Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1046 results about "Size change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

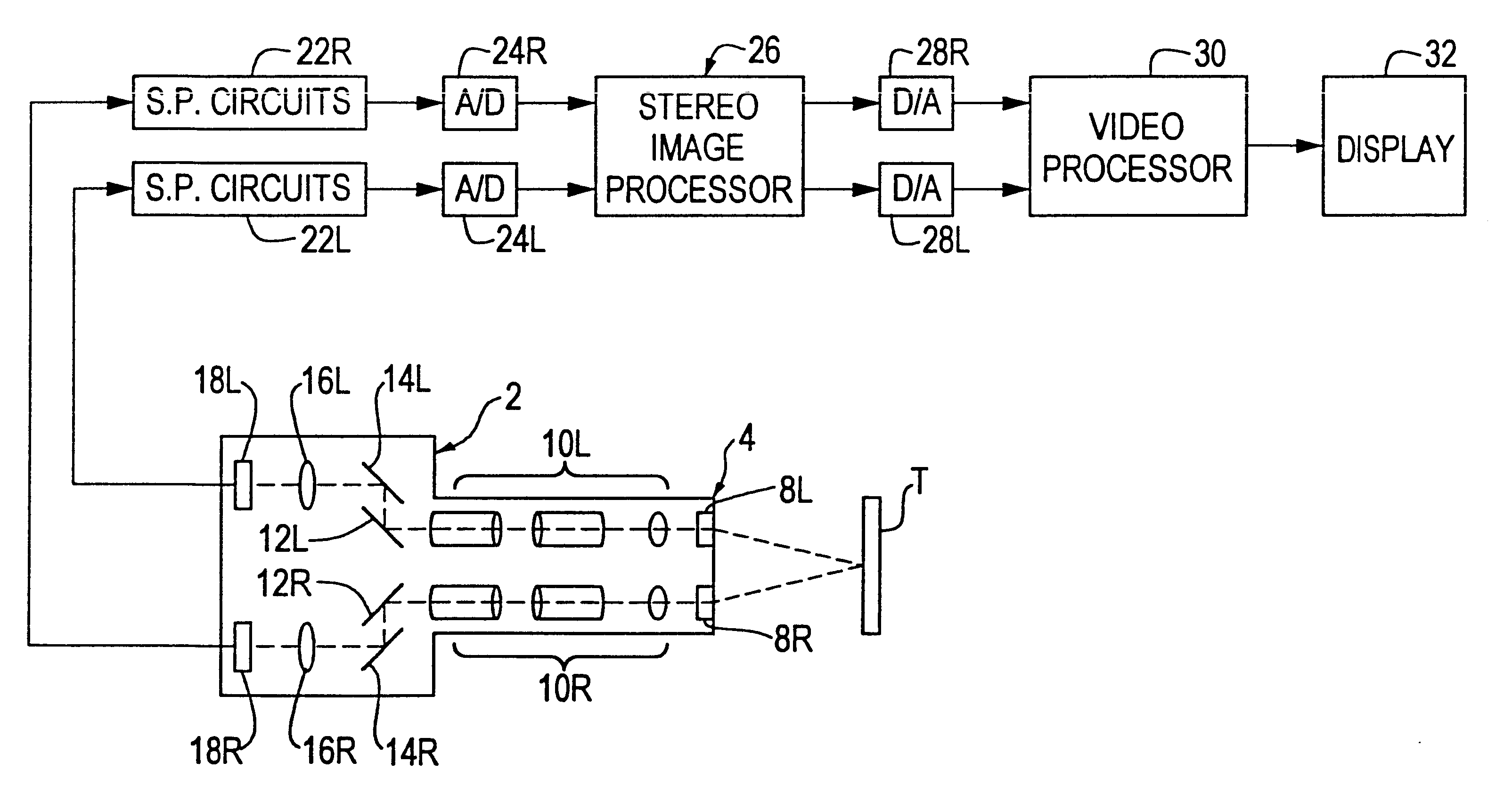

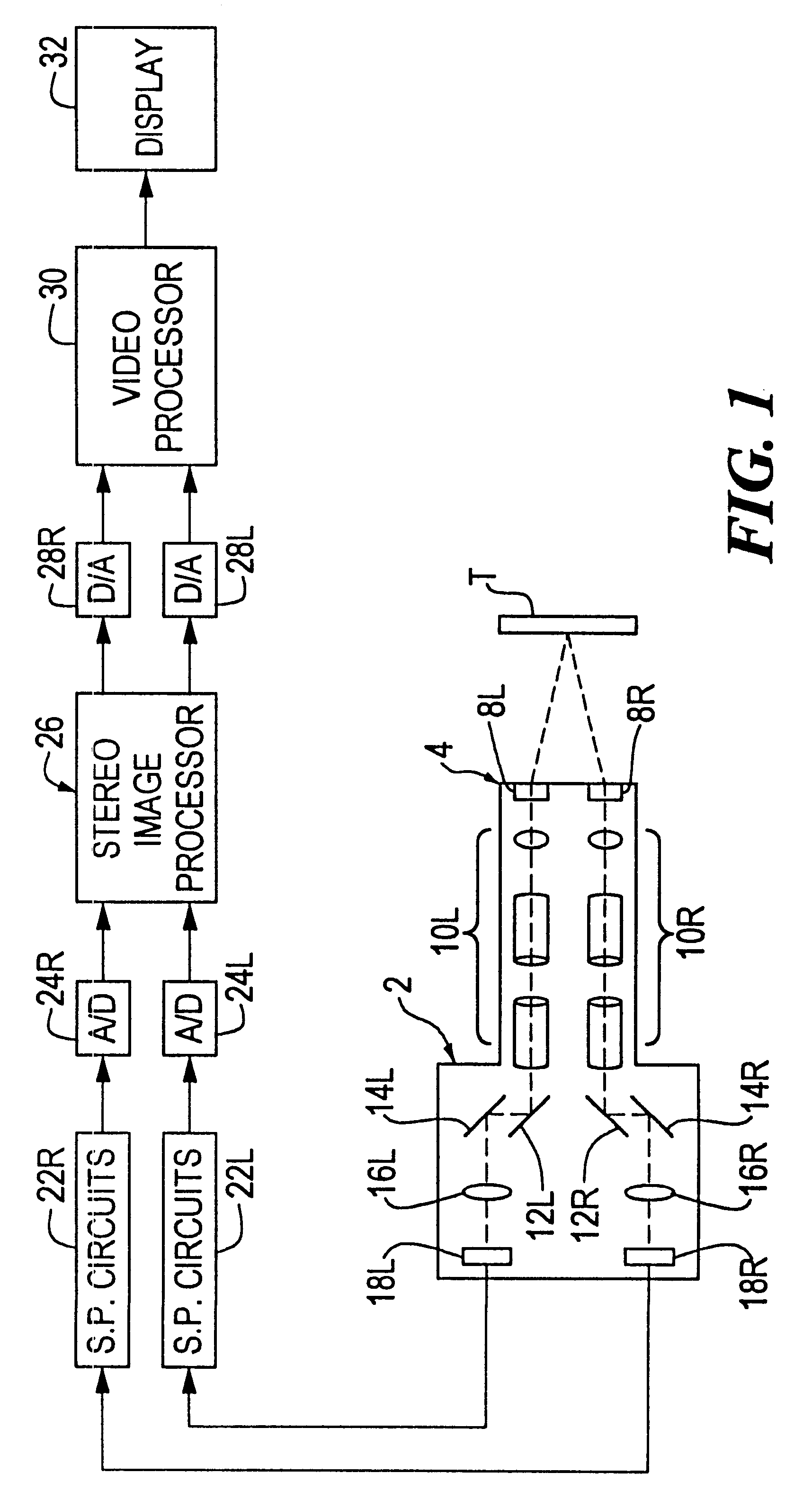

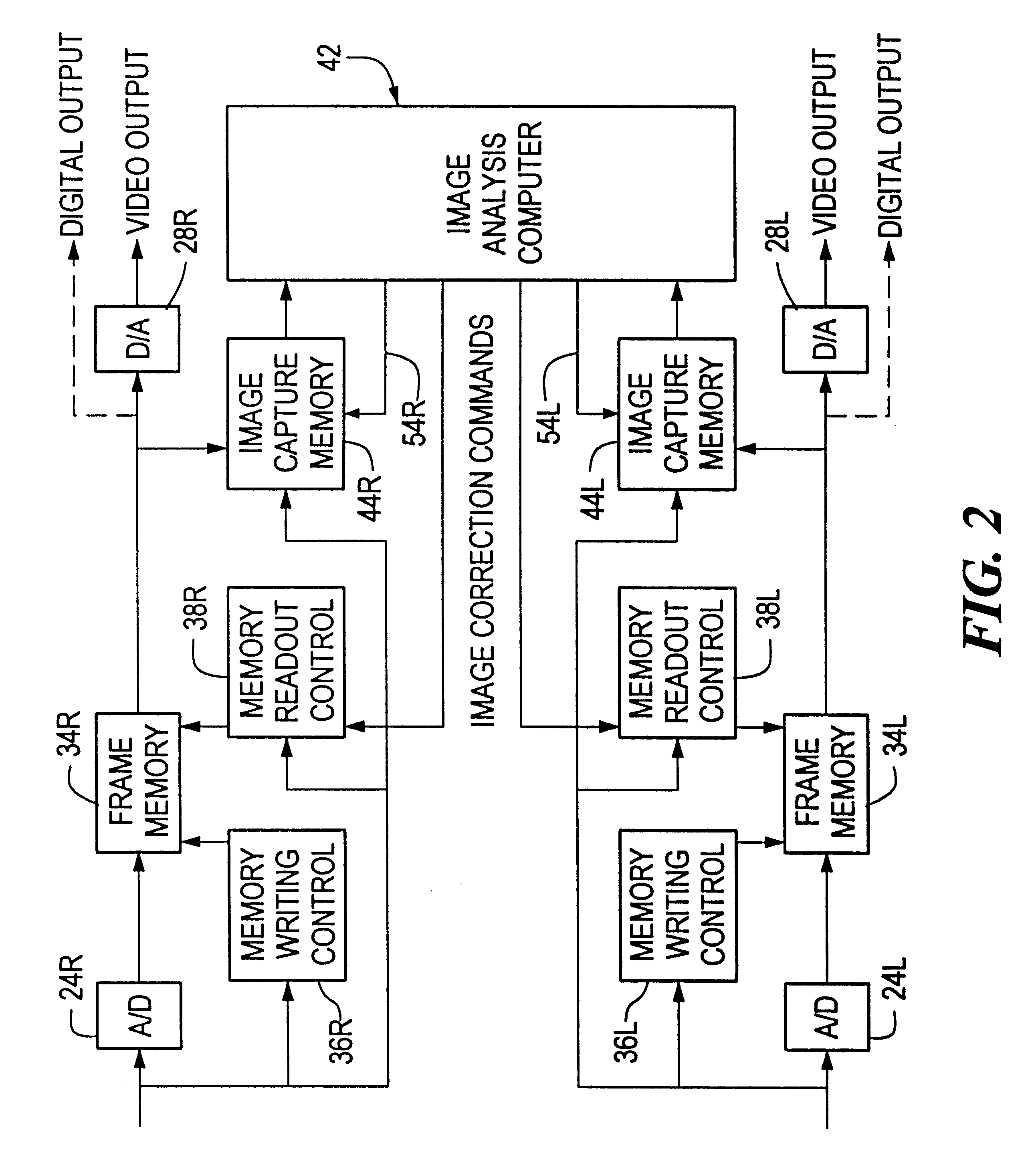

Method and apparatus for aligning stereo images

A method and apparatus are provided for correcting for optical misalignment of the dual (left and right) images produced by a stereo electronic endoscope, or of the corresponding dual images produced by coupling electronic imaging devices to each of two monocular teaching ports of a stereo optical endoscope. The stereo image alignment technique comprises electronically capturing the video image data of the dual images, and subsequently processing that data electronically to correct for optical alignment errors. The method involves digitizing the electronic data and digitally performing the equivalent of vertical image shift, and / or image size change, and / or image rotation as required to correct for any visual image misalignment.

Owner:VISTA MEDICAL TECH +1

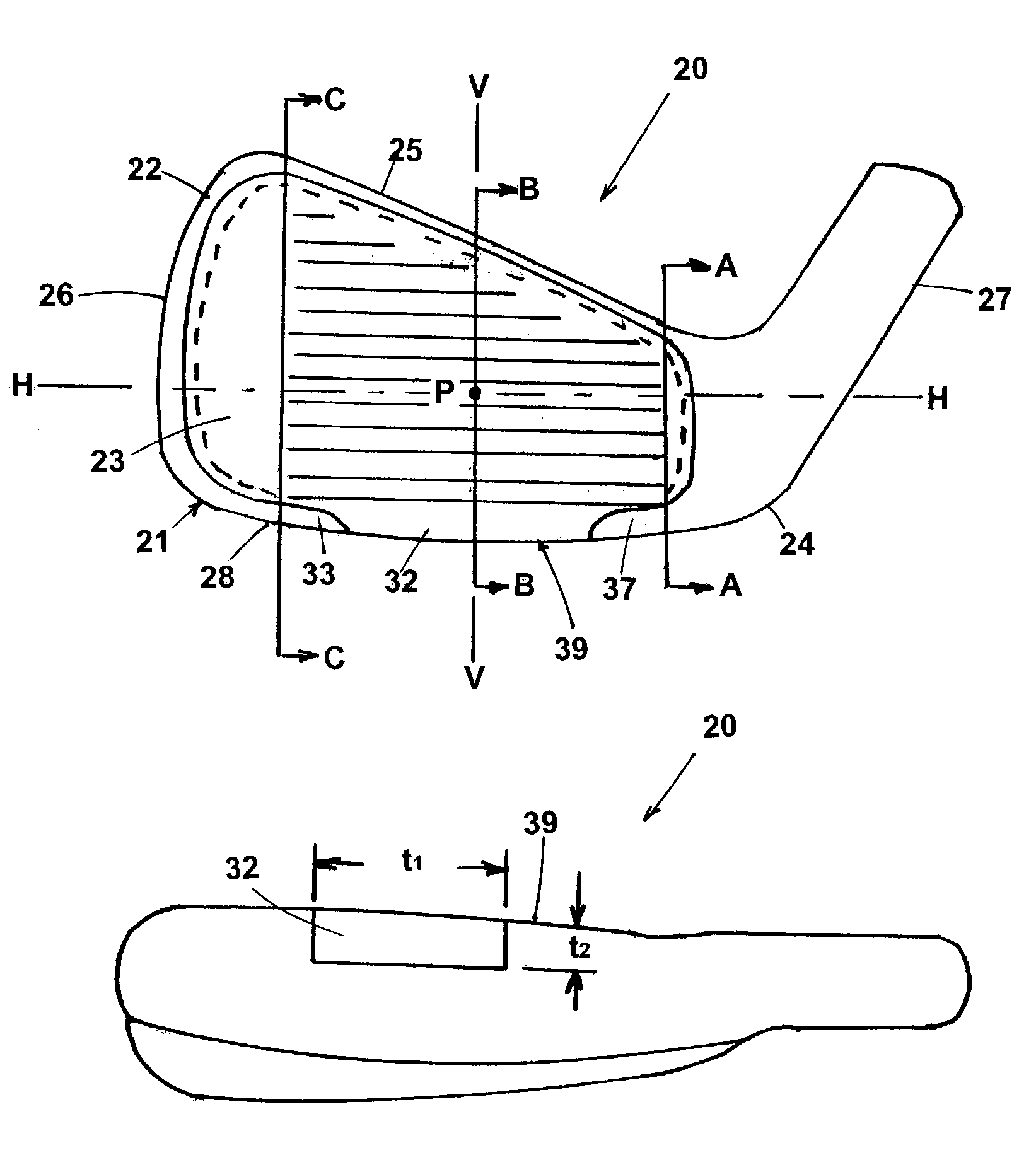

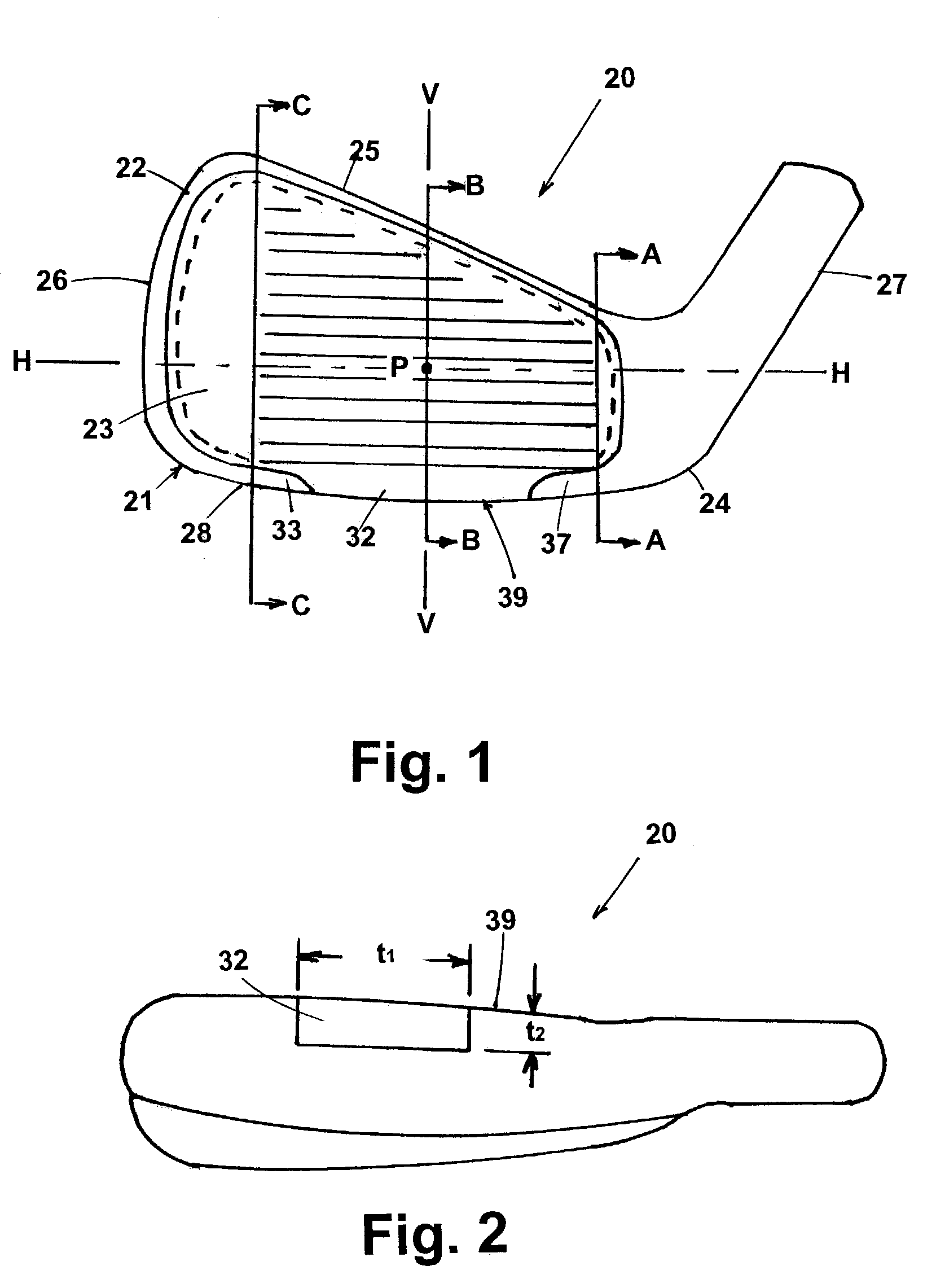

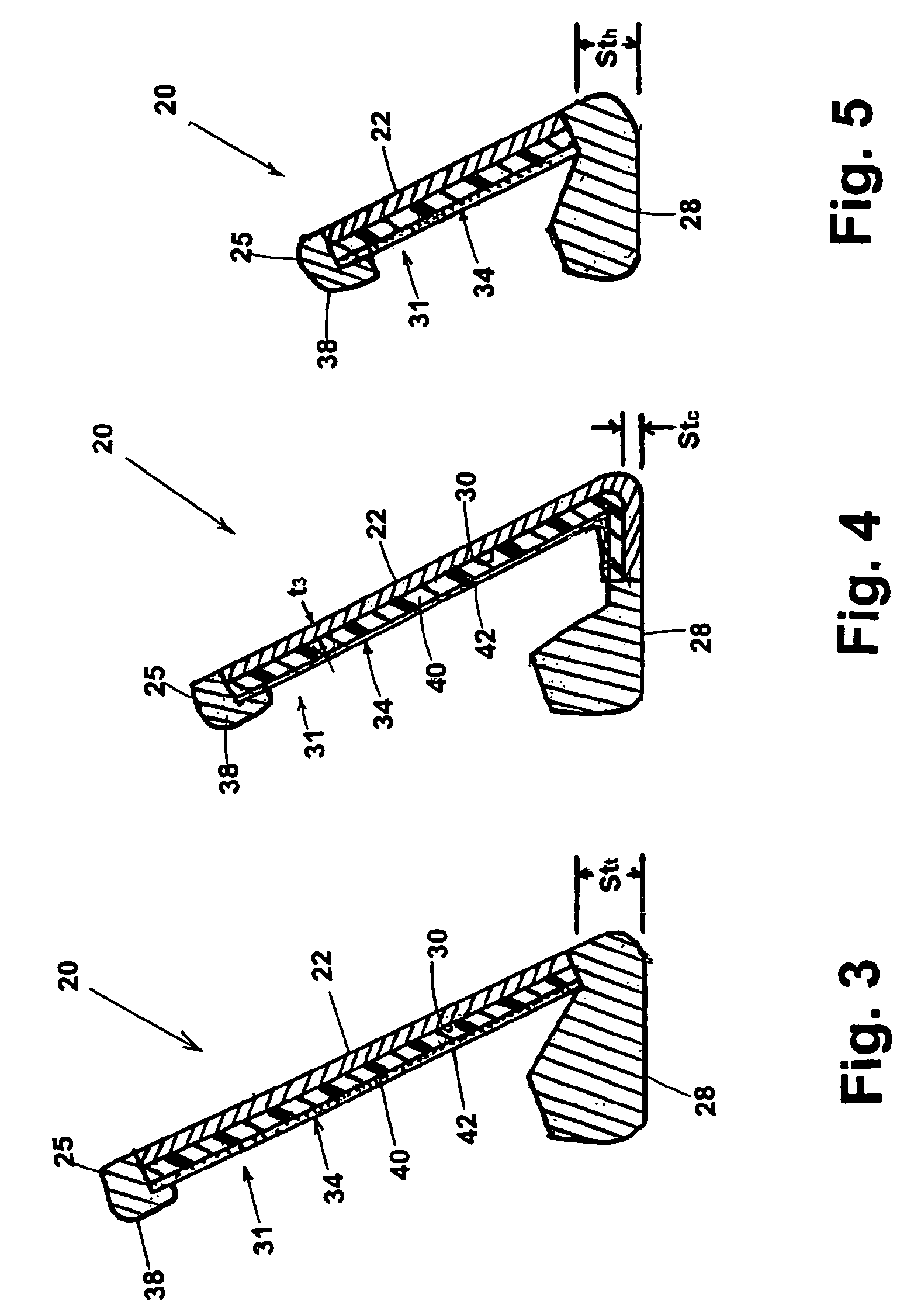

Golf club iron

An iron golf club head having a thin (less than 0.12 inches) first section that has an expanded unsupported front face region. The first section including a central portion forming part of a leading edge and wrapping around a sole section of the club, to create an increase the coefficient of restitution of the club head to greater than 0.8. The club head utilizes a rear insert that in addition to providing support for the front face, also allows for the fine tuning of swing weights with no change in geometry or size of the club head. This is accomplished this by the utilization of weight adjustment inserts that impregnate tungsten loaded plastic into sheets of carbon graphite and epoxy. The percentage of tungsten creating a weight range without any size change in the sheets.

Owner:ACUSHNET CO

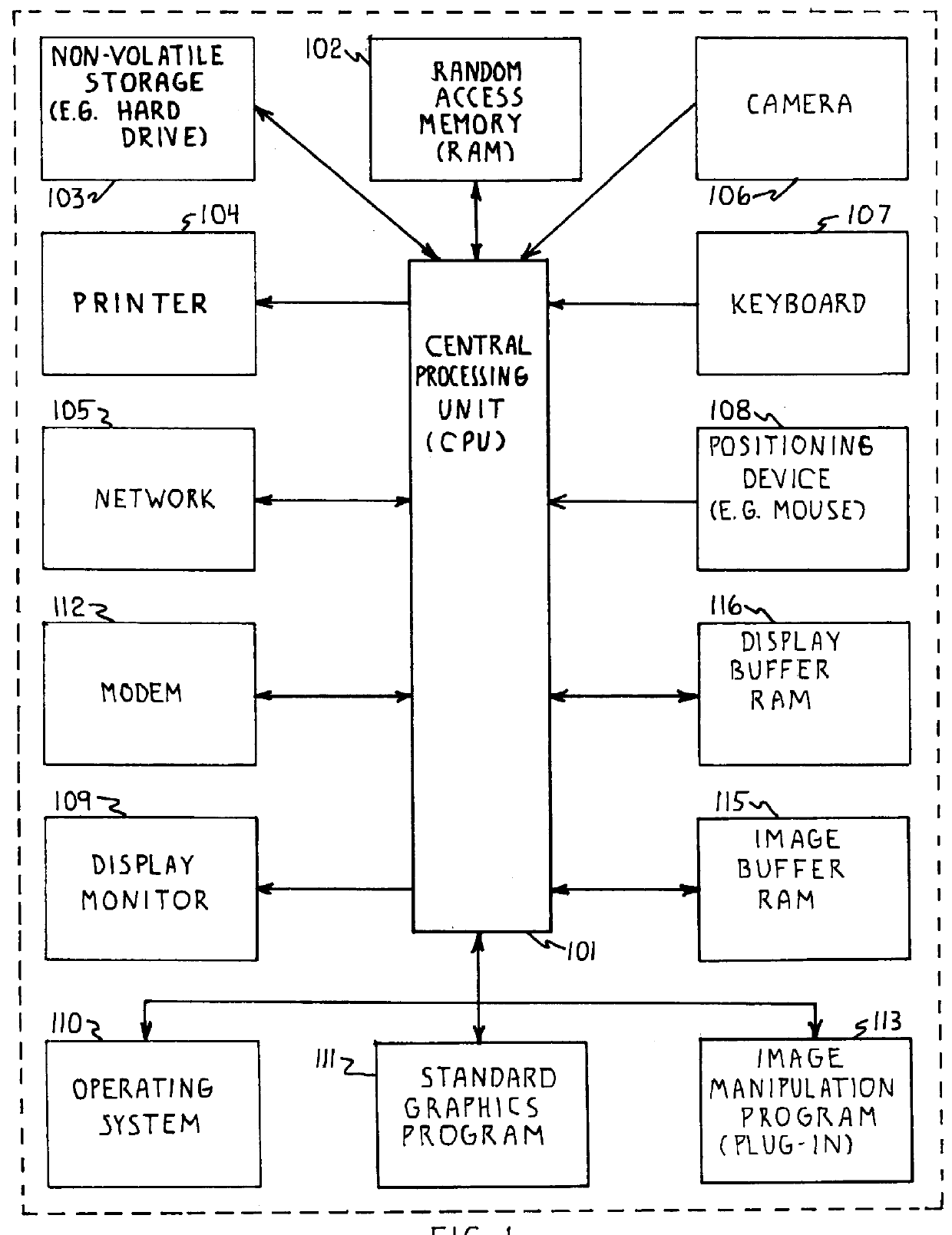

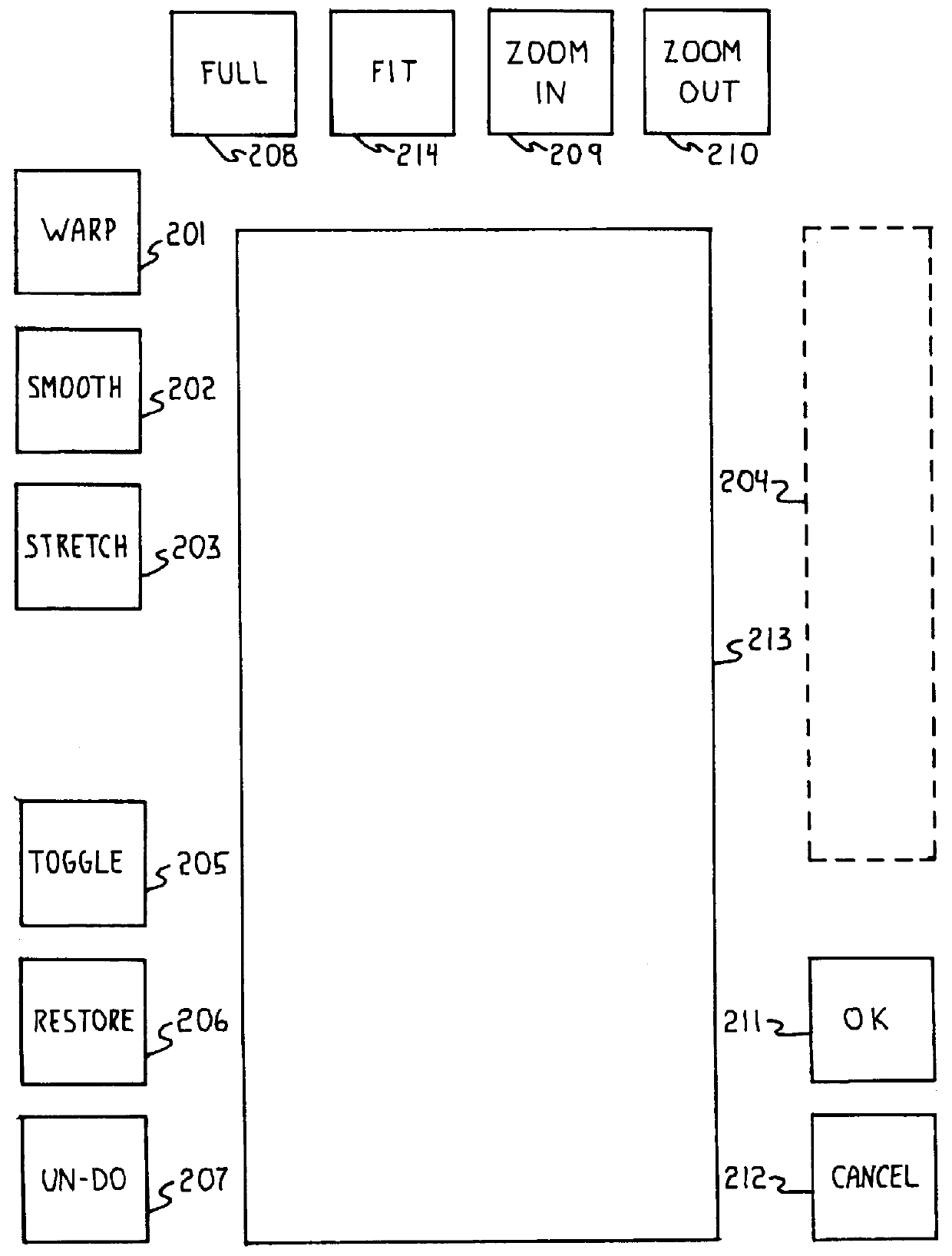

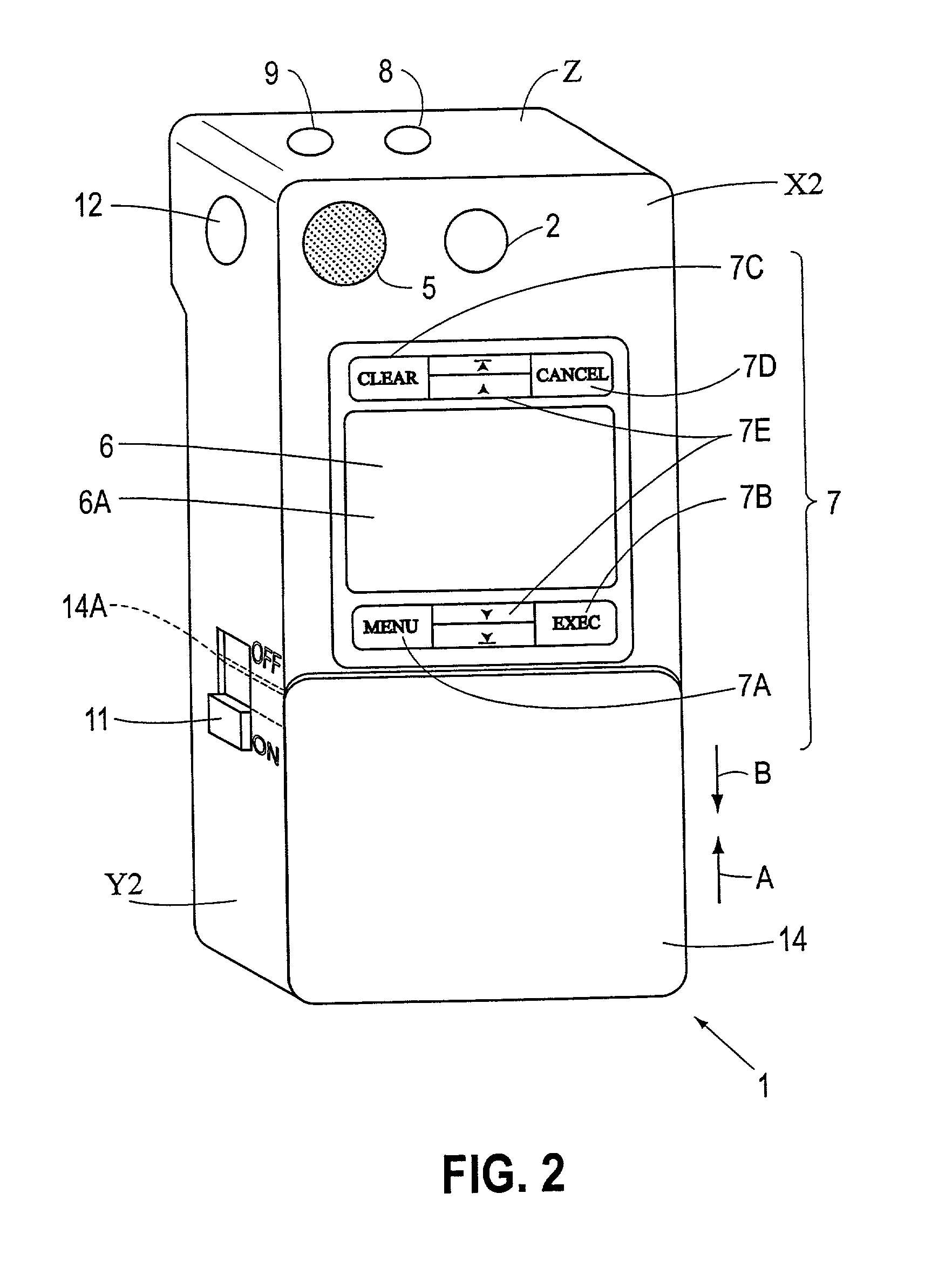

Apparatus for modifying graphic images

InactiveUS6084598AIncrease speedConsistent qualityDrawing from basic elementsGeometric image transformationChange managementShape change

A computer system modifies digital images of the human form as well as other objects. The computer system provides intuitive means for accessing warp, smooth, stretch, copy, and paste tools for image modification; undo, toggle and restore tools for change management; and zoom, fit, and full tools for image display sizing. The computer system is controlled by a program that uses a combination of novel approaches to make image manipulation fast and easy. Buttons are displayed only when they are actually available for use, based on the current system operating mode. The image sizing tools enable an image size change to accomodate the tool size without a required change to the cursor state or to the edit mode state. When regions are defined by the user, the cursor shape changes to indicate whether the cursor is located inside a region, outside the region, and on the region bounding box; allowing a user to perform different operations depending upon cursor location rather than depending upon, and requiring, user executed button pushing as a specific operation. The computer system uses display contexts and bitmap masks that enhance operation speed. Operations are always performed on the full image resolution rather than a displayed image resolution.

