Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6203results about How to "Improve flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

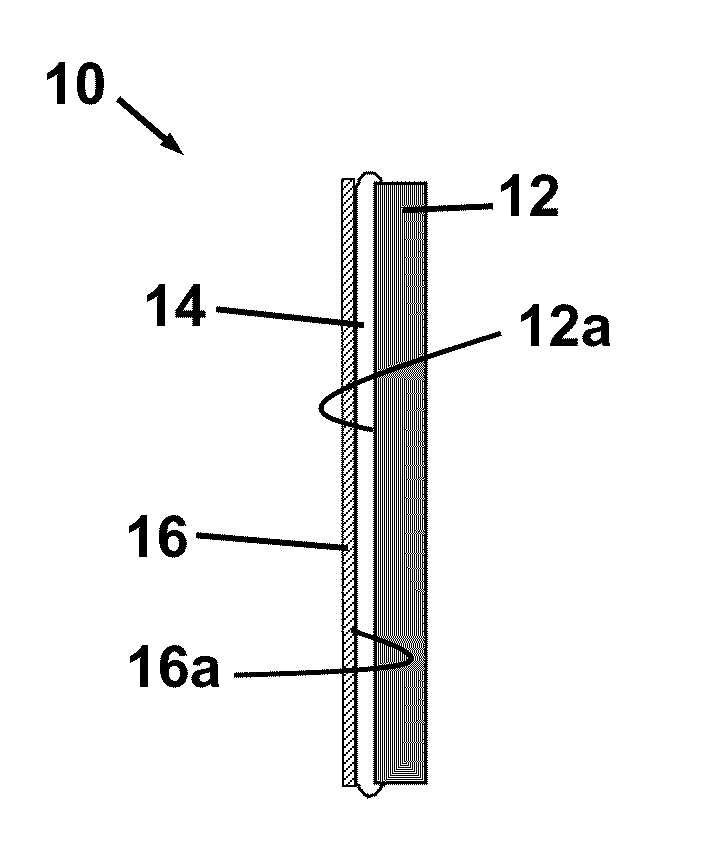

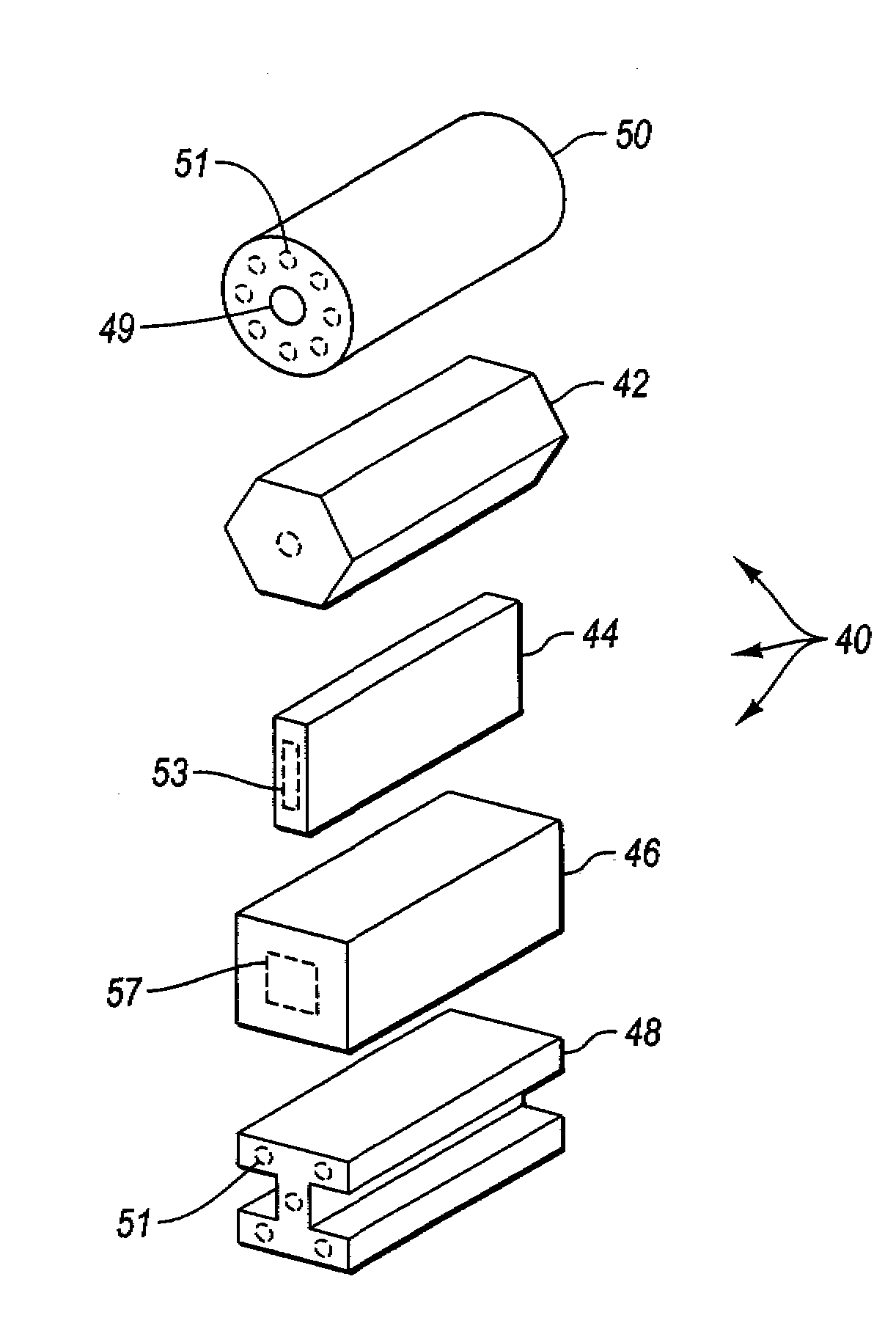

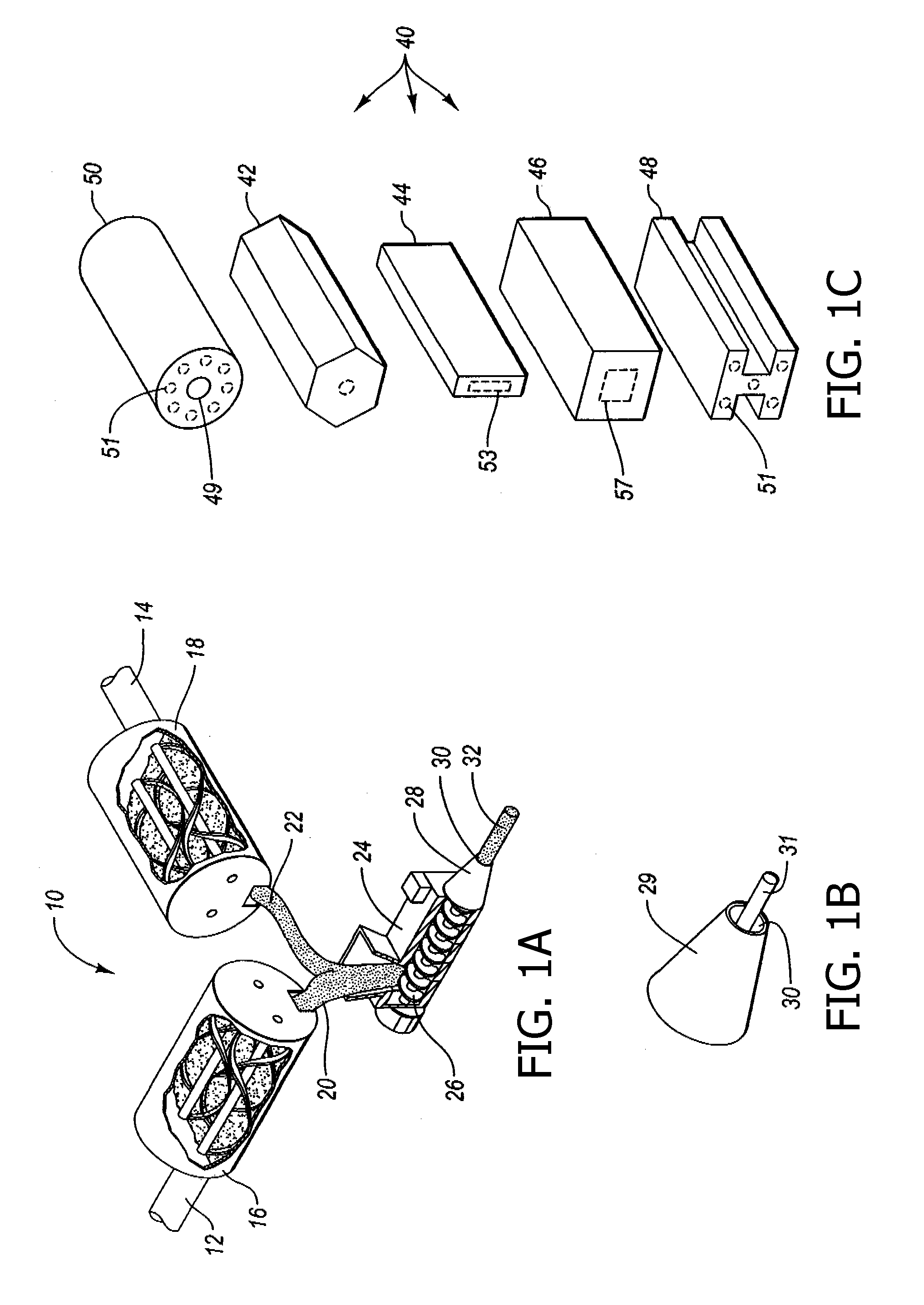

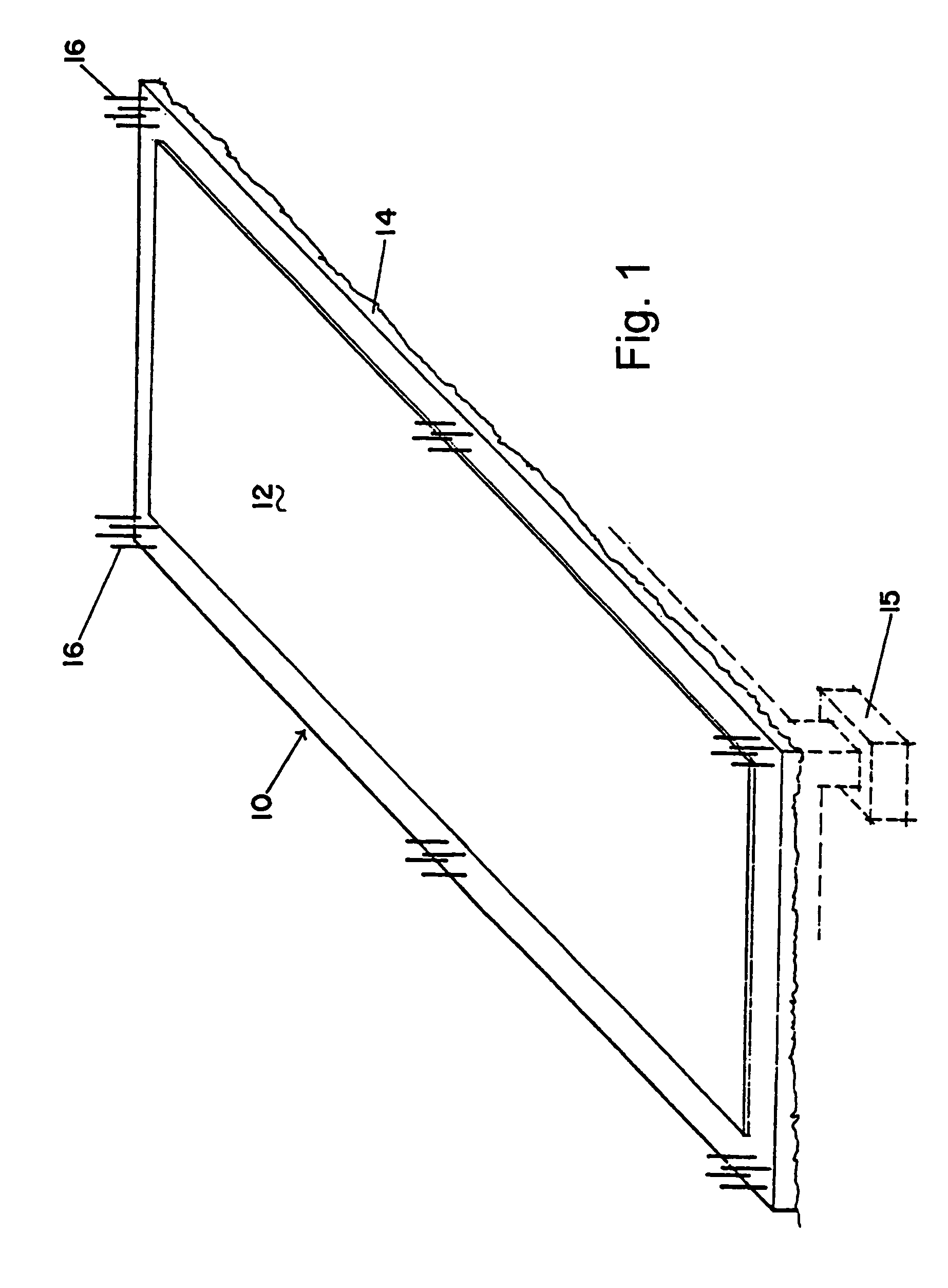

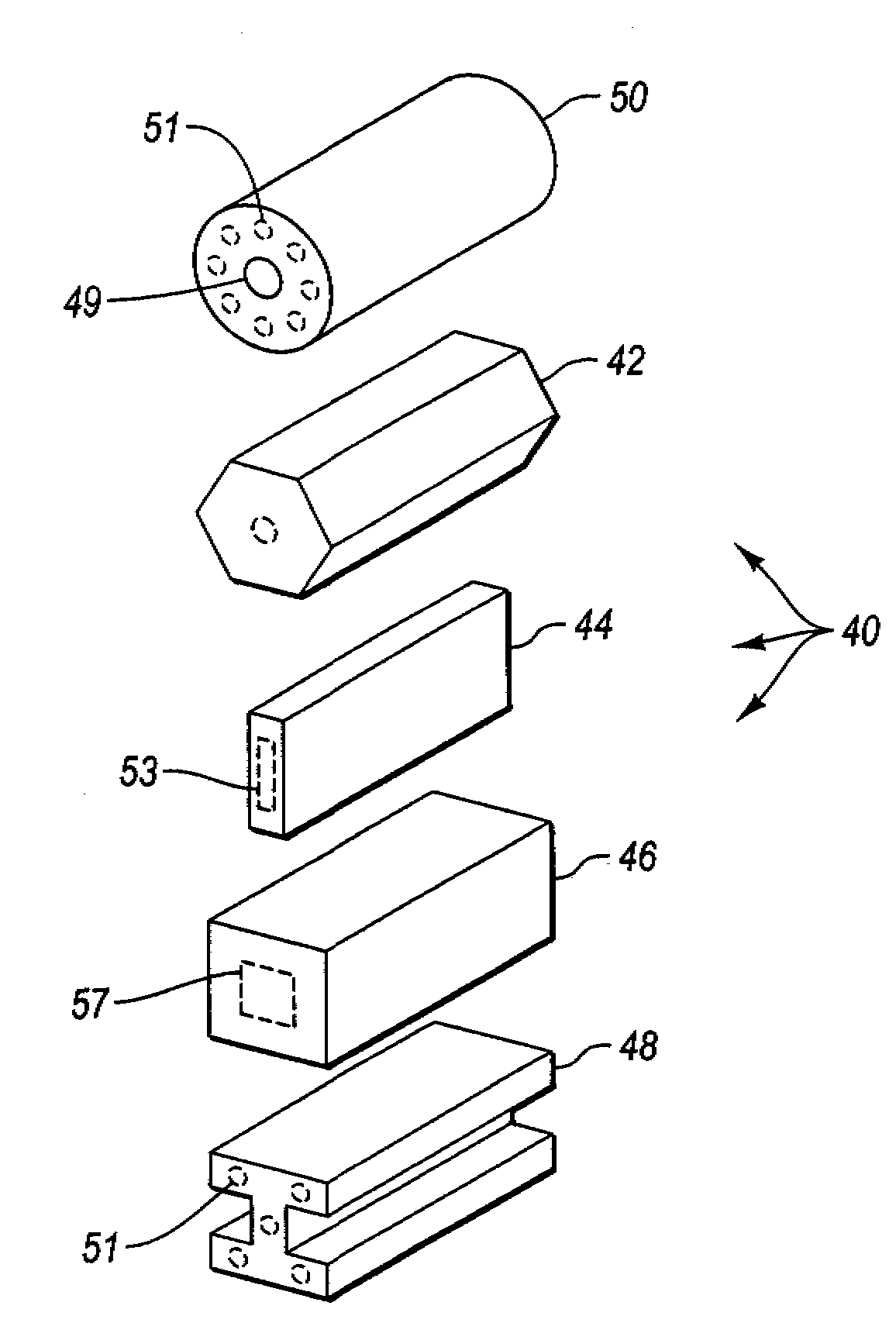

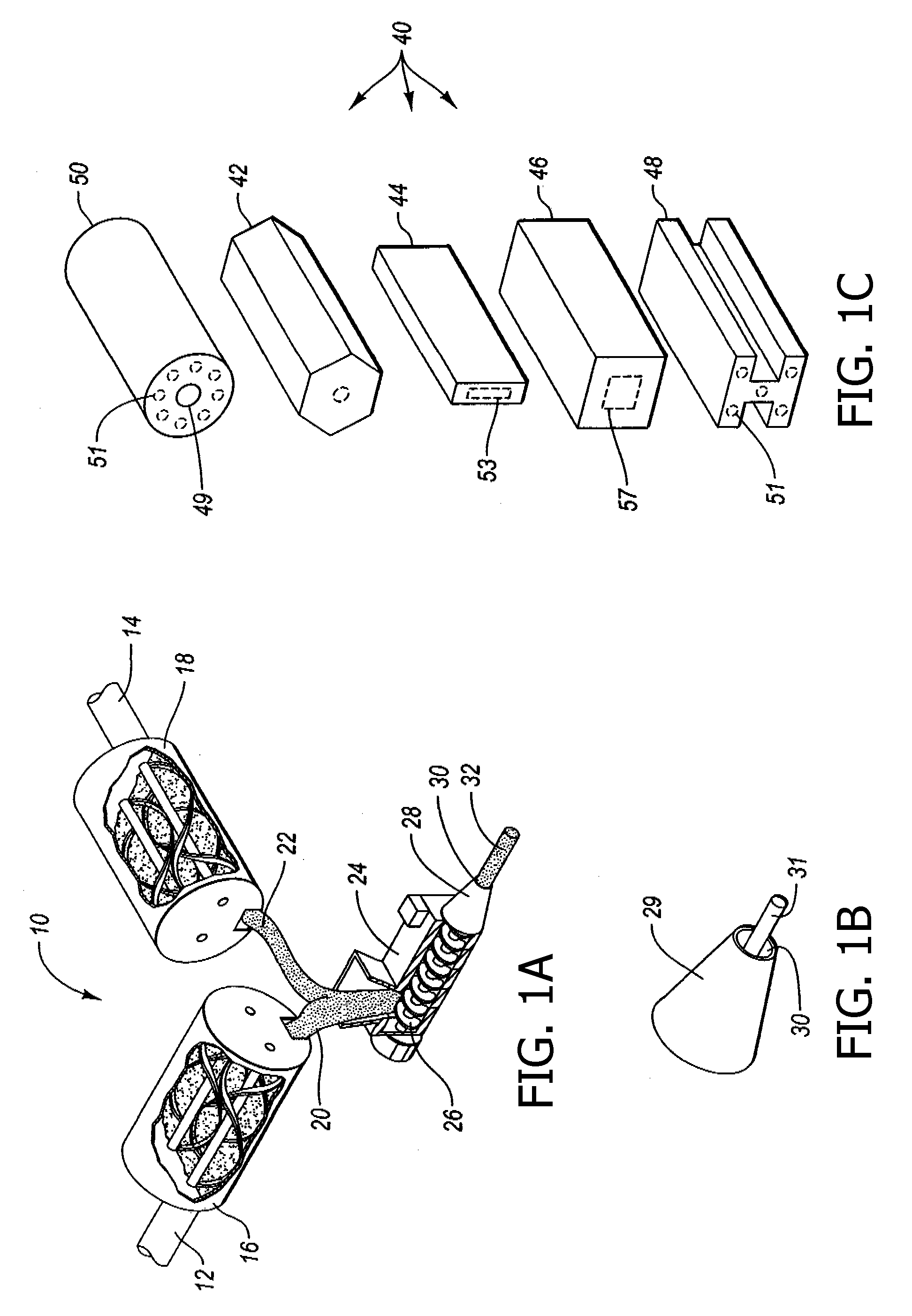

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

Impact-damage-resistant glass sheet

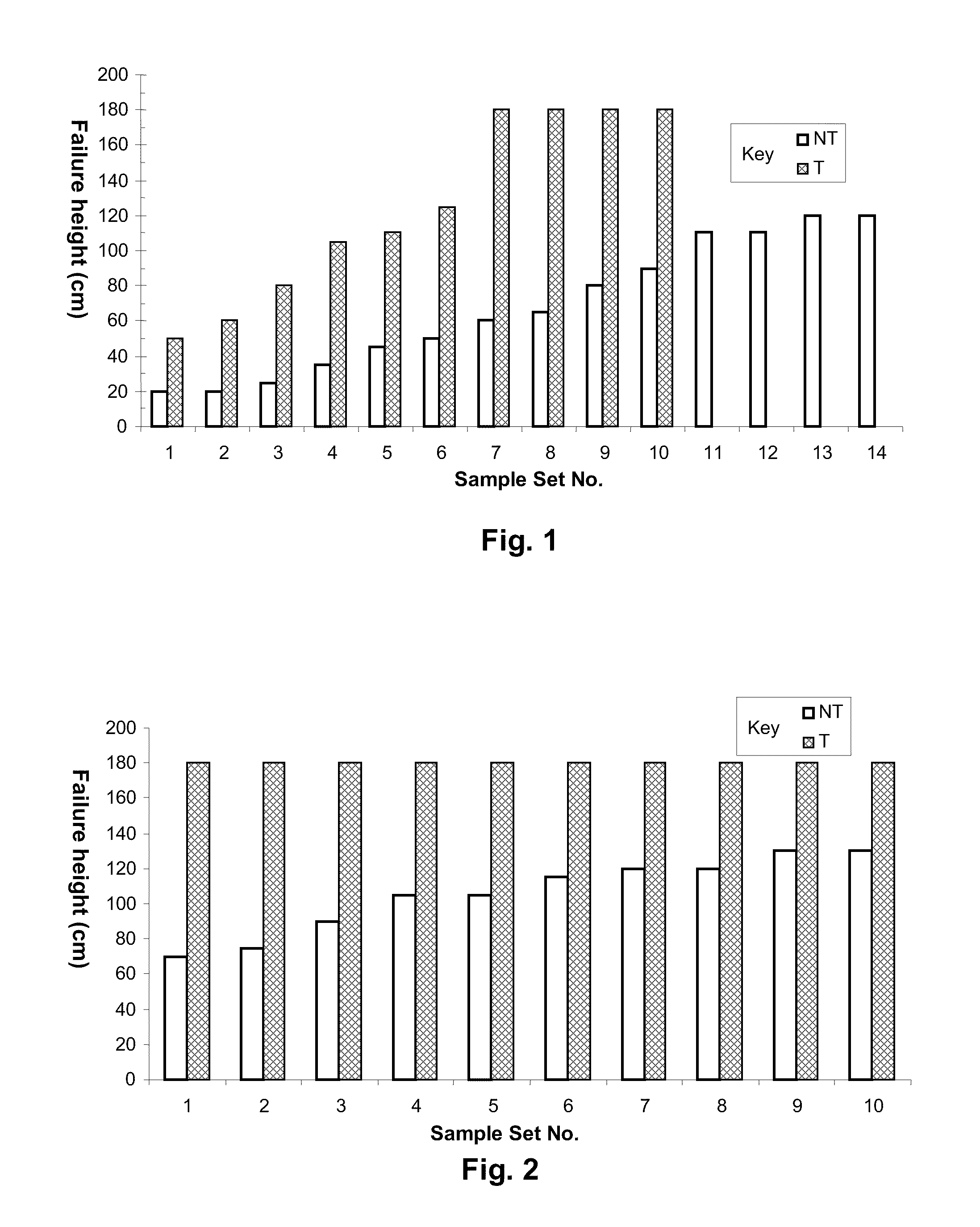

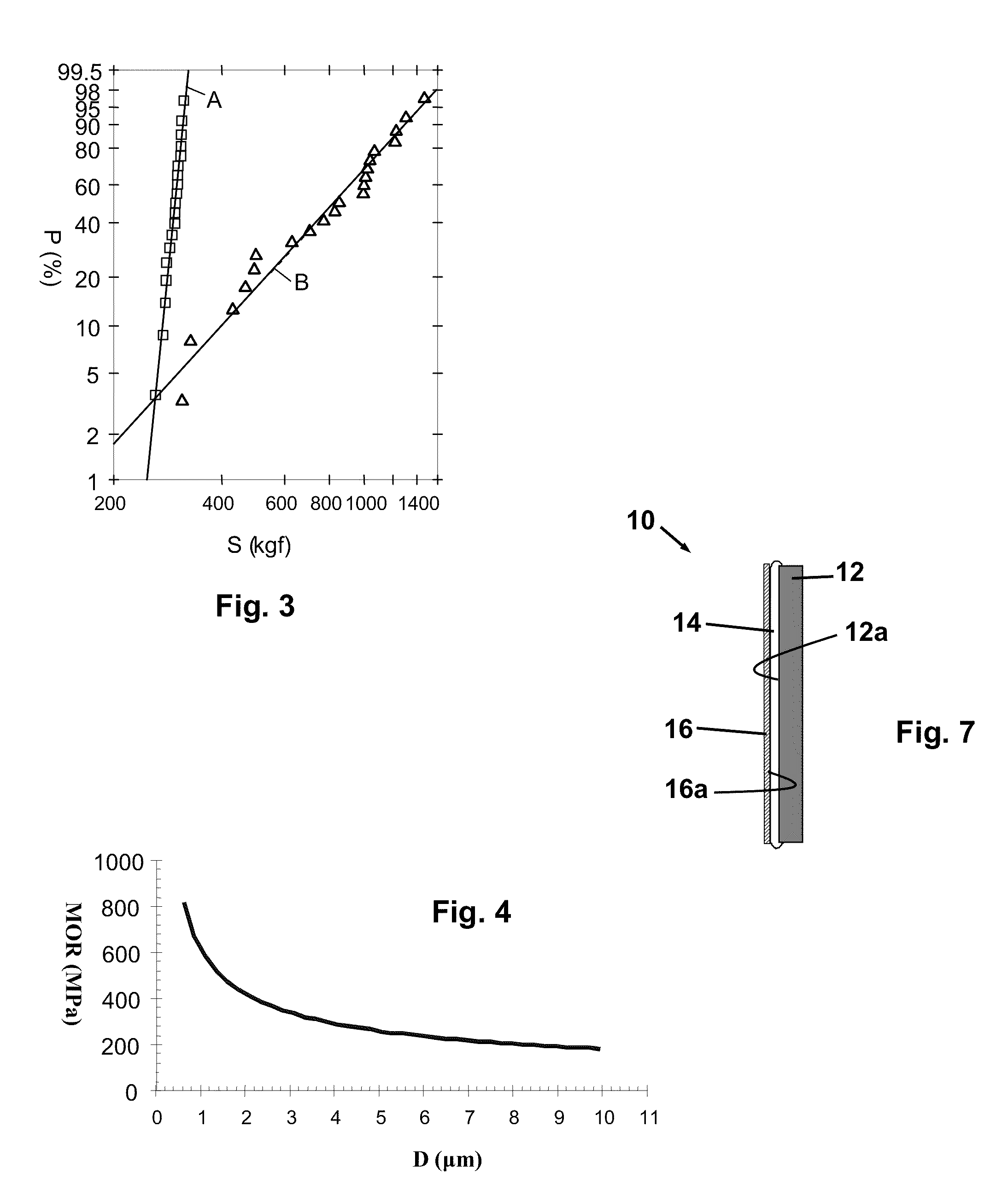

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

Wood-plastic composite material and prepration method thereof

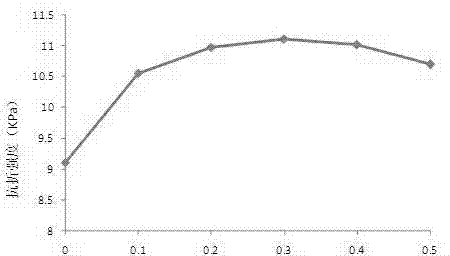

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

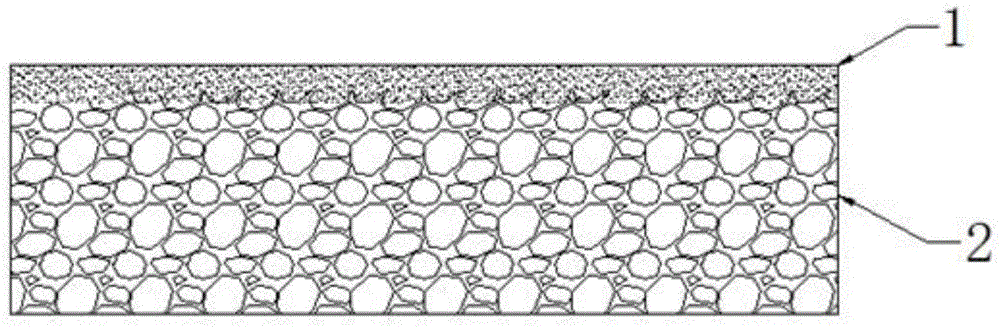

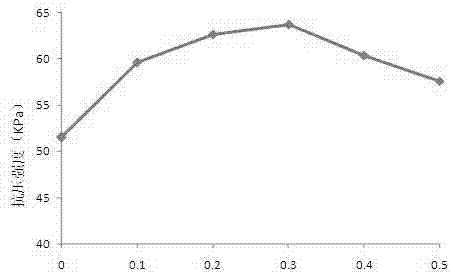

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

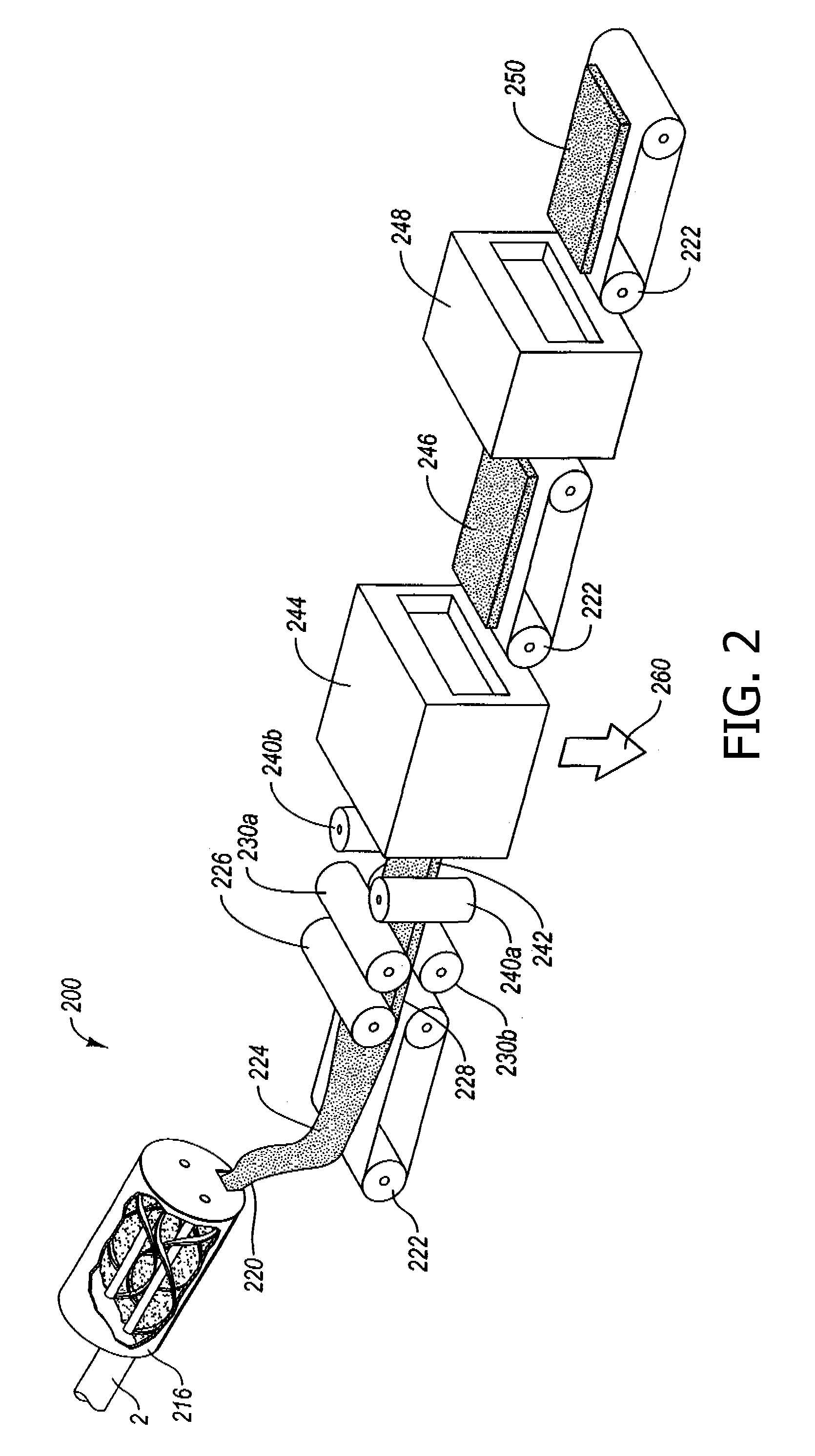

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

