Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

859 results about "Aramides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aramides is a genus of birds in the family Rallidae.

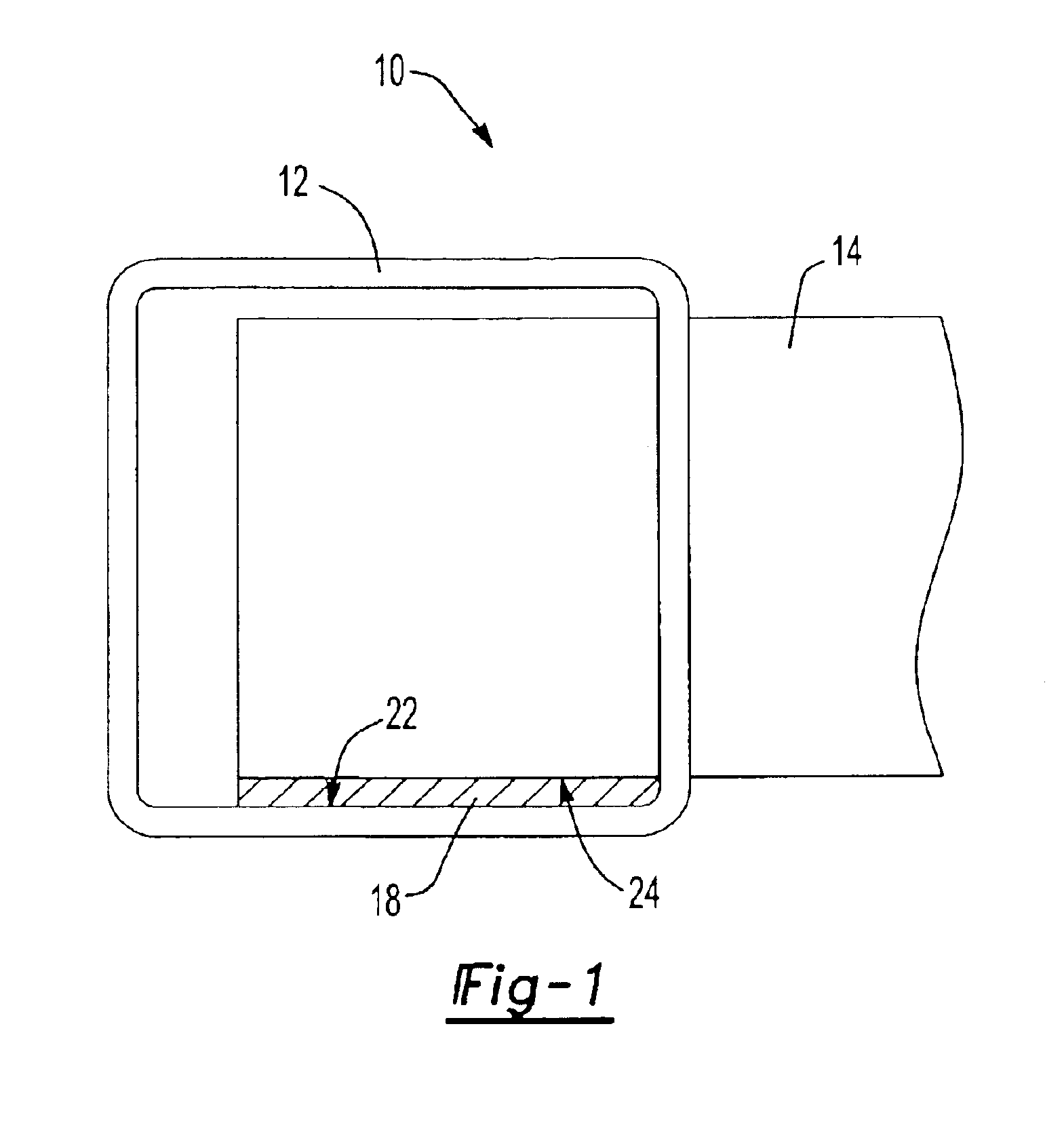

Activatable material

InactiveUS6846559B2Assist in flow controlPreventing fatigue crack growthSynthetic resin layered productsRecord information storageEpoxyElastomer

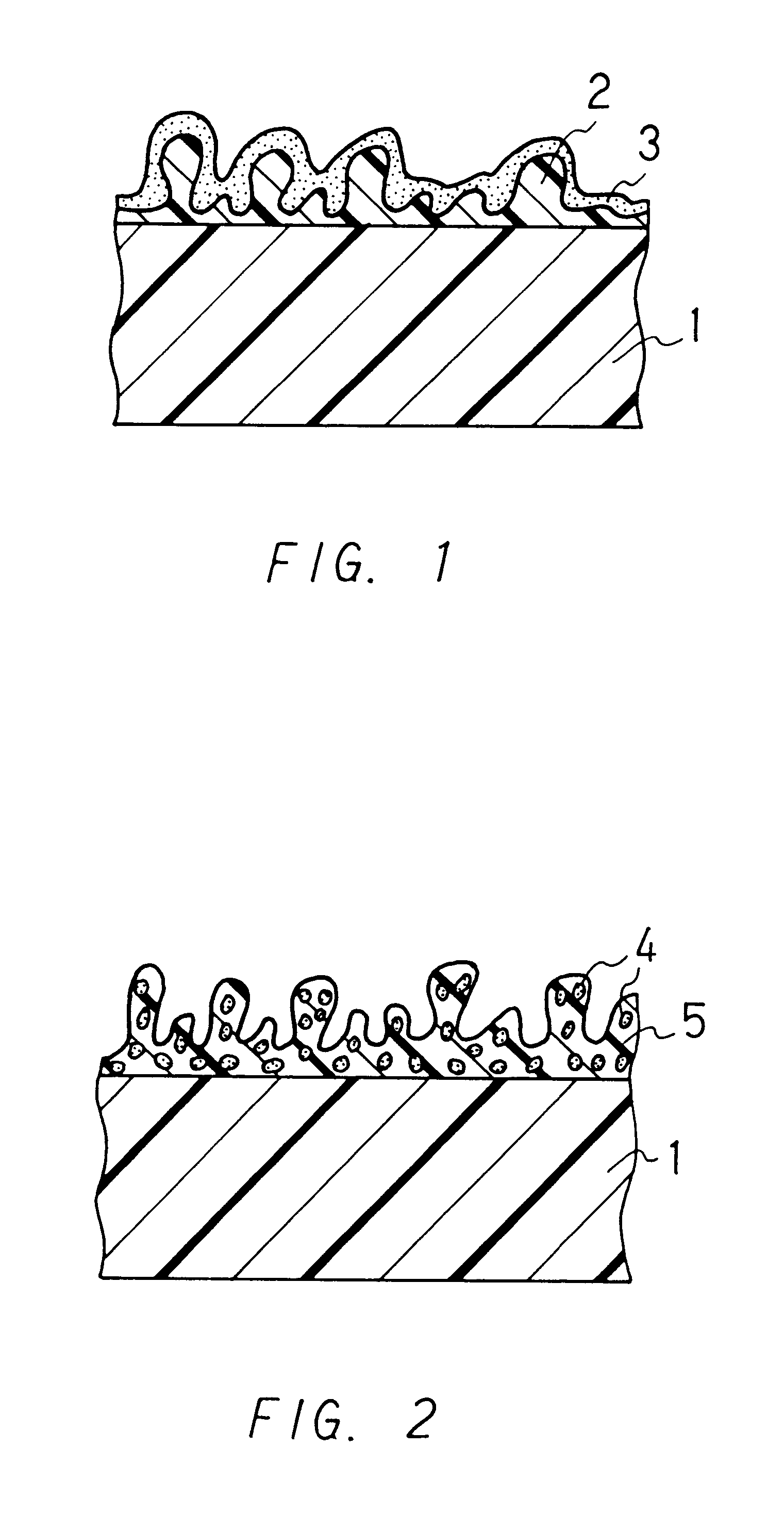

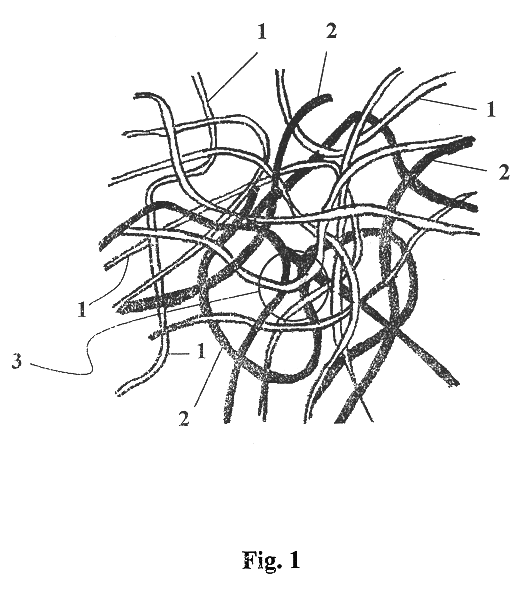

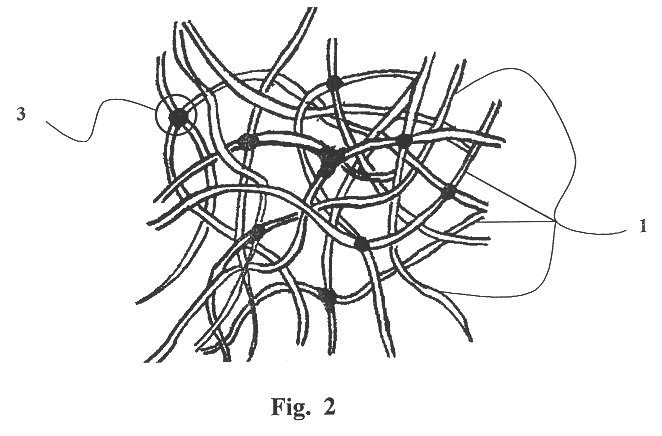

An activatable (e.g., heat expandable) material and articles incorporating the same is disclosed. The material includes an epoxy resin; an epoxy / elastomer hybrid or reaction product; a blowing agent; a curing agent; and optionally, a filler. In preferred embodiments, the material includes aramid fiber, nanoclay or both.

Owner:ZEPHYROS INC

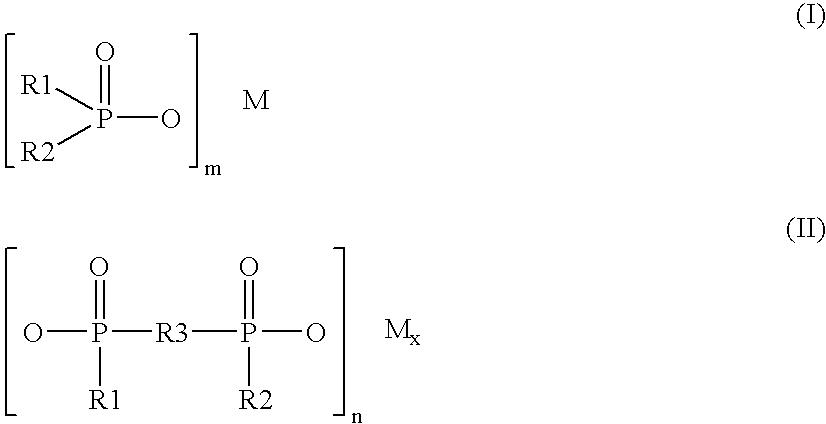

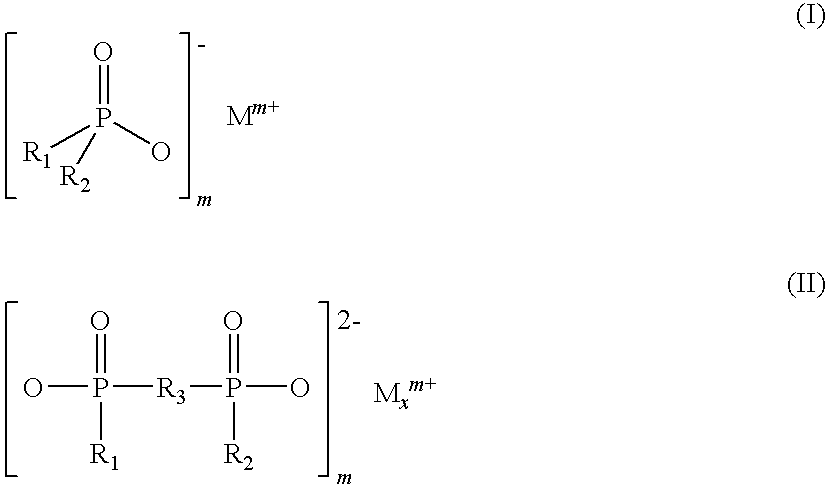

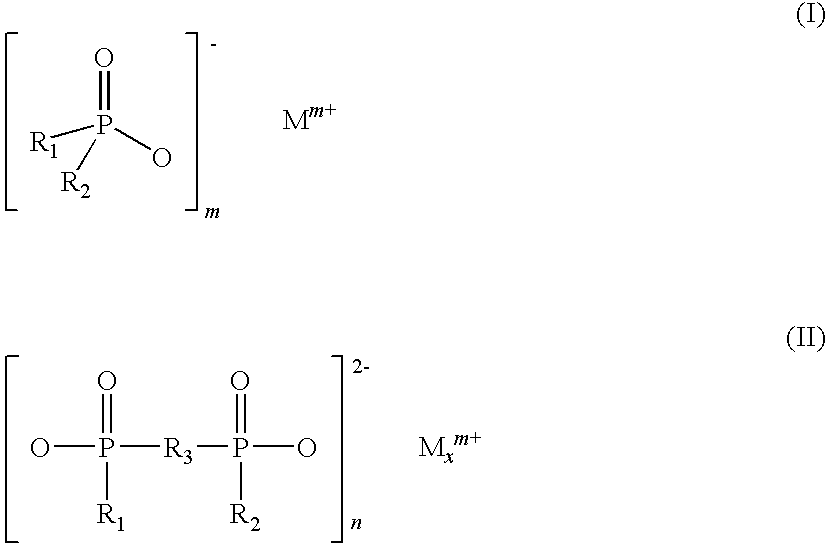

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

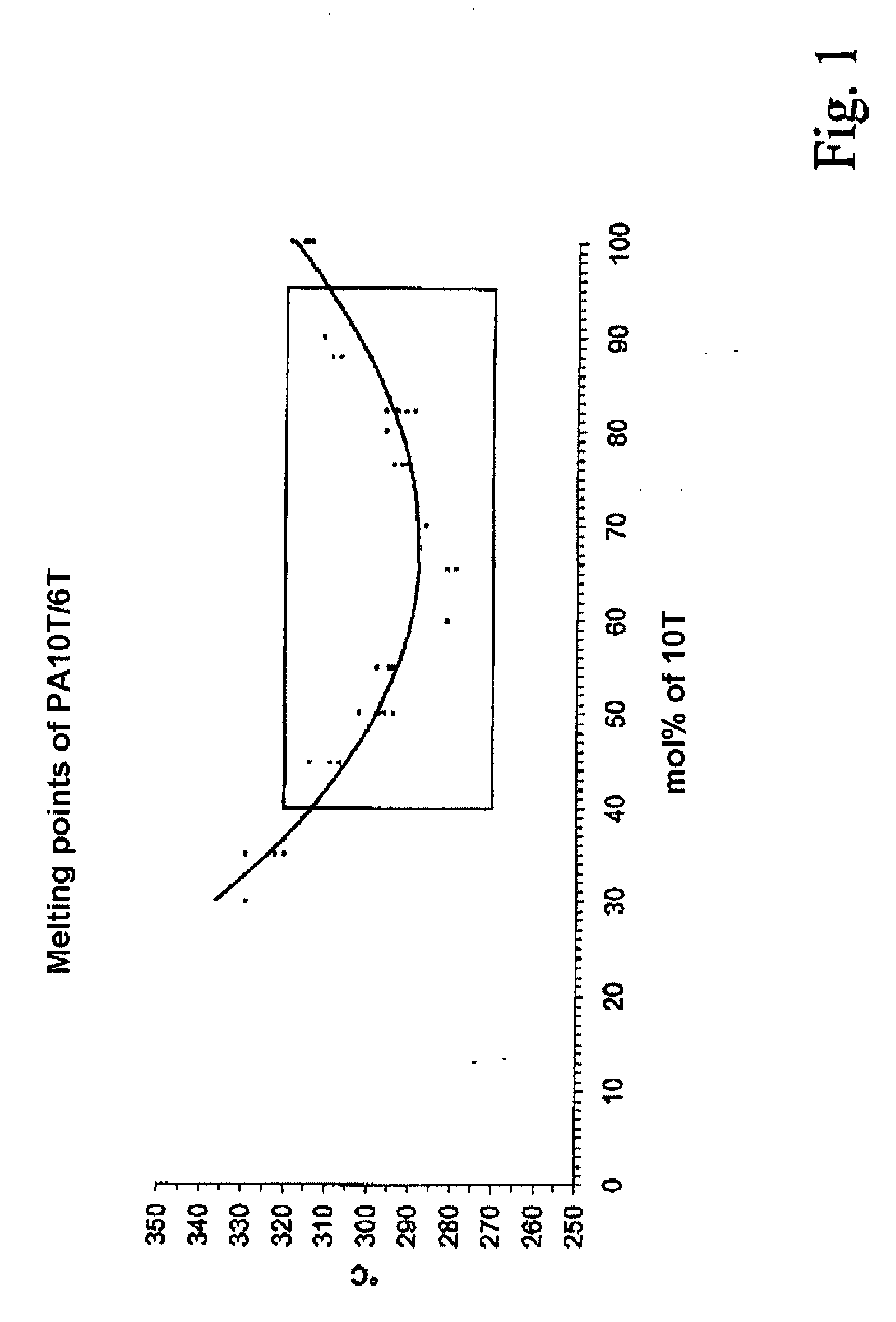

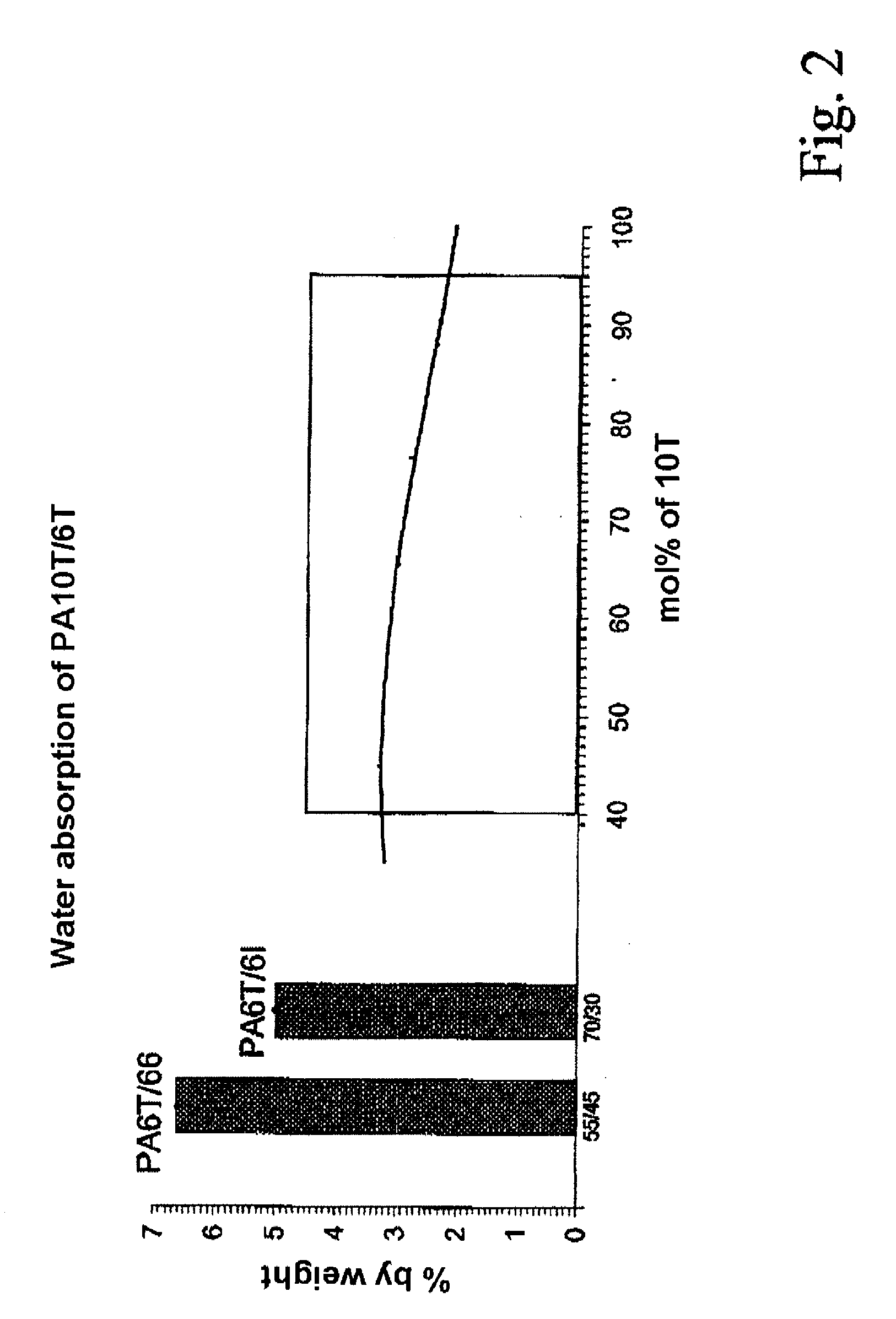

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

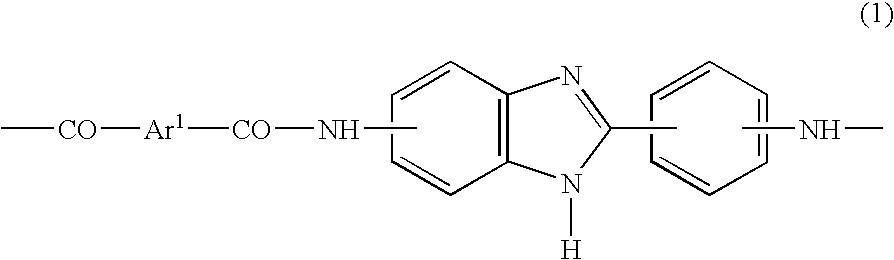

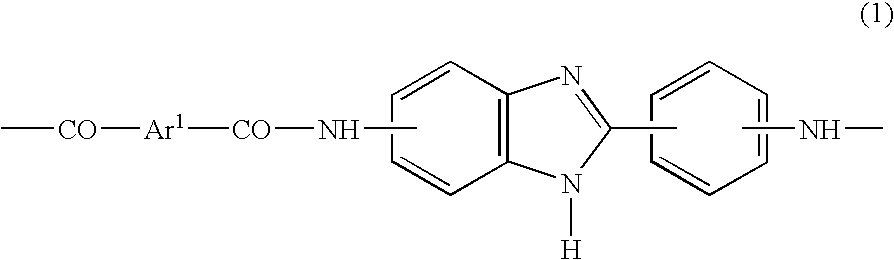

Heterocycle-containing aromatic polyamide fiber, method for producing the same, cloth constituted by the fiber, and fiber-reinforced composite material reinforced with the fiber

InactiveUS20100029159A1Improve balanceHigh strength holding ratioArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentAramidesFiber-reinforced composite

The heterocycle-containing aromatic polyamide fibers of the invention are excellent in balance among mechanical characteristics, particularly balance among tensile strength, initial modulus and strength in the direction perpendicular to the fiber axis, exhibit a high strength holding ratio under heat and humidity, and are excellent in flame retardancy, bulletproofness and cutting resistance, as compared to conventional aromatic polyamide fibers, and therefore can be favorably used in fields with severe mechanical characteristics and have stability to environmental variation. Accordingly, the heterocycle-containing aromatic polyamide fibers of the invention can be favorably used, for example, in fields including protective equipment, such as a helmet, a bulletproof vest and the like, a chassis for an automobile, a ship and the like, an electric insulating material, such as a printed circuit board and the like, and other various fields.