Owner:CHEKERYLLA JAMES

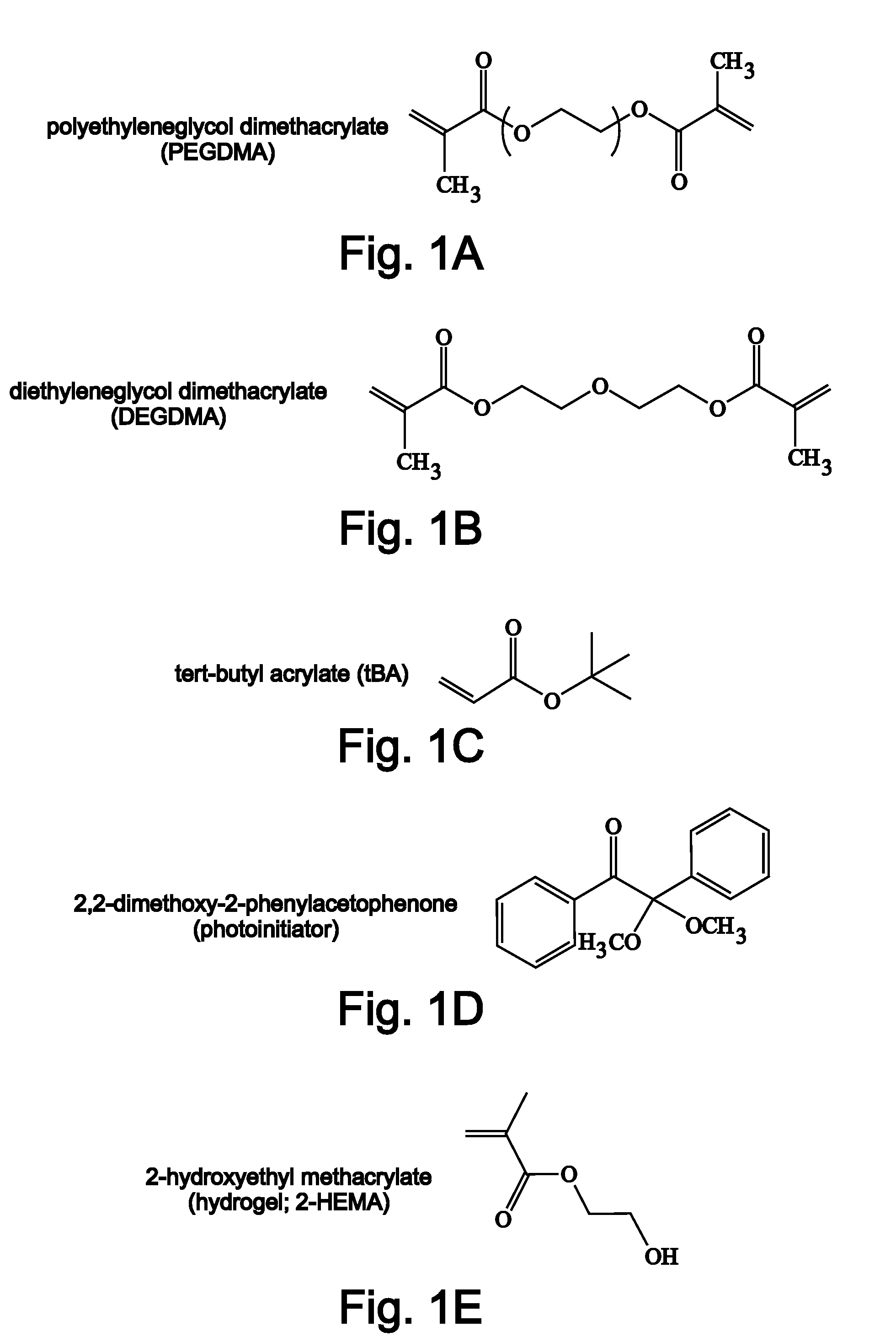

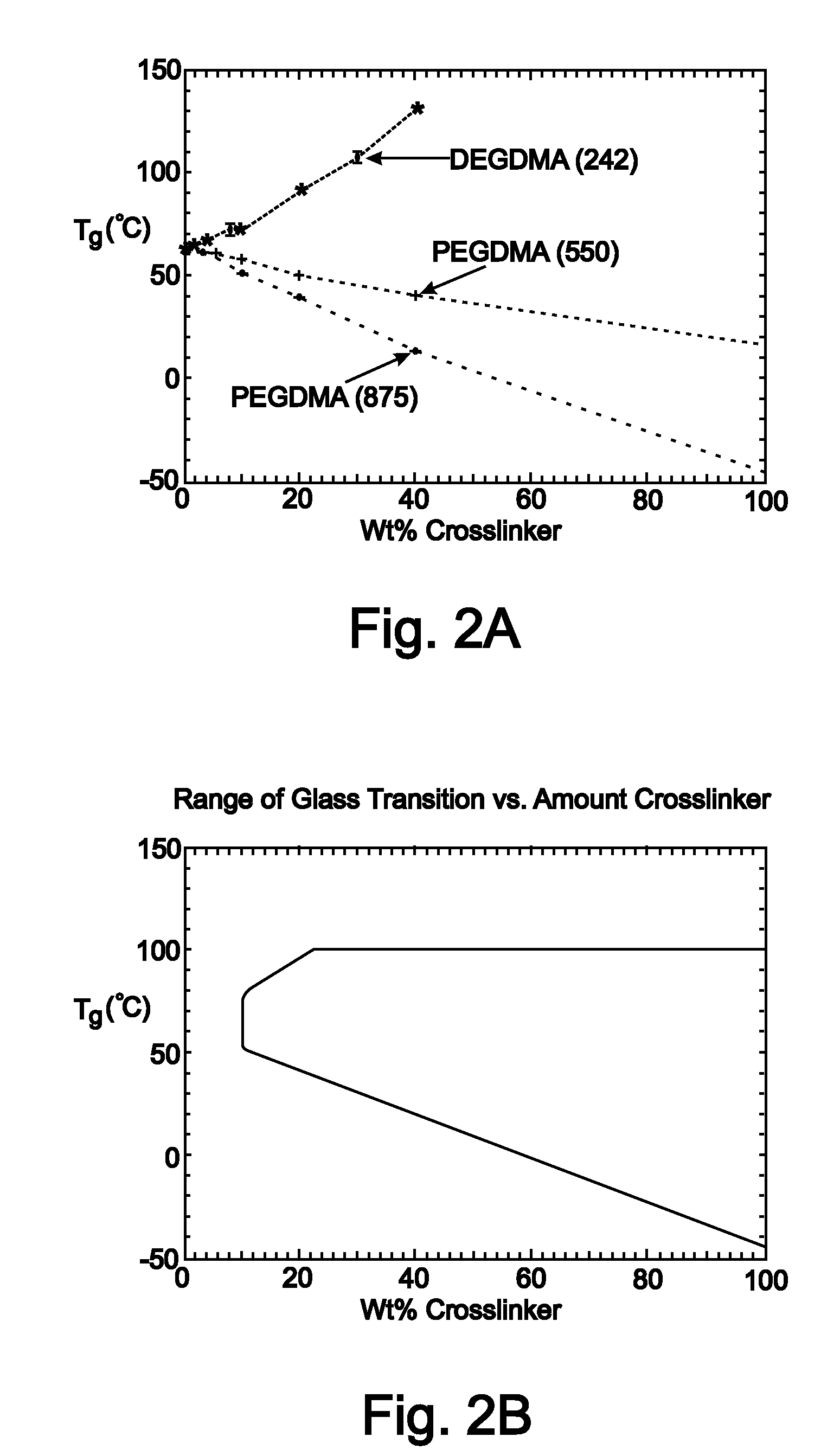

Shape Memory Polymer Medical Devices

Medical devices for in vivo medical applications are disclosed. The medical devices are constructed of shape memory polymer (SMP) materials capable of assuming a memory shape at physiological temperatures. These medical devices may be used in surgical procedures and in both vascular and non-vascular applications. These SMP medical devices have a post-implantation memory shape that is substantially identical to or slightly larger than the insertion site to adapt to vessel growth or size changes. SMP medical devices may be formed as stents or occlusion devices (i.e., plugs) having a number of different structural features. The SMP medical devices may be formed from a first monomer and a second cross-linking monomer, wherein the weight percentages of the first and second monomers are selected by performing an iterative function to reach a predetermined glass transition temperature (Tg) and a predetermined rubbery modulus to optimize post-implantation memory shape properties of the devices.

Owner:UNIV OF COLORADO THE REGENTS OF

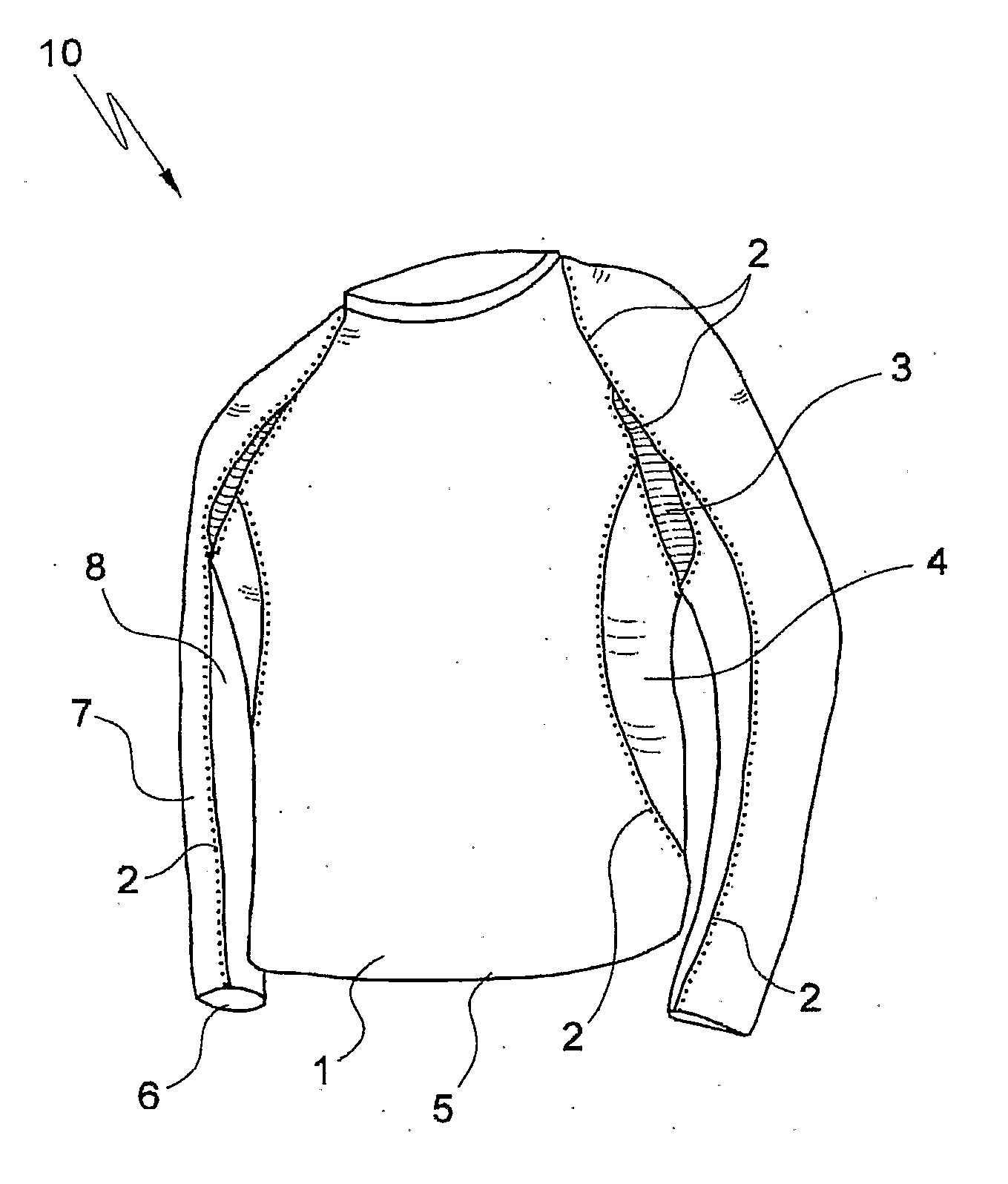

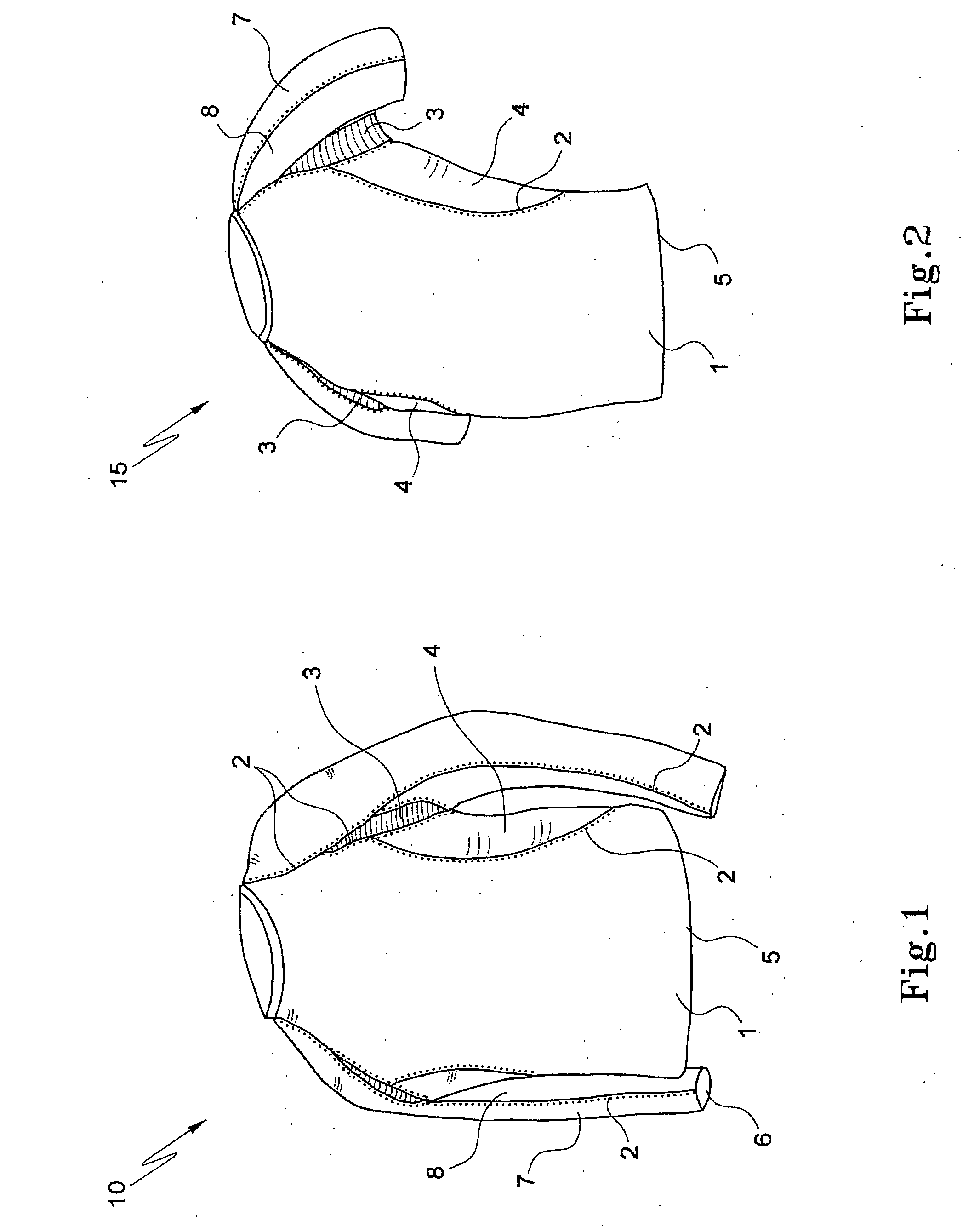

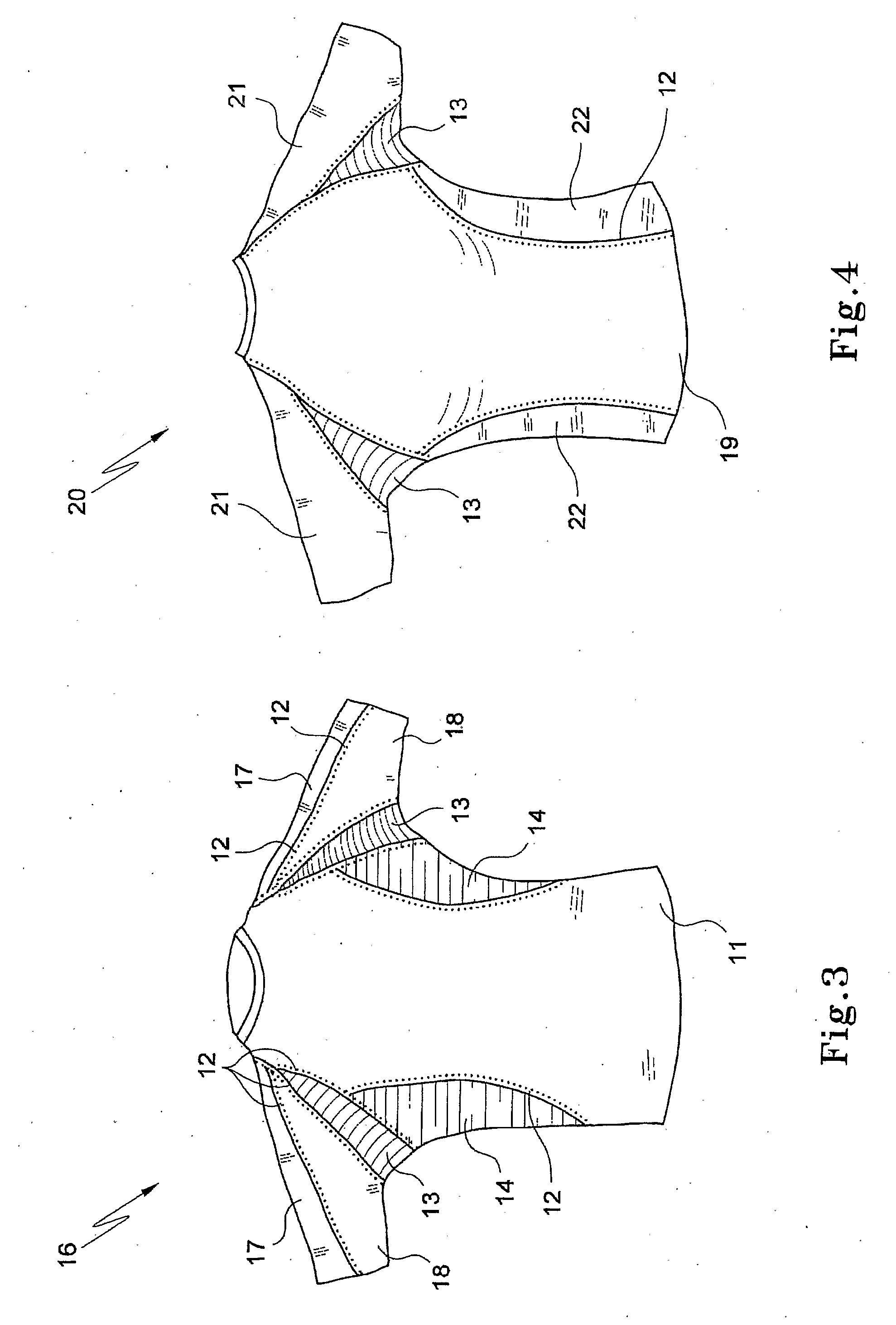

Compression Garments And A Method Of Manufacture

The invention provides a compression garment (50) for clothing a body part, such as a lower torso and the legs. The body part includes a muscle ridge, such as a lateral edge of the gluteus maximus (49). Compression garment (50) has first and second panels of stretchable material joined by a seam (32). At least part of the seam (32) is adapted to correspond to at least part of the muscle ridge, being at the edge of the gluteus maximus (49). The invention also provides a method of manufacturing a compression garment, using an algorithm to calculate size changes to produce desired compression.

Owner:SKINS INTEMATIONAL TRADING AG

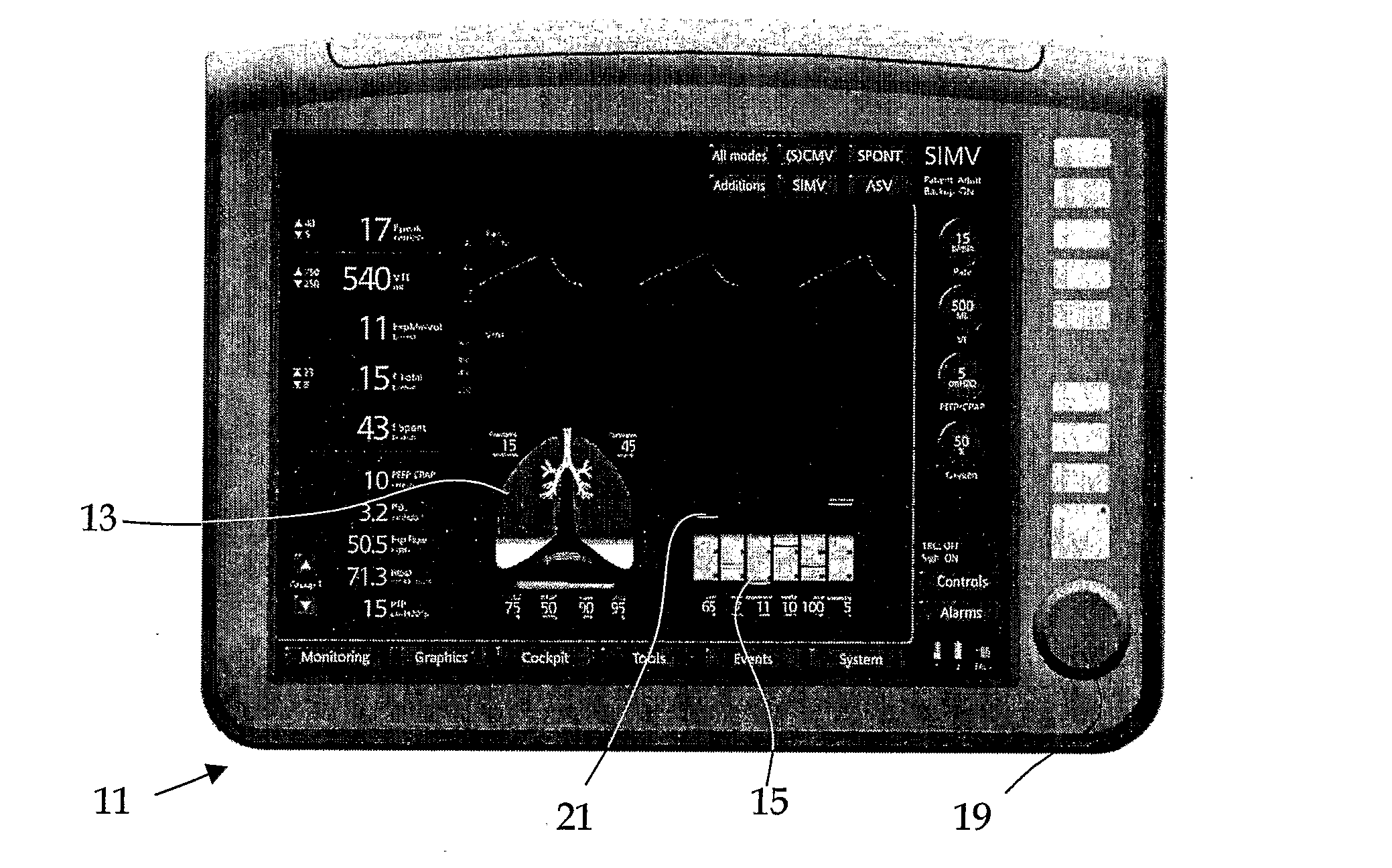

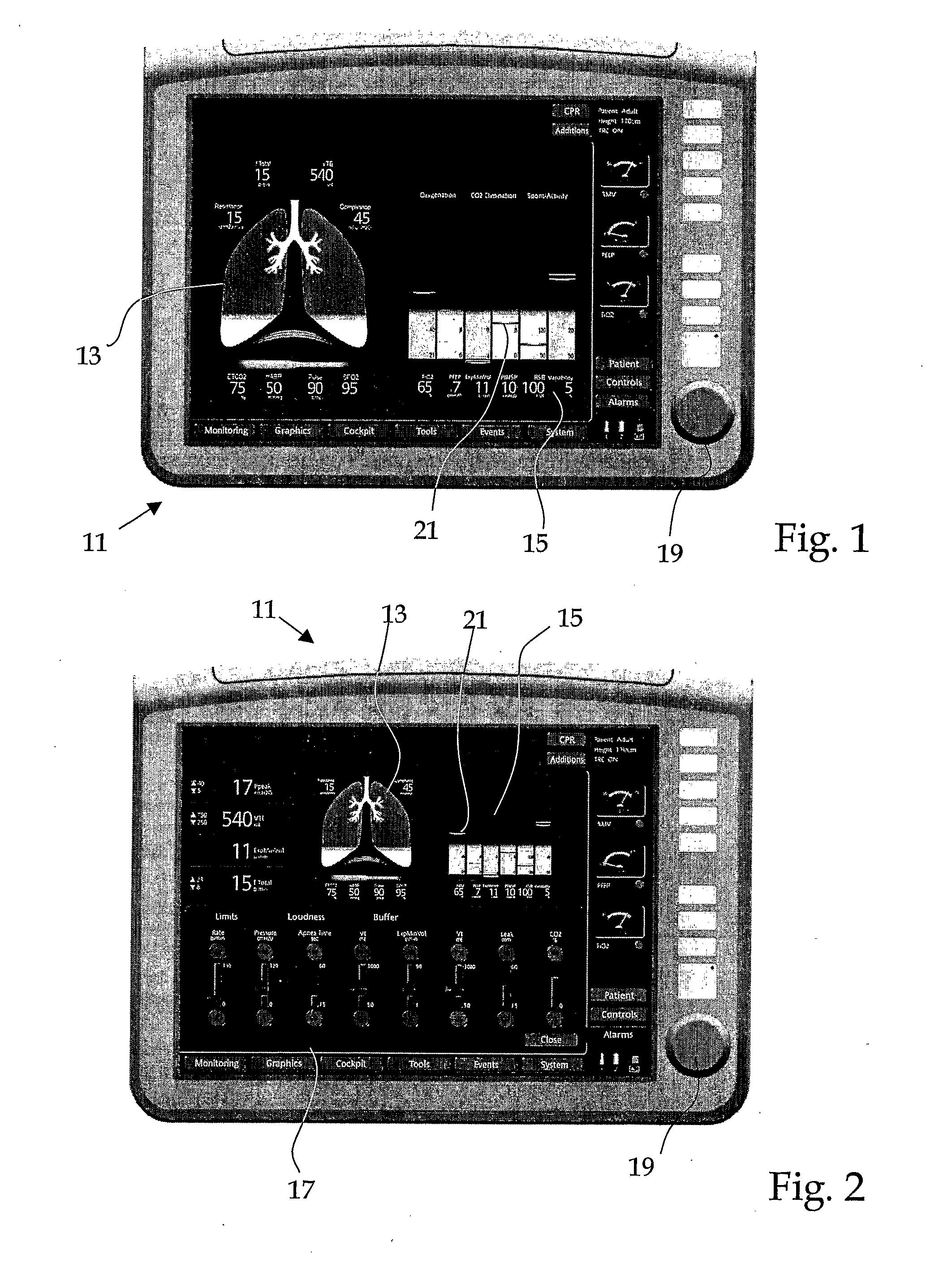

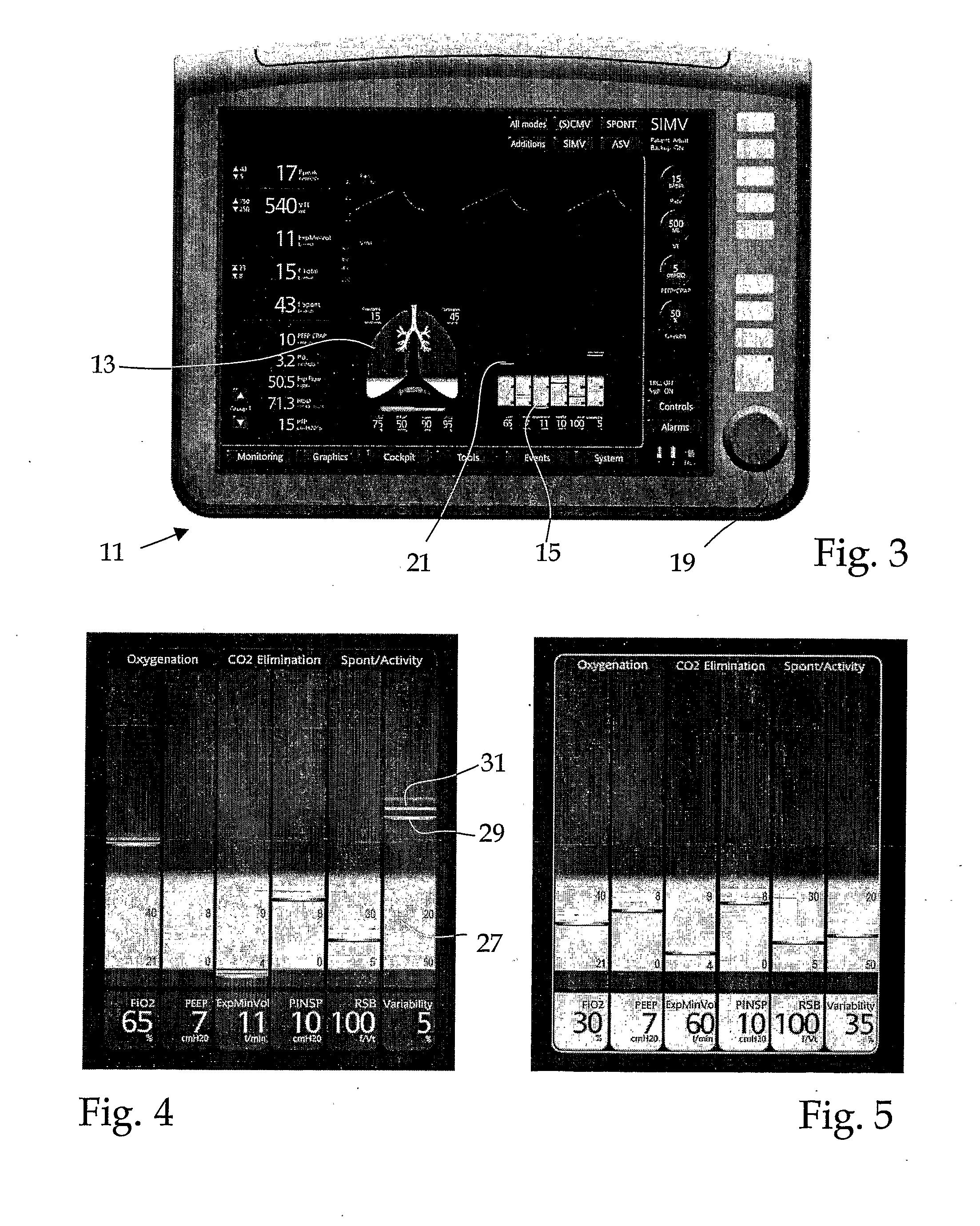

Method and a device for simplifying a diagnostic assessment of a mechanically ventilated patient

InactiveUS20090024008A1Increases intuitive readability of symbolImprove readabilityRespiratorsMedical devicesGraphicsAnimation

The invention relates to a method for acquiring several changing values and representing the acquired values on a monitoring screen, as well as to a device with a screen in order, on this, to represent changing values acquired during ventilation of the patient. The device comprises means for acquiring at least three changing values of different origin, and means for representing the values, which permit the acquired values to be qualitatively represented on the screen together in a single graphic element. This graphic element has a pictorial representation of a lung shape. The invention is characterised in that the means for representing the values are designed such that a volume change of the ventilated lung which is detected within each breath, is represented in an animated manner by way of size change of the lung shape corresponding to this corresponding volume change.

