Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Increase the surface compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemically toughened glasses

InactiveUS6518211B1Promote meltingNot affecting strain pointGlass/slag layered productsThin material handlingToughened glass

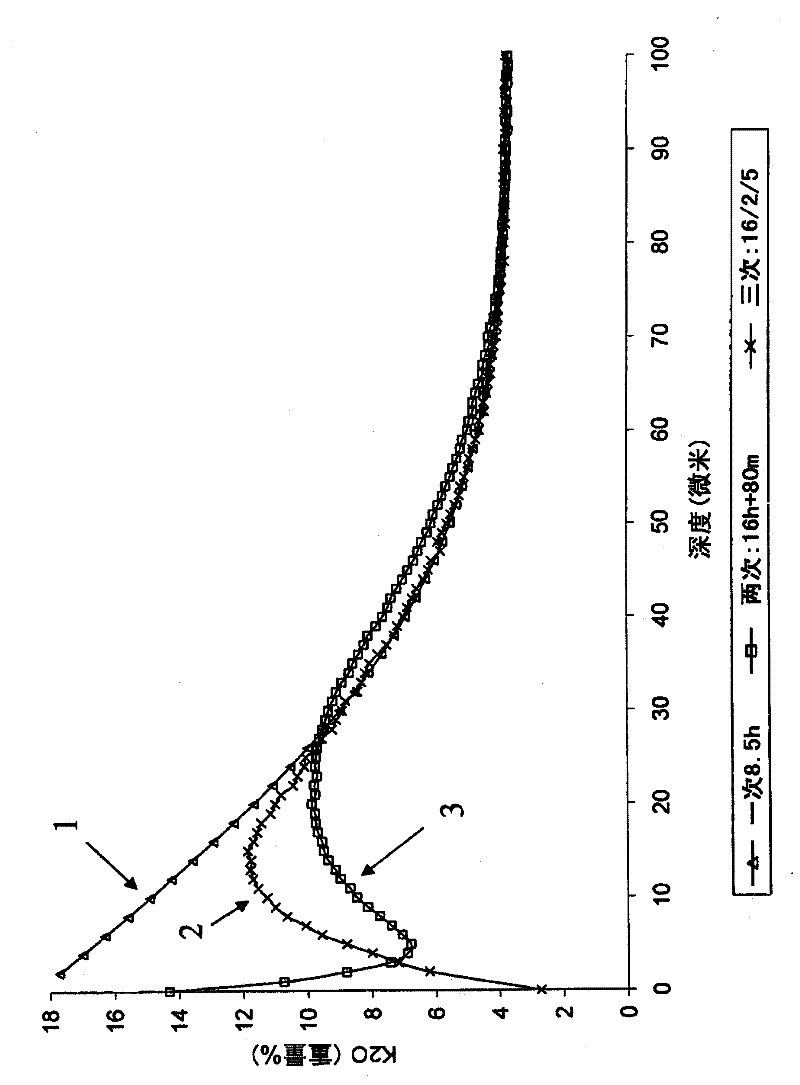

A glass composition capable of being chemically strengthened by ion-exchange within 100 hours to provide a glass with a surface compressive stress of greater then 400 MPa and an ion-exchange depth greater then 200 microns comprising: SiO2 58% to 70% (by weight), Al2O3 5% to 15%, Na2O 12% to 18%, K2O 0.1% to 5%, MgO 4% to 10%, CaO 0% to 1% with the provisos that the total of the Al2O3 and MgO is in excess of 13%, the total of the amounts of Al2O3 plus MgO divided by the amount of K2O is at least 3 and that the sum of the amounts of Na2O, K2O and MgO is at least 22%.

Owner:GKN AEROSPACE SERVICES LTD

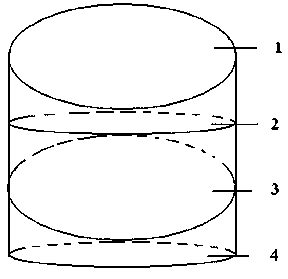

Laminated and ion-exchanged strengthened glass laminates

ActiveUS20140141217A1Increase compressive stressHigher depthGlass forming apparatusGlass/slag layered productsIonIon exchange