Owner:TEIJIN TECHNO PRODUCTS LTD

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

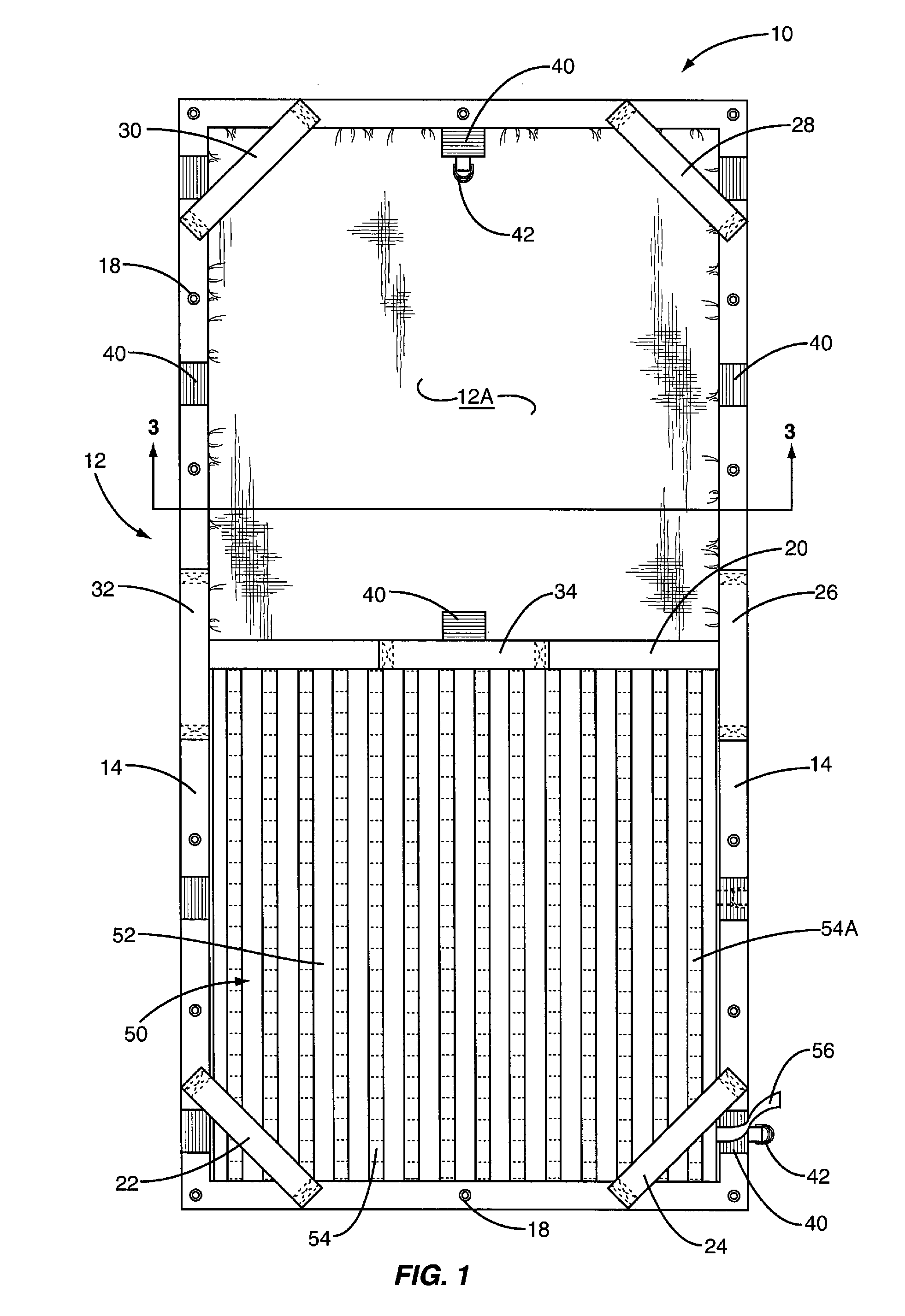

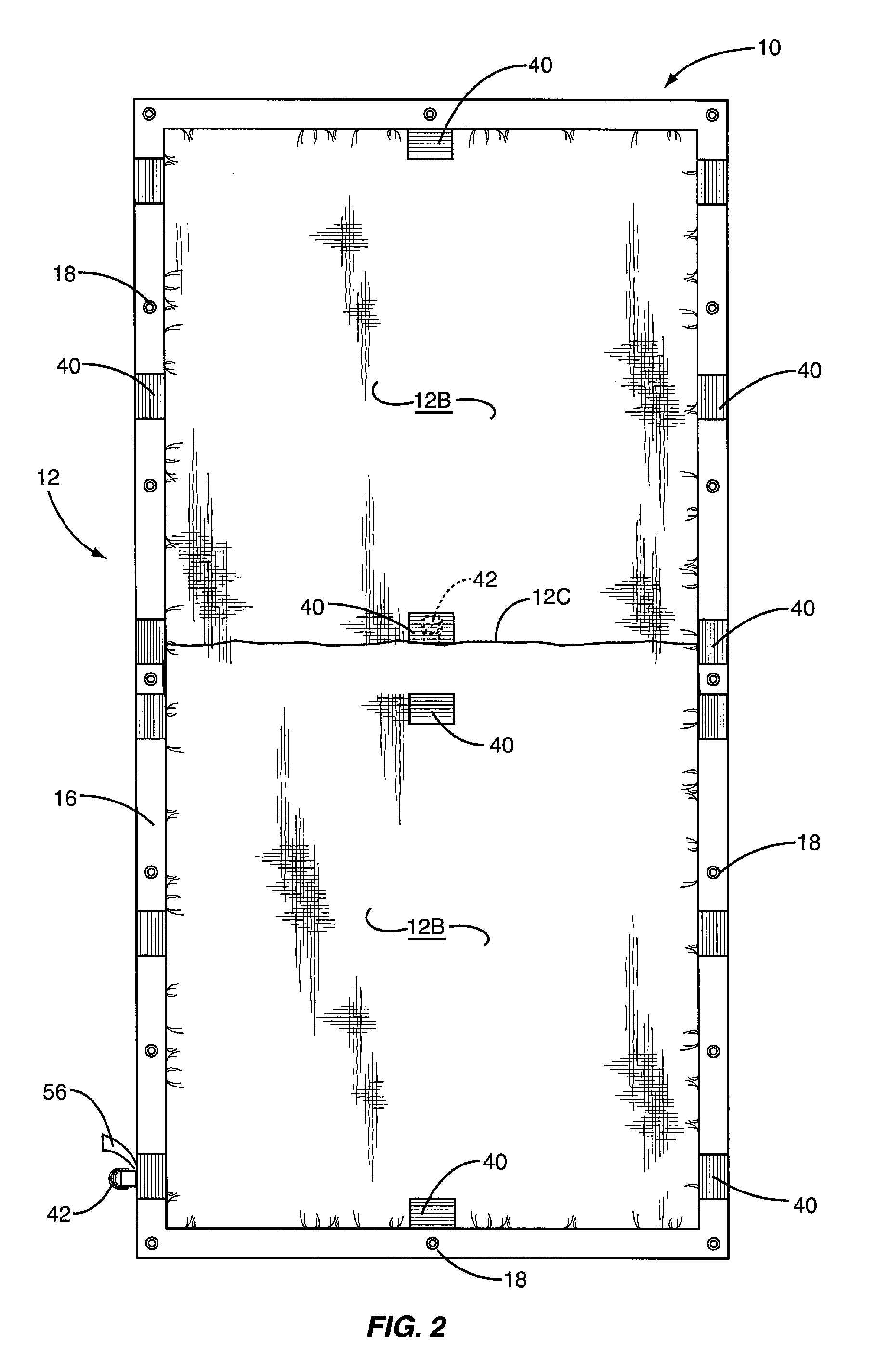

Ceramic armor apparatus for multiple bullet protection

Armor apparatus comprising a non-oxide ceramic element bounded to an aramid fiber composite baking. A special ceramic and a novel aramid fiber substrate are combined in a unique arrangement that permits a single armor system to provide protection against multiple types of ballistic attack. The armor apparatus may be used alone or as a supplementary armor system to provide increased protection from ballistic attack.

Owner:ARMORWORKS ENTERPRISES

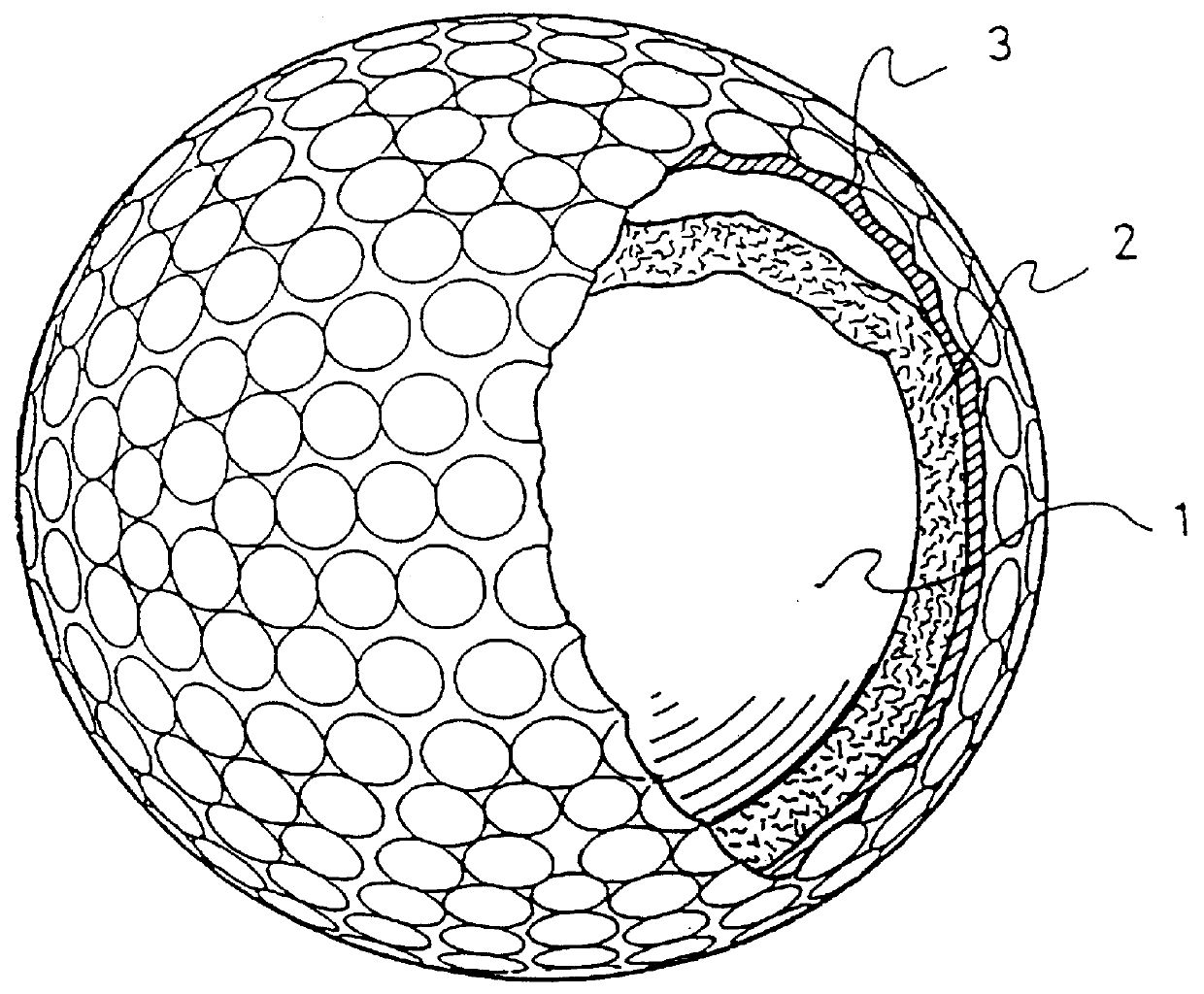

Golf ball with improved intermediate layer

A golf ball including an improved mantle composition which results in improved performance characteristics. The composition includes a soft, flexible resin, such as an elastomer, and a quantity of at least one hardness-enhancing material, such as a quantity of fibers or fiber segments, such as glass, carbon, aramid, and / or metallic fibers, and, optionally, at least one ionomer. The hardness-enhancing material can constitute about 1 to about 30 wt % of the intermediate layer. The composition of the intermediate layer enables the golf ball to maintain initial speed and distance of known golf balls, while improving upon spin rate and playability. Alternatively, spin rate and playability can be maintained, while improving upon the initial speed and distance.

Owner:TAYLOR MADE GOLF

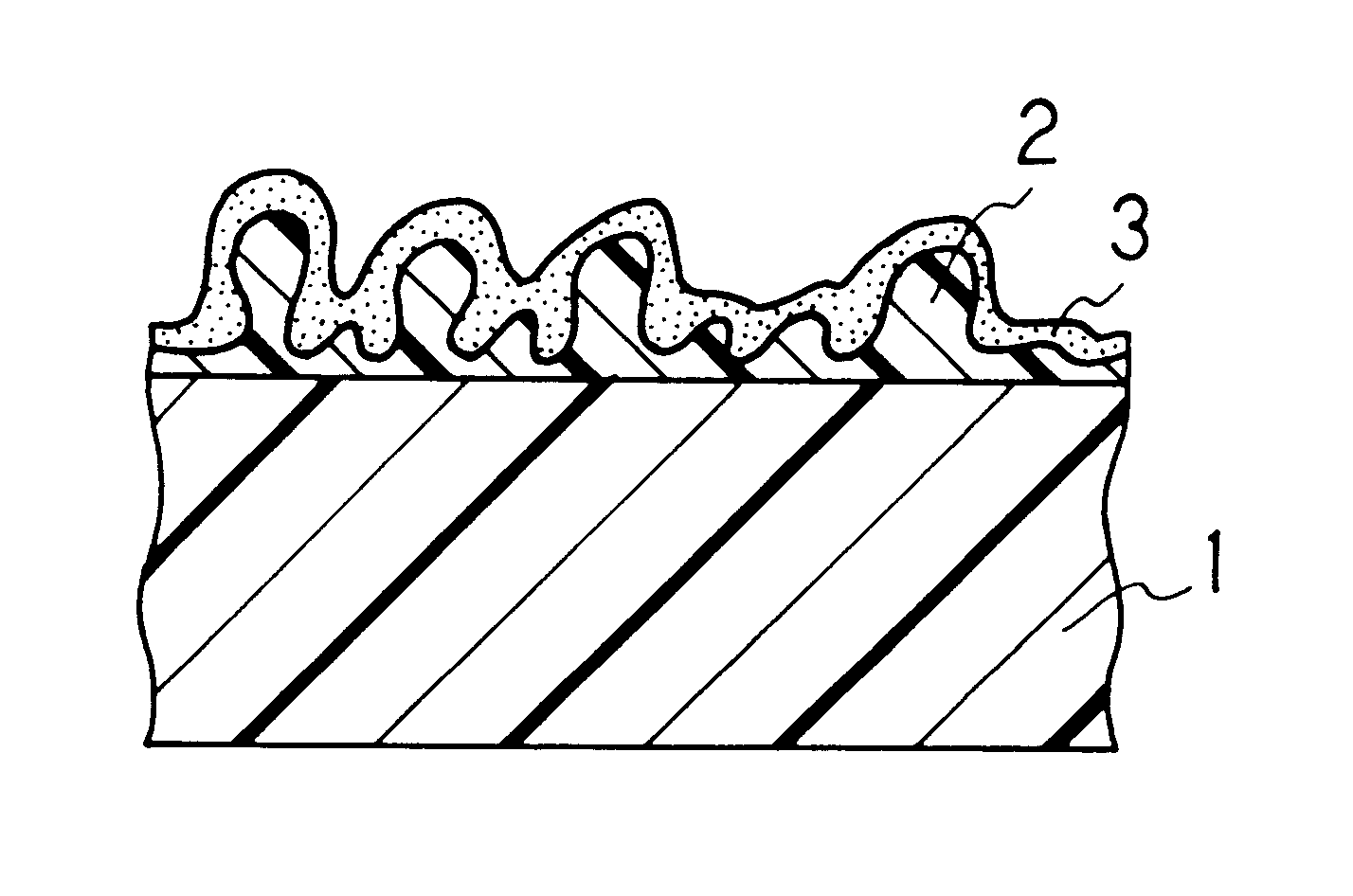

High performance insulations

A durable, low-density, high performance insulating material is suitable for use as a high temperature thermal and acoustic insulation. The insulation includes fiber batting made with non-thermoplastic fibers or blends of fibers such as aramid fibers and ceramic fibers, which are bound within at least some interstices by high temperature non-flammable thermoplastic binder such as polyphenylene sulfide. In addition, a fireblocking layer can be provided on at least one surface of the insulation to further improve fire ablation or flame retardance.

