Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

832results about How to "Good wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant thermoplastic elastomer and preparation method thereof

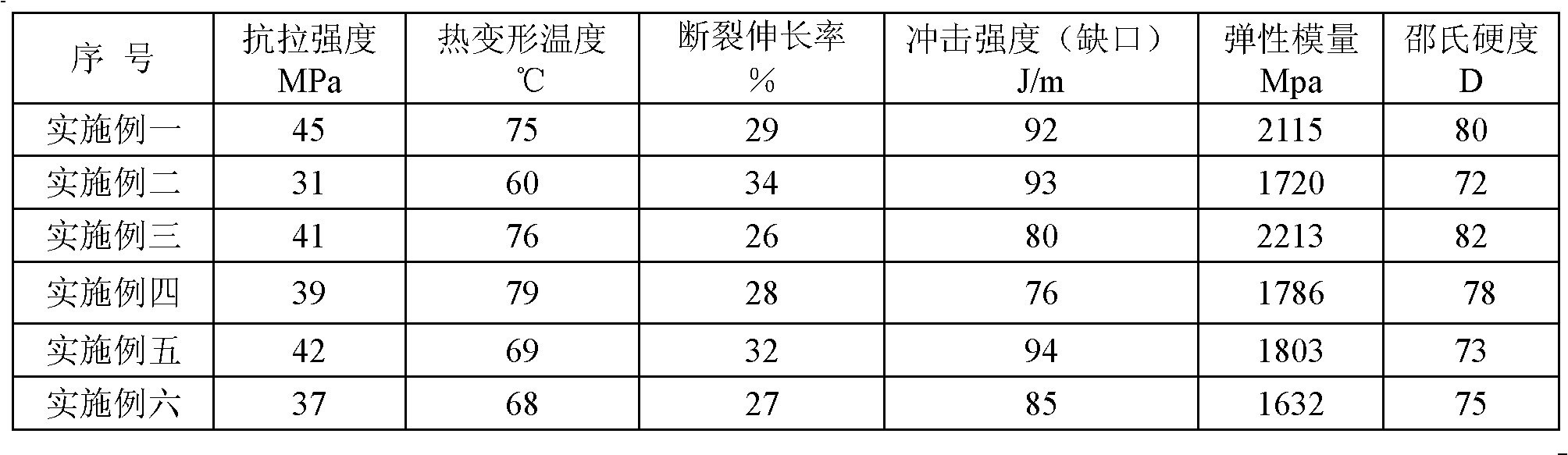

The invention discloses a wear-resistant thermoplastic elastomer, which is prepared from the following raw materials in percentage by weight: 10 to 80 percent of matrix resin, 10 to 60 percent of master batch, 0 to 42 percent of extending oil, 0 to 20 percent of thermoplastic resin, 0 to 30 percent of mineral filler, 0 to 1.5 percent of coupling agent, 0.1 to 2 percent of processing aid and 0.1 to 2 percent of stabilizing agent. The invention also discloses a method for preparing the wear-resistant thermoplastic elastomer. SBS, SEBS and the like are adopted as the matrix resin, and the problem of poor wear resistance of SBC thermoplastic elastomers is solved through improvement of a mixing formular and a process; the prepared thermoplastic elastomer has good wear resistance; compared with the TPU products with good wear resistance, the thermoplastic elastomer has low cost; in the whole process of modifying and producing the material, chemical solvents are not used, the influence on the environment is small, the halogen is free and the environment is protected; and the leftover material of the thermoplastic elastomer can be repeatedly used.

