Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Rifling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In firearms, rifling refers to the helical groovings that are machined into the internal (bore) surface of a gun's barrel, for the purpose of exerting torque and thus imparting a spin to a projectile around its longitudinal axis during shooting. This spin serves to gyroscopically stabilize the projectile by conservation of angular momentum, improving its aerodynamic stability and accuracy over smoothbore designs.

Muzzle flash suppressor

A flash suppressor of the open prong type having a twist in its structure formed of alternating grooves and flutes or prongs provides a highly effective flash suppression for small and medium caliber weapons and especially for automatic weapons and machine guns when placed on the end of their barrels. The orientation of the direction of the twist of the structure is in a direction opposite to the direction of the rifling in its firearm barrel. Various objective laboratory tests and subjective user evaluation on its performance prove out its effectiveness in terms of mitigating visible flash on shorten machine gun barrels as well as standard full length barrels used in critical helicopter black out operations using night vision equipment. In addition, precise aiming of a weapon equipped with the inventive flash suppressor exhibits lower dispersion of actual projectile impact compared to conventional flash suppressors.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

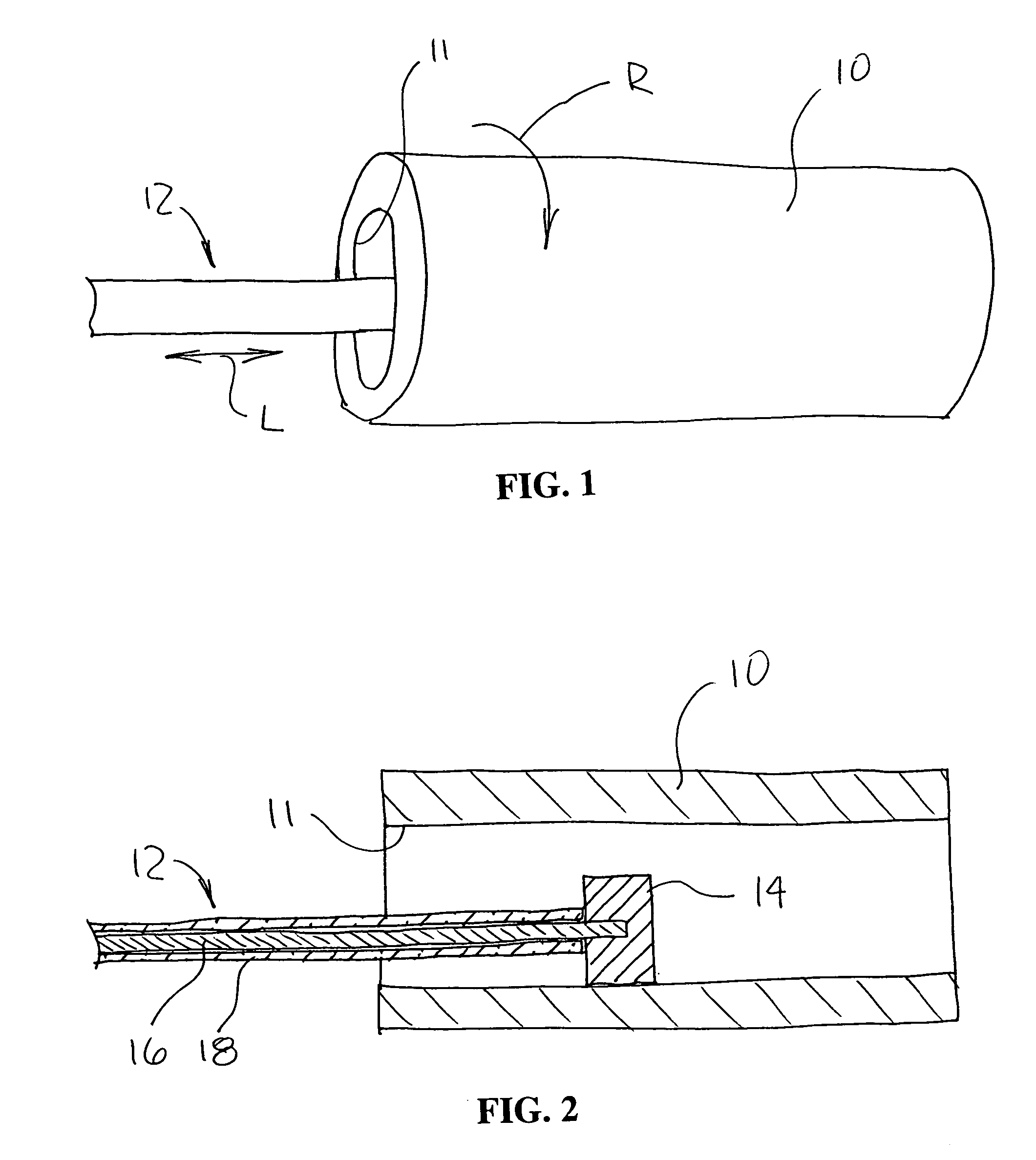

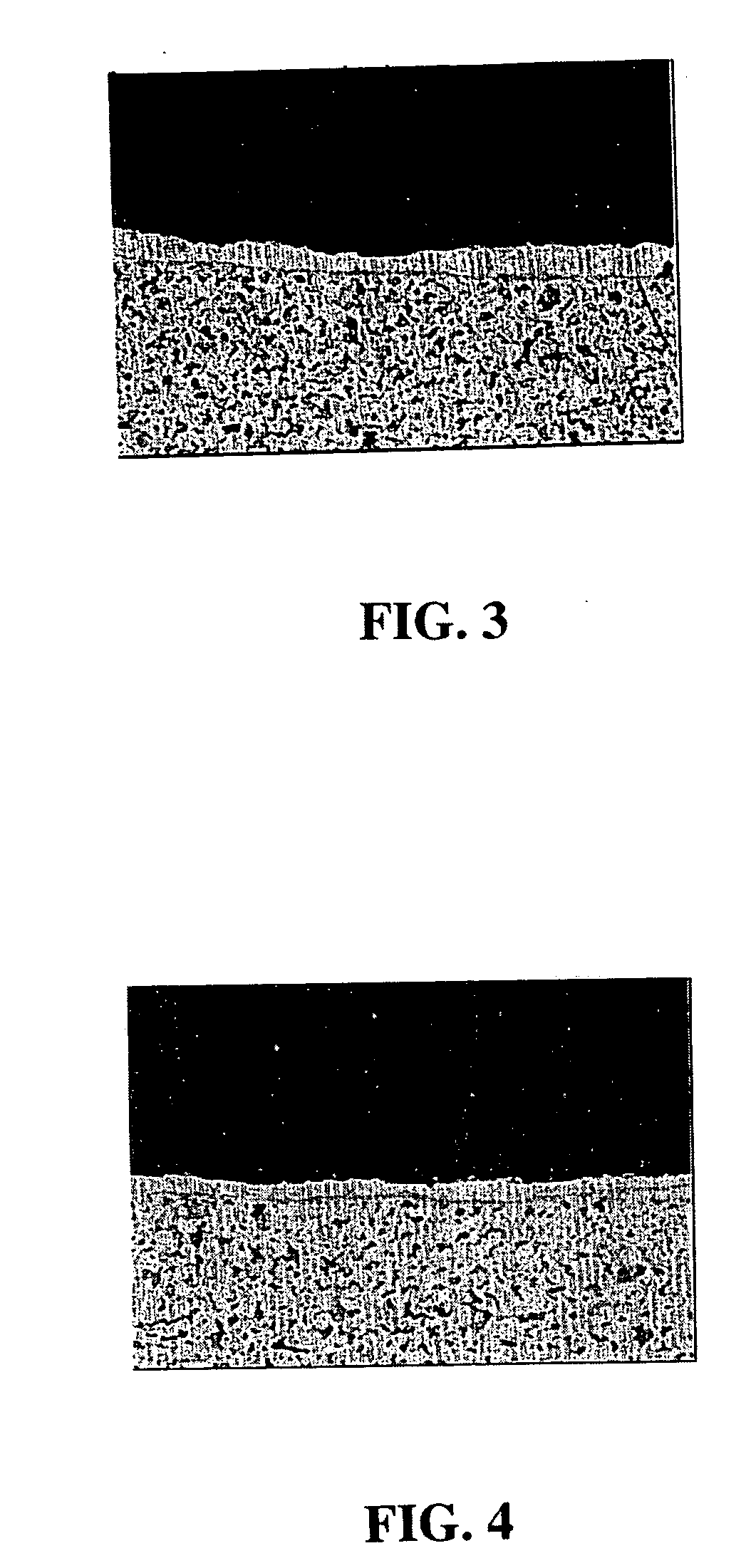

Micro-welded gun barrel coatings

InactiveUS20040140292A1High strengthImproved wear/erosion resistance and thermal managementArc welding apparatusPlasma welding apparatusWear resistantRifling

A micro-welding process is used to apply erosion and wear resistant coatings to the internal diameter of gun barrels. The applied coatings are then treated by methods such as honing and / or rotary forging. The protective micro-welded coatings may comprise ceramic, cermet and / or refractory metal materials, and may be used with rifled or smooth gun barrels of various sizes.

Owner:KELLEY JOHN E +2

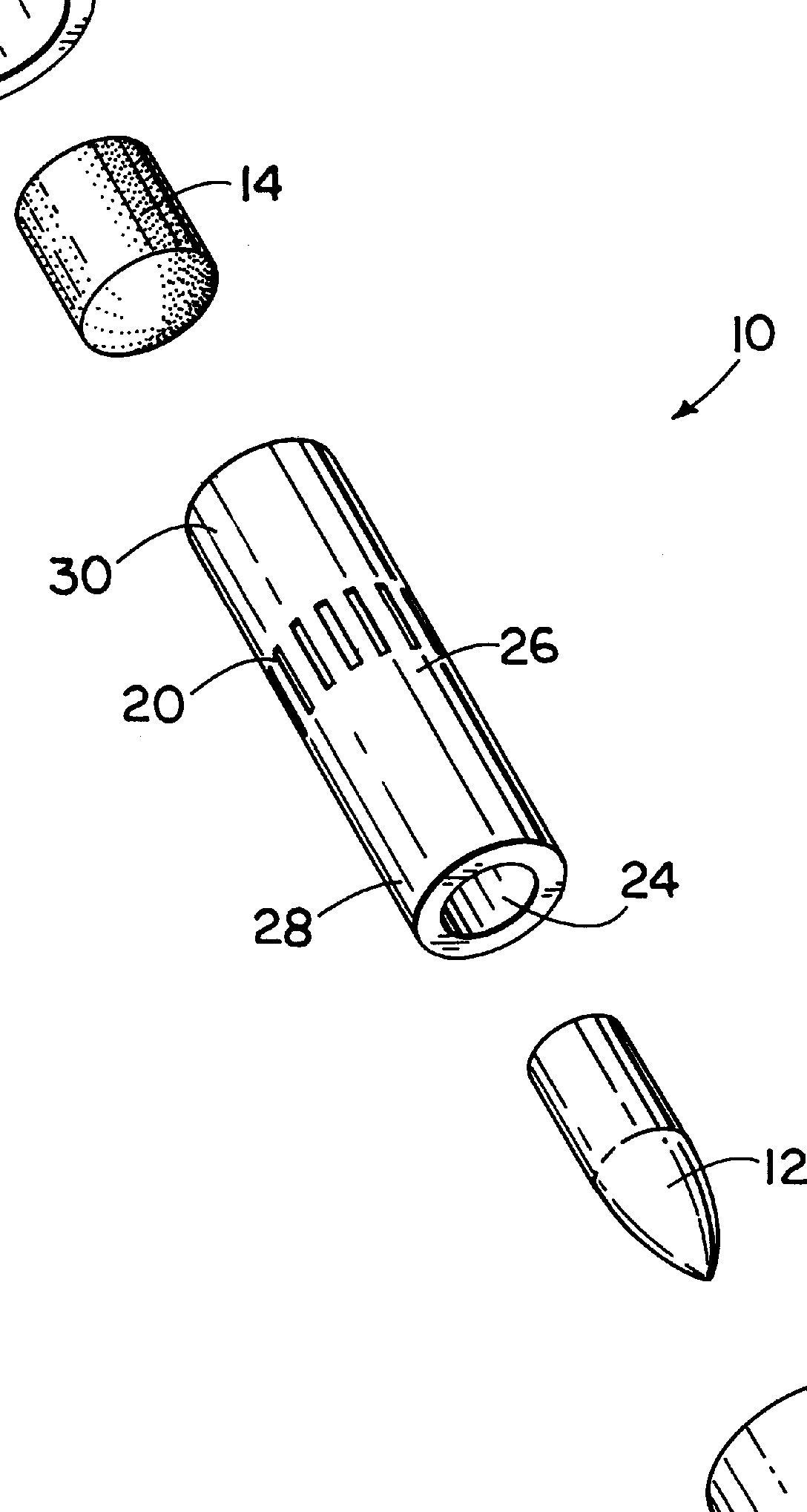

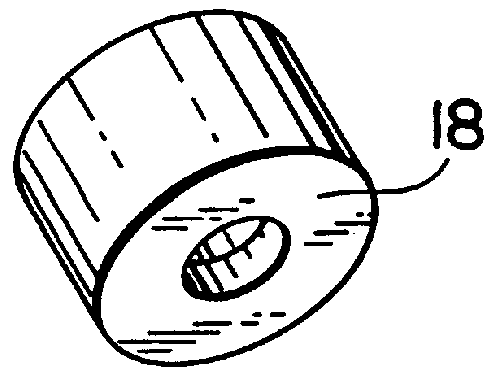

Modular load unit for muzzle loading firearms

InactiveUS6085454AEliminate deformationReduce frictionAmmunition projectilesCartridge extractorsModularityEngineering

A modular load unit that is received in a muzzle loading firearm having a bore and a rifling defined therein. The modular load unit has a hull, a projectile in a projectile receiving compartment, a projectile retaining cap removably received over the projectile, a cushion, a propellant in a propellant receiving compartment, and a propellant retaining cap removably received over the propellant. The modular load unit can be inserted into the bore of the muzzle loading firearm at any angle. Upon firing of the muzzle loading firearm, the cushion and the propellant receiving compartment sealingly engage the rifling.

