Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279 results about "Reactor design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactor design uses information, knowledge, and experience from a variety of areas-thermodynamics, chemical kinetics, fluid mechanics, heat transfer, mass transfer, and economics. Chemical reaction engineering is the synthesis of all these factors with the aim of properly designing a chemical reactor.

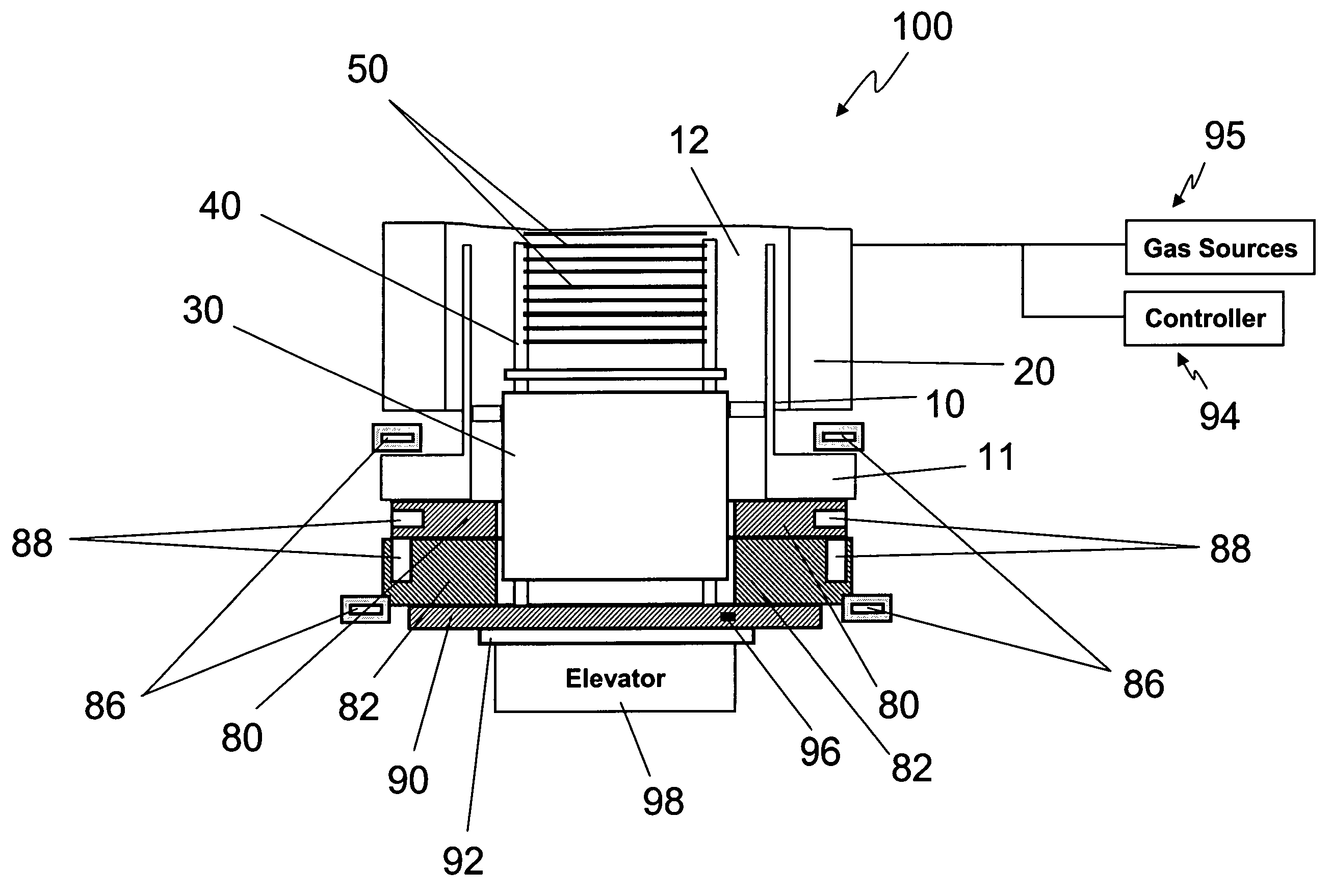

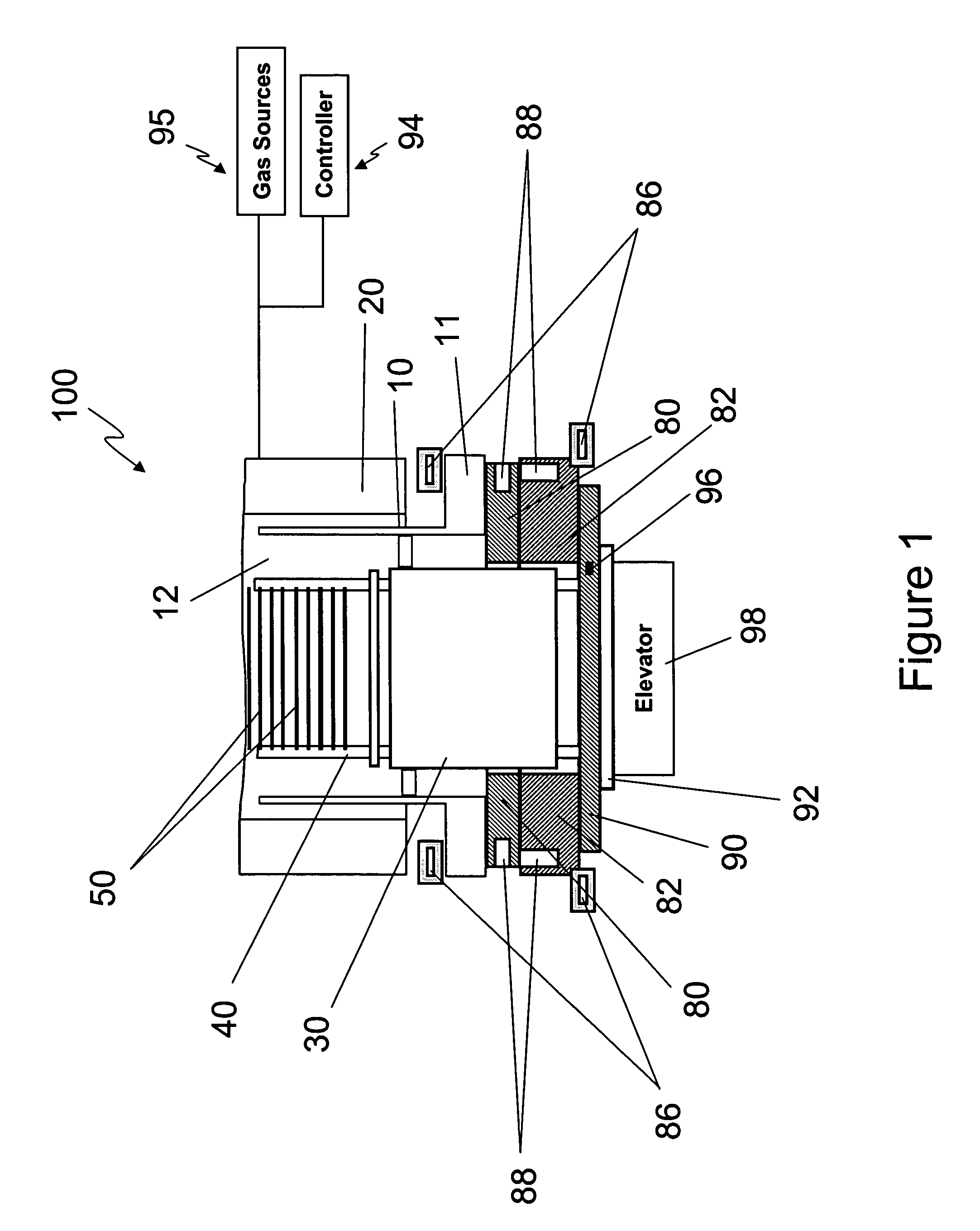

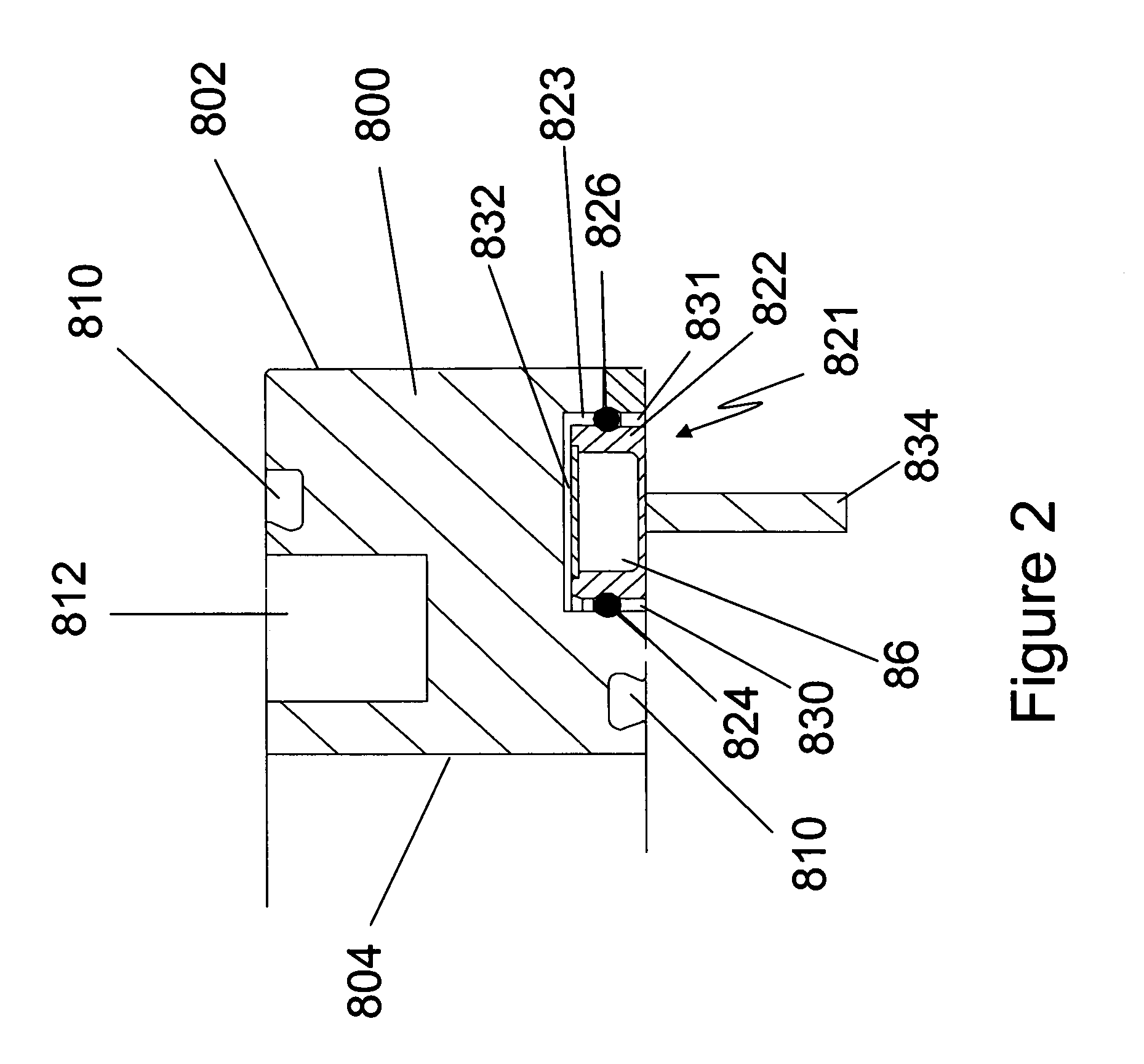

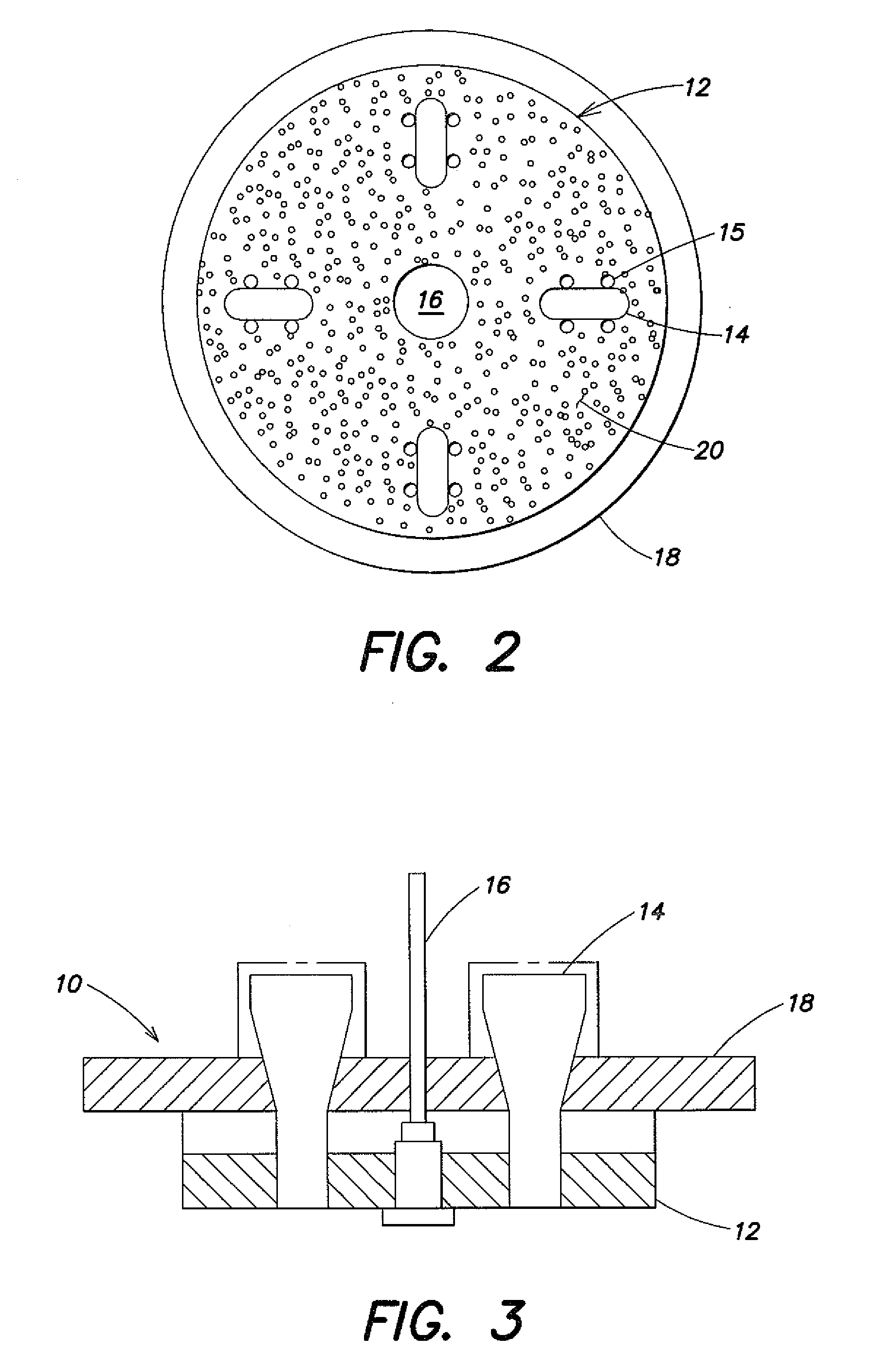

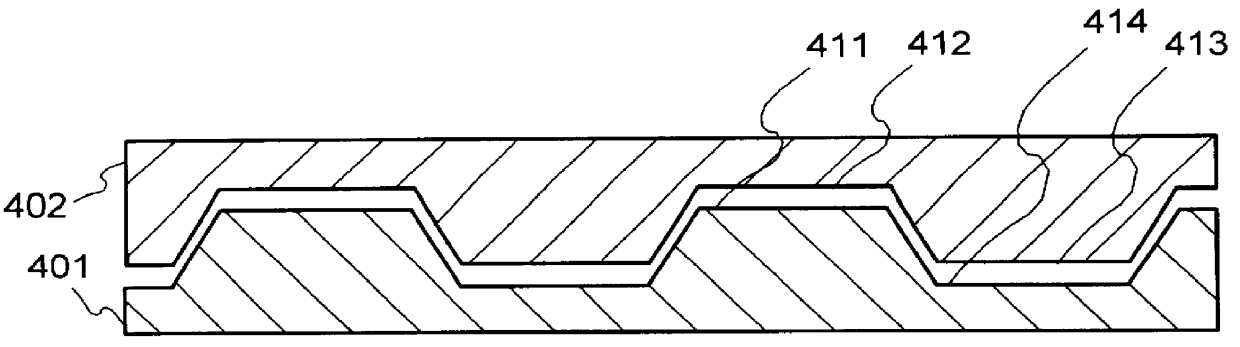

Reactor design for reduced particulate generation

ActiveUS7427571B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingParticulatesEngineering

Particle formation in semiconductor fabrication process chambers is reduced by preventing condensation on the door plates that seal off the process chambers. Particles can be formed in a process chamber when reactant gases condense on the relatively cool surfaces of a door plate. This particle formation is minimized by heating the door plate to a temperature high enough to prevent condensation before flowing reactant gases into the process chamber. The door plate can be heated using a heat source, e.g., a resistive heater, that is in direct contact with the door plate or the heat source can heat the door plate from a distance by radiative or inductive heating. In addition, the door plate can open to allow loading and unloading of a wafer load. As it passes flanges near the door plate, the wafer load can transfer heat to those flanges. To prevent overheating, the flange is provided with a coolant-containing channel having walls that are spaced from the flange by O-rings. The spacing of the channel walls to the flange can be varied to vary the amount of thermal contact and cooling achieved using the channels.

Owner:ASM INTERNATIONAL

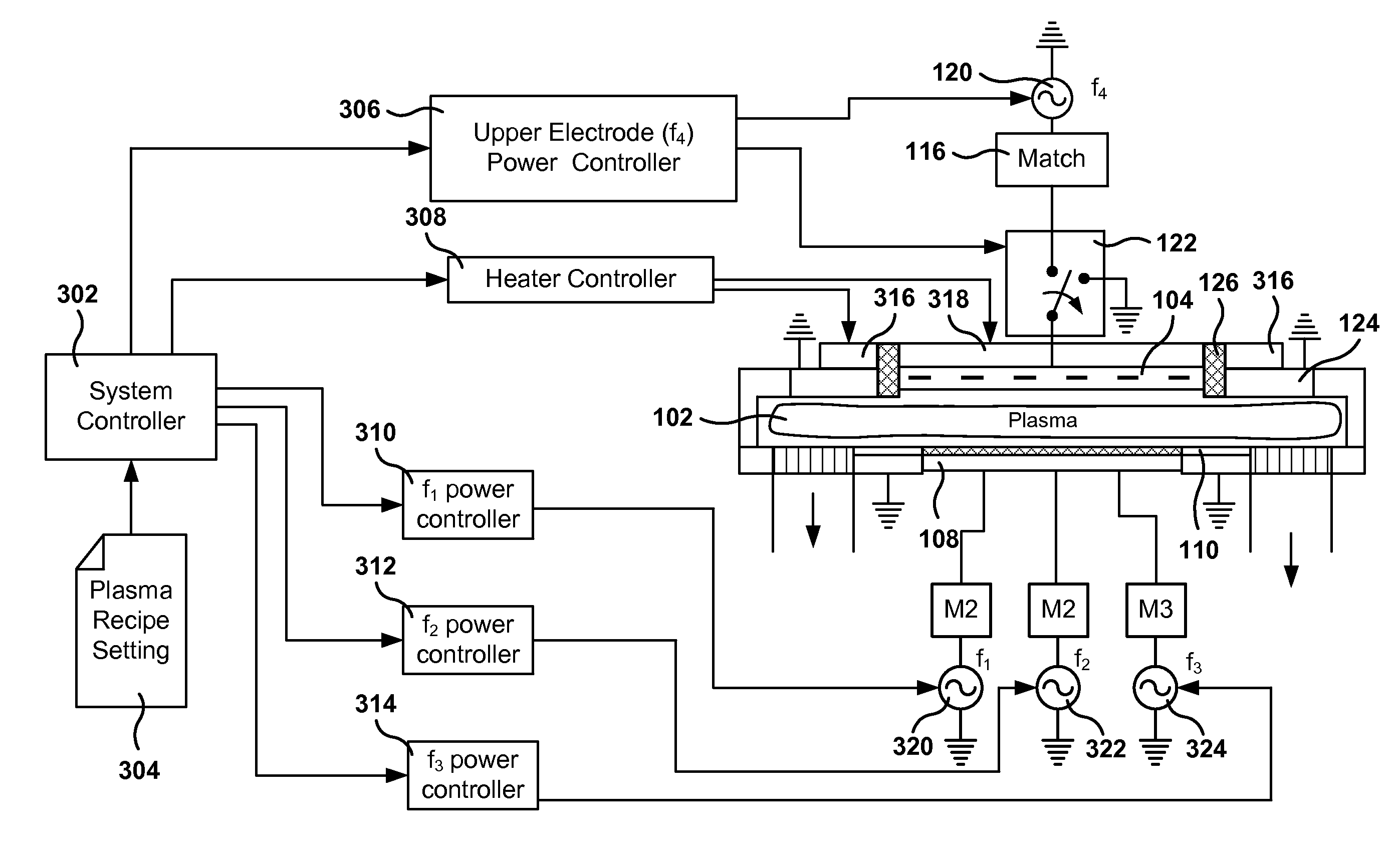

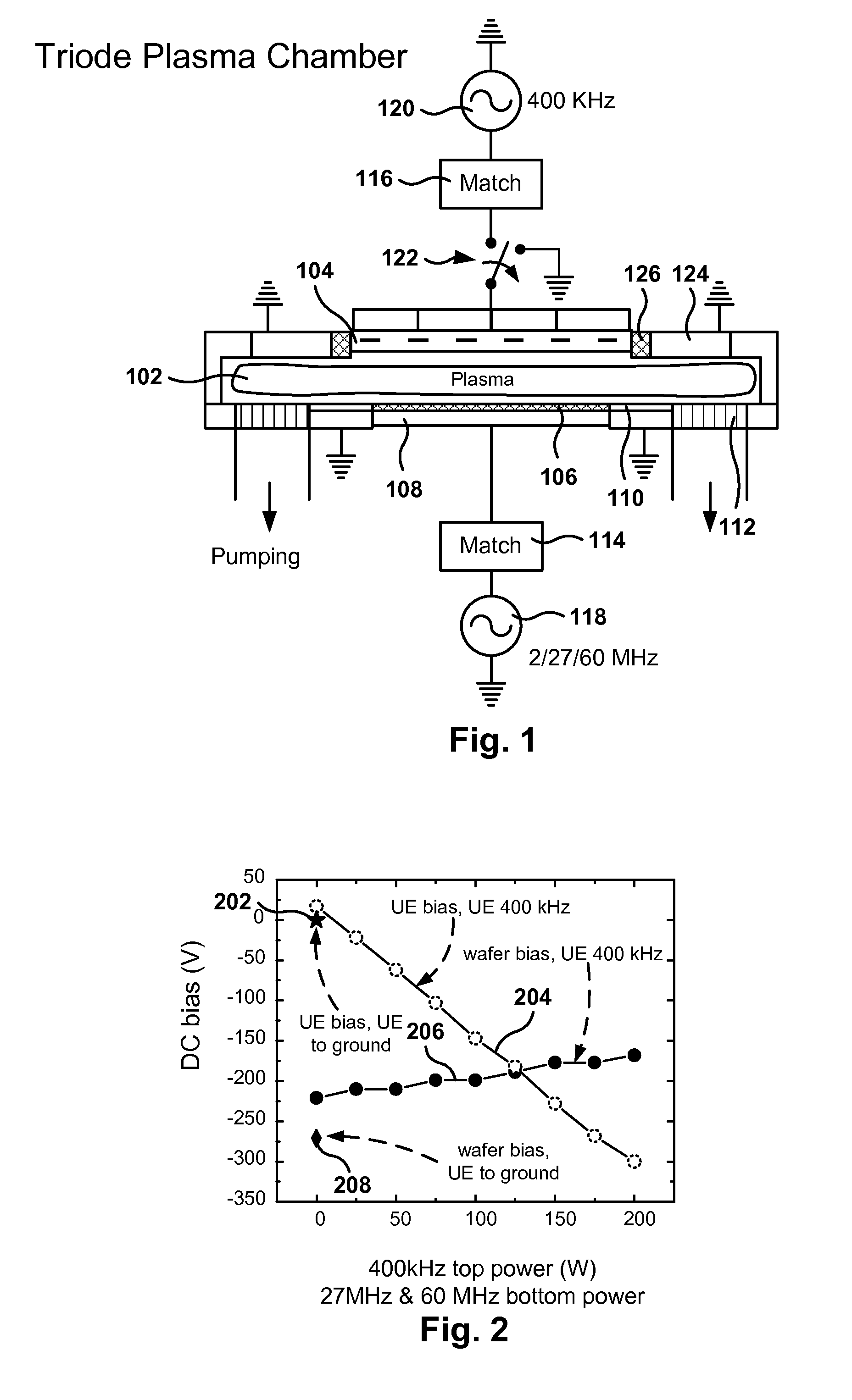

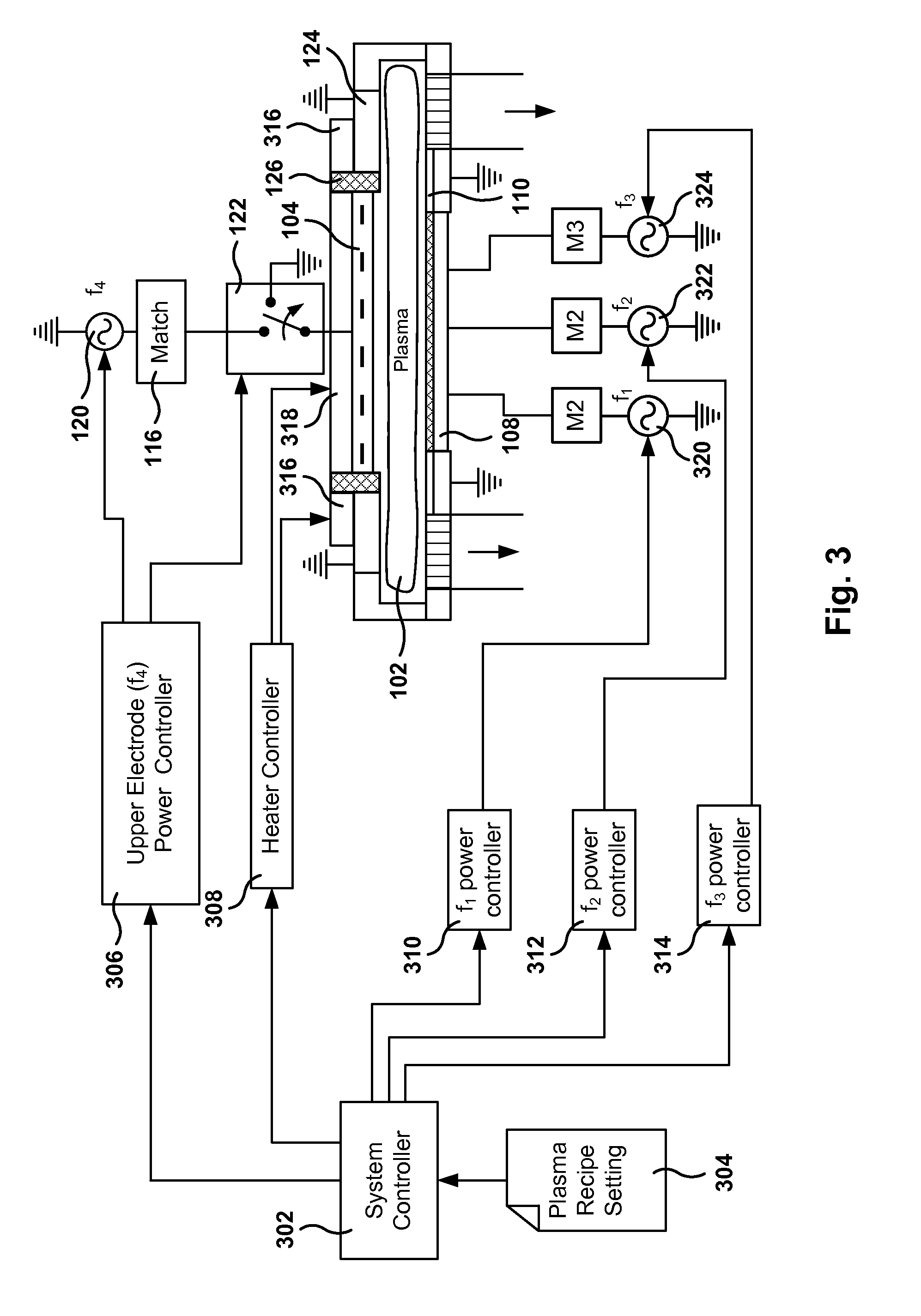

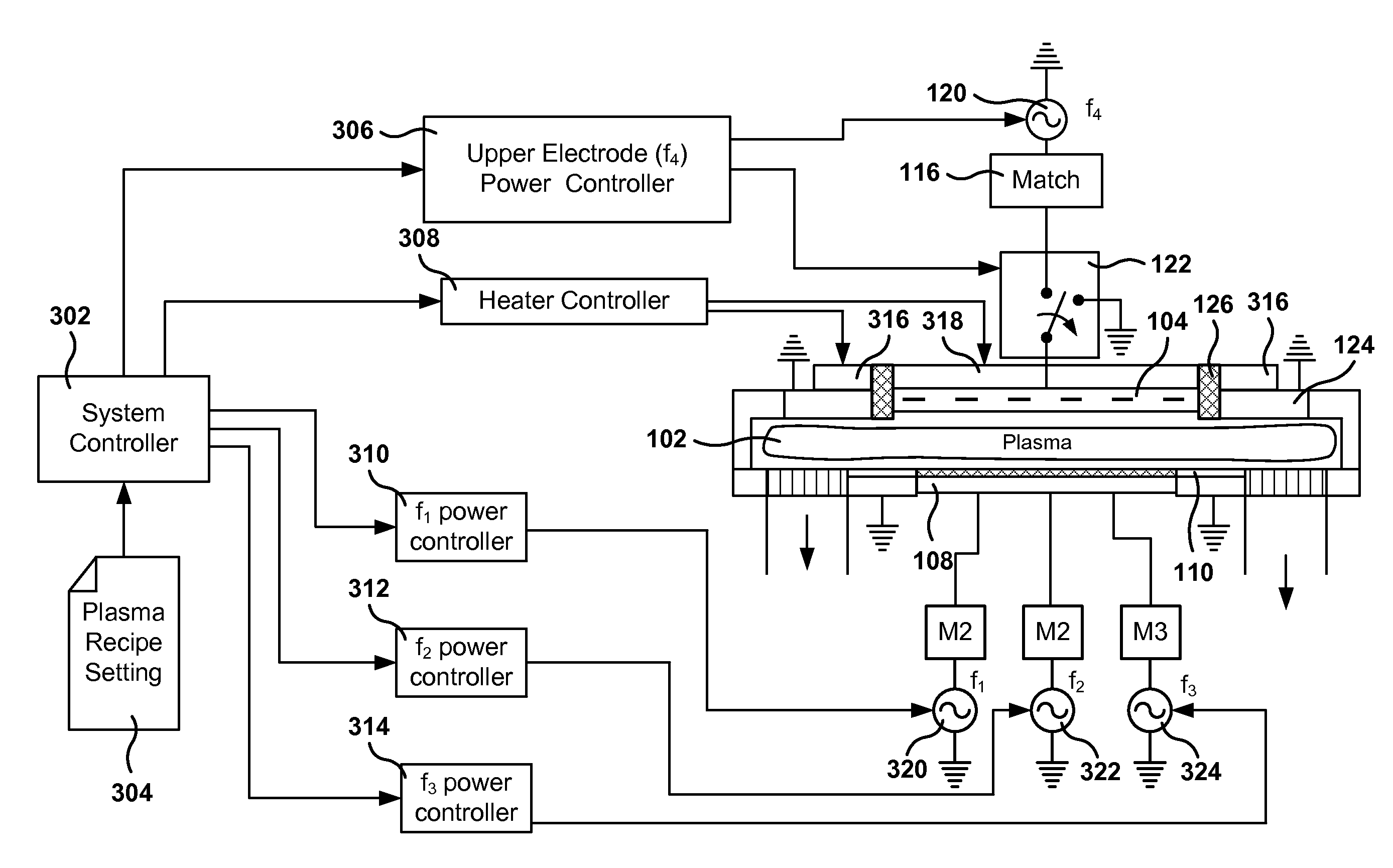

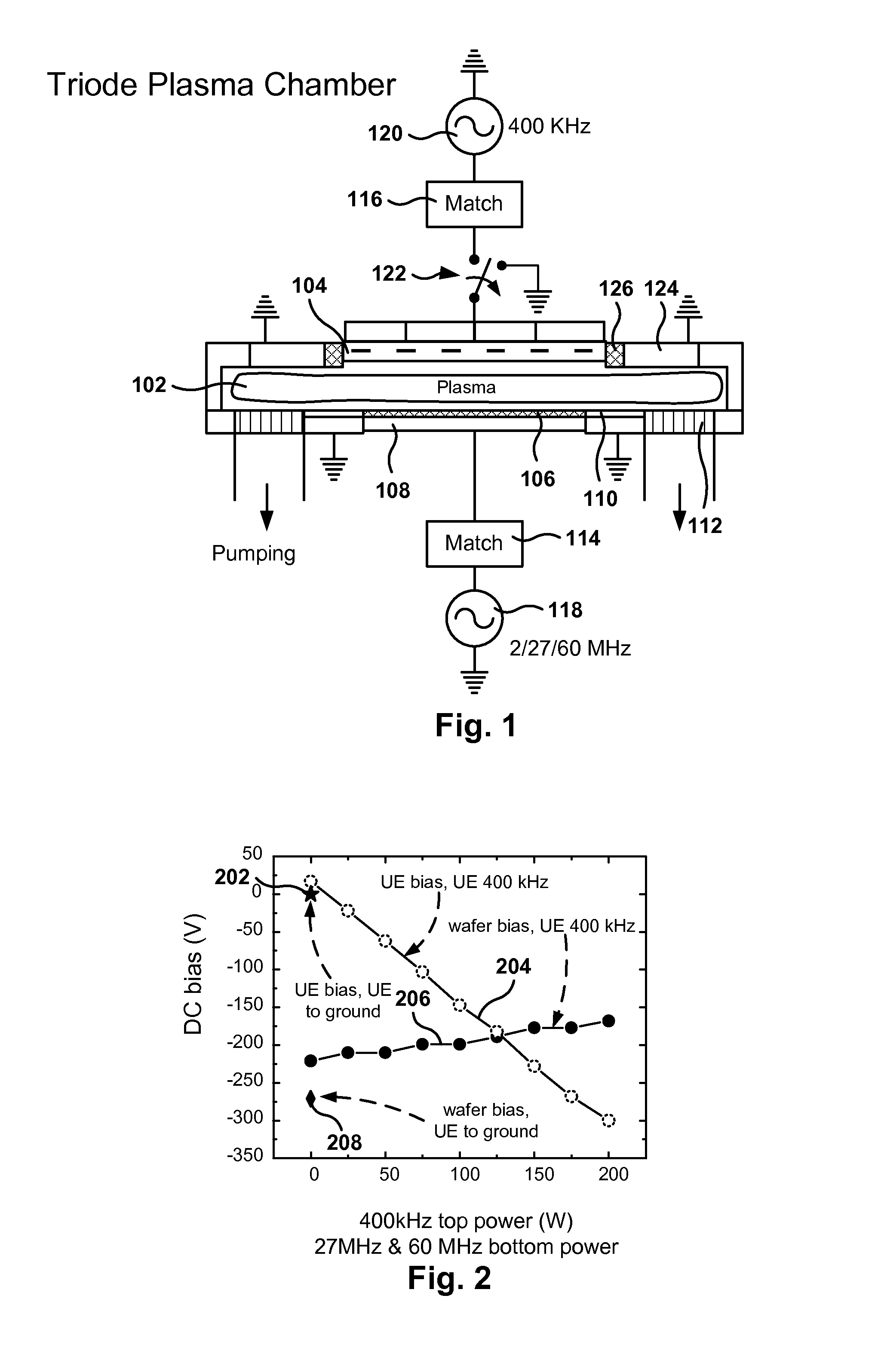

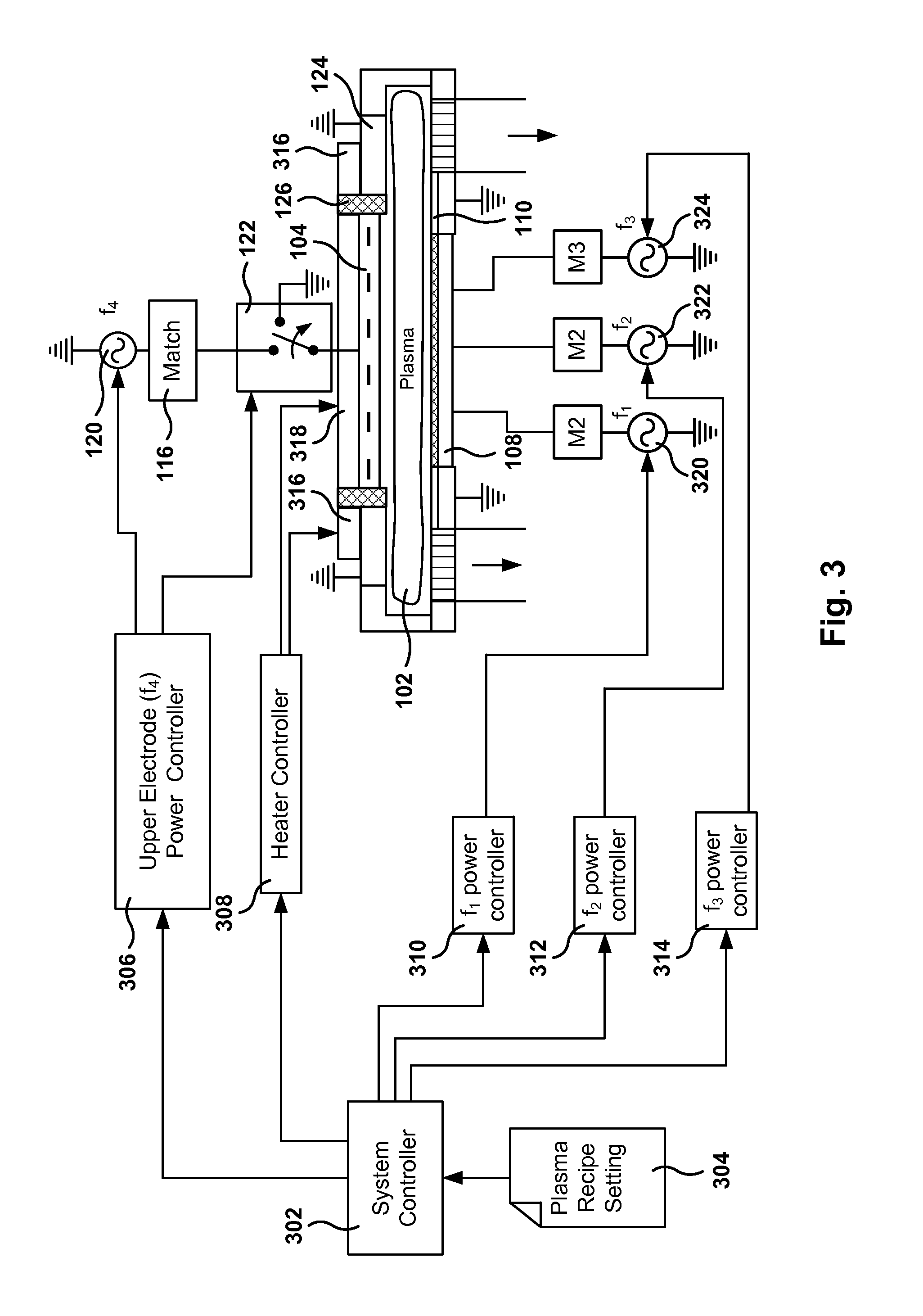

Triode reactor design with multiple radiofrequency powers

ActiveUS8652298B2Electric discharge tubesVacuum gauge using ionisation effectsReactor designEngineering

Methods, systems, and computer programs are presented for semiconductor manufacturing are provided. One wafer processing apparatus includes: a top electrode; a bottom electrode; a first radio frequency (RF) power source; a second RF power source; a third RF power source; a fourth RF power source; and a switch. The first, second, and third power sources are coupled to the bottom electrode. Further, the switch is operable to be in one of a first position or a second position, where the first position causes the top electrode to be connected to ground, and the second position causes the top electrode to be connected to the fourth RF power source.

