Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2926 results about "Fiber-reinforced composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fiber-reinforced composite (FRC) is a composite building material that consists of three components...

Selectively absorbable/biodegradable, fibrous composite constructs and applications thereof

A family of selectively absorbable / biodegradable, fibrous composite constructs includes different combinations of biostable and absorbable / biodegradable yarns assembled as initially interdependent, load-bearing components, transitioning to exhibit independent functional properties during in vivo end-use. The family of constructs consists of two groups, one group is made of fiber-reinforced composites of high compliance, absorbable matrices of segmented polyaxial copolyesters reinforced with multifilament yarn constructs, which are combinations of ultrahigh molecular weight polyethylene fibers and at least one absorbable / biodegradable fiber selected from silk fibers and multifilament yarns made from linear segmented, l-lactide copolyesters and poly (3-hydroxyalkanoates, are useful in orthopedic, maxillofacial, urological, vascular, hernial repair and tissue engineering applications. The second group is made of coated and uncoated, warp-knitted mesh constructs for use in hernial, vascular, and urological tissue repair and tissue engineering.

Owner:POLY MED

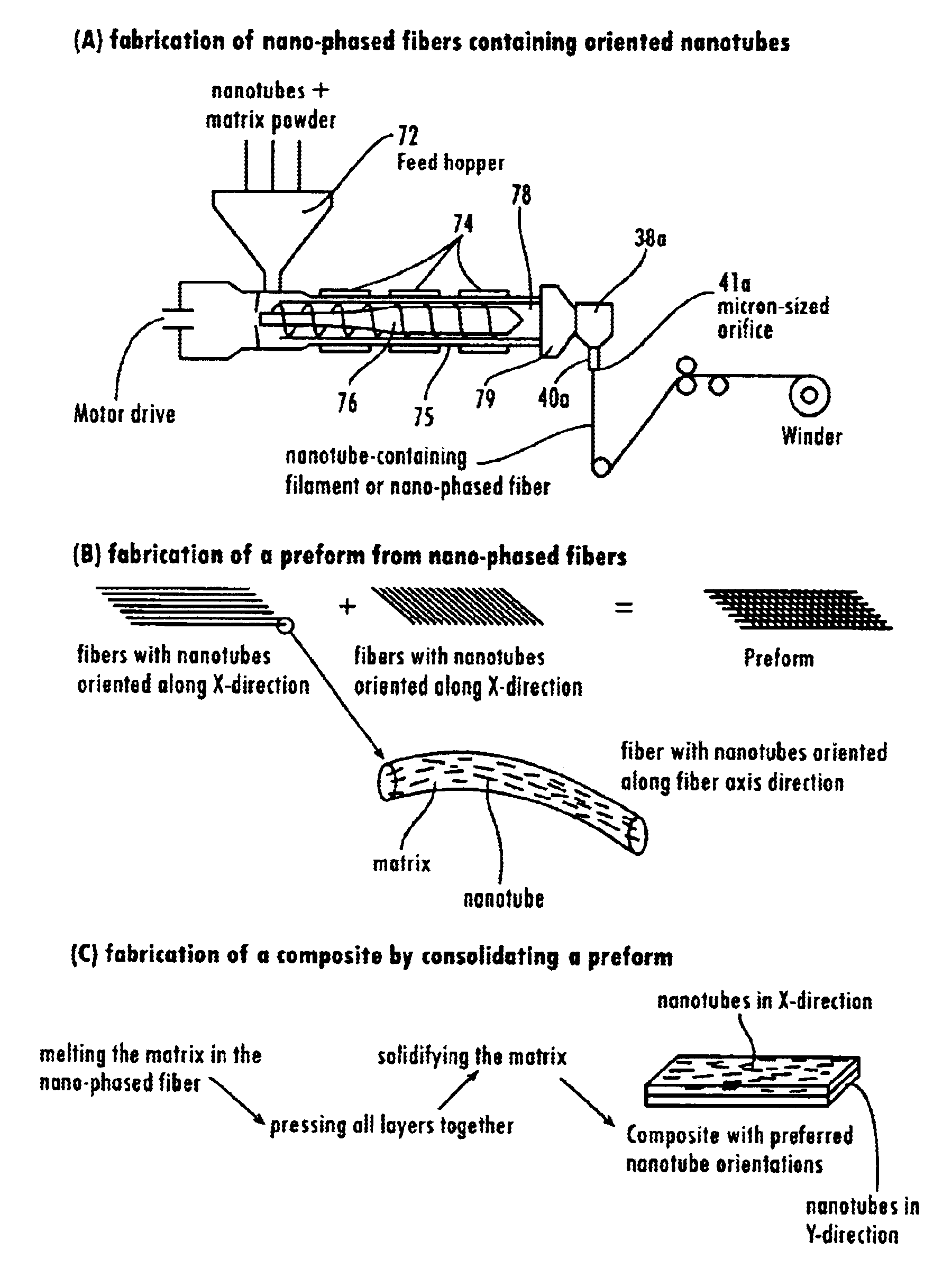

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

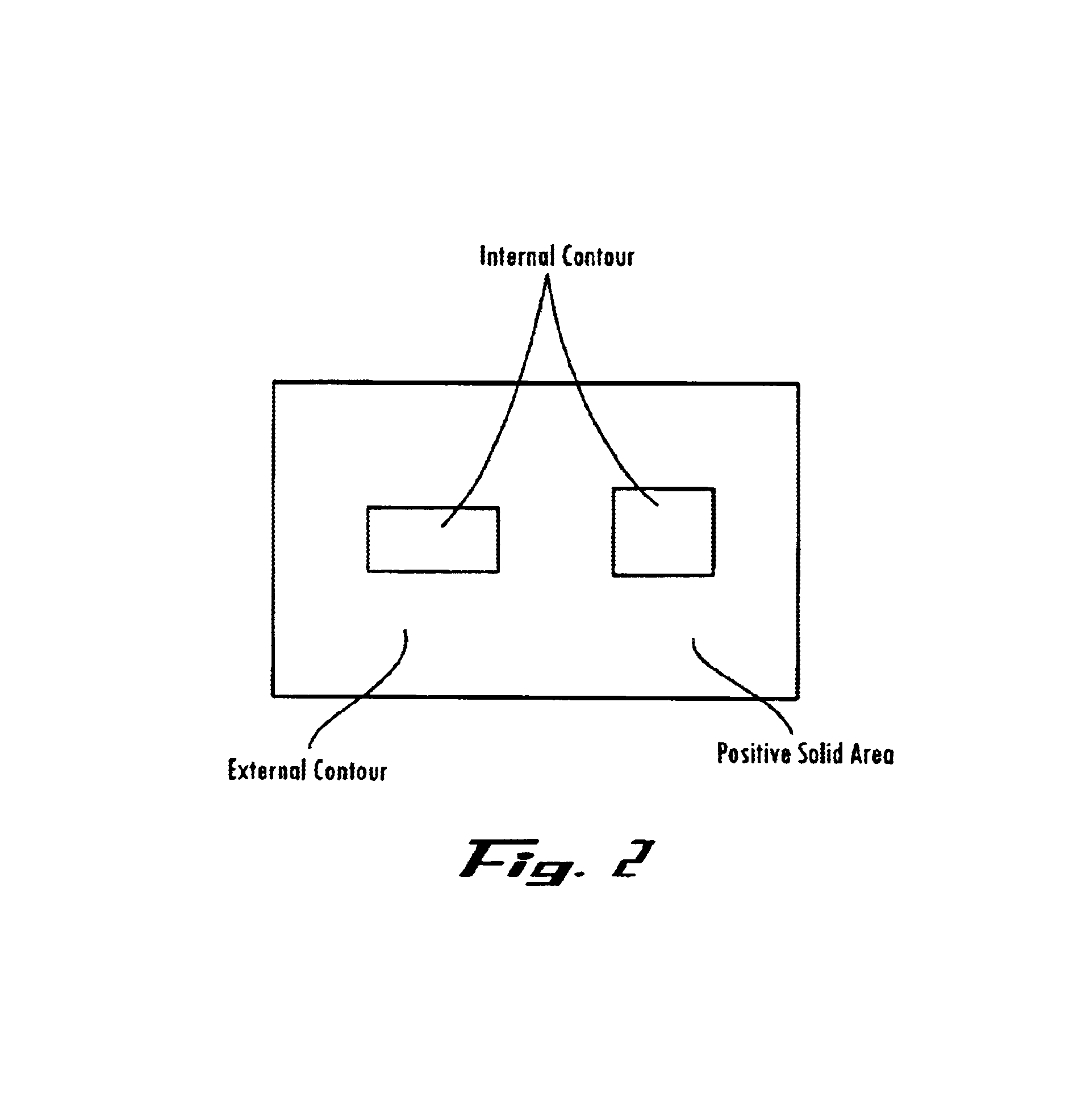

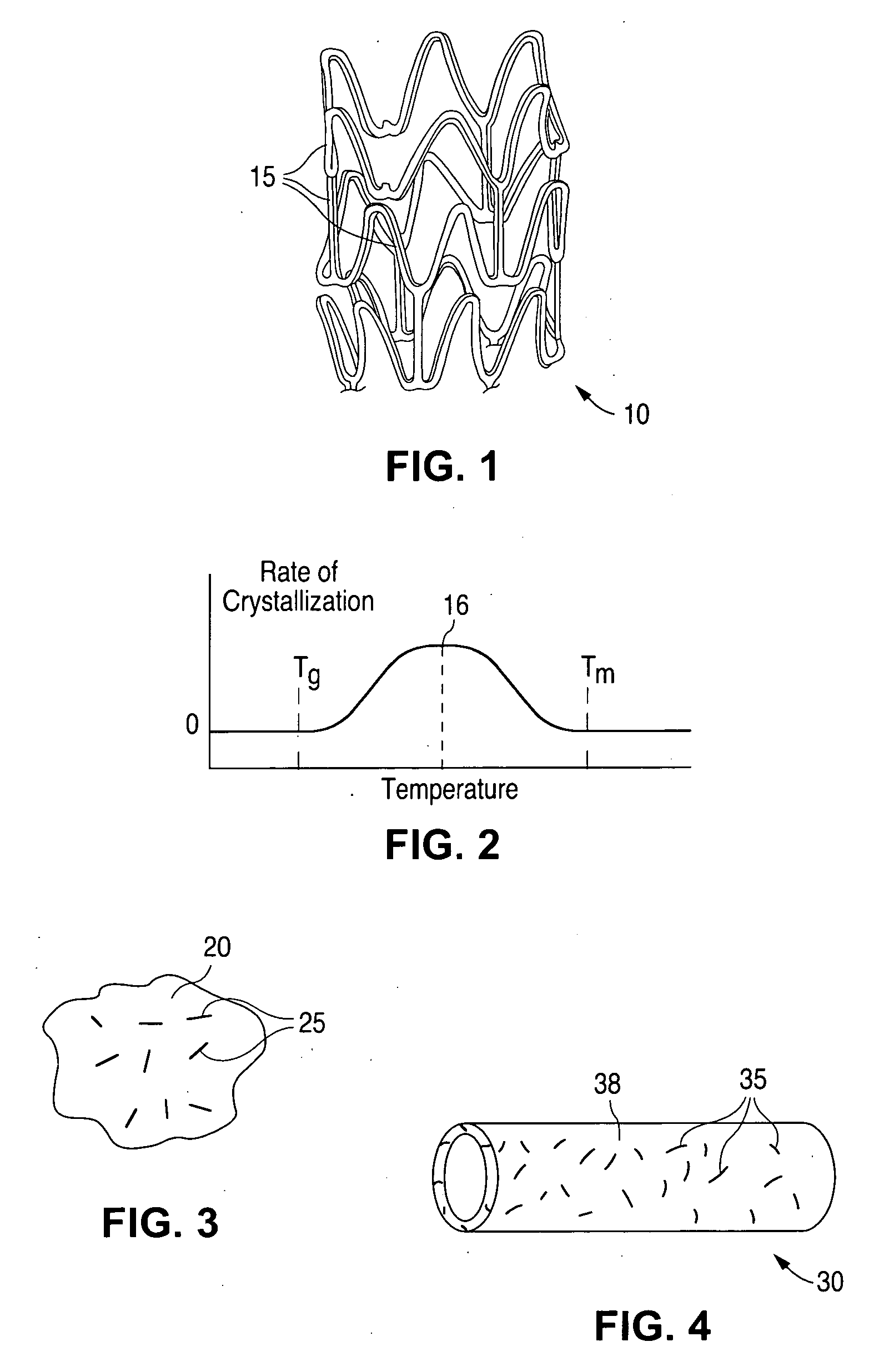

Fiber reinforced composite stents

InactiveUS20070038290A1Reduces radial profileLower softening temperatureStentsHollow filament manufactureInsertion stentFiber-reinforced composite

