Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4472 results about "Polymer composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

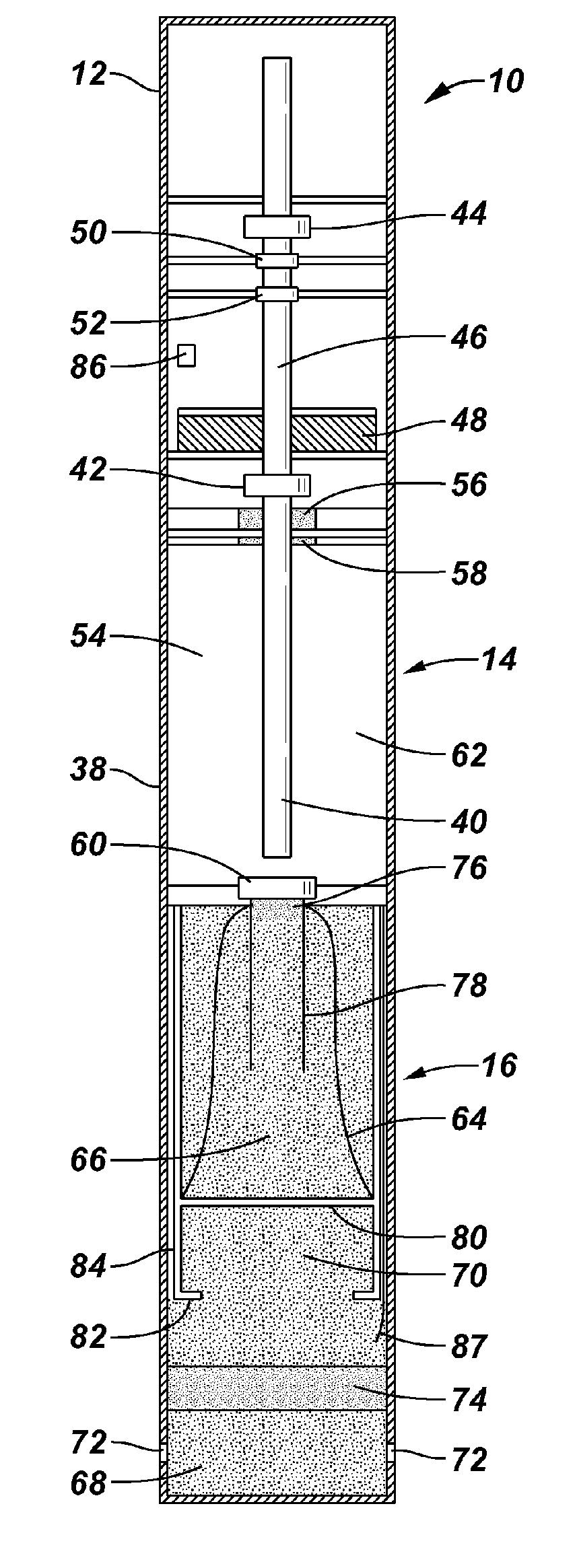

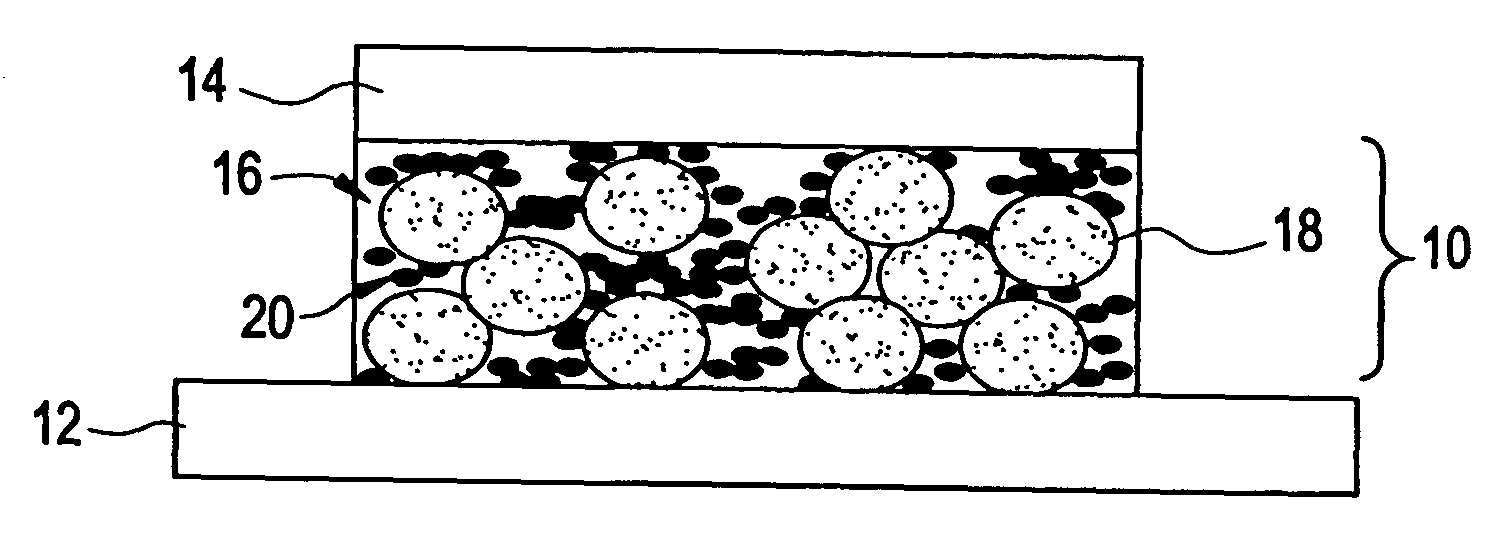

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

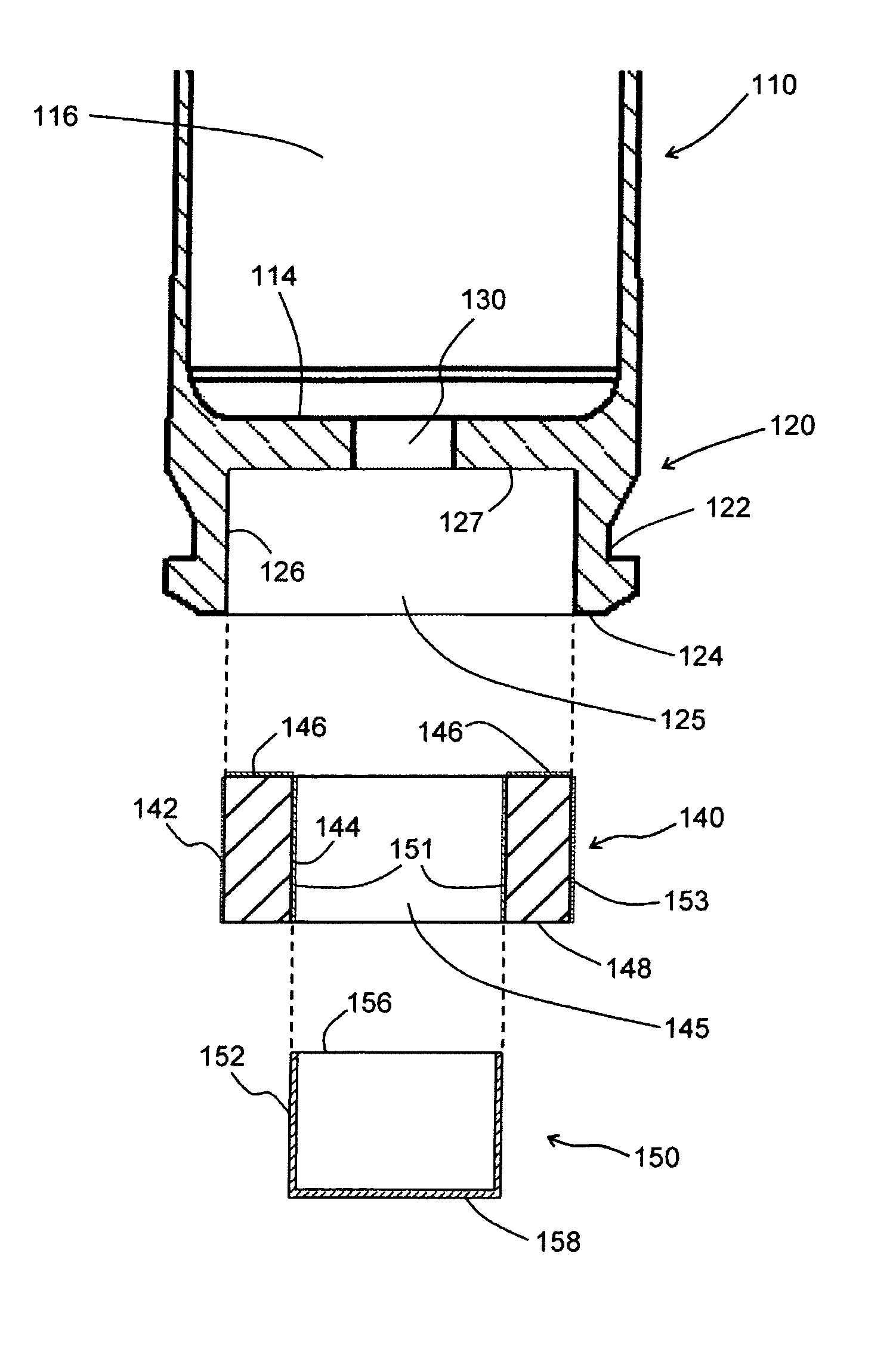

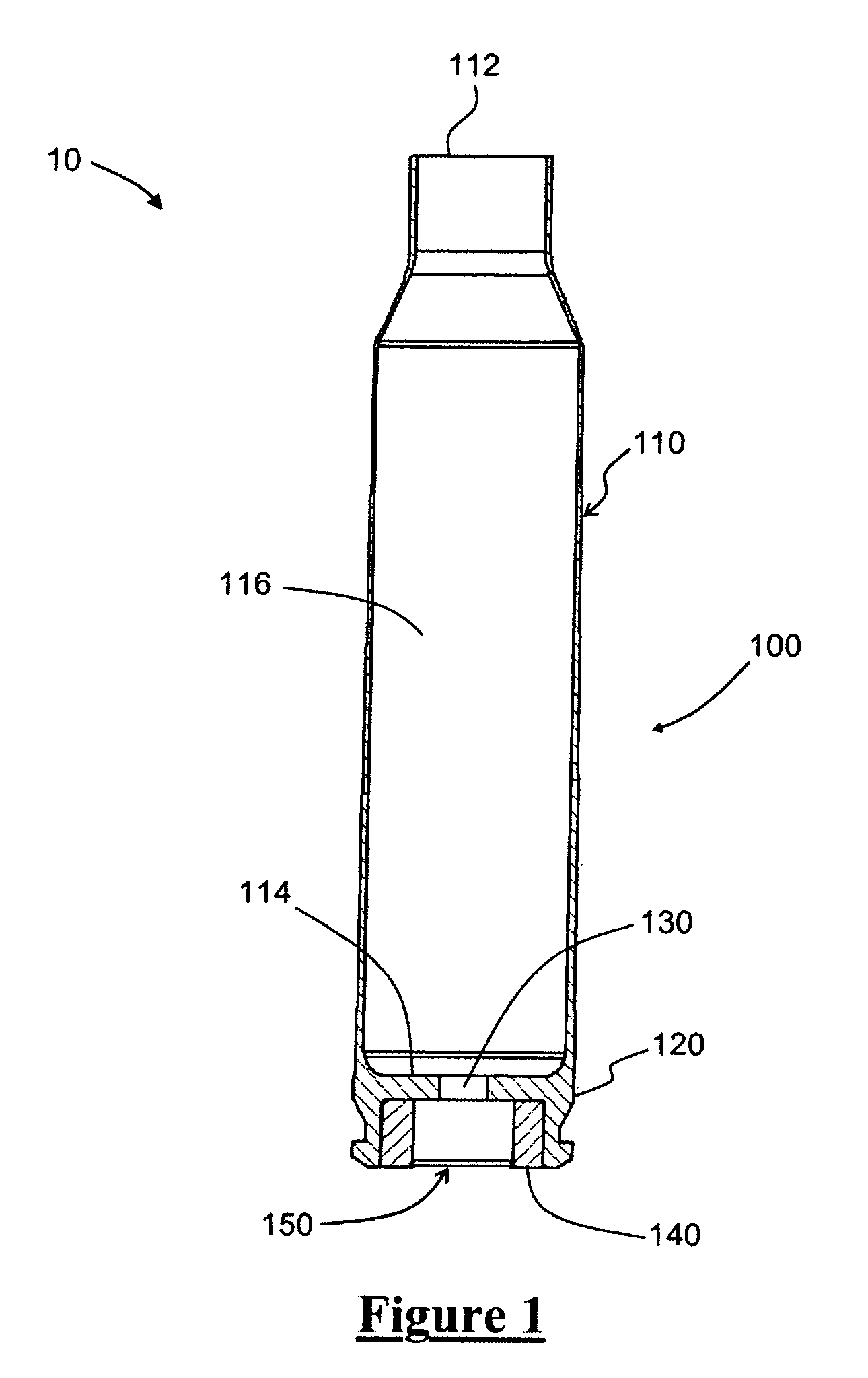

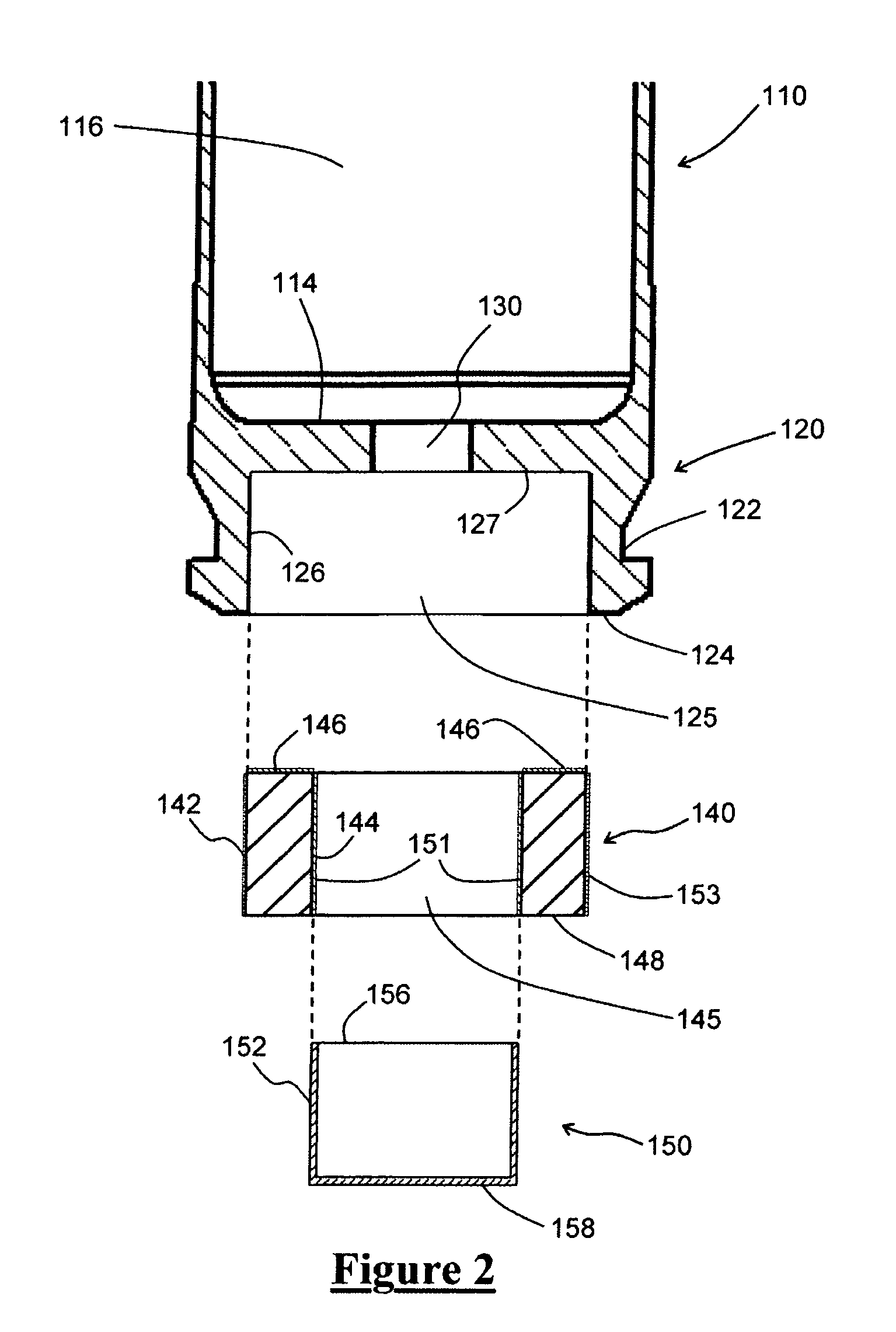

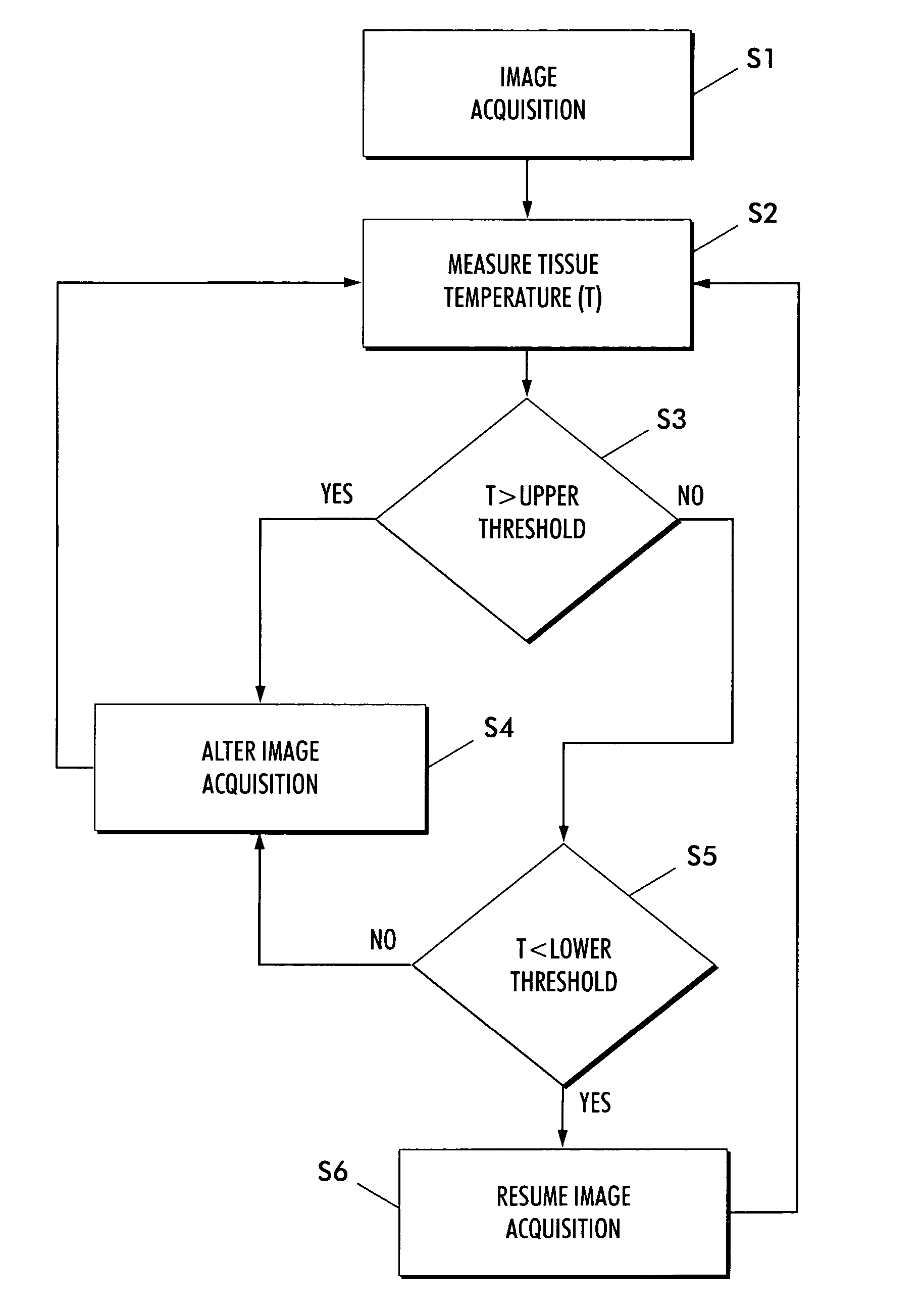

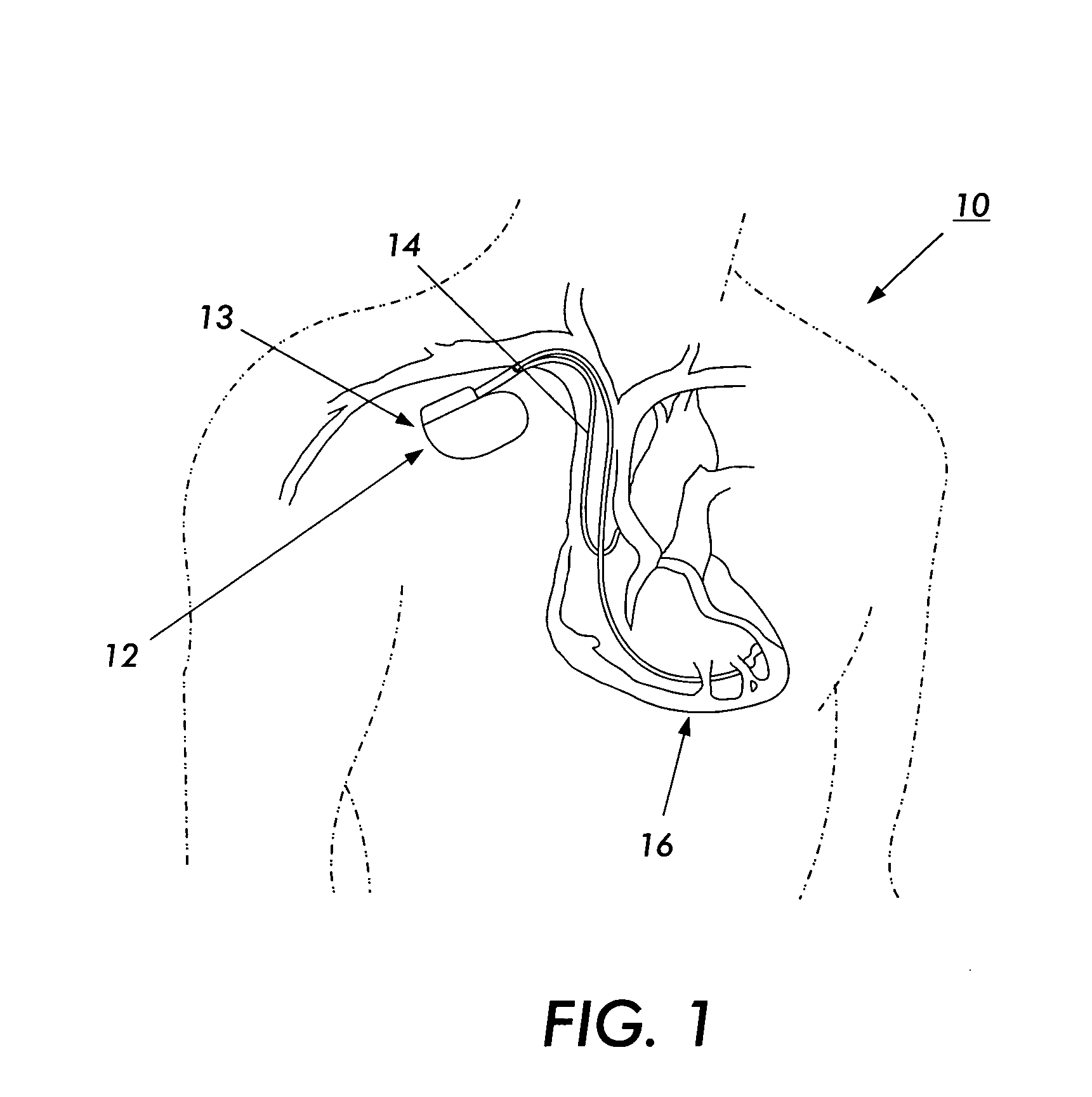

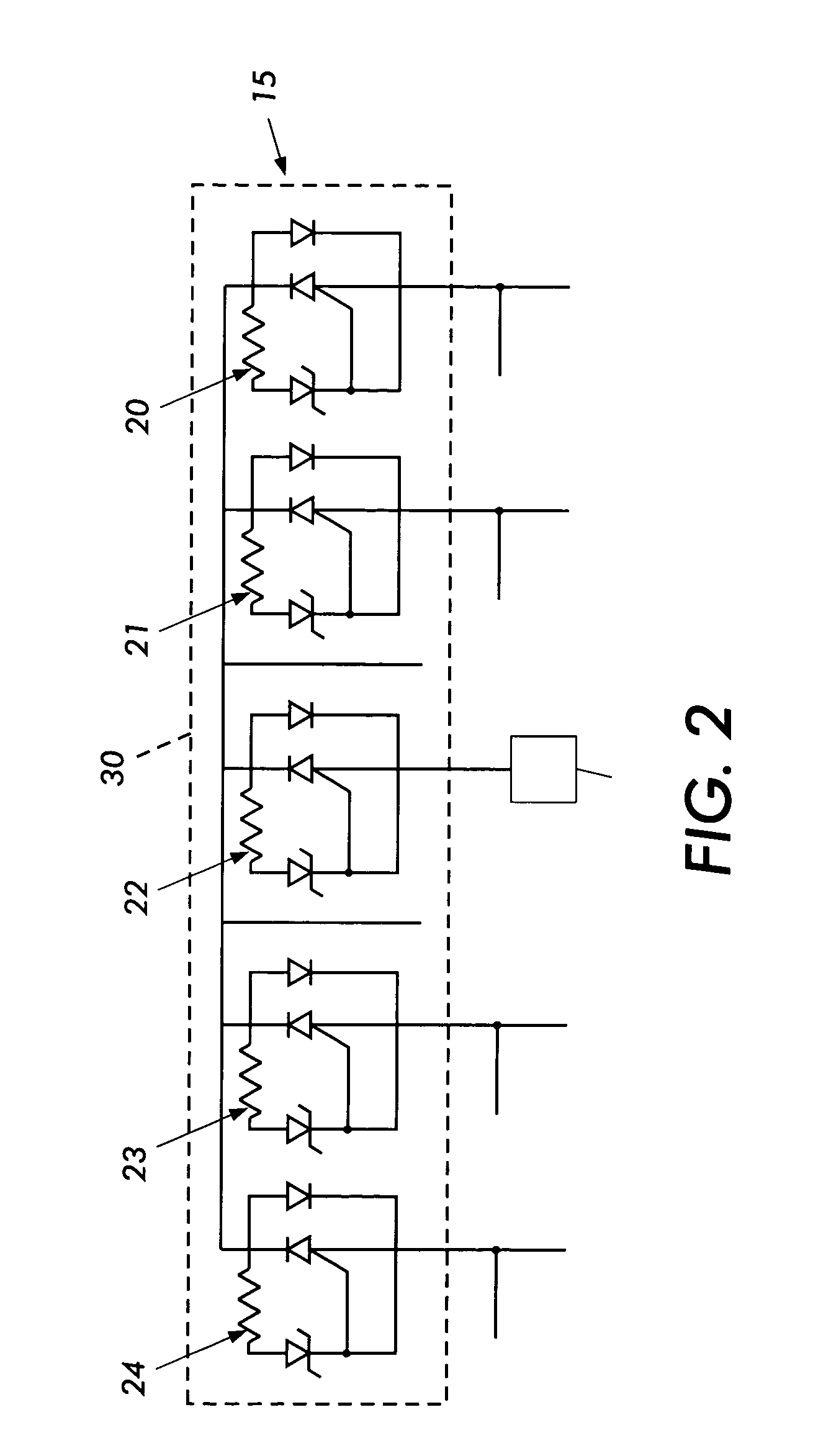

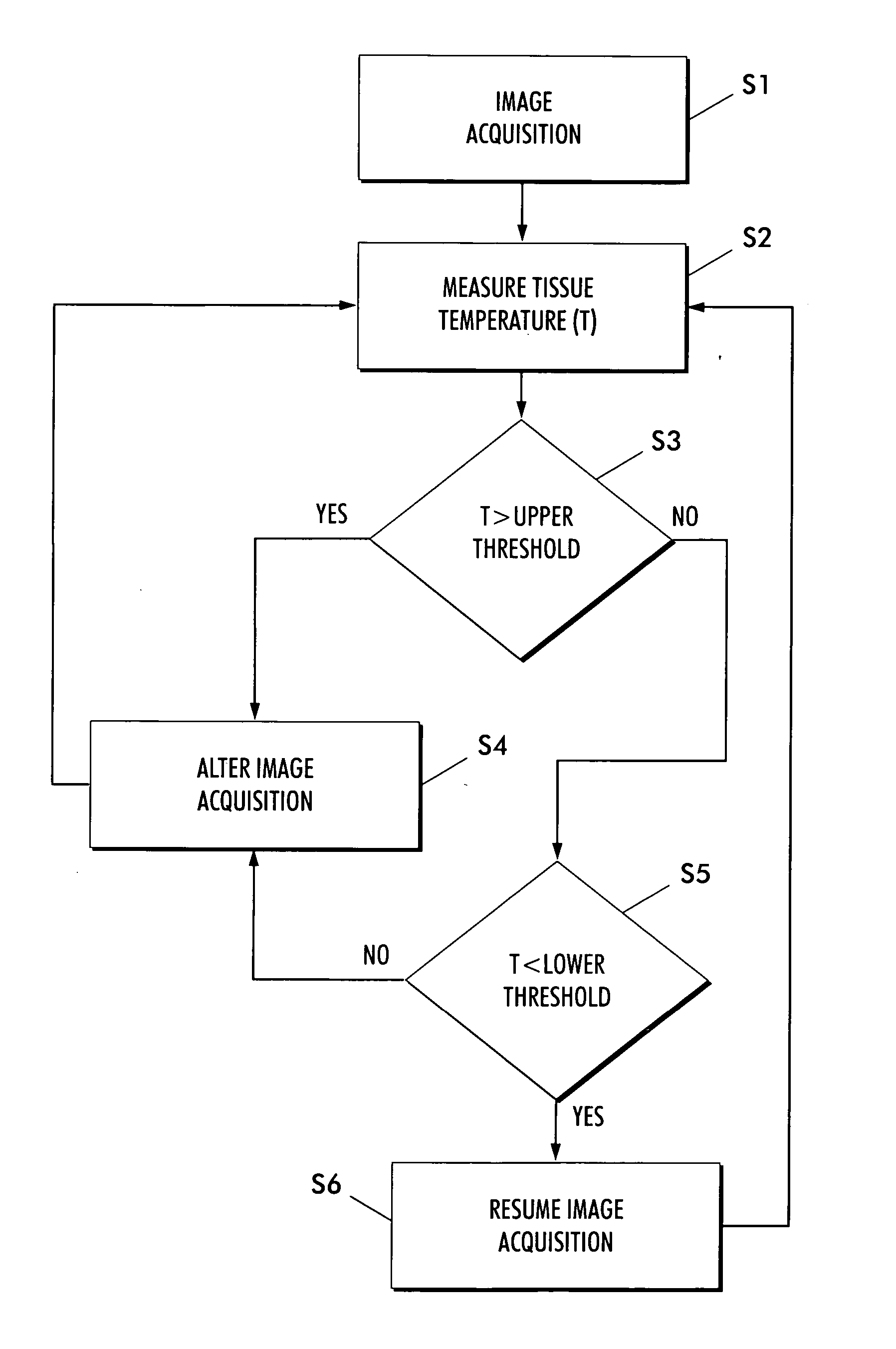

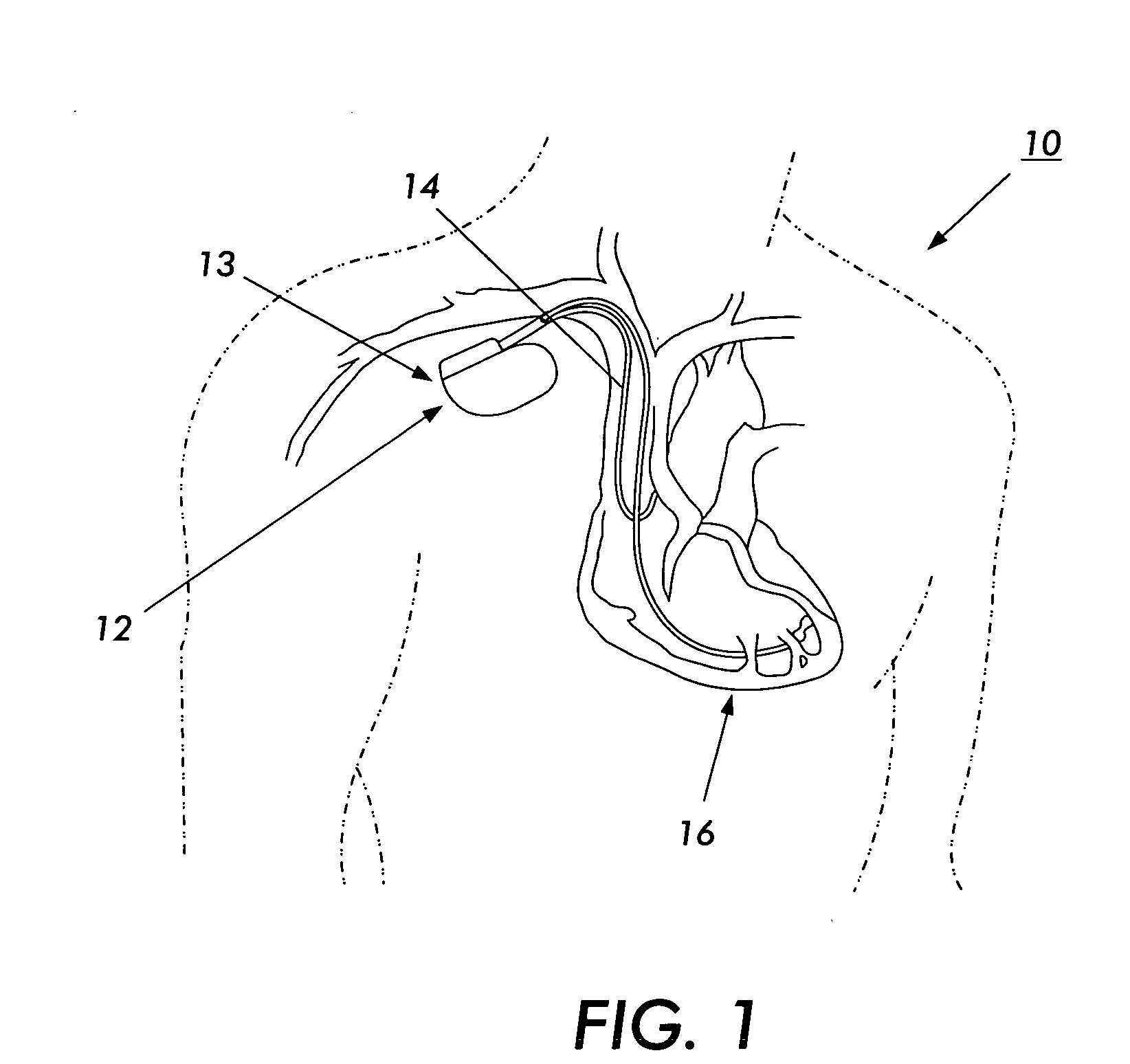

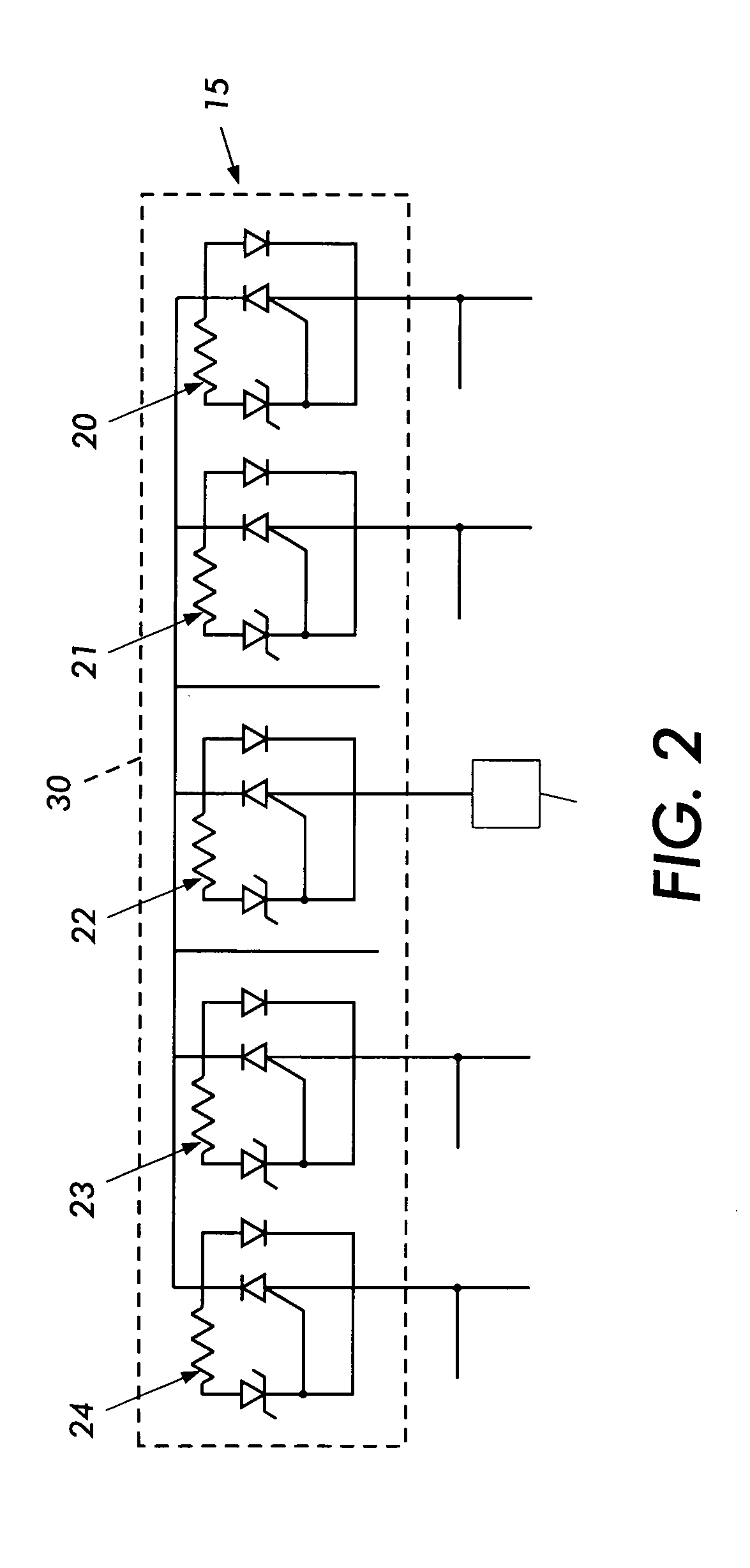

Device and method for preventing magnetic resonance imaging induced damage

An electromagnetic shield has a first patterned or apertured layer having non-conductive materials and conductive material and a second patterned or apertured layer having non-conductive materials and conductive material. The conductive material may be a metal, a carbon composite, or a polymer composite. The non-conductive materials in the first patterned or apertured layer may be randomly located or located in a predetermined segmented pattern such that the non-conductive materials in the first patterned or apertured layer are located in a predetermined segmented pattern with respect to locations of the non-conductive materials in the second patterned or apertured layer.

Owner:MEDTRONIC INC

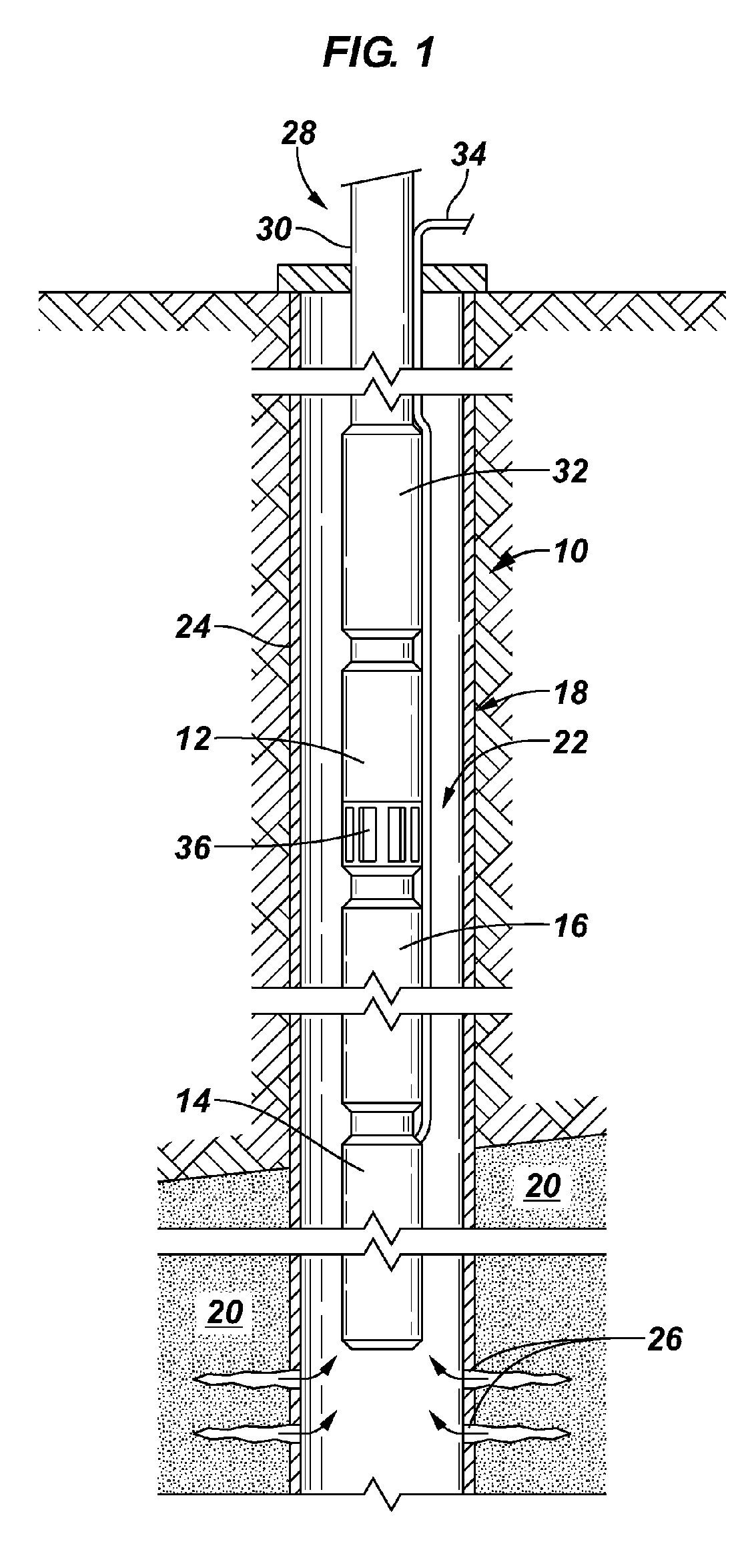

Polymeric Composites, Oilfield Elements Comprising Same, and Methods of Using Same in Oilfield Applications

InactiveUS20070142547A1Improve barrier propertiesImprove mechanical propertiesNon-metal conductorsLayered productsSubject matterEngineering