Owner:CAUDLE CARL E

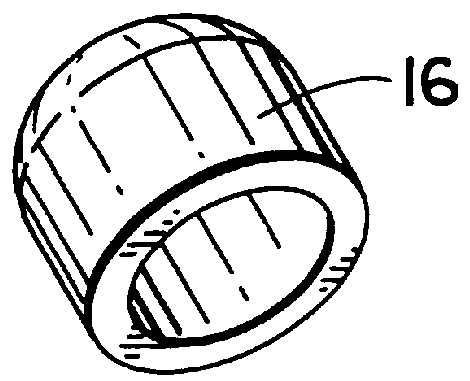

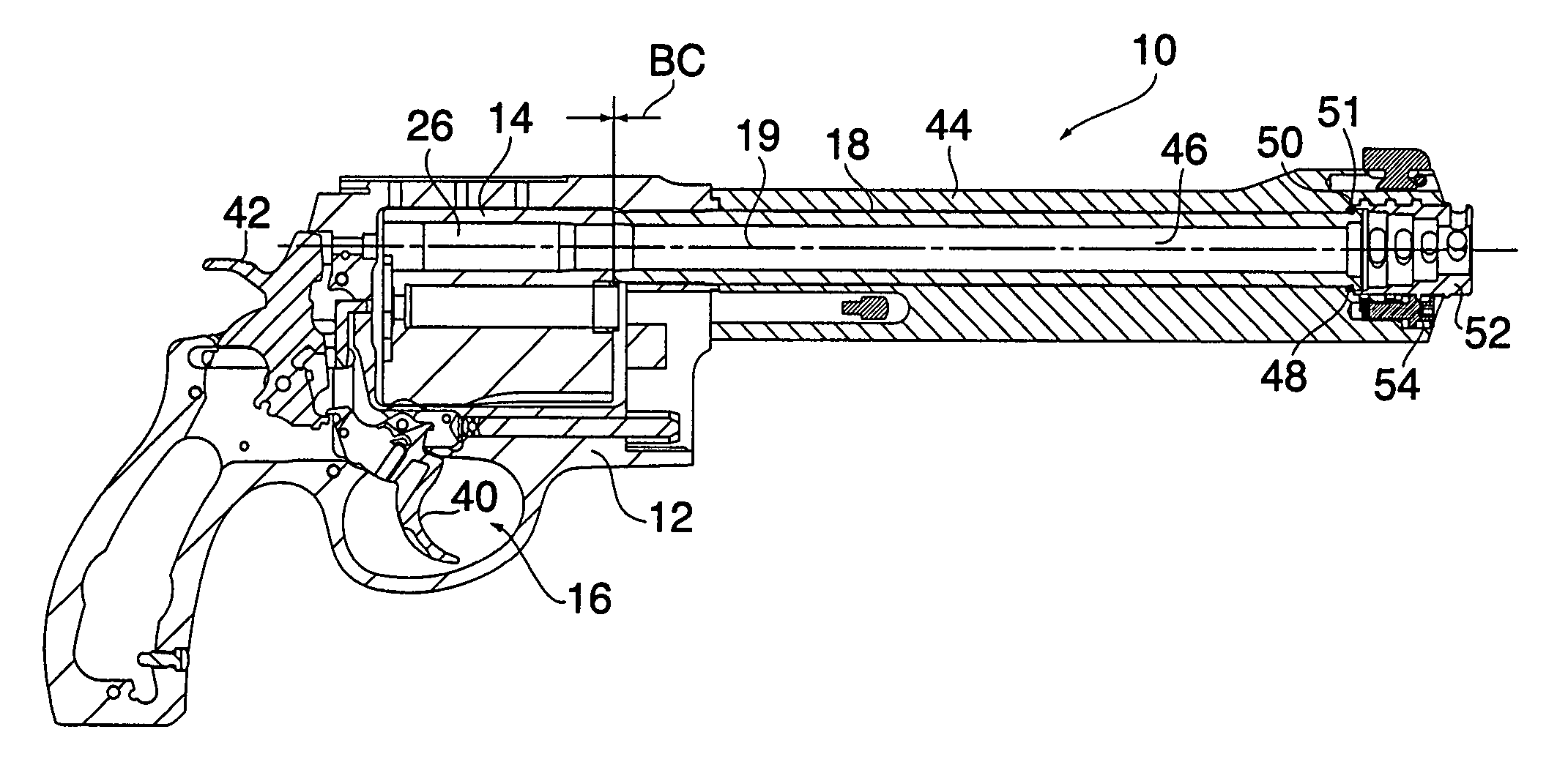

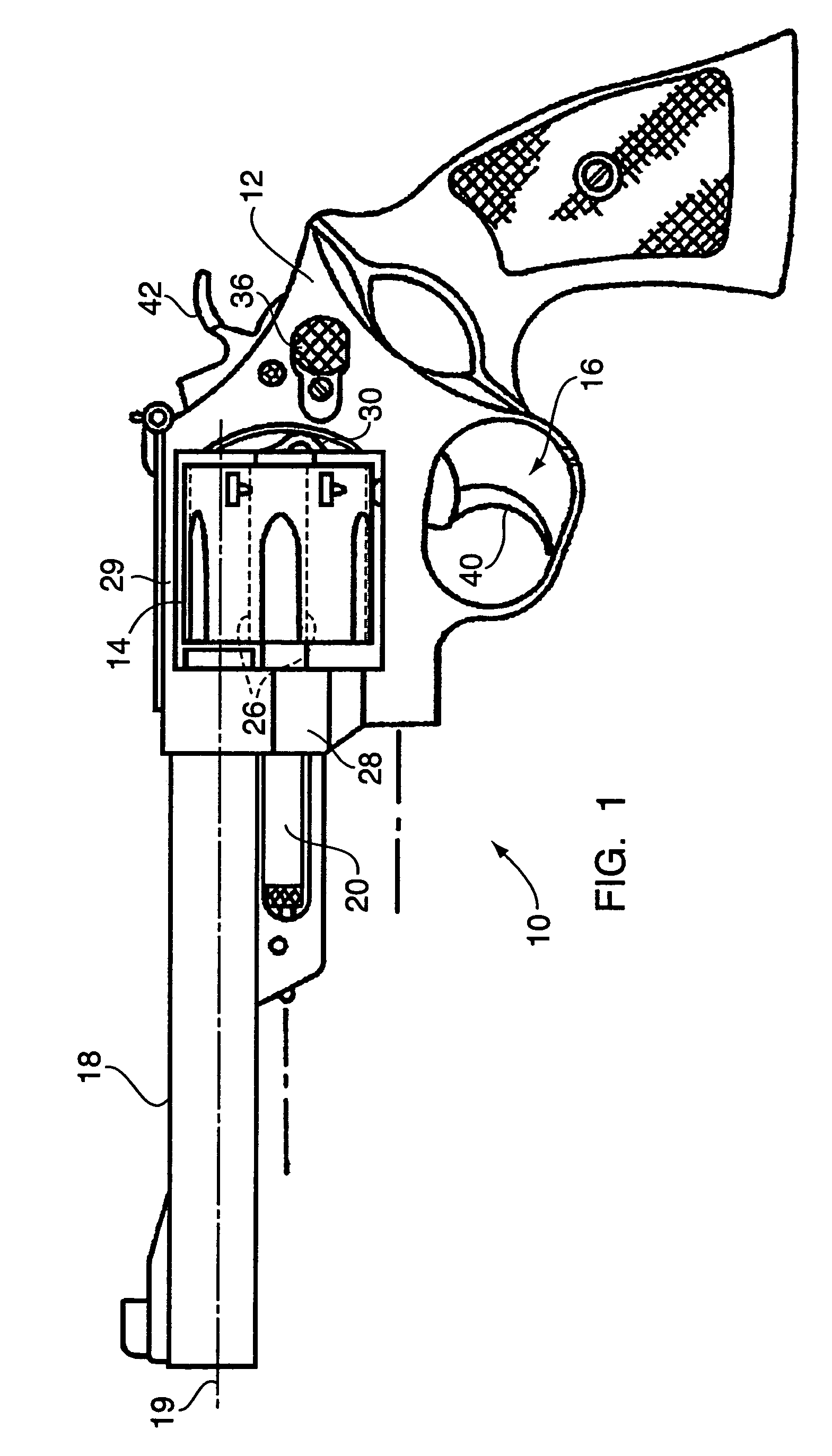

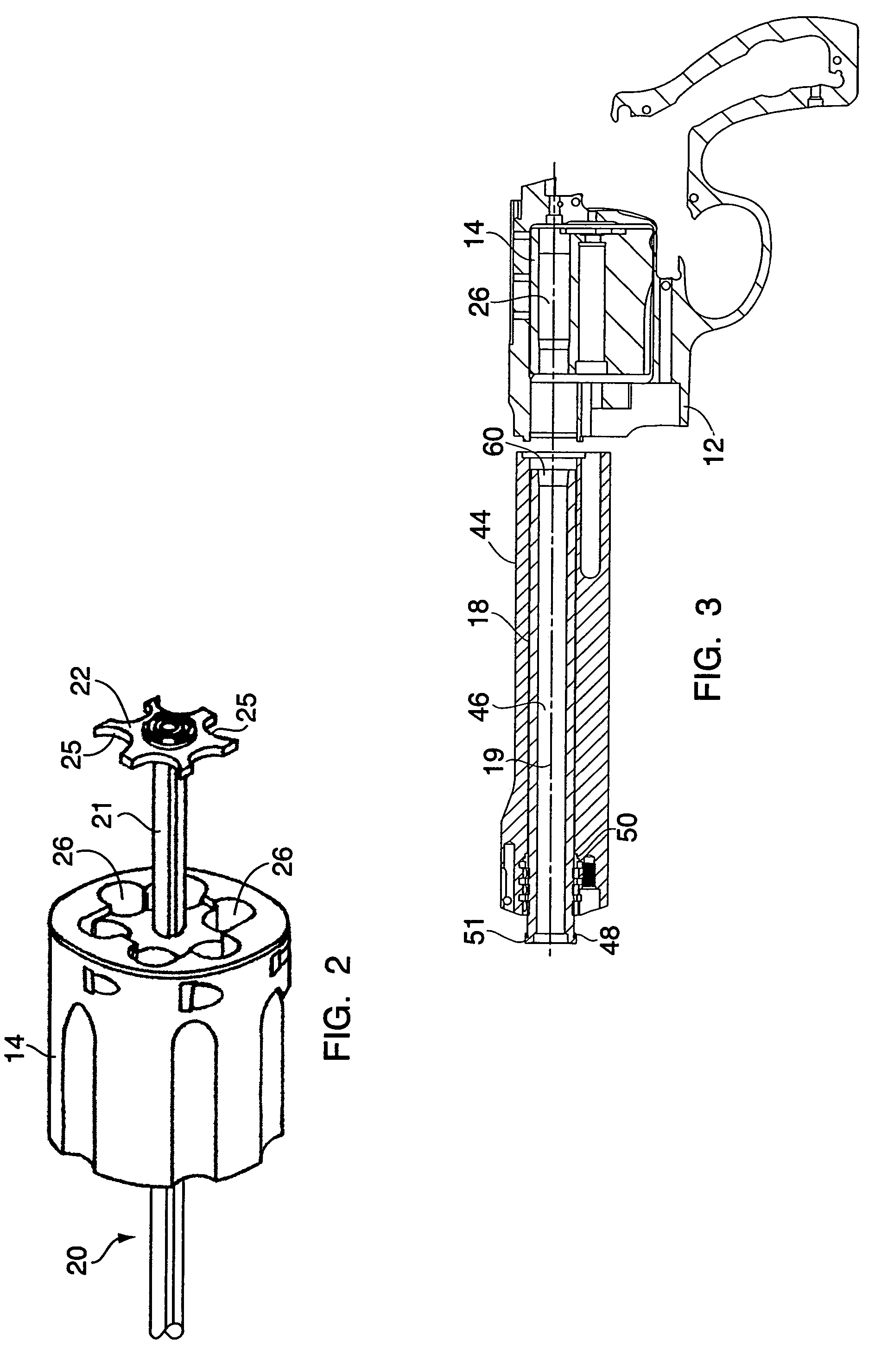

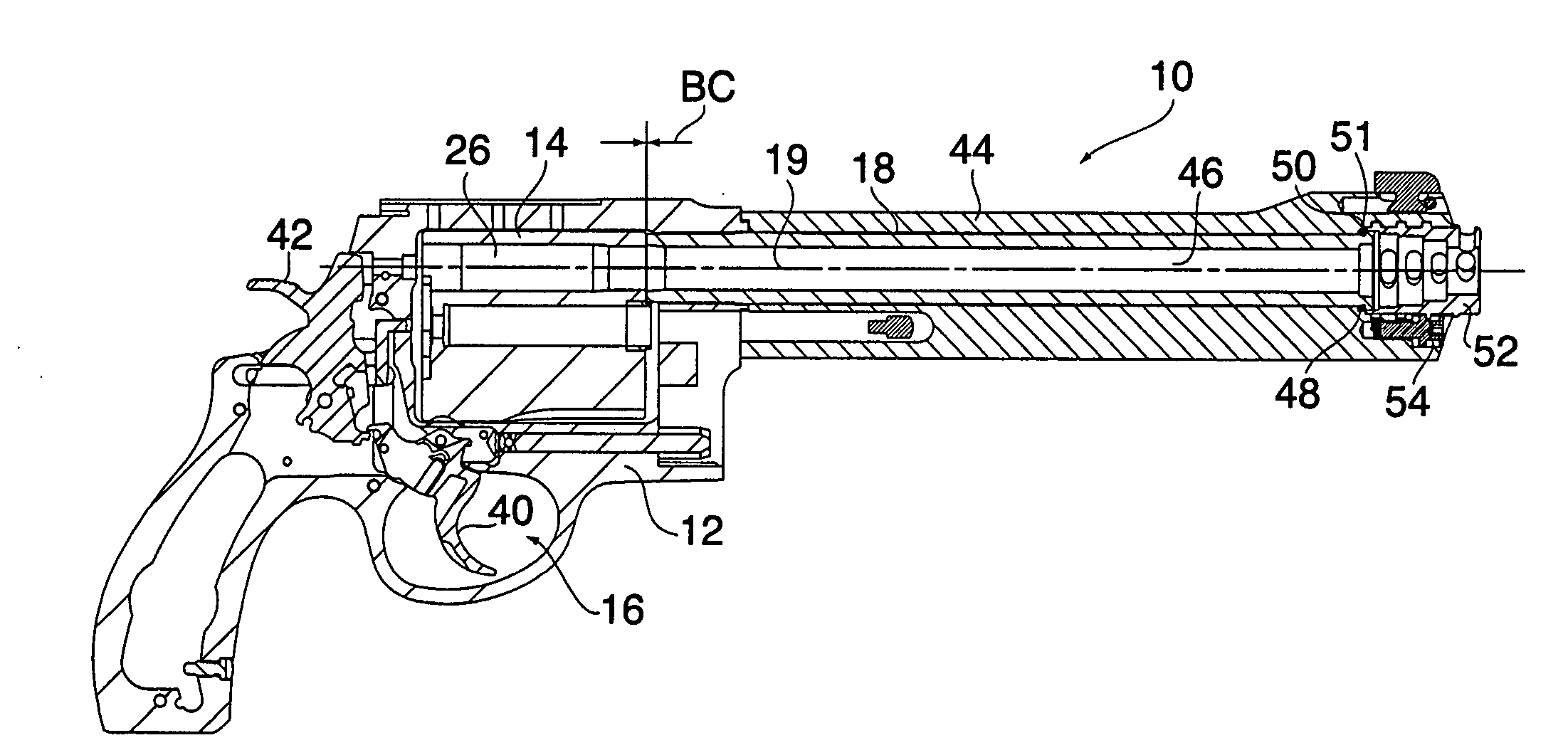

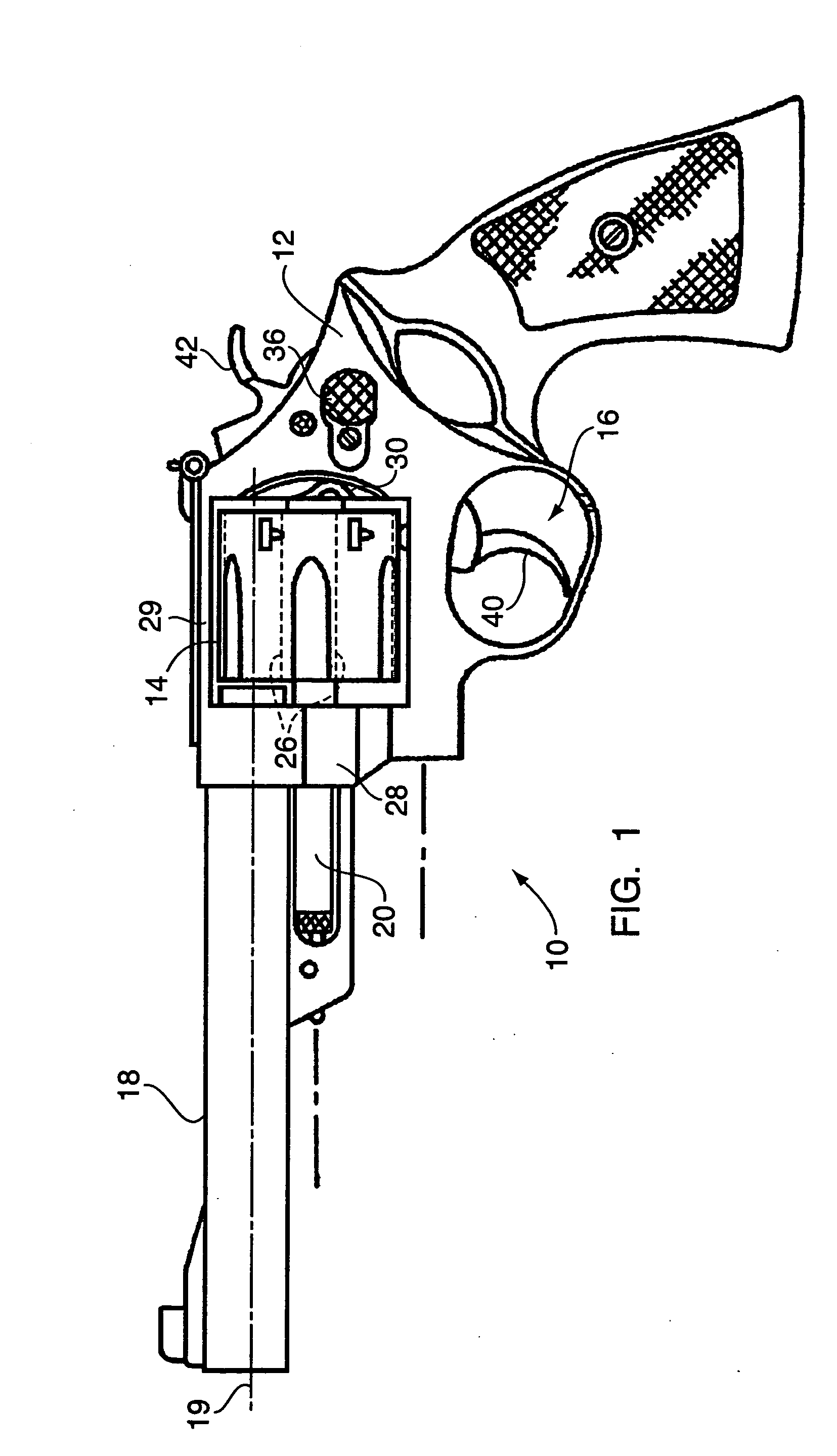

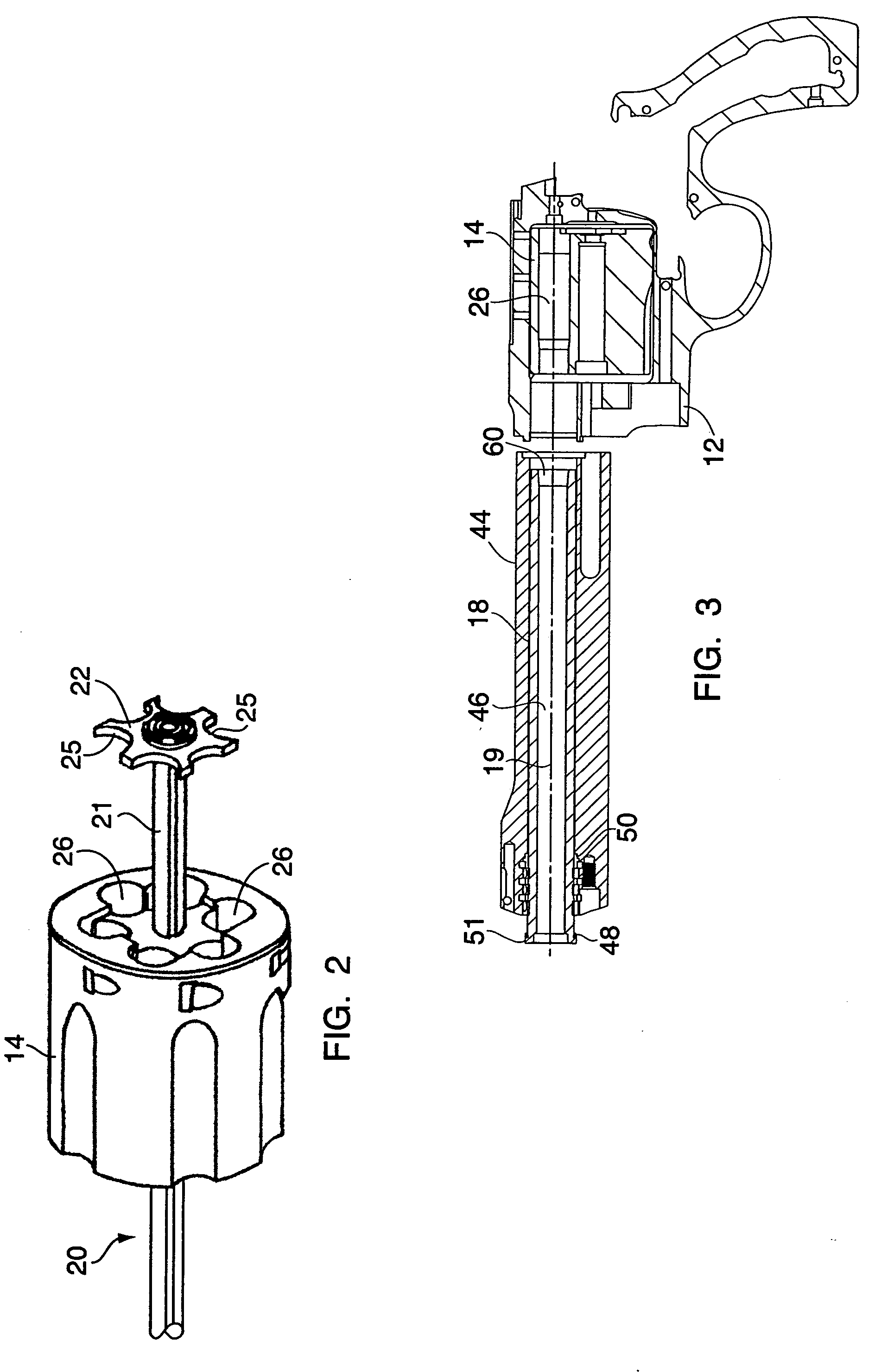

Revolver for firing high velocity ammunition

A revolver for firing high velocity ammunition includes a frame, a cylinder, a barrel, and a firing mechanism. The revolver may include one or more of the following, each of which is especially adapted for use in the context of firing high velocity ammunition: spacers for adjusting a barrel-cylinder gap, for eliminating broaching of the rearward surface(s) of the barrel; a forcing cone formed in the rearward opening of the barrel for accommodating deformed projectiles; a reflective surface (e.g., mirrored surface) provided on the cone and / or barrel rearward surfaces, for reducing erosion resulting from using high velocity ammunition; gain-twist rifling in the barrel for a smoother transition to full projectile velocity; a larger diameter, hardened firing pin bushing for minimizing brass flow in the rearward direction; and a front sight assembly that minimizes lateral shift or drift of the sight pin during firing.

Owner:SMITH & WESSON INC

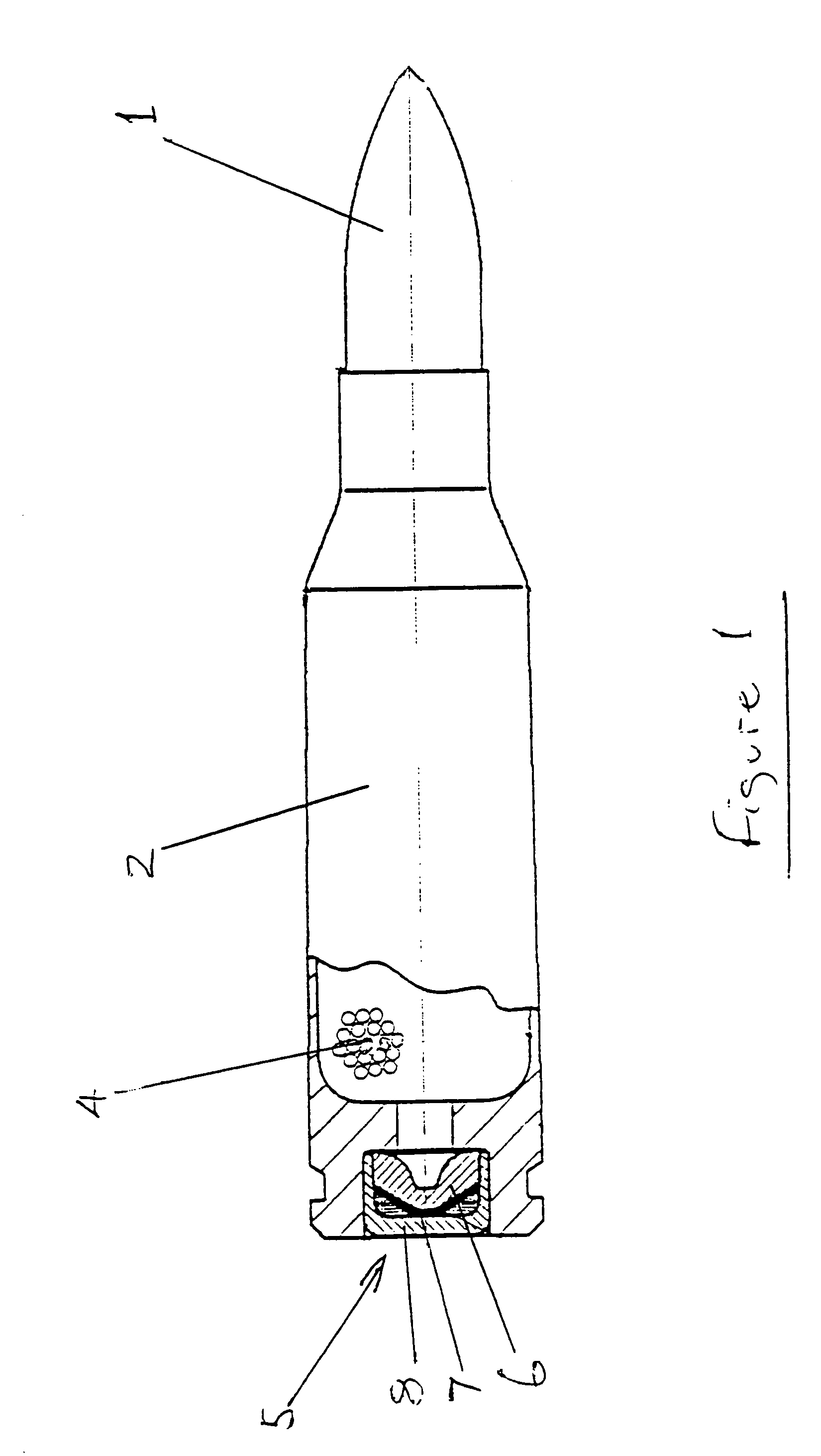

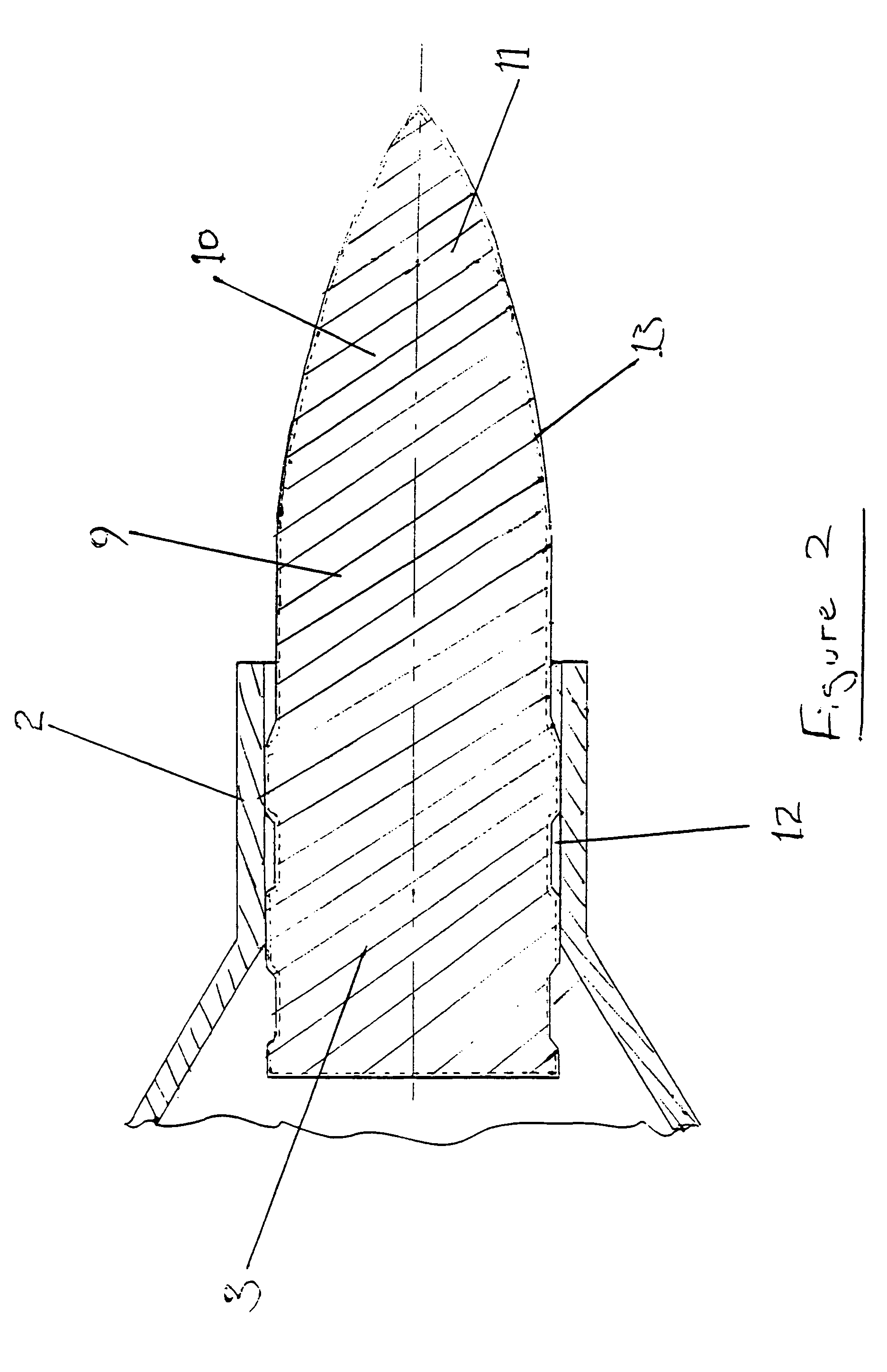

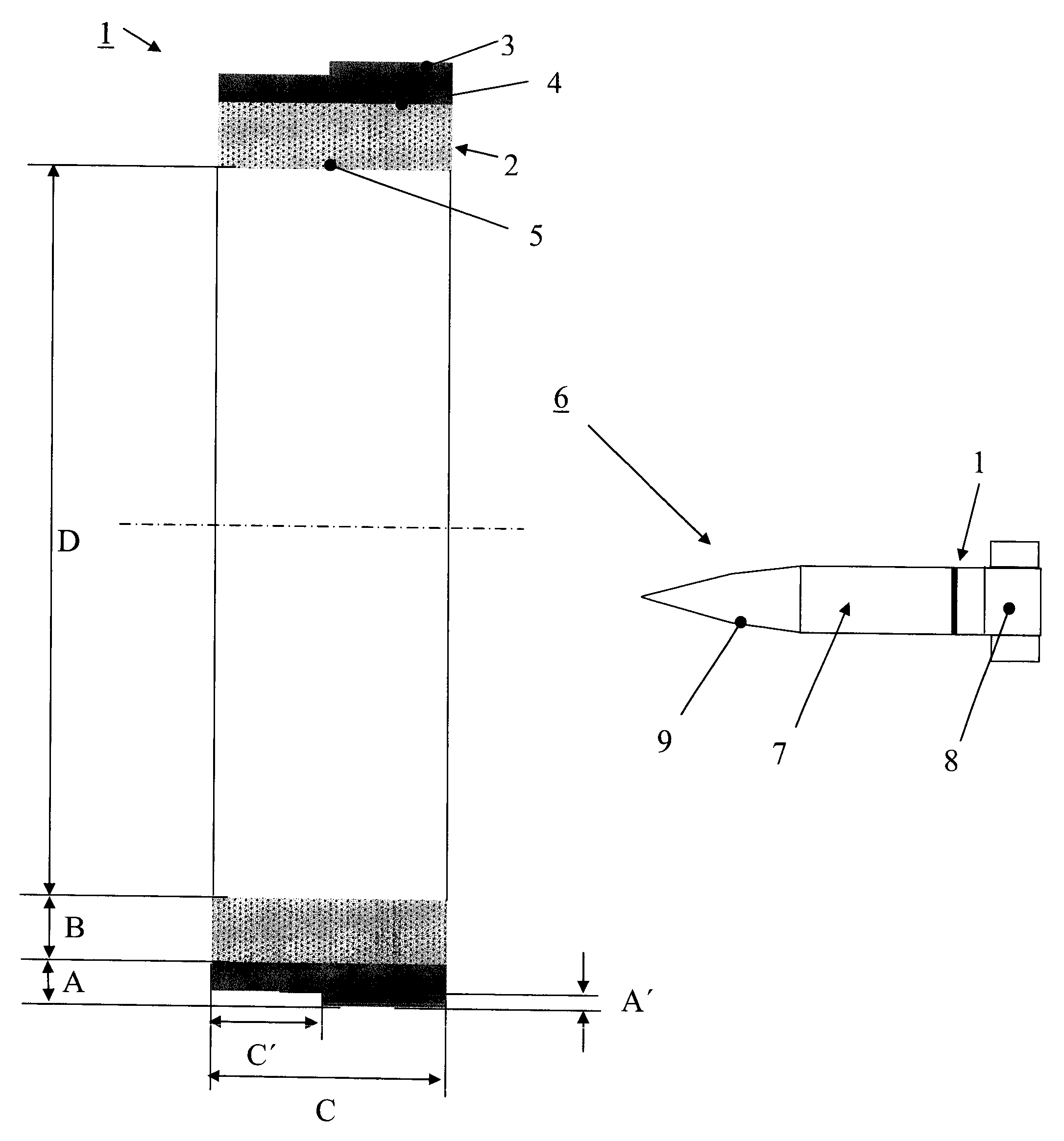

4.6 mm small arms ammunition

ActiveUS7210411B2Well formedReduce coefficient of frictionAmmunition projectilesProjectilesHardnessRifling

A round of ammunition for firing from a gun having a rifled barrel, especially a small arms weapon. The projectile (1) forming a part of the round is of steel or other material having a Vickers Hardness value not less than 550, and has a coating (13) of copper or copper alloy. The projectile has a forward body portion (9) which has a diameter similar to that of the lands of the rifling, and a rearward body portion (3) having a diameter which is similar to the diameter defined by the roots of the rifling grooves. The coating (13) is of a thickness not less than the depth of the said rifling grooves, so that the rifling engraves the coating but does not significantly engrave the underlying steel or other hard material. The advantages associated with a hard projectile material are thus obtained without substantially increasing barrel wear.

Owner:RUAG AMMOTECH

Revolver for firing high velocity ammunition

A revolver for firing high velocity ammunition includes a frame, a cylinder, a barrel, and a firing mechanism. The revolver may include one or more of the following, each of which is especially adapted for use in the context of firing high velocity ammunition: spacers for adjusting a barrel-cylinder gap, for eliminating broaching of the rearward surface(s) of the barrel; a forcing cone formed in the rearward opening of the barrel for accommodating deformed projectiles; a reflective surface (e.g., mirrored surface) provided on the cone and / or barrel rearward surfaces, for reducing erosion resulting from using high velocity ammunition; gain-twist rifling in the barrel for a smoother transition to full projectile velocity; a larger diameter, hardened firing pin bushing for minimizing brass flow in the rearward direction; and a front sight assembly that minimizes lateral shift or drift of the sight pin during firing.

