Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6617 results about "Cerium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium oxide may refer to either of the following: Cerium oxide, Ce₂O₃ Cerium oxide, CeO₂

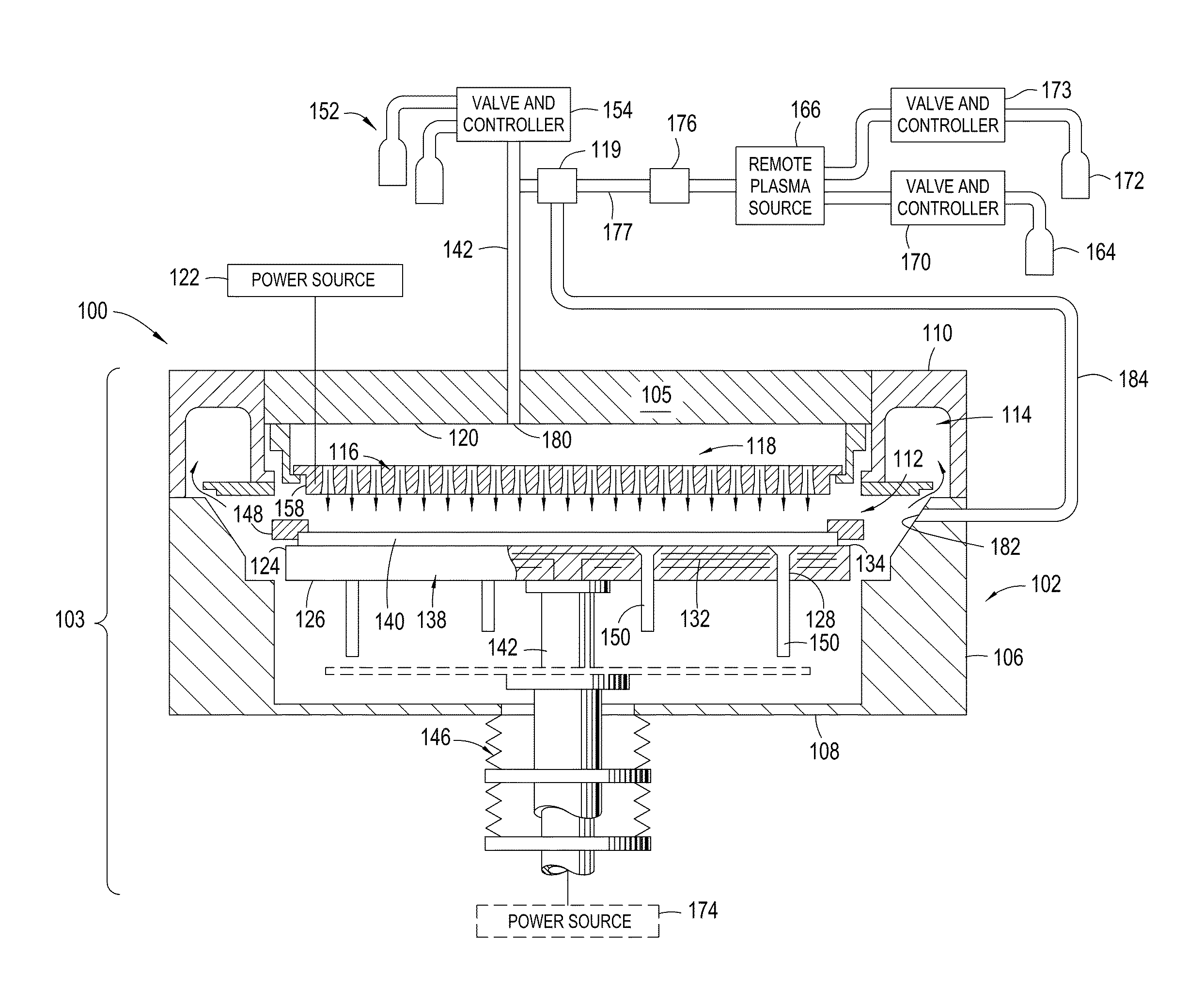

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

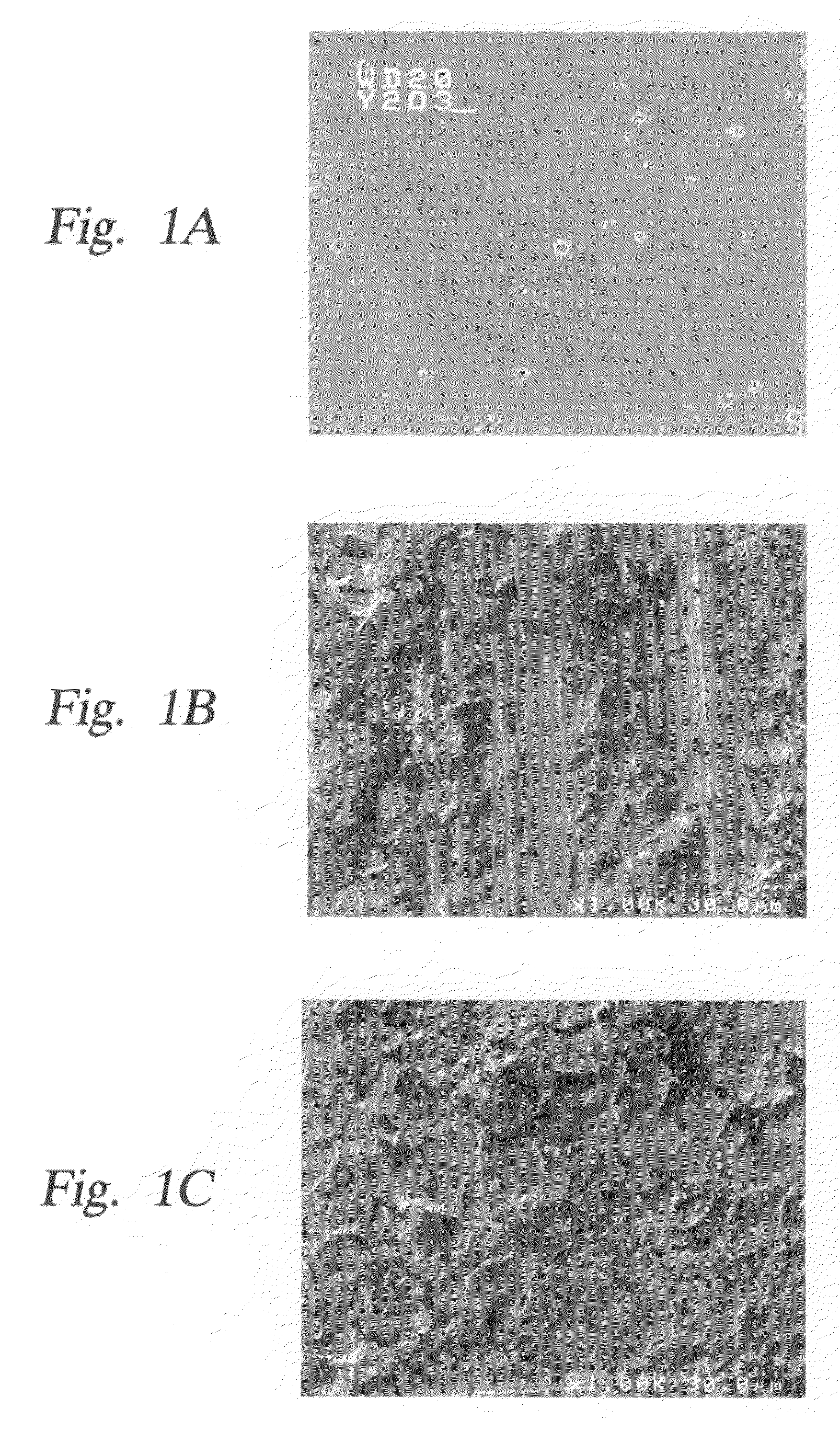

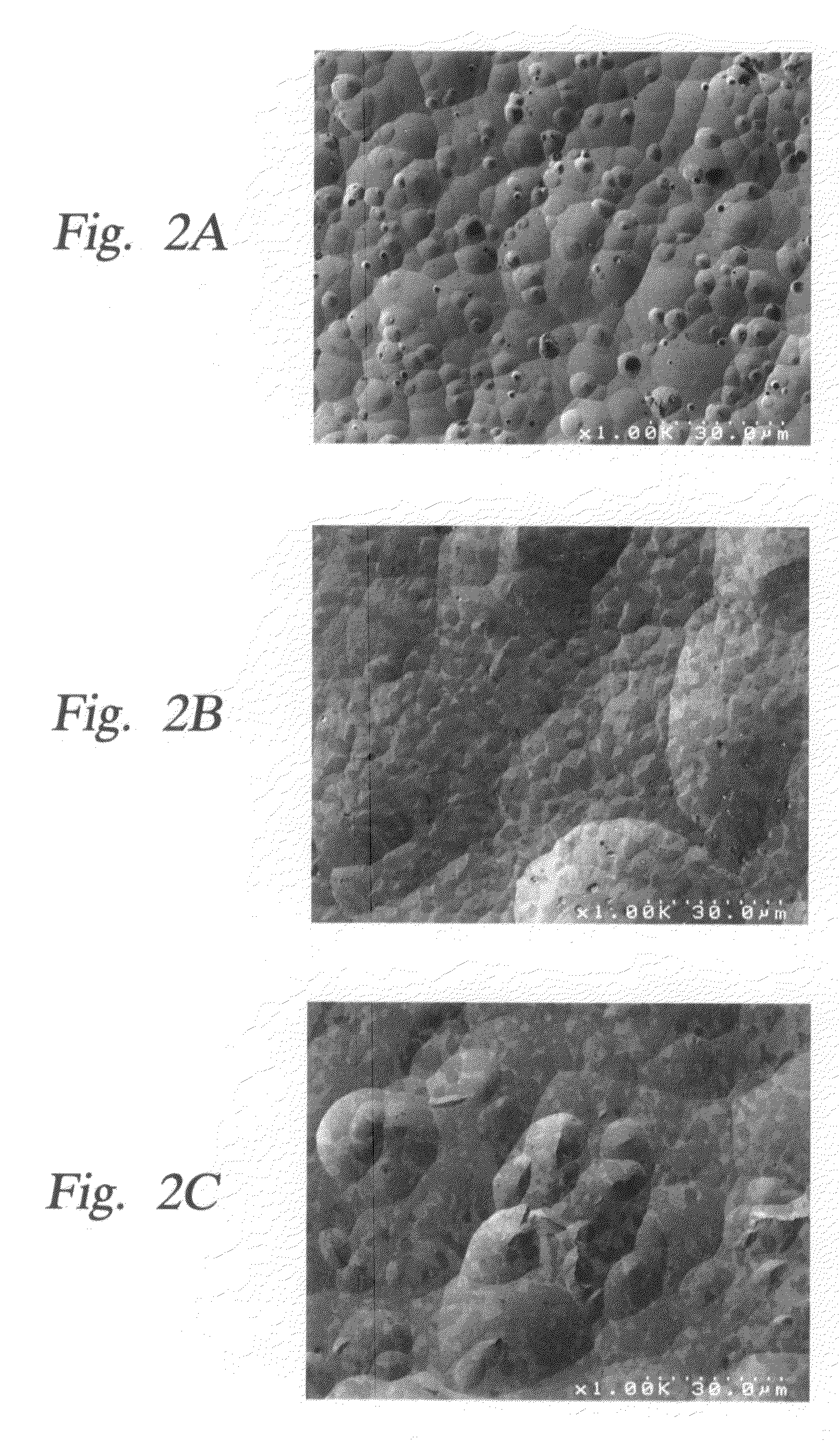

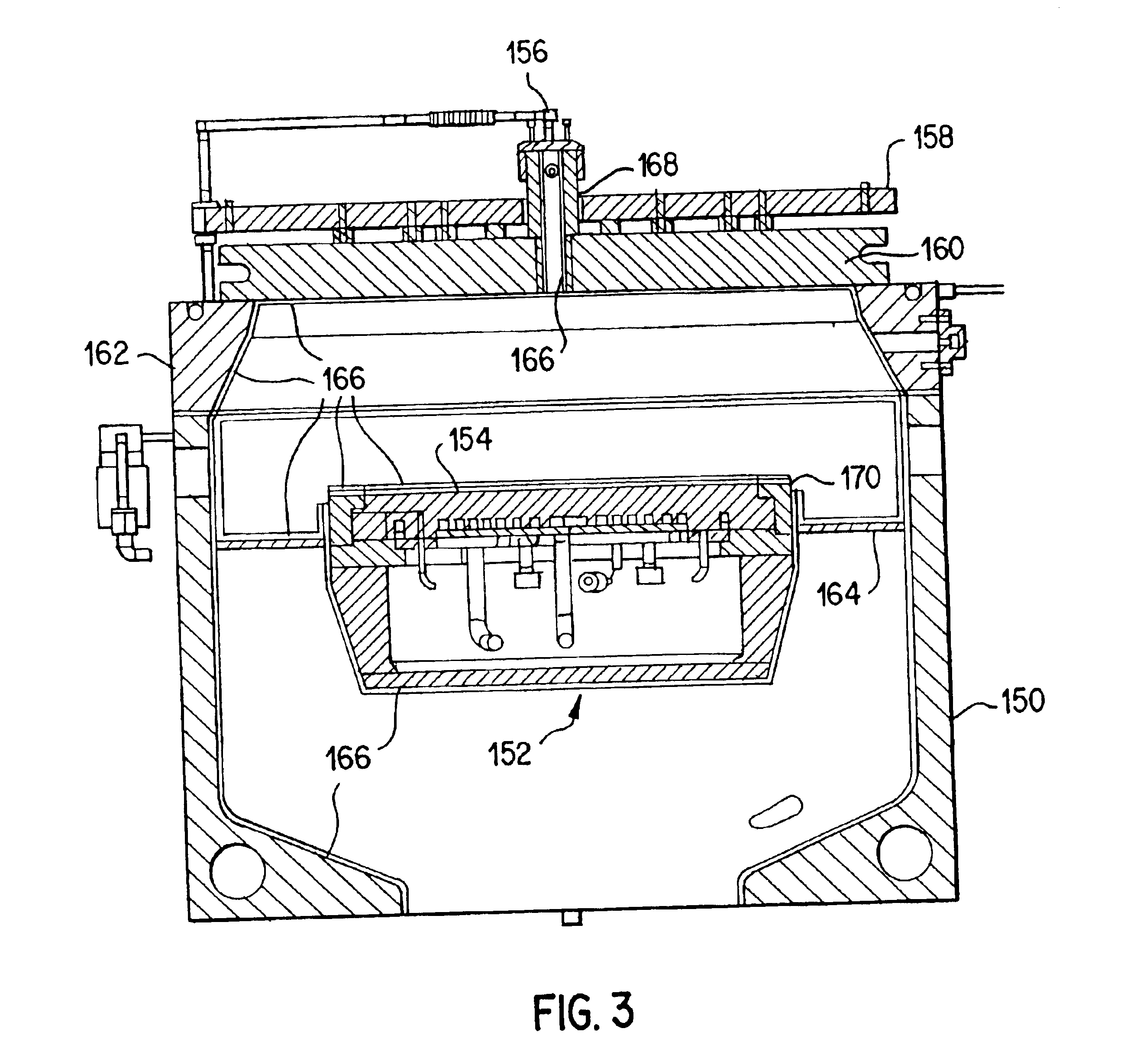

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

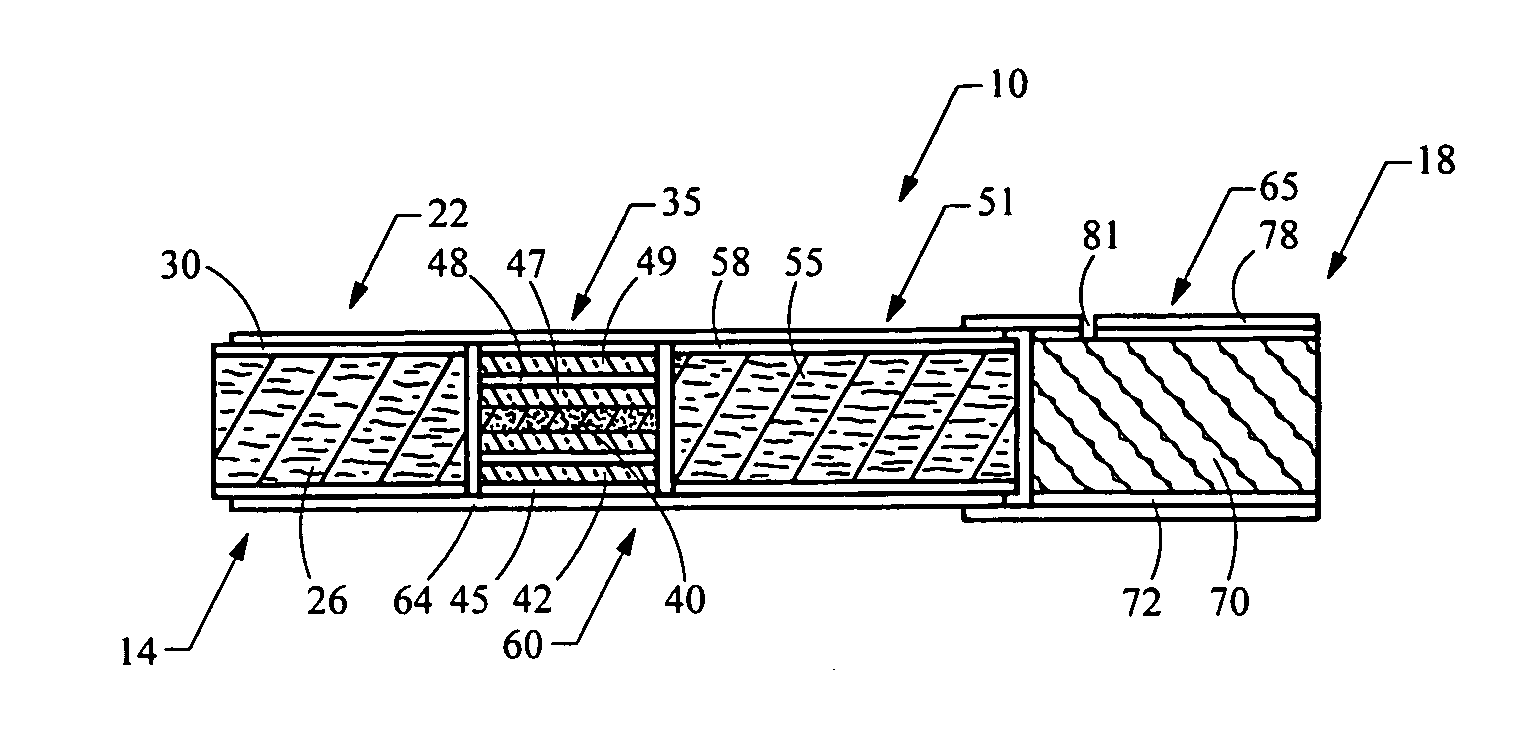

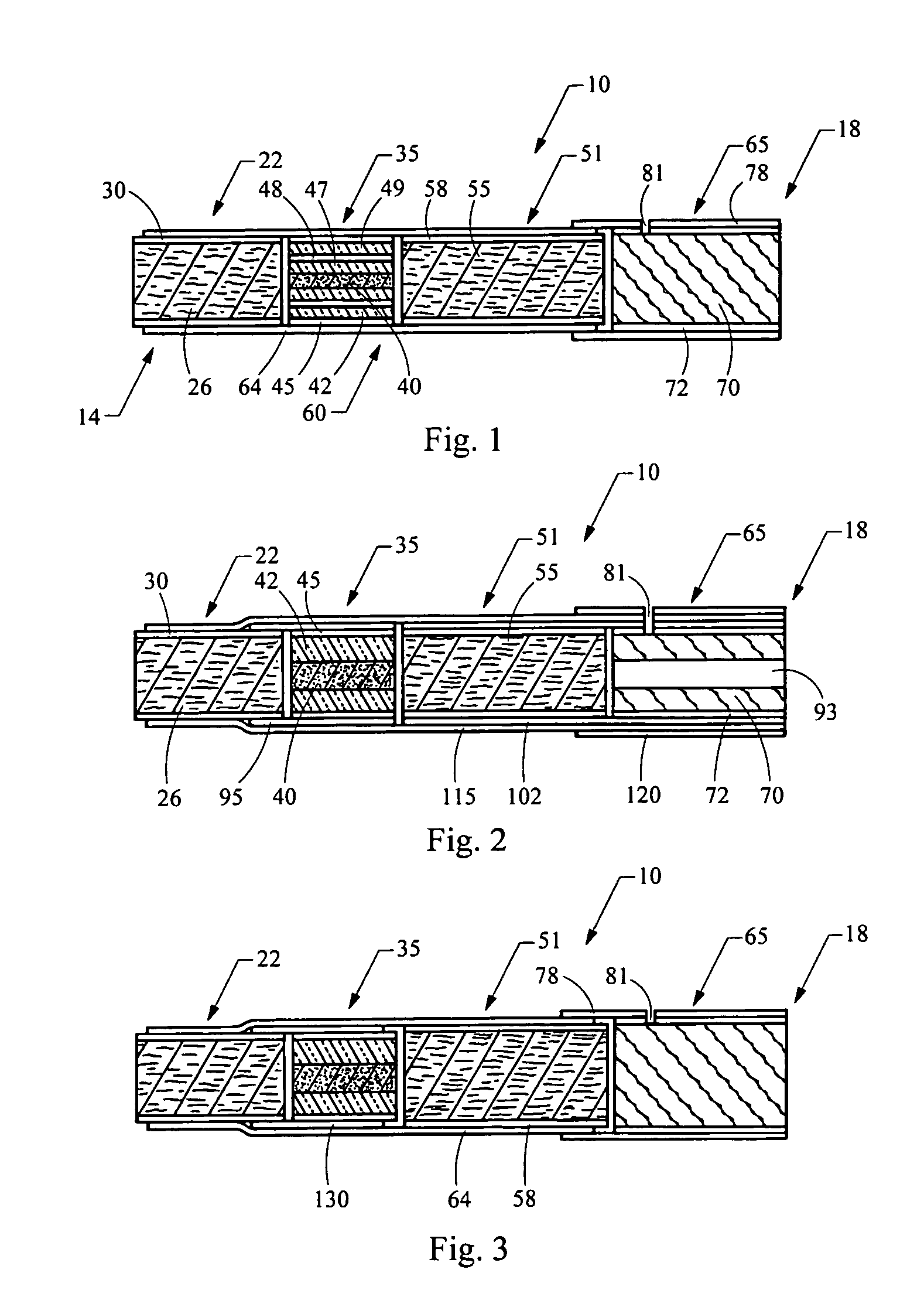

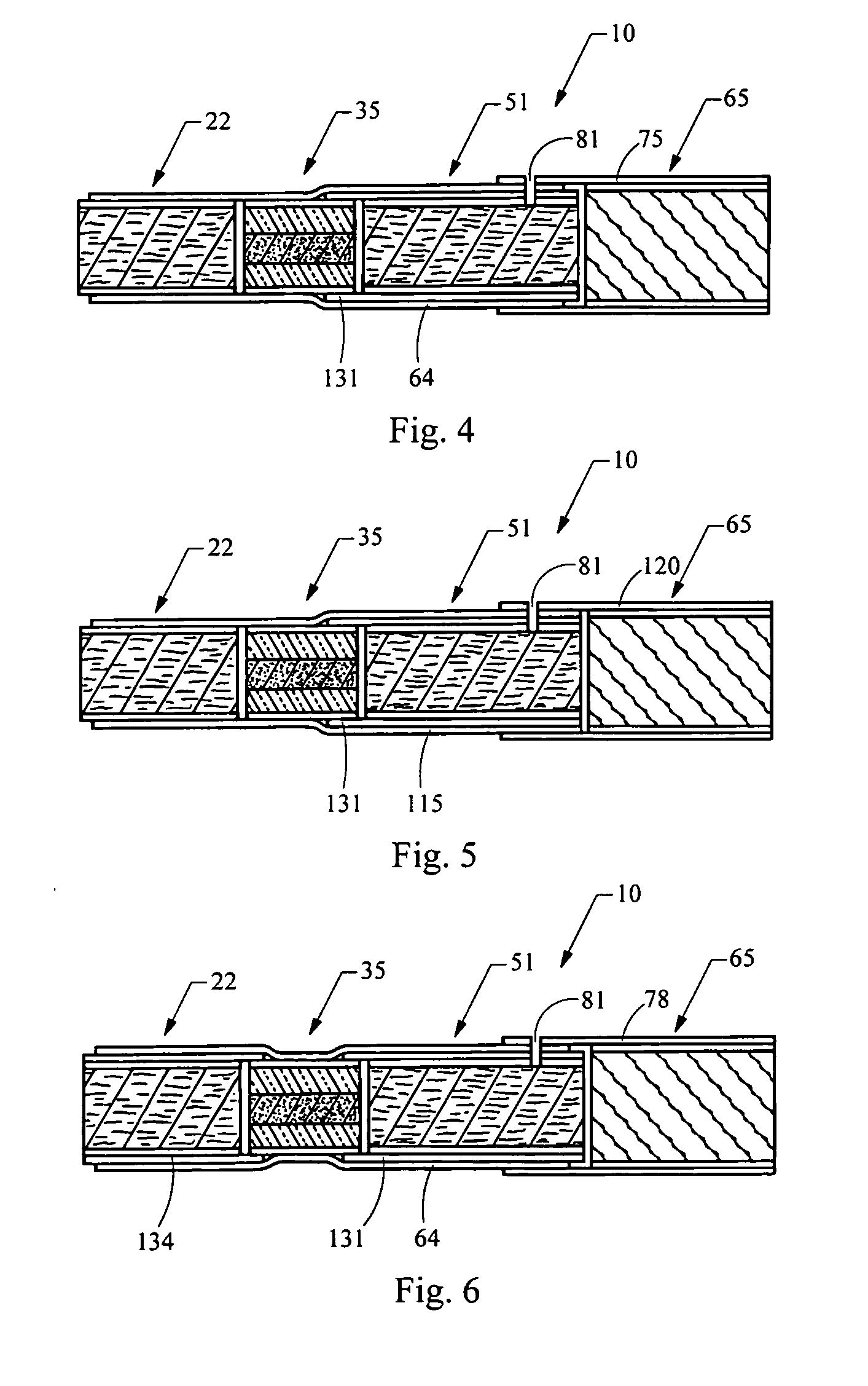

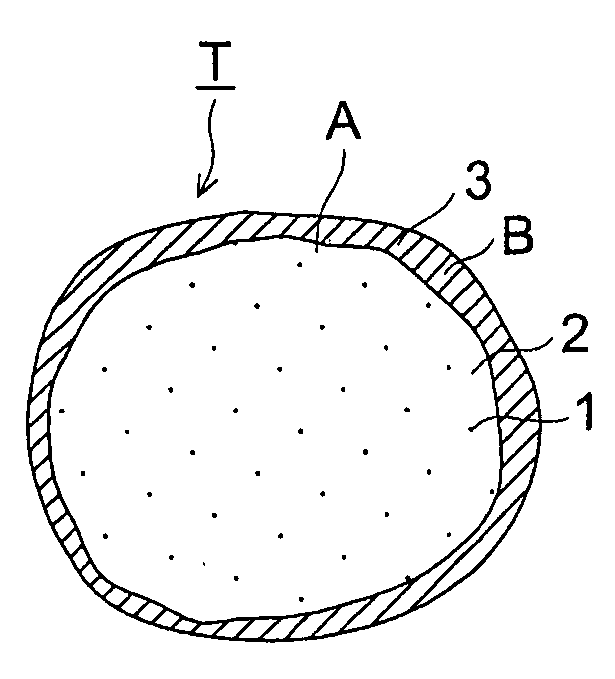

Smoking article

ActiveUS20070215168A1Reduce amountCarbon reductionTobacco preparationTobacco treatmentEngineeringFood flavor

