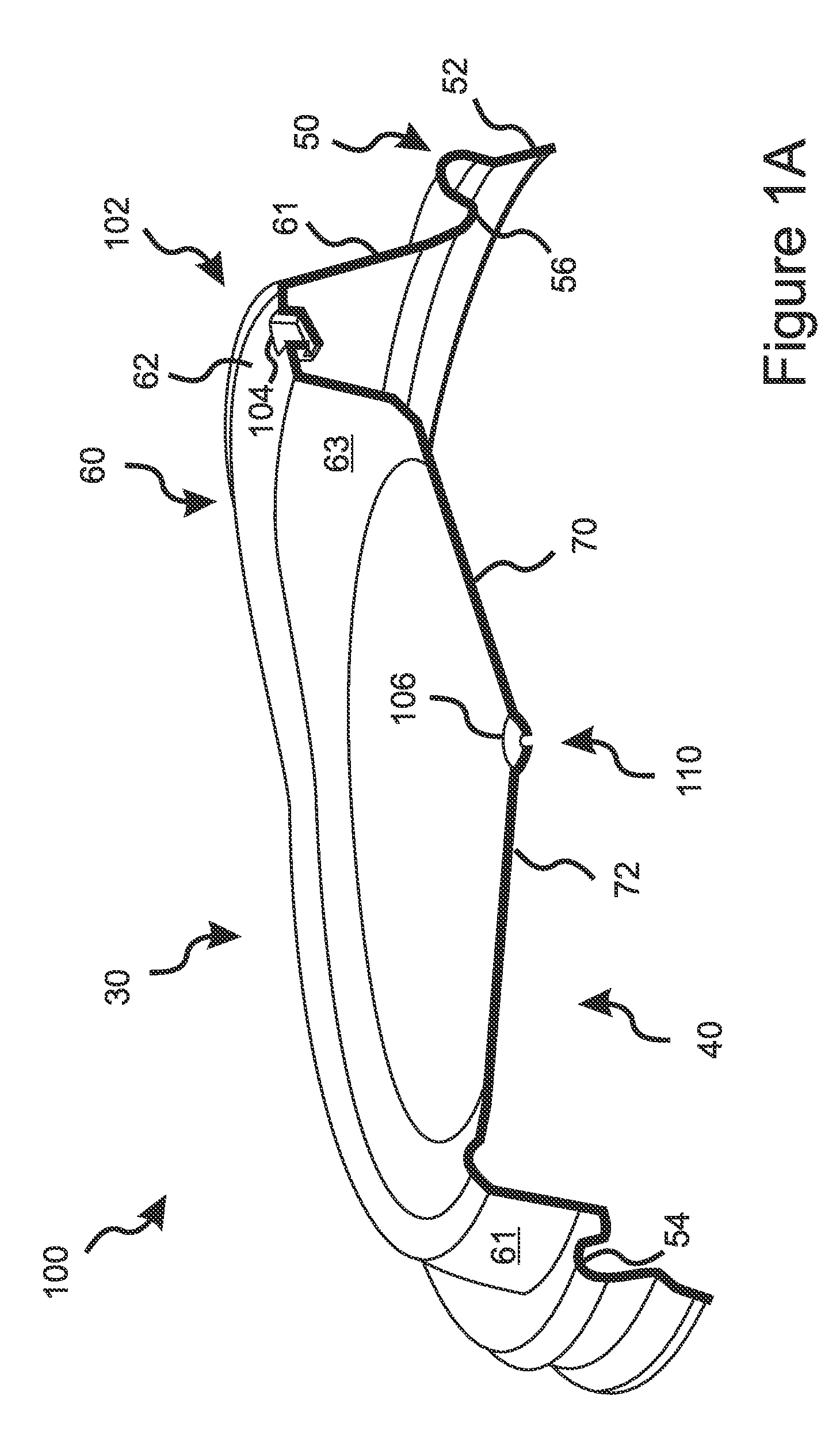

One-piece splash and spill resistant lid

A one-piece disposable cup lid enables drinking while inhibiting splashing and spilling by blocking straight-line paths through the lid and dispensing beverage through a well. A drinking spout can include a well having a sidewall, a bottom and a penetration into the cup, or a sloping lid section can intersect a raised rim to create a well therebetween, with a penetration in the sloping section or the rim configured to block straight-line paths, for example by upwardly hinging of a flap or depressing half of a split, convex bubble. Embodiments include baffles that force a beverage to flow through a convoluted path and / or through chambers before being consumed. Baffles can be formed in place, or by hinged movement of flaps after forming. Textures and / or protruding structures can intercept, direct, and / or influence surface tension as beverage flows across surfaces. Vent hole sizes and locations can further limit flow and spilling.