Owner:SMITH & WESSON

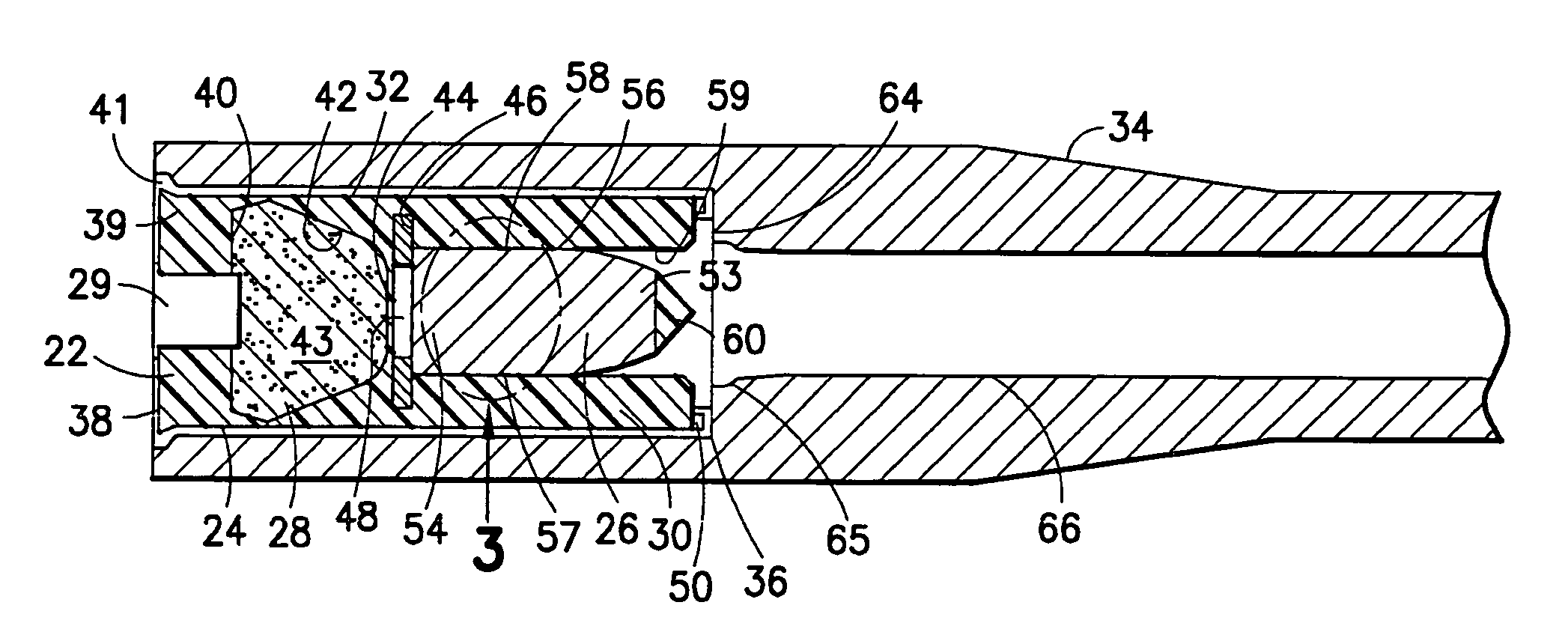

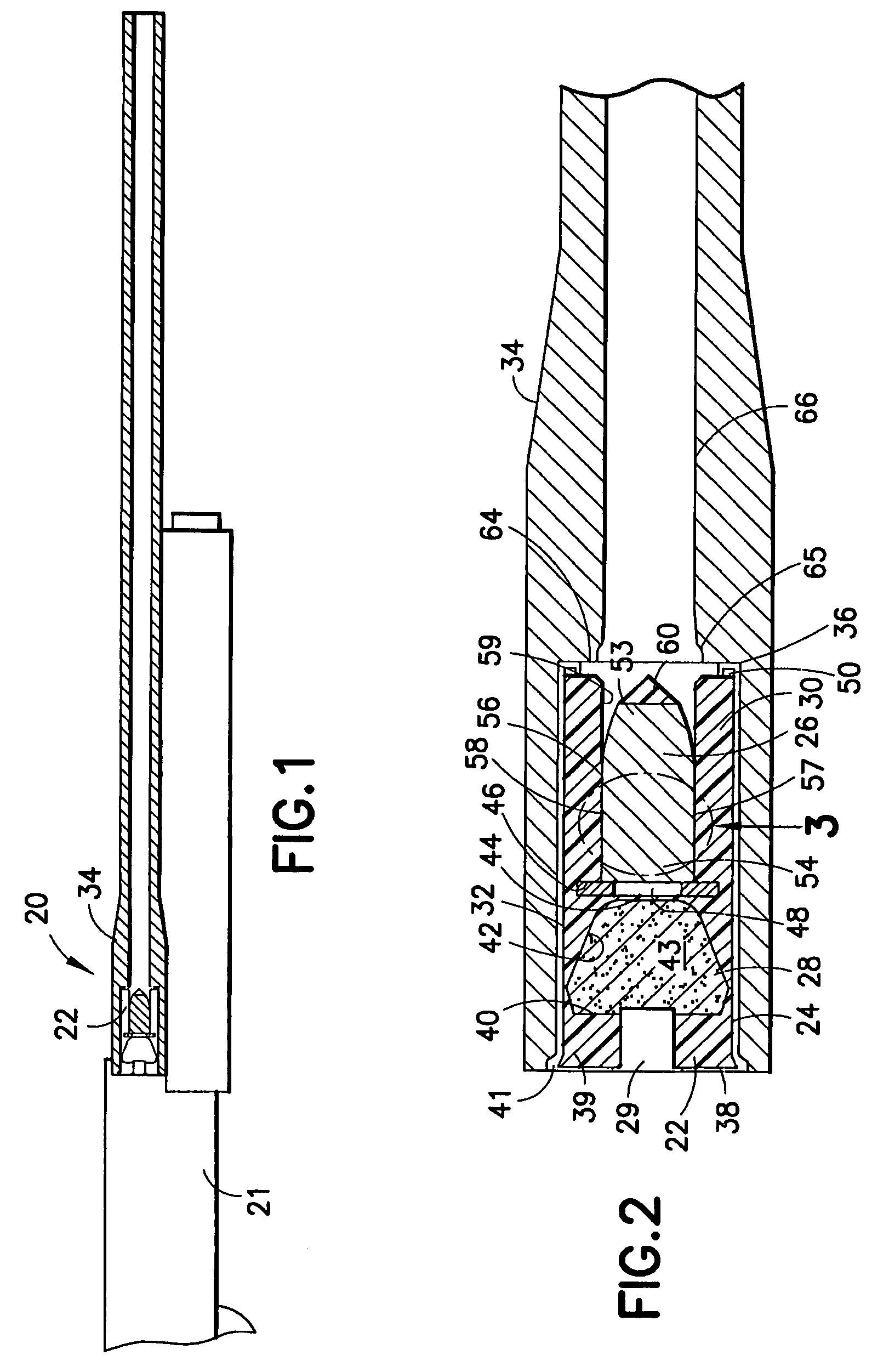

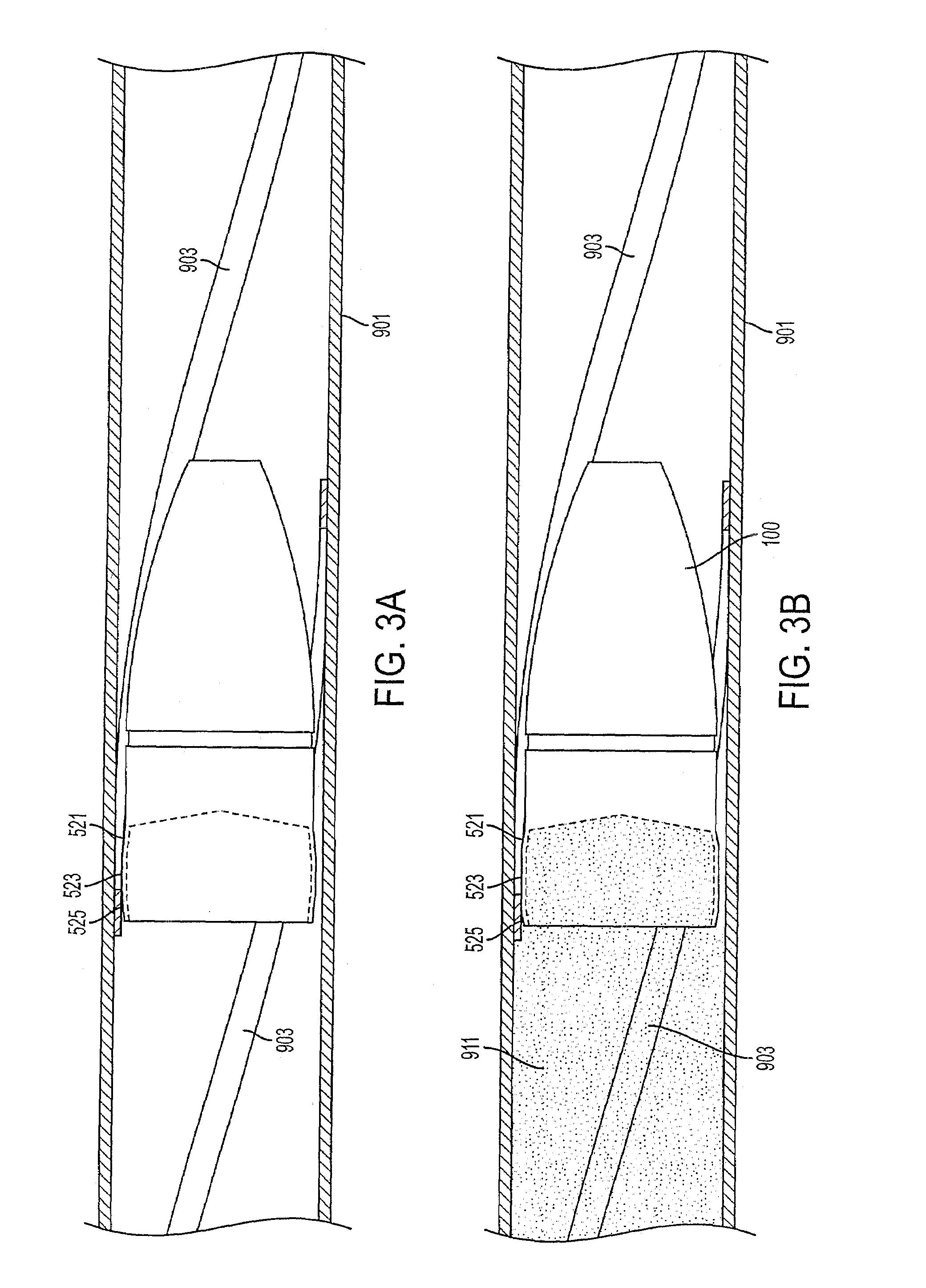

Short magnum shotshell cartridge and firing assembly

A sabot-retaining shotshell cartridge and firing assembly including a barrel or barrel insert for firing the sabot-retaining shotshell cartridge. The shotshell cartridge includes a cylindrical hull, a sub-caliber projectile, a propellant charge, and a sabot. A central pathway or thin membrane is defined within the base of the sabot between the sub-caliber projectile and propellant charge. The barrel or barrel insert for firing the cartridge includes a transitional area between chamber and sub-caliber rifled bore to retain sabot in the cartridge. Upon cartridge firing, propellant gases flow through central portion of sabot base propelling projectile out of the sabot and into sub-caliber rifled bore.

Owner:OLIN CORP

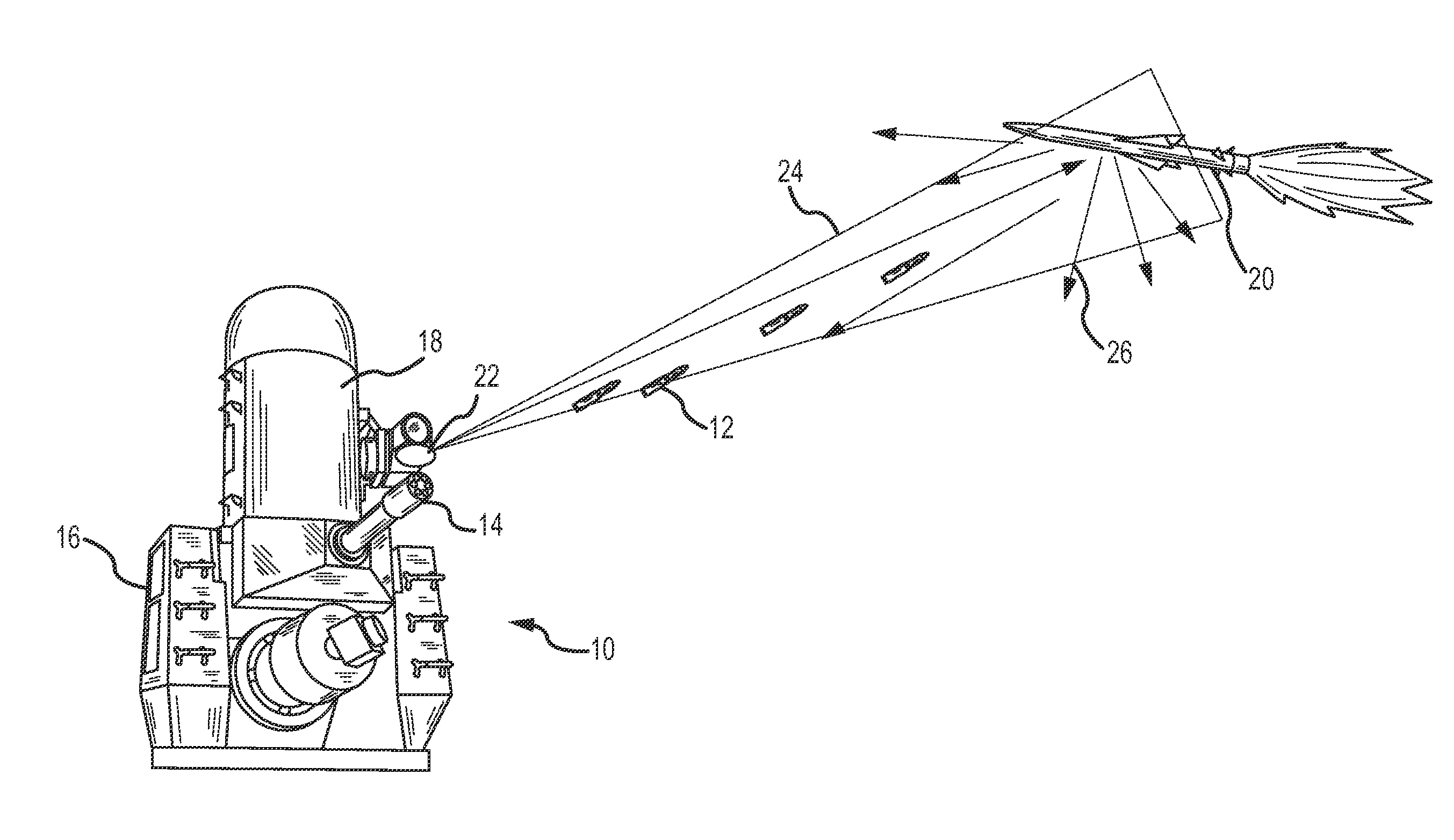

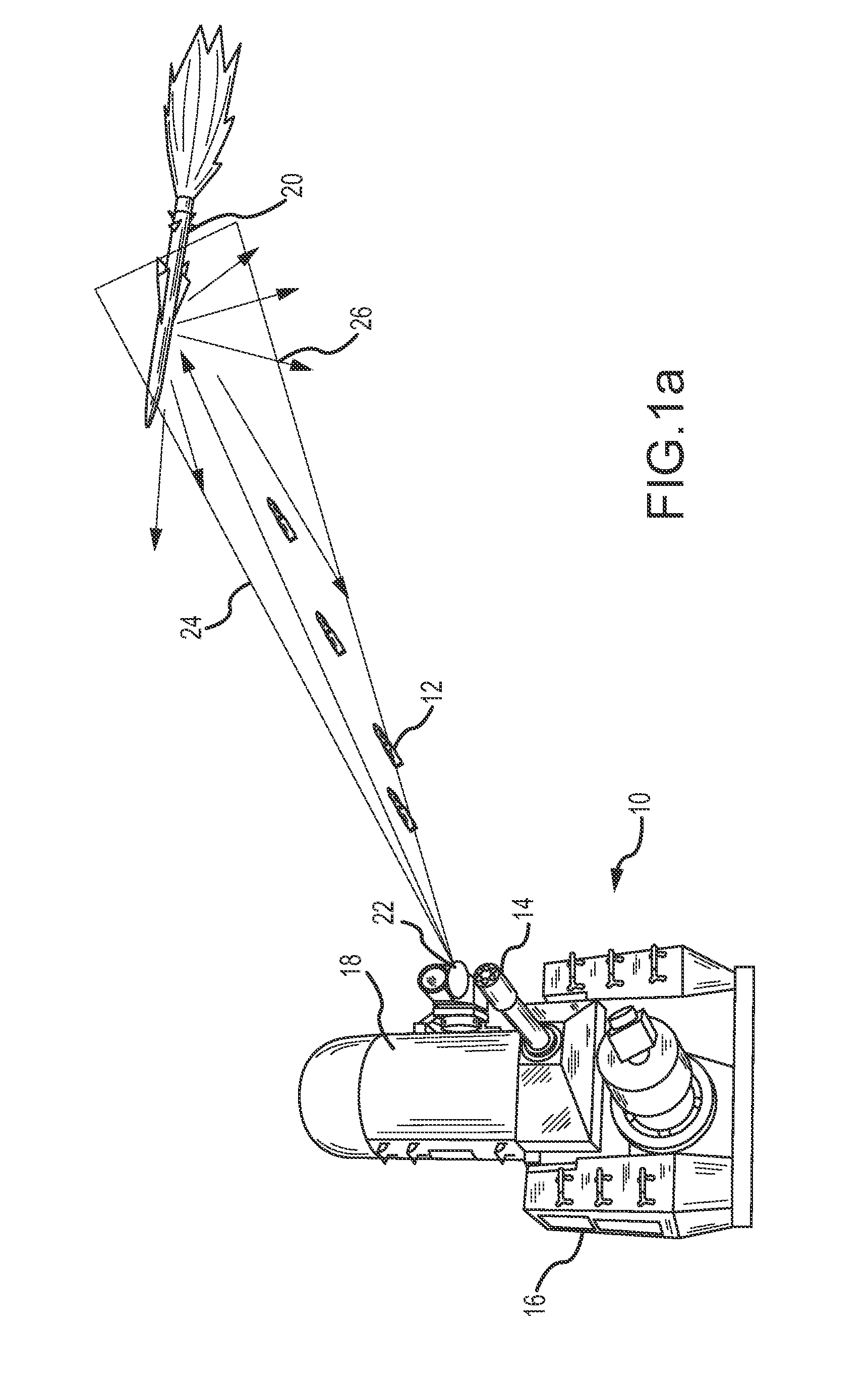

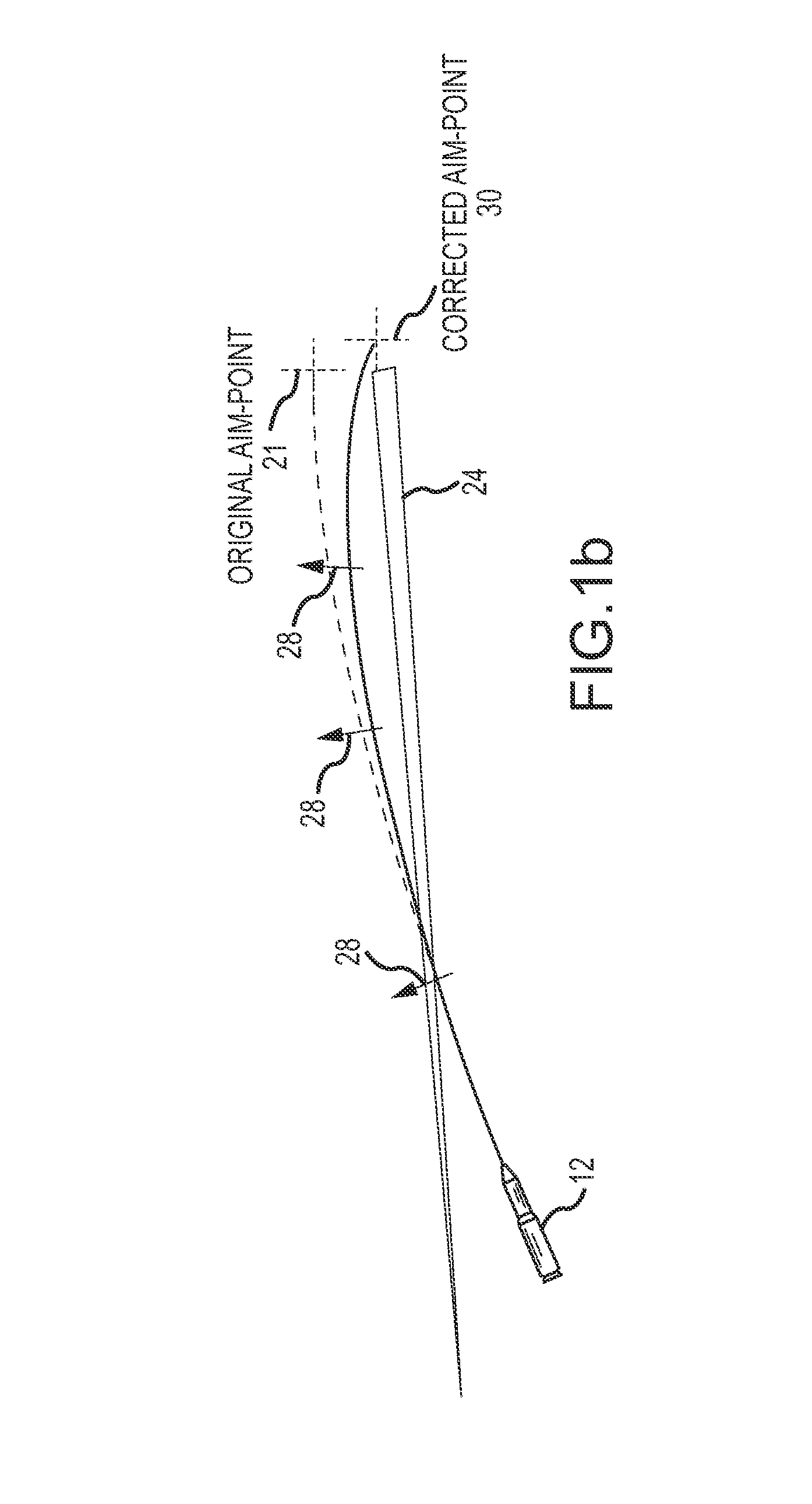

Gun firing method for dispersion of projectiles in a pattern

InactiveUS7017495B2Correction for dispersionAmmunition projectilesTraining ammunitionEngineeringRifling

A method for the dispersion of projectiles from guns capable of firing multiple projectiles in rapid succession whereby some of the projectiles are modified by moving the center of mass of the projectile away from it's central axis and oriented prior to firing. This, in combination with bring fired from a rifled gun barrel, imparts velocity to the projectile upon exiting the gun barrel at right angles to the barrel. This velocity along with the higher muzzle velocity will cause the modified projectile to diverge away from the trajectory of a standard projectile. The magnitude of the divergence will vary with the distance the projectile's center of mass is away from its central axis, and the placement of the modified projectile strikes around the bull's-eye will be determined by the loading orientation of the modified projectile. Firing a multiplicity of standard and modified projectiles in rapid succession will produce an accurate dispersion pattern on a target, increasing the hit probability on that target.

Owner:SEXTON RICHARD

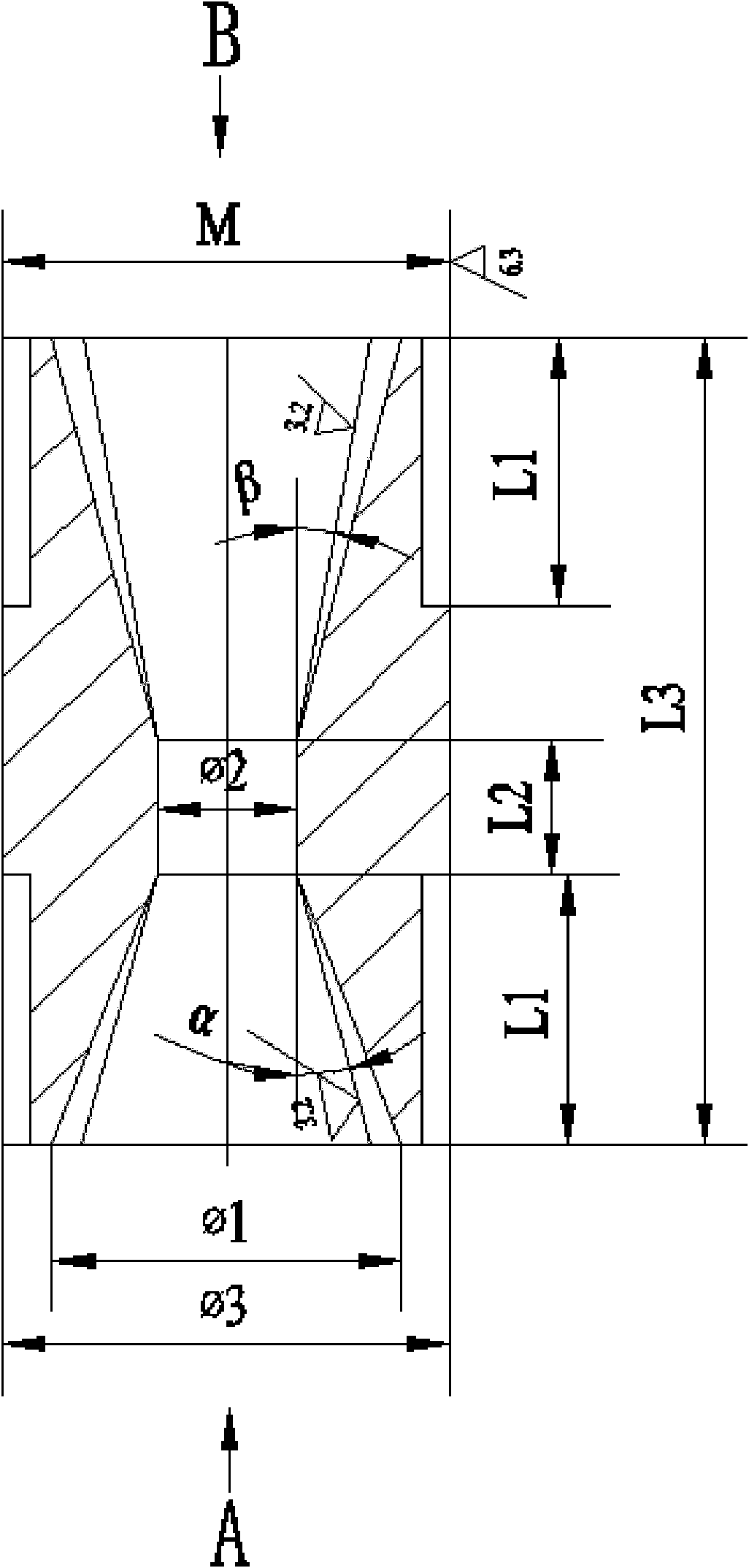

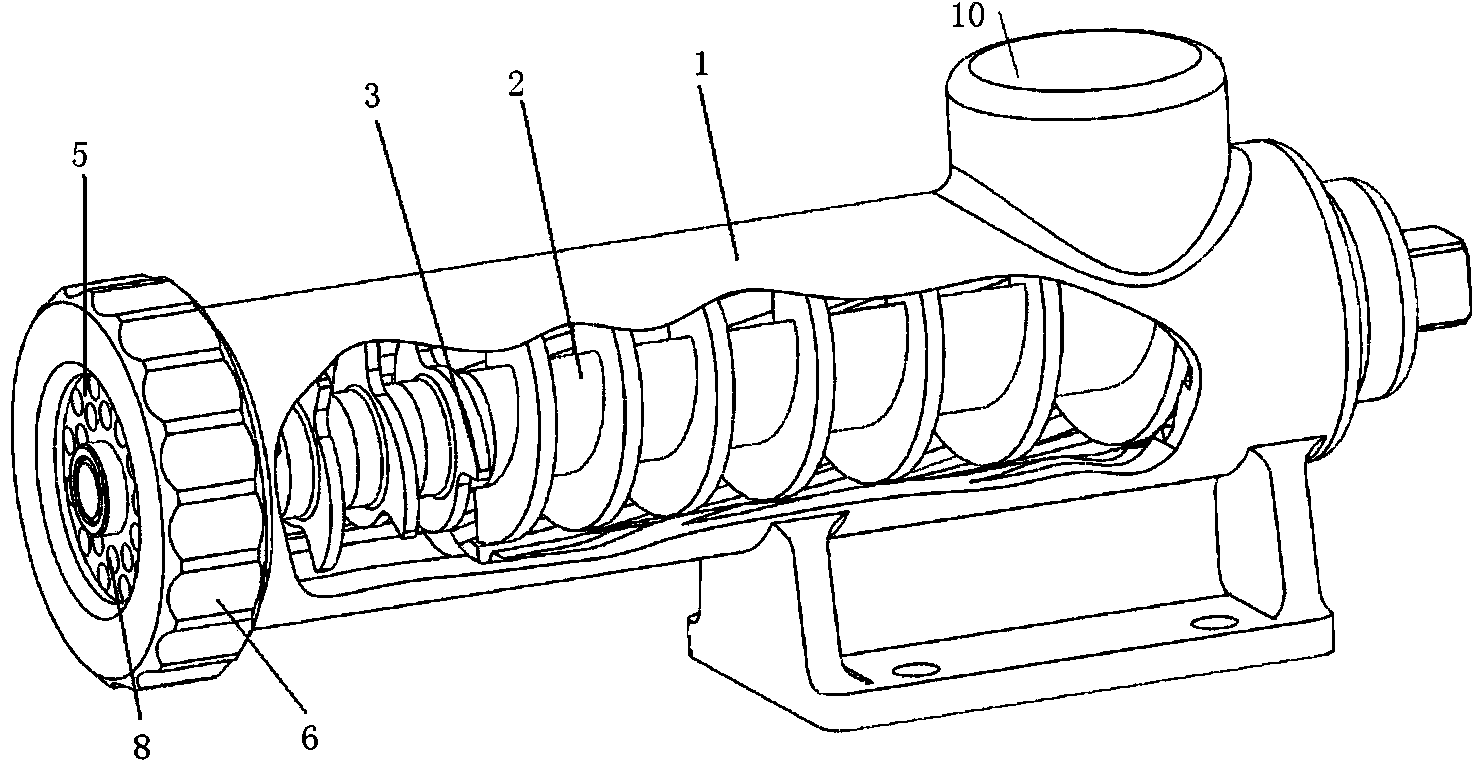

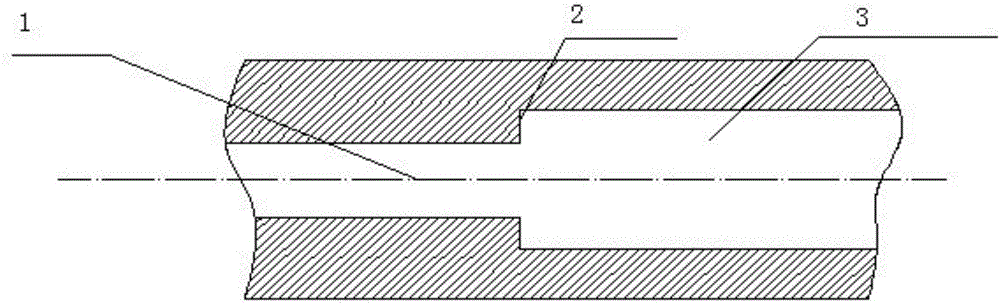

Vapor-liquid two-phase flow mixer

The invention discloses a vapor-liquid two-phase flow mixer, which is characterized in that: the vapor-liquid two-phase flow mixer has a bidirectional taper structure, and comprises an input end taper, an output end taper and a tube arranged between the input end taper and the output end taper; and riflings with opposite spiral directions are arranged in the input end taper and the output end taper. The mixer can further granularly mix vapor-liquid two-phase flow and ejects the vapor-liquid two-phase flow at a high speed through a nozzle; when the vapor-liquid two-phase flow inflows through the nozzle, the two-phase flow is accelerated under the action of the tapers on the inner surface of the nozzle; meanwhile, the two-phase flow is rotated under the action of the riflings on the taper surfaces; and when the accelerated and rotated two-phase flow inflows the ejection end, the two-phase flow is forcibly reversed and diffused by the protruding inverted taper riflings, so that air bubbles in the two-phase flow are crushed to achieve the effects of fining granules and improving the gas dissolution rate, the granularity is 0.1 to 1.0mu m, the gas-liquid surface area is increased by 30times, and the gas dissolution rate is 95 to 99 percent.