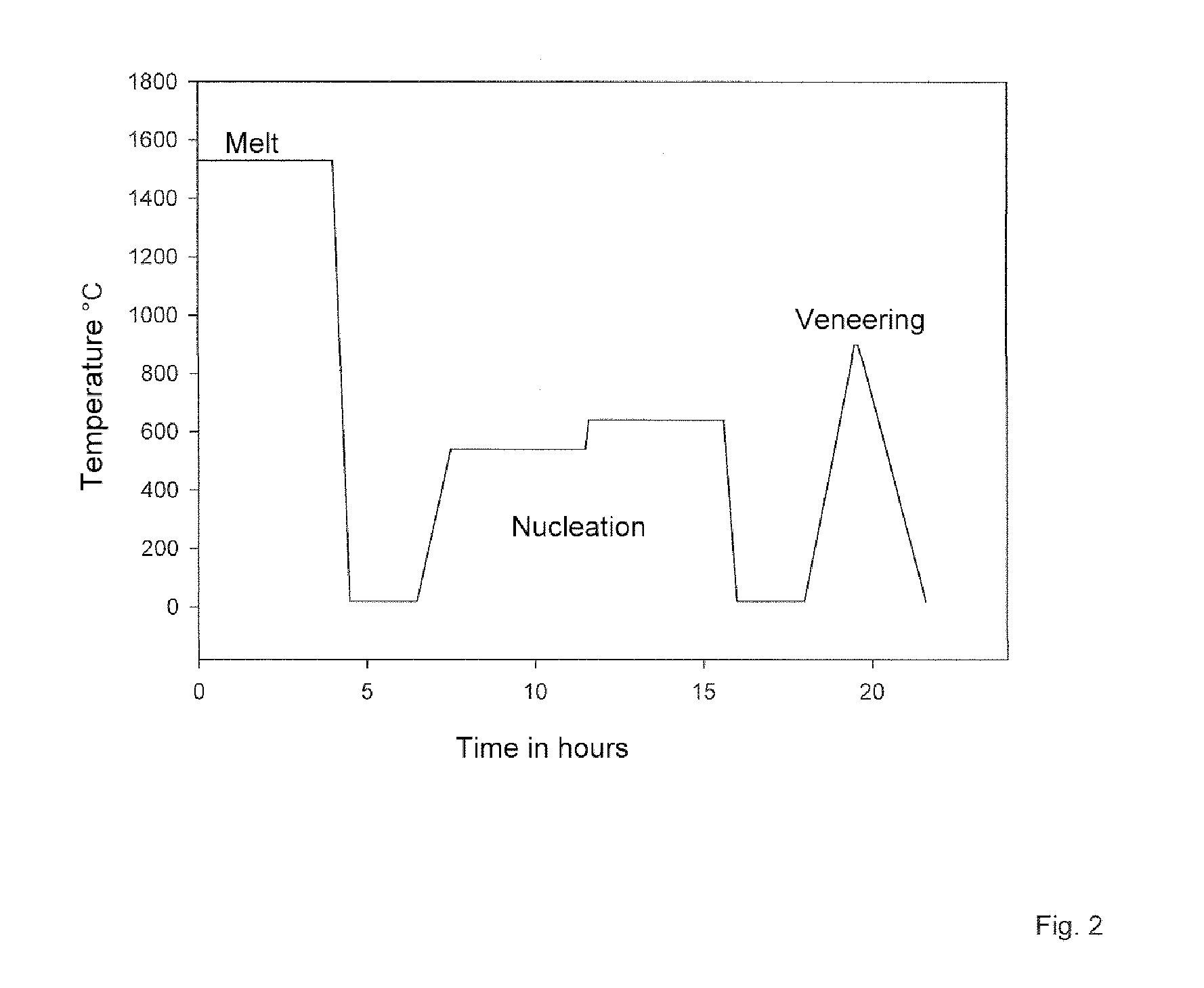

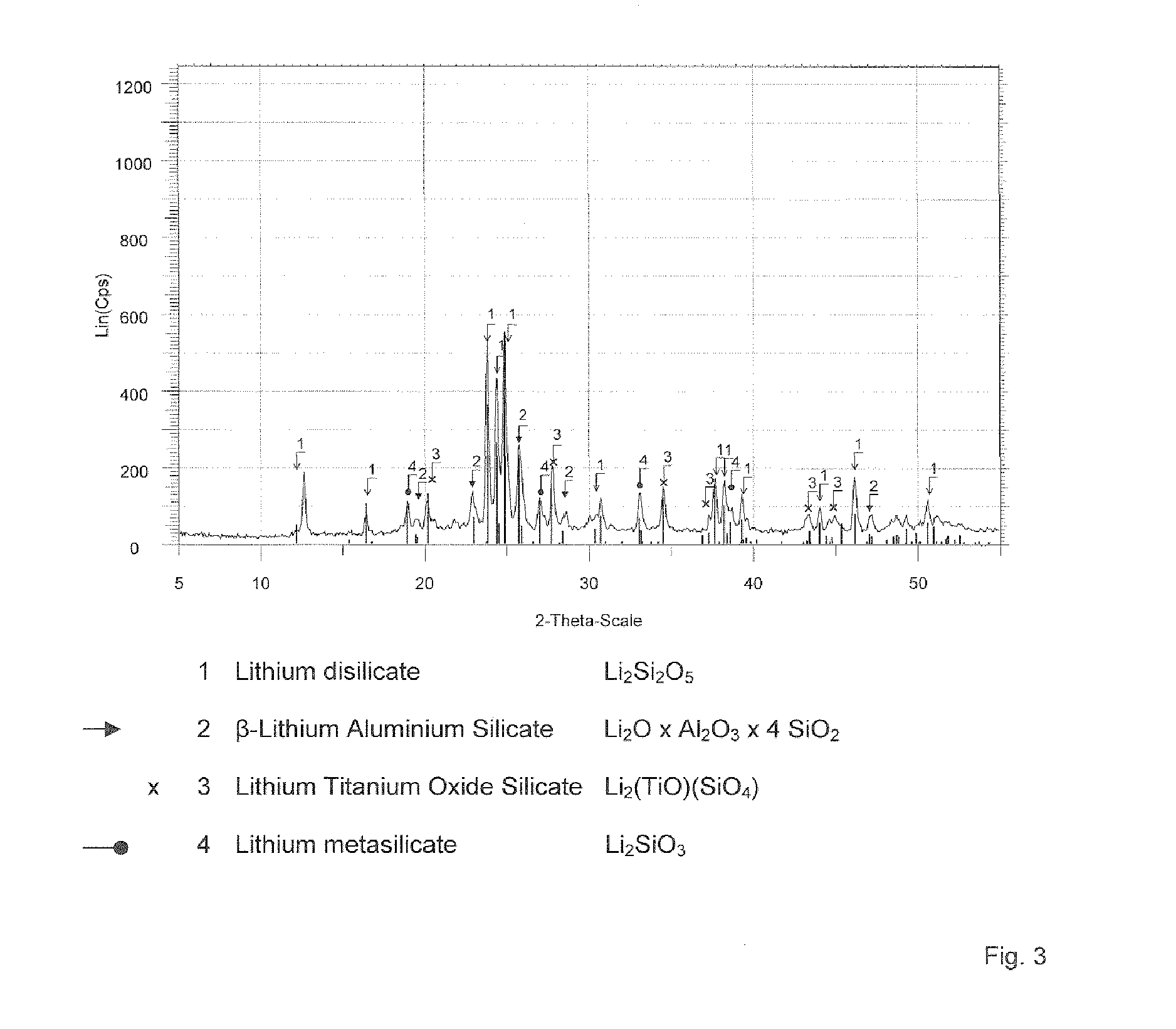

Veneer Ceramic for Dental Restorations and Method for Veneering Dental Restorations

ActiveUS20110030423A1Improve flexural strengthImprove adhesionDental implantsImpression capsFlexural strengthYttrium

The invention is directed to veneer ceramics for dental restorations of framework ceramics comprising yttrium-stabilized zirconium dioxide. It is the object of the invention to make possible a translucent veneer ceramic which has high flexural strength as well as excellent adhesion to the framework ceramic of yttrium-stabilized zirconium dioxide. According to the invention, this object is met in a veneer ceramic for dental restorations made of yttrium-stabilized zirconium dioxide which is produced from the following components:a)SiO258.0-74.0 percent by weightb) Al2O3 4.0-19.0 percent by weightc)Li2O 5.0-17.0 percent by weightd)Na2O 4.0-12.0 percent by weighte) ZrO2 0.5-6.0 percent by weight.