Owner:CGN JUNER NEW MATERIALS +1

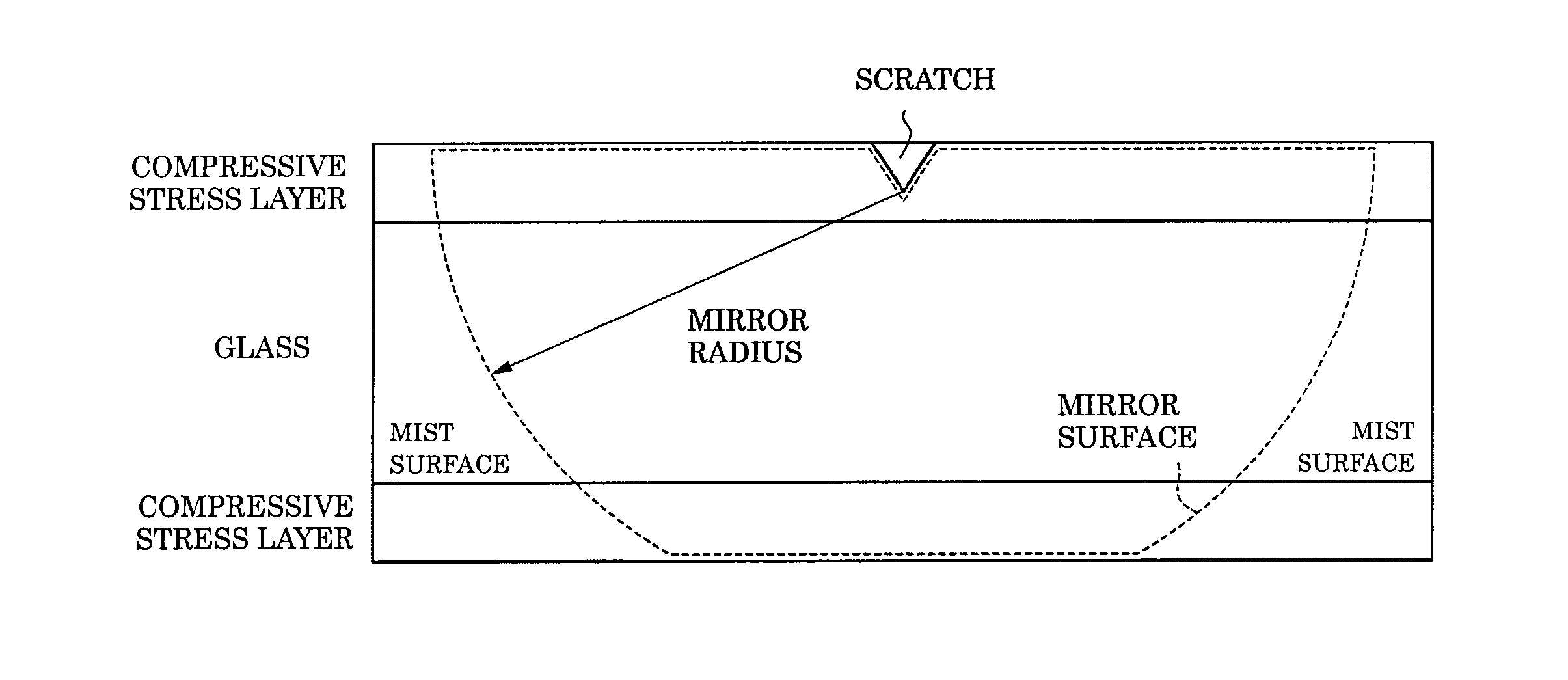

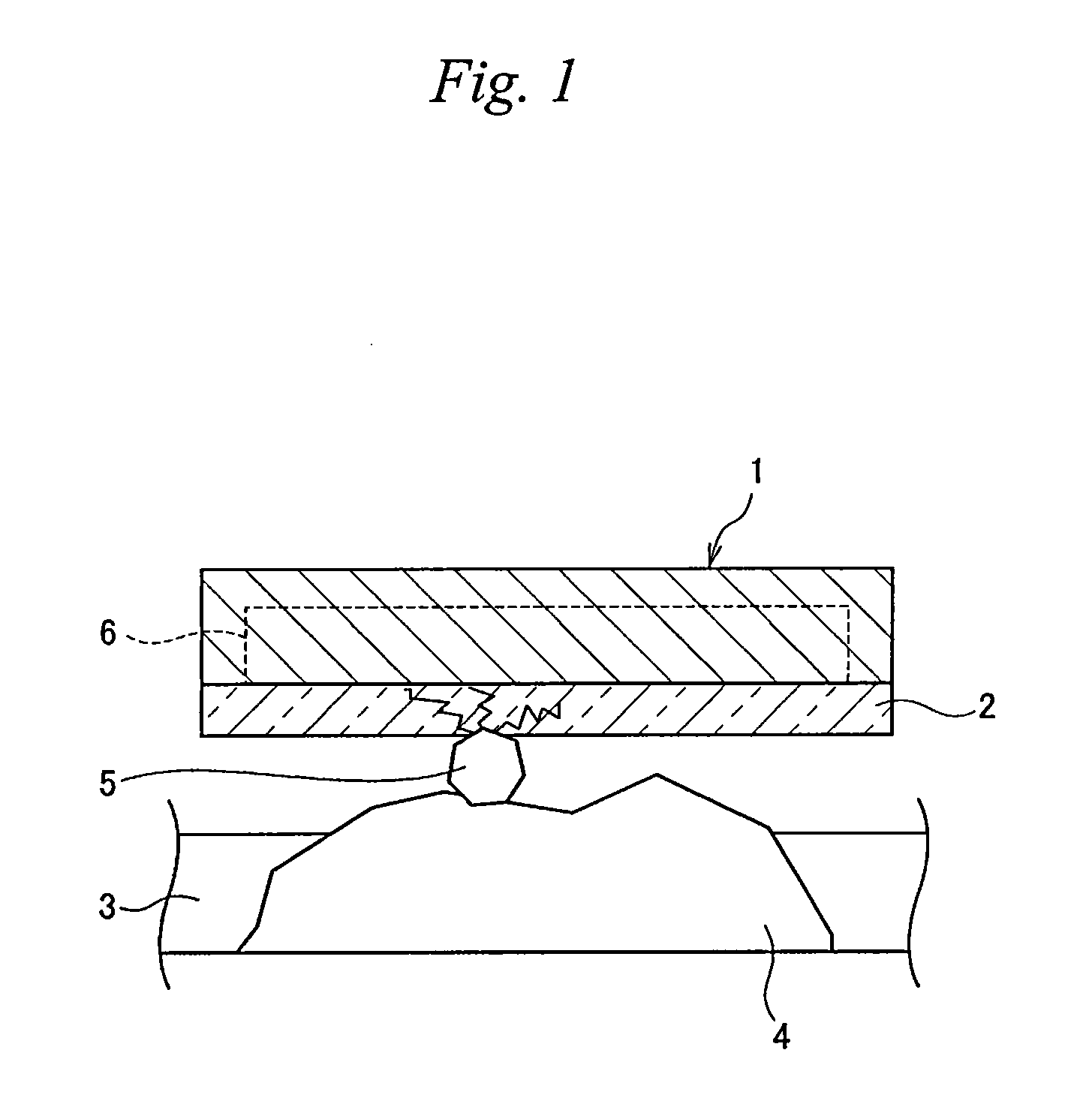

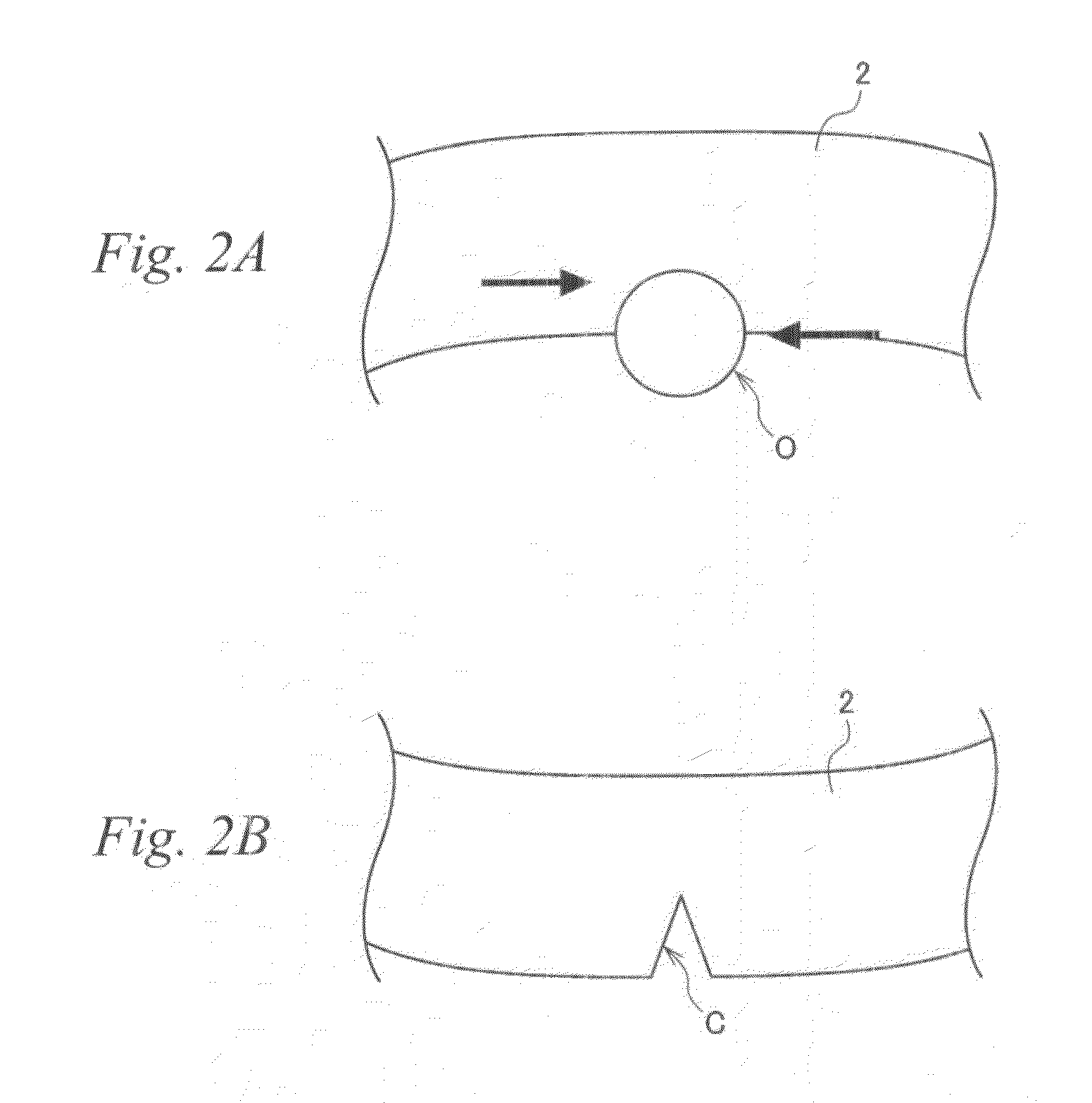

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

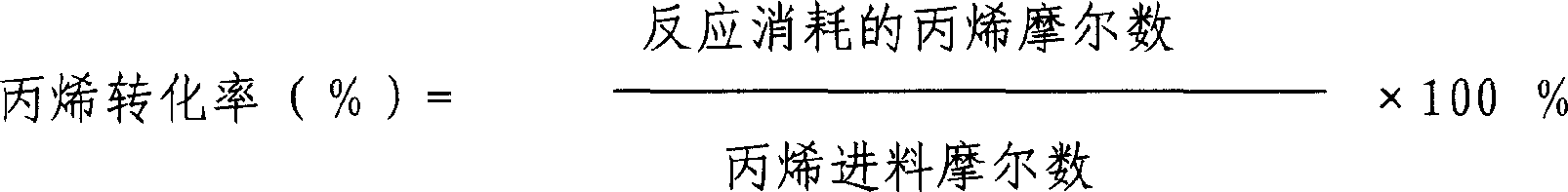

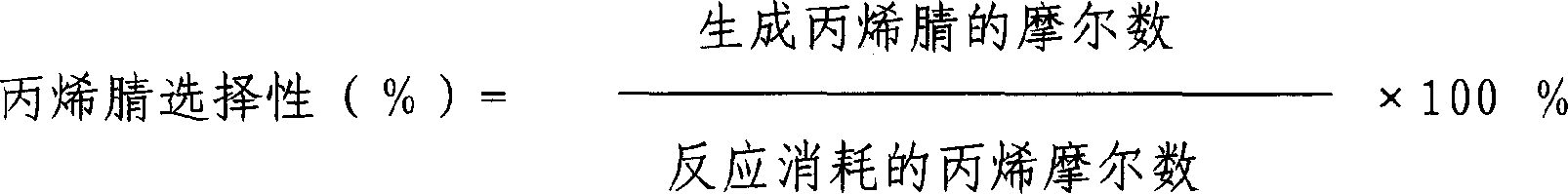

Fluid bed catalyst in use for oxidizing reaction of olefin ammonia

InactiveCN1600422AImprove wear resistanceHigh activityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedActive component

A fluidized-bed catalyst for the ammoxidation reaction of olefin is composed of the carrier consisting of nano-SiO2 and silica sol, and the active component Mo(12-g)BiaFebNicXdZfOgOx, where X is chosen from Mg, Co, Ca, Be, Cu, Zn, Pb, Sb, Mn and Cr, Y is chosen from La, Ce and Sm, Z is chosen from Li, K, Rb, Na and Cs, Q is chosen from B, W, P and V, a=0.1-6, b=0.01-10, c=0.01-10, d=0.01-10, e=0.01-10, g=0-2 and f is more than (0-0.5).

Owner:CHINA PETROLEUM & CHEM CORP

Composite abrasion resistant and thermal shock resistant pouring material

The invention relates to a composite abrasion resistant and thermal shock resistant refractory pouring material which is prepared by composition of corundum, andalusite, mullite and silicon carbide, and the formula is as follows: 30-40% of corundum of 5-3mm, 15-25% of andalusite and mullite of 3-1mm, 10-20% of andalusite and mullite of 1-0.088mm, 5-20% of silicon carbide of smaller than 0.08mm, 3-8% of alpha aluminum oxide of smaller than 0.020mm, 2-7% of silica fume, 3-8% of pure calcium aluminate cement, 0.05-0.4% of added water reducing agent and 4-6% of added water. The pouring material has the advantages of good abrasion resistance, thermal shock resistance, erosion resistance and high-temperature resistance, low thermal-conductivity and volume stability, thereby being applicable to being used as a refractory material for a kiln mouth of a rotary kiln and a coal nozzle in the cement industry, as well as a circulating fluidized bed and other harsh parts in the power industry.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

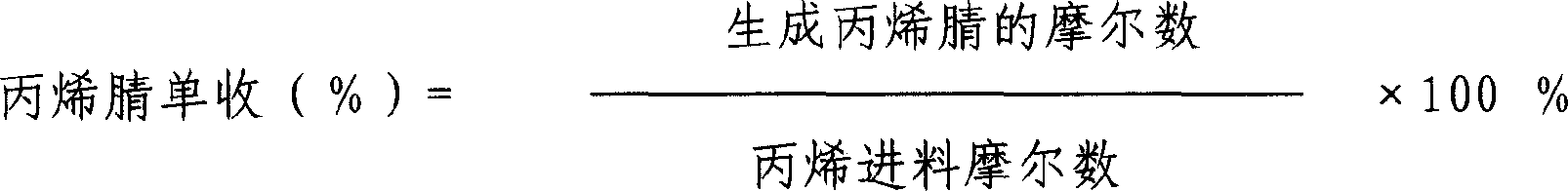

Laser restoring method of aircraft engine cylinder body

InactiveCN101787529AImprove wear resistanceGood wear resistanceMetallic material coating processesAirplaneBonding strength

The invention discloses a laser restoring method of an aircraft engine cylinder body, which ensures the aircraft engine cylinder body to be restored after being worn without rejection. The laser restoring method utilizes the laser energy to lead specified alloy material to be melted and coated on the part to be restored at an inner cavity of the aircraft engine cylinder body, and then leads the part to be processed in a mechanical way, thus ensuring the part to restore the physical dimension. After being restored, heat treatment is not needed to be carried out on the cylinder body, the needed hardness value can be obtained by a working surface, and the wear-resisting property is improved to some extent, so that a cylinder body which can be used again is obtained. As laser melt coating has the advantages of high bonding strength, small heat affected zone, no need of heat treatment and the like, the method is applicable to restoring the engine cylinder body. Meanwhile, in the process of the implementation, the method consumes little resource, causes no pollution and protects the environment.

Owner:安徽米特吉激光科技有限公司

Polyurethane heat-insulation structural adhesive and manufacturing method for heat-insulation aluminum profile

InactiveCN102079960AGood mechanical propertiesGood wear resistancePolyureas/polyurethane adhesivesToluene di-isocyanateChemistry

The invention discloses a polyurethane heat-insulation structural adhesive, which comprises components A and B, wherein the mass ratio of A to B is (90-110):(70-90); the component A comprises polyether polyol and auxiliaries; on the basis of the mass ratio of the auxiliaries to the polyether polyol, the auxiliaries comprise following components by weight percent: 0.1-0.3% of catalyst, 0.1-0.5% offlatting agent, 0.1-0.5% of de-foaming agent, 0.5-1.5% of chain extender, 0.1-5% of padding, 0.3-5% of plasticizer, 0.1-0.3% of anti-oxygen, and 0.1-0.3% of ultraviolet absorber; and the component B is isocyanate of MDI (methyl diphenylene diisocyanate) or TDI (toluene di-isocyanate). The invention also discloses a method for using the structural adhesive to prepare a heat-insulation aluminum profile. The polyurethane heat-insulation structural adhesive provided by the invention has advantages of excellent mechanical property, fatigue resistance, shock resistance, wear-resisting property, andstability. Room-temperature pouring and room-temperature solidifying processes are realized through the molding production; the pouring period is long; the molding production is not limited by temperature and the shape of aluminum profile; the operation is easily controlled; the rejection rate is low; and the molding production is beneficial to the popularization and application of the pouring type heat-insulation aluminum profile technique.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