Owner:HAMILTON MEDICAL AG

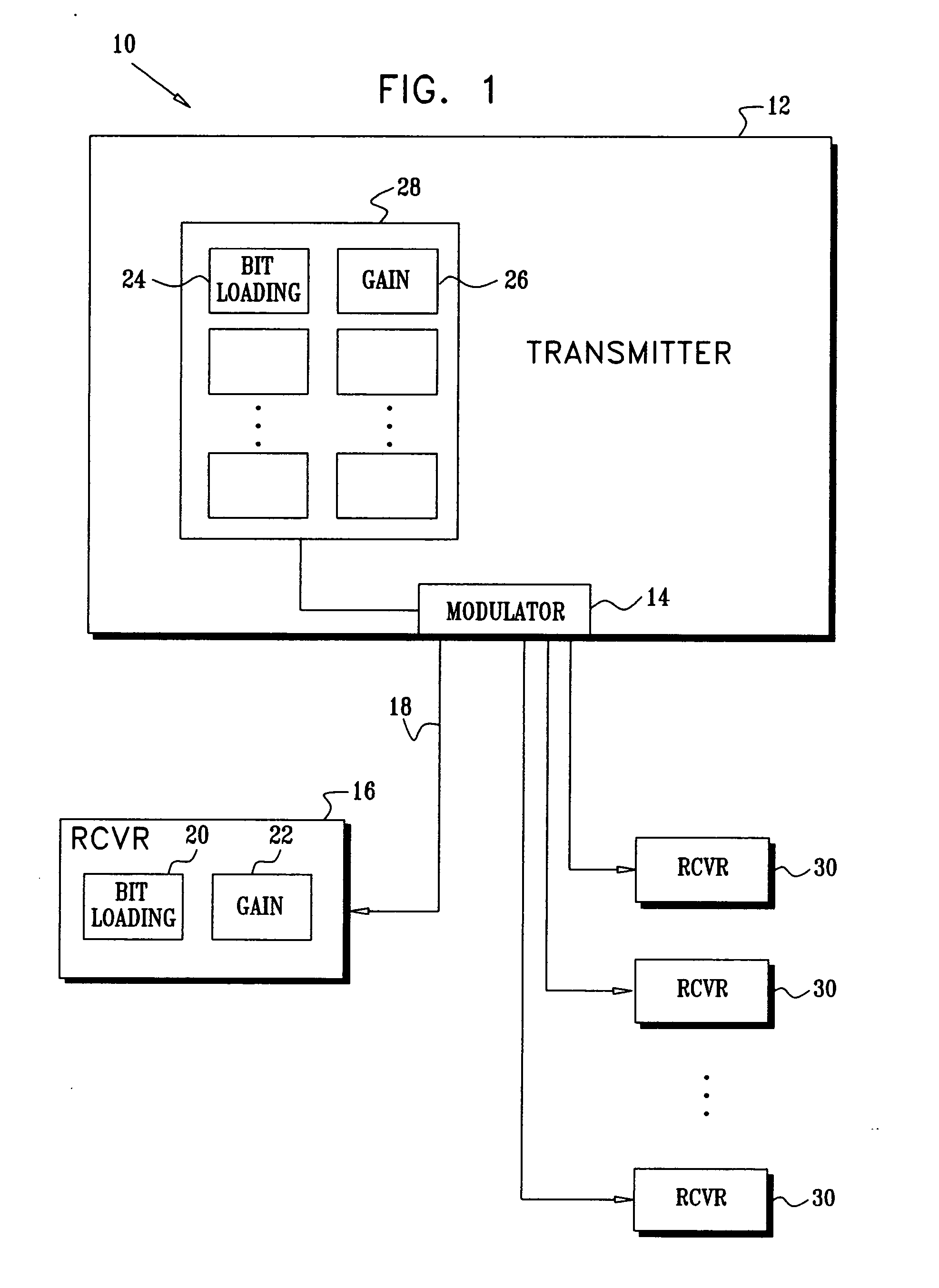

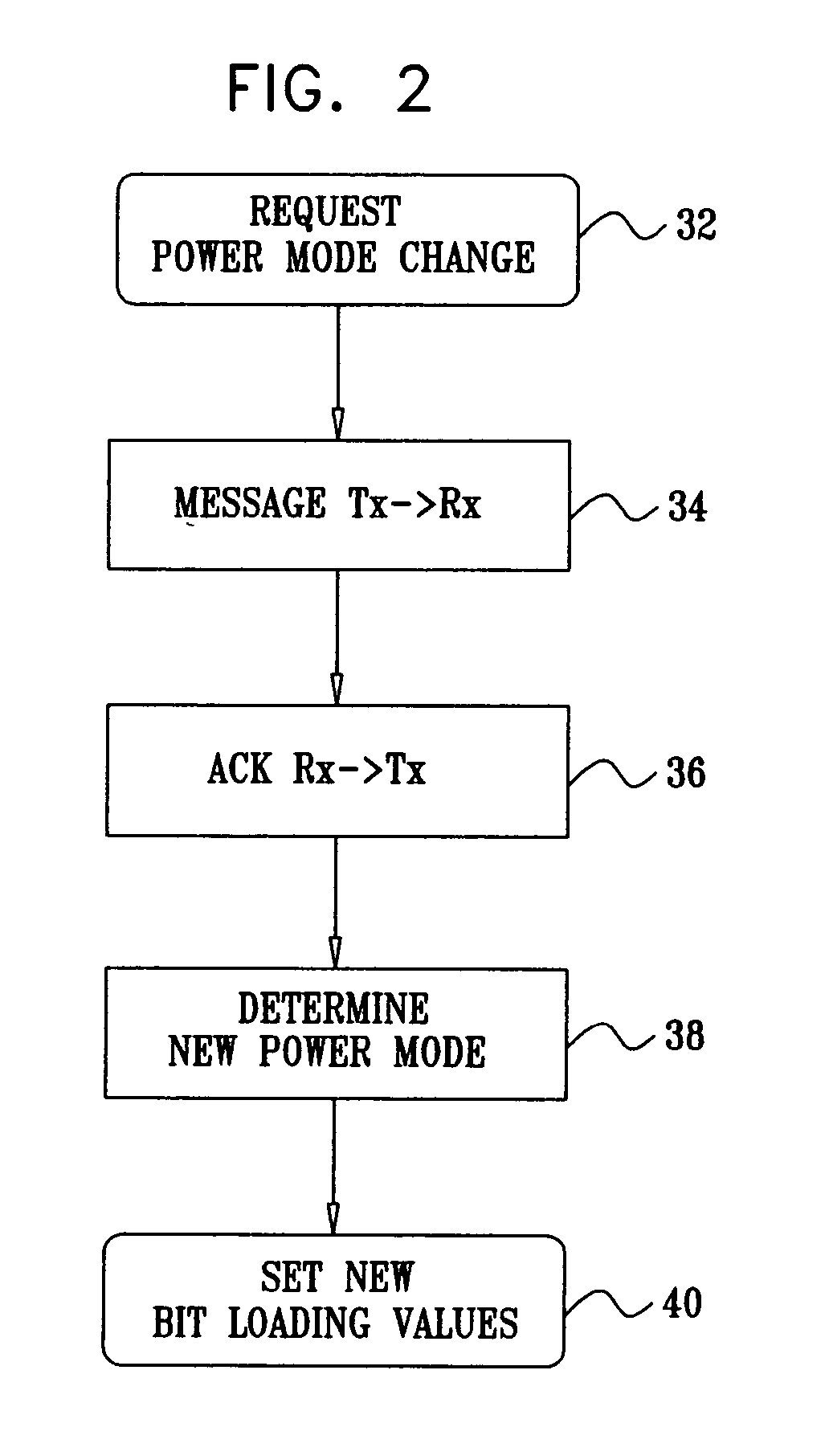

Power save mode transition using loading translation function

Methods and systems provide an efficient power save mode for multi carrier modems, such as DMT based ADSL and VDSL modems. Fast transitions from power save mode to full operational mode occur, without the overhead of transmitting large quantities of configuration information between the transmitter and receiver. Signal constellation size changes occurring while operating in power save mode to continue to apply once full operational mode is resumed. Multiple power save modes are enabled, each having a different level of power dissipation and crosstalk, both far end crosstalk and near end crosstalk. Power dissipation and crosstalk can thus be graduated on a line, according to a user-requested bit rate.

Owner:STMICROELECTRONICS SRL

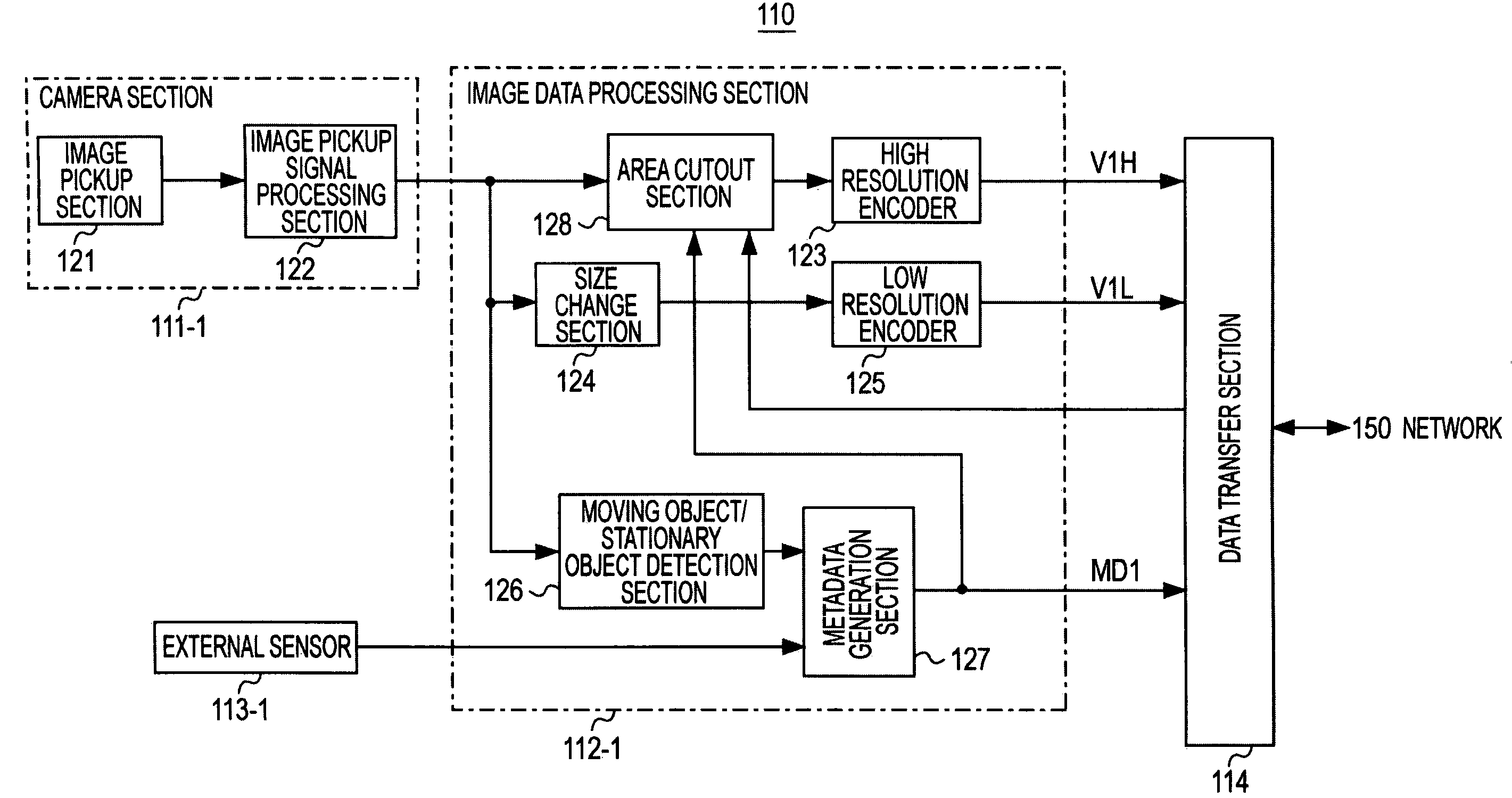

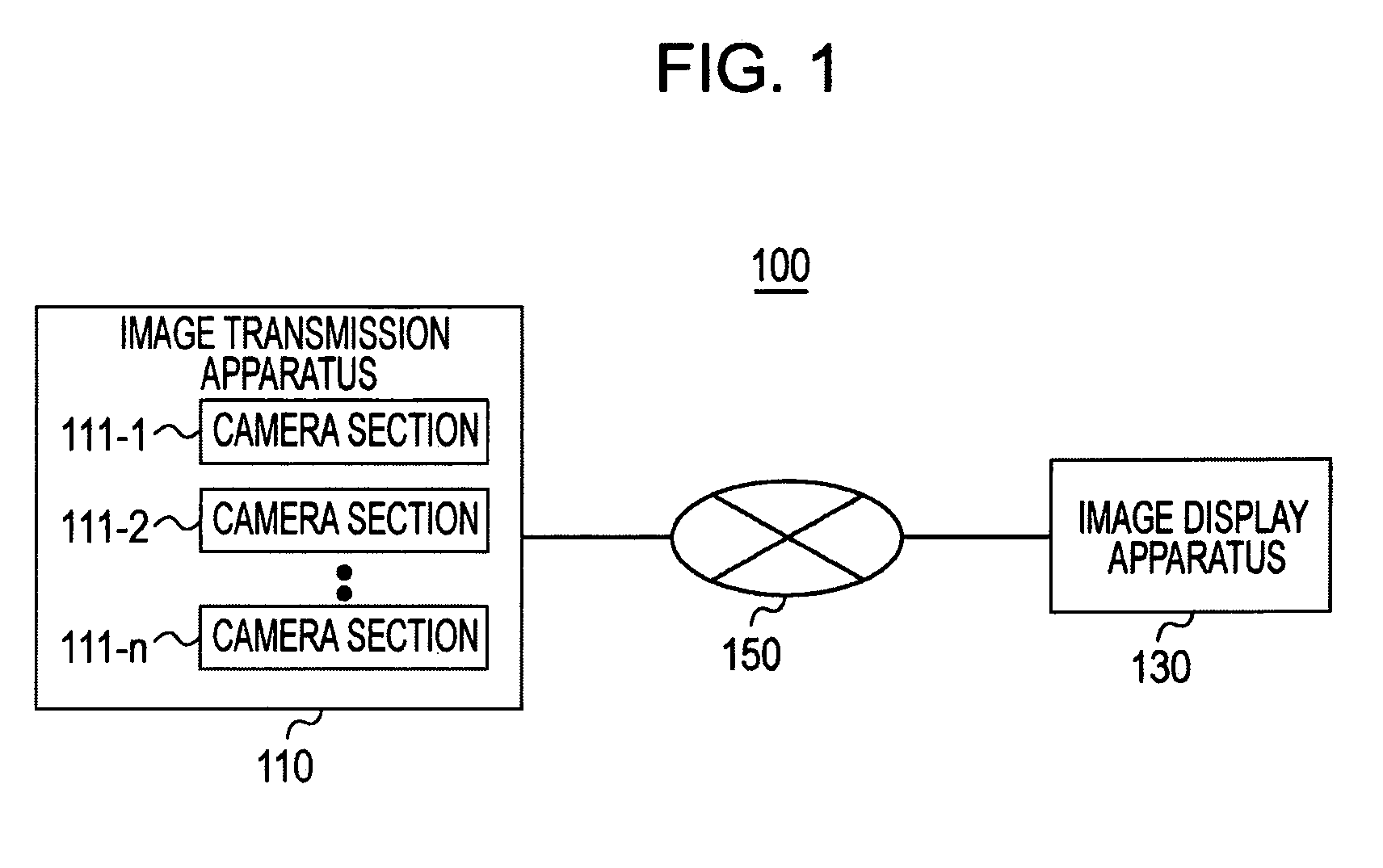

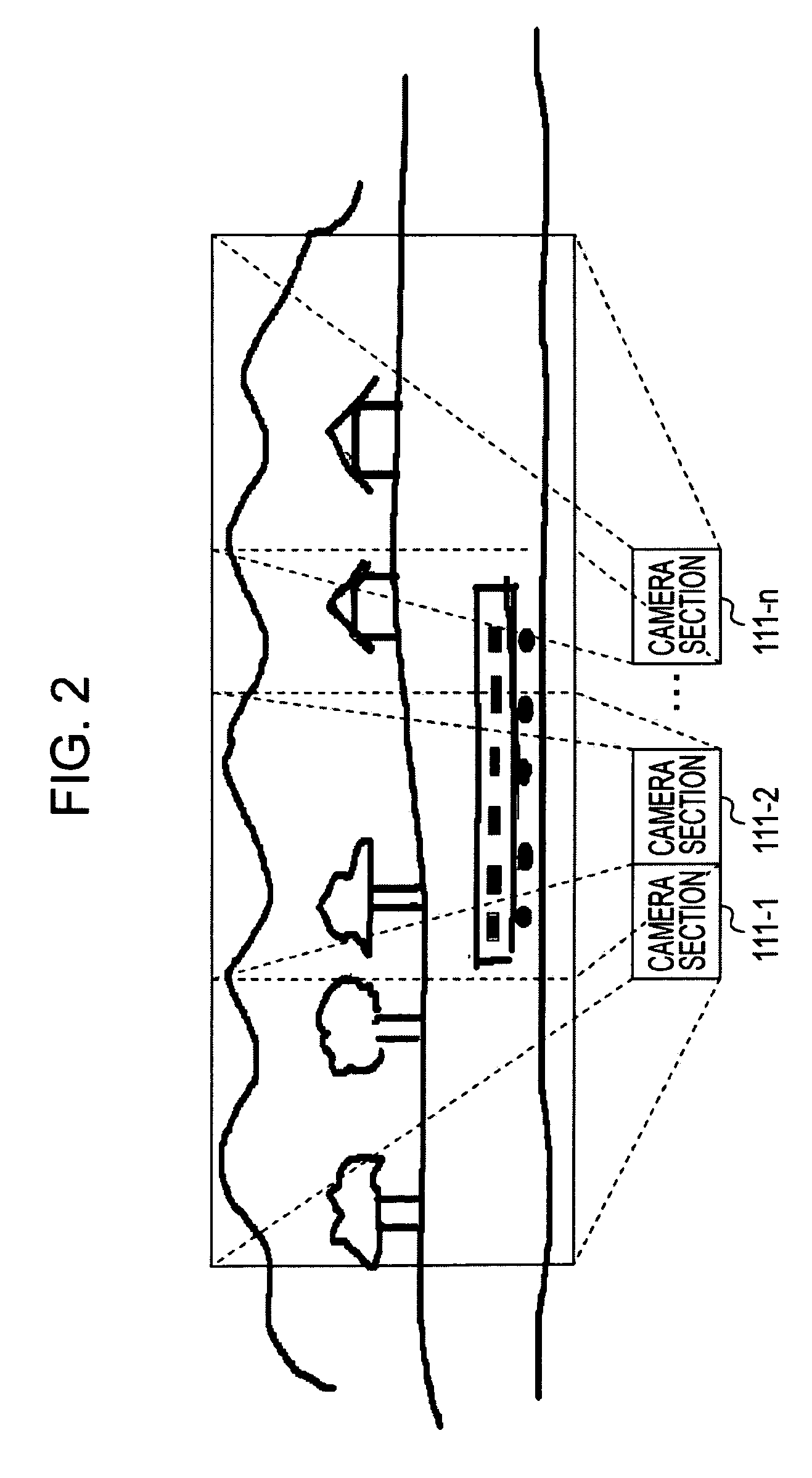

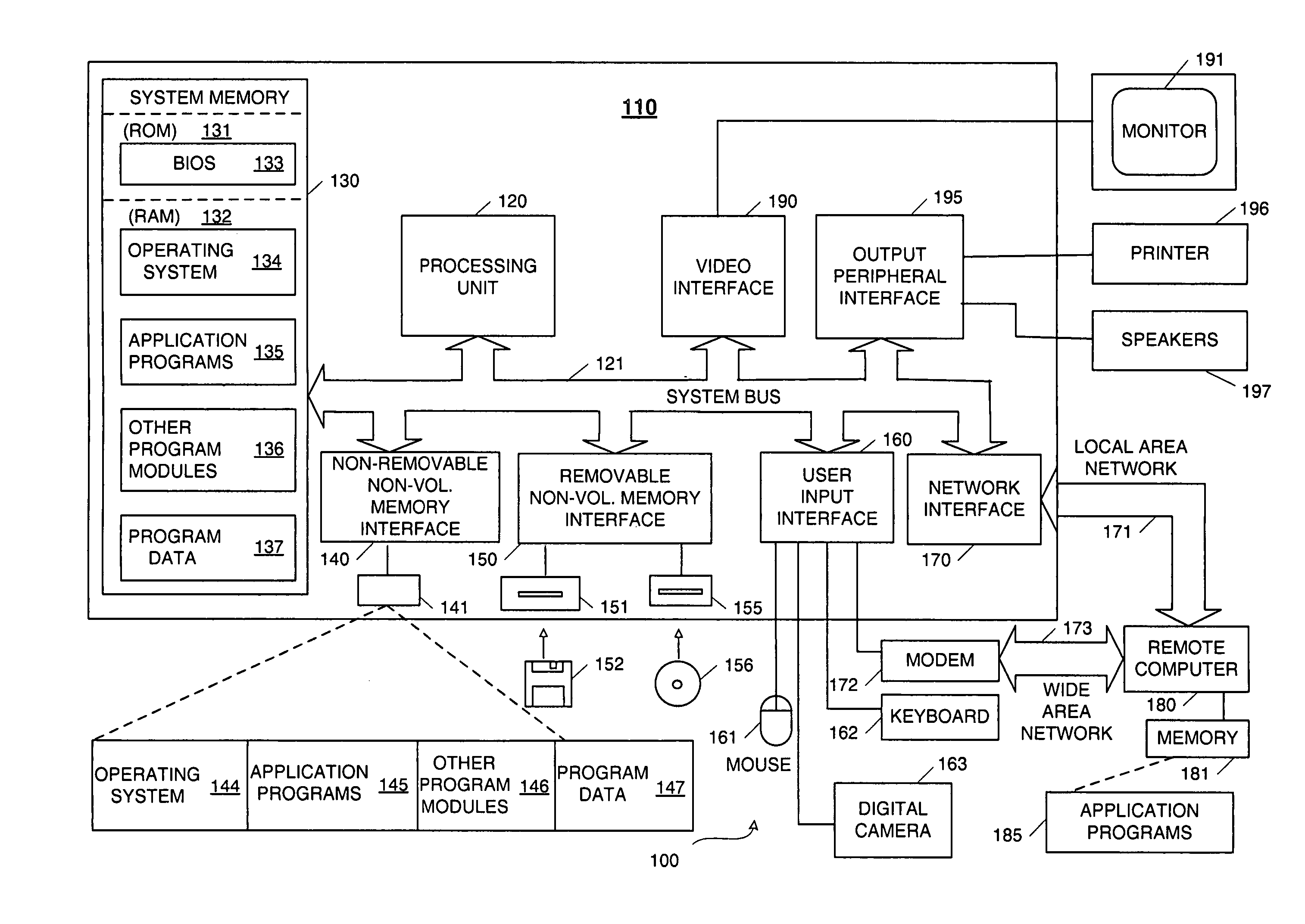

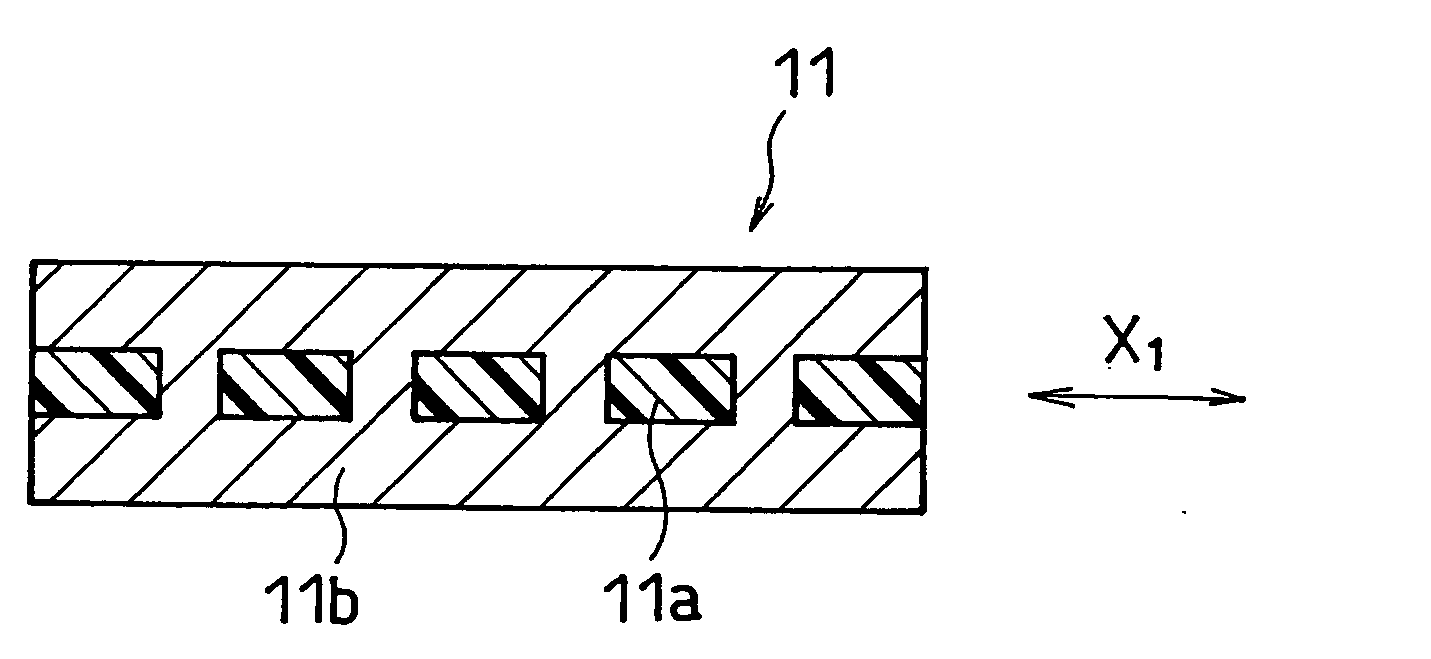

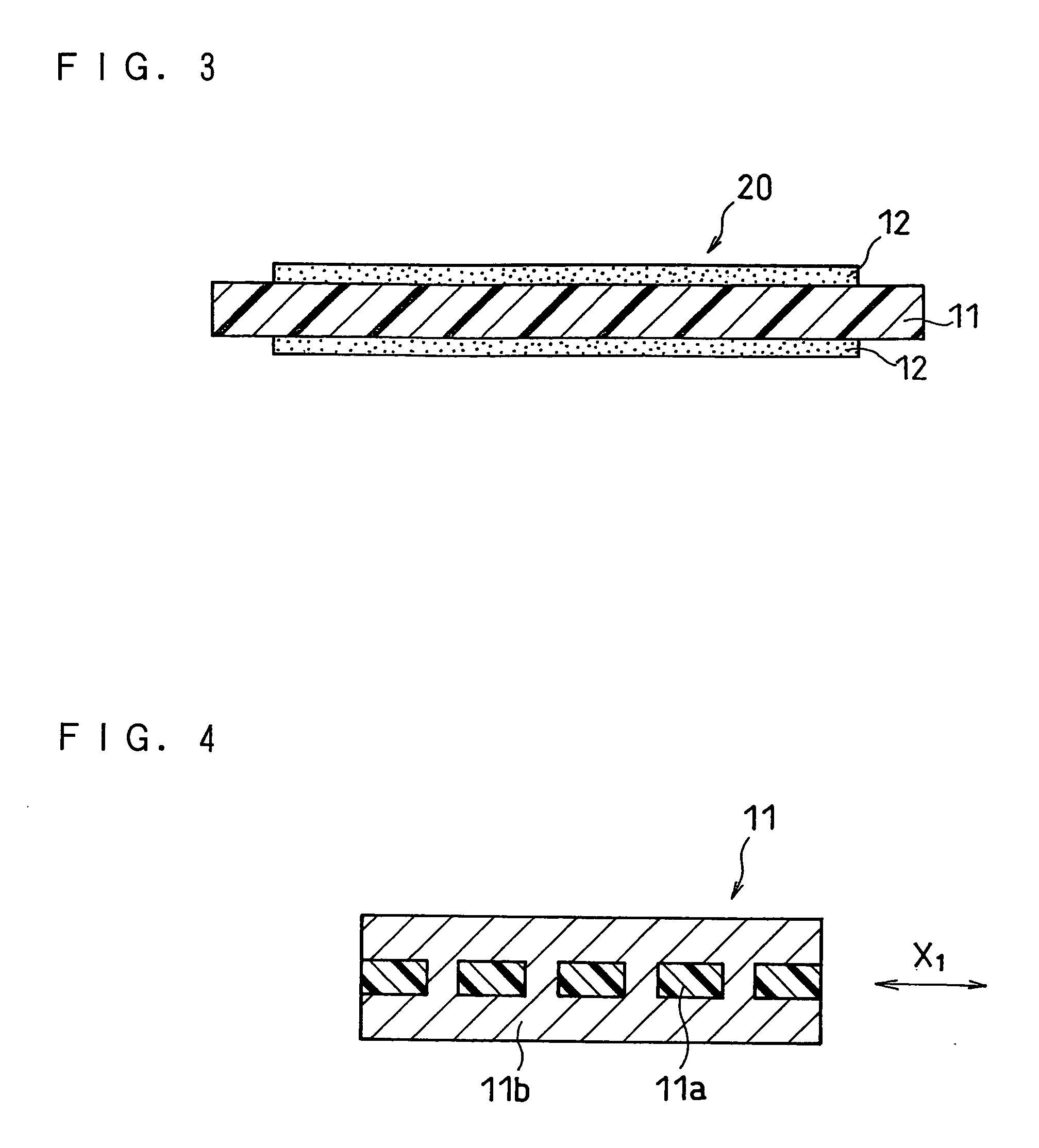

Image display system, image transmission apparatus, image transmission method, image display apparatus, image display method, and program

InactiveUS20080225132A1Reduce data processingReduce processing loadTelevision system detailsGeometric image transformationImage transferComputer graphics (images)

Camera sections pick up divided images obtained by dividing a panorama image to generate image data at a high resolution. Image data processing sections perform compression encoding on the image data at the high resolution through encoder to obtain first compressed image data. The image data processing sections perform size change to obtain image data at a low resolution and perform compression encoding on the image data through another encoder to obtain second compressed image data. A data transfer section transmits the first and second compressed image data through a network to an image display apparatus.