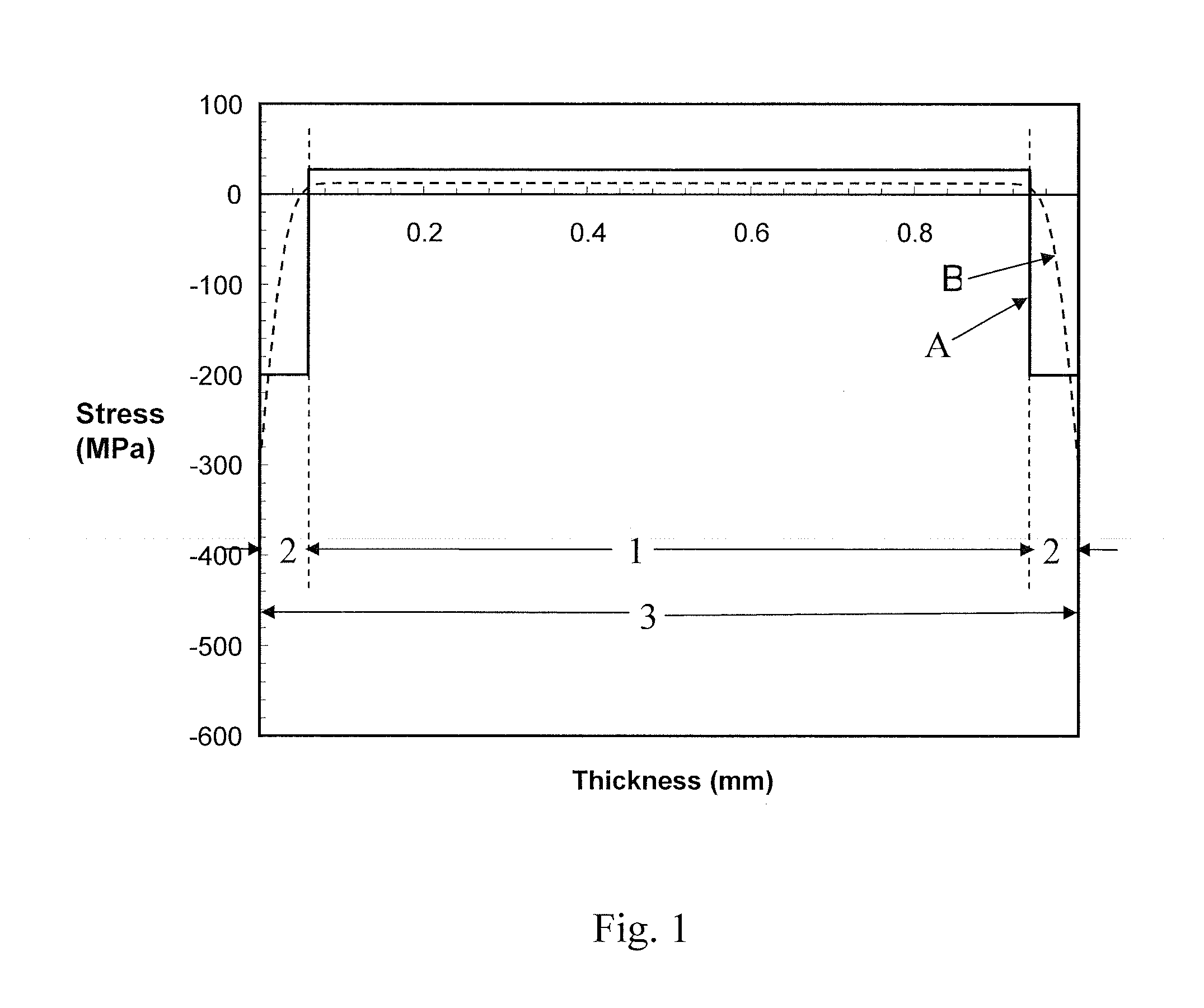

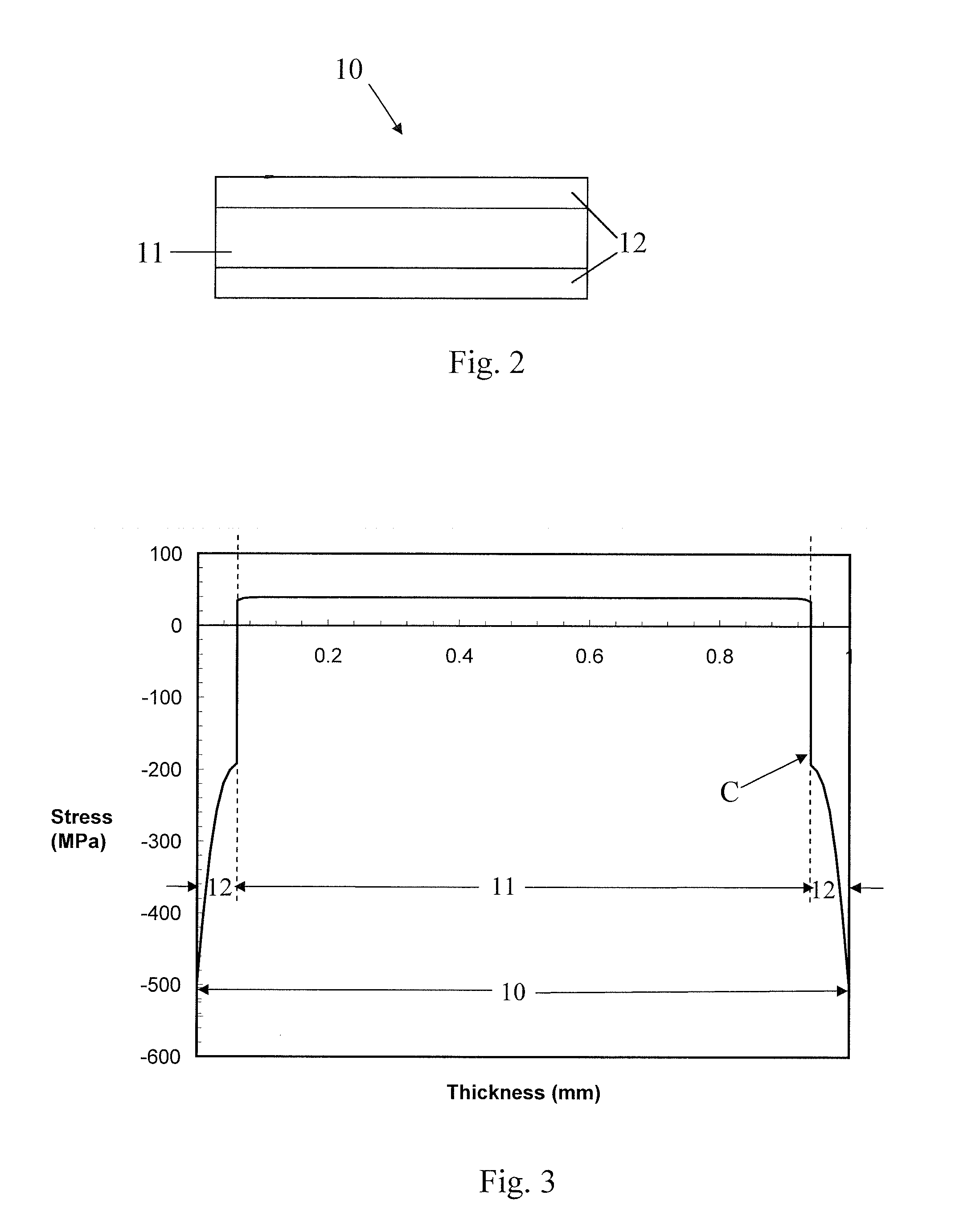

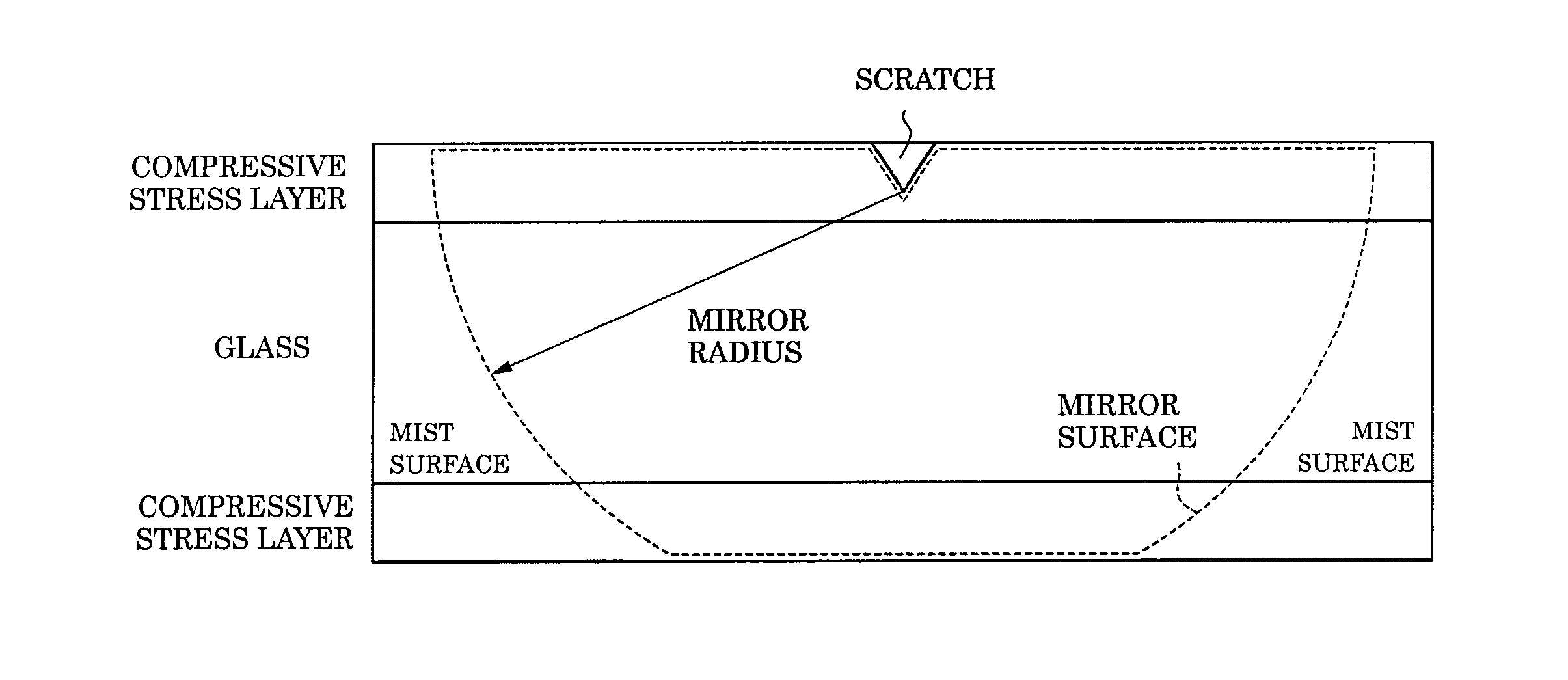

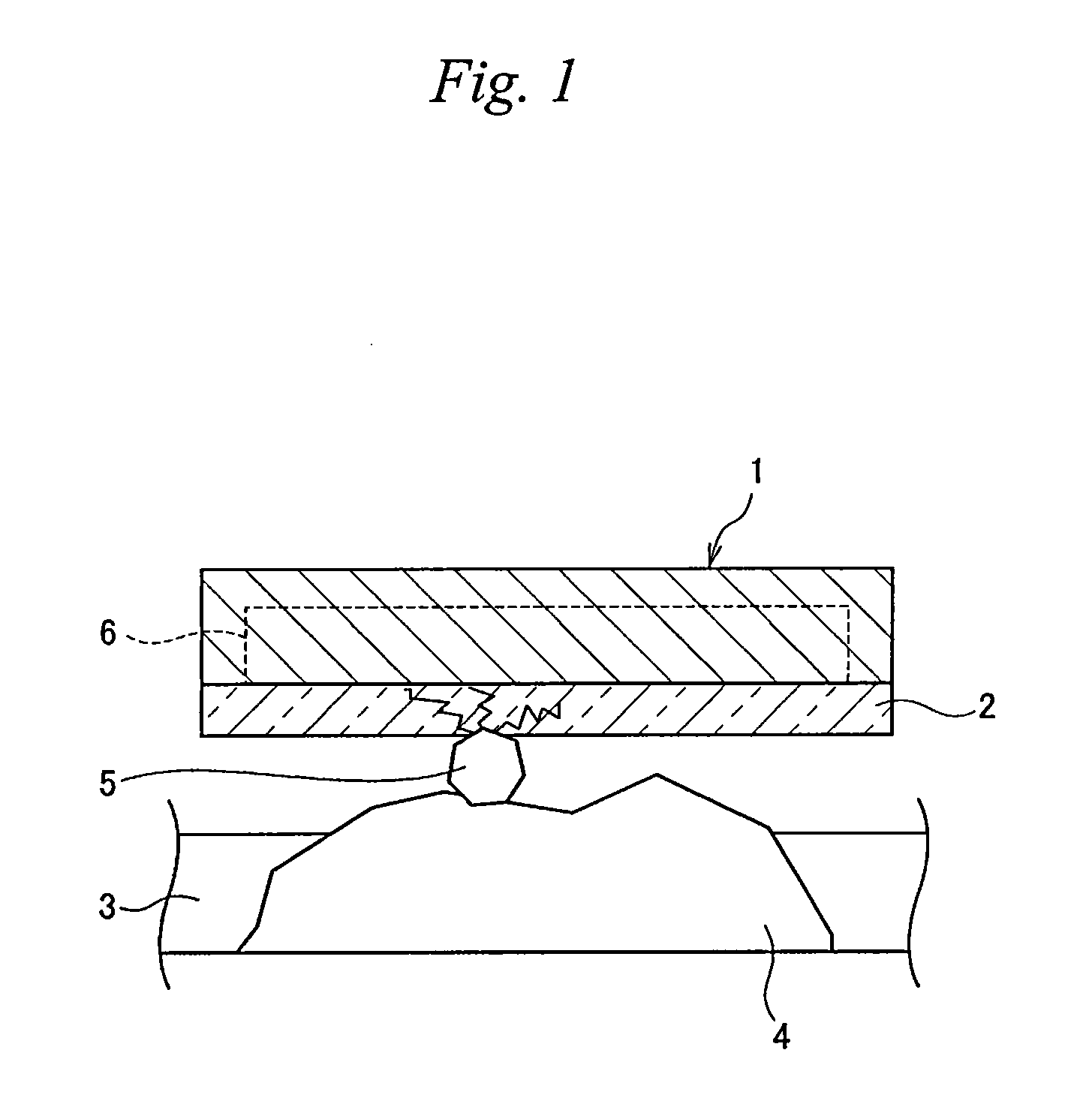

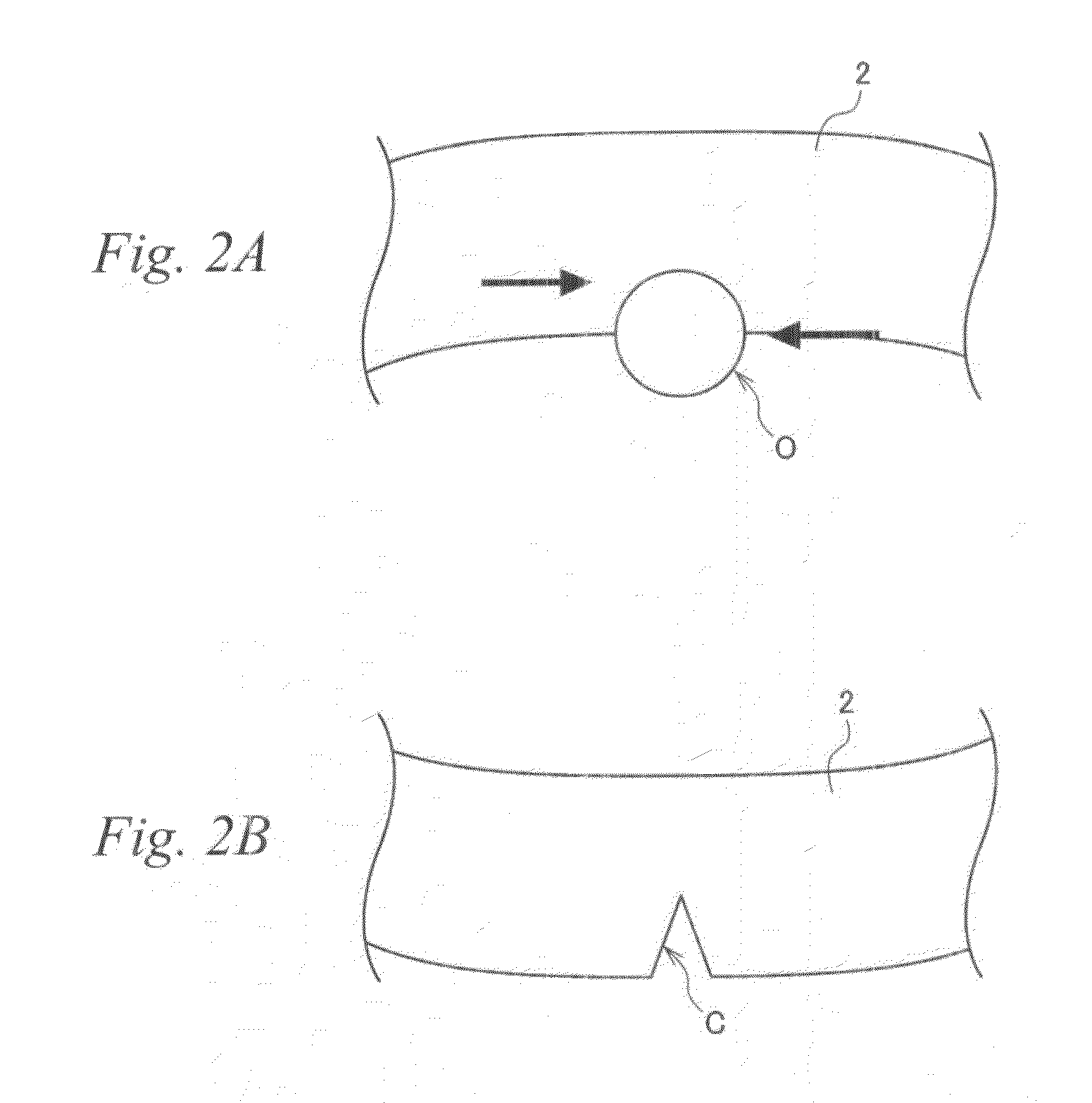

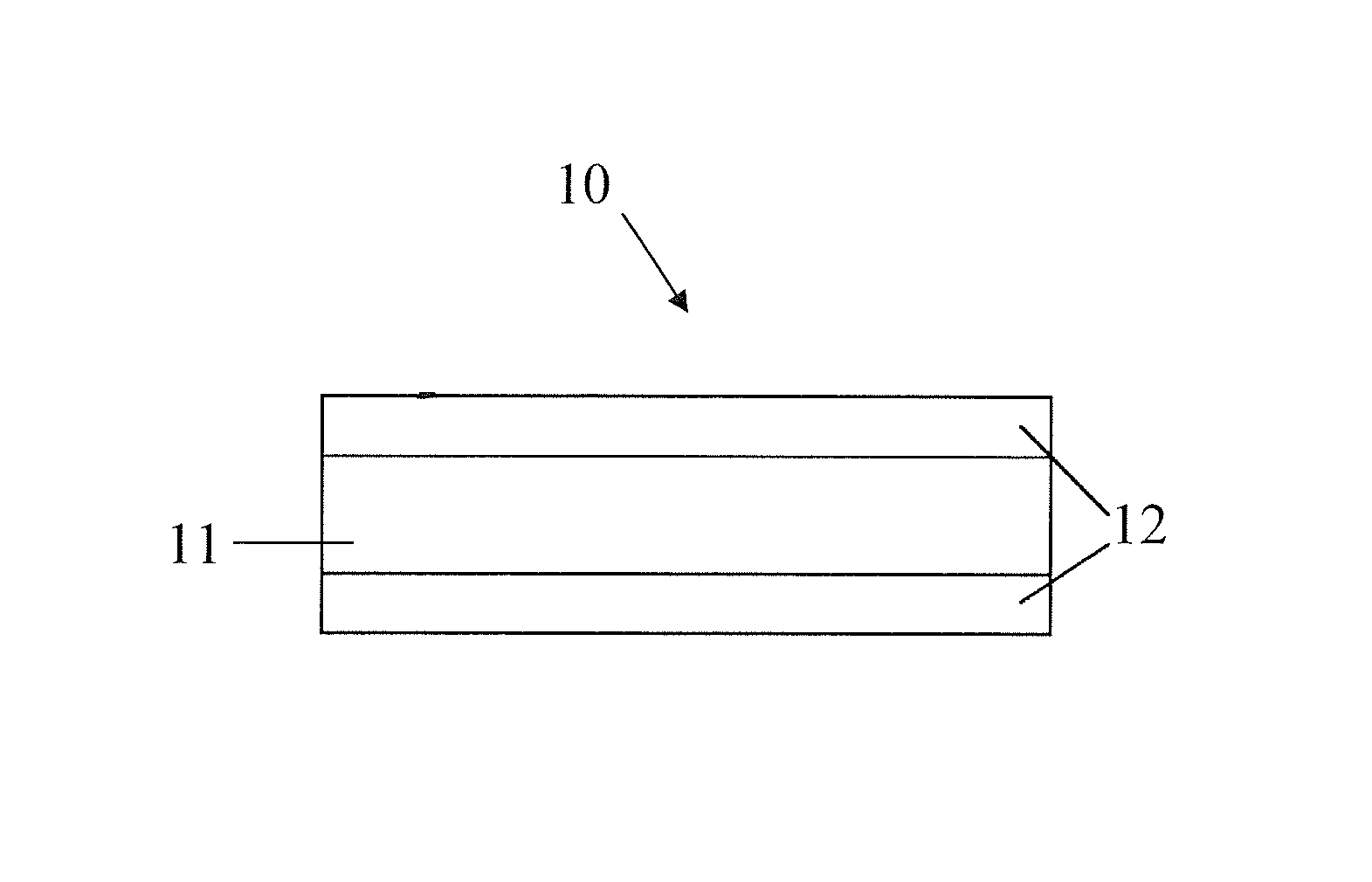

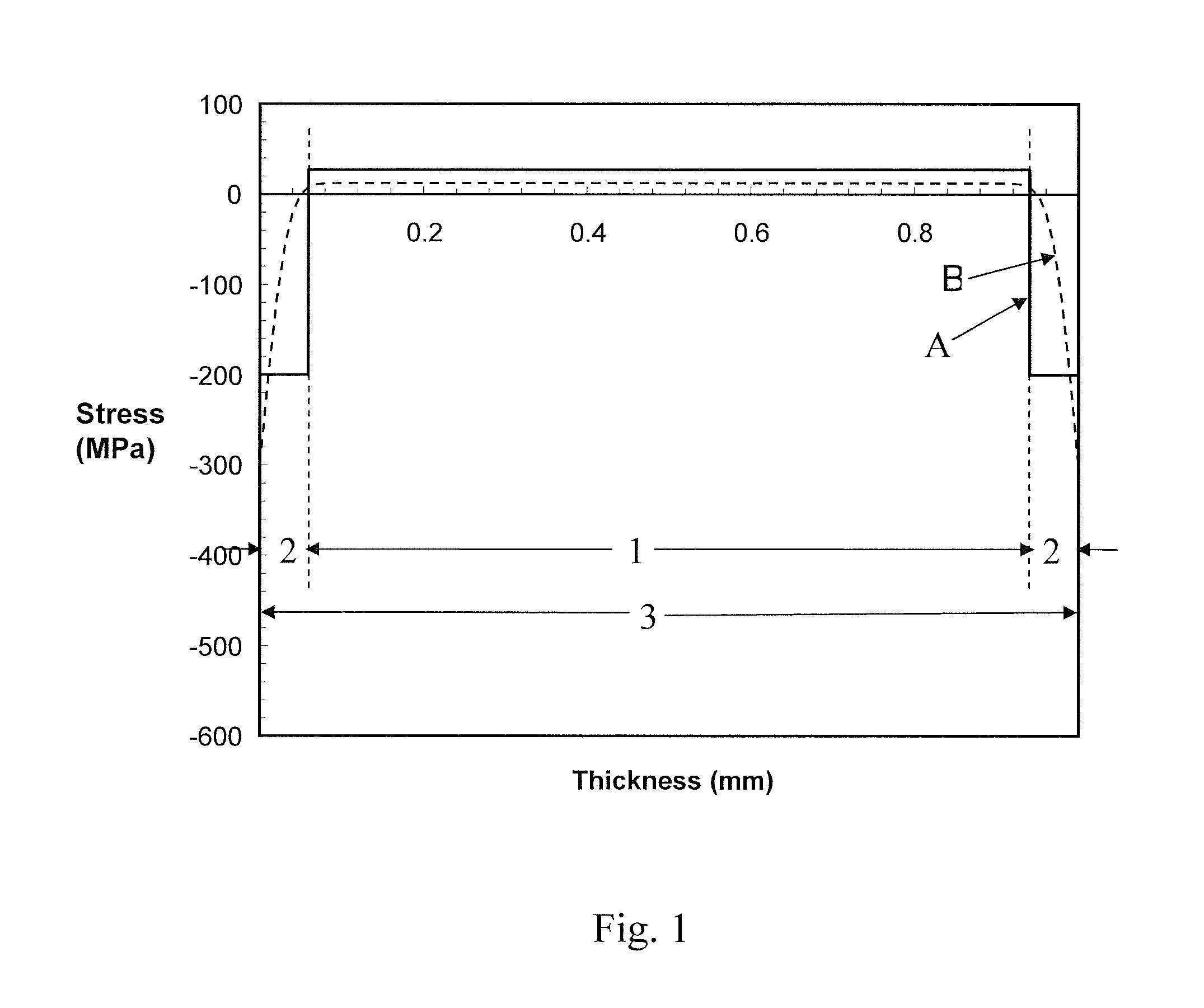

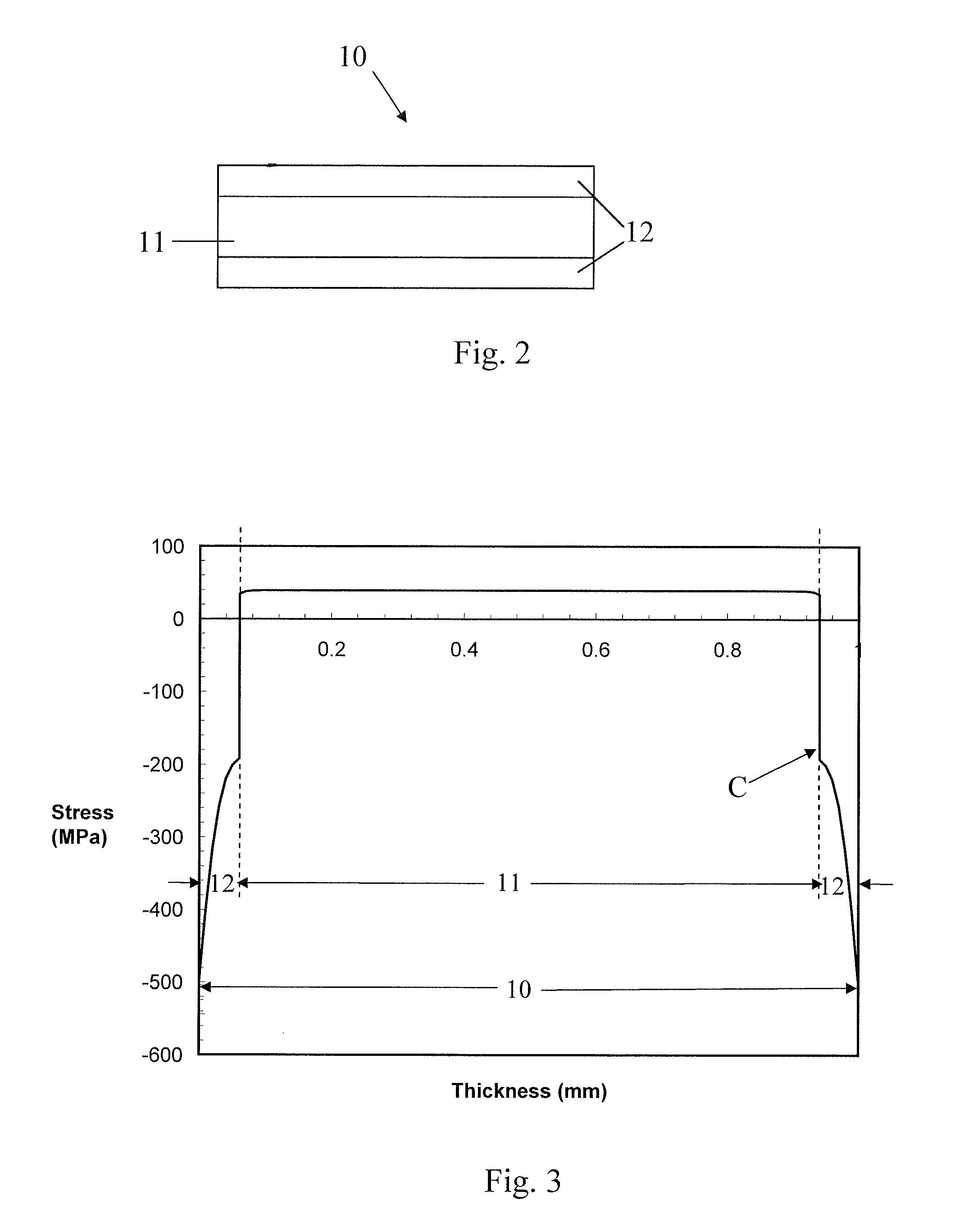

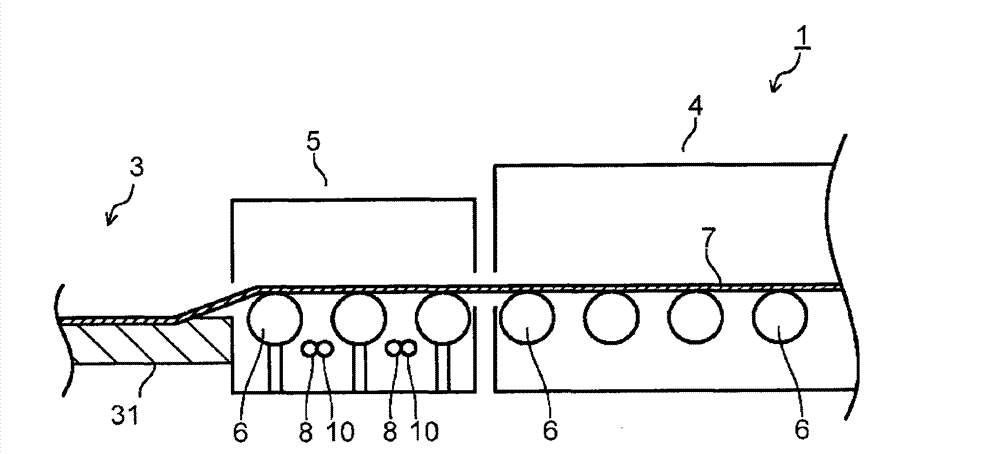

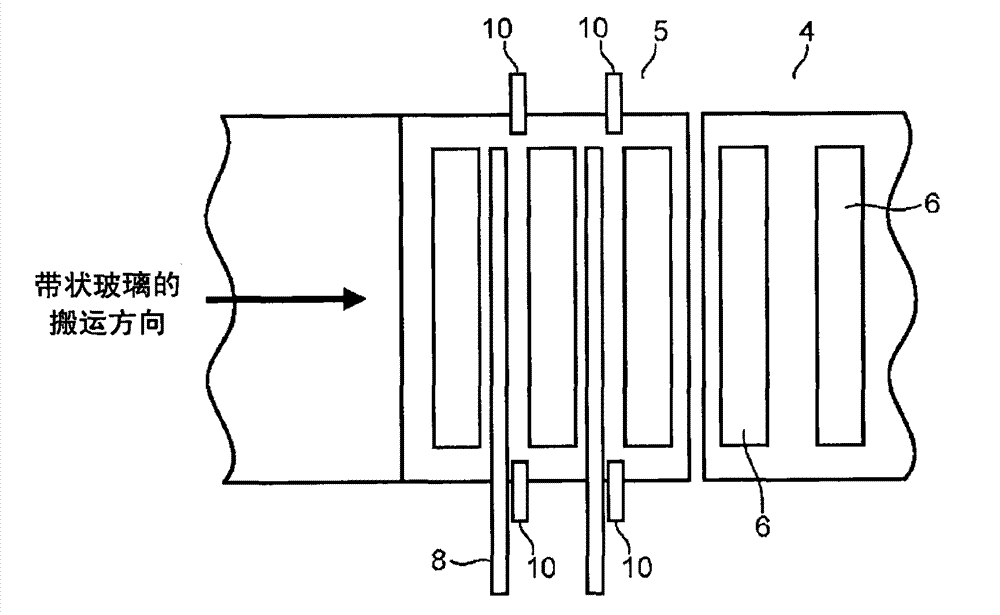

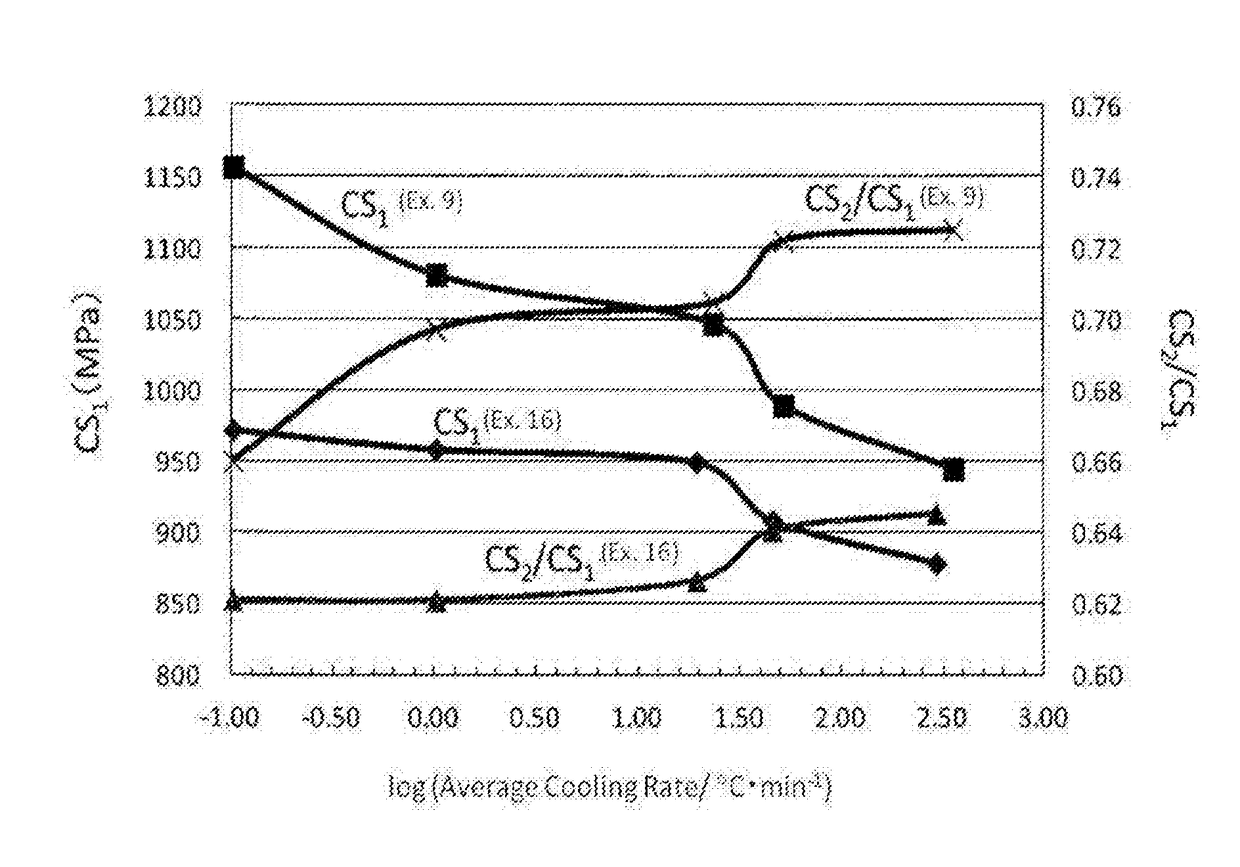

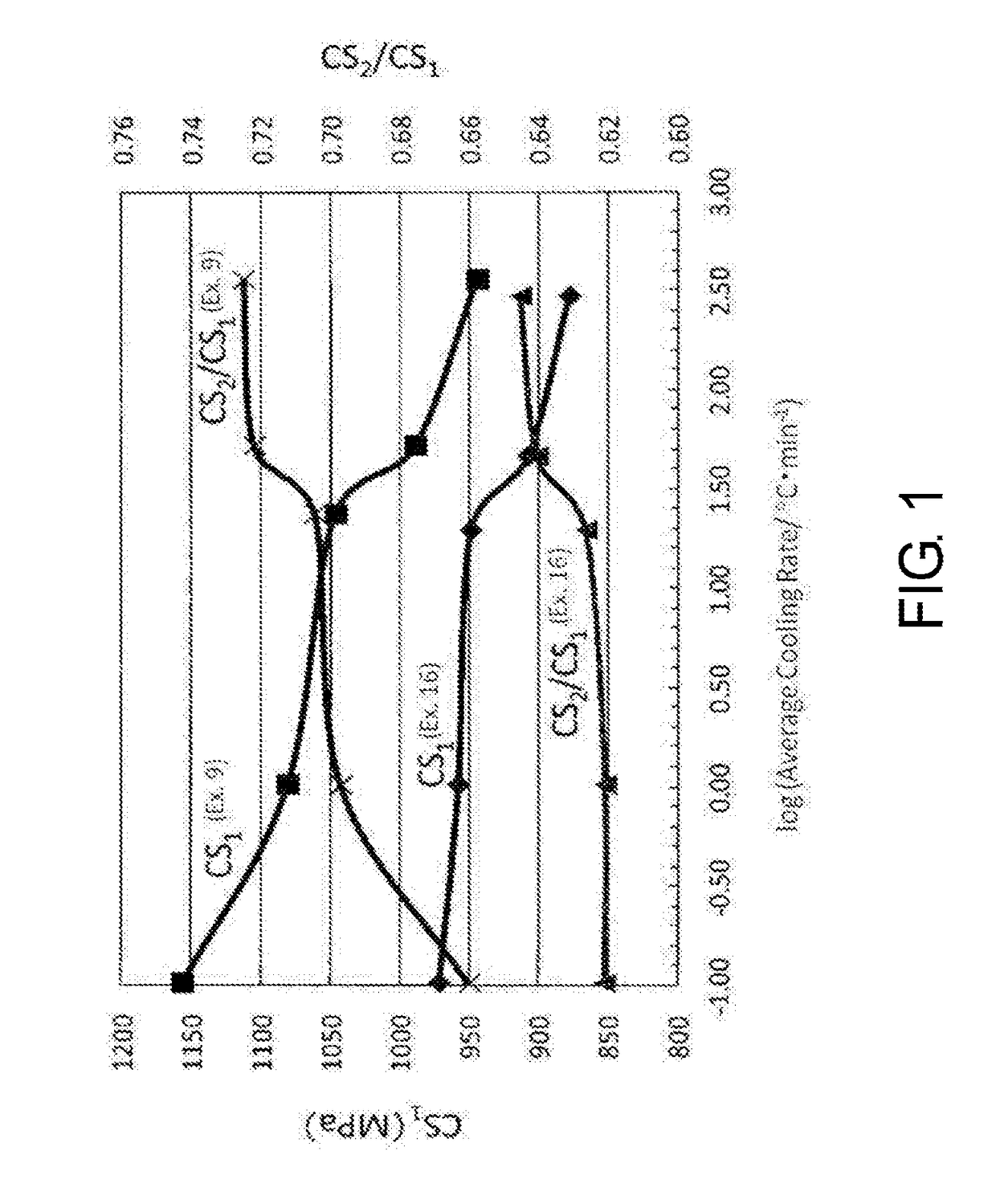

A method of making a glass sheet (10) comprises laminating a high CTE core glass (11) to a low CTE clad glass (12) at high temperatures and allowing the laminate (10) to cool creating compressive stress in the clad glass (12), and then ion exchanging the laminate (10) to increase the compressive stress in the outer near surface regions of the clad glass (12). The core glass (11) may include ions that exchange with ion in the clad glass (12) to increase the compressive stress in inner surface regions of the clad glass (12) adjacent to the clad glass / core glass interfaces. The glass laminate (10) may be formed and laminated using a fusion forming and laminating process and fusion formable and ion exchangeable glass compositions.

Owner:CORNING INC

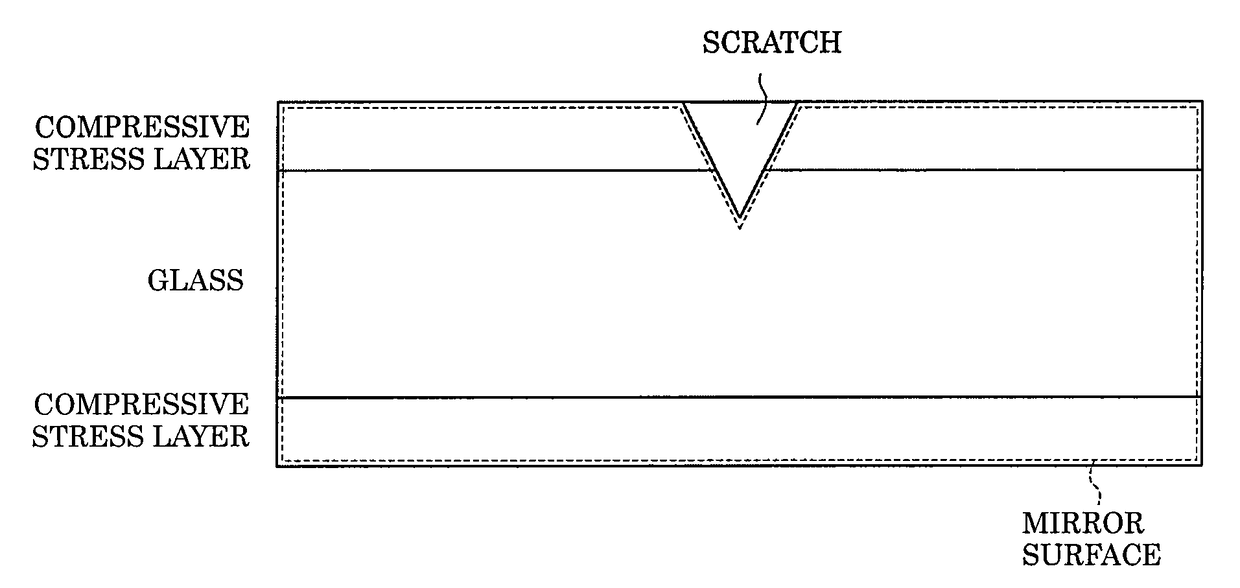

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

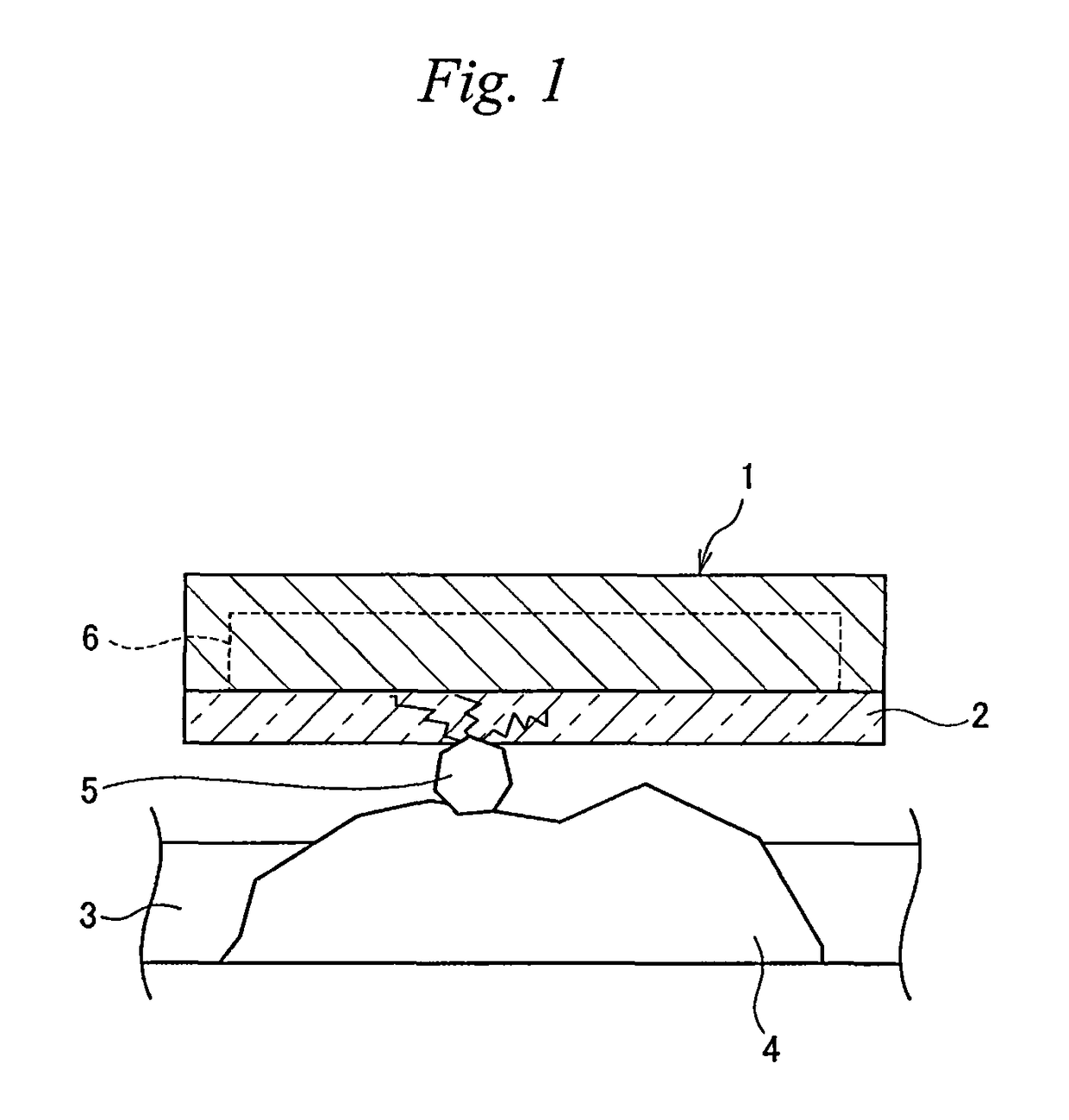

Glass with compressive surface for consumer applications

