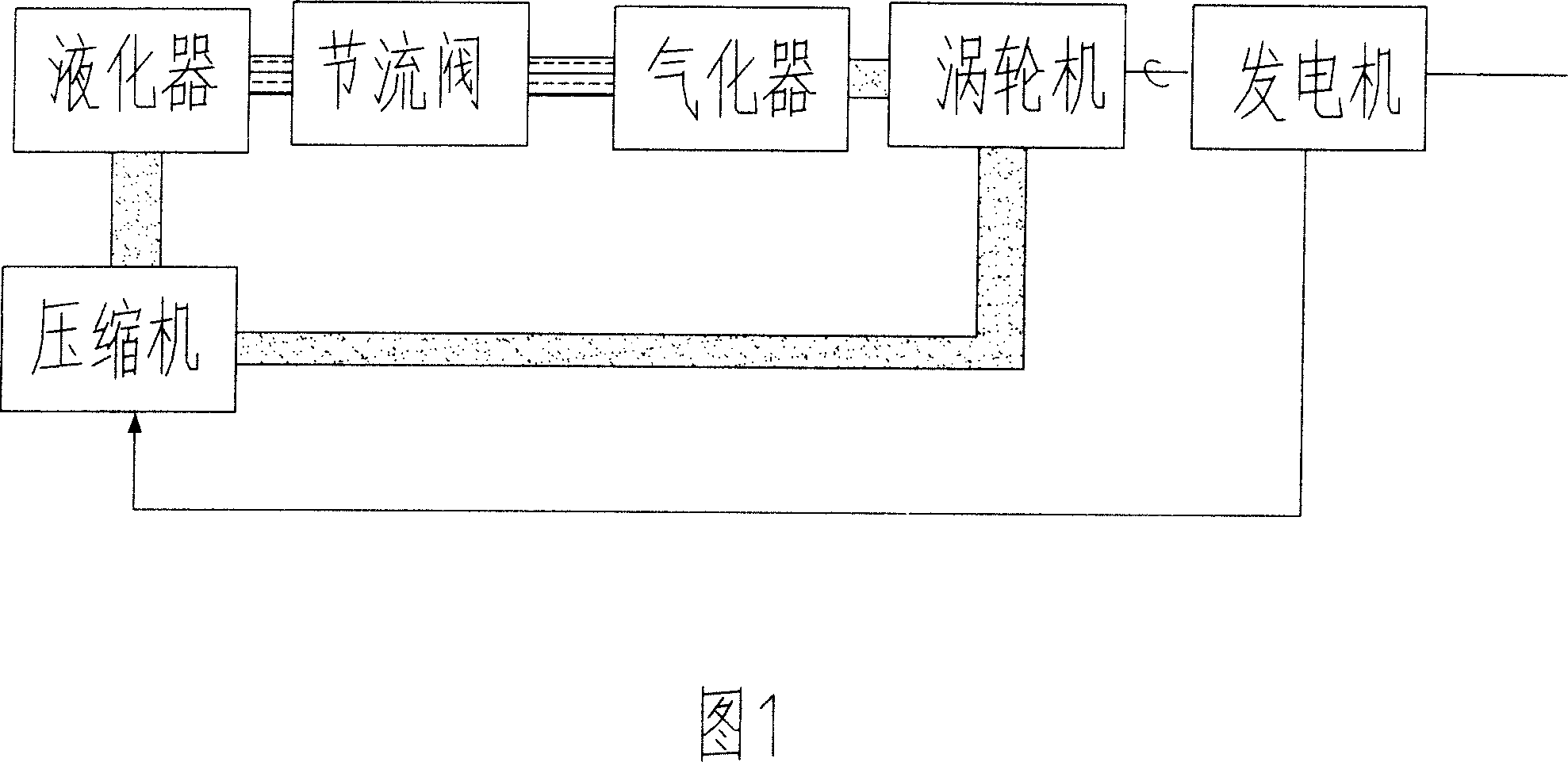

Single circulating heat pump generating apparatus

A power generation device, single-cycle technology, applied in electromechanical devices, steam engine devices, electrical components, etc., can solve the problems of inappropriate popularization and low system efficiency, and achieve the effect of alleviating atmospheric warming and energy crisis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 is a kind of non-heat exchange type single-cycle heat pump power generation device (as shown in Figure 2 ) provided according to the system block diagram shown in Figure 1, which consists of a liquefier 1, a vaporizer 2, a compressor 3, and a turbine 4 , generator 5, decompression and speed-up special-shaped pipe 6, airtight valve 7, throttle valve 8, the gasifier 1 is an external insulation layer 9, a built-in liquid working medium 10 and has a gas chamber and a high-pressure gas exhaust port The barrel-like structure of the container, its high-pressure gas exhaust port is connected to the decompression and speed-up special-shaped pipe 6 through the pipeline and the air-tight valve 7 installed on it, and the high-speed air outlet of the decompression and speed-up special-shaped pipe 6 is connected to the turbine 4 , the power output shaft of the turbine 4 is connected to the generator 5, its exhaust gas outlet is connected to the compressor 3, and the high-...