Owner:TEX TECH INDS INC

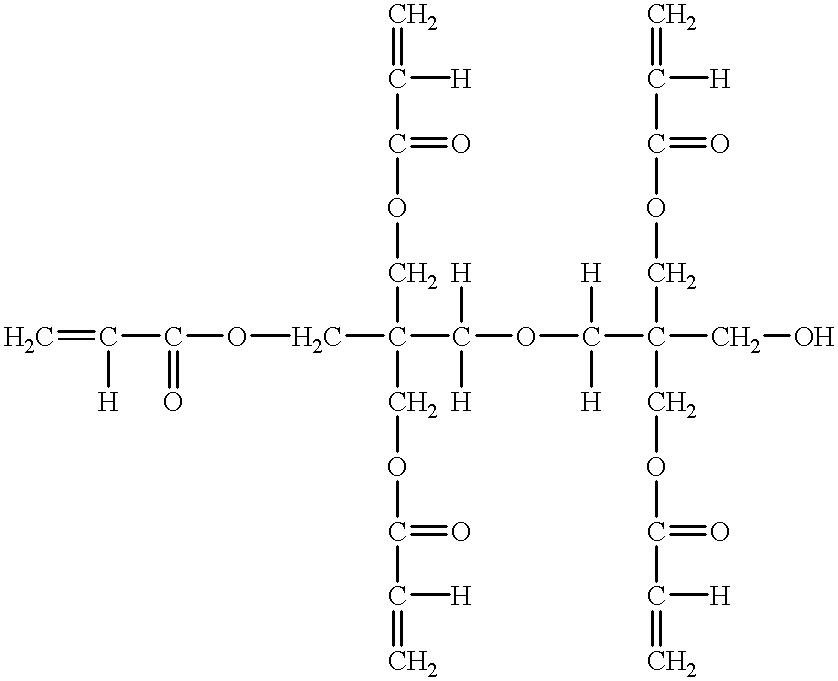

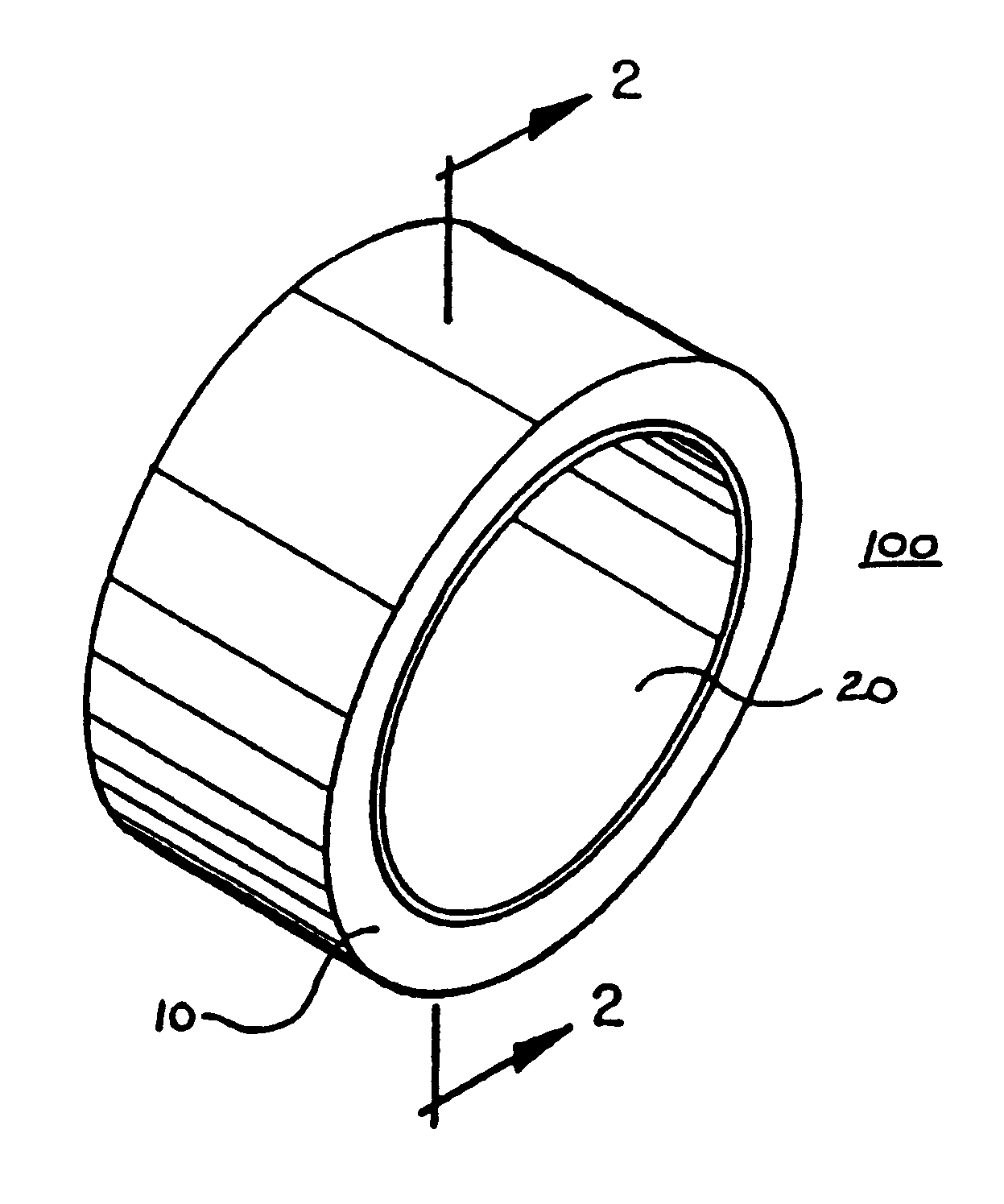

Self-lubricating bearing and coating

InactiveUS6180574B1Improve wear resistanceEasy bearing maintenanceNon-macromolecular adhesive additivesPretreated surfacesPentaerythritolAramides

A self-lubricating coating is provided which includes a mixture of a curable acrylate composition including a dipentaerythritol pentaacylate and a solid lubricant, such as polytetraflourethylenr. The curable acrylate composition may also include triethylene glycol dimethacrylate. An aramid pulp may also be added to the coating mixture. Also disclosed is a method of manufacturing the coating, and a self-lubricating bearing having the coating disposed on its surface.

Owner:REXNORD CORP

Puncture-and bullet proof protective clothing

Protective clothing for protection against puncture injuries is constructed from more than one layer of a fabric coated with hard solids. The hard solids are applied in accordance with abrasives technology. This protective clothing offers equally good protection against both knife- and needle-like puncture implements. For clothing intended to protect against puncture and projectile injuries, a package of 2-20 layers of a fabric coated with hard solids is combined with a package of 6-50 layers of an uncoated aramid woven fabric.

Owner:TEIJIN TWARON GMBH

High-temperature polyamide molding compounds reinforced with flat glass fibers

ActiveUS20090062452A1Advantage in mechanical propertyAdvantage in in processingRotary stirring mixersSpecial tyresFlat glassGlass fiber

The present invention relates to reinforced polyamide molding compounds containing high-melting partially aromatic polyamides and flat glass fibers, in particular with a rectangular cross section, i.e., glass fibers with a noncircular cross-sectional area and a dimension ratio of the main cross-sectional axis to the secondary cross-sectional axis of 2 to 6, in particular 3 to 6, most especially preferably from 3.5 to 5.0. The present invention also relates to a method for manufacturing polyamide molding compounds and molded articles manufactured therefrom, i.e., in particular injection-molded parts. The inventive molded parts have a high transverse stiffness and transverse strength.

Owner:EMS PATENT AG

Flame retardant fiber blends comprising flame retardant cellulosic fibers and fabrics and garments made therefrom

An intimate blend of staple fibers has from 10 to 75 parts by weight of at least one aramid staple fiber, from 15 to 80 parts by weight of at least one flame retardant cellulosic staple fiber, and from 5 to 30 parts by weight of at least one polyamide staple fiber. The intimate blend of staple fibers provides yarns and fabrics that are flame retardant, also referred to as fire resistant, and can be used to make flame retardant articles, such as clothing. The flame retardant fabrics may have a basis weight from 4 to 15 ounces per square yard.