Owner:上海热鑫热能科技有限公司

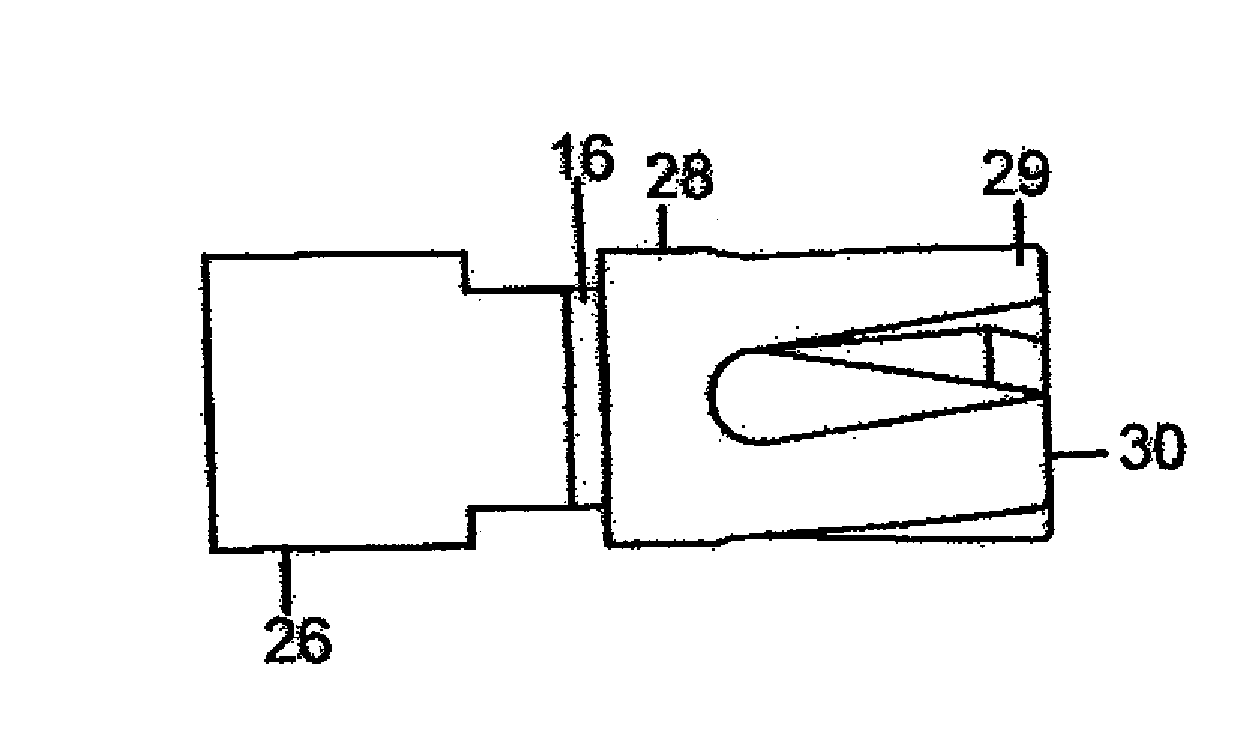

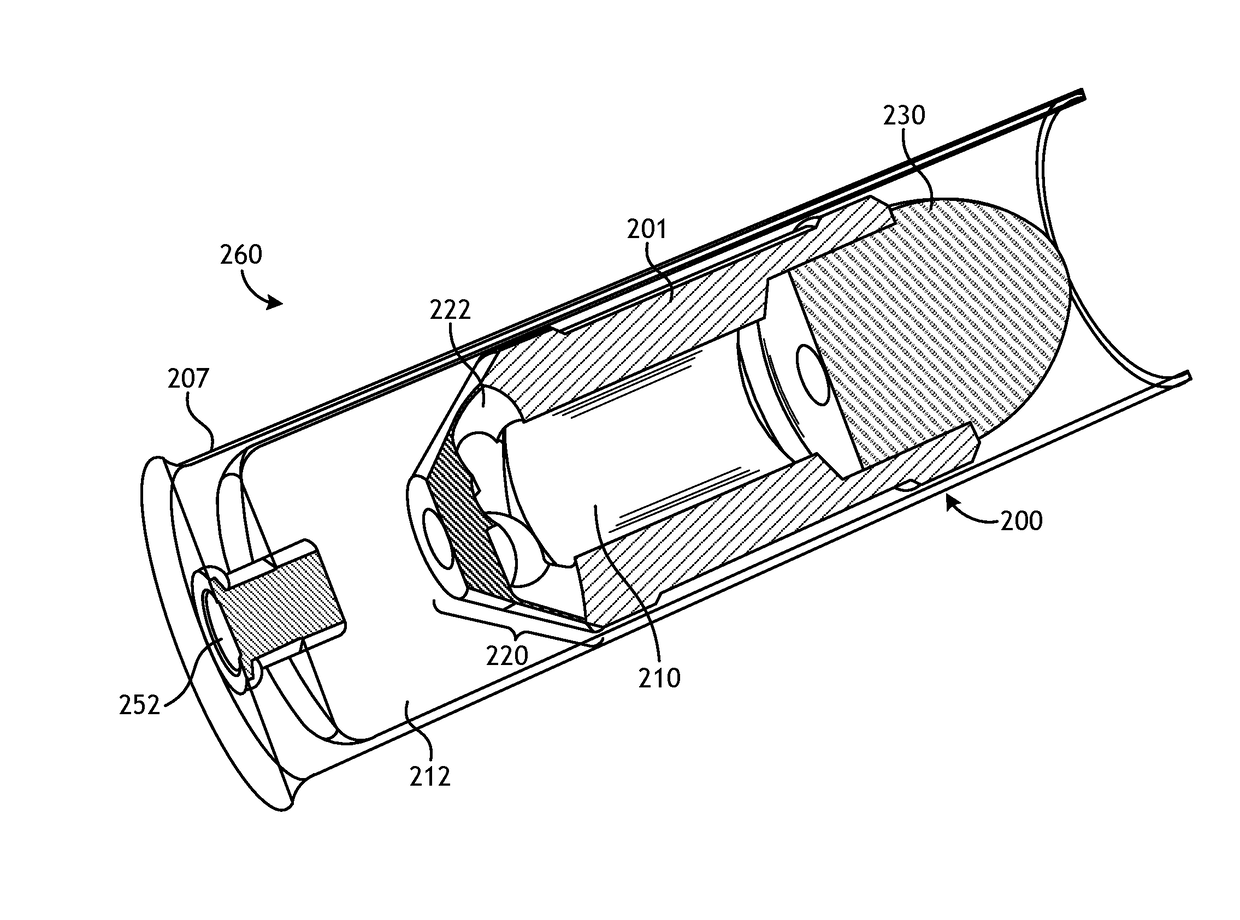

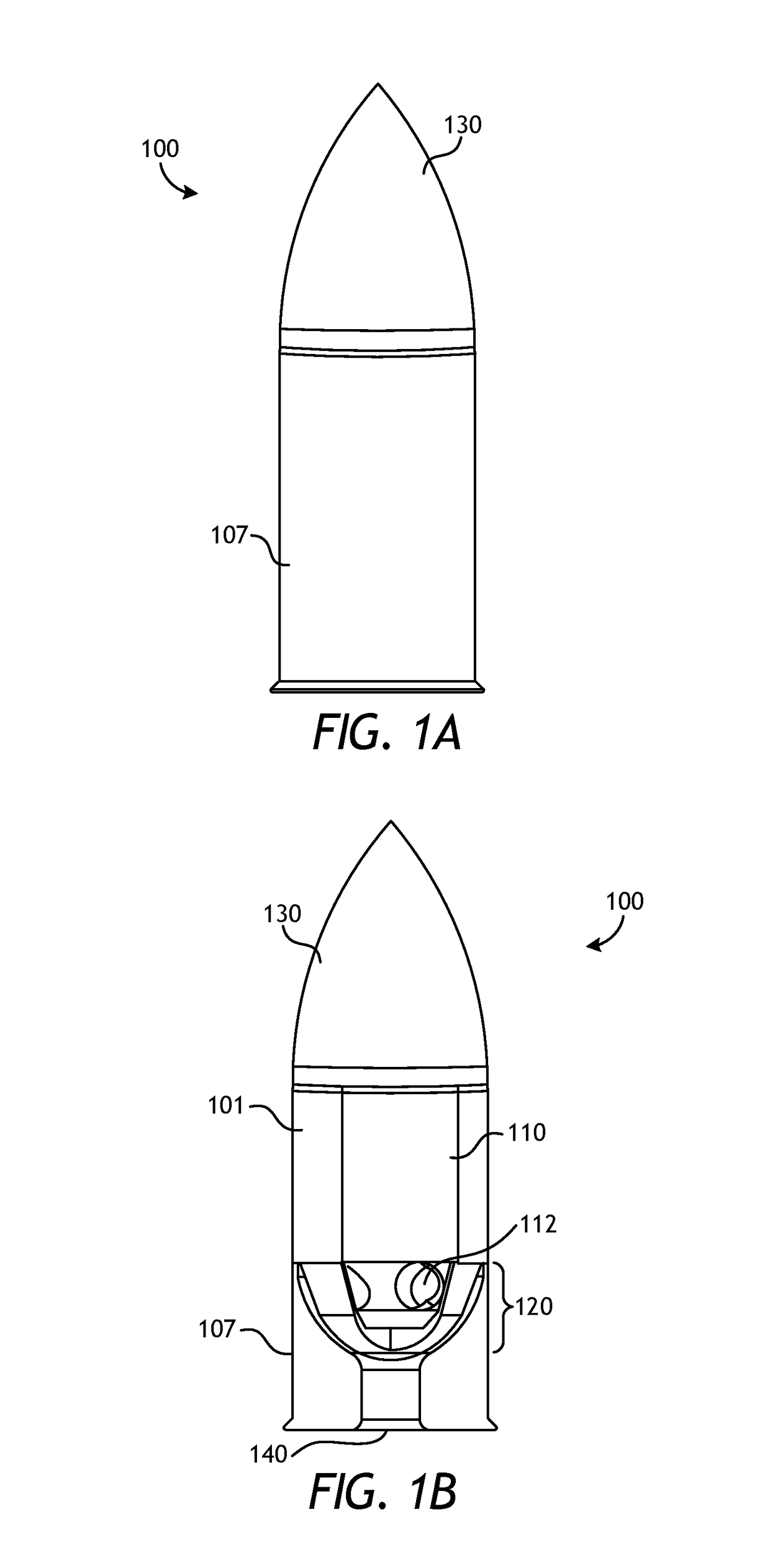

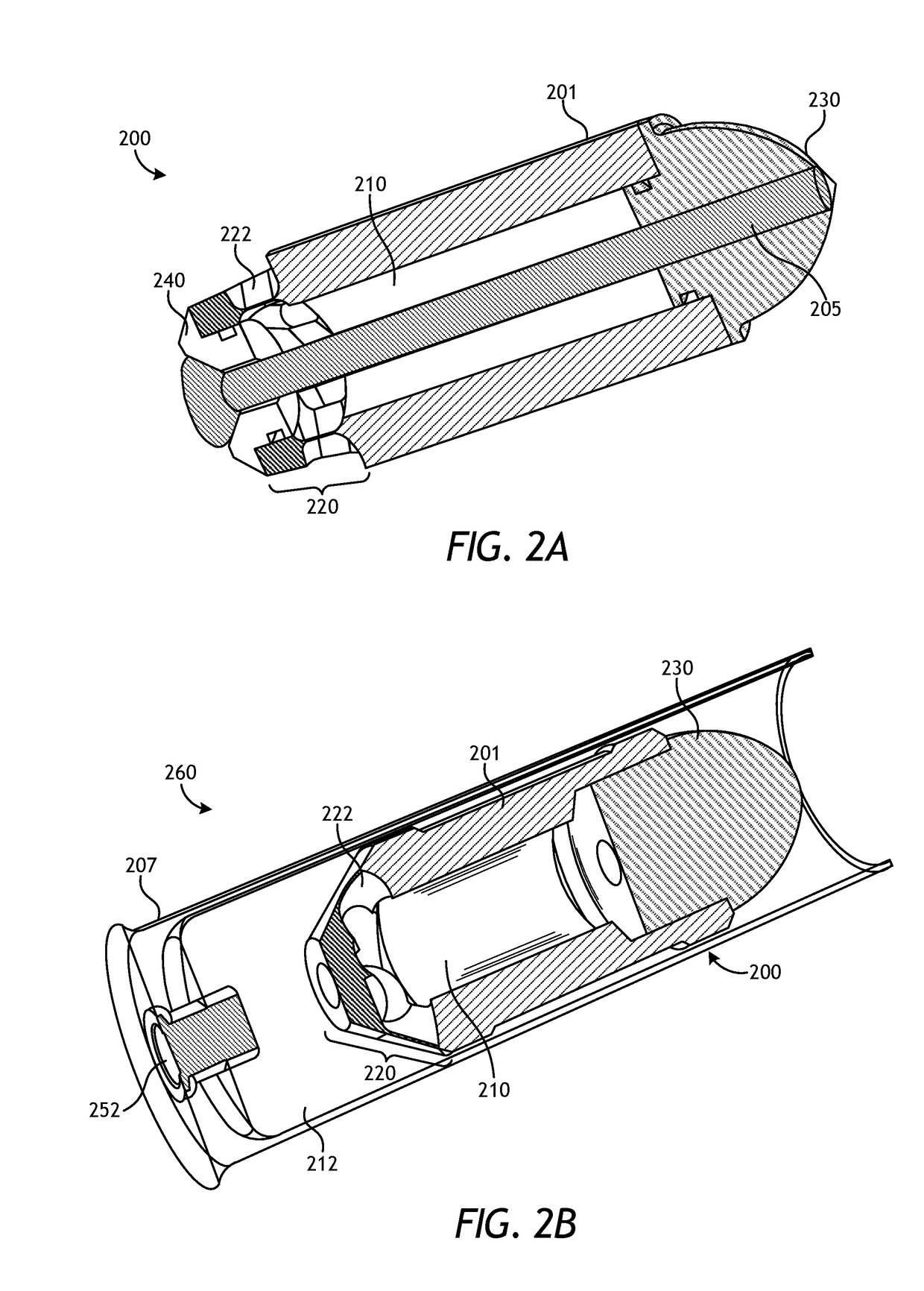

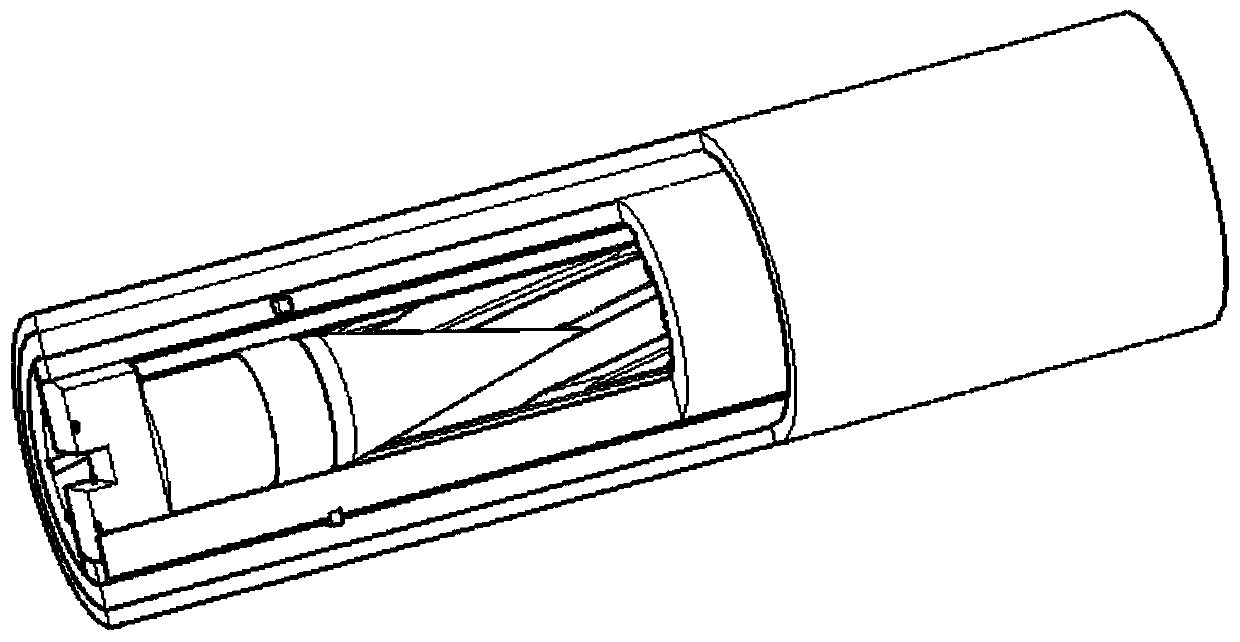

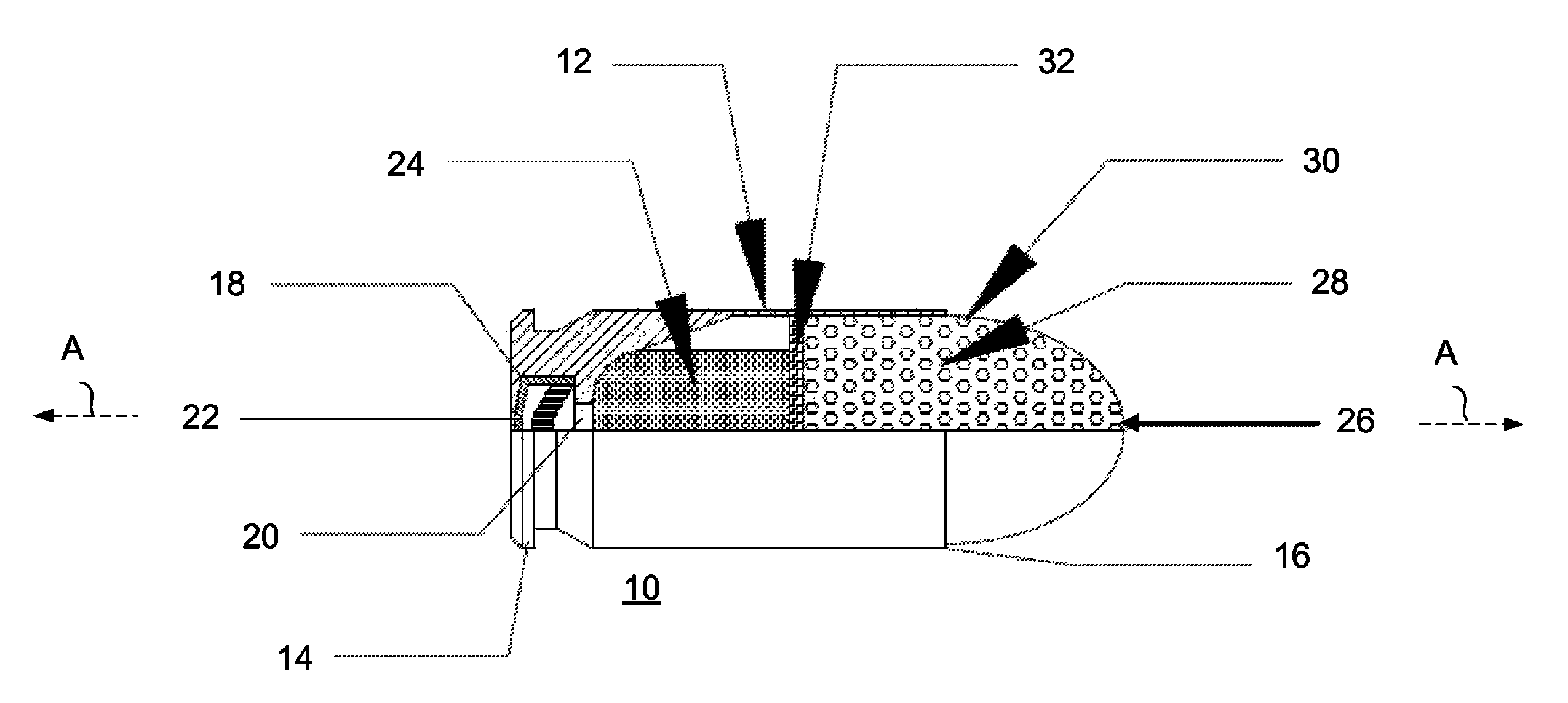

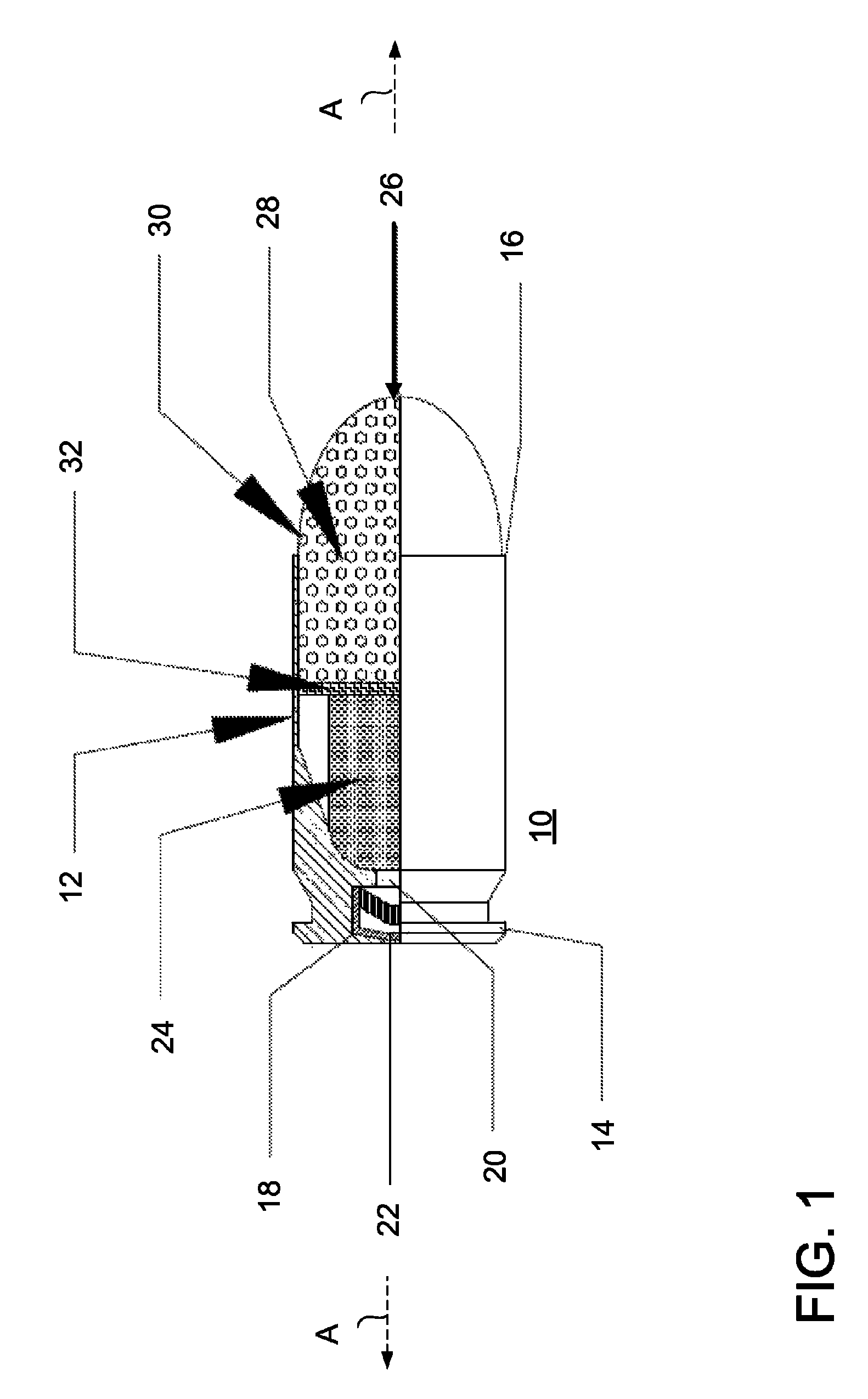

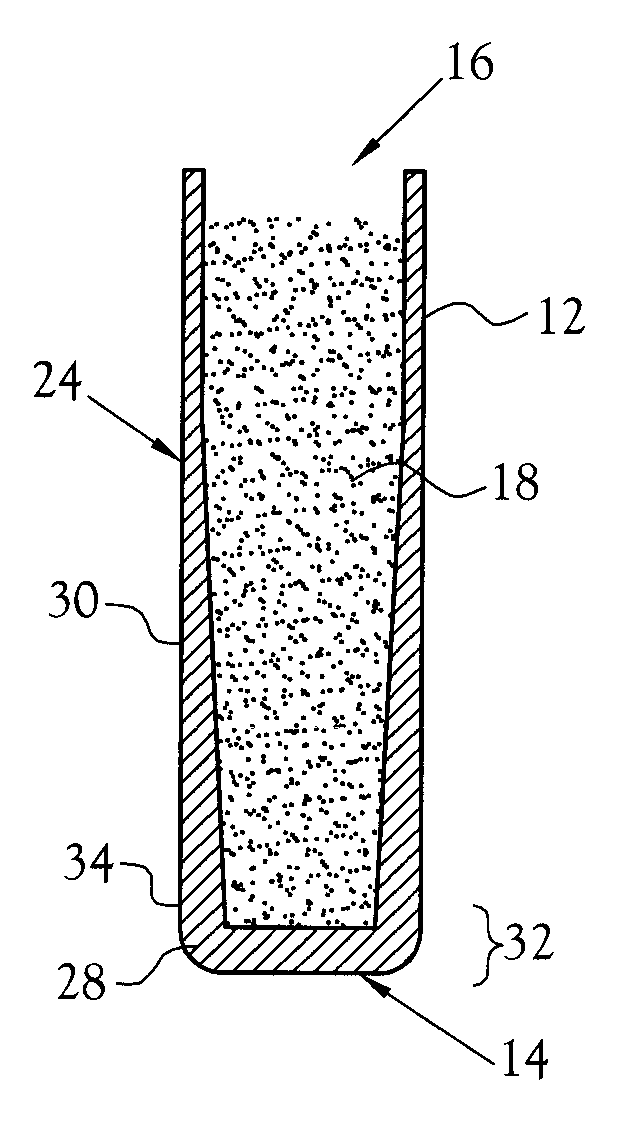

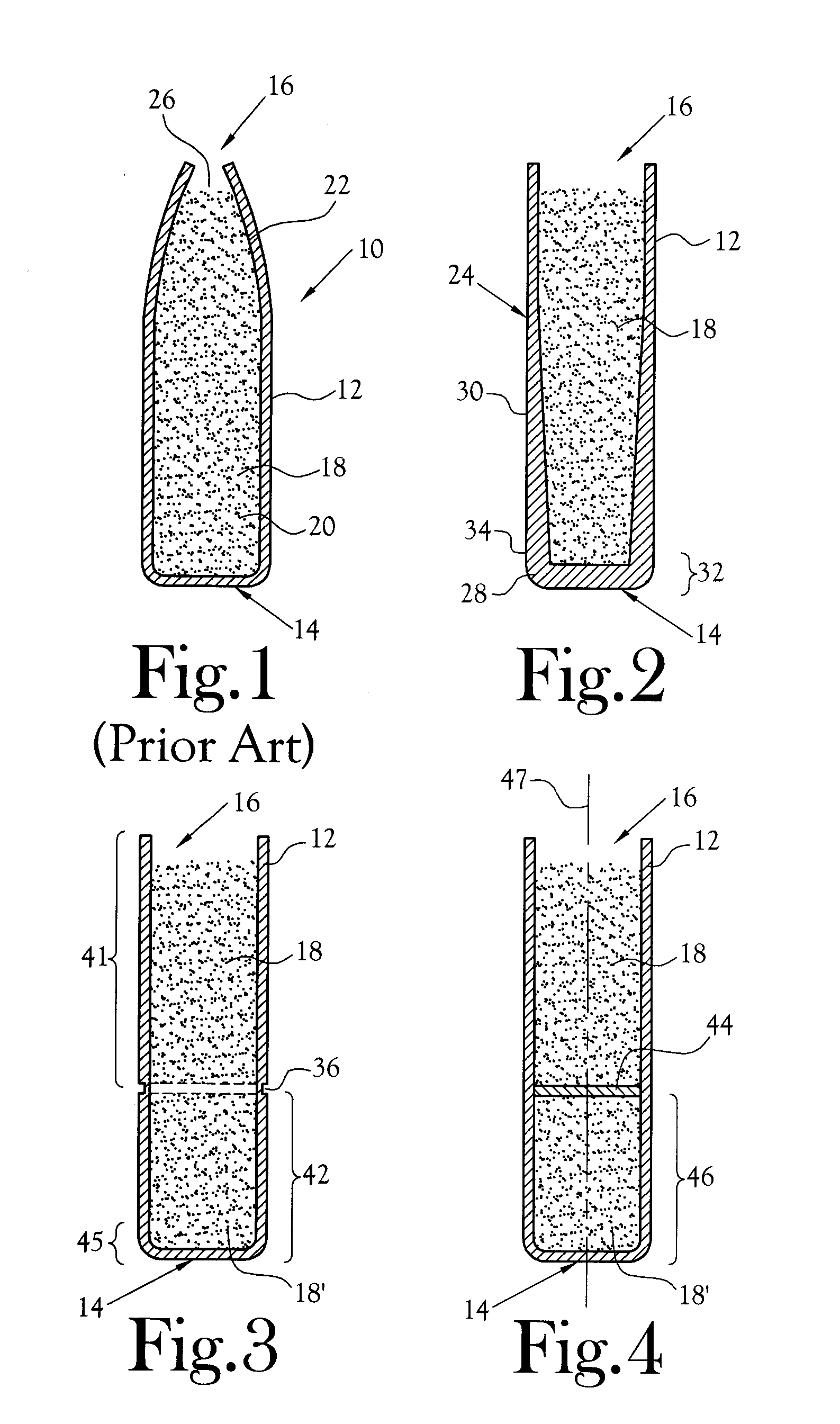

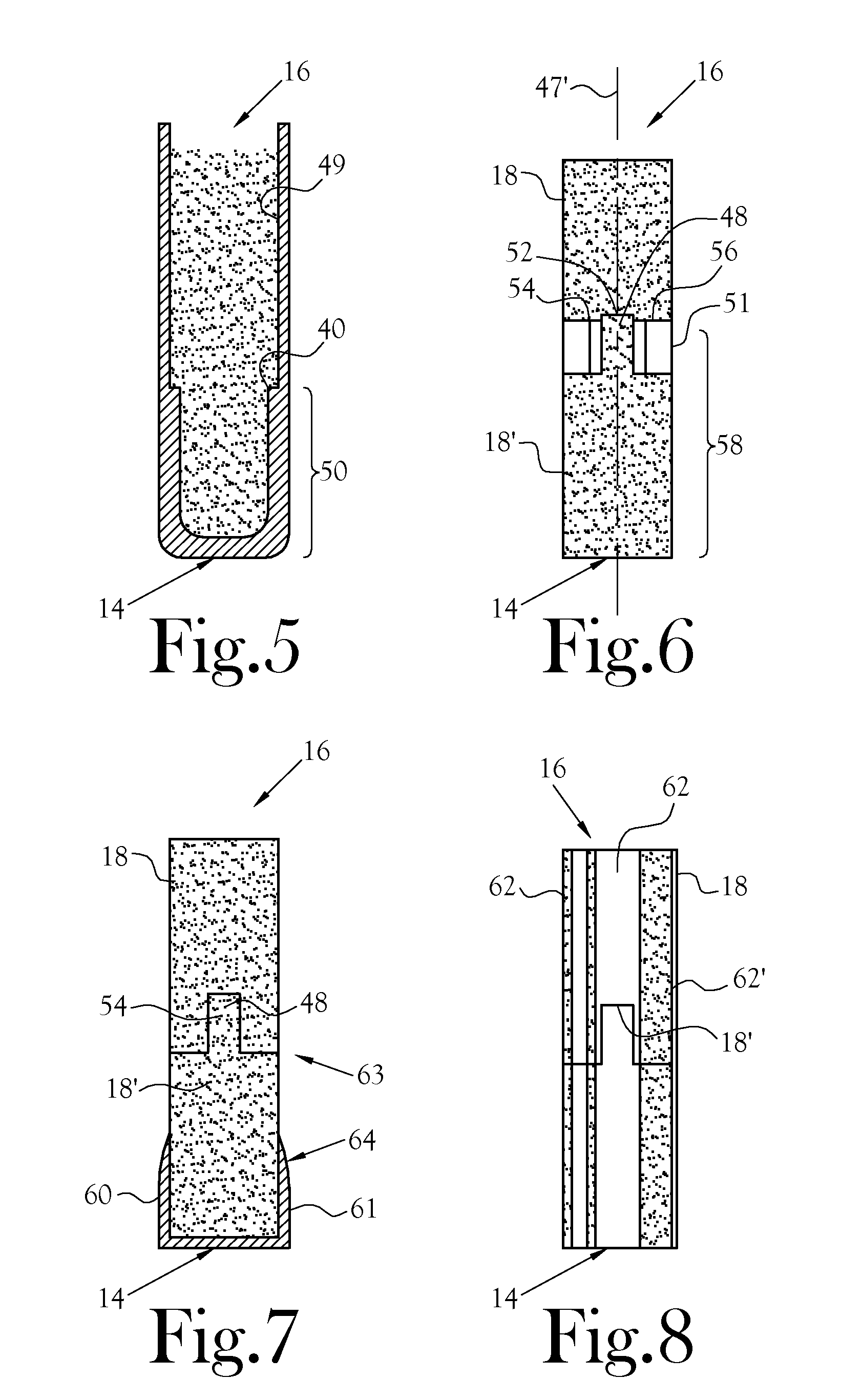

Self contained internal chamber for a projectile

ActiveUS20170322001A1Increase pressureGood flexibilitySelf-propelled projectilesCartridge ammunitionCombustionSpins

The present disclosure provides a projectile with a self-contained internal chamber. Reaction of propellant inside the internal chamber can generate high pressure and the resultant exhaust gases can be used for projectile linear acceleration, rotational acceleration or other purposes. Torque can be produced by exhausting the pressure via radially placed, tangential nozzles or other outlets and can be configured to induce sufficient projectile spin to stabilize the projectile without the need for barrel rifling. The internal chamber may be separate or integral to the projectile itself. The projectile may include two or more chambers or compartments internal to the chambers. The disclosed projectile allows for higher pressures in the internal chamber than in the barrel and greater flexibility on pressure manipulation in the barrel and the projectile, allowing for a more efficient propellant combustion and manipulation of projectile characteristics such as muzzle and rotational speeds.

Owner:DIMOSTHENIS PANOUSAKIS

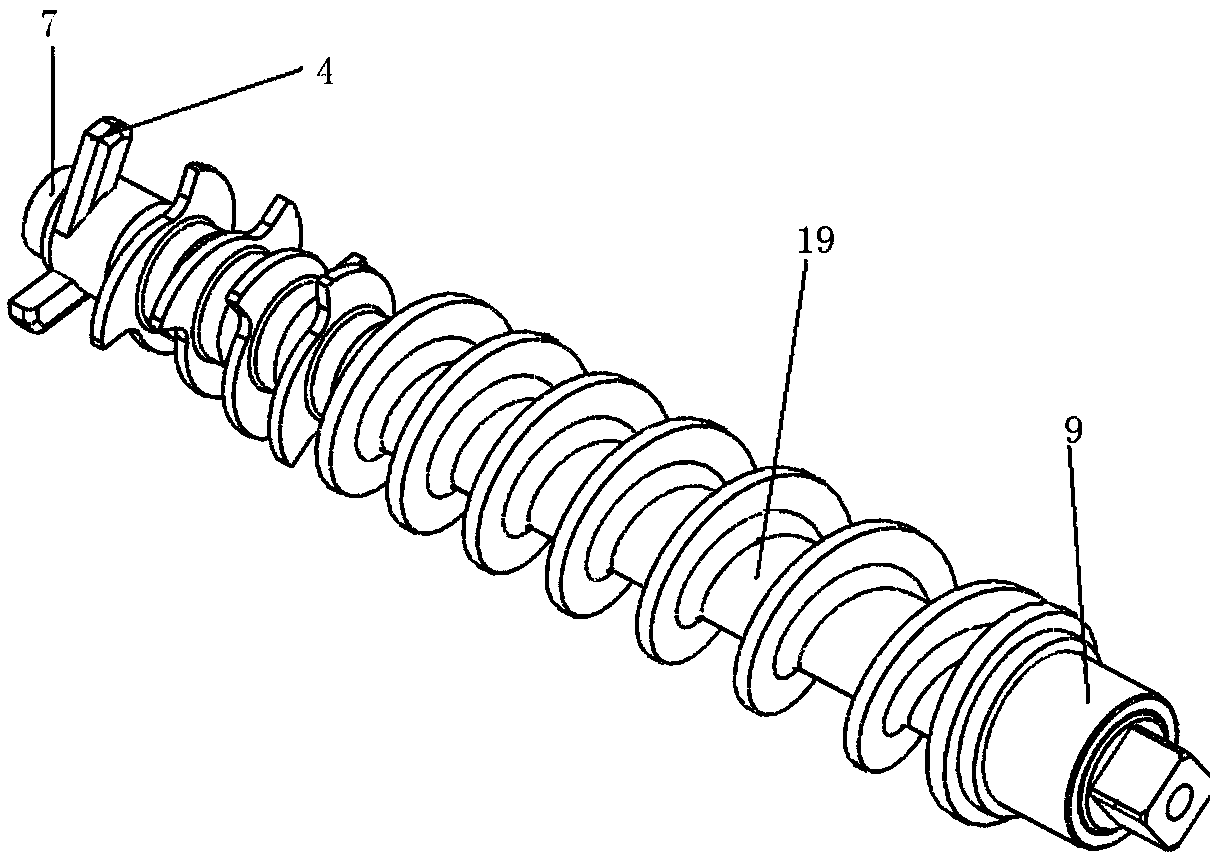

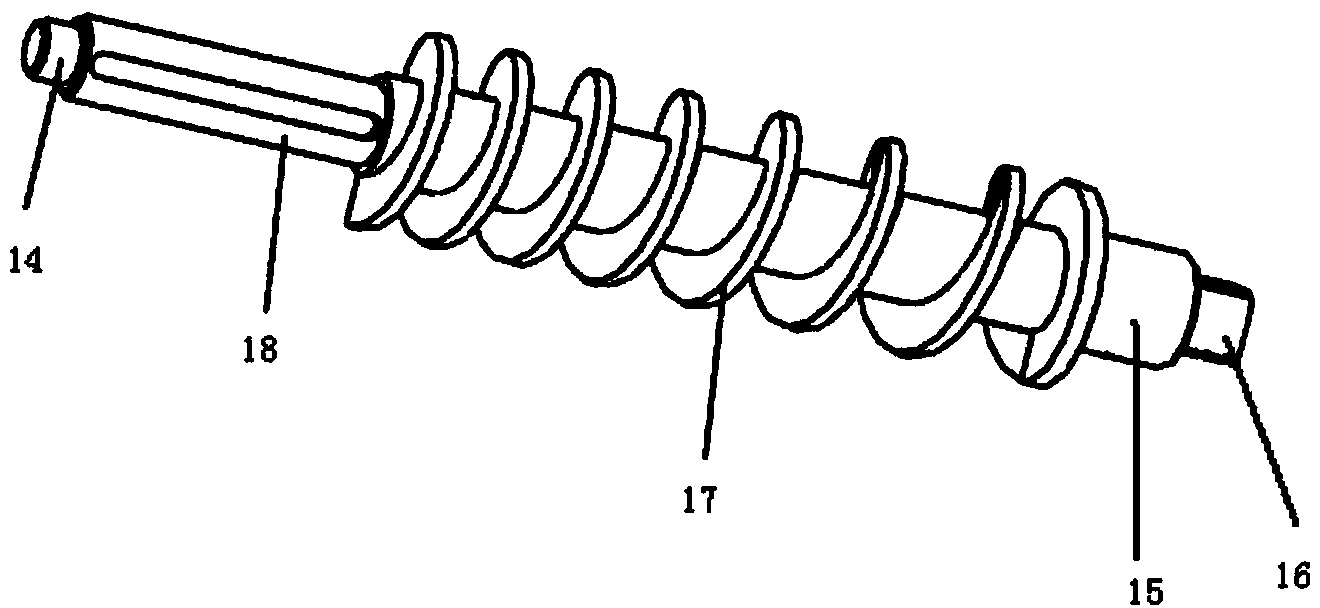

Meat grinder with blending function

A meat grinder with blending function is provided. A plurality of beating hammer claw wheels are arranged on the middle of a screw of the meat grinder, and a plurality of raised extrusion riflings are circumferentially arranged in the inner wall of the cylinder in a section corresponding to the beating hammer claw wheels, so that the meat cubes are applied with extrusion effect from rotating hammer claw wheels and extrusion riflings, and the meat cubes can release part of gelatin in the grinding process. Then minced meat slices are further cut by a porose disc and a cutter broken into granular meat stuffing. After slaking, the meat stuffing minced by the method provided by the invention has good water binding capacity, strong clustering capability and significant fleshy feeling, and can significantly improve the problems of lean taste and scattering in the meat stuffing ground by an existing meat grinder.