Owner:ABBOTT CARDIOVASCULAR

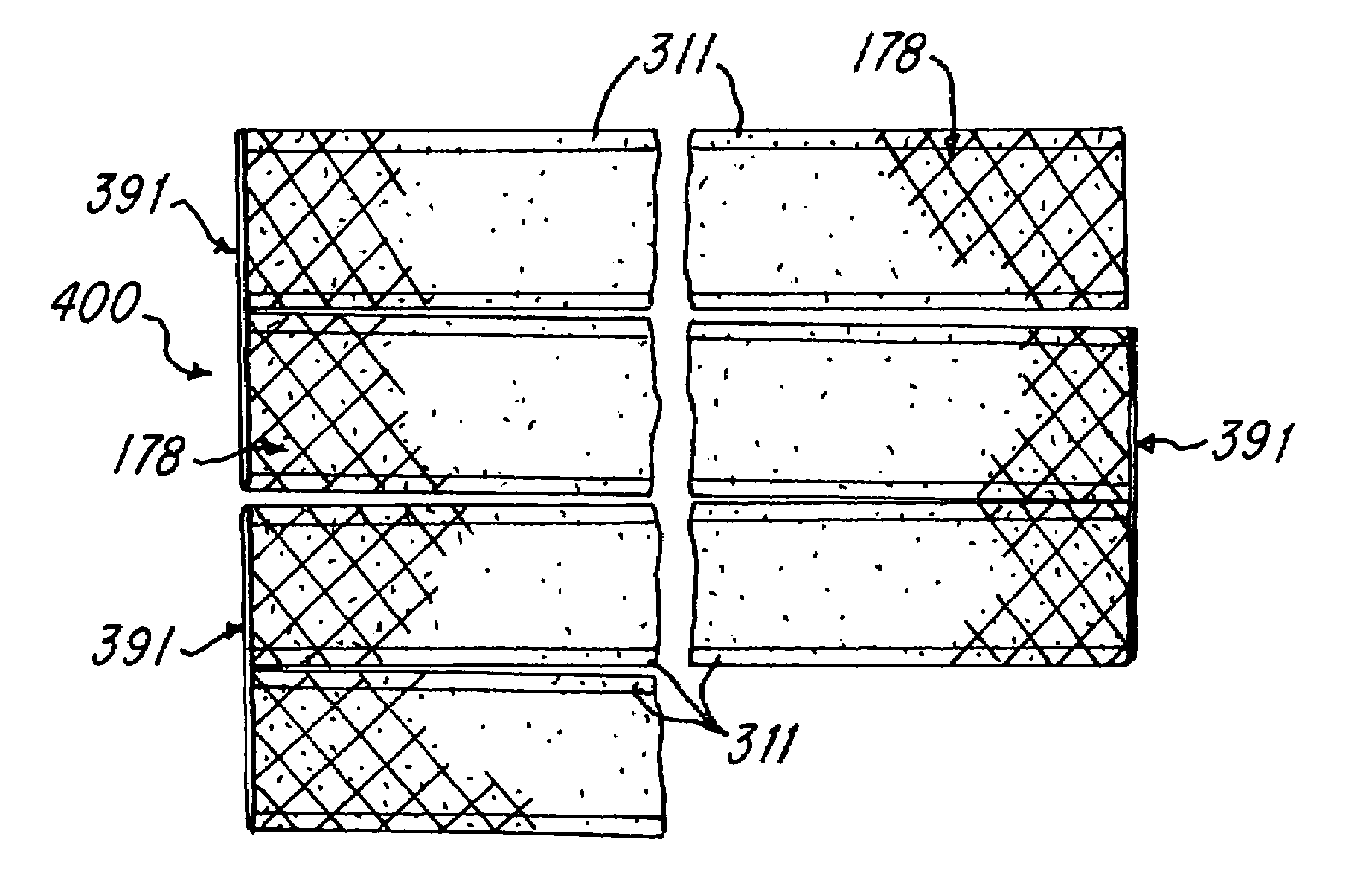

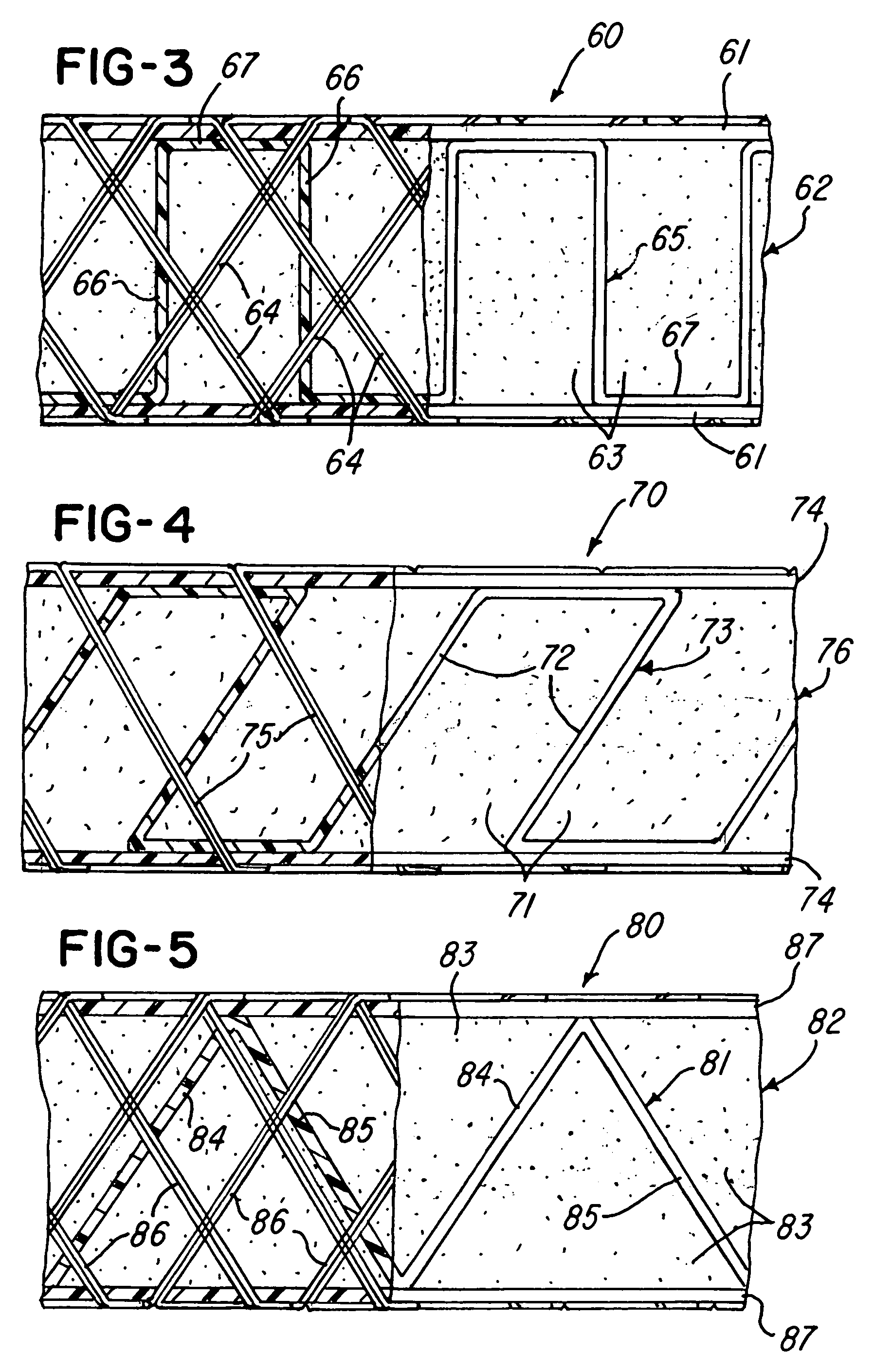

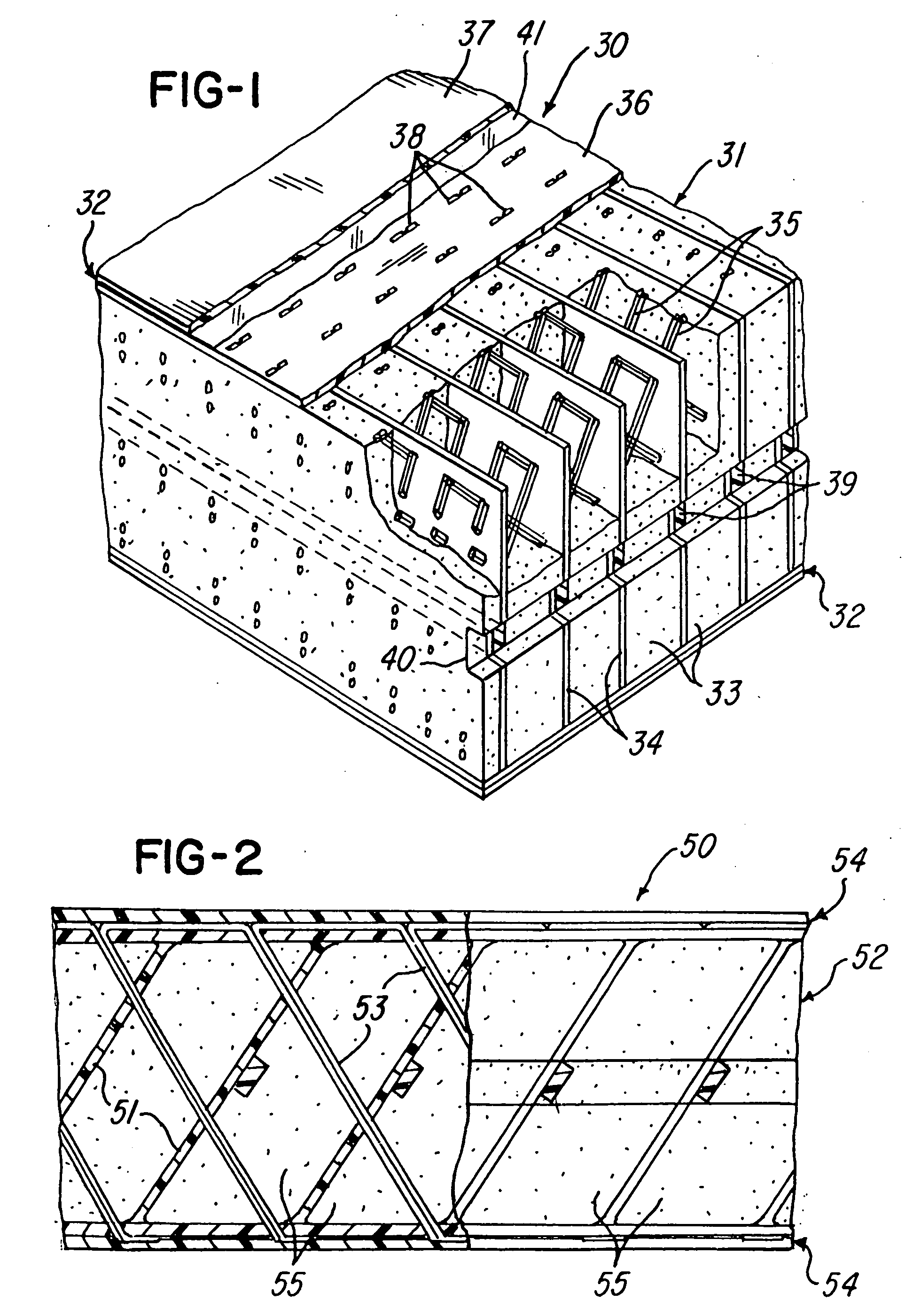

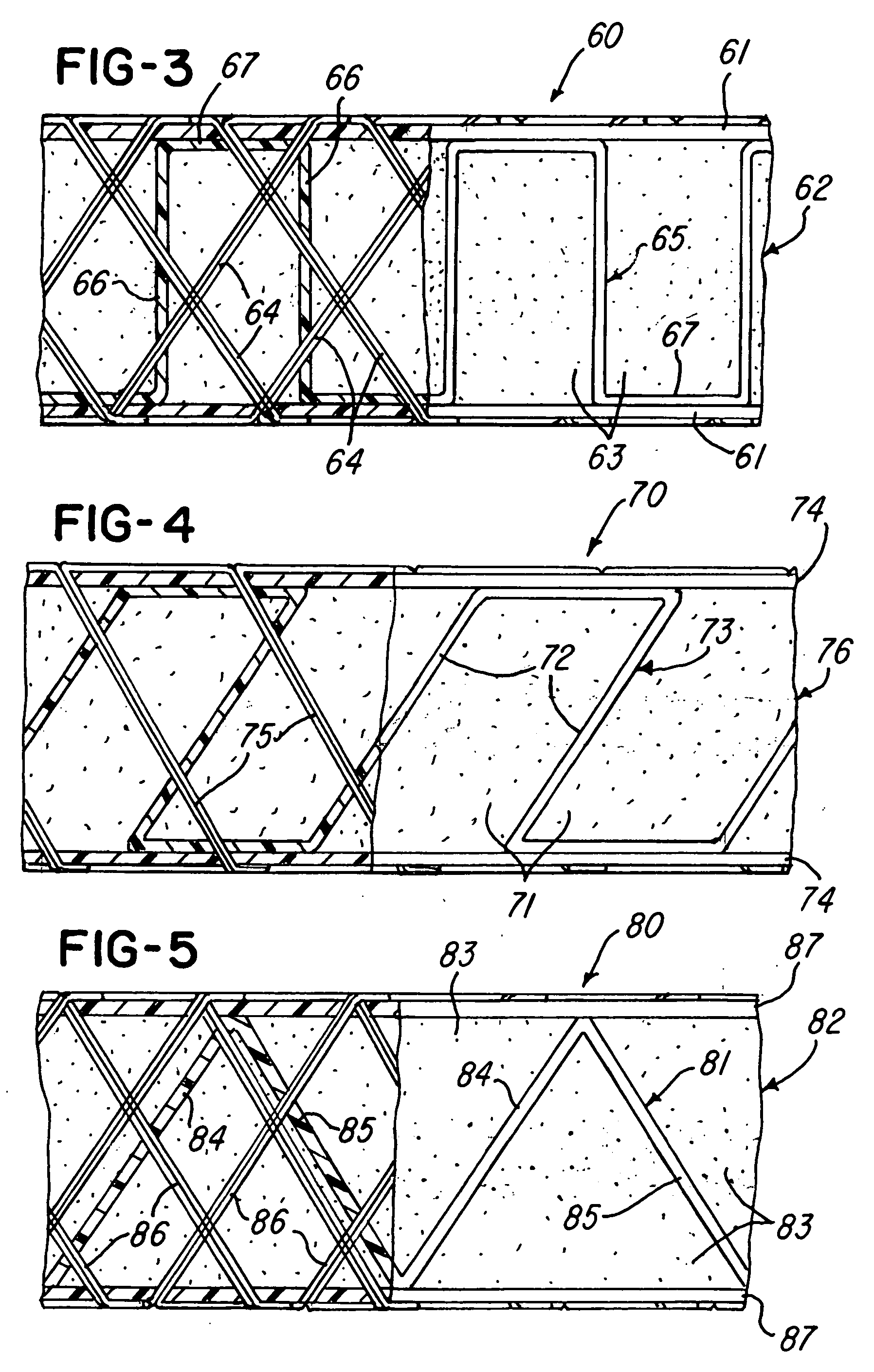

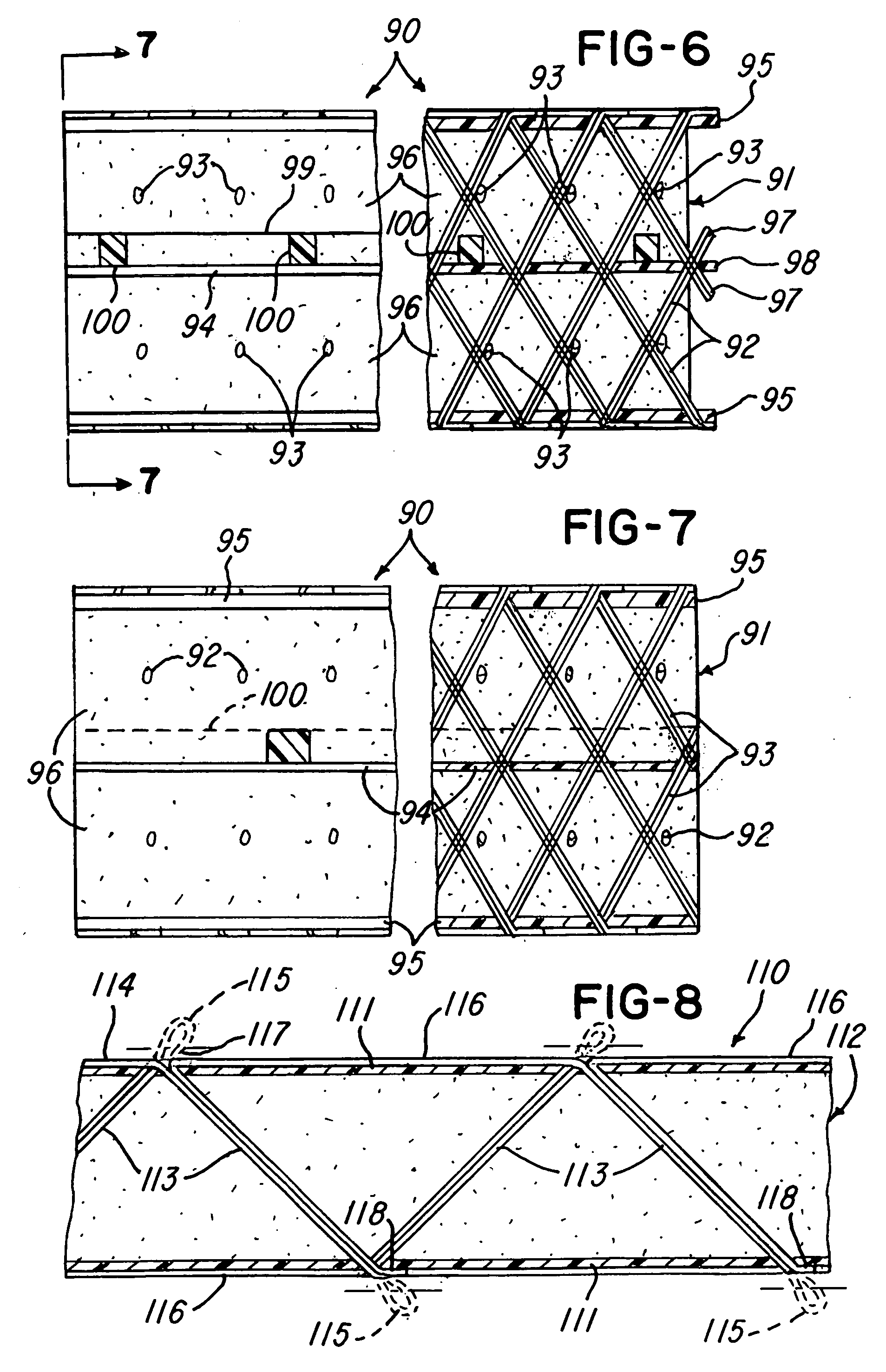

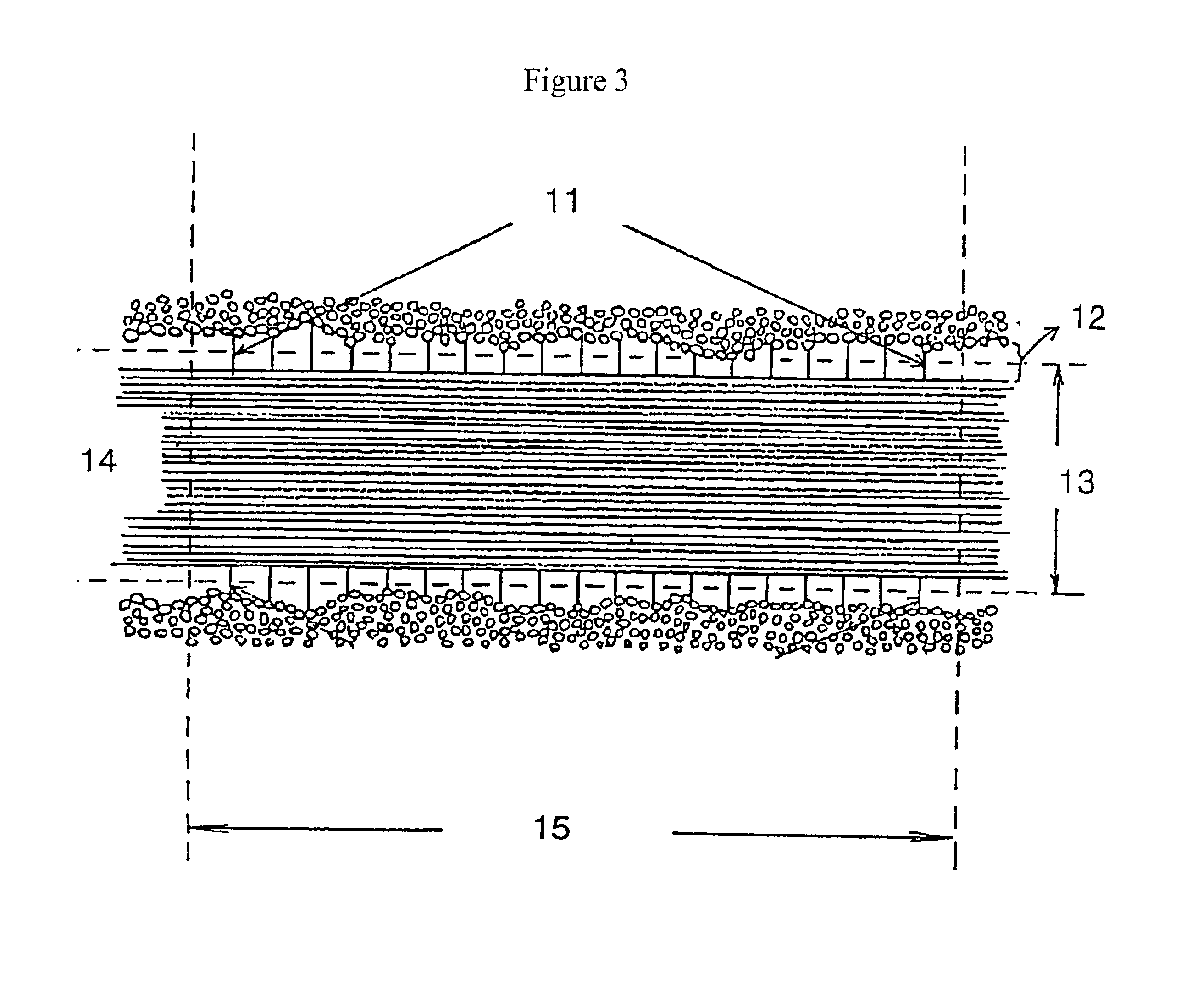

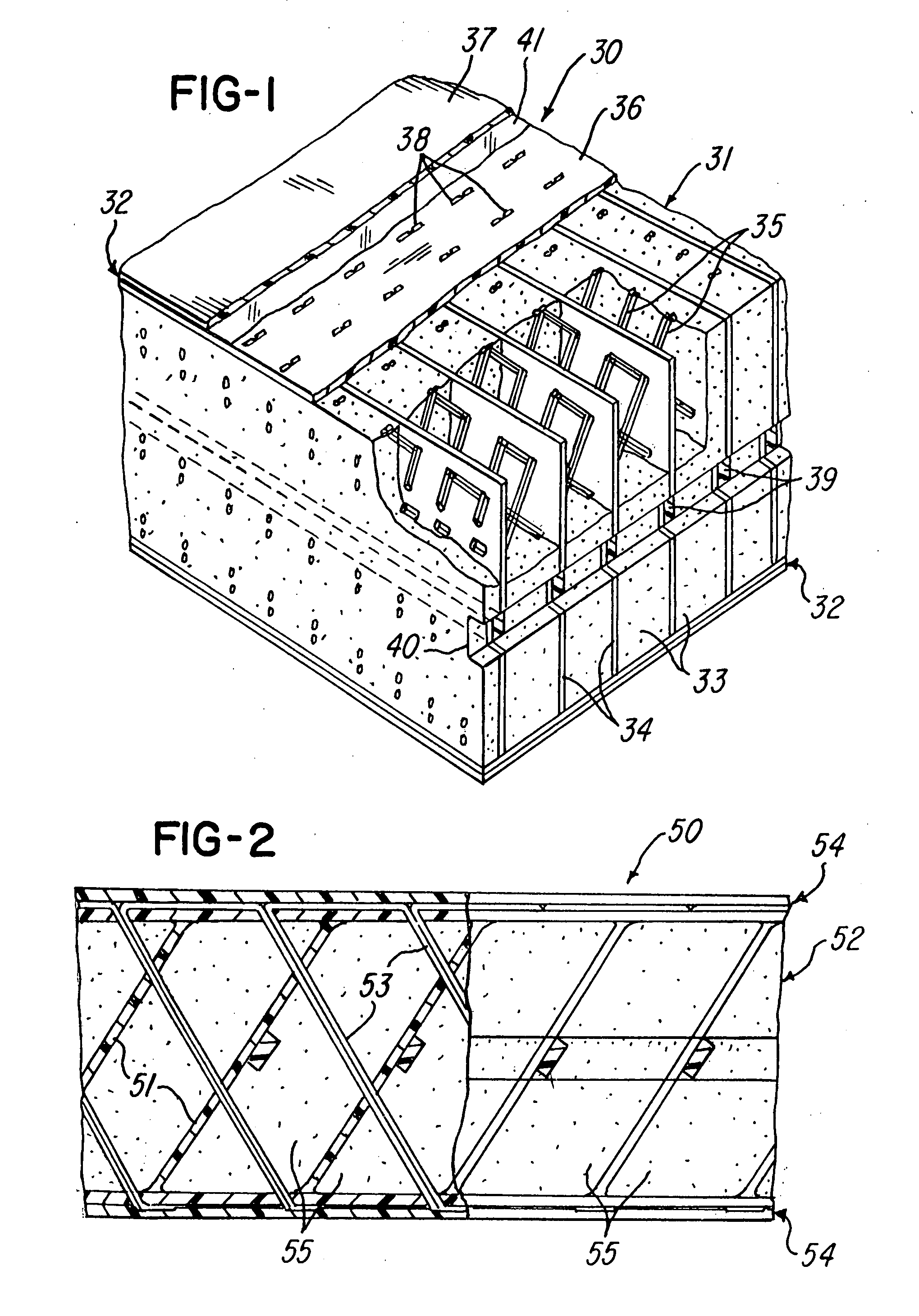

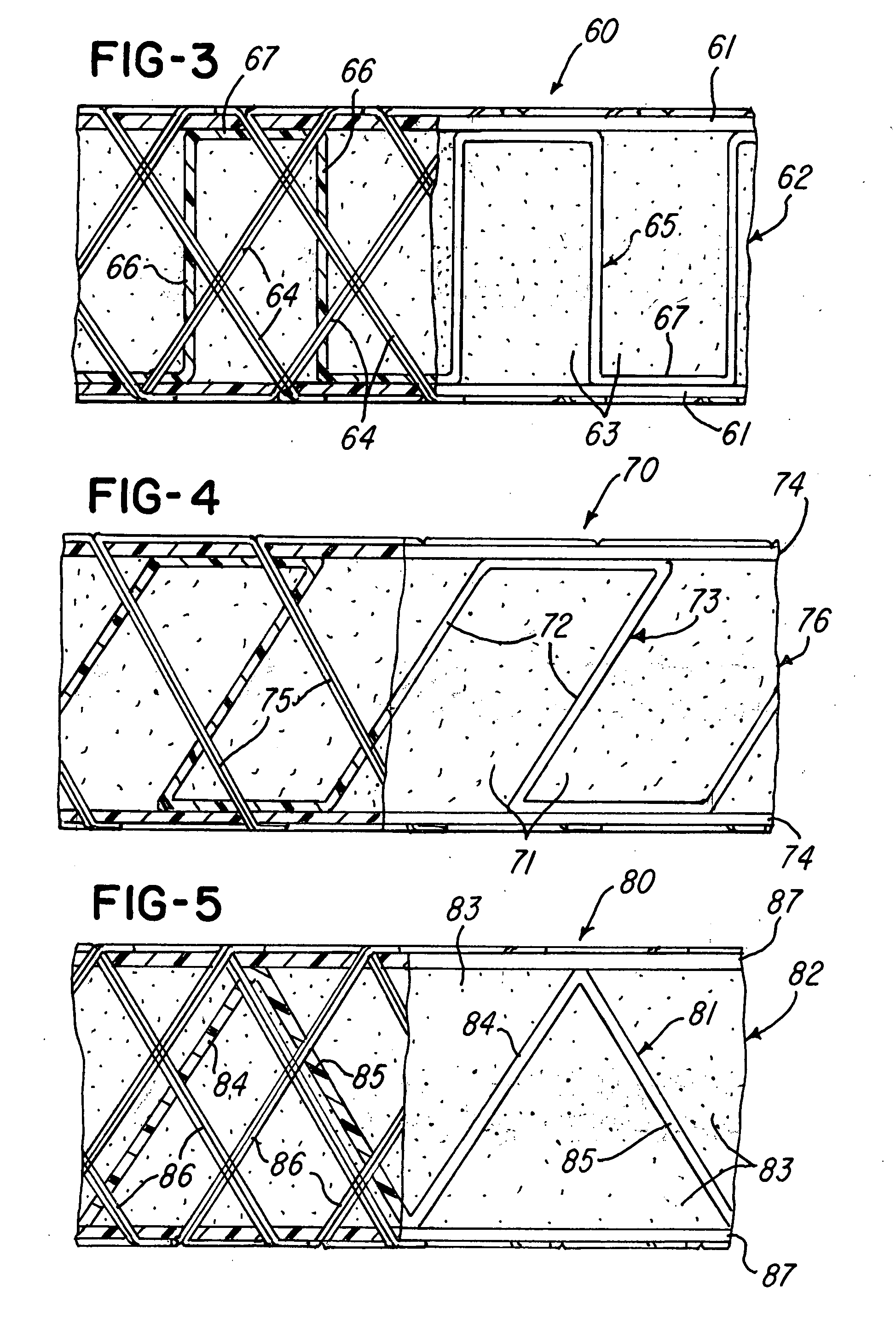

Fiber reinforced composite cores and panels

InactiveUS7393577B2Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

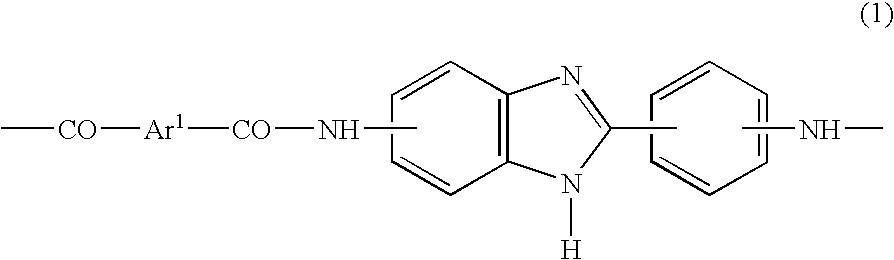

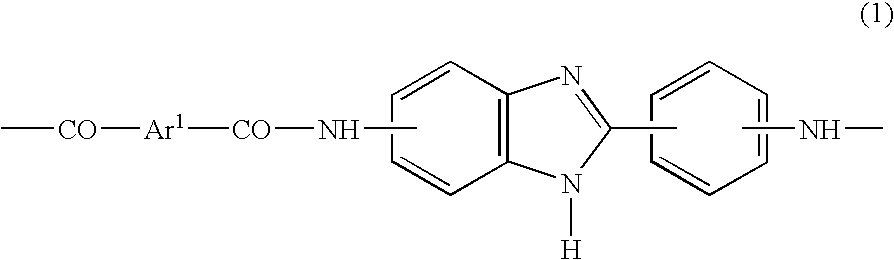

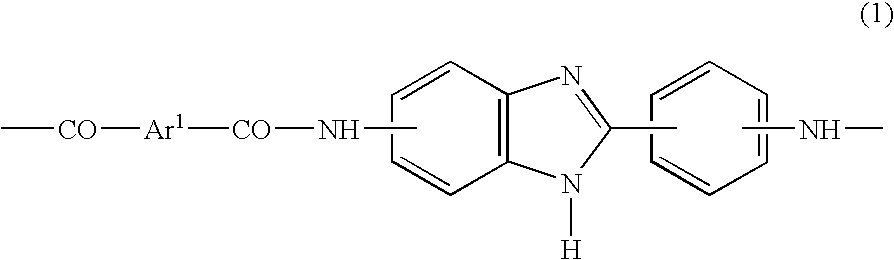

Heterocycle-containing aromatic polyamide fiber, method for producing the same, cloth constituted by the fiber, and fiber-reinforced composite material reinforced with the fiber

InactiveUS20100029159A1Improve balanceHigh strength holding ratioArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentAramidesFiber-reinforced composite

The heterocycle-containing aromatic polyamide fibers of the invention are excellent in balance among mechanical characteristics, particularly balance among tensile strength, initial modulus and strength in the direction perpendicular to the fiber axis, exhibit a high strength holding ratio under heat and humidity, and are excellent in flame retardancy, bulletproofness and cutting resistance, as compared to conventional aromatic polyamide fibers, and therefore can be favorably used in fields with severe mechanical characteristics and have stability to environmental variation. Accordingly, the heterocycle-containing aromatic polyamide fibers of the invention can be favorably used, for example, in fields including protective equipment, such as a helmet, a bulletproof vest and the like, a chassis for an automobile, a ship and the like, an electric insulating material, such as a printed circuit board and the like, and other various fields.

Owner:TEIJIN TECHNO PRODUCTS LTD

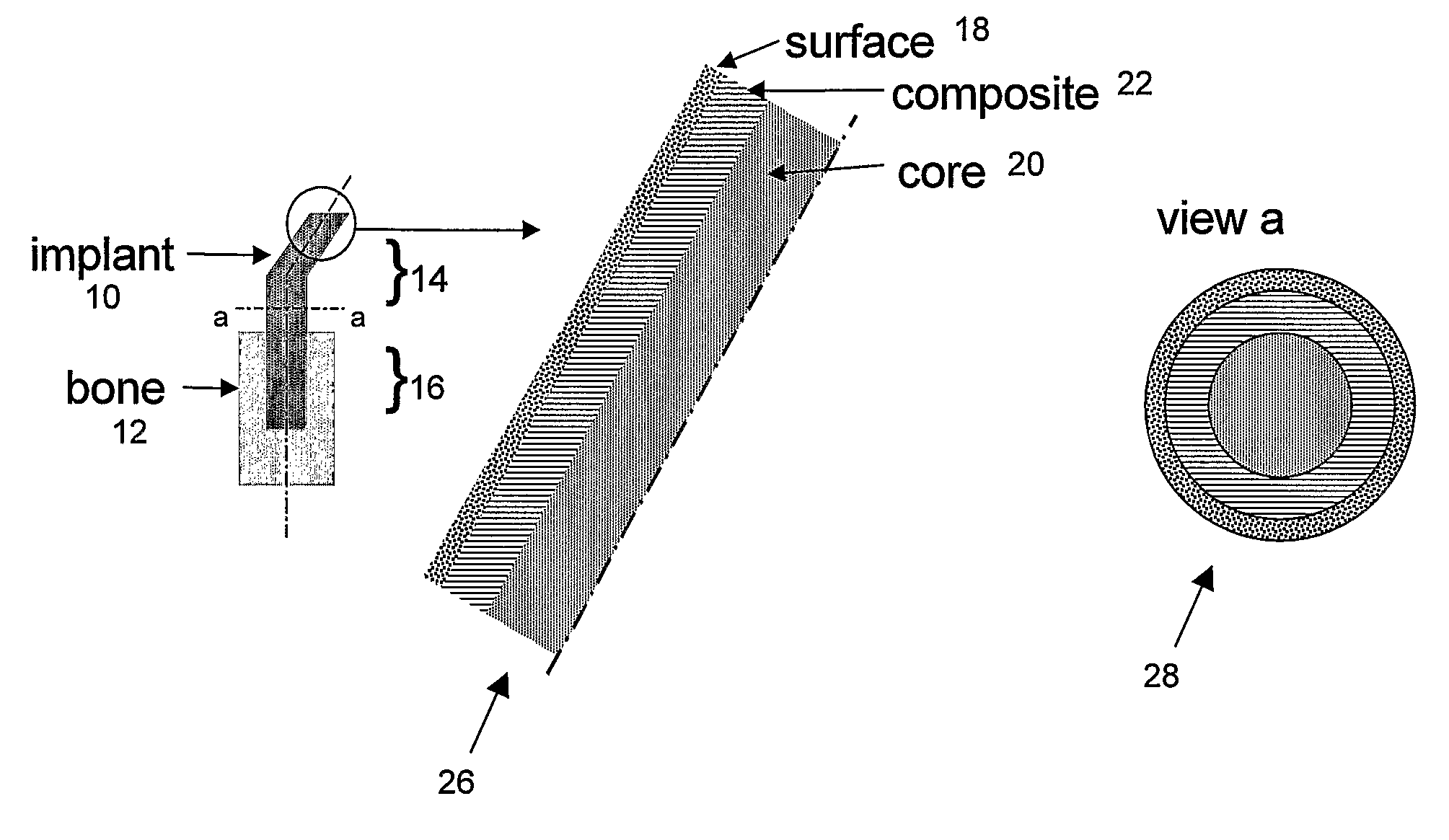

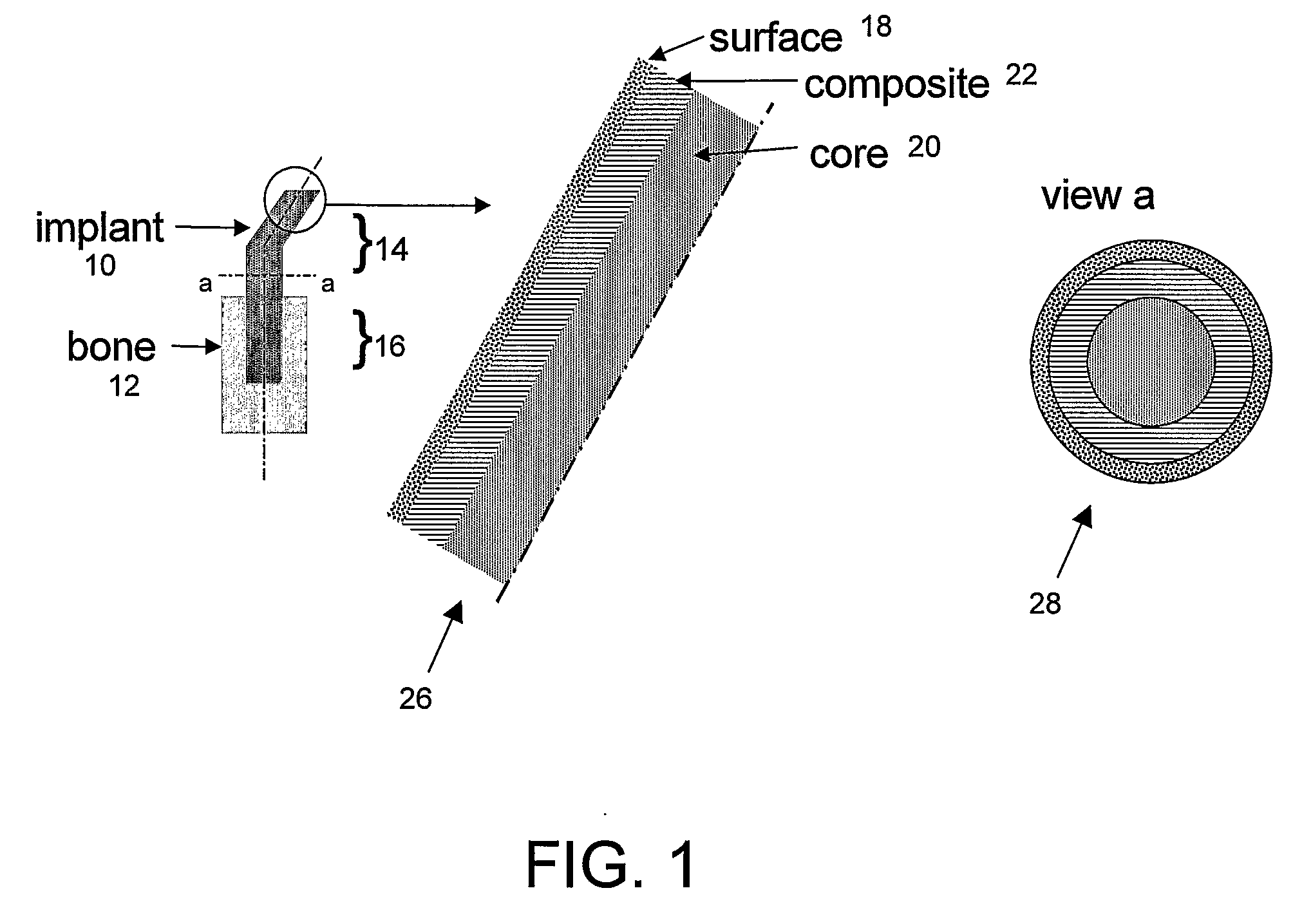

Implantable biomimetic prosthetic bone

InactiveUS20090177282A1Reduce riskMolten spray coatingLamination ancillary operationsNormal boneFiber-reinforced composite

Bone tissue at the interface of a bone implant is shielded from stresses found in normal bone because of the higher stiffness or rigidity in the implant versus in bone. The resulting “stress shielding” of the bone by the implant eventually results in resorption of bone at the bone-implant interface and ultimately necessitates replacement of the bone implant. To overcome these problems, an implantable biomimetic prosthetic bone having a porous surface, a fiber-reinforced composite structure, and a polymer-based core is disclosed. The prosthetic bone is a good match for structure, stiffness, viscoelastic properties, specific weight and overall structure as real bone or host tissues adjacent to the prosthetic bone. The prosthetic bone may be formed as a total hip prosthesis.

