Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3861results about "Solid fuel combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

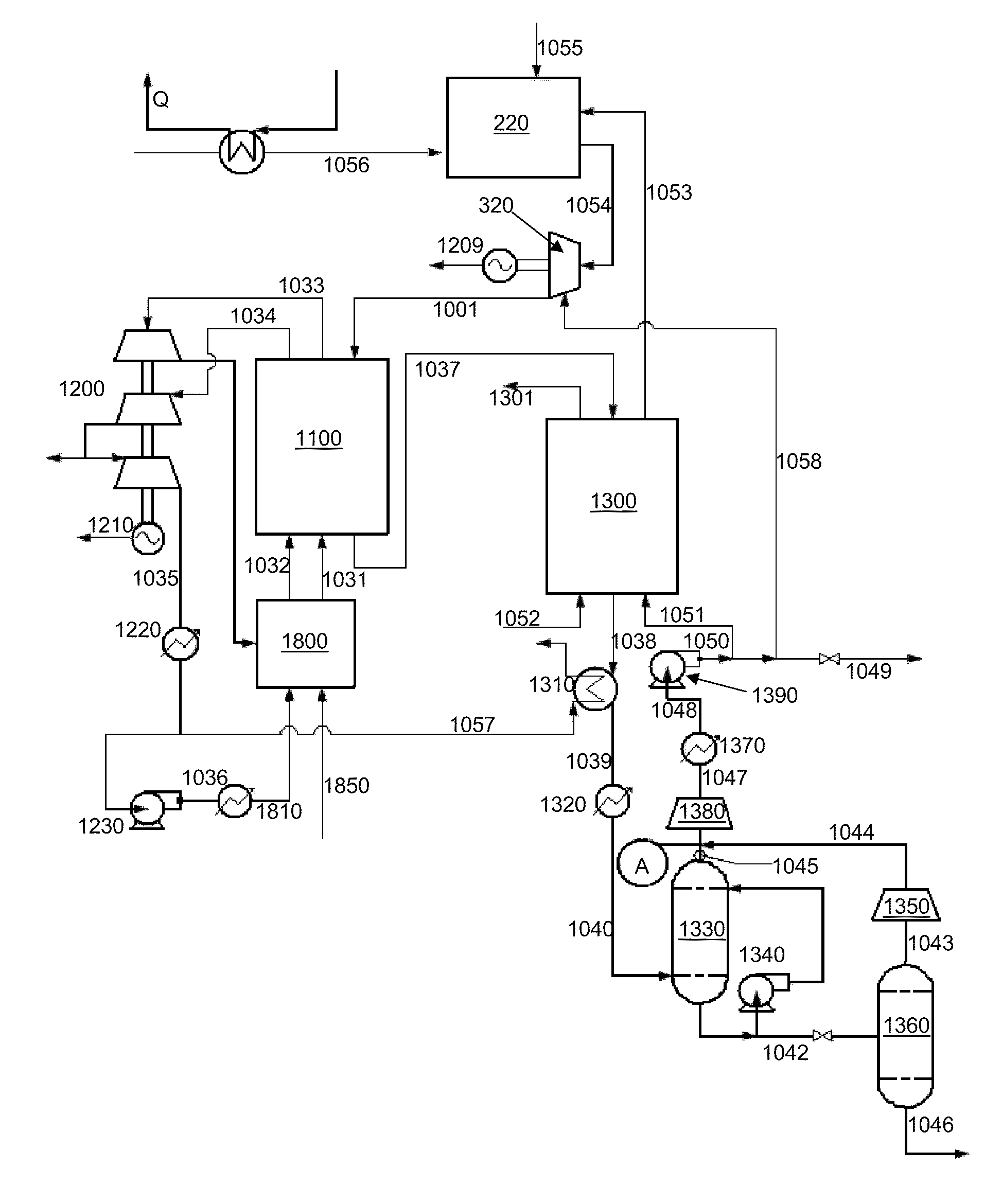

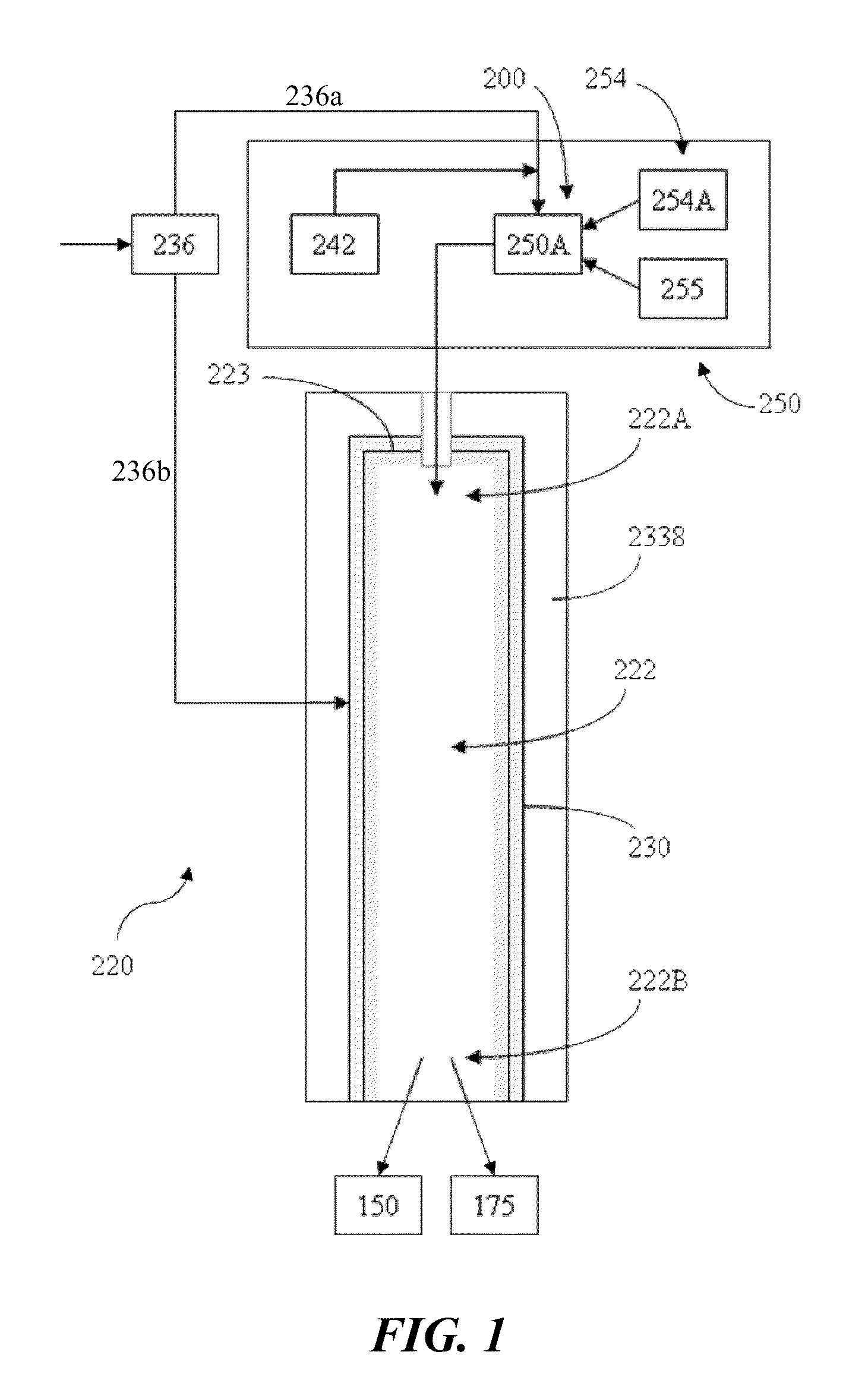

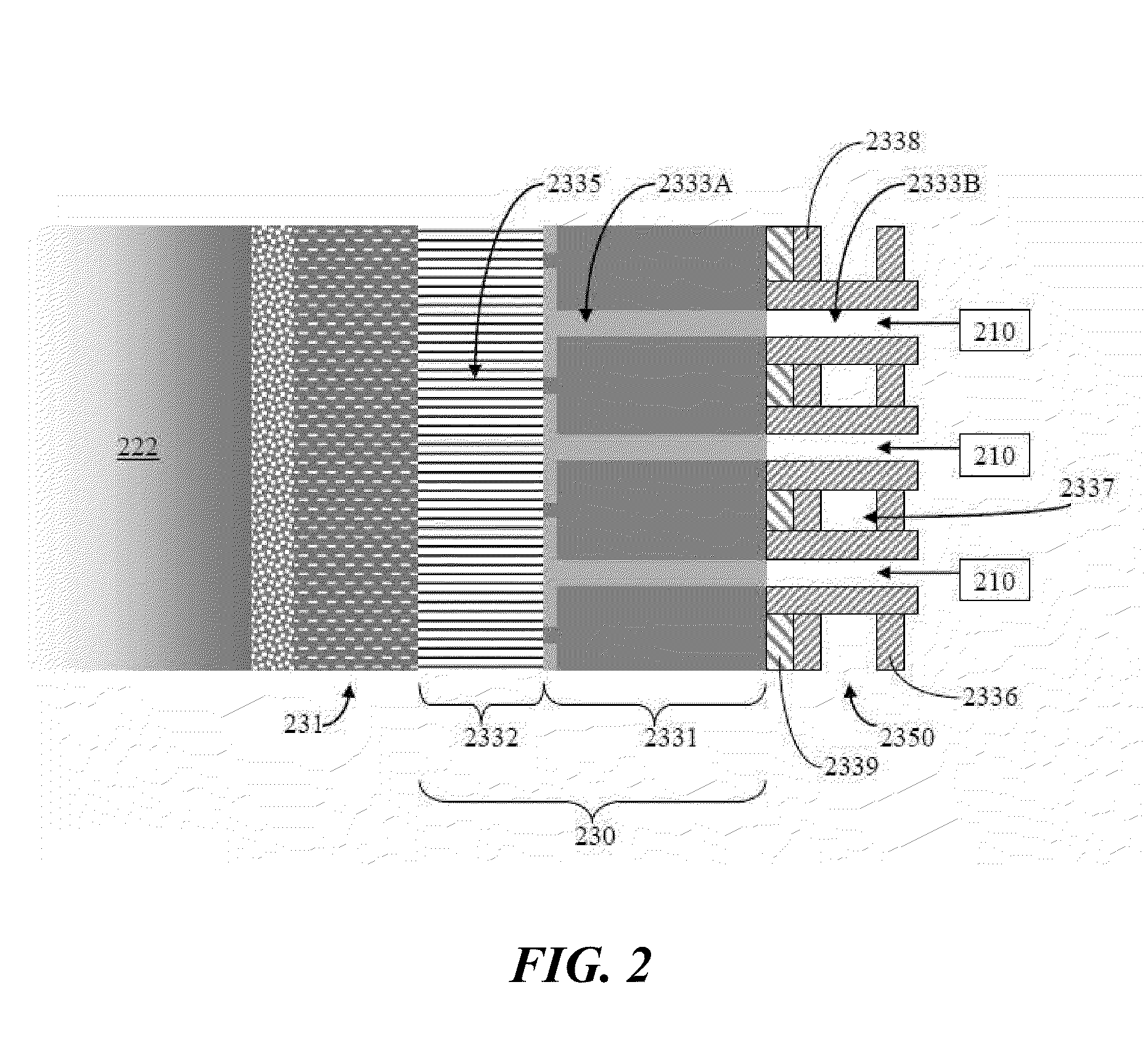

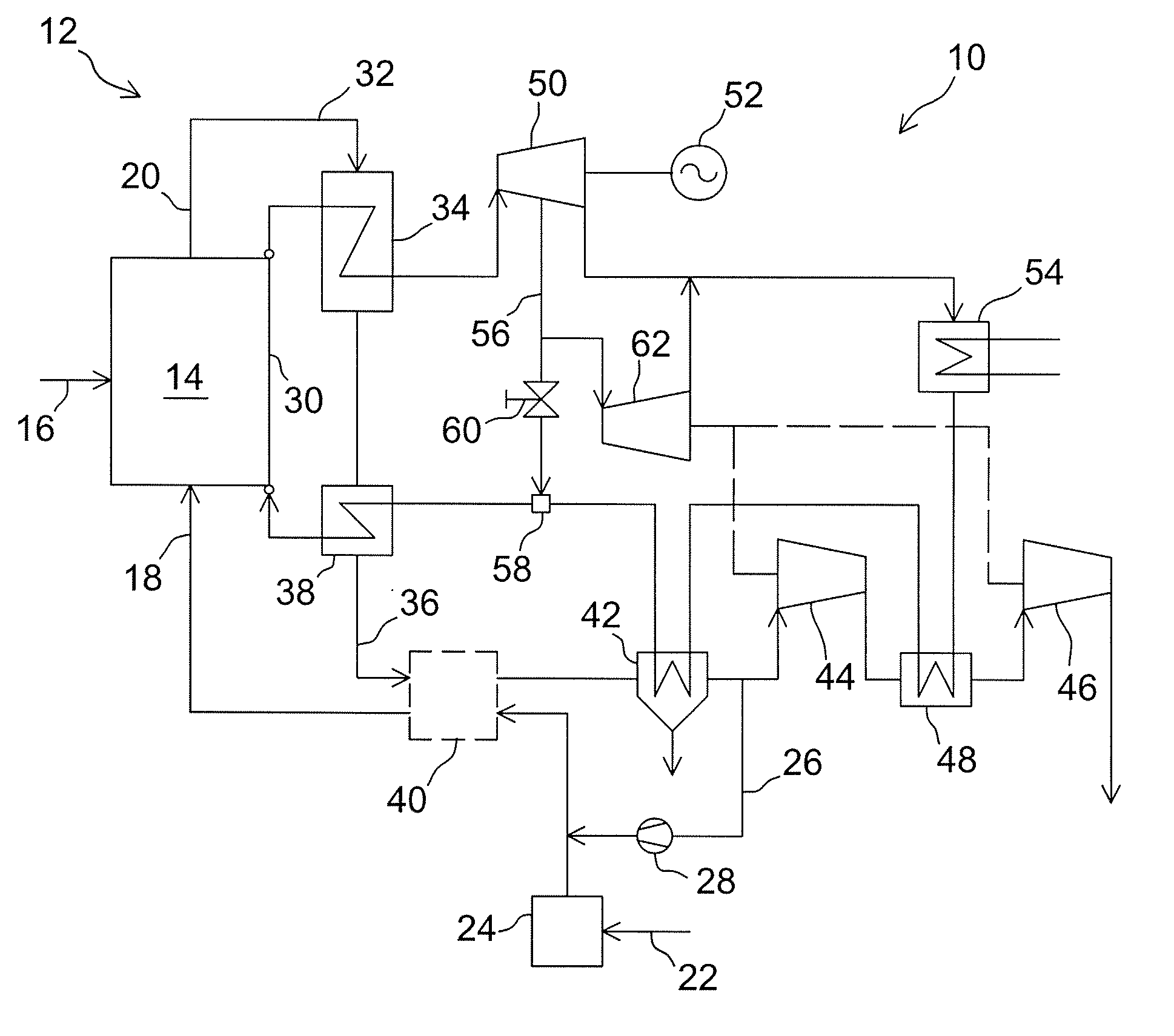

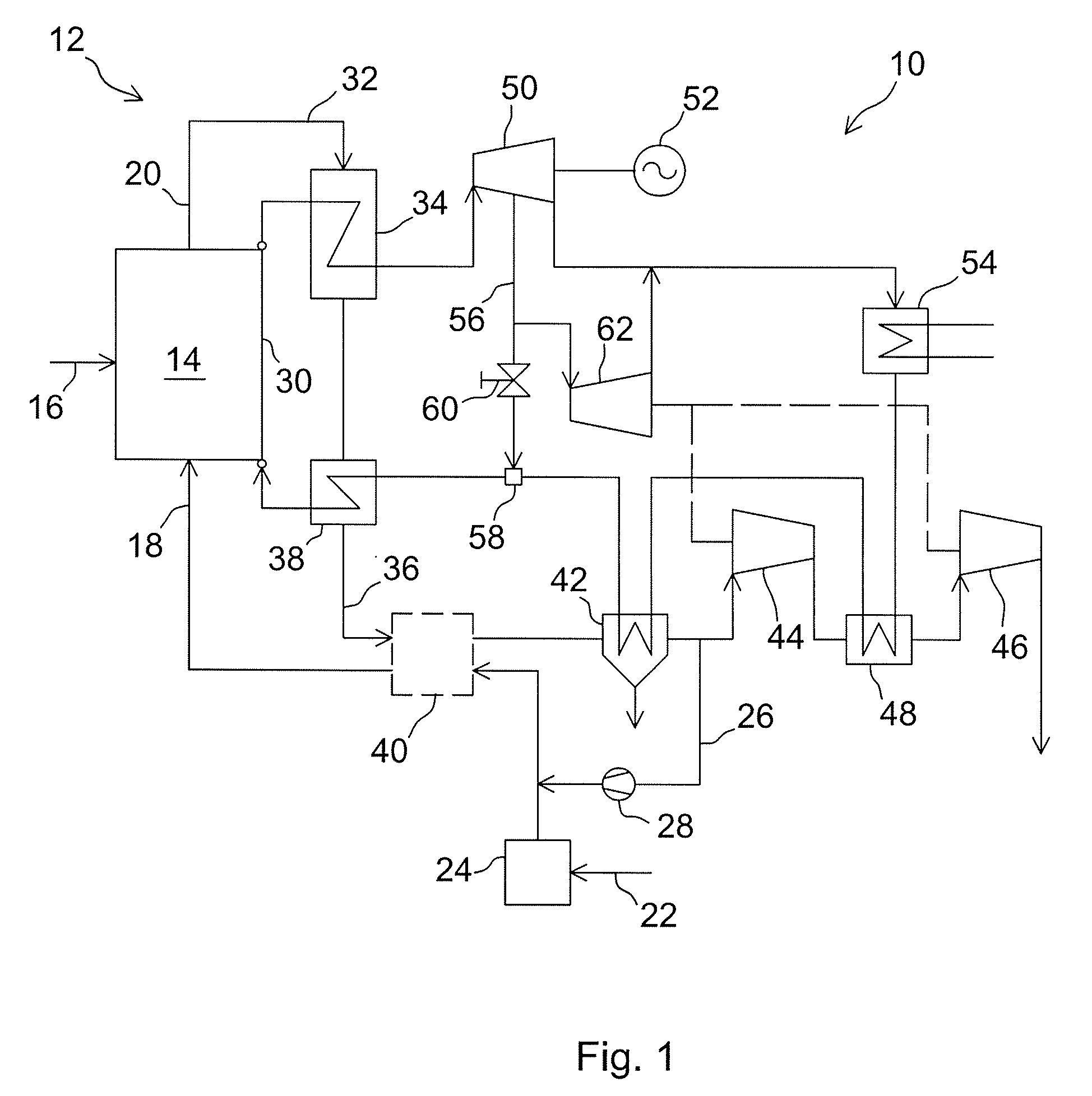

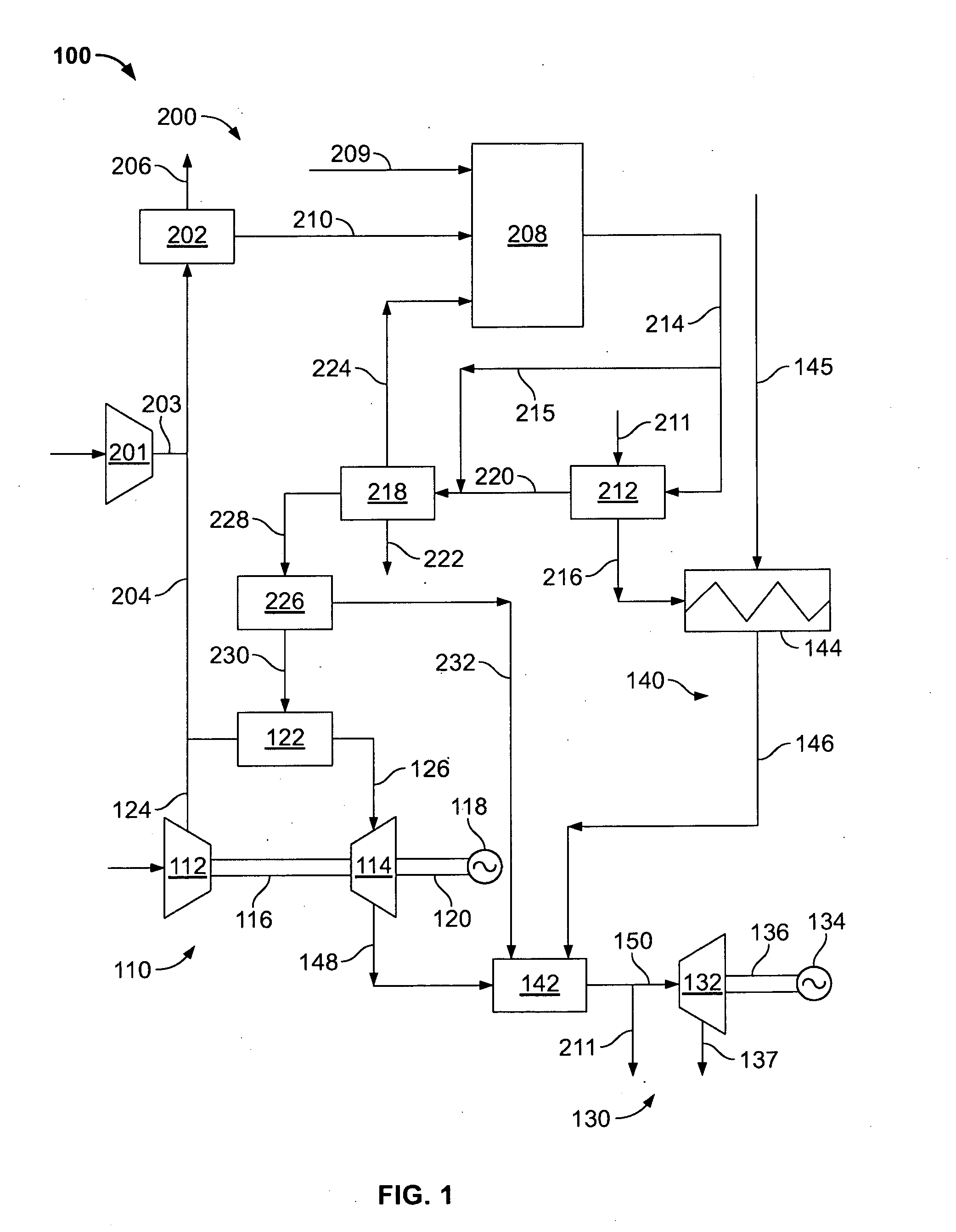

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

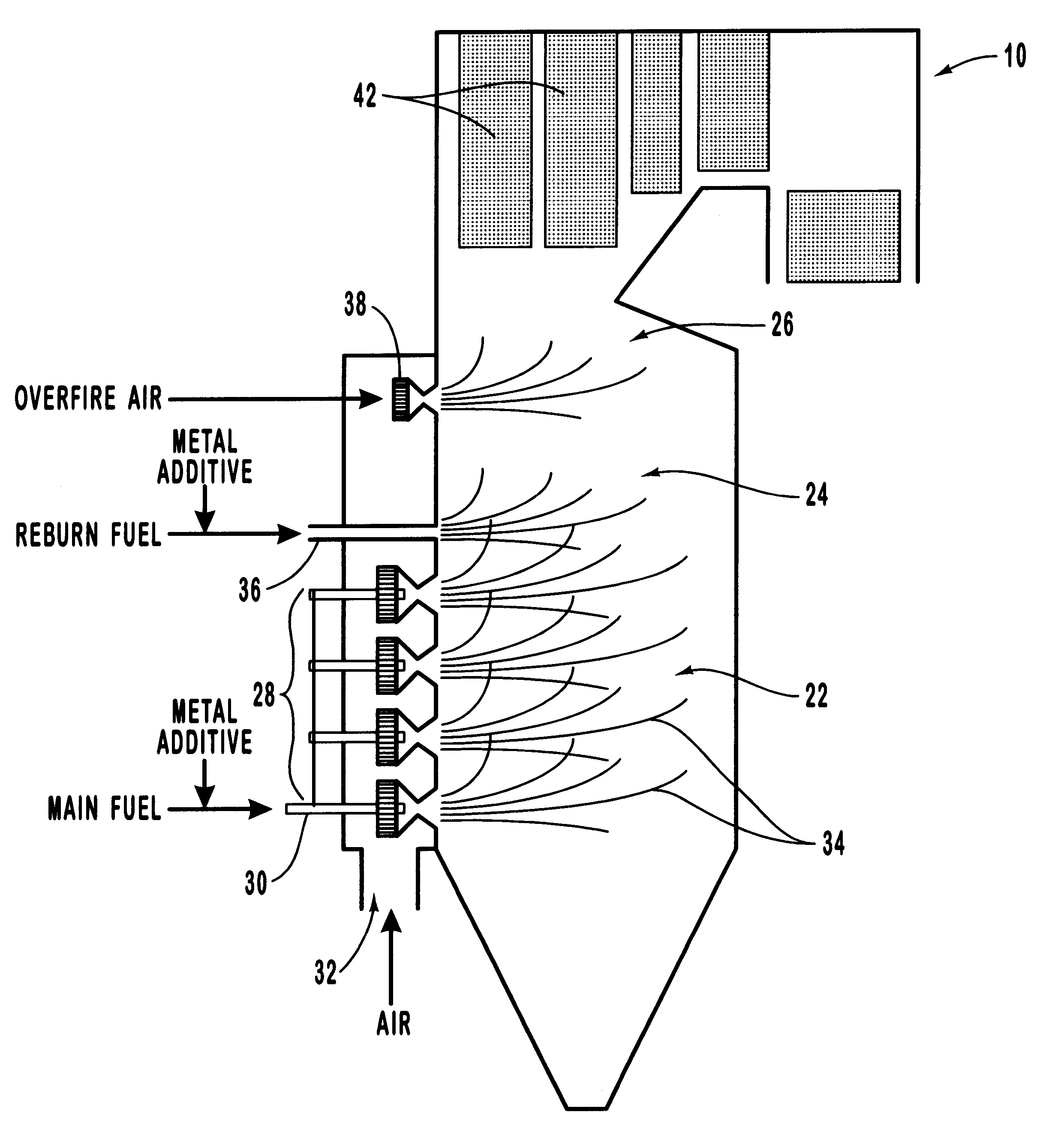

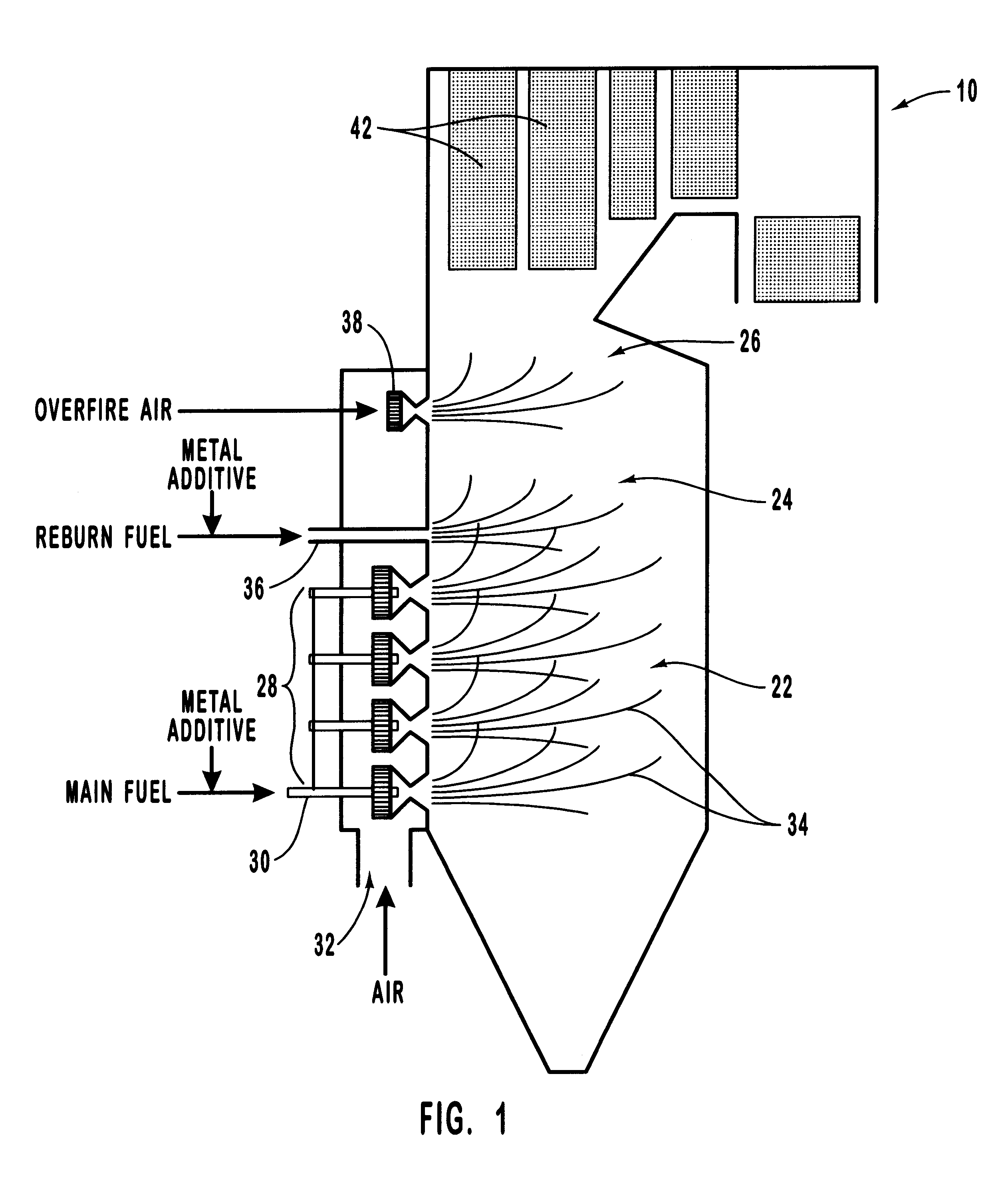

Method for reducing NOX in combustion flue gas using metal-containing additives

InactiveUS6206685B1Improved control deviceSure easyDispersed particle separationSolid fuel combustionAtmospheric airNitric oxide

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

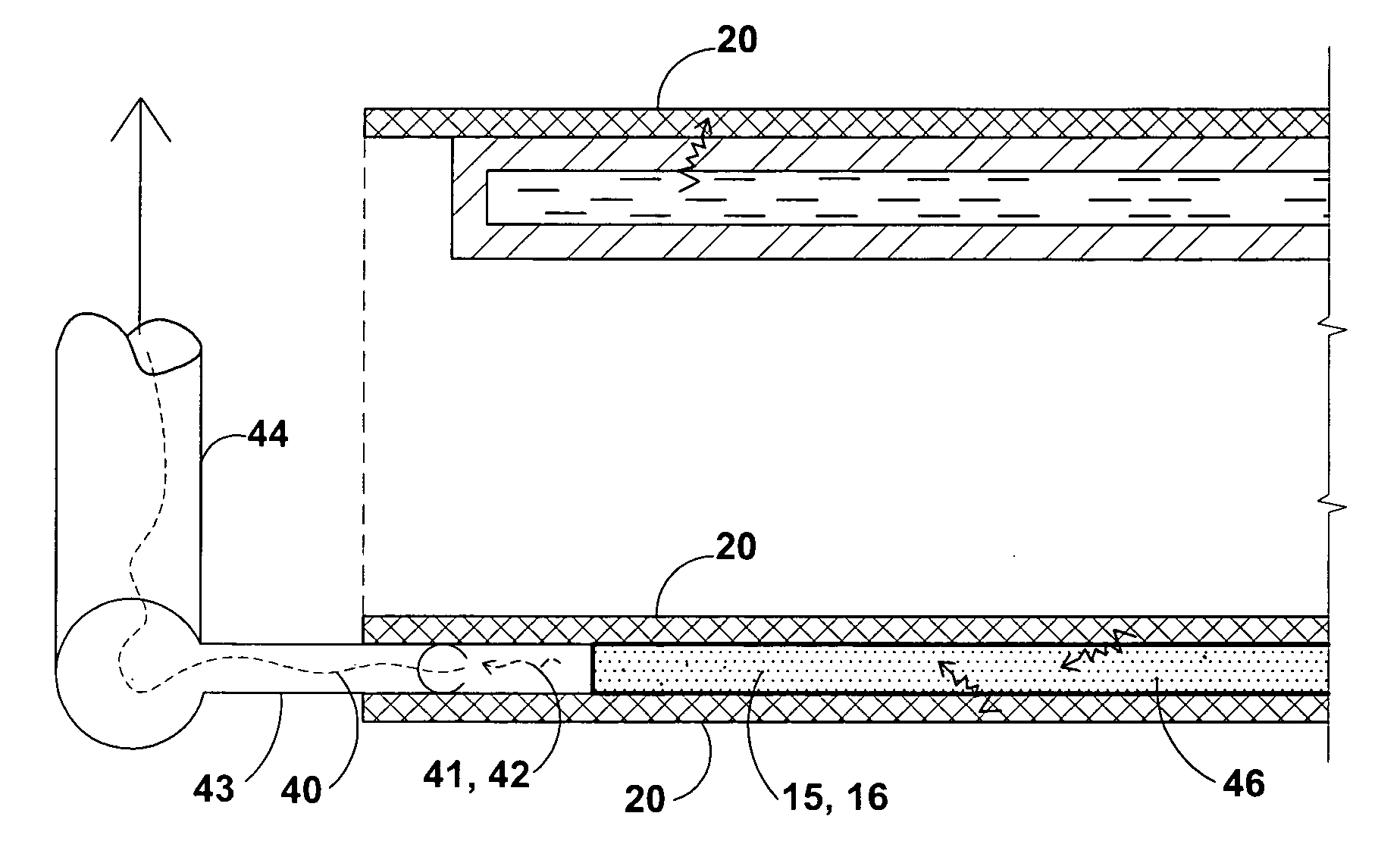

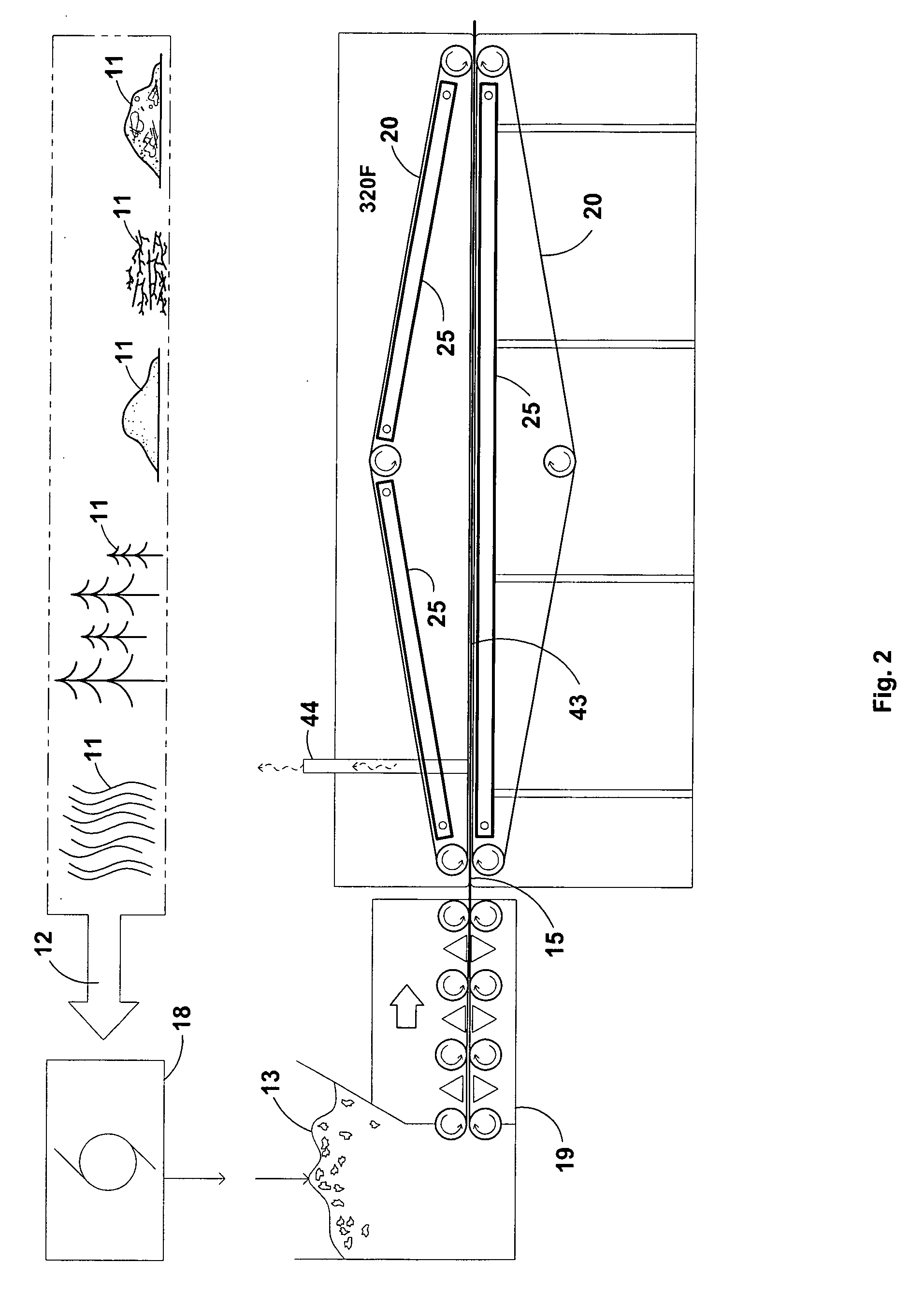

Method and apparatus for biomass torrefaction using conduction heating

InactiveUS20080223269A1Reduce air pollutionEasy to storeDrying solid materials with heatBiofuelsThermal contactConveyor belt

A method for torrefaction of wood which includes providing a first endless conveyor belt; heating the first endless belt; and positioning a planar wood product on the first belt to heat the wood product by conduction to achieve torrefaction. Other forms provide a second endless belt that disposed in sandwich relation to wood to be torrefied. Some embodiments of the method provide a metal chamber having opposed planar sides dimensioned and configured for receiving a wood sheet with the respective opposed sides of the wood sheet in intimate thermal contact with respective opposed sides of the metal chamber. Other embodiments include the apparatus for torrefaction of an associated wood sheet.