Owner:EI DU PONT DE NEMOURS & CO

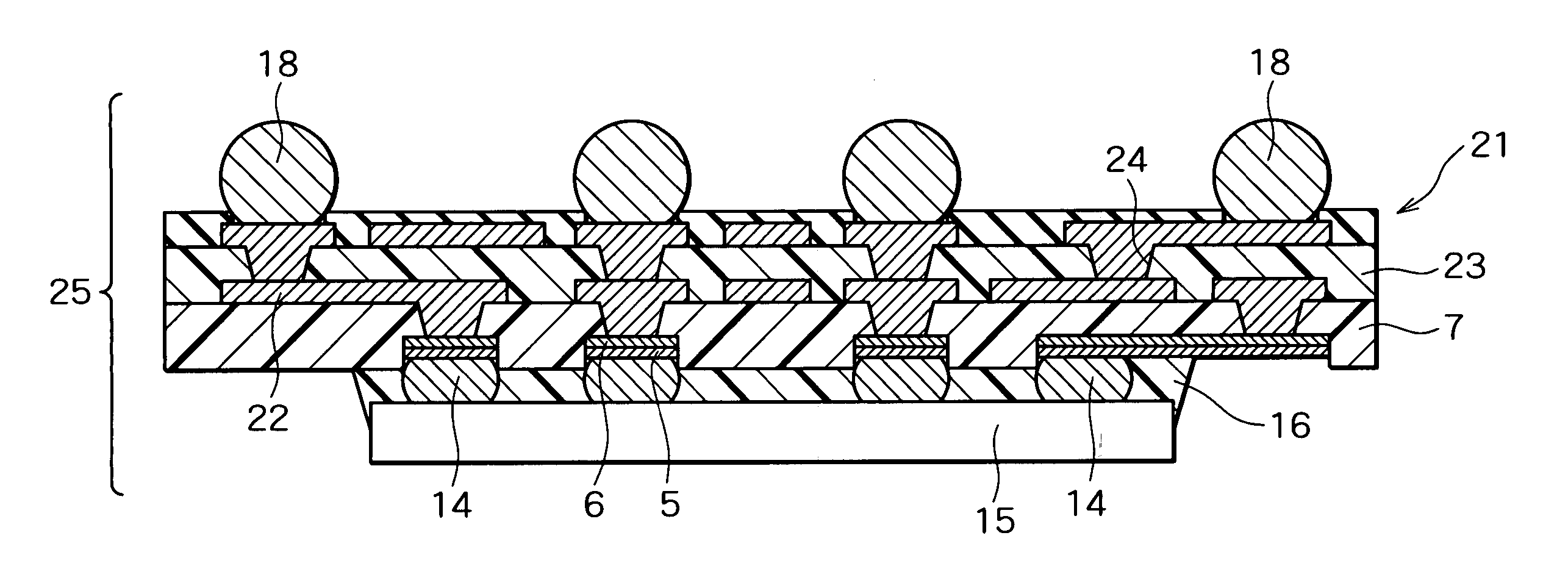

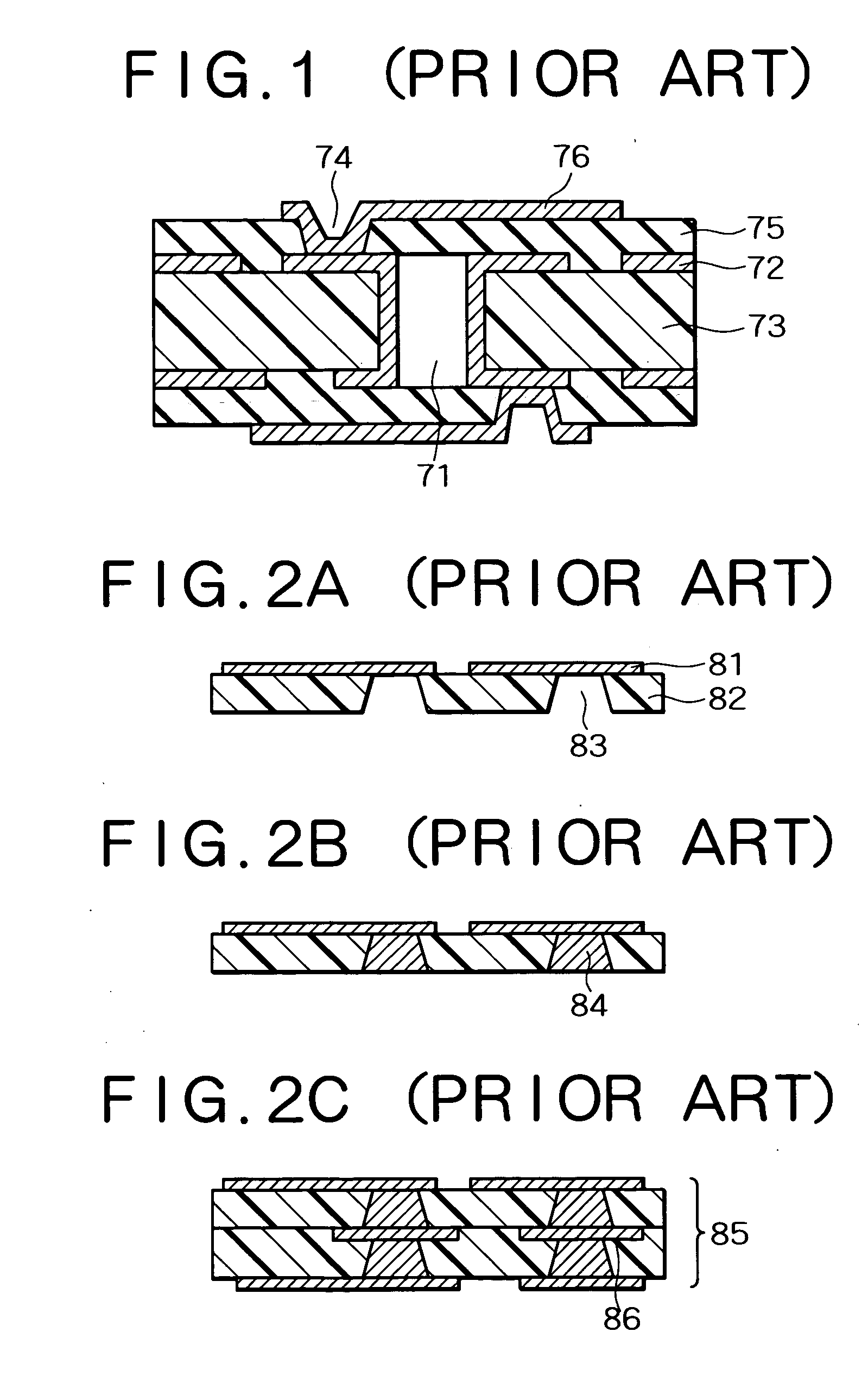

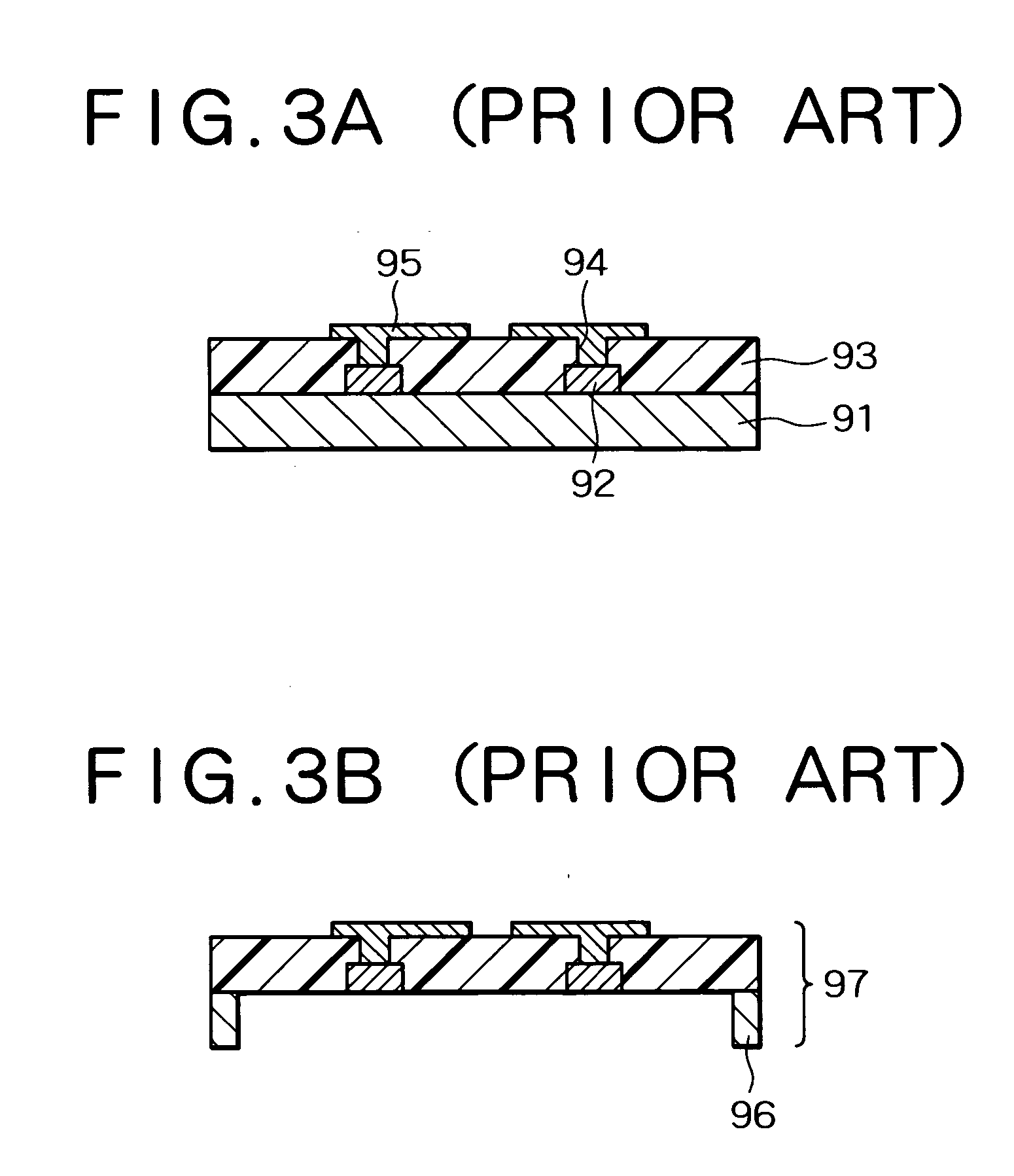

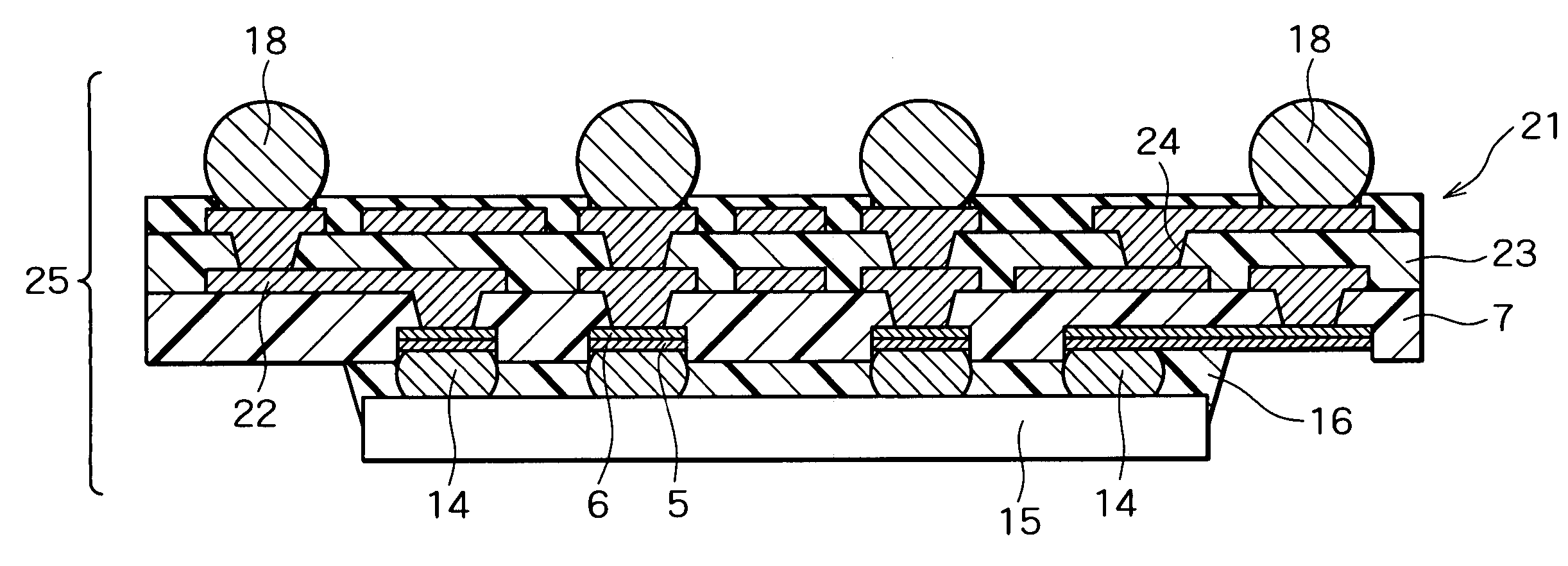

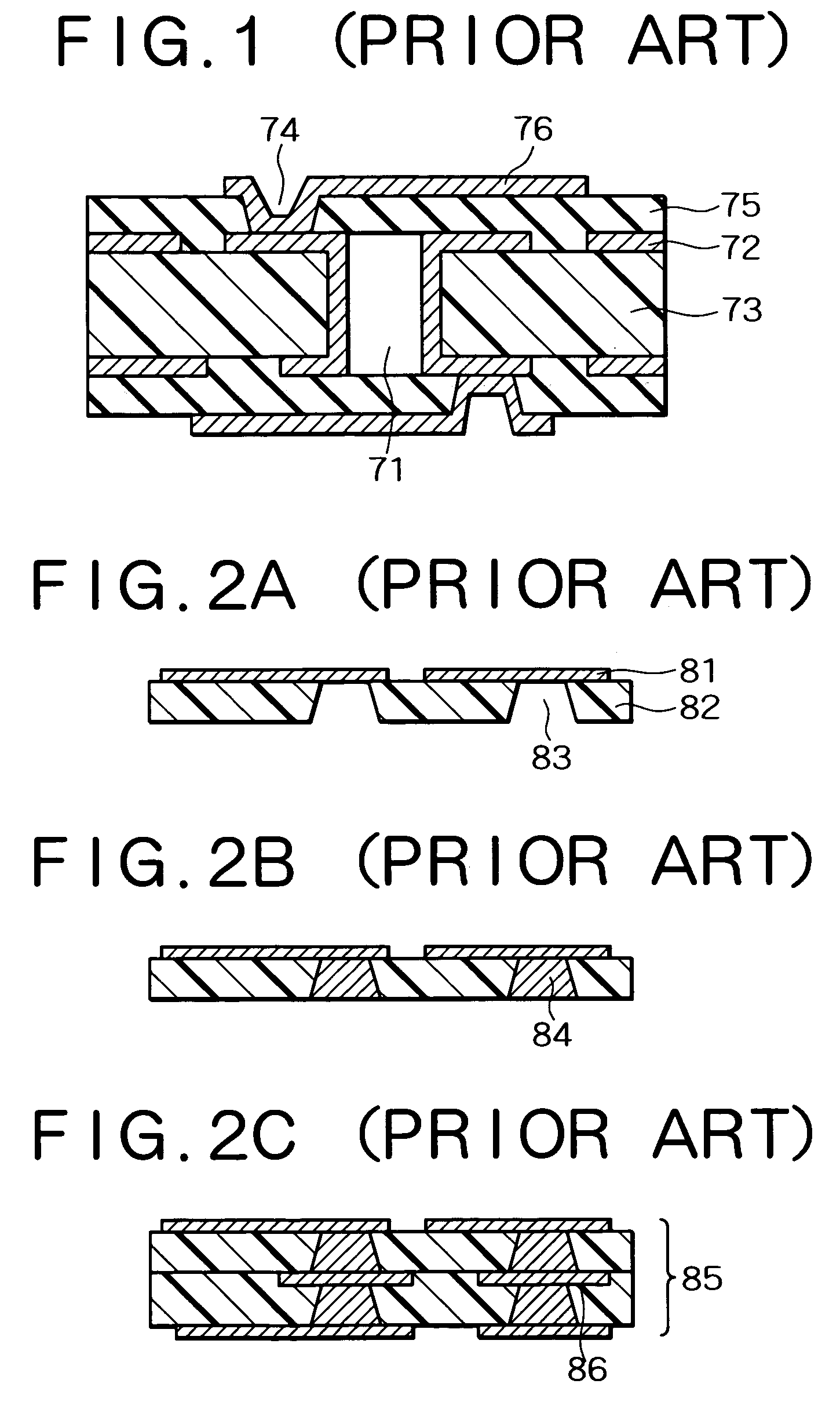

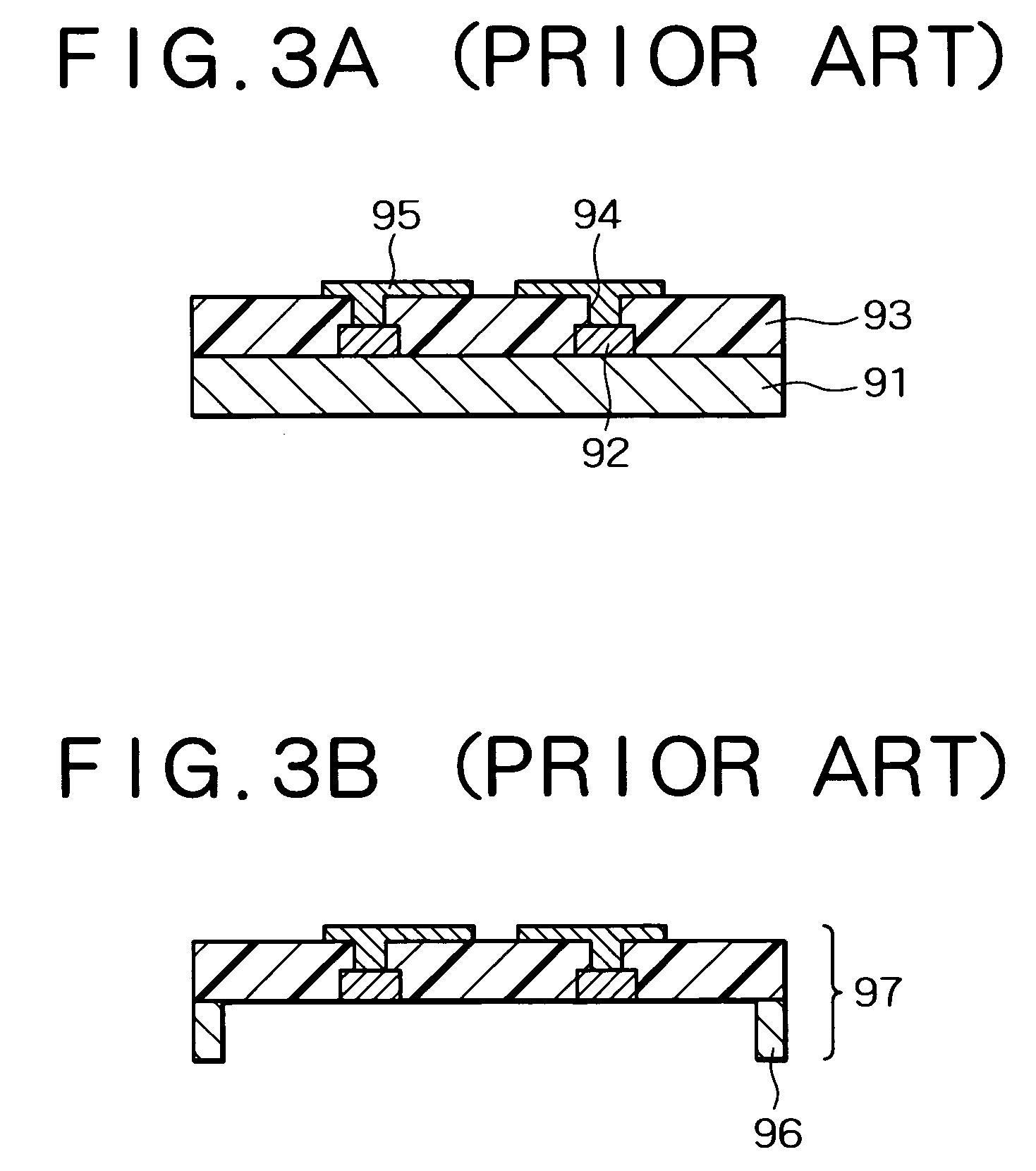

Wiring board and semiconductor package using the same

InactiveUS20050252682A1Easy to implementRelieve pressurePrinted electric component incorporationSemiconductor/solid-state device detailsBreaking strengthAramides

A wiring board has a base insulating film. The base insulating film has a thickness of 20 to 100 μm and is made of a heat-resistant resin which has a glass-transition temperature of 150° C. or higher and which contains reinforcing fibers made of glass or aramid. The base insulating film has the following physical properties (1) to (6) when an elastic modulus at a temperature of T° C. is given as DT (GPa) and a breaking strength at a temperature of T° C. is given as HT (MPa). (1) A coefficient of thermal expansion in the direction of thickness thereof is 90 ppm / K or less. (2) D23≧5 (3) D150≧2.5 (4) (D-65 / D150)≦3.0 (5) H23≧140 (6) (H-65 / H150)≦2.3

Owner:NEC CORP +1

Flame retardant fiber blends comprising modacrylic fibers and fabrics and garments made therefrom

An intimate blend of staple fibers has from 10 to 75 parts by weight of at least one aramid staple fiber, from 15 to 80 parts by weight of at least one modacrylic staple fiber, and from 5 to 30 parts by weight of at least one polyamide staple fiber. The intimate blend of staple fibers provides yarns and fabrics that are flame retardant, also referred to as fire resistant, and can be used to make flame retardant articles, such as clothing. The flame retardant fabrics may have a basis weight from 4 to 15 ounces per square yard.

Owner:EI DU PONT DE NEMOURS & CO

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

Use of polyamide compositions for making molded articles having improved adhesion, molded articles thereof and methods for adhering such materials

Owner:EI DU PONT DE NEMOURS & CO

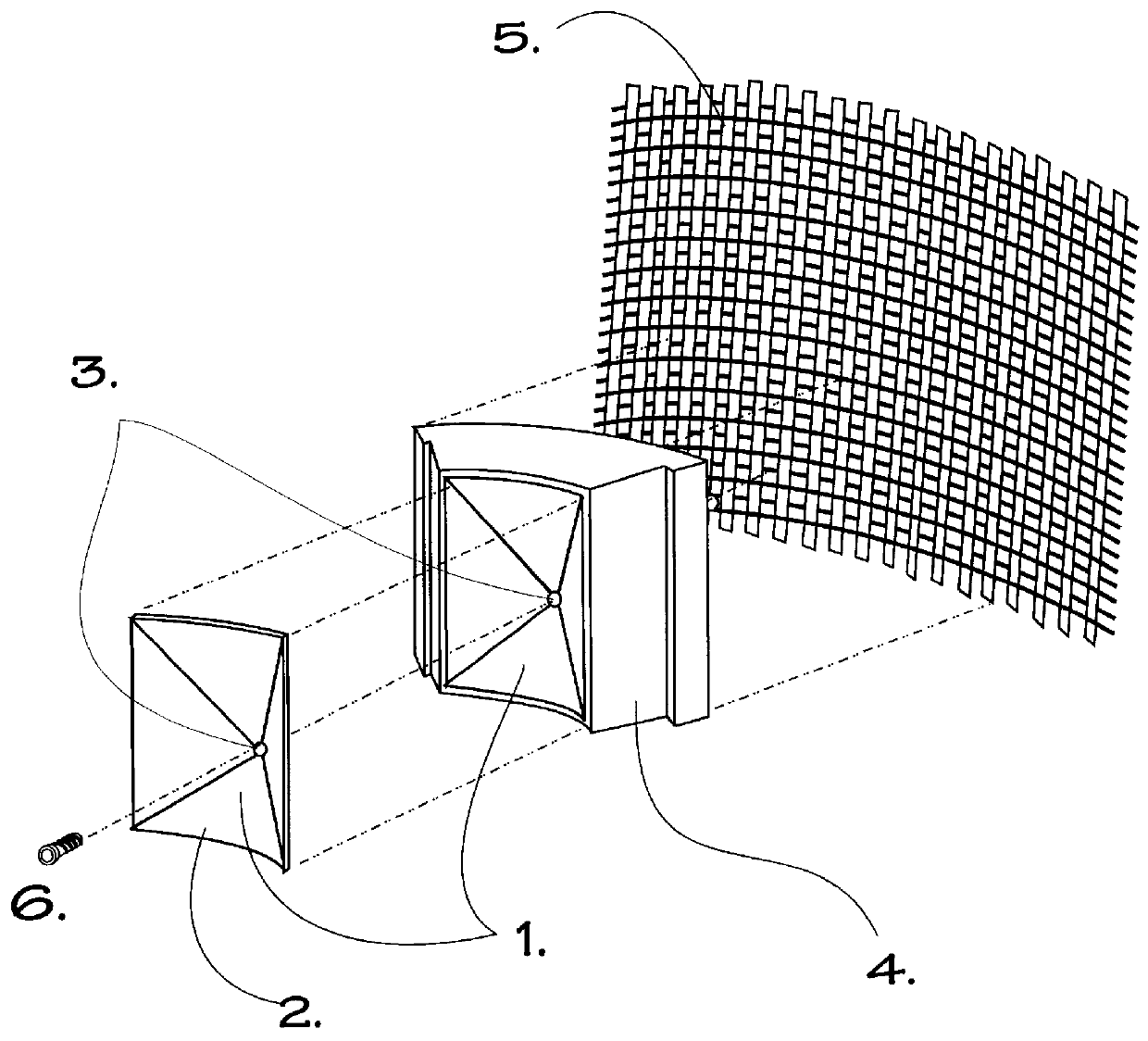

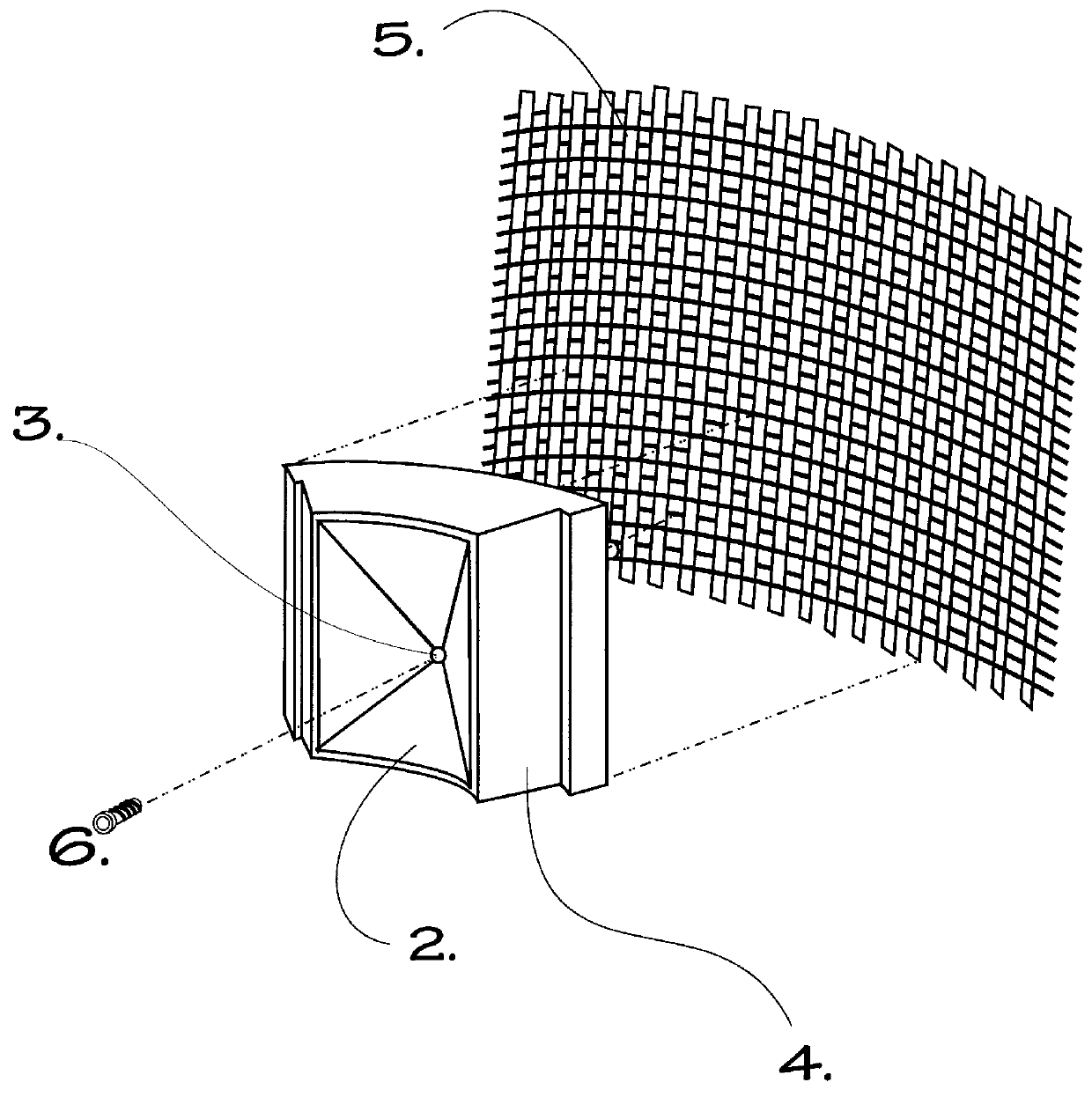

Method of construction for density screening outer transport walls

InactiveUS6033564AThin and inexpensiveReduced toleranceRotary centrifugesCeramic shaping apparatusBursting strengthDynamic balance

A method for combining three different means of constructing the concentric layers of the outer collecting wall for industrial size centrifuges, whereby treating the inward-facing elements of easily cast or stamped materials using processes such as Physical Vapor Deposition, Chemical Vapor Deposition or metal plating, transforms them into an innermost member with superior hardness and durability, and whereby said wear surface member or deposited layer is physically supported by a middle composite layer made up of one or more investment castings designed to optimally transfer centrifugally-induced compression loads from the innermost wear surface toward the outer surface of the composite wall, such castings being of ceramic, metals or other materials, and whereby the outer surface of said composite wall is comprised of a filament-wound hoop strength reinforcement layer, using aramid, graphic, carbon or such fibers mixed and embedded in resin, such that all highly desirable characteristics for a centrifuge outer, heavies-collecting wall are provided, including interior hardness and wear abrasion, incompressibility and intrinsic dynamic balance, and substantially higher hoop or bursting strength, than can be attained through any metal-crafted centrifuge outer wall, and, model for model, for substantially lower design and fabrication costs.

Owner:BERKELEY F FULLER

Wiring board and semiconductor package using the same

InactiveUS7397000B2Easy to implementRelieve pressurePrinted electric component incorporationSemiconductor/solid-state device detailsVitrificationBreaking strength

A wiring board has a base insulating film. The base insulating film has a thickness of 20 to 100 μm and is made of a heat-resistant resin which has a glass-transition temperature of 150° C. or higher and which contains reinforcing fibers made of glass or aramid. The base insulating film has the following physical properties (1) to (6) when an elastic modulus at a temperature of T° C. is given as DT (GPa) and a breaking strength at a temperature of T° C. is given as HT (MPa).(1) A coefficient of thermal expansion in the direction of thickness thereof is 90 ppm / K or less(2) D23≧5(3) D150≧2.5(4) (D−65 / D150)≦3.0(5) H23≧140(6) (H−65 / H150)≦2.3.

Owner:NEC CORP +1

High-temperature polyamide molding compounds reinforced with flat glass fibers

ActiveUS8324307B2Advantage in mechanical property and in processing and in surface qualitySpecial tyresFlat glassFiber

The present invention relates to reinforced polyamide molding compounds containing high-melting partially aromatic polyamides and flat glass fibers, in particular with a rectangular cross section, i.e., glass fibers with a noncircular cross-sectional area and a dimension ratio of the main cross-sectional axis to the secondary cross-sectional axis of 2 to 6, in particular 3 to 6, most especially preferably from 3.5 to 5.0. The present invention also relates to a method for manufacturing polyamide molding compounds and molded articles manufactured therefrom, i.e., in particular injection-molded parts. The inventive molded parts have a high transverse stiffness and transverse strength.

