Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11320 results about "Ridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ridge or a mountain ridge is a geographical feature consisting of a chain of mountains or hills that form a continuous elevated crest for some distance. The sides of the ridge slope away from narrow top on either side. The lines along the crest formed by the highest points, with the terrain dropping down on either sides, are called the ridgelines. Ridges are usually termed hills or mountains as well, depending on size.

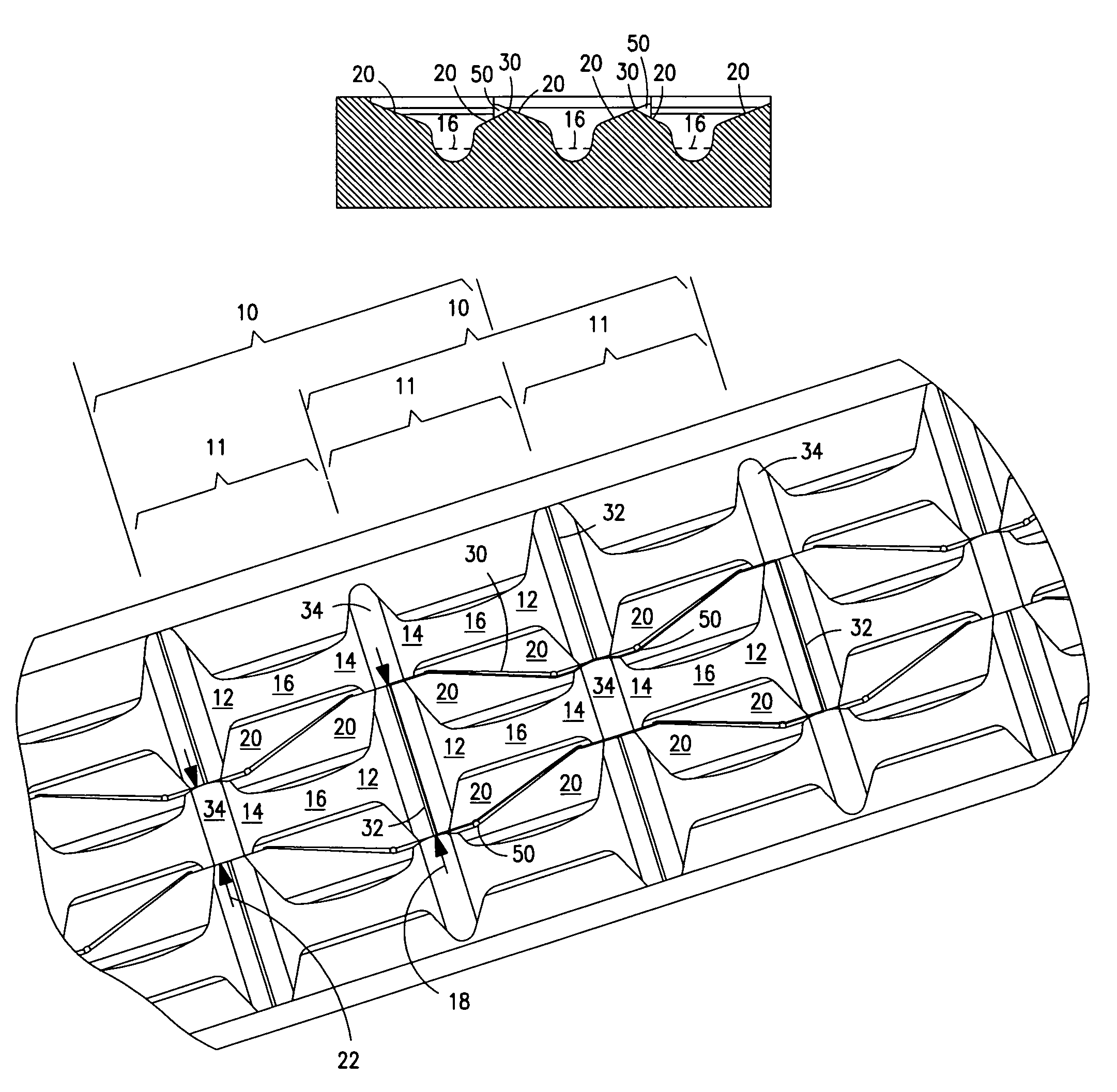

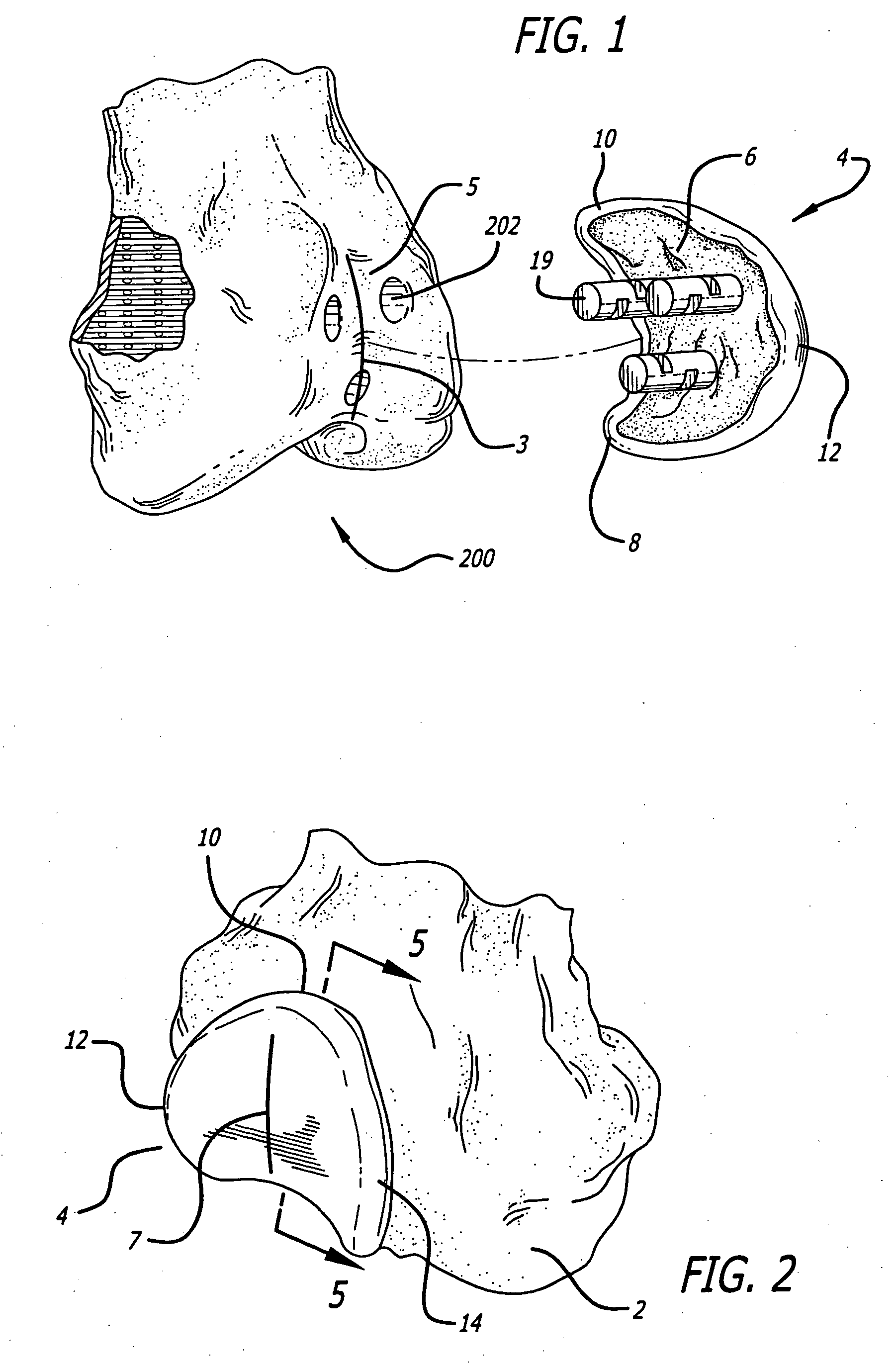

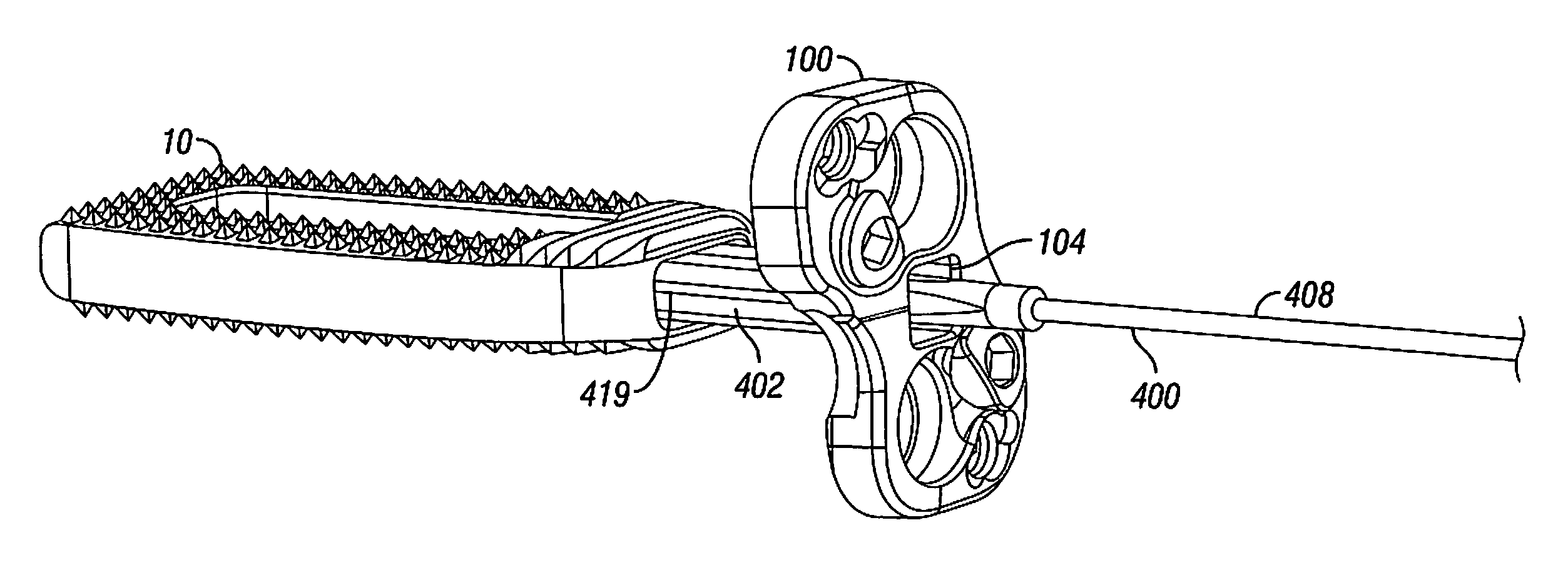

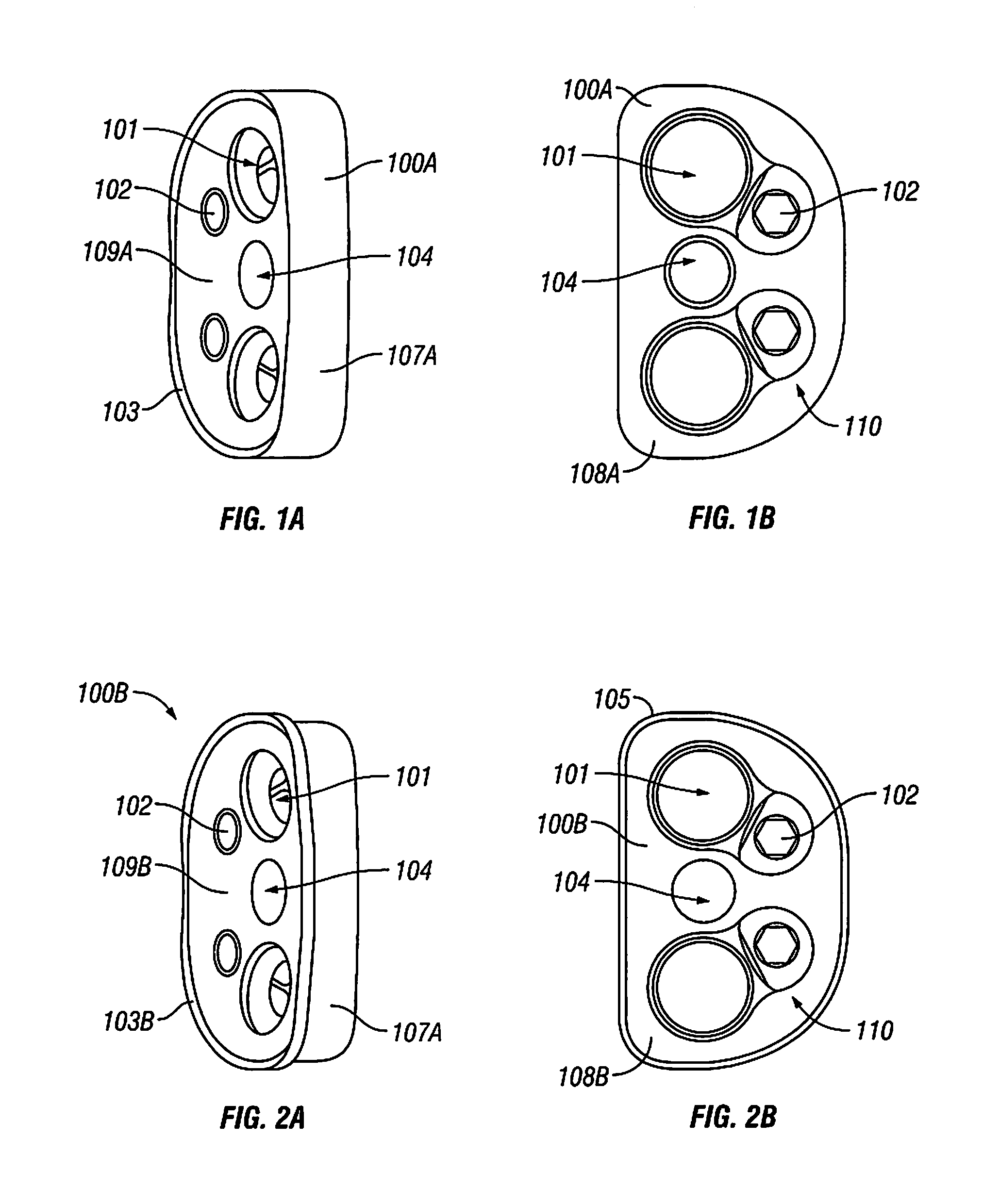

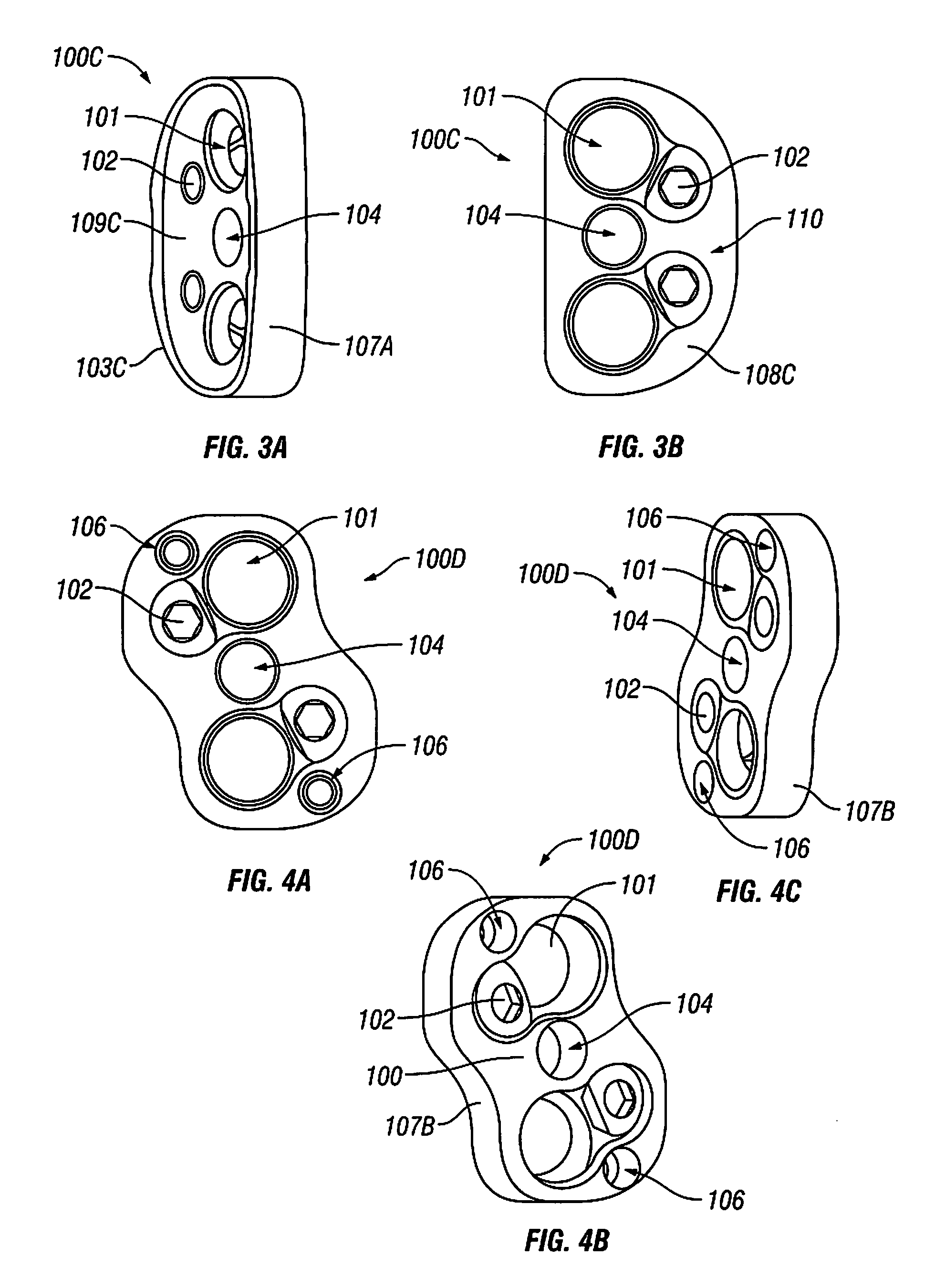

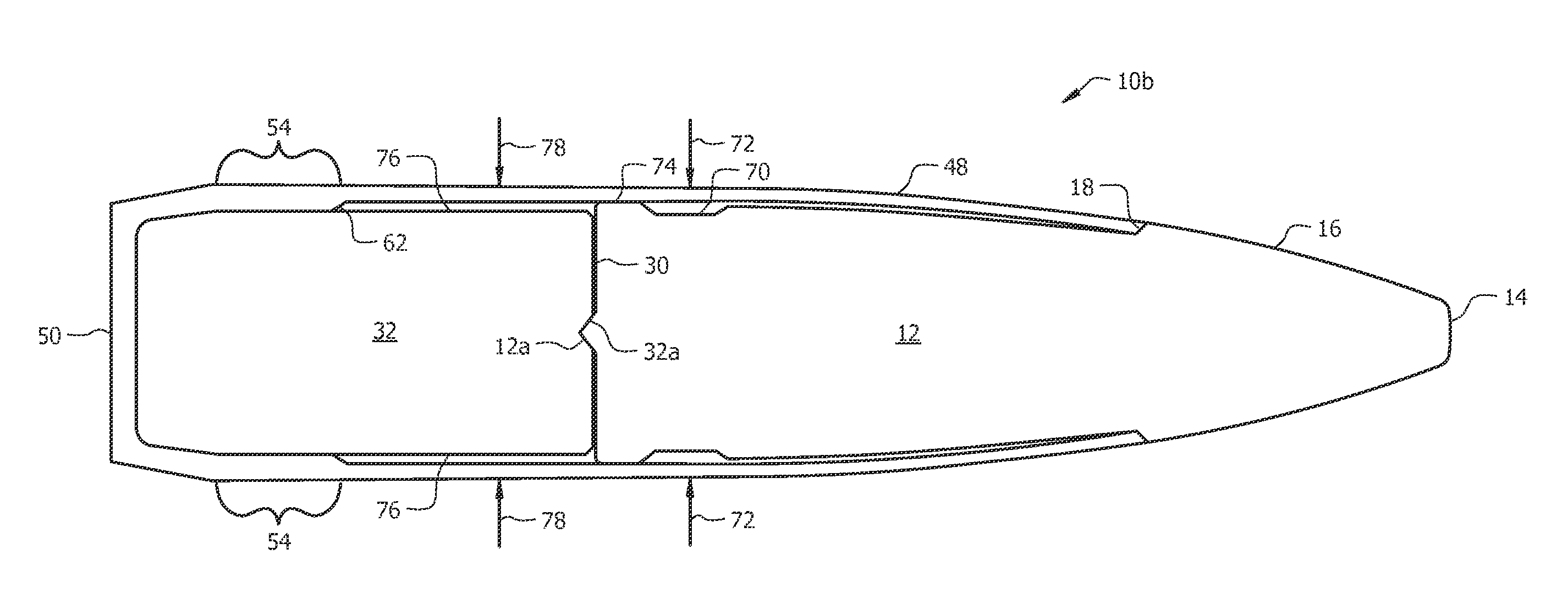

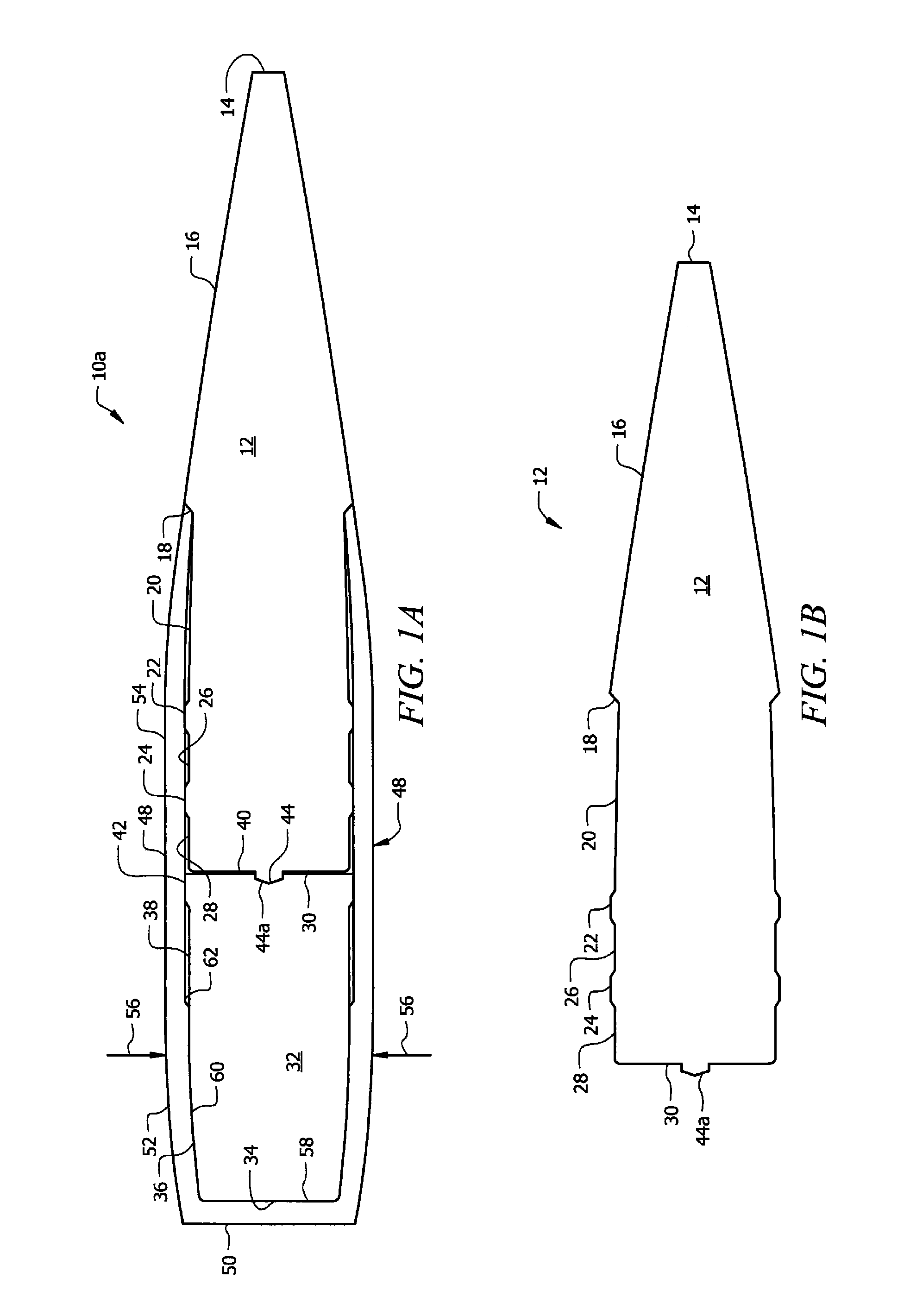

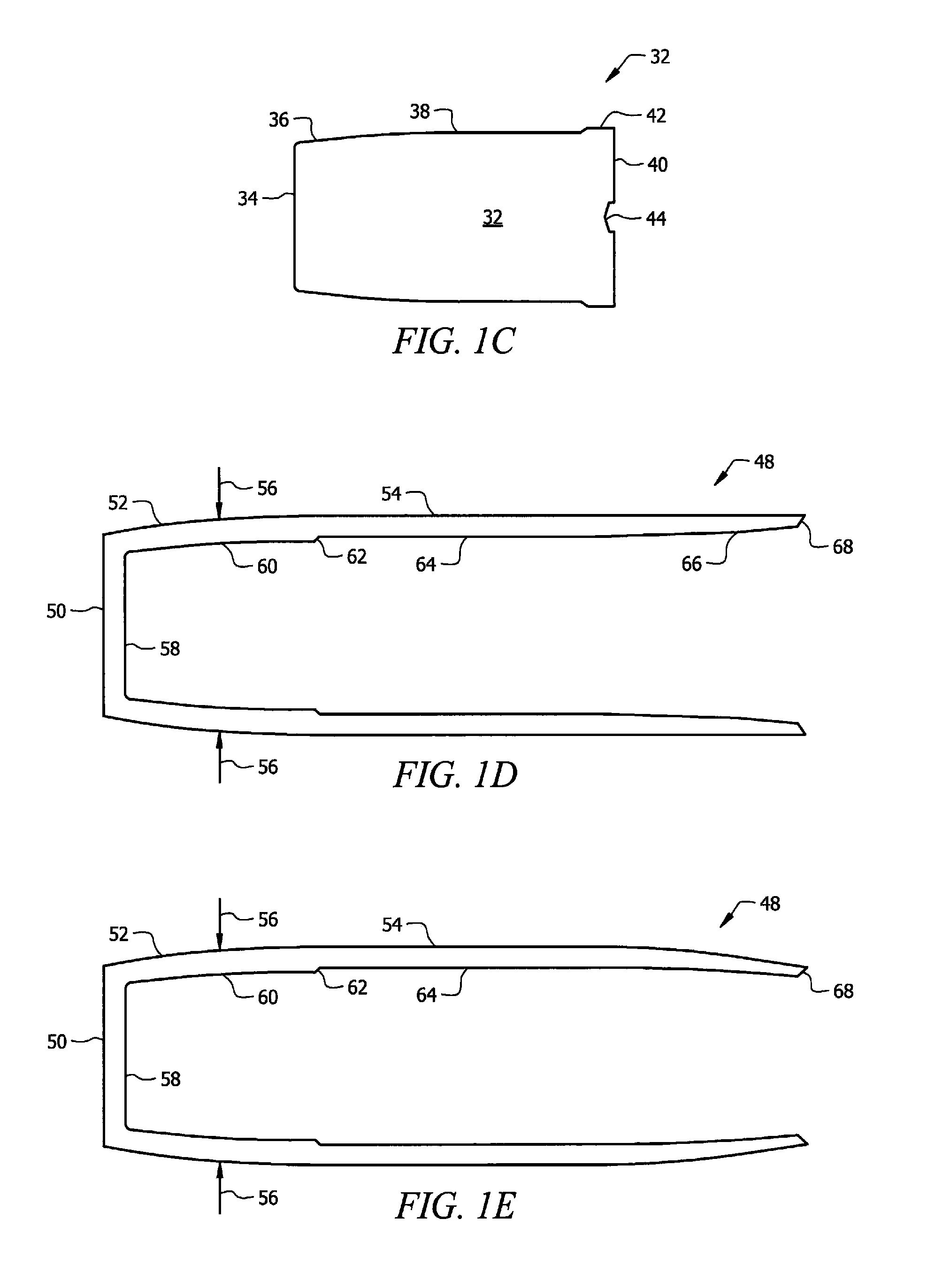

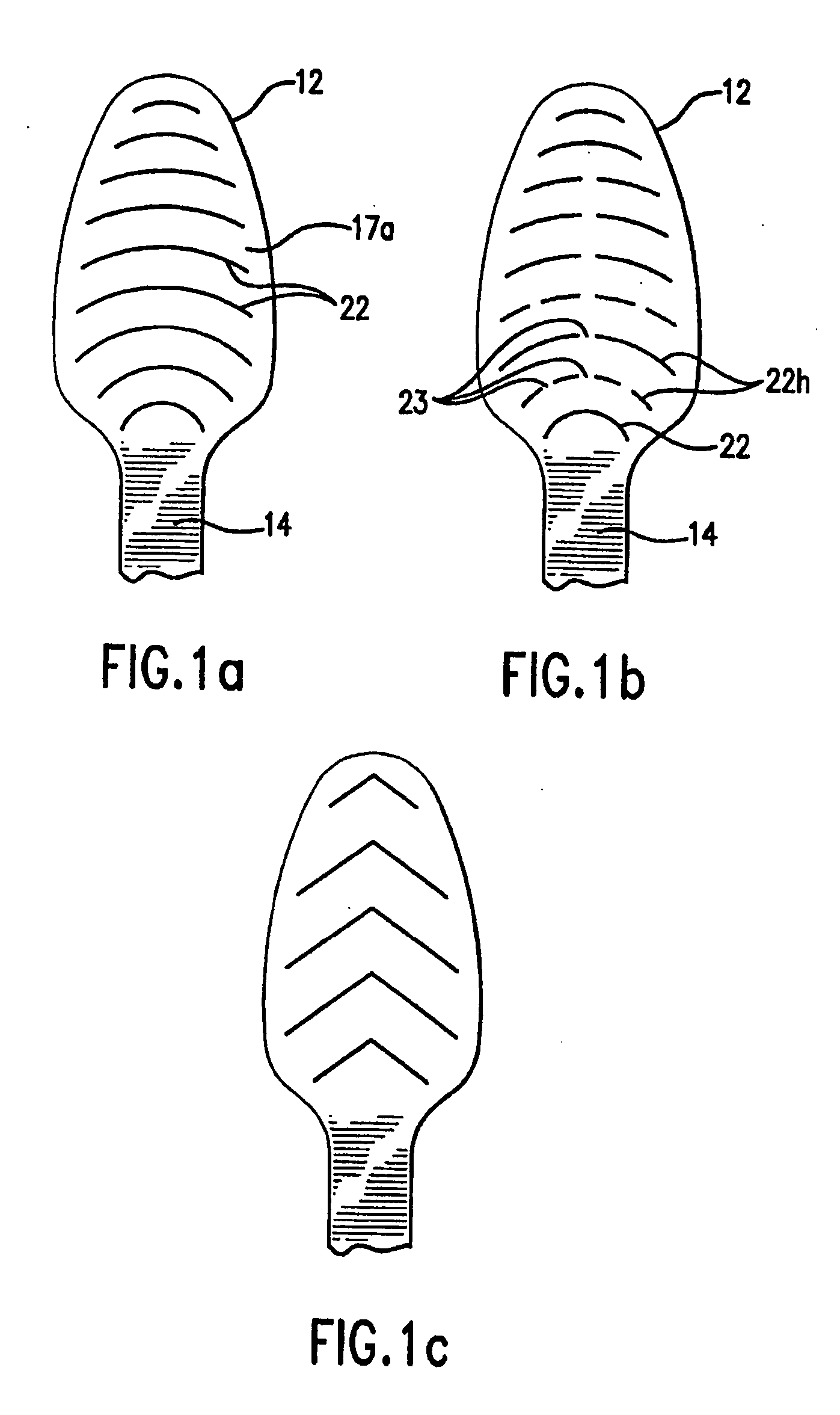

Surgical stapler anvil with nested staple forming pockets

InactiveUS6953138B1Increased lateral widthLittle lateral spaceSuture equipmentsStapling toolsMirror imageBiomedical engineering

A surgical stapler anvil provides an expanded leg-receiving target area for a staple forming pocket in a compact staggered array by narrowing the lateral width of the leg-clinching portion of a laterally adjacent pocket. Advantageously, the lateral spacing between adjacent rows of staple forming pockets can remain small, while the leg-receiving target area for laterally adjacent rows of pockets is significantly expanded. The staple forming pockets include two mirror image leg-forming cups. The cups are longitudinally aligned with their respective ascending leg clinching portions adjoining in the center of the pocket. Laterally spaced guide surfaces extend upwardly and outwardly from the clinching surface at the bottom of the cup to define an expanded leg-receiving target area at the distal ends of the pocket. Substantially planar laterally outward portions of the guide surface intersect with the guide surface of a laterally adjacent pocket to form a non-linear ridge.