Owner:NAT RES COUNCIL OF CANADA

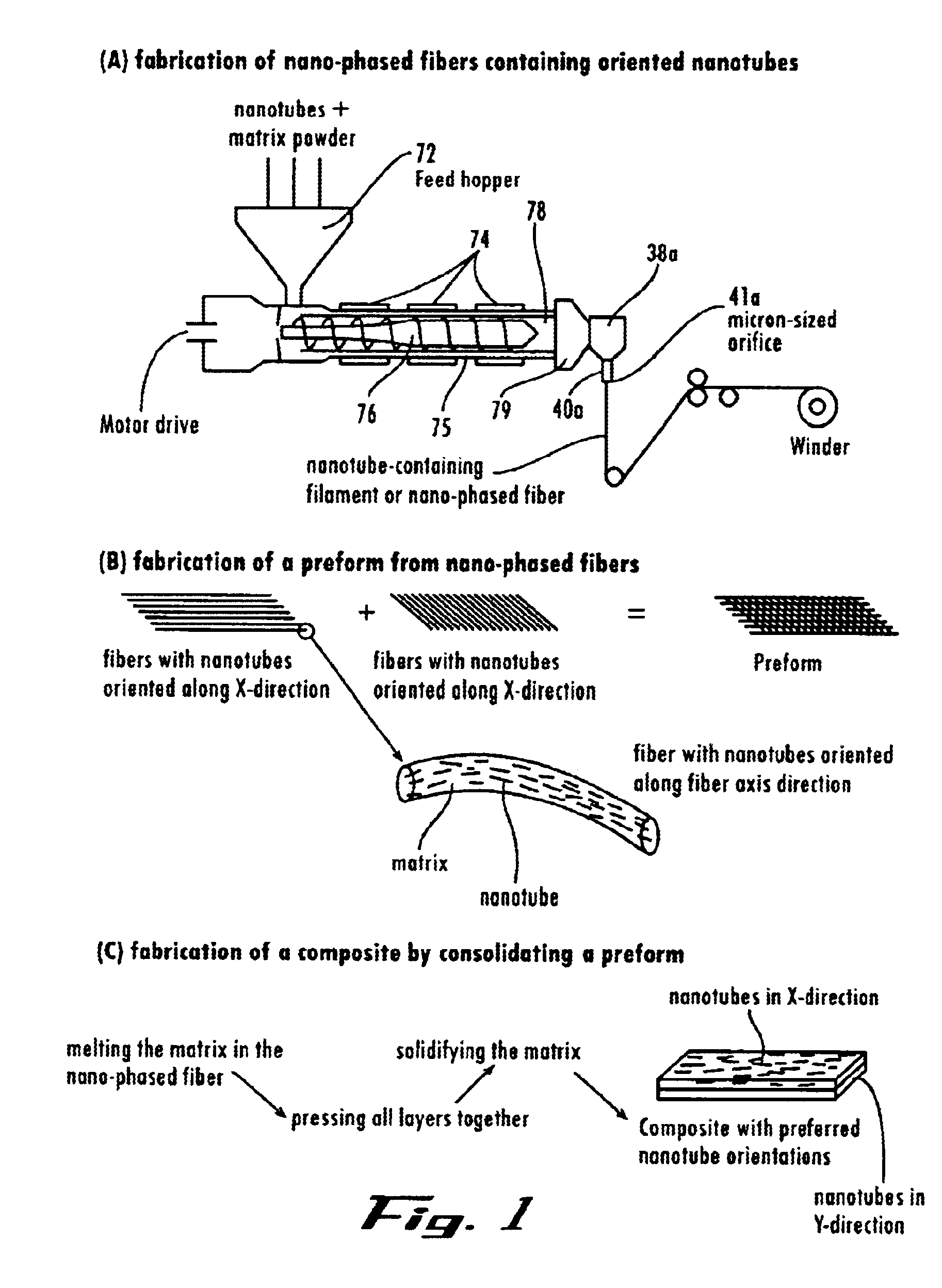

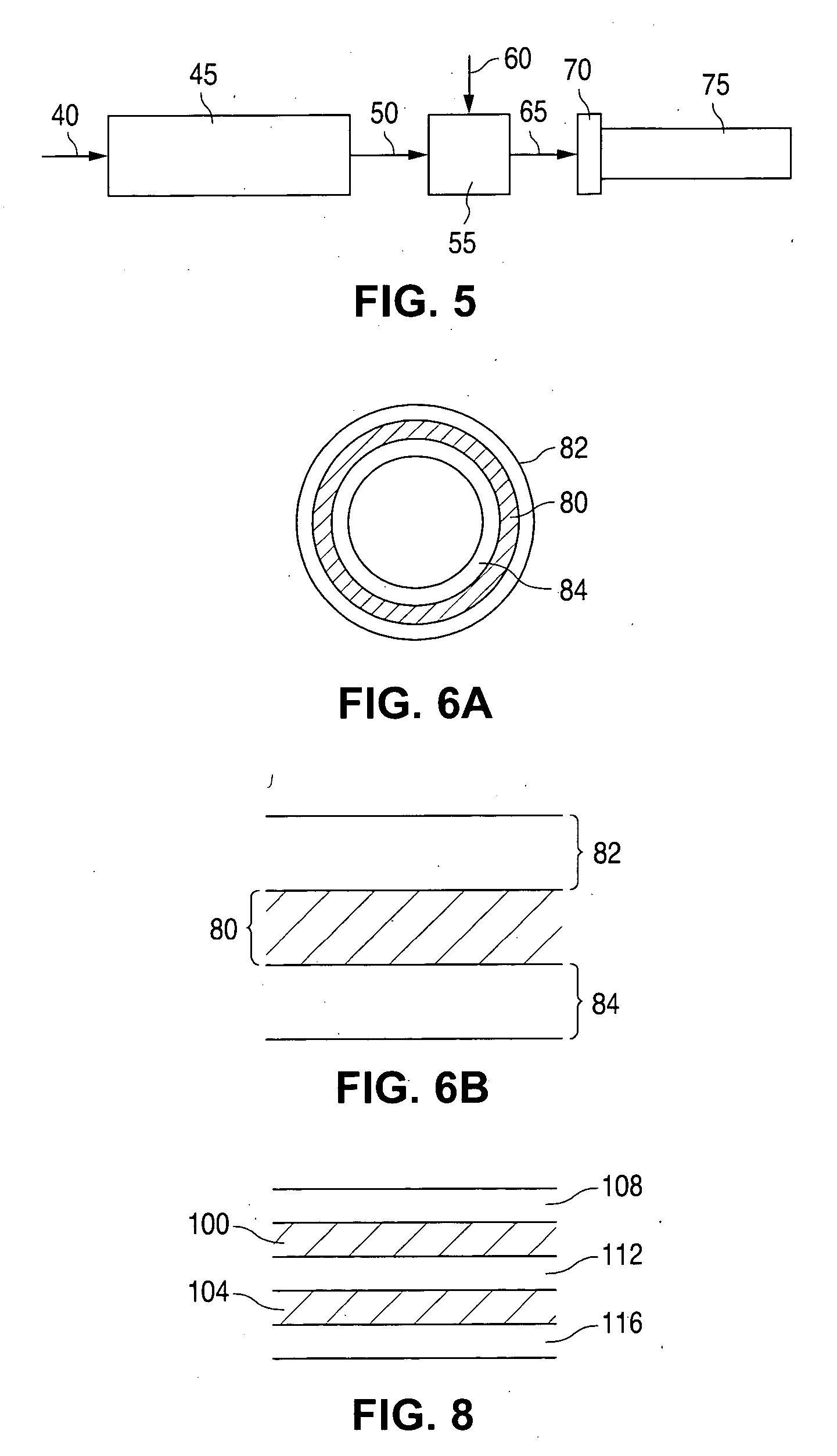

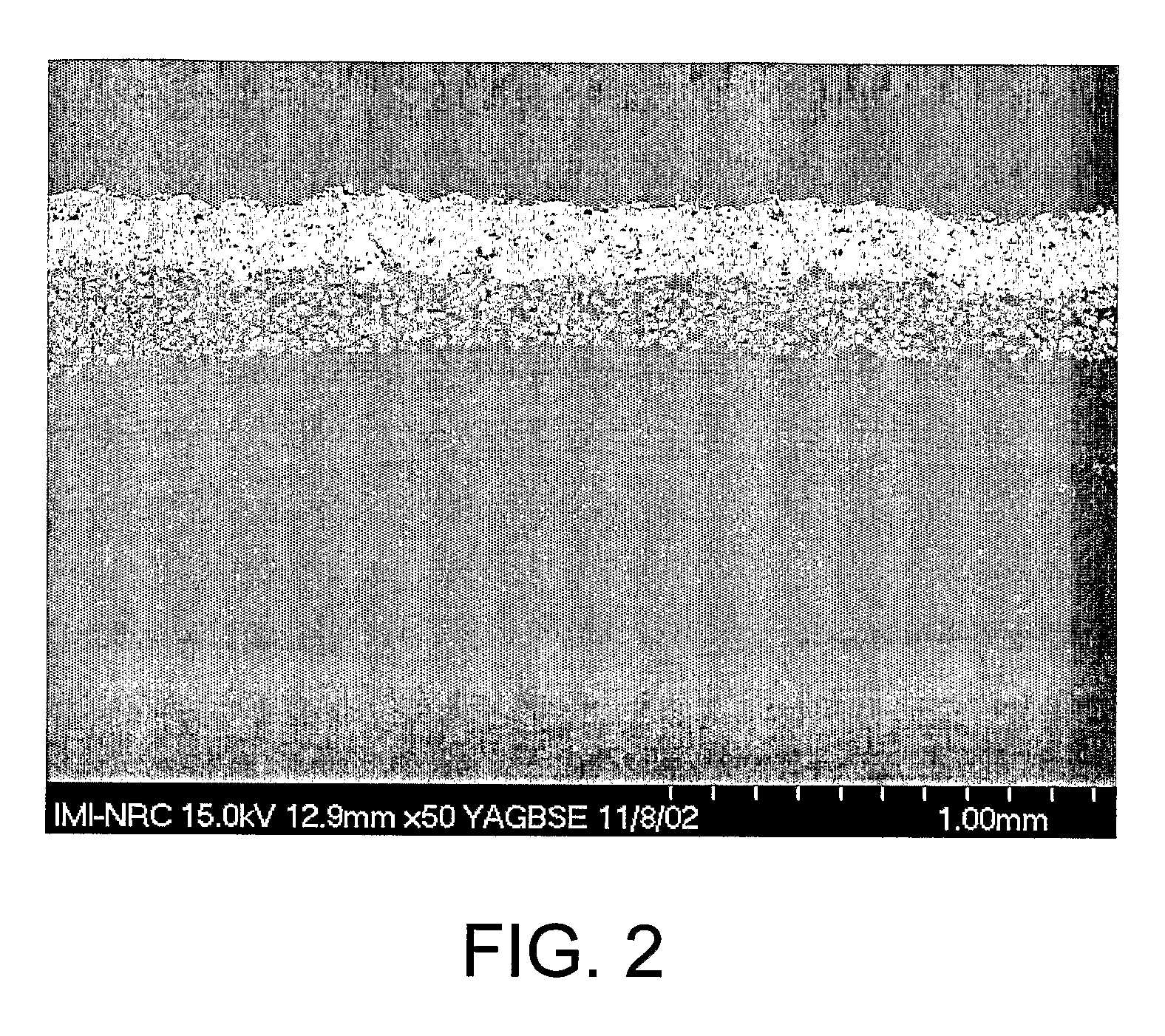

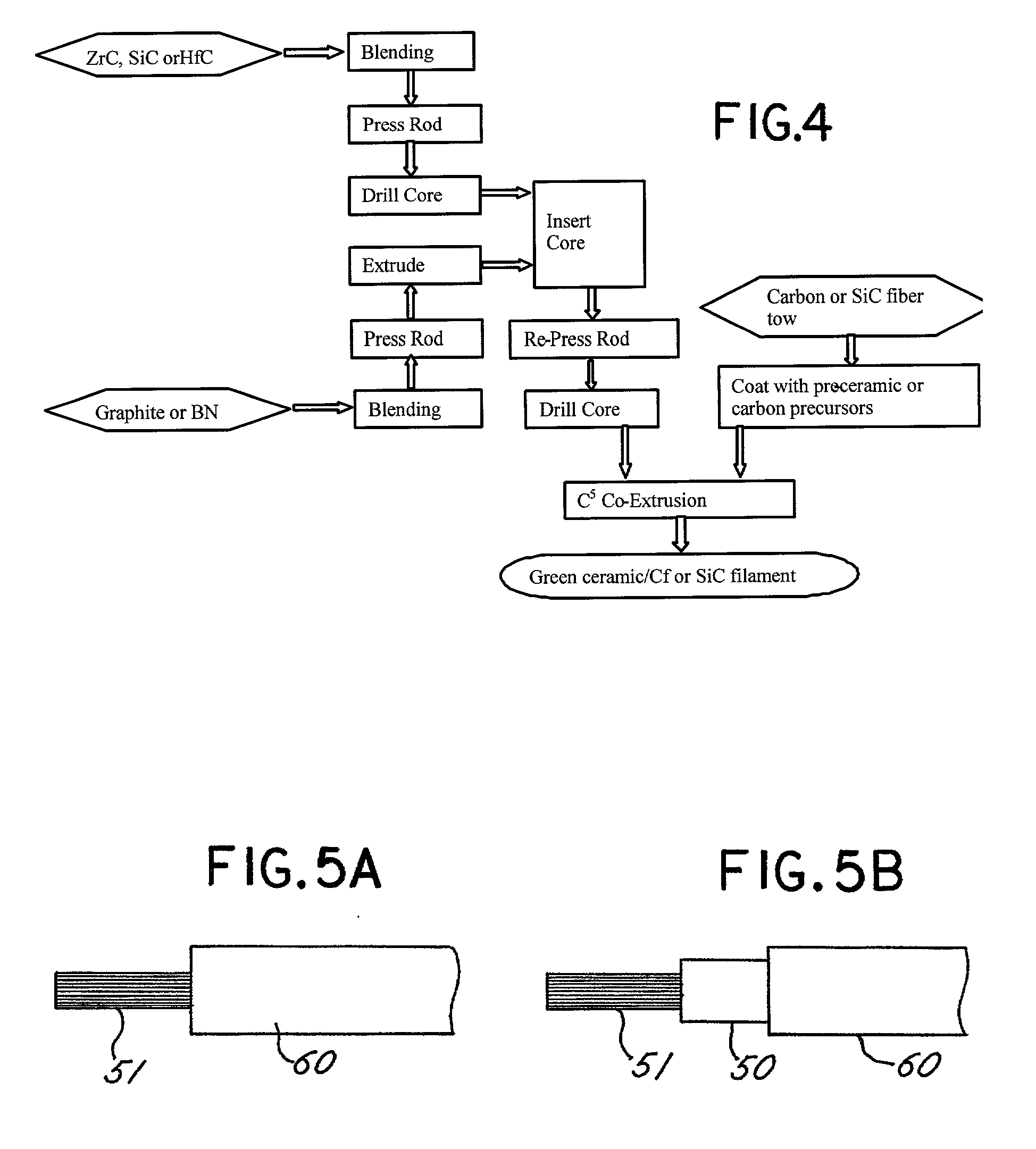

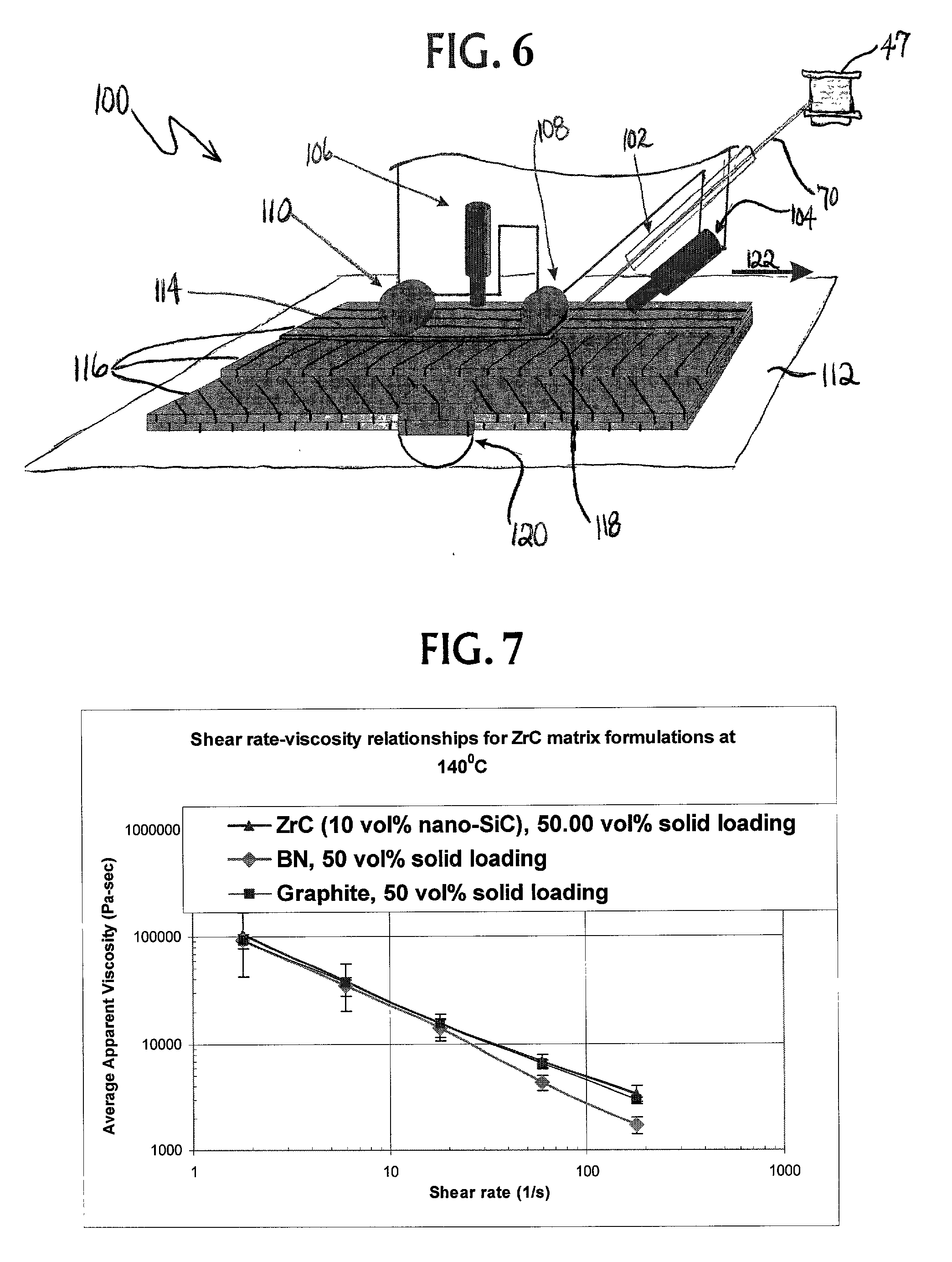

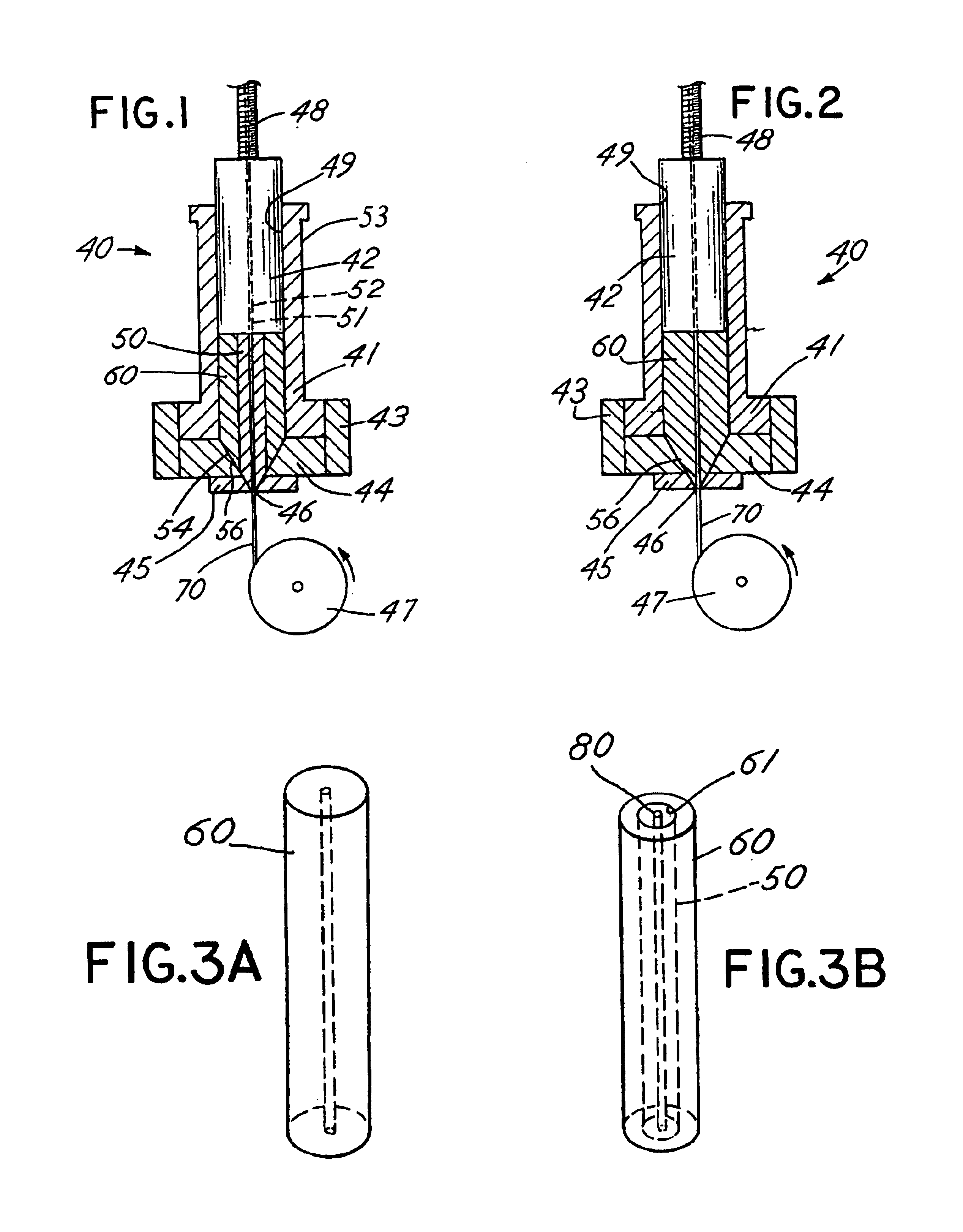

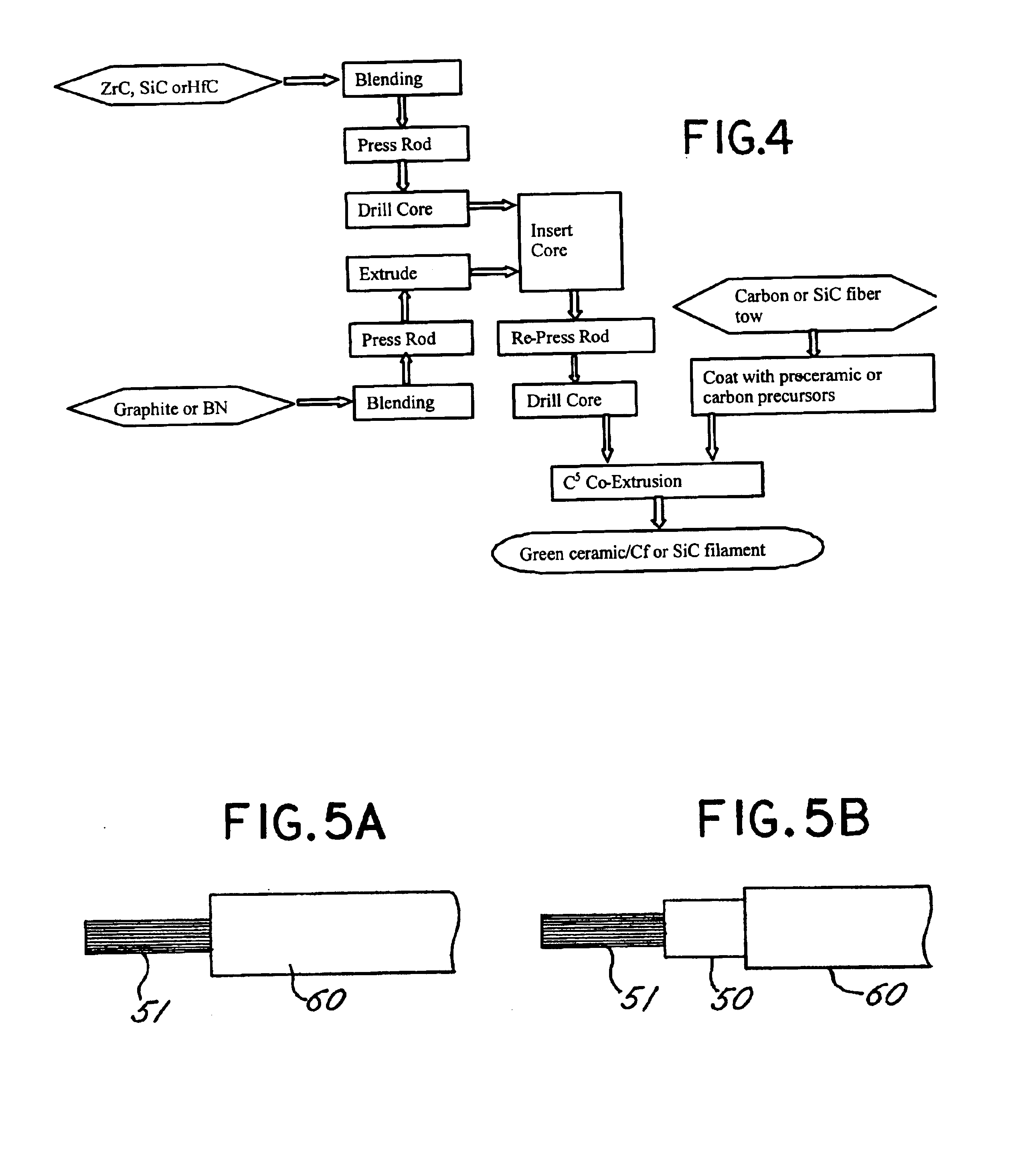

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Fiber reinforced composite cores and panels