Owner:SONY CORP

Modular, attachable objects with tags as intuitive physical interface facilitating user interaction with a computer

InactiveUS20050182857A1Input/output for user-computer interactionCathode-ray tube indicatorsSize changeModularity

A method, system, and device for adding modular tags, that can be associated with particular configurations, that can be attached to and / or read by a computer peripheral device and / or computer is described. A modular tag reader in a computer peripheral device and / or computer recognizes a modular tag and its associated software configuration, thereby directly initiating user intended actions without the user interacting with the software interfaces. A user can attach modular tags that are intuitively recognizable as performing a particular function, such as a color change, font size change, font style change, highlight operation, and application program initiation. Such modular tags are interpreted by a processor within the host computer and / or within the computer peripheral device to change a configuration in accordance with the tag.

Owner:MICROSOFT TECH LICENSING LLC

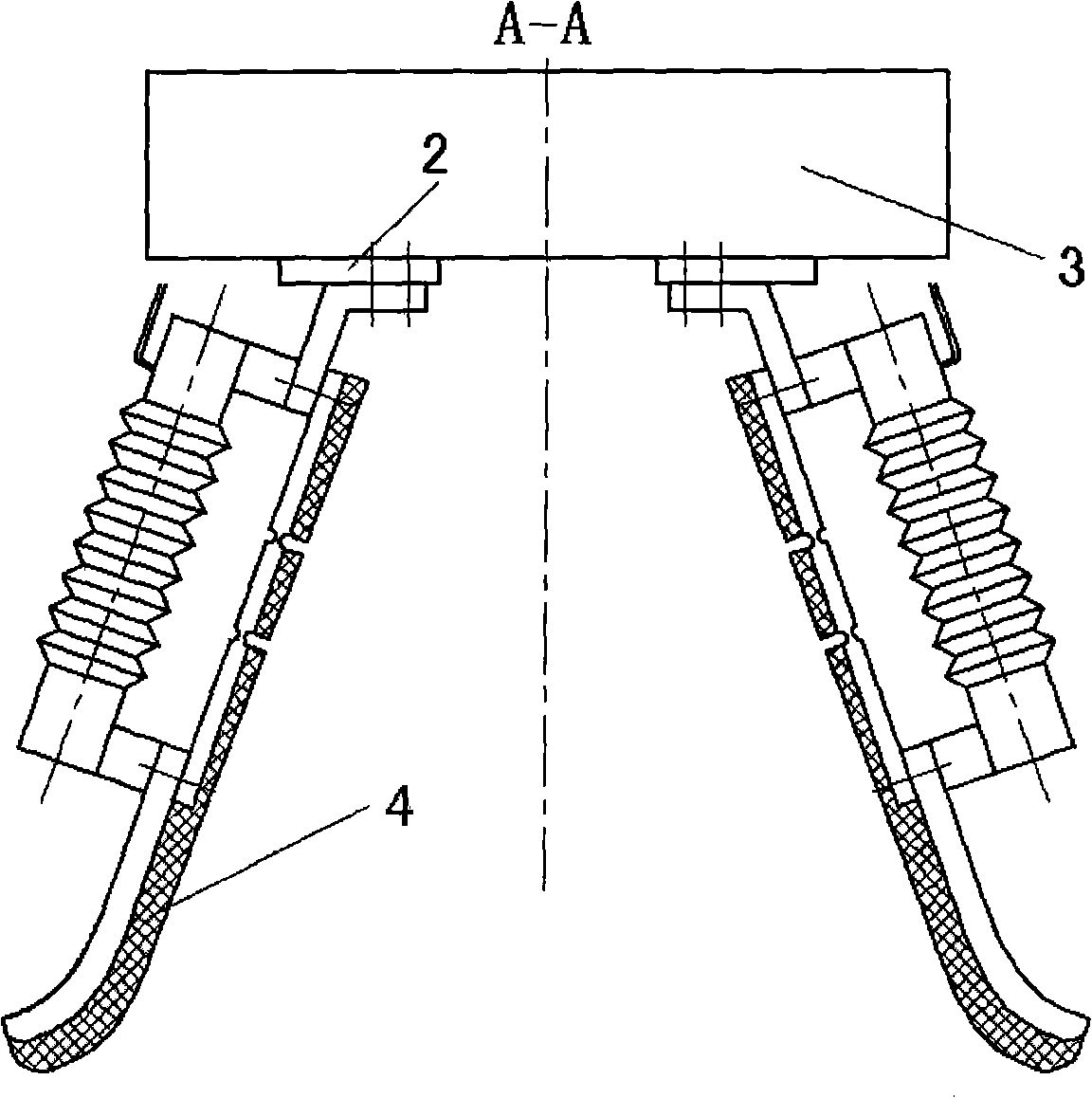

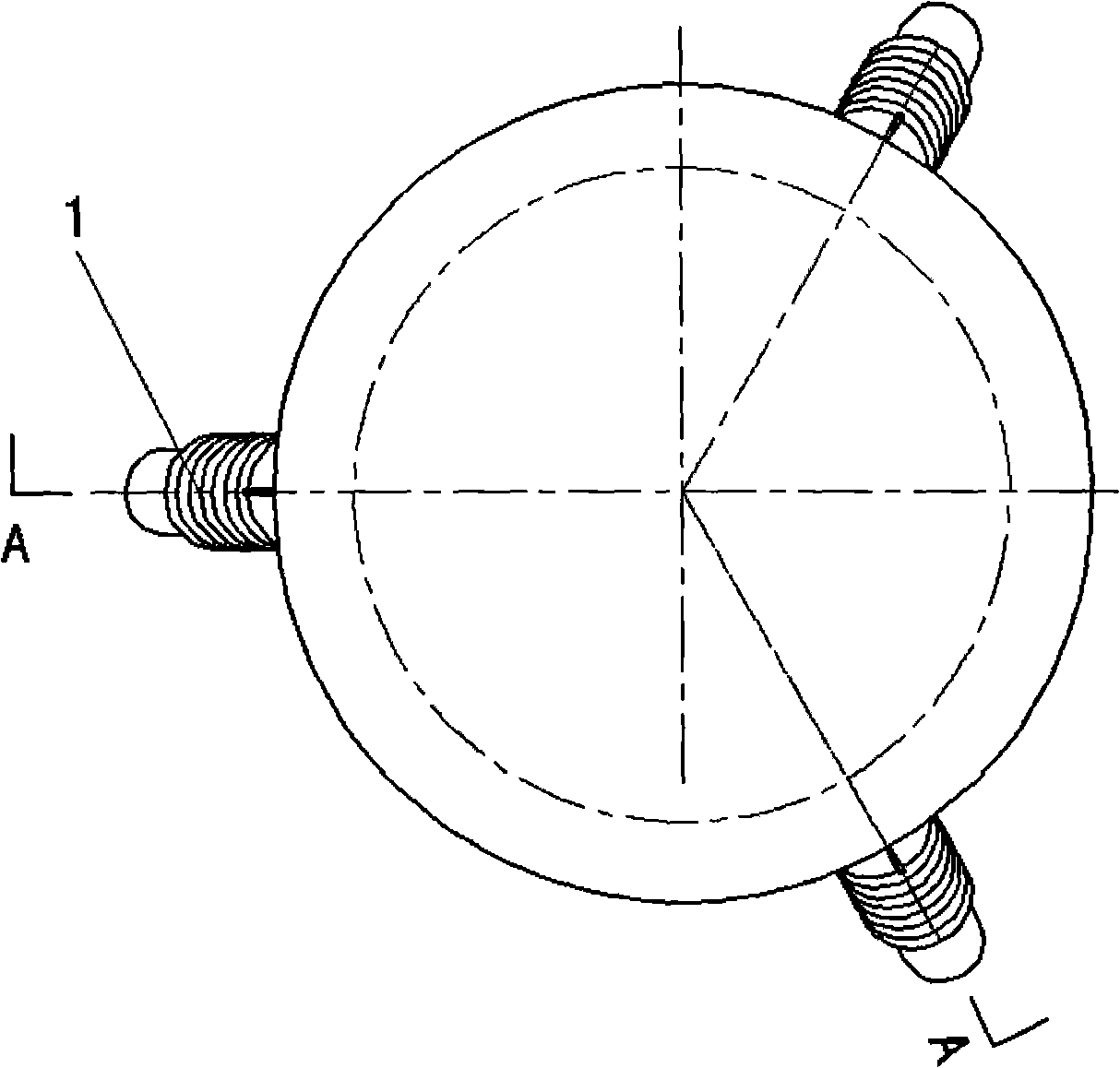

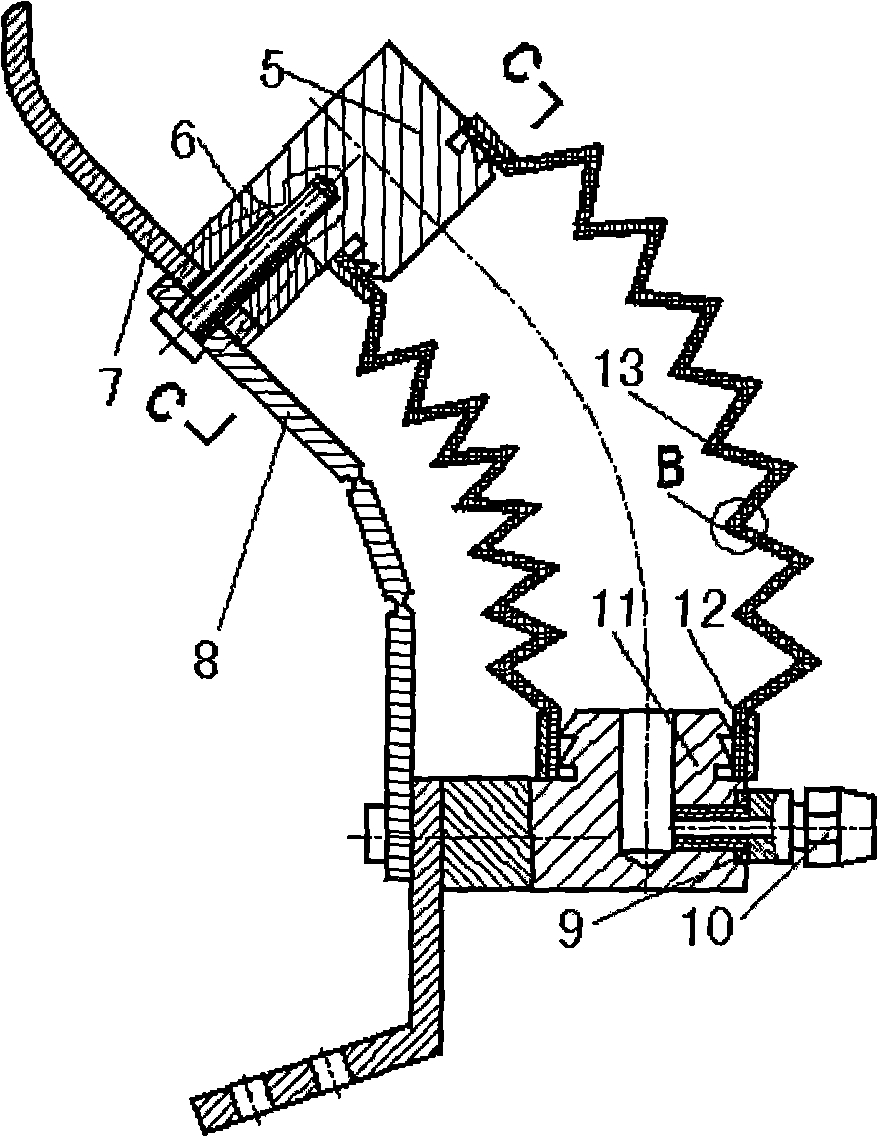

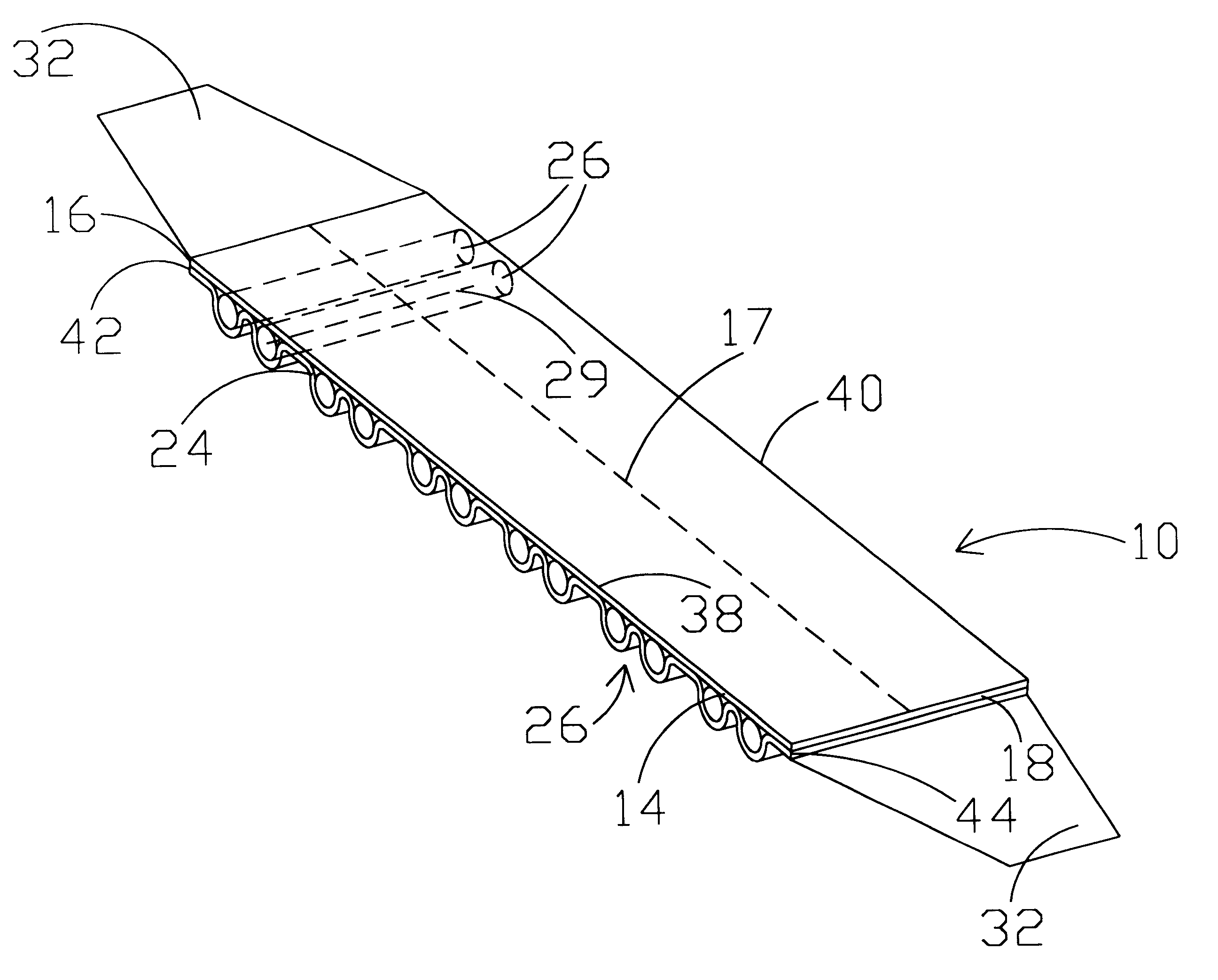

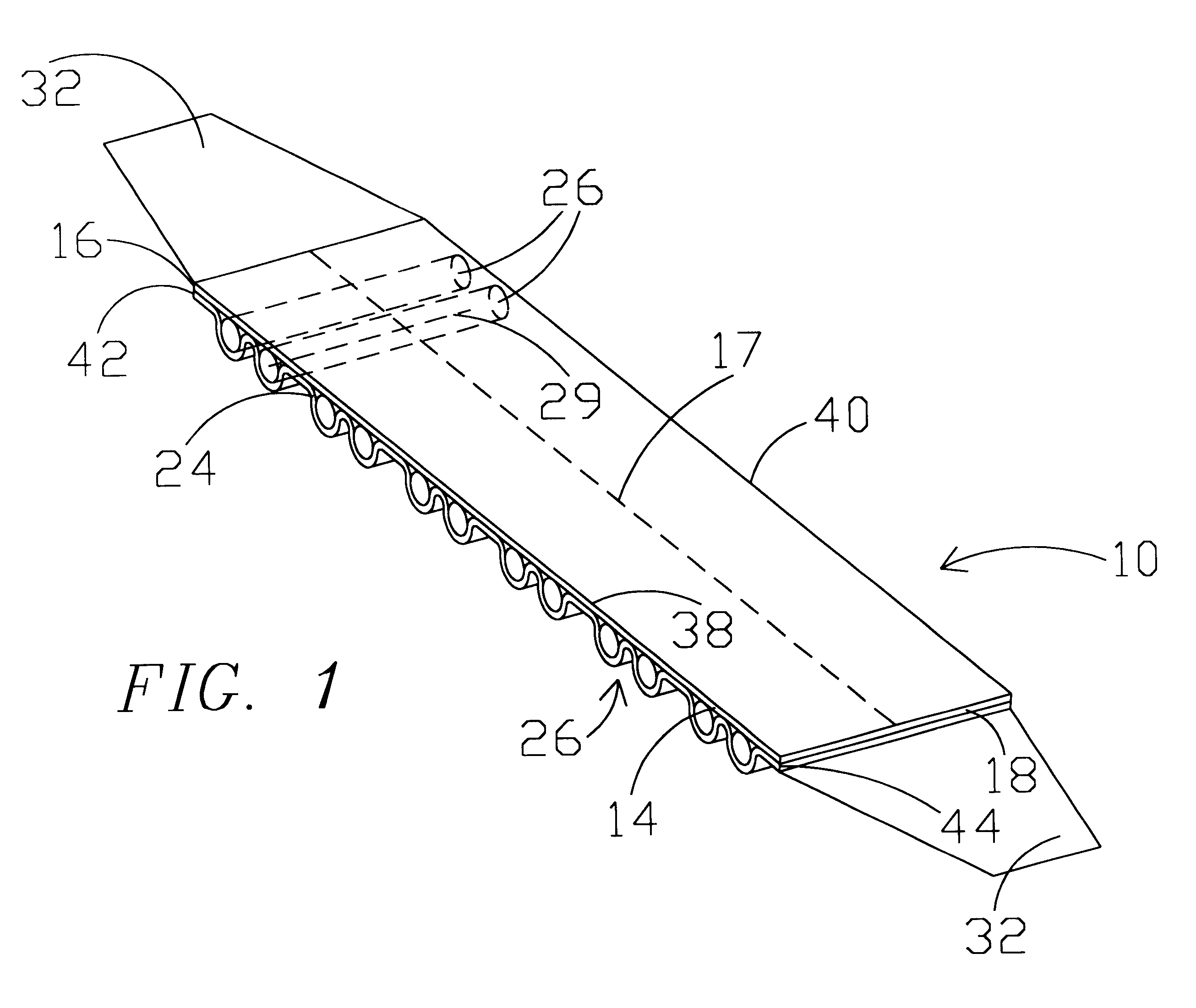

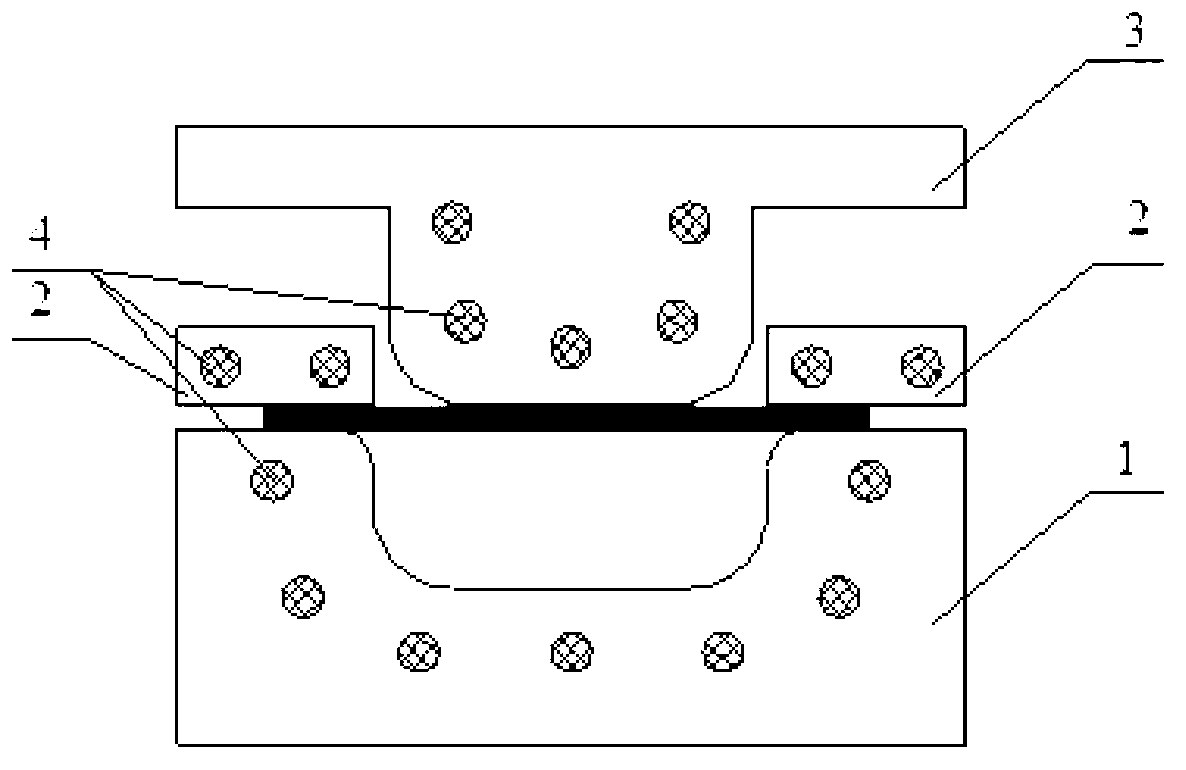

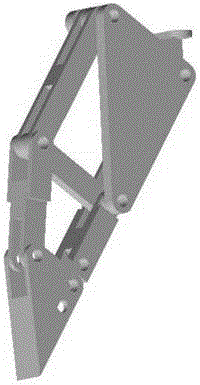

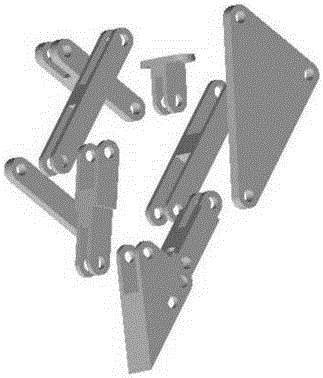

Articulated flexible manipulator

InactiveCN101554730AWith degrees of freedom and flexibilityBufferGripping headsPicking devicesSingle degree of freedomSize change

The invention relates to an articulated flexible manipulator which belongs to the technical field of the robots and the electromechanical integration. The manipulator is provided with three skillful fingers which are respectively arranged on three jaws of a three-jaw chuck, and the three skillful fingers produce chucking force by the function of fluid driving expansion muscle; each skillful fingeris provided with single artificial expansion muscle and a plurality of articulations with single degree of freedom, the artificial expansion muscle is flexible, axially-expandable, each smart fingeris assembled with a hinge framework or flexible hinge framework through the expansion muscle, the smart finger comprising a plurality of articulations with single degree of freedom is designed; the flexibility of the single expansion muscle and the structure of the articulations can realize the flexibility of the degree of freedom and the buffer of the chucking force, the skillful fingers have thecharacteristics of degree flexibility of freedom and chucking force buffer; and the manipulator is applied to chuck breakable brittle bodies and special bodies with shape and size change.

Owner:无锡锦臻自动化技术有限公司

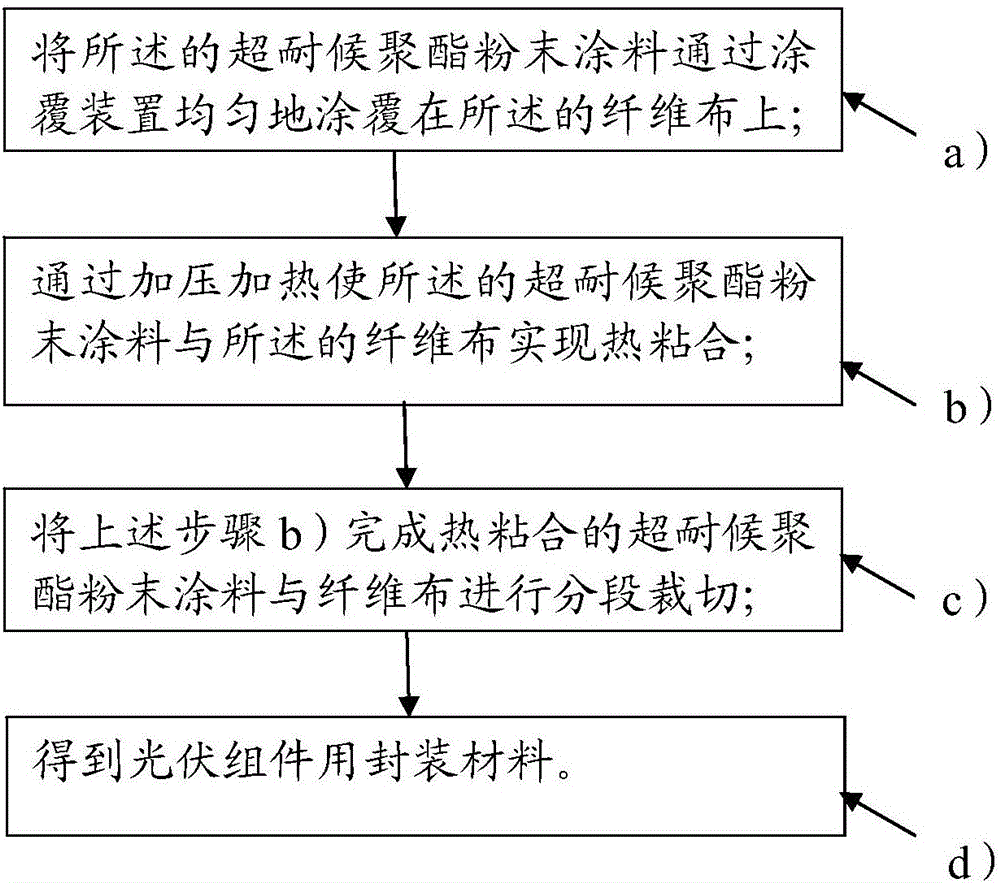

Packaging material for photovoltaic module and method for preparing packaging material

ActiveCN106283677AReduce weightReduce installation costsTextiles and paperPhotovoltaic energy generationFiberWeather resistance

The invention discloses a packaging material for a photovoltaic module. The packaging material is prepared from the following raw materials in parts by weight: 30-50 parts of fiber cloth woven by adopting a fiber material, and 50-70 parts of extra-weather-resistance polyester powder coating which is prepared from extra-weather-resistance polyester resin and a curing agent, wherein the fiber cloth is uniformly coated with the extra-weather-resistance polyester powder coating. The packaging material has low manufacture cost, can be used for effectively realizing light weight of the packaging material of a photovoltaic module, improving the assembly convenience and reducing assembly cost, and is suitable for large-scale popularization and application in the photovoltaic field. The invention further discloses a method for preparing the packaging material for the photovoltaic module, which realizes arbitrary size change of the photovoltaic module to adapt to the assembly requirement of different constructions, and the assembly application of the photovoltaic module can be further facilitated.

Owner:TIGER DRYLAC TAICANG +1

Magnetic therapeutic penile band device

InactiveUS6348033B1Facilitate necessary size adaptationIncrease in sizeElectrotherapySurgeryPenisAnatomical structures

A self-adjusting magnetic therapeutic band device, assembly, system and method of use is disclosed for use on, or in interaction with, a living penile organ of a human or animal. The invention is provided with differentially elastic layers and like fabricated or elastic layerings in embodiments of the invention as part of a securement or band-like piece, for securement, pocketing, and various spacings between, positioned magnetic groupings and magnetic components of embodiments of the invention, utilizing their opposing and like magnetic polar charges, to position the invention in contact with, and adjustment to, the changing sizes of a flaccid or erectile penile organ. The invention also contemporaneously provides a therapeutic magnetic field to tissue and anatomy adjacent or proximate to a pre-selected installation site on a penile organ. The invention utilizes various coupling systems or assemblies for such installation, achieving snug, contact-friendly interaction with a penile organ, while providing snug self-adjustment of the invention's layered band-like piece to various perimeter and size changes of the organ.