Owner:PAOLUCCIO JOHN A

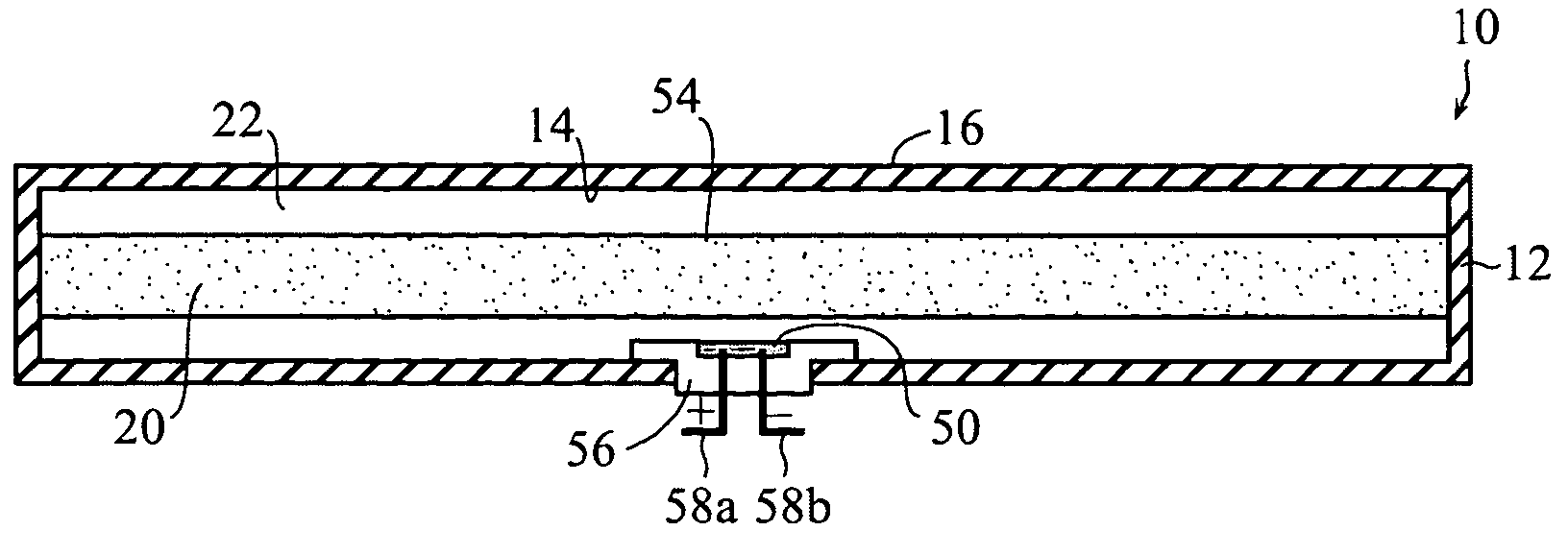

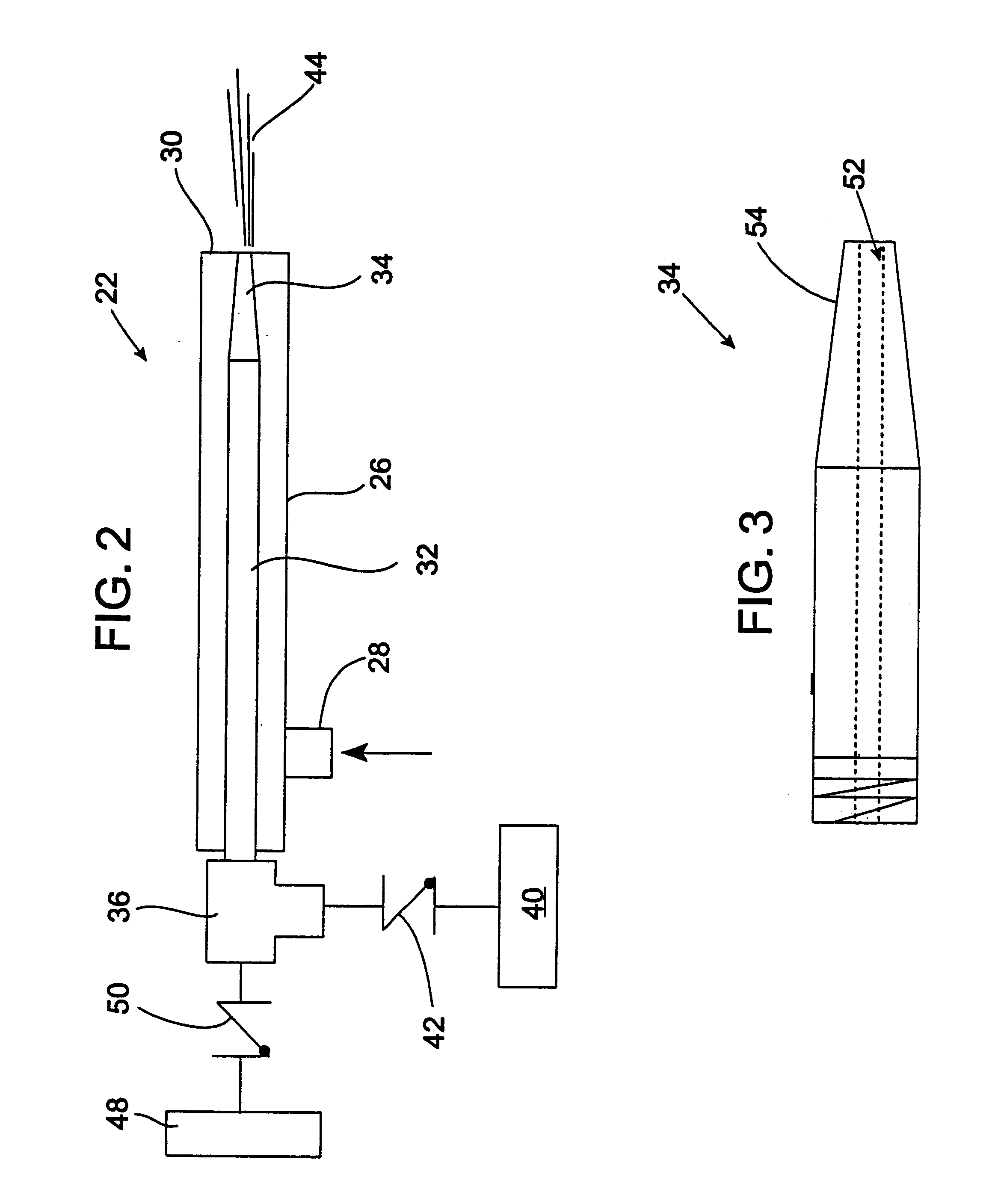

Self-contained heating unit and drug-supply unit employing same

InactiveUS20050079166A1Exothermal chemical reaction heat productionSemiconductor/solid-state device manufacturingSolid fuelEngineering

Heating units, drug supply units and drug delivery articles capable of rapid heating are disclosed. Heating units comprising a substrate and a solid fuel capable of undergoing an exothermic metal oxidation reaction disposed within the substrate are disclosed. Drug supply units and drug delivery articles wherein a solid fuel is configured to heat a substrate to a temperature sufficient to rapidly thermally vaporize a drug disposed thereon are also disclosed.

Owner:ALEXZA PHARMA INC

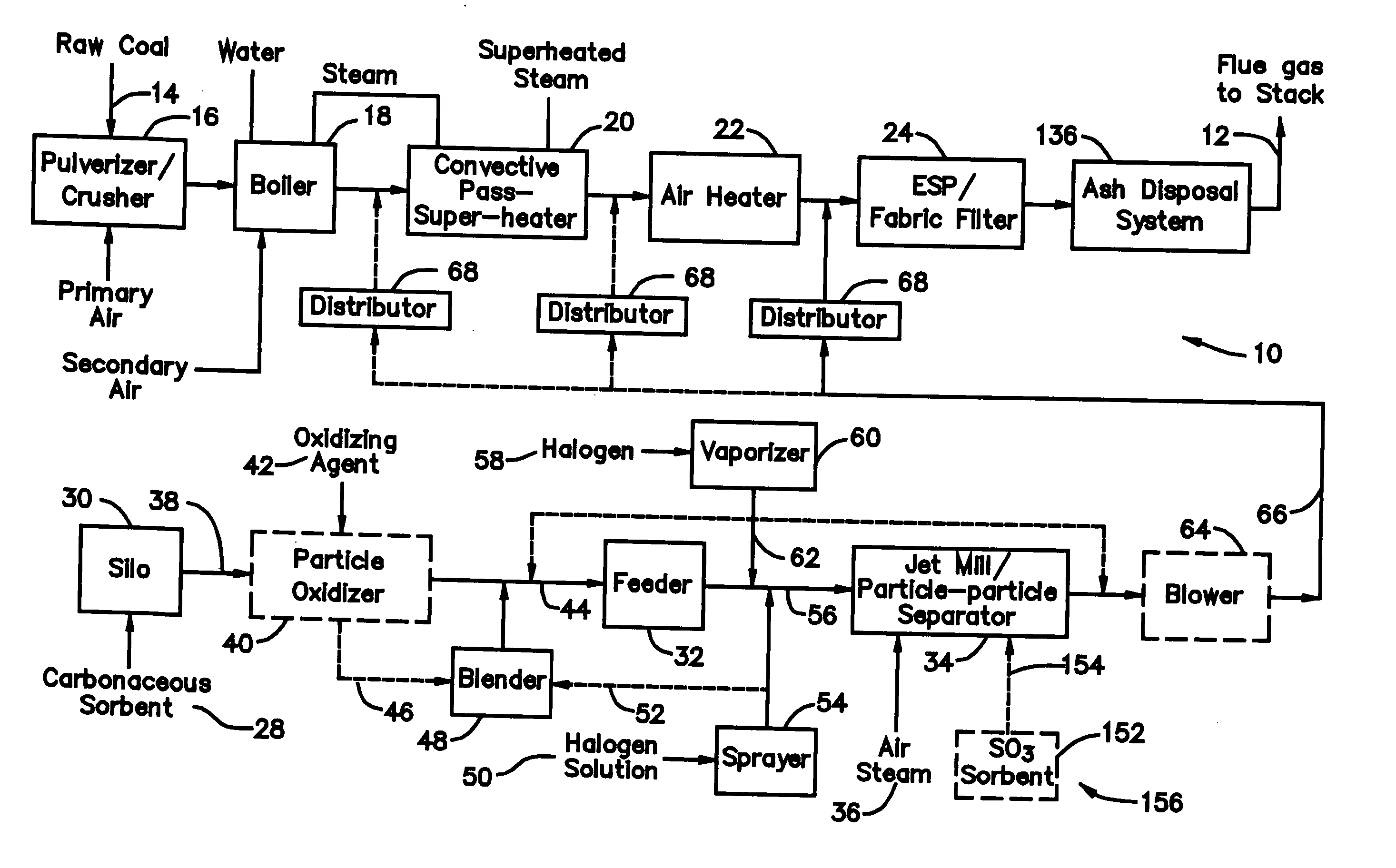

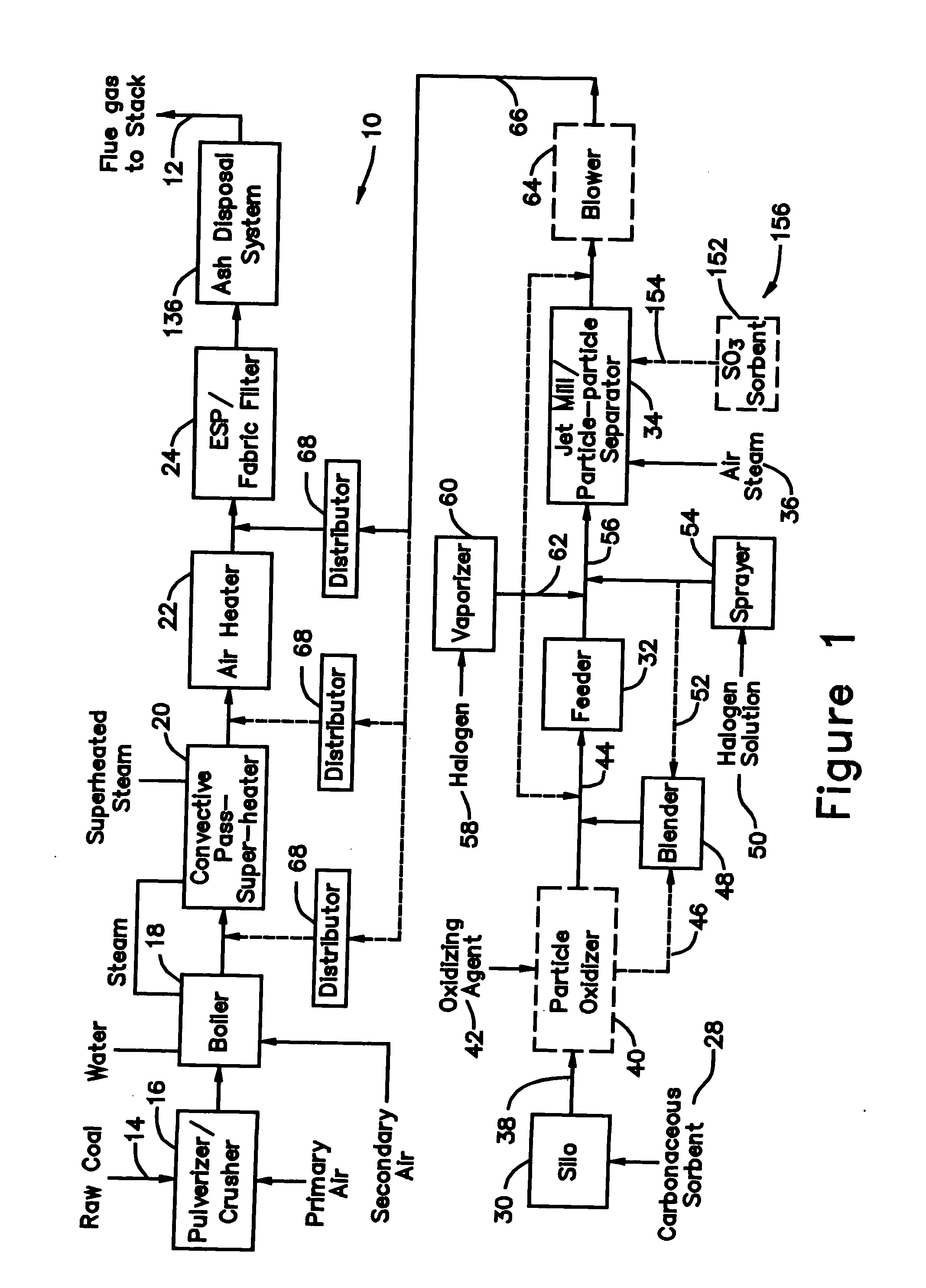

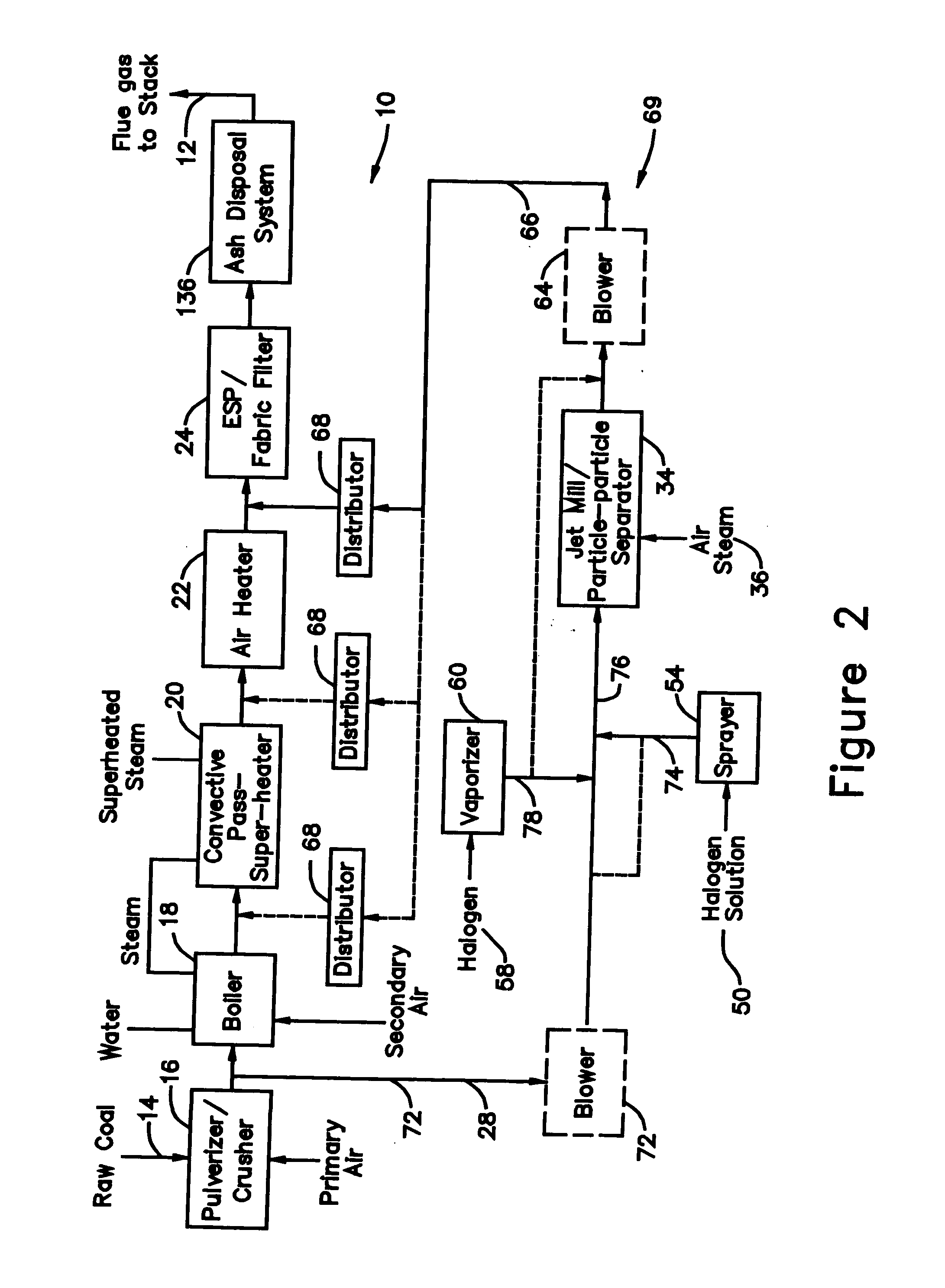

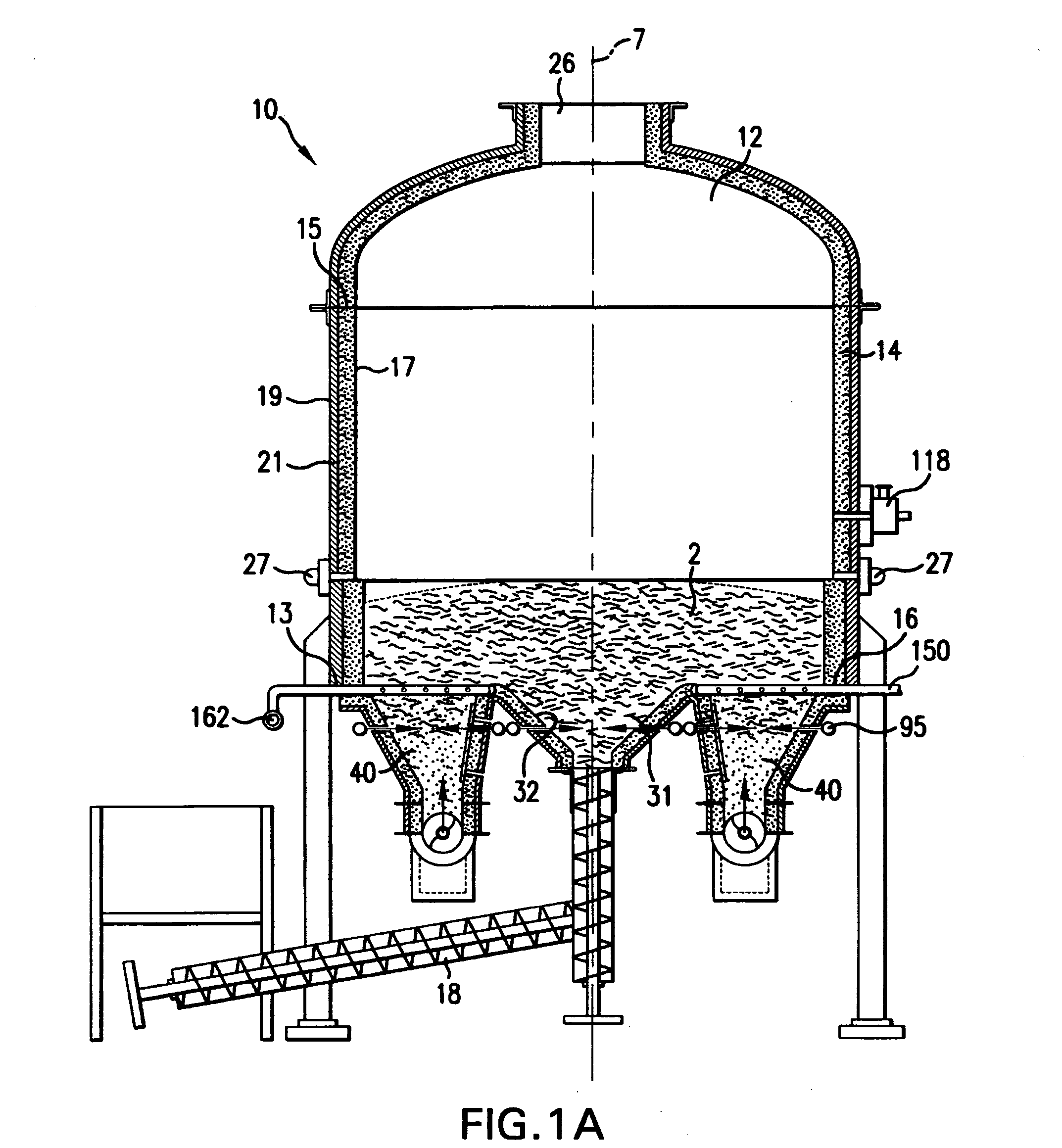

Control of mercury emissions from solid fuel combustion

ActiveUS20050039598A1Remove pollutantsEasy to captureGas treatmentEmission preventionSorbentSolid fuel

A system 26 for removing elemental mercury or mercury compounds handles carbonaceous sorbent 28 of a starter batch stored in a silo 30 in an agglomerated state. The sorbent 28 is fed by a feeder 32 to a separation device 34, which comminutes (if necessary) and de-agglomerates the sorbent particles 28 to their primary size distribution. This device 34 may be a particle-particle separator or a jet mill, where compressed air or high-pressure steam is the energy source. The de-agglomerated sorbent 28 of a contact batch created from the starter batch is conveyed by an airsteam for injection at a contact location 66 in a flue gas duct whereat carbonaceous sorbent of the contact batch adsorbs mercury from the flue gas.