ActiveCN102131740AIncrease the surface compressive stressReduce compressive stressIon exchangeContact force

The present invention provides a strengthened glass that does not exhibit frangible behavior when subjected to impact or contact forces, and a method of strengthening a glass. The glass may be strengthened by subjecting it to multiple, successive, ion exchange treatments. The multiple ion exchange treatments provide a local compressive stress maximum at a depth of the strengthened layer and a second local maximum at or near the surface of the glass.

Owner:康宁陶瓷材料(上海)有限公司 +1

Laminated and ion-exchanged strengthened glass laminates

ActiveUS9522836B2Higher depthHigh stressGlass forming apparatusGlass/slag layered productsIon exchangeOptoelectronics

A method of making a glass sheet (10) comprises laminating a high CTE core glass (11) to a low CTE clad glass (12) at high temperatures and allowing the laminate (10) to cool creating compressive stress in the clad glass (12), and then ion exchanging the laminate (10) to increase the compressive stress in the outer near surface regions of the clad glass (12). The core glass (11) may include ions that exchange with ion in the clad glass (12) to increase the compressive stress in inner surface regions of the clad glass (12) adjacent to the clad glass / core glass interfaces. The glass laminate (10) may be formed and laminated using a fusion forming and laminating process and fusion formable and ion exchangeable glass compositions.