Owner:IVOCLAR VIVADENT AG

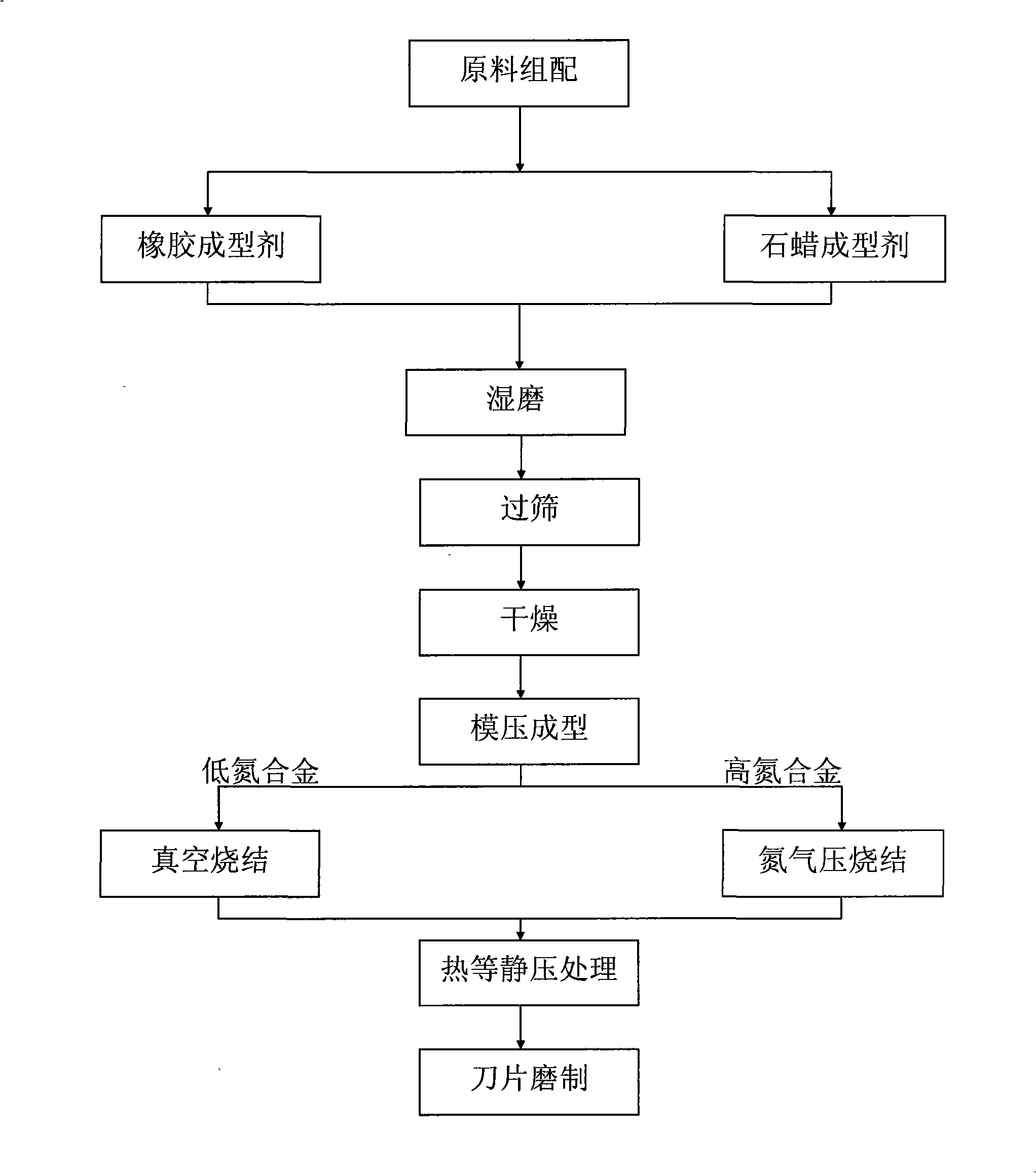

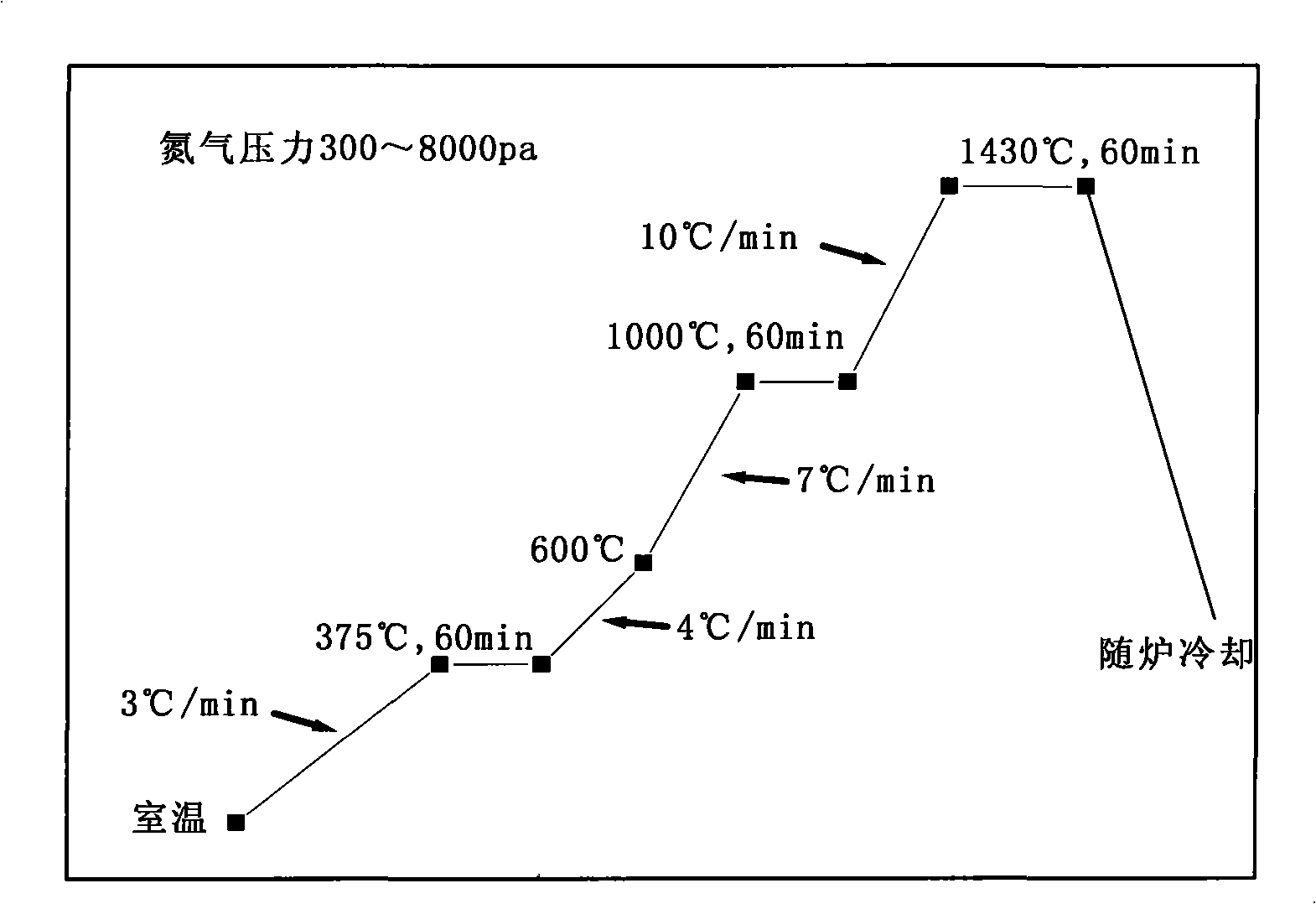

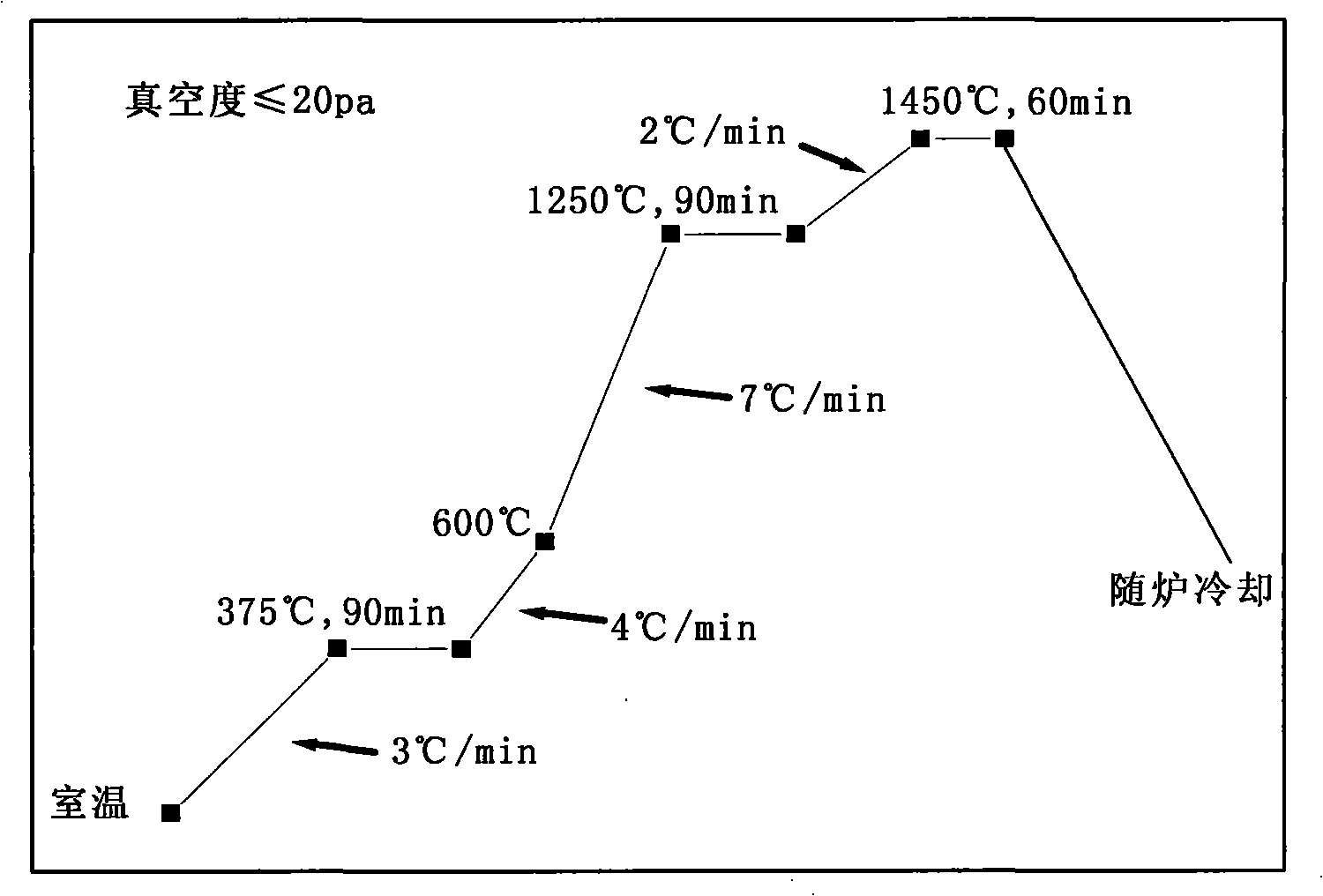

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

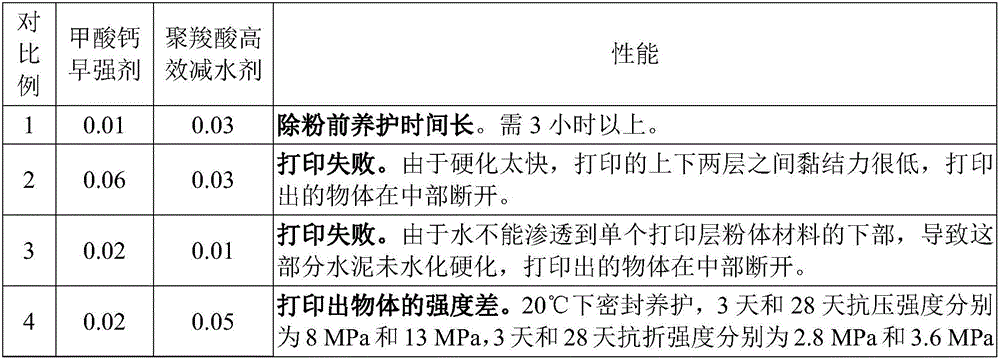

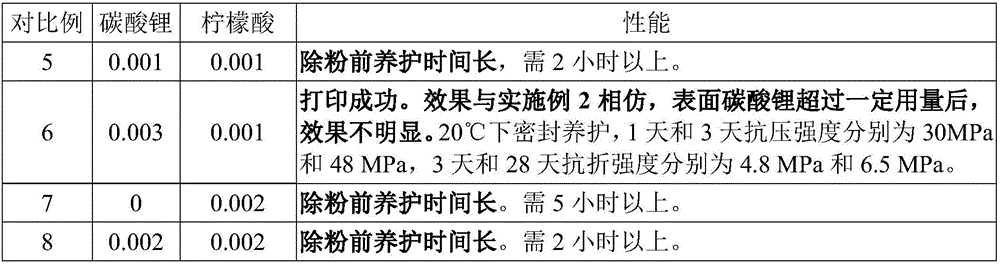

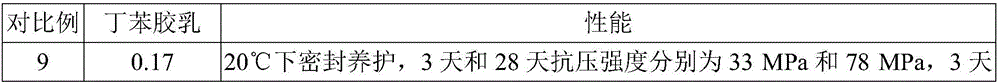

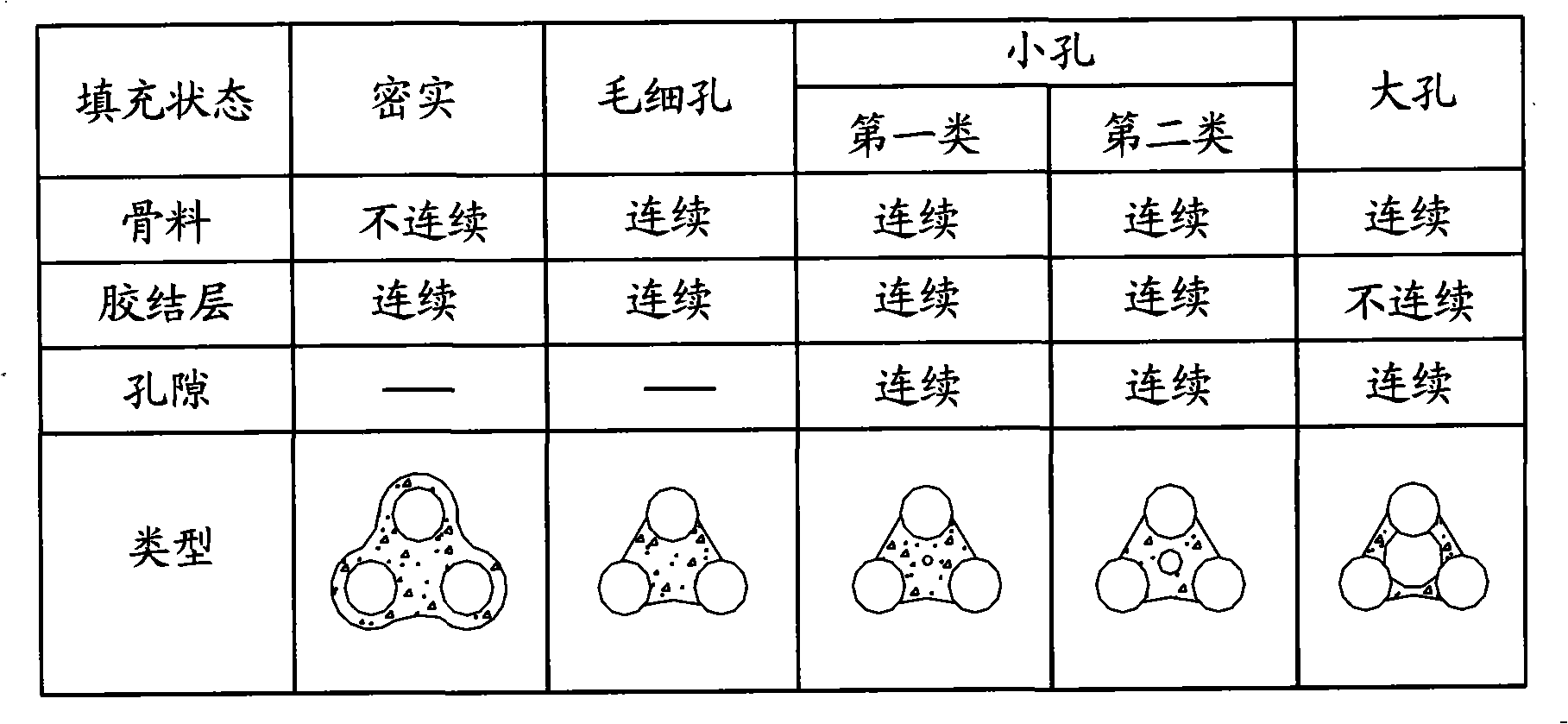

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

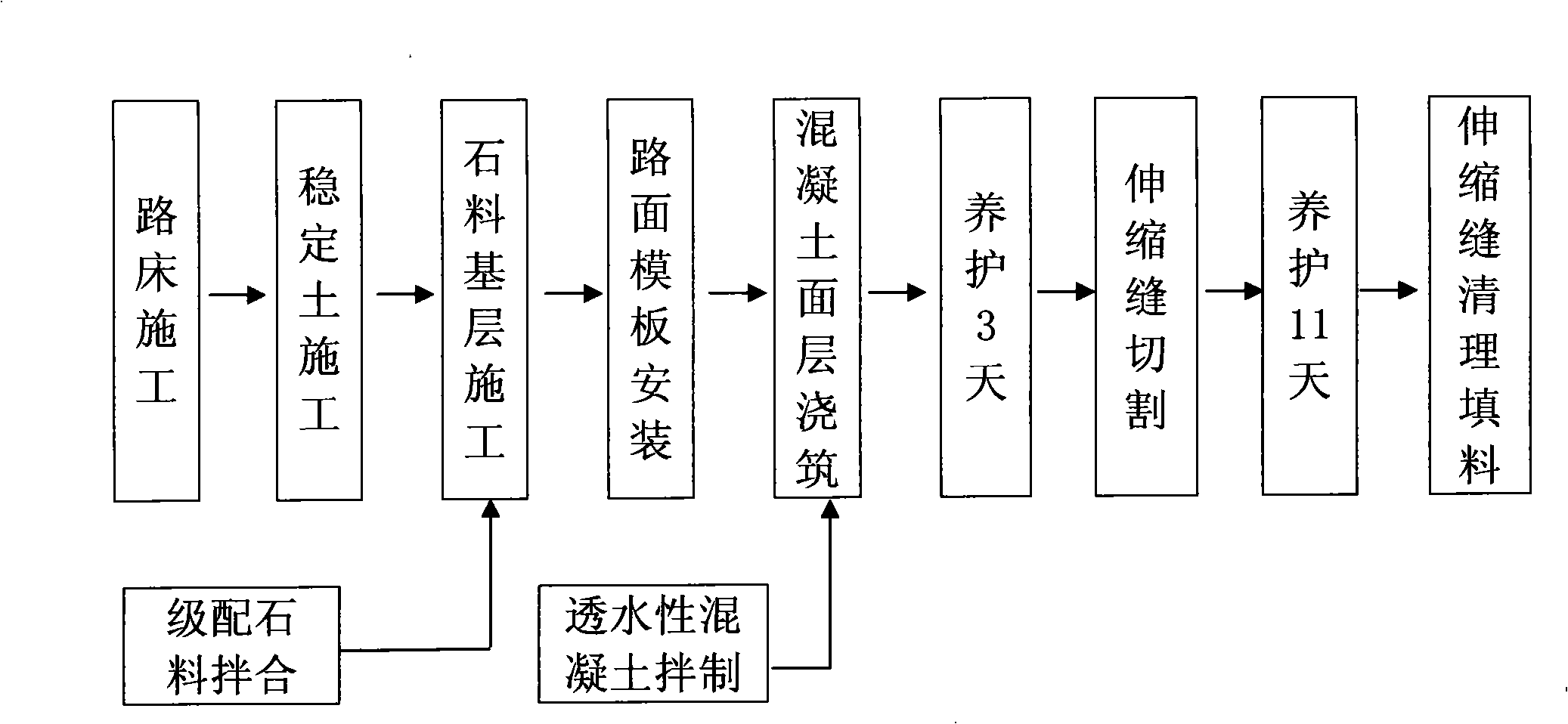

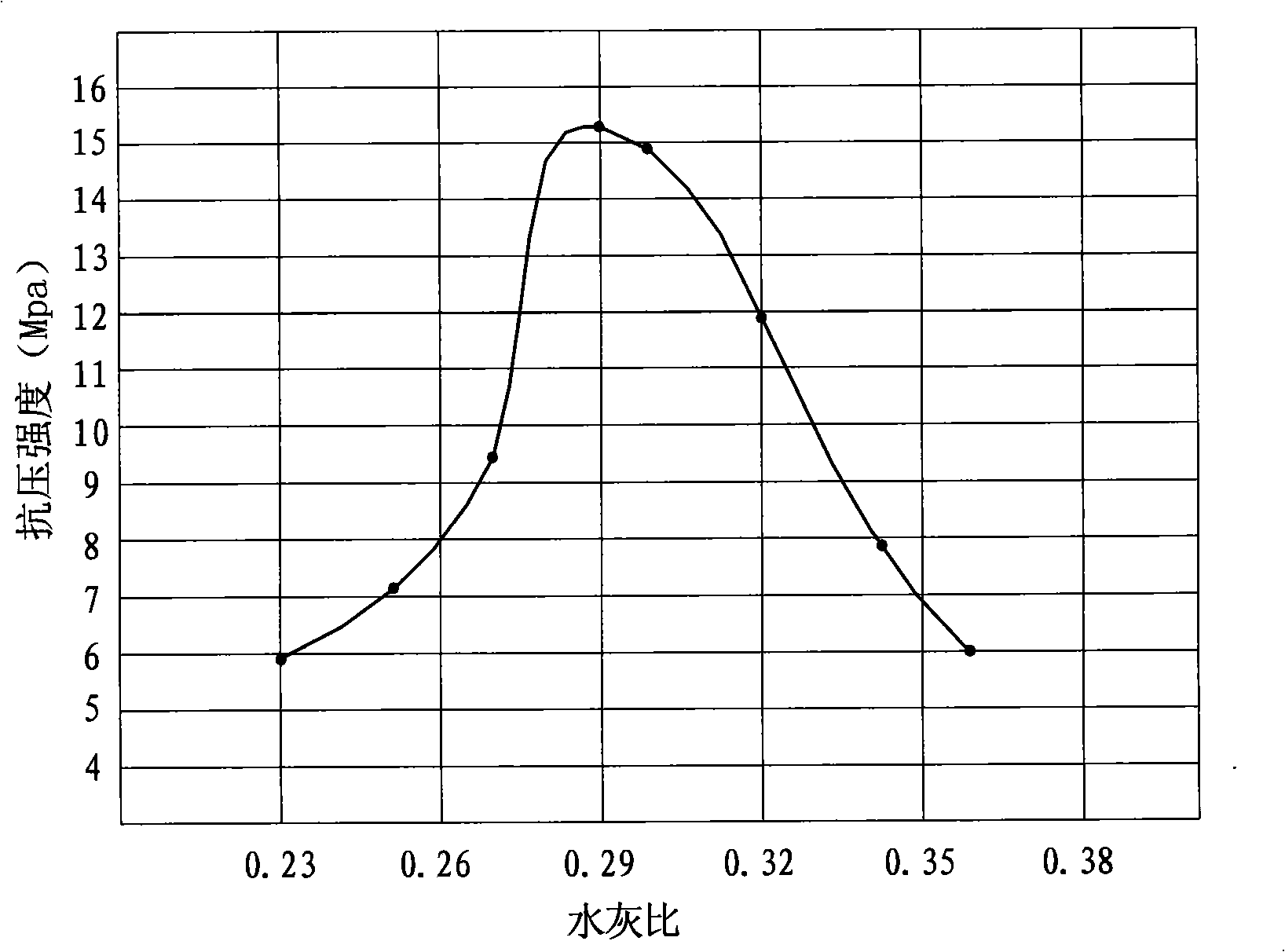

Water permeable concrete and pavement construction method

InactiveCN101293763AHigh strengthGood water permeabilityIn situ pavingsSolid waste managementFlexural strengthRoad surface

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Owner:HENAN GUOJI CONSTR GRP +1

Magnesium cementitious composition

InactiveUS20070017418A1Reduce shrinkReduce crackingSolid waste managementCeramicwareFiberAdditive ingredient

A cementitious product for applications such as stucco, plaster coating, fireproof coatings, casting / molding applications and flooring. The product is a blend of magnesium oxide and magnesium chloride. Suitable fillers such as bottom ash, fly ash, clinker and other pulverized materials may be added. Fibrous materials, foaming agents and surfactants may also be added to achieve product characteristics for specific application. Processes for blending the selected ingredients are also disclosed.