Owner:GENERAL ELECTRIC TECH GMBH

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

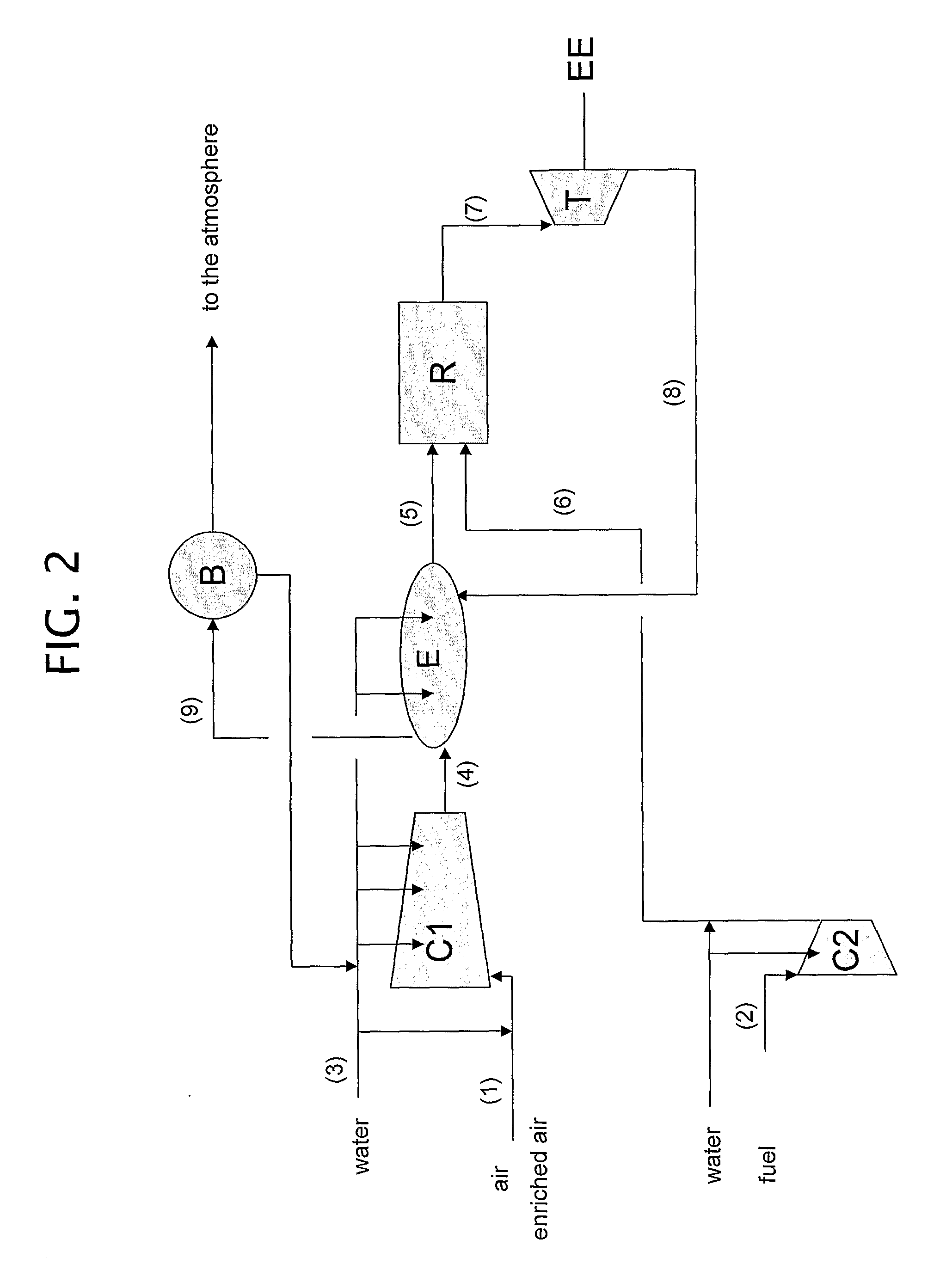

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

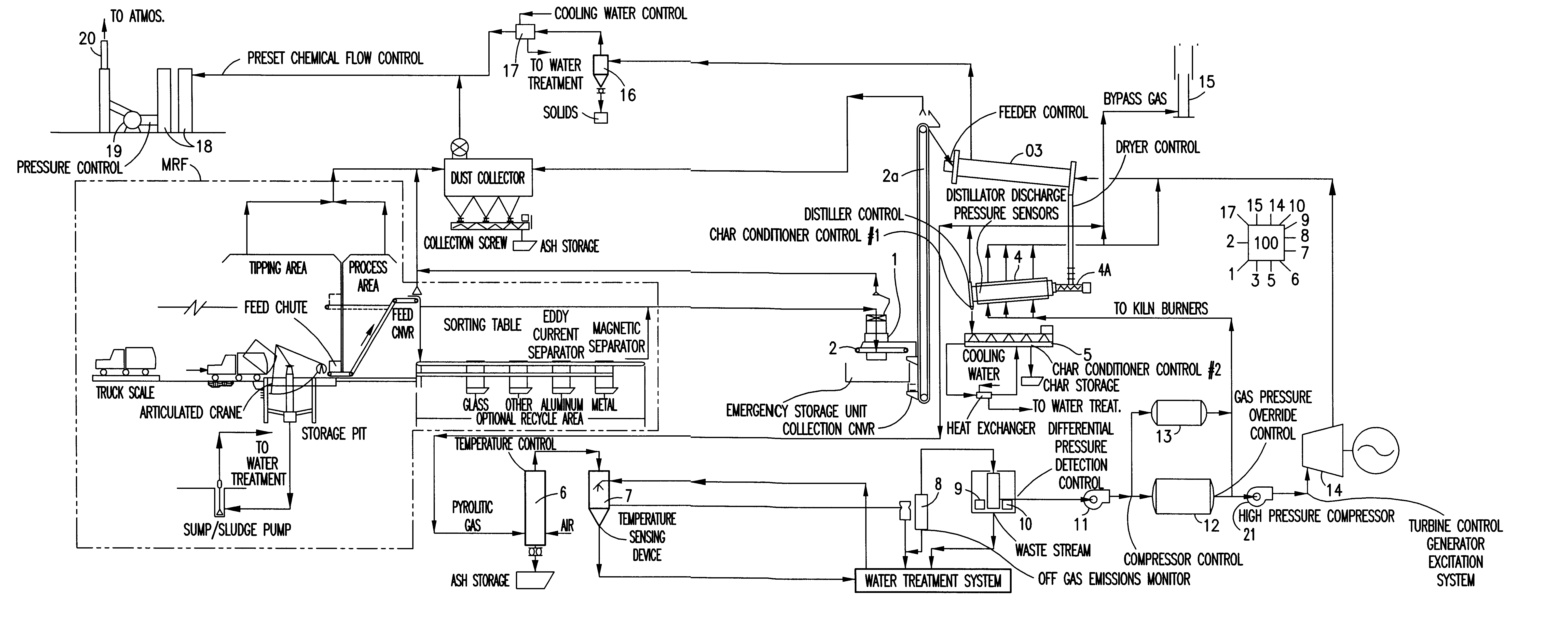

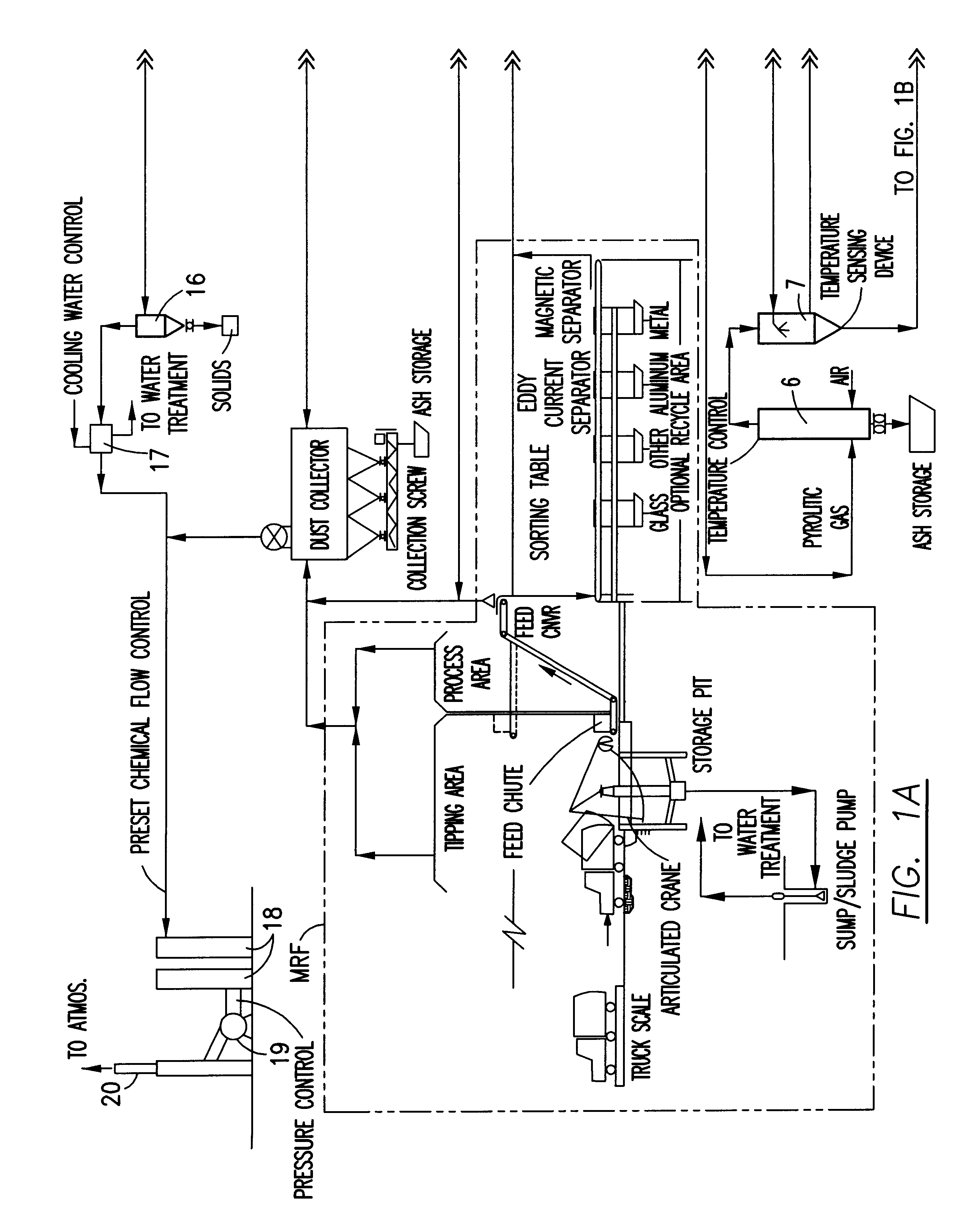

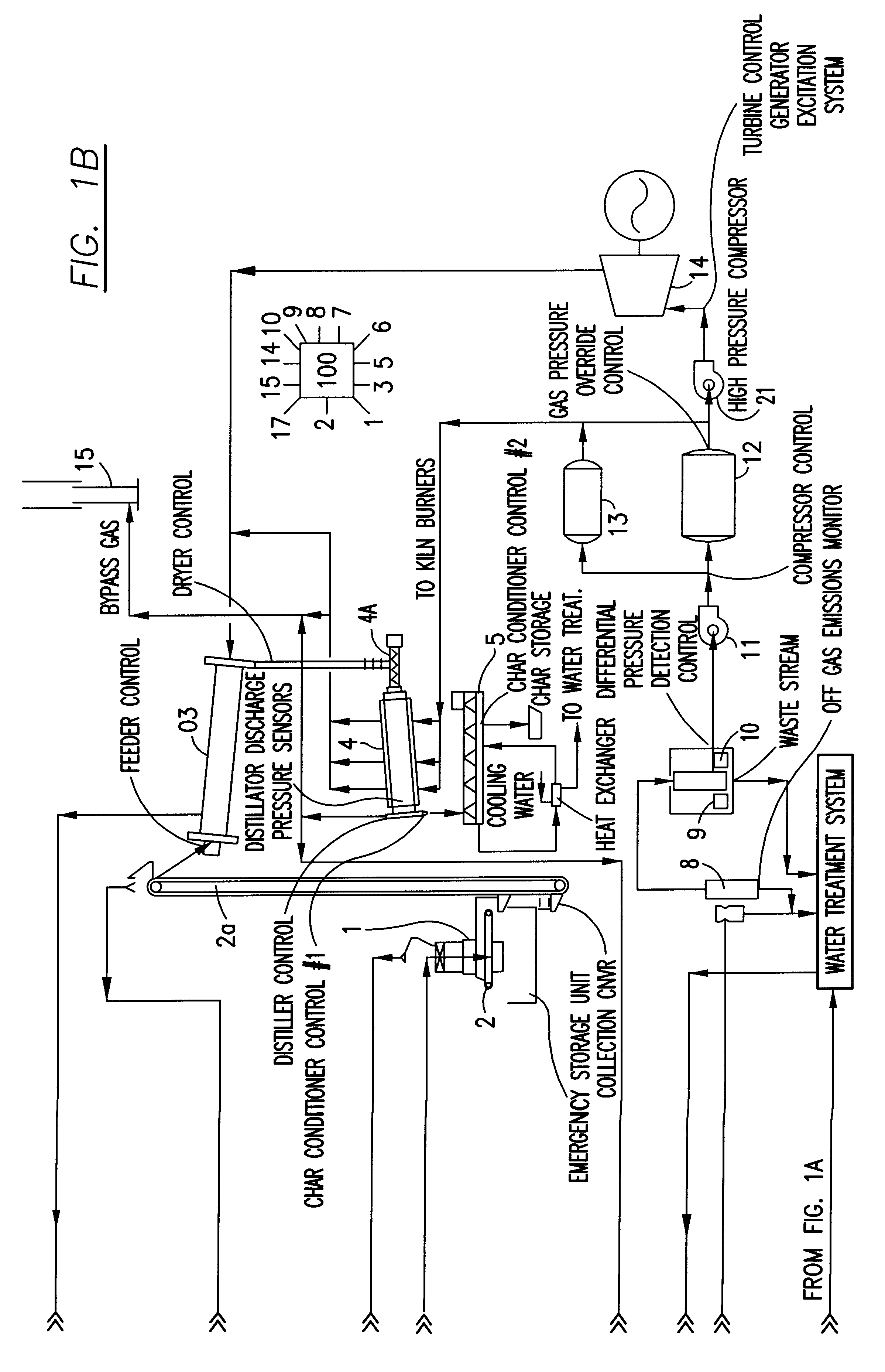

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

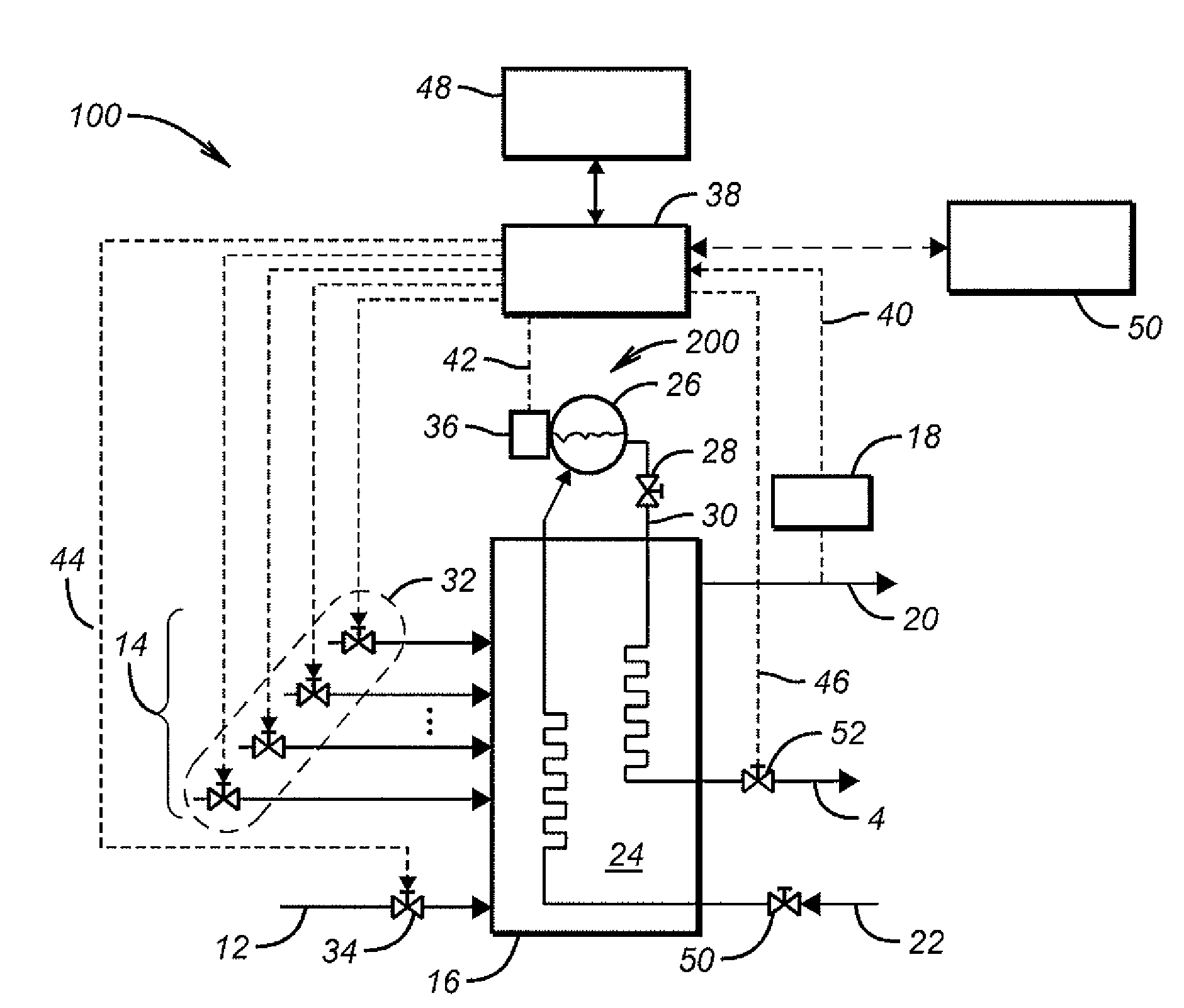

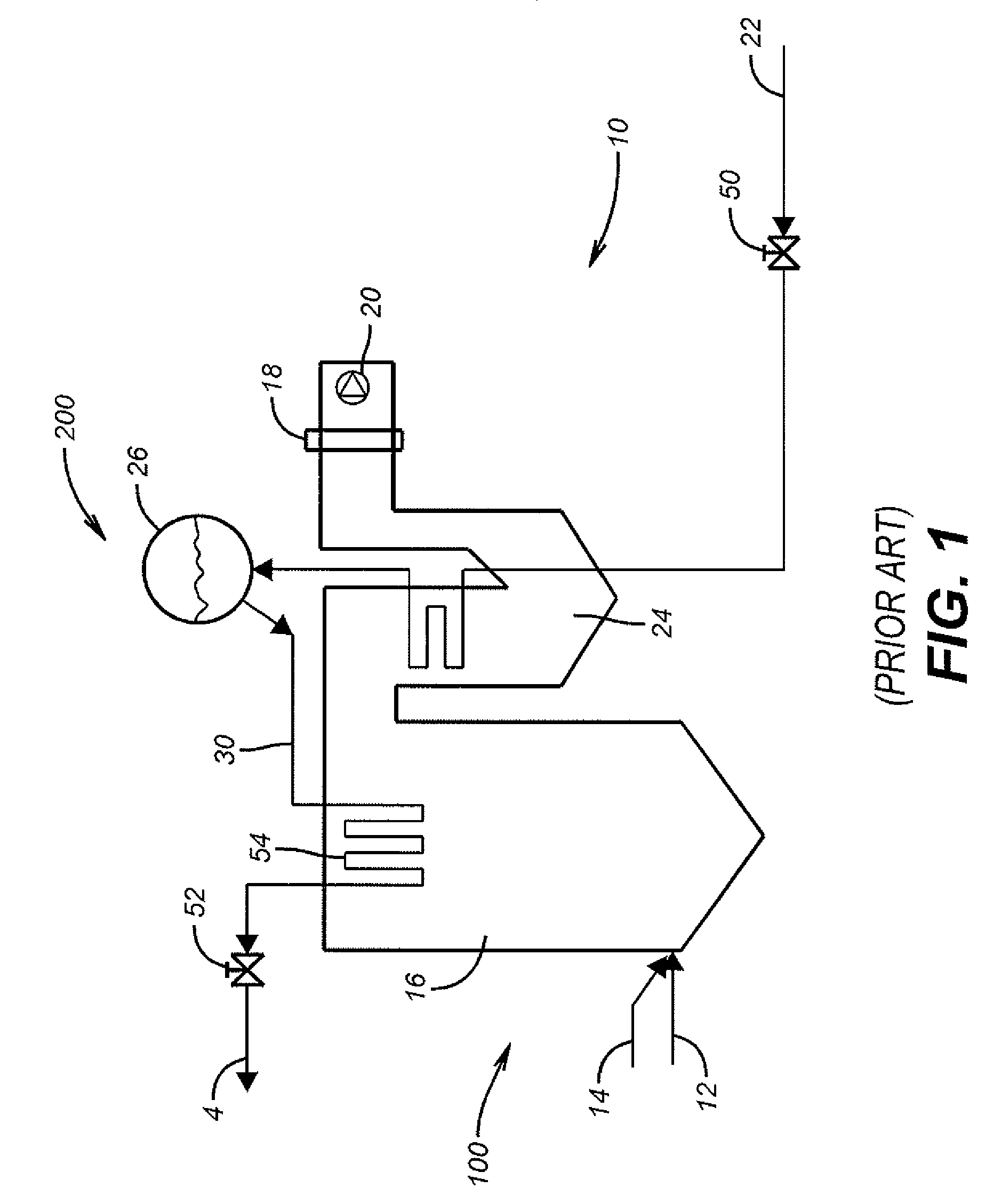

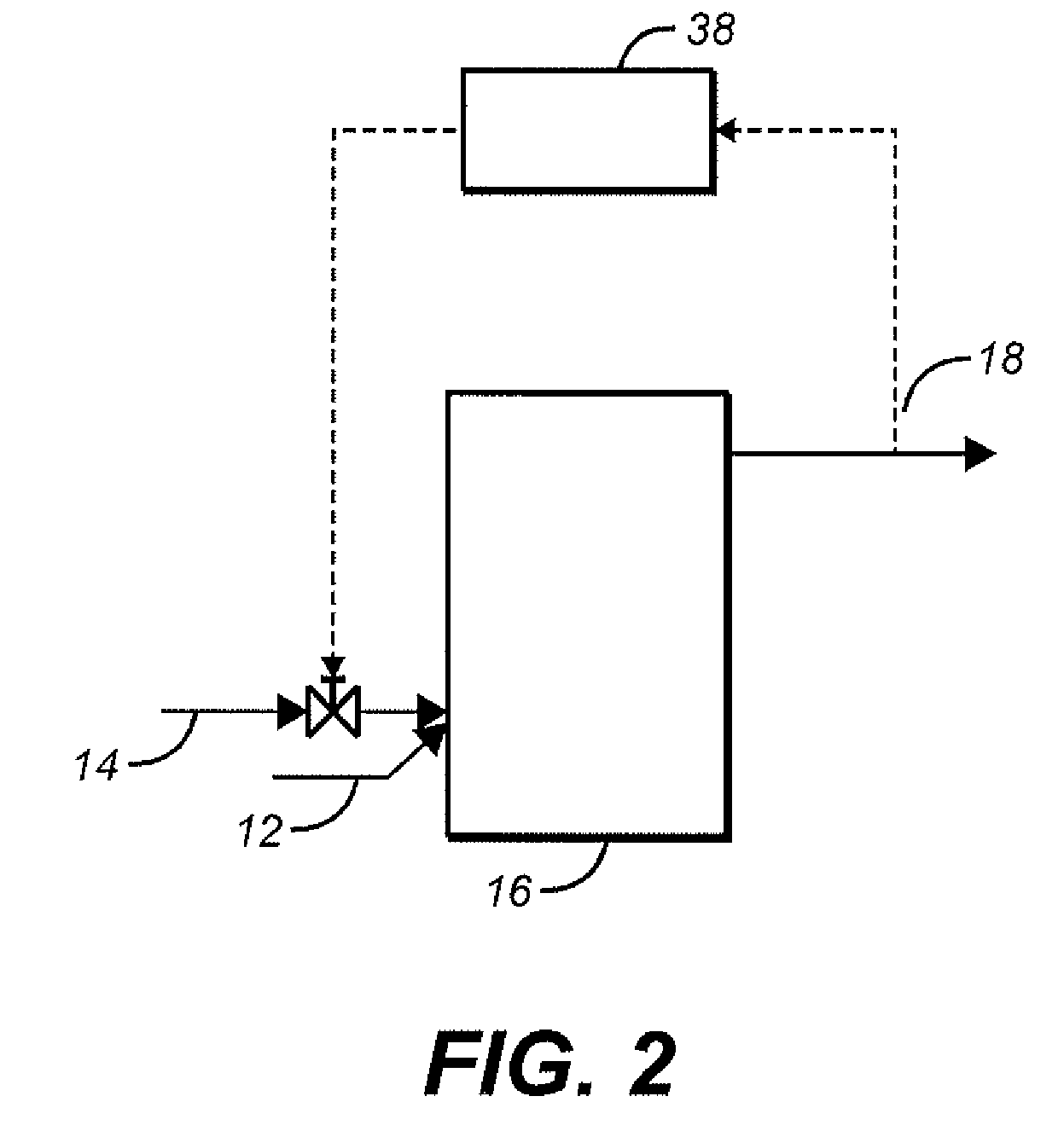

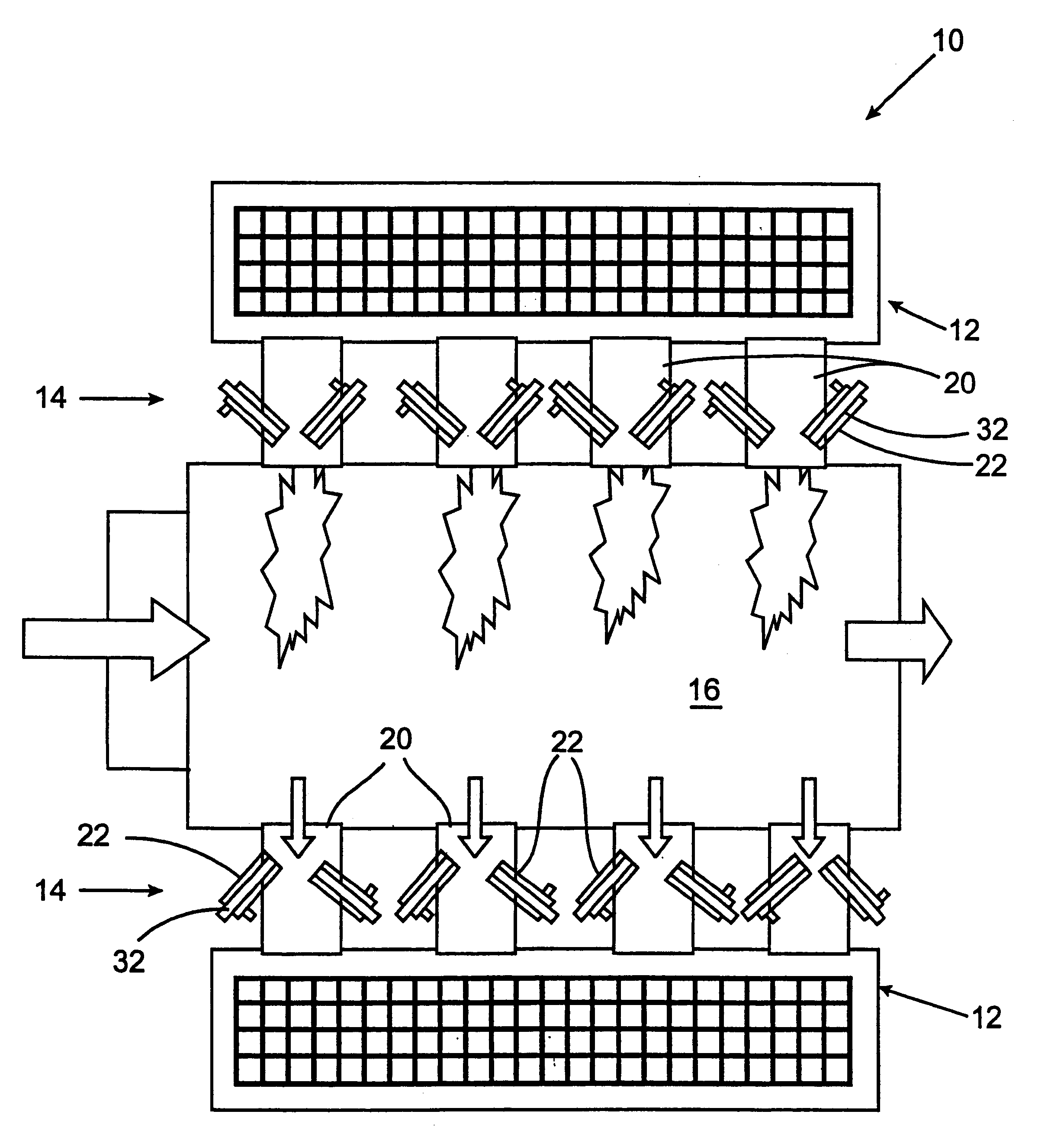

Real time optimization and control of oxygen enhanced boilers

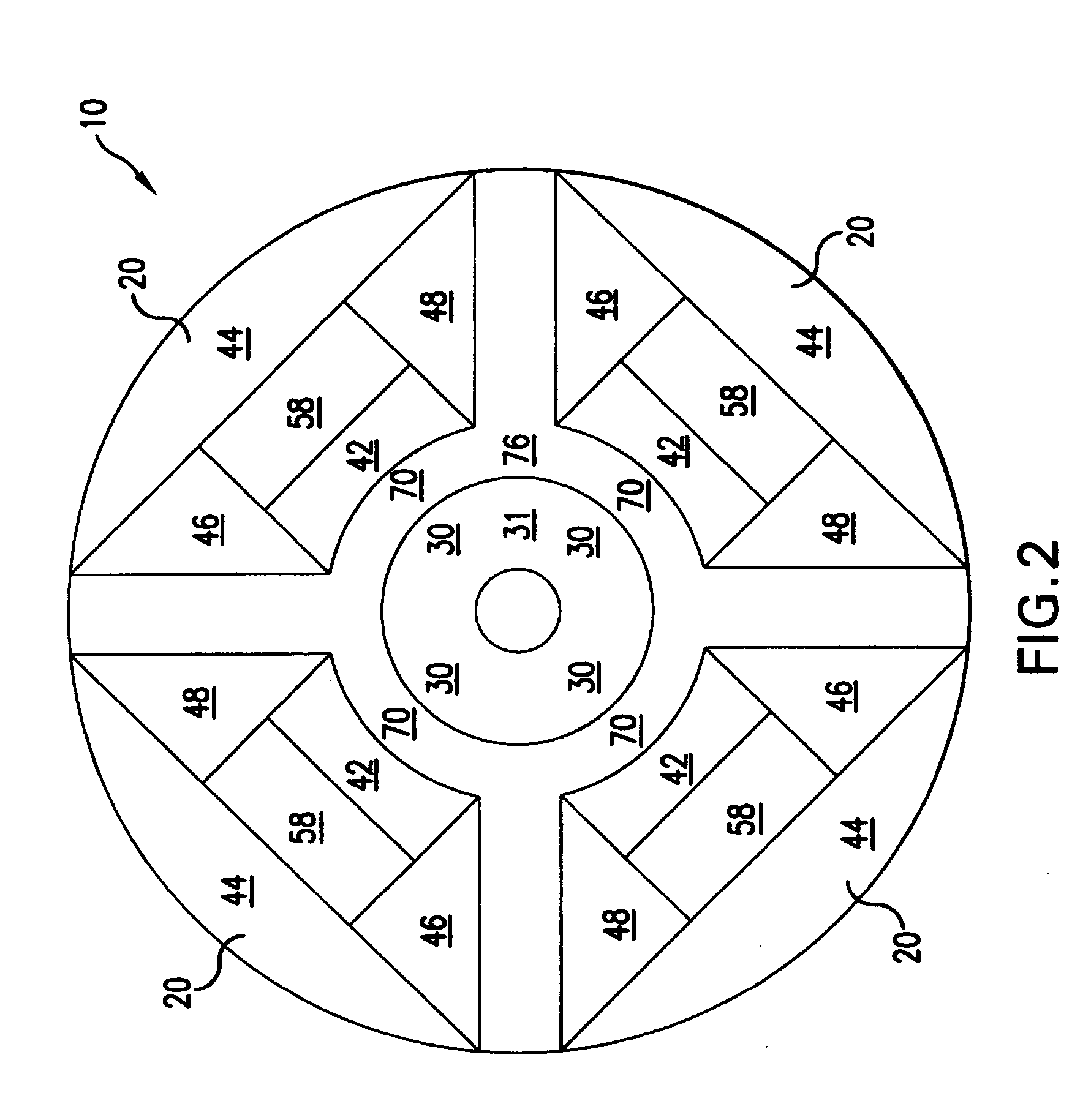

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

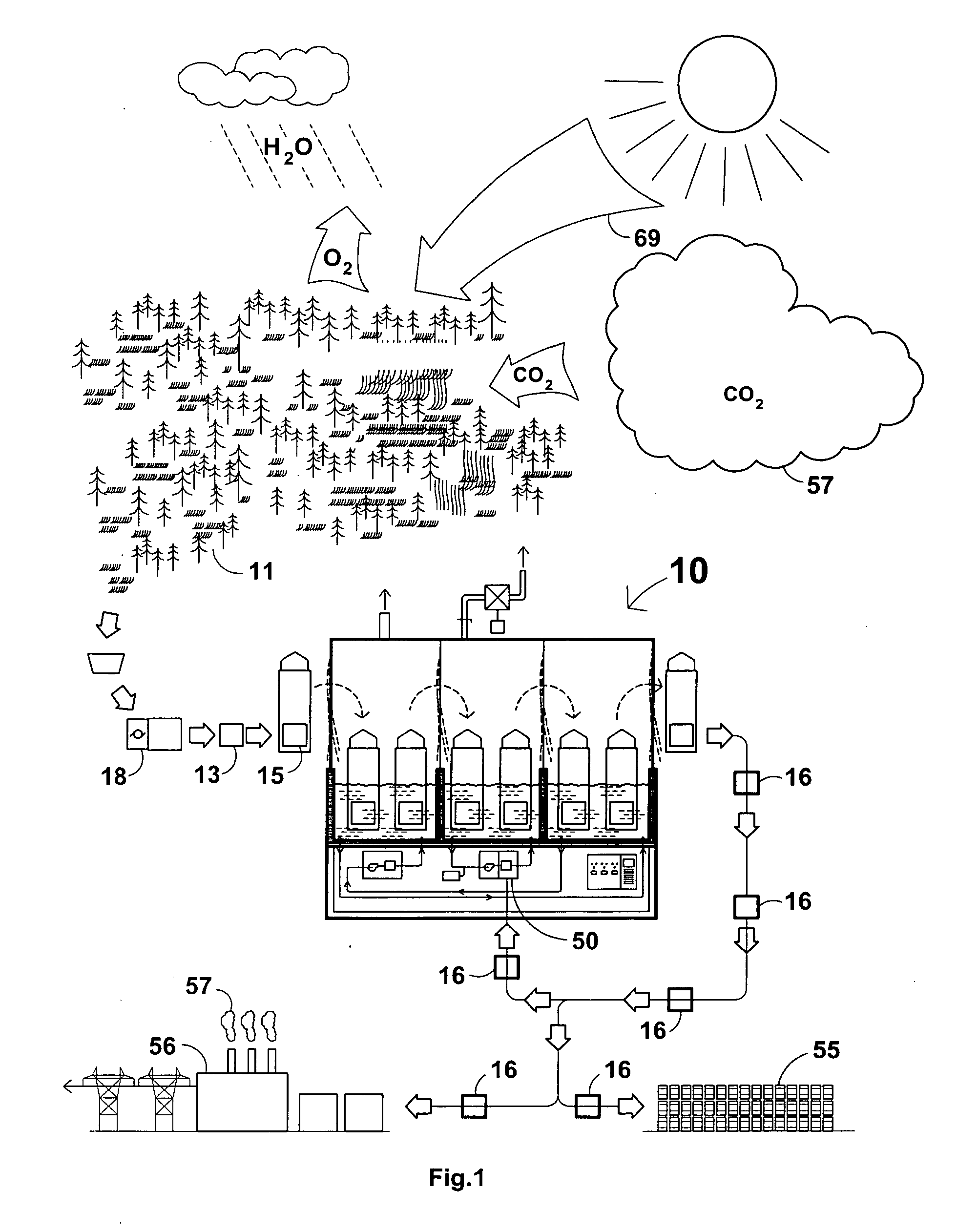

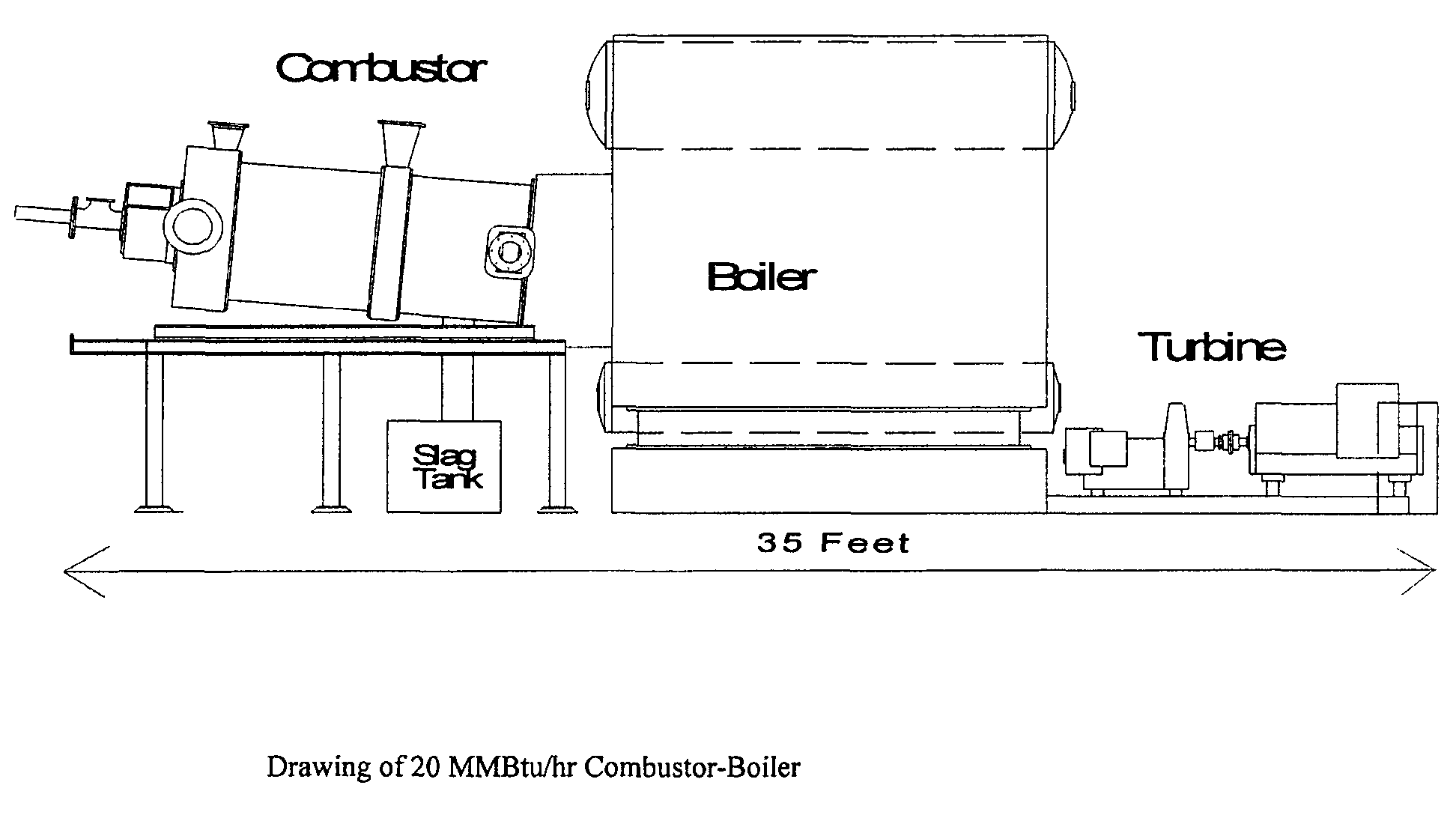

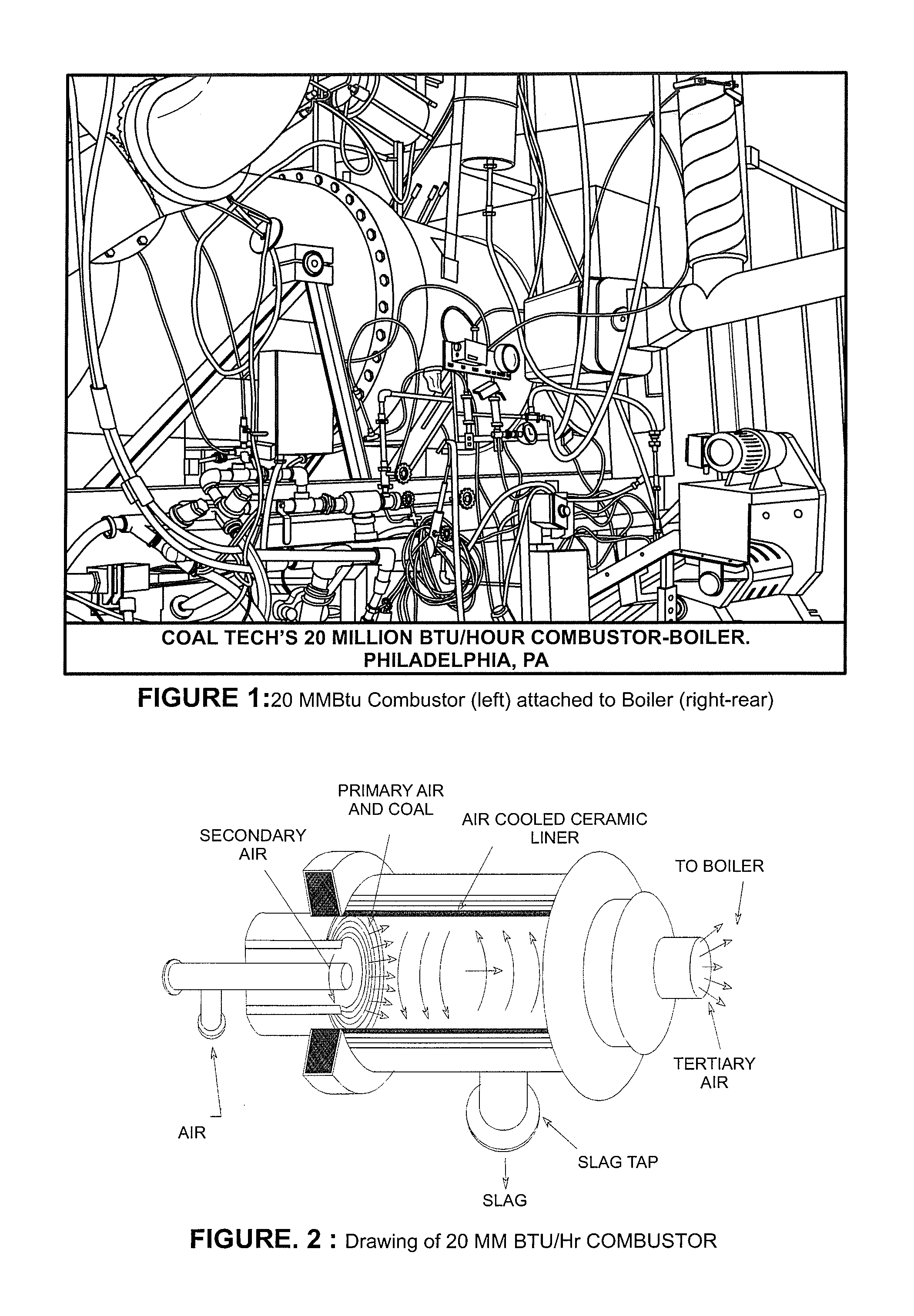

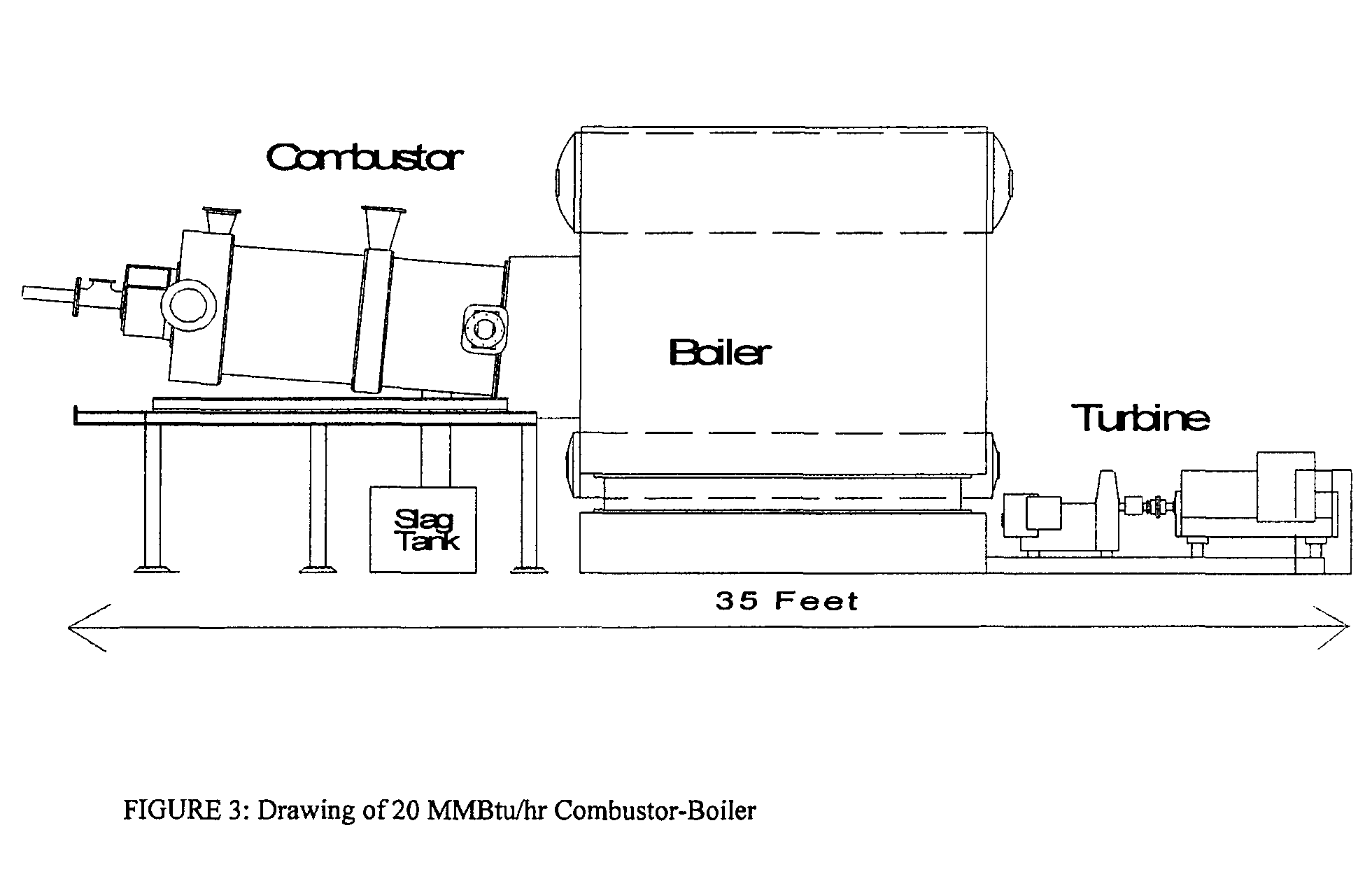

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

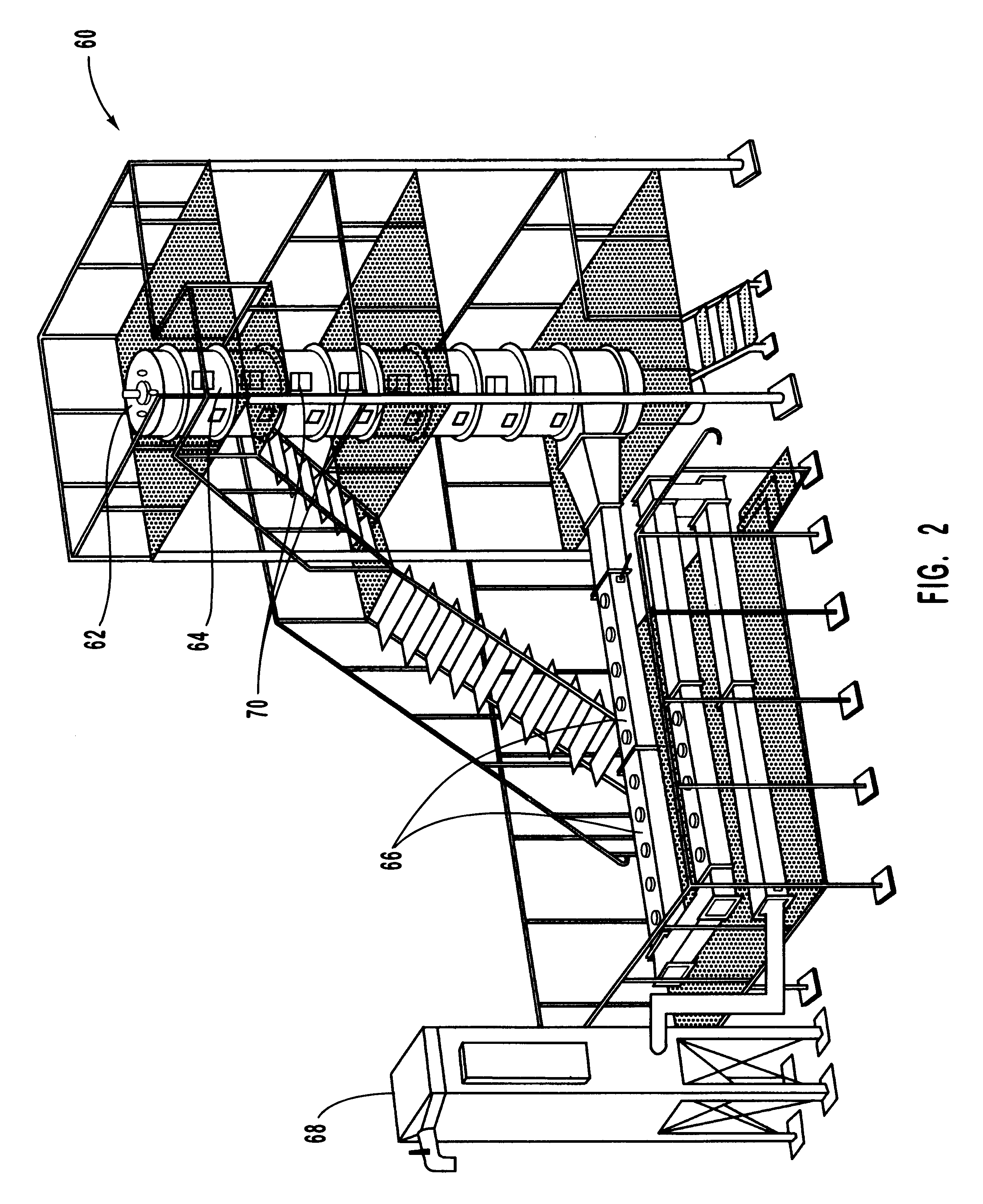

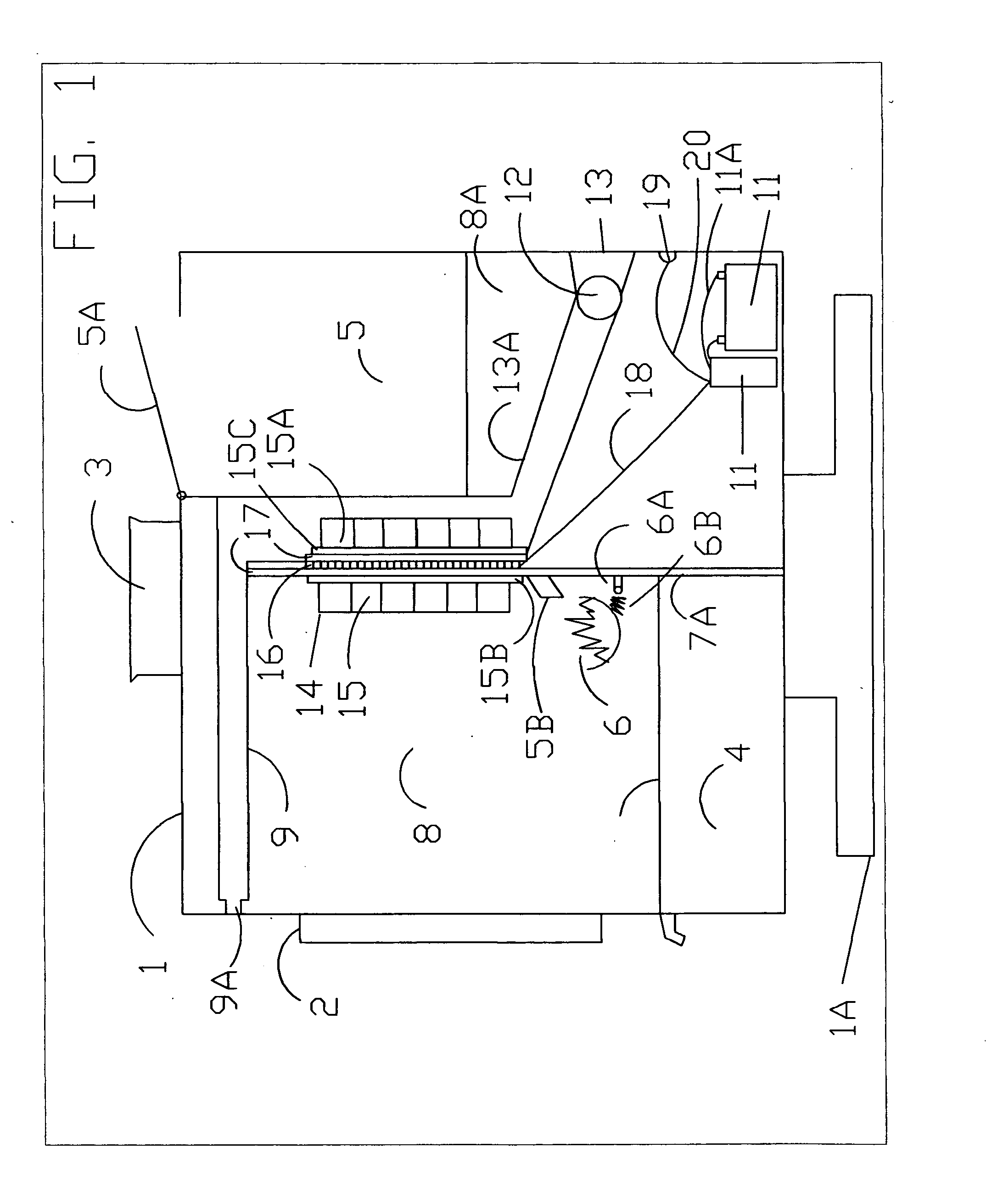

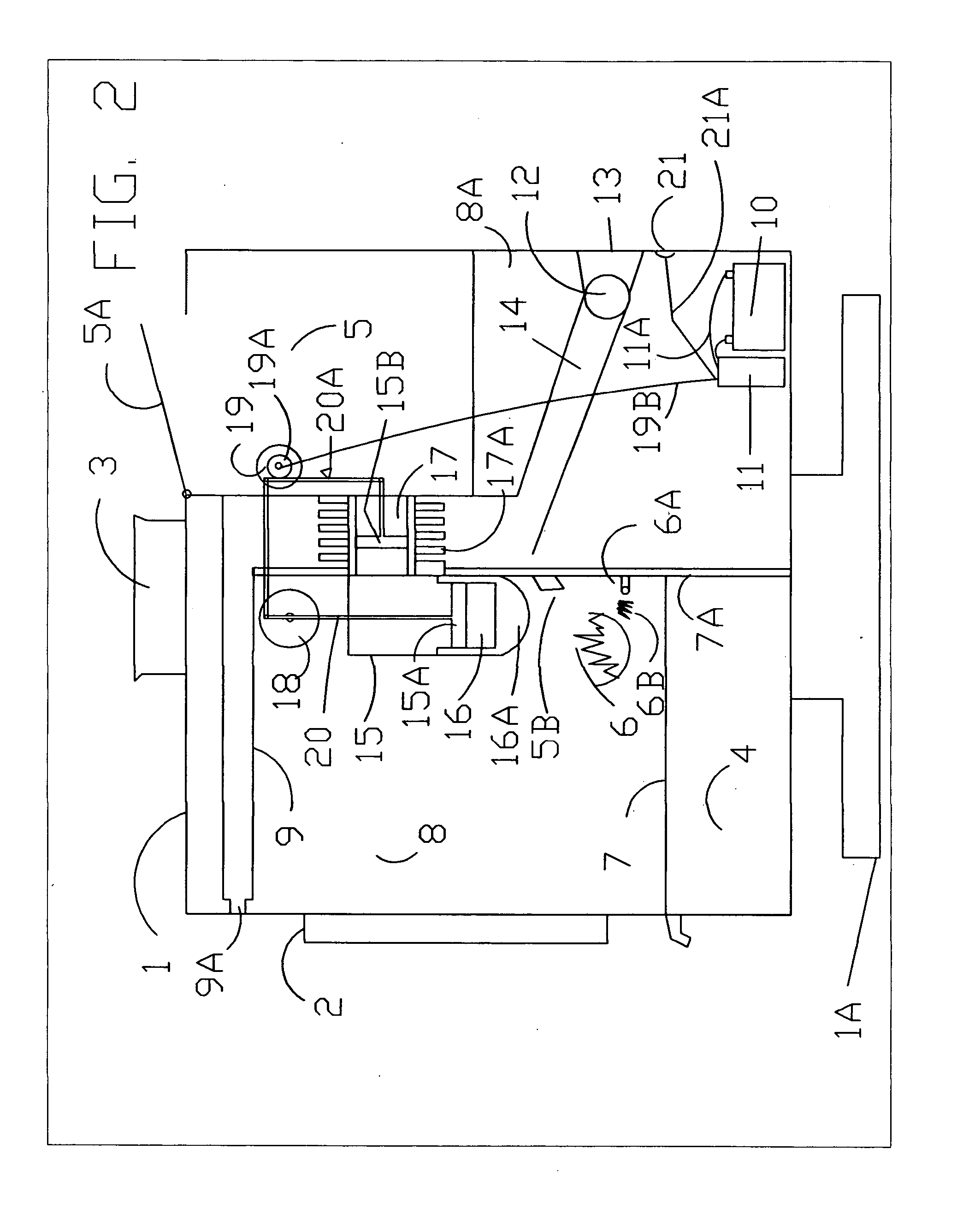