Owner:CHINA AGRI UNIV

Firearm projectile

Projectiles for firearms, specifically bullets, are discussed that include a rear thin-walled counter bore. The counter bore is designed to be a first size and shape when the bullet is loaded into the firearm and expand upon discharge of the firearm so as to force the walls of the counter bore into barrel rifling. The expansion may occur through the direct interaction of propellant gases with the counter bore walls, or at least partially indirectly though the inclusion of an expansion plug that is placed at least partially within the counter bore in a manner that the expansion plug can be driven further into the counter bore by the firing action of the firearm.

Owner:THOR INC

Electromagnetic gun with segmented combination between guide rail and rifling

The invention belongs to the field of electromagnetic emissions, and in particular relates to an electromagnetic gun with segmented combination between a guide rail and a rifling. The electromagneticgun comprises shells and bullet pivots, acceleration guide rails, rifling gun barrels, an insulation layer and a guide rail stable barrel, wherein the elastic pivots are rotatably connected with the shells; the acceleration guide rails comprise a first electromagnetic guide rail and a second electromagnetic guide rail which are oppositely arranged and have the same structure; the rifling gun barrels comprise a first rifling gun bore and a second rifling gun bore which are oppositely arranged and have the same structure; the two sides of the rifling gun bores are internally provided with symmetrical inclined rifling with the same rotation direction and the same winding degree, the inner diameter of the electromagnetic guide rails are larger than the inner diameter of the rifling gun barrelsand the two rifling gun bores and the two electromagnetic guide rails are staggered and vertically placed; the insulation layer is arranged between the acceleration guide rails and the rifling gun barrels to isolate the acceleration guide rails and the rifling gun barrels, so that the current flows only in the acceleration guide rail; and the guide rail stable barrel is arranged on the outer periphery of bore tubes. The structure of the electromagnetic gun enables the shells to obtain the linear acceleration in the bores and the obtain the rotation acceleration at the same time, so that theshell can obtain the larger rotation stability ability after the shells are shot out a muzzle, and the hit rate and damage ability of the shells are increased.