Oilfield elements and assemblies are described comprising a polymeric matrix formed into an oilfield element, and a plurality of expanded graphitic nanoflakes and / or nanoplatelets dispersed in the polymeric matrix. Methods of using the oilfield elements and assemblies including same in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Perovskite/polymer composite luminescent material and preparation method thereof

ActiveCN104861958ASimple and fast operationLow costNanoopticsLuminescent compositionsPhotoluminescenceStructural formula

The invention relates to a perovskite / polymer composite luminescent material and a preparation method thereof, which belong to the technical field of composite materials and luminescent materials, wherein the structural formula of the perovskite is R1NH3AB3 or (R2NH3)2AB4, A and B form a ligand octahedral structure, R1NH3 or R2NH3 are filled into gaps of the ligand octahedral structure which is formed through the A and the B, R1 is methyl, R2 is a long-chain organic molecular group, the A is any one of metal Ge, Sn, Pb, Cu, Mn, Sb and Bi, the B is any one of Cl, Br and I. The perovskite / polymer composite luminescent material which is made through the preparation method is high in luminescent intensity, high in luminescent color purity, excellent in light and thermal stability and excellent chemical resistant property and mechanical property, and lays the foundation for theory research and application of the perovskite / polymer composite luminescent material in high-performance photoluminescence devices, flexible display, lasers, nonlinear optical devices. The preparation method can obtain composite materials which can cover a whole visible region through luminescent wavelengths, and has wide application prospect in the fields of wide gamut light emitting diode (LED) and high performance displays and the like.