Owner:CATLETT JAMES A

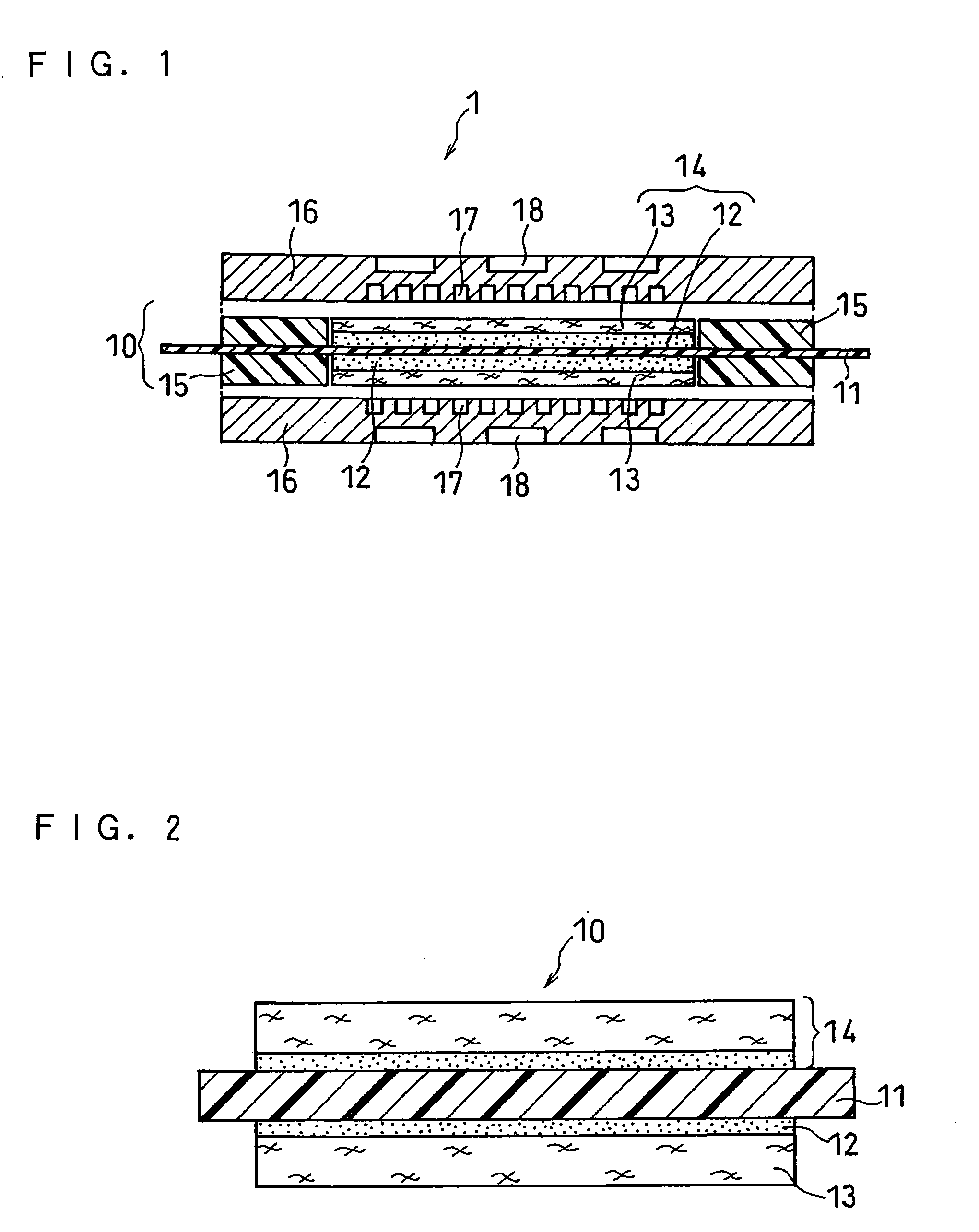

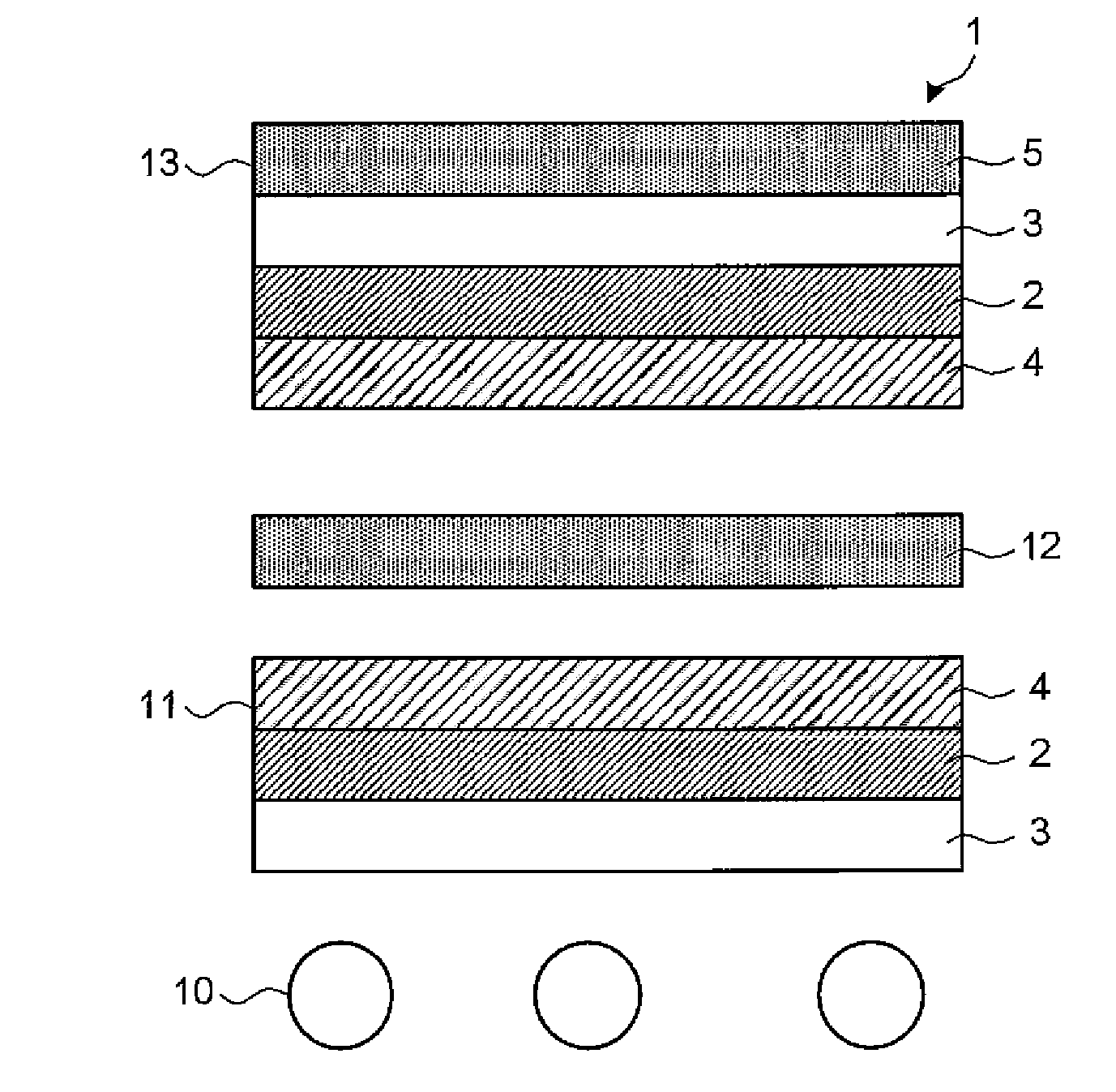

Composite electrolyte membrane, catalyst-coated membrane assembly, membrane-electrode assembly and polymer electrolyte fuel cell

InactiveUS20050227132A1High mechanical strengthAvoid size changeElectrolyte holding meansFuel cells groupingCoated membraneWrinkle skin

To provide a polymer electrolyte membrane having excellent size stability and excellent mechanical strength that can sufficiently prevent the size change due to the swelling condition, the displacement of the polymer electrolyte membrane and the formation of wrinkles during the production of the polymer electrolyte fuel cell, and can prevent damage during the production and operation of the polymer electrolyte fuel cell. In a composite electrolyte membrane including a porous reinforcement layer made of a resin and an electrolyte layer made of a polymer electrolyte and laminated at least one main surface of the reinforcement layer, the direction having a high tensile modulus of elasticity in the reinforcement layer is substantially corresponded with the direction having a high rate of size change in the electrolyte layer.

Owner:PANASONIC CORP

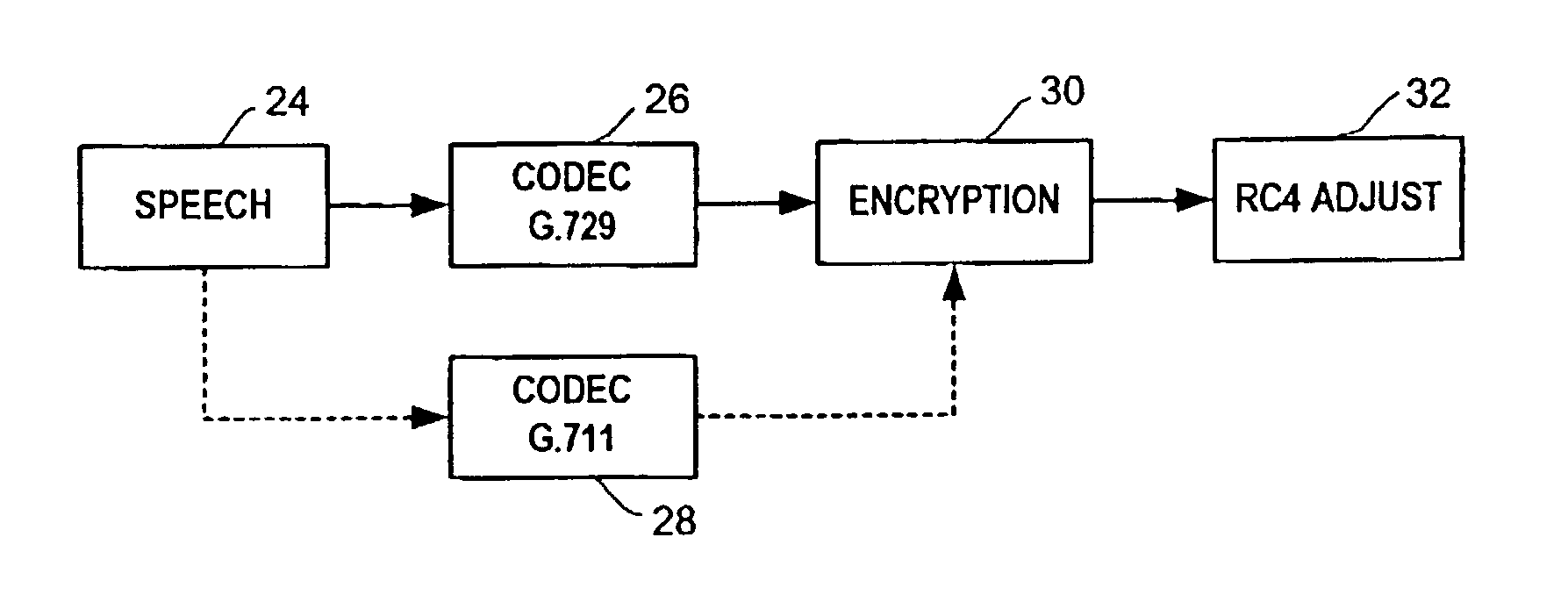

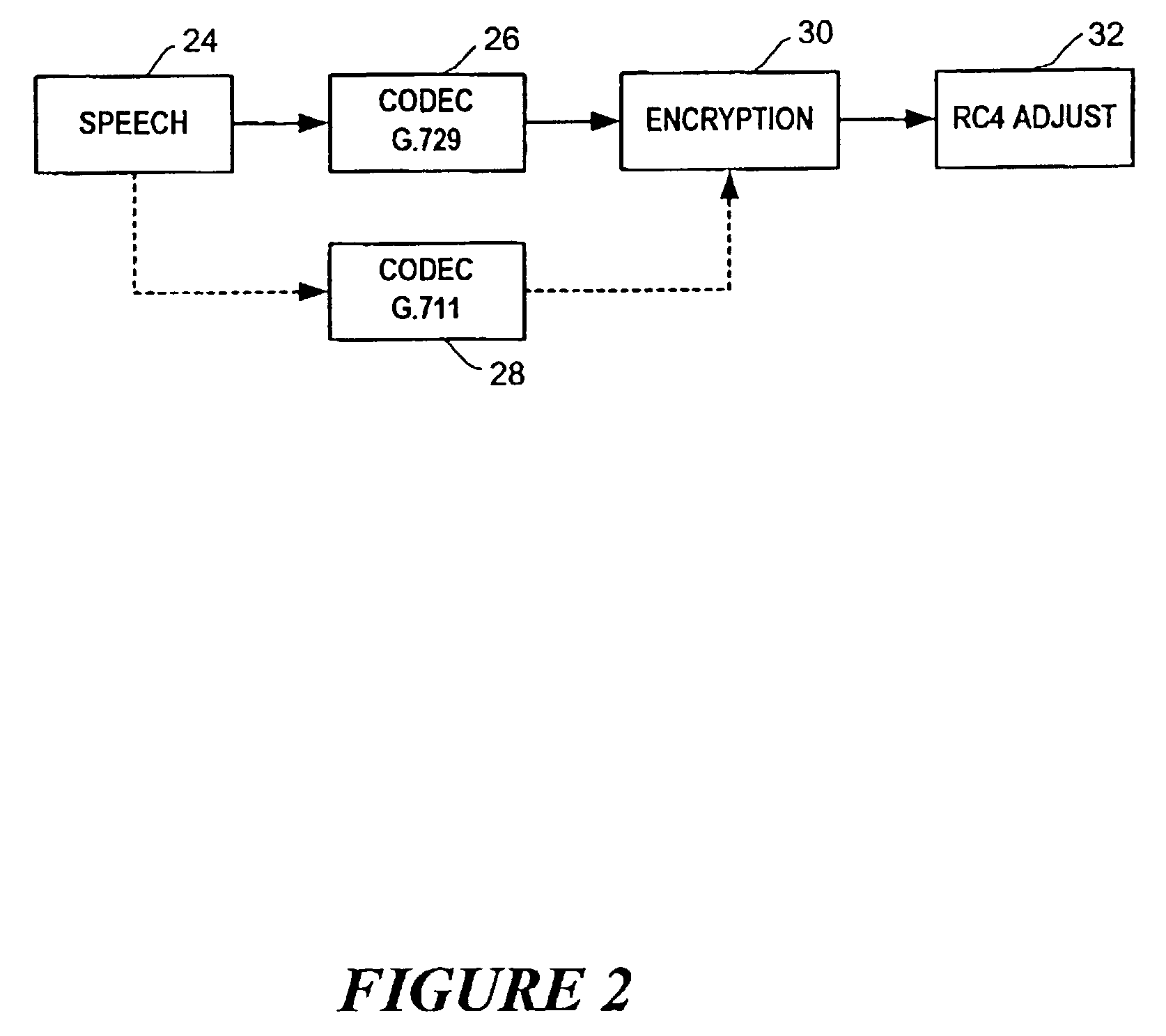

Changing a codec or MAC size without affecting the encryption key in PacketCable communication

ActiveUS7127604B2Synchronising transmission/receiving encryption devicesError detection/correctionComputer hardwareRC4

A technique is described to change the codec or MAC (message authentication code) size in a packet security unit for PacketCable communications during realtime voice transmissions is described. An algorithm that provides fast RC4 key advancing to prevent MIPS (millions of instruction cycles per second) overflow is used to perform codec or MAC size changes. The invention is performed without changing the keying material, where the sender and receiver must continue the RC4 encryption process from its state prior to the codec or MAC size change. A sender needs to preserve continuity of the timestamp across a codec change, since the timestamp reflects realtime. Changing the codec or MAC size is likely to change the frame parameters. To preserve continuity of the RC4 state and the timestamp across the codec / MAC size change, the sender TX and receiver RX generates a new frame number. The new frame number is applied to the first frame generated by the new codec or MAC size.

Owner:TELOGY NETWORKS

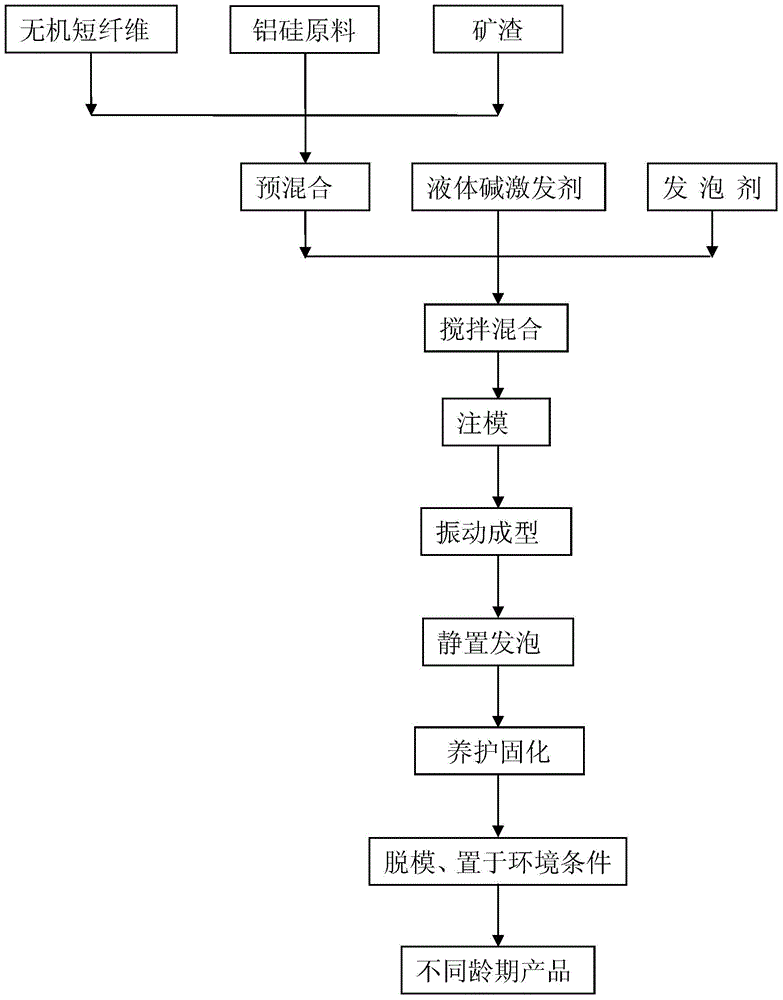

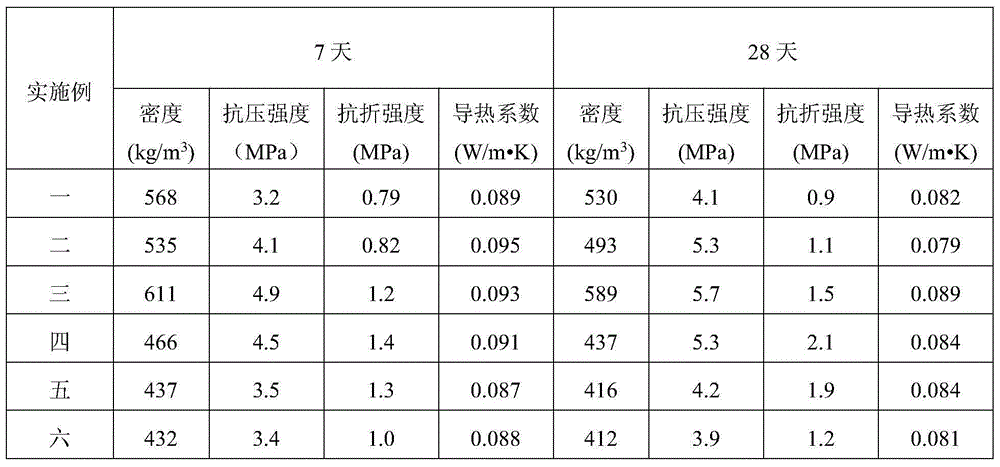

Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

InactiveCN103601524ARealize high value utilizationReduce pollutionCement productionCeramicwarePolymer scienceSlag

The invention discloses a fibre reinforced coal ash based geopolymer foam material and a preparation method thereof. The fibre reinforced coal ash based geopolymer foam material disclosed by the invention comprises the following components in percentage by weight: 50-70% of aluminium silicon raw material, 5-15% of slag, 3-8% of inorganic fibre, 15-30% of liquid alkaline exciting agent, 0.2-2% of foaming agent, and 2.5-3.5% of foam stabilizer. The preparation method disclosed by the invention comprises the step of also adding the foam stabilizer while adding the foaming agent by adopting the liquid alkaline exciting agent by taking the inorganic fibre as the reinforcing agent, the slag as the Ca adjusting agent and other solid raw materials (such as coal ash, metakaolin and silica fume) as powder for providing aluminium silicon. The light foam material prepared by the invention has the characteristics of being high in intensity, small in size change rate, low in water absorption and the like in the event of having same volume weight and heat conductivity of the similar materials, and is applied to various applications.

Owner:TIANJIN UNIV

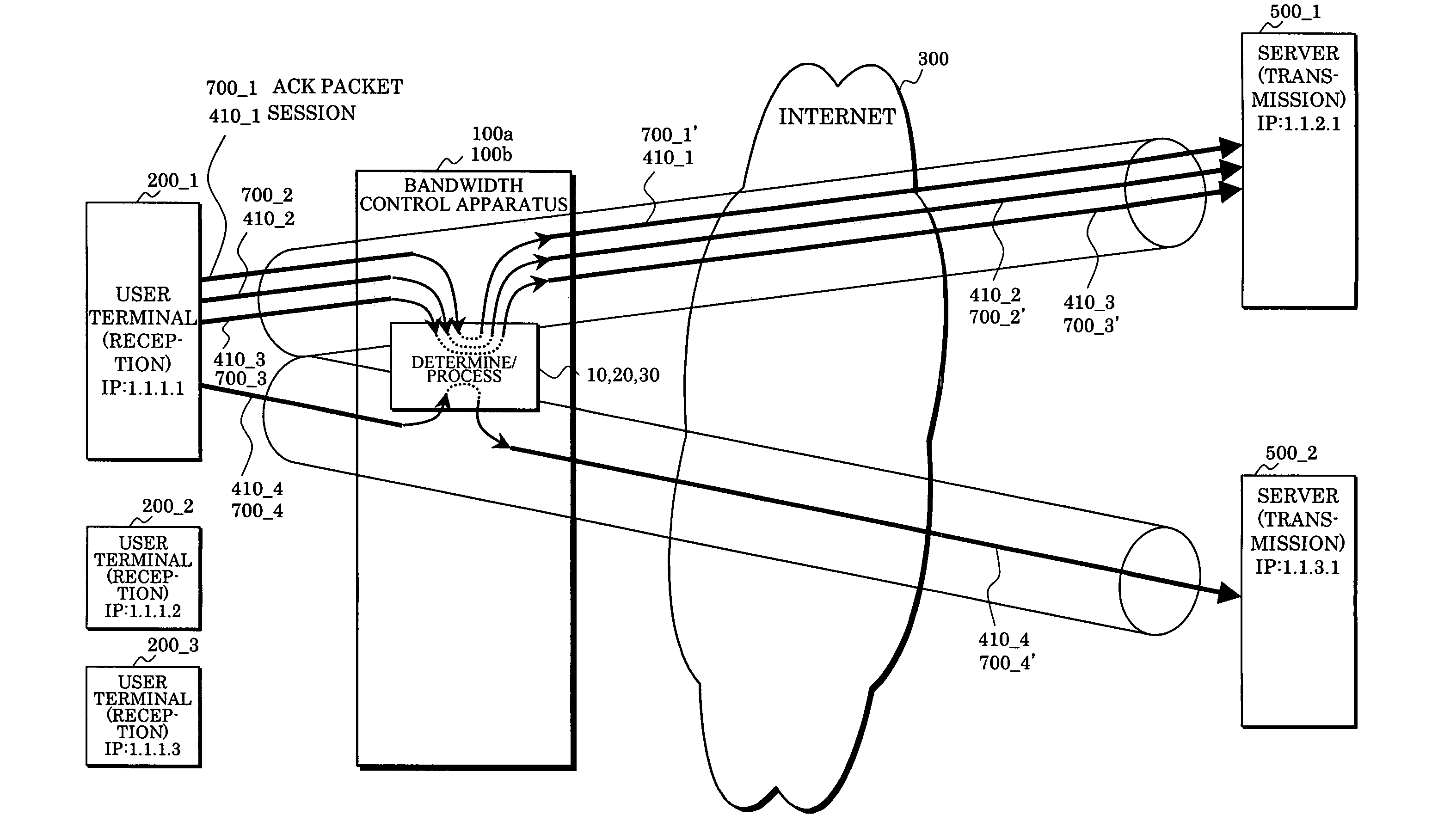

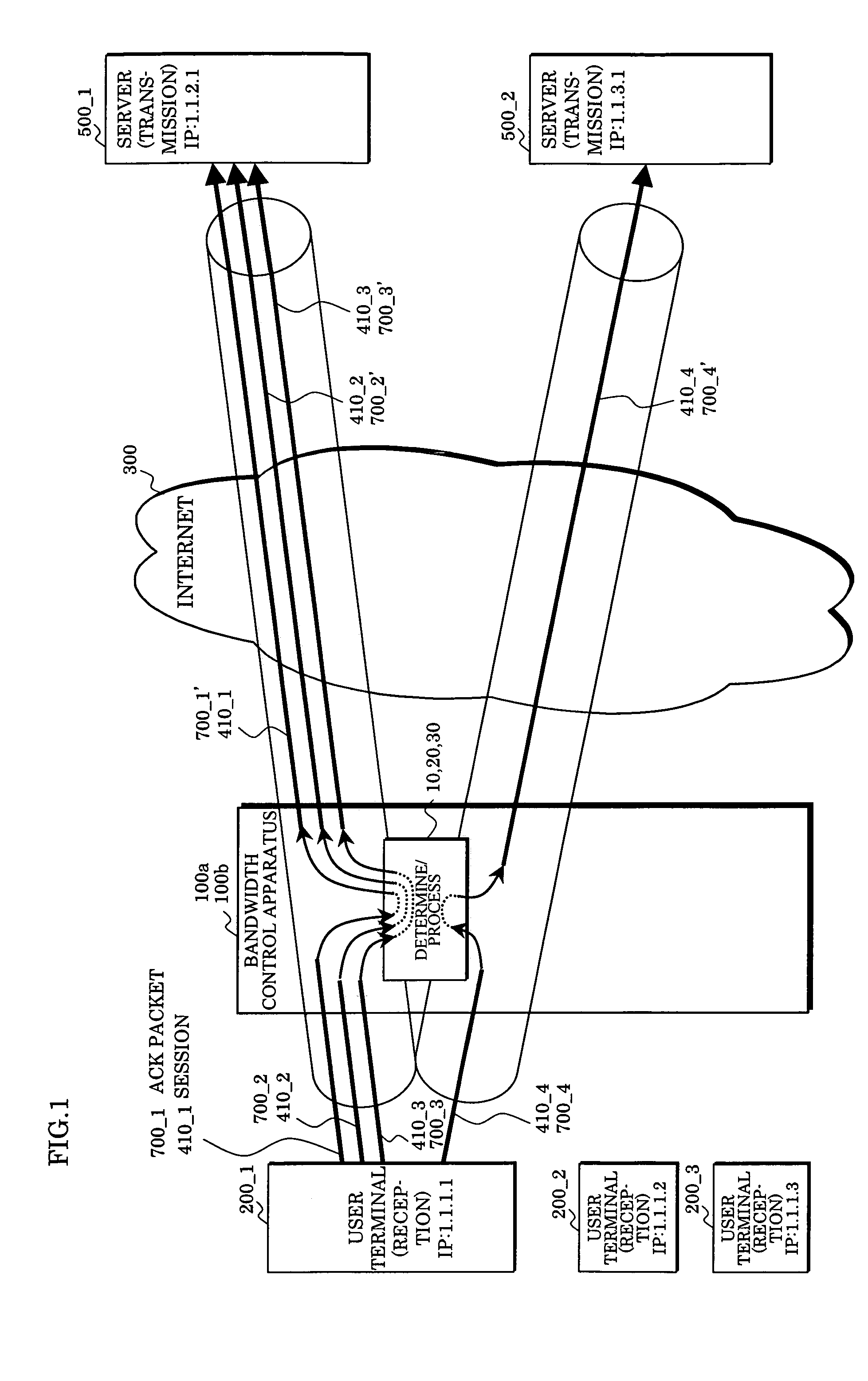

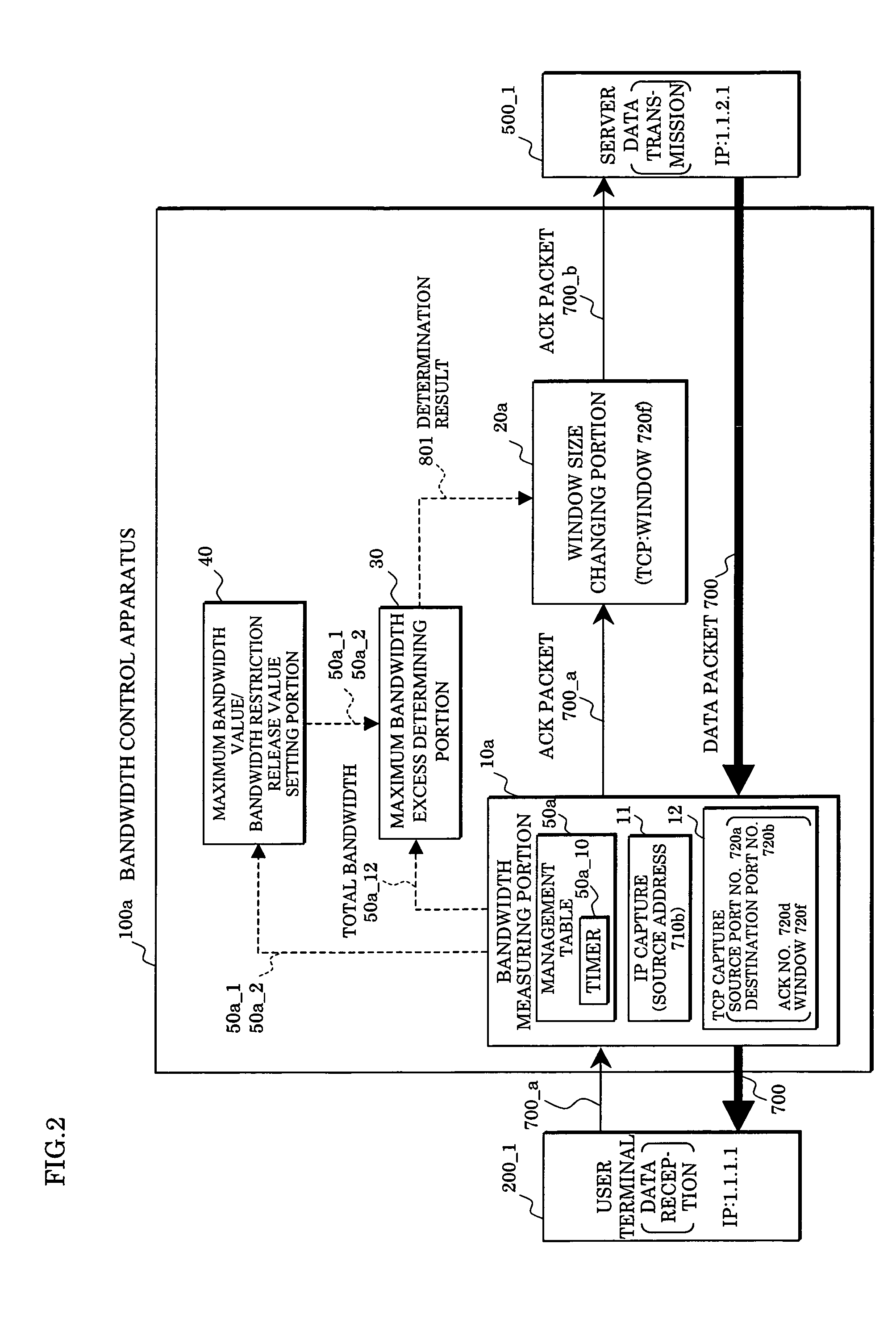

Bandwidth control apparatus

A bandwidth control apparatus in an IP network such as the Internet eliminates a packet discard for each user, and equally assigns bandwidths to the user. A bandwidth measuring portion measures a total bandwidth of a single or a plurality of TCP sessions for each user, and a window size changing portion reduces a window size of a TCP session ACK packet of a user whose total bandwidth value exceeds a maximum bandwidth preset. Alternatively, an ACK time changing portion delays a TCP session ACK packet of a user whose total bandwidth exceeds the maximum bandwidth value preset.