Owner:NANJING UNIV OF SCI & TECH

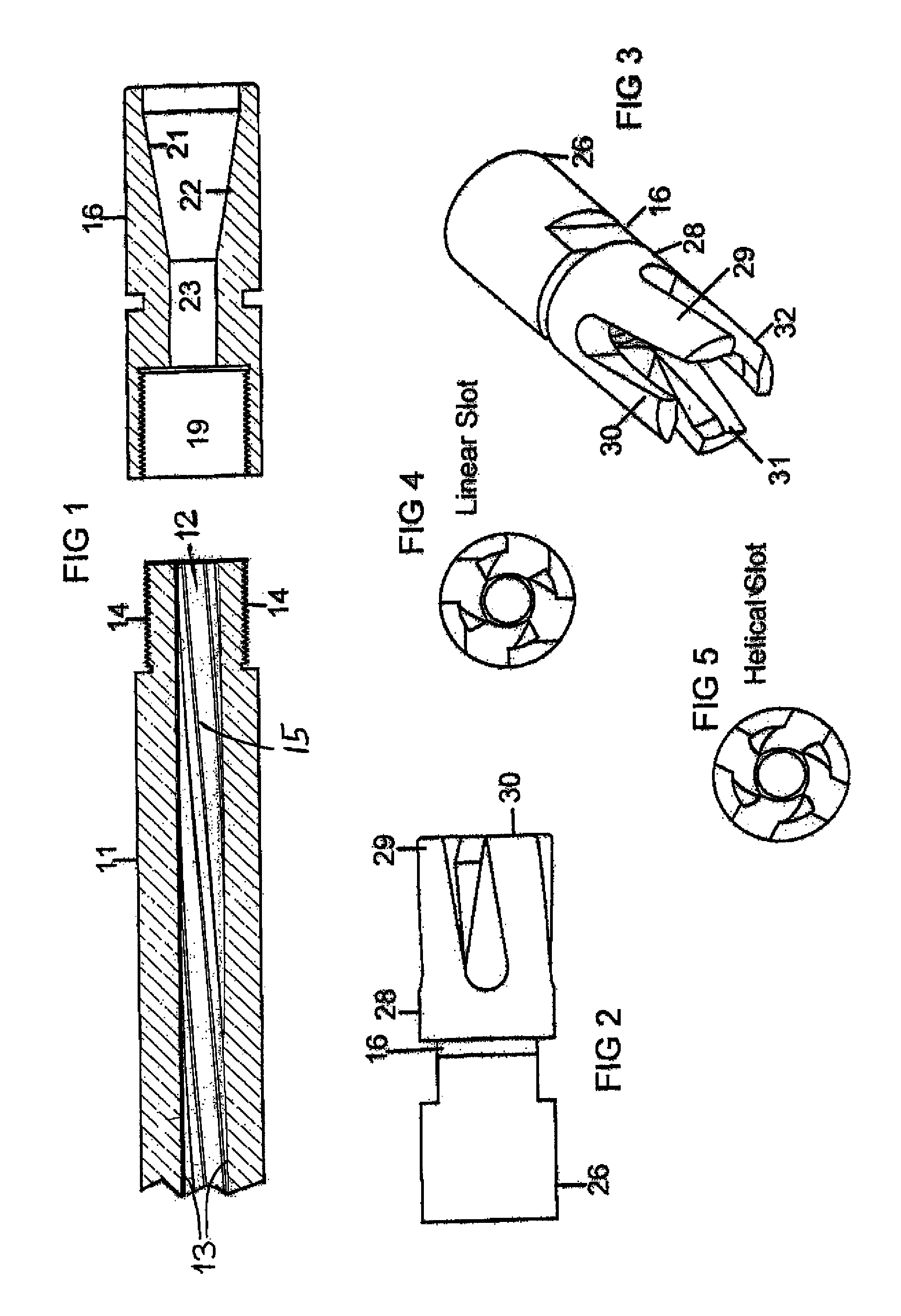

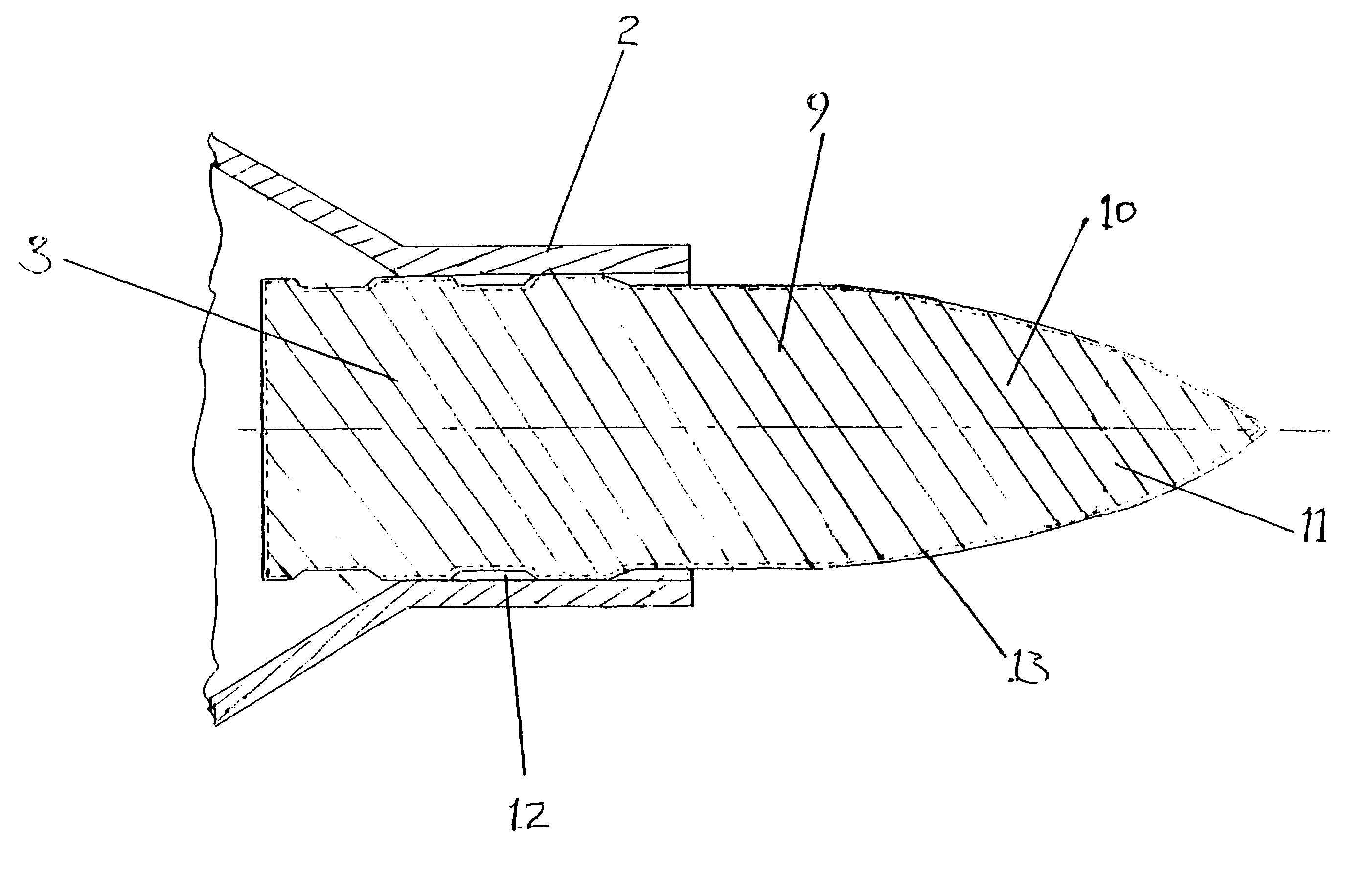

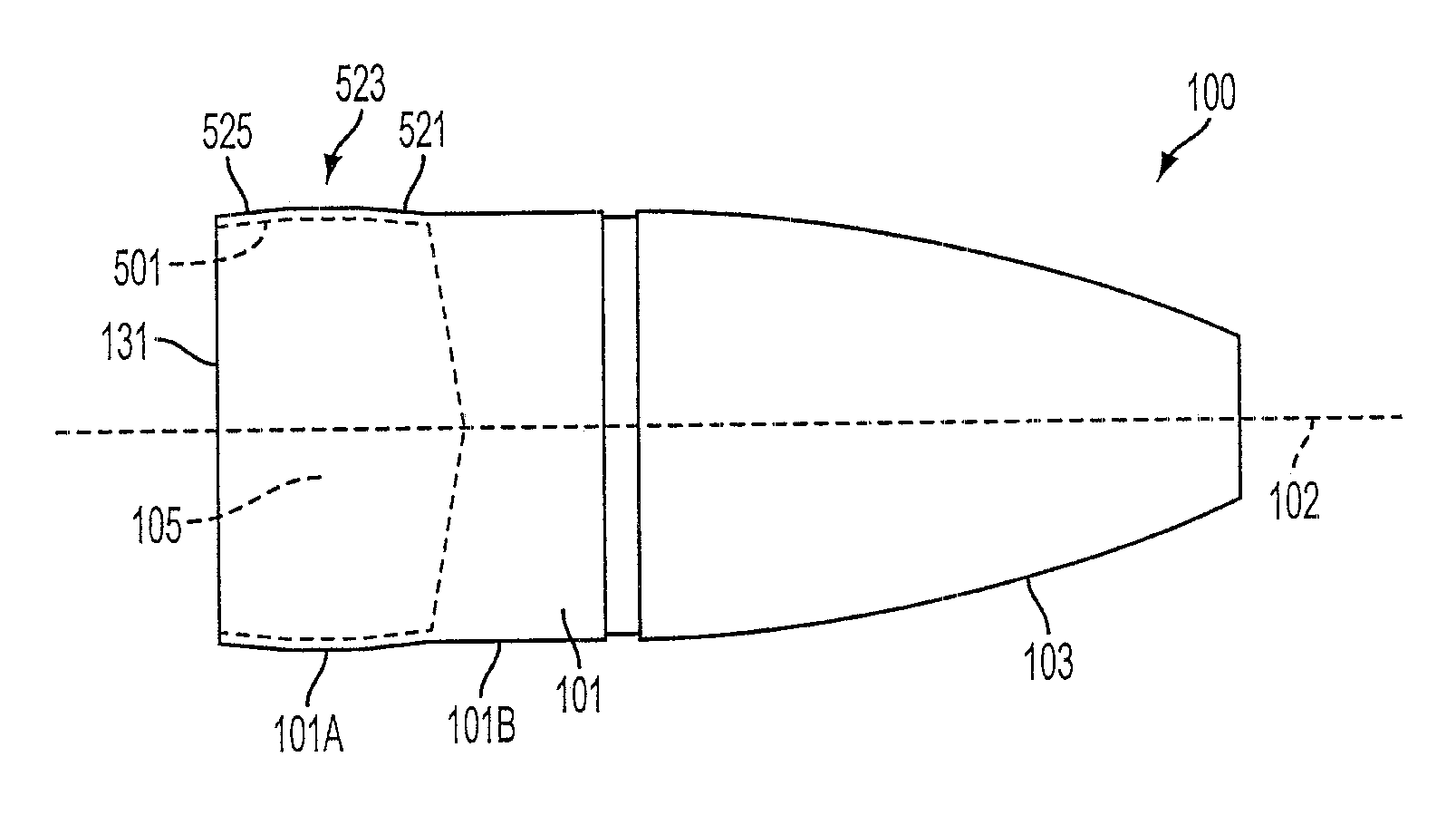

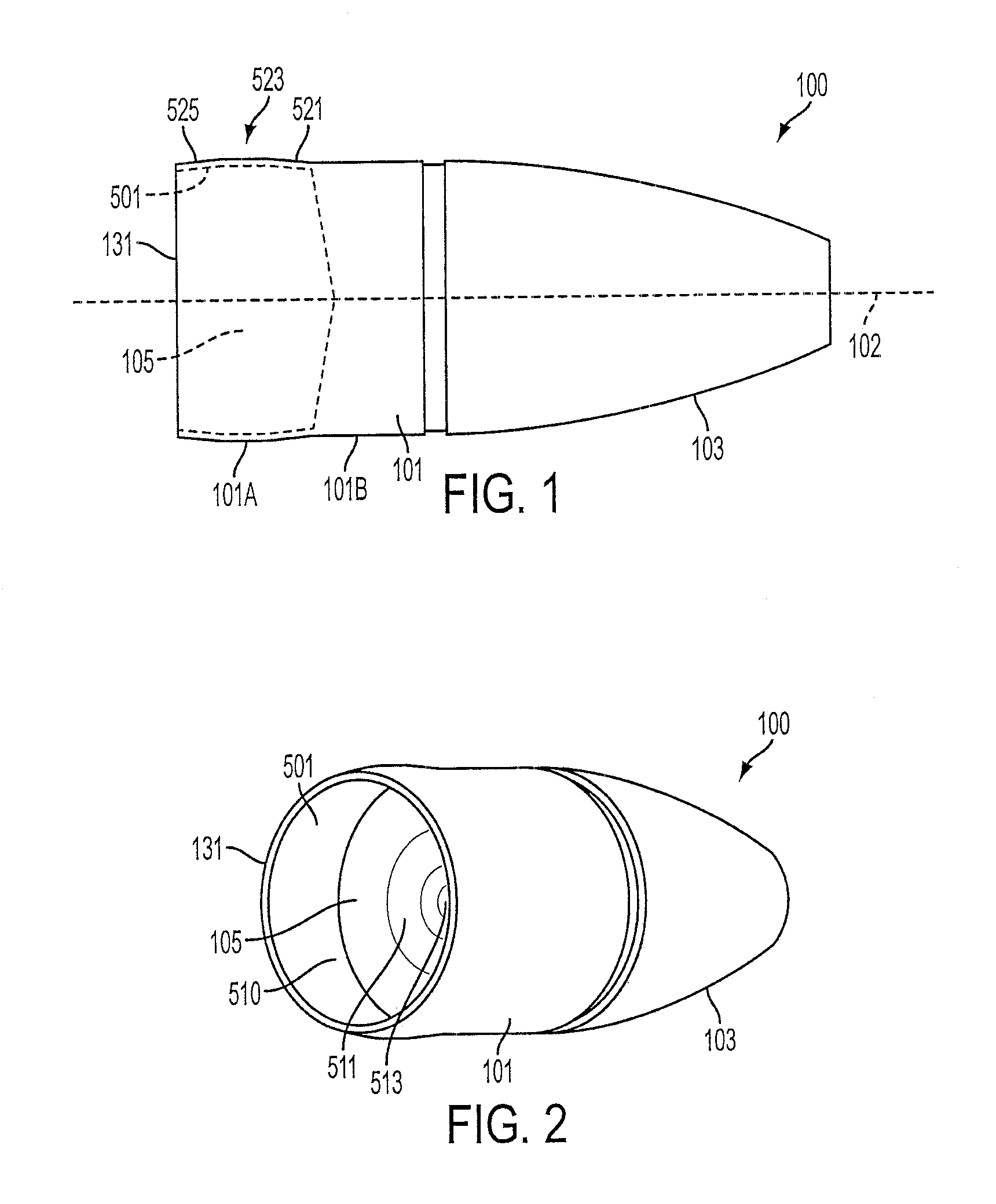

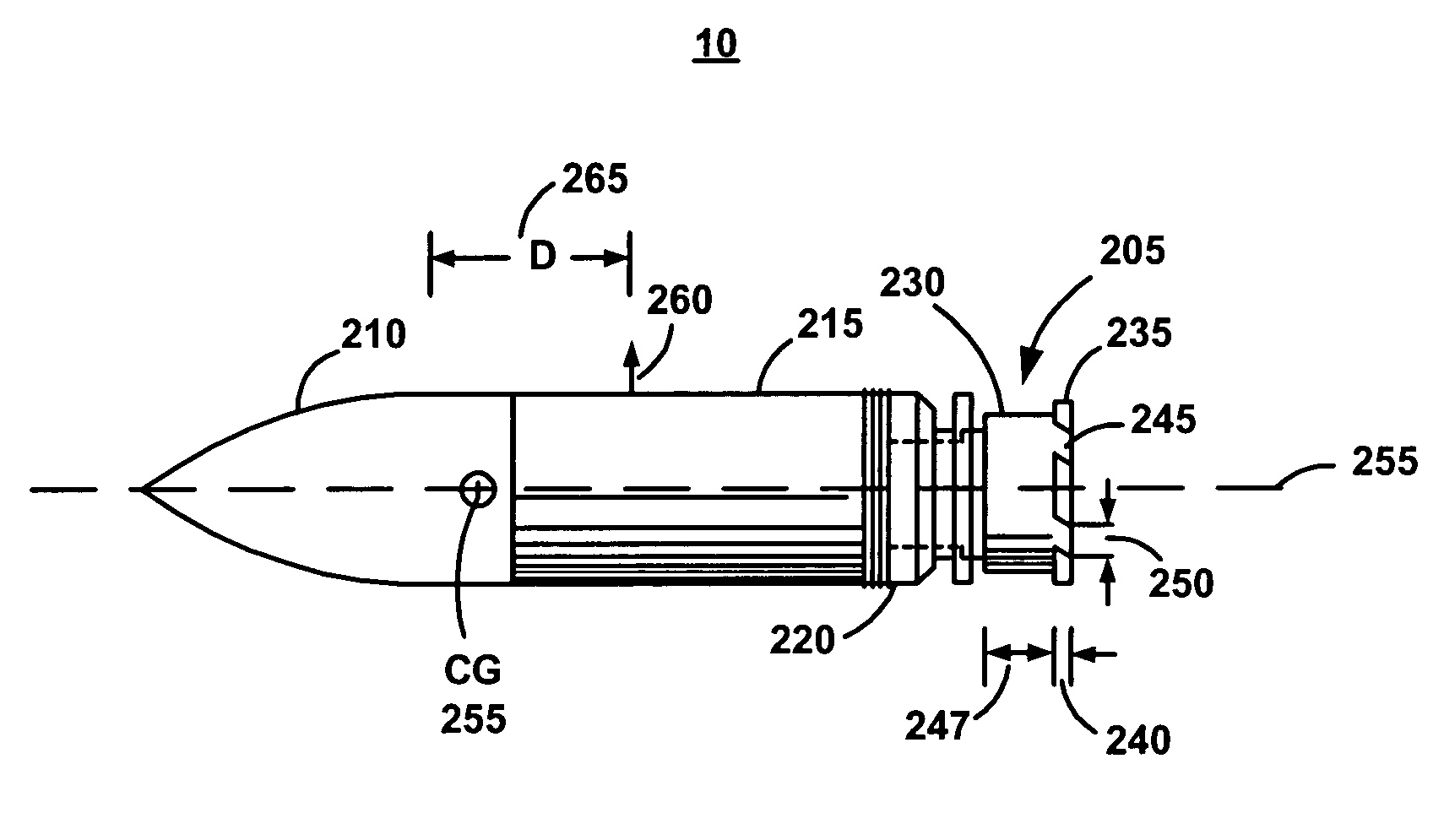

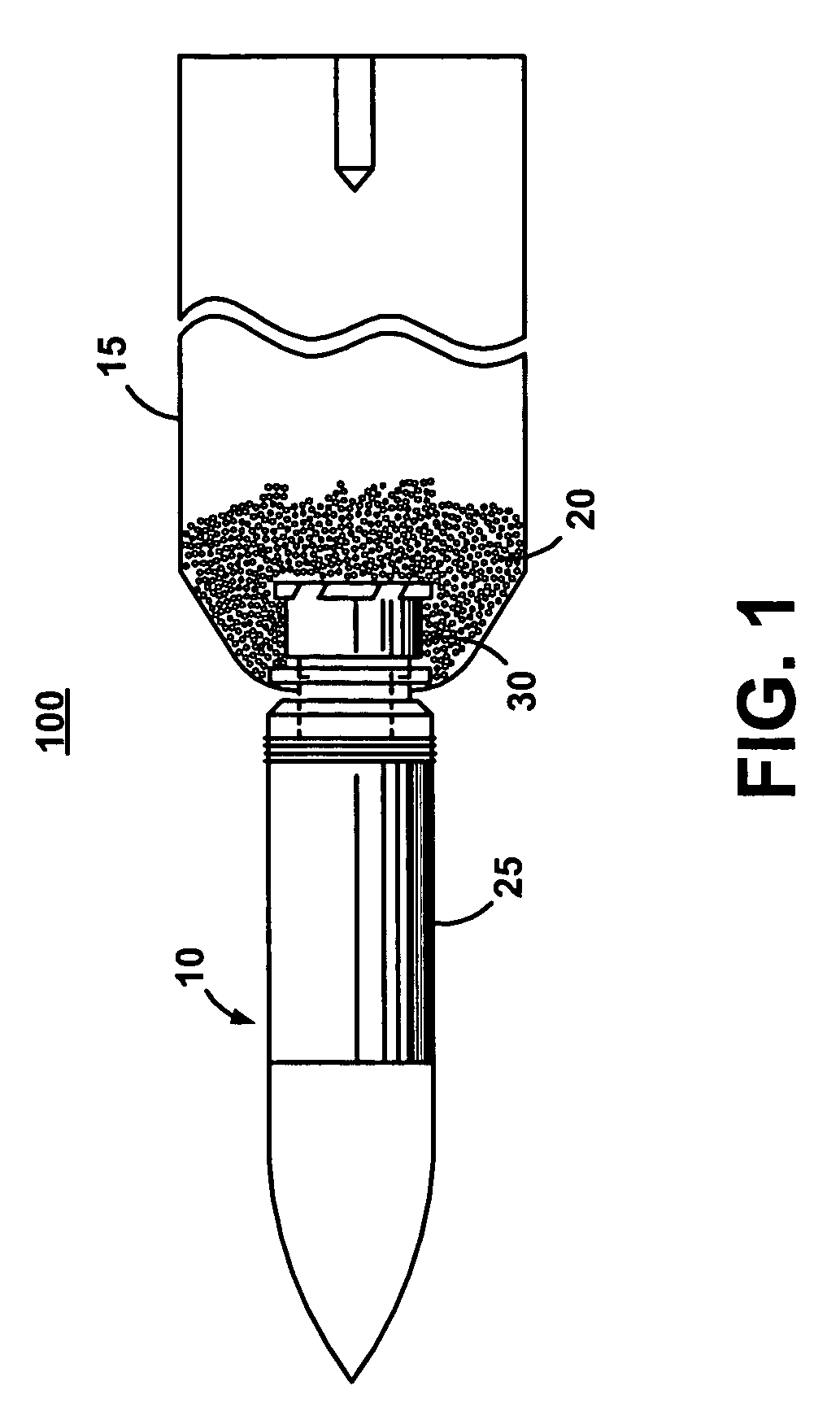

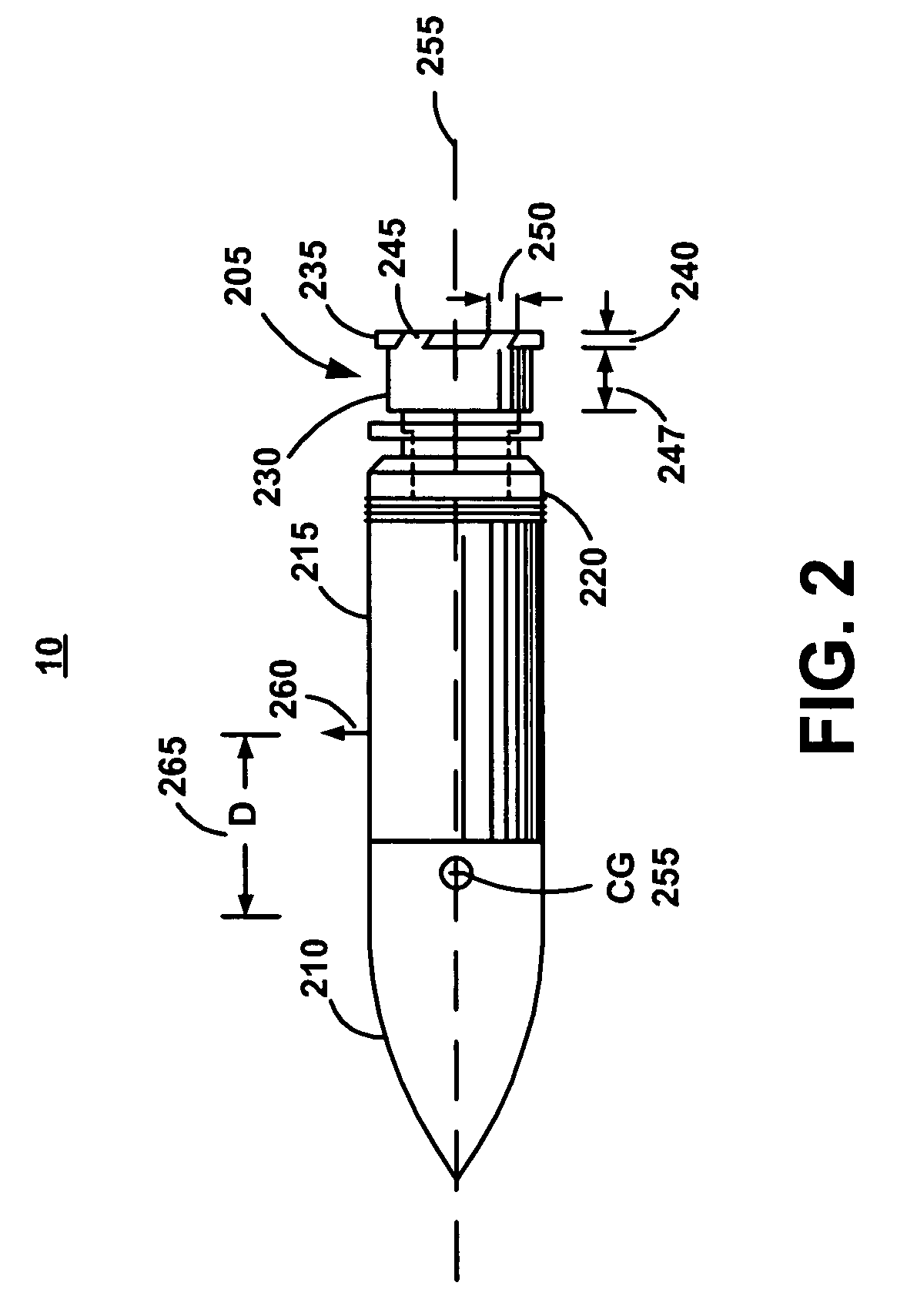

Finless training projectile with improved flight stability over an extended range

InactiveUS7150234B2Improve performanceLow costAmmunition projectilesTraining ammunitionStatic marginMass asymmetry

A finless cone-nosed, ogival-nosed, or combination ogive-cone nosed training projectile is statically stable, yet has adequate spin rate to compensate for aerodynamic or mass asymmetries. In addition, the training projectile can be fired from smooth bore or rifled cannons of various calibers, including 120 mm and 105 mm. Spin torque and stability augmentation are provided by a radially angled slotted tail flange attached to the rear of the training projectile, providing high performance and improved accuracy at low cost for use in training exercises. The training projectile has a higher static margin than conventional devices, and provides the ability to train personnel with a training projectile that achieves flight ranges similar to its matching tactical projectile, and has improved accuracy.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Gun firing method for the simultaneous dispersion of projectiles in a pattern

InactiveUS7845281B2Improve hit rateEasy to useAmmunition projectilesTraining ammunitionEngineeringRifling

A gun firing method whereby multiple projectiles segments that are contained within a cartridge are fired simultaneously in a symmetrical pattern. Some of the multiple projectile segments are modified by moving the center of mass of the projectile segments away from the central longitudinal axis of the cartridge. This in combination with bring fired from a rifled gun barrel will impart velocity to the modified projectile segments upon exiting the gun barrel at right angles to the gun barrel. This velocity along with the higher muzzle velocity will cause the modified projectile segments to diverge away from the trajectory of a standard projectile segment and strike the target away from the bullseye. The magnitude of the divergence will vary with the distance the projectile segment's center of mass is away from the central longitudinal axis of the cartridge. The placement of the modified projectile segments strikes around the bull's-eye will be determined by the orientation of the centers of mass of the modified projectile segments prior to firing. Simultaneously firing a multiplicity of standard and modified projectile segments will produce a symmetrical pattern on a target, which will substantially increase the hit probability of a gun.

Owner:SEXTON RICHARD FR

Gun firing method for the simultaneous dispersion of projectiles in a pattern

InactiveUS20100282110A1Improve hit rateEasy to useAmmunition projectilesTraining ammunitionEngineeringRifling

A gun firing method whereby multiple projectiles segments that are contained within a cartridge are fired simultaneously in a symmetrical pattern. Some of the multiple projectile segments are modified by moving the center of mass of the projectile segments away from the central longitudinal axis of the cartridge. This in combination with bring fired from a rifled gun barrel will impart velocity to the modified projectile segments upon exiting the gun barrel at right angles to the gun barrel. This velocity along with the higher muzzle velocity will cause the modified projectile segments to diverge away from the trajectory of a standard projectile segment and strike the target away from the bullseye. The magnitude of the divergence will vary with the distance the projectile segment's center of mass is away from the central longitudinal axis of the cartridge. The placement of the modified projectile segments strikes around the bull's-eye will be determined by the orientation of the centers of mass of the modified projectile segments prior to firing. Simultaneously firing a multiplicity of standard and modified projectile segments will produce a symmetrical pattern on a target, which will substantially increase the hit probability of a gun.

Owner:SEXTON RICHARD FR

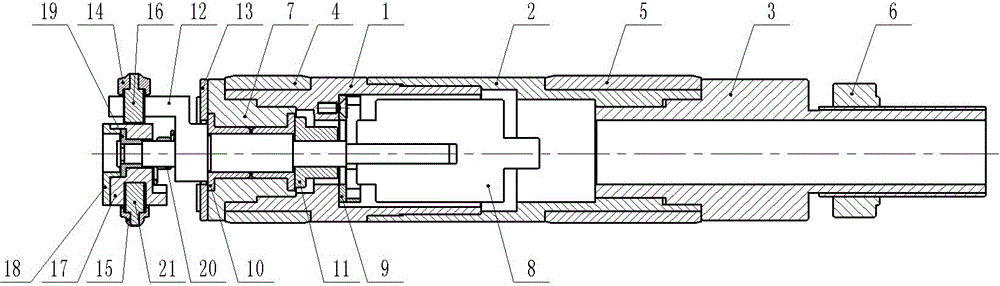

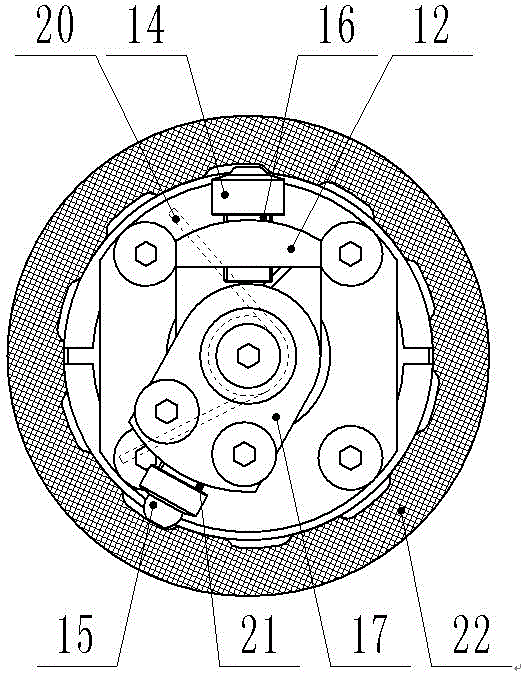

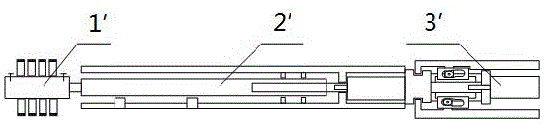

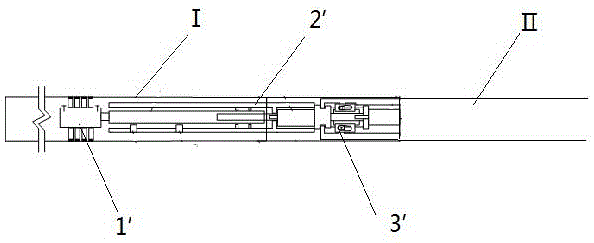

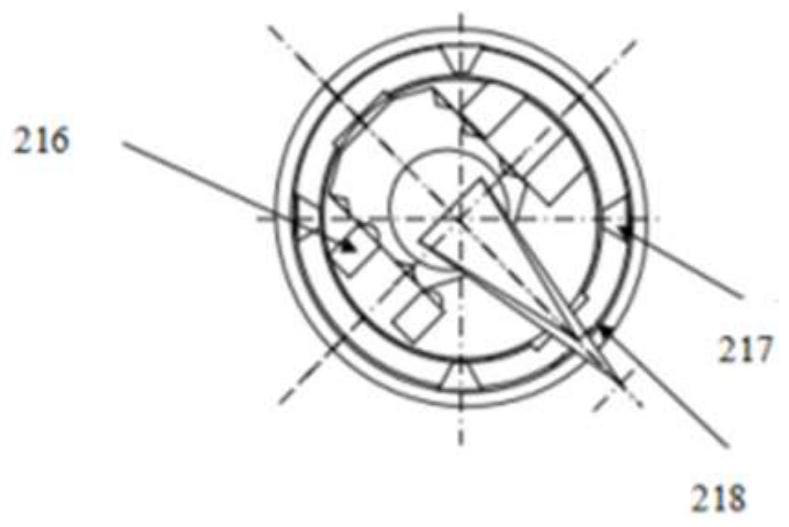

Detecting device for rifling angle of small-caliber gun barrel

The invention discloses a detecting device for rifling angle of a small-caliber gun barrel. The base of the device is used as the mounting carrier of the whole device. An adaptor seat is connected with the base through a screw thread. A front sliding copper sleeve and a back sliding copper sleeve respectively sleeve the base and the adaptor seat. A connecting shaft is connected with the other end of the adaptor seat through a screw thread. The other end of the connecting shaft is connected with a locking nut through a screw thread. A coder mounting sheet is fixedly connected with the inner hole of the base through a screw. A coder is snapped on the coder mounting sheet. A bearing seat is fixedly connected with the other end of the base through a screw thread. The detecting device is suitable for detecting the rifling angles of the small-caliber gun barrels with different specifications. Furthermore the detecting device has advantages of simple structure, easy operation, high detecting precision and high suitability for popularization.

Owner:中国兵器装备集团自动化研究所有限公司

Providing spin to composite projectile

Owner:GFY PROD LLC

High velocity ammunition system and firearm

A round of high velocity ammunition contained within a modified chamber of a conventional firearm has a cartridge case, a sabot mounted within the forward-end of the case and a carrying projectile matching the caliber of the firearm for engaging rifling in the firearm bore, and a quantity of a propellant charge sufficient to impart a muzzle velocity in excess of 25,000 (ft. / sec.) to the projectile. The cartridge case and the projectile cooperate with a rearwardly facing abutment surface of the chamber to confine the sabot which has an forwardly facing bearing surface coaxially surrounding a portion of the projectile and in abutting engagement with the abutment surface. When the round is fired substantially instantaneous dynamic forces generated by the gases of explosion propel the projectile from the chamber into and through the bore while simultaneously comprising the sabot to a fracture point. The fragmented sabot is entrained in the gases of explosion and escapes from the firearm through the muzzle end of the barrel.

Owner:SMITH & WESSON

Device and method for processing crop residue into nutritional products

ActiveUS20160037803A1Increase pressureIncrease internal temperatureMilk treatmentFeeding-stuffEngineeringCrop residue

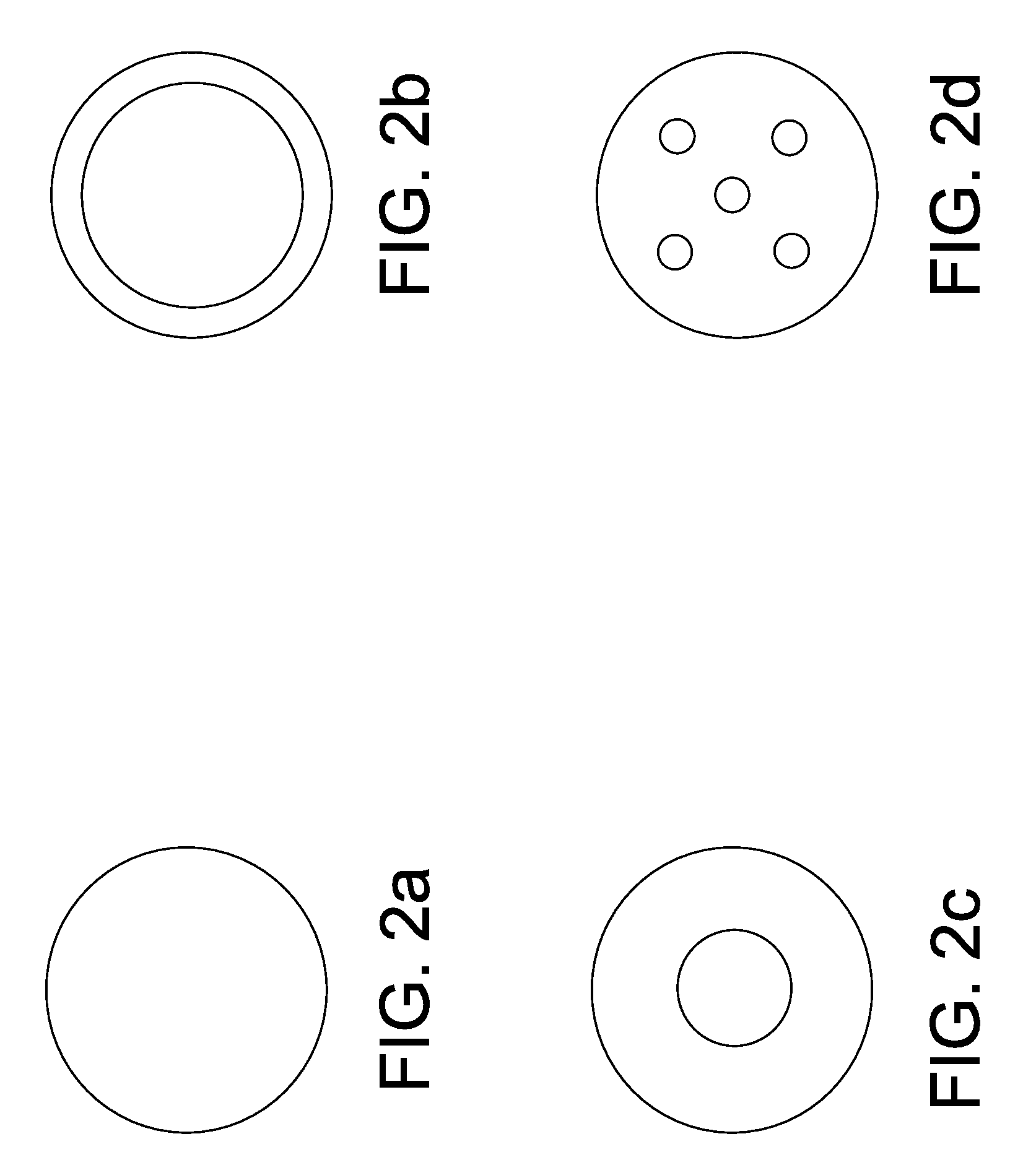

A pressure device has a rifled barrel, a rifled end cap, a section clamped to the barrel, a circular flange welded to a threaded male pipe connection, a plate with holes or a cone, a female cap receiving the plate and aligning the holes to the rifling in the barrel, and the flange threadily engaging the cap, securing the plate. The rifled barrel provides shearing, increased pressure, and higher temperatures upon the passing crop residue. The increased surface area of the rifling grooves increases temperature and pressure between the crop residue and the barrel wall. The rifling, when misaligned, creates a pressure chamber that further breaks down the molecules in the crop residue. The crop residue then enters a popper device. The pressure in the popper device forces the crop residue through the holes of plate or around an encased cone, relieving excess pressure and producing a nutritional animal feed.

