Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "Will not emit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

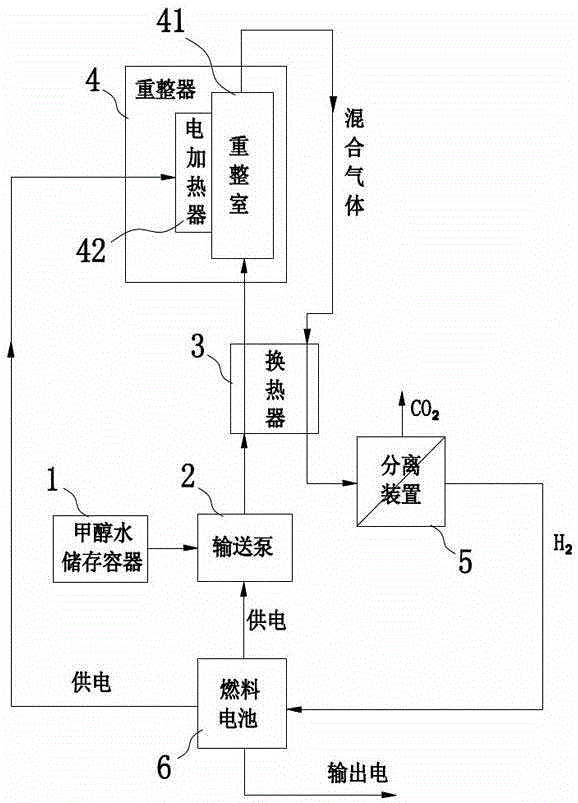

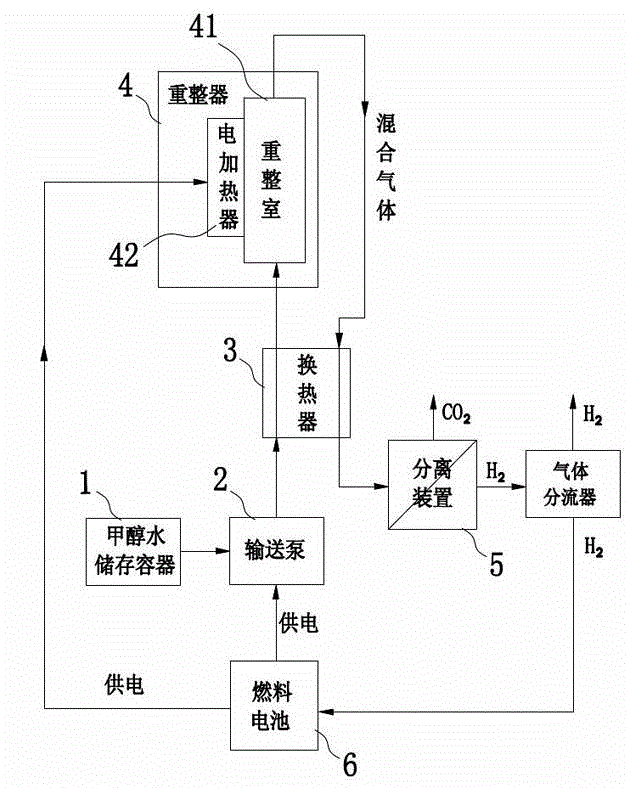

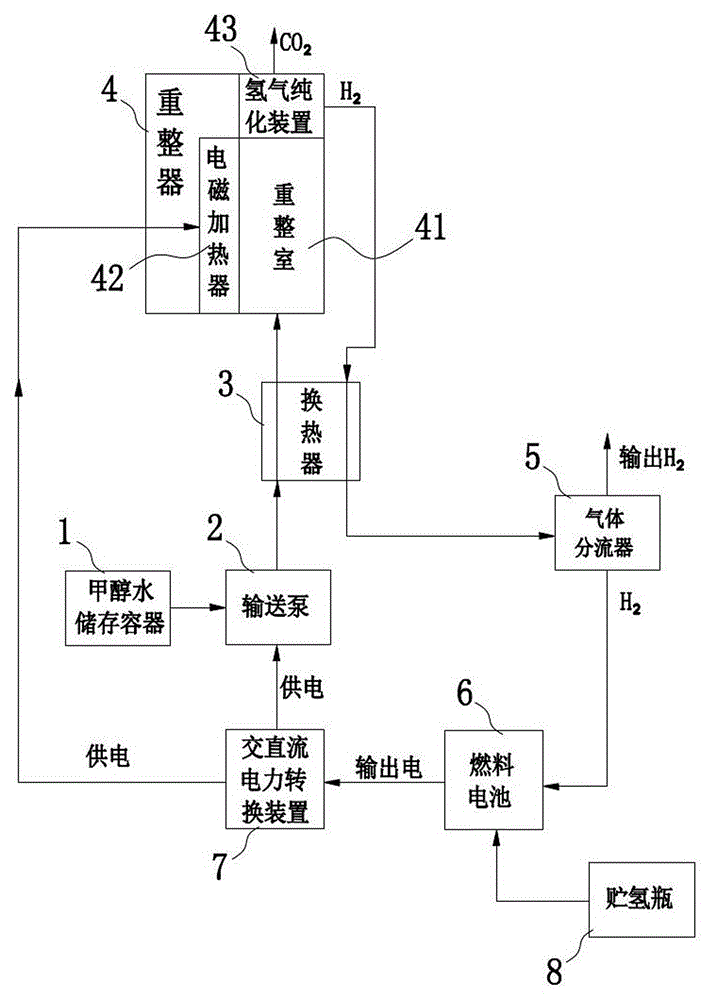

Electric generator based on methanol water hydrogen-making system and electricity generation method thereof

InactiveCN104362359ASolve the damageReduce structural complexityHydrogenFuel cell heat exchangeElectrochemical responseCombustion chamber

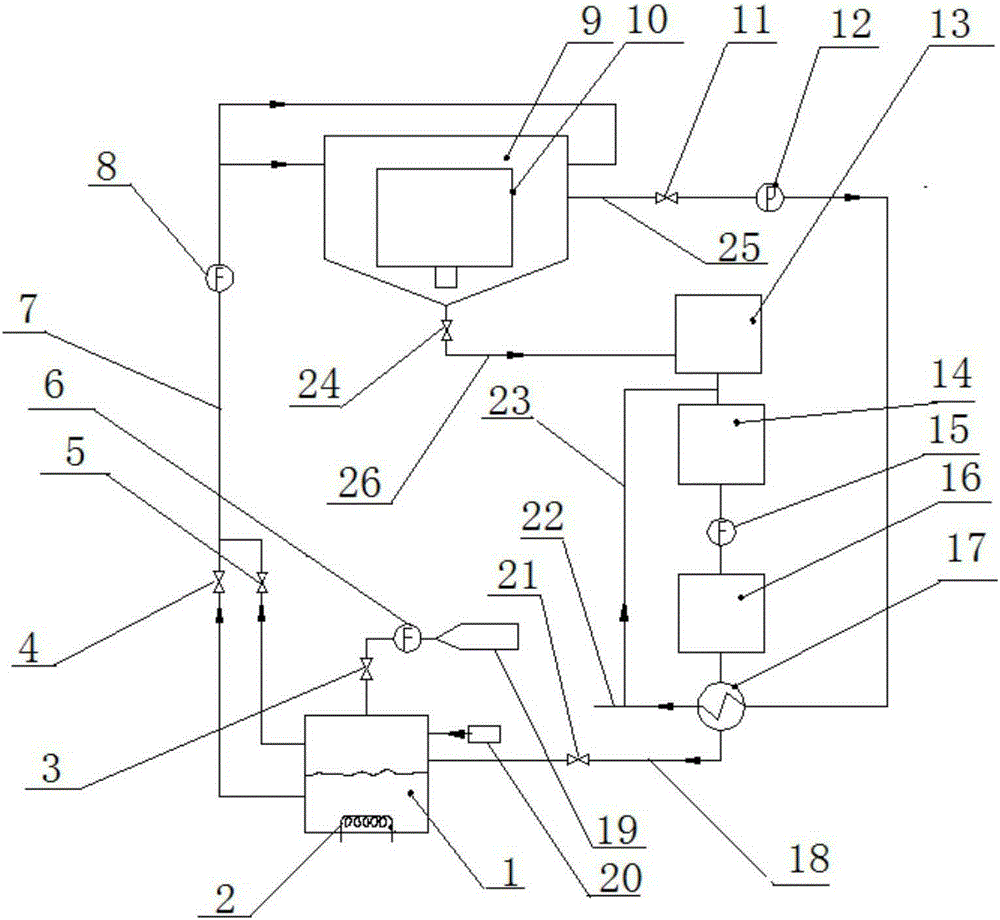

The invention discloses an electric generator based on a methanol water hydrogen-making system and an electricity generation method thereof. The electric generator comprises a methanol water storage container, a delivery pump, a heat exchanger, a reformer, a separation device and a fuel cell, wherein the delivery pump is used for delivering methanol and water to a reforming chamber of the reformer; the heat exchanger is used for carrying out heat exchange on the low-temperature methanol and water and a high-temperature mixed gas output from the reforming chamber; the reformer is provided with the reforming chamber and an electric heater, and the electric heater provides heat energy for the reforming chamber; and the high-temperature mixed gas which takes carbon dioxide and hydrogen as main parts is prepared in the reforming chamber, passes through the heat exchanger and then enters the separation device to be separated to obtain the hydrogen, and the hydrogen is delivered to the fuel cell and subjected to electrochemical reaction in the fuel cell to generate electric energy, a part of the electric energy provides electricity for the delivery pump and the electric heater, and the rest of the electric energy is output. According to the electric generator, the reformer has no need of being provided with a combustion chamber, an air inlet fan, an air inlet channel and a smoke window, the heating temperature inside the reformer is easily controlled and stable, and the reformer is simple in structure, stable in operation and low in overhaul difficulty.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

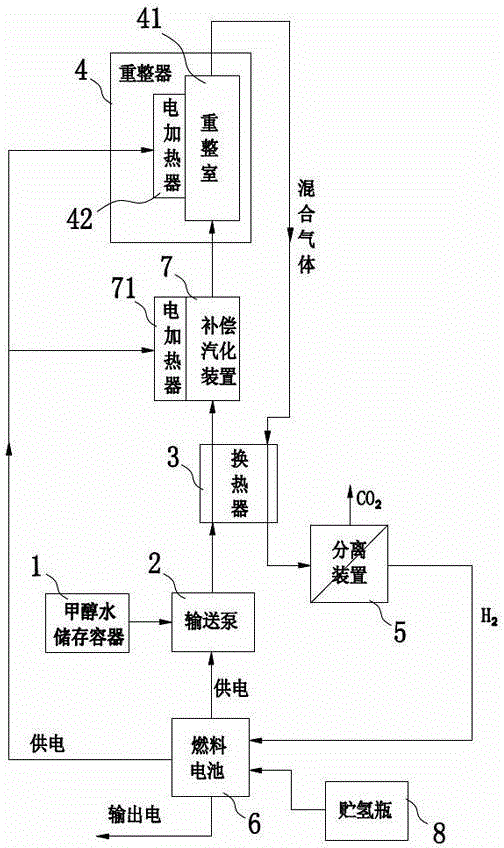

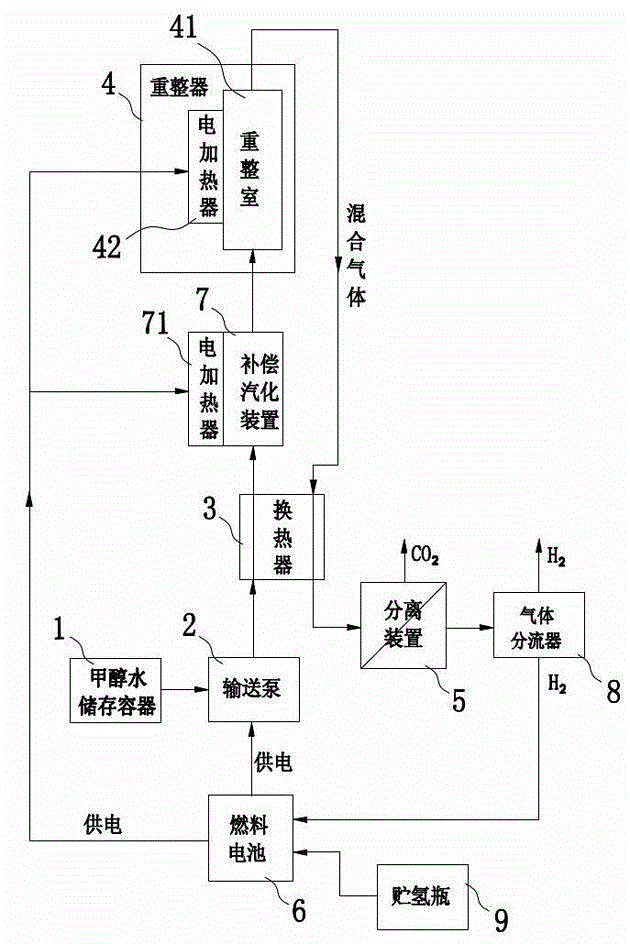

Methanol water hydrogen-making machine and hydrogen-making method thereof

InactiveCN104362355ASolve the damageReduce structural complexityHydrogenCell electrodesElectrochemical responseCombustion chamber

The invention discloses a methanol water hydrogen-making machine and a hydrogen-making method thereof. The methanol water hydrogen-making machine comprises a methanol water storage container, a delivery pump, a heat exchanger, a reformer, a separation device and a fuel cell, wherein the delivery pump is used for delivering methanol and water inside the methanol water storage container to a reforming chamber of the reformer; the heat exchanger is used for carrying out heat exchange on the low-temperature methanol and water and a high-temperature mixed gas output from the reforming chamber; the reformer is provided with the reforming chamber and an electric heater, and the electric heater provides heat energy for the reforming chamber; and the high-temperature mixed gas which takes carbon dioxide and hydrogen as main parts is prepared in the reforming chamber, passes through the heat exchanger and then enters the separation device to be separated to obtain the hydrogen, and a part of the hydrogen enters the fuel cell and generates electrochemical reaction in the fuel cell to generate electric energy to provide electricity for the delivery pump and the electric heater. According to the methanol water hydrogen-making machine, the reformer has no need of being provided with a combustion chamber, an air inlet fan, an air inlet channel and a smoke window, the heating temperature inside the reformer is easily controlled and stable, and the reformer is simple in structure, stable in work and low in overhaul difficulty.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