A smoking article, such as a cigarette, includes a carbonaceous heat source. A mouth end piece segment is located at the mouth end of the smoking article, and the mouth end piece segment allows the smoking article to be placed in the mouth of the smoker to be drawn upon. The smoking article further incorporates an aerosol-generating segment located between the heat generation segment and the mouth end piece segment. The aerosol-generating segment incorporates an aerosol-forming material (e.g., glycerin and flavors). The heat generation segment is in a heat exchange relationship with the aerosol-generating region such that heat generated by the burning fuel element acts to volatilize aerosol-forming material for aerosol formation. The carbonaceous heat source is in intimate contact with coarse, fine or ultrafine particles of materials such as cerium oxide, or mixtures of cerium oxide and palladium chloride.

Owner:R J REYNOLDS TOBACCO COMPANY

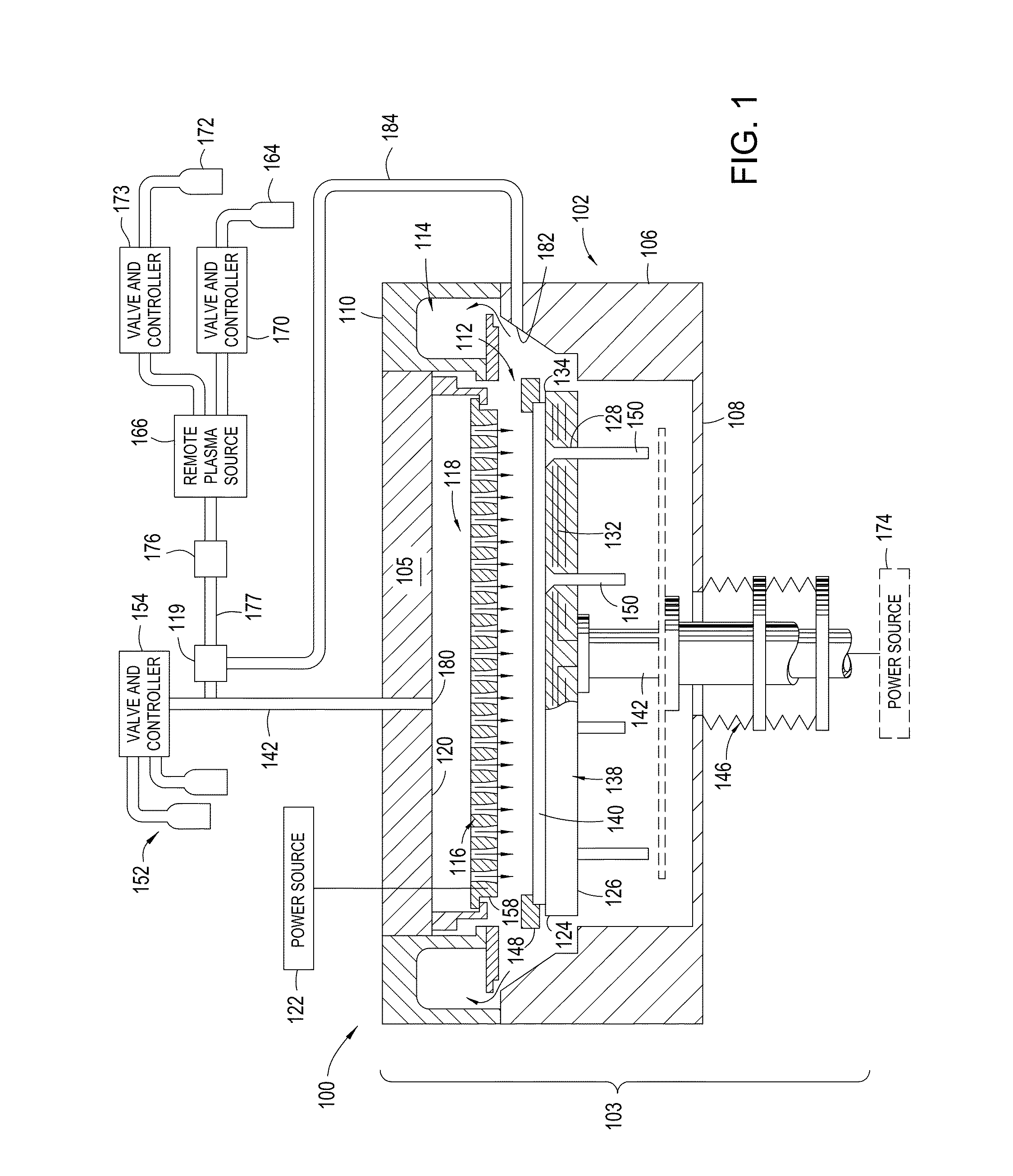

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Exhaust gas treatment catalyst for internal combustion engines with two catalytically active layers on a carrier structure

InactiveUS6348430B1Improve heat resistanceHigh activityInorganic chemistryInternal combustion piston enginesParticulatesPartial oxidation

A catalyst for treating the exhaust gas from internal combustion engines is provided, wherein the catalyst contains two catalytically active layers supported on a support. The first catalytically active layer contains a platinum group metal in close contact with all of the constituents of the first catalytically active layer, wherein the constituents of the first catalytically active layer include particulate aluminum oxide; particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides, and alkaline earth metal oxides. The second catalytically active layer, which is in direct contact with the exhaust gas, contains particulate aluminum oxide and at least one particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides. Rhodium is supported on part of the aluminum oxides in the second catalytically active layer or on the particulate oxygen storage material in the second catalytically active layer. By providing the platinum group metal in close contact with all of the constituents of the first catalytically active layer, improved conversion efficiency of the impurities in the exhaust gas can be achieved.