Owner:LAM RES CORP

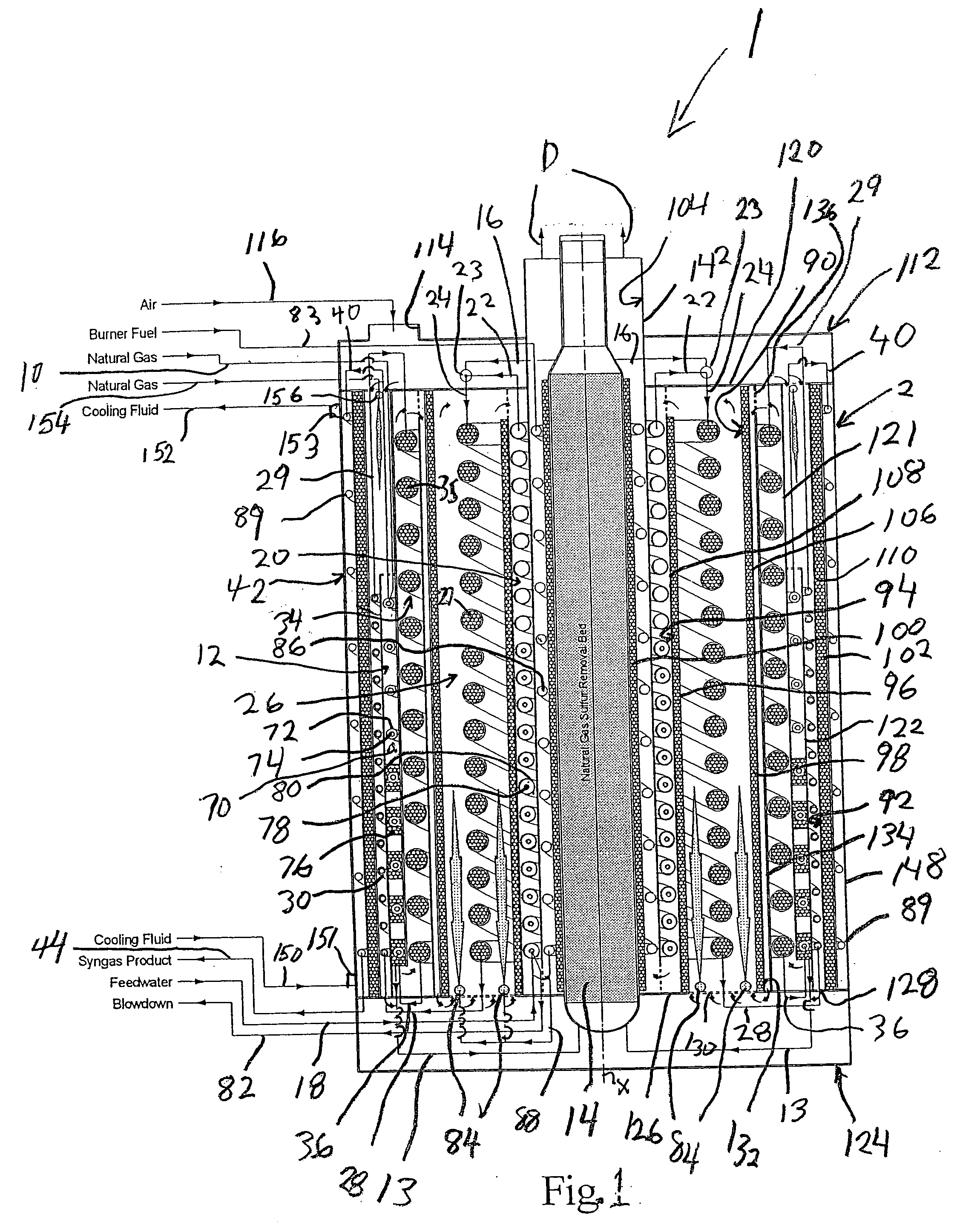

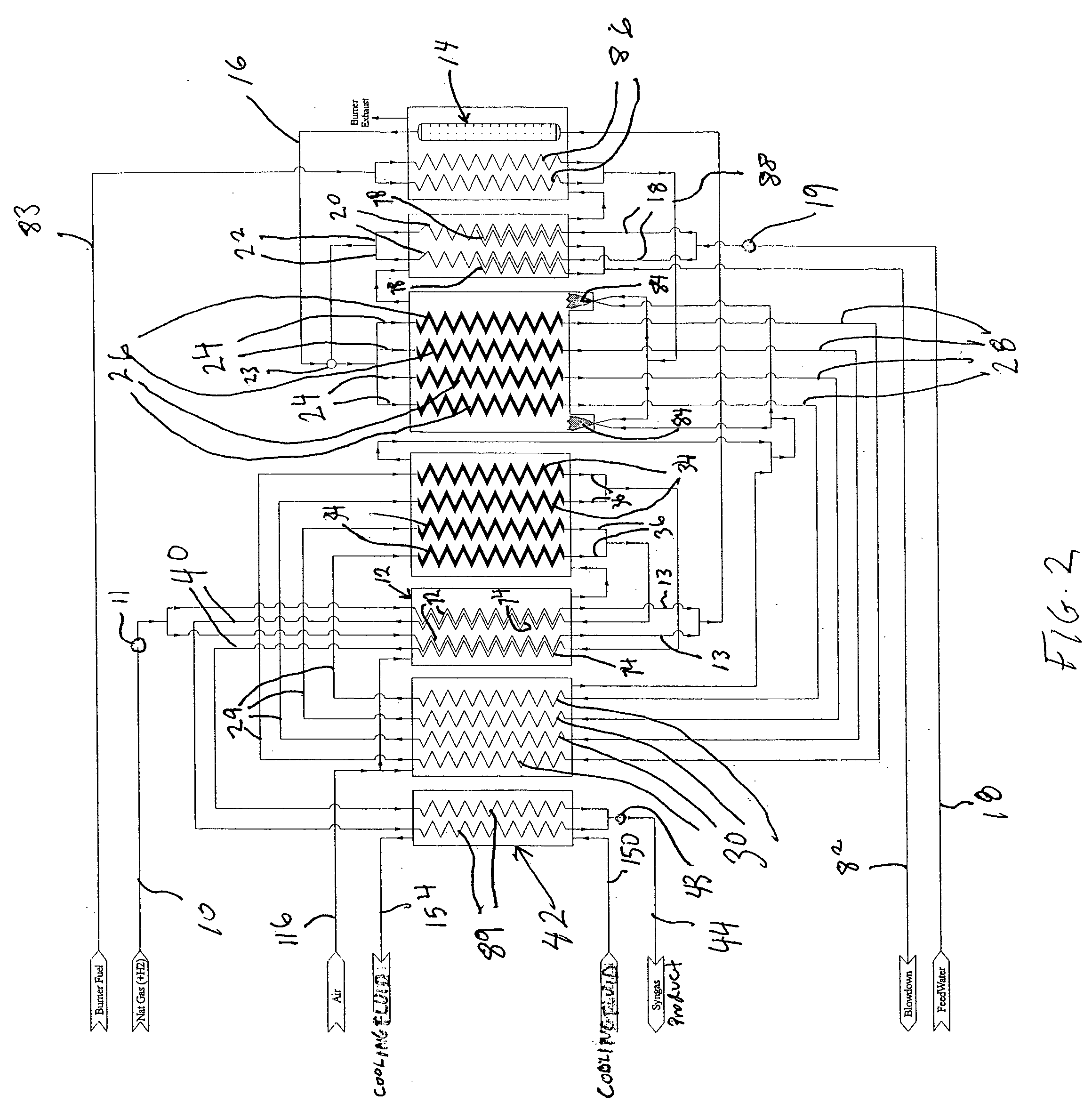

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

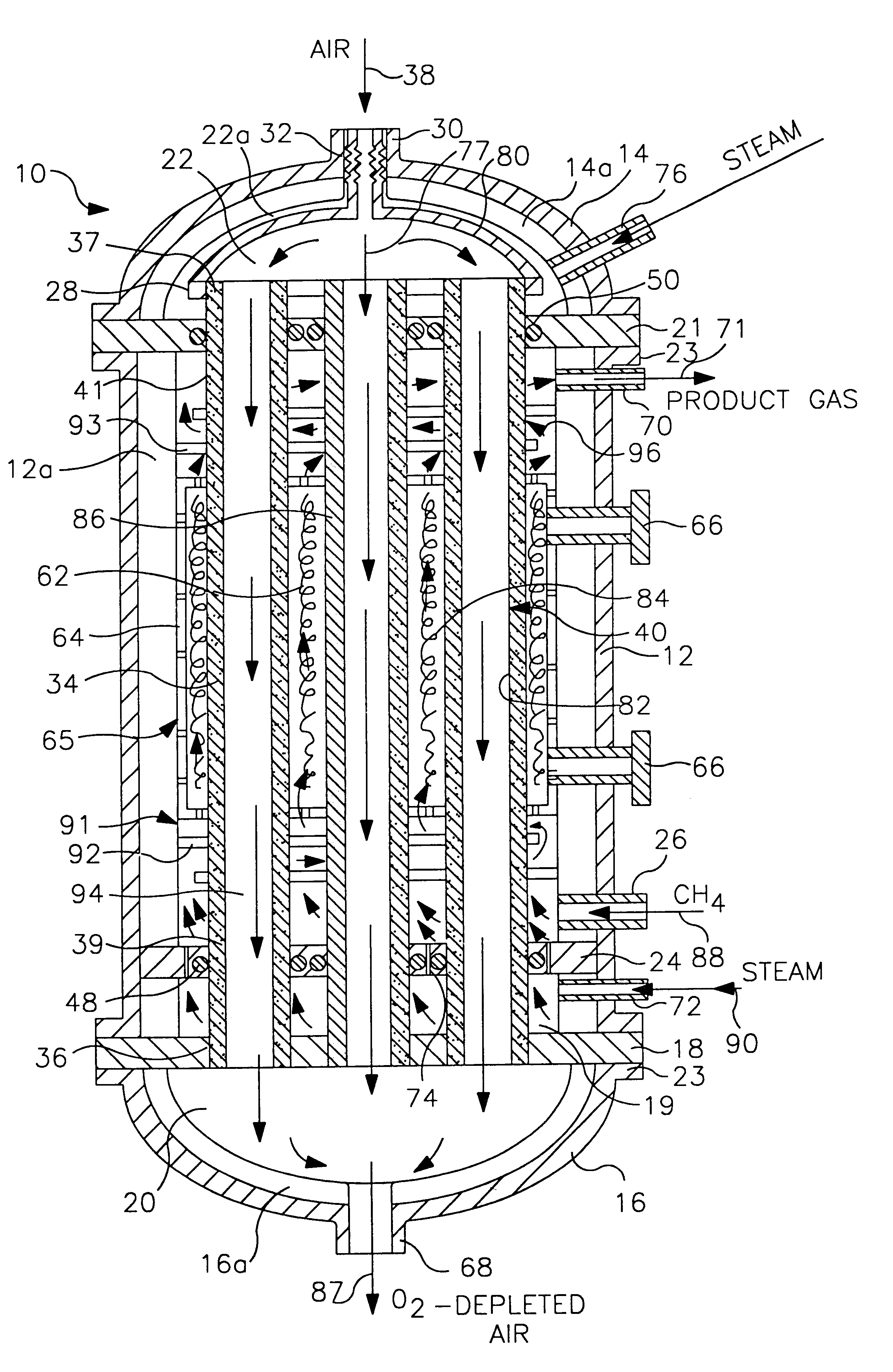

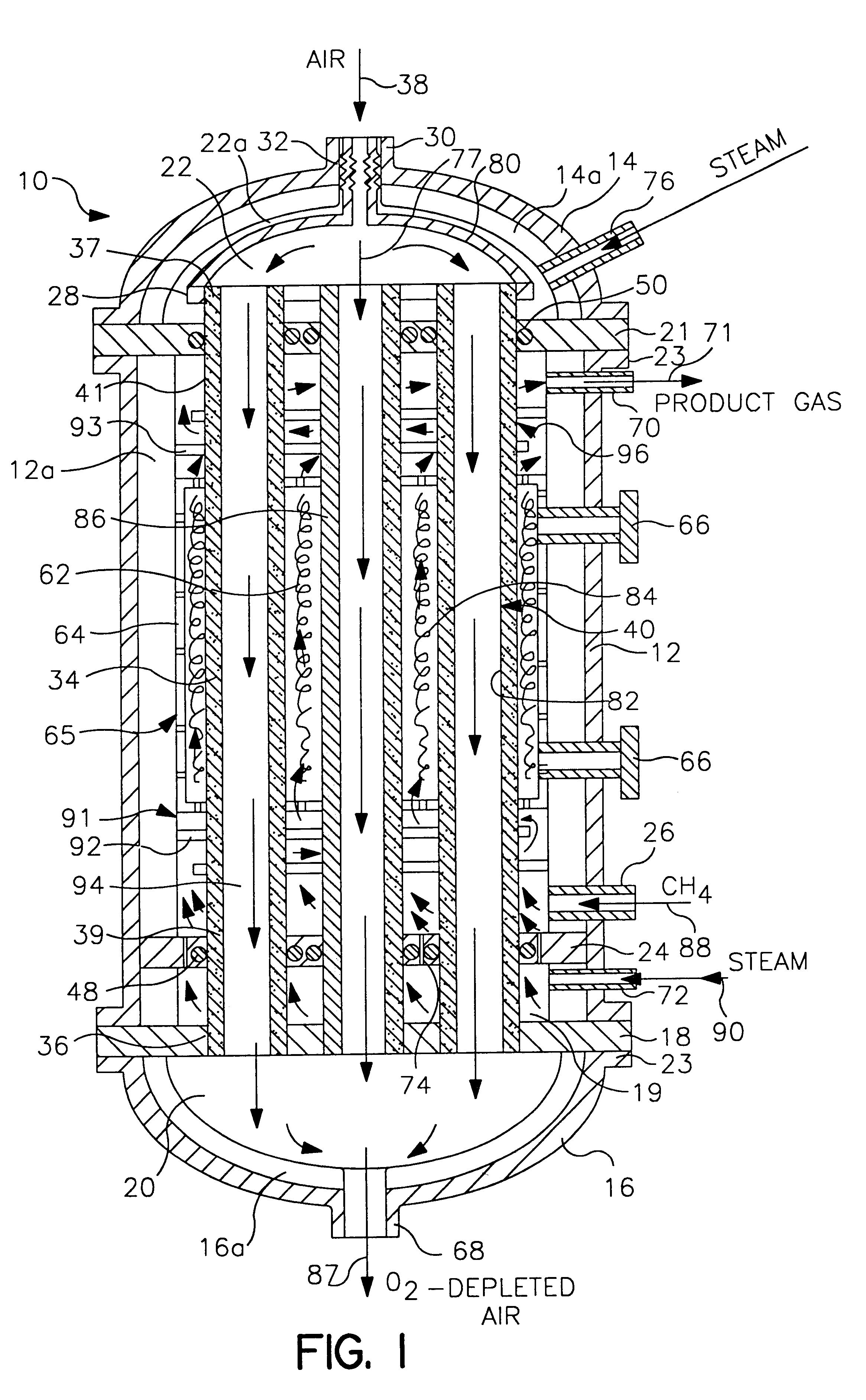

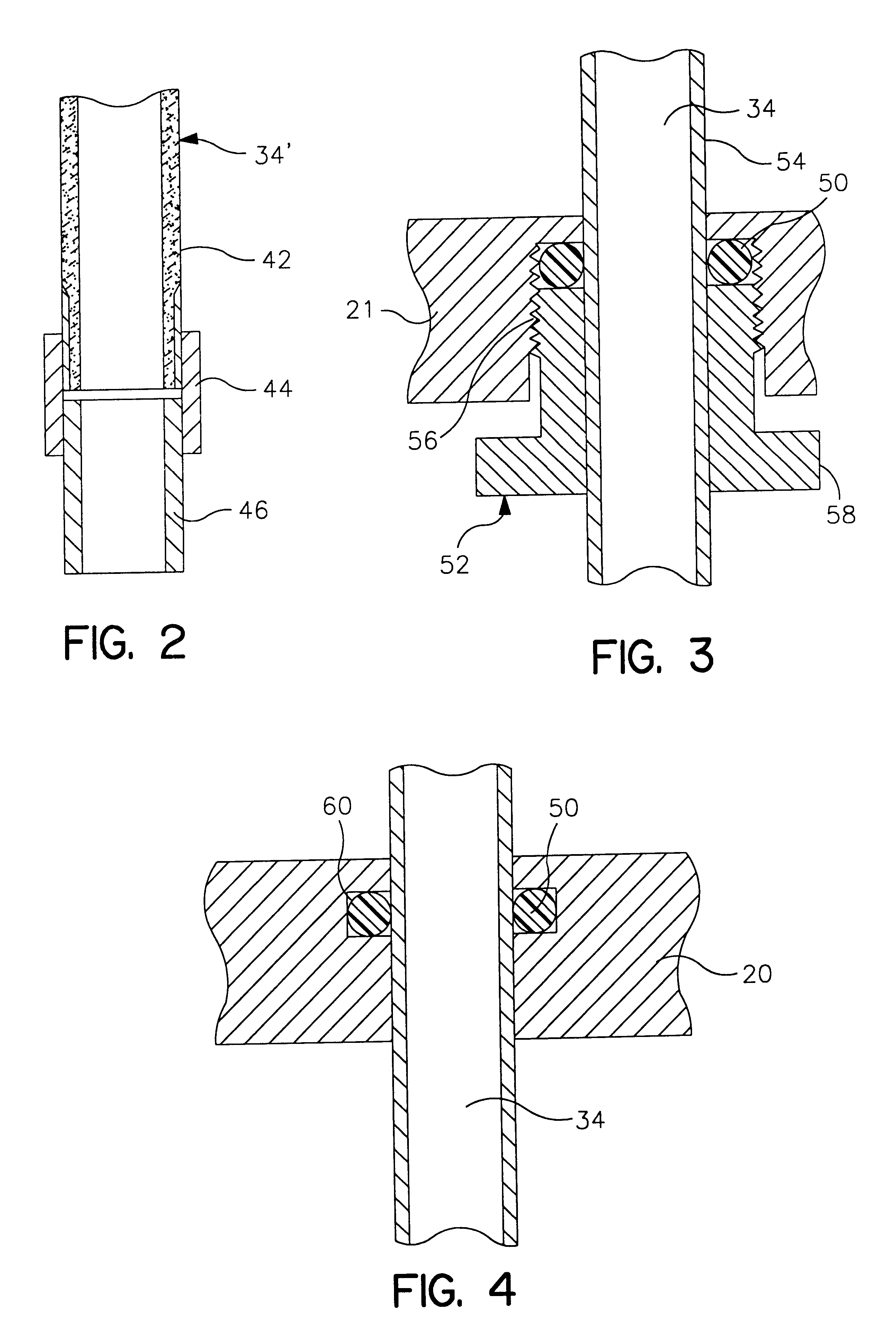

Process for producing a syngas

InactiveUS6402988B1Minimize the temperatures experienced by sealsMinimize pressure differenceCatalytic gas-gas reactionHydrogenSyngasReactor design

An exothermic reaction and an endothermic reaction are thermally combined in a reactor having at least one oxygen selective ion transport membrane that provides the exothermic reaction with oxygen from an oxygen-containing gas such as air. The thermal requirements of the endothermic reaction are satisfied by the exothermic reaction. Dependent on the reactor design employed, the exothermic and endothermic reactions may be gaseously combined.