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

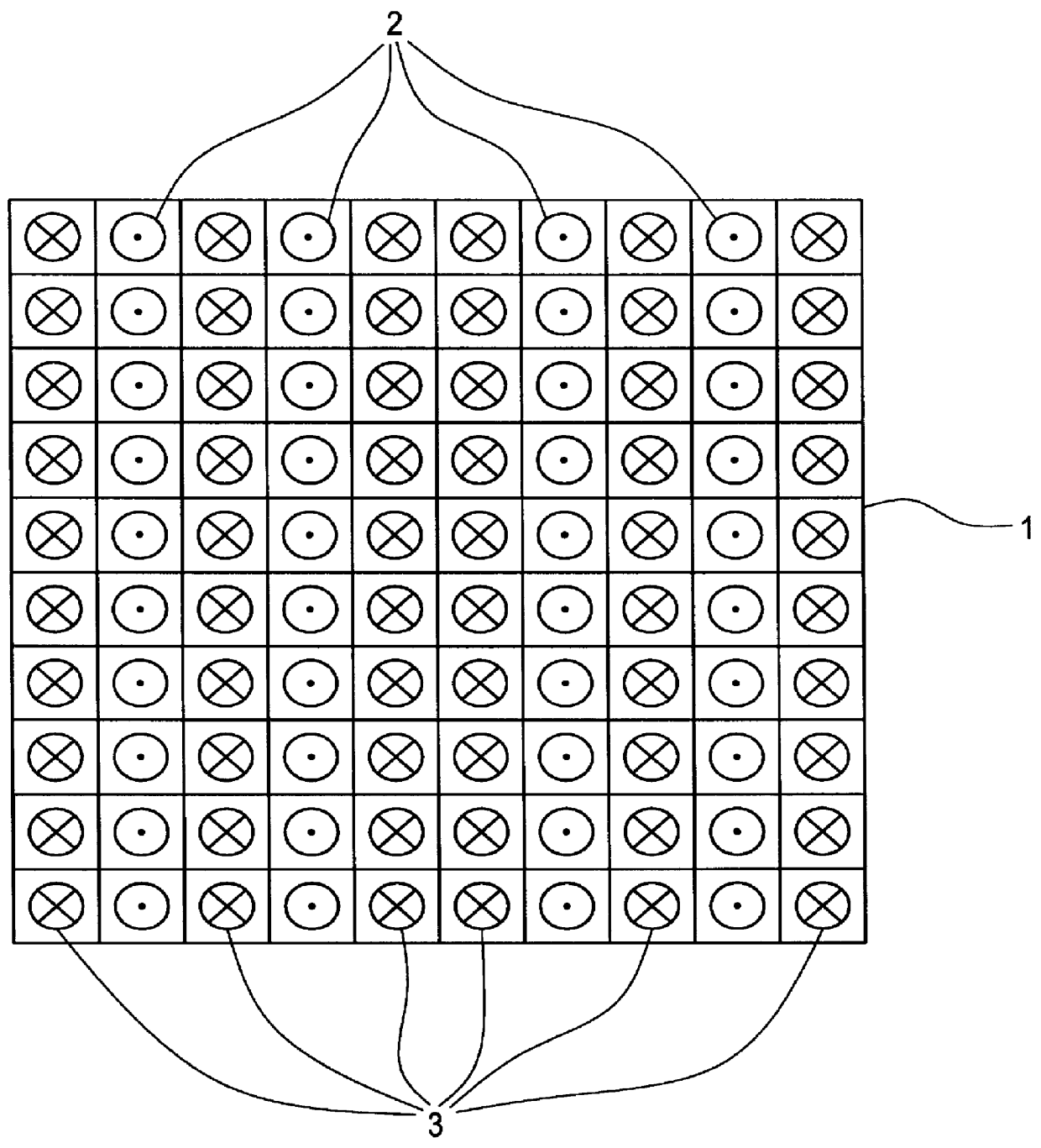

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

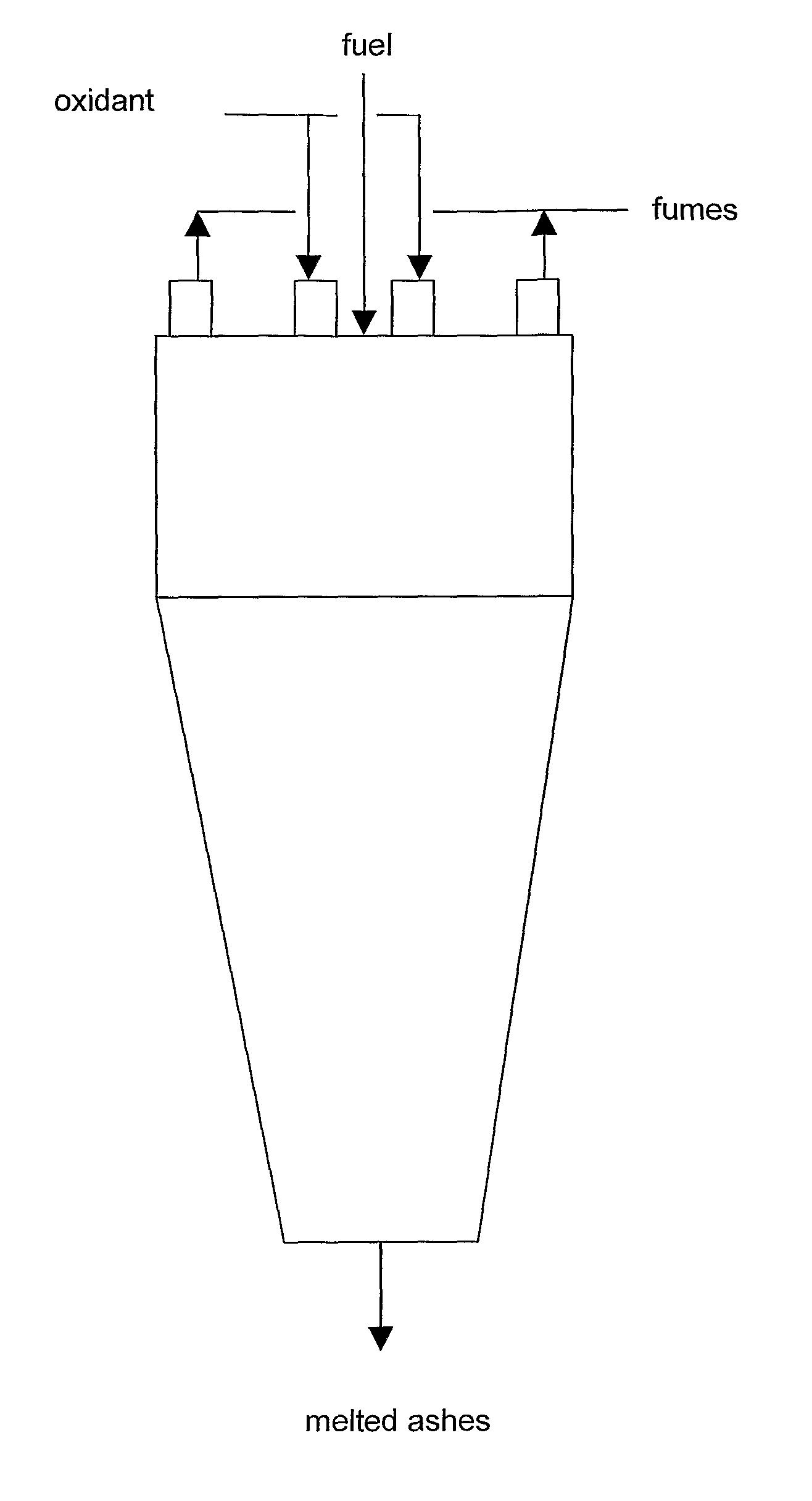

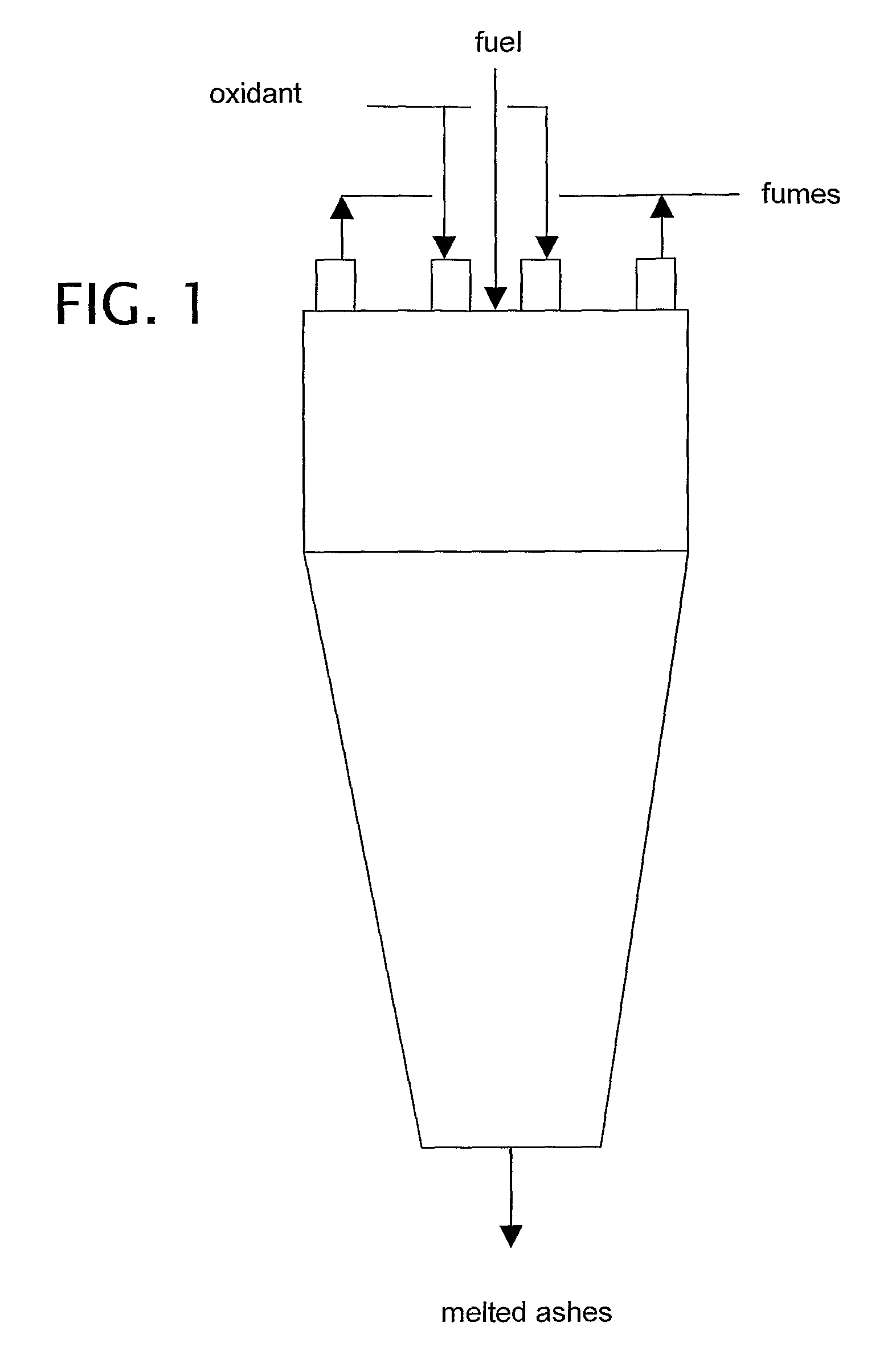

High-efficiency combustors with reduced environmental impact and processes for power generation derivable therefrom

A process for combusting solid liquid or gaseous fuels in a high temperature refractory-lined reactor with the aim of generating electric power comprises mixing at least one fuel with steam. The refactory material of the reactor and the opaque gases of the reaction environment bring about high power infrared radiation which substantially instantaneously preheats the reactants on input including said reactants being intrinsically transparent to infrared radiation (N2 / O2) but rendered opaque and thus absorbers of energy from infrared radiation thanks to dilution with steam. A high efficiency combustor is provided for carrying out the above-stated process.

