Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7110results about How to "Reduce cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

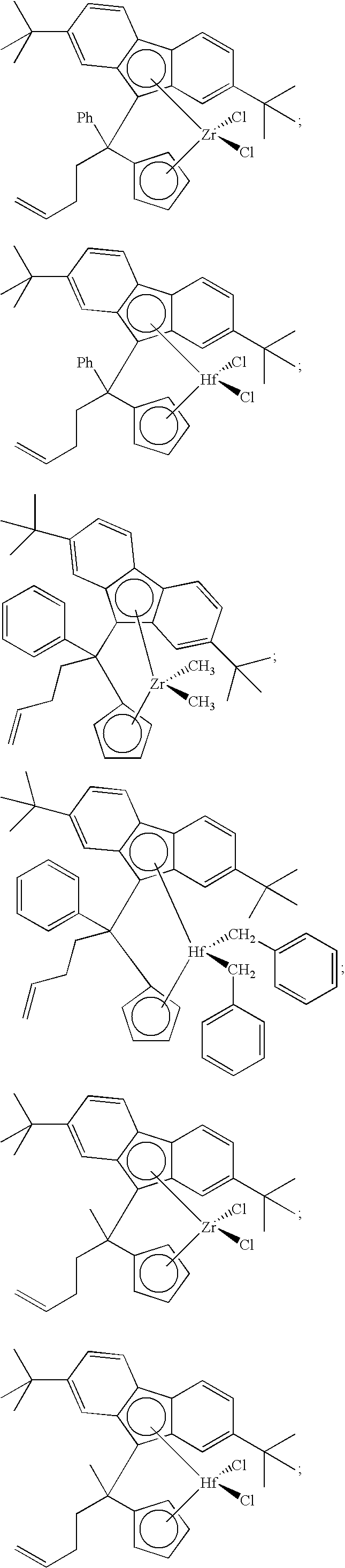

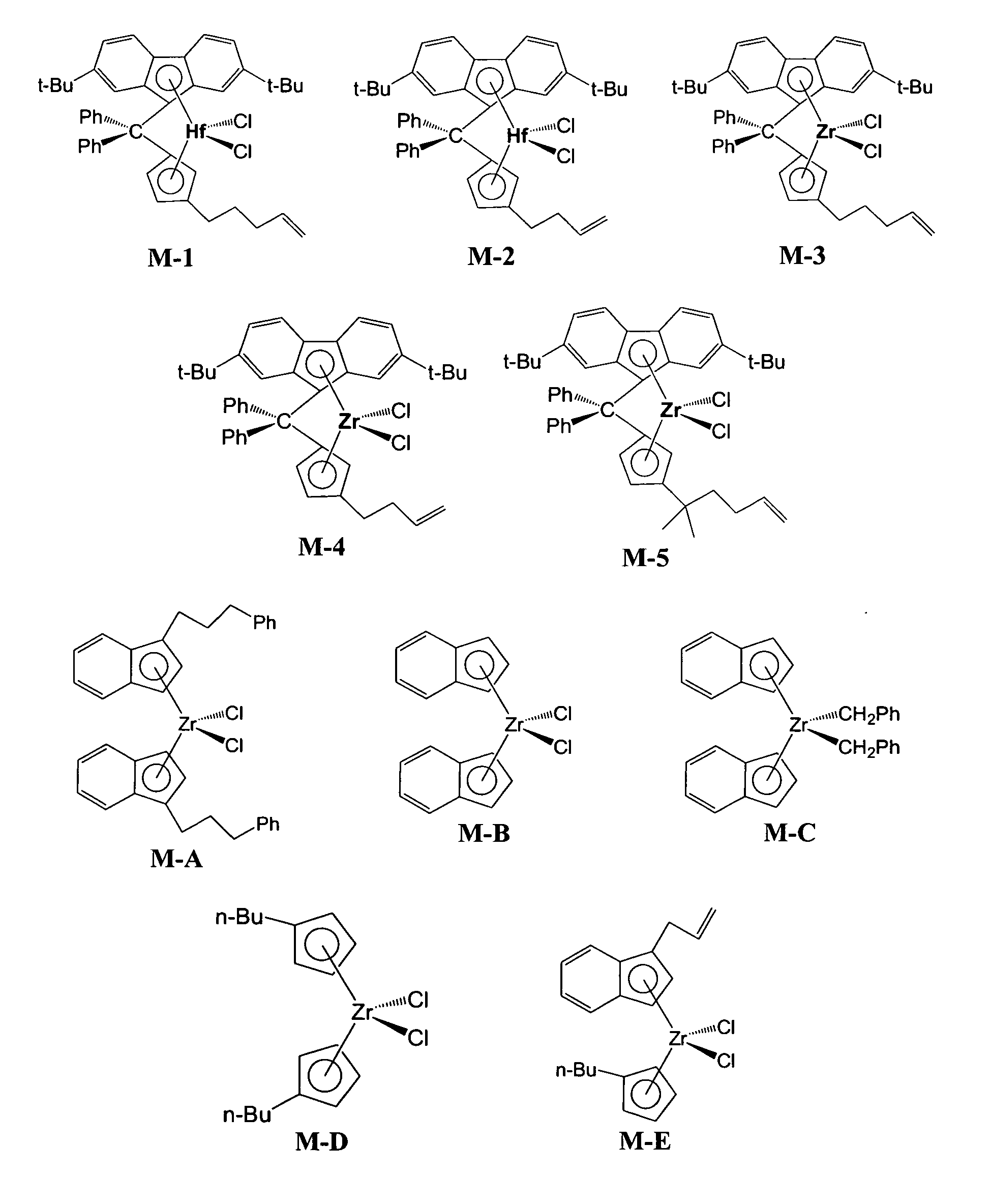

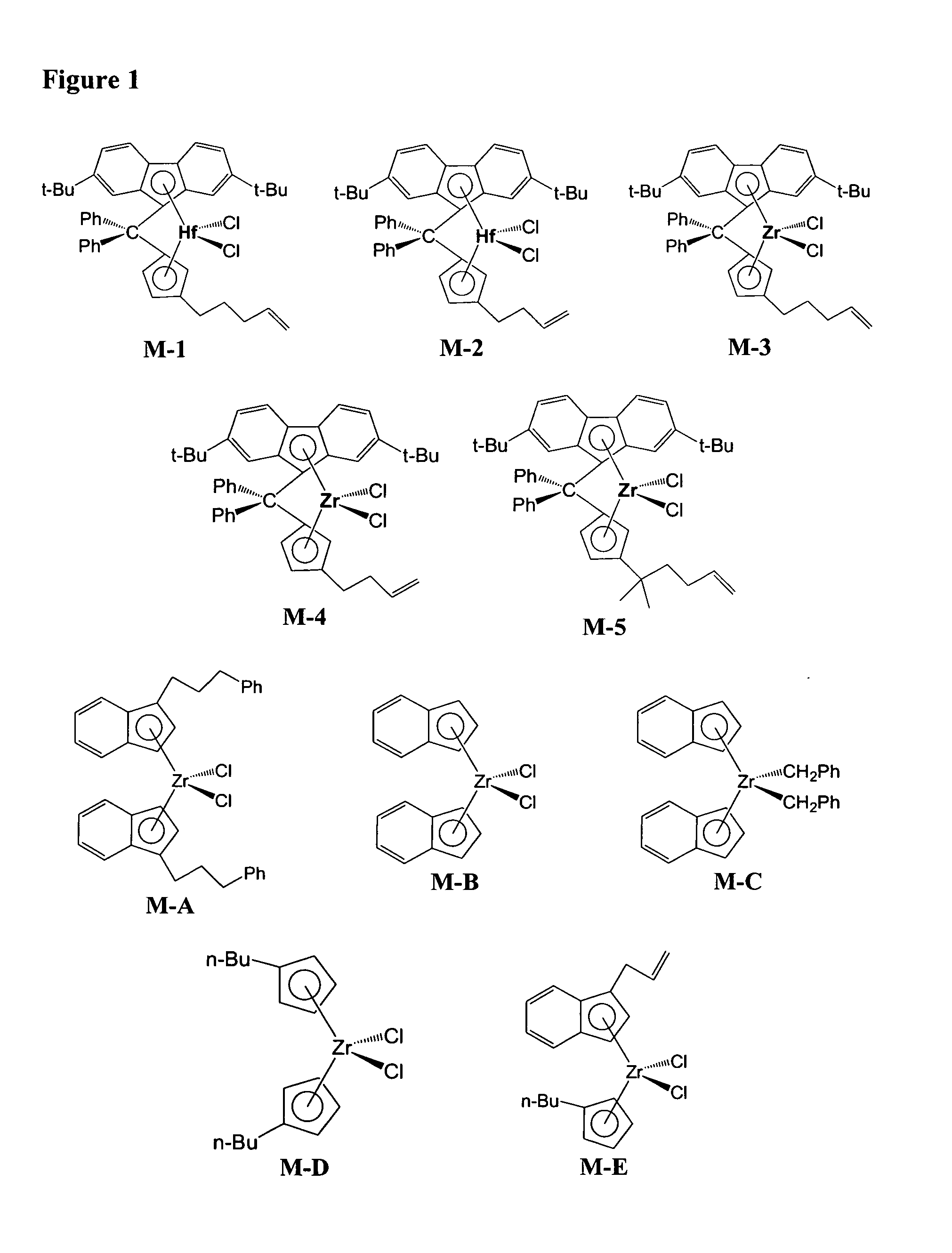

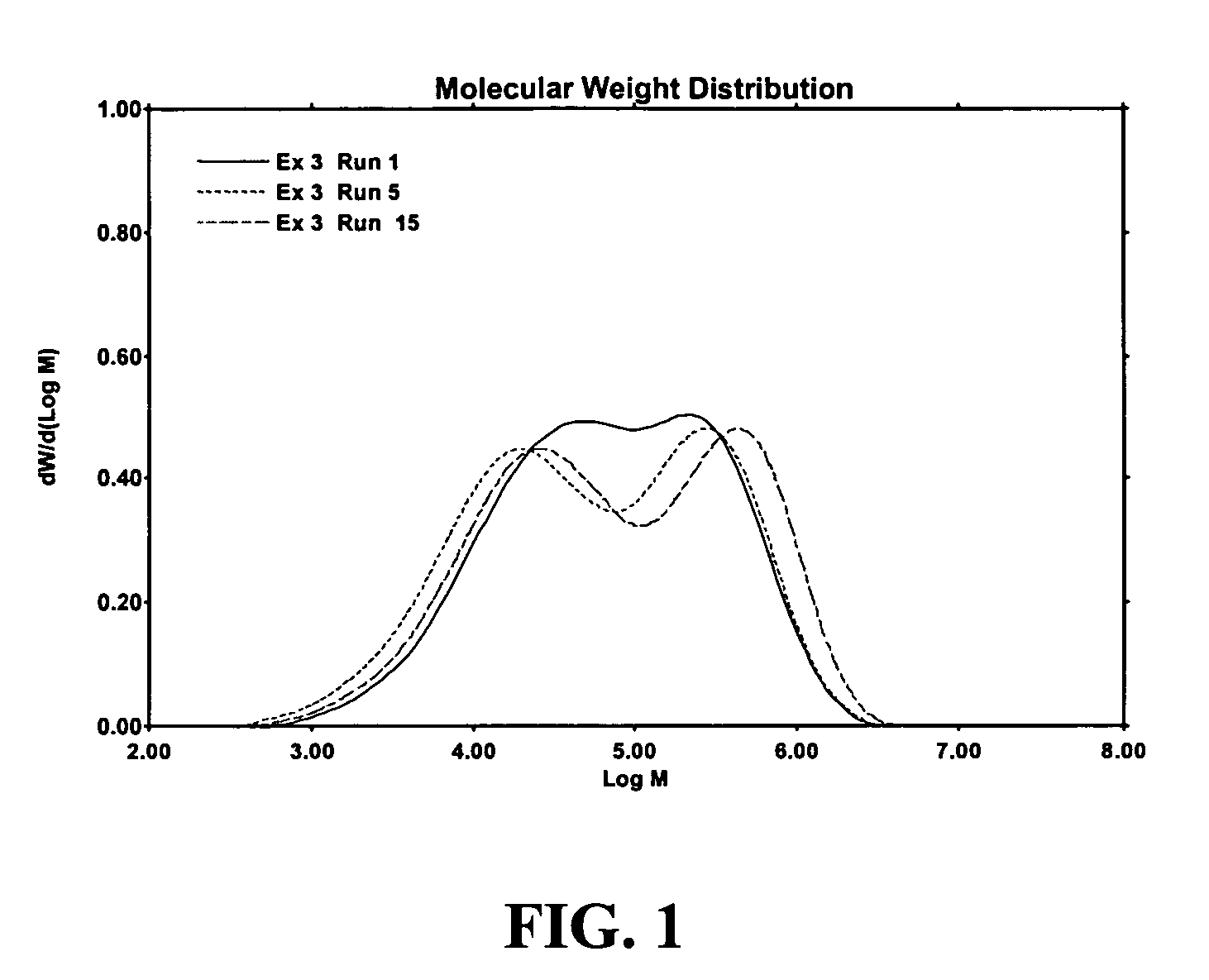

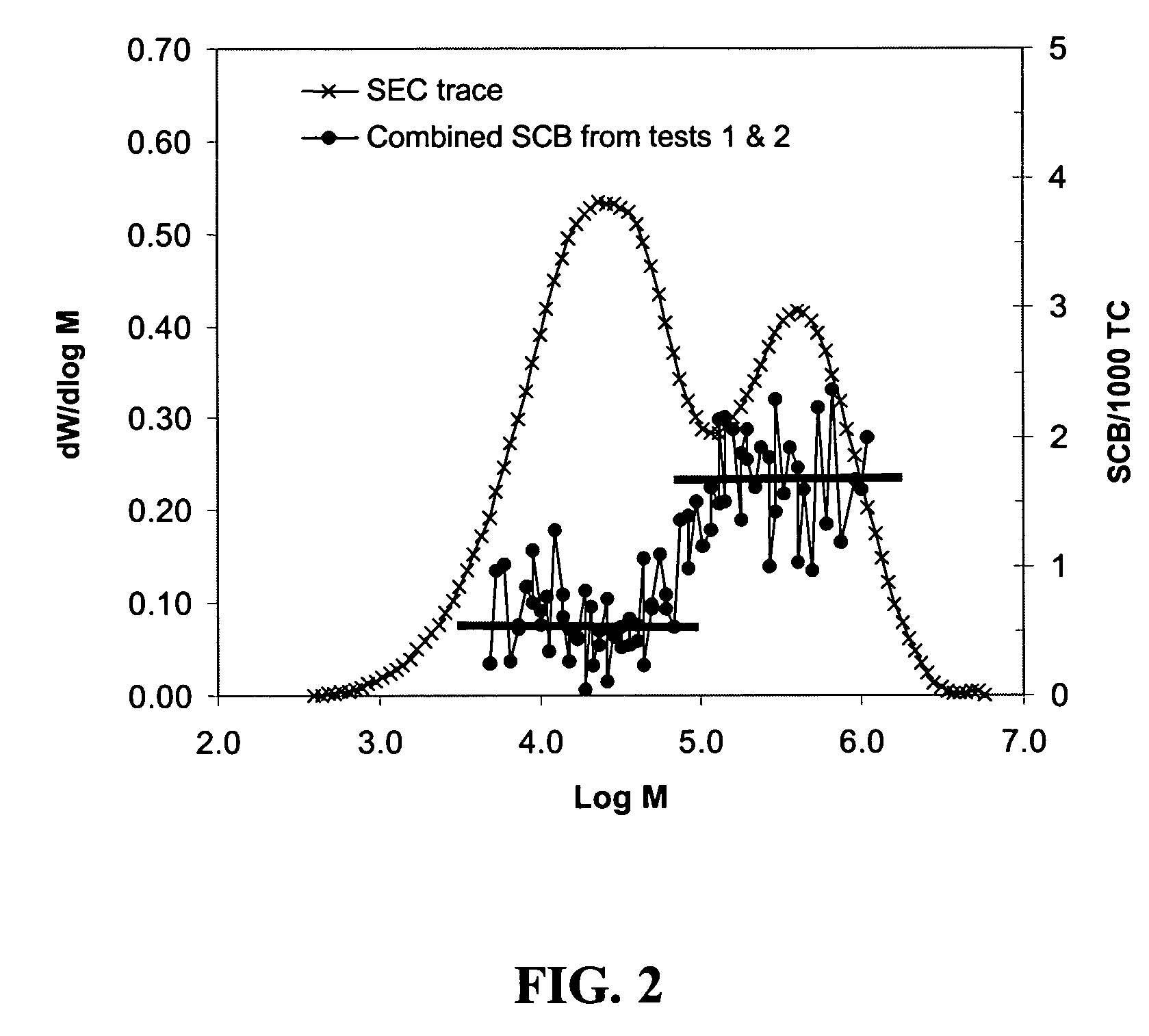

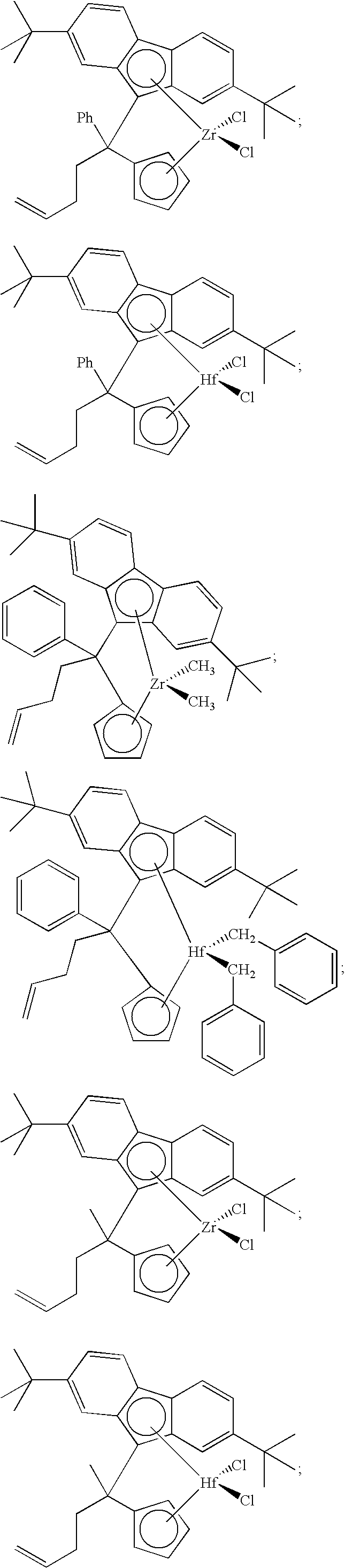

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7226886B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinImproved method

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. An improved method for preparing cyclopentadienyl complexes used to produce polyolefins is also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

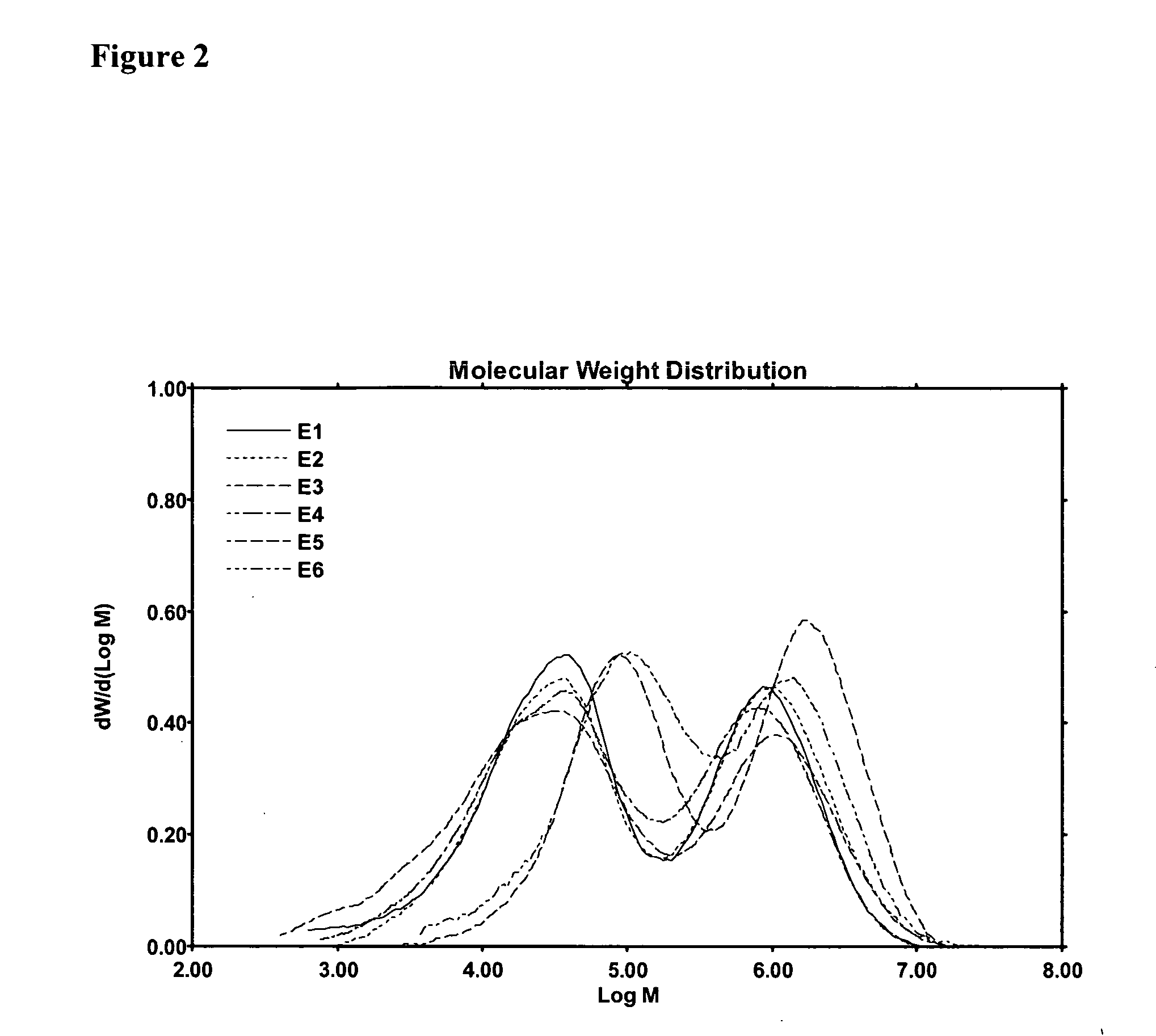

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS7619047B2Good balance of stiffnessHigh impact strengthGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEthylene PolymersEthylene

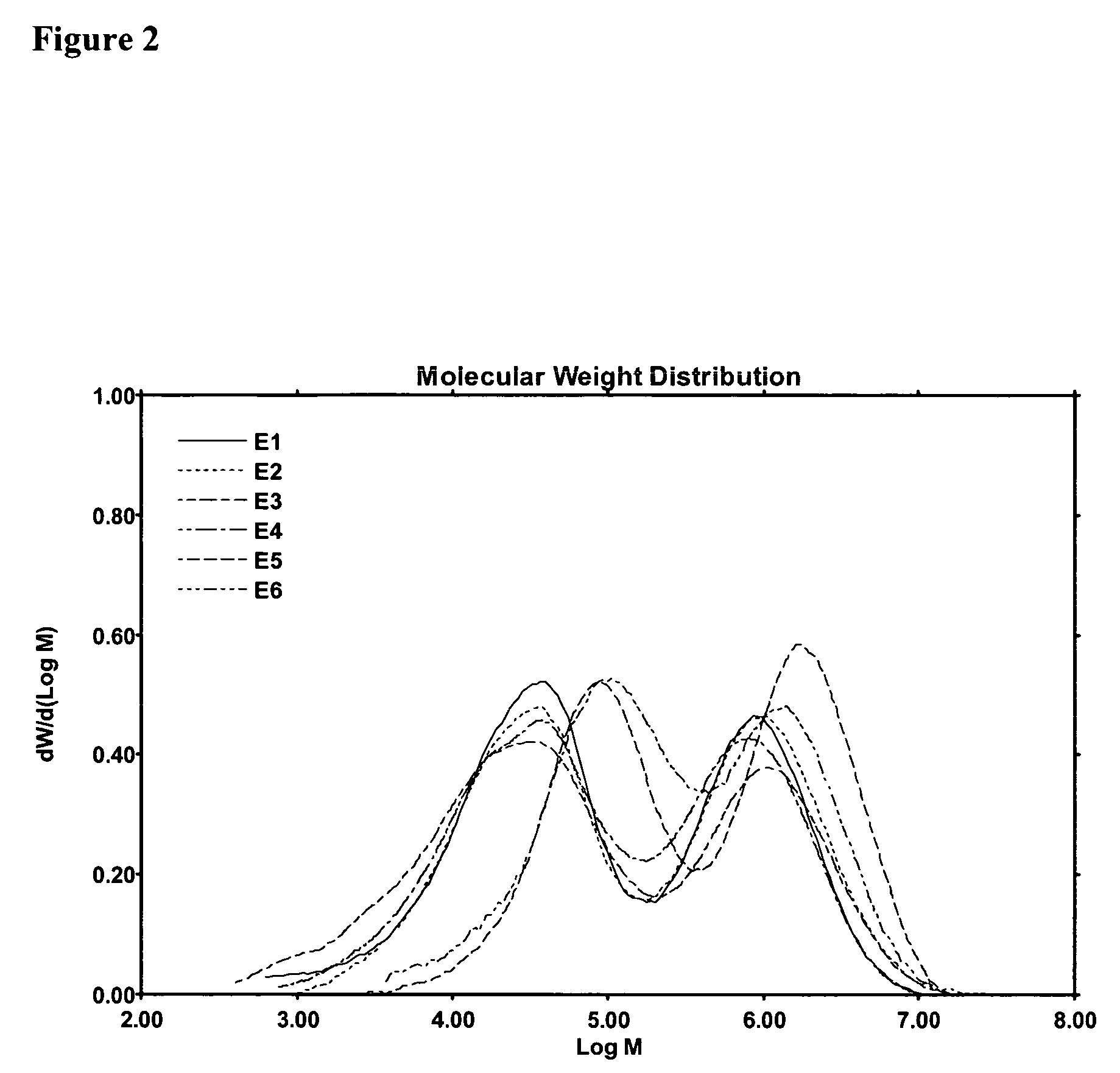

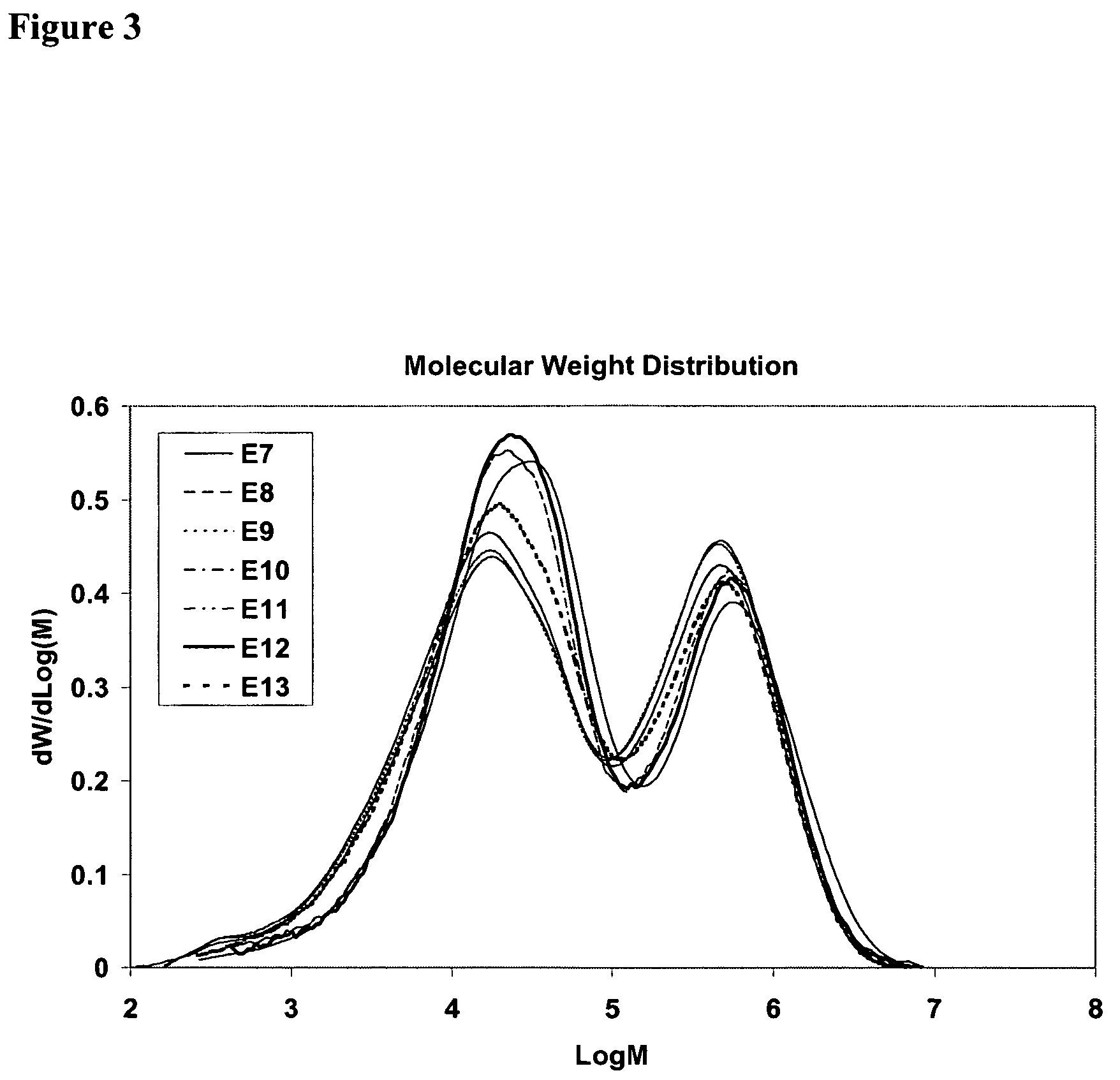

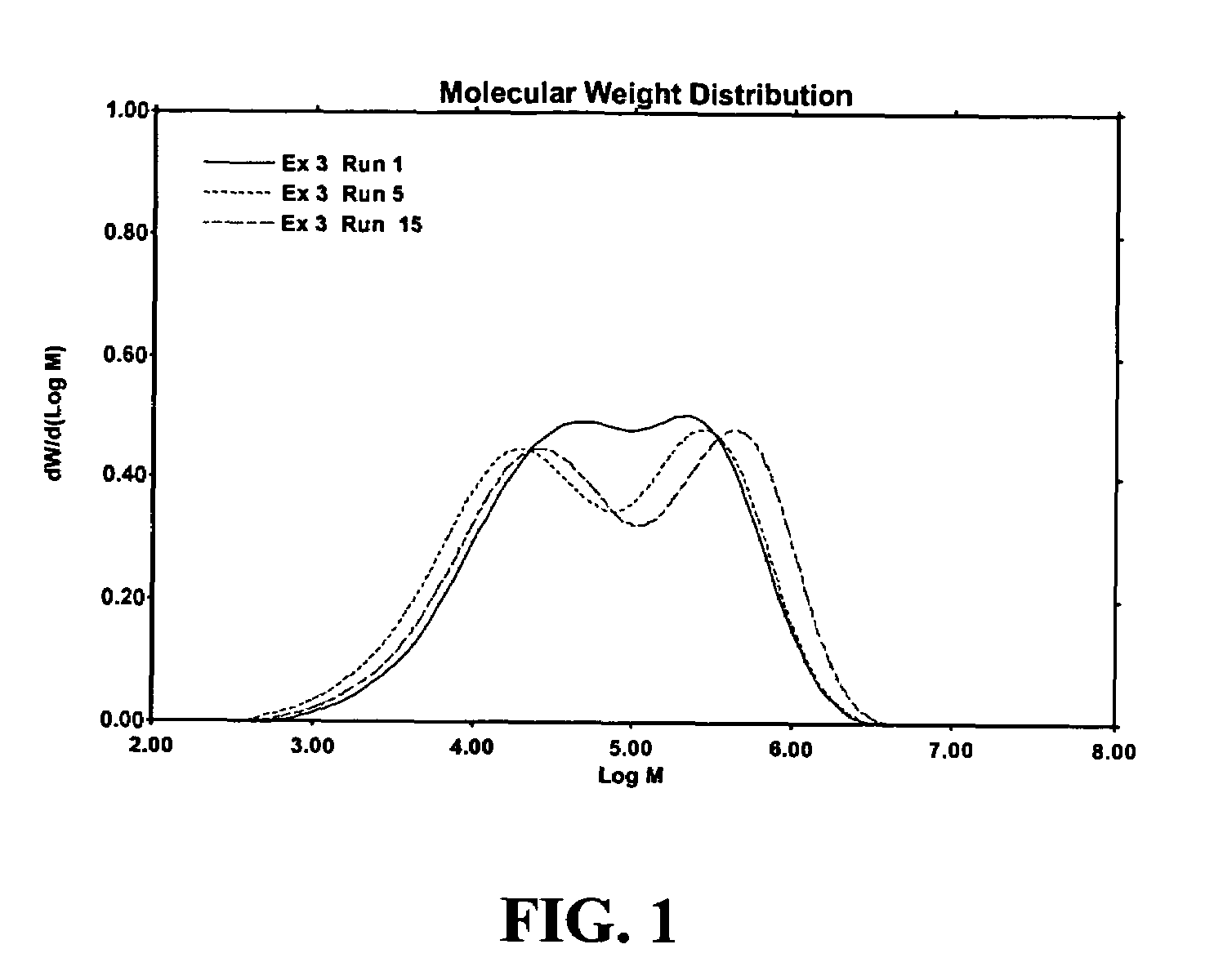

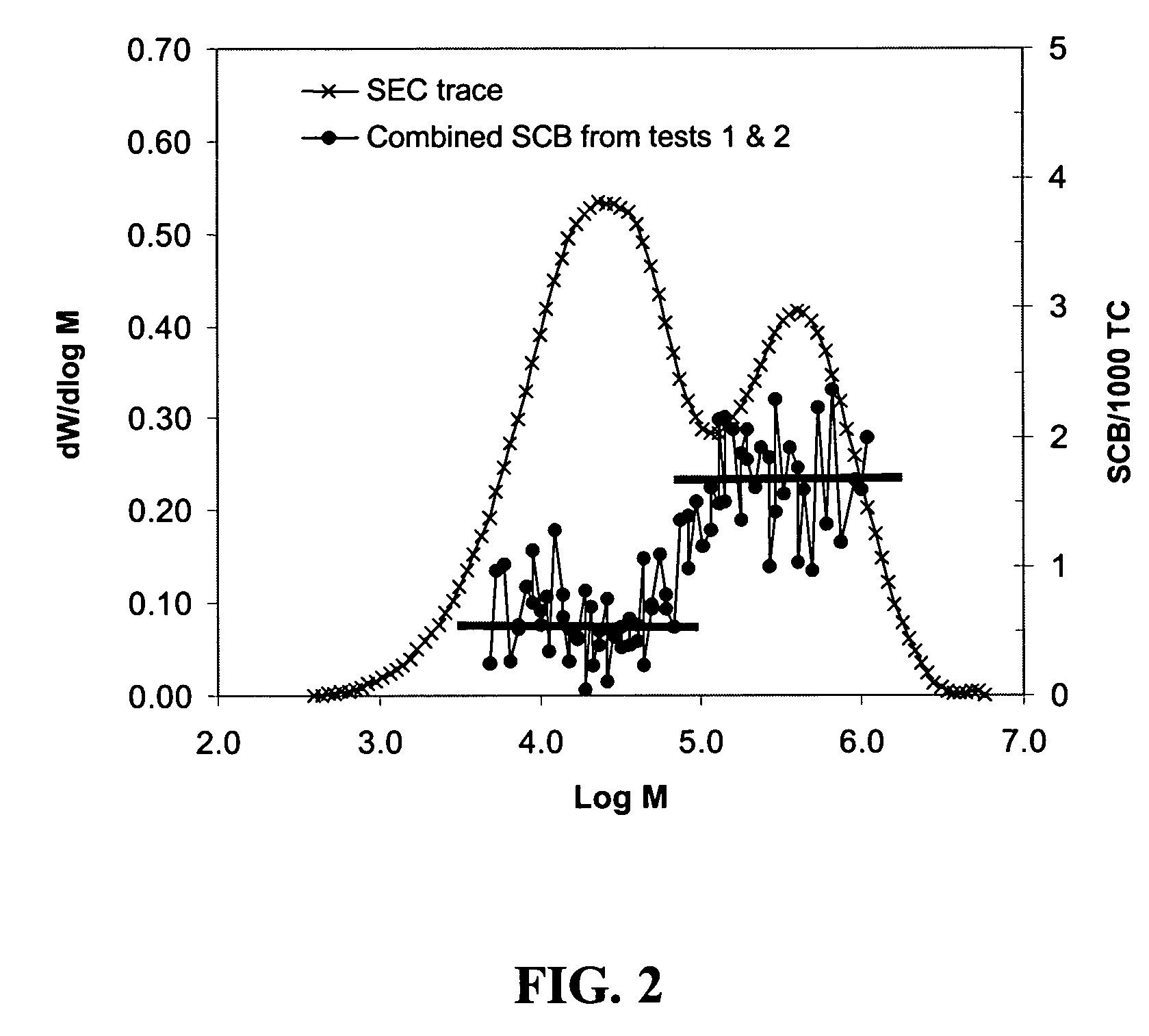

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7312283B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