Owner:DWORAK FR W

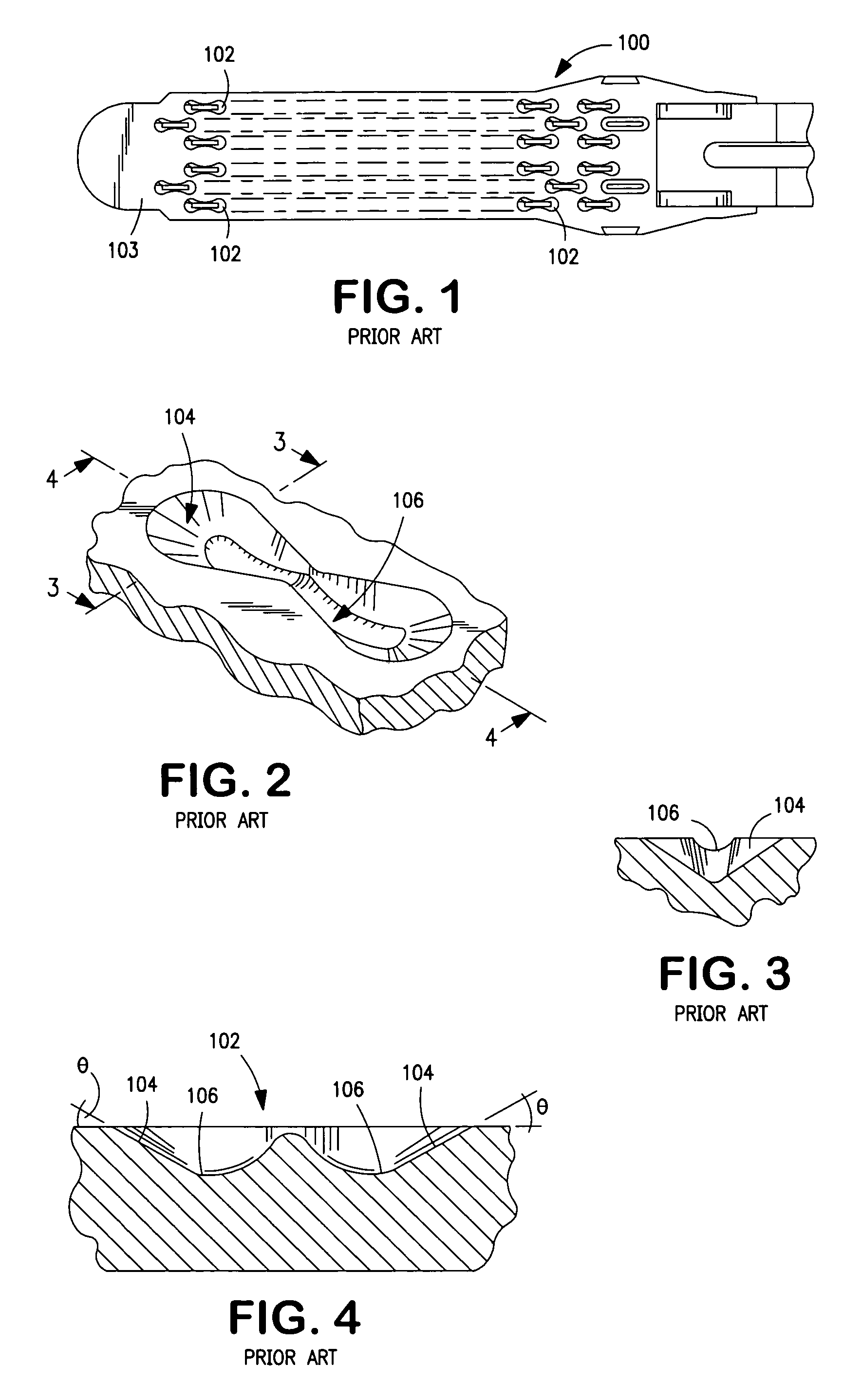

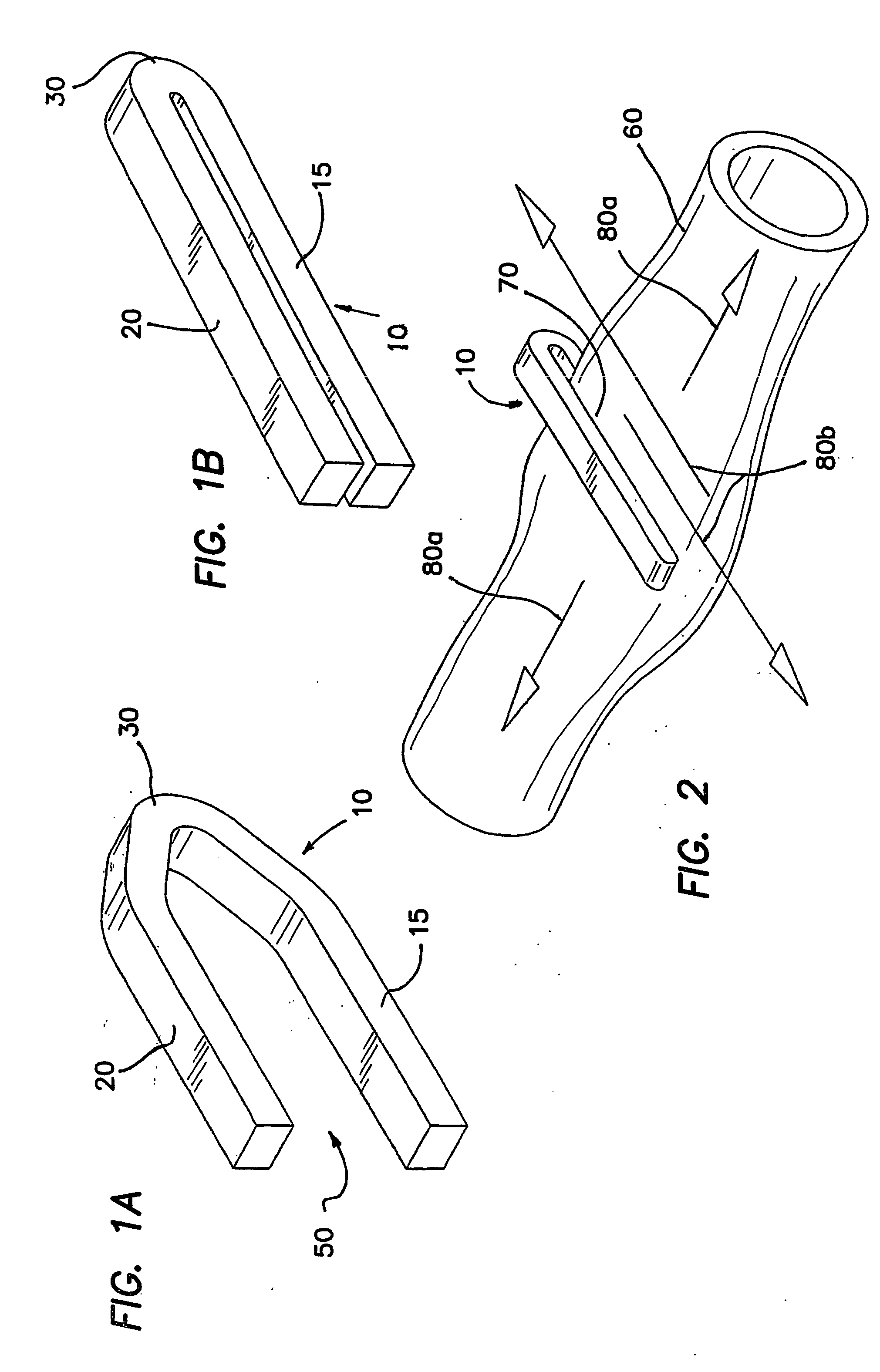

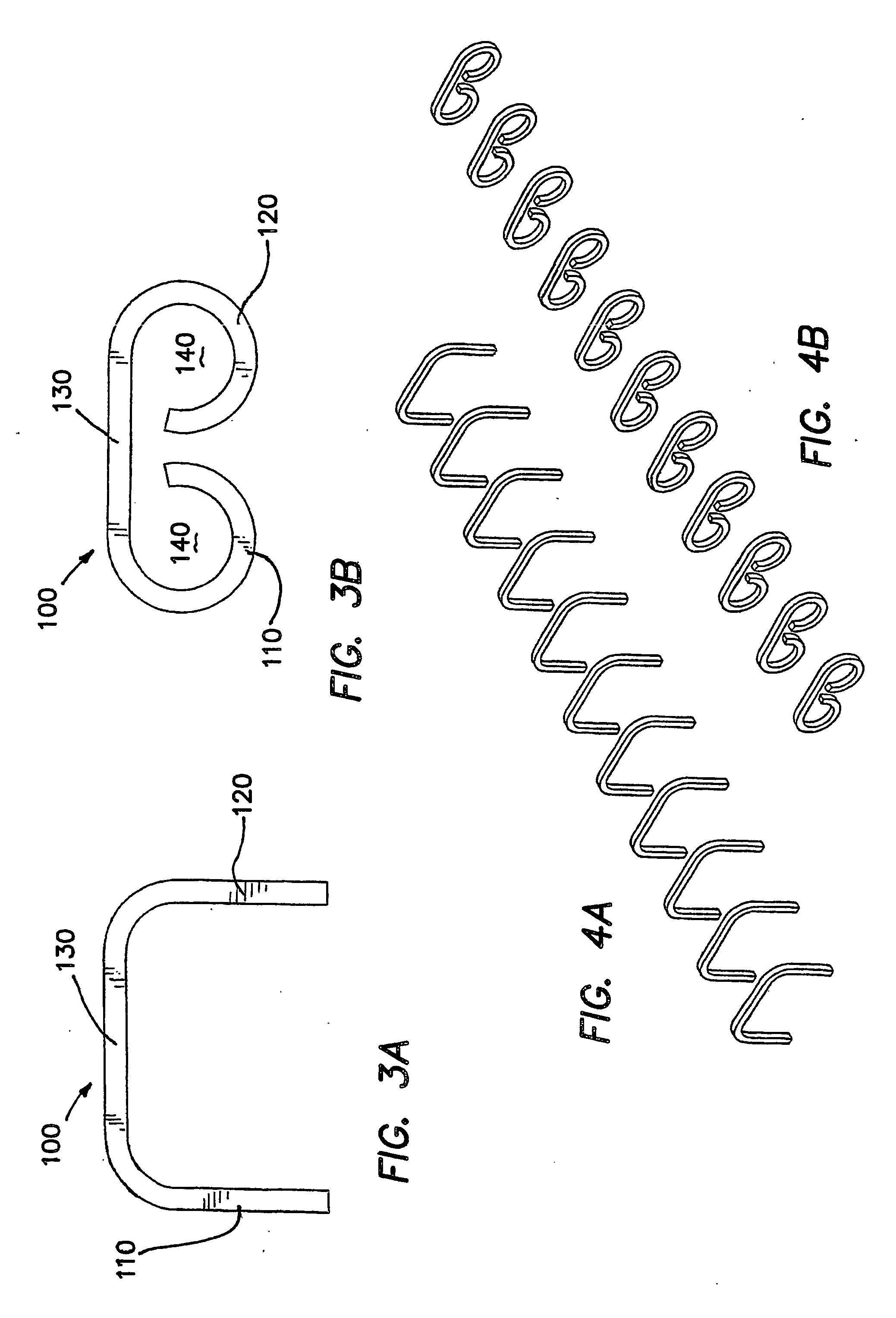

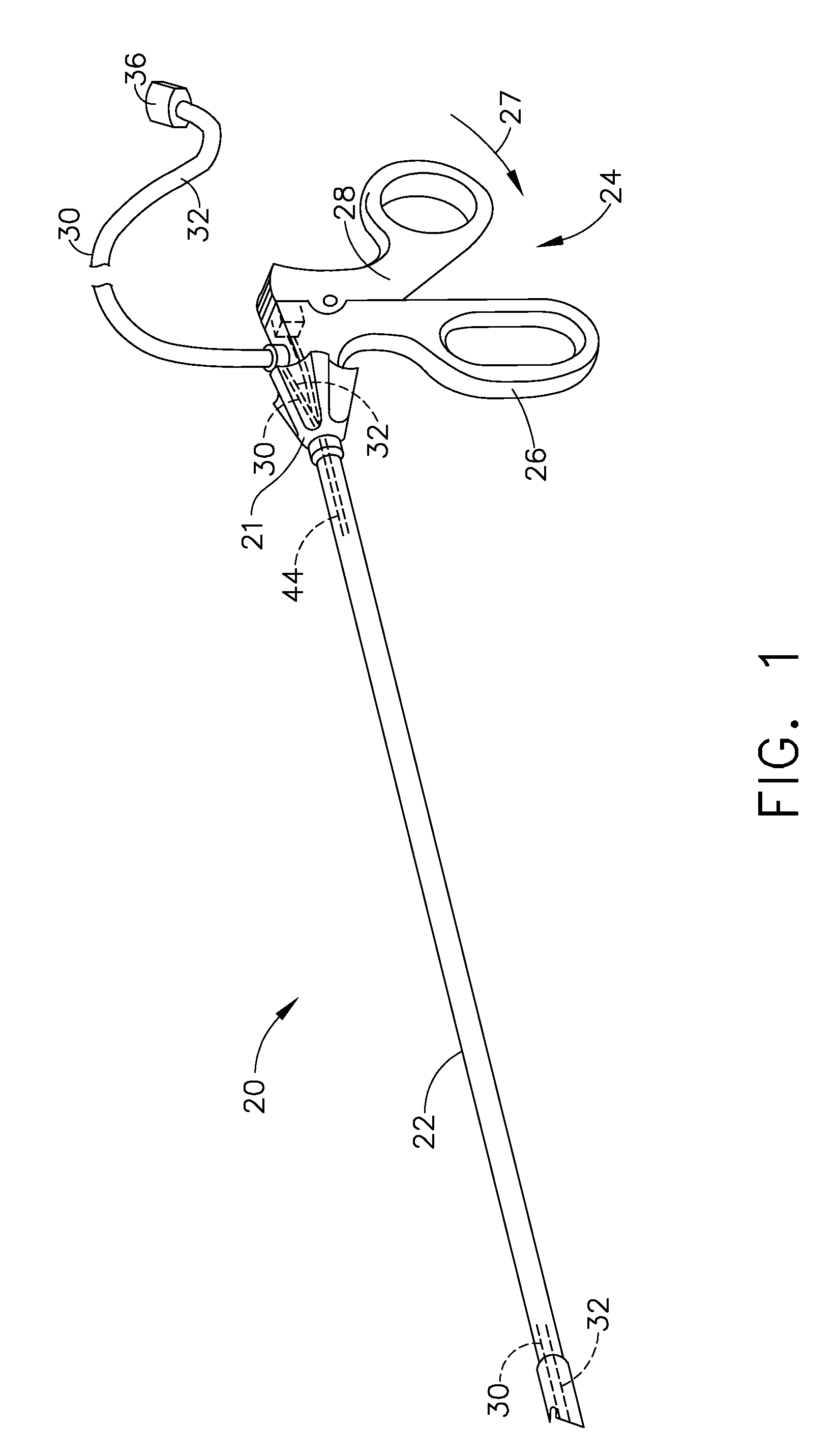

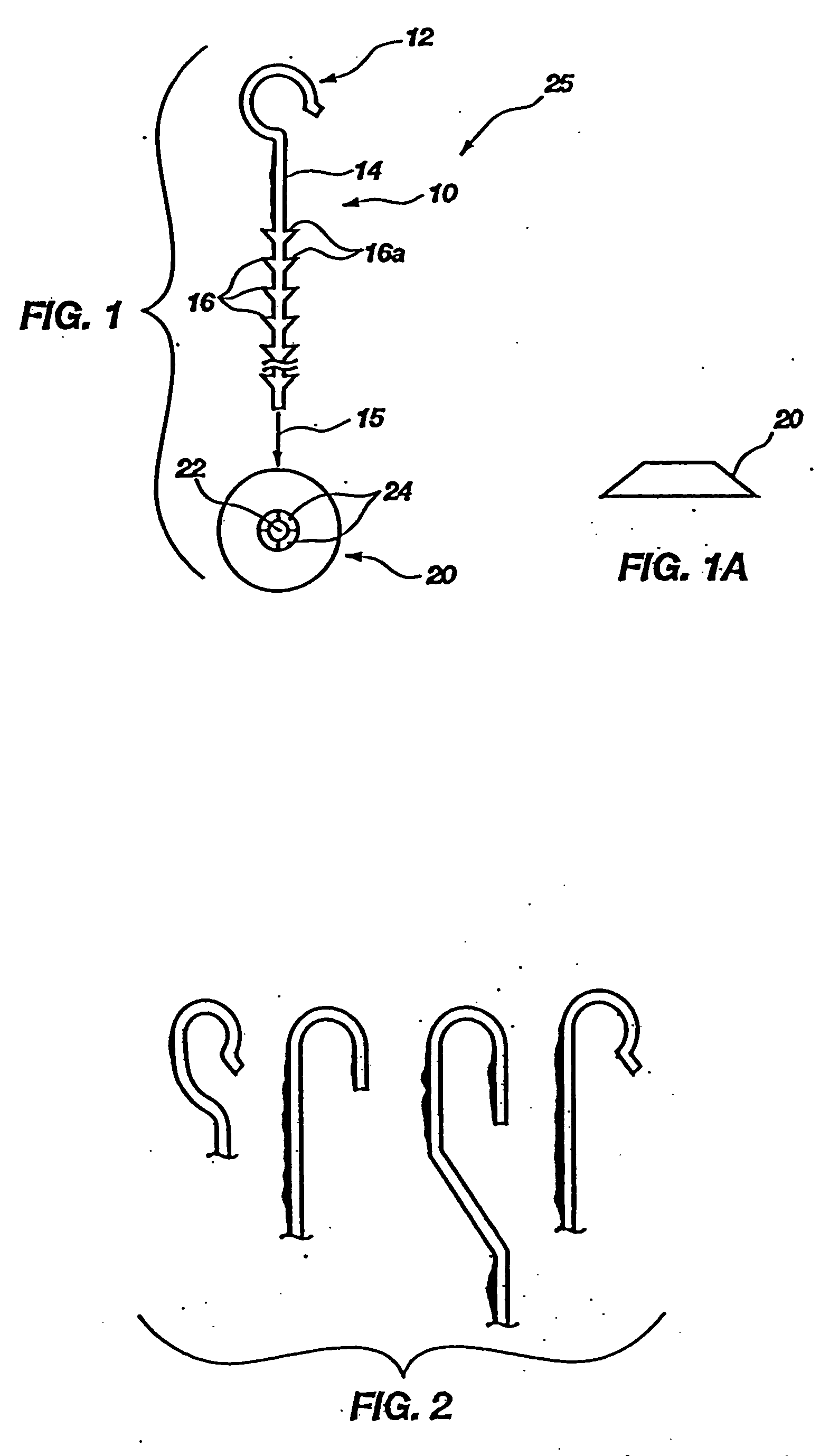

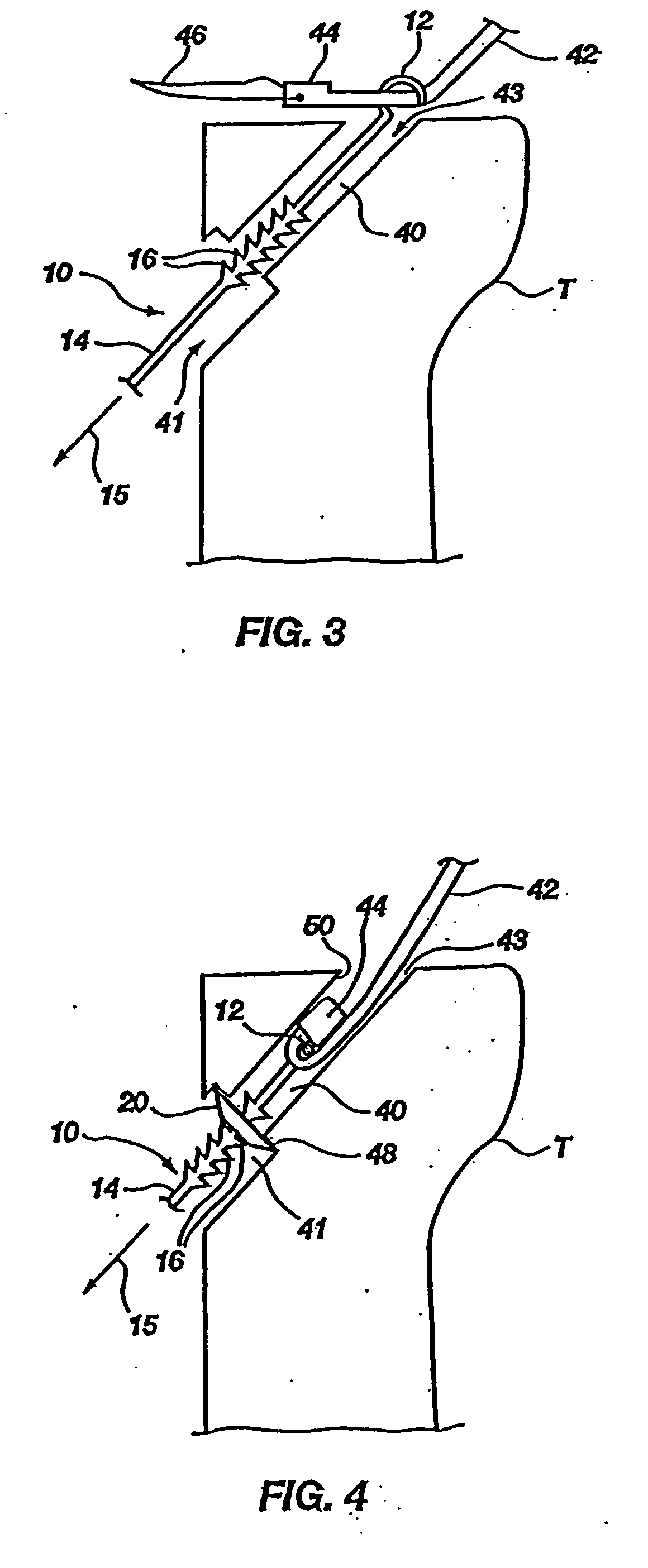

Surgical staple-clip and applier

InactiveUS20060100649A1Constrict or occludeNourishment to the body tissue is maintainedStaplesNailsSurgical stapleSurgical site

A surgical staple-clip including a clip component and a securing member is used in a wide range of surgical procedures. The staple-clip may be introduced to a surgical site in an un-assembled condition through a small port or trocar. An applier for the staple-clip comprising a pair of opposed jaw-like channels is provided to position and apply the clip component and the securing member. The clip component is positioned around a target tissue and is compressed or clamped upon the tissue using only the force required for a specific surgical procedure such as occlusion, ligation or fixation. When the clip component is properly applied, the securing member is urged forward and over the clip component to secure the staple-clip. The clip component may include traction enhancement features such as surface interruptions, bumps, valleys and ridges. With the staple-clip of the invention, the force required to constrict or occlude the tissue is separate from the force required to secure and maintain the staple-clip in position and, as a result, the body tissue is not over-compressed and nourishment to the body tissue is maintained. Other aspects of the invention include thumb actuated clip appliers for use in hand assisted laparoscopy (HAL). In one embodiment, a clip applier includes a handle and a thumb actuated mechanism that is used to slidably release clips onto a body tissue or vessel by sliding the thumb actuated mechanism forward and backward using only one hand. In another aspect of the invention, a two-stage clip is disclosed having a clip component and a staple component for securing the clip after it has been properly positioned.

Owner:APPL MEDICAL RESOURCES CORP

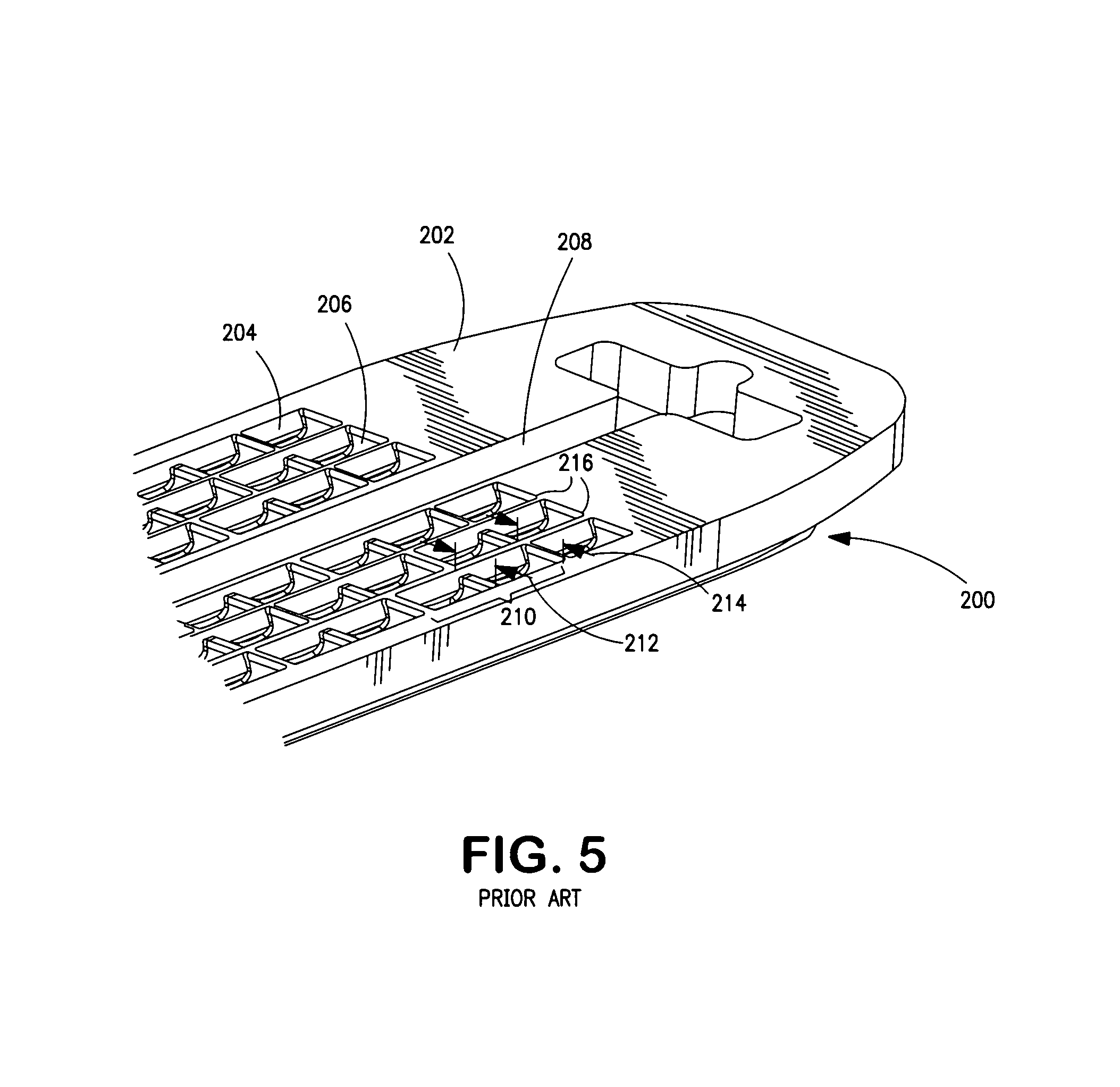

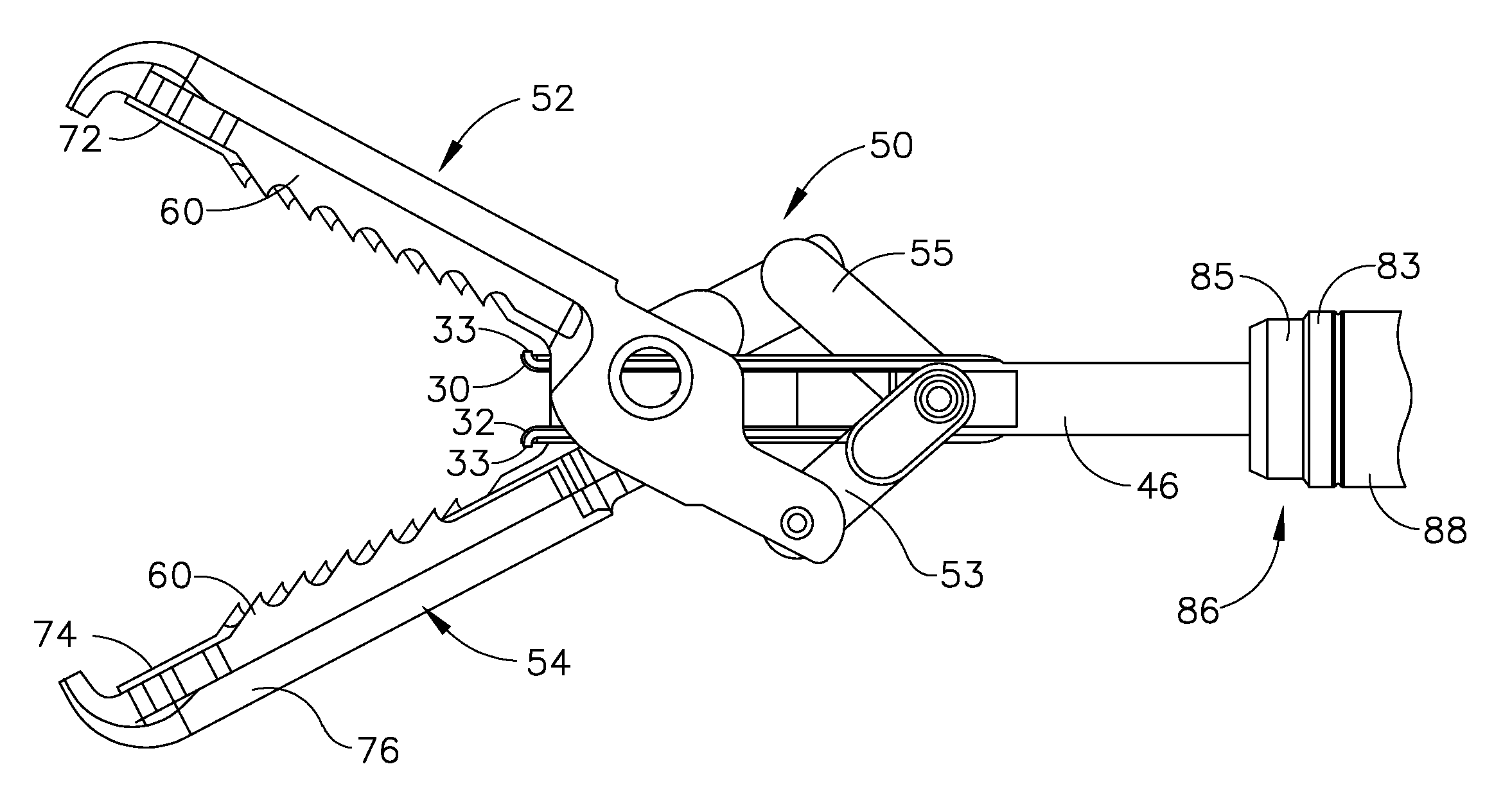

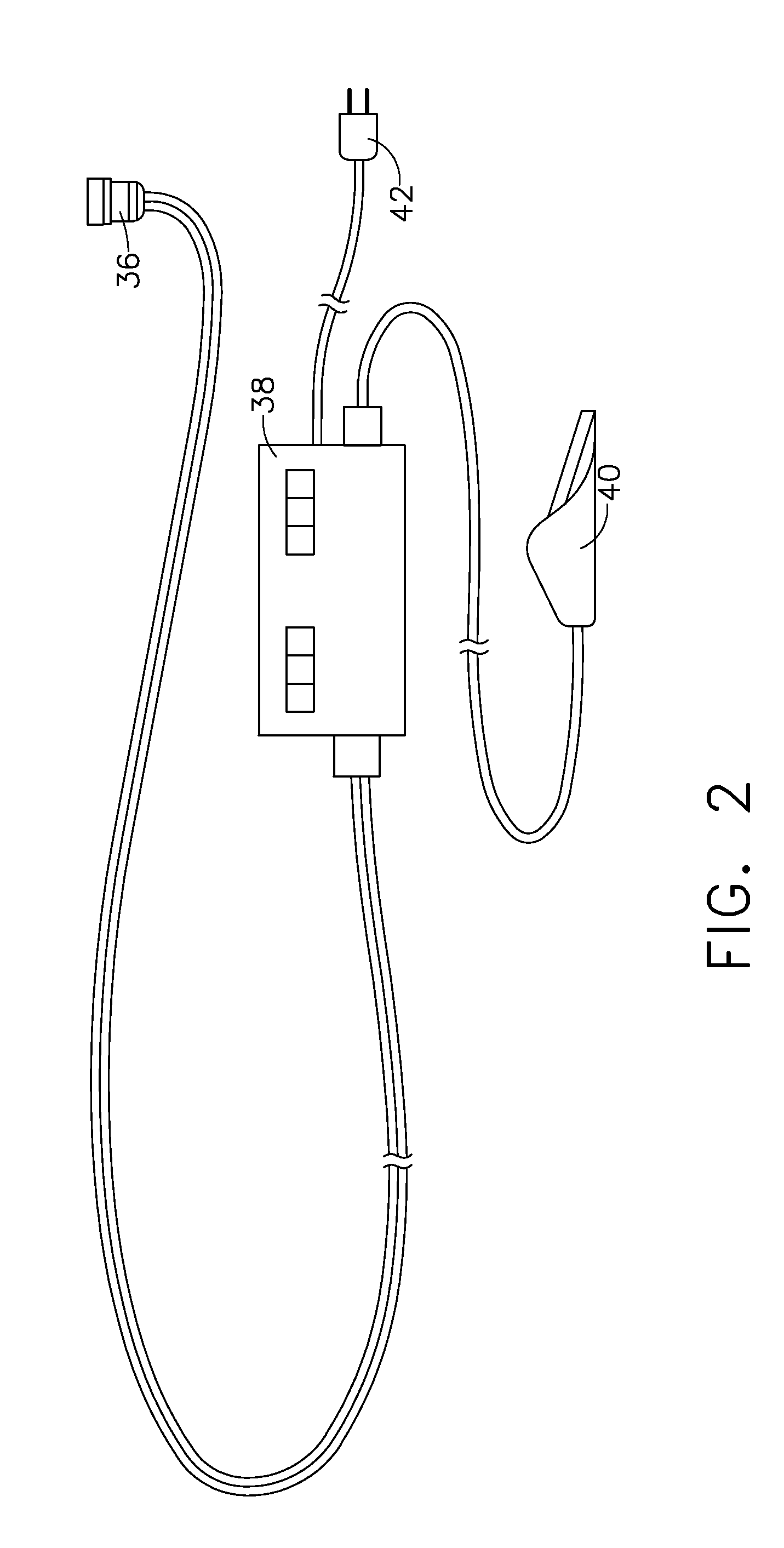

Bipolar forceps

ActiveUS8579897B2Likelihood that the wire may become damaged or broken can be reducedReduce the possibilityLavatory sanitorySurgical instruments for heatingEngineeringSurgical technical

In various surgical techniques, a bipolar forceps can be used to seal a vessel in two locations such that the vessel can be incised at a location positioned intermediate the two seal locations. The bipolar forceps can include a cutting element which can be configured to incise the vessel. In various embodiments, the cutting element can include a sharp edge which can be moved relative to the vessel. In at least one embodiment, the cutting element can be electrically connected to a source of energy. The bipolar forceps can include first and second electrodes positioned within first and second jaw members, respectively, wherein at least one of the jaw members can include a substantially tapered profile and can be configured to pull the vessel away from the surrounding soft tissue. Such jaw members can include ridges, teeth, and / or a textured outer surface configured to grip the soft tissue and / or vessel.