Owner:CORNING INC

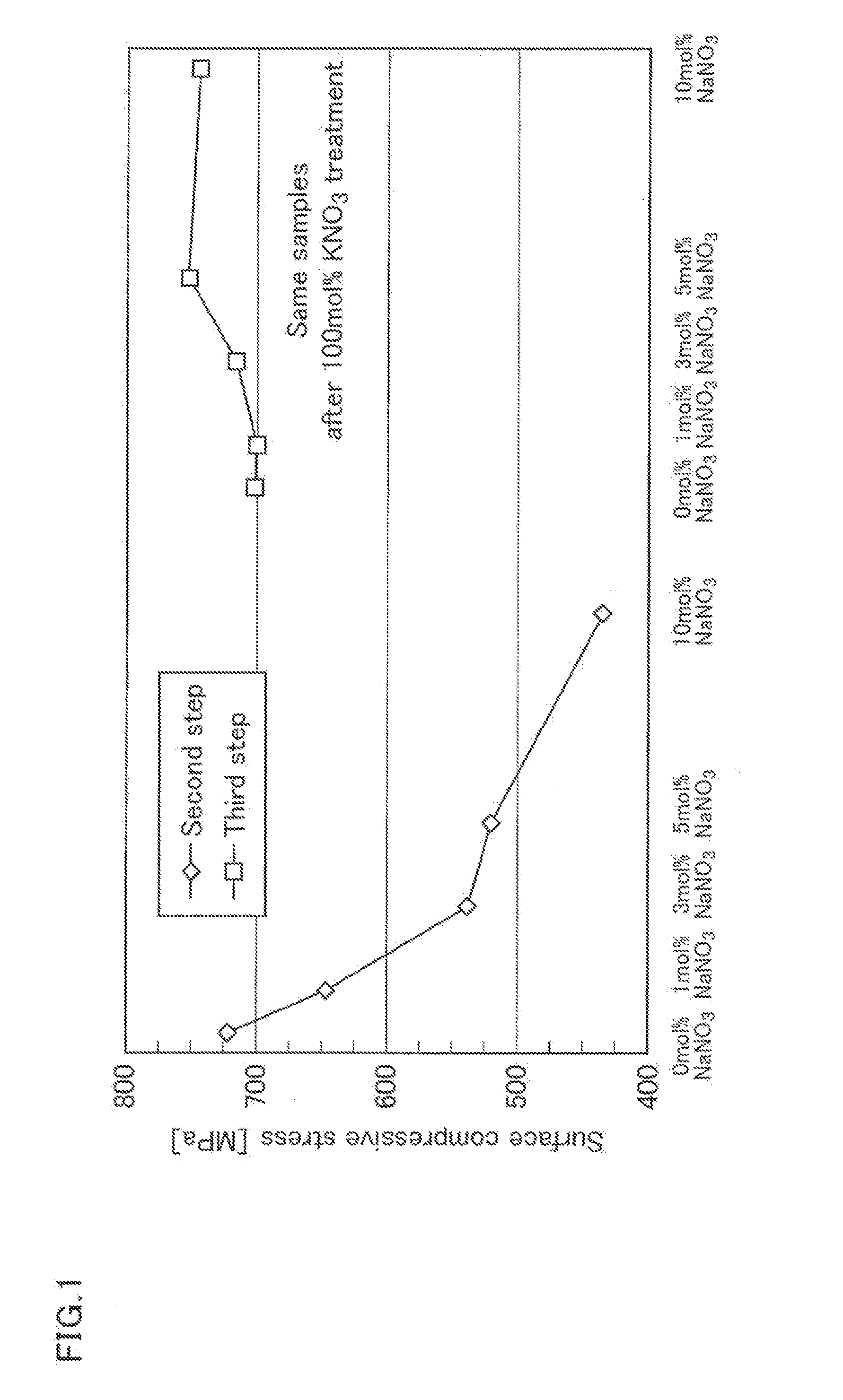

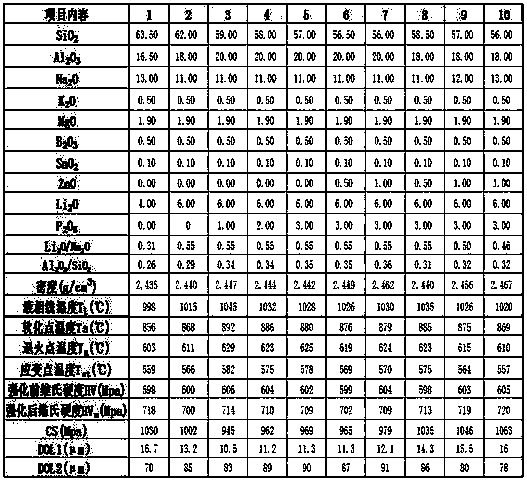

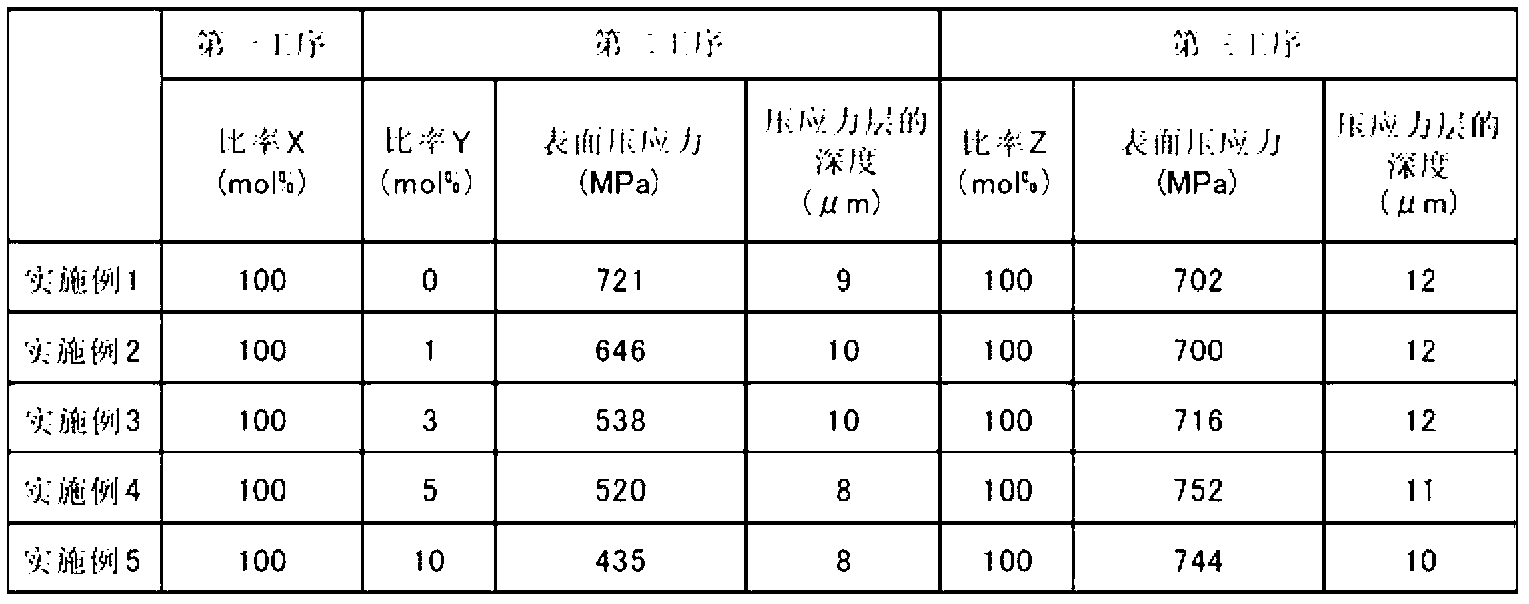

Method of manufacturing chemically strengthened glass plate

InactiveUS20130219966A1Increase the surface compressive stressEfficient productionIon exchangeGlass sheet

[Subject]An object of the present invention is to provide a method for manufacturing a chemically strengthened glass plate having a high surface compressive stress with high efficiency using a soda-lime glass, the composition of which is not particularly suited for chemical strengthening.[Solution]The present invention provides a method of manufacturing a chemically strengthened glass plate by ion-exchanging a glass base plate to replace alkali metal ions A that are the main alkali metal ion component of the glass base plate with alkali metal ions B having a larger ionic radius than the alkali metal ions A at a surface of the glass base plate,the unexchanged glass base plate made of a soda-lime glass,the method including:a first step of contacting the glass base plate with a first salt containing the alkali metal ions A, the first salt containing the alkali metal ions A at a ratio X, as expressed as a molar percentage of total alkali metal ions, of 90 to 100 mol %;a second step of contacting the glass plate with a second salt containing the alkali metal ions B after the first step, the second salt containing the alkali metal ions A at a ratio Y, as expressed as a molar percentage of the total alkali metal ions, of 0 to 10 mol %; anda third step of contacting the glass plate with a third salt containing the alkali metal ions B after the second step, the third salt containing the alkali metal ions B at a ratio Z, as expressed as a molar percentage of the total alkali metal ions, of 98 to 100 mol %.

Owner:CENT GLASS CO LTD

Process for Producing Hurricane-Resistant Glass

InactiveUS20090110914A1Promote balance between supply and demandEliminating the defect surface layer on the glassSynthetic resin layered productsGlass/slag layered productsMetallurgyCooling chamber

A method for producing hurricane-resistant glass, mainly includes the steps of: cutting and abrading the edges of a glass; feeding the glass into a tempering furnace and heating the glass to a critical state of the softening point; feeding the glass heated to a critical state of the softening point at a speed of 25-50 cm / s into a cooling chamber, to allow the glass to develop a surface compressive stress of not less than 150 MPa; etching the cooled glass with an etching solution; and rinsing surfaces of the glass. The invention further relates to the hurricane-resistant glass produced thereby and glass assemblies containing the said hurricane-resistant glass.

Owner:ZHUANG DAJIAN +1

Method for preparing special high-strength tempered glass for high-speed train

InactiveCN103553306AIncrease the surface compressive stressHigh speedGlass/slag layered productsGlass reforming apparatusToughened glassMaterials science

The invention relates to the field of tempered glass preparation, in particular relates to a method for preparing special high-strength tempered glass for a high-speed train, and provides a method for preparing special high-strength tempered glass for a high-speed train aiming at the defects of the prior art. The method is characterized in that high-strength single glass is prepared by using a method that a thermal tempering technique is taken as a main method and a chemical tempering technique is taken as an auxiliary method, and furthermore a glass conductive heating film and an anti-splashing film are added by using an interlay technique and a precision forming technique, so as to finally produce multi-layer high-speed train windproof glass with high strength and demisting and defrosting effectiveness. The high-speed train windproof glass prepared by using the method has the characteristics of high strength, good light translucency, uniform electrical heating and the like.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD +1

Display cover glass and display cover glass fabrication method

ActiveUS9840435B2Increase the surface compressive stressGood wear resistanceDigital data processing detailsThin material handlingDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:AGC INC