Owner:UMICORE AG & CO KG +1

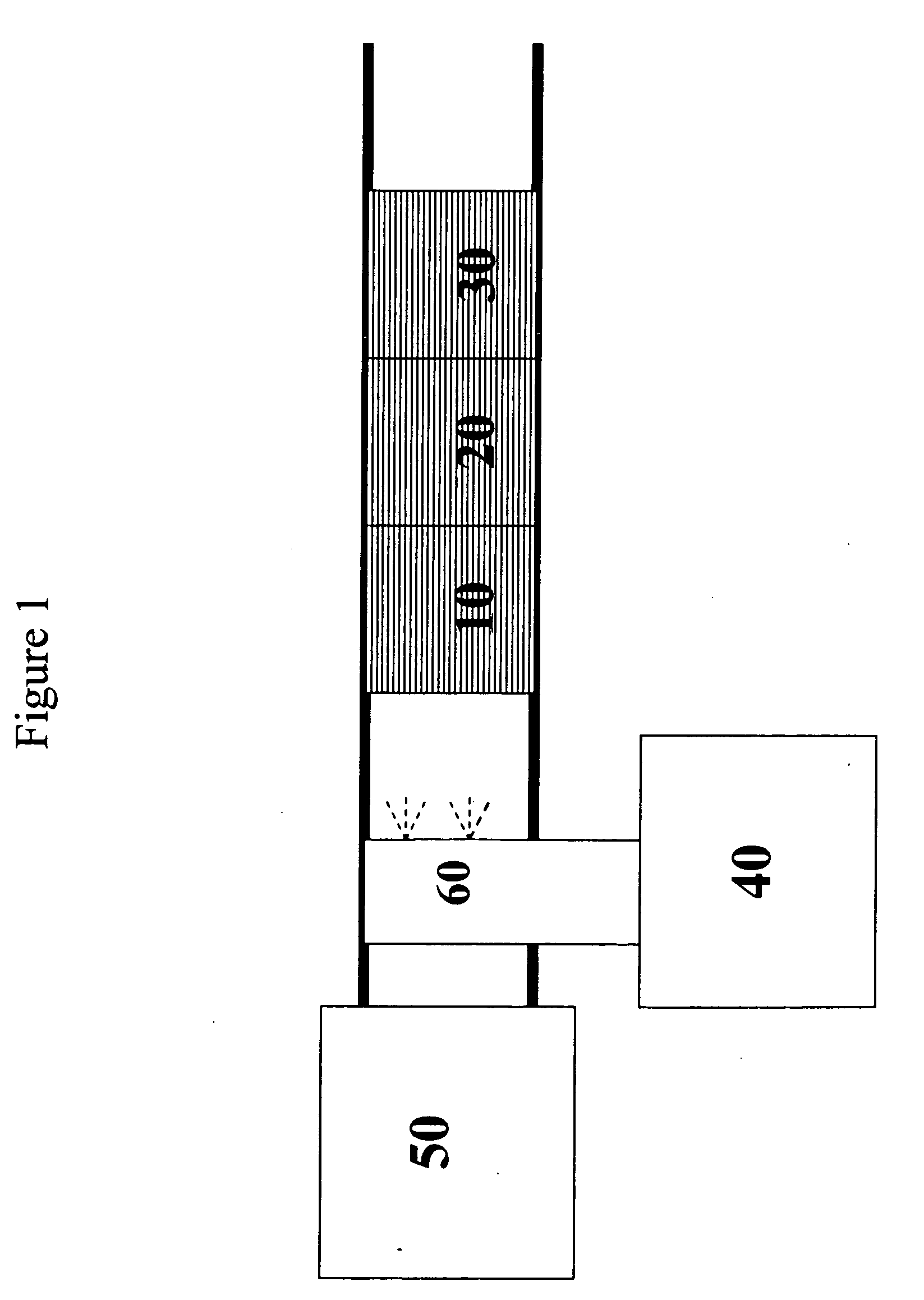

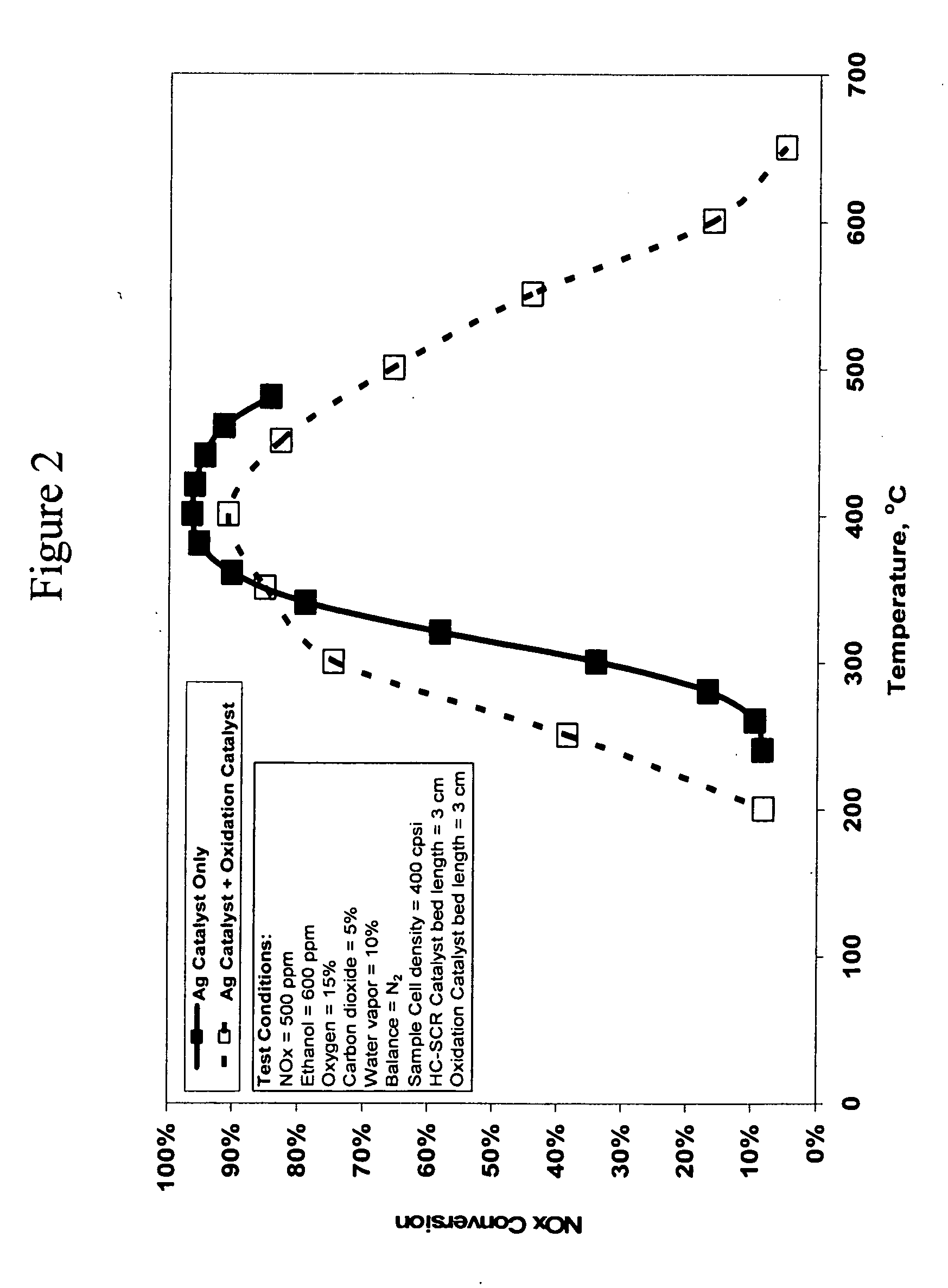

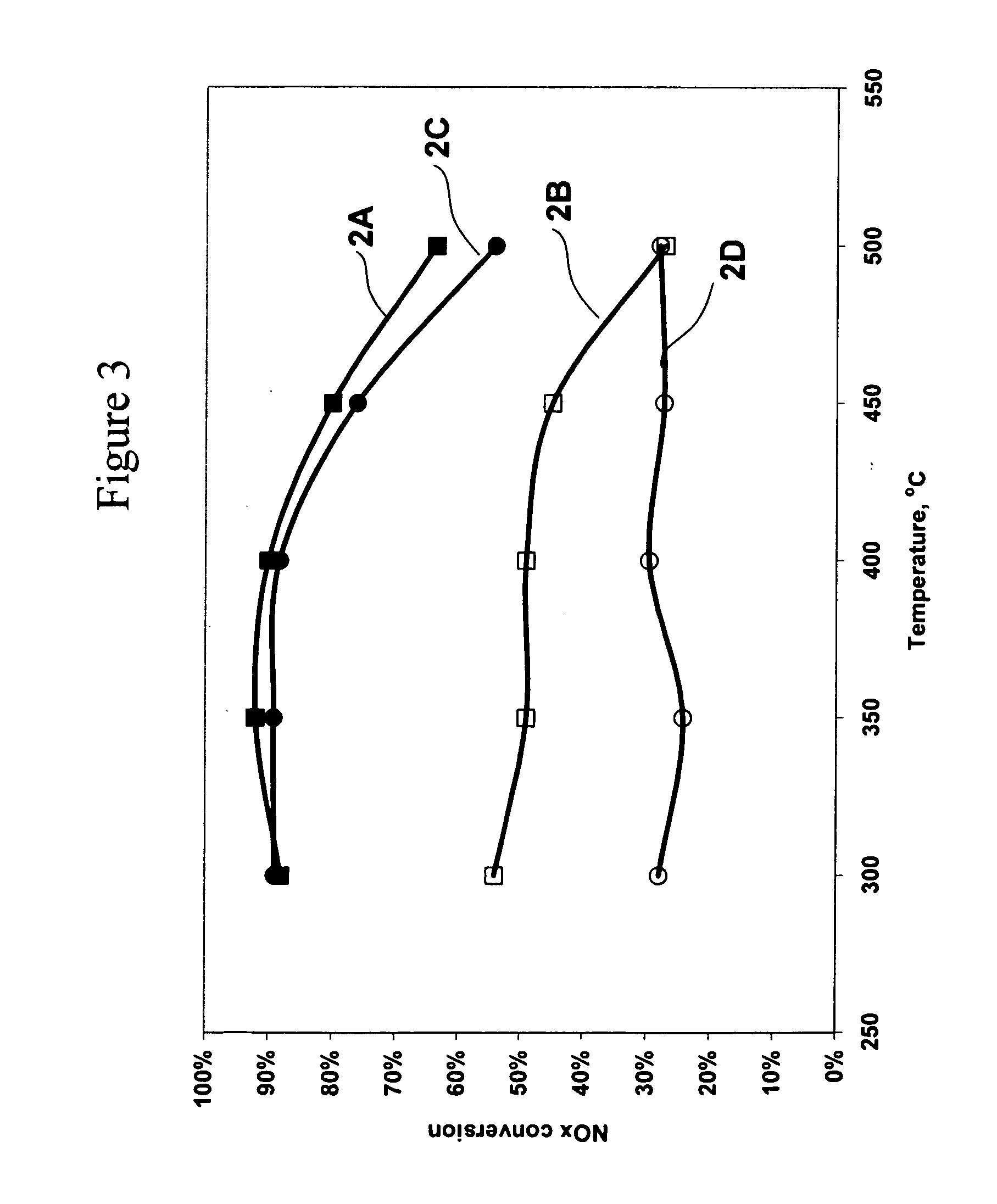

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

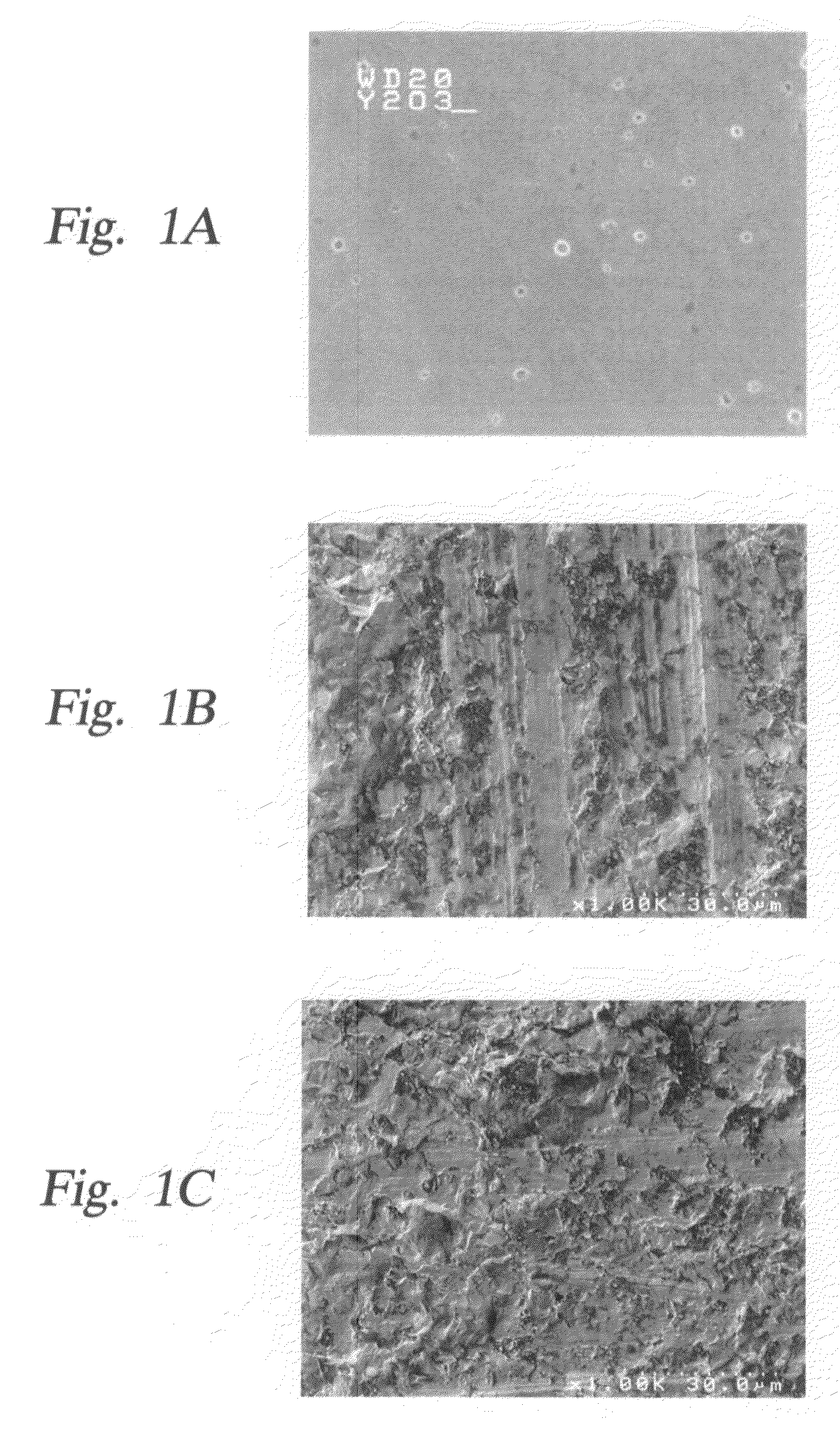

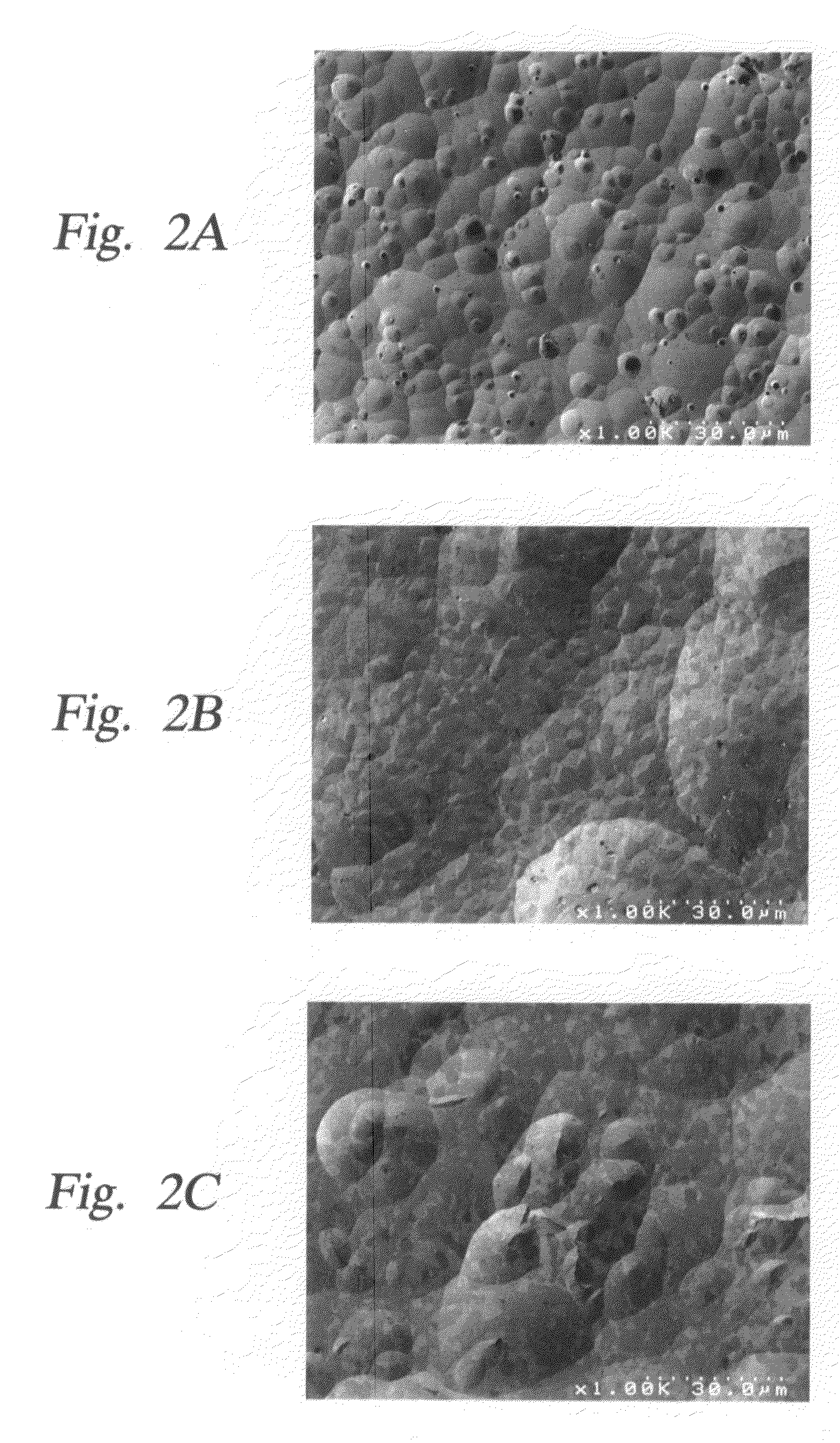

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

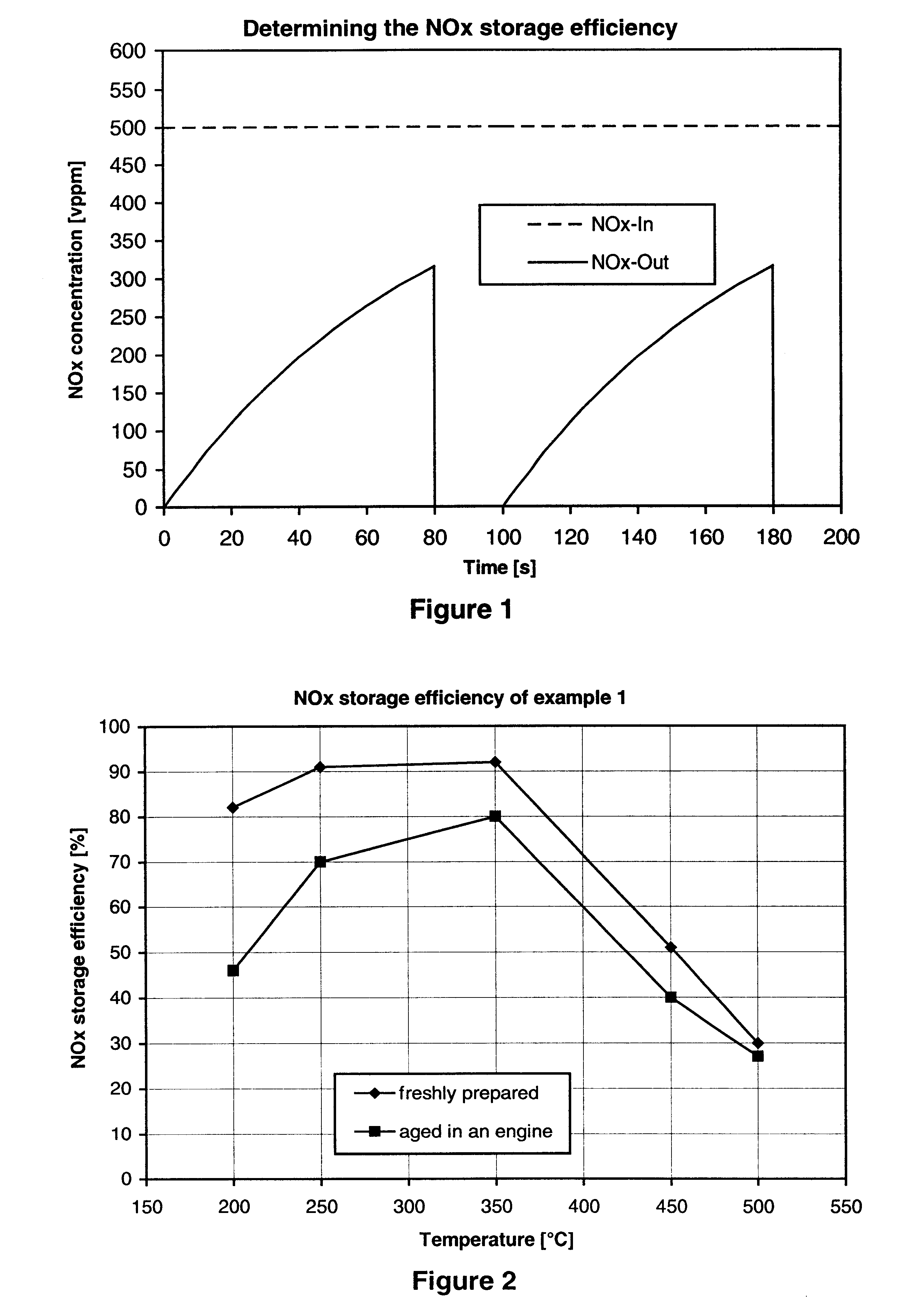

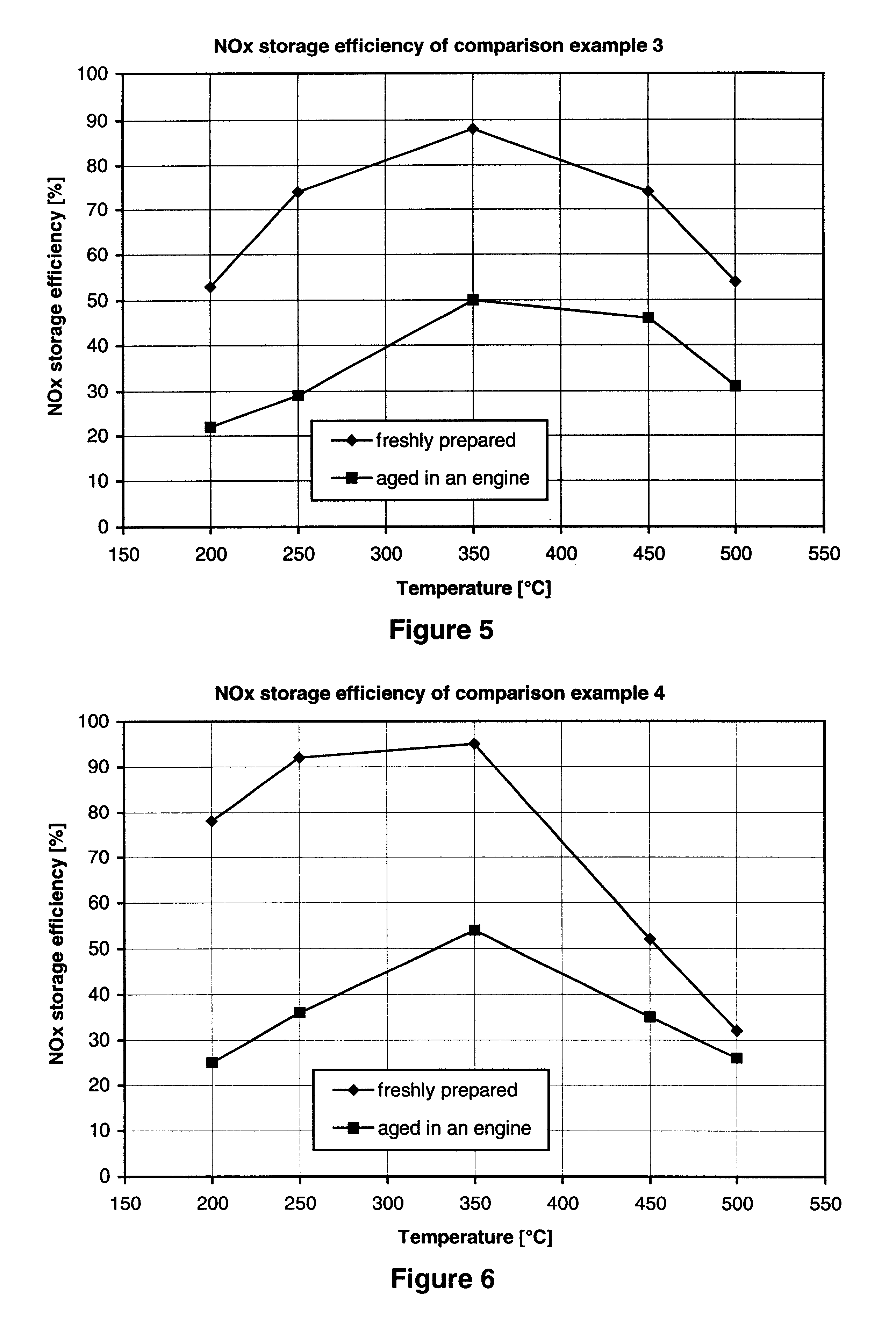

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

Unsaturated hydrocarbon hydrogenation catalyst, preparation method and applications thereof

ActiveCN102218323ASolve the problem of hydrogenationExpansion of comprehensive utilization channelsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCoalCerium oxide

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst which comprises a carrier, an active component and an additive; the active component is a mixture of nickel oxides and other metal oxides; the additive is at least two out of magnesia oxide, lanthanum oxide and ceria; counted by weight percentage, the unsaturated hydrocarbon hydrogenation catalyst comprises 5-15% of nickel oxides, 1-10% of other metal oxides, 1-10% of additive and remaining quantity of carrier; and the metal oxide is one or more oxides out of molybdenum oxide, cobalt oxide and ferric oxide. The invention also discloses a preparation method and applications of the unsaturated hydrocarbon hydrogenation catalyst. The unsaturated hydrocarbon hydrogenation catalyst has the advantages of high hydrogenation precision, strong side effect resistance, good thermal stability, long service life and the like, can be used for processing tail gas in indirect coal oil production industrial and can be also used for processing unsaturated hydrocarbon in synthesis gas.

Owner:THE NORTHWEST RES INST OF CHEM IND

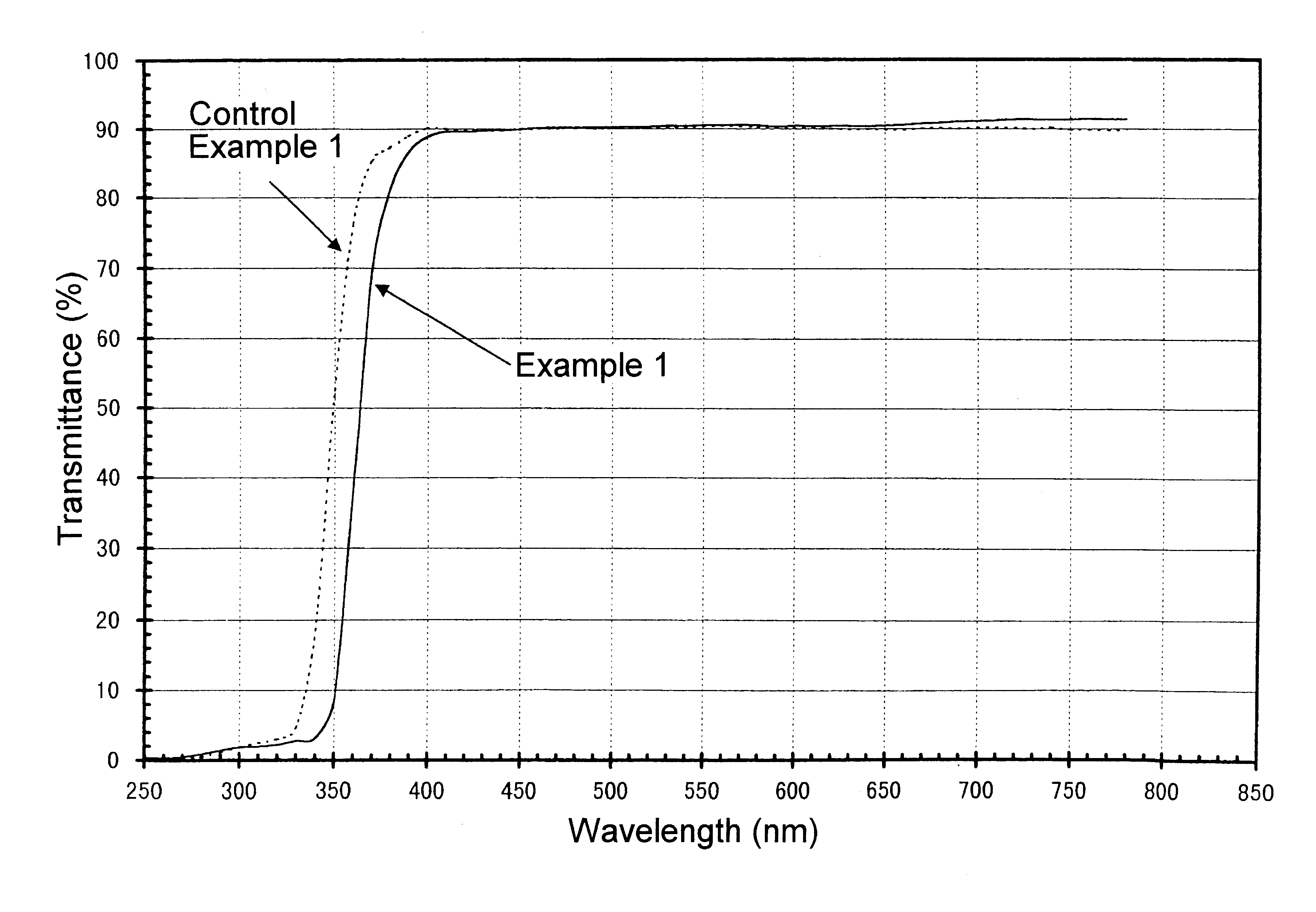

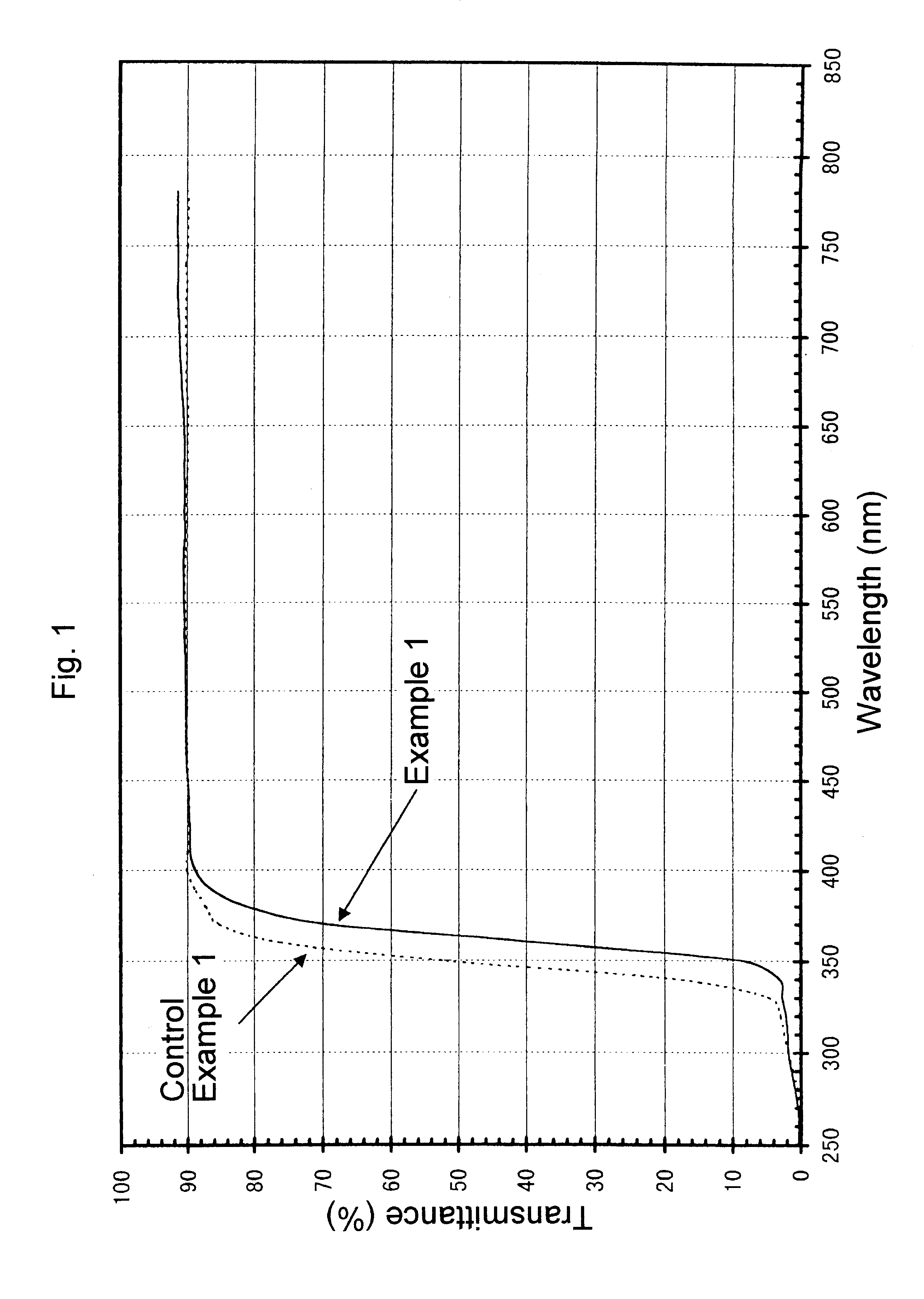

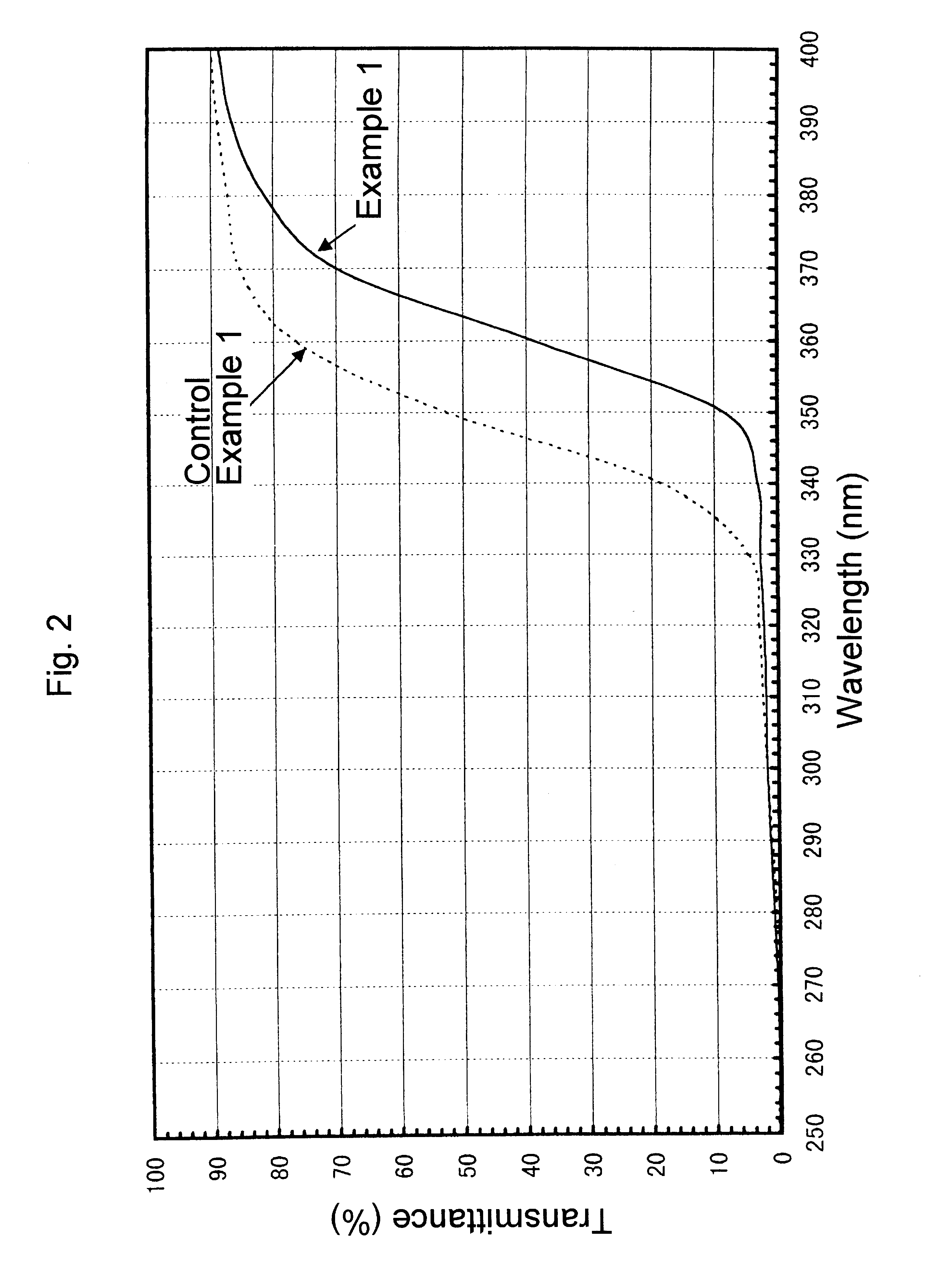

Ultraviolet radiation-absorbing, colorless, transparent soda-lime silica glass

An ultraviolet radiation-absorbing, colorless, transparent soda-lime-silica glass as well as glass bottles formed out of the glass are disclosed which, while maintaining high transmittance to light in the visible region and thereby allowing the contents to be seen clearly, absorbs ultraviolet radiation and thus prevents coloration, discoloration, fading in color or deterioration of the flavor of the contents caused by ultraviolet radiation. The glass is characterized in that its composition includes, in % by weight, SO3 . . . 0.15-0.4%; Cerium oxide . . . 0.2-1% (calculated as CeO2); Fe2O3 . . . 0.01-0.08%; FeO . . . 0-0.008%; Manganese oxide . . . 0.01-0.08% (calculated as MnO); and Cobalt oxide . . . 0-0.0005% (calculated as CoO).