Owner:ZHIJING NANOTECH CO LTD

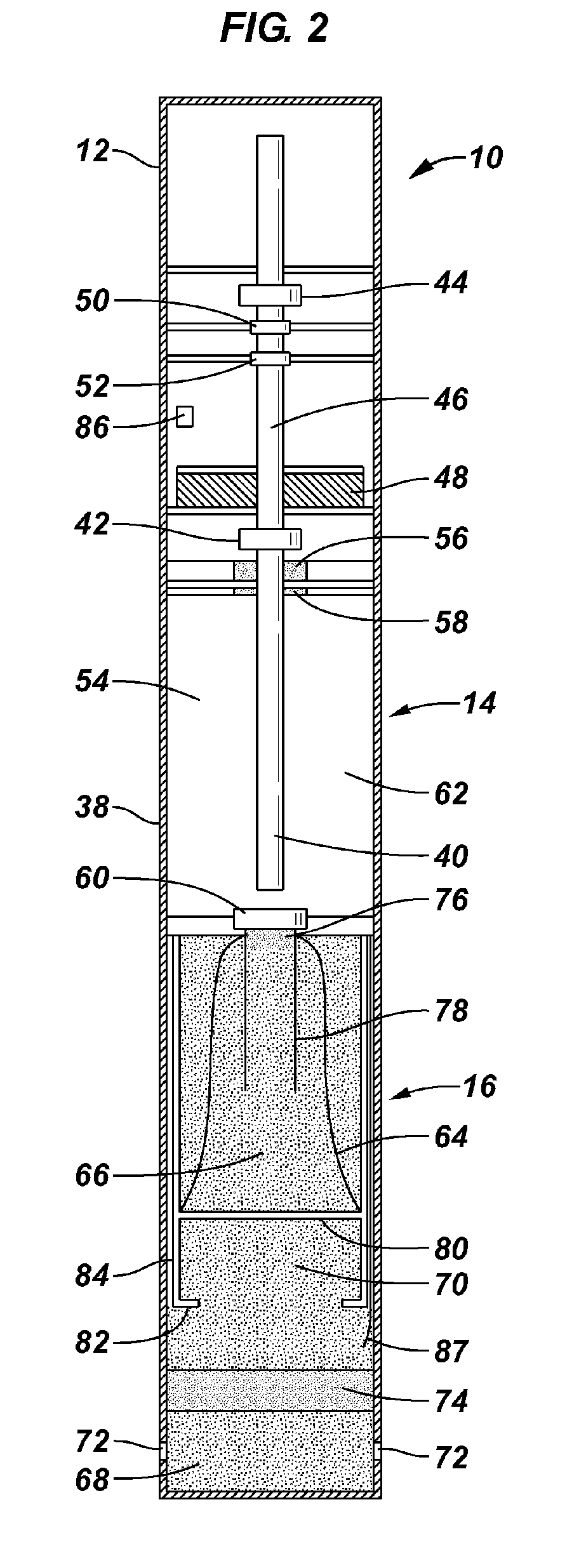

Surface modified particulate and sintered or injection molded products

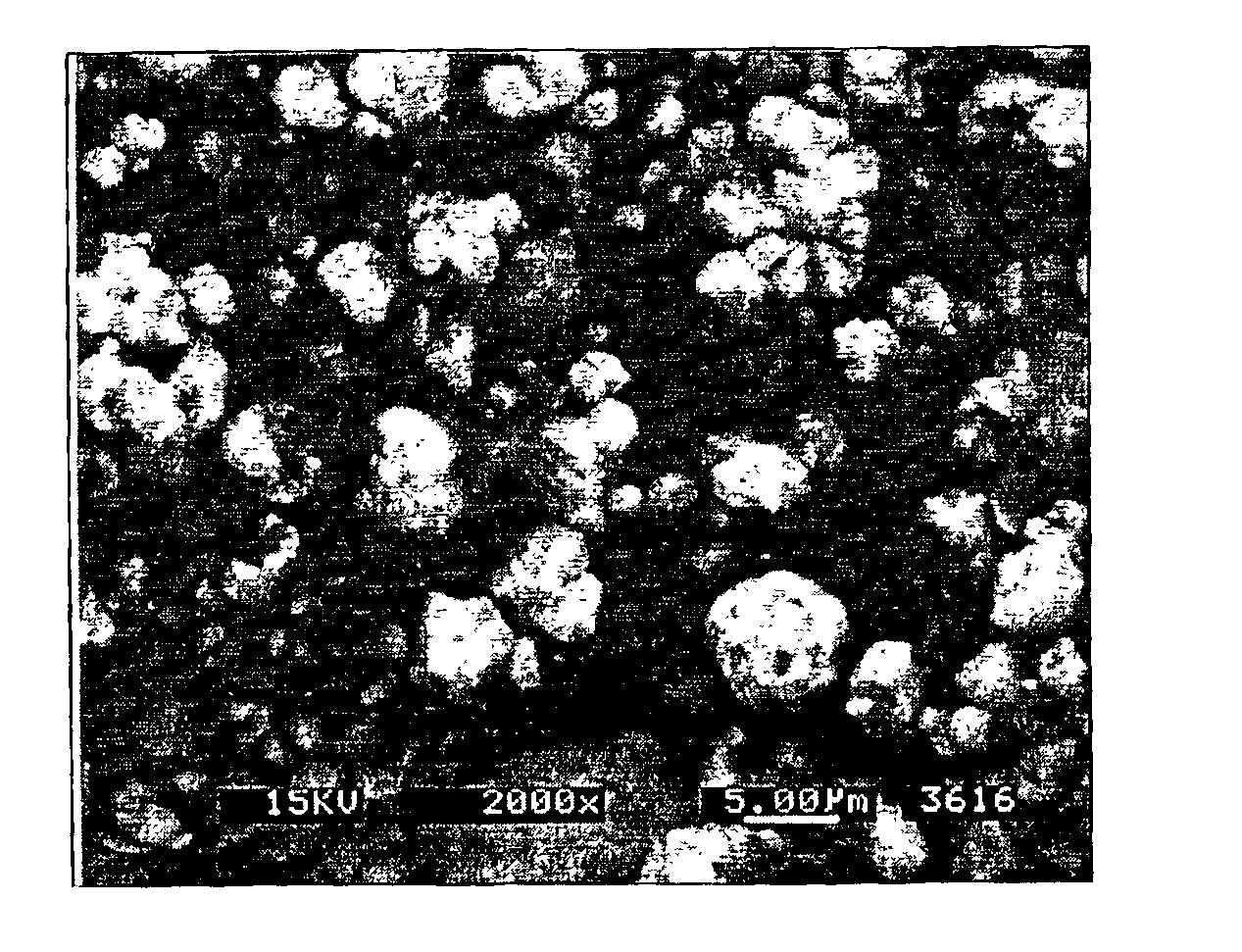

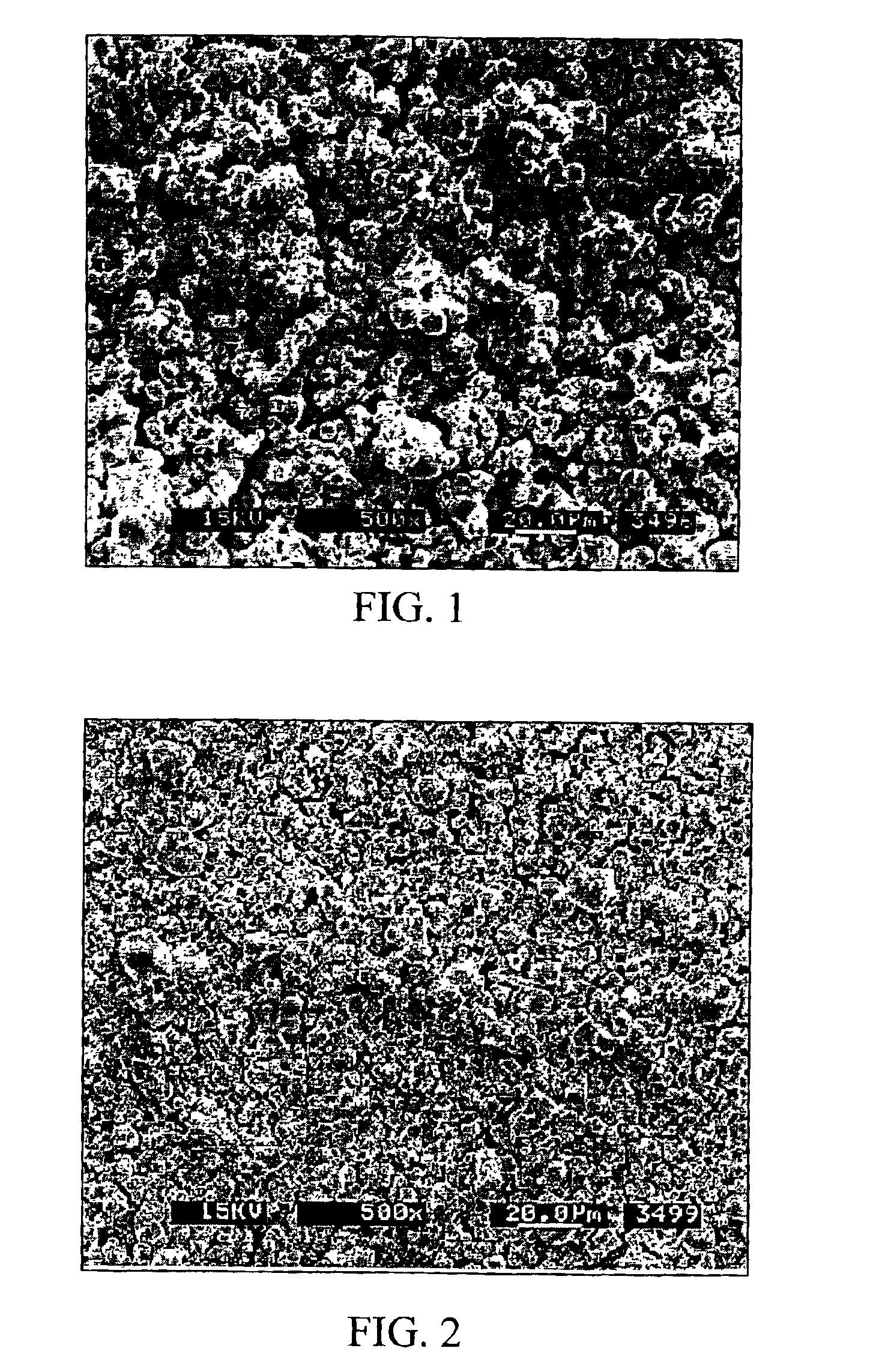

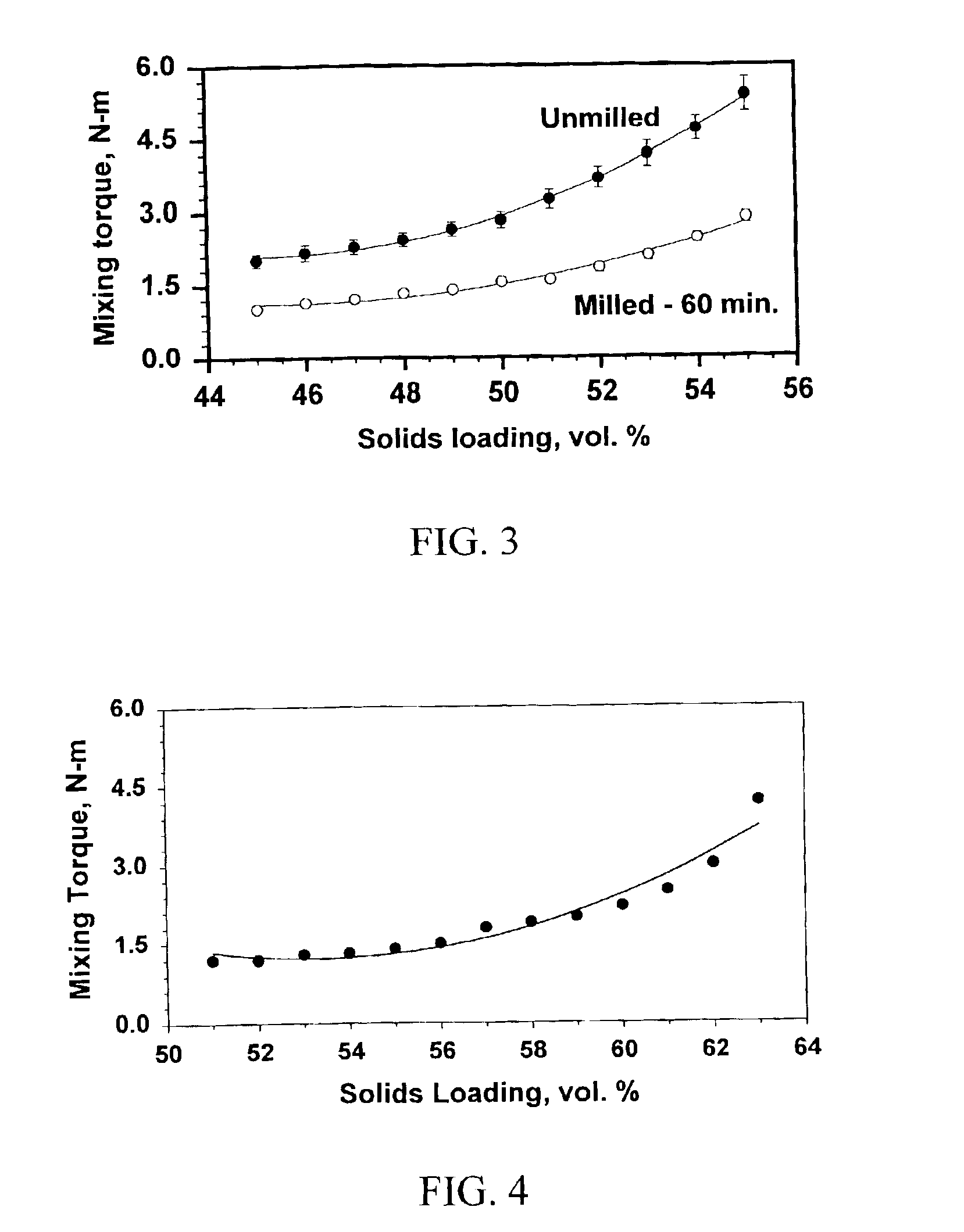

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

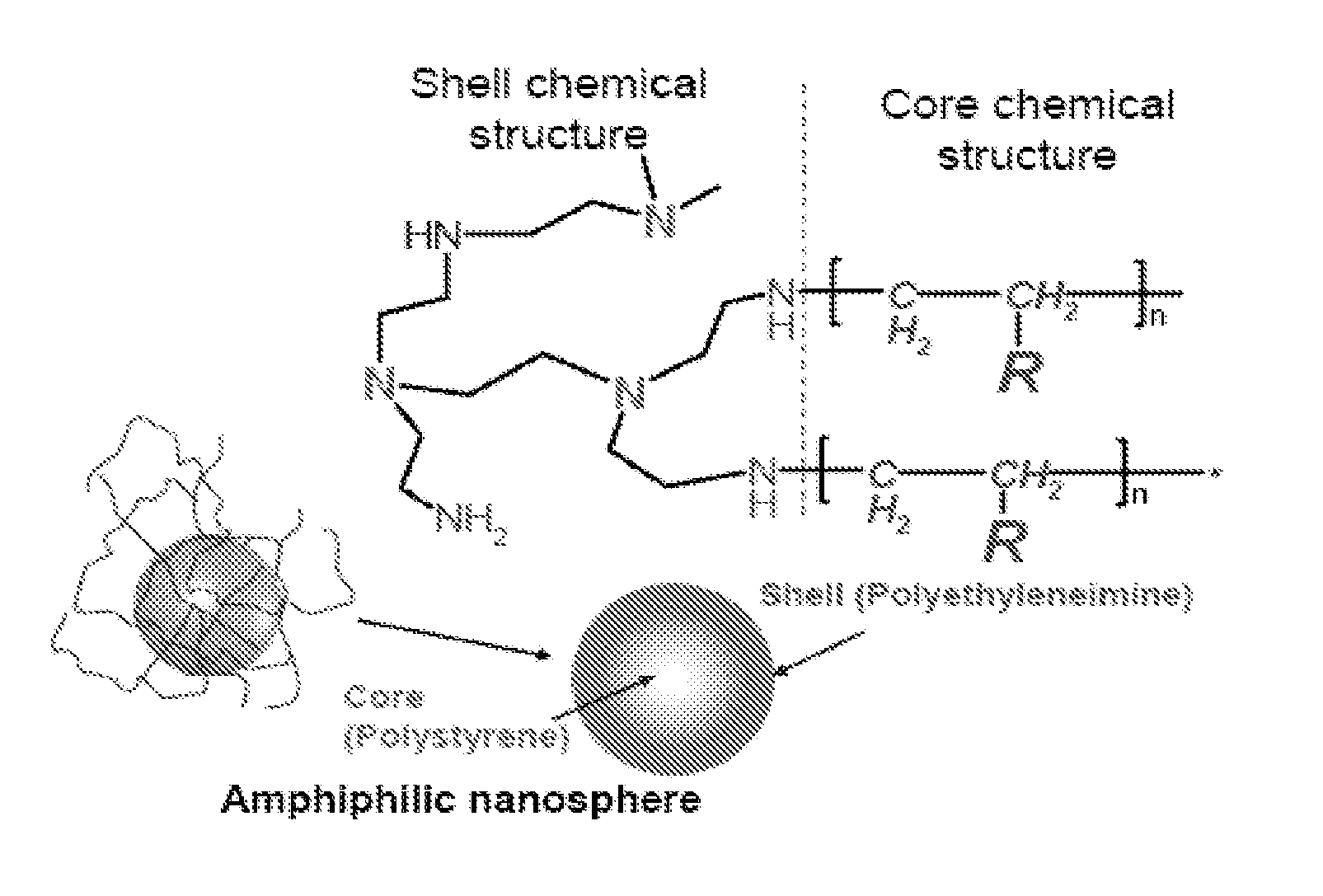

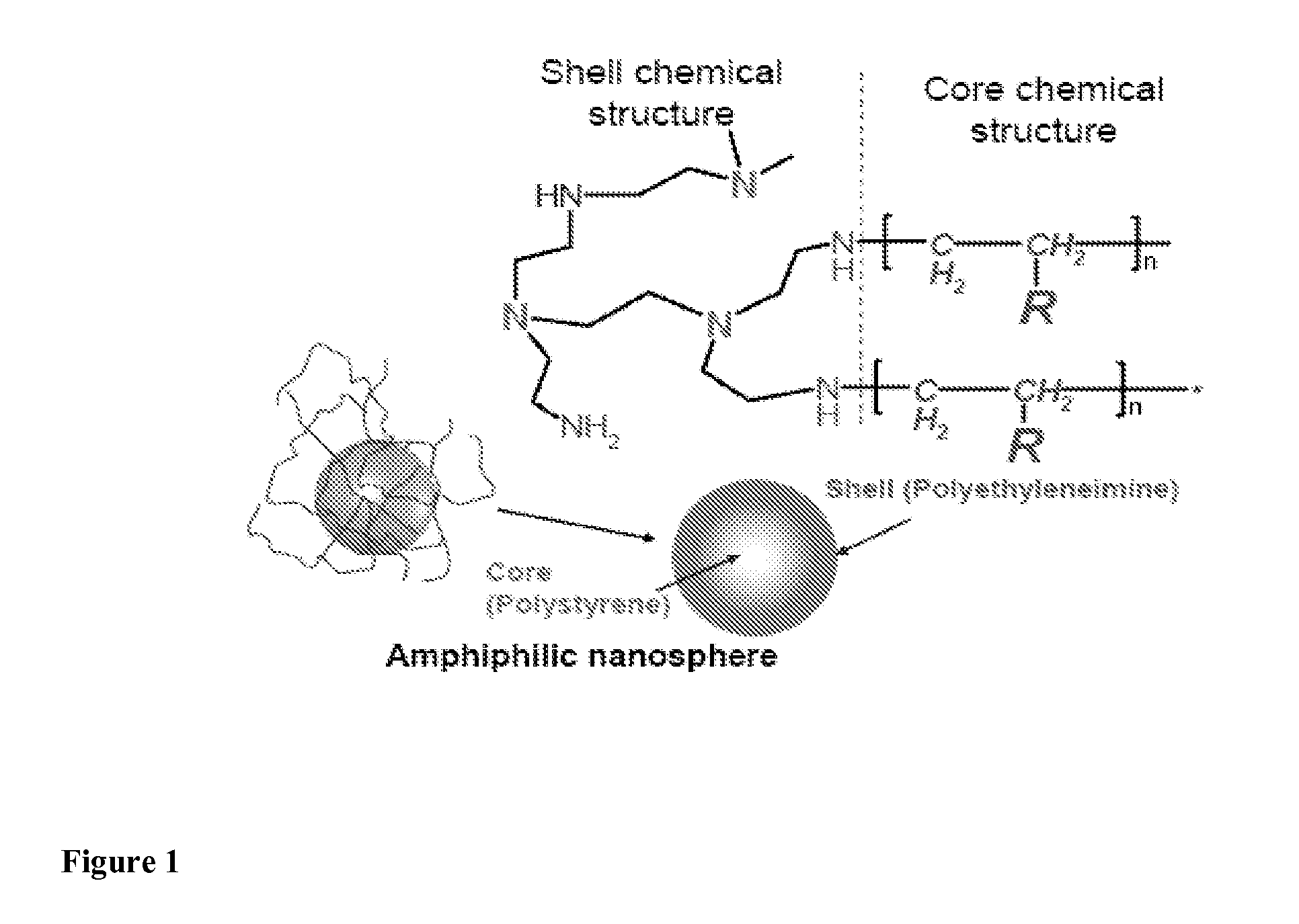

Toughened fiber reinforced polymer composite with core-shell particles

Embodiments disclosed herein include a resin composition comprising two or more different kinds of thermosetting resins, wherein at least one of the two or more different kinds of the thermosetting resins is a multifunctional resin, and a core-shell particle having a core and a shell, wherein a composition of the core is different from a composition of the shell and the composition of the shell has a branched polymer structure comprising at least one main chain and at least one side chain, the main chain or the side chain containing at least one functional group that reacts with the thermosetting resin, a method of manufacturing the resin composition, and a composite comprising a reinforcing fiber and the resin composition.

Owner:TORAY IND INC

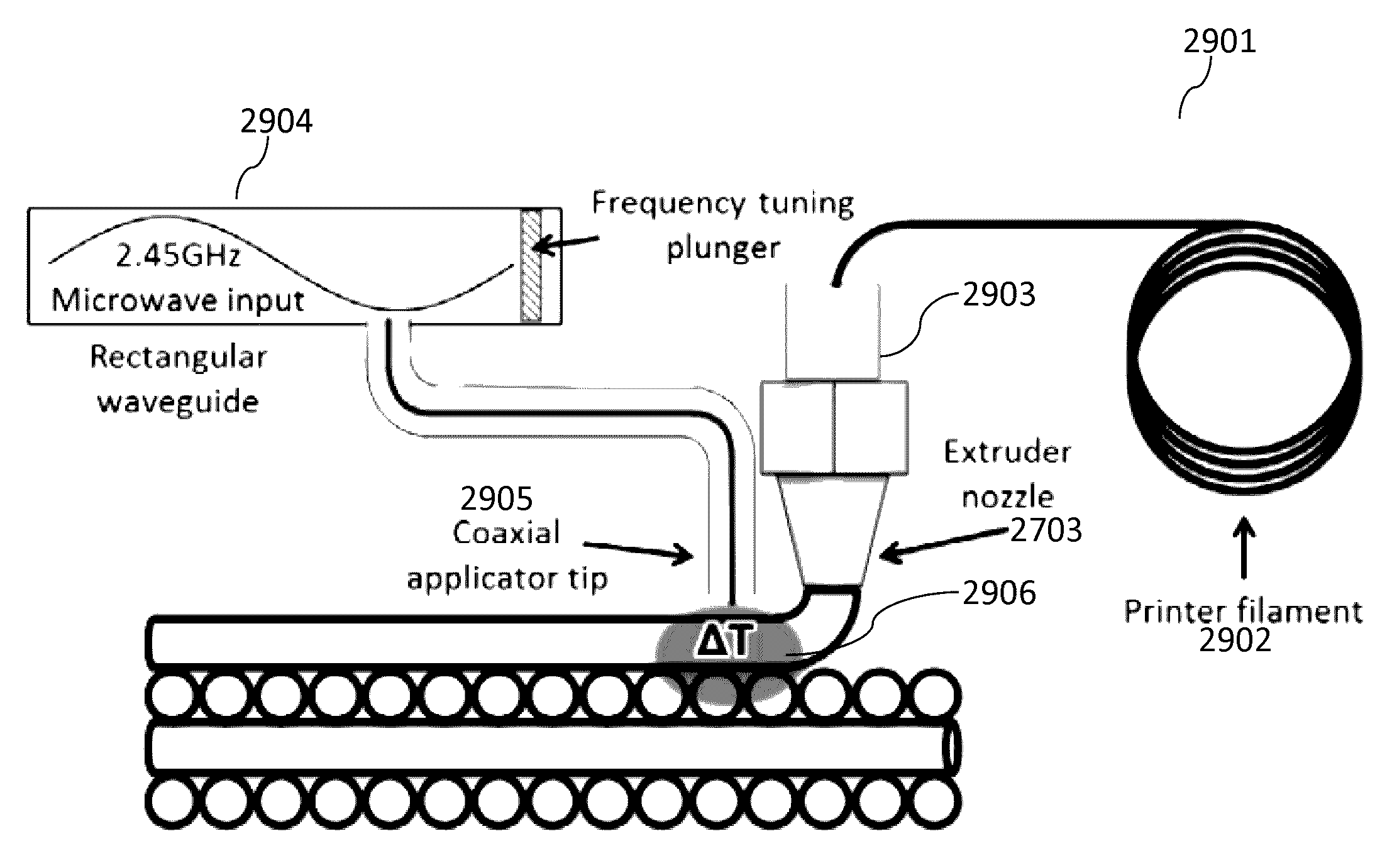

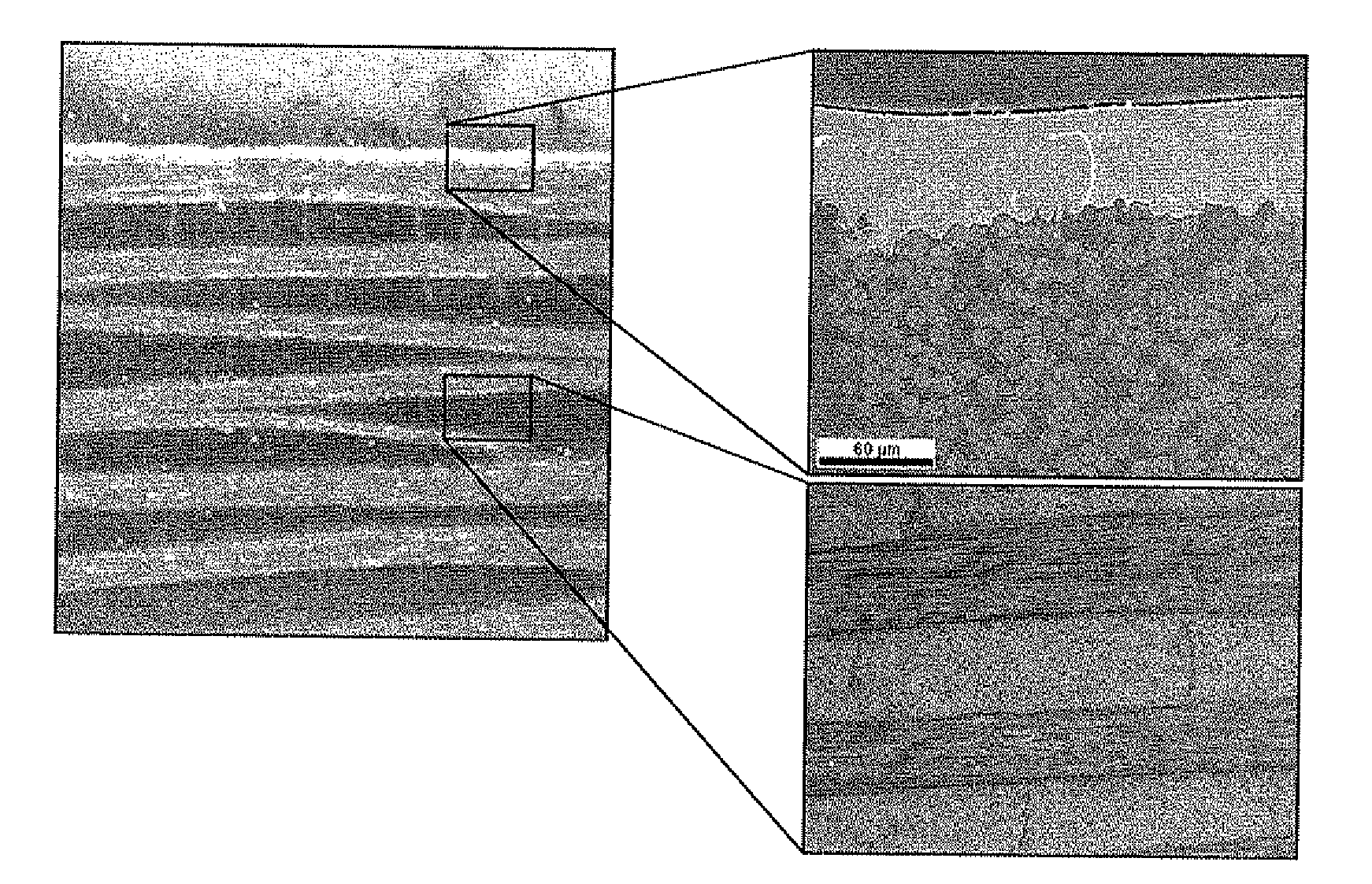

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

Tungsten/powdered metal/polymer high density non-toxic composites

InactiveUS6916354B2High bulk densityAmmunition projectilesShotgun ammunitionHigh densityVolumetric Mass Density