InactiveUS20050074593A1Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

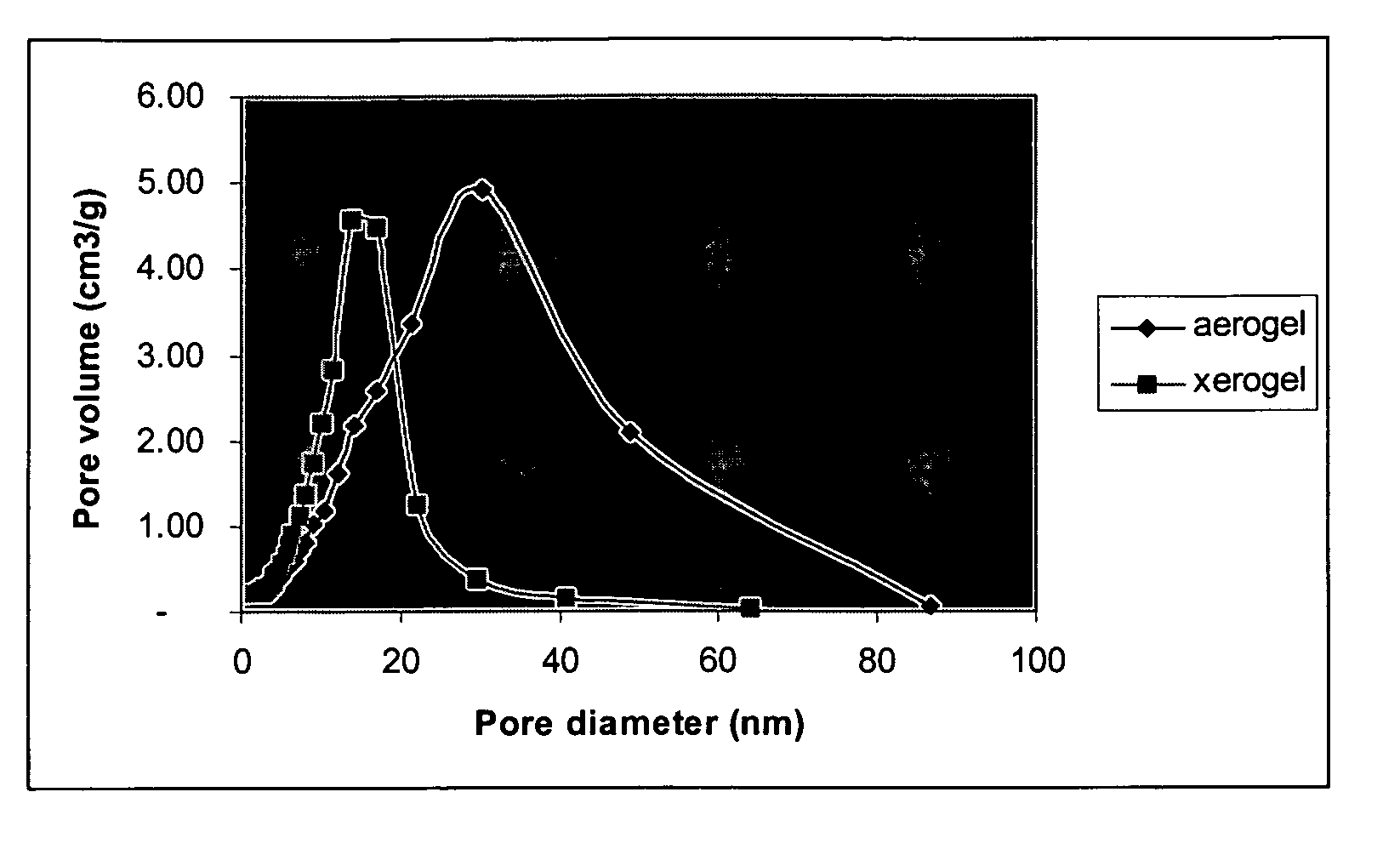

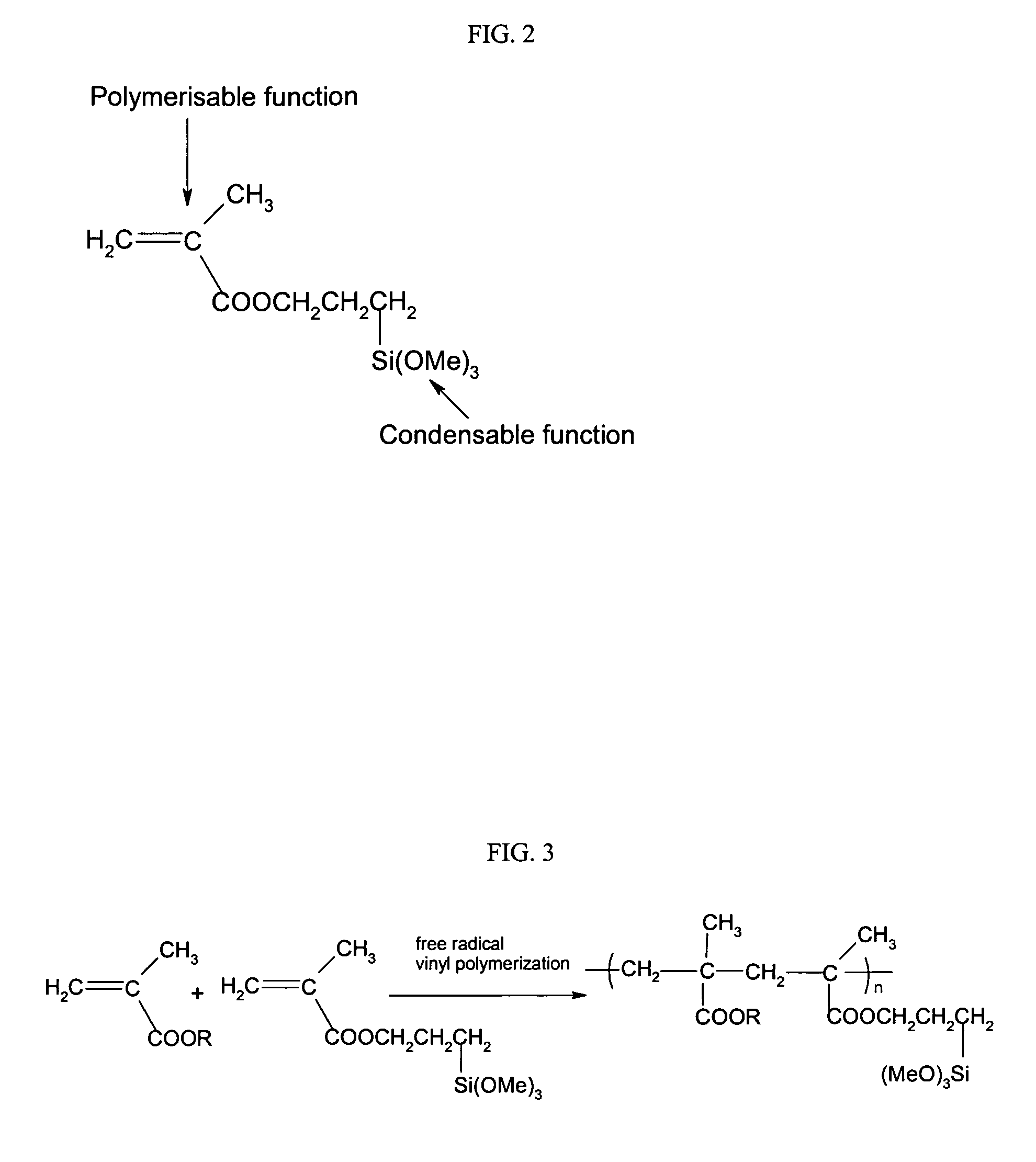

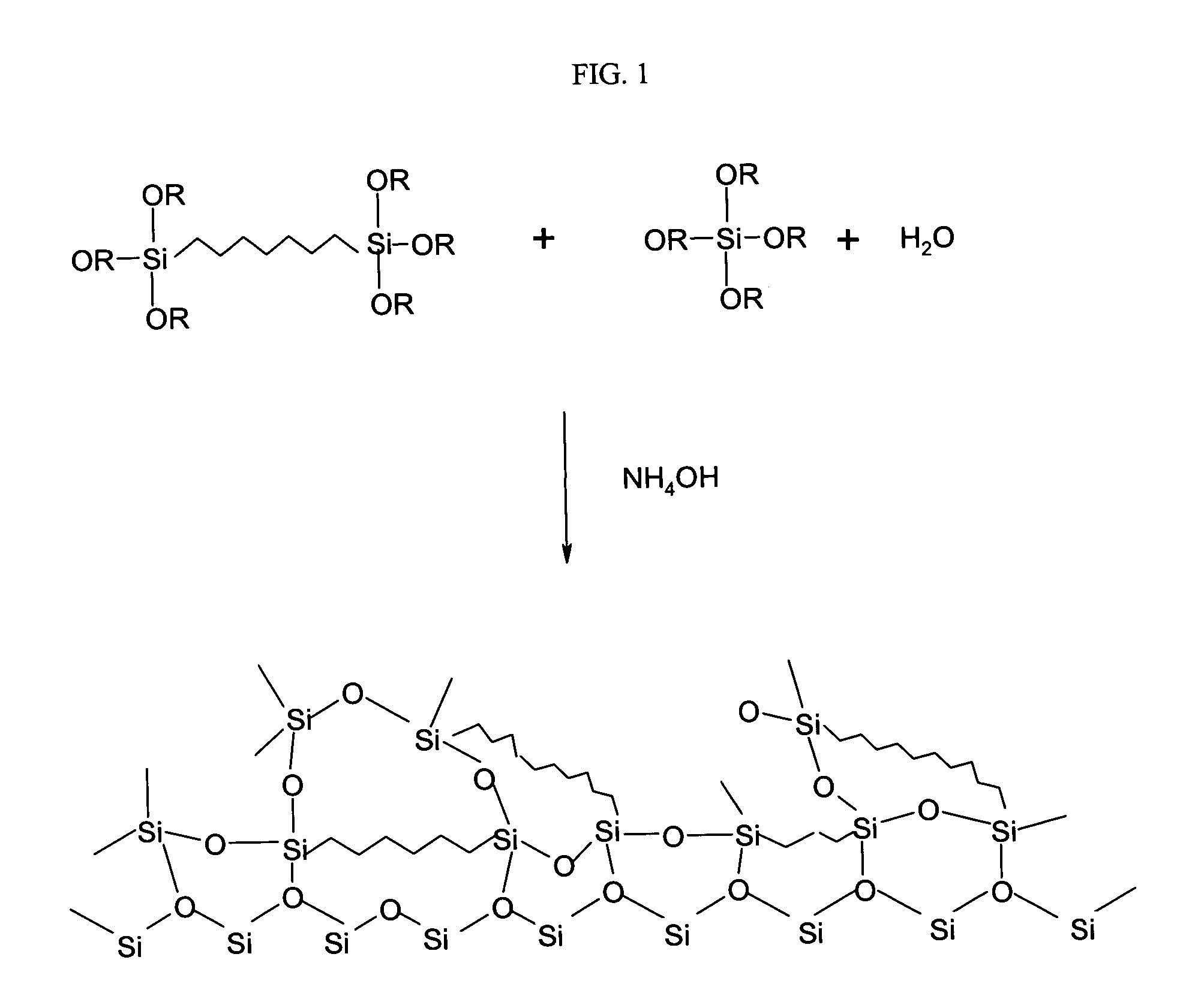

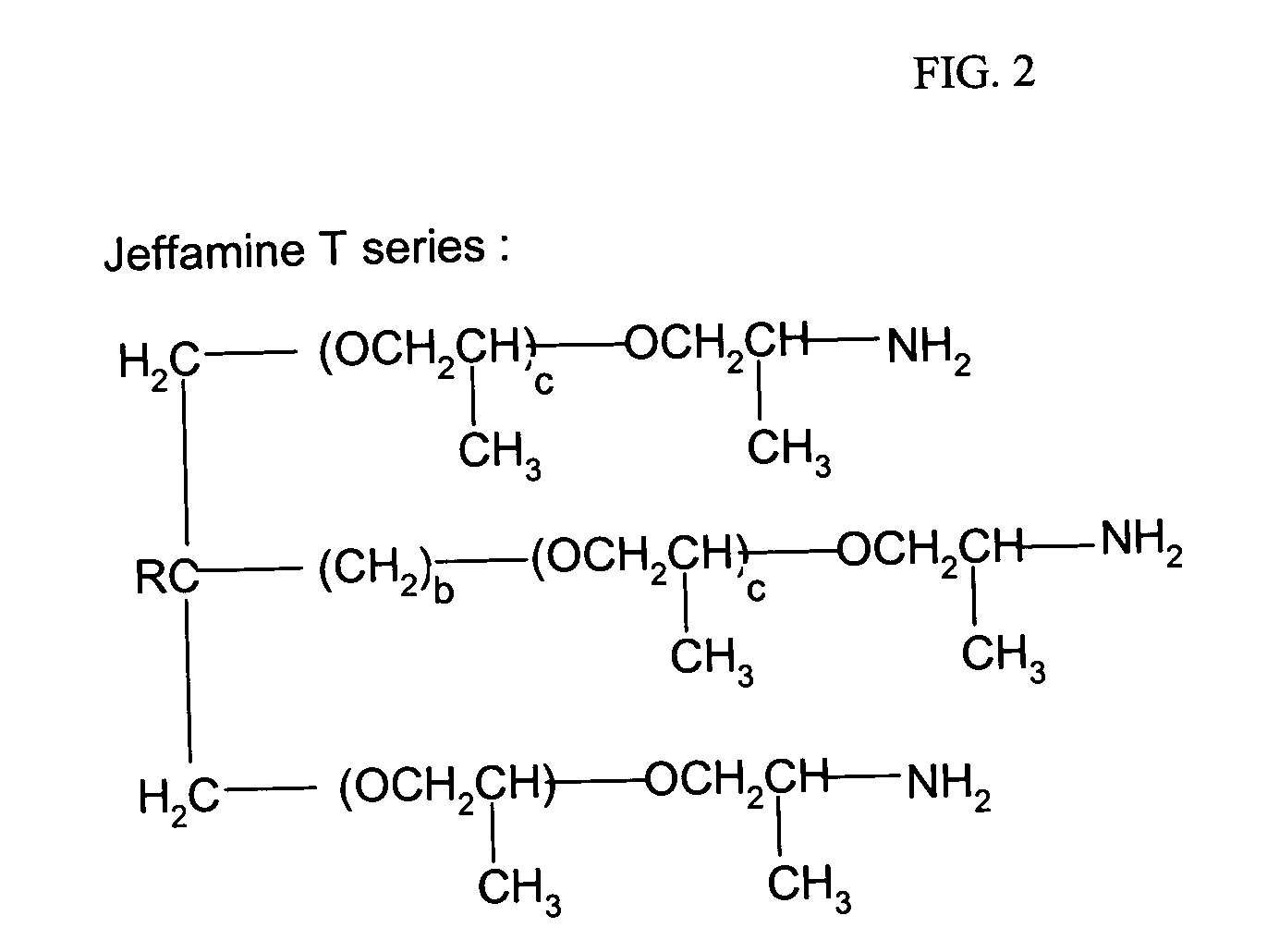

Ormosil aerogels containing silicon bonded polymethacrylate

InactiveUS20050192366A1Reduce uniformityAvoid phase separationMechanical clocksSilicon compoundsFiber-reinforced compositePoly methacrylate

Owner:ASPEN AEROGELS INC

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS6986853B2Repaired quickly and efficientlySufficient protectionMaterial nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

Ormosil aerogels containing silicon bonded linear polymers

ActiveUS20050192367A1Good physical and mechanical propertiesSynthetic resin layered productsWoven fabricsFiber-reinforced compositeSilicon

Owner:ASPEN AEROGELS INC

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

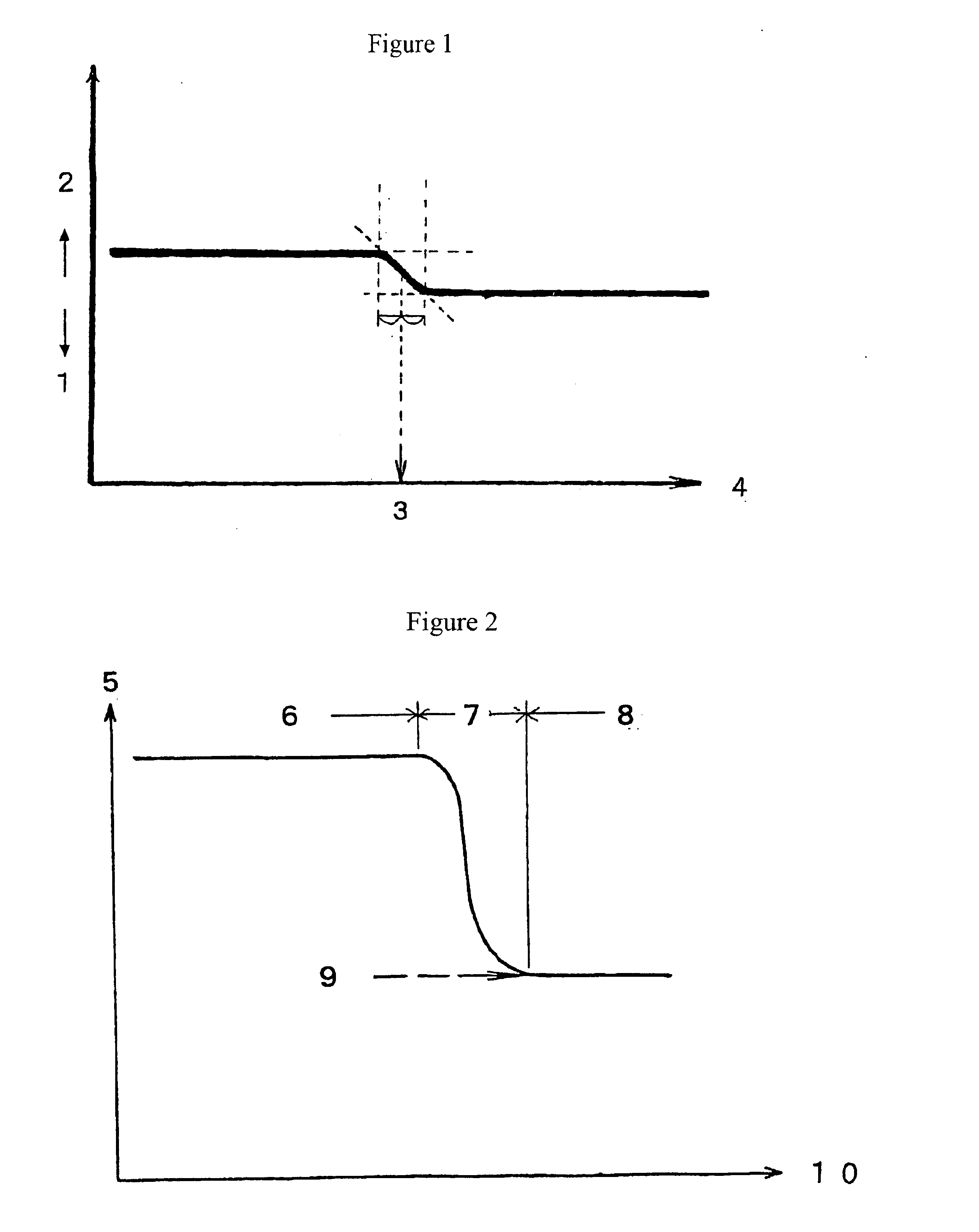

Epoxy resin composition for fiber-reinforced composite material prepreg, and fiber-reinforced composite material

The present invention relates to an epoxy resin composition for a fibre reinforced composite material, which is thermosetting resin composition where the glass transition temperature Tg of the cured material obtained by heating for 2 hours at 180° C. is at least 150° C., and the modulus of rigidity G'R in the rubbery plateau in the temperature region above the aforesaid Tg is no more than 10 MPa. In accordance with the present invention, it is possible to provide a fibre-reinforced composite material which is outstanding in its resistance to hot-wet environmental condition, impact resistance, and strength characteristics such as tensile strength and compression strength, and furthermore it is possible to provide a thermosetting resin composition and a prepreg outstanding in terms of their peel strength to a honeycomb core.

Owner:TORAY IND INC

Resin compositions for fiber-reinforced composite materials and processes for producing the same, prepregs, fiber-reinforced composite materials, and honeycomb structures

InactiveUS6045898ASufficient self adhesivenessReduce porosityLayered productsNon-woven fabricsPorosityFiber-reinforced composite

PCT No. PCT / JP97 / 00250 Sec. 371 Date Jan. 5, 1998 Sec. 102(e) Date Jan. 5, 1998 PCT Filed Jan. 31, 1997 PCT Pub. No. WO97 / 28210 PCT Pub. Date Aug. 7, 1997The present invention provides a prepreg having an excellent self adhesiveness to a honeycomb core, a low porosity when used as skin panels, an excellent surface smoothness due to a low surface porosity, and good tackiness and drapability. This invention also provides a honeycomb sandwich panel having a skin panel peel strength, an excellent impact resistance and an excellent hot water resistance, and a composition for a fiber reinforced composite material made from the prepreg and honeycomb sandwich panel. The fiber reinforced composite material made from the prepreg of the present invention can be used for airplanes, automobiles and other industrial applications, particularly as structural materials of airplanes, because of its excellent mechanical properties.

Owner:TORAY IND INC

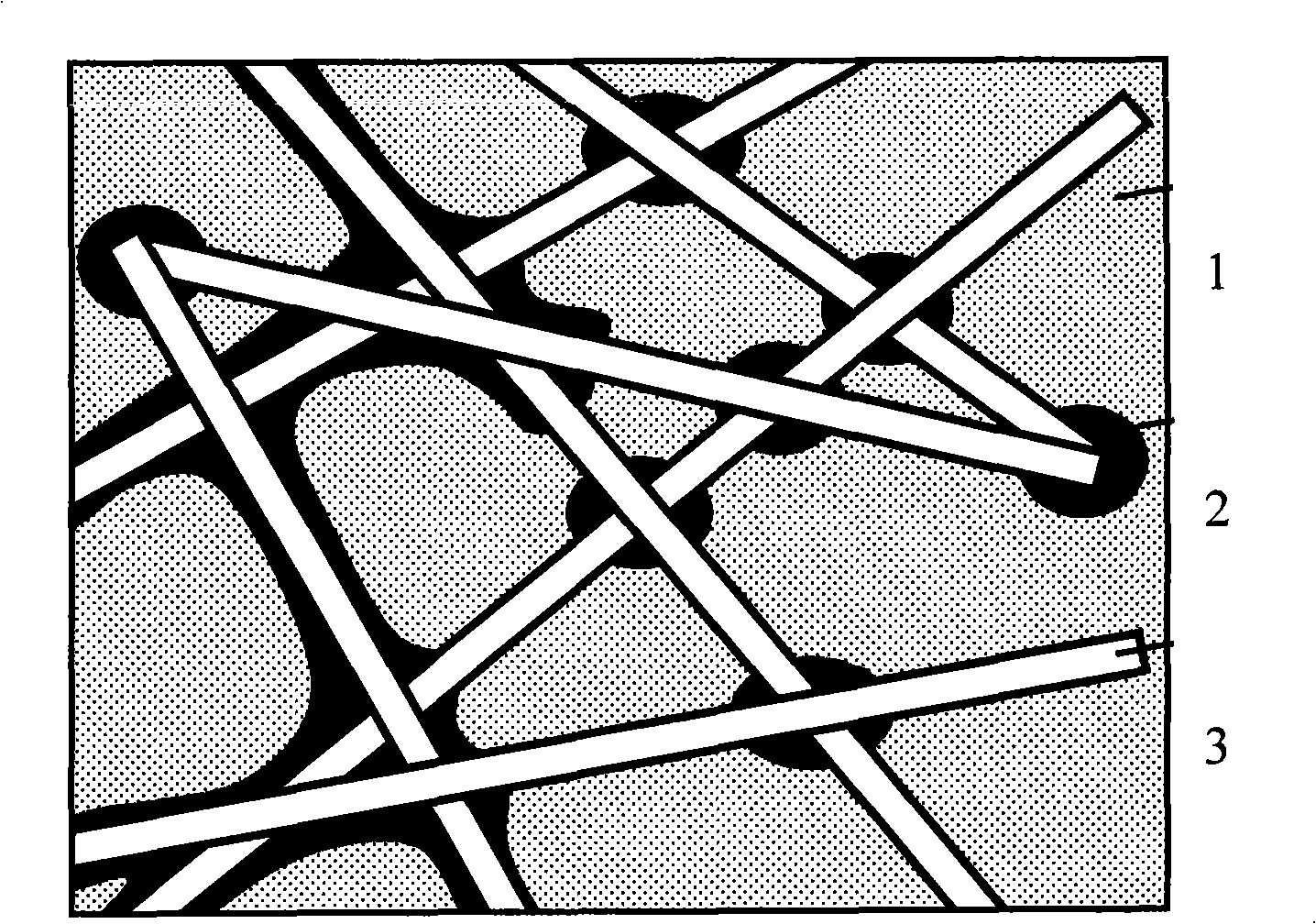

Fiber reinforced composite material and preparation thereof

The invention discloses a fiber reinforced composite material and a preparation method thereof. The fiber reinforced composite material comprises polymeric matrix and fibers and also comprises a solder which leads the fibers which are dispersed in the polymeric matrix to connect together so as to essentially form a three-dimensional network skeleton structure which is formed by the solder and the fibers and is independent in the polymeric matrix. The fiber reinforced composite material can use the fiber characteristics effectively, reduces the fiber usage, supplies higher heat resistance, electric conductivity or heat conductivity and has wide application prospect in the fields of transportation, electronic information and residential construction and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

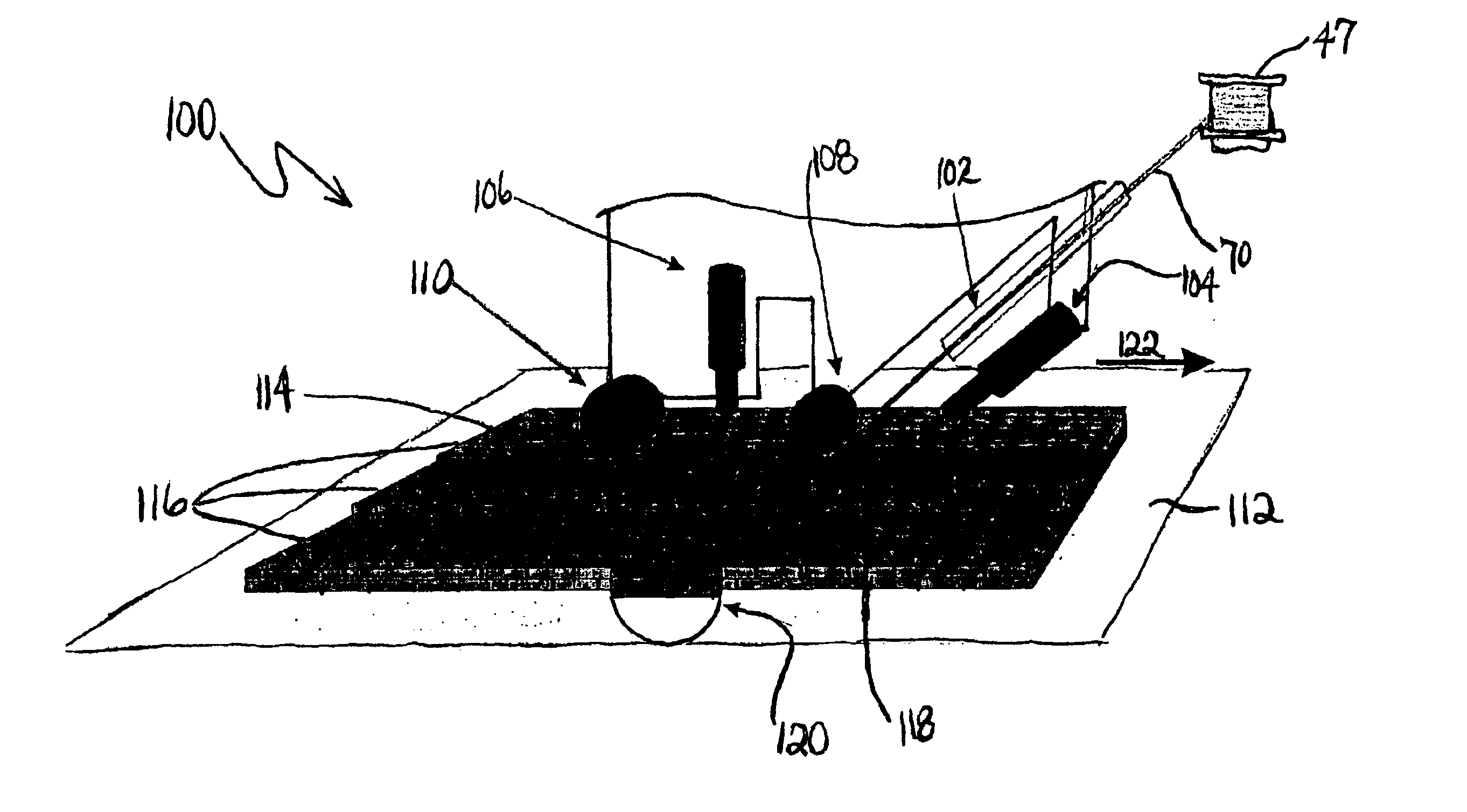

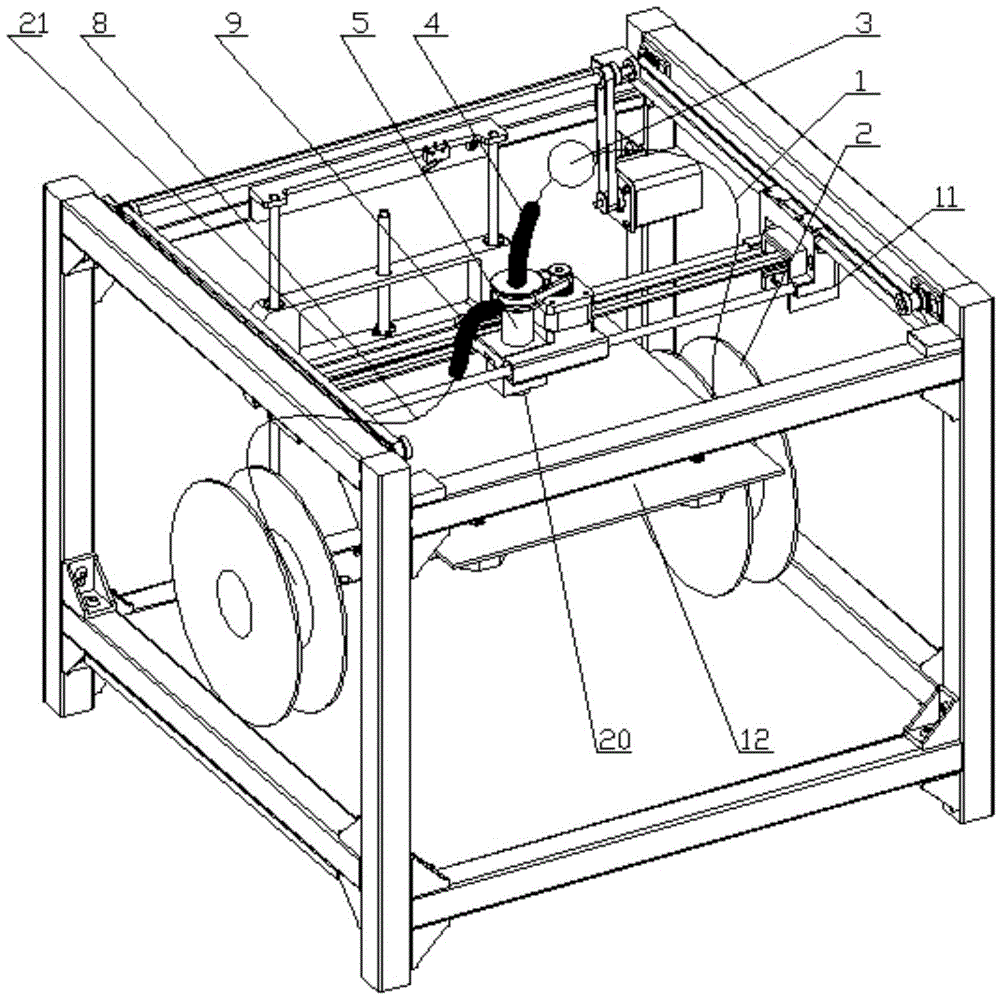

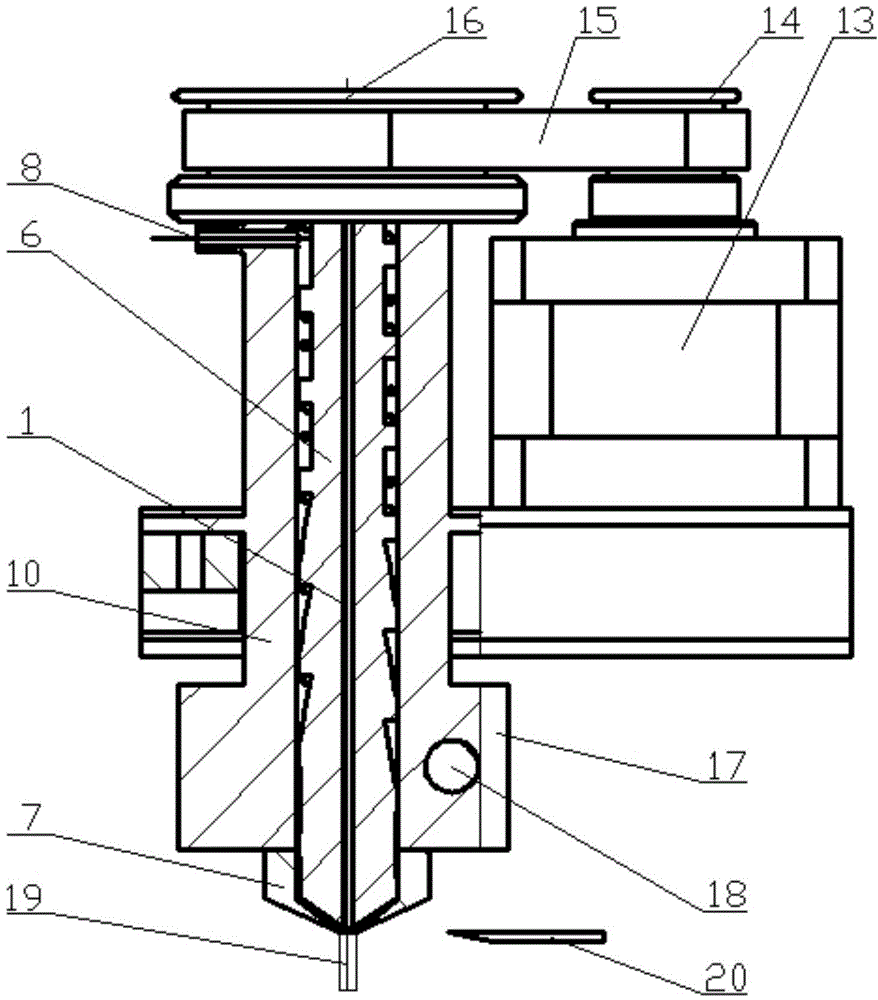

Continuous long-fiber reinforced-type composite material 3D printer and printing method thereof

The invention provides a continuous long-fiber reinforced-type composite material 3D printer and a printing method thereof. The 3D printer and the printing method are characterized in that the combination of the 3D printing technology and the composite material fiber placement technology achieves the 3D printing of a resin-based continuous long-fiber reinforced-type composite material, and the process does not need a die that is customized in advance and a pre-treated fiber pre-soaking belt, so that the cost is greatly decreased; meanwhile, the 3D printing method enables well and convenient control of the directions of the reinforced fibers in a manufactured part, and moreover, a composite material part with the customized mechanical property can be obtained easily, and the composite material part with a complex structure can be quickly manufactured; and compared with the original composite material fiber placement process, the printing method has the advantages that the application scope is wide, and the production efficiency is high.

