Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

385results about "Catalytic gas-gas reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

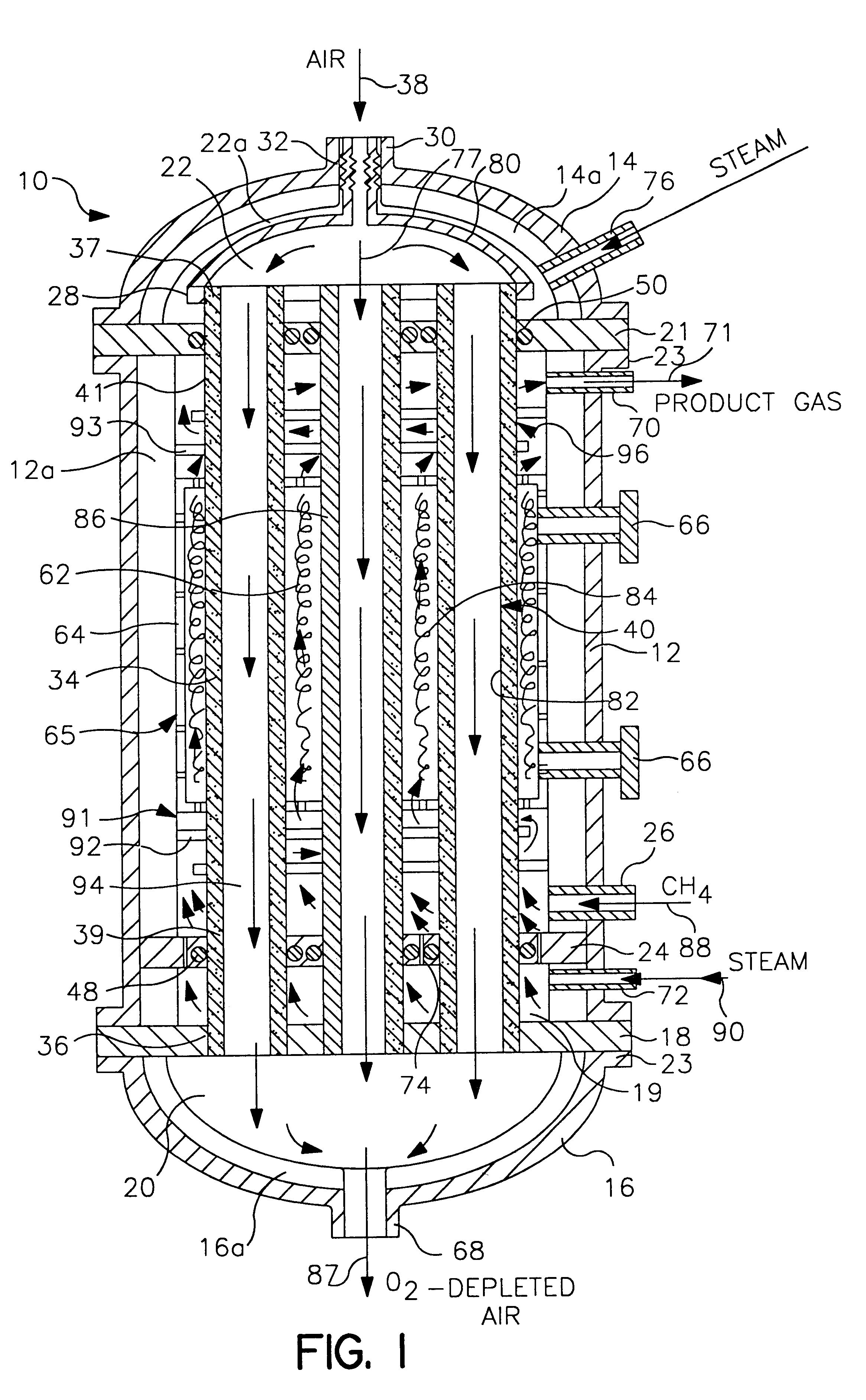

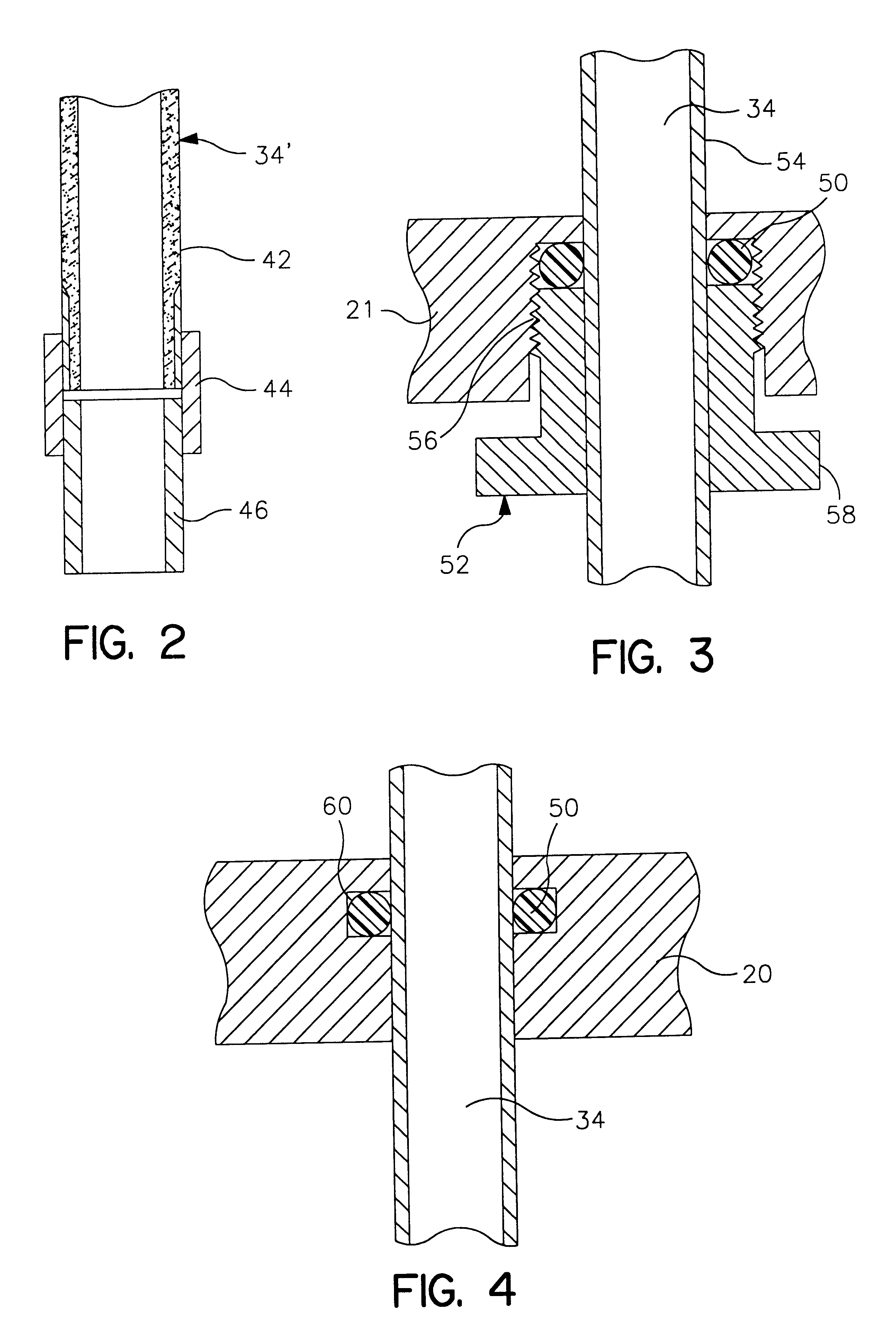

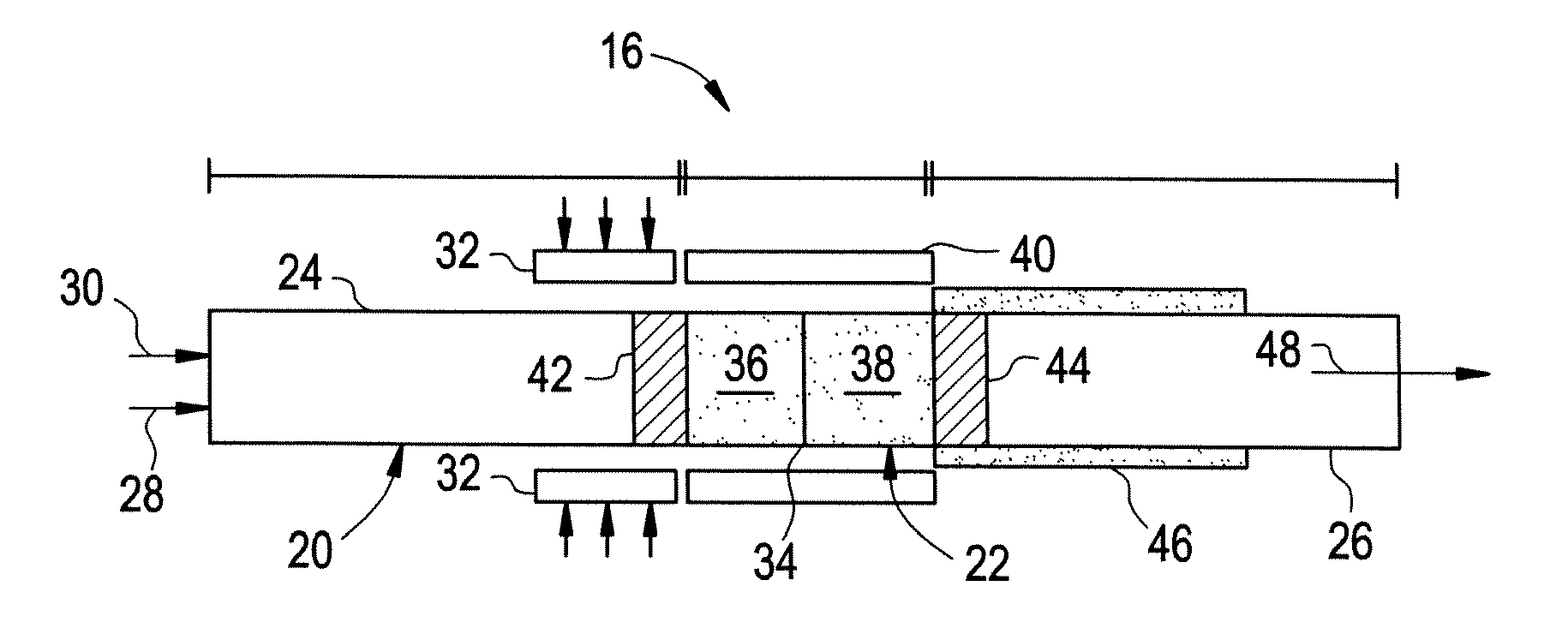

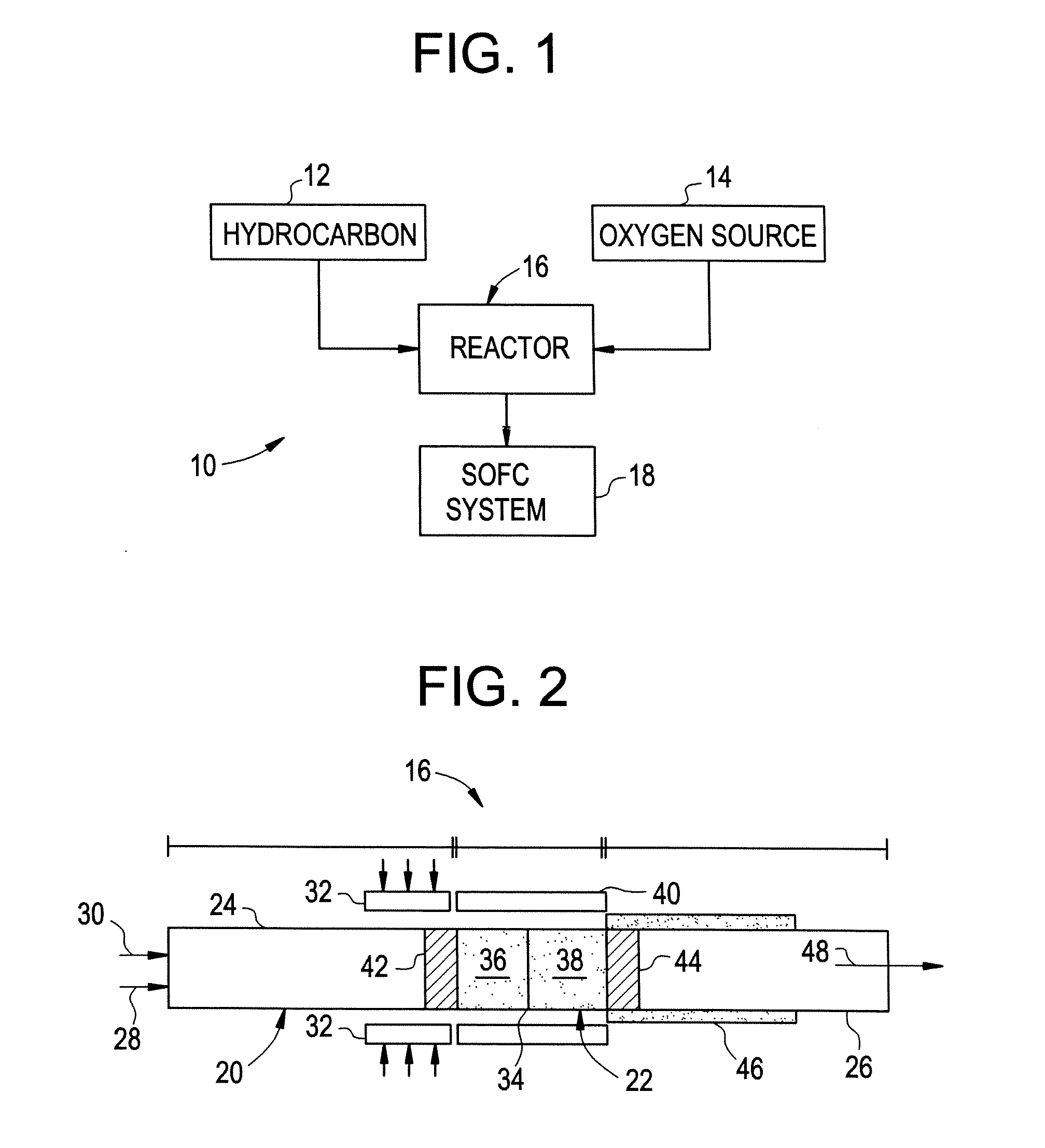

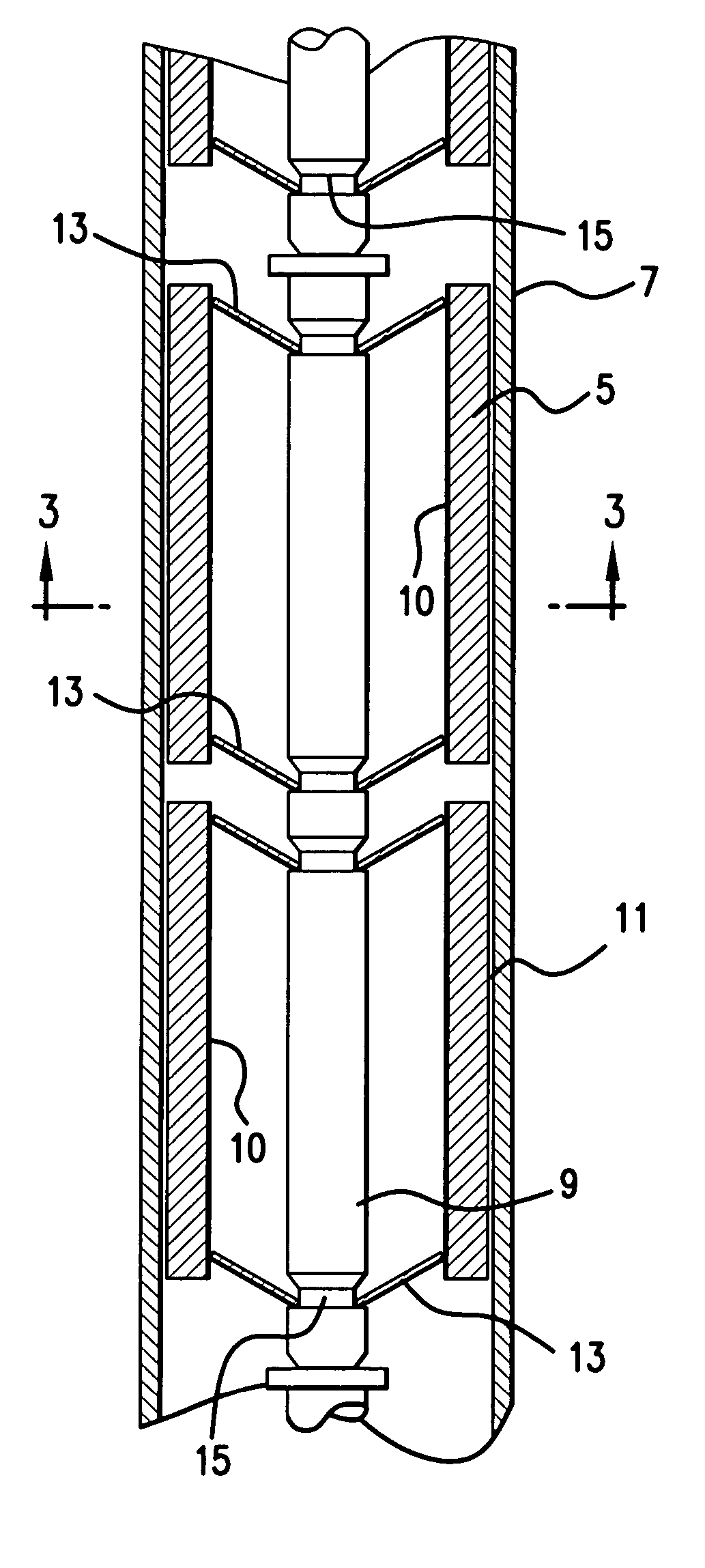

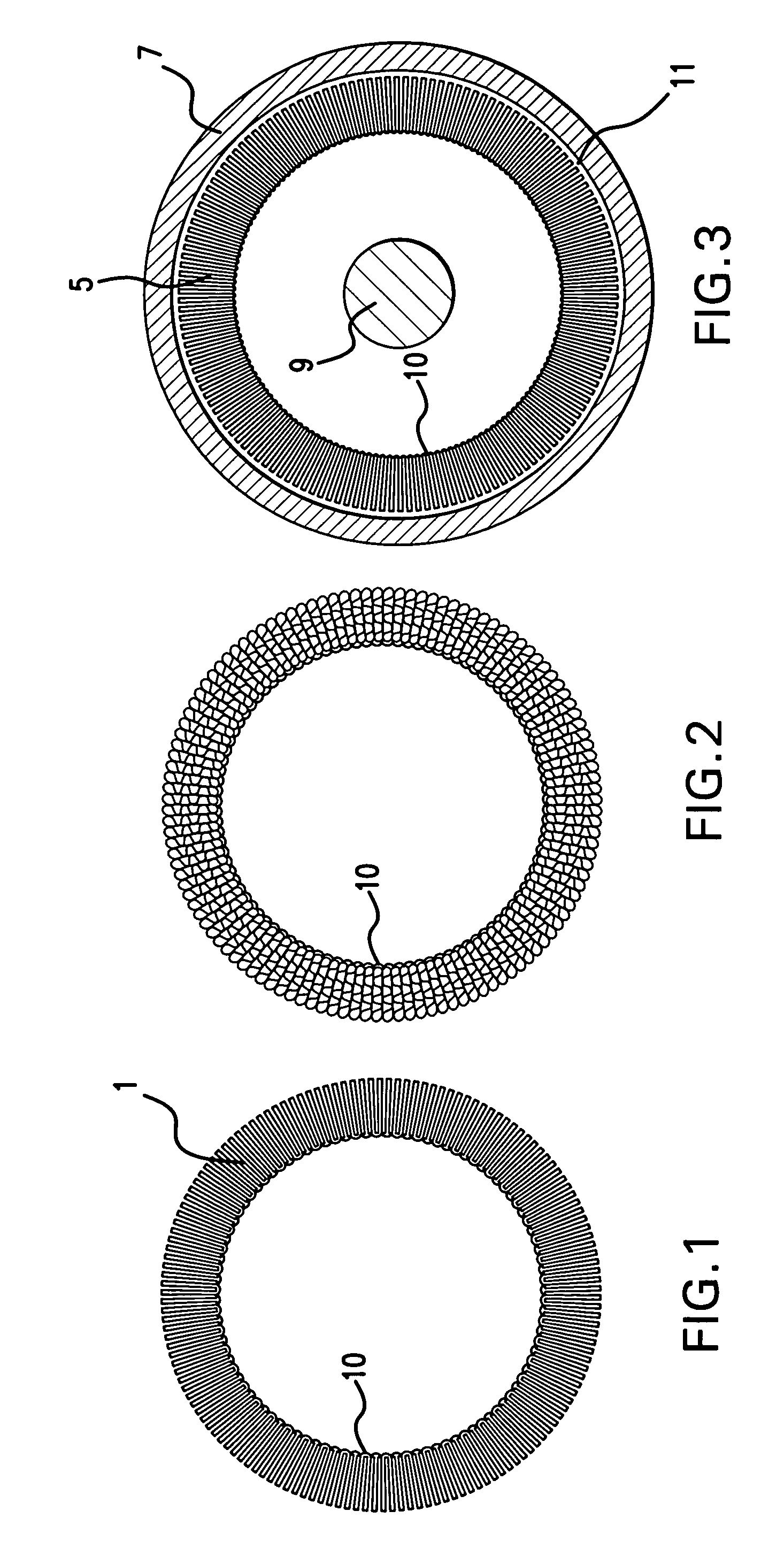

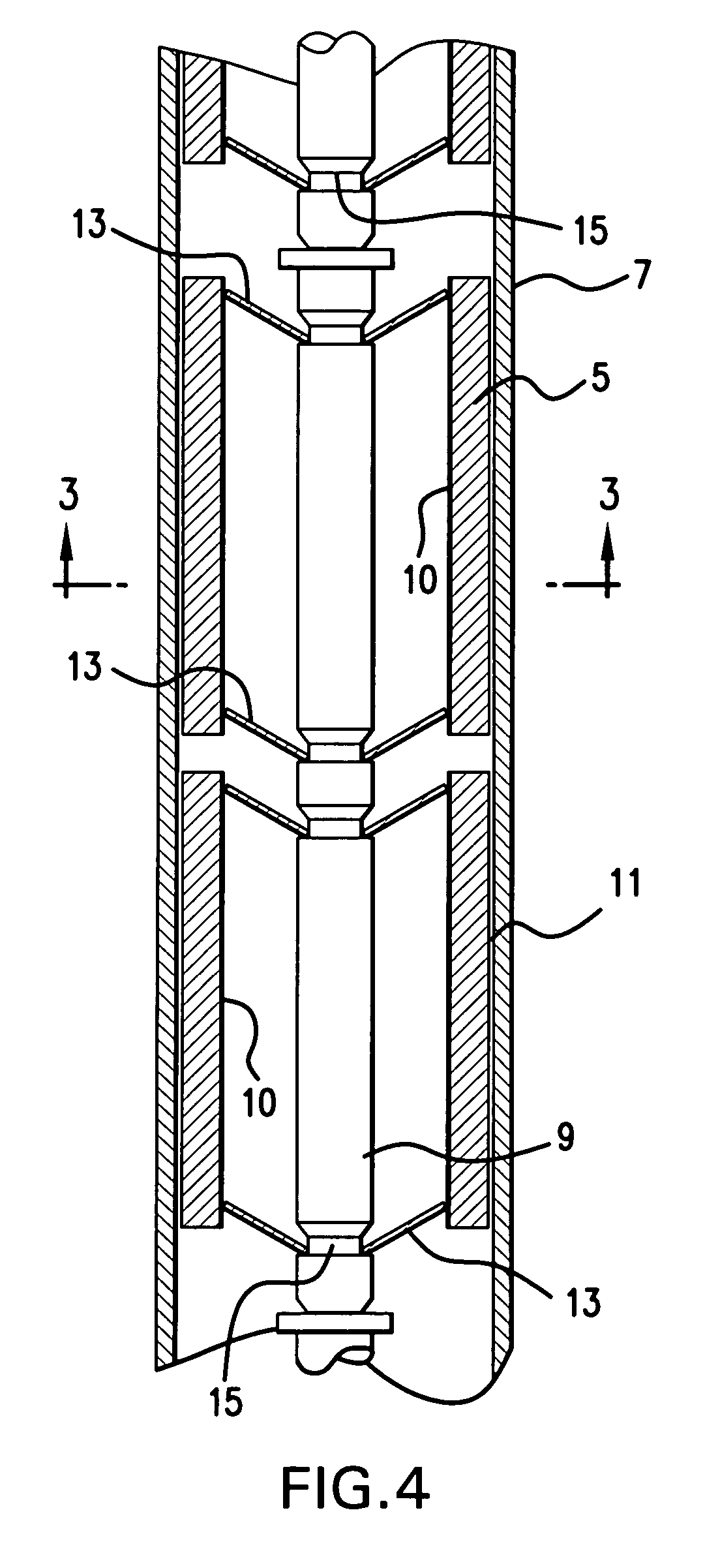

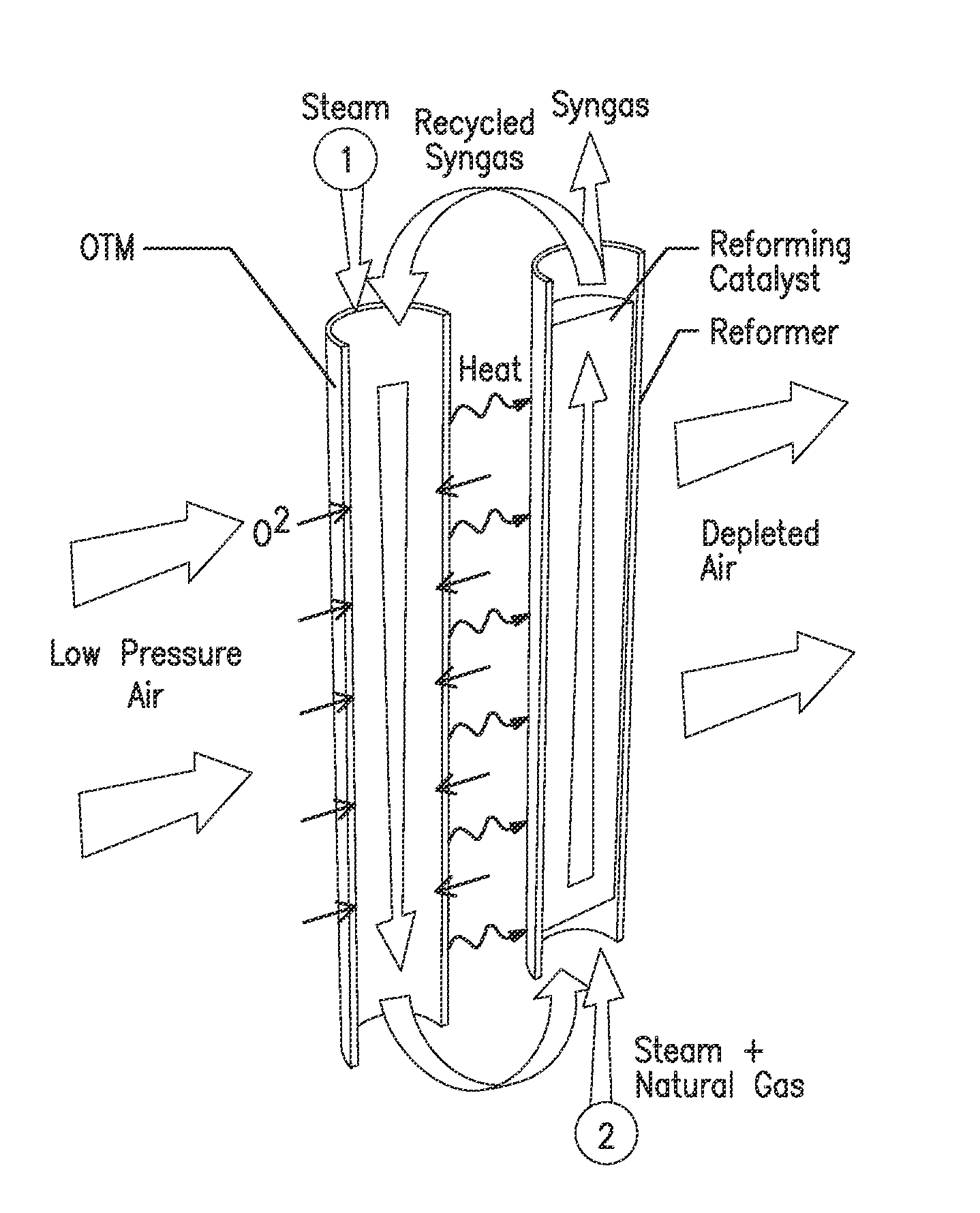

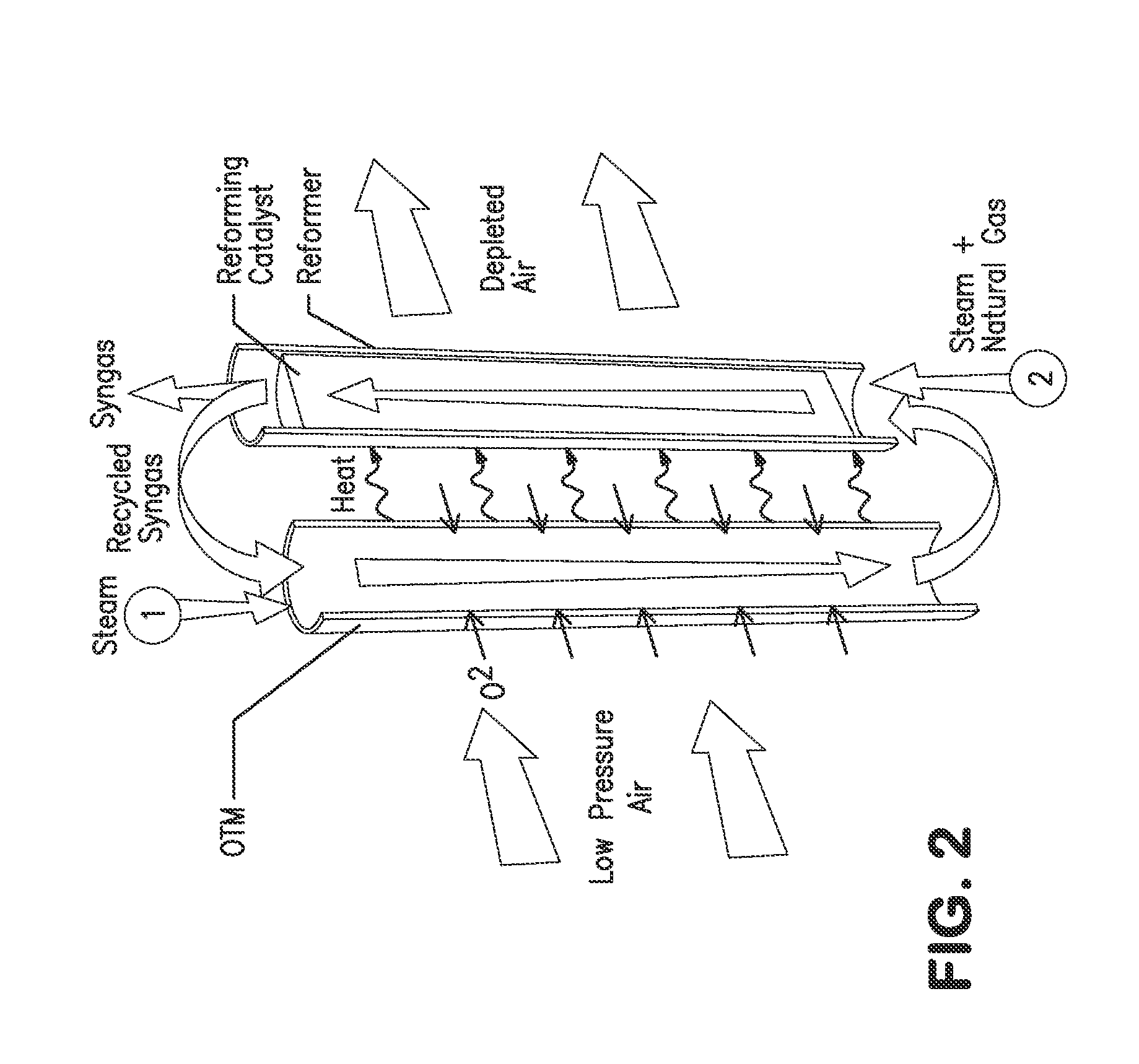

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

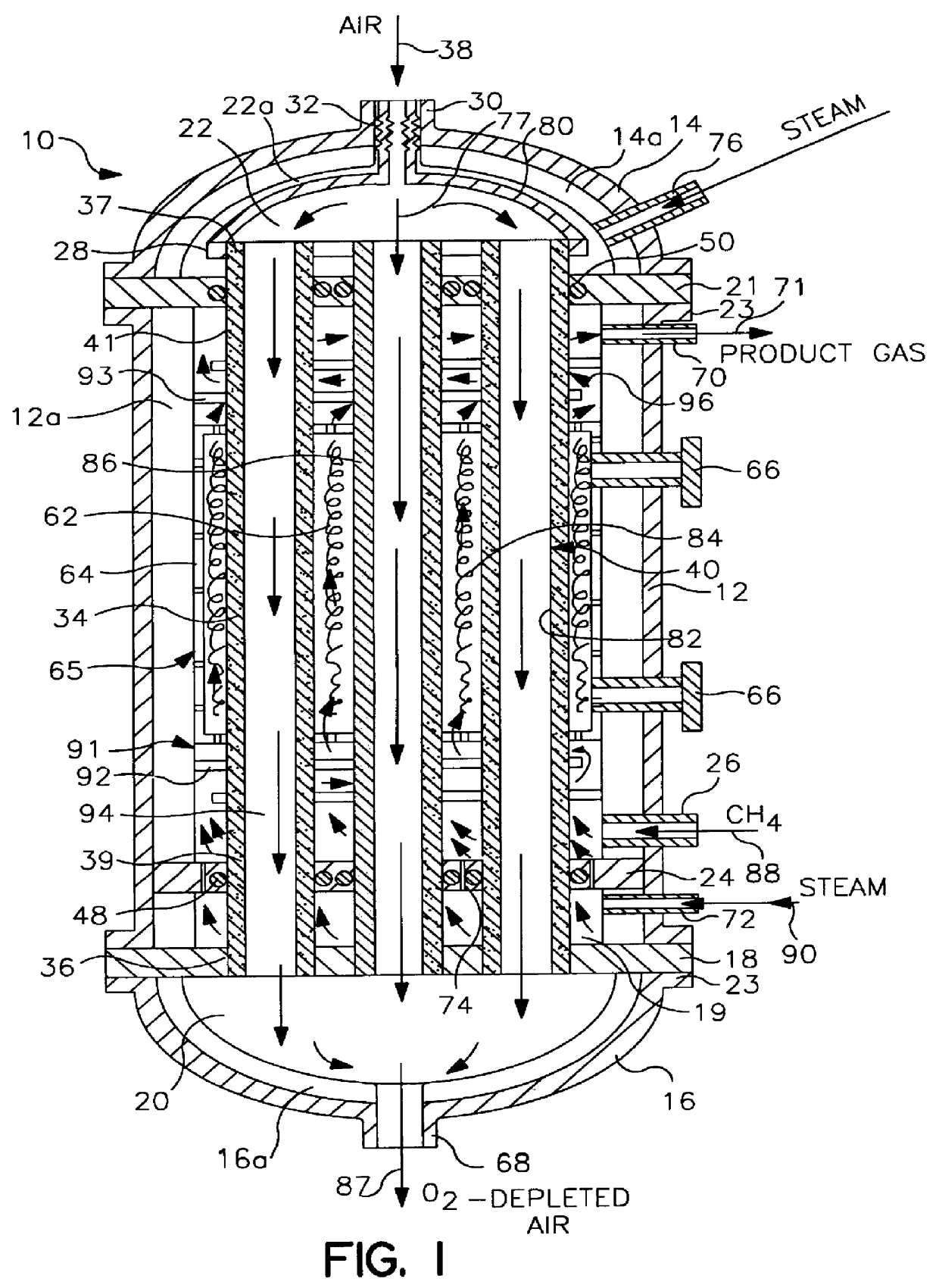

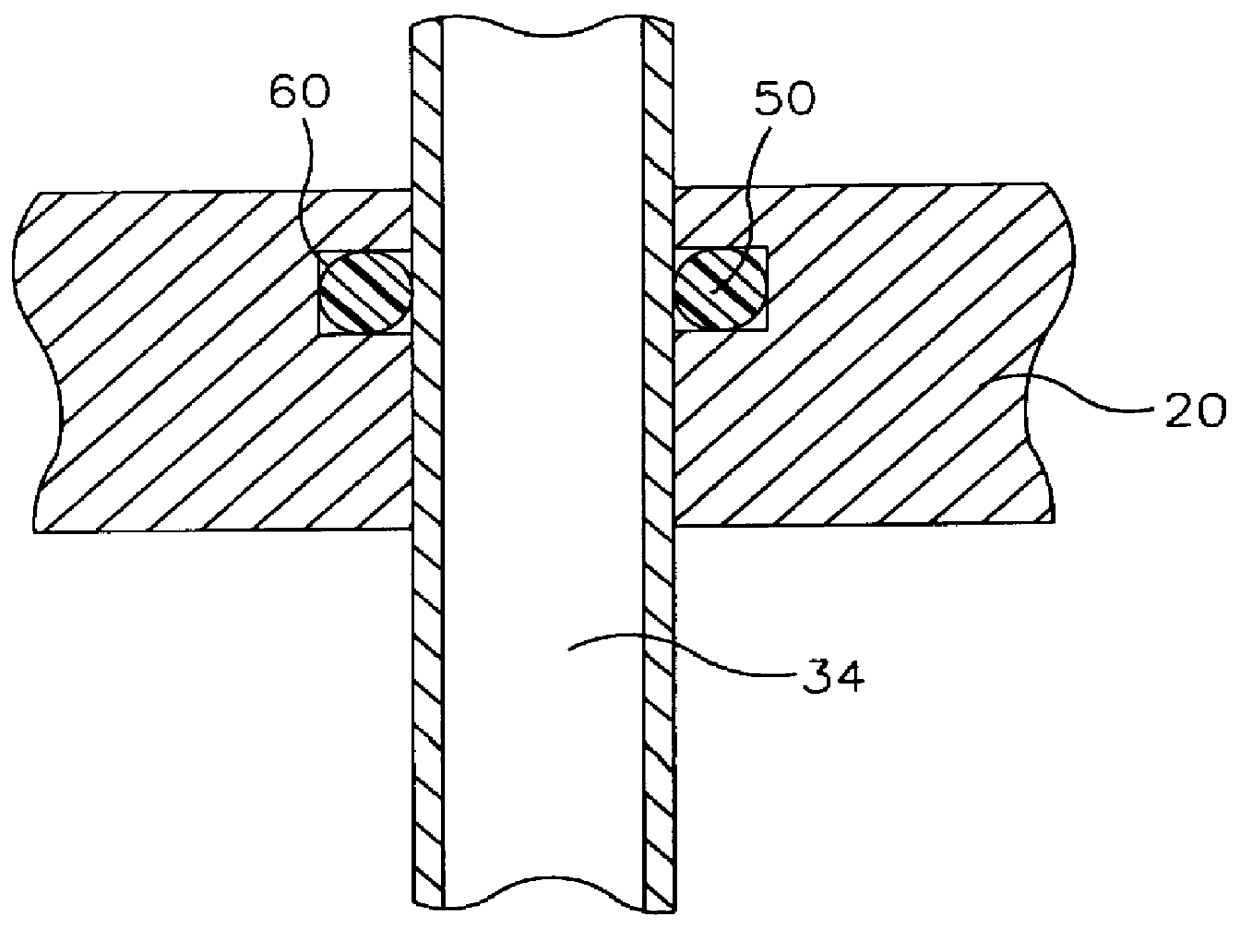

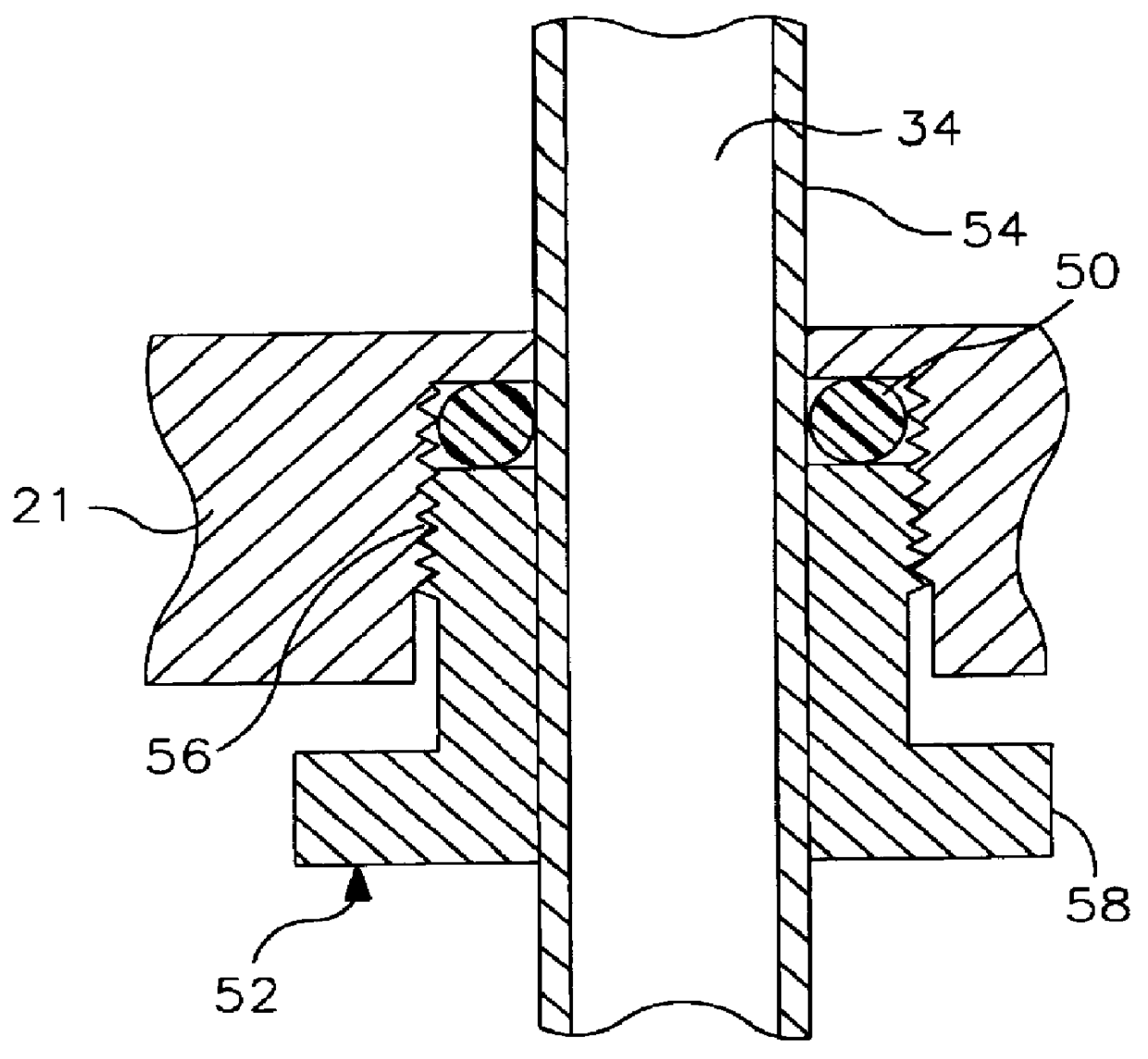

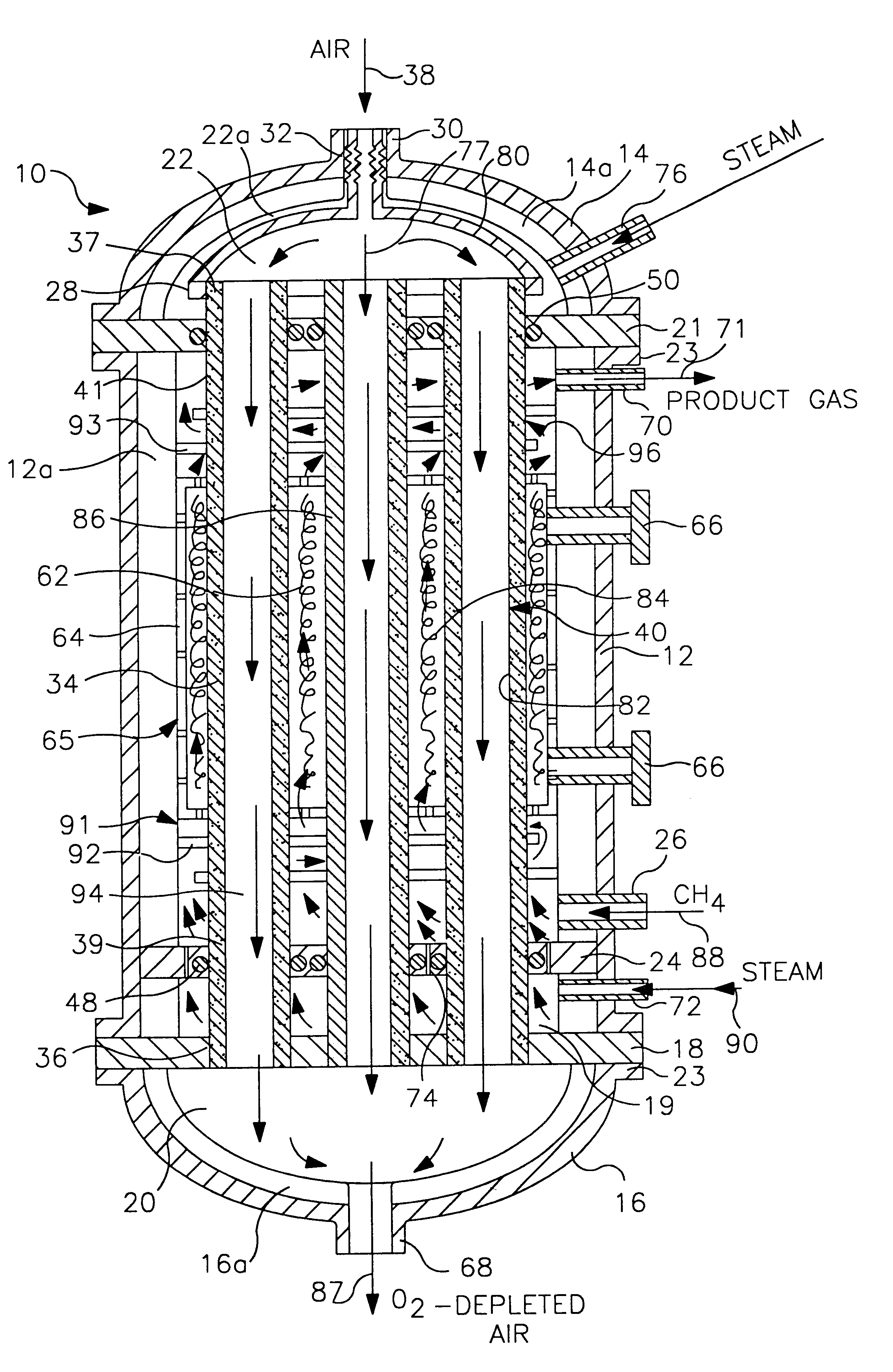

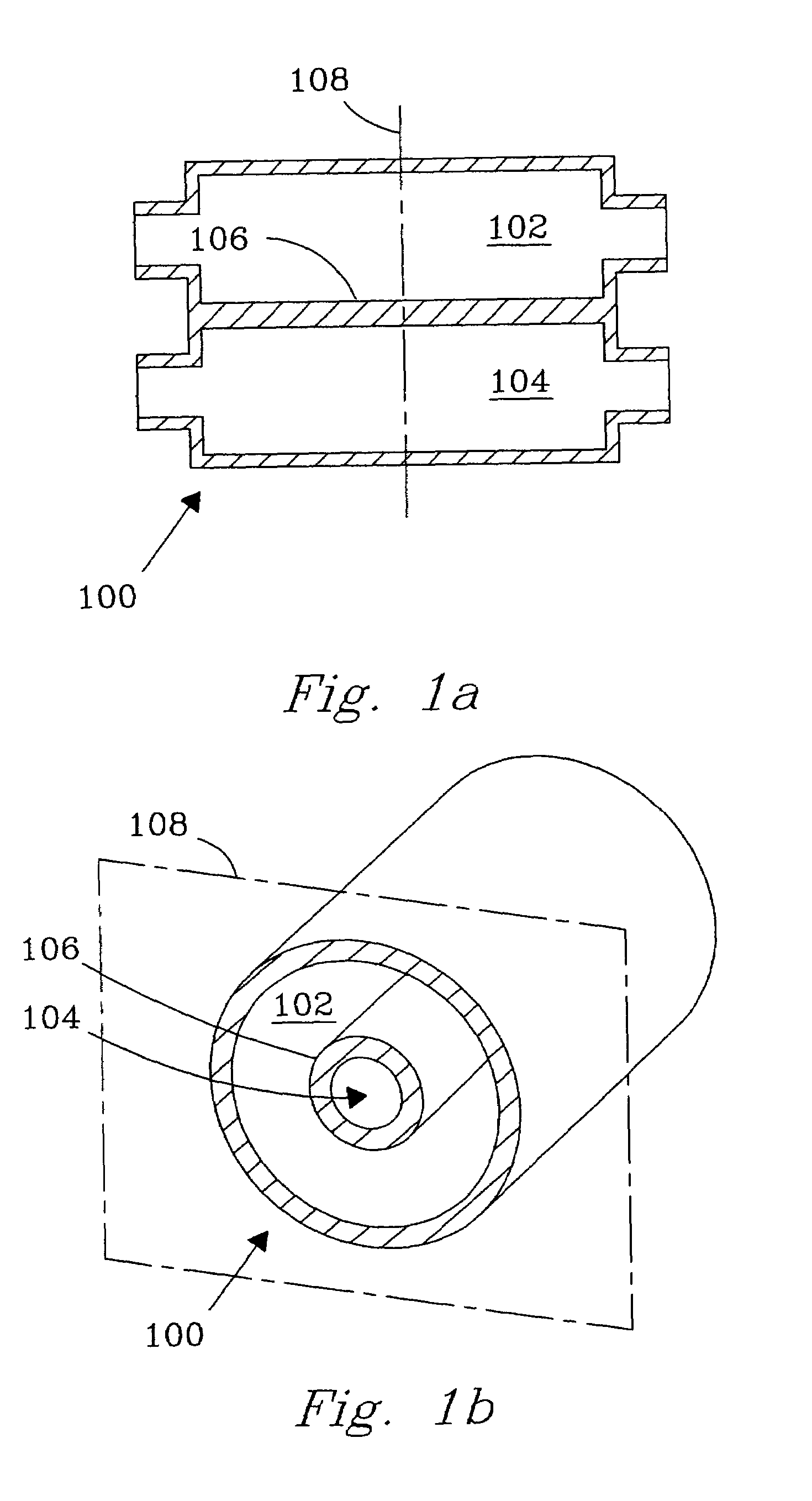

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

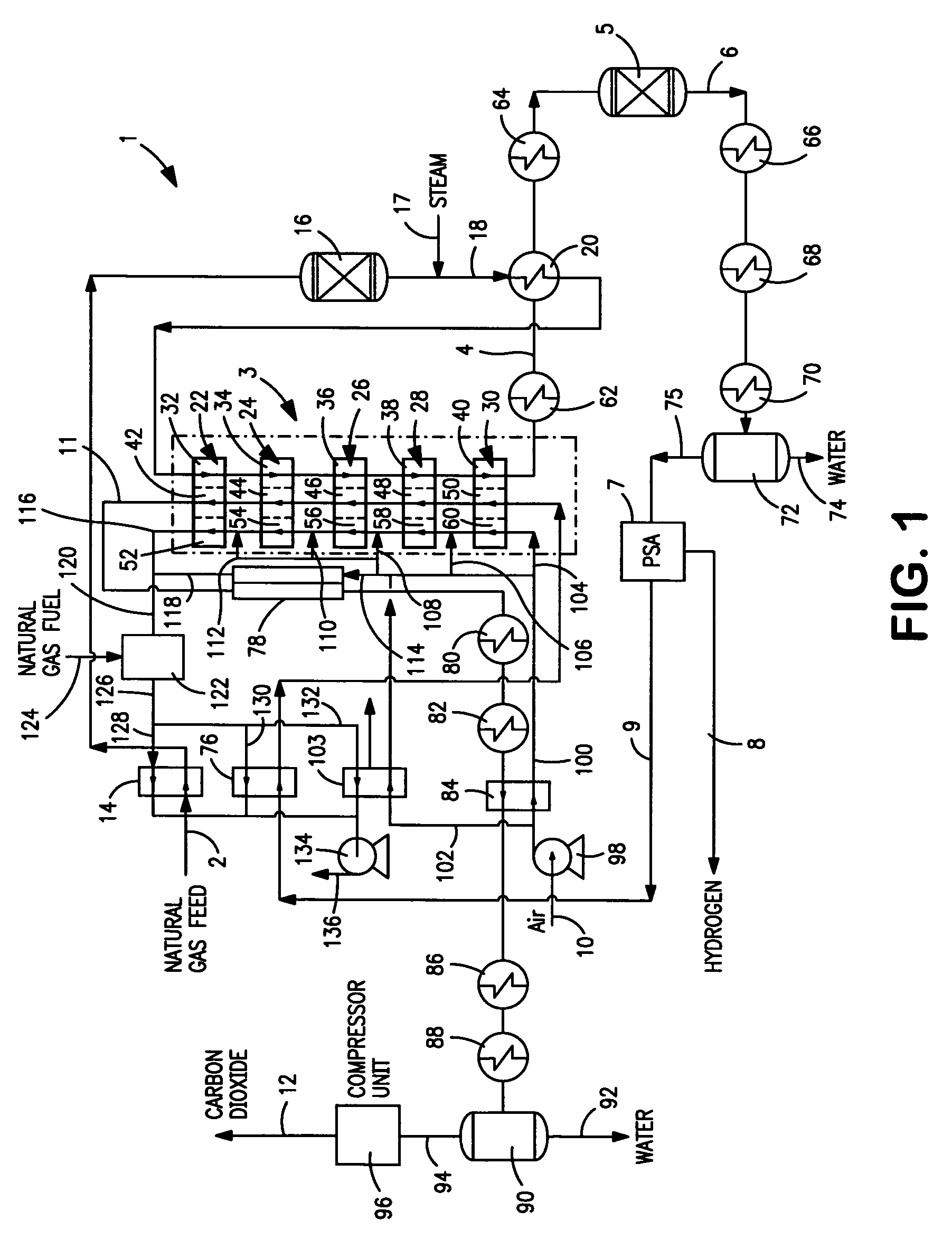

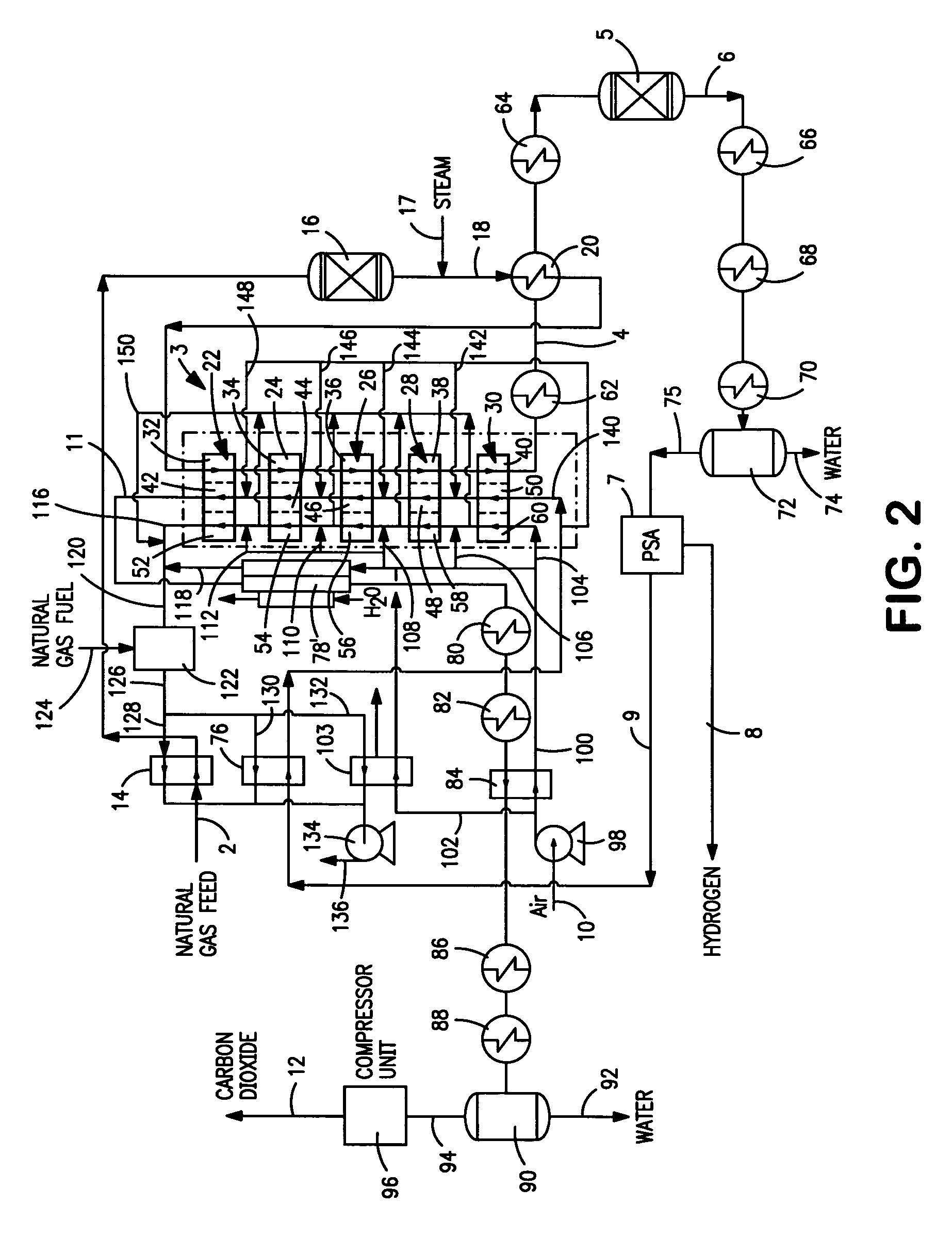

Process for producing a syngas

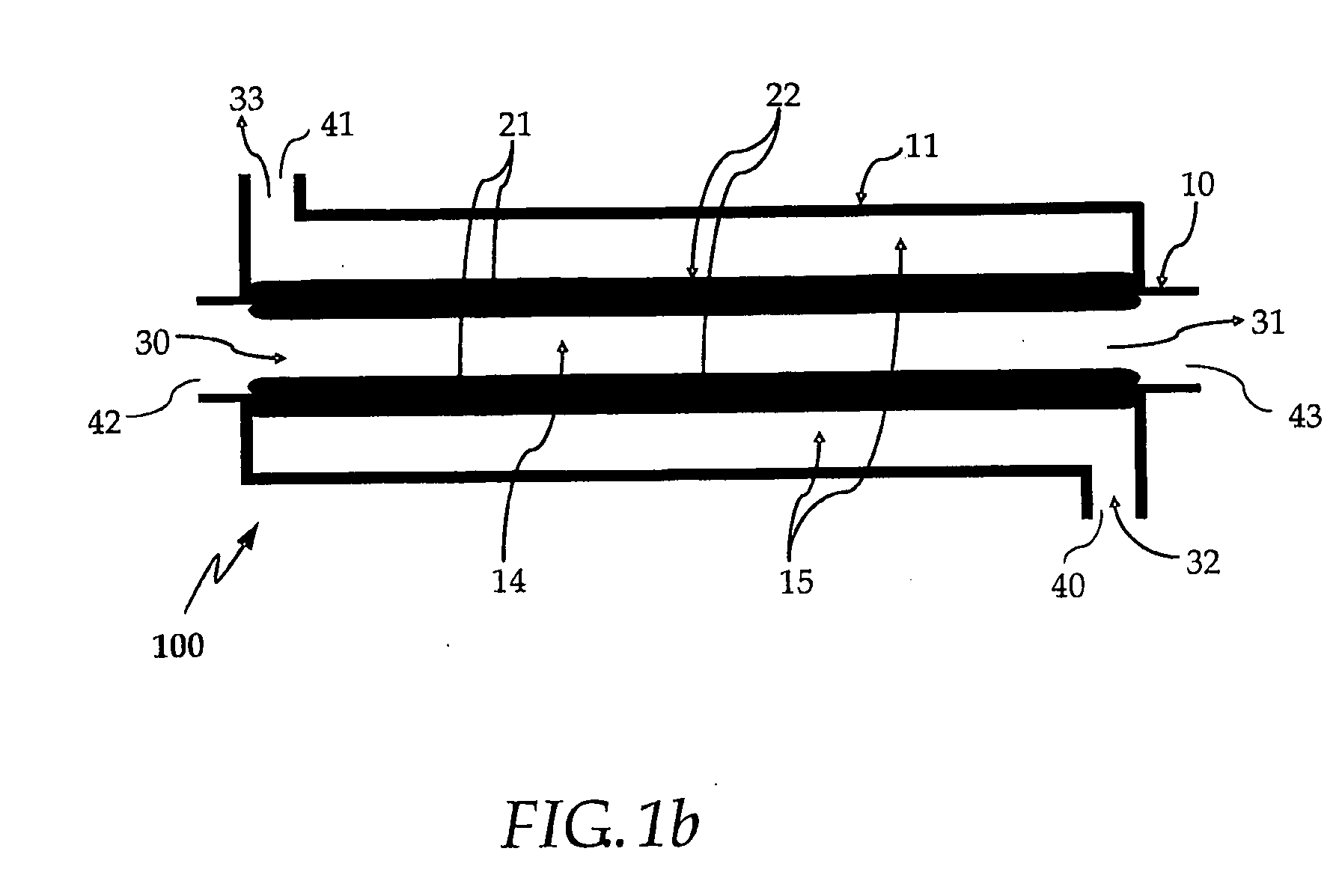

InactiveUS6402988B1Minimize the temperatures experienced by sealsMinimize pressure differenceCatalytic gas-gas reactionHydrogenSyngasReactor design

An exothermic reaction and an endothermic reaction are thermally combined in a reactor having at least one oxygen selective ion transport membrane that provides the exothermic reaction with oxygen from an oxygen-containing gas such as air. The thermal requirements of the endothermic reaction are satisfied by the exothermic reaction. Dependent on the reactor design employed, the exothermic and endothermic reactions may be gaseously combined.