Owner:ETHICON ENDO SURGERY INC

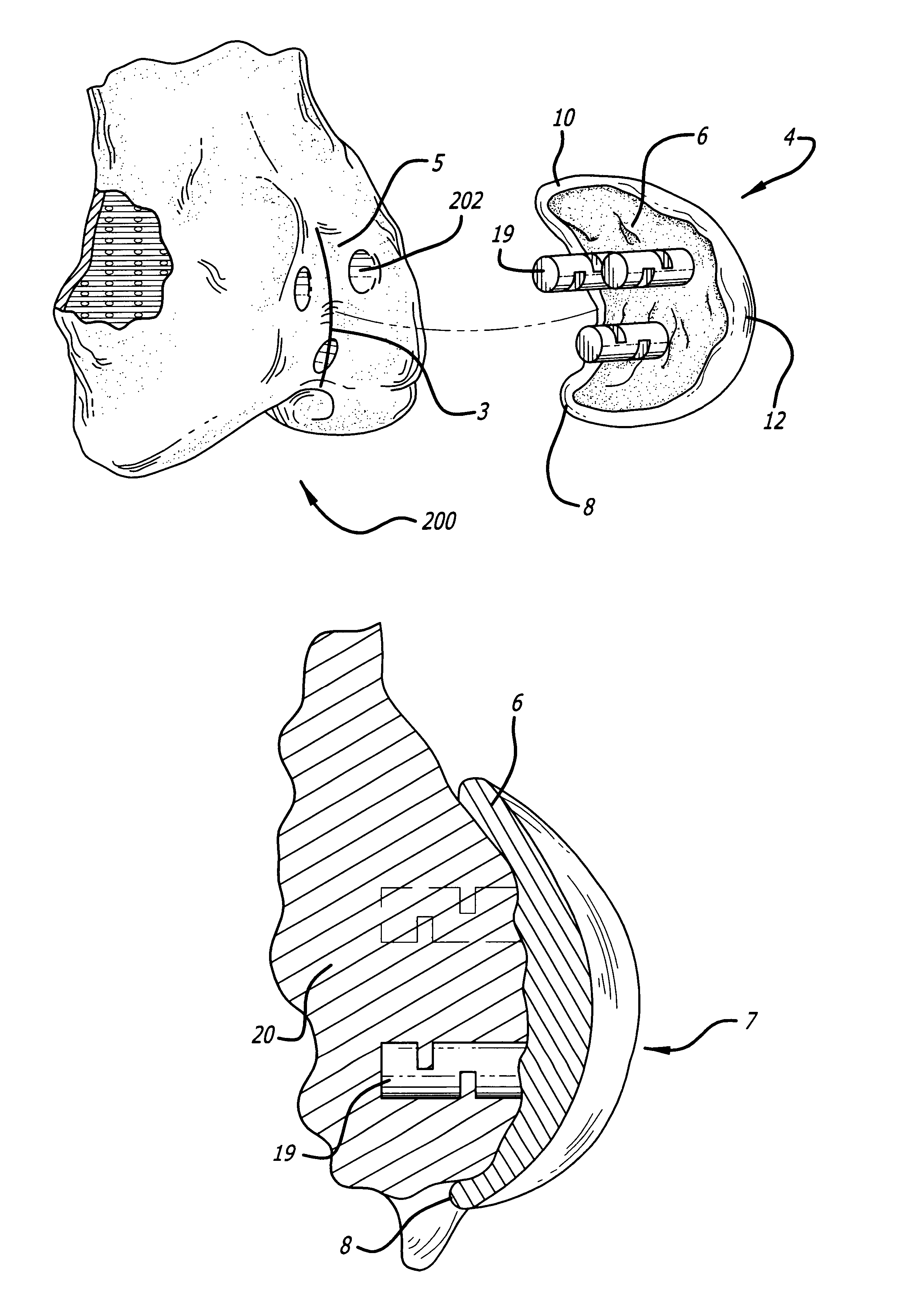

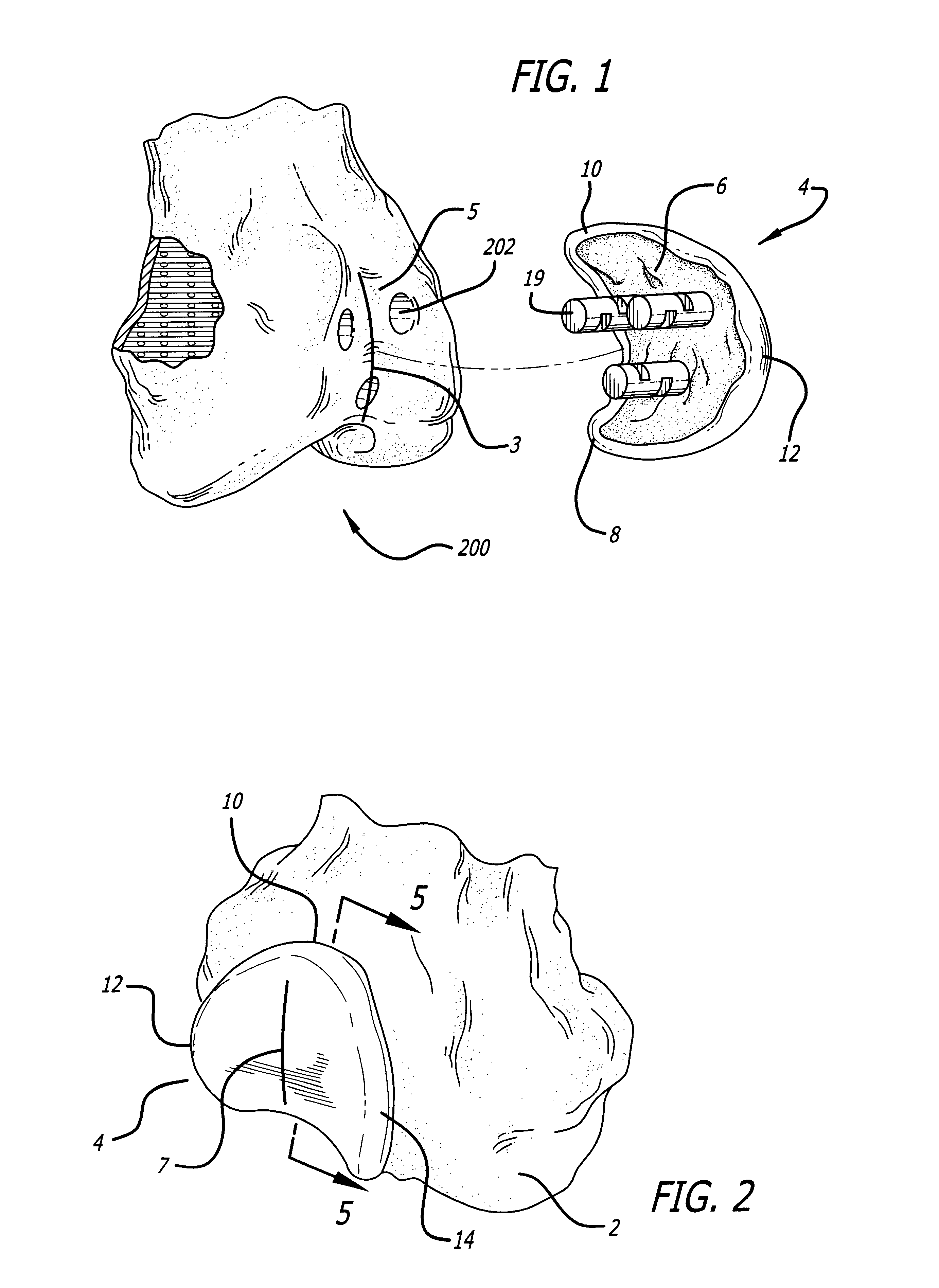

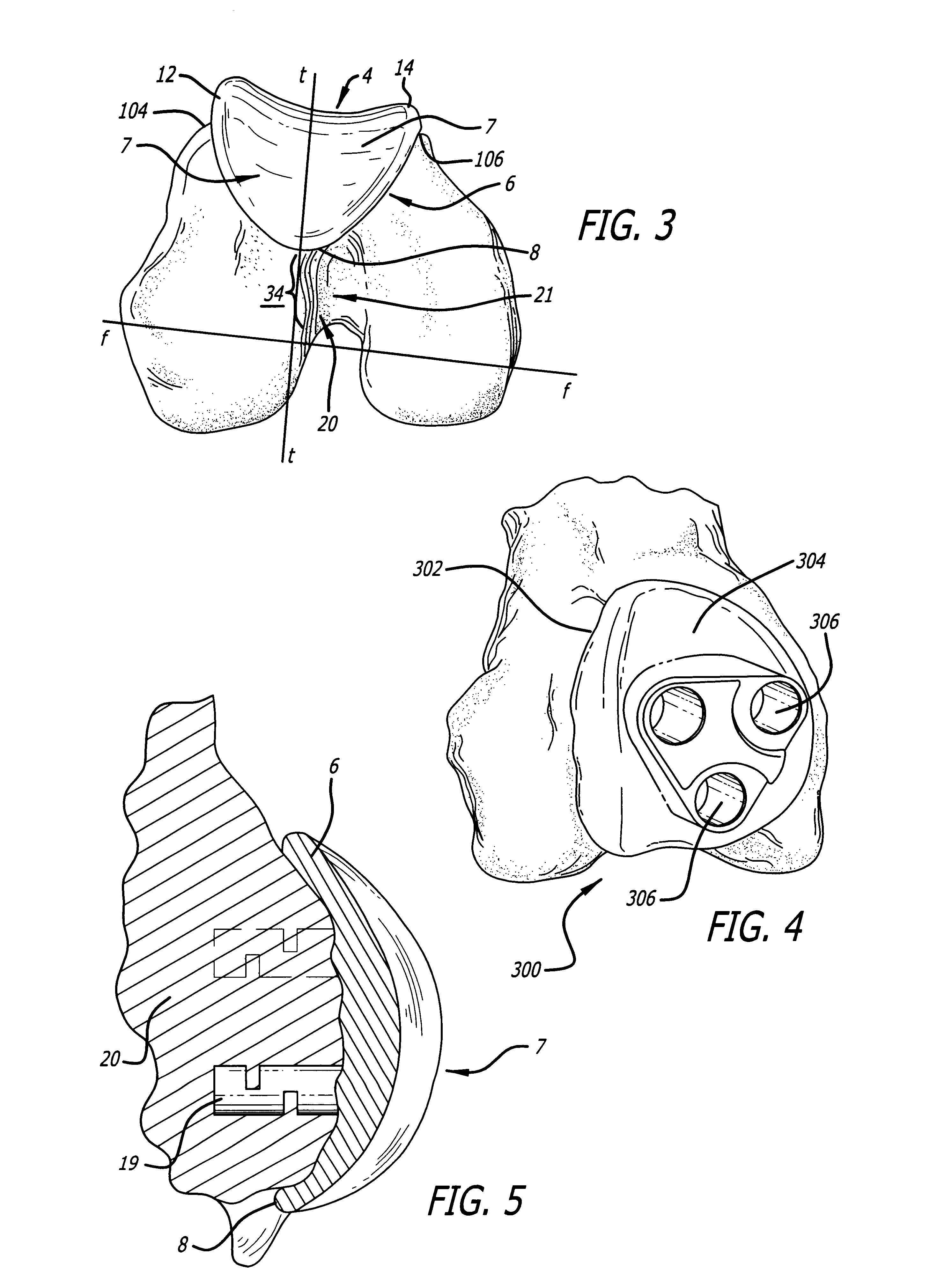

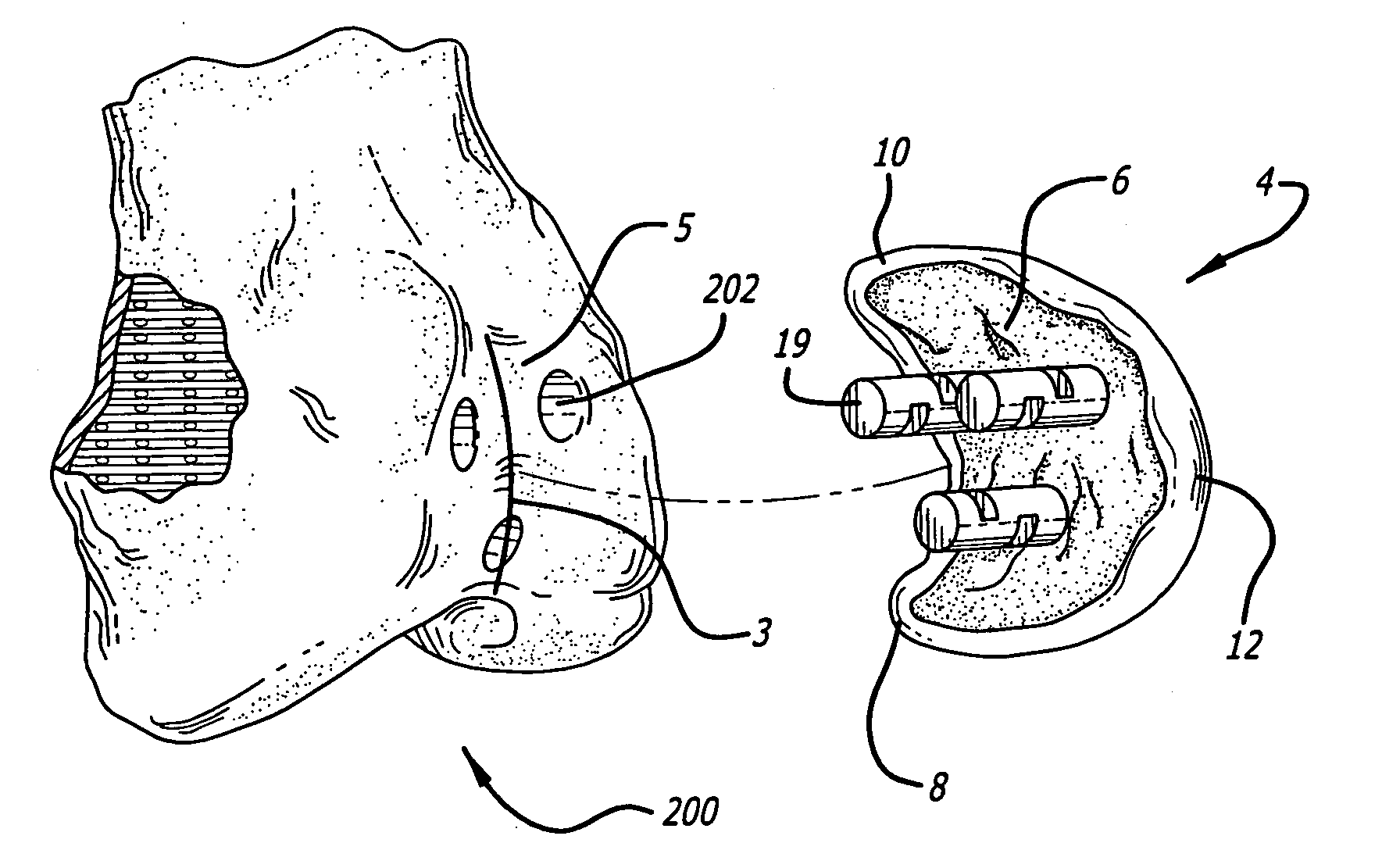

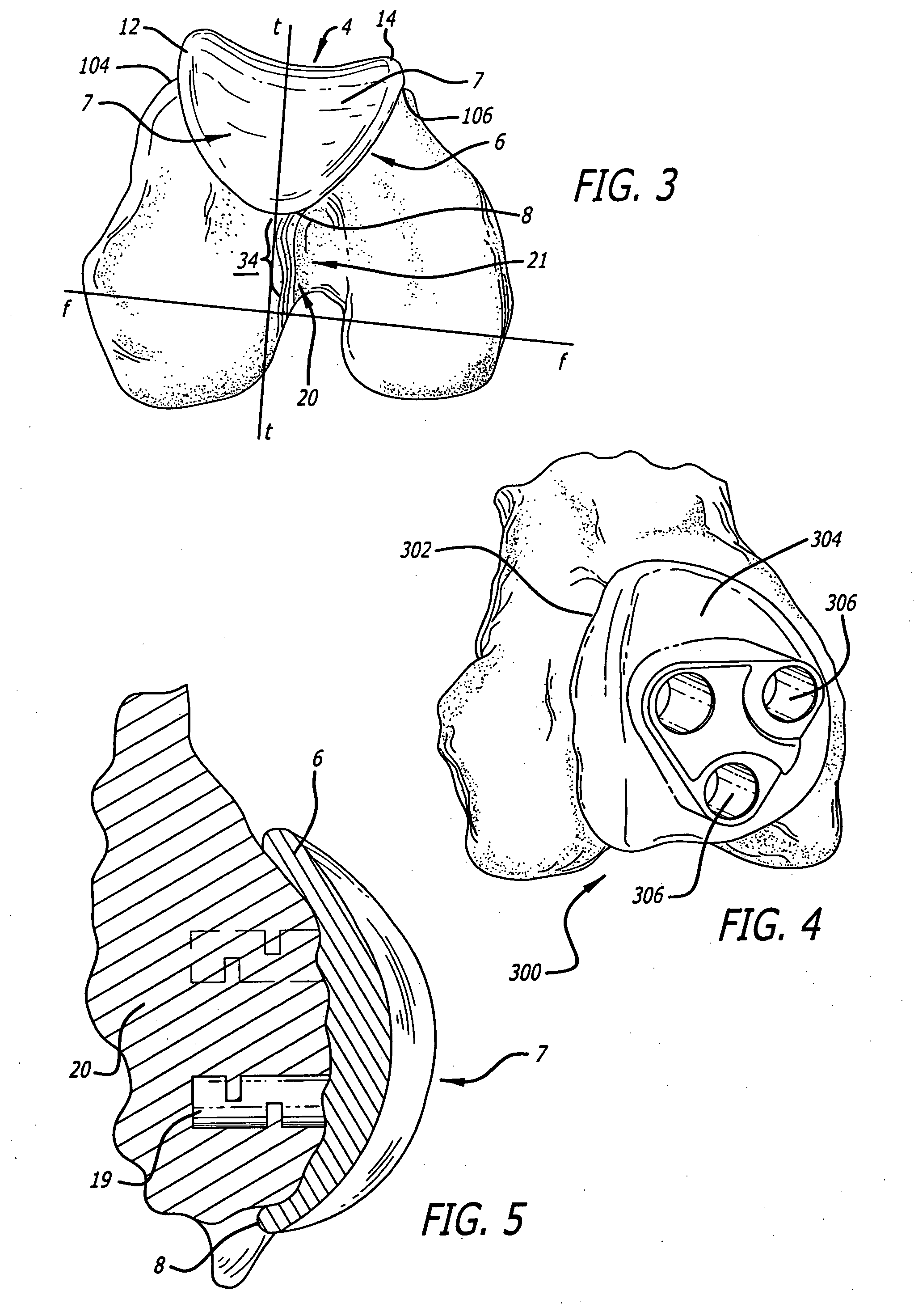

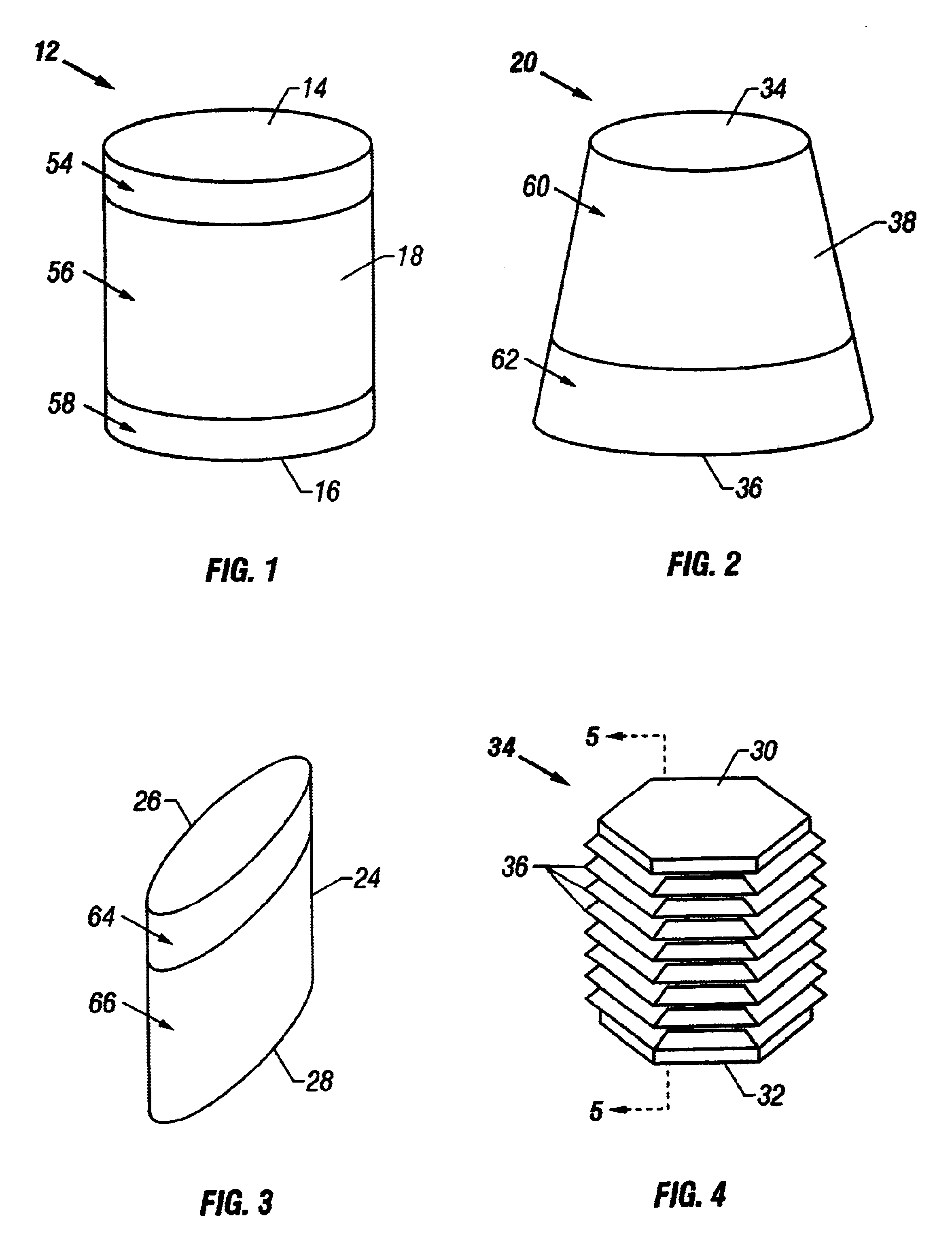

Custom replacement device for resurfacing a femur and method of making the same

InactiveUS6712856B1Joint implantsComputer-aided planning/modellingArticular surfacesRight femoral head

A replacement device for resurfacing a joint surface of a femur and a method of making and installing such a device is provided. The custom replacement device is designed to substantially fit the trochlear groove surface, of an individual femur. Thereby creating a "customized" replacement device for that individual femur and maintaining the original kinematics of the joint. The replacement device may be defined by four boundary points, and a first and a second surface. The first of four points is 3 to 5 mm from the point of attachment of the anterior cruciate ligament to the femur. The second point is near the bottom edge of the end of the natural articulatar cartilage. The third point is at the top ridge of the right condyle and the fourth point at the top ridge of the left condyle of the femur. The top surface is designed so as to maintain centrally directed tracking of the patella perpendicular to the plane established by the distal end of the femoral condyles and aligned with the center of the femoral head.