Owner:ELLIOTT CARTRIDGE COMPANY CANADA

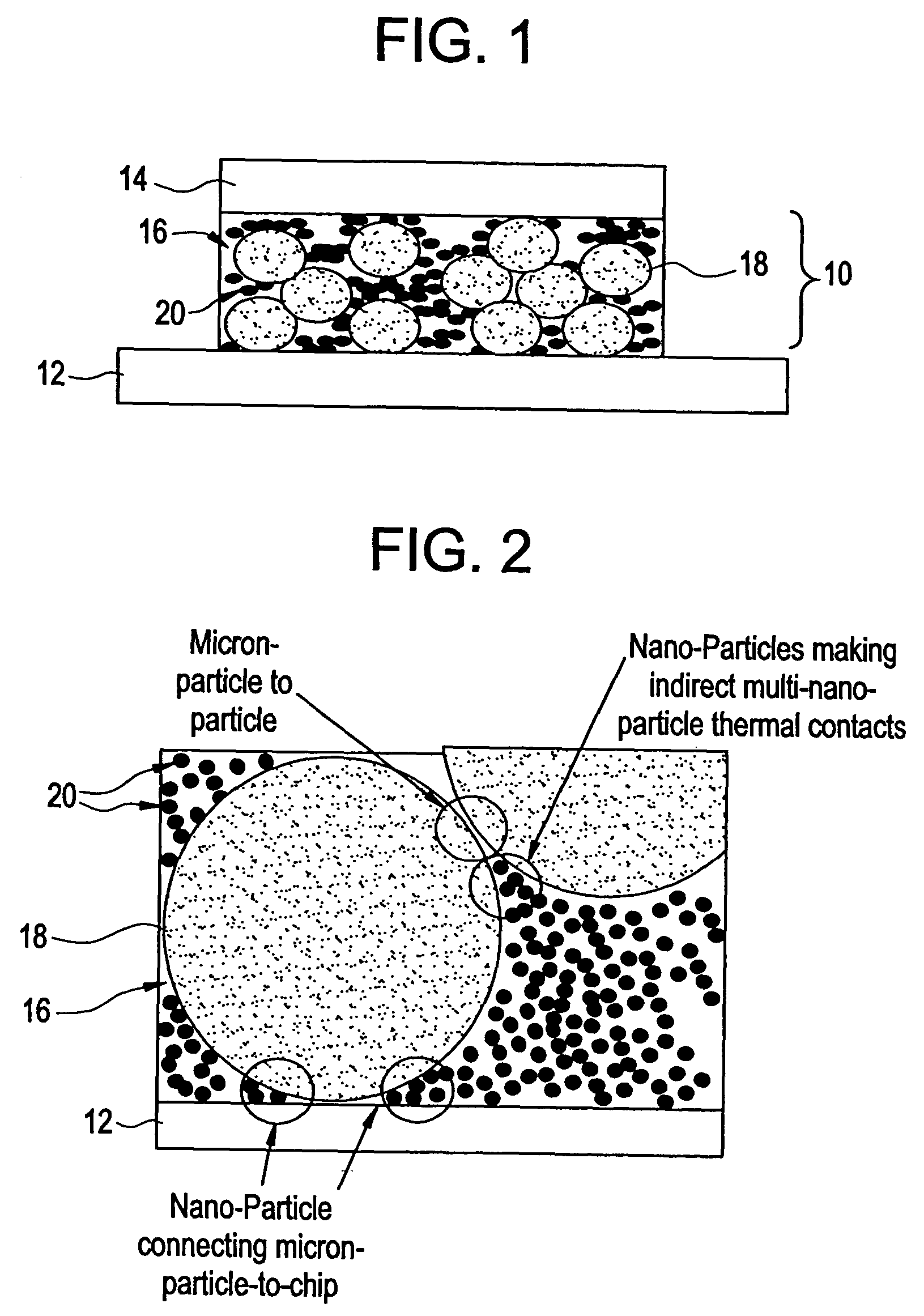

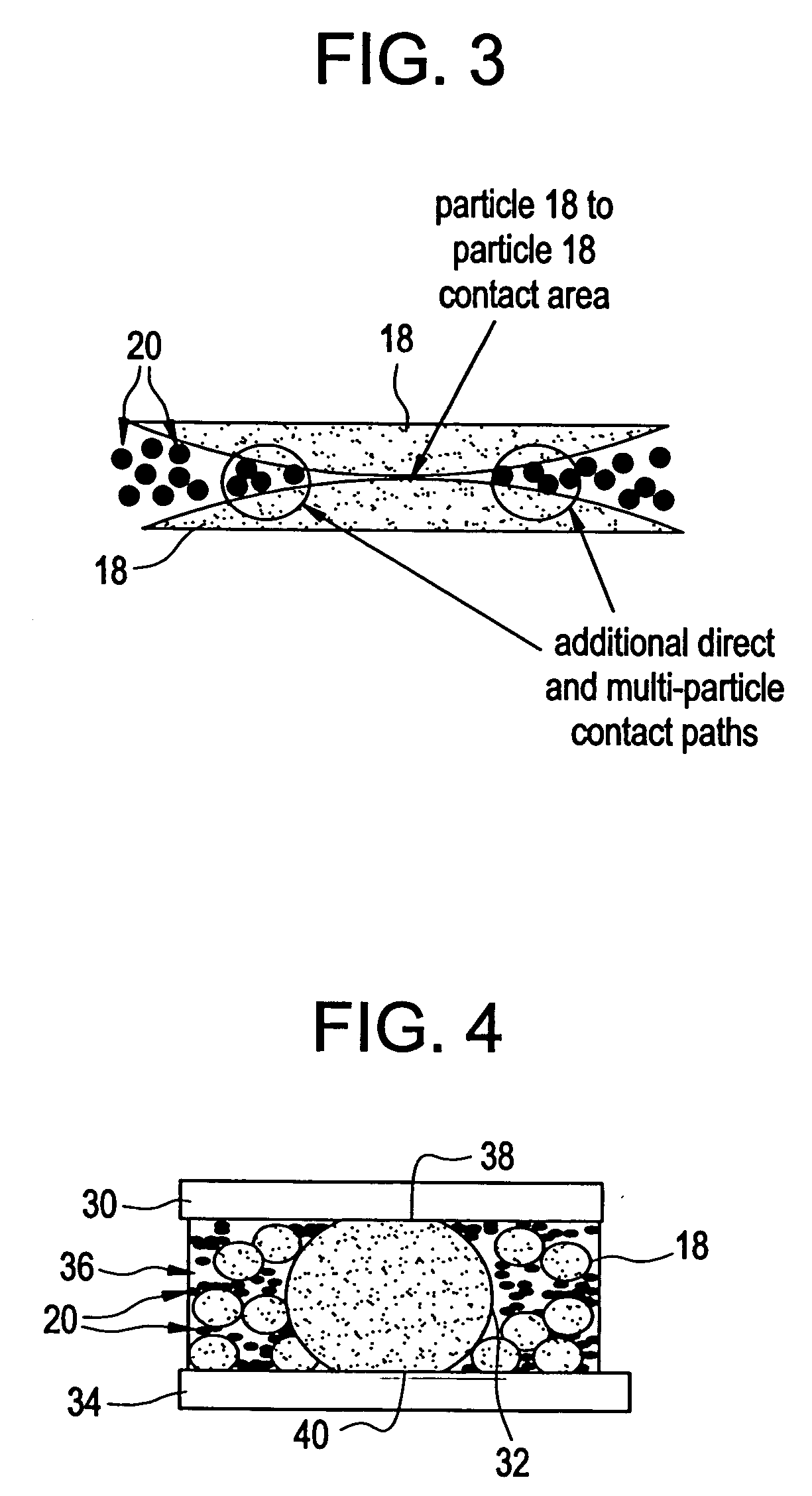

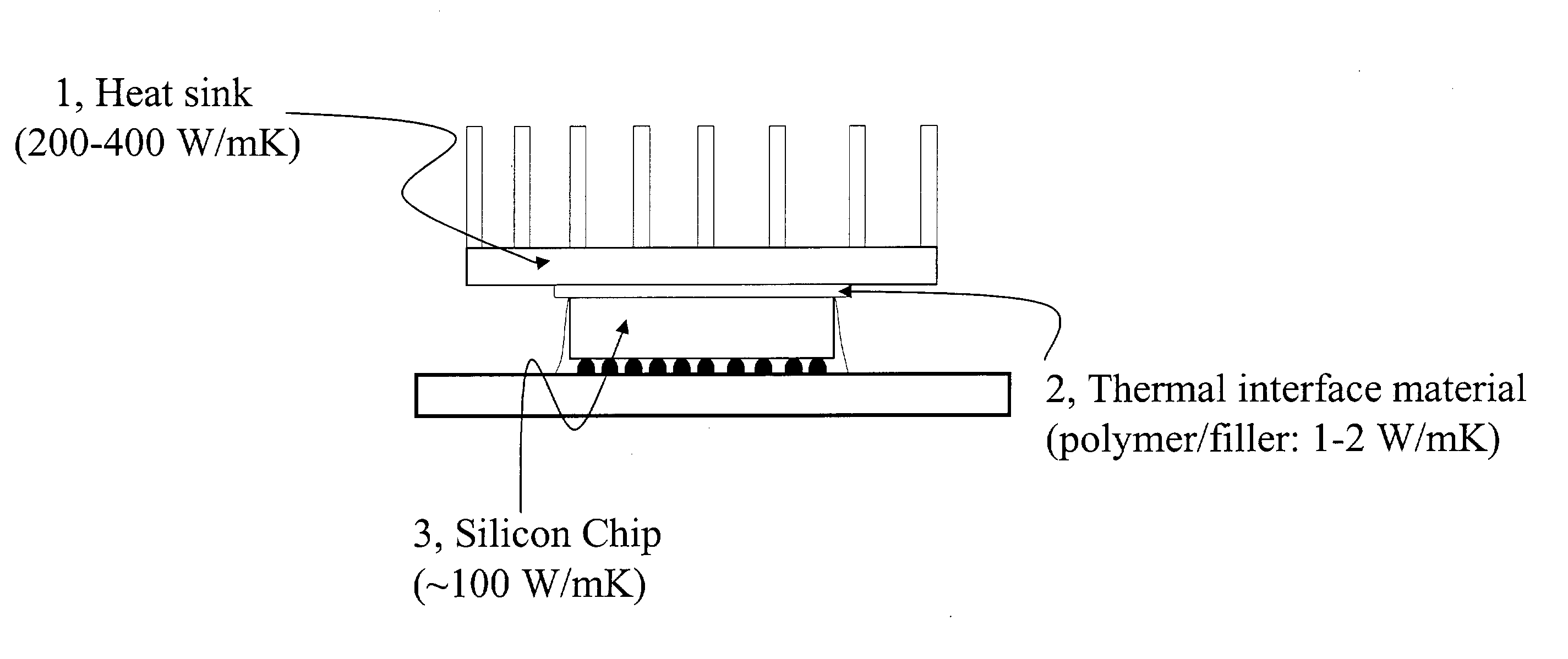

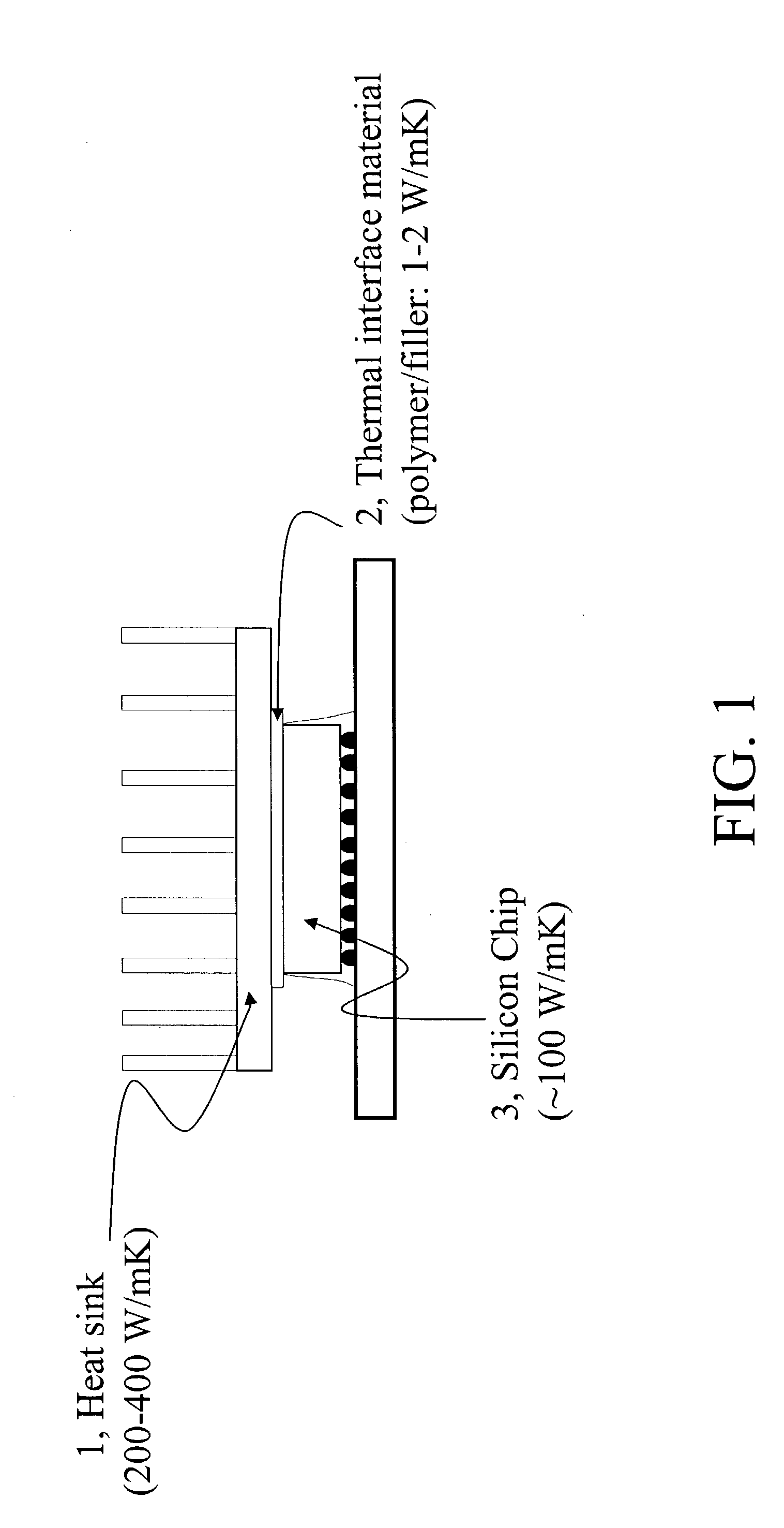

Thermal conductive material utilizing electrically conductive nanoparticles

ActiveUS20050045855A1Improve heat transfer efficiencySemiconductor/solid-state device detailsConductive materialNanoparticleInterfacial resistance

Thermal interface compositions contain both non-electrically conductive micron-sized fillers and electrically conductive nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Such compositions are electrically non-conductive. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

Implantable tissue compositions and method

InactiveUS7919112B2Improve overall lifespanPromotes localized deliveryNervous disorderAntipyreticWater insolubleFixation method

Novel implantable tissue fixation methods and compositions are disclosed. Methods and compositions of tissue, fixed using polymeric and / or variable length crosslinks, and di- or polymercapto compounds are described. Also described are the methods and compositions wherein the tissue is fixed using biodegradable crosslinkers. Methods and compositions for making radio-opaque tissue are also described. Methods and compositions to obtain a degradable implantable tissue-synthetic biodegradable polymer composite are also described. Compositions and methods of incorporating substantially water-insoluble bioactive compounds in the implantable tissue are also disclosed. The use of membrane-like implantable tissue to make an implantable drug delivery patch are also disclosed. Also described are the compositions and methods to obtain a coated implantable tissue. Medical applications implantable tissue such as heart valve bioprosthesis, vascular grafts, meniscus implant, drug delivery patch are also disclosed.

Owner:PATHAK HLDG

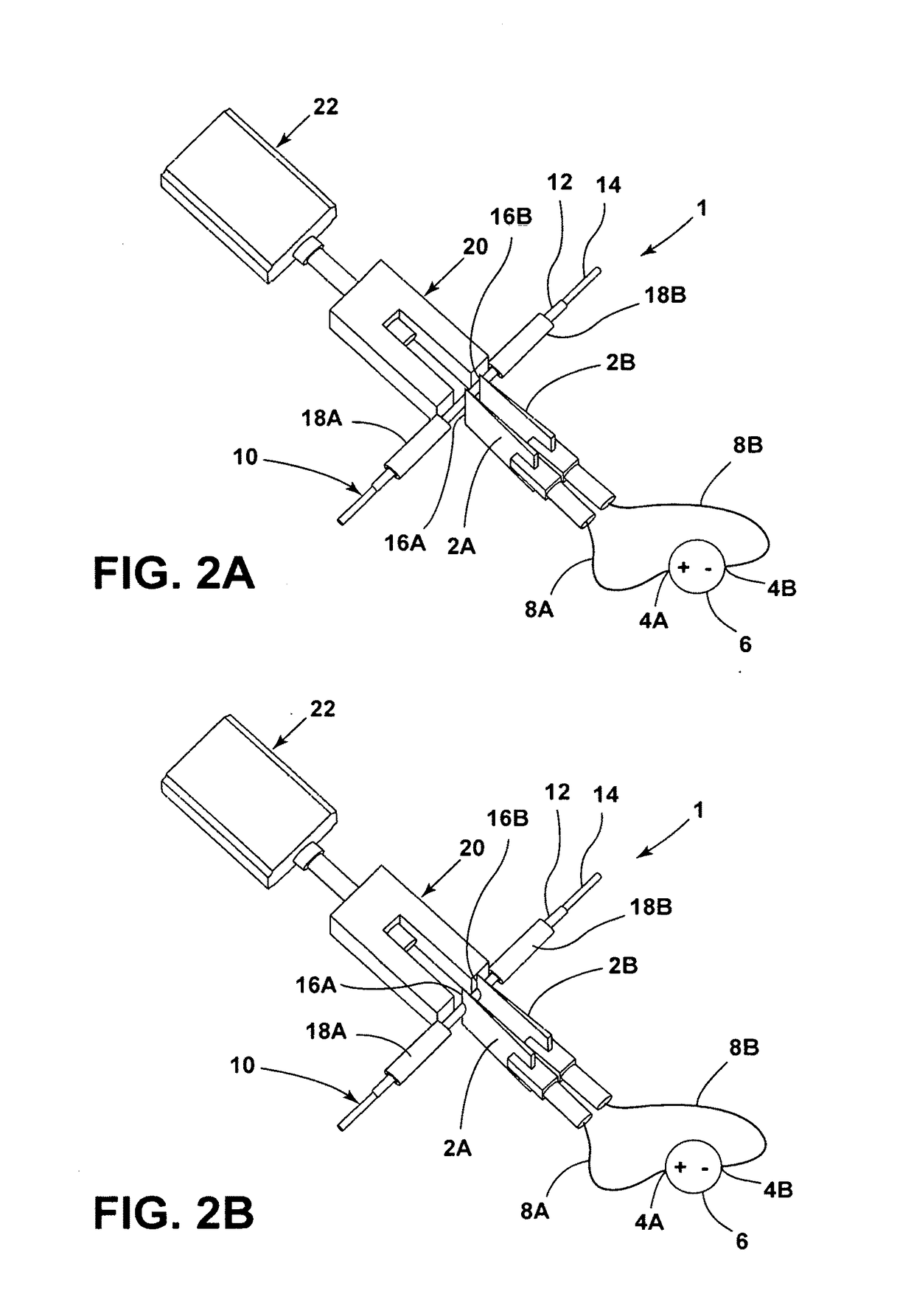

Device and method for preventing magnetic-resonance imaging induced damage

An electromagnetic shield has a first patterned or apertured layer having non-conductive materials and conductive material and a second patterned or apertured layer having non-conductive materials and conductive material. The conductive material may be a metal, a carbon composite, or a polymer composite. The non-conductive materials in the first patterned or apertured layer may be randomly located or located in a predetermined segmented pattern such that the non-conductive materials in the first patterned or apertured layer are located in a predetermined segmented pattern with respect to locations of the non-conductive materials in the second patterned or apertured layer.

Owner:MEDTRONIC INC

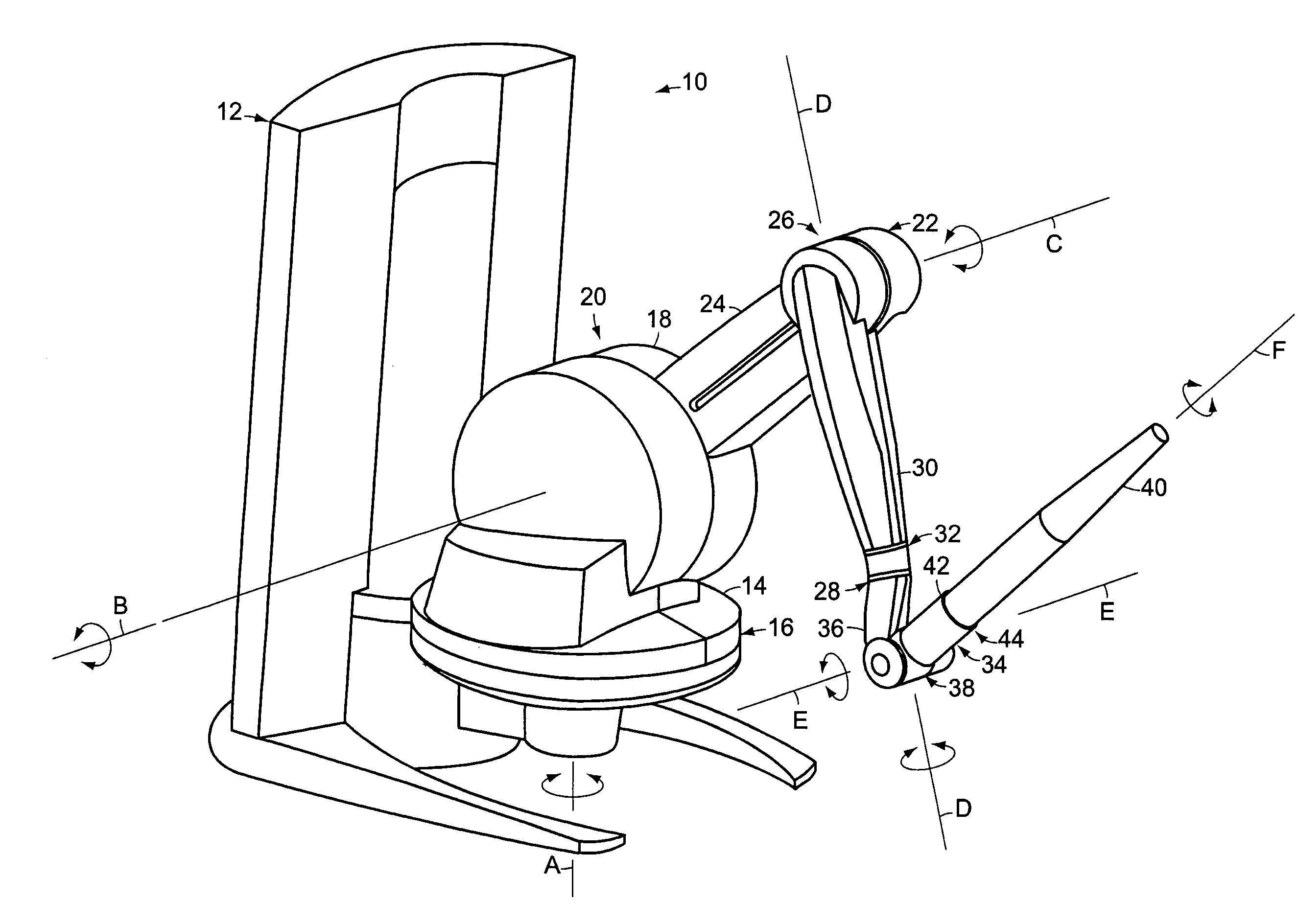

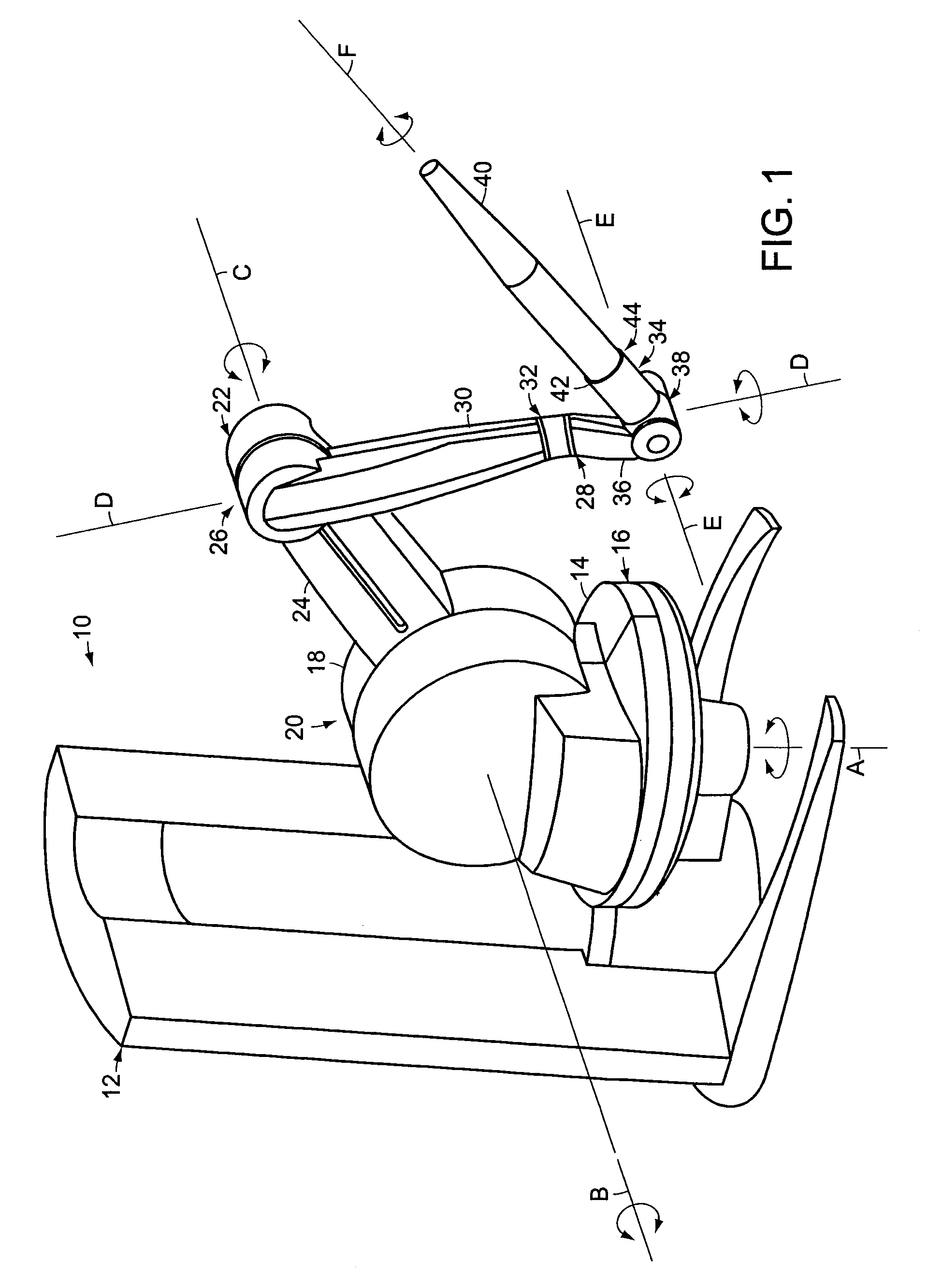

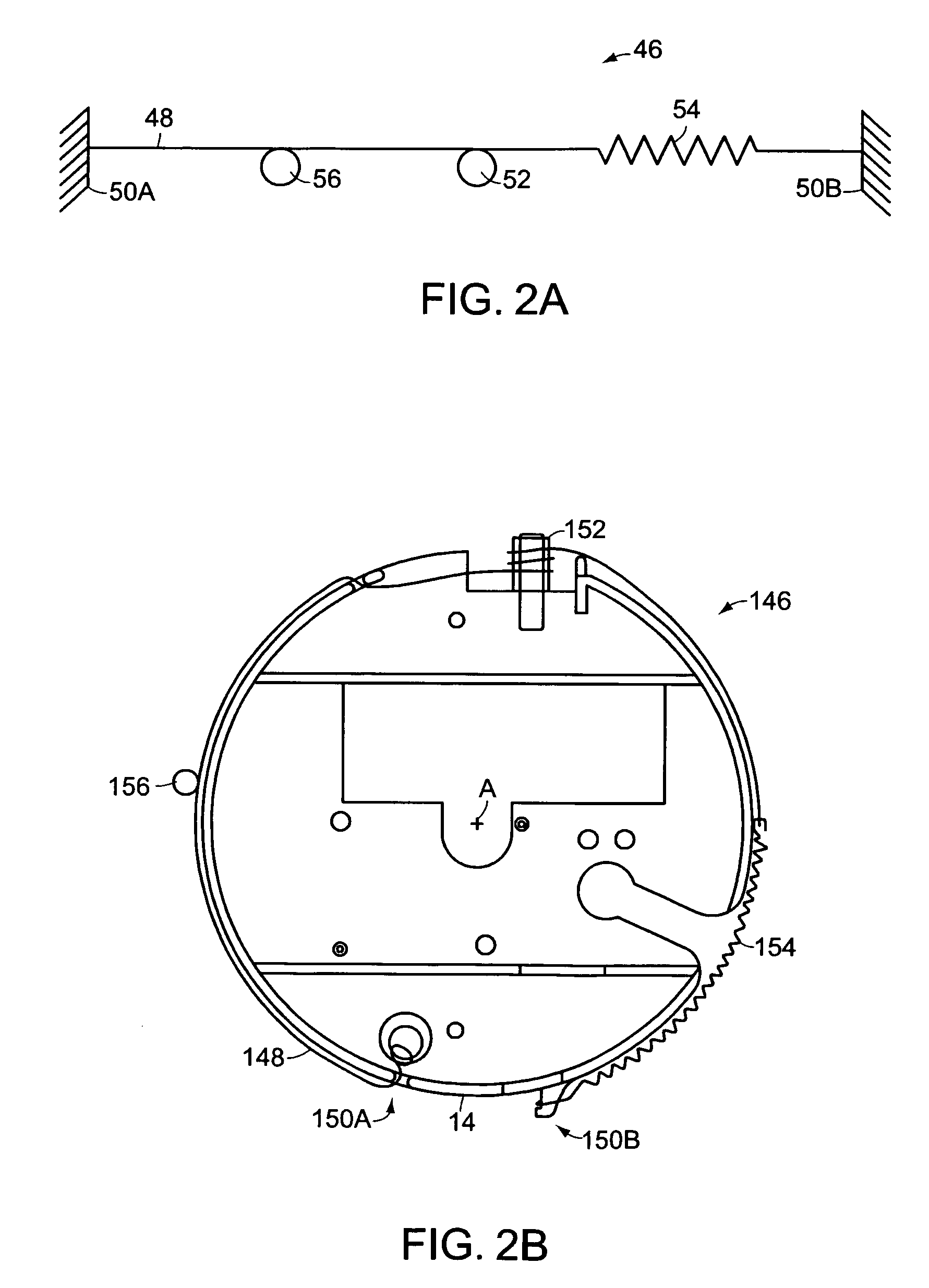

Force reflecting haptic interface

InactiveUS6985133B1Prevent reboundIncrease stiffnessCathode-ray tube indicatorsInput/output processes for data processingEngineeringActuator

A six degree of freedom force reflecting haptic interface includes three powered axes and three free axes, all of which are tracked so that the position of a user connection element in the work volume can be determined. The interface includes cable drives with polymer composite or metallic cables, automatic cable tensioning devices, and grounded actuator capstans. A nested hub and transfer drive provide a compact, weight balanced interface. User comfort and safety features are also provided.