Owner:PRAXAIR TECH INC +1

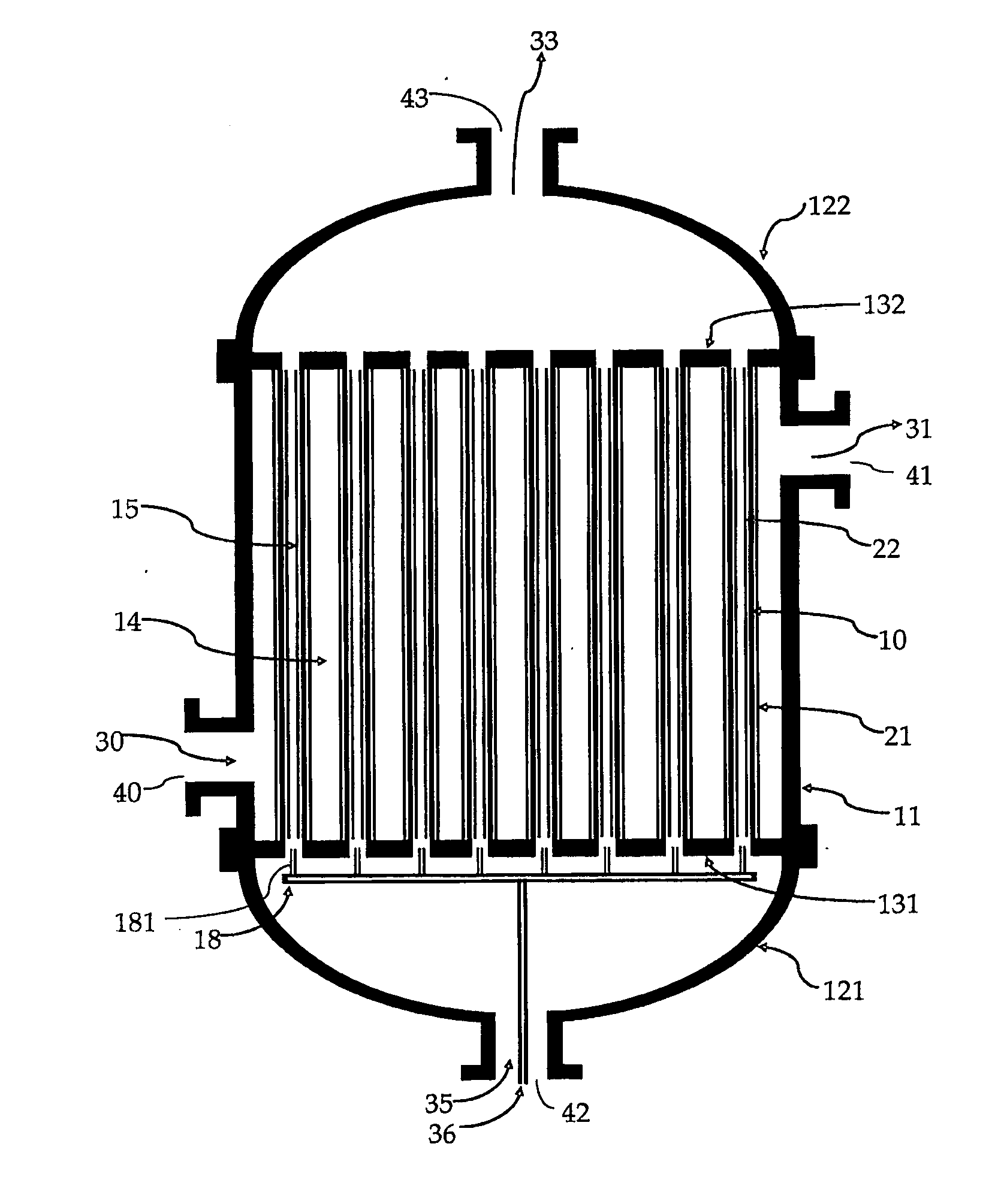

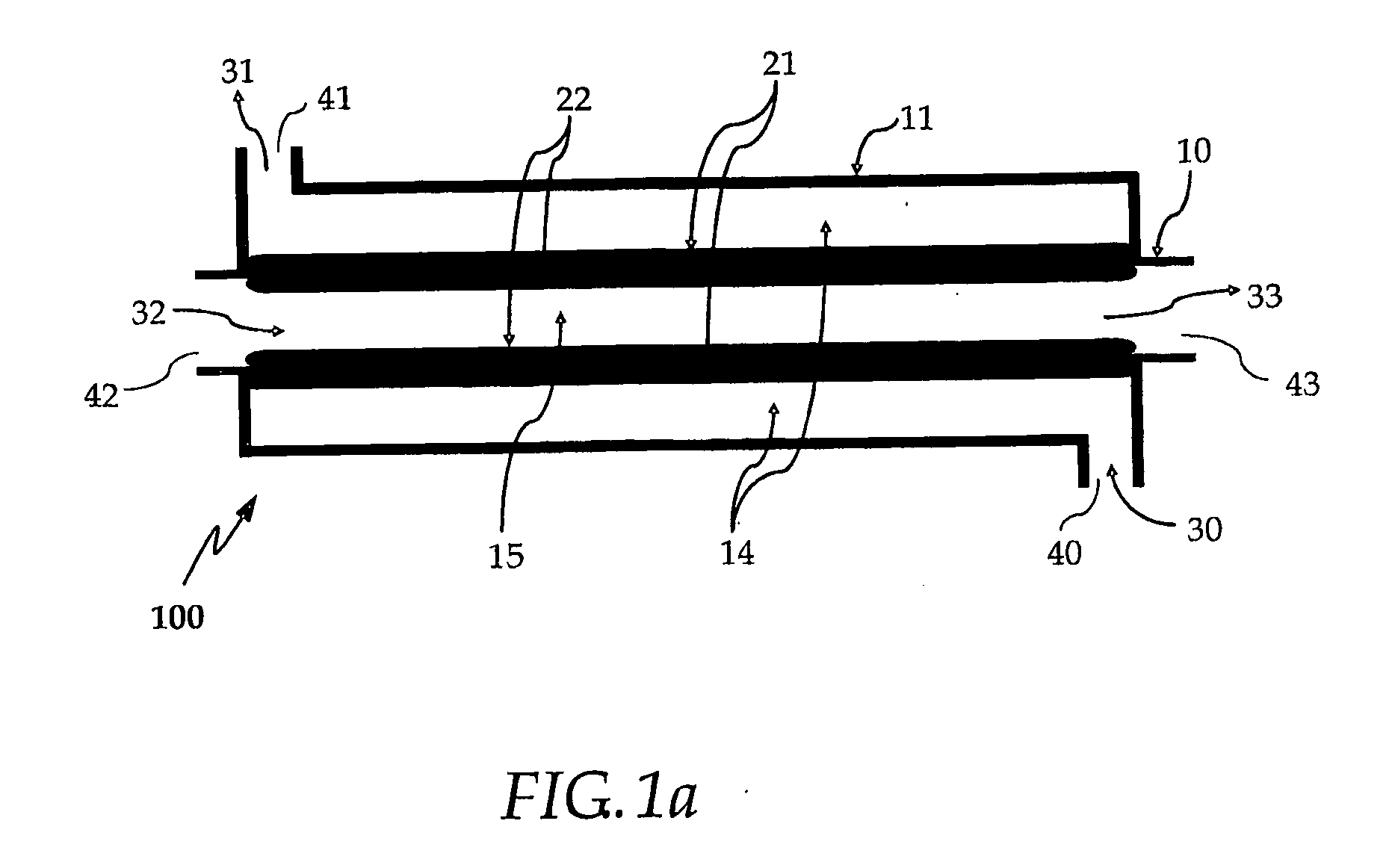

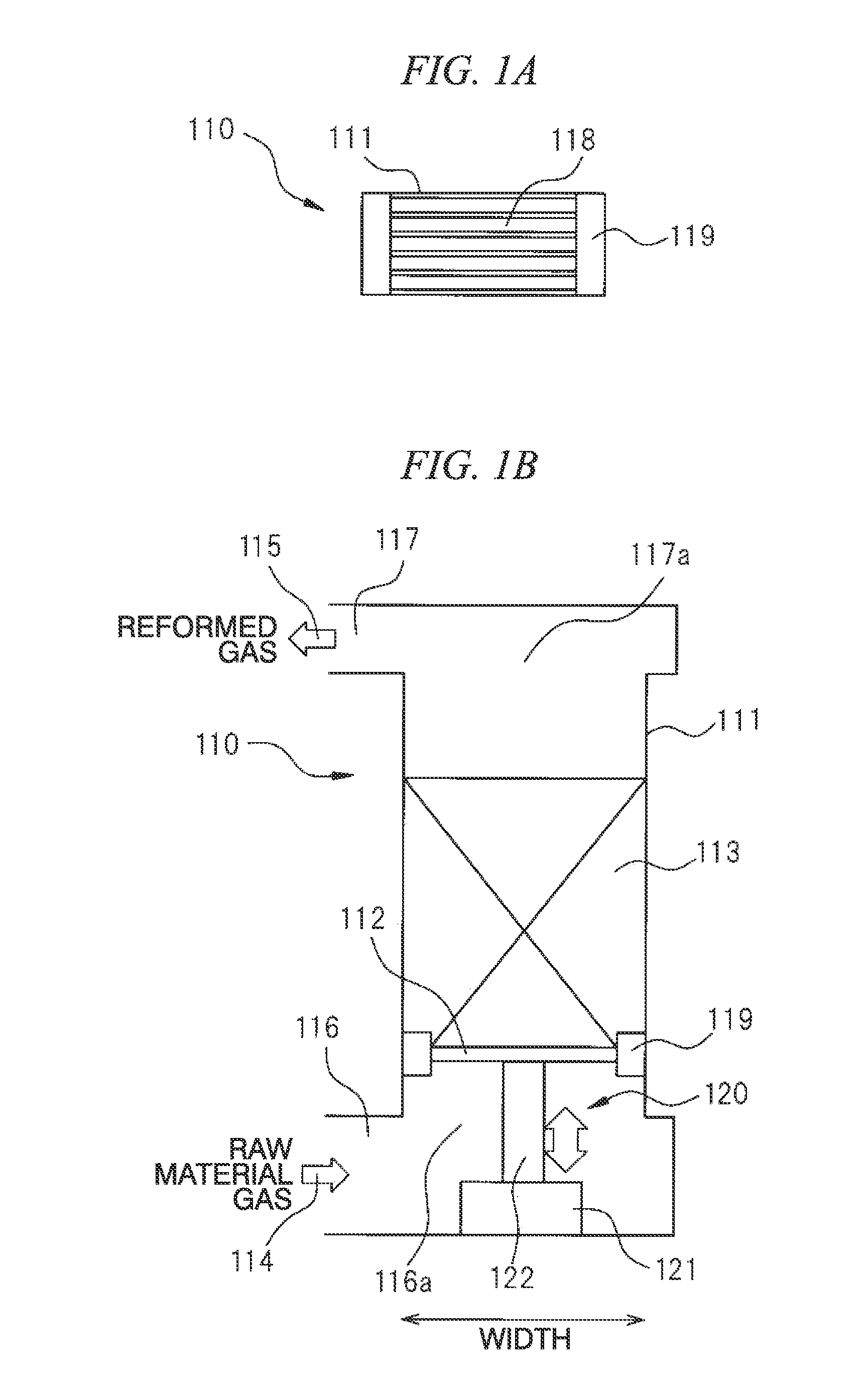

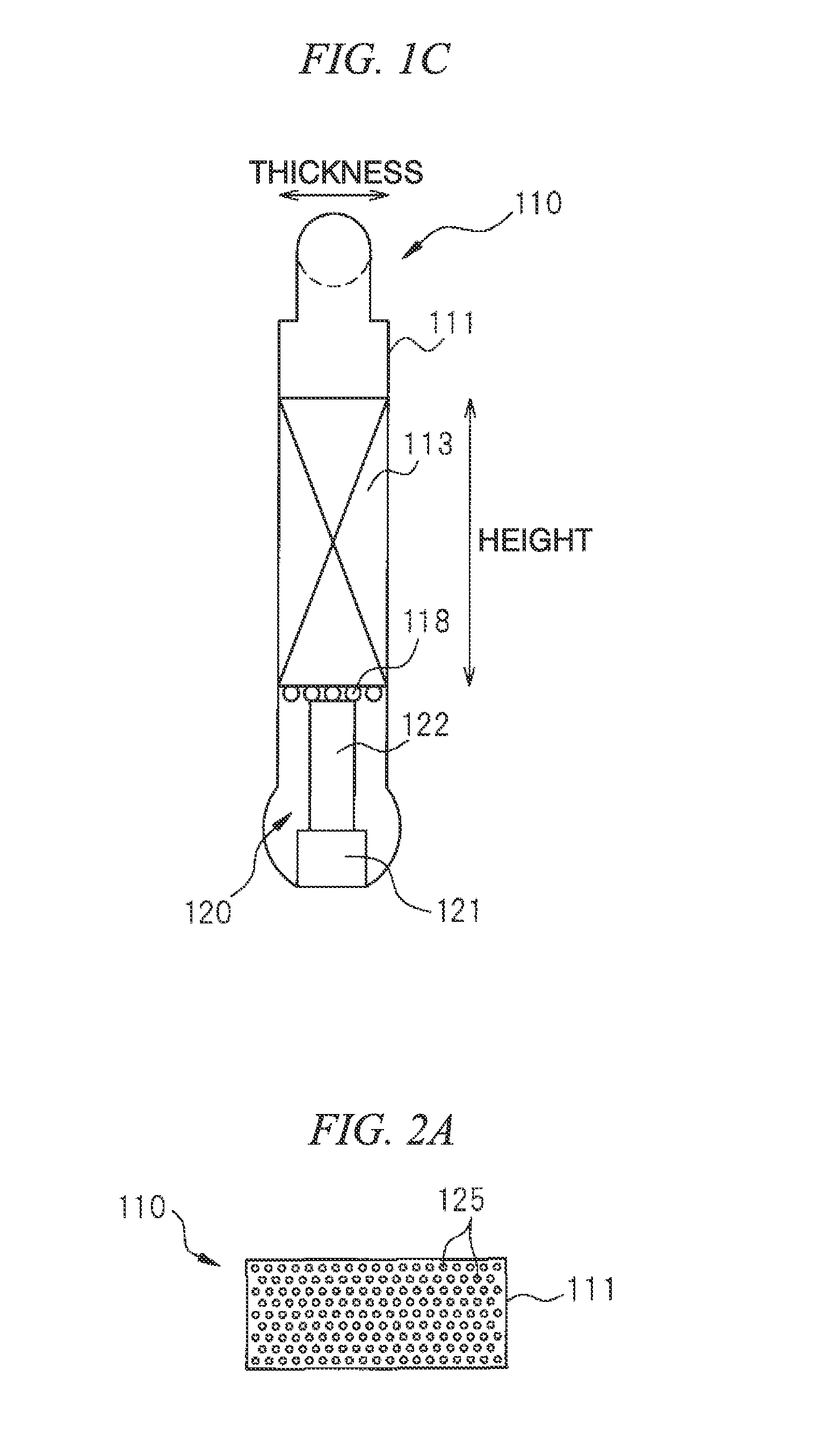

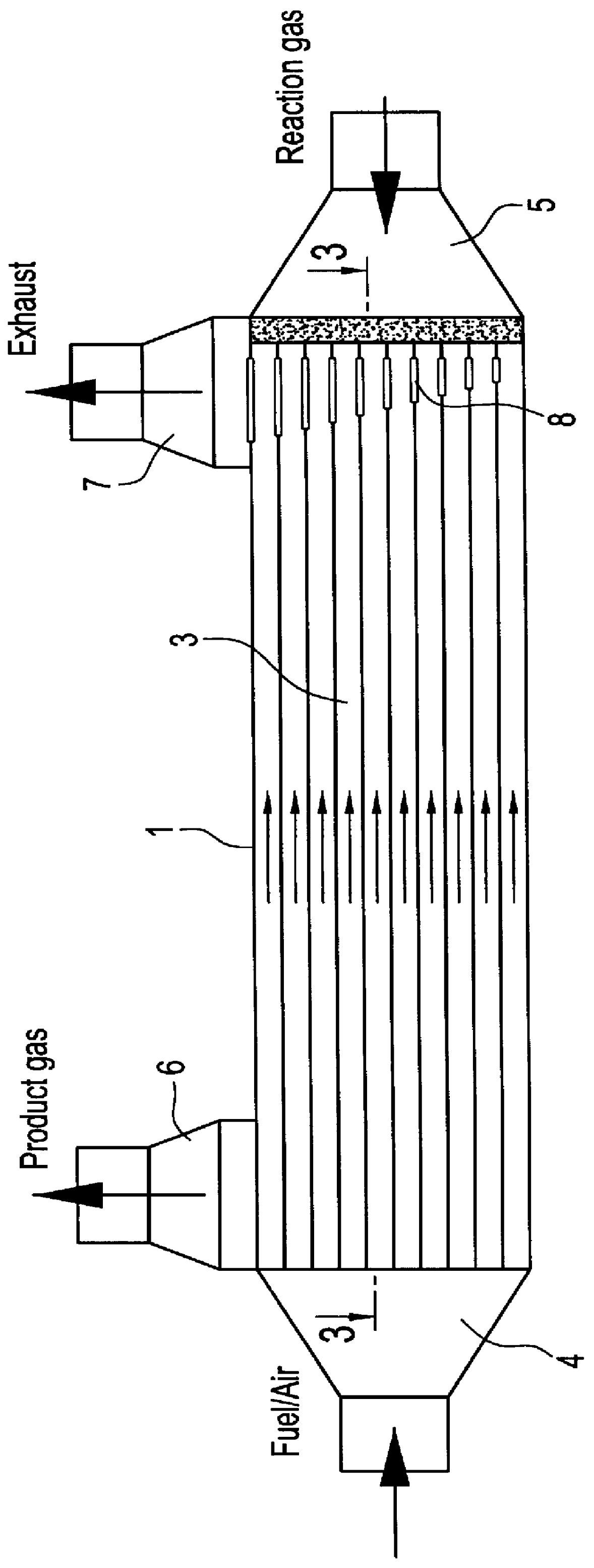

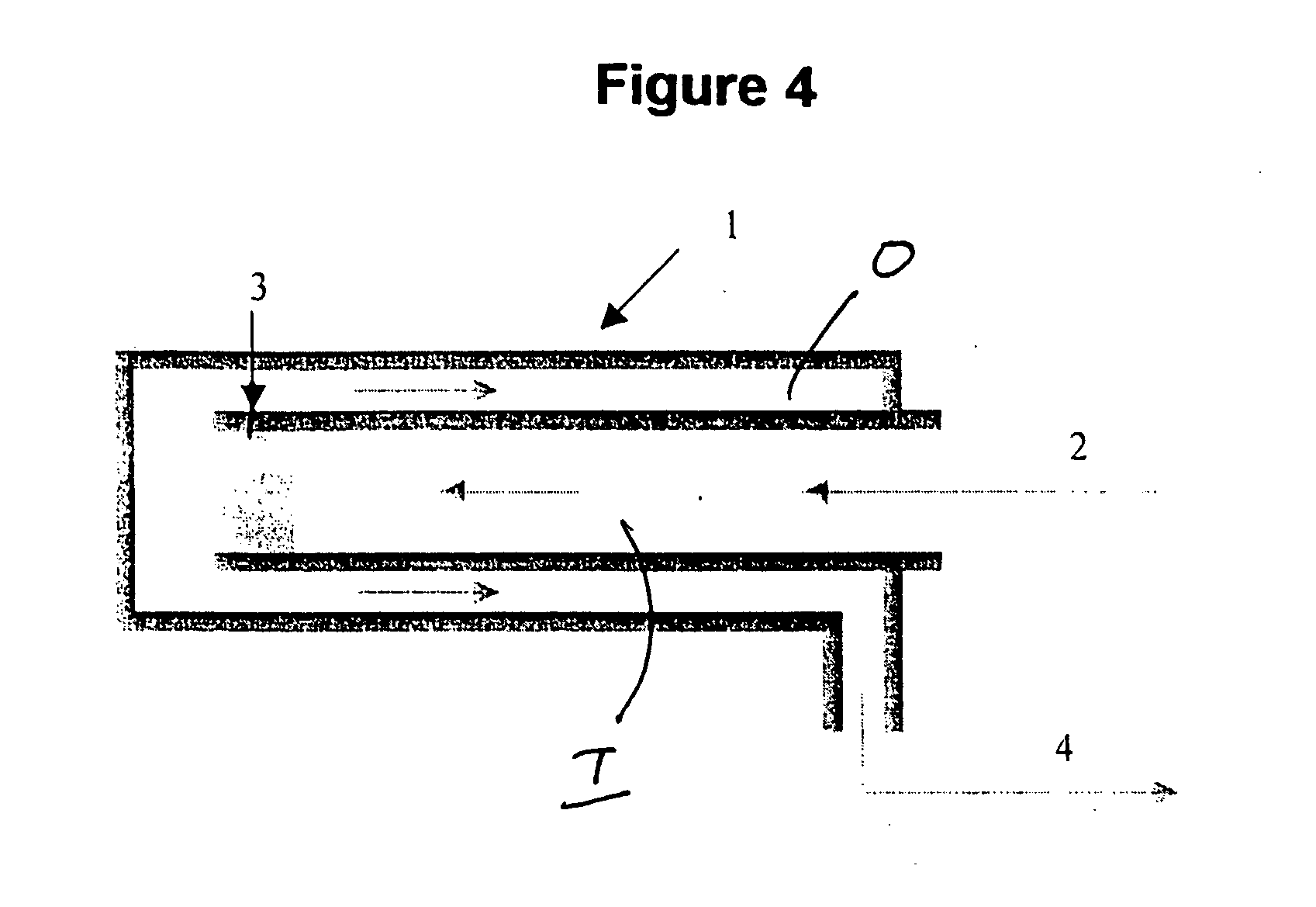

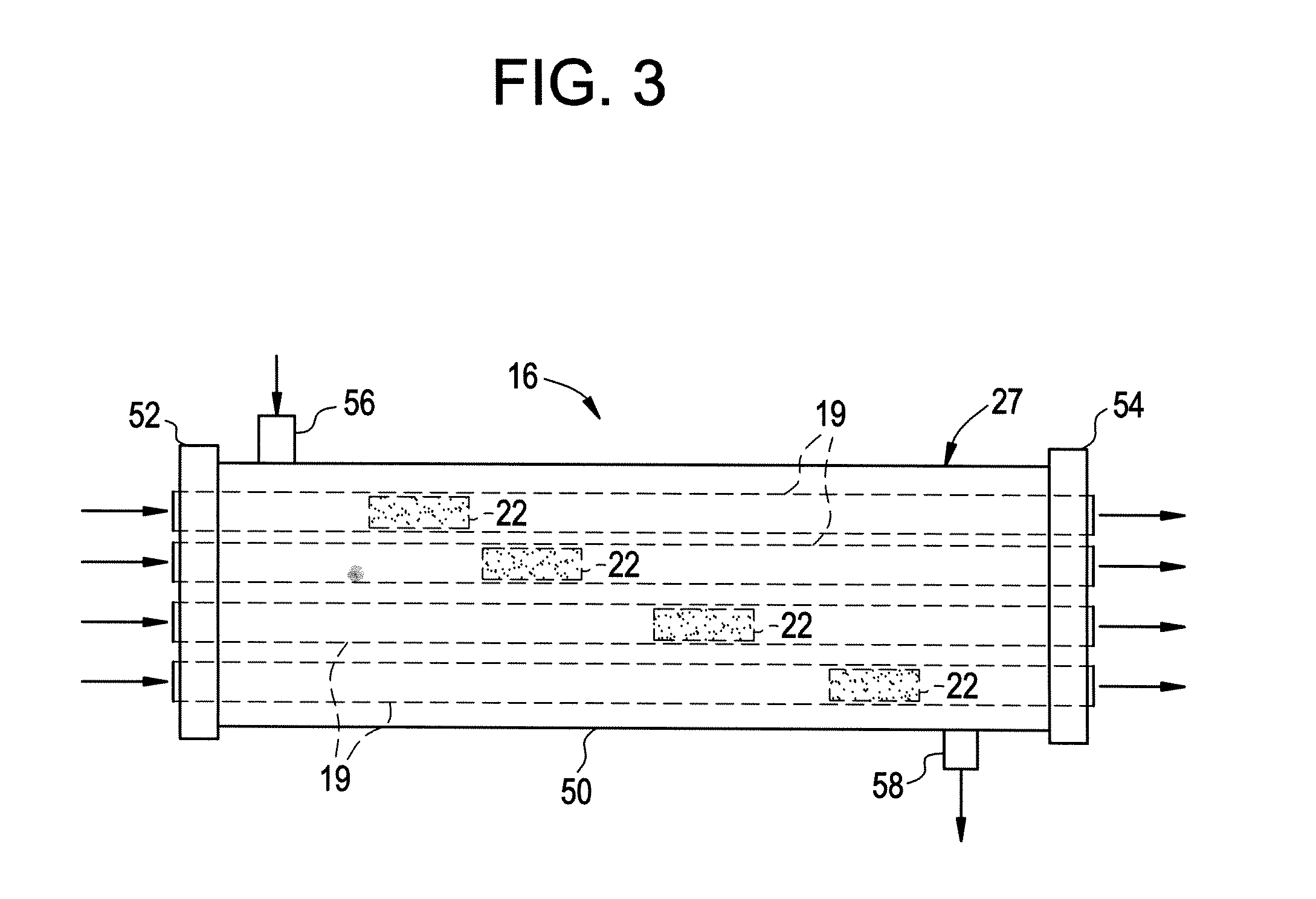

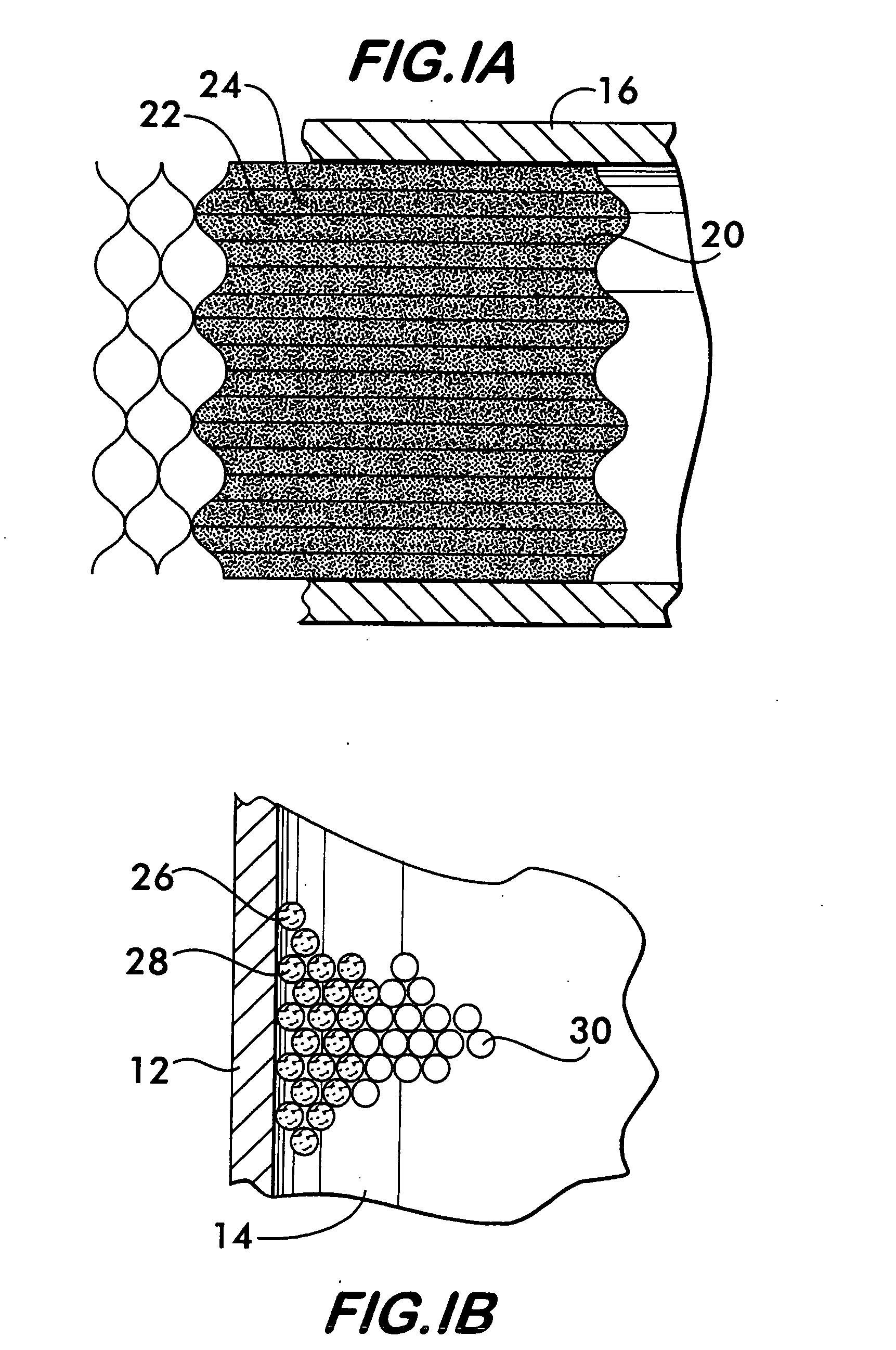

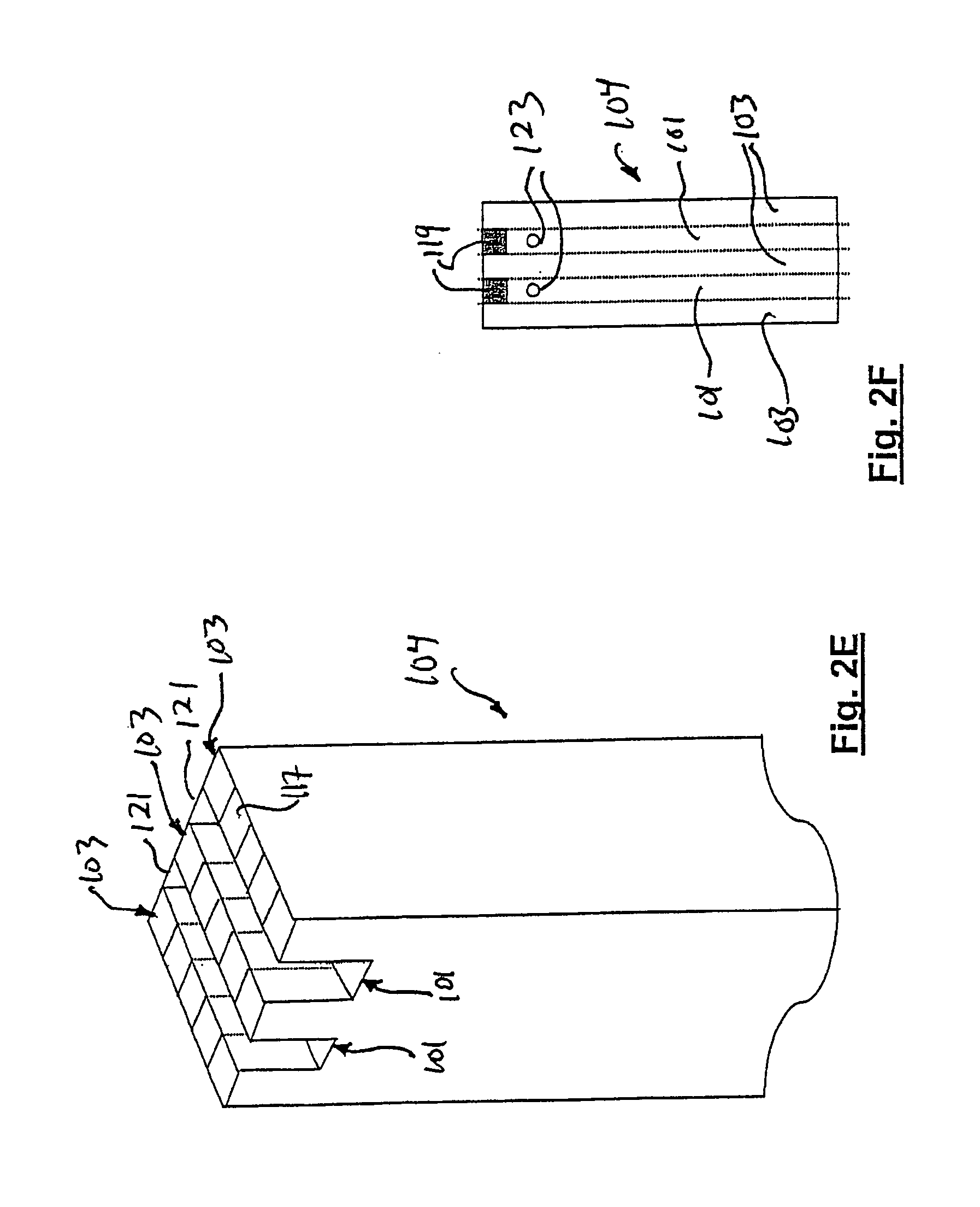

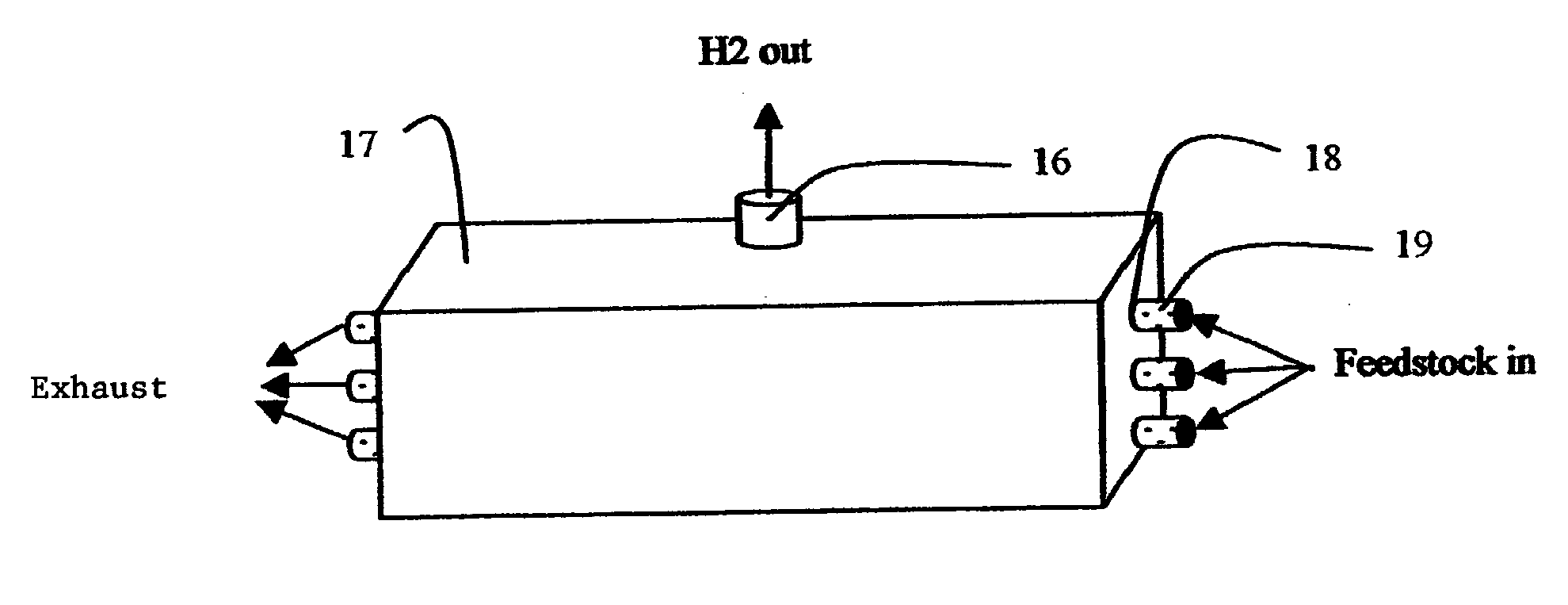

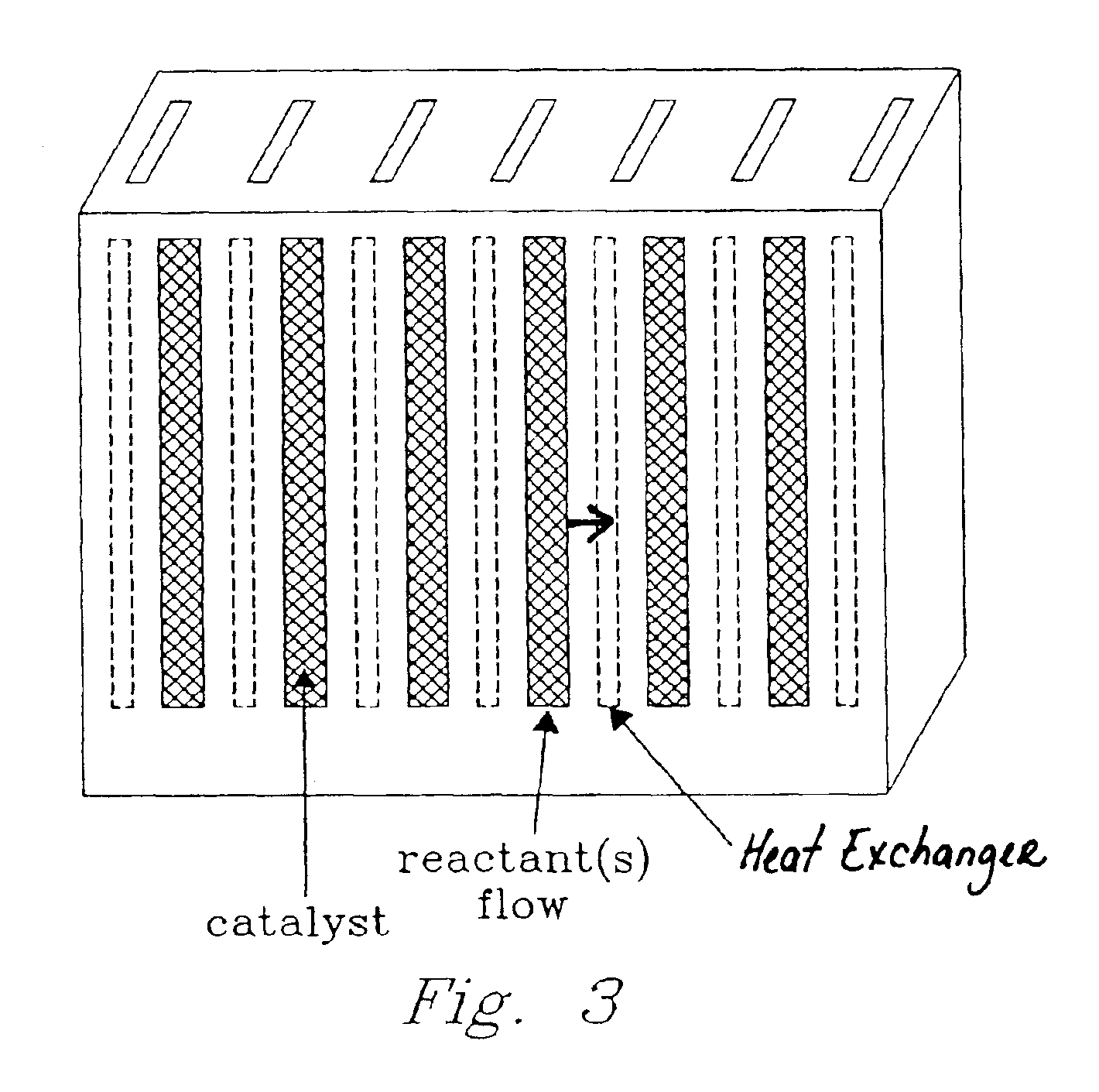

Highly heat integrated reformer for hydrogen production

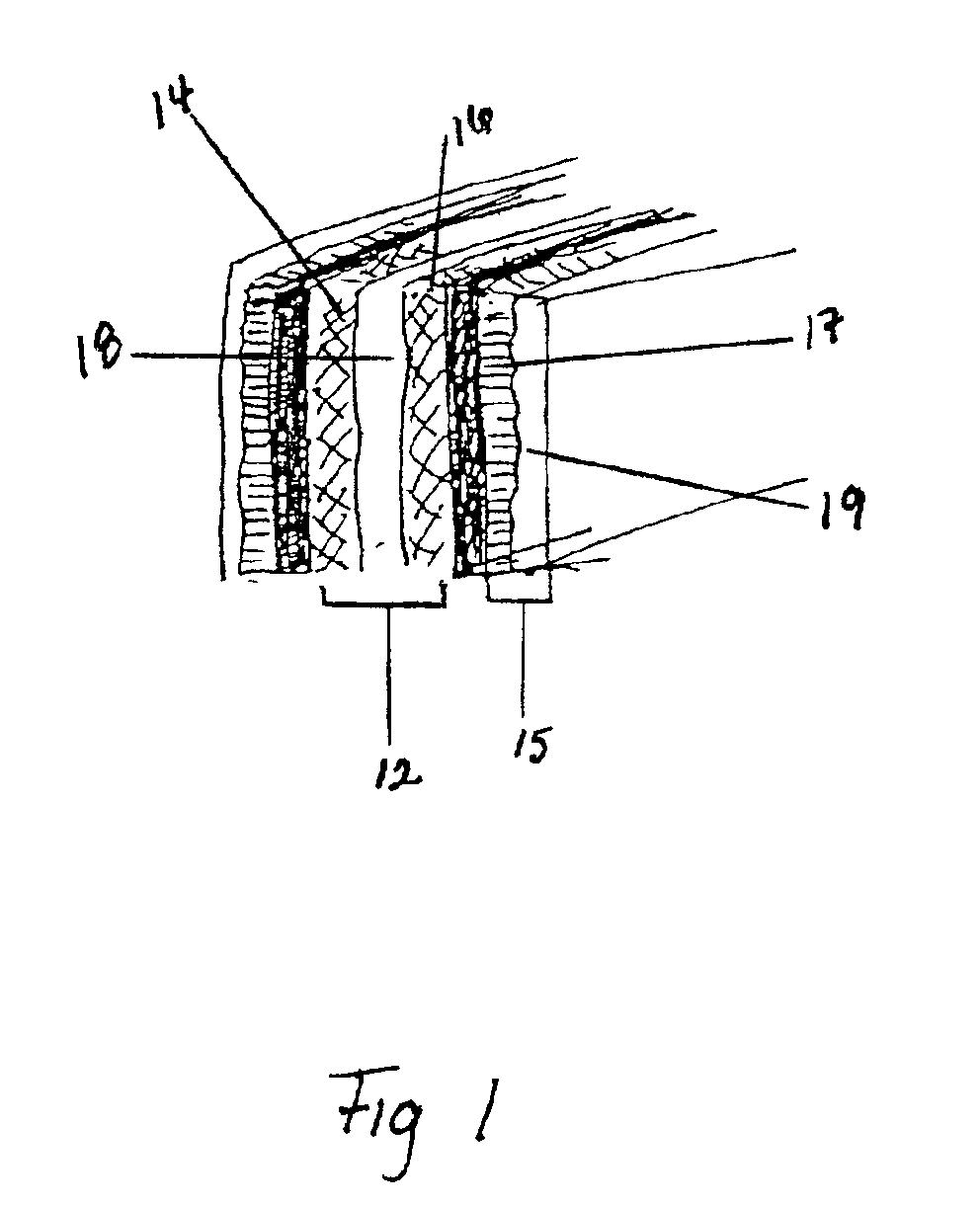

InactiveUS20100178219A1Improve distributionEasy to introduceCatalytic gas-gas reactionHydrogenCatalytic reformingSteam reforming

Described herein is a highly heat integrated steam reformer / combustor assembly that can be used in a fuel processor for hydrogen production from a fuel source. The assembly comprises a reforming section and a combustion section separated by a wall. Catalyst able to induce the reforming reactions is coated on the wall facing the reforming section. Catalyst able to induce the combustion reactions is coated on the wall facing