Owner:EMS PATENT AG

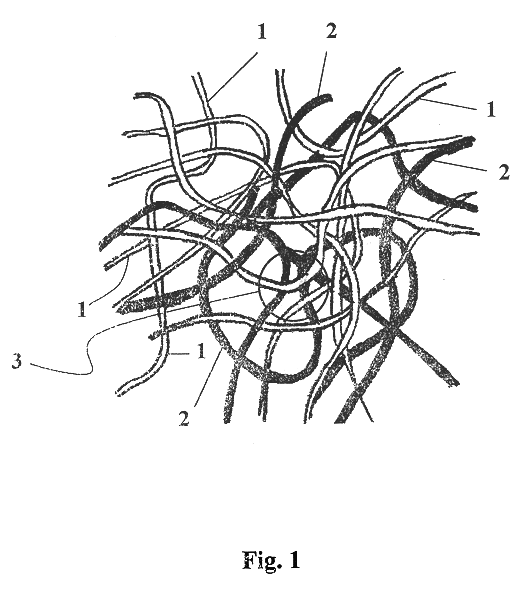

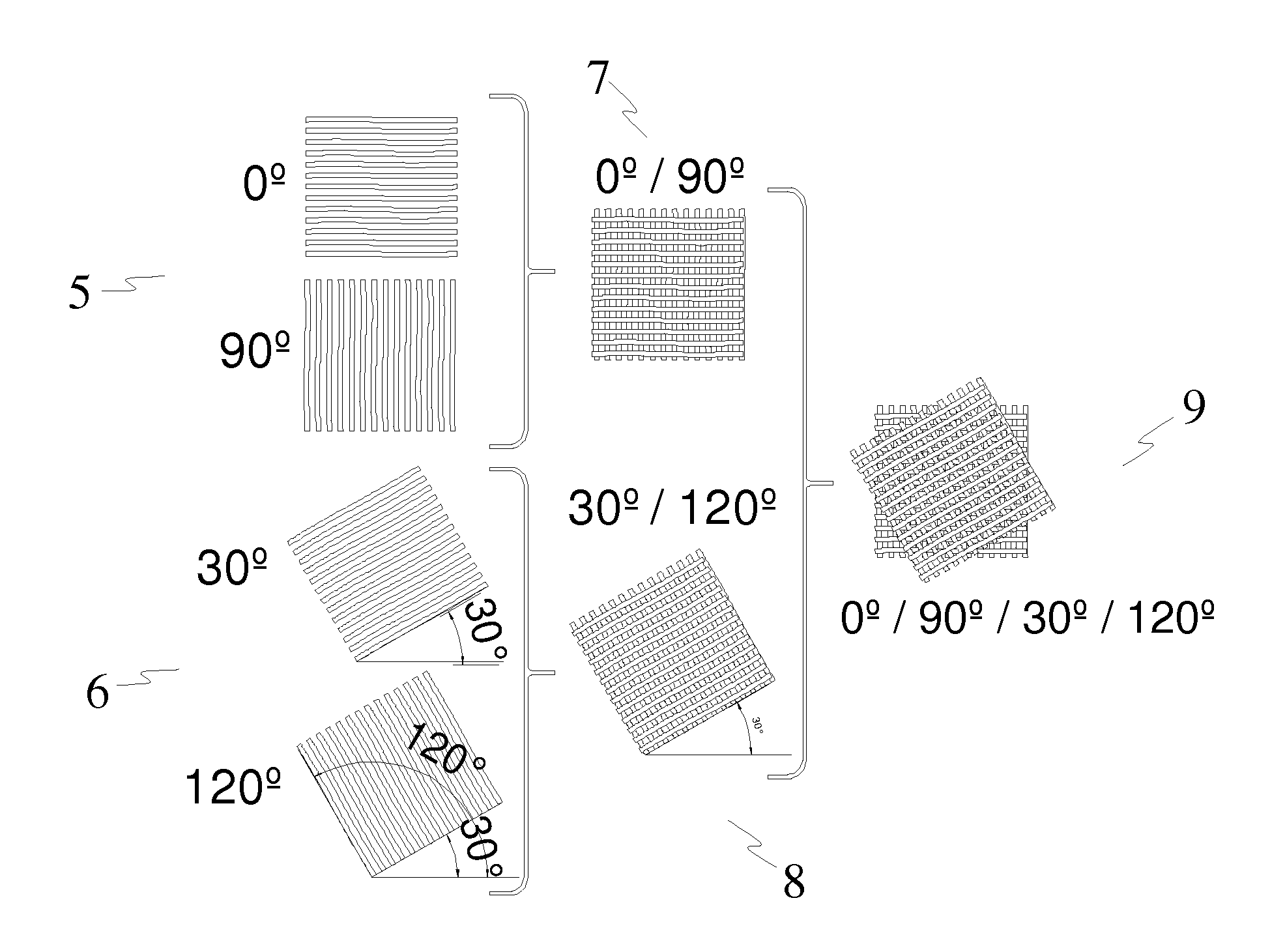

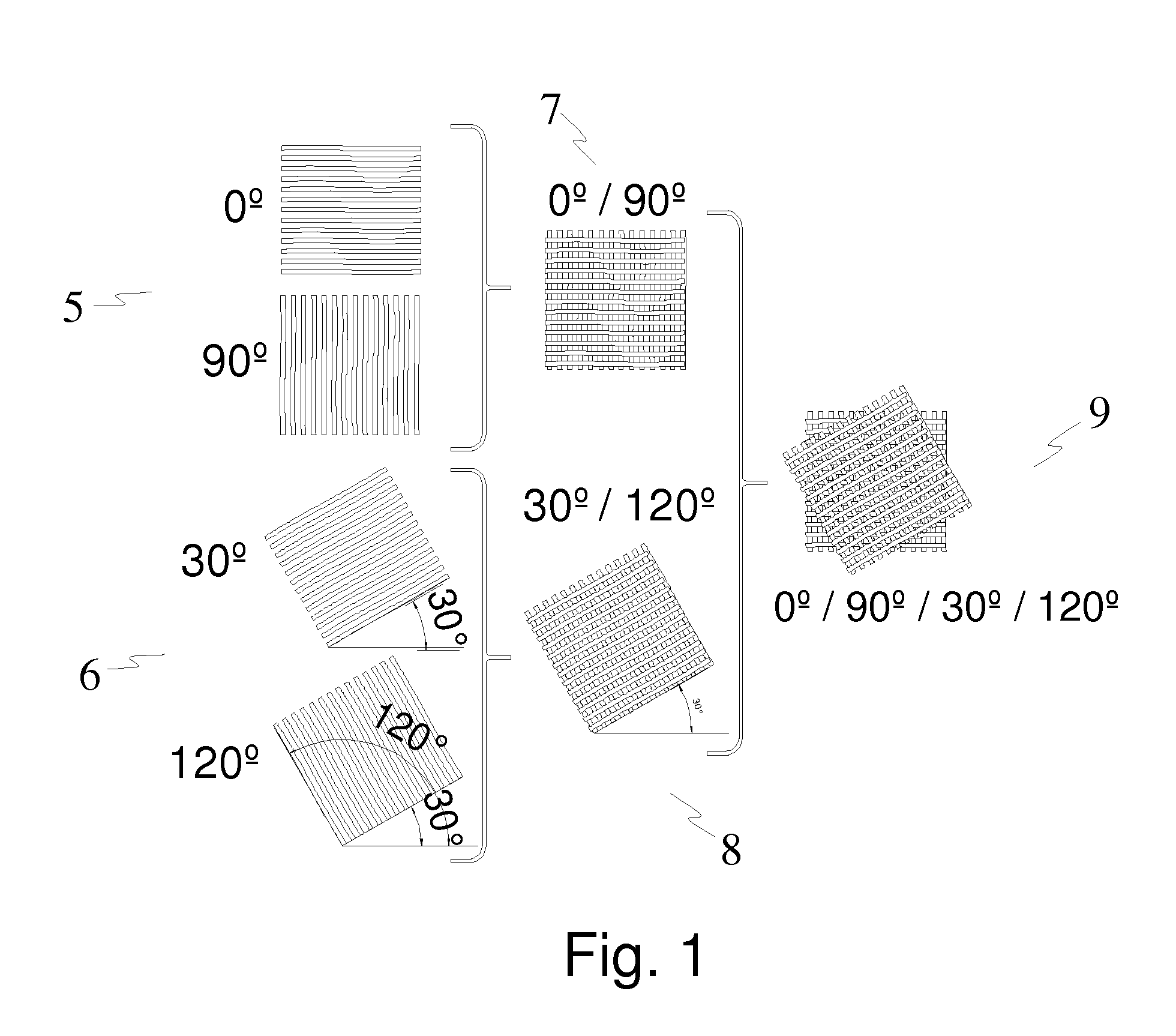

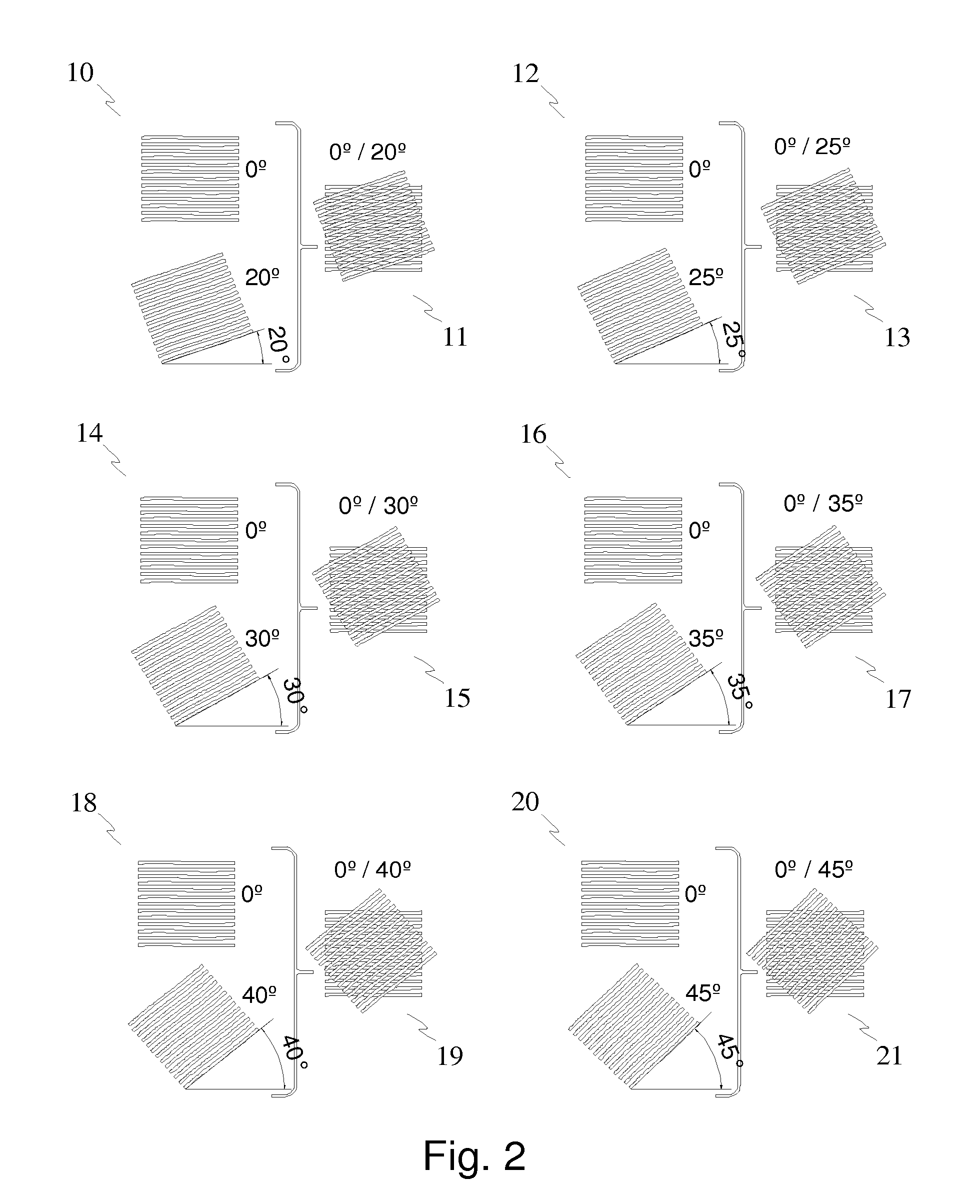

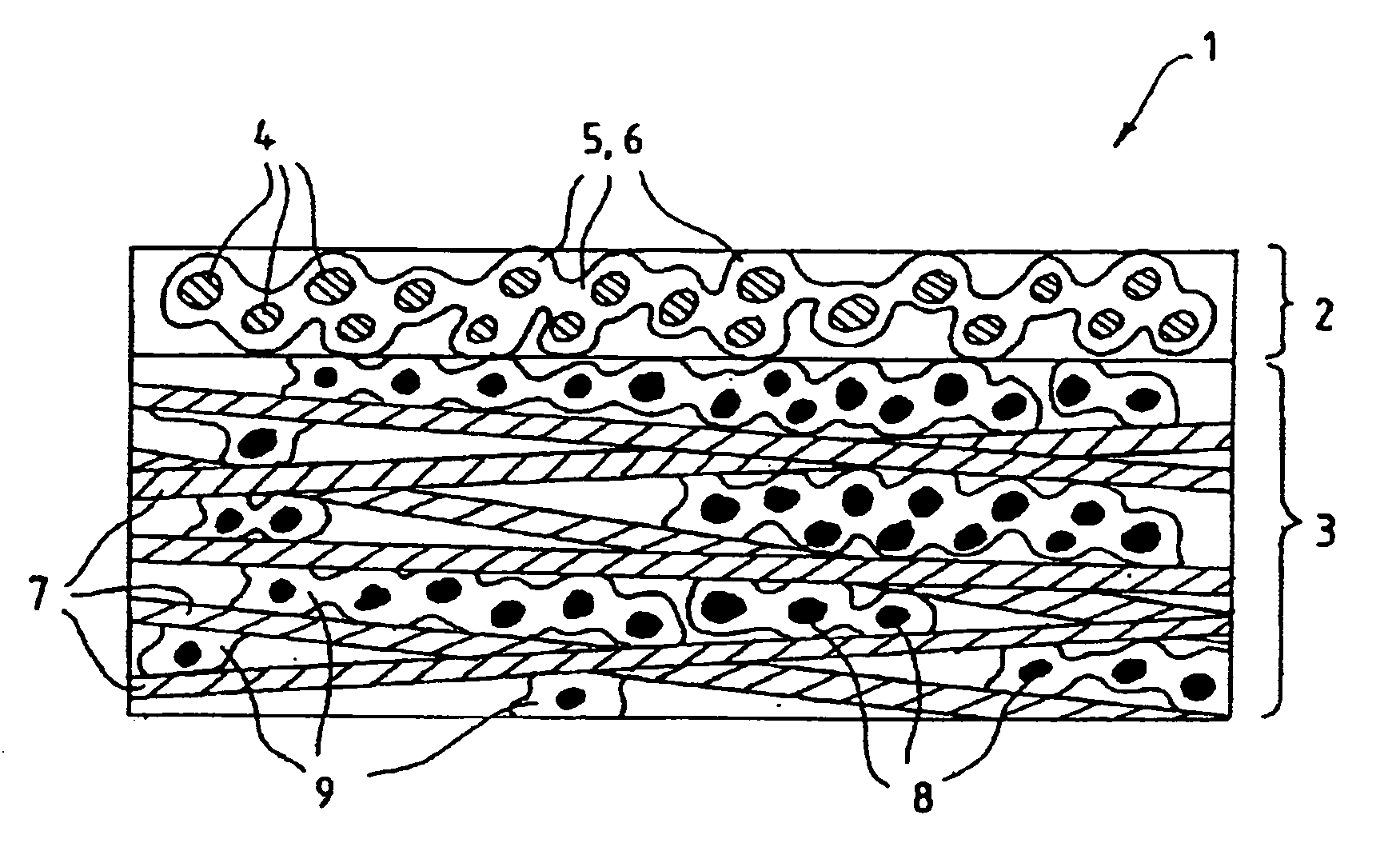

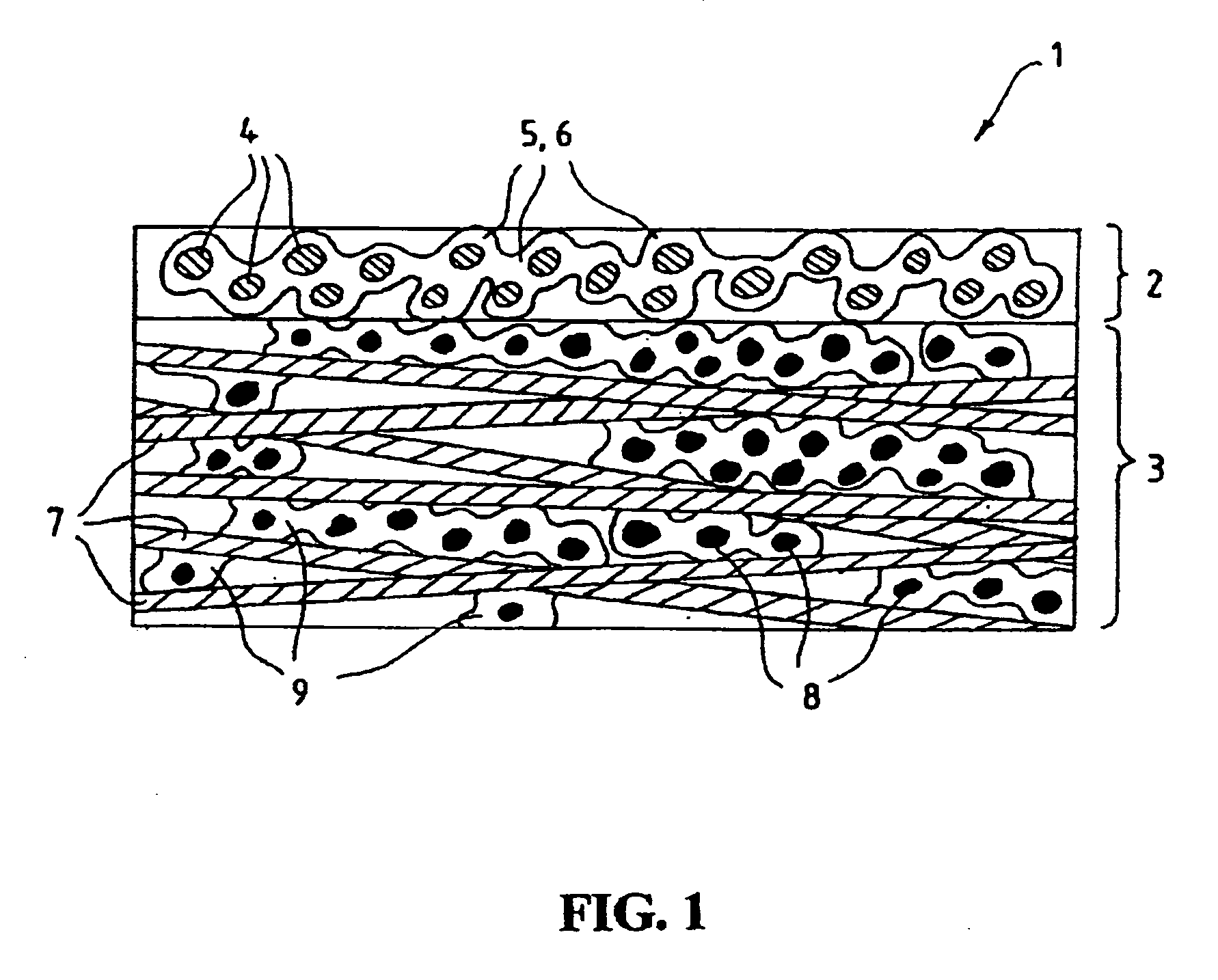

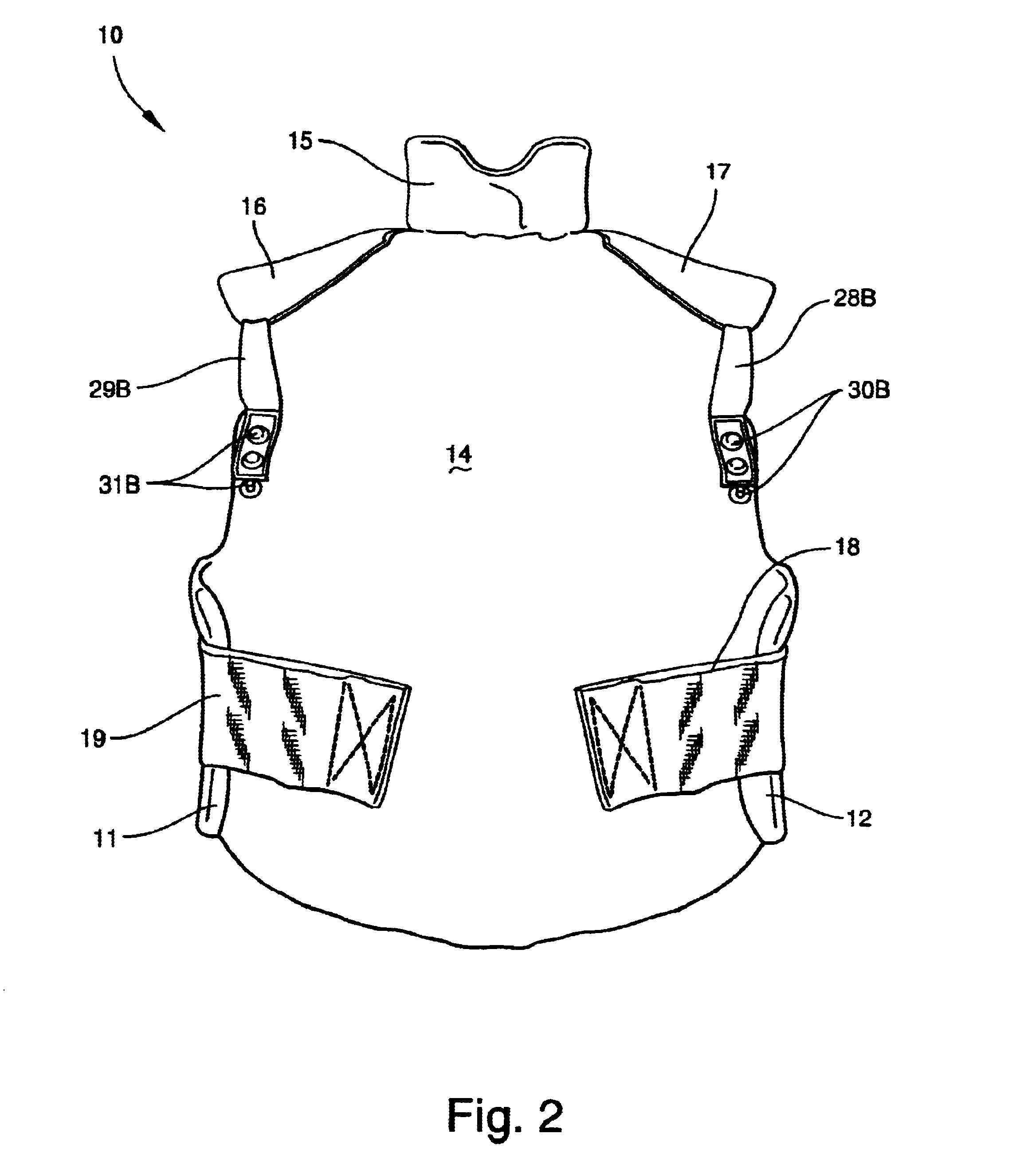

Multi-layer non - woven fabric multi-use material for ballistic and stab resistance comprising impregnated and oriented fiber non - woven fabric layers; manufacturing, method, and protection garment produced thereby

InactiveUS20130219600A1Good flexibilityImprove the immunityChemical protectionHeat protectionFiberAramides

Multi-layer non-woven fabric material composed of non-woven fiber sheets of aramide / polyethylene fibers, impregnated with resin and / or a filler material, and oriented at various angles, which is used for manufacturing protection garments. The invention also describes a method for manufacturing said multi-layer non-woven fabric material and the protection garments thus obtained.