Owner:KINAMED

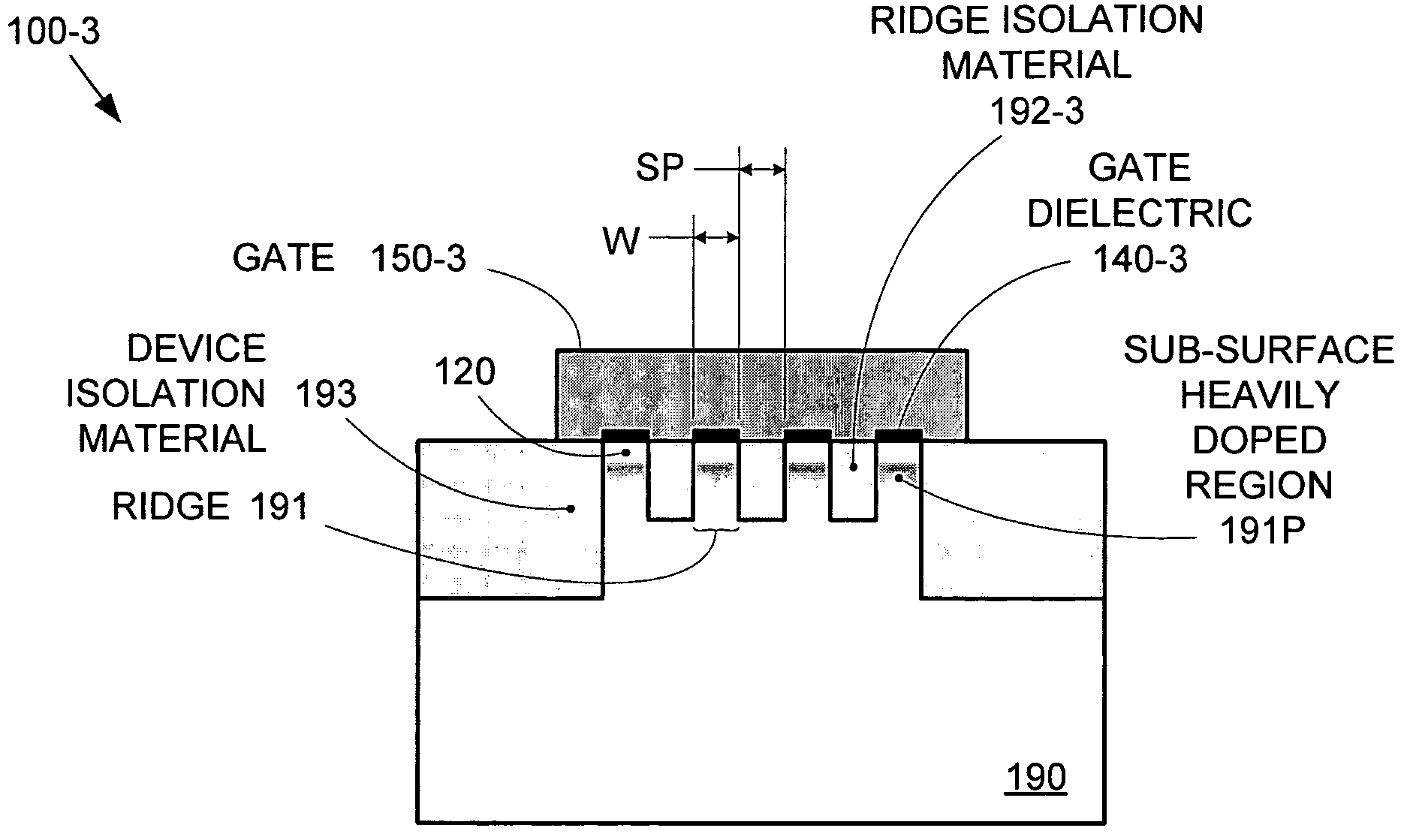

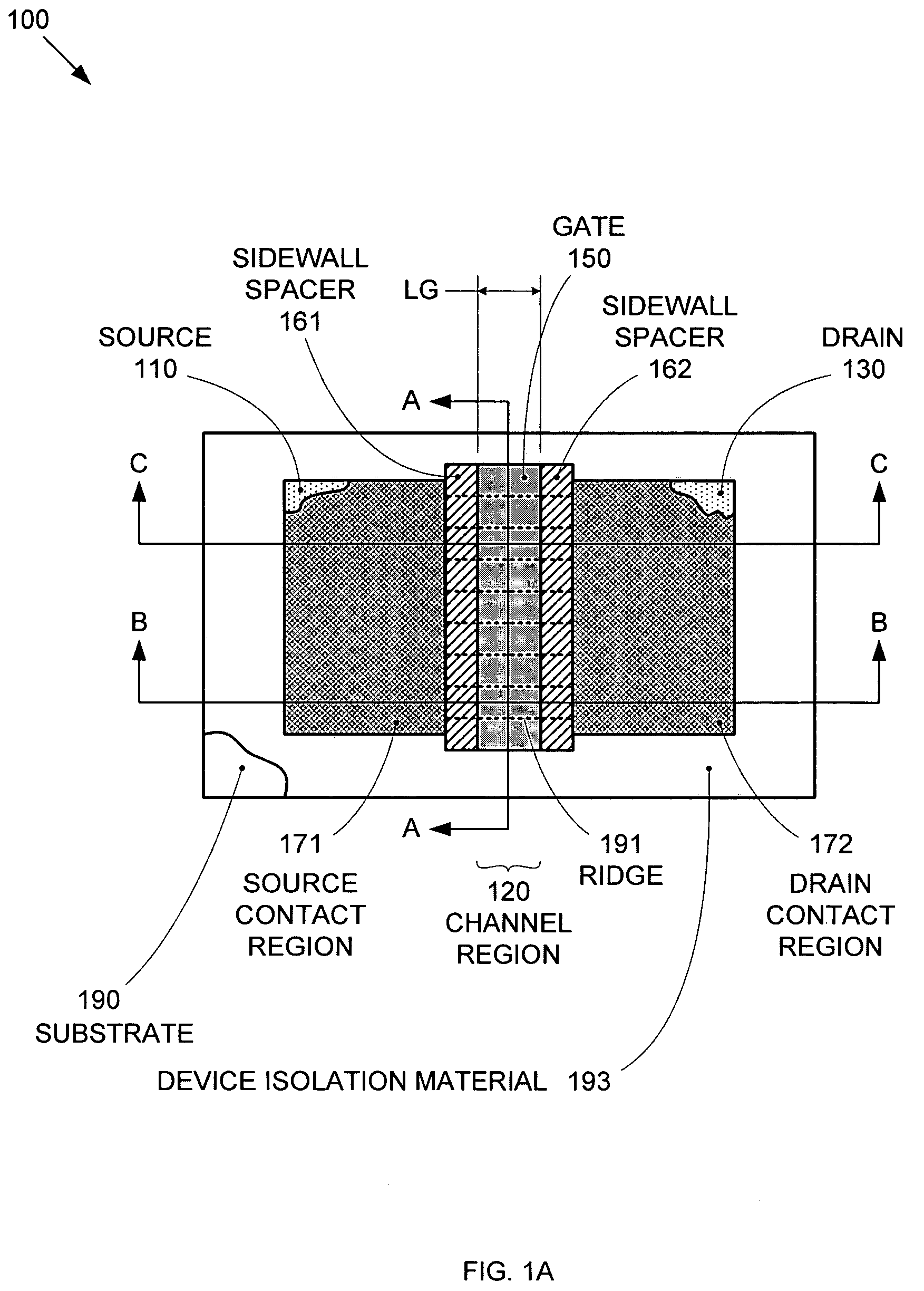

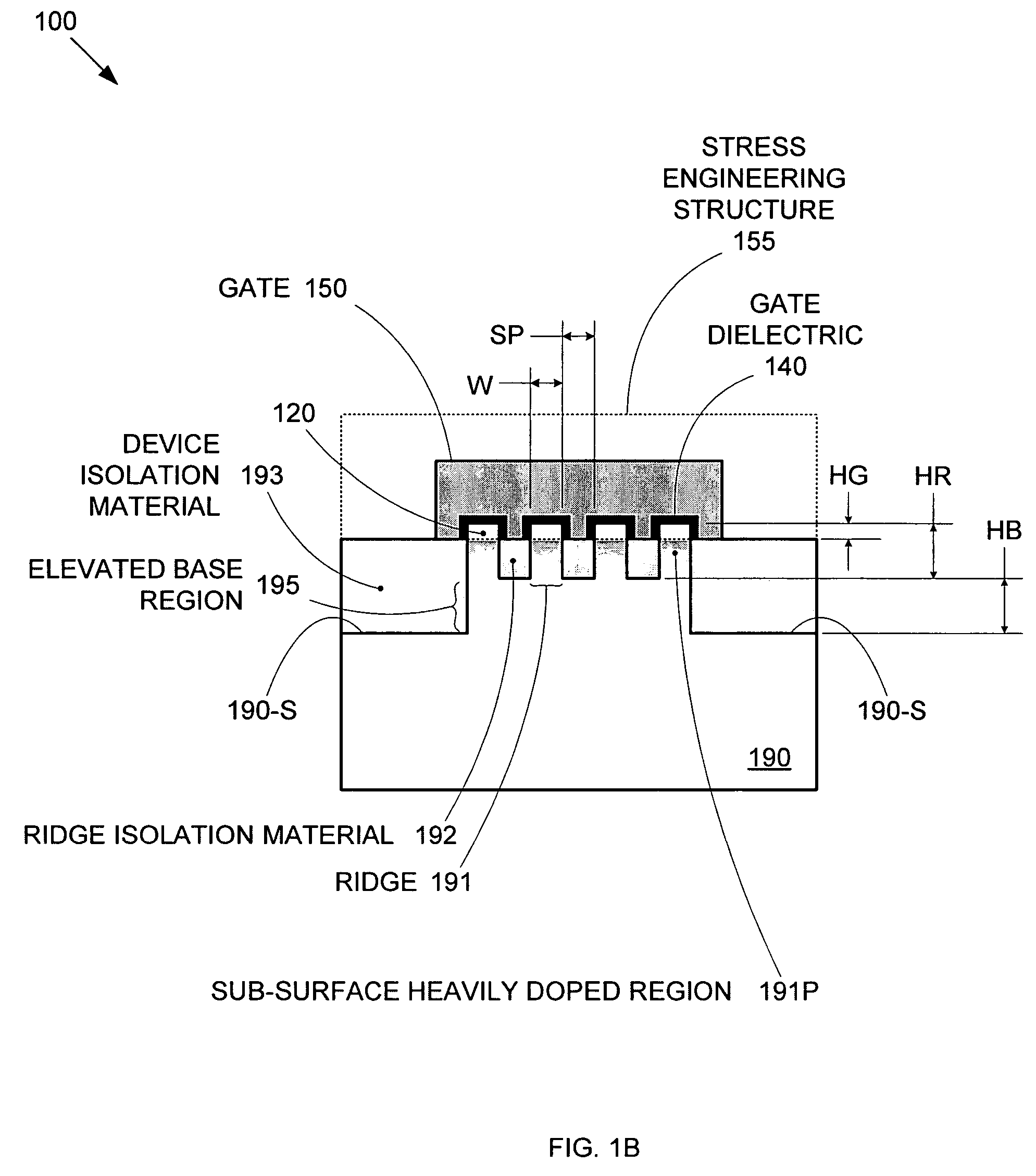

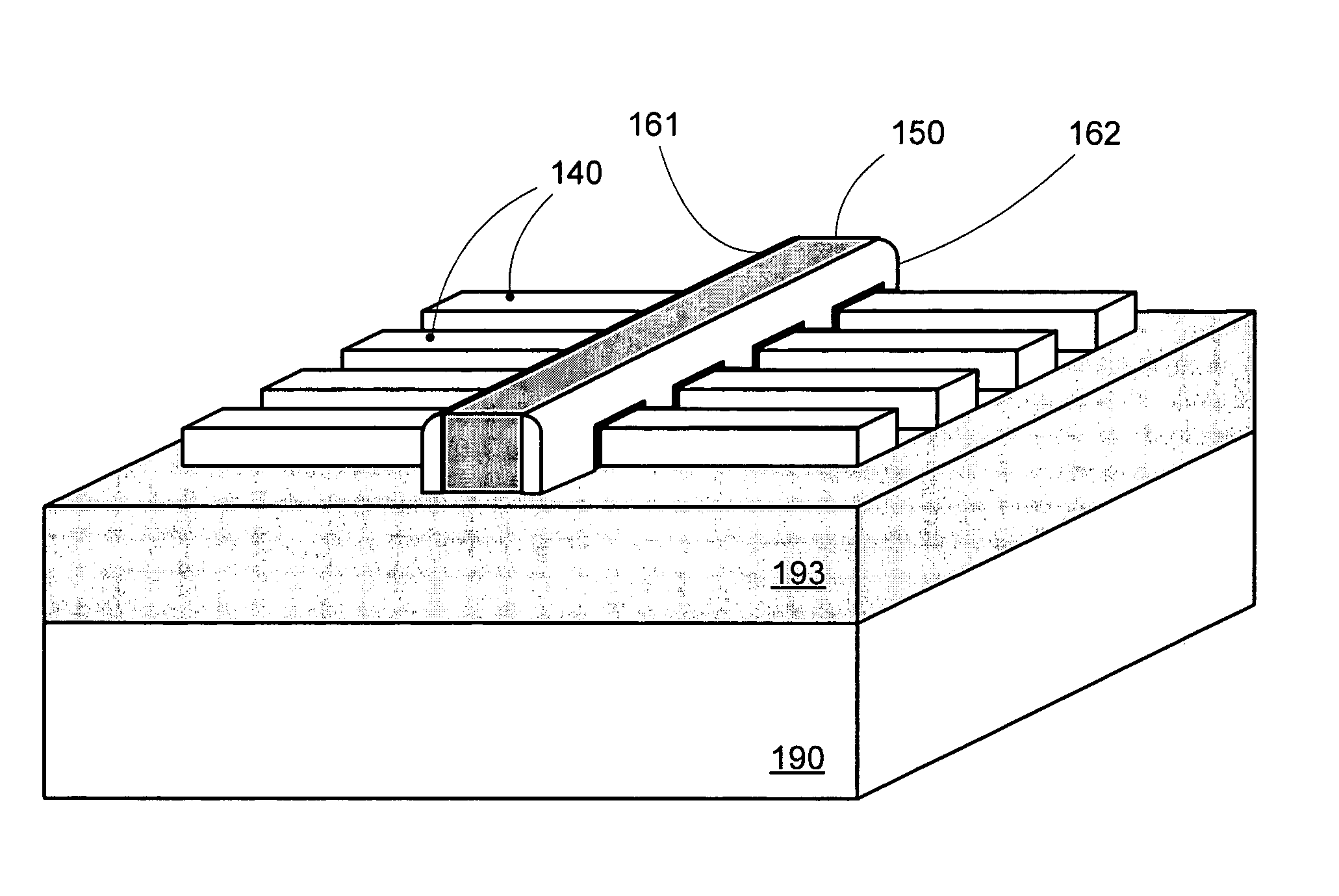

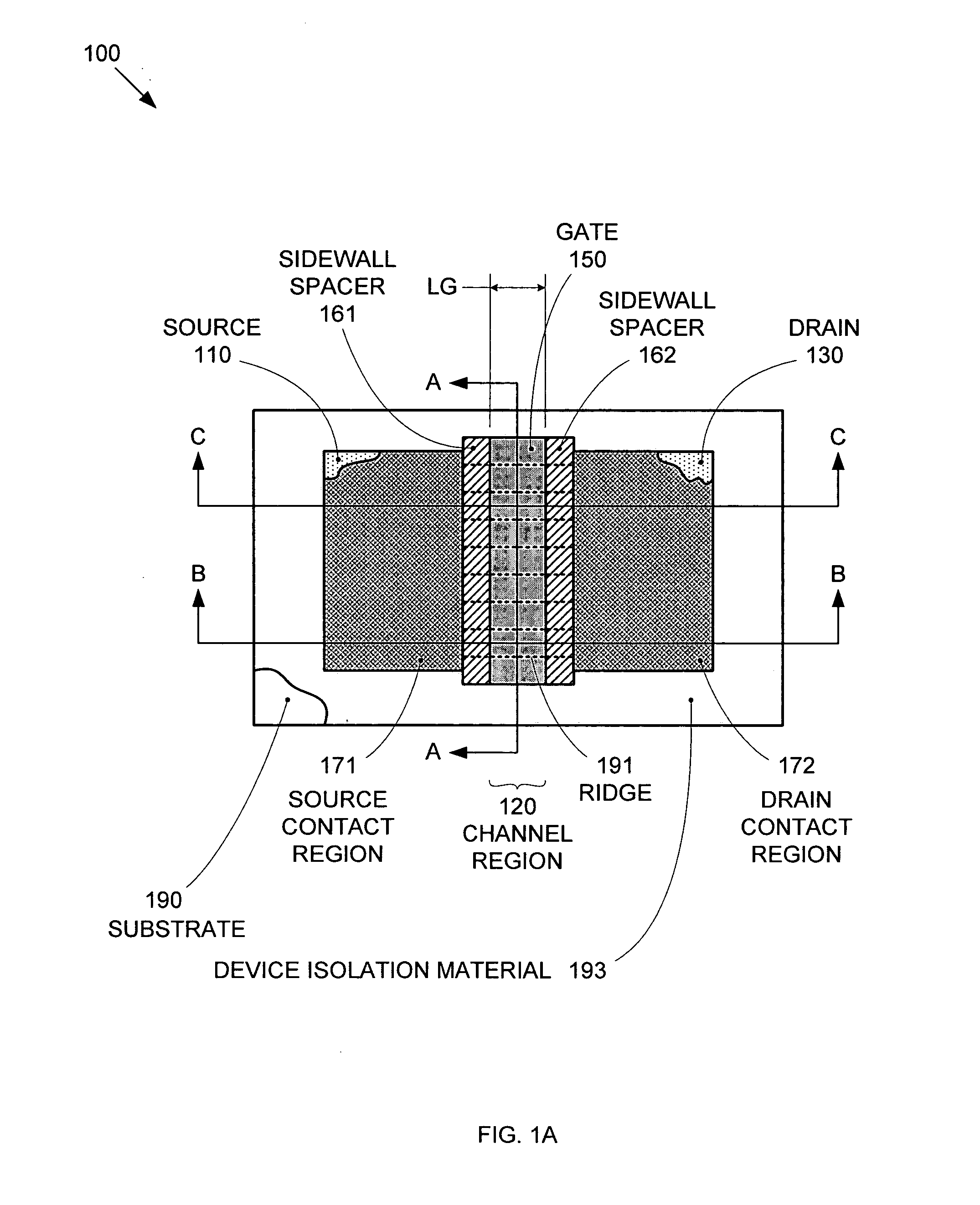

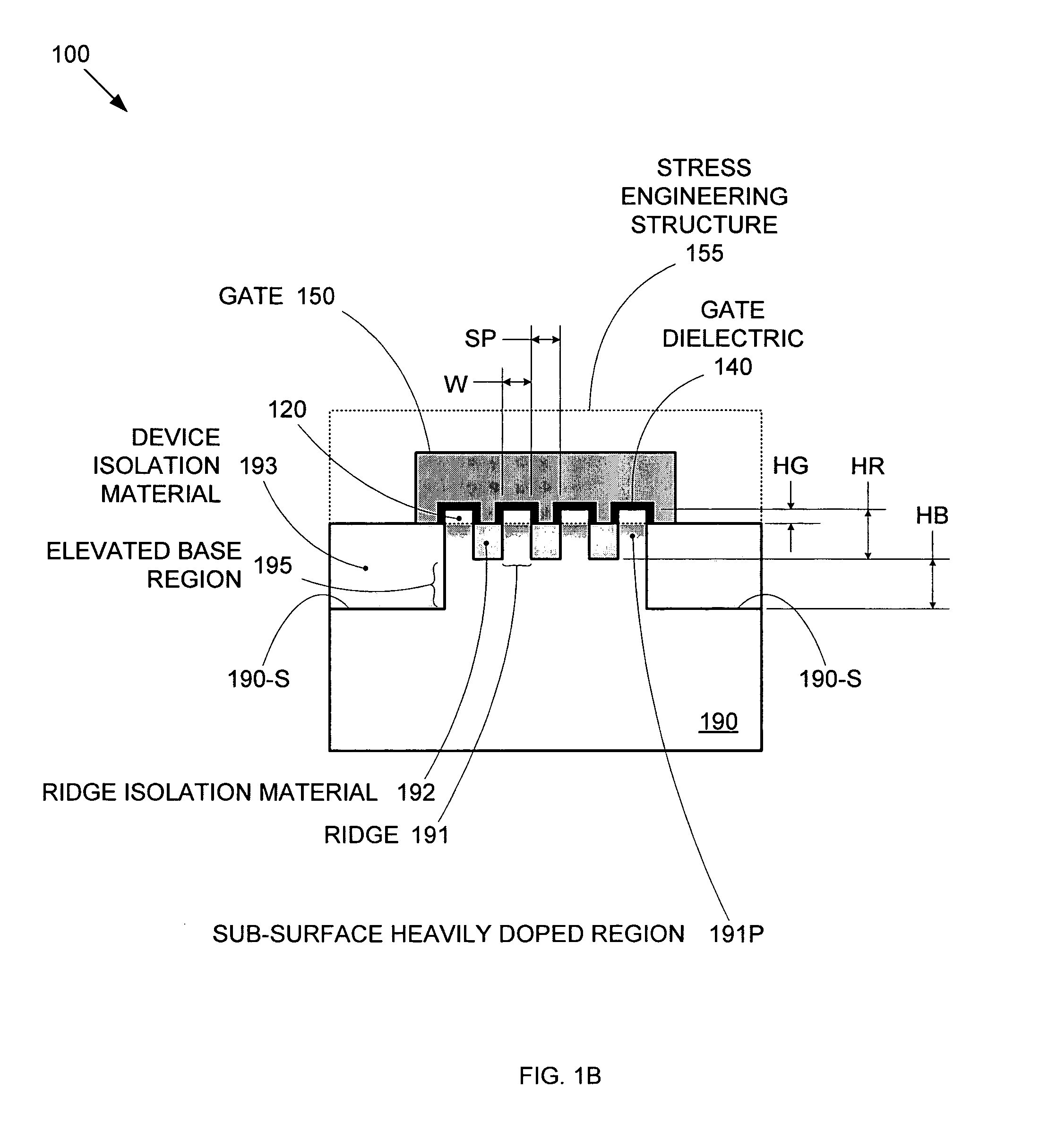

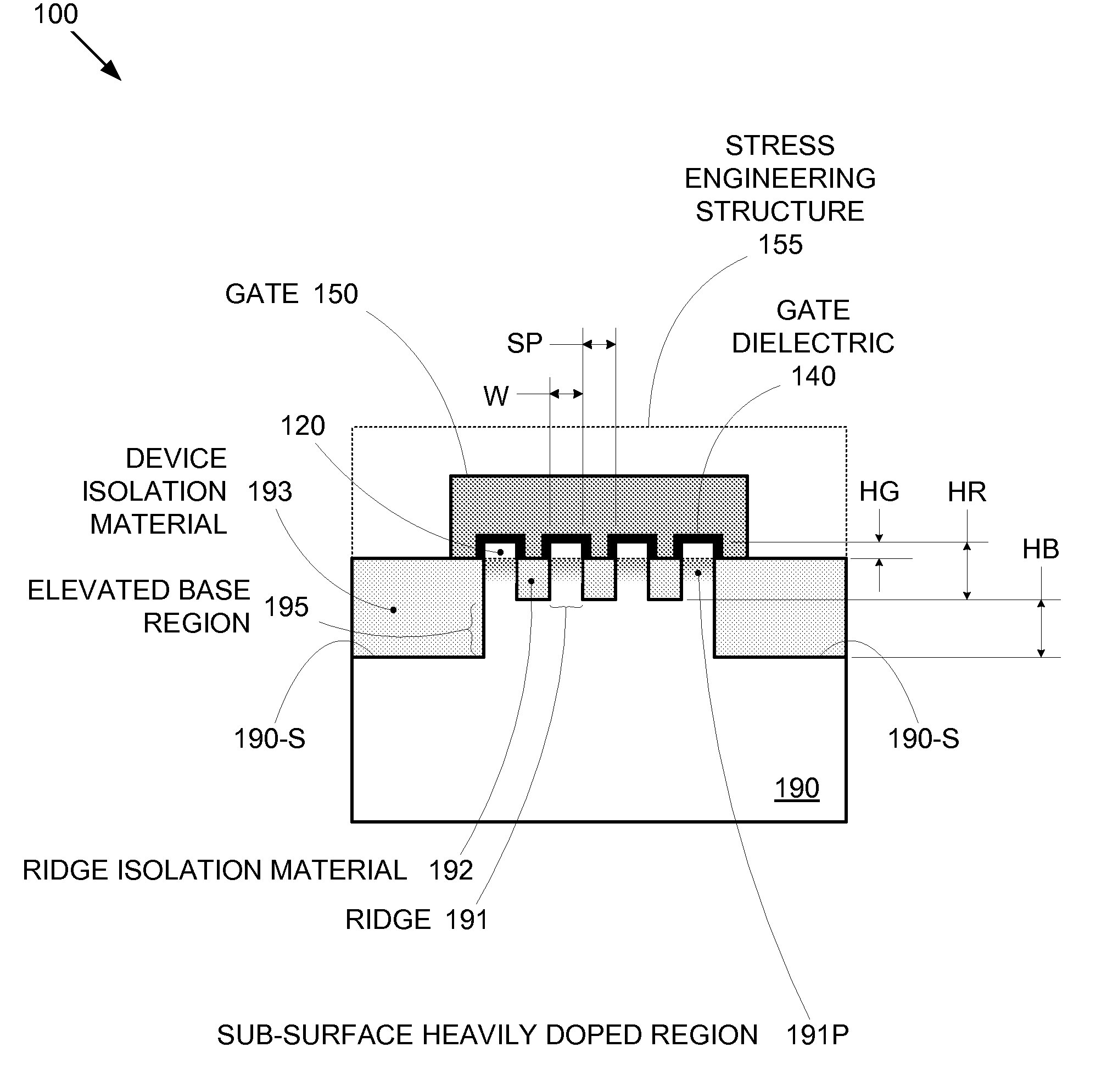

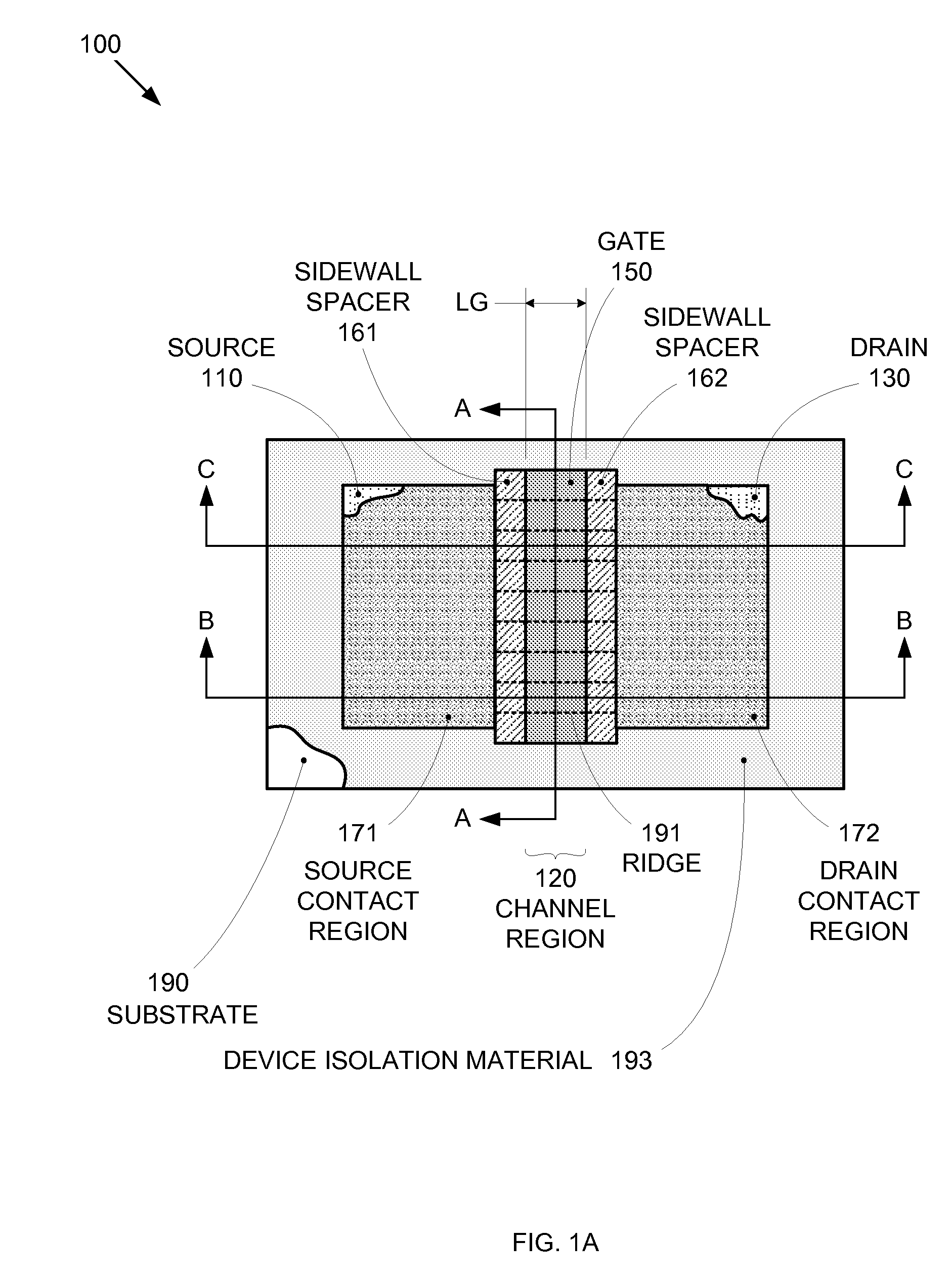

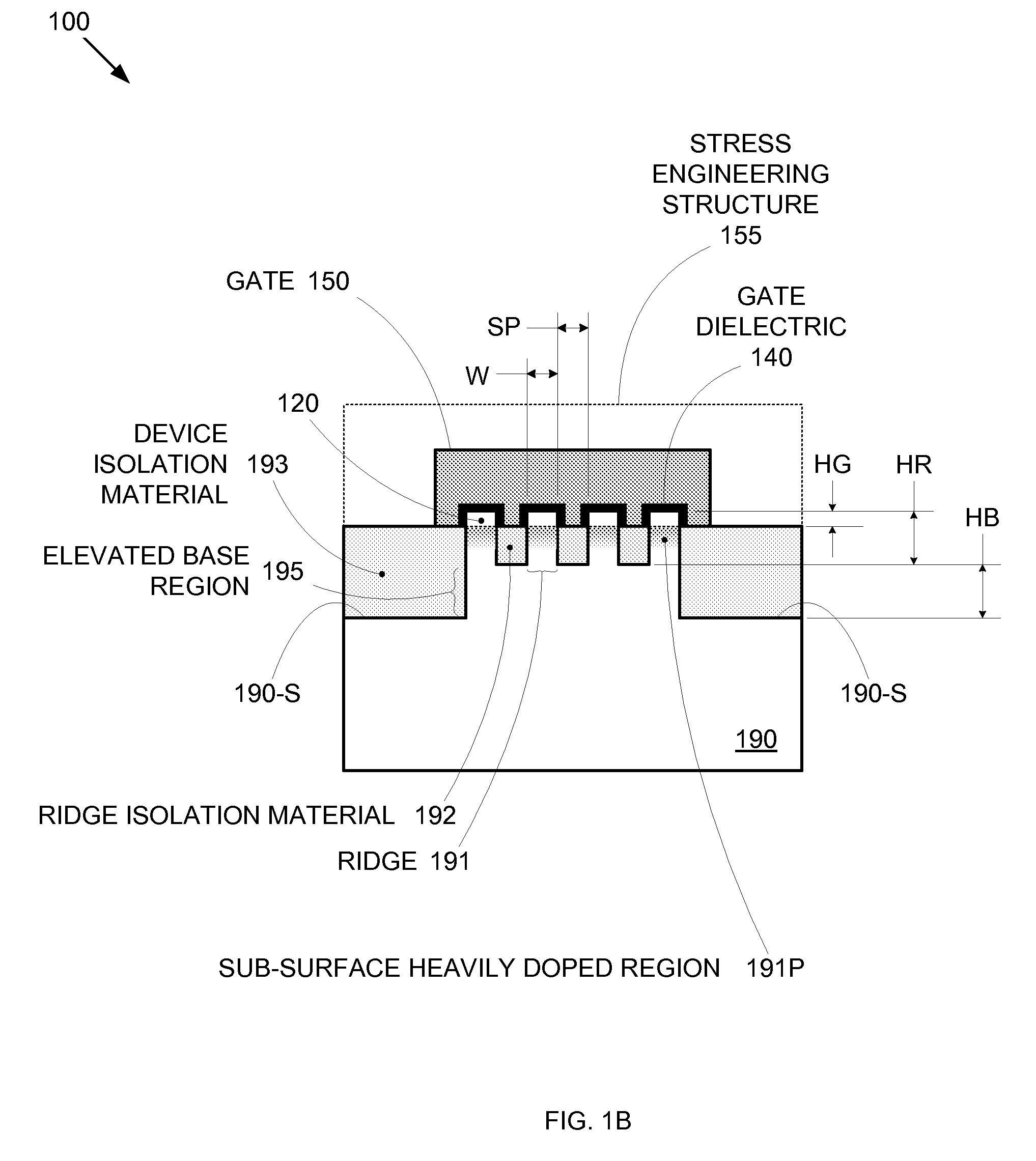

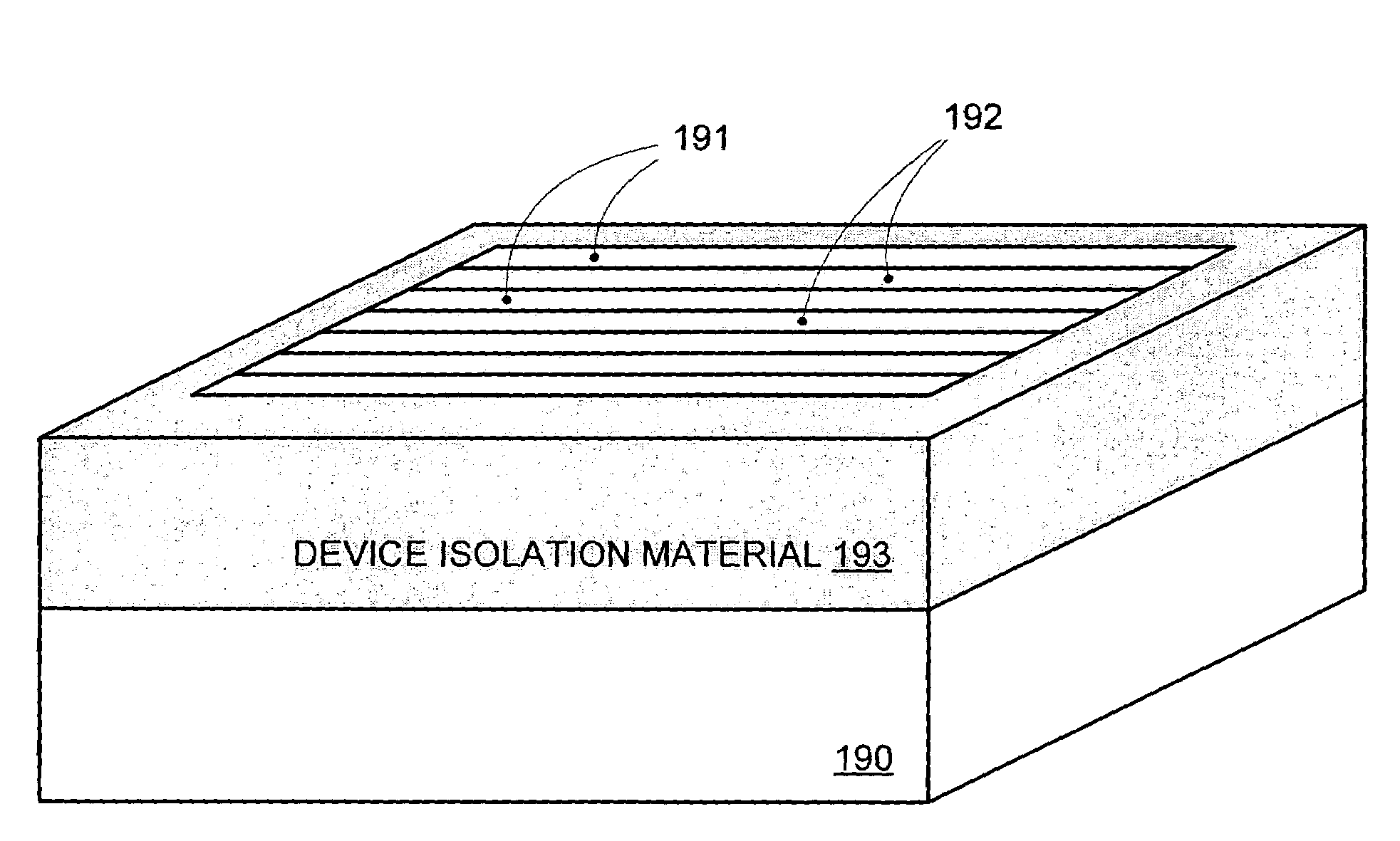

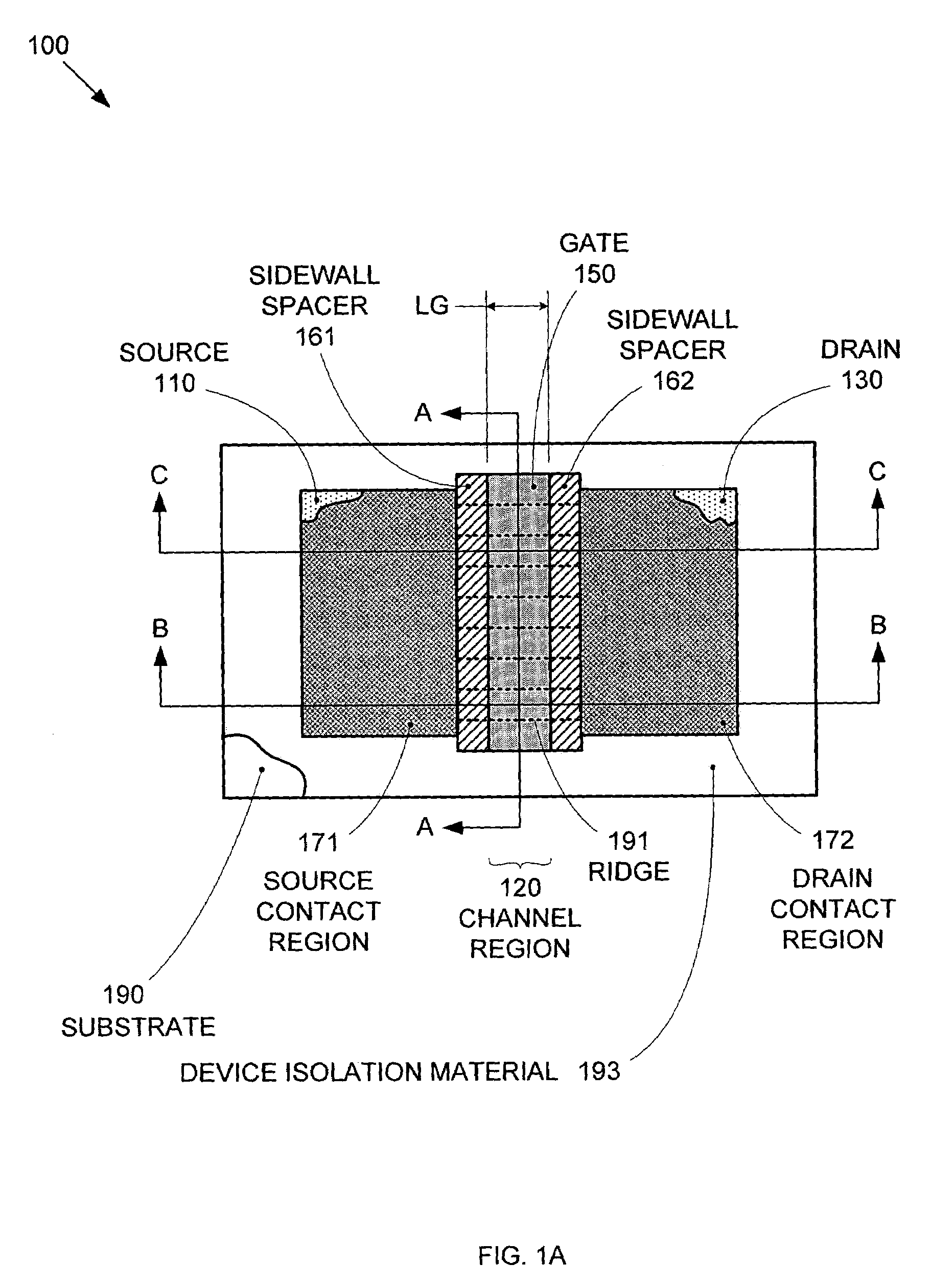

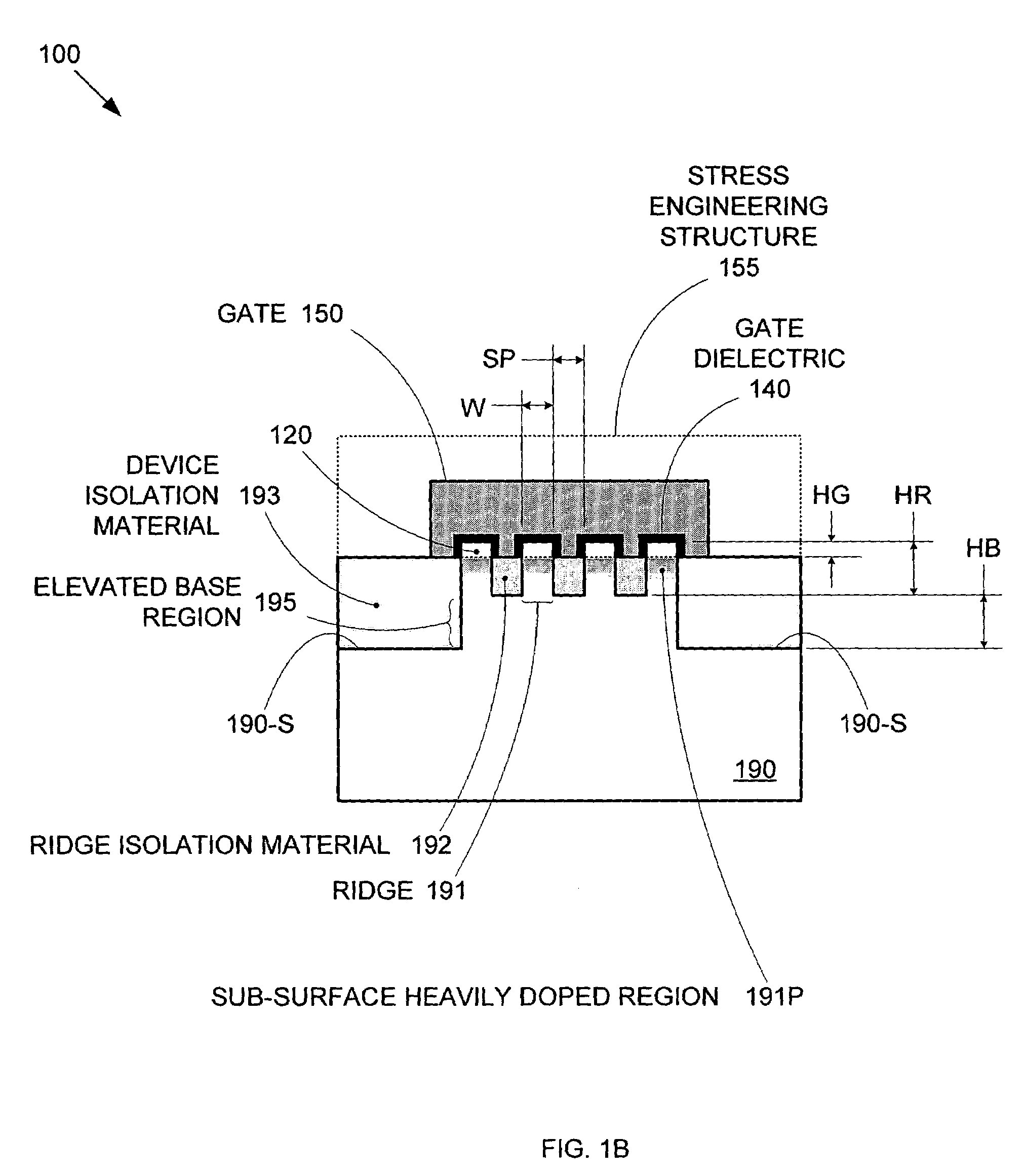

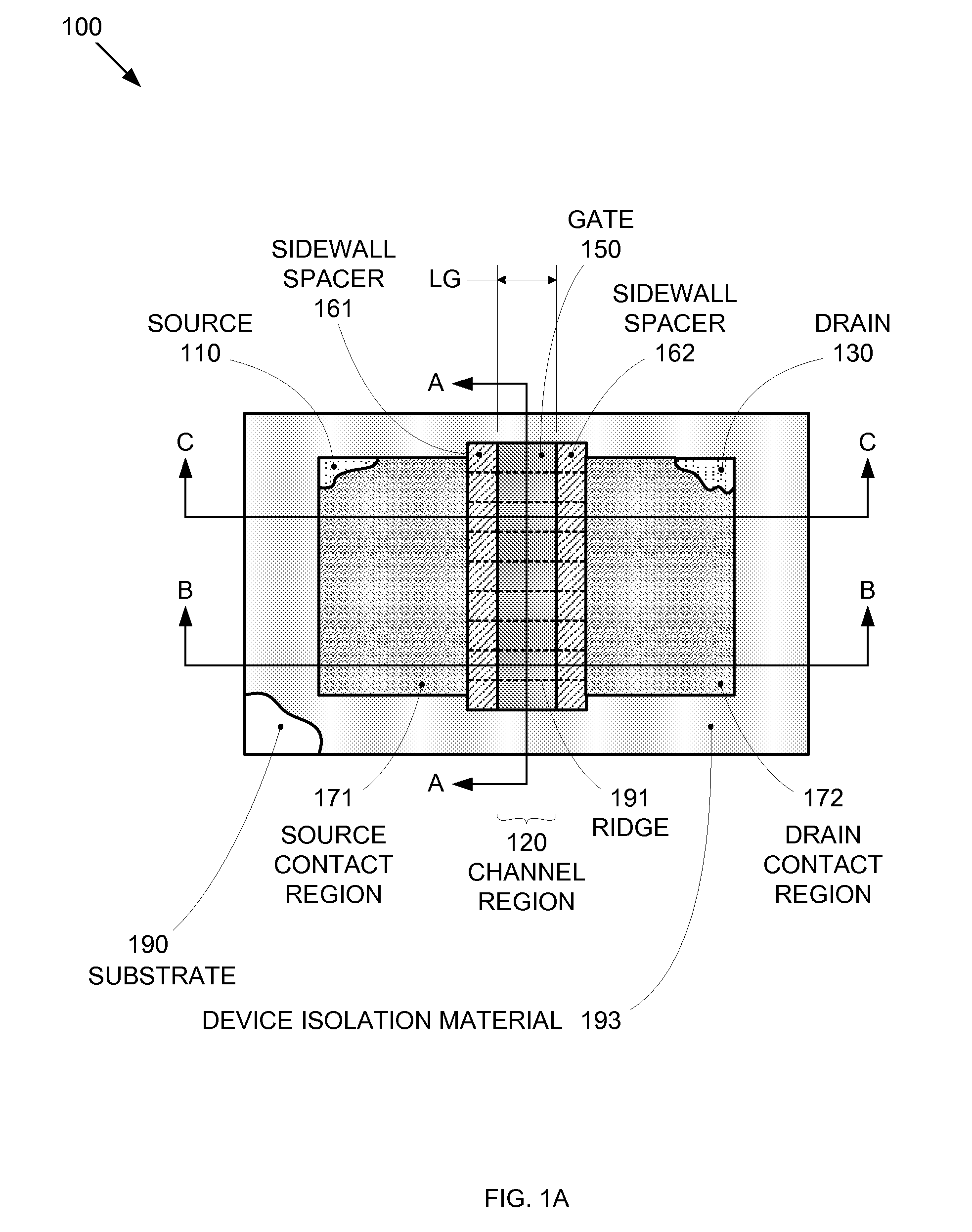

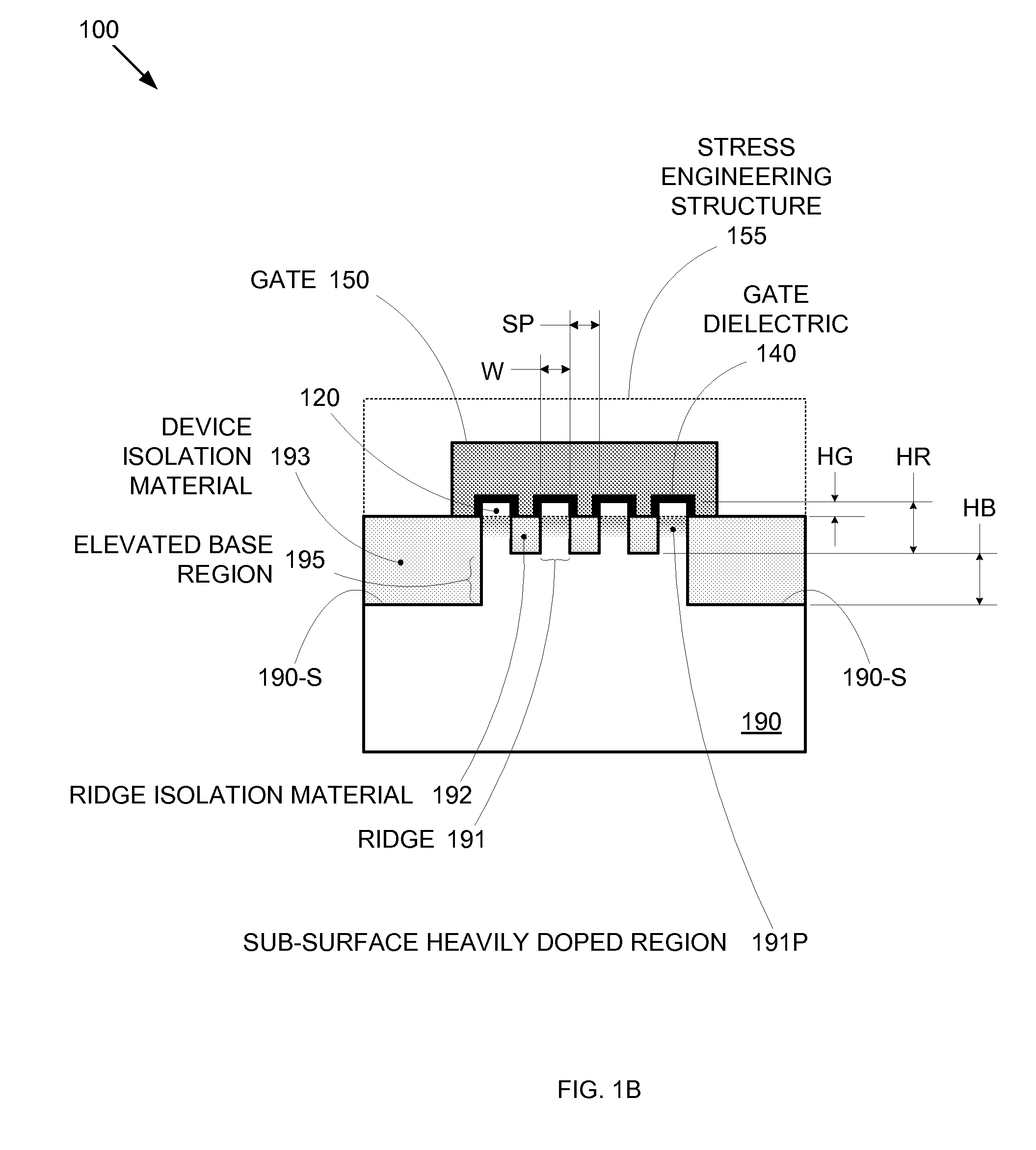

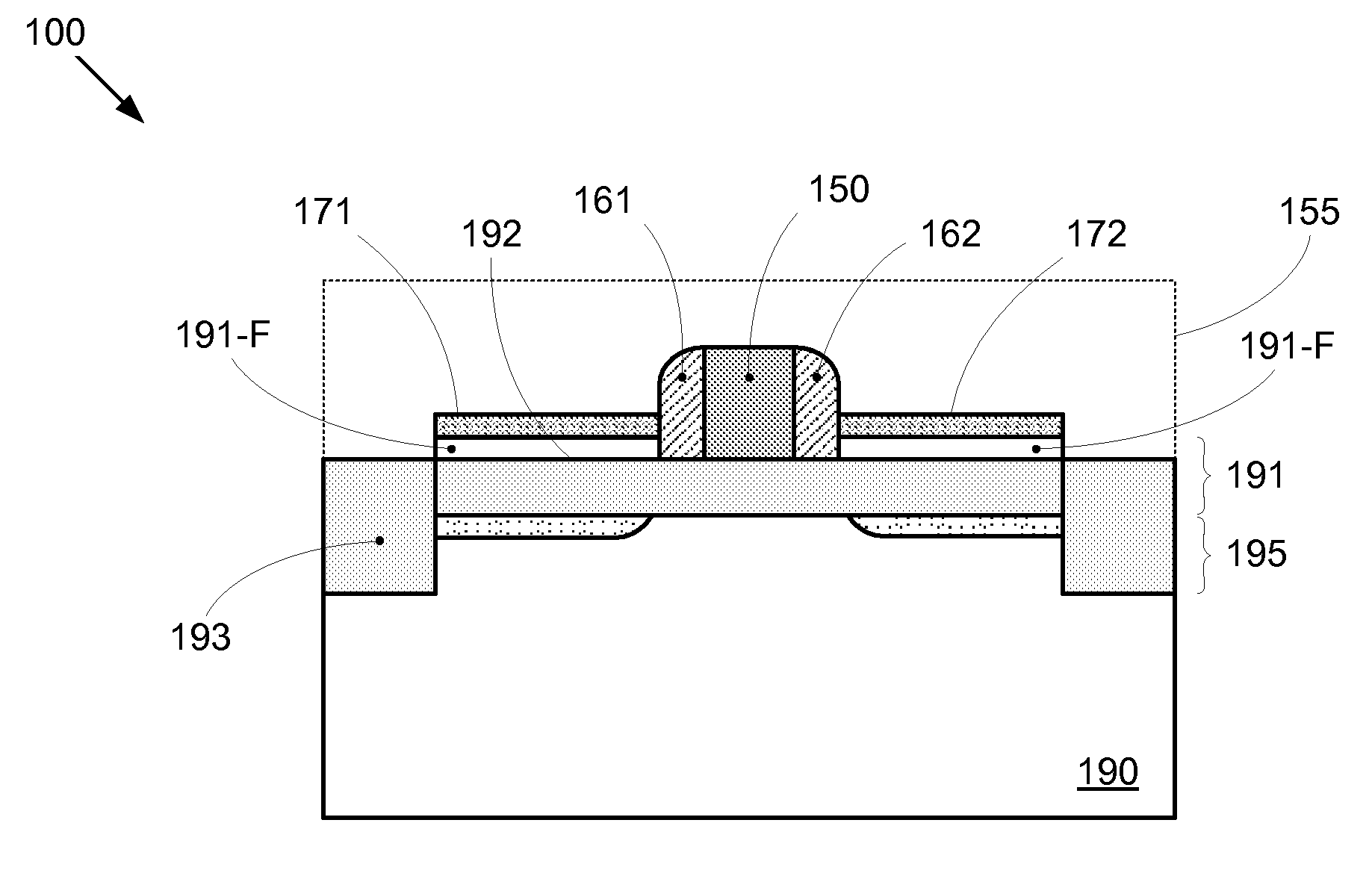

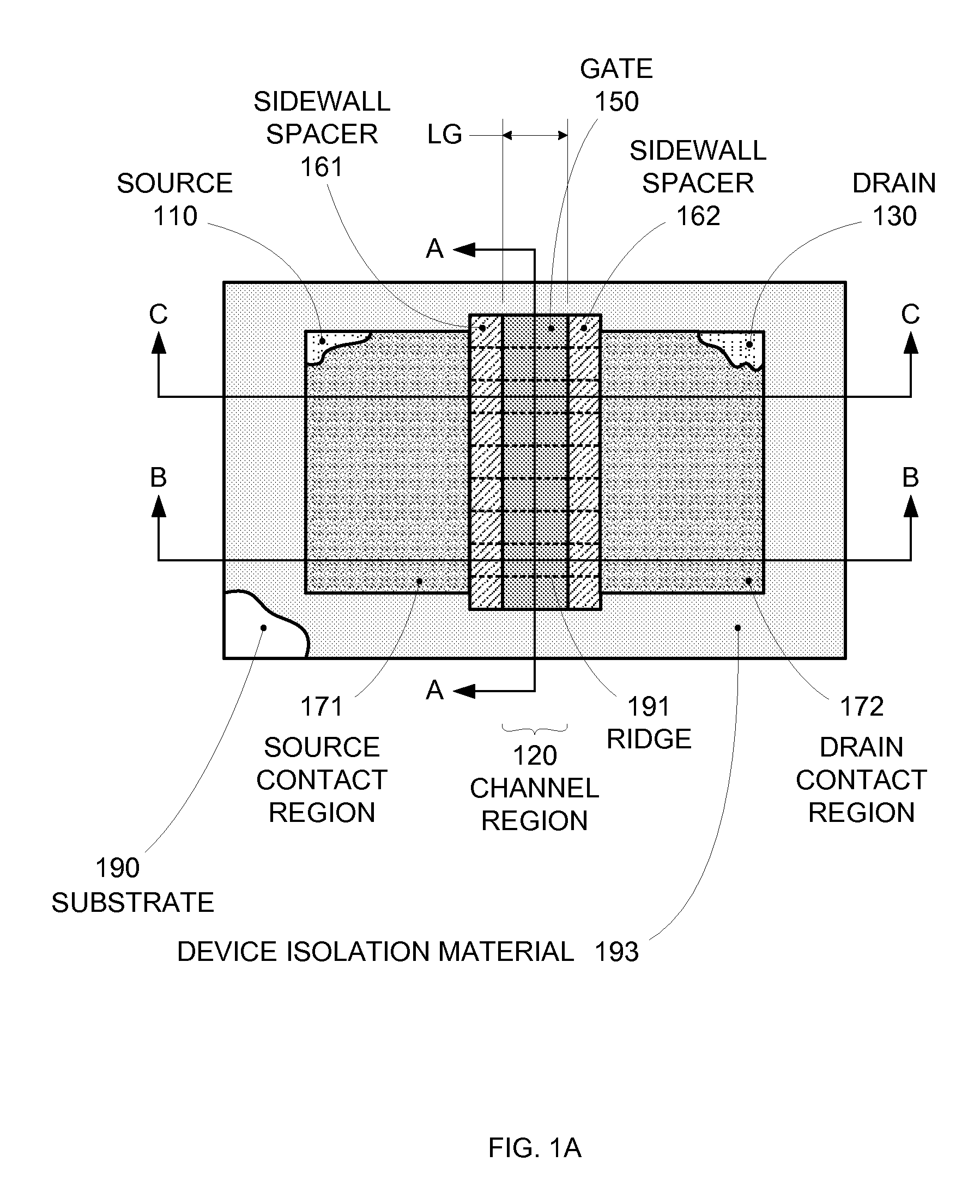

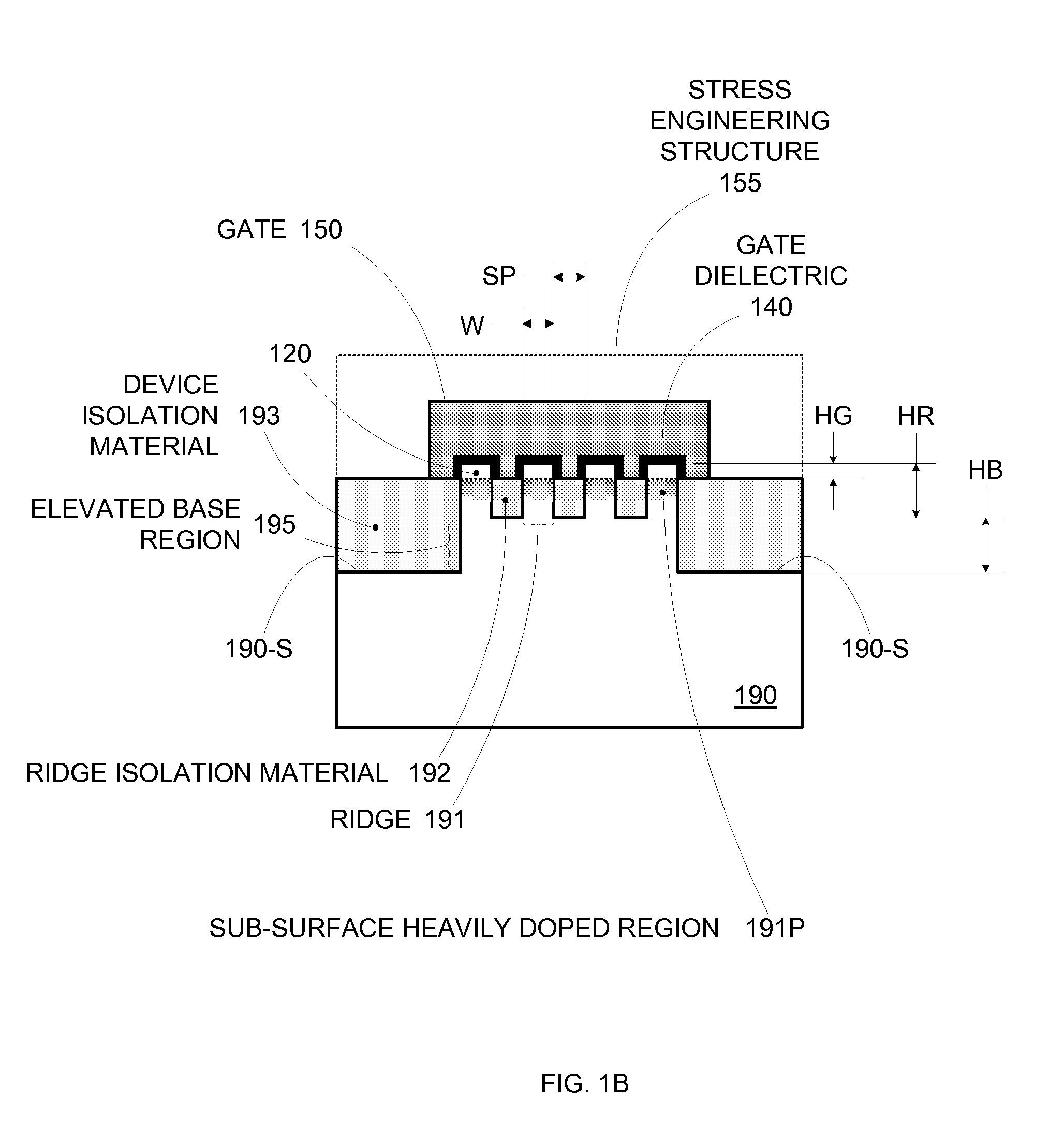

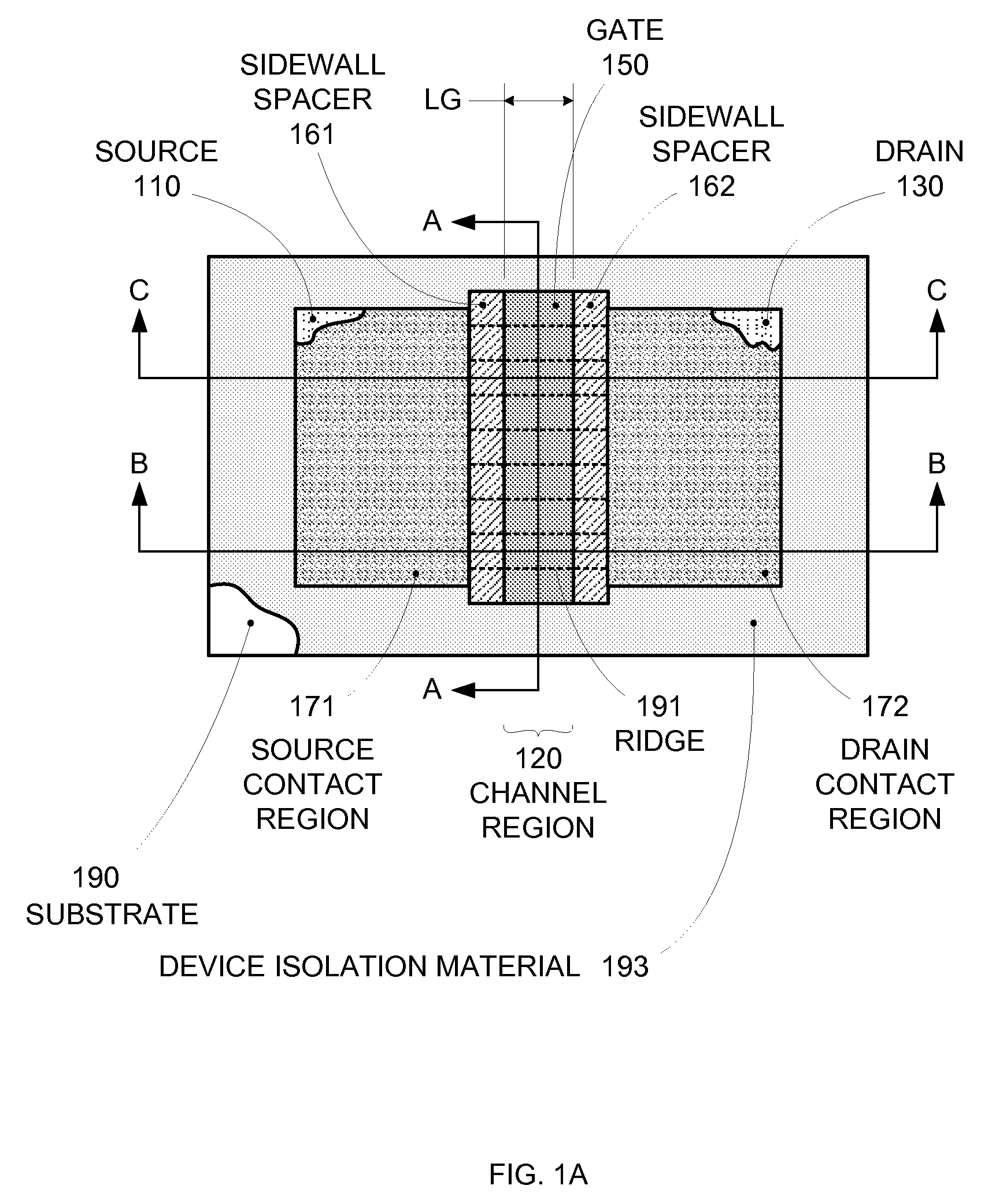

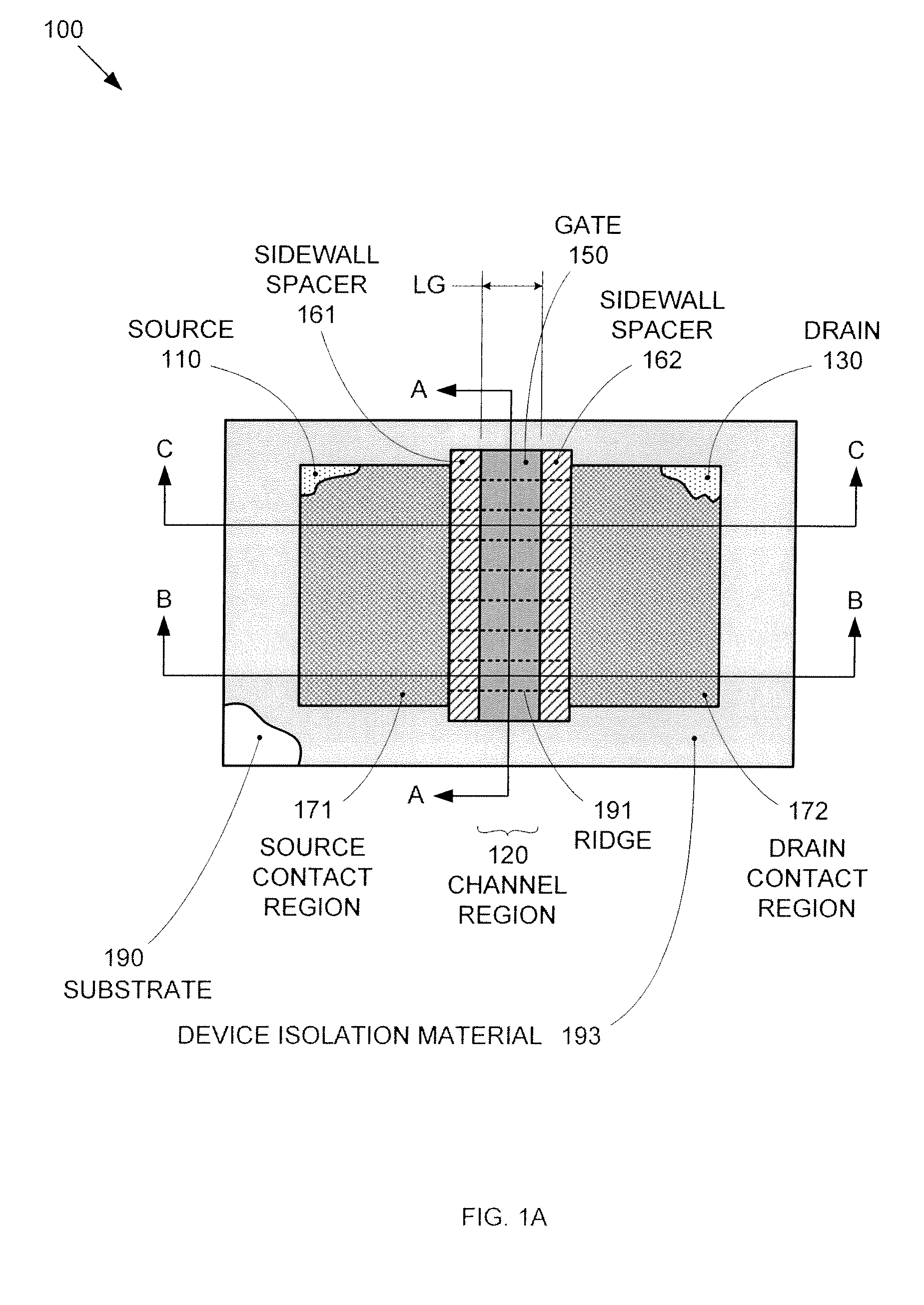

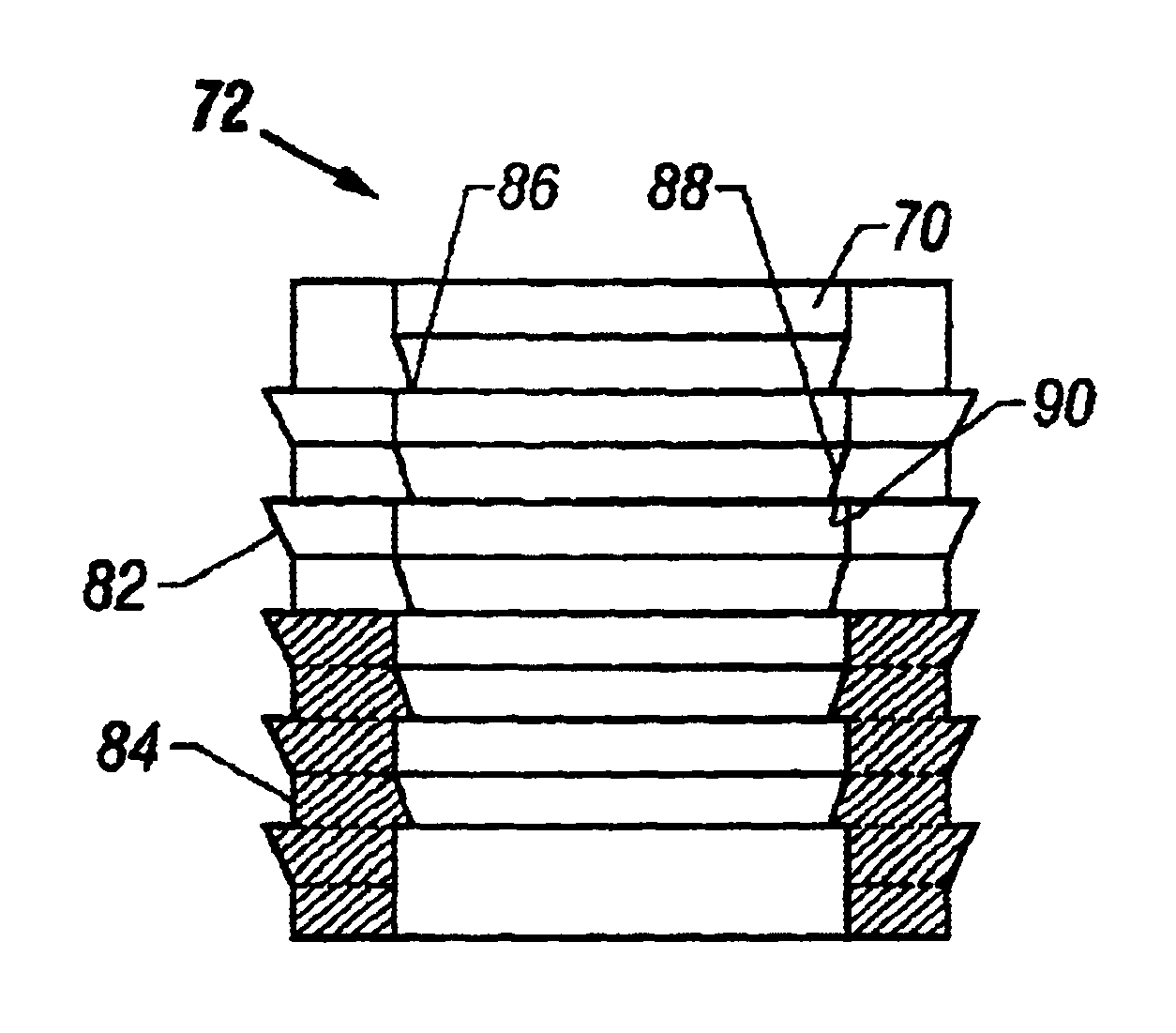

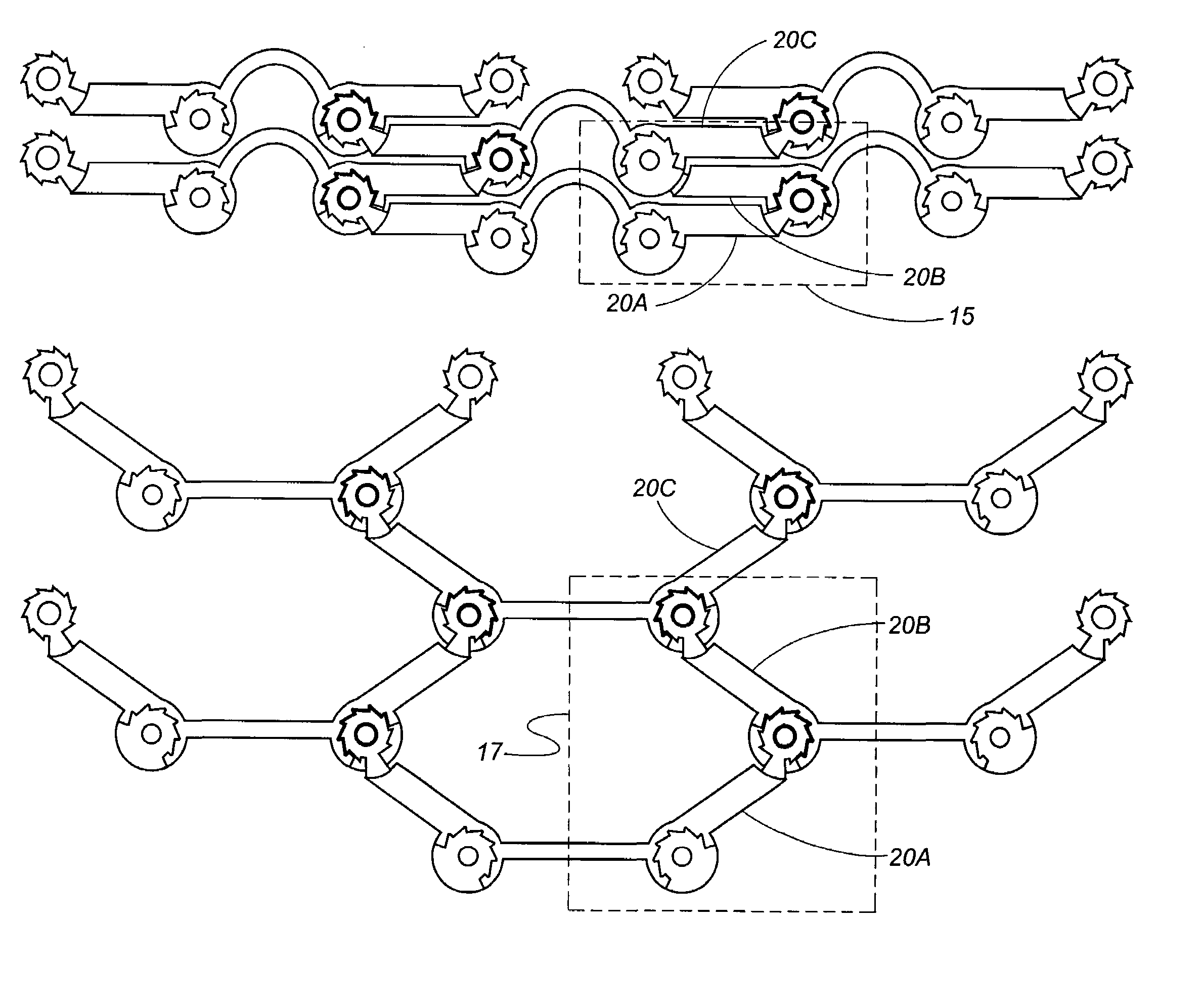

Segmented channel MOS transistor

ActiveUS7247887B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETLithographic artist