the combustion section. A steam and fuel mixture is supplied to the reforming section where it is reformed to product hydrogen. A fuel and air mixture is supplied to the combustion section where it is combusted to supply the heat for the reformer. Catalytic combustion takes place on the combustion catalyst coated on one side of the wall while catalytic reforming takes place on the reforming catalyst coated on the other side of the wall. Heat transfer is very facile and efficient across the wall. Multiple such assemblies can be bundled to form reactors of any size.

Owner:HELBIO HYDROGEN & ENERGY PRODN SYST

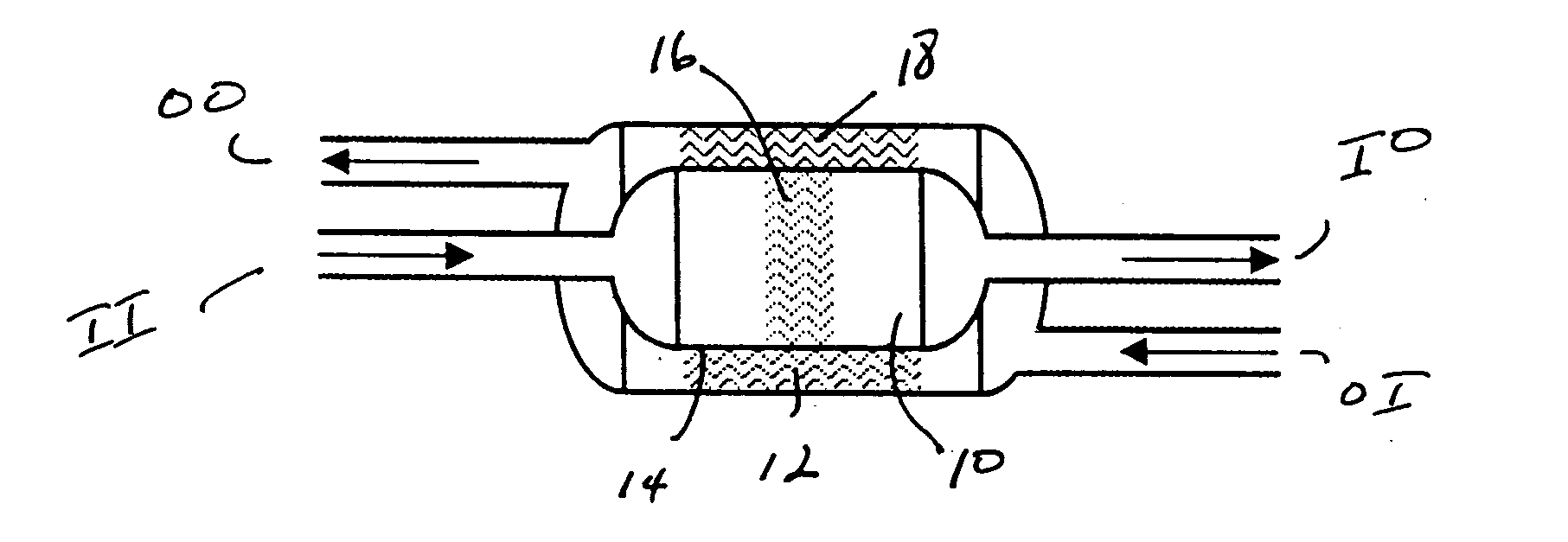

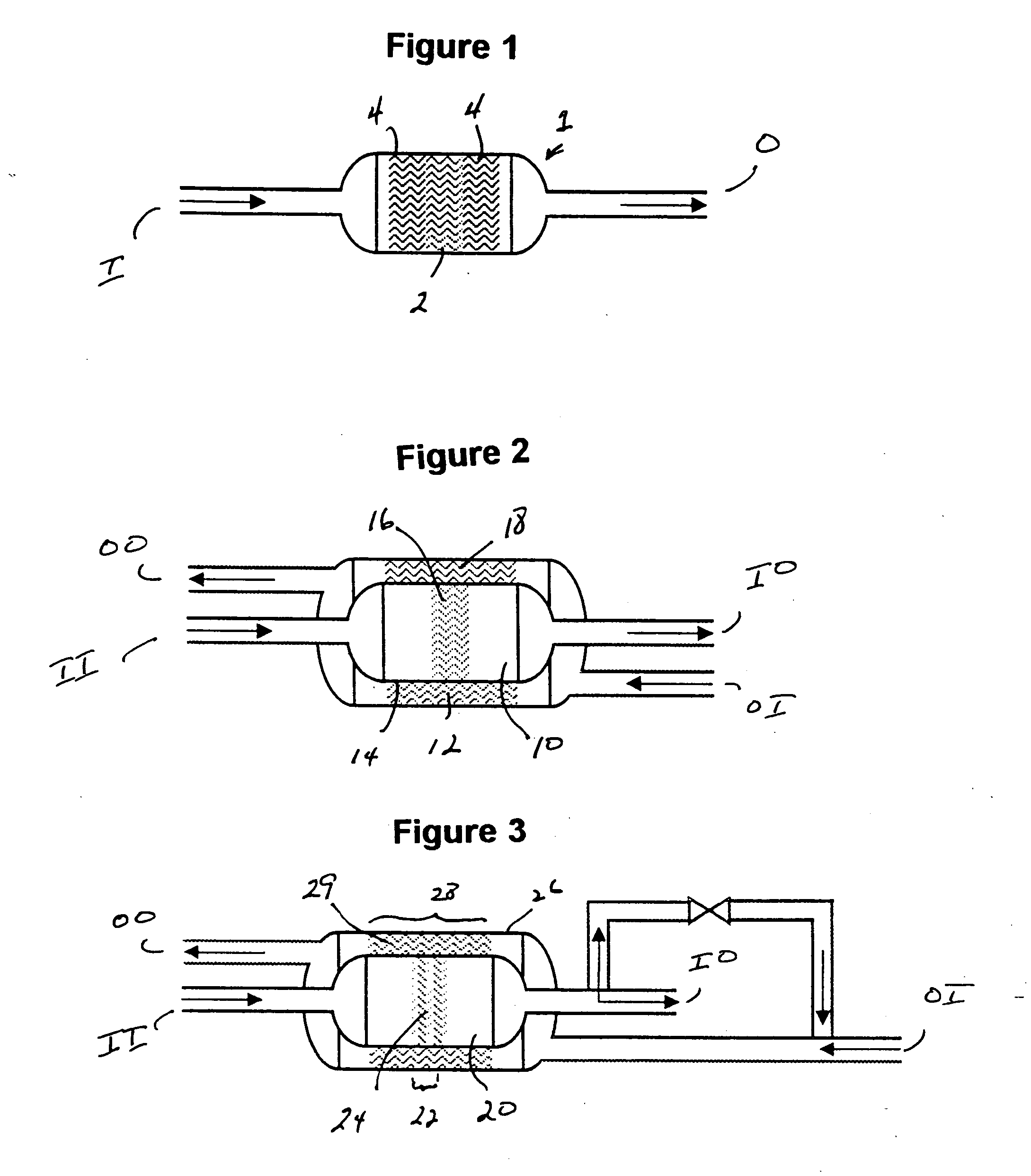

Methods of conducting simultaneous exothermic and endothermic reactions

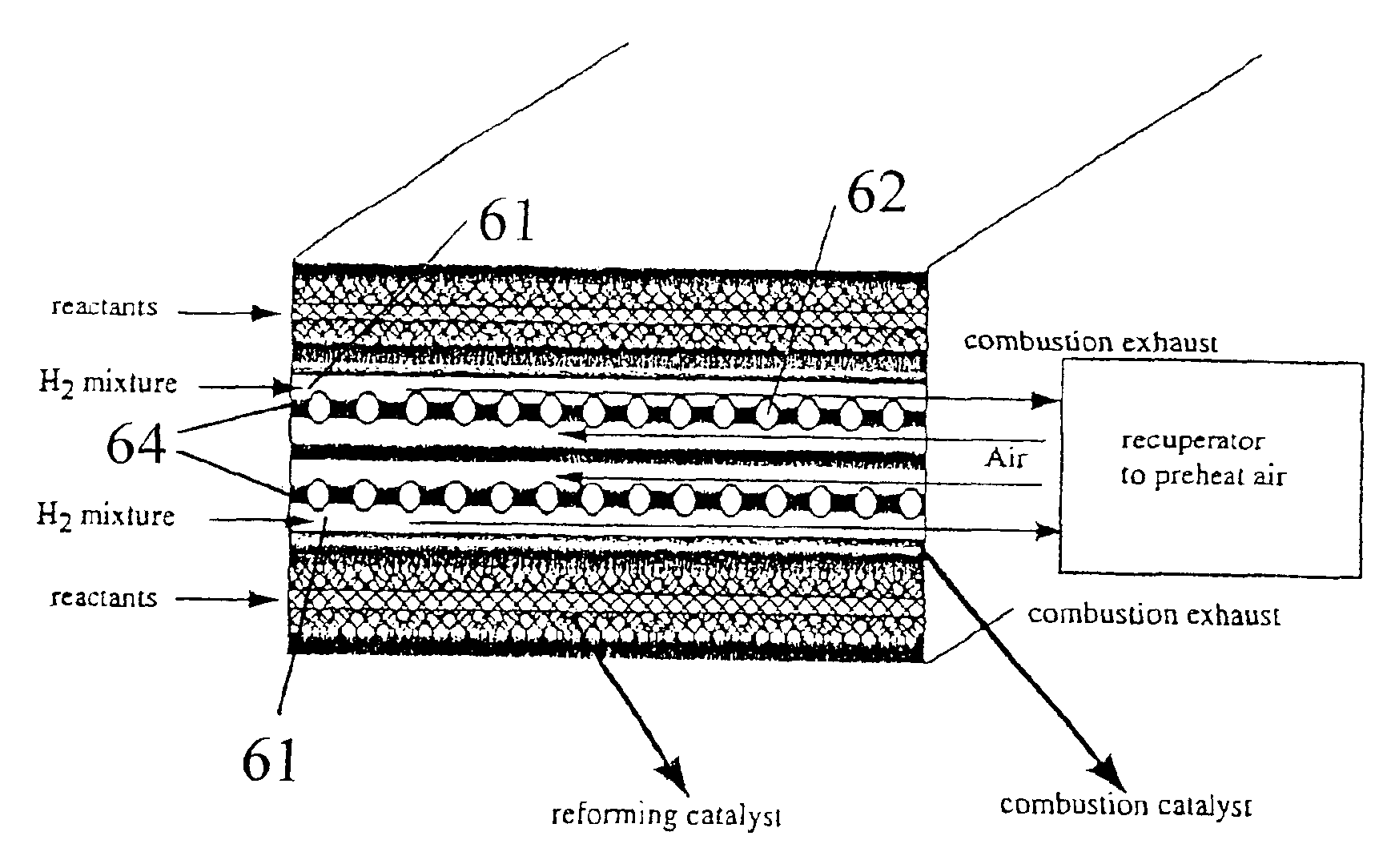

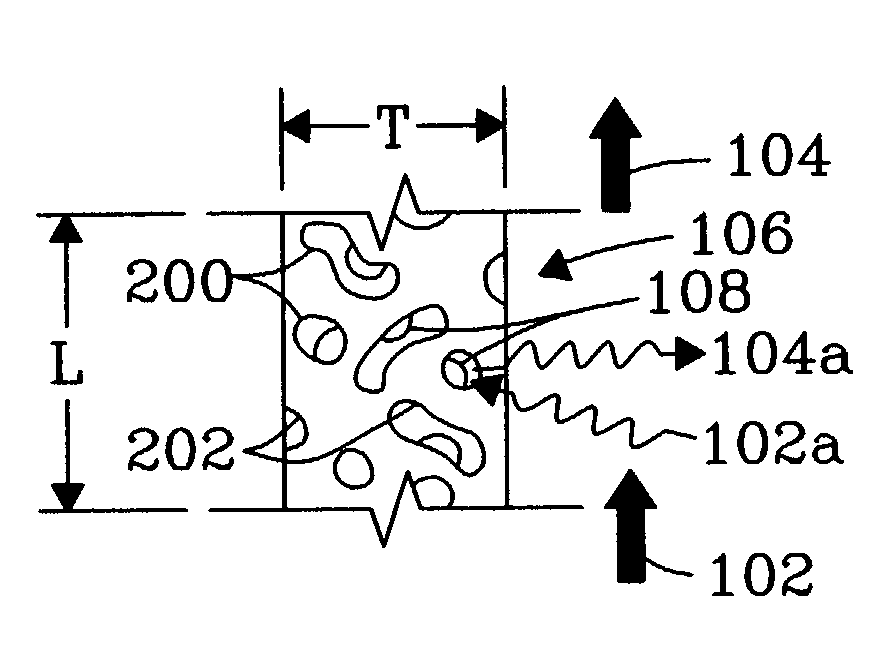

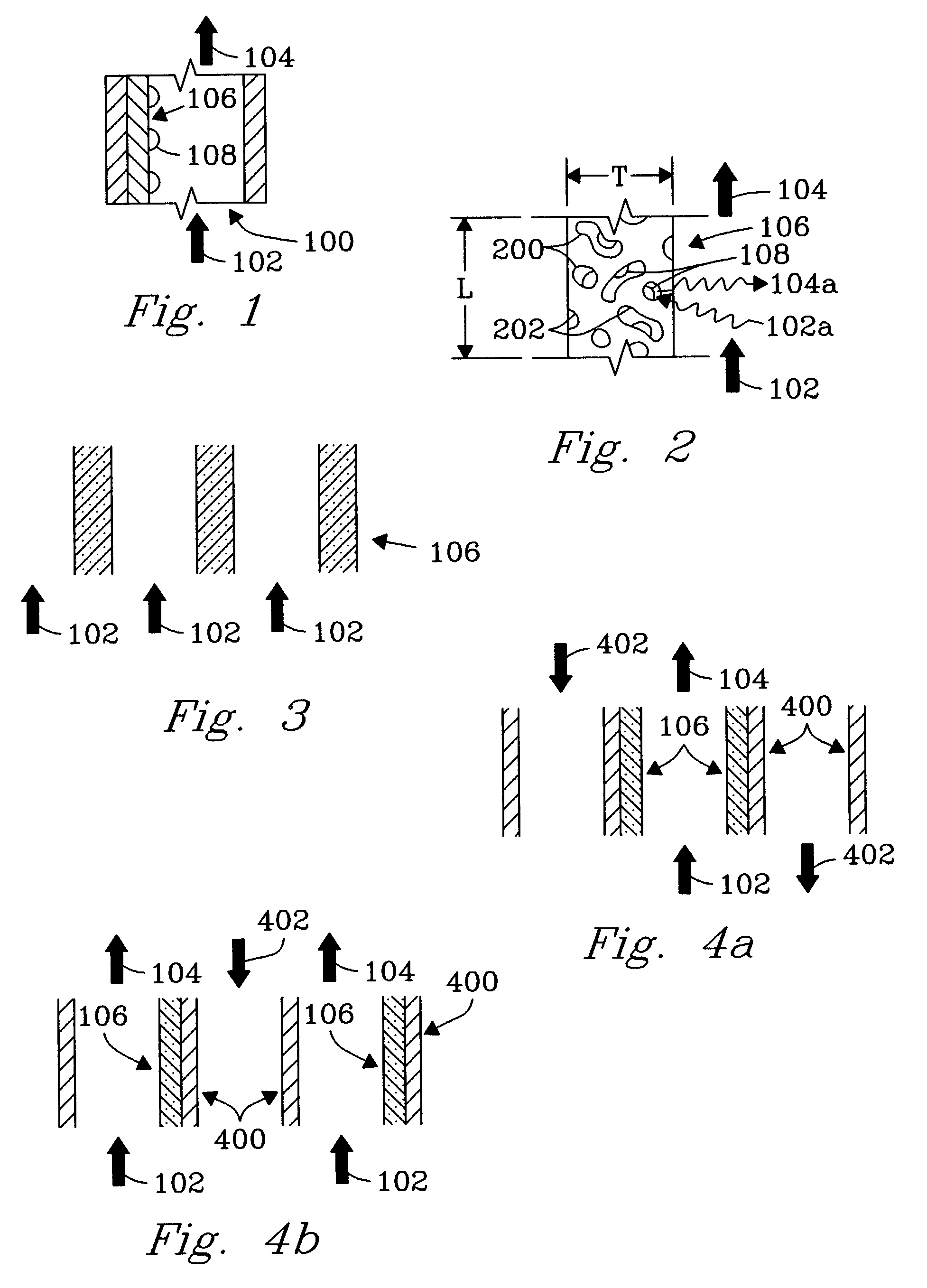

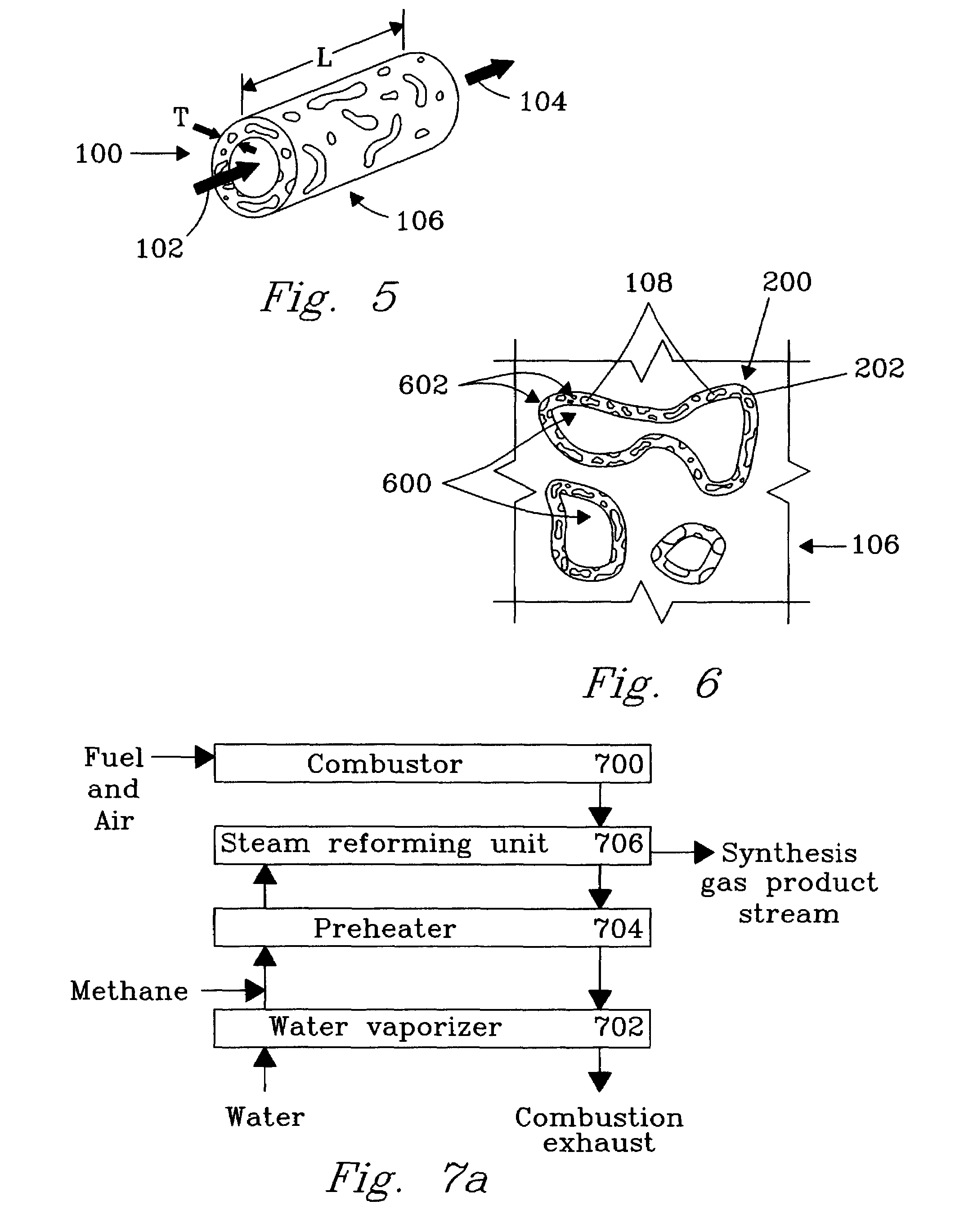

InactiveUS6969506B2High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberEngineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for free flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