Owner:SCHEW +1

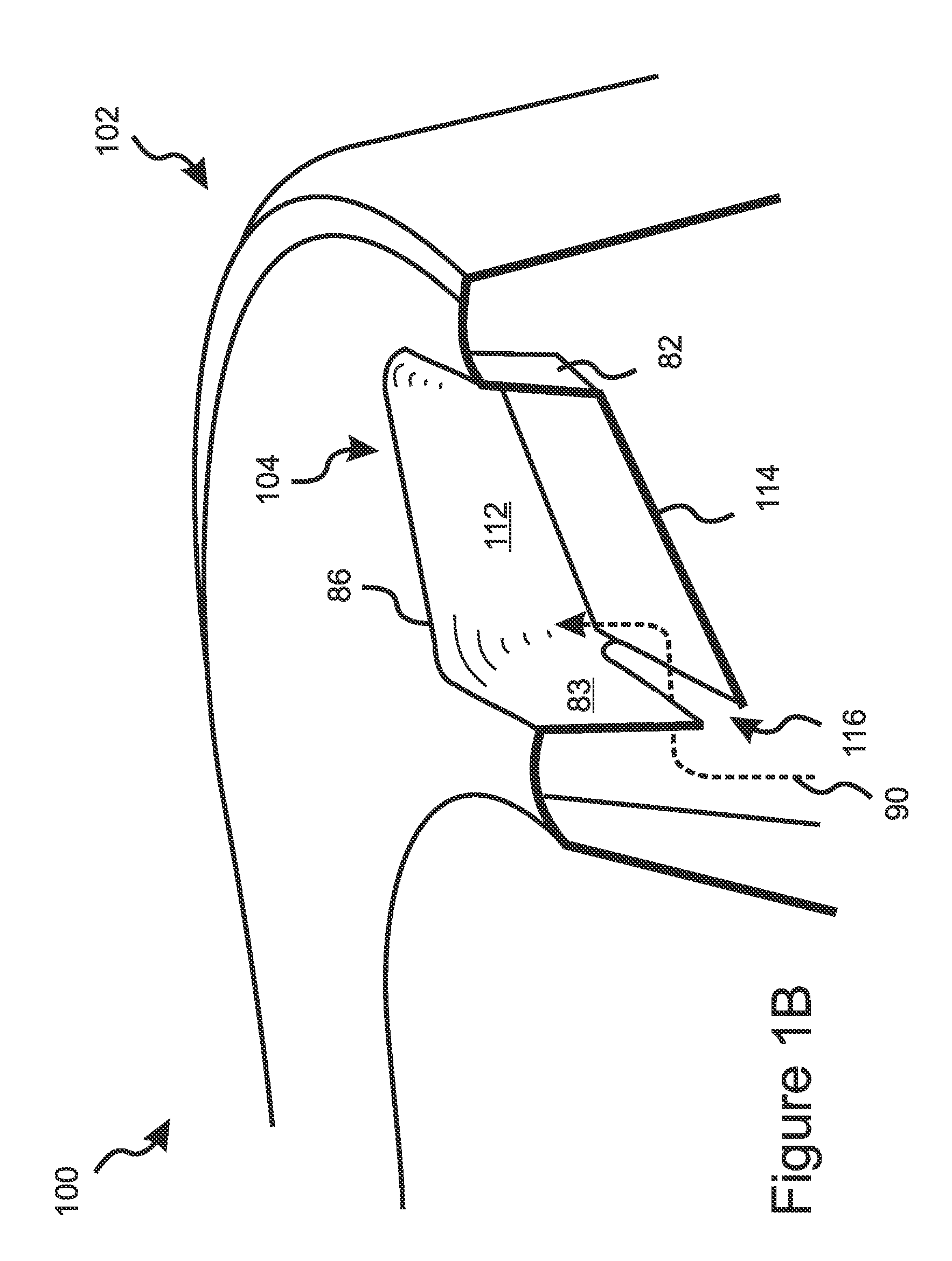

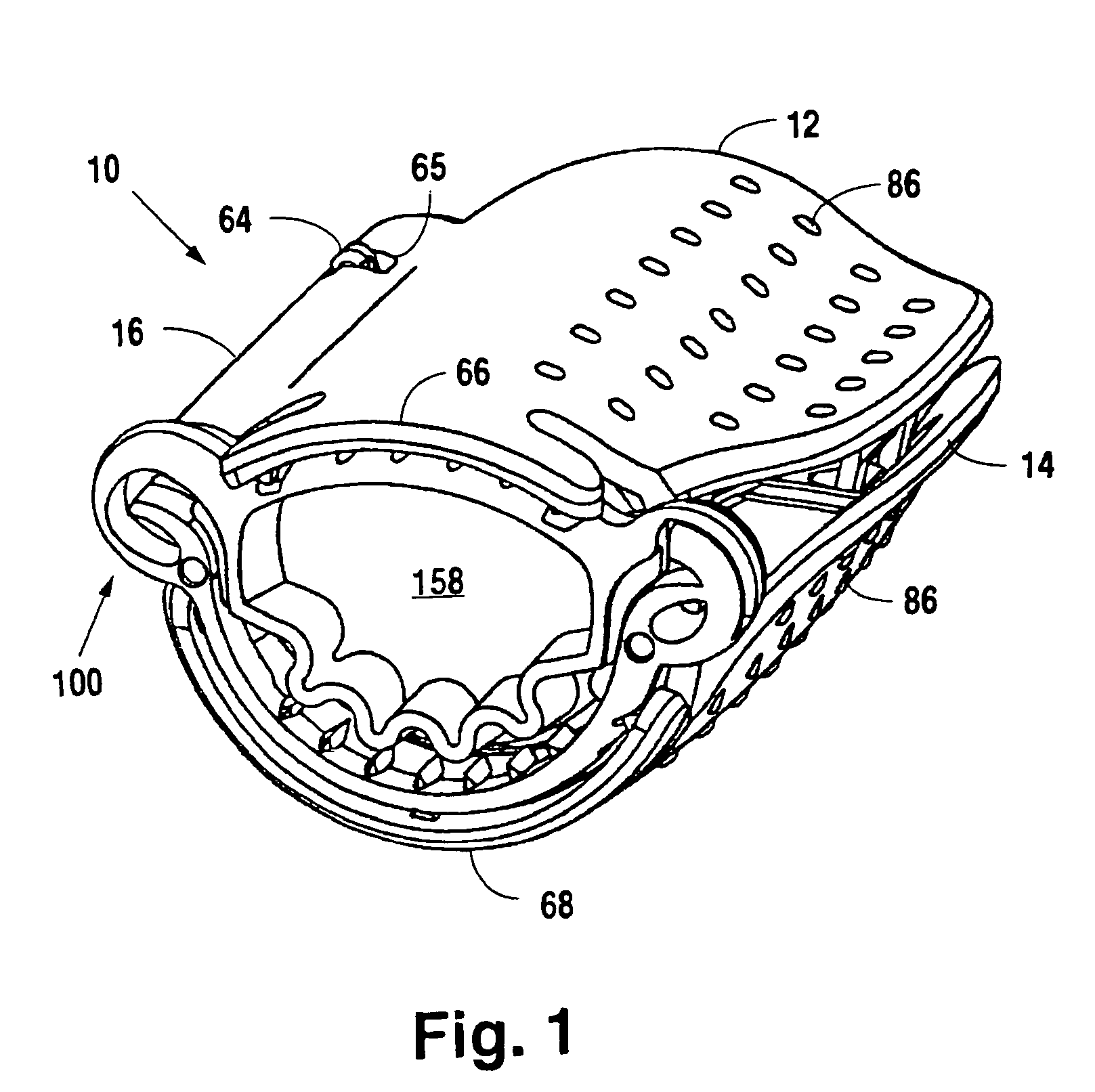

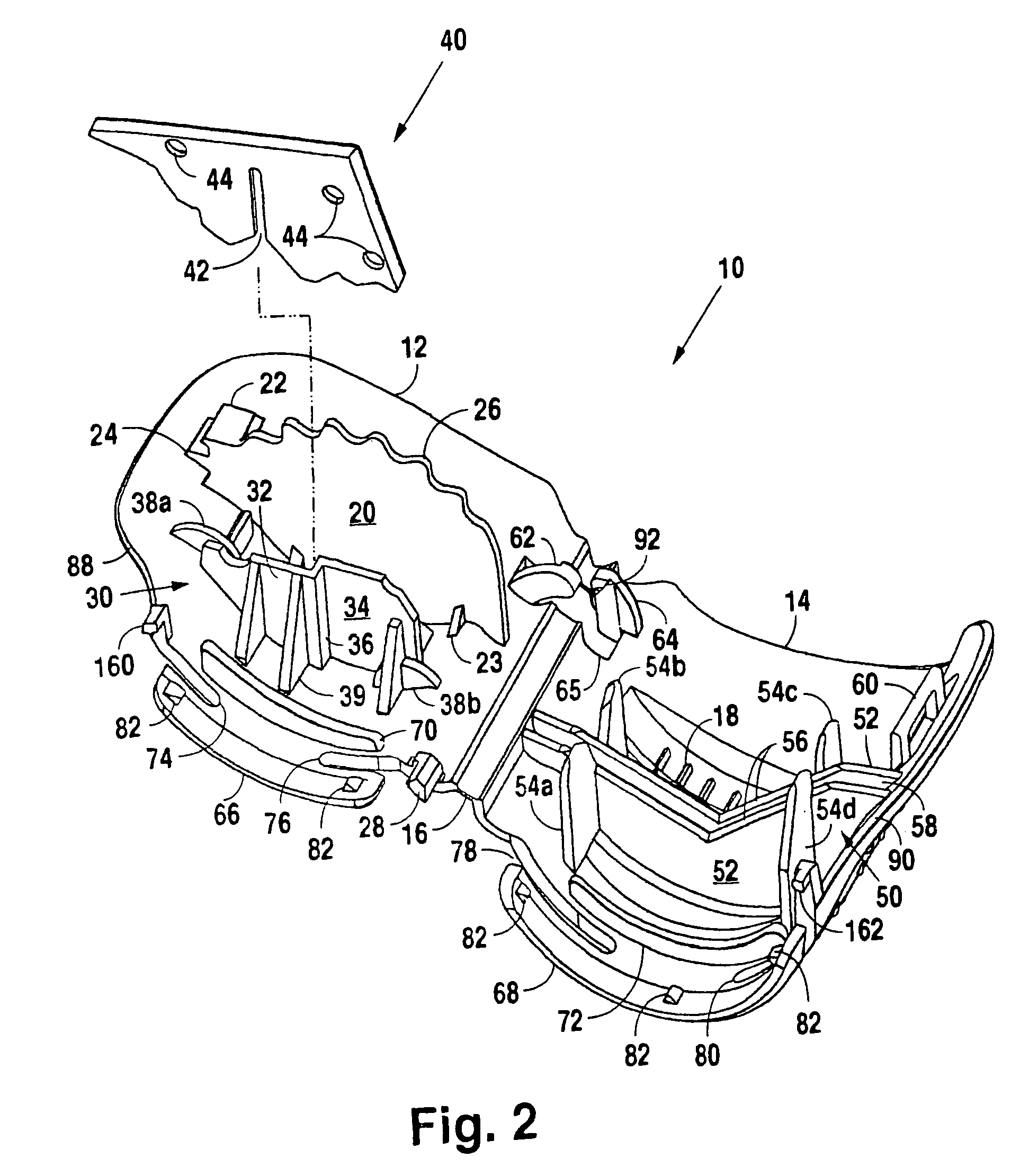

Umbilical cord clamp and cutter

InactiveUS7402164B2Prevent splashAvoid re-openingVaccination/ovulation diagnosticsDiagnostic recording/measuringBlood samplingMechanical engineering

A novel umbilical cord clamp and a combined umbilical cord clamp and cutter are provided for clamping and cutting umbilical cords in one motion. The cutter comprises two shells joined by a longitudinal hinge. A transverse blade is mounted in one shell, and a cutting support is mounted in the other shell across from the blade. One or more removable clamps may be engaged with the shells to be removable from the shells after cutting. Alternatively, a self-winding or plastically deformable band may be engageable with the shells. The cutter and its associated removable clamp(s) may be coordinated with an identifier, such as a color, number, or letter. Blood sampling and diagnostic features may be included with the cutter. The removable clamps may have an openable closure.