Owner:PRAXAIR TECH INC +1

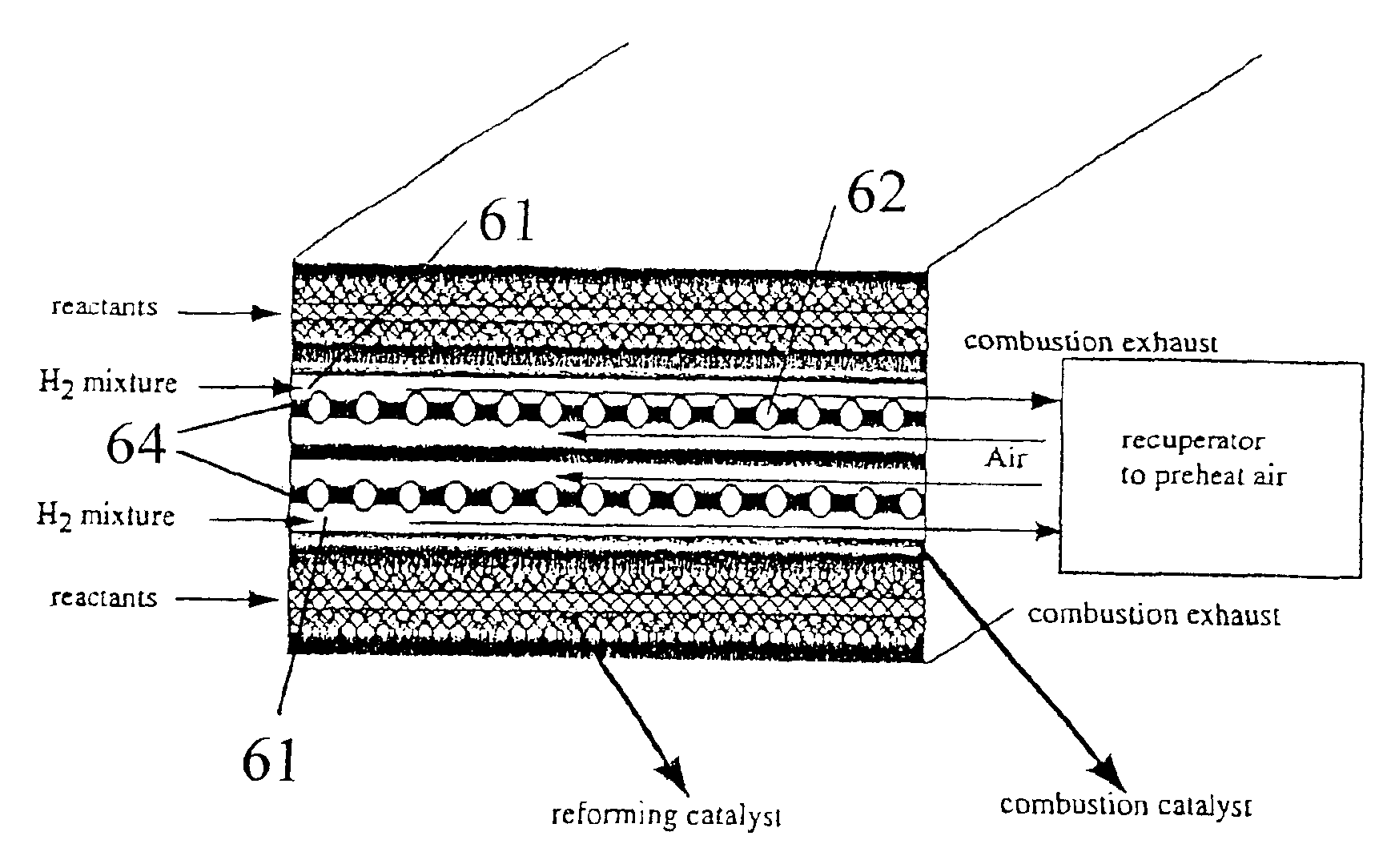

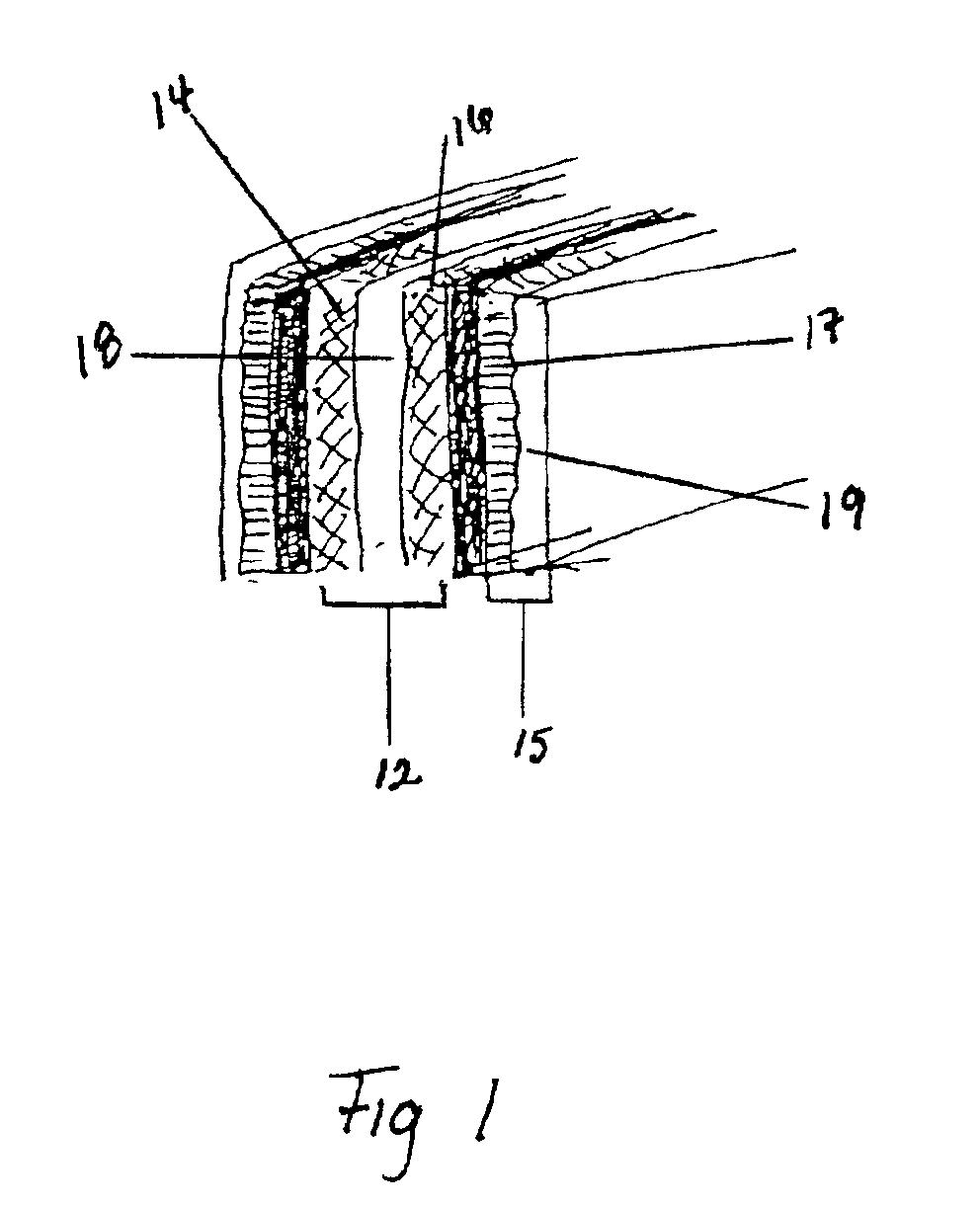

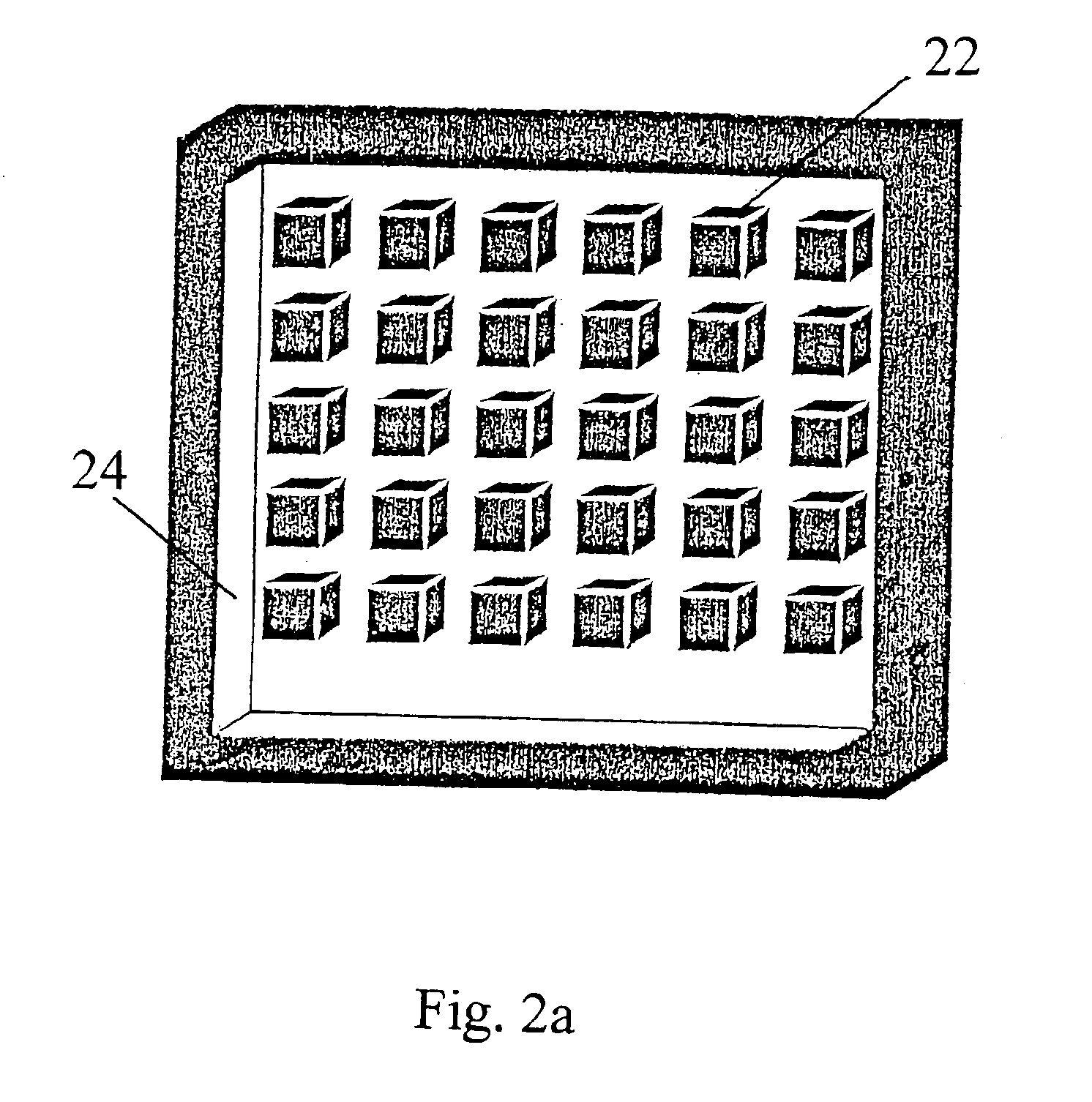

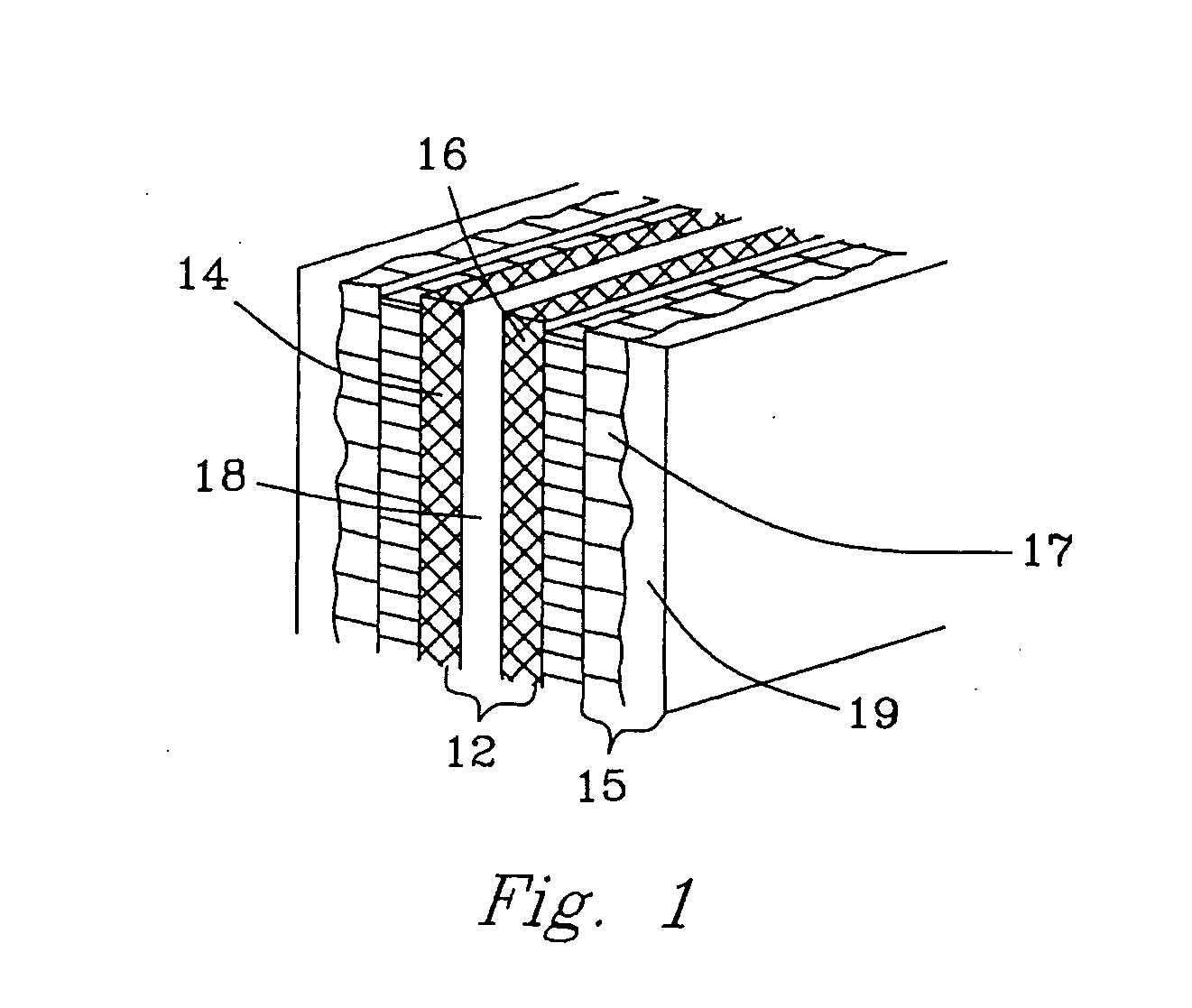

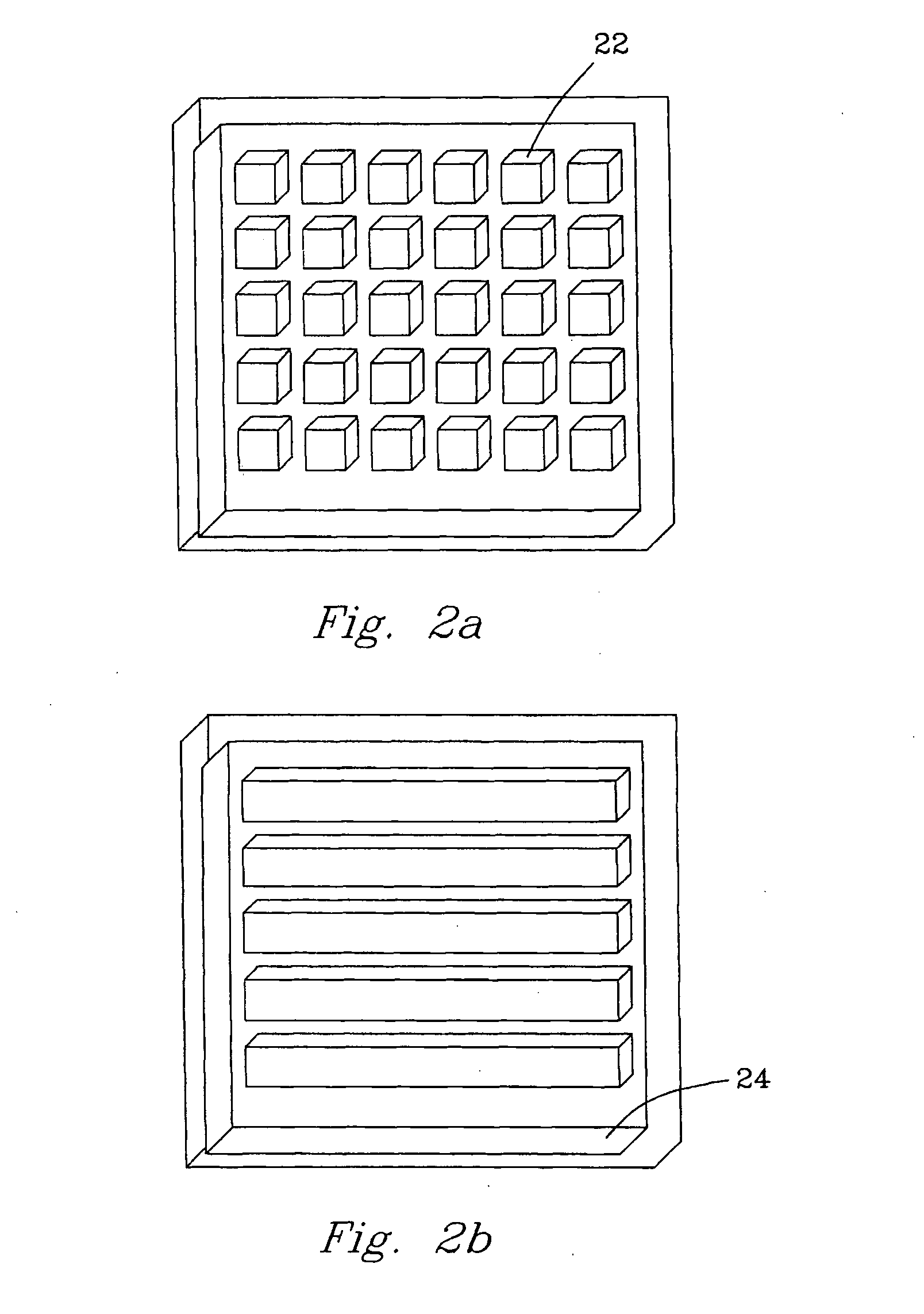

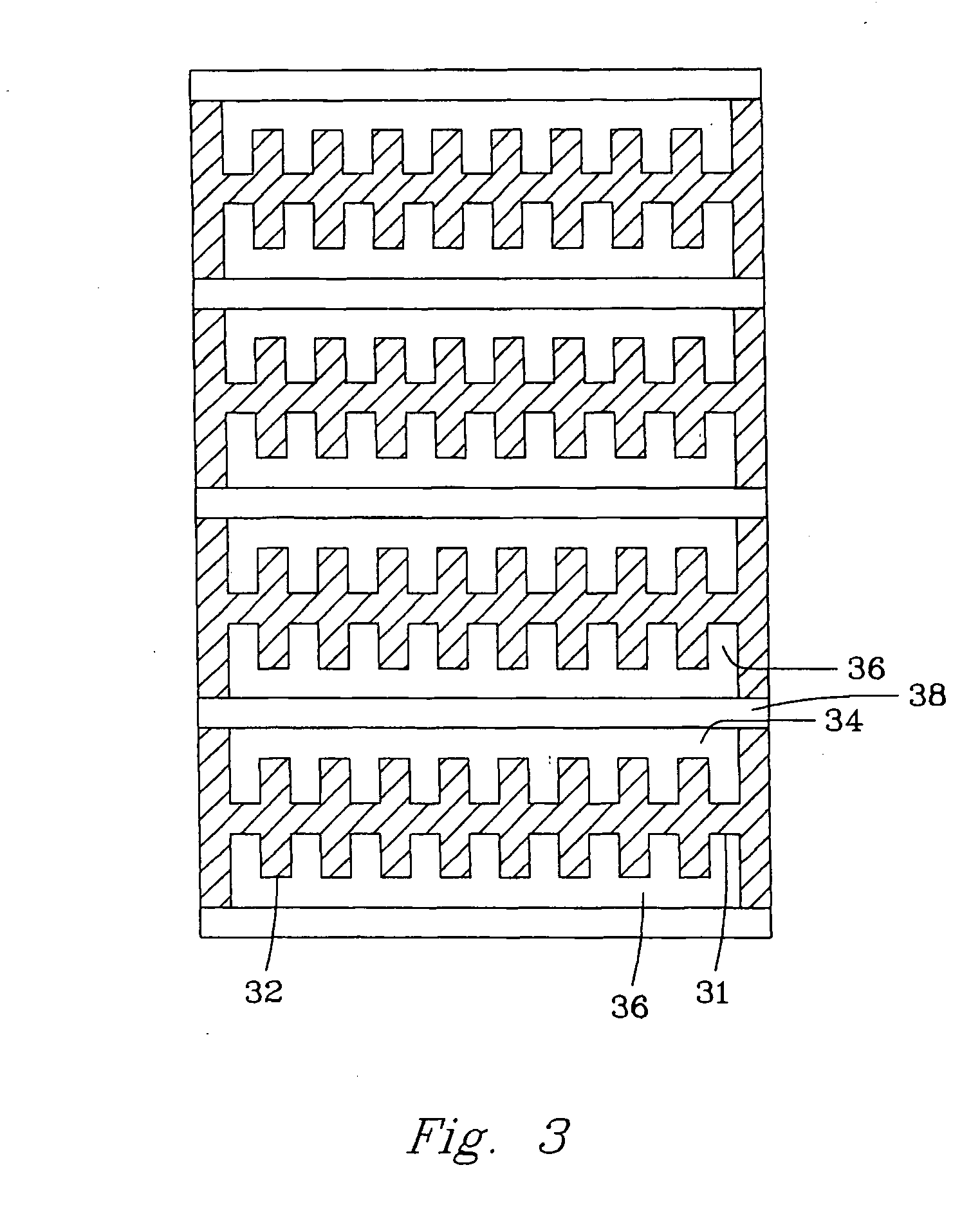

Methods of conducting simultaneous exothermic and endothermic reactions

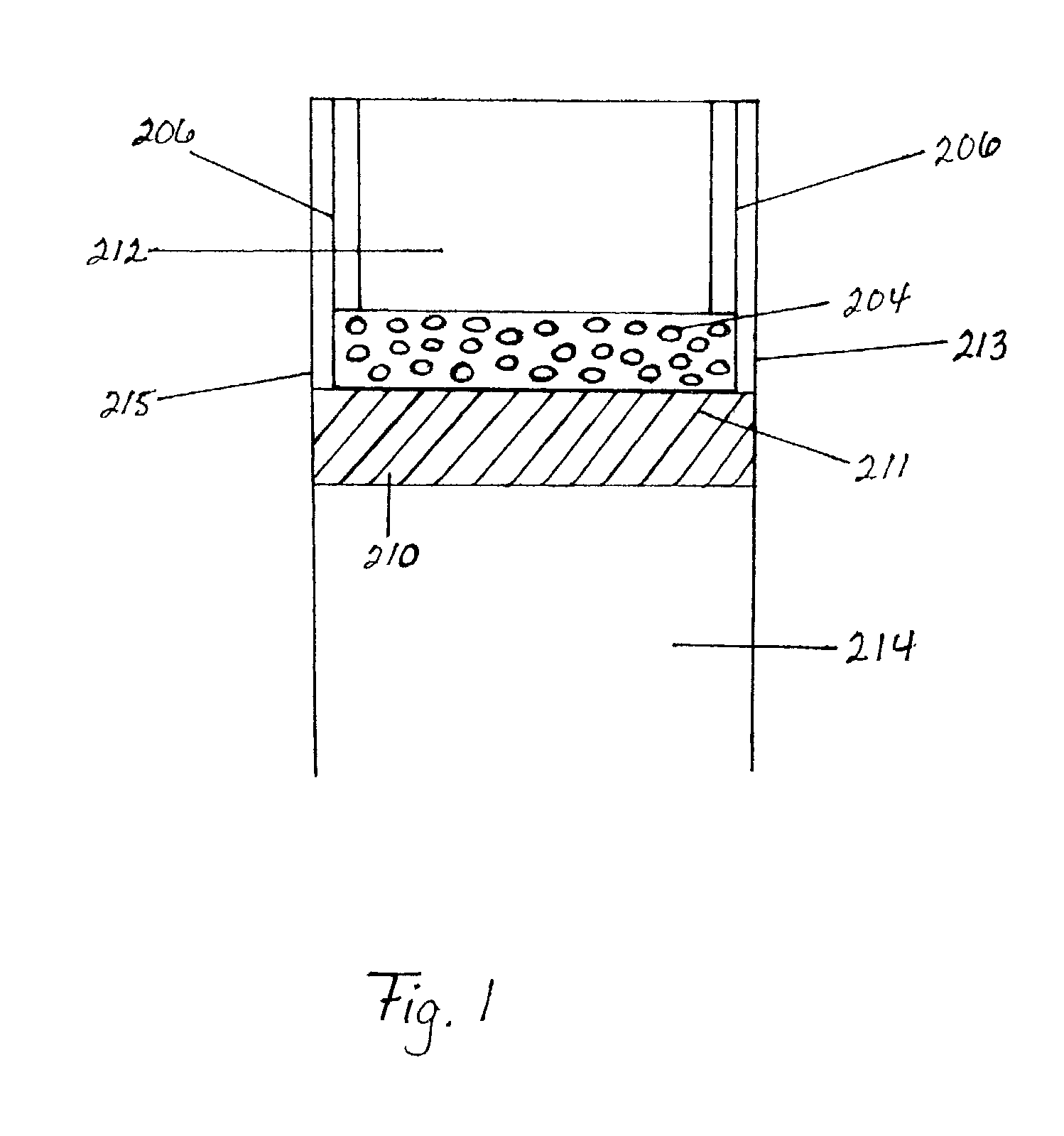

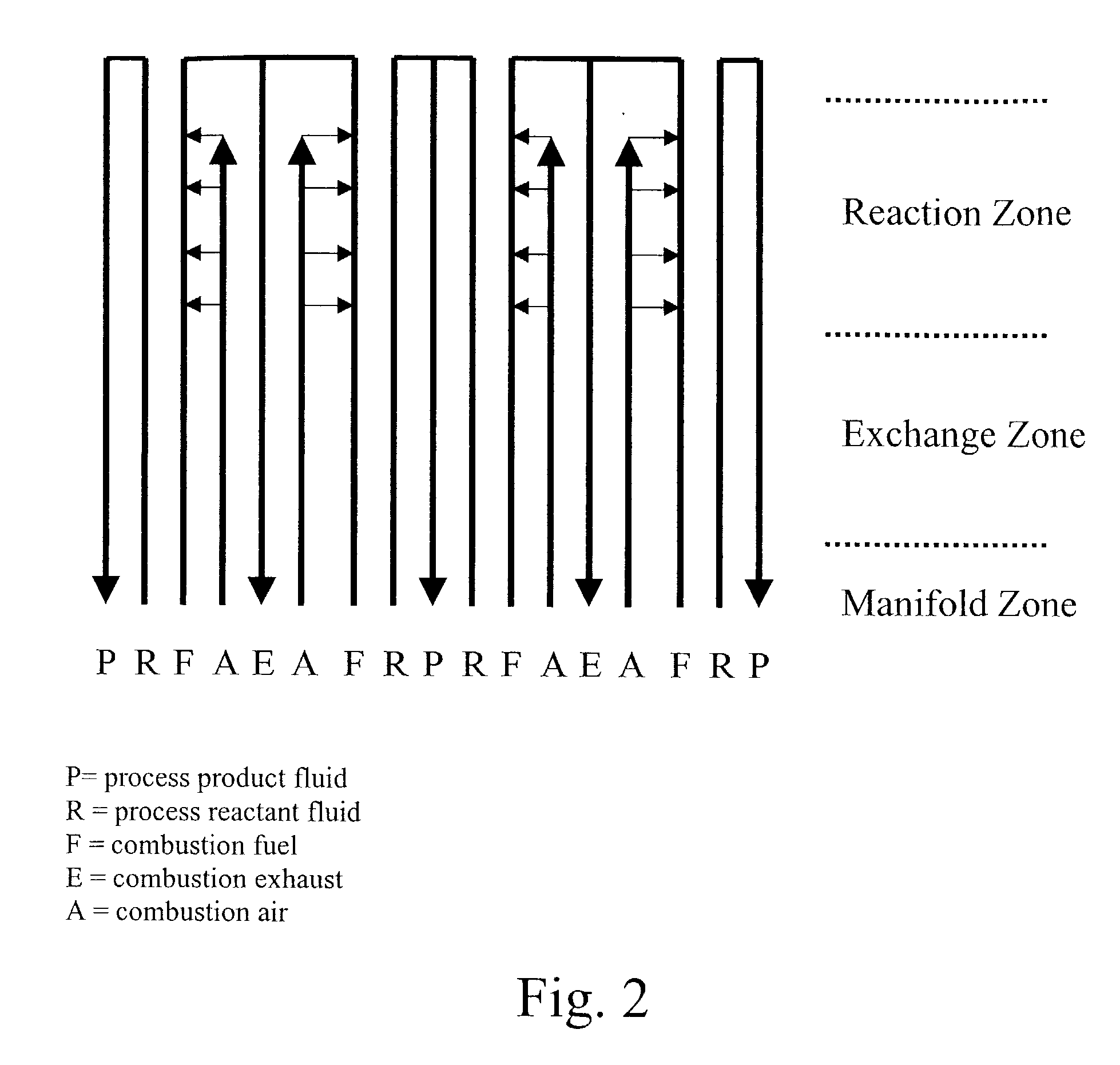

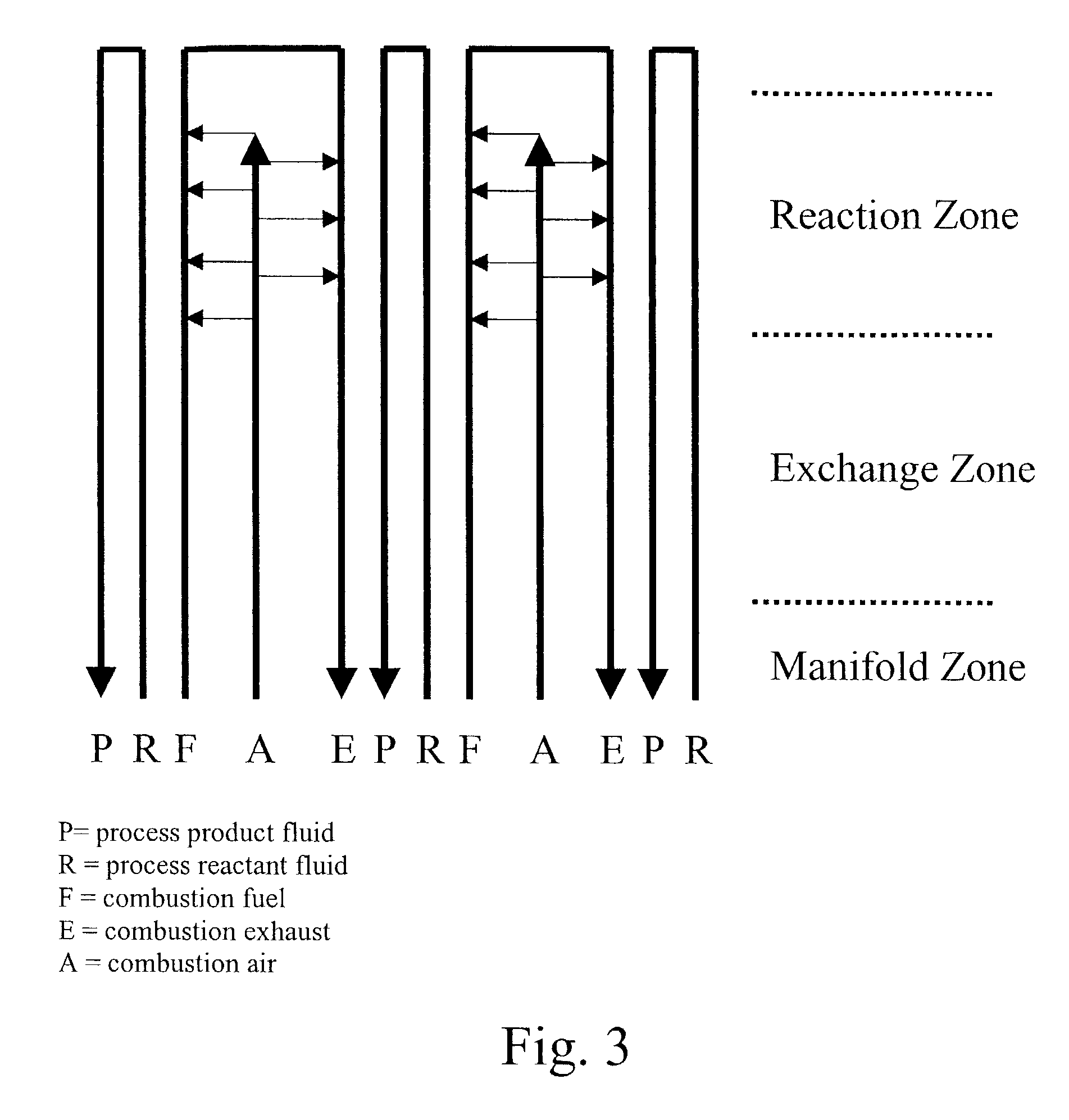

InactiveUS6969506B2High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberEngineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for free flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

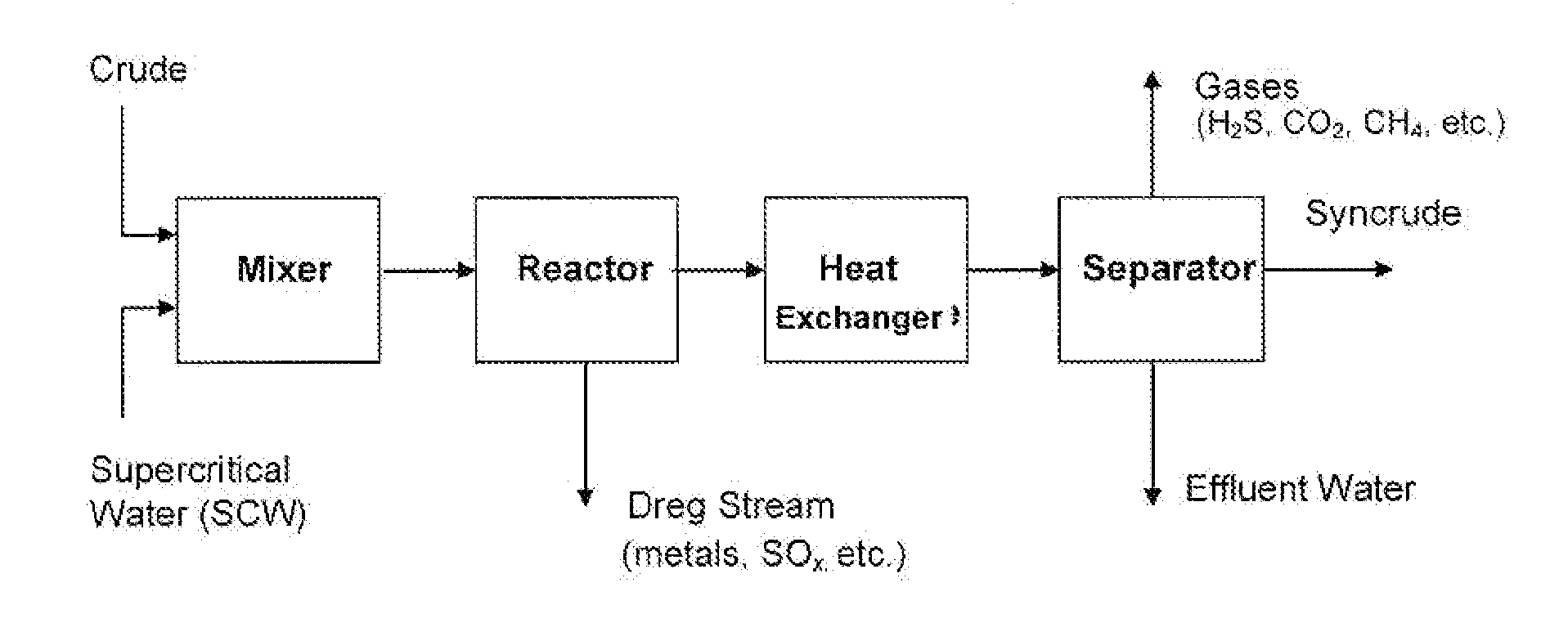

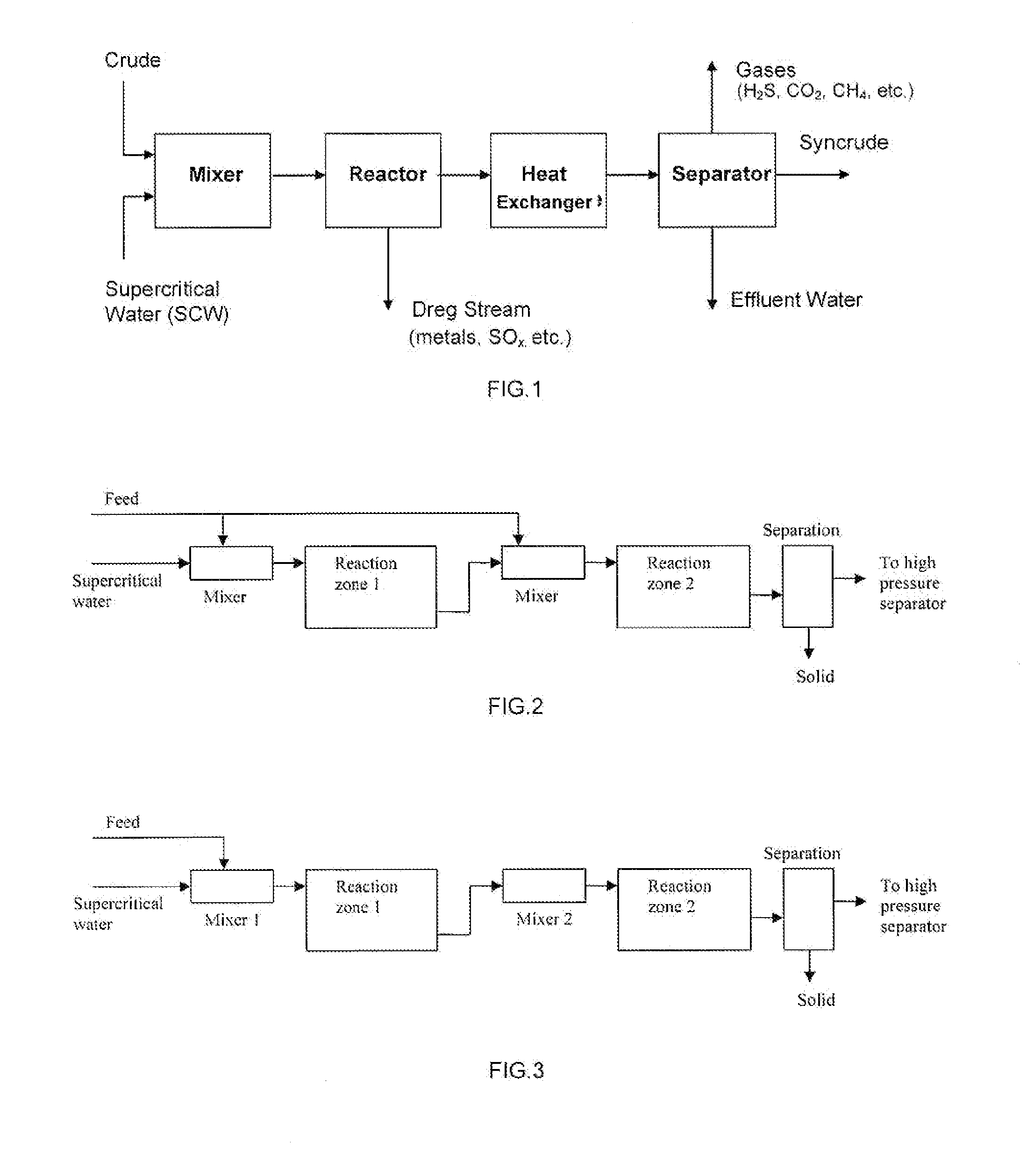

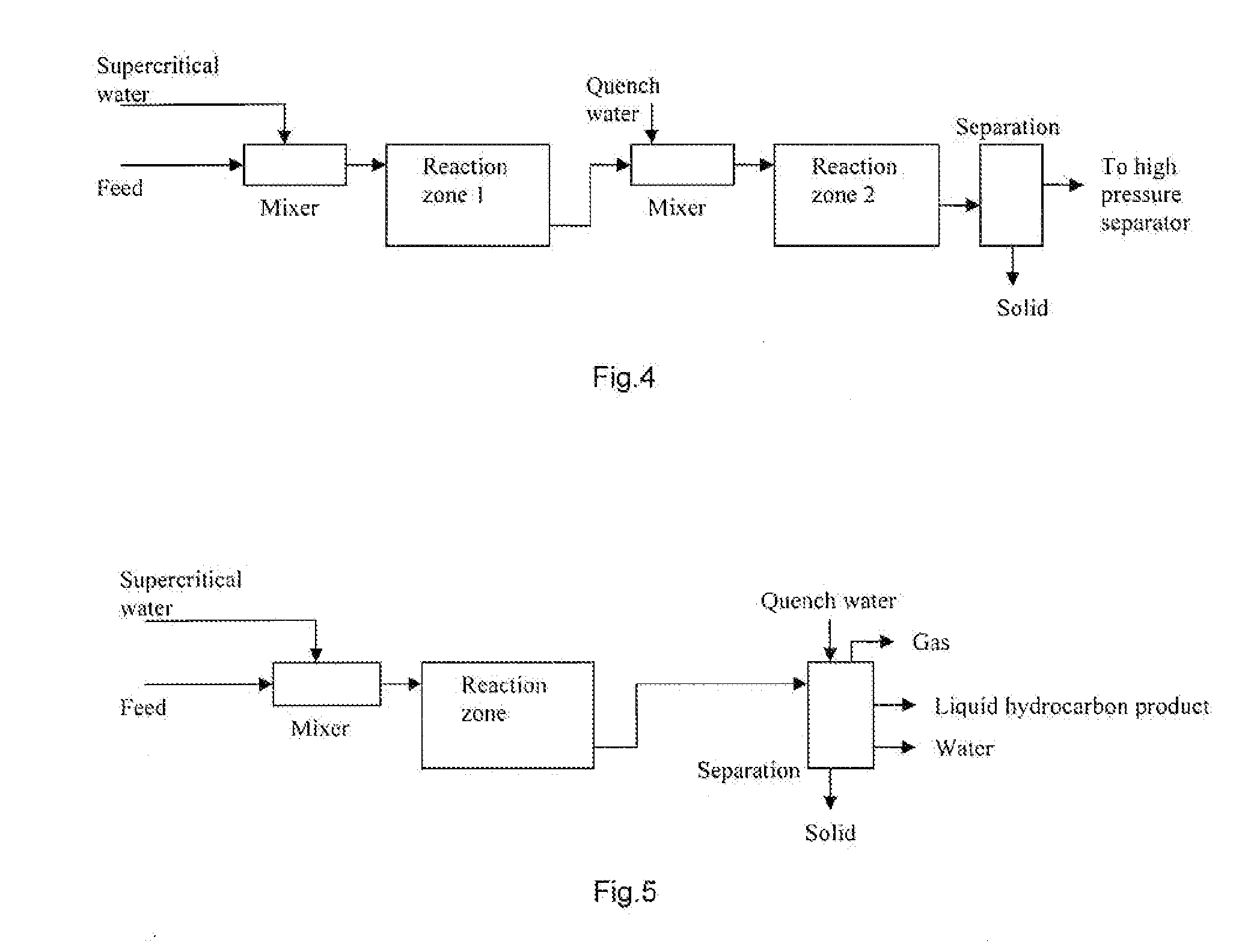

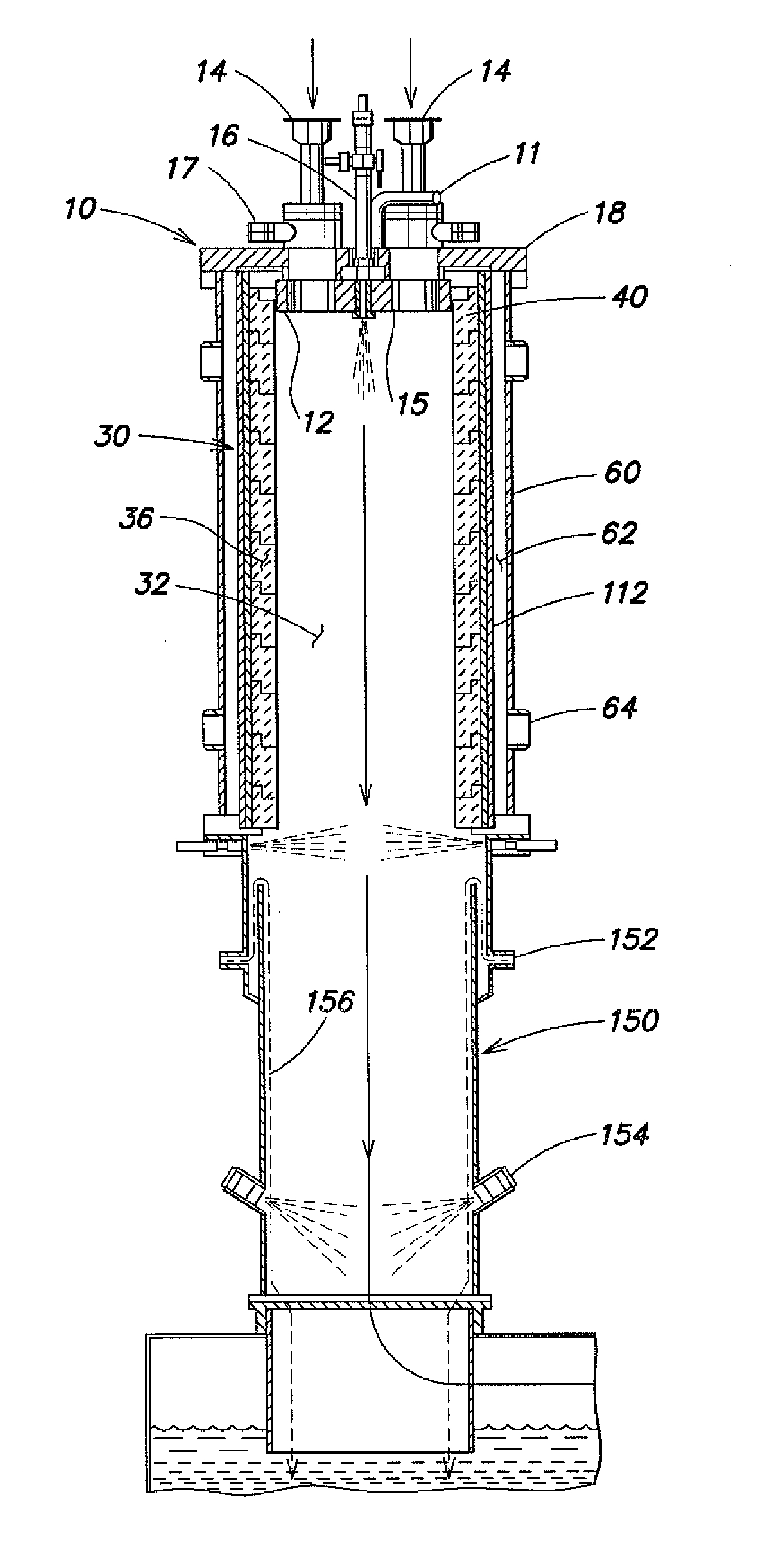

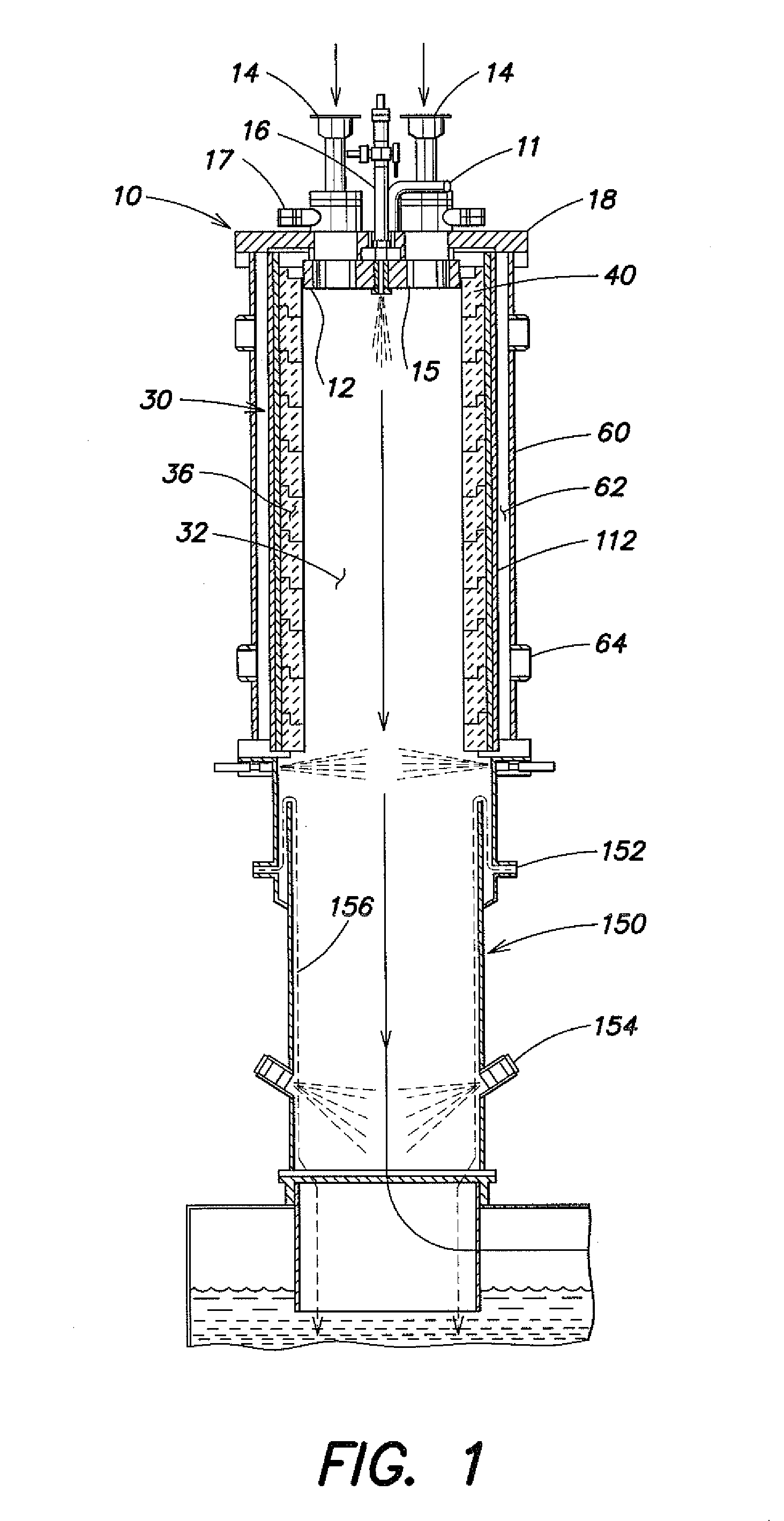

Process and reactor for upgrading heavy hydrocarbon oils

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API) lower viscosity, lower residuum content, etc.) is described. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. A reactor design to carry out the process is also described,