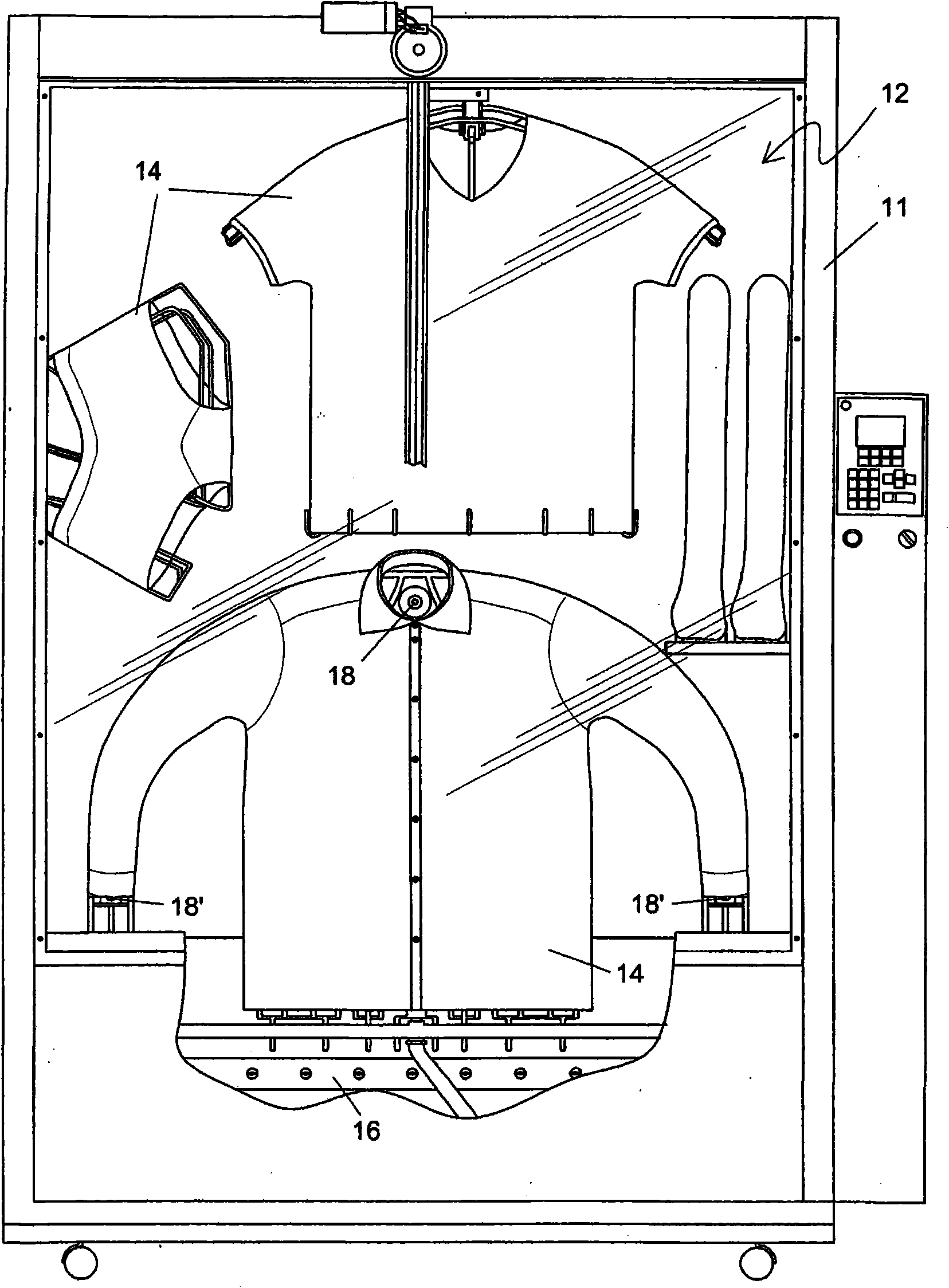

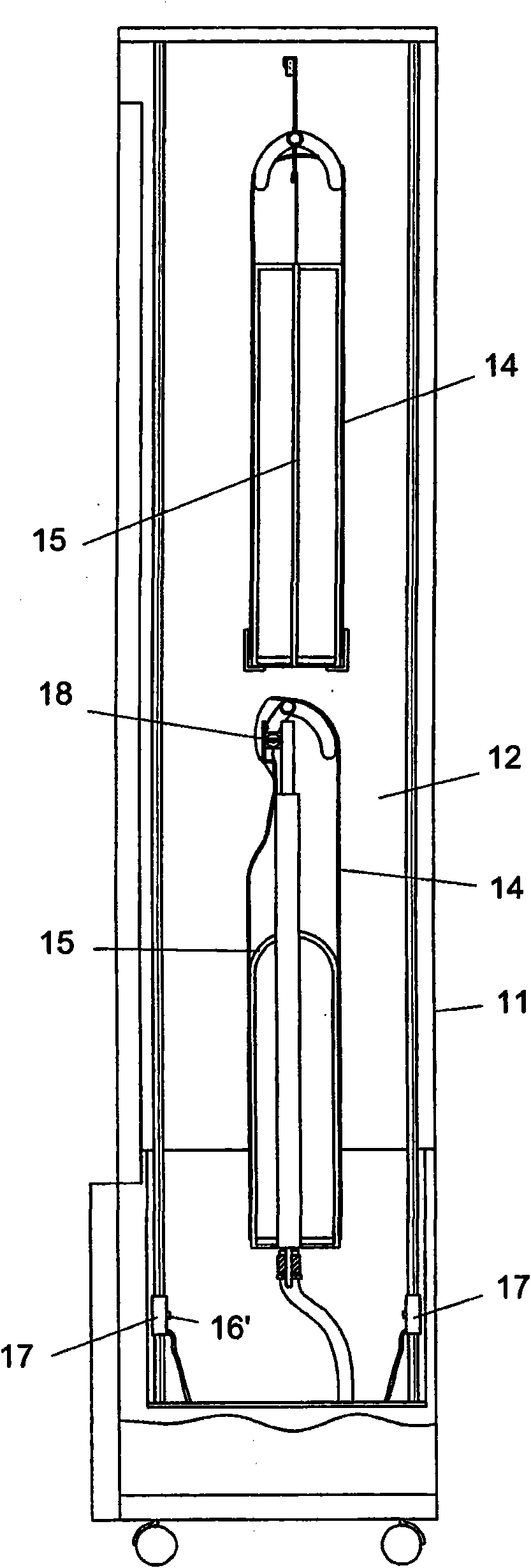

Machine for cleaning, washing, drying and ironing clothes and garments

ActiveCN101842529ANo need to useEasy to cleanApparel holdersDry-cleaning apparatusEngineeringLaundry

The present invention relates to a multifunction machine for laundries, which comprises a body or frame (11) defining a treatment chamber (12) hermetically closed and equipped with means (15) for hanging elements (14), such as bed linen, clothes and garments, to be treated; means for removing stains, a wash and rinse; means for drying; and means for ironing said elements while they are hanging and stretched out in said treatment chamber.

Owner:塞尔焦·扎利奥

Methanol-water reforming hydrogen making machine and hydrogen making method thereof

InactiveCN104986731AAvoid heat wasteExtend your lifeHydrogenChemical industryCarbon dioxideHeating efficiency

The invention discloses a methanol-water reforming hydrogen making machine and a hydrogen making method thereof. The methanol-water reforming hydrogen making machine comprises a methanol-water storage container, a delivery pump, a heat exchanger and a reformer. The reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device. The electromagnetic heater comprises an electromagnetic coil and a metal magnet, the electromagnetic coil can generate a high frequency magnetic field after being powered up, and the metal magnet can be inducted by the magnetic field to give out heat, so that heat energy is provided for the reforming chamber. The reforming chamber is used for conducting a reforming hydrogen making reaction of methanol and water, and high temperature mixed gas mainly containing carbon dioxide and hydrogen is obtained; after heat of the high temperature mixed gas output from the reforming chamber is separated by the hydrogen purification device, hydrogen can be obtained from the hydrogen producing end of the hydrogen purification device. The methanol-water reforming hydrogen making machine is long in service life, small in amount of maintenance, small in heat lag, accurate to control, high in starting speed of the reformer, high in heat efficiency and even in heating.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

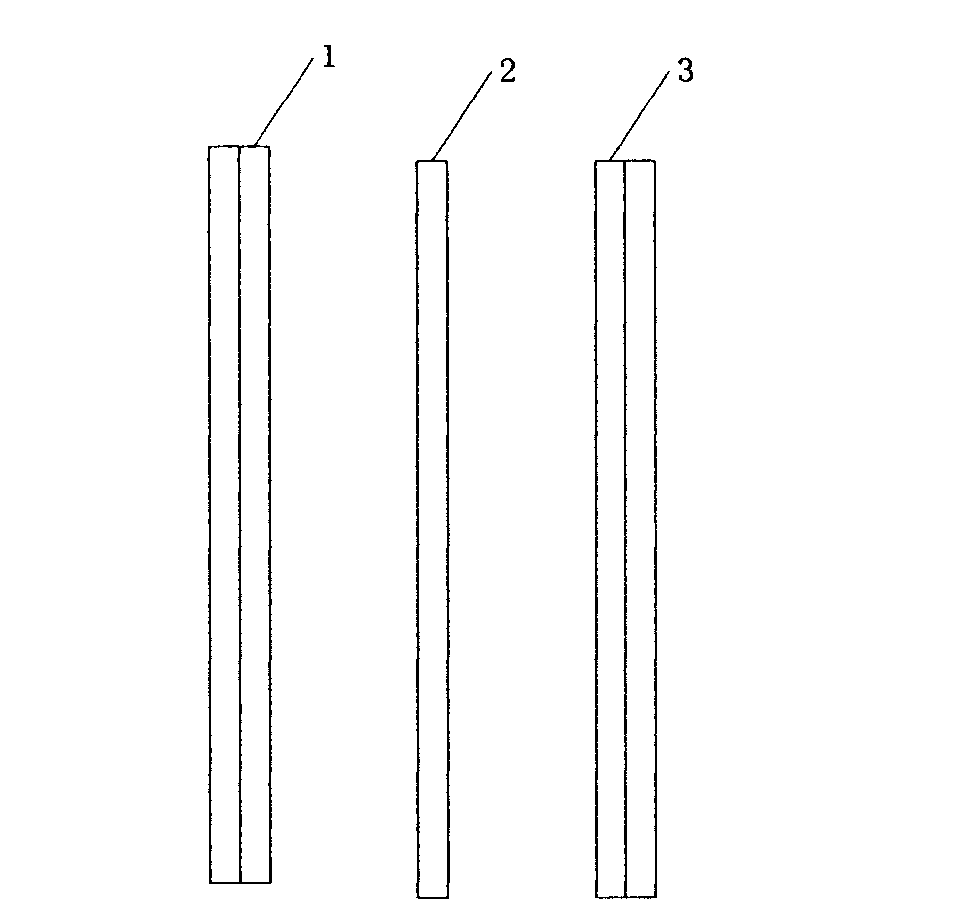

Polymer lithium ion battery and making method thereof

InactiveCN103811802AWill not emitEasy to produceCell component detailsElectrolyte accumulators manufactureAcrylonitrilePhysical chemistry

The invention discloses a making method of a polymer lithium ion battery. The method comprises the following steps: 1, adding an aqueous dispersion of a lithium acrylate-acrylonitrile copolymer into deionized water; 2, immersing the positive and negative electrodes of a battery in the deionized water to make the lithium acrylate-acrylonitrile copolymer attached to the positive and negative electrodes of the battery; and 3, gelating at 50-85DEG C for 30-240min 1-2 times after the molding of the battery to respectively form a gel electrolyte coating on the positive and negative electrodes of the battery. Compared with methods using a vinylidene fluoride-hexafluoropropene copolymer, the method using the above lithium acrylate-acrylonitrile copolymer synthesis technology has the advantages of simplicity, low cost and benefiting for the mass use of the technology. The invention also discloses the polymer lithium ion battery.

Owner:深圳市崧鼎实业有限公司

Method for preparing high purity (99.9 percent) 4,4'-difluorobenzophenone

InactiveCN102531872ASynthetic process conditions are mildRecycling technology is matureCarbonyl compound preparation by condensationLiquid chlorineHydration reaction

The invention discloses a method for preparing high purity (99.9 percent) 4,4'-difluorobenzophenone, wherein 4-fluorotoluene and liquid chlorine are taken as starting raw materials and then are processed through chlorination reaction, hydration reaction and condensation reaction, and high purity (99.9 percent) 4,4'-difluorobenzophenone is obtained finally. The method gives up the conventional synthetic route; 4-fluorotoluene is processed through chlorination, hydration and condensation firstly to obtain 4,4'-difluorobenzophenone, wherein the melting point of 4,4'-difluorobenzophenone ranges from 107 to 108 DEG C, and the purity of 4,4'-difluorobenzophenone is 99.9 percent; the purity of 4,4'-difluorobenzophenone exceeds the conventional technical standard (99.7 percent) of English ICI (Imperial Chemical Industries Ltd.); in the preparation technology of the method, the adopted raw materials are easy to get, the synthesis process conditions are mild, and almost no environment hazards can be caused. The method satisfies the technical requirements of special engineering plastic containing polyether-ether-ketone on monomers.

Owner:JINTAN CHUNFENG CHEM

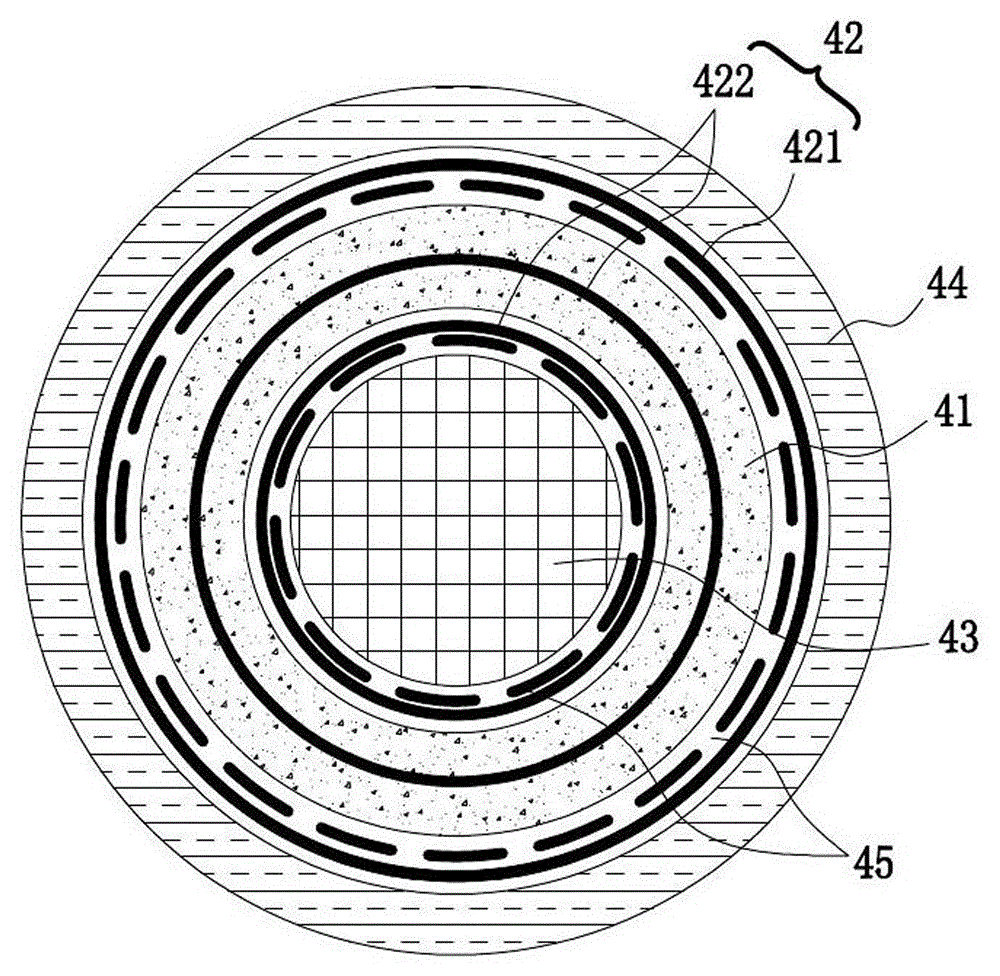

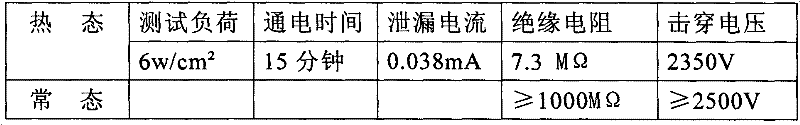

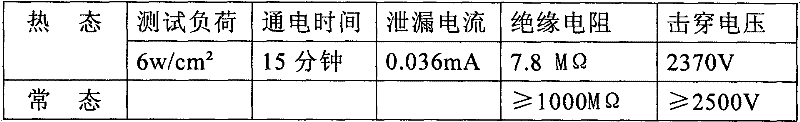

Preparation method of magnesia heat-conducting insulating material for electric heating tube

ActiveCN102254652ANo pollution in the processImprove moisture resistanceMetallic oxidesElectric fusesGranularity

The invention discloses a preparation method of a magnesia heat-conducting insulating material for an electric heating tube. The preparation method comprises the following steps: crushing electric-fused magnesia powder with purity not less than 96% into magnesia powder with different granularities of 50-60 meshes, 60-80 meshes, 80-140 meshes, 140-200 meshes, 200-325 meshes and 320 meshes; mixing sequentially according to the weight ratio of 25%, 20%, 25%, 15%, 10% and 5%; deironing; stoving, sequentially and uniformly mixing with talcum powder, active alpha-Al2O3, mullite powder and rear earth catalyst according to 100, 35, 17, 6 and 2 parts by weight in sequence so as to prepare an environment-friendly magnesia heat-conducting insulating material for the electric heating tube. The property of the electric heating tube made from the heat-conducting insulating material cannot be changed when the temperature is over 250 DEG.C, cannot produce any toxic gas and cannot pollute the environment.

Owner:DASHIQIAO MEIR MAGNESIUM PROD

Protein feed raw material prepared from Asian carps and preparation method for protein feed raw material

InactiveCN104000008AImprove protein digestibilityHigh nutritional valueAnimal feeding stuffFermentation starterLactobacillus acidophilus

The invention discloses a protein feed raw material prepared from Asian carps and is used for animal breeding and a preparation method for the protein feed raw material. The preparation method comprises the steps of performing smashing pretreatment on the Asian carps, mixing the smashed Asian carps with a microorganism preparation, and then performing fermentation so as to obtain the high-quality protein feed raw material with balanced protein and amino acid. The protein feed raw material can be widely applied to livestock breeding and animal aquaculture. Strains of a microorganism leavening agent comprise at least three of bacillus subtilis, saccharomyces cerevisiae, lactobacillus plantarum, lactobacillus acidophilus and pediococcus pentosaceus. A method which is low in energy consumption and low in cost and does not have any waste emission is supplied to deep processing of the Asian carps, so that the ecological problem caused by the Asian carps in America can be effectively controlled, and protein resources of the Asian carps are fully used; the prepared protein feed raw material can guarantee no loss of nutrition of the raw material, and polypeptides, cellulose, oligopeptide, oligopeptide mixtures, trace elements and the like can be generated; the optimal nutrition is supplied to animal breeding.