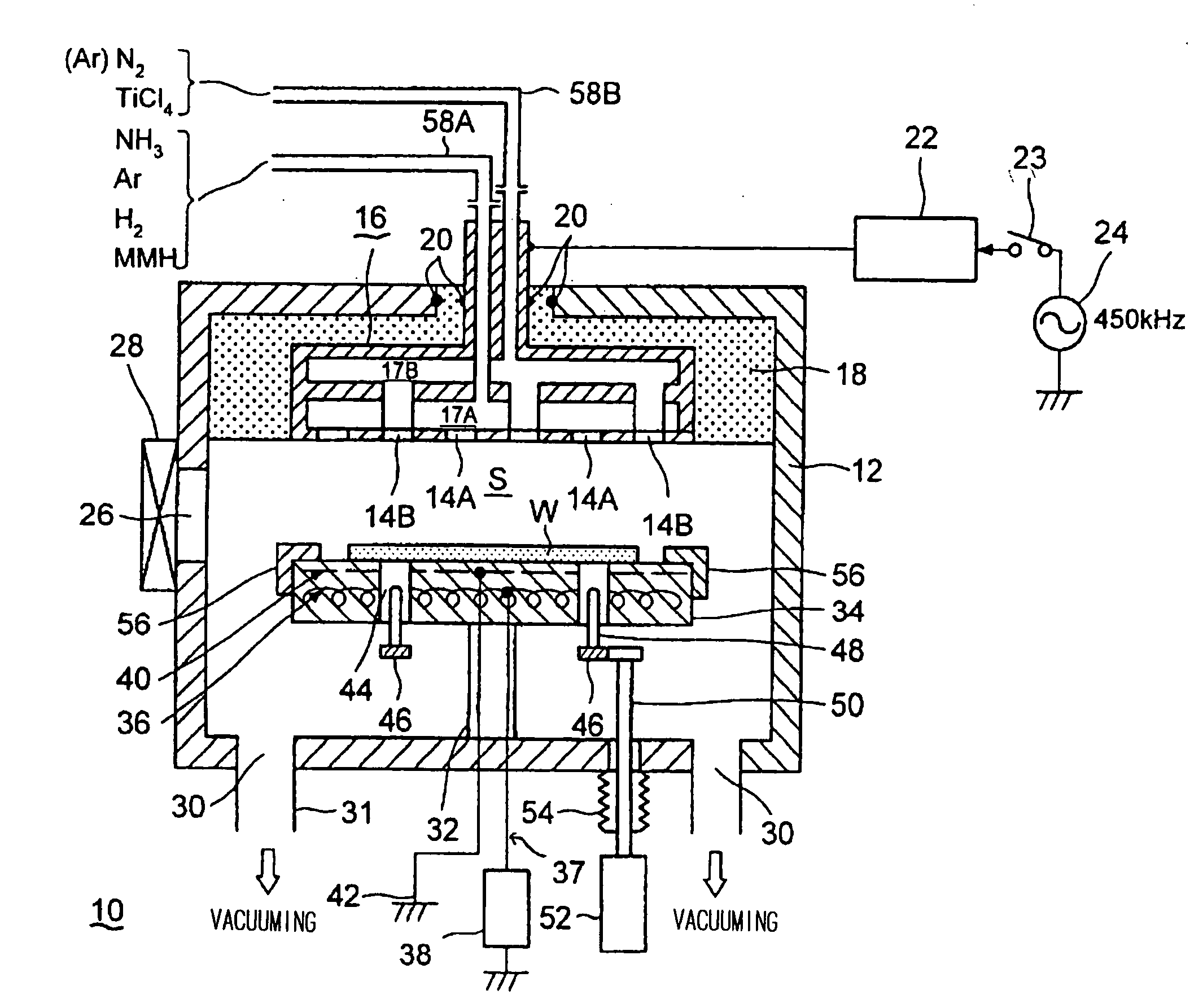

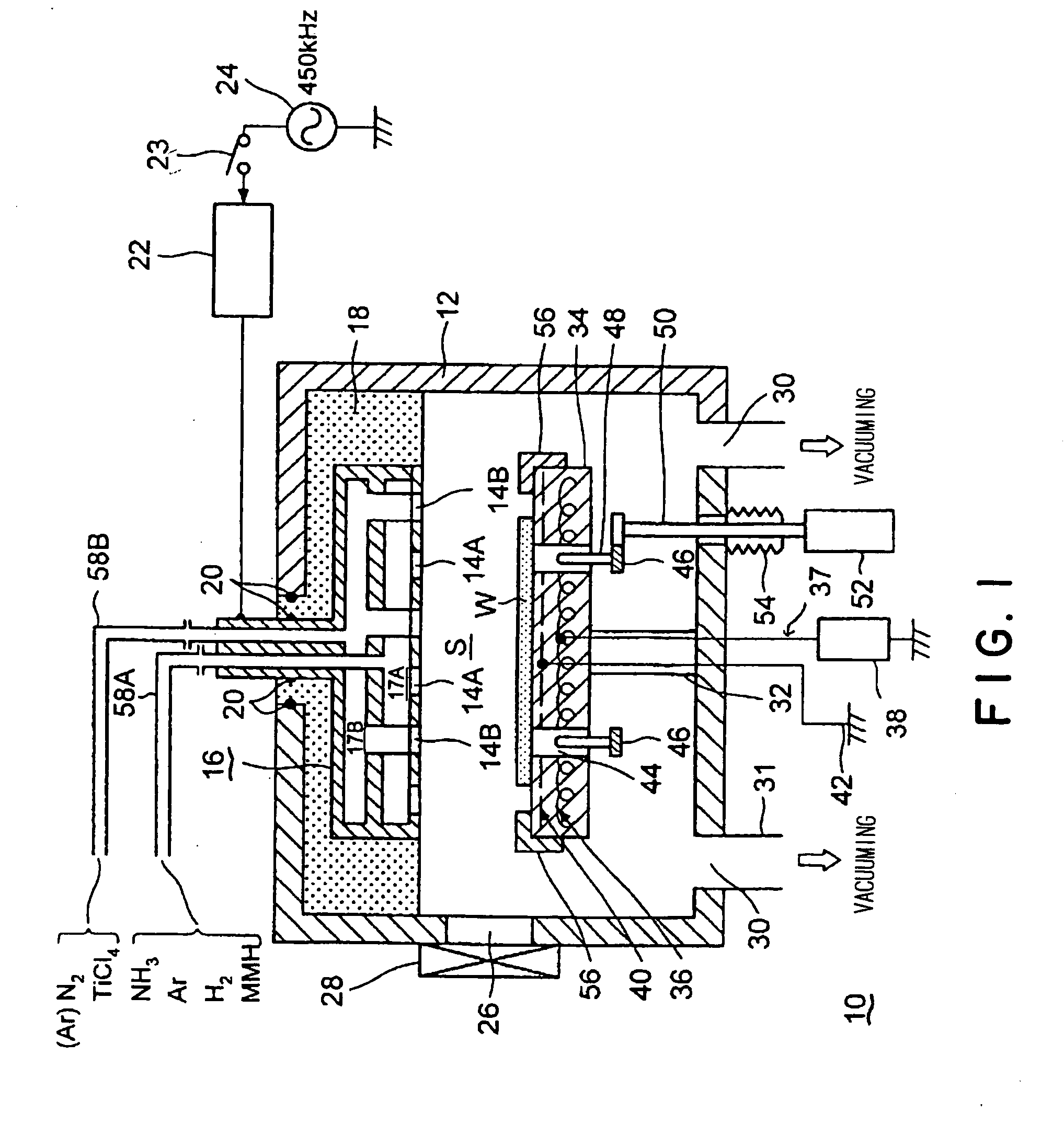

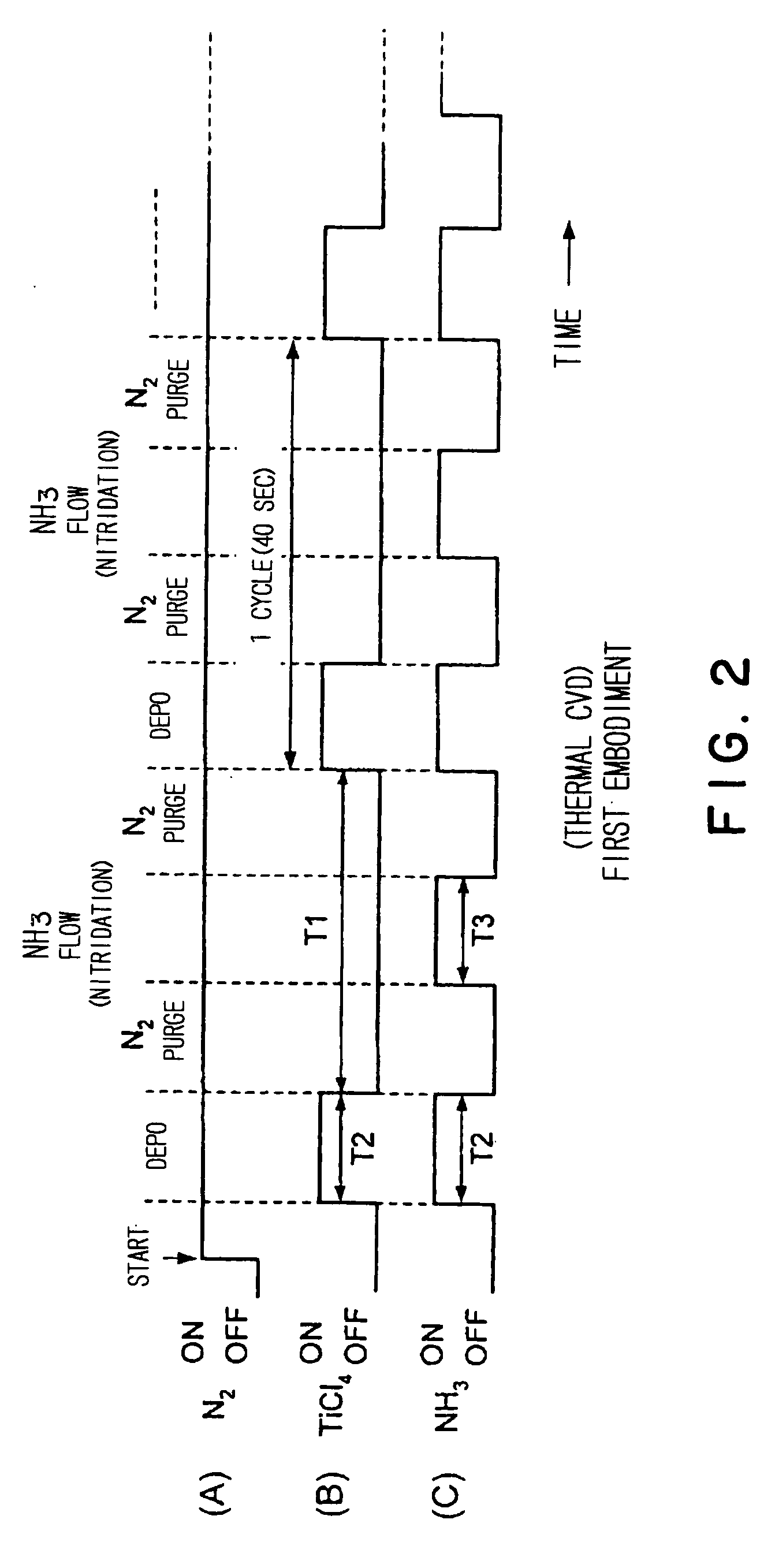

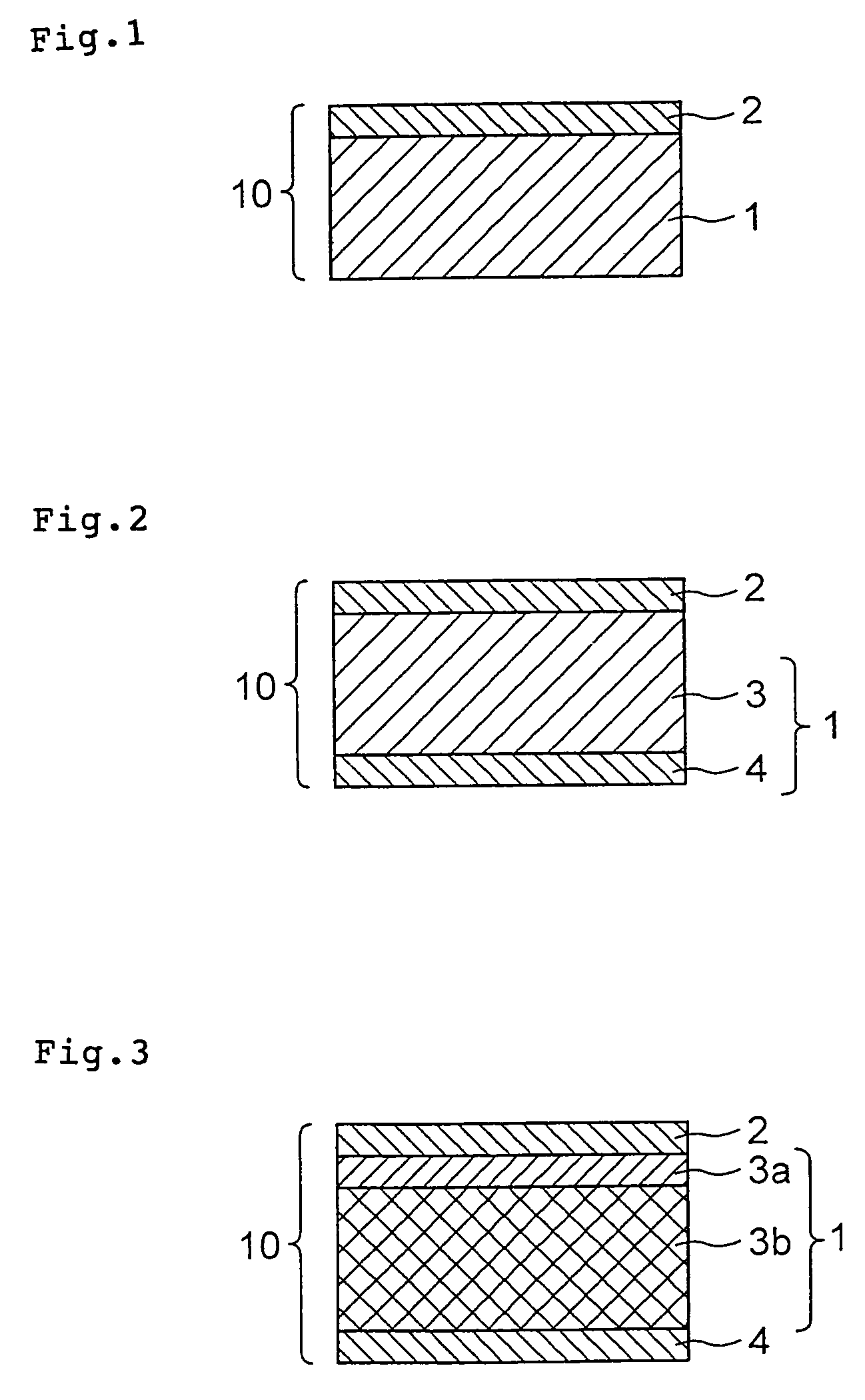

Method for forming film

InactiveUS20060193980A1Less micro crackEfficient solutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenProduct gas

The present invention relates to a method of forming a metal-nitride film onto a surface of an object to be processed in a processing container in which a vacuum can be created. The method of the invention includes: a step of continuously supplying an inert gas into a processing container set at a high film-forming temperature; and a step of intermittently supplying a metal-source gas into the processing container, during the step of continuously supplying the inert gas. During the step of intermittently supplying the metal-source gas, a nitrogen-including reduction gas is supplied into the processing container at the same time that the metal-source gas is supplied, during a supply term of the metal-source gas. The nitrogen-including reduction gas is also supplied into the processing container for a term shorter than a non-supply term of the metal-source gas, during the non-supply term of the metal-source gas. A film thickness of the metal-nitride film formed during the one supply term of the metal-source gas is not more than 60 nm. According to the invention, although the film-forming process is conducted at a relatively high temperature, a metal-nitride film can be deposited whose chlorine density is low, whose resistivity is low, and in which fewer cracks may be generated.