Owner:THE UTOPIA GRP

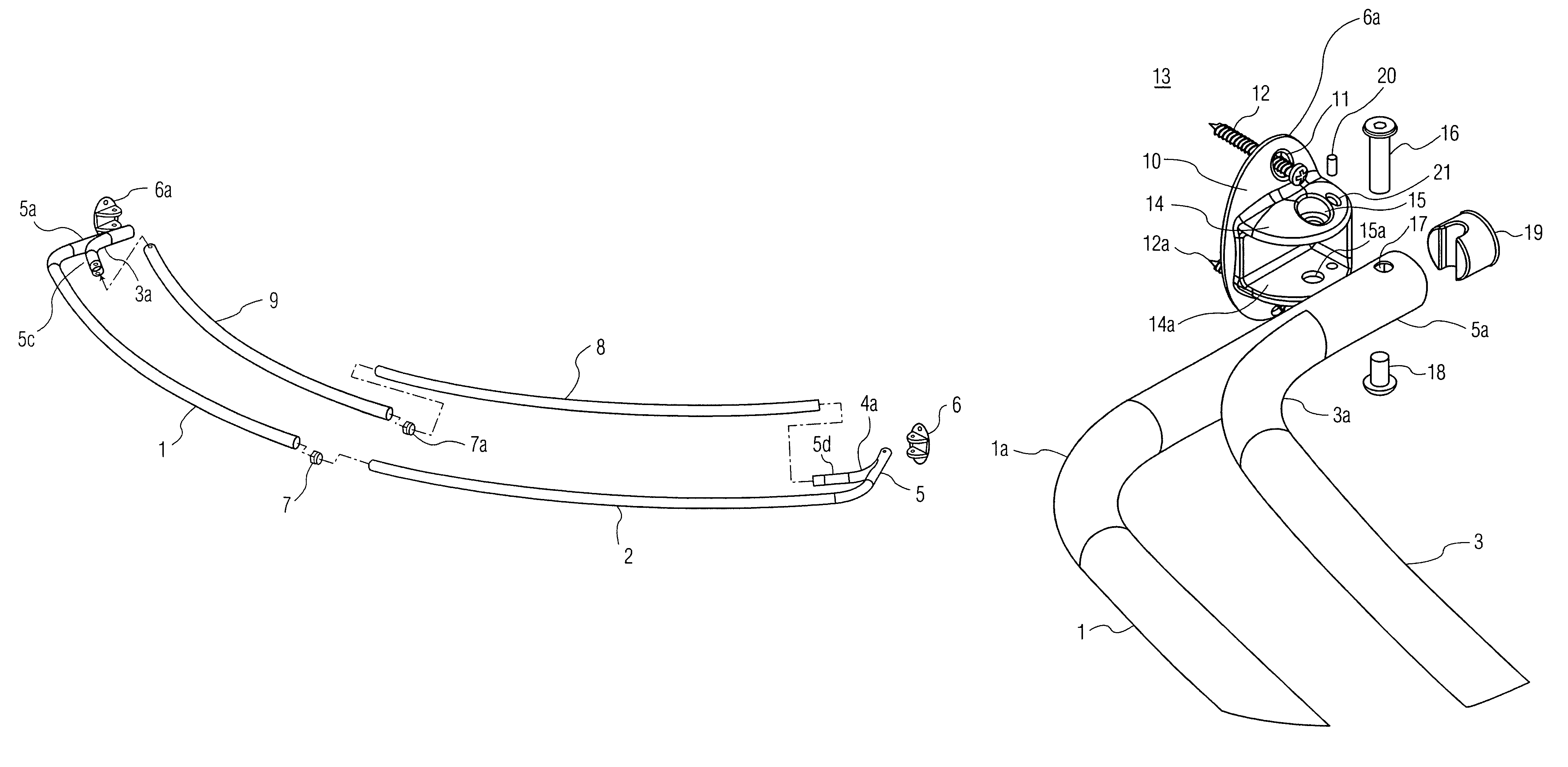

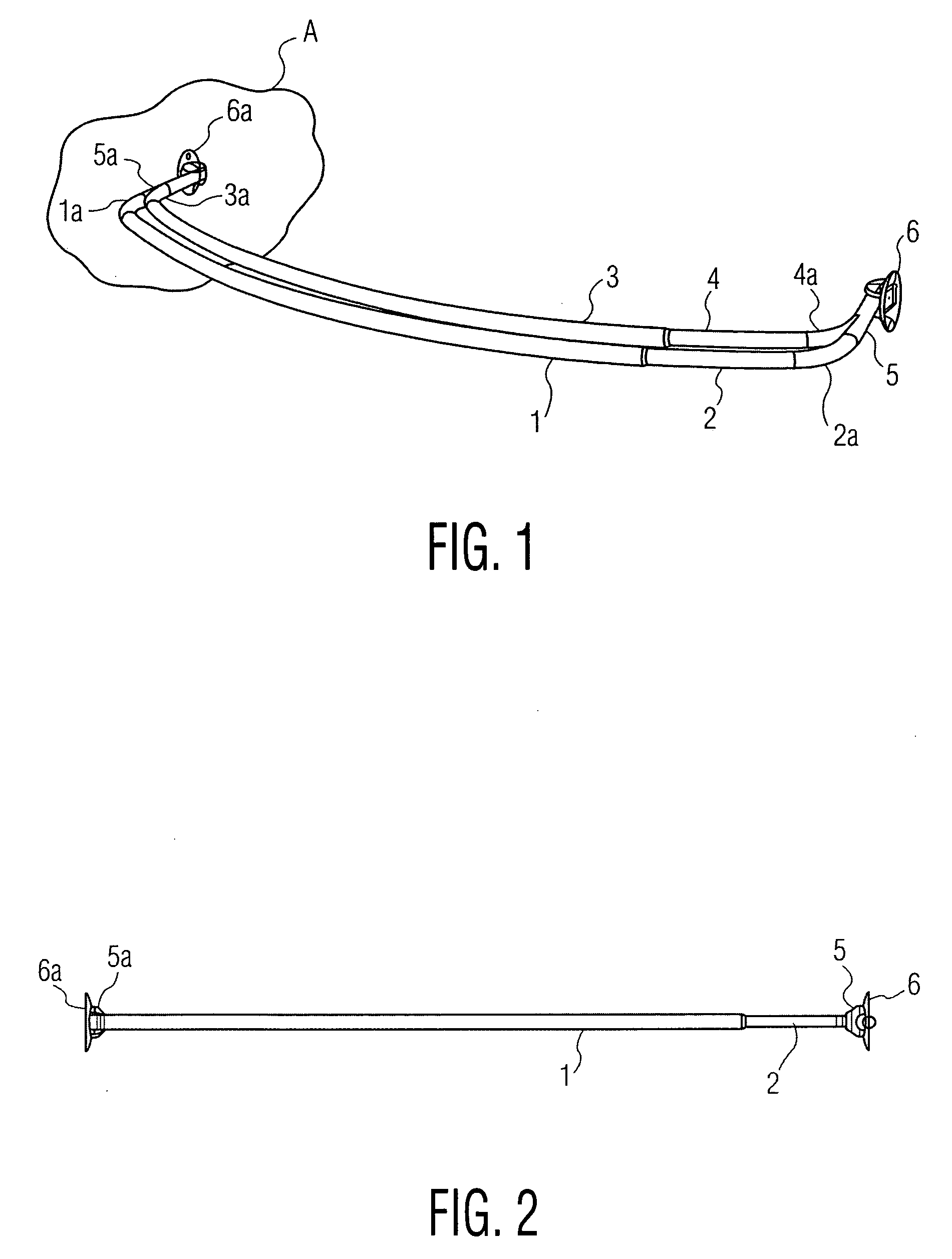

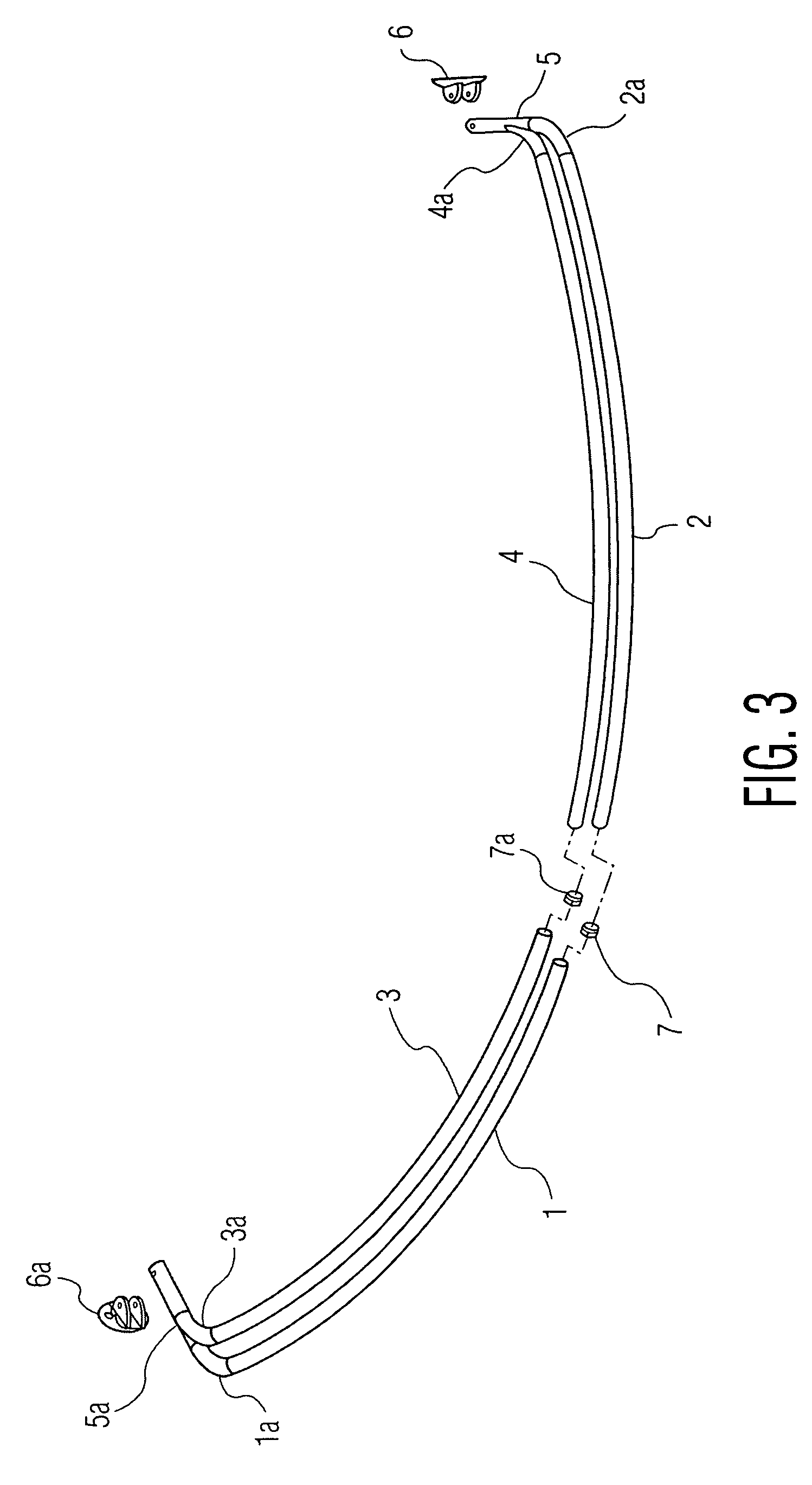

Adjustable curved double curtain rod shower assembly

An adjustable curved double curtain rod shower assembly for hanging and supporting the weight of two shower curtains and attached to the walls of a shower area and forms a shower enclosure area and the curtain rod assembly comprises:(a) two adjustable curved curtain rods in a horizontal plane one an inner rod and the second an outer rod and each rod comprises a first and a second tubular section wherein the first section fits into the second section thereby providing for telescopic adjustment of each of the rods and two end pieces that join the ends of each of the two adjustable rods together;(b) two end hanging means having pivotably positioned therein the two end pieces wherein each of the hanging means is attached to the walls of the shower enclosure and when shower curtains are attached to each of the rods form an enclosed shower area.

Owner:DECOLIN INC

Efficient fruit cleaning device

The invention discloses a high-efficiency fruit cleaning device, which comprises a base. Support plates are arranged on the left and right sides of the base, and support plates are fixedly arranged between the support plates. The top of the support plate is connected to a cleaning pool through ball rotation. The inner wall is provided with a number of uniformly distributed stirring blades, and the bottom of the cleaning tank is fixedly connected with a rotating shaft. The rotating shaft passes through the supporting plate, and a driven gear is installed on the rotating shaft. The bottom of the supporting plate is fixedly equipped with a first motor, and the first motor The motor shaft at the bottom end is connected with a driving gear, and the driving gear meshes with the driven gear; a fixing seat is fixedly arranged on the top of the support plate, and a second motor is arranged on the fixing seat, and the motor shaft at the bottom end of the second motor is connected with a The lifting screw rod is connected with a screw seat matched with the lifting screw rod, and the screw seat is fixedly connected with a cover plate. The present invention adopts the cleaning mode in which the fruit box matches the cleaning tank, and the cover plate covers the cleaning tank during cleaning, thereby avoiding water splashing.

Owner:临泉县生产力促进中心

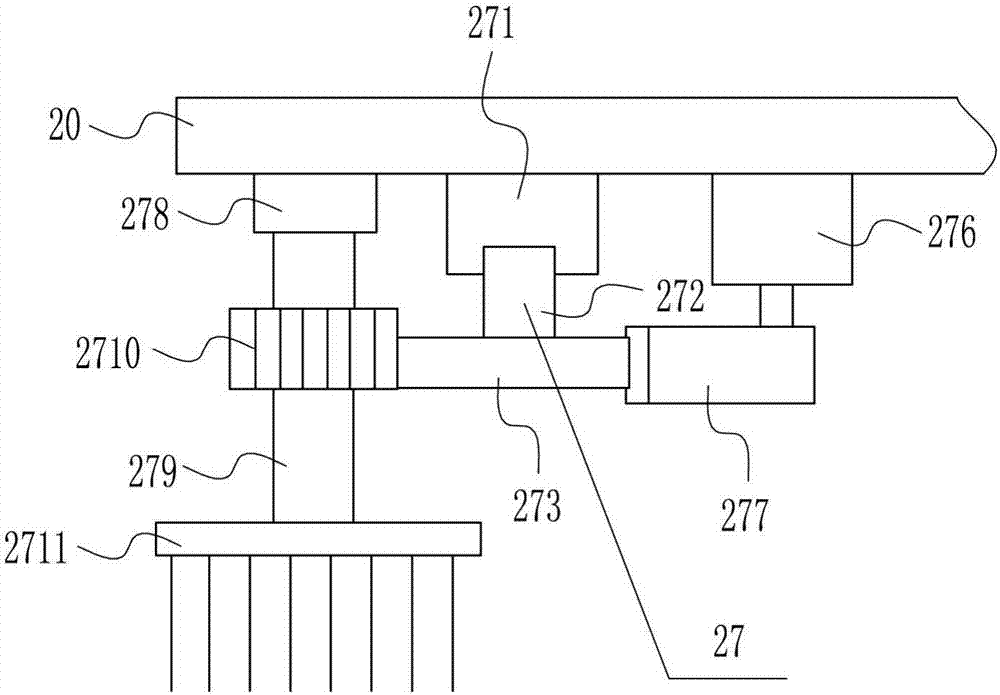

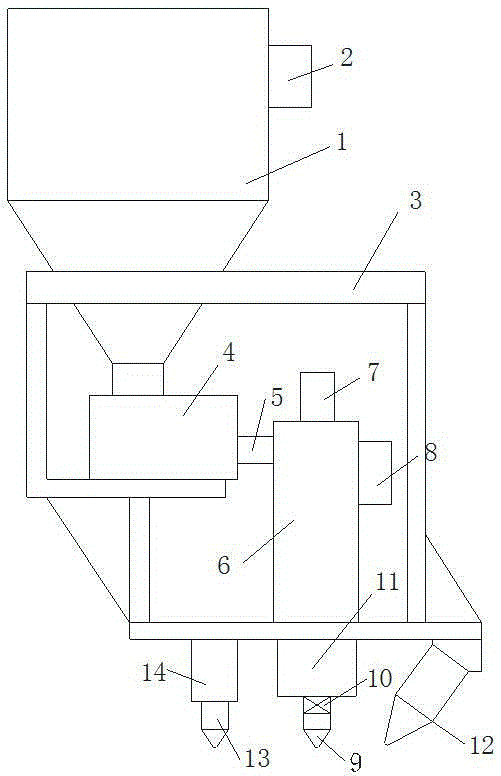

3D printing device integrating material supplying, fluxing and crystal leveling assistance