Owner:CHEVROU USA INC

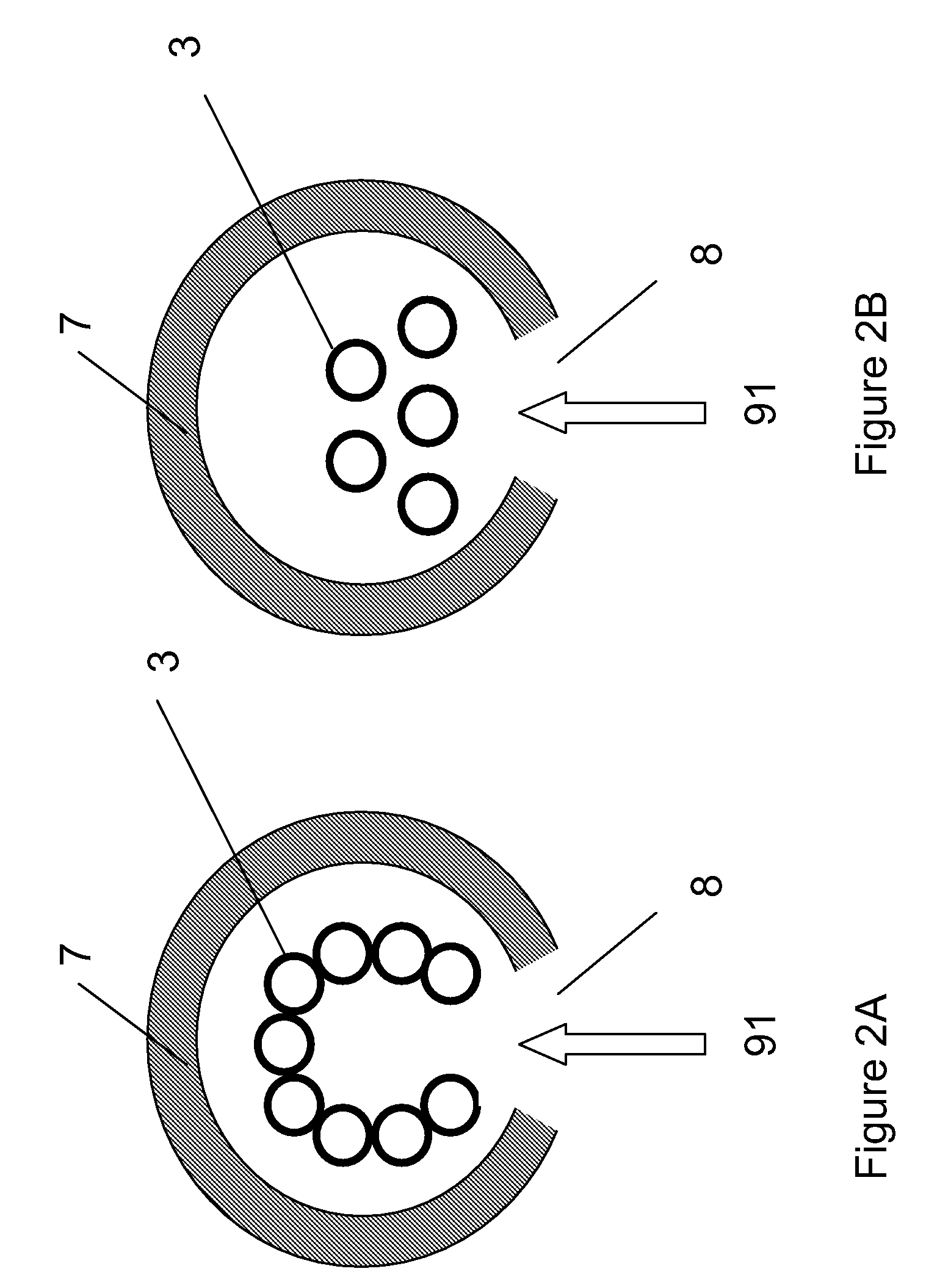

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

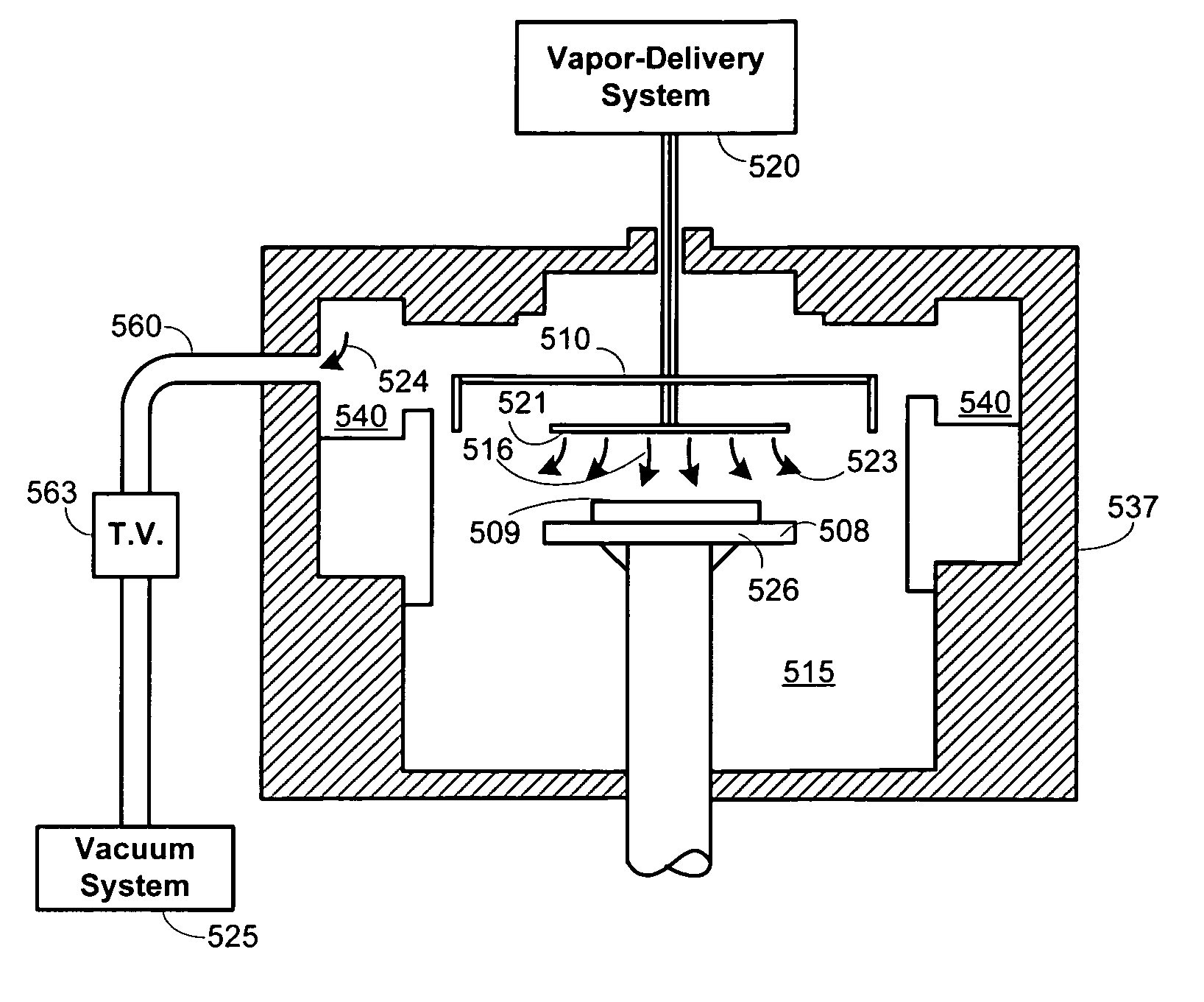

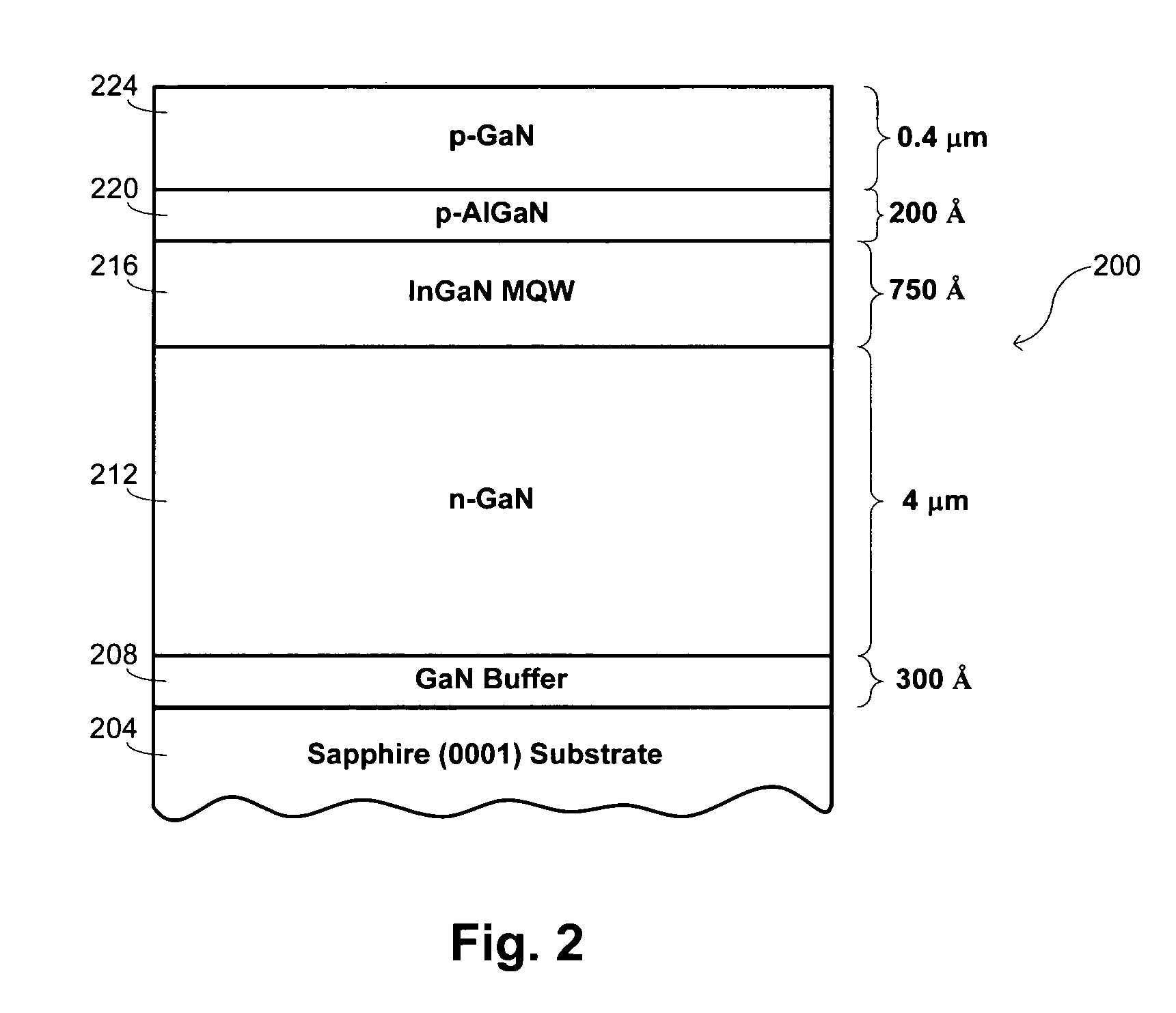

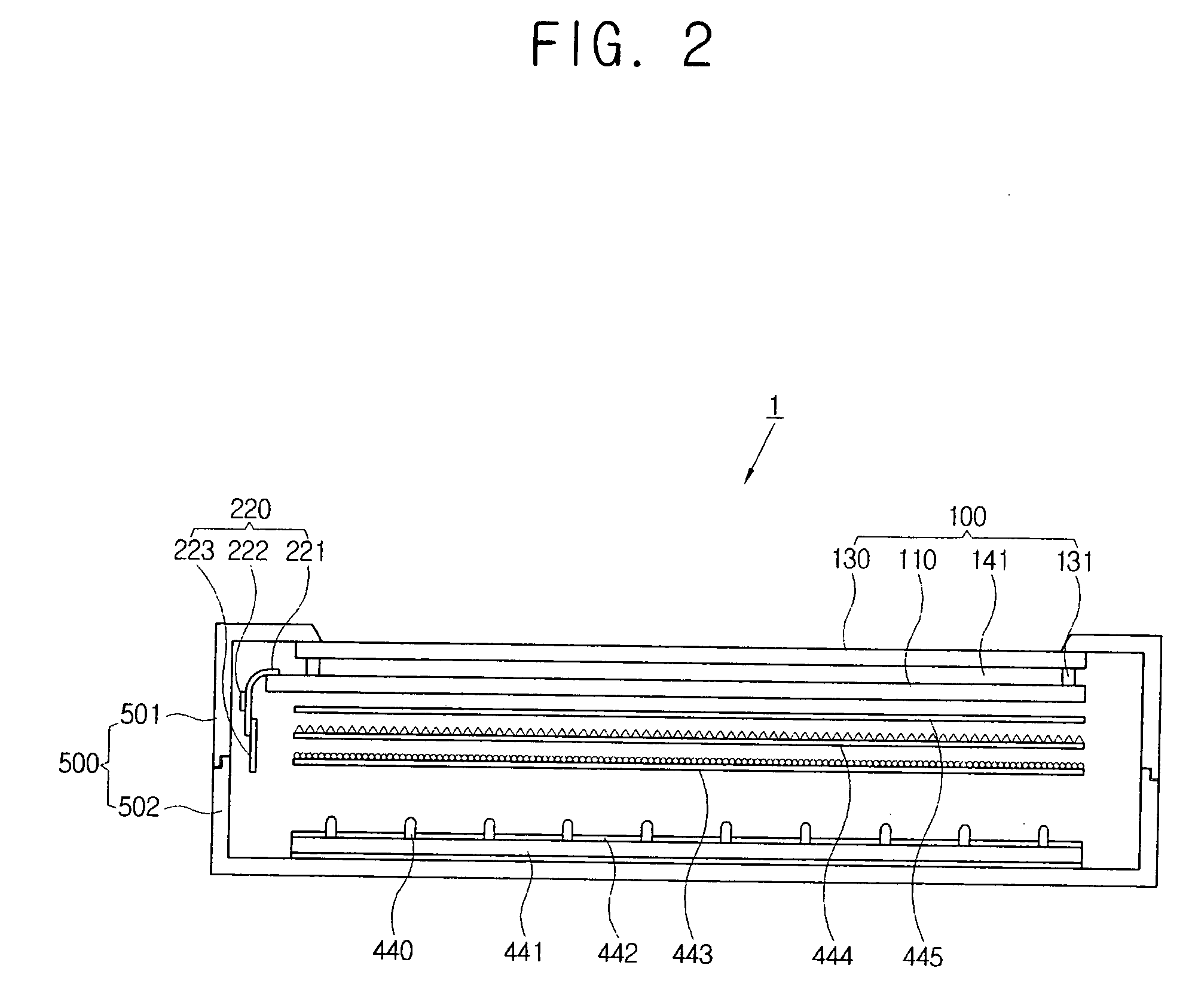

Hotwall reactor and method for reducing particle formation in GaN MOCVD

InactiveUS20080050889A1Suppress formationPolycrystalline material growthSemiconductor/solid-state device manufacturingReactor designChemical vapor deposition

Systems and methods to suppress the formation of parasitic particles during the deposition of a III-V nitride film with, e.g., metal-organic chemical vapor deposition (MOCVD) are described. In accordance with certain aspects of the invention, a hotwall reactor design and methods associated therewith, with wall temperatures similar to process temperatures, so as to create a substantially isothermal reaction chamber, may generally suppress parasitic particle formation and improve deposition performance.

Owner:APPLIED MATERIALS INC

Methods of conducting simultaneous endothermic and exothermic reactions

InactiveUS7250151B2Reduce the formation of nitrogen oxidesHigh thermal cycling durabilityFurnace componentsChemical/physical/physico-chemical microreactorsCombustion chamberProcess engineering

Integrated Combustion Reactors (ICRS) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results, and / or results that can not be achieved with any prior art devices.

Owner:VELOCYS CORPORATION

Reactor design to reduce particle deposition during process abatement

InactiveUS20060104879A1Reduce accumulationReduce reactor chamber crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

Concentrated sulfuric acid hydrolysis of lignocellulosics

InactiveUS6063204AMinimize and preclude potential backflowEliminate requirementsPressurized chemical processOther chemical processesUnit operationFermentable sugar

A process, system, and apparatus for effectively and economically producing fermentable sugars from cellulosic feedstocks is described. The economic viability of using wood and / or agricultural waste, containing large fractions of cellulose and hemicellulose is highly dependent on the method used for hydrolysis. Underlying the gist of this invention are newly discovered methods, means, and techniques by which both the pentosans and hexosans comprising the hemicellulose fraction of the selected feedstock and the hexosans comprising the cellulose fraction of the selected feedstock can be quickly and efficiently converted in a single pass through a single device to fermentable sugars containing minimal quantities of degradation products known to inhibit fermentation. Successful operation of this new hydrolysis process employing a new reactor design can produce fermentable sugars at rates and efficiencies previously thought unattainable by reducing the number of processing steps, pieces of equipment, and unit operation previously used.

Owner:FARINA GEORGE E

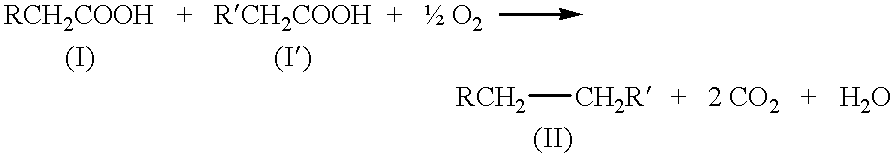

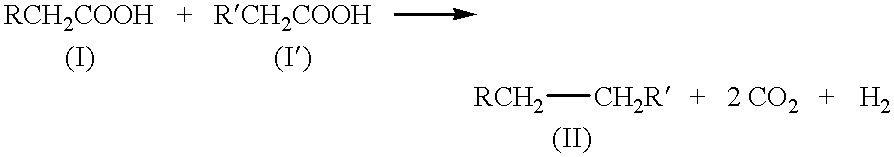

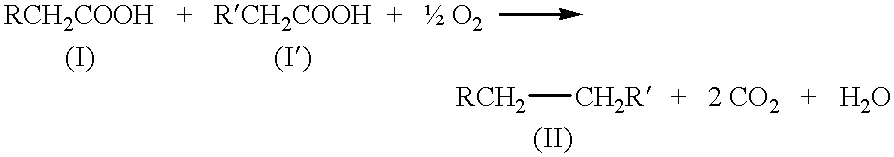

Kolbe electrolysis in a polymer electrolyte membrane reactor

InactiveUS6238543B1Electrolysis componentsElectrolytic organic coupling reactionsPlatinumPolymer electrolytes

Disclosed is a process, for the electrolytic coupling of carboxylic acids, carried out in a polymer electrolyte membrane reactor. The reactor design (1) discloses the use of gaseous or neat liquid reactants without the use of organic cosolvents, (2) prevents the loss of platinum, and (3) permits the use of oxygen reduction to water as the cathode reaction.

Owner:EI DU PONT DE NEMOURS & CO +1

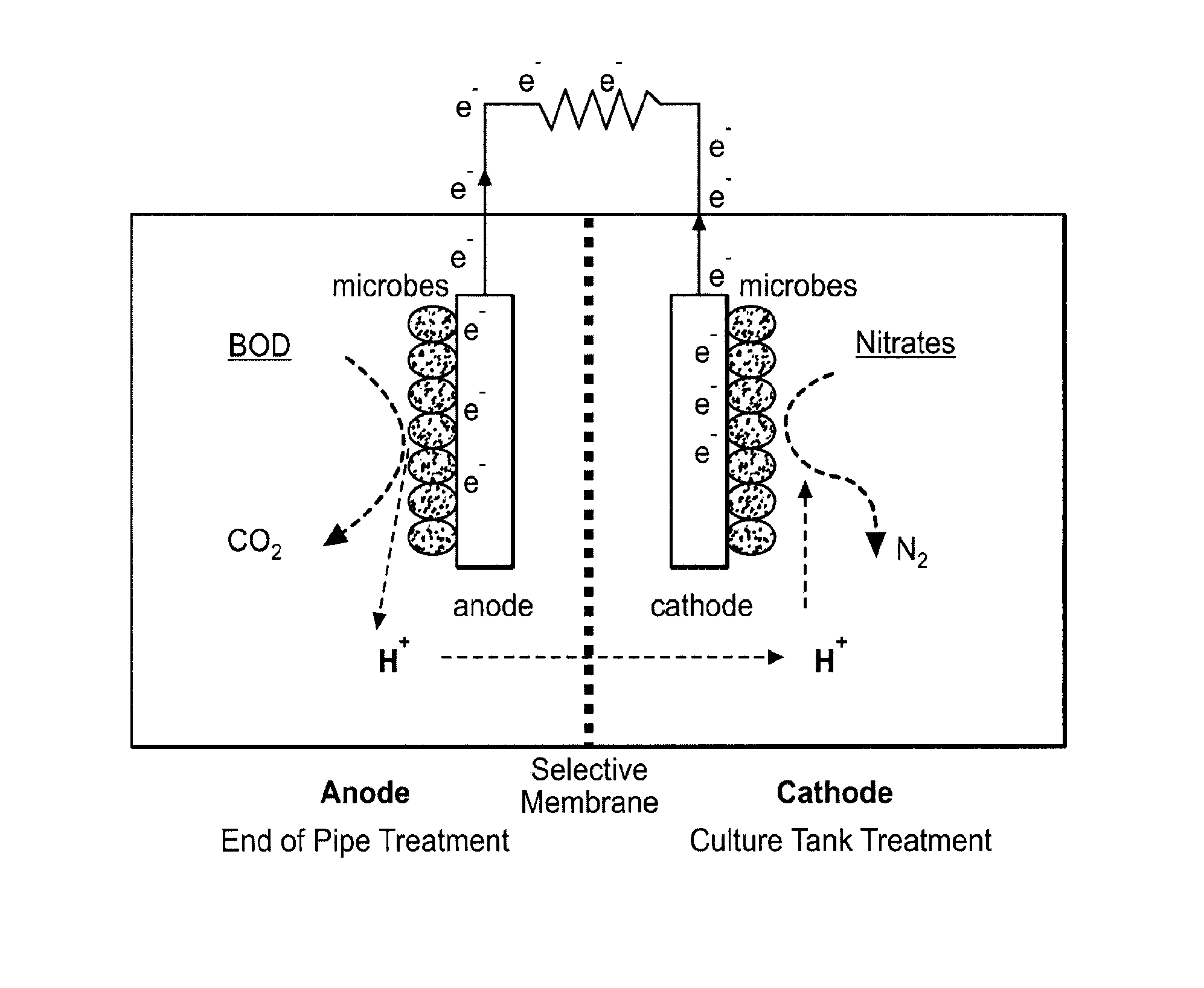

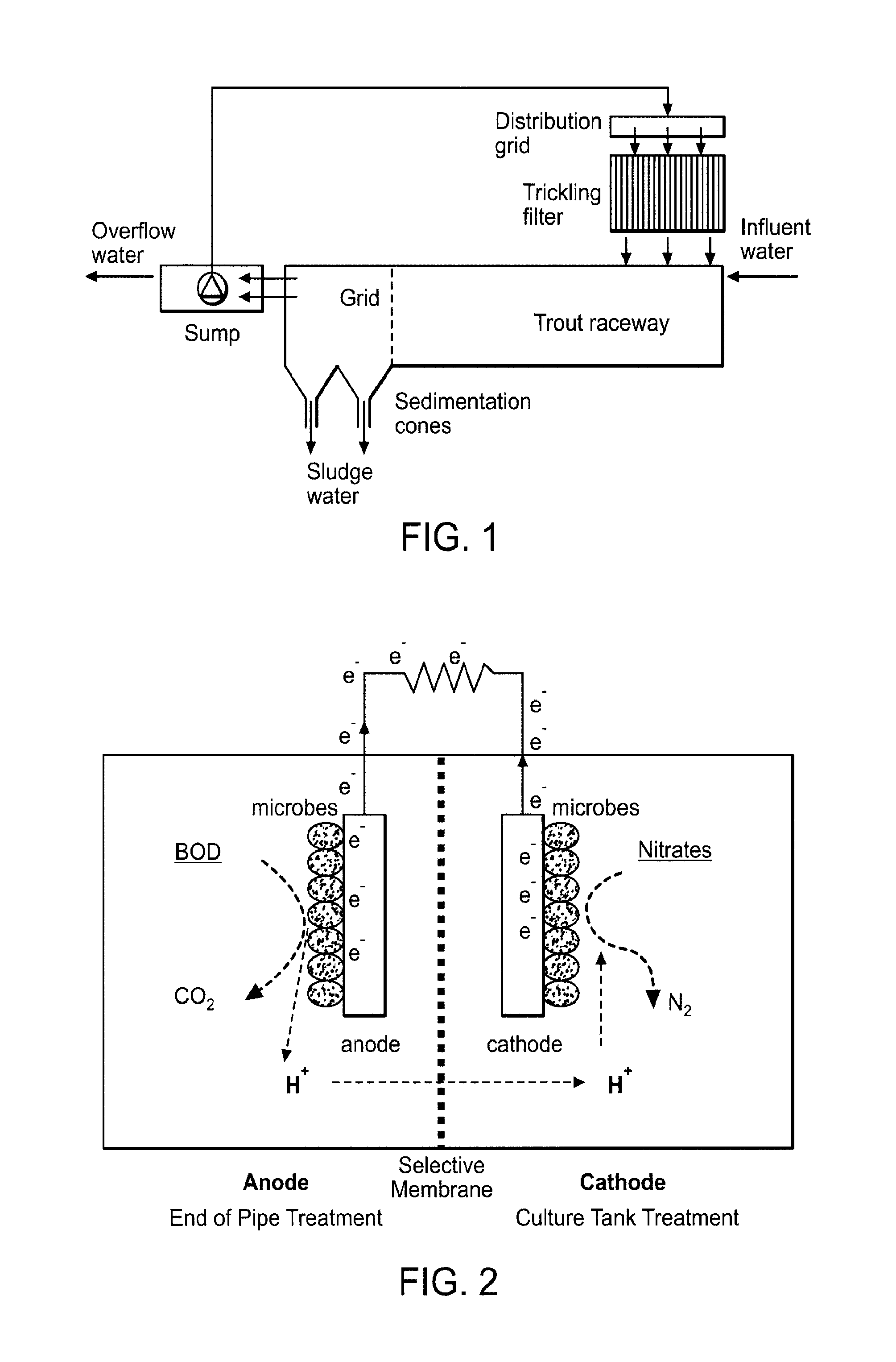

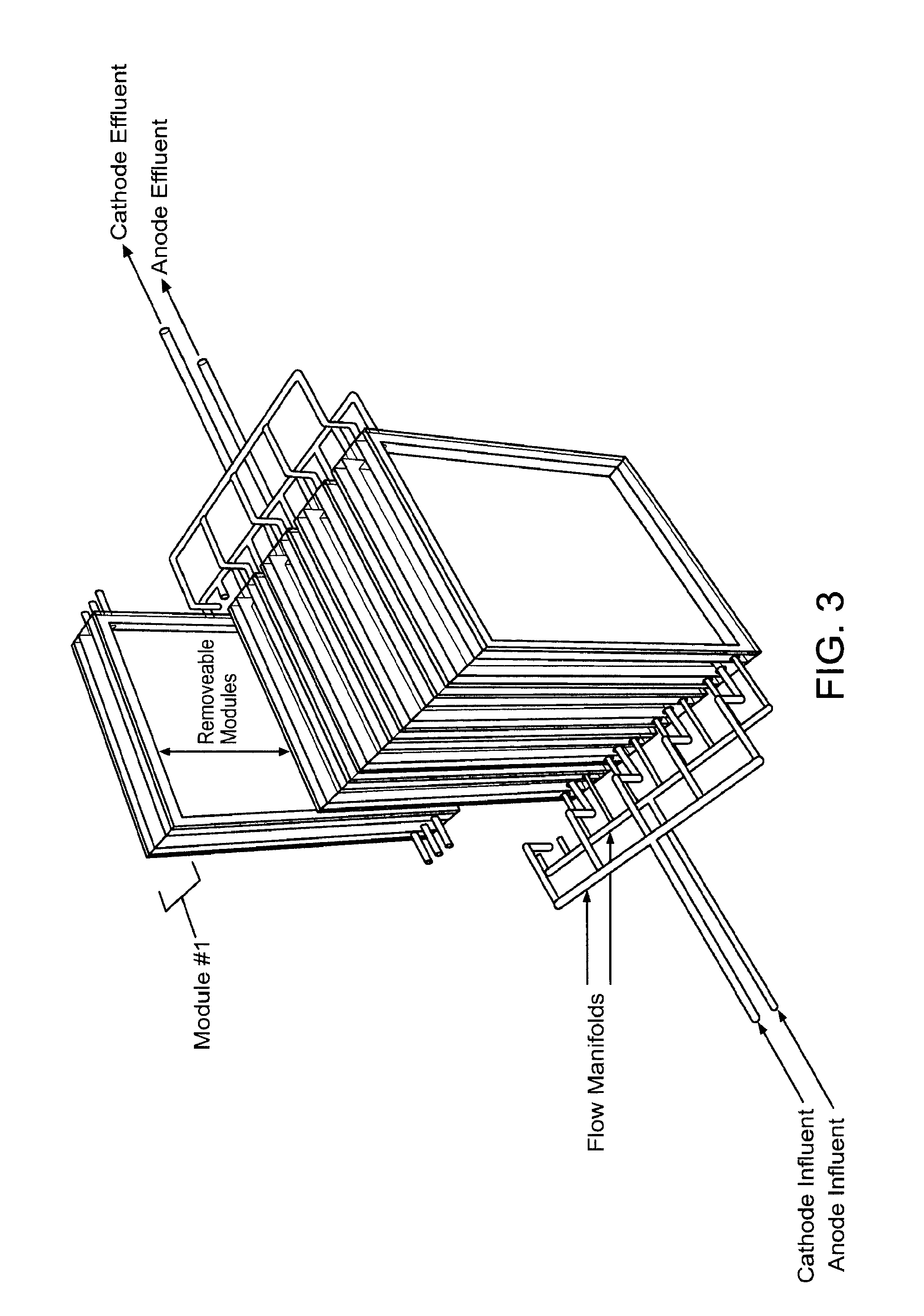

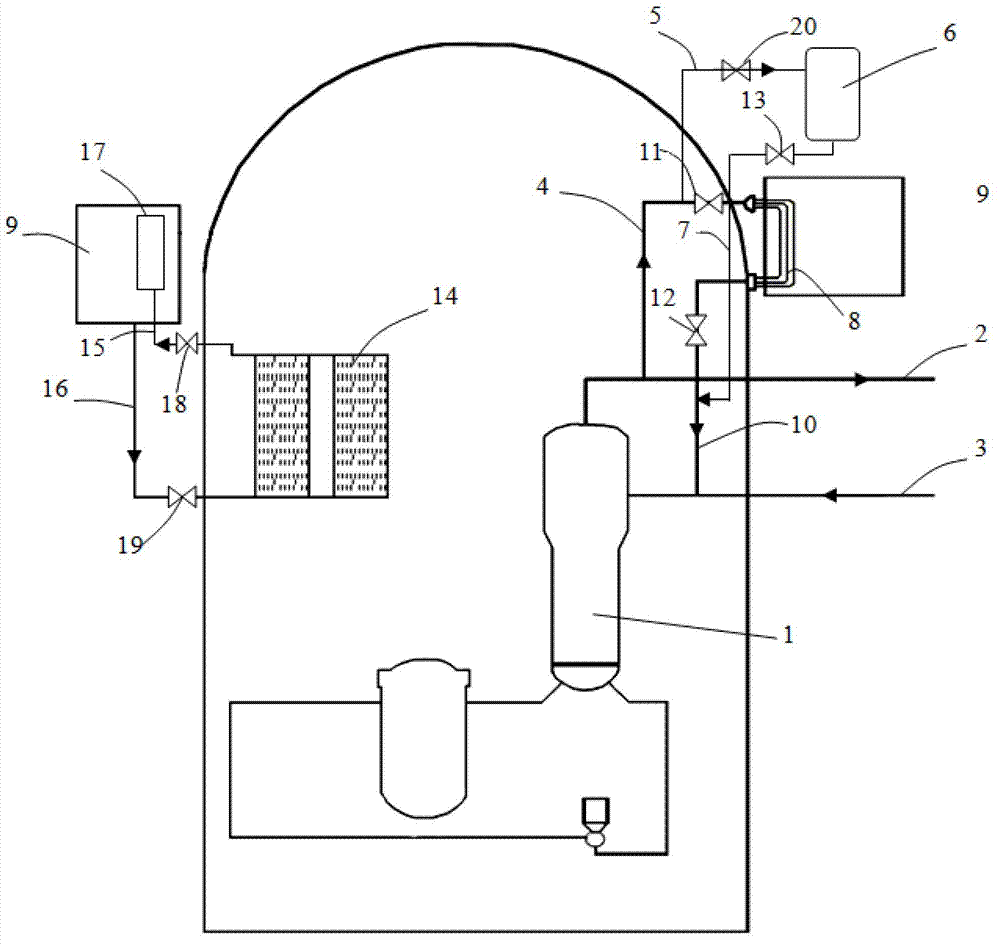

Denitrification and ph control using bio-electrochemical systems

ActiveUS20130112601A1Simple methodReduce compoundingWater treatment parameter controlTreatment using aerobic processesChemical oxygen demandNitrate

The present invention provides reactor designs, component designs, and operating schemes for removing nitrates and chemical oxygen demand from any suitable wastewater stream. The invention also provides reactor designs, component designs, and operating schemes designed to modify and improve pH and water quality in wastewater streams.

Owner:CAMBRIAN INNOVATION

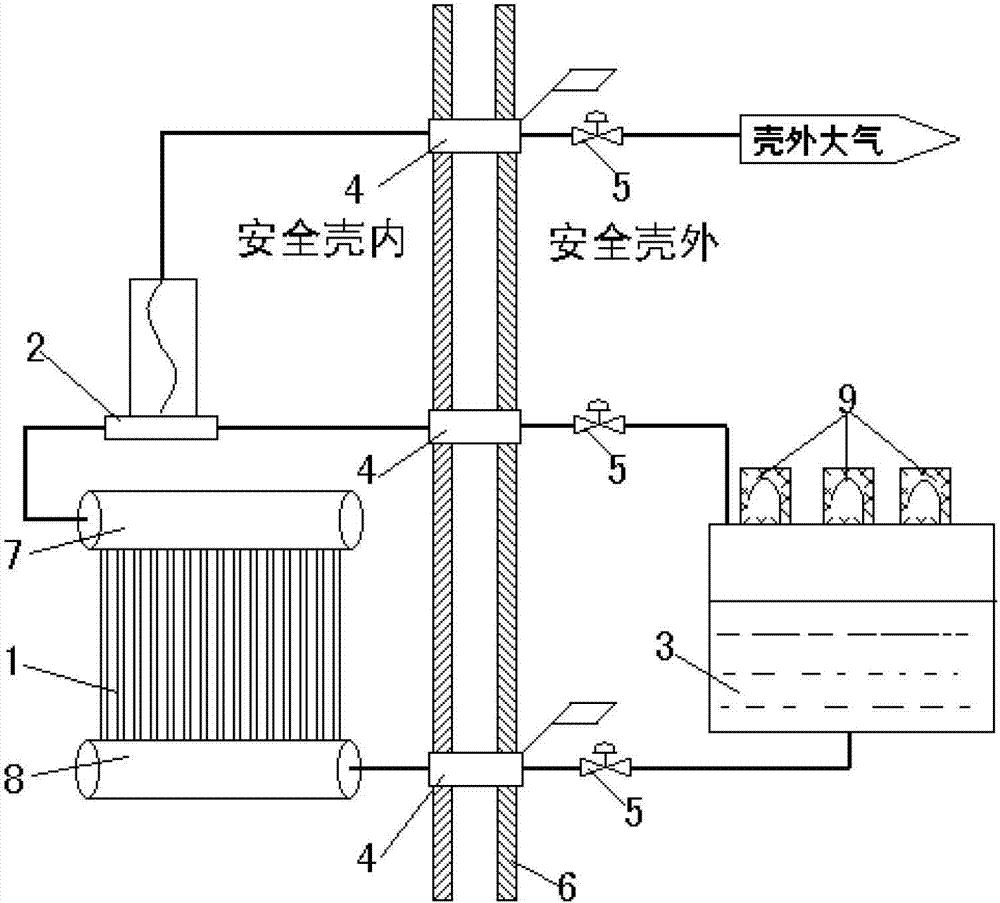

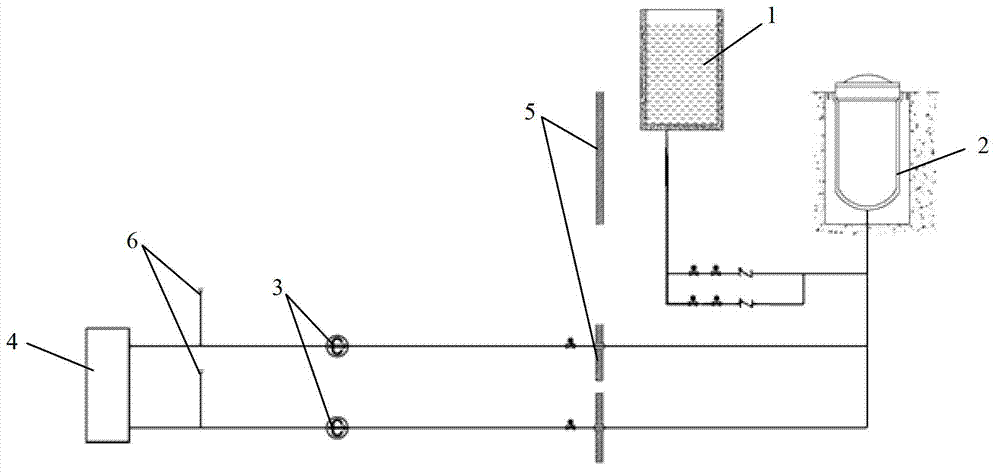

Passive heat removal device for dealing with station blackout accident

InactiveCN102867550AIntegrity guaranteedNo action requiredNuclear energy generationCooling arrangementRadioactive agentReactor design

The invention relates to reactor design technology, in particular to a passive heat removal device for dealing with a station blackout accident. The passive heat removal device structurally comprises a secondary side passive residual heat removal system and a passive containment heat export system, and the secondary side passive residual heat removal system is used for exporting residual heat of a reactor core and sensible heat of various devices of a reactor coolant system, so that a reactor is maintained to be in a safe shutdown state. The passive containment heat export system is used for exporting heat in a containment released by the reactor core so as to maintain integrity of the containment. The secondary side passive residual heat removal system and the passive containment heat export system share a hot water tank. The passive heat removal device for dealing with the station blackout accident is capable of exporting decay heat of the reactor core and heat in containment space released by the reactor core under the working condition of the station blackout accident, and melting probability of the reactor core and probability of radioactive substances released to the environment are evidently lowered.