Owner:TOKYO ELECTRON LTD

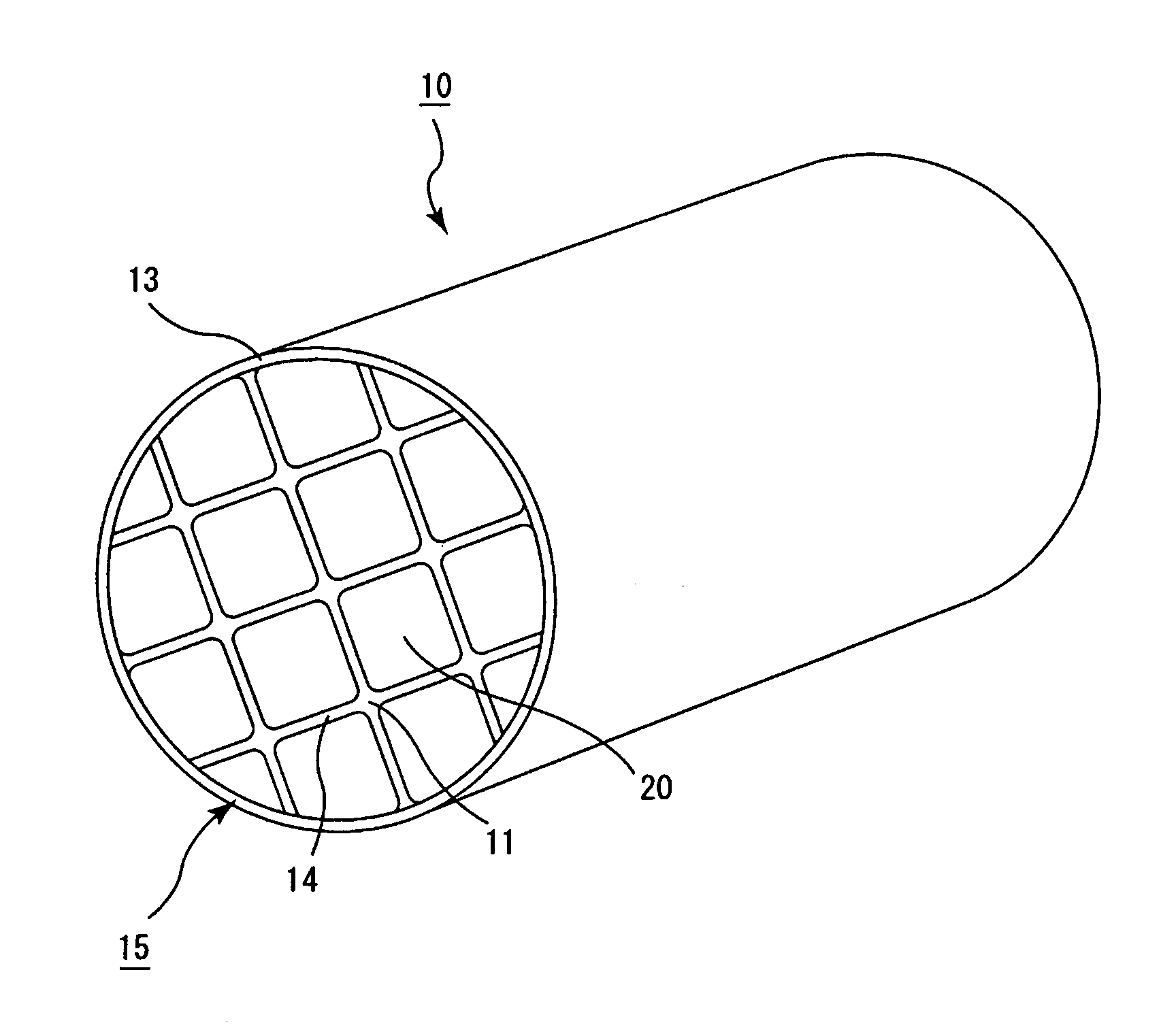

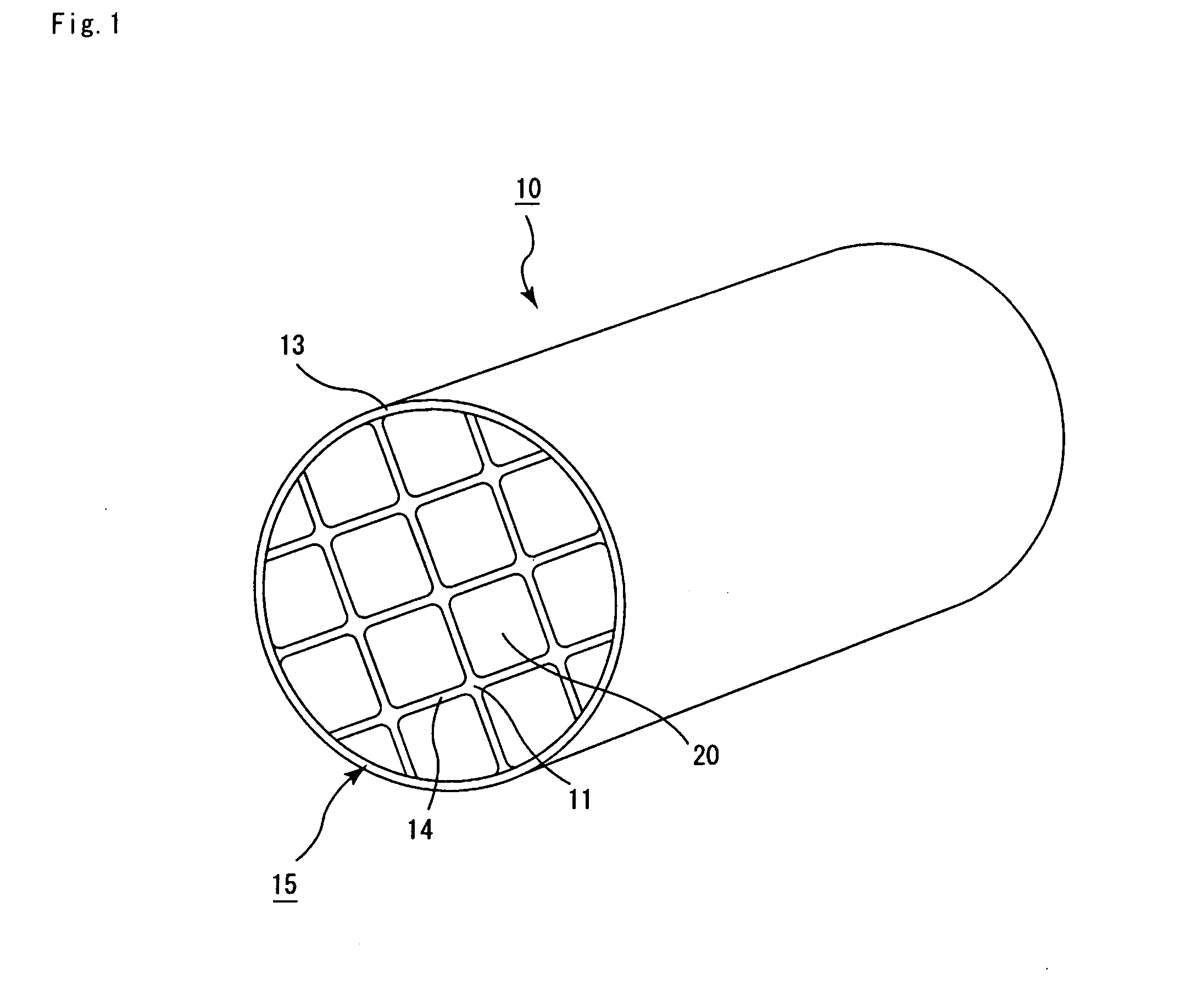

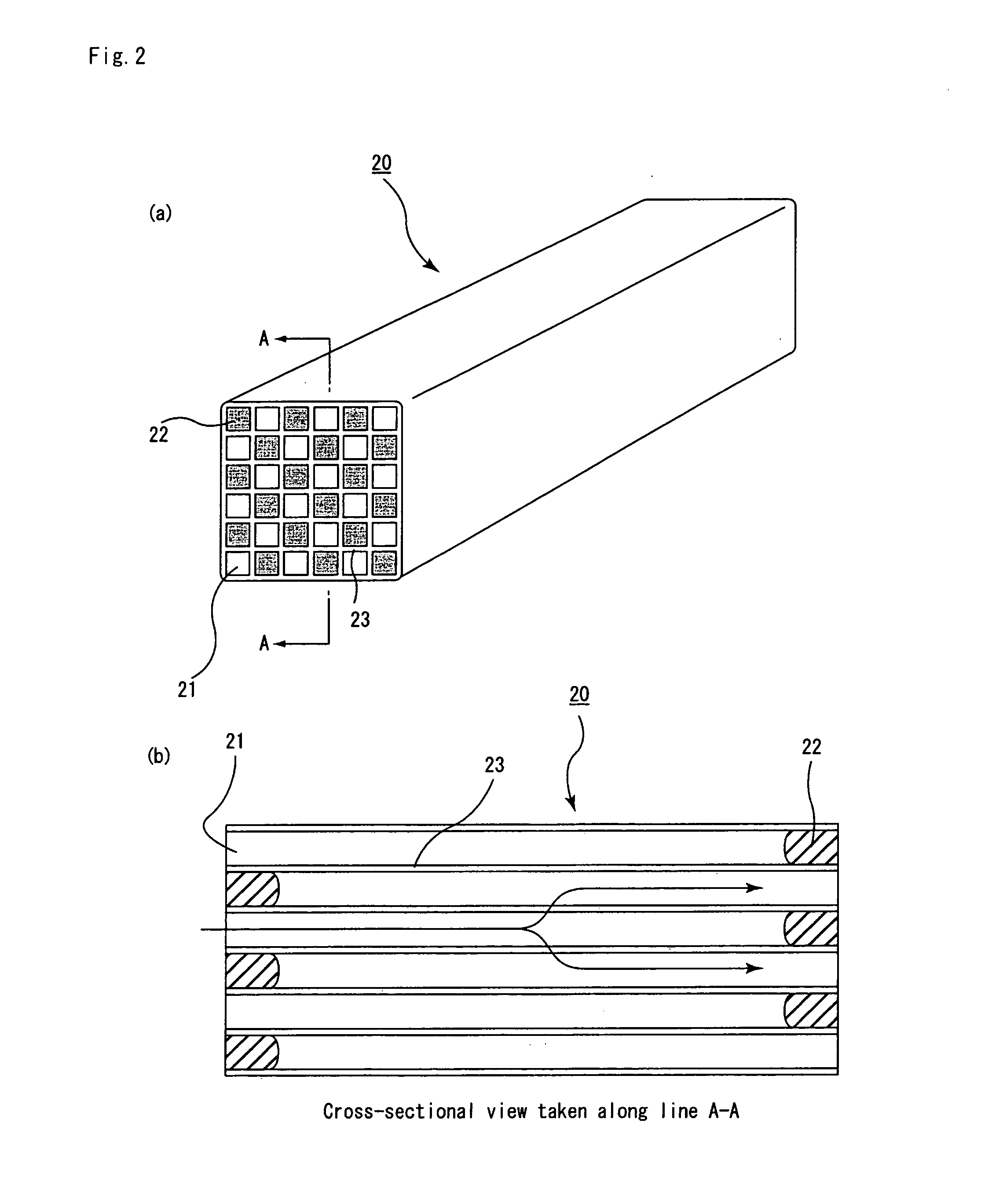

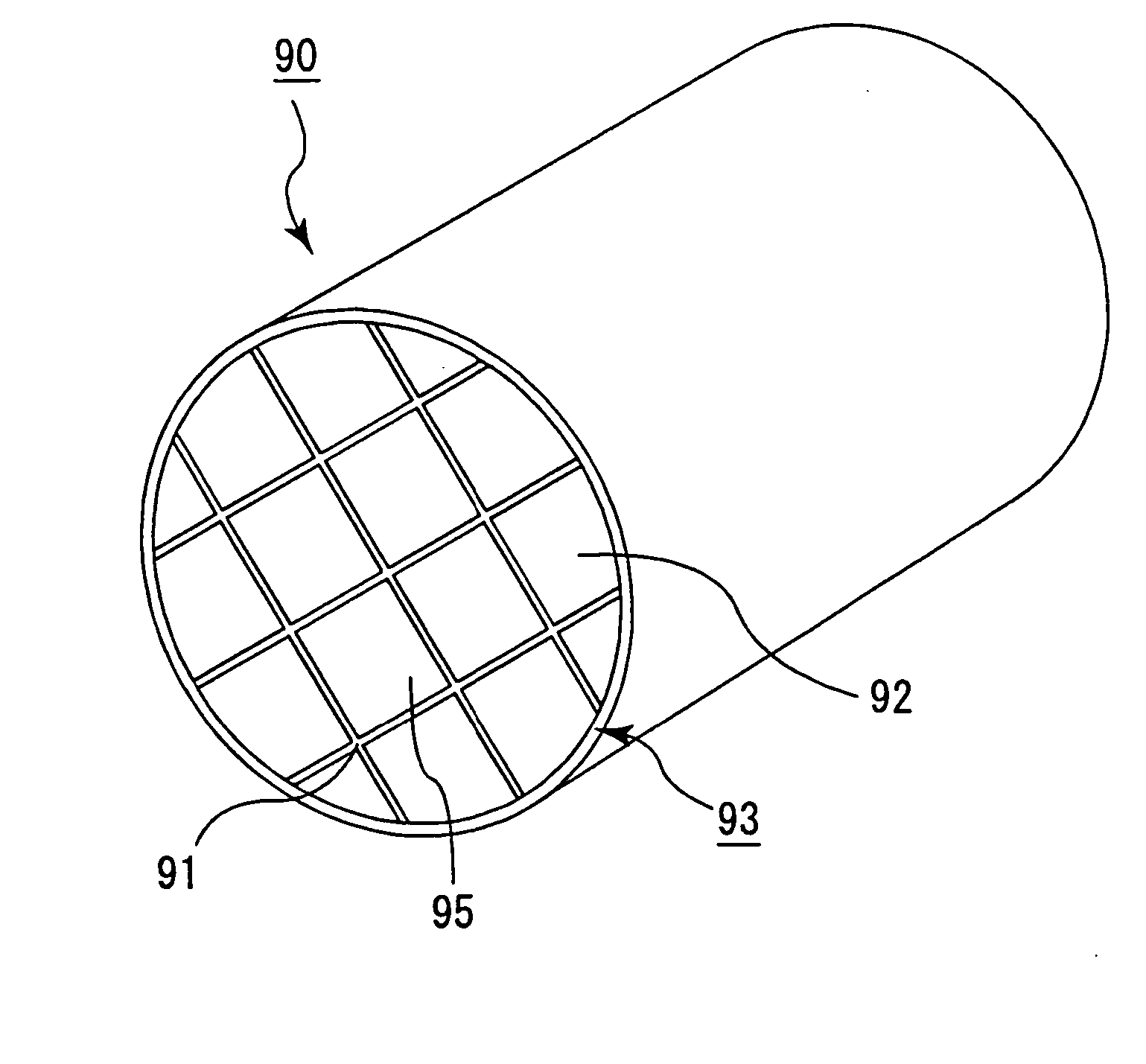

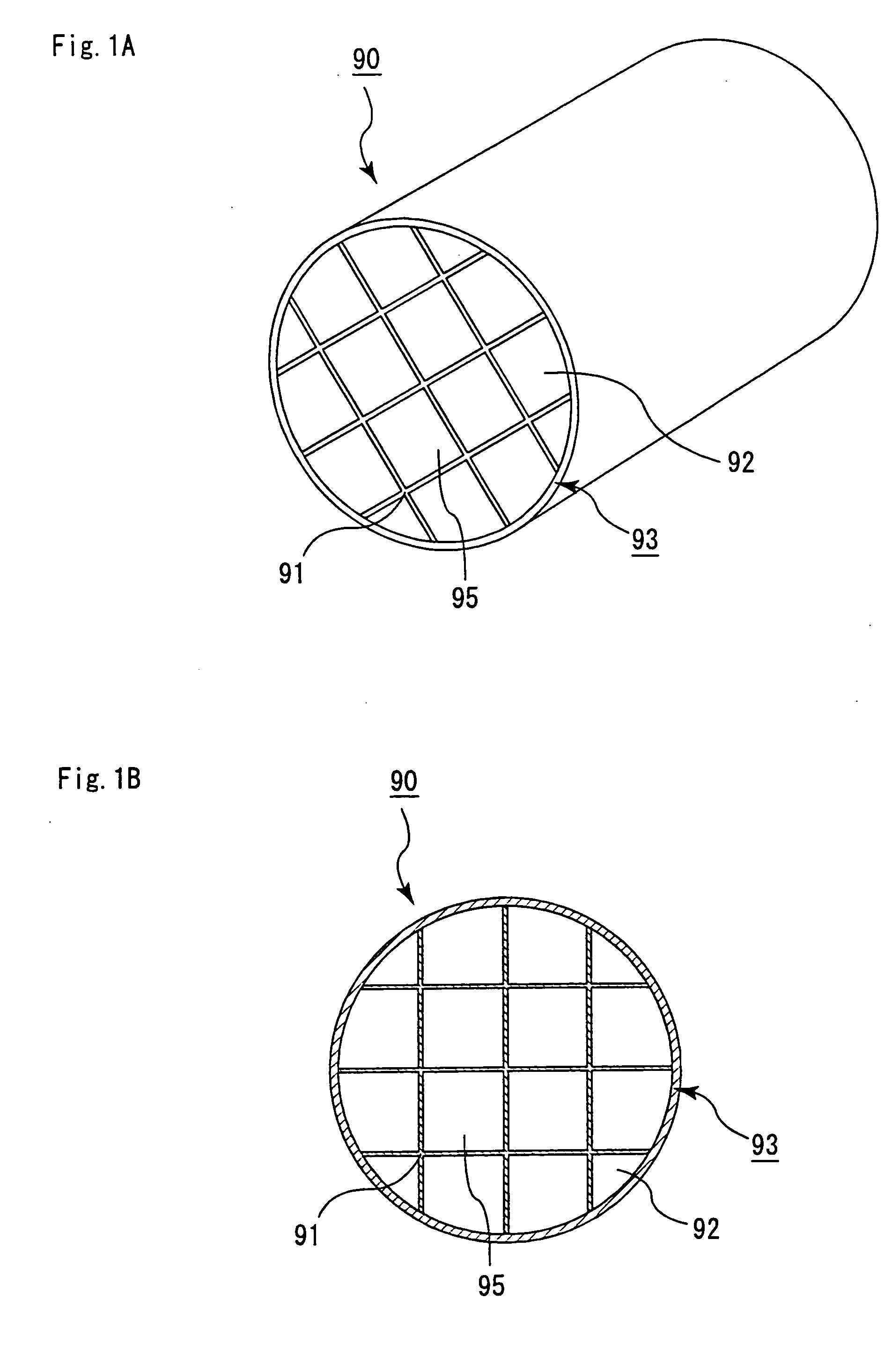

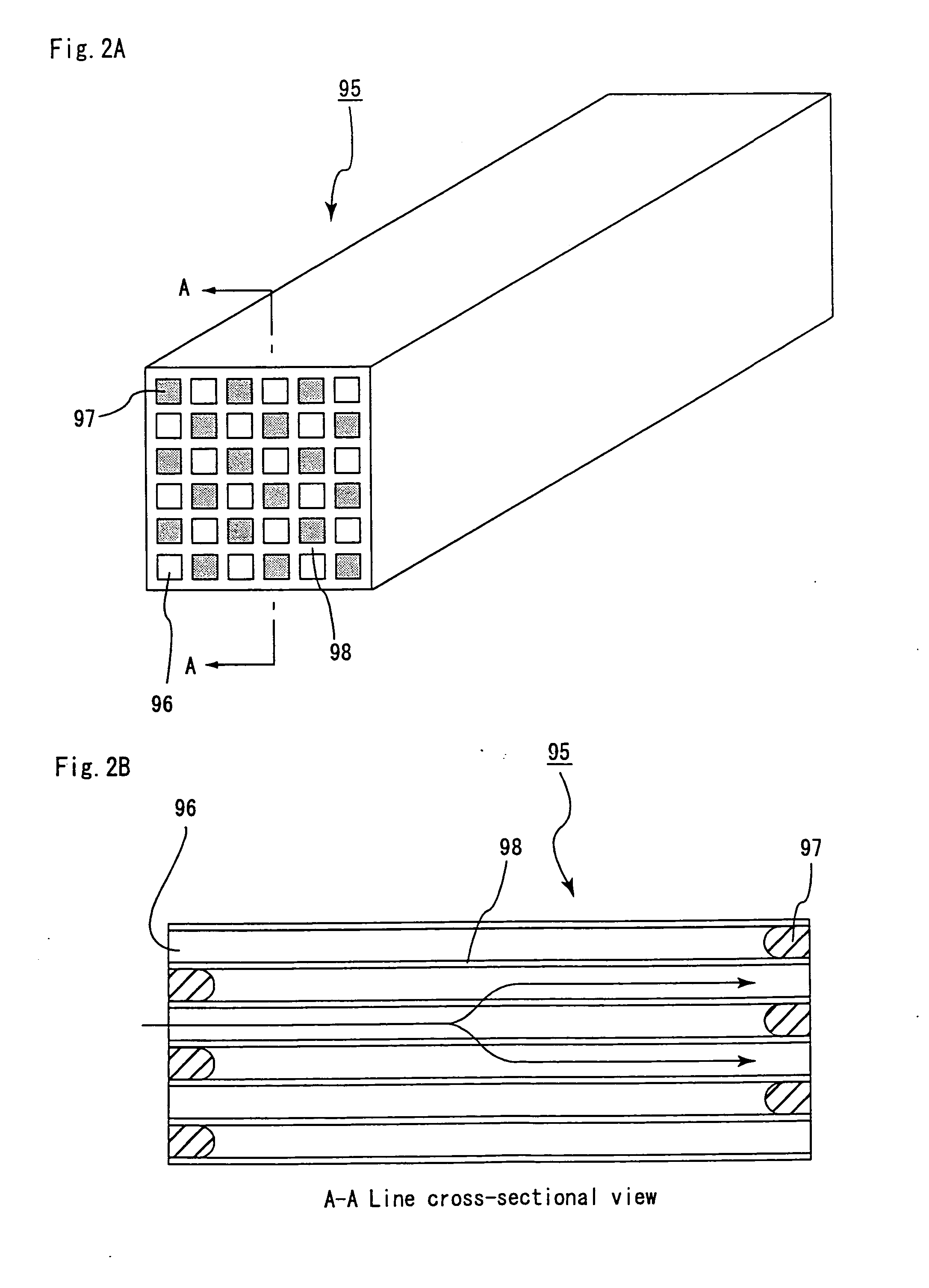

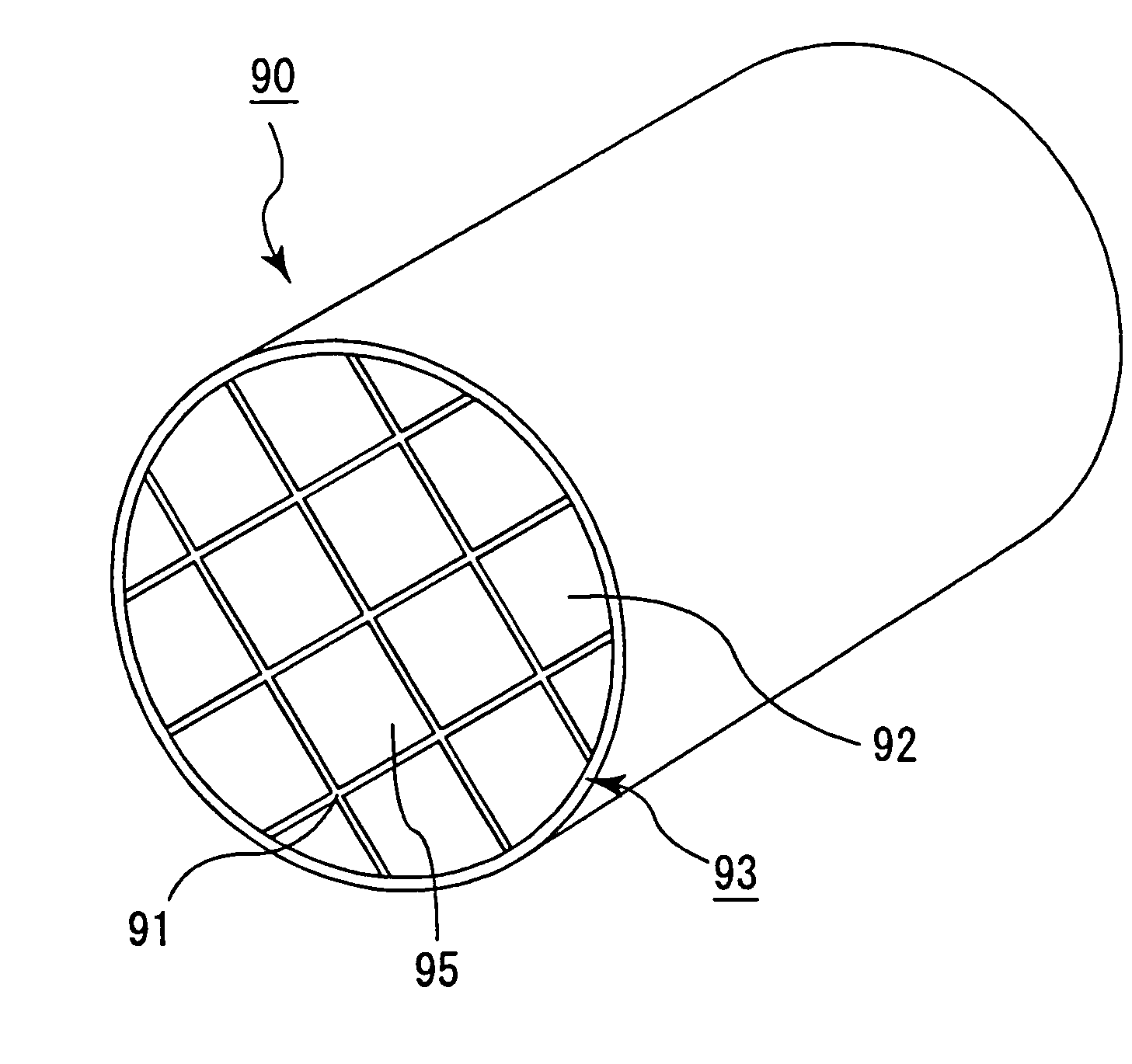

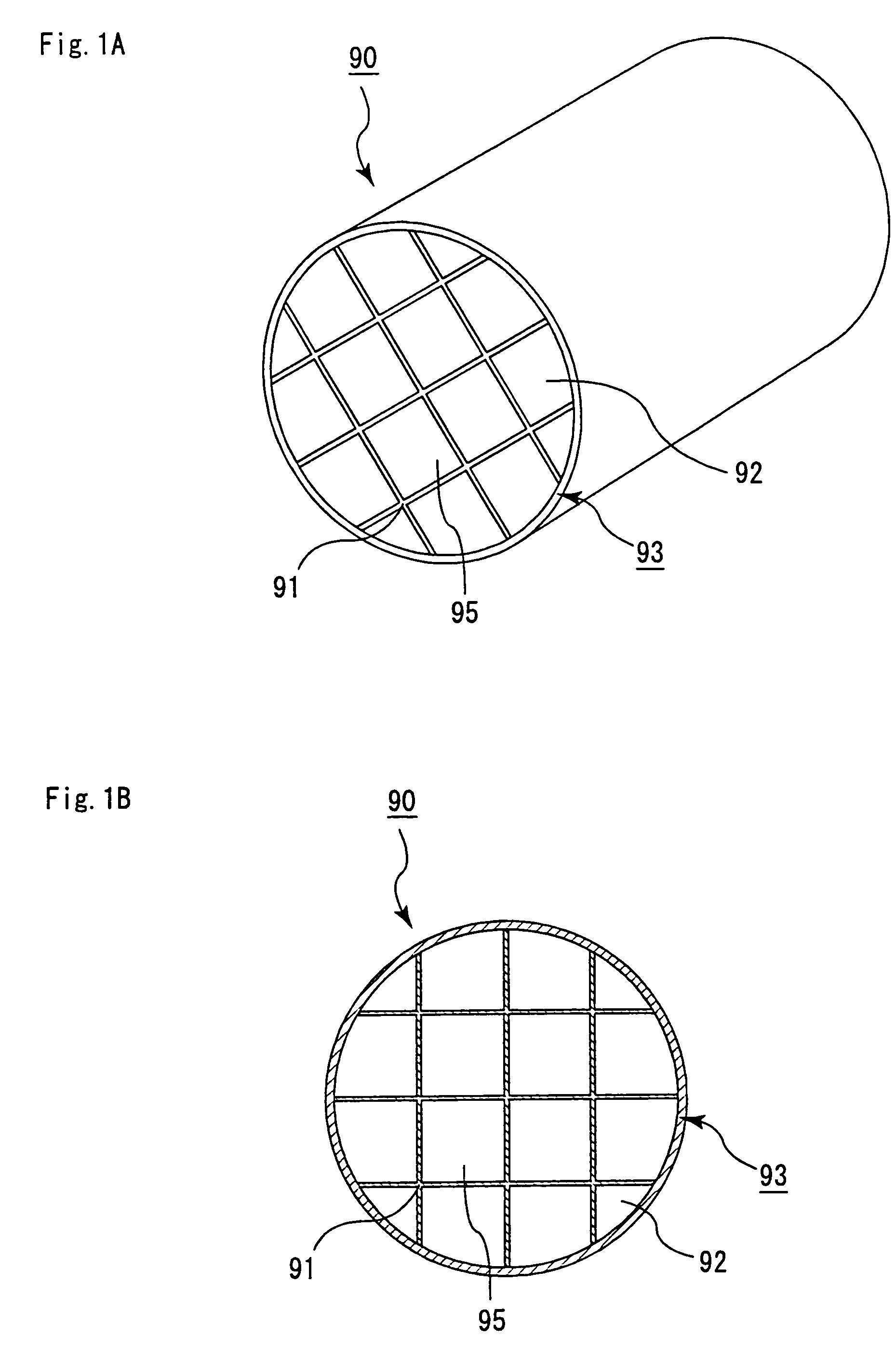

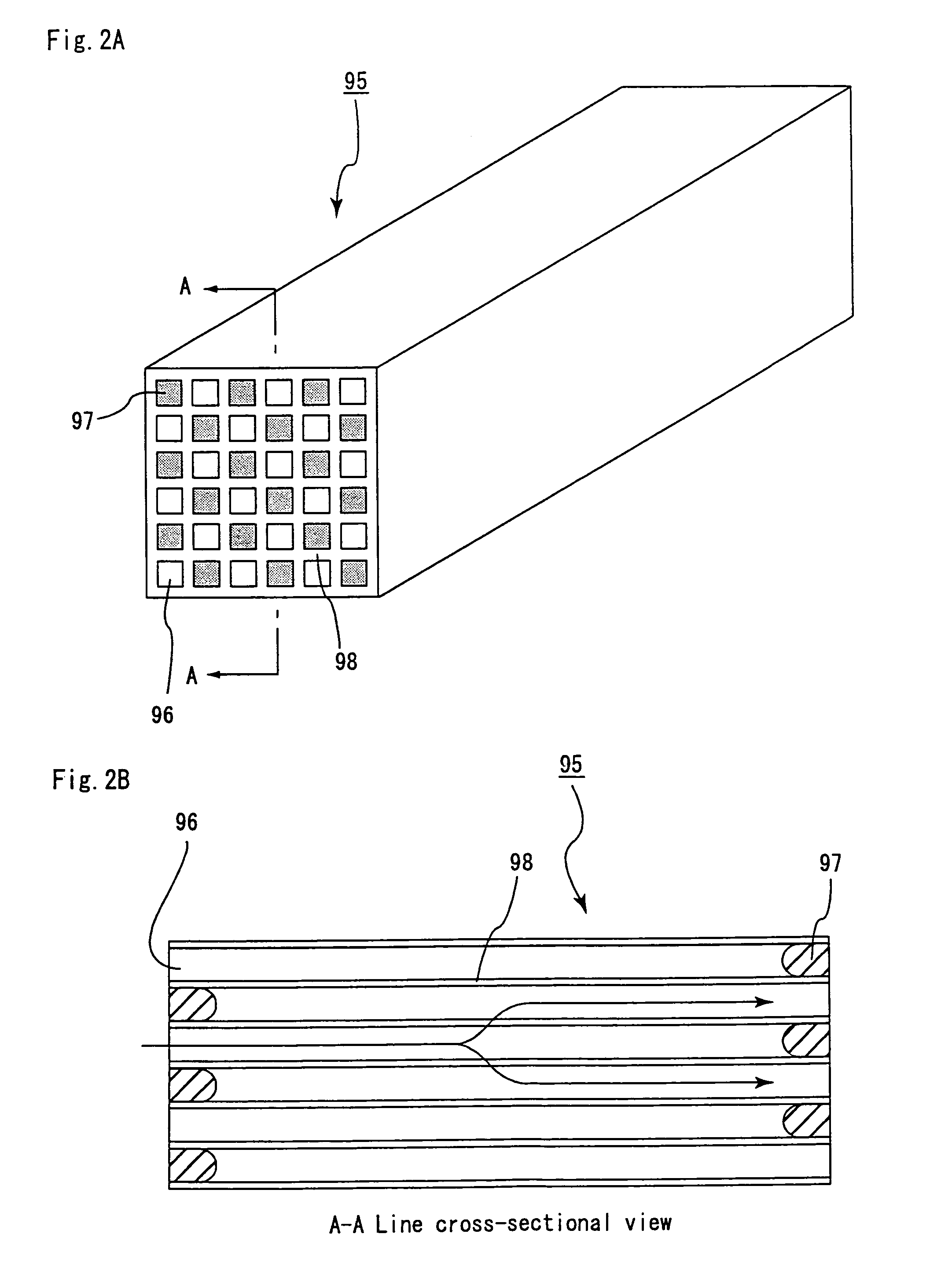

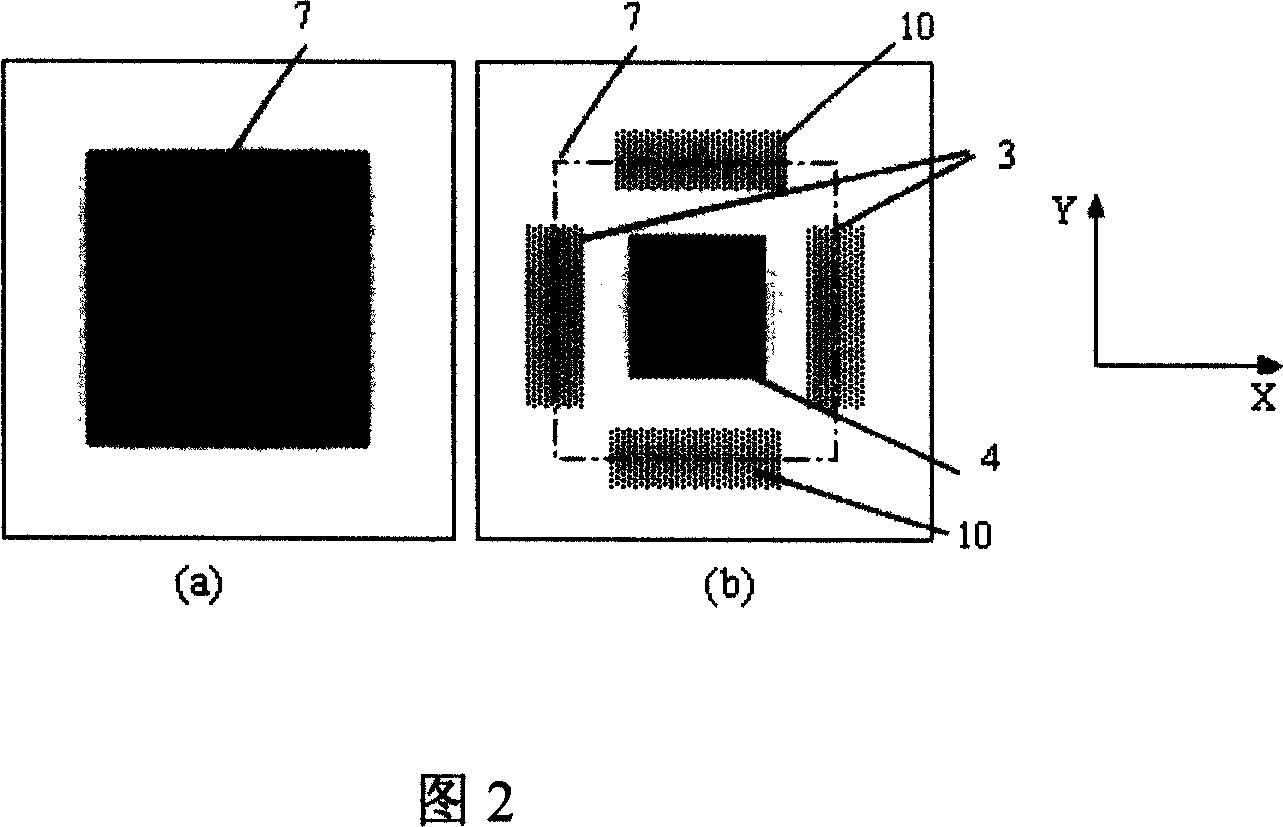

Honeycomb filter for clarification of exhaust gas

InactiveUS20050180898A1Increased durabilityReduce crackingCombination devicesInternal combustion piston enginesParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases. A plurality of rectangular columnar porous ceramic members are combined with one another through a sealing material layer to constitute a ceramic block, each of the rectangular columnar porous ceramic member including a number of through holes that are placed in parallel with one another in the length direction with a partition wall interposed therebetween. A sealing material layer is also formed on a circumference portion of the ceramic block, and the partition wall that separates the through holes functions as a filter for collecting particulates. On a cross section perpendicular to the length direction of the porous ceramic member of the ceramic block, the maximum width L (mm) of the crisscross portion of the sealing material layer is 1.5 to 3 times greater than the minimum width I (mm) of the sealing material layer.

Owner:IBIDEN CO LTD

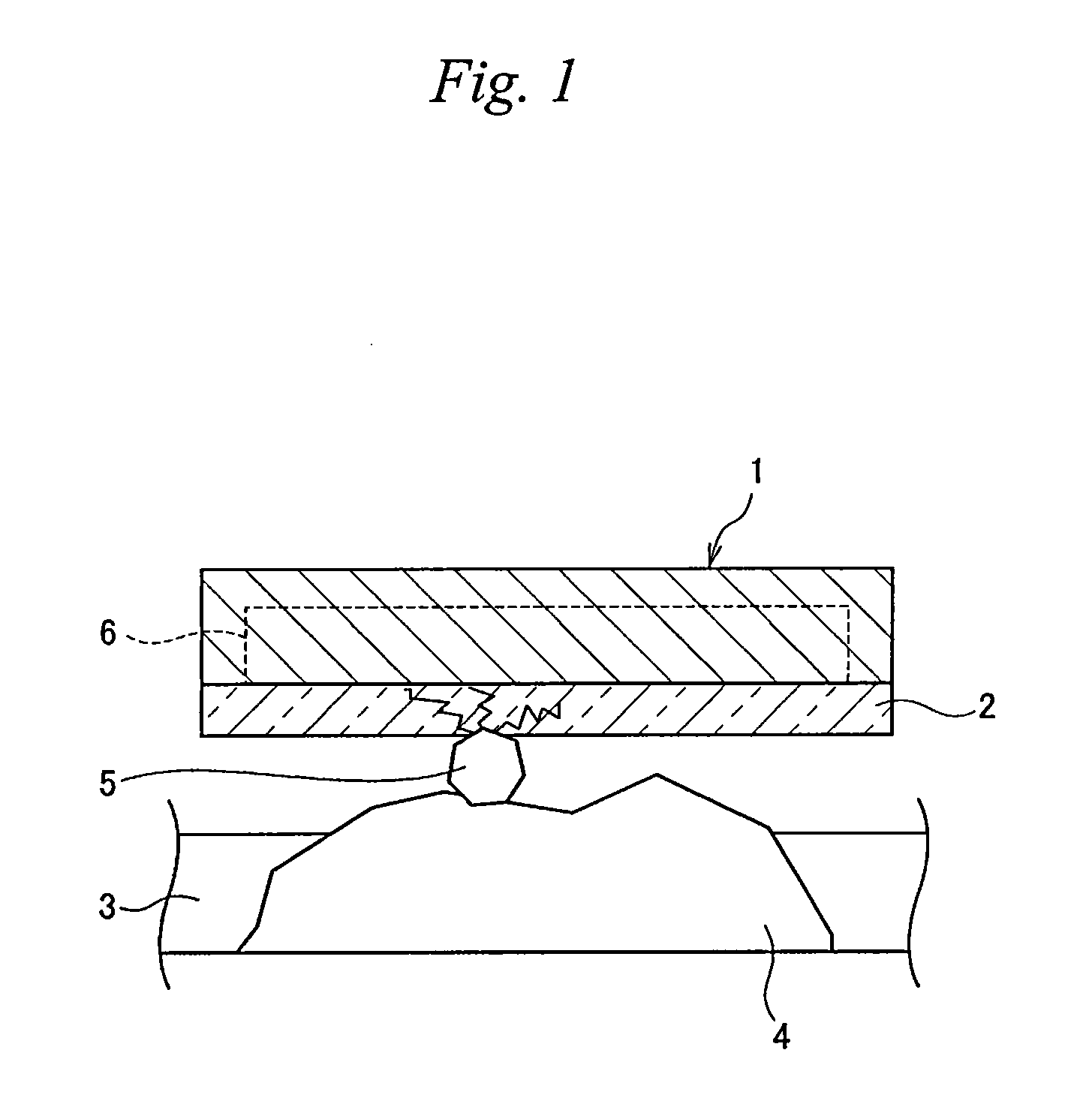

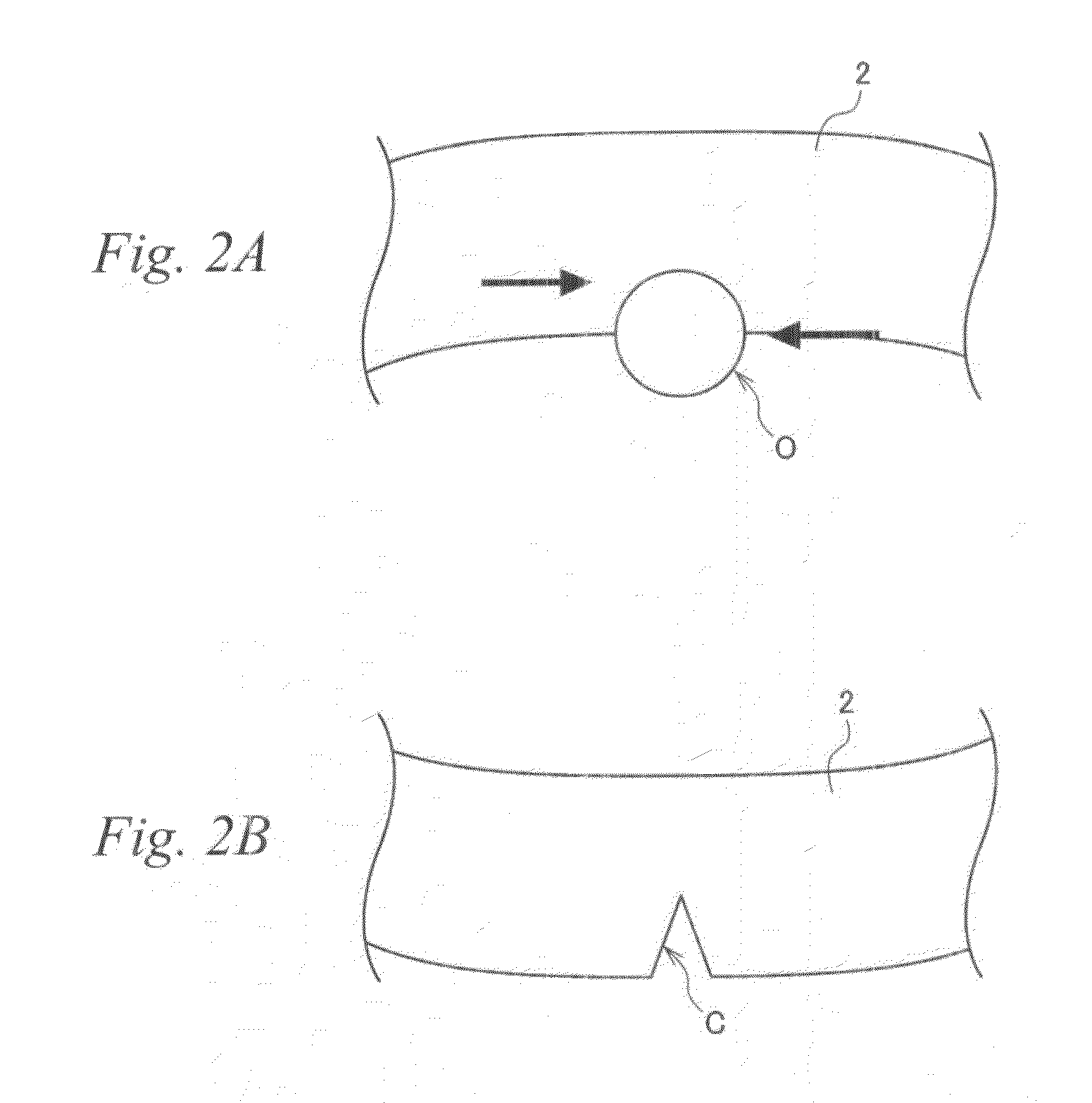

Wafer machining adhesive tape, and its manufacturing method and using method

InactiveUS7358158B2Reduce crackingSmall sizeSynthetic resin layered productsSolid-state devicesEngineeringSilicon

An adhesive tape having an adhesive layer formed on one side of a substrate layer, which renders it possible to minimize the extent of development of chipping or fragmentation (nicks) or crack in chip when the silicon wafer, to which this tape is adhered, is cut into chips using a dicer. The adhesive layer of the tape has a storage modulus G′ of 1 MPa or more at a temperature of 15 to 35° C., and preferably tan δ as represented by the ratio of a loss modulus G″ to the storage modulus G′ is 0.05 or less. The adhesive layer is preferably constructed principally of an olefin polymer.