Owner:NIHON YAMAMURA GLASS CO LTD

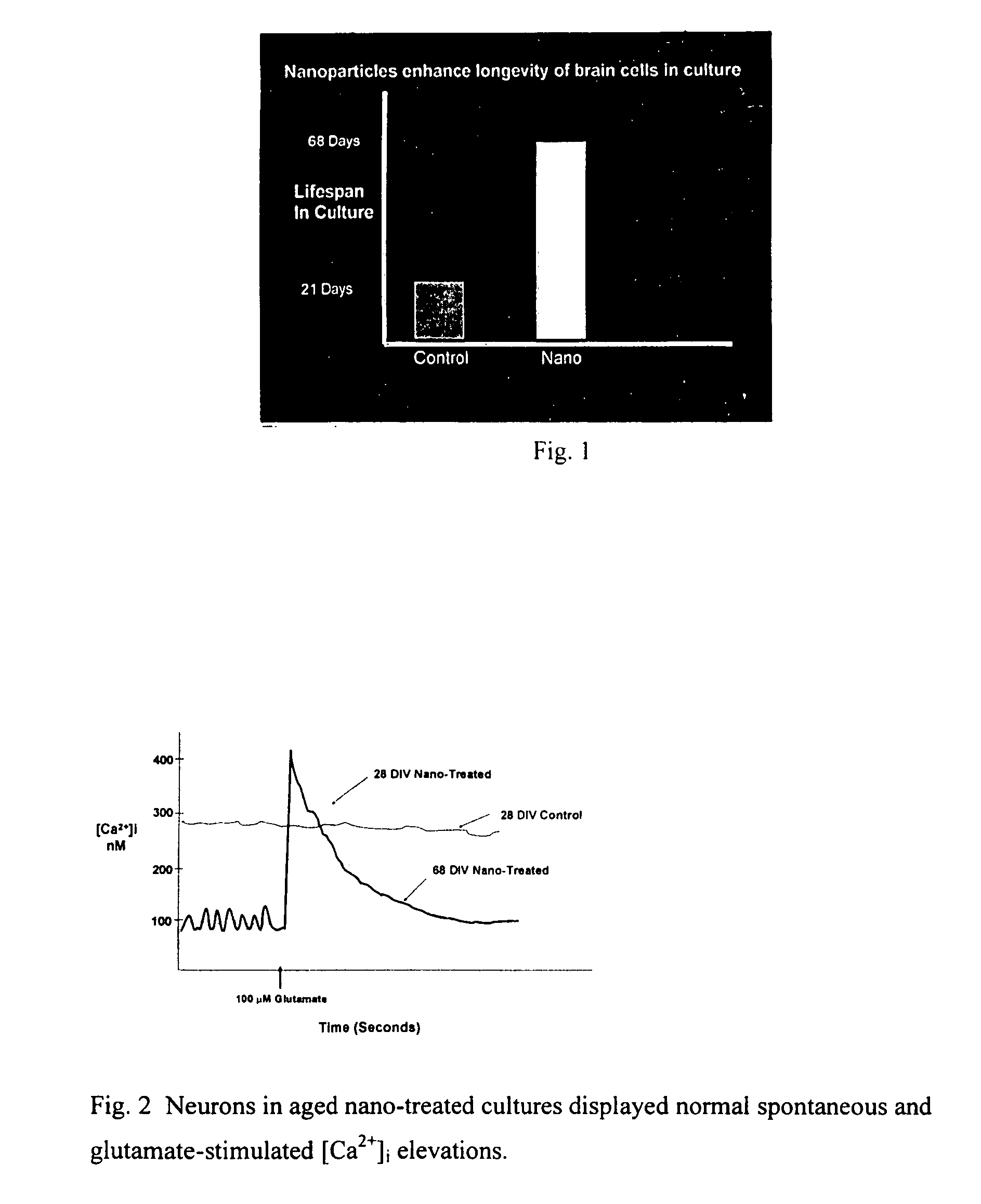

Cerium oxide nanoparticles and use in enhancing cell survivability

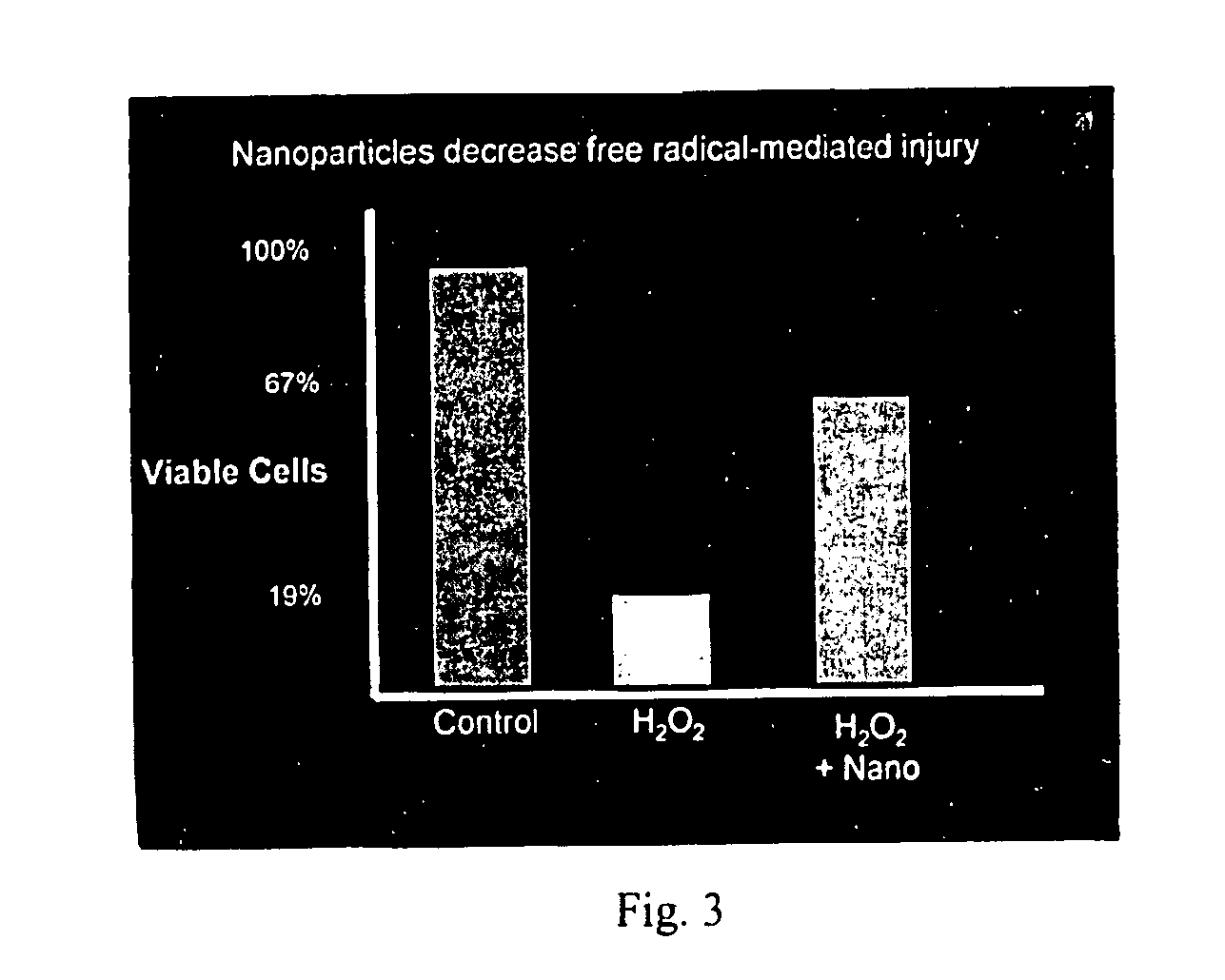

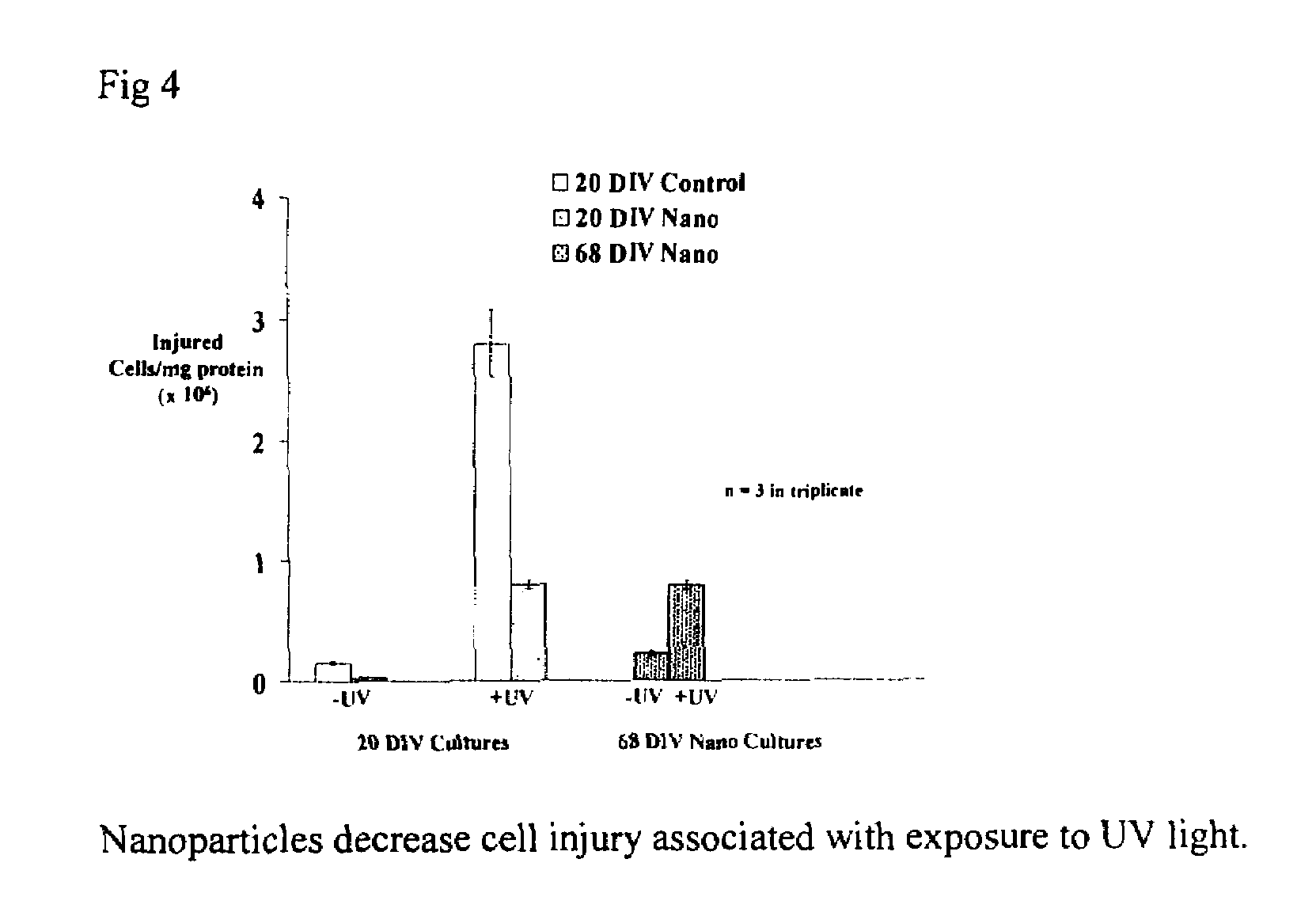

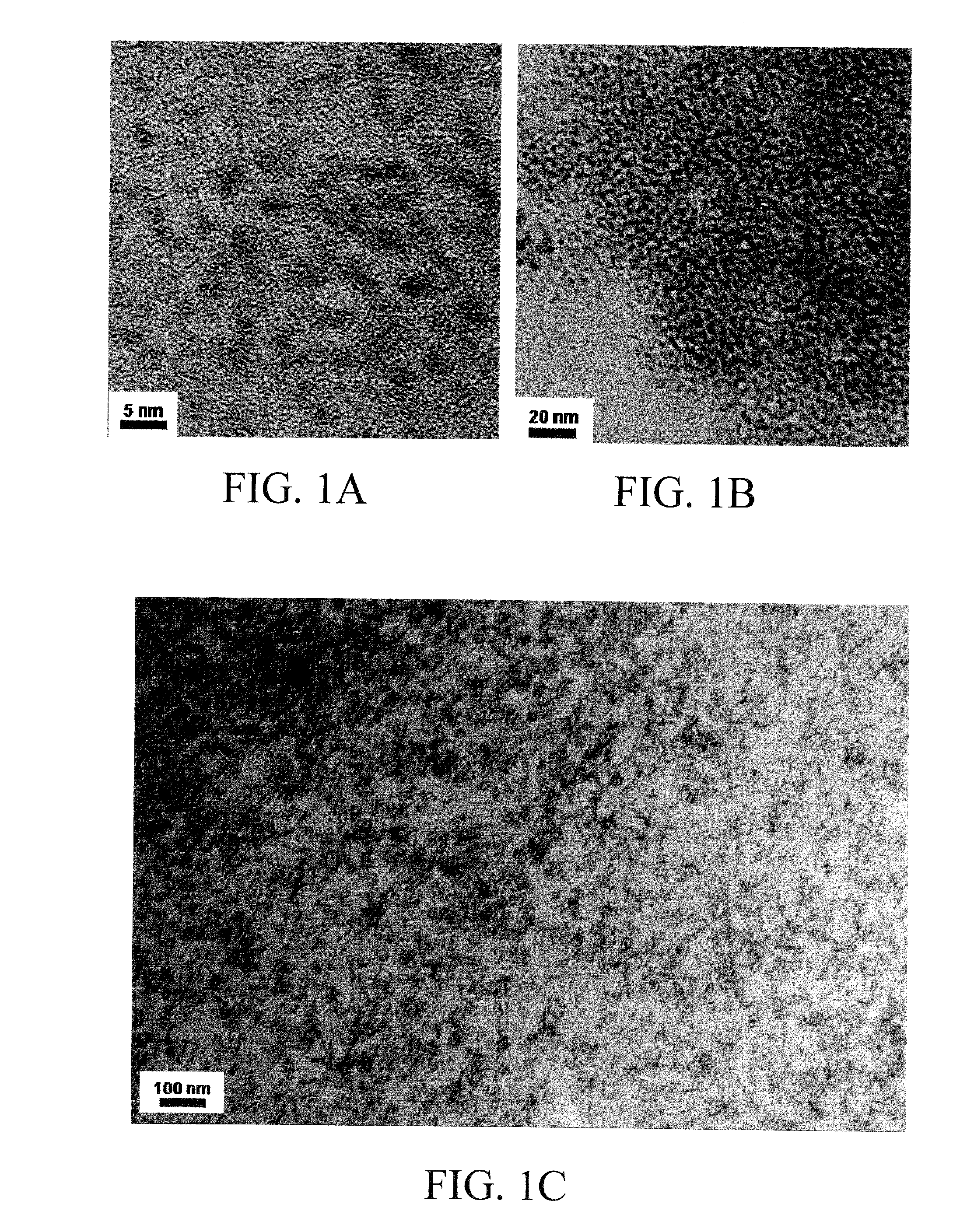

Novel, nonagglomerated, engineered, ultra fine Cerium Oxide particles the size of approximately 2 to approximately 10 nm and methods for preparation of the particles. The resultant particles enhance the longevity of cells in culture. Applications of the particles include benefits for wound healing, treating arthritis and joint diseases, anti-aging and the treating of inflammations.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