ActiveCN105383060AImprove densification performanceImprove bindingAdditive manufacturing apparatusCeramic shaping apparatusSize changeEngineering

A 3D printing device integrating material supplying, fluxing and crystal leveling assistance comprises a support, a material bin, a first forced feeding mechanism, a second forced feeding mechanism, an auxiliary heating head and a crystal leveling assistance vibrating head, wherein the material bin, the first forced feeding mechanism, the second forced feeding mechanism, the auxiliary heating head and the crystal leveling assistance vibrating head are all mounted on the support. The material bin, the first forced feeding mechanism and the second forced feeding mechanism are sequentially connected. A nozzle is connected to a discharging outlet of the second forced feeding mechanism, and a heating device is arranged at the discharging outlet. The auxiliary heating head and the crystal leveling assistance vibrating head are arranged at the bottom of the support and located in front of and behind the nozzle respectively. The device is easy to operate, stable, reliable and convenient to maintain; the compactness of formed workpieces in the 3D printing process is improved, interlayer bonding of the formed workpieces is good, and the cost is low; through material selection, size changes and process adjustment of corresponding components, the device can be suitable for fused deposition of powder materials of different types.

Owner:JINAN LUYANG TECH

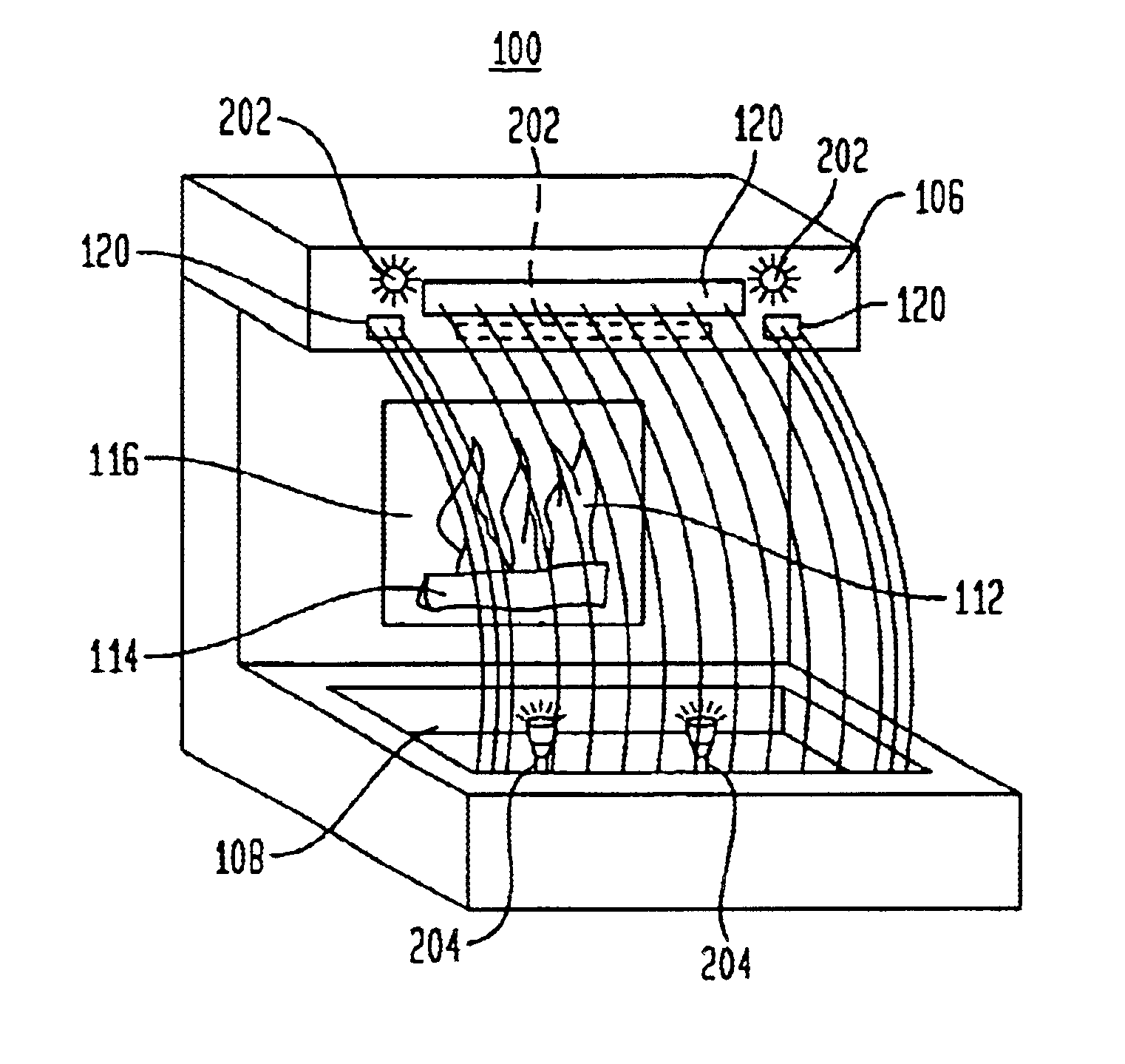

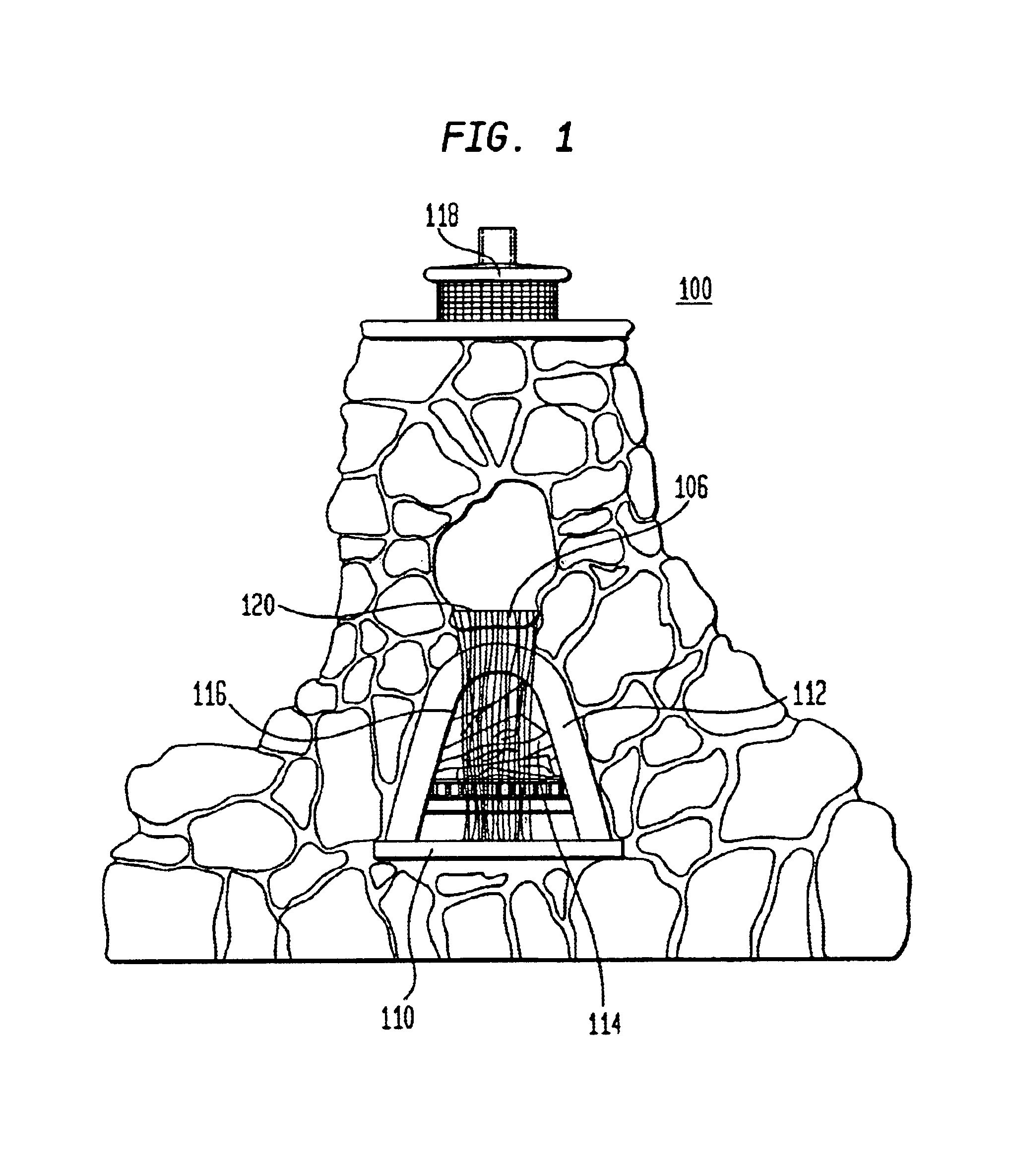

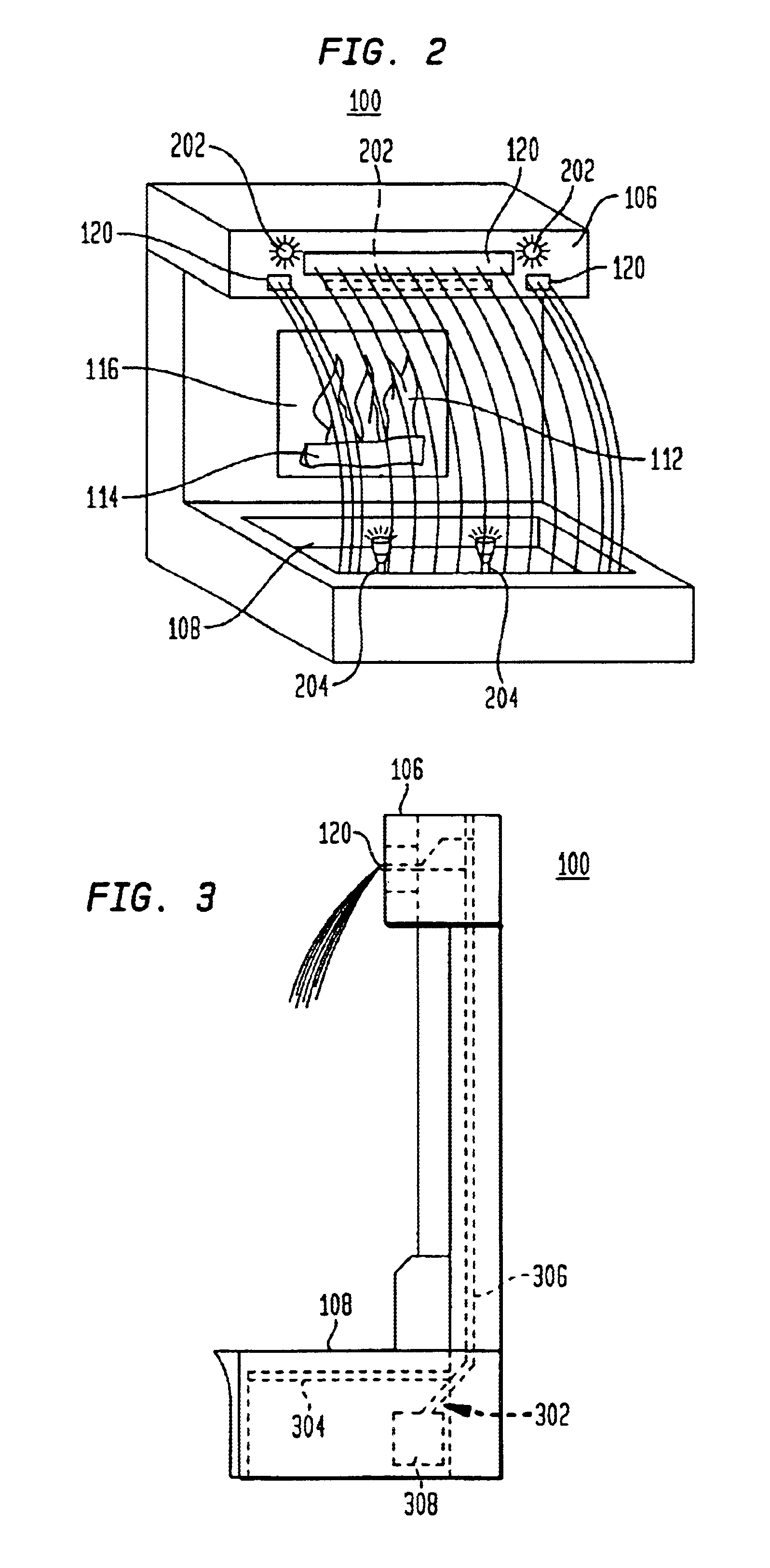

Fireplace with waterfall

A fireplace including a fire box having a means for producing flames, a trough positioned in front of or around the fire box, and a hood positioned above the fire box and extending out from the fireplace beyond a front opening in the fire box. Positioned in the trough is a plumbing assembly having a pump and piping for transporting water from the trough upward and through an opening in the hood positioned above the fire box. The hood extends outward beyond the fire box such that water will fall freely in front of the fire box containing the flames and into the trough. One or more nozzles may be connected to the piping near one or more openings in the hood to adjust the trajectory of the water as it falls from the hood.