Owner:DENNIS ANDREW C

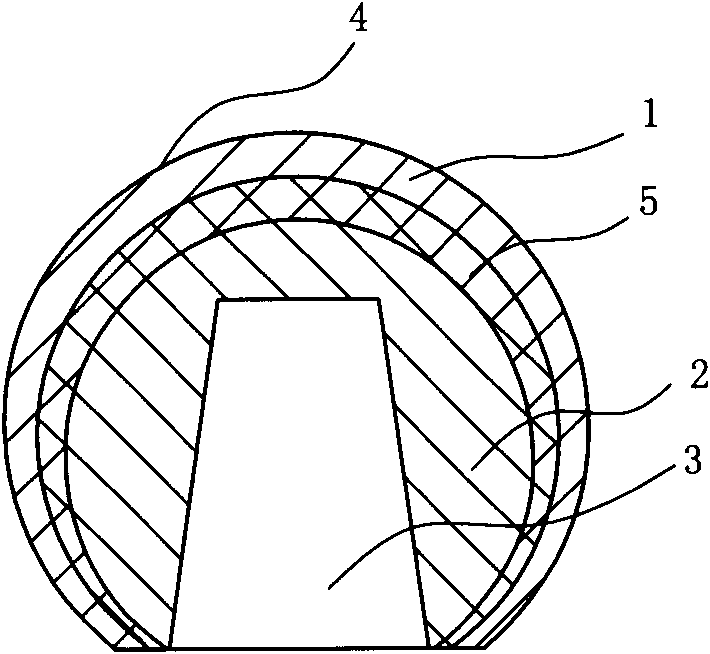

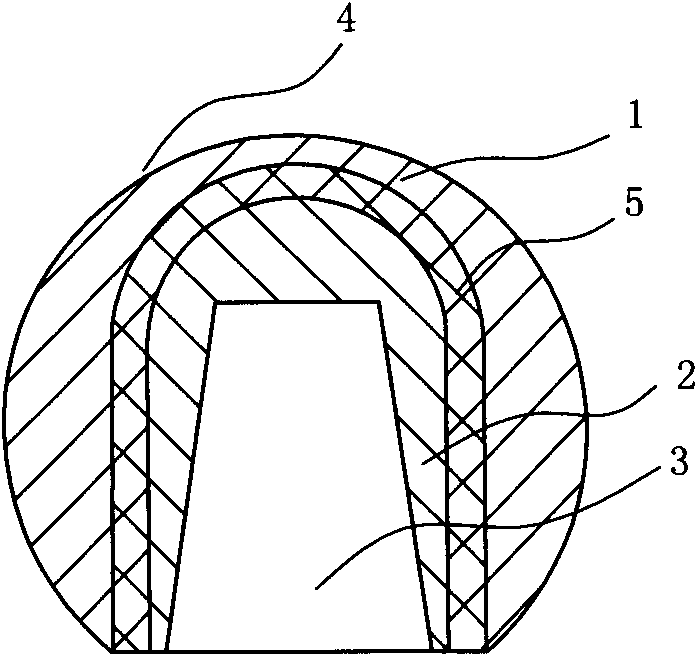

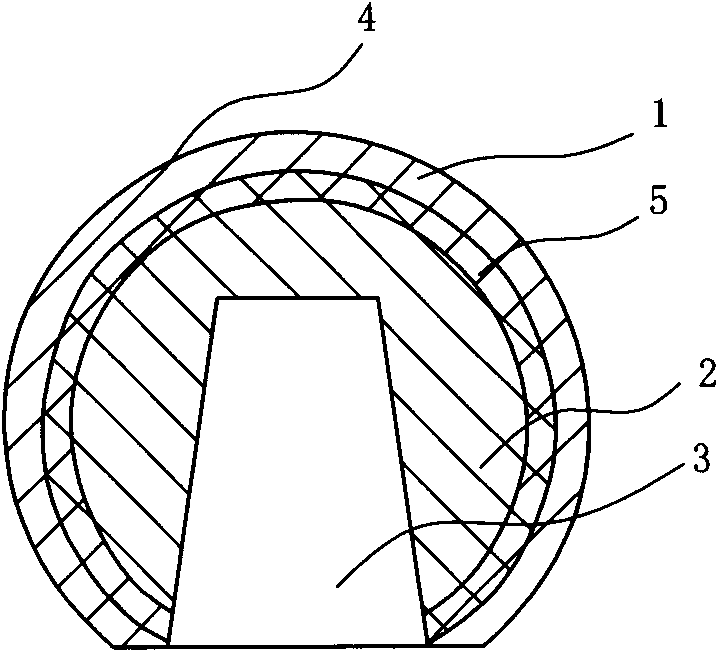

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

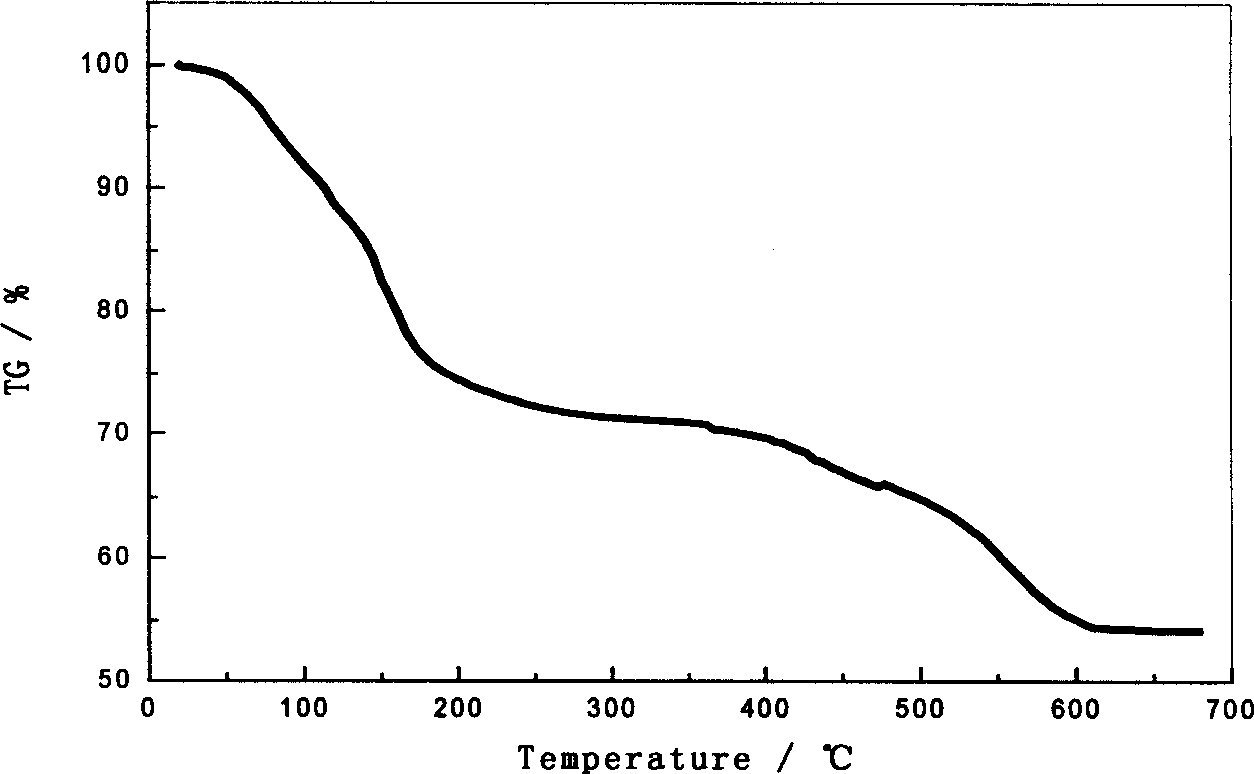

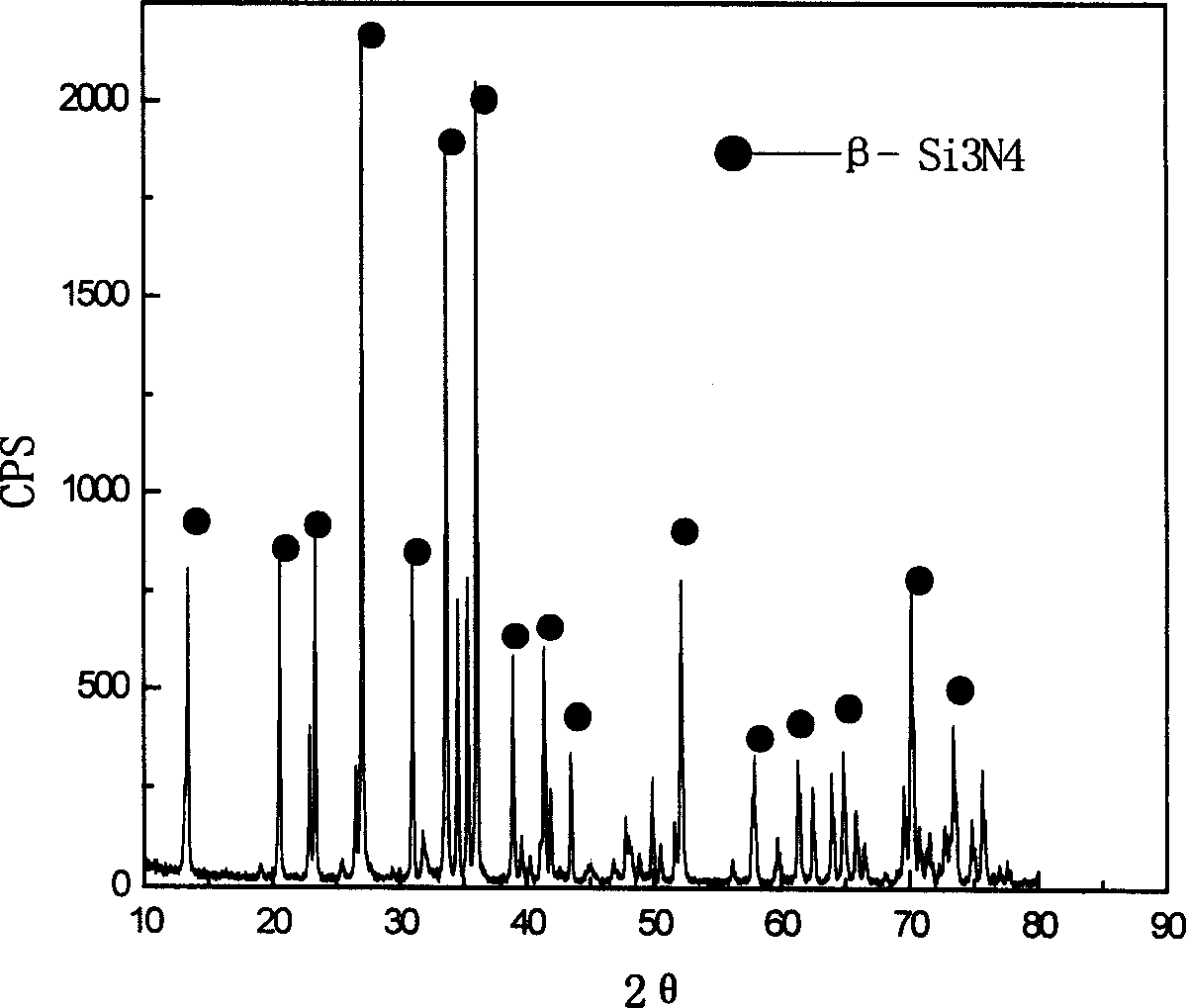

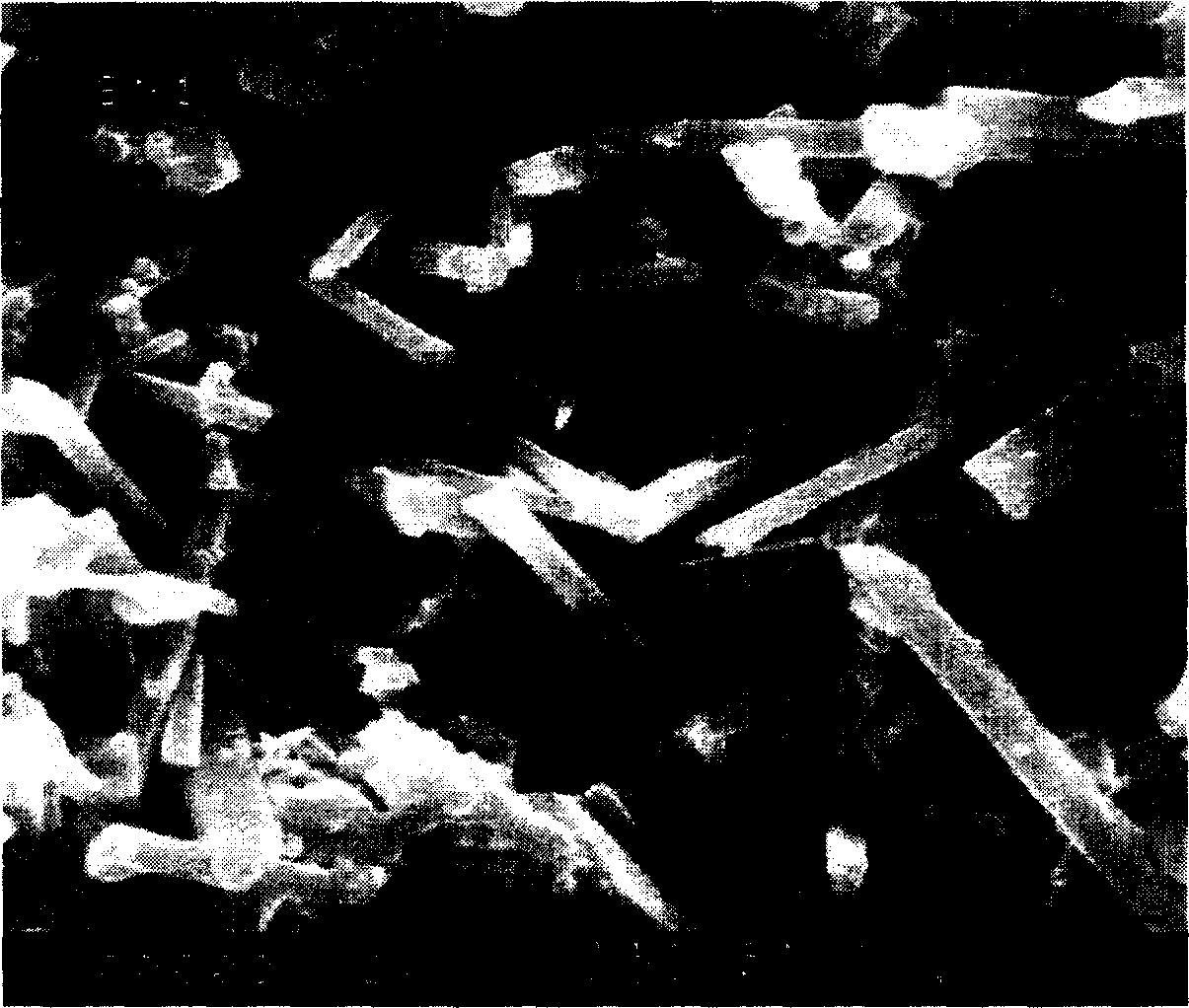

Method for preparing silicon nitride/silicon carbide porous ceramic

The present invention belongs to the field of porous ceramic material technology, and is the preparation process of one low cost and high performance porous silicon nitride / silicon carbide ceramic. The preparation process includes compounding material, forming and sintering as the conventional ceramic material preparing steps. It features that phenolic resin used as pore creating agent and carbon source is in-situ produced into SiC phase through the carbon hot reduction during sintering; and that Si3N4, Al2O3, Y2O3 and phenolic resin in certain proportion are produced into slurry through adding anhydrous alcohol and mixing for 12-24 hr and stoved into powder; and that the ceramic powder is processed through formation, cracking to eliminate glue, carbon hot reduction and sintering to produce the porous ceramic material with porosity of 40-70 %, strength of 70-160 MPa and low cost.

Owner:XI AN JIAOTONG UNIV

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

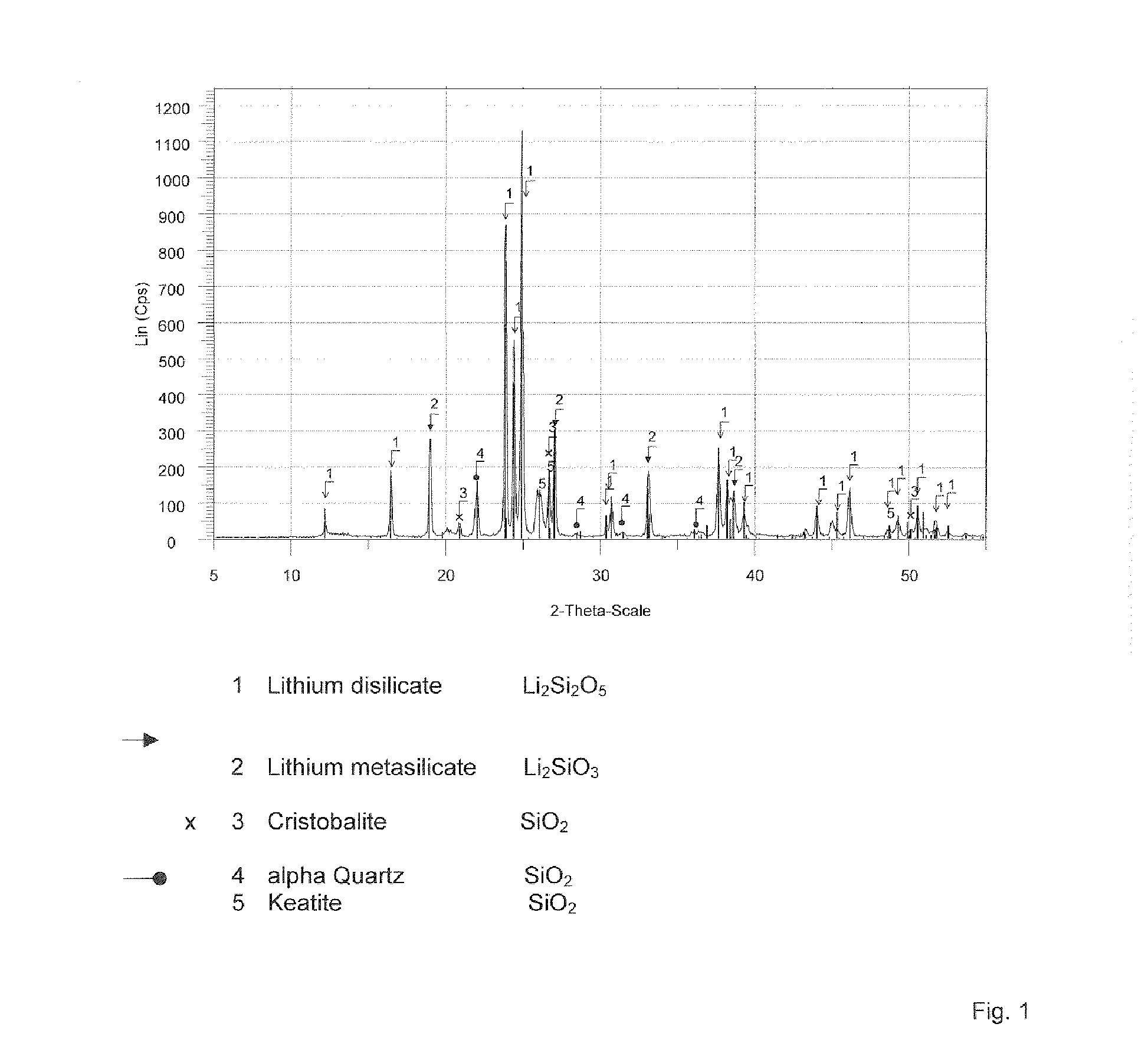

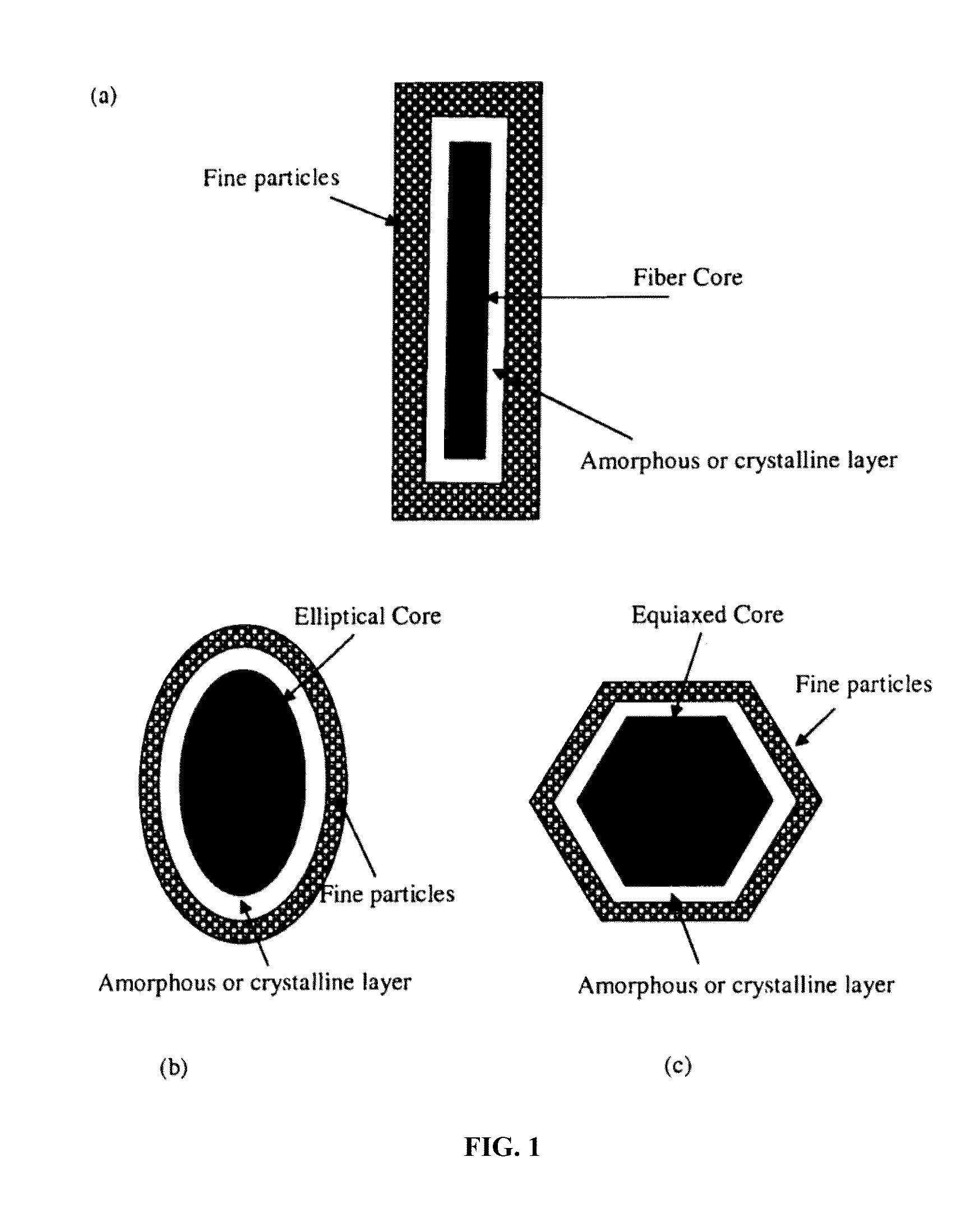

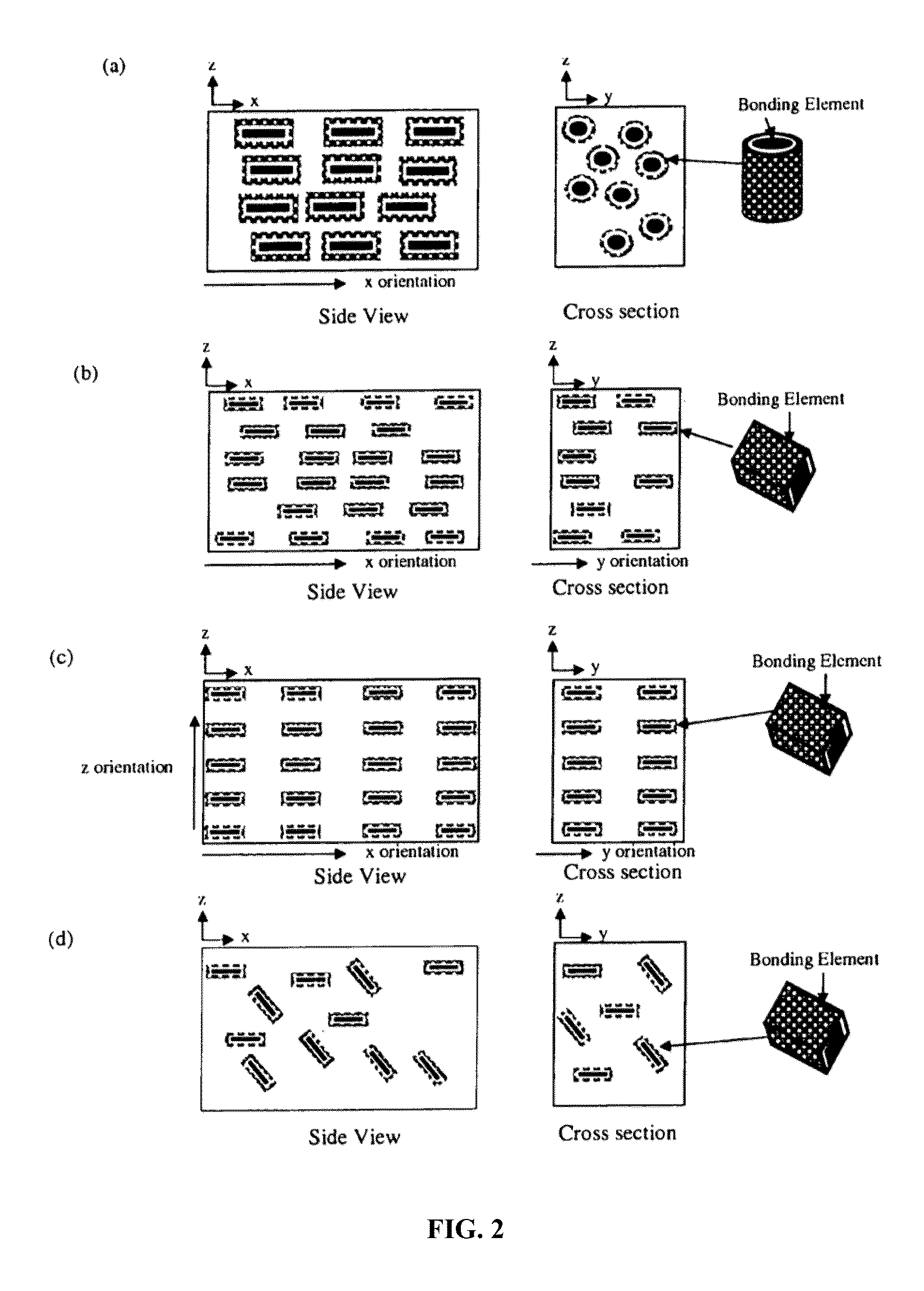

Lithium silicate amorphous or crystalline glass overlaying top surface of zirconia and preparation methods thereof