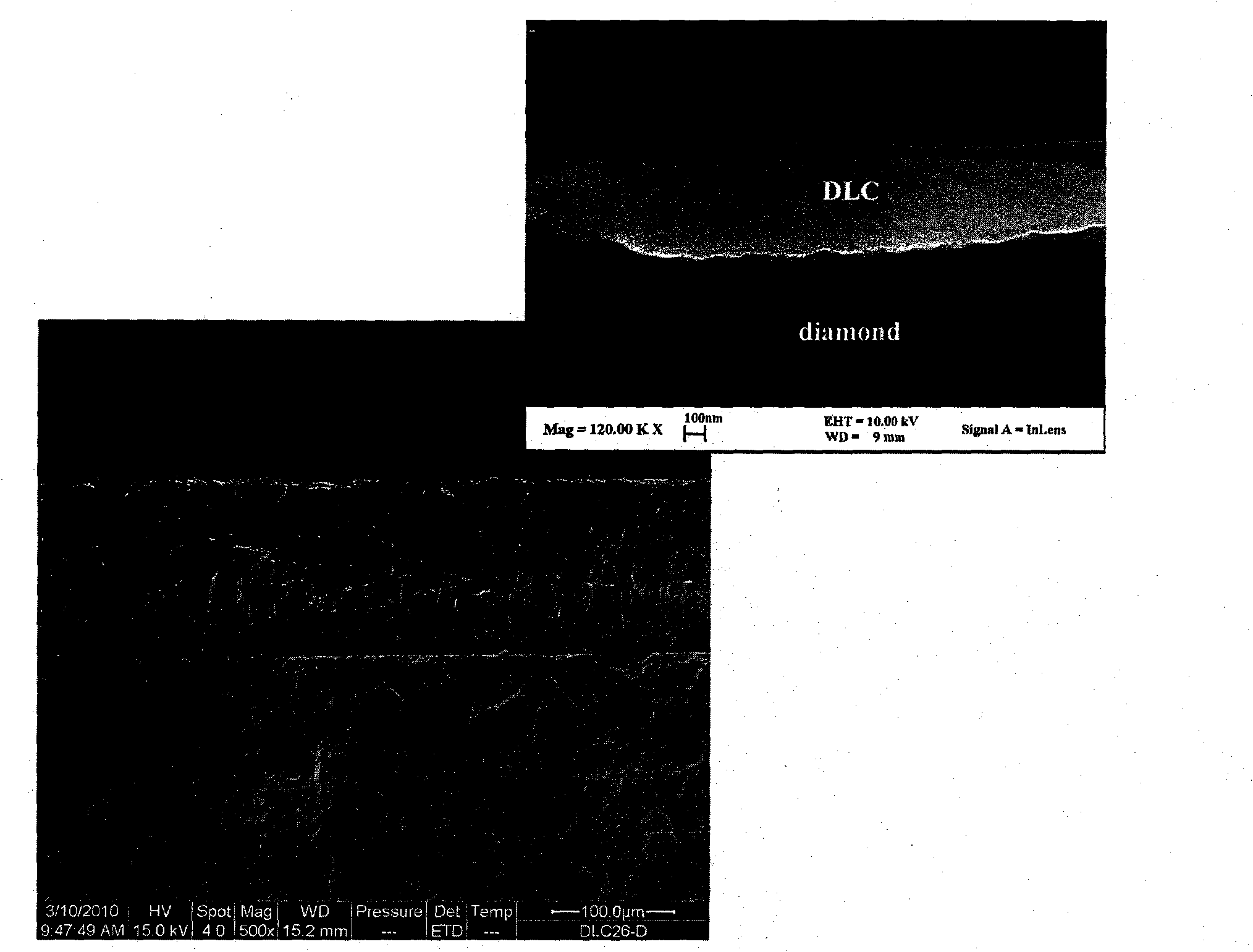

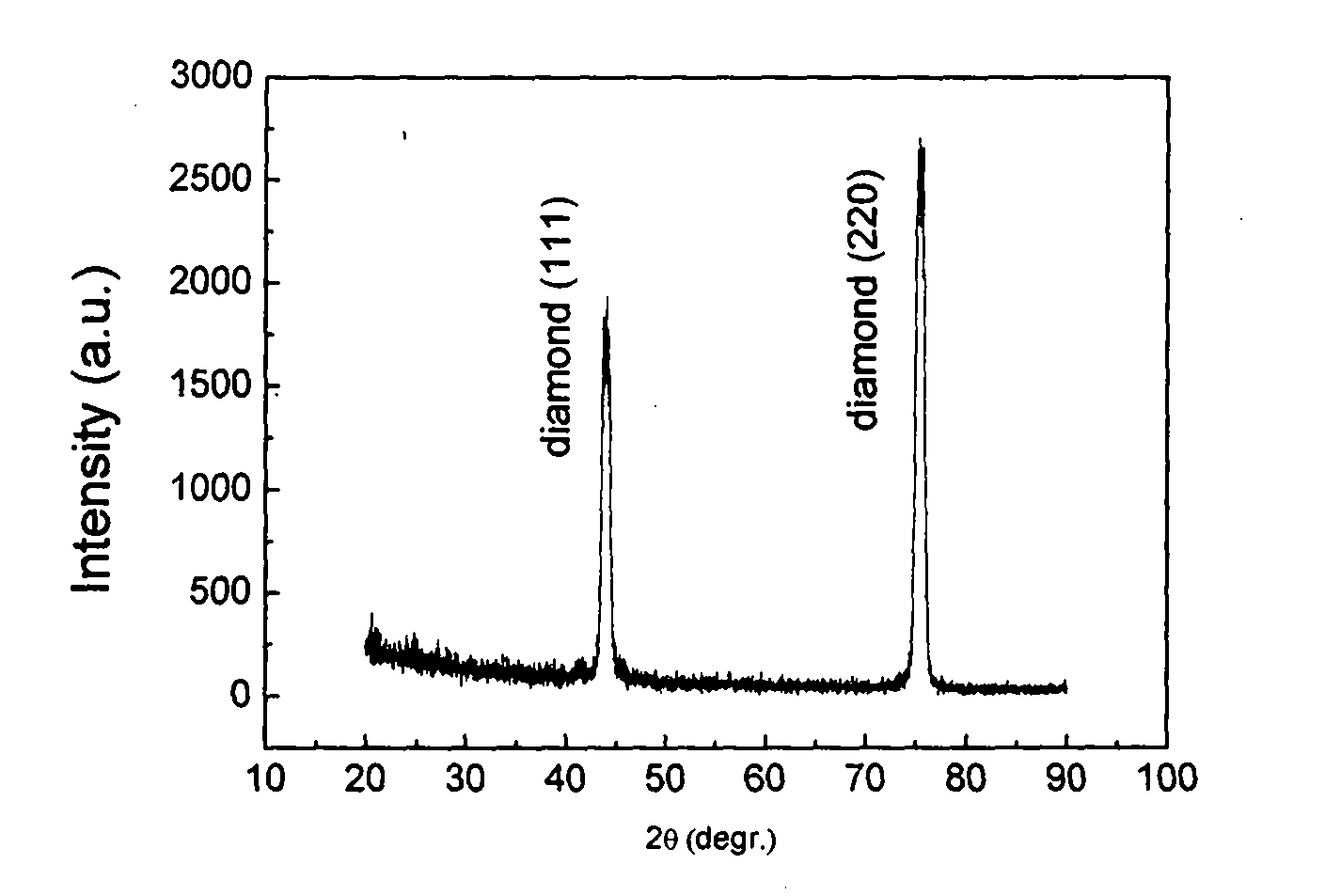

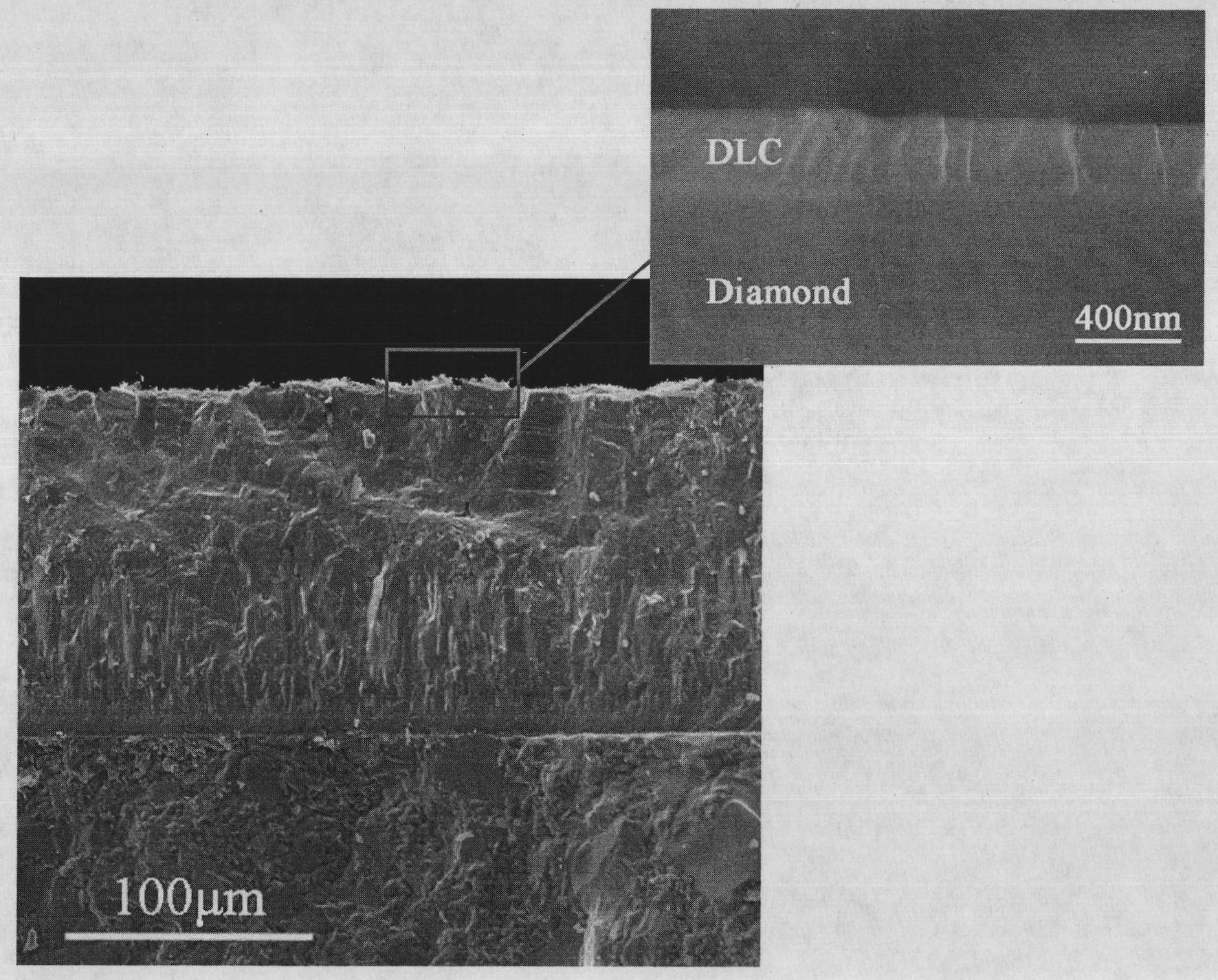

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

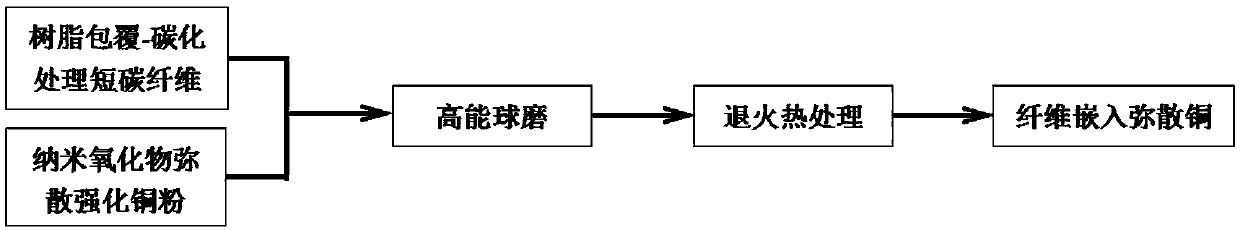

Short carbon fiber modified high friction composite and preparing method and application thereof

ActiveCN108018506AImprove conductivityGood wear resistanceFriction liningInternal oxidationCarbonization

The invention relates to a short carbon fiber modified high friction composite and a preparing method and application thereof, and belongs to the technical field of friction materials. Raw materials used by the short carbon fiber modified high friction composite comprise 1wt.% to 3wt.% of resin coating-carbonization treatment short carbon fibers and larger than or equal to 15wt.% of nanometer oxide dispersion strengthened copper powder. In the nanometer oxide dispersion strengthened copper powder, nanometer oxide is generated in an in-situ manner. The preparing method comprises the steps thatthrough combination of internal oxidation and reduction, the nanometer oxide dispersion strengthened copper powder is prepared, meanwhile, the resin coating-carbonization treatment short carbon fibersand the nanometer oxide dispersion strengthened copper powder are processed through the proper ball milling annealing process to obtain composite pre-alloying copper powder; the powder is mixed withother components to be subject to pressing and sintering, and a finished product is obtained. The designed and prepared copper-base composite is excellent in mechanical property, high temperature resistance and wear resistance, and the preparing process is simple.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

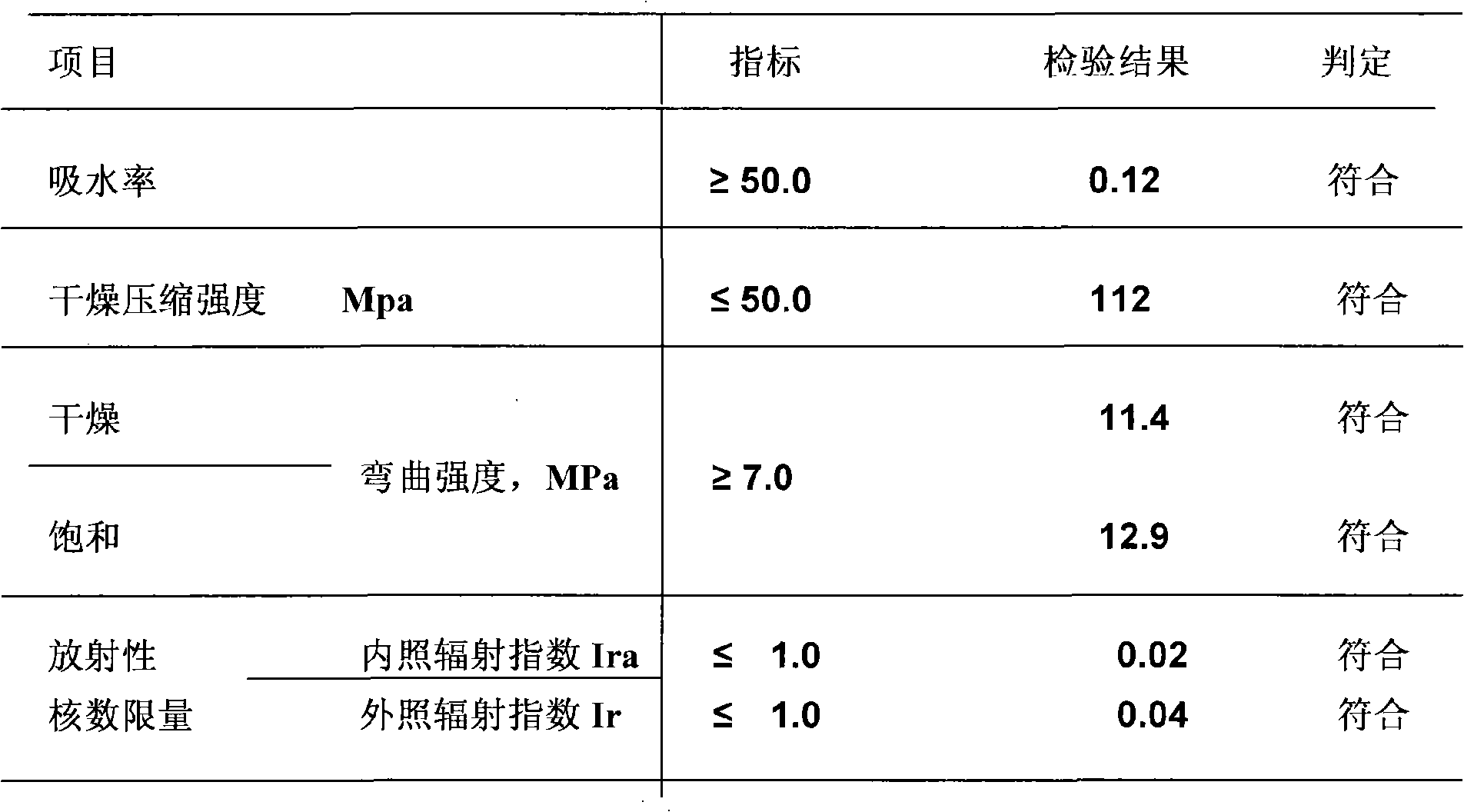

Artificial stone panel and manufacturing method thereof

InactiveCN101328039AGood wear resistanceNoble and elegant decorative effectCalcium carbonateArtificial stone

The invention discloses a artificial stone plate prepared by adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin. The preparation method includes the following steps: firstly modifying the aluminium hydroxide and / or calcium carbonate to get surface modified aluminium hydroxide and / or calcium carbonate or pure aluminium hydroxide powder, then adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin, uniformly mixing and stirring the mixture in a high speed stirring reactor, adding surface modified aluminium hydroxide and / or calcium carbonate powder or pure aluminium hydroxide powder, stirring and casting the mixture into a mould after vacuum defoamtion, heating up to 60-80 DEG C and curing to get the artificial stone and marble panel.

Owner:覃庆峰

Multielement high-chromium wear-resisting cast-iron sieve-plate and production thereof

An antiwear multi-element screening plate made of high-Cr cast iron contains C (2.2-3.2 wt.%), Cr (18-28), Mn (0.6-1.5), Si (0.4-1.0), Mo (0.4-1.5), Ni (0.5-1.2), Nb (0.1-0.5), Ca (0.01-0.08), Zn (0.008-0.050), Mg (0.002-0.010), Ce (0.003-0.10), Ti (0.08-0.15) and Fe (rest). It is made up by electric furnace and cold hardened resin-sand mould. Its advantages are high bending strength, hardness, antiwear performance and impact toughness, and low cost.

Owner:XI AN JIAOTONG UNIV

Ultraviolet light curing fingerprint resistant paint

InactiveCN101250340AExcellent anti-fingerprintGood wear resistancePolyurea/polyurethane coatingsFingerprintPolymer chemistry

The invention discloses ultraviolet light curing anti-fingerprint paint, which comprises components with percentage by weight of 5-25 wt% high function aliphatic polyurethane acrylic ester, 10-30 wt% acrylic ester modified by fluorine, 5-20 w% large molecular resin, 10-25 wt% trifunctionanal function aliphatic polyurethane acrylic ester, 5-15 wt% double function acrylic ester, 1-5 wt% photo initiator, 15-40 wt% diluent and 0.01-1 wt% auxiliary agent, wherein high function aliphatic polyurethane acrylic provides hardness and high abrasion resistance, acrylic ester modified by fluorine is formed by grafting fluorine monomer with acrylic ester. The anti-fingerprint paint can permanently reduce the surface tension of painting film, and eliminates the generation of fingerprints.