Owner:MULTI AXIAL

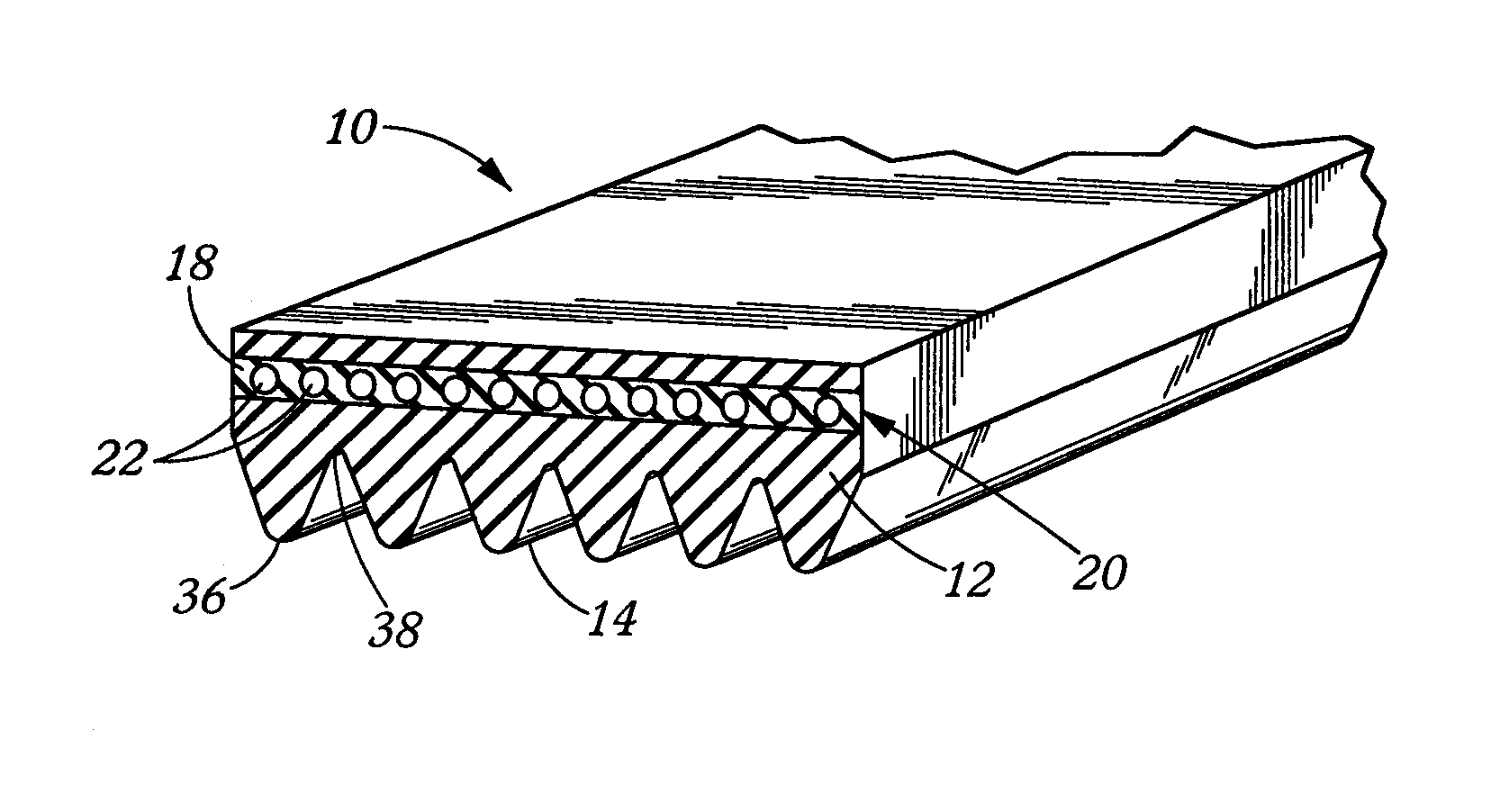

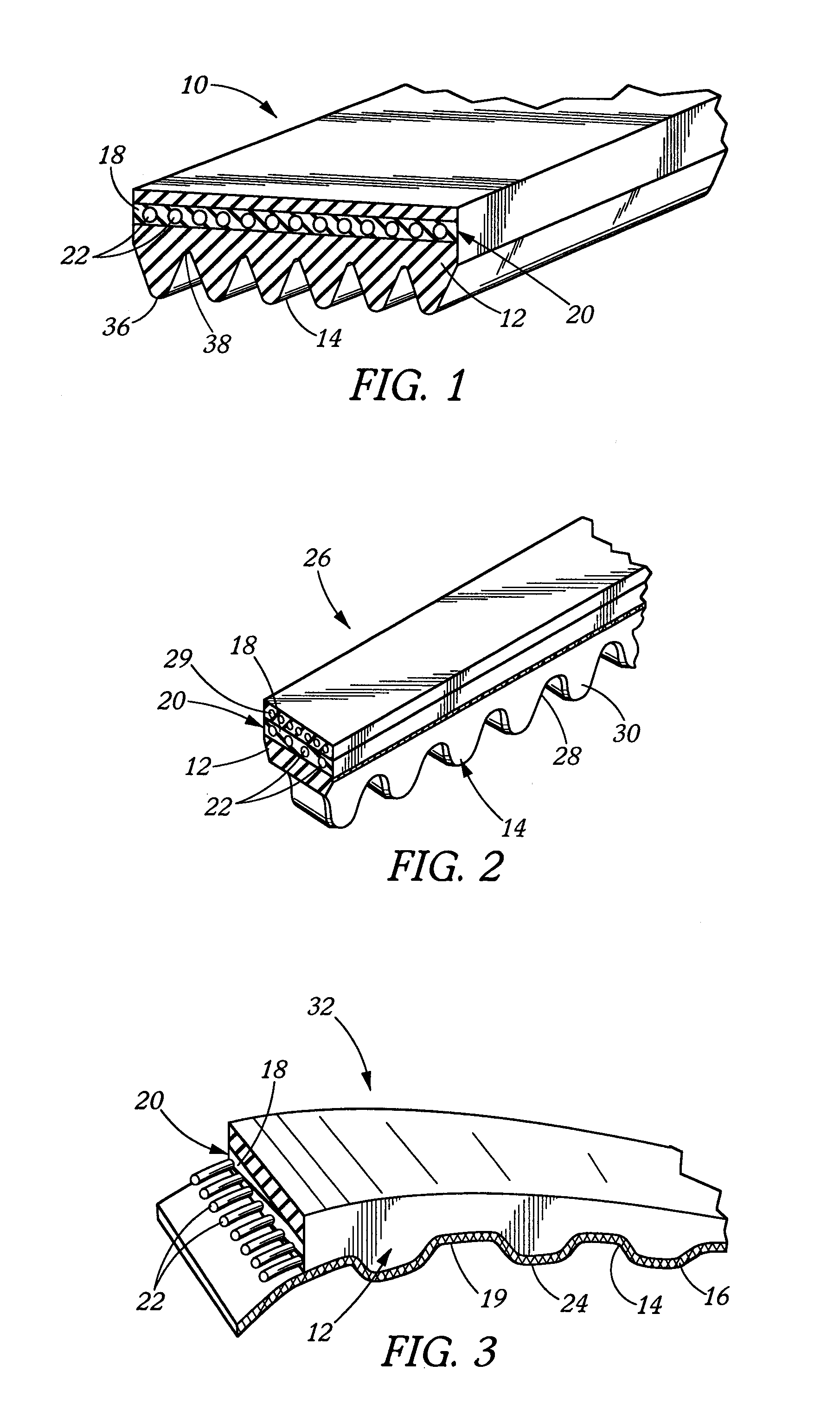

Power transmission belt and cord adhesive system and adhesion method

ActiveUS20090142572A1Improve balanceLow costV-beltsRopes and cables for vehicles/pulleyPolyesterElastomer

Owner:THE GATES CORP

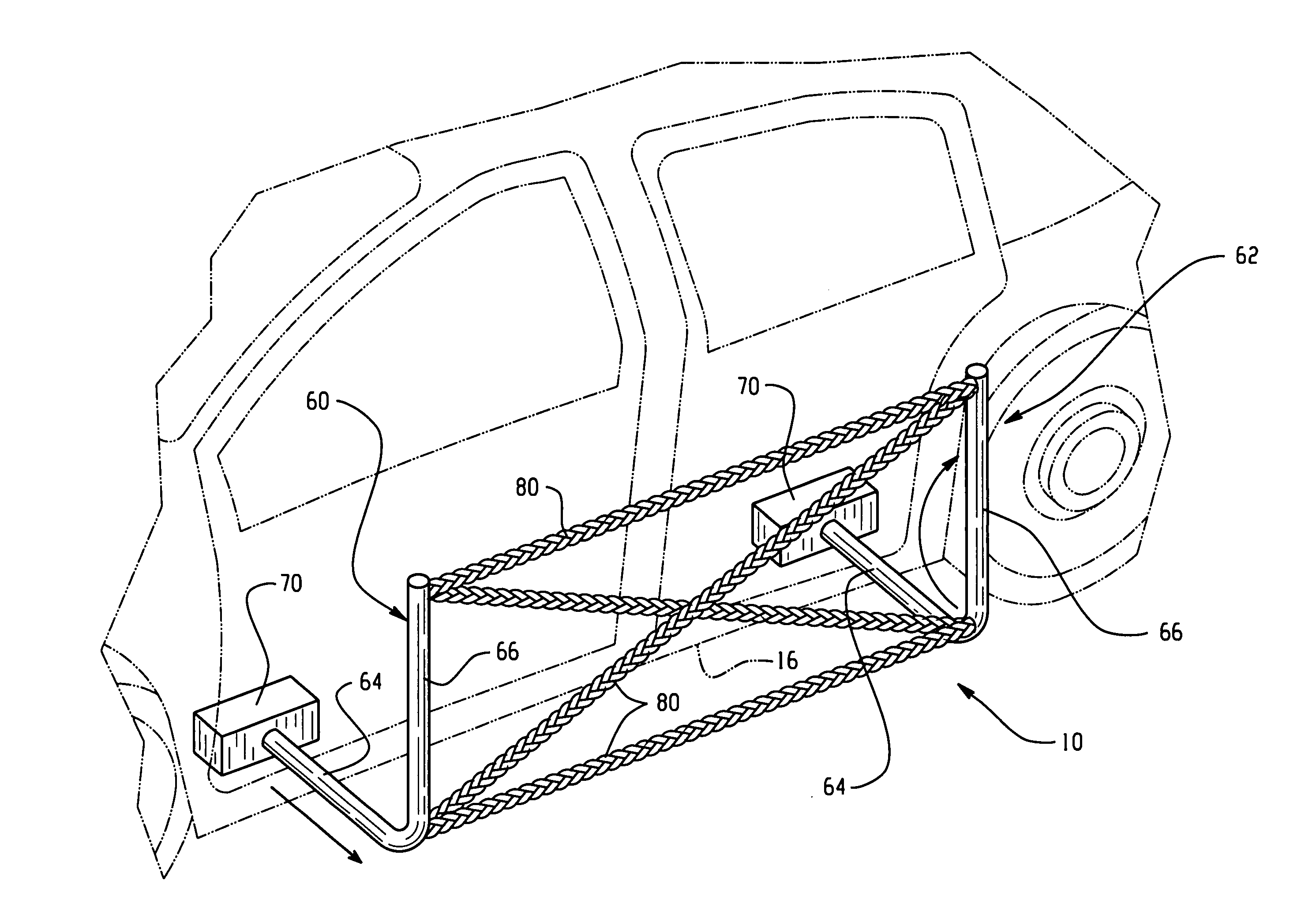

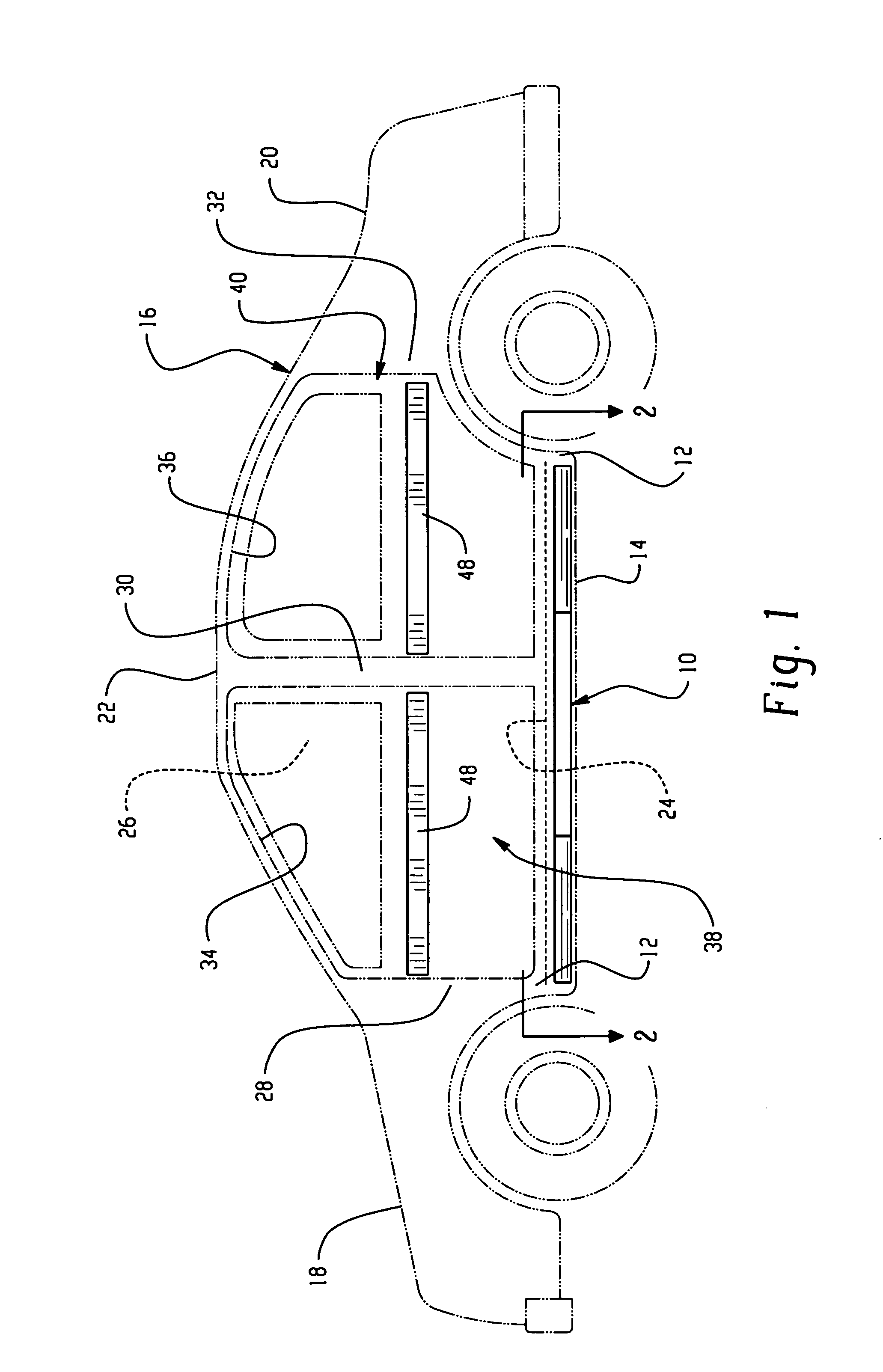

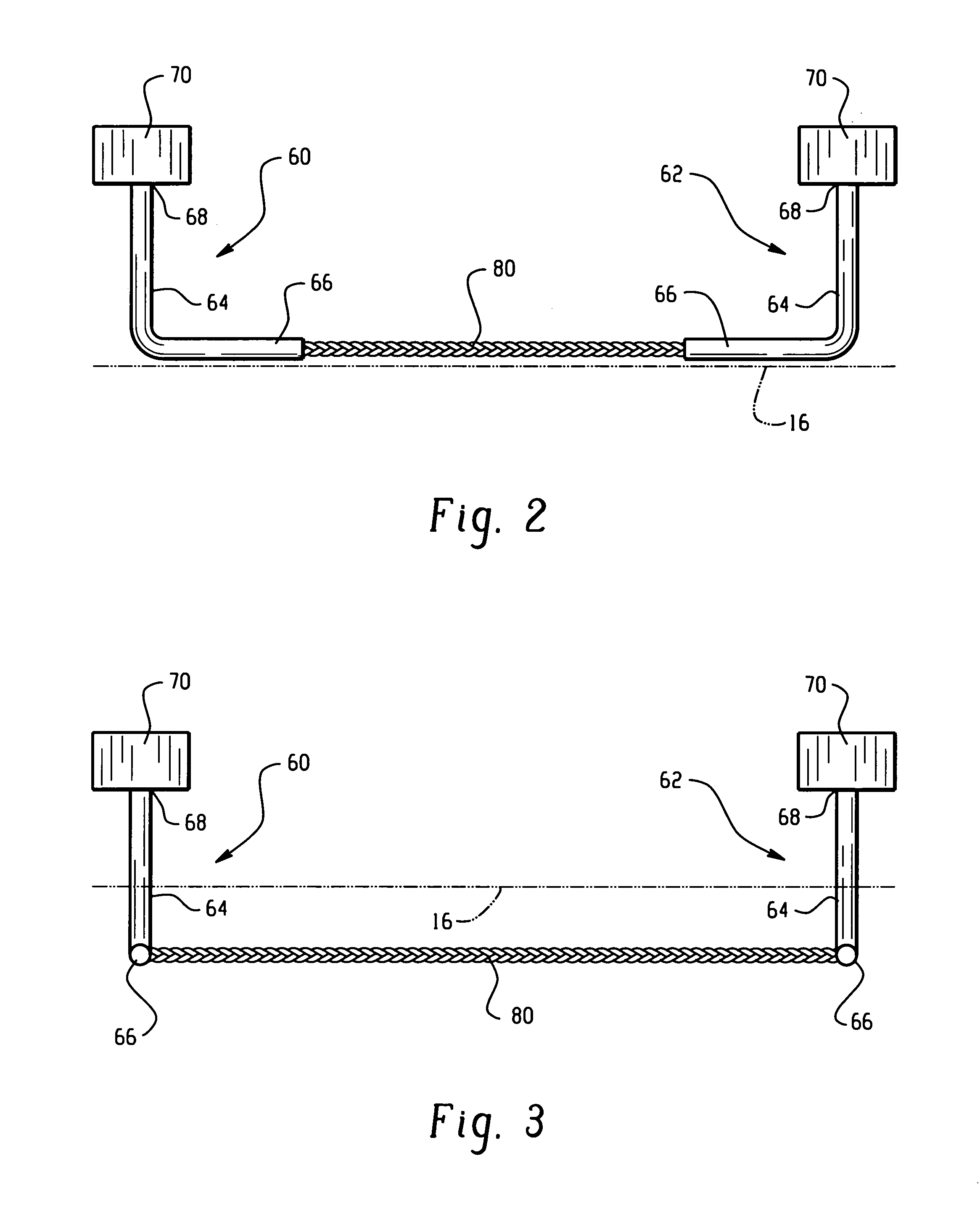

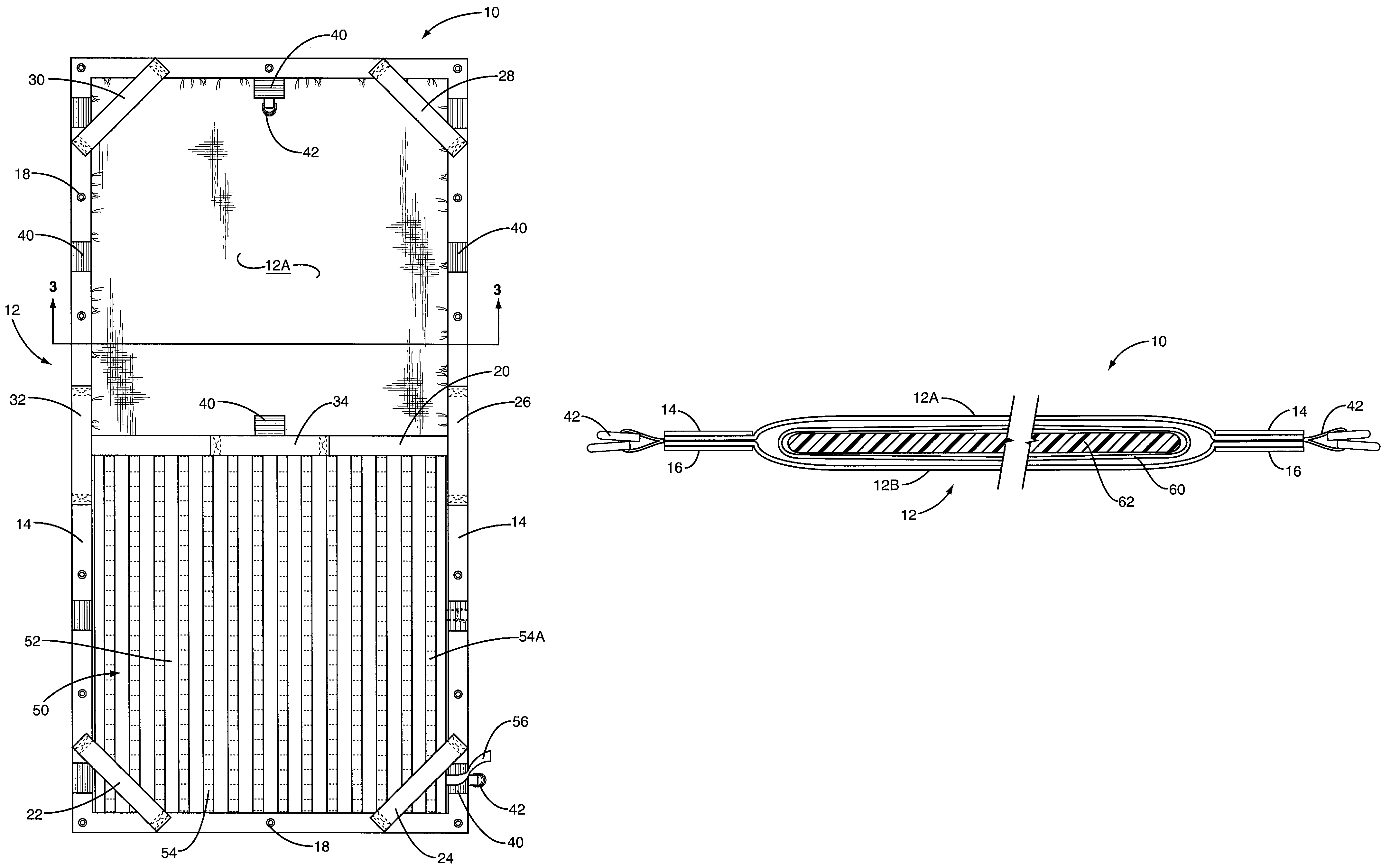

Motor vehicle body with side impact protection

A side impact protection system for a motor vehicle body having a stowed position and a deployed position, the system includes a first L-shaped rigid structure comprising a first portion and a second portion; a second L-shaped rigid structure comprising a first portion and a second portion; a synthetic cable fixedly attached to the second portions of the first and second L-shaped rigid structures, wherein the synthetic cable is made from a plurality of helically braided bundles of fibers selected from a group consisting of aramid fibers and liquid crystal polymer fibers characterized by strain-at-failure exceeding about 3 percent; and a deployment device in operative communication with the first portions of the first and second L-shaped rigid structures to selectively extend the first portion outwardly from the deployment device, and wherein in a stowed position the second portions are at about the same plane and in a deployed position the second portions are parallel and the synthetic cables form a web-like structure. Processes for suppressing intrusion into a passenger compartment of a motor vehicle body by an object laterally impacting the vehicle body are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fluid diffusion layers