Owner:CHINA NUCLEAR POWER ENG CO LTD

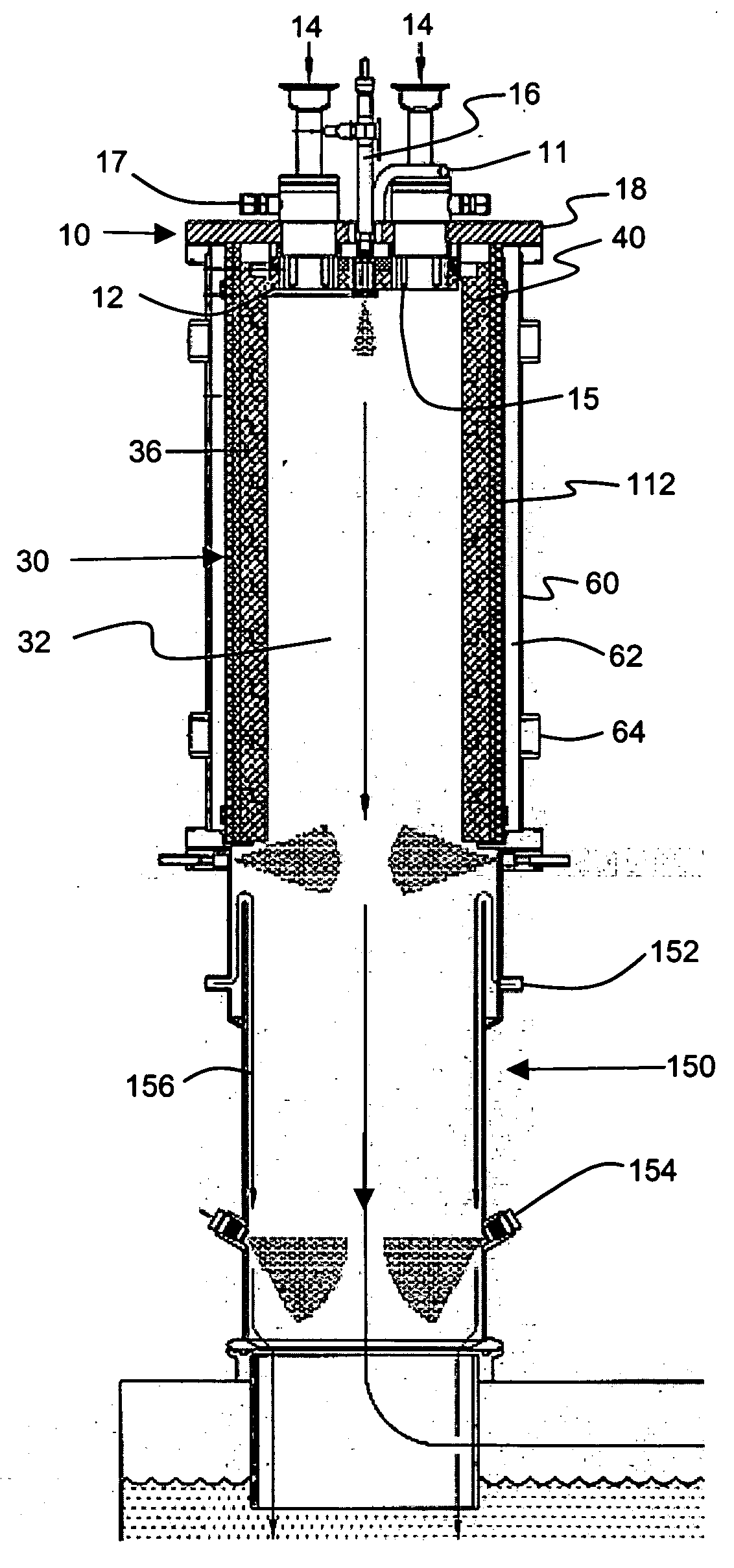

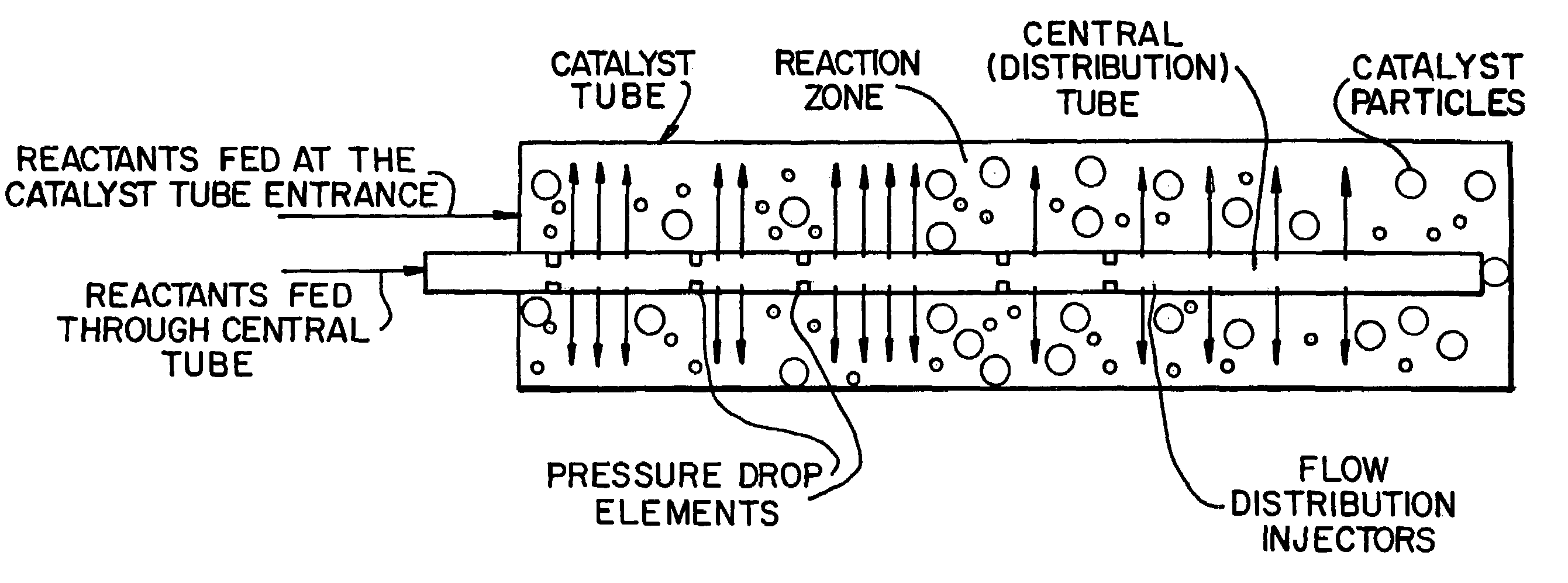

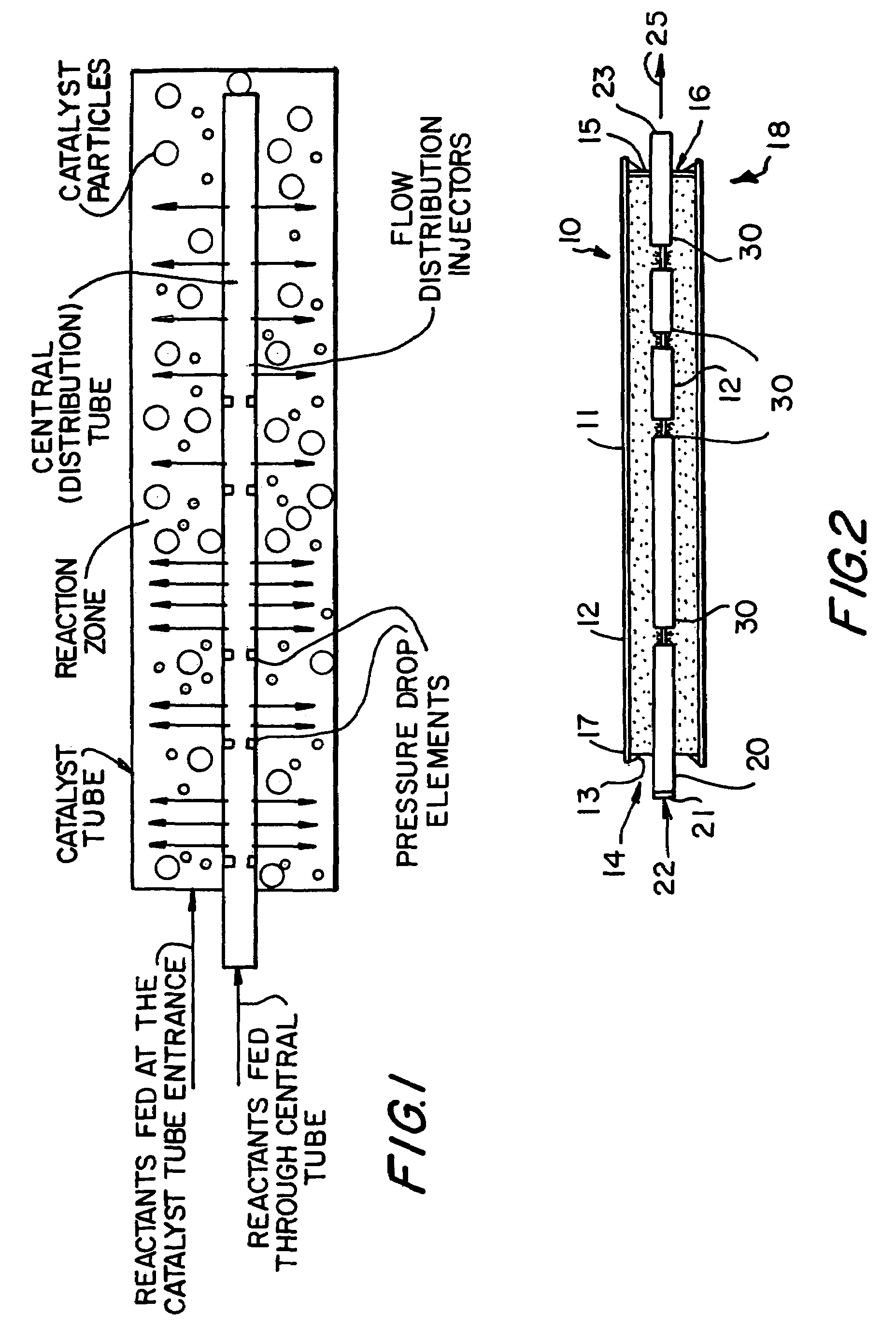

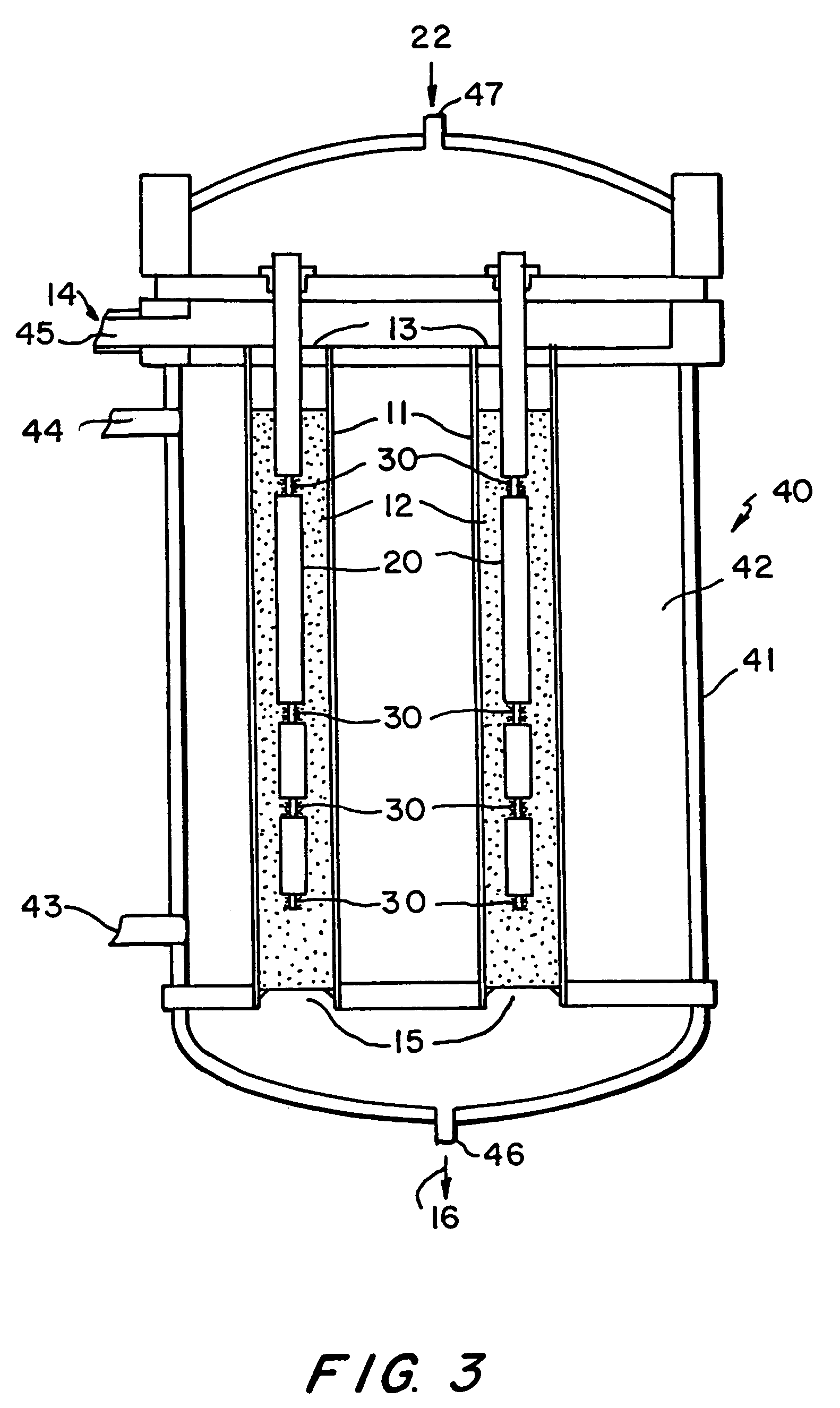

Apparatus for the controlled optimized addition of reactants in continuous flow reaction systems

InactiveUS6977064B1Improve catalytic performanceProcess control/regulationCombination devicesChemical reactionPartial oxidation

An apparatus for performing continuous flow chemical reactions such as oxidation, oxidative dehydrogenation and partial oxidation processes involving a reactor design characterized by controlled / optimized addition of a reactant with the objective of: (i) avoiding the explosion regime of the reactant mixture (e.g., hydrocarbon / oxidant mixture); (ii) maximizing the selectivity of the reaction to the desired product; (iii) limiting the reactor temperature gradient and therefore the threat of reaction runaway; and (iv) controlling the operating temperature of the reaction zone so that desirable temperature range is maintained over the entire zone.

Owner:SAUDI BASIC IND CORP SA

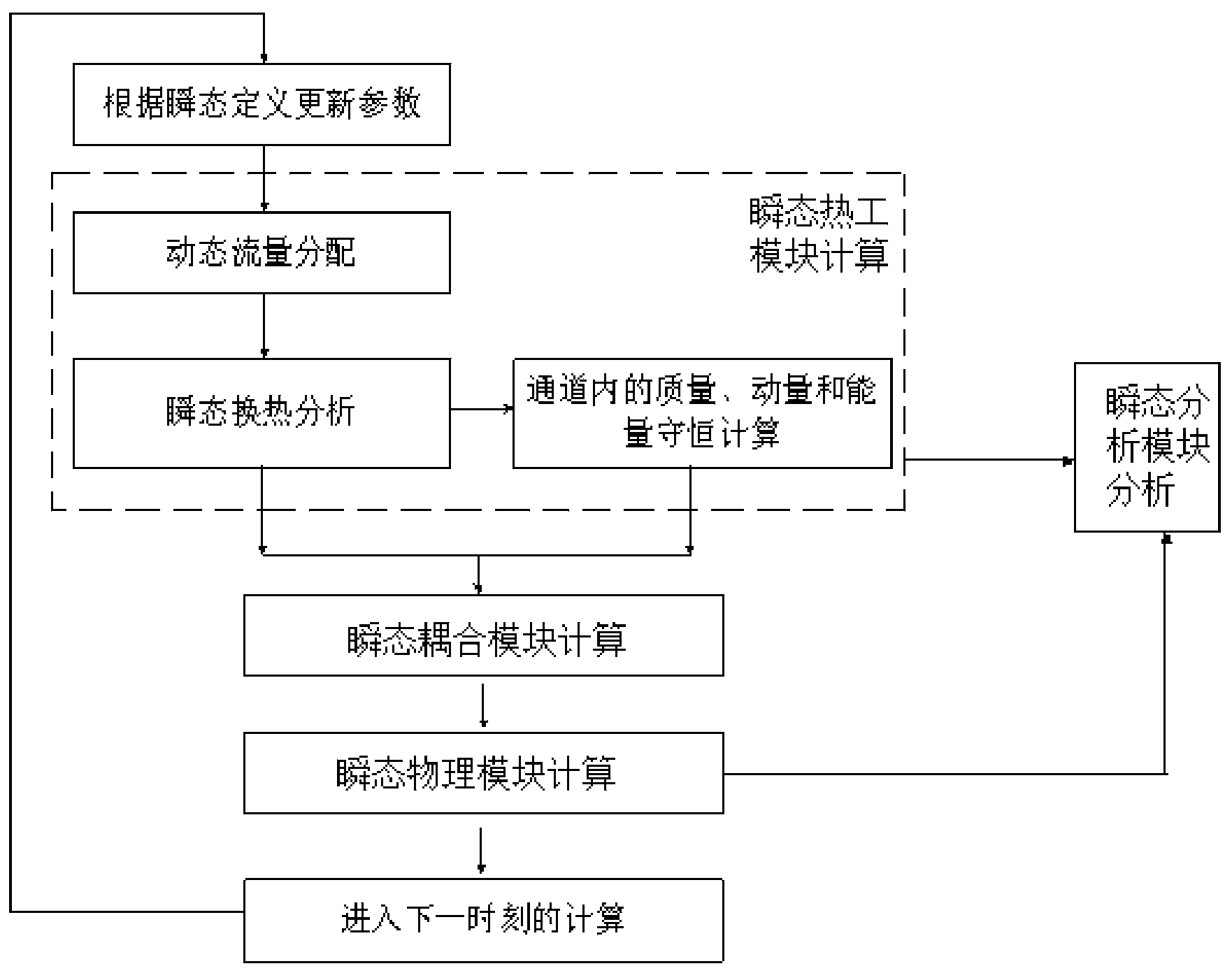

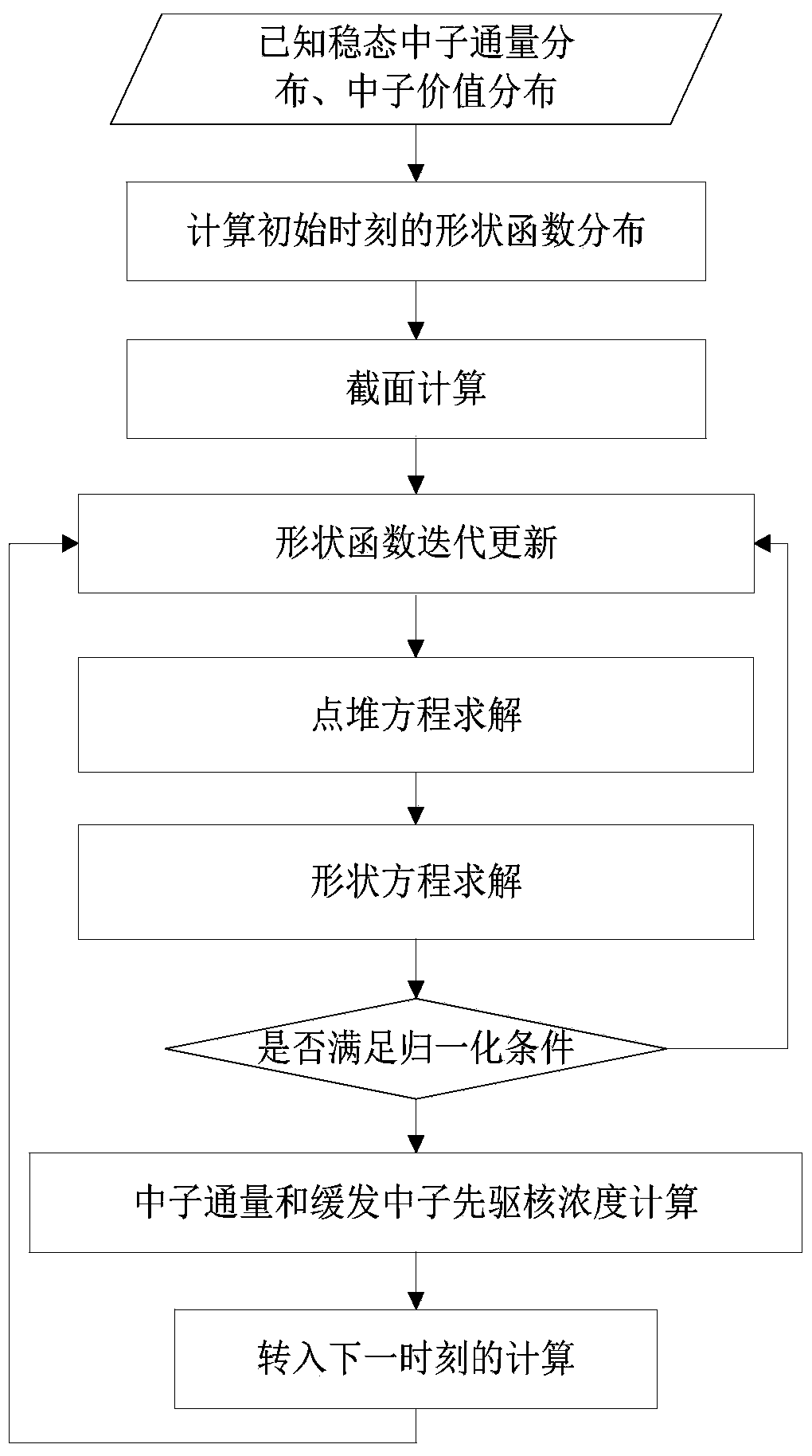

Safety analysis calculating device for transient nuclear heat coupling of supercritical water reactor

InactiveCN103902784AImprove economyImprove reliabilitySpecial data processing applicationsInformation technology support systemSystems analysisCoupling

The invention discloses a safety analysis calculating device for transient nuclear heat coupling of a supercritical water reactor, and belongs to the field of nuclear power plant design and reactor safety analysis. The safety analysis calculating device for transient nuclear heat coupling of the supercritical water reactor is applicable to the supercritical water reactor. According to the safety analysis calculating device, a transient physical analysis program is built by using the space-time disperse solution of a double-group space-time kinetic equation, a transient heat engineering analysis program is built through calculation of flow distribution among channels and the solution of flowing heat exchange inside the channels, on this basis, a physical calculation program is embedded into a transient system analysis program to build a supercritical transient coupling analysis program so as to analyze safety of a system. Particularly, due to the fact that a space-time kinetics quasi-static solution model built through the double-group neutron space-time kinetic equation is combined with a multi-channel analysis method, compared with a sub-channel model, the calculation time is shortened on the basis that precision is ensured, then economy of the supercritical water reactor design is improved, and the safety analysis calculating device accords with the development trend of safety analysis.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

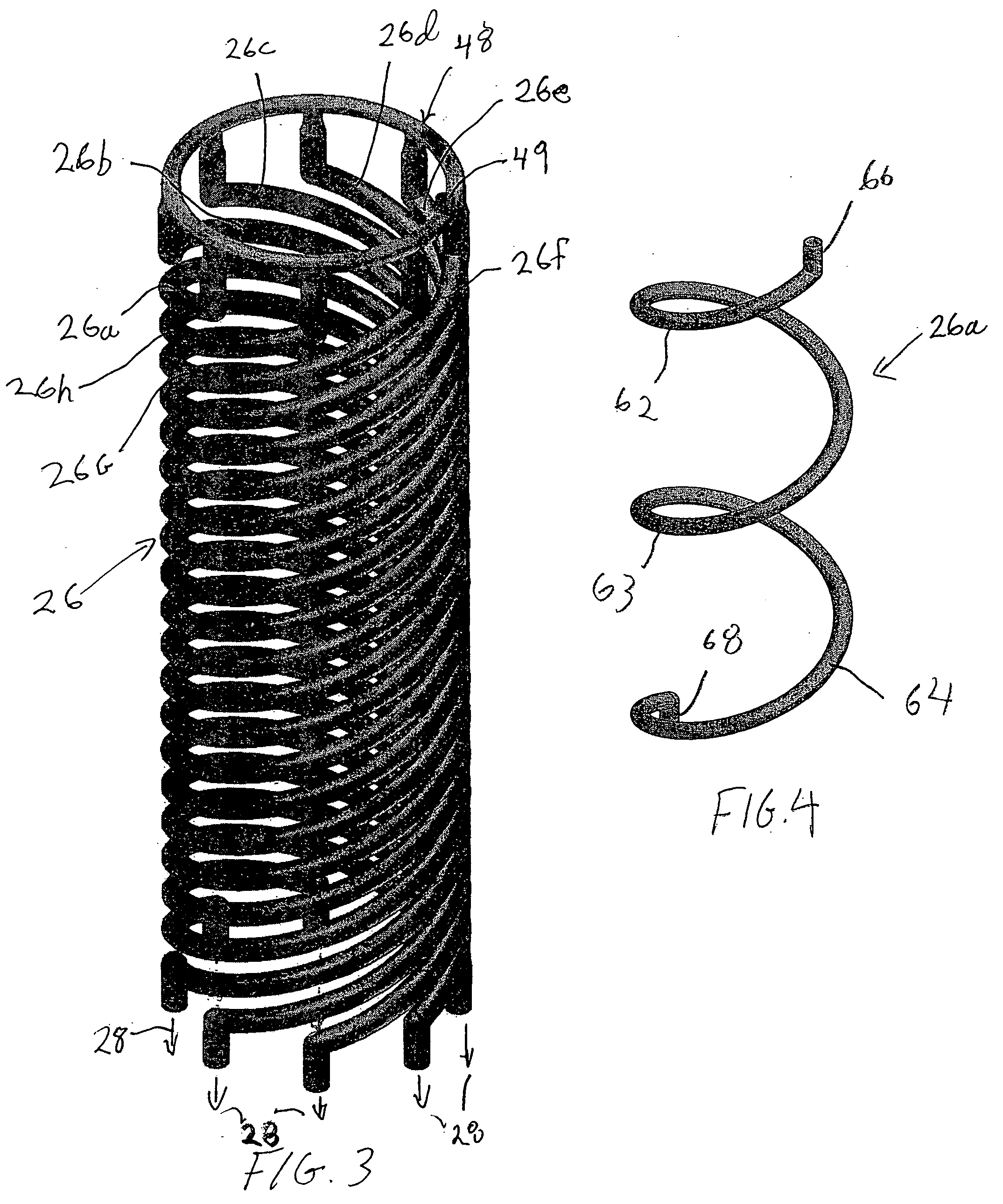

Catalytic reactor

InactiveUS20060045828A1Reduce sulfur contentIncrease heatHydrogenPhysical/chemical process catalystsChemical reactionReaction zone

A catalytic reactor is provided with one or more reaction zones each formed of set(s) of reaction tubes containing a catalyst to promote chemical reaction within a feed stream. The reaction tubes are of helical configuration and are arranged in a substantially coaxial relationship to form a coil-like structure. Heat exchangers and steam generators can be formed by similar tube arrangements. In such manner, the reaction zone(s) and hence, the reactor is compact and the pressure drop through components is minimized. The resultant compact form has improved heat transfer characteristics and is far easier to thermally insulate than prior art compact reactor designs. Various chemical reactions are contemplated within such coil-like structures such that as steam methane reforming followed by water-gas shift. The coil-like structures can be housed within annular chambers of a cylindrical housing that also provide flow paths for various heat exchange fluids to heat and cool components.