Owner:HUIZHOU CHANGRUNFA PAINT

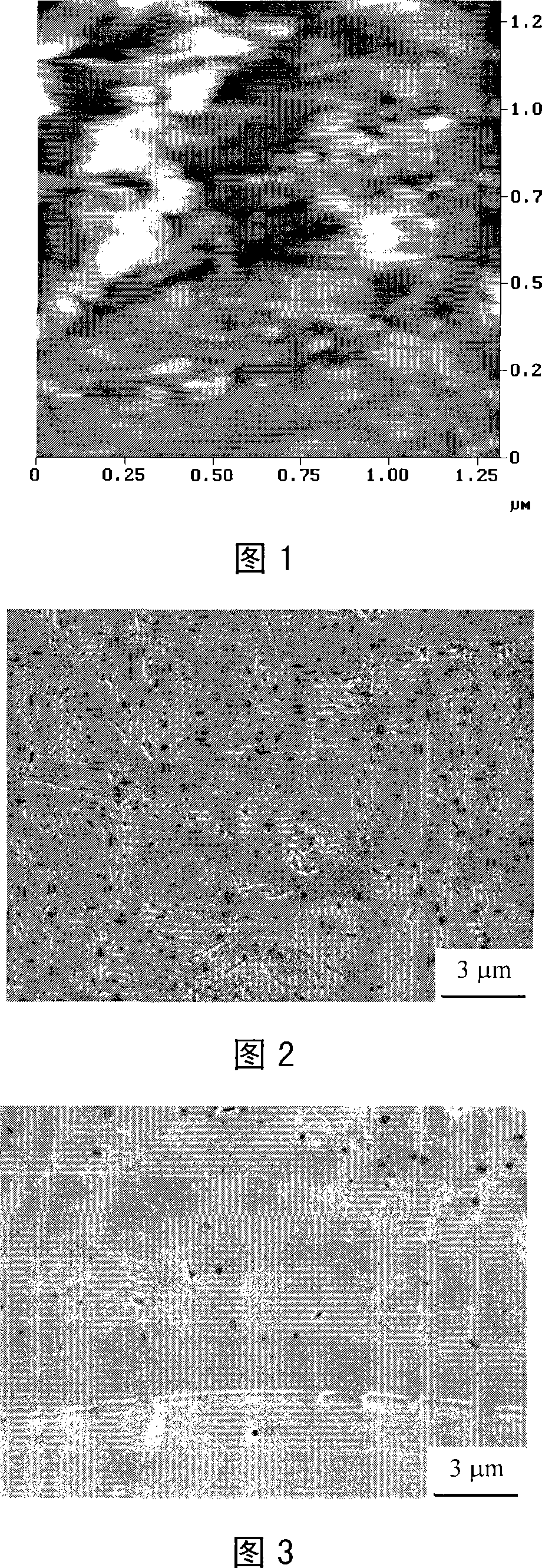

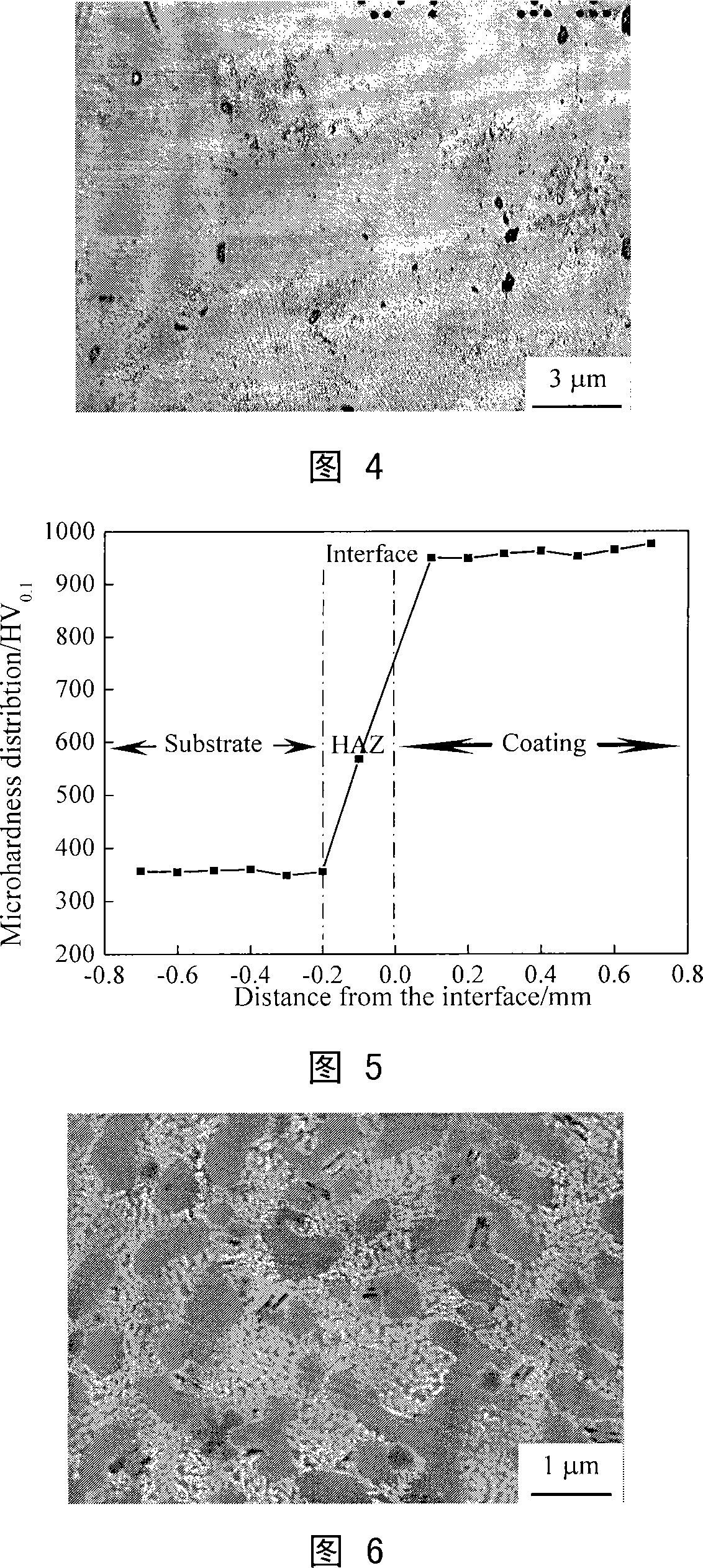

Method for preparing nano/submicron TiB-TiC enhanced titanium-base composite material (TiB+TiC)/Ti

InactiveCN101144159AGood wear resistanceHigh hardnessLaser beam welding apparatusHeat inorganic powder coatingOxideHardness

The present invention discloses a preparation method for nanometer / submicron TiB-TiC reinforced titanium matrix composite (TiB TiC) / Ti. The method comprises steps that after a precursor body selected from Ti, B 4 C, and rare earth oxide CeO 2 powder is uniformly mixed, plasma densified granulation is performed to the precursor body to assemble the precursor body into binding grains with the grain size of about 30 micron, and cold spraying of the binding grains onto a titanium Ti-6Al-4V alloy substrate is performed, and the thickness is controlled between 0.5 and 1.0 mm. Then liquid light absorbing coating which mainly comprises nano oxide and other kinds of auxiliary agent and enhances the laser absorption rate on the CO 2 is coated on the surface of the pre-assembled coating; laser scanning is performed to the pre-assembled coating, to obtain the nanometer / submicron TiB-TiC reinforced titanium matrix composite (TiB TiC) / Ti. The present invention can organically combine the high hardness degree and the high chemical stability of ceramic material with the high tensibility and the high intensity of the titanium alloy, solve the fatal disadvantages of large titanium alloy friction coefficient and poor wear resistance, etc., and thereby can be applied to the modification of the titanium alloy components on aerospace planes and navigation ships, and the titanium alloy components of acid proof pumps and acid proof valves.

Owner:SHANGHAI UNIV OF ENG SCI

Nanometer composite structure protective coating made from high hardness CrAlSiN and preparation method of nanometer composite structure protective coating

ActiveCN104928637AGood wear resistanceSimple processVacuum evaporation coatingSputtering coatingRadio frequencyIon

The invention relates to a nanometer composite structure protective coating made from high hardness CrAlSiN and a preparation method of the nanometer composite structure protective coating. The preparation method comprises the following steps: (1) cleaning matrixes, and then performing ion cleaning; (2) preparing a CrN transition layer: sending the matrixes processed in the step (1) to a sputtering chamber, so that the CrN transition layer is deposited, a Cr target material is controlled by a direct current cathode, and a 200-300nm CrN transition layer is deposited; and (3) preparing a CrAlSiN layer, wherein a CrAlSi composite target material is controlled by a radio frequency cathode, and 2-4 mum of a CrAlSiN nanometer composite coating is deposited on the surface of the CrN transition layer. The coating not only has high hardness of 43.6GPa, but also has excellent high-temperature oxidation resistance and excellent corrosion resistance, so that the protective coating disclosed by the invention can be used as a protecting coating for a high-speed dry cutting cutter and equipment with high loads in other fields. The preparation method has the characteristics of simple technology, high deposition speed, low cost, high bond strength and the like, and has the advantages of high production efficiency, low energy consumption, low equipment requirements, and the like.