Owner:MITSUI CHEM INC

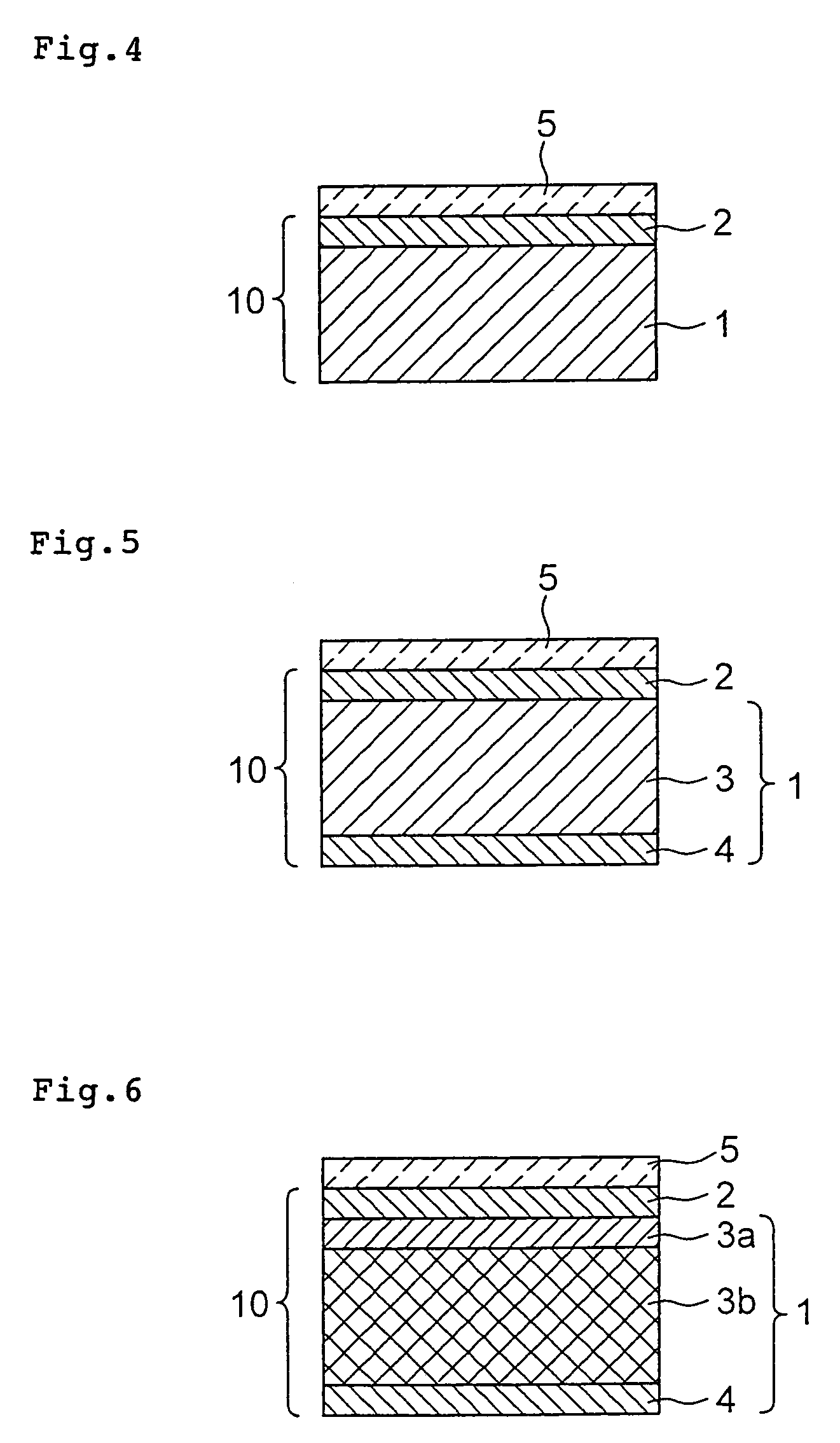

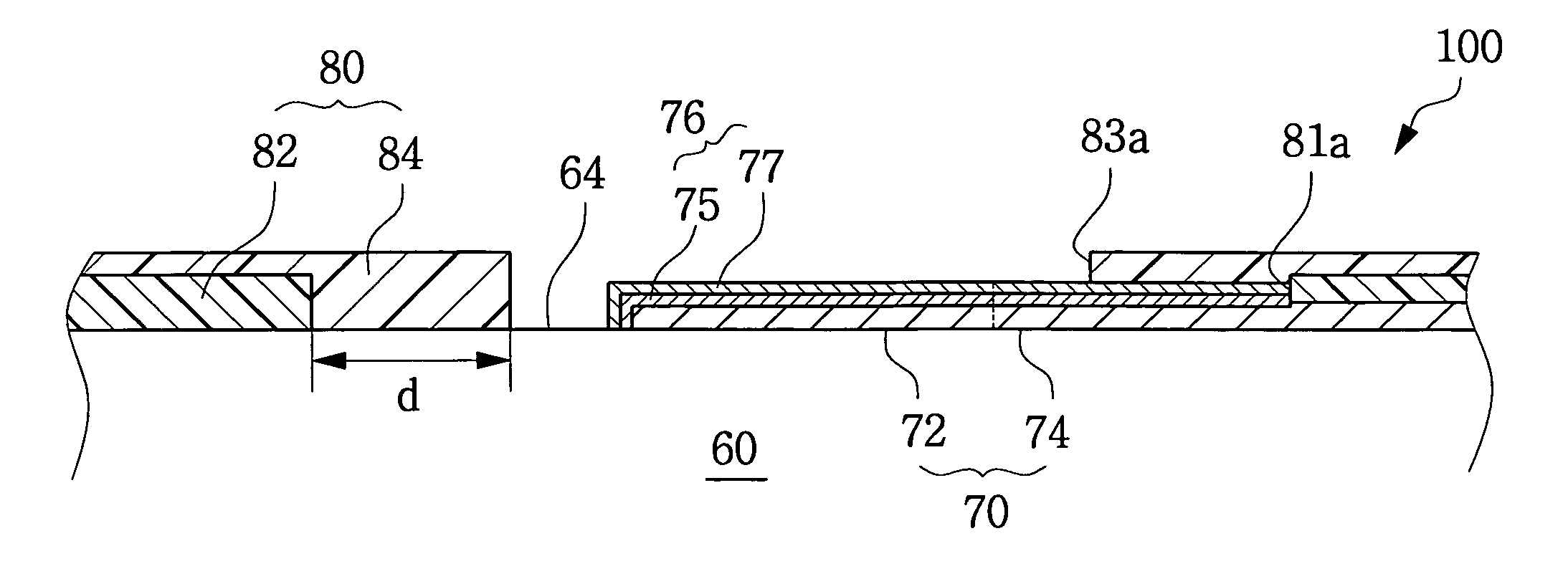

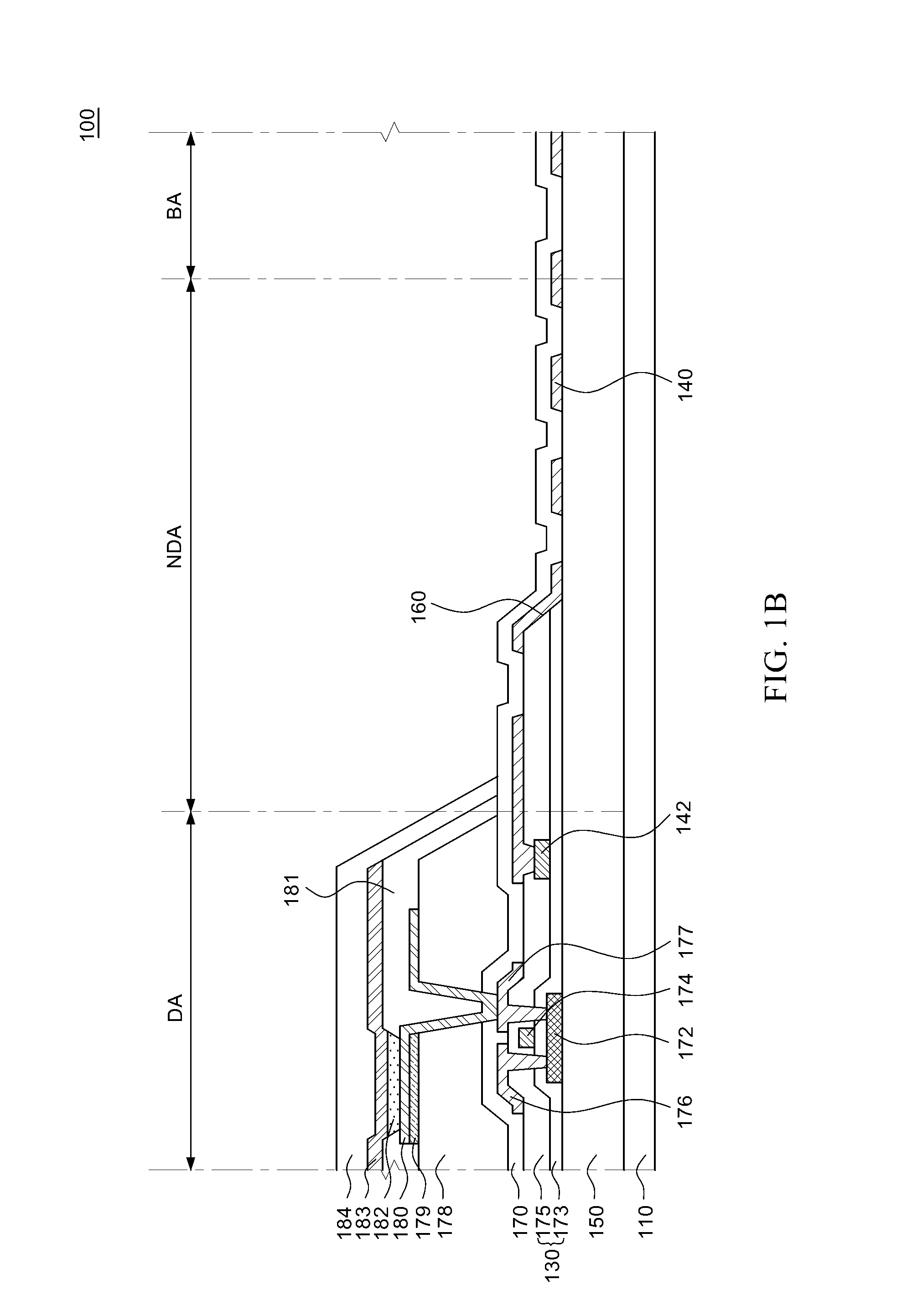

Display device with micro cover layer and manufacturing method for the same

ActiveUS9276055B1Guaranteed uptimeGood adhesionFinal product manufactureSolid-state devicesDisplay deviceFlexible display

Owner:LG DISPLAY CO LTD

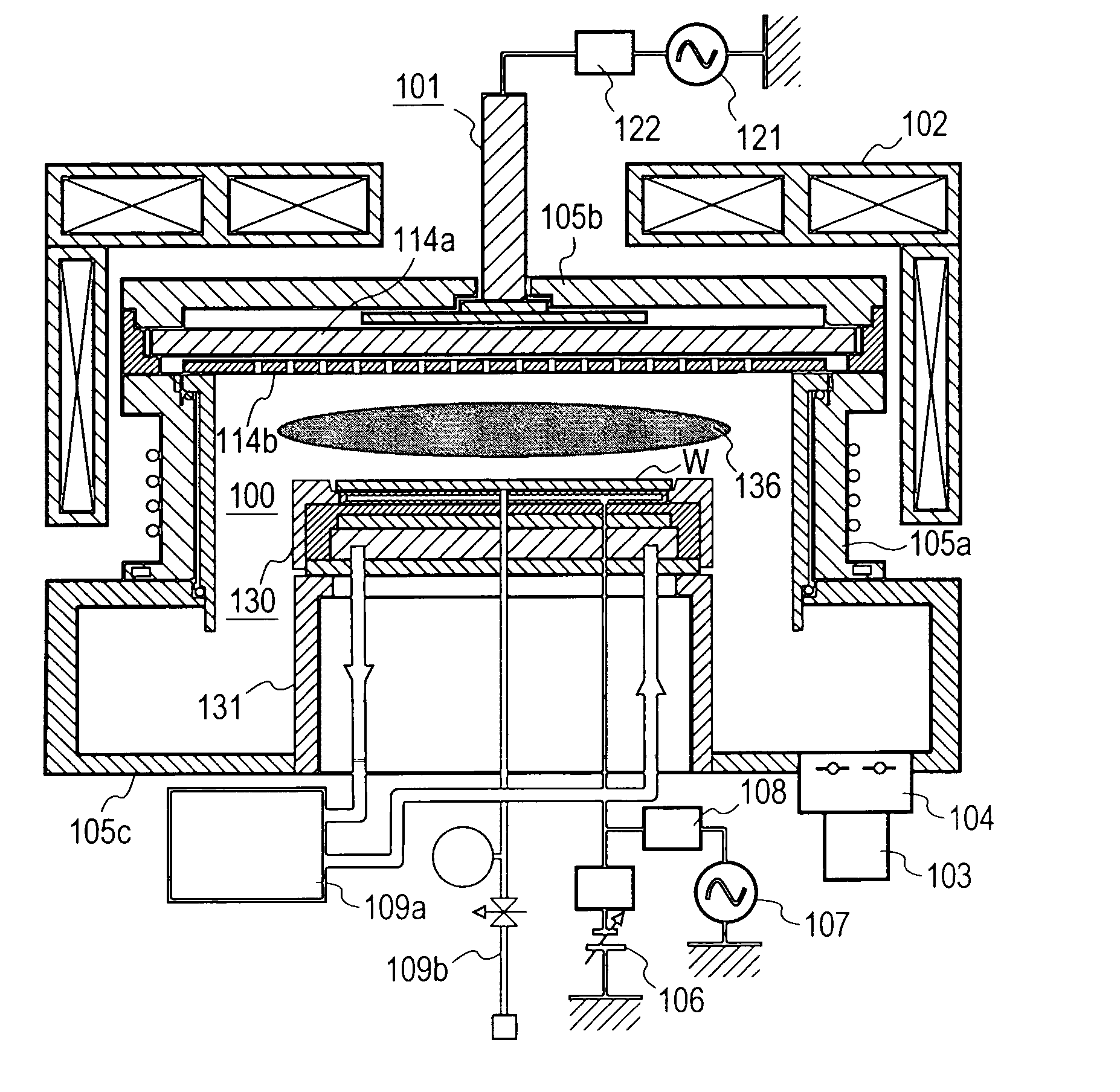

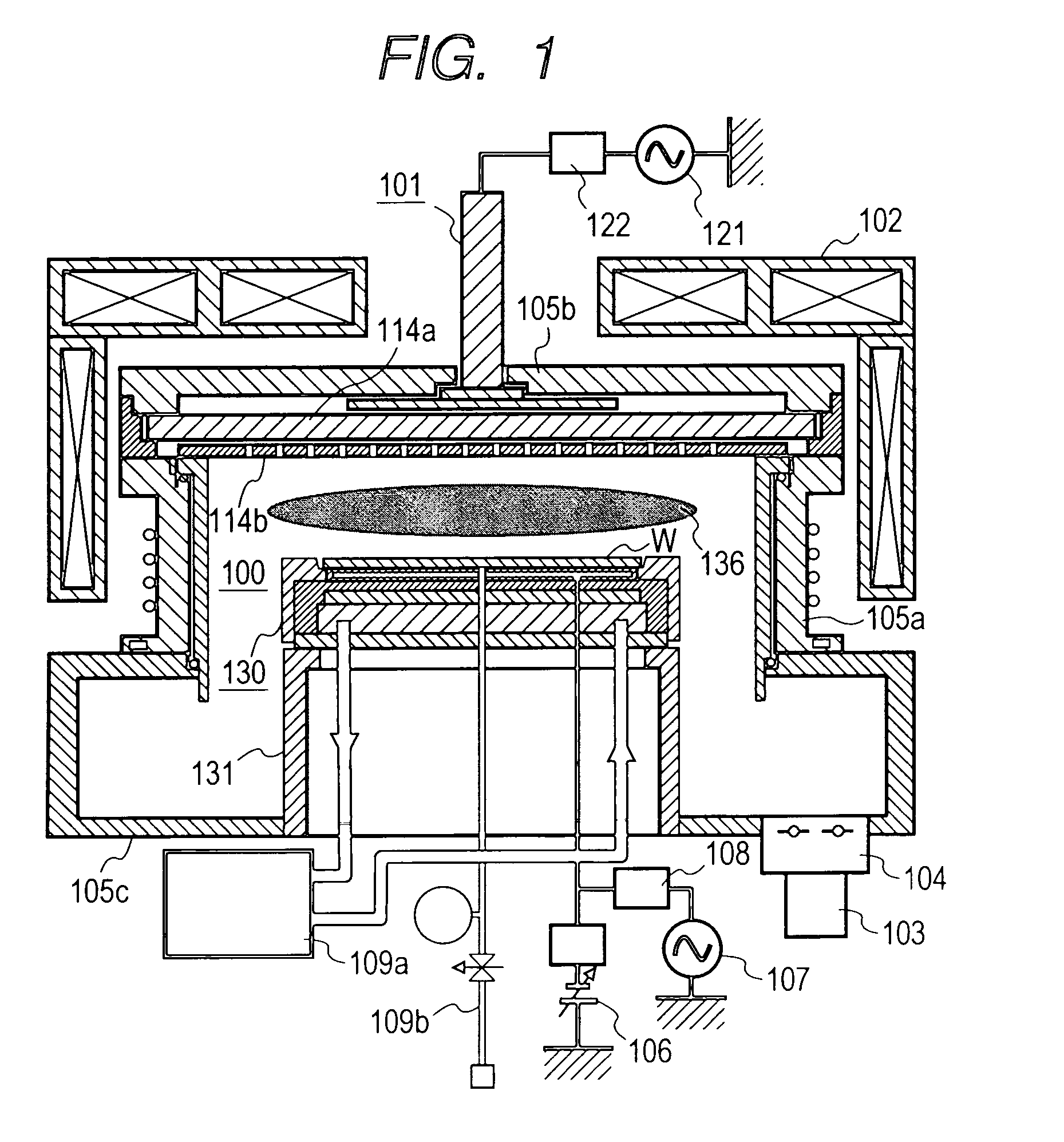

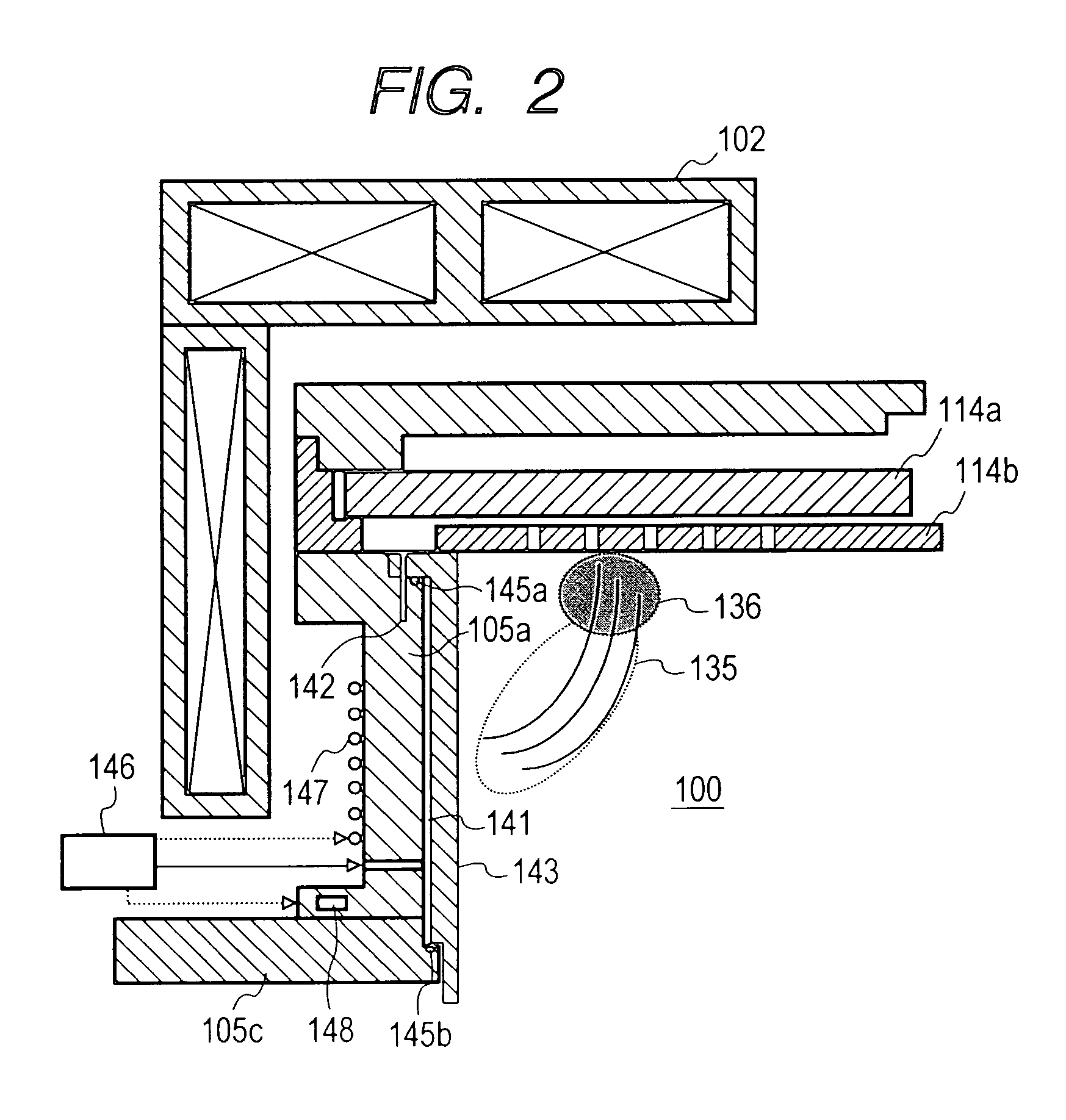

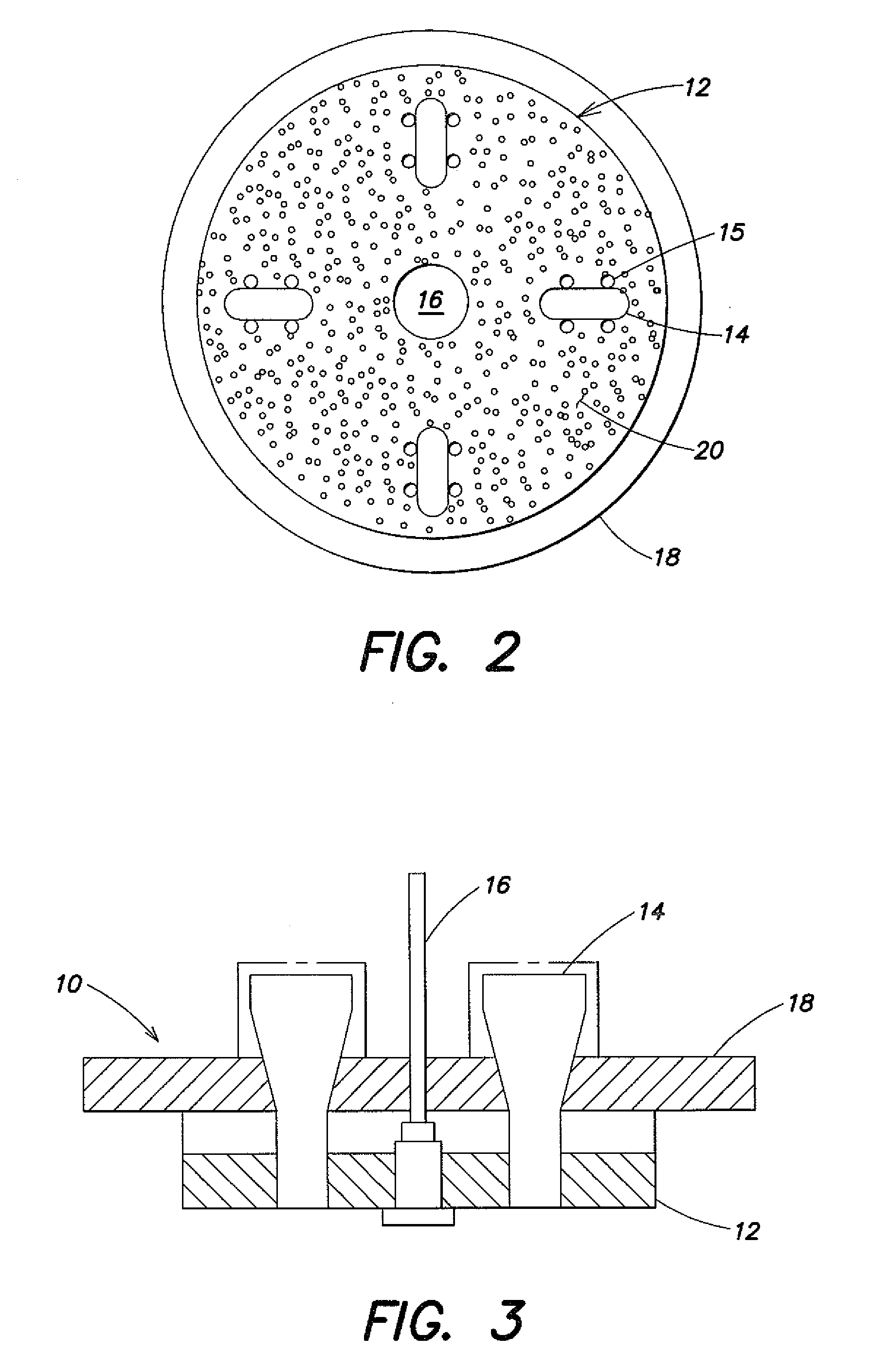

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

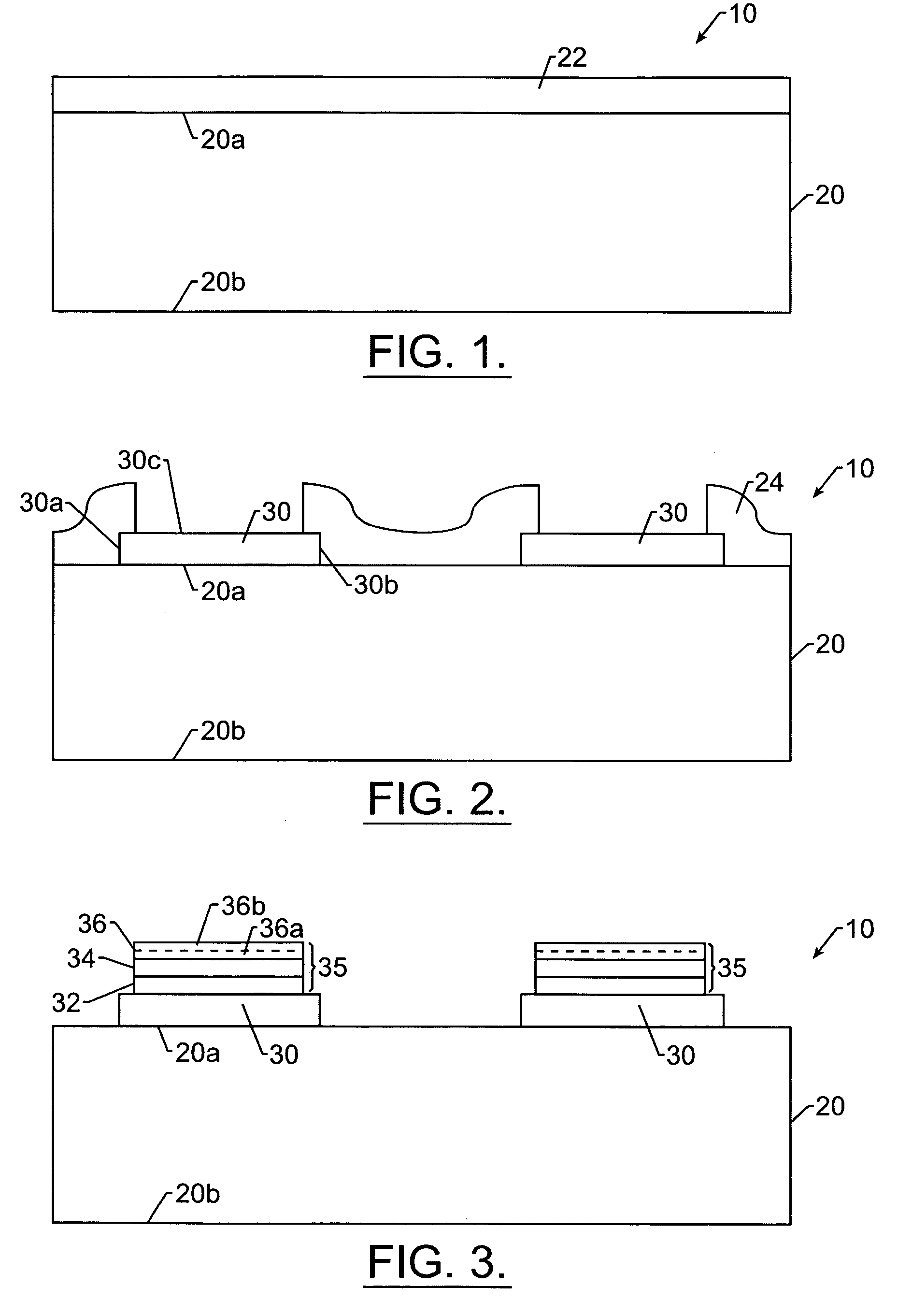

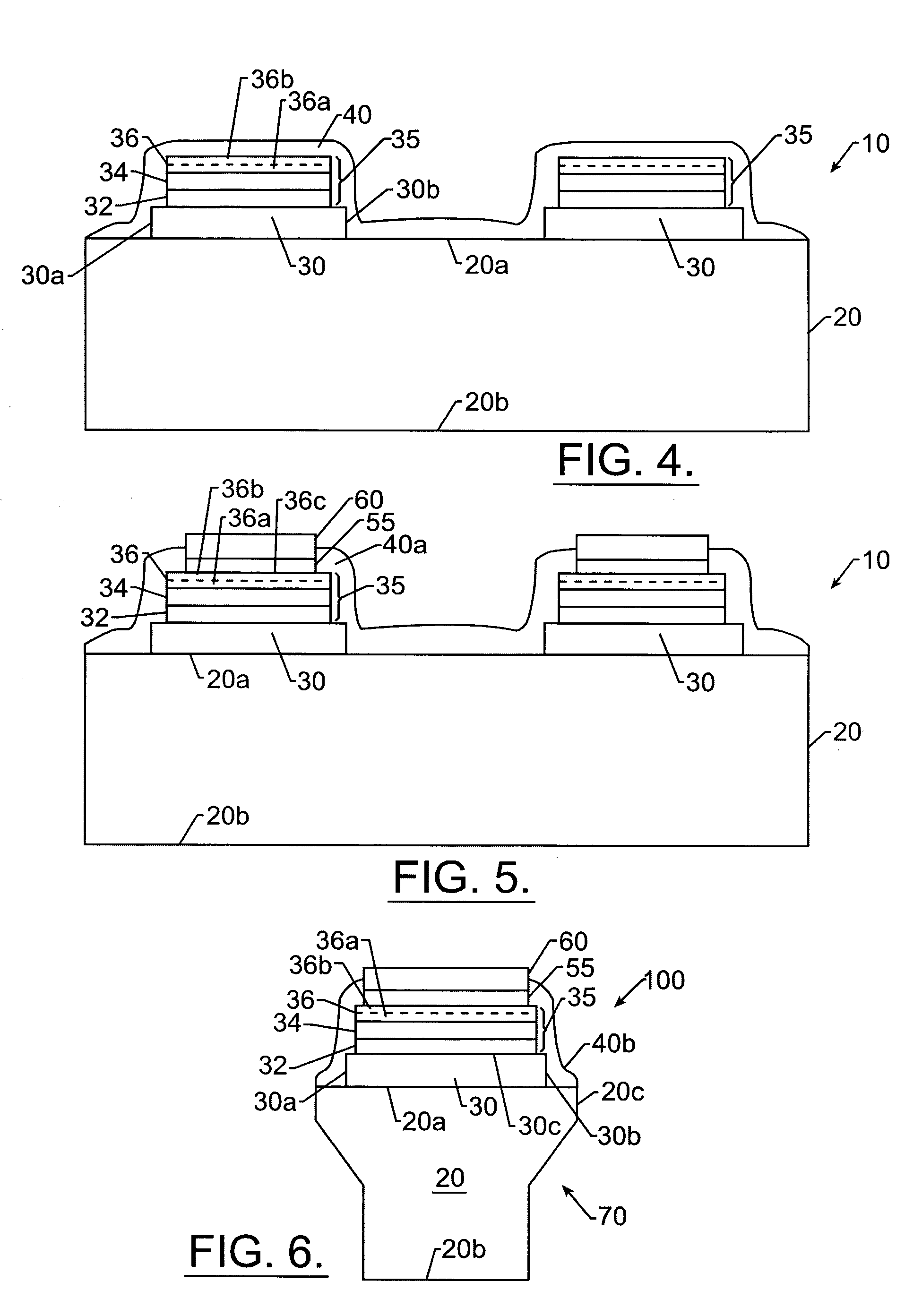

Light emitting diodes including barrier layers/sublayers

InactiveUS7211833B2Promote migrationReduce crackingSemiconductor/solid-state device detailsSolid-state devicesLight emitting deviceLight-emitting diode

Semiconductor light emitting devices, such as light emitting diodes, include a substrate, an epitaxial region on the substrate that includes a light emitting region such as a light emitting diode region, and a multilayer conductive stack including a reflector layer, on the epitaxial region. A barrier layer is provided on the reflector layer and extending on a sidewall of the reflector layer. The multilayer conductive stack can also include an ohmic layer between the reflector and the epitaxial region. The barrier layer further extends on a sidewall of the ohmic layer. The barrier layer can also extend onto the epitaxial region outside the multilayer conductive stack. The barrier layer can be fabricated as a series of alternating first and second sublayers.