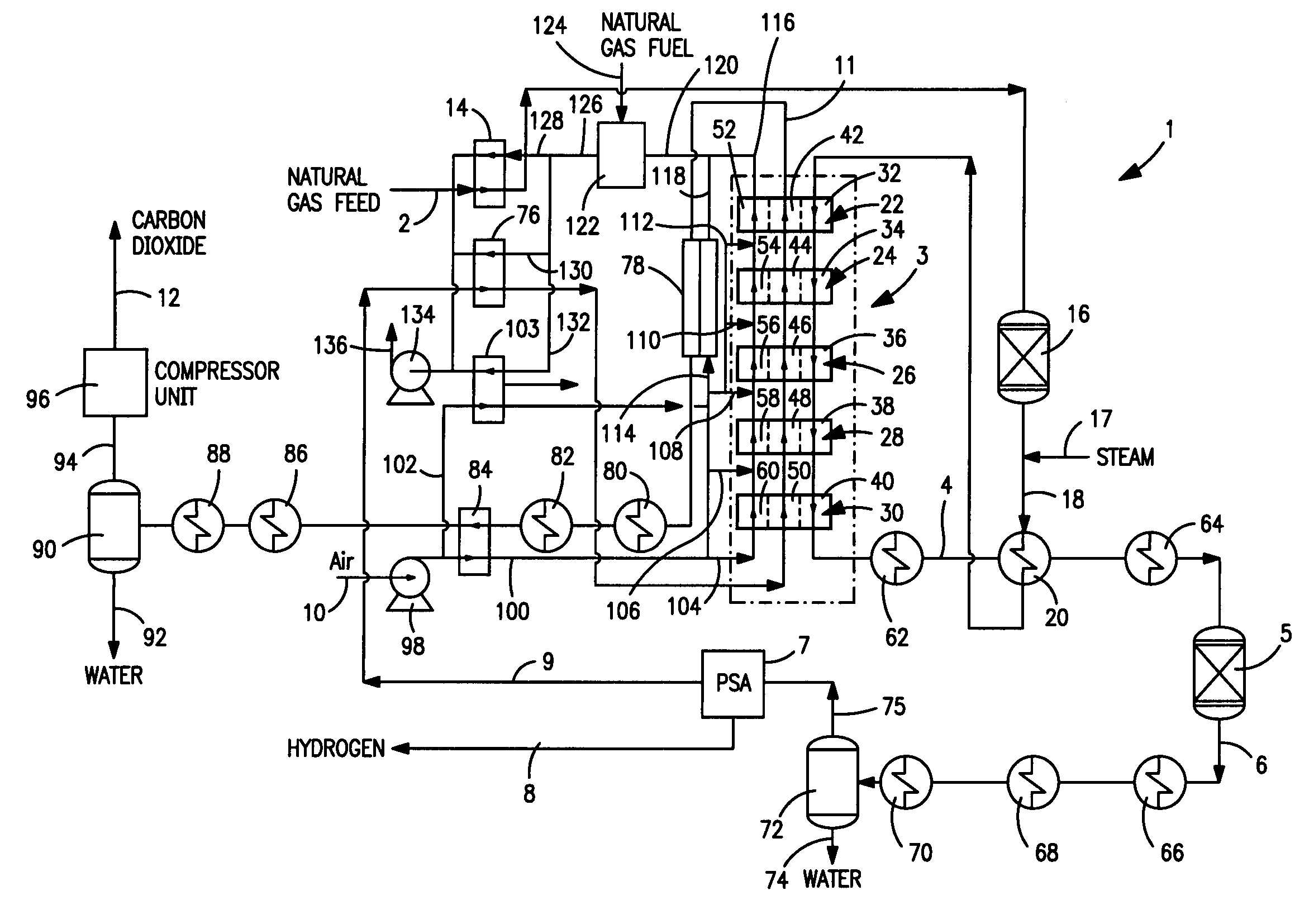

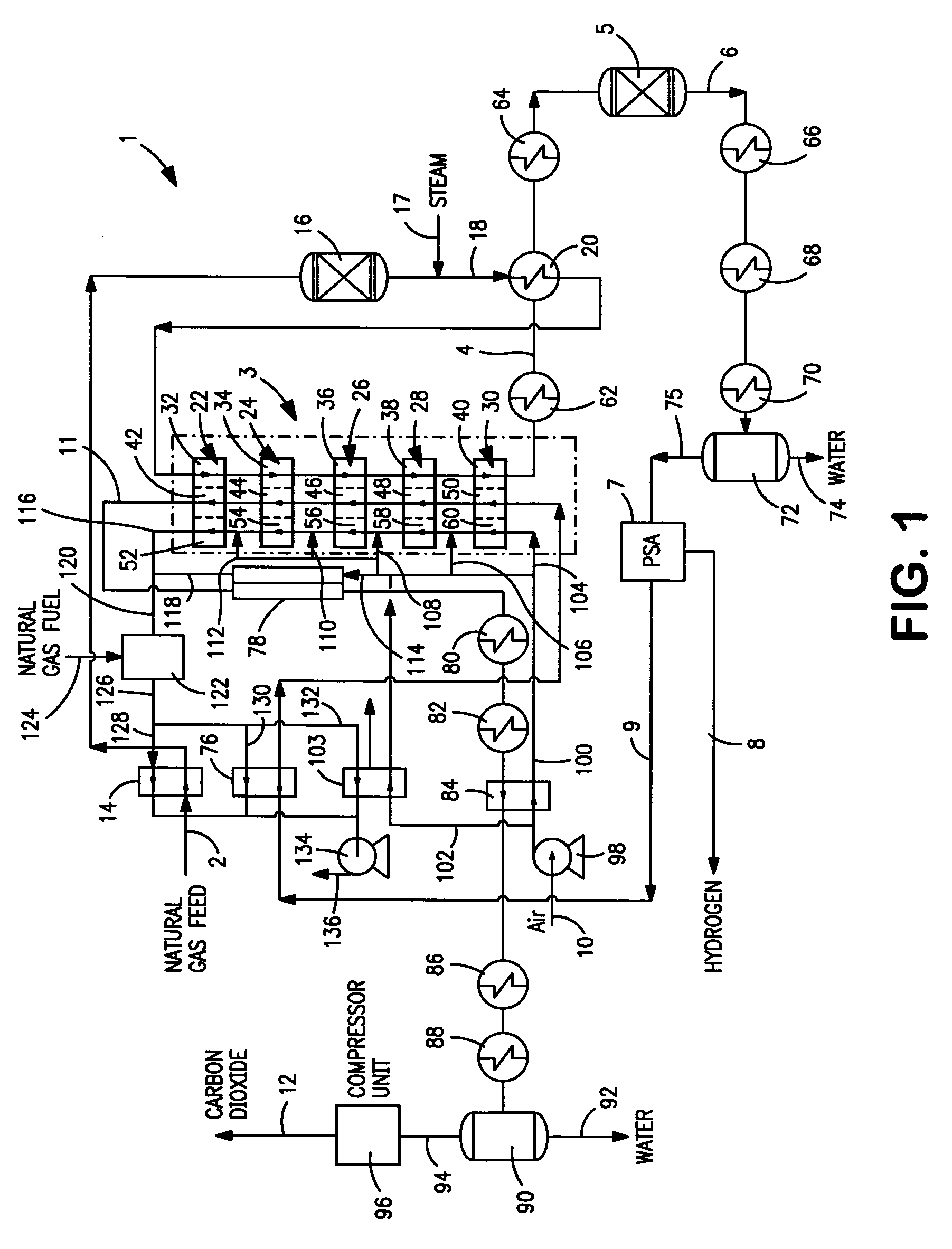

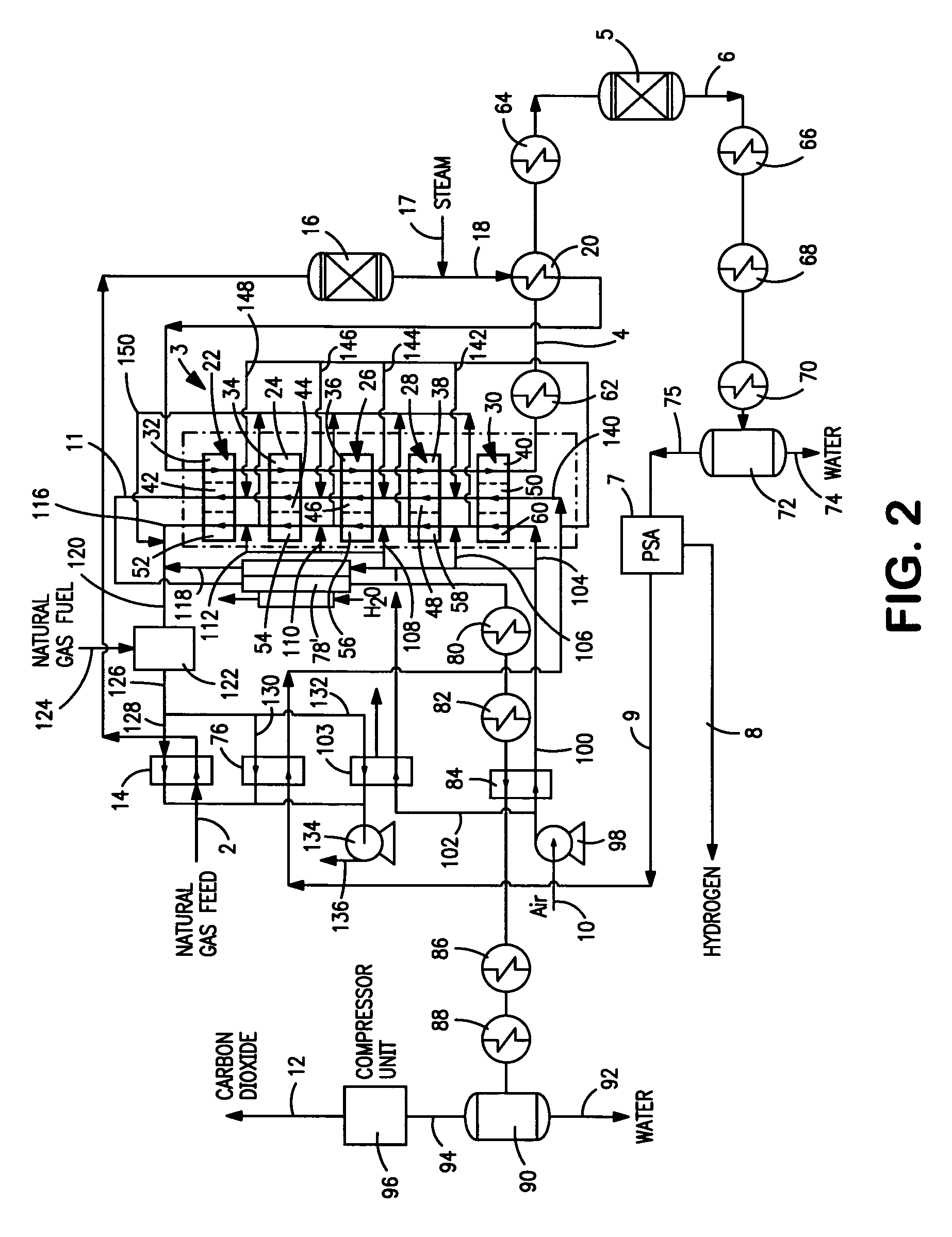

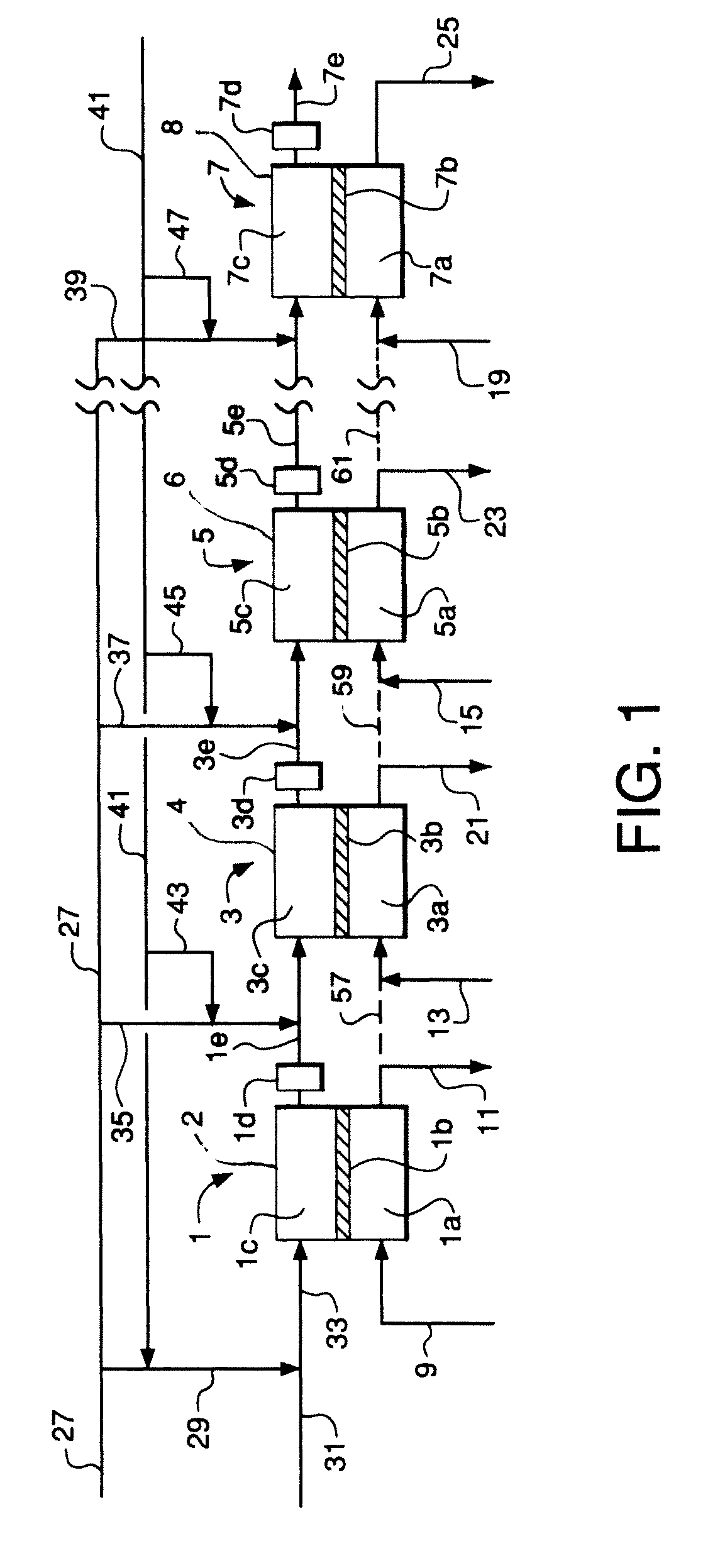

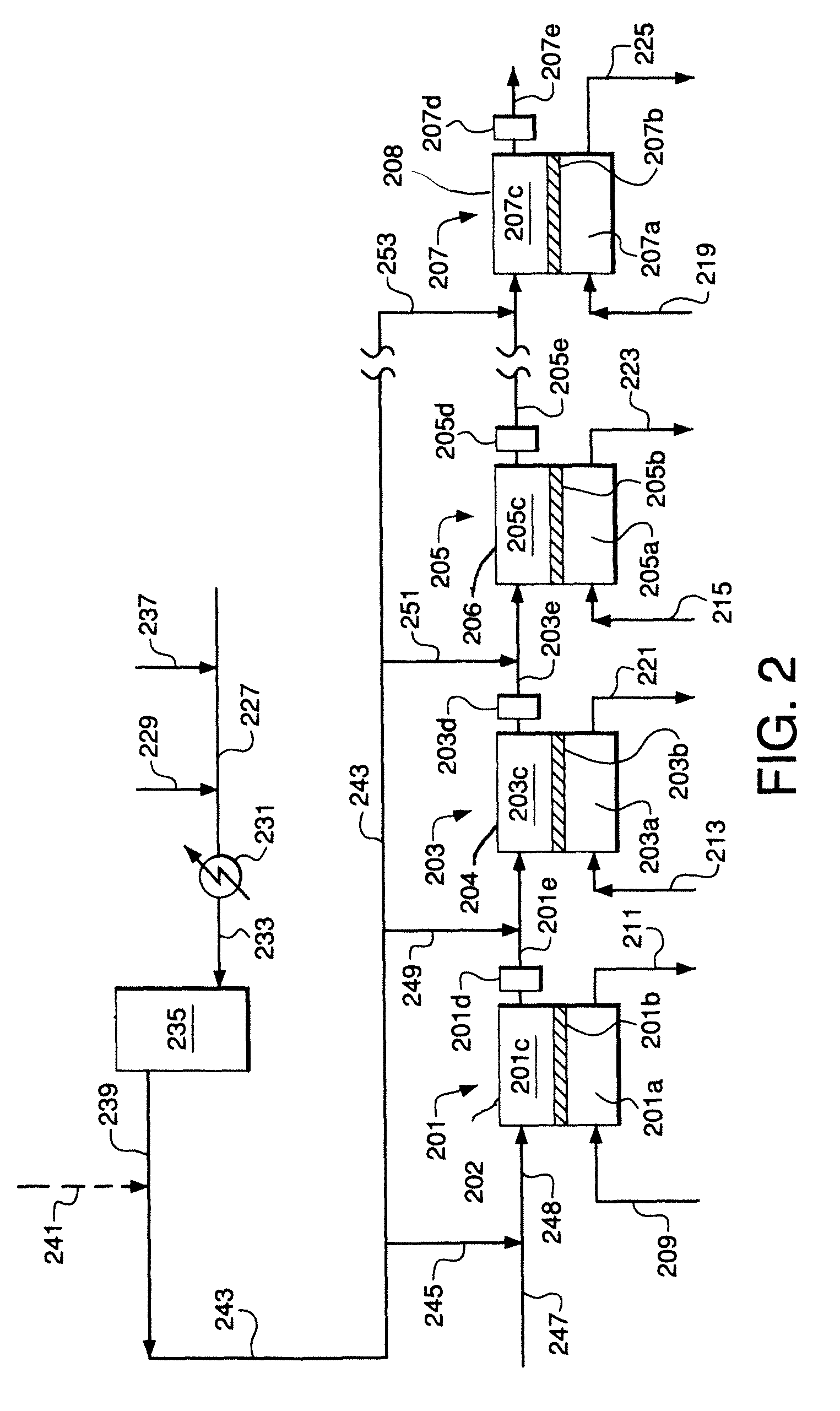

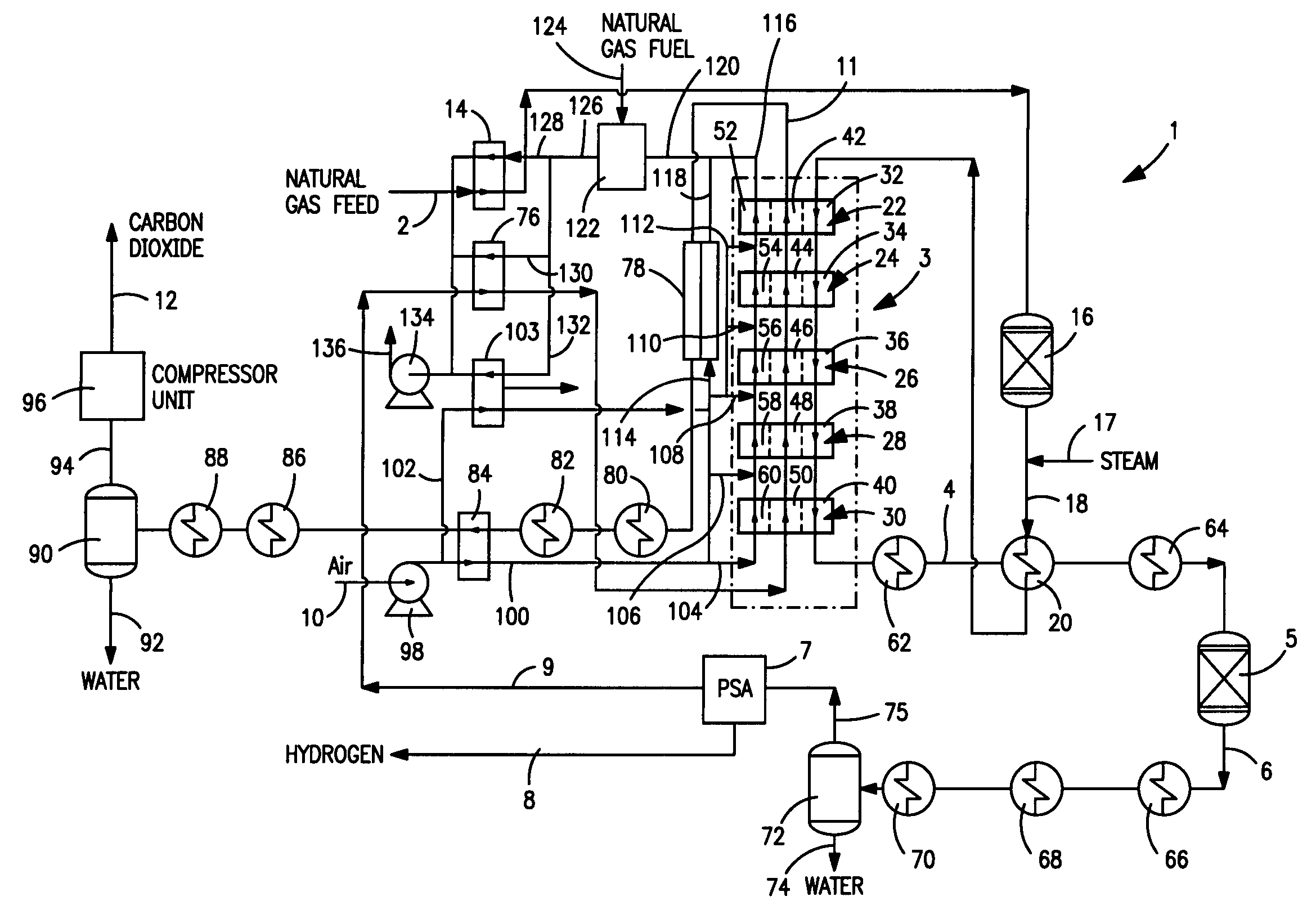

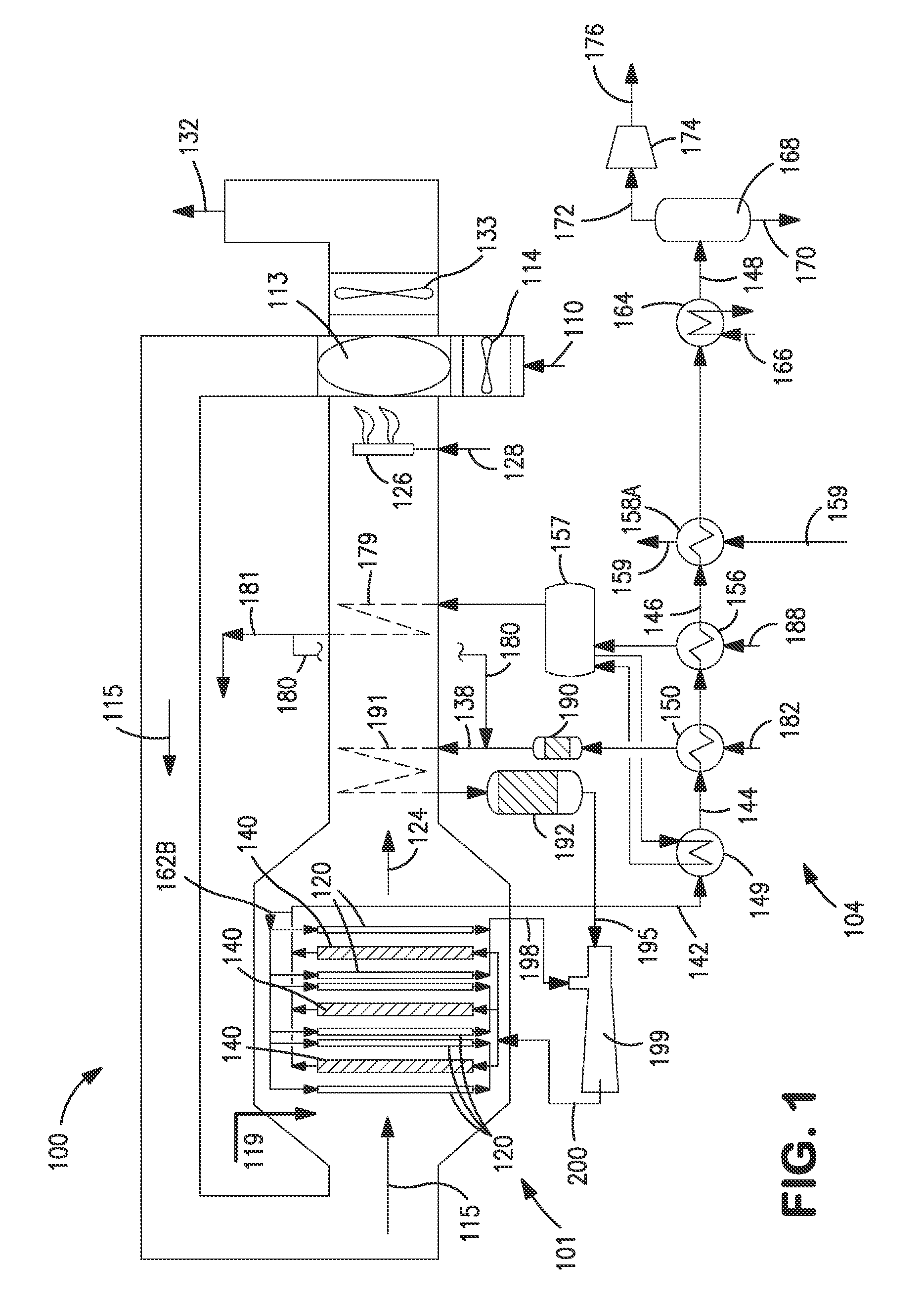

Method and apparatus for producing synthesis gas

InactiveUS20070289215A1Increase the number ofCatalytic gas-gas reactionOxygen/ozone/oxide/hydroxideSyngasCombustion

A method and apparatus for reacting a hydrocarbon containing feed stream by steam methane reforming reactions to form a synthesis gas. The hydrocarbon containing feed is reacted within a reactor having stages in which the final stage from which a synthesis gas is discharged incorporates expensive high temperature materials such as oxide dispersed strengthened metals while upstream stages operate at a lower temperature allowing the use of more conventional high temperature alloys. Each of the reactor stages incorporate reactor elements having one or more separation zones to separate oxygen from an oxygen containing feed to support combustion of a fuel within adjacent combustion zones, thereby to generate heat to support the endothermic steam methane reforming reactions.