Owner:SHANGHAI NEWARC COATING TECH CO LTD

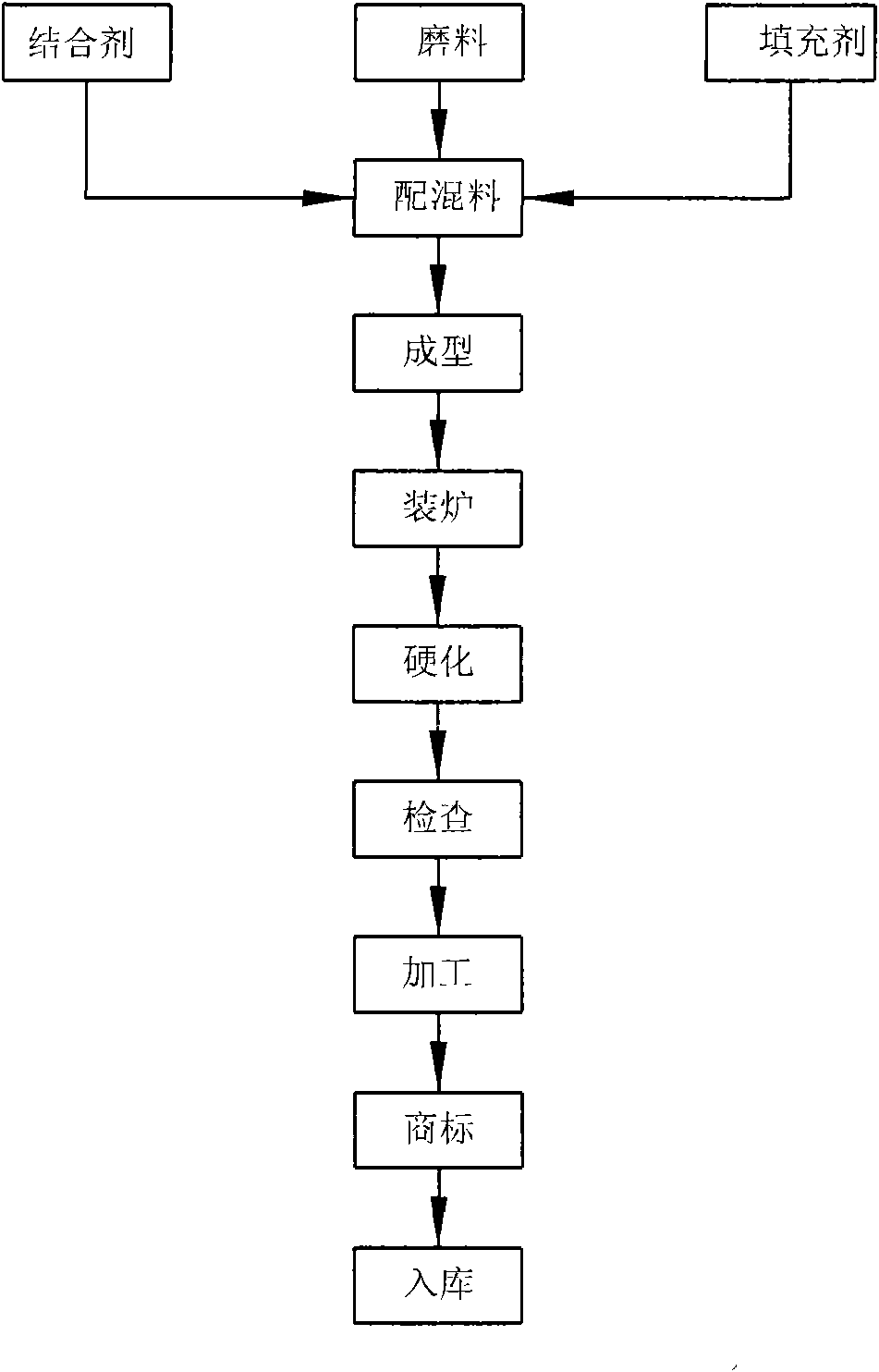

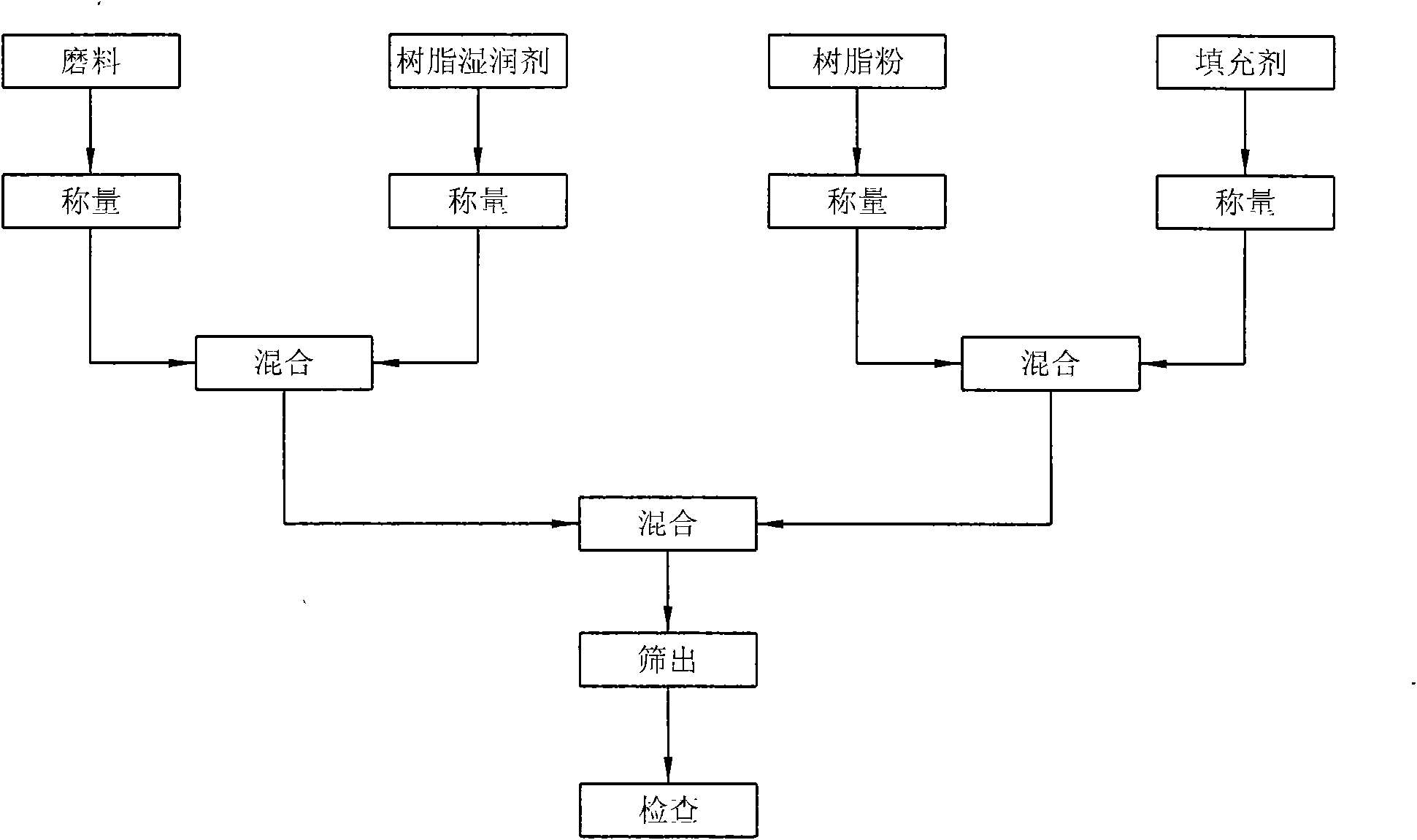

Fiber-reinforced resin heat-resistant high-speed abrasive cutting wheel and processing method thereof

ActiveCN101966693AGood heat resistanceGood wear resistanceAbrasion apparatusGrinding devicesWear resistantTitanium dioxide

The invention belongs to the field of abrasive wheels, and in particular relates to a fiber-reinforced resin heat-resistant high-speed abrasive cutting wheel with a large diameter and a flake structure and a processing method thereof. In the invention, the abrasive wheel is divided into a center reinforced part and a cutting part which adopt different formulas, wherein the formula of the center reinforced part has the advantages of high strength and good cohesiveness with a fiber glass reinforced net, and because the center reinforced part does not use zirconia alumina and other materials with a relatively higher price, the cost is saved. By adding iron sulfide powder, cryolite powder and titanium dioxide fine powder to the cutting part, and optimizing the respective proportion, the heat resistance and wear resistance of the cutting part are enhanced and the cutting ratio is improved. The abrasive wheel of the invention has the advantages of good heat-resistant property, good wear-resistant property, high cutting ratio and low cost.

Owner:山东鲁信四砂泰山磨具有限公司

Diamond sintered body and method for producing same

InactiveUS20100112332A1High strengthGood wear resistanceDrawing diesLayered productsTungstenChromium

Provided are a diamond sintered body having higher strength and more excellent wear resistance than a conventional diamond sintered body, and a method for producing such a diamond sintered body. The diamond sintered body includes diamond particles, a binder, and a void. The diamond particles have a content of not less than 80% by volume but less than 98% by volume. The binder includes a solid solution containing at least one element selected from a group consisting of titanium, zirconium, vanadium, niobium, and chromium, carbon, and tungsten, as well as an iron group element. Neighboring ones of the diamond particles are bonded to one another. The method provides such a diamond sintered body.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

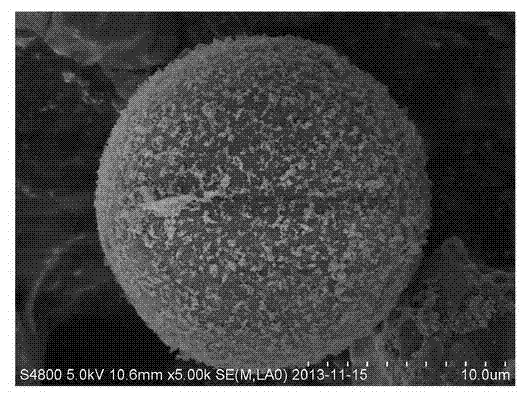

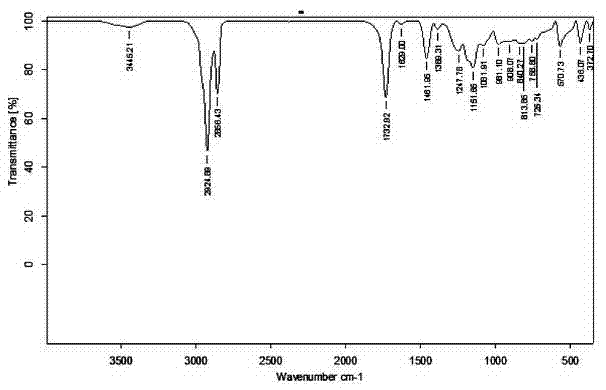

Silicon nitride-modified phase-change and energy-storage microcapsule and preparation method thereof

ActiveCN103805142AGood wear resistanceHigh thermal conductivityHeat-exchange elementsMicroballoon preparationThermal conductivitySilicon nitride

The invention discloses a silicon nitride-modified phase-change and energy-storage microcapsule, comprising a shell material and a cladded core material, wherein the shell material comprises the following raw materials in parts by weight: 50-100 parts of high-molecular polymers and 1-20 parts of silicon nitride powder which is evenly dispersed into the high-molecular polymers; the core material comprises 50-100 parts of organic phase-change and energy-storage materials and 1-20 parts of silicon nitride powder which is evenly dispersed into the organic phase-change and energy-storage materials. The invention also provides a preparation method of the phase-change energy-storage microcapsule. The thermal conductivity of the phase-change and energy-storage material is improved, overheat and overcold degrees in the phase-change process are inhibited, and meanwhile, the thermal endurance and the abrasive resistance, the thermal shock resistance, the fatigue resistance and the like also are improved. The silicon nitride-modified phase-change and energy-storage microcapsule is relatively simple in preparation technology, available in raw materials, strong in controllability, and applicable to the industrial large-scale production, an existing industrial processing technology can be fully utilized, and the performance of the phase-change and energy-storage microcapsule is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

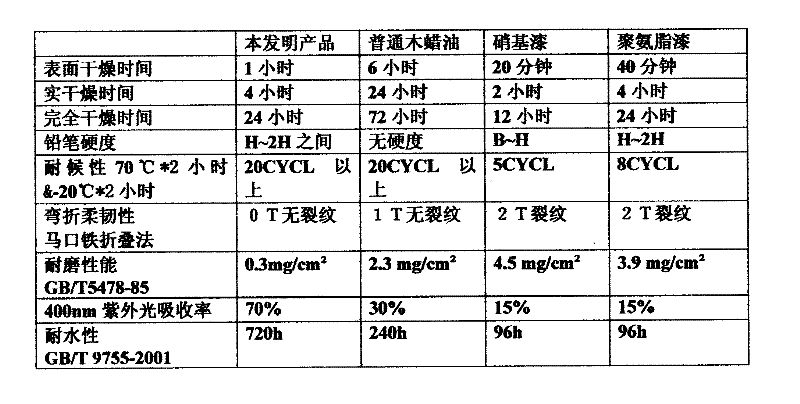

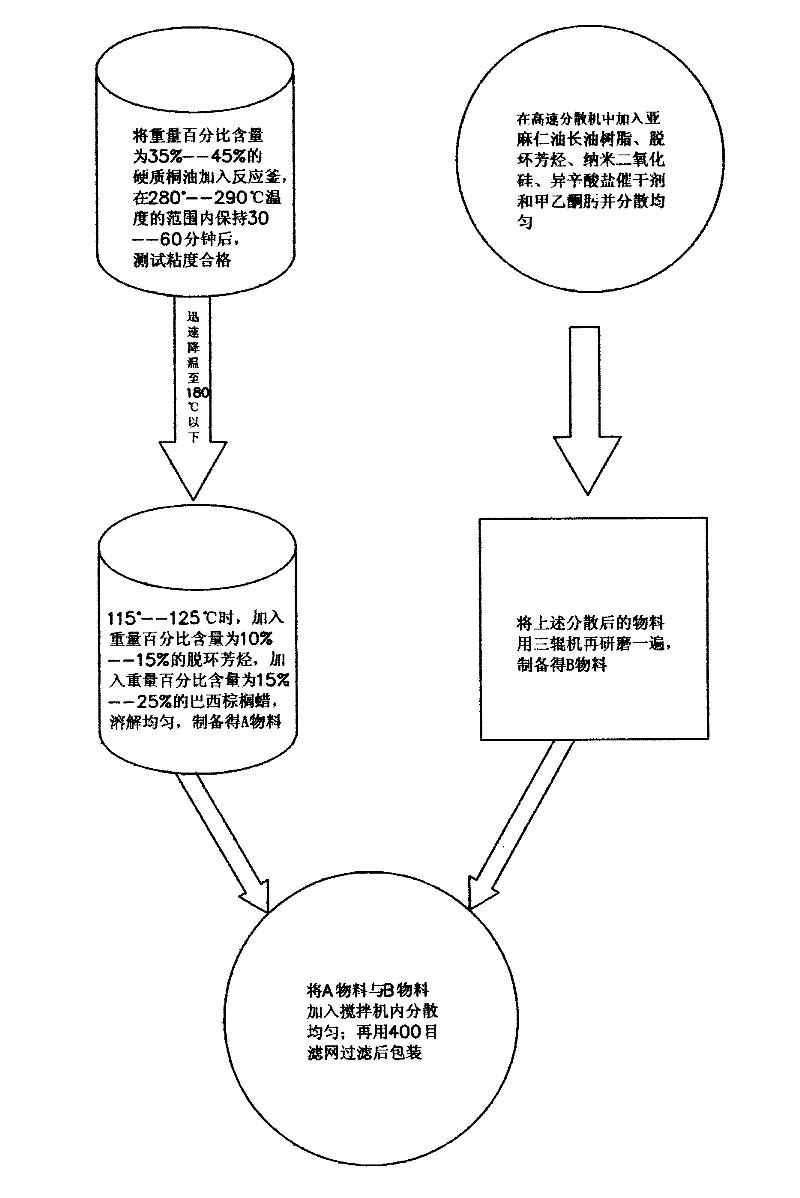

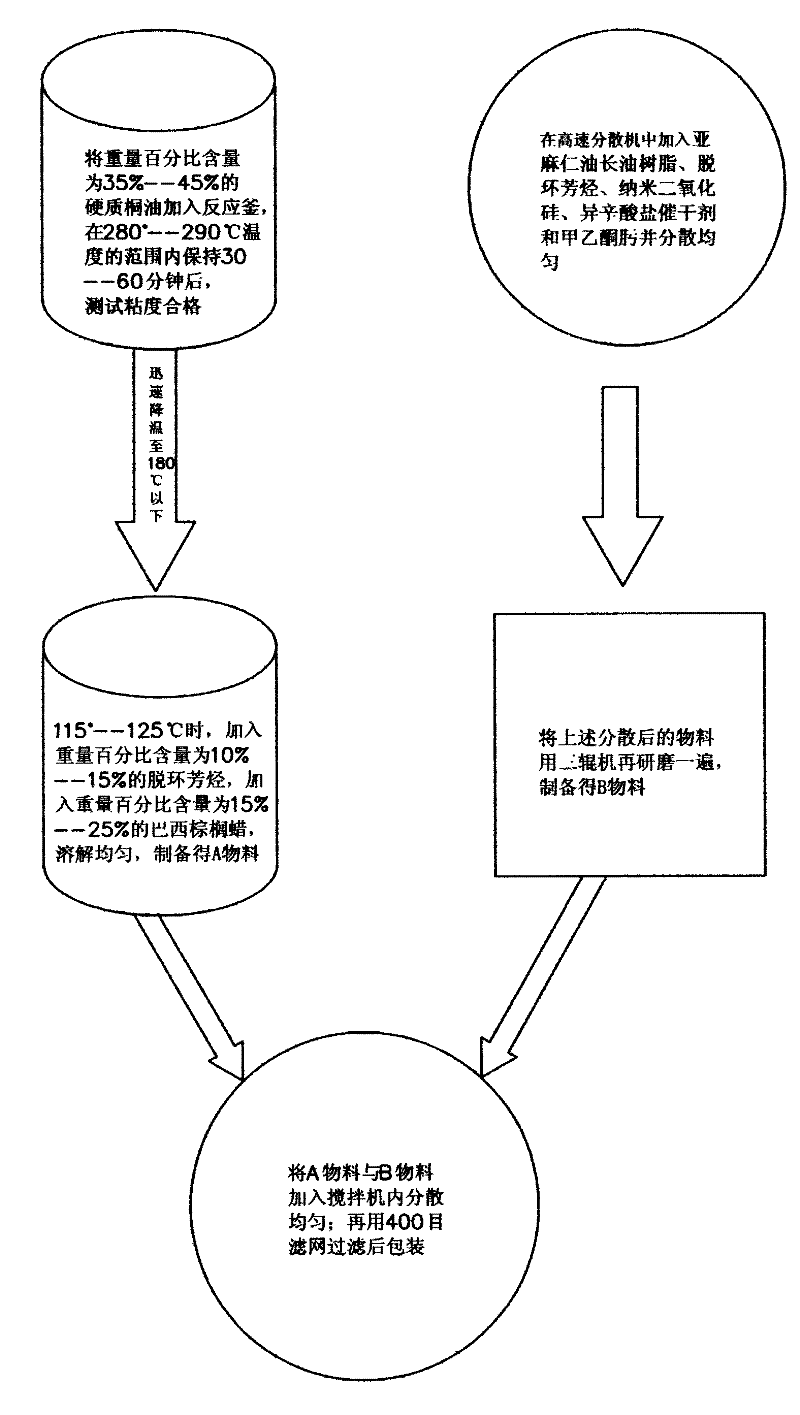

Nano silicon dioxide modified hard wood wax oil and preparation method thereof

InactiveCN102408828AMaintain wood grain penetration protectionAchieve waterproof, mildew, crack and other three protection effectsWax coatingsPolyester coatingsDistillationLinseed oil

The invention discloses a nano silicon dioxide modified hard wood wax oil and a preparation method thereof. The invention aims to overcome the defects of low drying speed and low hardness in the existing wood wax oil, and to be applied to furniture application instead of common wood wax oil or nitrocellulose paint / polyurethane paint. The product comprises the following raw materials in percentage by weight: 35-45% of modified hard tung oil or linseed oil, 15-25% of carnauba wax of which the softening point is 85-95 DEG C, 15-25% of linseed oil long oil alkyd of which the oil length is 78-80% and the solid content is higher than 98%, 3-5% of nano silicon dioxide of which the particle size is 60-80 nm, 20-30% of decyclized aromatic hydrocarbon of which the distillation range is 160-200 degrees, 1-2% of isooctoate compound drying agent and 0.3-0.5% of methylethylketoxime. The preparation method comprises the following steps: preparing a material A, preparing a material B, and mixing the material A and the material B.