Owner:ITEA SPA

Coke oven reconstruction

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

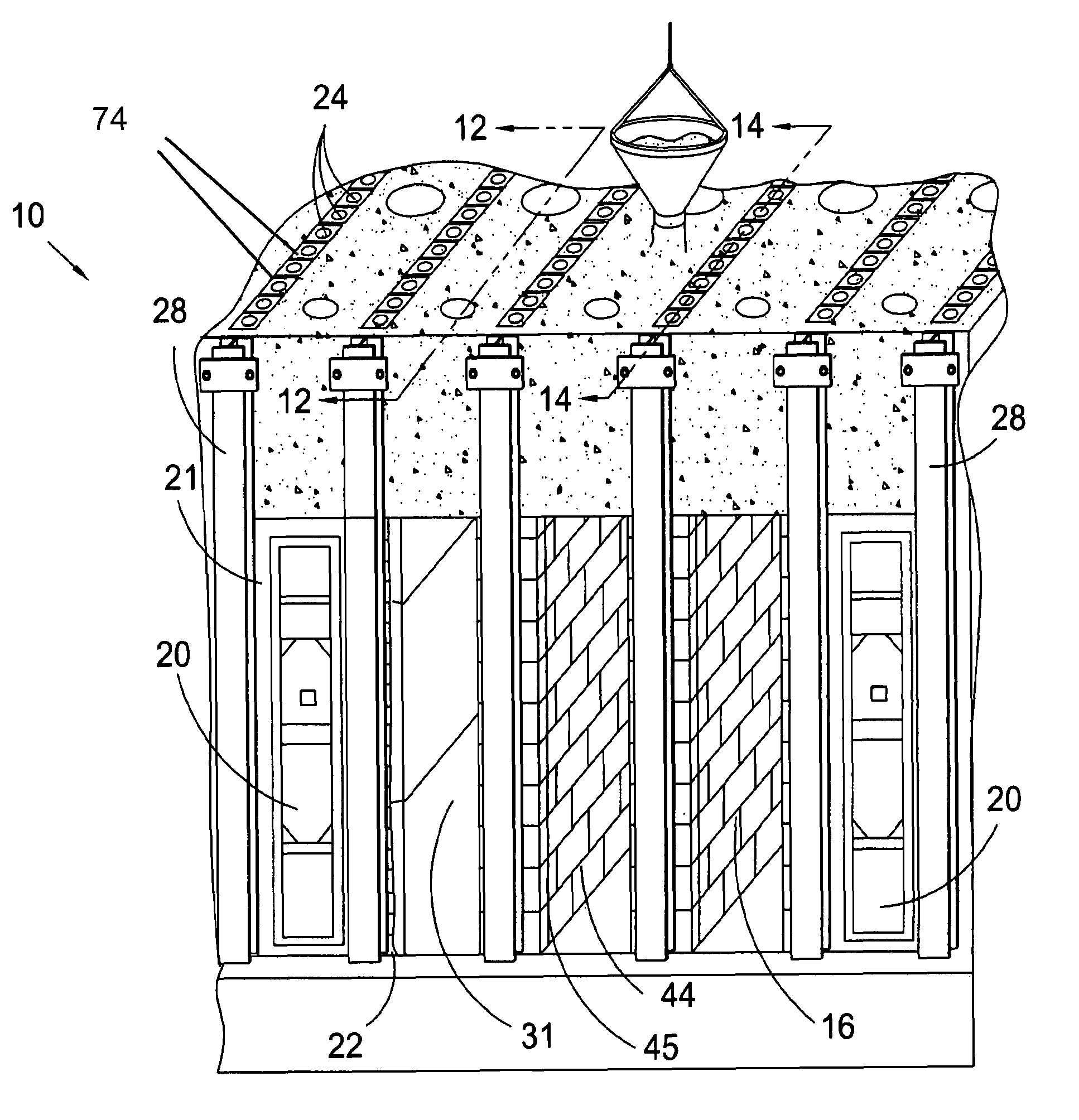

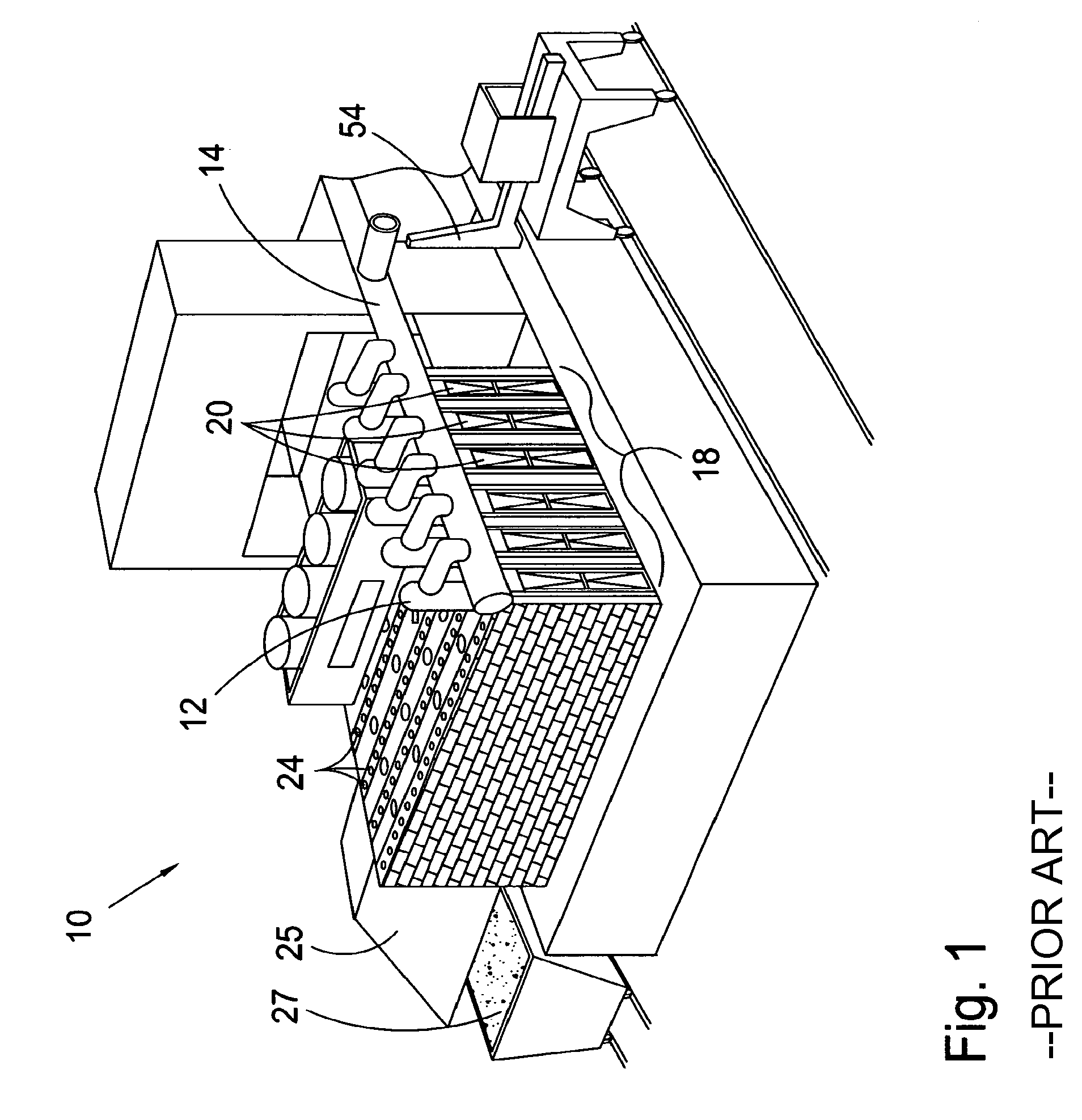

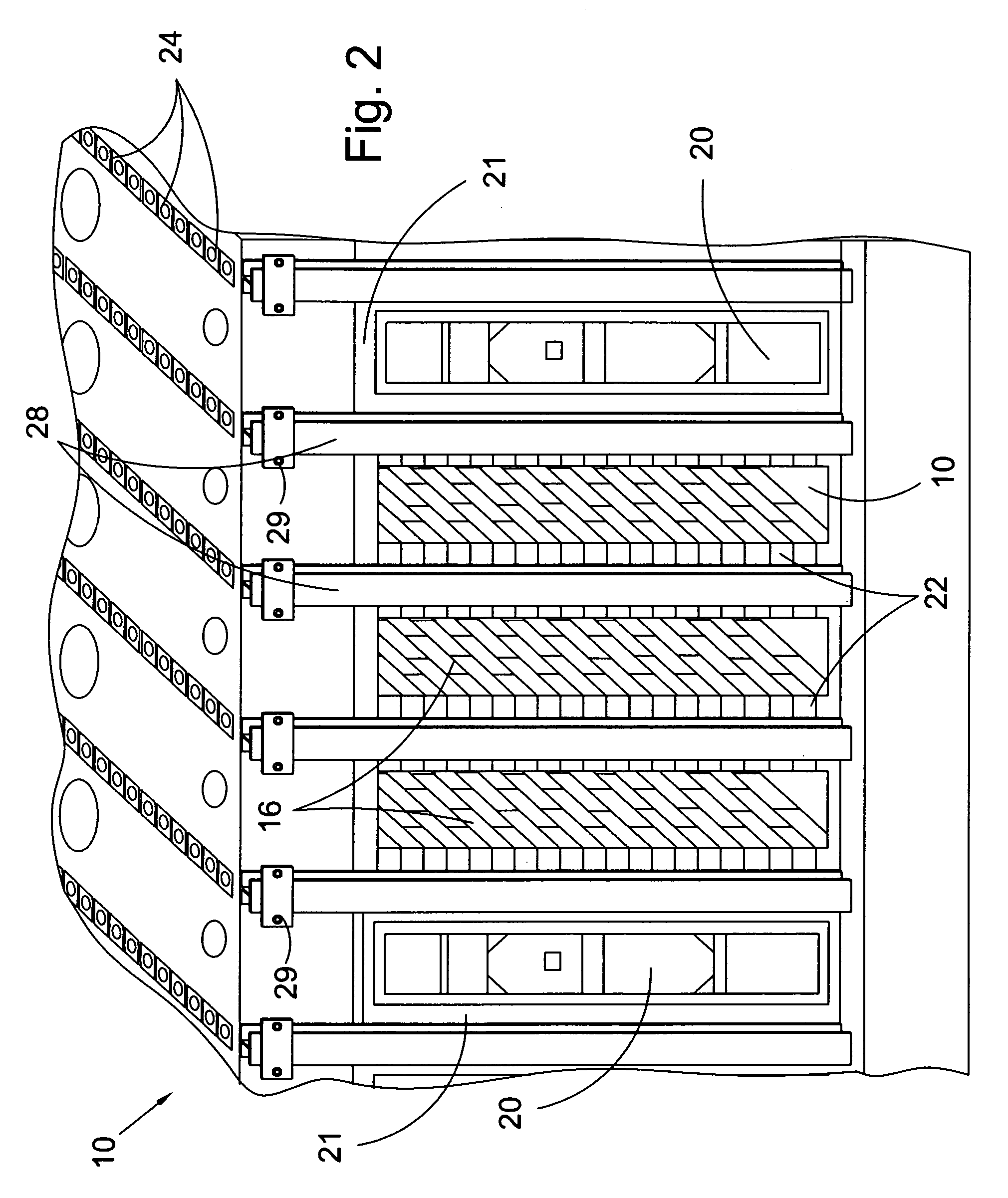

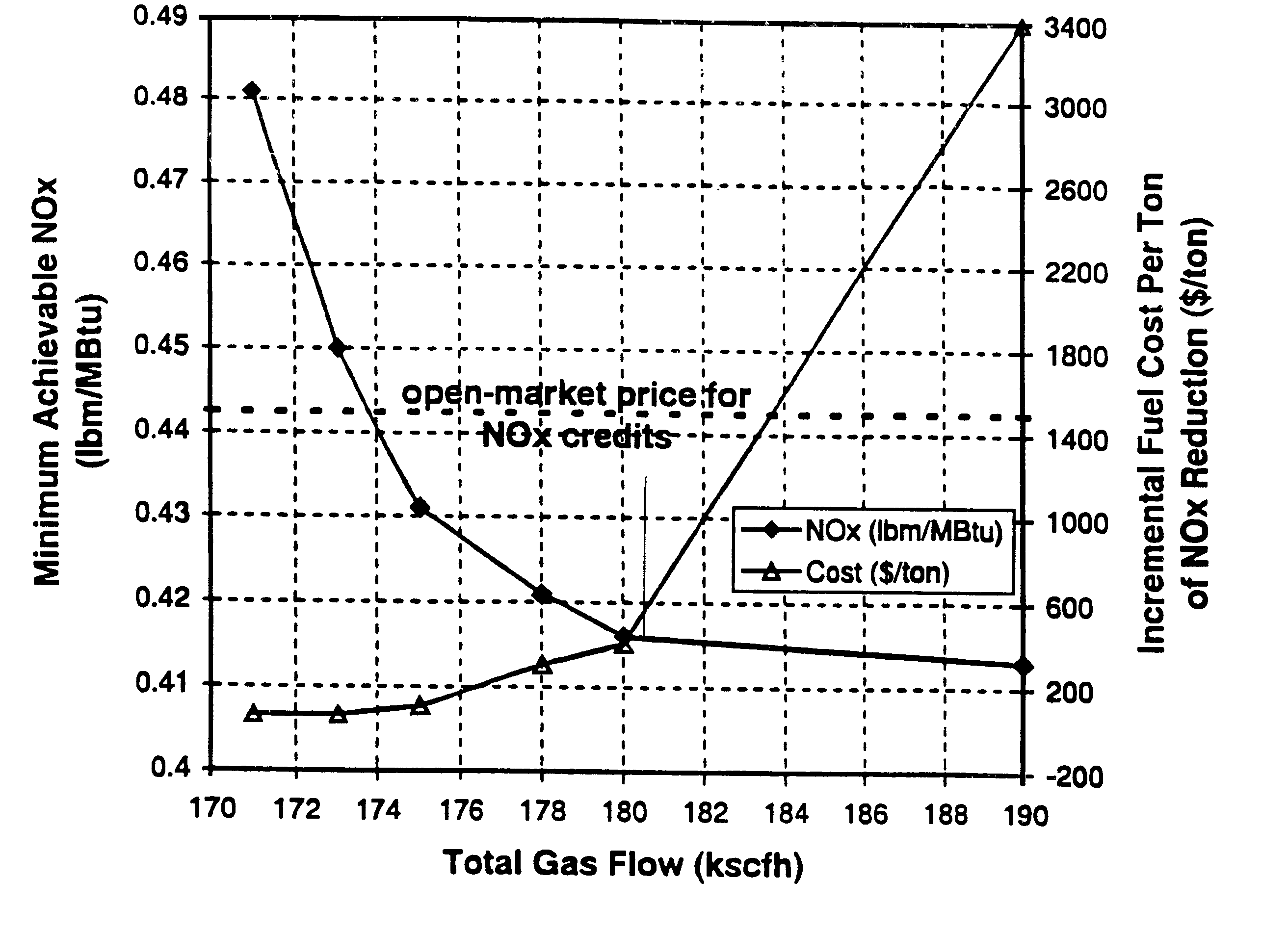

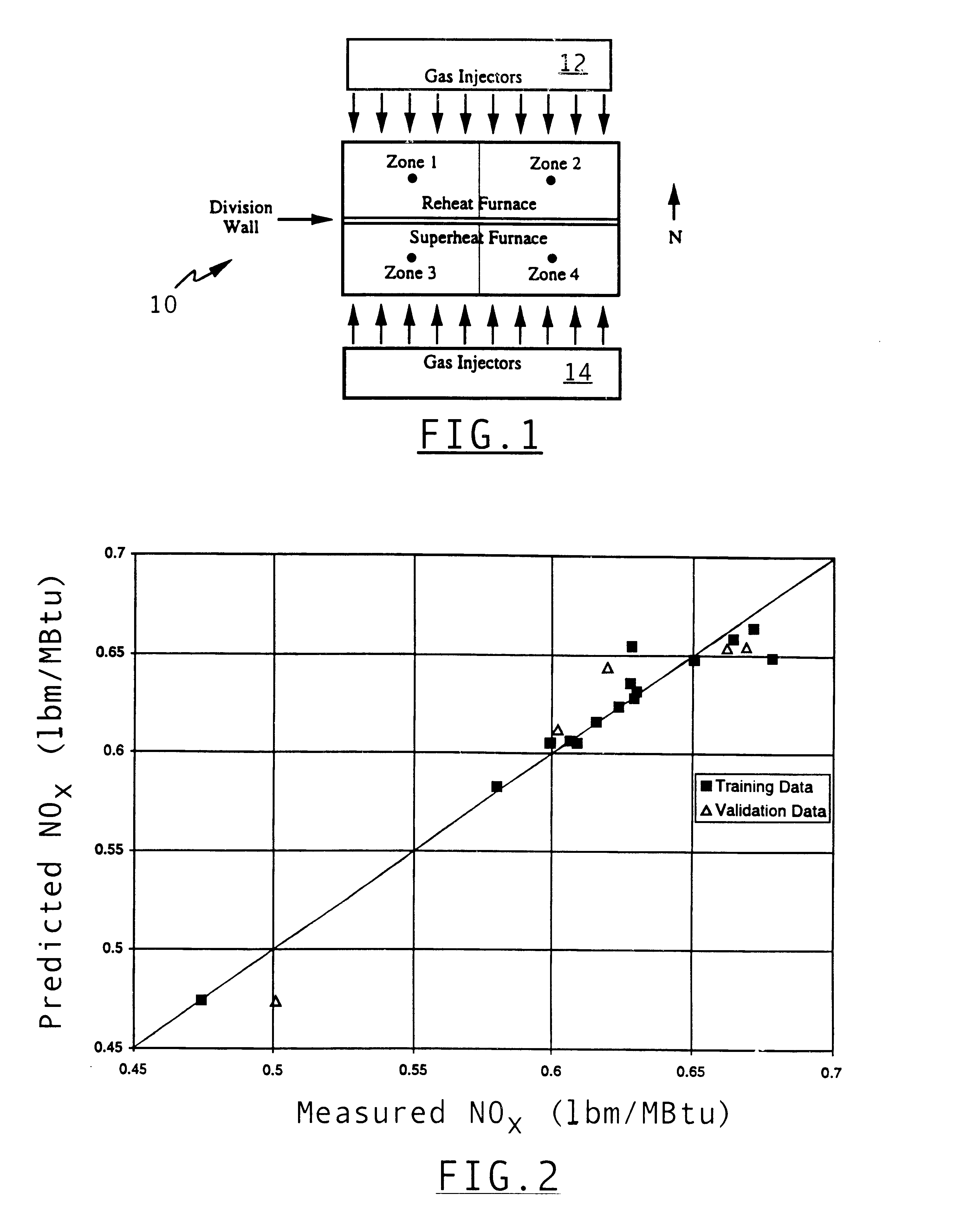

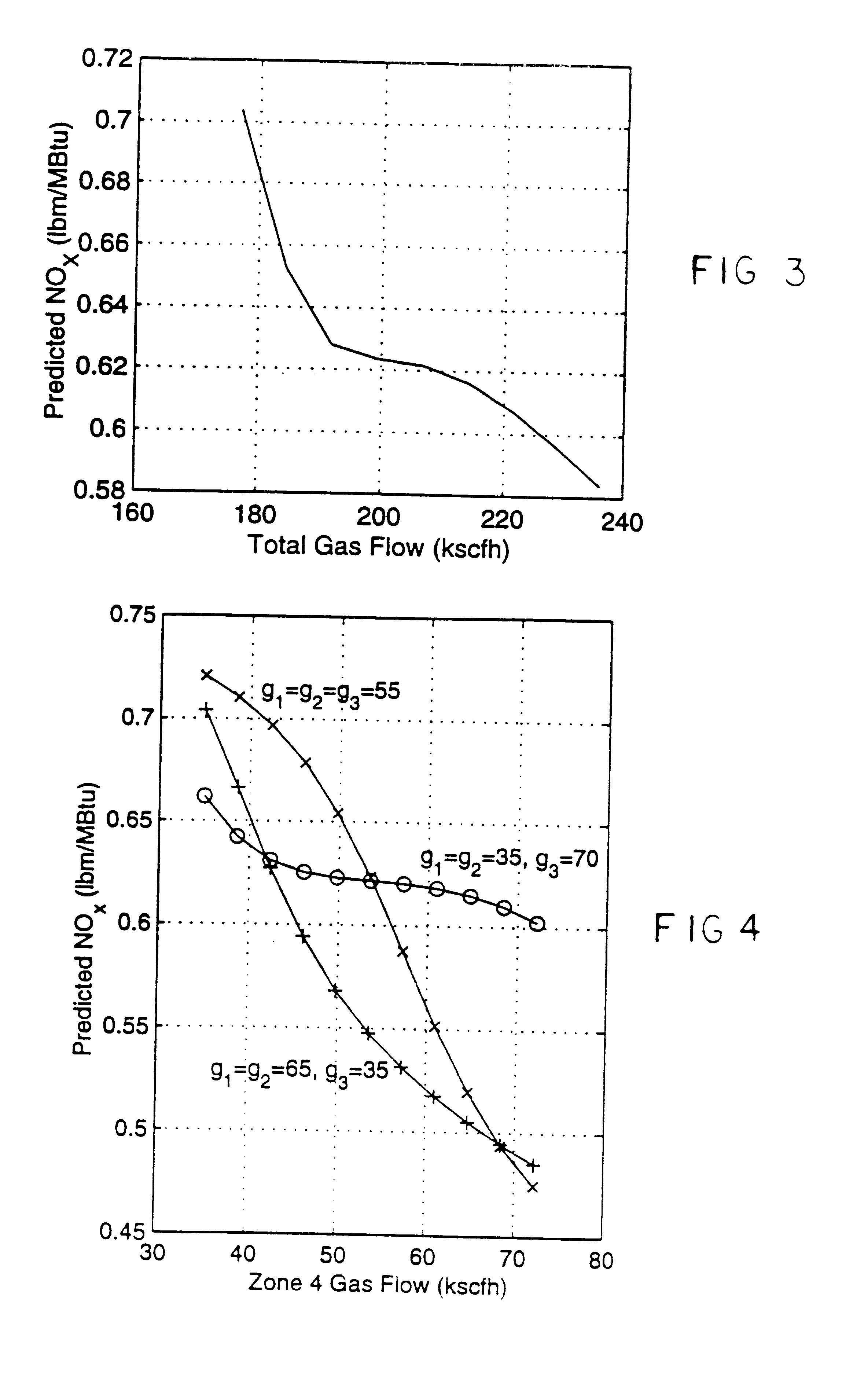

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

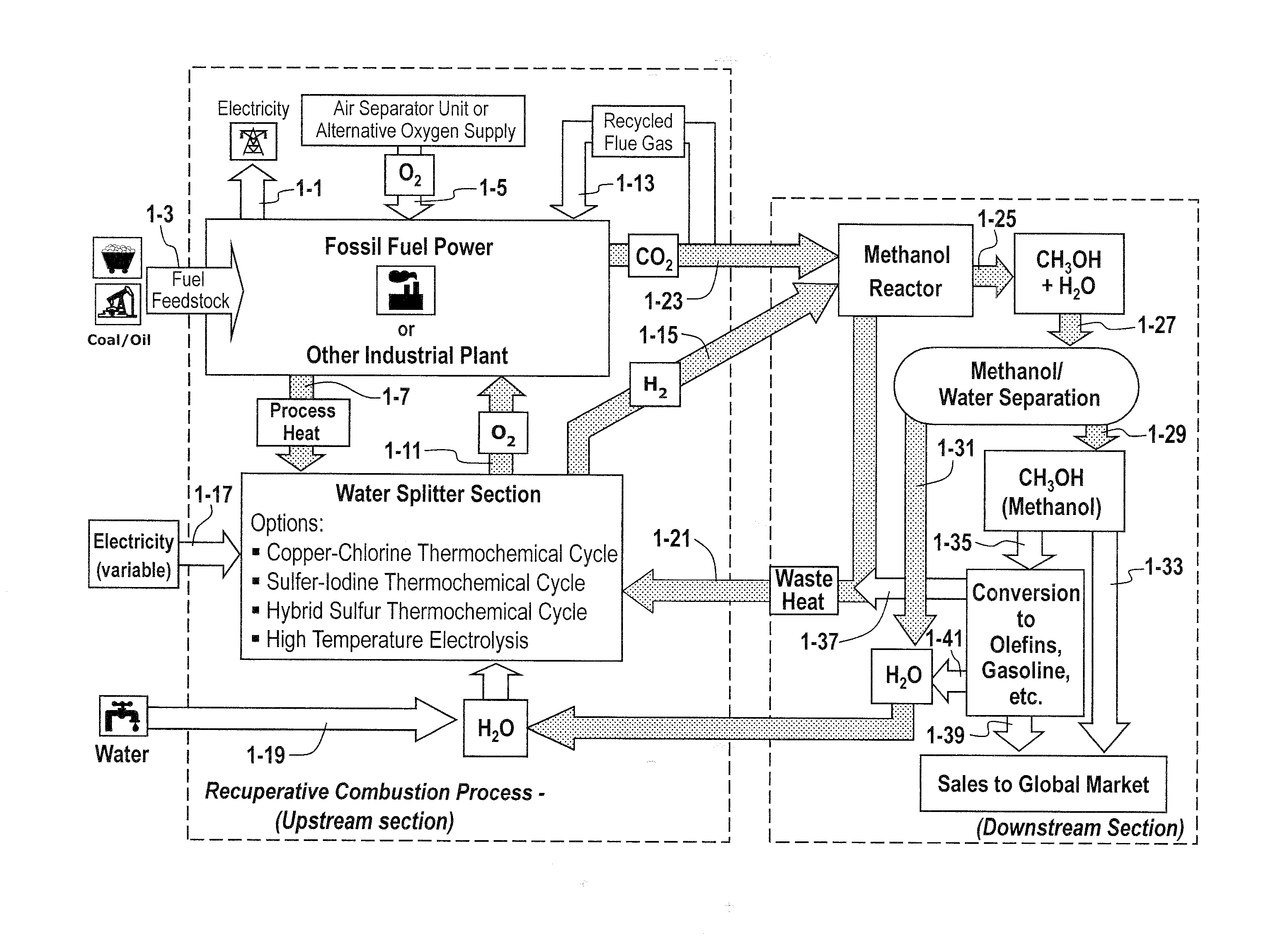

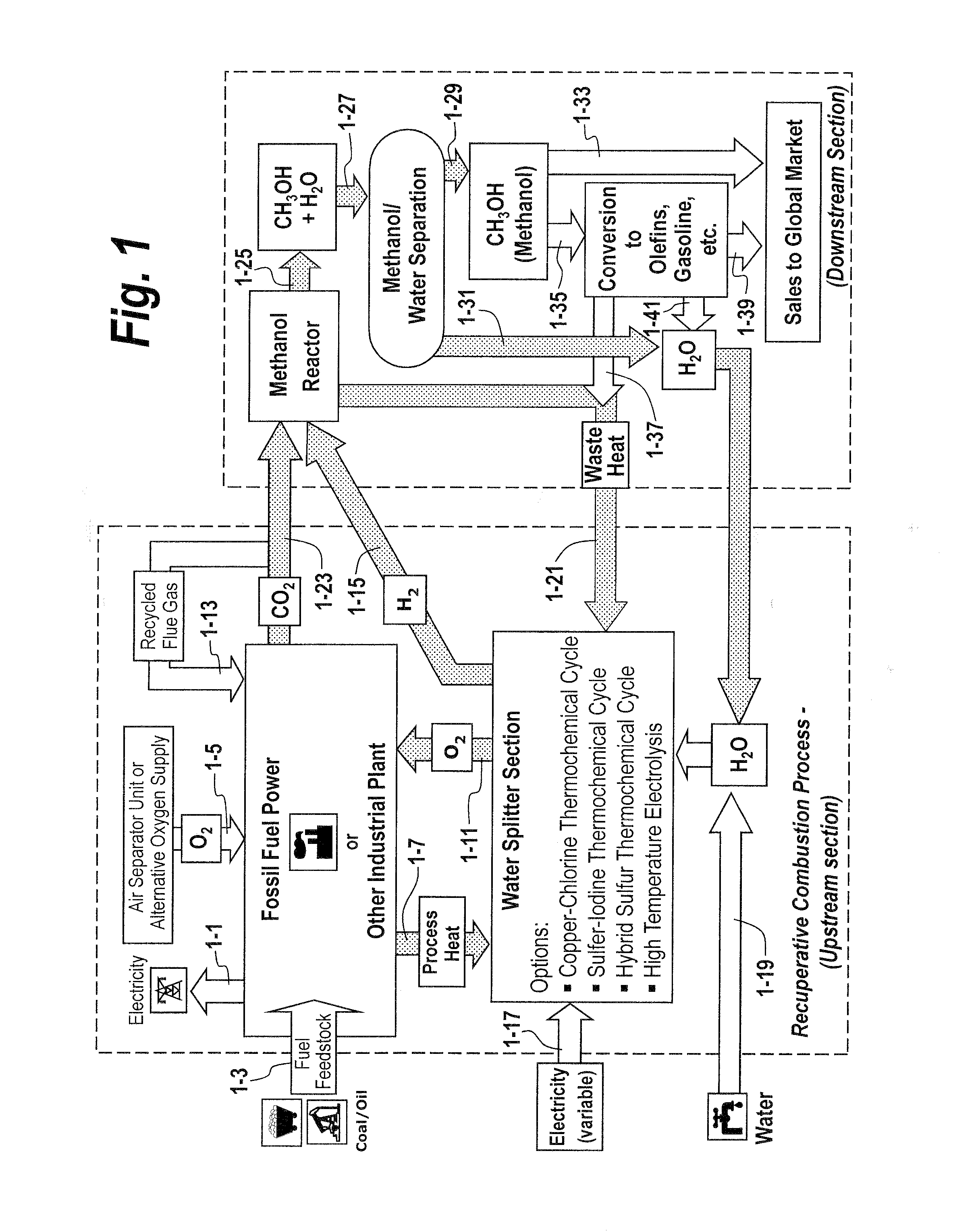

Recuperative combustion system

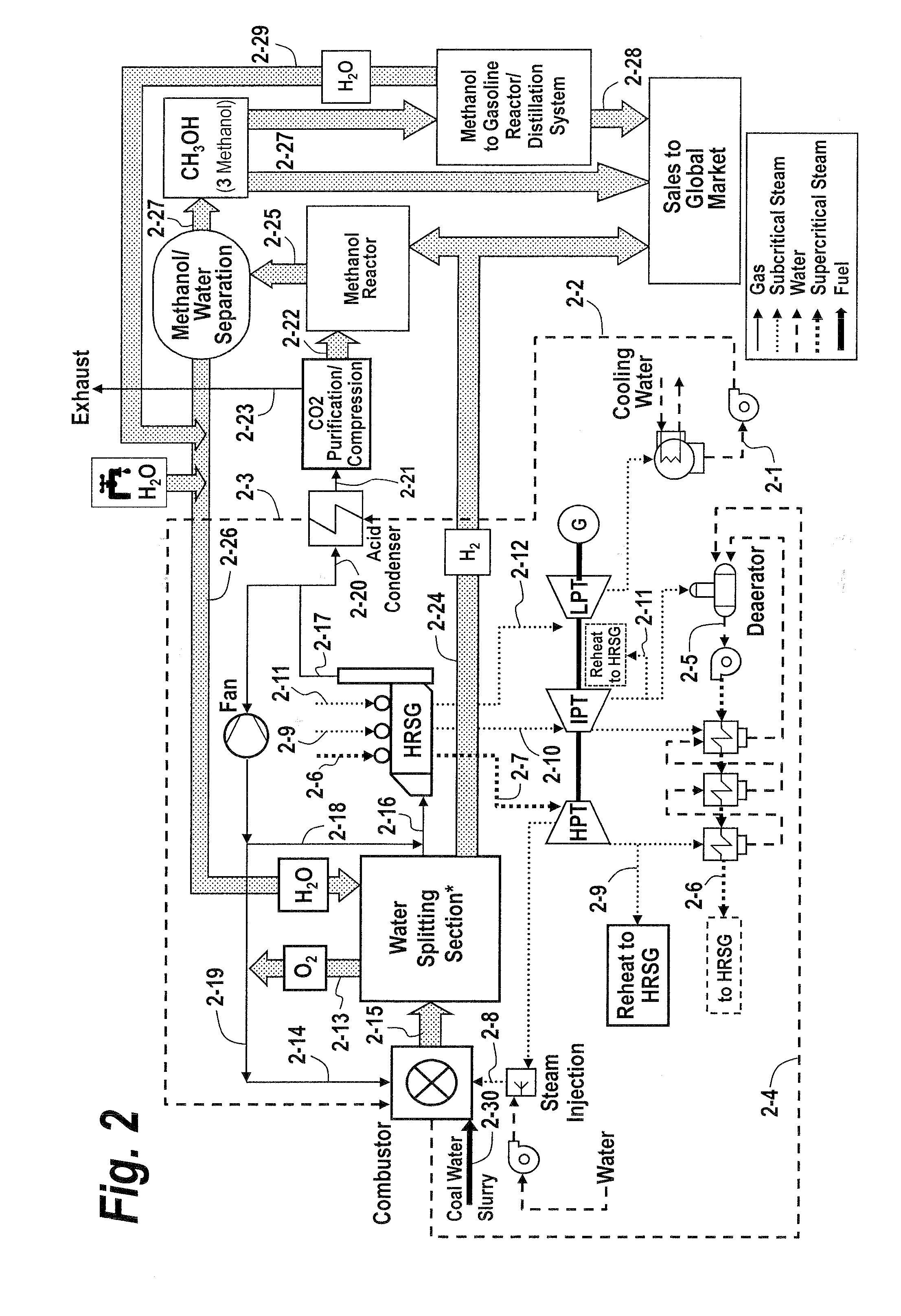

InactiveUS20110041740A1Reducing and eliminating amount of oxygenSolid fuel combustionIndirect carbon-dioxide mitigationOxygenDimethyl ether

The methods and systems described herein relate to a recuperative combustion system that recuperates energy from fuel combustion that would otherwise be lost. The recuperative combustion system minimizes or eliminates the need for an air separator unit through the use of a clean water splitter section, consisting of a thermochemical cycle or high-temperature electrolysis. Water is split into its component hydrogen and oxygen, primarily with process heat from the combustion process. The oxygen produced by the water splitter provides oxygen necessary for oxy-fuel combustion, thereby reducing or eliminating the need for the power intensive air separator unit and / or external oxygen source, significantly increasing the efficiency of the oxy-fuel combustion cycle. Hydrogen produced by the water splitter may be used for a variety of industrial uses, or combined with carbon dioxide (captured from the flue gases produced by said combustion process) to produce methanol. Methanol can further be refined in a methanol to gasoline reactor to produce dimethyl ether, olefins or high grade gasoline. Described herein are methods and systems that 1) increase oxy-fuel combustion efficiency, 2) produce hydrogen for a suite of industrial / energy uses, and 3) capture carbon dioxide and convert it to high value hydrocarbons.

Owner:REILLY TIMOTHY J

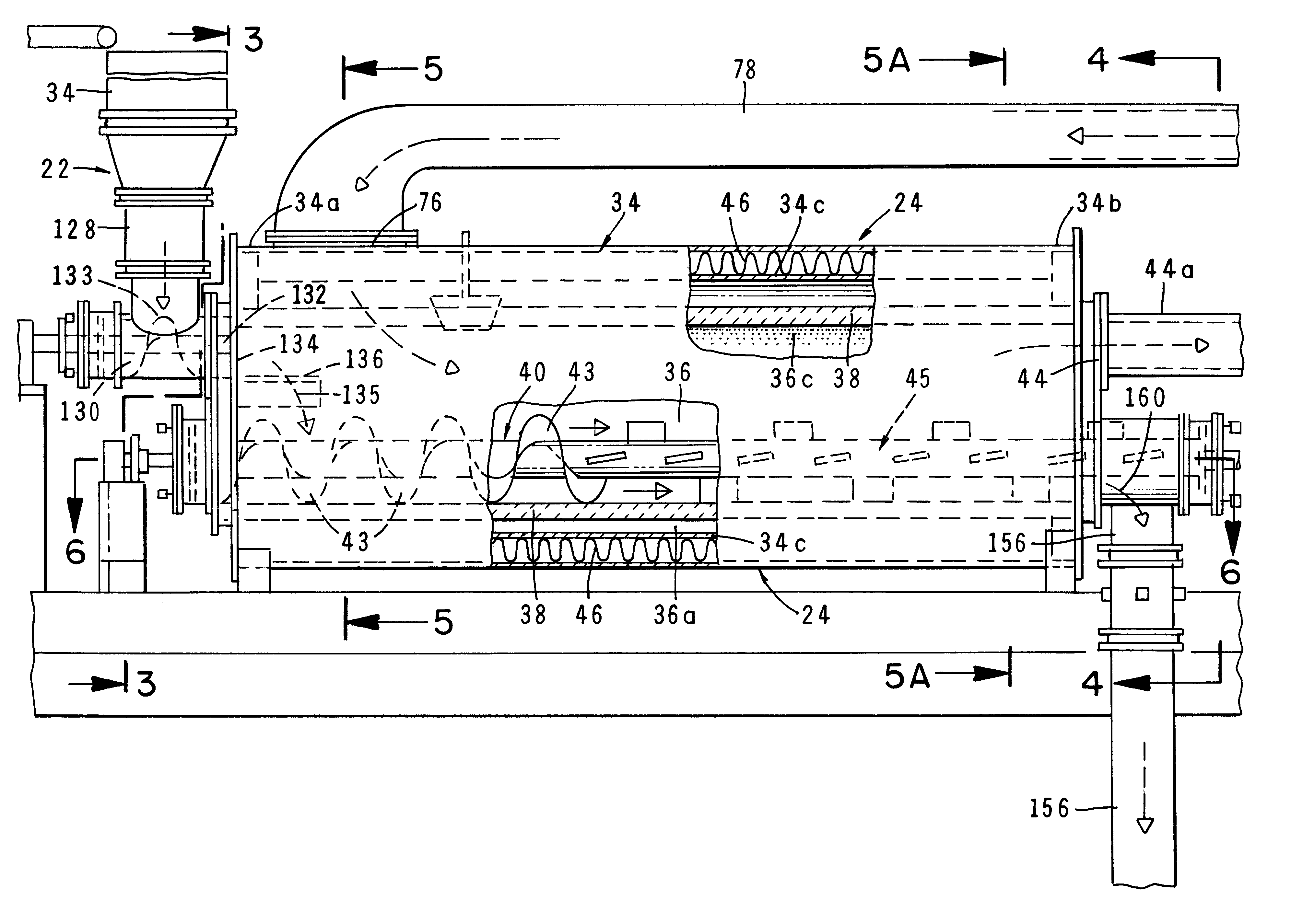

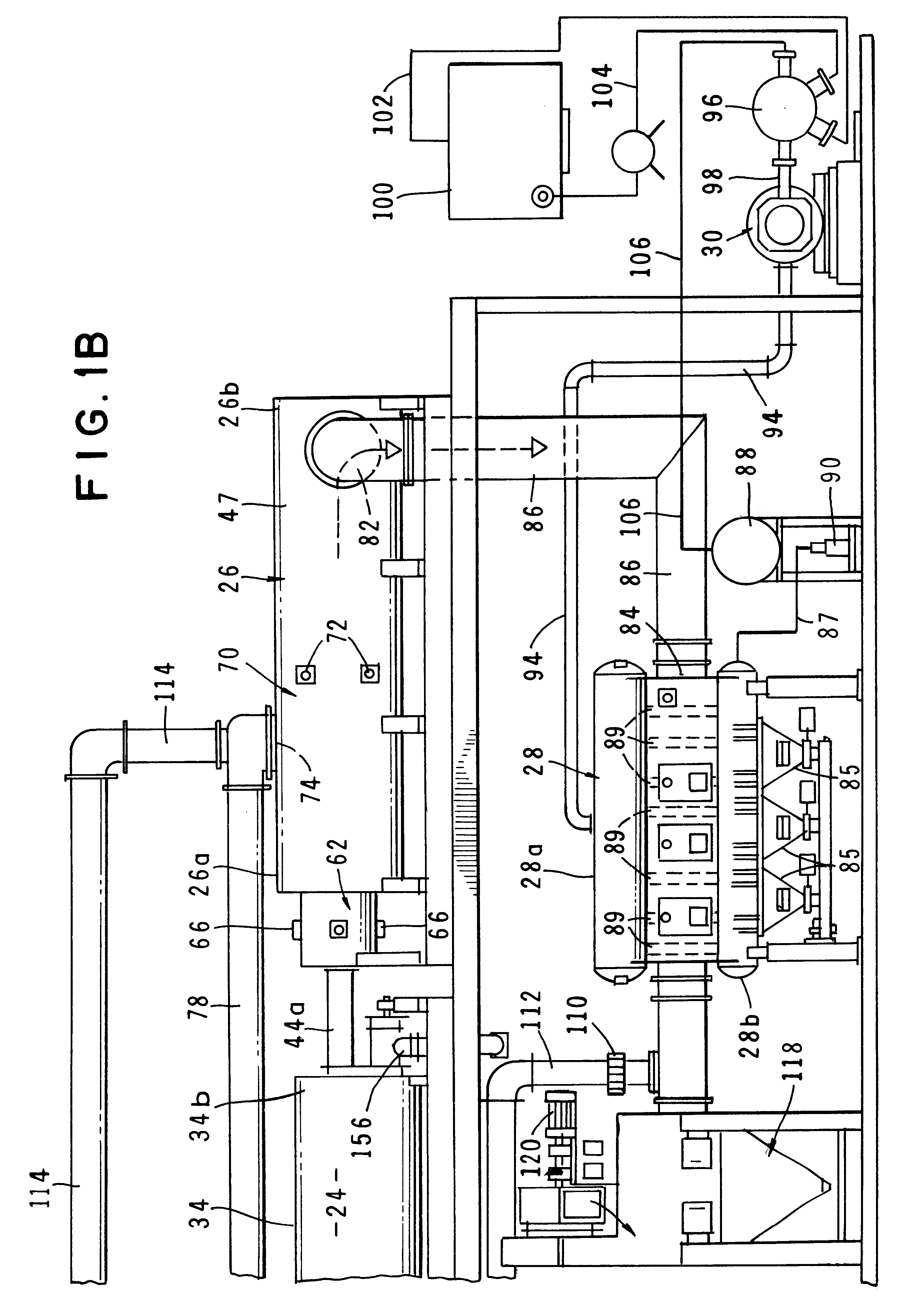

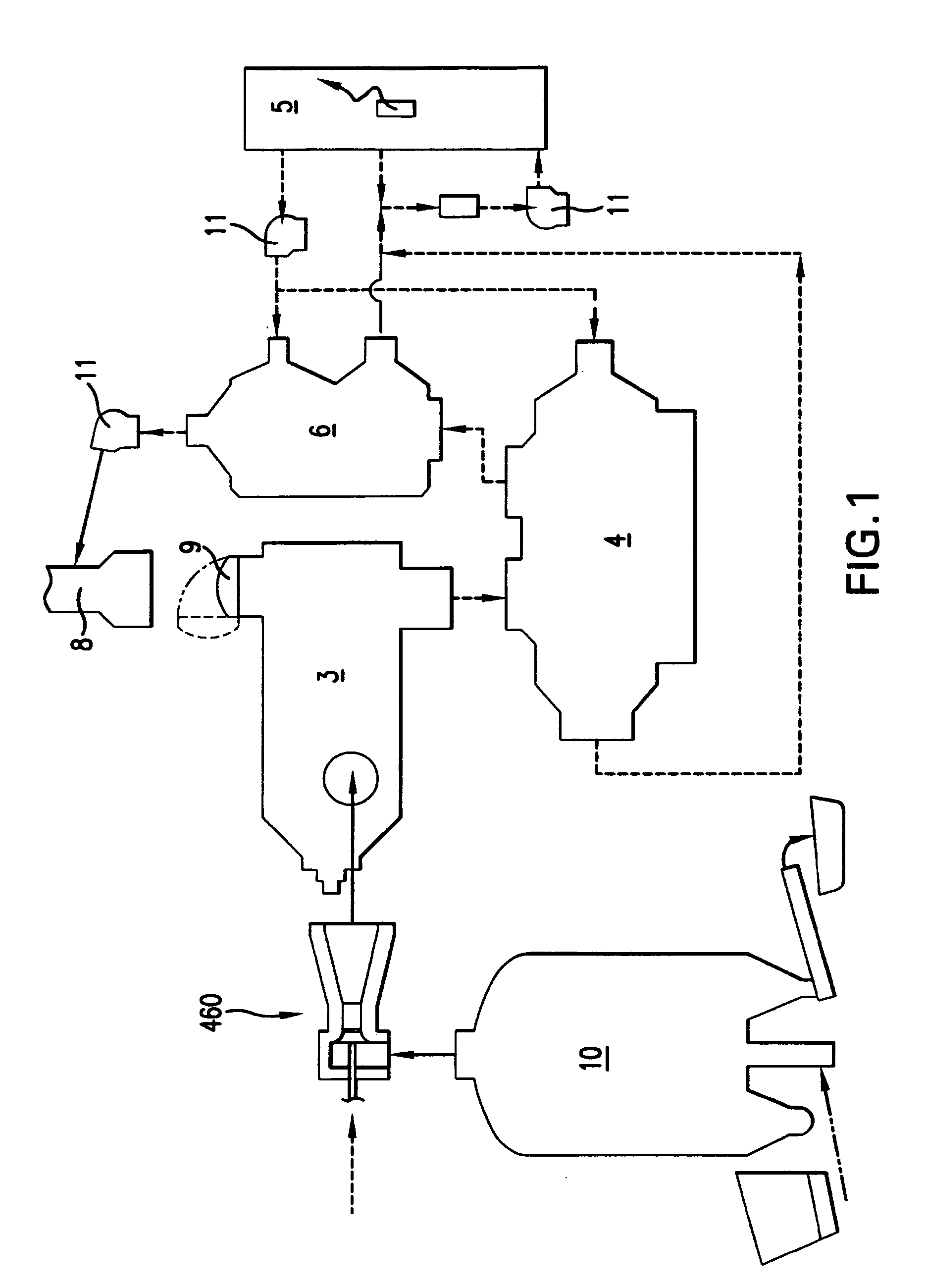

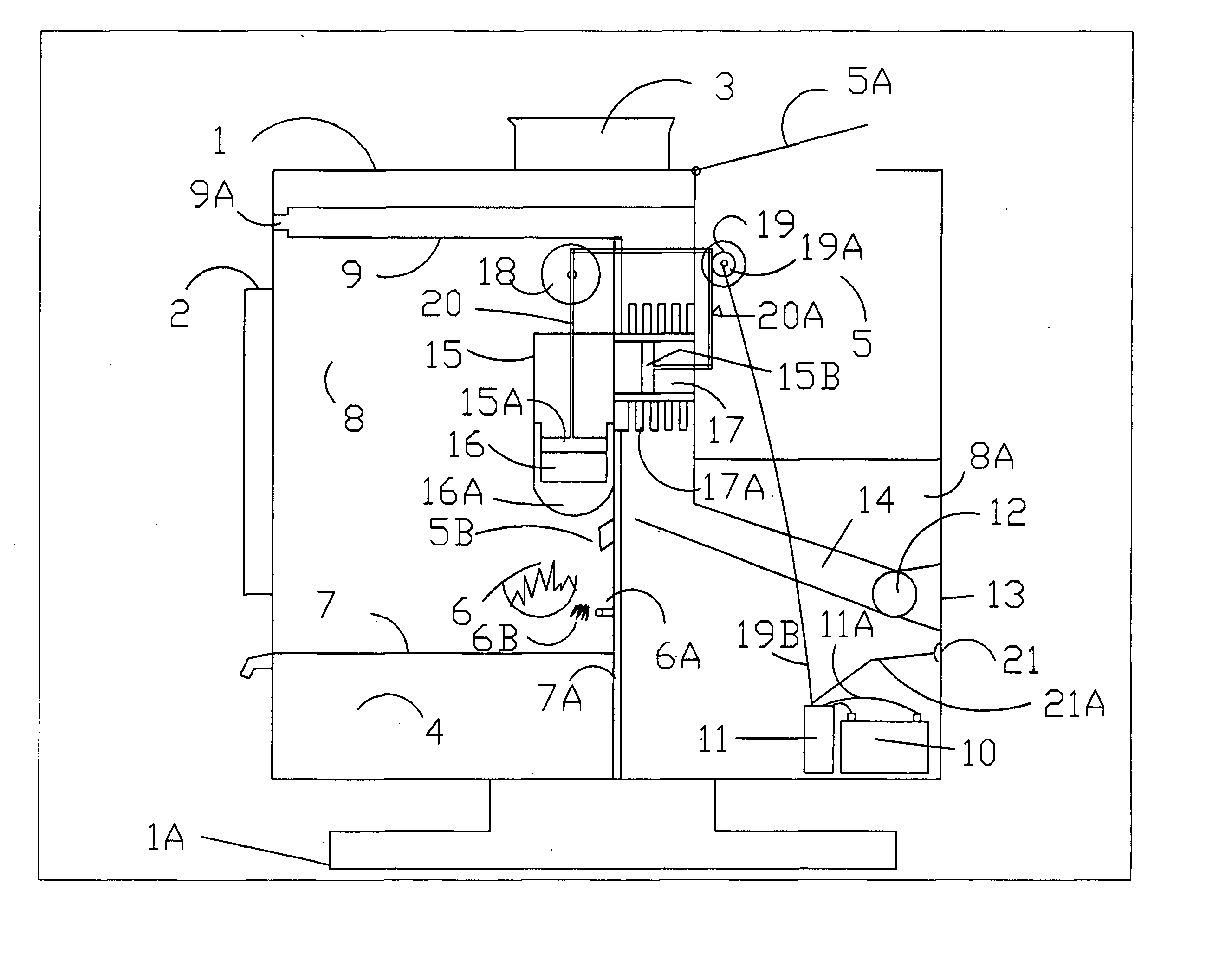

Method and apparatus for treatment of waste

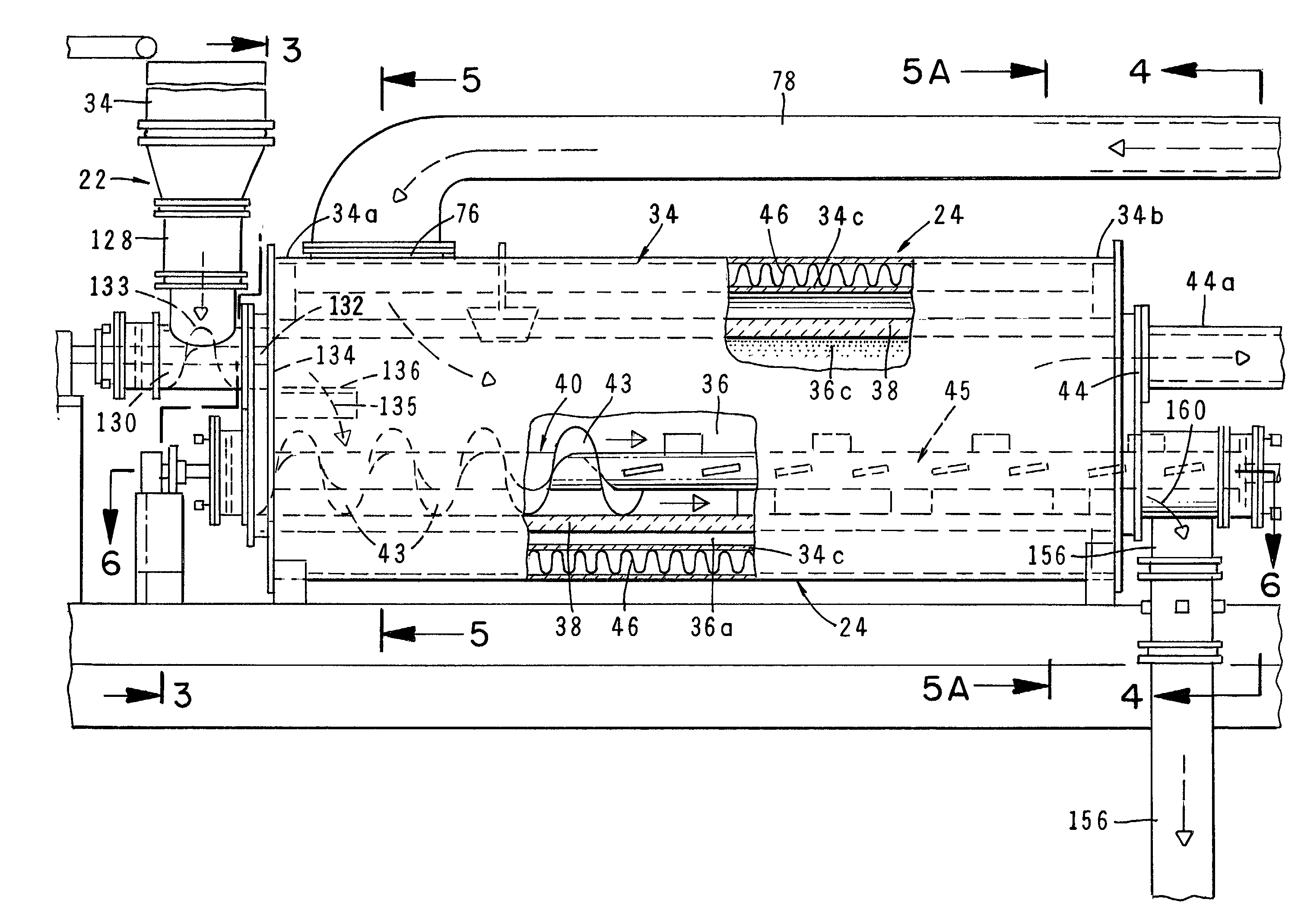

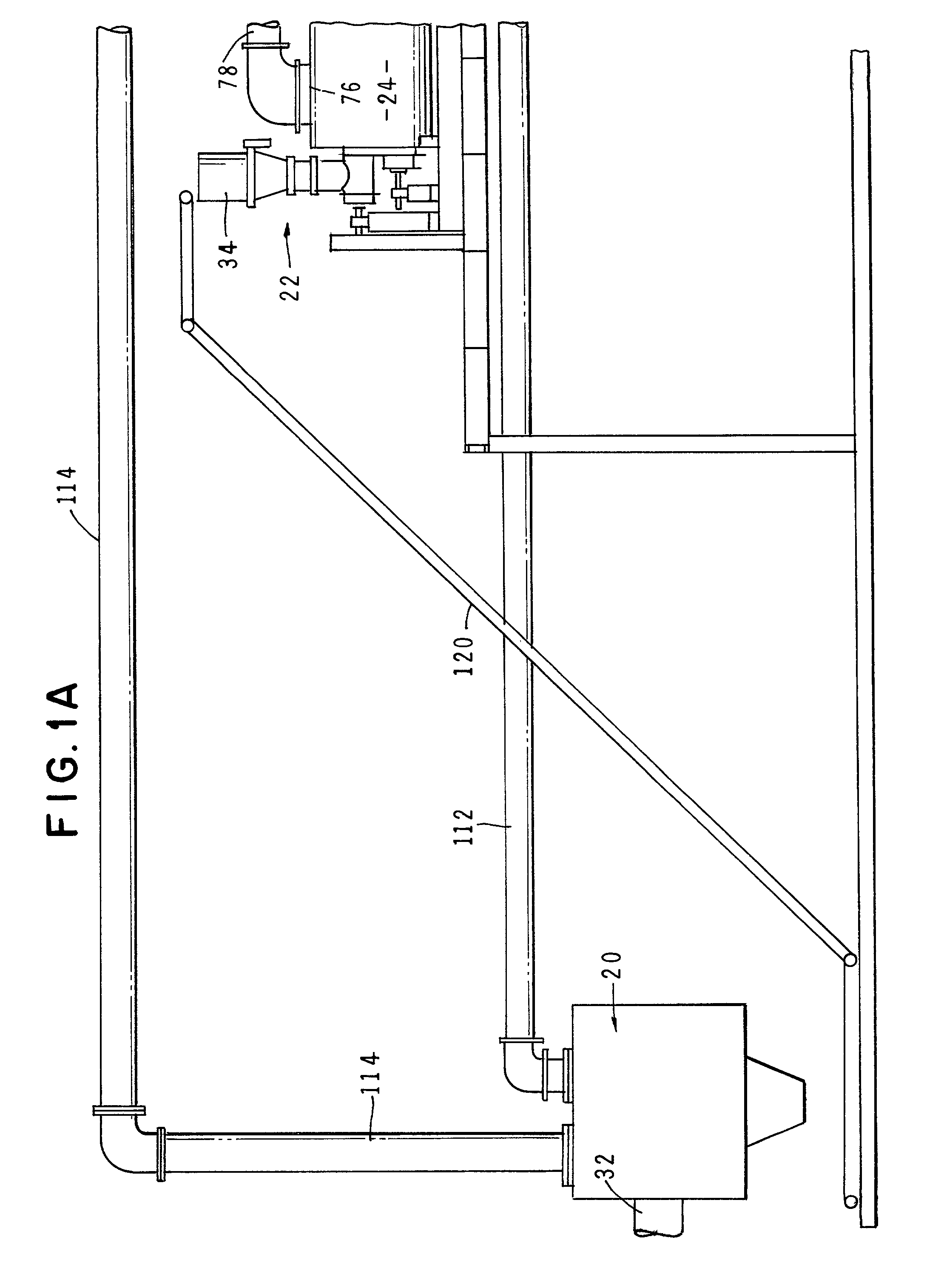

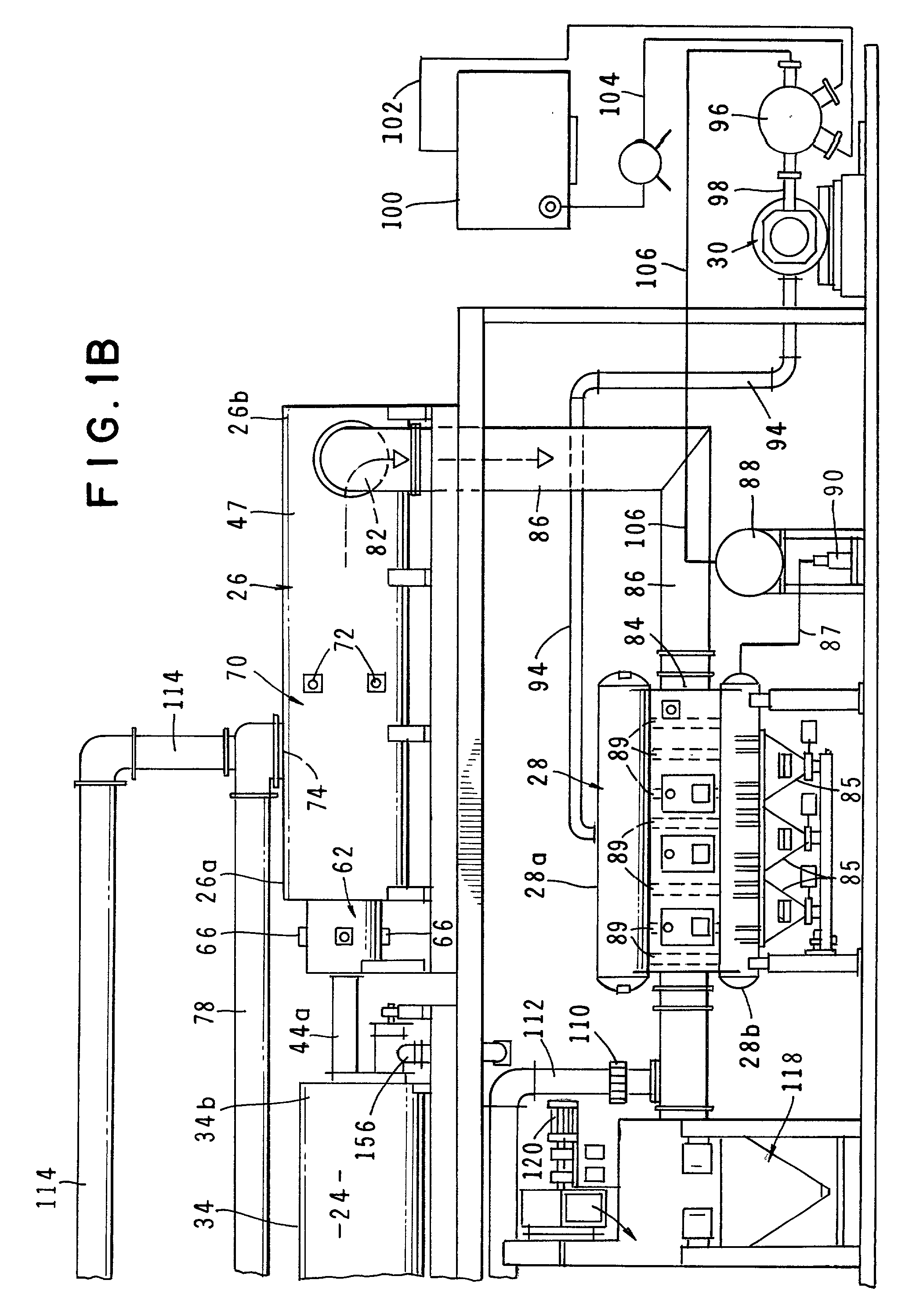

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

Self powered pelletized fuel heating device

InactiveUS20070221205A1Low costGood engineering designDomestic stoves or rangesSolid fuel combustionLow voltageEngineering

A self powered pelletized fuel heating device comprising a thermal electric generator (TEG) unit therein powering a typical collection of low voltage system components including a storage power unit. Non-typically, the heating device requires no external power supply and relies on thermodynamic principles using the pelletized fuel as a heat source. The TEG is configured and positioned optimally for conventional operation and installation requirements without modification to normal form or function.

