Paint composition

A composition and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor coating feel, and achieve the effects of excellent wear resistance and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

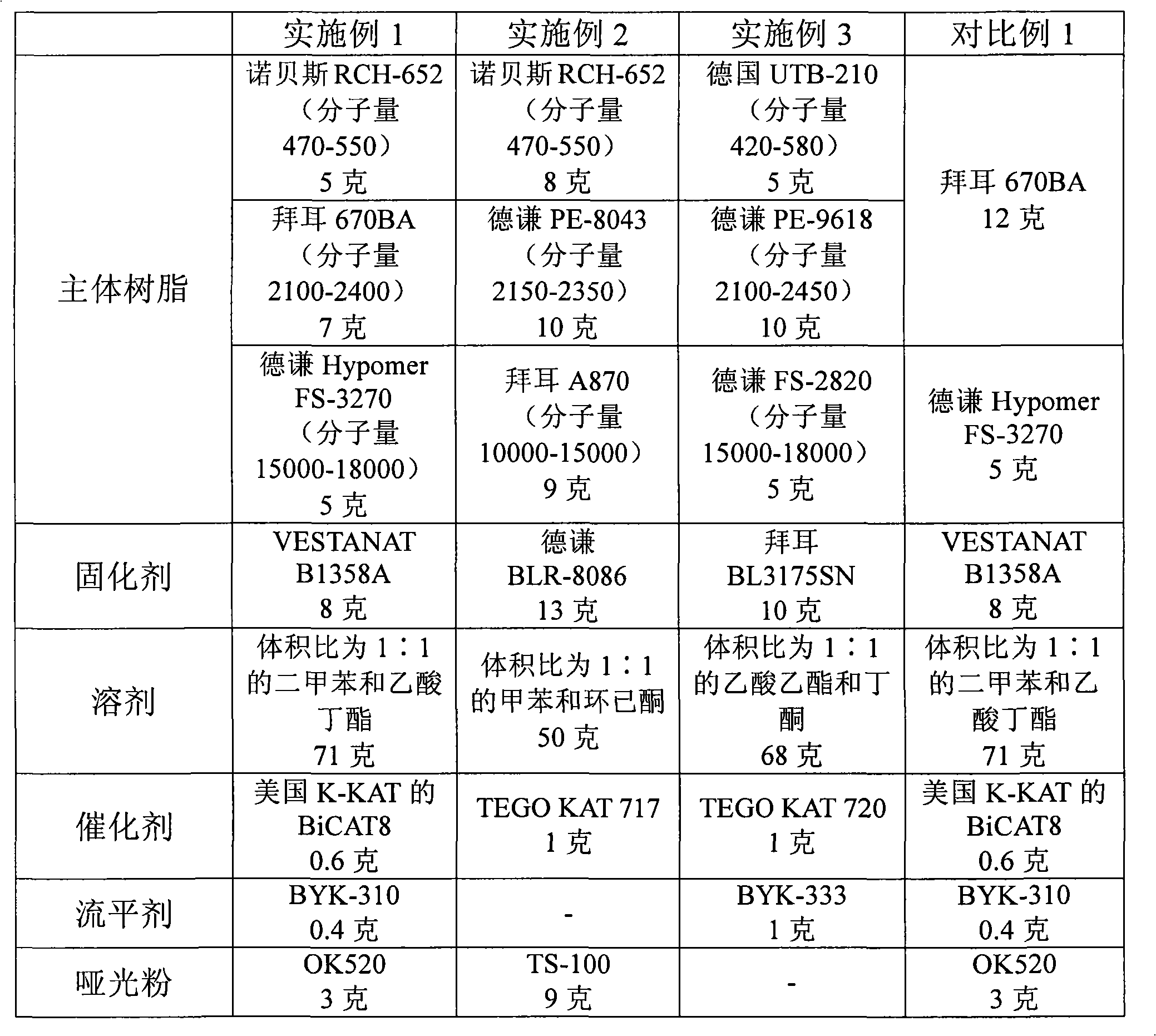

[0025] Use raw material as shown in table 1, prepare coating composition according to the following method:

[0026] (1) After mixing the main resin, curing agent and optional matte powder, stir at 25°C for 40 minutes at a speed of 1200 rpm, and mix well;

[0027] (2) First add a solvent to the mixture obtained in step (1), stir and dissolve it thoroughly, then add a catalyst and an optional leveling agent and mix evenly to obtain a coating composition.

[0028] Table 1

[0029]

[0030] Coating method

[0031] The coatings prepared in Examples 1-3 and Comparative Example 1 were sprayed on the surface of the silicone rubber key with an automatic spraying line, and the film thickness was 15 microns. Then infrared baked at 145° C. for 30 minutes to obtain a test sample.