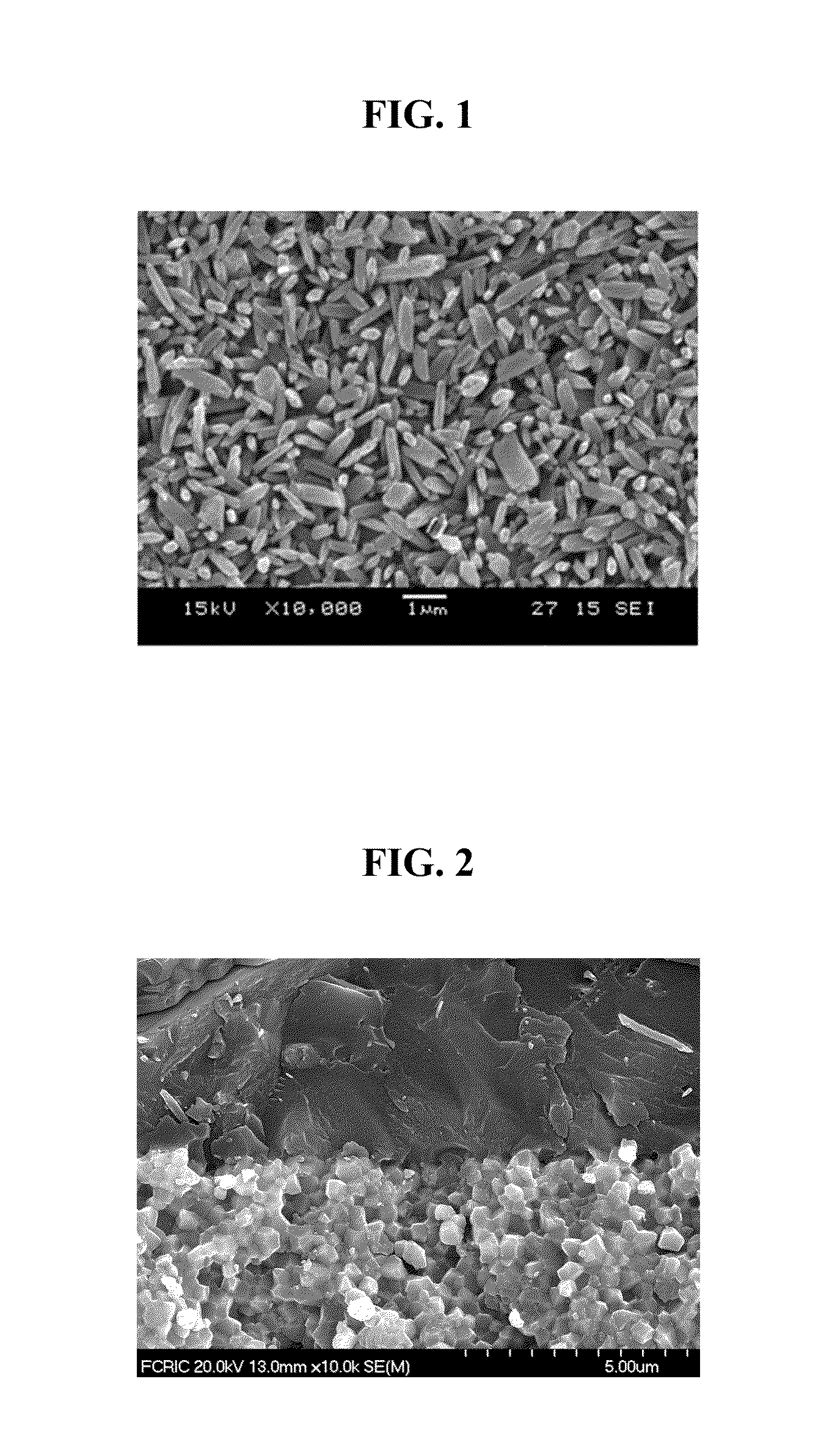

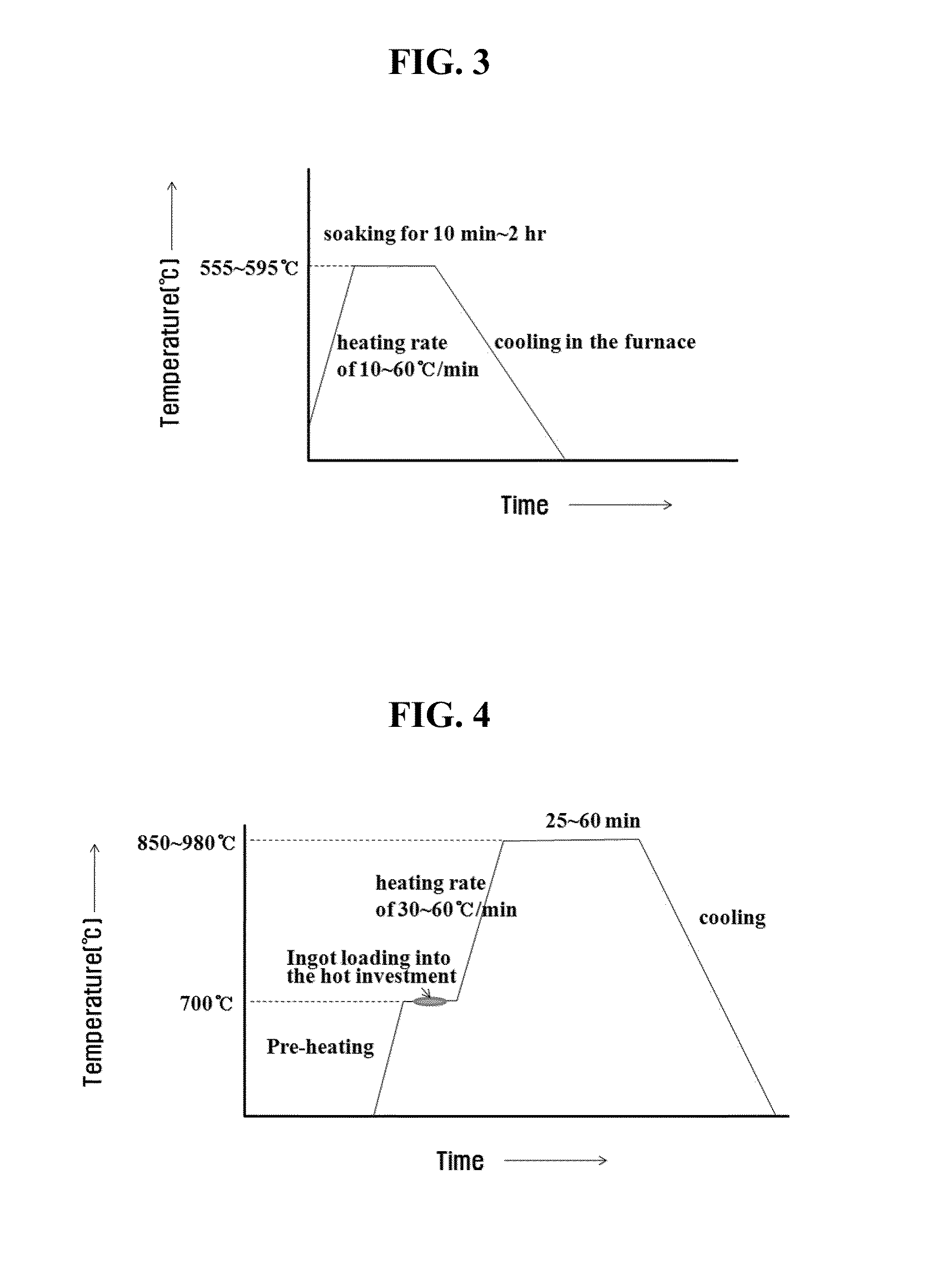

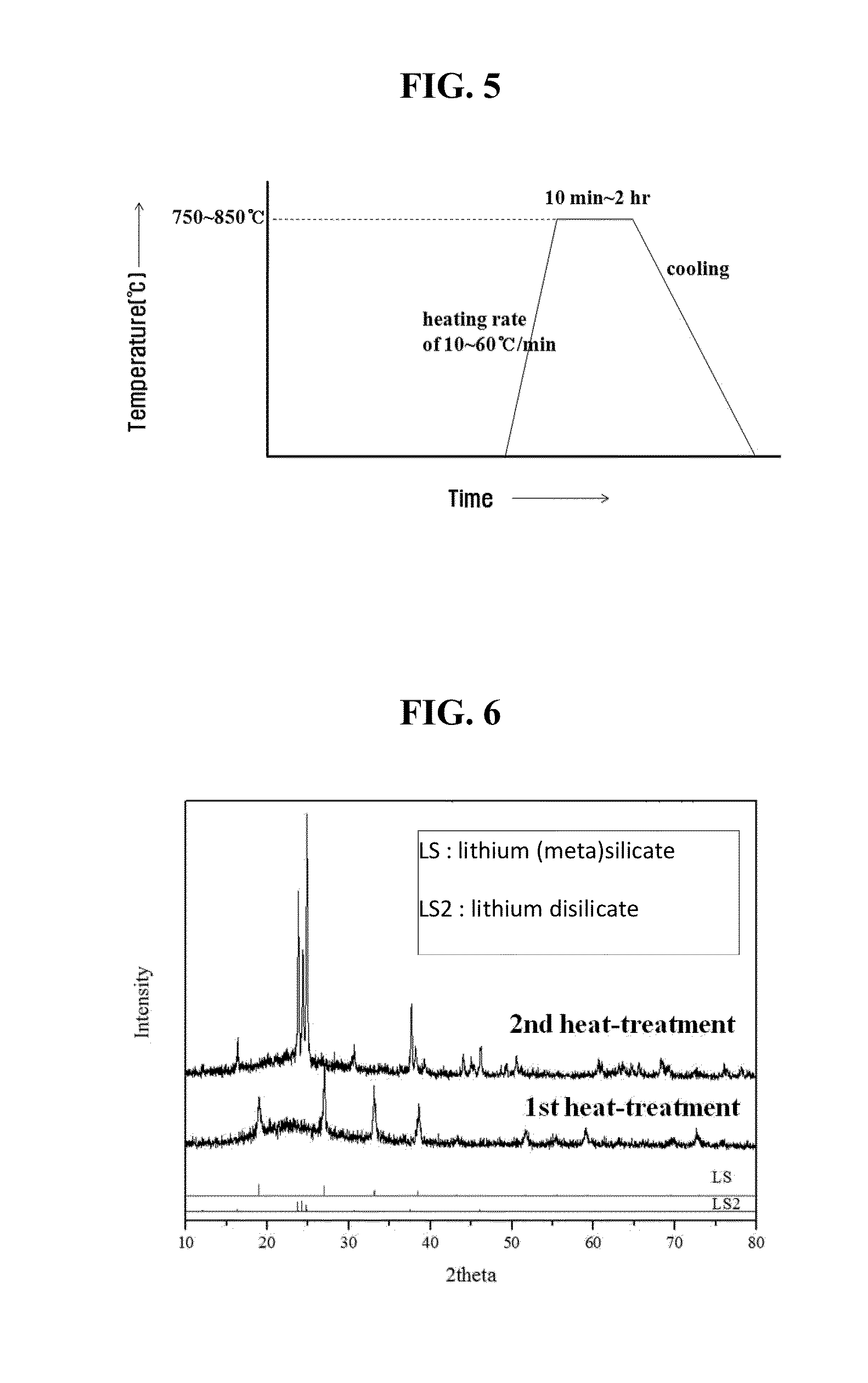

ActiveUS20150104655A1High bonding strengthMore flexural strengthBlowing machine gearingsGlass furnace apparatusLithiumVitrification

Exemplary embodiments of the present disclosure provide a lithium silicate crystalline or amorphous glass overlaying the top surfaces of zirconia and the manufacturing process thereof. More specifically, exemplary embodiments of the present disclosure provide a lithium silicate glass or lithium silicate crystalline glass with high light transmittance and good coloring characteristics and the manufacturing process thereof, which overlays the top surface of zirconia with high mechanical strength, frameworks, or copings.The lithium silicate crystalline or amorphous glass may include 10-15 wt % Li2O, 71.1-85.0 wt % SiO2, 2-5 wt % P2O5 working as nuclear formation agent, 1-5 wt % Al2O3 to increase glass transition temperature and softening temperature, as well as chemical durability of the glass, and 0.01-1.0 wt % ZrO2 which increases the binding strength of the zirconia substructure.