Owner:COUGHLIN DAVID P

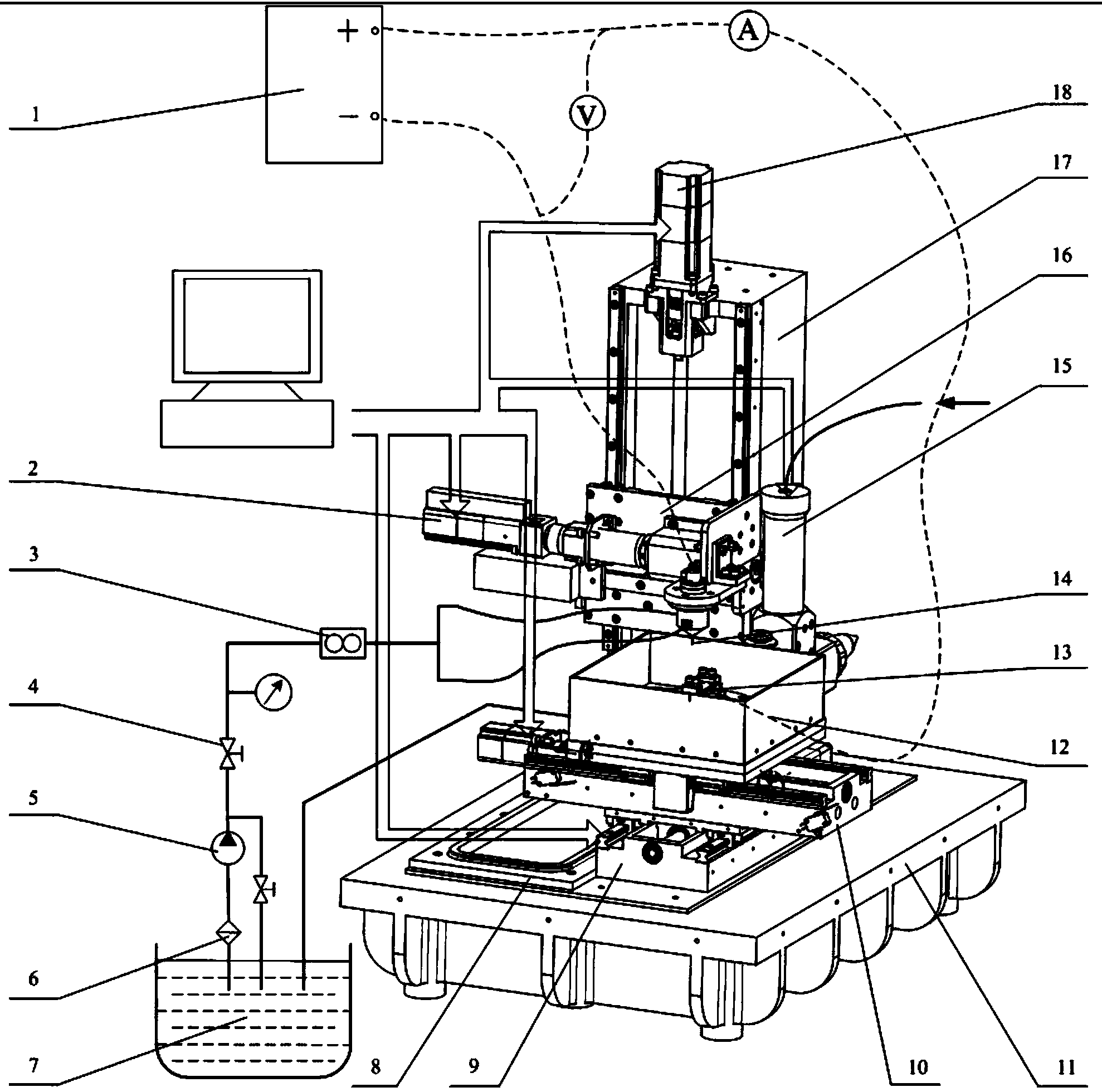

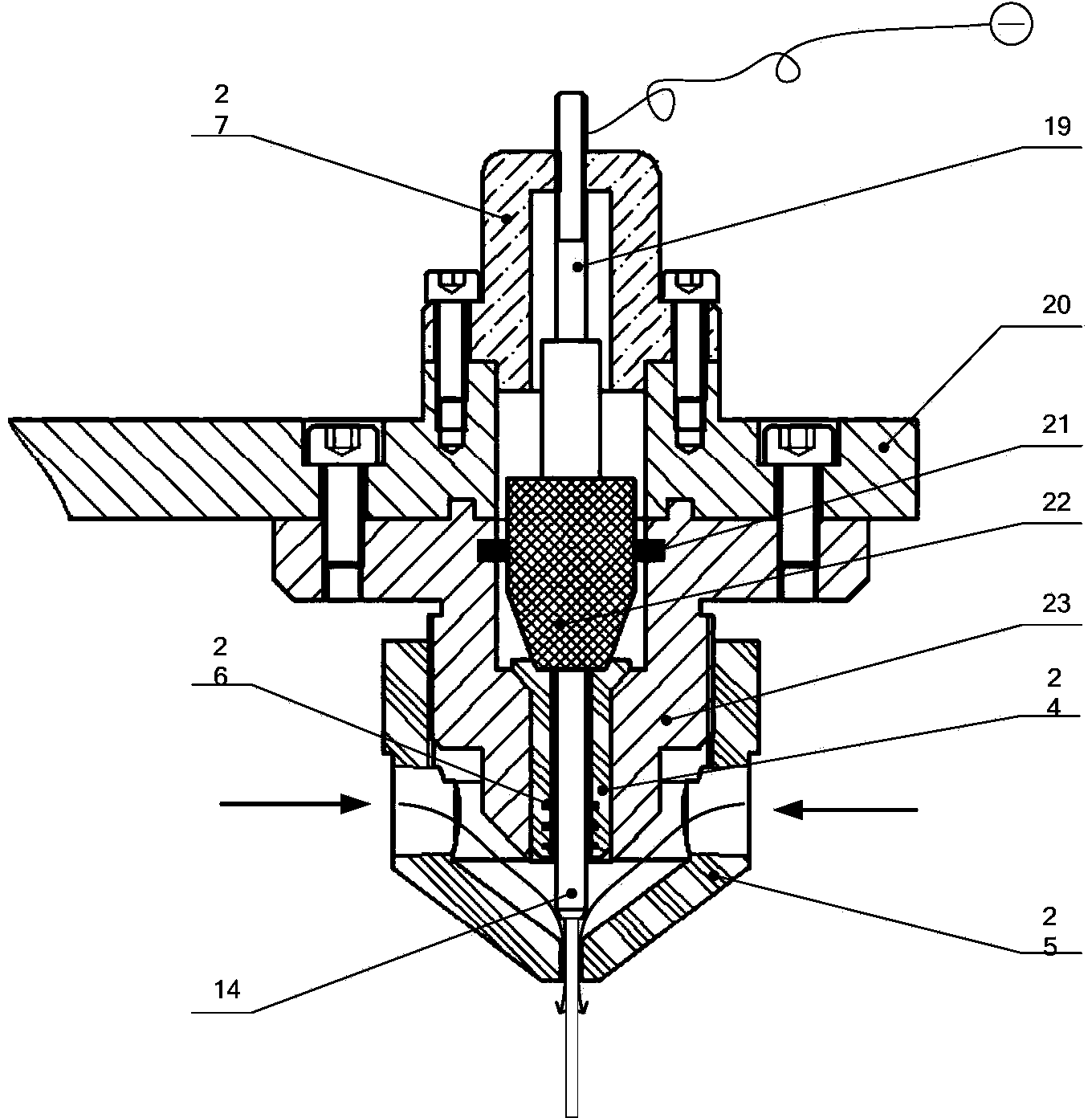

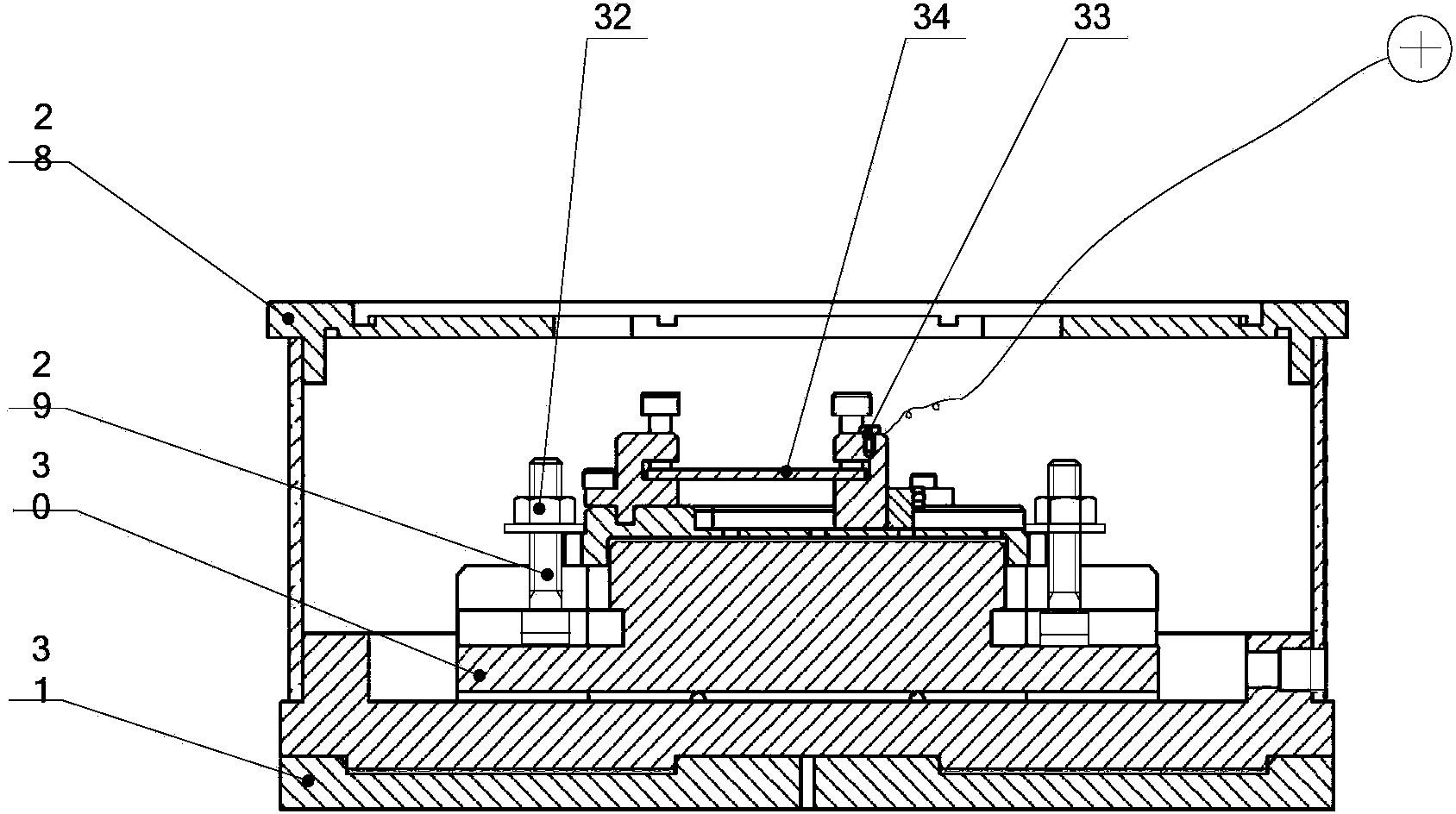

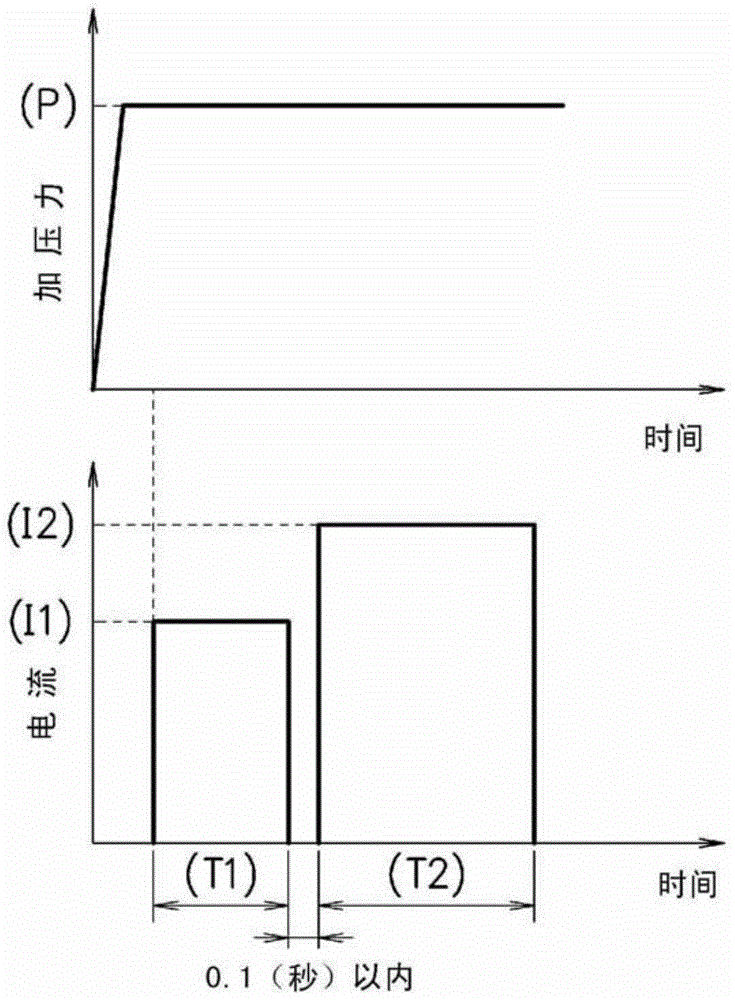

Laser-electrolysis composite machining device and method of tiny holes in non-recast layer

The invention discloses a laser-electrolysis composite machining device and method of tiny holes in a non-recast layer. The device and method aim to solve the problem that in the prior art, it is difficult to effectively machine tiny holes without defects. The device comprises a machine tool base and a machine tool stand column, wherein the machine tool base is provided with a workpiece fixture, and the machine tool stand column is perpendicularly arranged on the machine tool base. An electrolysis machining cathode spray nozzle and a laser emission head are arranged