Owner:FUJITSU LTD

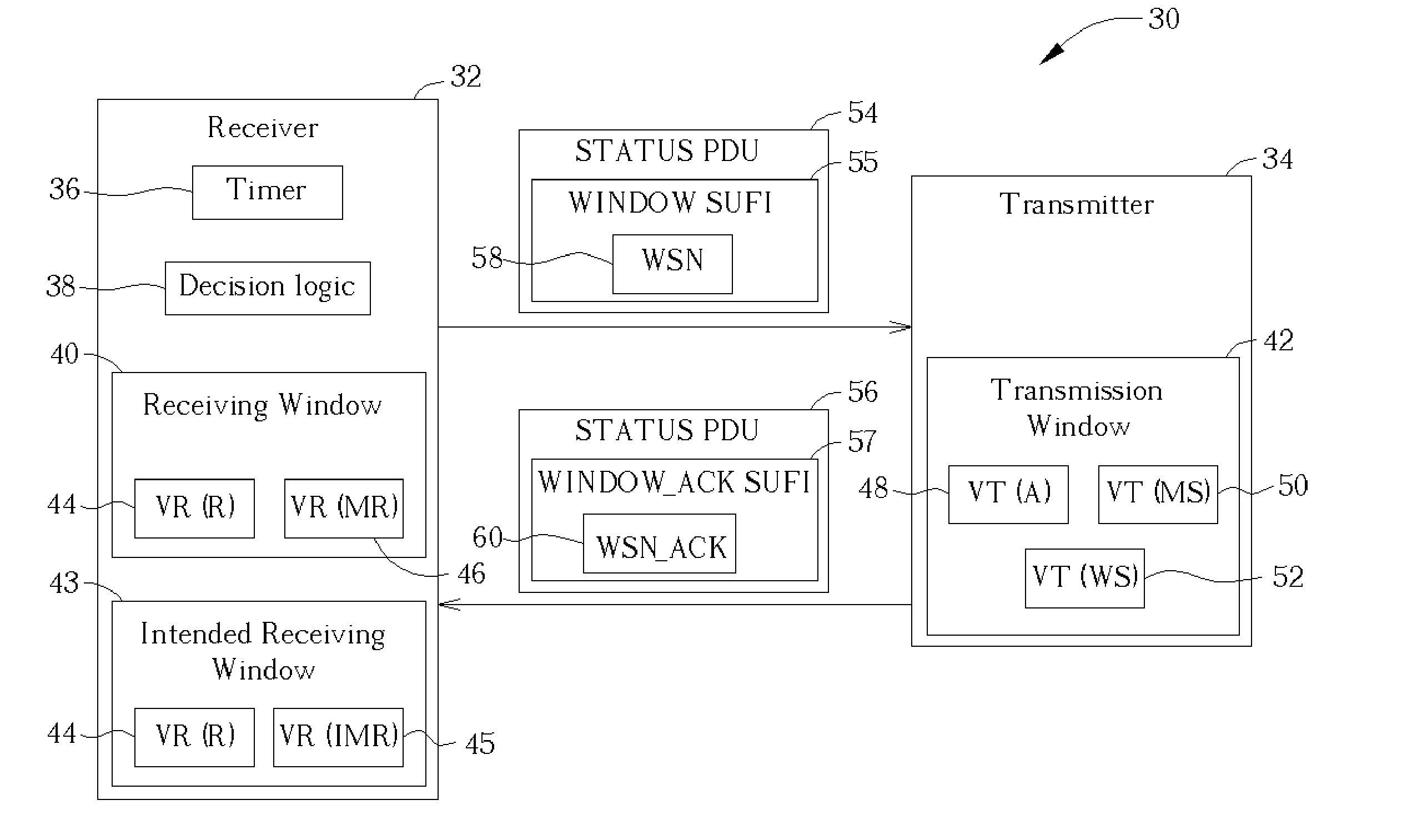

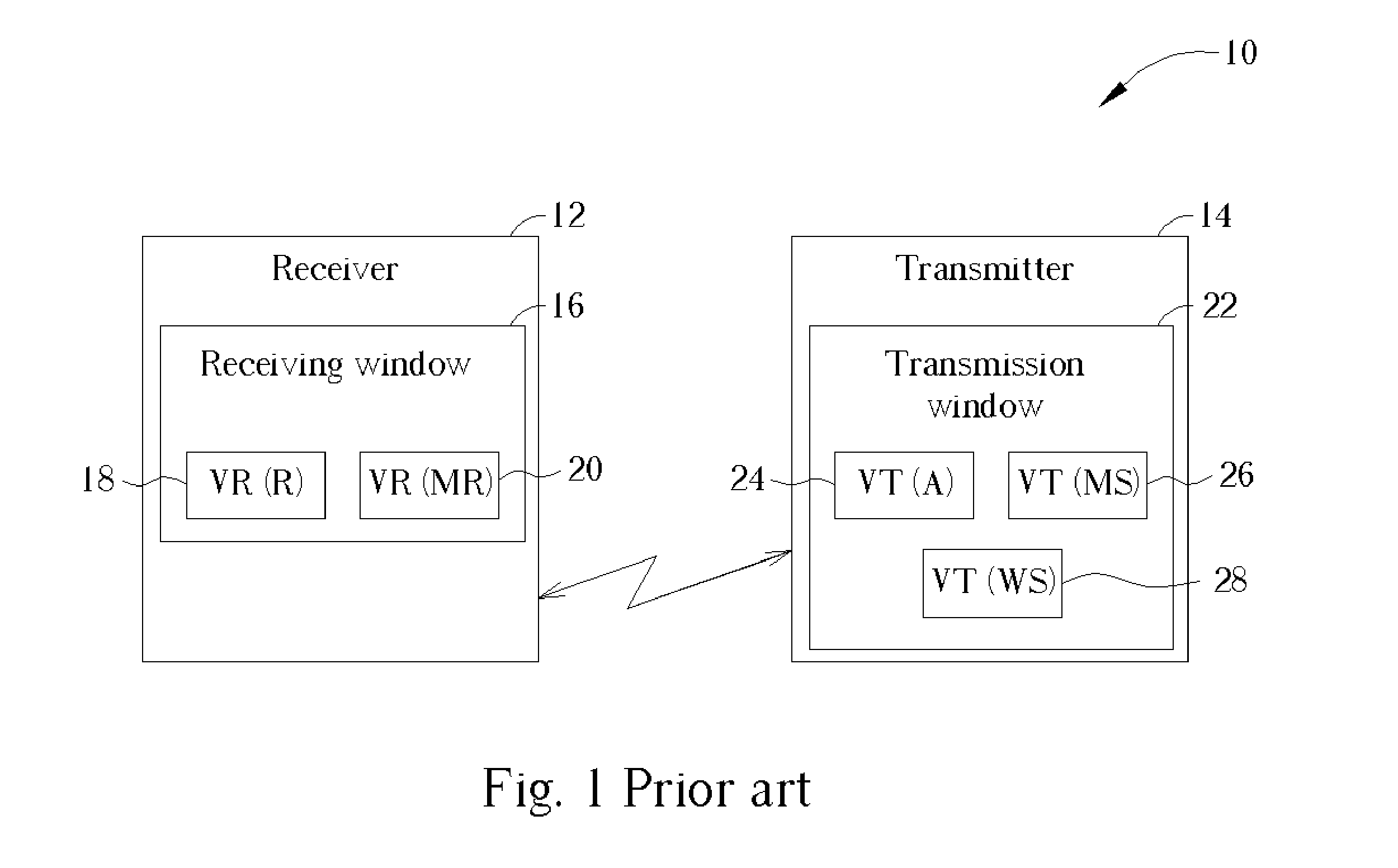

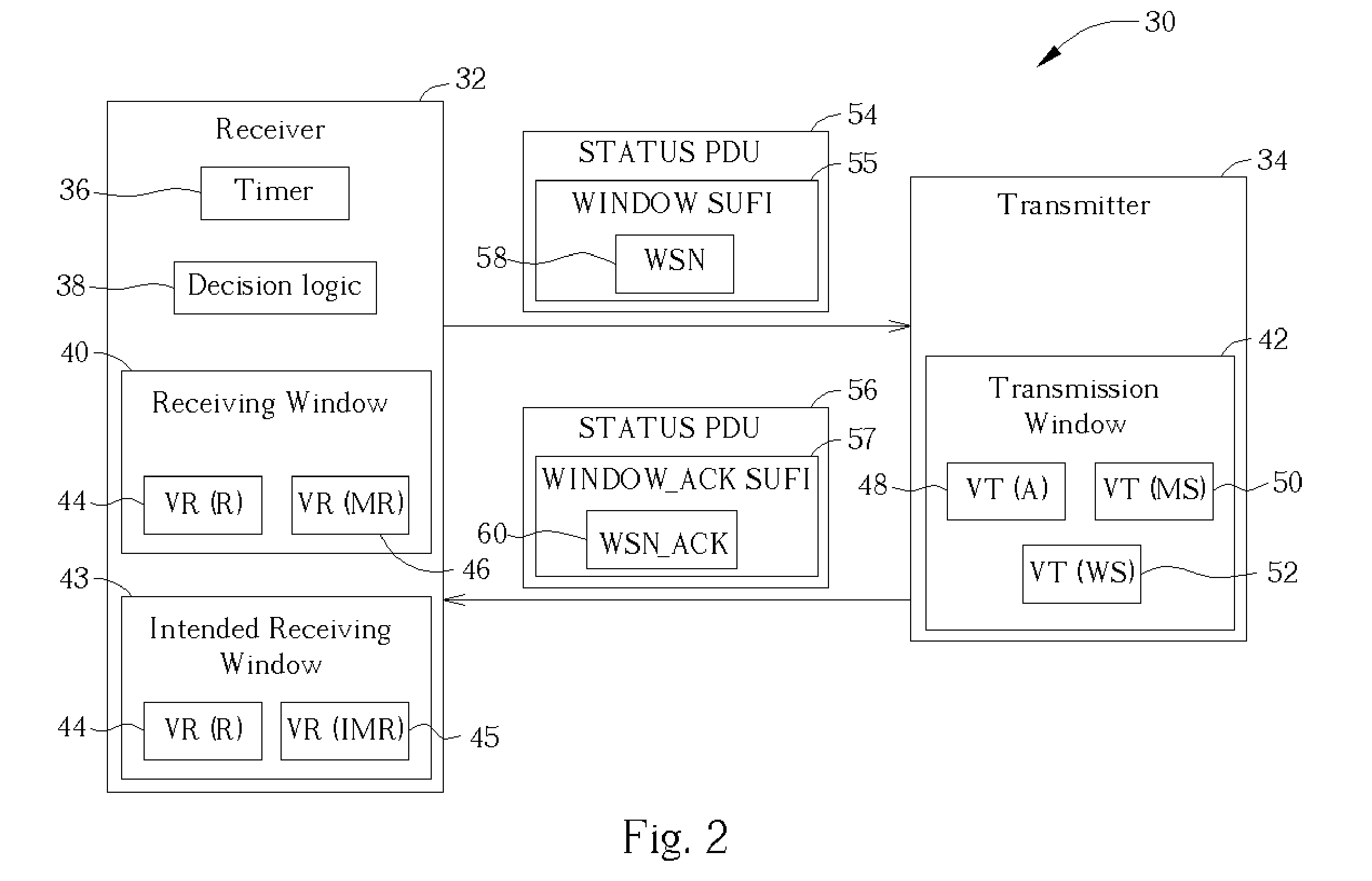

Method of controlling a receiver and a transmitter in a wireless communication system to handle a transmission window size change procedure

InactiveUS20050041586A1Decrease size of transmission windowImproves radio transmission efficiencyError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemSize change

A method of controlling a receiver and a transmitter to handle a transmission window size change procedure is disclosed. The method includes driving the receiver to deliver a control message having a window size parameter to the transmitter for adjusting a transmission window size of the transmitter, and driving the transmitter to output an acknowledgement message to the re- ceiver and adjust the transmission window size according to the window size parameter when the transmitter receives the control message.

Owner:INNOVATIVE SONIC

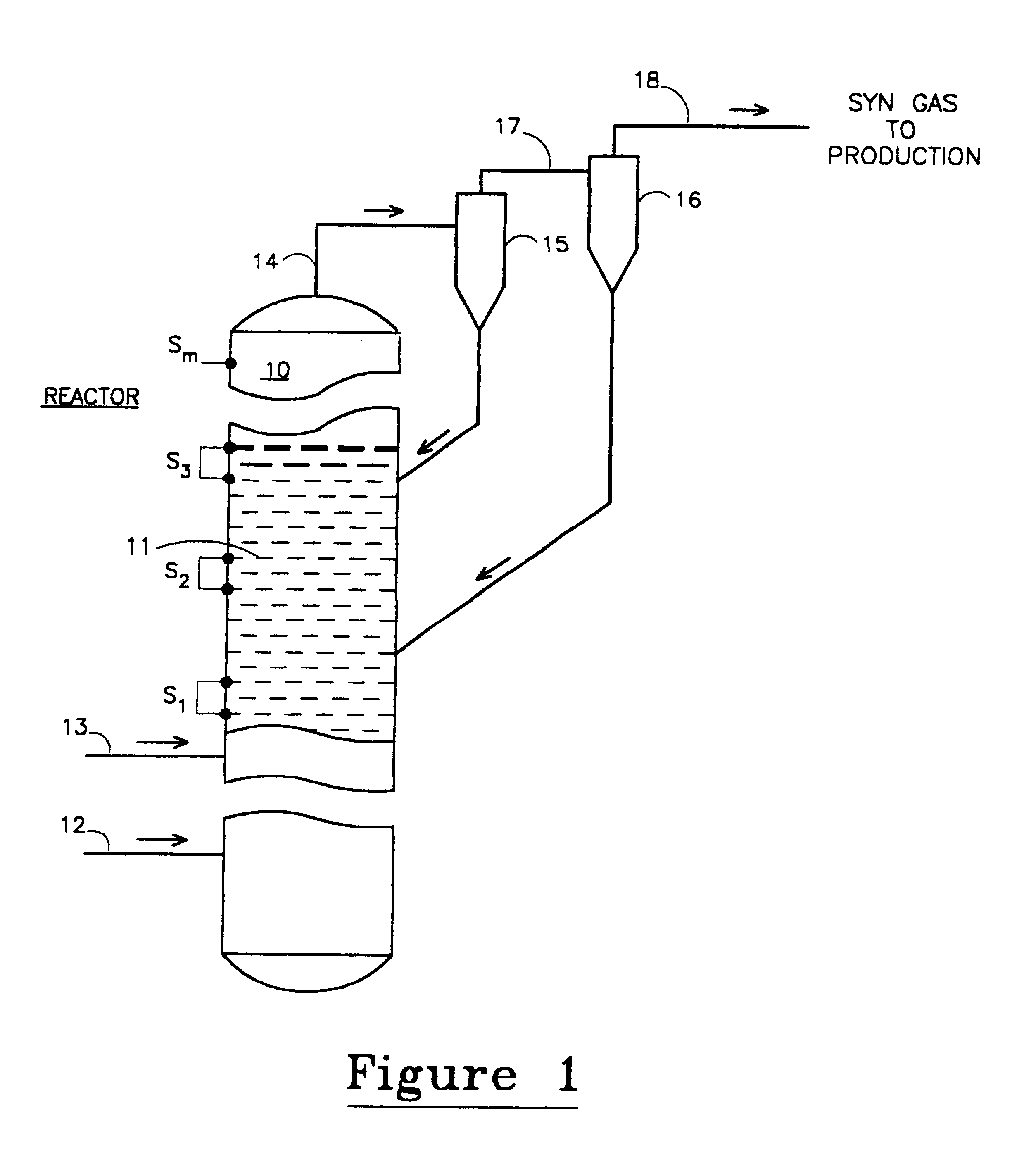

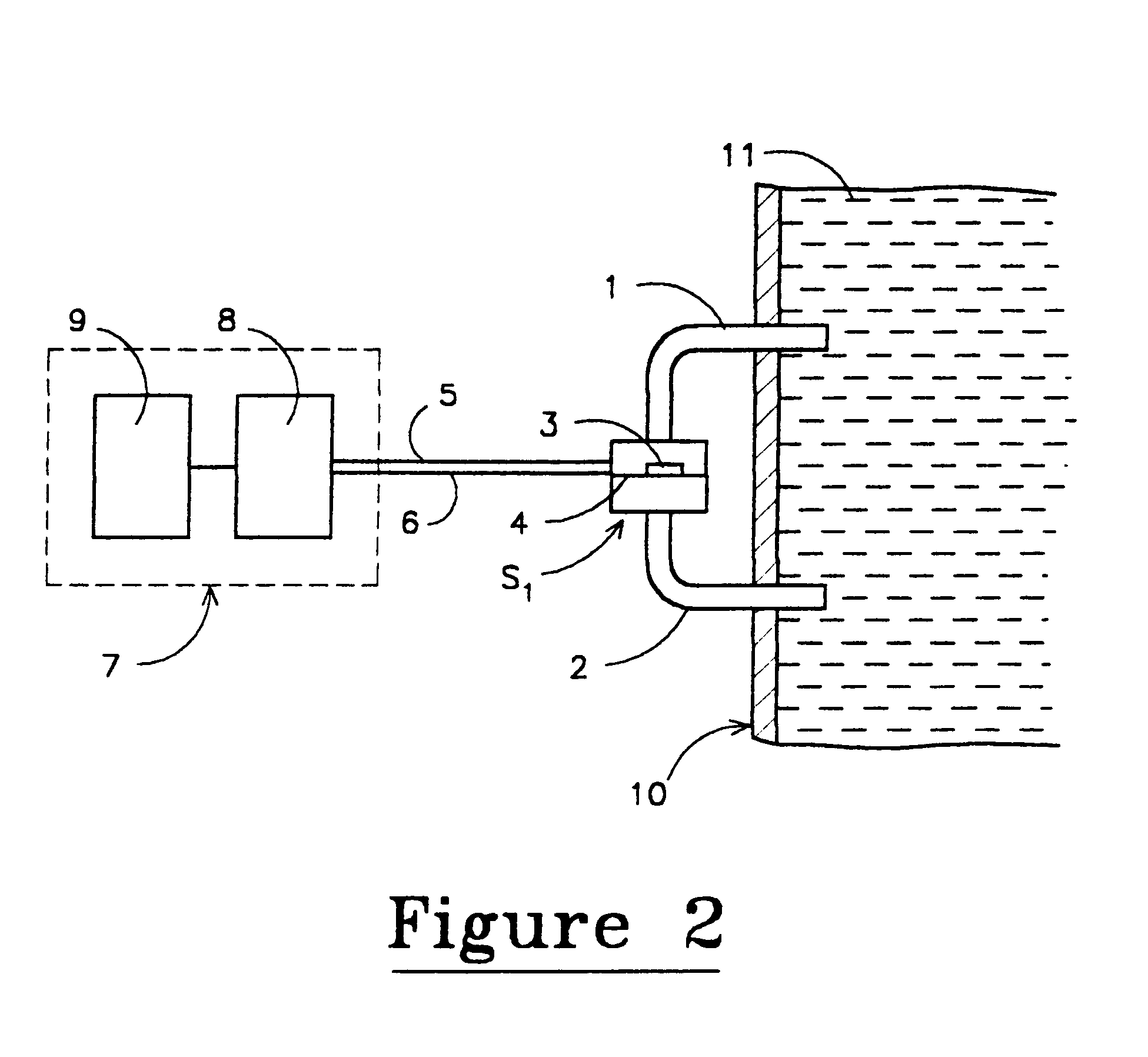

Process for detecting and monitoring changes in properties of fluidized bed solids by pressure difference fluctuation measurement

InactiveUS6301546B1Flow propertiesMaterial analysis by optical meansParticulatesDifferential pressure

A process for detecting, and monitoring, changes in the properties of a fluidized bed of particulate solids, especially a fluidized bed of particulate catalytic solids at elevated temperature wherein a low molecular weight hydrocarbon is converted, in the presence of steam and oxygen, to synthesis gas. Measurement is made of the magnitude of differential pressure fluctuations taken at different levels of bed elevation and these are recorded as a standard deviation, or normalized standard deviation, and directly related to particle size changes caused by agglomeration (growth) and / or attrition (size reduction). Operation of the process requires the use of fast response pressure transducers that are located in the bed and connected to an A / D board of a PC which records and accumulates the data for processing, and analysis.

Owner:EXXON RES & ENG CO

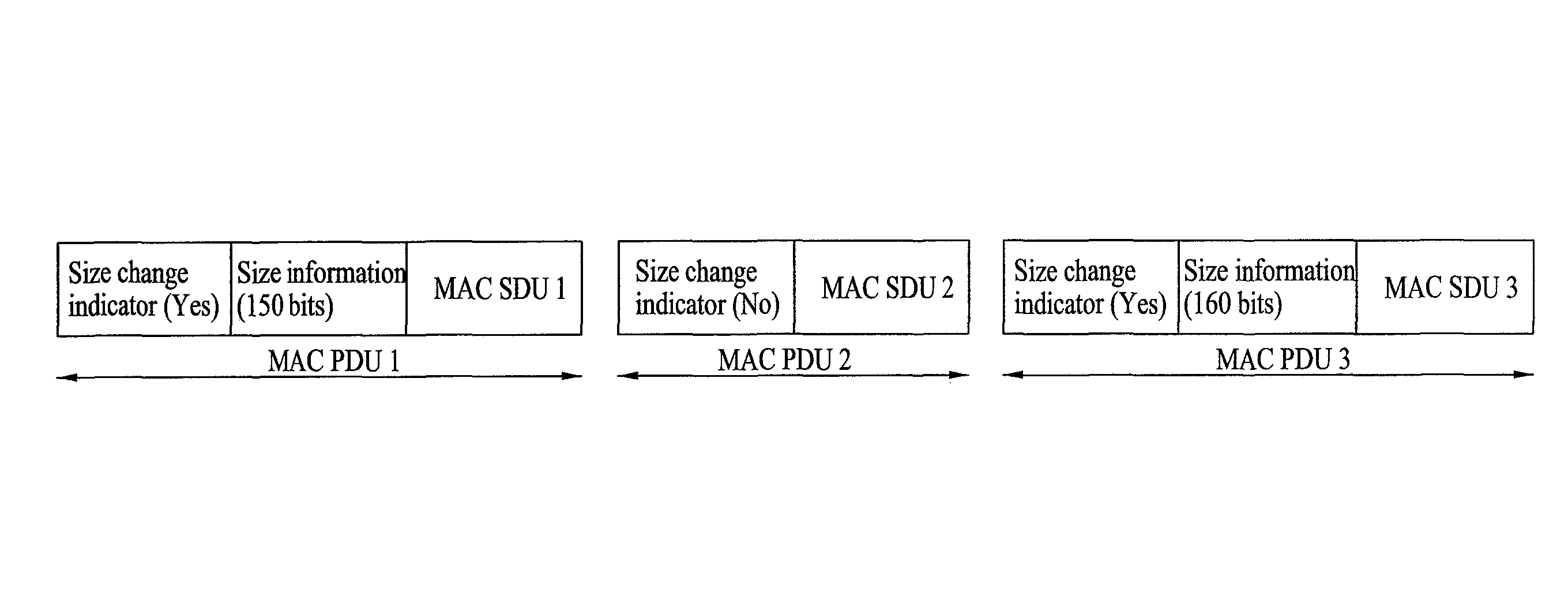

Method of transmitting data in a wireless communication system

InactiveUS8027363B2Effective resourcesEliminate the problemNetwork traffic/resource managementTime-division multiplexCommunications systemSize change

A method of configuring a lower layer data block in a protocol layer of a transmitting side of a wireless communication system comprises receiving upper layer data from an upper layer, and configuring a second lower layer data block to include a first upper layer data block comprising at least part of the upper layer data, and a size change indictor indicating whether a size of the first upper layer data block is identical with a size of a second upper layer data block included in a first lower layer data block.

Owner:LG ELECTRONICS INC

Vent device for use with a respiratory device

ActiveUS20140261427A1Improve comfortIncrease costOperating means/releasing devices for valvesBreathing masksAccelerometerBreathing gas

A vent device for a respiratory device, comprising one or a plurality of vents configured with a variable aperture size for communicating a flow of breathable gas. Said vent device being configured so that the cross section profile exposed to the flow of breathable gas communicating through the vent does not change as the aperture size changes. A vent device may comprise of a plurality of the said vents, wherein the aperture size of each vent may be controlled independently or together, and may be controlled according to one or more input signals from one or more sensors. Examples of suitable input signals include flow, pressure, noise, accelerometer outputs, orientation of a patient or presence of any obstructions. A patient interface or a patient conduit may comprise the vent device, or the vent device may be configured to connect with a patient interface or a patient conduit.

Owner:RESMED LTD

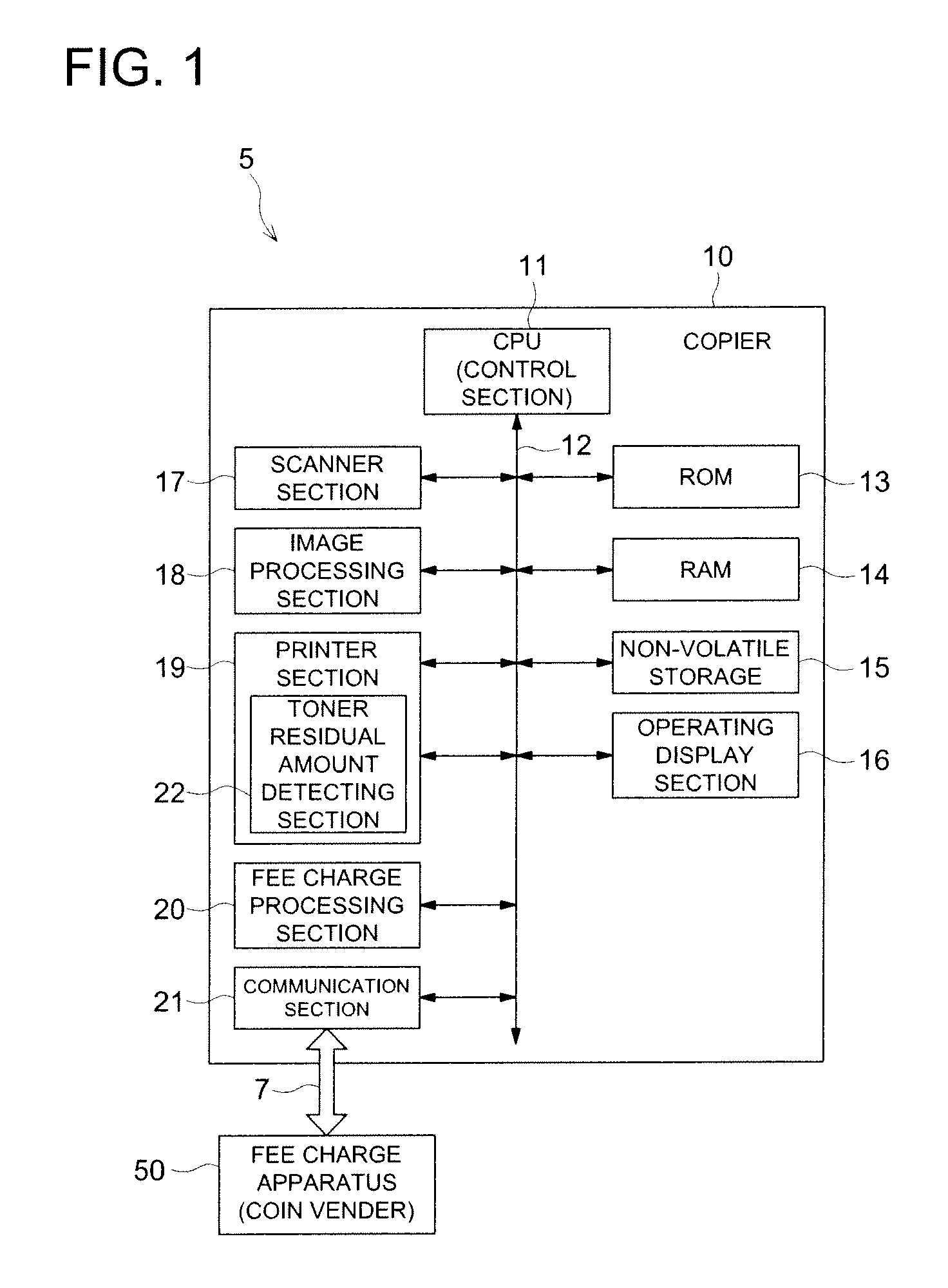

Image Processing Apparatus

InactiveUS20090279108A1Eliminate deteriorationReduce image sizeDigitally marking record carriersDigital computer detailsImaging processingPower processing

There is described an image processing apparatus, which makes it possible not only to eliminate the deterioration of the perceptibility, but also to determine the pages being suitable for applying the predetermined image processing. The control section determines specific pages, being suitable for applying a predetermined image processing, based on the attributes detected by the detecting section, so as to apply the predetermined image processing to the specific pages. On the other hand, the control section applies image processing, including a variable power processing, to both the partial image area and the partial character area by employing different magnification factors, so as to generate a size-changed partial image area and a size-changed partial character area, and to arrange both of them into a predetermined imaginary area being smaller than an area of the original image, so as to accommodate them within the predetermined imaginary area.