Owner:3D SYST INC

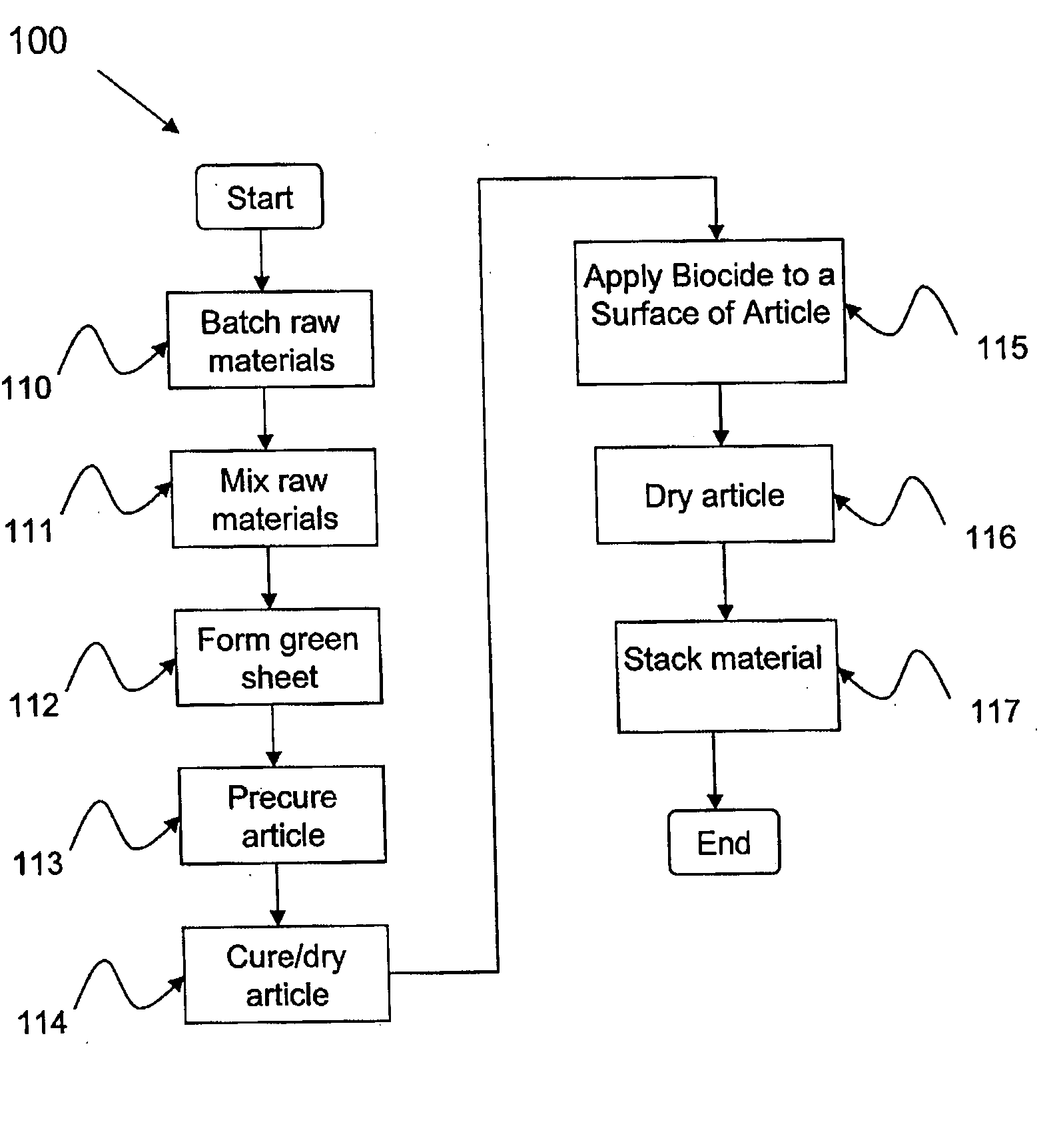

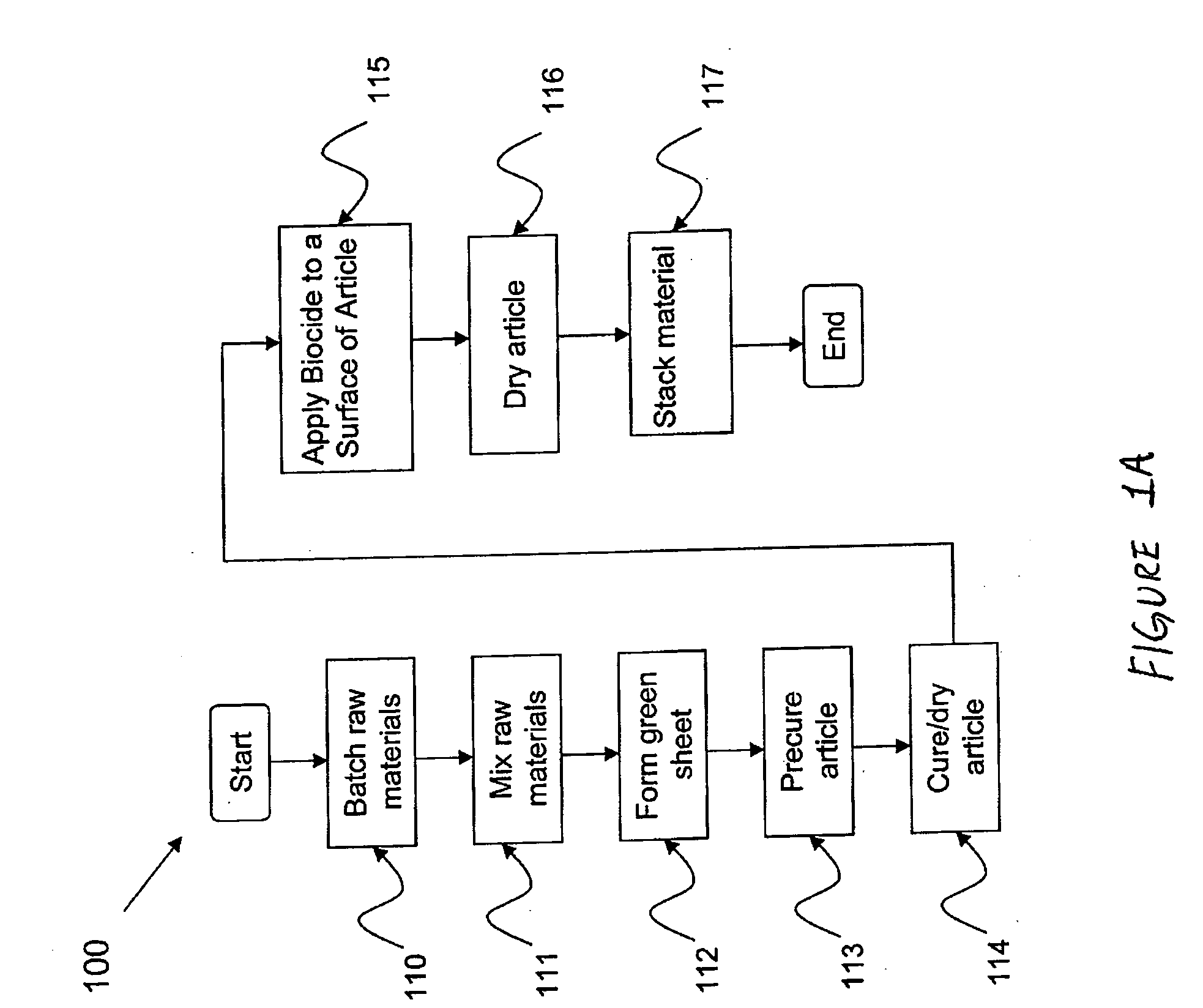

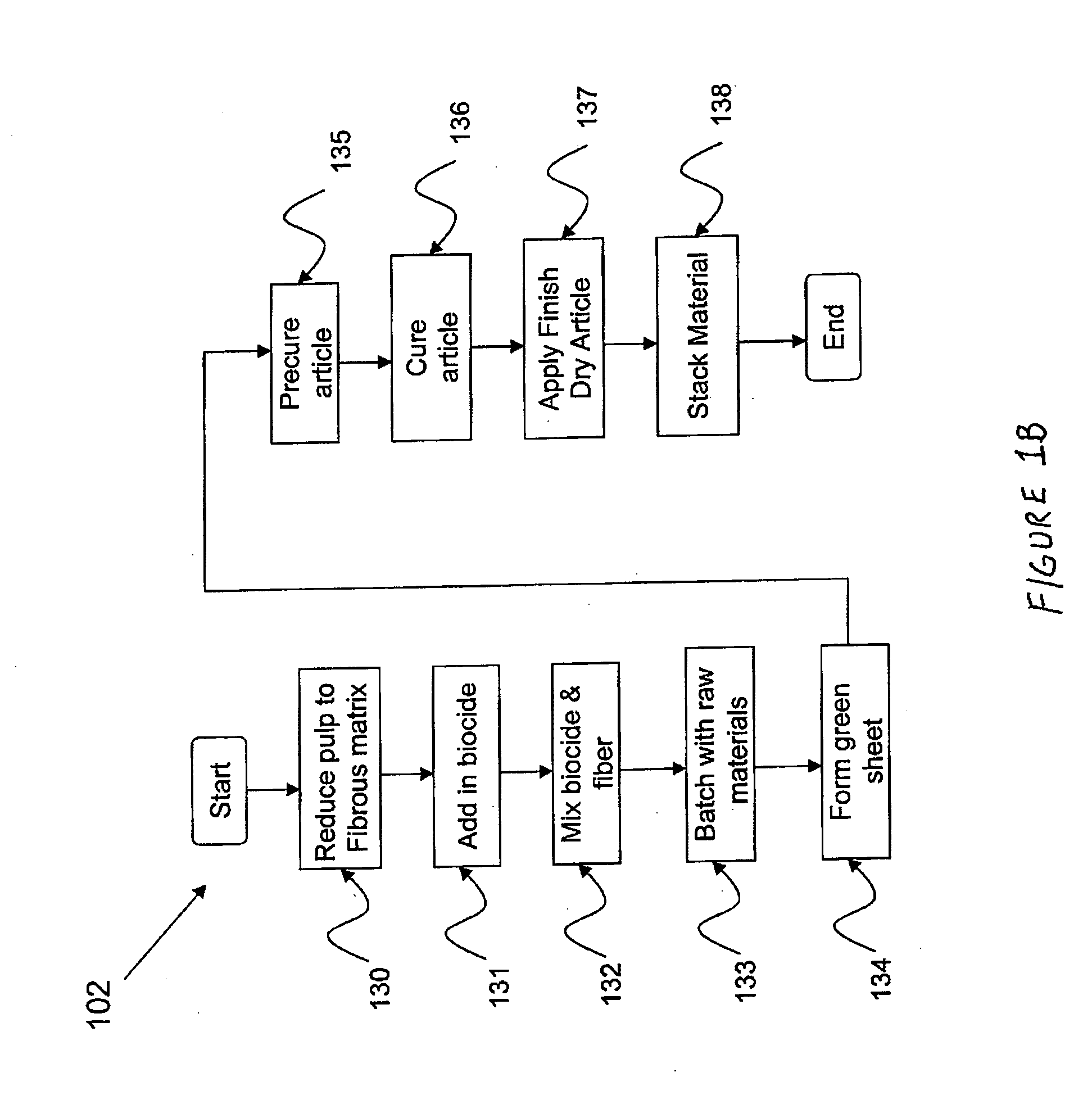

Building materials with bioresistant properties

InactiveUS20050126430A1Effective biocide treatmentAffecting performanceFireproof paintsAntifouling/underwater paintsFiberBiological resistance

A building article incorporating a biocidal agent, such as copper oxine, that inhibits the growth of mold, fungi, algae, mildew, bacteria, lichen, and other undesirable biological growth is provided. The biocidal agent can be a biocide, fungicide, germicide, insecticide, mildewcide, or the like. The biocidal agent can be interspersed throughout the matrix of the article; applied as a surface treatment to the article; or applied as a treatment to the fibers reinforcing the article. The building article can include tile backer boards, decks, soffits, trims, decking, fencing, roofing, cladding, sheathing, and other products. The building article can also include a variety of different composite materials such as cement, gypsum, wood, and wood / polymer composites.

Owner:JAMES HARDIE TECH LTD

Polymers containing functionalized carbon nanotubes

A polymer composite composed of a polymerized mixture of functionalized carbon nanotubes and monomer which chemically reacts with the functionalized nanotubes. The carbon nanotubes are functionalized by reacting with oxidizing or other chemical media through chemical reactions or physical adsorption. The reacted surface carbons of the nanotubes are further functionalized with chemical moieties that react with the surface carbons and selected monomers. The functionalized nanotubes are first dispersed in an appropriate medium such as water, alcohol or a liquefied monomer and then the mixture is polymerized. The polymerization results in polymer chains of increasing weight bound to the surface carbons of the nanotubes. The composite may consists of some polymer chains imbedded in the composite without attachment to the nanotubes. The resulting composite yields superior chemical, physical and electrical properties over polymer composites that are only physically mixed and without binding to the surface carbons of the nanotubes.

Owner:HYPERION CATALYSIS INT

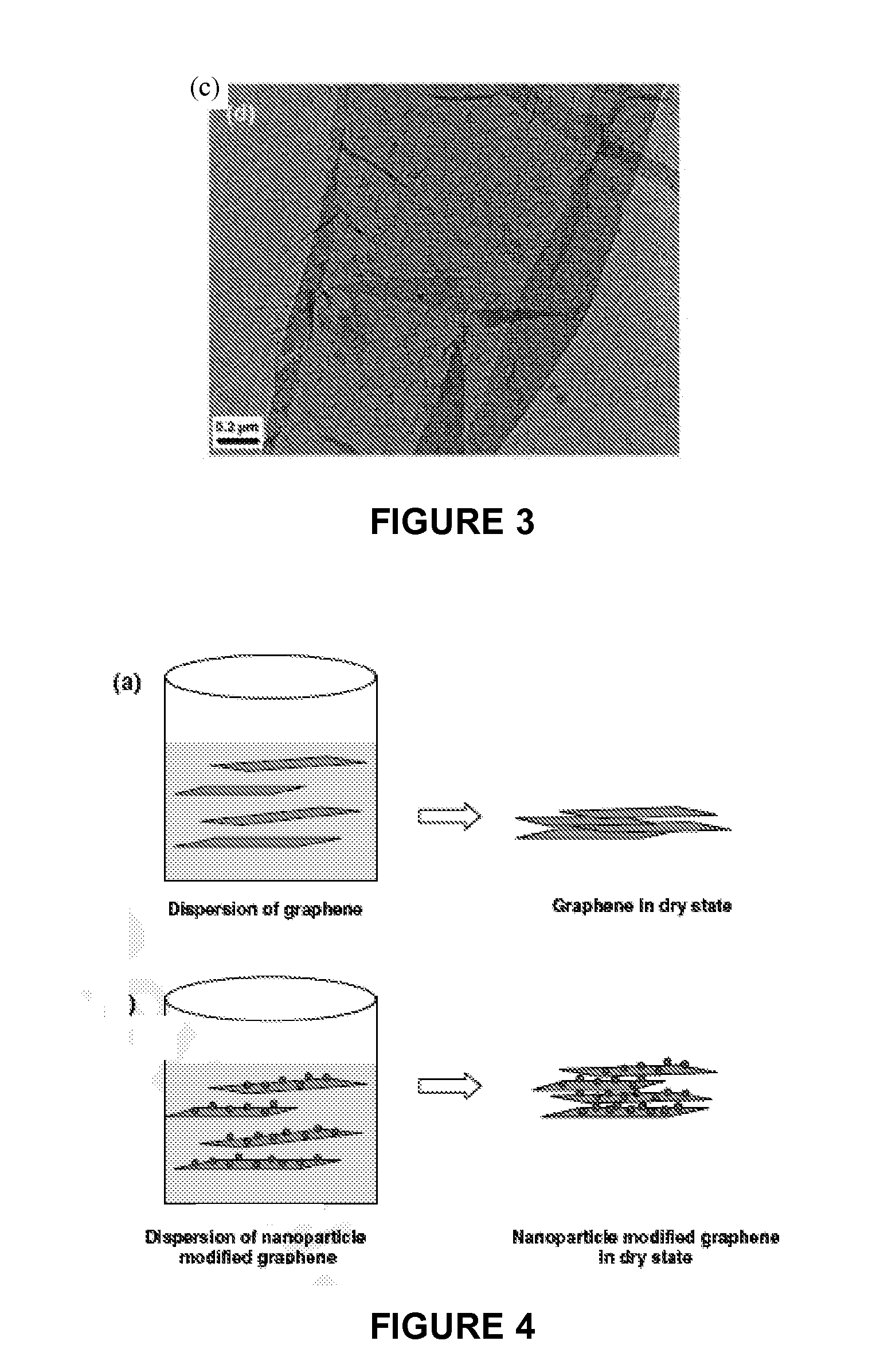

Synthesis of graphene sheets and nanoparticle composites comprising same

A method for producing isolatable and dispersible graphene sheets, wherein the graphene sheets may be tailored to be soluble in aqueous, non-aqueous or semi-aqueous solutions. The water soluble graphene sheets may be used to produce a metal nanoparticle-graphene composite having a specific surface area that is 20 times greater than aggregated graphene sheets. Graphene sheets that are soluble in organic solvents may be used to make graphene-polymer composites.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

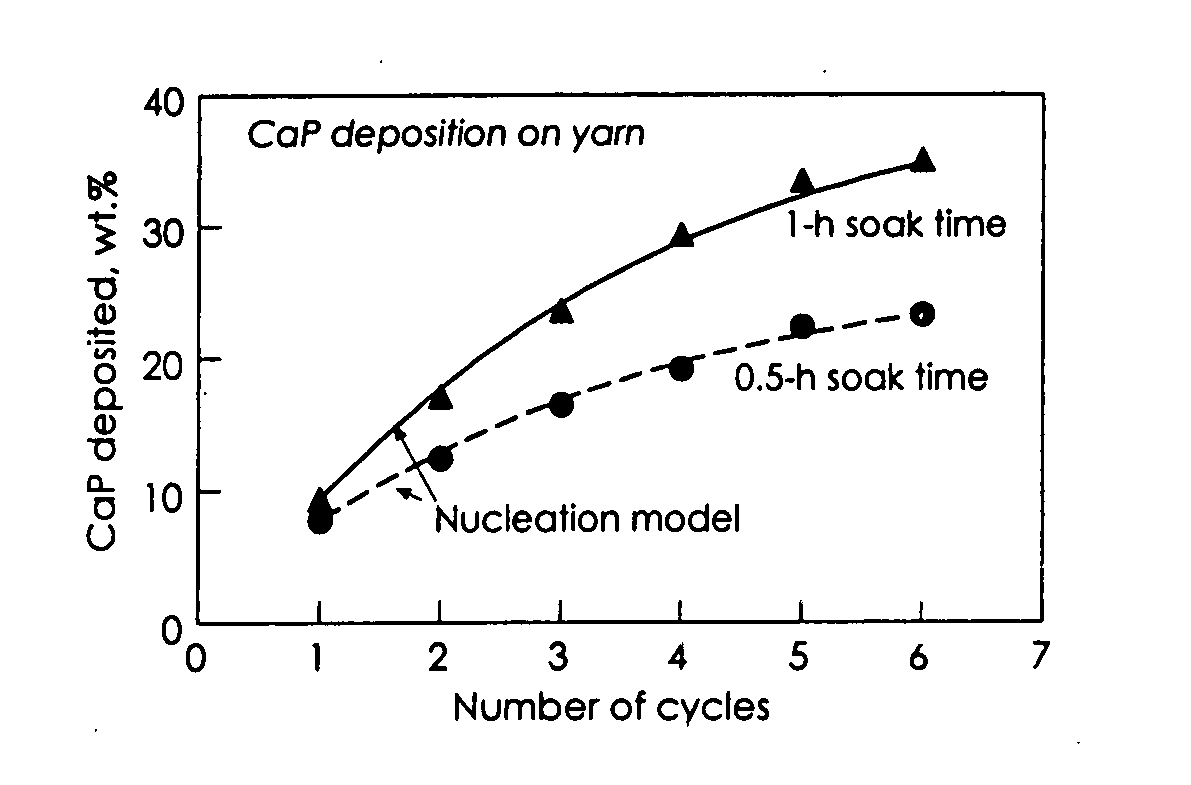

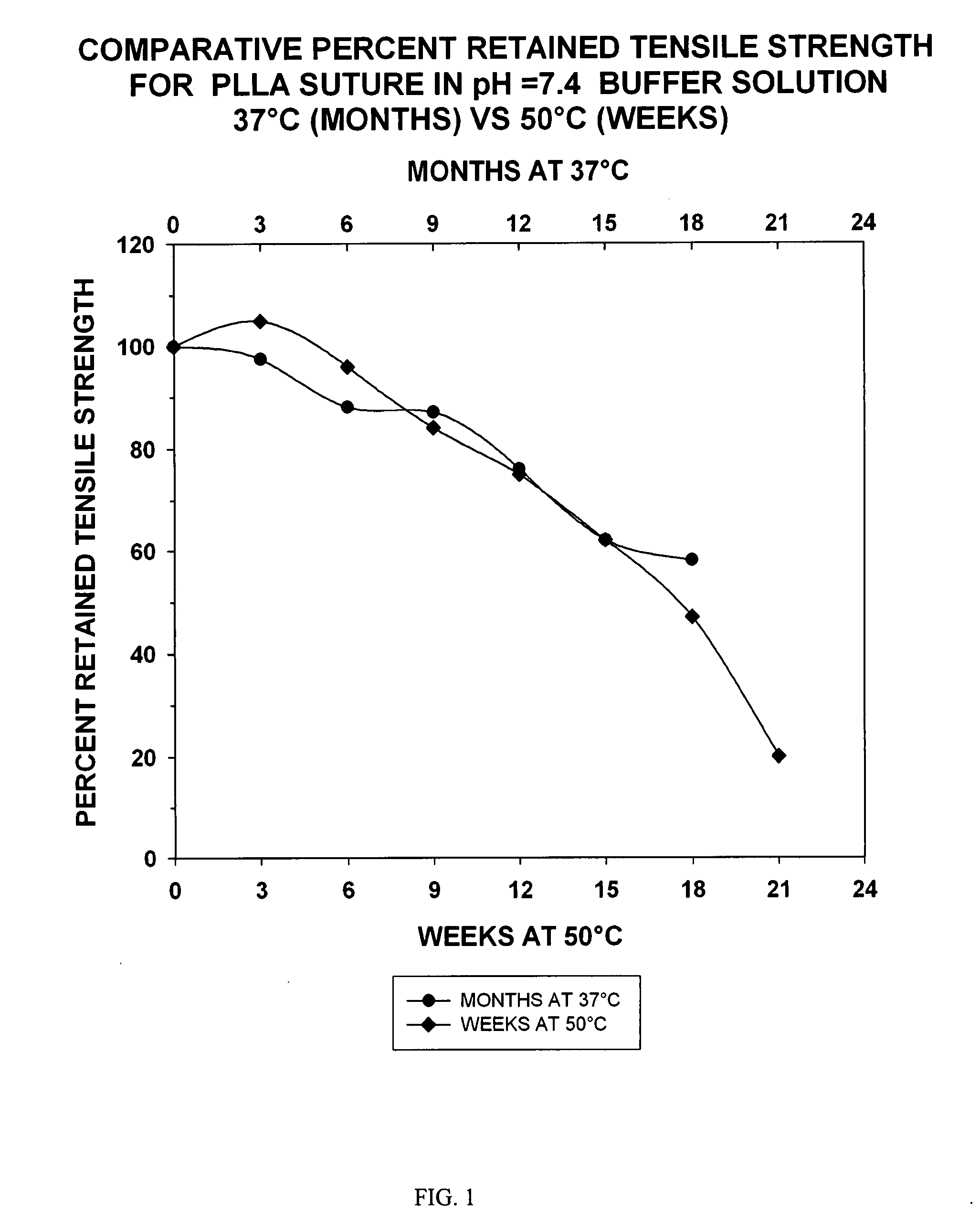

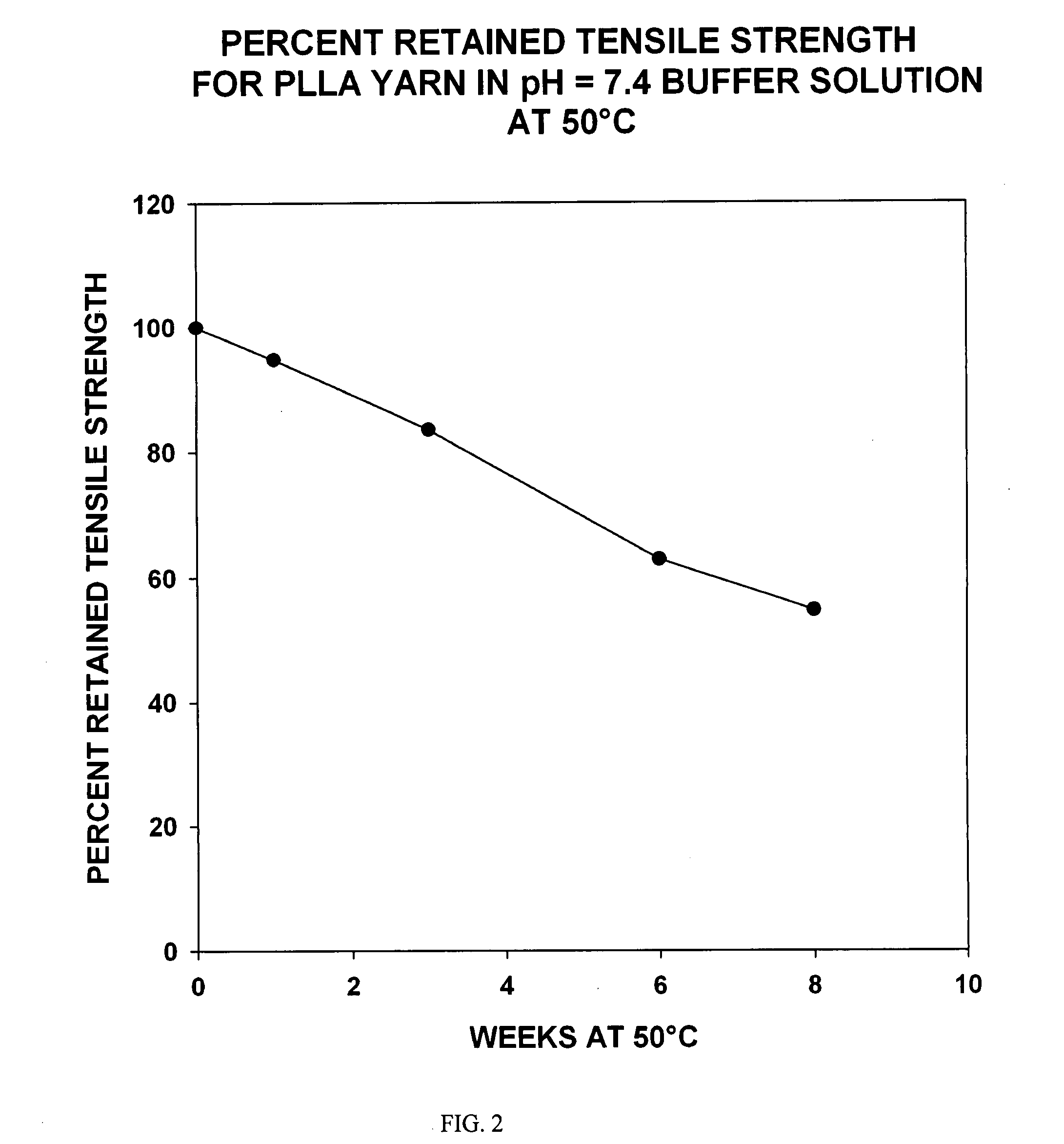

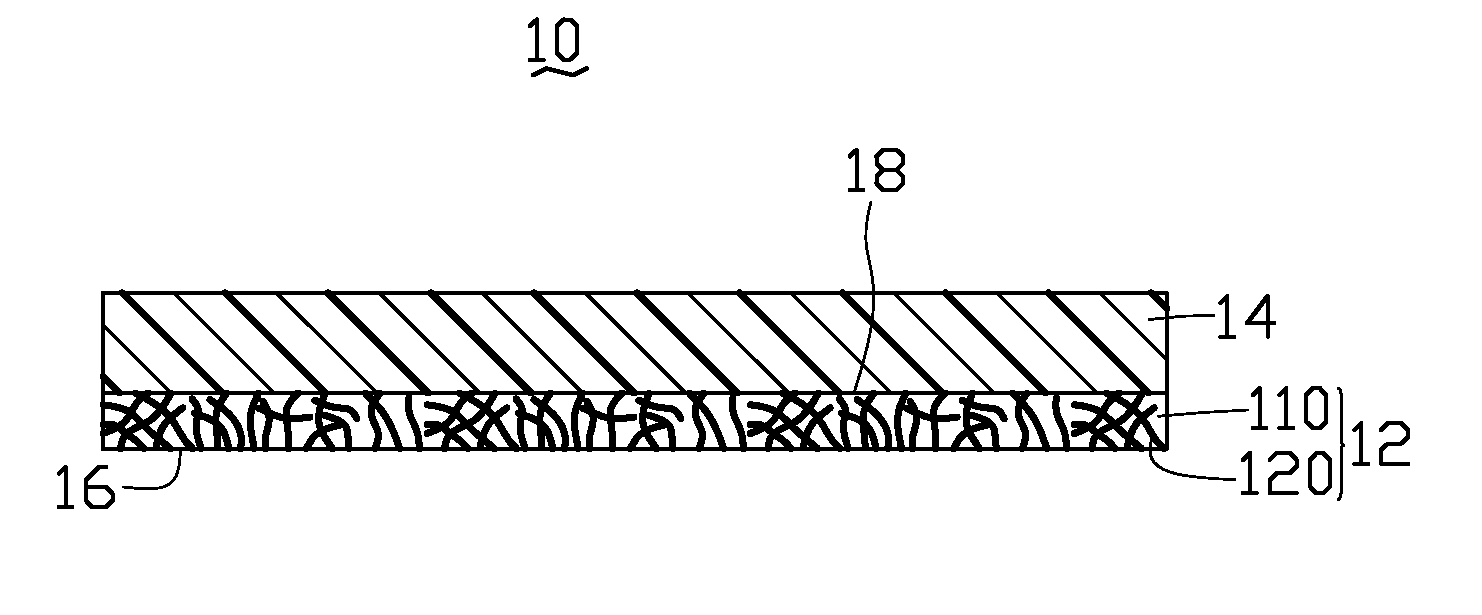

Calcium phosphate polymer composite and method

A bone-repair composite includes a core and a sheath. The core is a first primary unit including a combination of a first set of yarns coated with a calcium phosphate mineral layer. The first set of yarns being made from a first group of one ore more polymers. The sheath is a second primary unit a combination of a second set of yarns or one or more polymer coatings. The second set of yarns being made from a second group of one or more polymers, wherein the composite is made by covering the core with the sheath, and the composite is compression molded to allow the sheath to bond to the core. The bone-repair composite has a bending modulus comparable to that of a mammalian bone, such that the ratio of the core to the sheath is provided to maximize the mechanical strength of the bone-repair composite to mimic the mammalian bone.