Owner:SHANGHAI CHUANGBO FOOD TECH DEV

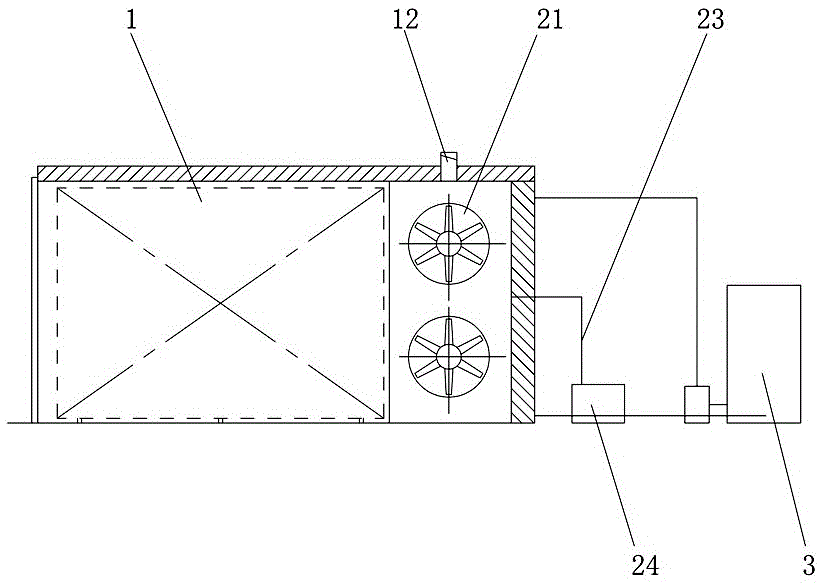

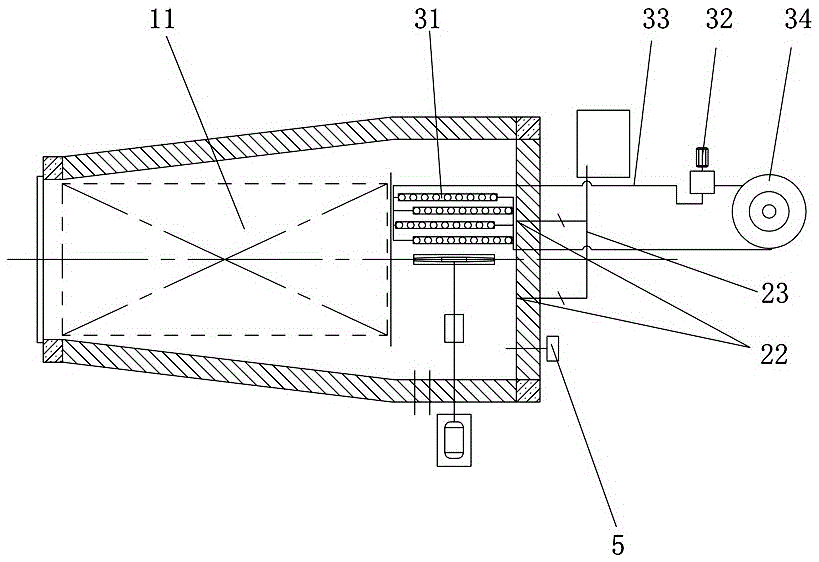

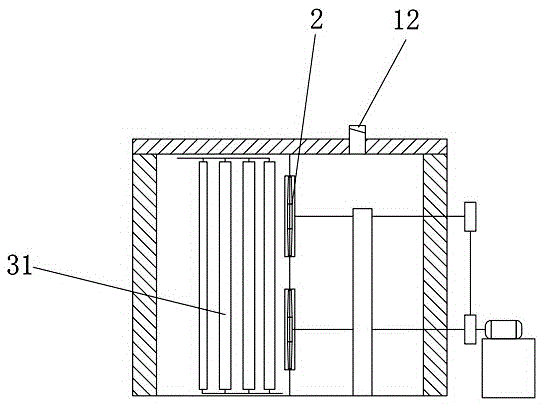

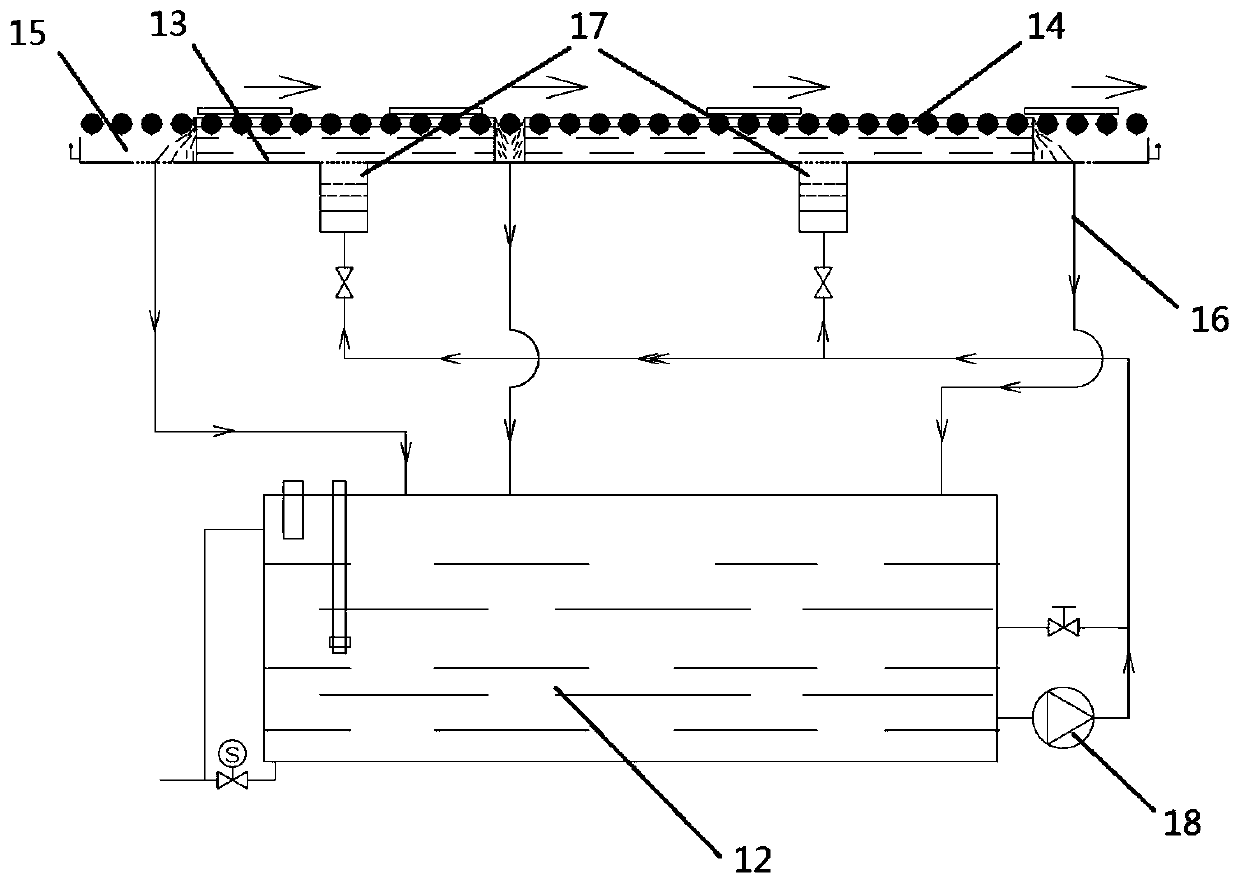

Method and device for drying easily-dried wood

ActiveCN105627699AFast dryingReduce energy consumptionDrying solid materials with heatDrying machines with local agitationProcess engineeringHeating system

The invention discloses a method and device for drying easily-dried wood. The method for drying the easily-dried wood comprises the steps of wood accumulating, temperature rise preheating, temperature rise drying, constant-temperature drying, temperature reducing drying and cooling drawing. The device for drying the easily-dried wood comprises a drying kiln body, and a drying kiln body gate is arranged on the drying kiln body. The device for drying the easily-dried wood further comprises a ventilation and dehumidification system, a heating system, a detection and control system and a saturated steam generator. A wood accumulating area is arranged in the drying kiln body. An air inlet capable of being opened or closed is formed in the drying kiln body. The ventilation and dehumidification system, the heating system and the saturated steam generator are all communicated with the wood accumulating area. The detection and control system is used for detecting drying parameters in the drying kiln body and electrically connected with the ventilation and dehumidification system, the heating system, the saturated steam generator and the air inlet. The method and device have the beneficial effects of being high in drying speed, low in energy consumption, small in pollution to environment and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

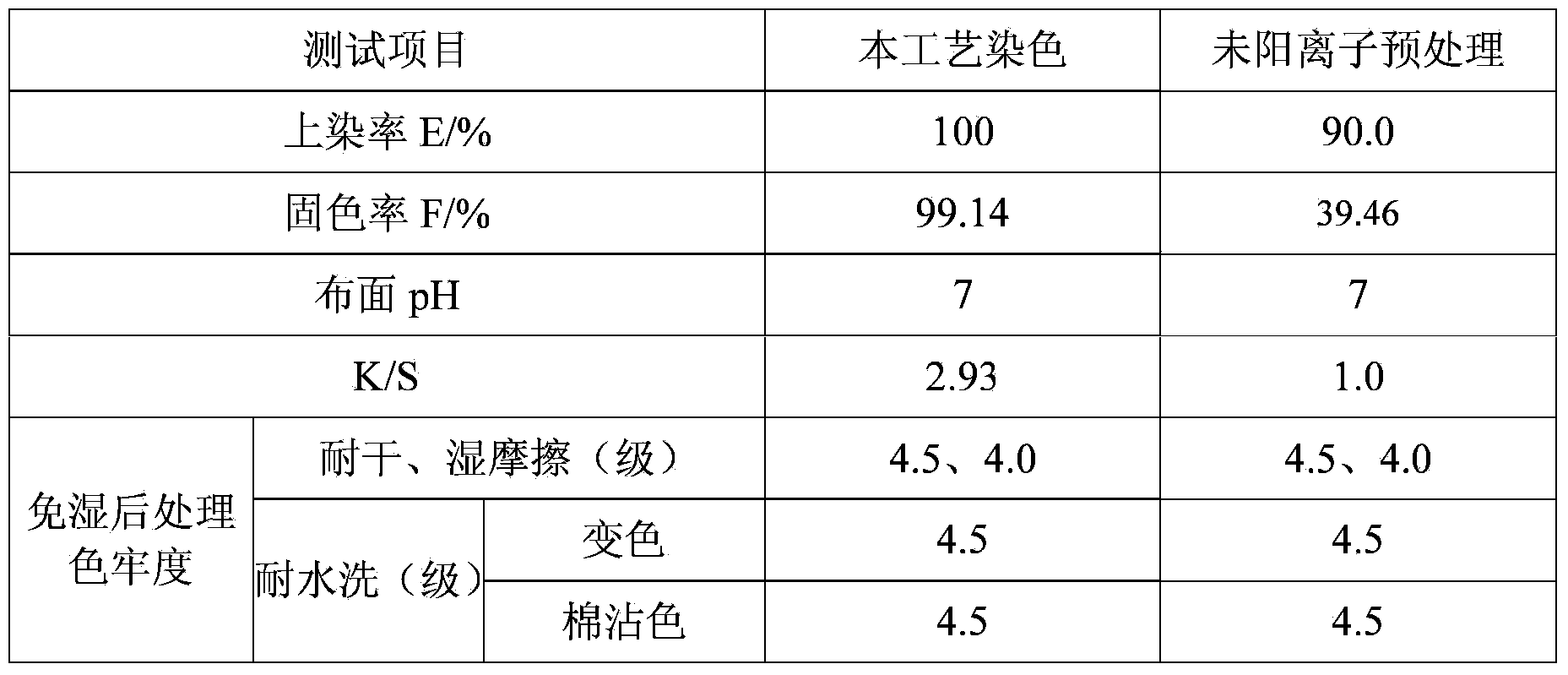

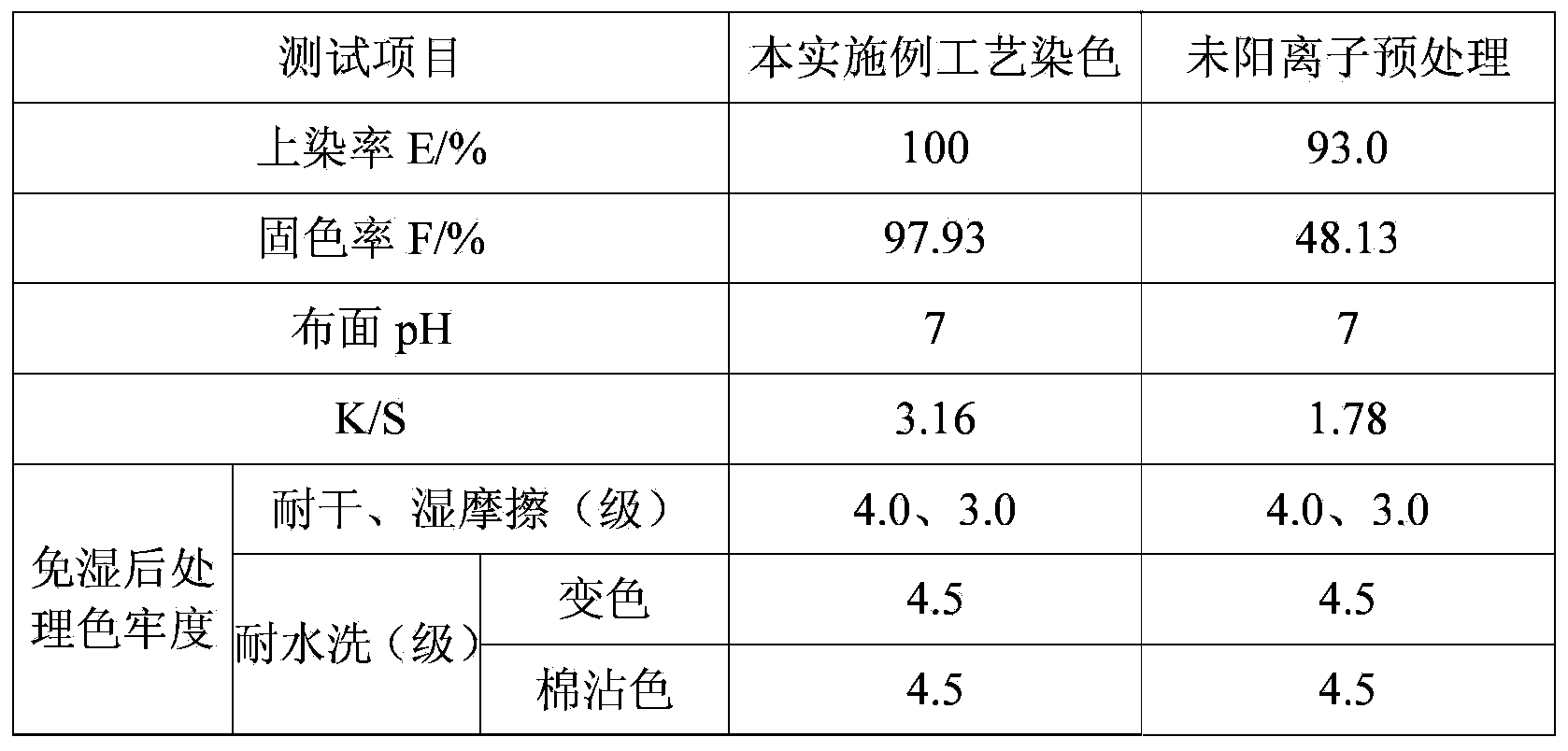

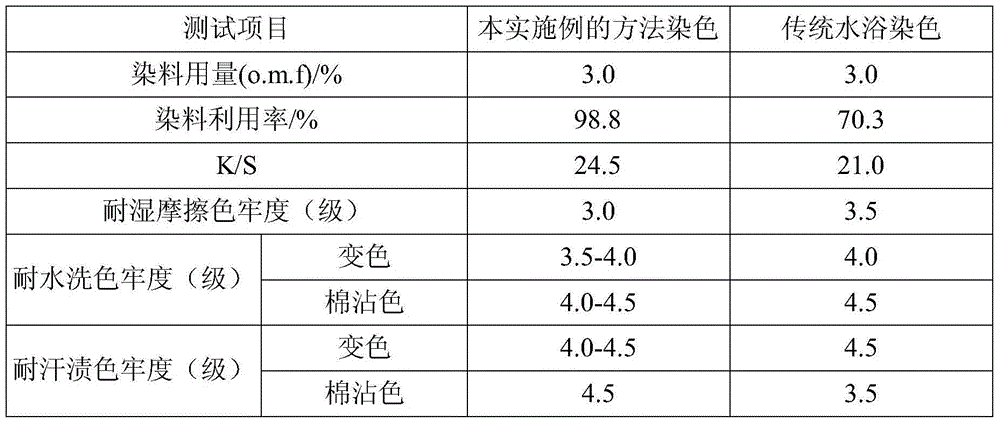

Active dye non-aqueous solvent dyeing method without wet post-treatment

The invention provides an active dye non-aqueous solvent dyeing method without wet post-treatment. The method comprises the following steps: carrying out cation modification on a cotton textile; mixing the modified cotton textile with an active dye and a good solvent of the active dye; heating to a dyeing temperature at a speed of 1 DEG C / min and dyeing; adding a poor solvent of the active dye in the heating process and preserving heat for a period of time, wherein the volume ratio of the good solvent of the active dye to the poor solvent of the active dye is 1 to (3-20) and the mass ratio of the good solvent of the active dye to the cotton textile is (2-50) to 1; and drying the cotton textile to finish dyeing, wherein the good solvent of the active dye is a non-aqueous solvent which can be used for dissolving the active dye but is not subjected to a chemical reaction with the active dye, and the poor solvent of the active dye is a non-aqueous solvent which cannot be used for dissolving the active dye and is not subjected to a chemical reaction with the active dye. The active dye non-aqueous solvent dyeing method provided by the invention has a high fixation rate and does not need a wet post-treatment step.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