Owner:XI AN JIAOTONG UNIV

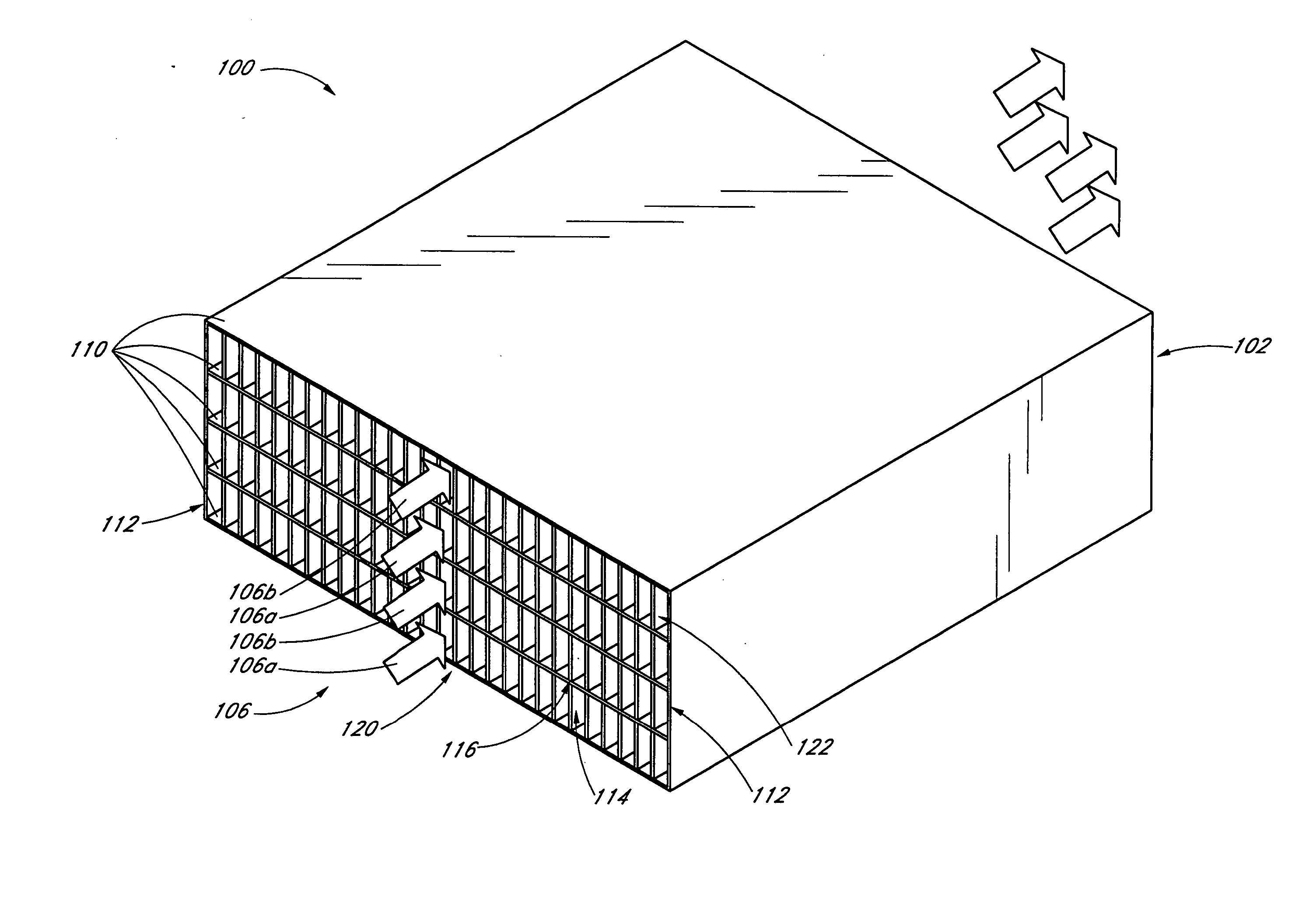

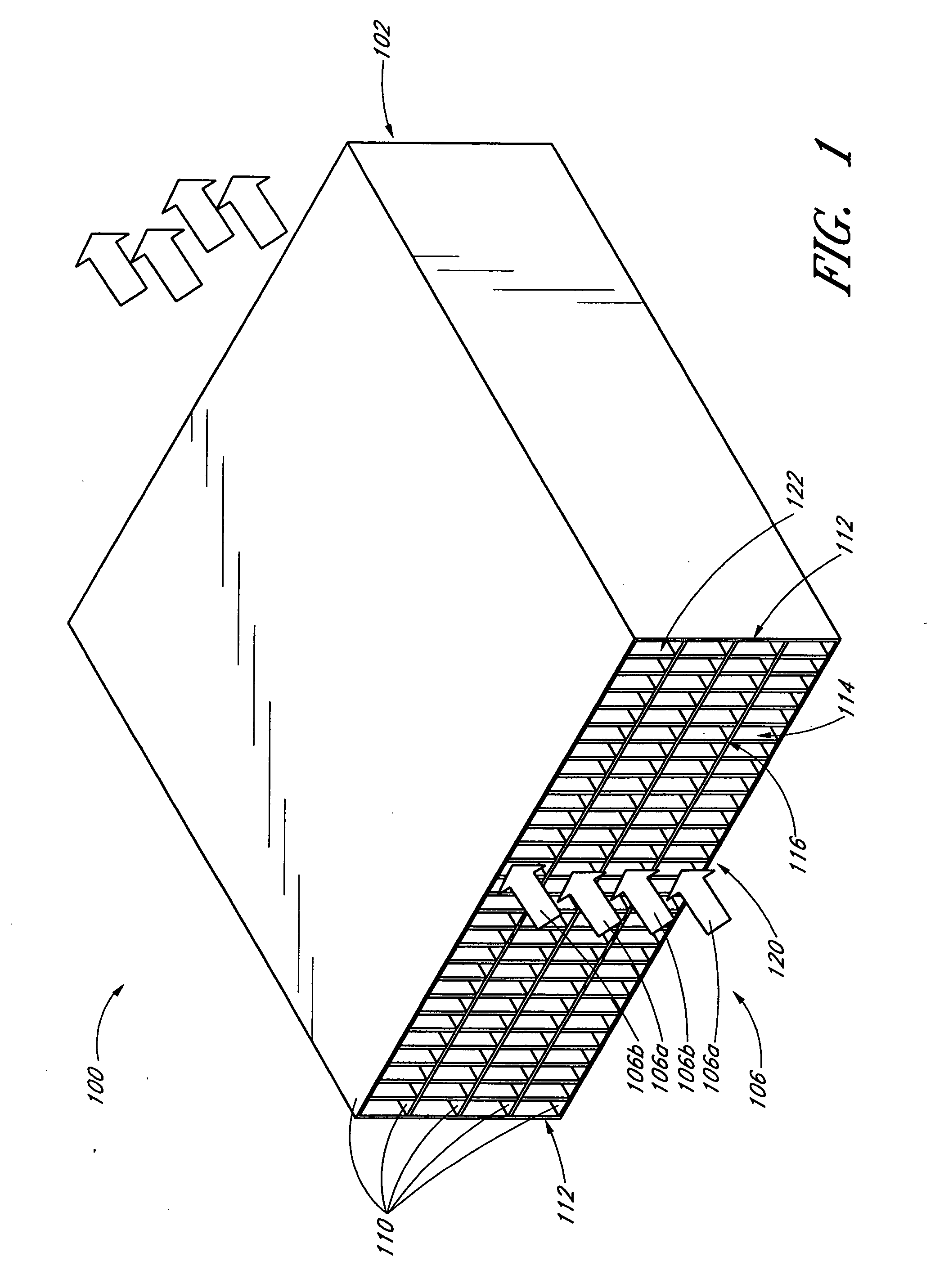

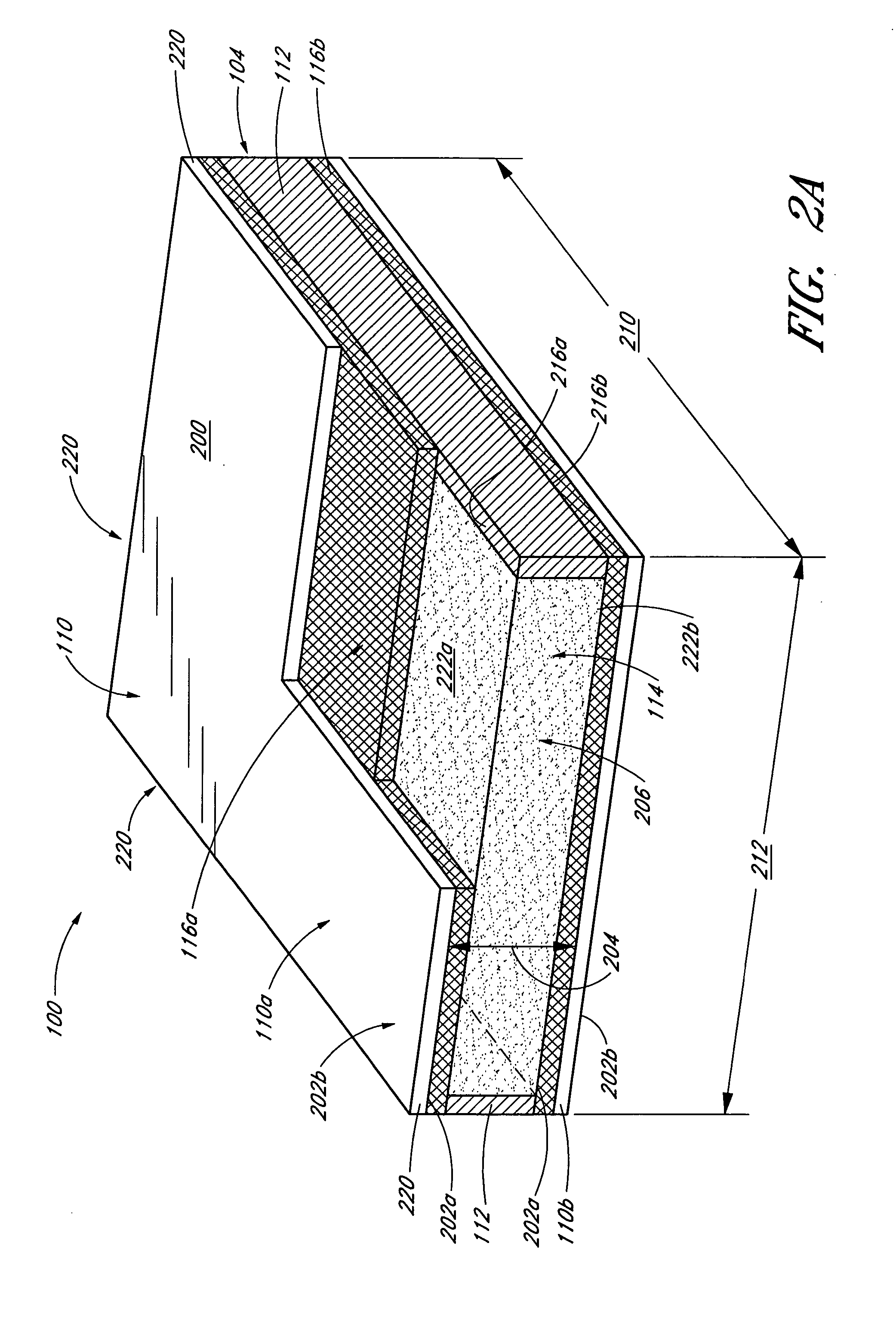

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

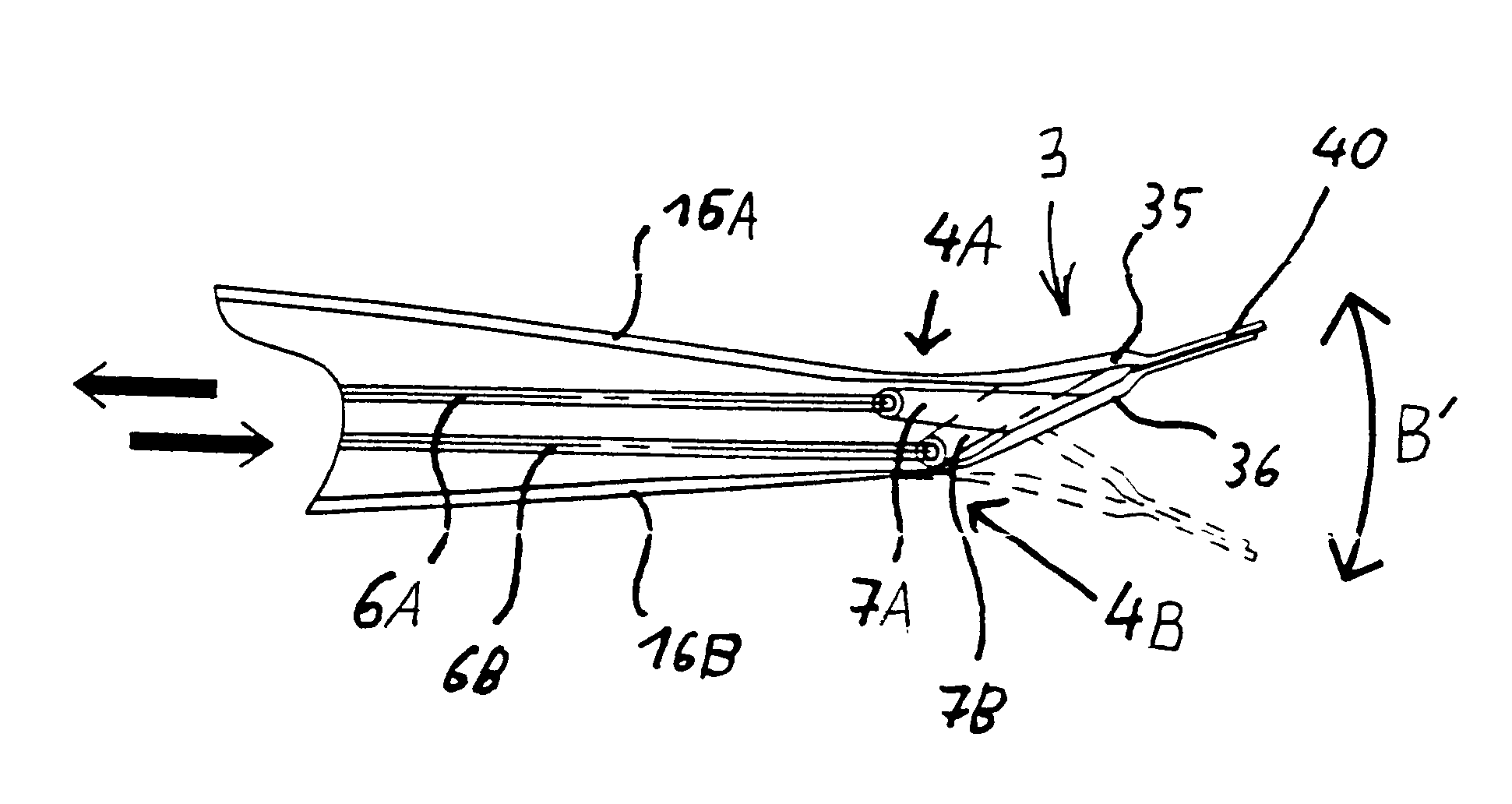

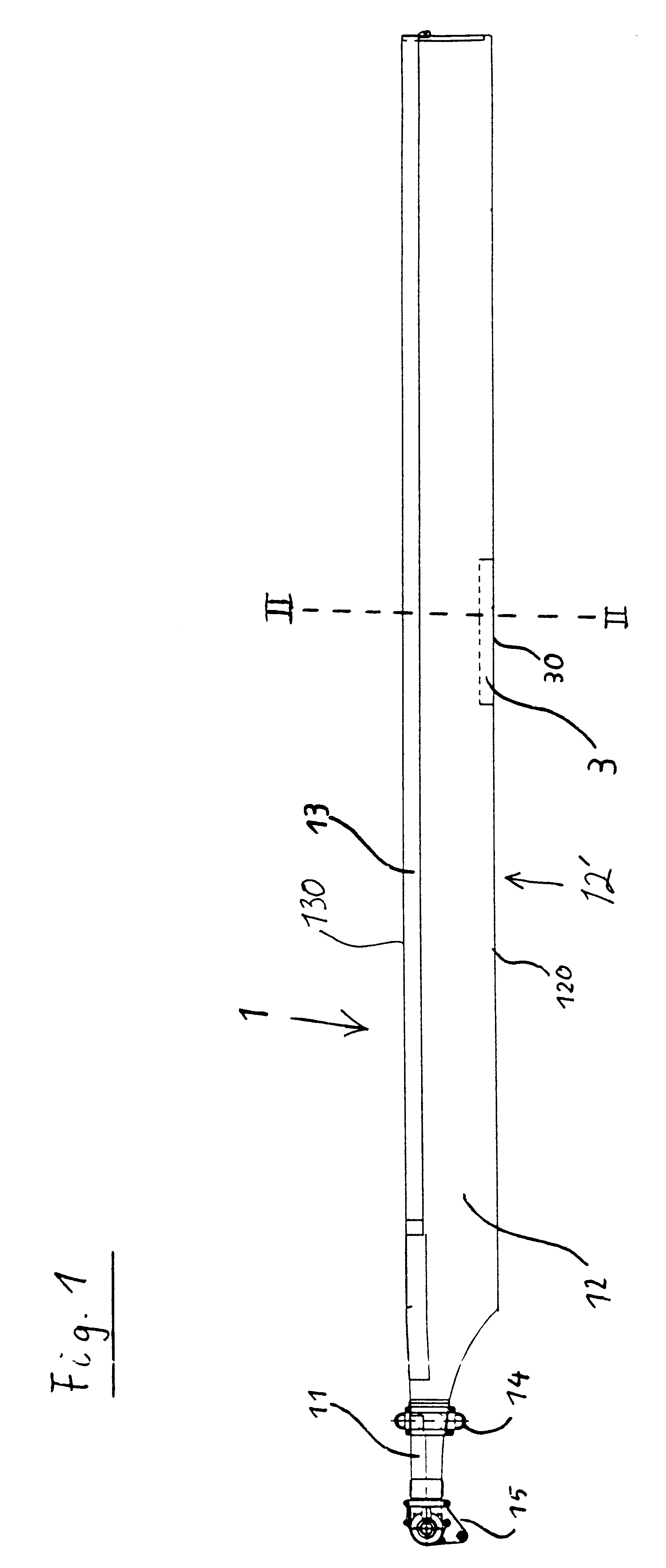

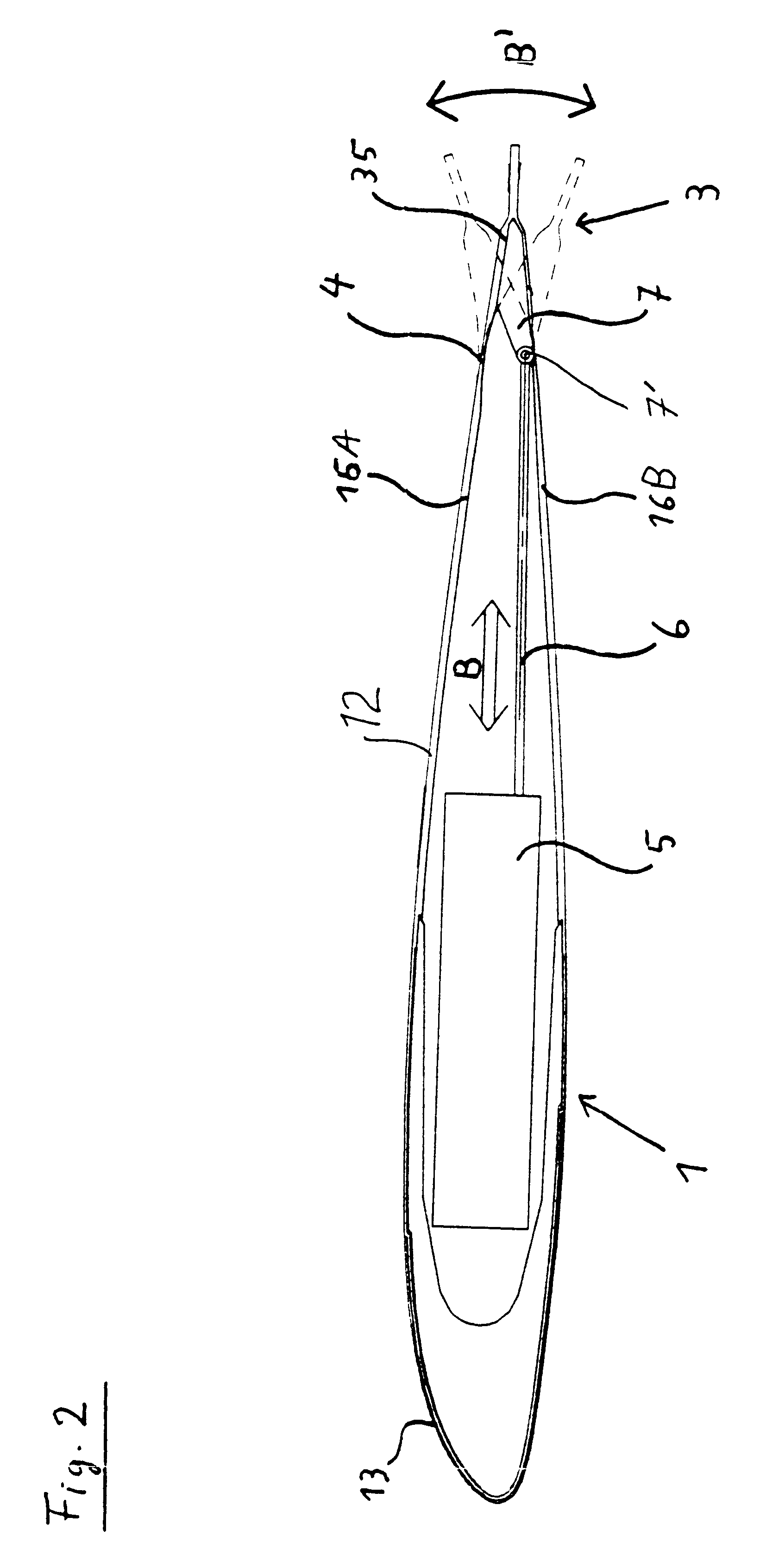

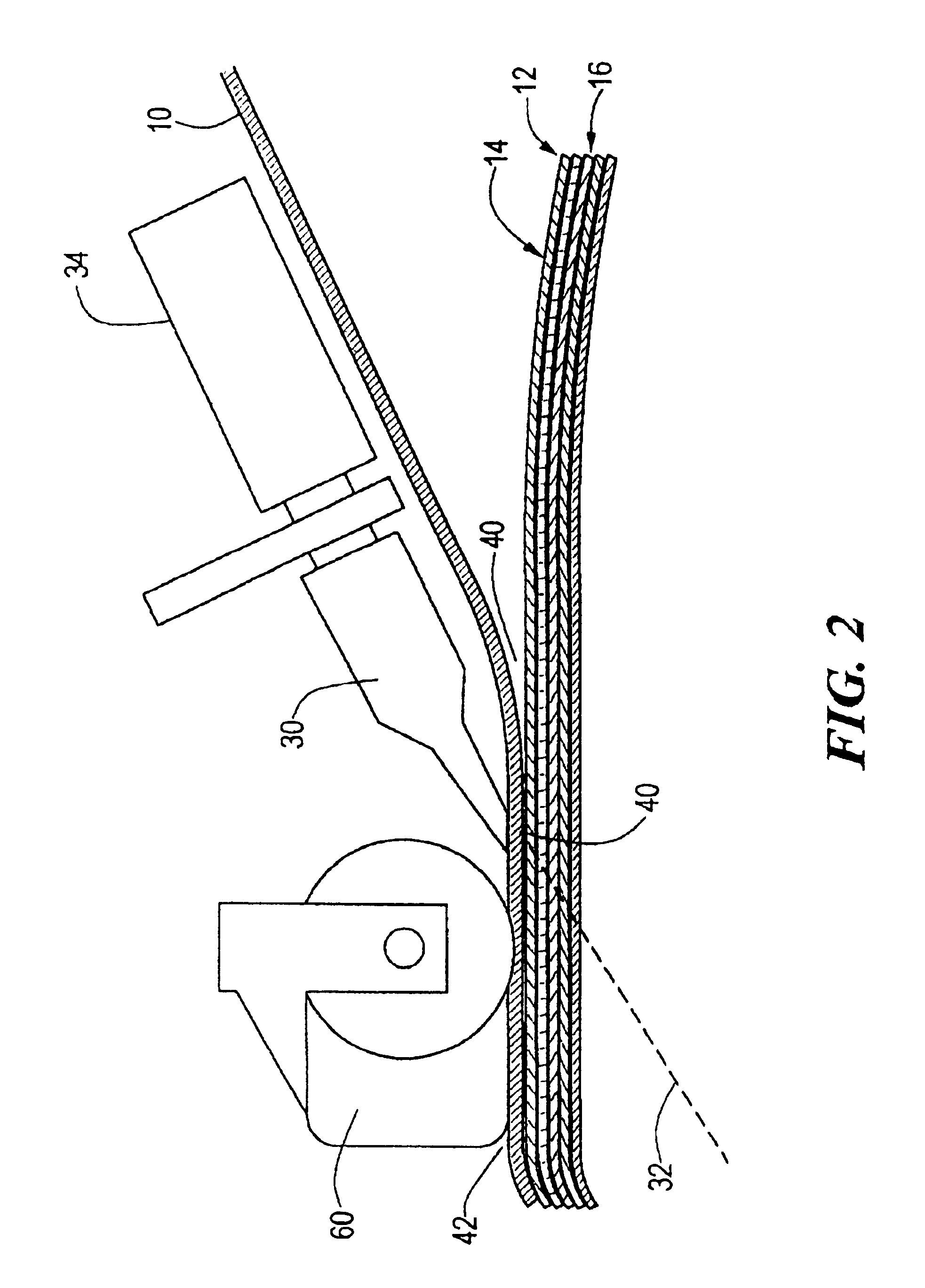

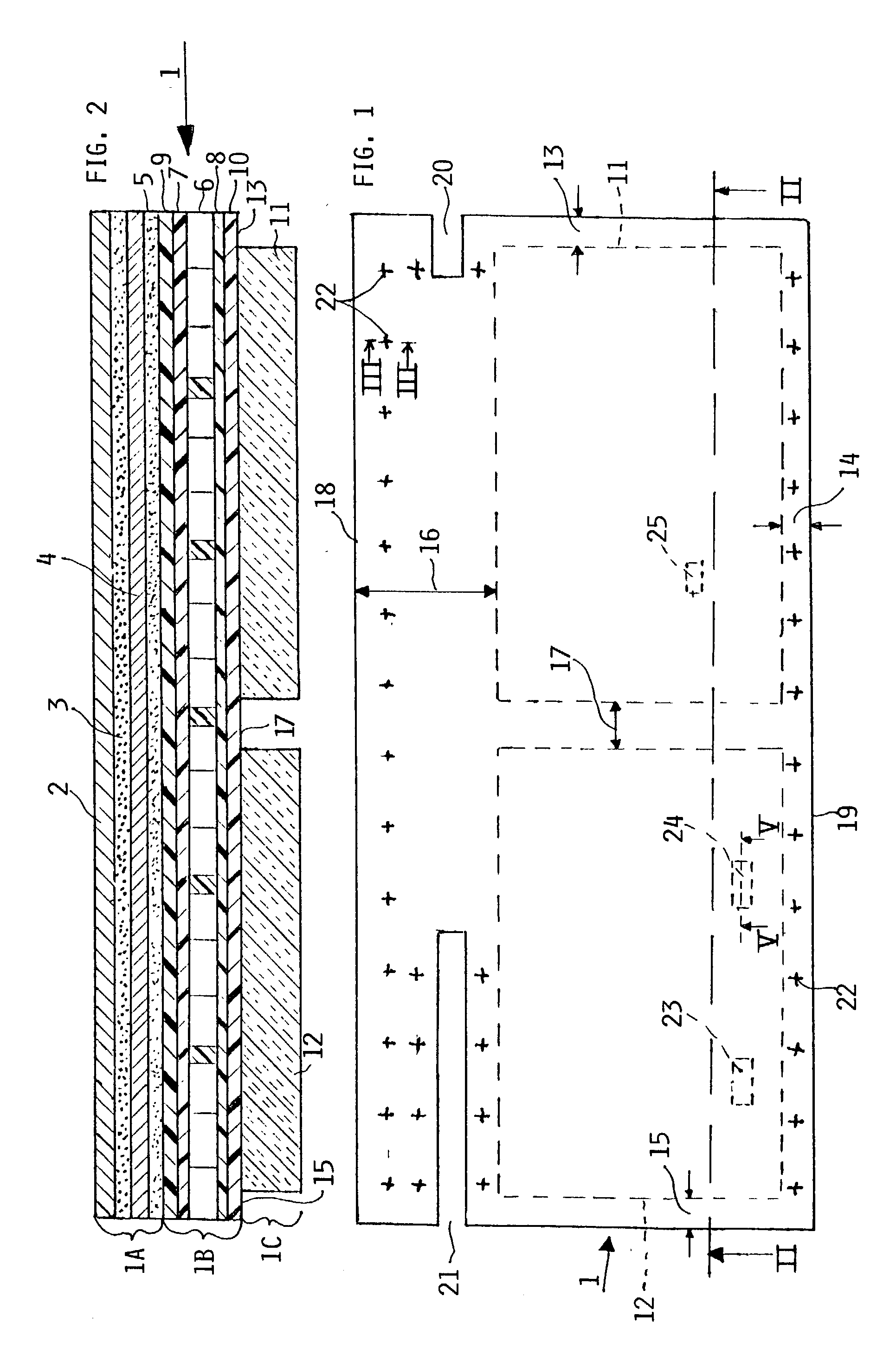

Helicopter rotor blade with a movable flap

InactiveUS6168379B1Durable and wear-resistant flexiblyImprove inspectionPropellersAircraft stabilisationPiezoelectric actuatorsFiber-reinforced composite

A helicopter rotor blade includes a main airfoil body (12) and a movable control flap (3) incorporated in the trailing edge profile of the airfoil body. The flap (3) is movably connected to the main airfoil body (12) by a flexibly bendable junction element (4), and is actuated by a piezoelectric actuator unit (5) via a push / pull rod (6) and a lever arm (7), whereby the control flap is deflected relative to the main airfoil body. The junction element (4) is preferably a continuous integral fiber-reinforced composite component having a flexible bending portion (42) with a reduced thickness in comparison to the adjoining portions, whereby the reinforcing fibers extend continuously through the joint in the direction of the connection between the main airfoil body and the flap.