Owner:TELEFLEX MEDICAL INC +1

Absorbent compositions with clay aerogels and methods for forming absorbent compositions

InactiveUS20080132632A1Low densityComponents is relatively effectiveAnimal housingLitterPolymer composites

Lightweight, highly absorbent compositions including clay aerogels are suitable for use in the home as well as in industry and have particular suitability for use as animal litter. The compositions can further include components, for example as part of the mixture and / or as a coating on a surface of the clay aerogel component, that have properties, for example, that aid in malodor reduction, clumping, or the like, or combinations thereof. Also, clay aerogel polymer composites, formed from various types of clay and (co)polymers, which are relatively low density materials having myriad applications are disclosed. Numerous methods for preparing the clay aerogel polymer composites are disclosed.

Owner:CASE WESTERN RESERVE UNIV

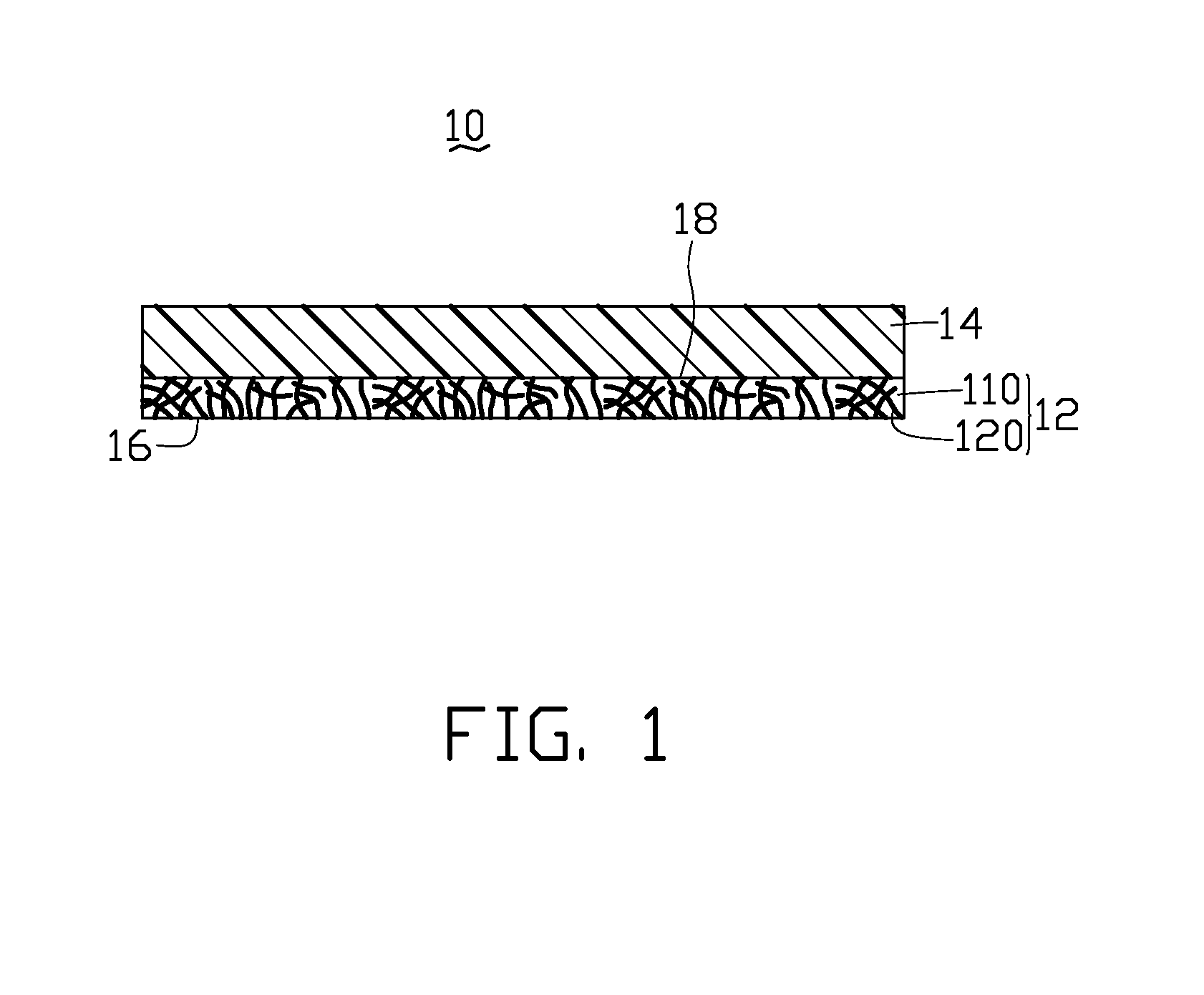

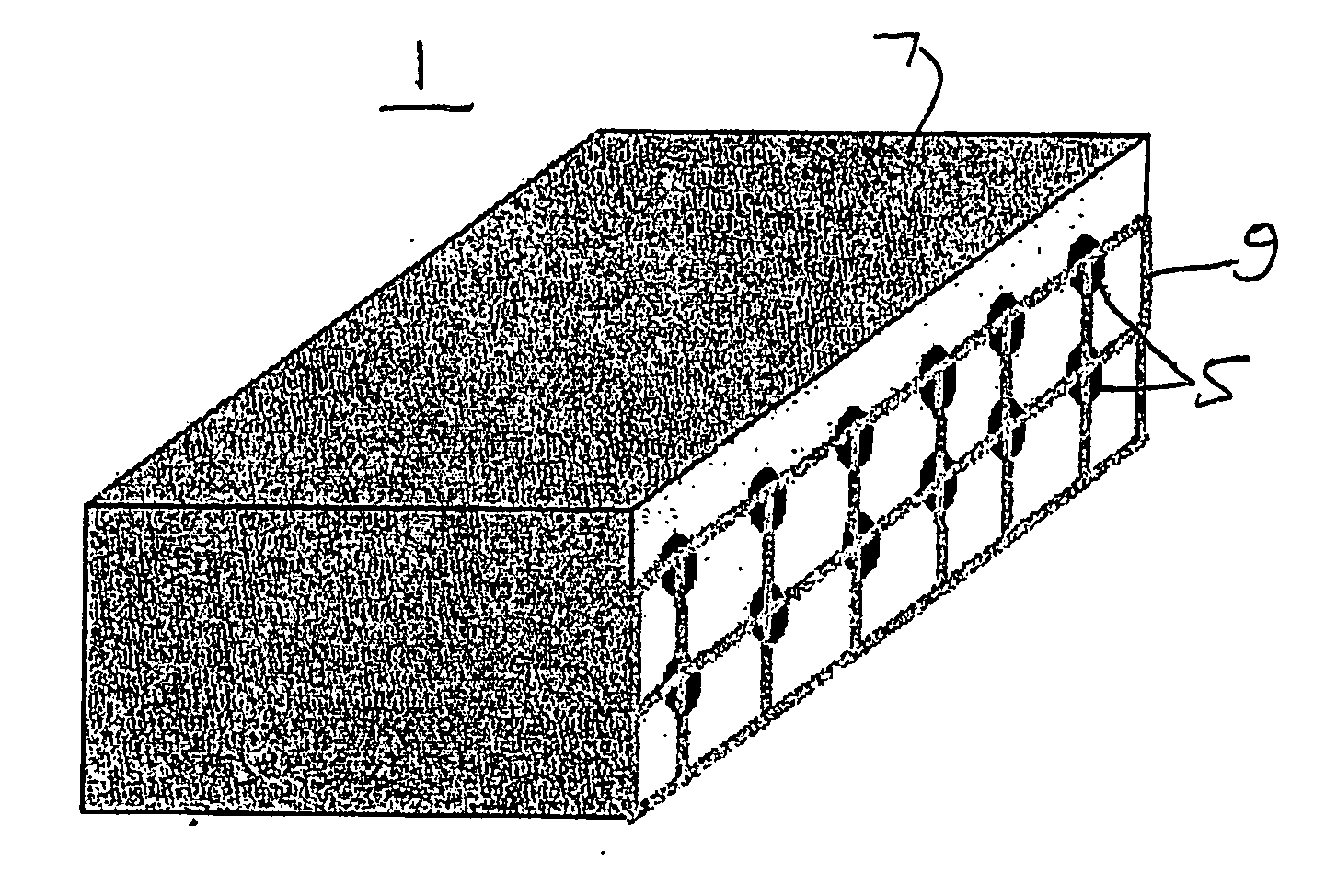

Carbon nanotube composite

InactiveUS20080063860A1Synthetic resin layered productsRecord information storagePolymer compositesNanotube

A carbon nanotube / polymer composite is described. The carbon nanotube / polymer composite includes at least one polymer material layer and at least one carbon nanotube / polymer composite layer. The carbon nanotube / polymer layer includes a polymer material and a plurality of carbon nanotubes embedded in the polymer material, wherein the carbon nanotube / polymer layer includes a top surface and a bottom surface opposite to the top surface, at least one of the top surface and bottom surface contacts with the adjacent polymer material layer, and the carbon nanotubes respectively contact at least one respective adjacent carbon nanotube to thereby yield a network of contacting carbon nanotubes.

Owner:TSINGHUA UNIV +1

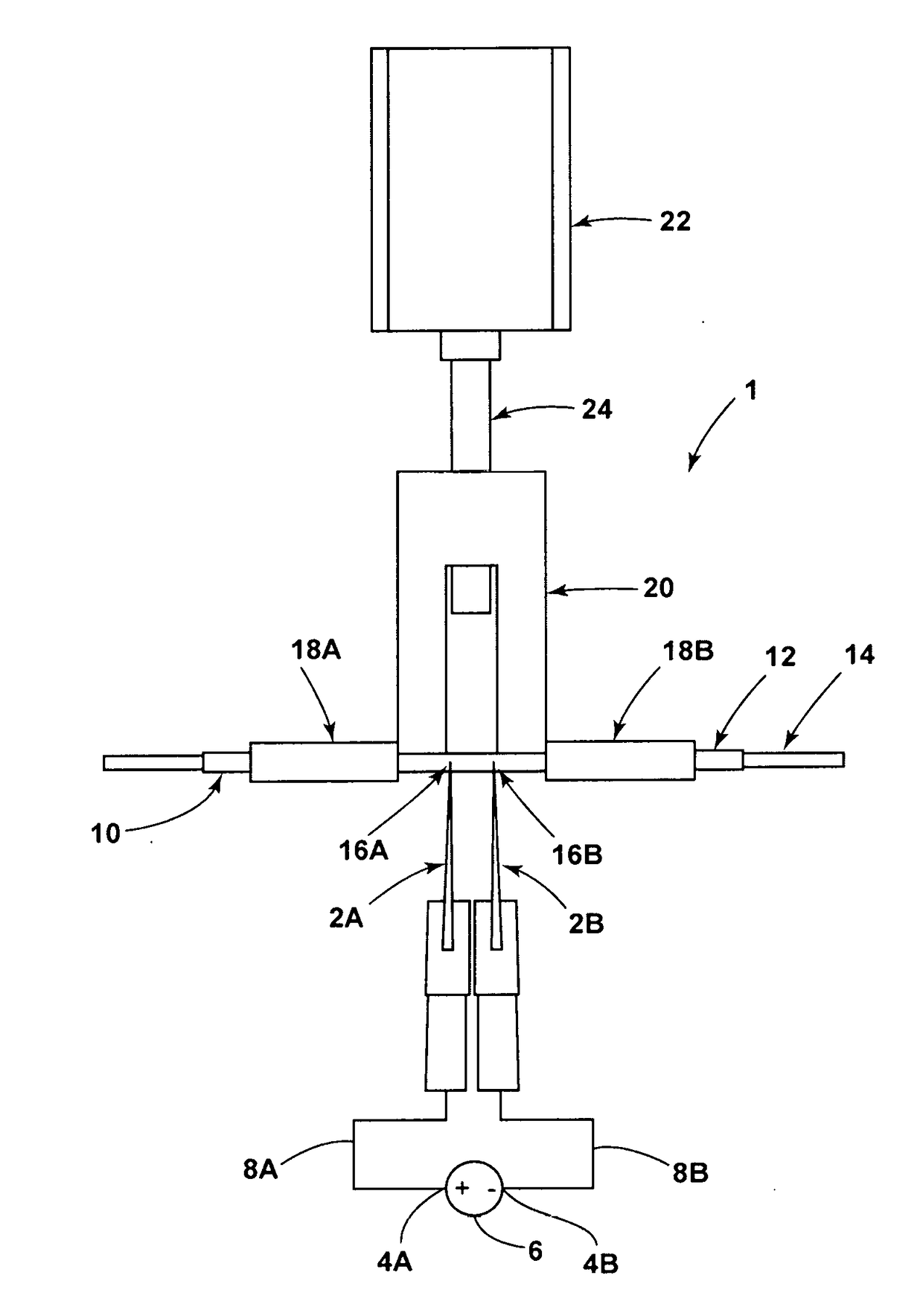

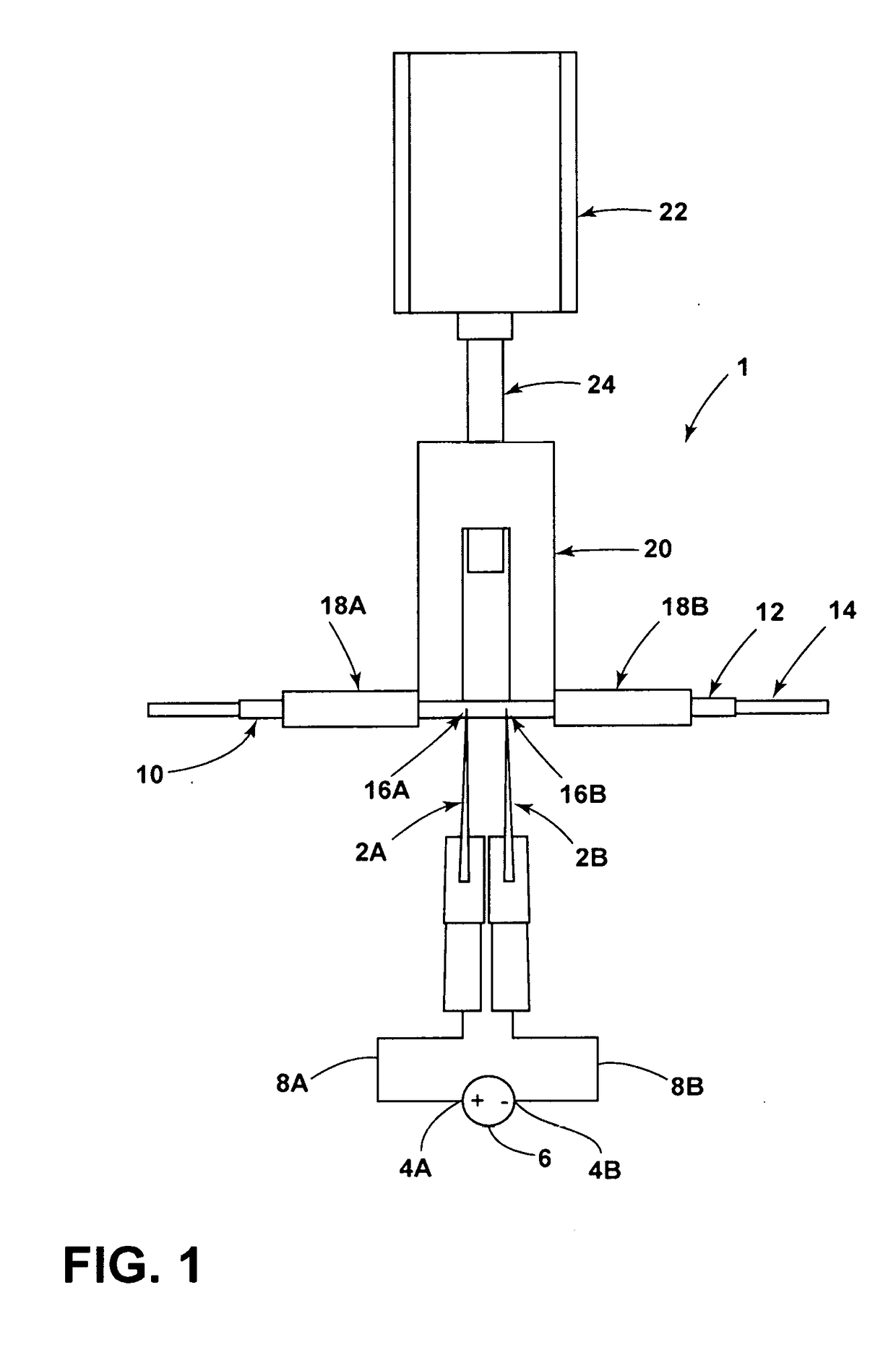

Cutting mechanism for carbon nanotube yarns, tapes, sheets and polymer composites thereof

ActiveUS20170129182A1Easy to cutRobust cutting method3D object support structuresManufacturing data aquisition/processingPower flowCarbon nanotube yarn

A cutting mechanism includes electrodes that are utilized to cut or score a non-conductive outer material of a filament or sheet. The electrodes contact a conductive reinforcing material of the filament or sheet to complete an electric circuit. Electric current flows through and heats the conductive material to oxidize or otherwise separate / cut the conductive material and any remaining non-conductive material.

Owner:NAT INST AEROSPACE ASSOC +1

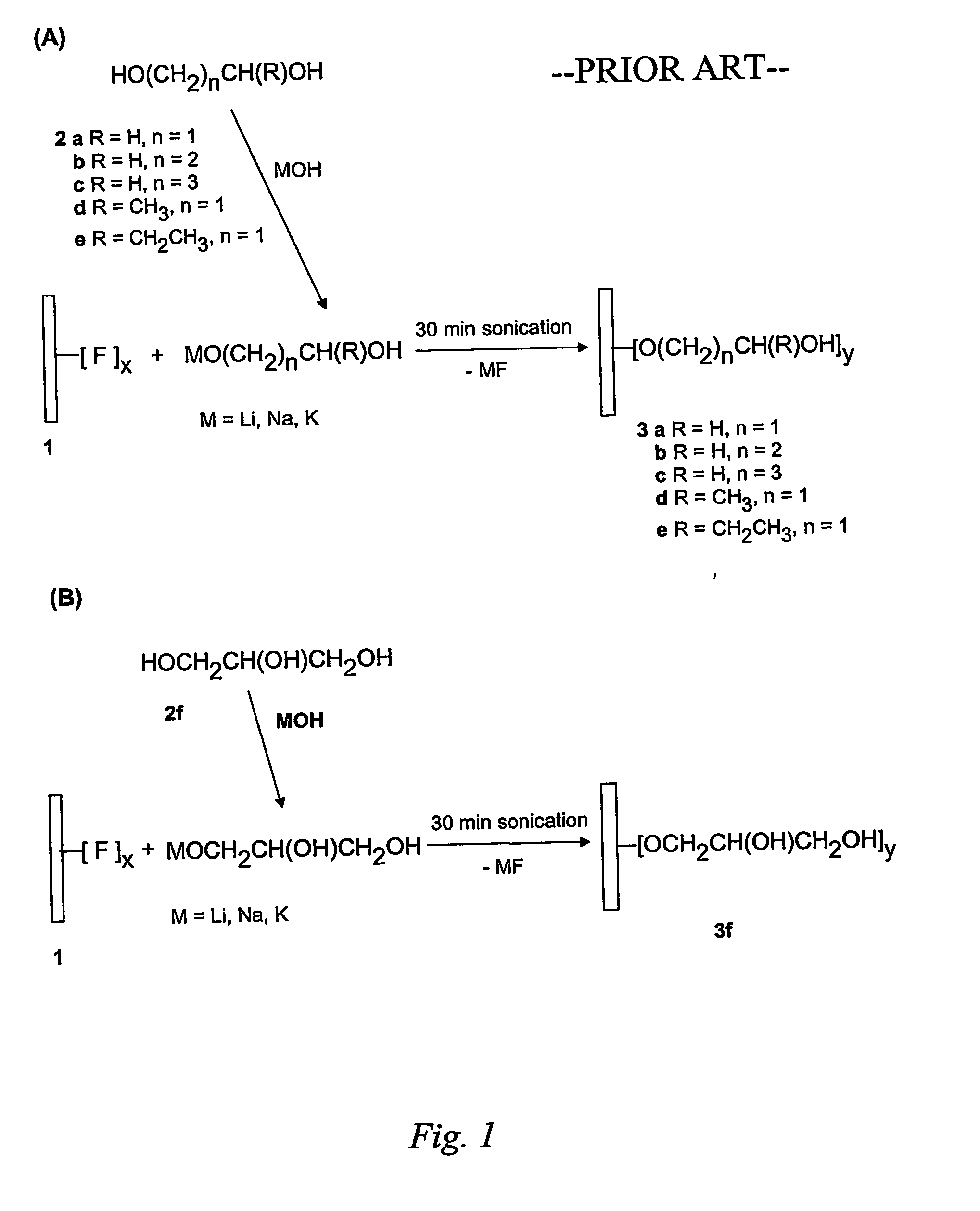

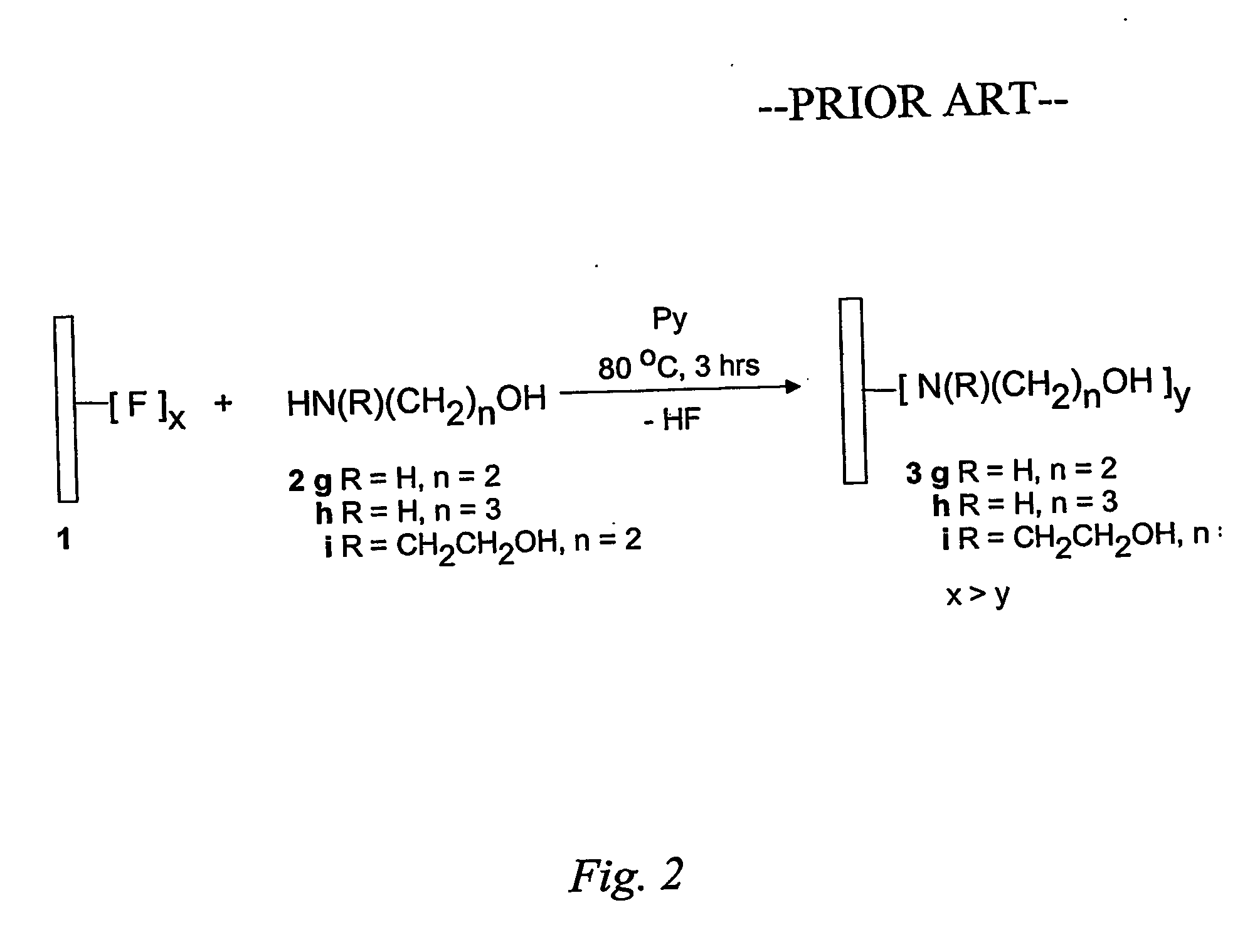

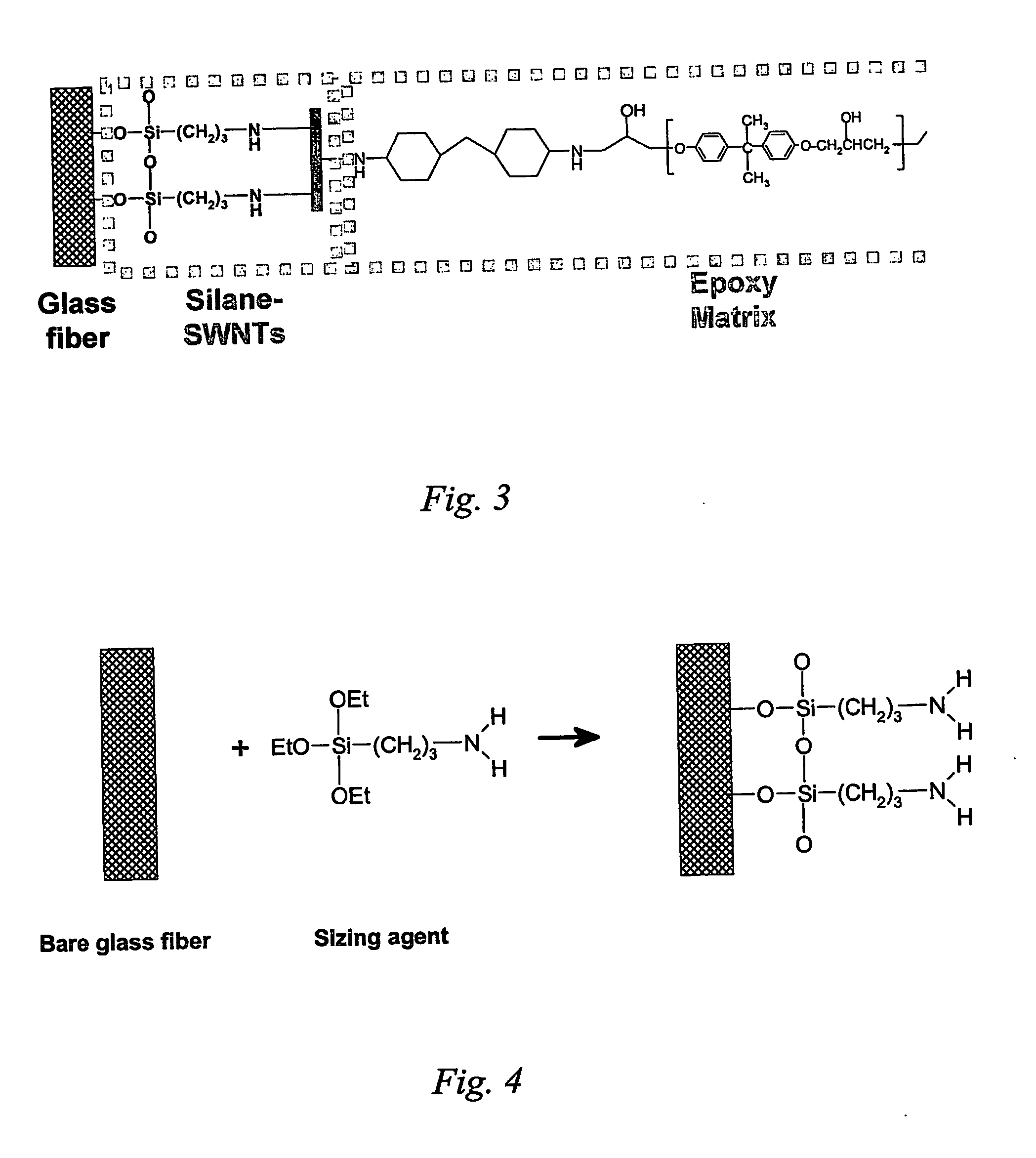

Sidewall Functionalization Of Carbon Nanotubes With Organosilanes For Polymer Composites

InactiveUS20070298669A1Improve the level ofStrong attachmentMaterial nanotechnologySilicon organic compoundsPolymer compositesPolymer chemistry

The present invention is directed to methods of functionalizing carbon nanotubes (CNTs), particularly single-wall carbon nanotubes (SWNTs), with organosilane species, wherein such functionalization enables fabrication of advanced polymer composites. The present invention is also directed toward the functionalized CNTs, advanced CNT-polymer composites made with such functionalized CNTs, and methods of making such advanced CNT-polymer composites.