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

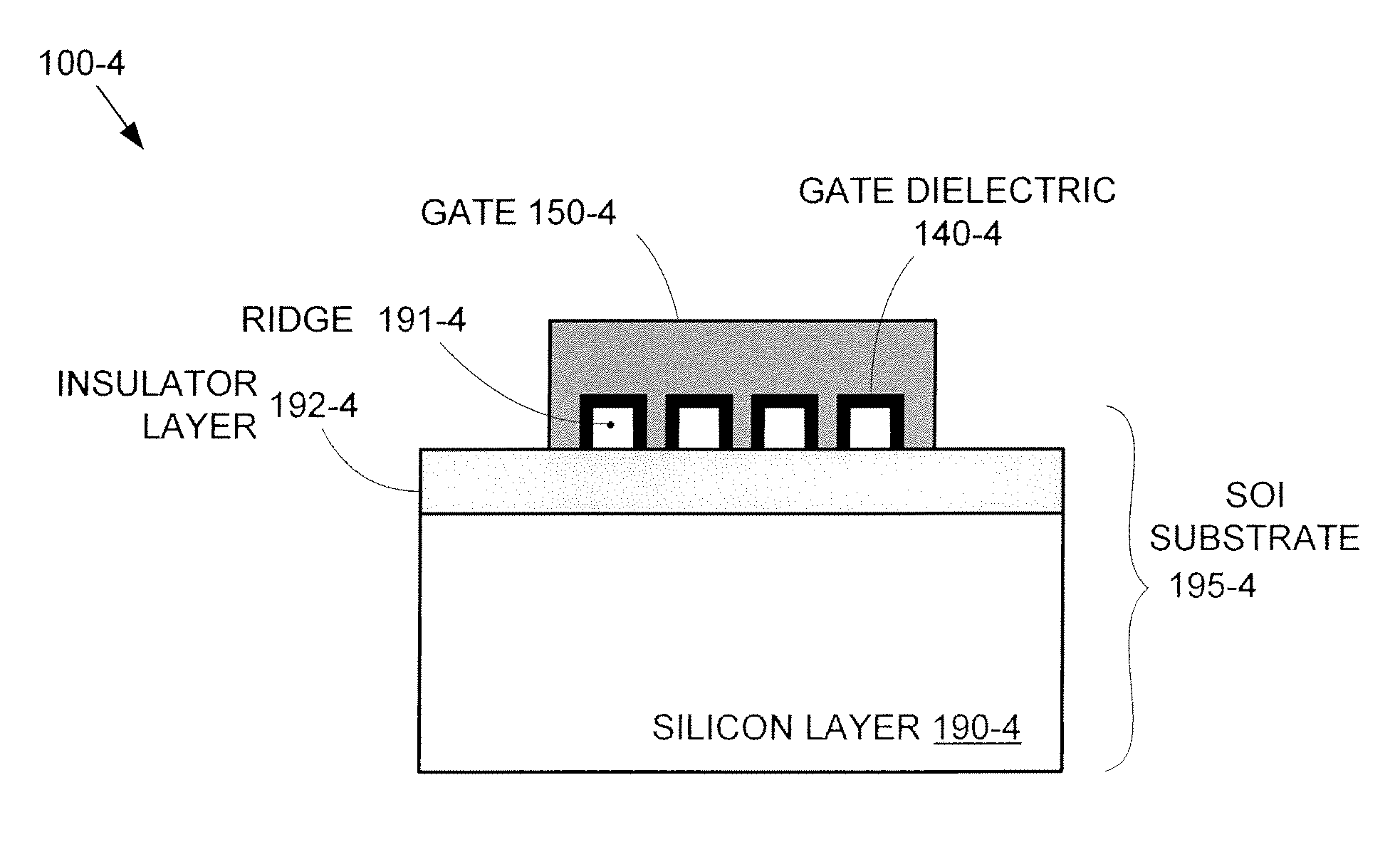

Integrated circuit on corrugated substrate

ActiveUS7190050B2Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

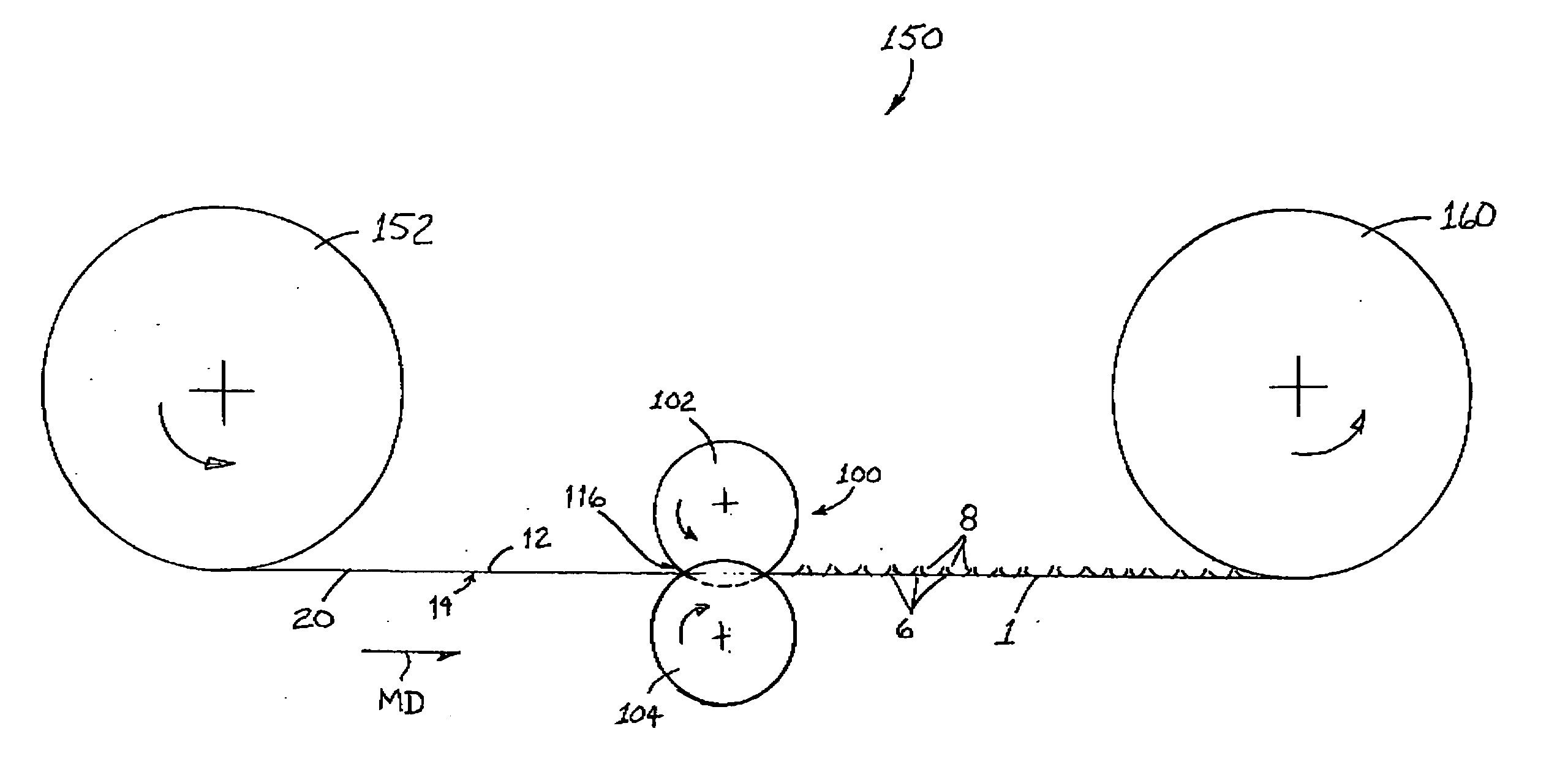

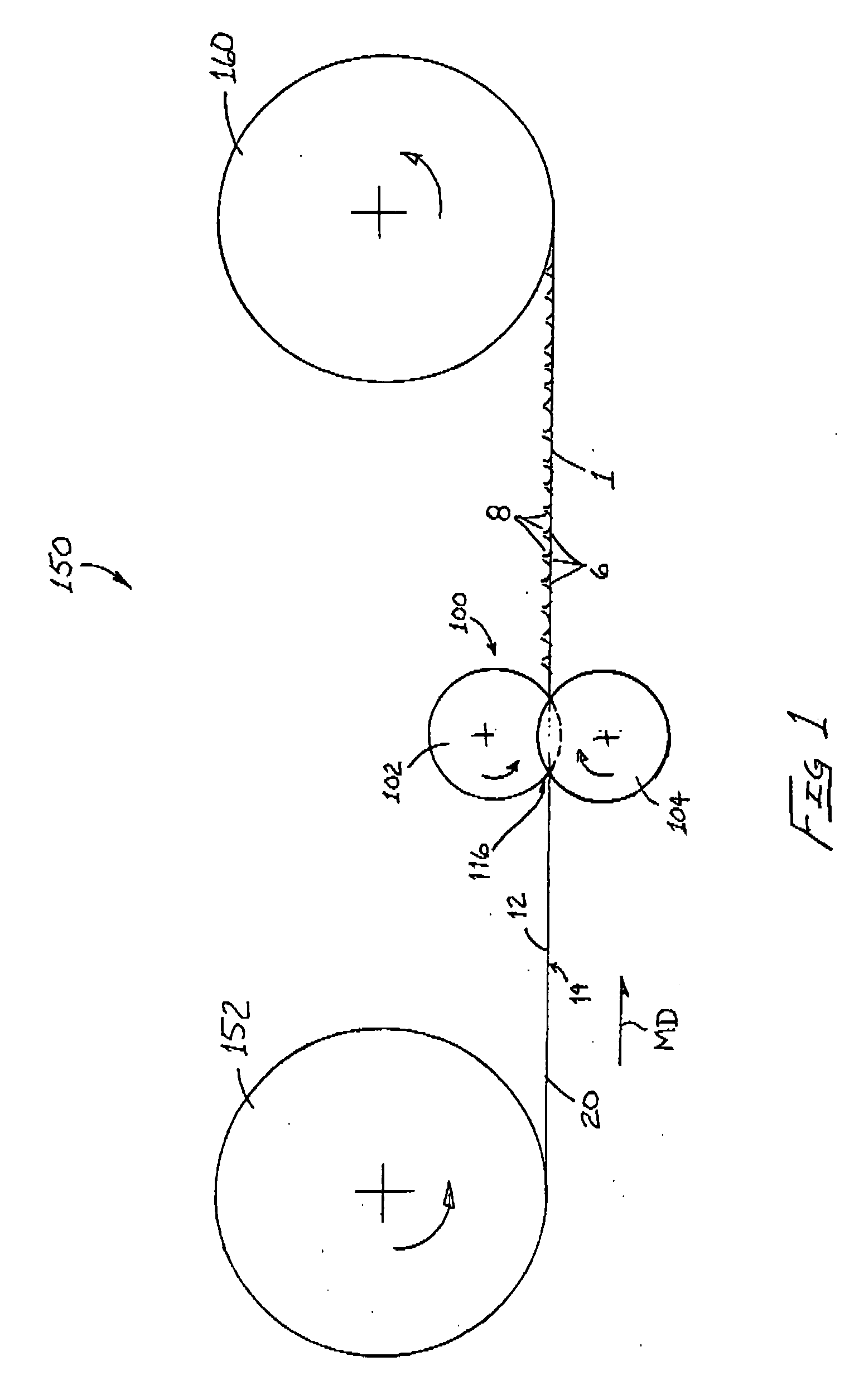

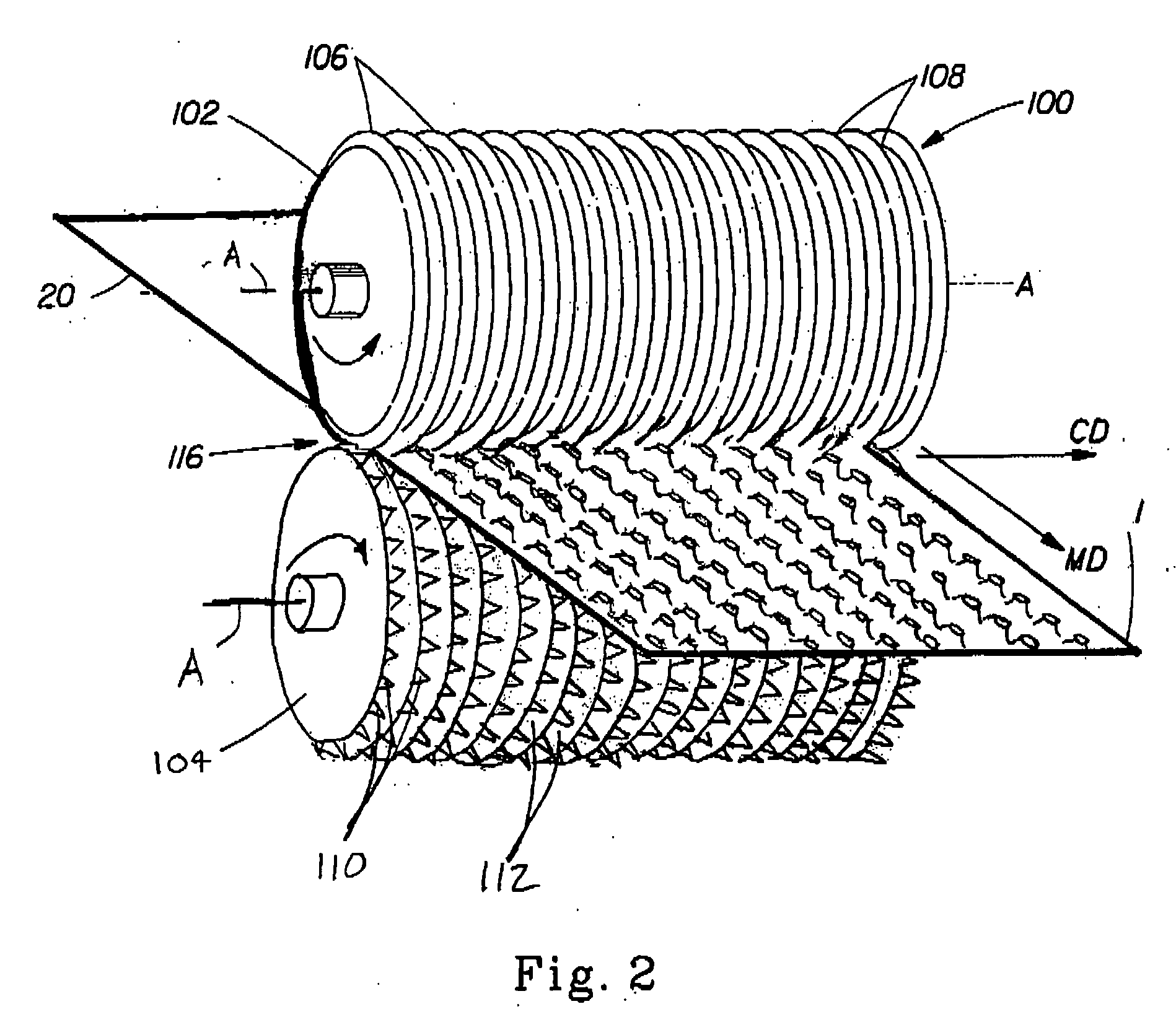

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

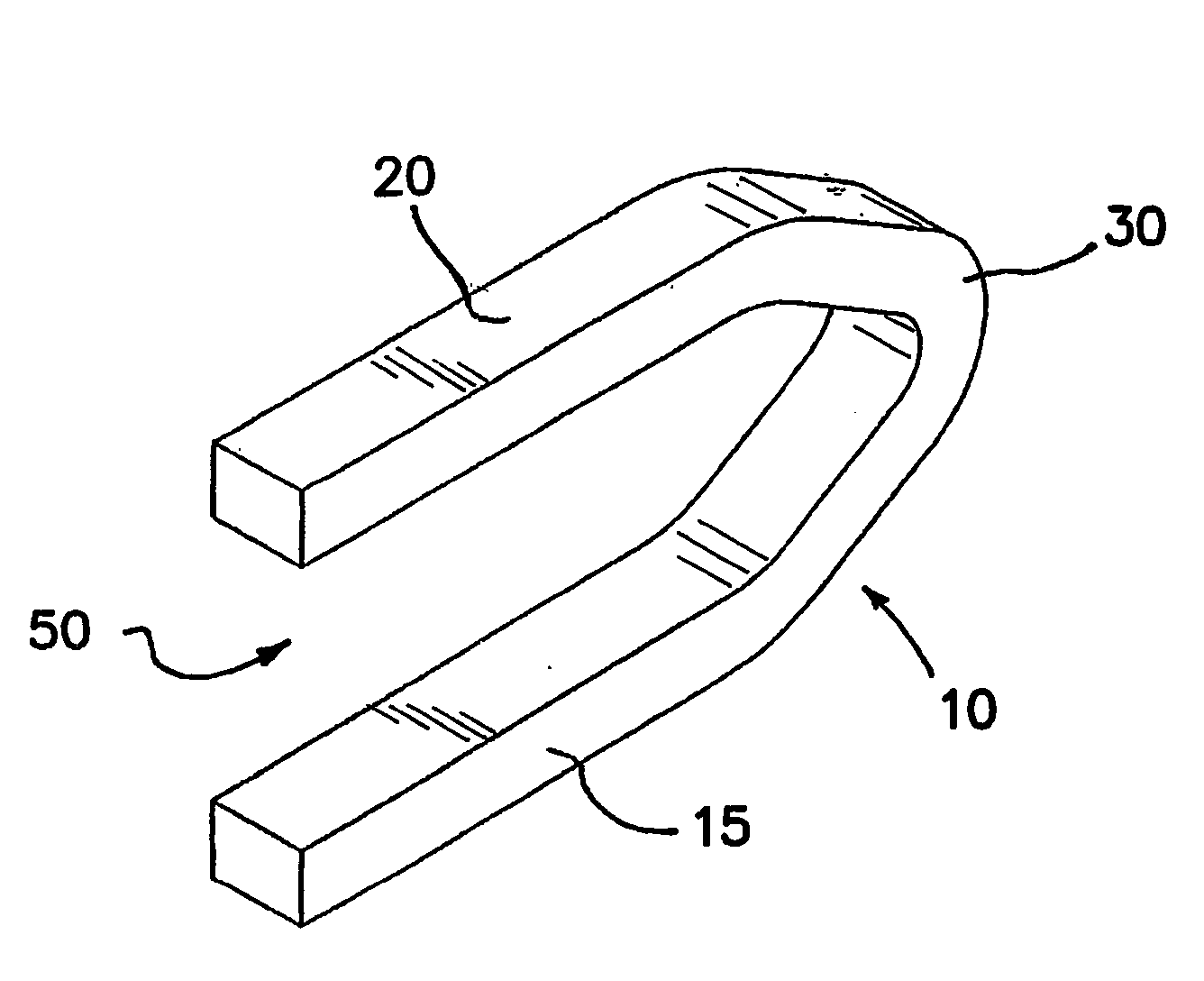

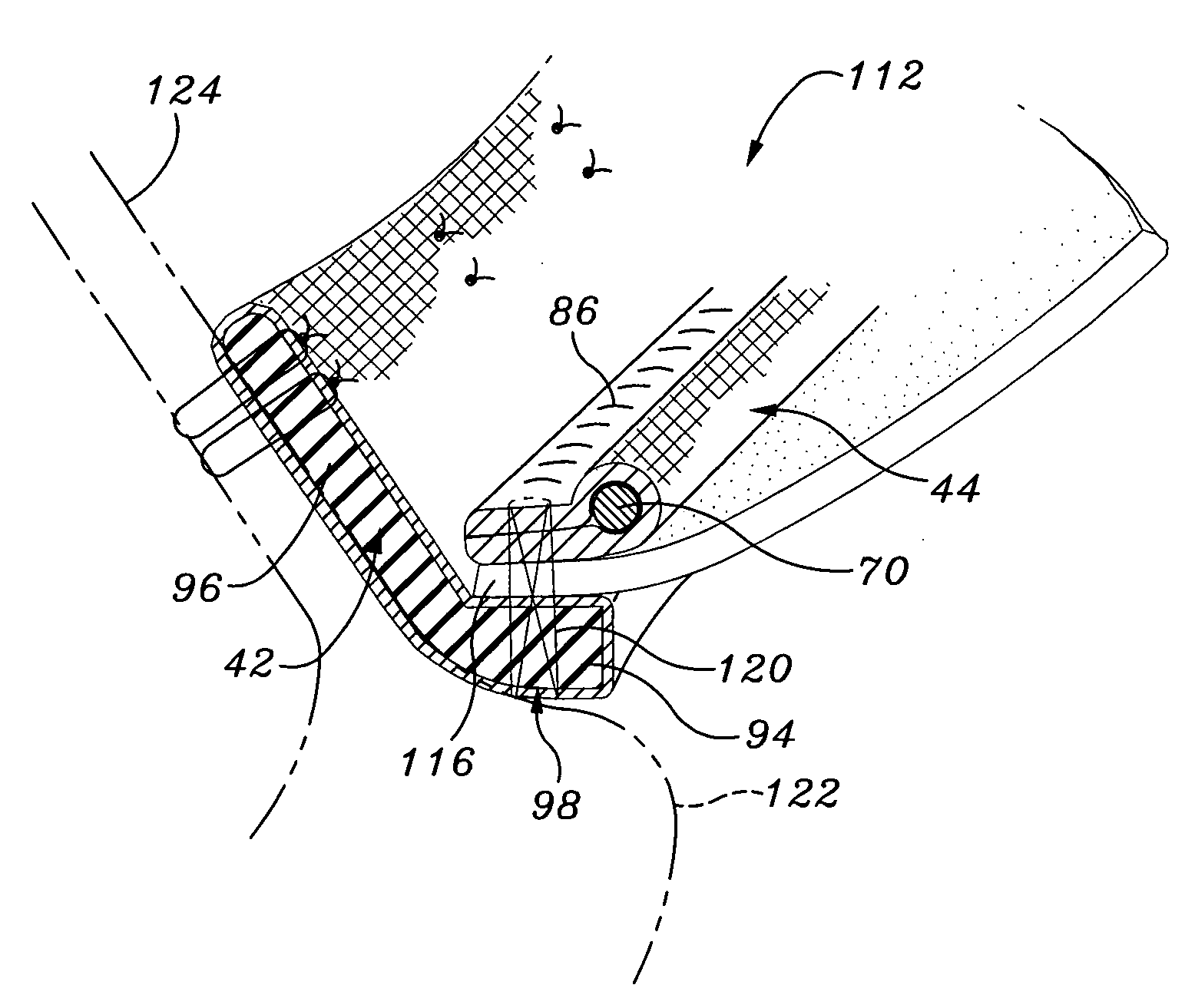

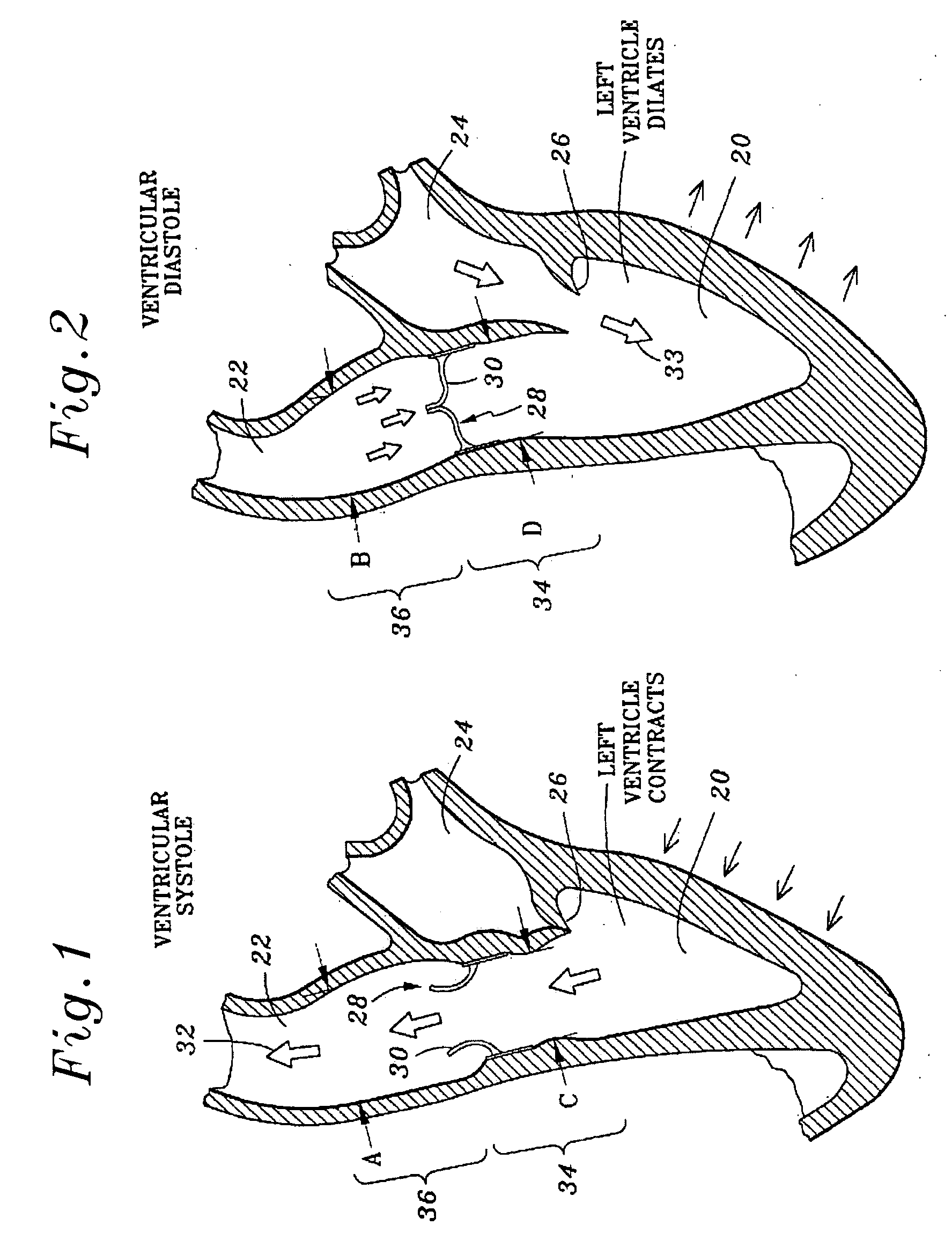

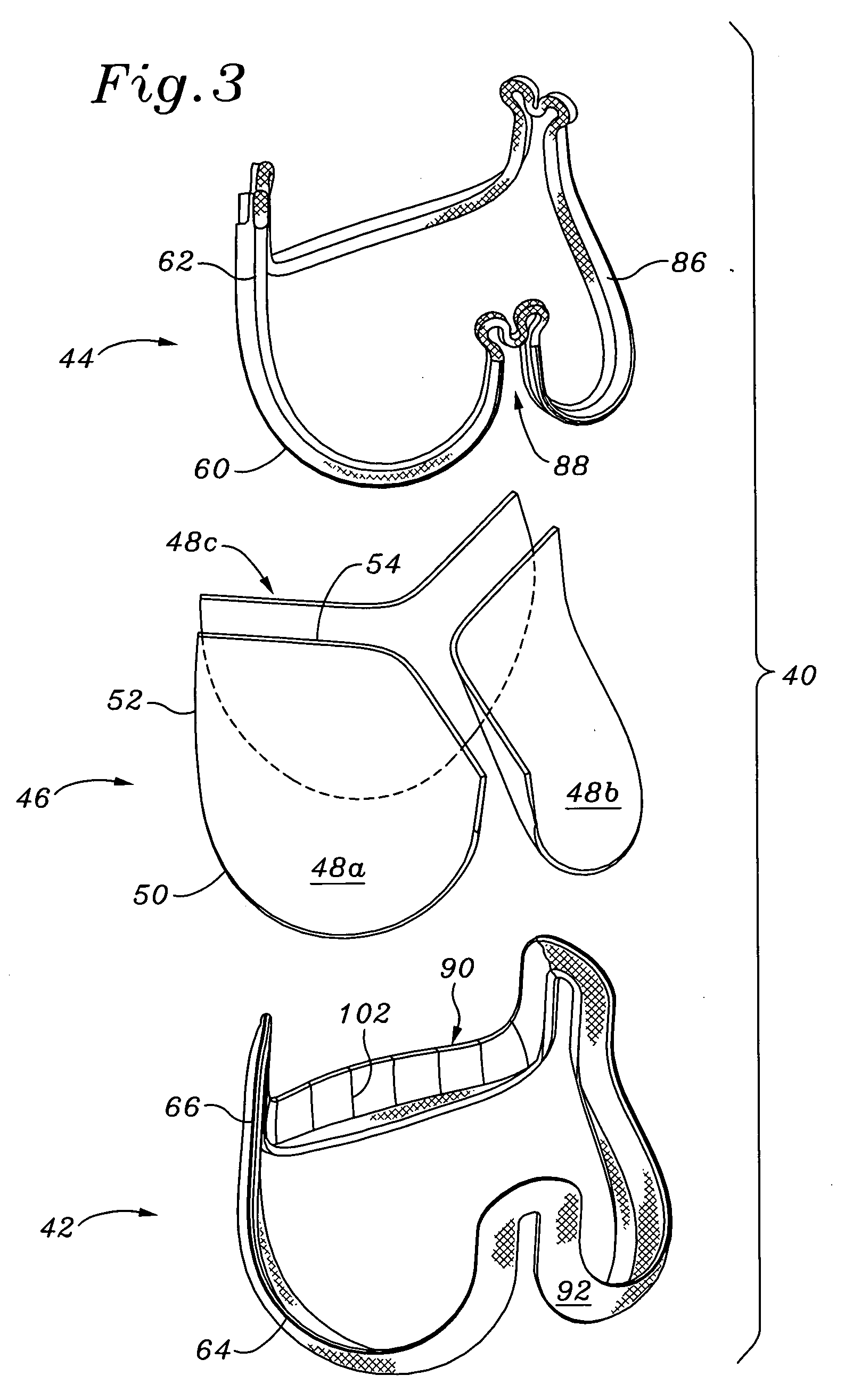

Highly flexible heart valve connecting band

ActiveUS20060229719A1Facilitates supra-annular attachmentIncrease flexibilityHeart valvesInsertion stentTissues types

A connecting band for a highly flexible tissue-type heart valve having a stent with cusps and commissures that are permitted to move radially. The connecting band follows the cusps and commissures and extends outwardly. The valve is connected to the natural tissue along the undulating connecting band using conventional techniques, such as sutures. The connecting band may be a cloth-covered inner suture-permeable member and attaches to the underside of the valve at the cusps to provide support to the stent and to the outer side of the valve at the commissures. The connecting band includes commissure portions defining generally axial gaps that help permit flexing of the valve. The inner member may include one or more slits along the cusps to enhance flexibility. The inner member may further include a continuous outwardly projecting sewing ridge around its periphery which includes a series of ribs separated by grooves around the inflow edge of the cusps. The sewing ridge enables supra-annular implant of a valve constructed with the connecting band.