Owner:HAAS & CO GMBH

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

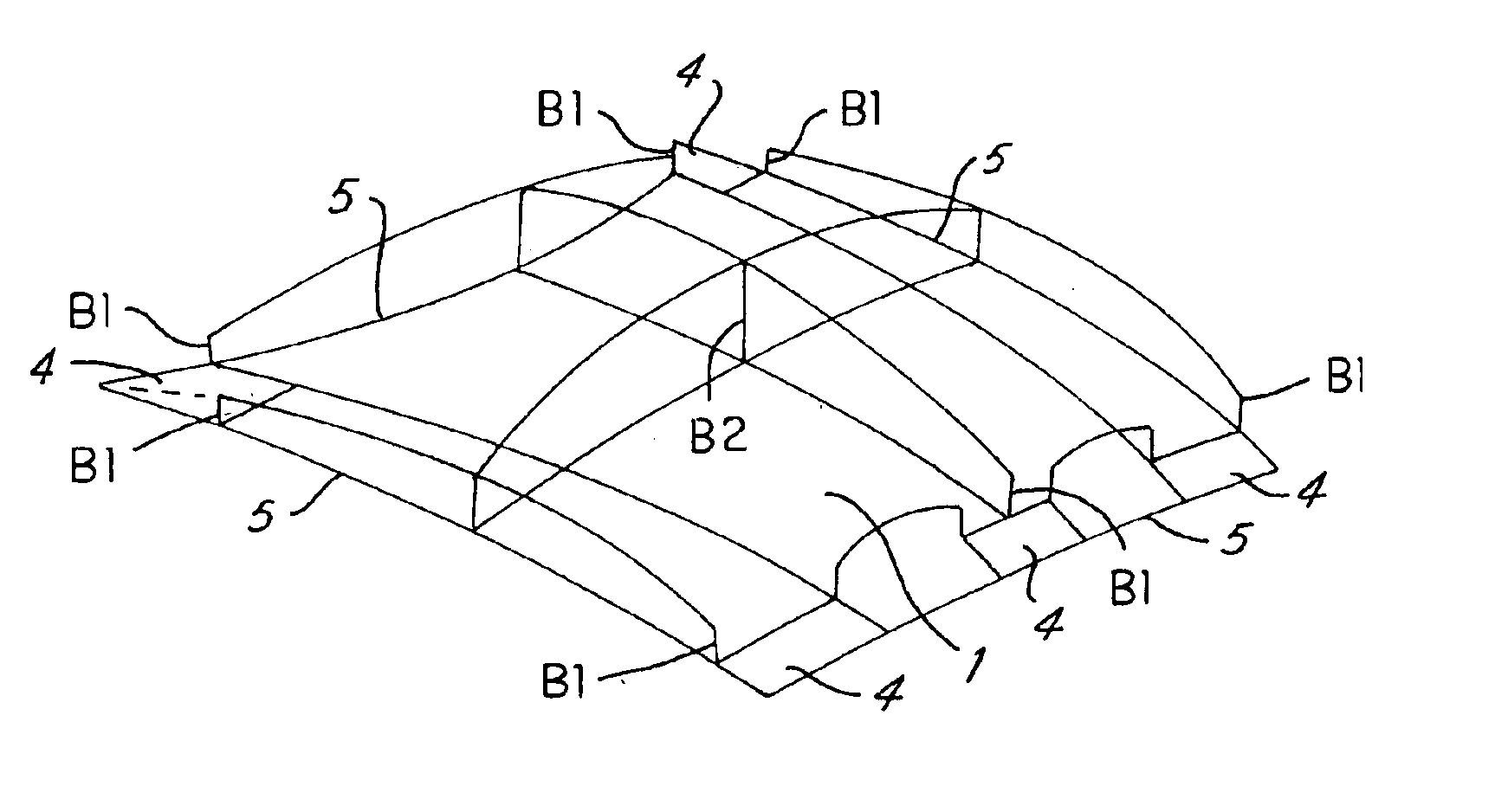

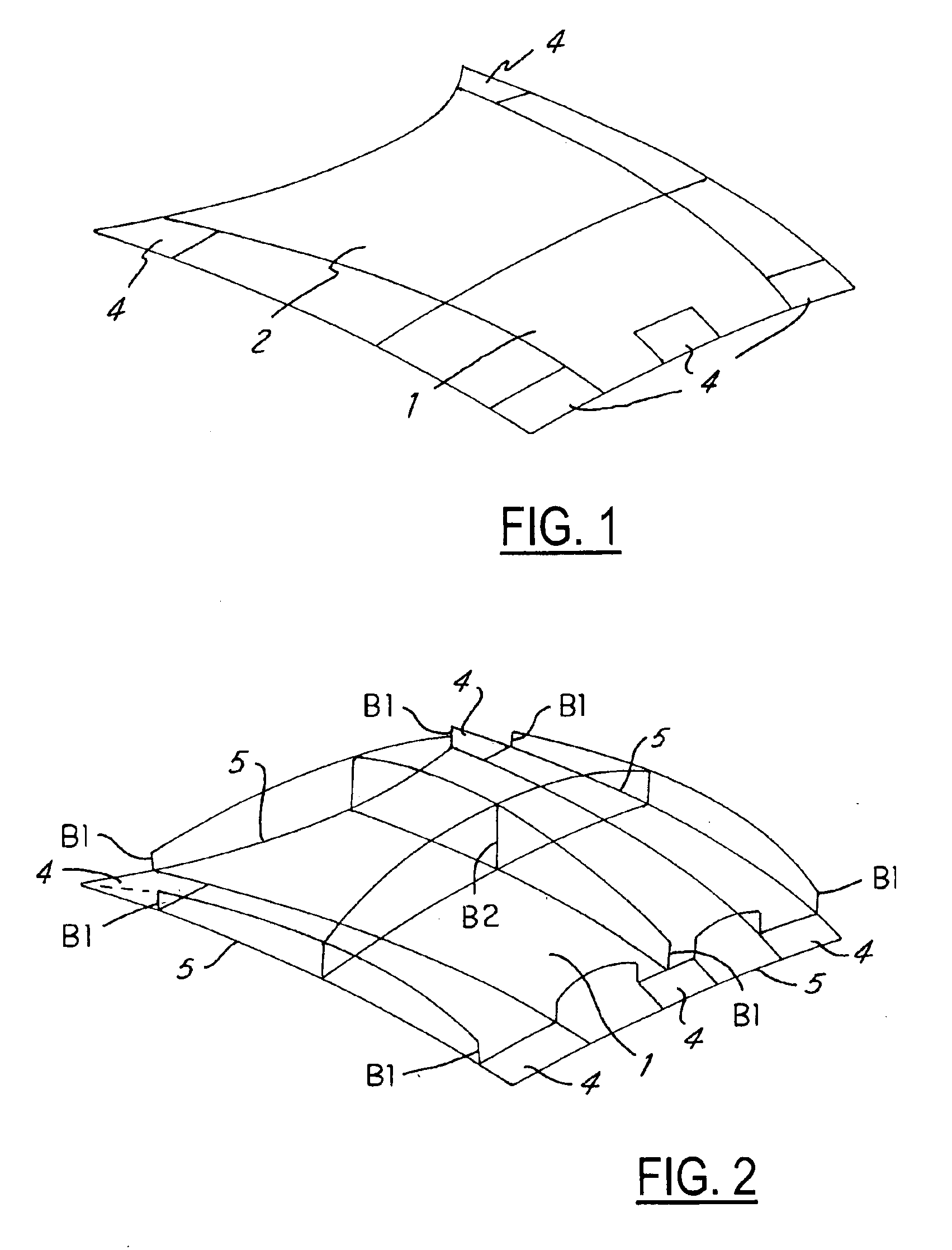

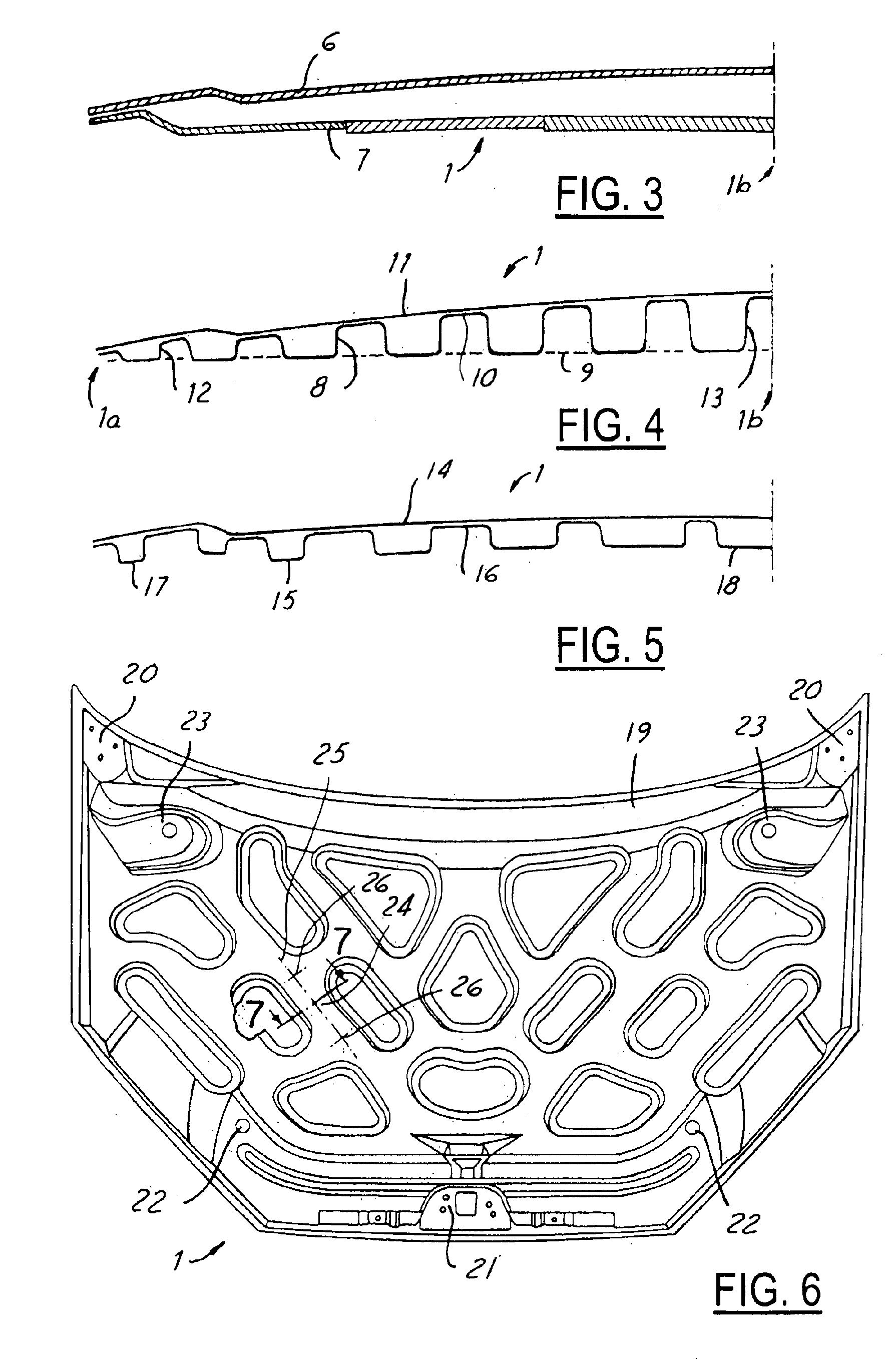

Engine hood for motor vehicles for the protection of pedestrians

InactiveUS6883627B1Easy to adaptEven mass distributionVehicle seatsPedestrian/occupant safety arrangementMobile vehicleFlexural strength

An engine hood for motor vehicles possesses a deformable head impact zone for the protection of pedestrians in the event of a collision with the motor vehicle. The engine hood is composed of two or more load-bearing shells and has a flexural strength profile which is low adjacent the edges and increases continuously toward the middle of the hood. At the same time, the engine hood has a uniform mass distribution ovcr the entire surface. Consequently, irrespective of the position the engine hood, the same characteristic for the head impact is achieved everywhere. The advantageous embodiment of the engine hood provides a reinforcing panel with regularly arranged beads, at most three beads forming a junction point so as to reduce local rigidities.

Owner:FORD GLOBAL TECH LLC

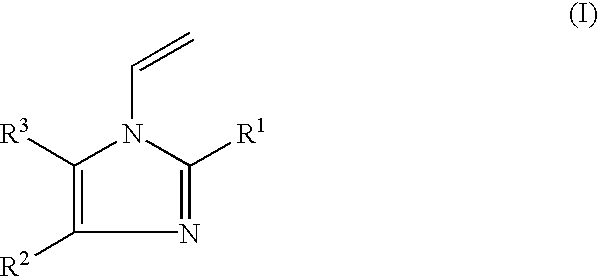

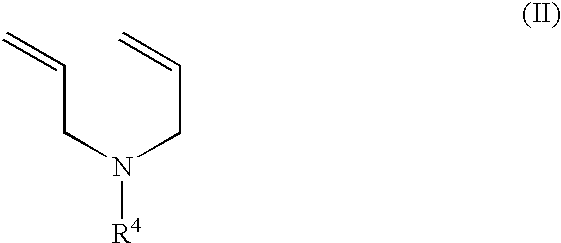

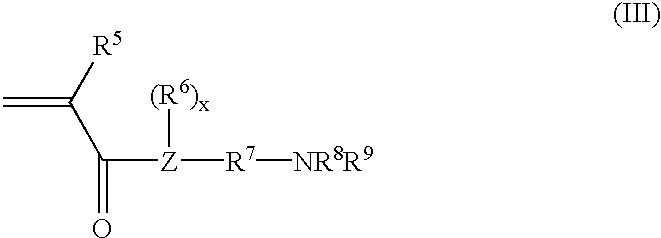

Propellantless pump sprays and pump foams containing an anionic copolymer of methacrylic acid and ethyl acrylate

InactiveUS6482394B1Improve flexural strengthImprove distributionCosmetic preparationsHair cosmeticsAnionic polymersEthyl acrylate

Hair treatment compositions in the form of pump sprays and pump foams that are free from propellant gases comprise at least one cationic and at least one anionic polymer having methacrylic and ethyl units.

Owner:BASF AG

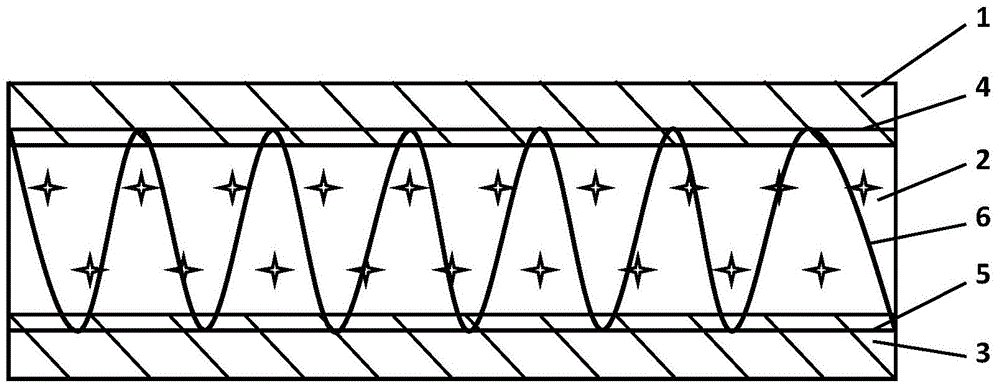

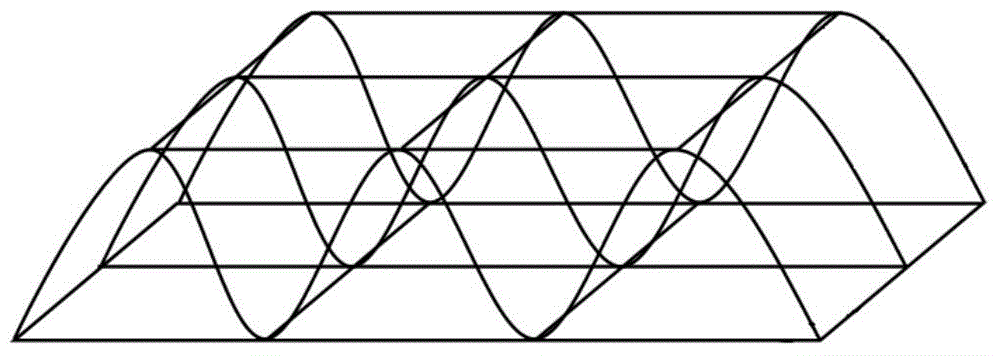

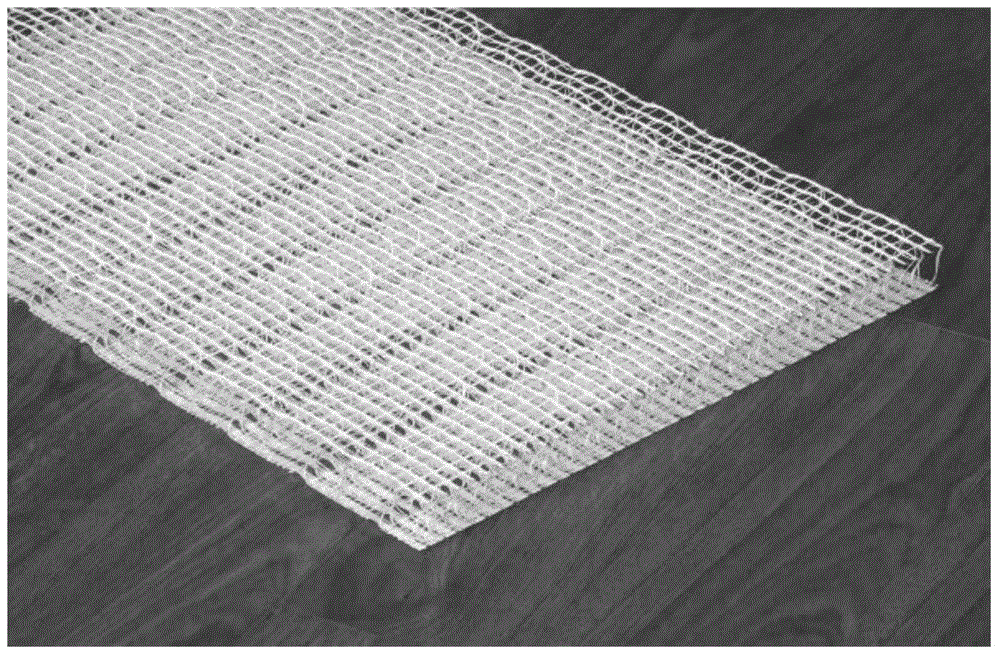

Novel fiber reinforced composite heat insulation plate and preparing method of novel fiber reinforced composite heat insulation plate

InactiveCN105002991AImprove adhesionAvoid Fire HazardsLaminationLamination apparatusPolymer modifiedSurface layer

The invention discloses a novel fiber reinforced composite heat insulation plate and a preparing method of the novel fiber reinforced composite heat insulation plate, wherein the novel fiber reinforced composite heat insulation plate comprises a decoration surface layer, a bottom layer and a heat insulation core layer; the heat insulation core layer is clamped between the decoration surface layer and the bottom layer; the decoration surface layer and the bottom layer are made of polymer modified mortar; the heat insulation core layer is manufactured by injecting inorganic foaming materials into three-dimensional fiber fabrics; the decoration surface layer is connected with the upper part of the heat insulation core layer; and the bottom layer is connected with the lower part of the heat insulation core layer. The composite heat insulation plate has the advantages that the heat isolation and heat preservation effects are good; the weight is light; the intensity is high; and the durability is high. The composite heat insulation plate can be used as a heat insulation roof plate or a heat insulation external wall plate and the like for a mainstream building.

Owner:CHINA BUILDING MATERIALS ACAD

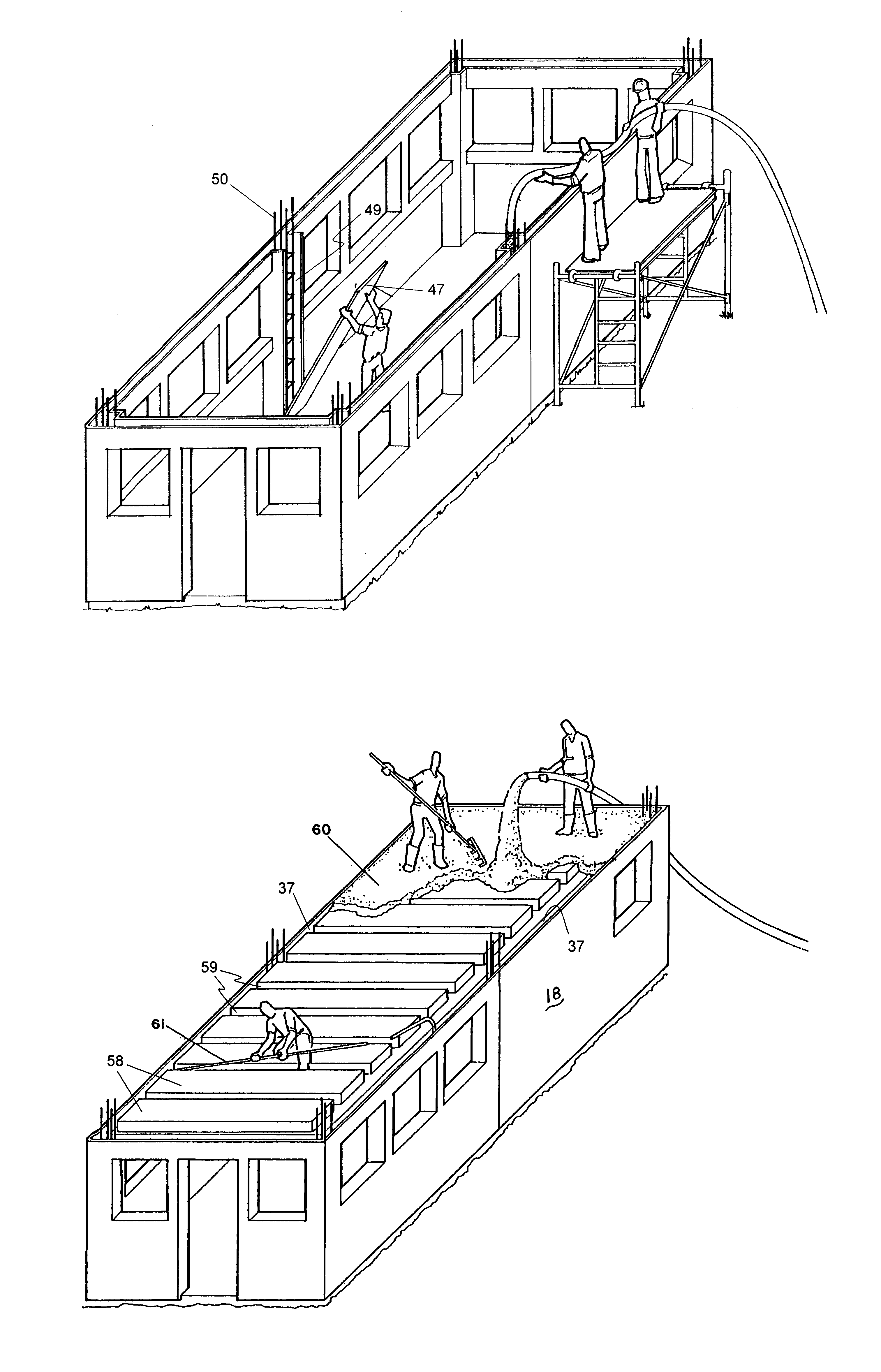

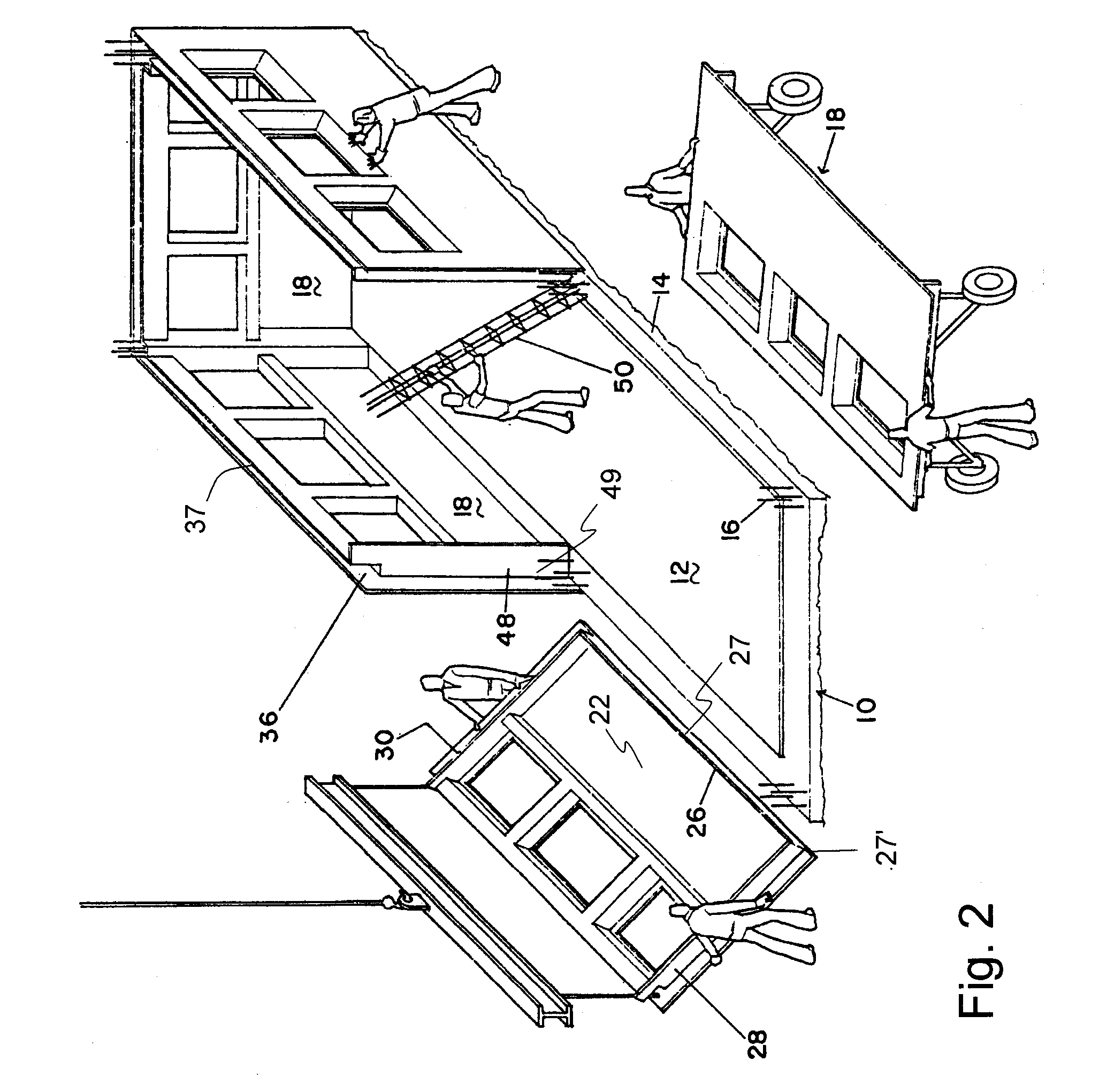

Modular system of permanent forms for casting reinforced concrete buildings on site

A permanent form building assembly includes one or more GRC forms having a one or more open cavities and a reinforcement structure. The GRC forms are designed and configured for a predetermined application. The reinforcement structure is inserted within the open cavities of the GRC forms prior to filling with concrete.

Owner:MARTY OSCAR

High strength steel fibre concrete and making method thereof

InactiveCN1451626AHigh strengthImprove bearing capacitySolid waste managementHigh strength concreteConstruction aggregate

A steel fibre reinforced high-strength concrete is prepared from cement, flyash, silicon ash, water, steel fibres, sand, broken stone and water-reducing agent through providing raw materials and mould, sequentially and proportionally mixing, stirring, pouring in mould, vibration, natural curing, demoulding, standard curing and inspection.