Owner:深圳市圣马斯科技有限公司

Copper ammonia fiber colored woven fabric and manufacturing process thereof

InactiveCN101173401AGood wear resistanceGood hygroscopicityMercerising of sliversSingeingUptake ratePlain weave

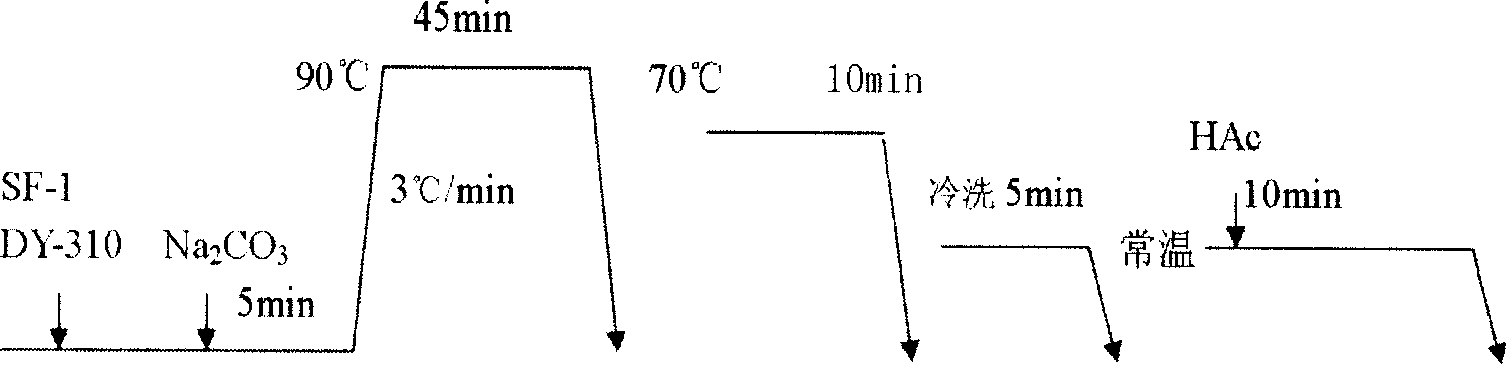

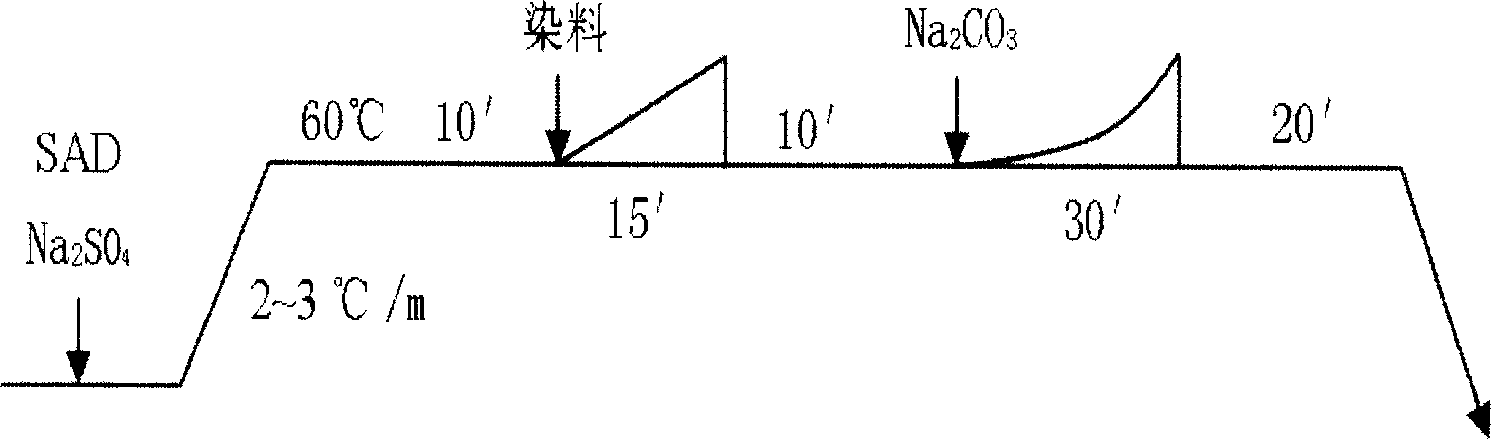

The invention relates to a cuprammonium rayon yarn-dyed fabric and the corresponding manufacturing process. The fabric is woven by interlacing a pure cotton yarn and a cuprammonium rayon yarn; wherein, the warp of the fabric is 32 to 40 pure cotton dyed yarn, and the weft of the fabric is 32 to 40 cuprammonium rayon dyed yarn; the fabric texture is 11 / 13 compound twill or plain weave poplin. The manufacturing process mainly comprises yarn preparation, weaving, finishing and finished product examination, and the key of the process lies in the pre-treatment, dyeing, and post-treatment of the weft and the finishing of the fabric. The invention has the advantages that: for the fabric, the property of strength and good wear resistance of the cuprammonium rayon is rational utilized; the hygroscopicity, the air permeability, the antistatic property, the soft, smooth and qualitative texture, the wearing comport and the excellent wearability of the fabric are ensured; for the manufacturing process, shortcomings such as uneven dyeing, big color difference between inner and outer layers of the package, big color difference between batches and low one time dyeing rate in the package dyeing caused by high dyeing uptake rate, high dyeing uptake amount and high fixation amount of the cuprammonium rayon are overcome.

Owner:天津市荣泽纺织有限公司

Low-sulfure diesel oil antifriction dispersion multi-effect additive composition

ActiveCN1552826AGood wear resistanceStrong adsorption and capture abilityLiquid carbonaceous fuelsOxidation resistantMulti effect

A wear-resistant dispersing multi-effect additive composition of low-sulfur diesel fuel includes components A and B, wherein, component A consisting of reacted product or mixture obtained by reacting phenol acids with alkenyl succimide under 60-200degC for 0.5-20 hours at 0.5-5:1 mole ratio under existence of organic solvent; and component B consisting of reacted product or mixture of natural oil and fat and amine and / or alcohol with weight ratio of A : B = 1:0.1-10. The invention achieves additive amount 20-2000ppm of multi-effect additive composition in diesel, good lubricity and resistance to oxidation as diesel stabilizing agent, wearproofing agent and dispersing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paint composition

ActiveCN101684387AGood wear resistanceGood solvent resistancePolyurea/polyurethane coatingsSolventPolyester