Embodiment 4-6 and comparative example 2

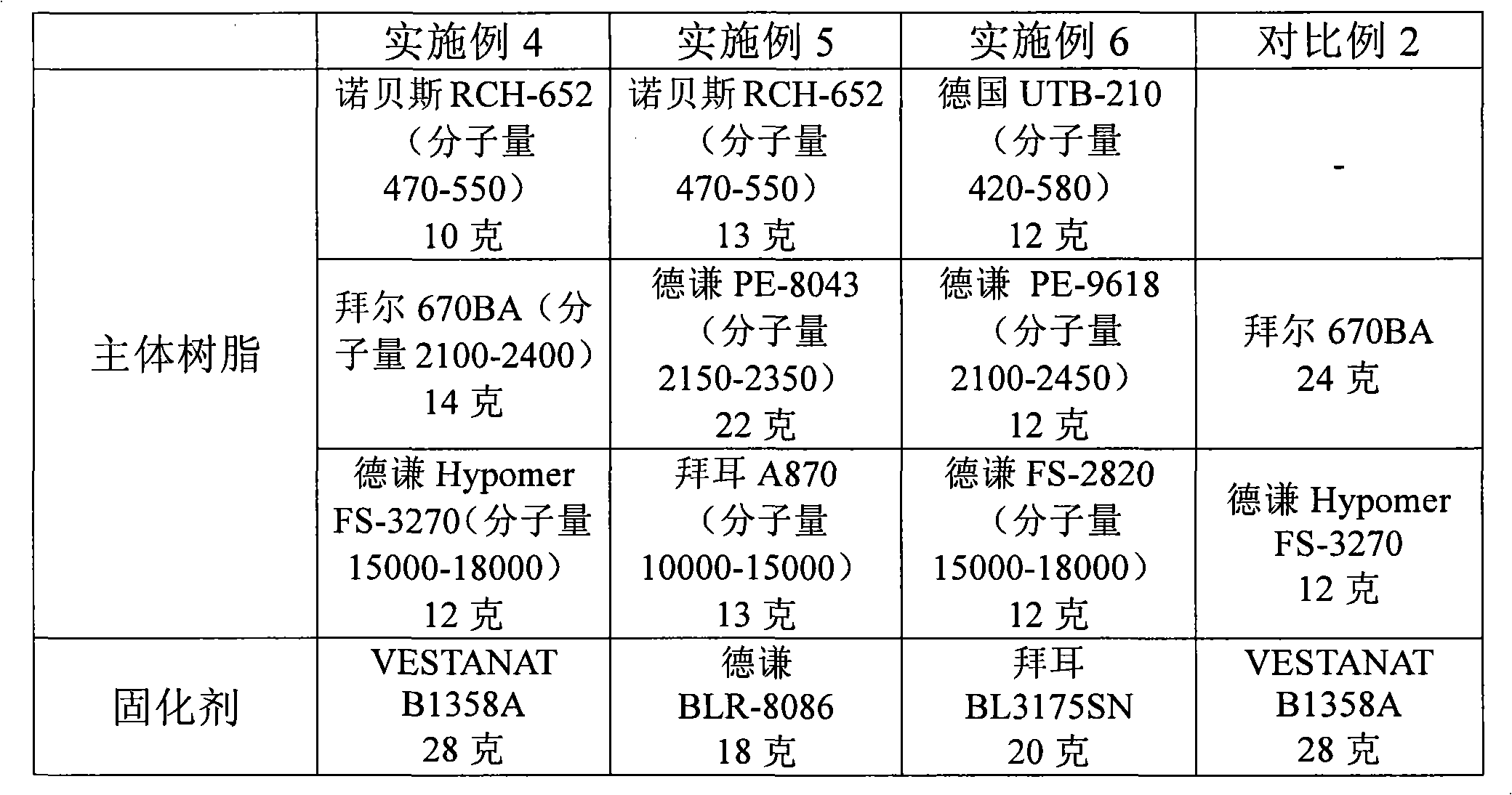

[0033] According to raw material as shown in table 2, prepare the coating composition used as printing ink according to the following method:

[0034] (1) After mixing the slightly branched polyester polyol A, the slightly branched polyester polyol B and the pigment, stir at a speed of 800-1600 rpm for 20-60 minutes at normal temperature and pressure, and mix well;

[0035] (2) join the product that step (1) obtains and grind in the grinder, until the ink fineness of testing grinding with scraper fineness gauge is about 5 microns;

[0036] (3) Add hydroxyacrylic resin and curing agent to the product obtained in step (2) and mix uniformly;

[0037] (4) Add solvent, catalyst and optional leveling agent and matt powder to the product obtained in step (3) and mix evenly.

[0038] Table 2

[0039]

[0040]

[0041] Coating method

[0042] The coating compositions prepared in Examples 4-6 and Comparative Example 2 were coated on the surface of the silicone rubber keys by sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com