Owner:杨果林 +1

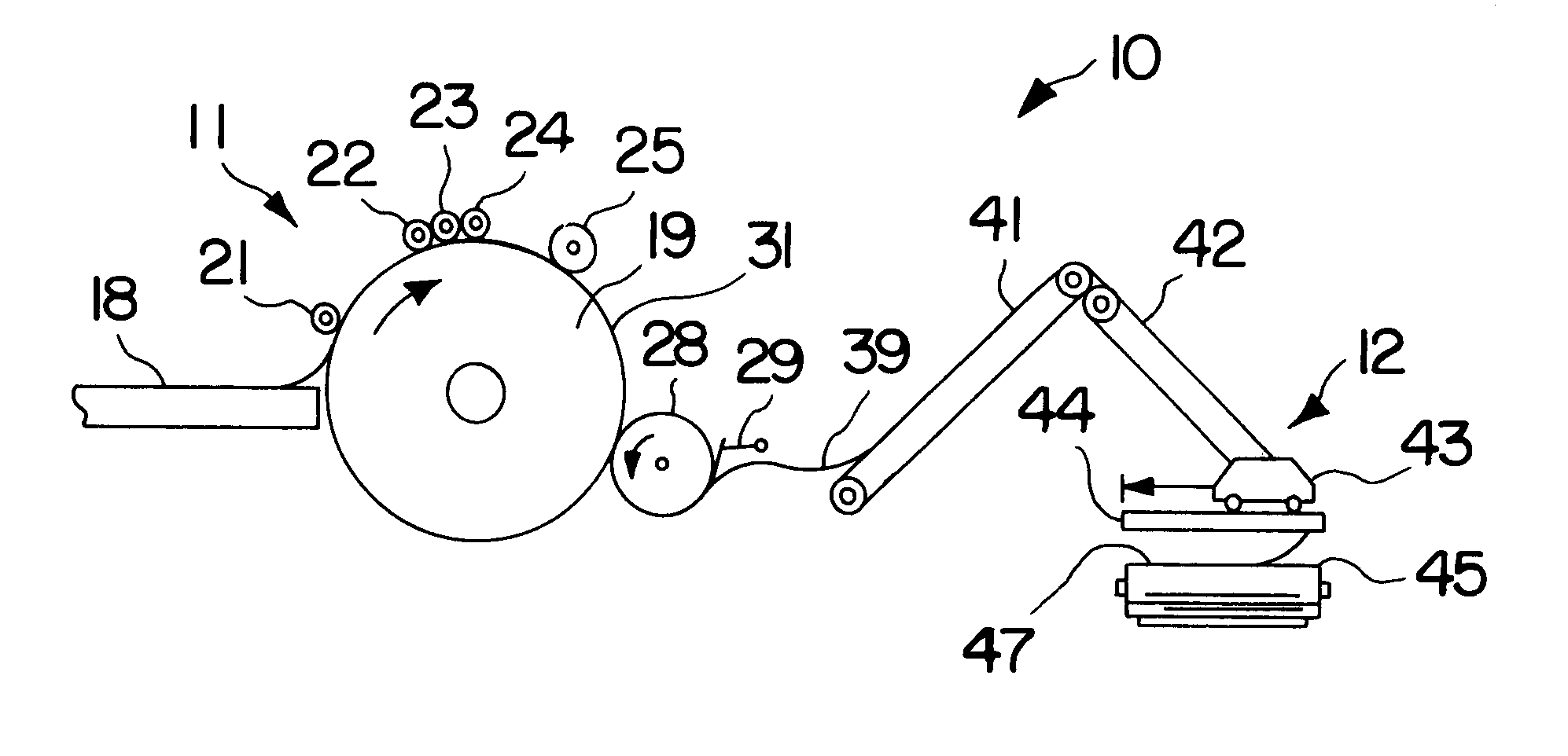

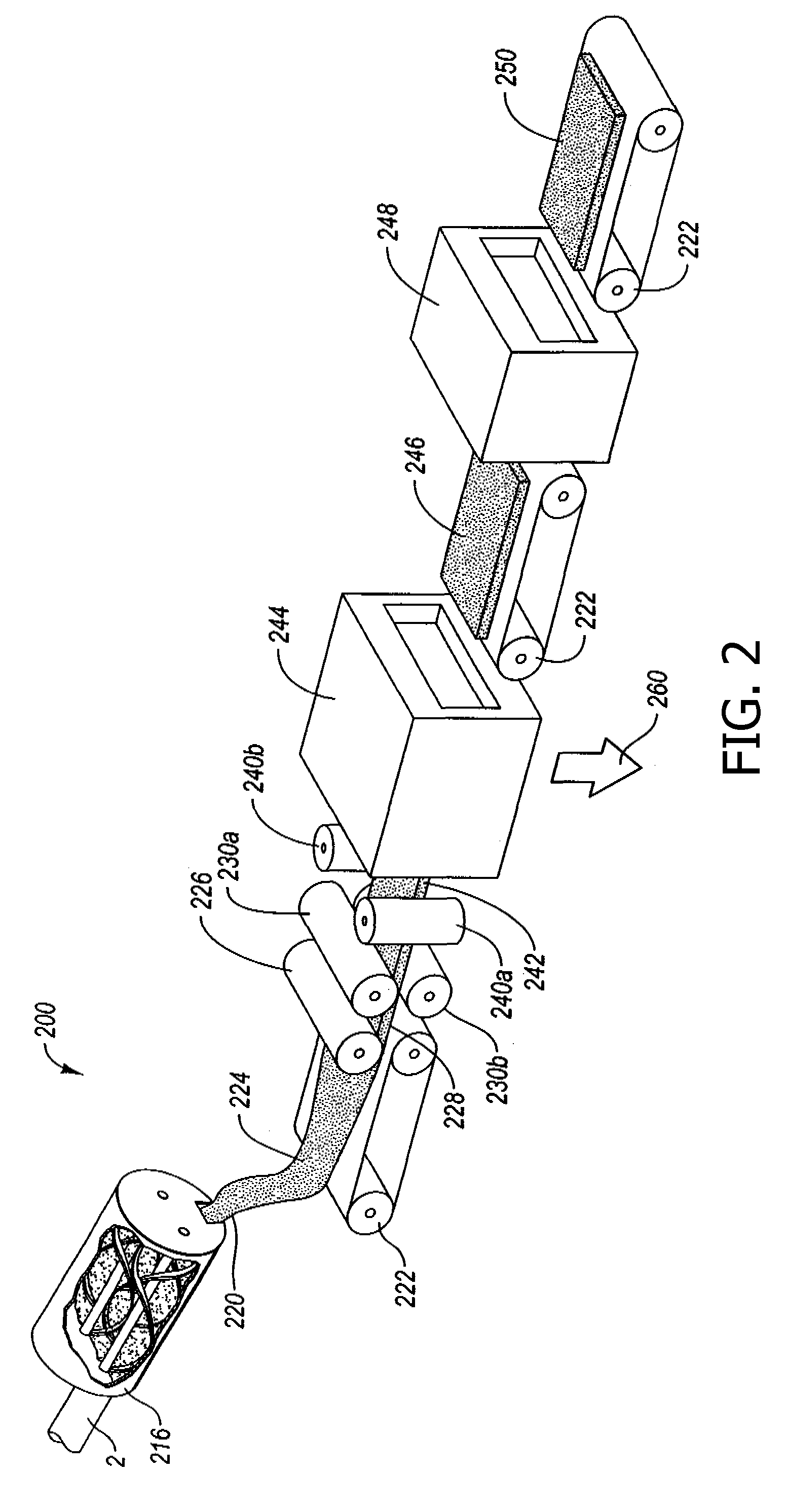

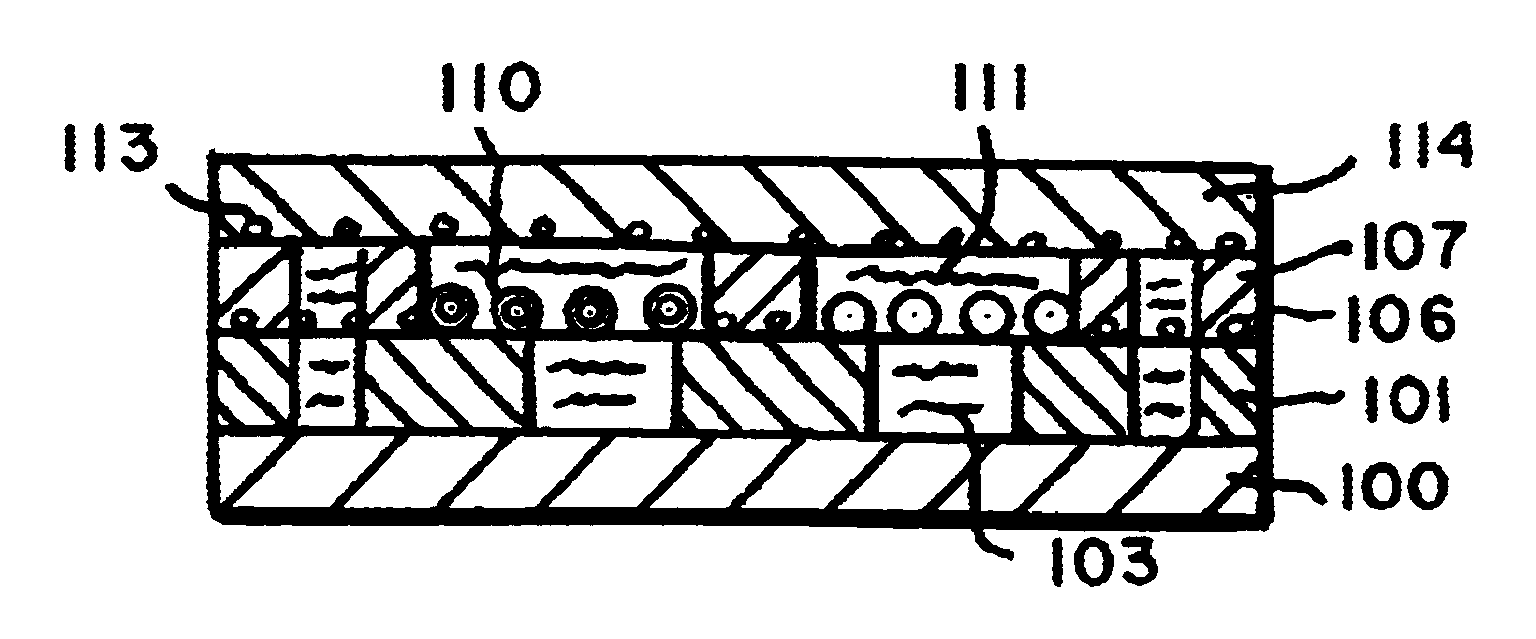

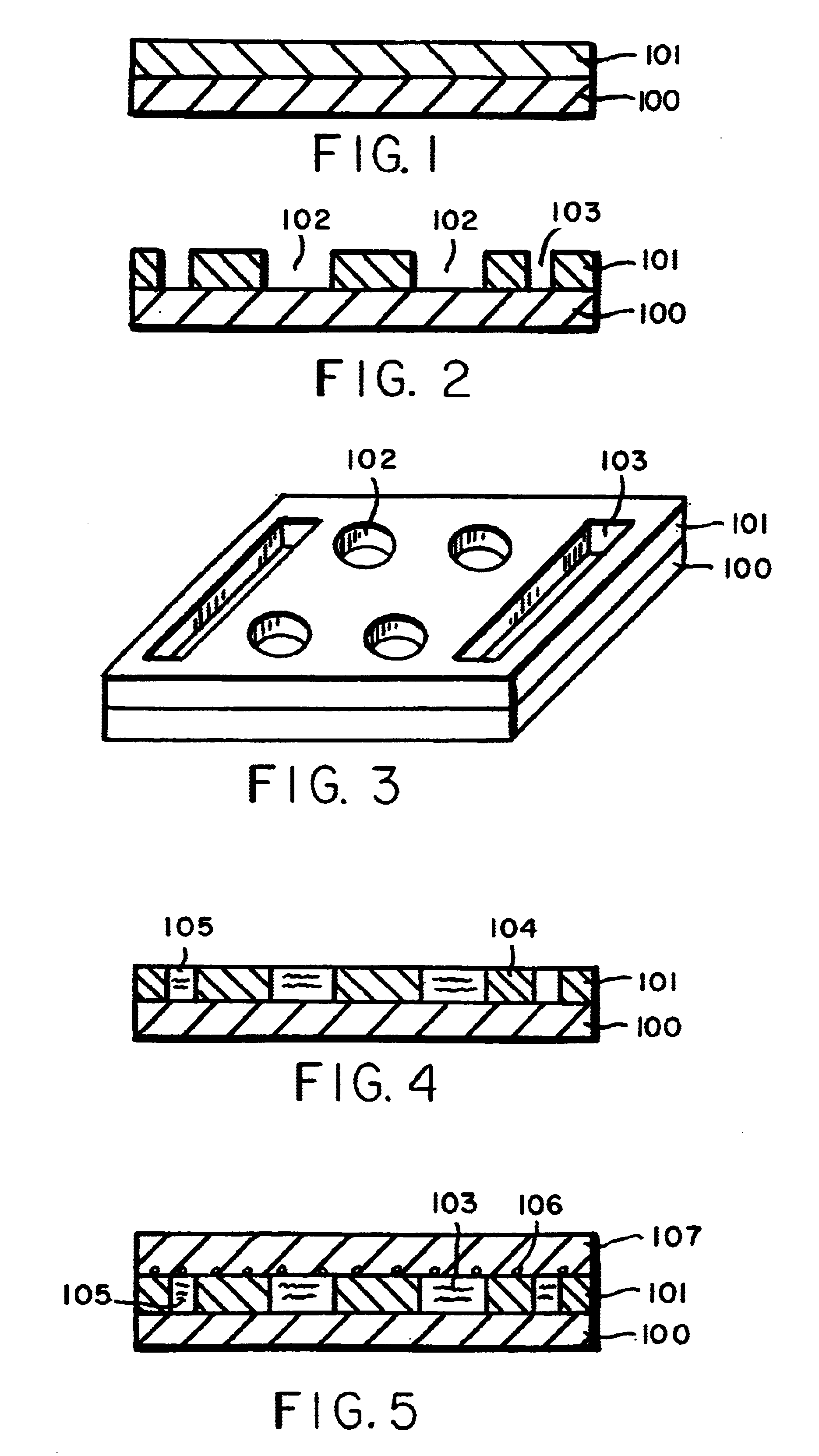

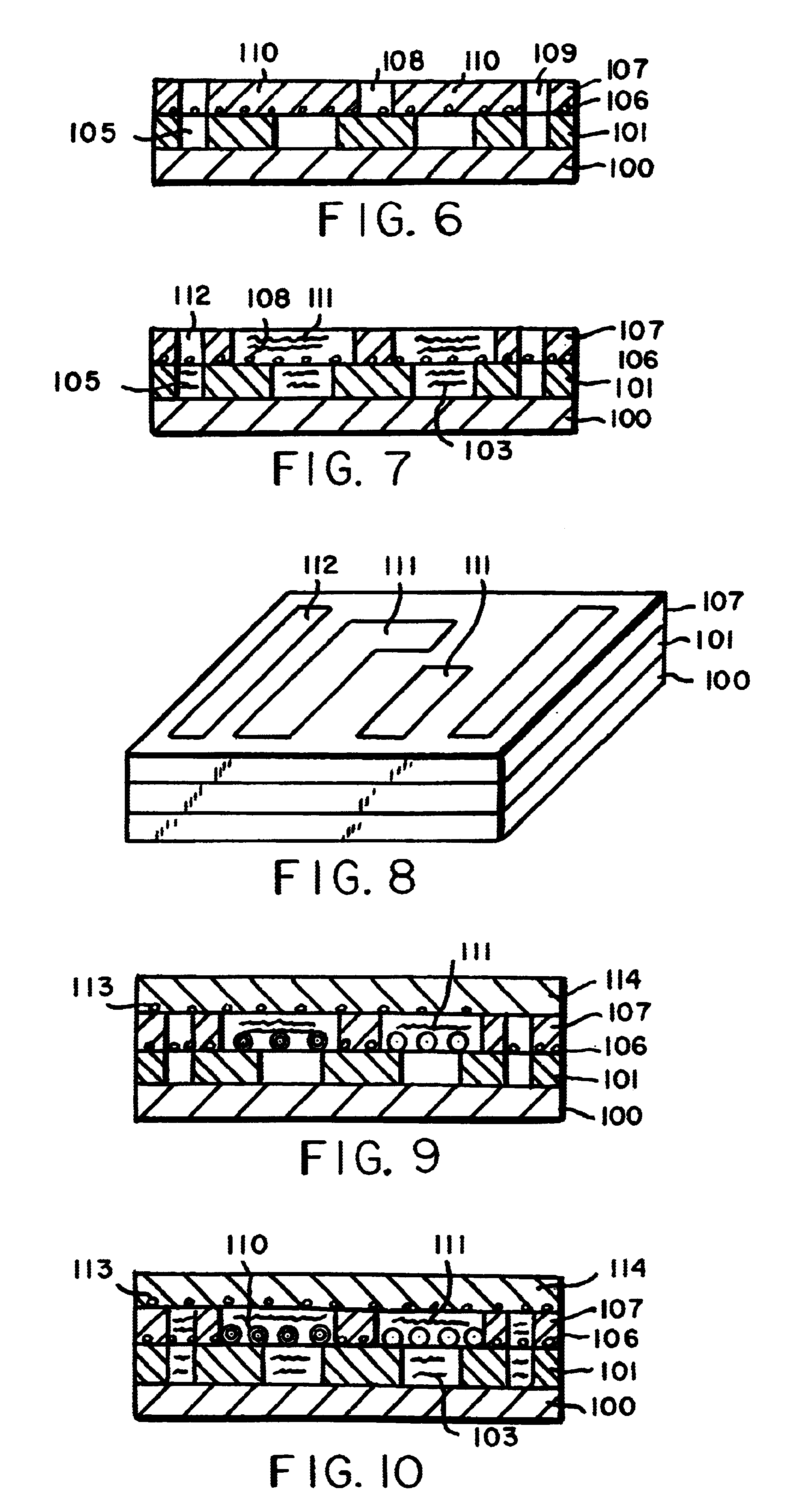

Non-woven fibrous batts, shaped articles, fiber binders and related processes

InactiveUS6296795B1Improve effectivenessImprove satisfactionWood working apparatusFlat articlesFiberParticulates

A process for producing a shaped article from a bonded, non-woven, fibrous batt of fibers comprising a number of steps. There is first provided (A) a dry, solid, heat-responsive fiber-binder; and (B) a moisture-responsive fiber-binder which is a dry, solid, particulate, raw, ungelled starch which swells and becomes sticky upon contact with moisture. The heat-responsive fiber-binder is contacted with the fibers to form a raw batt with the heat-responsive fiber-binder loosely adhering to the fibers of the batt. The moisture-responsive fiber-binder is contacted with the fibers to form a raw batt with the moisture-responsive fiber-binder loosely adhering to the fibers of the batt. The batt is heated to a temperature above the binding temperature of the heat responsive fiber-binder but below the scorching or melting point of the fibers thereby activating the heat-responsive fiber-binder whereupon the heat-responsive fiber-binder engages the intersections of the fibers binding the fibers together at their intersections thereby converting the raw batt into a partially cured batt. The partially cured batt is contacted with steam, thereby causing the moisture-responsive fiber binder to swell, become sticky and further bind the fibers. Fiber binders and shaped articles are described.