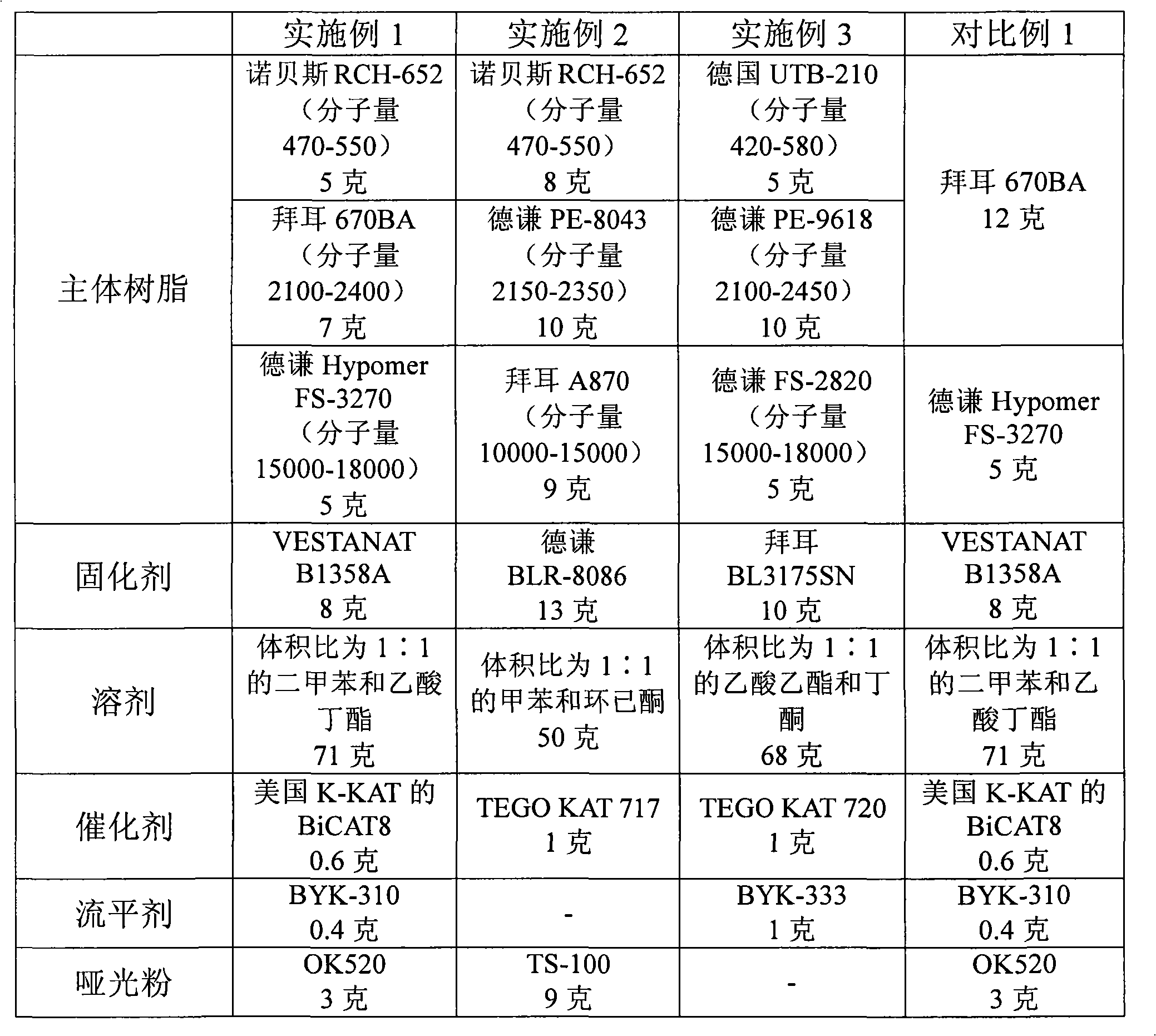

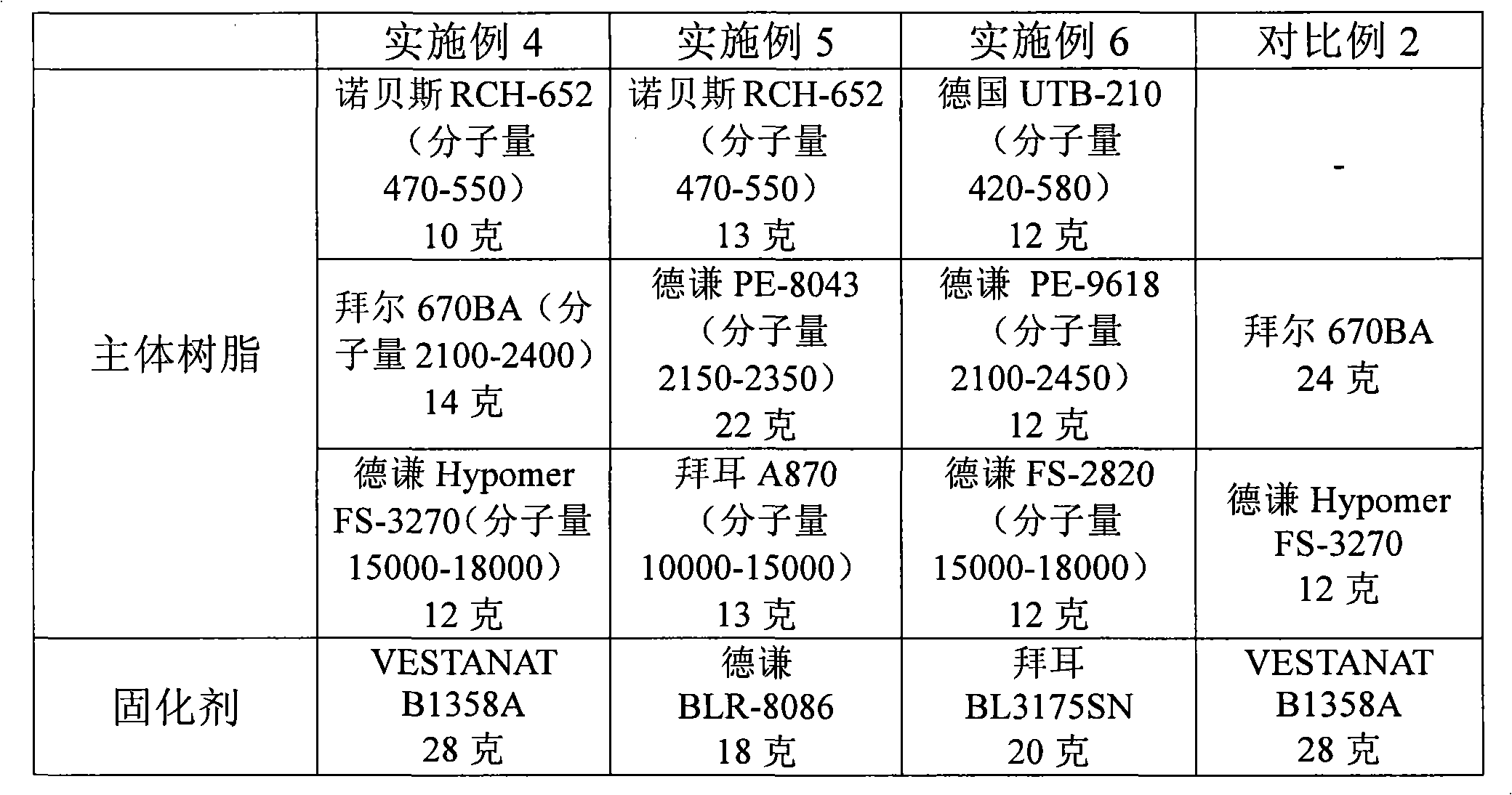

The invention provides a paint composition, comprising: main body resin, a curing agent, a solvent and a catalyst, wherein the main body resin comprises micro branch polyester polyol and hydroxy acrylic resin, the micro branch polyester polyol A, and micro branch polyester polyol B, the weight average molecular weight of the micro branch polyester polyol A is 400-600, and the weight average molecular weight of the micro branch polyester polyol B is 1800-2500. The coatings obtained from the paint composition of the invention has advantages of excellent abrasive resistance, chemical resistance,solvent resistance, and well adhesive attraction and environment reliability, also has soft and smooth tactility.

Owner:BYD CO LTD

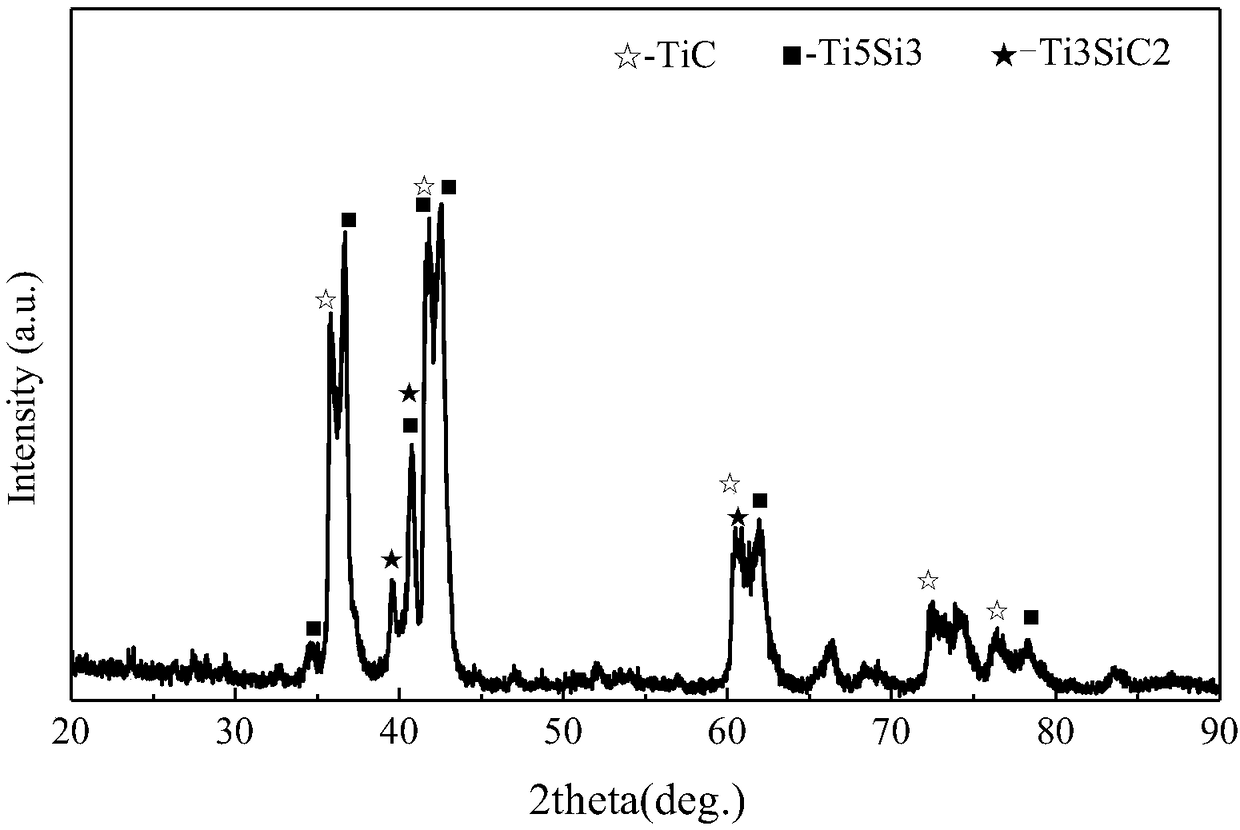

Plasma spraying method used for preparing titanium-silicon-carbon composite coating layer

The invention discloses a plasma spraying method used for preparing a titanium-silicon-carbon composite coating layer. The plasma spraying method comprises following steps: raw material powder, including 55 to 80% of Ti powder, 10 to 30% of Si powder, and 10 to 15% of graphite powder, is weighted at a mass ratio; the raw material powder is mixed with deionized water, a gel, and a dispersant so asto obtain a mixed slurry; the mixed slurry is subjected to spray drying so as to obtain an agglomerate composite powder; and a bonding layer is coated with the obtained spray material powder via spraying so as to obtain the titanium-silicon-carbon composite coating layer. The thickness of the titanium-silicon-carbon composite coating layer ranges from 200 to 300<mu>m. The obtained titanium-silicon-carbon composite coating layer is high in coating hardness, and excellent in wear resistance.

Owner:HEBEI UNIV OF TECH

RE alloyed antiwear high manganese steel

InactiveCN101020989AGood wear resistanceExtended service lifeMartensitic microstructureMaterials science

The present invention relates to one kind of RE alloyed antiwear high manganese steel, and belongs to the field of metallurgical technology. The RE alloyed antiwear high manganese steel consists of C 0.90-1.30 wt%, Si 0.30-0.80 wt%, Mn 11.00-14.00 wt%, Cr 2.00-2.50 wt%, RE 0.30-0.35 wt%, S not more than 0.03 wt%, P more than 0.06 wt%, and Fe for the rest. The RE alloyed antiwear high manganese steel has homogeneous austenite structure, high toughness, high wear resistance, fine crystal grains and long service life.

Owner:寇生瑞

Nylon 66 composition for petroleum sucker rod centralizer material

InactiveCN101760022AHigh strengthGood wear resistanceDrilling rodsDrilling casingsPolyamideLubrication

The invention relates to the polyamide composition field, particularly to a nylon 66 composition for a petroleum sucker rod centralizer material, the material is mainly used for producing injection-molding petroleum sucker rod centralizers. The material is prepared by the following raw materials(by weight proportion): 30-60% of nylon 66 slices, 5-15% of nylon 6 slices, 5-15% of compatibilzer, 0.1-0.7% of anti-oxidant, 0.5-1.5% of lubricating agent, 20-35% of fiber glass,0.1-0.5% of color master batch, and 0.1-0.7% of inorganic mineral. The preparation method is as follows: 1. weighing the above raw materials; 2. besides the glass fiber, adding materials into a high-mix machine for mixing; 3. adding the mixed raw materials into the glass fiber, and put putting the mixture into a twin screw extruder for extruding granulation. The beneficial effects of the invention are that: the product of the invention can continuously maintain the characteristics of high efficient lubrication, wear resistance and high temperature oxidation resistance at high temperature of 184 DEG C, thereby greatly improving thermal stability.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

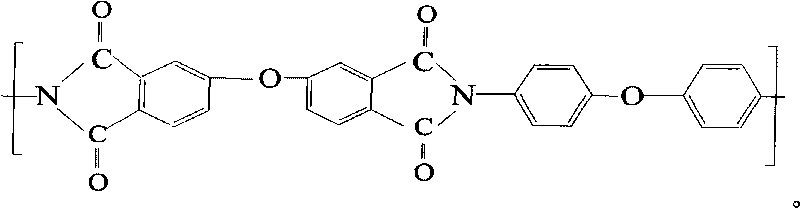

Carbon fiber reinforced polymer-based self-lubricating material and preparation method thereof

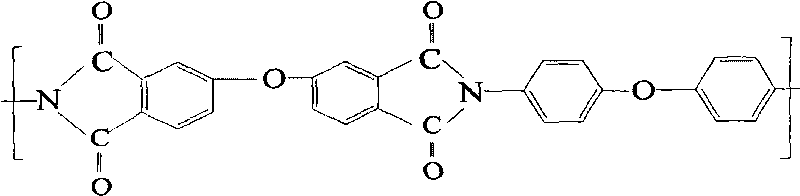

InactiveCN101747626AReduce coefficient of frictionGood wear resistanceCarbon fiber reinforced polymersPolyimide

The invention relates to a carbon fiber reinforced polymer-based self-lubricating material and a preparation method thereof. The composition and mass fraction of the material are: polyimide of 30-50 percent, chopped carbon fiber of 10-20 percent, molybdenum disulfide of 10-40 percent and antimony trioxide of 10-30 percent. The invention has the advantages of high mechanical strength, low friction coefficient, low wear rate and the like, and can be processed to be used as a sliding vane, a bearing and the like. Moreover, the invention improves the friction reducing capability and the wear resistance of the material, and prolongs the service life of the material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Wear-resistant hard composite material using graphene as filler and preparation method thereof

The invention belongs to the field of macromolecular composite materials and in particular relates to a wear-resistant hard composite material using a novel nanocarbon material graphene as a filler and a preparation method thereof. The composite material is a hard composite material plate formed by blending and hot-pressing a polymer matrix and the graphene, and is prepared through the following steps: mixing the graphene, the polymer matrix and a rare earth stabilizing agent uniformly; melting and blending by using a torque rheometer to obtain a block-shaped composite; hot-pressing by using a flat vulcanizing machine to obtain the hard composite plate, wherein the composite material comprises 0.1-3wt% of two-dimensional graphene nanocarbon material. The polymer-based composite material using the carbon material as the filler has the characteristics of light weight, easiness in processing, corrosion resistance, friction resistance and the like, and is widely applied in the fields of national defense industry and automobiles. The composite material can meet the increasingly higher tribological performance requirements of the fields of aviation, aerospace, automobiles, machinery and the like on the existing high-performance polymer composite materials; the preparation process of the composite material is simple; industrial production is realized easily.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

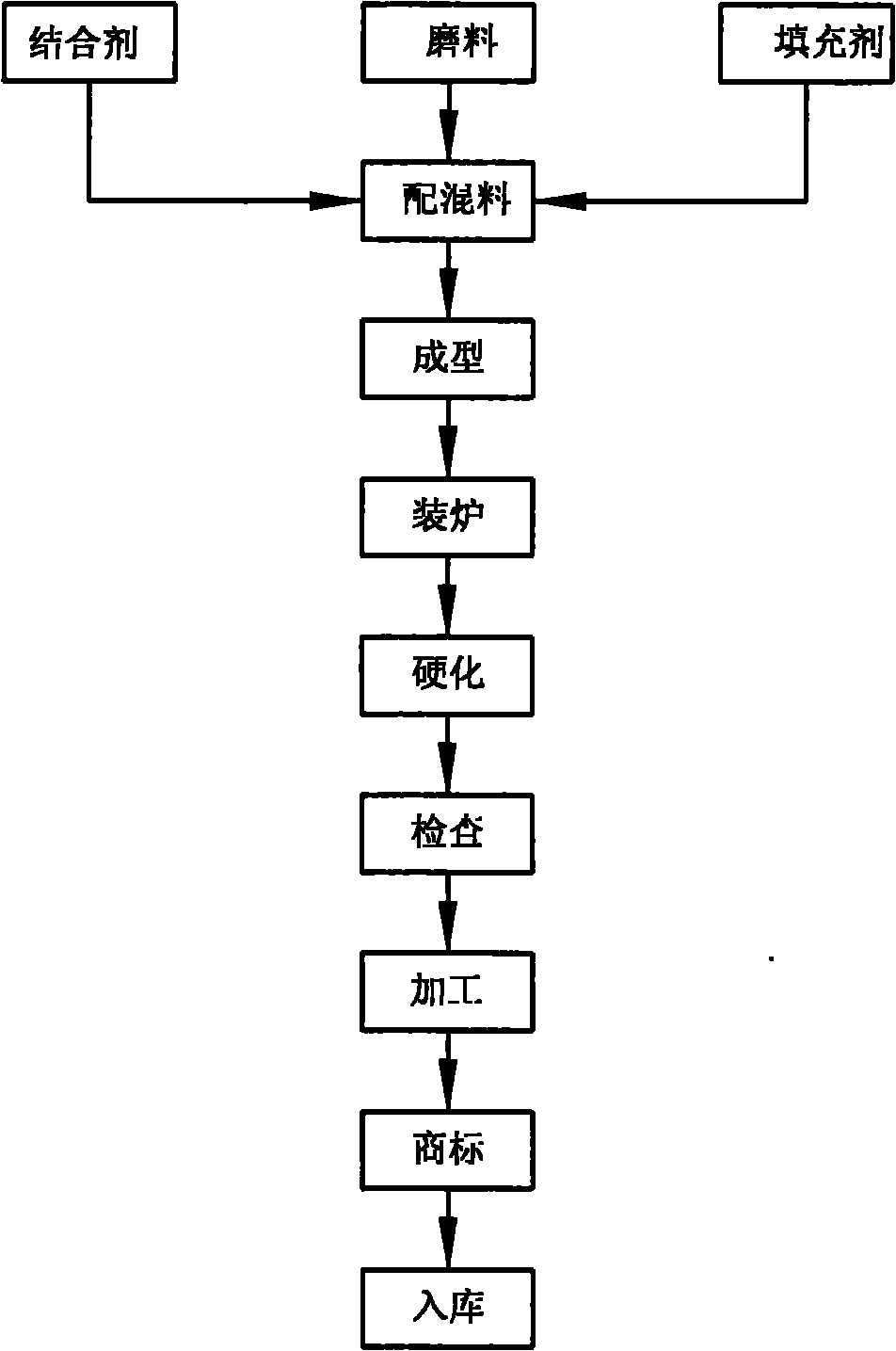

Rare earth polishing disc

InactiveCN102114615AGood wear resistanceRelieve pressureAbrasion apparatusCerium oxideMagnesium sulphate heptahydrate