Owner:PETERFREUND LAURIE A +1

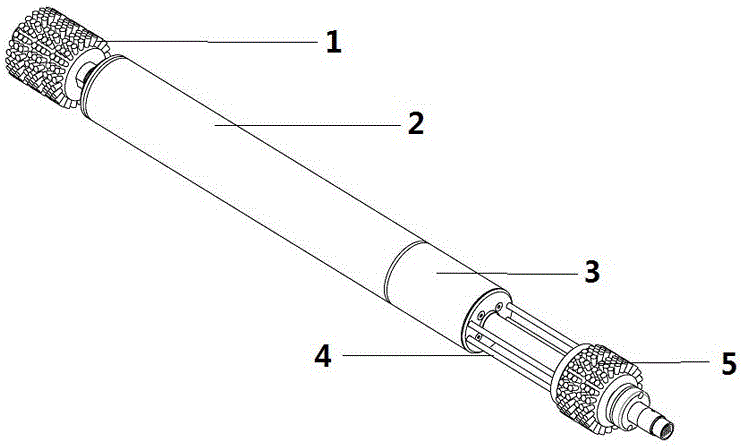

Automatic bore scrubbing device and bore scrubbing system

The invention relates to a pipeline washing and pipeline maintaining device, in particular to a bore scrubbing device. Since carbon is accumulated inside a bore and mixtures of carbon and metal filing are generated on a rifling of the bore after a gun is used, the bore scrubbing device is used for scrubbing the bore so as to improve the gun precision. The bore scrubbing device comprises a head scrubbing head device, a reciprocating drive device and a brake device, and is characterized by further comprising a head-tail linkage device and a tail scrubbing head device; the head scrubbing head device is driven by the reciprocating drive device; the brake device is used for fixing the bore scrubbing device to the inner wall of the bore; and the head-tail linkage device is used for correlating the tail scrubbing head device with the head scrubbing head device. The bore scrubbing device has the advantages that as the head scrubbing head device and the head scrubbing head device are adopted, an additional bore does not need to be additionally arranged, and comprehensive scrubbing can be achieved; and due to supporting of the head and tail, the axis of the bore scrubbing device is prevented from inclining relative to the axis of the bore, movement resistance of the bore scrubbing device is reduced, two-end scrubbing is conducted simultaneously, and the effect is remarkably improved.

Owner:上海尔速机械设备有限公司

Gun-launched ballistically-stable spinning laser-guided munition

Owner:RAYTHEON CO

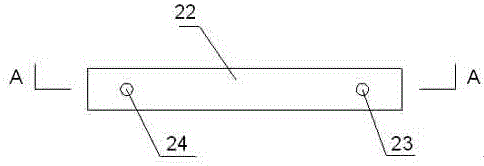

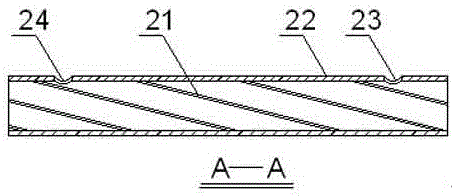

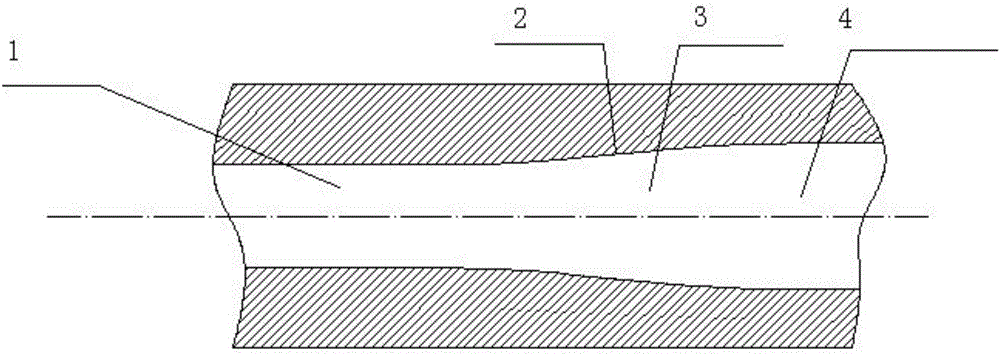

Grouting sleeve for steel bar connection

InactiveCN106801488AImprove tensile propertiesImprove shear resistanceBuilding reinforcementsShear capacitySteel bar

The invention discloses a grouting sleeve for steel bar connection, which comprises a sleeve body, wherein a grouting opening is formed at one end of the sleeve body; a grout outlet is formed at the other end of the sleeve body. The grouting sleeve is characterized in that the sleeve body is made of a seamless steel pipe; two or more riflings are arranged on an inner wall of the sleeve body; convex rifling ribs and concave rifling grooves are formed on the inner wall of the sleeve body; spacings between the adjacent rifling ribs are equal. The grouting sleeve takes the seamless steel pipe as a raw material, and the two or more riflings are arranged on an inner wall of the steel pipe, so that the tensile capacity, the shear capacity and the compressive capacity of the sleeve are good; the full-grouting or semi-grouting sleeve is manufactured according to different requirements, so that the sleeve is simple in structure and convenient to process and manufacture, and avoids the defects of high production waste, high pollution and high cost of the existing grouting sleeve.

Owner:SHENZHEN CITY MODERN BUILDING SCI & TECH

Rifle barrel and method of determining rifling twist for very long range accuracy

A rifle having a rifled barrel and a cartridge having a bullet having a diameter, a length, a ballistic coefficient (BC), and a muzzle velocity (V1) greater than 1250 ft / sec are related to achieve accuracy at very long range in that the twist of the rifling is substantially equal to:83.7÷(bulletlength×2BCbulletdiameter)×bulletdiameter×[1+(V3V1×0.667)]where: V2 is the entry speed for the transonic, i.e. 1,250 ft / sec., and V3 is V1 minus V2. A rifle barrel for receiving a bullet has rifling twist according to the relationship. A method uses the relationship to determine the rifling twist for a rifle barrel receiving a known bullet. Another method uses the relationship to design a cartridge for a known barrel rifling. The relationship is particularly applicable for bullets having a high BC, such as 0.325 or greater.

Owner:BARTOLI DAVID JOHN

Traceable Frangible Projectile

A frangible projectile useful in a round of gun ammunition wherein, upon striking a target, the projectile selectively disintegrates, leaving intact at least one portion or appurtenance of the projectile which is recoverable for purpose of identification of rifling markings thereon and / or other analysis.

Owner:DORIS NEBEL BEAL INTER VIVOS PATENT TRUST PAWLEYS ISLAND

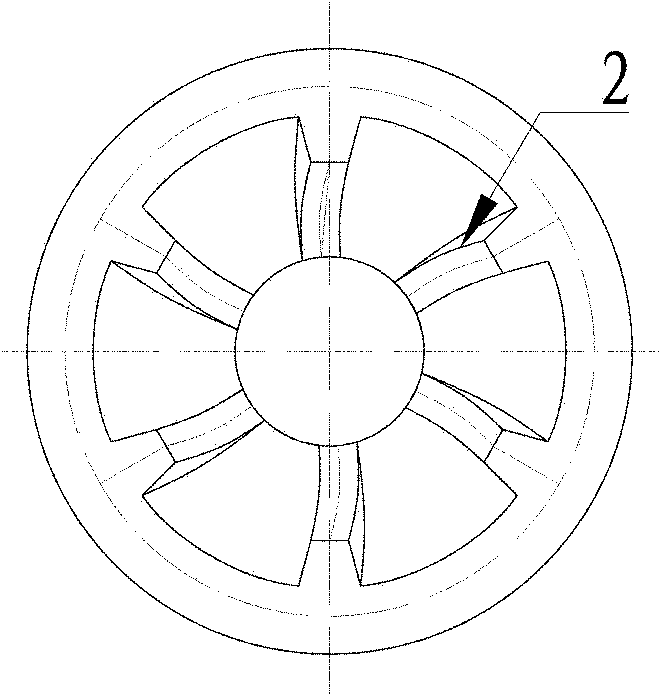

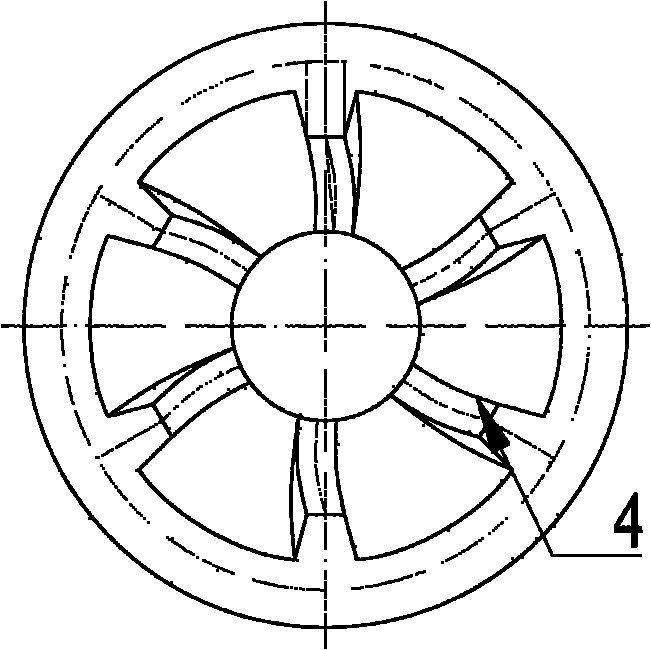

Weapon system composed of multi-section gun tube and fluid-driven spinning projectile and method

PendingCN106839868AIncrease kinetic energyAvoid vigorous squeezingBarrelsProjectilesEngineeringWeapon system

The invention discloses a multi-section gun tube, a fluid-driven spinning projectile and a weapon system composed of the multi-section gun tube and the fluid-driven spinning projectile. A volute hole or slot is formed in the rear or tail part of the projectile to guide a propellant gas and is combined with the multi-section gun tube, so that the projectile can form spinning in a hydrodynamic way instead of depending on rifle cutting. By virtue of such a trial, the projectile spinning can also be realized while the high bore pressure, high initial speed and low resistance of a smoothbore gun are achieved, and the costs of the gun tube and the projectile are reduced.

Owner:朱锐泷

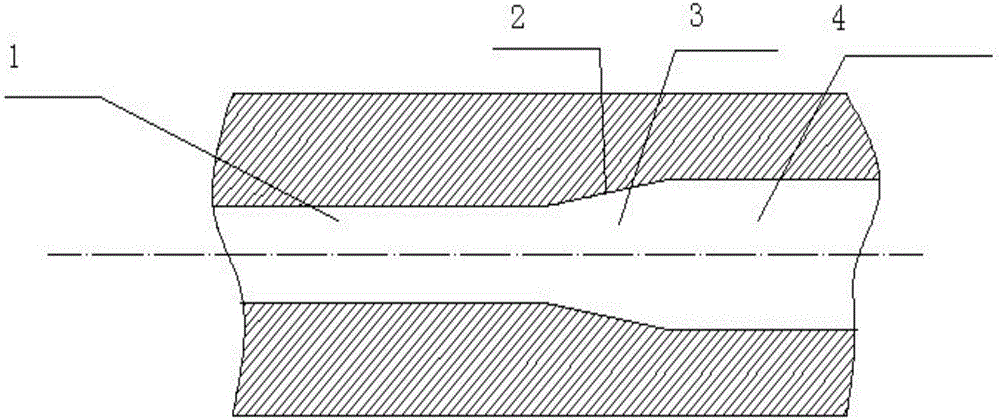

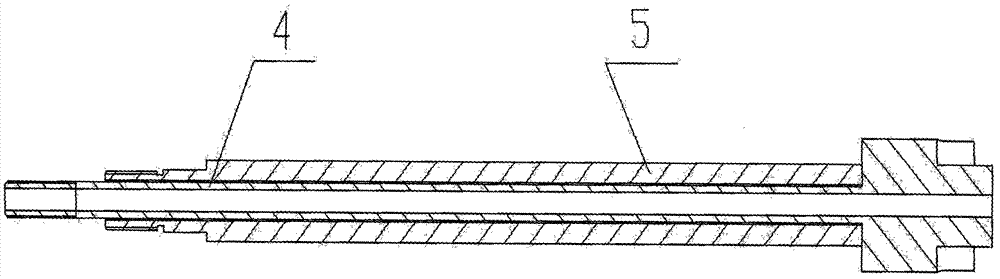

Broaching tool for machining small-caliber gun body tube inner hole rifling

The invention relates to a broaching tool for machining small-caliber gun body tube inner hole rifling, and belongs to the technical field of machining. The broaching tool comprises a bracing wire tool rod, a bracing wire tool apron and a bracing wire tool bit. A tool clamp of the bracing wire tool apron is arranged in a tool clamp mounting hole of a tool apron body through a connecting shaft, the tool clamp is made to rotate around the tool clamp mounting hole of the tool apron body, and the bracing wire tool bit is fixed in a mounting groove in the upper surface of the tool clamp. A core rod is inserted into the tool apron body. The rear end of the tool apron body is in threaded connection with a tool rod body of the bracing wire tool rod, the rear end of the core rod is in threaded connection with a pull rod of the bracing wire tool rod, the tool rod body and the tool apron body are controlled through a pulling plate on a machine tool spindle box to move front and back relative to the pull rod and the core rod, and the core rod drives the front end of the tool clamp to vertically swing through two tapered columns. The bracing wire broaching tool is simple in structure and convenient to use, the tool is accurately stretched out and drawn back in the radial direction in the mechanical broaching process of the small-caliber gun body tube rifling, and therefore the broaching machining of the rifling is achieved.