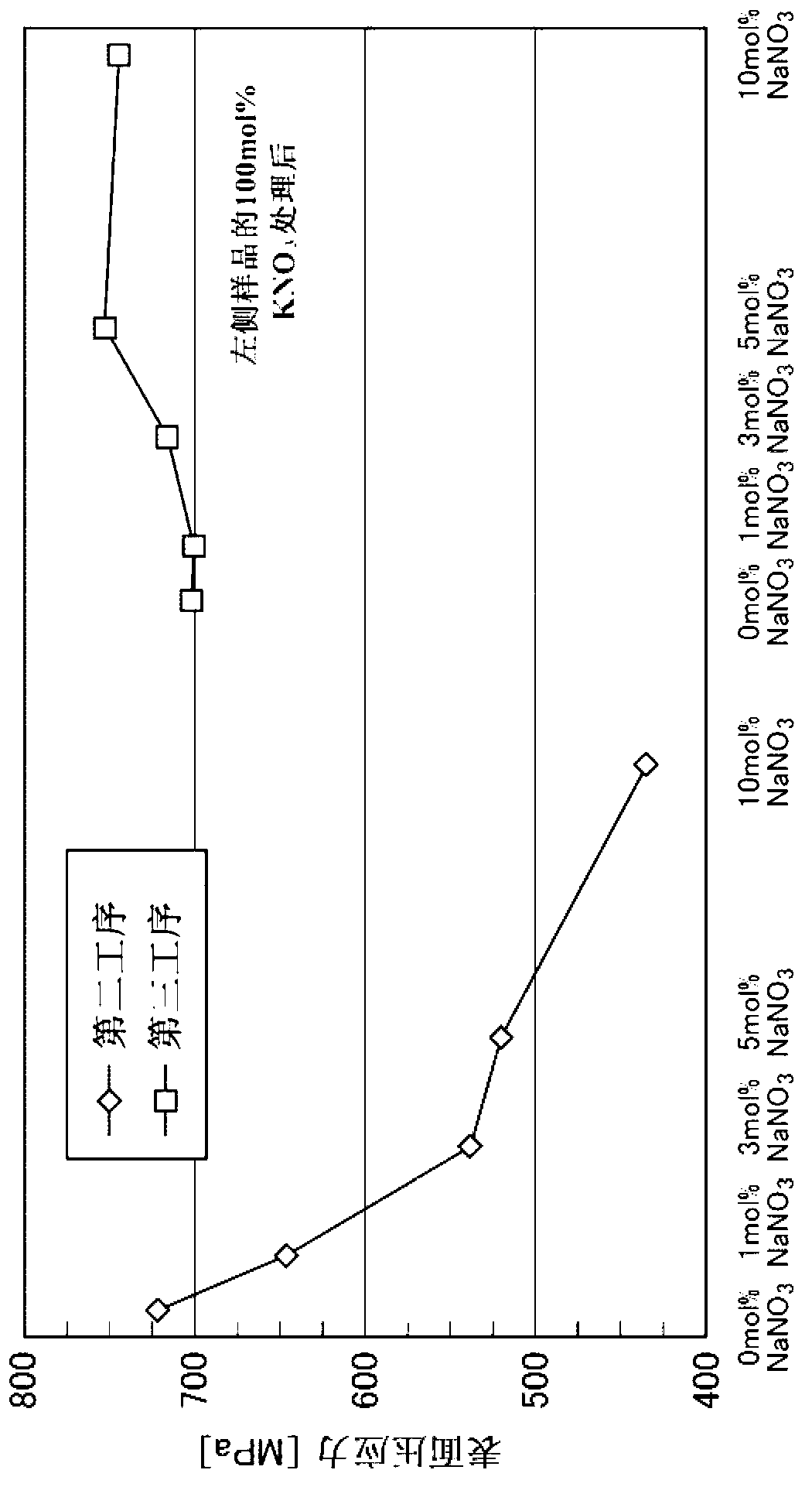

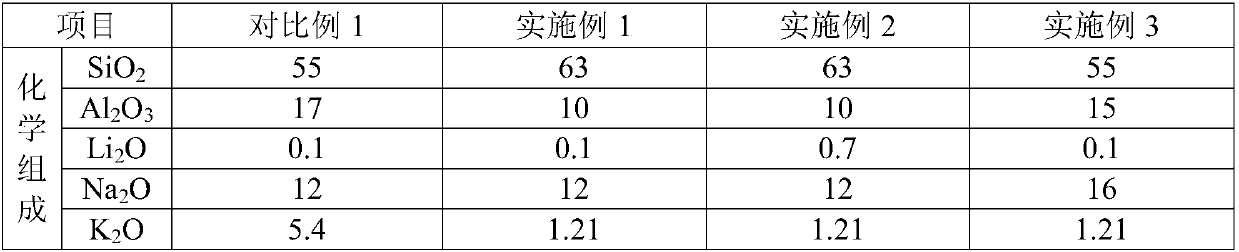

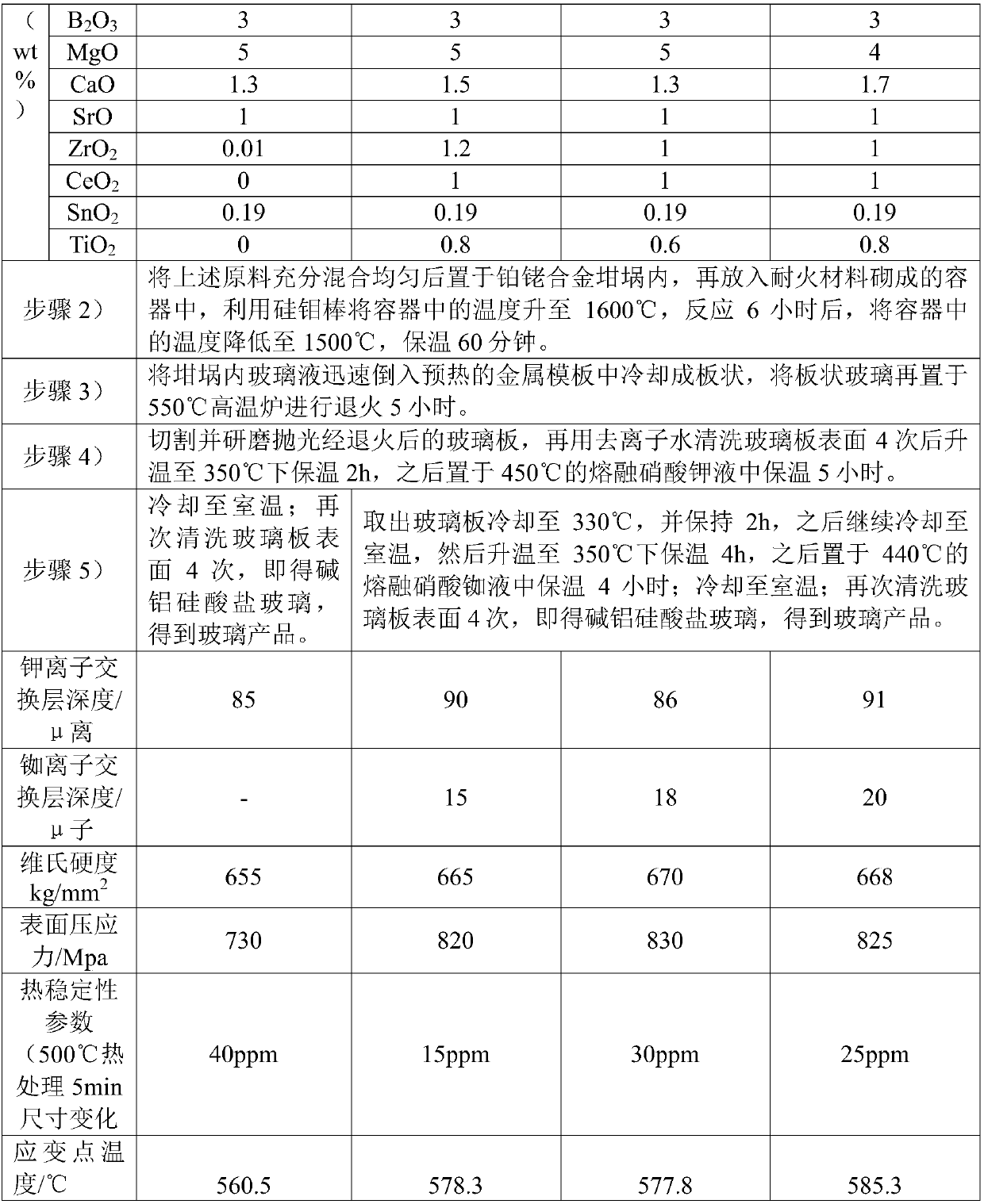

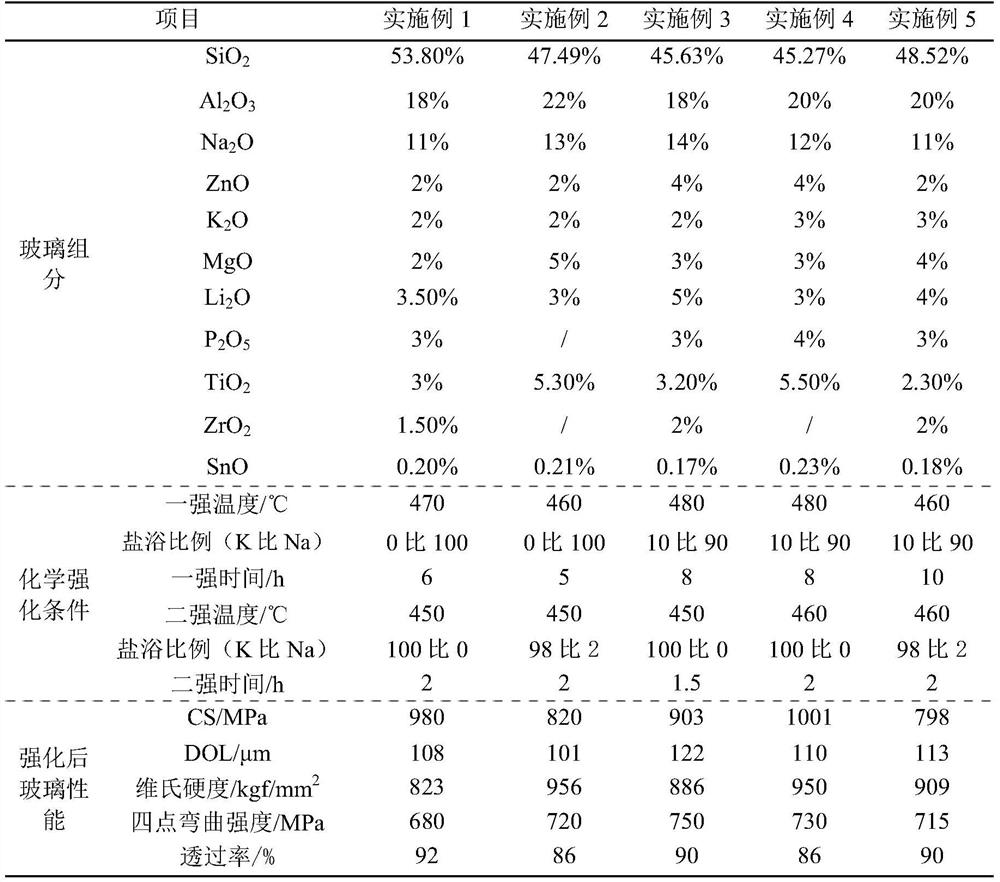

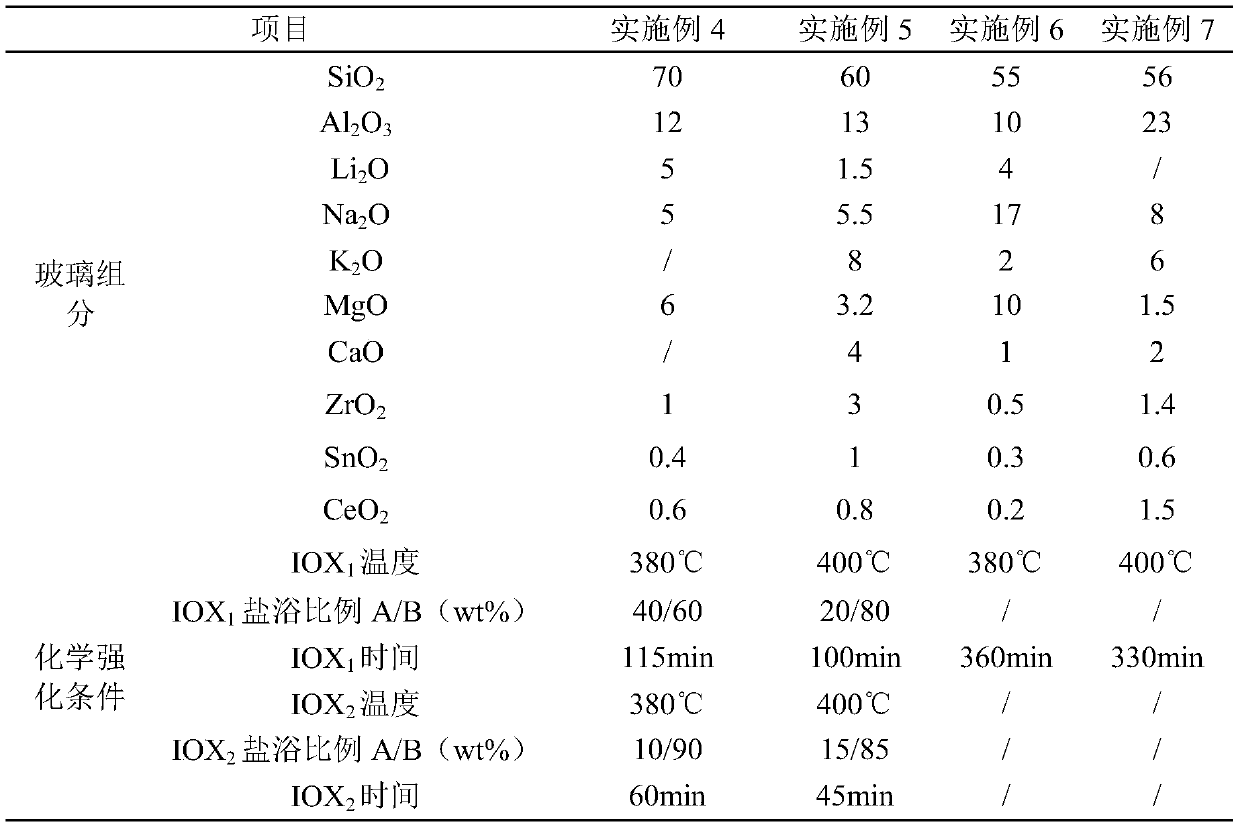

Two-step-method chemically strengthened alkali aluminosilicate glass composition and preparation method thereof

The invention belongs to the technical field of glass materials, and particularly relates to a two-step-method chemically strengthened alkali aluminosilicate glass composition and a preparation methodthereof. The two-step-method chemically strengthened alkali aluminosilicate glass composition comprises the following components in percentages by mole: 53-65% of SiO2, 16-22% of Al2O3, 0.01-0.5% ofB2O3, 4-8% of Li2O, 8-14% of Na2O, 0.01-1% of K2O, 0.01-3% of MgO, 0-1% of ZnO, 0-4% of P2O5 and 0-0.1% of SnO2. The formula of glass is optimized and lithium and phosphorus are added in the glass toobtain the composition, the composition is chemically strengthened by a two-step method, thus, glass has high surface pressure stress and a deep ion exchange layer, and the surface hardness, scratch resistance and falling resistance of the glass are improved.

Owner:KORNERSTONE MATERIALS TECH

Method of manufacturing chemically strengthened glass plate

InactiveCN103214172AEfficient preparationIncrease the surface compressive stressGlass tempering apparatusIon exchangeGlass sheet

The present invention provides a method of manufacturing a chemically strengthened glass plate by ion-exchanging a glass base plate to replace alkali metal ions A that are the main alkali metal ion component of the glass base plate with alkali metal ions B having a larger ionic radius than the alkali metal ions A at a surface of the glass base plate, the unexchanged glass base plate made of a soda-lime glass, the method including: a first step of contacting the glass base plate with a first salt containing the alkali metal ions A, the first salt containing the alkali metal ions A at a ratio X, as expressed as a molar percentage of total alkali metal ions, of 90 to 100 mol %; a second step of contacting the glass plate with a second salt containing the alkali metal ions B after the first step, the second salt containing the alkali metal ions A at a ratio Y, as expressed as a molar percentage of the total alkali metal ions, of 0 to 10 mol %; and a third step of contacting the glass plate with a third salt containing the alkali metal ions B after the second step, the third salt containing the alkali metal ions B at a ratio Z, as expressed as a molar percentage of the total alkali metal ions, of 98 to 100 mol %.

Owner:CENT GLASS CO LTD

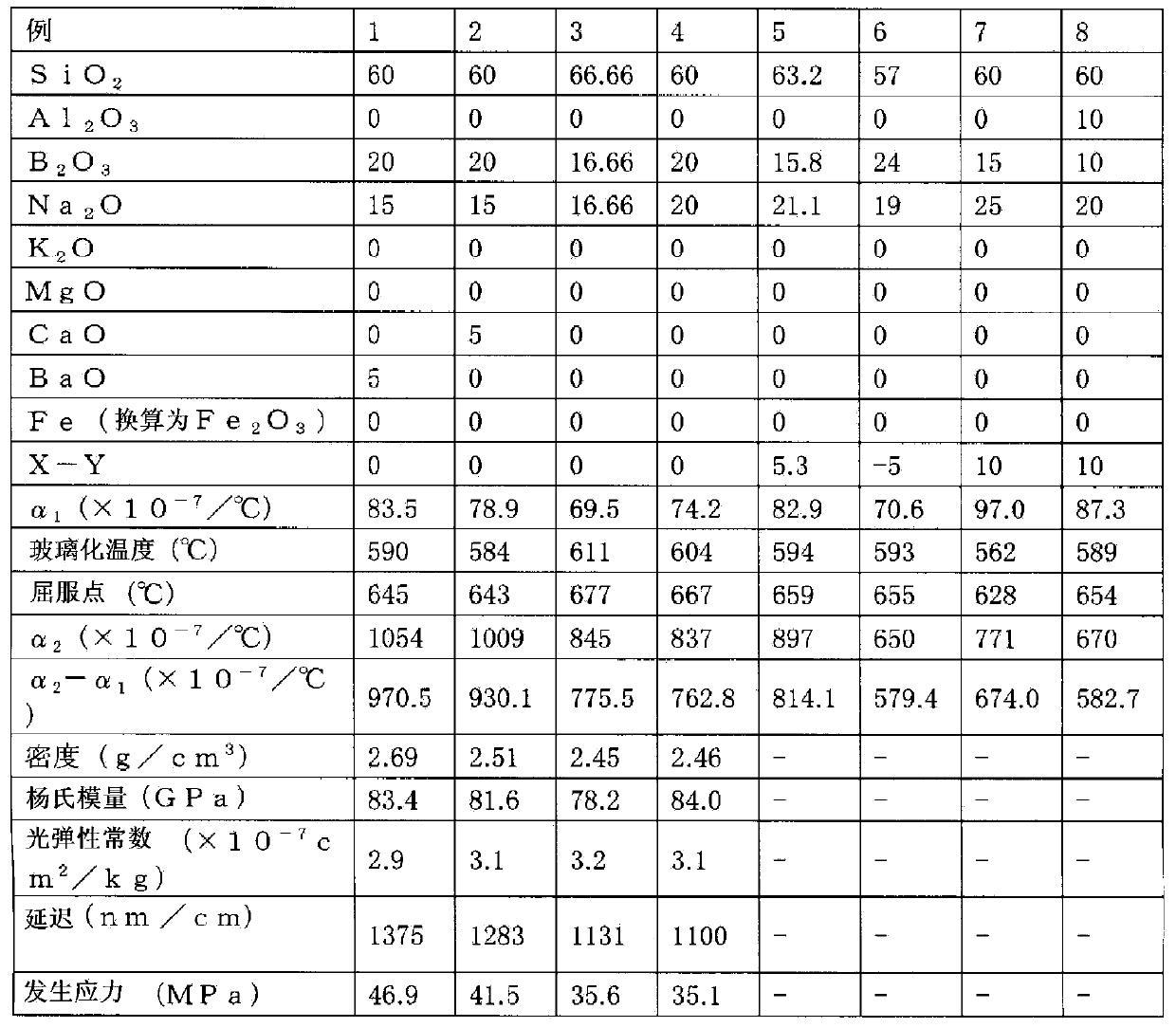

Glass plate to be tempered

InactiveUS20140242391A1Low coefficient of thermal expansionImprove scratch resistanceGlass/slag layered productsGlass tempering apparatusThermal expansionHigh surface

To provide a glass plate to be tempered, which has a low thermal expansion coefficient at relatively low temperature, and which can have a sufficiently high surface compression stress by a conventional heat tempering process, even when it is thin. A glass plate to be tempered, which contains B2O3 in a range of from 12.5 to 35 mol % in its composition, the difference [X−Y] between the total content X of compounds selected from MgO, CaO, BaO, Na2O and K2O in the composition and the content Y of B2O3 in the composition being within a range of from −5 to 10 mol %, and which is to be tempered by heating and quenching.

Owner:ASAHI GLASS CO LTD

Glass plate for tempering

InactiveCN103827051AIncrease the surface compressive stressImprove scratch resistanceGlass tempering apparatusThin material handlingHigh surfaceThermal expansion

Provided is a glass plate for tempering, which is characterized by having a small thermal expansion coefficient under a relatively low temperature, even when the plate is thin, while obtaining a sufficiently high surface compression by the steps involved in conventional thermal tempering. A glass plate for tempering is characterized by having a composition comprising 12.5 to 35 mol% of B2O3; having a composition wherein the difference [X-Y] between the total content X of compound selected from the group consisting of MgO, CaO, BaO, Na2O, and K2O and the total content Y of B2O3 is within a range of -5 to 10 mol%; and being subjected to tempering by heating and quenching.

Owner:ASAHI GLASS CO LTD

Hurricane-proof glass manufacturing technique

InactiveCN1990402AAvoid ignoring other aspects of performanceAvoid destructionGlass tempering apparatusThin material handlingAcid etchingGlass manufacturing

The invention relates to a process of preparing anti-hurricane glass, comprising following steps: cutting and edging glass; heating glass in the tempering furnace to softening point; feeding the glass into cooling room at speed of 25-50 cm / s, the air pressure in cooling room should be controlled at 6.5-7.5 * 103 Pa to make the surface compressive stress reach to more than 150 MPa; putting glass into acid-etching slot for suitable acid etching; washing glass surface with clean water; coating the surface with organic silicon protecting membrane. The invention is characterized by low production cost and short producing time.

Owner:庄大建 +1

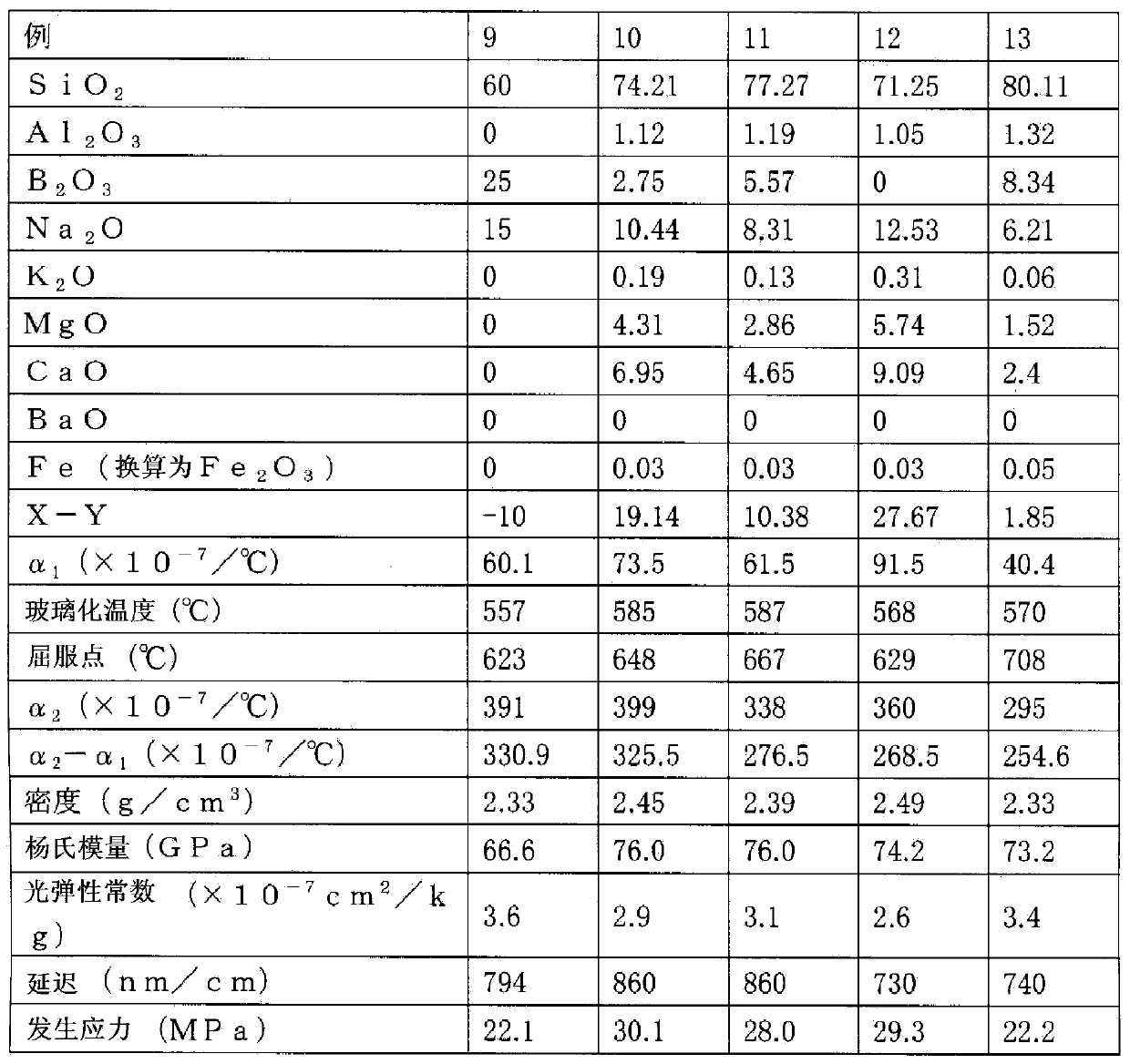

Fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass and method for performing chemically-toughened enhancement by using fused salt

The invention provides a fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass. The fused salt comprises the following compositions: KNO3, KOH, KCl and K2CO3, wherein a mass ratio of KOH to K2CO3 in the fused salt is 0.05-0.4; a mass ratio of KCl to K2CO3 is 0.075-1.0; and a mass ratio of KNO3 to K2CO3 is 100:(1.0-4.0). The invention further provides a method for performing chemically toughened enhancement by using the fused salt for chemical enhancing of medium-aluminum and high-aluminum silicate glass. The fused salt formula disclosed by the invention indicates a formula composition range suitable for chemical enhancing of the medium-aluminum and high-aluminum glass. According to the formula, corrosion on the glass surface can be avoided, and the chemically enhanced glass has high transmittance; and meanwhile, due to the formula disclosed by the invention, the surface stress and stress layer depth of the chemically enhanced glass can be greatly improved.