Embodiment 2

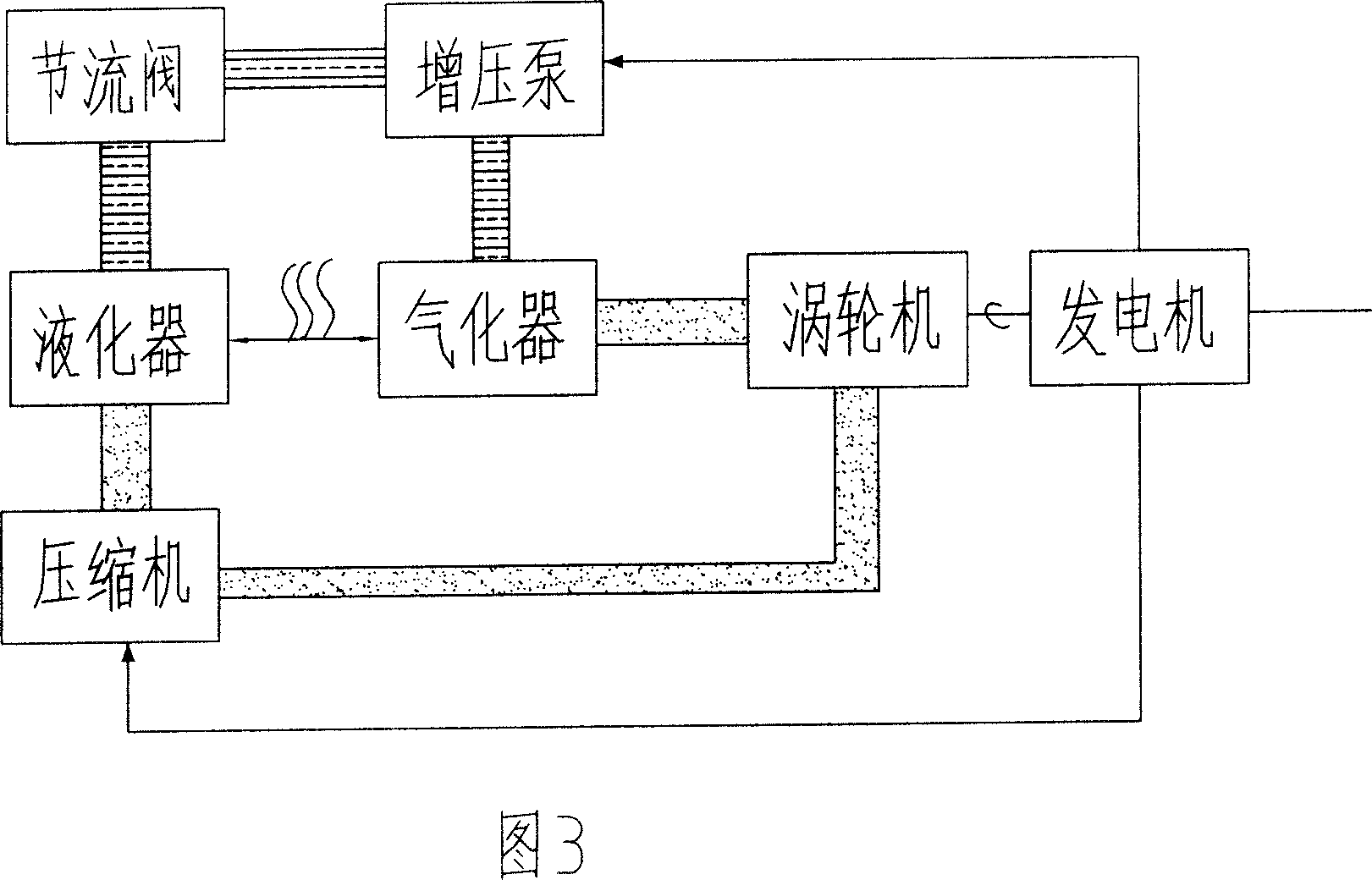

[0019] Embodiment 2 is a kind of internal exchange type single-cycle positive feedback heat pump power generation device (as shown in Figure 4) provided according to the system block diagram shown in Figure 3, which consists of a liquefier 1, a vaporizer 2, a compressor 3, a turbine 4. Generator 5, airtight valve 7, throttle valve 8, booster pump 11 constitute. This gasifier 2 is a container with a barrel structure with an external insulation layer 9, a liquid working medium 10 inside, and an air chamber and a high-speed air outlet. 4 is connected, the power output shaft of the turbine 4 is connected to the generator 5, and its exhaust gas outlet is connected to the compressor 3, and the high-temperature and high-pressure gas outlet of the compressor 3 is connected to the liquefier 1, and the liquefier 1 and the vaporizer 2 form a thermal Exchanger, liquefier 1 can be a spiral tube or a pipe with cooling fins, its main body is placed in the liquid working medium 10 of the vapo...

Embodiment 3

[0022] Embodiment 3 is an externally heated single-cycle positive feedback heat pump power generation device (as shown in FIG. 5 ) according to the system structure shown in FIG. 3 . The difference from Example 1 is that, in addition to a liquefier 1, a vaporizer 2, a compressor 3, a turbine 4, a generator 5, an airtight valve 7, a throttle valve 8, and a booster pump 11, it also has a heating Chamber 12, the heating chamber 12 has a special-shaped tubular structure, one end of which is connected to the exhaust port of the gasifier 2, and the other end is connected to the turbine 4, and the main part of the liquefier 1 is wound around the casing of the heating chamber 12 in the form of a coil Outside, it forms a heat exchanger with the heating chamber 12, and the output port of the normal temperature liquid working medium of the liquefier 1 is connected with the vaporizer 2 through the pipeline and the throttle valve 8 and the booster pump 11 installed on it.

[0023] Working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com