Owner:EDWARDS LIFESCIENCES CORP

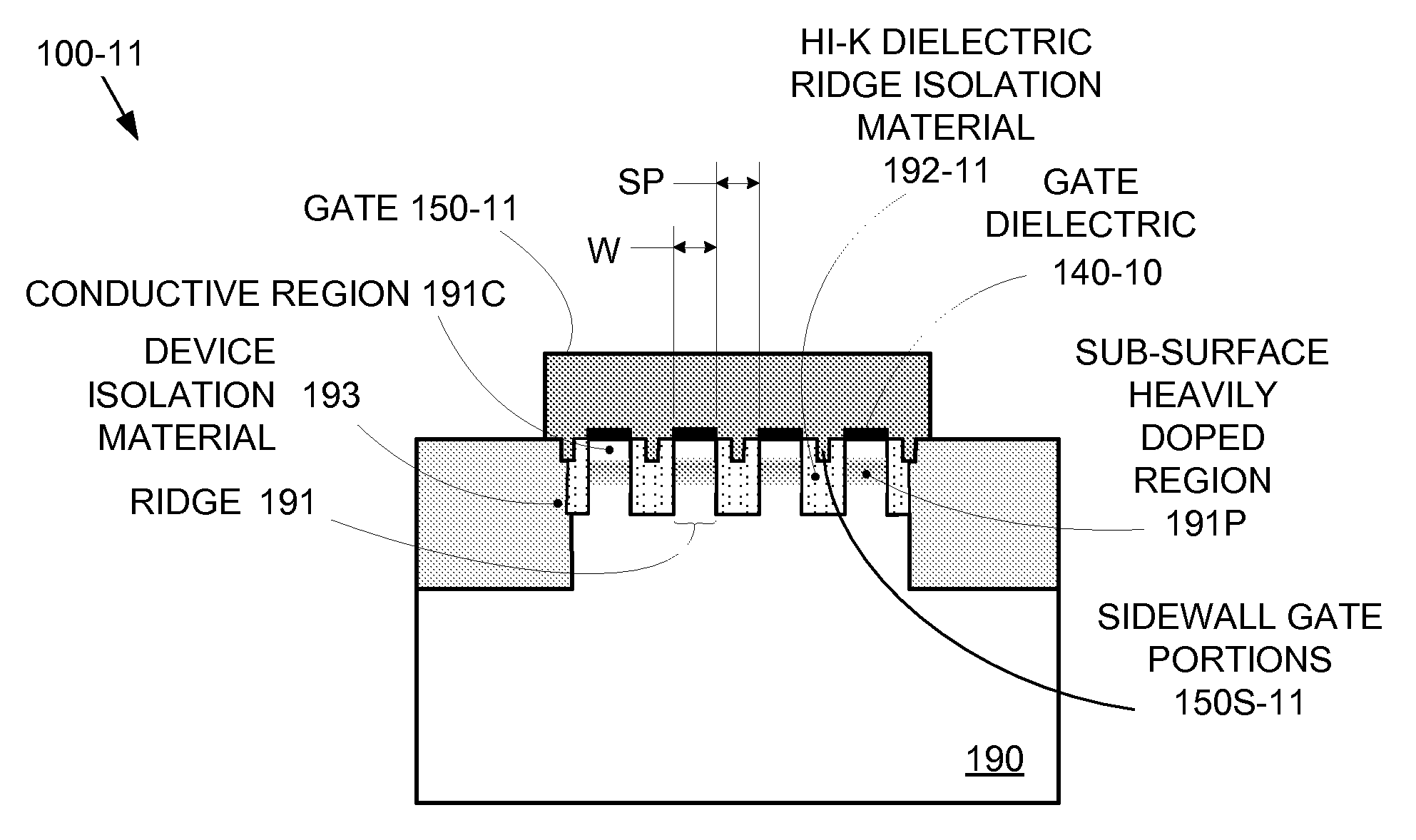

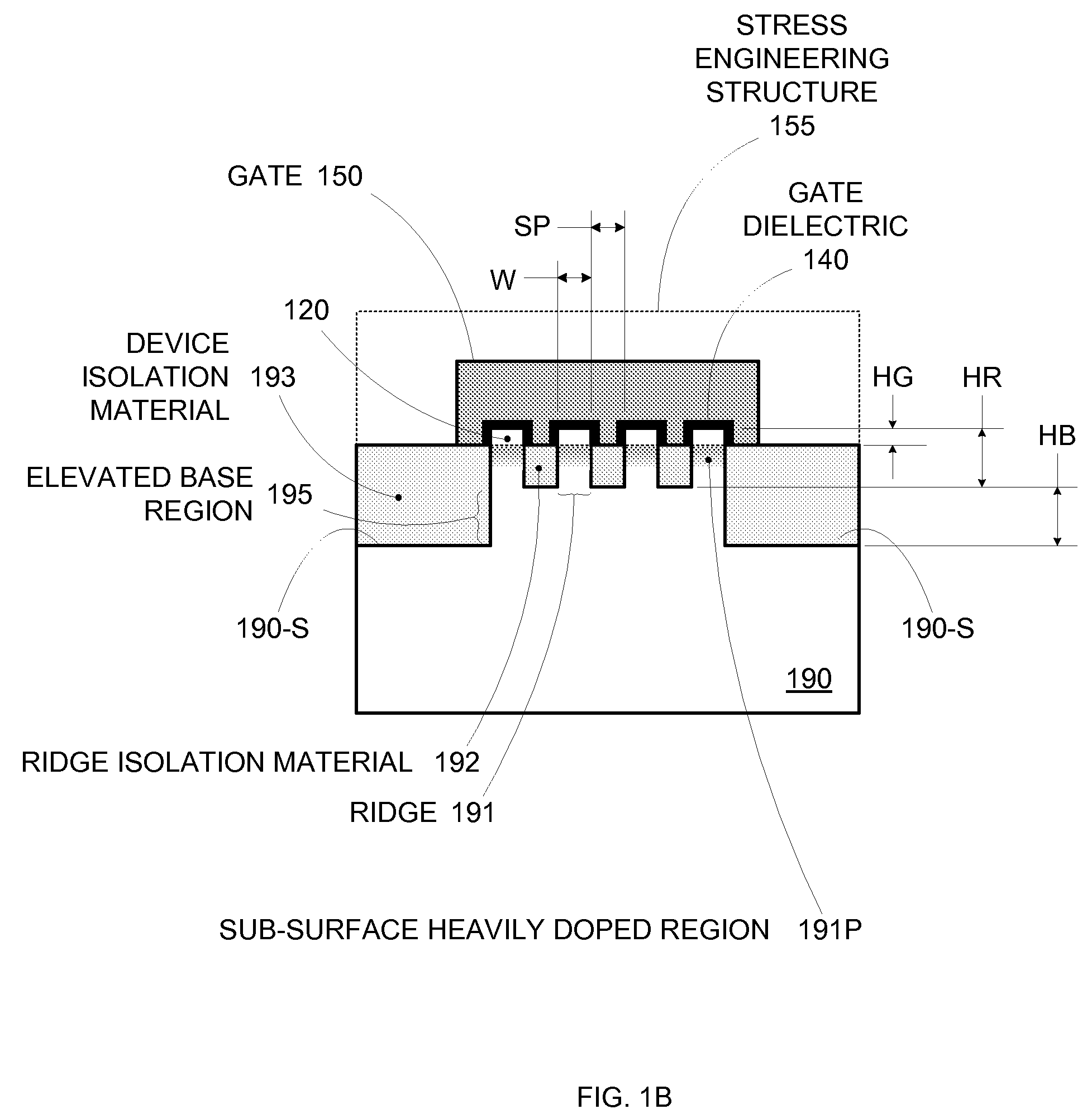

Enhanced Segmented Channel MOS Transistor with Multi Layer Regions

ActiveUS20070120156A1Increase costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Method of IC production using corrugated substrate

ActiveUS7265008B2Improve performance consistencyImprove performanceLaser detailsSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

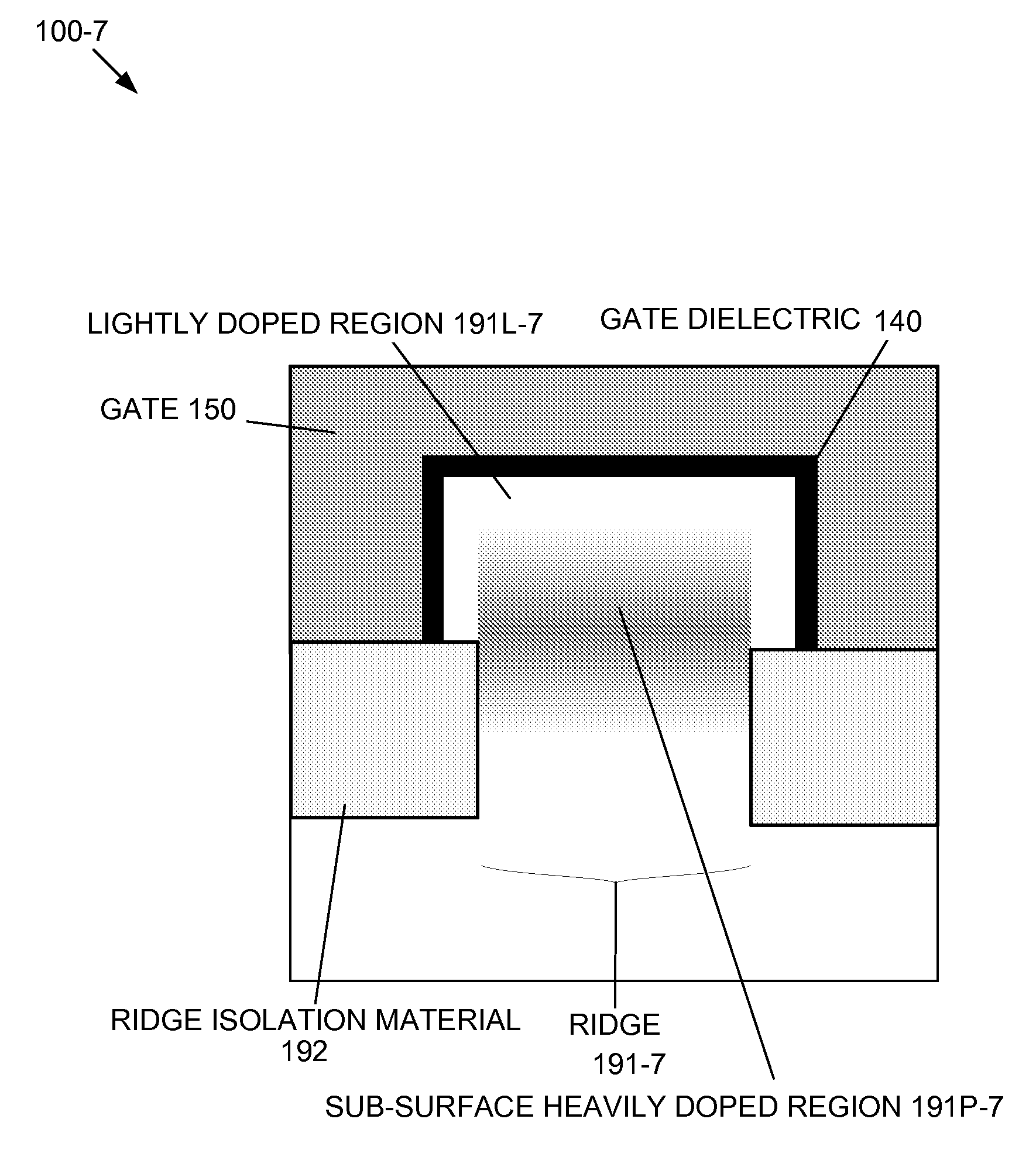

Enhanced segmented channel MOS transistor with narrowed base regions

ActiveUS7508031B2Improve performance consistencyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably produced. Ridges on the corrugated substrate can be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials, high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Enhanced Segmented Channel MOS Transistor with High-Permittivity Dielectric Isolation Material

ActiveUS20070122953A1Increase costImprove performanceTransistorSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Enhanced segmented channel MOS transistor with high-permittivity dielectric isolation material

ActiveUS7605449B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Custom replacement device for resurfacing a femur and method of making the same

InactiveUS20040098133A1Joint implantsComputer-aided planning/modellingArticular surfacesRight femoral head

Owner:KINAMED

Integrated Circuit On Corrugated Substrate

ActiveUS20070132053A1Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETSemiconductor materials

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Spinal Plate

ActiveUS20130060337A1Improve securityImprove stabilityInternal osteosythesisJoint implantsSet screwIliac screw

Spinal plates with additional features to improve the stability of the interface between the plate and the underlying bone. A bone plate may include one or more sharp ridges along the periphery of its underside. When attached to bone, the ridge digs into the bone and increases stability. A bone plate may alternatively or additionally include one or more holes for optional spikes, which may be inserted once the plate is attached to the bone. By separating the spikes and including them as an optional component, the plate may enhance stability while reducing or eliminating the chance of the spike injuring the patient. Furthermore, bone screws may incorporate alternating notches and ridges into the head of the screw. The notches and ridges may interface with a set screw, thereby preventing rotation and loosening of the screw.

Owner:GLOBUS MEDICAL INC

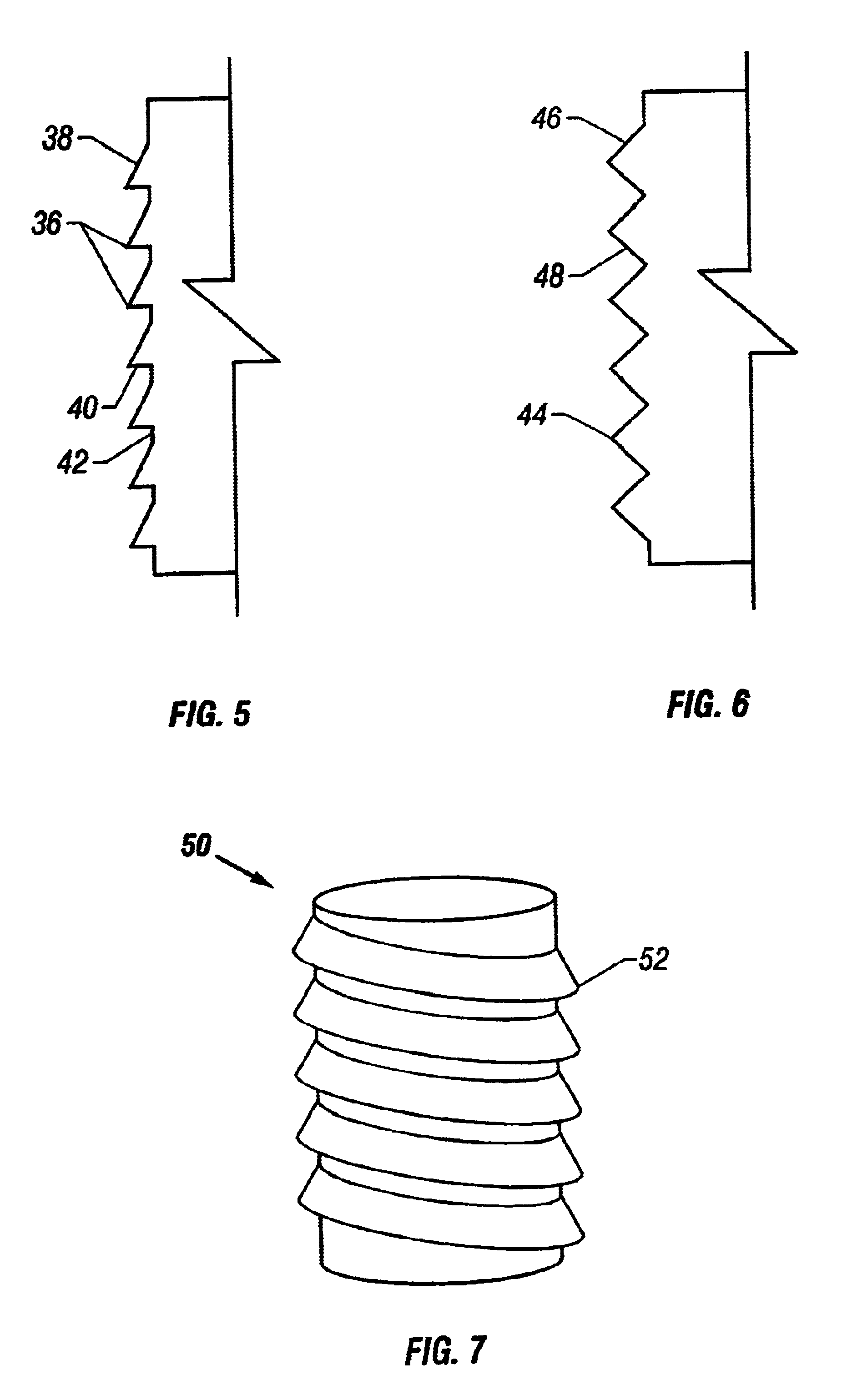

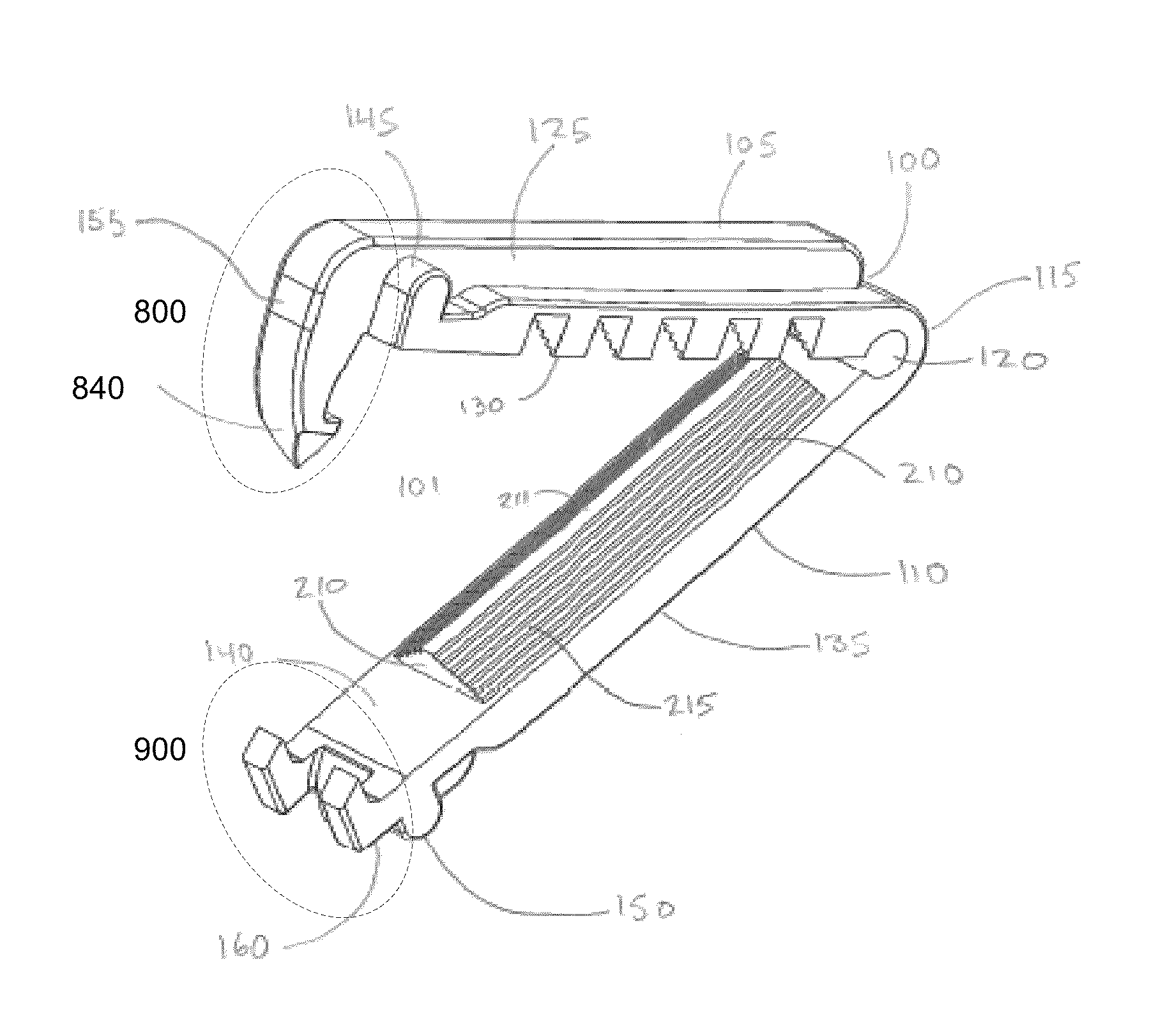

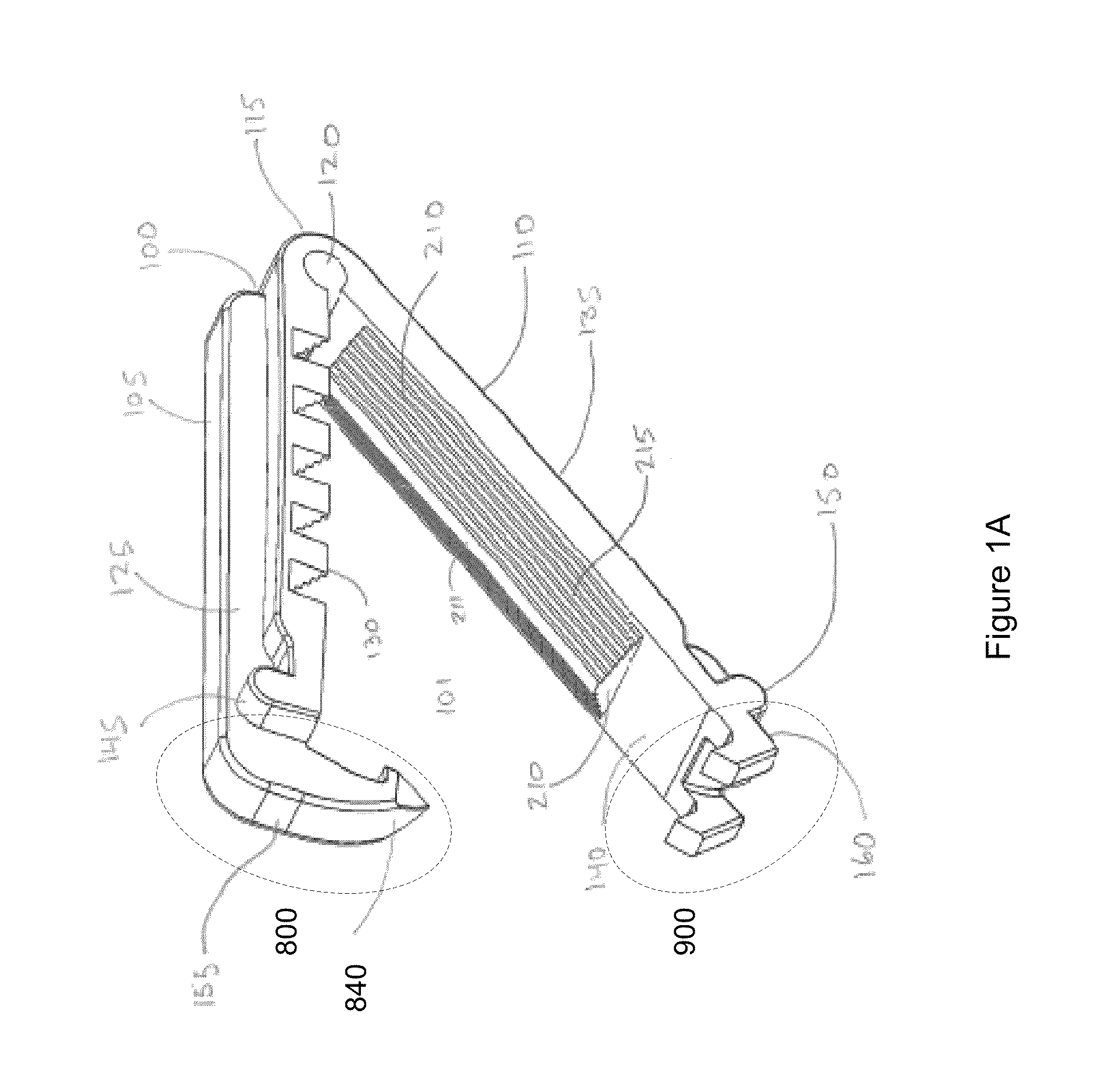

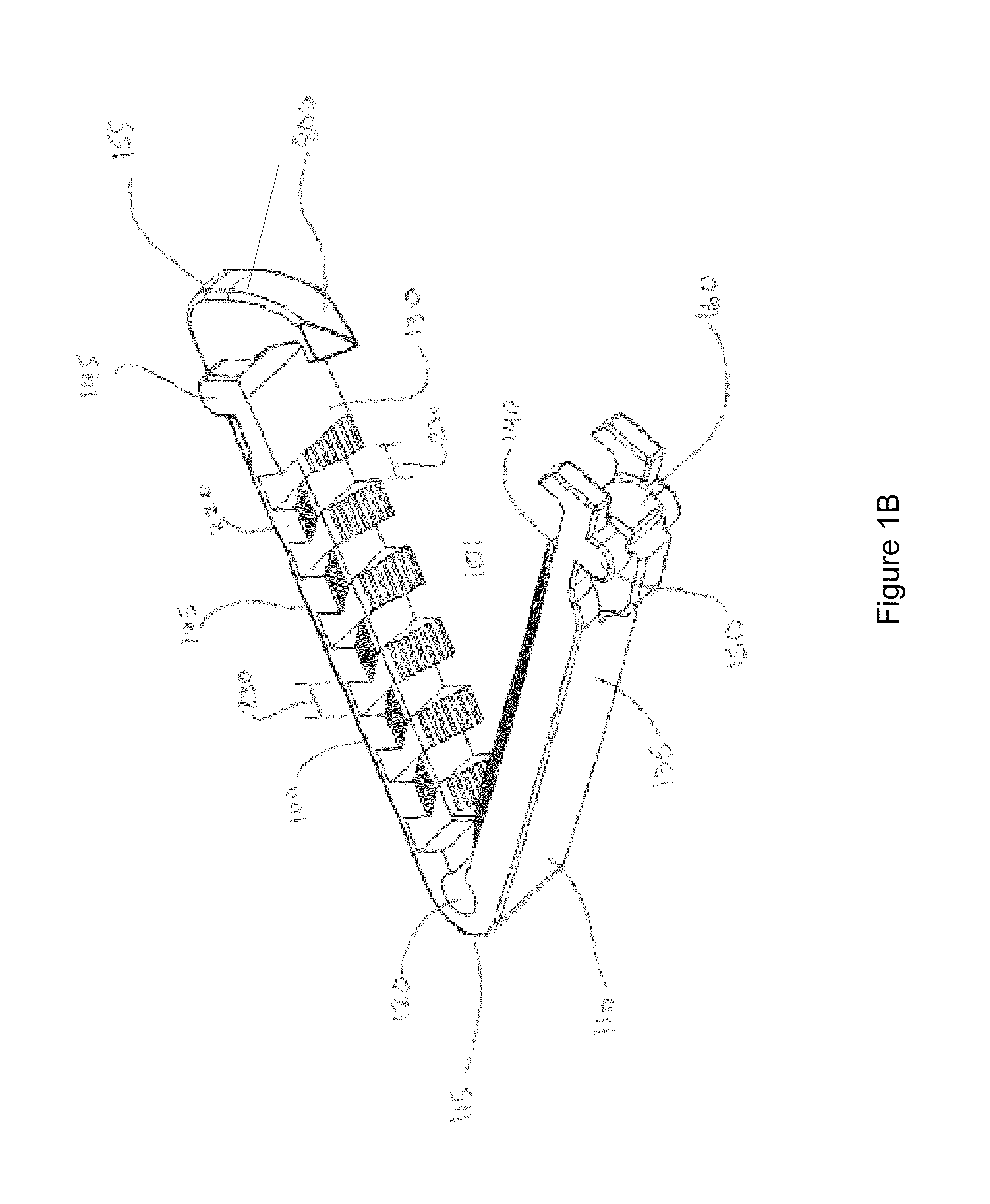

Allograft spinal implant

InactiveUS7018412B2Enhancing fusion of boneImprove fusionInternal osteosythesisBone implantSpinal implantBiomedical engineering

An allograft spinal implant includes a generally planar superior end face, a generally planar inferior end face and a generally cylindrical sidewall. The generally cylindrical sidewall extends between the superior end face and the inferior end face. At least one of the superior end face and the inferior end face includes a plurality of concentric circular ridges.

Owner:ZIMMER BIOMET SPINE INC

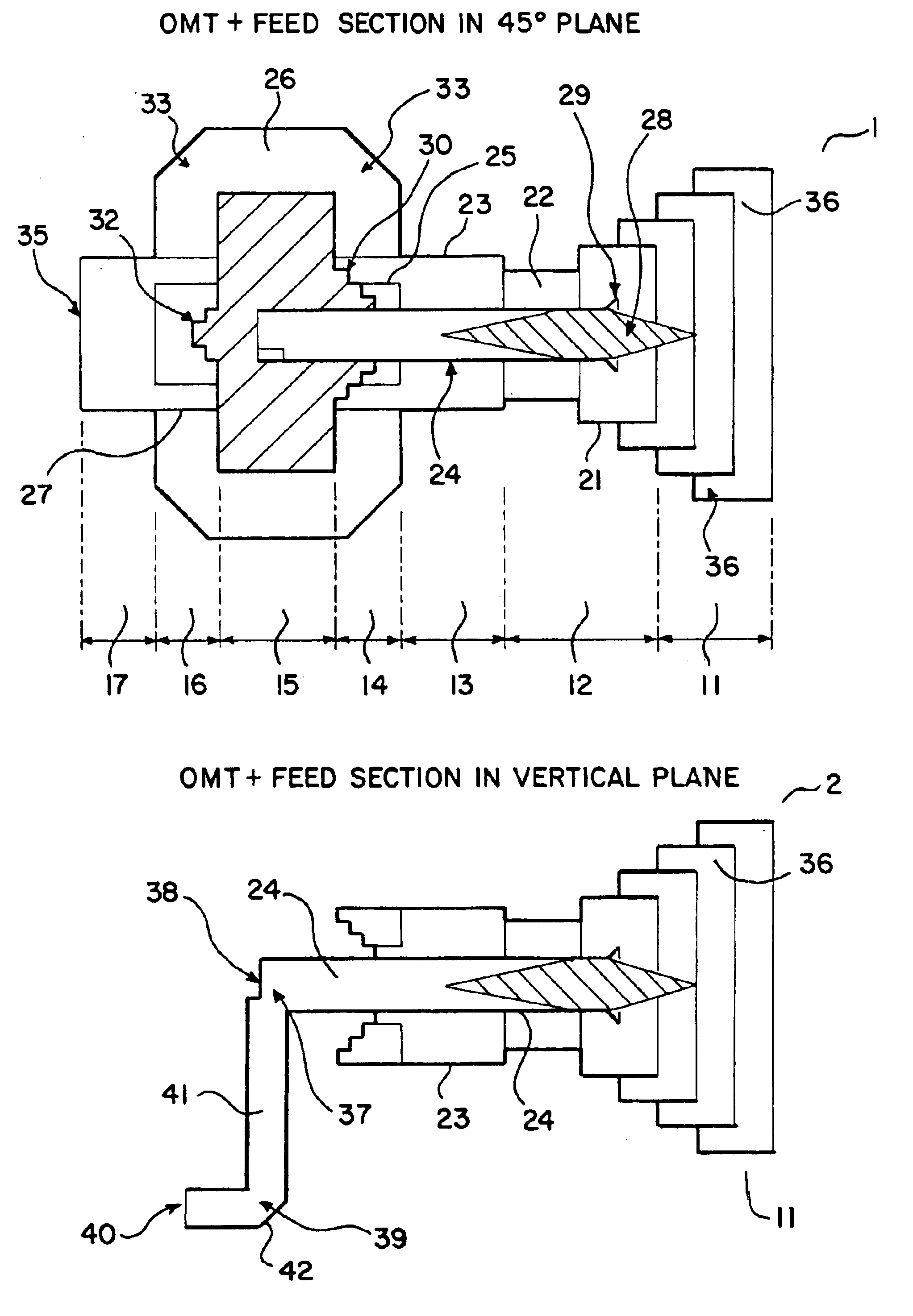

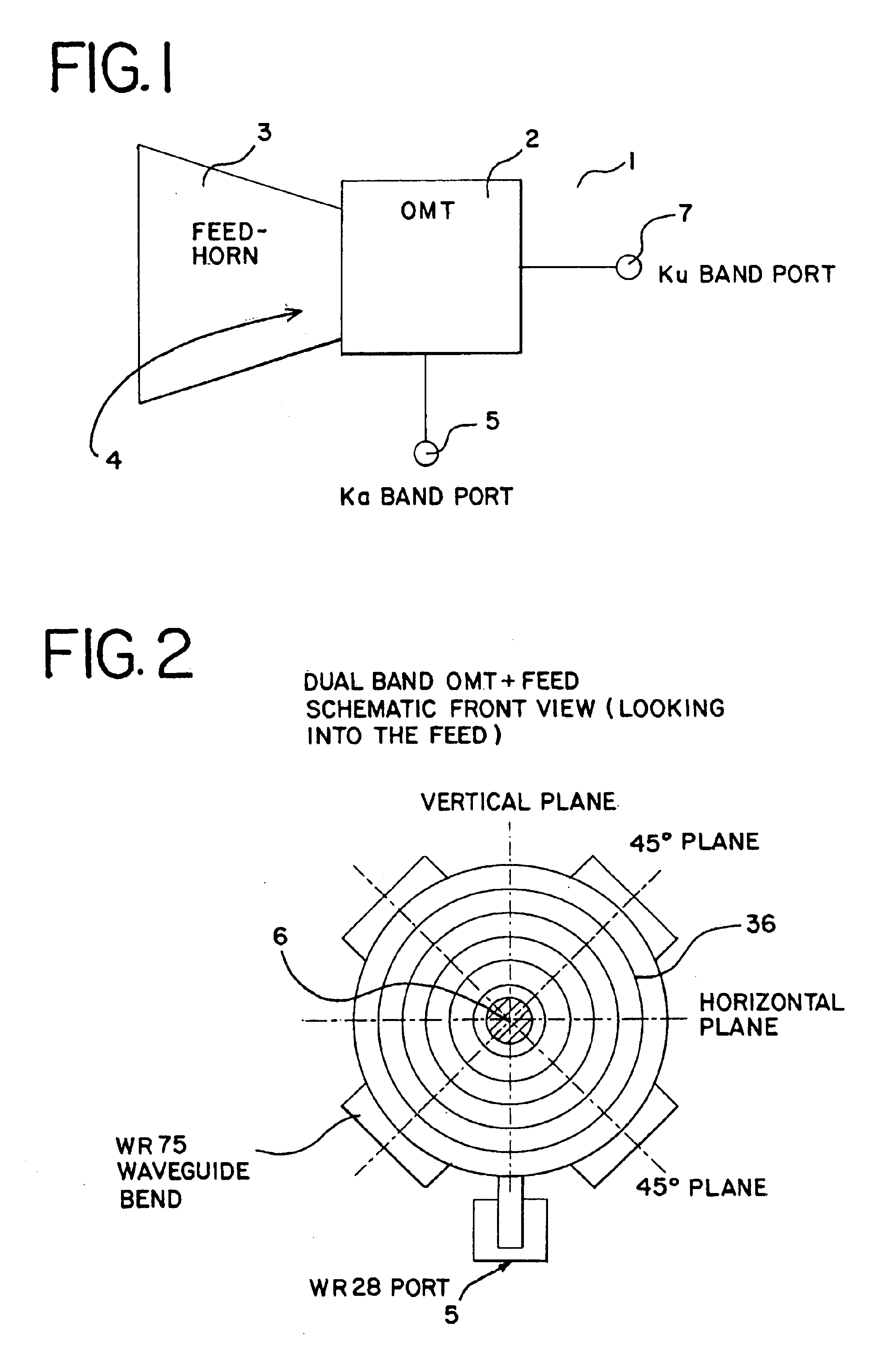

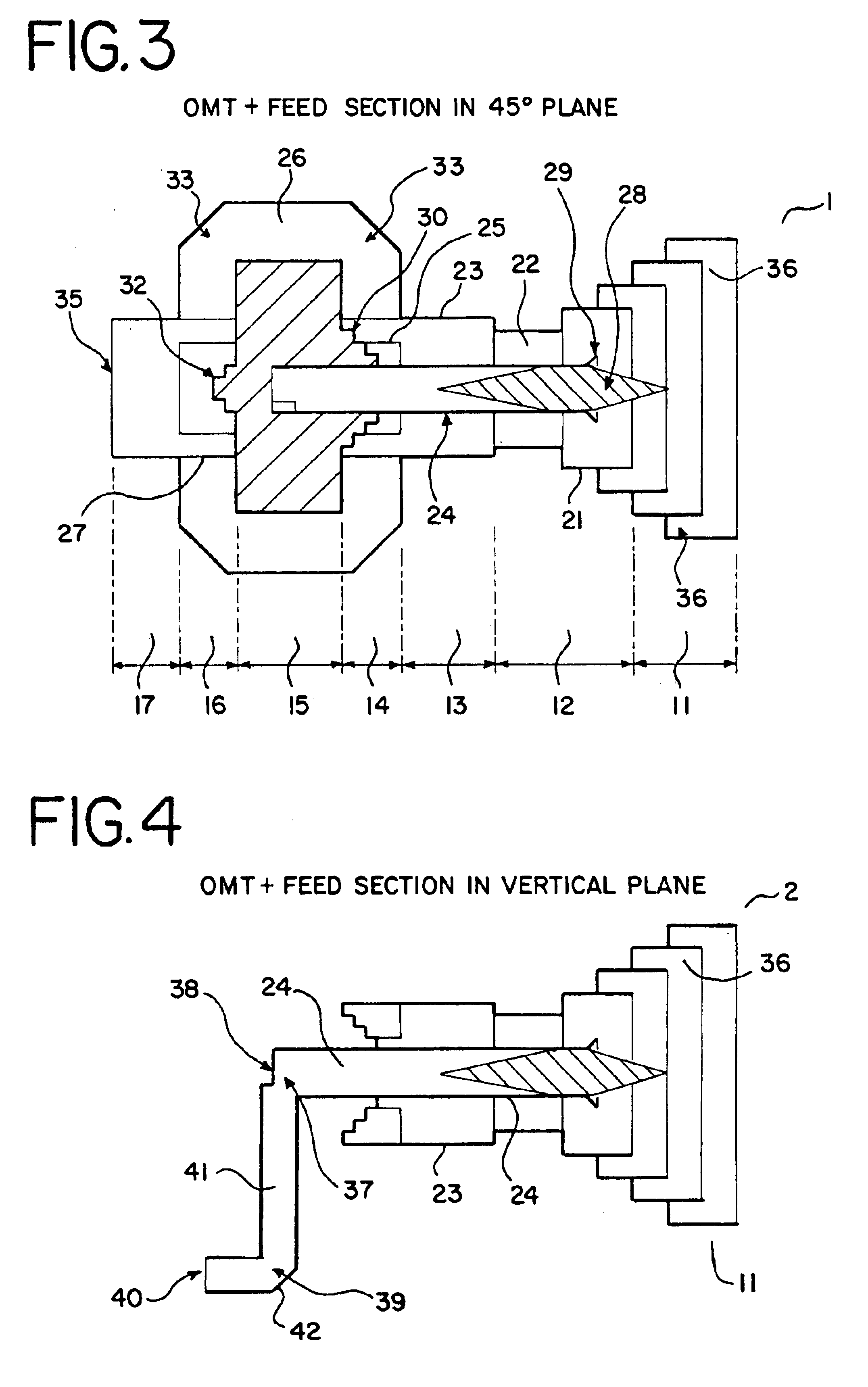

Ka/Ku dual band feedhorn and orthomode transduce (OMT)

InactiveUS6714165B2Simultaneous aerial operationsAntennas earthing switches associationRidge waveguidesTransducer

A dual band, higher and lower frequency range transducer with a circular coaxial waveguide feed is described having a first junction for connection of a lower frequency range outer waveguide of the coaxial waveguide feed to at least two rectangular or ridge waveguides offset from the longitudinal axis of the transducer and a second junction for connection of the at least two rectangular or ridge waveguides to a further waveguide. A third junction is provided for connecting an inner waveguide of the coaxial waveguide feed to a higher frequency range waveguide. The transducer comprises at least first and second parts joined across a first plane substantially perpendicular to the longitudinal axis and including at least a portion of the higher frequency range waveguide extending within the first plane of the join. A seal such as an "O" ring seal may be placed easily in the plane of the join thus preventing moisture ingress. Similarly, a feed horn and input and output ports may be sealingly attached to the first and second parts of the transducer. The first and second junctions are preferably impedance matched turnstile junctions.

Owner:NEWTEC CY

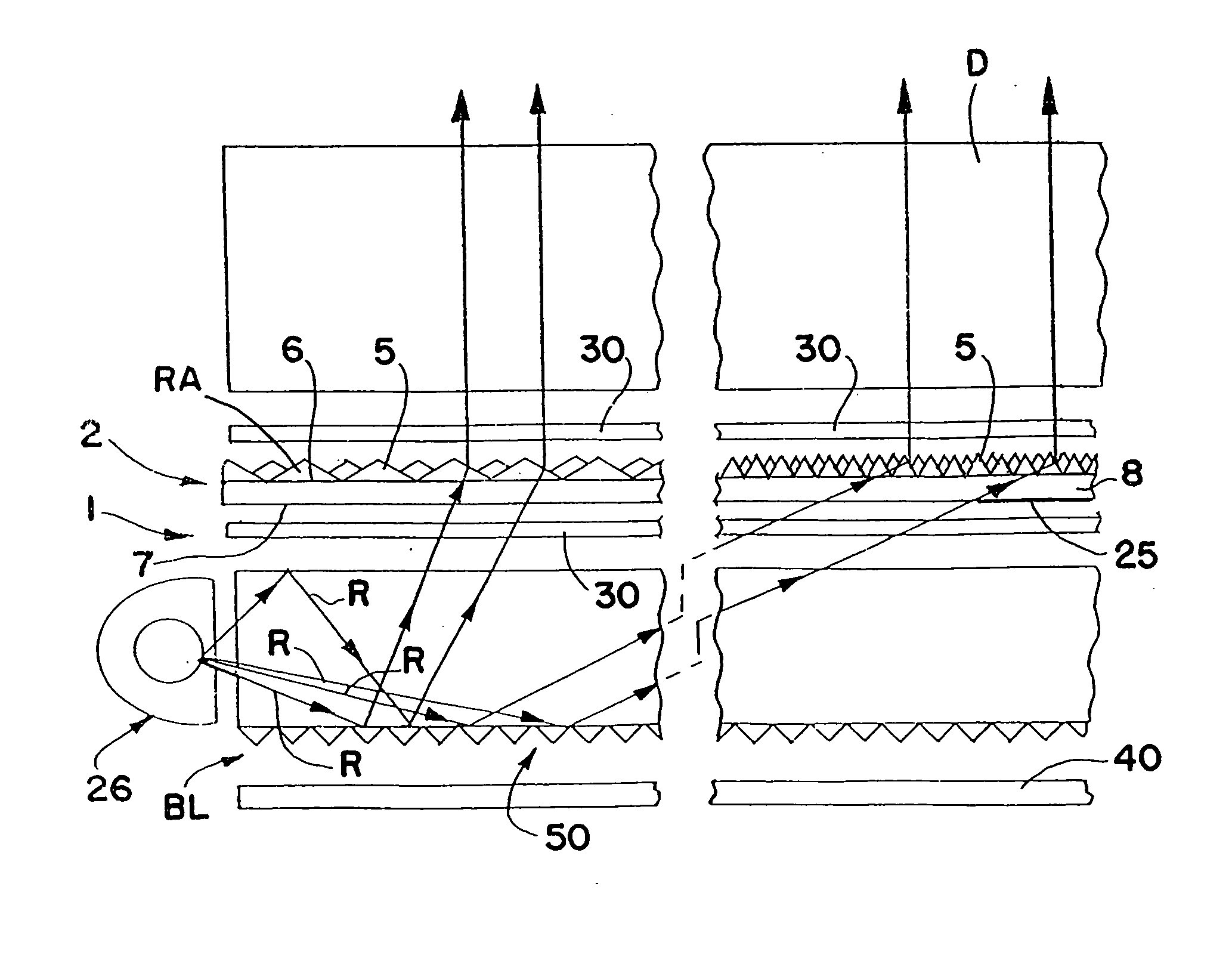

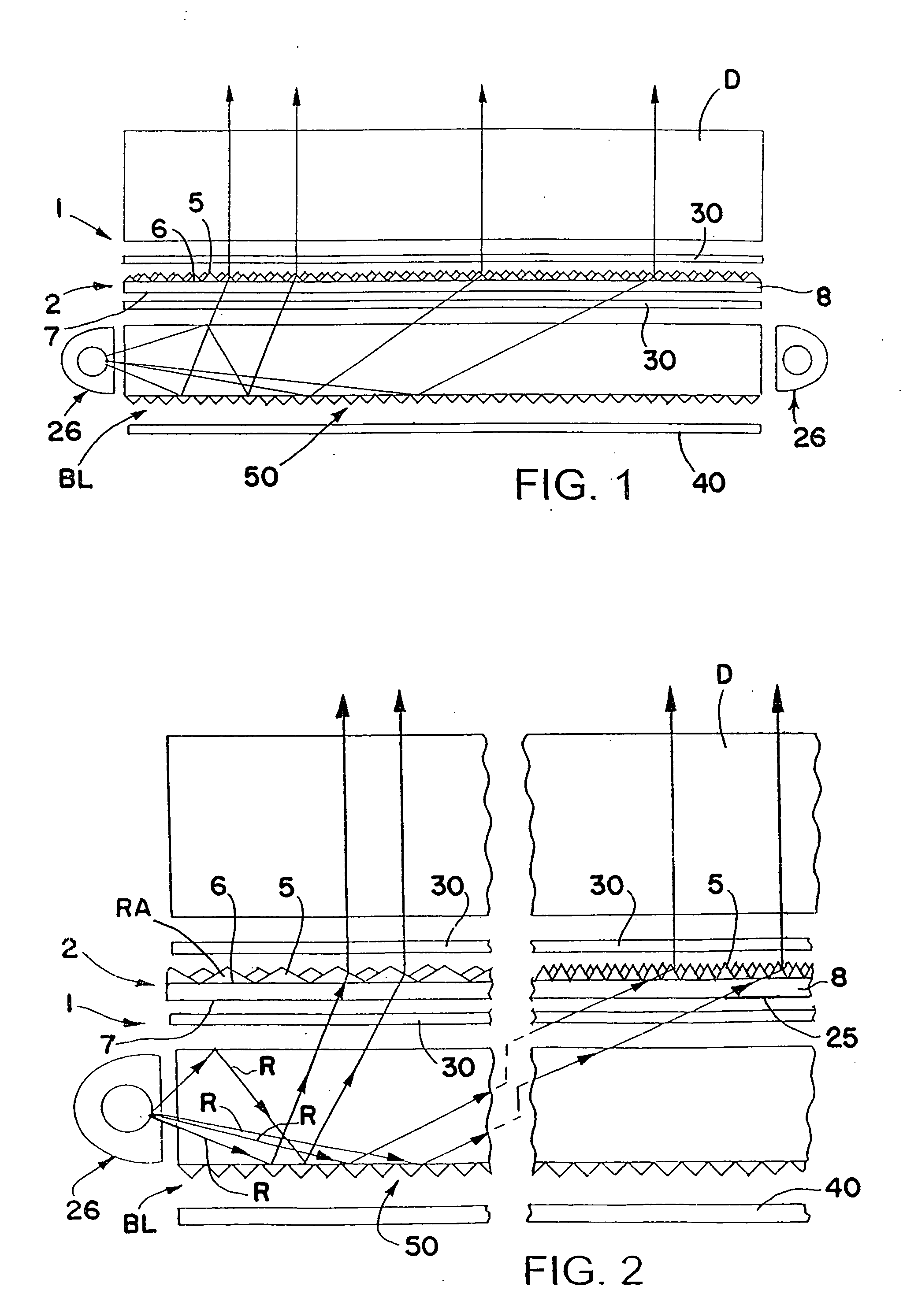

Methods of cutting or forming cavities in a substrate for use in making optical films, components or wave guides

InactiveUS20050024849A1Small in in lengthSmall in widthMechanical apparatusFlat articlesEngineeringRidge

The methods involve using a tool to cut or form multiple optical element shaped cavities in a surface of a substrate without rotating the tool or substrate during the cutting or forming process. At least some of the cavities are cut or formed to have at least two surfaces that come together to form a ridge and that are quite small relative to the length and width of the substrate. Thereafter the substrate is used to form optical films, components or wave guides having multiple optical elements on at least one surface corresponding to the cavities in the substrate.