Owner:WUHAN UNIV OF TECH

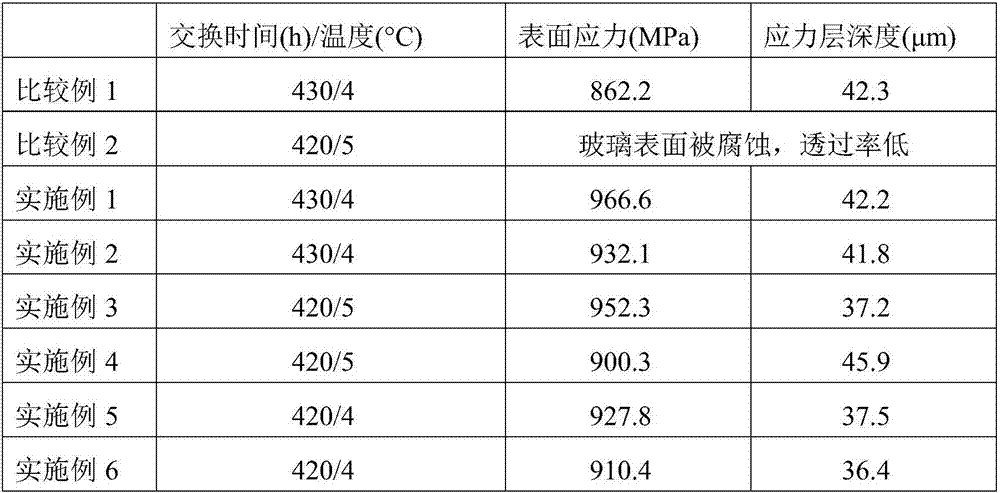

Method for manufacturing glass and glass

InactiveCN102775050AHigh strengthIncrease the surface compressive stressGlass tempering apparatusIdentification meansCompound (substance)Potassium ions

The invention provides a method for manufacturing glass capable of producing glass substrates which have good performances and high strength and good protective functions even the substrates are thin. In the method of manufacturing glass, after a sodium concentration reduction process for making sodium concentration on a glass surface lower than sodium concentration in the central part of glass, a chemical reinforcement processing process is performed in which the glass is dipped in fuse salt containing potassium ions to replace part of sodion in the glass with the potassium ion.

Owner:ASAHI GLASS CO LTD

High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

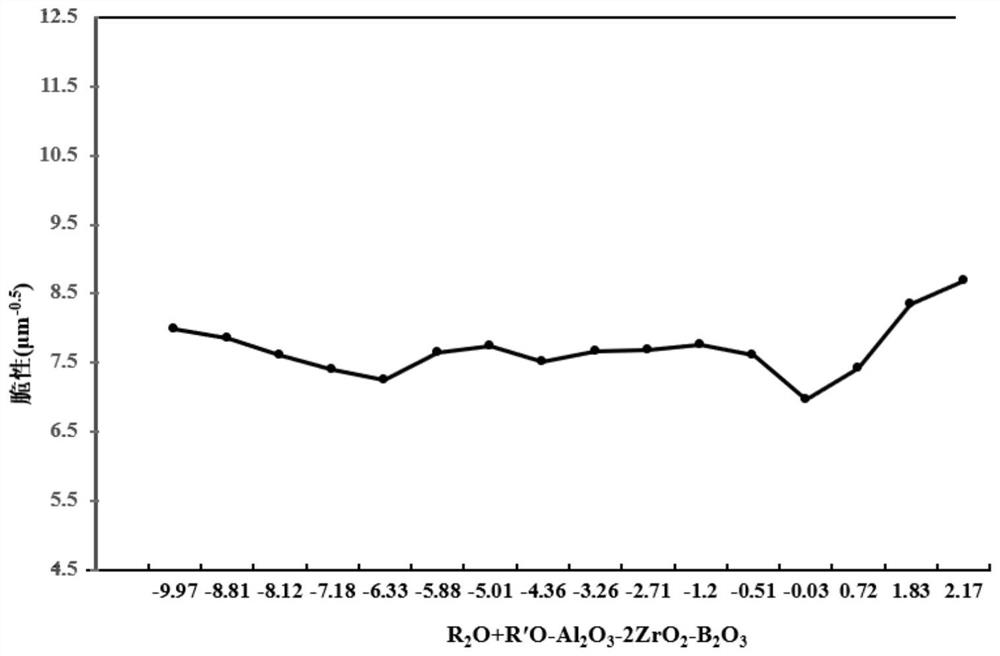

The invention provides high-strength and low-brittleness aluminosilicate glass as well as a strengthening method and an application thereof. The glass is prepared from the following components in percentage by mole; 56%-70% of SiO2, 8%-25% of Al2O3, 1%-10% of B2O3, 0-15% of Li2O, 6%-20% of Na2O, 0-10% of K2O, 0-5% of MgO, 1%-5% of ZrO2 and 0.1%-1% of SnO2. The strengthening method comprises the following steps: preparing raw materials according to the components of the glass, melting and clarifying the raw materials, and forming the glass; and carrying out ion exchange on the glass in a salt bath of potassium nitrate and sodium nitrate at 360-450 DEG C to obtain the chemically strengthened aluminosilicate glass which can be applied to mobile device protection and fixed device protection.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Glass and chemically strengthened glass

InactiveUS20170305789A1Increase the surface compressive stressReduce frequencyPhotochemistryChemically strengthened glass

Owner:ASAHI GLASS CO LTD

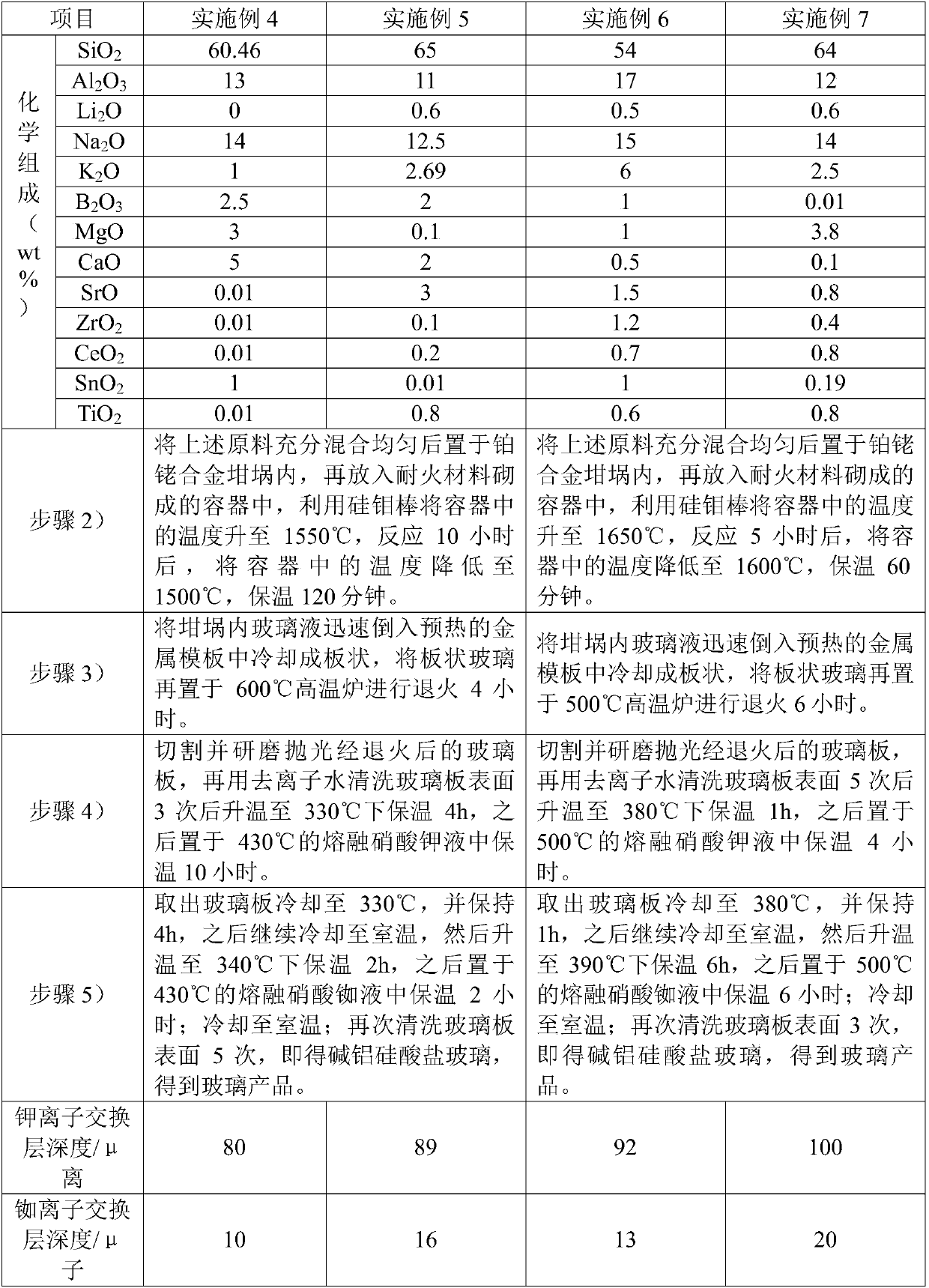

High-strength glass for display device and preparation method of glass

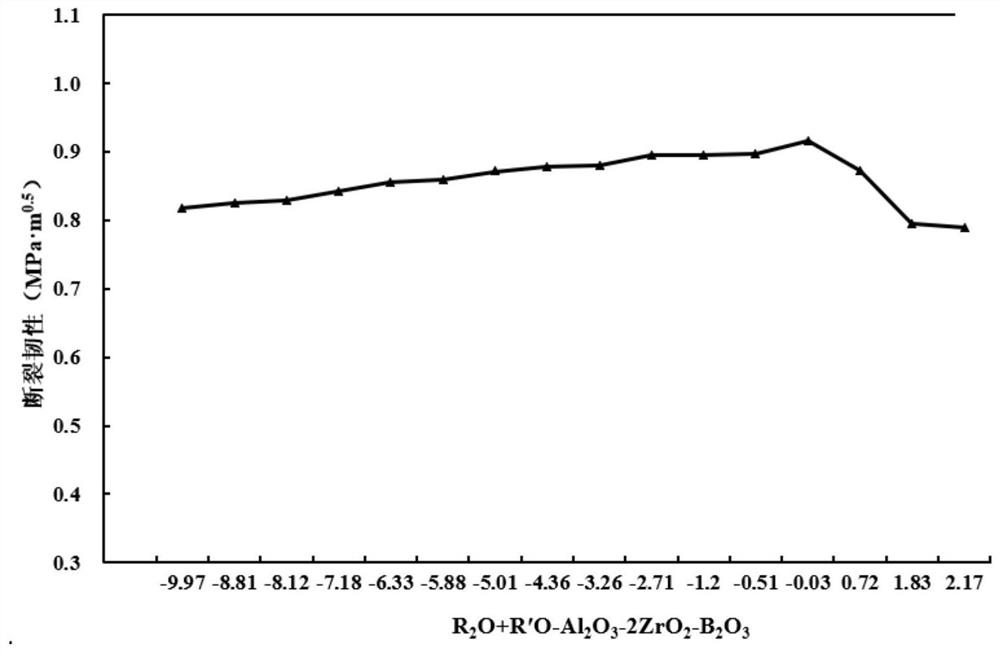

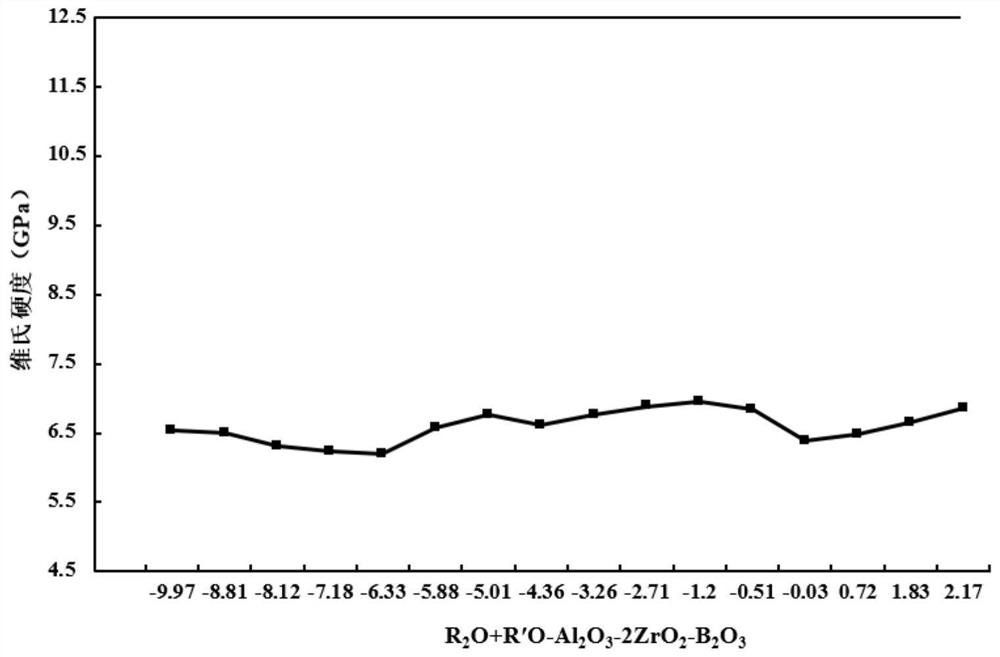

The invention discloses a high-strength glass for a display device and a preparation method of the glass. The strength of the glass can be improved from two aspects of component design and strengthening method, wherein the components exert a significant synergistic effect; through the introduction of new components CeO2 and TiO2, and the content relationships among various components are defined,in particular (Na2O+K2O) / Al2O3 and K2O / (Na2O+Li2O) are maintained in a certain range, the amount of ion exchange and the depth of the ion exchange are improved, and through the definition of the synergistic effect among the TiO2, ZrO2 and the CeO2, the thermal stability and the performance of ion exchange of the glass are improved. Finally, through the adoption of twice ion exchange, the mechanical property of the glass is greatly improved, so that the glass provided by the invention has relatively high surface compressive stress, Vickers hardness and excellent strain point and thermal stability, has the properties of compression resistance, scrape resistance and scratch resistance, and can be widely applied to a protective cover plate of the display device.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

InactiveCN112919813AGood chemical stabilityModerate melting temperatureGlass tempering apparatusTelephone set constructionsPotassium nitrateIon exchange

The invention discloses lithium-aluminum-silicon microcrystalline glass as well as a strengthening method and application thereof. The glass comprises the following components in percentage by mass: 45%-75% of SiO2, 10%-25% of Al2O3, 0-4% of ZrO2, 3%-5% of Li2O, 10%-18% of Na2O, 0-5% of K2O, 0-6% of P2O5, 0-7% of TiO2, 2%-7% of MgO, 0-10% of ZnO and 0-1% of SnO. The strengthening method comprises the following steps: preparing raw materials, and performing melting and molding to obtain mother glass; carrying out heat treatment to obtain microcrystalline glass; carrying out ion exchange on the microcrystalline glass in molten salt at the temperature of 390-500 DEG C for 3-10 hours to obtain primarily strengthened microcrystalline glass; and finally, soaking the glass ceramic subjected to primary strengthening in molten salt consisting of potassium nitrate and sodium nitrate for 1-2.5 hours to obtain the lithium-aluminum-silicon glass ceramic.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

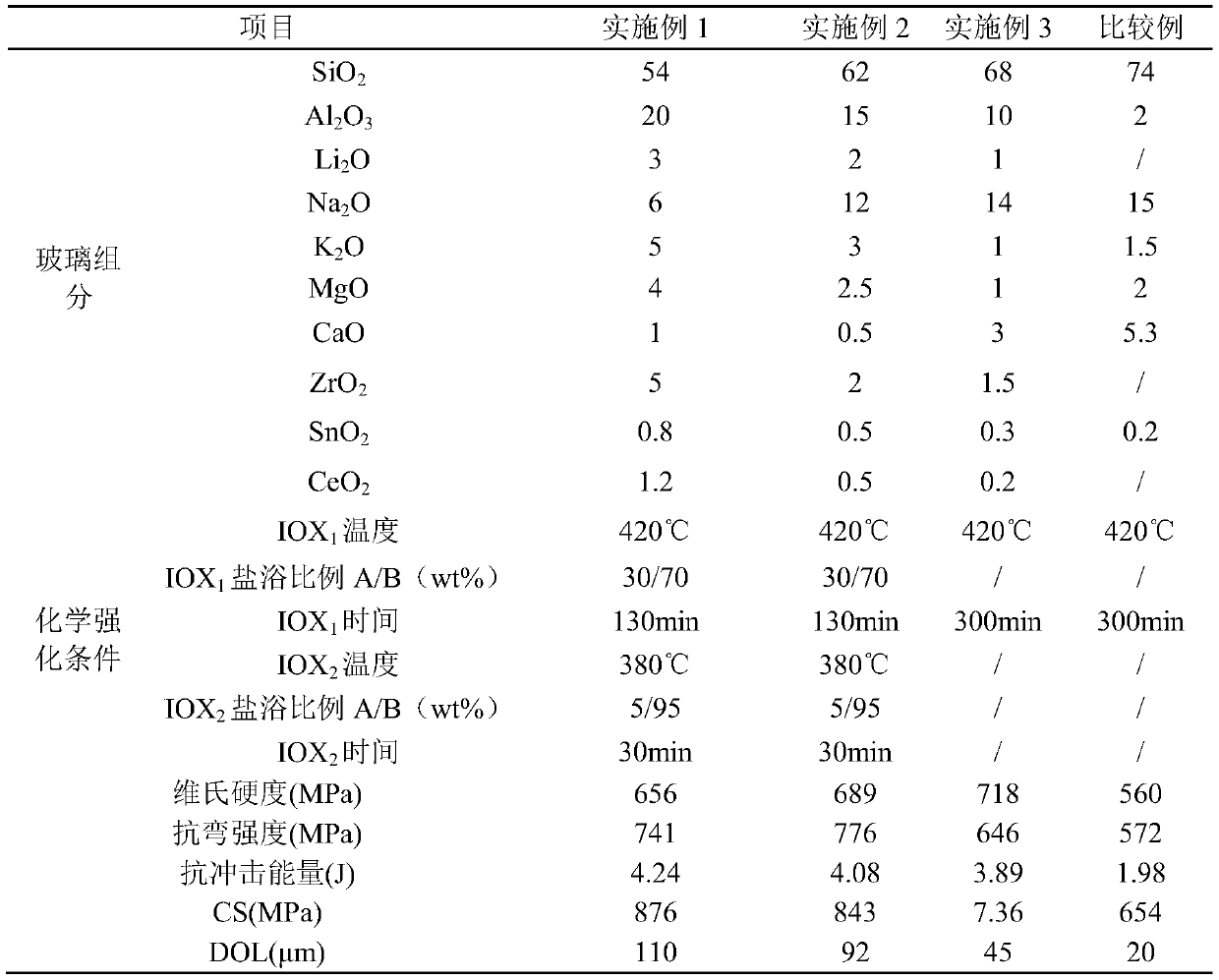

Scratch-resistant and external-impact-resistant ion exchange glass and preparation method thereof