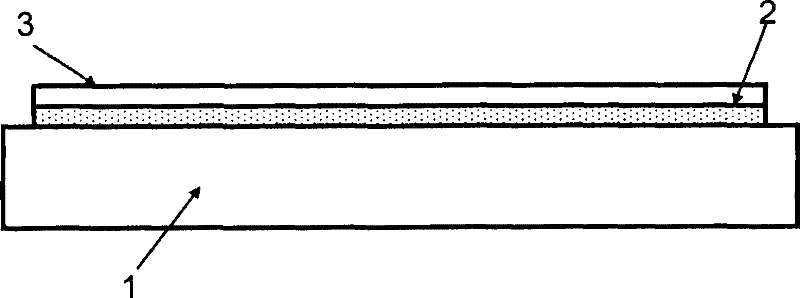

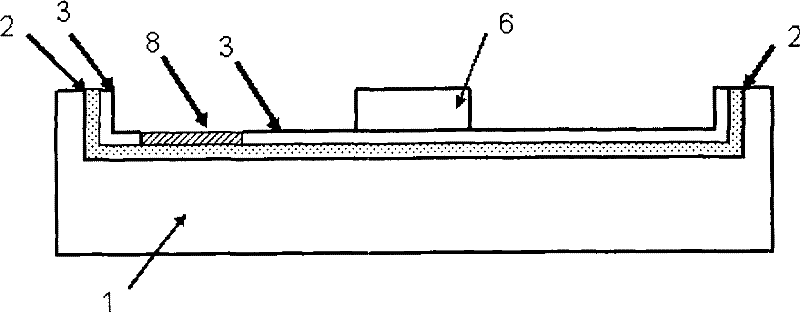

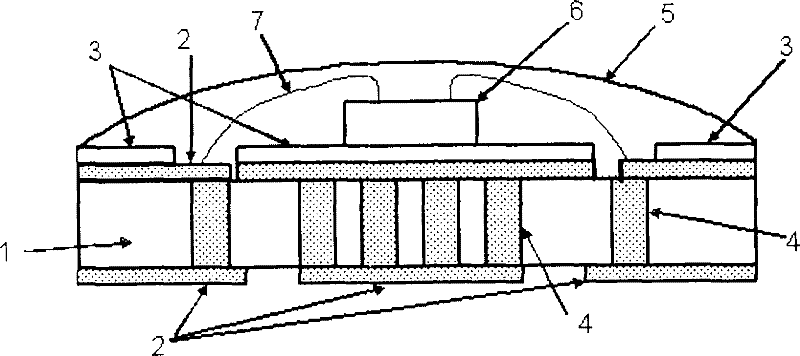

Substrate for mounting light-emitting element and light-emitting device employing the substrate

InactiveCN102214775AWarpage suppressionReduce gapSolid-state devicesSemiconductor devicesReflective layerLight emitting device

Owner:AGC INC

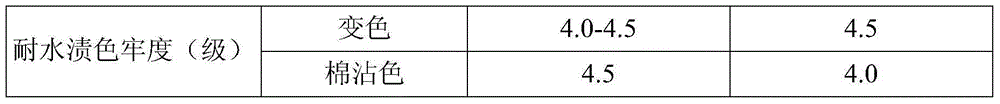

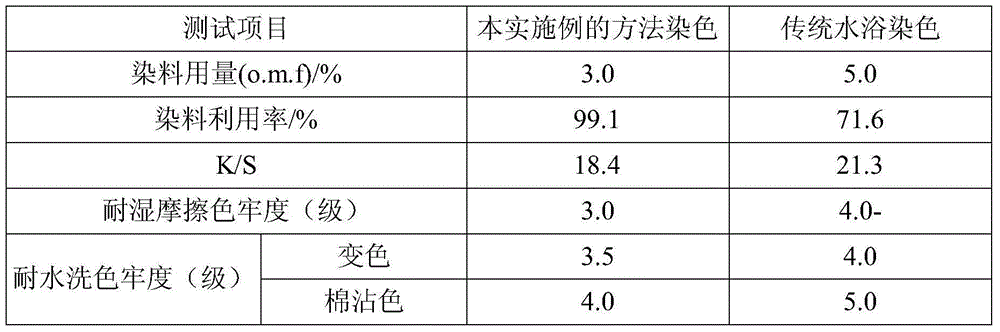

High-fixation-rate non-aqueous solvent dyeing method for reactive dyes

The invention provides an active dye non-aqueous solvent dyeing method with high color fixation rate. The method comprises the following steps: swelling a cotton fabric in an aqueous solution of an alkaline substance until the moisture content is 30 to 200 percent, and then drying the cotton fabric; mixing the dried cotton fabric with active dye and good solvent of the active dye, adding poor solvent of the active dye in the heating process, and preserving the heat until the temperature reaches a dyeing temperature; placing the dyed cotton fabric in an organic solution with more than two nucleophilic group compounds, and preserving the temperature for a period of time; then placing the cotton fabric in an organic solution with more than two electrophilic group compounds to be reacted; taking out the cotton fabric, neutralizing and washing the cotton fabric, and completing the dyeing. By adopting the active dye non-aqueous solvent dyeing method, little water is used, and the utilization rate of the dye is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

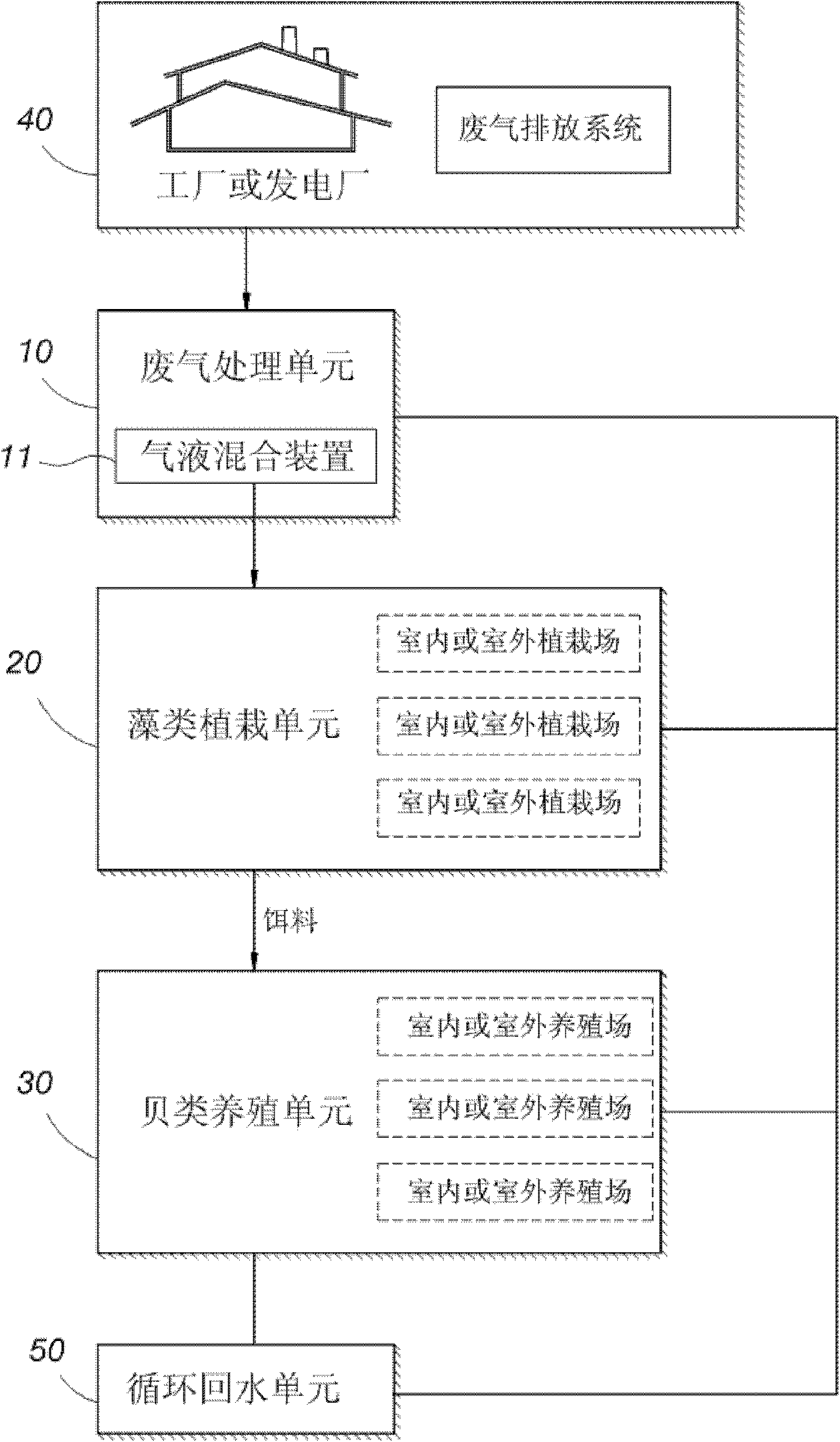

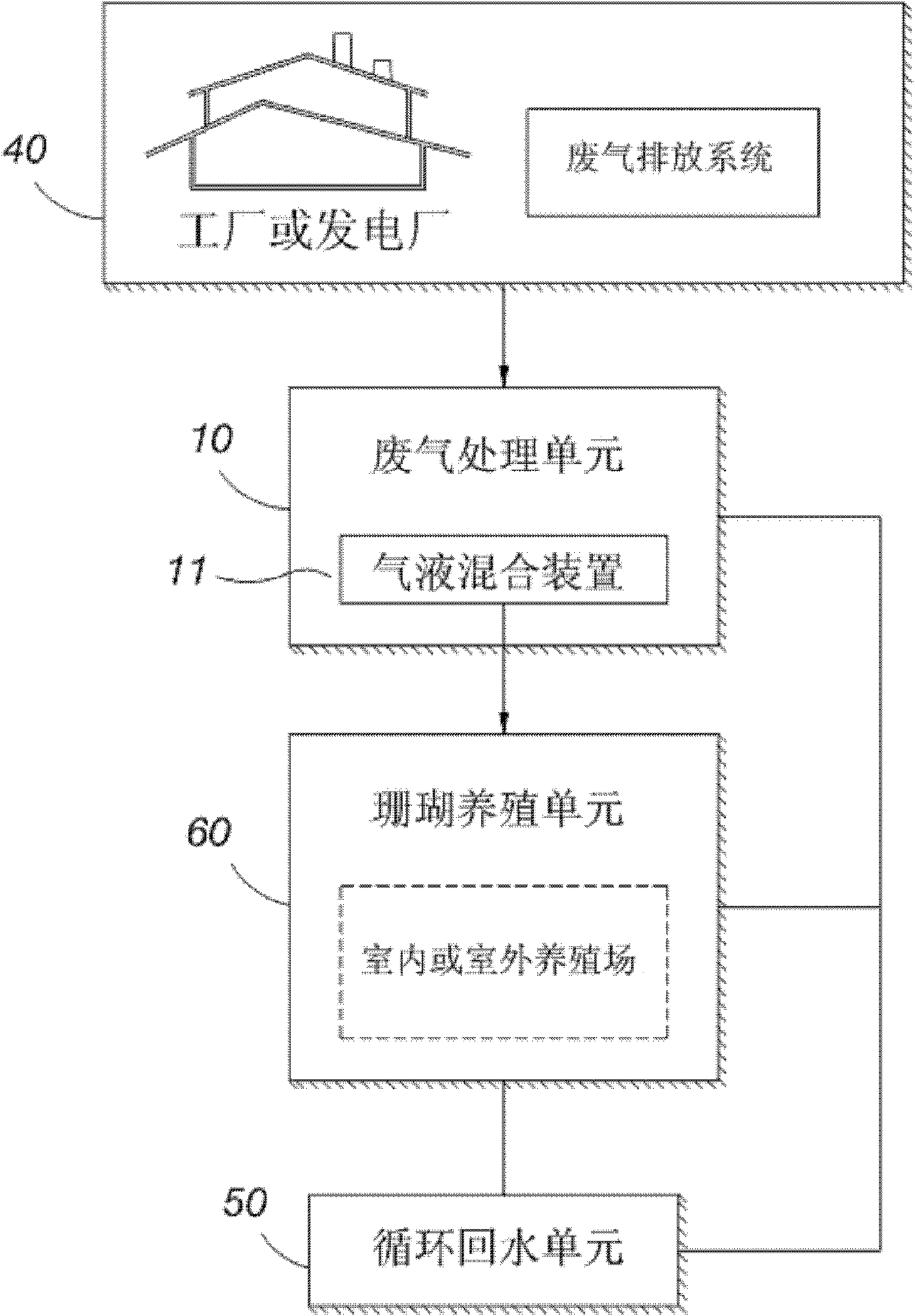

Method and system for fixing carbon dioxide by combining shellfish or coral breeding

InactiveCN103301746ALower carbon dioxide levelsWill not emitCarbon compoundsDispersed particle separationAlgaeWaste gas

The invention relates to a method and system for fixing carbon dioxide by combining shellfish or coral breeding. The invention aims to fix carbon by utilizing a shellfish or coral breeding system, so that the carbon dioxide in the waste gas is absorbed, and the carbon in the carbon dioxide can be semi-permanently fixed. The method provided by the invention comprises the following steps: dissolving carbon dioxide in the waste gas in water through a mist spray washing method, cultivating algae by utilizing water containing carbon dioxide, and providing the algae for the shellfish to serve as foods required by growth, or directly providing the algae for symbiotic algae of corals for growing the corals, wherein in the process, the carbon element in the carbon dioxide can be converted into the calcium carbonate as the main component of the shellfish and coral bones. Furthermore, because the calcium carbonate is difficultly decomposed, the carbon can be semi-permanently fixed, so that the aims of cultivation and environment friendliness can be fulfilled, and the method is a highly technical thought by utilizing the natural law and has a high industrial value.

Owner:赖珏光 +1

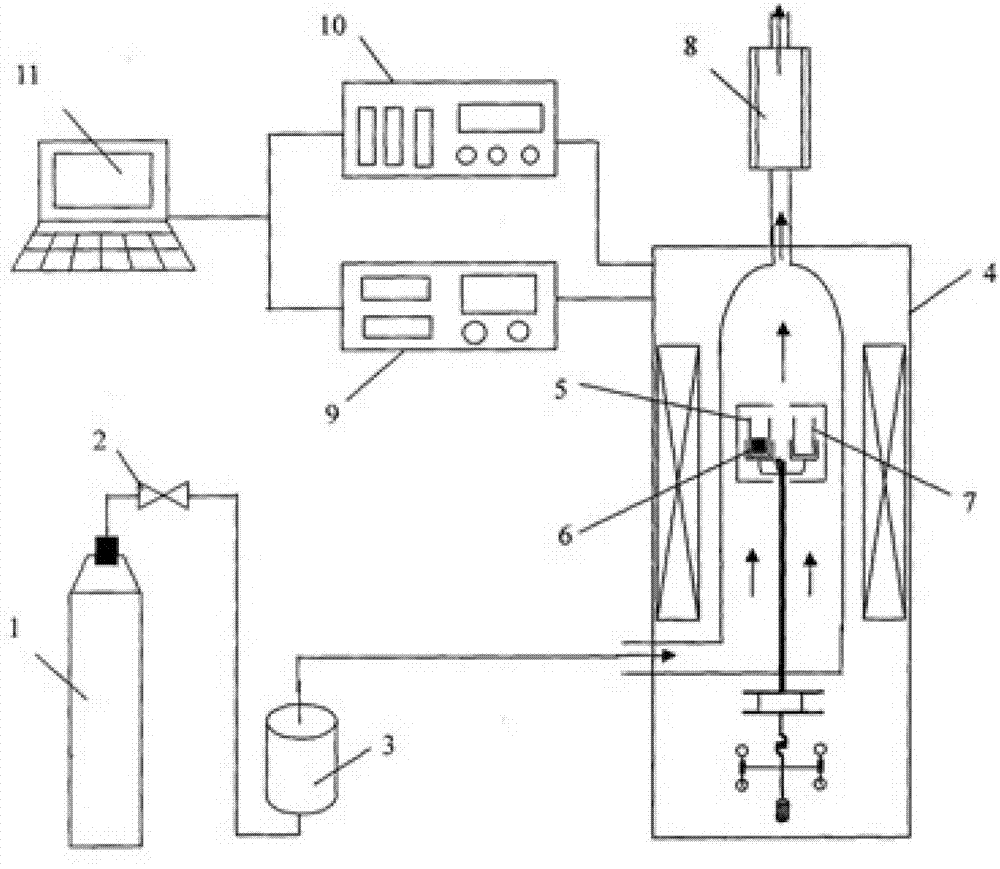

Device and method for detecting reducibility of iron ore

The invention provides a device and a method for detecting reducibility of iron ore. The device comprises an air supply system, a thermogravimetric scale, a tail gas treatment system, a temperature control system, a gas control system and a compute data processing system. In the test process, a test sample 5 is placed in a crucible; a contrastive empty crucible is placed at the other end, and temperature is raised according to a predetermined temperature raising system. The method comprises the following steps: detecting by using a differential thermal scale device mainly based on a thermogravimetry theory; collecting temperature data and quality data in real time in the reaction process; and recording a thermogravimetric curve in the test where weight changes along with the temperature. The device provided by the invention is convenient to operate, small in volume and good in safety because harmful gases produced in the reduction process are discharged after being treated by the tail gas treatment system.