Owner:SOLID STATE OPTO

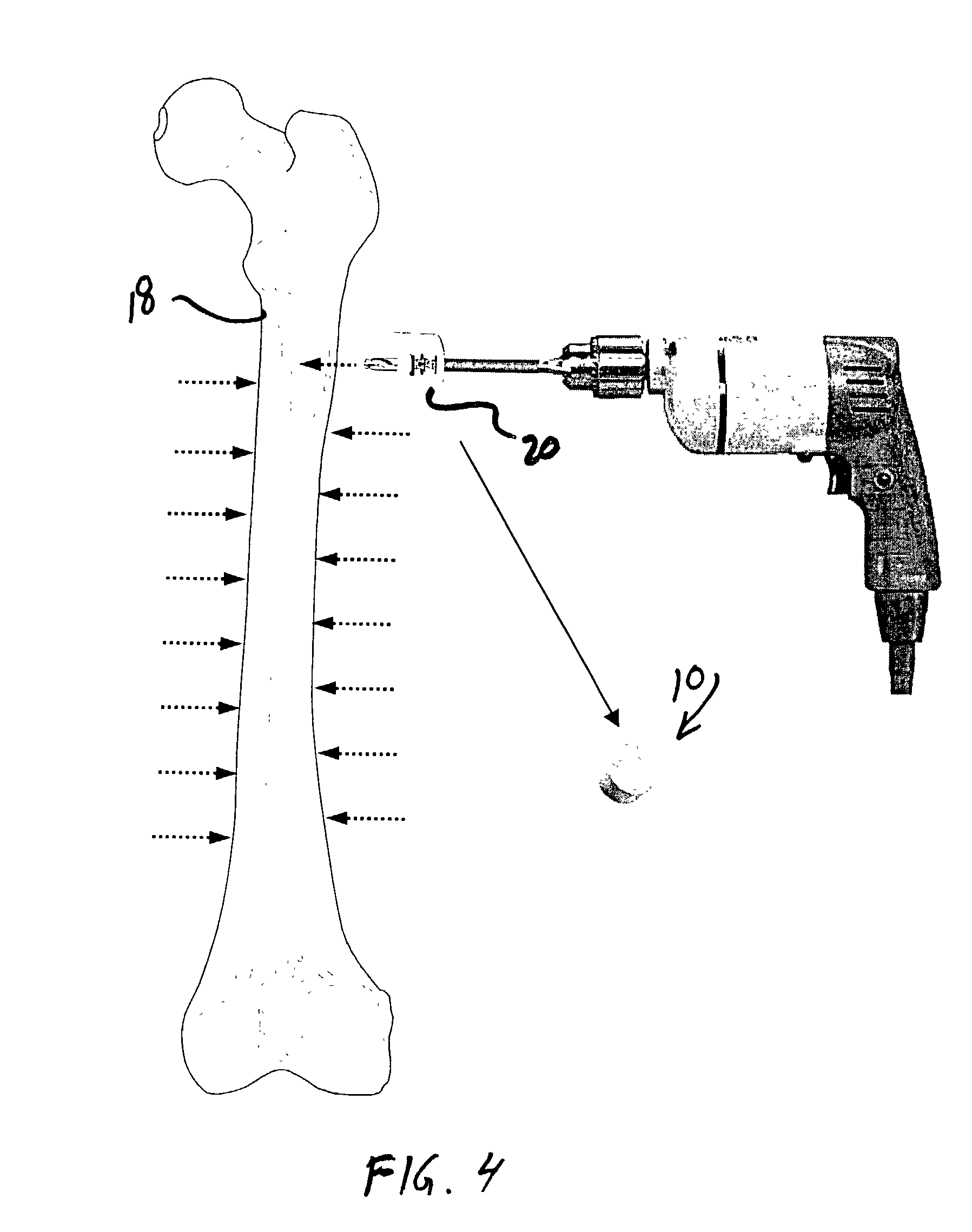

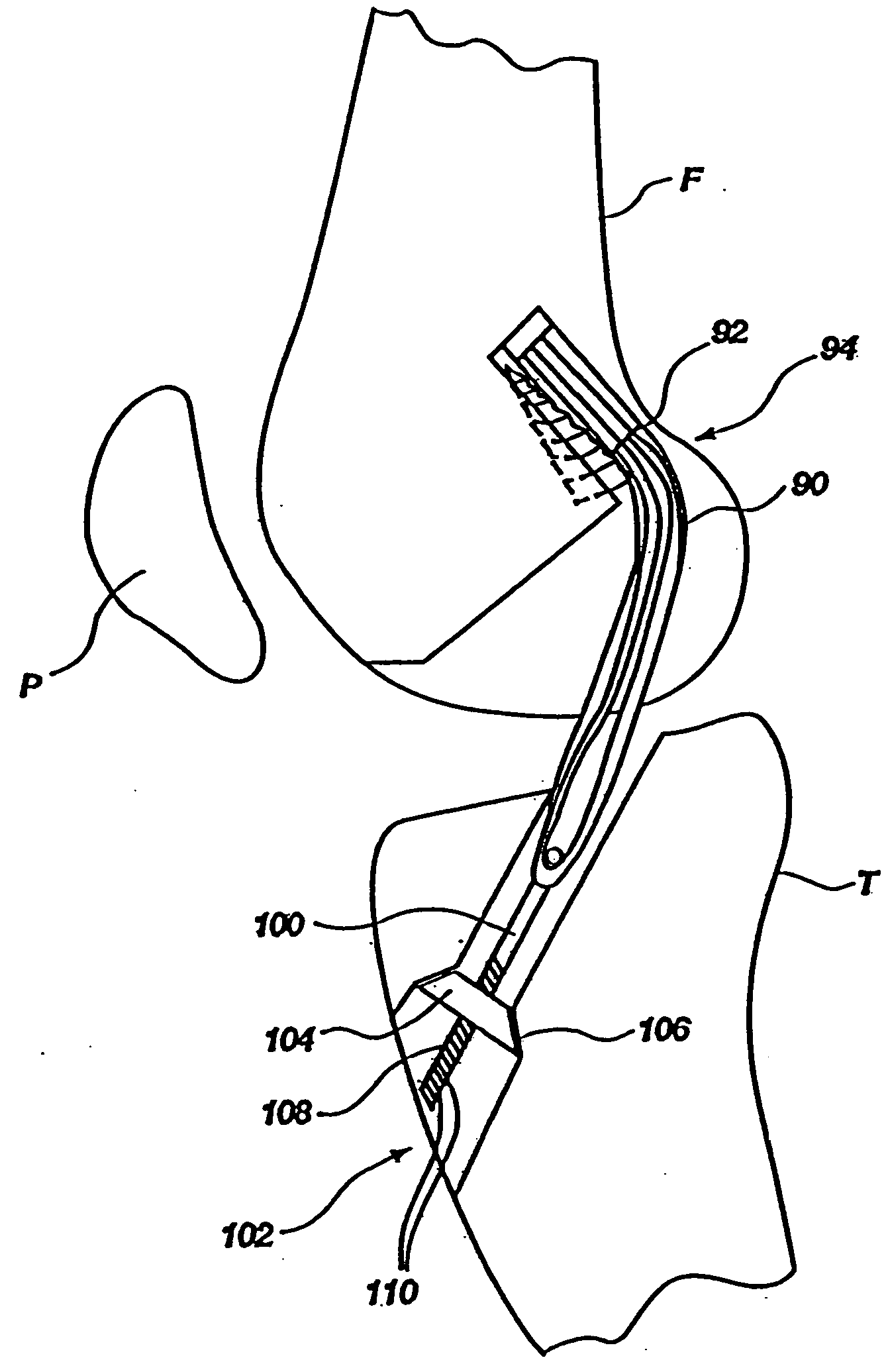

Endosteal tibial ligament fixation with adjustable tensioning

A system for endosteal tibial ligament fixation with adjustable tensioning is disclosed. A grasping hook located on a shaft is used to draw a ligament graft into a contoured drill hole formed in a bone. A series of slanted ridges on the shaft can pass in only one direction through a securing push nut residing in the contoured drill hole, resulting in an interference fit that secures the attachment system, while allowing the tension of the ligament graft to be adjusted.

Owner:CLARK RON +1

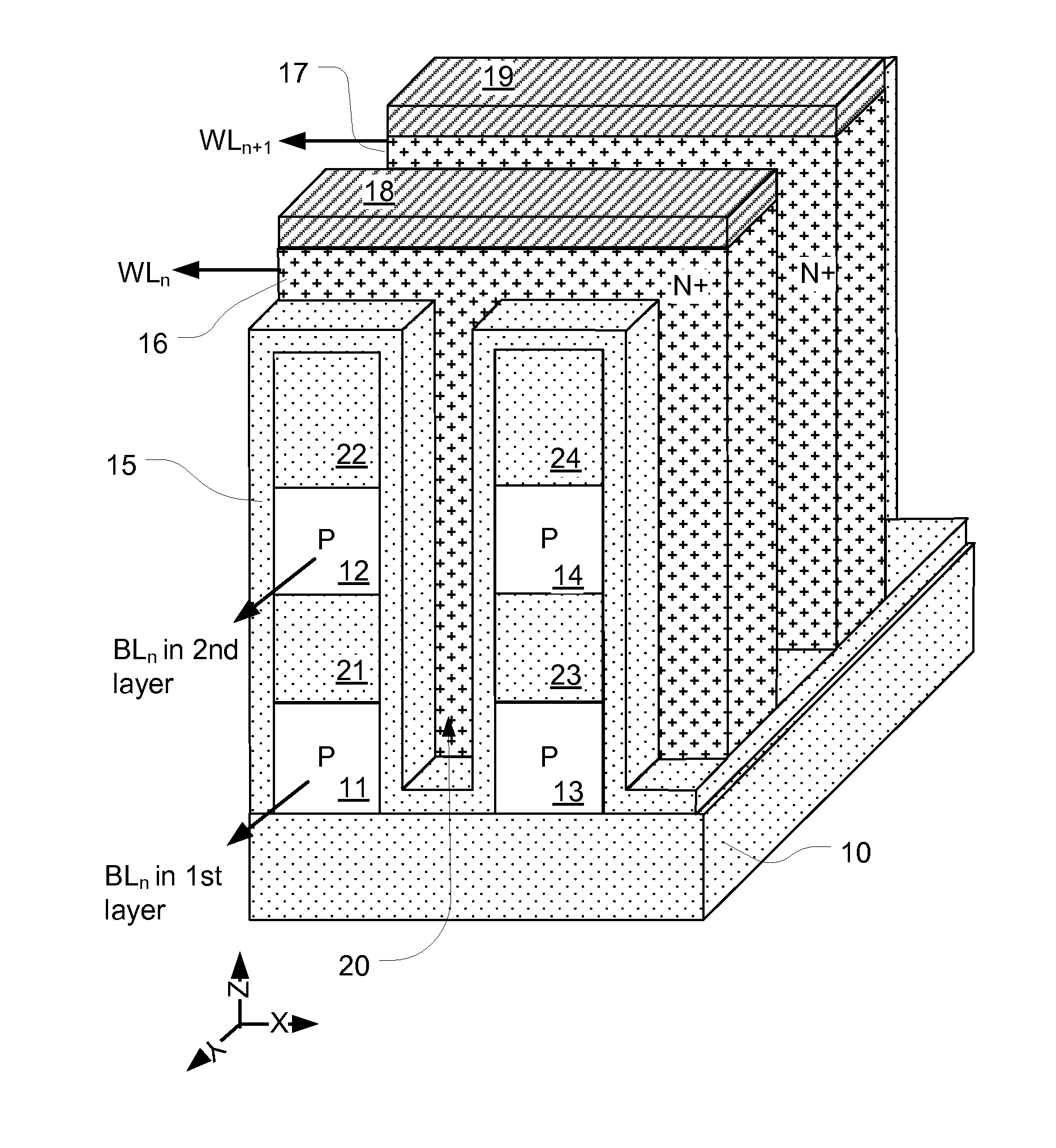

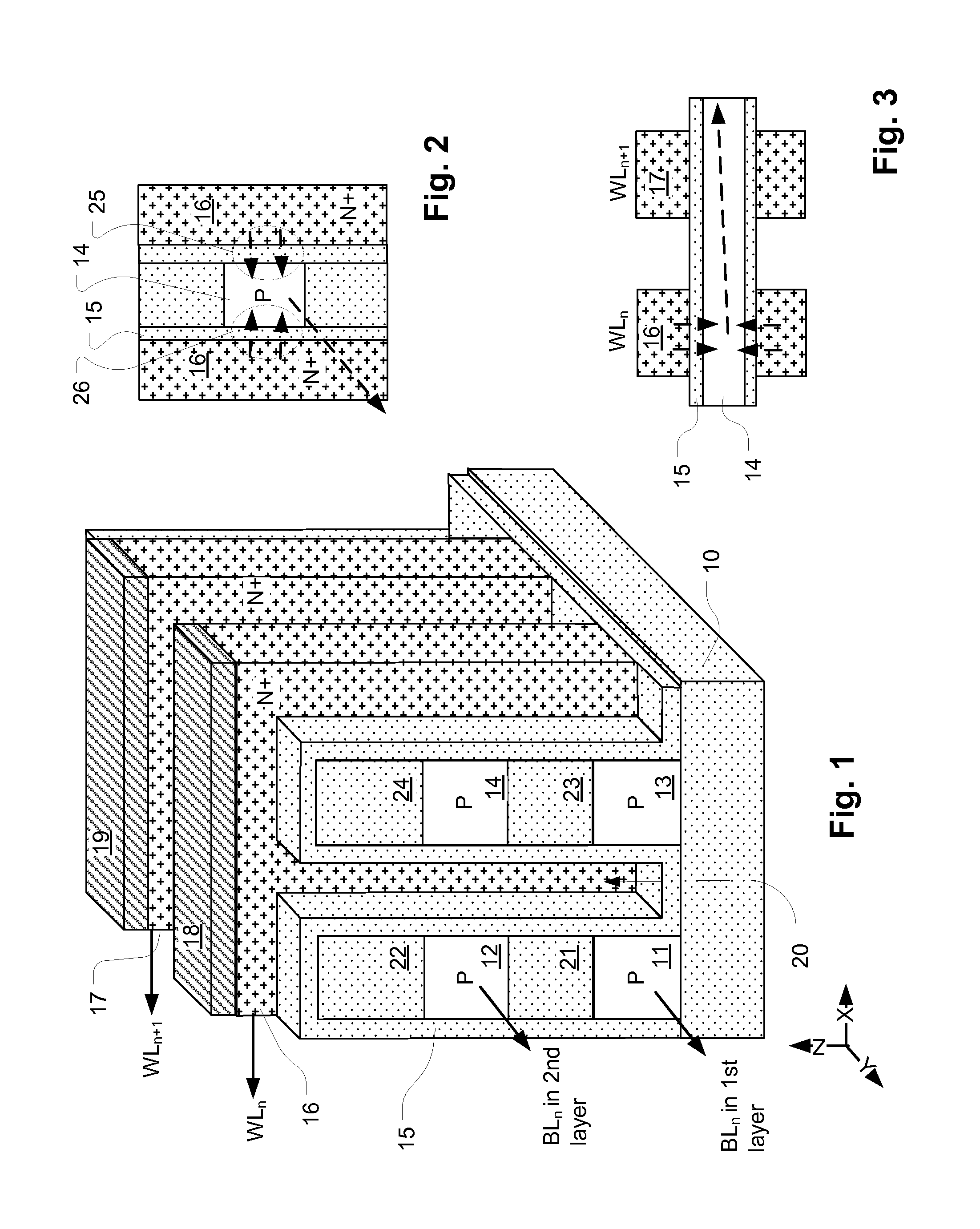

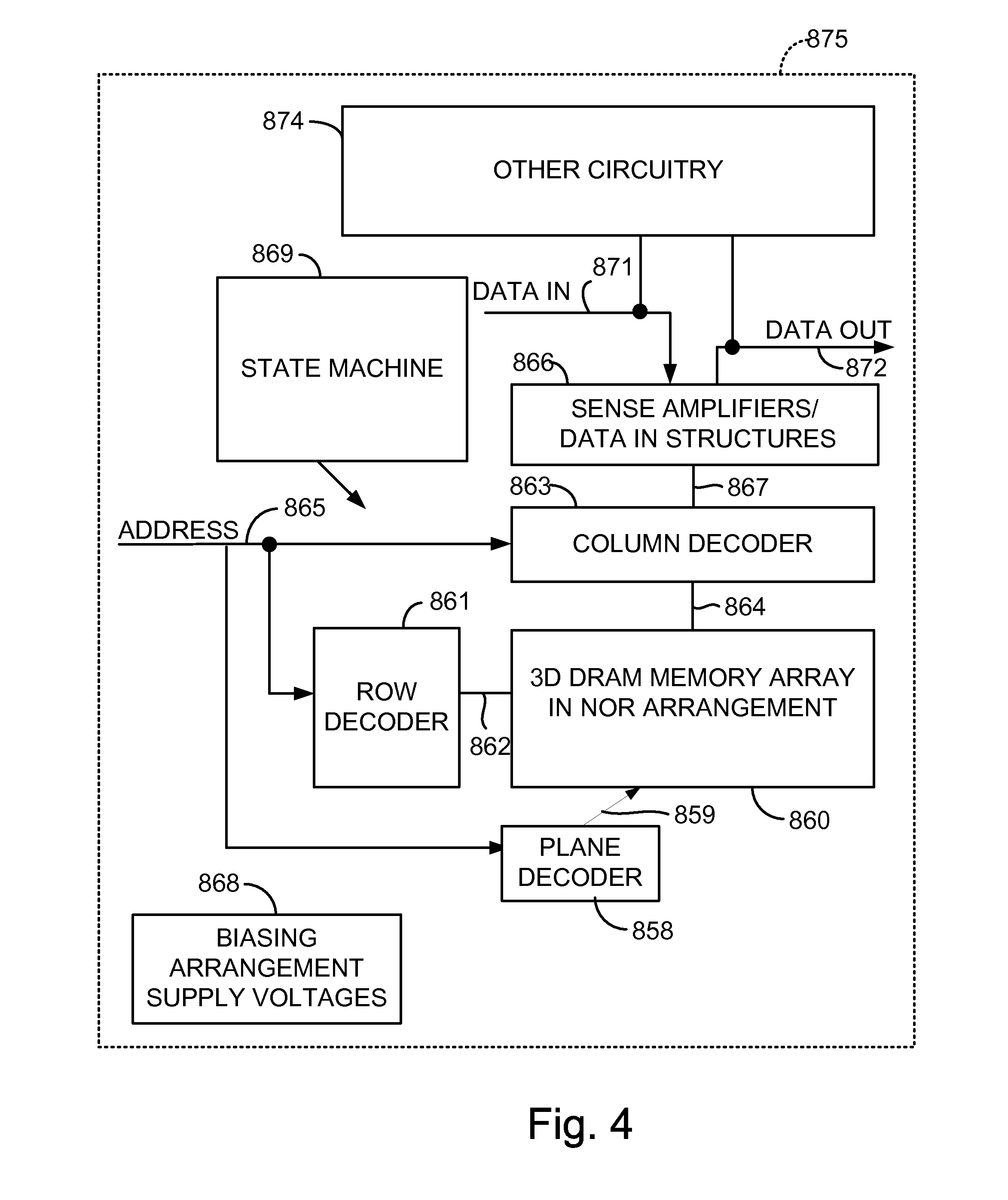

Memory Architecture of 3D NOR Array

A 3D memory device includes a plurality of ridge-shaped stacks of memory cells. Word lines are arranged over the stacks of memory cells. Bit lines structures are coupled to multiple locations along the stacks of memory cells. Source line structures are coupled to multiple locations along each of the semiconductor material strips of the stacks. The bit line structures and the source line structures are between adjacent ones of the word lines.

Owner:MACRONIX INT CO LTD

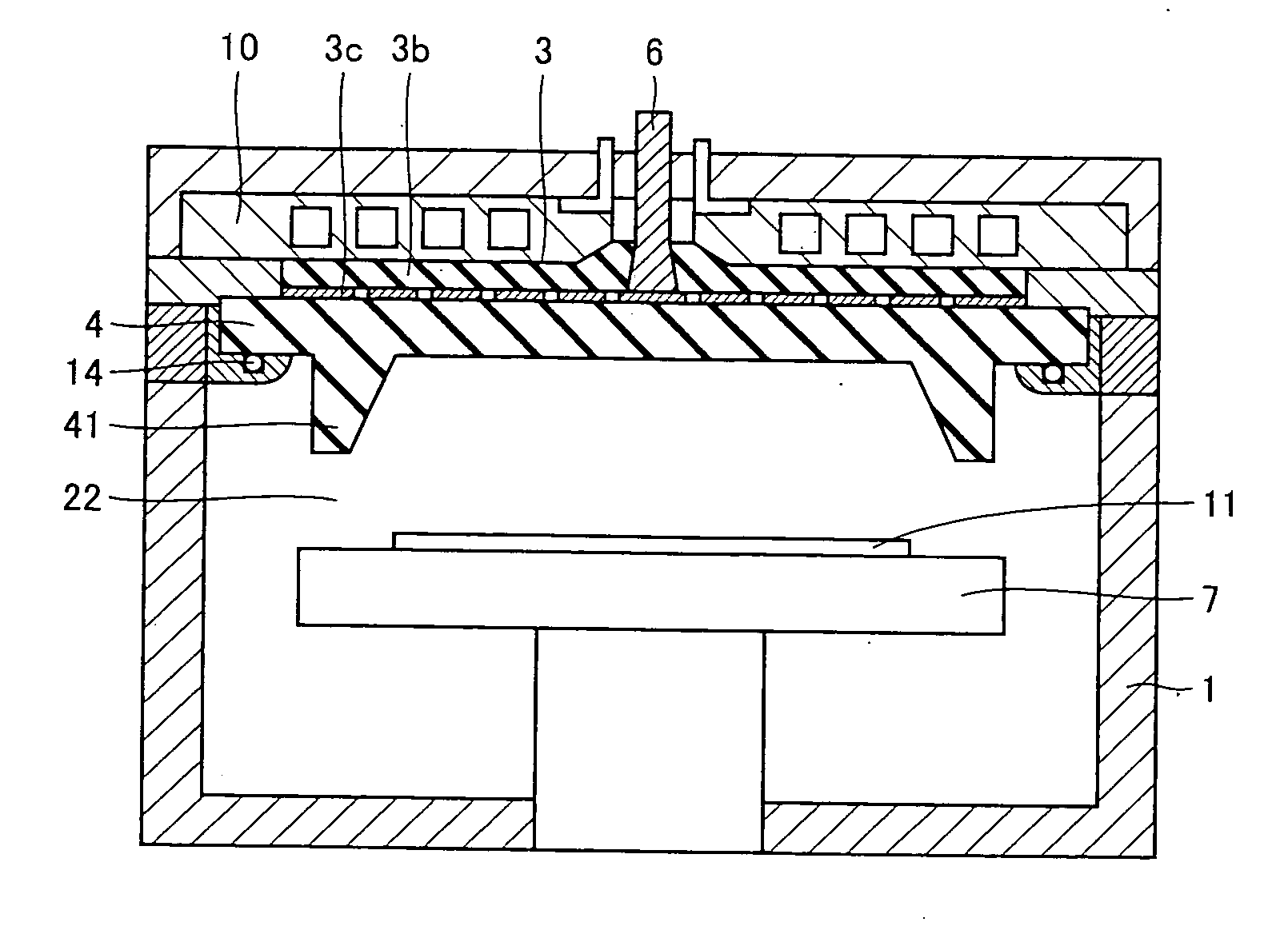

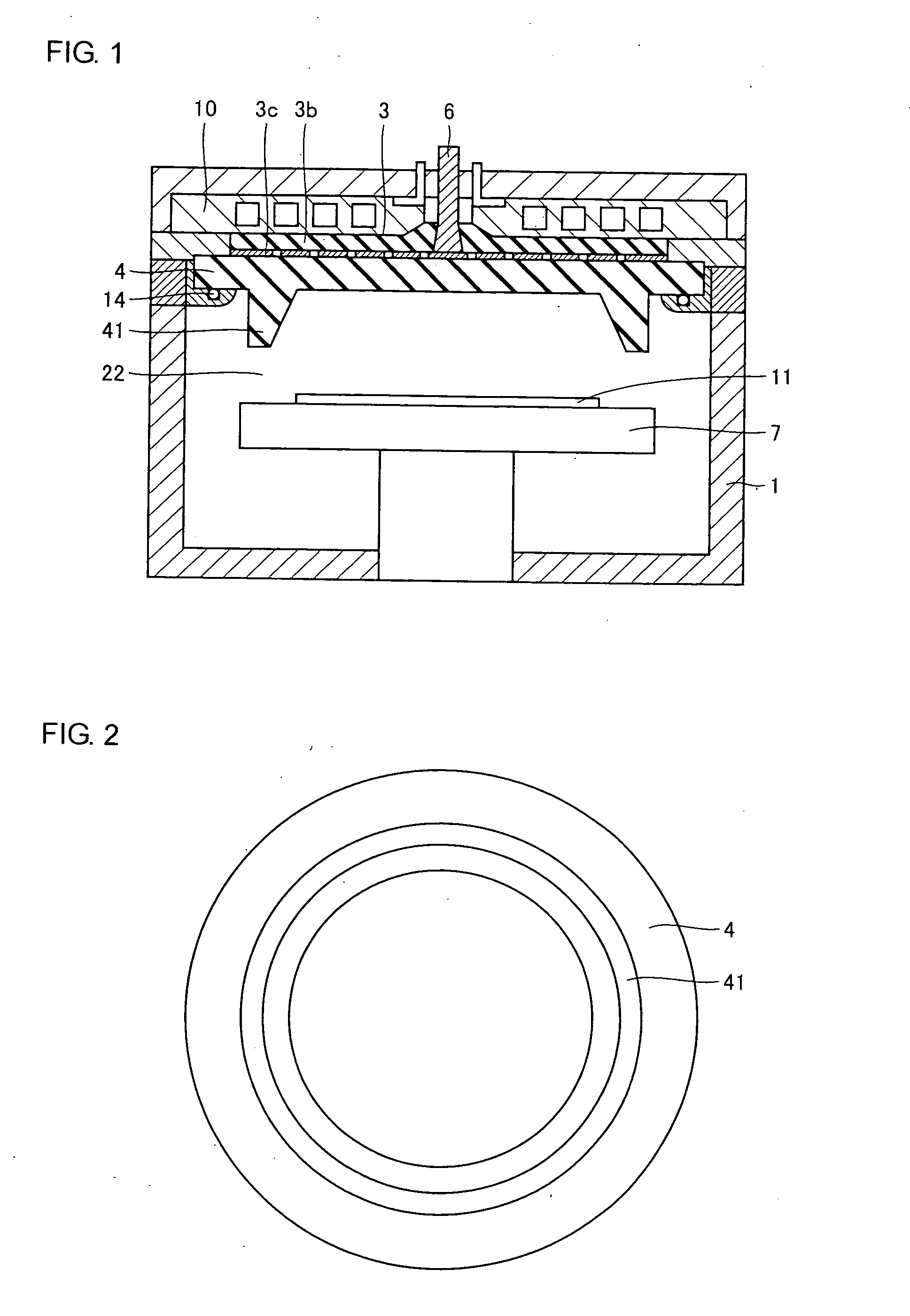

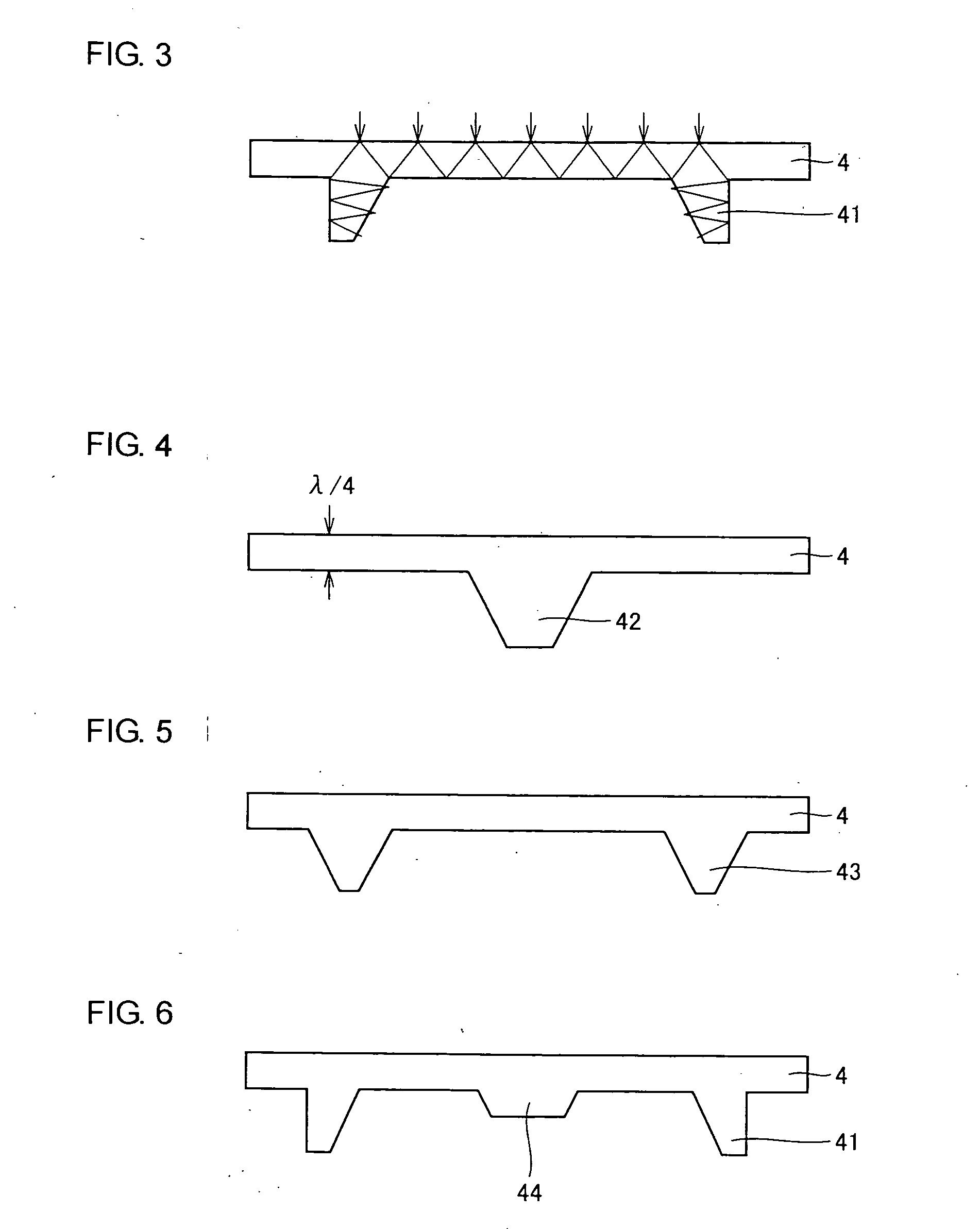

Plasma processing equipment

InactiveUS20070113788A1Region can be greatPromote absorptionElectric discharge tubesSemiconductor/solid-state device manufacturingResonanceEngineering

Resonance can be surely provided under any plasma condition in such a manner that an antenna (3) is arranged in an opening of an upper part of a chamber (1) to produce an electromagnetic field generated by a microwave, a top plate (4) for sealing the opening of the chamber (1) is provided under the antenna (3), a ring-shaped ridge (41) is provided on a lower surface of the top plate (4) such that a thickness thereof in a diameter direction is tapered so as to be varied sequentially. Thus, only one kind of top plate has the same effect as a top plate having various thicknesses, so that absorption efficiency to the plasma can be considerably improved and the plasma can be generated stably over a range from a high pressure to a low pressure.

Owner:TOKYO ELECTRON LTD

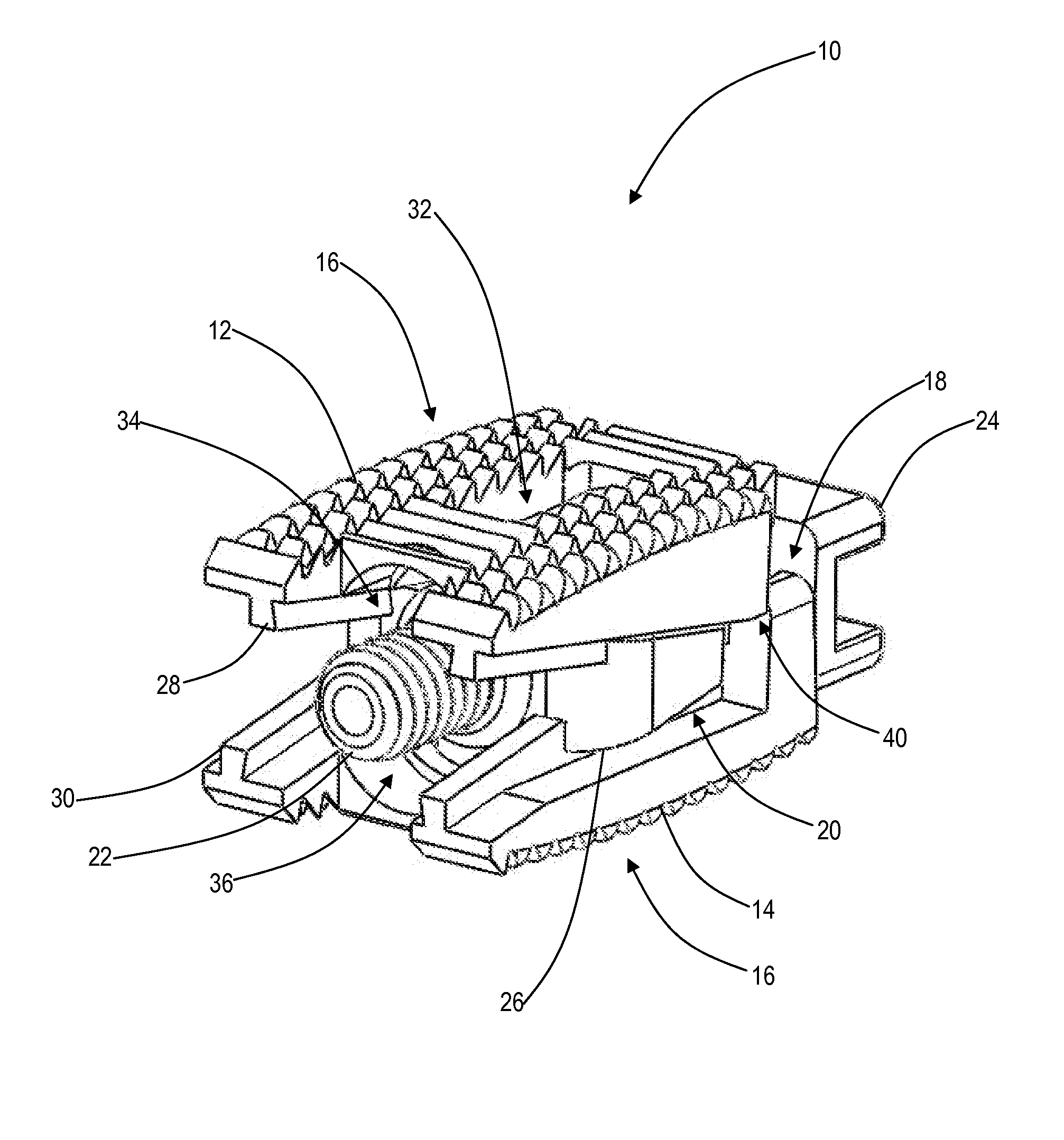

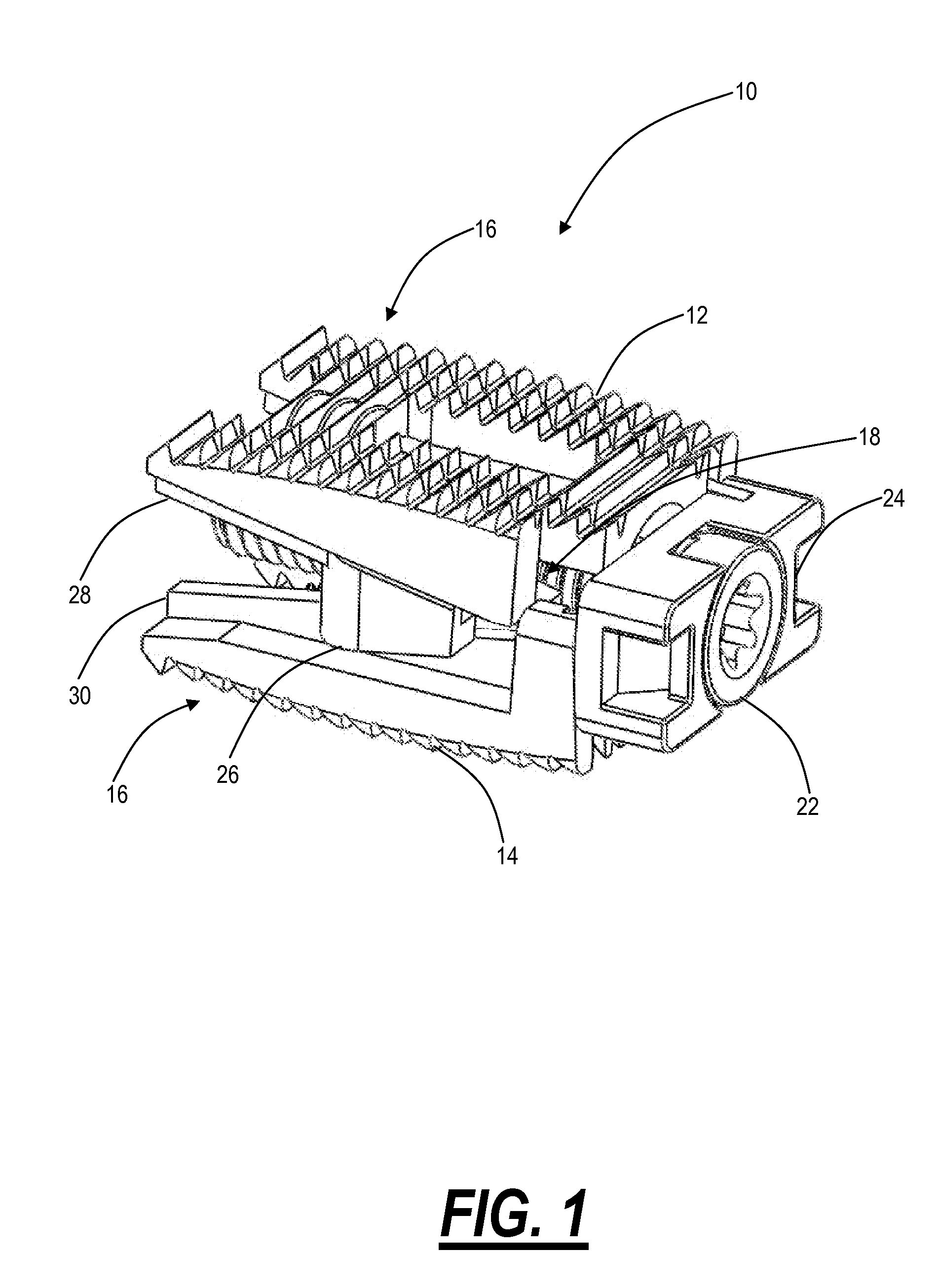

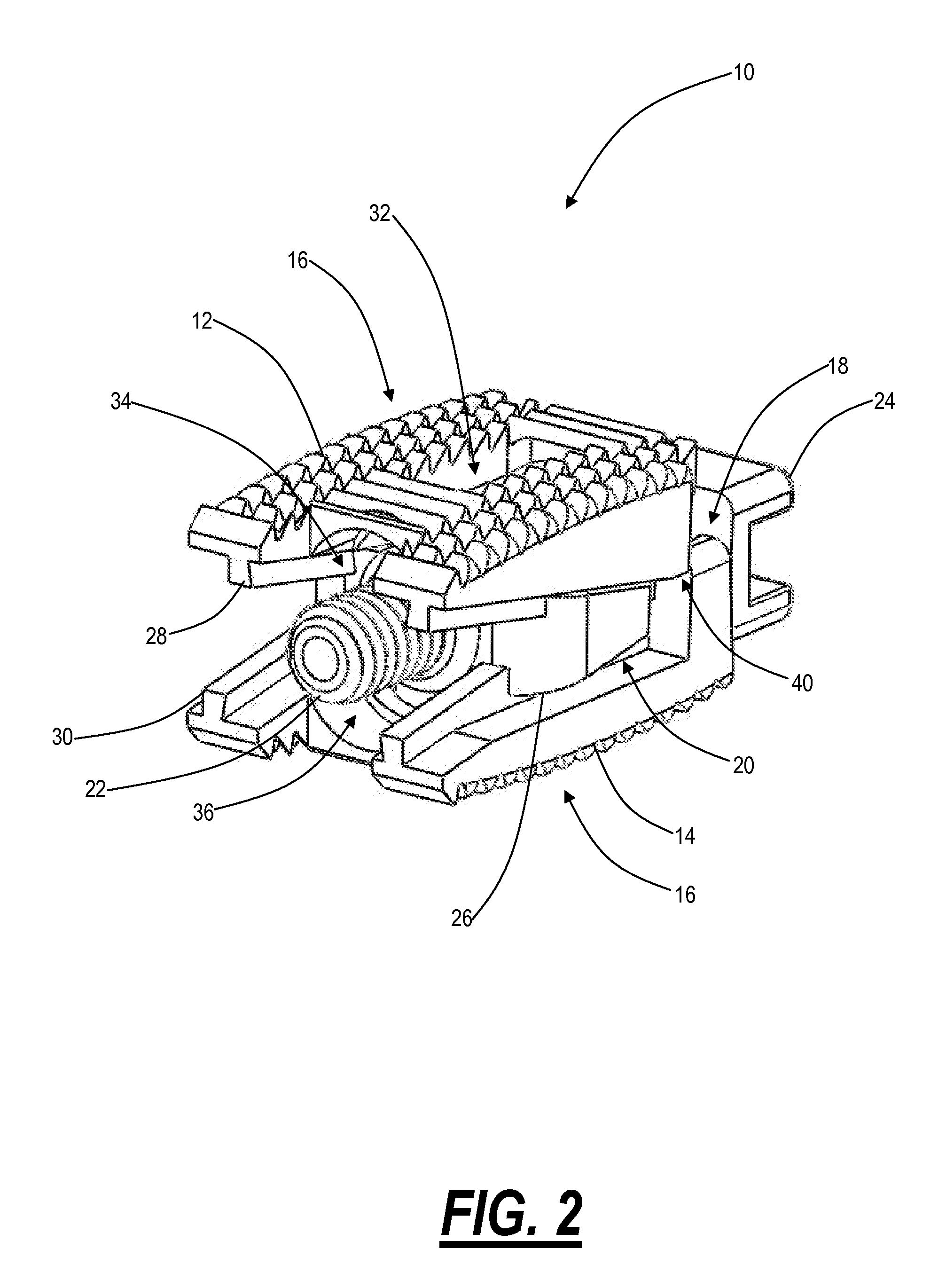

Expandable intervertebral implant and associated surgical method

ActiveUS8795366B2Uniform thicknessSecurely holdJoint implantsSpinal implantsLamina terminalisIntervertebral space

The present invention provides an expandable intervertebral implant that is selectively disposed in the intervertebral space and deployed, thereby in-situ distracting, realigning, and / or stabilizing or fusing a portion of the spine of a patient in the treatment of injury, disease, and / or degenerative condition. The expandable intervertebral implant includes a superior member and an inferior member, each of which has a partially or substantially wedge or prismatic shape and a partially or substantially convex or other-shaped surface that is suitable for engaging the substantially concave surfaces of the associated bony superior and inferior intervertebral endplates. Once disposed in the intervertebral space, the expandable intervertebral implant is actuated and deployed, with the superior member and the inferior member moving apart from one another, seating against the associated intervertebral endplates, and distracting, realigning, and / or stabilizing them to a desired degree. The external surface of each of the superior member and the inferior member is provided with a plurality of ridges or other friction structures, providing purchase with the associated intervertebral endplates.