Owner:PRAXAIR TECH INC

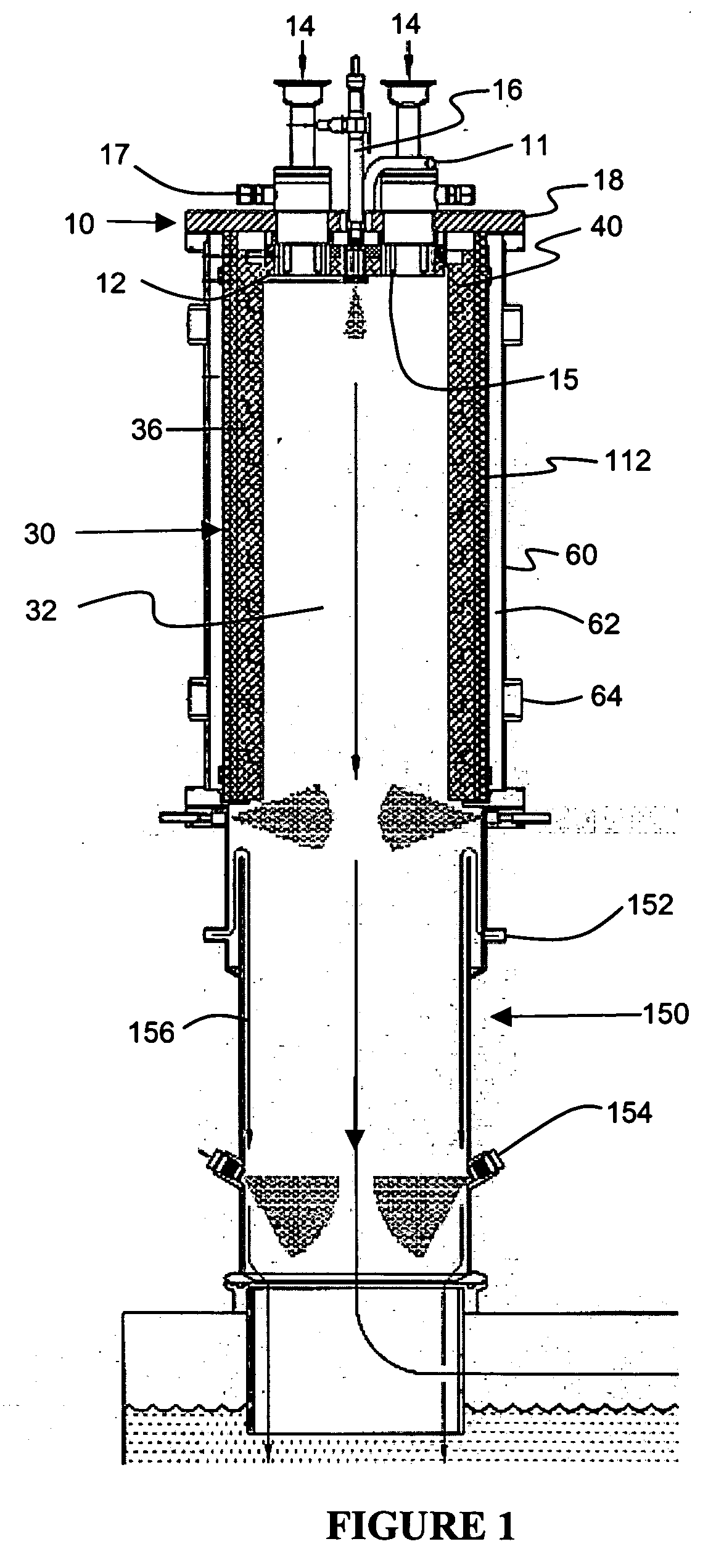

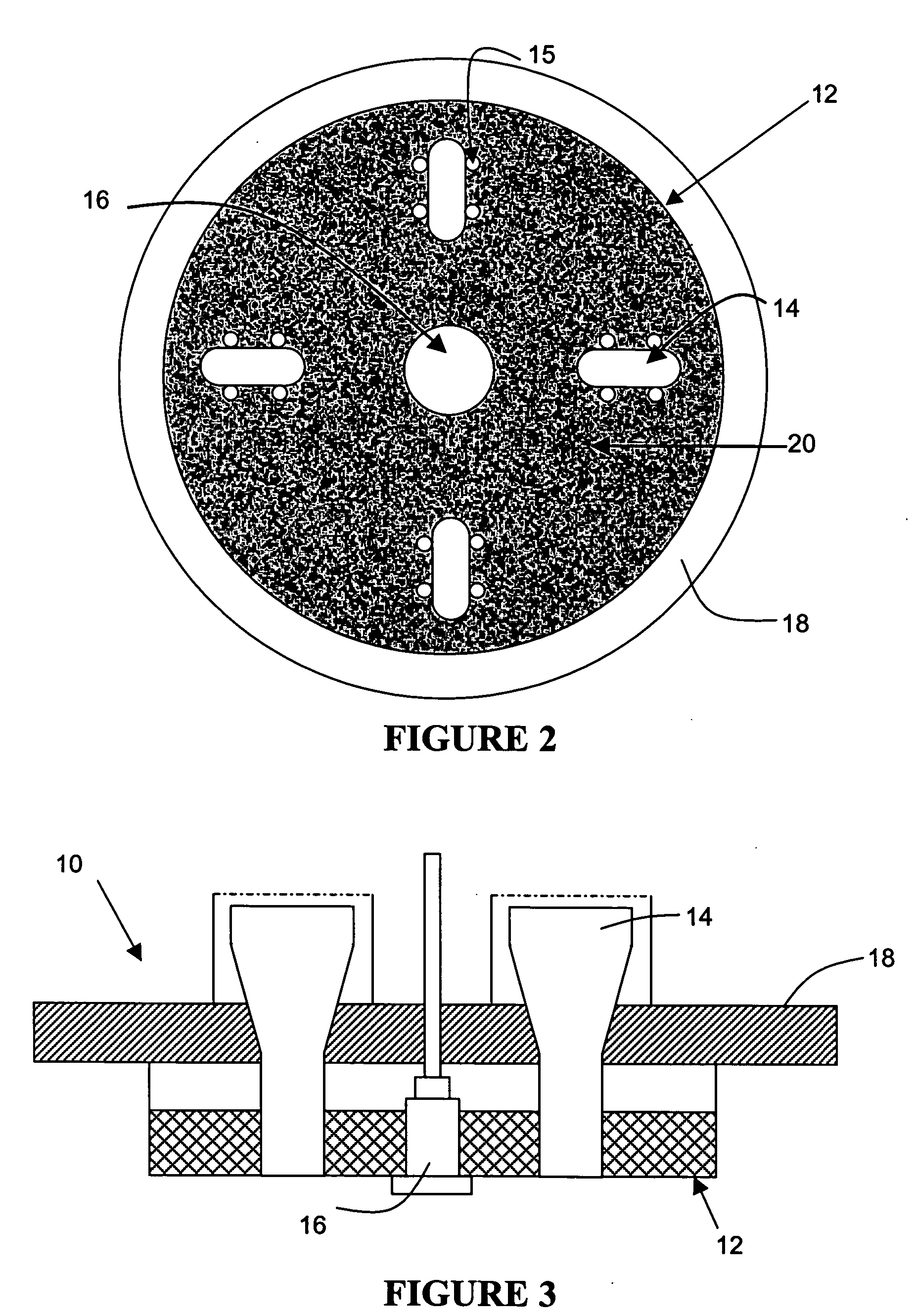

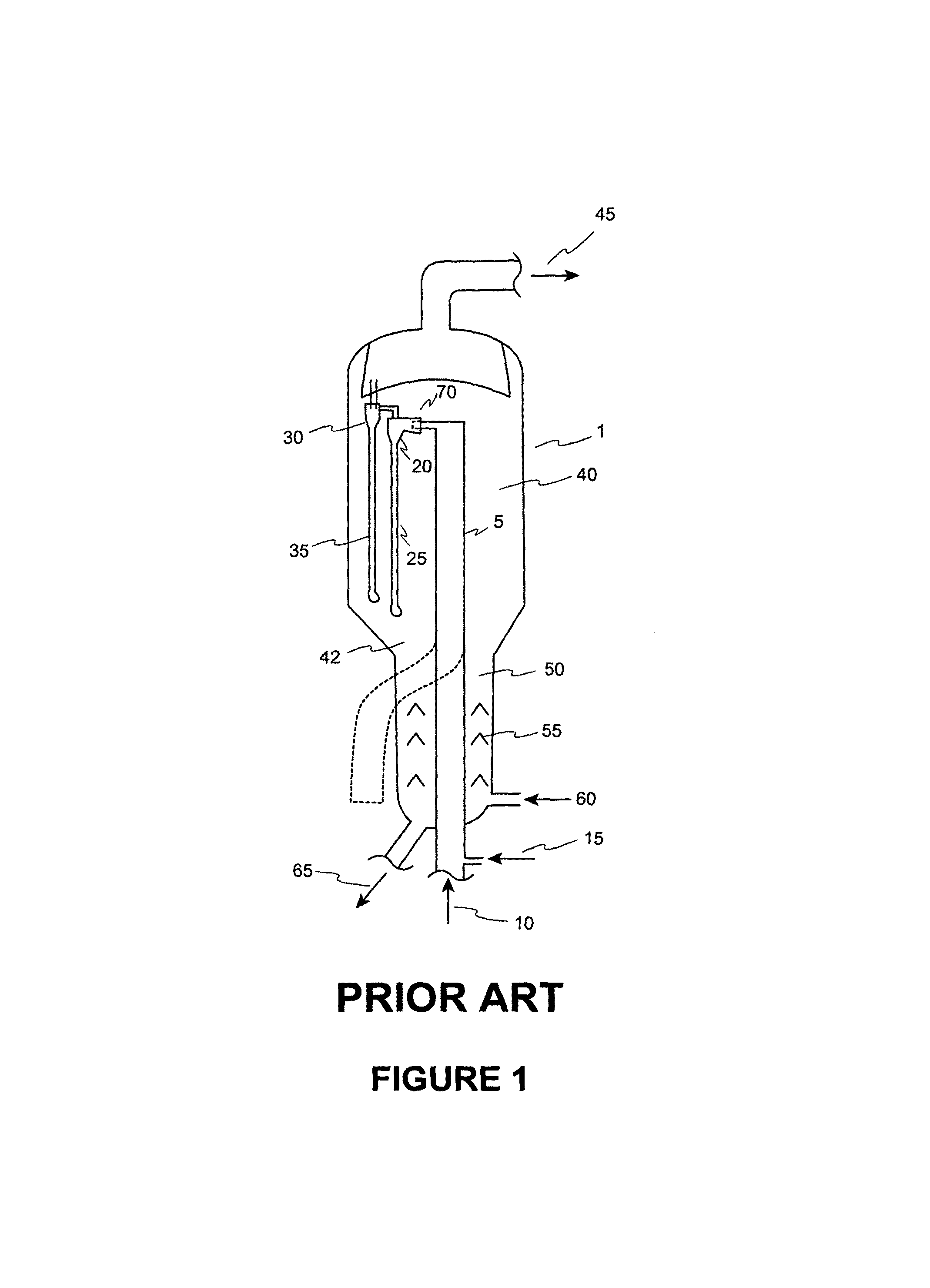

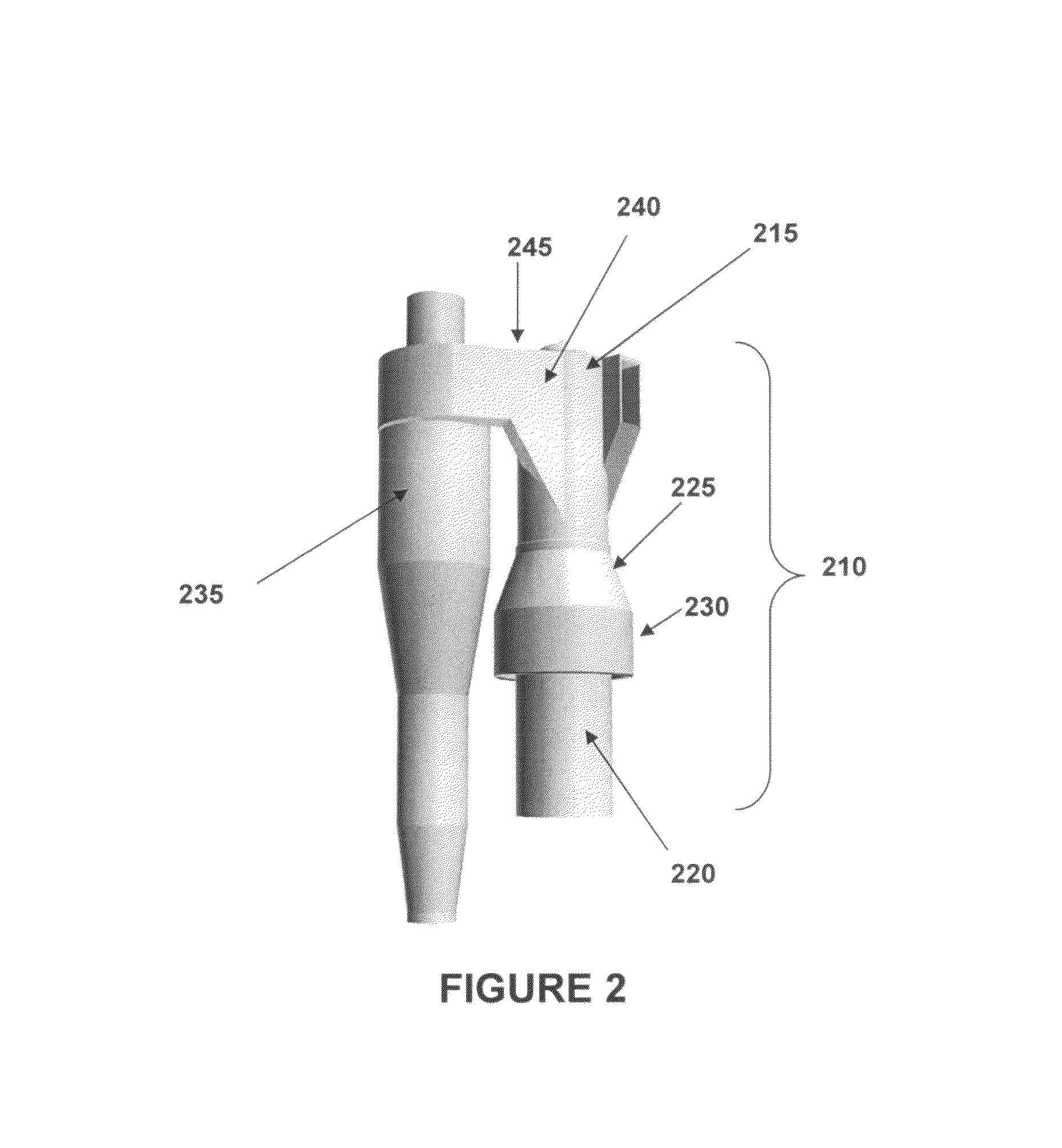

FCC reactor and riser design for short contact-time catalytic cracking of hydrocarbons

The present invention is an improved design and operation of a short contact time Fluid Catalytic Cracking (FCC) Reactor wherein the upper internal riser and a lower internal riser are in fluid connection with one another and provide an improved disengaging zone for entraining the vapors from the dilute phase area of the FCC reactor. Detailed preferred embodiments include improvements over the prior art to the internal central riser, riser termination apparatus, cyclone separators, and a coke mitigation baffle system, as well as associated improved fluid catalytic cracking processes utilizing the novel reactor design.

Owner:EXXON RES & ENG CO

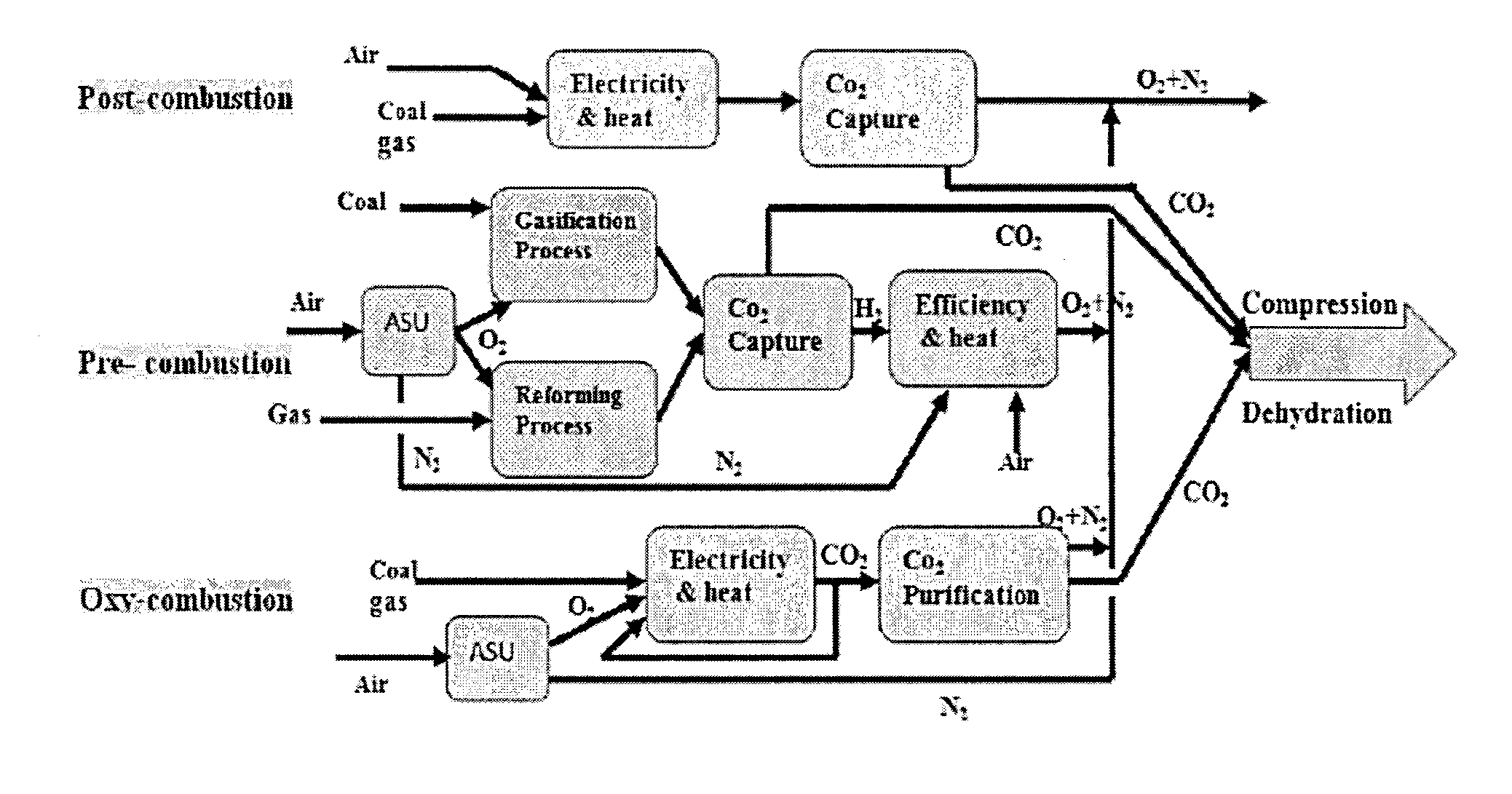

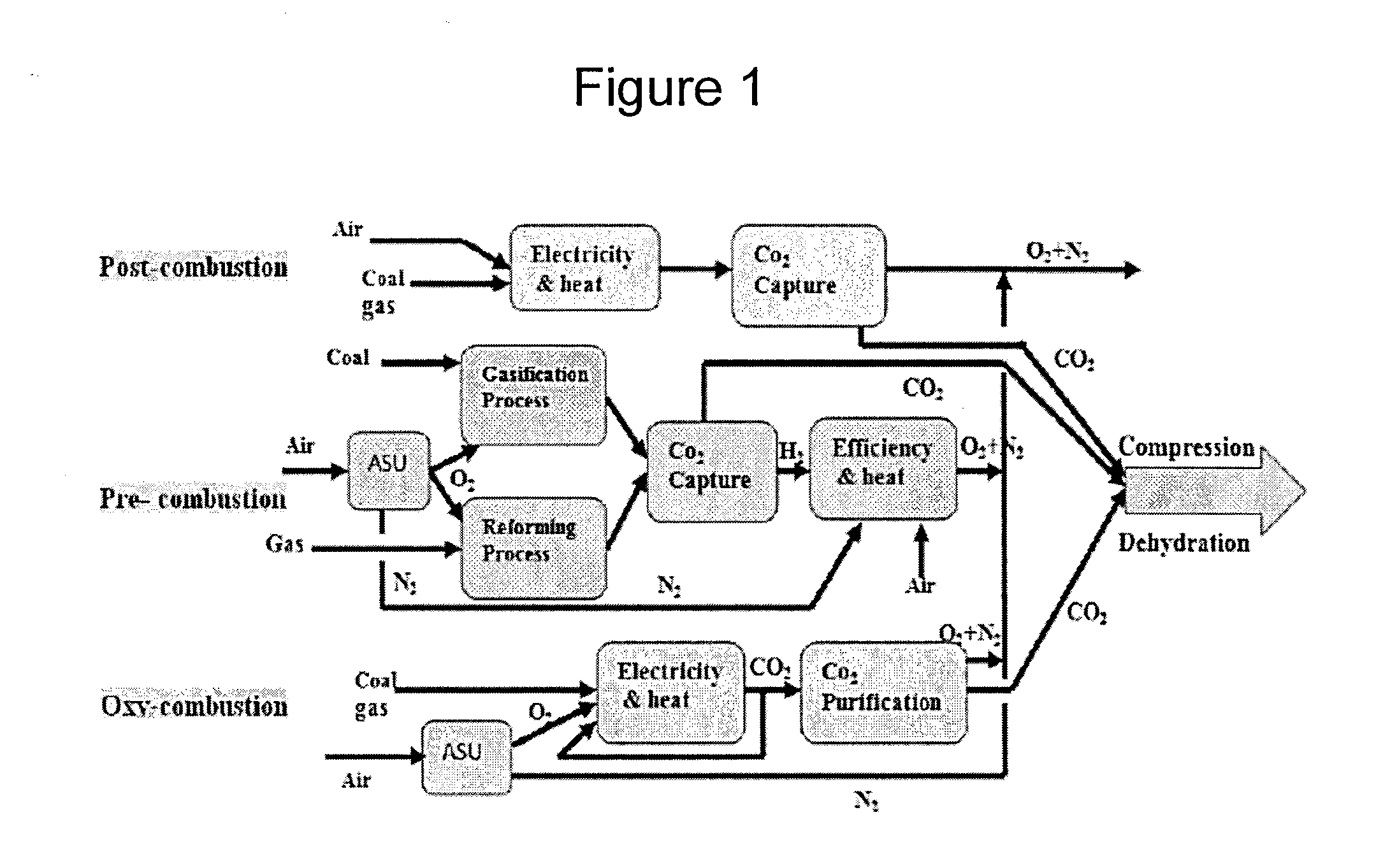

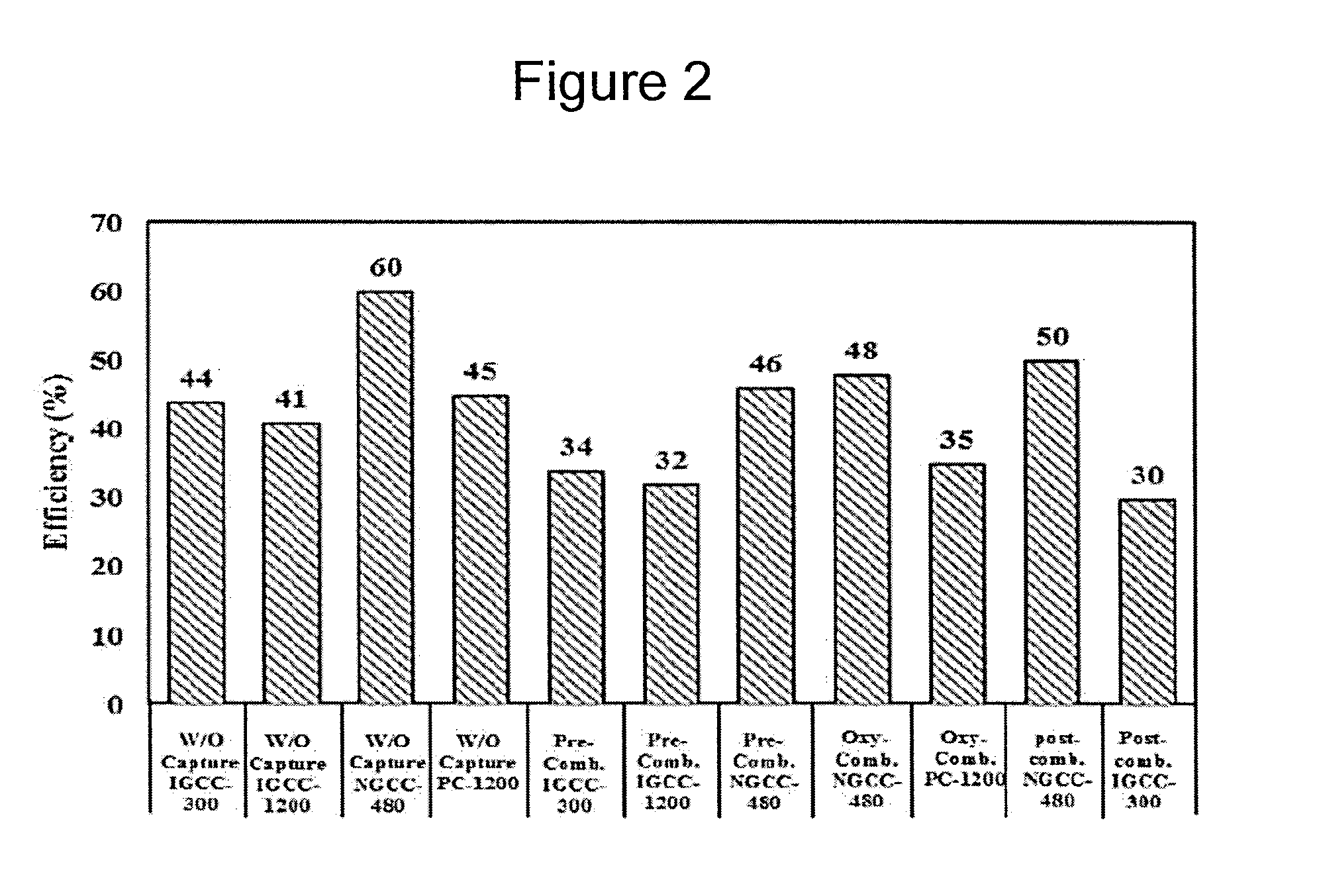

Applications of oxy-fuel combustion technology into gas turbine combustors and ion transport membrane reactors

InactiveUS20150267611A1Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberAtmospheric air

Experimental and numerical investigations on an atmospheric diffusion oxy-combustion flame in a gas turbine model combustor are conducted. The combustor is fuelled with CH4CH4 and a mixture of CO2 and O2 as oxidizer. The stability of the oxy-combustion flame is affected when the operating percentage of oxygen in the oxidizer mixture is reduced below 25%. A new 3D reactor design is introduced for the substitution of ITM reactors into a gas turbine combustor. A new oxygen permeation equation model has been developed by fitting the experimental data available in the literature for a LSCF ion transport membrane. The monolith structure design ITM reactor is capable of delivering power ranging from 5 to 8 MWe based on cycle first law efficiency.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

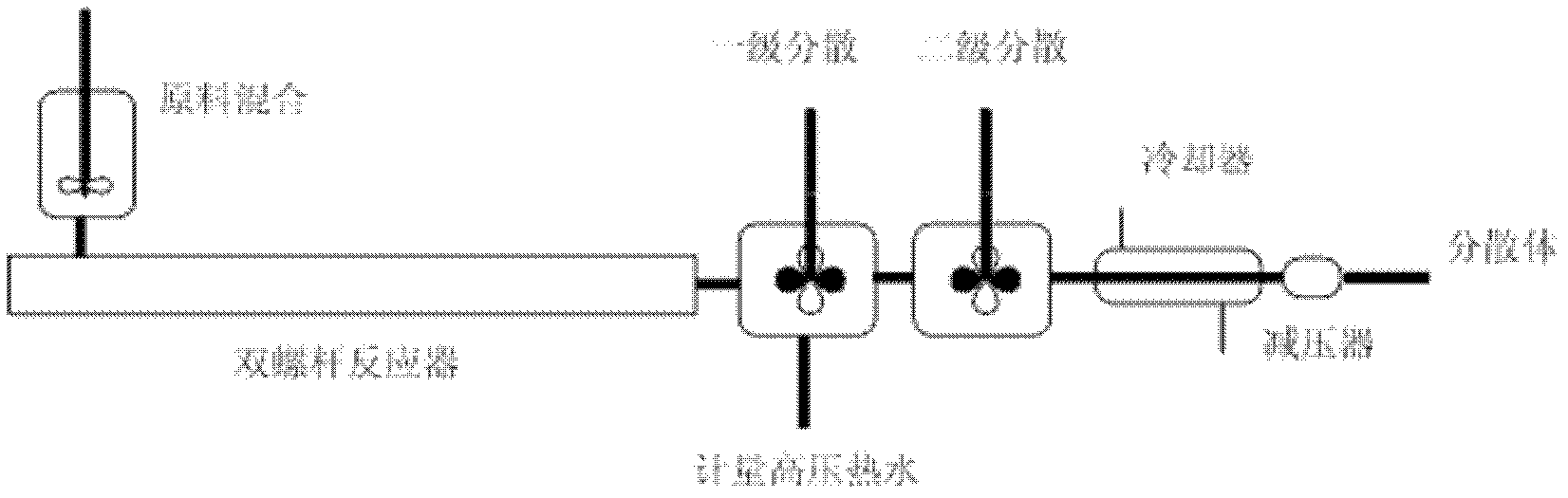

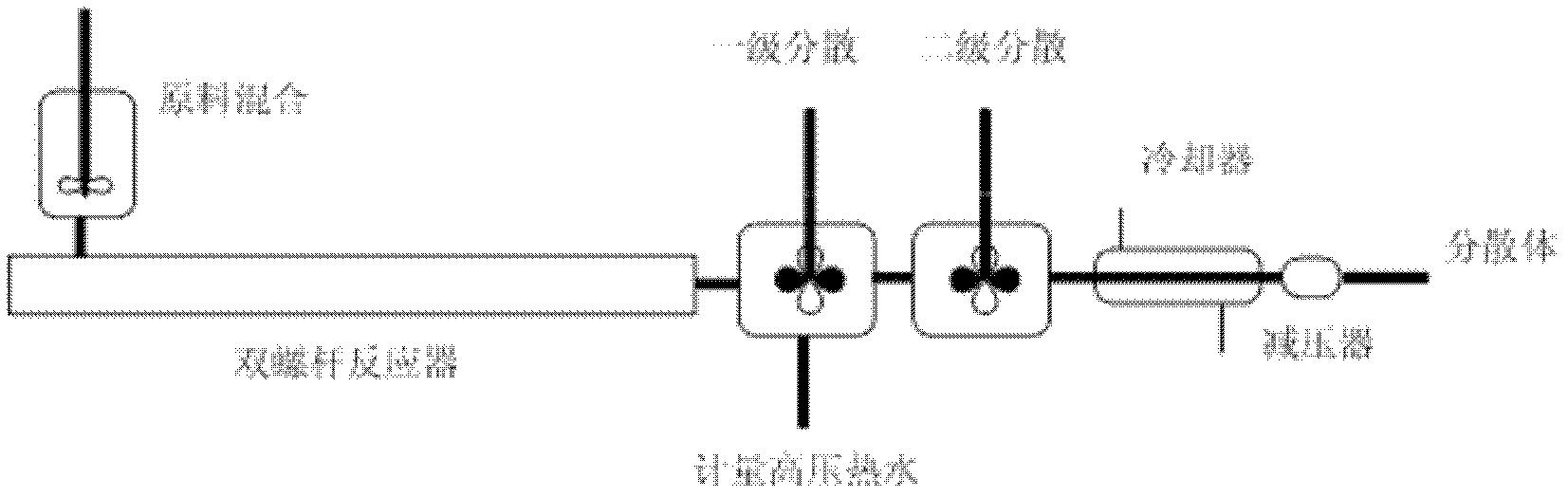

Double-screw reactor design based continuous production process of aqueous polyurethane dispersion

InactiveCN102633971ASuitable for productionShorten the production cyclePolyurethane dispersionPolymer science

The invention discloses a double-screw reactor design based continuous production process of aqueous polyurethane dispersion, comprising the steps of mixing aqueous polyurethane synthetizing raw materials, injecting the aqueous polyurethane synthetizing raw materials into a double-screw reactor, polymerizing for 3-15min at a temperature of 120-200 DEG C in the double-screw reactor, squeezing the polymerized polyurethane prepolymer out via the double-screw reactor, squeezing the polymerized polyurethane prepolymer into two pressure mixers connected in series, mixing the polymerized polyurethane prepolymer with water at a temperature of 90-150 DEG C, cooling and decompressing the reactant to obtain the aqueous polyurethane dispersion, wherein mechanical dispersion or ultrasonic dispersion can be adopted by the mixers. The production process disclosed by the invention has the advantages that: no solvent or few organic solvent can be used in the process; the production cycle is very short: the process from entering a continuous production device of the raw materials to obtaining products only takes 3-15min; and the fully automatic control on the process is realized.

Owner:王武生

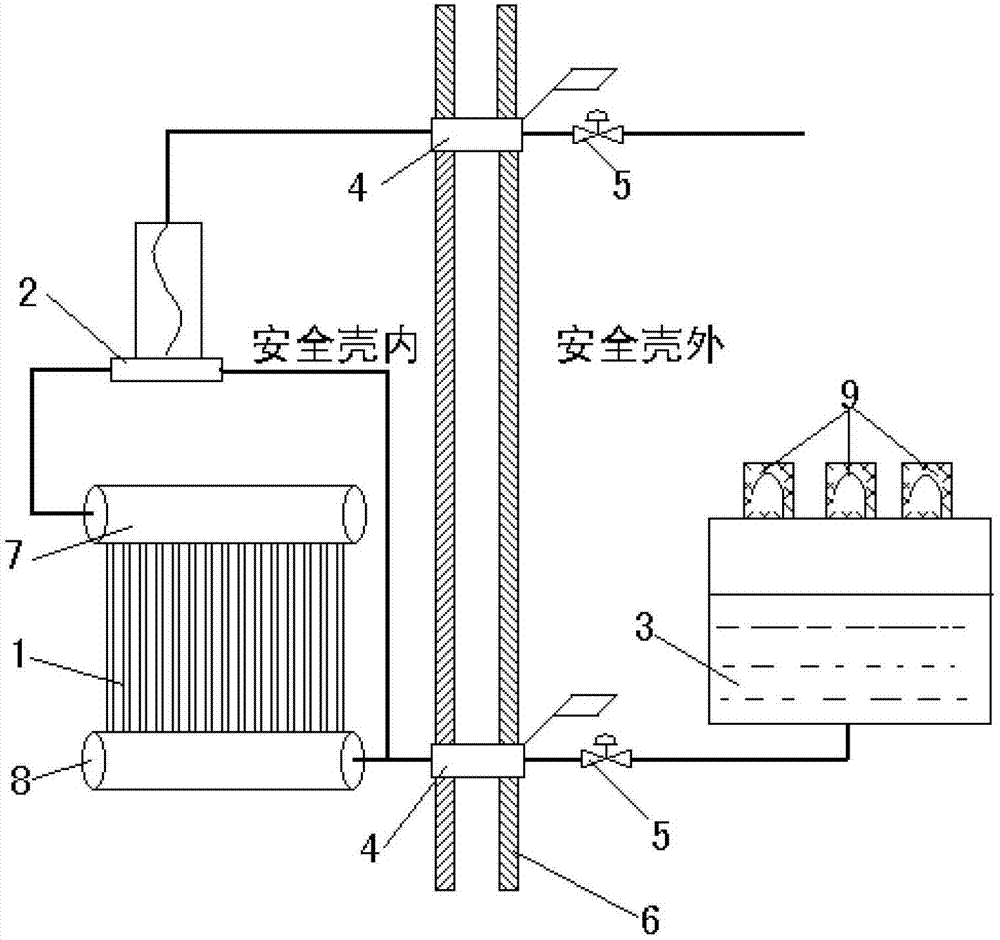

Passive direct evaporation type cooling system for double-layer concrete containment

ActiveCN102737738ARealize passive cooling functionRealize the boiling phenomenonNuclear energy generationCooling arrangementExternal energyAtmospheric air

The present invention relates to a reactor design technology, and specifically to a passive direct evaporation type cooling system for a double-layer concrete containment. The system comprises a heat exchanger arranged inside a containment, a cooling water tank arranged outside the containment, and a steam water separation device. According to the present invention, the retention time of cooling water in the heat exchanger is increased to force the cooling water to generate a phase change, and a large amount of heat inside the containment is taken away through phase change latent heat of the water; when the temperature of the containment is less than 100 DEG C, natural circulation flow of the system is low or zero; when the severe accident is generated in the nuclear power station and the containment temperature is more than 100 DEG C, water inside the heat exchanger is heated and expands until the water is evaporated, the separated water returns back to the cooling water tank, the steam is discharged into the atmosphere outside the containment, the system is put into operation, and the natural circulation is formed. With the system of the present invention, the whole process does not require intervention by nuclear power station operators, and whether the system is put into operation is automatically selected according to the containment temperature, such that the passive system is completely achieved, the human intervention factor during accident generation is substantially reduced, and the containment cooling function is achieved independent of external energy sources.

Owner:CHINA NUCLEAR POWER ENG CO LTD

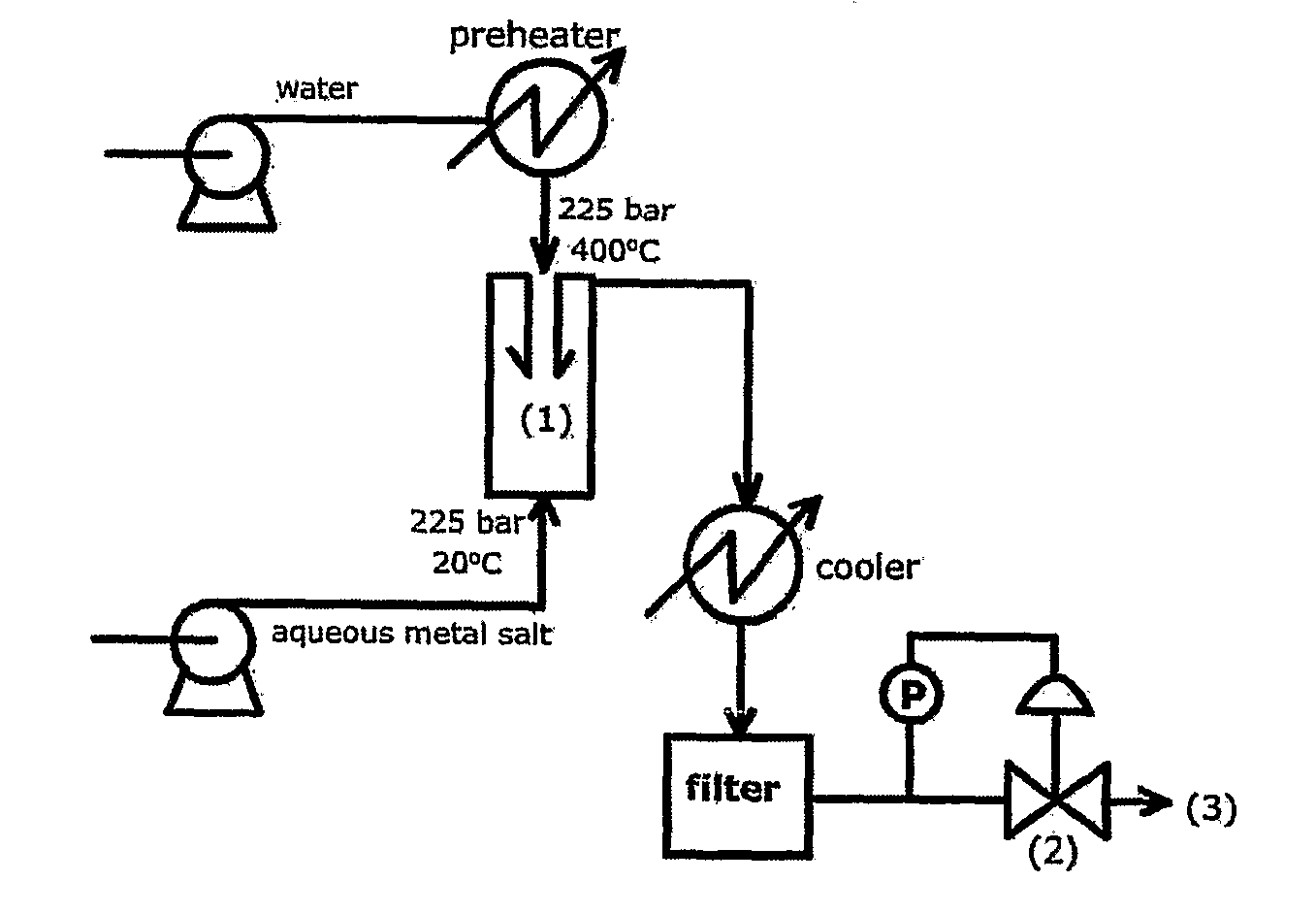

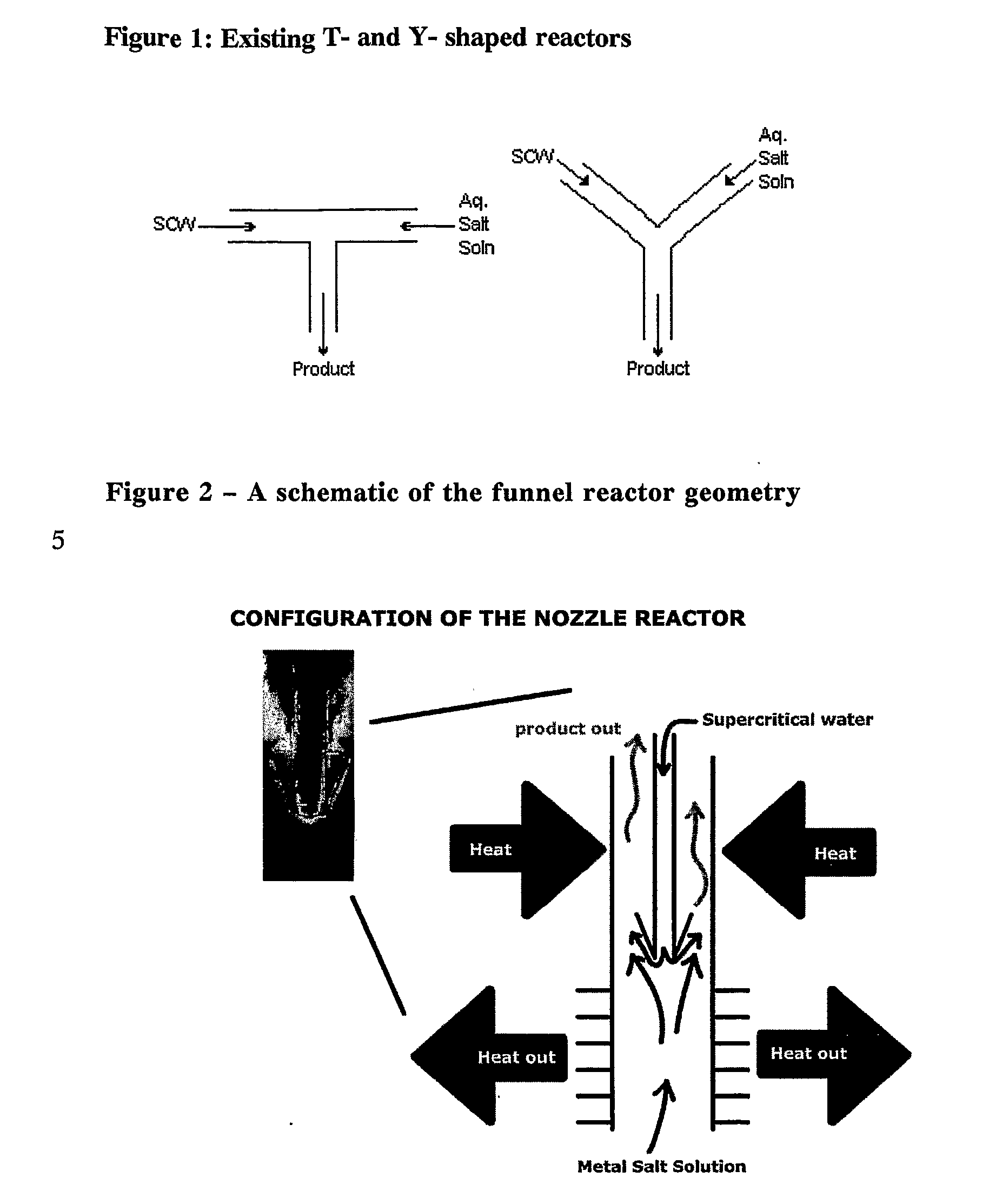

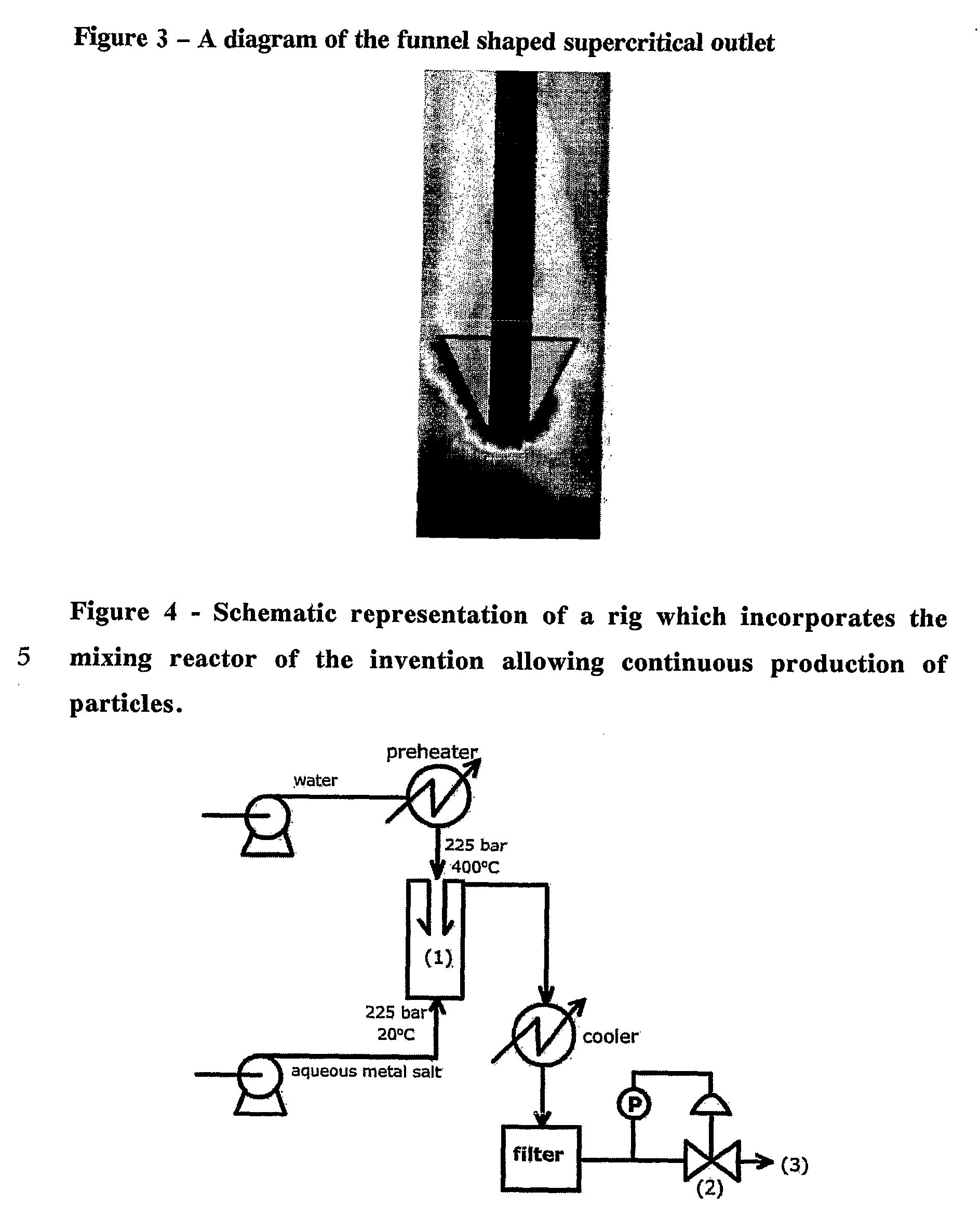

Counter Current Mixing Reactor

ActiveUS20070206435A1Minimize blockingEliminate mixingRare earth metal oxides/hydroxidesFlow mixersMetal oxide nanoparticlesReactor design

A mixing reactor for mixing efficiently streams of fluids of differing densities. In a preferred embodiment, one of the fluids is supercritical water, and the other is an aqueous salt solution. Thus, the reactor enables the production of metal oxide nanoparticles as a continuous process, without any risk of the reactor blocking due to the inefficient mixing inherent in existing reactor designs.