Owner:UNIV OF SCI & TECH BEIJING

Preparation for orthosilicic acid

InactiveCN101279737AReduce manufacturing costSimple preparation processProductsReagentsSilicic acidHazardous substance

The invention relates to a method for preparing orthosilicic acid, the chemical formula of orthosilicic acid is H4SiO4. The method is characterized by the following steps: A, SiO2 and water are mixed according to the weight ratio of 10-20:100 and strongly stirred and NaOH or KOH solution is dropped until the pH value reaches 8-9 below the temperature of 15 DEG C; B, under strong stirring, the mixture is oil-bath heated until the temperature comes to 50-55 DEG C and reacts for 2-3 hours to obtain even solution; C, the solution is cooled to room temperature and under strong stirring, CO2 gas is fed into the even solution until the pH value is less than or equal to 4; D, choline chloride is added, wherein the weight ratio of choline chloride and the solution obtained from the step C is 20-45:100, then stirred for 10-20 minutes to obtain stable orthosilicic acid solution, wherein, the silicon content of the stable orthosilicic acid solution is 2-2.5 percent. The method of the invention has low cost to prepare orthosilicic acid, environmentally friendly preparation technique and no hazardous and noxious substances discharging during the preparation process; the orthosilicic acid solution obtained has the advantages of multifunction and long preservation time.

Owner:嘉兴市红日化工有限公司

Copper zinc silver alloy metal nano-filtration membrane and preparation method thereof

ActiveCN102145260AWith antibacterial dechlorinationWill not cause secondary pollutionSemi-permeable membranesVacuum evaporation coatingFiltration membraneGas phase

The invention discloses a copper zinc silver alloy metal nano-filtration membrane and a preparation method thereof, and relates to a novel water purification material. The copper zinc silver alloy metal nano-filtration membrane comprises the following components in percentage by mass: 40 to 50 percent of copper, 49.8 to 58.5 percent of zinc and 0.2 to 1.5 percent of silver, or 80 to 90 percent ofcopper, 9.8 to 18.5 percent of zinc and 0.2 to 1.5 percent of silver. The preparation method comprises the following steps of: putting a base material into physical vapor deposition vacuum equipment,vacuumizing, and cleaning and activating the base material; and performing physical vapor deposition on the base material, and plating the copper zinc silver alloy nano-filtration membrane on the base material. The nano-filtration membrane has the functions of bacteria resistance, chlorine removal and the like, is a novel water purification material, has no ions of NO3<-1>, SO4<-2> and the like, and does not cause secondary pollution to water; and the nano-filtration membrane has high efficiency of removing residual chlorine and harmful heavy metal ions such as lead ions, mercury ions, hexavalent chromium, arsenic ions and the like in water, and has good effect. The production process is environment-friendly, and no waste water is drained.

Owner:XIAMEN RUNNER IND CORP

Three-ingredient eutectic ionic liquid and preparation method thereof

InactiveCN103193710ALow costWill not emitUrea derivatives preparationOrganic compound preparationIonHemoglobin subunit delta

The invention relates to three-ingredient eutectic ionic liquid and a preparation method thereof. The three-ingredient eutectic ionic liquid consists of ILC, REC and HBD, wherein ILC is ionic liquid with chloride ions which serve as negative ions, REC is a chloridized rare-earth metal salt, and HBD is a compound with multiple hydrogen bonds. The preparation method comprises the following steps of: uniformly mixing ILC, REC and HBD according to the molar ratio of 1 to 1 to n (n= 0.5-4), heating up to the temperature of 100-140 DEG C, and then, carrying out heat preservation for 2-4 hours until a mixture is completely dissolved. According to the ionic liquid disclosed by the invention, the melting point is extremely low, the viscosity is low, the conductivity is high, the dissolution performance is good, and the rare-earth metal salt has Lewis acidity and catalysis performance, so that the ionic liquid can be widely applied to organic synthesis reaction, the preparation of nano and mesoporous materials, gas absorption and the like; and the preparation process is simple, the raw materials are readily available, the cost is low, no organic solvents are used and no toxic substances are emitted during reaction, no byproducts are produced, and the ionic liquid is biodegradable, so that the ionic liquid is suitable for industrial production.

Owner:DONGHUA UNIV

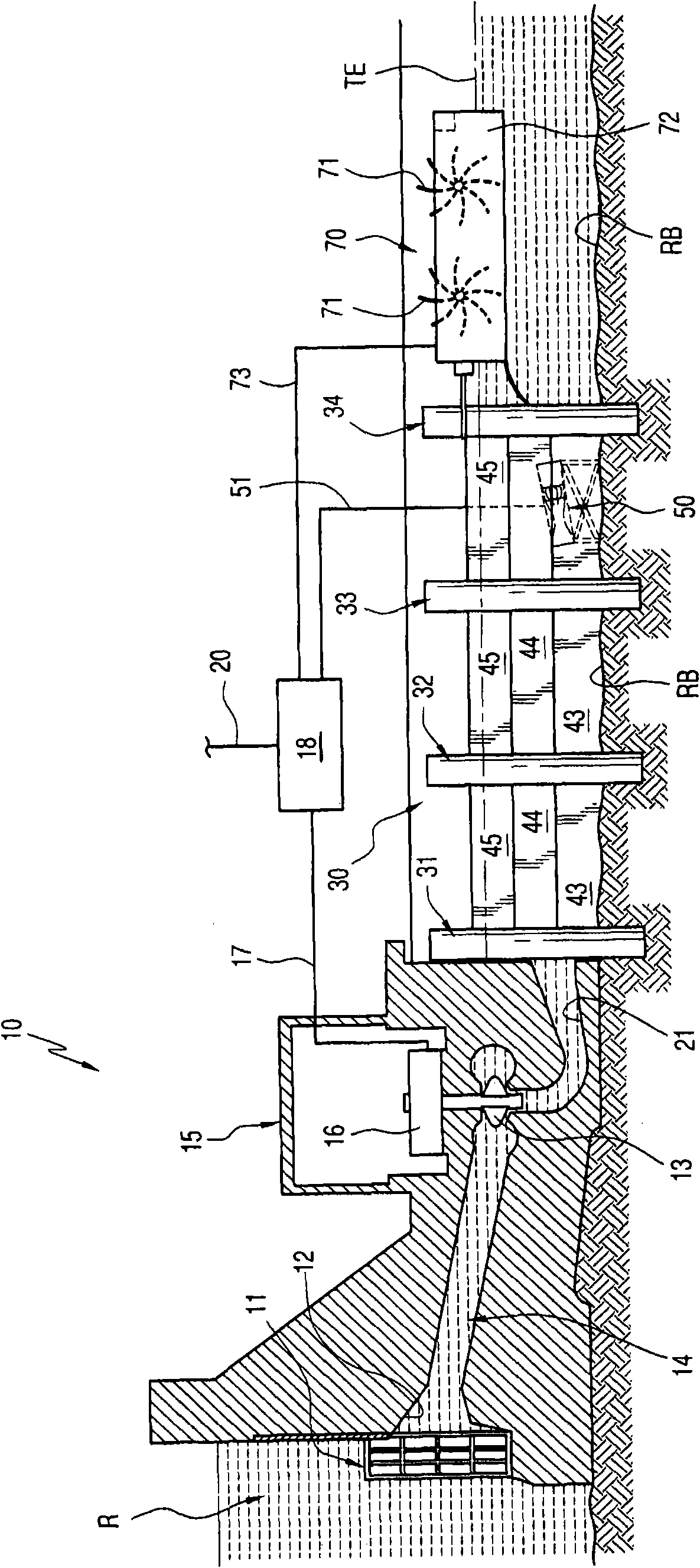

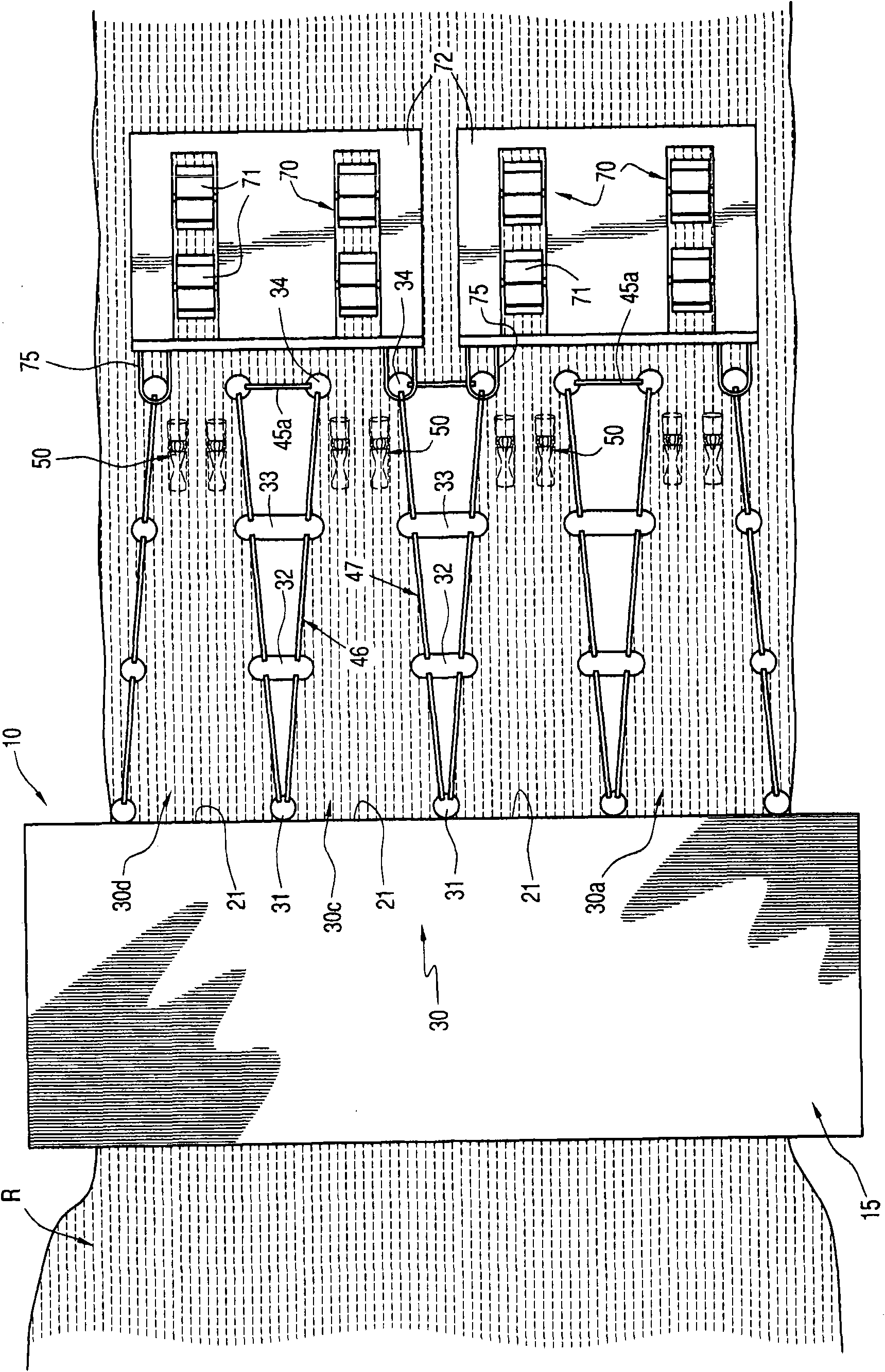

Apparatus for hydroelectric power production expansion

InactiveCN101560941AOptimum hydraulic surface flow conditionsWill not emitWater-power plantsReaction enginesEngineeringElectric generator

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:威廉・洛厄尔・凯利

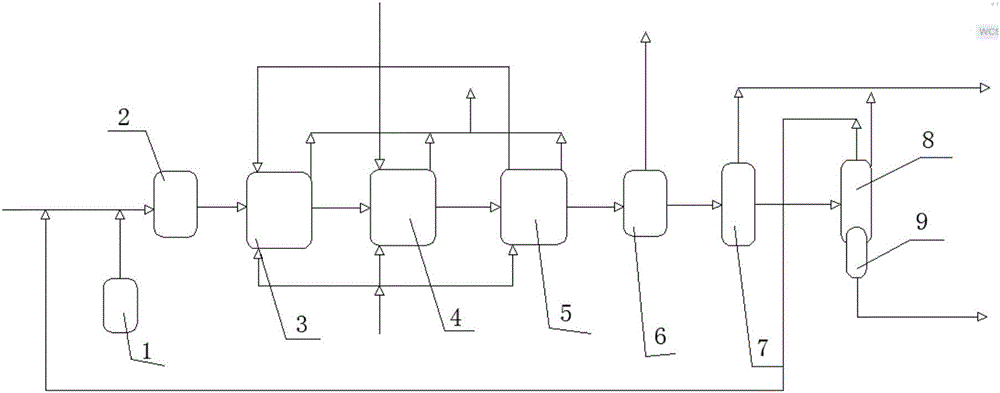

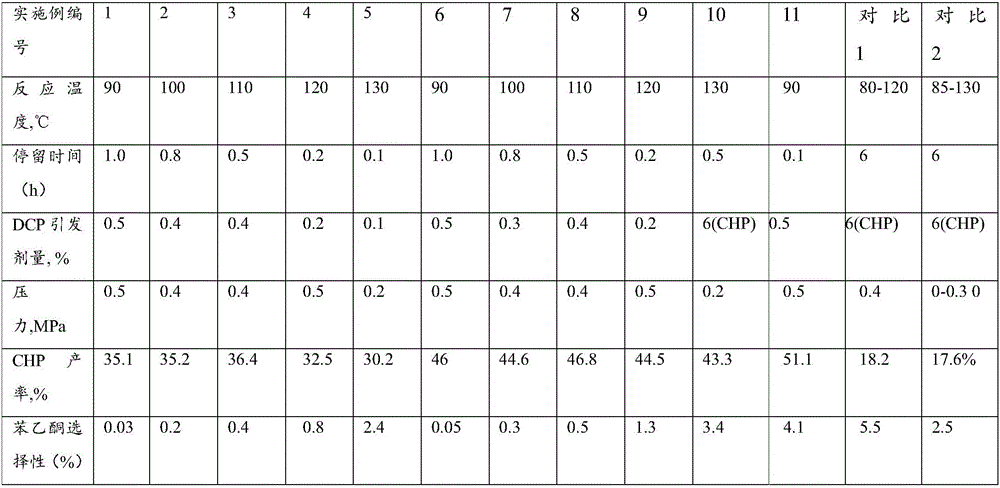

Method and device for preparing cumene hydroperoxide through cumene oxygenation

ActiveCN106588734ALarge specific surface areaIncrease reaction rateOrganic compound preparationChemical/physical/physico-chemical microreactorsMicroreactorReaction temperature

The invention provides a method and a device for preparing cumene hydroperoxide through cumene oxygenation. The method is characterized in that in a microreactor group formed by one microreactor or more microreactors connected in series, cumene and an initiating agent are supplied to a first microreactor in the first microreactor group, then a reaction product obtained after oxidizing reaction flows into a second microreactor in the first microreactor group for the oxidizing reaction, continuous flow type oxidizing reaction is carried out sequentially through recurrence till the reaction product finally flows into the last one microreactor for the oxidizing reaction, and purification is carried out finally; in every oxidizing reaction process, oxygen is supplied to all microreactors, and a mole ratio of cumene supplied to the first microreactor to the total oxygen supplied to all microreactors is 0.1:5. The problems that the reaction temperature fluctuation of the traditional technology is large, and the production efficiency and the productivity are low are solved.