Owner:RICE UNIV

Polymeric composite including nanoparticle filler

InactiveUS20070106006A1Increase potential environmental impactReduce load levelHalloysiteNanoparticle

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

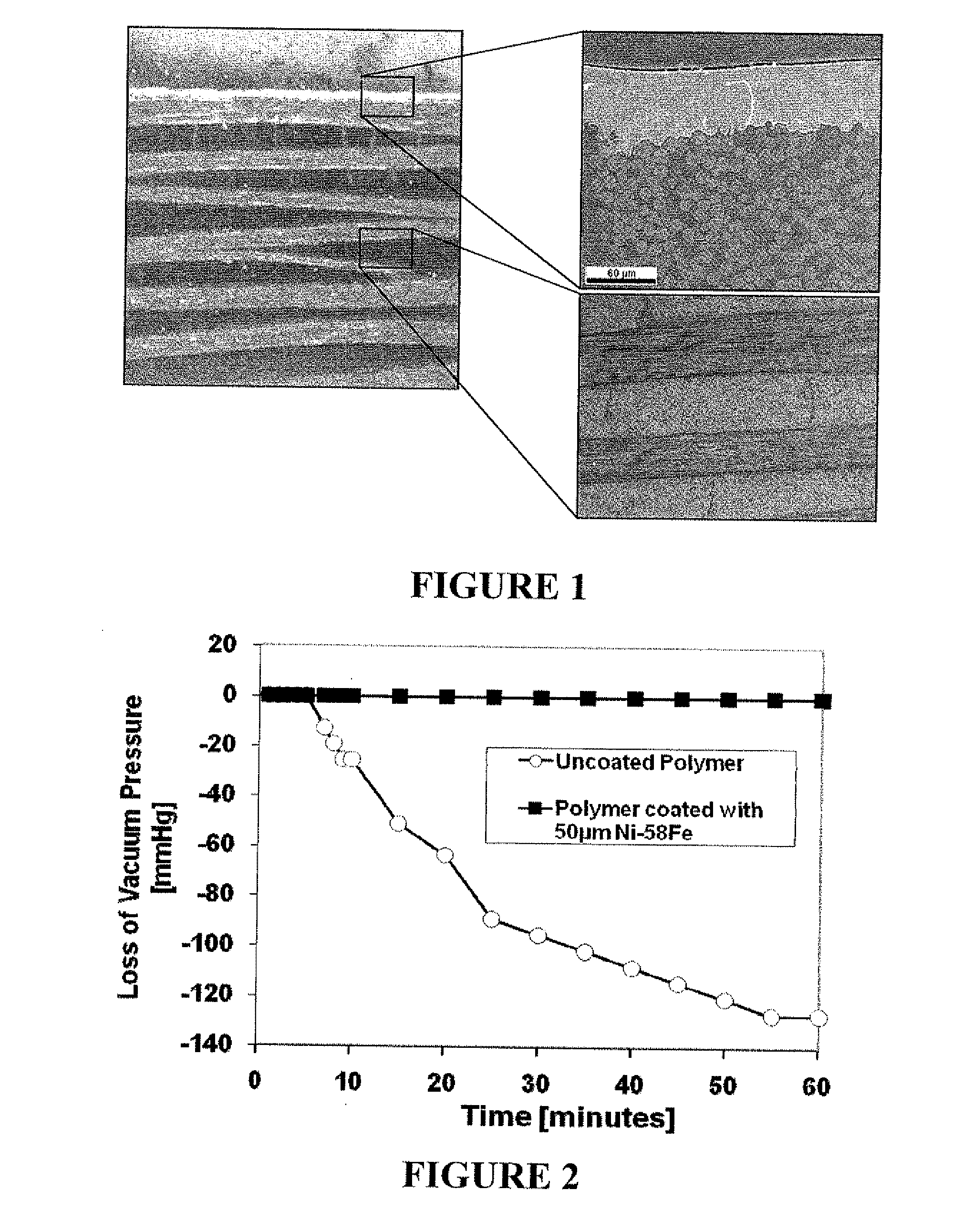

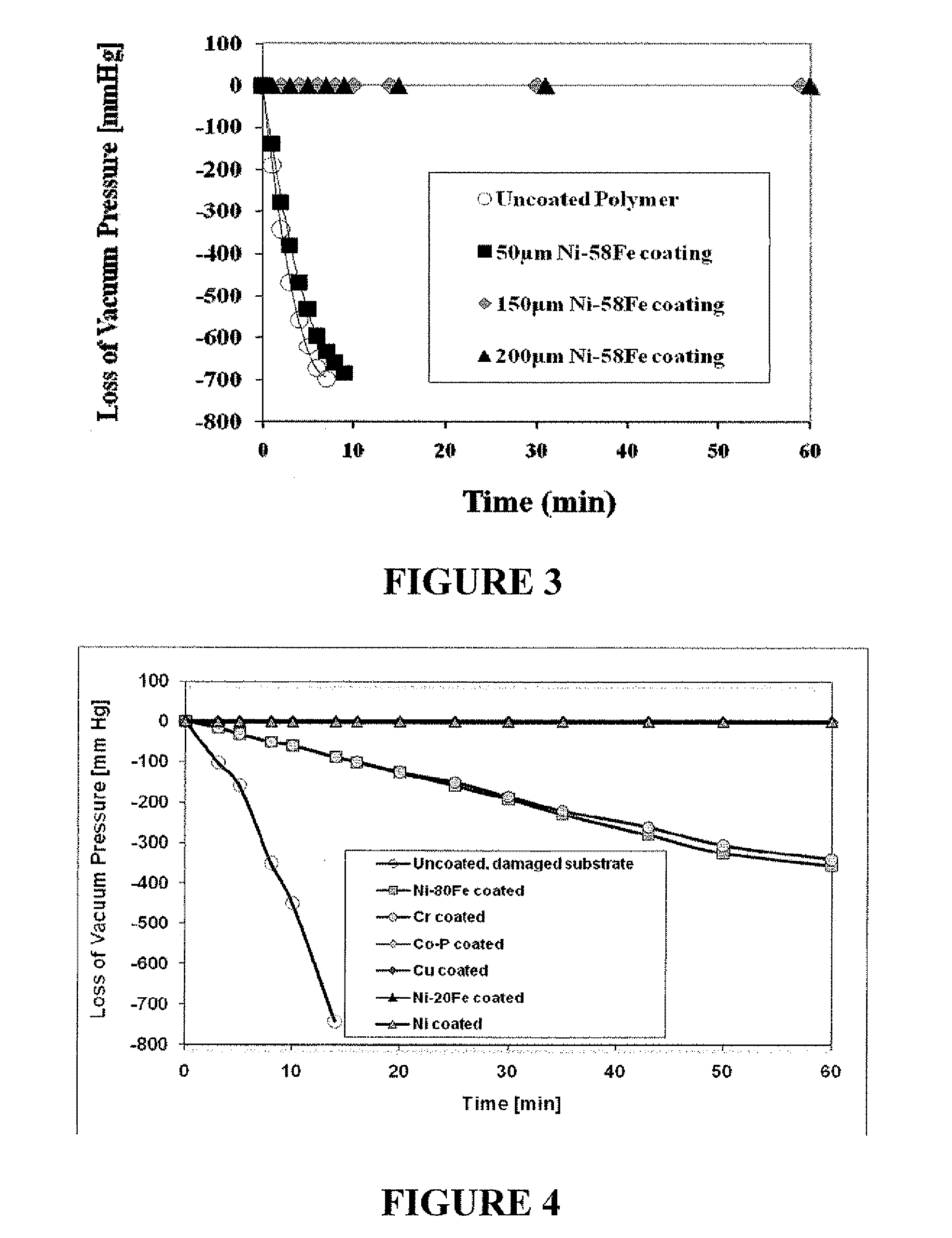

Metal-coated polymer article of high durability and vacuum and/or pressure integrity

InactiveUS20100304063A1Increased durabilityEnhance pressure integrityPretreated surfacesSolid state diffusion coatingPolymer compositesPolymer substrate

Metal-coated polymer articles containing structural substantially porosity-free, fine-grained and / or amorphous metallic coatings / layers optionally containing solid particulates dispersed therein on polymer substrates, are disclosed. The substantially porosity-free metallic coatings / layers / patches are applied to polymer or polymer composite substrates to provide, enhance or restore vacuum / pressure integrity and fluid sealing functions. Due to the excellent adhesion between the metallic coating and the polymer article satisfactory thermal cycling performance is achieved. The invention can also be employed as a repair / refurbishment technique. The fine-grained and / or amorphous metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, aerospace and automotive parts and other components exposed to thermal cycling and stress created by erosion and impact damage.

Owner:INTEGRAN TECH

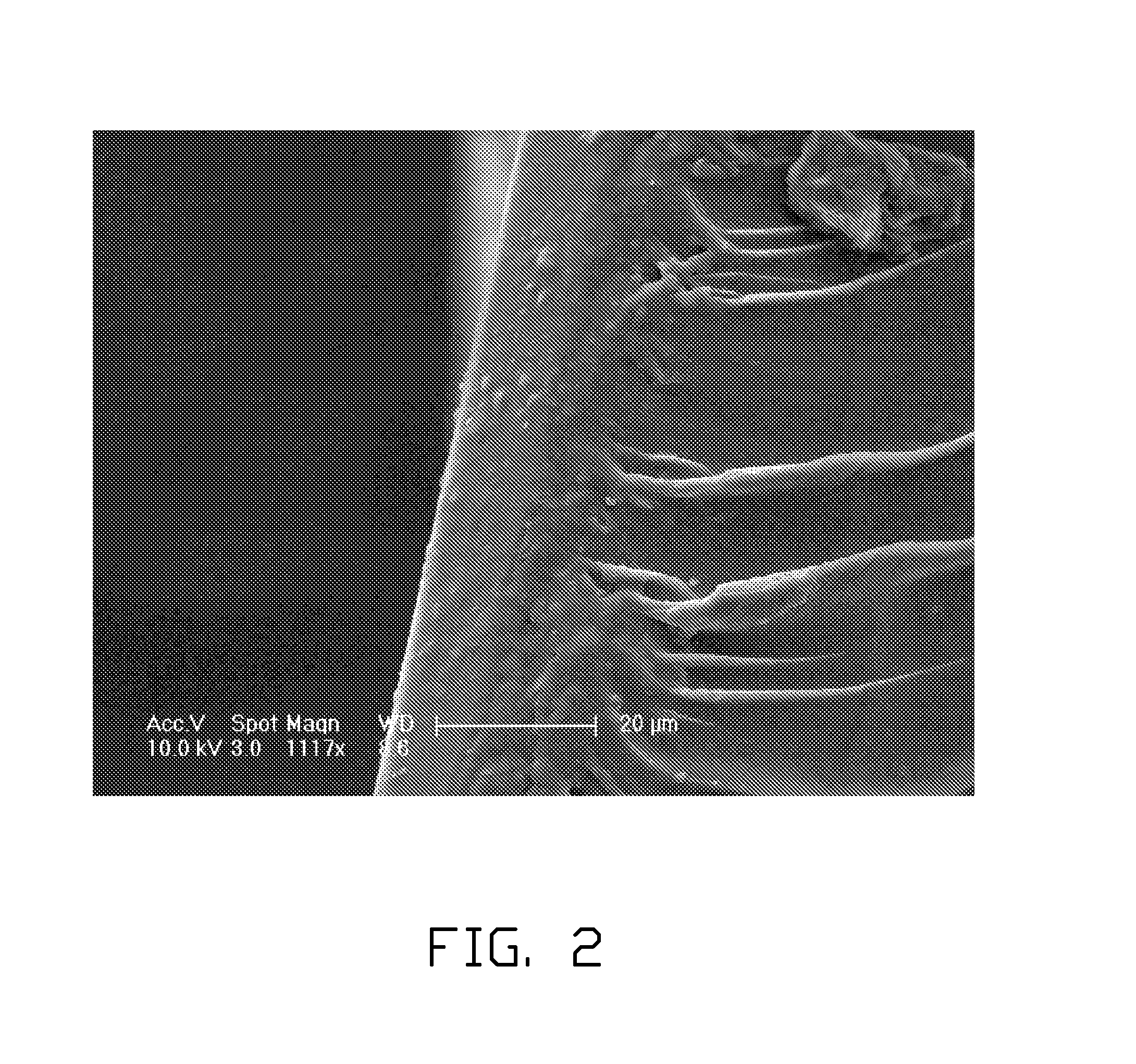

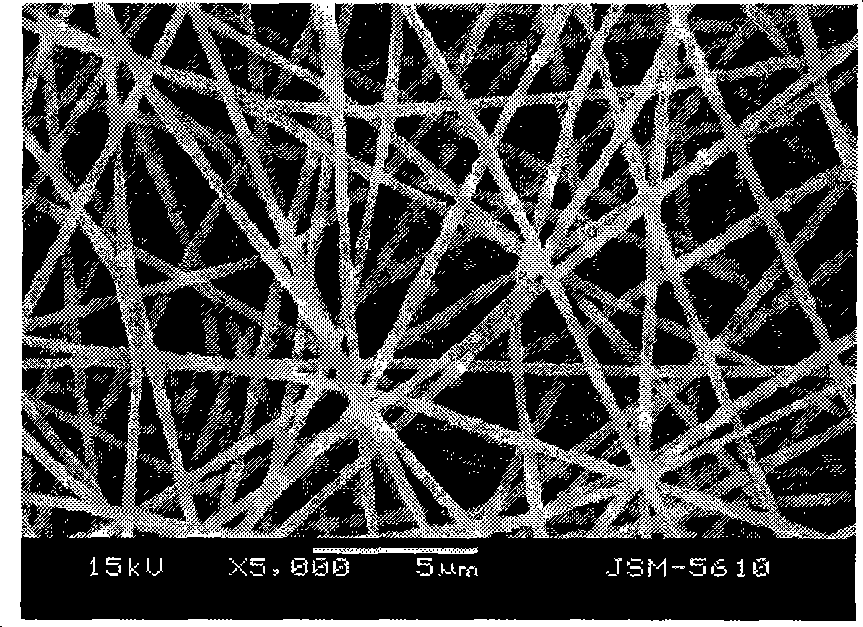

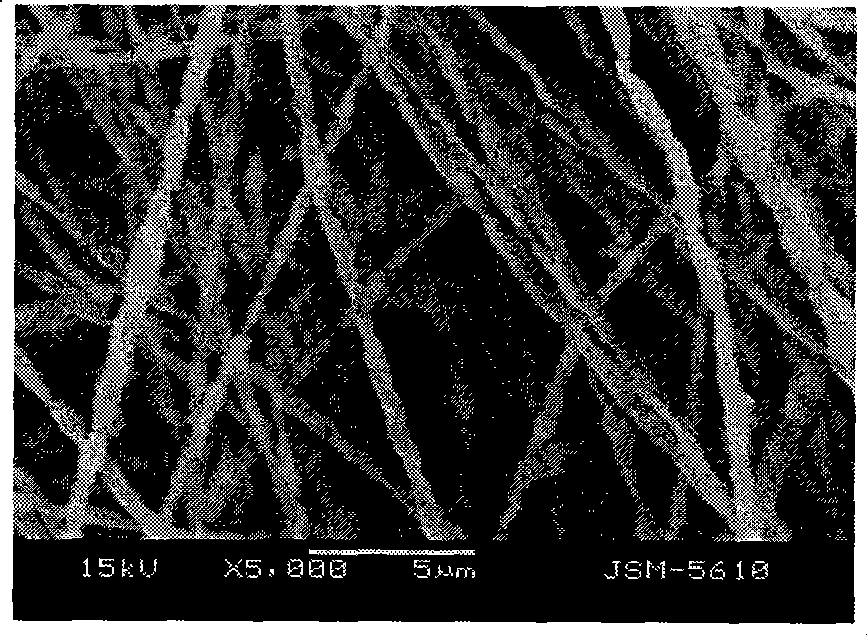

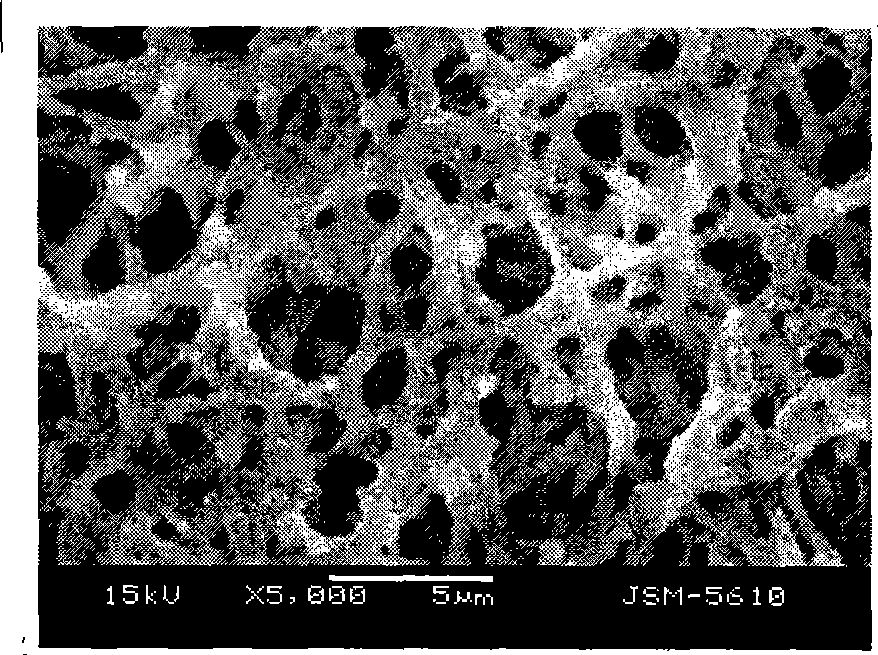

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

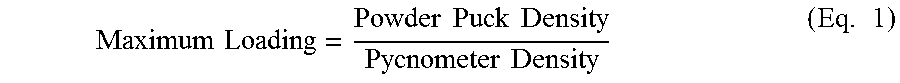

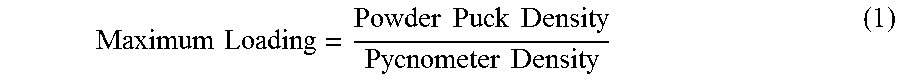

Drug/polymer composite materials and methods of making the same

InactiveUS20070009564A1Powder deliveryPharmaceutical non-active ingredientsSolventPolymer composites

A method of forming a drug / polymer composite material is carried out by combining a drug material with a polymer material under pressure in the presence of a compressed gas solvent (e.g., carbon dioxide) to form the drug / polymer composite material. Drug / polymer composite materials and shaped articles (e.g., subcutaneous drug depots) which may be produced by a process are also described, along with methods of use thereof.