Owner:KONICA MINOLTA BUSINESS TECH INC

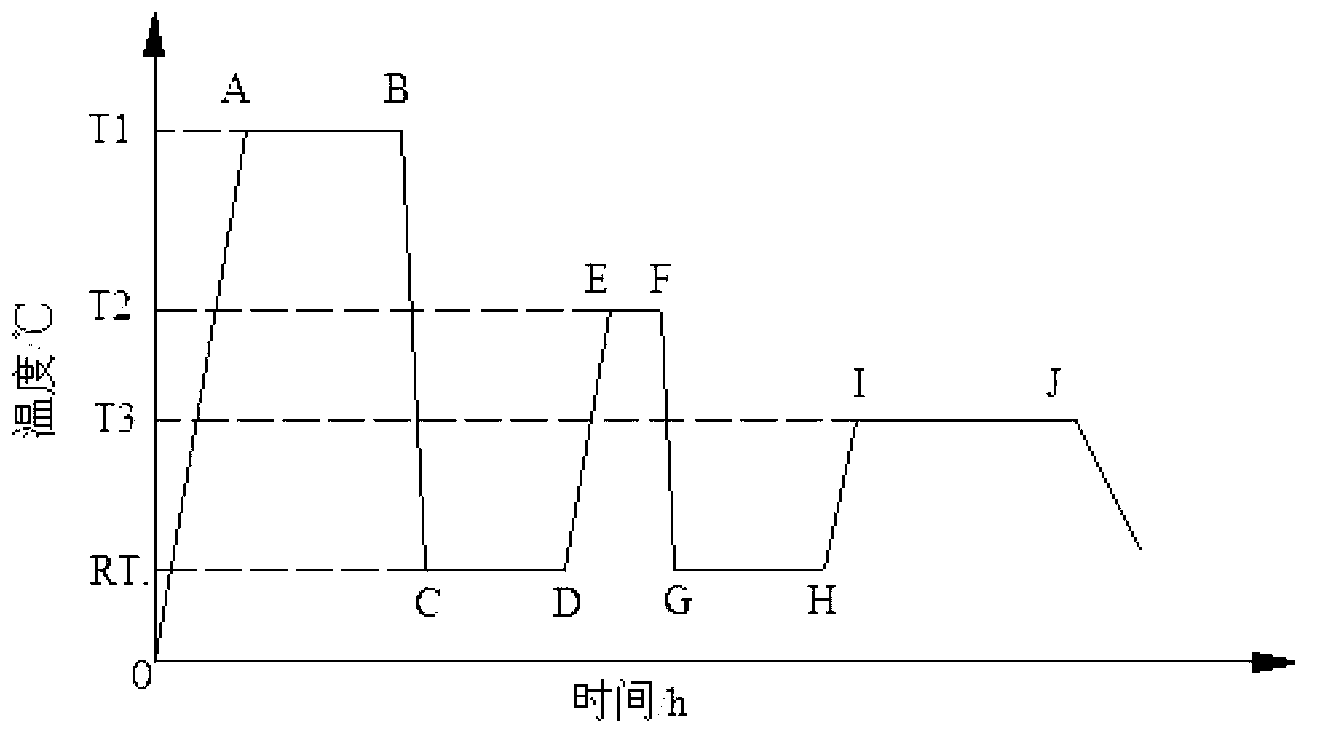

Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

InactiveCN102974675AGuaranteed shape and size accuracyAvoid quick transfersShaping toolsSize changeSupersaturated solid solution

The invention discloses a heat forming method for an aluminum alloy sheet metal part after solid solution and water quenching, relates to a heat forming method for a heat-treatable strengthening aluminum alloy sheet metal part and aims at solving the technical problems that existing heat-treatable strengthening aluminum alloy is large in shape and size change in the process of heat treatment after the heat-treatable strengthening aluminum alloy is formed first, heat melting forming and cold mold quenching technique requires transfer locating and forming to be fast, in an aluminum alloy sheet metal part cold-hot compound mold forming method, control on temperature of an aluminum alloy slab is difficult, in-mold cooling and quenching speed after forming is slow and not beneficial for obtaining a supersaturated solid solution, requirements for forming equipment are high, and the like. The forming method includes the flowing steps: carrying out the solid solution and the water quenching to the aluminum alloy slab, then, placing the aluminum alloy slab in a hot-state mold to carry out secondary heating, and carrying out aging treatment after pressing forming. According to the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching, the requirements for the forming equipment are not high, precision of shape and size of the aluminum alloy sheet metal part is high, strength is greatly improved, and the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching is suitable for the heat-treatable strengthening aluminum alloy such as 2000 series aluminum alloy, 6000 series aluminum alloy and 7000 series aluminum alloy.

Owner:HARBIN INST OF TECH

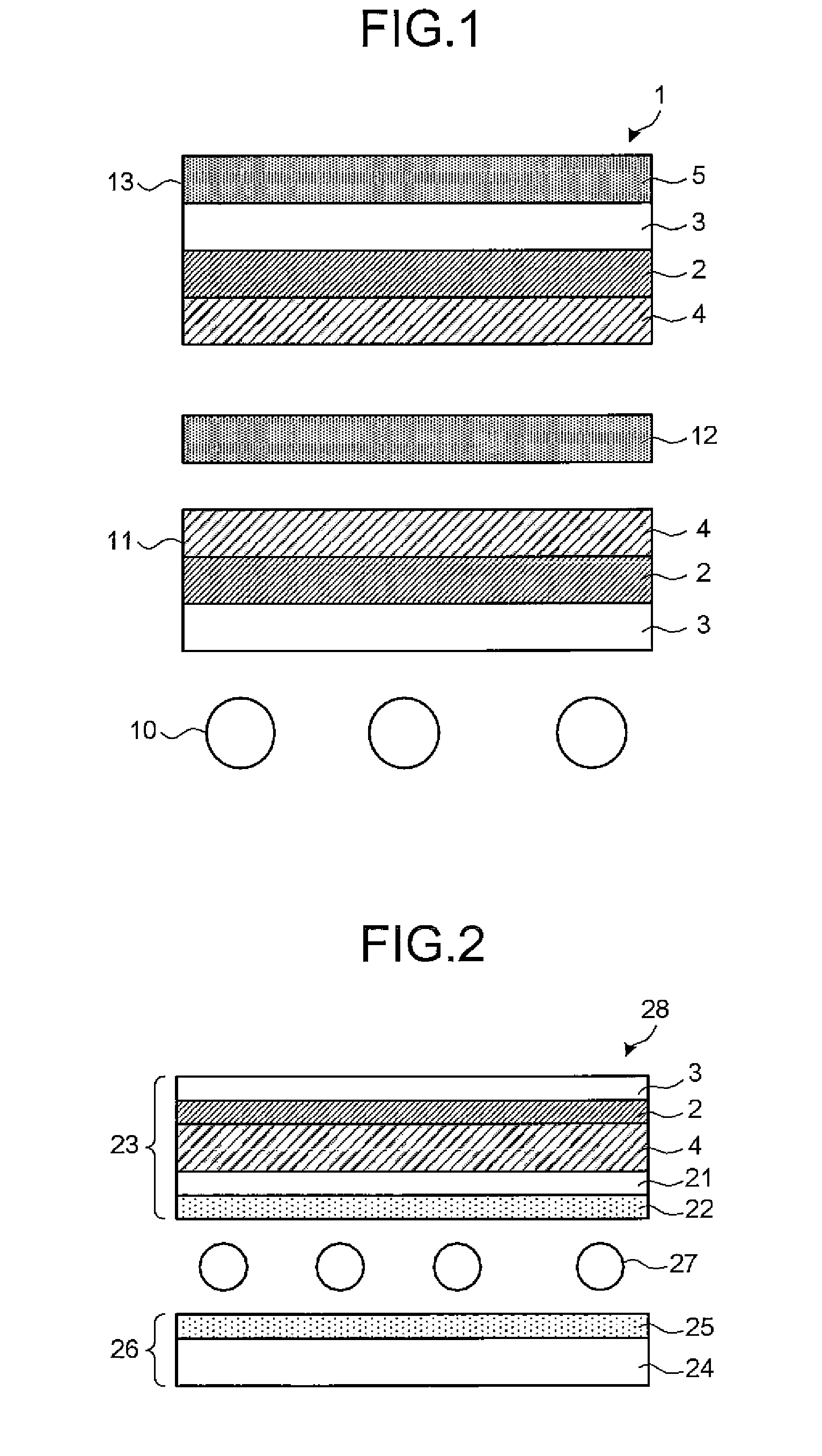

Polarization plate, liquid crystal display device and protective film

ActiveUS20090257003A1Sufficient visibilityExcellent abrasion resistanceAdhesive processesMirrorsTectorial membraneVisibility

Provided are a polarization plate which has a high mechanical strength, which does not impair a visibility even under a high temperature and high humidity, which is excellent in flexibility and abrasion resistance, and which reduces a visible disturbance such as color unevenness due to a size change, as well as a liquid crystal display device using the polarization plate. A film composed of a plurality of layers composed mainly of thermoplastic resins is used as a first protection film used for a visible side of the polarization plate, and at least one surface layer of this first protection film is composed mainly of an acrylic resin. Furthermore, a second protection film having a specific property is disposed at a side of a liquid crystal cell.

Owner:ZEON CORP

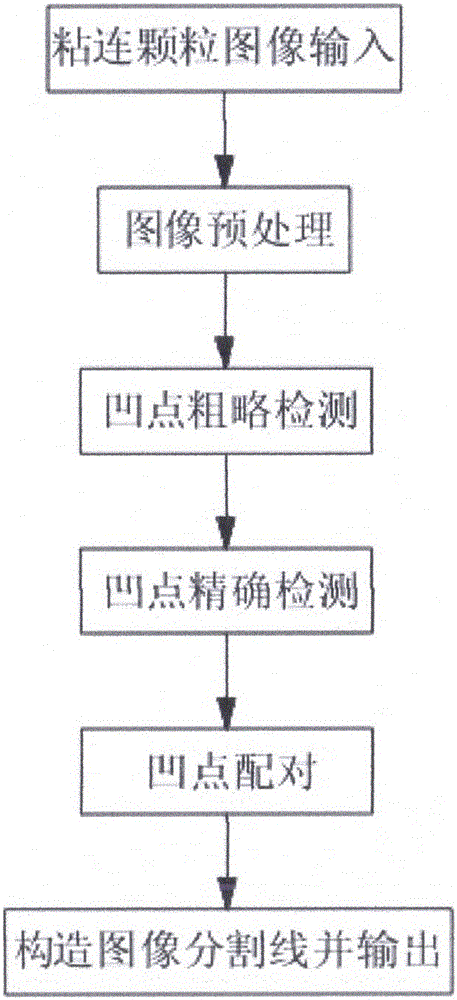

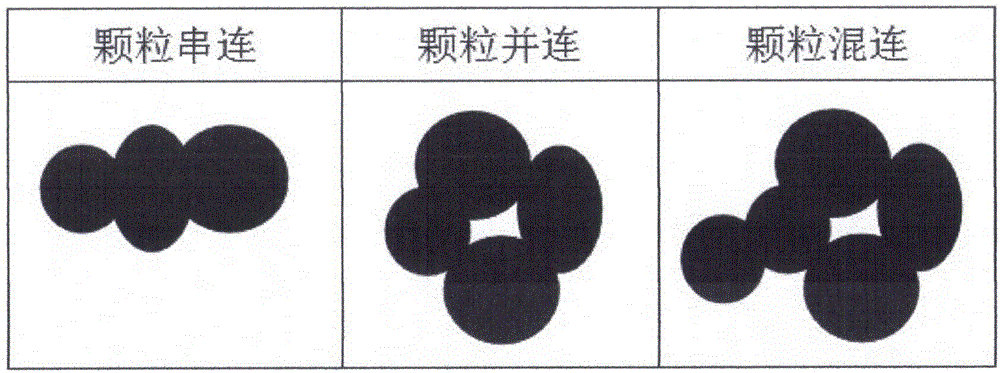

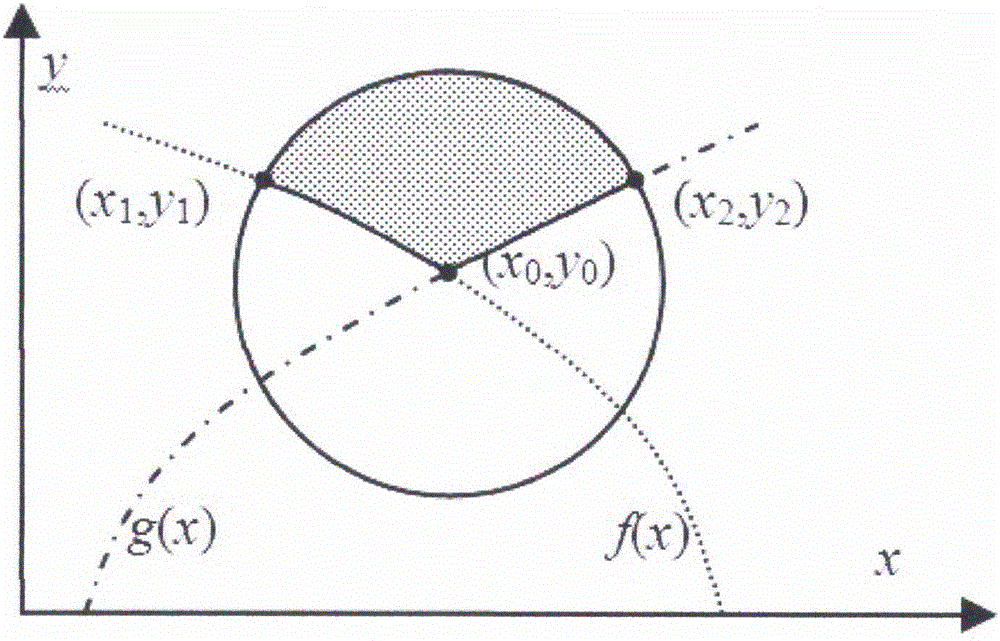

Circular masking-out area rate determination-based adhesive particle image concave point segmentation method

The present invention relates to a circular masking-out area rate determination-based adhesive particle image concave point segmentation method. The method comprises the following steps of 1) carrying out the image pre-processing to obtain a binary image of a particle image; 2) carrying out the concave point rough detection to obtain an angular point image of the particle image; 3) carrying out the concave point accurate detection, and utilizing an area rate method to obtain all concave points capable of being used for the particle segmentation in a regional contour; 4) carrying out the concave point pairing, wherein the selected concave point pairs are used as the segmentation points of an adhesive particle image; 5) constructing a segmentation line of the particles, obtaining the contour coordinates of individual particles, and combining the coordinates of two segmentation points to obtain the complete particle contour. According to the present invention, by combining an angular point detection method and a method based on concave point analysis, an operand problem brought by purely utilizing the concave point search based on area is avoided; by setting few parameters, a lot of sample training is not needed; at the same time, the segmentation paths can be replanned, thereby being able to adapt to the different shape and size change of the images.

Owner:WEIFANG UNIVERSITY

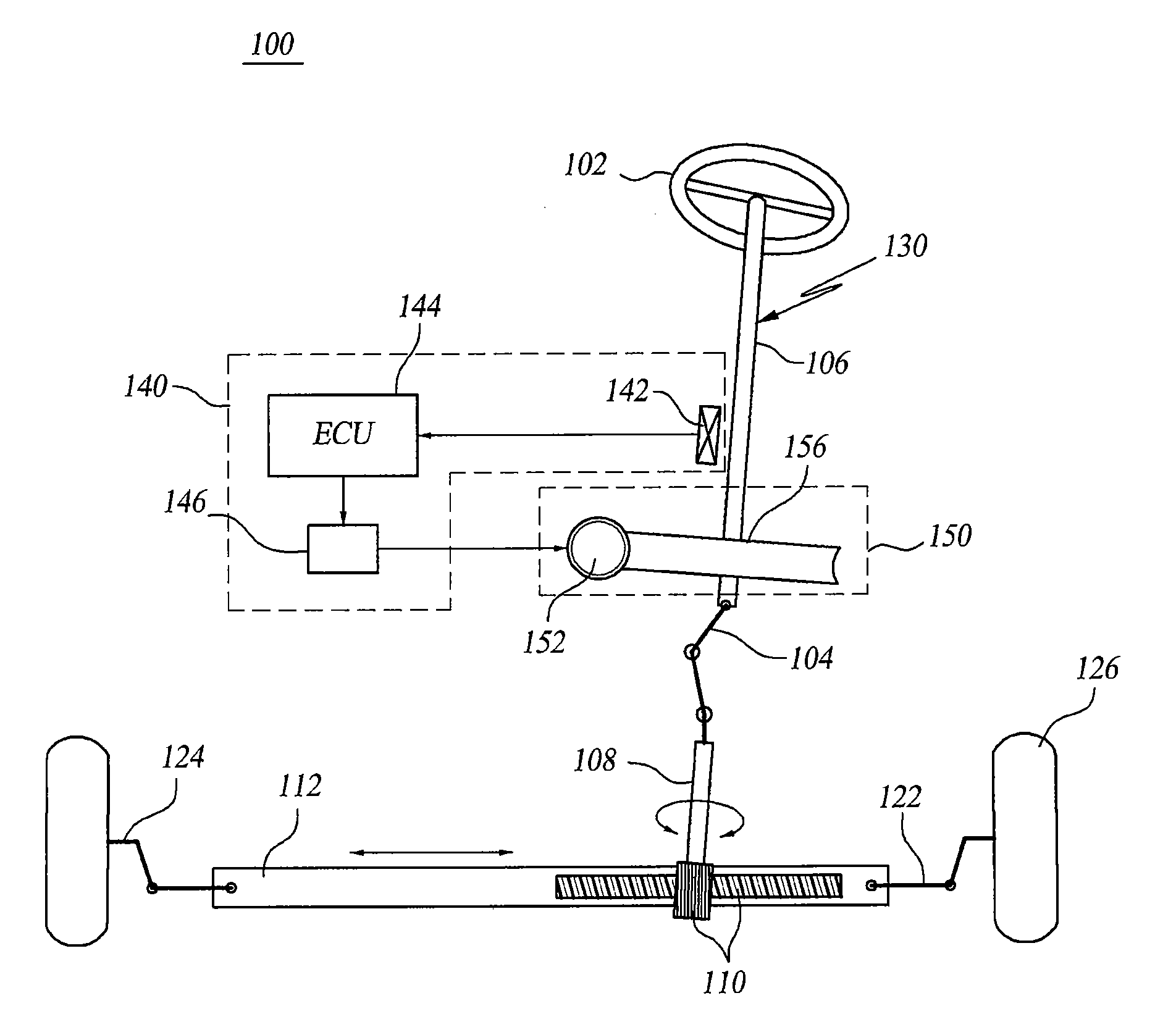

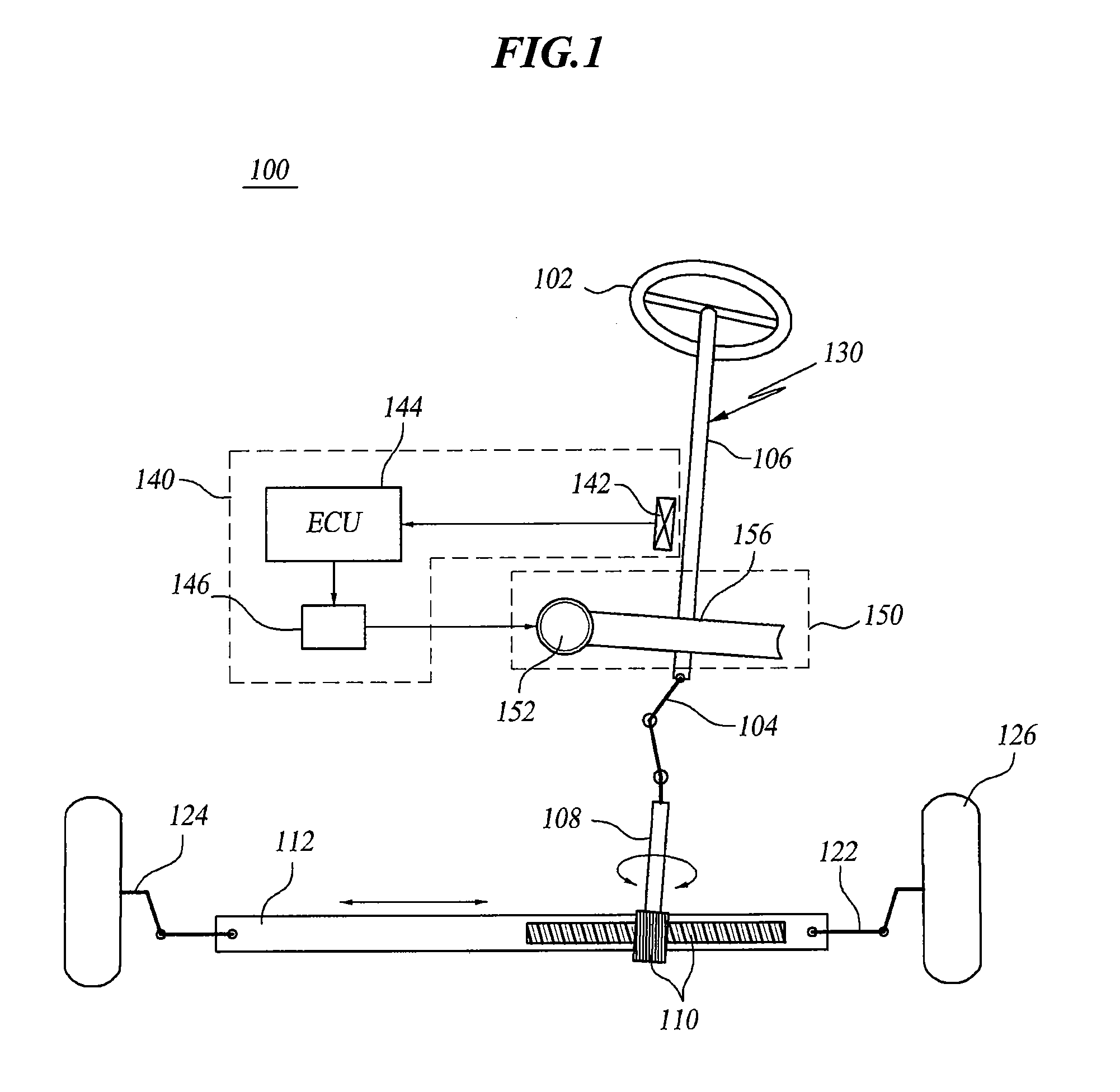

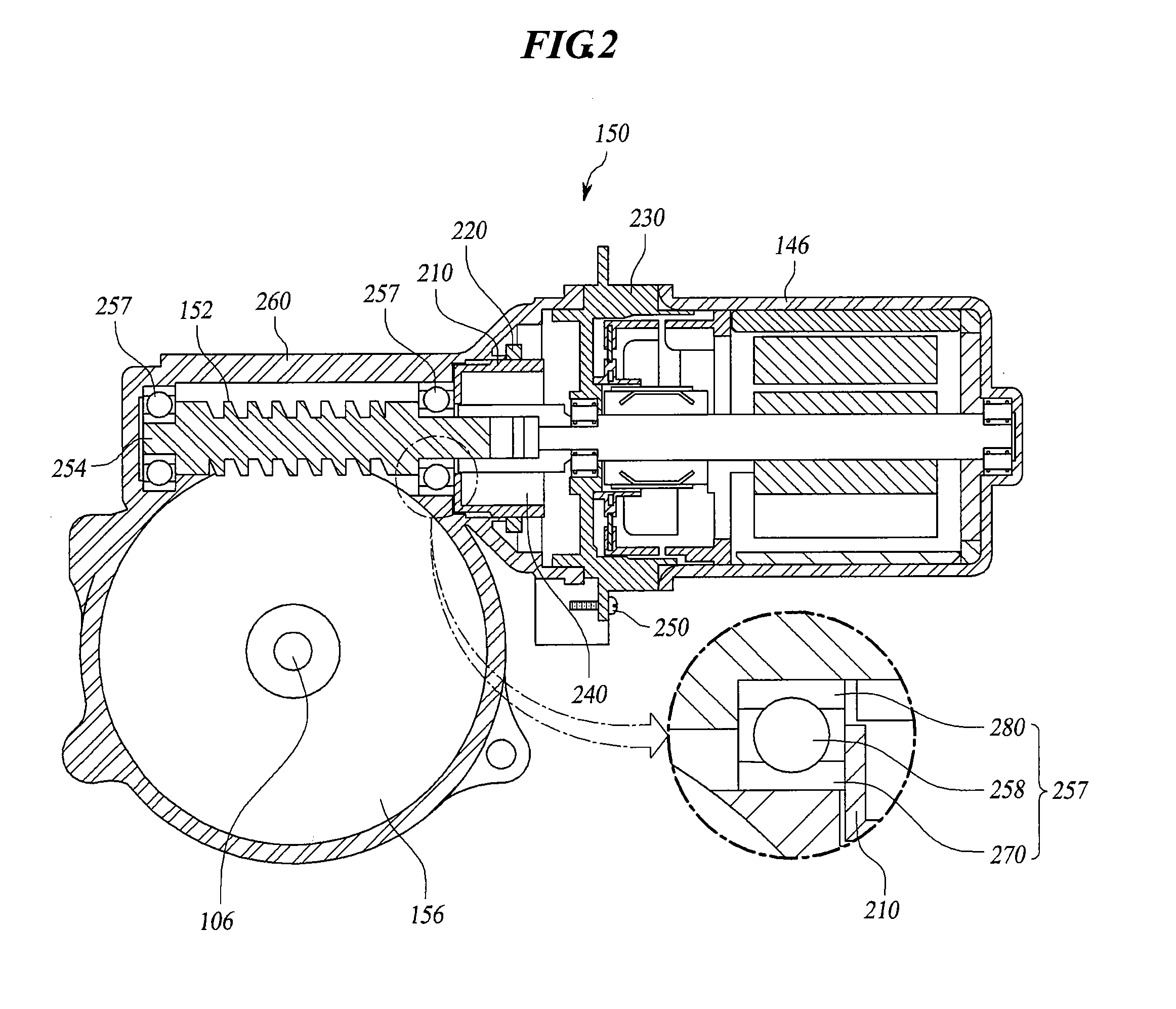

Reducer of electric power steering apparatus

ActiveUS20110067946A1Eliminate playBlocking may occurMechanical steering gearsElectrical steeringDriver/operatorSize change

Disclosed is a reducer of an electric power steering apparatus, which can prevent the steering feeling of a driver, and the performance from being reduced by minimizing an increase in the torque, caused by moisture absorption of a worm wheel, and a size change due to the moisture absorption, and also can eliminate the playing caused by wearing of a worm and the worm wheel, and inhibit the occurring of a rattle noise caused by a backlash and a reversely input load.

Owner:HL MANDO CORP

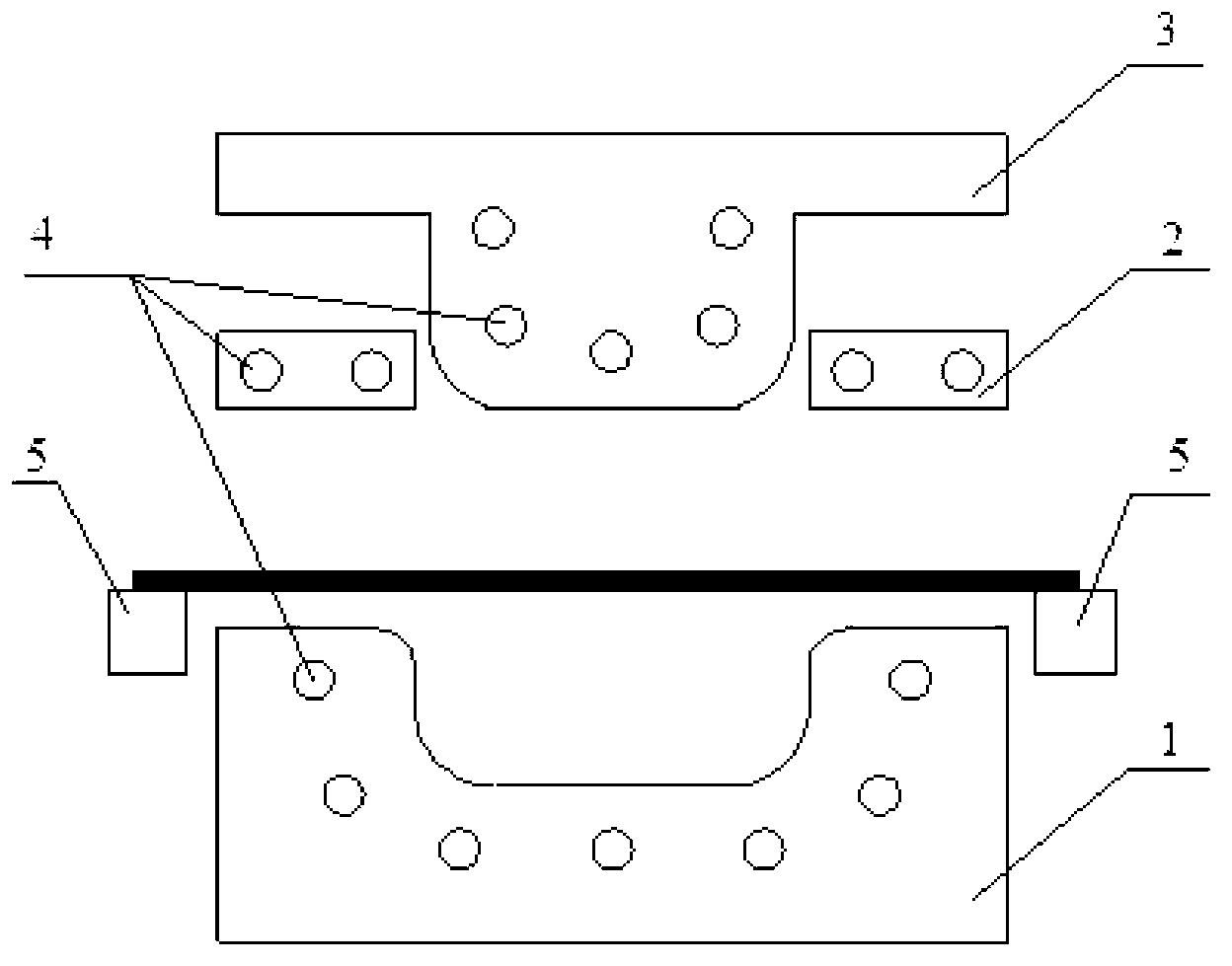

Dual-motor drive cooperatively-controlled under-actuated manipulator

ActiveCN105835051AAchieve regulationDoes not deform the objectProgramme-controlled manipulatorGripping headsLinear motionMotor drive

The invention relates to a dual-motor drive cooperatively-controlled under-actuated manipulator. The dual-motor drive cooperatively-controlled under-actuated manipulator is composed of a driving component and two under-actuated finger components. Each finger component is composed of a finger root joint, a middle finger joint and a fingertip joint. Two stepper motors convert rotational motion into linear motion through a leading screw and nut mechanism and push the finger root joints and the middle finger joints of the two finger components. The fingertip joints overcome the torsion spring action by adopting the under-actuated principle. The dual-motor drive cooperatively-controlled under-actuated manipulator is optimally designed according to the characteristics of to-be-grabbed objects which are inconsistent in shape and size or loose, soft, hard and brittle in material and is applied to the occasions where the shape and size change needs to be met, the grabbing force needs to be strictly controlled, and reliable grabbing of the objects needs to be ensured; and the under-actuated manipulator belongs to the technical field of robot and mechanical and electrical integration application and is connected with a robot body and especially suitable for grabbing, sorting and the like of food, agricultural products and light industrial products in the production and logistics fields.