Owner:SINOPEC ENG GRP CO LTD

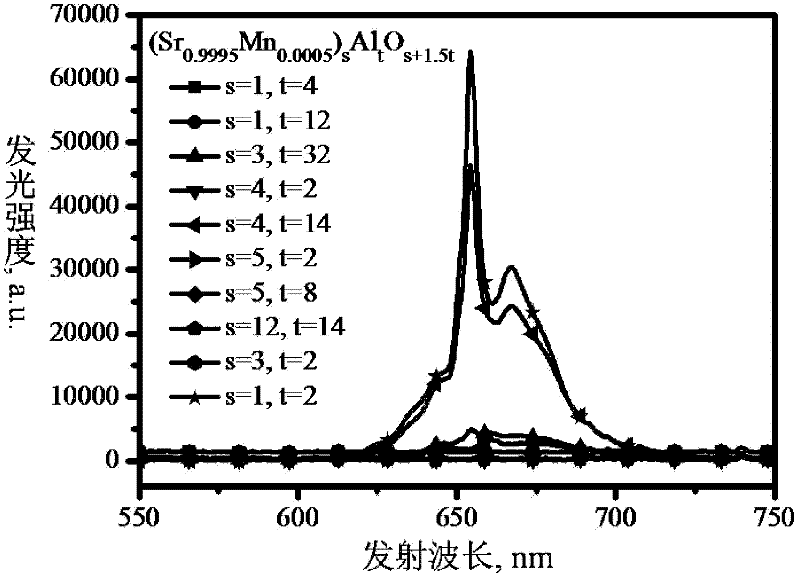

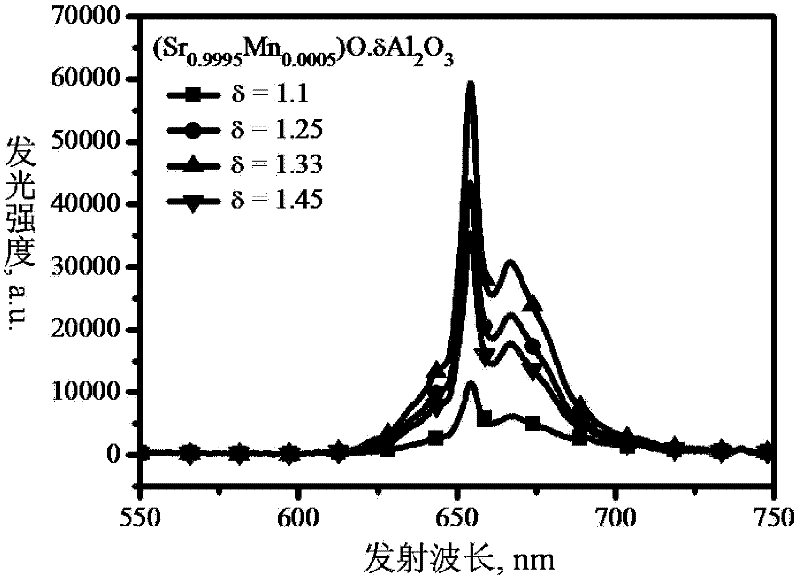

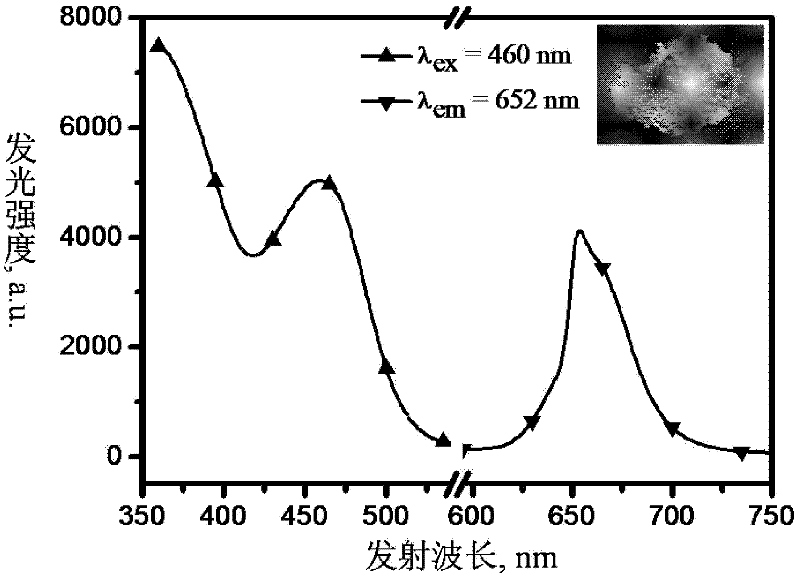

LED red fluorescent material and its preparation method

ActiveCN102352244AWide range of raw materialsLow costLuminescent compositionsRoom temperatureLight excitation

The invention discloses a LED red fluorescent material and its preparation method, wherein the composition of the LED red fluorescent material is expressed in a general formula (M1-rMnr)sAltOs+1.5t, wherein 0<r<=1.0; 1<=s<=12; 2<=t<=32, M is one or more from Sr, Ba, Ca, Mg and Zn; The preparation method comprises the following steps: mixing the raw materials according to the proportion and grinding to obtain a mixture, calcining the mixture under the temperature of 1100-1600 DEG C for 1-20 hours and cooling to the room temperature to obtain the sintered products, fragmenting the sintered products and grinding to obtain the fluorescent material. The LED red fluorescent material is capable of radiating with high efficiency by adopting 420-480nm blue light excitation or 380-420nm near ultraviolet light excitation. No harmful exhaust gas with a great amount is discharged to environment during the preparation process.

Owner:HEFEI UNIV OF TECH

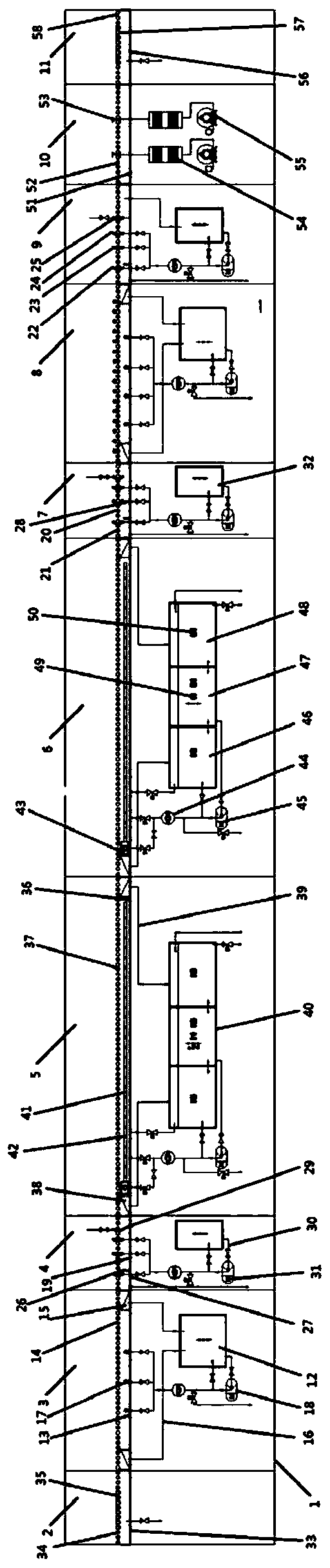

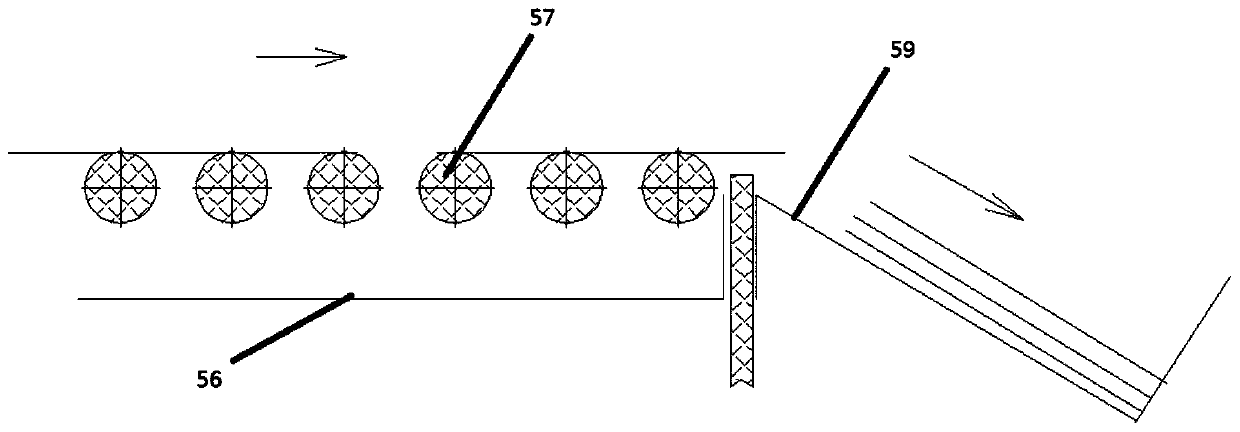

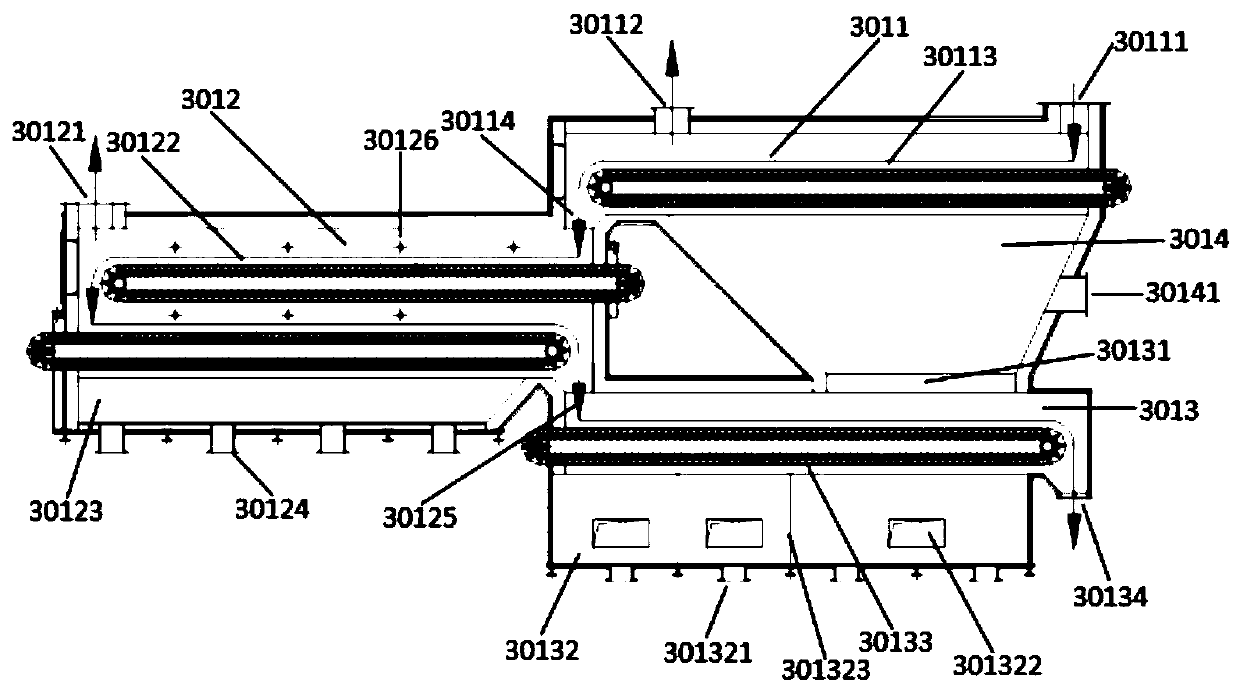

Chain-type alkali polishing production line and chain-type alkali polishing method for crystalline silicon battery piece

PendingCN110534408AReduce usageAvoid generatingFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidWastewater

The invention relates to the technical field of solar cell preparation. The invention relates to a chain-type alkali polishing production line and a chain-type alkali polishing method for a crystalline silicon battery piece. The chain-type alkali polishing production line comprises a closed box, the closed box is internally provided with a feeding system, a first acid pickling system, a first water washing system, a first polishing system, a second polishing system, a second water washing system, a second acid pickling system, a third water washing system, a drying system and a discharging system which communicate with one another, wherein each of the first acid pickling system and the second acid pickling system comprises an acid storage tank filled with a hydrofluoric acid solution. Theinvention further discloses a chain-type alkali polishing method for the crystalline silicon battery piece. According to the production line, only the hydrofluoric acid solution is used as the cleaning solution in the acid pickling process, NOx is prevented from being generated from the source, waste water containing HNO3 cannot be discharged, and the problem of environmental pollution in the crystalline silicon solar cell preparation process can be effectively solved.