Owner:CREELED INC

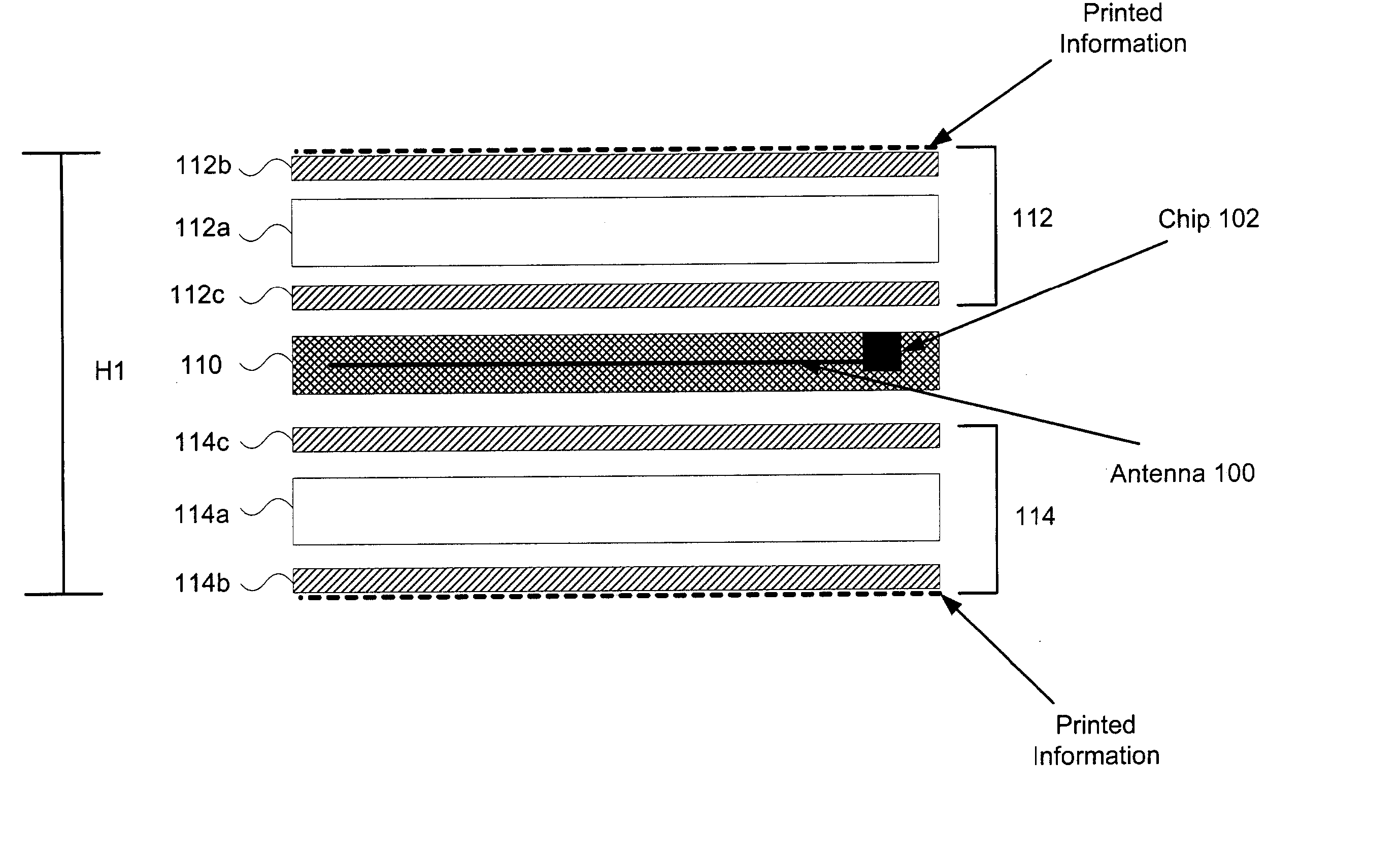

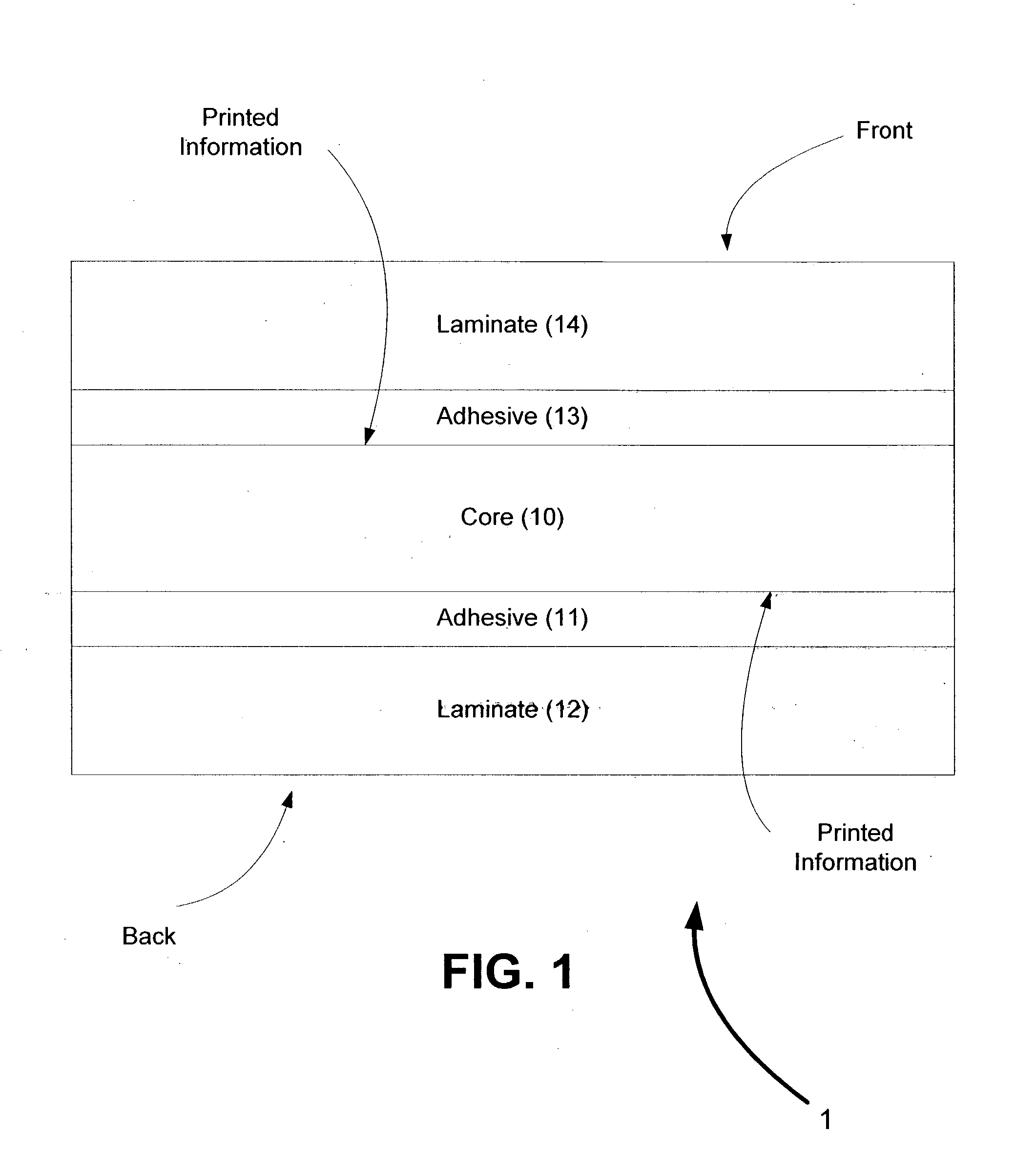

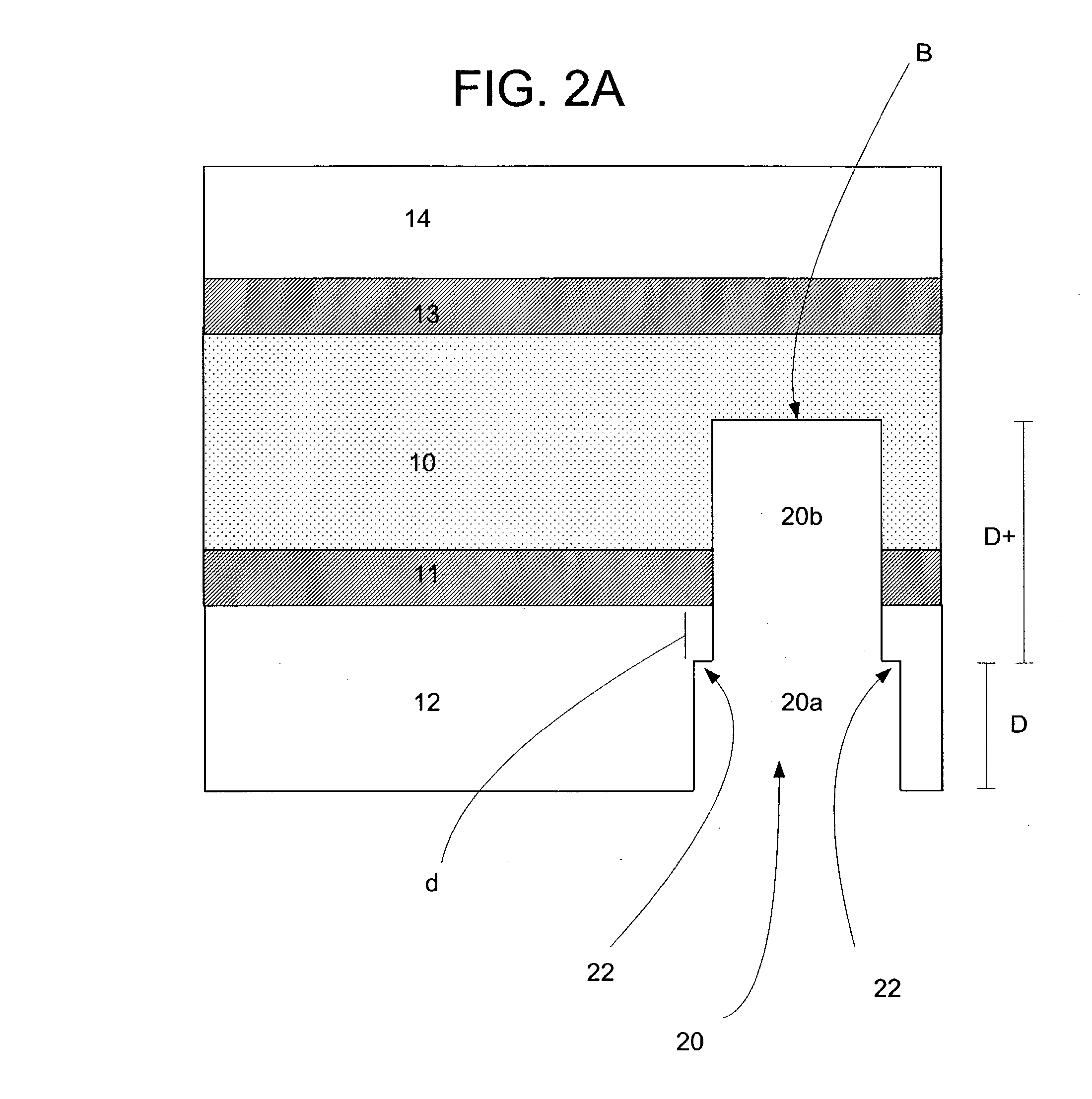

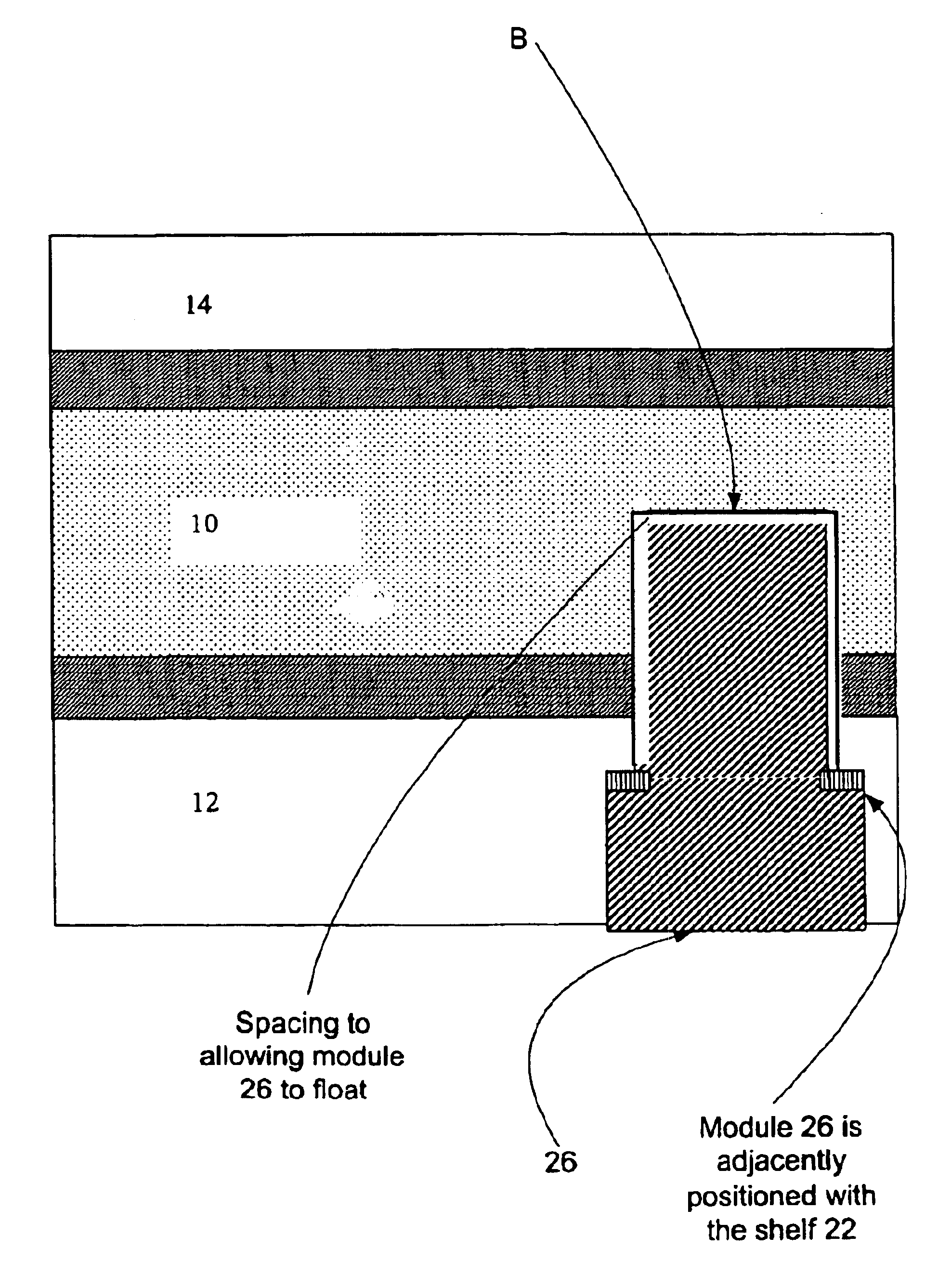

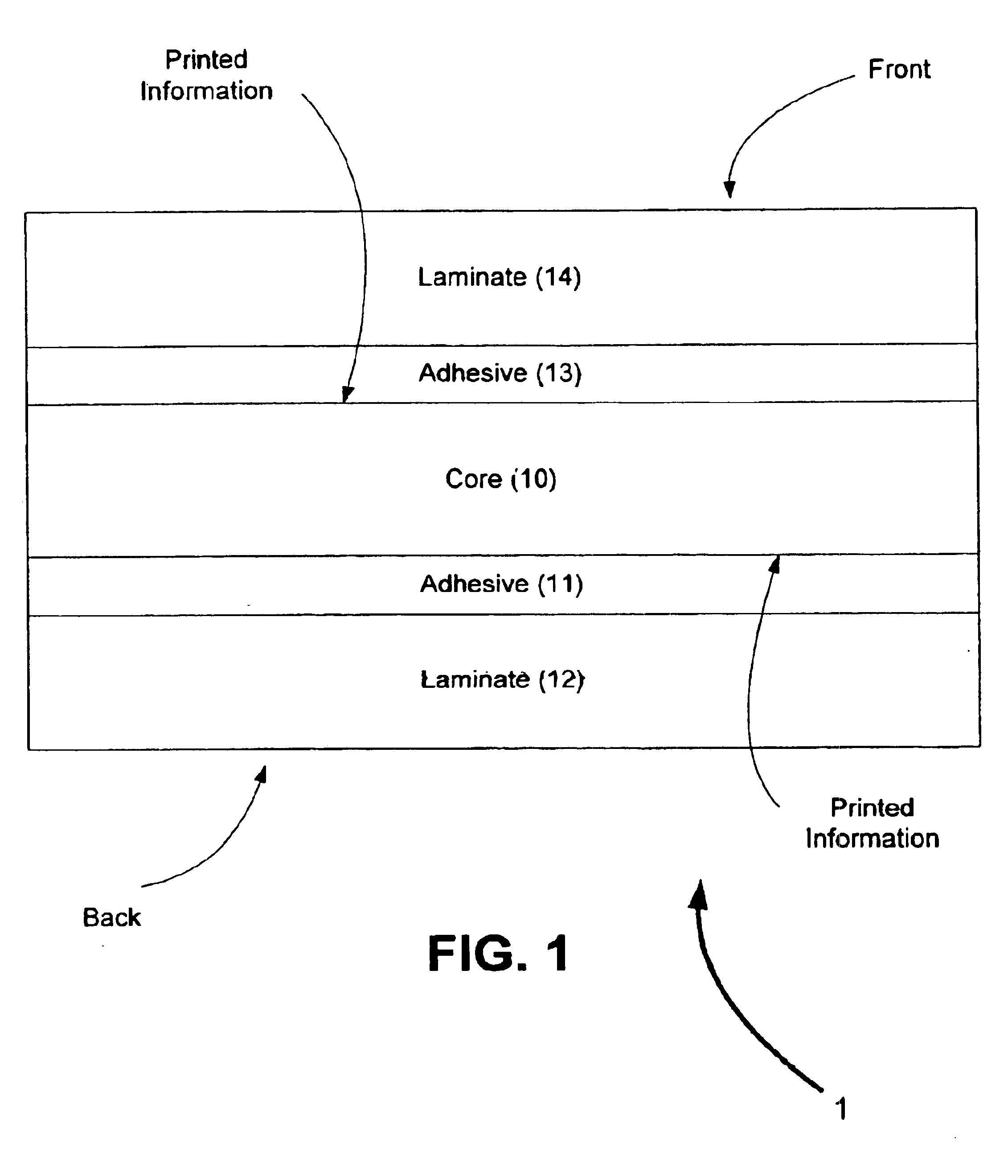

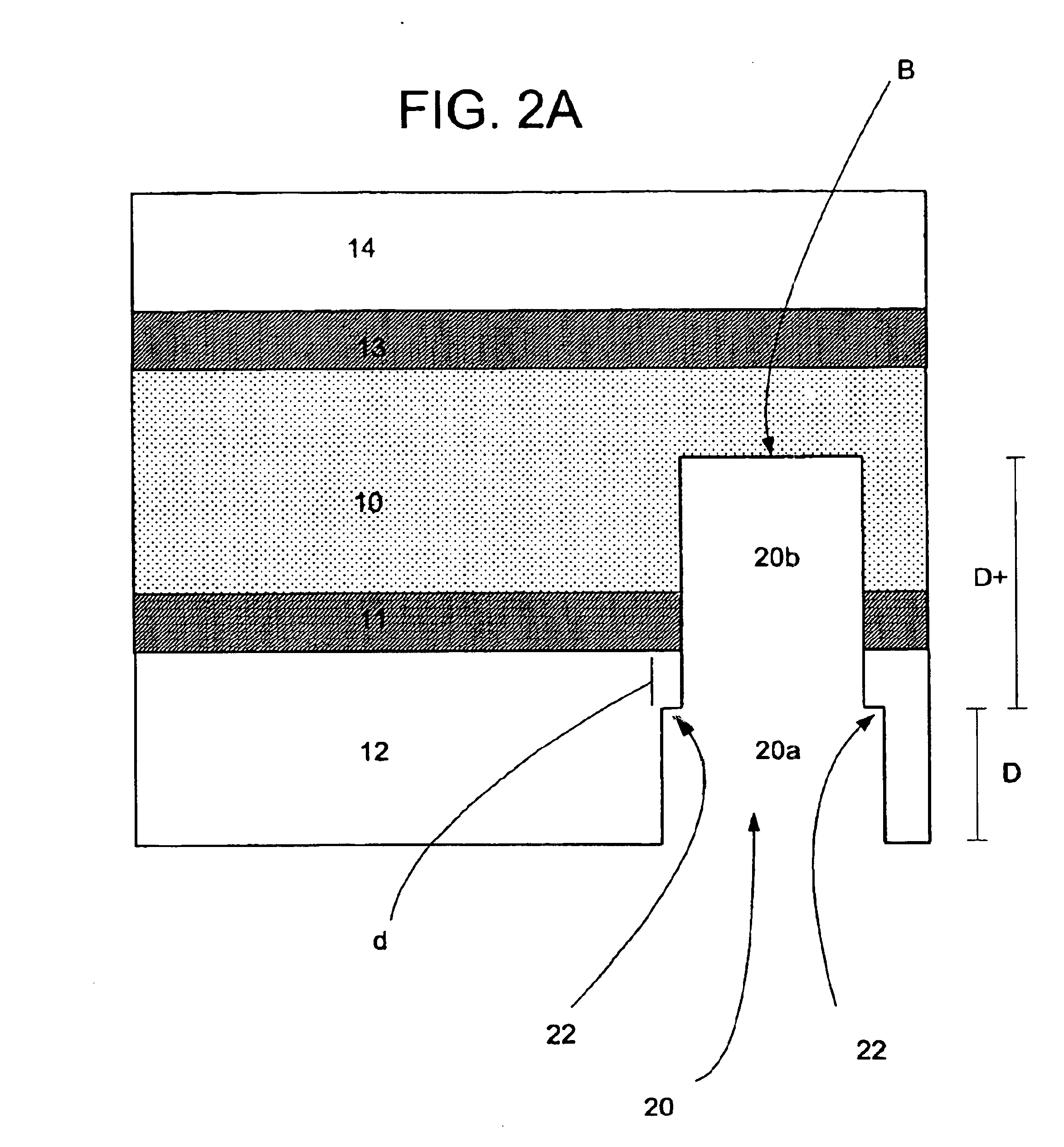

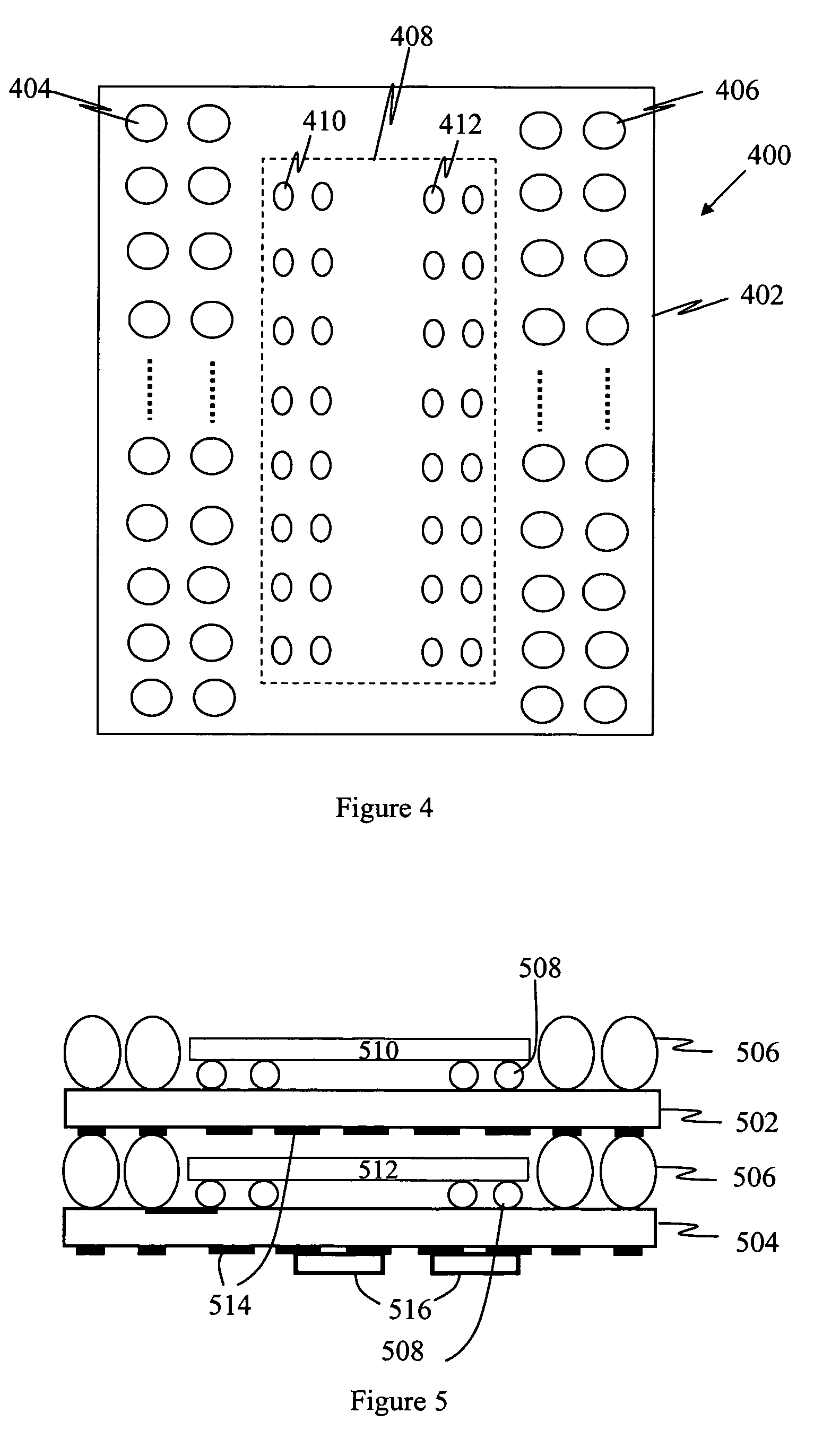

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS20030178495A1Improve security levelReduce chanceLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

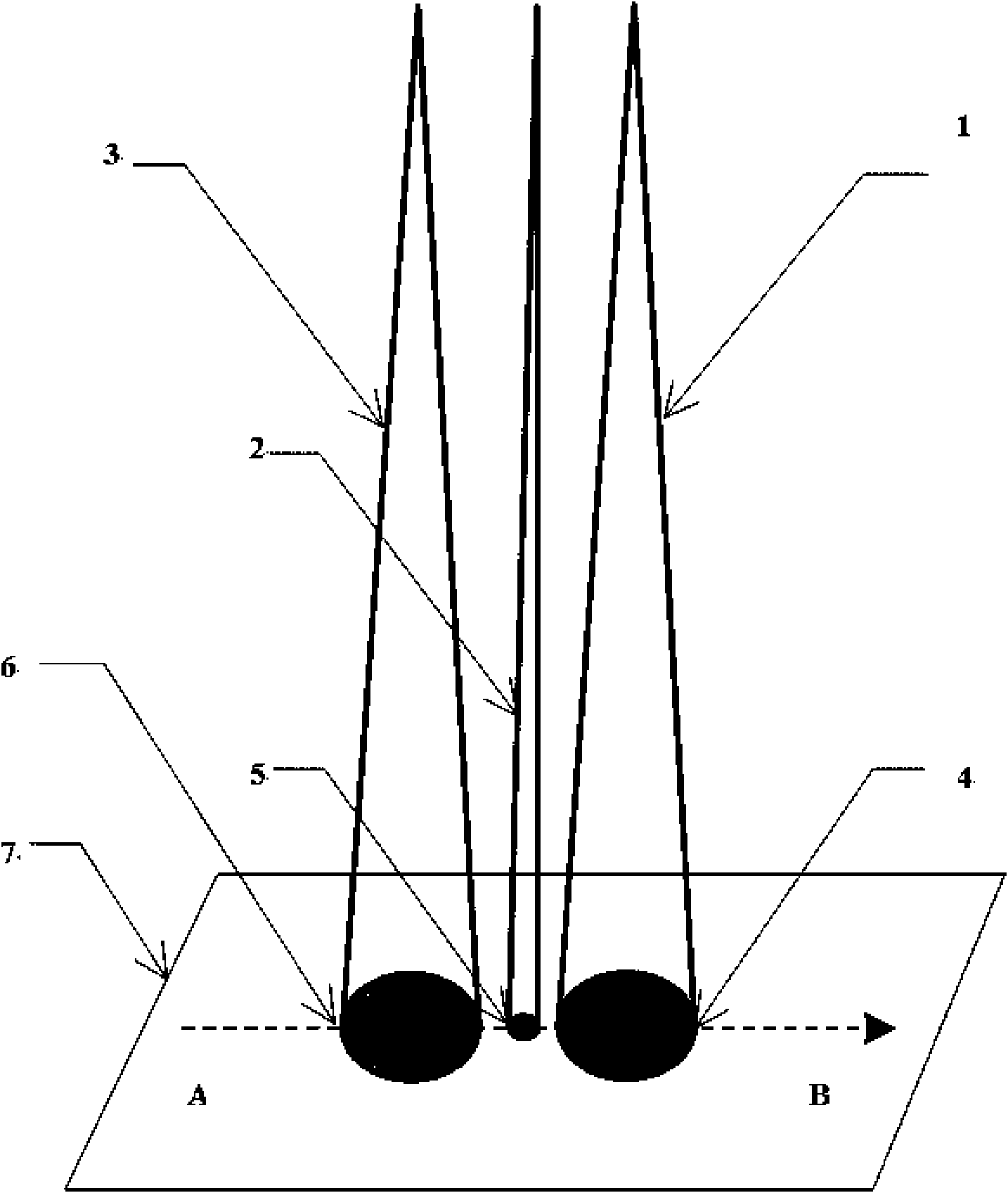

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS6843422B2Reduce crackingQuality improvementLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS20050229565A1High strengthIncreased durabilityCombination devicesCatalyst protectionLeast squaresHoneycomb structure

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1−D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3−D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