Owner:INNOVA SPINAL TECH

High volume multiple component projectile assembly

A projectile includes a head, a tail, and an interface that interconnects the head and tail. Multiple sections of the interface are deformed by being compressed radially inwardly into respective annular recesses formed between the interface and the head and tail during manufacturing or by rifling when the projectile is fired. The amount of deformation is controlled by the depth of each of the annular recesses. In all embodiments, annular ridges formed in the head, the tail, or both, define the longitudinal extent of the annular recesses. The interface includes an annular obturation region and has a beveled open leading end to facilitate insertion of the head and tail into the interface.

Owner:LIBERTY OPCO LLC

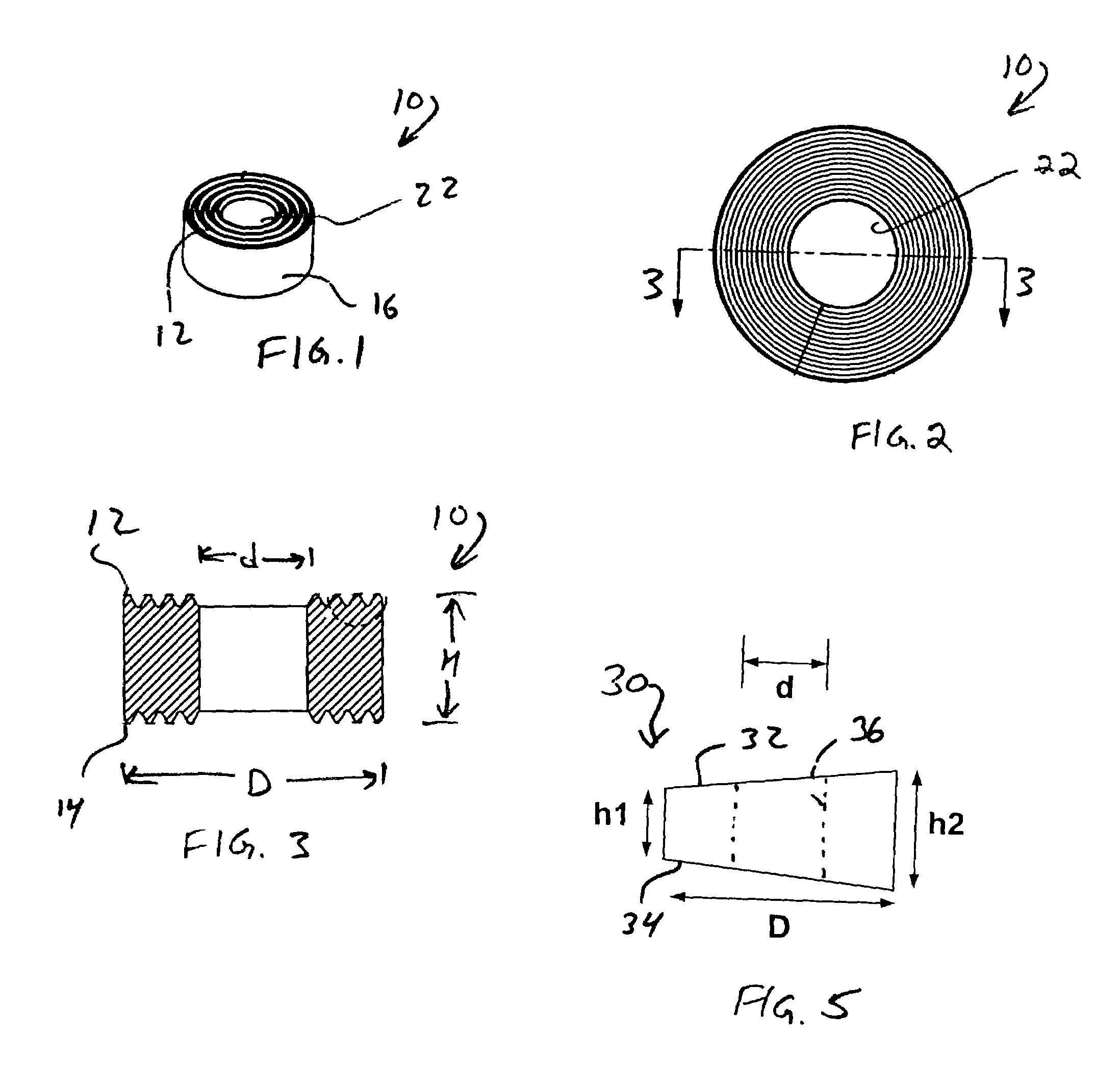

Cartilage repair plug

InactiveUS6632246B1Facilitate cell ingrowthMechanically fixedBone implantDiagnosticsCartilage repairSurgical department

A cartilage plug, which is made from a biocompatible, artificial material, that is used to fill a void in natural cartilage that has been resected due to traumatic injury or chronic disease is disclosed. Alternatively, the plug may be relied upon to anchor a flowable polymer to subchondral bone. The plug is prebricatable in any size, shape, and contour and may be utilized either singly or in a plurality to fill any size void for any application. The plug may be formed of a laminated structure to match the physiological requirements of the repair site. Additionally, ridges may be formed about the periphery of each plug to facilitate its anchoring to surrounding cartilage, bone and / or adjacent plugs. A procedure for resecting damaged or diseased cartilage and for implanting a replacement plug or plugs according to this invention, as well as a set of instruments for effecting the procedure, and a self-contained system for orthopedic surgeons, which includes a variety of differently sized and shaped plugs, as well as a set of instruments for the procedure are also disclosed.< / PTEXT>

Owner:ABS

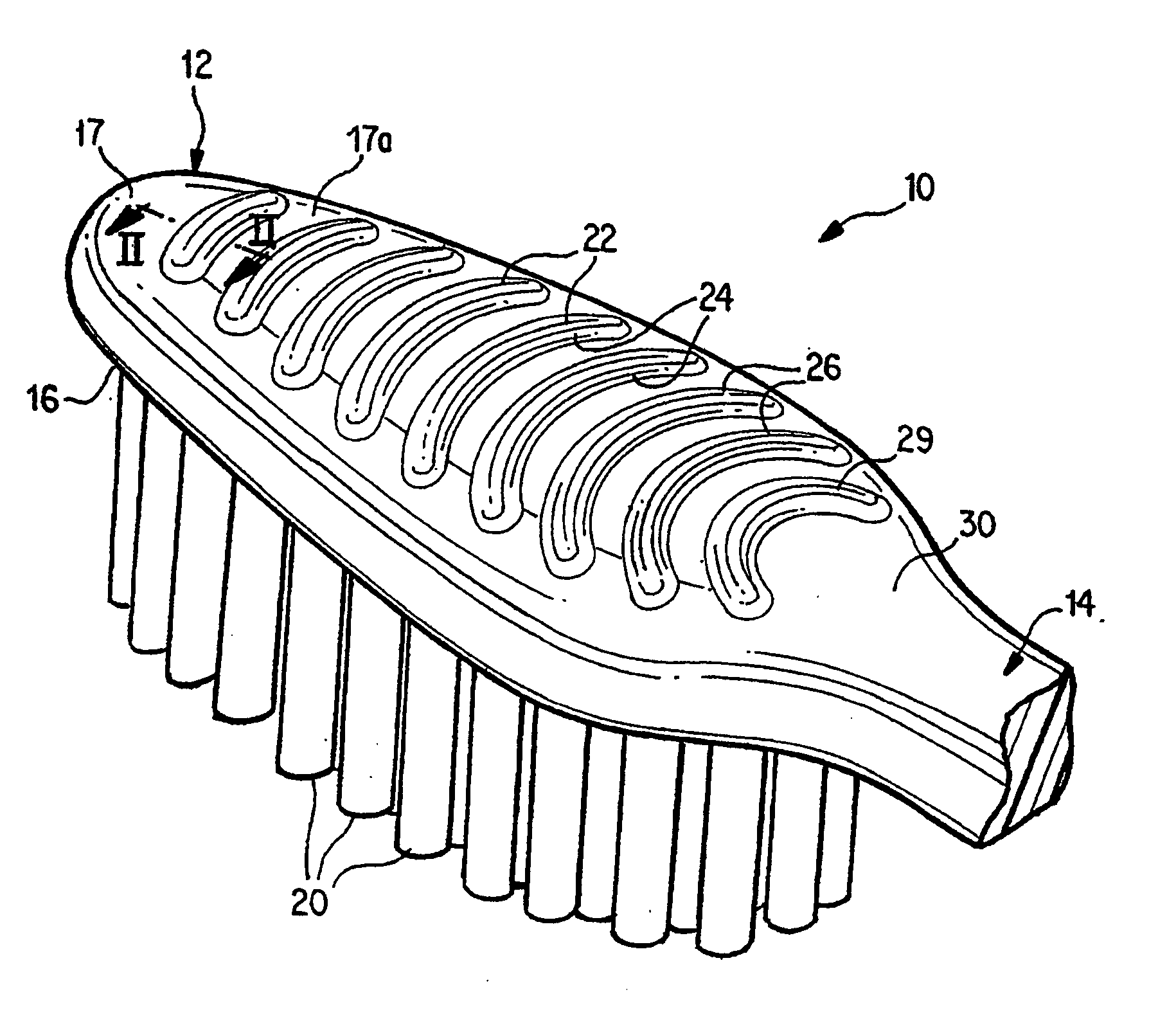

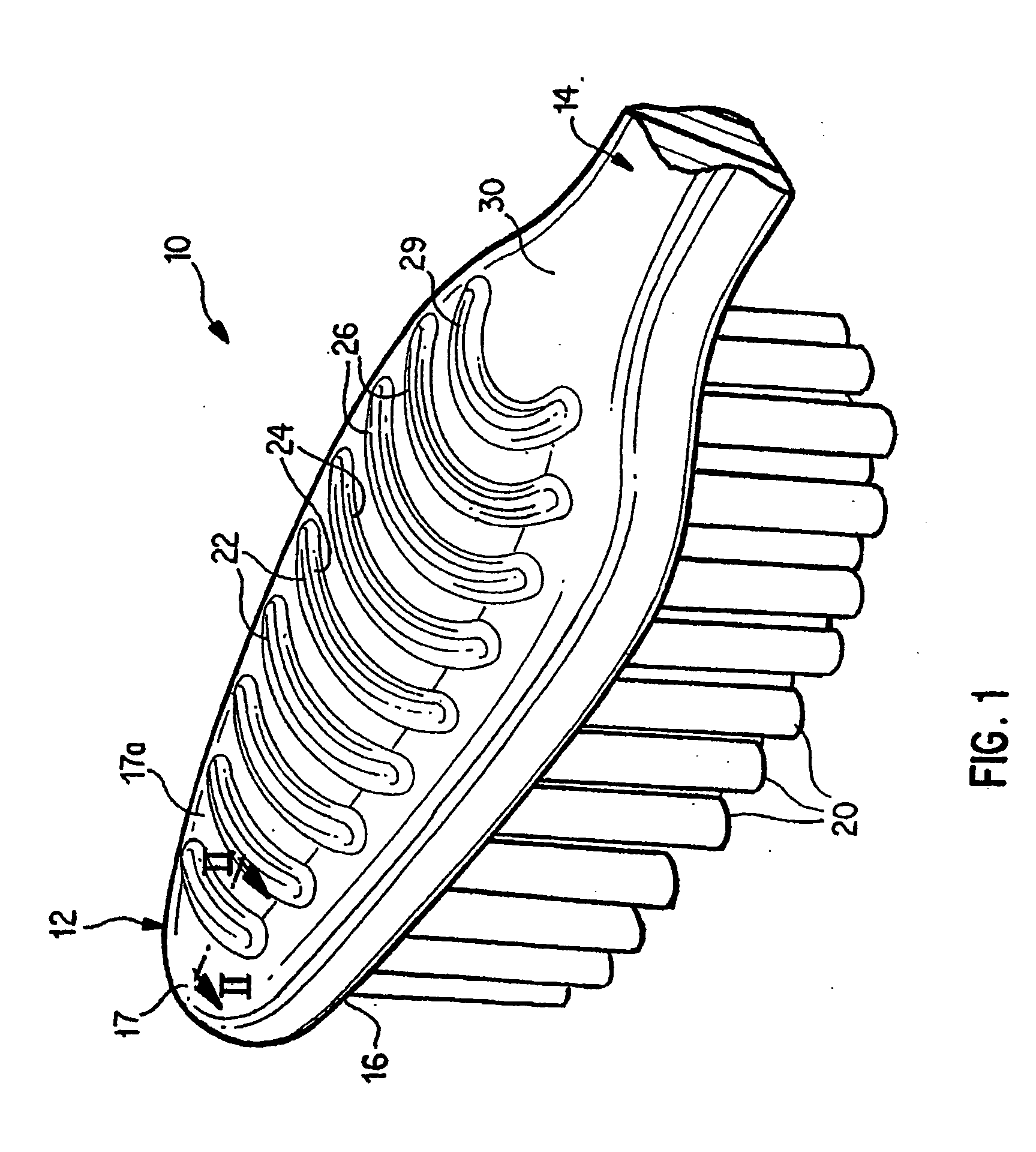

Oral care implement

ActiveUS20060010628A1Easy to cleanEfficient removalEar treatmentCarpet cleanersCleansers skinMouth care

An oral care implement including a handle and a head with a tongue cleanser. The tongue cleanser has at least one ridge which is at least as wide as it is high. In one preferred construction, the ridges are shaped so as to define a concave surface facing generally toward the handle. The ridges also preferably include aligned segments from front to back that are oriented at different angular positions.

Owner:COLGATE PALMOLIVE CO

Tissue spreading vascular clips with locking mechanism and non-slip clamping surfaces

A surgical clip includes a pair of opposed arms joined at one end by an integrally formed flexible hinge and a hinge lock. A male head element near the free end of one arm is configured to spread tissue when the male head element is urged towards a head mating element near the end of the opposite arm. The clamping side of an arm may include a protruding feature, such as a wedge shape elongated ridge, while the clamping side of the opposite arm includes a corresponding trough or aperture that receives the protruding feature. Clamping surfaces may include non-slip protrusions, such as ribs, ridges, cones or pins. An applicator holding feature, such as a boss, near the hinge prevents the clip from yawing and becoming askew during application.

Owner:TYCO HEALTHCARE GRP LP

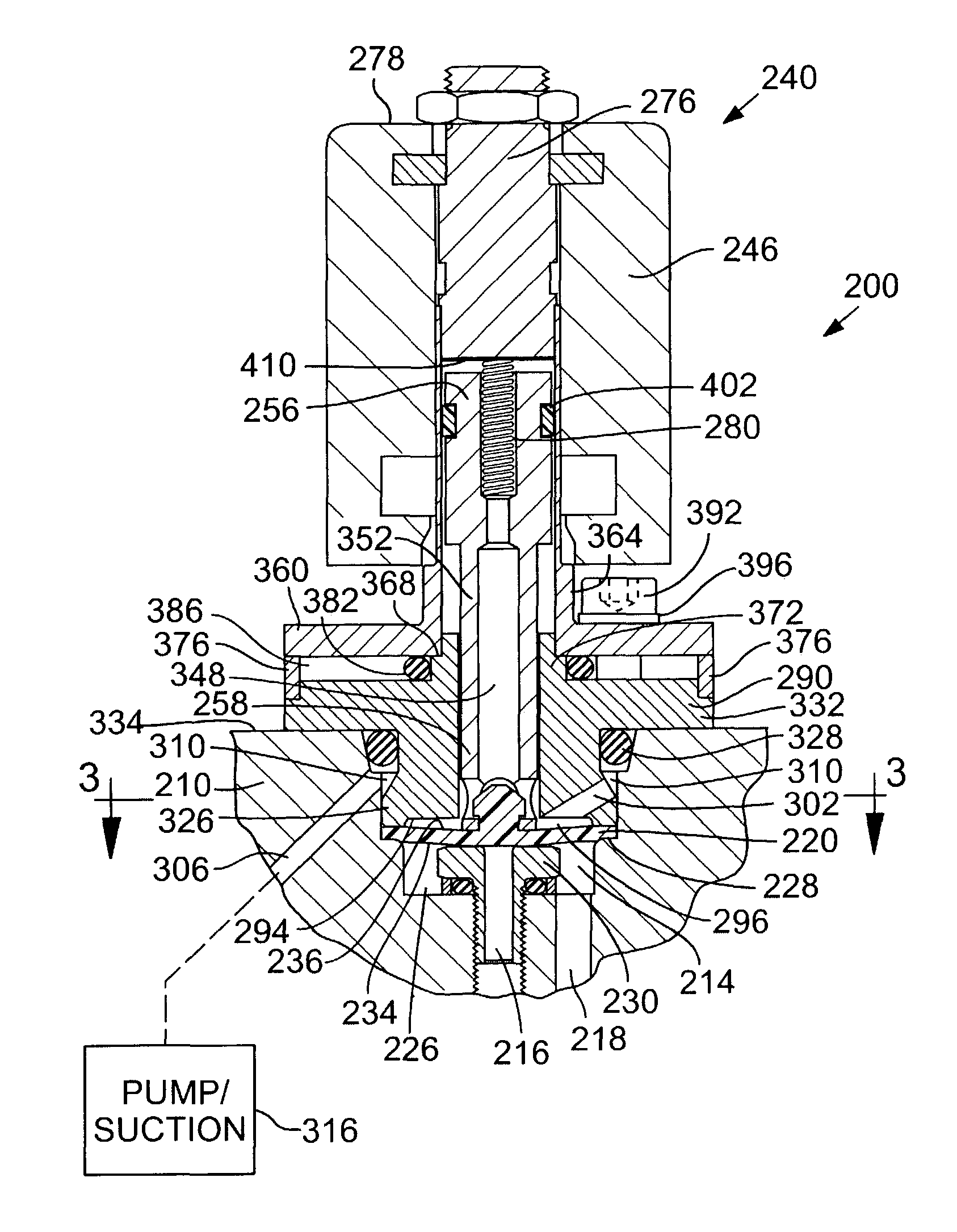

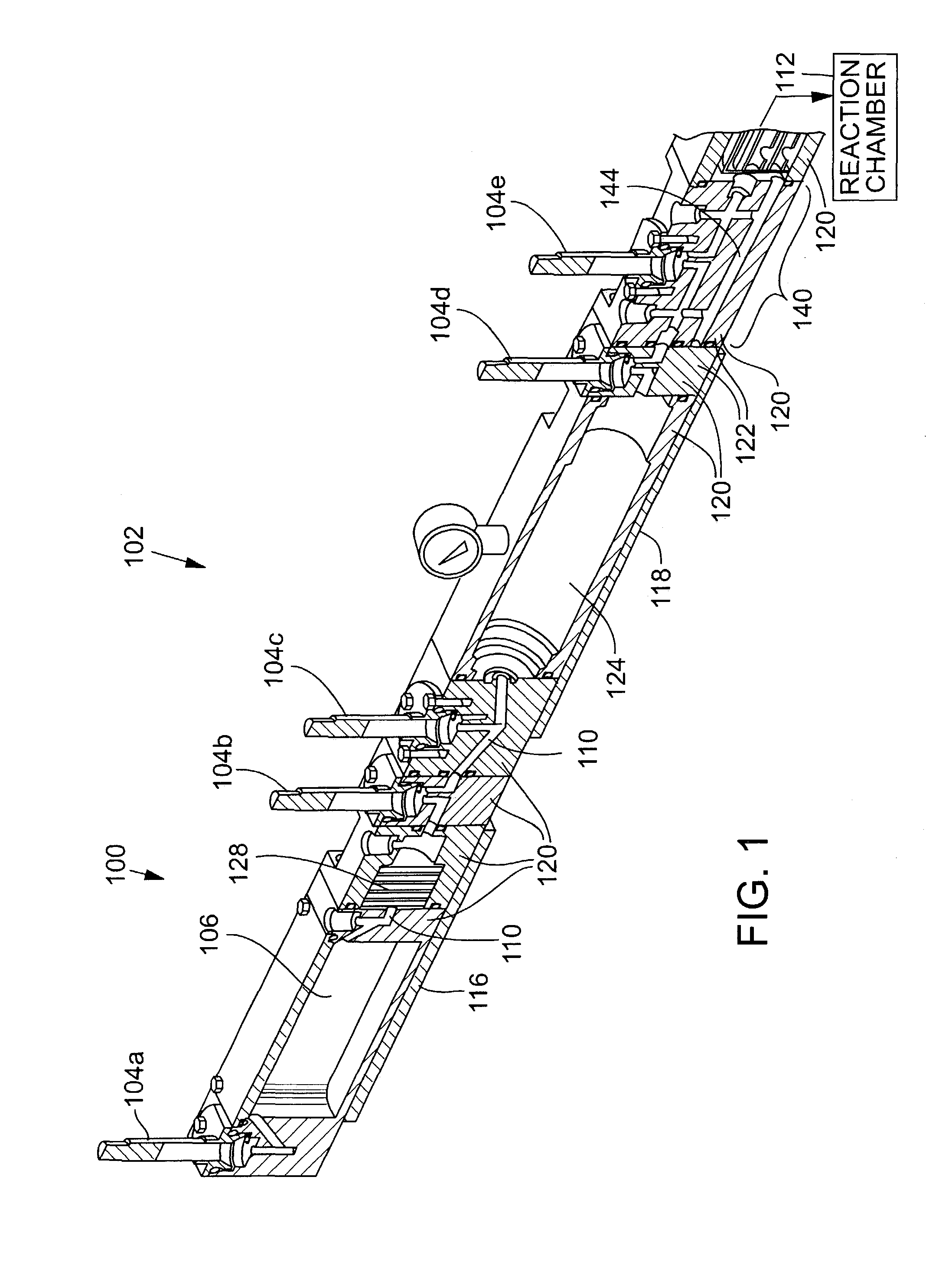

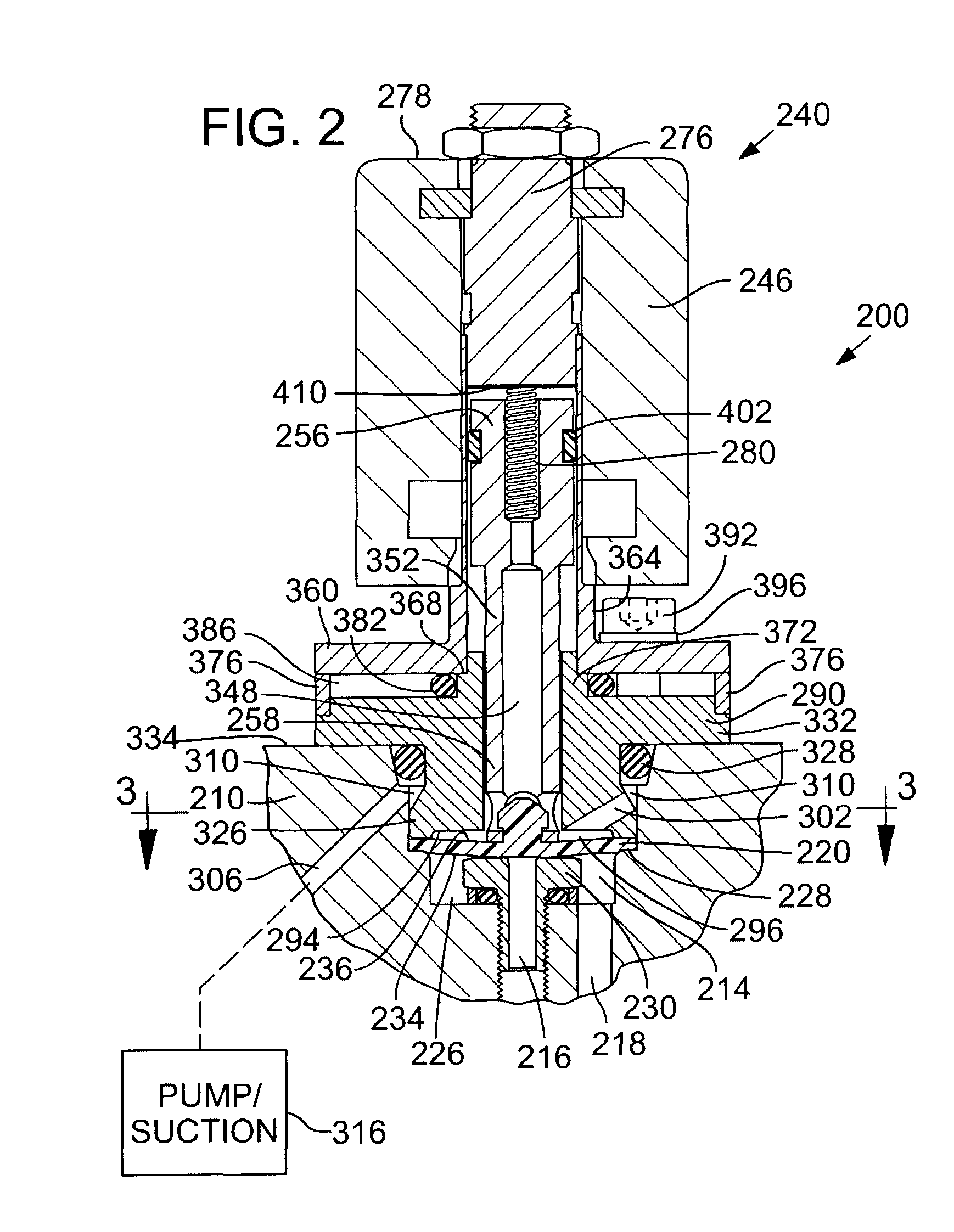

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

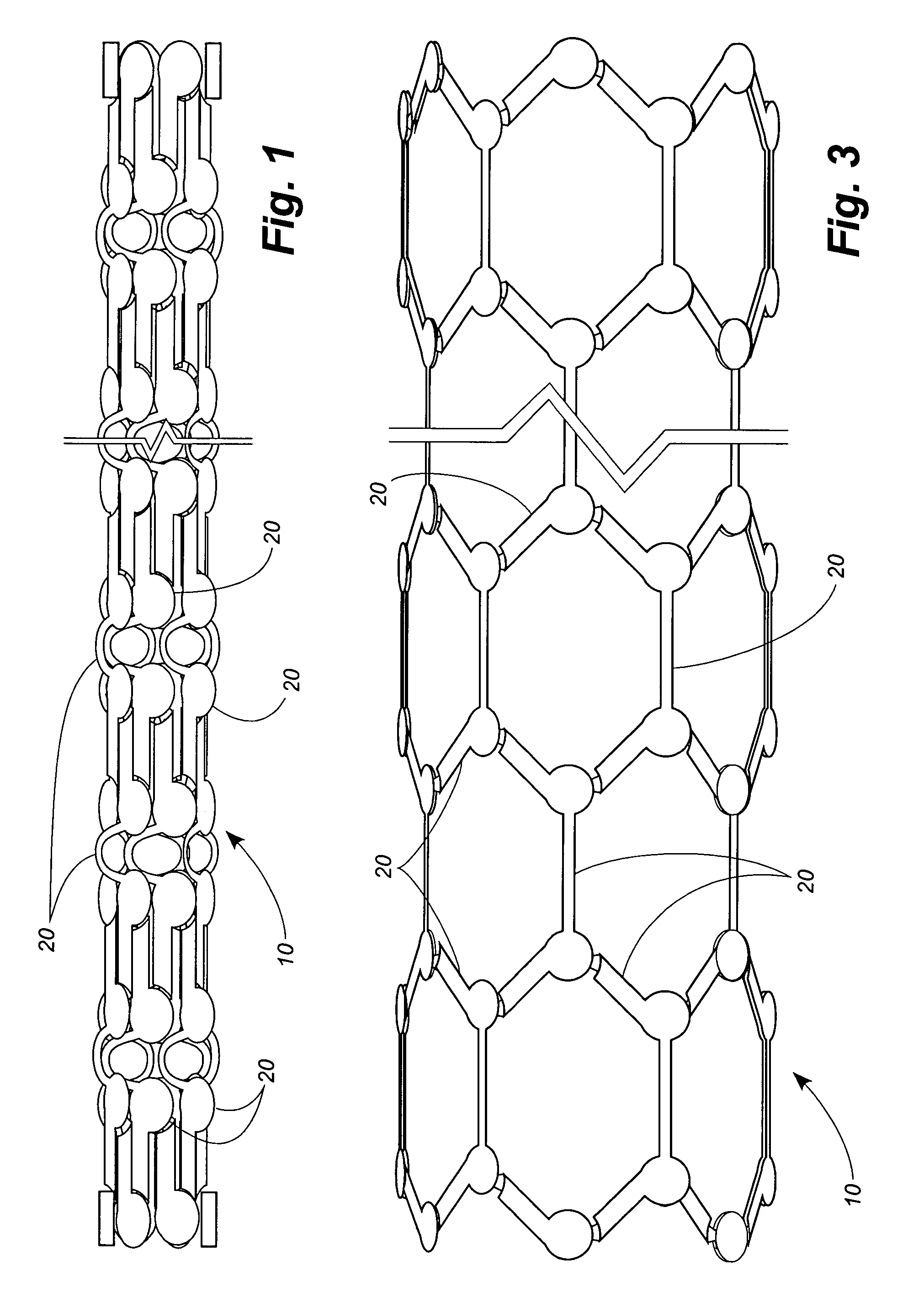

Stent with micro-latching hinge joints

A stent is constructed using interconnected links having micro-mechanical latching mechanisms. The micro-mechanical latching elements allow relative rotational movement of interconnected links in one rotational direction but restrict relative rotational movement of the two links in the opposite direction. The micro-mechanical latch surface features are formed using microelectronic mechanical systems (MEMS) manufacturing methods. The male surface of the latching components contains an array of ridges or protrusions, and the receiving surface contains a matching array of recesses. The array of ridges or protrusions and the corresponding recesses have uniformly dissimilar slopes that result in a substantially greater frictional force in one direction than in the opposite direction. The separation distance between the two surfaces is such that the male latch surface is engaged with the receiving surface recesses in the low stress “locked” state, preventing motion in the undesired direction. Each male ridge or protrusion can be underlined by a void that promotes elastic deflection when sliding in the desired direction and recovery into the ‘locked’ state when aligned with the recesses.

Owner:MIRUS LLC

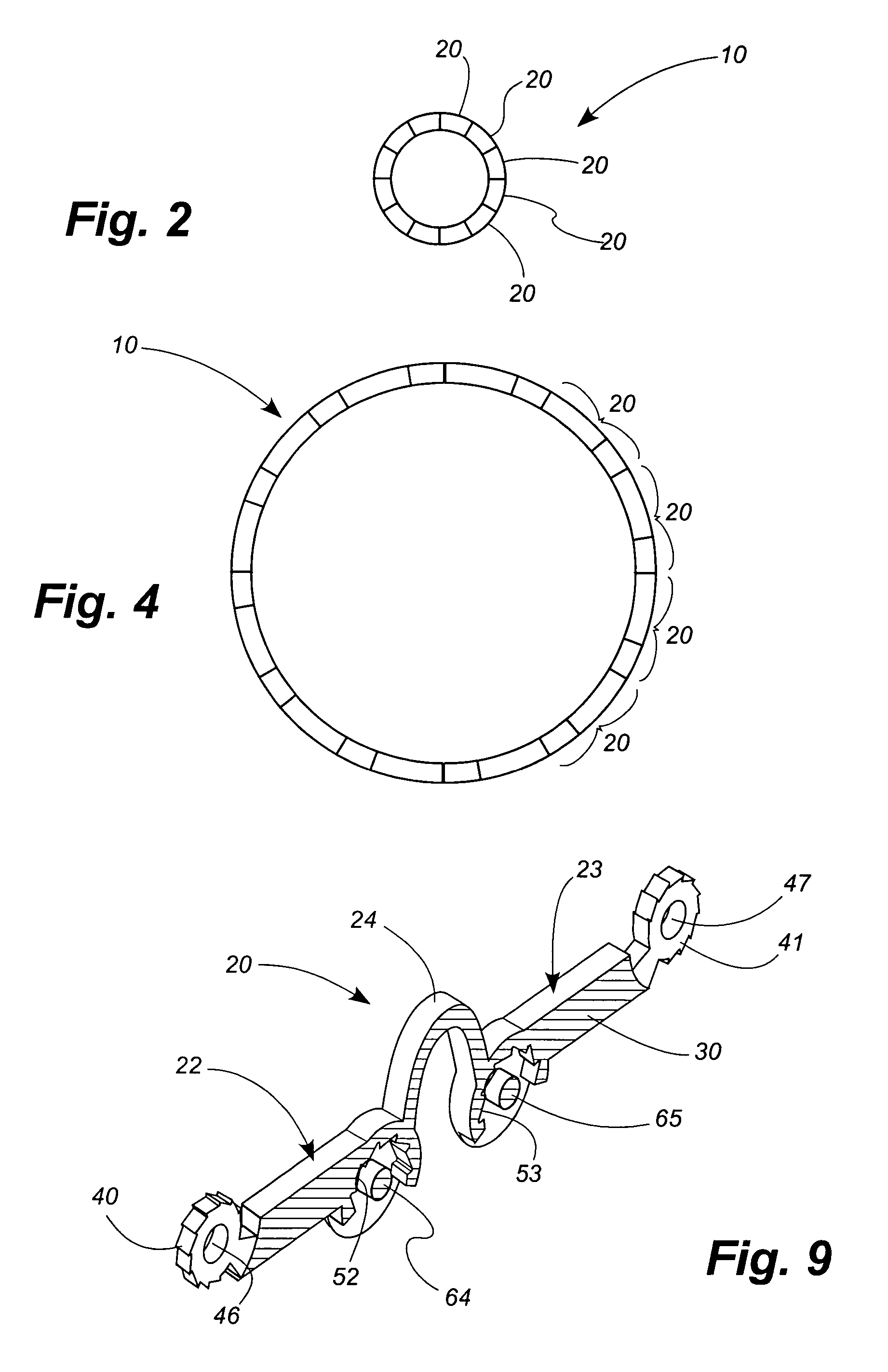

Method for diagnosing heart disease, predicting sudden death, and analyzing treatment response using multifractal analysis

InactiveUS6993377B2Reducing minimum sizeIncreased analytic detailMedical simulationMedical report generationTest batterySudden death

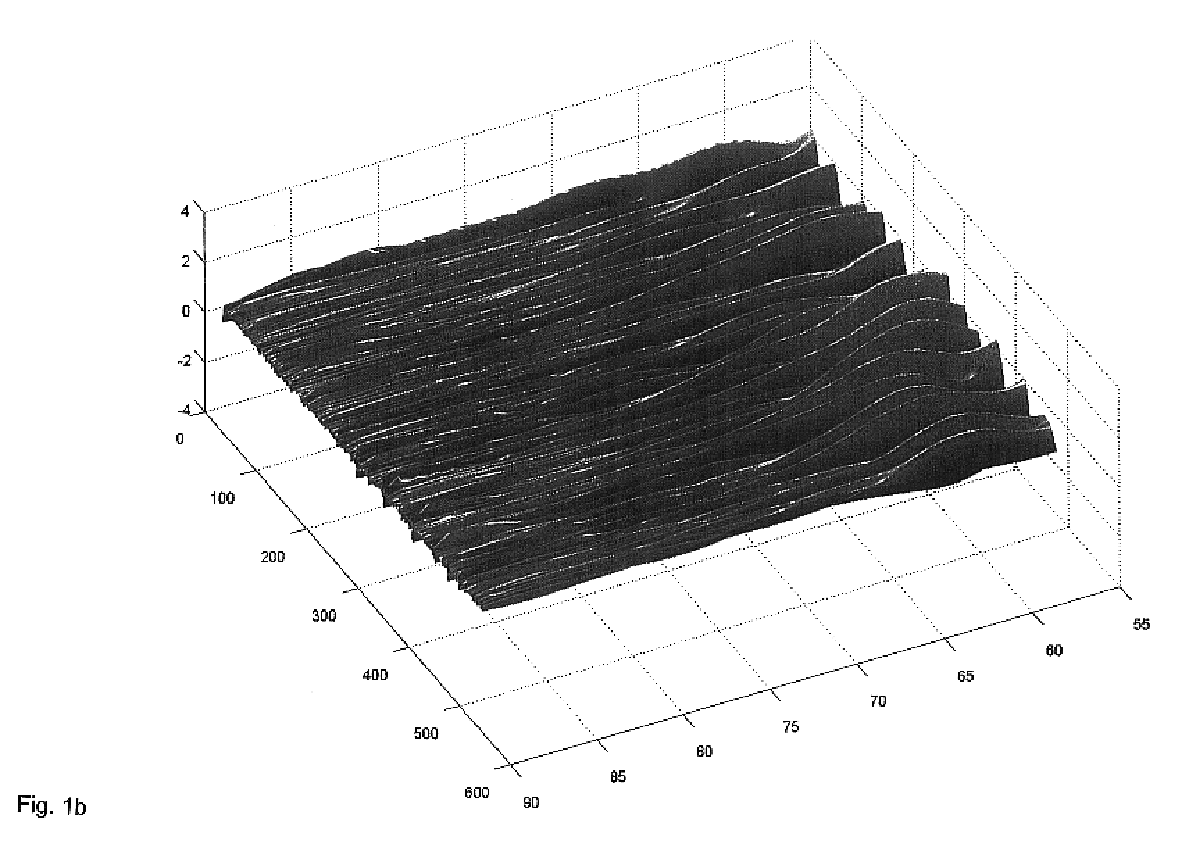

A method of analyzing electrocardiogram (EKG) data for use in the diagnosis of heart disease, prognosis of cardiac conditions, and the monitoring of heart disease therapies is disclosed. The method utilizes a wavelet-based multifractal analysis with one or more of (1) a discrete wavelet smoothing step to remove the effects of abnormal beats; (2) “Levy flight” analysis to detect the frequency of abnormal beats known to adversely affect the multifractal (MF) analysis; and (3) MF alpha analysis, a multifractal extension of monofractal short term (ST) alpha analysis. The invention further comprises an EKG test battery comprising Levy flight anomalous beat / beat cluster screening, followed by (ST) MF alpha analysis and MF Holder analysis (when validated by the Levy flight analysis). The wavelet smoothing step can also be used to classify human EKGs by observing the effect of sequential smoothing on the MF Holder coefficient. Alternative choices to the wavelet smoothing approach to removal of abnormal beat effects include probability distribution function analysis to determine the MF Holder coefficient directly, abnormal beat ridge skeleton removal to remove the offending beats based on a direct multifractal spectrum calculation, and the calculation of various types of entropy coefficients for the EKG time series.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com