Owner:苏州昊建自动化系统有限公司

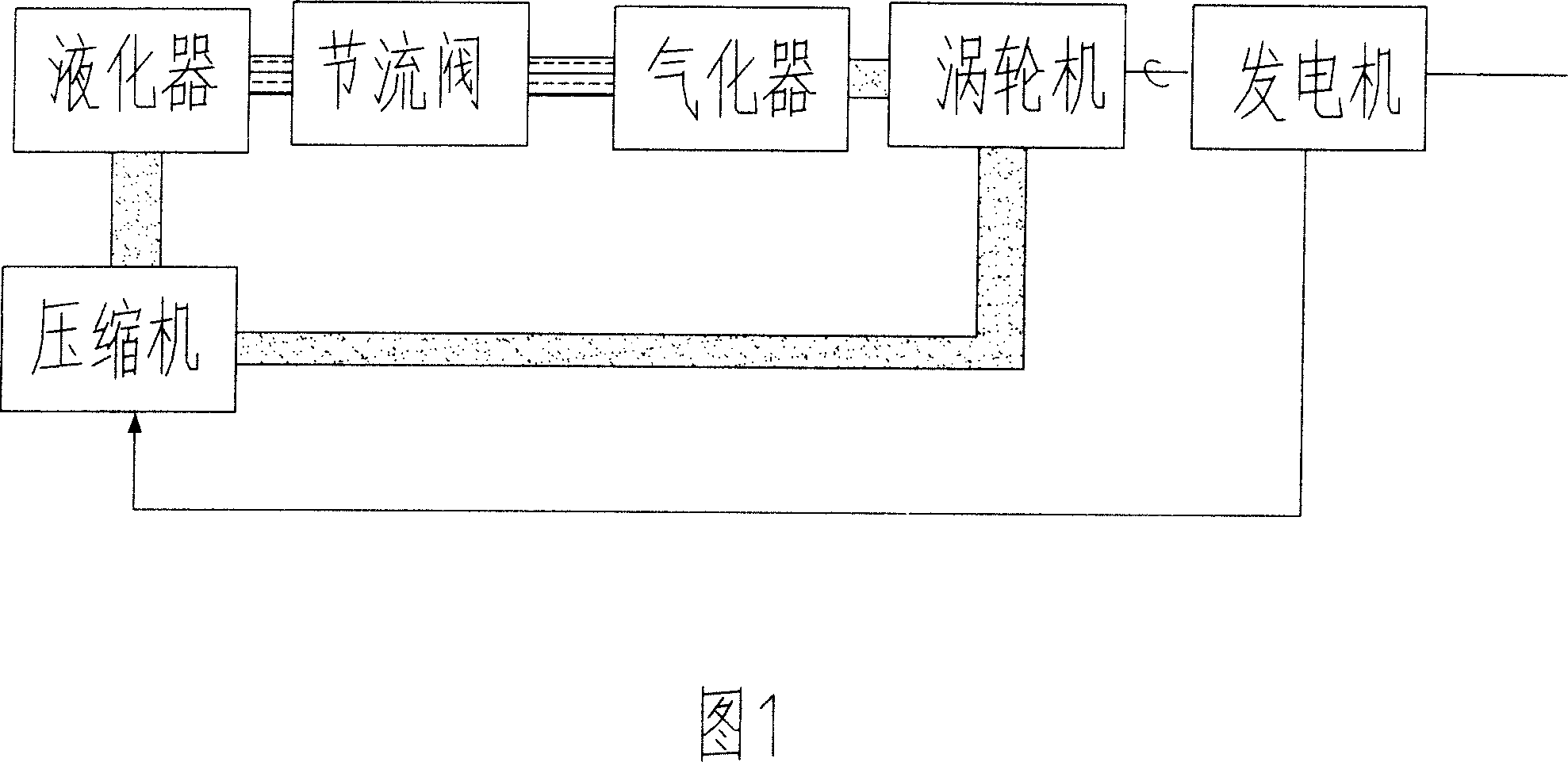

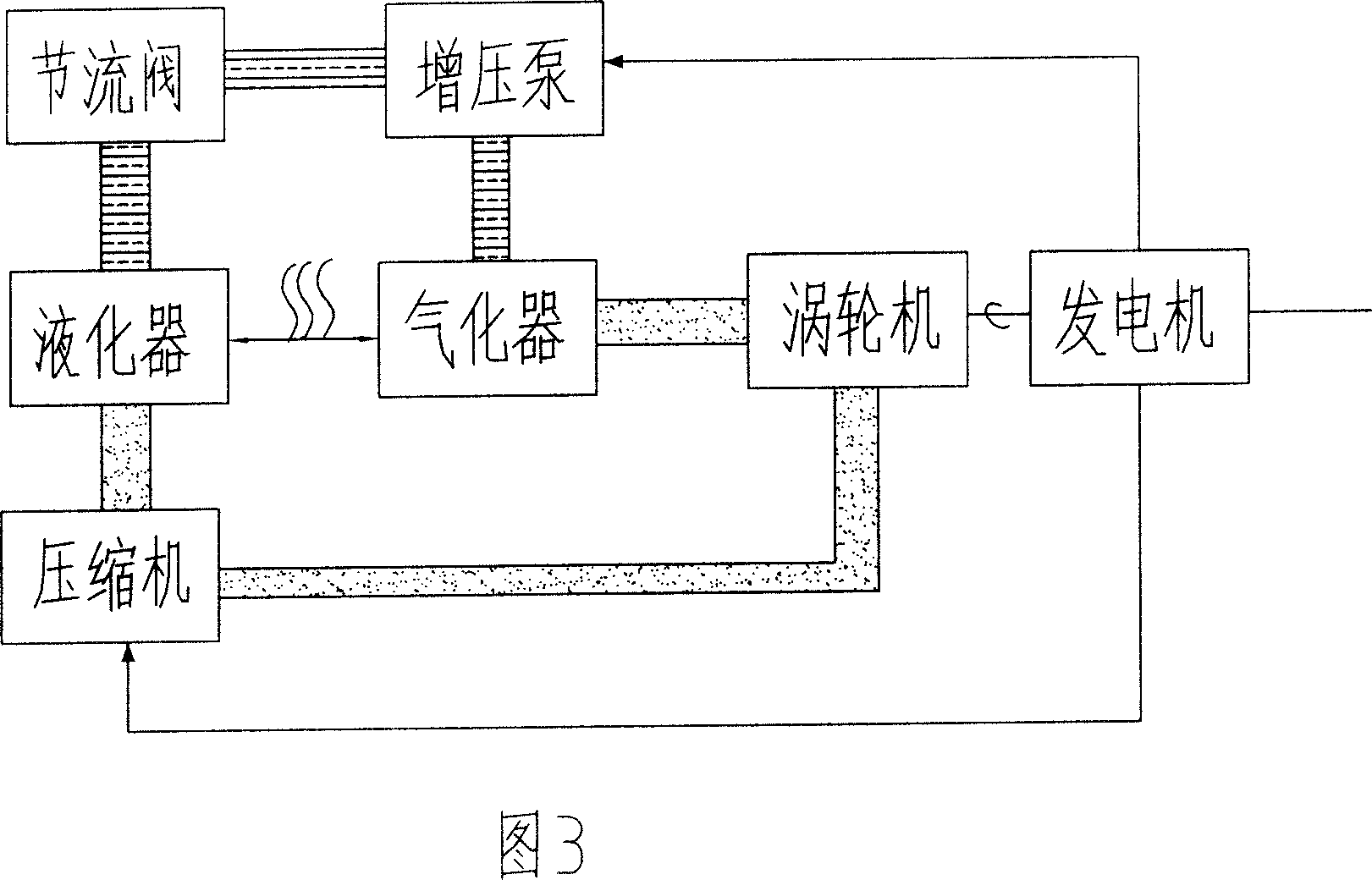

Single circulating heat pump generating apparatus

InactiveCN100999999AWill not emitAlleviate the energy crisisMechanical energy handlingSteam engine plantsThermal energyMechanical energy

The present invention relates to heat pump power generator, and is especially one kind of single cycle heat pump power generator. The single cycle heat pump power generator includes one gasifier utilizing disorder heat energy in the air as energy source to gasify the liquid working medium and to generate high speed gas flow, one turbogenrator set powered with the high speed gas flow to convert the mechanical energy into electric energy, one compressor to compress the off gas from the turbine into high temperature and high pressure gas and to convey the high temperature and high pressure gas to the liquefier connected to the gasifier for heat exchange, and one booster pump to convey the normal temperature liquid after heat exchange to the gasifier. The present invention has only one cycle loop for both heat collection and generating electricity.

Owner:李治国

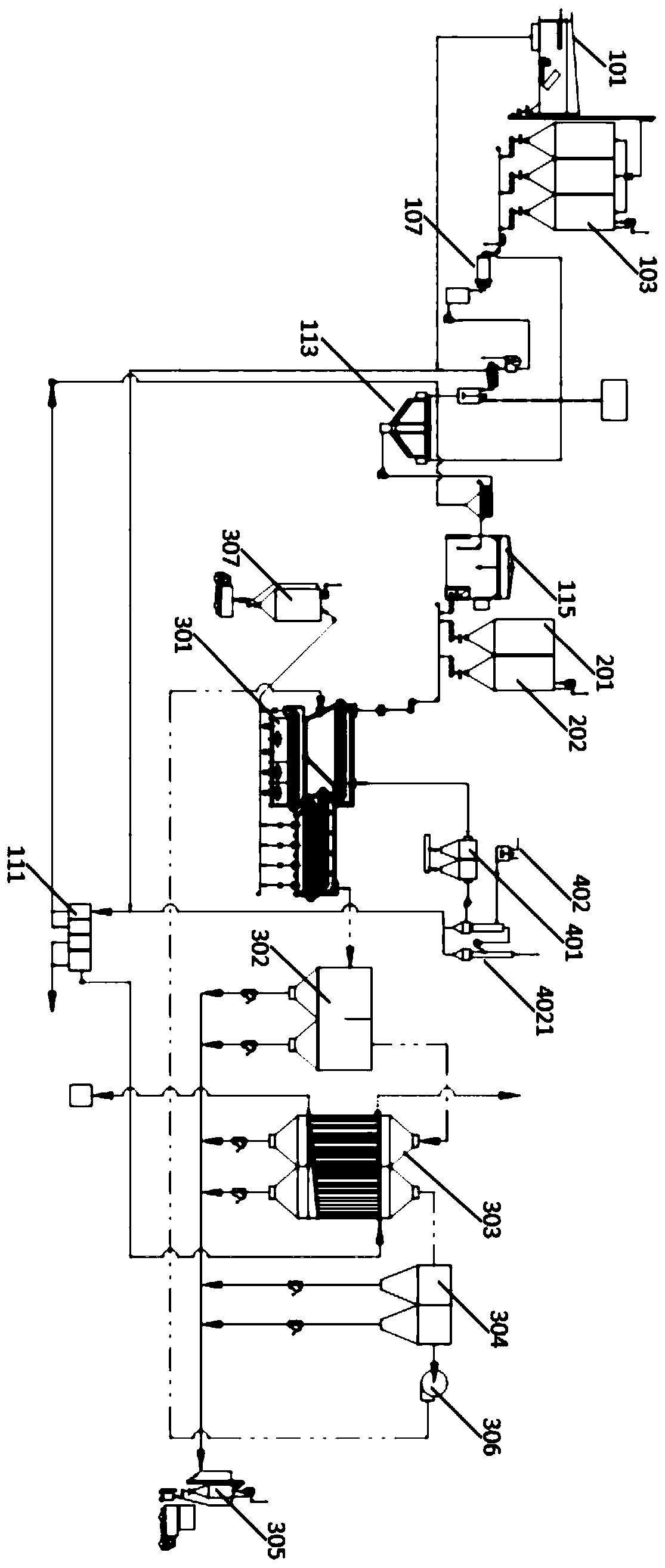

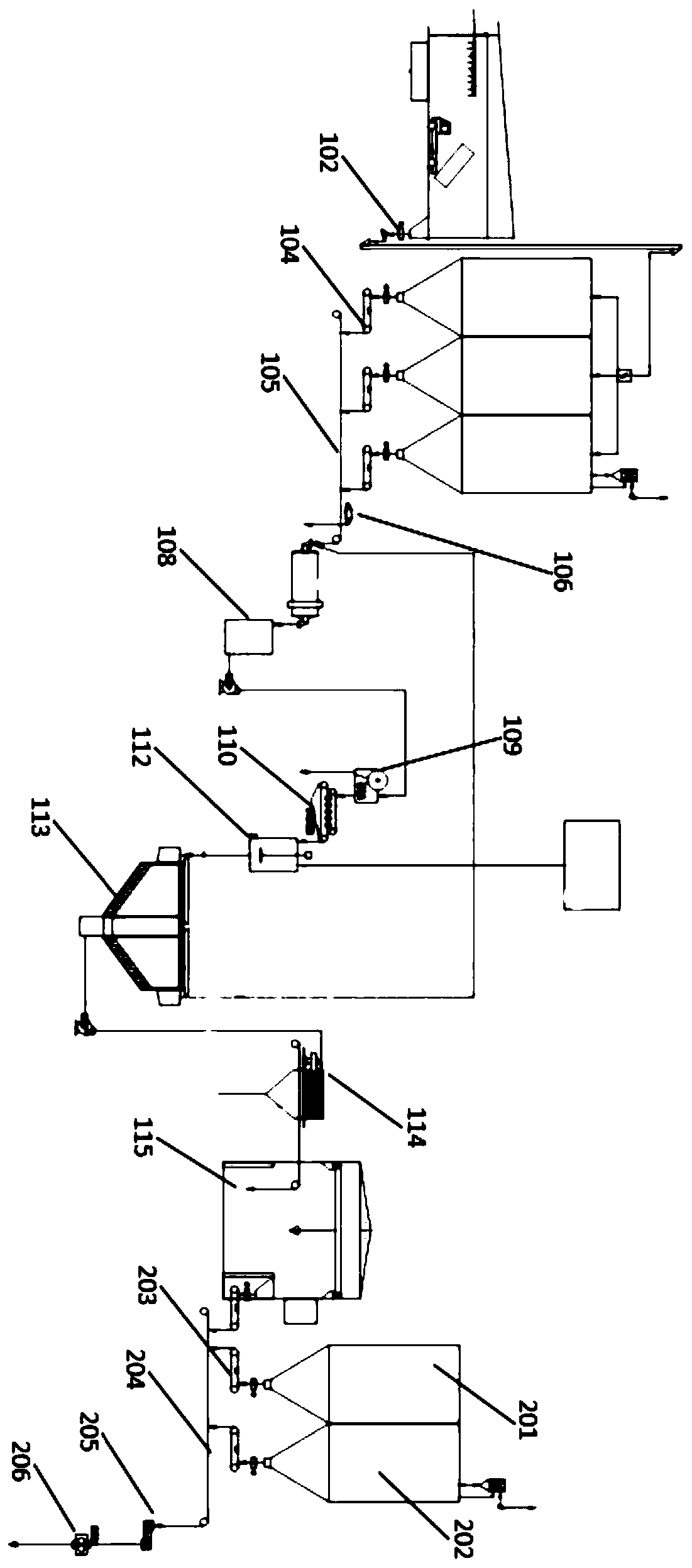

System and method for disposing steel plant collected dust through chain plate type high-temperature reduction furnace

PendingCN111270077AFast responseImprove reduction efficiencyCombination devicesWater/sewage treatmentPelletizingProcess engineering

The invention discloses a system and method for disposing steel plant collected dust through a chain plate type high-temperature reduction furnace. The system comprises a washing dechlorination system, a pelletizing granulation system, a volatile zinc extraction system and a flue gas treatment system; and the volatile zinc extraction system comprises the chain plate type high-temperature reductionfurnace, an oxidizing chamber, a brine evaporation and flue gas settling machine, a high-temperature static dust collector and a solid storage which are connected in sequence, the high-temperature static dust collector is connected with the chain plate type high-temperature reduction furnace through an exhaust fan, the chain plate type high-temperature reduction furnace comprises a furnace body and a cavity wrapped with the furnace body, and the cavity is composed of an evaporation preheating part, a high-temperature reduction part and a cooling part. The chain plate type high-temperature reduction furnace is utilized as main incineration refining equipment, and the equipment is simple and unique in structure, convenient to operate and low in cost.

Owner:长沙中硅环保科技有限公司

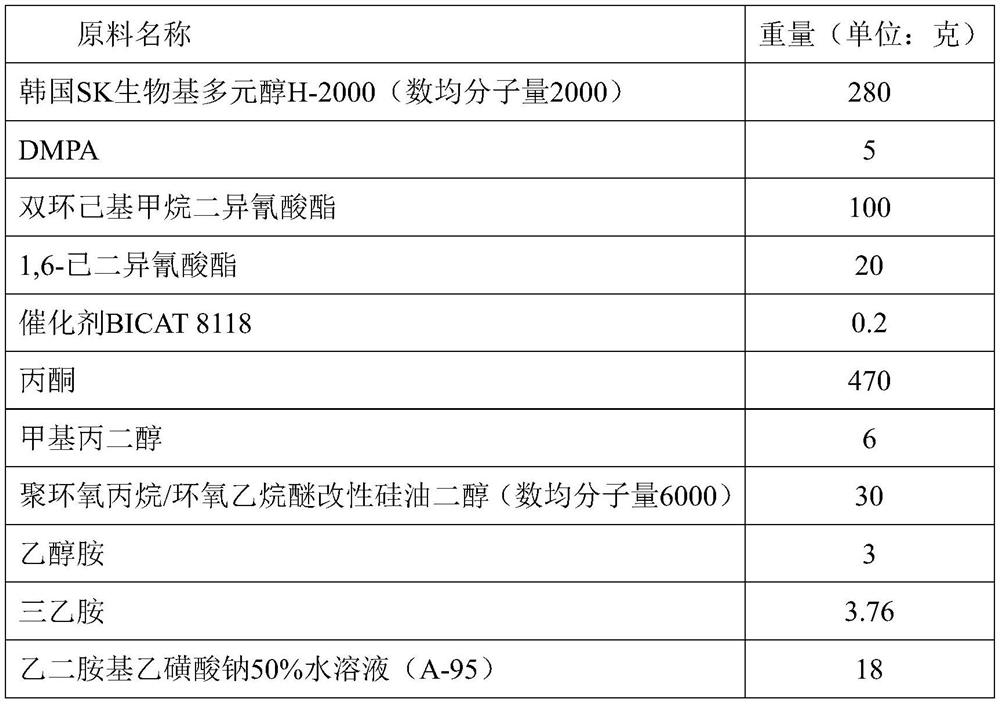

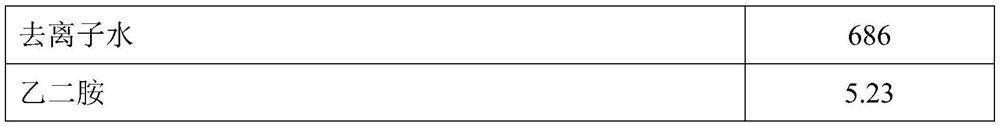

Organic silicon modified bio-based waterborne polyurethane resin composition and preparation method thereof

PendingCN112225871AGood renewabilityGood normal and low temperature folding resistanceTextiles and paperPolyesterPolymer science

The invention relates to the technical field of waterborne synthetic leather, in particular to an organic silicon modified bio-based waterborne polyurethane resin composition and a preparation methodthereof. The composition comprises polymer polyol, a chain extender, micromolecular diamines, polyisocyanates, a diluent and water, wherein the polymer polyol comprises (a) an organosilicon polyol and(b) at least one selected from a polyether polyol, a polyester polyol and a bio-based polyol with a number average molecular weight of 500-8000. By introducing a specific organic silicon raw materialinto the bio-based waterborne polyurethane, the strength and the flexibility of the resin can be improved, and the folding resistance, the wear resistance, the heat resistance, the mechanical property, the biodegradability, the jungle aging resistance and the like of the waterborne polyurethane resin can be remarkably improved.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD

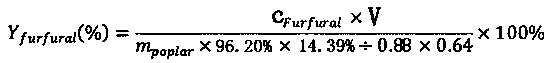

Comprehensive utilization method of lignocellulose biomass

ActiveCN111395025AAvoid damageWon't happenFinely-divided material pretreatmentCellulose material pulpingFiberDepolymerization

The invention discloses a comprehensive utilization method of lignocellulose biomass. According to the method, a lignocellulose raw material is pretreated by p-toluenesulfonic acid to realize efficient conversion and utilization of each component after component separation; a lignin-containing biomass-based hydrogel is prepared from a fiber material containing residual lignin by virtue of a dissolution-regeneration method; the hemicellulose and the cellulose degradation product can be converted into furfural through a hydrolysis method; and lignin is prepared into a lignin depolymerization product which can be used as an aviation fuel precursor through hydrogenization depolymerization. According to the comprehensive utilization method of the lignocellulose biomass, all components of lignocellulose can be utilized in a high-valued mode, the loss is small in the high-valued utilization process, the yield is high, the preparation process is simple, and harmful pollutants cannot be discharged into air.