above the workpiece fixture, wherein the electrolysis machining cathode spray nozzle and the laser emission head are fixed to the machine tool stand column and are driven through a conversion motor. The electrolysis machining cathode spray nozzle and the laser emission head are arranged with the axes in the same plane, and converted through the conversion motor, so that the advantages of high efficiency in laser machining and good quality in electrolysis machining are integrated, and high-quality and efficient machining of tiny group holes is achieved.

Owner:临沂市奥林欧克工具有限公司

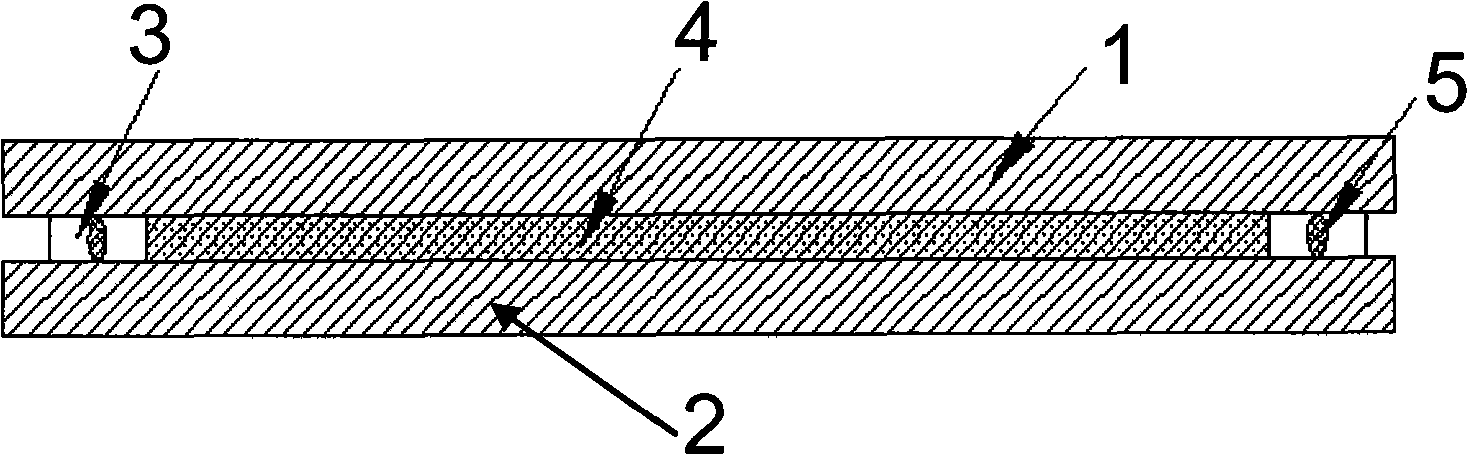

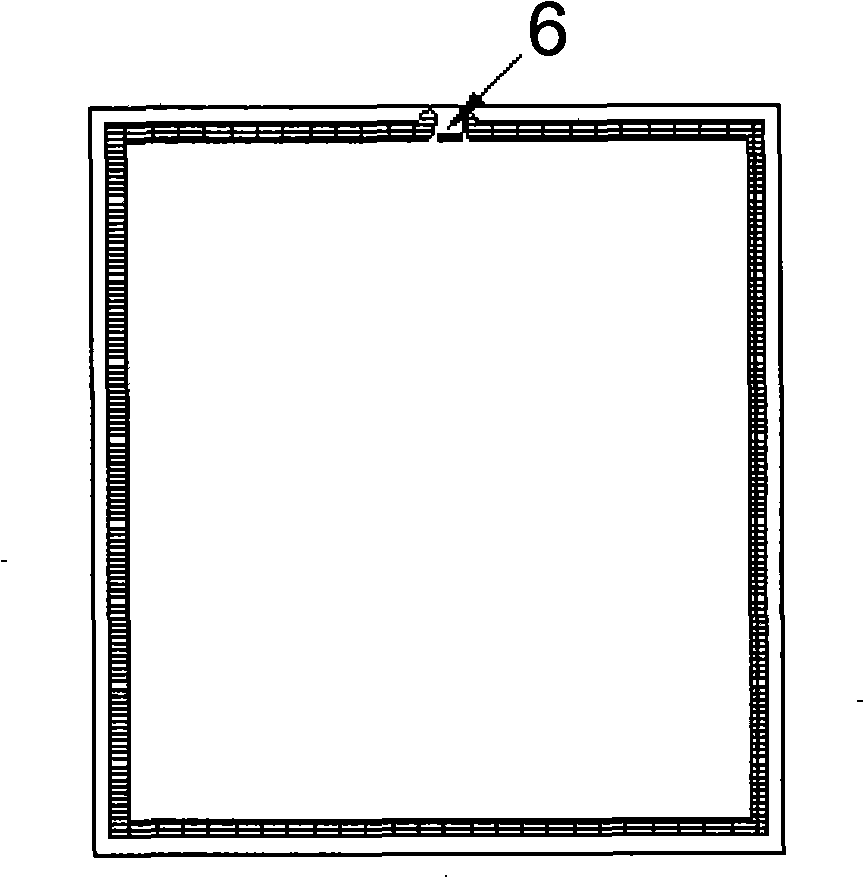

Capacitance touch screen and making method thereof

InactiveCN101359267AAvoid scatteringImprove light transmittanceInput/output processes for data processingColor saturationTransmittance