Owner:LANDON RICHARD BENSON

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

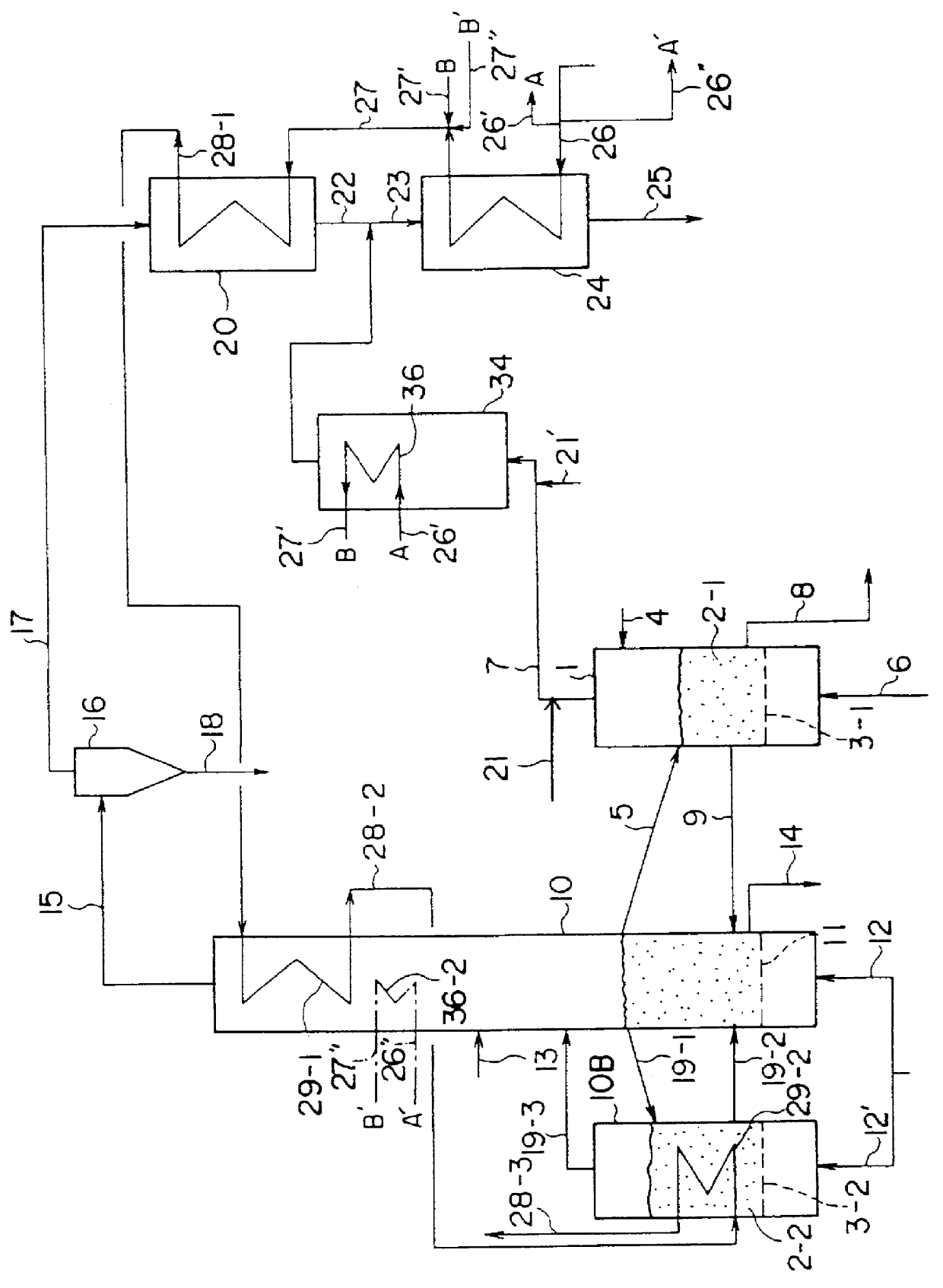

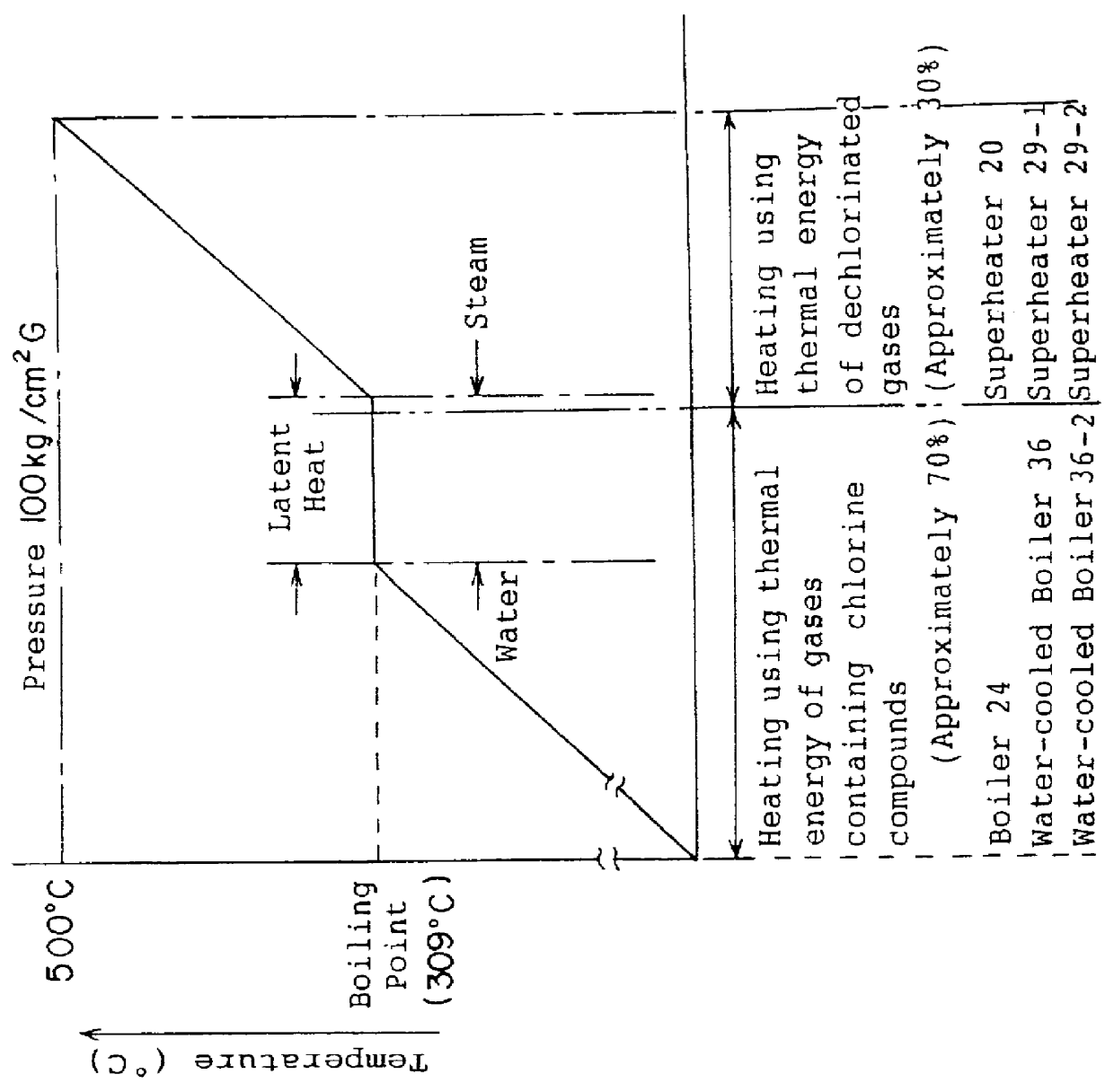

Method and apparatus for producing superheated steam using heat from the incineration of waste material

PCT No. PCT / JP97 / 00573 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32161 PCT Pub. Date Sep. 4, 1997According to the present invention, boiler water is pressurized so that its boiling point is set at approximately 200 DEG C. to 320 DEG C. The boiler water is heated in at least two stages. Thermal energy of gases containing chlorine compounds is used to heat the water to its boiling point. Thermal energy of gases which do not contain chlorine compounds is used to heat the water from its boiling point until superheated steam of a given temperature is generated. The heating which uses the thermal energy of gases containing chlorine compounds is accomplished using the thermal energy from the combustion of pyrolysis gases obtained from a pyrolysis means in which waste material is supplied into a chamber containing a fluidized bed medium which has been heated to at least 300 DEG C., and a pyrolytic reaction is induced. The heating which uses the thermal energy of gases which do not contain chlorine compounds is accomplished using the thermal energy obtained from a char combustion means to combust char in which a char mixture consisting of unpyrolyzed residue and fluidized bed medium removed from the pyrolysis means is fluidized by a stream of air, and the unpyrolyzed residue is combusted.

Owner:MITSUBISHI HEAVY IND LTD

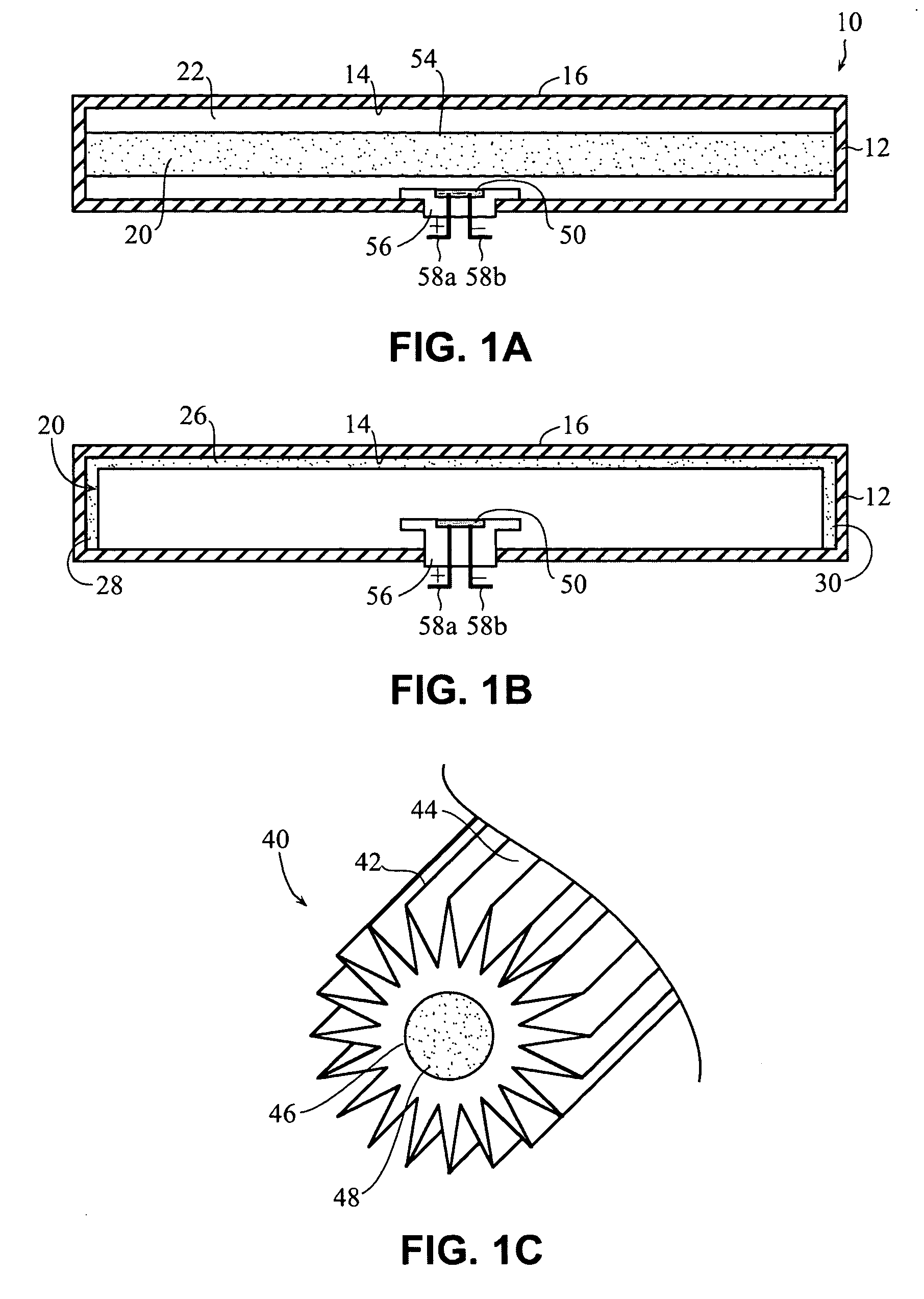

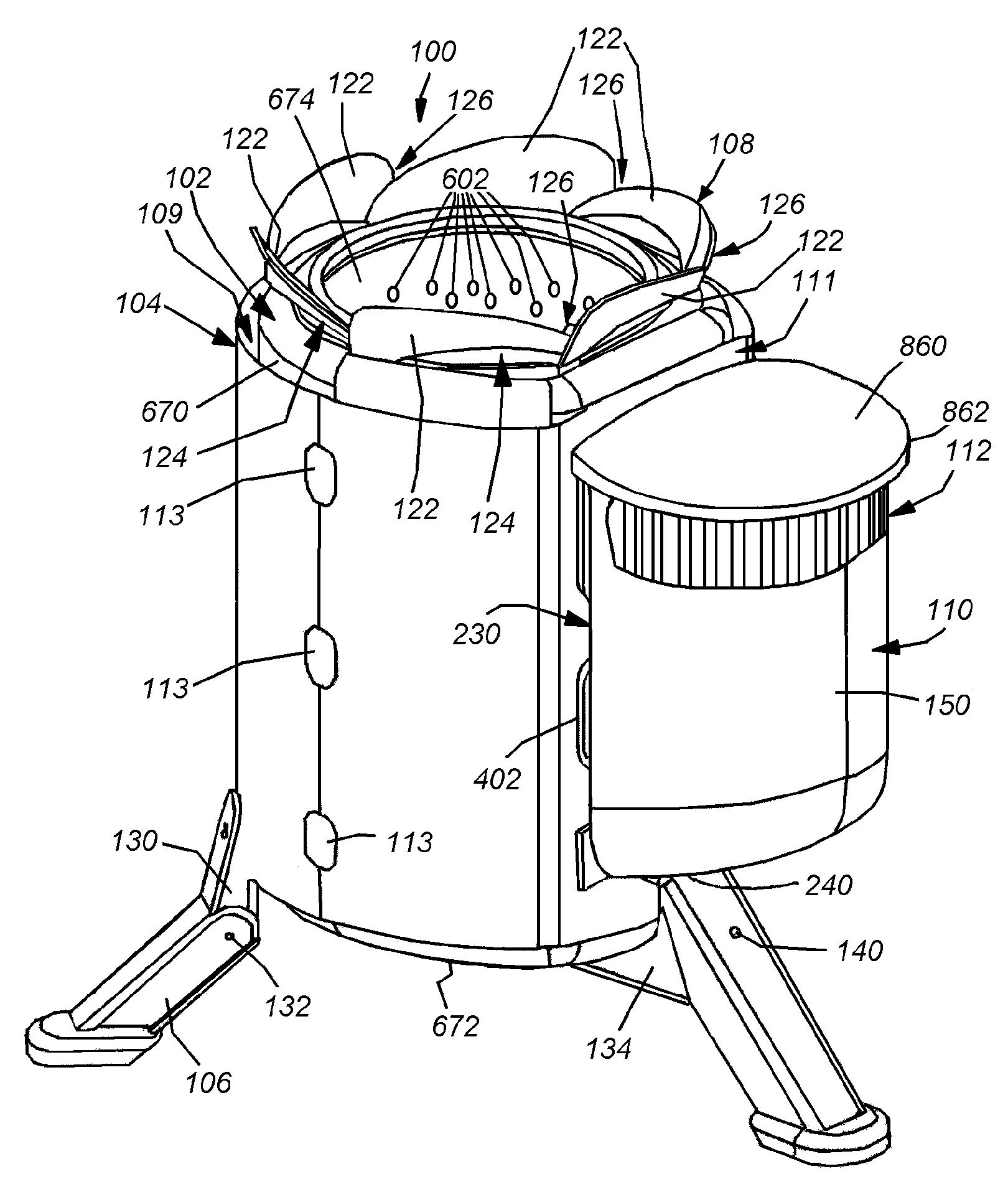

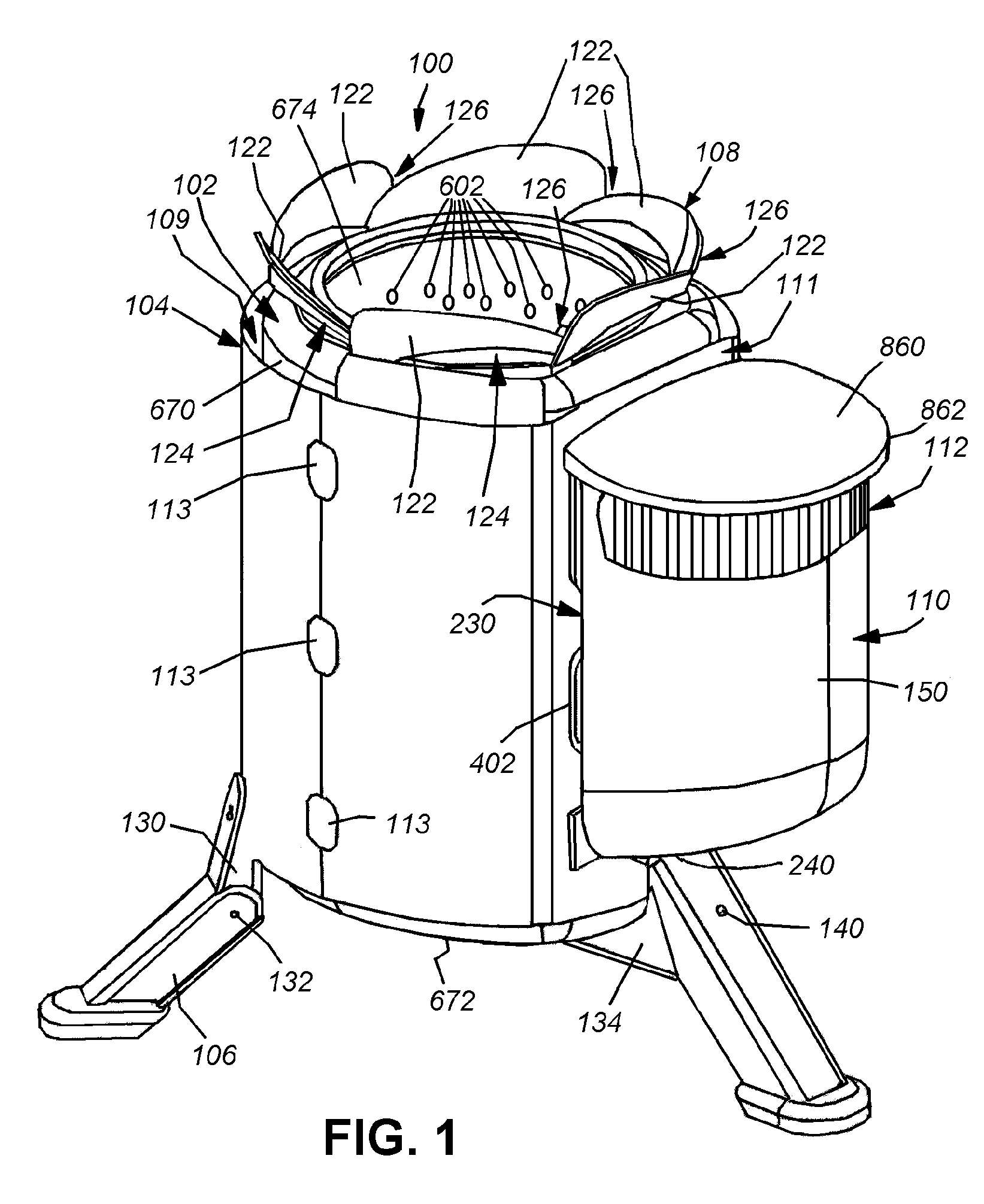

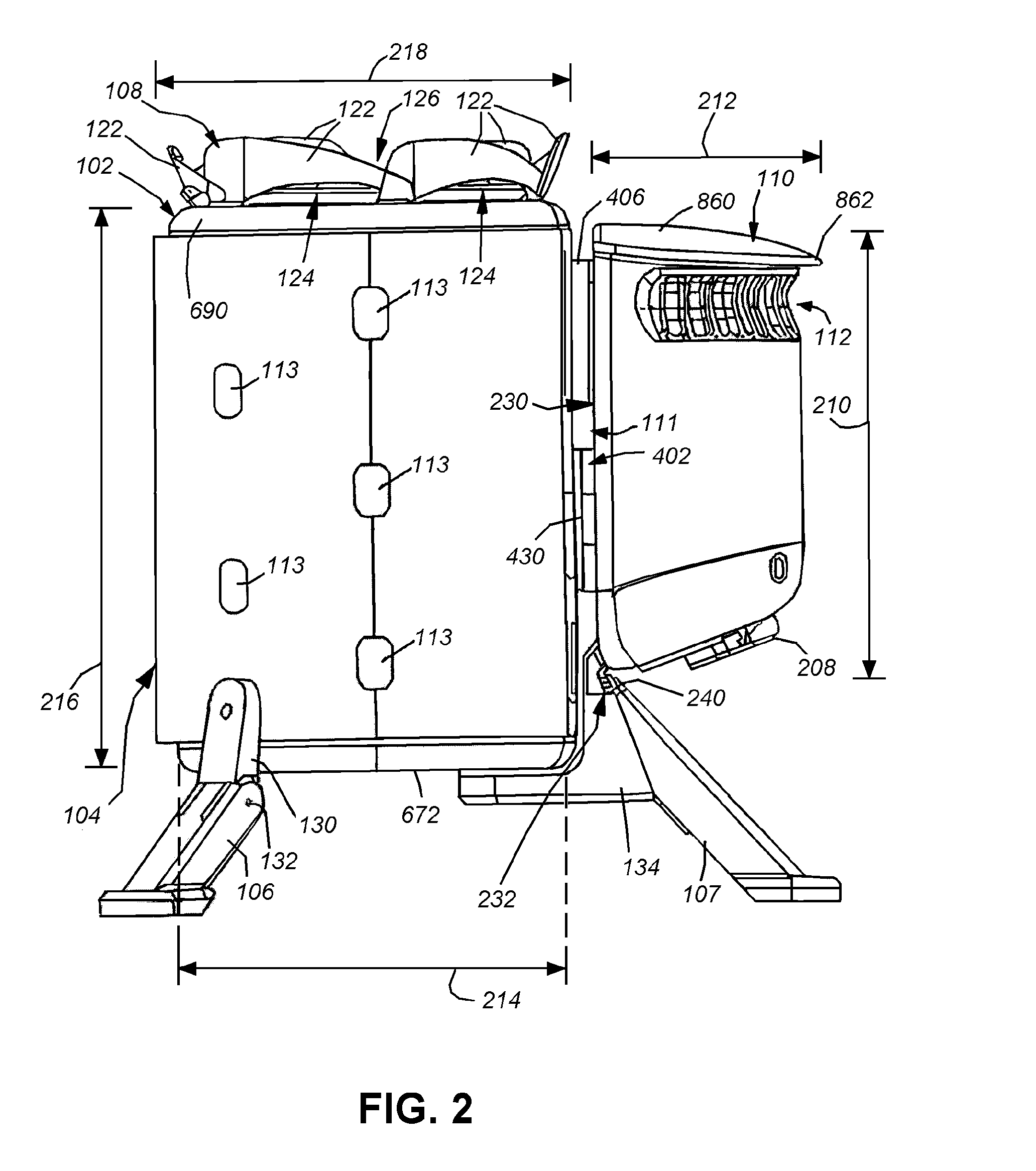

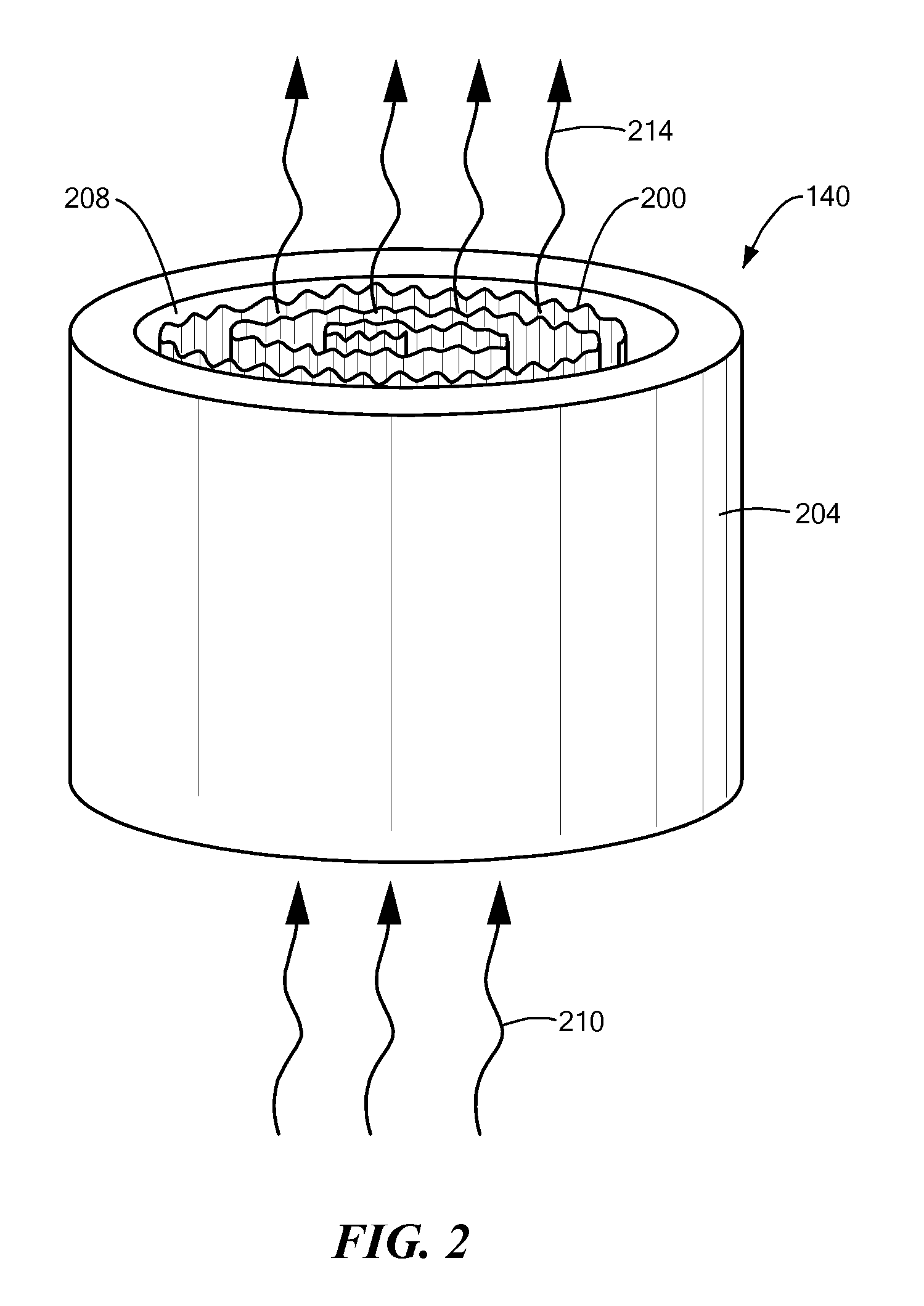

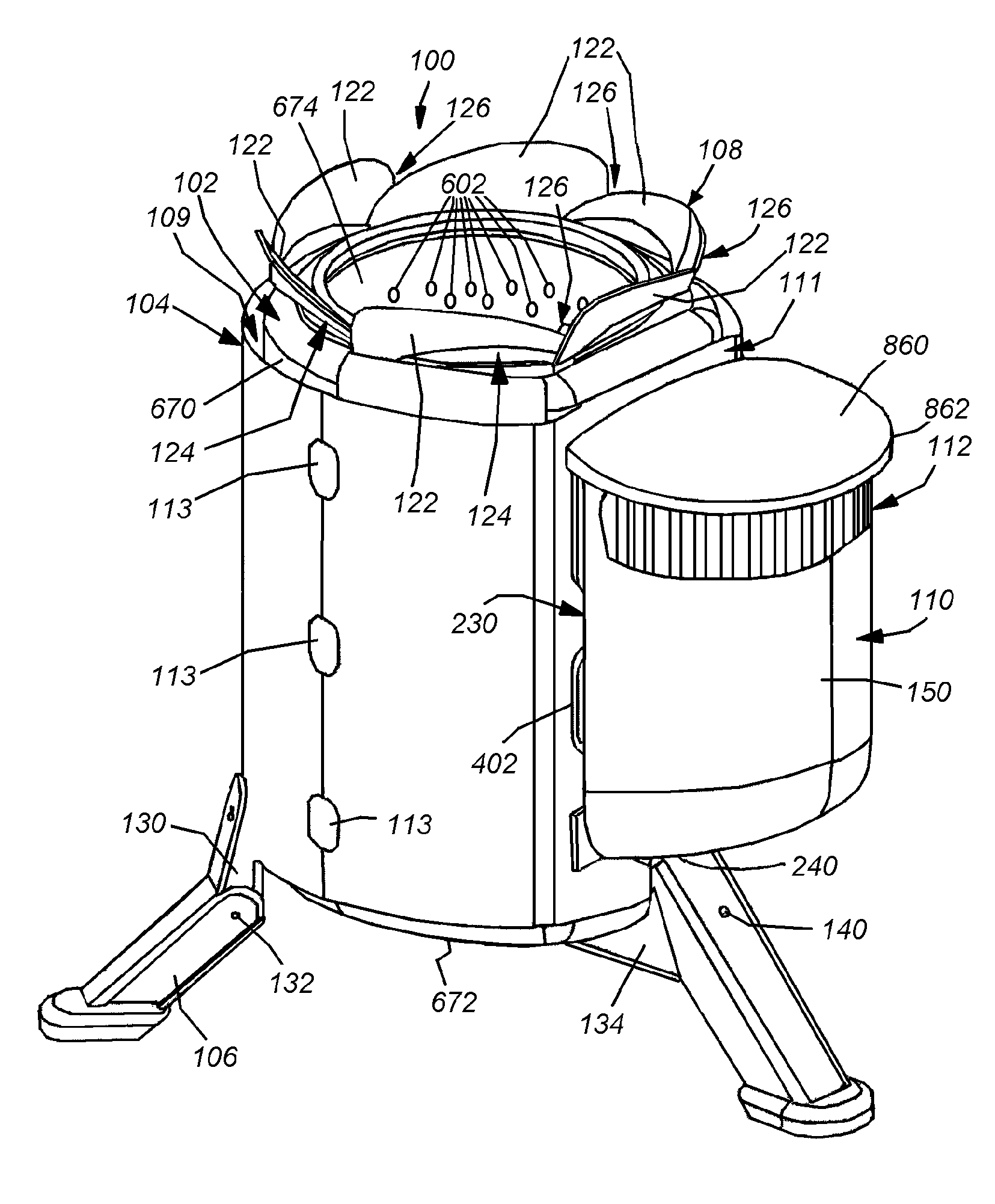

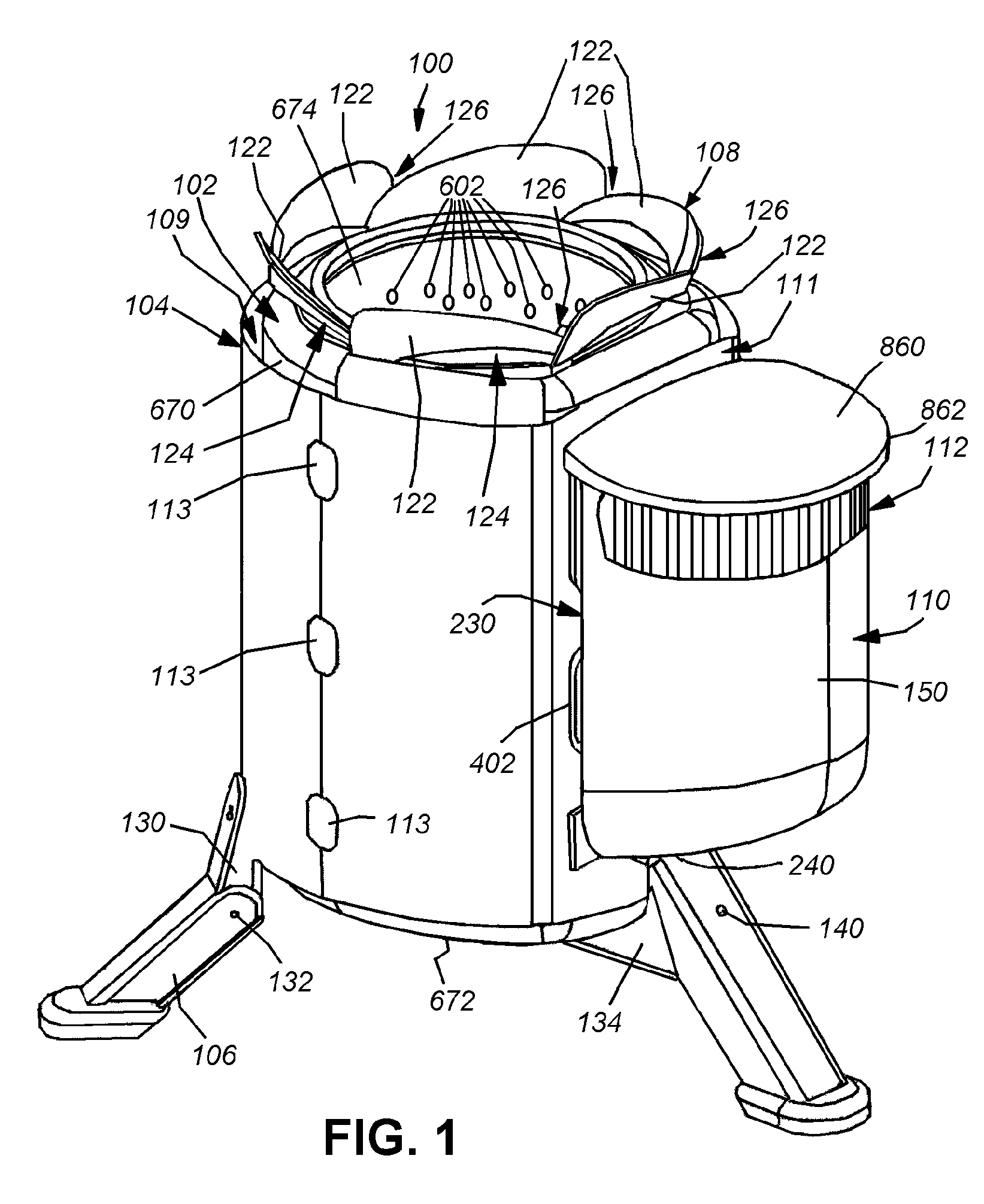

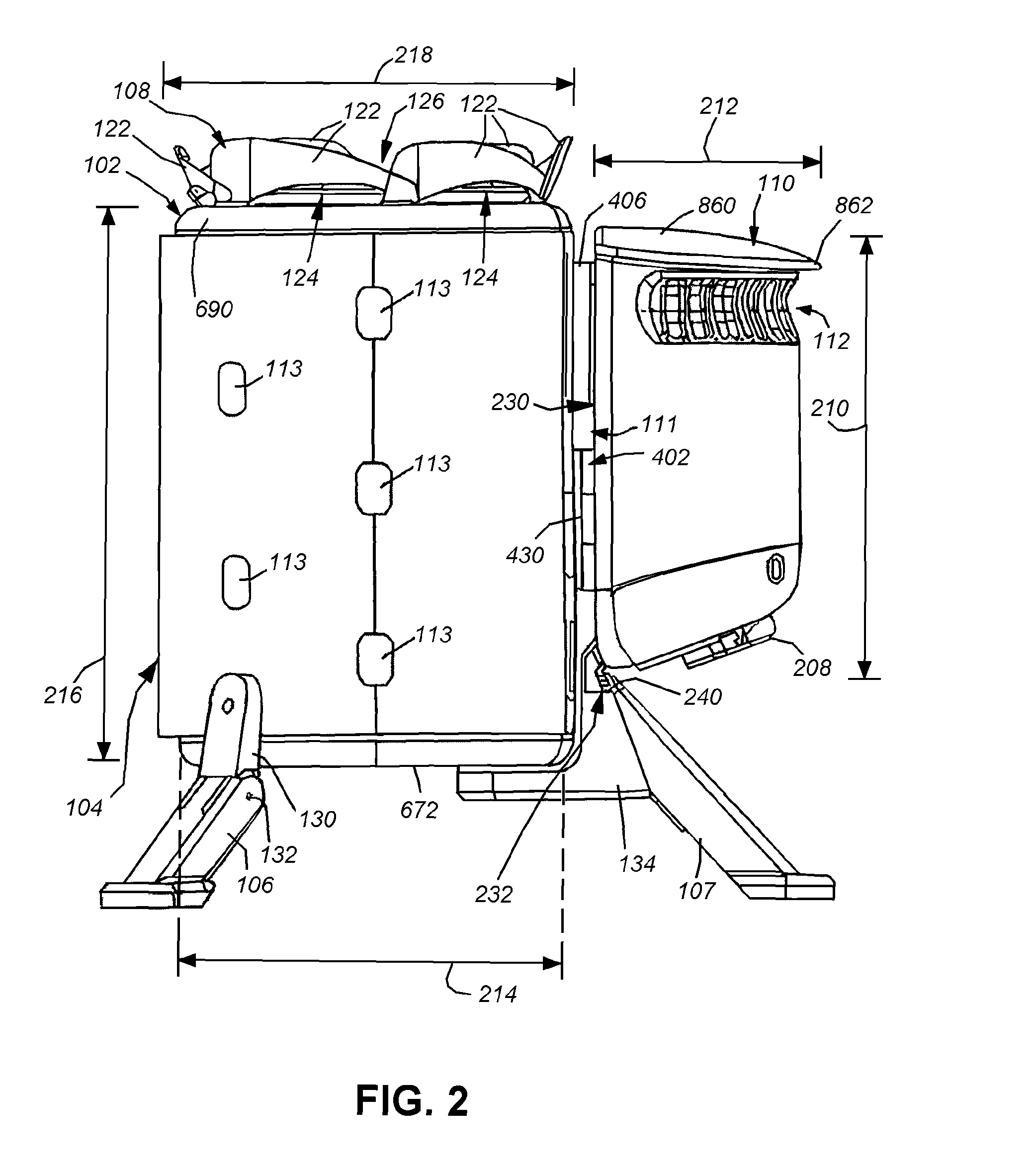

Portable combustion device utilizing thermoelectrical generation

ActiveUS20100083946A1Reduces kindling periodEfficient combustionIncandescent ignitionThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit. The opposing side of the TEG is also in contact with a heat sink to remove heat from the TEG device through interaction with ambient air that passes over the vanes from a port located along the side of the TEG housing. A motor and fan near the heat sink to draw air away the heat sink and aid in the cooling of the heat sink, and force air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between the inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