Owner:PROMETHEAN PARTICLES

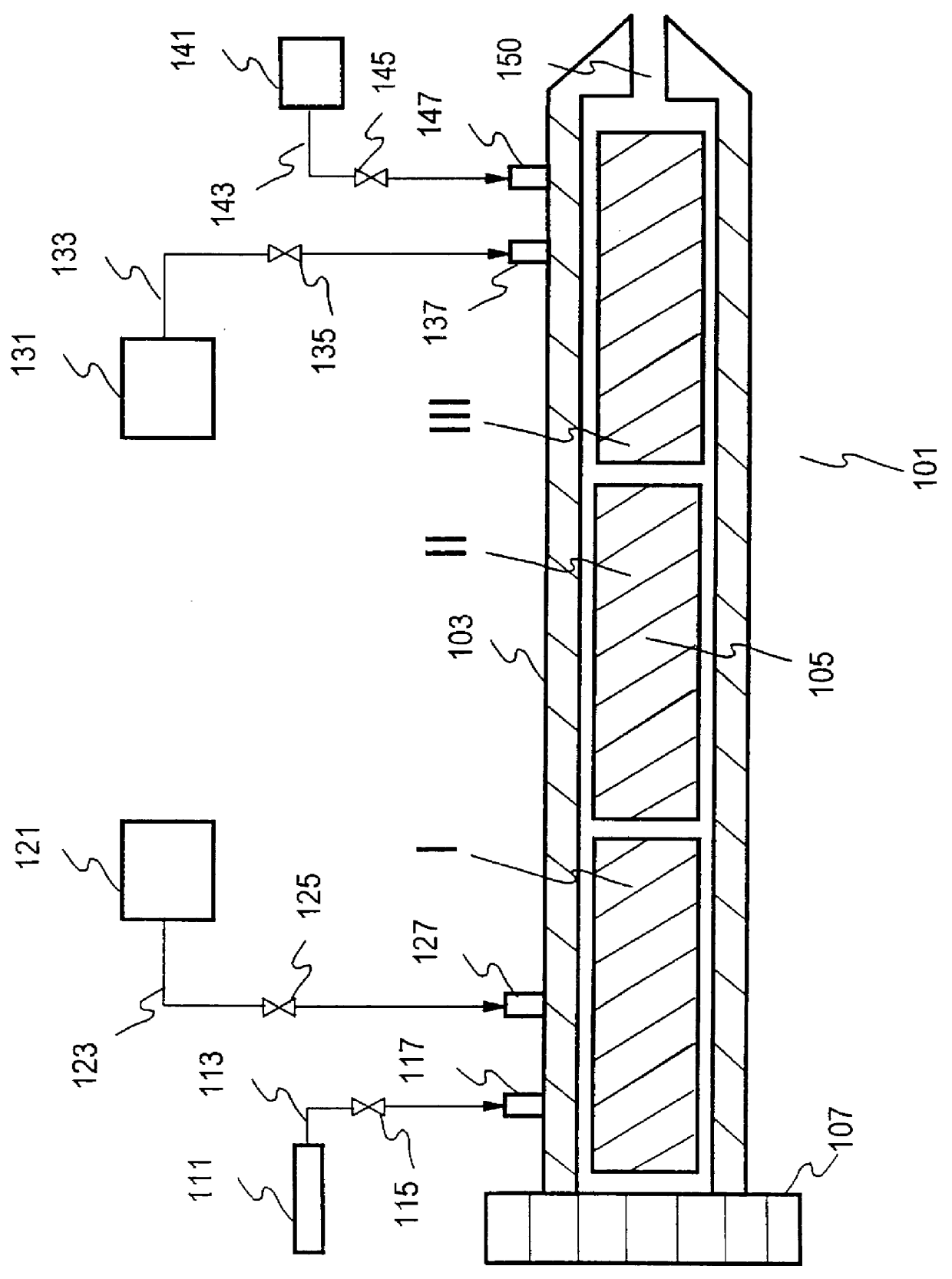

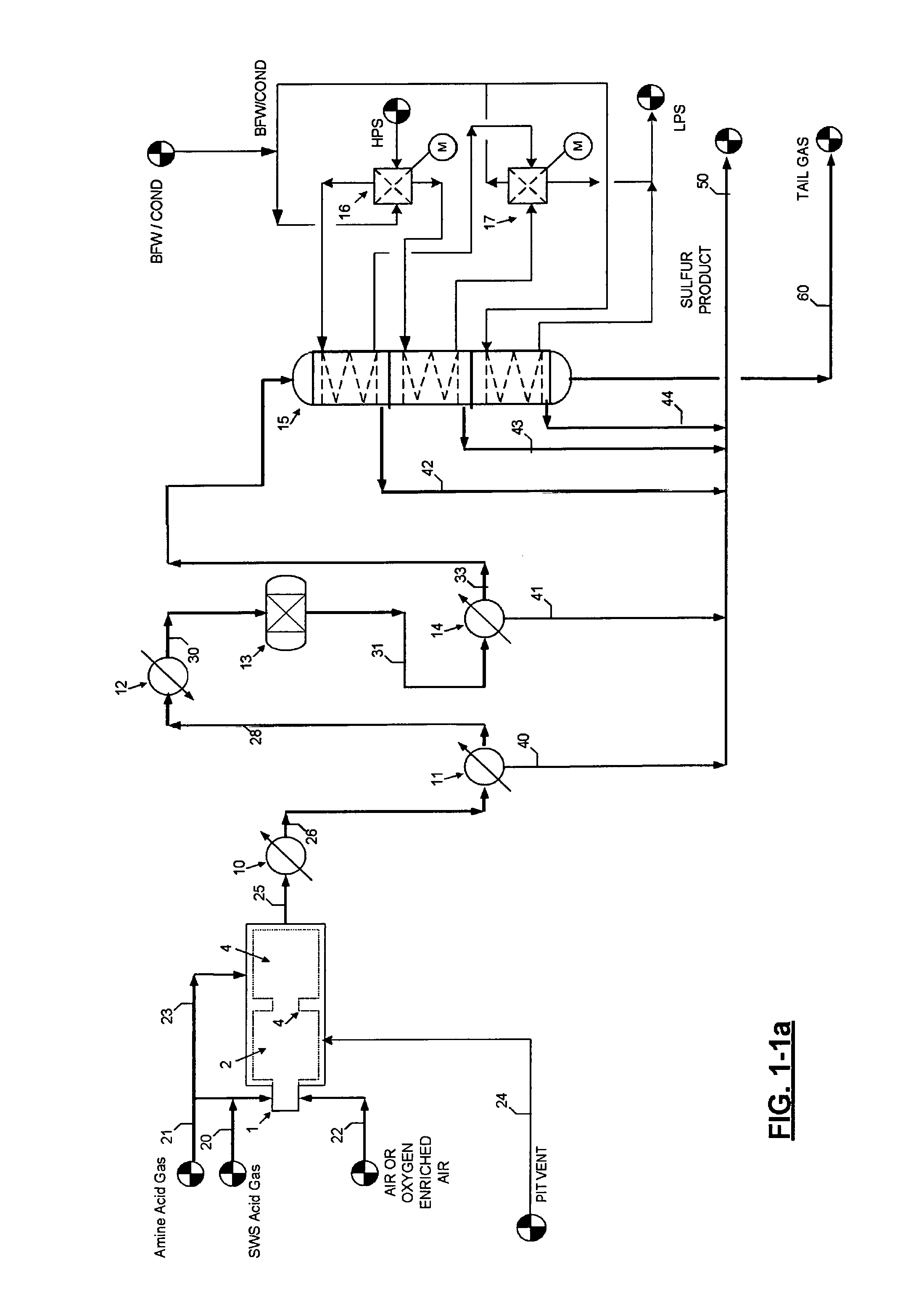

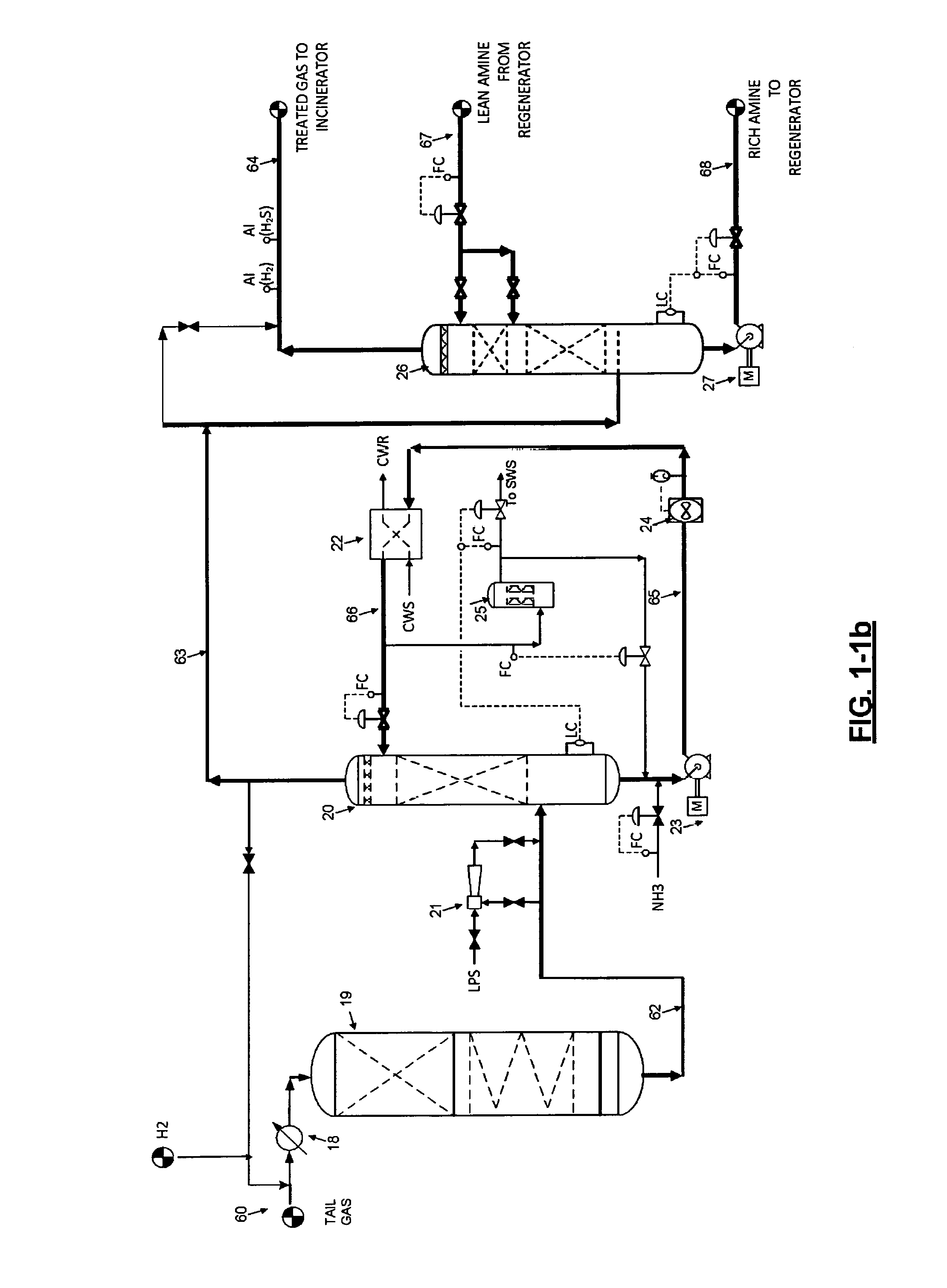

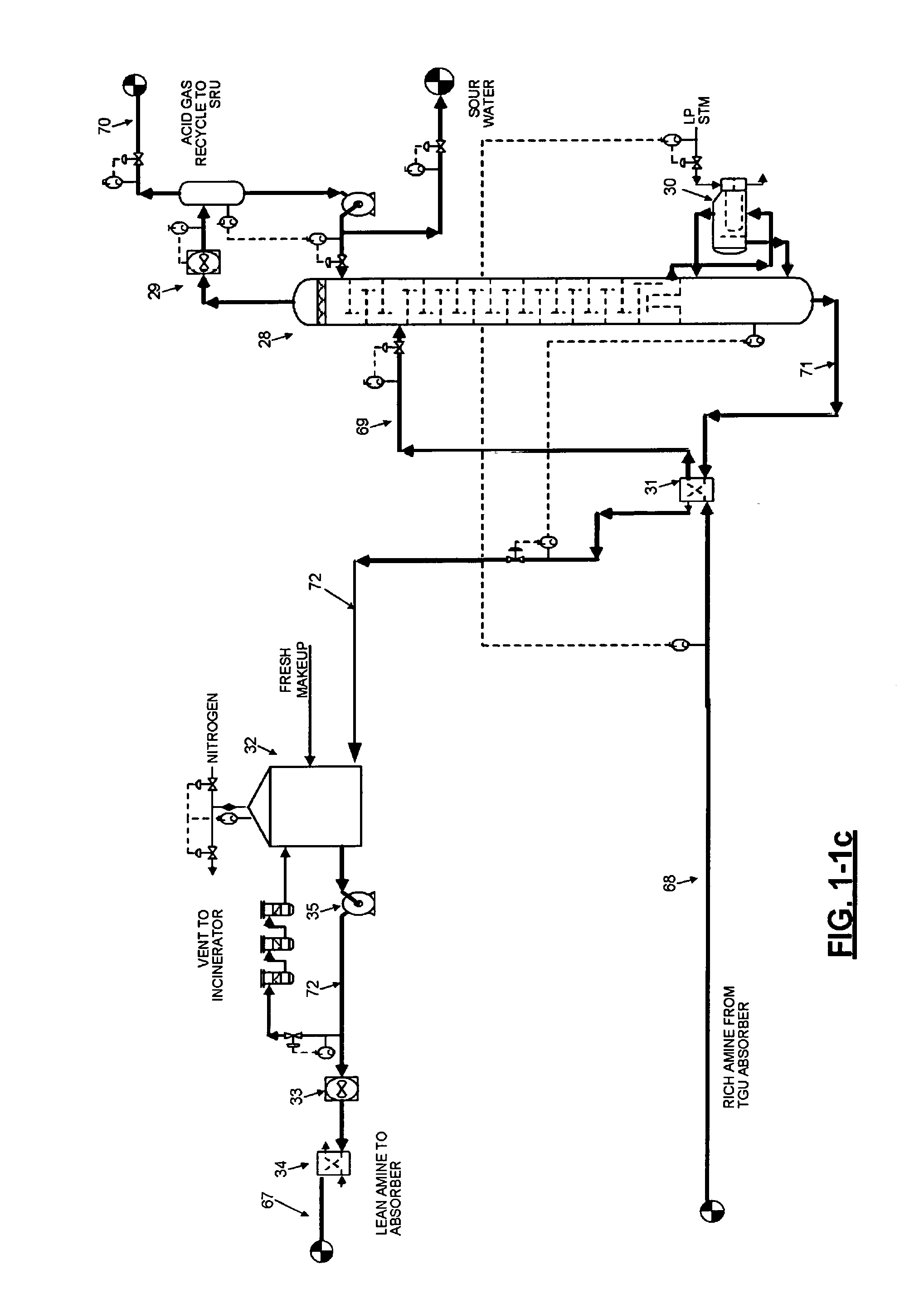

Supersulf- a process with internal cooling and heating reactors in subdewpoint sulfur recovery and tail gas treating systems

ActiveUS20170044015A1High sulfur recoverySolve large capacityDispersed particle separationSulfur preparation/purificationSulfurHydrogenation reaction

SuperSulf process refers to an innovative reactor design consisting of internal cooling and heating thermoplate exchangers where it is filled by the Claus type catalysts between plates in the SRU and hydrogenation catalysts in the tail gas unit. SuperSulf reactor consists of 3 reactor zones in the sulfur recovery which operates as a SubDewPoint process where the mode of operation are controlled by switching valves on the utilities streams high pressure steam and high quality water and steam where the first 2 zones operate as hot and cold and switches to cold and hot where the produced sulfur is condensed. The third zone operates as cold all the time where consists of the last sulfur condenser by producing Low pressure steam. The tail gas unit consists of 2 reactor zones of hydrogenation reactor and hydrolysis reactor with internal plate cooling then followed by the tail gas amine with a selective solvent. The thermal incineration system can meet less than 50 ppmv of SO2 and with caustic incineration less than 10 ppmv of SO2 resulting zero emission.

Owner:RAMESHNI MAHIN +1

Triode reactor design with multiple radiofrequency powers

ActiveUS20130126475A1Electric discharge tubesVacuum gauge using ionisation effectsReactor designEngineering

Methods, systems, and computer programs are presented for semiconductor manufacturing are provided. One wafer processing apparatus includes: a top electrode; a bottom electrode; a first radio frequency (RF) power source; a second RF power source; a third RF power source; a fourth RF power source; and a switch. The first, second, and third power sources are coupled to the bottom electrode. Further, the switch is operable to be in one of a first position or a second position, where the first position causes the top electrode to be connected to ground, and the second position causes the top electrode to be connected to the fourth RF power source.

Owner:LAM RES CORP

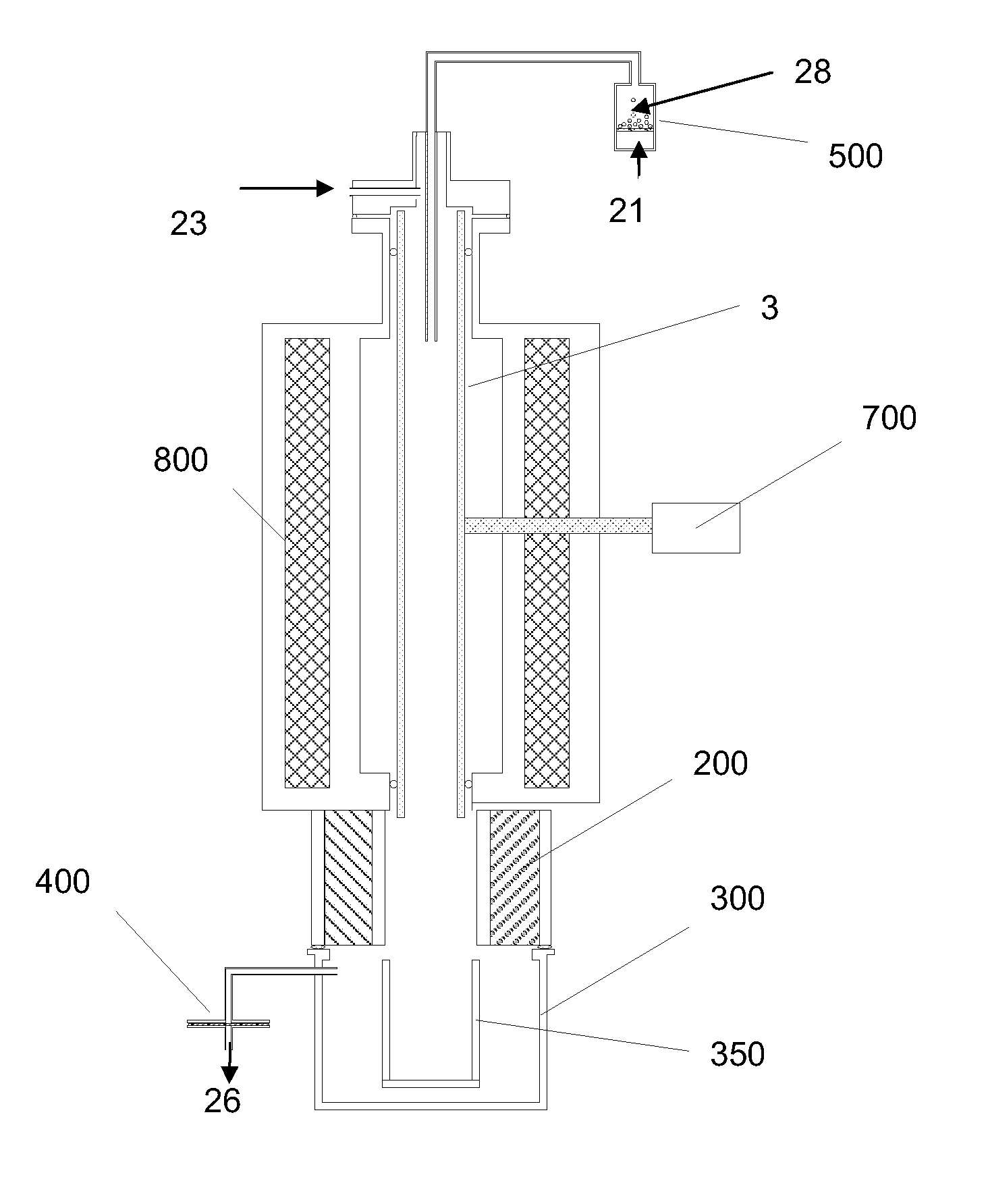

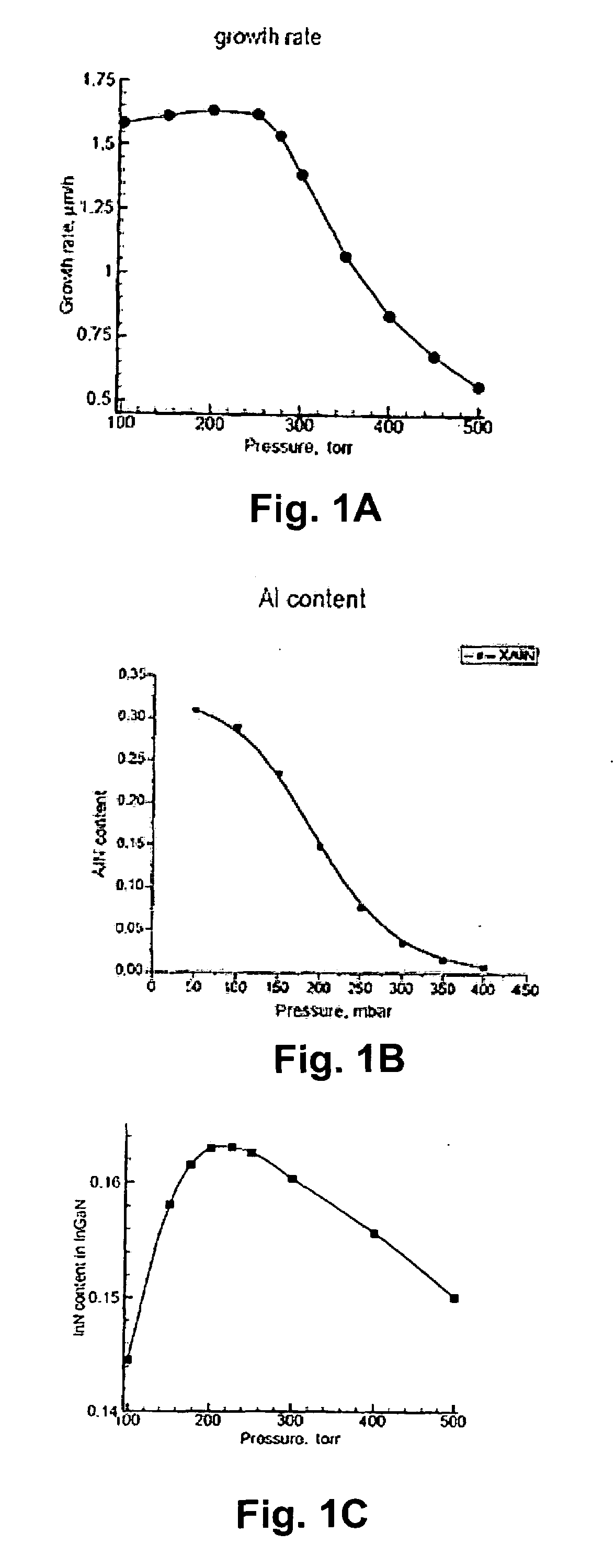

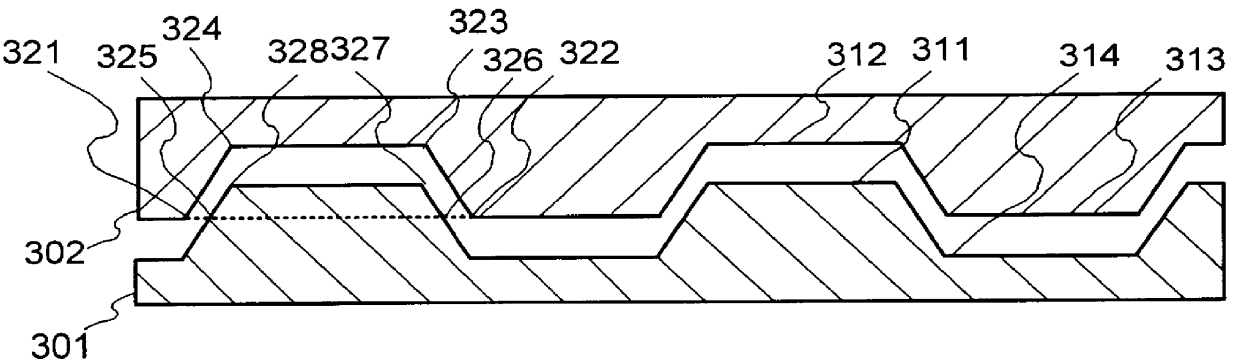

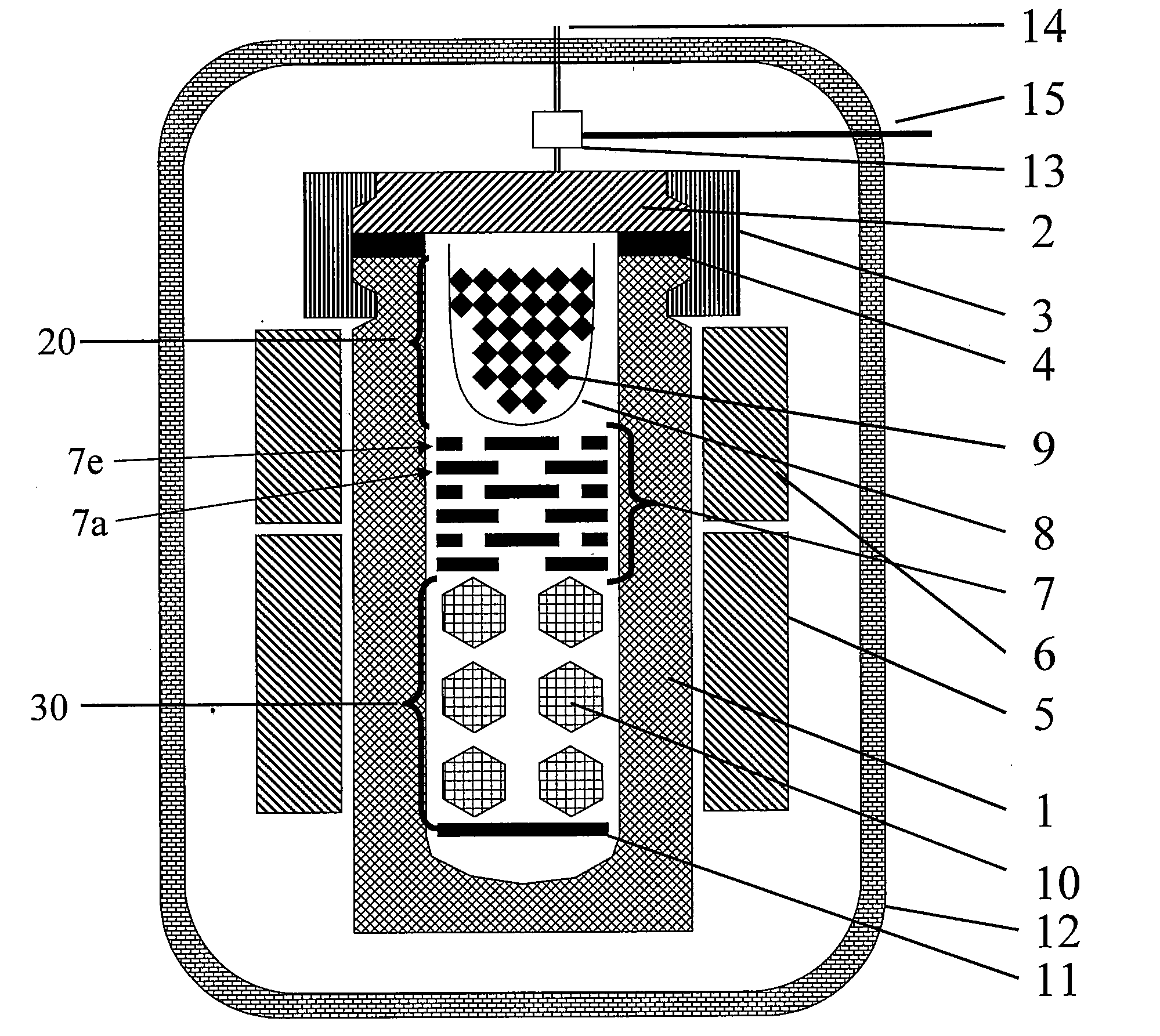

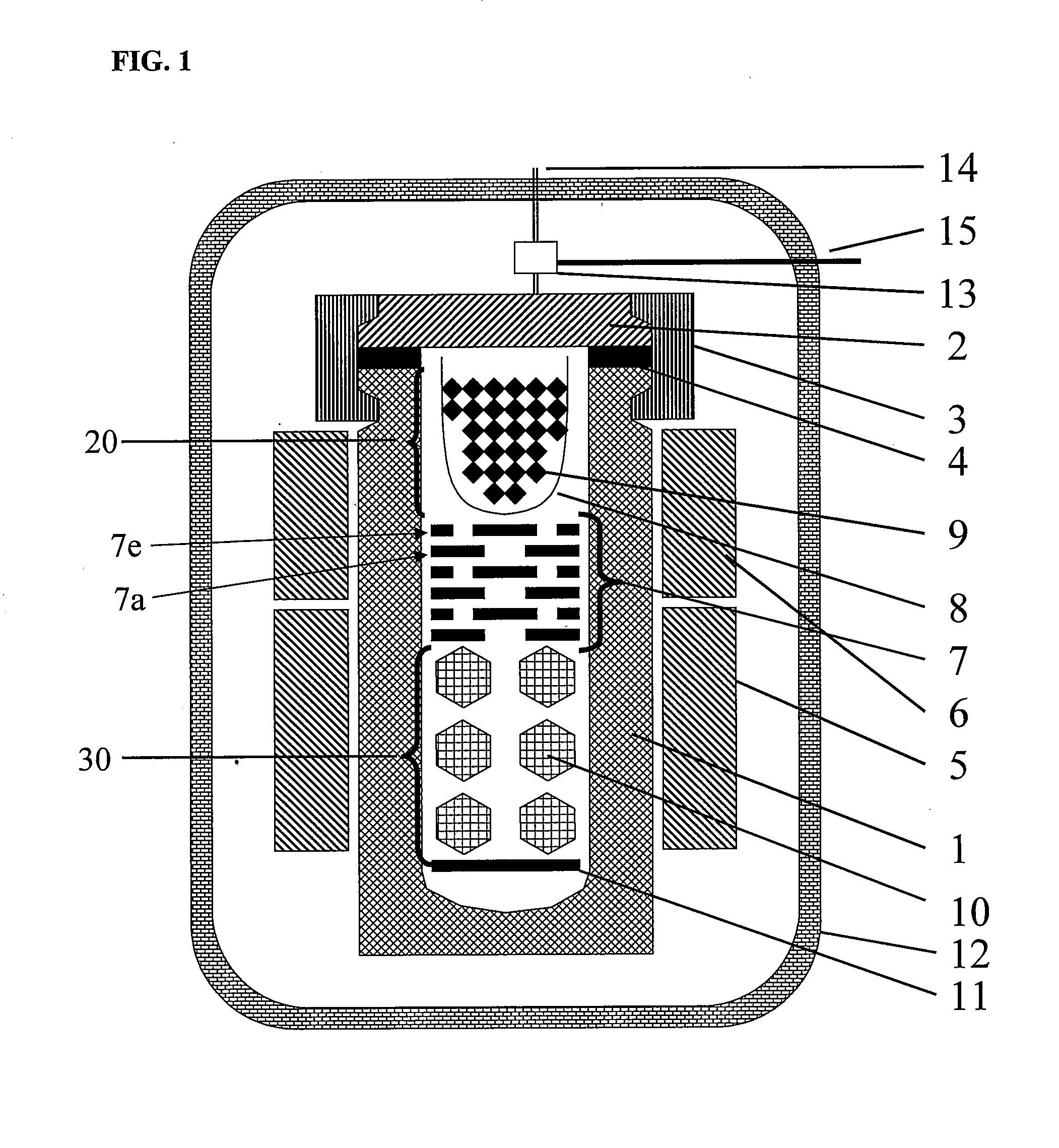

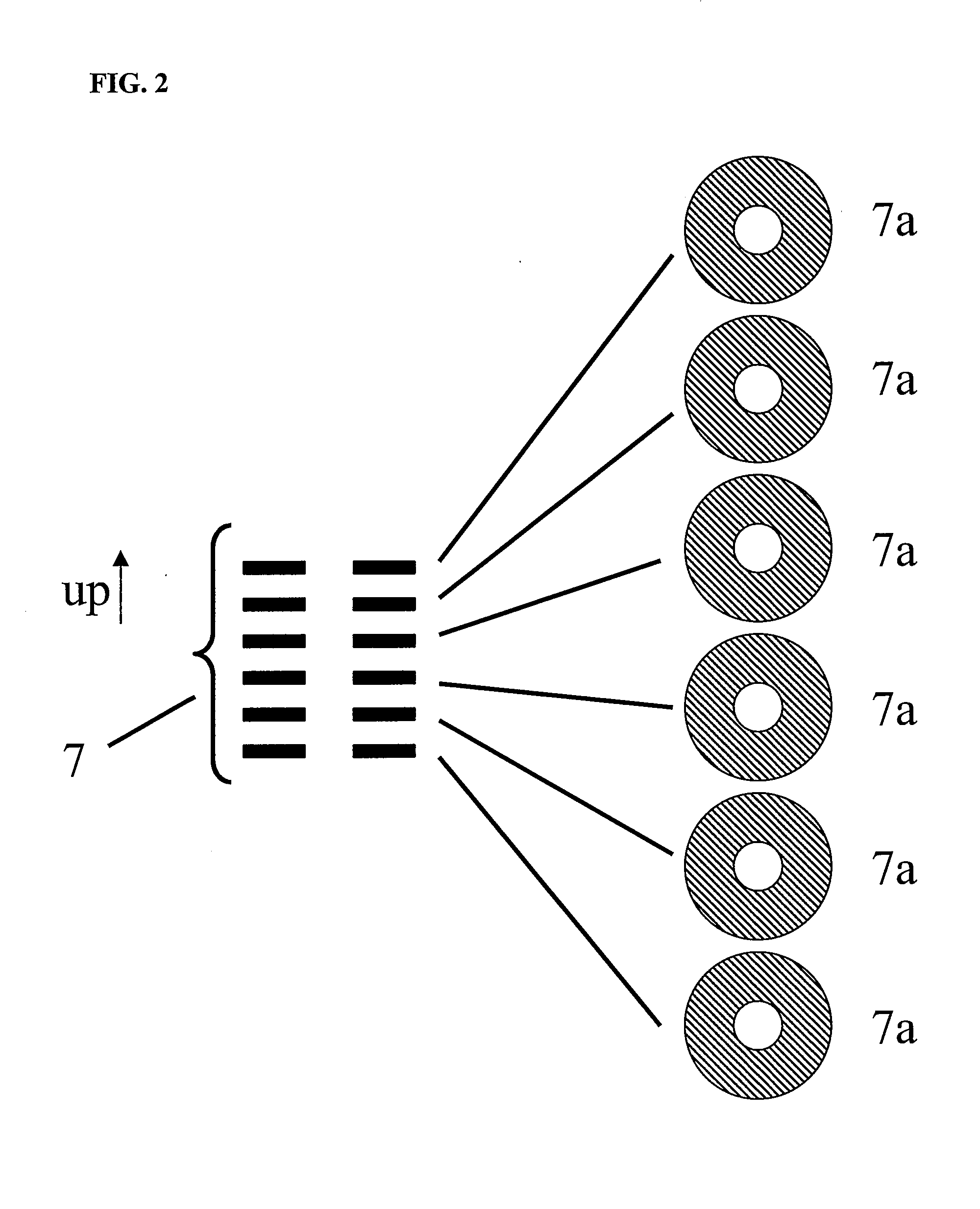

Reactor design for growing group iii nitride crystals and method of growing group iii nitride crystals

InactiveUS20100095882A1Quality improvementDecreasing total amount of transportAfter-treatment apparatusPolycrystalline material growthReactor designTemperature difference

The present disclosure proves for new design of reactors used for ammonothermal growth of III nitride crystals. The reactors include a region intermediate a source dissolution region and a crystal growth region configured to provide growth of high quality crystals at rates greater than 100 μm / day. In one embodiment, multiple baffle plates having openings whose location is designed so that there is no direct path through the intermediate region, or with multiple baffle plates having differently sized openings on each plate so that the flow is slowed down and / or exhibit greater mixing are described. The disclosed designs enables obtaining high temperature difference between the dissolution region and the crystallization region without decreasing conductance through the device.

