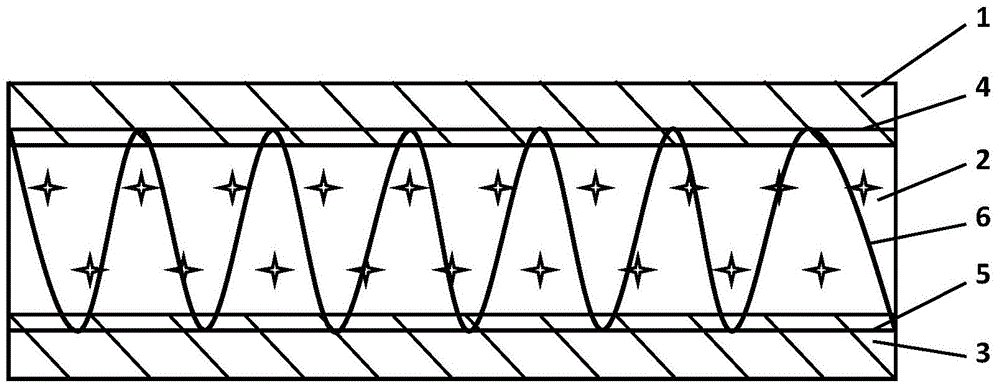

Novel fiber reinforced composite heat insulation plate and preparing method of novel fiber reinforced composite heat insulation plate

A fiber-reinforced composite, thermal insulation board technology, applied in thermal insulation, chemical instruments and methods, building components, etc., can solve the problems of poor corrosion resistance, hidden fire hazards, low impact resistance, etc. Fire hazard, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment prepares the above-mentioned novel fiber-reinforced composite insulation board according to the following steps:

[0067] (1) Mix the raw materials in the following proportions by weight, and stir evenly to obtain polymer modified mortar, which is used as the bottom mortar: 112.5kg (45.0%) of sulfoaluminate cement, 87.5kg (35.0%) of sand, Modified polypropylene emulsion 20kg (8.0%), water 29kg (11.6%), polycarboxylate superplasticizer 0.75kg (0.3%), powder defoamer 0.25kg (0.1%);

[0068] (2) The template is installed on the production line, and a layer of PVA coil is laid in the template;

[0069] (3) Pour the bottom mortar onto the formwork, and pass the height limit of the scraper on the production line to form a 5mm thick bottom layer;