Owner:QILU UNIV OF TECH

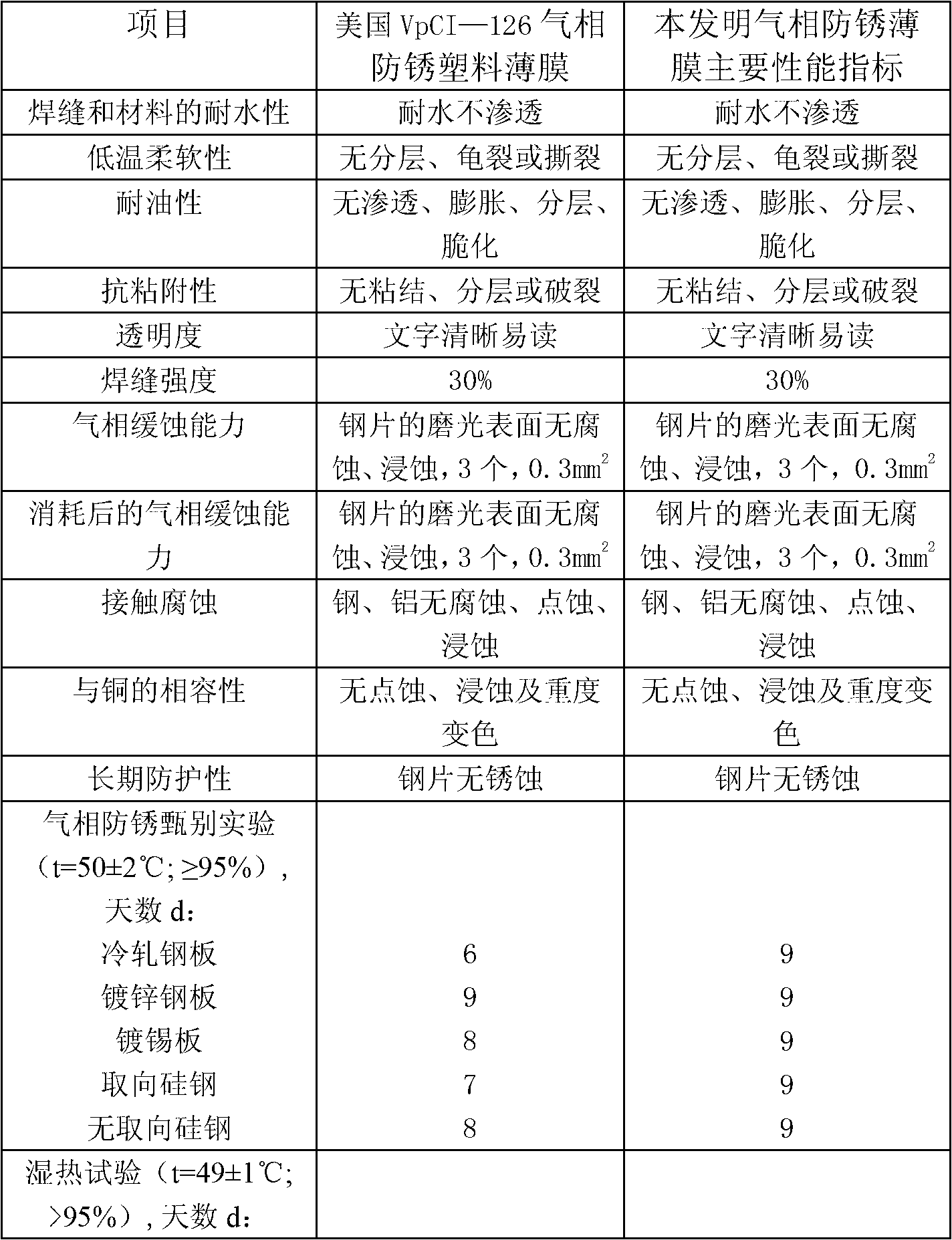

Environment-friendly vapor phase rust-proof film

The invention discloses an environment-friendly vapor phase rust-proof film which is formed by carrying out mixing, coextrusion and blow molding on 85-95% of matrix plastic and 15-5% of additive by weight. The additive comprises the following components by weight percent: 70-85% of vapor phase inhibitor, 2-5% of dispersed lubricant and 10-28% of carrier plastic. The vapor phase inhibitor is formed by combining sodium benzoate, tungstate and morpholine unit-containing diamine type, and the weight ratio of sodium benzoate to tungstate to diamine type containing morpholine unit is (1-3):(1-2.5):(1-3). The environment-friendly vapor phase rust-proof film has the characteristics of high strength, stable sealing performance, good rust-proof performance and single material, and is energy-saving and environment-friendly. Each component has synergistic effect, and inherent physical and chemical rust-proof performances of each component can be fully exerted.

Owner:上海福岛新材料科技有限公司

Cleaning and drying method and device through steam and superheated water

ActiveCN105149263AFast cleaningReduce power equipment usageCleaning using liquidsMaterial cycleSolvent

The invention discloses a cleaning and drying method and device through steam and superheated water. No chemical cleaning solvent is used, and workpieces are cleaned through super-strong dirt removing capacity of the steam and the superheated water, so that safety and no toxicity are achieved, and the cleaning speed is high; differential-pressure jet and differential-pressure liquid drainage are used, power required by cleaning and liquid drainage is provided, energy consumption and the device failure rate are reduced, and the cleaning duration is shortened; centrifuge dripping and vacuum drying technologies are combined, and recycling of heat is achieved; gas exhausted by a vacuum pump preheats a water supplement pipe, and heat and moisture in the gas are recovered. Oil and water can be separated easily, cleaning water can be recycled, and the loss of water is quite low during cleaning. Heat and substances in a cleaning system are recycled, the cleaning process is performed in the sealed system, and accordingly secondary pollution is avoided.

Owner:无锡新弘田环保技术有限公司

Firewood straw direct-combustion boiler and combustion process thereof

InactiveCN101556075ALow running costLow costSolid fuel combustionWater heatersCombustion chamberAtmospheric air

The invention belongs to the technical field of boilers and boiler burning and in particular discloses a firewood straw direct-combustion boiler and a combustion process thereof, wherein the boiler comprises a boiler body, a dust collecting chamber, and a thermolysis combustion chamber with a water jacket, a water cooling grate is arranged at the lower end of the thermolysis combustion chamber, a reinforcing combustion chamber is arranged below the water cooling grate and communicated with a boiler gas distributing chamber which is communicated with a boiler heat exchange chamber, the top end of the boiler heat exchange chamber is connected with a chimney communicated with the atmosphere, and the water jacket and the water cooling grate are respectively communicated with a water tank of the boiler heat exchange chamber at one side of the thermolysis combustion chamber. In such technical proposal, the combustion process of the boiler is combined with the structure thereof, thereby realizing the direct combustion of firewood straws, solving the problems of low heat value of the firewood straws and low heat intensity, providing a practical and feasible approach capable of leading to the full use of the firewood straw energy for the firewood straw treatment during the agricultural production and also reducing the environment pollution caused by burning the firewood straws.

Owner:王惠生 +1

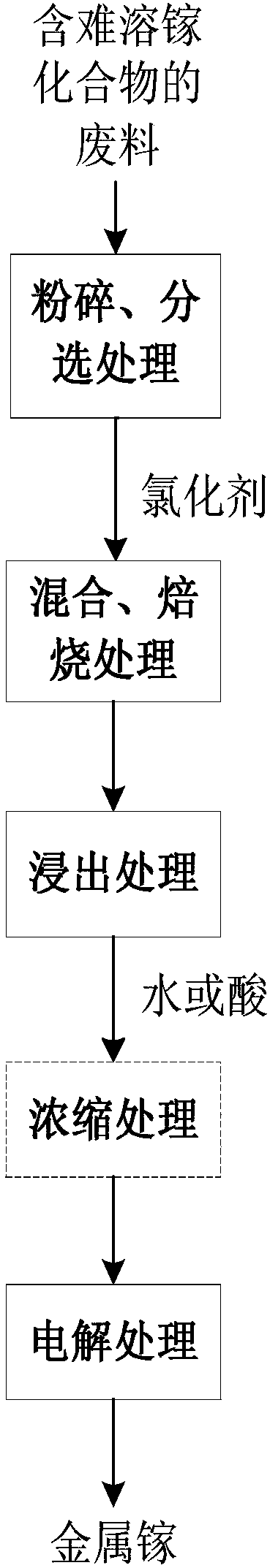

Method for recycling gallium from indissolvable gallium compounds and gallium recycled by virtue of method

ActiveCN108374091AImprove leaching rateEfficient leachingPhotography auxillary processesProcess efficiency improvementElectrolysisLeaching rate

The invention provides a method for recycling gallium from indissolvable gallium compounds and gallium recycled by virtue of the method. The method comprises the steps of mixing waste containing the indissolvable gallium compounds with a chlorinating agent, sintering, leaching a sintered product, and carrying out electrolysis, so as to obtain metal gallium. According to the method, the waste containing the indissolvable gallium compounds is mixed with the chlorinating agent and is sintered, and the difficulty-leached gallium compounds are converted into easily-leached gallium chloride, so thatthe leaching rate of gallium is greatly increased, the recycling rate of gallium reaches 98% or above, and the purity of metal gallium can reach 99.9wt%. The process flow is simple, the consumed timeis relatively short, the waste gas and the dust which are harmful to the environment are not discharged, and the method has wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

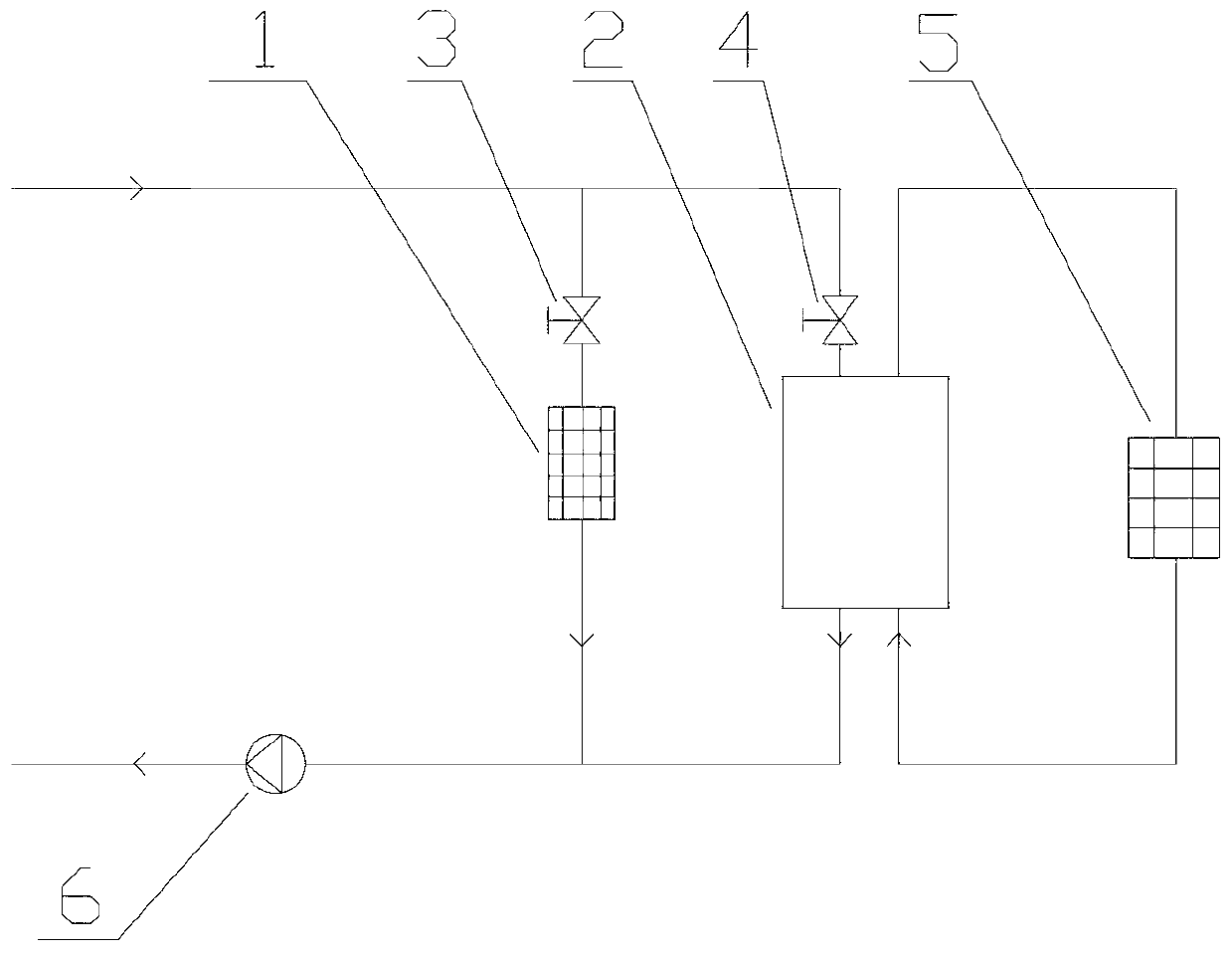

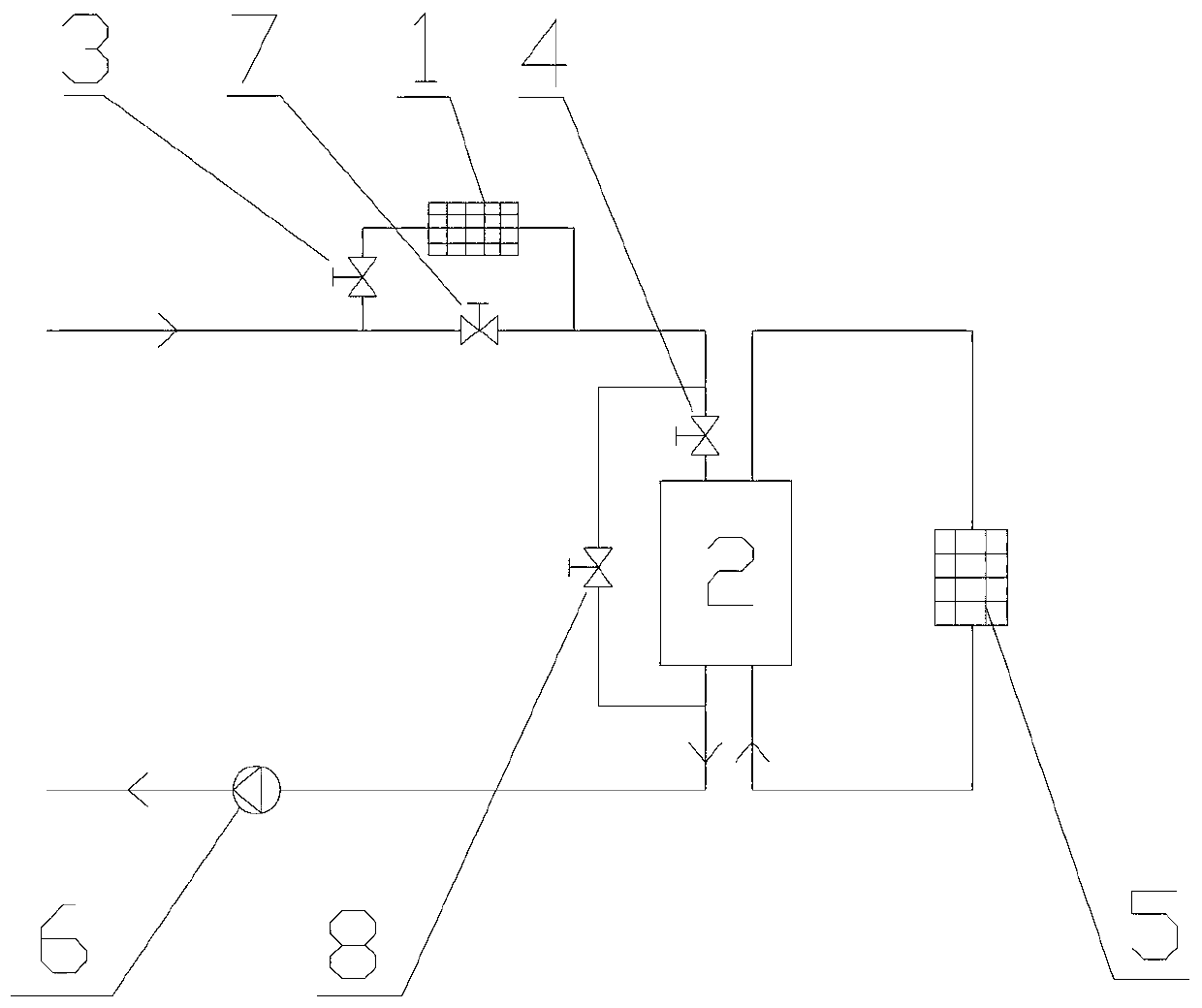

Air conditioner outdoor unit system

ActiveCN103344024AReduce consumptionSave energySpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlEvaporation

The invention provides an air conditioner outdoor unit system which is provided with a cooling device. The cooling device comprises a first cooling branch with an evaporation cooling module (1), a second cooling branch with an auxiliary refrigeration module (2) and a temperature control module, wherein the evaporation cooling module (1) is used for carrying out evaporation cooling on refrigerants flowing in the evaporation cooling module (1), the auxiliary refrigeration module (2) is used for carrying out heat-exchange cooling on refrigerants flowing in the auxiliary refrigeration module (2), and the temperature control module is used for controlling the cooling device according to monitored outdoor environment temperature to select a mode to carry out switching over between the first cooling branch and the second cooling branch. The air conditioner outdoor unit system can achieve the fact that the outdoor environment temperature is used for cooling the air conditioner outdoor unit system.

Owner:SUGON DATAENERGYBEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com