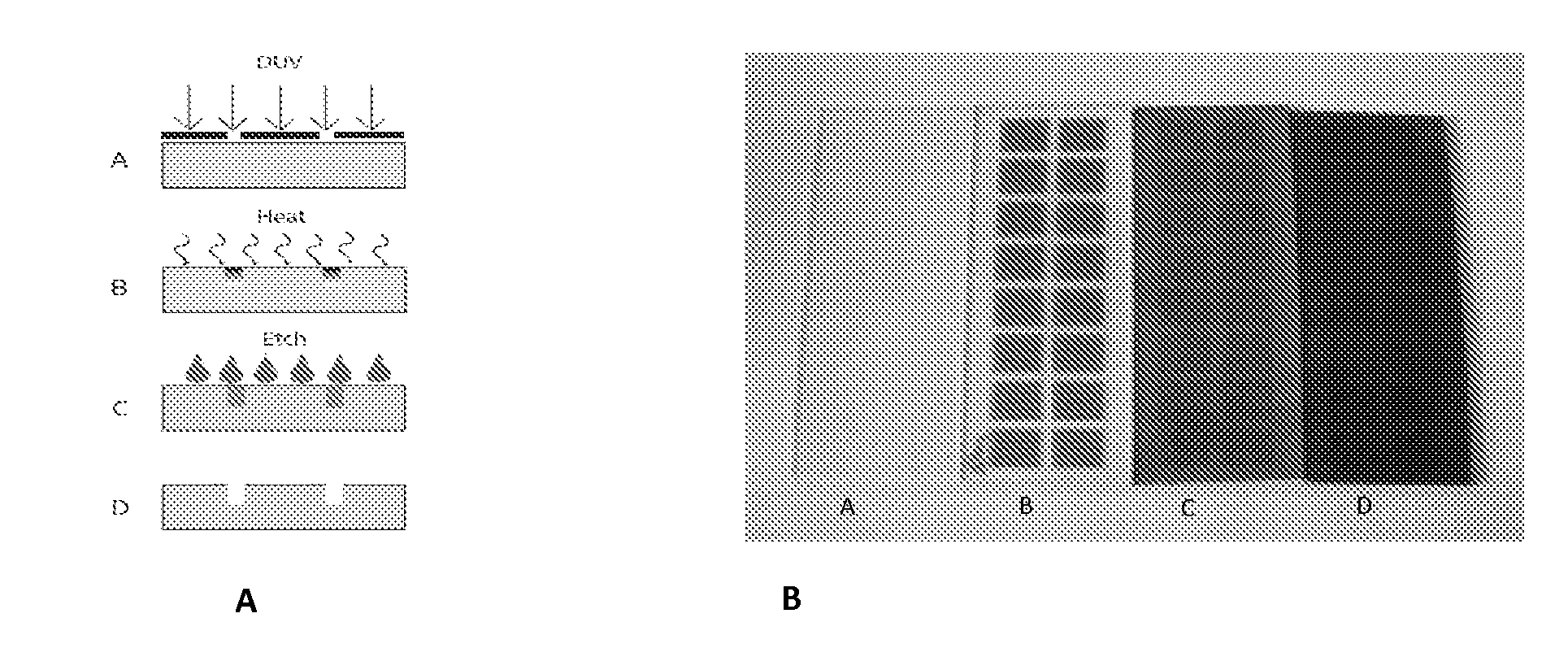

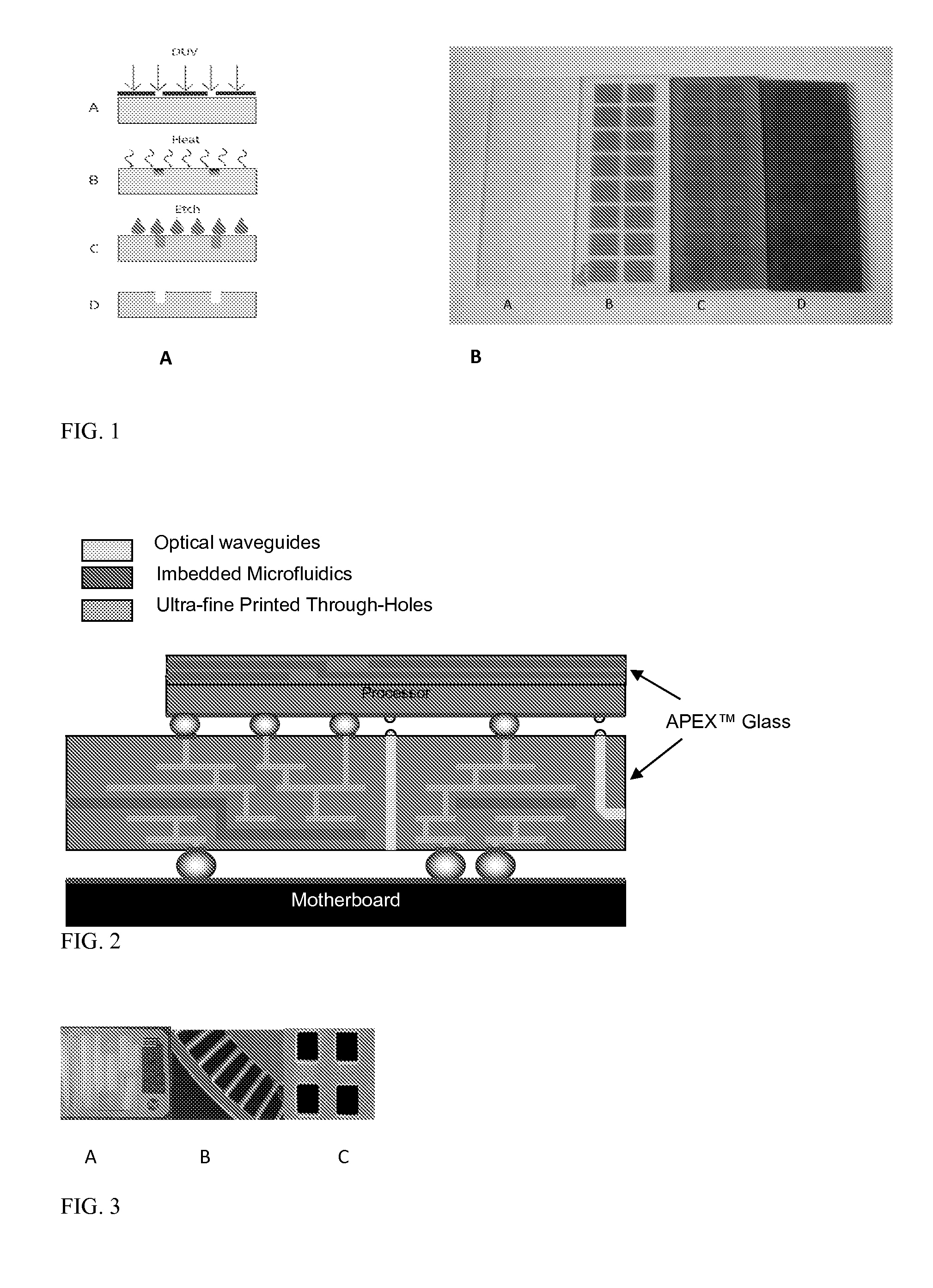

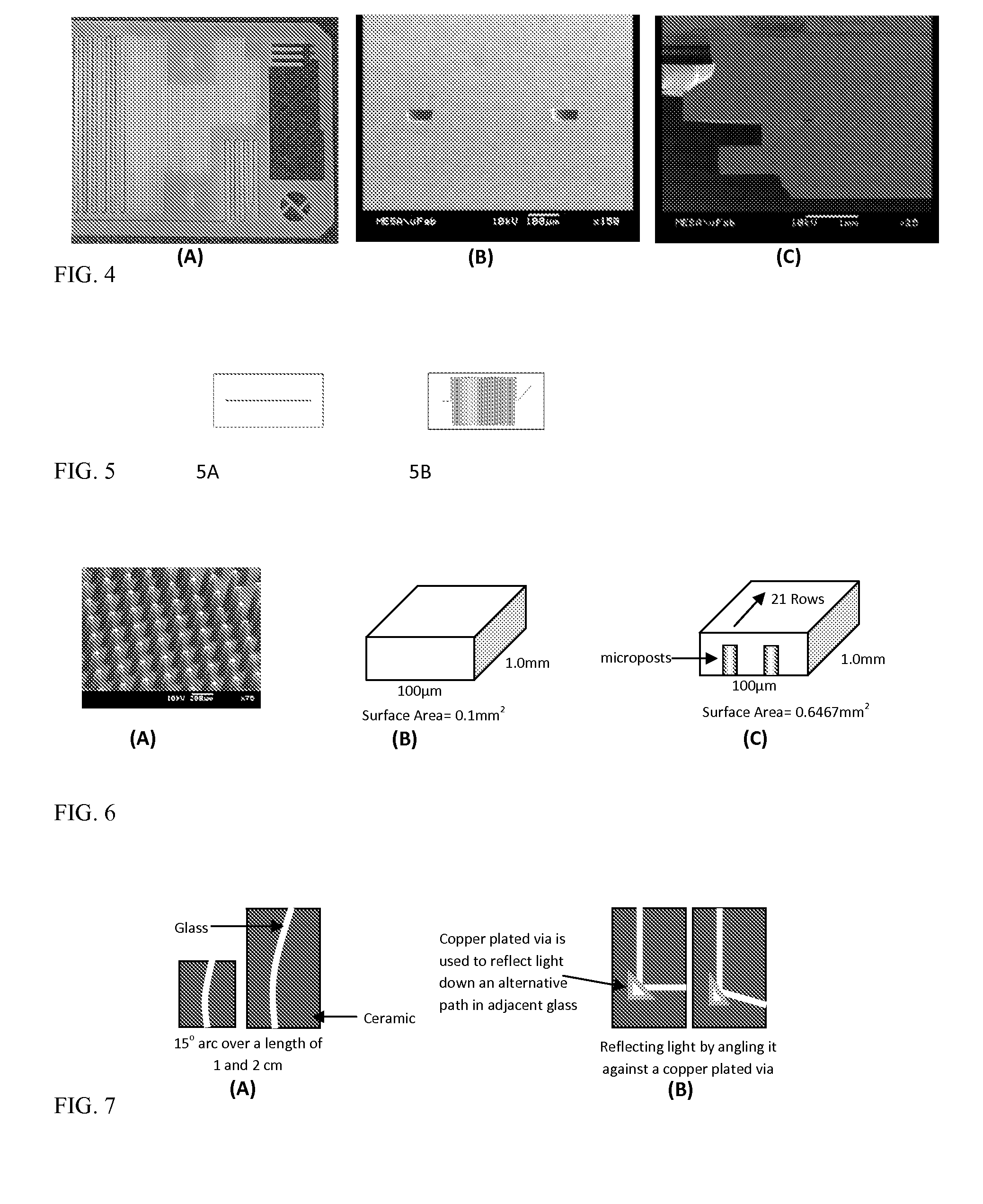

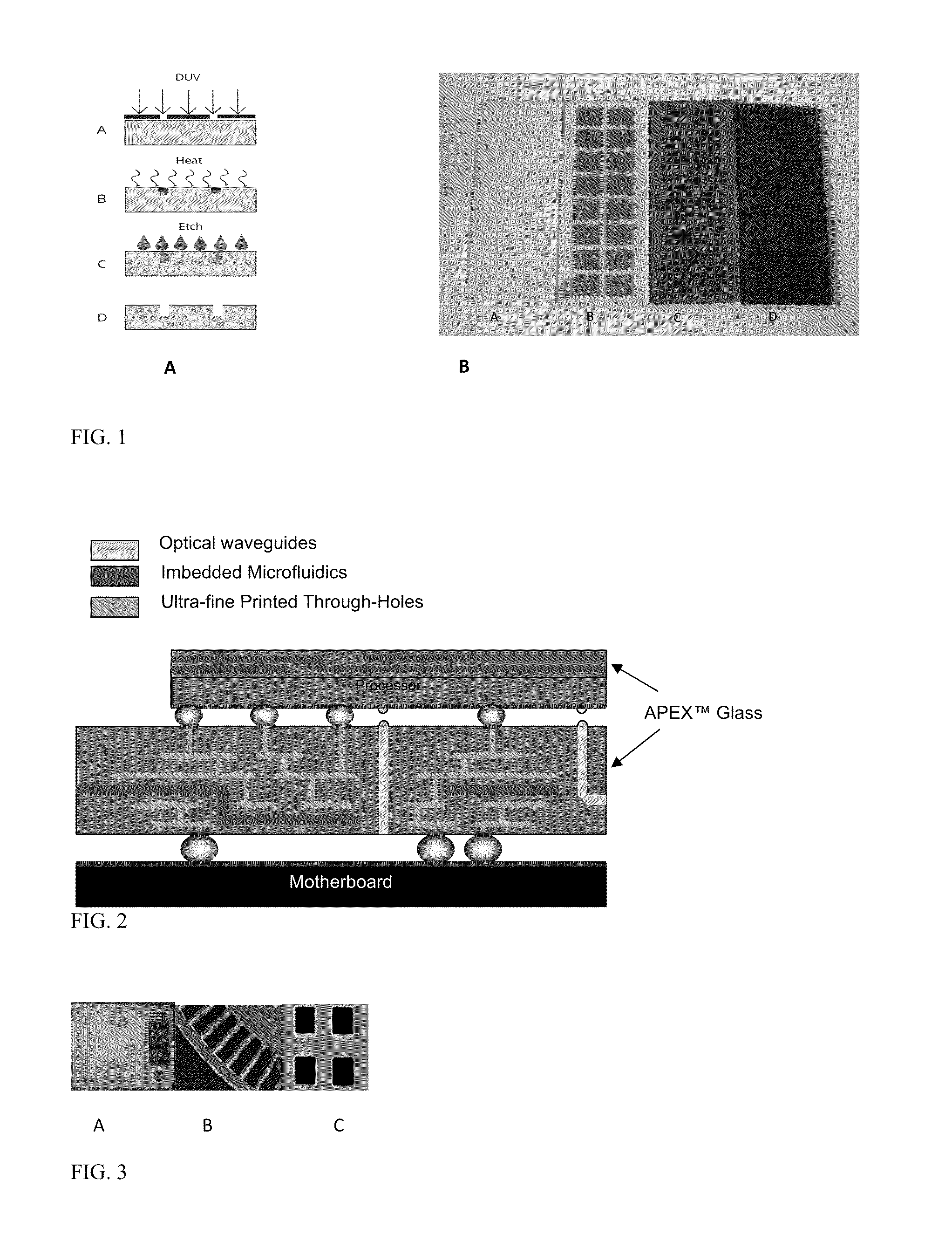

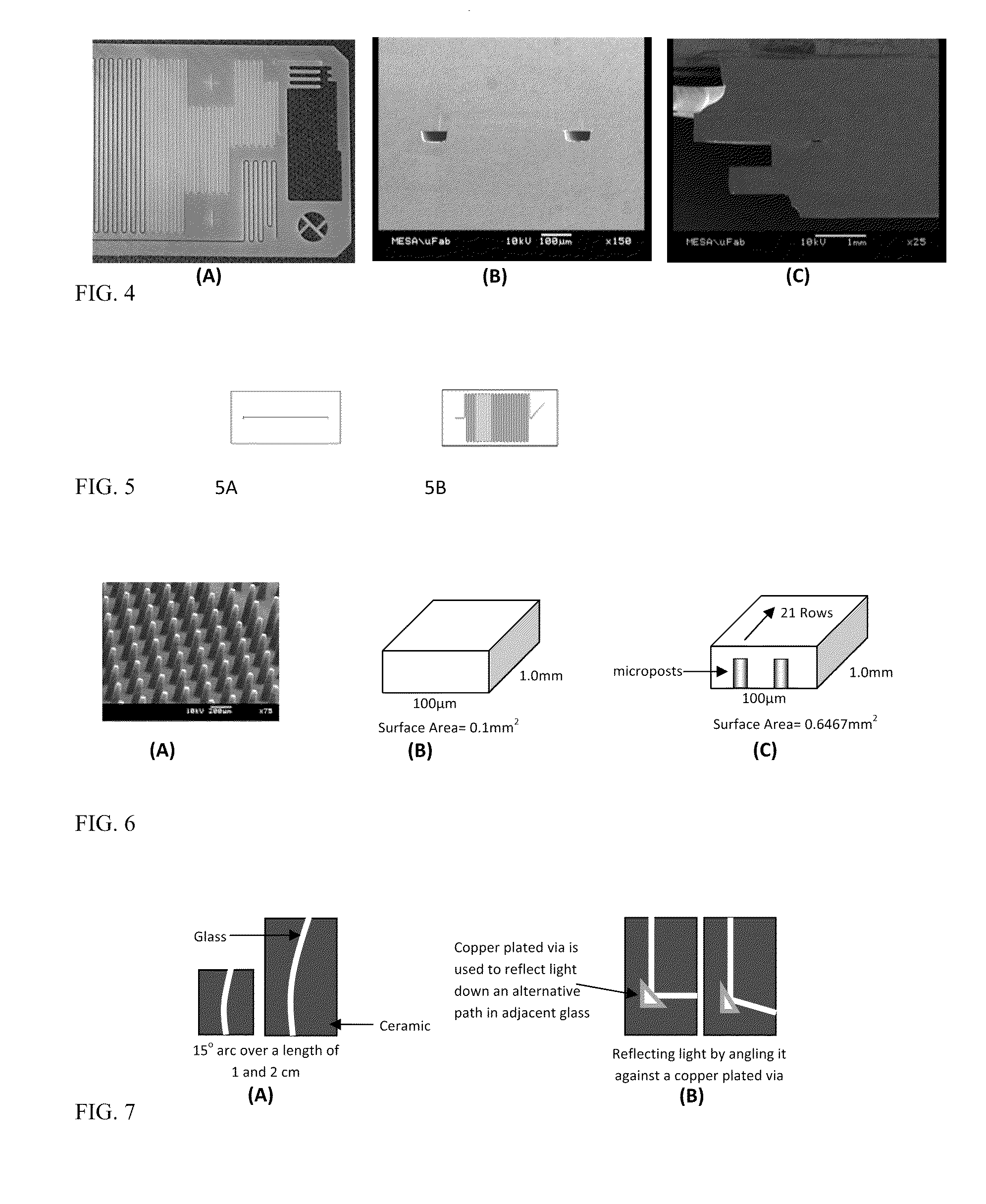

Methods to fabricate a photoactive substrate suitable for microfabrication

ActiveUS20110195360A1Solid-state devicesSemiconductor/solid-state device manufacturingLithium oxideGlass transition

Owner:3D GLASS SOLUTIONS INC

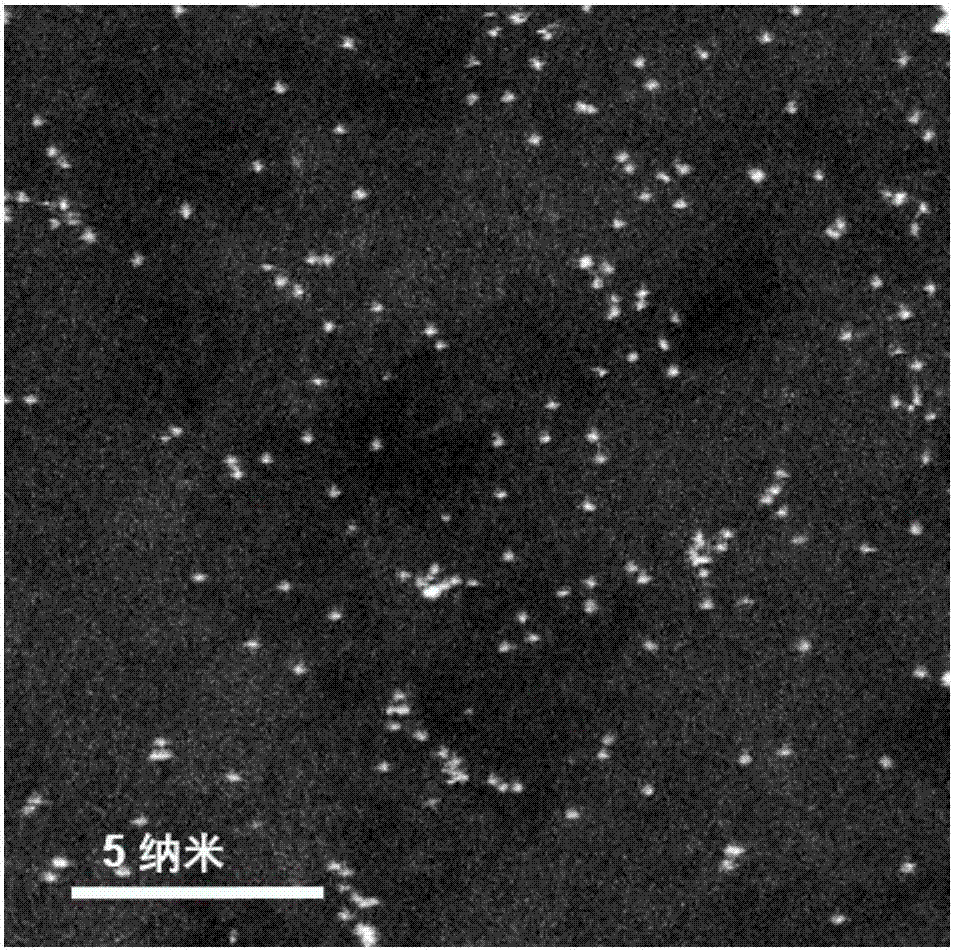

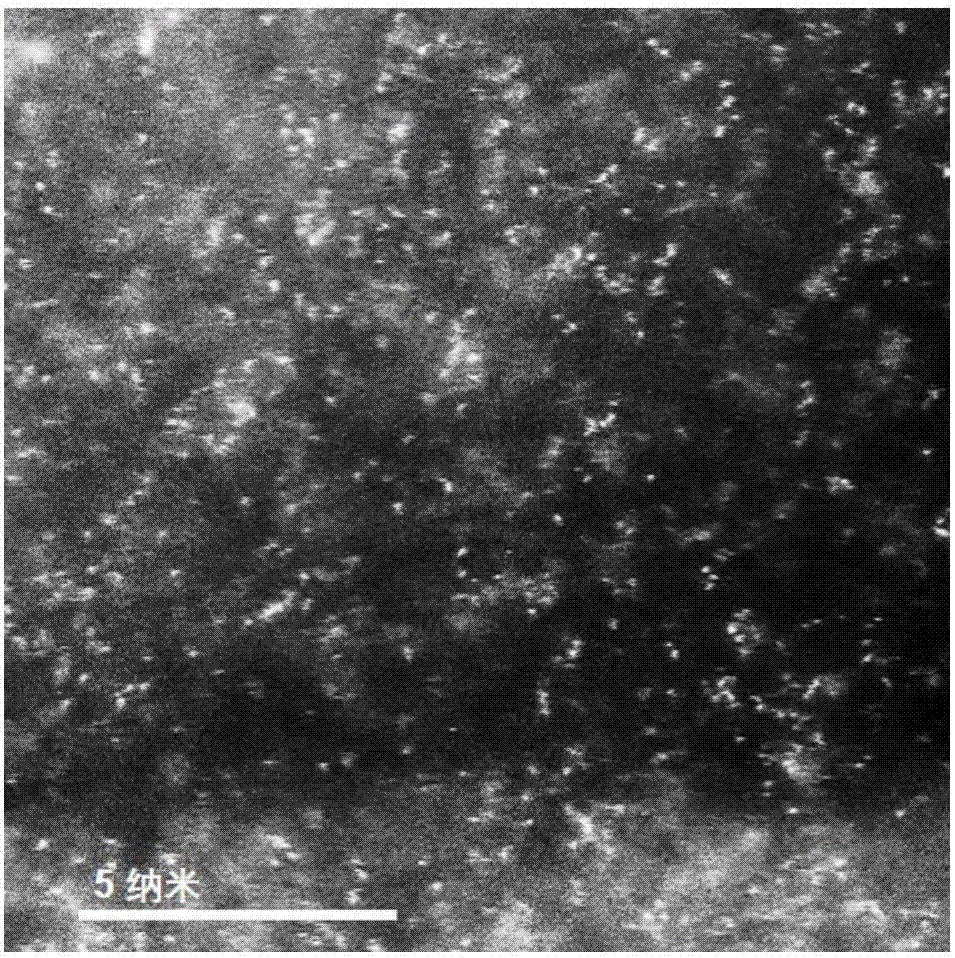

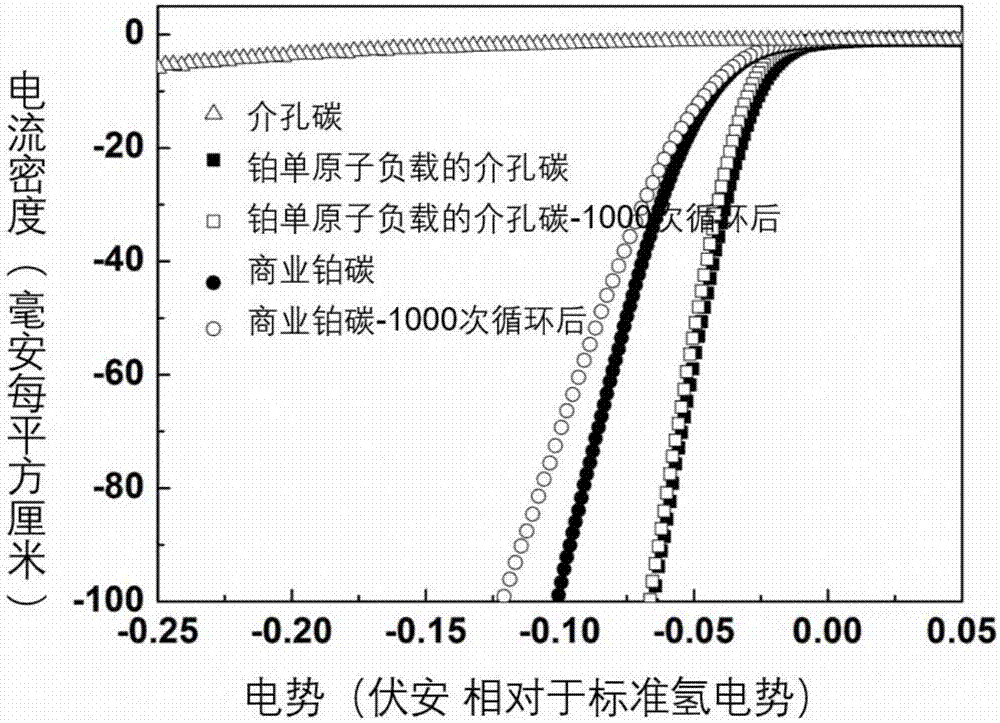

Preparation method of metal mono-atoms

ActiveCN106914237AImprove performanceLow costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsCarbon filmFiltration

The invention relates to a preparation method of metal mono-atoms and belongs to the technical field of materials science and engineering. The metal mono-atoms prepared through the method may include: Pt, Ag, Au, Pd, Rh, Ir, Ru, Co, Ni and Cu, and metal mono-atoms supported on TiO2, zinc oxide, cerium oxide, aluminum oxide, silicon oxide, ferric oxide, manganese oxide, C3N4, mesoporous carbon, ultrathin carbon films, graphene, carbon nano tubes or molecular sieve materials, etc. The method includes the steps of: preparing a precursor solution in a certain concentration, and freezing the solution; and under an ice phase, processing ice cubes by means of external field or reaction between reactants in the ice cubes, and when the ice cubes are molten, a mono-atom solution is finally produced; mixing the mono-atom solution with different materials, performing ultrasonic treatment, filtration, cleaning and drying to finally obtain the mono-atoms supported on various materials. The preparation method is quick, has high product density, allows mass production, is high in efficiency and has wide application range, and compared with a co-precipitation method and an impregnation method, the method has significant advantages.