Owner:PRAXAIR TECH INC +1

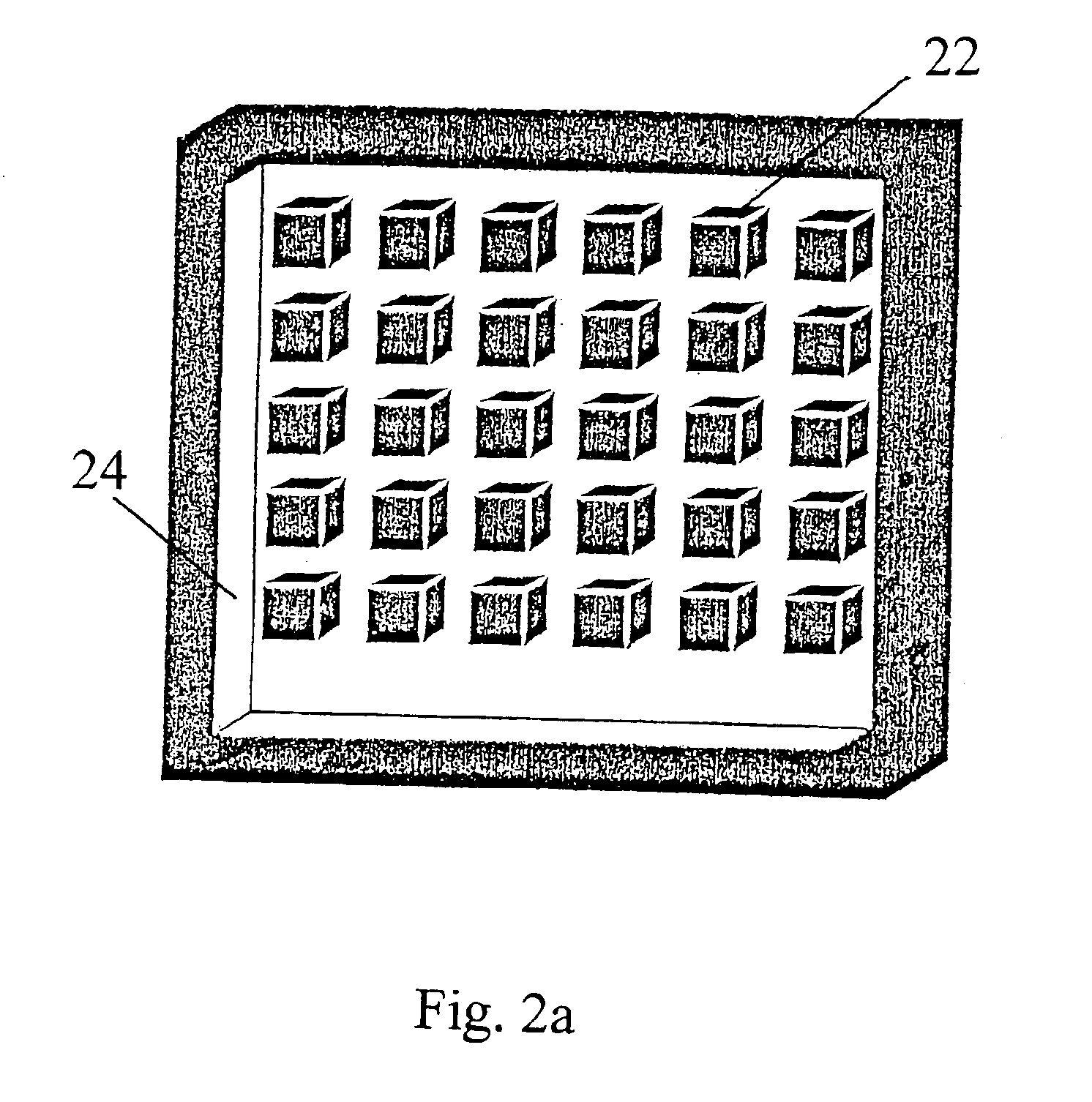

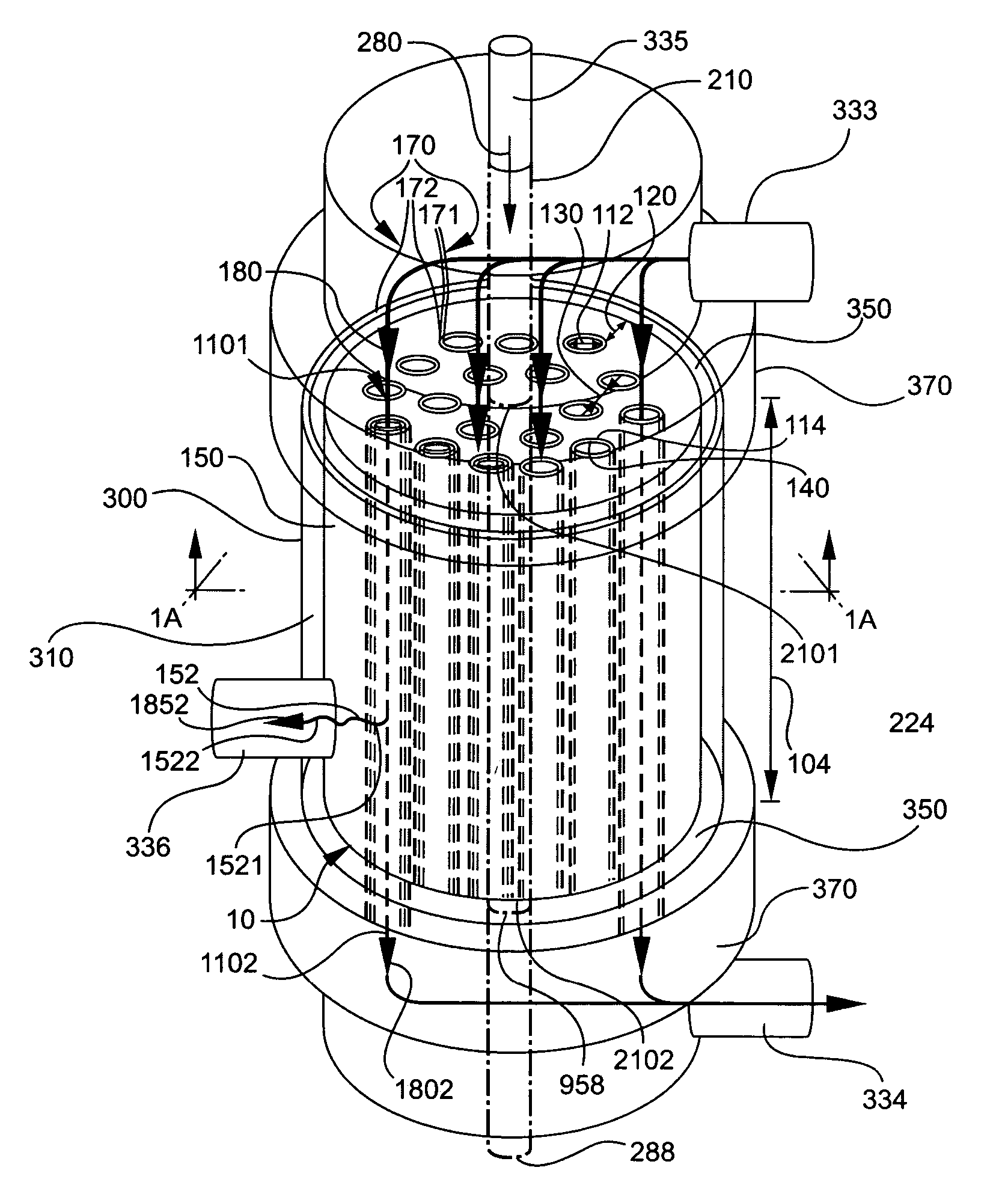

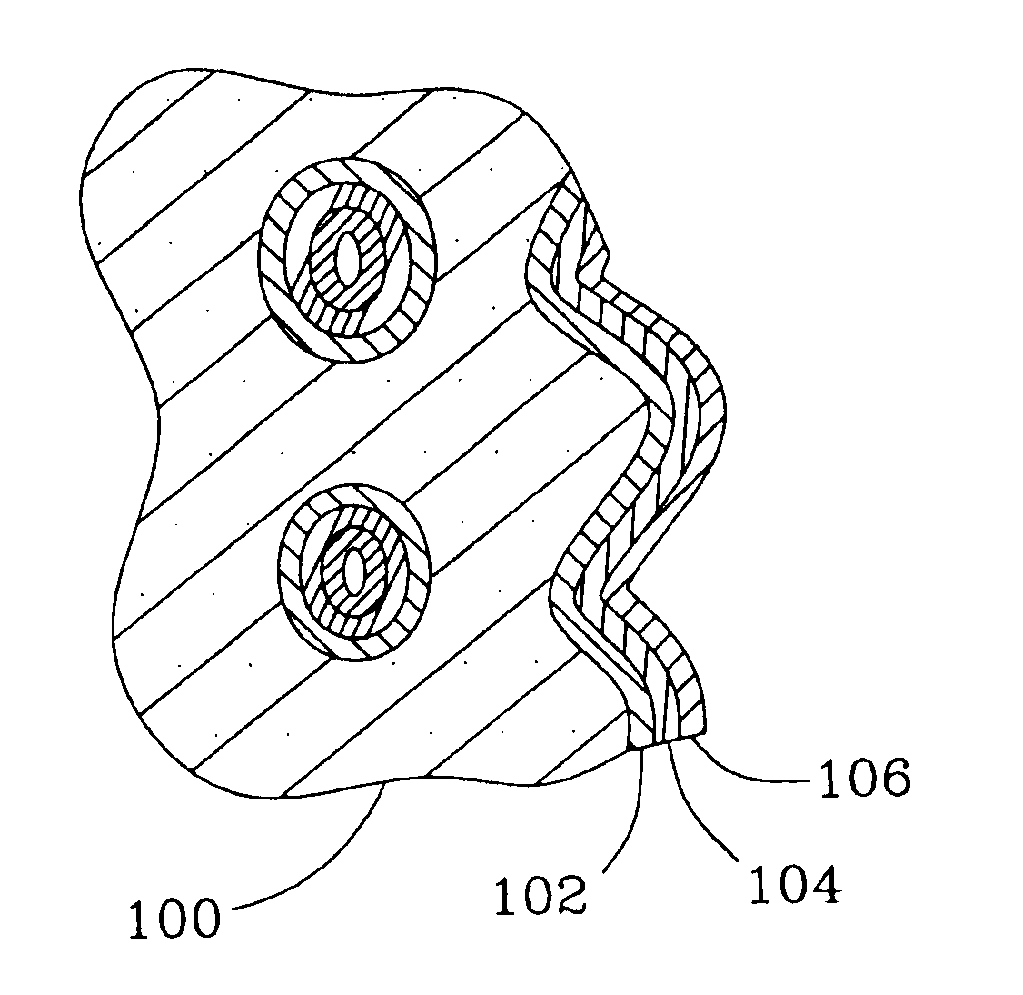

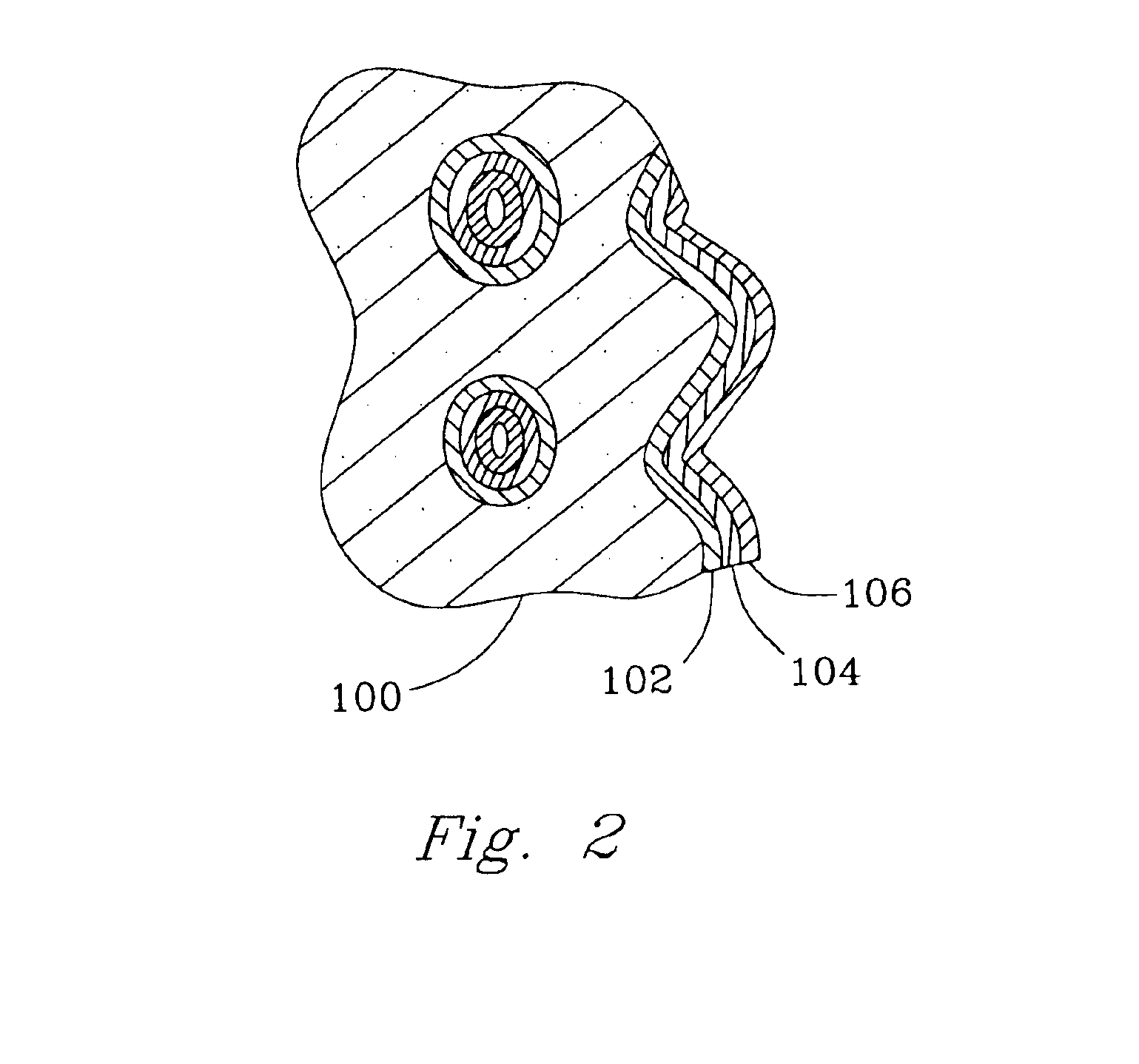

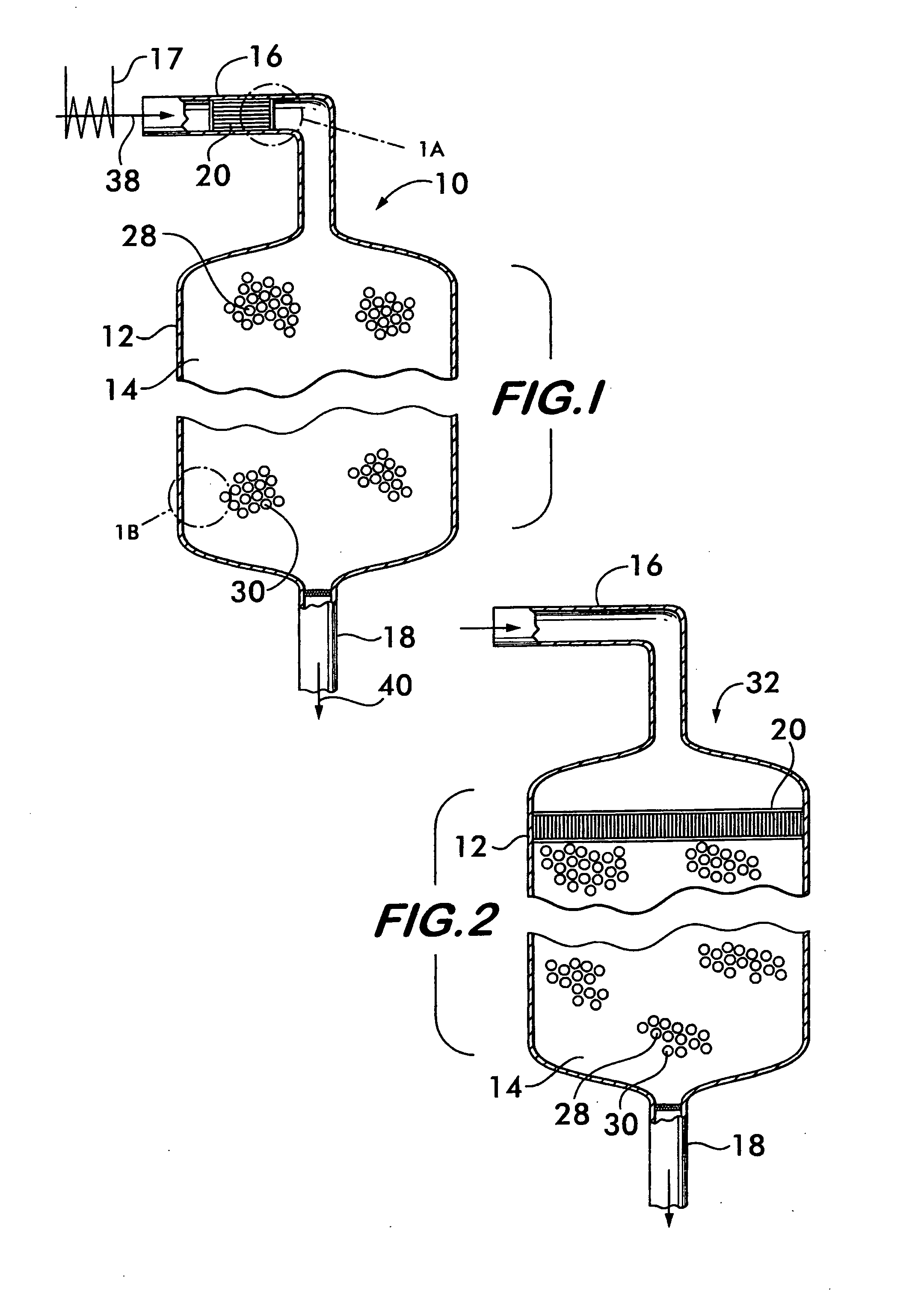

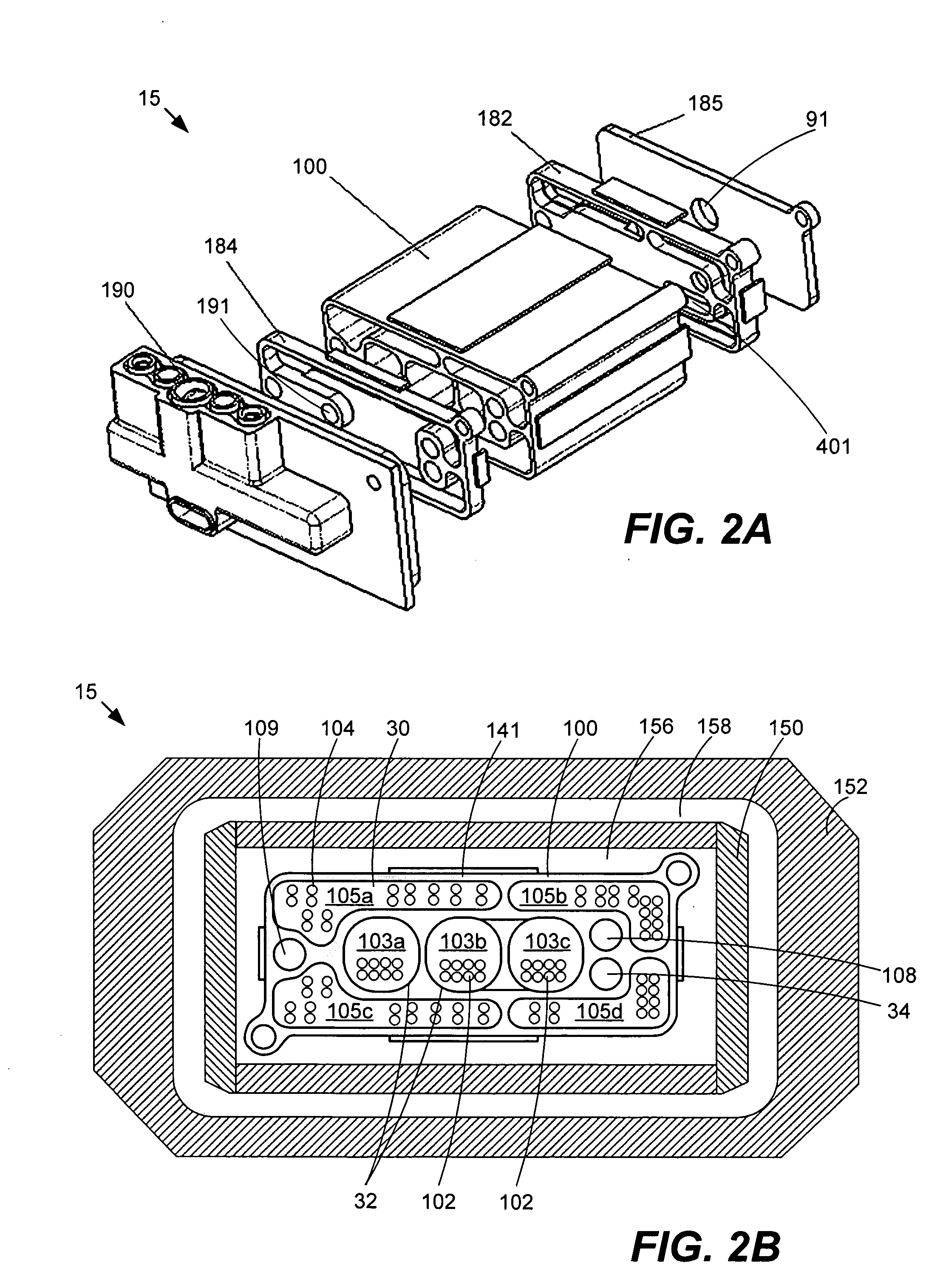

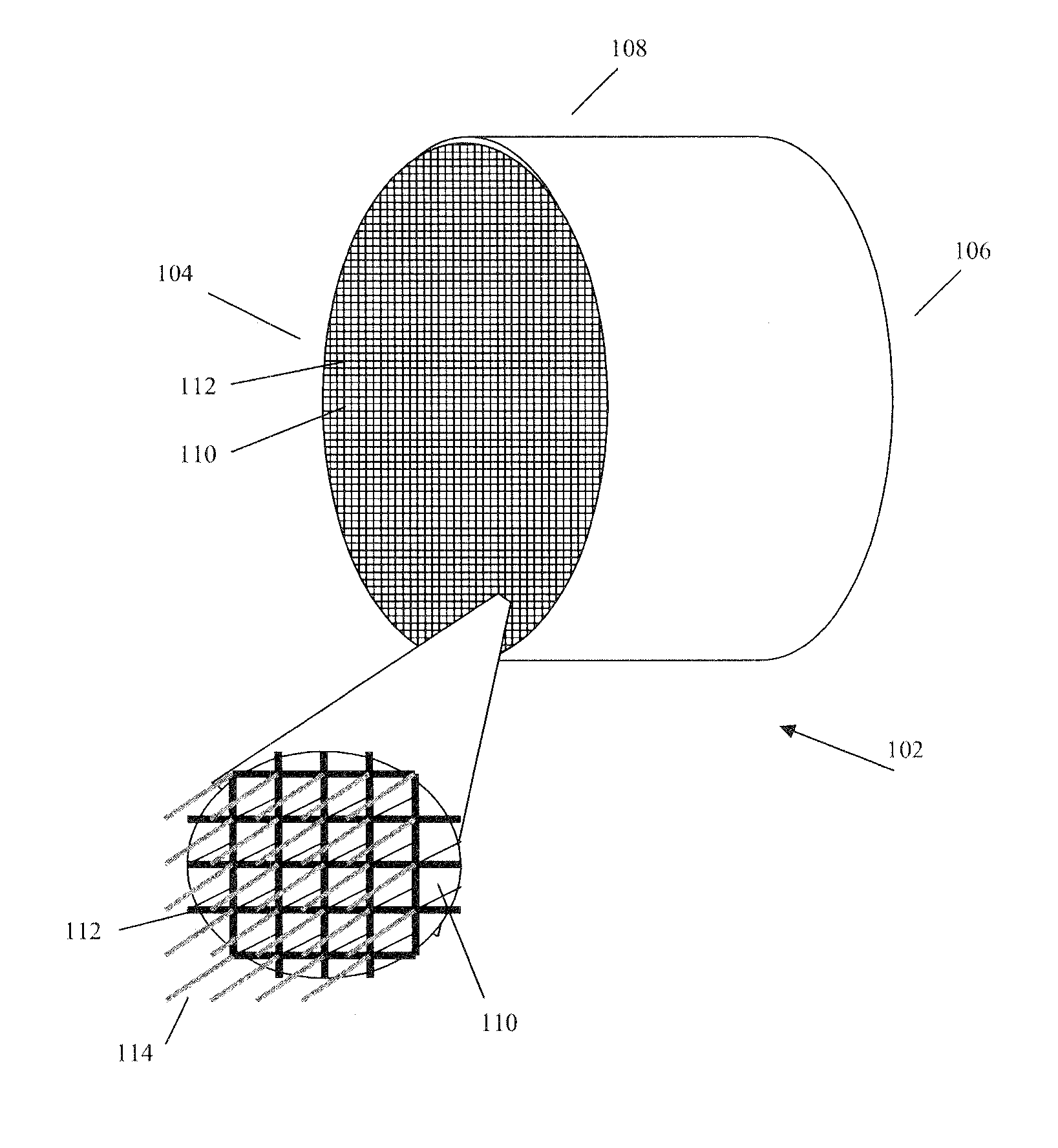

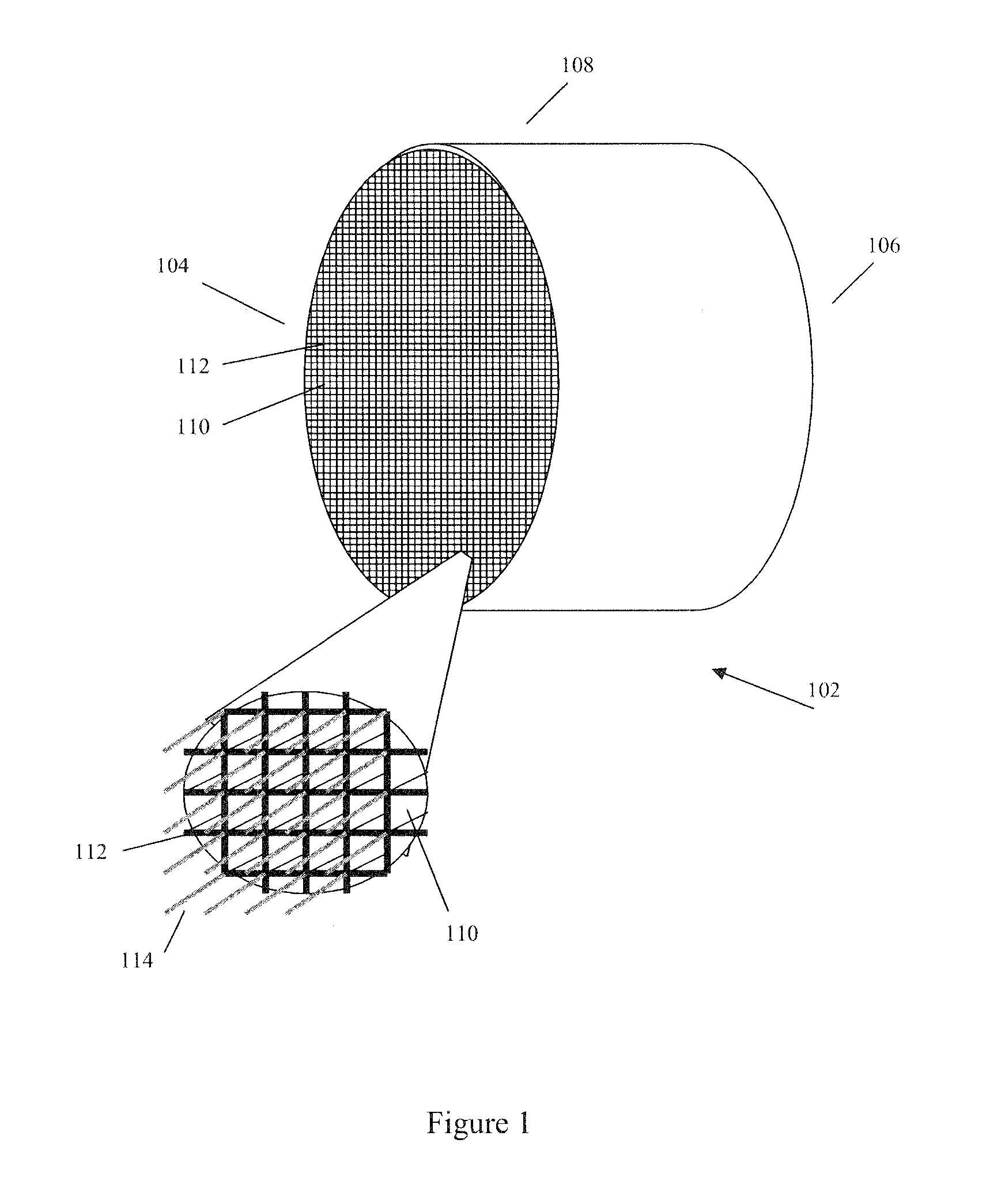

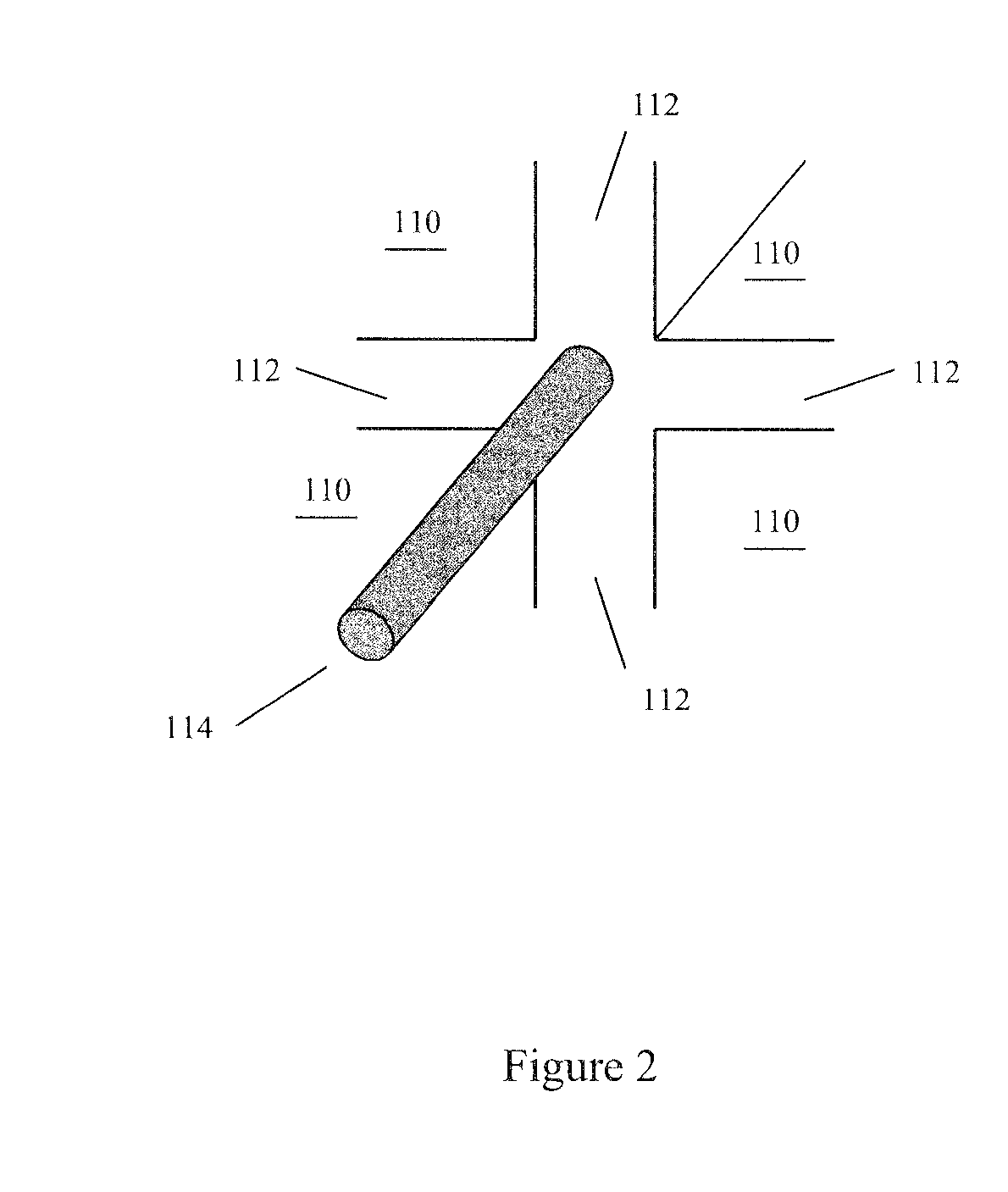

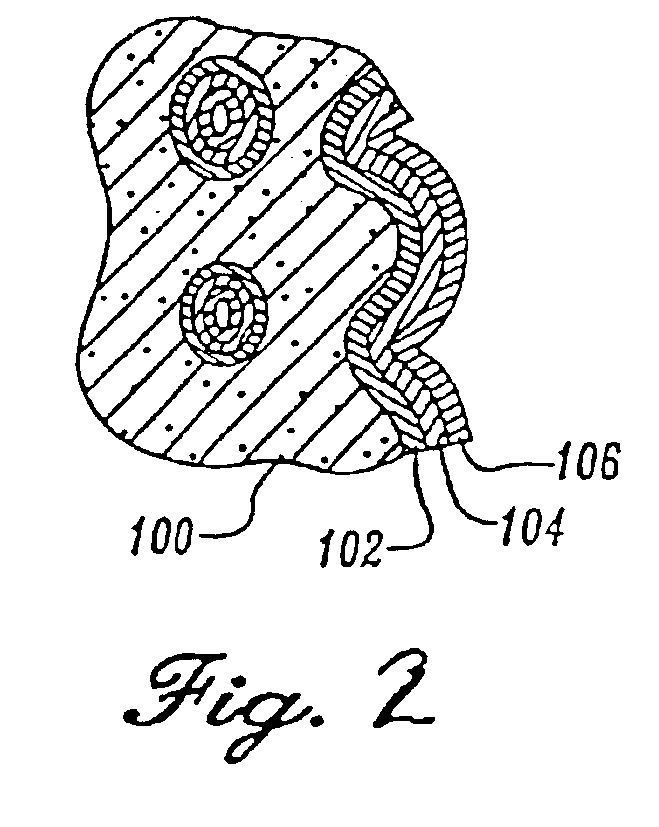

Multi-channel cross-flow porous device

InactiveUS20060090651A1Dispersed particle filtrationTransportation and packagingStream flowEngineering

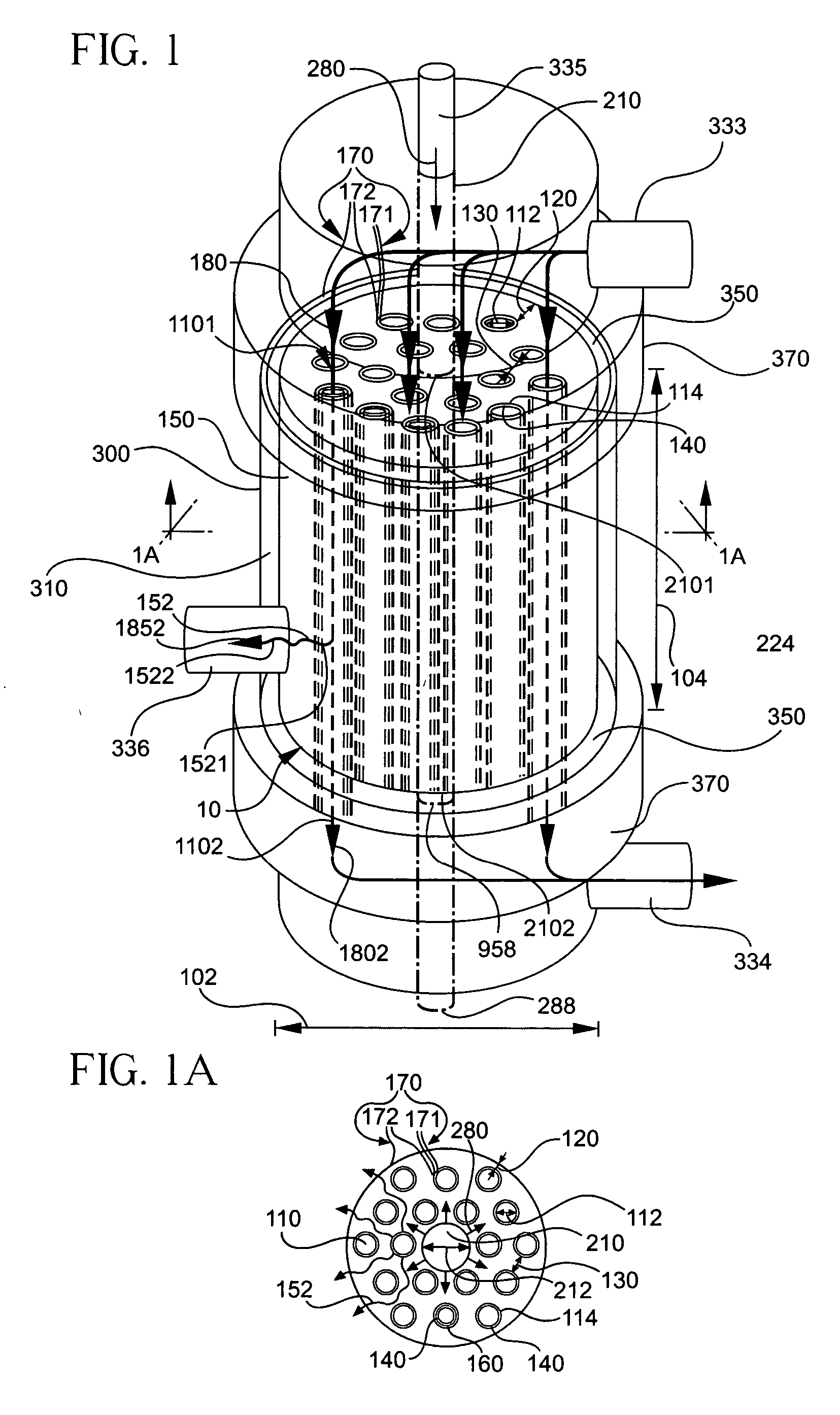

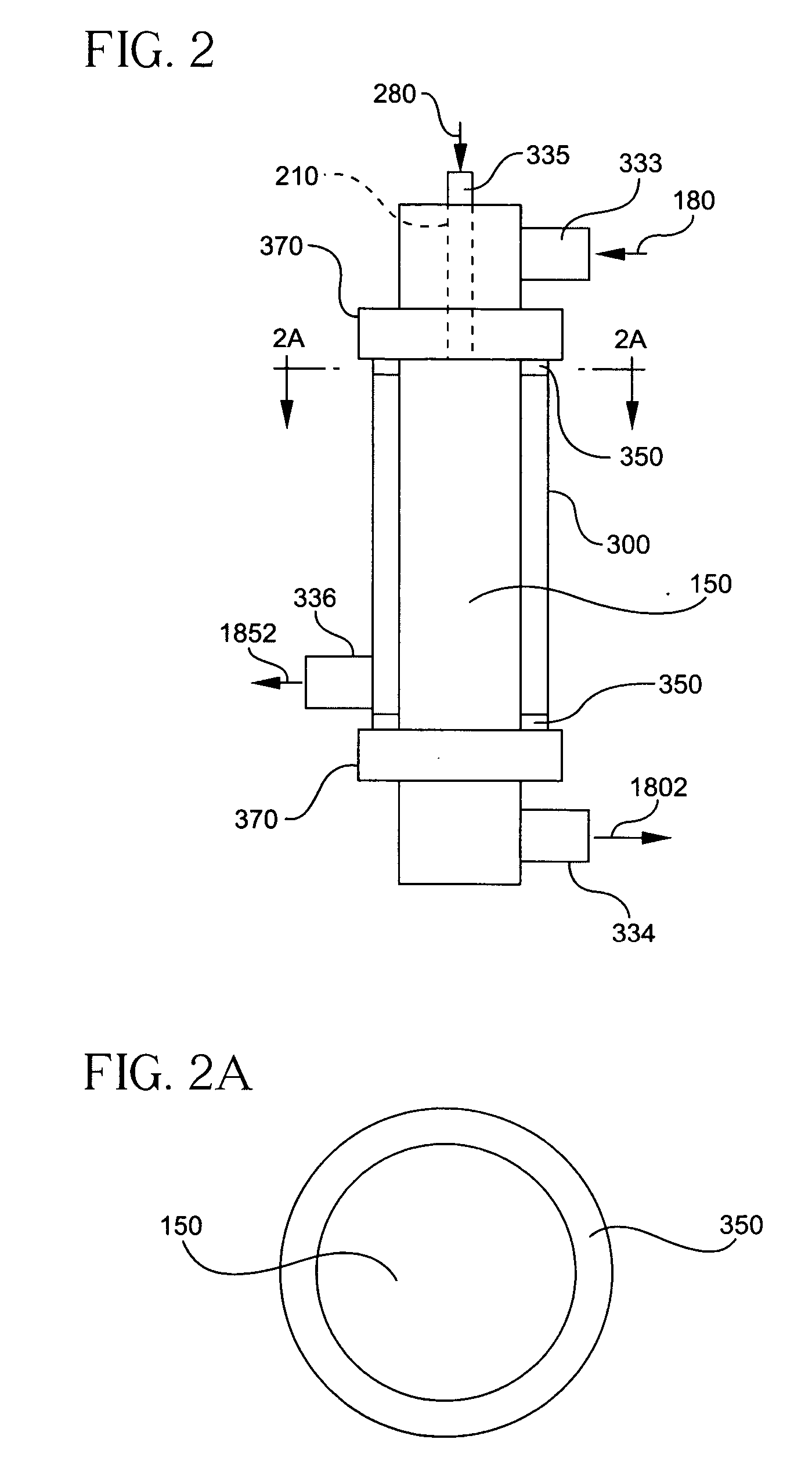

A multi-channel modular device (10) processes between two fluid streams of different compositions. The device (10) includes a porous body (150) having a first plurality of feed-flow pathways (110) disposed in the body (150) for transporting a first stream (180). A pathway wall (114) surrounds each of the first plurality of feed-flow pathways (110) for processing the first stream (180) into a first composition (1852) and a second composition (1802). At least one feed-flow inlet (1101) is disposed in the body (150) for introducing the first stream (180) into the first plurality of feed-flow pathways (110). At least one feed-flow outlet (1102) is disposed in the body (150) for discharging the remaining first stream containing the second composition (1802). At least one second pathway (210) is disposed in the body (150) for transporting a second stream (280) having a second inlet (2101) and a second outlet (2102). A networked plurality of fluid conduits (152) formed in the porous body (150) provides the flow-conduit for the second stream (280) to sweep the first composition (1852) from each of the first plurality of the feed-flow pathways (110) to the second outlet (2102). A vessel (300) ports the inlets (1101 and 2101) and outlets (1102 and 2102) to provide a second stream flow access and for spacing the body within and away from the inner surfaces of the vessel (300) to provide a gap (310) for access. A partition (350) is disposed in the gap between the body and the vessel for diverting the flow within the gap (310).

Owner:CORNING INC

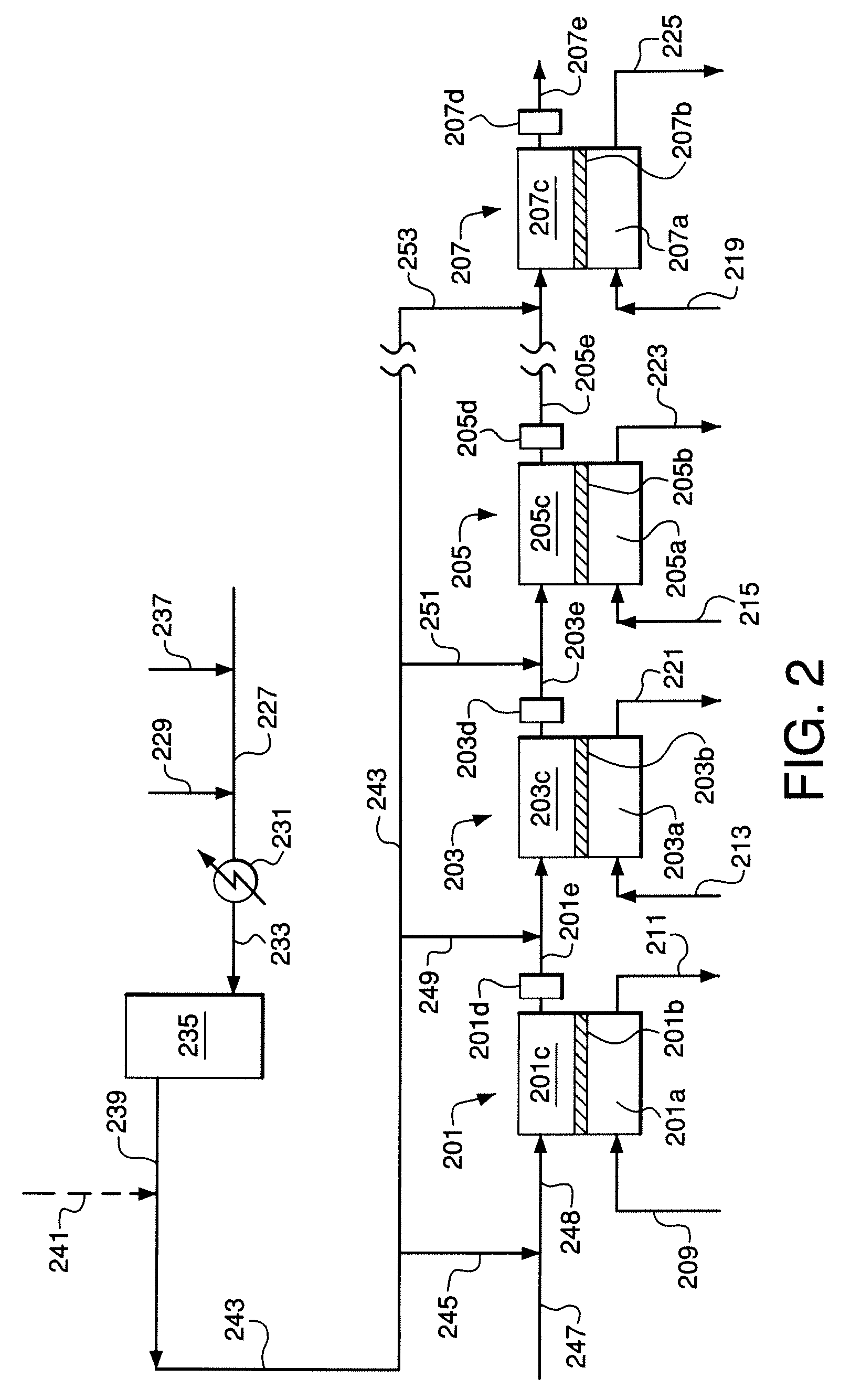

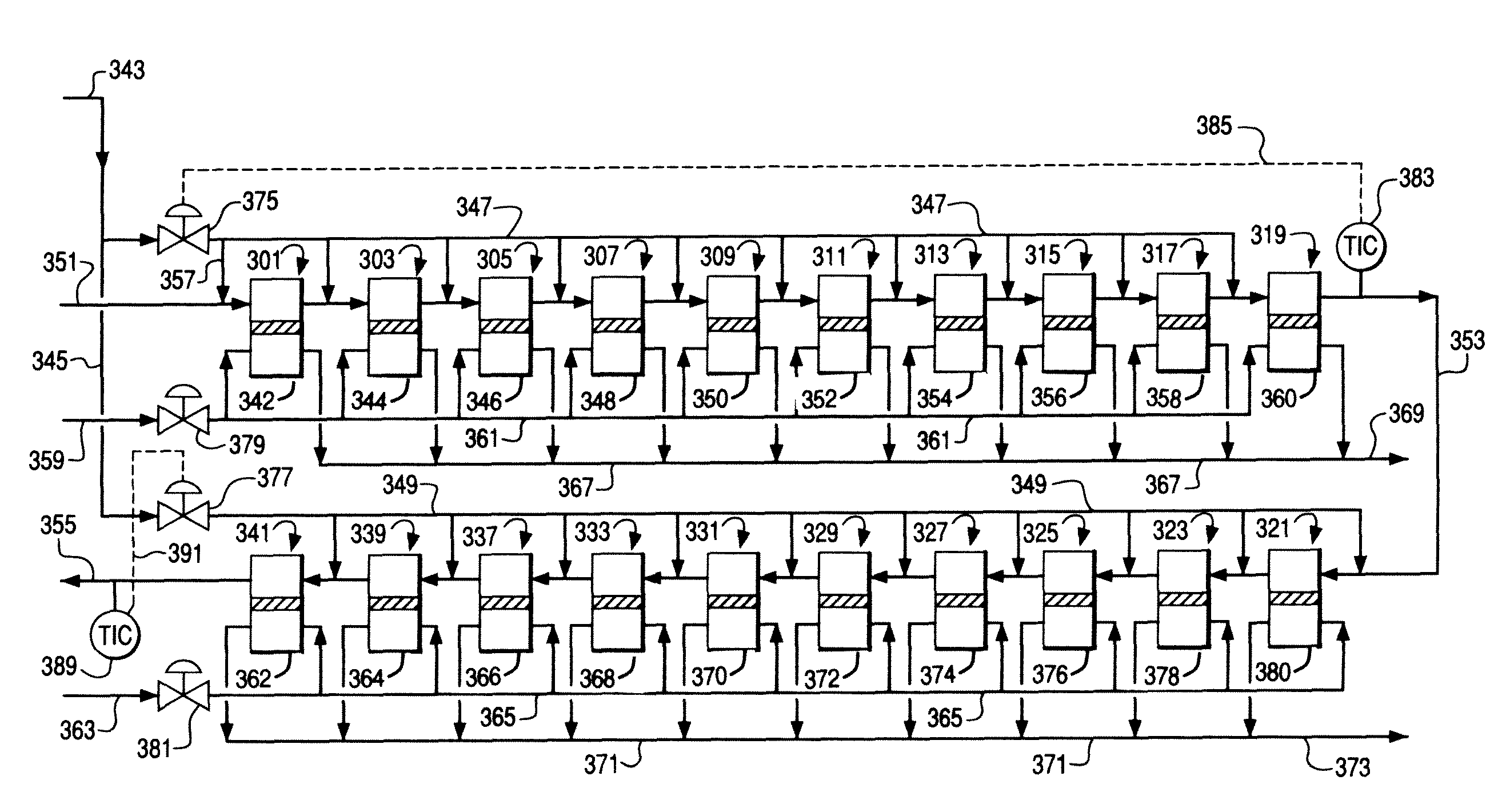

Staged Membrane Oxidation Reactor System

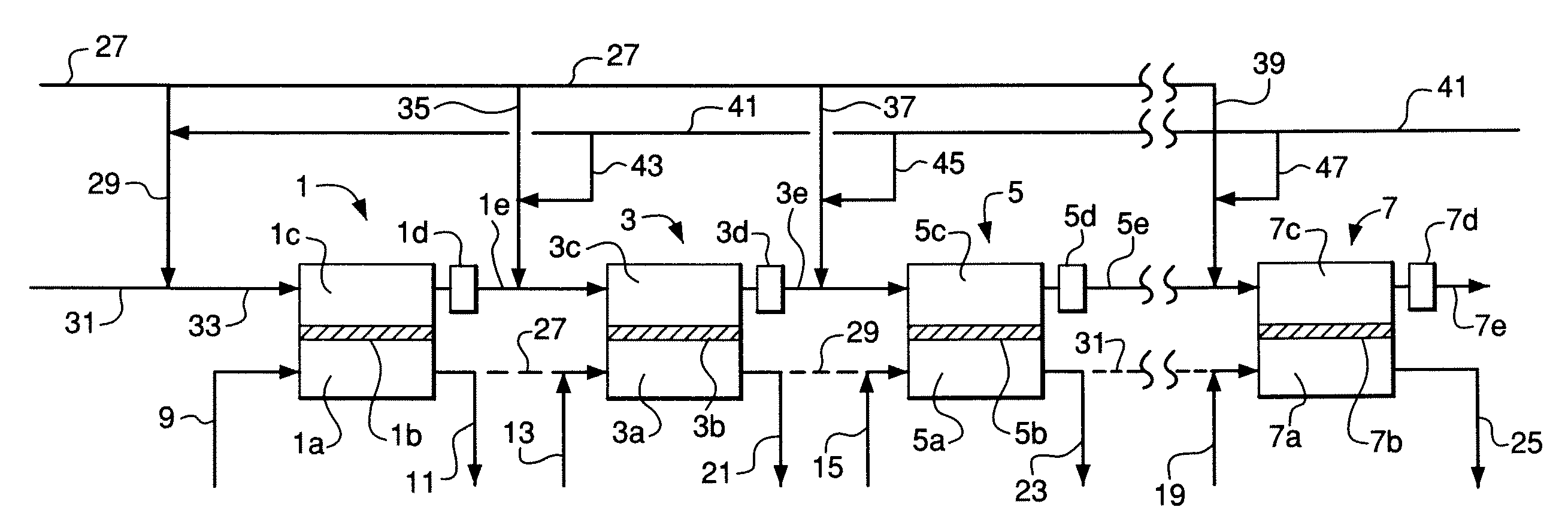

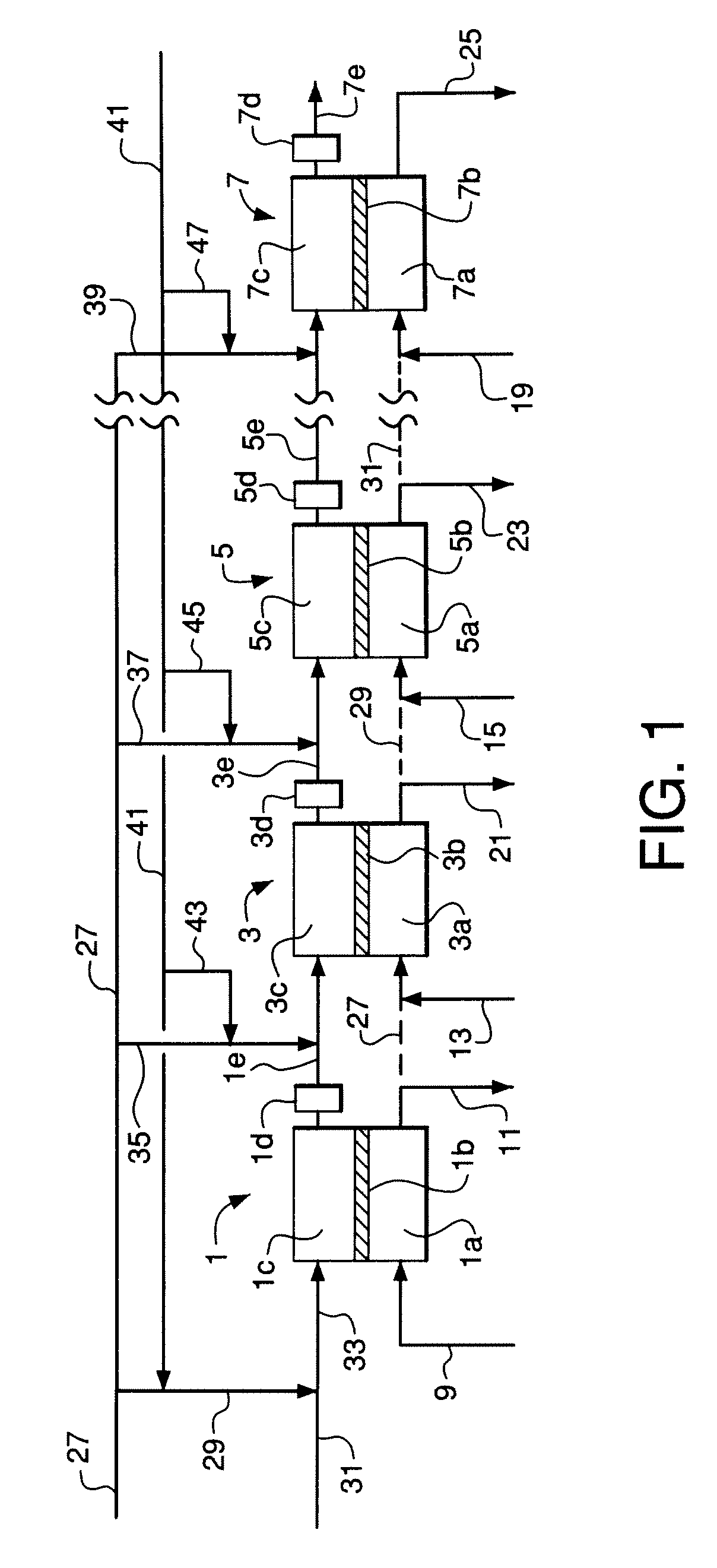

Ion transport membrane oxidation system comprising (a) two or more membrane oxidation stages, each stage comprising a reactant zone, an oxidant zone, one or more ion transport membranes separating the reactant zone from the oxidant zone, a reactant gas inlet region, a reactant gas outlet region, an oxidant gas inlet region, and an oxidant gas outlet region; (b) an interstage reactant gas flow path disposed between each pair of membrane oxidation stages and adapted to place the reactant gas outlet region of a first stage of the pair in flow communication with the reactant gas inlet region of a second stage of the pair; and (c) one or more reactant interstage feed gas lines, each line being in flow communication with any interstage reactant gas flow path or with the reactant zone of any membrane oxidation stage receiving interstage reactant gas.