Owner:MICELL TECH INC

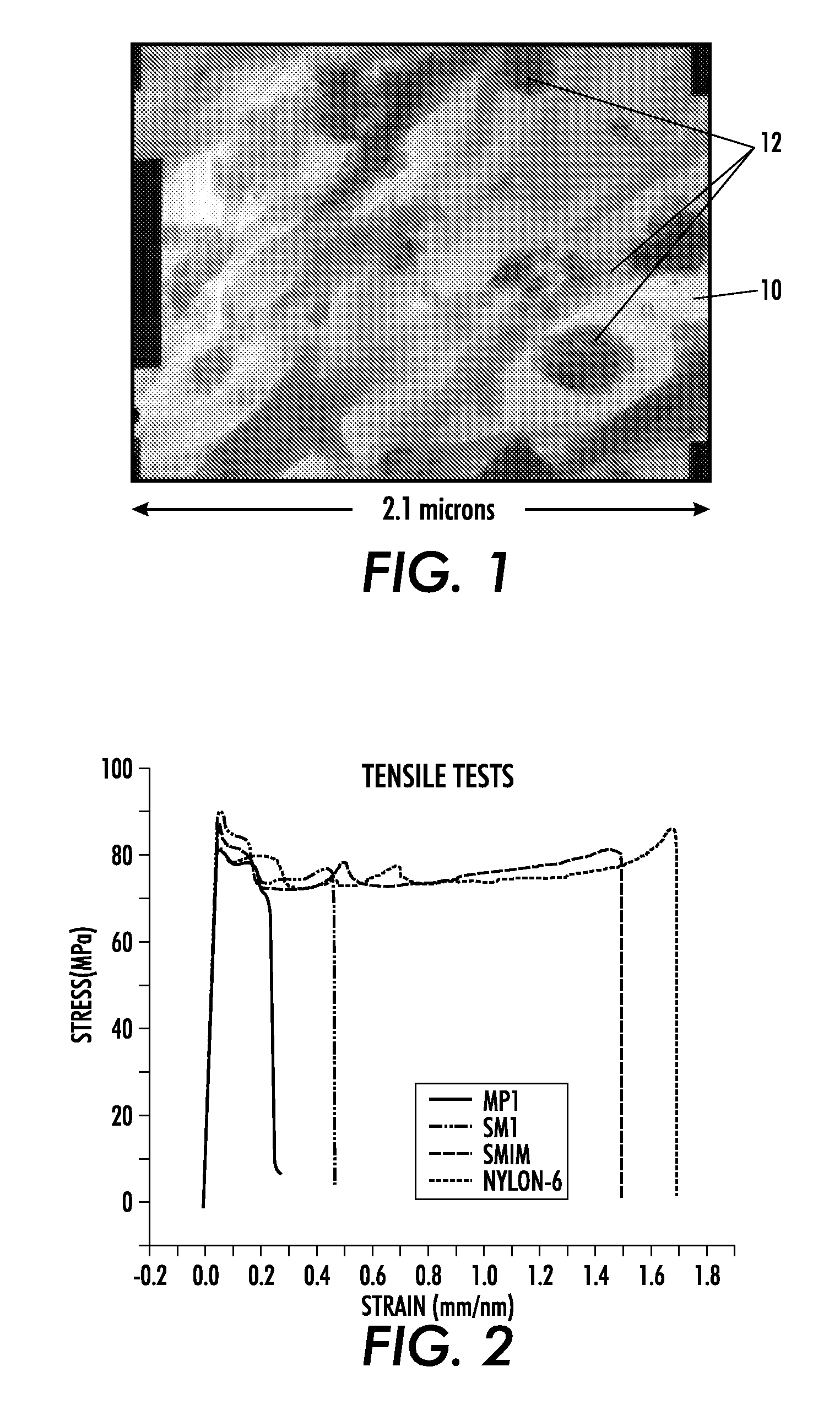

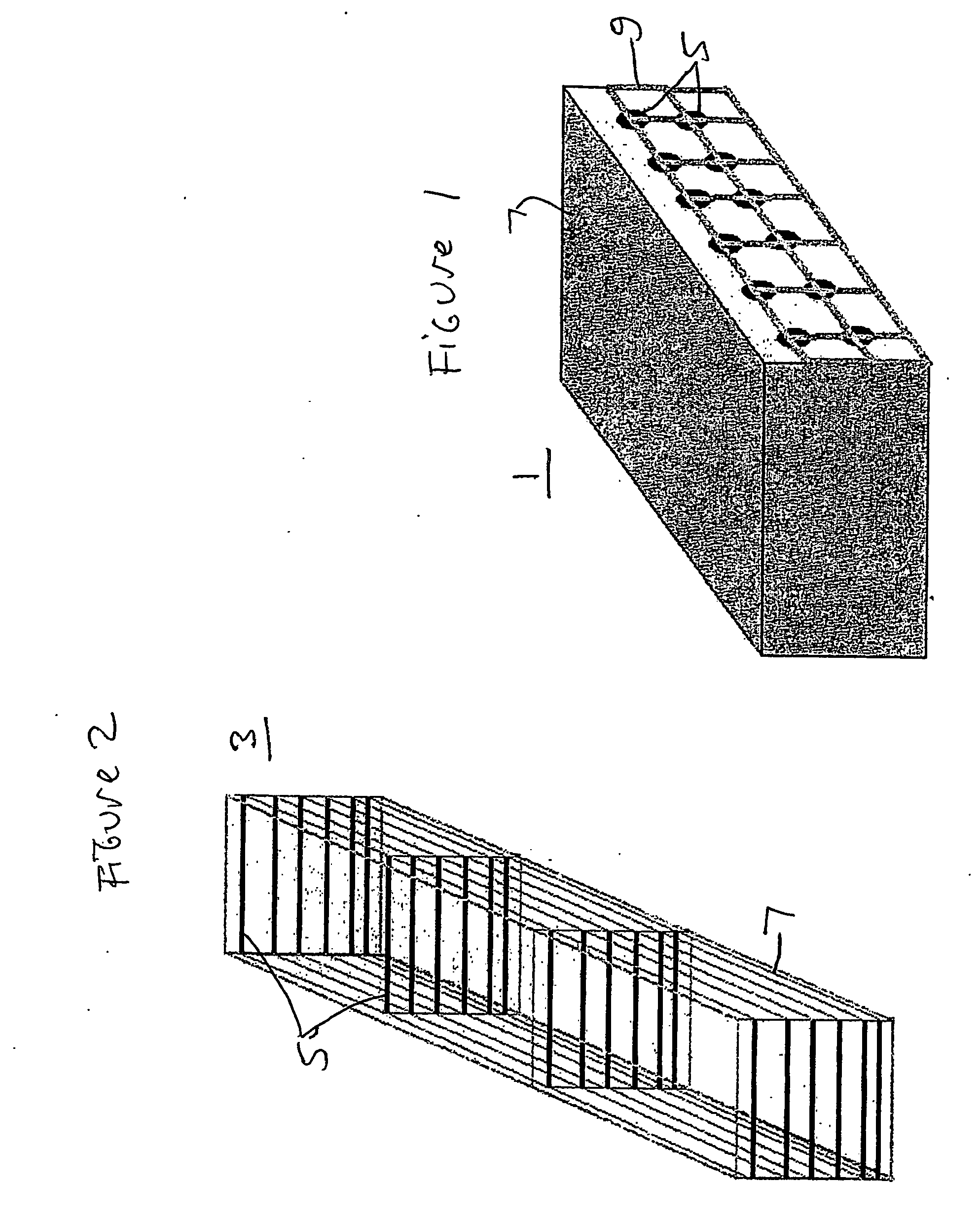

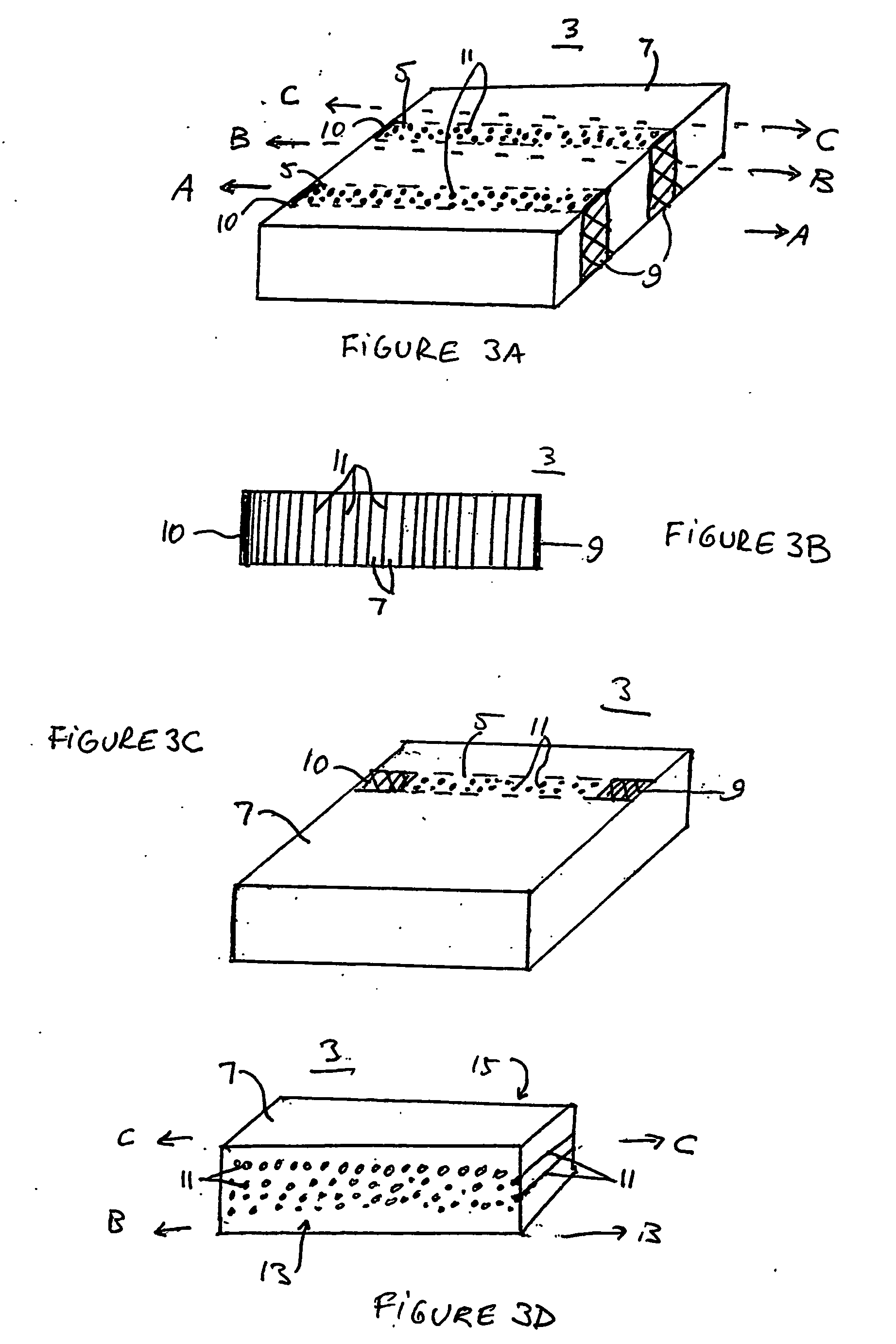

Embedded nanotube array sensor and method of making a nanotube polymer composite

ActiveUS20070138010A1Material nanotechnologyAntenna adaptation in movable bodiesPolymer compositesMaterials science

A method of producing polymer / nanotube composites where the density and position of the nanotubes (11) within the composite ca be controlled. Carbon nanotubes (11) are grown from organometallic micropatterns. These periodic nanotube arrays are then incorporated into a polymer matrix (7) by deposing a curable polymer film on the as-grown tubes. This controlled method of producing free-standing nanotube / polymer composite films may be used to form nanosensor (3) which provide information regarding a physical condition of a material (20), such as an airplane chassis or wing, in contact with the nanosensor (3).

Owner:RENESSELAER POLYTECHNIC INST

Organic matrices containing nanomaterials to enhance bulk thermal conductivity

InactiveUS20050161210A1Improve heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesNanoparticleInterfacial resistance

Thermal interface compositions contain nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

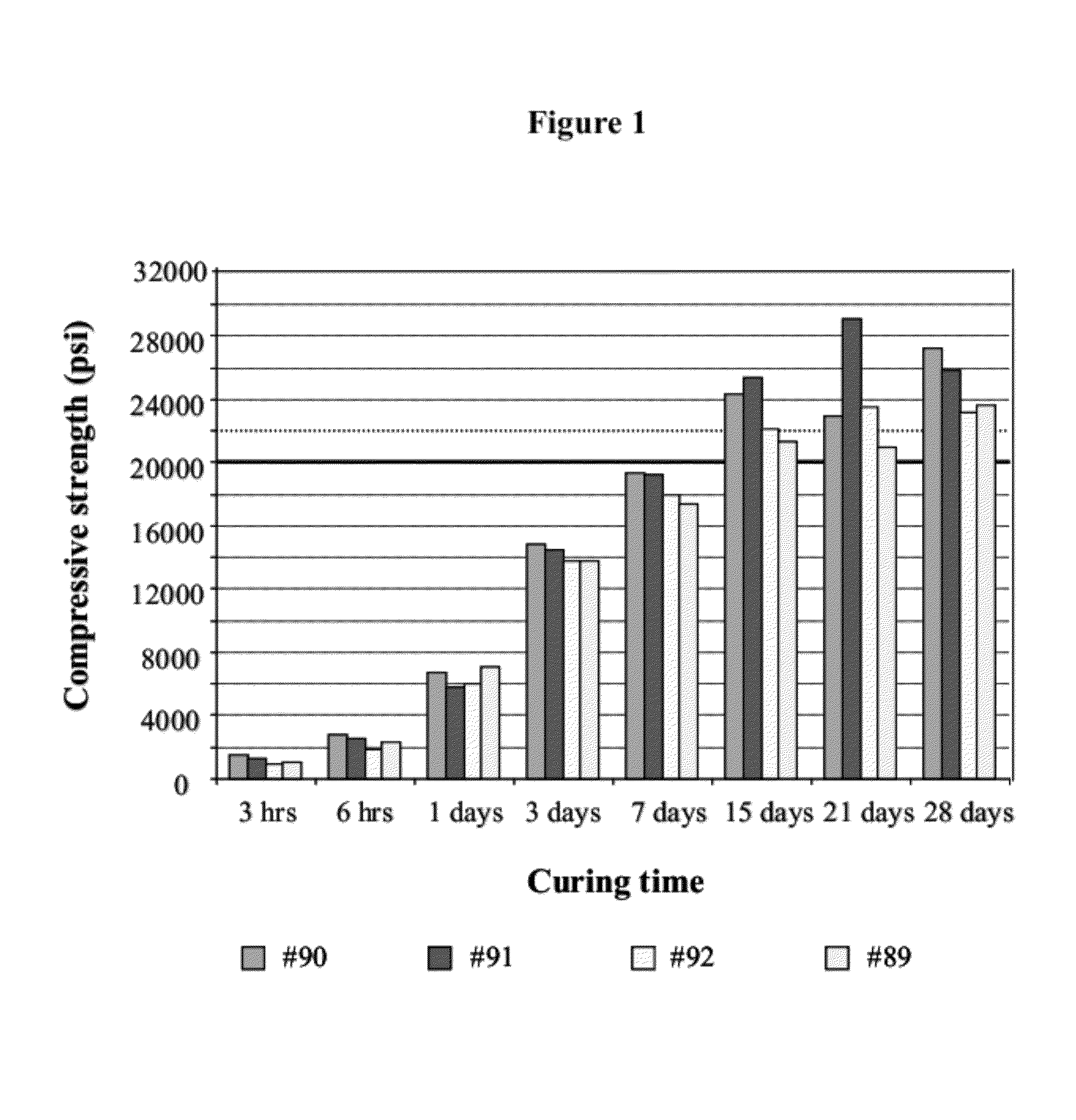

Geopolymer composite for ultra high performance concrete

A geopolymer composite ultra high performance concrete (GUHPC), and methods of making the same, are provided herein, the GUHPC comprising: (a) a binder comprising one or more selected from the group consisting of reactive aluminosilicate and reactive alkali-earth aluminosilicate; (b) an alkali activator comprising an aqueous solution of metal hydroxide and metal silicate; and (c) one or more aggregate.

Owner:CATHOLIC UNIV OF AMERICA

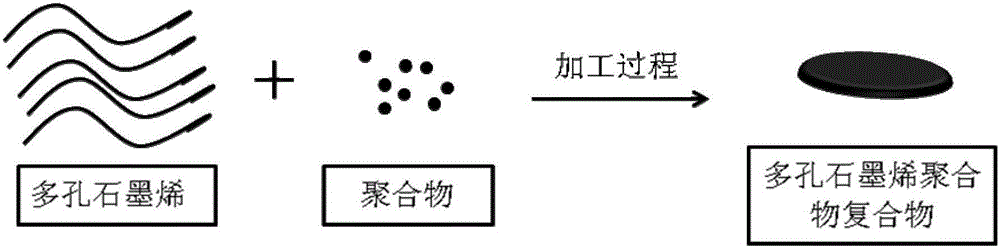

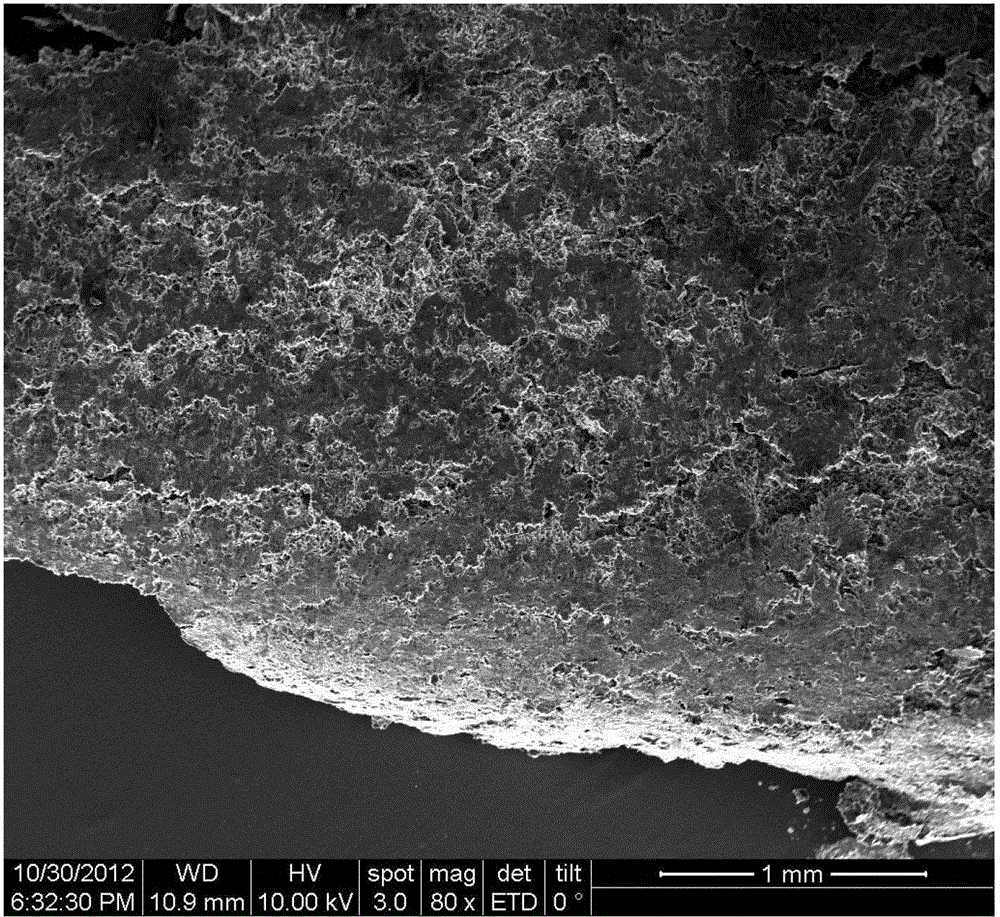

Porous graphene/polymer composite structure and preparation method and application thereof

The invention discloses a porous graphene / polymer composite structure, and a preparation method and application thereof. The composite structure mainly comprises a compound formed by porous graphene and more than one polymer and / or polymer monomer. The preparation method comprises the following steps of: compounding polymers and / or polymer monomers with porous graphene to form a target product, wherein the compounding manner comprises single-screw / double-screw fusing processing, injection molding, blow molding, melt spinning, solution spinning, electrostatic spinning, electrostatic spraying, powder metallurgy, liquid mixing or high speed mechanical stirring dispersion. The invention is simple in process, wide in source of raw materials, easy to implement in large scale, low in cost, safe, environment-friendly and free from toxic and harmful wastes, and the product obtained is excellent in thermal and electric properties, and has wide application prospect in the fields of heat conduction, radiation, electric conduction, anti-static electricity, electromagnetic shielding and the like.

Owner:苏州格瑞丰纳米科技有限公司

Nanotube polymer composite and methods of making same

The invention relates to derivatized, well-dispersed CNTs that have enhanced miscibility with organic agents. Composite materials may be made using such CNTs. The composite materials, in turn, may be used in optical and electronic applications.

Owner:RENESSELAER POLYTECHNIC INST

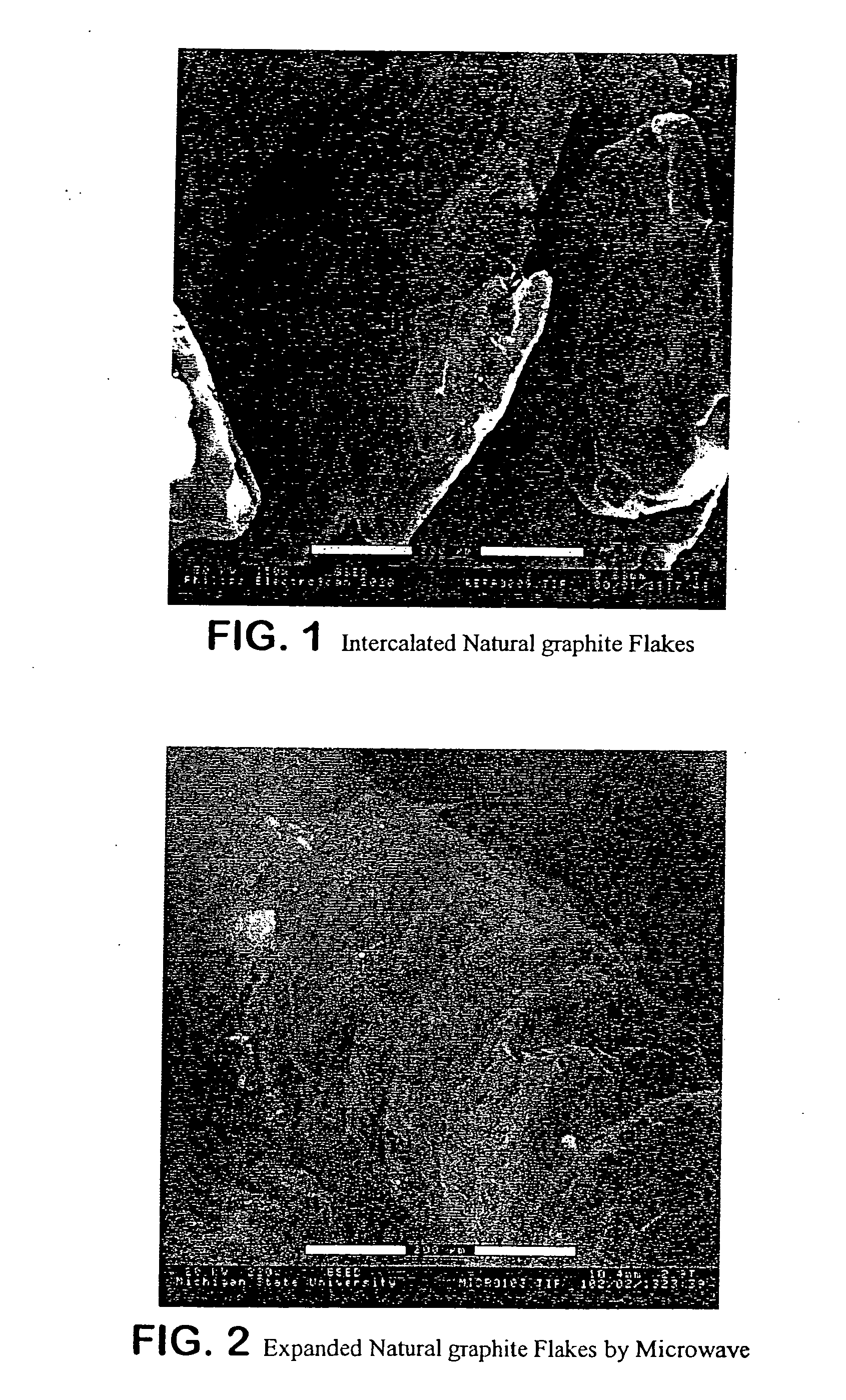

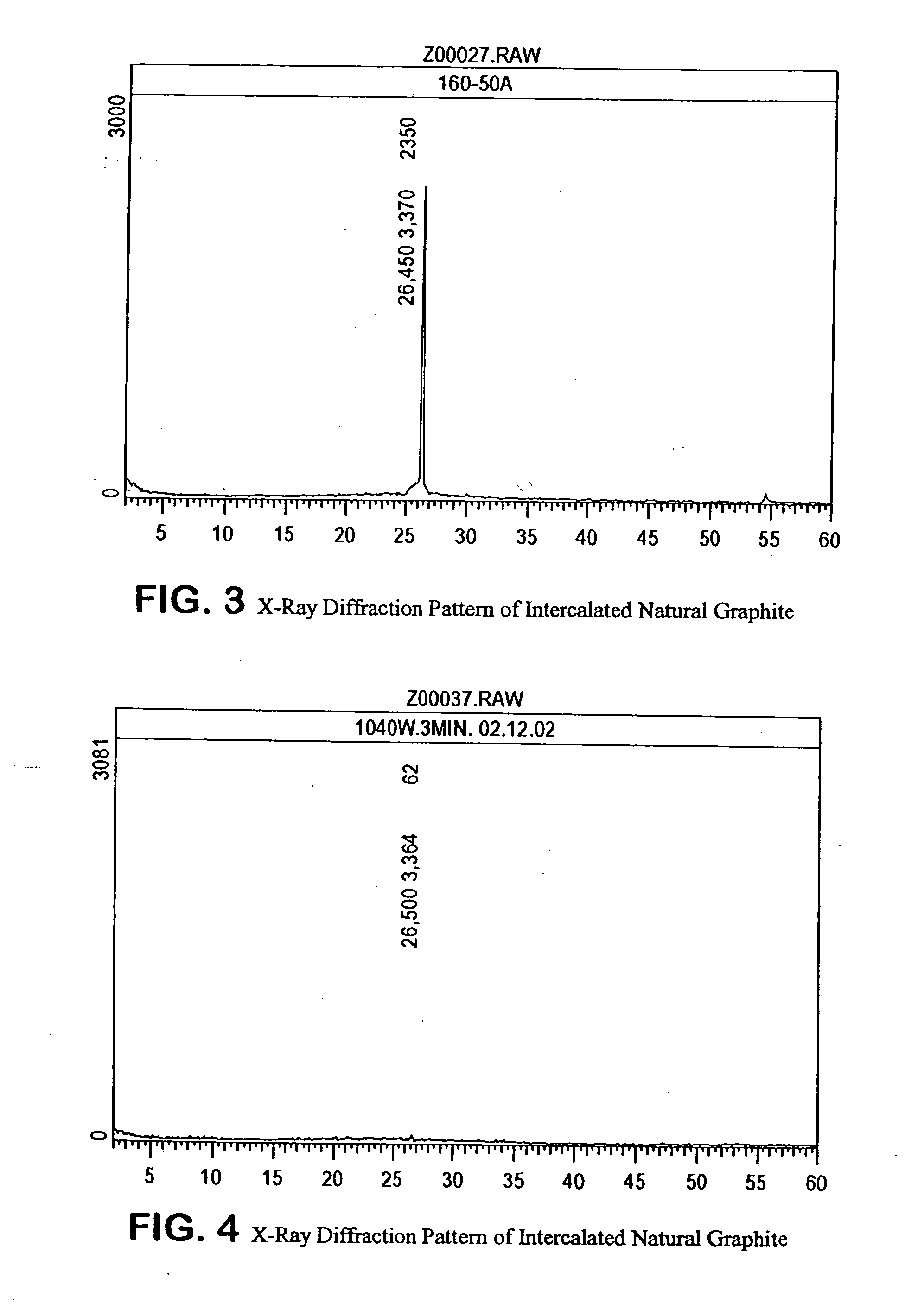

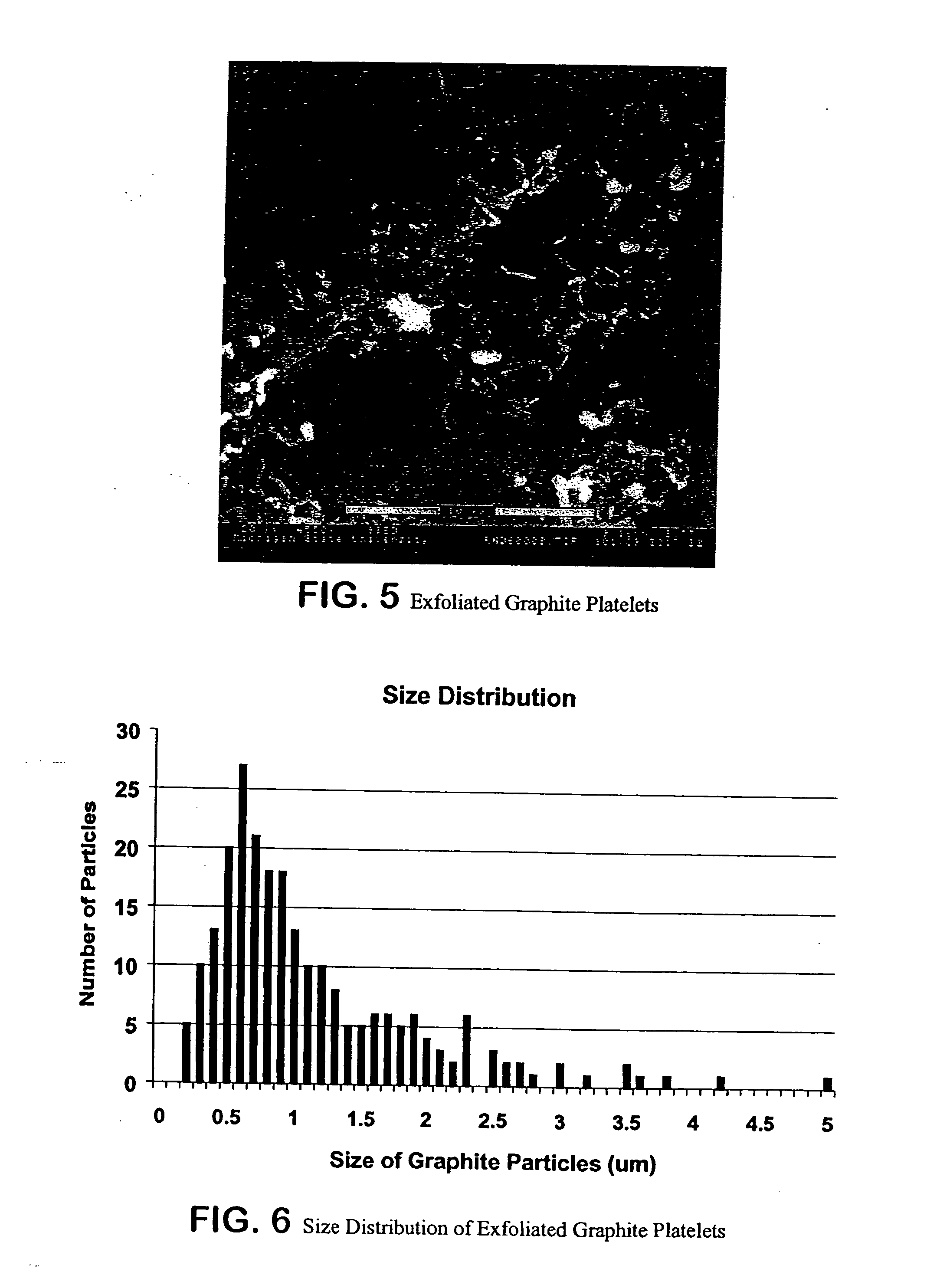

Expanded graphite and products produced therefrom

ActiveUS20060231792A1Improve mechanical propertiesImprove thermal conductivityHydrogenOther chemical processesGaseous atmospherePolymer composites

Graphite nanoplatelets of expanded graphite and polymer composites produced therefrom are described. The graphite is expanded from an intercalated graphite by microwaves or radiofrequency waves in the presence of a gaseous atmosphere. The composites have barrier and / or conductive properties due to the expanded graphite.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com