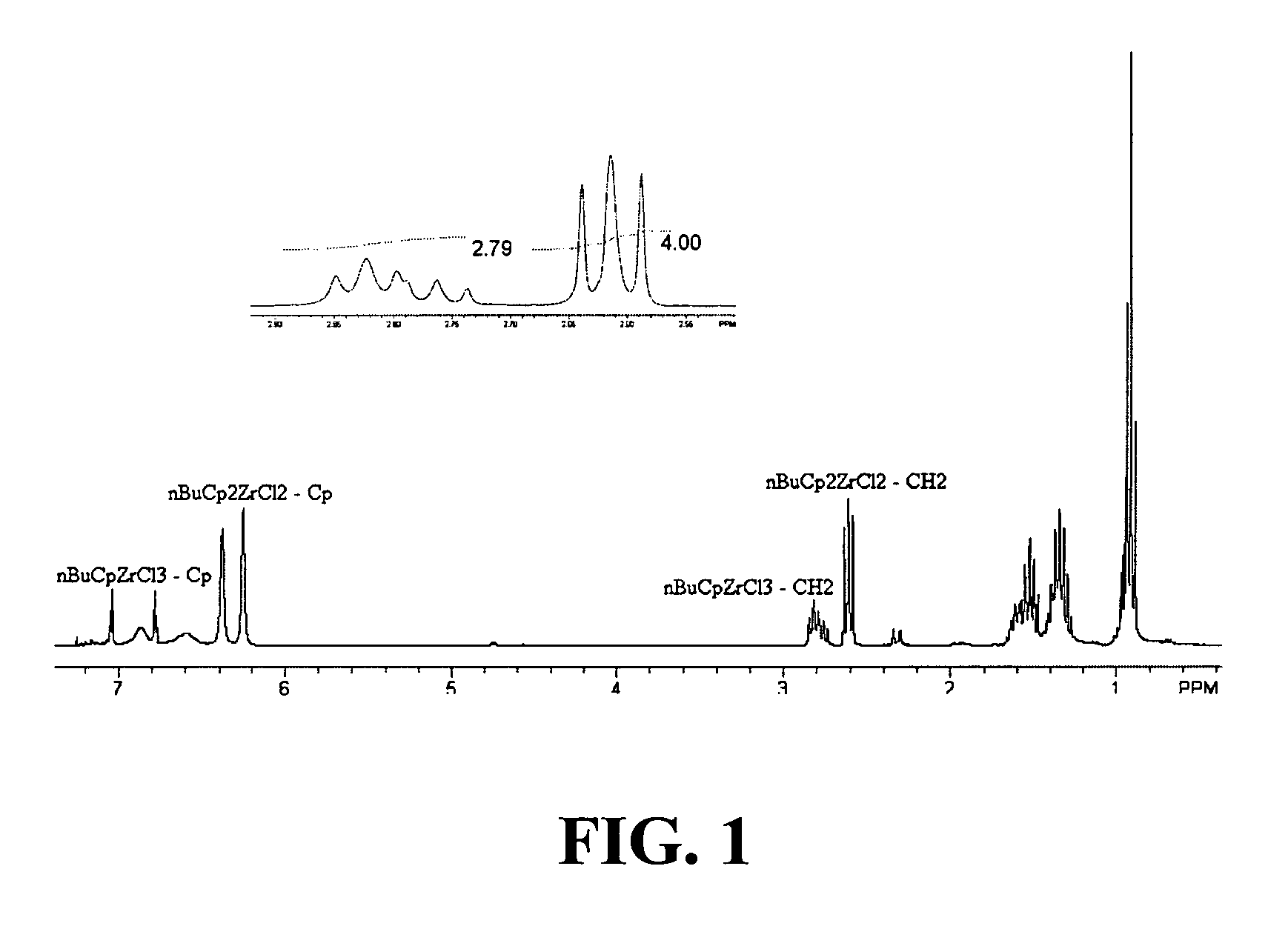

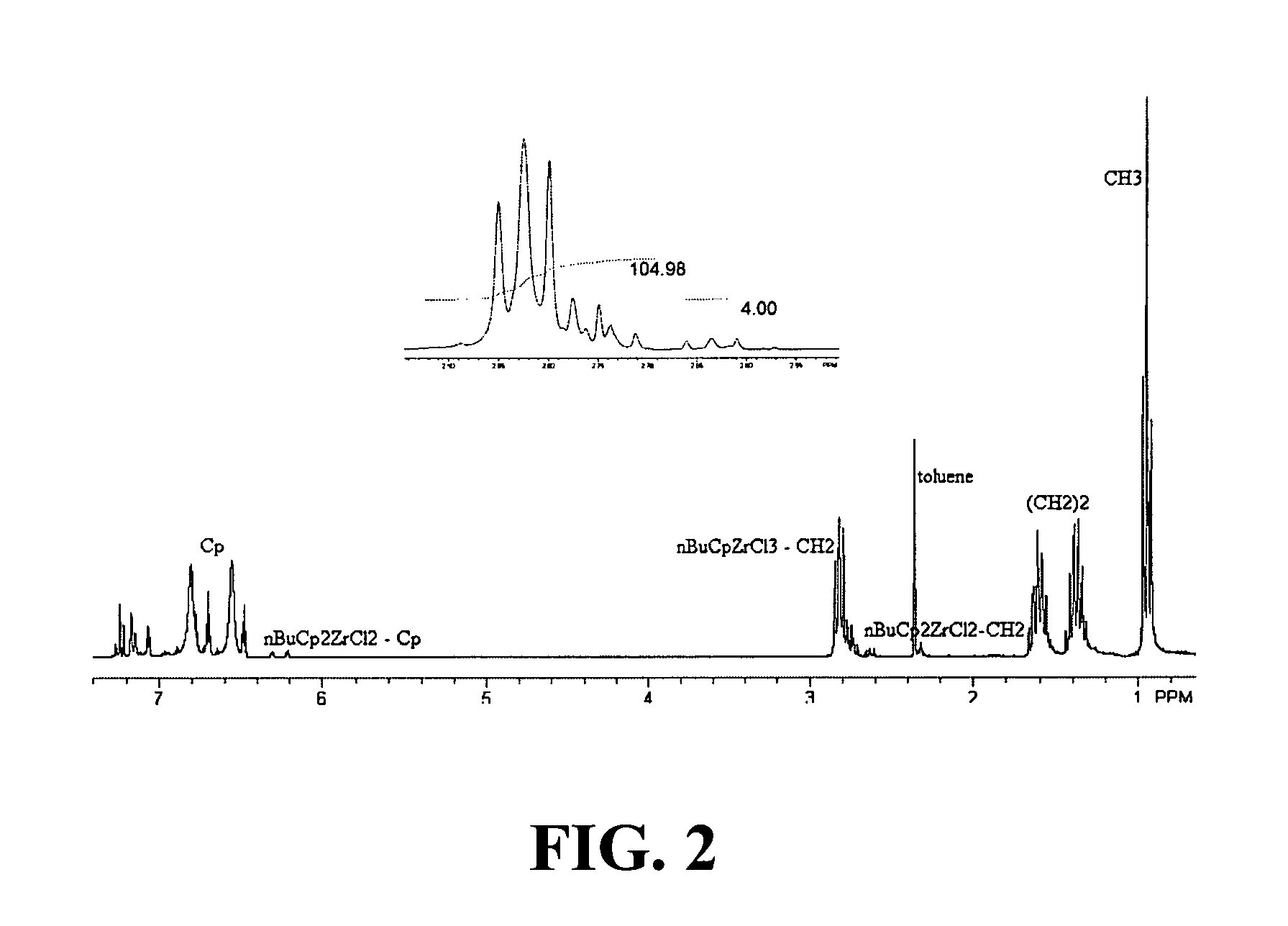

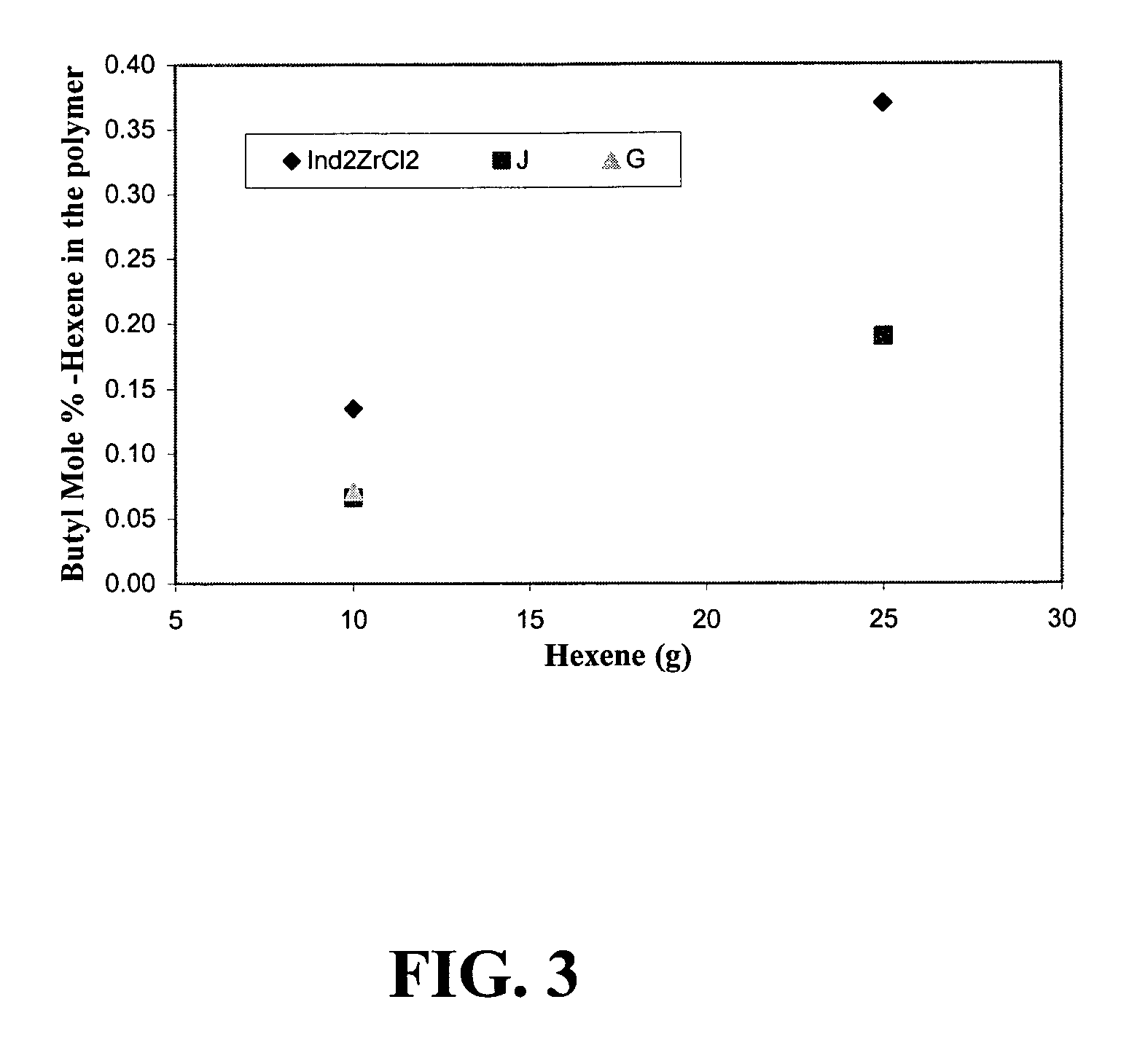

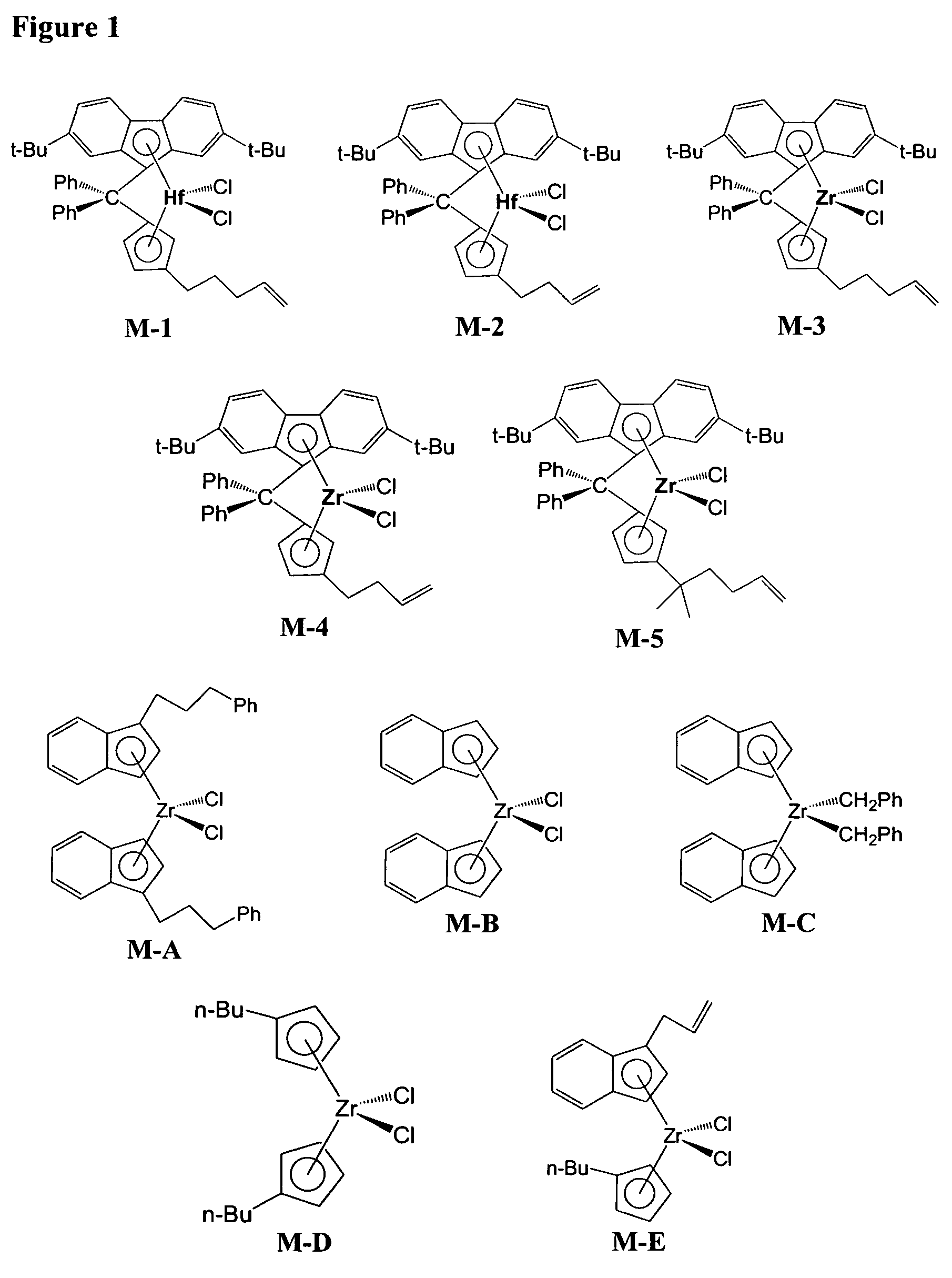

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS20070197374A1Good balanceSlow crack growthOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsChemistryMetal

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

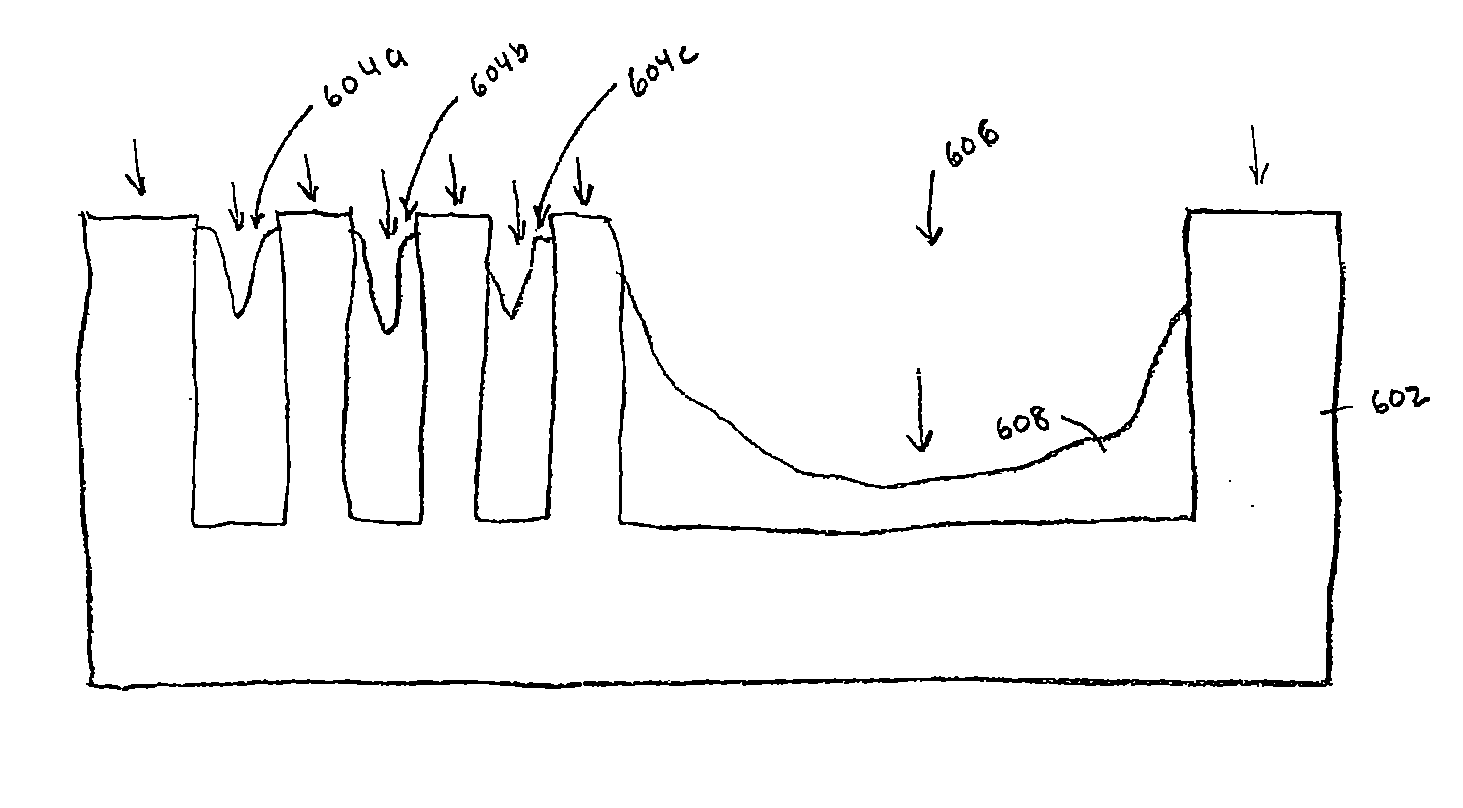

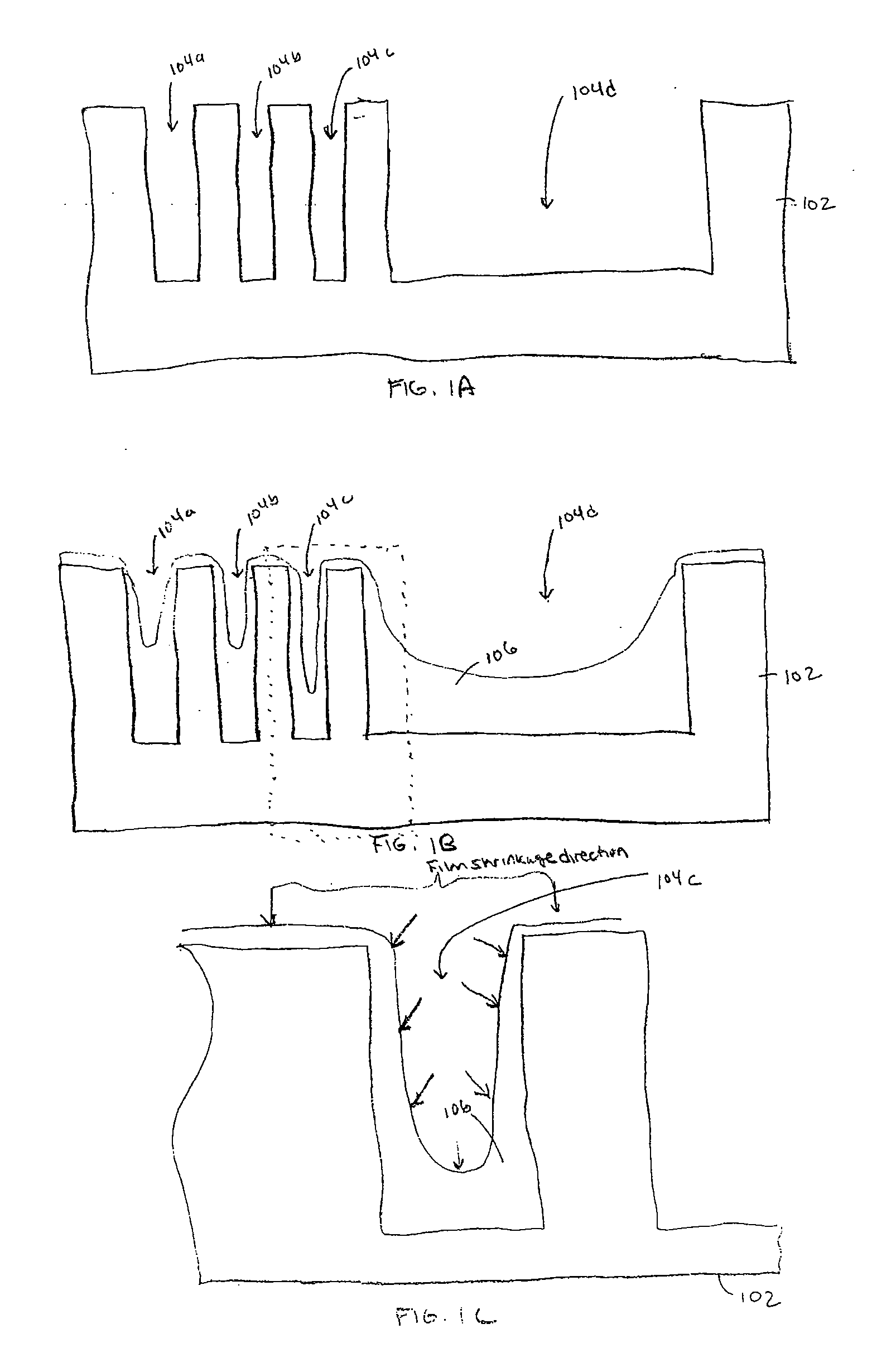

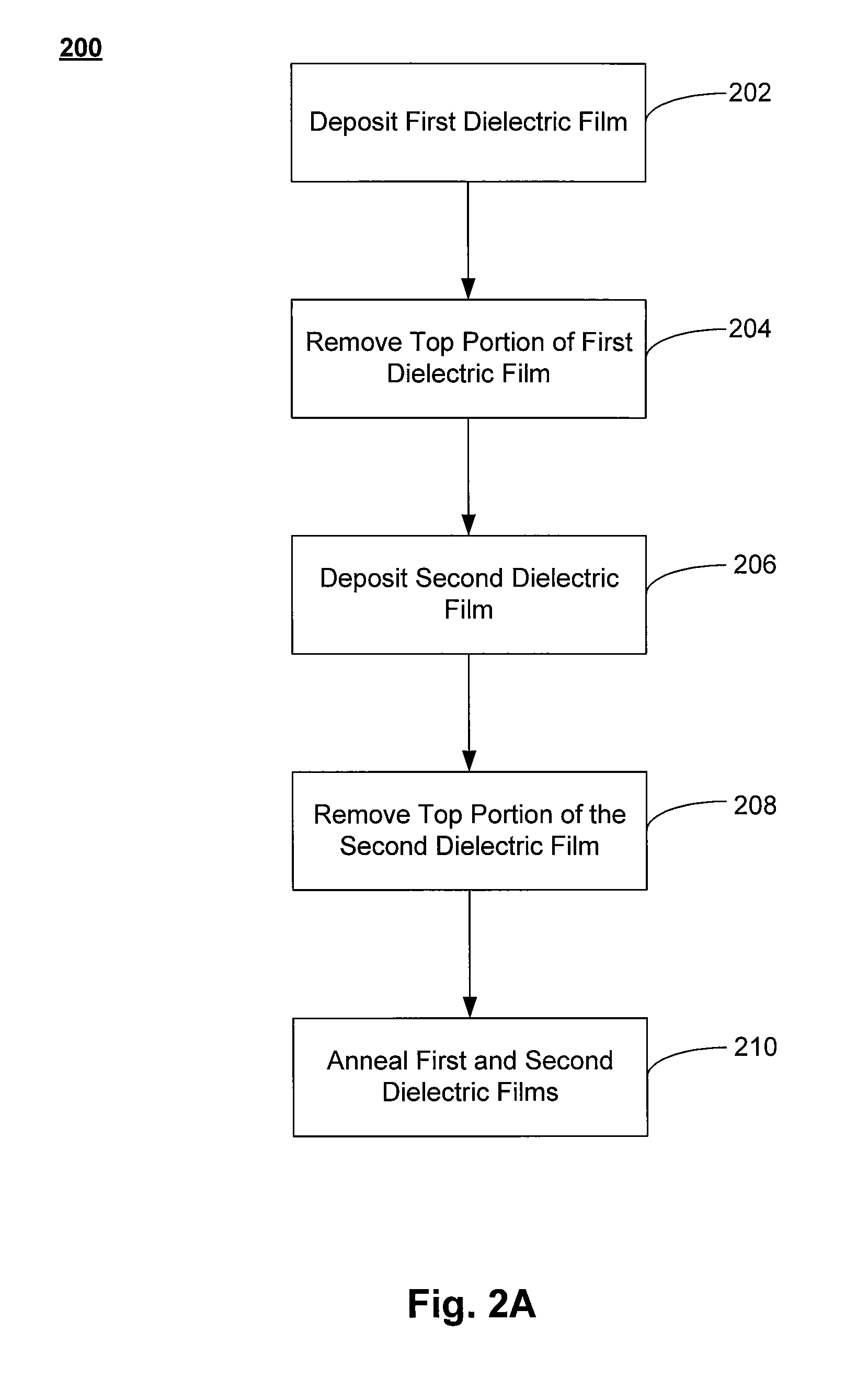

Dielectric deposition and etch back processes for bottom up gapfill

ActiveUS20070298585A1No increase in cracking of filmLow stress levelSemiconductor/solid-state device manufacturingStress levelDielectric layer

Methods to reduce film cracking in a dielectric layer are described. The methods may include the steps of depositing a first dielectric film on a substrate and removing a top portion of the first dielectric film by performing an etch on the film. The methods may also include depositing a second dielectric film over the etched first film, and removing a top portion of the second dielectric film. In addition, the methods may include annealing the first and second dielectric films to form the dielectric layer, where the removal of the top portions from the first and the second dielectric films reduces a stress level in the dielectric layer.

Owner:APPLIED MATERIALS INC

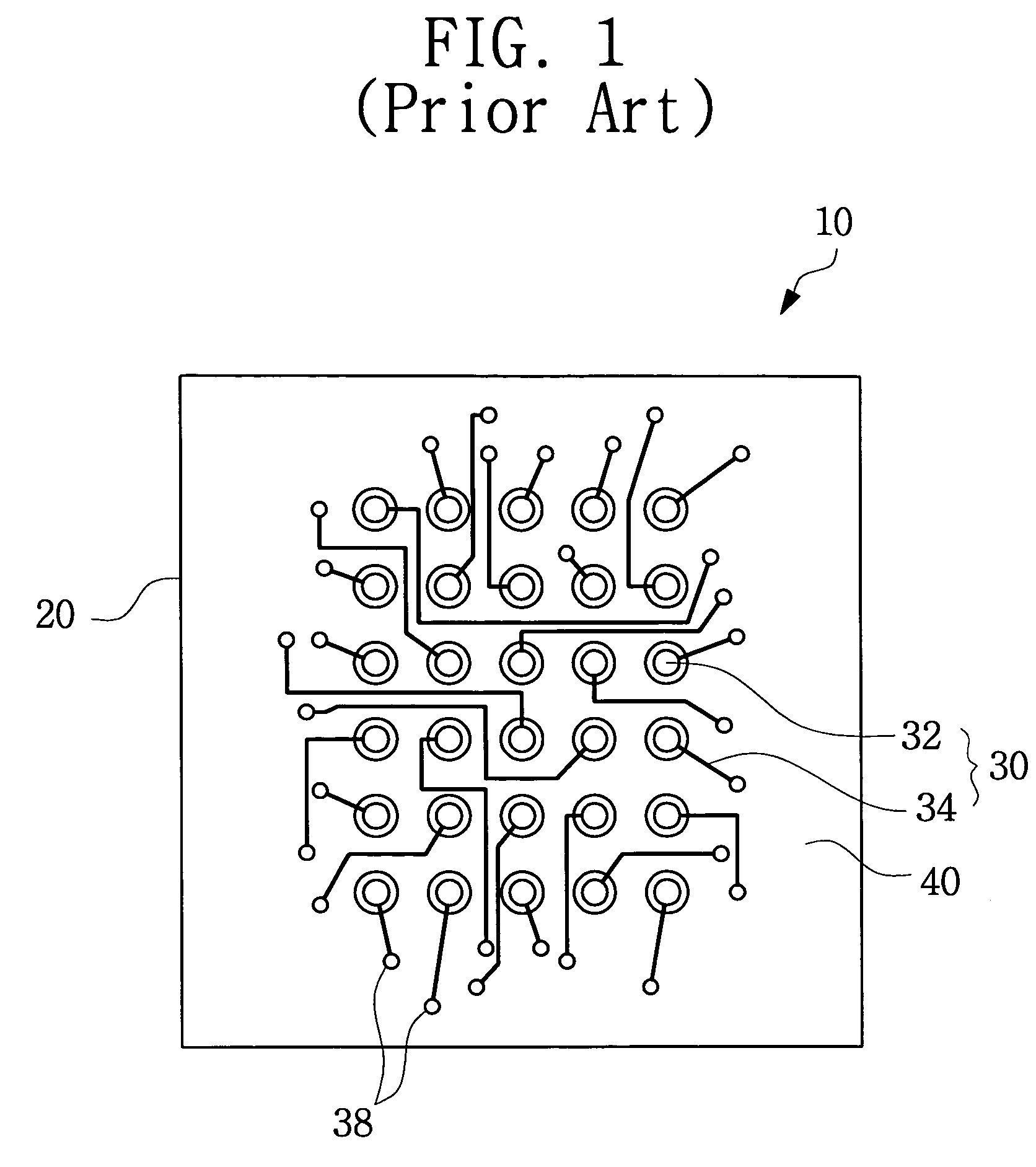

Non-solder mask defined (NSMD) type wiring substrate for ball grid array (BGA) package and method for manufacturing such a wiring substrate

ActiveUS7098407B2Reduce crackingReduce stress concentrationPrinted circuit assemblingSemiconductor/solid-state device detailsStress concentrationSolder mask

In one embodiment, a pad is formed on a substrate surface. The pad is connected with a connecting pattern. A first mask is formed on the substrate. The first mask has a first opening exposing at least a portion of the pad and a portion of the connecting pattern. A second mask is formed on the first mask. The second mask has a second opening exposing at least a portion of the pad and a portion of the connecting pattern. A boundary surface or sidewall of the first opening is not coplanar with a boundary surface or sidewall of the second opening. Therefore, stresses may be prevented from concentrating on the boundary surface of the first opening, thereby allowing dispersion of the stresses and restraining pattern cracks.

Owner:SAMSUNG ELECTRONICS CO LTD

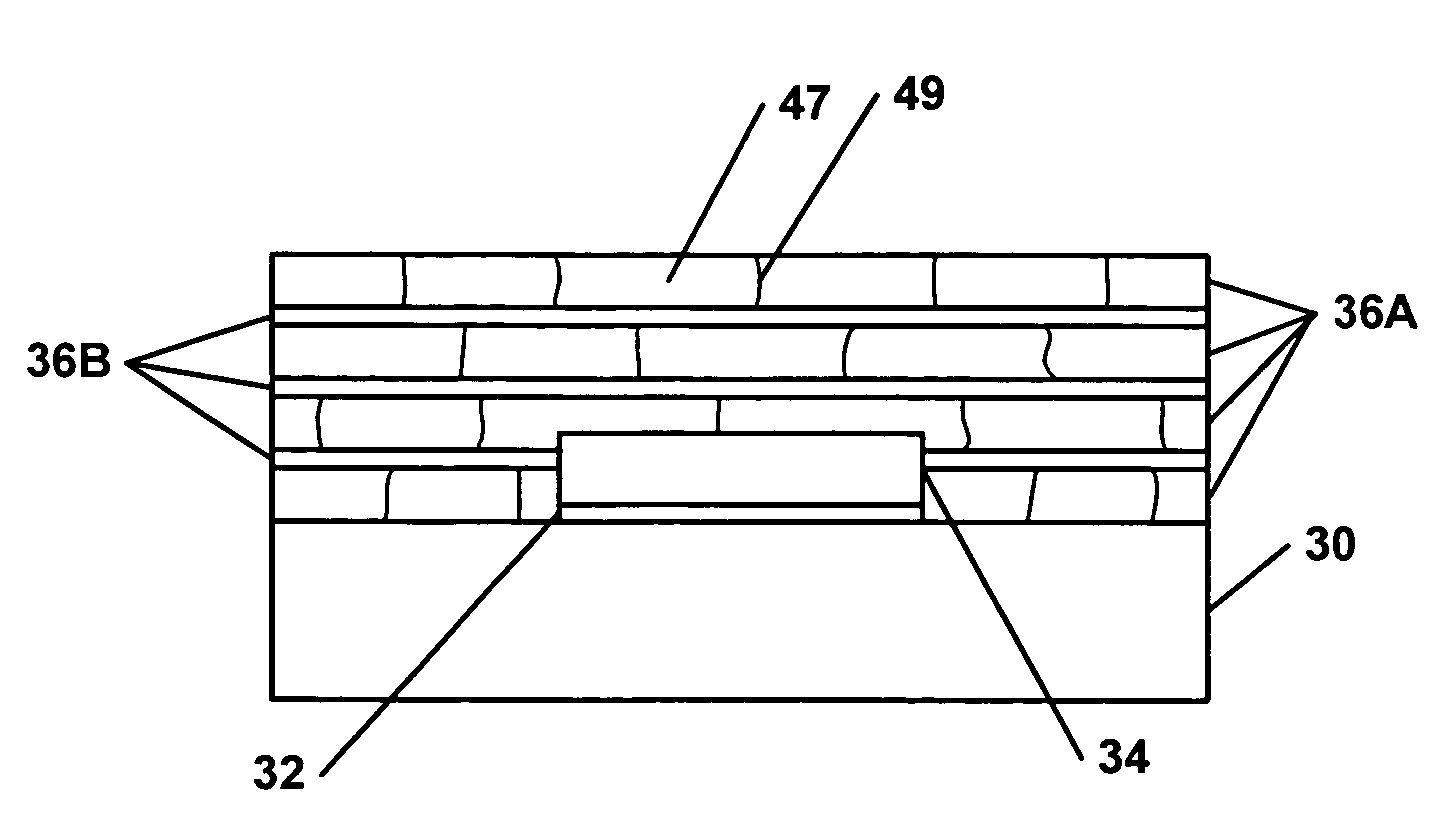

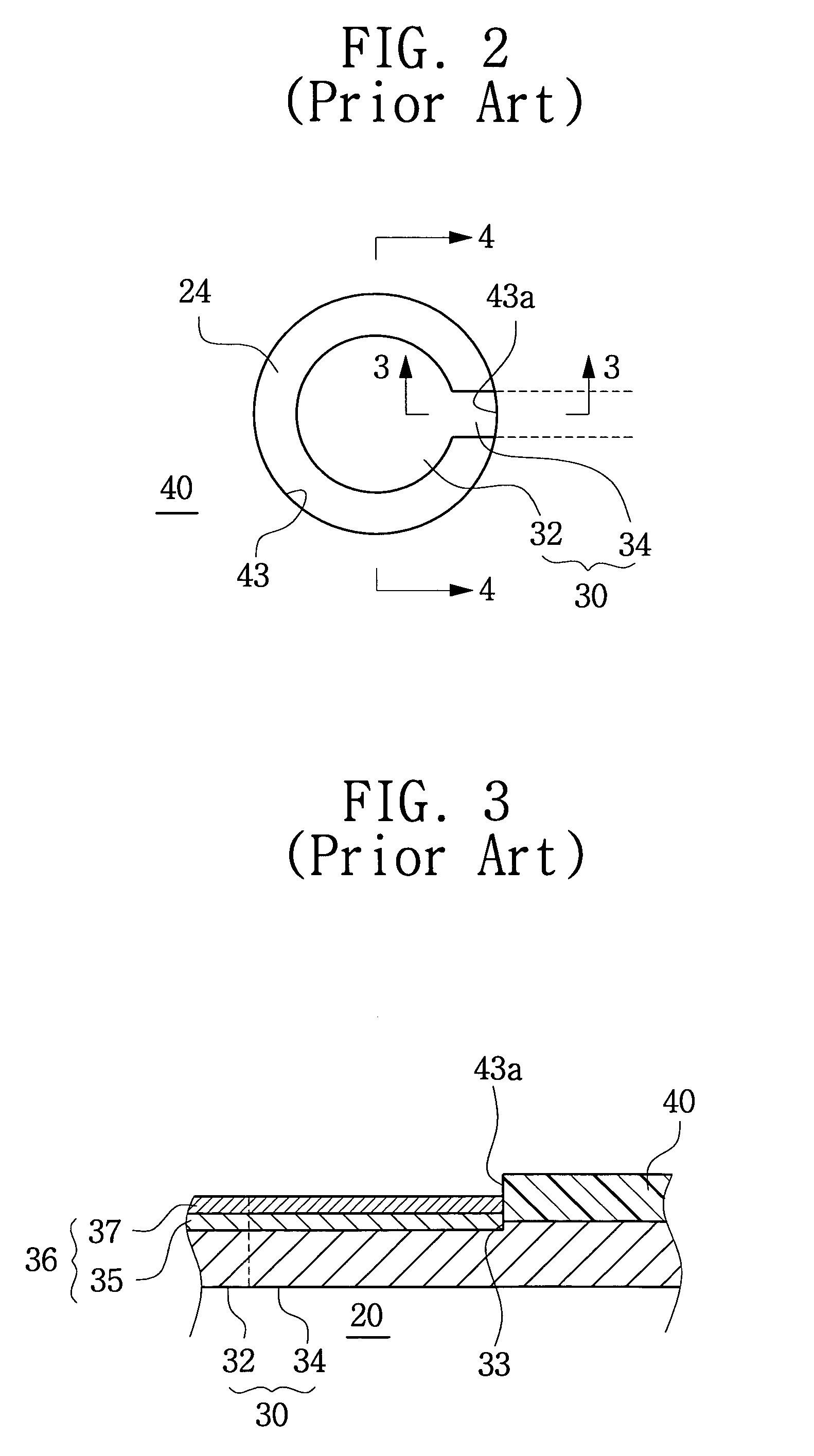

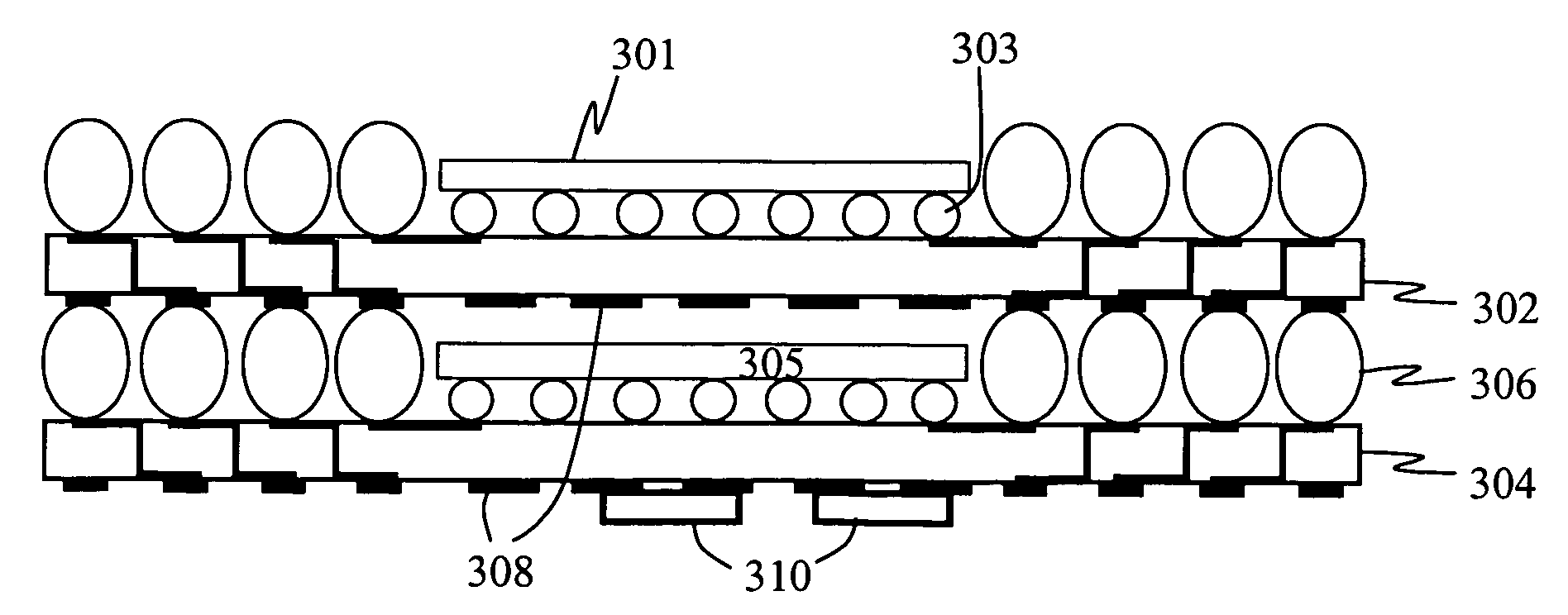

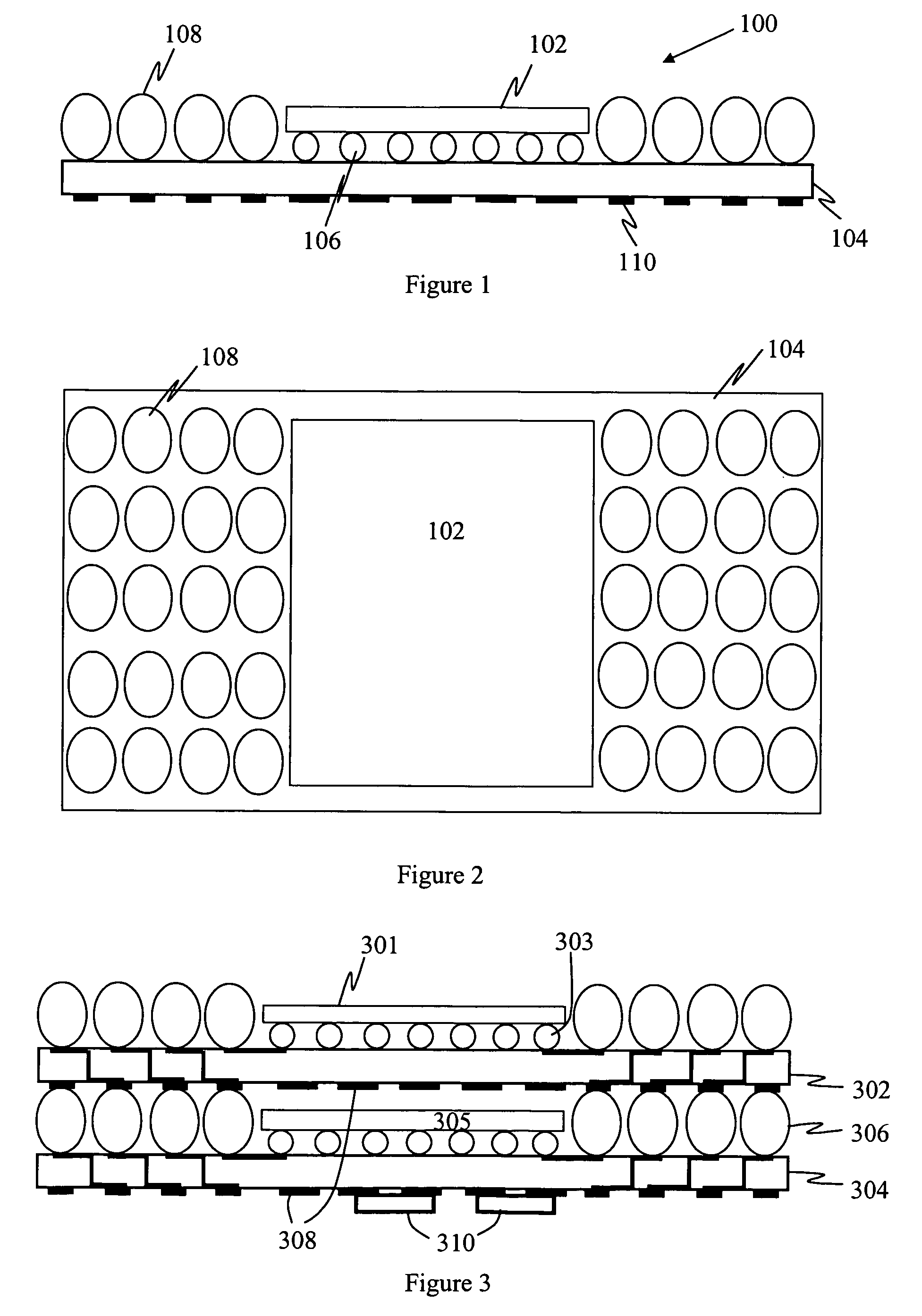

Stackable electronic assembly

InactiveUS7180165B2Reduce crackingImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCombined useEngineering

On implementation of the invention provides a stackable chip-scale package for improving memory density that may be mounted within a limited area or module. A novel staggered routing scheme enables the use of the same trace routing at every level of the stacked architecture for efficiently accessing individual memory devices in a chip-scale package stack. The use of a ball grid array chip-scale package architecture in combination with thermally compatible materials decreases the risk of thermal cracking while improving heat dissipation. Moreover, this architecture permits mounting support components, such as capacitors and resistors, on the chip-scale package.