Owner:TSINGHUA UNIV

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

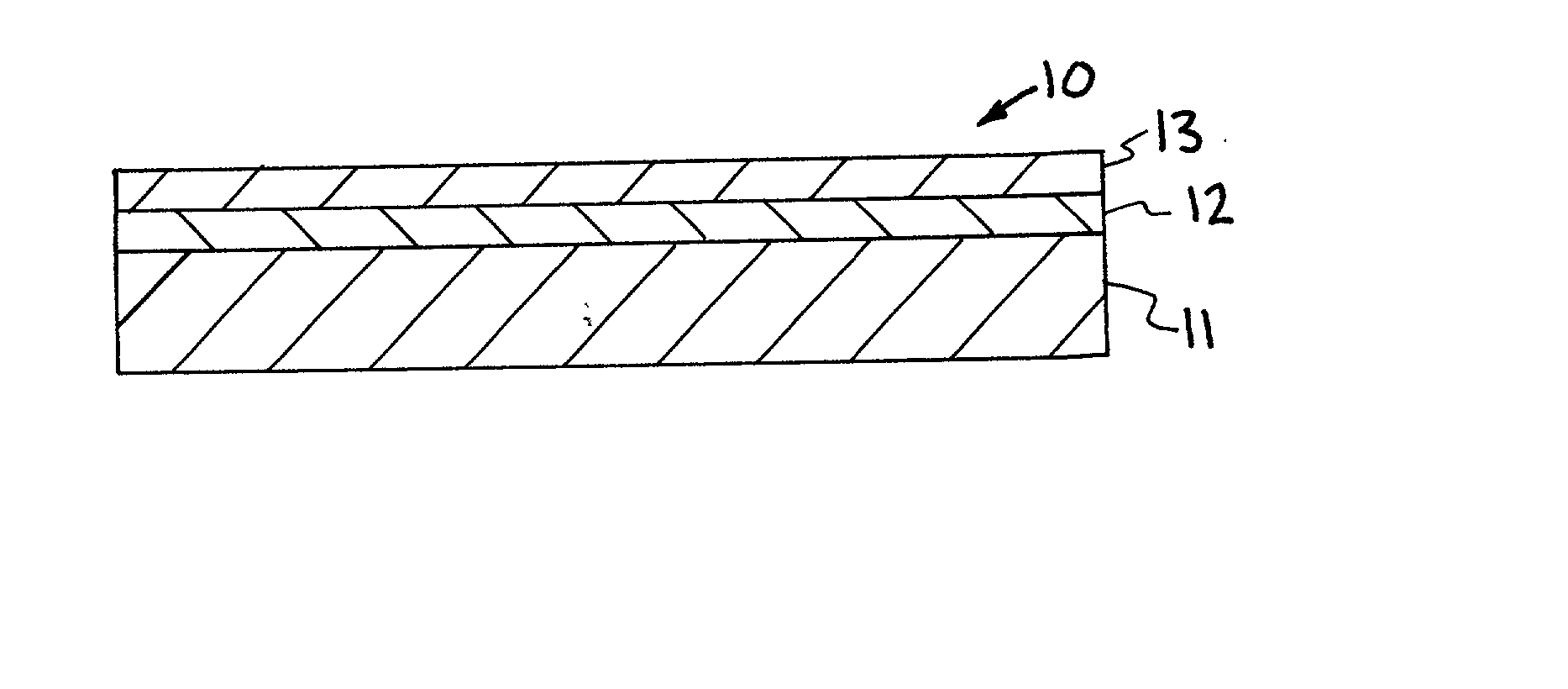

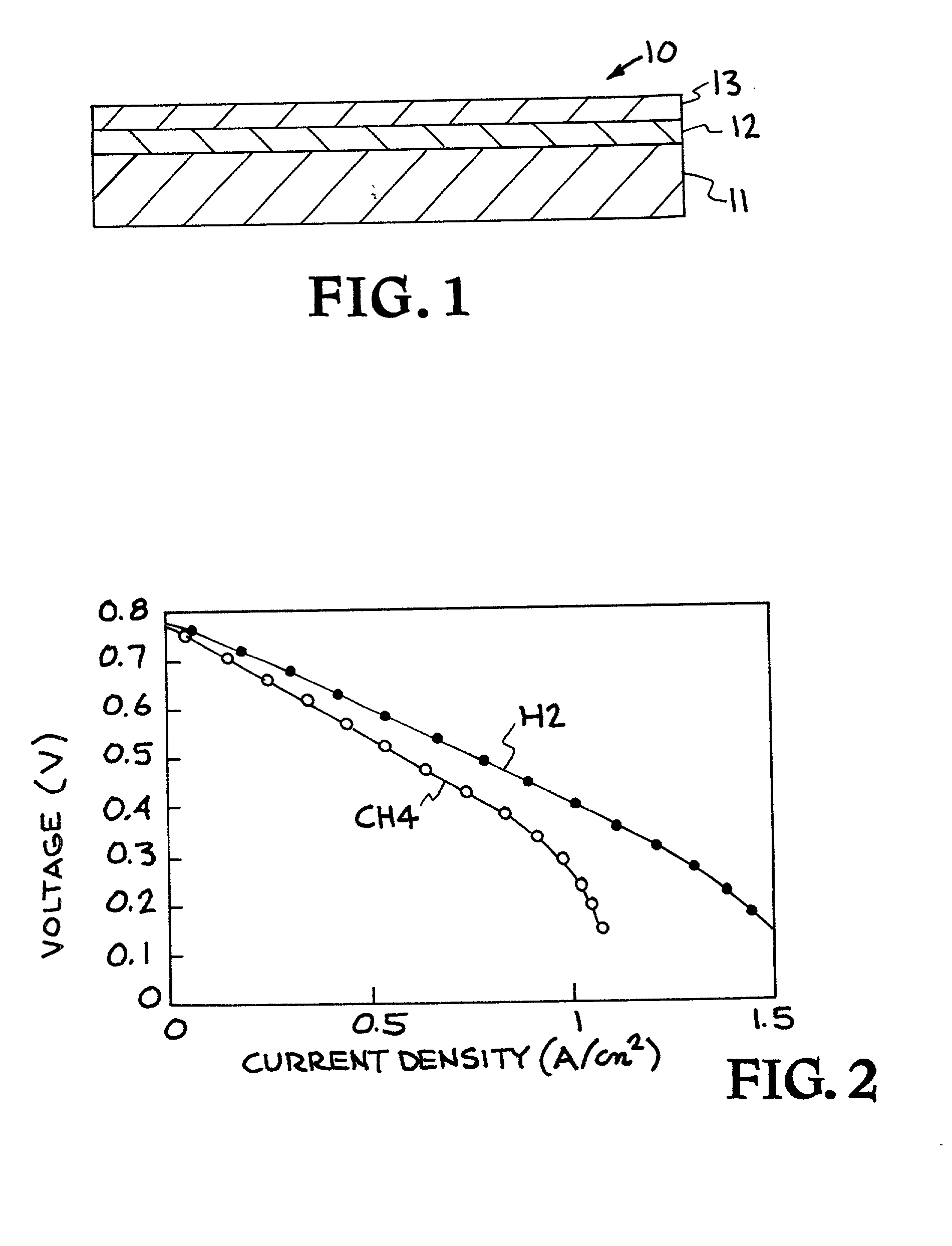

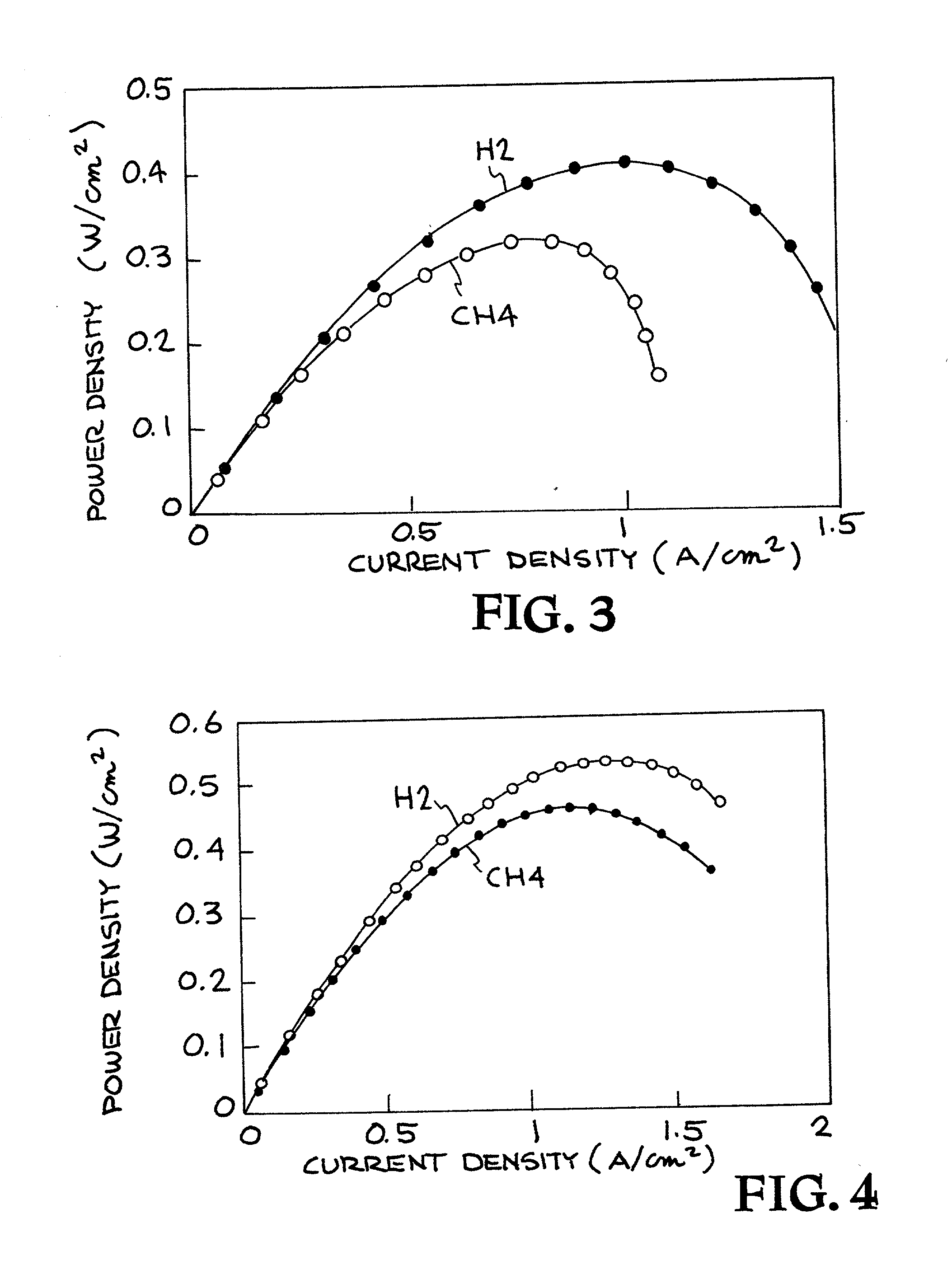

Ceria-based solid oxide fuel cells

InactiveUS20020127455A1Improve power densityMore option for sealingCell electrodesFuel cell auxillariesCerium(IV) oxideCobalt

High-performance intermediate temperature solid oxide fuel cells (SOFCs). The SOFCs are ceria-based structures that can achieve a power output of 300 mW / cm.sup.2 at an operating temperature below 600.degree. C. By way of example, the fuel cell as an anode made of NiO / doped-ceria, a thin film of doped-ceria and / or doped zirconia electrolyte is deposited on the anode, and a cathode of cobalt iron based material, such as (La, Sr)(Co, Fe)O.sub.3 or cobalt, ion, magnesium based material, is deposited on top of the electrolyte, and can operate at a temperature of 550.degree. C. The various layers may be deposited by colloidal spray deposition or aerosol spray casting.

Owner:RGT UNIV OF CALIFORNIA

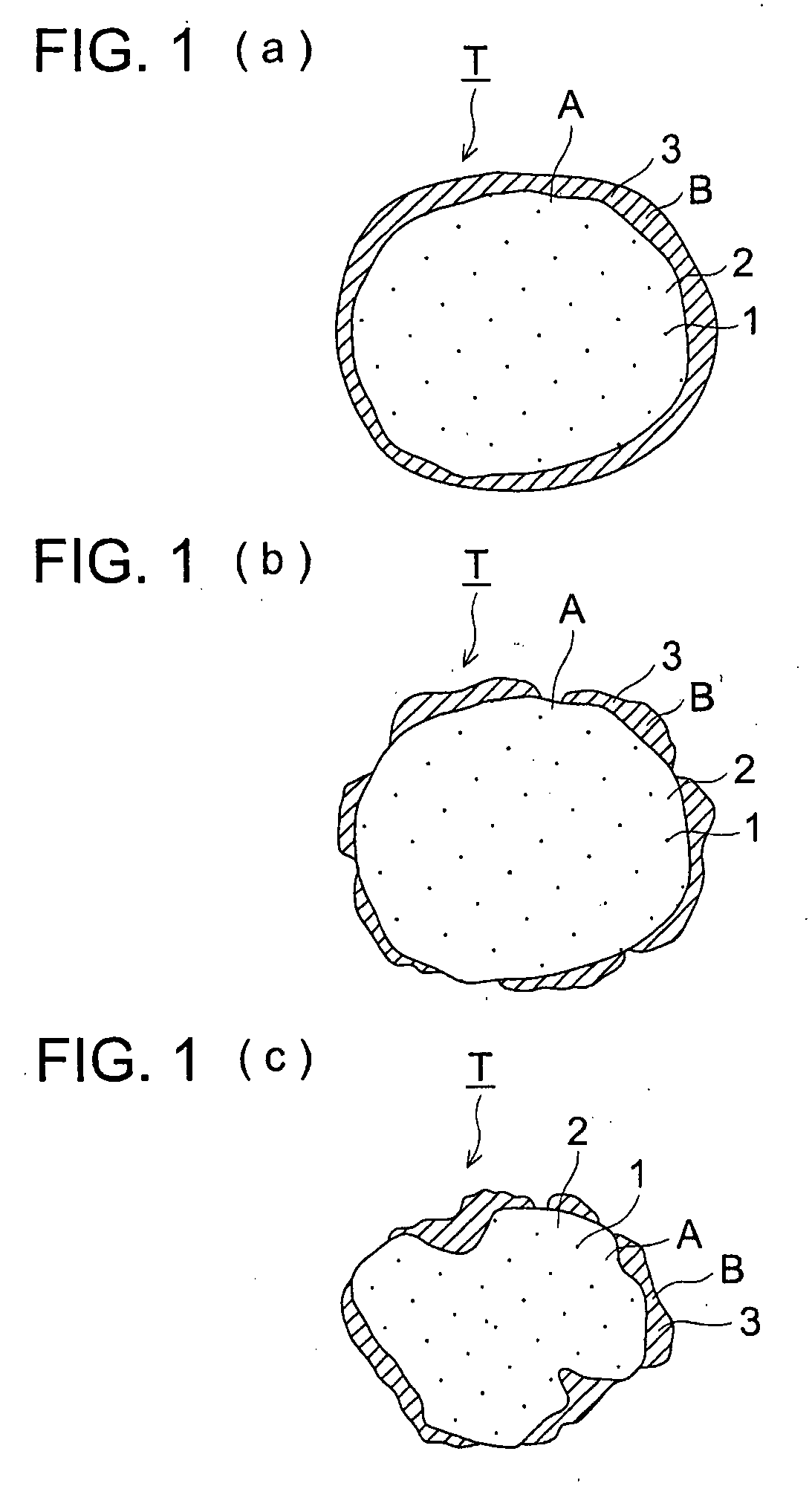

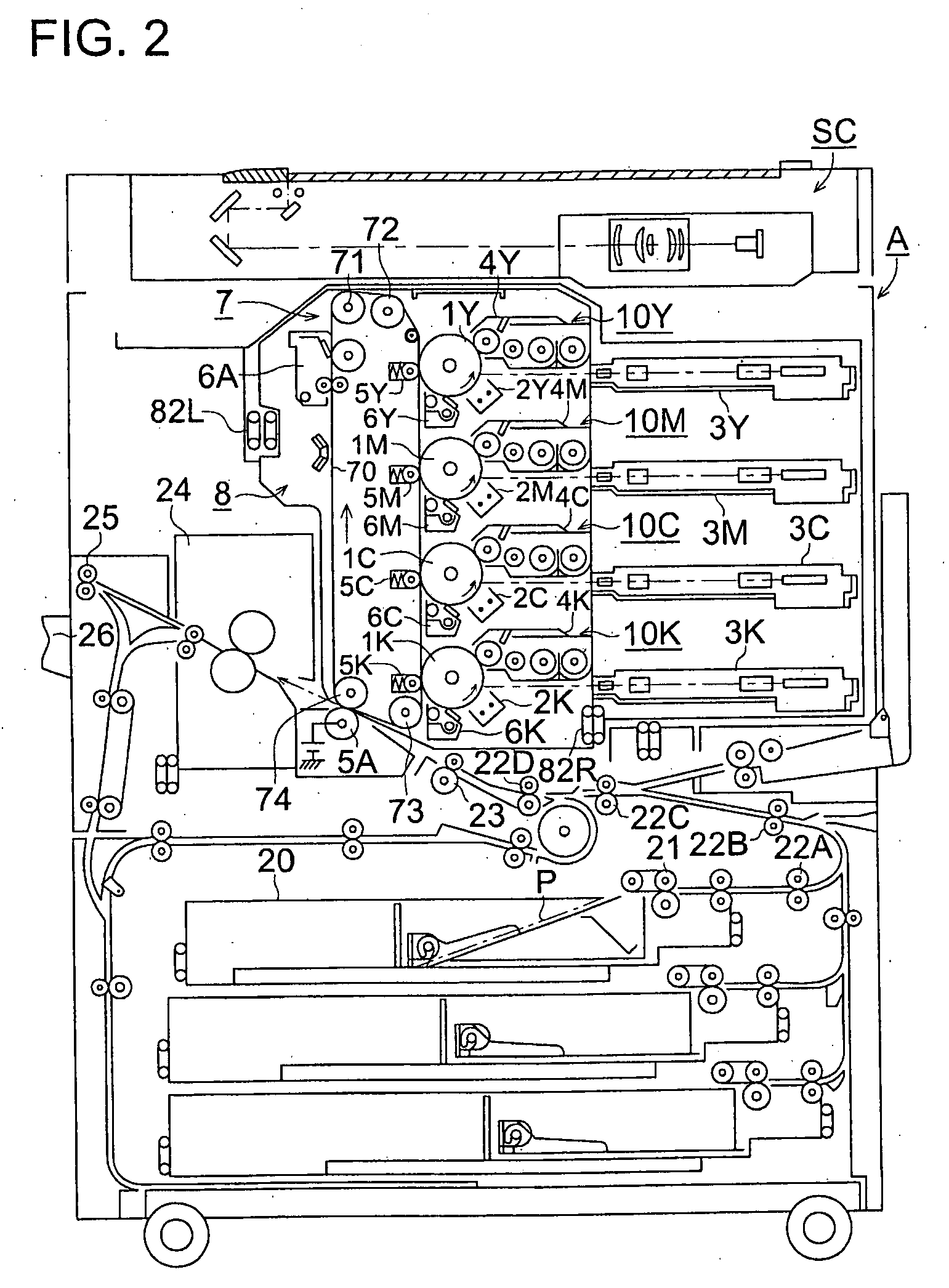

Electrophotographic color toner

InactiveUS20090286176A1Improved in the low-temperature fixation suitabilityHigh image quality improved in the glossinessDevelopersPolyester resinMagenta

A set of a yellow toner, a magenta toner, a cyan toner and a black toner is disclosed. Each of the color toners contains a colored particle and cerium oxide particles, the colored particle containing an amorphous polyester resin, a crystalline polyester resin, a colorant and a releasing agent; and the yellow toner contains C.I. Pigment Yellow 74, the magenta toner contains C.I. Pigment Red 122 and C.I. Pigment Red 238, the cyan toner contains any one of C.I. Pigment Blue 15:1, C.I. Pigment Blue 15:2 and C.I. Pigment Blue 15:3, and the black toner contains carbon black and any one of C.I. Pigment Blue 15:1, C.I. Pigment Blue 15:2 and C.I. Pigment Blue 15:3.

Owner:KONICA MINOLTA BUSINESS TECH INC

Clear glass composition with high visible transmittance

A high transmittance fairly clear / neutral colored glass composition is provided. An oxidizing agent(s) such as cerium oxide (e.g., CeO2) or the like is added to the glass batch in order to realize very oxidized conditions (i.e., to significantly lower the redox of the resulting glass). As a result of the oxidizing agent(s) used in the batch, the iron is oxidized to a very low FeO (ferrous state) content. For example, this may result in a glass having a glass redox value of no greater than 0.12 (more preferably <=0.10; even more preferably <=0.08; and most preferably <=0.05) and a % FeO (i.e., ferrous content) of from 0.0001 to 0.05%. In certain example embodiments, in order to compensate for yellow or yellow-green coloration a small amount of cobalt (Co) may be provided in the glass to enable it to realize a more neutral color.

Owner:GUARDIAN GLASS LLC

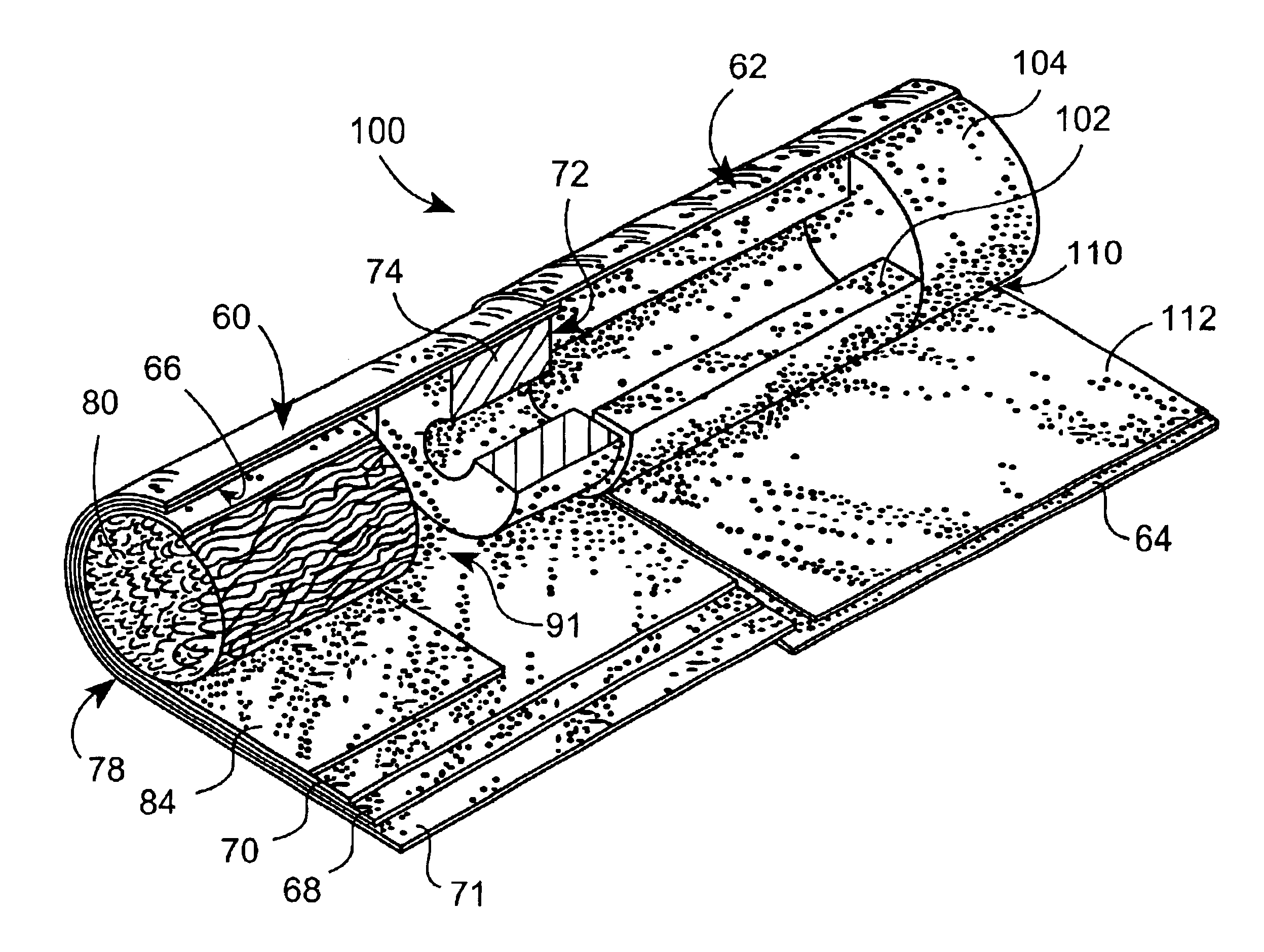

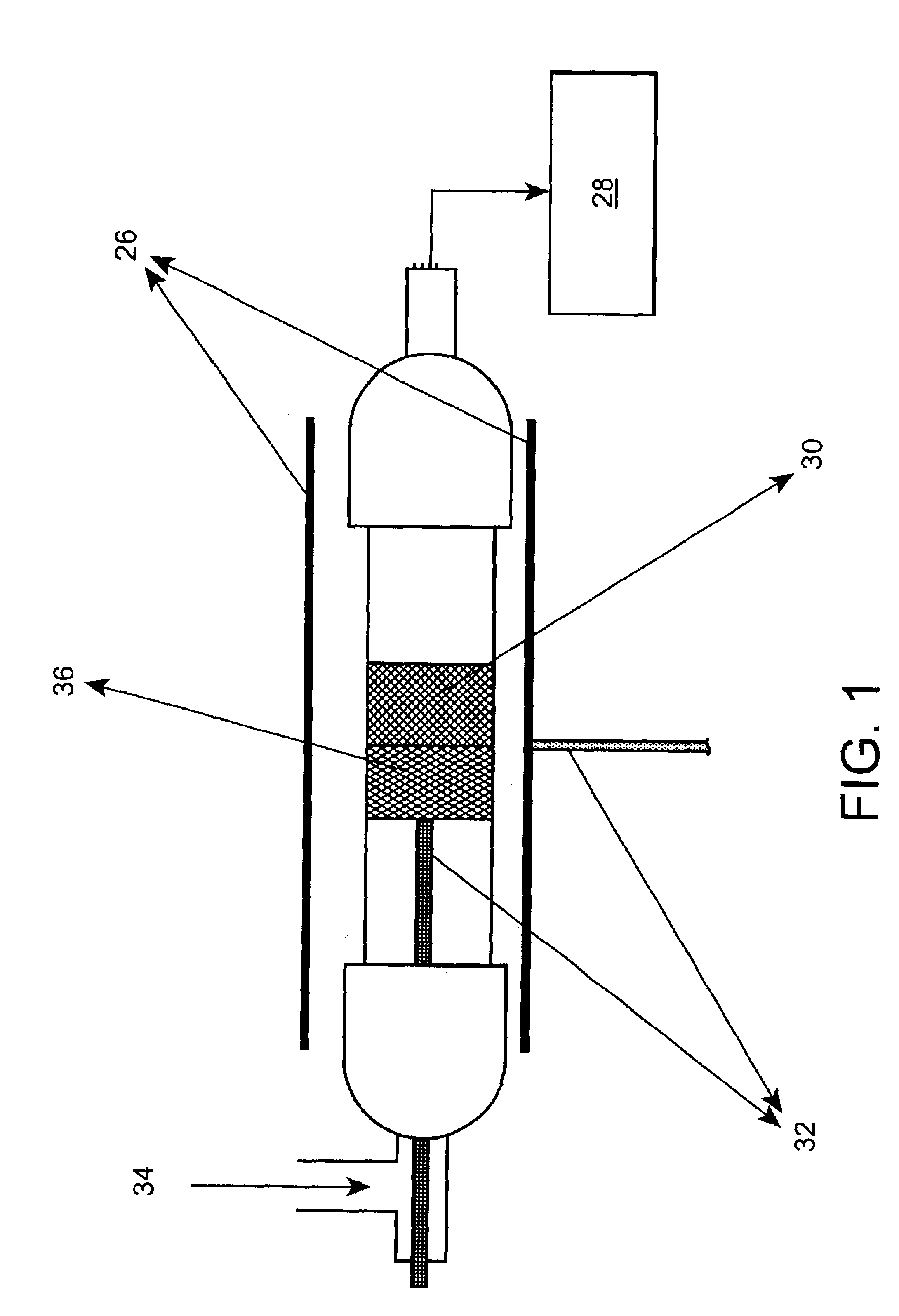

Nanocomposite copper-ceria catalysts for low temperature or near-ambient temperature catalysis and methods for making such catalysts

InactiveUS6857431B2Reduce the amount requiredTobacco preparationNon-fibrous pulp additionPtru catalystHydrocotyle bowlesioides

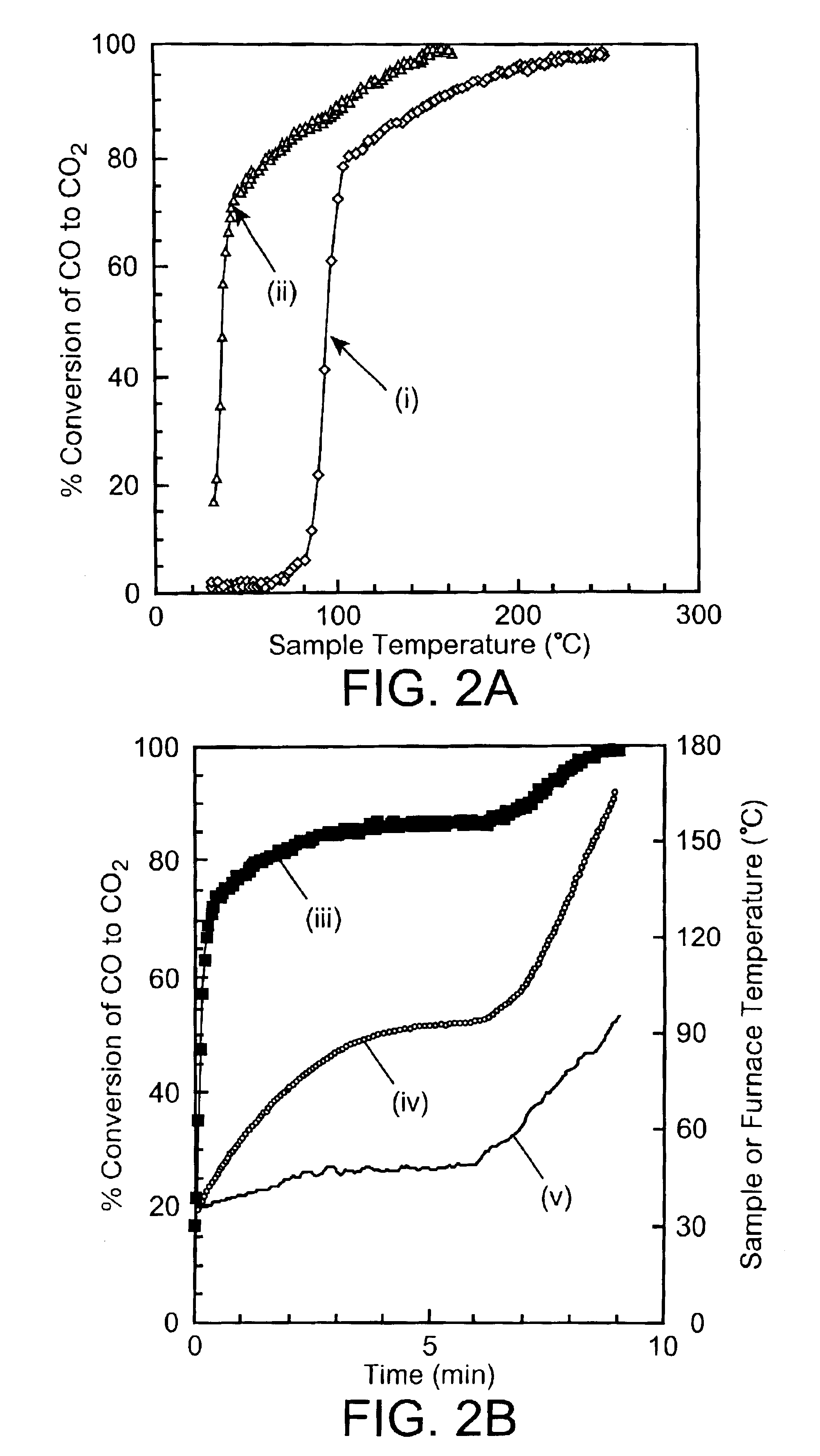

Nanocomposite copper-ceria catalysts are provided, which comprise copper oxide nanoparticles, copper nanoparticles, or a mixture thereof combined with ceria nanoparticles. Methods for making such catalysts are also provided, which involve the steps of (i) combining ceria nanoparticles in an aqueous suspension with copper 2,4-pentanedionate to form a slurry; (ii) heating the slurry formed in step (i) under an inert gas atmosphere or an oxygen-argon atmosphere, at a temperature and for a time sufficient to cause decomposition of the copper 2,4-pentanedionate to form copper nanoparticles and / or copper oxide nanoparticles that are combined with the ceria nanoparticles; and (iii) optionally, subjecting the product formed in step (ii) to a heat treatment process under conditions effective to convert at least some of the copper nanoparticles to copper oxide nanoparticles. The nanocomposite copper-ceria catalysts are useful for low-temperature and near-ambient temperature catalysis, such as the oxidation of carbon monoxide, the reduction of nitric oxide and the conversion of hydrocarbons. The nanocomposite copper-ceria catalysts have a variety of potential applications, for example, in vehicle exhaust emission systems of automobiles and diesel engines, cold starting of automobile engine, fuel cells, lasers, hydrocarbon conversion reactors, air filters for the conversion of carbon monoxide and / or indoor volatile organic compounds, and smoking articles.