Owner:SIXPOINT MATERIALS

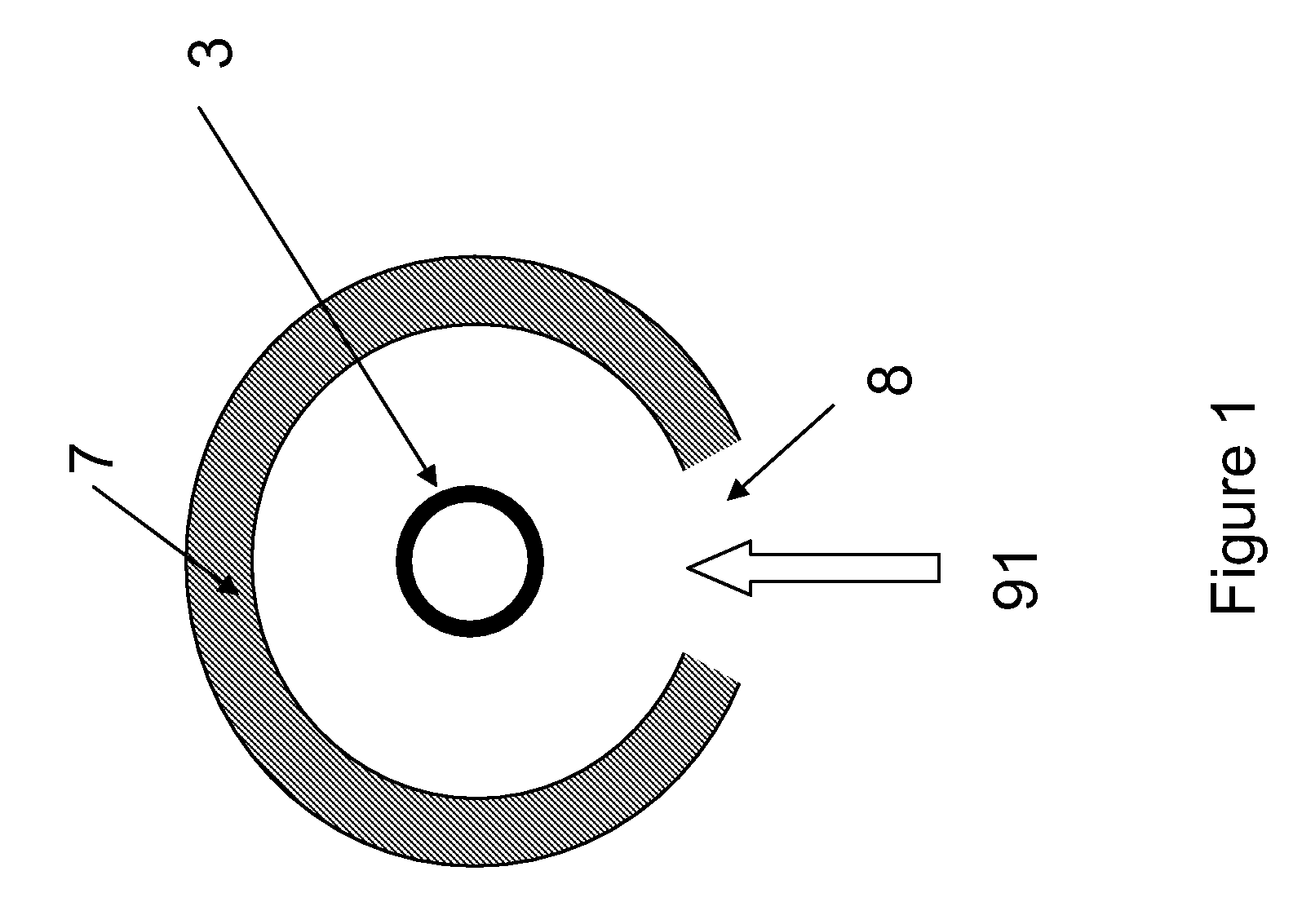

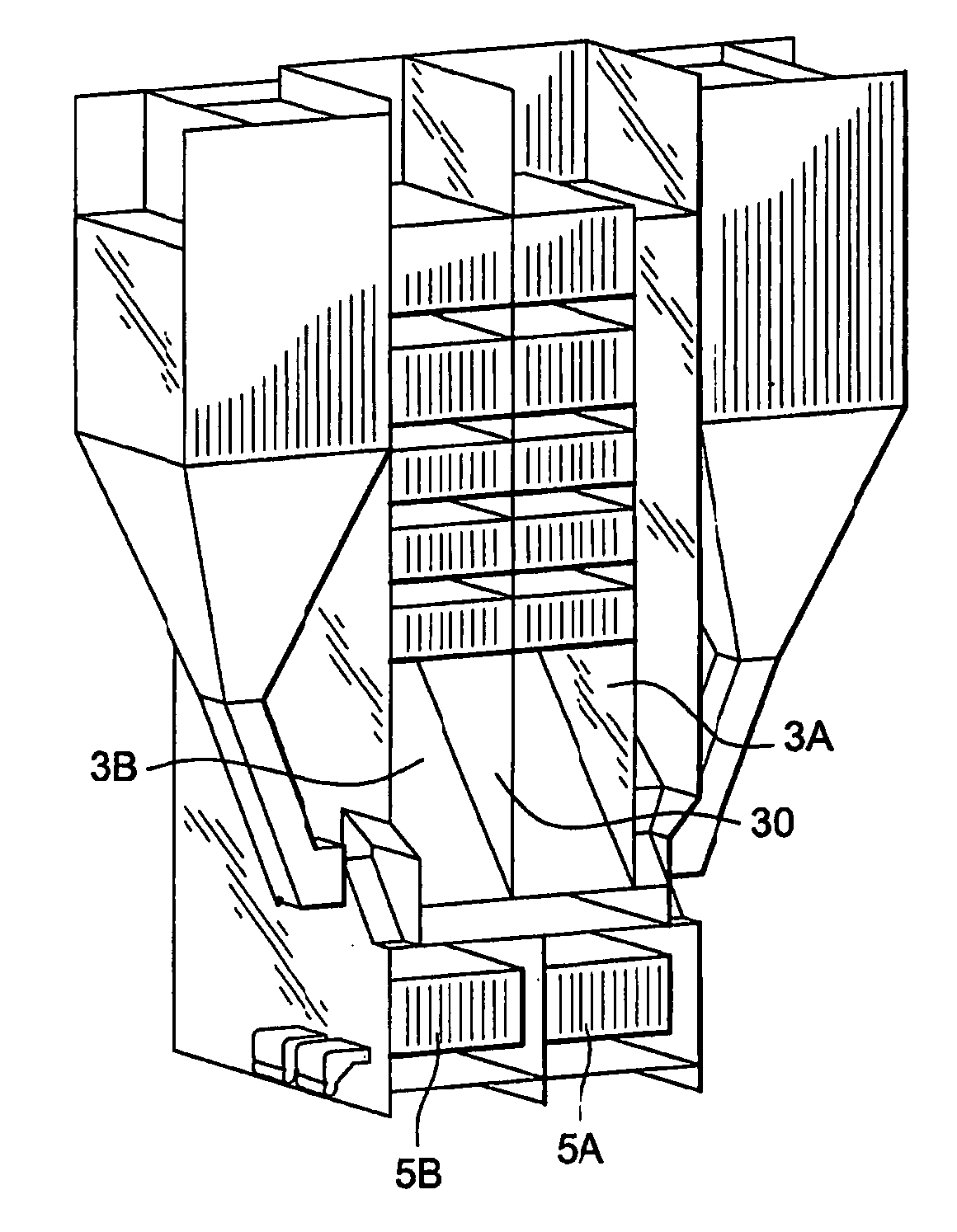

Circulating fluidized bed reactor with a convertible combustion method

InactiveUS20070079773A1Easy to operateFluidized bed combustionSteam/vapor condensersCombustionFlue gas

The invention relates to a circulating fluidized bed reactor designed to be fed with air and convertible to operate with an oxygen-rich mixture, comprising a reaction chamber (1) horizontally bounded by vertical walls, at least two centrifugal separators (2A, 2B) and a heat recovery element called a heat exchanger cage (3), a reactor also comprising means for introducing a fluidization gas into the reaction chamber using at least one wind box (4) placed under the reaction chamber, and for maintaining a circulating fluidized bed of particles in said chamber, means for transferring gas which must be dedusted from the chamber to the separators, means for discharging the particles separated from the separators and means for transferring the dust-free gases from the separators to the exchanger cage. According to the invention: said reaction chamber comprises at least one partially internal vertical partition wall (10) forming two subchambers (1A, 1B) communicating together and each communicating with at least one separator, said exchanger cage (3) comprises a partially internal vertical partition wall (30) forming two subcages (3A, 3B) communicating together and each communicating with at least one separator, these partition walls being arranged in order to create a passage for the flow of the flue gases into one of said subchambers and into one of said subcages corresponding to operation by oxygen feed in the reaction chamber.

Owner:GENERAL ELECTRIC TECH GMBH

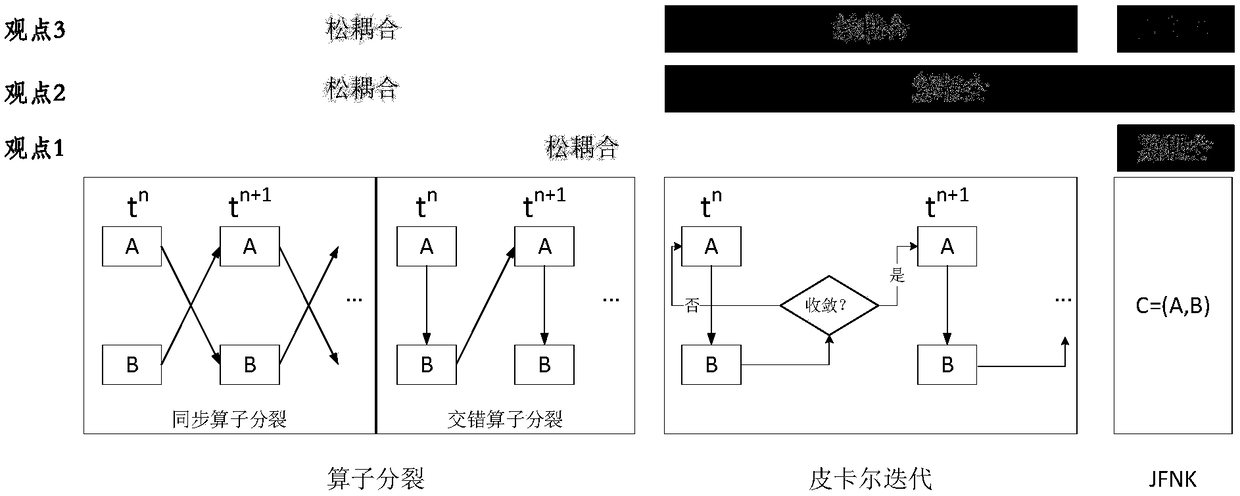

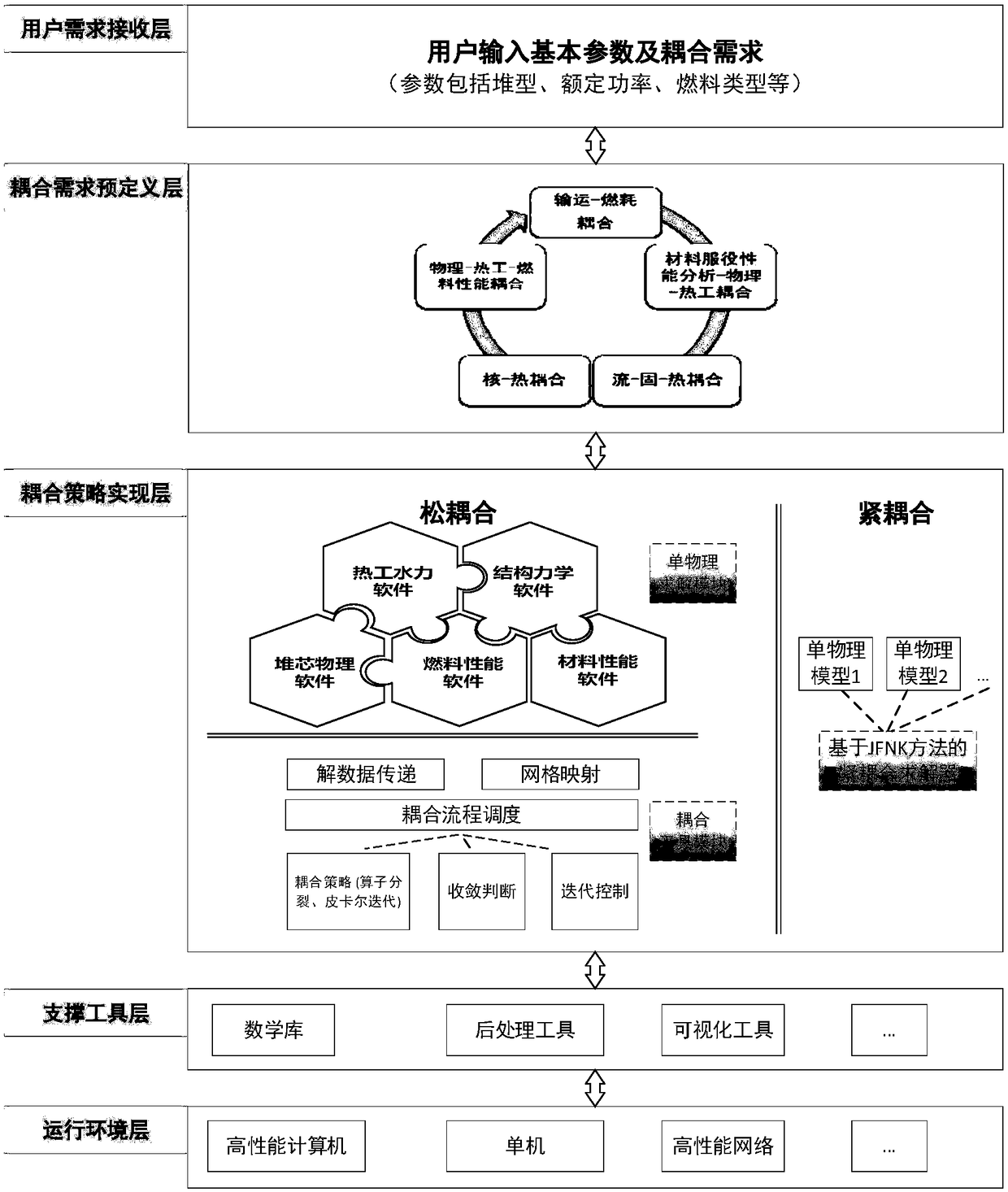

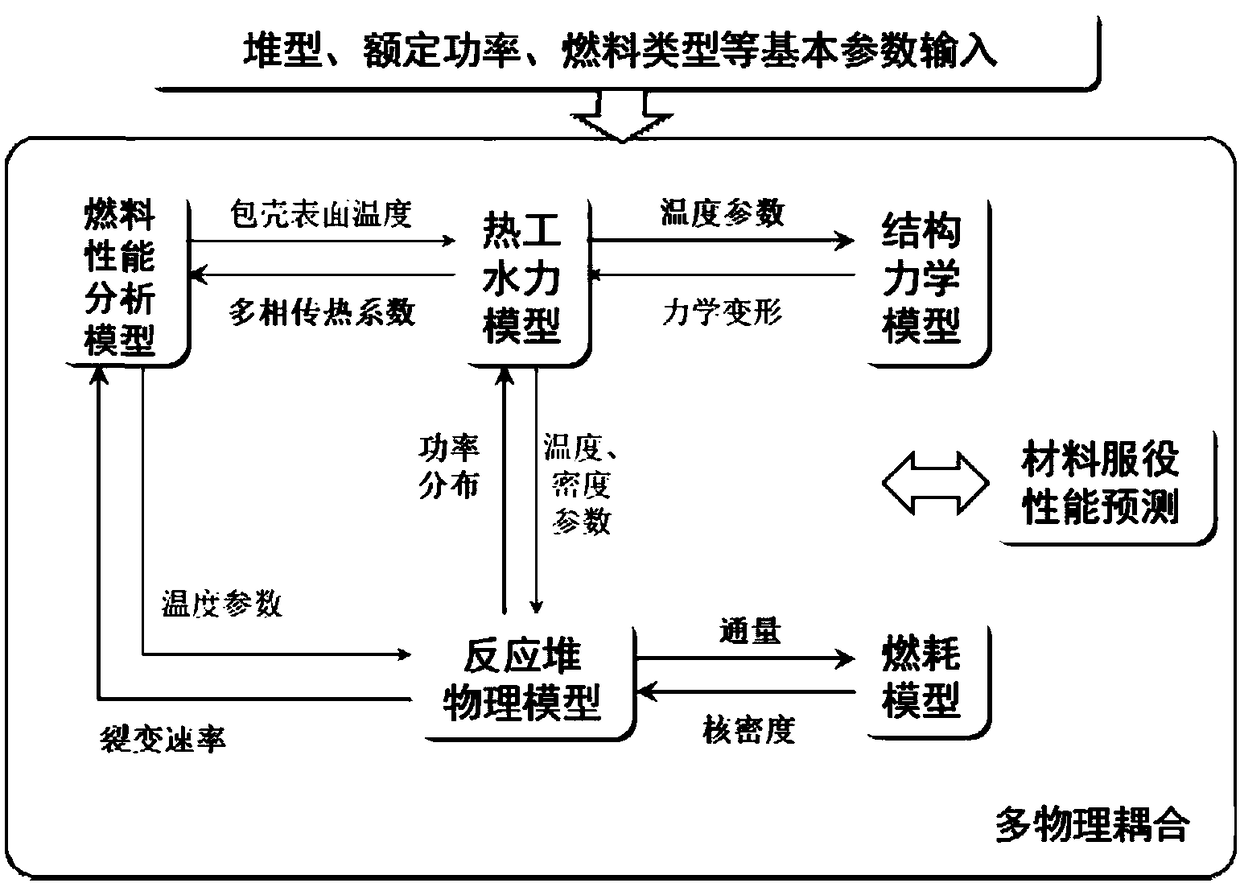

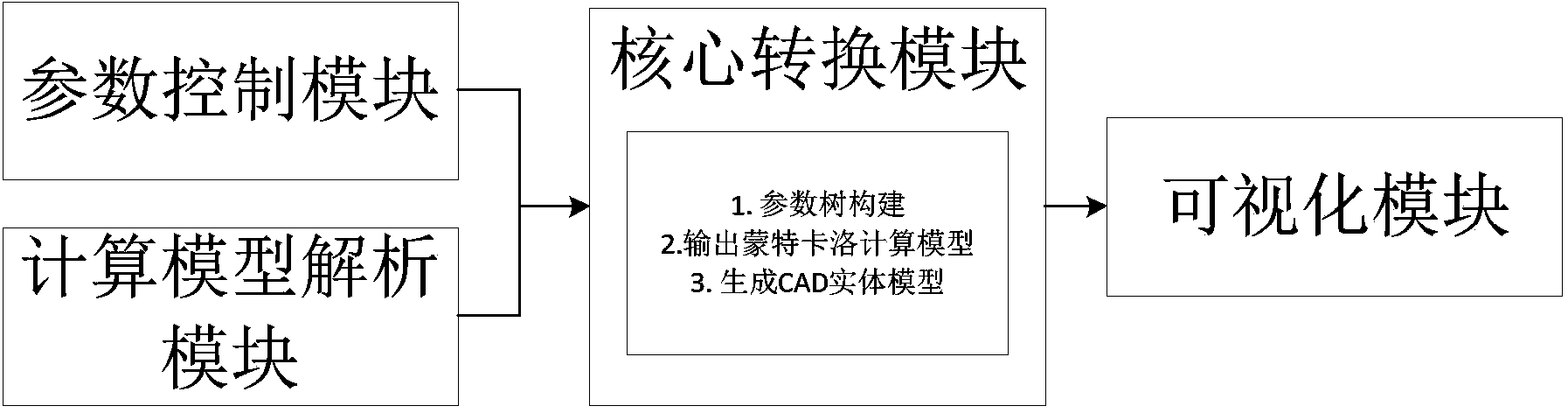

Multi-physically coupled system and method for reactor simulation

ActiveCN109063235ARealize the transportation-fuel consumption coupling requirementsFulfilling Nuclear-Thermal Coupling RequirementsDesign optimisation/simulationSpecial data processing applicationsNuclear reactorEngineering

The invention provides a multi-physical coupling system for reactor simulation, which is designed according to the multi-physical coupling requirements of a nuclear reactor, comprises a bottom supporttool and integrates a plurality of coupling strategies. A system includes a top layer user demand receiving layer, a coupling requirements predefined layer, a coupling implementation layer, a supporttool layer, the five hierarchies of the runtime environment layer, which combines the scheduling of coupled computing flow and the update and transfer of interface parameters, grid mapping between different computing programs, the transfer of solution data between programs in different spatial discrete modes, coupling strategy, coupling process control, bottom support tools and high performance environment extension can be provided. It is very important for new reactor design, optimization of nuclear power plant in service, optimization of operation simulation under different conditions, anddemonstration and prediction of serious accident sequence.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY +2

Integrated reactors, methods of making same, and methods of conducting simultaneous exothermic and endothermic reactions

InactiveUS20060153751A1High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberProcess engineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for flee flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

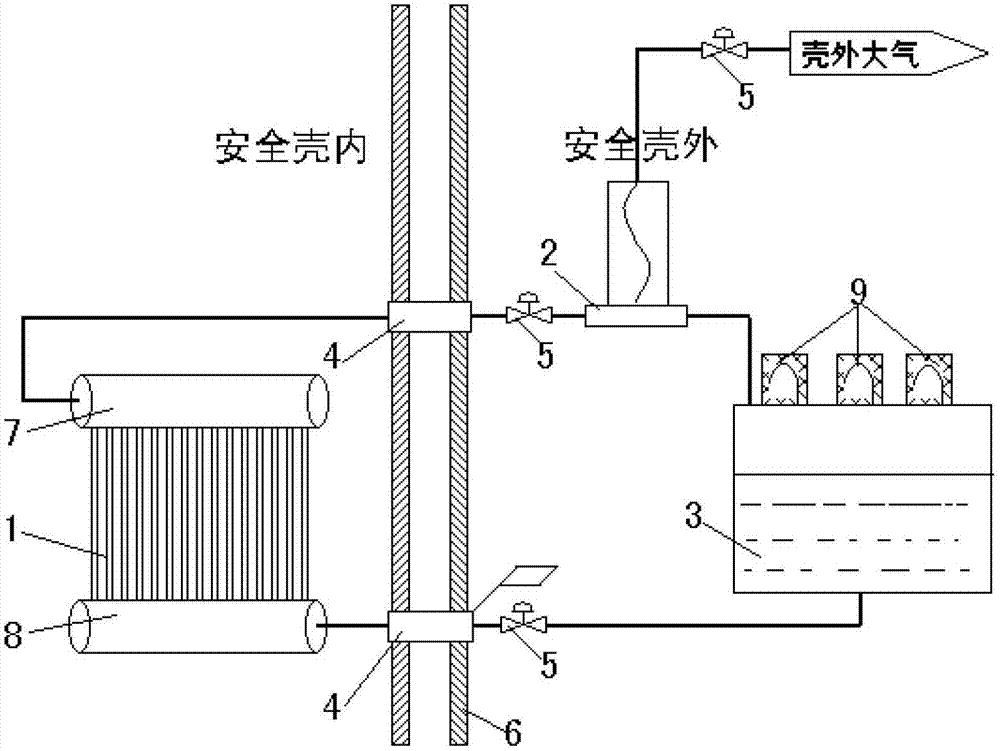

Reactor cavity water injection cooling system with combination of active and passive power

ActiveCN102867549ARapid cycle coolingLong-term cycle coolingNuclear energy generationCooling arrangementCountermeasureReactor design

The invention belongs to reactor design technology and particularly relates to a reactor cavity water injection cooling system with a combination of active and passive power. The reactor cavity water injection cooling system structurally comprises a passive reactor cavity water injection tank and reactor cavity water injection cooling pumps, the passive reactor cavity water injection tank is connected with a reactor cavity through a passive injection line, the reactor cavity water injection cooling pumps are arranged outside a containment, inlet tubes of the reactor cavity water injection cooling pumps are connected with a refueling water tank, and outlet tube lines of the reactor cavity water injection cooling pumps penetrate through the containment and are connected with the reactor cavity. As a countermeasure for serious accidents, the reactor cavity water injection cooling system has safety functions of taking away reactor core fusant, exhausting reactor core heat and avoiding melting in a multi-redundant and diversified way of combining active power with passive power when the accidents happen.

Owner:CHINA NUCLEAR POWER ENG CO LTD

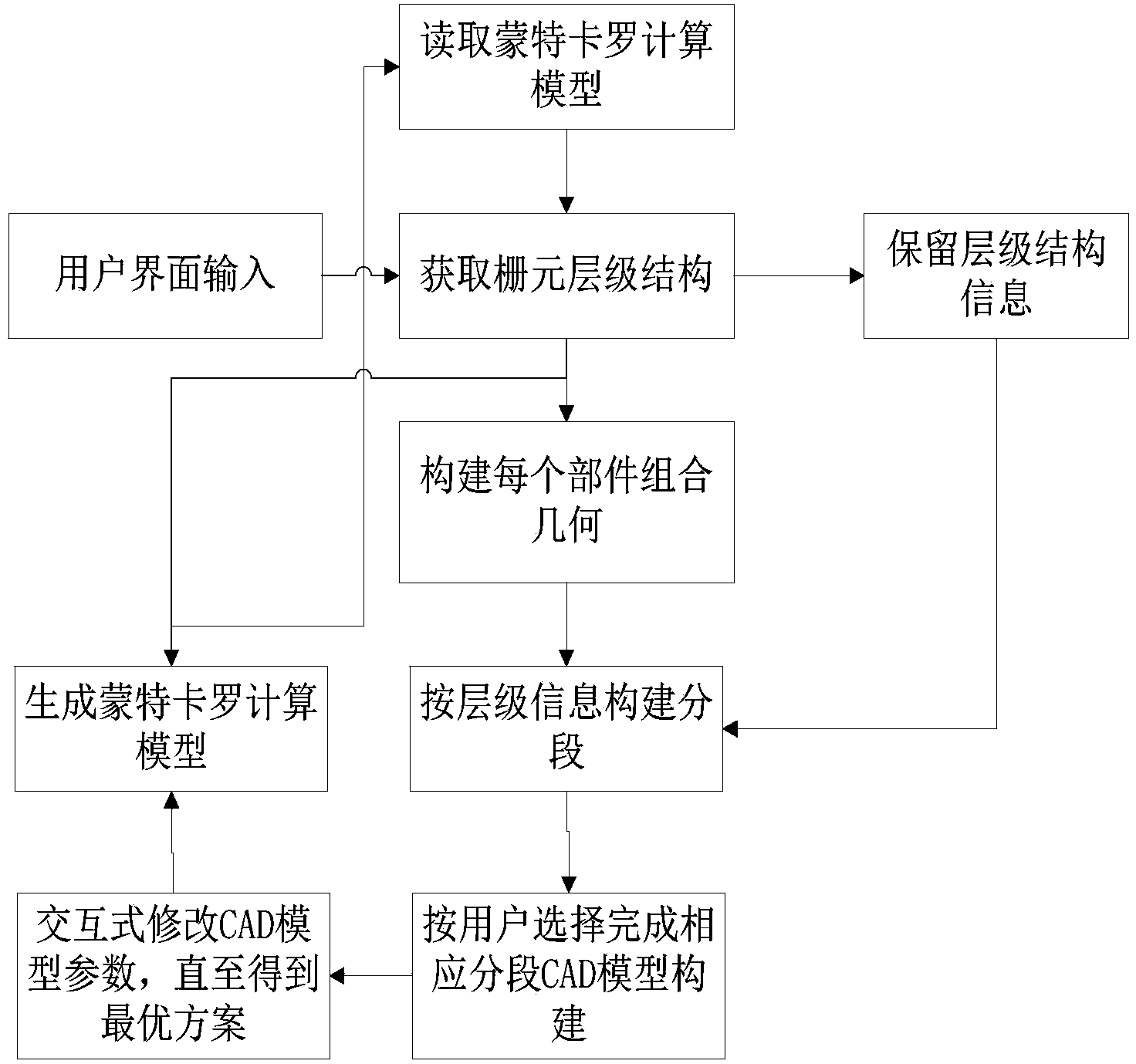

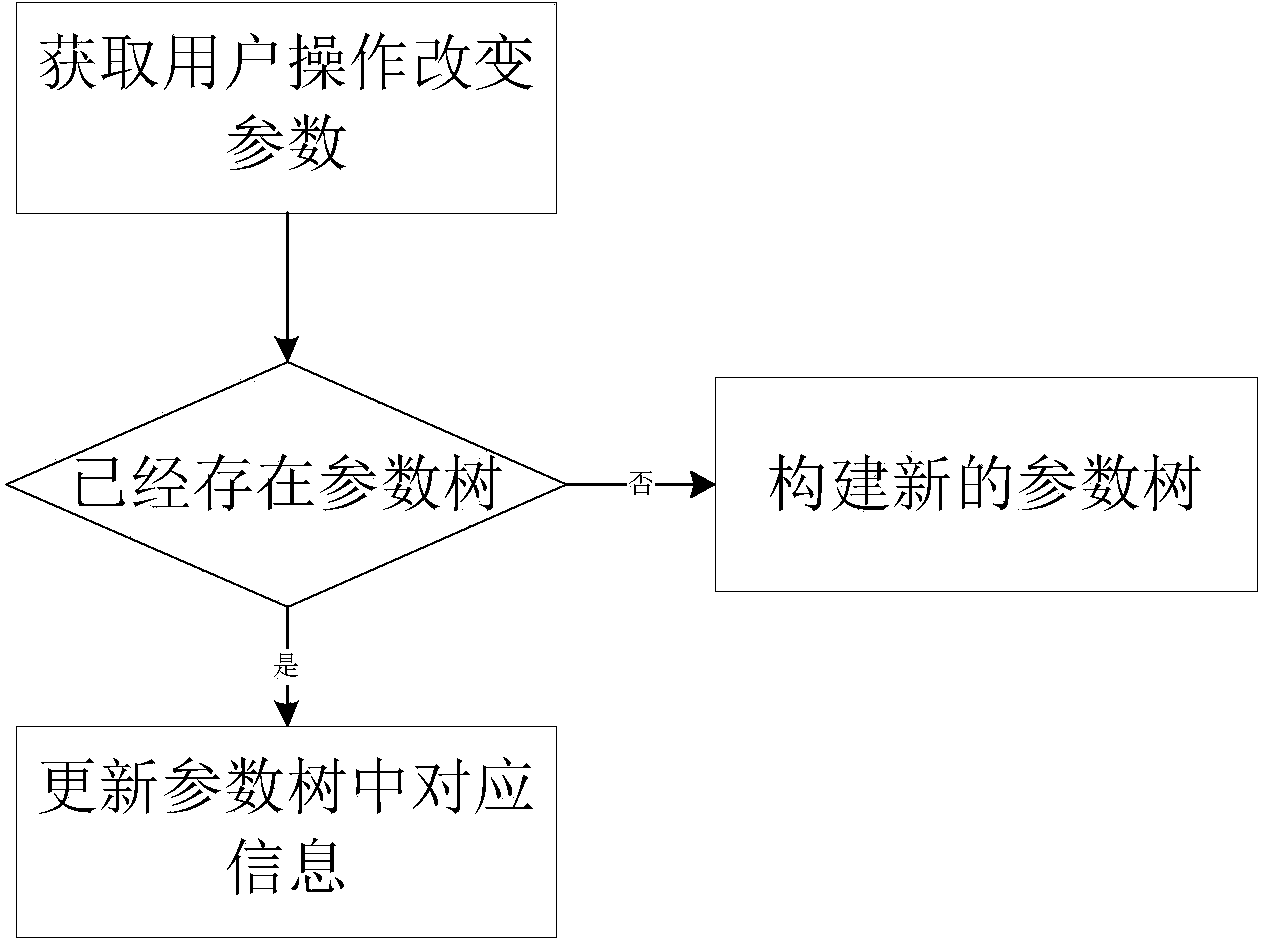

Reactor core iterative design system based on Monte Carlo calculation

ActiveCN104298836AAvoid cumbersomenessImprove modeling efficiencySpecial data processing applications3D-image renderingComputational modelCore component

The invention discloses a modeling system which is used in reactor design and used for reactor core component design. According to the modeling system, the geometric specificity of a fission reactor core is analyzed, a great amount of repeatedly constructed geometries are adopted, a CAD engineering model and a Monte Carlo calculation model of the fission reactor core are automatically established by establishing parameters, the Monte Carlo calculation model is used for radiating and transporting input of a Monte Carlo calculation program, and the significant physical quantity of the reactor core can be calculated after the Monte Carlo calculation model is obtained. By constantly evaluating the physical parameters of the calculation result, the modeling system can be used for performing repeated iteration correction on a design scheme of the fission reactor core till a reactor core scheme which makes a user satisfactory is made. The modeling system has the benefits that the tediousness that Monte Carlo calculation programs are written and files are input manually is avoided, the whole modeling process is very visible, the probability of mistakes is greatly reduced, and the design time of the reactor core is shortened.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com