Owner:SANMINA-SCI CORPORATION

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS20070043176A1Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS7348049B2High strengthReduce crackingCombination devicesCatalyst protectionHoneycomb structureMaterials science

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1-D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3-D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

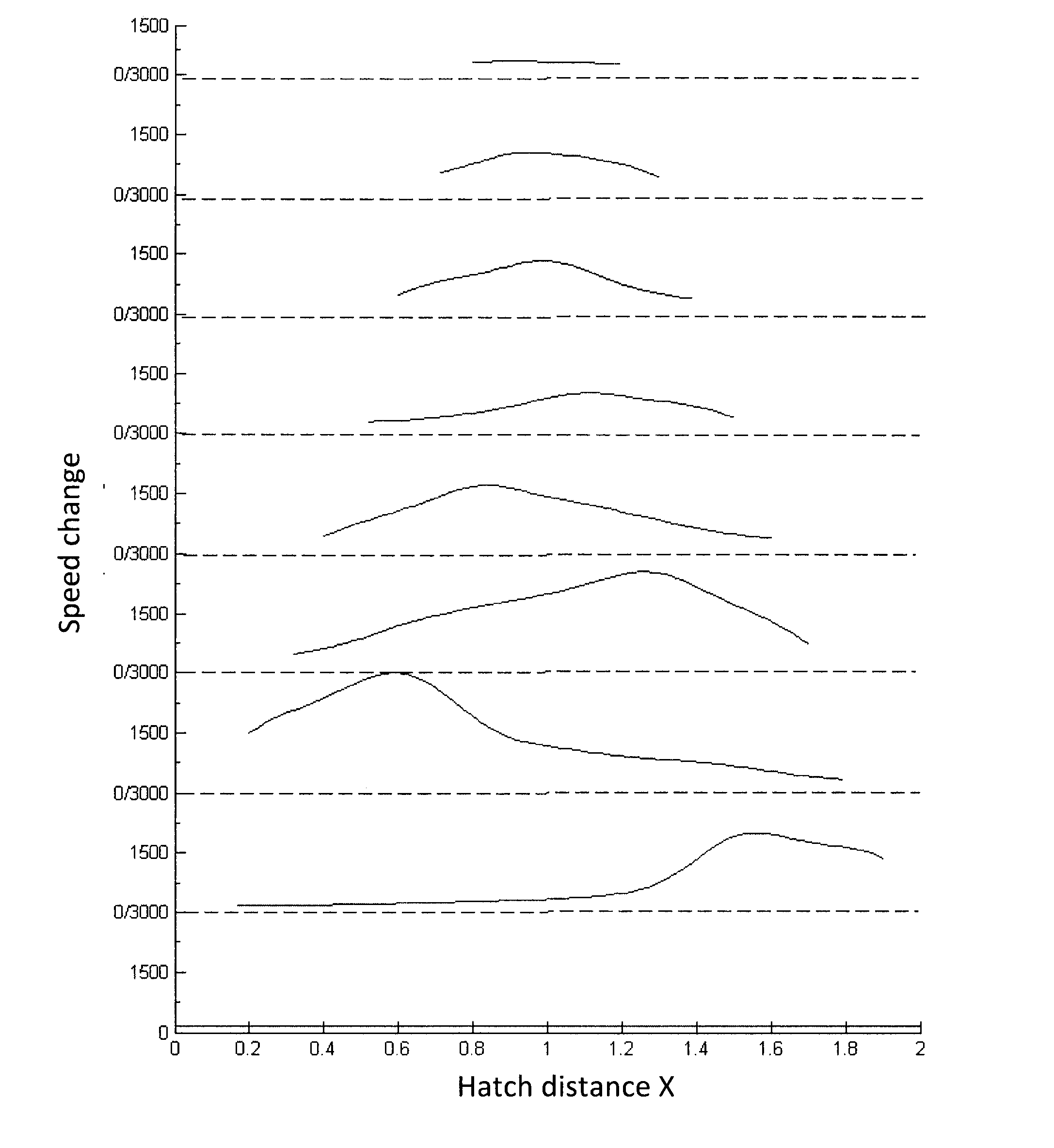

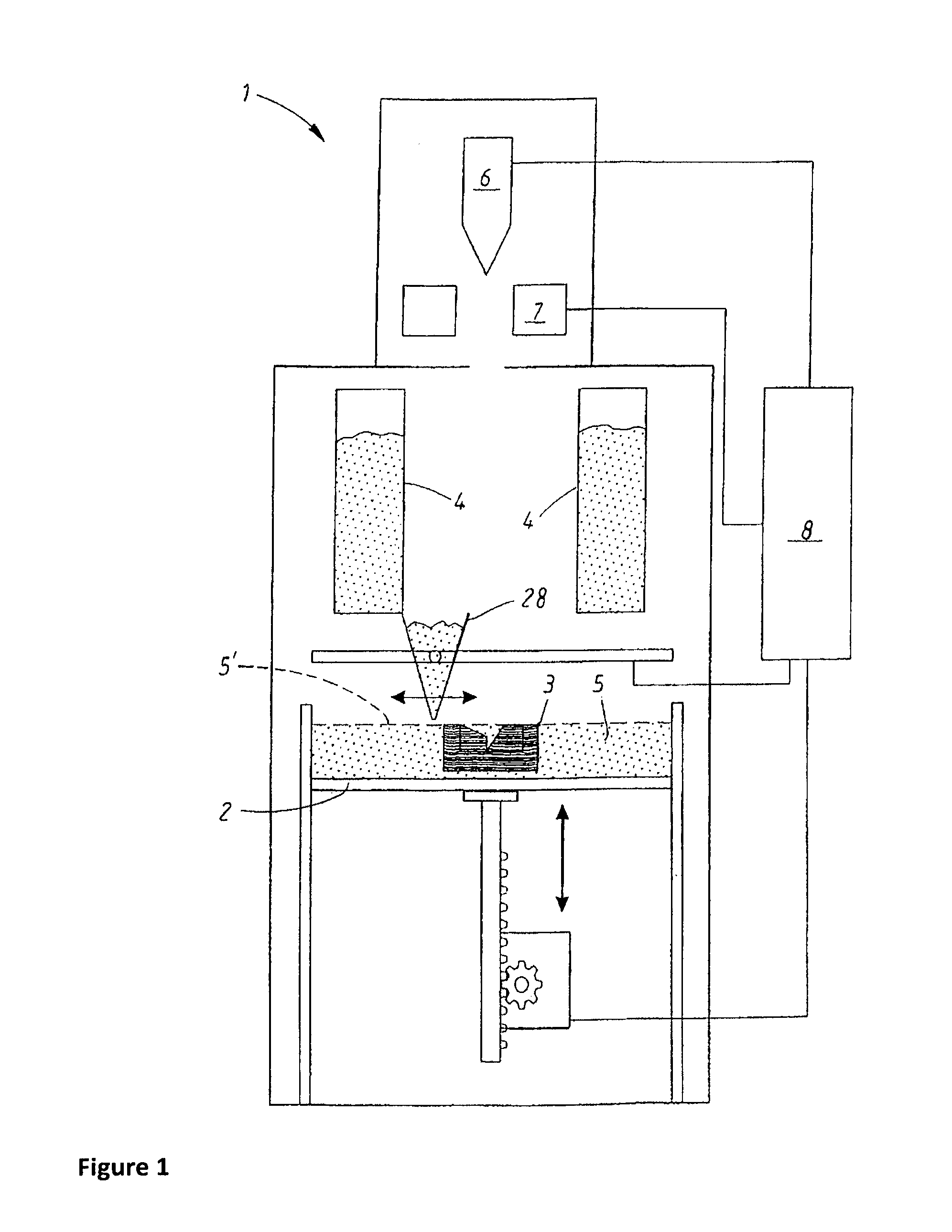

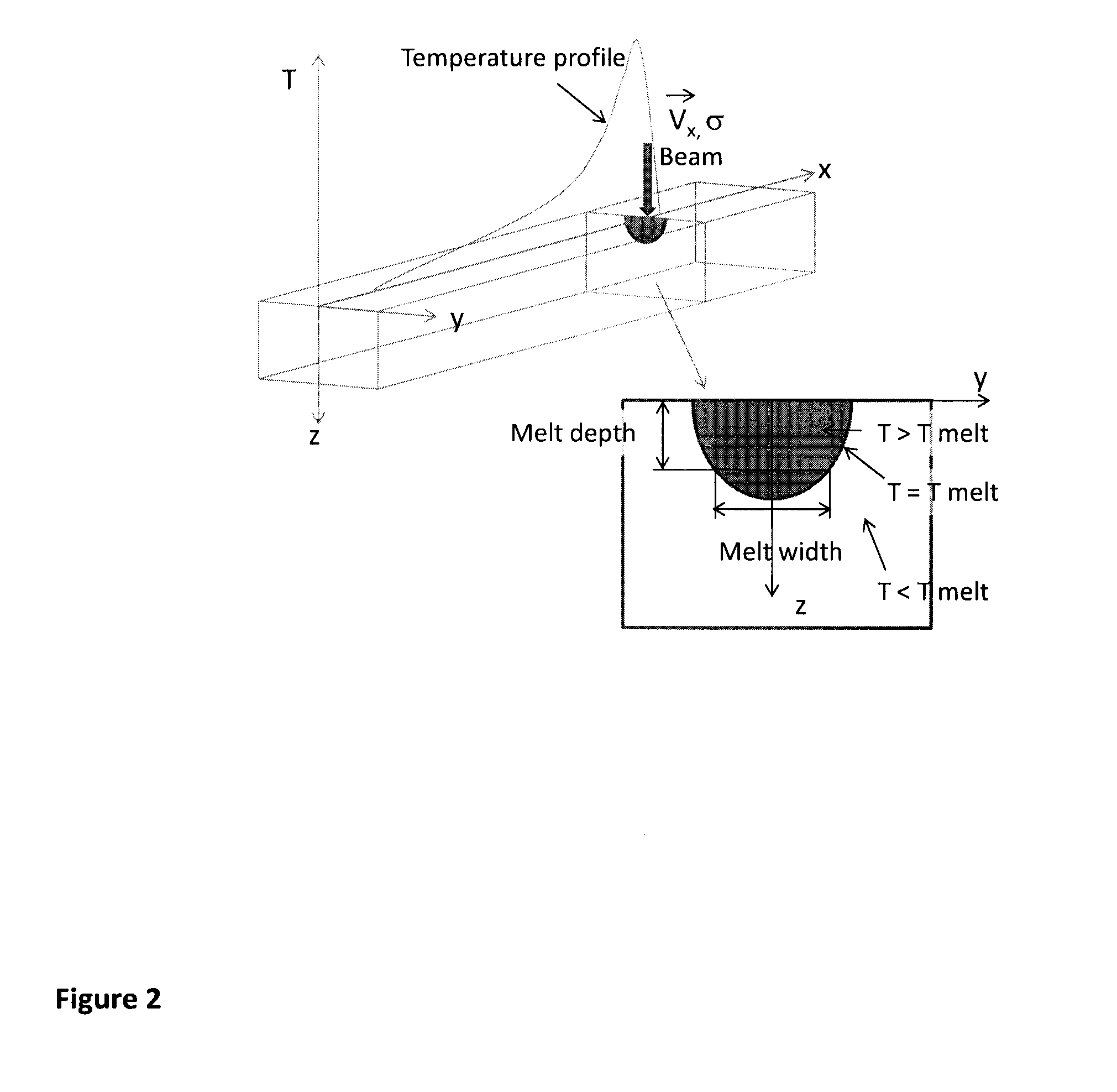

Method for production of a three-dimensional body

ActiveUS20130300035A1Improve product performanceRelieve pressureAdditive manufacturing apparatusTemperatue controlLight beamSupply energy

The invention concerns a method for production of a three-dimensional body by successively providing powder layers and fusing together of selected areas of said layers, which areas correspond to successive cross sections of the three-dimensional body, wherein the method comprises the following steps for at least one of said layers: applying the at least one powder layer onto a working area, and fusing together a selected area of the at least one powder layer by supplying energy from a radiation gun to the selected area. The invention is characterized in that it comprises the steps of: establishing an intended beam path that is to be used when fusing together the selected area of the at least one powder layer, calculating a temperature in the at least one powder layer along the intended beam path as a function of a specific energy deposition of an imaginary beam that is assumed to move along the intended beam path, adjusting the specific energy deposition of the imaginary beam along the intended beam path depending on the calculated temperature and on conditions set for the step of fusing together the selected area, and providing, based on the calculations and the adjustments, an operating scheme for the specific energy deposition of the real beam to be used for the intended beam path when fusing together the selected area of the at least one layer.

Owner:ARCAM AB

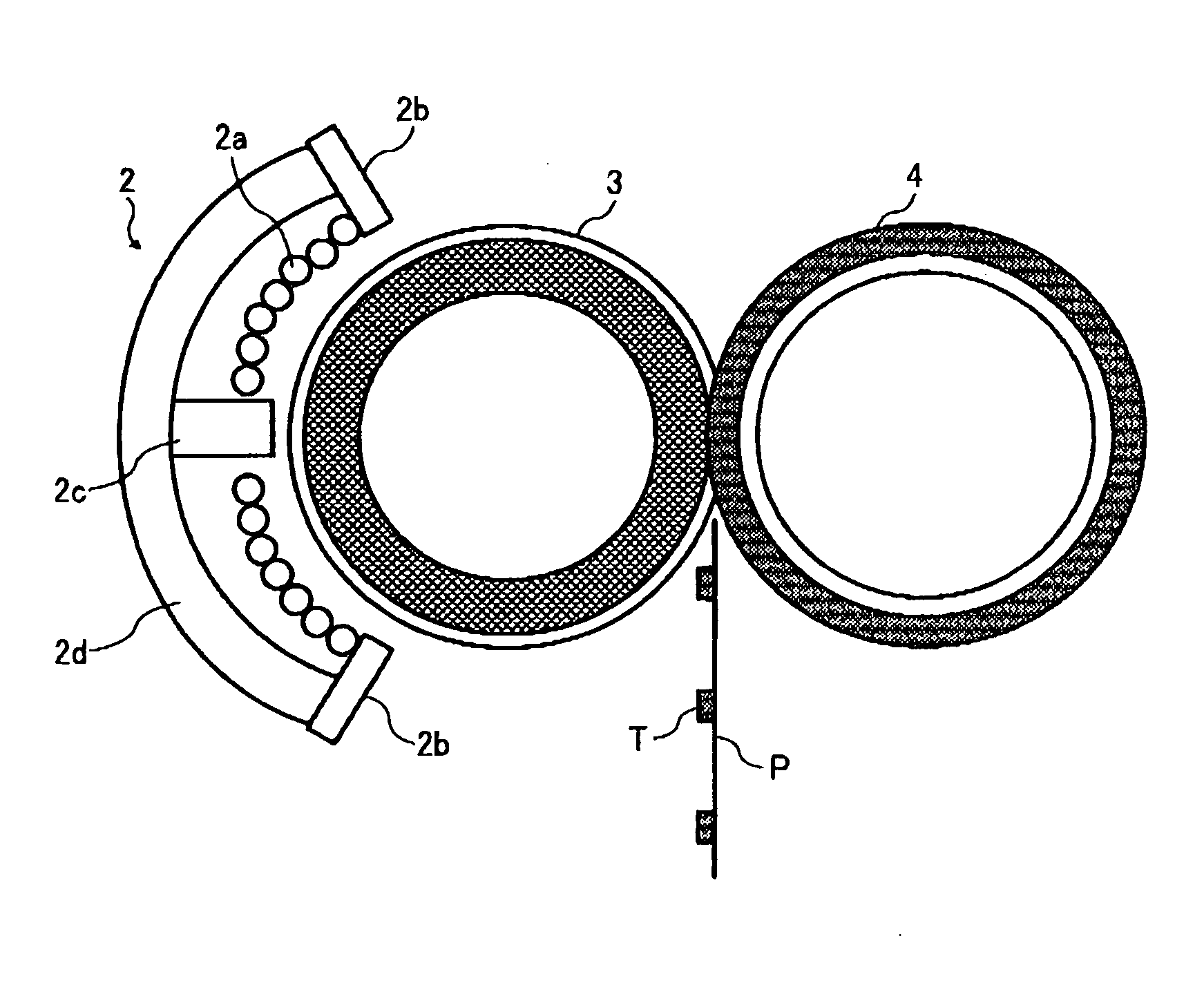

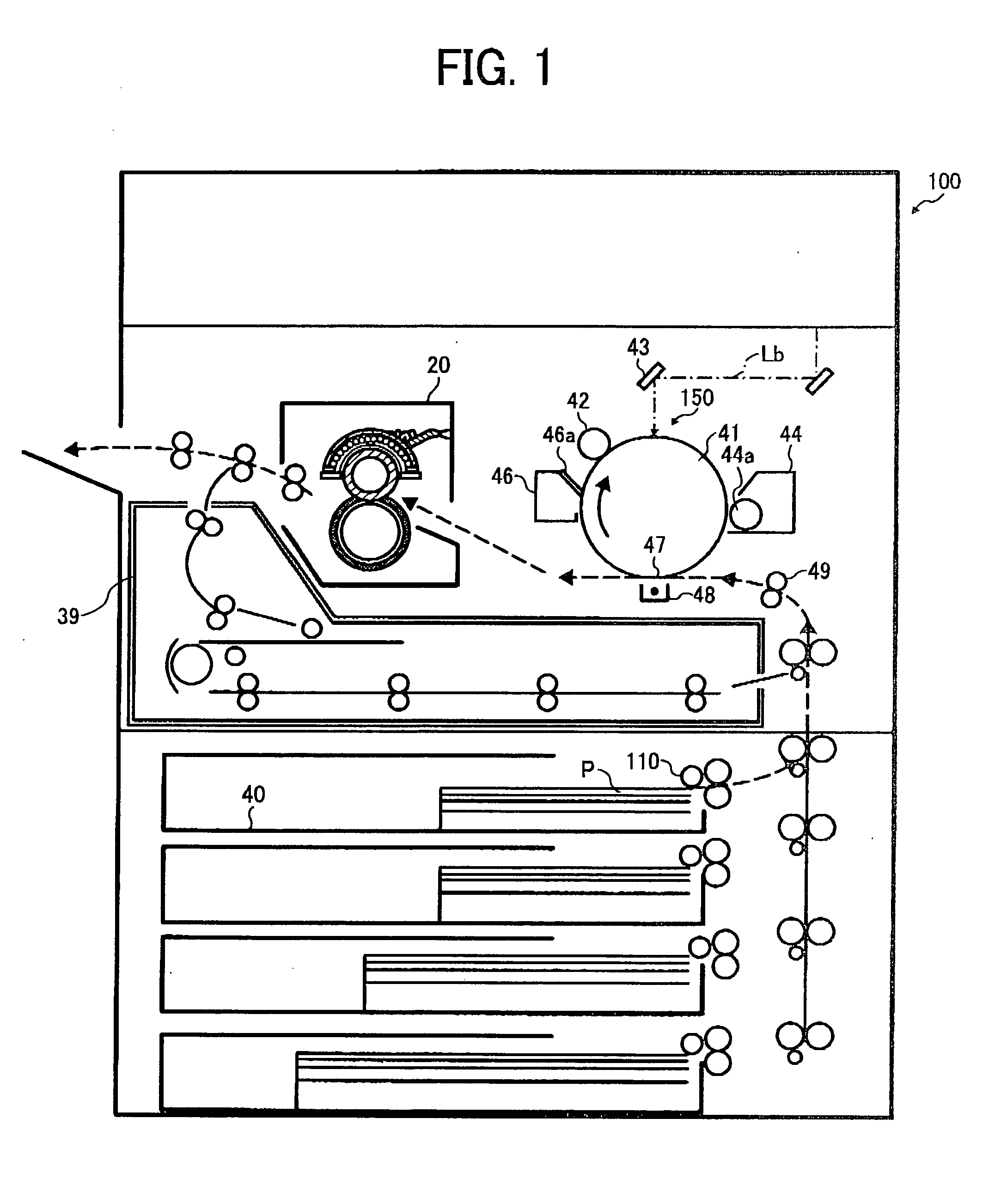

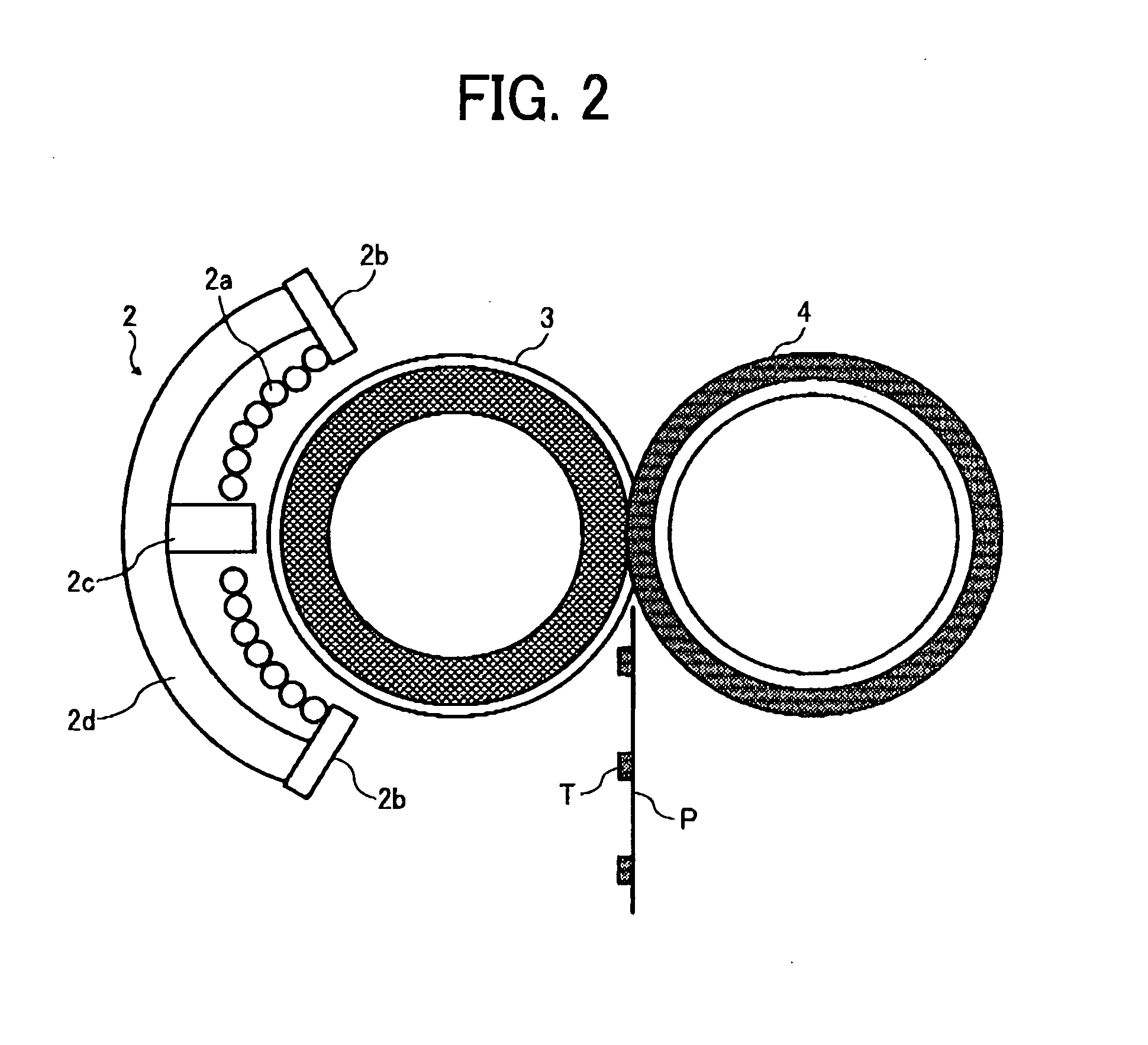

Fixing device and image forming apparatus including same

ActiveUS20080232873A1Reduce crackingAffects image formationElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a fixing device to fix a toner image on a recording medium by applying heat. Such a fixing device includes at least a magnetic flux generator, a heat generating roller, a magnetic shunt layer, and a protective layer. The magnetic flux generator is configured to generate magnetic flux. The heat generating roller including a heat generating layer is configured to generate heat by the magnetic flux. The magnetic shunt layer may be formed independently of the heat generating layer. The protective layer is provided on an inner surface of the magnetic shunt layer and configured to cover a crack formed in the magnetic shunt layer during fabrication of the magnetic shunt layer. An image is fixed onto the recording medium by the heat from the heat generating roller. Alternatively, the magnetic shunt layer may be integrally provided with the heat generating layer.

Owner:RICOH KK

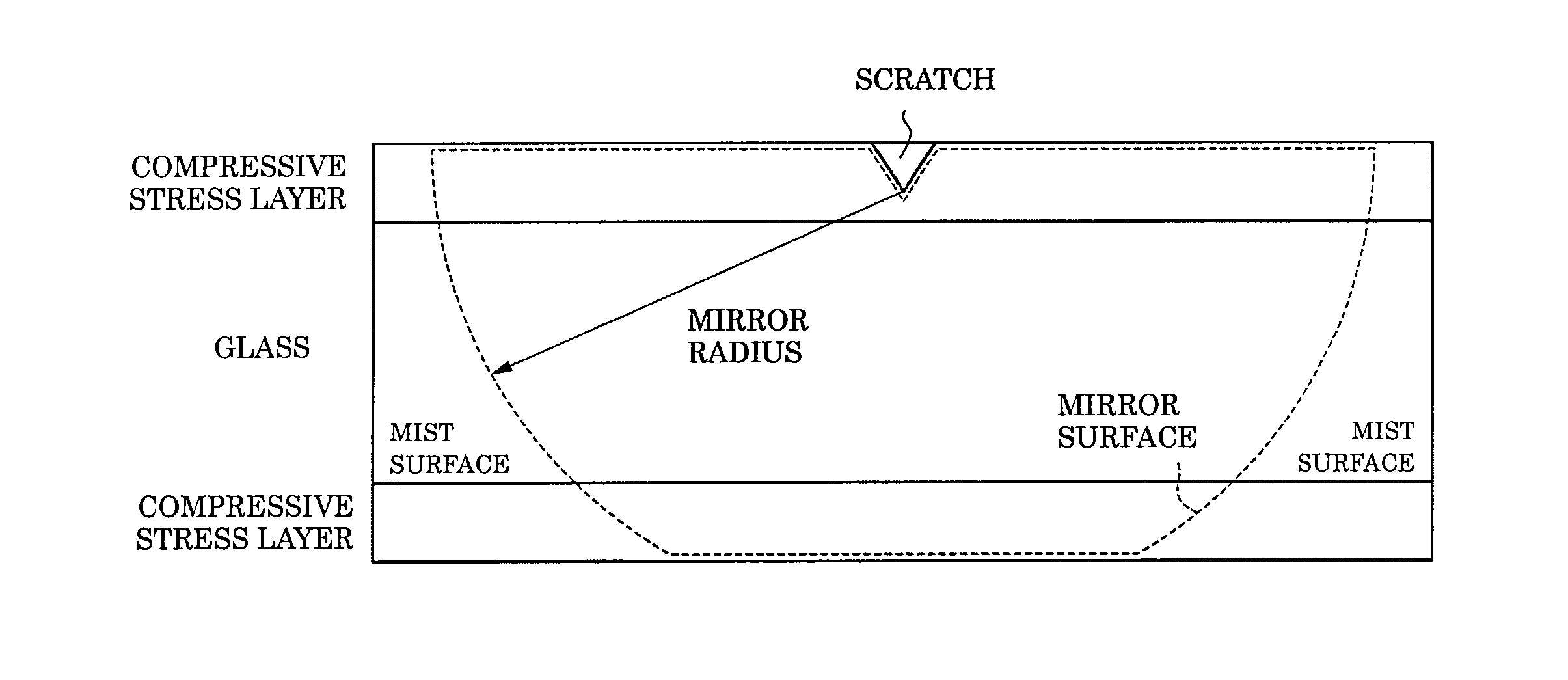

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

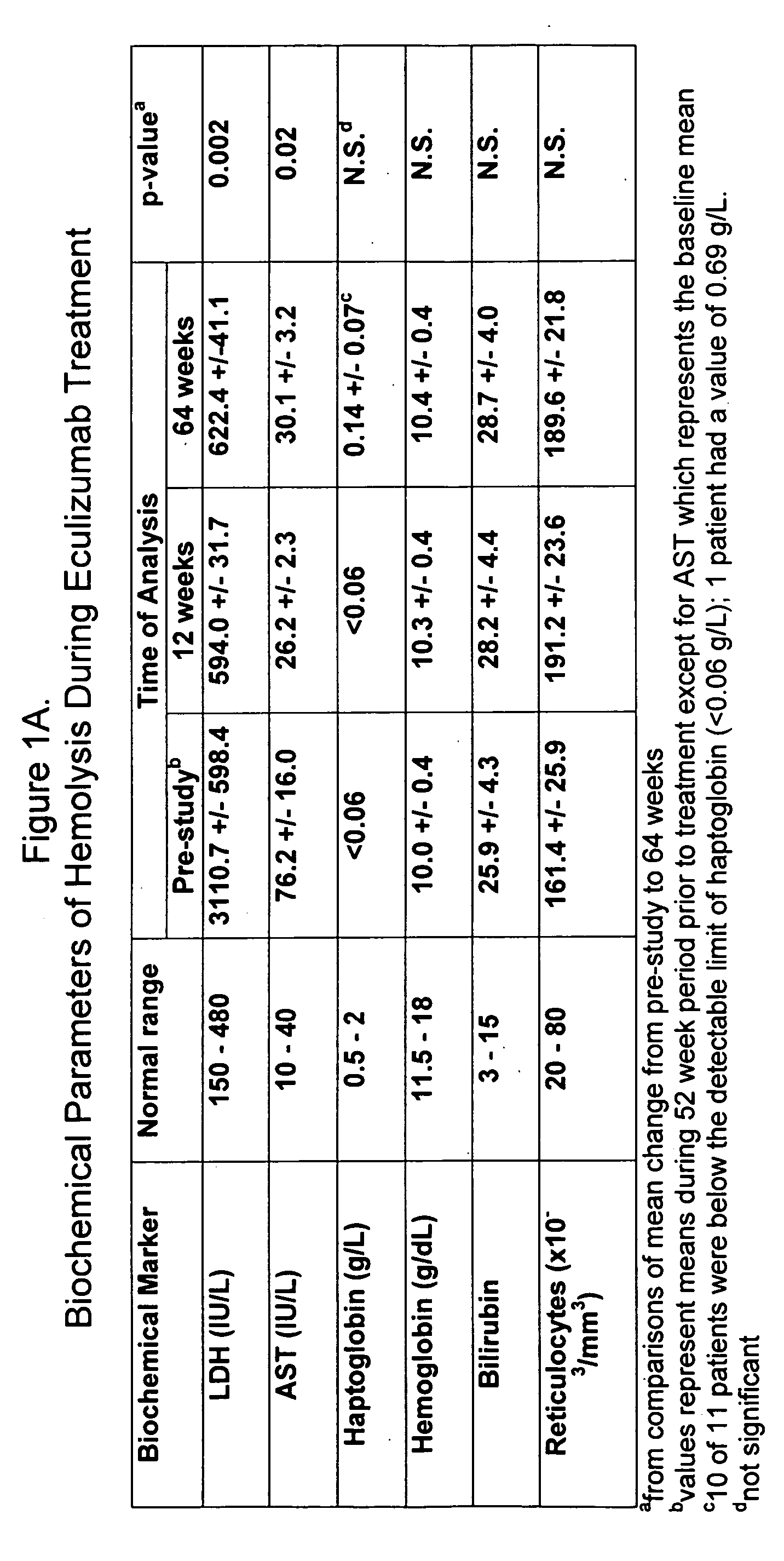

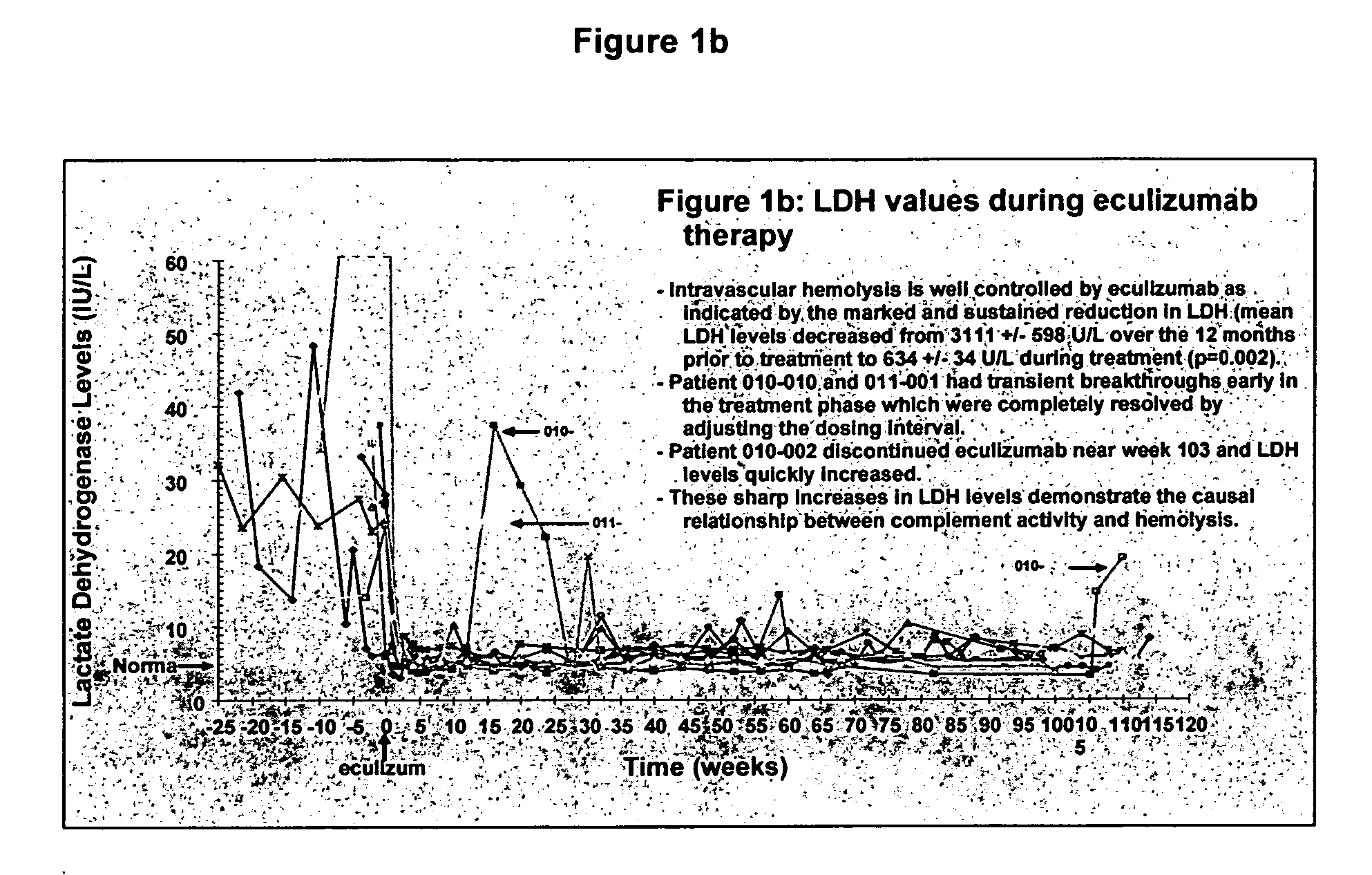

Method of treating hemolytic disease

InactiveUS20050191298A1Reduce crackingRaising serum levelPeptide/protein ingredientsGenetic material ingredientsCompound (substance)Paroxysmal nocturnal hemoglobinuria

Paroxysmal nocturnal hemoglobinuria or other hemolytic diseases are treated using a compound which binds to or otherwise blocks the generation and / or the activity of one or more complement components, such as, for example, a complement-inhibiting antibody.