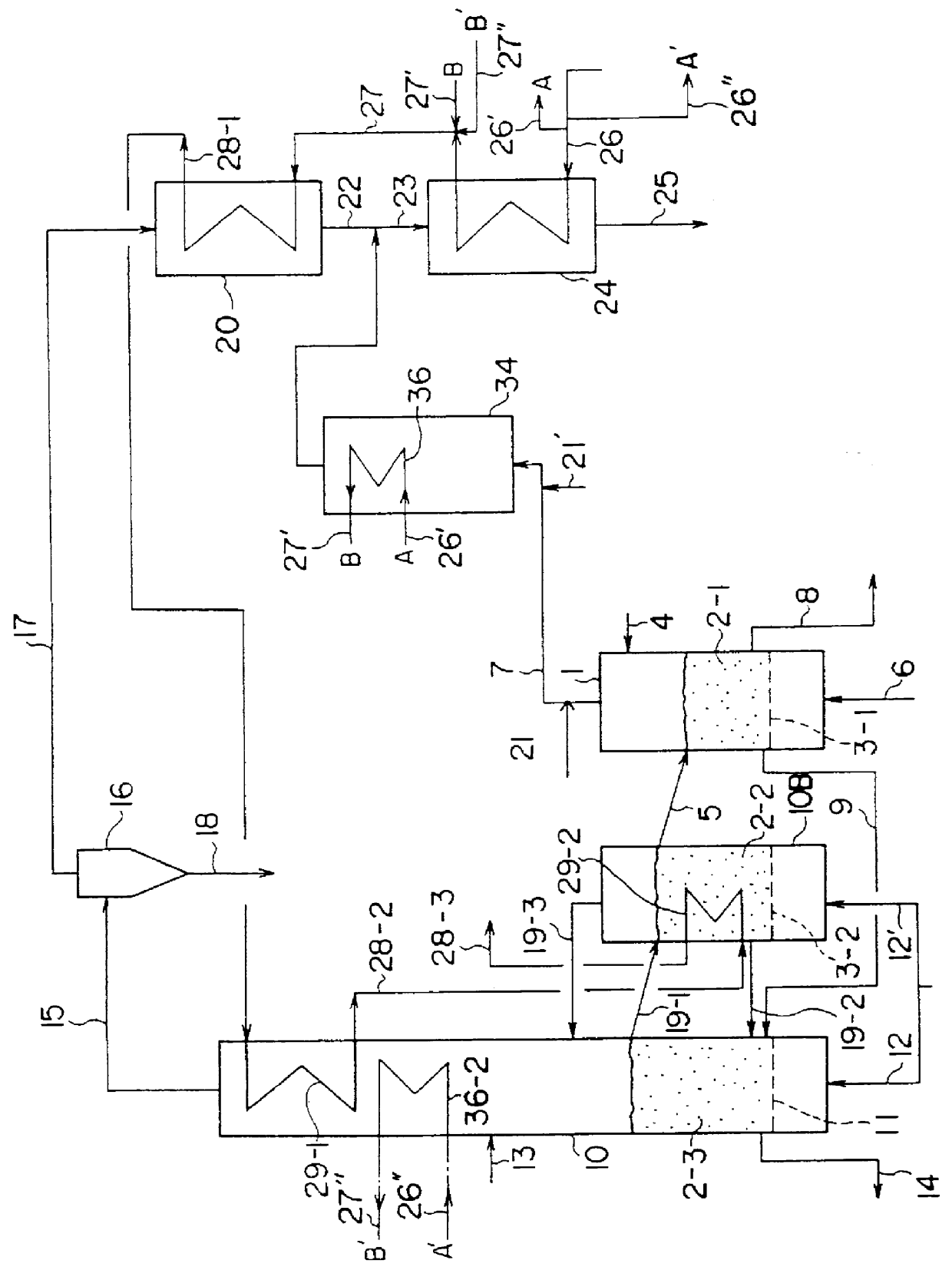

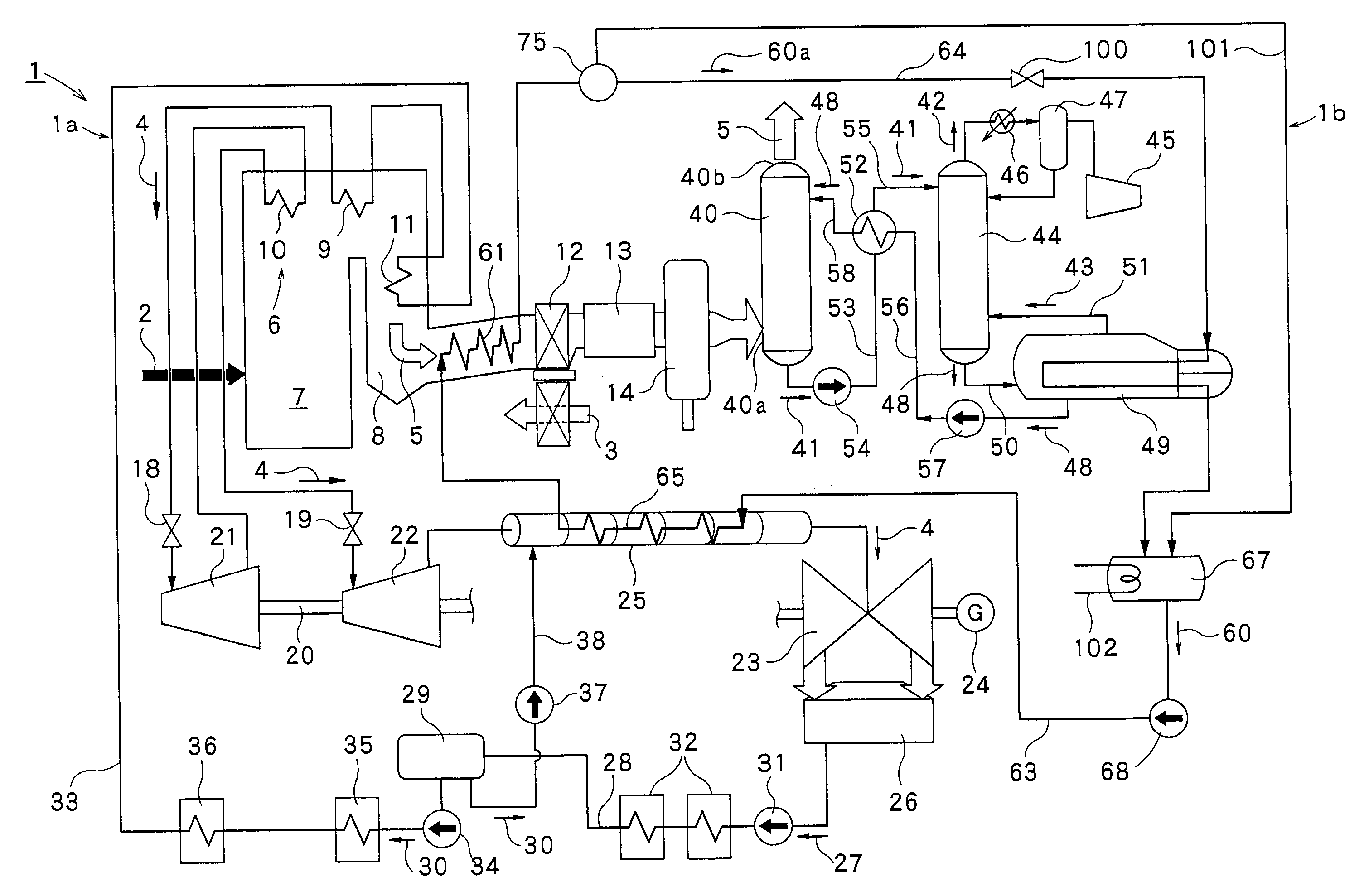

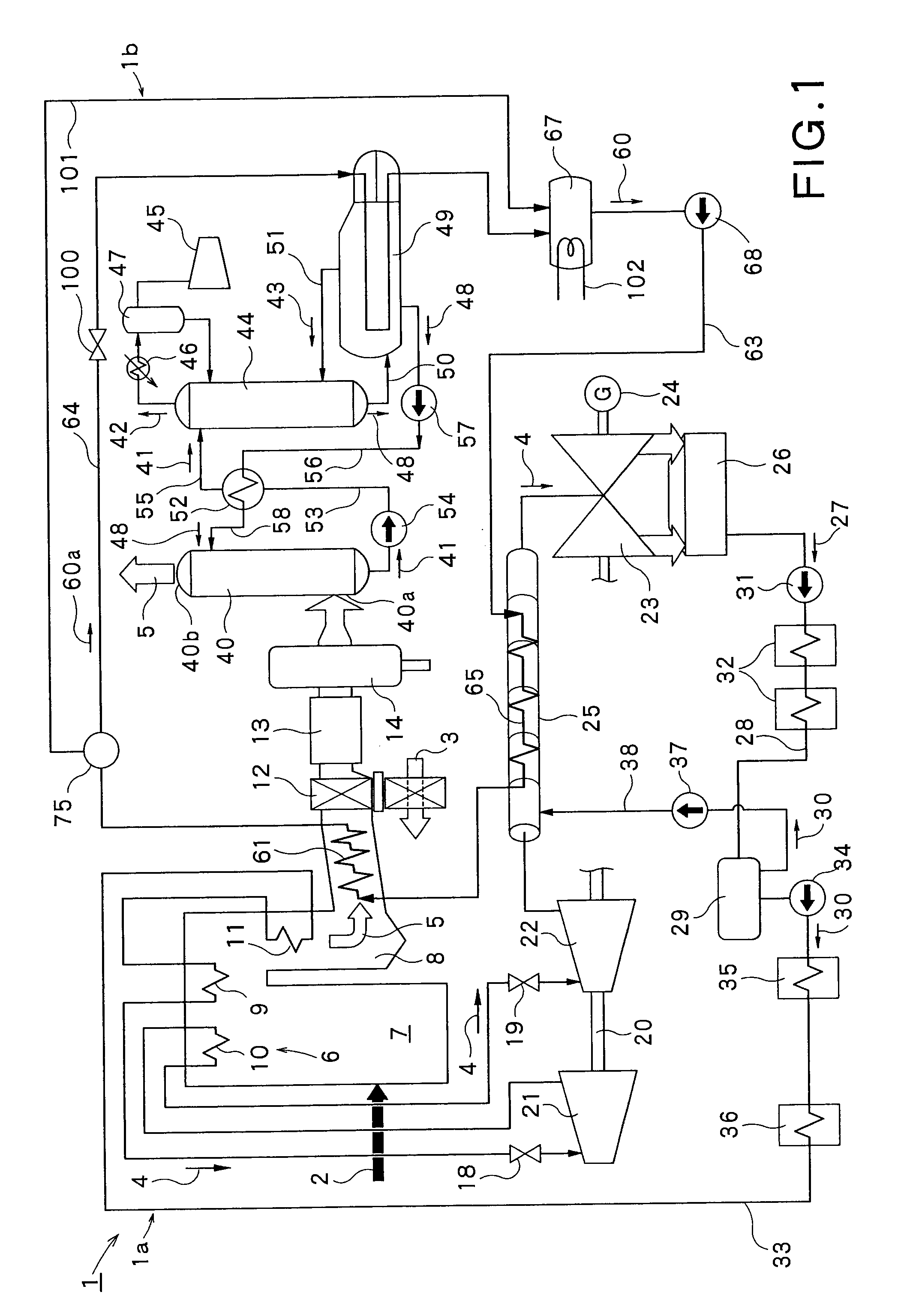

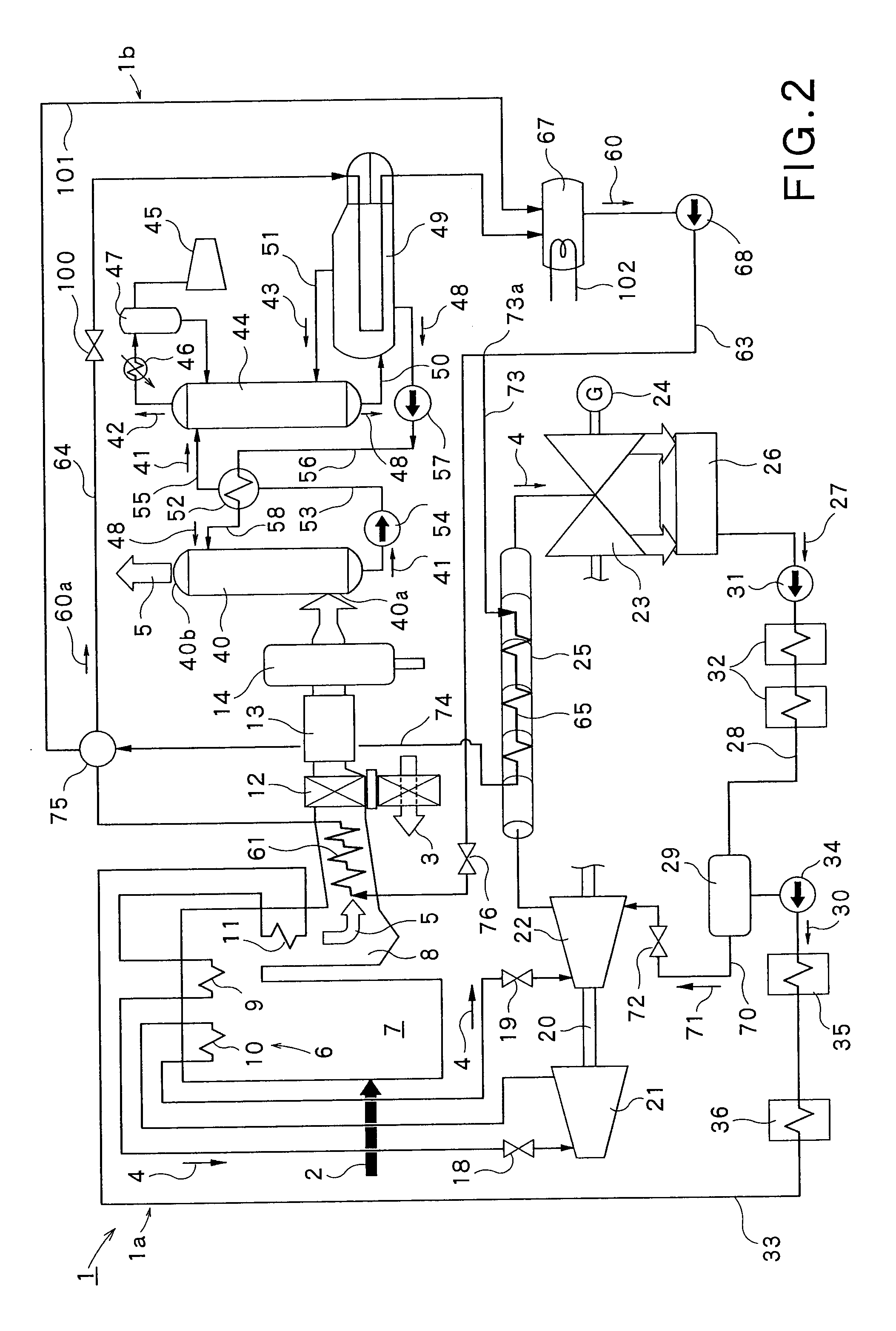

Carbon-dioxide-capture-type steam power generation system

InactiveUS20100050637A1Avoid power generation efficiencyImprove efficiencyLiquid degasificationCarbon compoundsCo2 absorptionReboiler

A carbon-dioxide-capture-type steam power generation system 1 according to the present invention comprises a boiler 6 producing an exhaust gas 5 by combusting a fuel 2 and having a flue 8; an absorbing unit 40 being configured to absorb the carbon-dioxide contained in the exhaust gas 5 into an absorbing solution; and a regenerating unit 44 being configured to release the carbon dioxide gas from the absorbing solution absorbing the carbon dioxide and discharge the released carbon dioxide gas. Further, in this system, a reboiler 49 is provided for receiving a heating-medium as heat source, producing a steam 43 and supplying the produced steam 43 to the regenerating unit 44. Additionally, in the flue 8 of the boiler 6, a boiler-side heat exchanger 61 is provided for heating the heating-medium by the exhaust gas 5 passing therethrough.

Owner:KK TOSHIBA

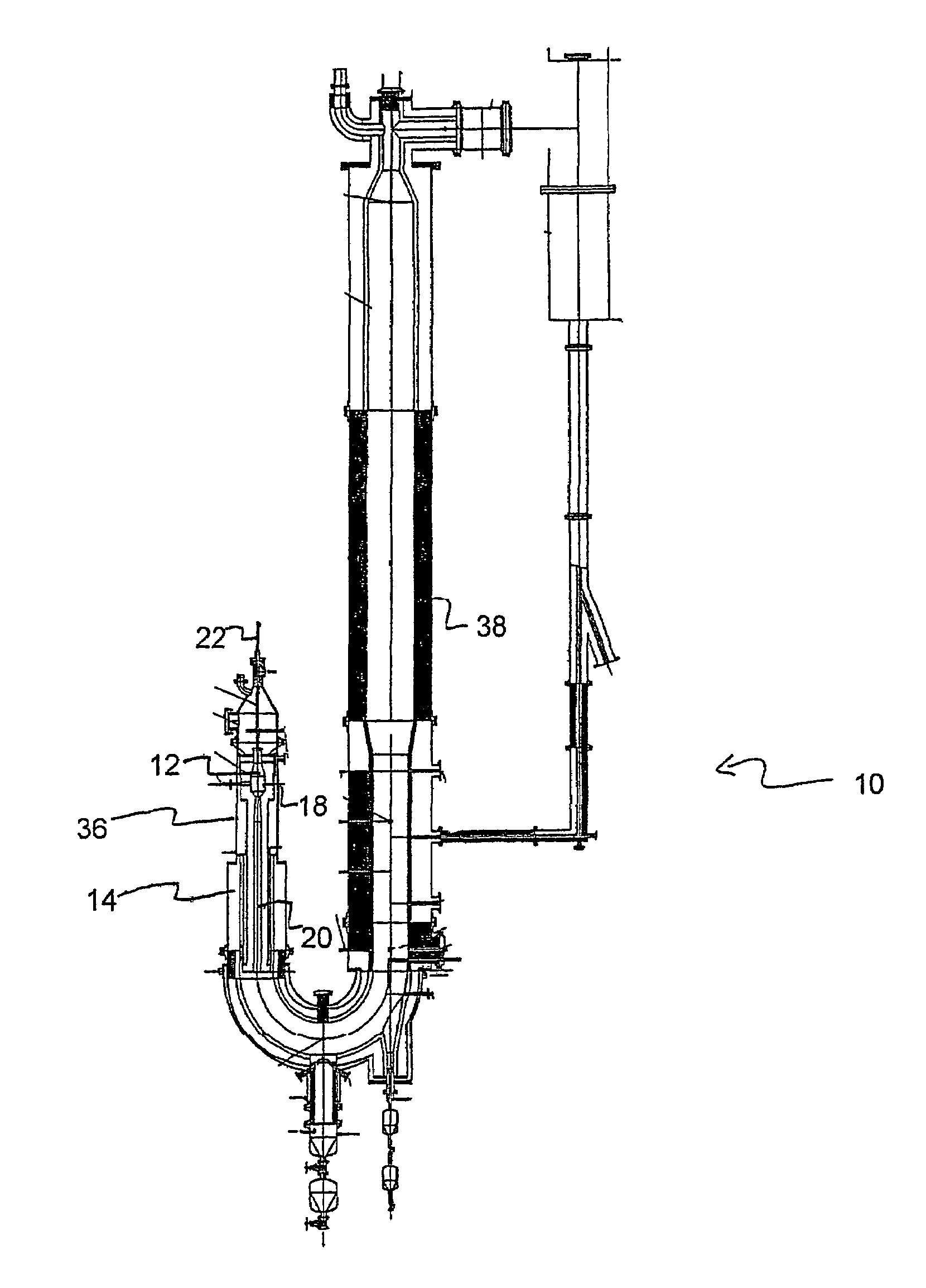

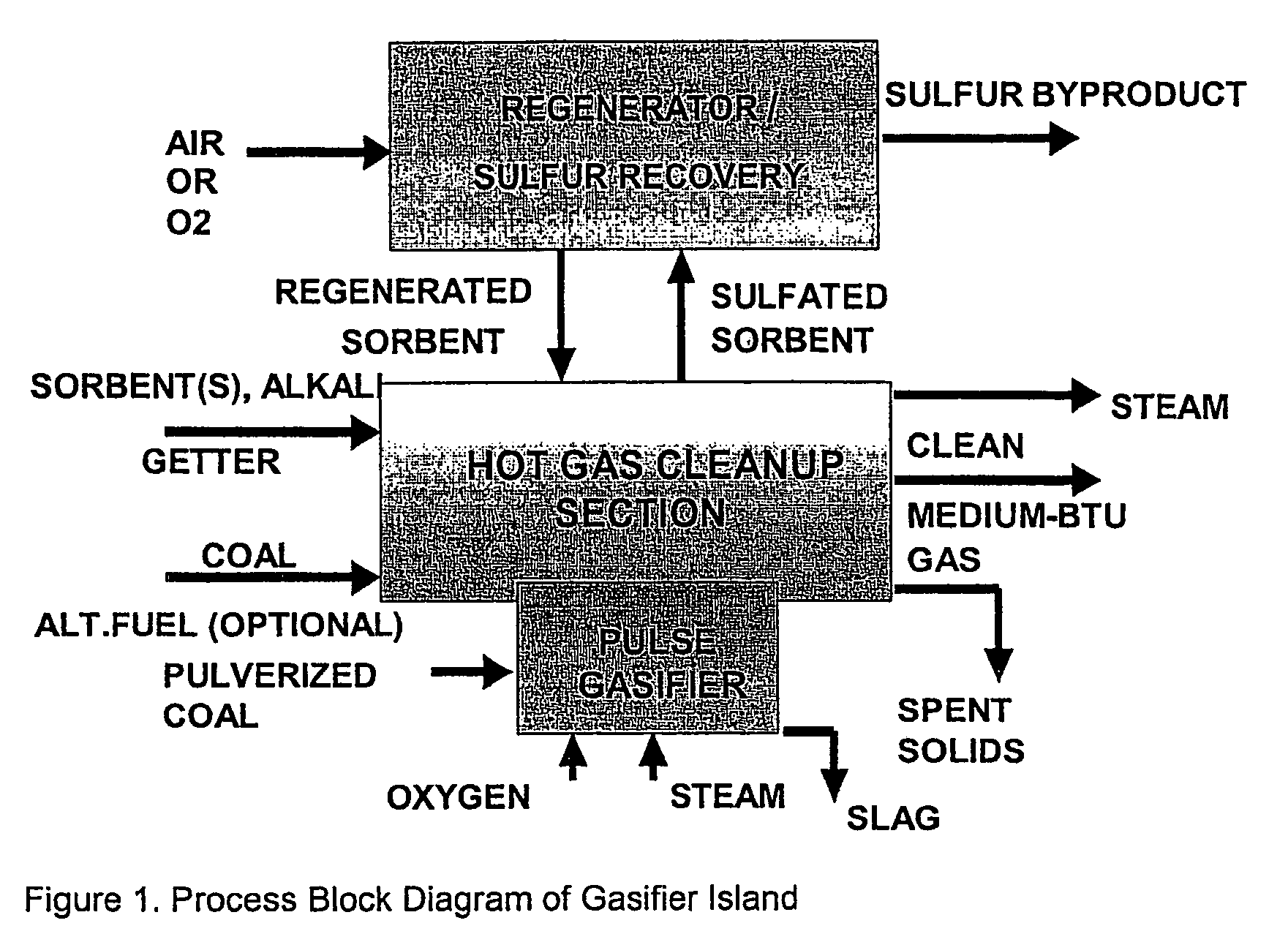

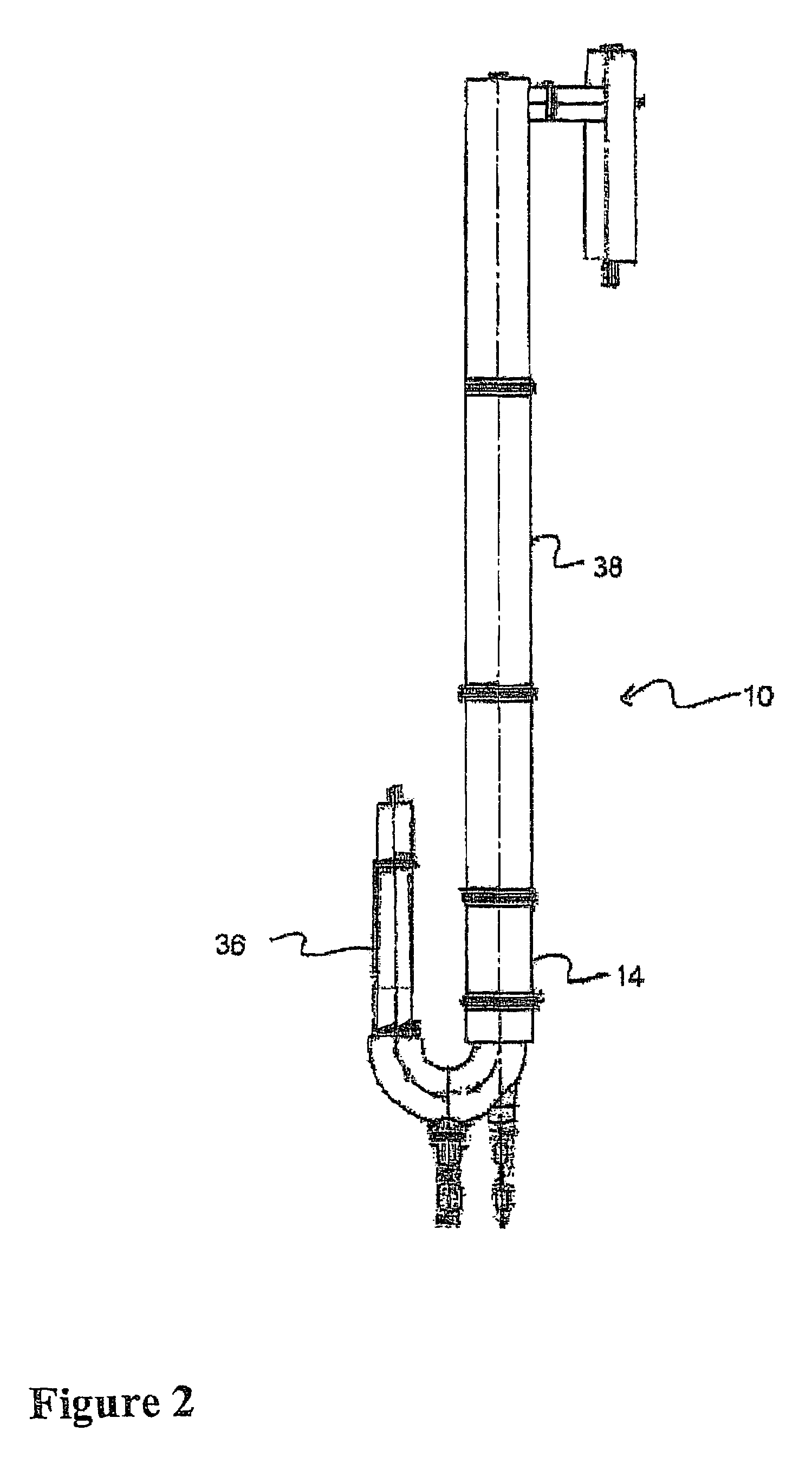

Pulse gasification and hot gas cleanup apparatus and process

InactiveUS6997118B2Easy to useConducive to agglomerationAuxillary pretreatmentGasifier mechanical detailsSteam reformingElectricity

A gasifier system and process comprises a pulse combustion device in communication with a fluid channel for producing a gas stream having heat or fuel value. The pulse combustion device is operated under sub-stoichiometric conditions such that combustion and steam reforming both occur in the fluid channel. The pulse combustion device also produces a pulsating combustion product stream and an acoustic pressure wave. The acoustic pressure wave serves to cause agglomeration of particles contained within the combustion stream for easy removal. In one embodiment, a sulfur capturing agent is injected into the fluid channel for not only removing sulfur from the combustion product stream but for also facilitating particle agglomeration. Ultimately, a gas stream containing hydrogen is produced that may be used in various processes, such as in the production of electricity.

Owner:MFG & TECH CONVERSION INT

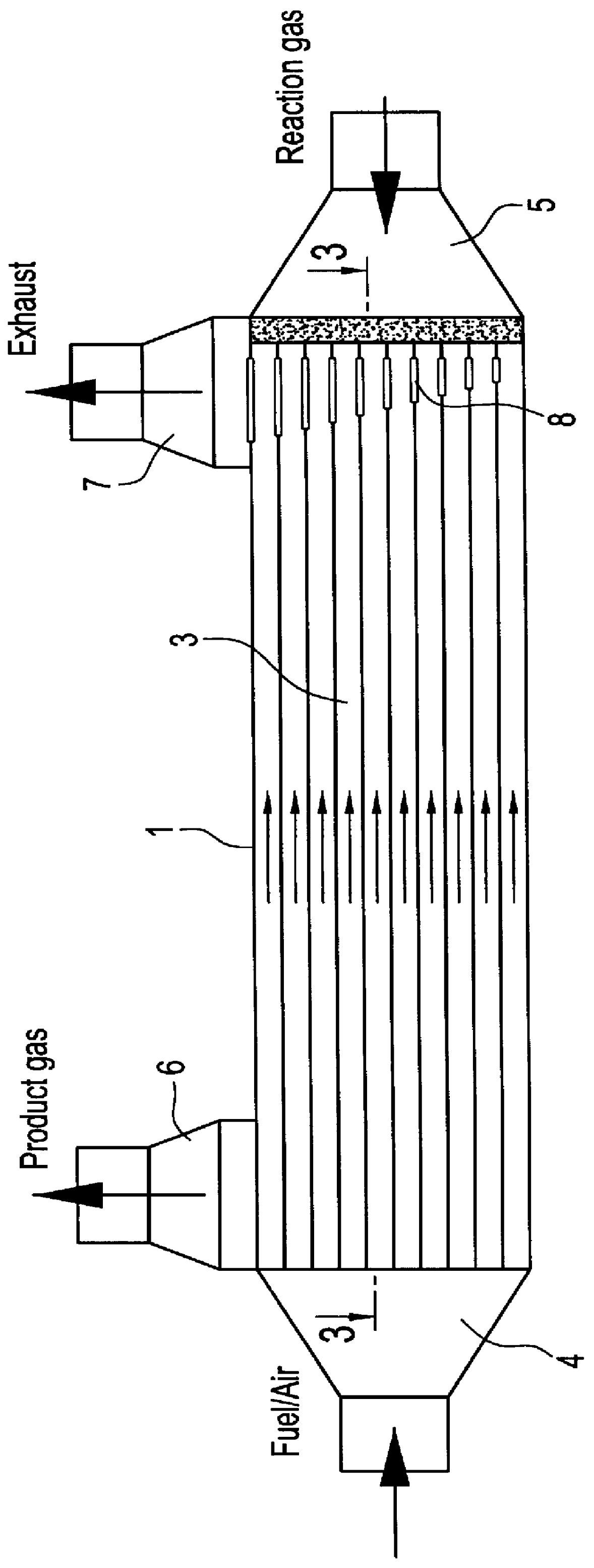

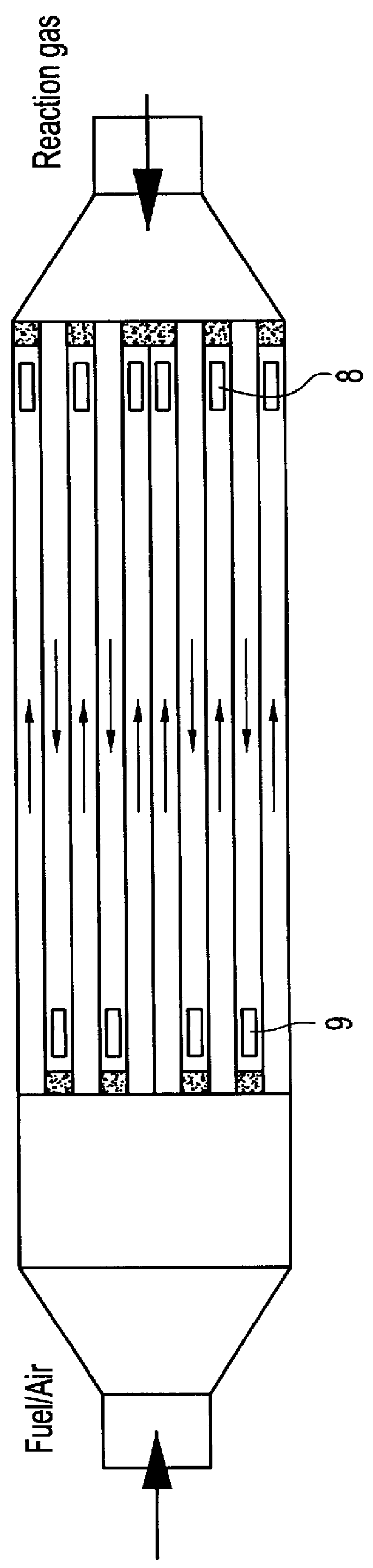

Reactor for performing endothermic catalytic reactions

InactiveUS6056932ACatalytic gas-gas reactionPhysical/chemical process catalystsOrganic chemistryCatalytic combustion

A reactor for performing endothermic catalytic reactions is disclosed formed of a monolithic counterflow reactor with parallel heating and reaction channels. The internal walls of the reaction channels are coated with a catalyst for the catalytic reaction to be performed, while the internal walls of the heating channels have a catalyst for the catalytic combustion of a fuel gas / air mixture.