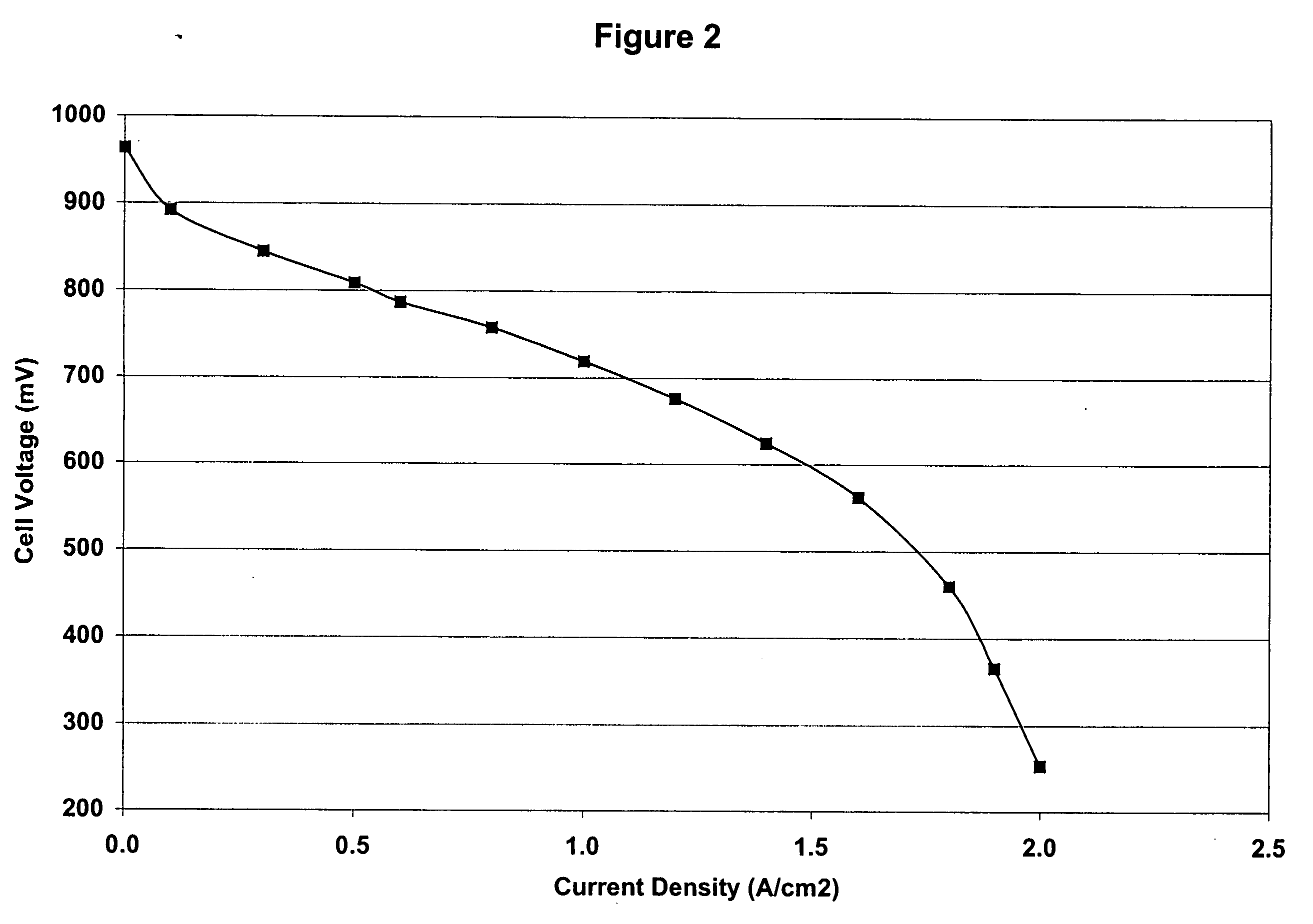

InactiveUS20070087120A1High char yieldMembranesSemi-permeable membranesHigh current densityPolymer science

Fluid diffusion layers with favorable mechanical, physical and structural properties are prepared for fuel cell electrodes by: impregnating a porous carbonaceous web with a matrix comprising a polymer having pyrrolidone functionality and a high carbon char yield resin, such as activated aramid fiber pulp, lignins, phenolics, benzoxazines and phthalonitriles; and carbonizing the matrix. The polymer is optionally oxidized before carbonizing. The matrix may also include conductive fillers and / or pore formers. The fluid diffusion layers are particularly suitable for use in continuous roll-to-roll MEA processing of GDLs for use in solid polymer electrolyte fuel cells operating at high current densities and / or in highly humidified conditions.

Owner:BDF IP HLDG

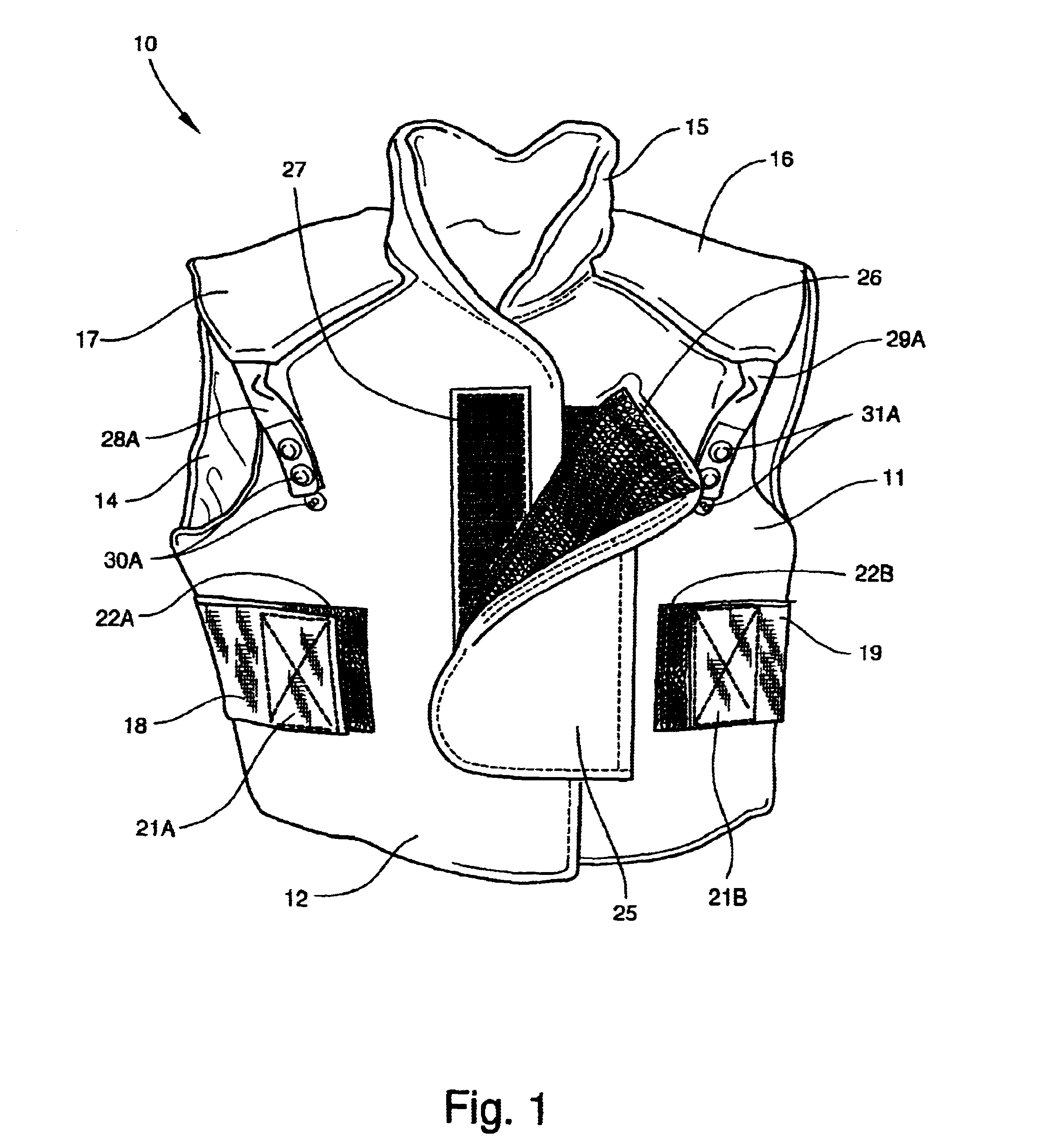

Lightweight soft body-armor product

InactiveUS6651543B2Improve the immunityReduce weightPersonal protection gearArmour platesYarnFoot per second

A ballistic panel is provided for being incorporated into a lightweight soft body-armor product adapted for covering an area of the body. The ballistic panel includes an assembly of woven fabric plies with warp and fill yarns formed of bundled aramid fibers. The plies have a collective areal density of no greater than 1.30 pounds per square foot, and a V50 ballistic limit of no less than 1925 feet per second using a .22 caliber, 17 grain FSP at 0 degrees obliquity.

Owner:ARMORWORKS ENTERPRISES

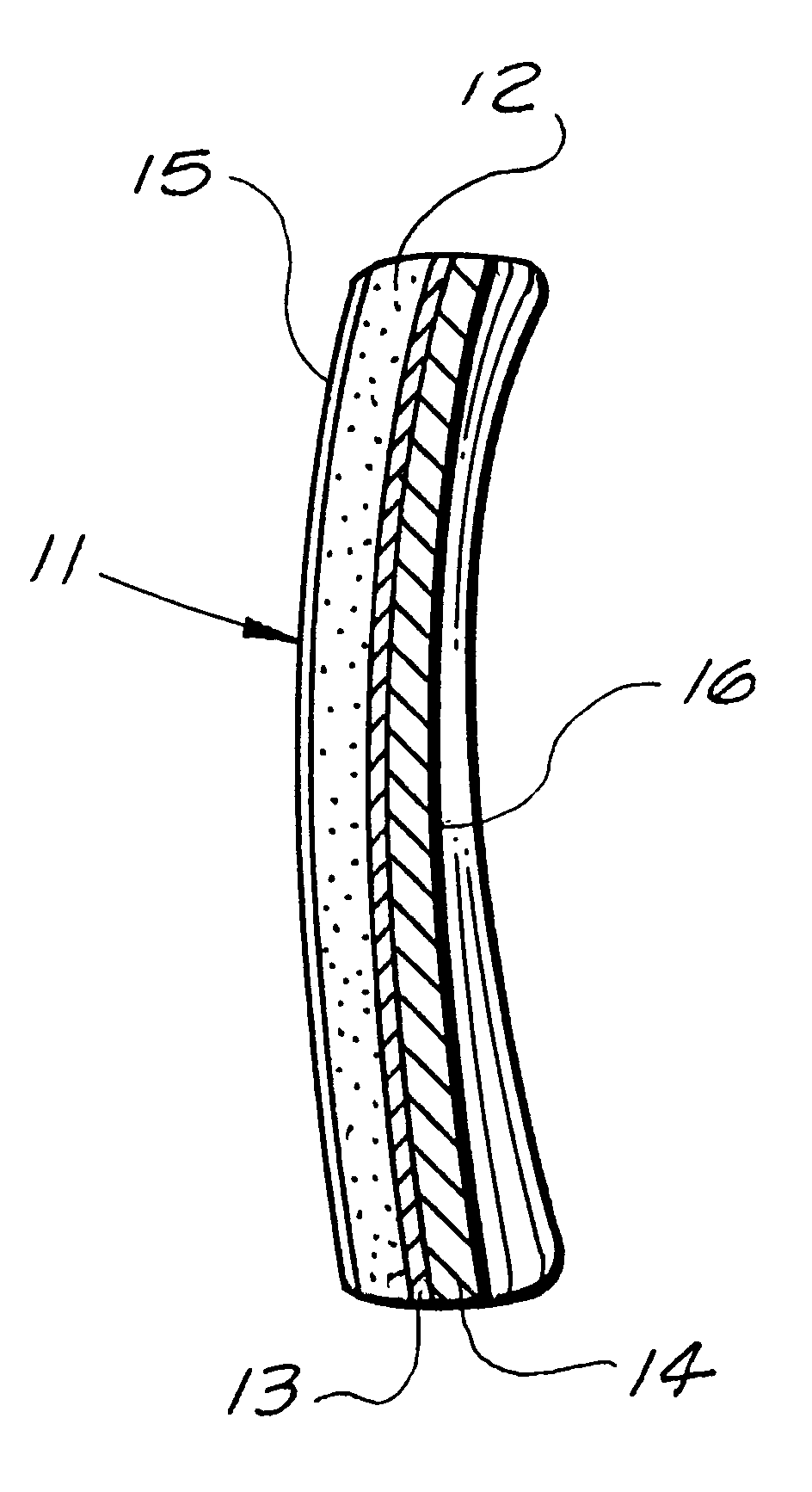

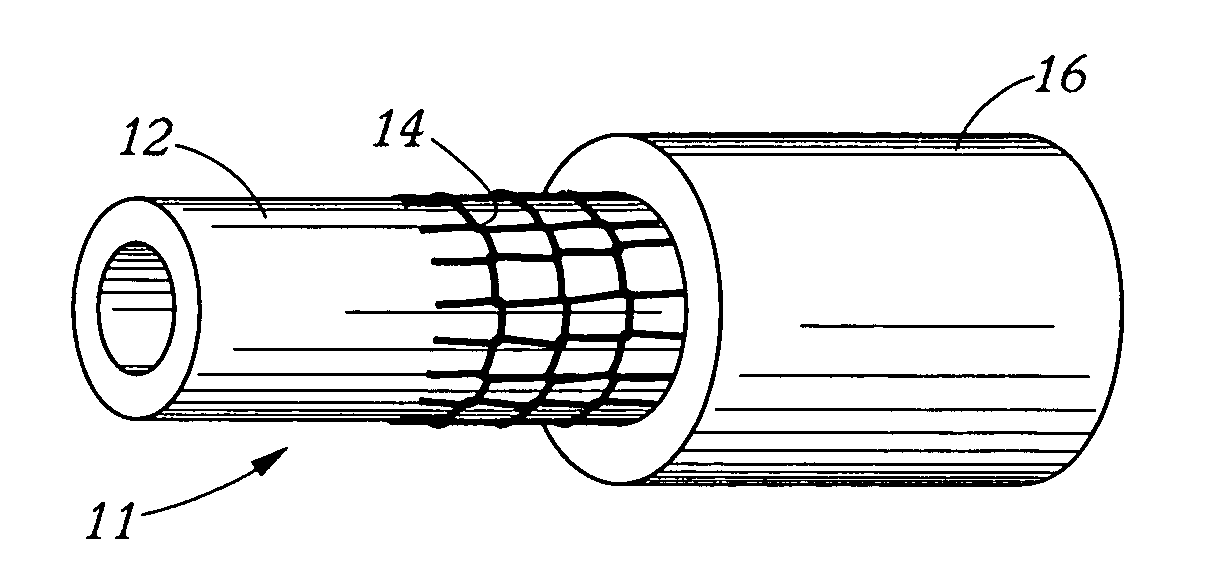

Fluid transfer hose reinforced with hybrid yarn

ActiveUS20080072984A1Improve adhesionDramatic performance improvementEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