Owner:AIR PROD & CHEM INC

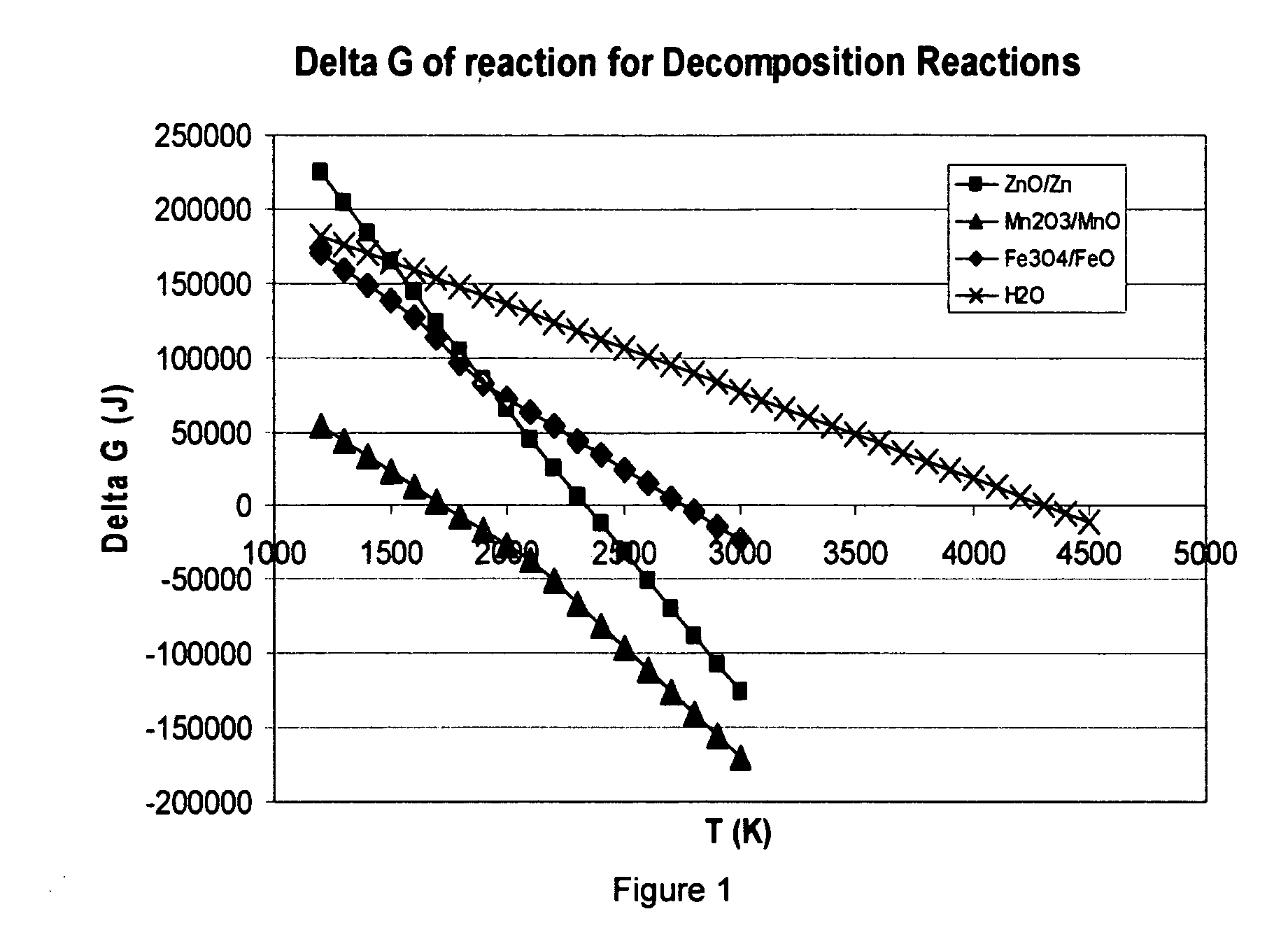

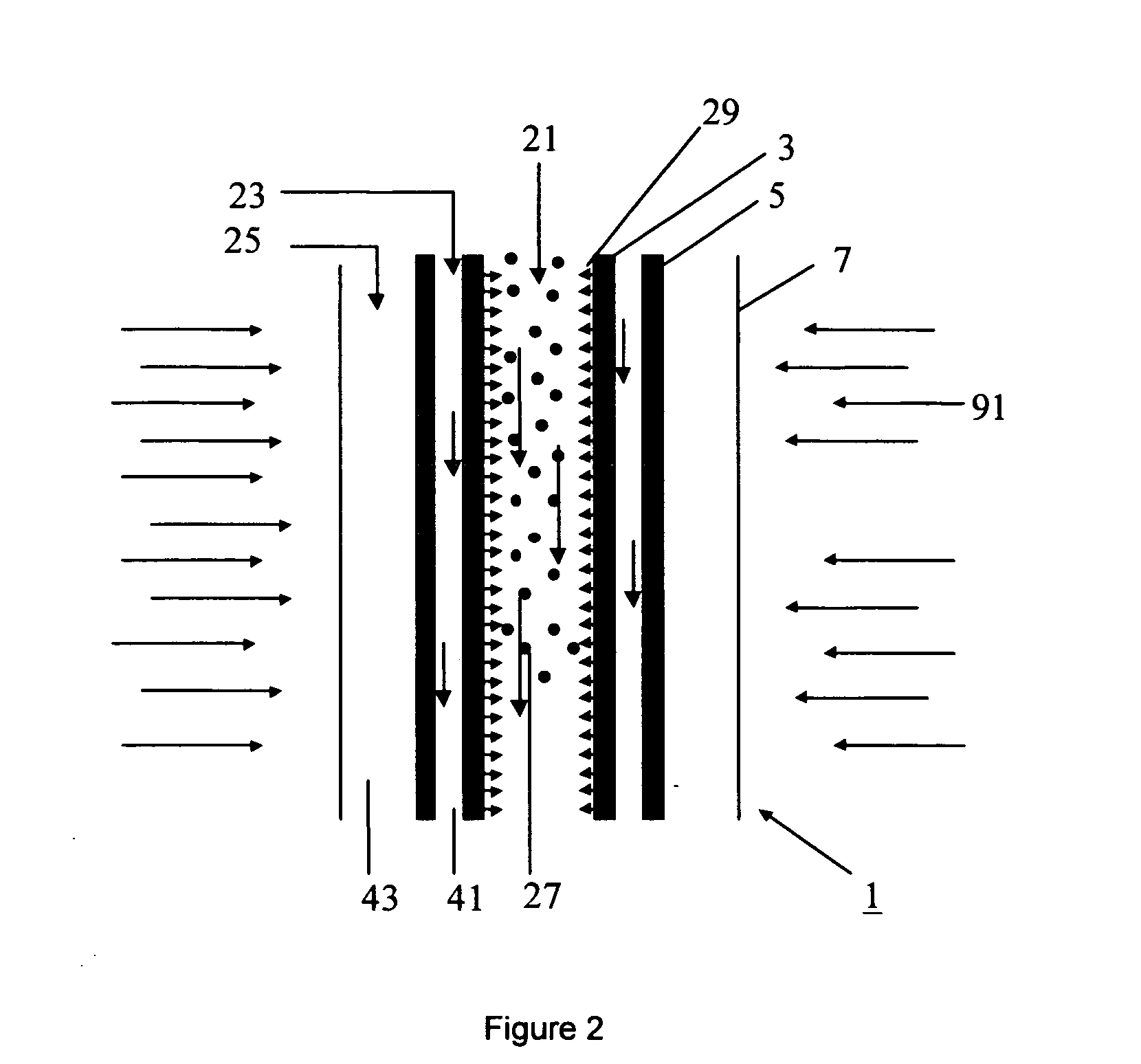

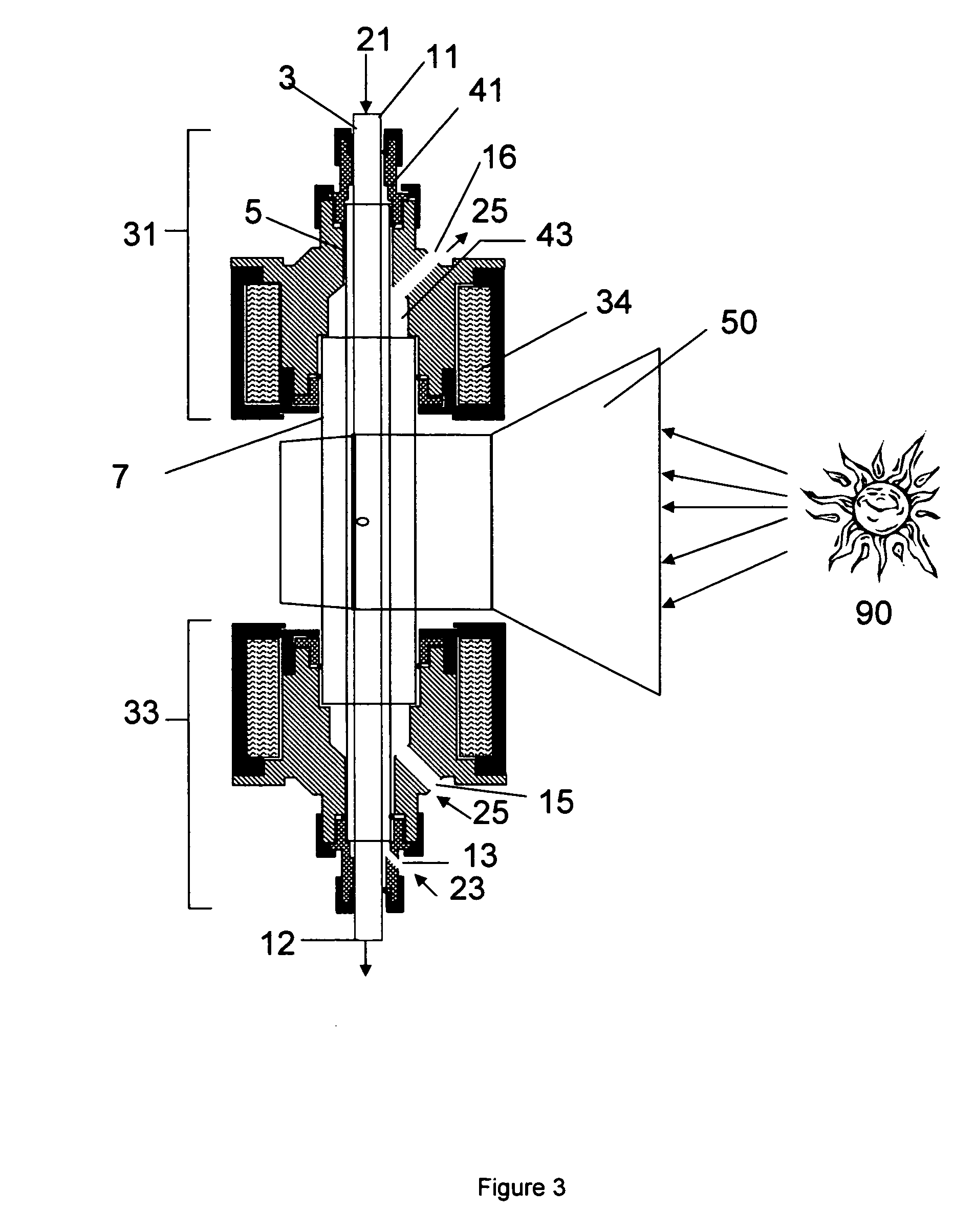

Metal-oxide based process for the generation of hydrogen from water splitting utilizing a high temperature solar aerosol flow reactor

InactiveUS20060188433A1Suppress heterogeneous nucleationReduce recombinationCatalytic gas-gas reactionZinc oxides/hydroxidesHydrogenReactor system

The invention provides methods for reduction of metal oxide particles using a high temperature solar aerosol reactor. The invention also provides metal-oxide based processes for the generation of hydrogen from water splitting using a high temperature solar aerosol reactor. In addition, the invention provides solar thermal reactor systems suitable for use with these processes.

Owner:UNIV OF COLORADO THE REGENTS OF +1

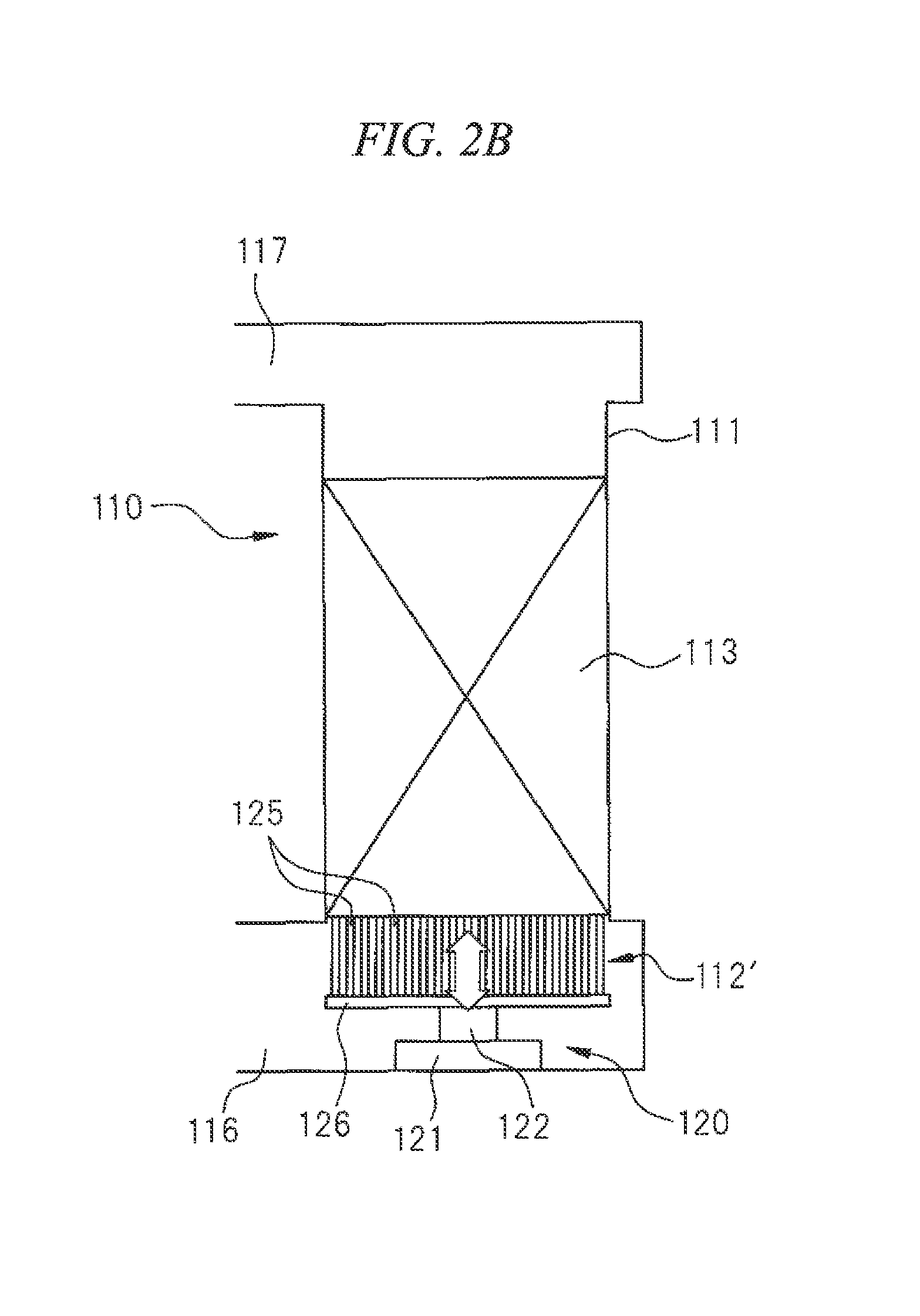

Continuous fixed-bed catalytic reactor and catalytic reaction method using same

ActiveUS20150010467A1Efficient removalImprove efficiencyCatalytic gas-gas reactionGaseous chemical processesFixed bedChemistry

A continuous fixed-bed catalytic reactor includes an inflow path for raw material gas for a catalytic reaction and an outflow path for reformed gas, a catalytic reaction container that is connected to the inflow path and the outflow path and holds a clumpy catalyst, catalyst holders that have a ventilation property and hold the clumpy catalyst, and a driving mechanism that moves the clumpy catalyst up and down by moving the catalyst holders up and down.

Owner:NIPPON STEEL CORP

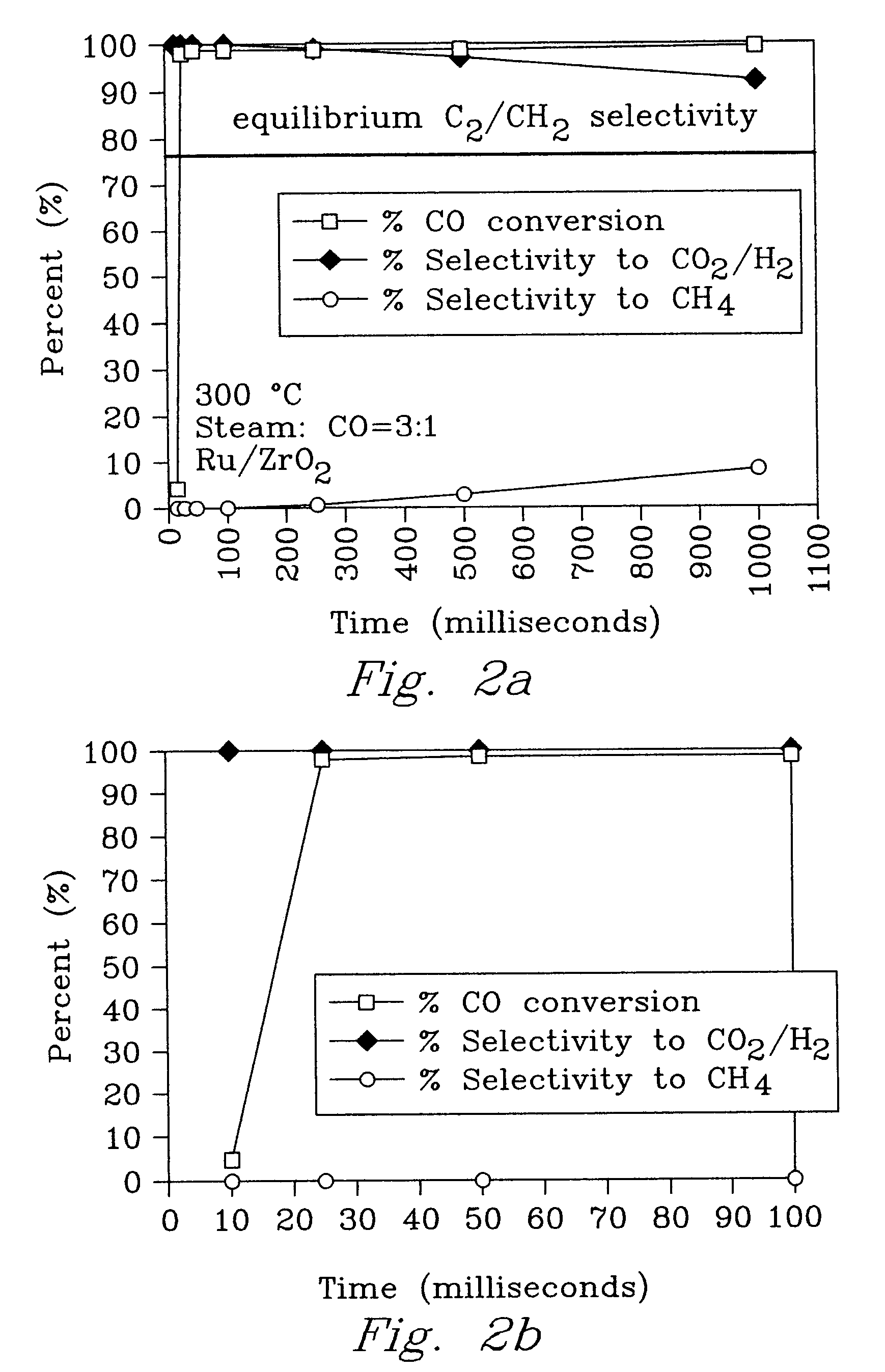

Method and apparatus for obtaining enhanced production rate of thermal chemical reactions

InactiveUS7045114B2Reduce formationReaction is slowOrganic chemistry methodsChemical/physical/physico-chemical microreactorsSteam reformingChemical reaction

Reactors and processes are disclosed that can utilize high heat fluxes to obtain fast, steady-state reaction rates. Porous catalysts used in conjunction with microchannel reactors to obtain high rates of heat transfer are also disclosed. Reactors and processes that utilize short contact times, high heat flux and low pressure drop are described. Improved methods of steam reforming are also provided.

Owner:BATTELLE MEMORIAL INST

Reactor for performing endothermic catalytic reactions

InactiveUS6056932ACatalytic gas-gas reactionPhysical/chemical process catalystsOrganic chemistryCatalytic combustion

A reactor for performing endothermic catalytic reactions is disclosed formed of a monolithic counterflow reactor with parallel heating and reaction channels. The internal walls of the reaction channels are coated with a catalyst for the catalytic reaction to be performed, while the internal walls of the heating channels have a catalyst for the catalytic combustion of a fuel gas / air mixture.

Owner:DEGUSSA AG

Production of hydrogen by autothermic decomposition of ammonia

This invention relates to the autothermal decomposition of ammonia to produce high purity hydrogen. This invention also relates to a fuel cell system wherein hydrogen that is produced from the autothermic decomposition of ammonia is used as fuel to a fuel cell.

Owner:GOETSCH DUANE A +1

Staged membrane oxidation reactor system

Owner:AIR PROD & CHEM INC

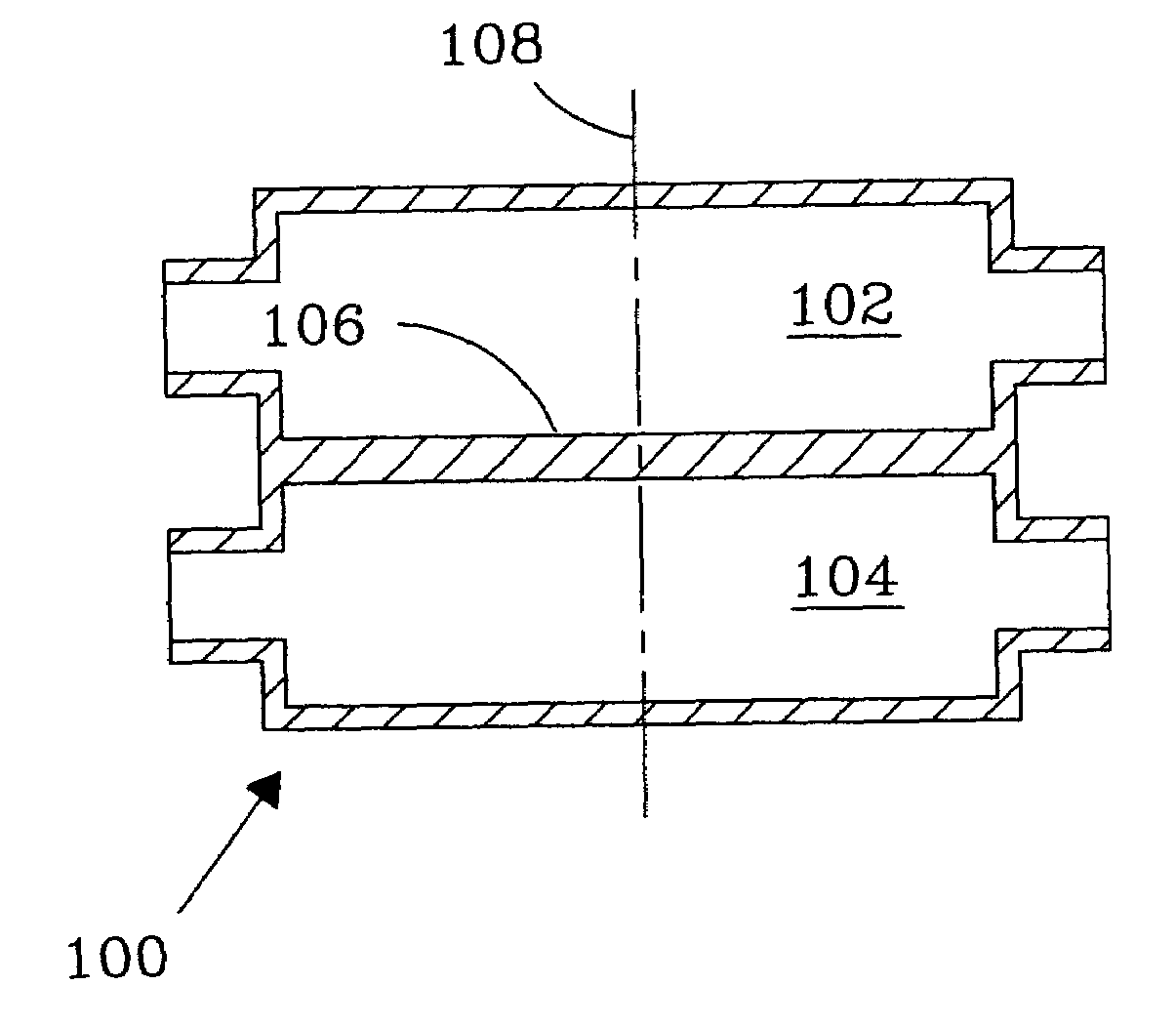

Catalytic partial oxidation processor with heat exchanger for converting hydrocarbon fuels to syngas for use in fuel cells and method

InactiveUS20050081444A1Reduce the possibilitySafe, reliable and efficient operationCatalytic gas-gas reactionHydrogenPartial oxidationHydrogen

A catalytic partial oxidation processor comprising at least one catalytic partial oxidation reactor disposed in a shell having an inlet and outlet such that heat from partial oxidation in the reactor transfers from the reactor to heat exchange fluid in the shell. The heat transfer serves to keep the precatalyst zone of the partial oxidation reactor cool and the post catalyst section of the partial oxidation reactor hot while also providing an efficient heat recovery system. A system for producing electric power comprises such a catalytic partial oxidation processor and a fuel cell disposed for receiving the exit gas stream and consuming the hydrogen to produce electric power. Corresponding methods are also disclosed.

Owner:GENERAL ELECTRIC CO

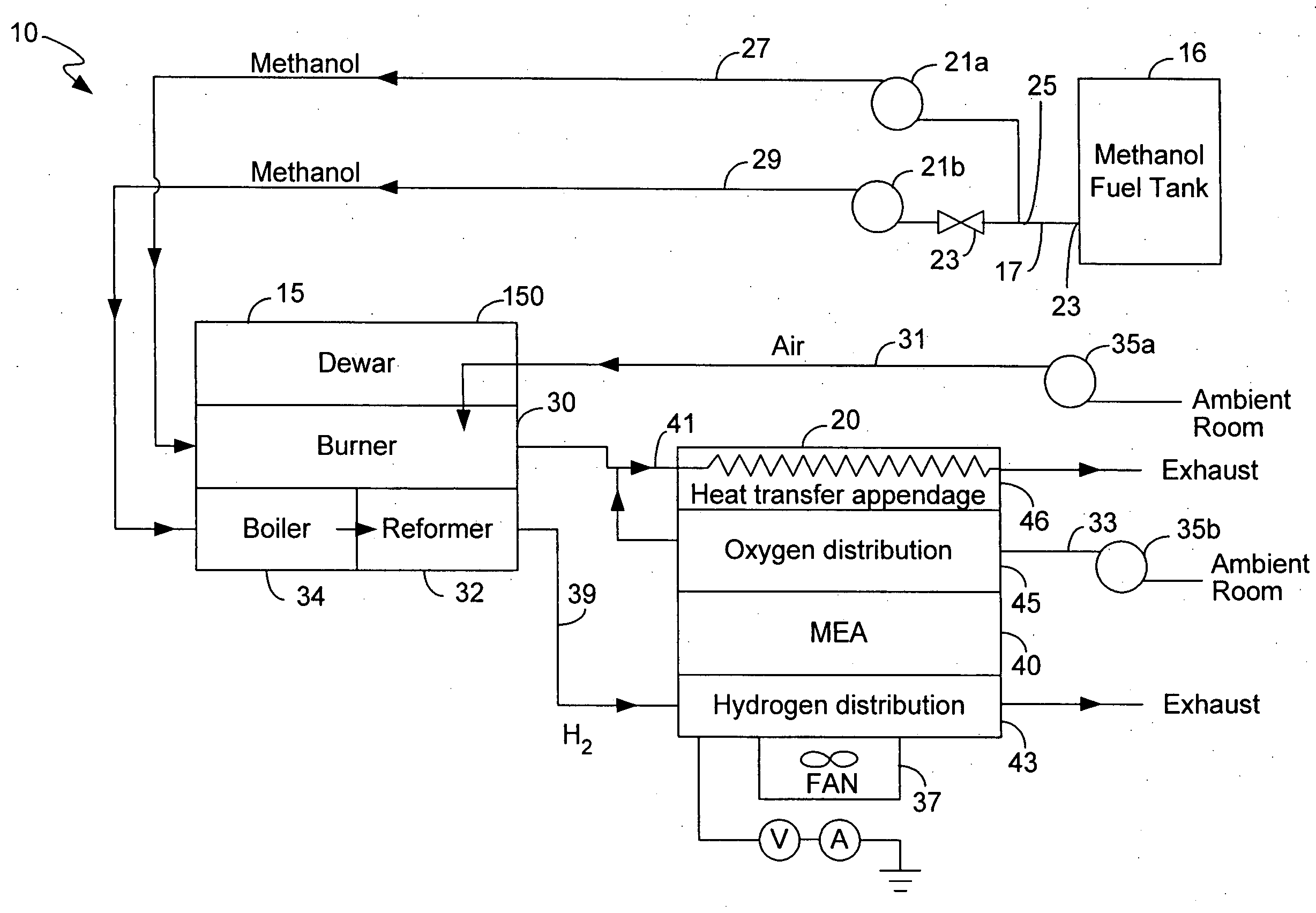

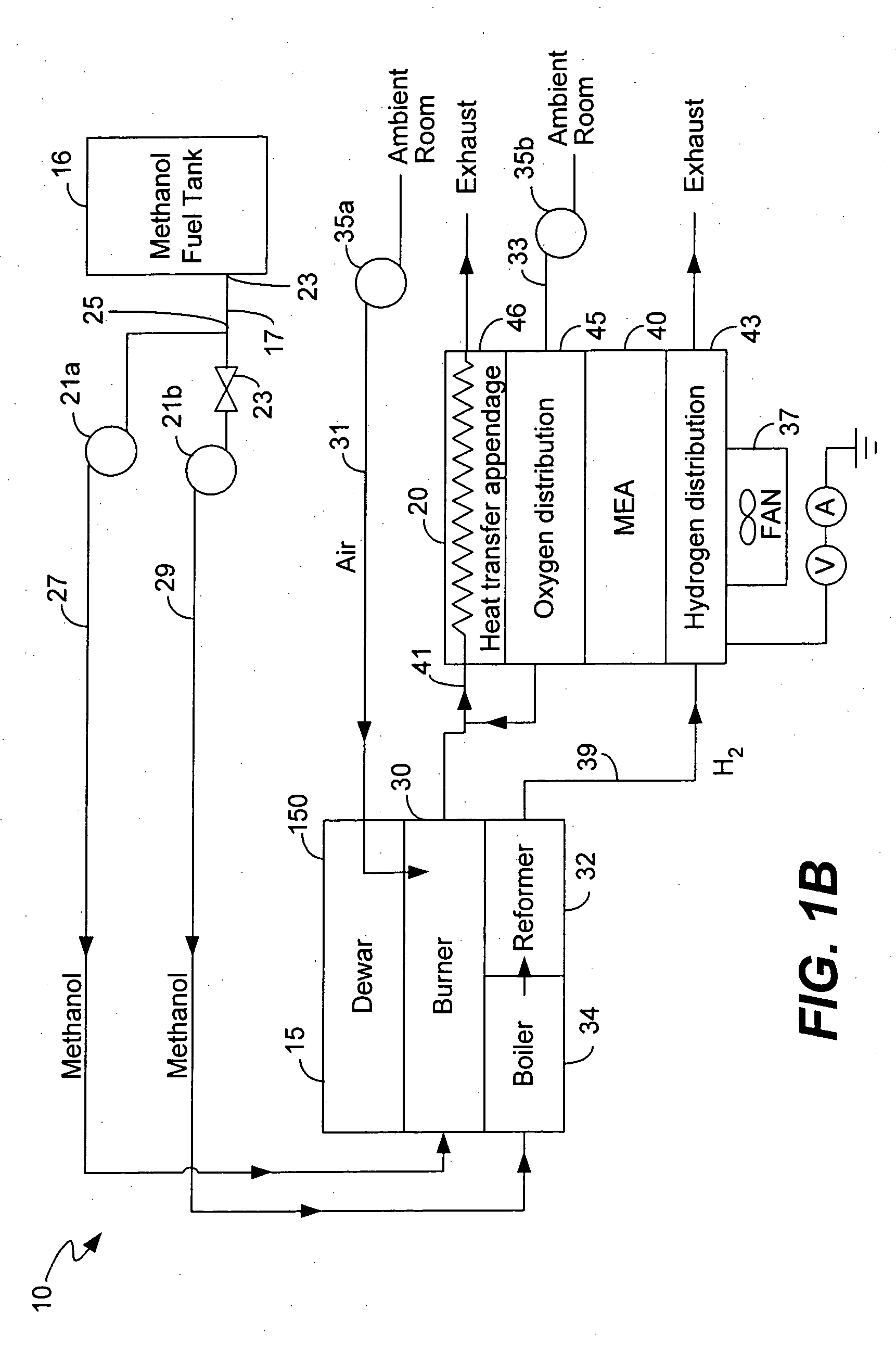

Annular fuel processor and methods

ActiveUS20050011125A1Promote productionIncreased hydrogen productionPressurized chemical processLevel controlCombustorHydrogen

Described herein is a fuel processor that produces hydrogen from a fuel source. The fuel processor comprises a reformer and burner. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel source. Voluminous reformer chamber designs are provided that increase the amount of catalyst that can be used in a reformer and increase hydrogen output for a given fuel processor size. The burner provides heat to the reformer. One or more burners may be configured to surround a reformer on multiple sides to increase thermal transfer to the reformer. Dewars are also described that increase thermal management of a fuel processor and increase burner efficiency. A dewar includes one or more dewar chambers that receive inlet air before a burner receives the air. The dewar is arranged such that air passing through the dewar chamber intercepts heat generated in the burner before the heat escapes the fuel processor.