Owner:PHILIP MORRIS USA INC

Methods to fabricate a photoactive substrate suitable for microfabrication

InactiveUS20110217657A1Improve performanceSmall layer thicknessContact member manufacturingPhotosensitive materialsLithium oxideSilicon dioxide

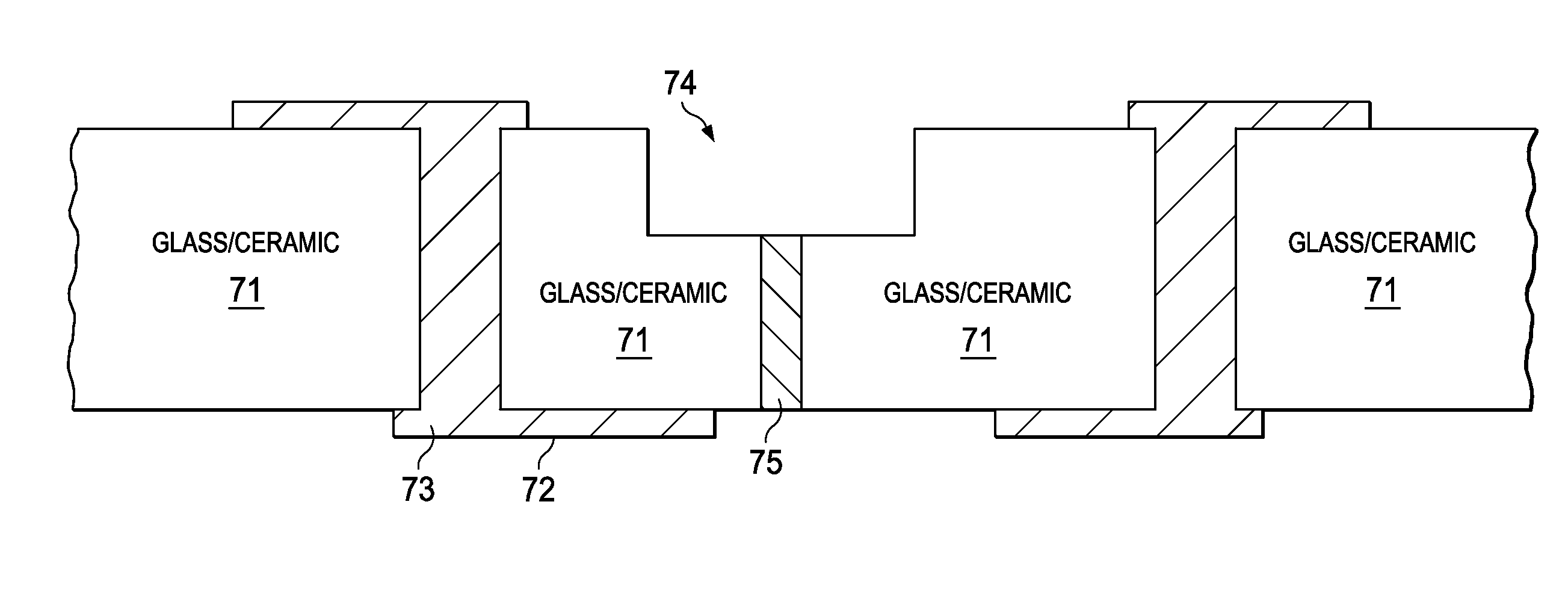

A method of fabrication and device with holes for electrical conduction made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form the one or more depressions or through holes for electrical conduction in the device.

Owner:LIFE BIOSCI

Co-catalyst for purifying exhaust gas

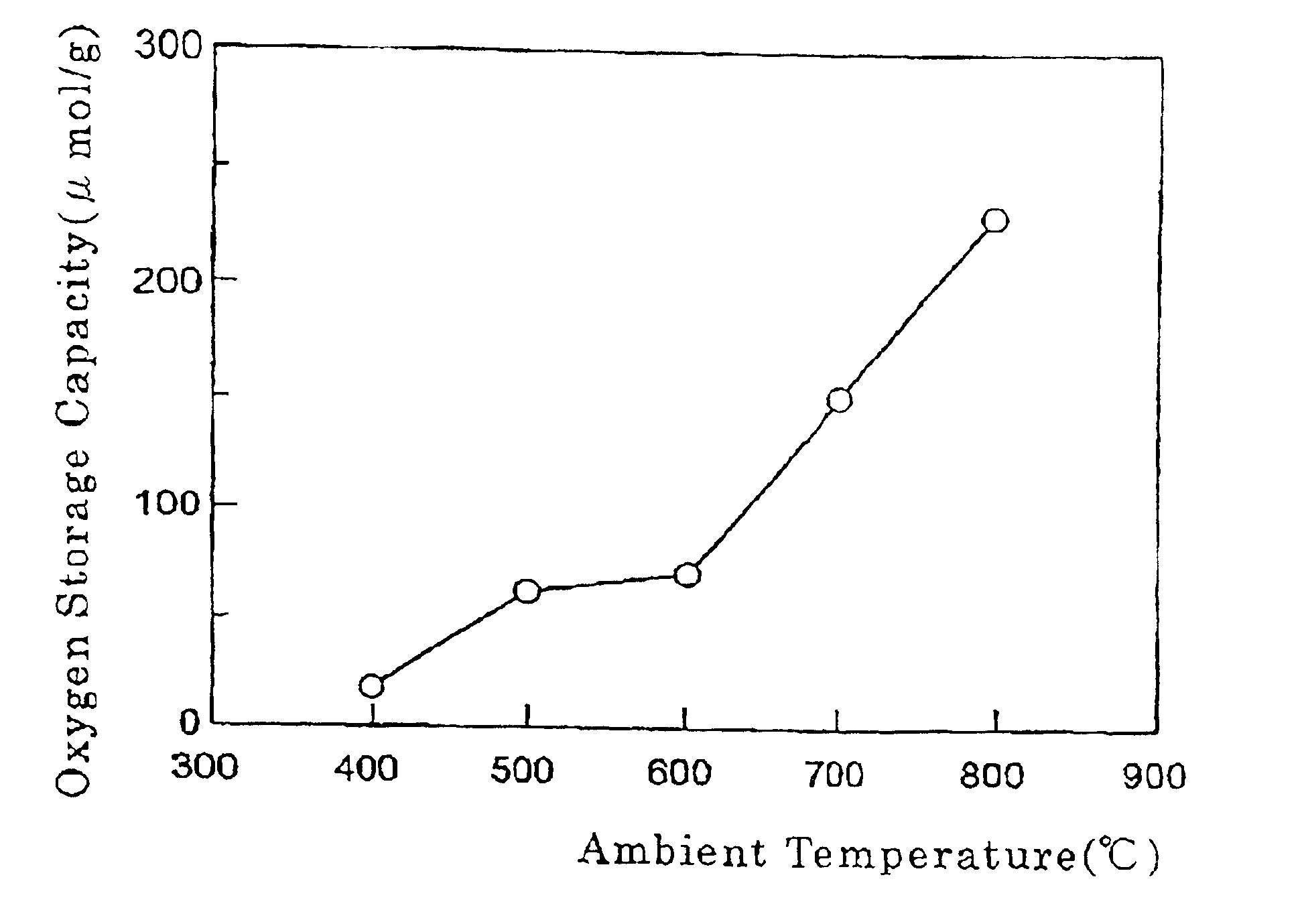

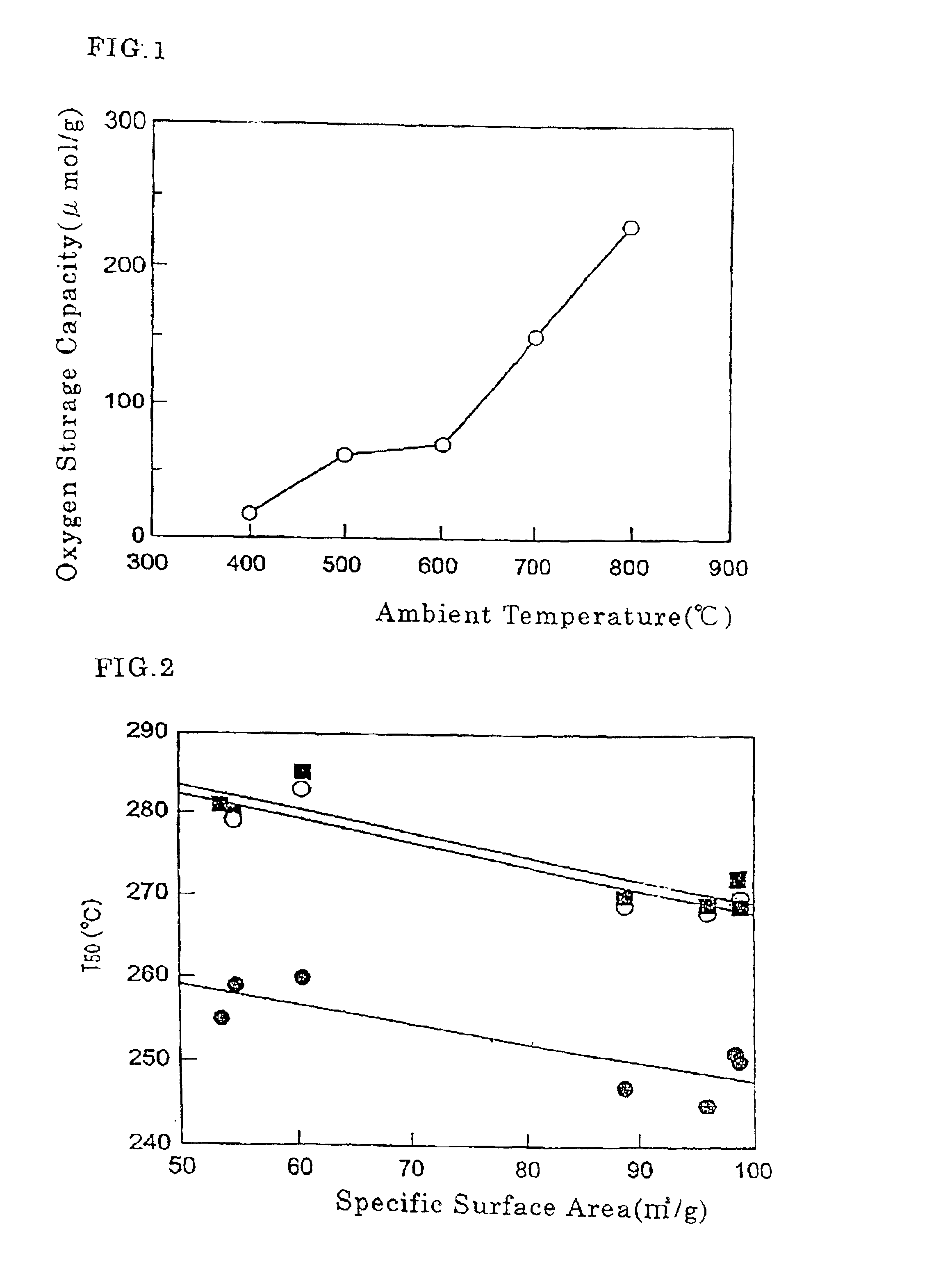

InactiveUS6831036B1Improve heat resistanceImprove oxygen storage capacityInternal combustion piston enginesOther chemical processesRare-earth elementPtru catalyst

A co-catalyst for purifying an exhaust gas which can be used for a loner period of time as an actual catalyst by using the cerium oxide in the conventional co-catalyst for purifying the exhaust gas as a cerium-containing complex oxide for elevating the resistance to heat and suppressing the performance reduction due to thermal deterioration and by making a specific surface area and an oxygen storage capacity over specified values. A co-catalyst for purifying an exhaust gas of the present invention includes a composite oxide including (a) cerium; and (b) at least one element selected from the group consisting of zirconium, yttrium, strontium, barium and a rare-earth element supported on a particulate aluminum oxide support; a specific surface area of the co-catalyst after sintering being not less than 40 m2 / g; an oxygen storage capacity at 400° C. being not less than 10 mumols / g and an oxygen storage capacity at 700° C. being not less than 100 mumols / g.

Owner:MITSUI MINING & SMELTING CO LTD

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

Cmp polishing slurry and method of polishing substrate

InactiveUS20070218811A1Decrease of residual film thicknessGreat polishing pressurePigmenting treatmentOther chemical processesStrong acidsSlurry

A CMP polishing slurry of the present invention, contains cerium oxide particles, a dispersant, a polycarboxylic acid, a strong acid having a pKa of its first dissociable acidic group at 3.2 or less, and water, the pH of the polishing slurry is 4.0 or more and 7.5 or less, wherein the strong acid is contained 100 to 1,000 ppm or 50 to 1,000 ppm, or the strong acid is a monovalent strong acid contained 50 to 500 ppm or is a bivalent strong acid contained 100 to 1,000 ppm. The preferable polycarboxylic acid is a polyacrylic acid. The present invention allows polishing in the CMP methods of surface-smoothening an interlayer dielectric film, a BPSG film and a shallow-trench-isolation insulation film with high speed operation efficiently and easier process management and cause smaller fluctuation in film thickness due to difference in pattern density.

Owner:HITACHI CHEM CO LTD

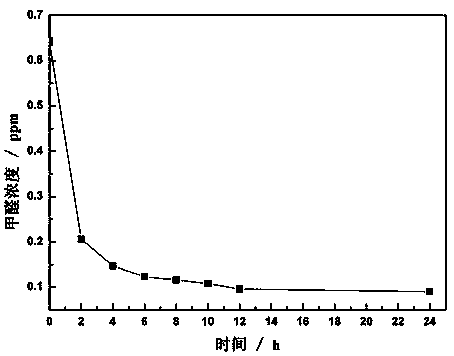

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

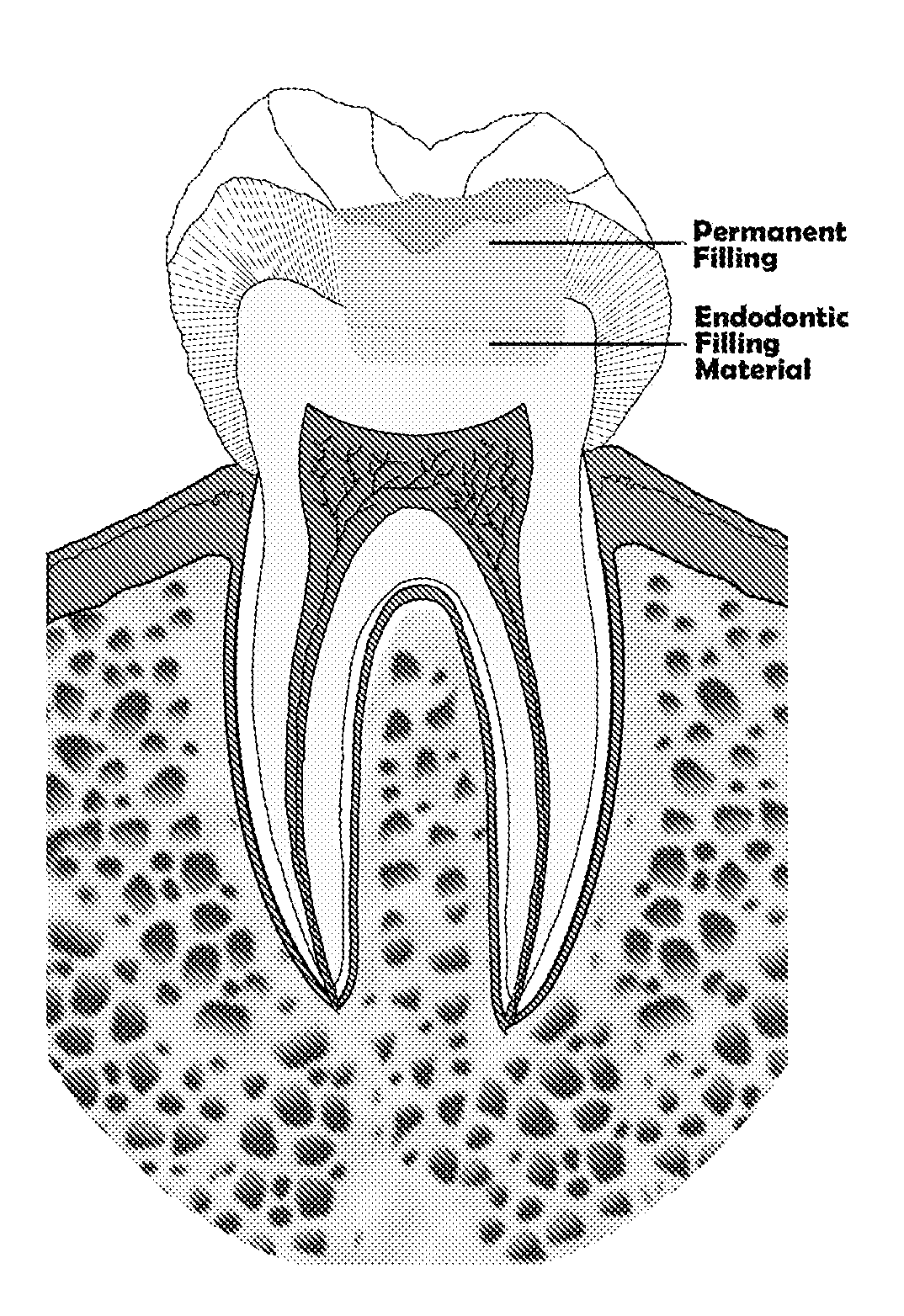

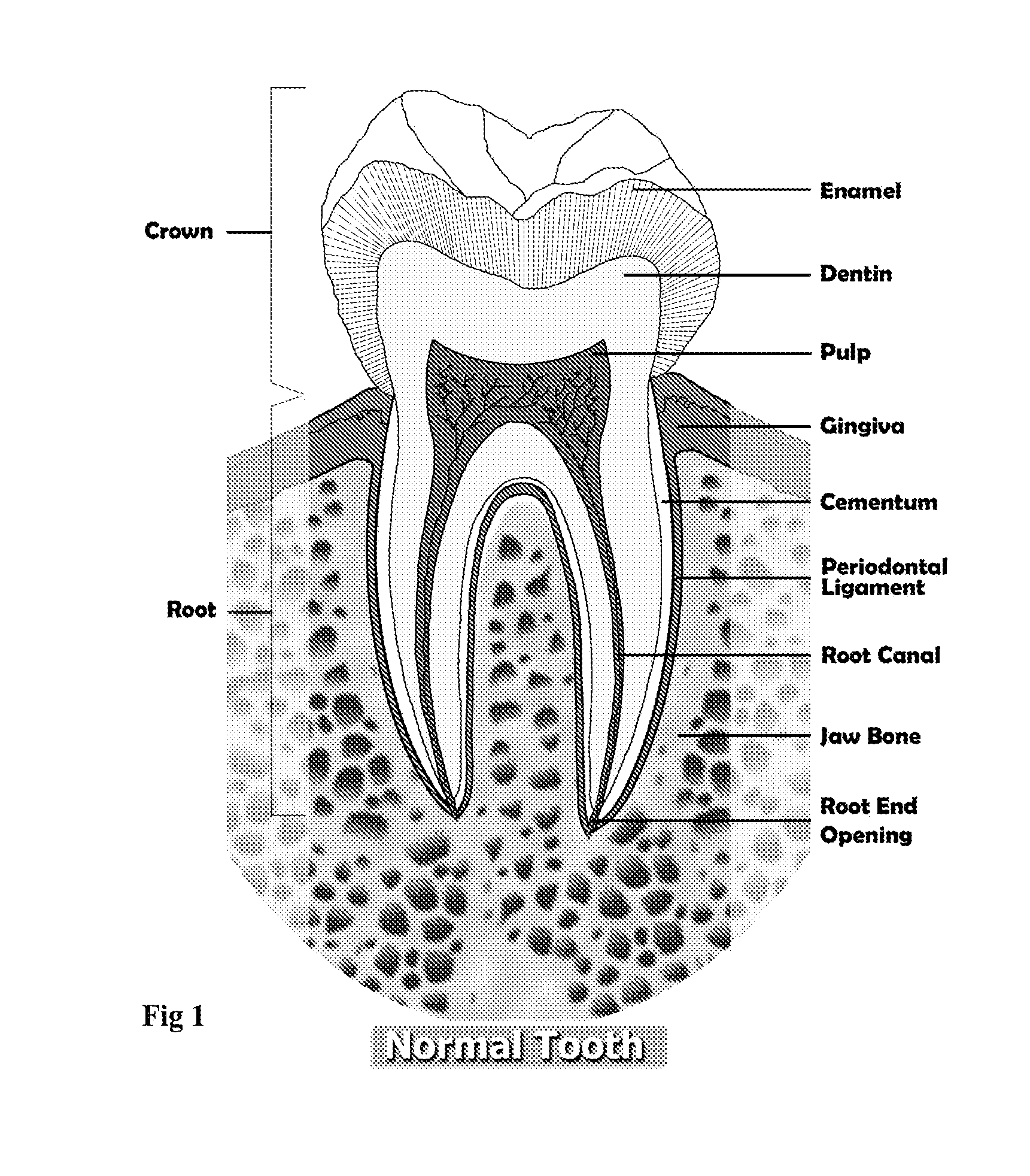

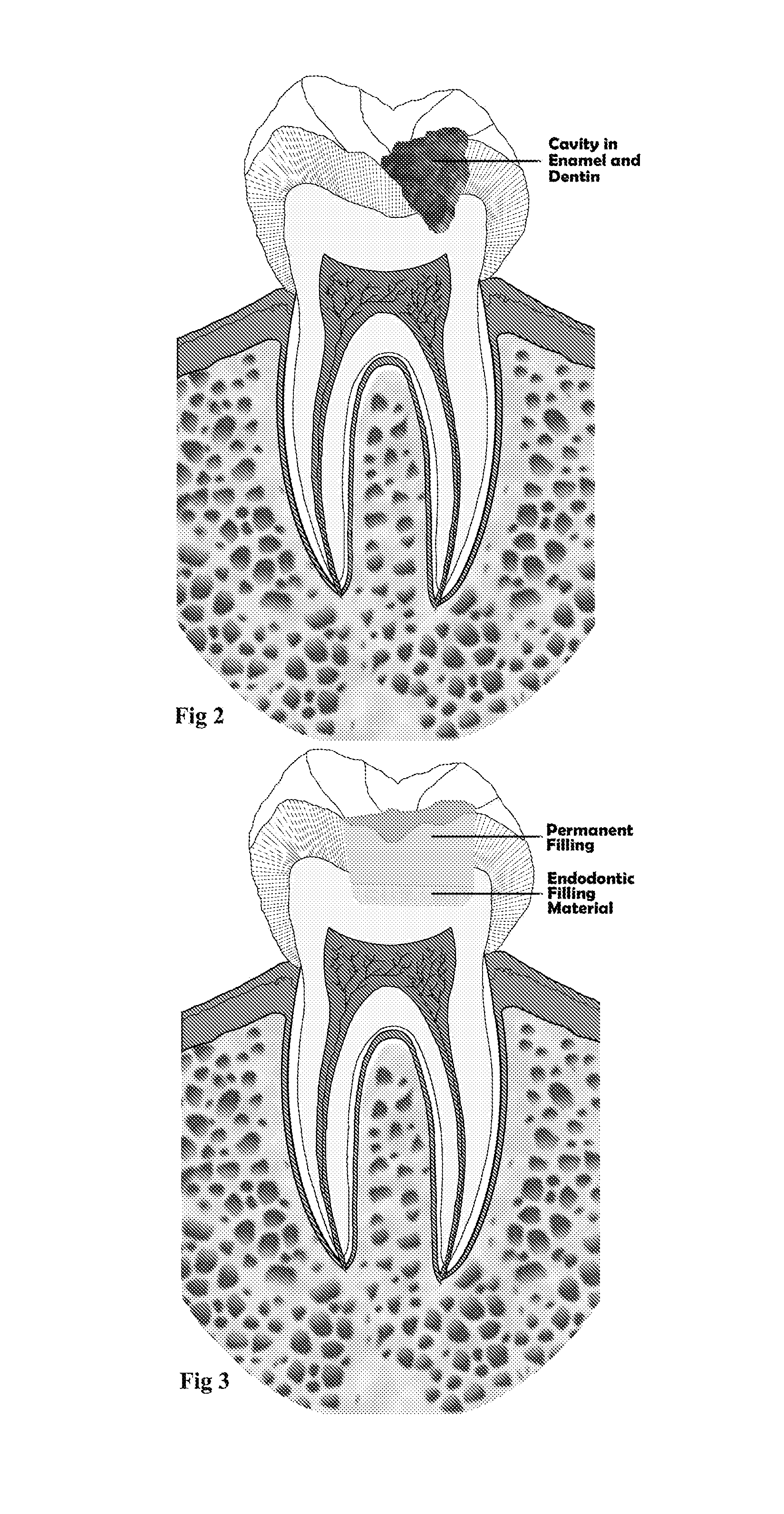

Endodontic filling material

InactiveUS20080206716A1Improve sealingEasily manipulationAntibacterial agentsOther chemical processesCalcium silicateHigh concentration

The present invention is a bioactive endodontic material and its use for filling the tooth and bone cavities. The present invention, by using calcium salt, calcium oxide, calcium silicate, and calcium phosphate compounds as essential constituents, and mixing them with a water base solution, prepares a bioactive calcium and phosphate enriched material. The enriched material (cement) comprises high concentration of water-soluble calcium and phosphate, and immediately forms hydroxyapatite during and after setting. The cement is biocompatible, antibacterial, capable to form an effective seal against reentrance of microorganisms into the filled cavity, compatible to handle and set in an aqueous environment, and able to stimulate hard tissue healing.