Owner:DEGUSSA AG

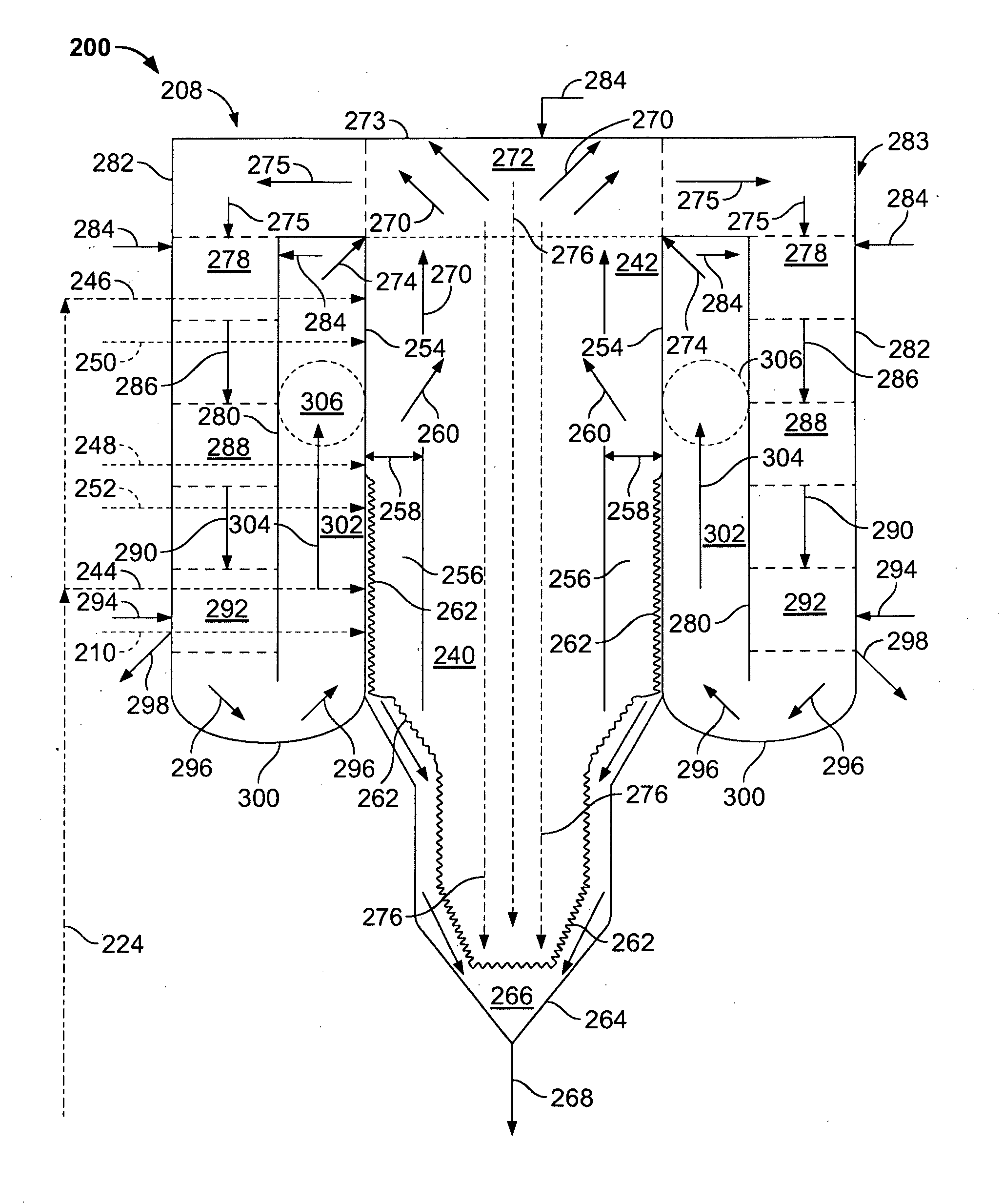

Method and apparatus to facilitate substitute natural gas production

ActiveUS20100018115A1Easy to operateReduce installationMuffle furnacesGasifier mechanical detailsForming gasProduct gas

A method of producing substitute natural gas (SNG) includes providing a gasification reactor having a cavity defined at least partially by a first wall. The reactor also includes a first passage defined at least partially by at least a portion of the first wall and a second wall, wherein the first passage is in heat transfer communication with the first wall. The reactor further includes a second passage defined at least partially by at least a portion of the second wall and a third wall. The method also includes coupling the cavity in flow communication with the first and second passages. The method further includes producing a first synthetic gas (syngas) stream within the cavity. The method also includes channeling at least a portion of the first syngas stream to the first and second passages.

Owner:AIR PROD & CHEM INC

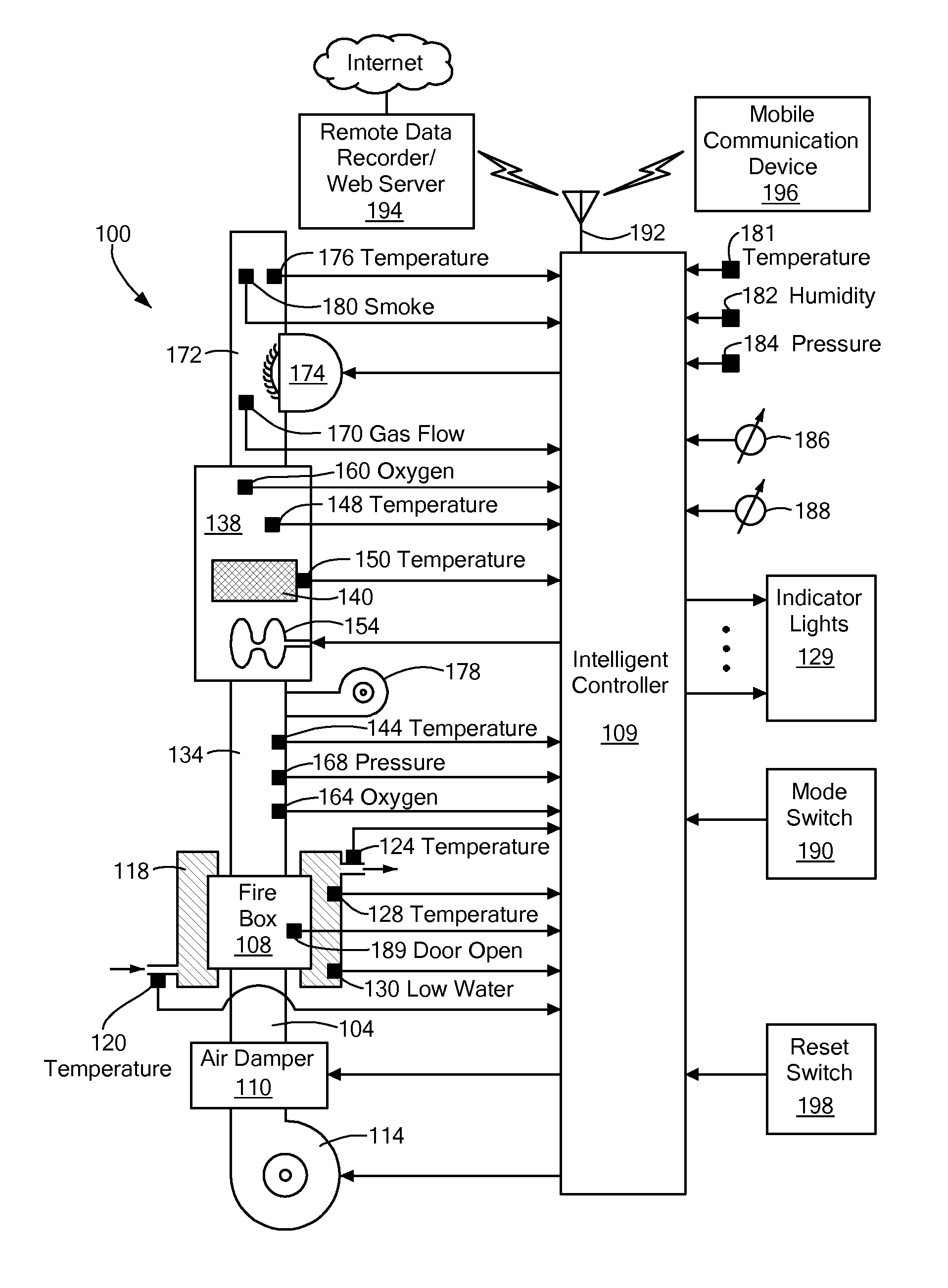

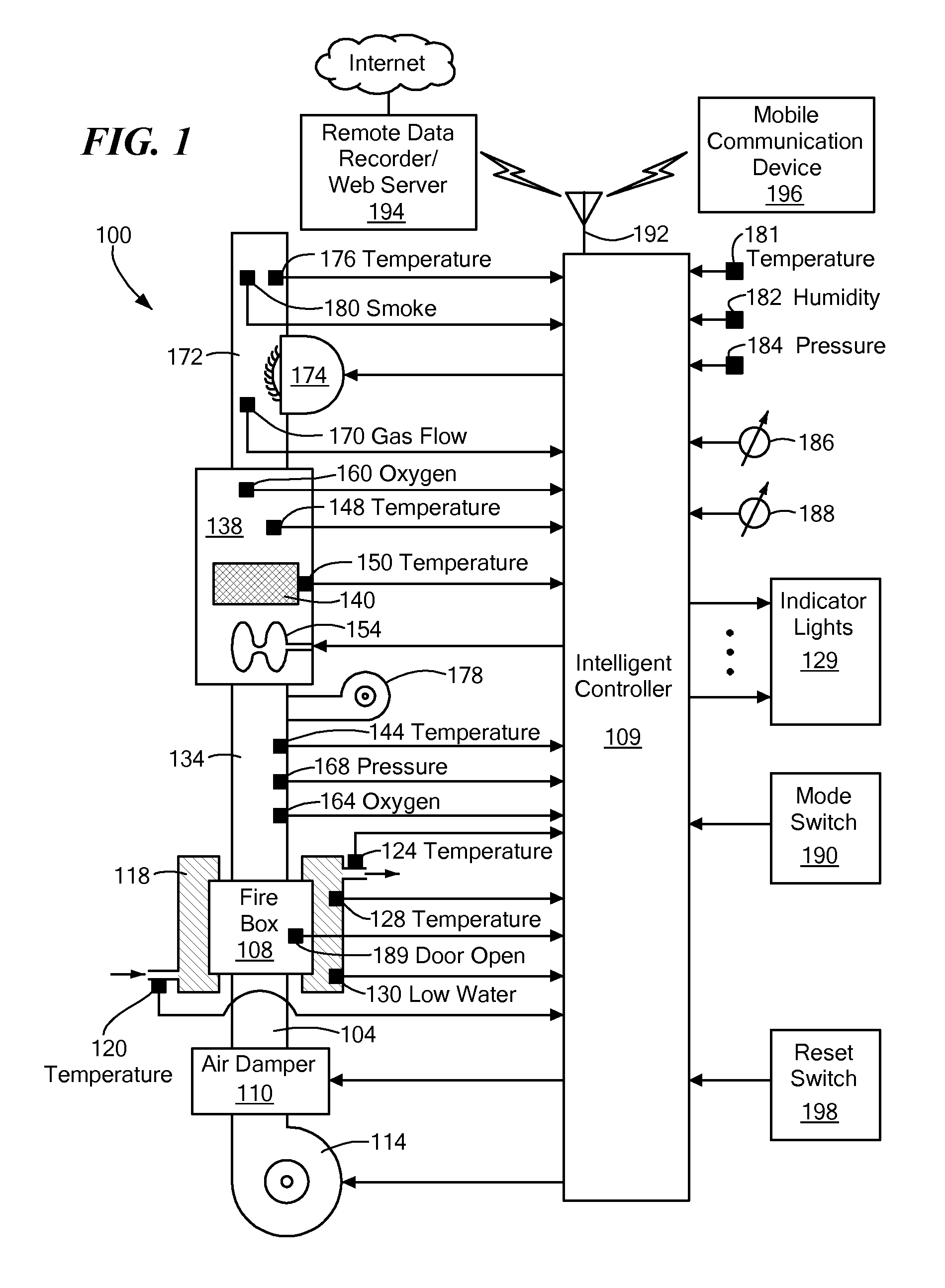

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

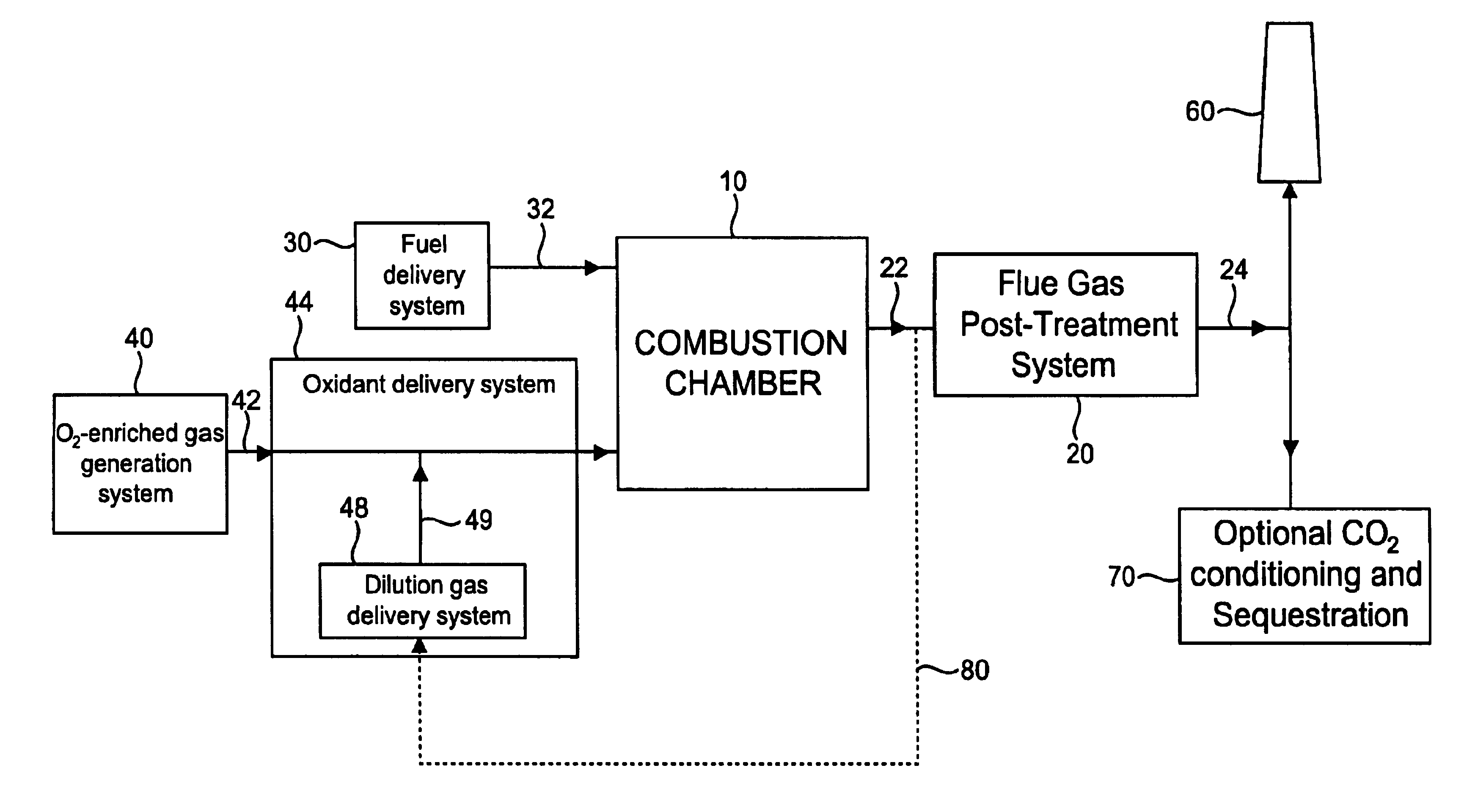

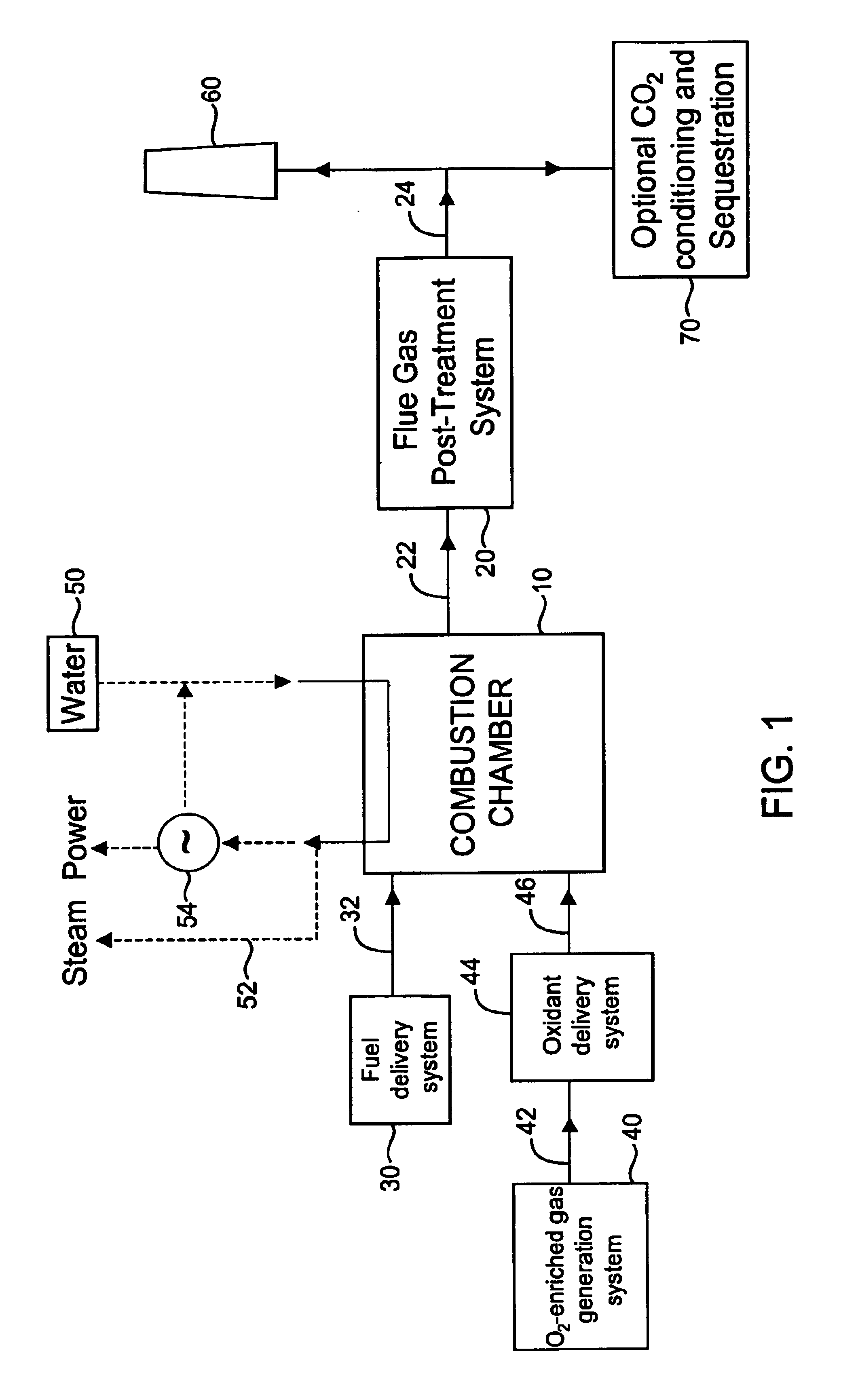

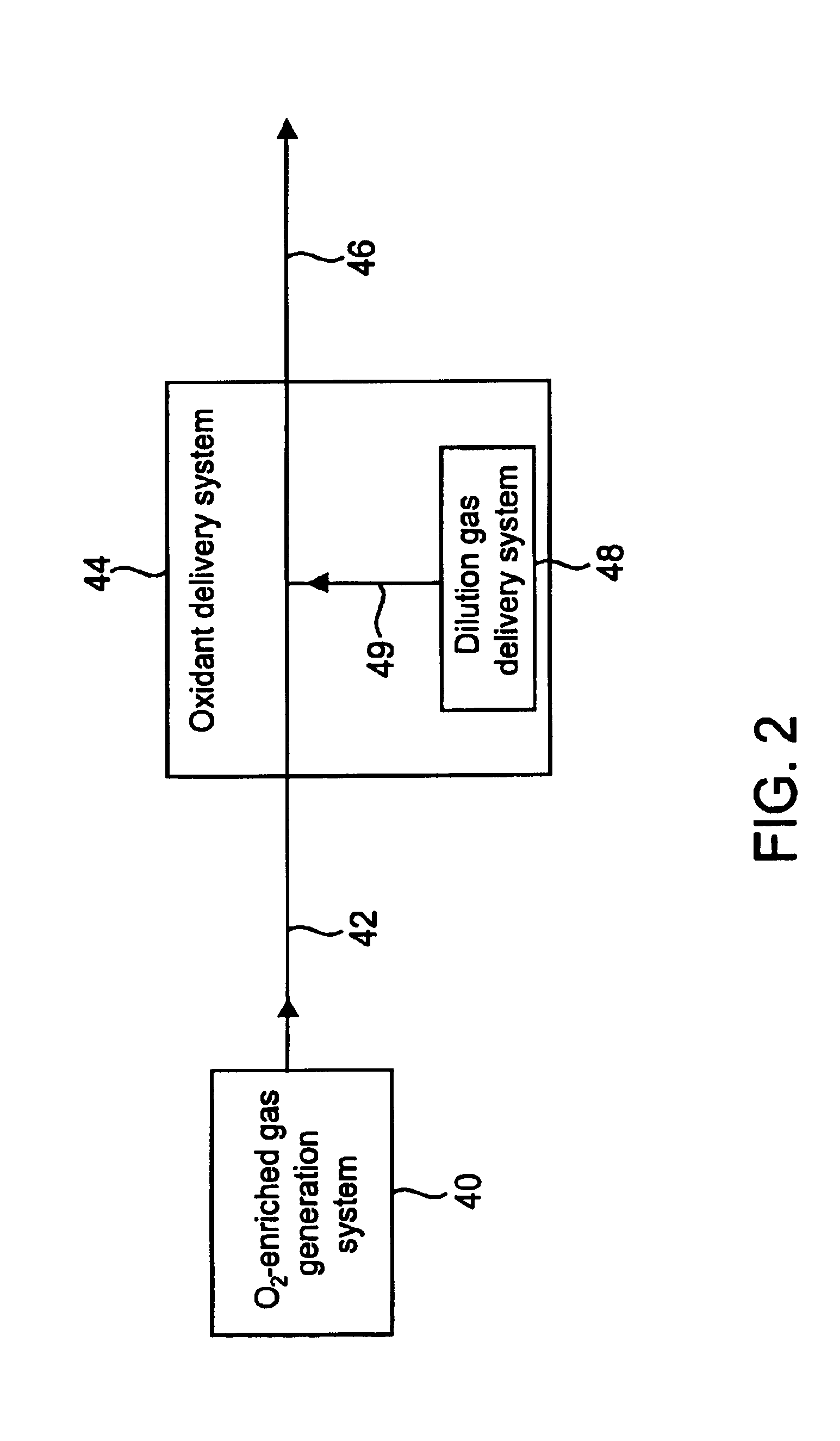

Steam-generating combustion system and method for emission control using oxygen enhancement

InactiveUS6935251B2Low costReduce mass flow rateUsing liquid separation agentEmission preventionParticulatesHigh concentration

A steam-generating combustion system includes an oxygen enriched gas provided as at least part of an oxidant stream. A combustion chamber receives and combusts a fuel in the oxidant stream and generate steam. The combustion chamber generates flue gas having a flue gas volume which is smaller than a volume of flue gas generated by the combustion chamber when operated with air as the oxidant stream. A flue gas pollutant control system receives the flue gas from the combustion chamber and reduces at least one of particulate matter, SOx, NOx, and mercury. The reduction in flue gas volume allows the implementation of much smaller pollutant control equipment, since the size of the pollutant control units is mainly based on the volume or mass flow rate of flue gas to be treated. Moreover, the system including oxygen-enriched gas in the oxidant will lead to concentrated levels of the pollutants in the flue gas. The high concentrations of pollutants will enhance their absorption in the different pollutant control systems, improving removal efficiency for all species.

Owner:AIR LIQUIDE AMERICA INC +1

Portable combustion device utilizing thermoelectrical generation

ActiveUS8297271B2Shorten the overall cycleIncrease heatTobacco treatmentThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit. The opposing side of the TEG is also in contact with a heat sink to remove heat from the TEG device through interaction with ambient air that passes over the vanes from a port located along the side of the TEG housing. A motor and fan near the heat sink to draw air away the heat sink and aid in the cooling of the heat sink, and force air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between the inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

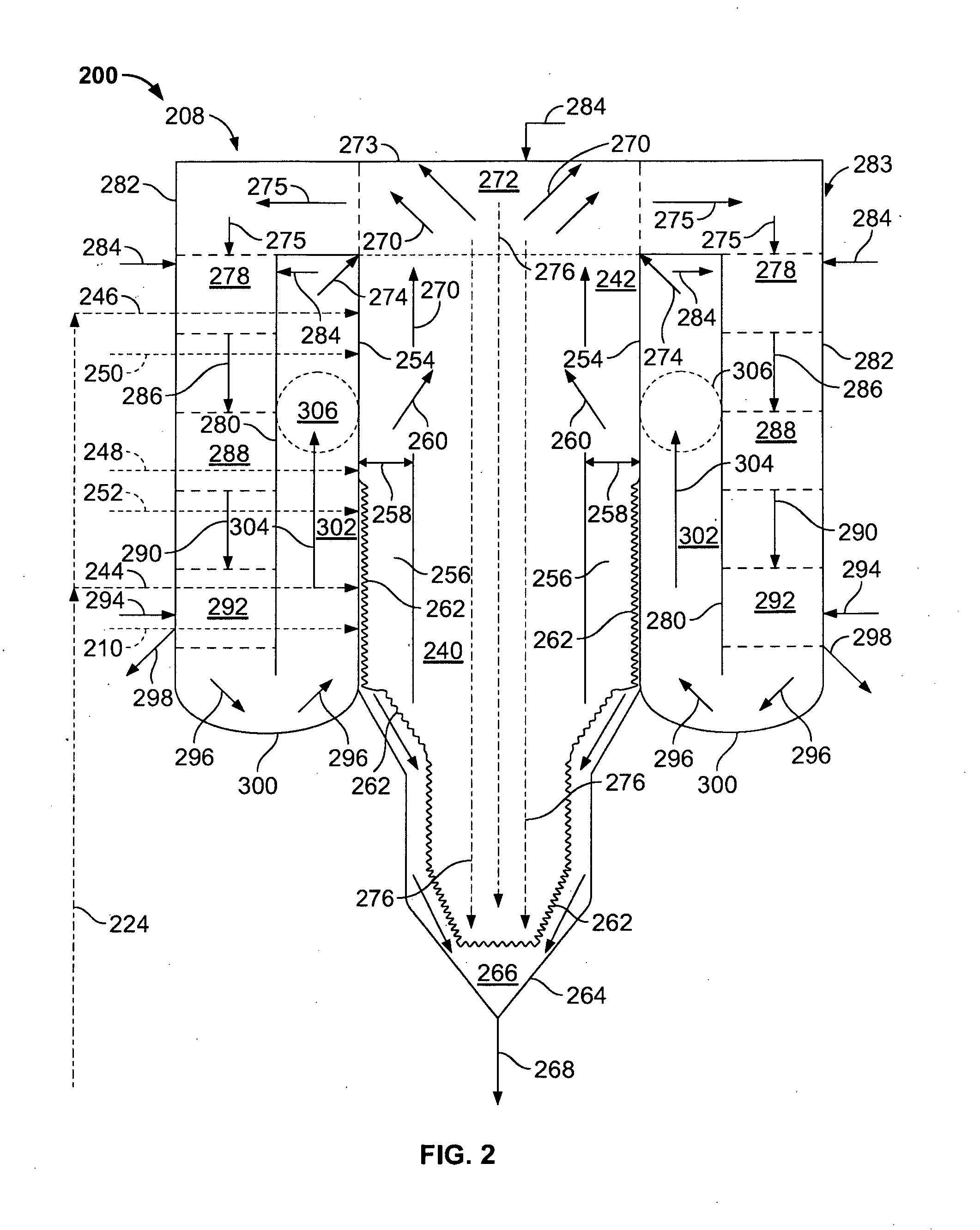

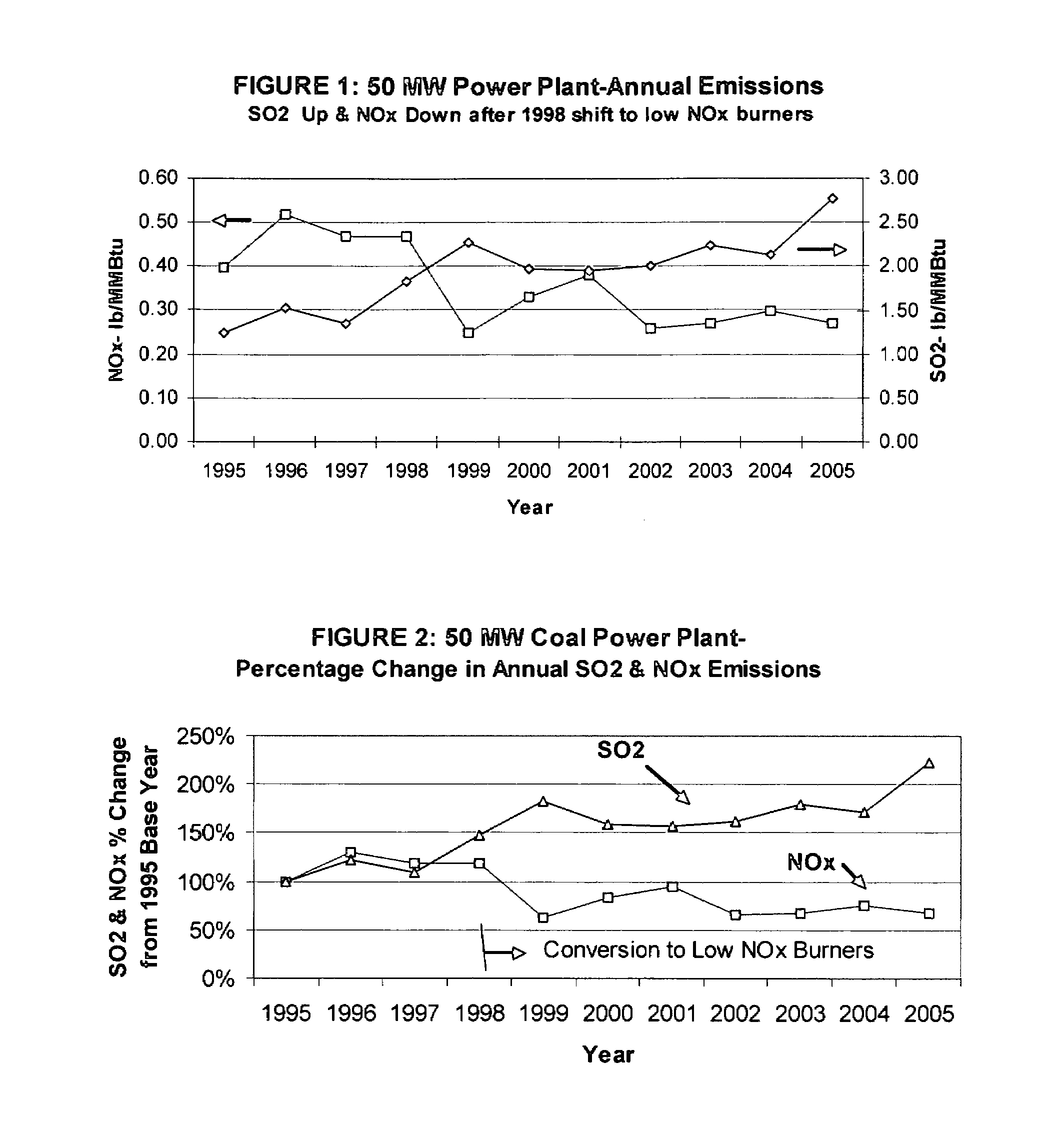

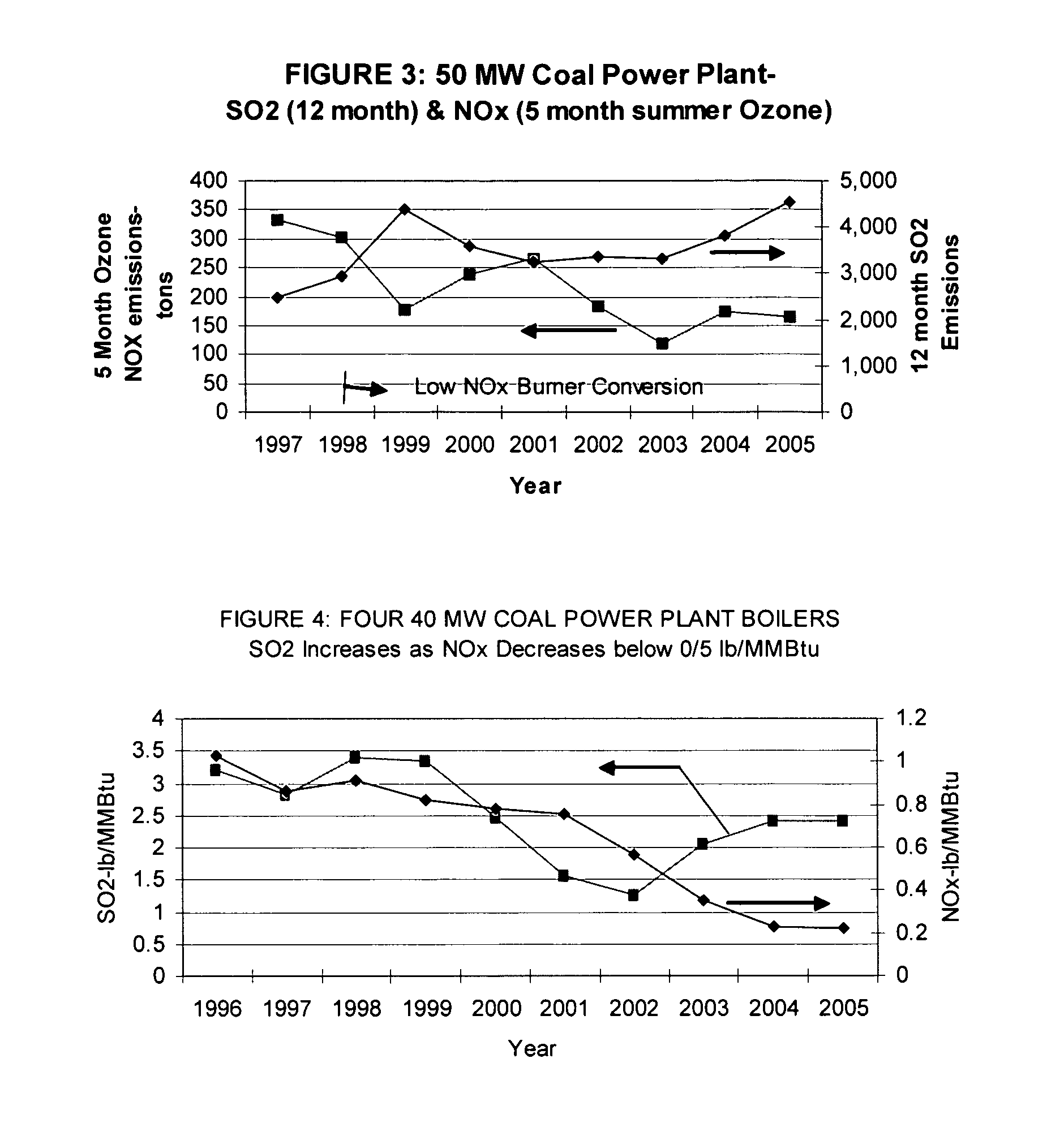

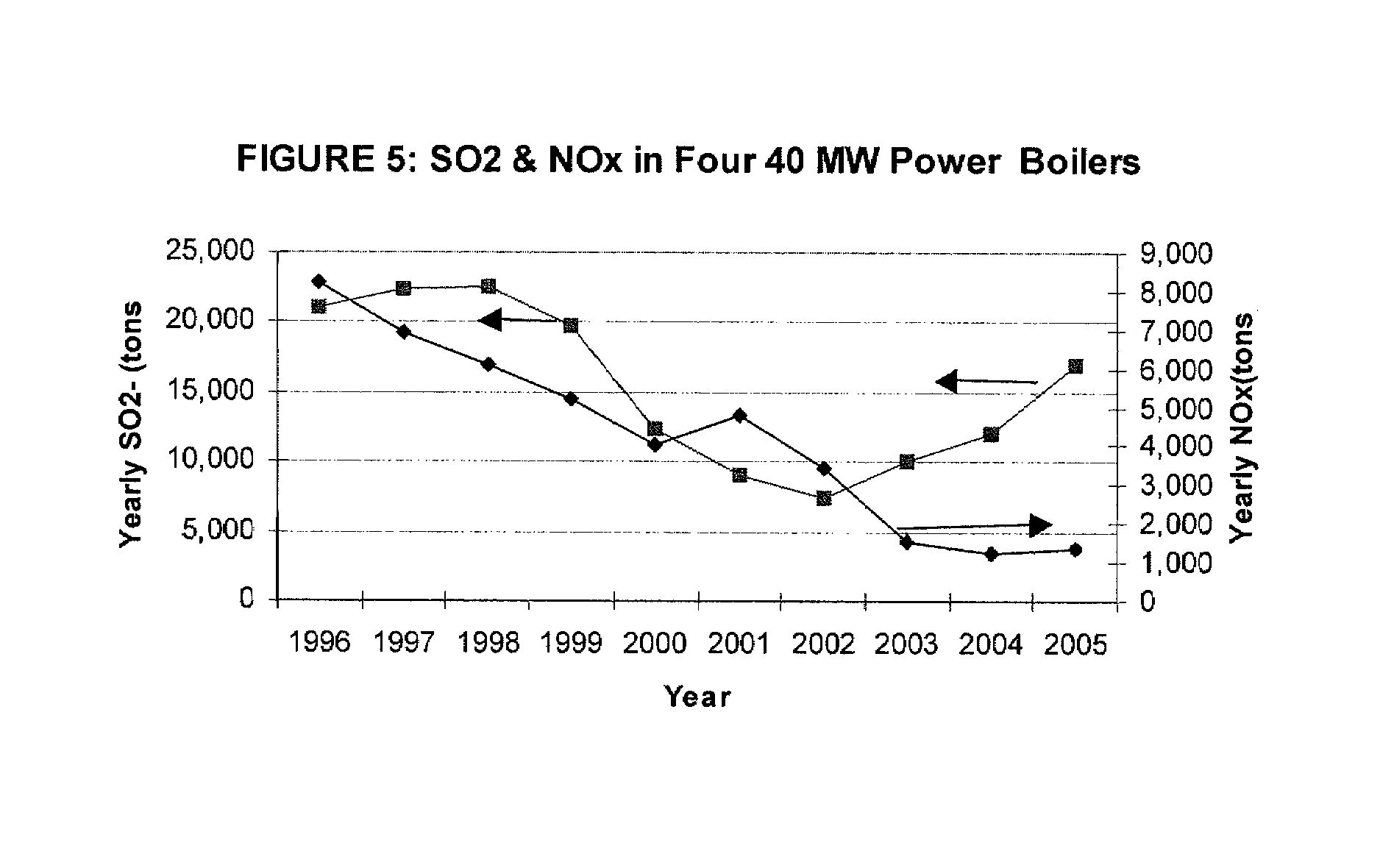

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com