Owner:AIRBUS HELICOPTERS DEUT GMBH

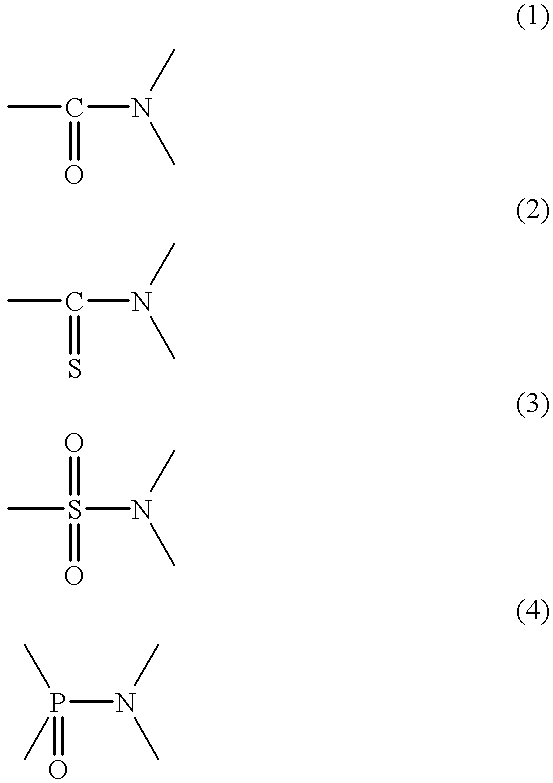

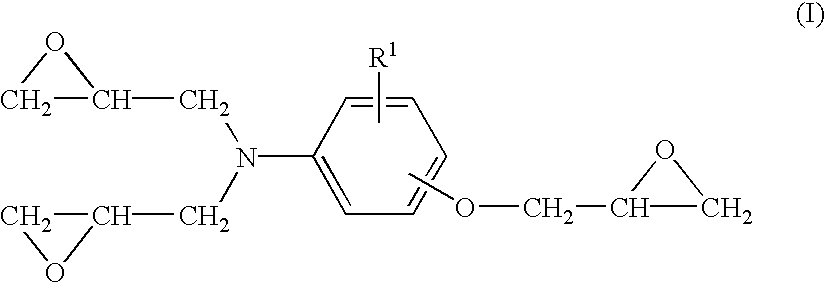

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

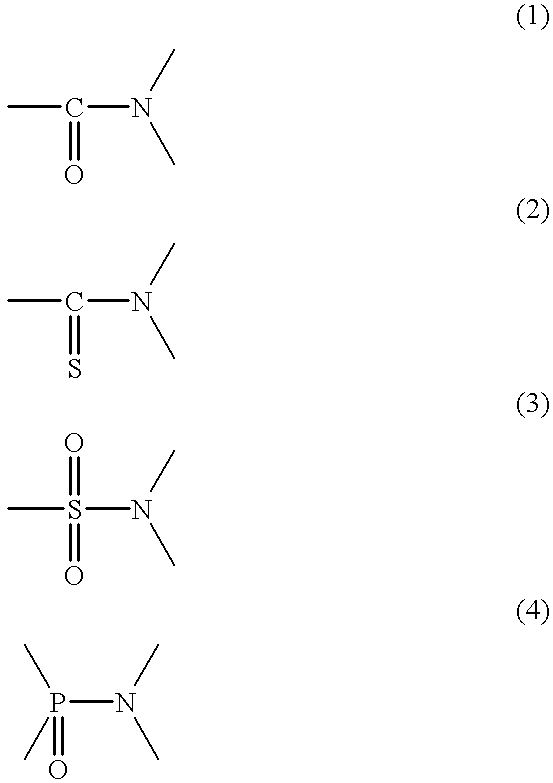

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

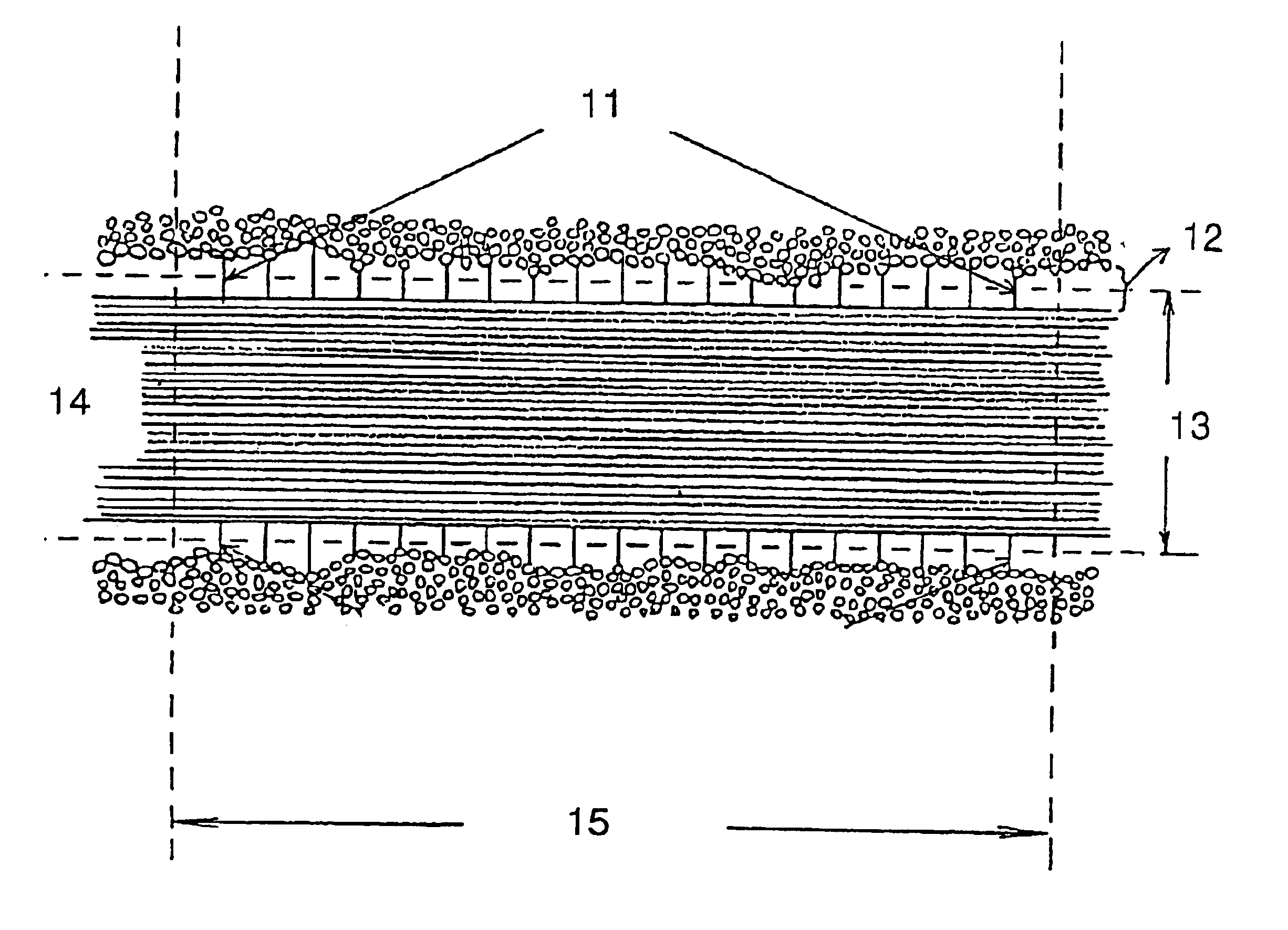

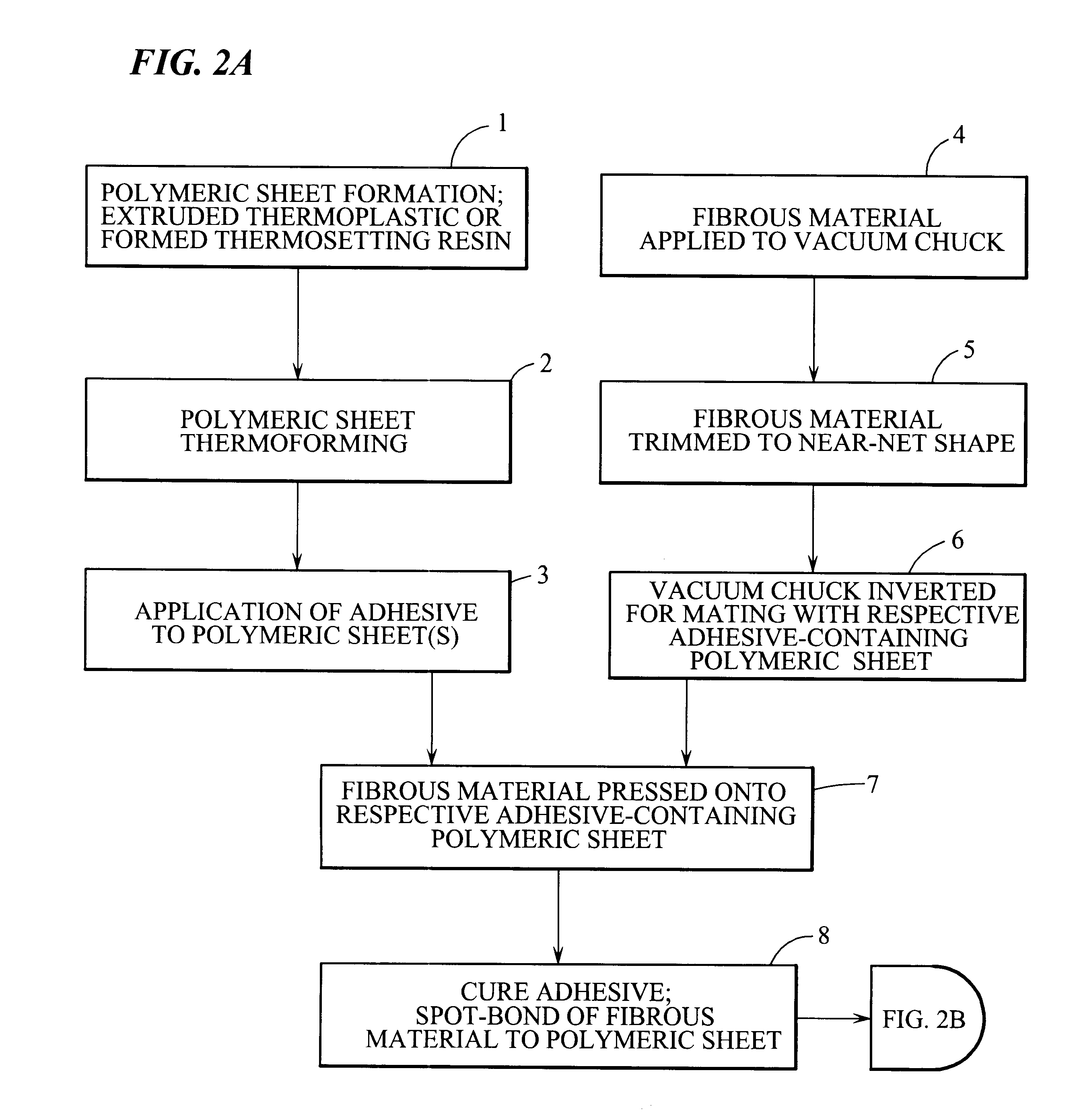

Ultrasonic method of fabricating a thermosetting matrix fiber-reinforced composite structure and the product thereof

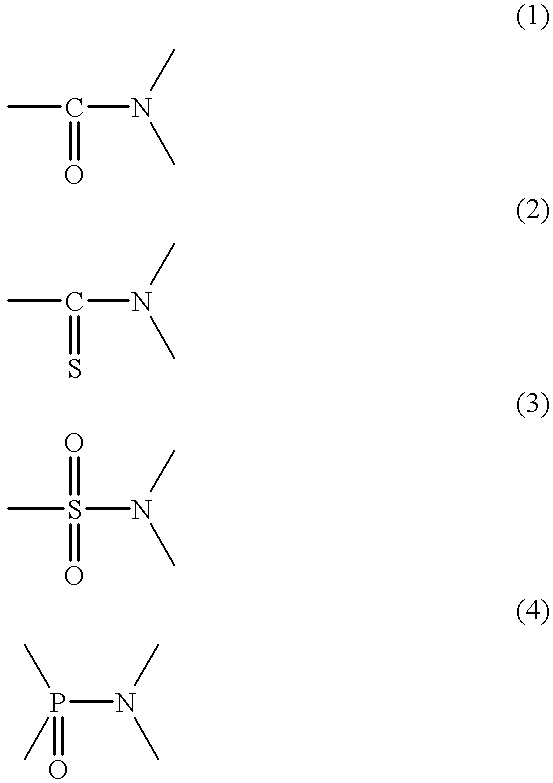

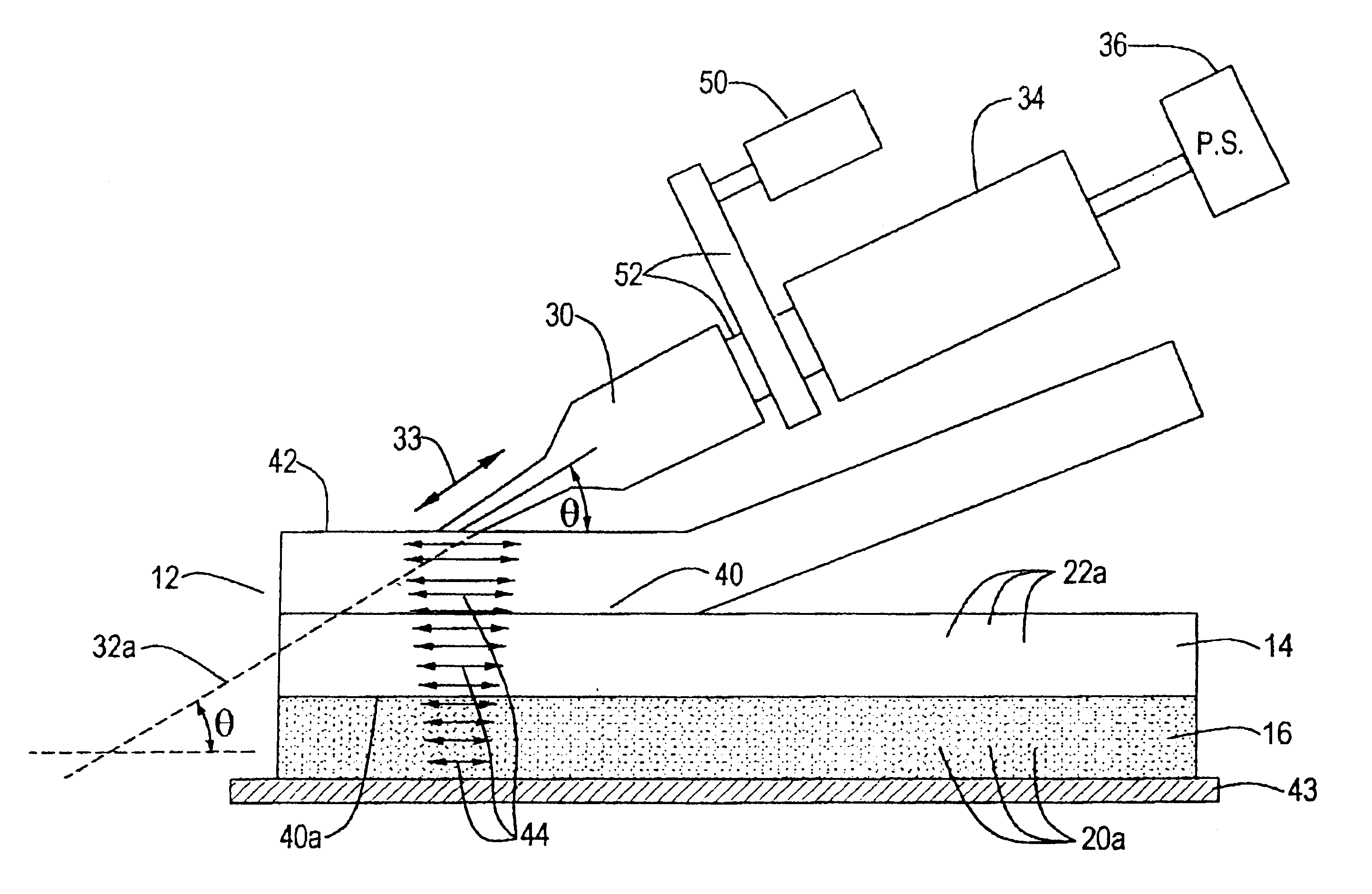

A method of fabricating a thermosetting matrix, fiber reinforced composite structure wherein a stack of fiber reinforced thermosetting material plies are assembled; an ultrasonic horn is engaged with a top surface of the upper most ply, oriented at an acute angle with respect to the top surface, and energized to induce a shear wave in the plies to heat the plies. The horn is moved along the upper most ply to consolidate the plies and the energy level applied to the horn is sufficient to reduce the viscosity of the thermoset resin to the point where the plies can be debulked but not high enough to fully cross-link the resin so that another ply can still be fully cross-linked to the uppermost ply. Pressure is applied to the plies as the horn moves to debulk the plies.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

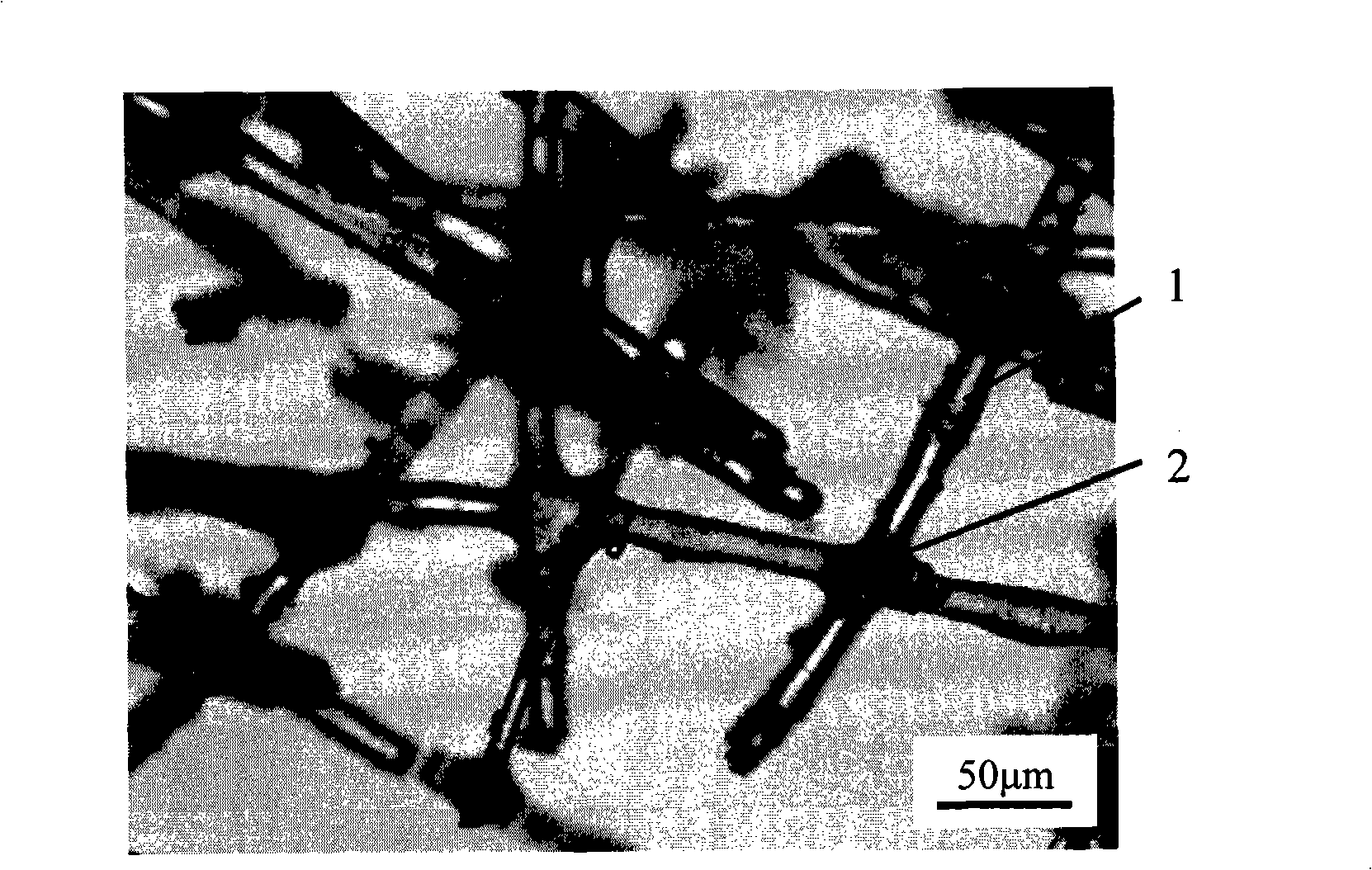

Surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and preparing method

ActiveCN105818476AMitigating Galvanic CorrosionImprove resilienceLamination ancillary operationsLaminationCarbon nanotubeFiber-reinforced composite

The invention discloses a surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and a preparing method.Three-dimensional carbon fiber frameworks with different bore diameters are prepared as required, and after surface pretreatment, diamond, carbon nanometer tubes and graphene are subjected to chemical vapor deposition; then the mixture and matrix materials are compounded, wherein the matrix materials are metal or polymers; the carbon-fiber-reinforced metal-based or polymer-based composite material with the three-dimensional net-shaped framework structure is obtained.A three-dimensional continuous heat conduction channel is formed in the composite material through the surface-modification three-dimensional net-shaped carbon fibers, and therefore the heat conduction performance of the composite material is greatly improved; meanwhile, according to space distribution of carbon fibers in the matrix material, the mechanical performance of the composite material can also be improved, and the density and the thermal expansion coefficient can be decreased; the thermal expansion coefficient, the mechanical performance and the thermal performance can be further regulated and controlled by adding zero-dimensional particle reinforcement.

Owner:CENT SOUTH UNIV

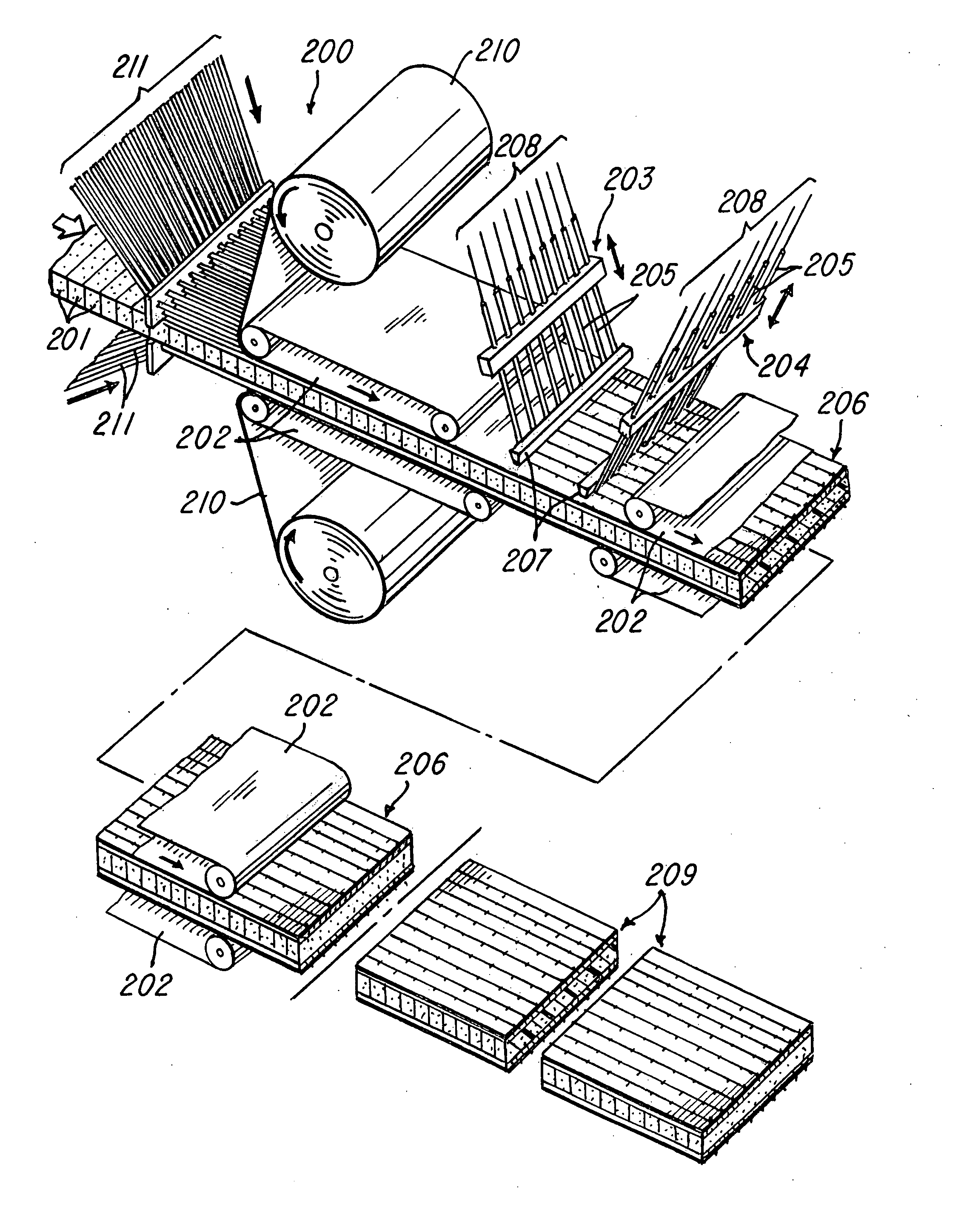

Fiber reinforced composite cores and panels

InactiveUS20100266833A1Produced economicallyReduce intensityLamination ancillary operationsLaminationEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips, and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins. Continuously wound strips or strip sections may be continuously fed either longitudinally or laterally into molding apparatus which may receive skin materials to form reinforced composite panels.