Owner:SHANXI NORTH MACHINE BUILDING

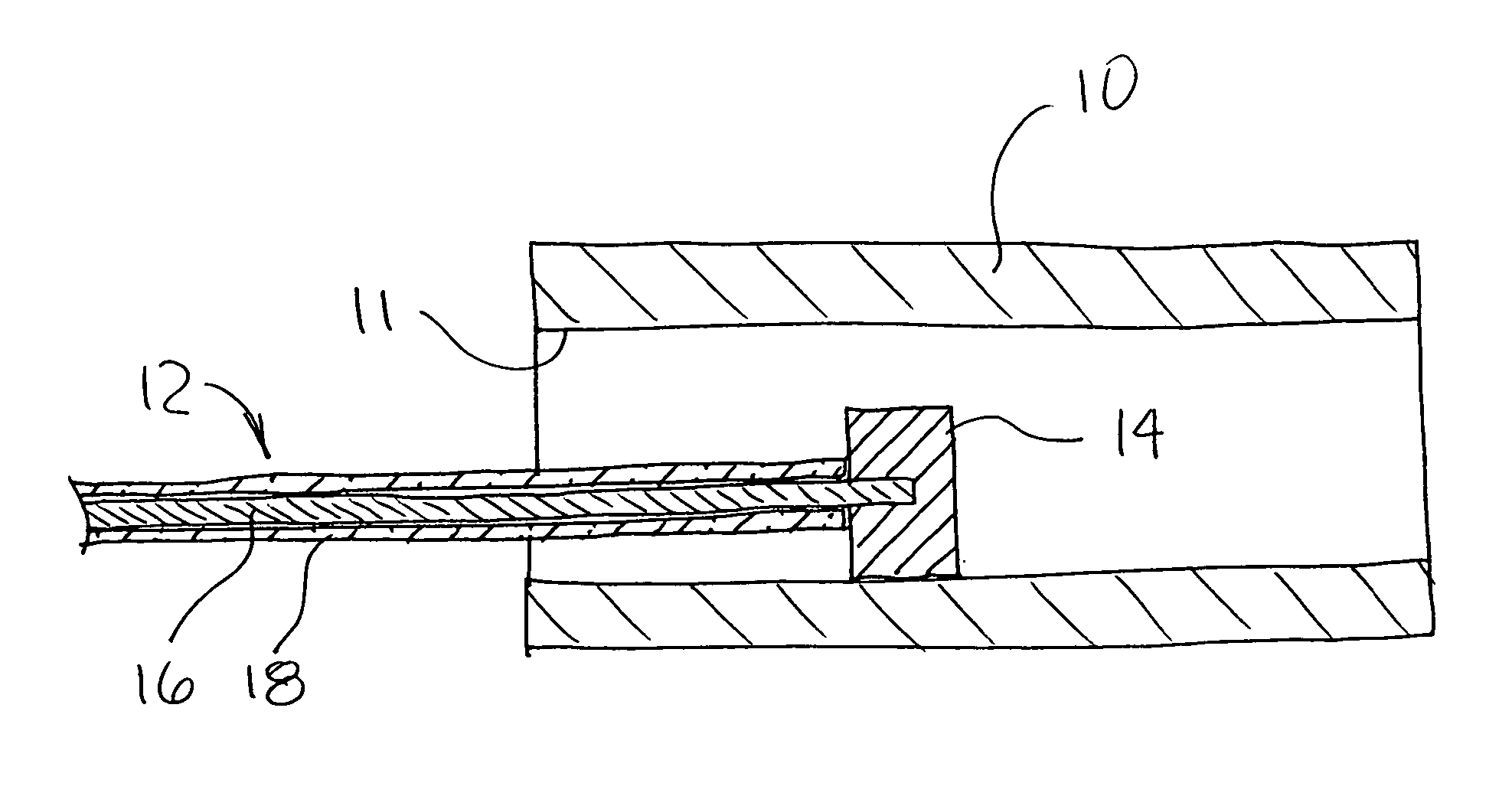

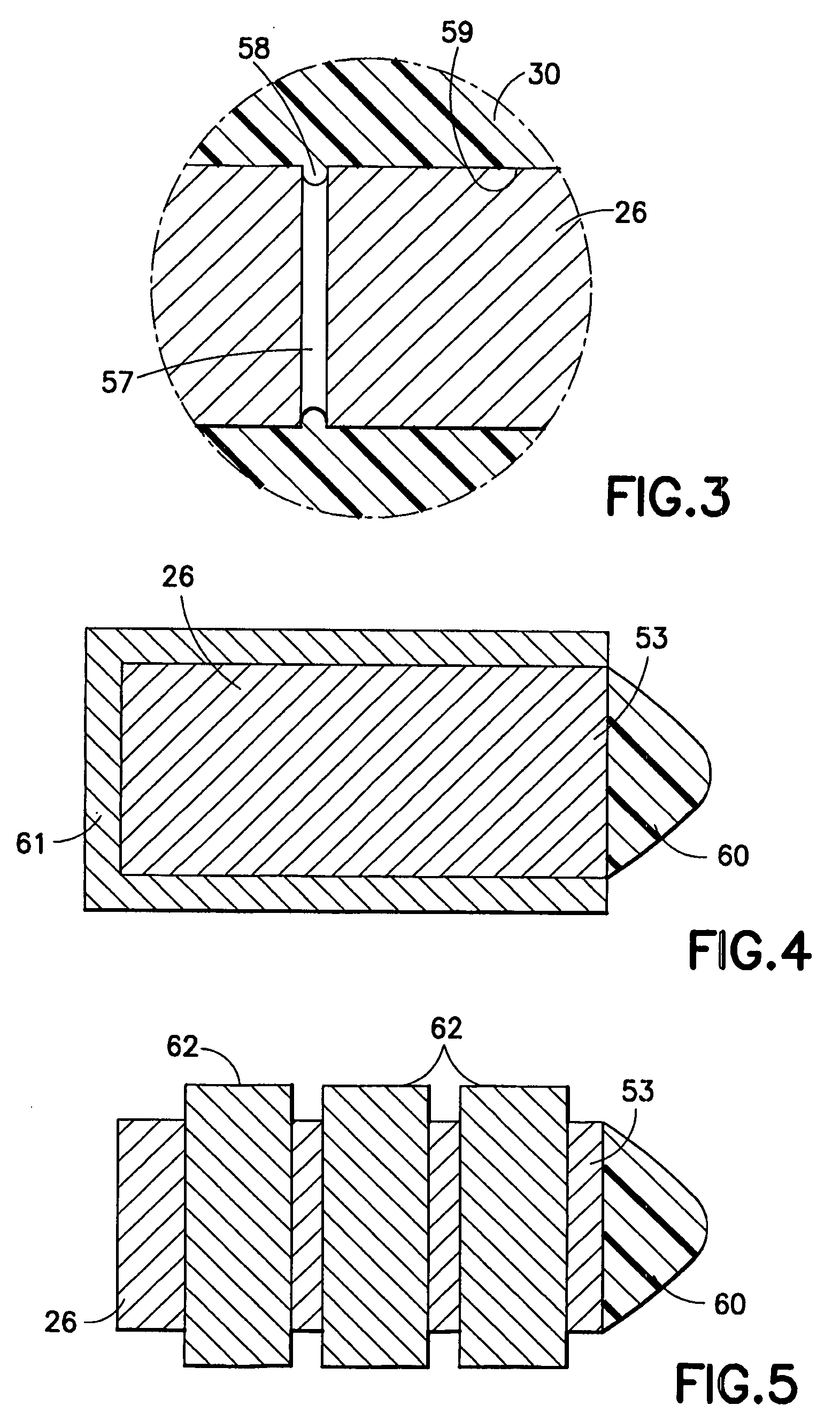

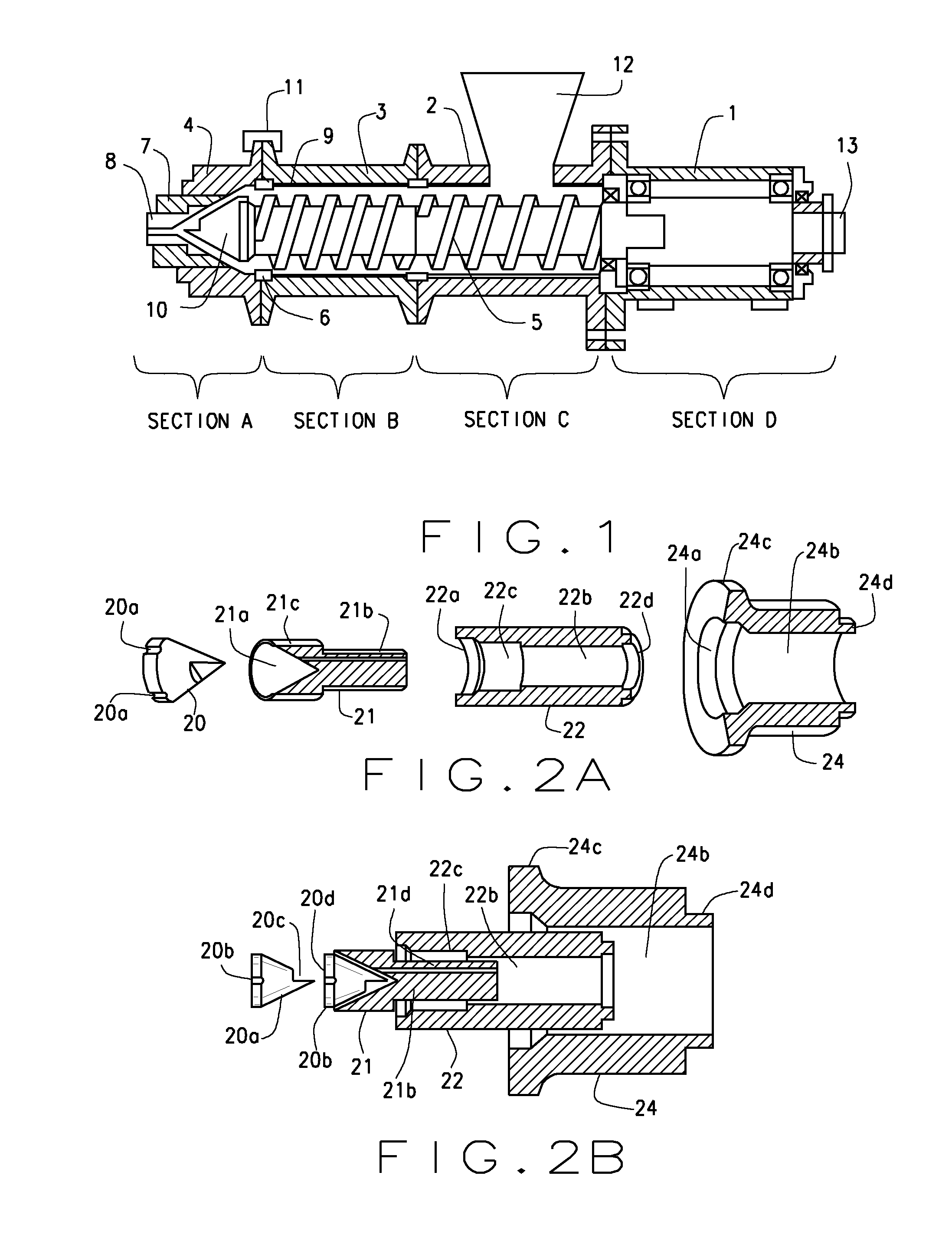

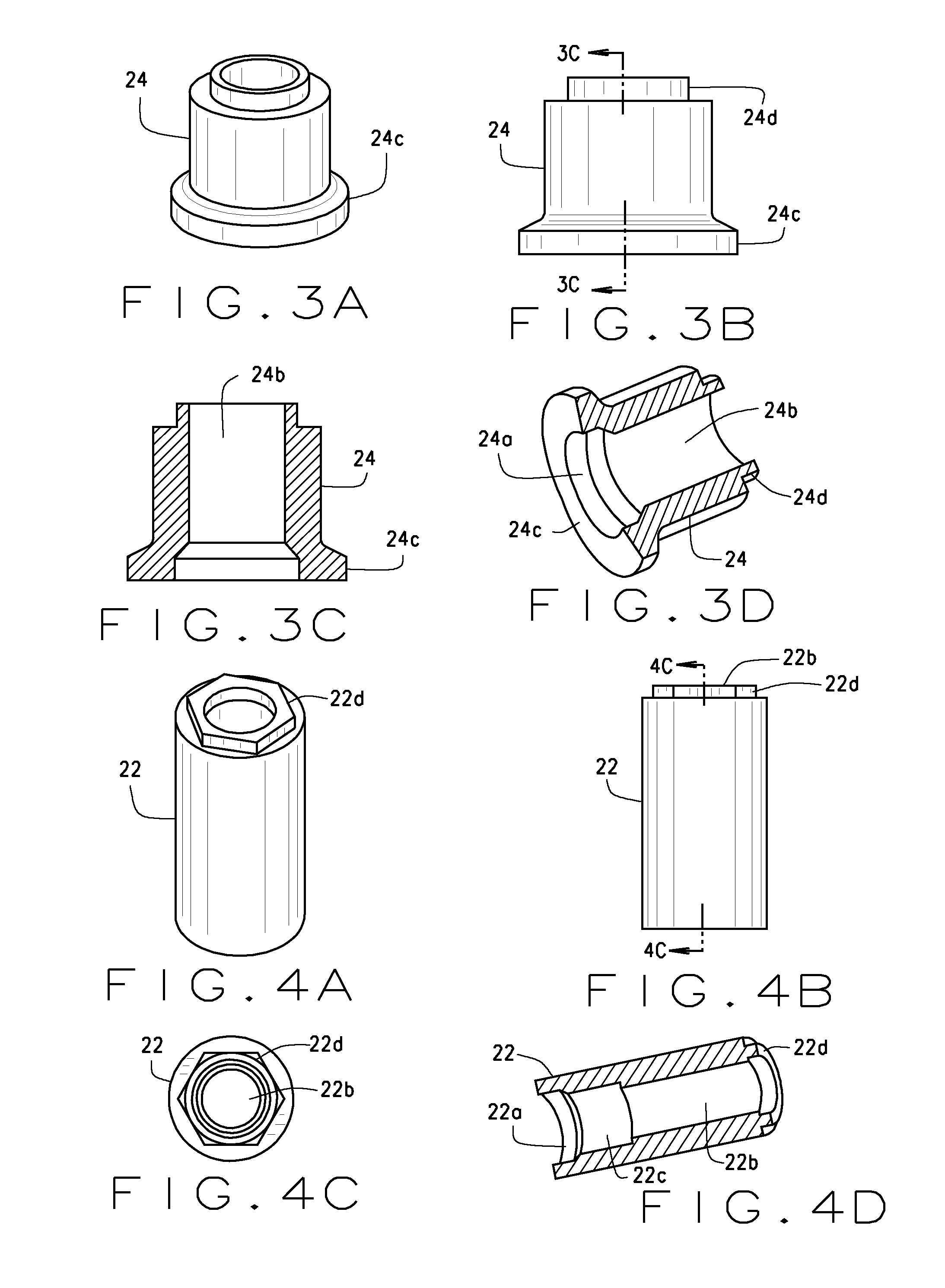

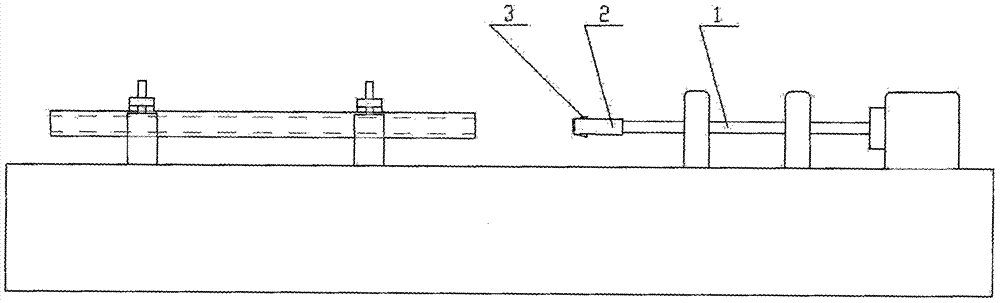

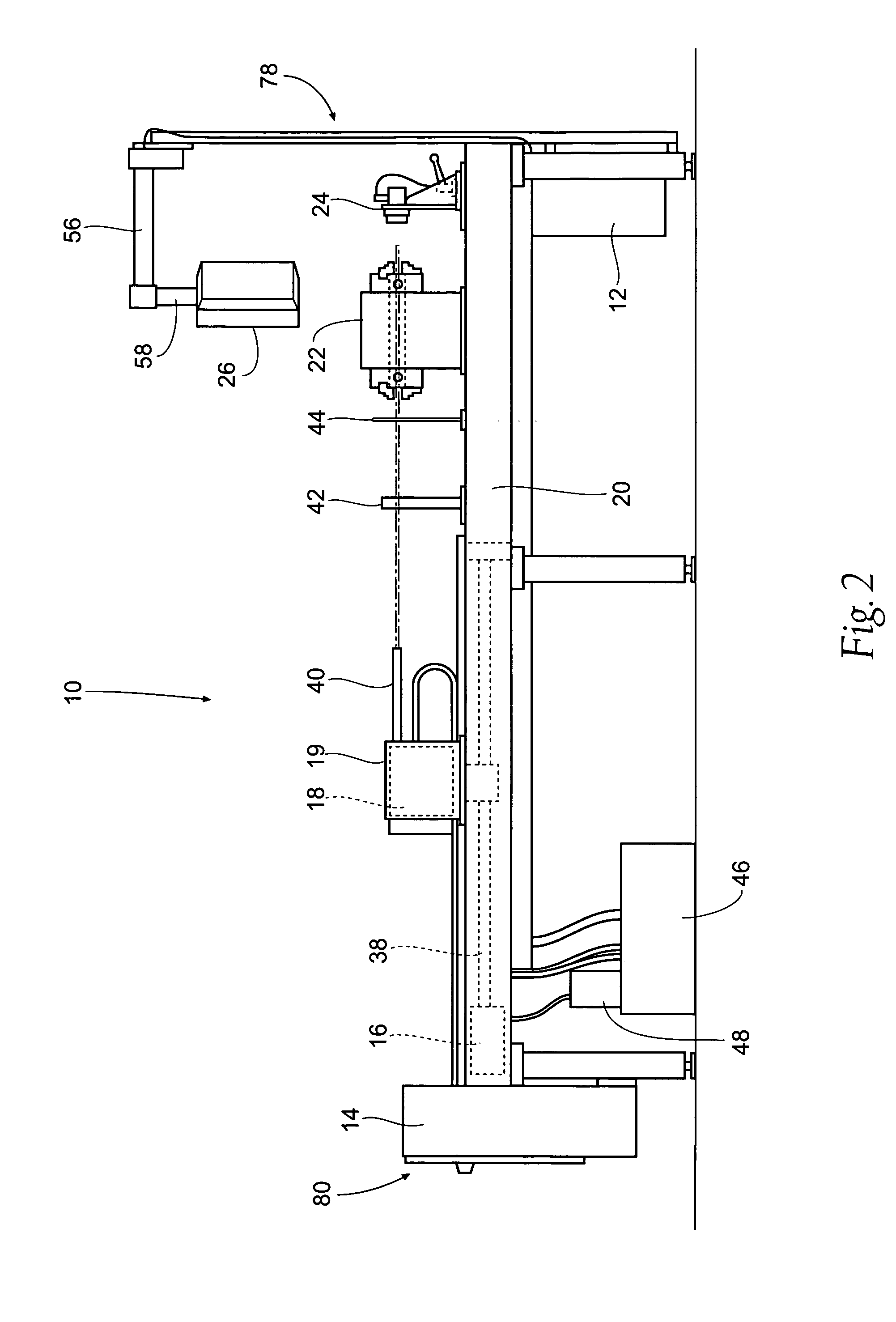

Method and apparatus for rifling a firearm barrel

A computer numerically controlled apparatus is provided for rifling a gun barrel. The apparatus automates the known method of rifling a gun barrel. The apparatus includes a frame, a rod, a cutting tool, a rod holder, and a system of servos to move the rod holder and to rotate the rod. The apparatus includes a CPU runs a program which controls the servos based on operating parameters entered by the operator. The operating parameters are entered through a graphical user interface which also allows the operator to monitor the status of the rifling process. The operator can calibrate the system and enter the twist rate, number of grooves, cut degree, cutting speed, return speed, and number of passes to complete. The apparatus includes a puck which engages the end of the rod and is adapted to index the rod and change the cutting depth of the cutting tool.

Owner:BARTLEIN TRACY M +2

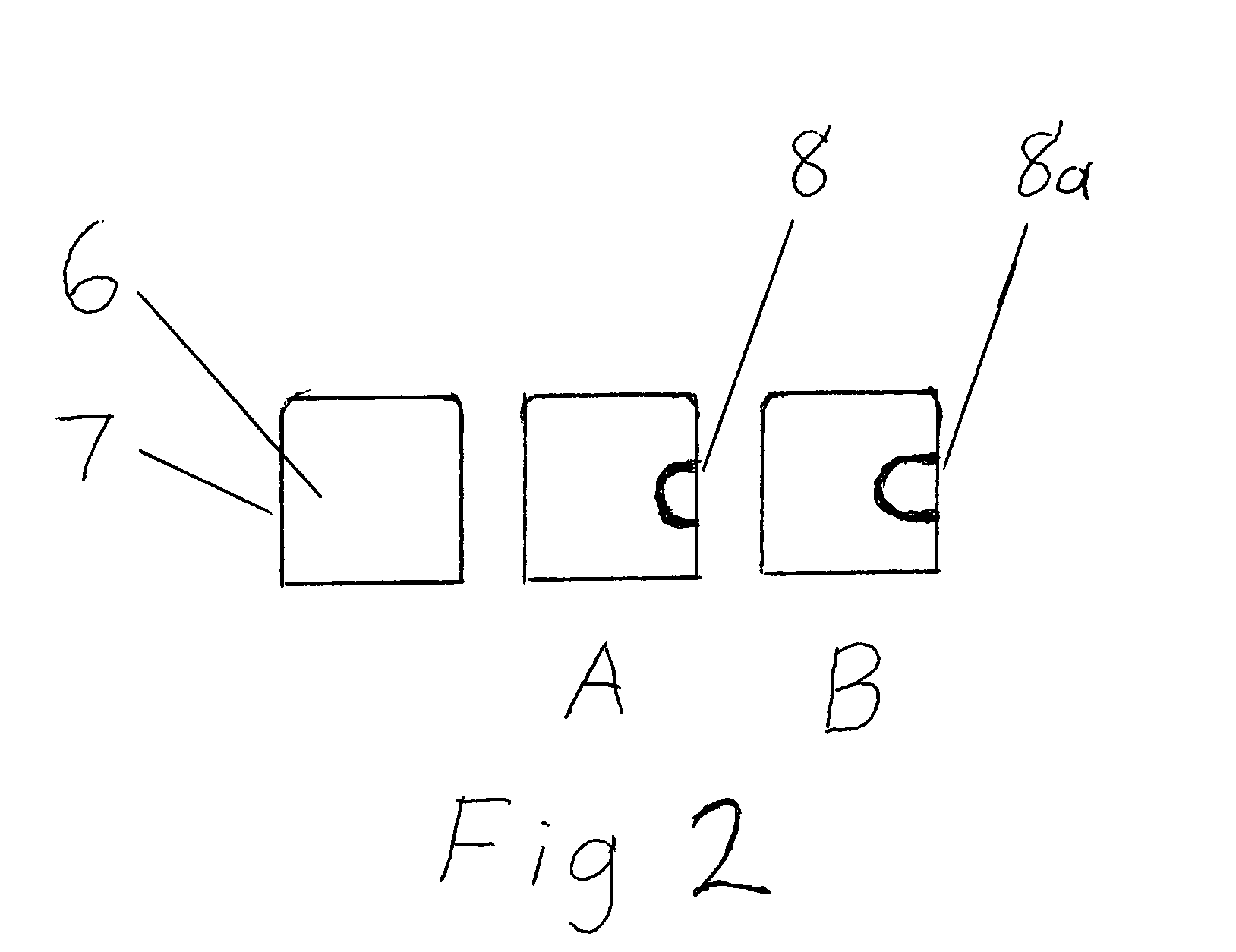

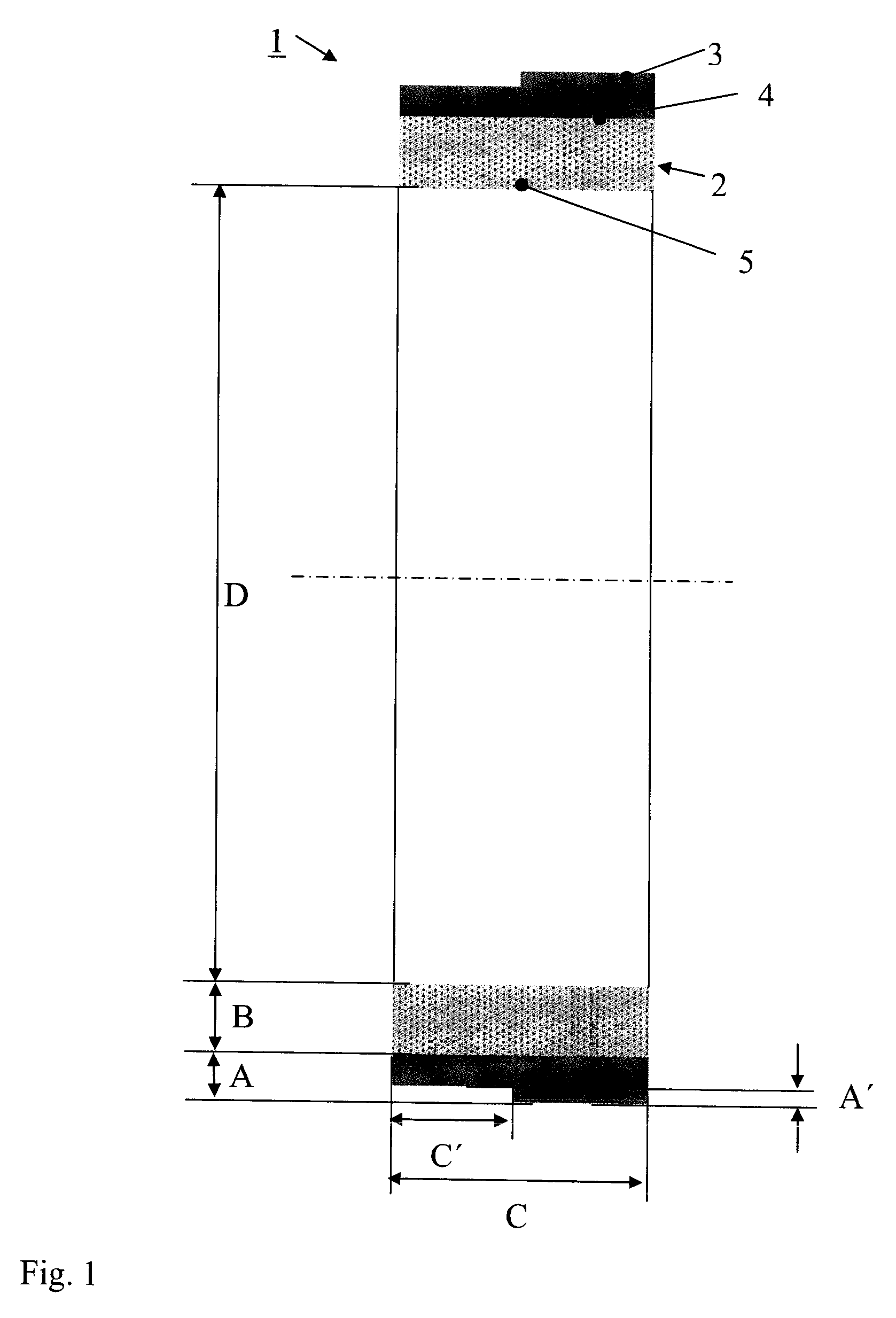

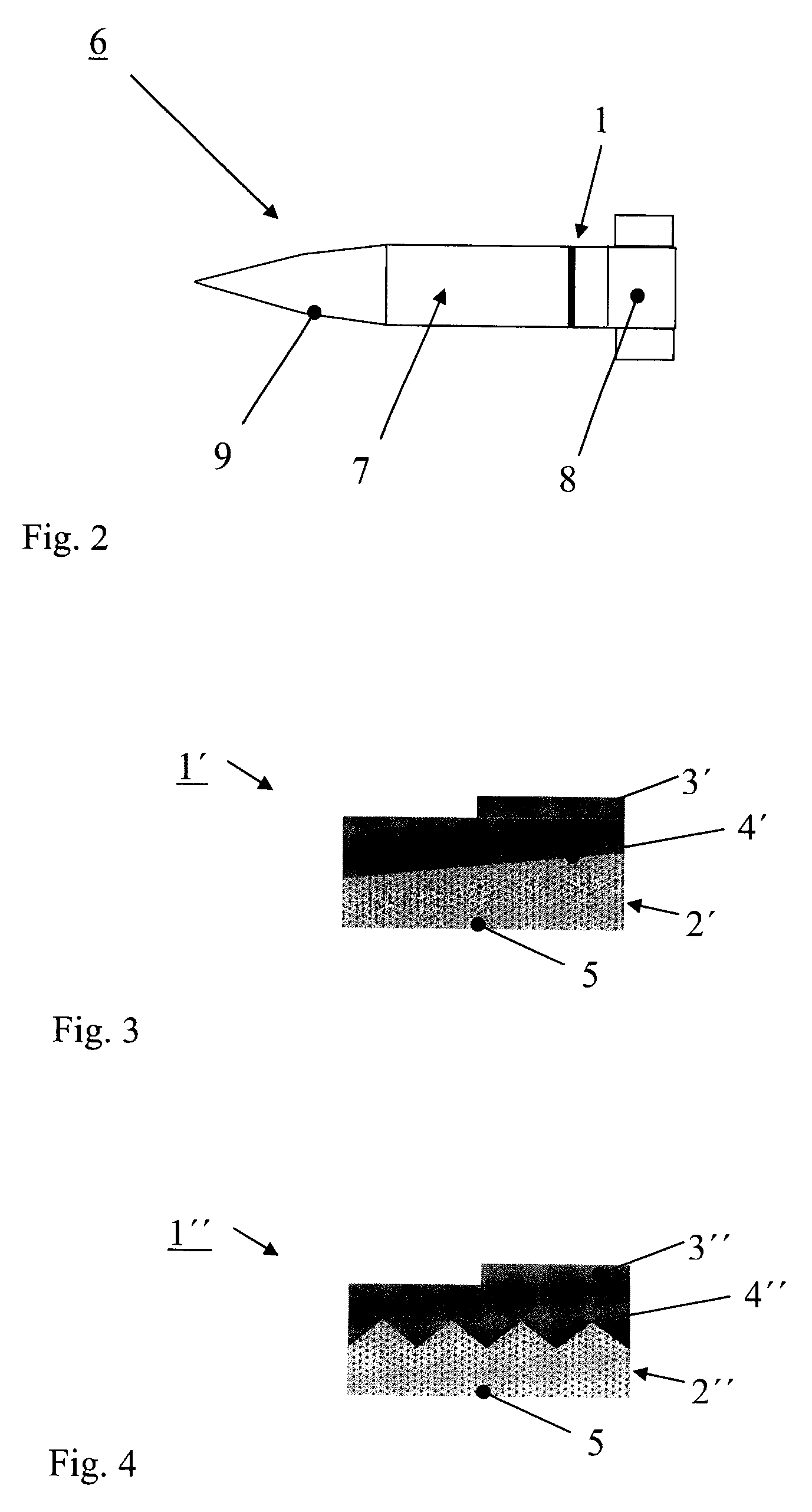

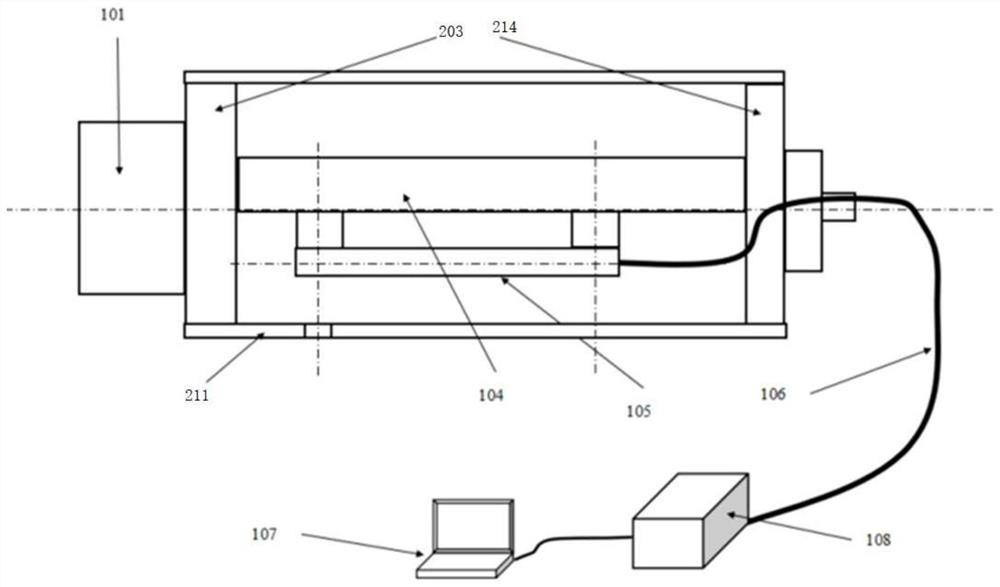

Permanent slipping rotating band and method for producing such a band

ActiveUS8950335B2Increased riskReduce riskAmmunition projectilesProjectilesEngineeringPolymer composites

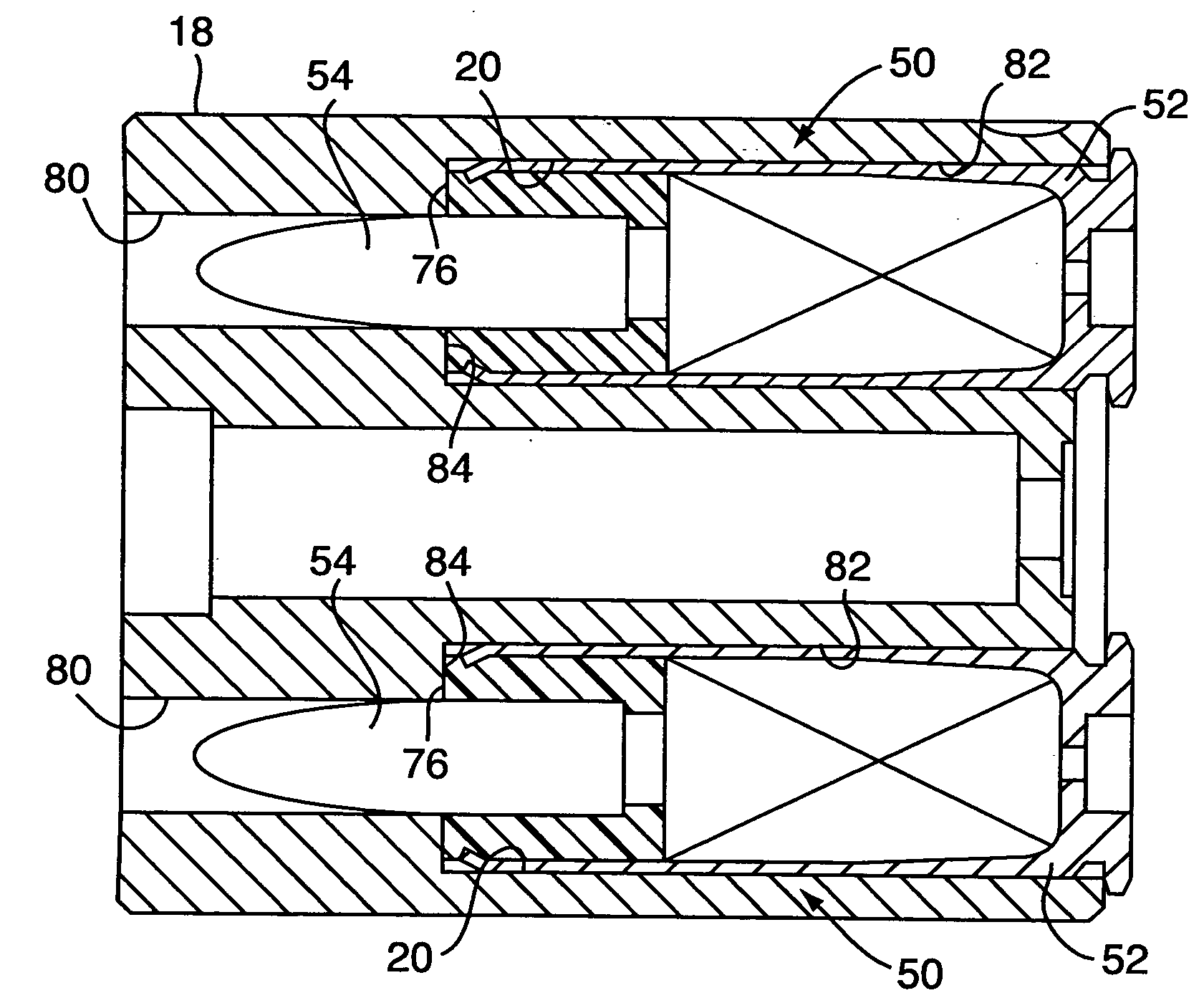

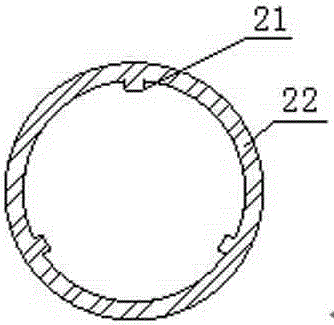

The invention relates to a projectile (6) provided with a slipping rotating band (1) which is designed for firing from a weapon system with a rifled barrel. The rotating band (1) comprises an inner ring (2) and an outer ring (3) that seals against the barrel. The outer ring is fitted on the outer surface of the inner ring and the inner ring is slippably fitted on the projectile. The rotating band (1) is configured to remain fitted on the projectile (6) from launcher to target by virtue of the fact that the inner ring (2) is made of fibre-reinforced polymer composite or particle-reinforced polymer composite, or fibre-reinforced metal matrix composite or particle-reinforced metal matrix composite. The invention also relates to a slipping rotating band (1) and to a method for producing a slipping rotating band (1) in which the outer ring (3) is affixed to the inner ring (2).

Owner:BAE SYST BOFORS

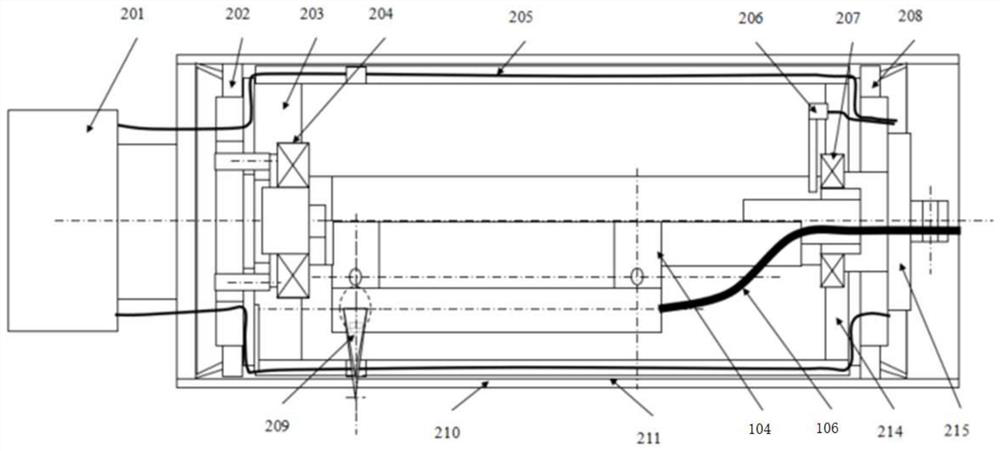

Artillery barrel rifling inner diameter measuring system and method

PendingCN113804117ACompact structureSolve the problem of strictly limited installation sizeUsing optical meansLight sensingEngineering

The invention discloses an artillery barrel rifling inner diameter measuring system and method. The system comprises a measuring vehicle unit, a laser displacement sensor controller and a control computer, the measuring vehicle unit is connected with the laser displacement sensor controller through a probe optical cable, and the laser displacement sensor controller is connected with the control computer. The inner diameter of the artillery barrel is converted into the eccentricity of the probe of the laser displacement sensor and the distance measurement value converted from reflected light sensed by the probe, the probe is small in structure, and the problem that the installation size is strictly limited is solved. In addition, the measuring system is more stable. In addition, measurement and calculation data of the diameter of the inner wall of the artillery barrel come from distance parameters measured by a laser displacement sensor probe and are related to the eccentric position of the probe.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com