The invention relates to a scratch-resistant and external-impact-resistant ion exchange glass and a preparation method thereof. The glass comprises the following components in percentages by mass: 54%-70% of SiO2, 10%-23% of Al2O3, 0-5% of Li2O, 5%-17% of Na2O, 0-8% of K2O, 1%-10% of MgO, 0-4% of CaO, 1%-5% of ZrO2, 0.3%-1% of SnO2 and 0.2%-1.5% of CeO2. The preparation method comprises the following steps of step 1, preparing raw materials according to the components of the glass in percentages by mass, melting and clarifying the raw materials, and then molding the raw materials into the glass; and step 2, chemically strengthening the glass to obtain the scratch-resistant and external-impact-resistant ion exchange glass. Compared with soda-lime glass, the glass has stronger impact strength and surface scratch resistance, and has better protection capability on electronic products.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

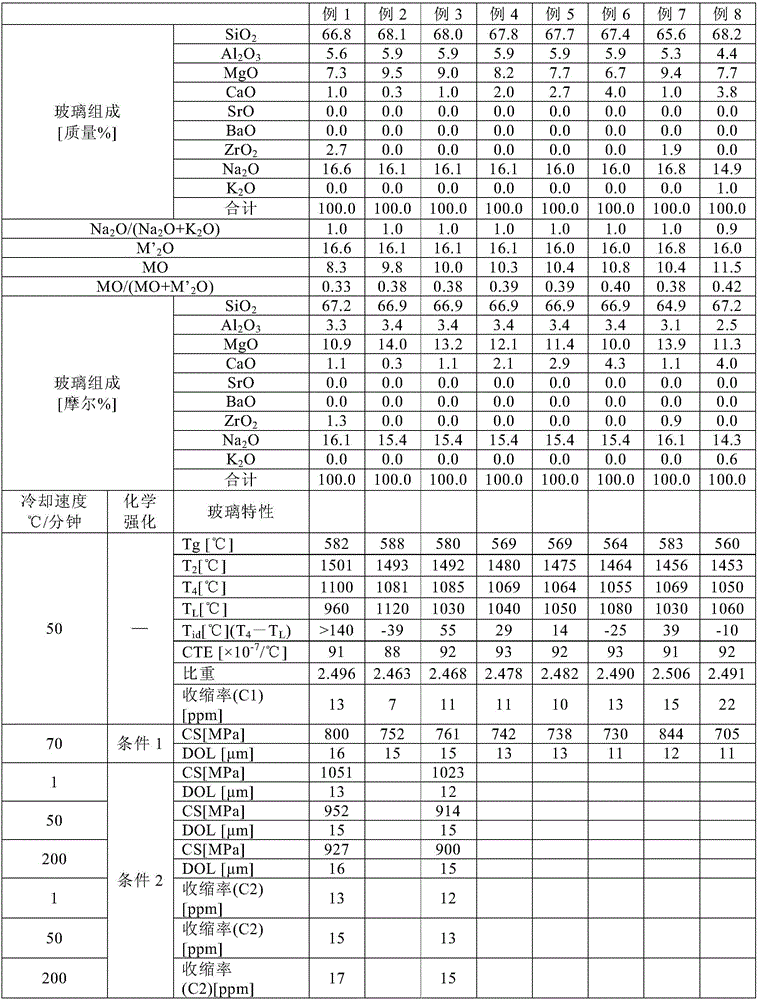

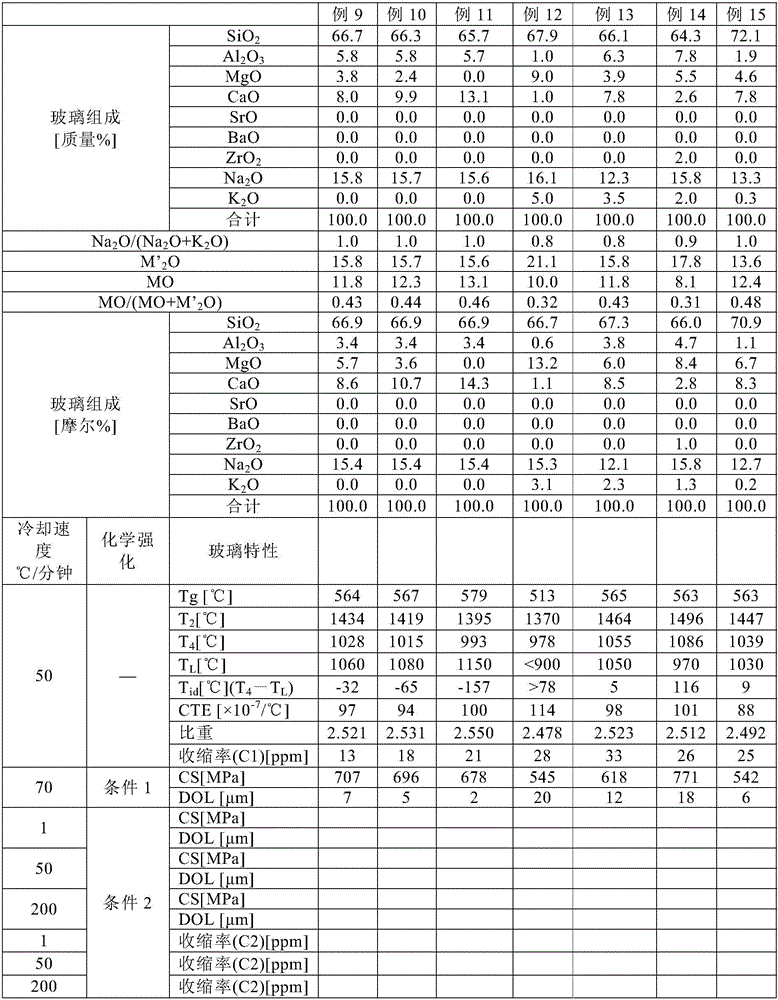

Glass for chemical strengthening, and chemically strengthened glass

ActiveCN106470951APosition deviation is not easy to occurLow shrinkageGlass productionGlass sheetHeat treated

Provided are: a glass for chemical strengthening, suitable for a display member and having high precision of film formation and patterning (not being prone to positional misalignment) on a glass sheet and low compaction in heat treatment at low temperature (150-300 DEG C) during manufacturing of a display member, even in the case of a glass sheet manufactured by a fusion method or the like in which the cooling rate during glass forming is high; and a chemically strengthened glass obtained using the glass for chemical strengthening. A glass for chemical strengthening, obtained by melting and cooling a glass raw material, the glass for chemical strengthening containing, in percent by mass in terms of oxide, 61-75% SiO2, 2.5-10% Al2O3, 6-12% MgO, 0.1-8% CaO, 14-19% Na2O, and 0-1.8% K2O.

Owner:ASAHI GLASS CO LTD

Glass composition, glass composition for chemcial strengthening, strengthened glass article, and cover glass for display

A glass composition of the present invention includes, in mol %, 66 to 72% SiO2, 1 to 4% Al2O3, 8 to 15% MgO, 1 to 8% CaO, 12 to 16% Na2O, and 0 to 1% K2O. A total content of MgO and CaO is in a range of 12 to 17%, and a molar ratio of CaO to the total content of MgO and CaO is in a range of 0.1 to 0.4. The glass composition of the present invention is suitable for production by the float process, and is suitable for chemical strengthening.

Owner:NIPPON SHEET GLASS CO LTD

Manufacturing method of high-strength LED (light-emitting diode) glass bulb

InactiveCN102659307AFacilitated DiffusionThick stress layerGlass tempering apparatusPotassium fluoridePotassium hydroxide

The invention discloses a manufacturing method of a high-strength LED (light-emitting diode) glass bulb. The manufacturing method comprises the following steps: (1) preheating the LED glass bulb which is washed cleanly to the temperature of 350 DEG C, and performing heat preservation for 0.5h; (2) preparing mixed molten salt, heating to the temperature of 400-480 DEG C, performing the heat preservation for 1-3h, then immersing the LED glass bulb into the mixed molten salt with the temperature of 400-480 DEG C, soaking for heat preservation for 5-8h; and (3) after soaking, taking the LED glass bulb out of the mixed molten salt, annealing to room temperature, and washing to finally obtain the high-strength LED glass bulb, wherein the mixed molten salt is formed by mixing a potassium nitrate molten salt serving as a main raw material with additives including potassium hydroxide, potassium fluoride, aluminum oxide and diatomite. According to the manufacturing method disclosed by the invention, by adopting the mixed molten salt based on optimized proportion, the speed and the depth of ion exchange are improved, the surface compression stress of glass is increased, and the strength, the impact resistance and the thermal stability of the LED glass bulb are further improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

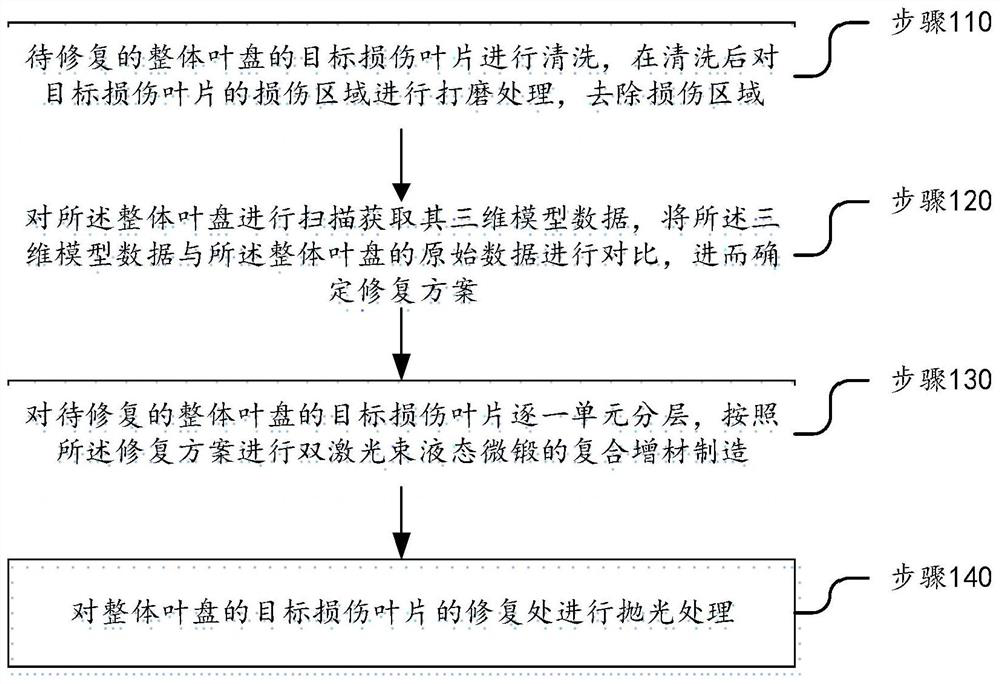

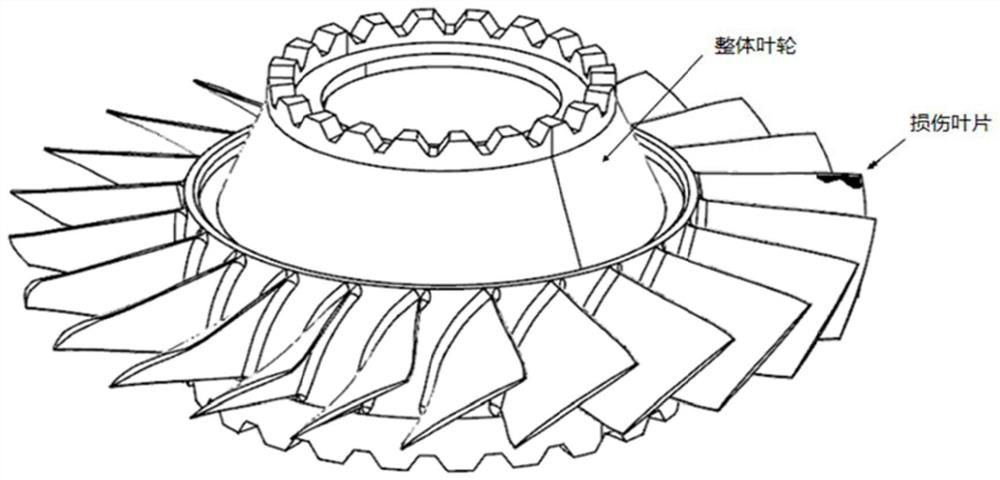

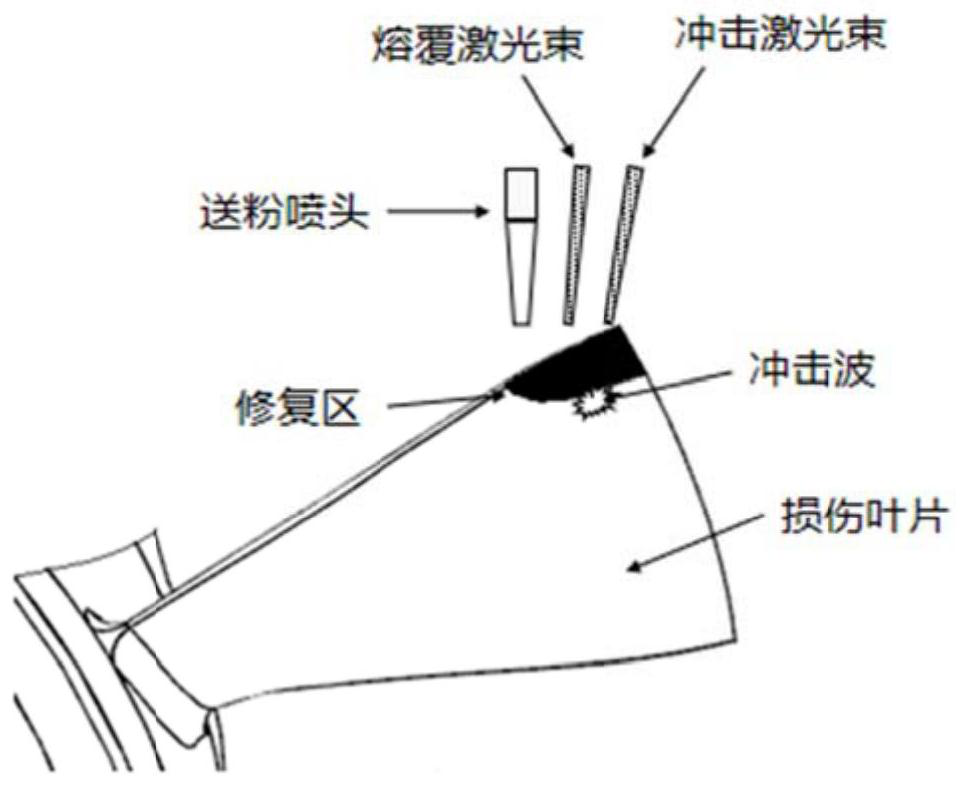

Damaged blade repairing method and device for blisk based on double laser beams

PendingCN112195468AEasy to excludeReduce stressAdditive manufacturing apparatusMetallic material coating processesEngineeringMechanical engineering

The invention provides a damaged blade repairing method for a blisk based on double laser beams. The method comprises the following steps: 110, damaged areas of target damaged blades of the to-be-repaired blisk are removed; 120, three-dimensional model data of the target damaged blades are obtained, and a repair scheme is determined; 130, the target damaged blades of the to-be-repaired blisk are subjected to unit layering one by one, and composite additive manufacturing of double-laser-beam liquid micro-forging is conducted according to the repair scheme; and 140, polishing treatment is conducted on the repaired parts of the target damaged blades of the blisk. In a molten pool state repairing layer formed through laser cladding, impact waves are applied to the molten pool state repairing layer through pulse lasers, pressure and vibration are generated in the repairing layer, gas exhausting and air hole reducing are facilitated, repairing is more uniform, internal stress of the repairing area is removed, grains are refined, surface pressure stress is improved, and the repairing internal quality and mechanical and mechanical comprehensive performance are improved.