Owner:BUCK GEORGE S

Wood-like composite materials and methods of preparation thereof

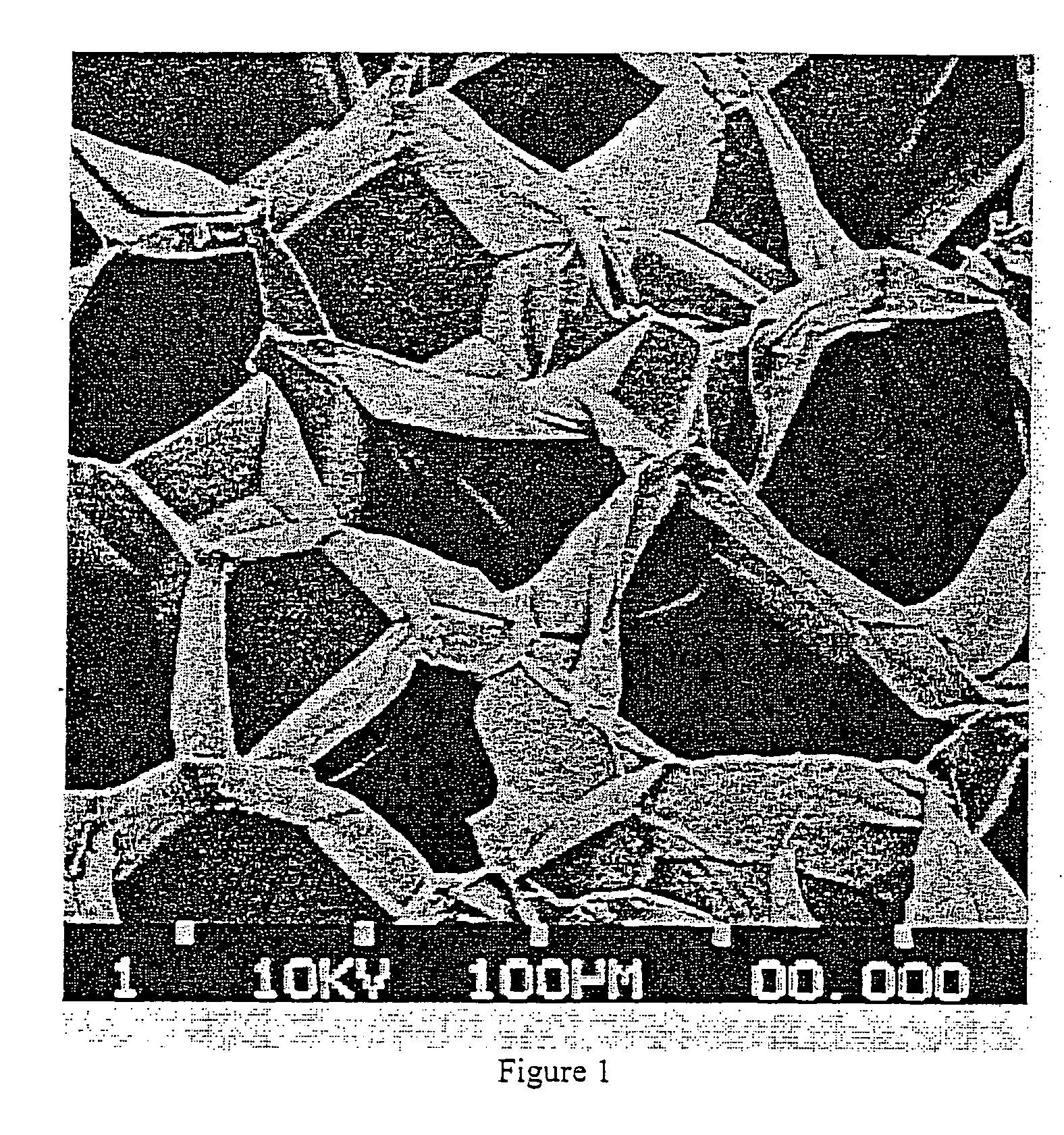

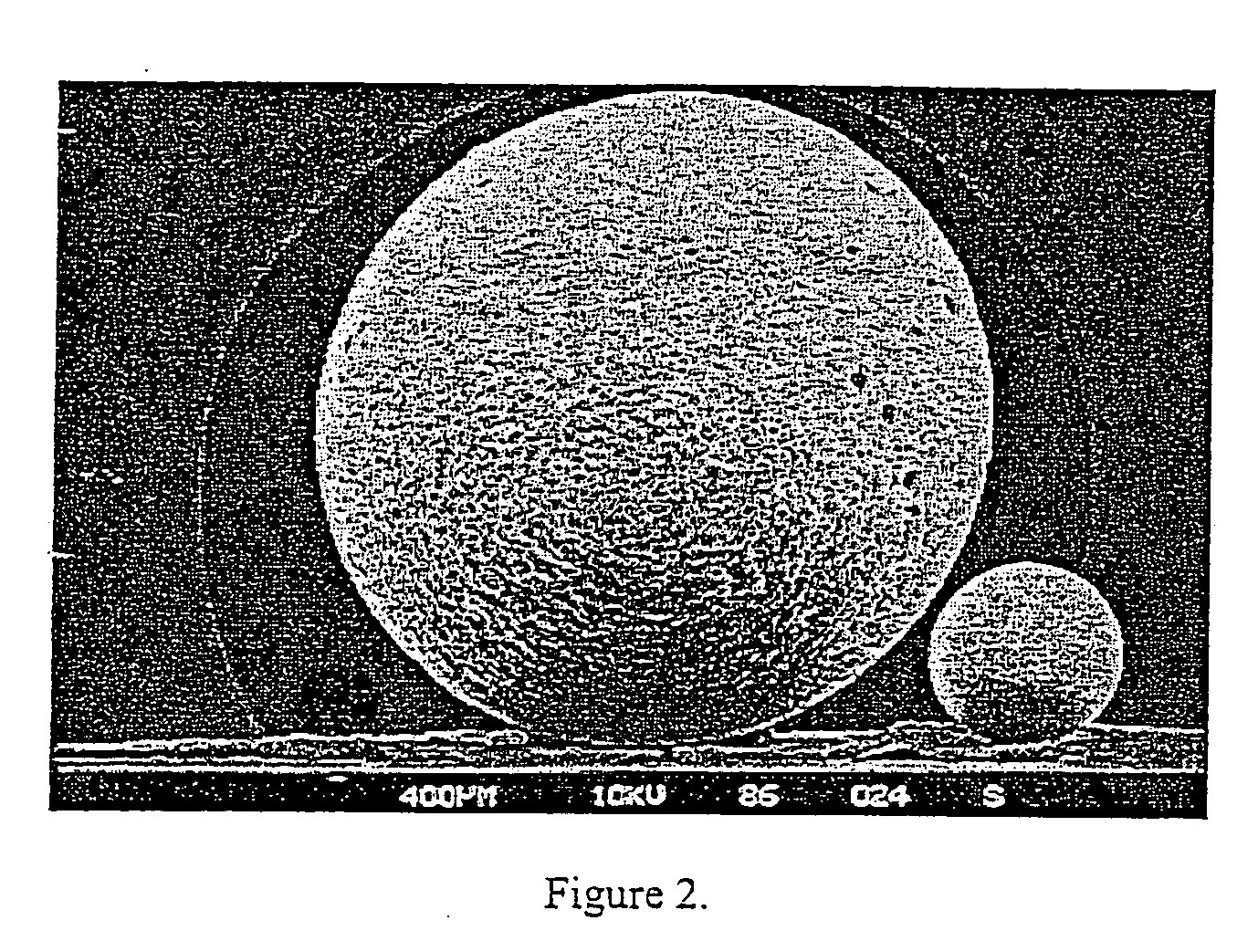

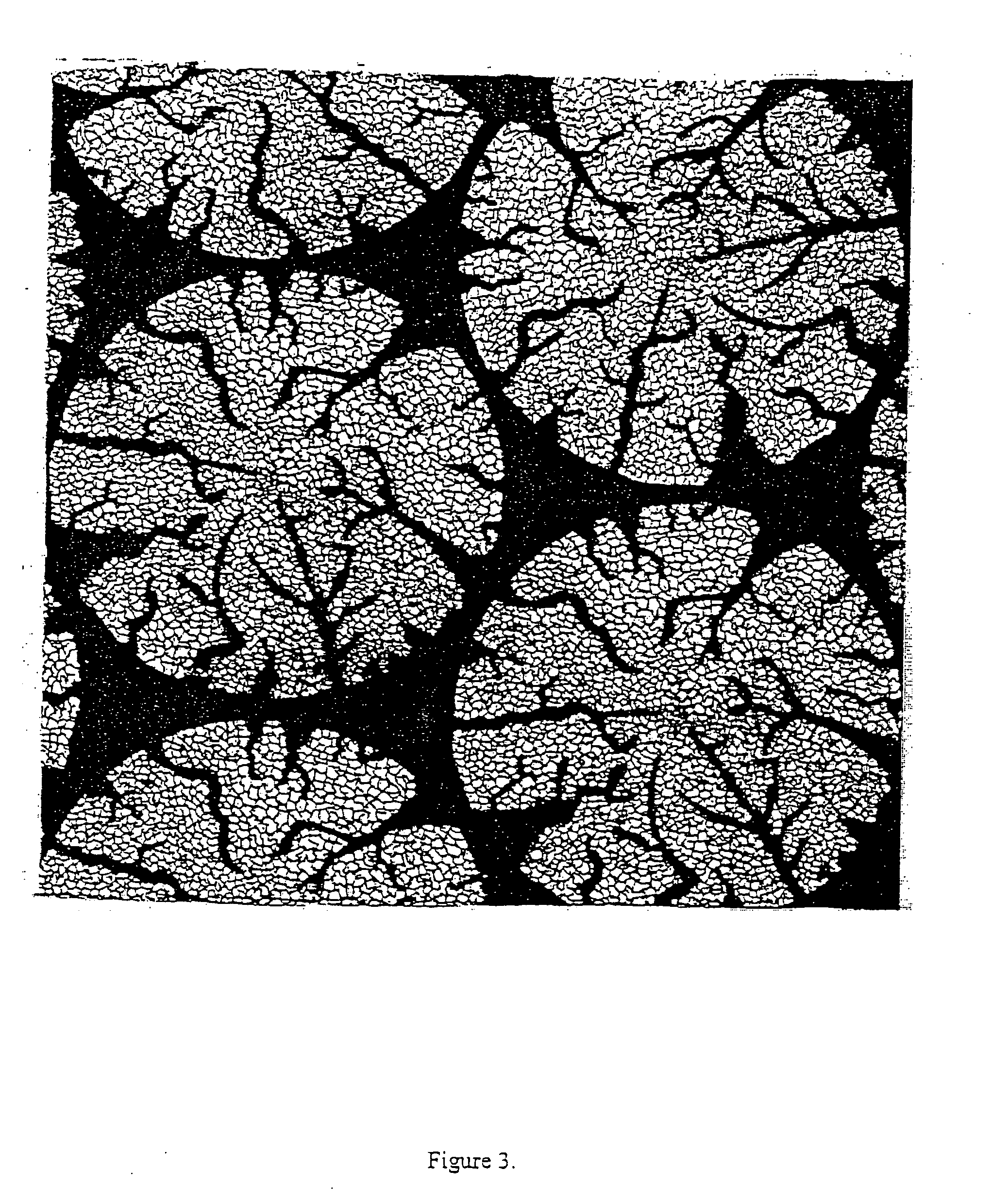

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

Rare earth alloy powder-modified Ti(C,N)-based metal ceramic and preparation method thereof

The invention discloses a rare earth alloy powder-modified Ti(C,N)-based metal ceramic and a preparation method of the metal ceramic. The metal ceramic comprises Co and Ni or at least two of components selected from Co, Ni as well as Fe as a bonding phase, Ti(C,N) as a basic hard phase and optionally at least one of metallic carbides; and a rare earth alloy powder modifier 0.1-3wt% of the total mass of the metal ceramic. The preparation method comprises treating a raw material through a wet-grinding and mixing process, a die-forming process, a vacuum-degreasing process and a low-pressure sintering process to prepare the rare earth alloy powder-modified Ti(C,N)-based metal ceramic. On the premise of keeping high hardness and high wear resistance, the Ti(C,N)-based metal ceramic prepared according to the invention has excellent comprehensive performance, can be greatly improved in strength and tenacity and can also be widely applied to various cutting tools and wear-resistant parts.

Owner:SICHUAN UNIV

Ceramic cladding powder and preparation method thereof

InactiveCN101423398AThere will be no phenomenon of grain aggregation and growthEvenly distributedCeramic coatingTitanium nitride

The invention relates to ceramic coating powder the ceramic phase of which is coated by a metallic phase cobalt or / and a metallic phase nickel. The metallic phase cobalt and the metallic phase nickel are obtained by means of a liquid phase reduction method; and the ceramic phase is at least one of titanium carbonitride, titanium carbide, titanium nitride, tungsten carbide, silicon carbide, niobium carbide, tantalum carbide, aluminum oxide, zirconium oxide, magnesium oxide, boron nitride and silicon nitride. A method for preparing the ceramic coating powder is the liquid phase reduction method to carry out a reduction reaction between cobalt or / and nickel ions in a plating solution to generate the metallic phase cobalt or / and nickel which is deposited on the surface of a ceramic core to form the ceramic coating powder; and the process steps are as follows: (1) pre-treatment of the ceramic powder; (2) preparation of the plating solution; (3) liquid-phase reduction reaction; and (4) plating post treatment.

Owner:SICHUAN UNIV

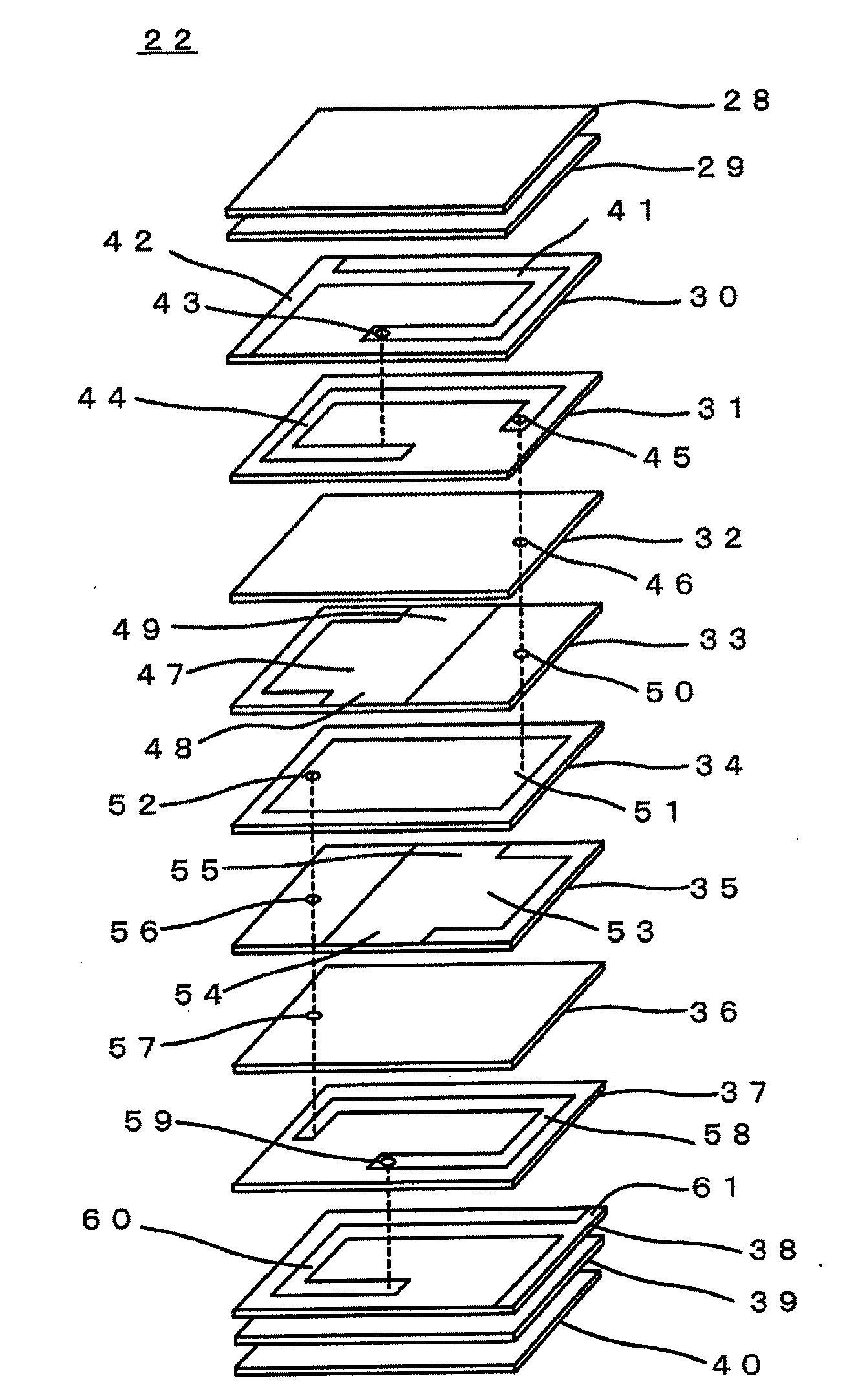

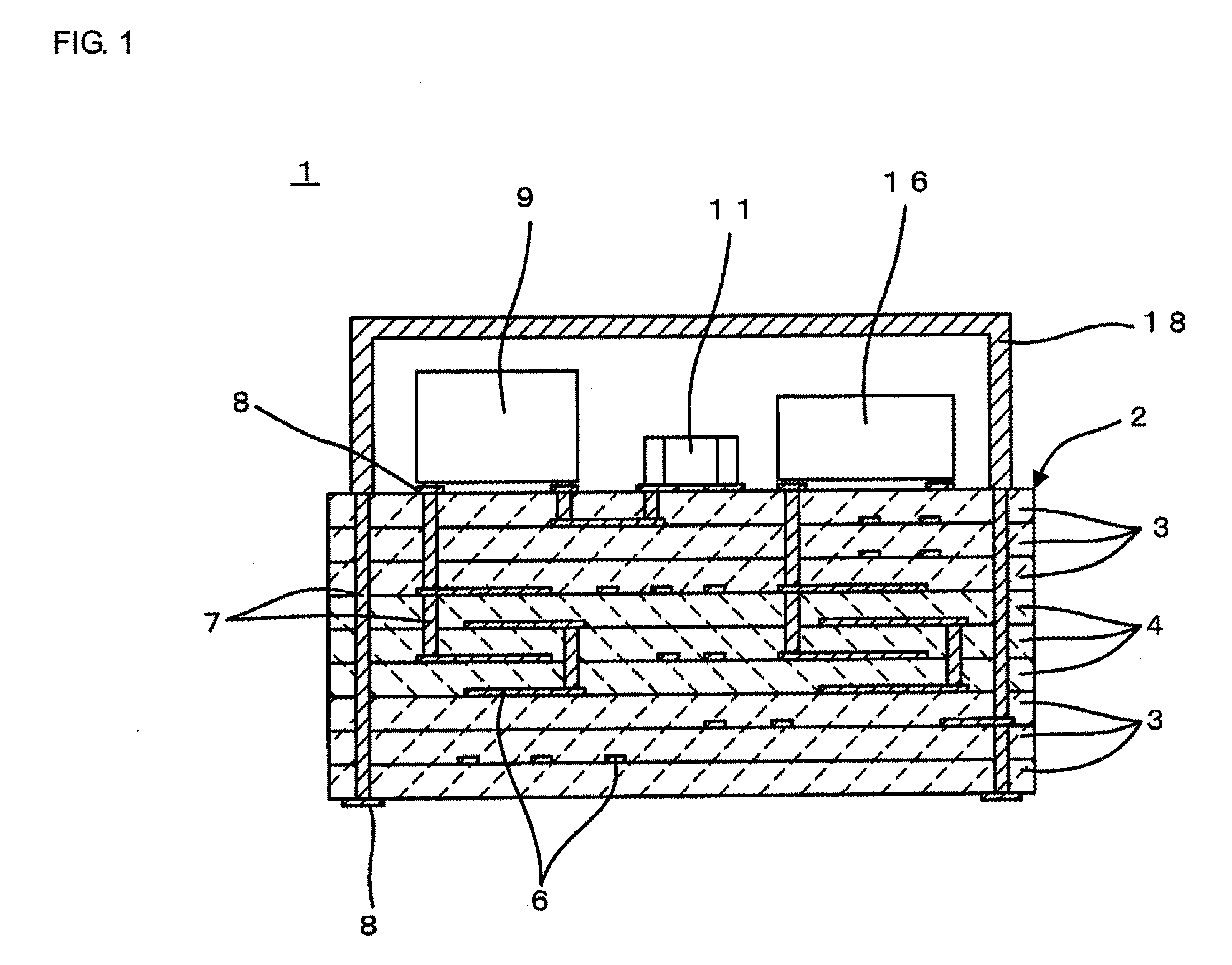

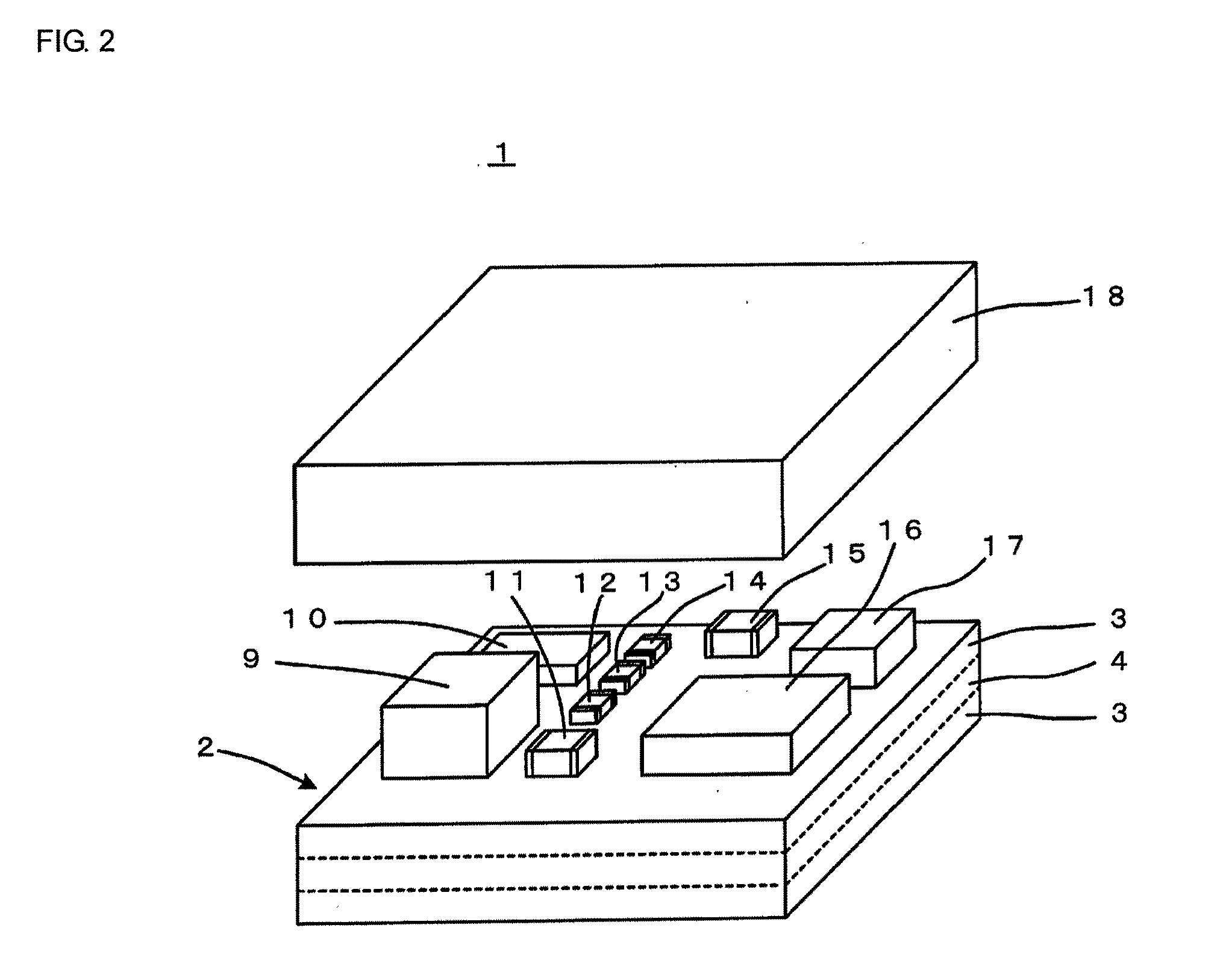

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20120276310A1Low densityReduce hardnessEnvelopes/bags making machineryCeramic extrusion diesPorosityBuilding product

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Sequential build circuit board

InactiveUS6944945B1Improve flexural strengthImprove rigiditySemiconductor/solid-state device detailsSolid-state devicesGlass fiberInterconnection

A method for manufacture of a circuit board and the board formed by the novel method. The method comprises selective plating of metallic reinforcing members, solder mount pads, signal and interconnections sequentially. The resultant board is desirably free of glass fiber reinforcement.

Owner:SHIPLEY CO LLC

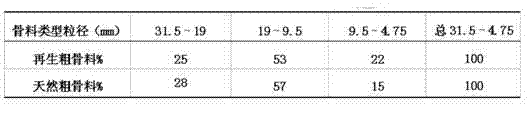

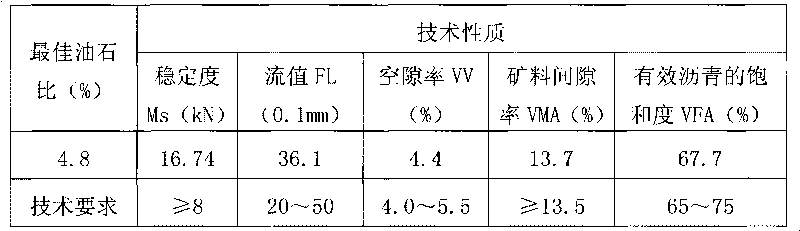

Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

The invention discloses a recycled aggregate medium-dry hard concrete prepared by using building waste, which comprises the following raw materials of coarse aggregate, fine aggregate, a gelatinizing agent, a water reducing agent and water, wherein the gelatinizing agent comprises cement and coal ash, and the coarse aggregate comprises 50-100 percent of recycled coarse aggregate prepared from thebuilding waste. A preparation method of the recycled aggregate medium-dry hard concrete comprises the following steps of: pretreating the building waste, removing impurities, remaining waste concrete, waste bricks and the like; crushing and screening to prepare the recycled coarse aggregate; mixing the recycled coarse aggregate, natural sand, cement and water according to the proportion, adding the coal ash and the water reducing agent, stirring uniformly to obtain a mixture; and squeezing and forming the mixture, curing for 2 days to obtain the recycled aggregate medium-dry hard concrete. The invention solves the problems of worsening ecological environment and the like caused by difficulty in treating the building waste; and the building wastes are used for manufacturing the recycled aggregate for replacing natural aggregate, the increasingly deficient natural aggregate and damage degree to the ecological environment are reduced, and the living environment of human beings is protected. The recycled aggregate medium-dry hard concrete prepared by using the method has high strength and high abrasive resistance, and can be used for building base installations such as city roads, housing constructions and the like.

Owner:云南华威废弃物资源化有限公司

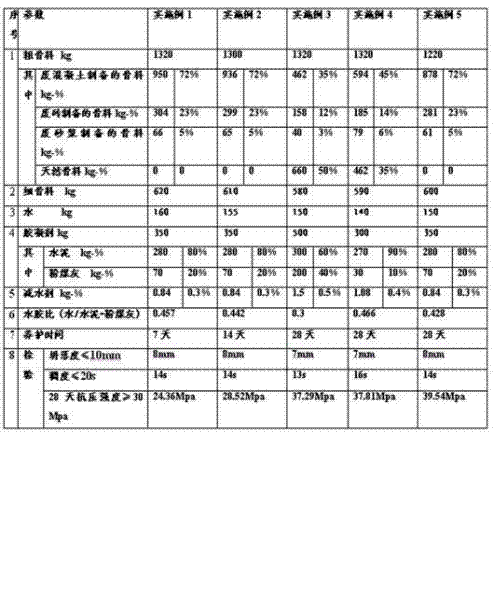

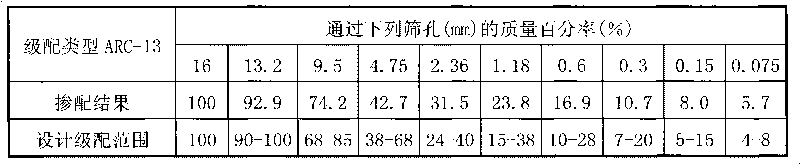

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com