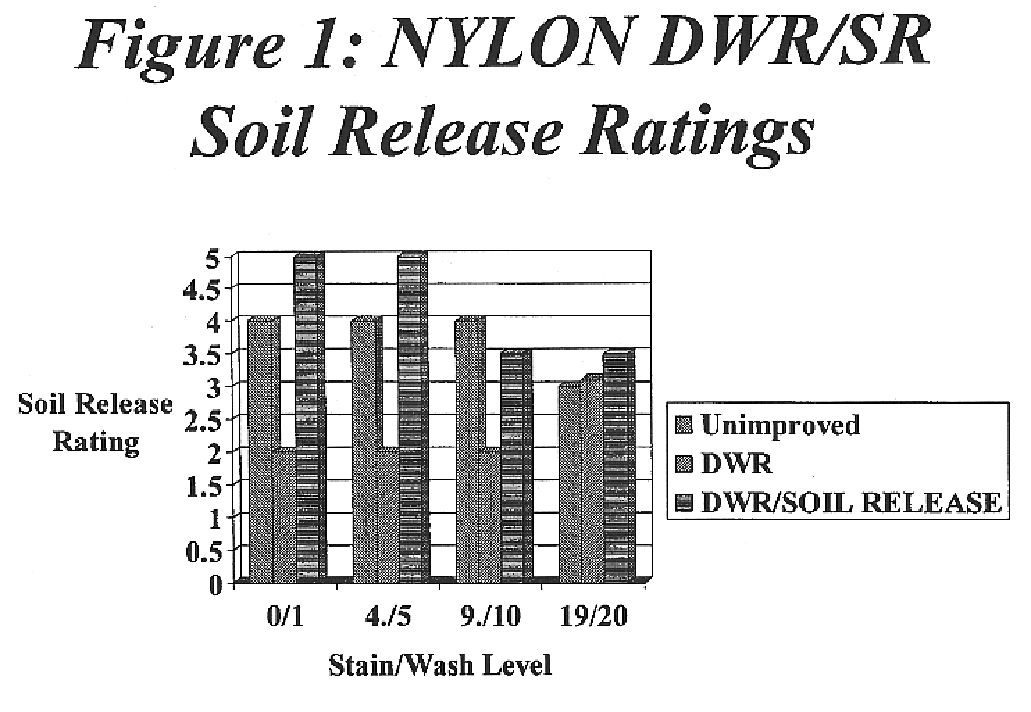

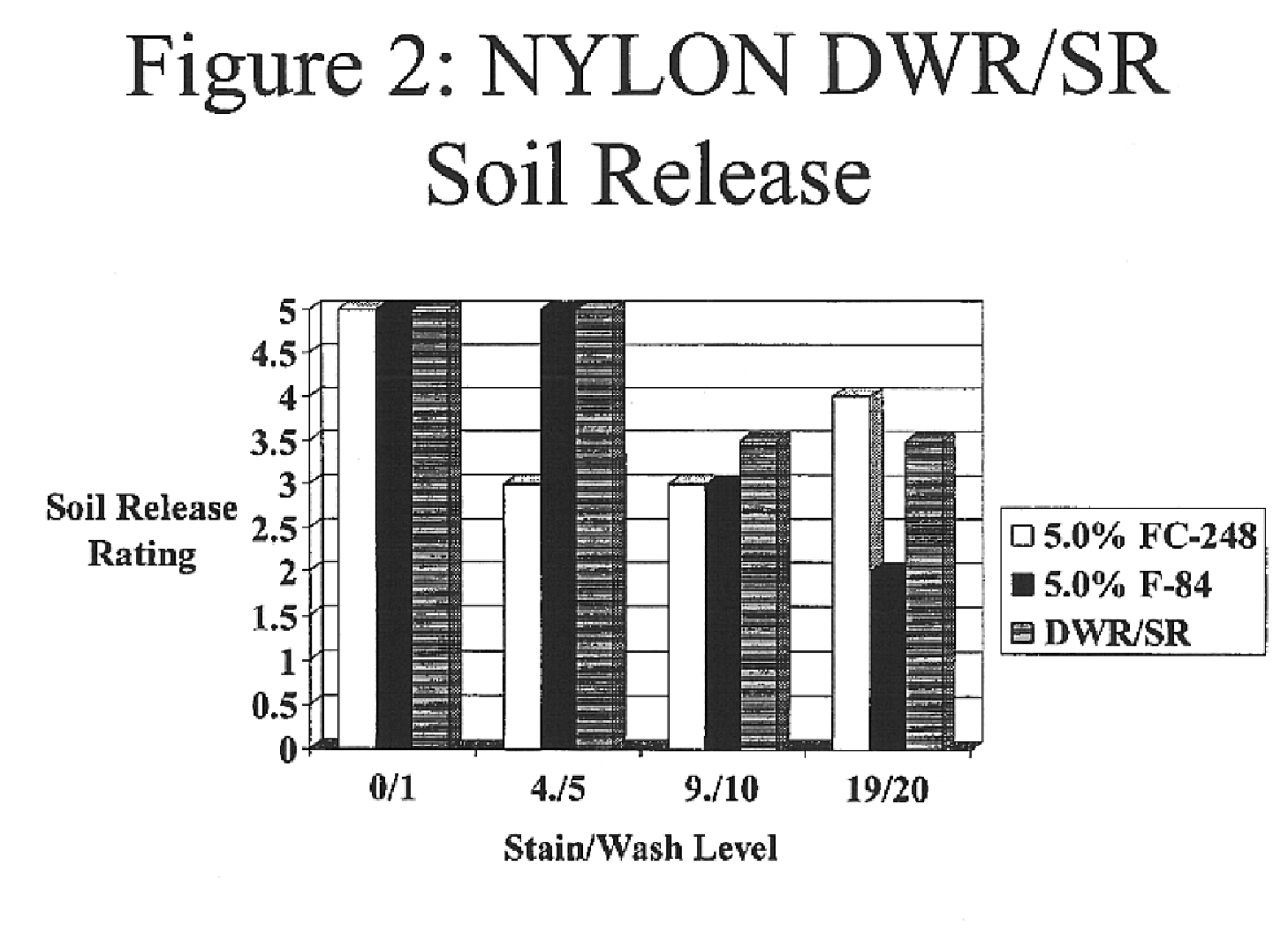

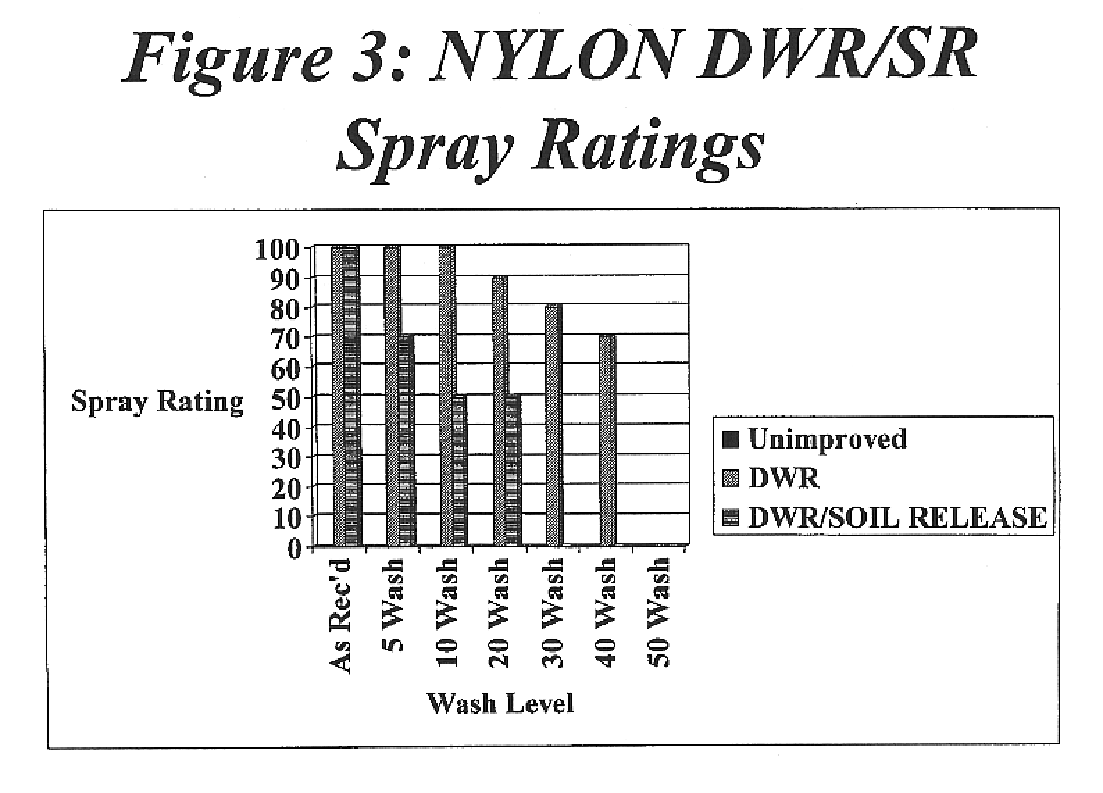

Method of producing textile substrates having improved durable water repellency and soil release

InactiveUS6818253B2Improved durable water and oil repellencyFacilitated releaseOther chemical processesSynthetic resin layered productsPolyesterAramides

Owner:MILLIKEN & CO

Flame resistant semicaromatic polyamide resin composition and articles therefrom

Polyamide compositions containing semi-crystalline polyamide, amorphous polyamide, non-halogenated flame retardant, zinc borate and fillers that have a high stiffness and hardness, a low warpage, and external appearance, such as gloss and reduced corrosion effects on melt processing equipment.

Owner:EI DU PONT DE NEMOURS & CO

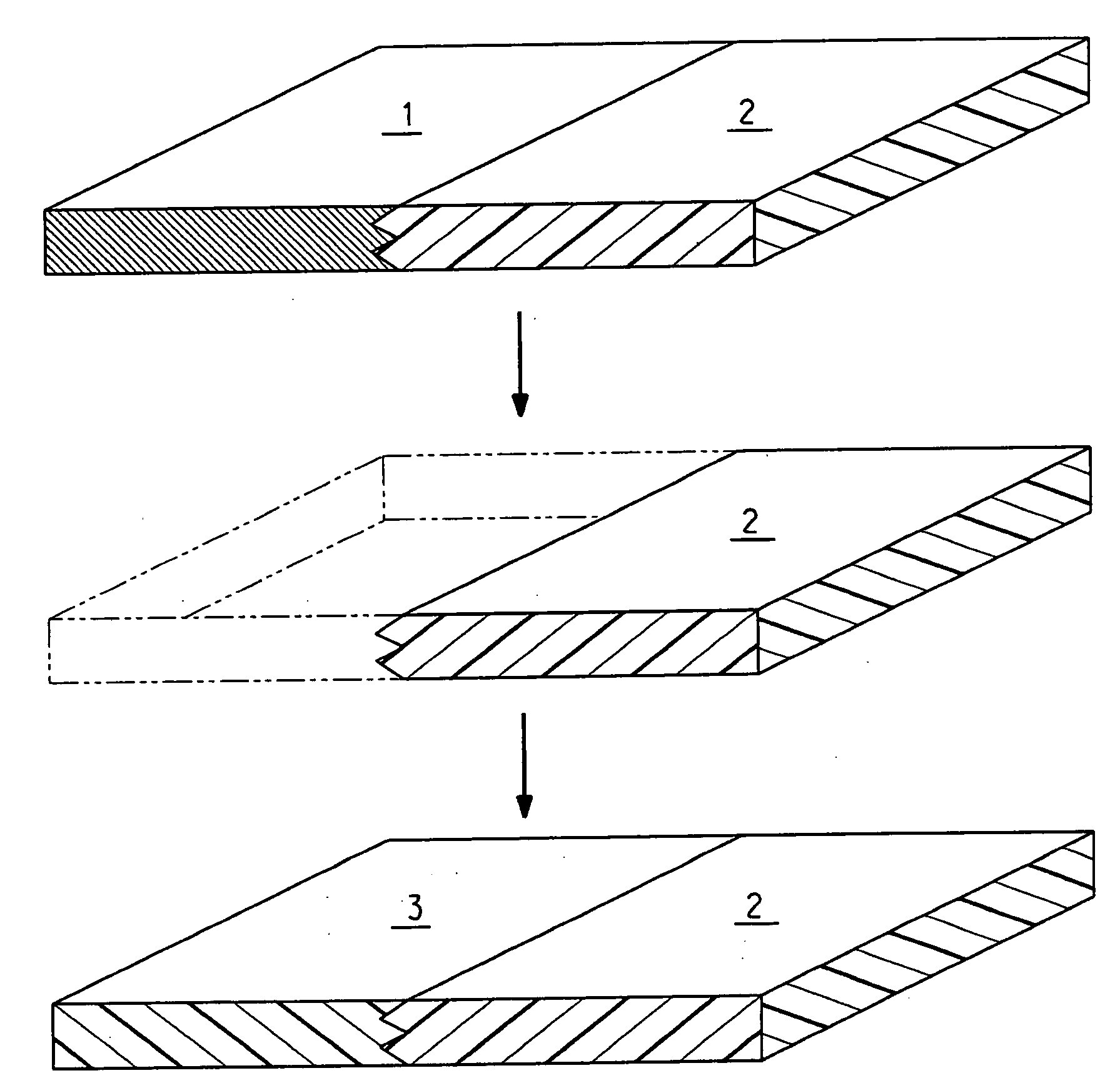

Composite of aluminum alloy and resin and manufacturing method thereof

ActiveUS20090274889A1High bonding strengthImprove productivitySemi-permeable membranesThermometers using material expansion/contactionElectronHigh productivity

Combining good metal chassis and good synthetic resin structures, achieving mass production with high productivity, and enabling free design of shapes and structures, are all important considerations in electronic devices, household electric appliances and the like. Moreover, the need for components that are useful in reducing the weight and increasing the strength of various parts and structures is not restricted to electronic devices and household electric appliances. The surface of an aluminum alloy shaped product is covered with ultrafine recesses by being dipped in an eroding aqueous solution, or has formed thereon a metal oxide layer covered with the openings of ultrafine pores by anodizing. On the resin side, there is prepared a polyamide resin compounded with an impact resistance modifier, a mixture of an aliphatic polyamide and an aromatic polyamide, or a mixture of aromatic polyamides. The aluminum alloy shaped product is inserted into an injection mold, and a polyamide-type resin composition is injected onto the surface of the aluminum alloy shaped product, to manufacture an integrated composite.

Owner:TAISEI PLAS CO LTD

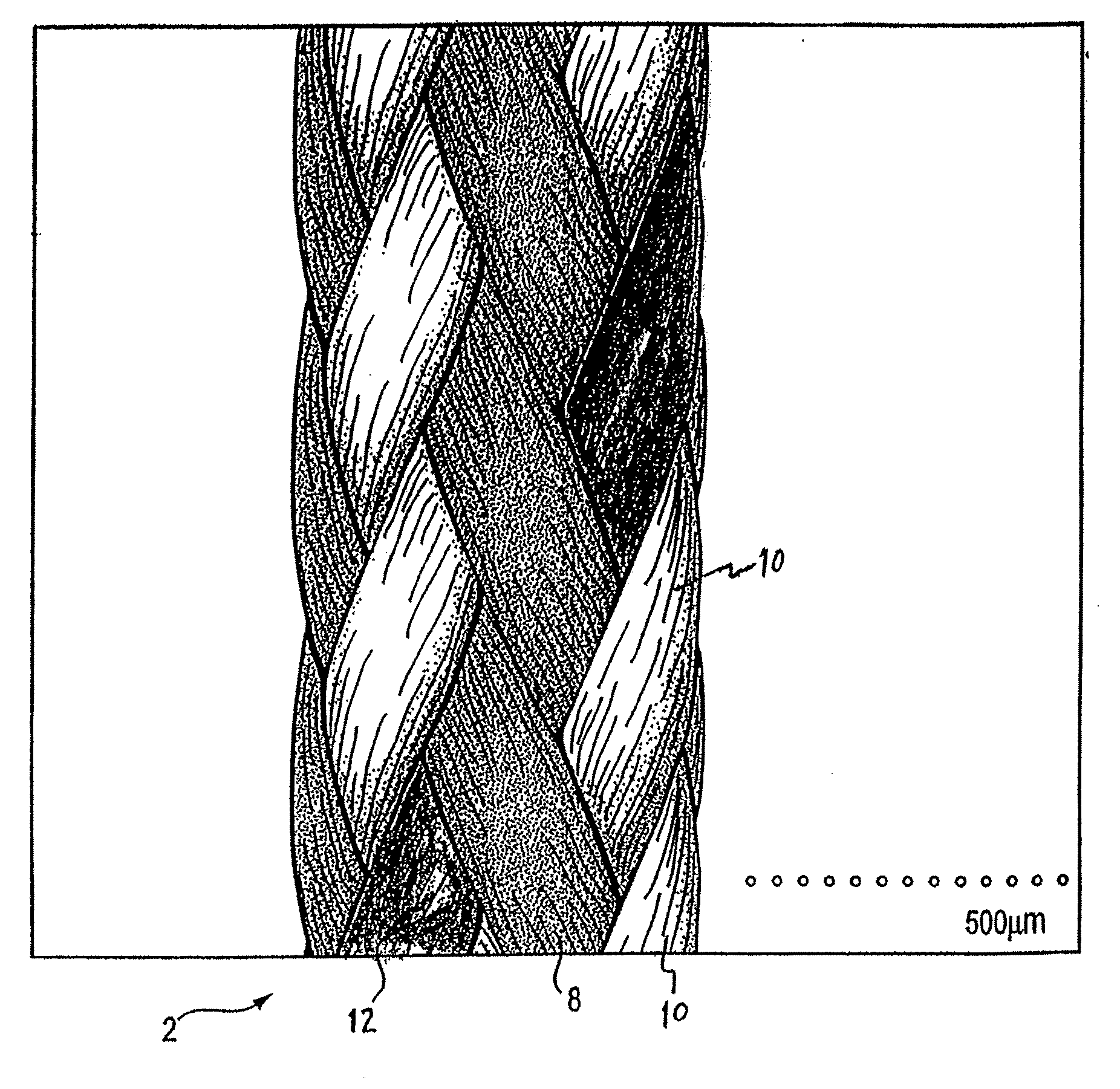

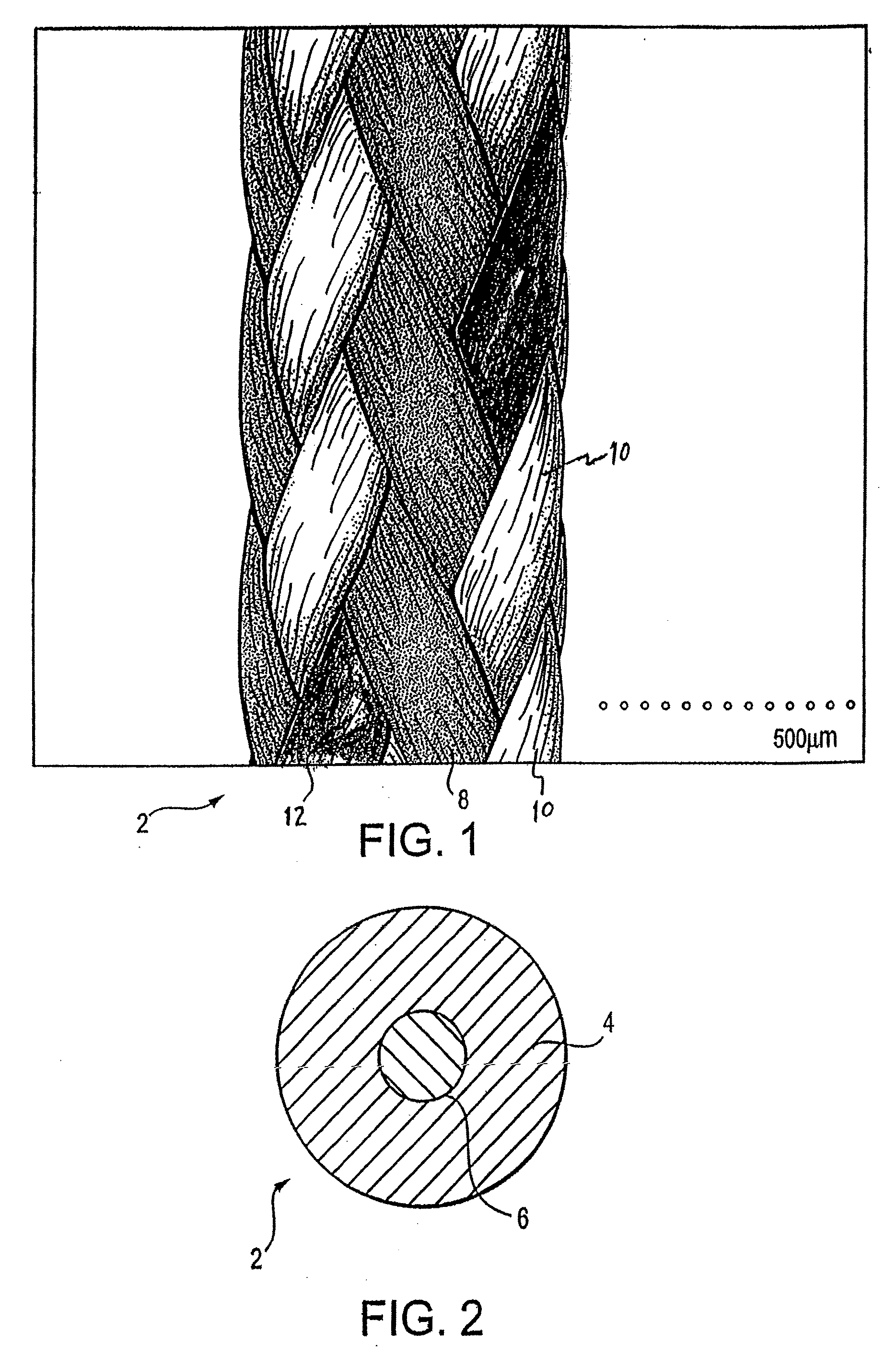

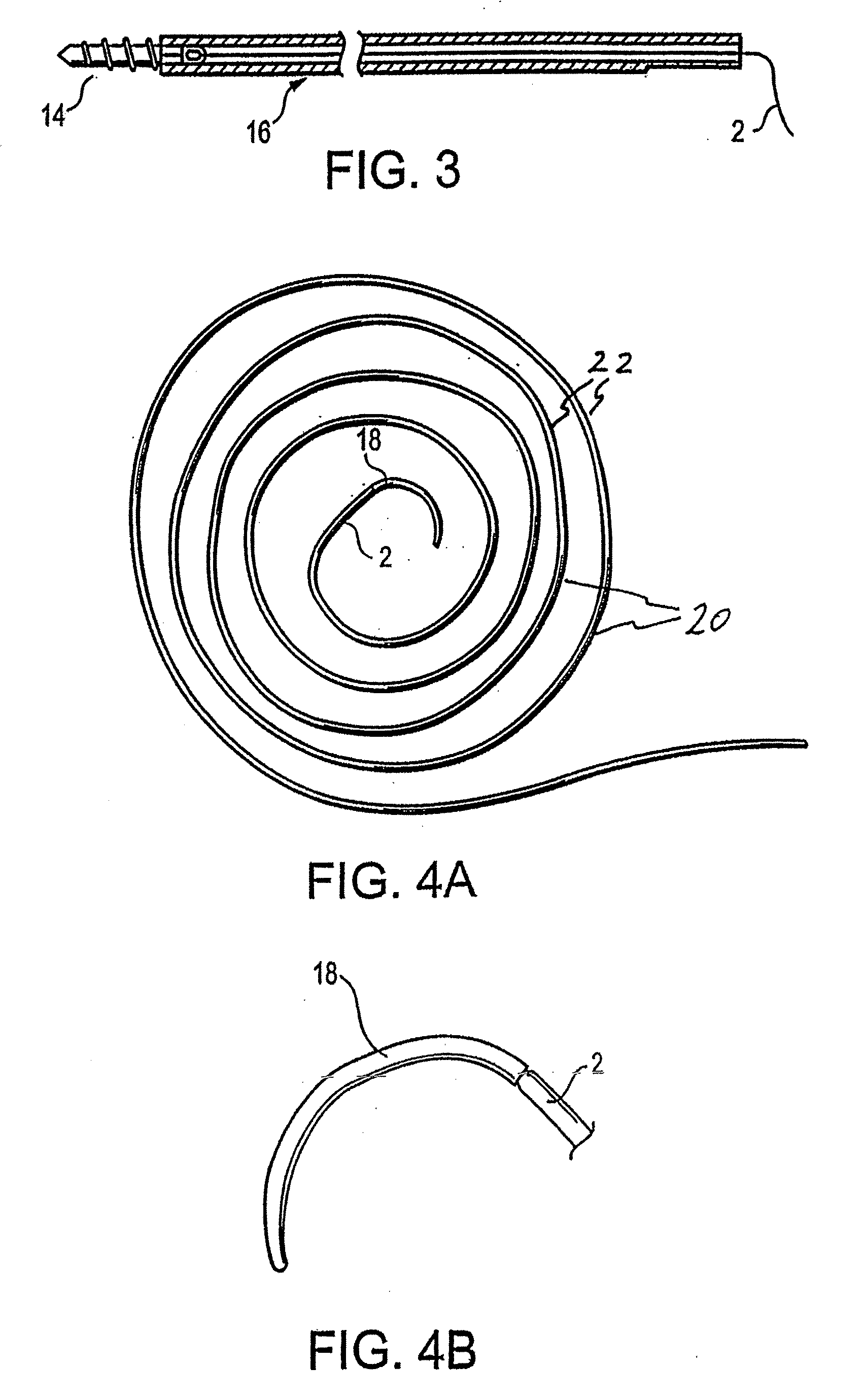

Suture with filaments formed of polyether-ketone variant

A high strength abrasion resistant surgical suture material with improved tie down characteristics and tissue compliance with braided yarns formed of ether-ketone variant. The suture features a multifilament jacket formed of braided yarns of ether-ketone variant, optionally braided with yarns of polyester, silk, nylon, ultrahigh molecular weight polyethylene or aramid fibers. The braided jacket surrounds a core formed of twisted yarns of ether-ketone variant or ultrahigh molecular weight polyethylene. The suture has exceptional strength, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

Ballistic blanket

A ballistic blanket is provided and includes a pliable outer shell or housing that encompasses an inner ballistic core which is housed or contained within an inner shell or housing. Secured to exterior portions of the ballistic blanket are a series of handles and one or more attaching straps or buckles that facilitate the securement of devices such as a carrier panel. In one design, the interior ballistic core comprises a high performance fiber such as an aramid fiber, high molecular weight polyethylene, a combination of high performance fiber types, or a non-woven thermoplastic composite.

Owner:CARTER GERALD D +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com