Owner:ADVENT TECH LLC

Stackable structural reactor

Owner:JOHNSON MATTHEY PLC

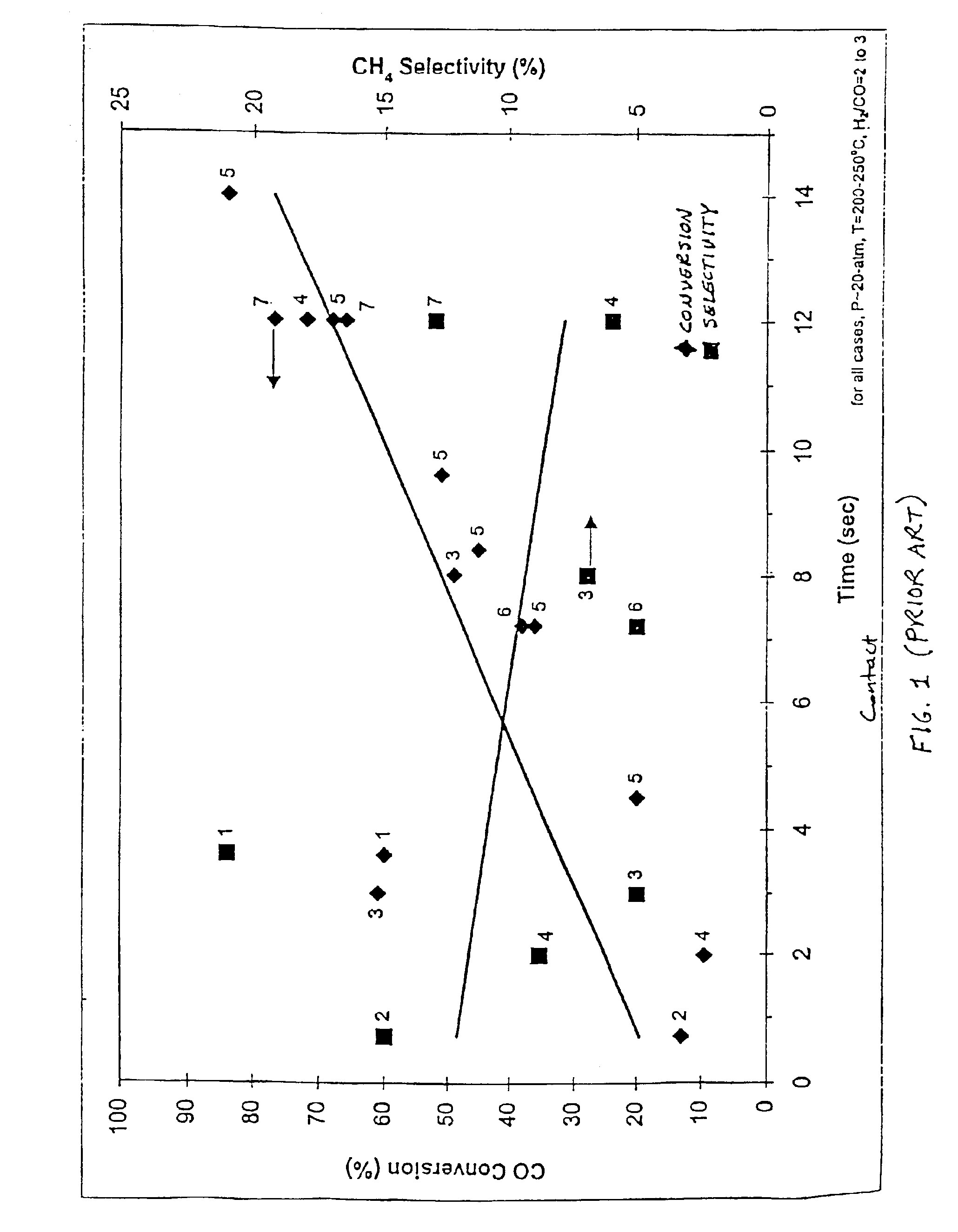

Catalyst structure and method of fischer-tropsch synthesis

InactiveUS7045486B2Short staySpeed up the conversion processOrganic chemistry methodsChemical/physical/physico-chemical microreactorsSynthesis methodsCooling chamber

The present invention includes a catalyst structure and method of making the catalyst structure for Fischer-Tropsch synthesis that both rely upon the catalyst structure having a first porous structure with a first pore surface area and a first pore size of at least about 0.1 μm, preferably from about 10 μm to about 300 μm. A porous interfacial layer with a second pore surface area and a second pore size less than the first pore size is placed upon the first pore surface area. Finally, a Fischer-Tropsch catalyst selected from the group consisting of cobalt, ruthenium, iron and combinations thereof is placed upon the second pore surface area. Further improvement is achieved by using a microchannel reactor wherein the reaction chamber walls define a microchannel with the catalyst structure is placed therein through which pass reactants. The walls may separate the reaction chamber from at least one cooling chamber. The present invention also includes a method of Fischer-Tropsch synthesis.

Owner:BATTELLE MEMORIAL INST

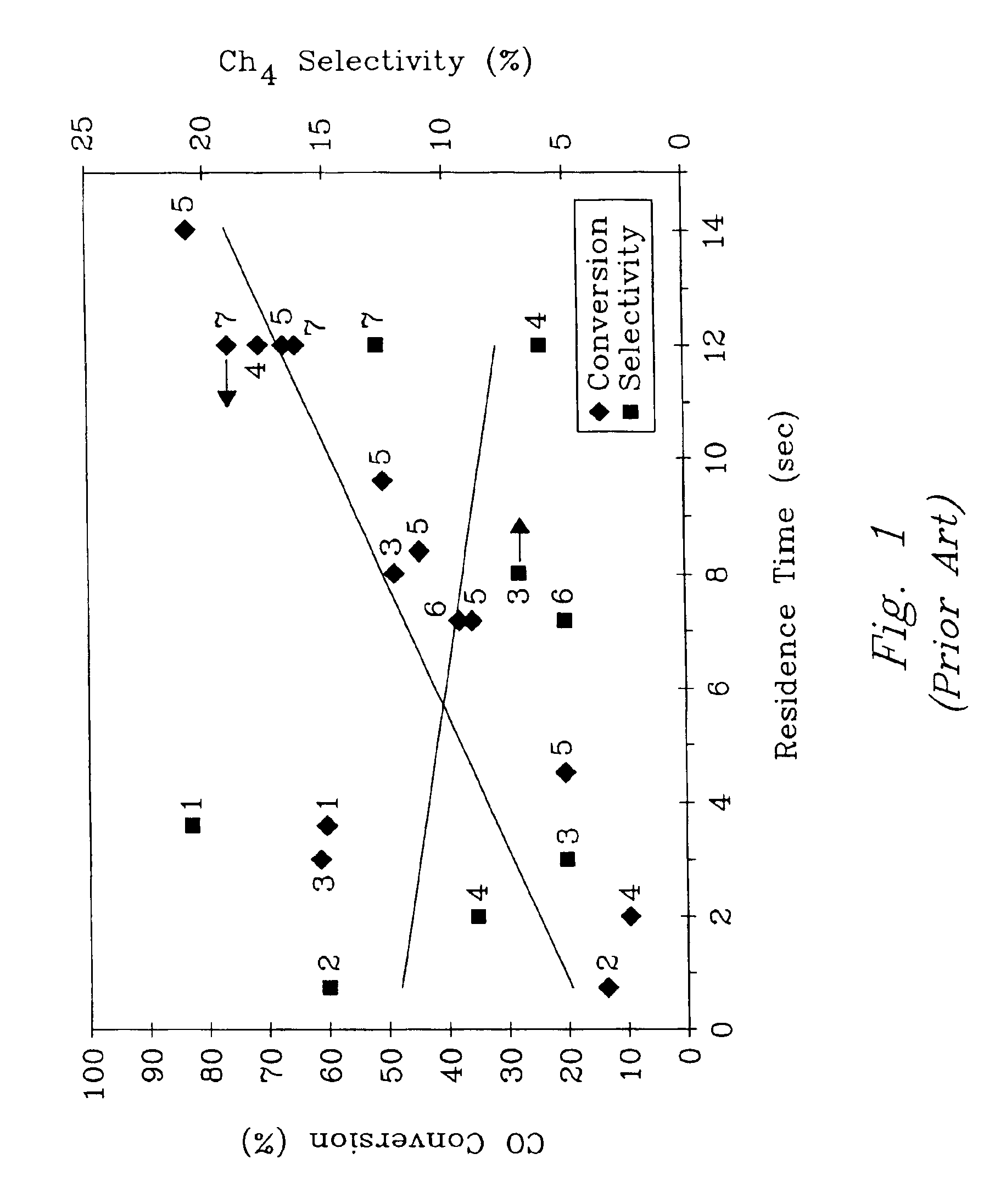

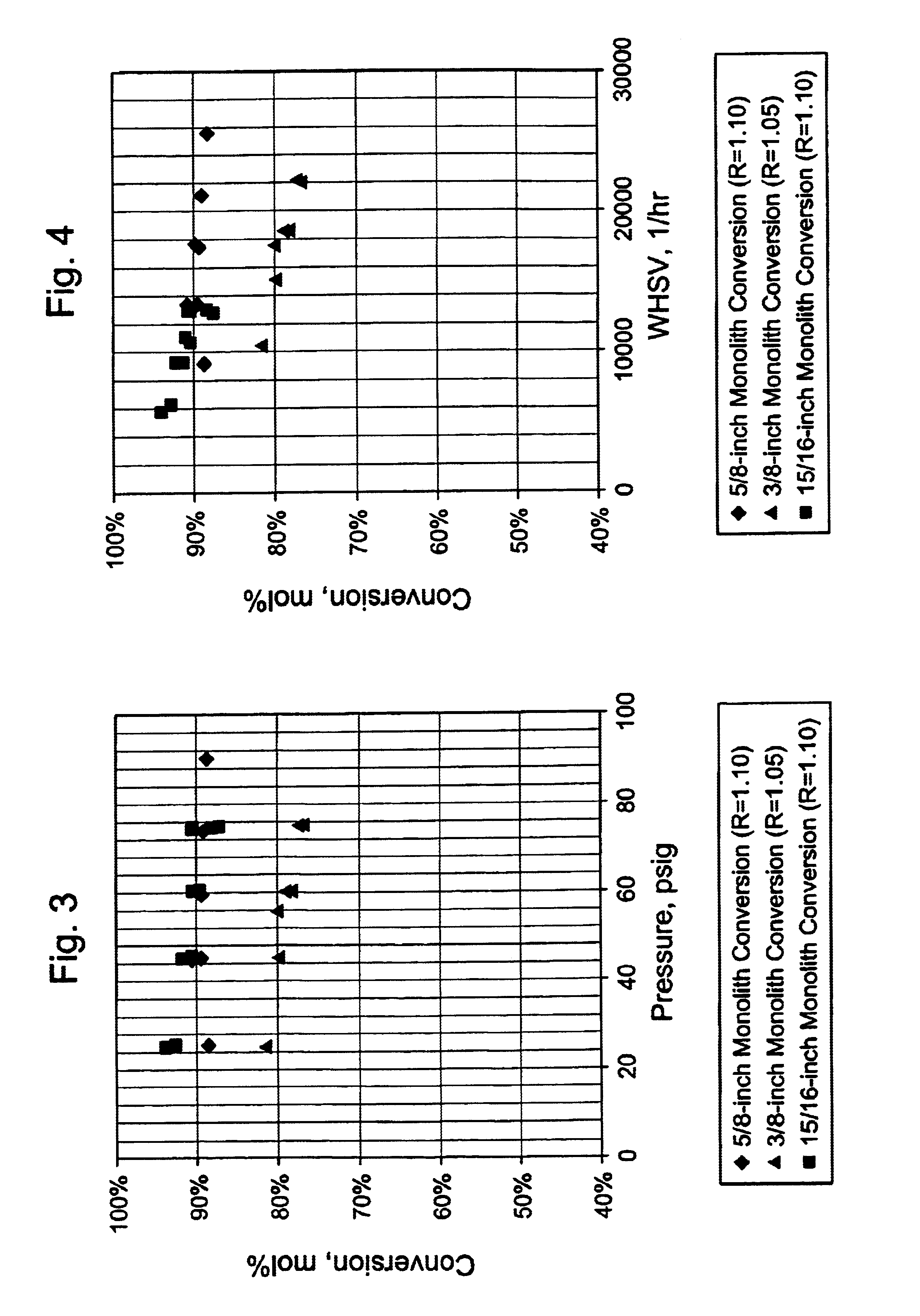

Process and apparatus for production of hydrogen using the water gas shift reaction

InactiveUS20080128655A1Lower carbon dioxide levelsCatalytic gas-gas reactionHydrogenForming gasWater-gas shift reaction

A process and a reactor vessel for production of hydrogen via the water gas shift reaction at CO / CO2 ratios above 1.9, and steam to gas rations below 0.5, are disclosed. The process includes first reacting a feed gas mixture of carbon monoxide and steam in the presence of a precious metal catalyst on a structural support, yielding a resultant gas, and then reacting the resultant gas in the presence of a non-precious metal catalyst on a support medium. The reactor vessel includes a chamber having an inlet duct and an outlet. A structural support having the precious metal catalyst is positioned upstream of the non-precious metal catalyst positioned within the chamber. The structural support may be positioned within the inlet duct or within the chamber. The support medium may be a granular medium or a structural support.

Owner:AIR PROD & CHEM INC

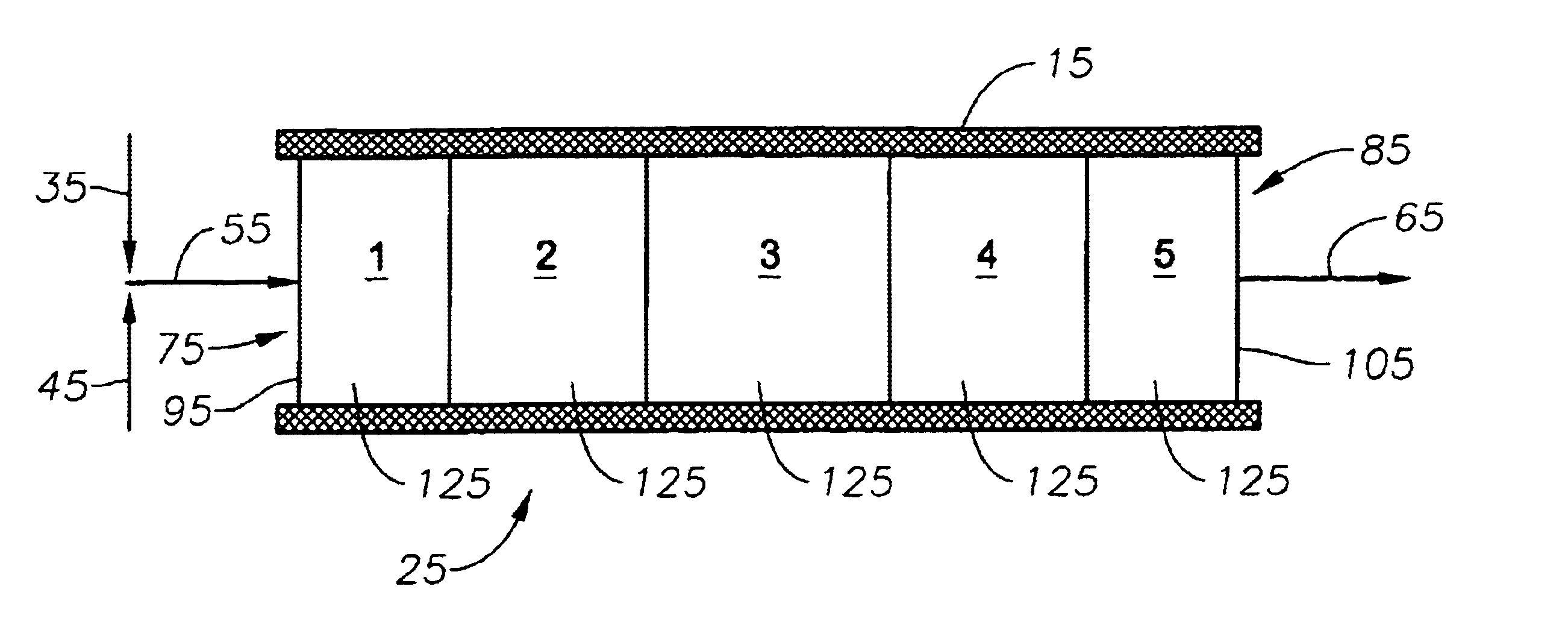

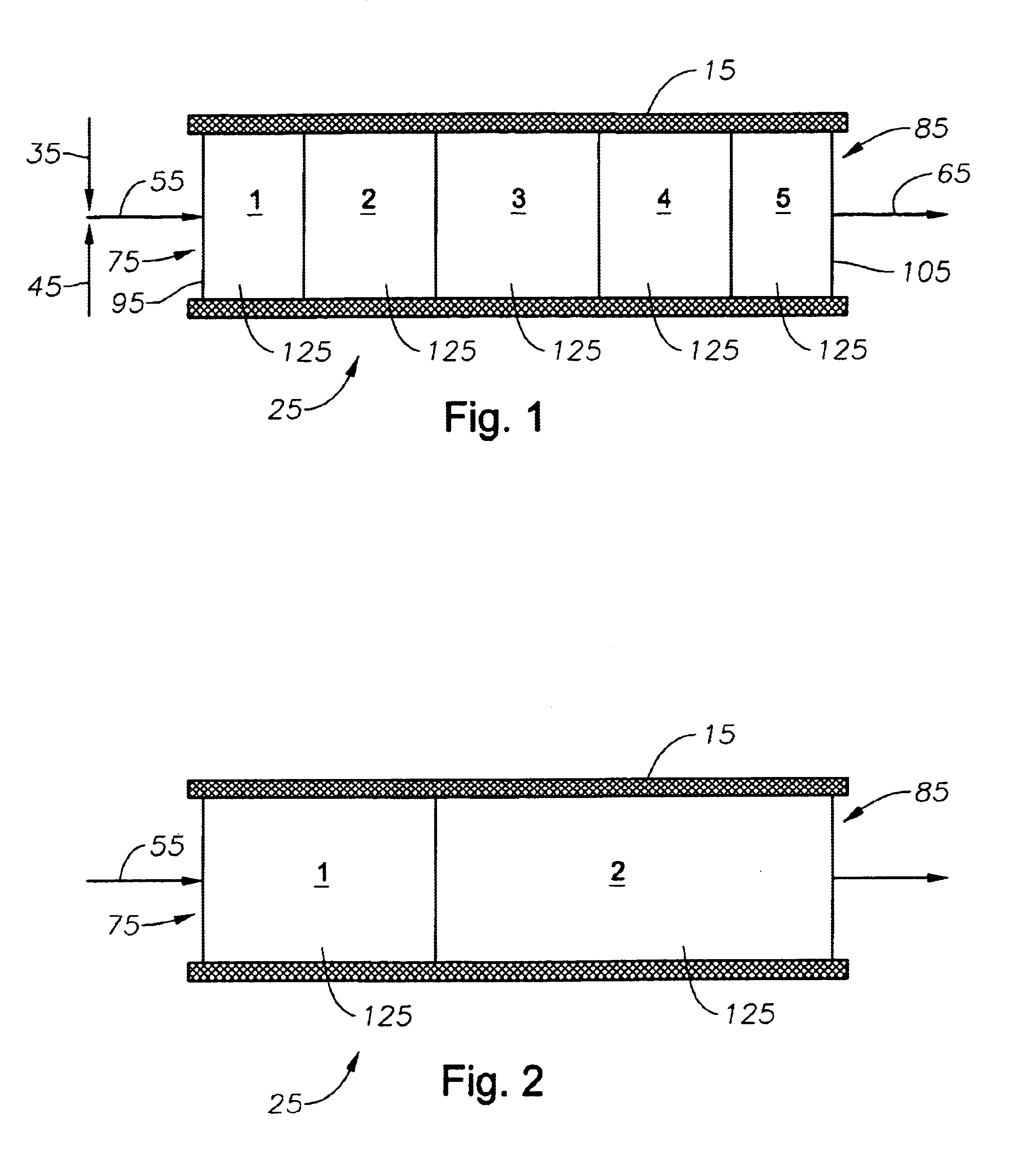

Thermally coupled monolith reactor

InactiveUS20070009426A1Easy to useMaximize heat transferCatalytic gas-gas reactionPhysical/chemical process catalystsChemical treatmentGas phase

The invention comprises, in one form thereof, a chemical processing method to thermally contact an endothermic and an exothermic reaction without mixing the two streams, utilizing a thermally coupled monolith reactor (TCMR). A ceramic or metal monolith is modified to produce a structure containing at least two sets of discrete flow paths and which are separated by a number of common walls. Manifolds are arranged such that one reaction mixture flows through one set of channels and a different reaction mixture flows through the second. Catalytic material, which is active for the relevant reaction, is coated onto the inner walls of each of the sets of channels. The two reactions are chosen such that one is exothermic and one is endothermic, such that the energy required by the endothermic process is supplied directly through the dividing wall from the exothermic process occurring on the opposing side. This method of heat transfer completely decouples the gas phase hydrodynamics from the heat transfer process.

Owner:ZEROPOINT CLEAN TECH

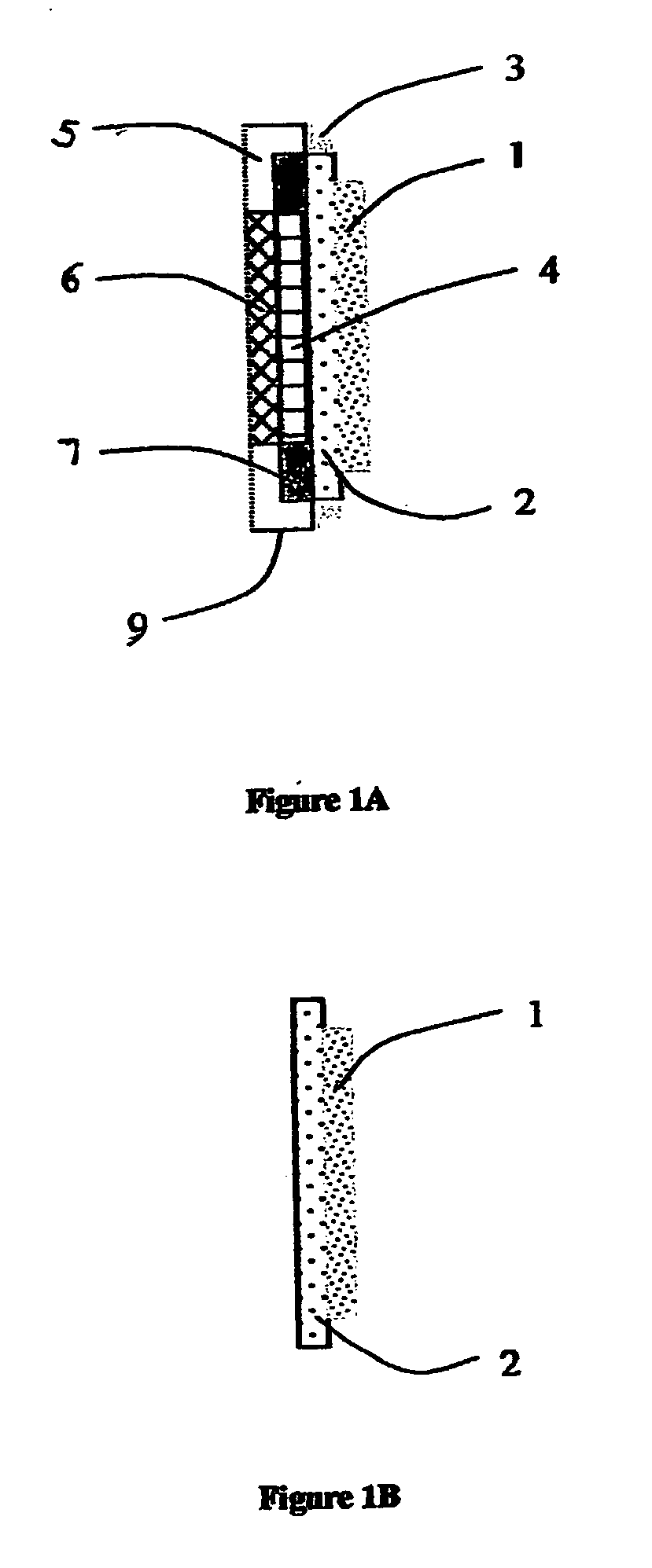

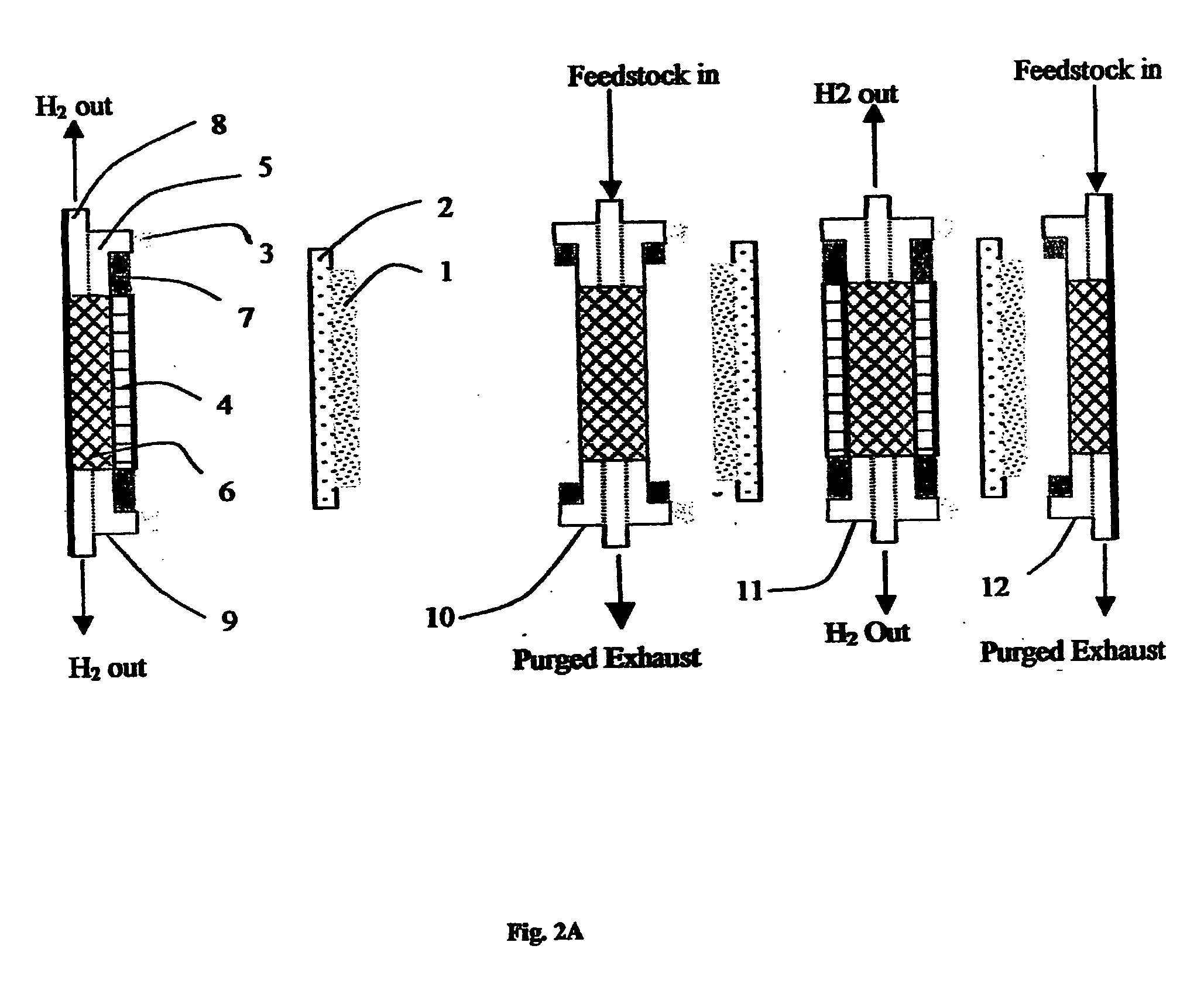

Single stage membrane reactor for high purity hydrogen production

InactiveUS20070157517A1Improve responseEasy to operateCatalytic gas-gas reactionMembranesSteam reformingMembrane reactor

Hydrogen generating method and apparatus. The apparatus comprises a mixed phase protonic-electron conducting cermet membrane (2), wherein said membrane is coated with porous metal or composite catalyst (1) effective to decompose hydro-carbon and water reactants into a hydrogen-rich syngas at elevated temperature and pressure. The hydrogen ions are continuously withdrawn in situ by diffusing them through the mixed phase conducting cermet membrane (2) to the second membrane side where the hydrogen ions can be reconstituted into molecular hydrogen with a supply of electrons. The method favorably shifts the equilibrium of steam reforming and water gas shift reaction by use a single stage, high efficiency and high purity membrane reactor.

Owner:TSAY DAVID +2

Chemical reactor for gas phase reactant catalytic reactions

InactiveUS6984363B2Lower overall pressure dropSufficient reactionCombination devicesChemical/physical/physico-chemical microreactorsPorosityChemical reaction

The present invention is a chemical reactor for catalytic chemical reactions having gas phase reactants. The chemical reactor has reactor microchannels for flow of at least one reactant and at least one product, and a catalyst material wherein the at least one reactant contacts the catalyst material and reacts to form the at least one product. The improvement, according to the present invention is: the catalyst material is on a porous material having a porosity that resists bulk flow therethrough and permits molecular diffusion therein. The porous material further has a length, a width and a thickness, the porous material defining at least a portion of one wall of a bulk flow path through which the at least one reactant passes.

Owner:BATTELLE MEMORIAL INST

Method and apparatus for producing synthesis gas

InactiveUS7686856B2Increase the number ofHydrogen productionHydrogen/synthetic gas productionSyngasCombustion

Owner:PRAXAIR TECH INC +1

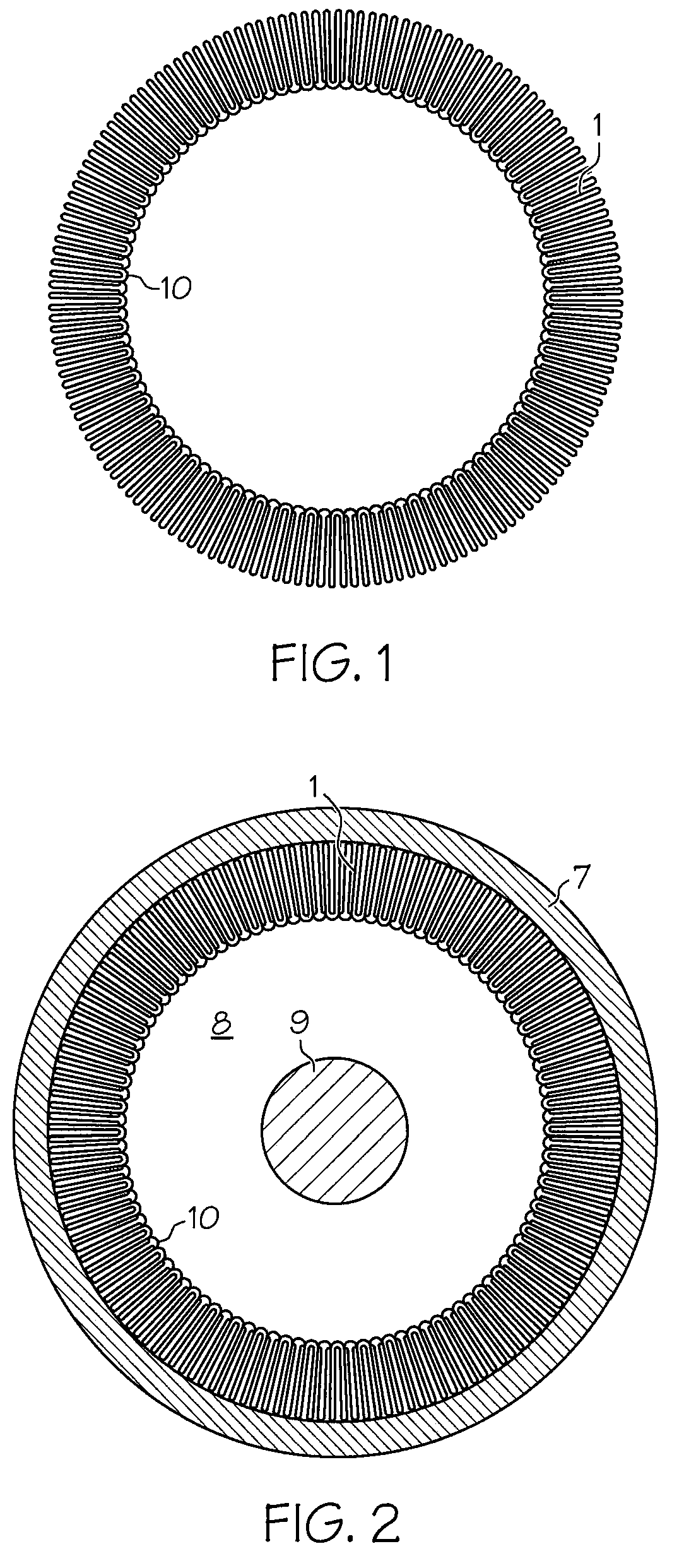

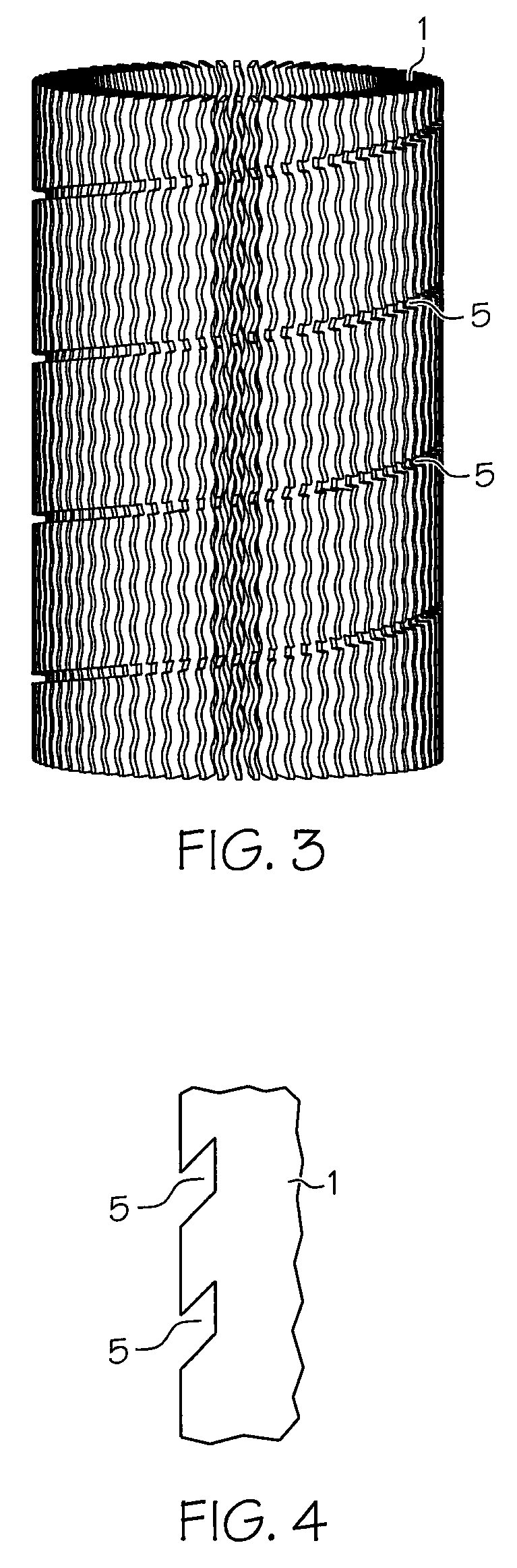

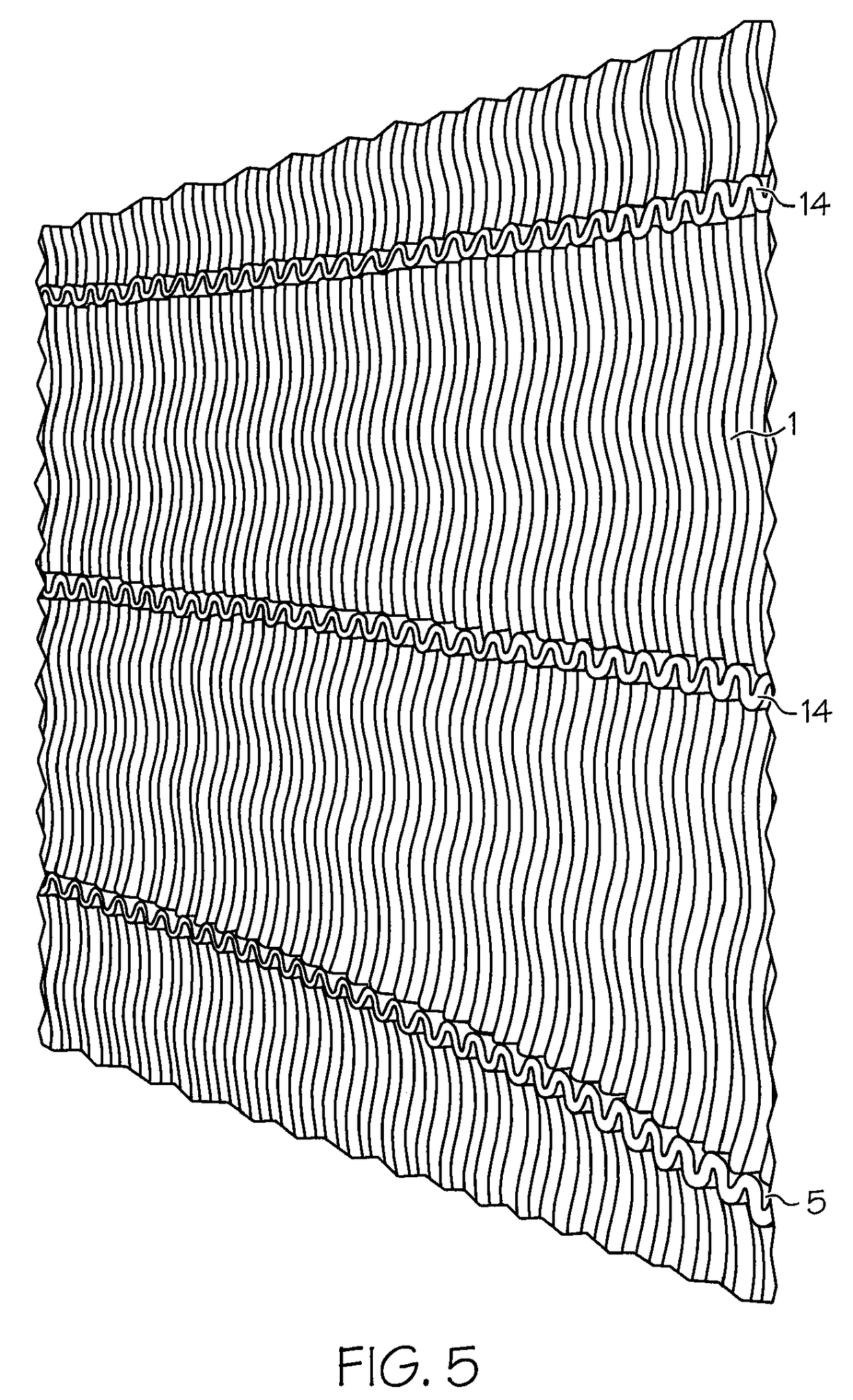

Reactor having improved heat transfer

ActiveUS20070025893A1Inhibition formationIncrease heatCombination devicesCatalytic gas-gas reactionNuclear engineeringHeat exchanger

A catalytic reactor or heat exchanger includes a monolith defining a plurality of leaves, the monolith having a generally annular cross-section. The monolith is disposed within a generally cylindrical outer tube, and around a corrugated inner tube. The reactor includes a device for urging the monolith radially outward, so as to maintain contact between the monolith and the outer tube. Such device may include a coned washer, or it may be defined by a folded flap that is integral with the inner tube. In either case, the reactor compensates for metal creep, and virtually insures continued contact between the monolith and the outer tube.