Owner:JIANGNAN UNIV

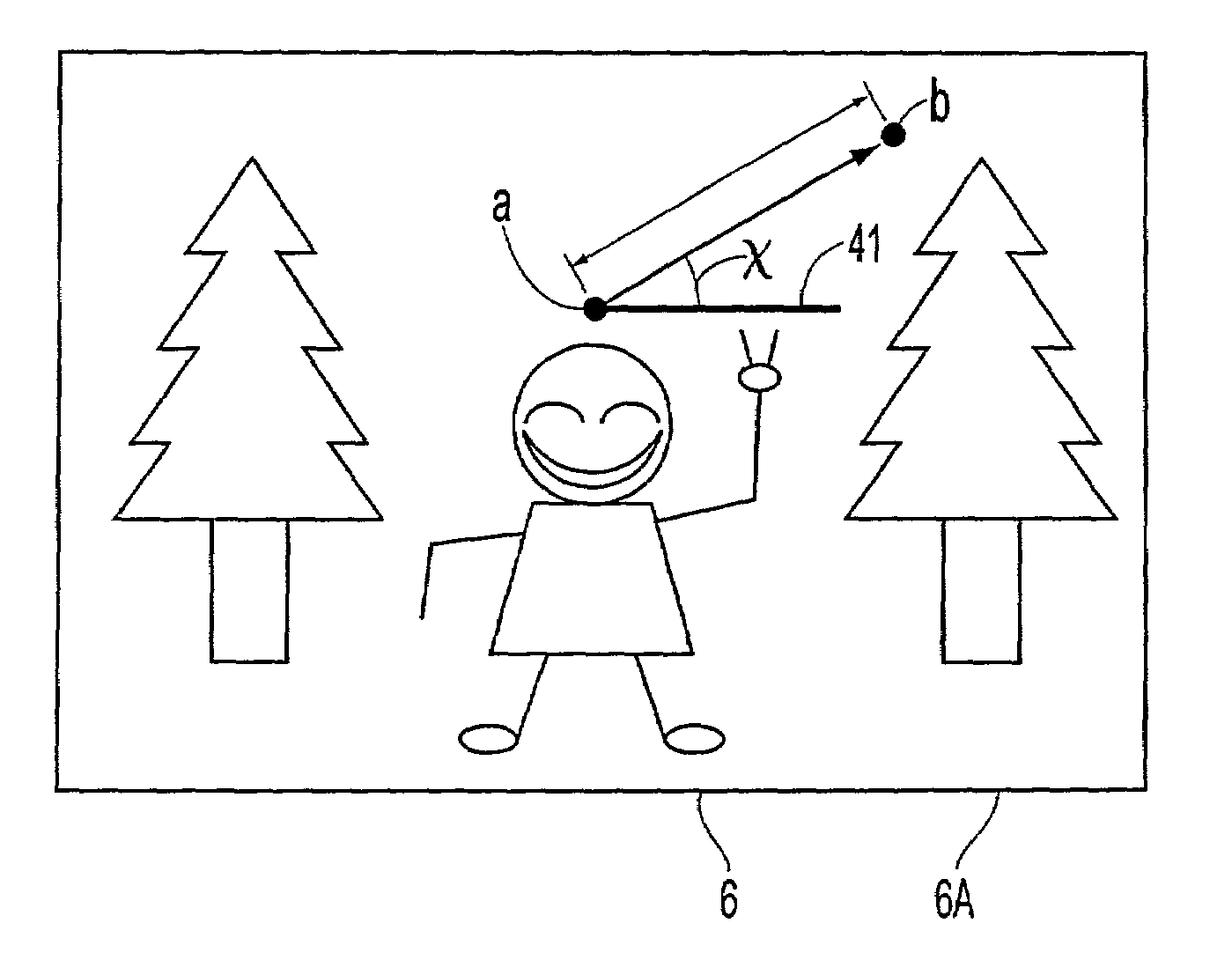

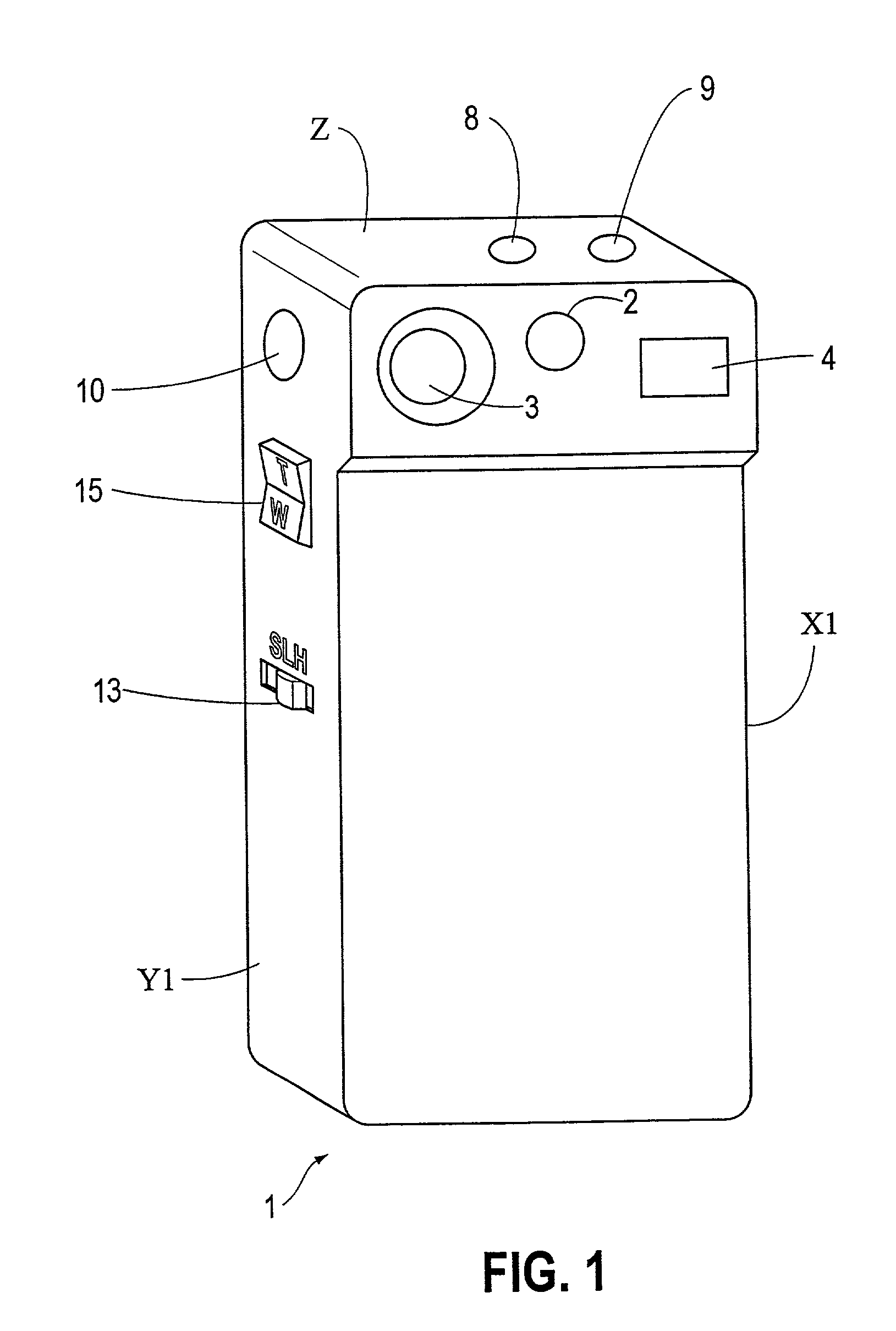

Digital camera including a zoom button and/or a touch tablet useable for performing a zoom operation

InactiveUS7154544B2Reduce in quantityChange focal lengthTelevision system detailsColor television detailsCamera lensInformation processing

An information processing device includes a shooting lens assembly, a photoelectric conversion element, a memory, a display screen, a zoom designation device and an image size changing device (e.g., a controller). The photoelectric conversion element receives light from an object that is collected by the shooting lens assembly and converts the collected light into electrical signals representative of the object. The memory stores image data that is representative of objects. The display screen displays images of the object corresponding to the electrical signal converted by the photoelectric conversion element or images corresponding to the image data stored in the memory. The image size changing device magnifies or reduces an image size of the image displayed on the display screen regardless of whether the image is being supplied from the photoelectric conversion element or the memory.

Owner:NIKON CORP

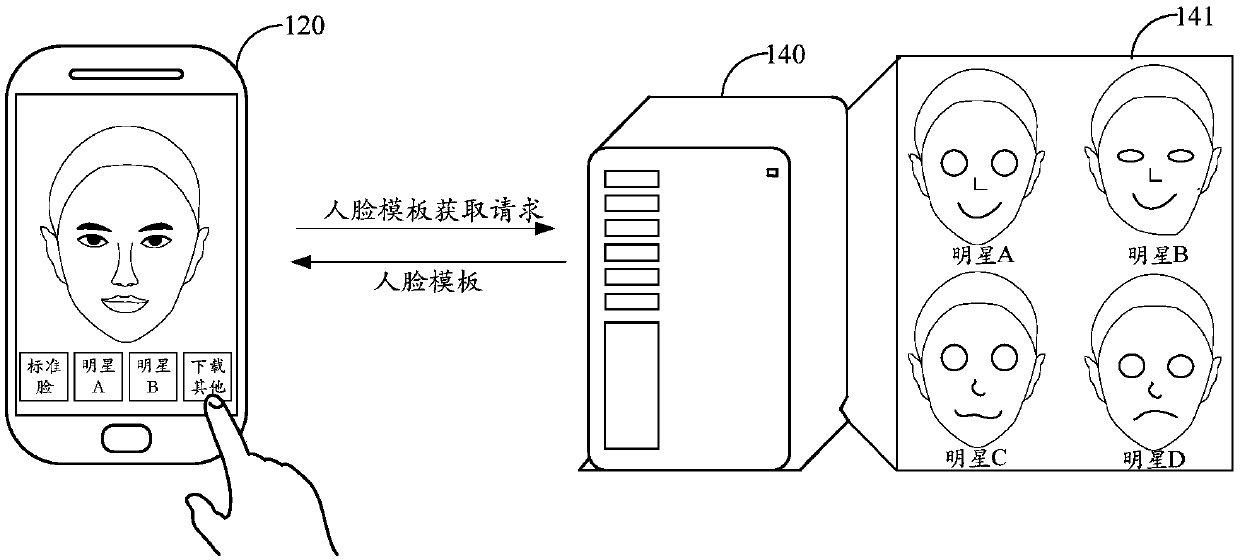

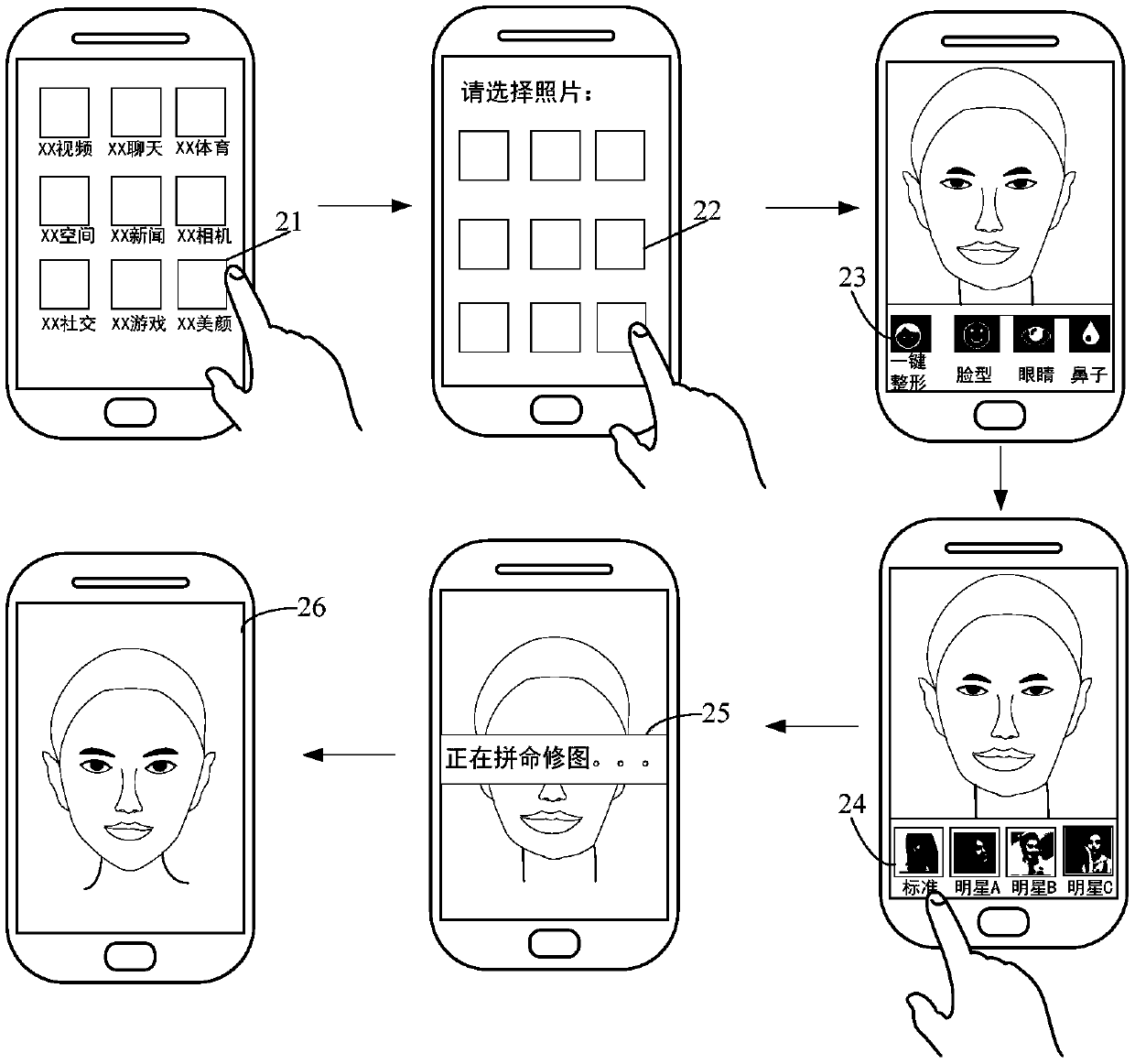

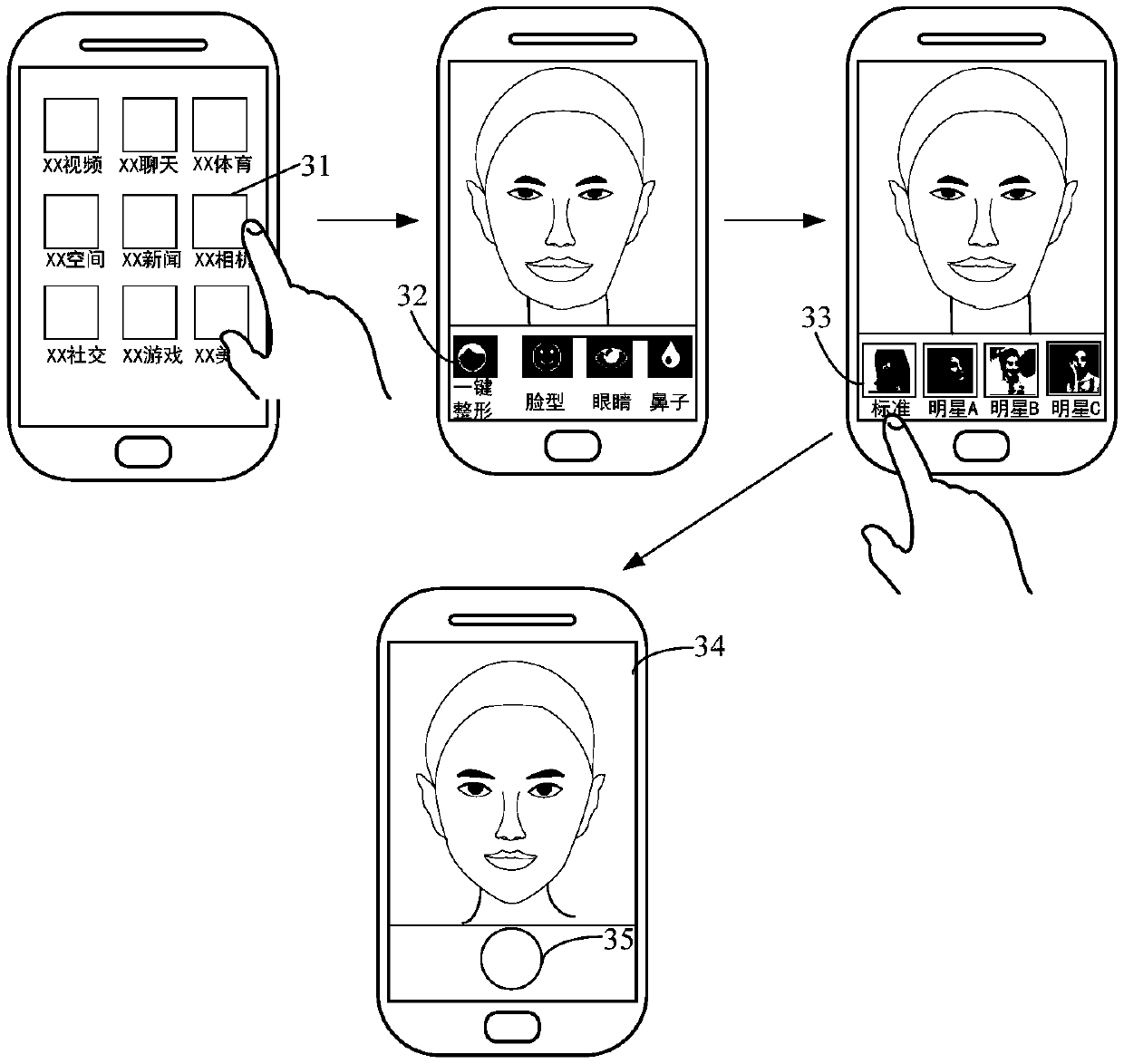

Face beautifying method and device, terminal and storage medium

ActiveCN109584151AImprove beauty effectRealize targeted formulationImage enhancementImage analysisPattern recognitionImaging processing

The invention discloses a face beautifying method and device, a terminal and a storage medium, and belongs to the field of image processing. The method comprises the steps of obtaining a target face contained in a target image; Generating adjustment parameters corresponding to the target face according to the target face and the reference face, the adjustment parameters comprising a face shape adjustment parameter and a five-sense-organ adjustment parameter; Generating a displacement vector according to the facial form adjustment parameter and the five-sense-organ adjustment parameter, whereinthe displacement vector is used for representing the facial form of the target face and the size change, position change and angle change conditions of the five sense organs in the adjustment process; Adjusting the face shape and the five sense organs of the target face according to the displacement vector; And displaying the adjusted target face. According to the embodiment of the invention, thedifference between different faces is considered, the adjusting strategy conforming to the target face characteristics is formulated according to the difference between the target face and the reference face, targeted formulation of the beautifying strategy is realized, and then the face beautifying effect is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

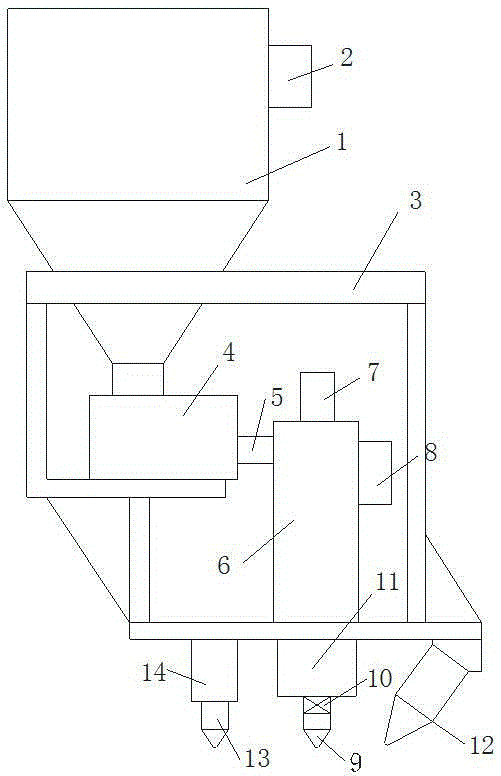

3D printing device integrating material supplying, fluxing and crystal leveling assistance

ActiveCN105383060AImprove densification performanceImprove bindingAdditive manufacturing apparatusCeramic shaping apparatusSize changeEngineering

A 3D printing device integrating material supplying, fluxing and crystal leveling assistance comprises a support, a material bin, a first forced feeding mechanism, a second forced feeding mechanism, an auxiliary heating head and a crystal leveling assistance vibrating head, wherein the material bin, the first forced feeding mechanism, the second forced feeding mechanism, the auxiliary heating head and the crystal leveling assistance vibrating head are all mounted on the support. The material bin, the first forced feeding mechanism and the second forced feeding mechanism are sequentially connected. A nozzle is connected to a discharging outlet of the second forced feeding mechanism, and a heating device is arranged at the discharging outlet. The auxiliary heating head and the crystal leveling assistance vibrating head are arranged at the bottom of the support and located in front of and behind the nozzle respectively. The device is easy to operate, stable, reliable and convenient to maintain; the compactness of formed workpieces in the 3D printing process is improved, interlayer bonding of the formed workpieces is good, and the cost is low; through material selection, size changes and process adjustment of corresponding components, the device can be suitable for fused deposition of powder materials of different types.

Owner:JINAN LUYANG TECH

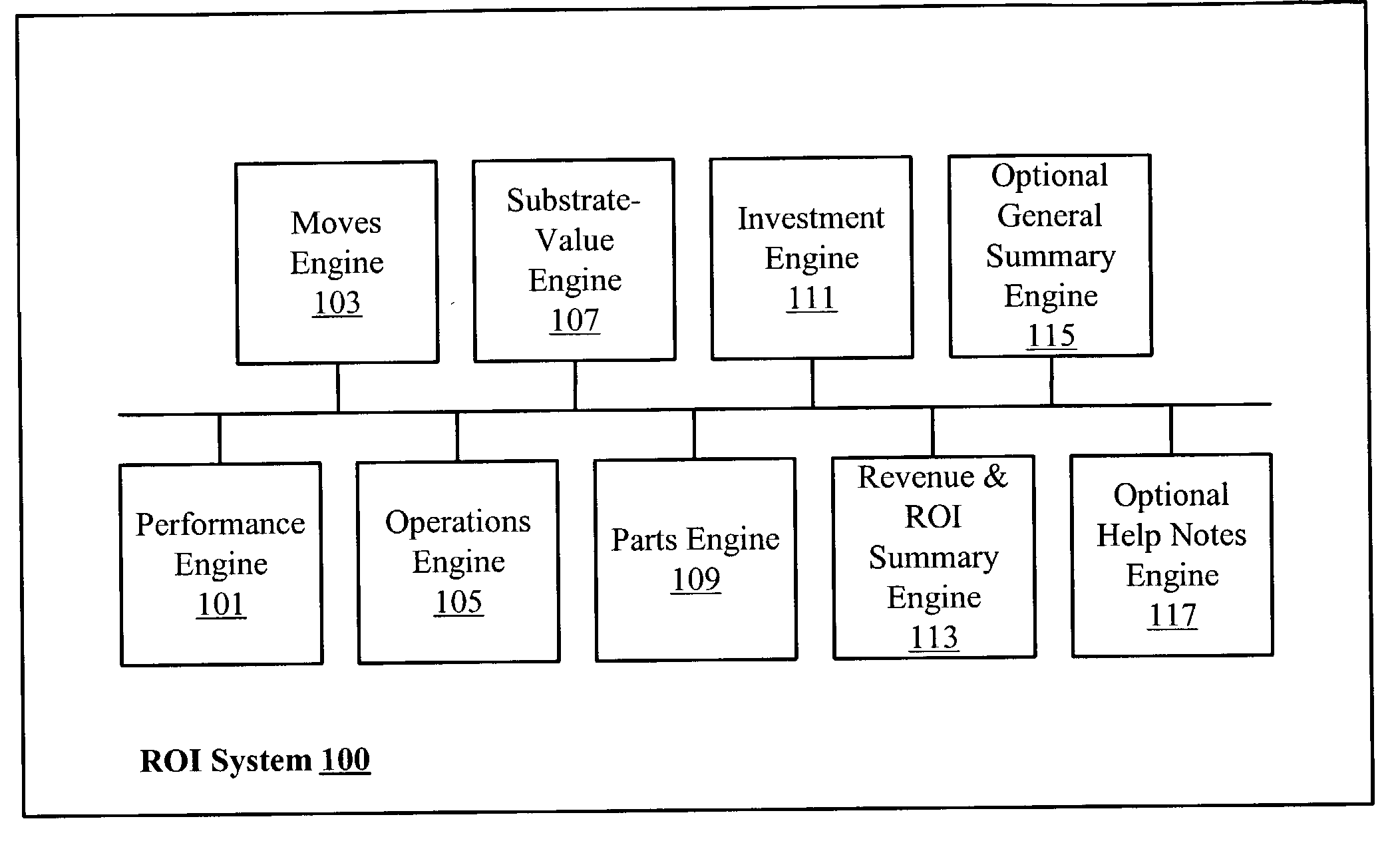

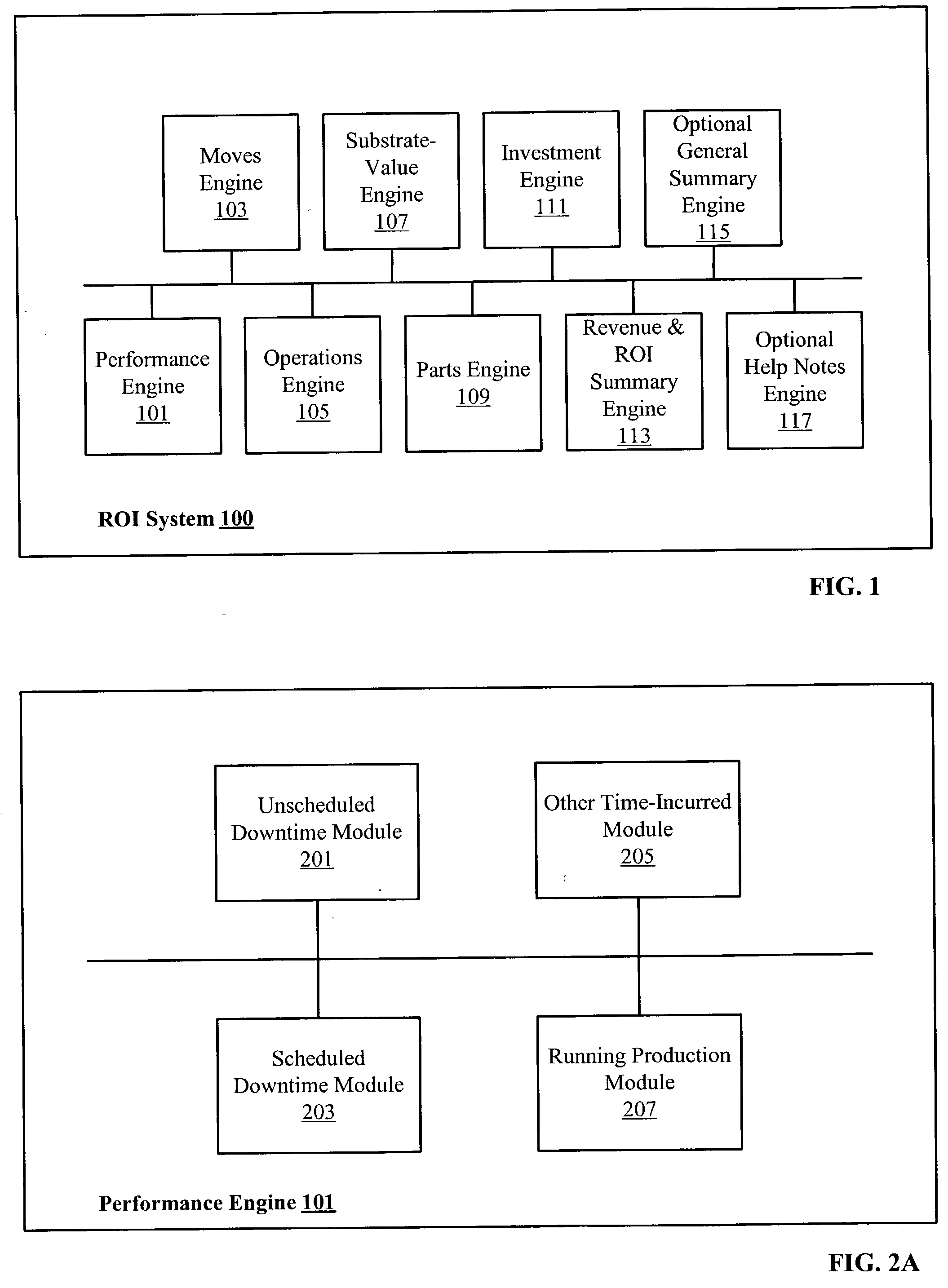

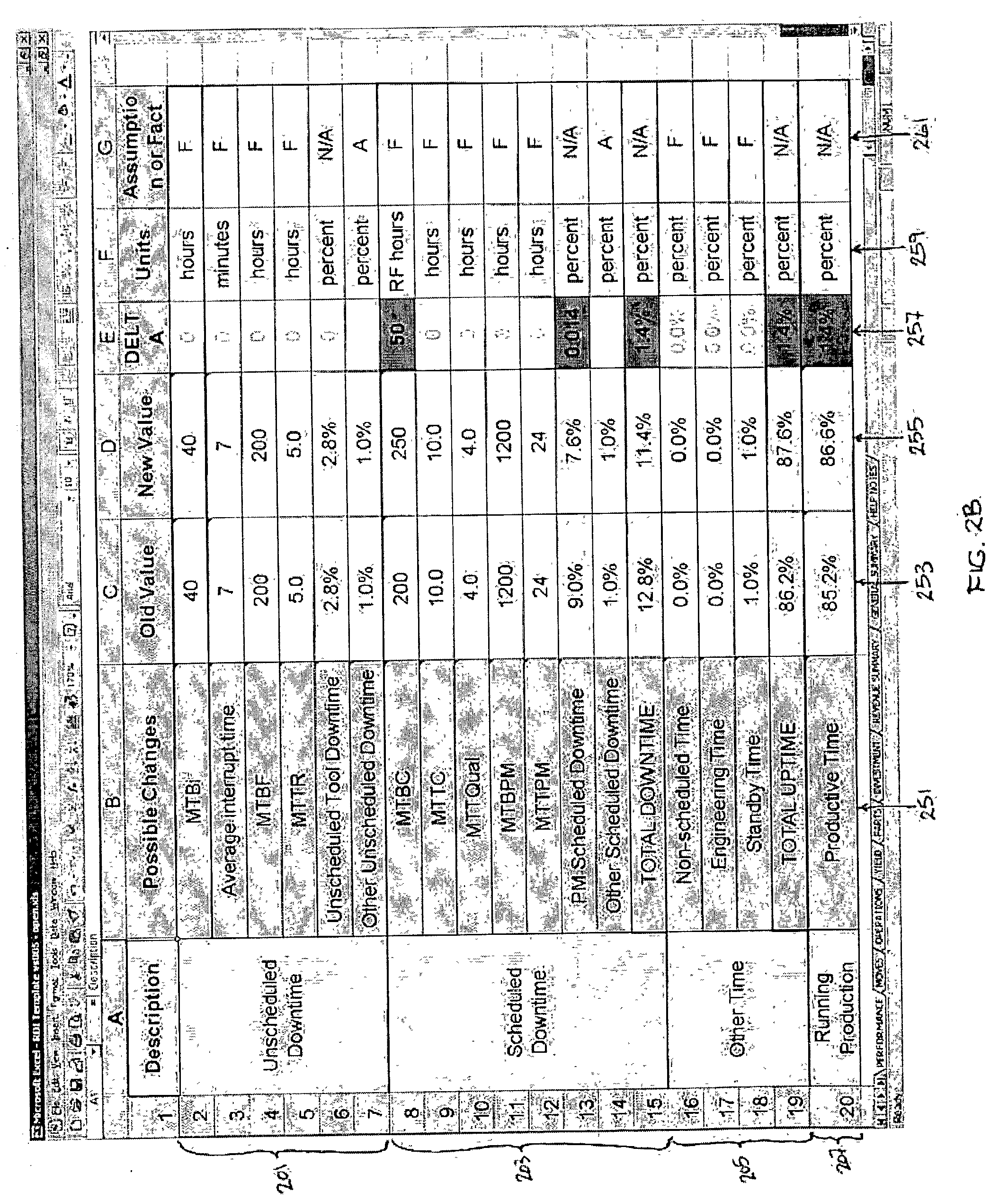

System and method for determining a return-on-investment in a semiconductor or data storage fabrication facility

A return-on-investment (ROI) modeling system and method of the present invention calculates a return-on-investment for various scenarios in a semiconductor or data storage fabrication facility ("fab"). The ROI system and method of the present invention calculates the ROI based upon having fab operational details entered. The ROI calculation may be performed for an entire fab or a particular fab processing line. The present invention compares the ROI of a current operation with a contemplated change or set of changes. A complete set of pertinent factors having a relevant or significant impact on an accurate ROI calculation is taken into consideration. Further, the present invention determines costs associated with, for example, the installation of a new tool, downtime costs, short-loop test runs, split-lot testing, design-rule shrinks, and wafer-size changes. If a fab is not currently operating at maximum capacity, an embodiment of the invention calculates an increased capacity capability.

Owner:LAM RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com