Owner:ASGARY SAEED

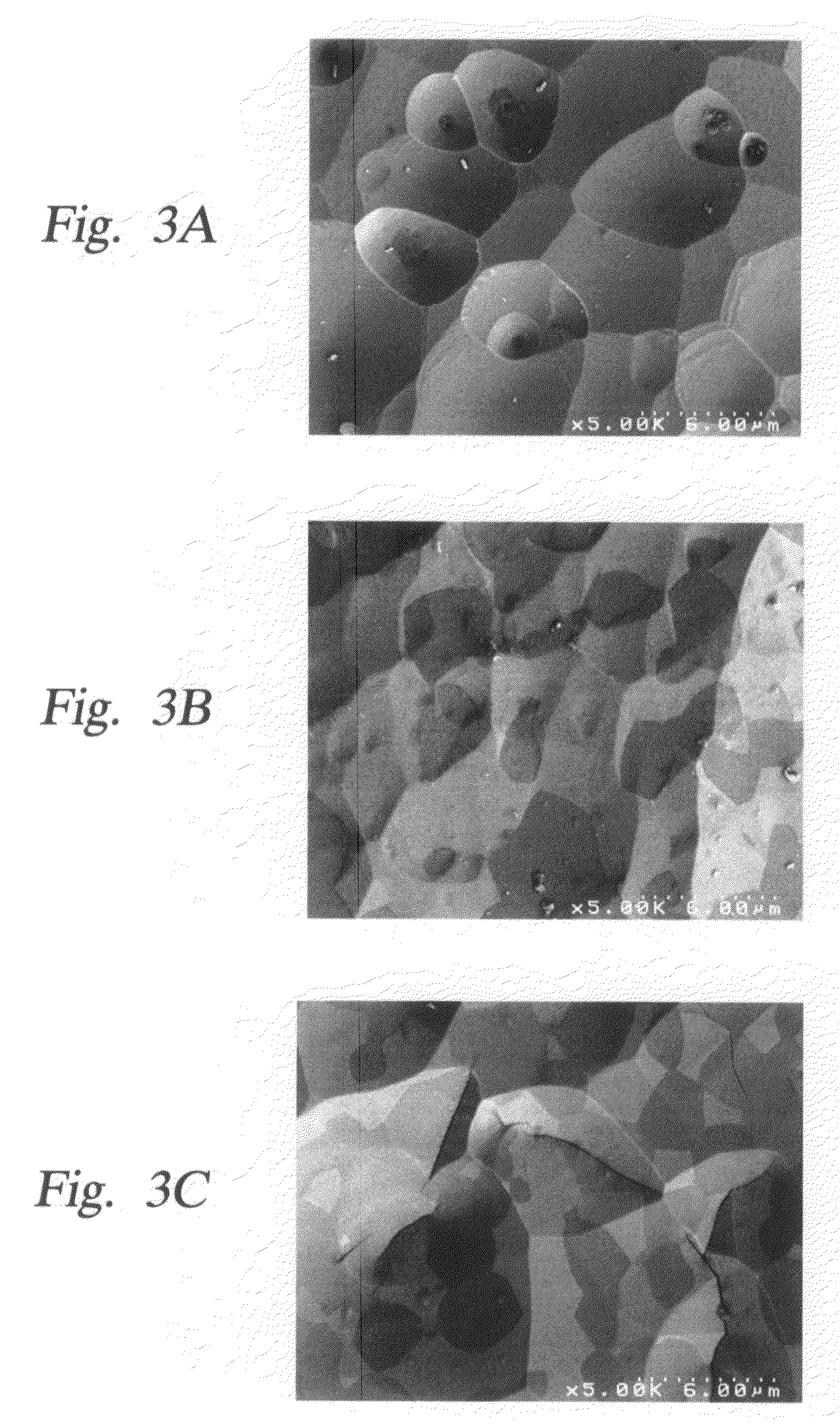

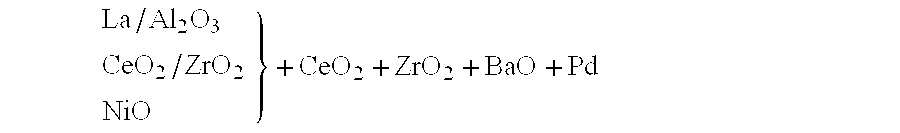

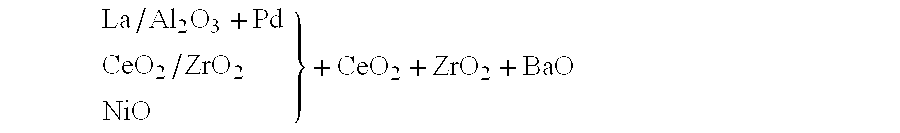

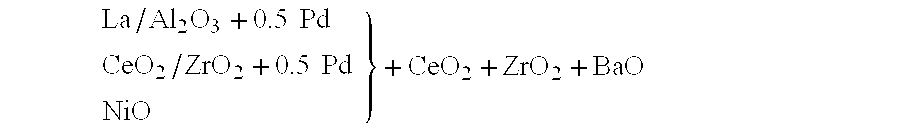

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

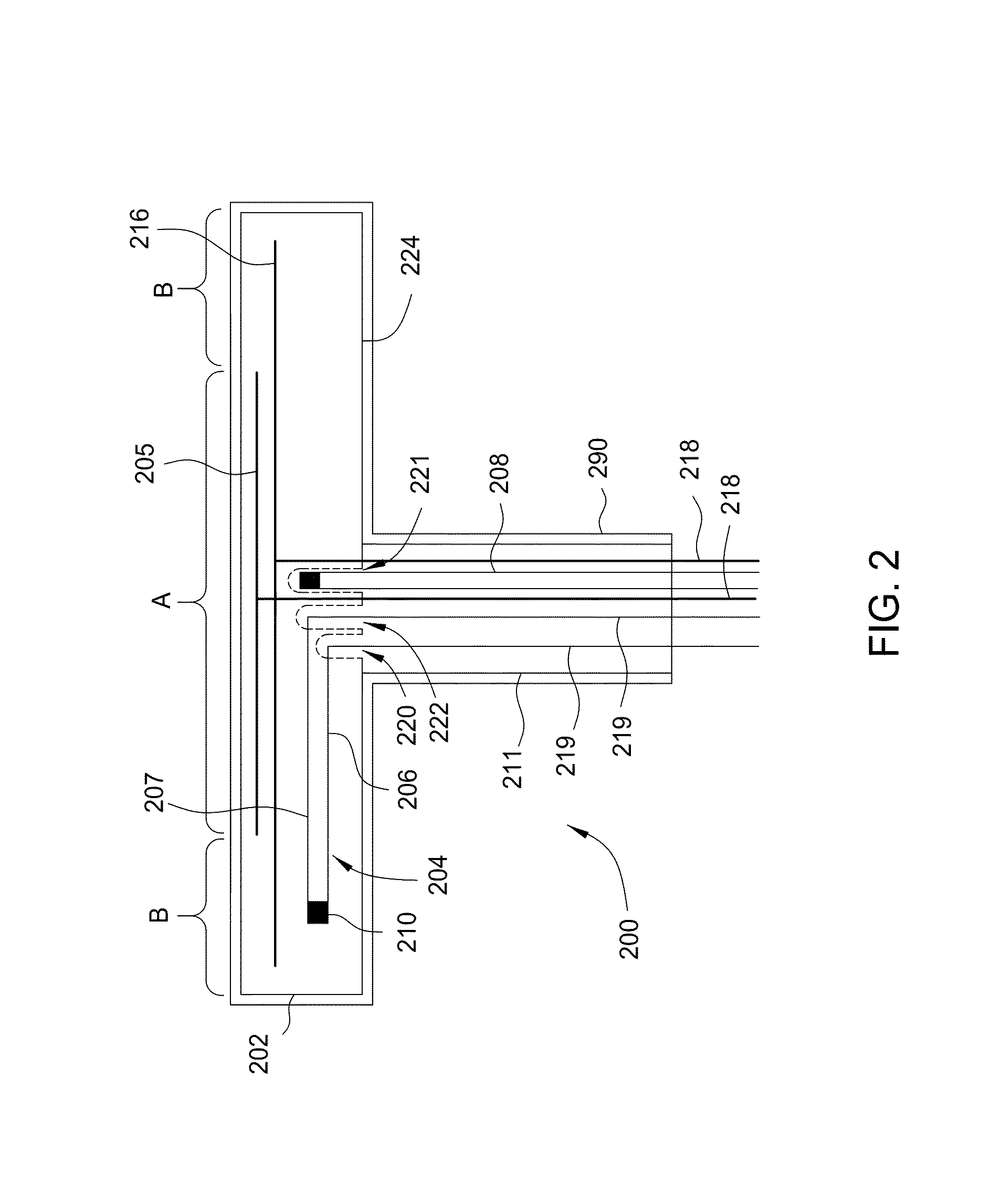

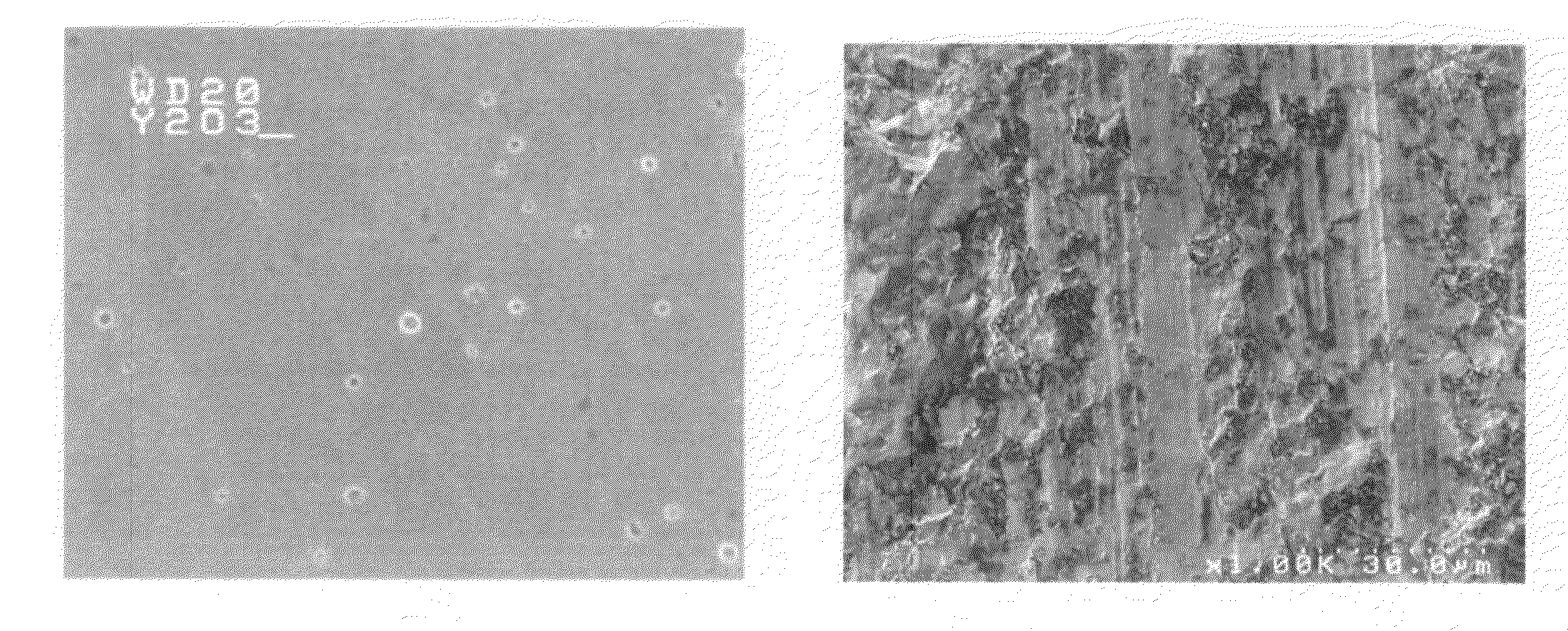

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

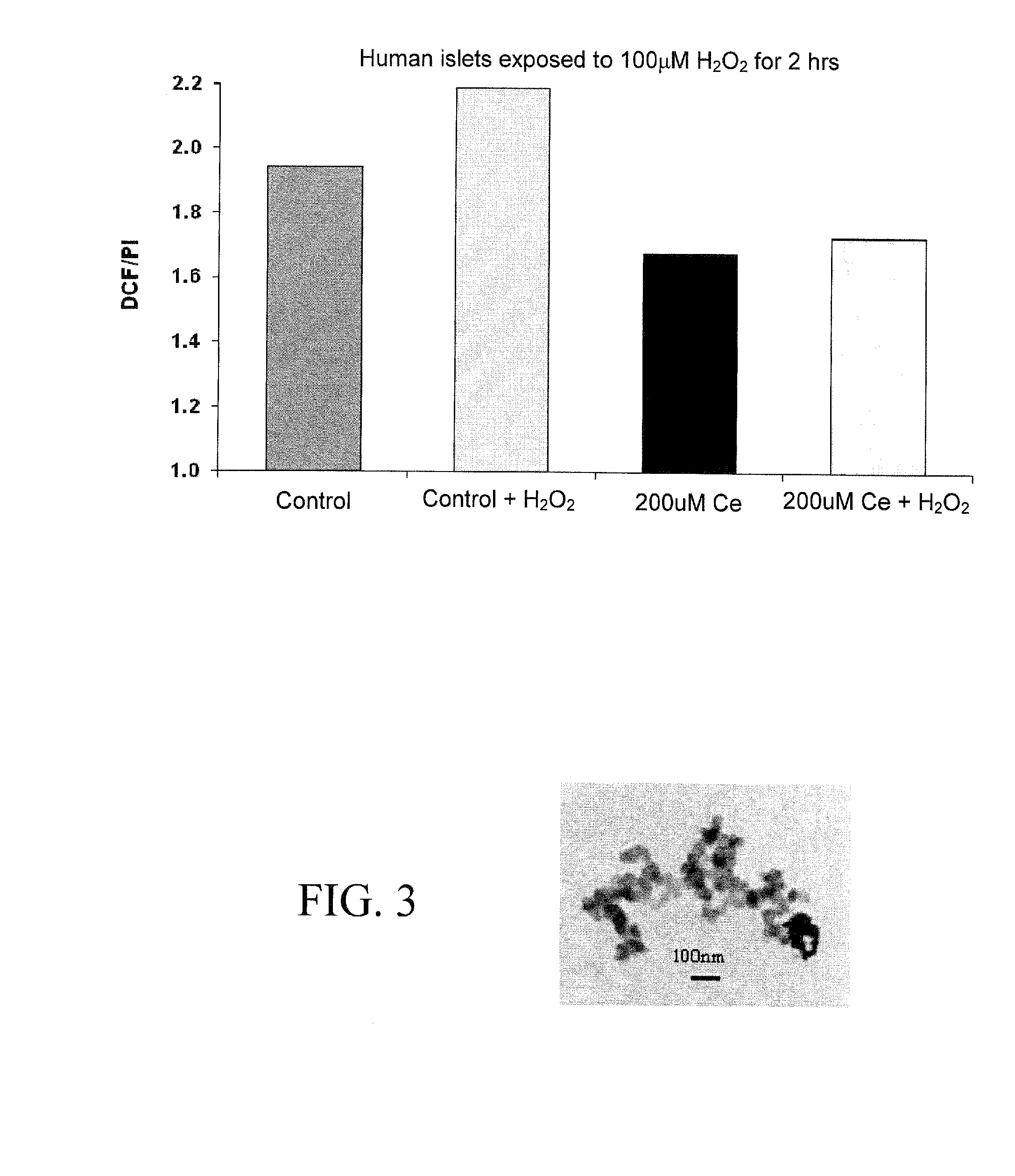

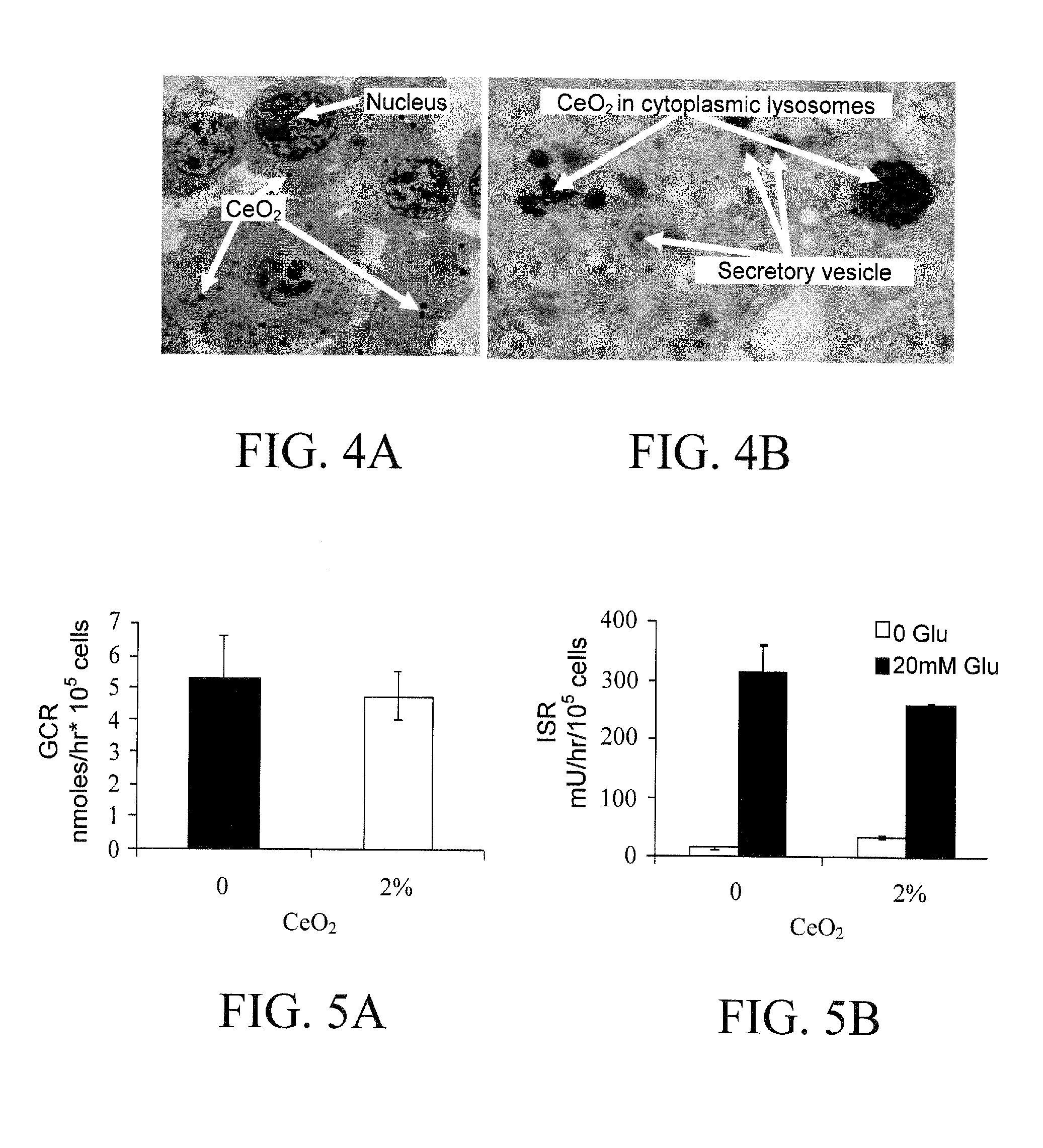

Nanoparticles for Protection of Cells from Oxidative Stress

InactiveUS20100172994A1Increase the number ofImprove survivabilityHeavy metal active ingredientsBiocideMetal oxide nanoparticlesMedicine

The present invention concerns metal oxide semiconductor nanoparticles with free radical scavenging activity, compositions comprising such nanoparticles, methods for their use, and methods for their production. In one aspect, the invention concerns a method for enhancing the survival or viability of transplanted cells, comprising administering an effective amount of metal oxide semiconductor nanoparticles to a target anatomical site of a subject before, during, or after administration of transplant cells to the subject. Preferably, the metal oxide nanoparticle is a cerium oxide (ceria) nanoparticle.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

Calcium oxide-based ceramic core for casting titanium alloy and manufacturing method thereof

The invention discloses a calcium oxide-based ceramic core for casting titanium alloy and a manufacturing method of the calcium oxide-based ceramic core. The calcium oxide-based ceramic core comprises the following components by weight percent: 1.0-15.0% of zirconium dioxide, 0.5-10.0% of yttrium oxide, 0.05-0.1% of thorium oxide and the balance of calcium oxide, and the sum of the contents of the above the component is 100%. According to the ceramic core, the bending strength is 15-30Mpa at room temperature, the bending strength is 5-10Mpa at high temperature, the high-temperature deflection is 0.2-0.5%, the firing shrinkage ratio is 1-1.5%, and the porosity is 40-50%. Compared with the existing commercial alumina-based ceramic core and silicon oxide-based ceramic core, the calcium oxide-based ceramic core of the invention greatly reduces the reactivity with molten titanium, and has the advantages of high temperature resistance, easiness in core leach, low in cost and the like.

Owner:BEIHANG UNIV

CO oxidation promoters for use in FCC processes

InactiveUS7045056B2Improved CO oxidation promotion activityCatalytic crackingMolecular sieve catalystsLanthanideCopper

A composition for controlling CO and NOx emissions during FCC processes comprises (i) acidic oxide support, (ii) cerium oxide, (iii) lanthanide oxide other than ceria such as praseodymium oxide (iv), optionally, oxide of a metal from Groups Ib and IIb such as copper, silver and zinc and (v) precious metal such as Pt and Pd.

Owner:ENGELHARD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com