Owner:JOHNSON MATTHEY PLC

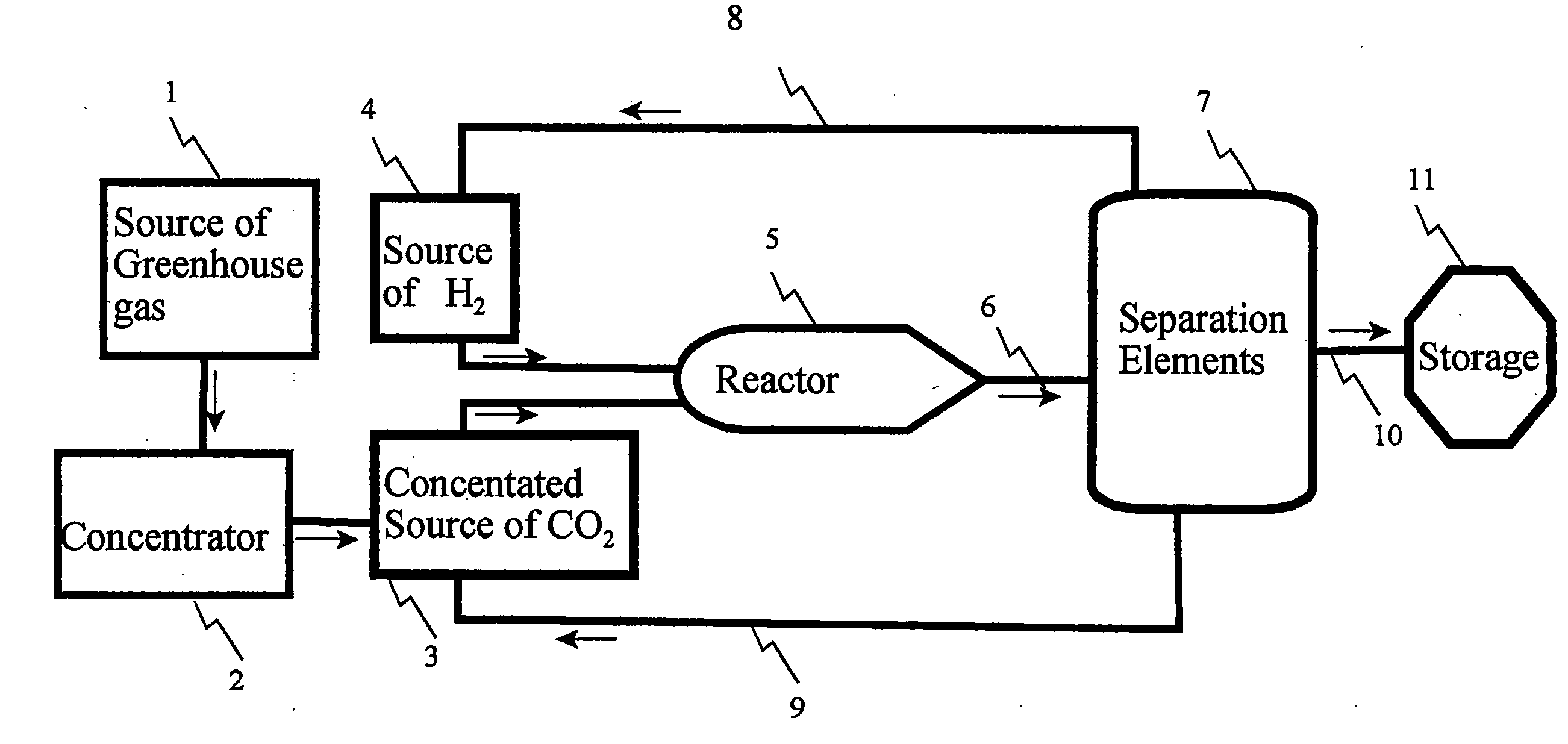

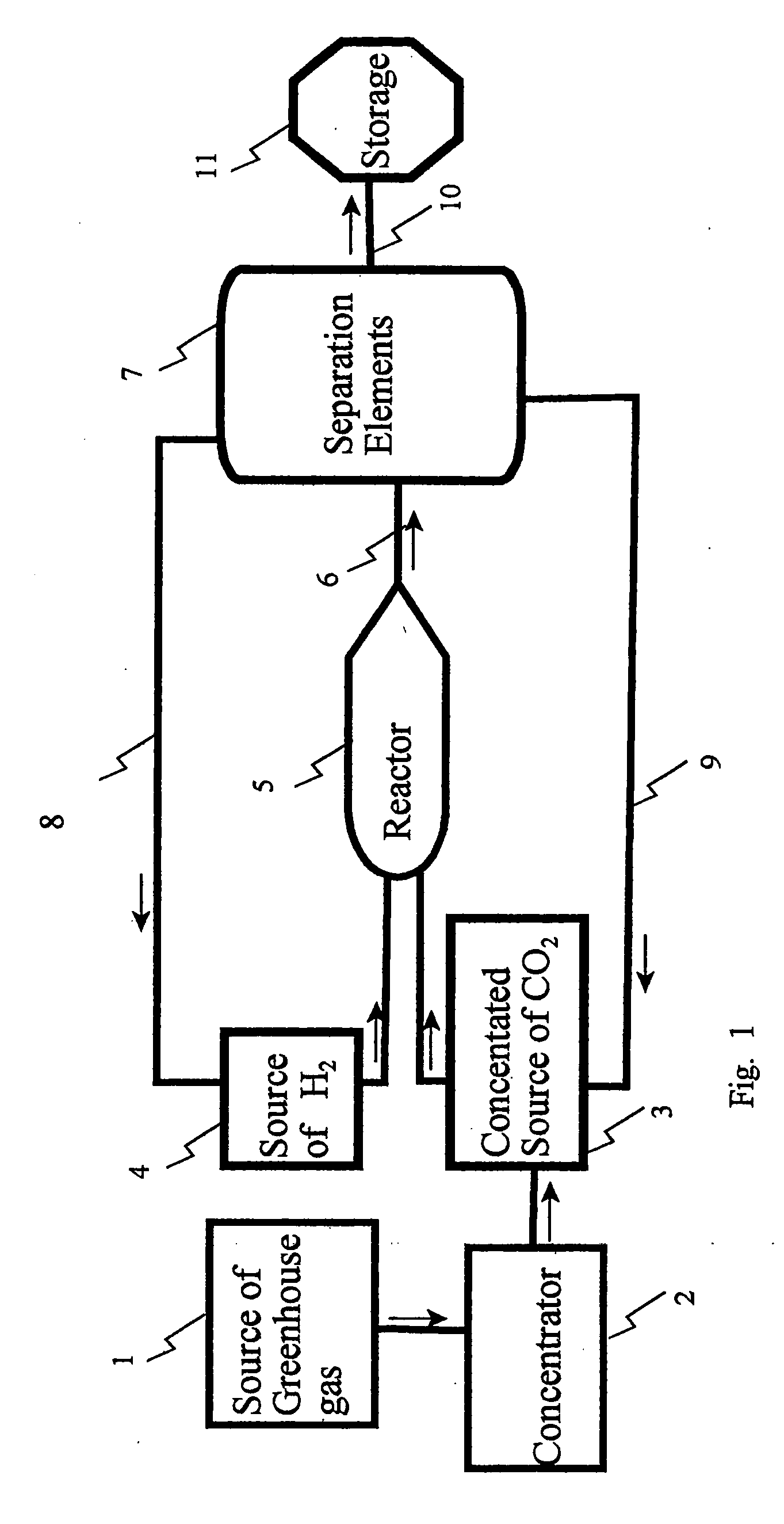

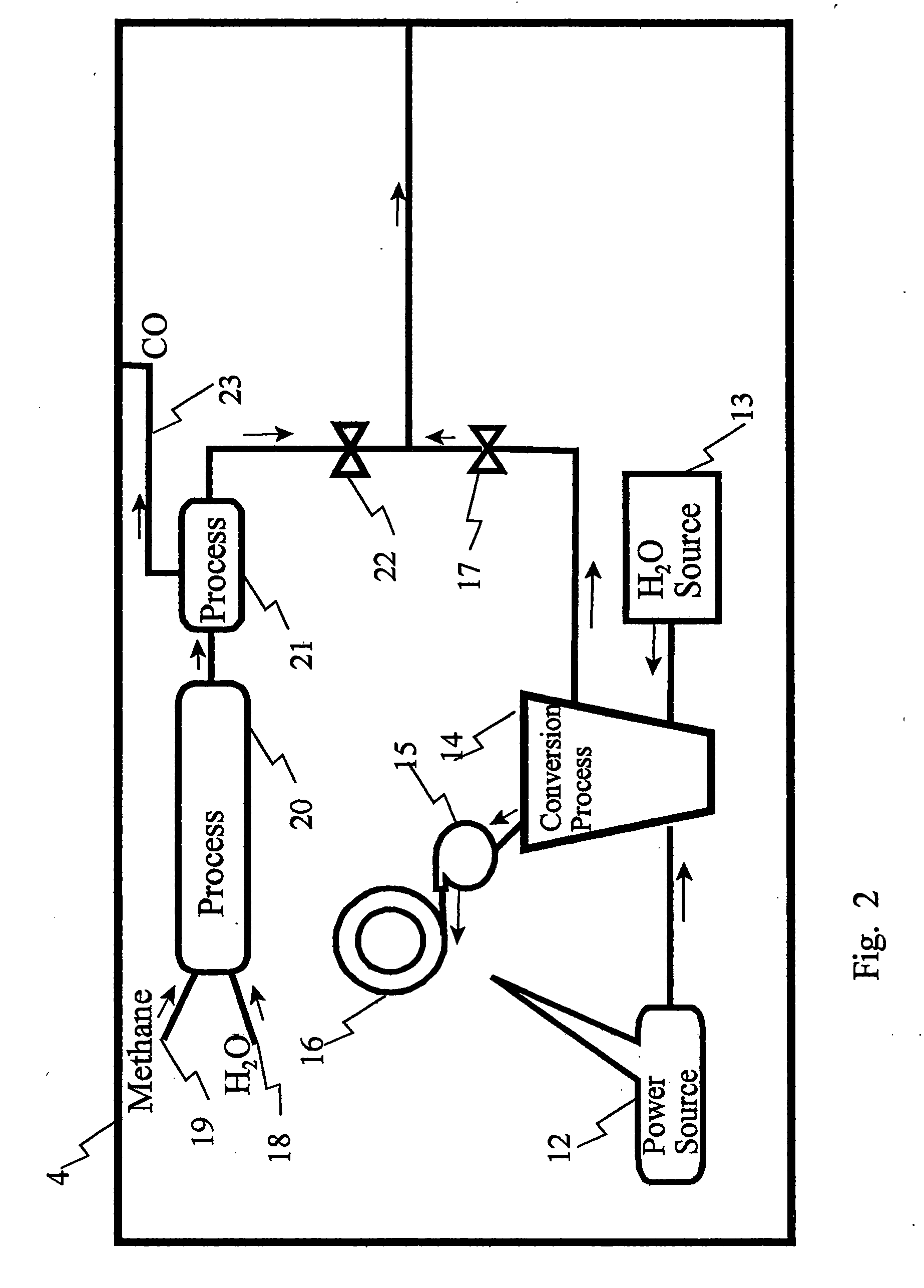

Producing ethanol and saleable organic compounds using an environmental carbon dioxide reduction process

Carbon dioxide, from a greenhouse gas source, is reacted with hydrogen, developed in an environmentally friendly process, such as from solar energy based electrolysis, to produce a mixture of ethanol and other saleable organic compounds. The ethanol and other saleable organic compounds mixture may contain substantial percentages of methanol, ethanol, and dimethylether in addition to other components which have chemical structures of predominantly carbon and hydrogen or carbon, hydrogen and oxygen. The saleable organic compounds, such as methane, methanol and ethanol may be used as a combustible fuel thus developing a green energy cycle. A portion of the organic compounds may be separated into essentially pure components and used as chemical process feed stocks. The essentially pure organic compounds may be further reacted with suitable chemical compounds to modify said organic compounds. A portion of the organic compounds may be sequestered for long or short time periods by placing them in suitable storage thus providing a mechanism for sequestering carbon dioxide and storing

Owner:CAMPBELL GREGORY A

Catalyst system for enhanced flow syngas production

InactiveUS6887456B2Increase conversionsHigh selectivityHydrogen/synthetic gas productionBulk chemical productionSyngasProduct gas

A method and apparatus for converting a hydrocarbon and oxygen containing gas feed stream to a product stream, such as syngas, including catalytically partially oxidizing the hydrocarbon feed stream over a catalyst bed. The catalyst bed has a downstream section which is less resistant to flow than the upstream section.

Owner:PHILLIPS 66 CO

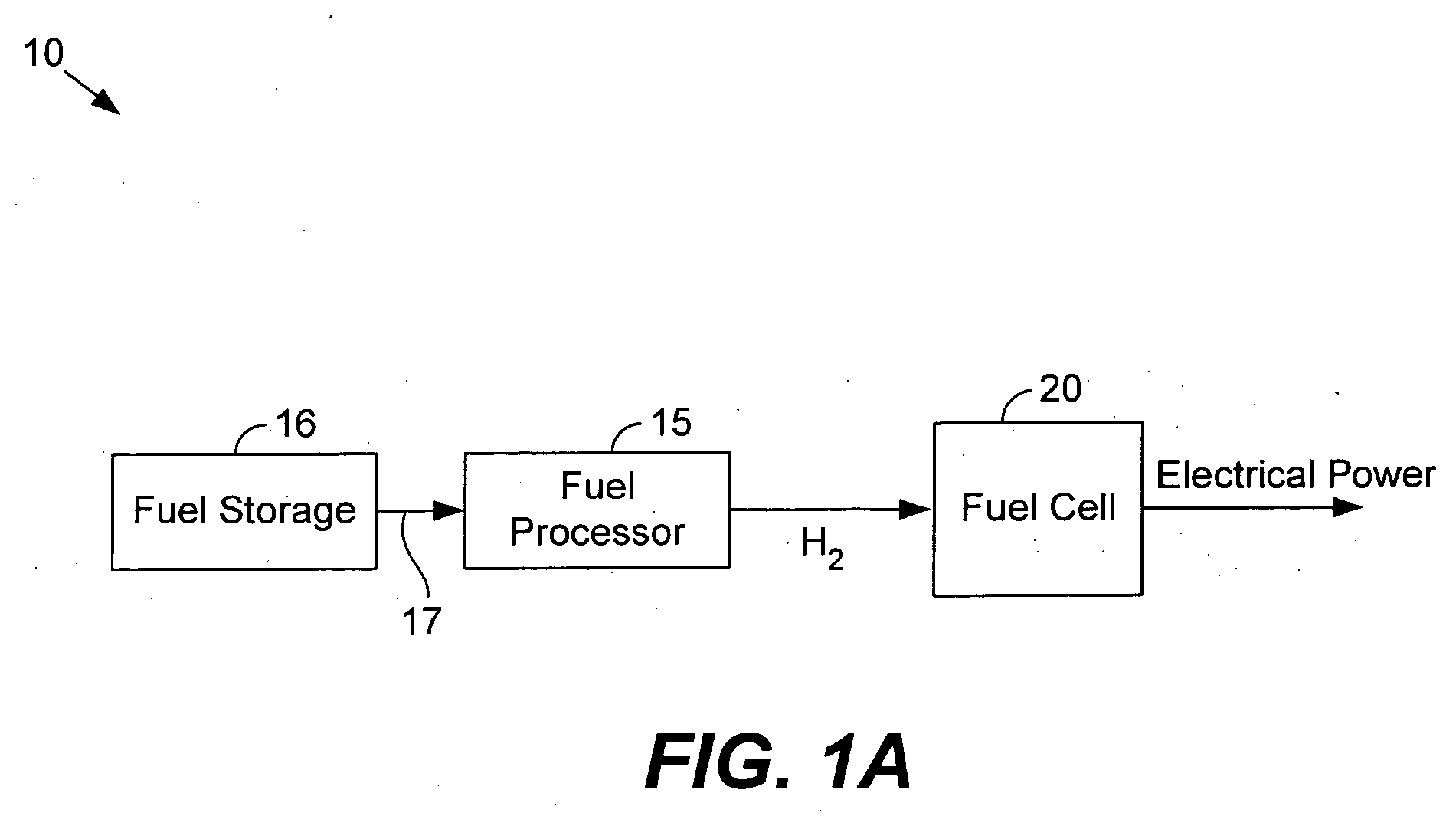

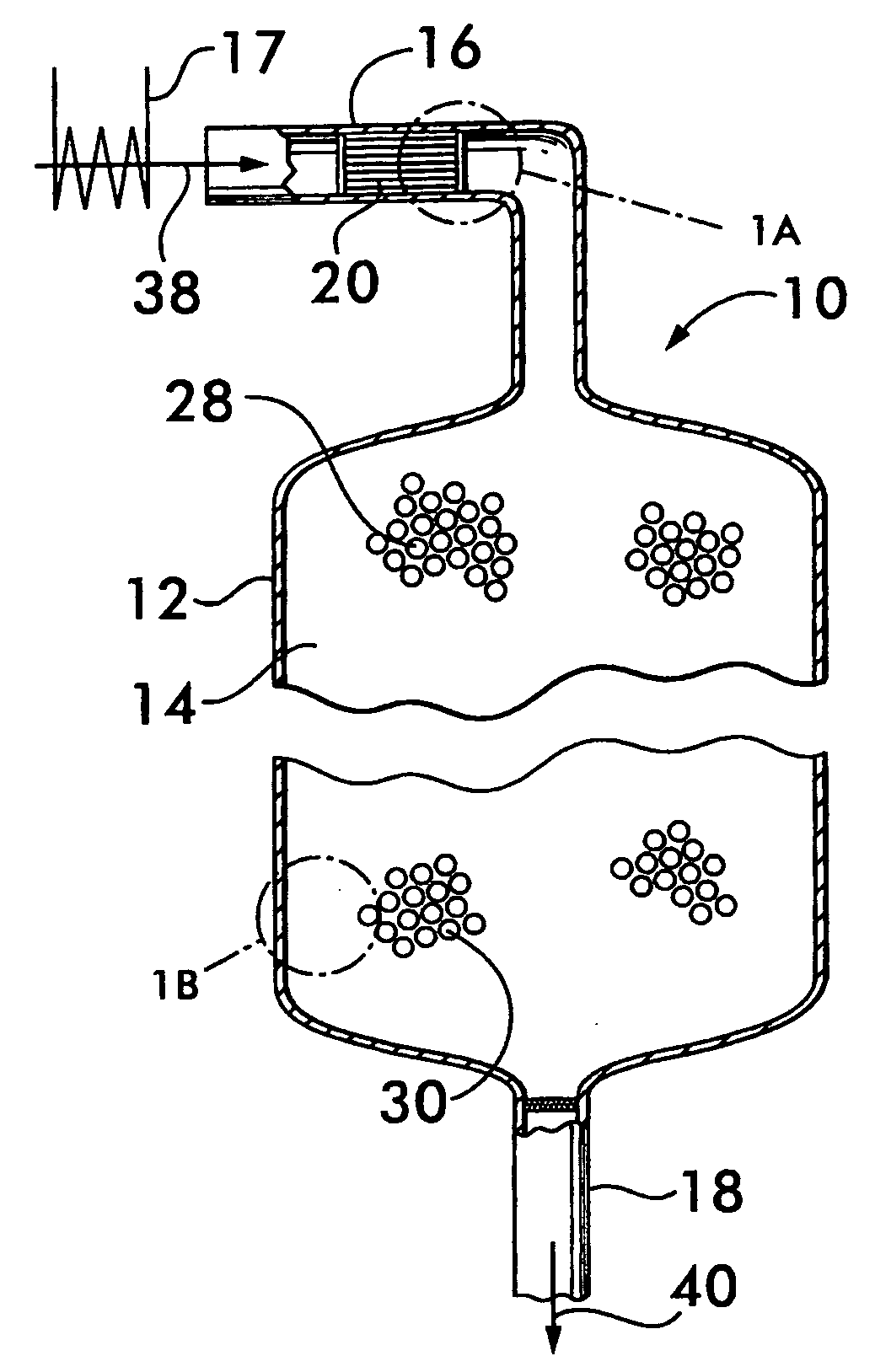

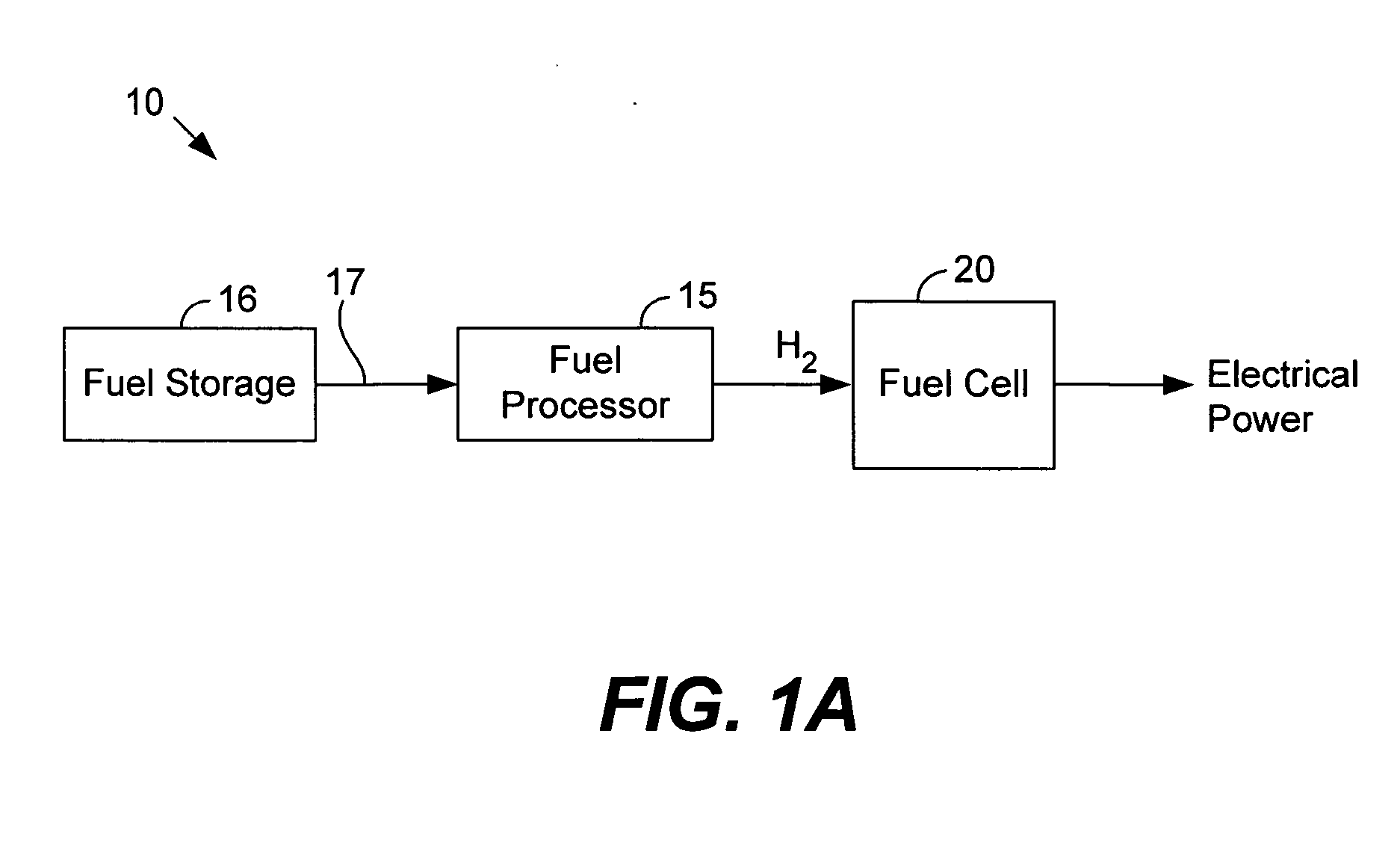

Fuel processor for use with portable fuel cells

InactiveUS20060156627A1Promote hydrogen productionReduce fuel processor sizeCatalytic gas-gas reactionGaseous chemical processesFuel cellsHydrogen

The invention relates to a fuel processor that produces hydrogen from a fuel. The fuel processor comprises a reformer and a heater. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel; the heater provides heat to the reformer. Multipass reformer and heater chambers are described that reduce fuel processor size. Single layer fuel processors include reformer and heater chambers in a compact form factor that is well suited for portable applications. Some fuel processors described herein place an electrically resistive material in contact with a thermally conductive material to heat fuel entering the fuel processor. This is particularly useful during start-up of the fuel processor. Fuel processors described may also include features that facilitate assembly.

Owner:ULTRACELL ACQUISITION

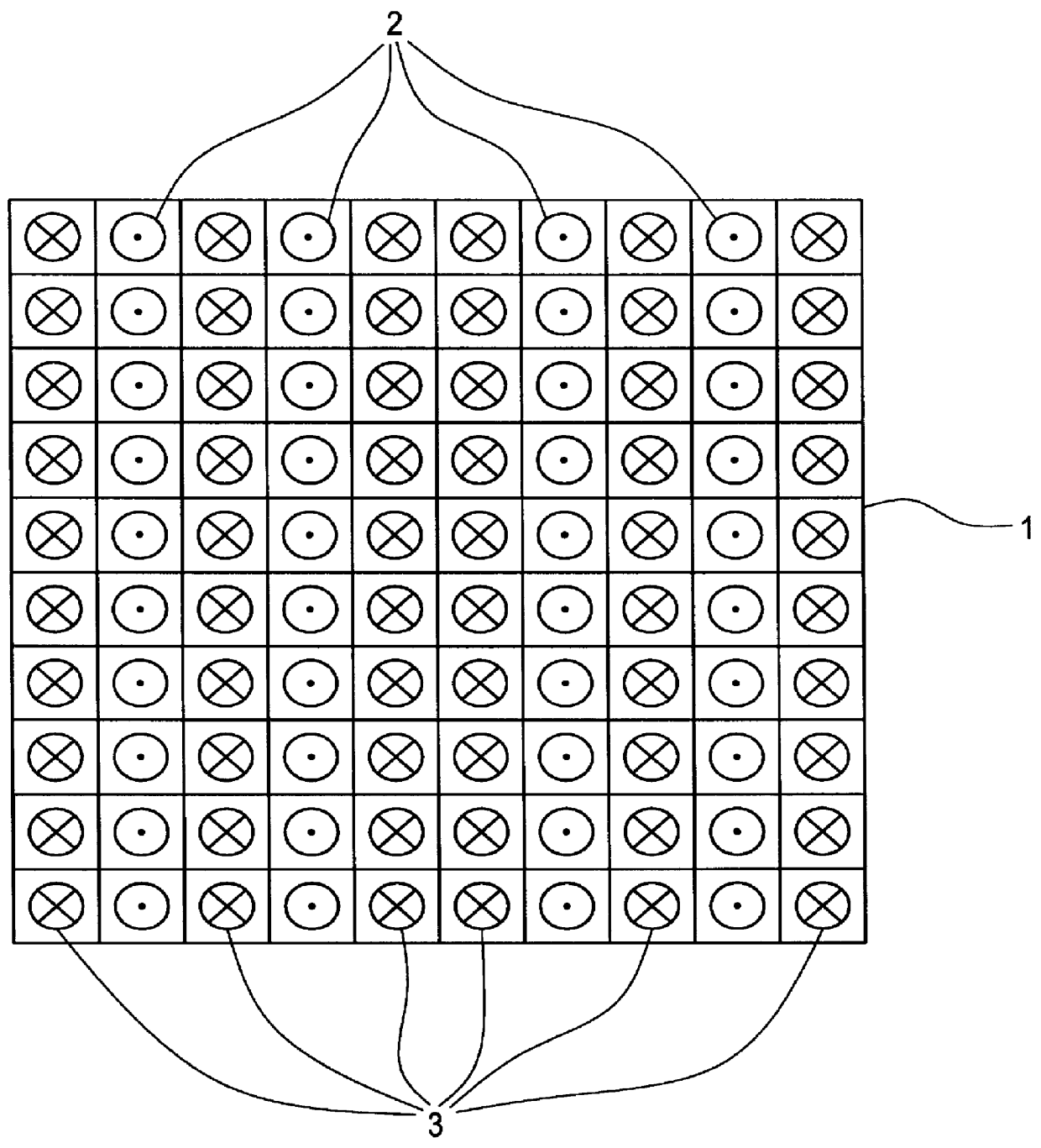

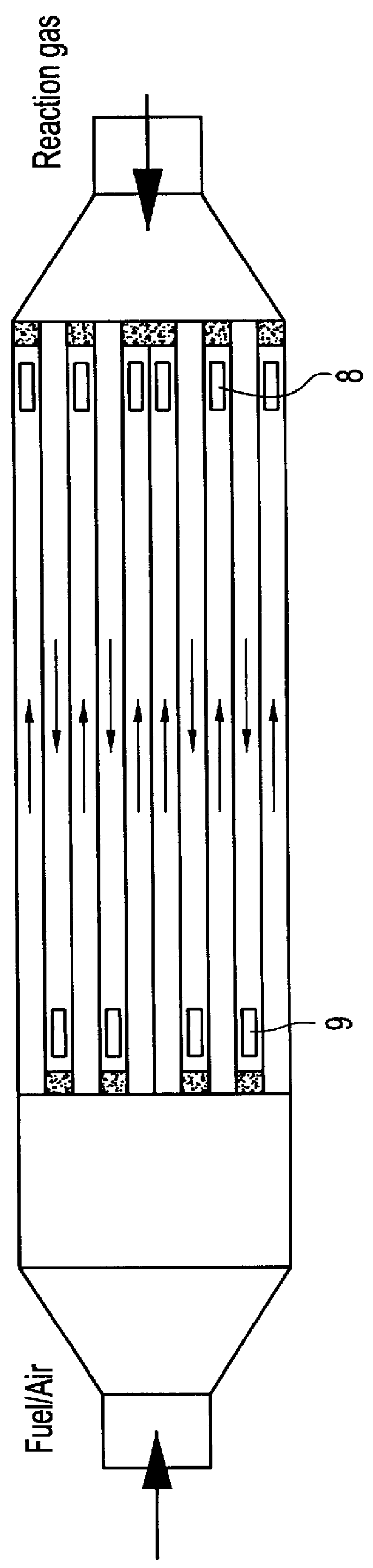

Ceramic oxygen transport membrane array reactor and reforming method

A commercially viable modular ceramic oxygen transport membrane reforming reactor for producing a synthesis gas that improves the thermal coupling of reactively-driven oxygen transport membrane tubes and catalyst reforming tubes required to efficiently and effectively produce synthesis gas.

Owner:PRAXAIR TECH INC

Parallel Passage Fluid Contactor Structure

A parallel passage fluid contactor structure for chemical reaction processes has one or more segments, where each segment has a plurality of substantially parallel fluid flow passages oriented in an axial direction; cell walls between each adjacent fluid flow passages and each cell wall has at least two opposite cell wall surfaces. The structure also includes at least one active compound in the cell walls and multiple axially continuous conductive filaments either embedded within the cell walls or situated between the cell wall surfaces. The conductive filaments are at least one of thermally and electrically conductive, are oriented in axially, and are in direct contact with the active compound, and are operable to transfer thermal energy between the active material and the conductive filaments. Heating of the conductive filaments may be used to transfer heat to the active material in the cell walls. Methods of manufacturing the structure are discussed.

Owner:INVENTYS THERMAL TECH

Catalyst structure and method of fischer-tropsch synthesis

InactiveUS6982287B2Speed up the conversion processHigh methane selectivityCombination devicesExhaust apparatusContact timeMetal foam

The present invention includes Fischer-Tropsch catalysts, reactions using Fischer-Tropsch catalysts, methods of making Fischer-Tropsch catalysts, processes of hydrogenating carbon monoxide, and fuels made using these processes. The invention provides the ability to hydrogenate carbon monoxide with low contact times, good conversion rates and low methane selectivities. In a preferred method, the catalyst is made using a metal foam support.

Owner:BATTELLE MEMORIAL INST

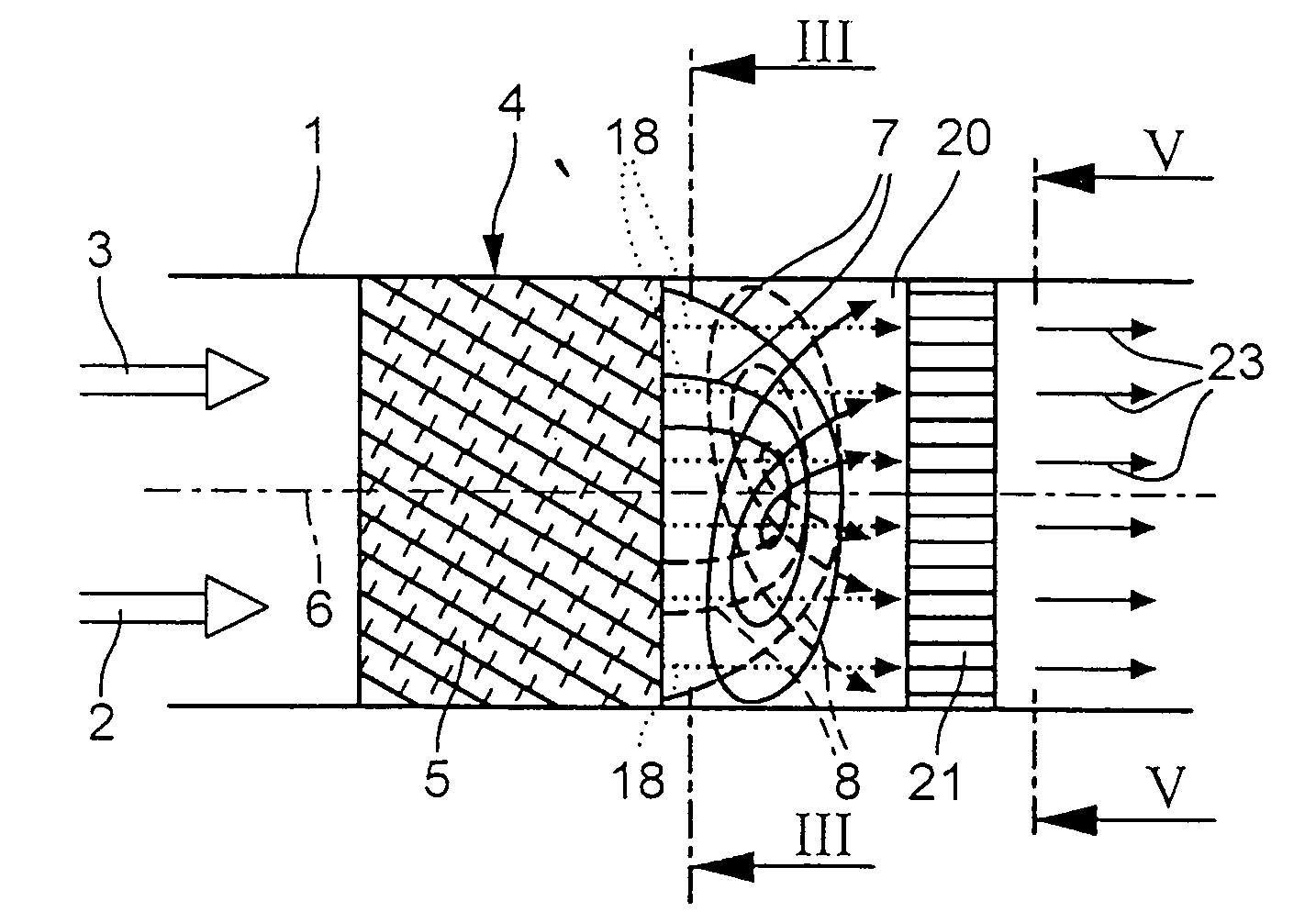

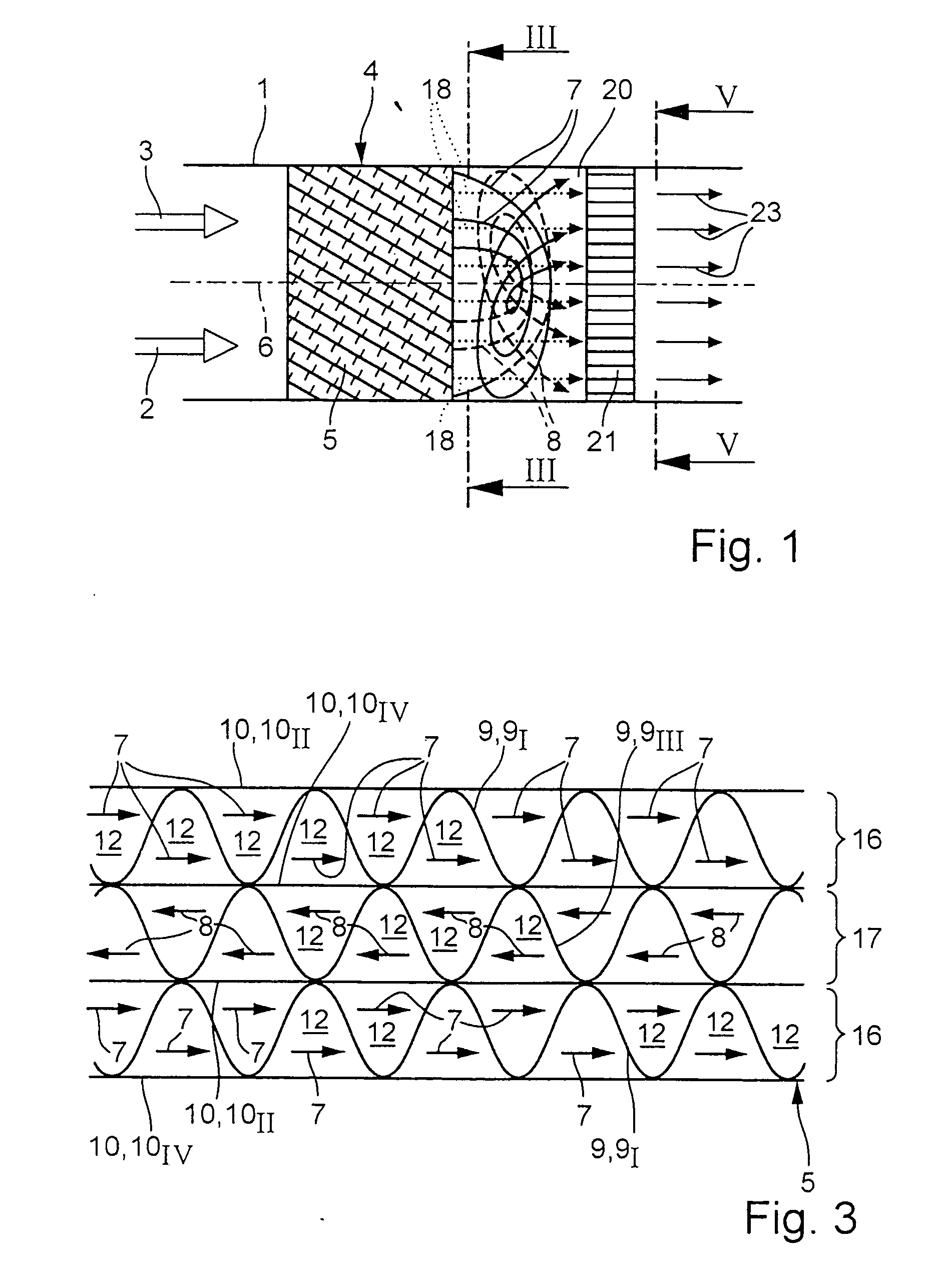

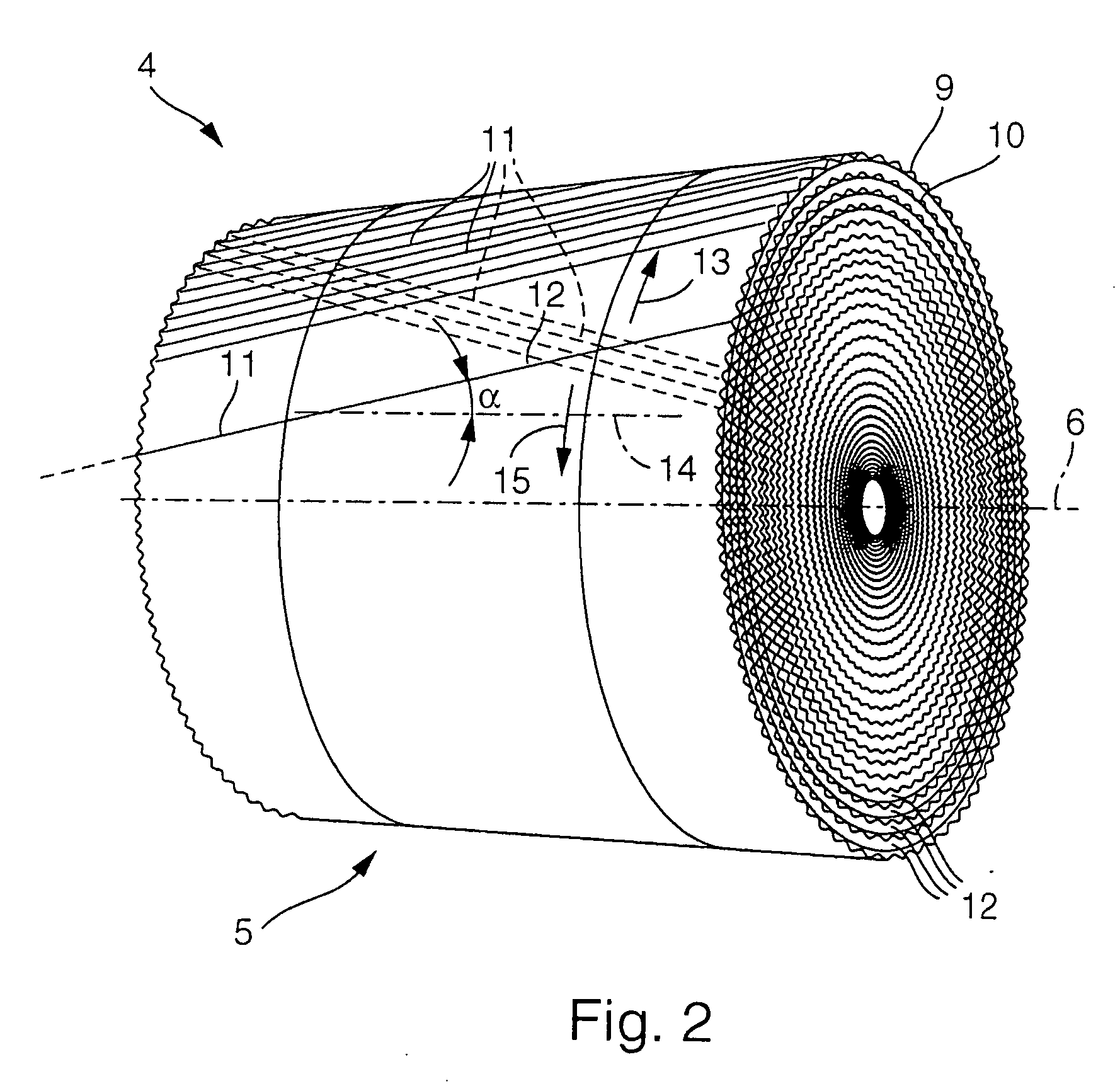

Method and device for mixing fluid flows

The present invention relates to a method for mixing at least two separate fluid flows (2, 3), in particular for a burner of a power plant. To improve the mixing, a plurality of swirl flows (7, 8), which are annular and concentric with respect to a longitudinal center line (6), are generated from the fluid flows (2, 3), in such a manner that radially adjacent swirl flows (7, 8) have opposite directions of rotation.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com