The invention discloses a capacitive touch screen and a manufacturing method; the capacitive touch screen comprises an upper glass substrate, a lower glass substrate and a sealant; the upper glass substrate and the lower glass substrate are bonded through the sealant; and transparent colorless gel is filled between the upper glass substrate and the lower glass substrate. The manufacturing method of the capacitive touch screen comprises the following steps: the upper glass substrate and the lower glass substrate are bonded together through the sealant to form a touch screen box; the glue is poured into the touch screen box; and the glue is solidified as the transparent colorless gel. The manufacturing method is simple in process. As no air layer exists, the capacitive touch screen can effectively prevent the scattering of the air layer to increase the light transmittance, the contrast and the color saturation. The capacitive touch screen can well improve the display effect.

Owner:BYD CO LTD

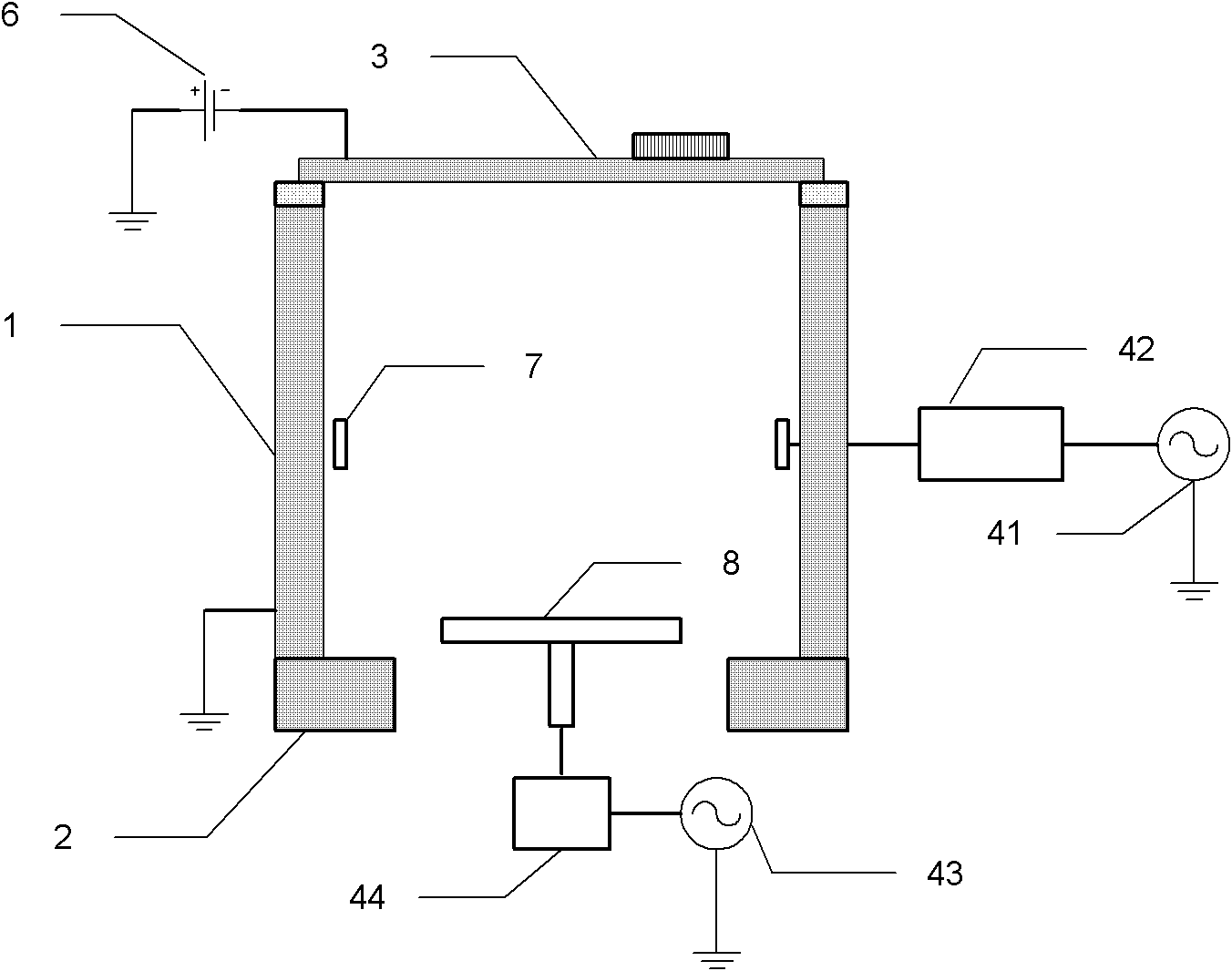

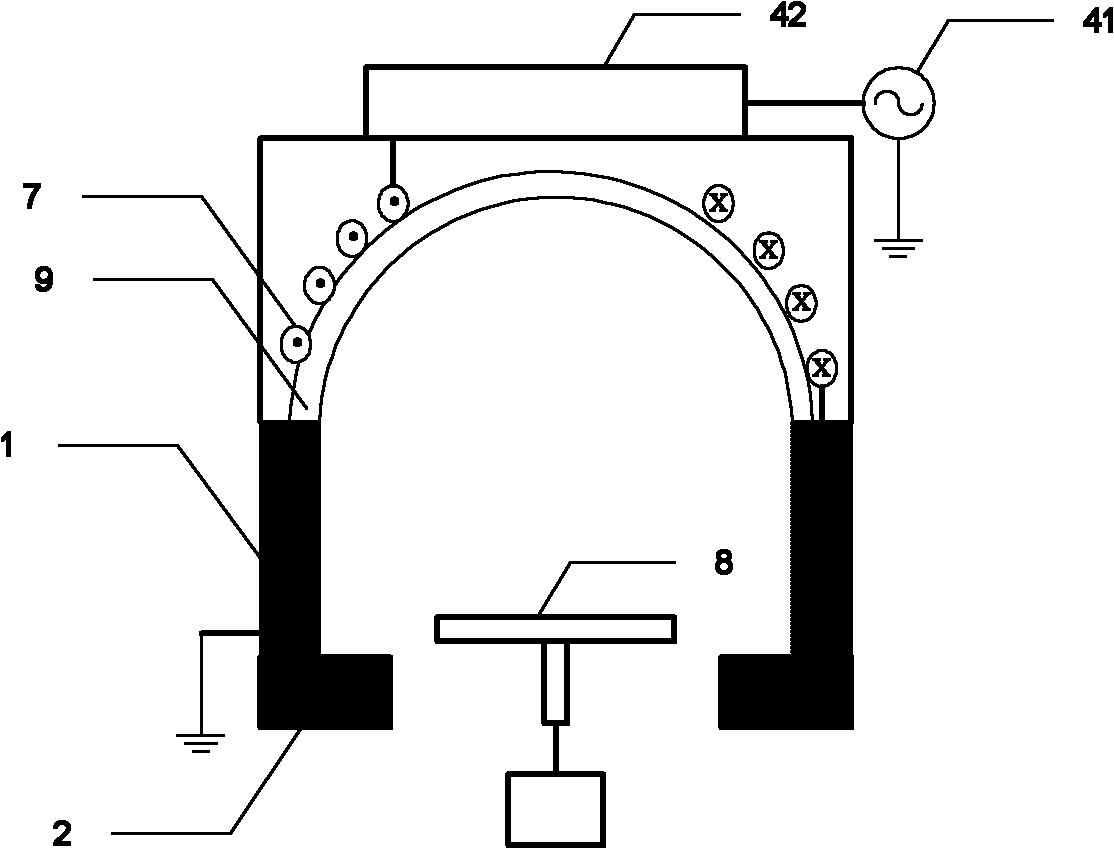

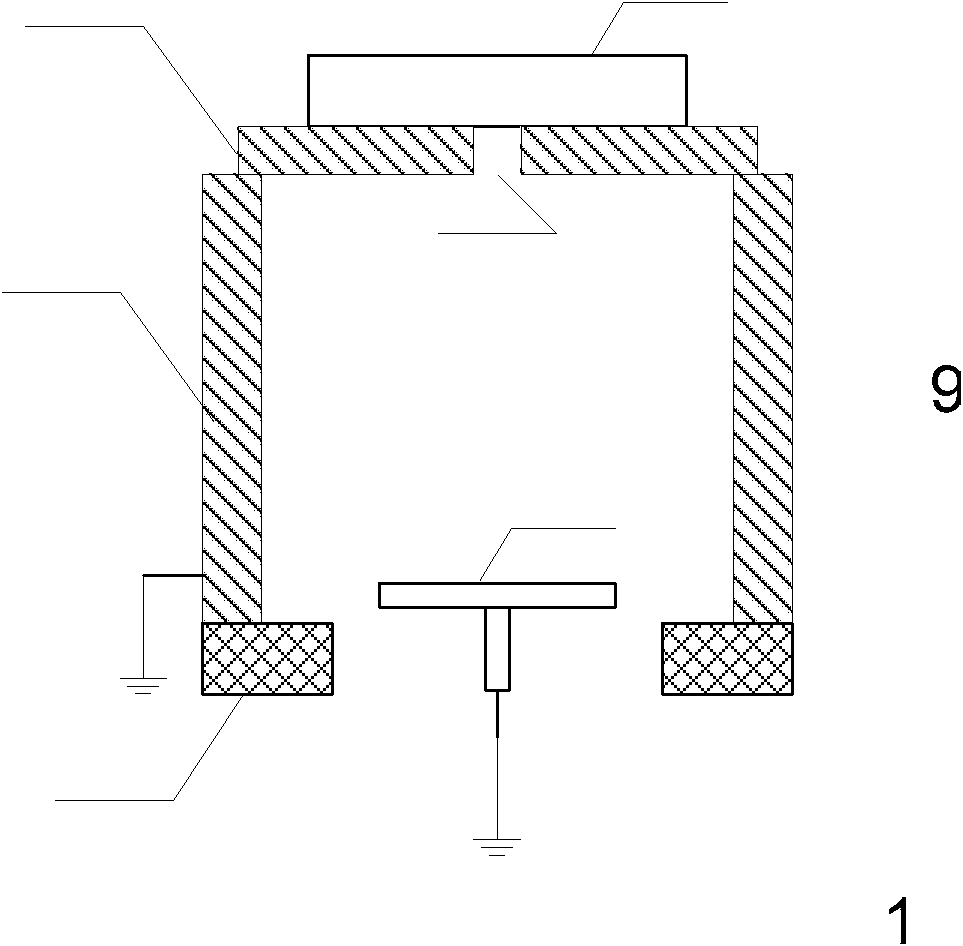

Sputtering chamber, pre-cleaning chamber and plasma processing equipment

ActiveCN102418073AExtended service lifeAvoid pollutionElectric discharge tubesVacuum evaporation coatingSputteringEngineering