The invention discloses a rare earth polishing disc which has high cutting efficiency, good wear resistance property and high surface brightness. To be different from the existing polishing disc, the rare earth polishing disc mainly comprises rare earth polishing powder, resin, magnesium sulfate or white sugar, curing agent and accelerating agent, wherein the rare earth polishing powder comprises the following compositions in percentage by weight: more than or equal to 60 percent but less than or equal to 99.99 percent of cerium oxide, and more than or equal to 0.01 percent but less than or equal to 40 percent of lanthanum oxide, the content of the rare earth polishing powder can achieve 65 percent, the relative particles of the rare earth polishing powder is small, the brightness of a polished object can be greatly improved compared with the original polishing disc, and the polishing time of the surface of a product can be shortened to be about 0.6 second, so that the working efficiency is improved, the wear resistance property is greatly improved, 1,000-1,200 NO.40 crystal balls can be polished by the original polishing disc with the same size, while the rare earth polishing disc can polish 4,000 NO.40 crystal balls.

Owner:珠海市吉昌稀土有限公司

Carbon fiber composite line for automobile clutch surface patch, preparation method and application thereof

The invention provides a carbon fiber composite line for automobile clutch surface patch and the application thereof in preparation of an automobile clutch. The carbon fiber composite line for the automobile clutch comprises a carbon fiber long filament and a carbon fiber core spun yarn with the carbon fiber long filament as the core yarn, and does not comprise metal wires; the carbon fiber composite line also can comprise glass fiber twistless roving, a glass fiber twistless extrusion yarn and chemical fiber roving. The invention also provides the automobile clutch surface patch comprising the carbon fiber composite line. With the adoption of the carbon fiber composite line, the environmental pollution and waste of resources caused by copper wires and other metal wires in the automobile clutch are solved, and the performances of the automobile clutch are also improved.

Owner:NANTONG XINYUAN SPECIAL FIBER

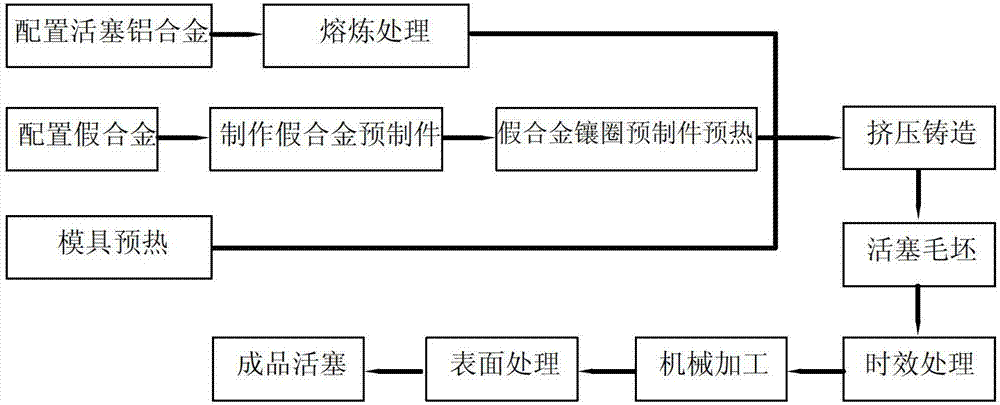

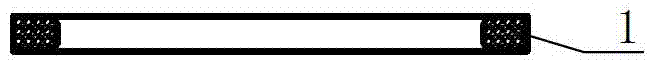

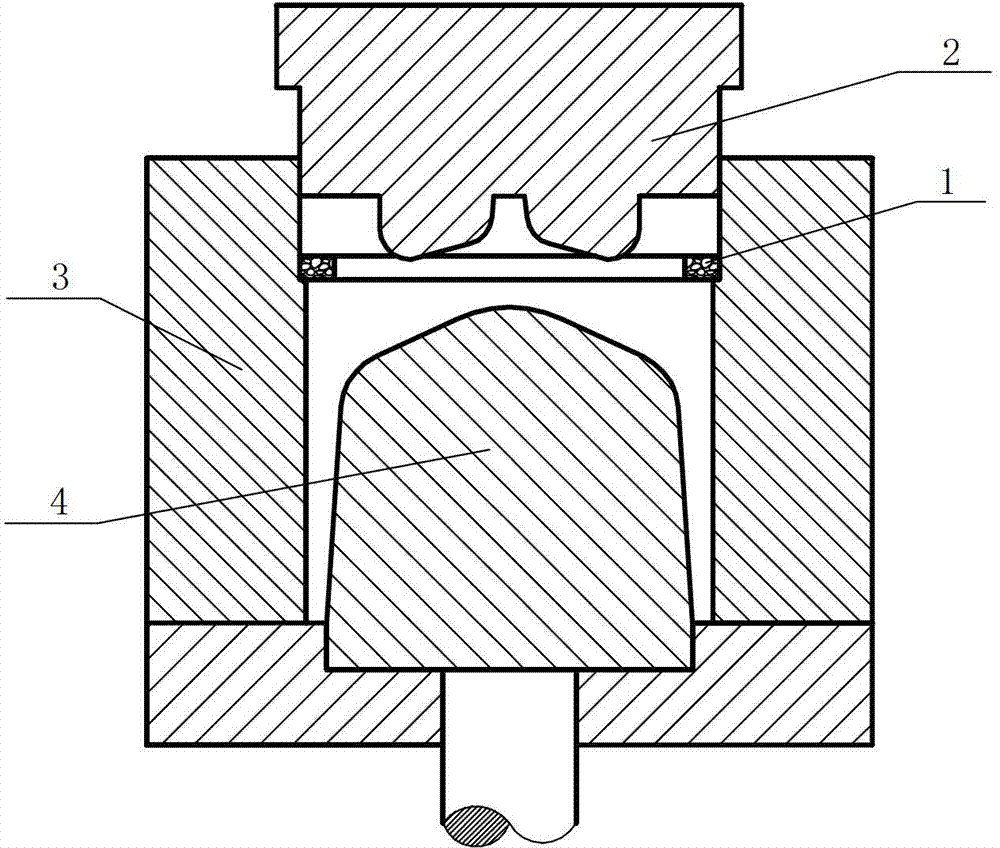

Extrusion casting manufacture method of piston with reinforced pseudo-alloy circular groove

InactiveCN103042195AGood wear resistanceImprove use reliabilityPiston ringsPlungersAir coolingAluminium alloy

The invention relates to an extrusion casting manufacture method of a piston with a reinforced pseudo-alloy circular groove. The extrusion casting manufacture method is characterized by including the preparation process steps: firstly, preparing aluminum alloy for the piston; secondly, preparing pseudo-alloy components; thirdly, manufacturing a pseudo-alloy preformed part, uniformly mixing pseudo-alloy powder particles, and pressing and sintering the mixed particles via a die so that a pseudo-alloy insert ring preformed part is formed; fourthly, melting, namely, placing the prepared aluminum alloy for the piston into a melting furnace for melting, and refining, deteriorating, homogenizing and refining alloy liquid after melting; fifthly, preheating the pseudo-alloy preformed part; seventhly, performing extrusion casting; eighthly, performing aging heat treatment for a piston blank and performing air cooling after the piston blank taps off; and ninthly, machining and performing surface treatment for the piston blank so that an aluminum piston finished product is obtained. Compared with the prior art, the extrusion casting manufacture method has the advantages that the piston with the reinforced circular groove is good in wear resistance, compact in material internal texture and remarkably improved in mechanical performance, and the method is high in process efficiency and low in manufacture cost.

Owner:北方材料科学与工程研究院有限公司 +1

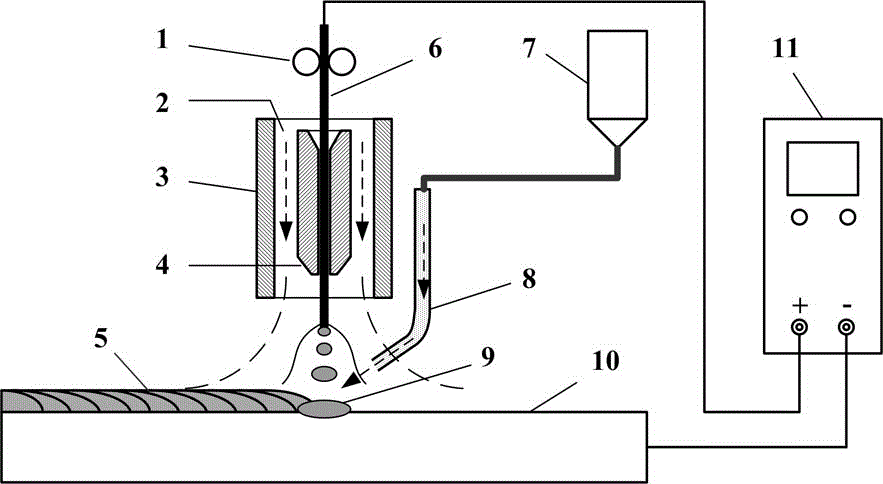

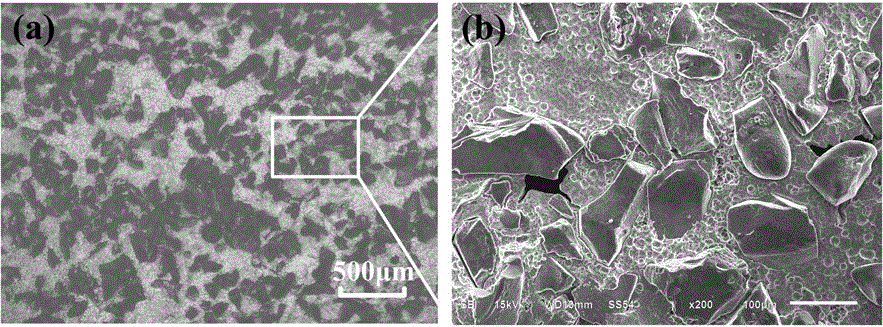

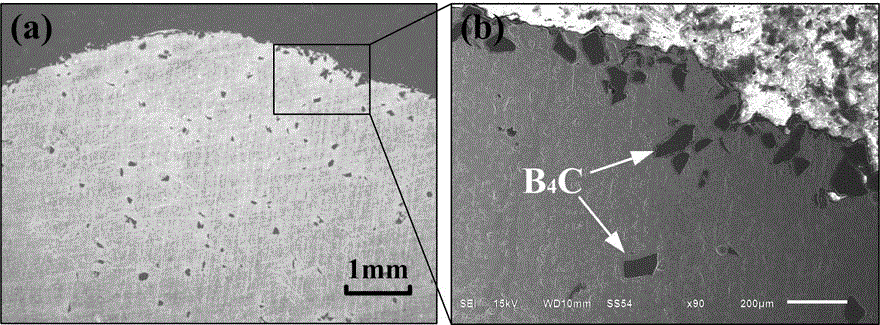

Aluminum alloy surface B4C particle reinforced Al base composite cladding layer and preparation method

ActiveCN106513929AWell combinedGood wear resistanceArc welding apparatusMetallic material coating processesAlloy substrateAlloy surface

The invention discloses an aluminum alloy surface B4C particle reinforced Al base composite cladding layer and a preparation method, overcomes the problem that a traditional technology is difficult to remove compact oxide films quickly grown on surfaces of aluminum and an alloy of the aluminum, solves the problems of difficult powder feeding due to light mass of B4C particles and weak wettability with aluminum alloy molten liquid, and effectively leads the B4C particles in the aluminum alloy surface layer to form an Al base composite cladding layer with excellent metallurgic bonding. In cooperation with the powder-wire composite cladding technical scheme, by using consumable electrode inert gas protective welding-MIG welding, aluminum alloy welding wires are transited to the aluminum alloy wire, the side injection of the B4C particles is assisted to fuse in the Al base cladding layer, that is, the B4C particle reinforced Al base composite cladding layer is prepared on the aluminum alloy surface. The B4C particle reinforced Al base composite cladding layer and an aluminum alloy substrate are excellently bonded, and the B4C particles in the cladding layer and an Al matrix are excellently bonded, and obvious defects such as air holes and cracks are avoided; and the aluminum alloy surface B4C particle reinforced Al base composite cladding layer is higher in wear resistance compared with 45 steel.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com