Owner:ALEXION PHARMA INC

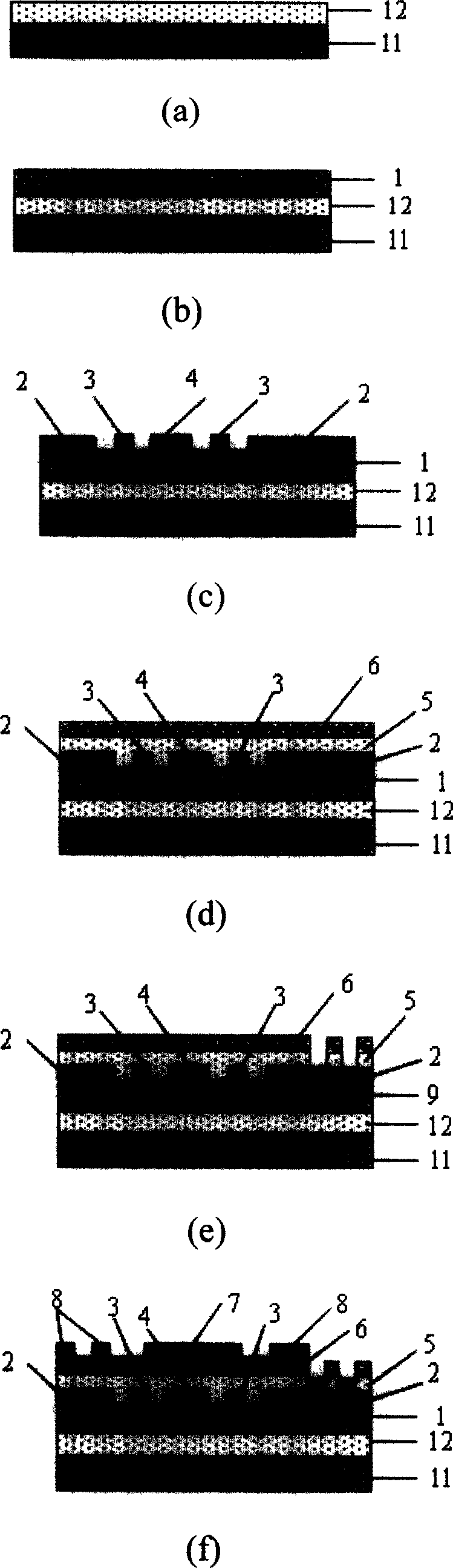

Flexible capacitance type touch sensor production method

InactiveCN101059380ALow costImprove yieldSemi-permeable membranesForce measurementElectricitySensor array

The invention relates to a method for producing flexible capacitor touch sensor, characterized in composed of middle layer preparation of PDMS, preparation of flexible PI substrate, graph metal sensitive electrode and relative electric connection, preparation of a first high-elasticity dielectric layer PDMS and a second flexible dielectric layer PI, graph metal drive electrode and relative electric connection, graph a top flexible insulation protective layer PI, separation of the flexible capacitor touch sensor. The invention optimizes and combines techniques, to realize the compatibility of organic flexible material PDMS, PI and traditional MEMS technique. And the capacitor touch sensor has compact structure, high mechanical strength, and high flexibility, while the product can contact the surface with any curvature to sense the volumes of normal force and tangent force, and be applied for the production of flexile capacitor touch sensor array.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

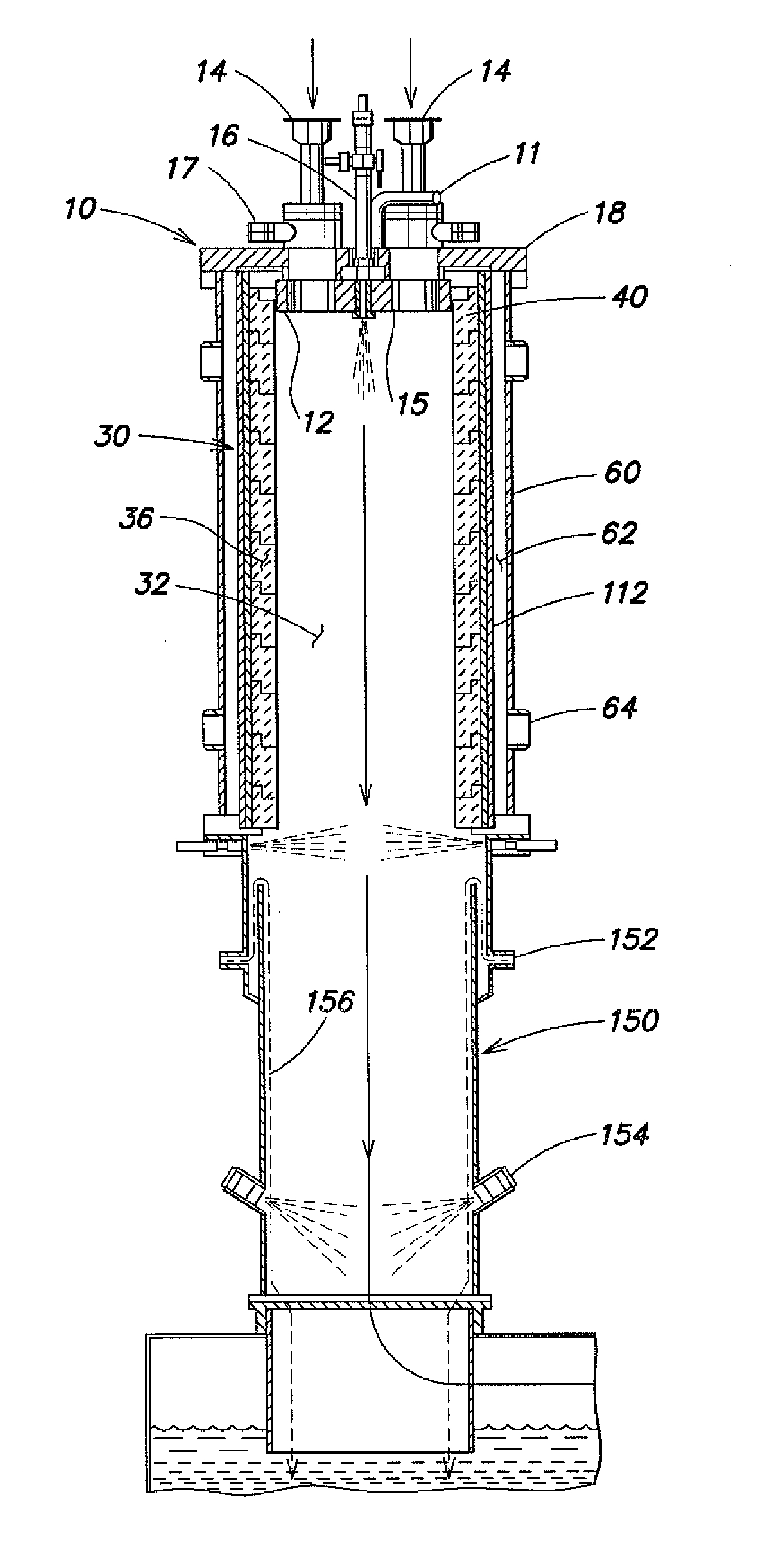

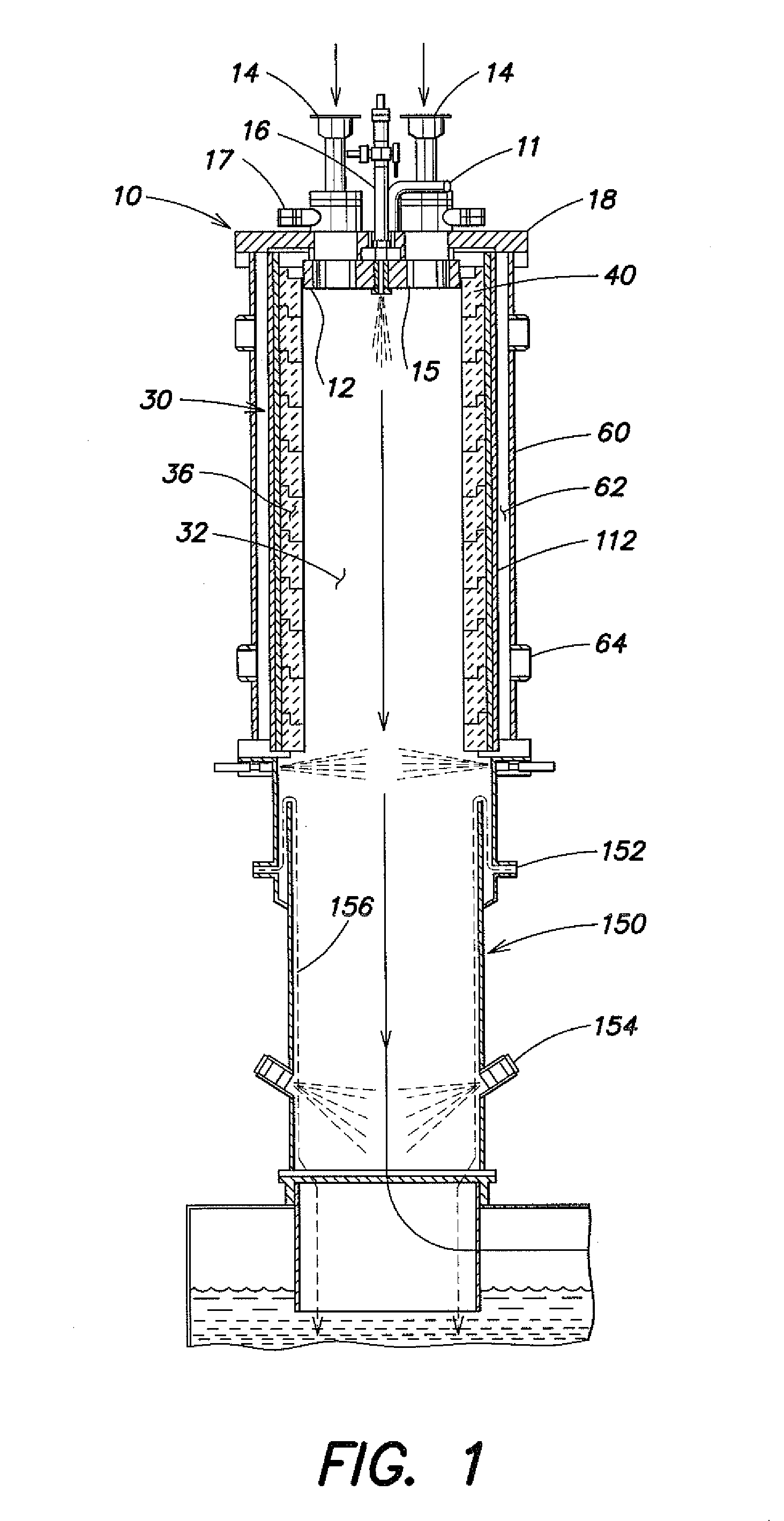

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

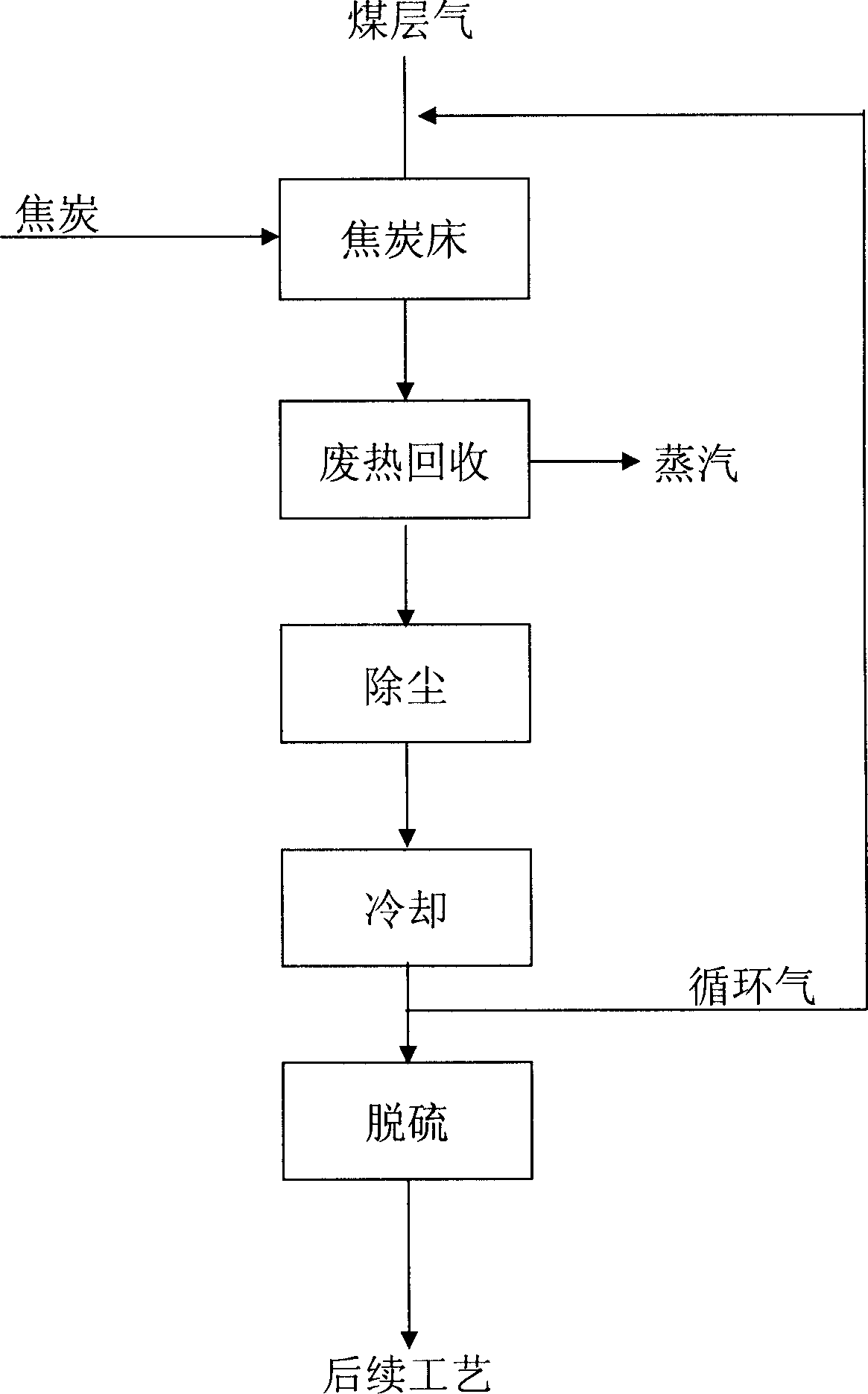

Coal bed gas coke deoxidization technique

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

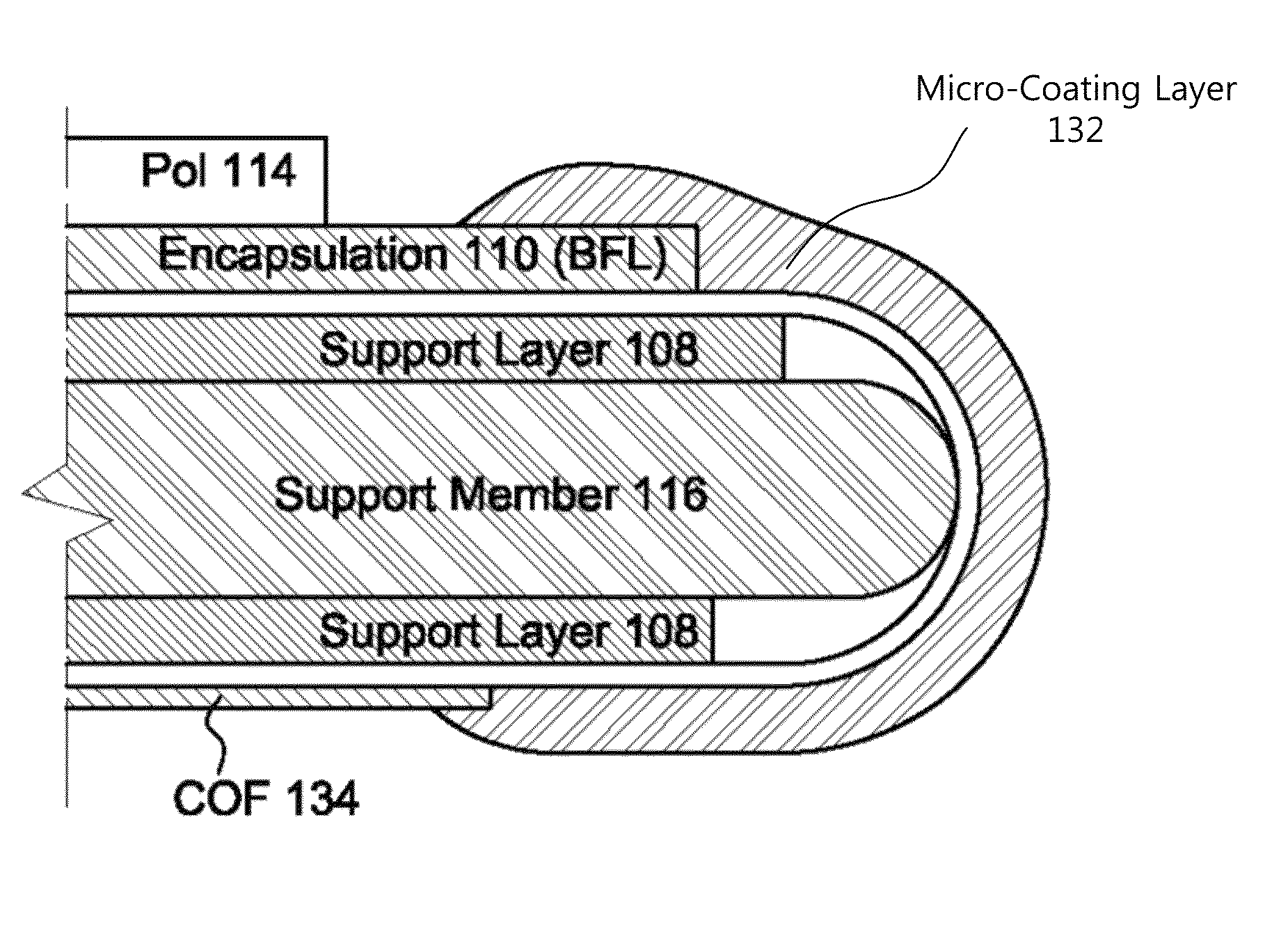

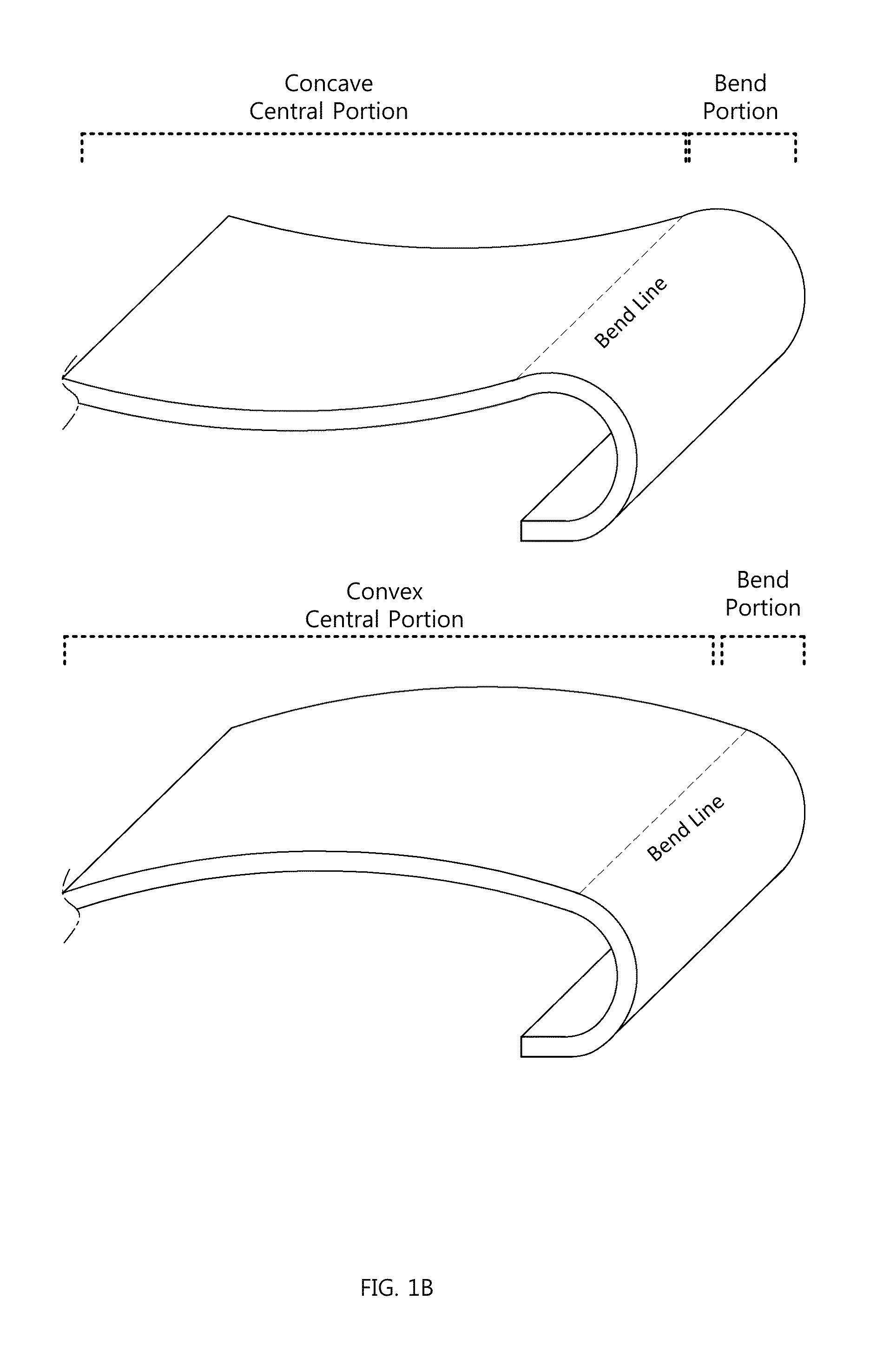

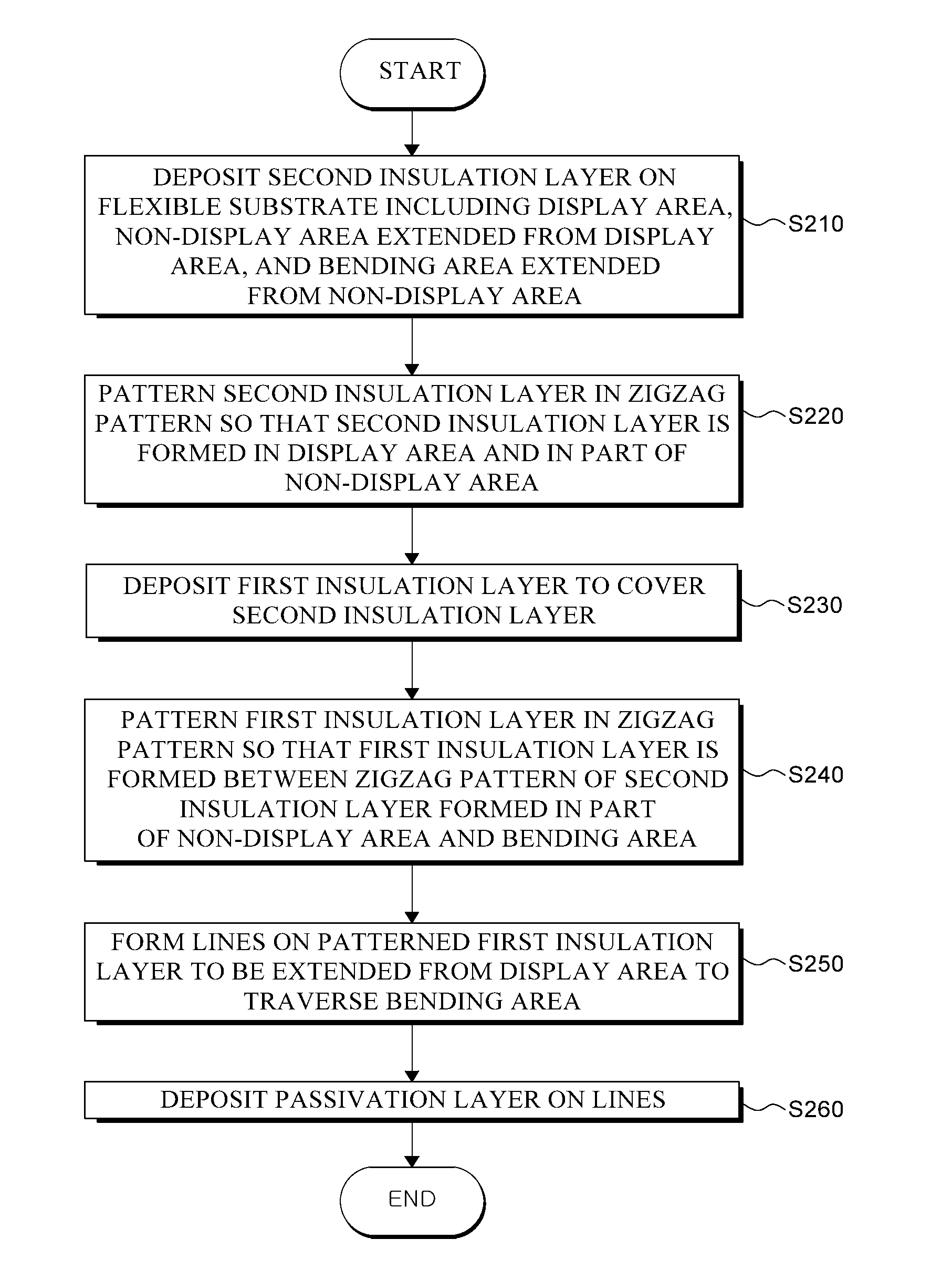

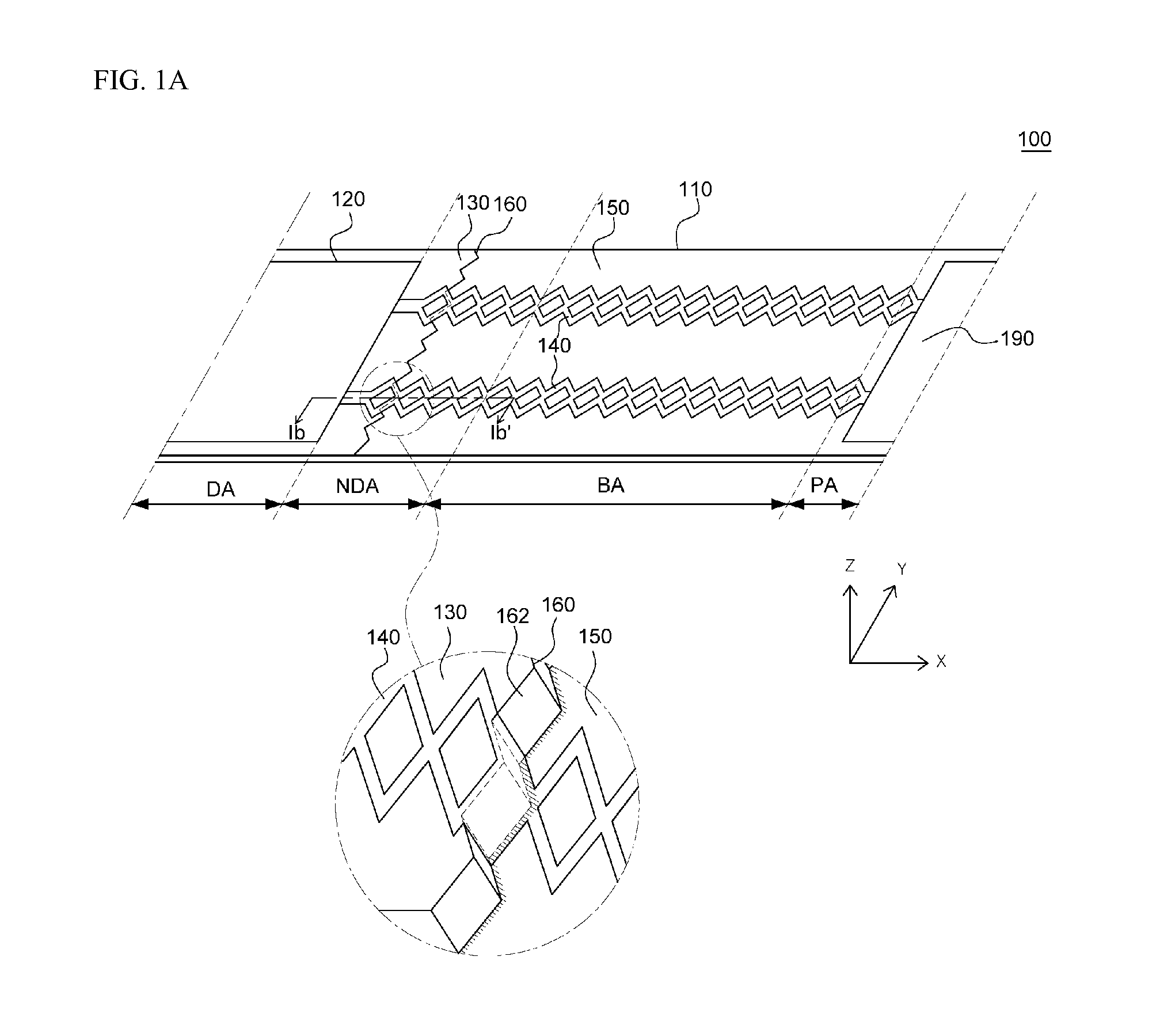

Flexible organic light emitting display and method of manufacturing the same

ActiveUS20150179728A1Crack suppressionReduce frequencySolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

Provided is a flexible organic light-emitting display device. The flexible display device includes a flexible substrate having a display area, a non-display area, and a bending area. On the flexible substrate, a first insulation layer is formed in a part of the non-display area. The first insulation layer includes a zigzag pattern. A plurality of wirings are electrically connected to the display area and are extended to traverse the non-display area and the bending area and are disposed on the first insulation layer. On the first insulation layer and the plurality of wirings, a passivation layer is formed. By virtue of a zigzag pattern of the first insulation layer, the frequency of occurrence of cracks in the passivation layer is reduced.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com