Owner:METYX USA INC

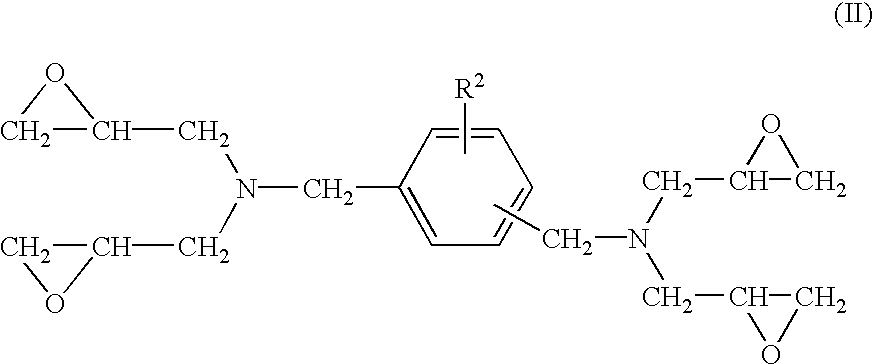

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

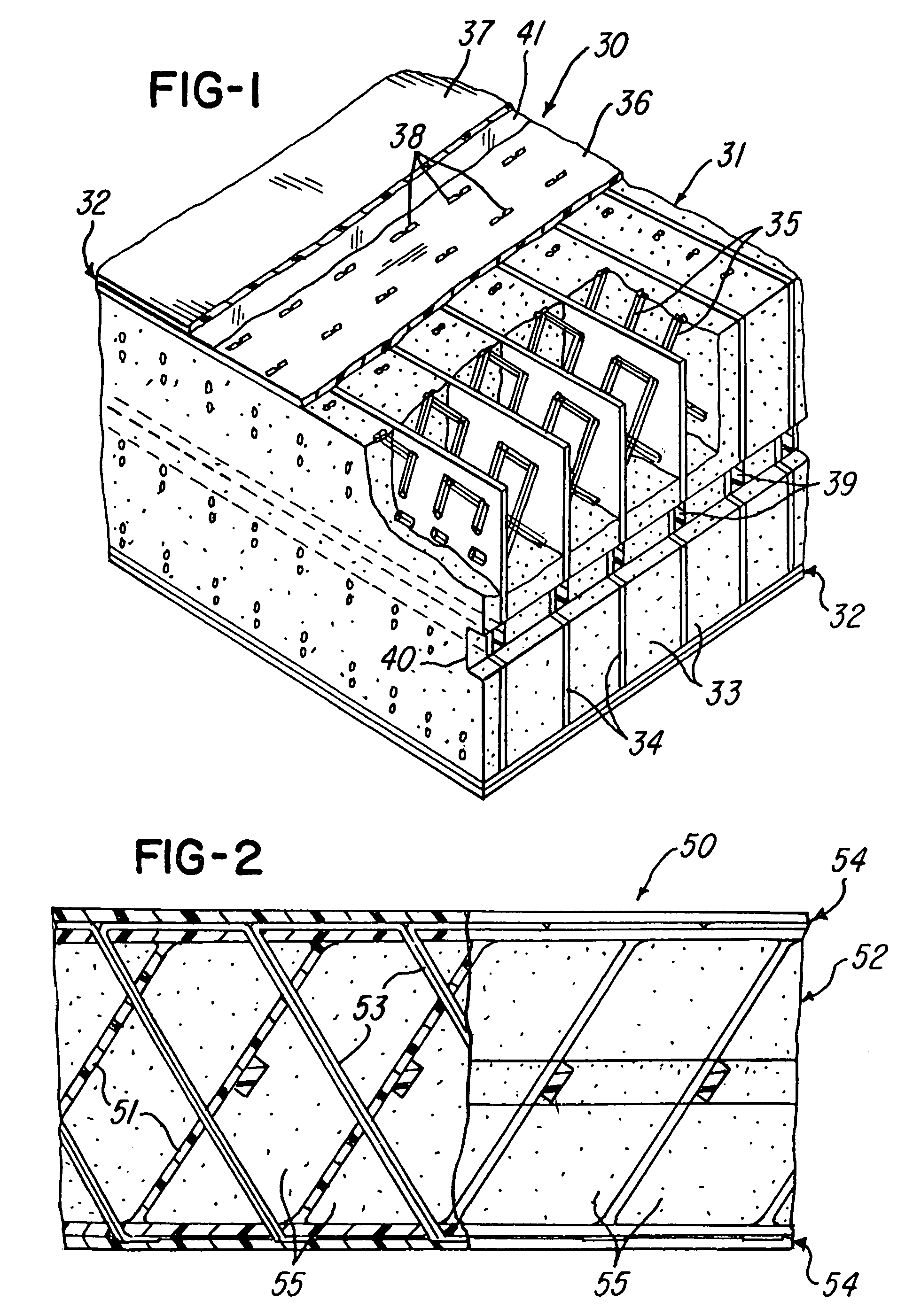

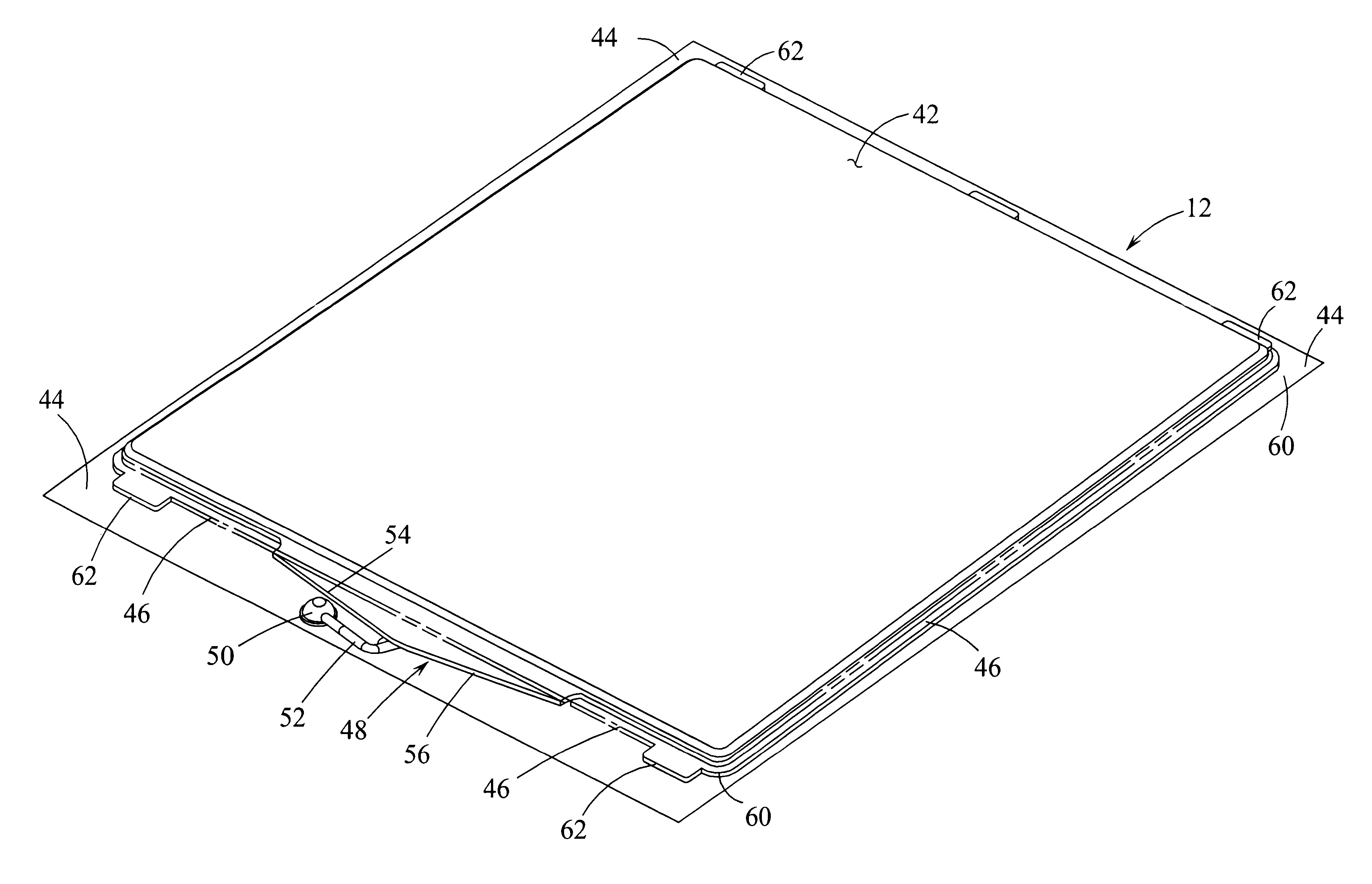

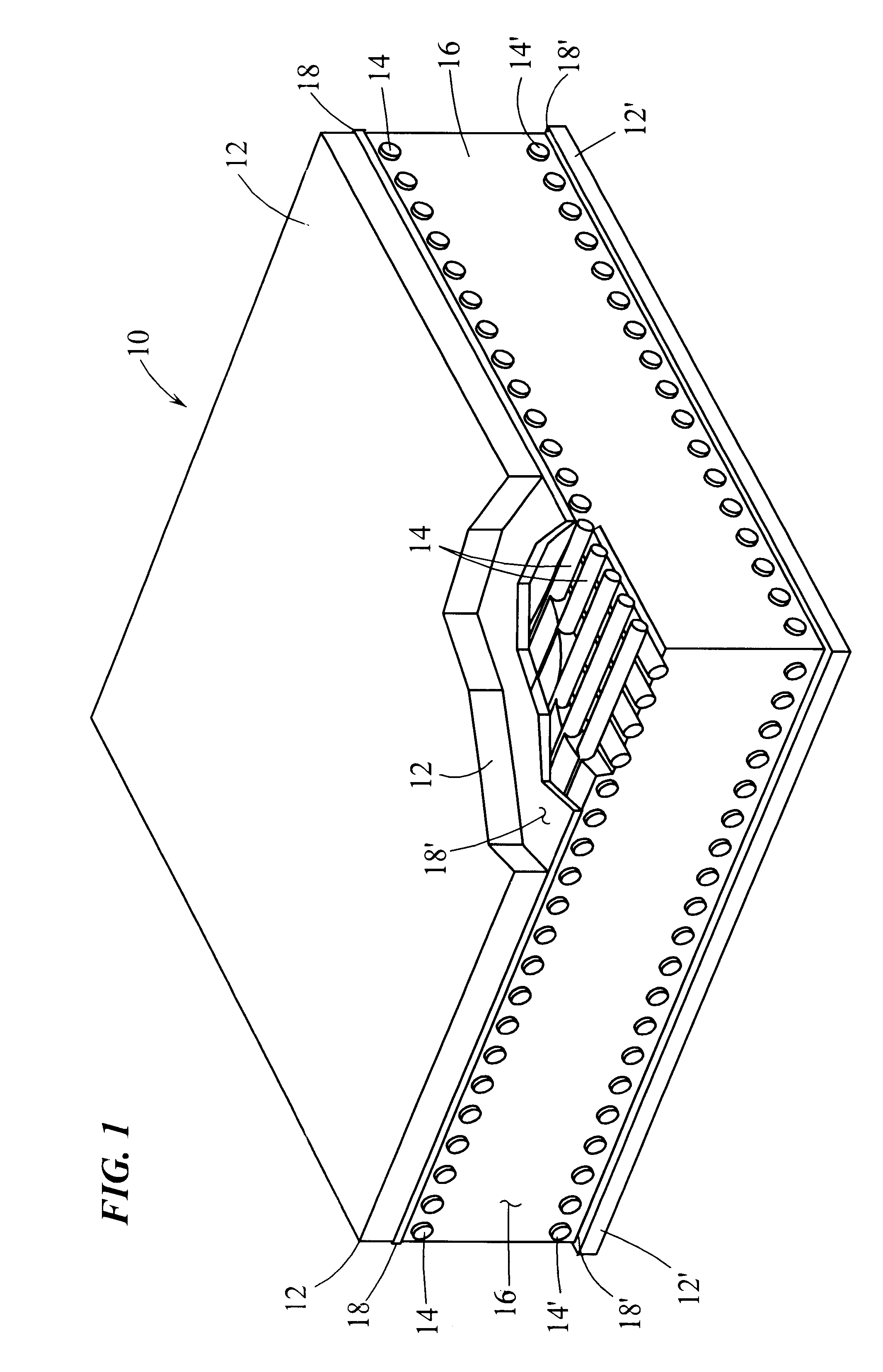

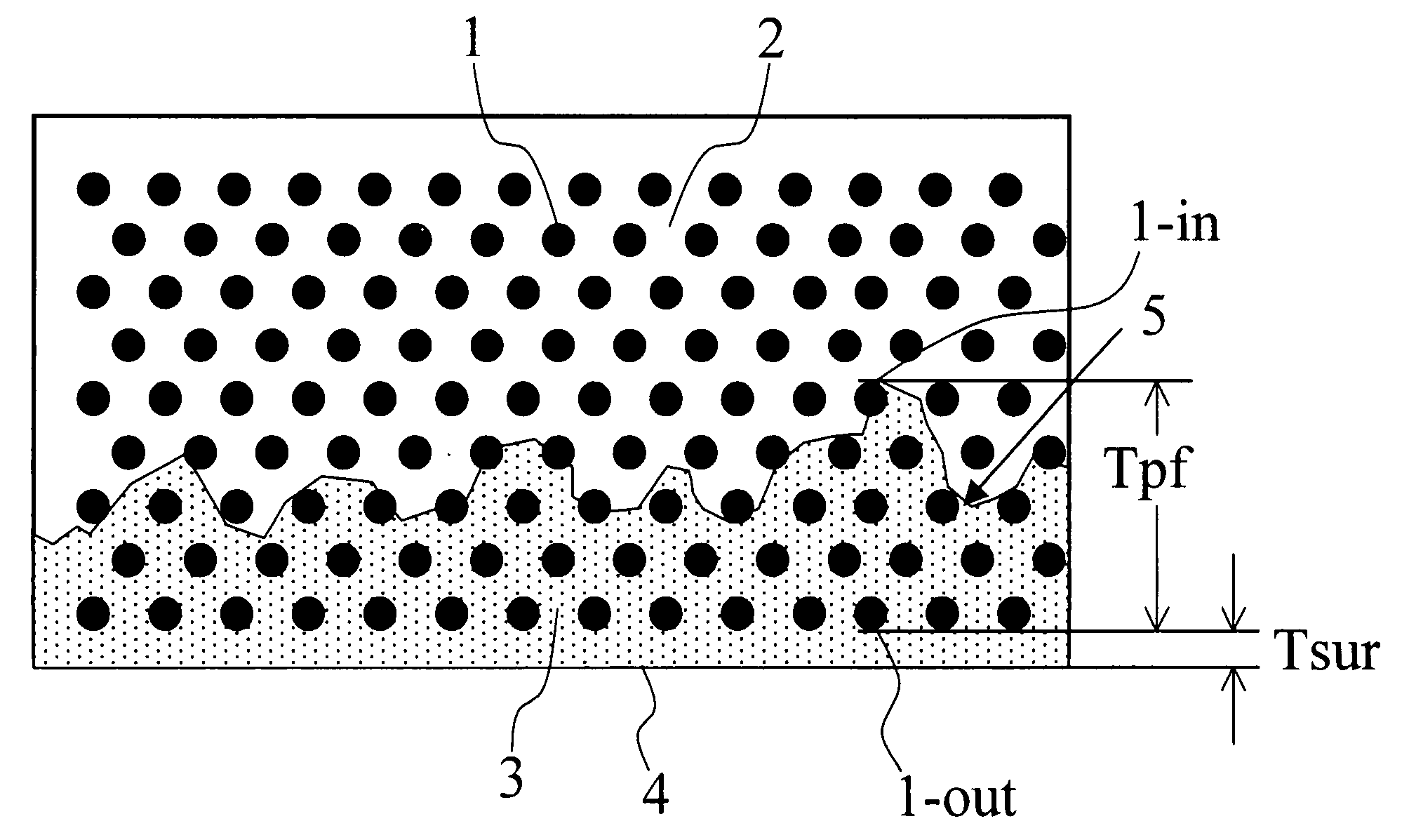

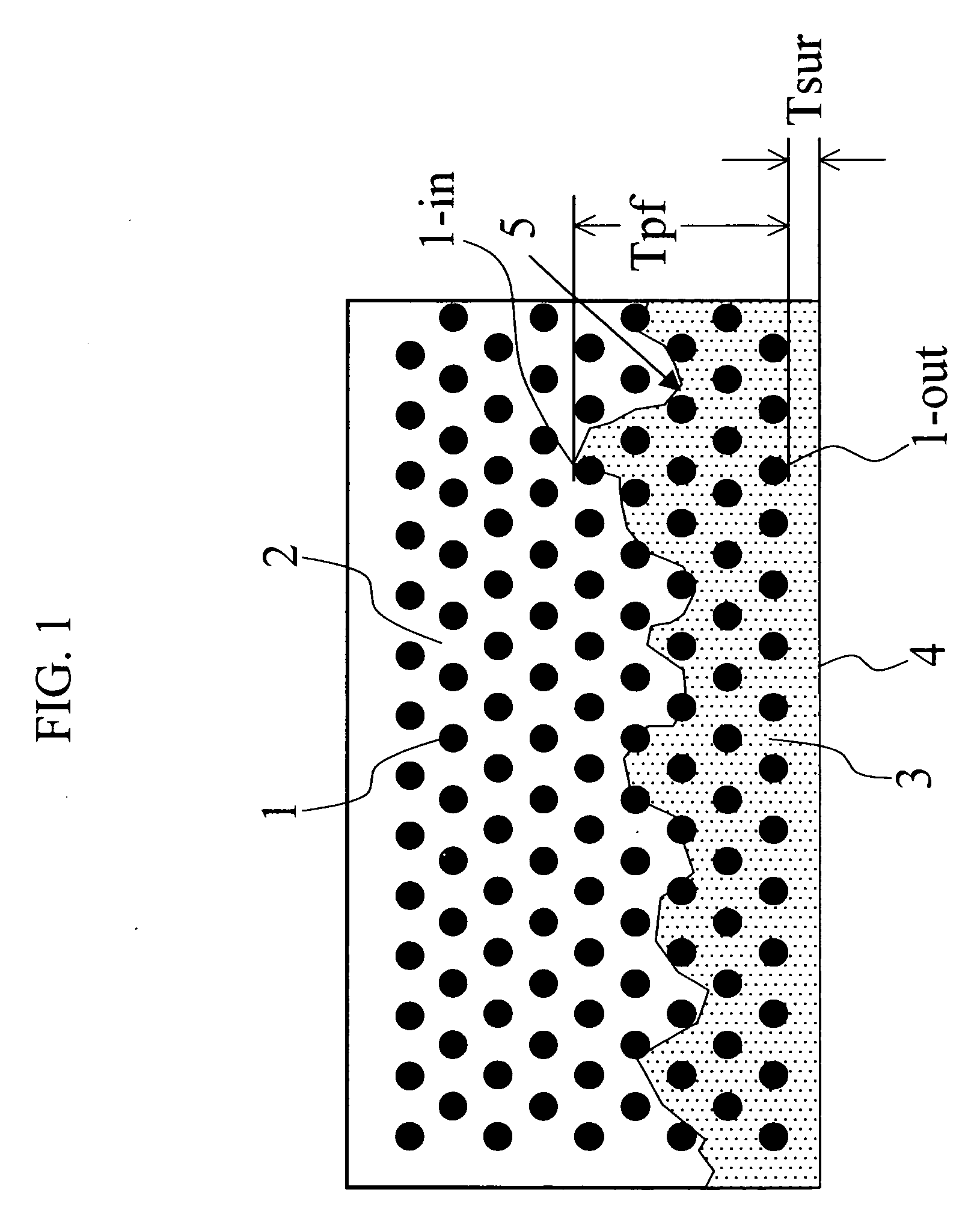

Fiber-reinforced composite structure

InactiveUS6331028B1Fast fillFast impregnationLayered productsWoven fabricsFoaming agentVacuum pressure

A fiber-reinforced composite structure has two molded outer polymeric layers spaced apart from each other and defining a cavity therebetween. Each molded outer polymeric layer defines a sealing surface extending about a periphery of the respective layer, and the opposing sealing surfaces cooperate to define a hermetic seal extending about a periphery of the cavity. One or more multi-directional fiber reinforcement layers are adhesively attached in a discontinuous manner to each outer polymeric layer, and define a first region of the cavity extending between each respective outer polymeric layer and adjacent fiber reinforcement layer, and a second region of the cavity extending between the fiber reinforcement layers. A core is located between the two outer polymeric layers, and is made of a resinous core material capable of exhibiting a foamed character and a resinous character. The resinous core material has a blowing agent activatable upon exposure to a predetermined vacuum pressure within the cavity to convert the core material within the second region of the cavity from a resinous character to a foamed character and thereby fill the second region of the cavity with the foamed core material. Each multi-directional fiber reinforcement layer is impregnated with the core material exhibiting a relatively dense, resinous character, and each first region of the cavity is substantially filled with the core material exhibiting a resinous character to fixedly secure the multi-directional fiber reinforcement layers to the outer polymeric layers. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

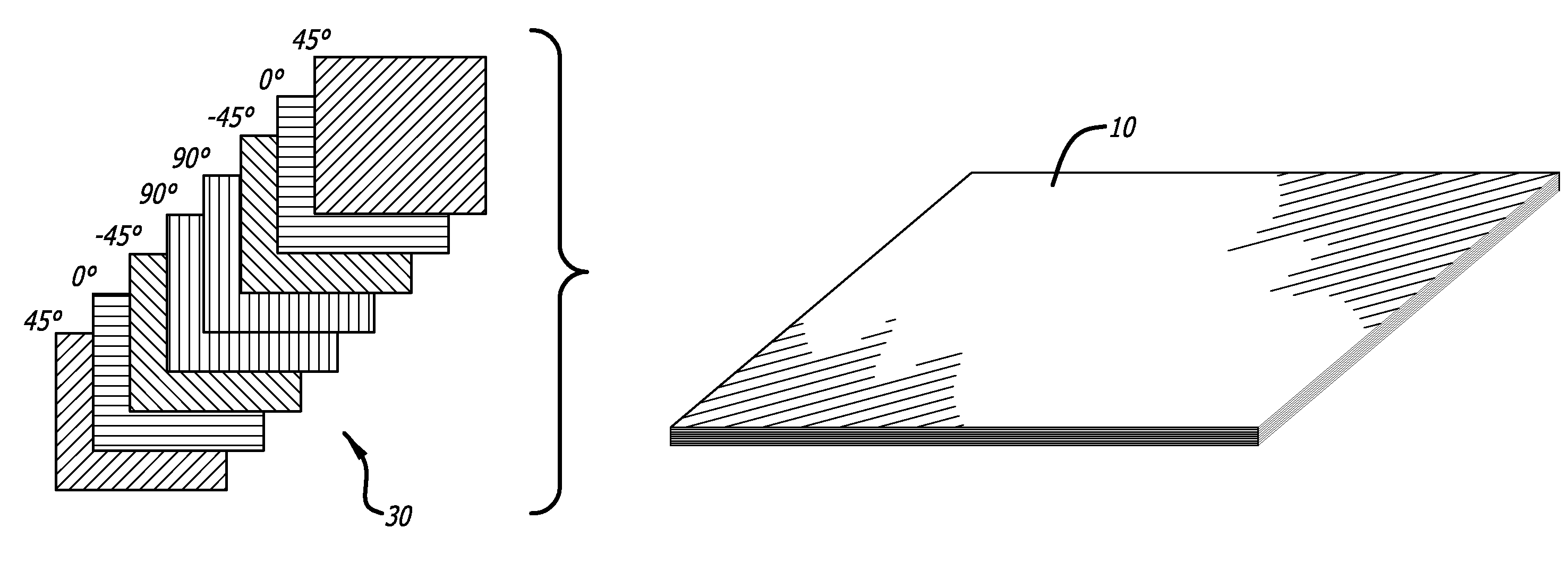

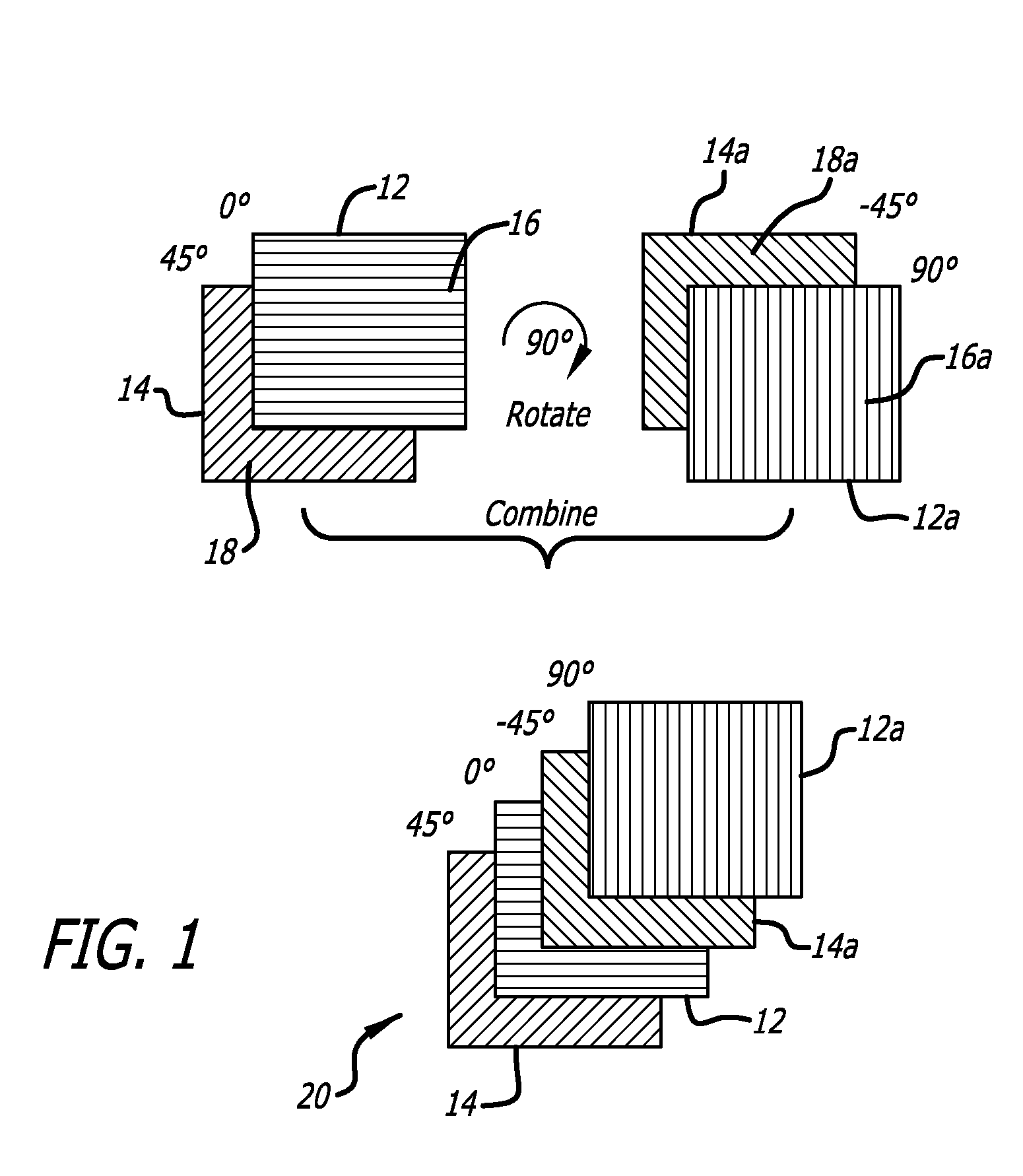

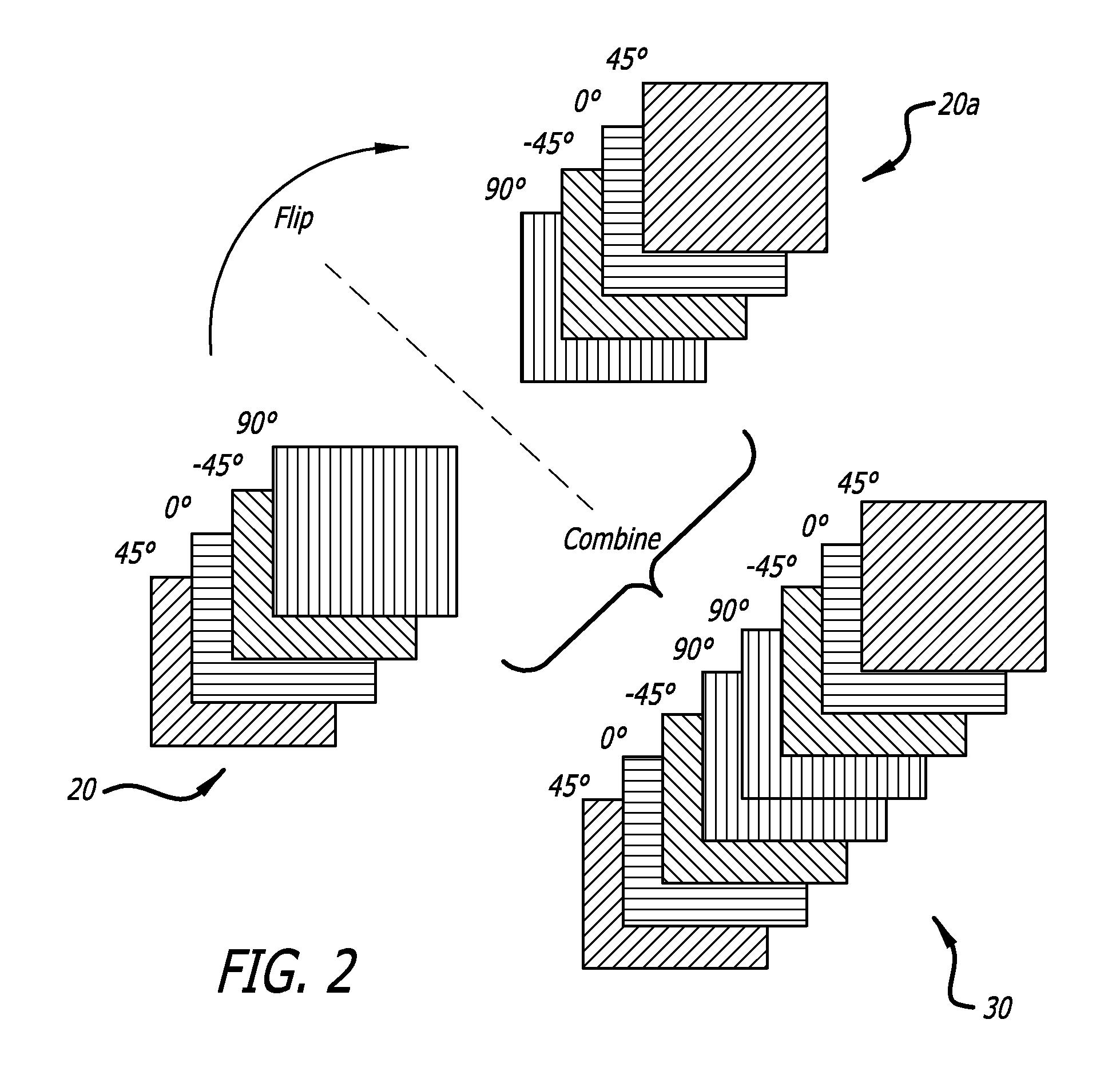

Method of molding complex composite parts using pre-plied multi-directional continuous fiber laminate

ActiveUS20110064908A1Simple processLayered productsEfficient propulsion technologiesShell moldingFiber-reinforced composite

Layers of unidirectional (UD) fiber prepreg are formed into a pre-plied, multi-directional, continuous fiber laminate that is used as a molding compound to form three dimensional structures. Cut-outs from the laminate are slotted and folded along fold lines to provide near-net-shaped preforms that may be compression molded to form fiber-reinforced composite structures having complex shapes.