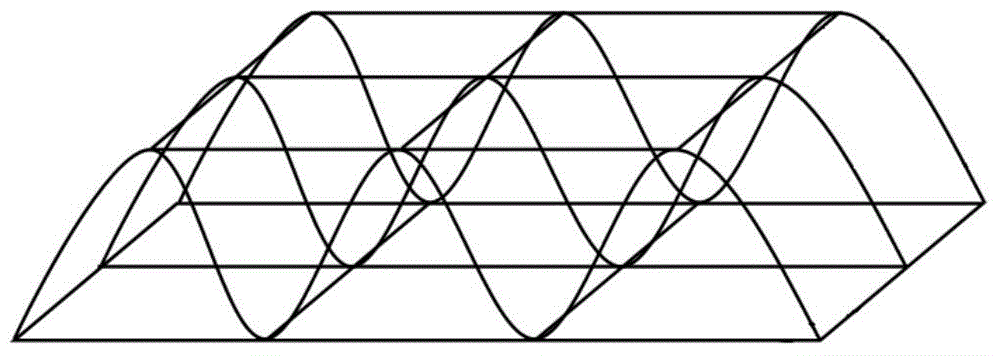

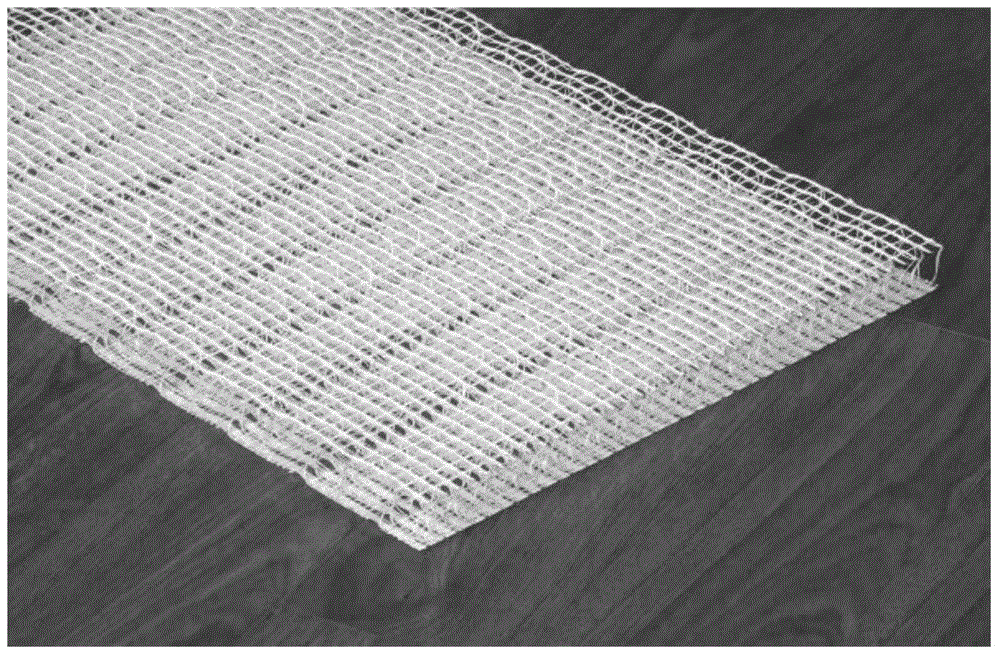

[0070] (4) Laying a three-dimensional fiber fabric with a thickness of 150mm on the bottom layer, after vibrating for 3 minutes by a vibrator under the production line, the bottom layer is initially set for 15 minut...

Embodiment 2

[0078] This embodiment prepares the above-mentioned novel fiber-reinforced composite insulation board according to the following steps:

[0079] (1) Mix the raw materials in the following proportions by weight, and stir evenly to obtain polymer modified mortar, which is used as the bottom mortar: 135kg (18%) of ordinary Portland cement, 90kg (12%) of metakaolin, fine 296.25kg (39.5%) of stones, 120kg (20%) of modified silicone acrylic emulsion, 75.75kg (10.1%) of water, 2.25kg (0.3%) of naphthalenesulfonate water reducer, 0.75kg (0.1%) of liquid defoamer );

[0080] (2) The template is installed on the production line, and a layer of kraft paper is laid in the template;

[0081] (3) Pour the bottom mortar onto the formwork, and pass the height limit of the scraper on the production line to form a 15mm thick bottom layer;

[0082] (4) Lay a three-dimensional fiber fabric with a thickness of 100mm on the bottom layer, vibrate for 3 minutes through a vibrator under the producti...

Embodiment 3

[0090] This embodiment prepares the above-mentioned novel fiber-reinforced composite insulation board according to the following steps:

[0091] (1) Mix the raw materials of the following weight percent ratios, stir evenly, and make polymer modified mortar, which is used as the bottom mortar: Portland cement 157.5kg (31.5%), fly ash 75kg (15%), Ceramic chips 225kg (45%), polystyrene emulsion 40kg (8.0%), water 0.5kg (0.1%), calcium nitrite 1.5kg (0.3%), melamine series water reducer 0.5kg (0.1%) ;

[0092] (2) The template is installed on the production line, and a layer of PVA coil is laid in the template;

[0093] (3) pour the bottom mortar onto the formwork, and form a 10mm thick bottom layer through the height limit of the scraper on the production line;

[0094] (4) Lay a three-dimensional fiber fabric with a thickness of 200mm on the bottom layer, vibrate for 3 minutes through a vibrator under the production line, and set the bottom layer for 18 minutes;

[0095] (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com