The invention discloses a sputtering chamber, a pre-cleaning chamber and plasma processing equipment. The sputtering chamber comprises a cavity, a target, an electrostatic chuck and an inductance coil, wherein the target is arranged at the top end of the cavity and is connected with a power supply; the electrostatic chuck is arranged at the bottom of the cavity; and the inductance coil is arranged at the outer side of the cavity. The sputtering chamber can be used for preventing the inductance coil from being sputtered by plasma, thereby the service life of the inductance coil is prolonged, the use cost of the sputtering chamber is reduced, particle pollution sources in the sputtering chamber are reduced, the pollution caused by particles deposited on the surface of the inductance coil to processed workpieces is avoided and the utilization rate of the target is improved. According to the pre-cleaning chamber, a top cover can be designed to be an easily-processed structure, so that an arched structure with higher processing cost is avoided, and further the processing cost of the top cover is reduced, the adhesive force of the particles and the top cover is improved and the pollution of the particles attached to the surface of the top cover to the processed workpieces positioned below the top cover is reduced and even avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

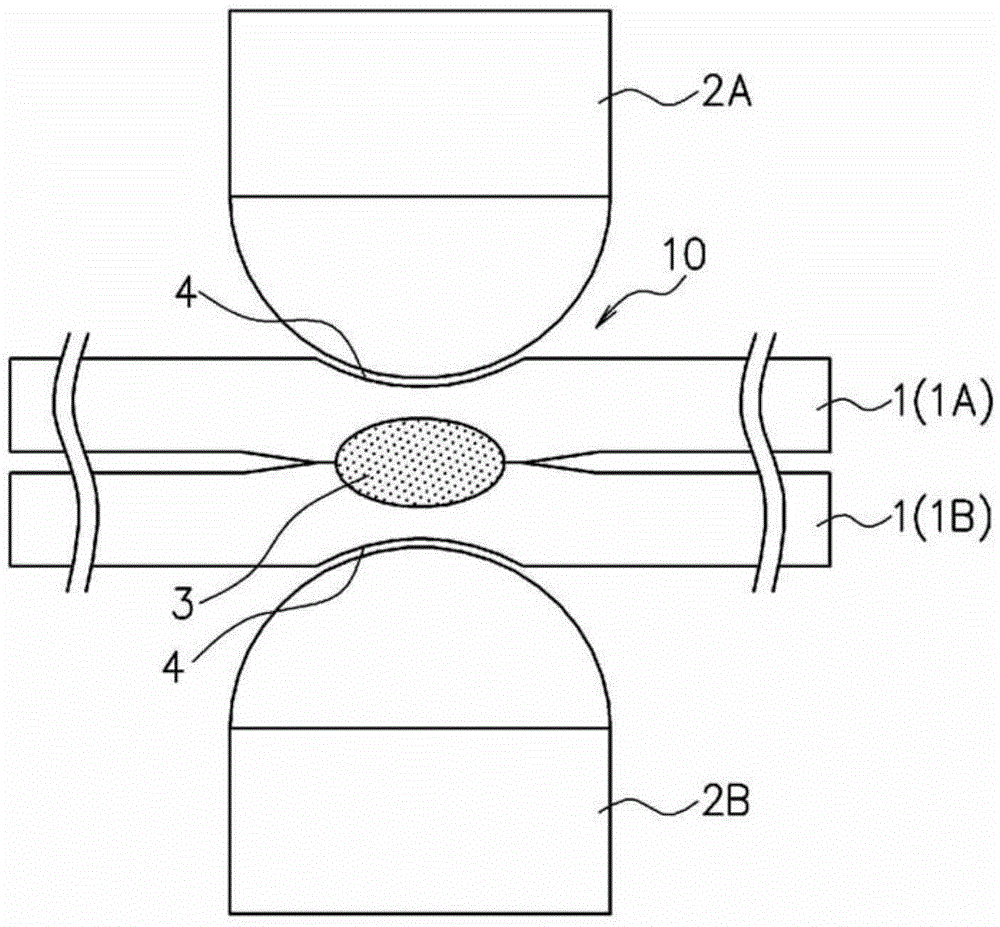

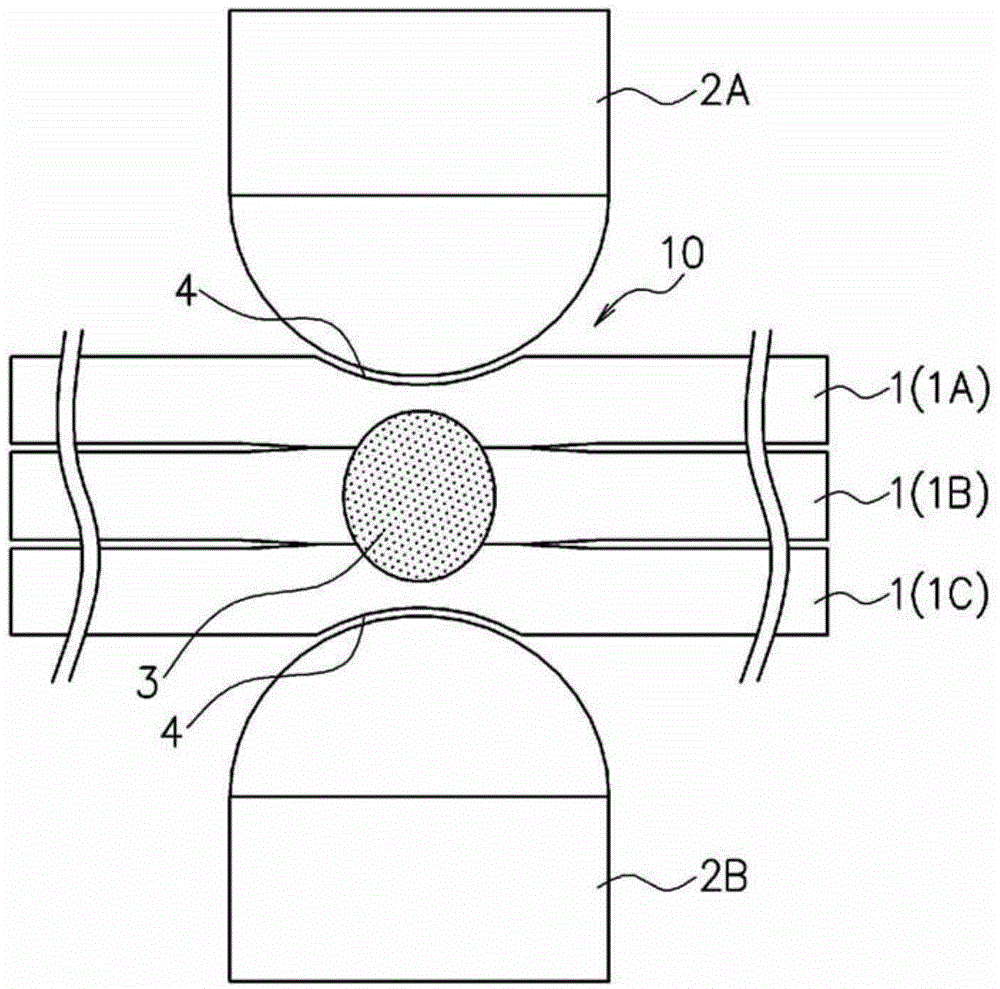

Spot welding method for high-strength steel sheet excellent in joint strength

ActiveCN104661784AImprove reliabilityHigh strengthWelding electric suppliesWelding/soldering/cutting articlesPower flowSheet steel

When two high-strength steel sheets (1A, 1B) having a sheet thickness ratio of 2 to 5, inclusive, and both having a tension strength of 780 MPa to 1850 MPa, inclusive, are overlapped with each other and resistance spot welding is performed, a first energizing process that is a preliminary energization with an applied pressure of P1 kN and a welding current of I1 kA and a second energizing process that is a main energization with an applied pressure of P2 kN and a welding current of I2 kA are performed, wherein the sheet thickness ratio is defined as the ratio of the total steel sheet thickness to the thickness of a steel sheet on the thinner side (the thickness per sheet if the two steel sheets (1A, 1B) have the same thickness). The applied pressures P1 and P2 are set to a constant applied pressure of P = P1 = P2 through the first energizing process and the second energizing process. In addition, when an average sheet thickness of the steel sheets (1A, 1B) is assumed to be t mm, the applied pressure P is set in the range expressed by the formula {0.5 ≤ P ≤ 3.0t(1 / 3)}. The welding current I1 is set in the range of 30% to 90%, inclusive, of the welding current I2. The second energizing process is initiated within 0.1 s after the completion of the first energizing process.

Owner:NIPPON STEEL CORP

Cutting device

InactiveCN107737992AEasy to collectEasy to cleanShearing machinesMaintainance and safety accessoriesFiltrationElectric machinery

The invention relates to the technical field of cutting and processing, and discloses a cutting device, which includes a base. Both sides of the top of the base are fixedly connected with fixed seats, and the top of the fixed seats are fixedly connected with lifting columns. A guide groove is opened on one side of the column, and the inside of the guide groove is movably connected with a first slider. The top of the lifting column is fixedly connected with a fixed column, and a servo motor is installed inside the fixed column. The output of the servo motor The shaft is fixedly connected with a first threaded rod, and the first threaded rod is located inside the lifting column. The cutting device collects the dust generated by cutting through the collection tank on the workbench, filters it through the leak plate, sprays water mist through the atomizing nozzle on one side of the collection tank, and makes the dust floating in the air fall through the second connecting pipe It enters the treatment tank, is filtered and purified by the purification layer, and enters the water tank through the outlet pipe for recycling, which saves energy and is easy to clean.

Owner:郑艳峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com