Owner:HEXCEL

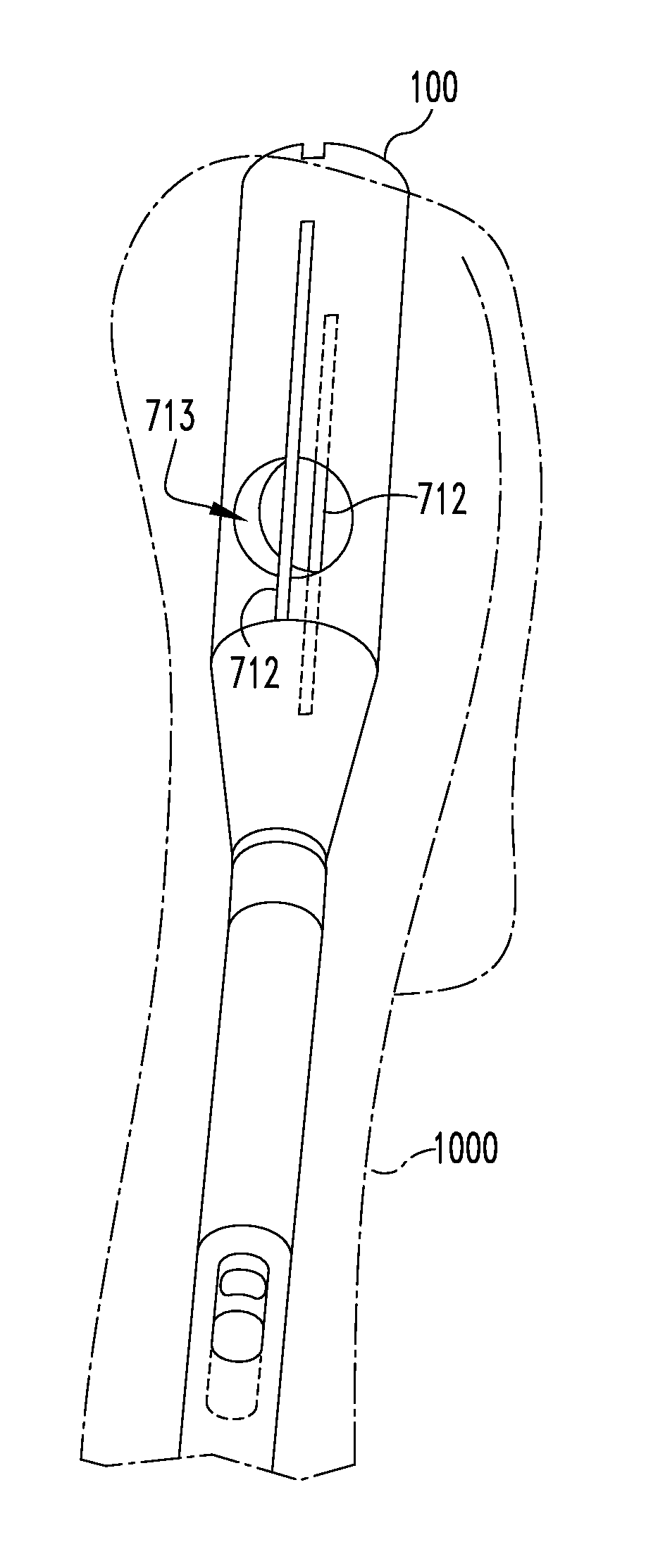

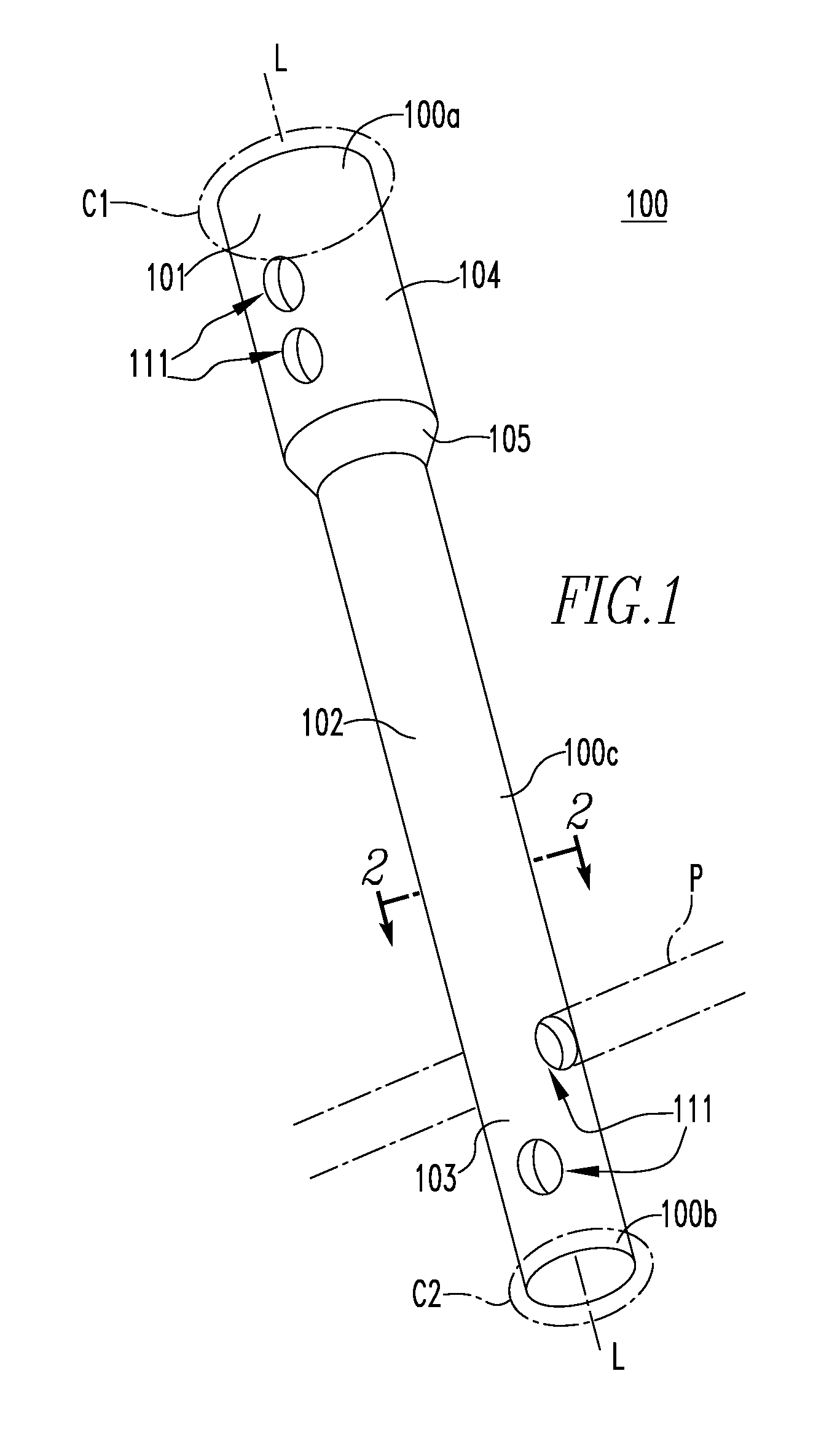

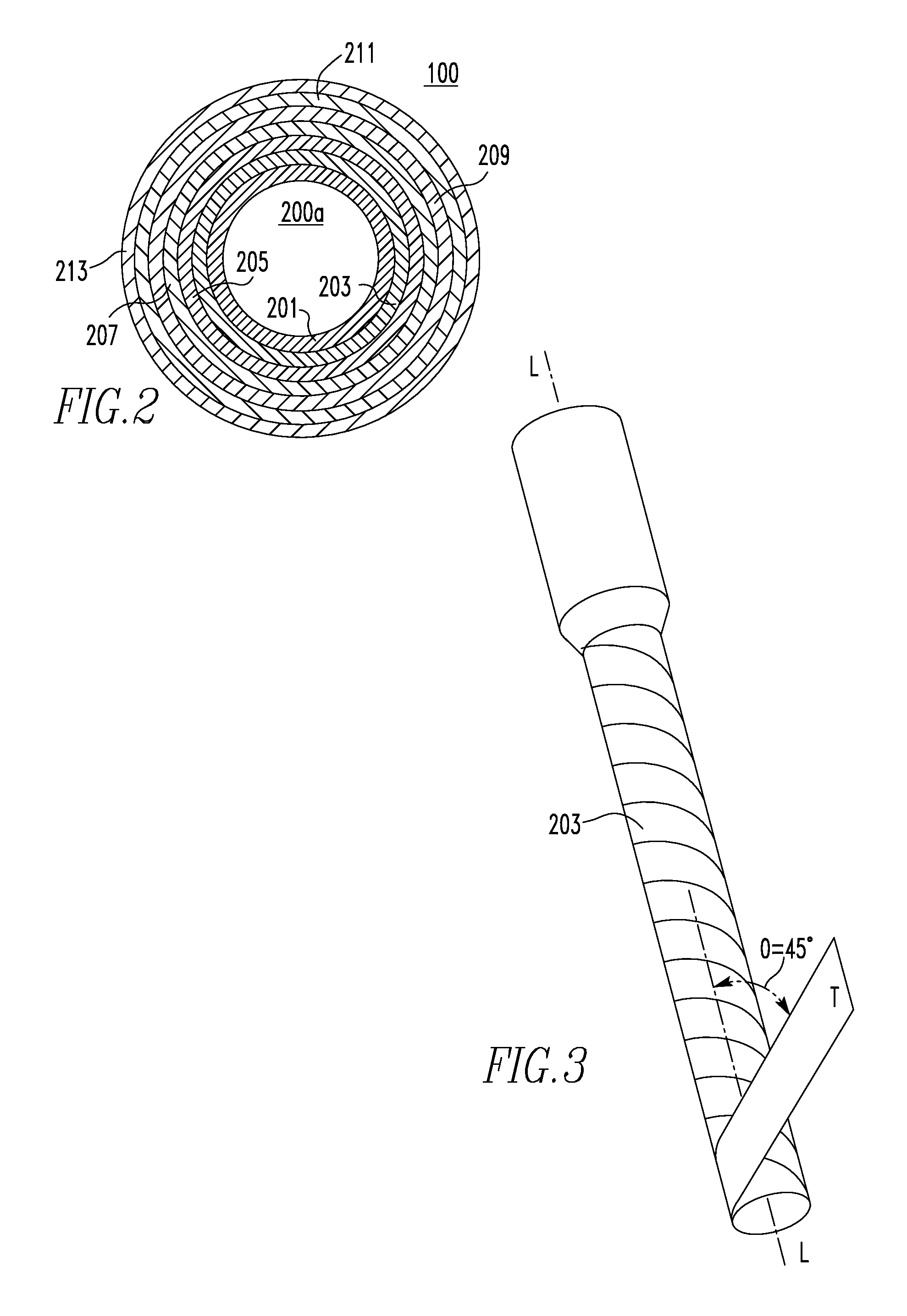

Composite internal fixators

ActiveUS20120059376A1Desired performanceInternal osteosythesisJoint implantsModel selectionElement analysis

A multi-layer, fiber-reinforced composite orthopaedic fixation device having a design selected based on a desired characteristic of the orthopaedic fixation device. The design may be selected according to a model of the device, the model defining design constraints, and the design may comprise a pattern of the fiber angle for each layer. The selection of a design may be analyzed using finite element analysis to determine whether the design will comprise the desired characteristic.

Owner:SMITH & NEPHEW INC

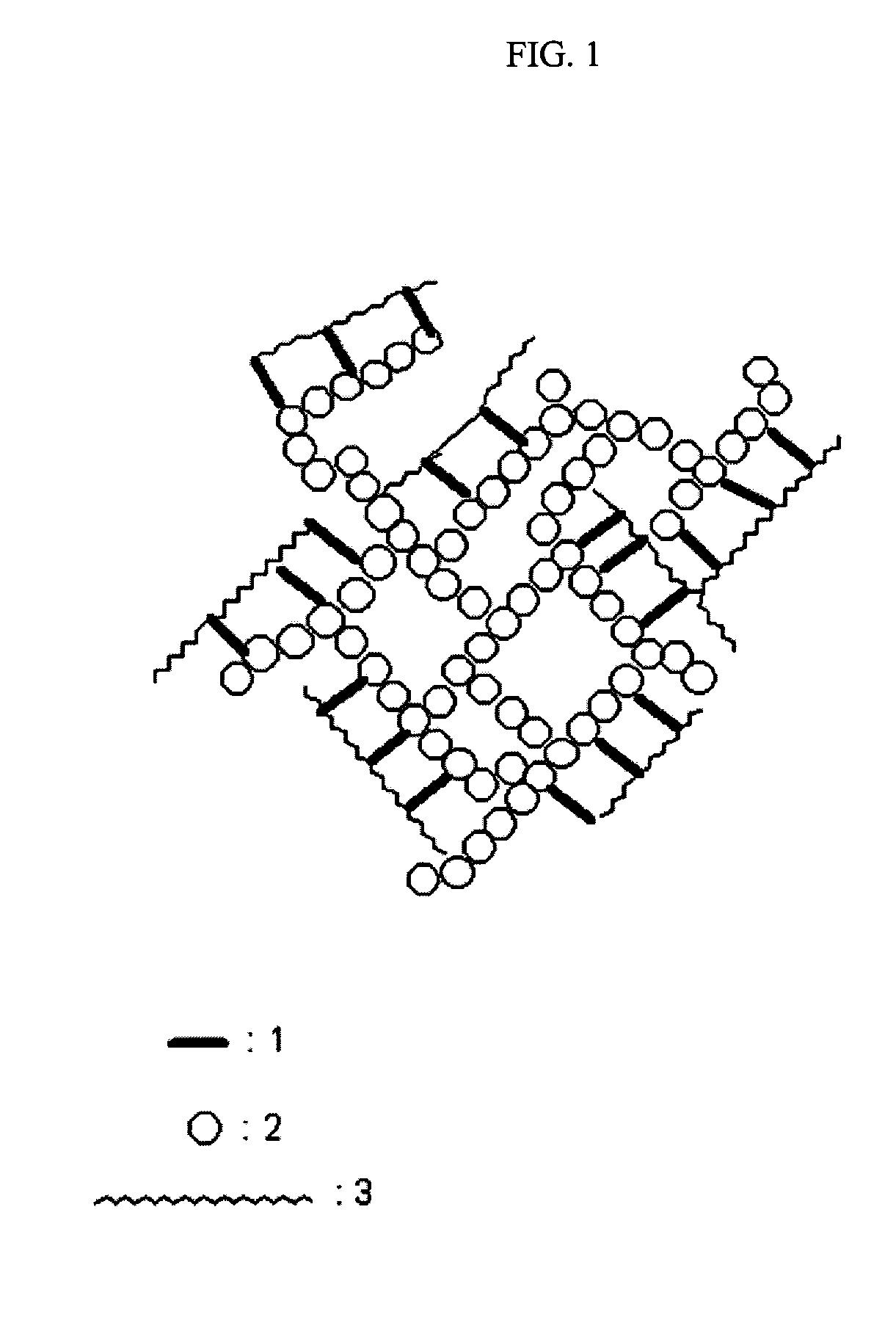

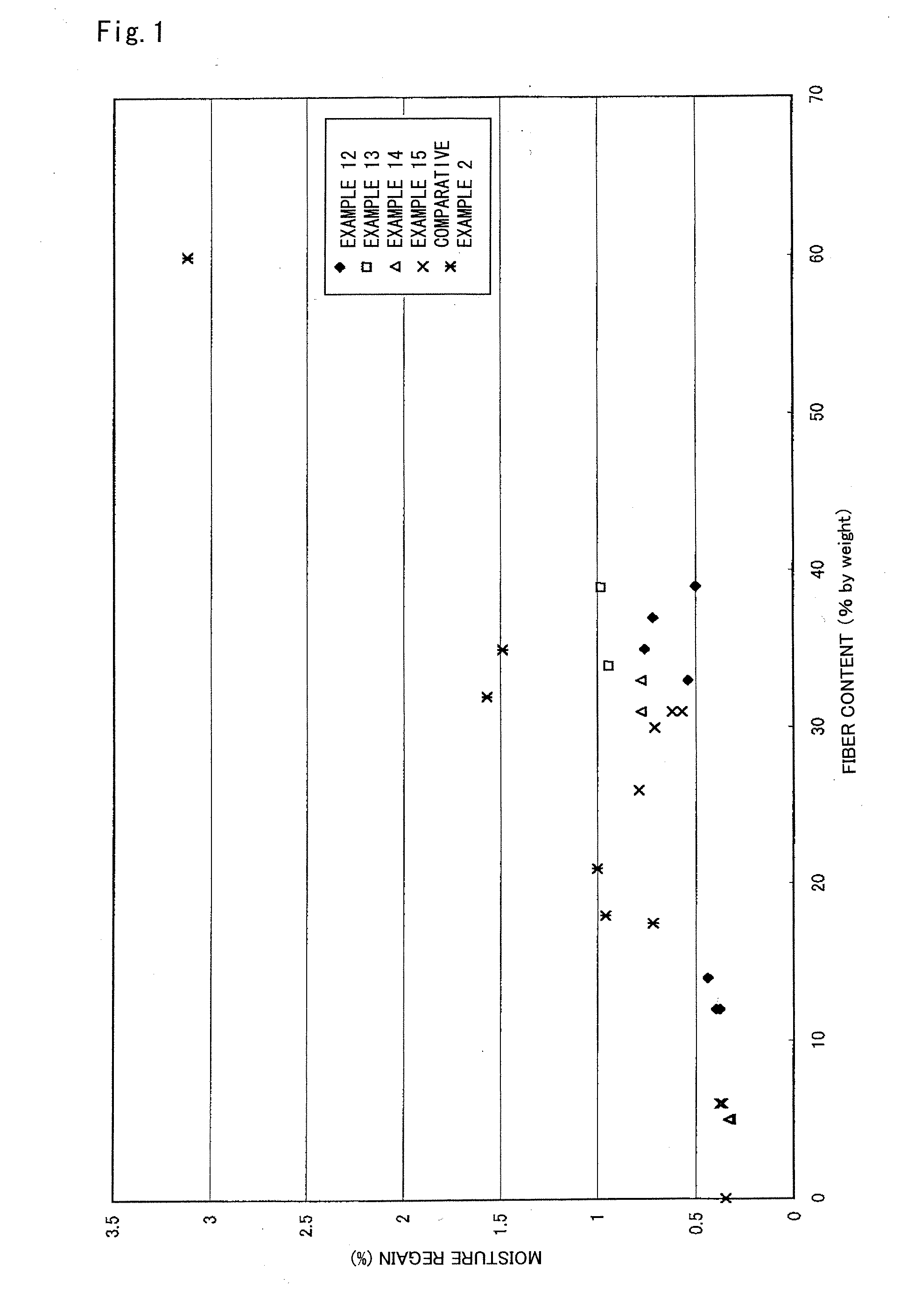

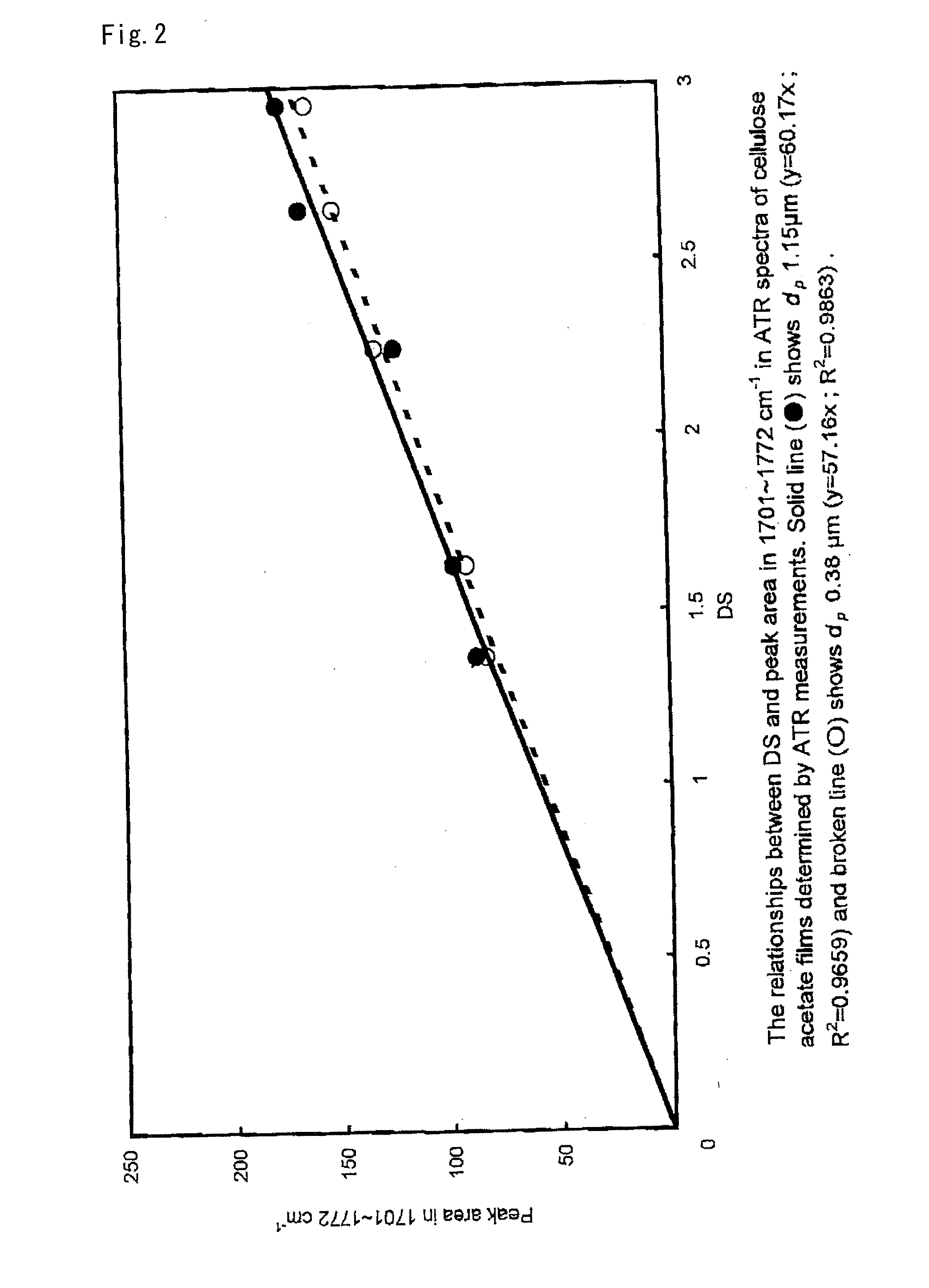

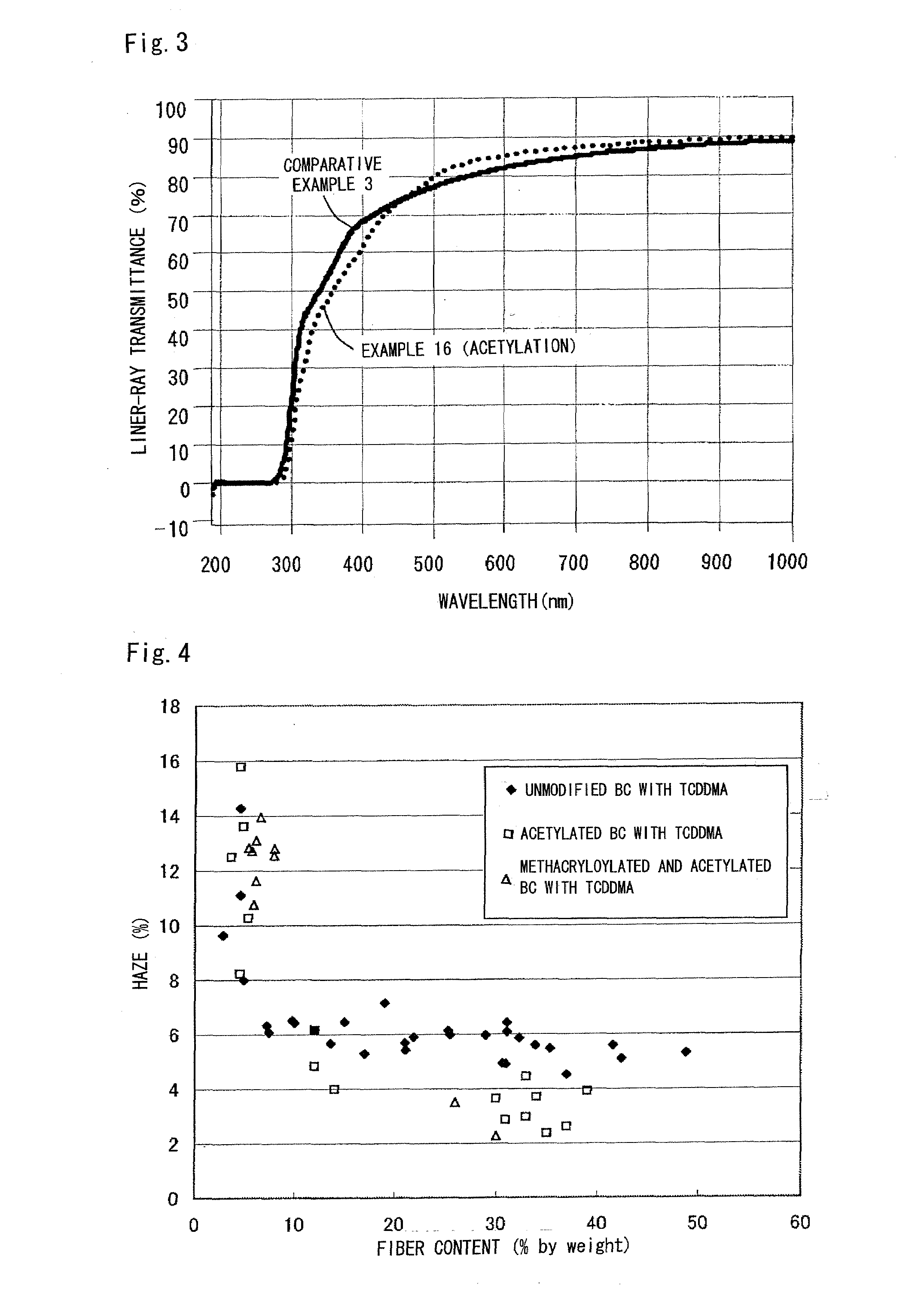

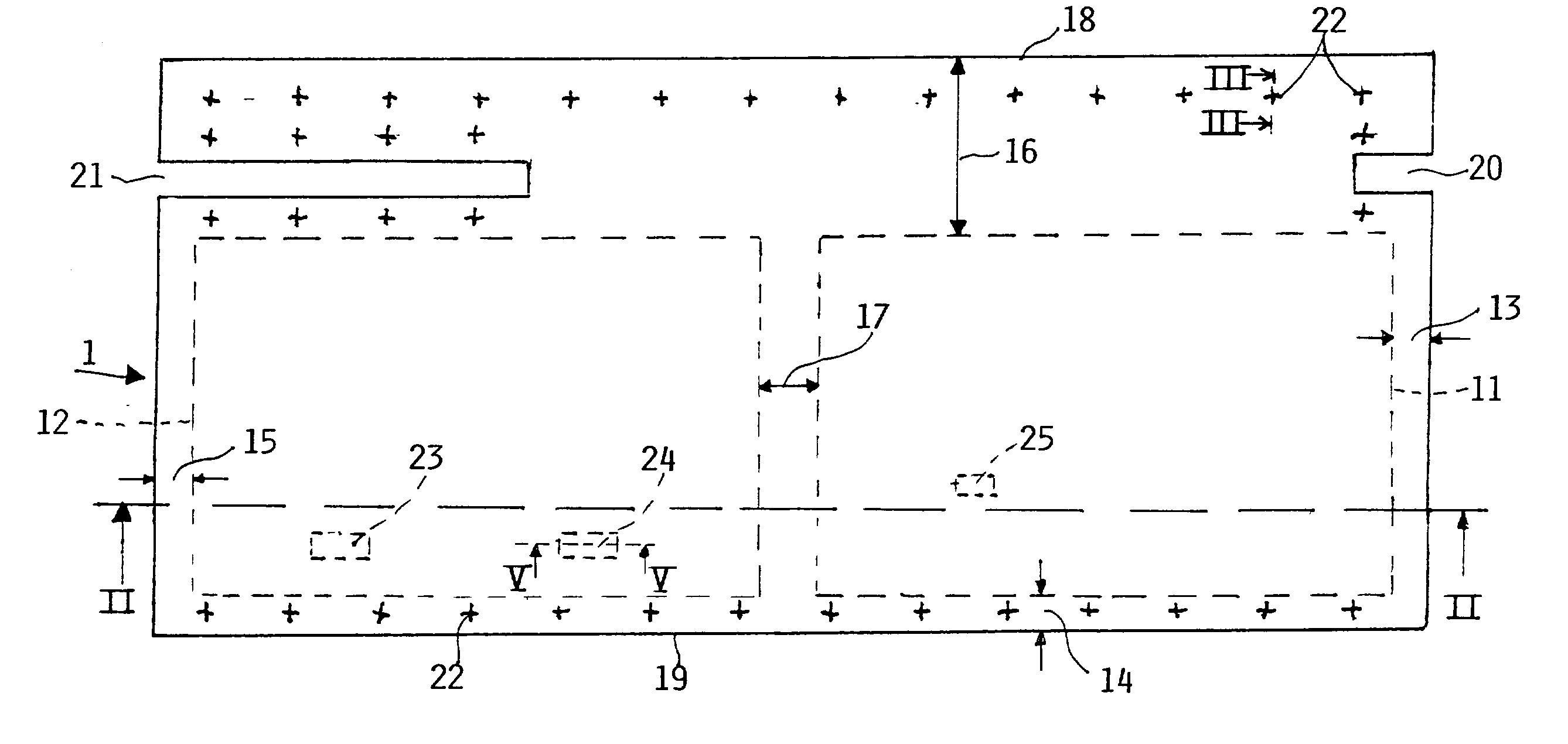

Fiber-reinforced composite material and process for producing the same

ActiveUS20090054552A1Moisture absorptivity and transparencySolid-state devicesThin material handlingAlcoholFiber-reinforced composite

Disclosed is a highly transparent fiber-reinforced composite material including an assembly of cellulose fibers of 4 to 200 nm average fiber diameter impregnated with a matrix material so as to not only remedy the moisture absorbency attributed to cellulose fibers but also further improve transparency. There is provided a fiber-reinforced composite material including an assembly of cellulose fibers impregnated with a matrix material. In the fiber-reinforced composite material, hydroxyl groups of cellulose fibers are chemically modified through a reaction with one or more chemical modifiers selected from the group consisting of an acid, an alcohol, a halogenating reagent, an acid anhydride, and an isocyanate so that the ratio of a functional group introduced by the chemical modification is 5 to 40 percent by mole based on the hydroxyl groups of cellulose fibers before the chemical modification. The chemical modification of hydroxyl groups of cellulose fibers can reduce the hydrophilicity of cellulose fibers to thereby reduce the moisture absorbency of fiber-reinforced composite material. Further, the affinity between cellulose fibers and matrix material can be enhanced to thereby further improve transparency.

Owner:MITSUBISHI CHEM CORP +2

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS20020180077A1Material nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

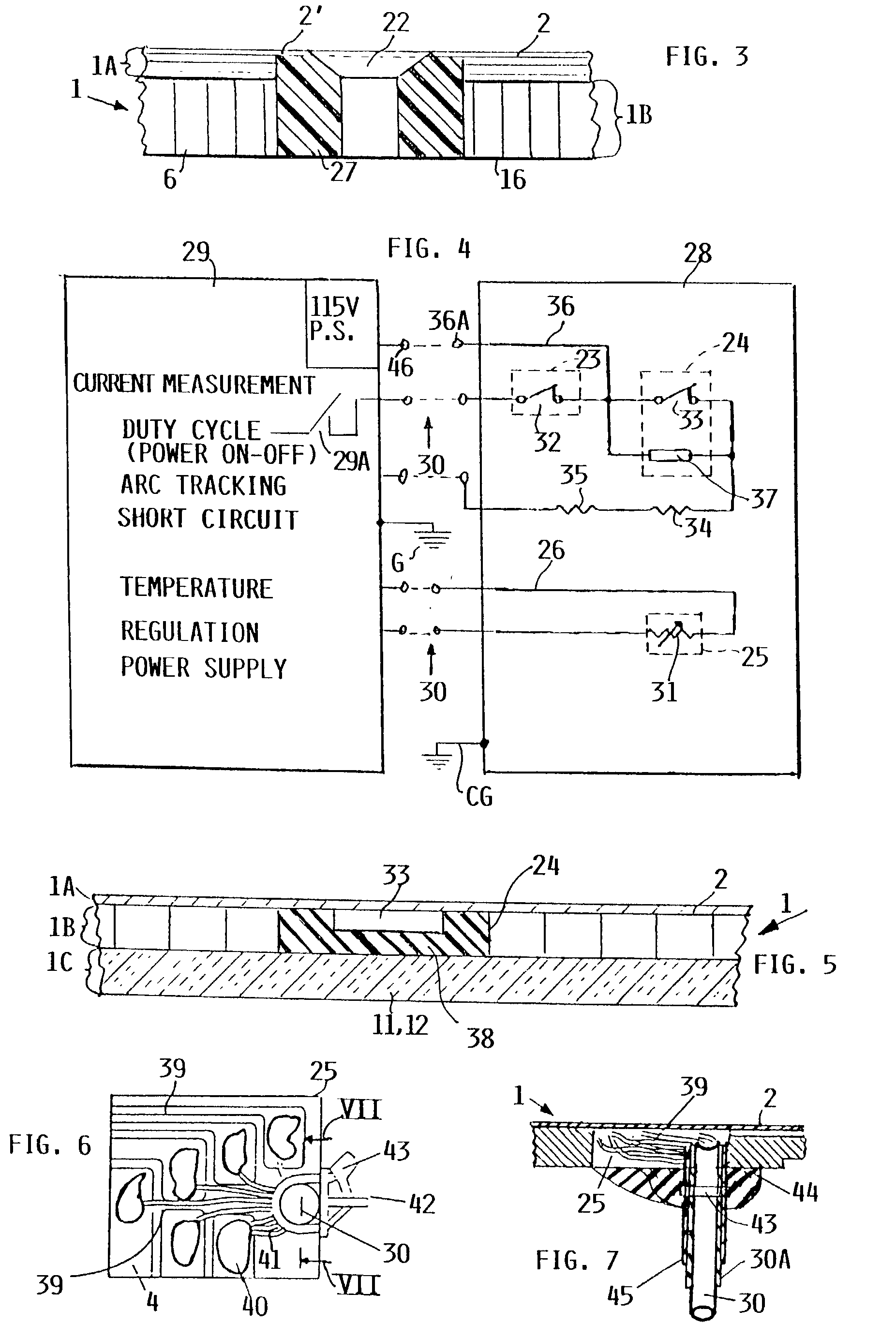

Electrically heated aircraft composite floor panel

InactiveUS20020168184A1Avoid temperature riseReduce consumptionFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

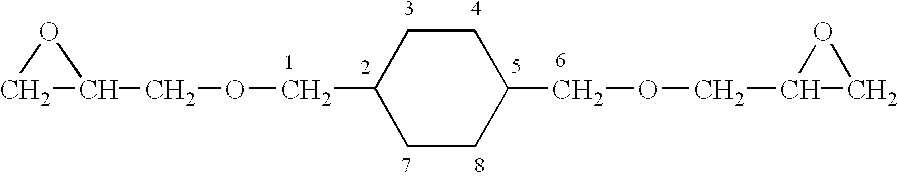

Epoxy Resin Composition for Carbon-Fiber-Reinforced Composite Material, Prepreg, Integrated Molding, Fiber-Reinforced Composite Sheet, and Casing for Electrical/Electronic Equipment

ActiveUS20080166511A1Improve mechanical propertiesLight weightPigmenting treatmentPlastic/resin/waxes insulatorsEpoxyHalogen

The present invention provides a light-weight fiber-reinforced composite material that has excellent flame retardance and mechanical properties and never emits a halogen gas. The present invention also provides a prepreg and en epoxy resin composition suited to obtain the above described fiber-reinforced composite material. The present invention also provides an integrated molding which is produced using the above described fiber-reinforced composite material, thereby suitable for use in electric / electronic casings. The epoxy resin composition is such that it contains the following components [A], [B] and [C]:[A] epoxy resin,[B] amine curing agent, and[C] phosphorus compound,wherein the concentration of the component [C] is 0.2 to 15% by weight in terms of phosphorus atom concentration.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com