Owner:GUANGDONG LASER PEENING TECH CO LTD +1

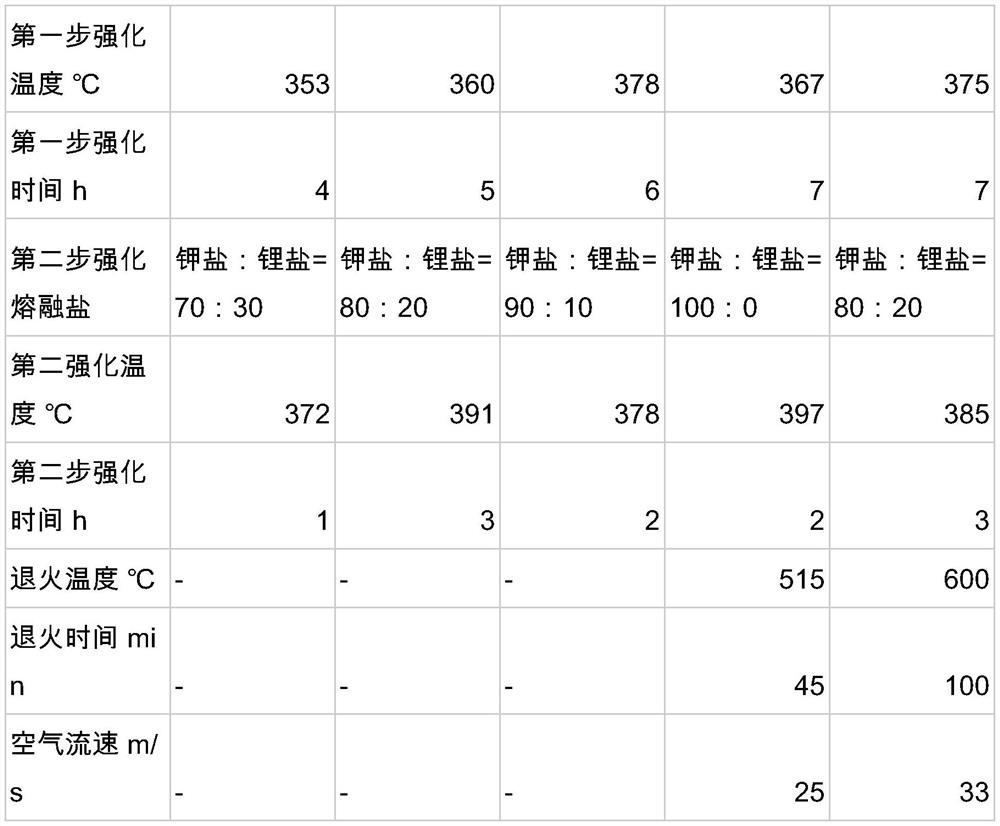

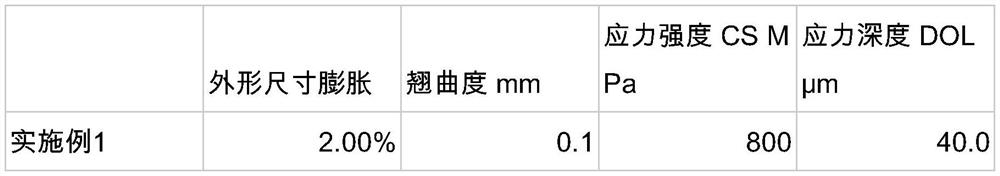

Cover plate glass strengthening process

ActiveCN111875264ADepth of protectionIncrease the surface compressive stressGlass tempering apparatusSurface cleaningPhysical chemistry

A cover plate glass strengthening method comprises the following steps: primary strengthening: cleaning the surface of cover plate glass to be strengthened, immersing the cover plate glass into ion exchange molten salt in a strengthening furnace, controlling the temperature at 350-380 DEG C, immersing the cover plate glass for 4-7 hours, and carrying out ion exchange, wherein the molten salt beinga molten liquid of more than one of potassium salt, sodium salt and lithium salt; secondary strenthening: controlling the temperature of a strengthening furnace to be 370-400 DEG C, soaking the coverplate glass into molten salt liquid of potassium salt and lithium salt with the mass fraction being 70-100:0-30, soaking is conducted for 1-3 hours, then putting the cover plate glass in a closed container to be cooled to the room temperature, so that the strengthened cover plate glass is obtained. The stress depth of the reinforced cover plate glass is 40-65 microns, the surface stress strengthis 800-1300 MPa, the warping degree is lower than 0.1 mm, and the boundary dimension expansion rate is lower than 2%.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

Alkaline aluminosilicate protective glass capable of realizing ion exchange and preparation method thereof

InactiveCN106698928AIncrease the surface compressive stressMeet performance requirementsProtective glassesIon exchange

The invention discloses an alkaline aluminosilicate protective glass capable of realizing ion exchange and a preparation method thereof. The alkaline aluminosilicate protective glass capable of realizing ion exchange comprises the following components in percentage by mass: no less than 59.2% and no more than 63.9% of SiO2, no less than 15% and no more than 19.51% of Al2O3, no less than 1% and no more than 5.7% of B2O3, no less than 11.54% and no more than 13.36% of Na2O, no less than 0% and no more than 5% of K2O, no less than 1.35% and no more than 3% of MgO, no less than 0 and no more than 0.42% of CaO and no less than 0.1% and no more than 0.4% of SnO2. The glass disclosed by the invention has a high surface compressive stress and a deep ion exchange layer, the surface compressive stress reaches 850 MPa or above, and the ion exchange layer depth reaches 57 mu m or above; and the glass is scratch-resistant, thereby meeting the service performance requirement of the product.

Owner:IRICO DISPLAY DEVICES

Chemically strengthened glass

ActiveUS11312656B2Increase the surface compressive stressLarge compression depthIdentification meansComposite materialChemically strengthened glass

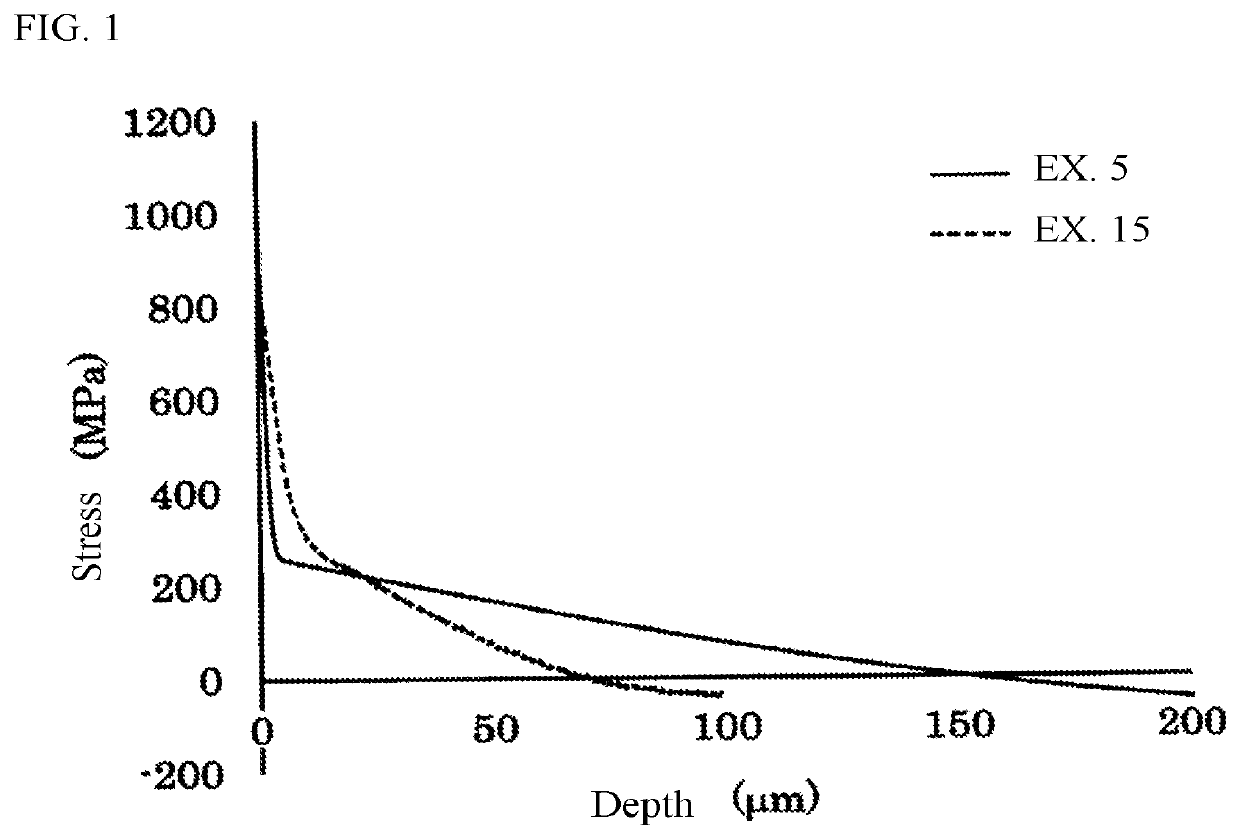

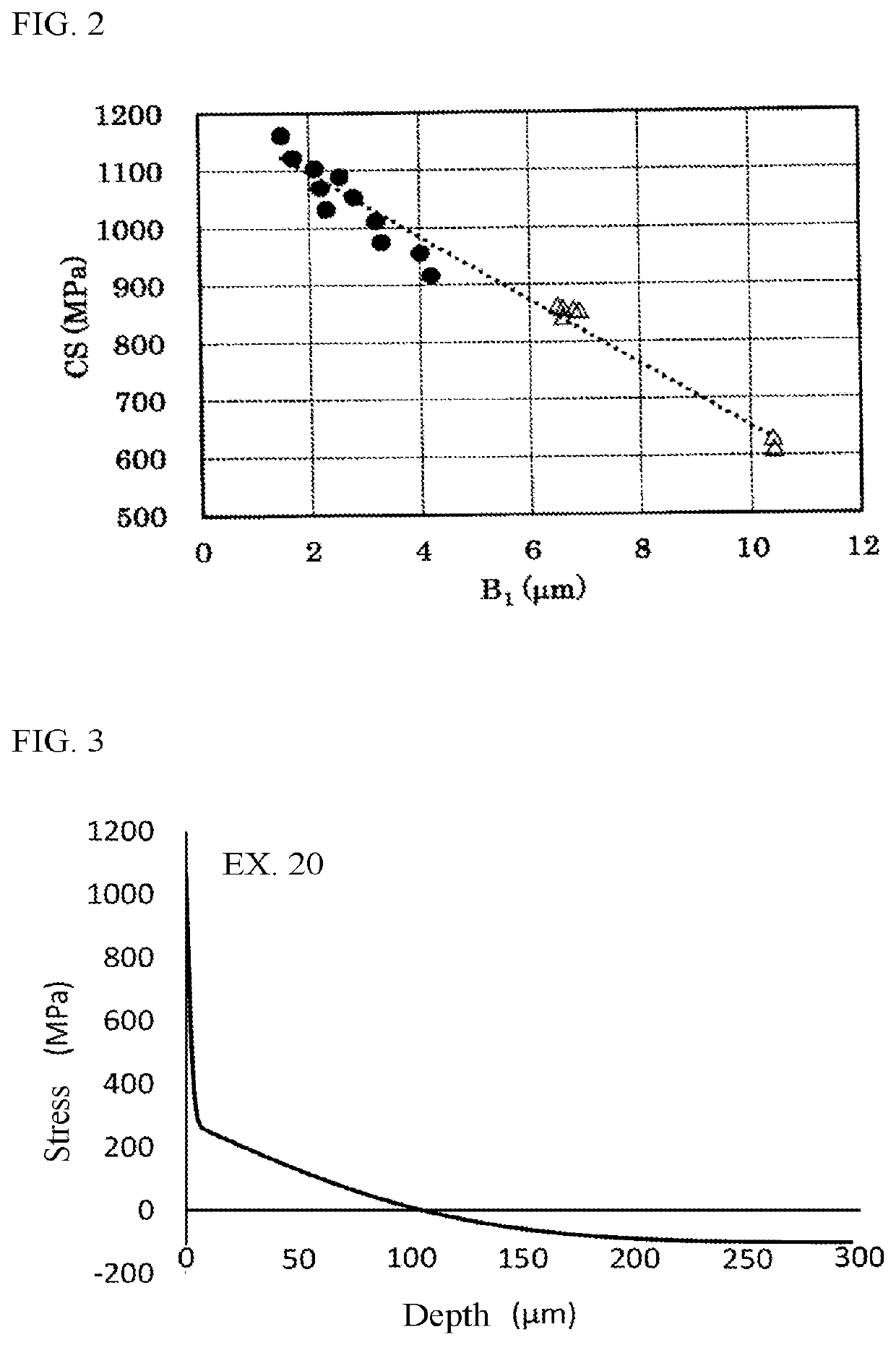

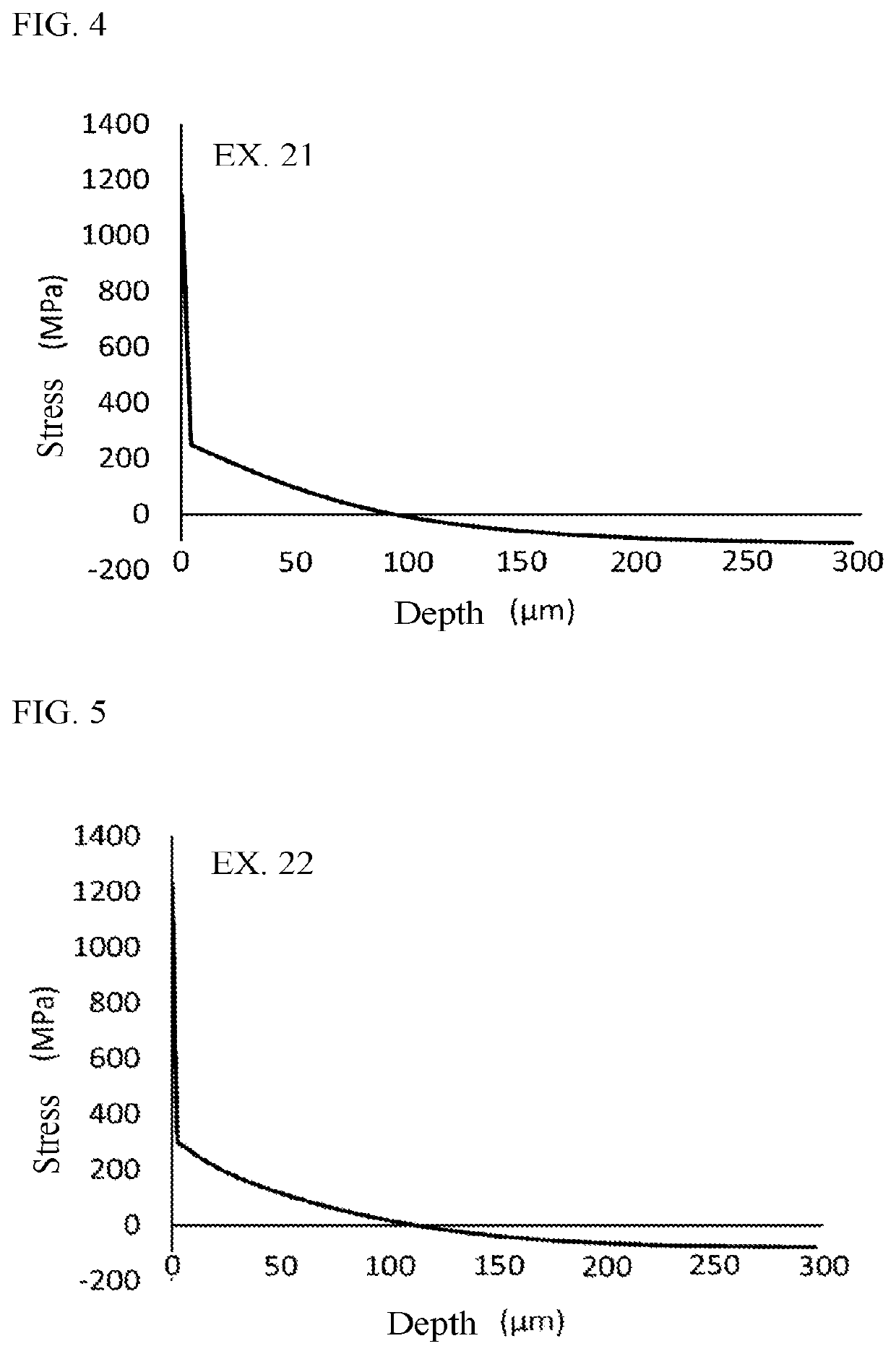

The present invention relates to a chemically strengthened glass satisfying A1 [MPa] of 600 or more, A2 [MPa] of 50 or more, B1 [μm] of 6 or less, B2 [μm] of 10% or more of t [μm], C [MPa] of −30 or less, and A1 / B1 [MPa / μm] of 100 or more when the chemically strengthened glass has a thickness t [μm] and a profile of a stress value [MPa] at a depth x [μm] from a glass surface is approximated by an error least-squares method in a region of 0<x<3t / 8 using the following function while defining a compressive stress as positive and a tensile stress as negative: A1erfc(x / B1)+A2erfc(x / B2)+C, in which erfc is a complementary error function, and relations of A1>A2 and B1<B2 are satisfied.

Owner:AGC INC

Rocker bearing high carbon-chrome steel outer ring composite treatment technology

InactiveCN101135344AExtend your lifeIncrease the surface compressive stressValve arrangementsBearing componentsHigh surfaceNitrogen

The invention is characterized in that: 1. The inner ring and the outer ring of the rocker bearing is heated in an heating furnace under 815-830 degree C for 2-5 hours, at same time carbon potential 0.9-1.2 is charged into the heating furnace and the volume ratio to nitrogen potential is 3-6%; 2. The inner ring and the outer ring of the rocker bearing after heat treatment are coarsely ground and sprayed by ceramic pills whose diameter is 2-5mm in 40-100m / s speed for 15-30 minutes. Advantages: ideal residual autenite content, high surface pressure and long service life.

Owner:上海百信轴承有限公司

Frame bumping-resistant mobile phone tempered membrane and manufacturing method thereof

InactiveCN108178504AImprove cooling effectAvoid crackingClimate change adaptationGlass shaping apparatusFrequent fallingIon exchange

The invention discloses a frame bumping-resistant mobile phone tempered membrane and a manufacturing method thereof. The body of the frame bumping-resistant mobile phone tempered membrane comprises, by weight, 85-90 parts of silica, 5-8 parts of boron oxide, 2-3 parts of sodium oxide and 3-5 parts of graphite powder with the particle size being 10-20 [mu]m, and the surface of the body undergoes 80% NaNO3 and 20% KNO3 mixed molten salt ion exchange treatment, wherein a starch modified acrylamide colloid membrane is fixed outside a frame modifying layer. The frame bumping-resistant mobile phonetempered membrane has the advantages of good heat tearing resistance, good toughness, good resistance to surrounding impact, coexistence of the tensile stress and the crushing stress of the surface ofthe frame glass body, and self-buffering performance, and is suitable for frequent falling bumping conditions in fixed frame sizes.

Owner:宁波华众和创工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com