Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

468 results about "Bursting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bursting strength is a measurement that shows how much force an object can take before it ruptures. This measurement is applied only to sheet materials, such as cloth, paper or plastic. ... Bursting strength is commonly referenced when packaging goods. Shippers will then know their packaging is strong enough to handle the weight of the materials inside.

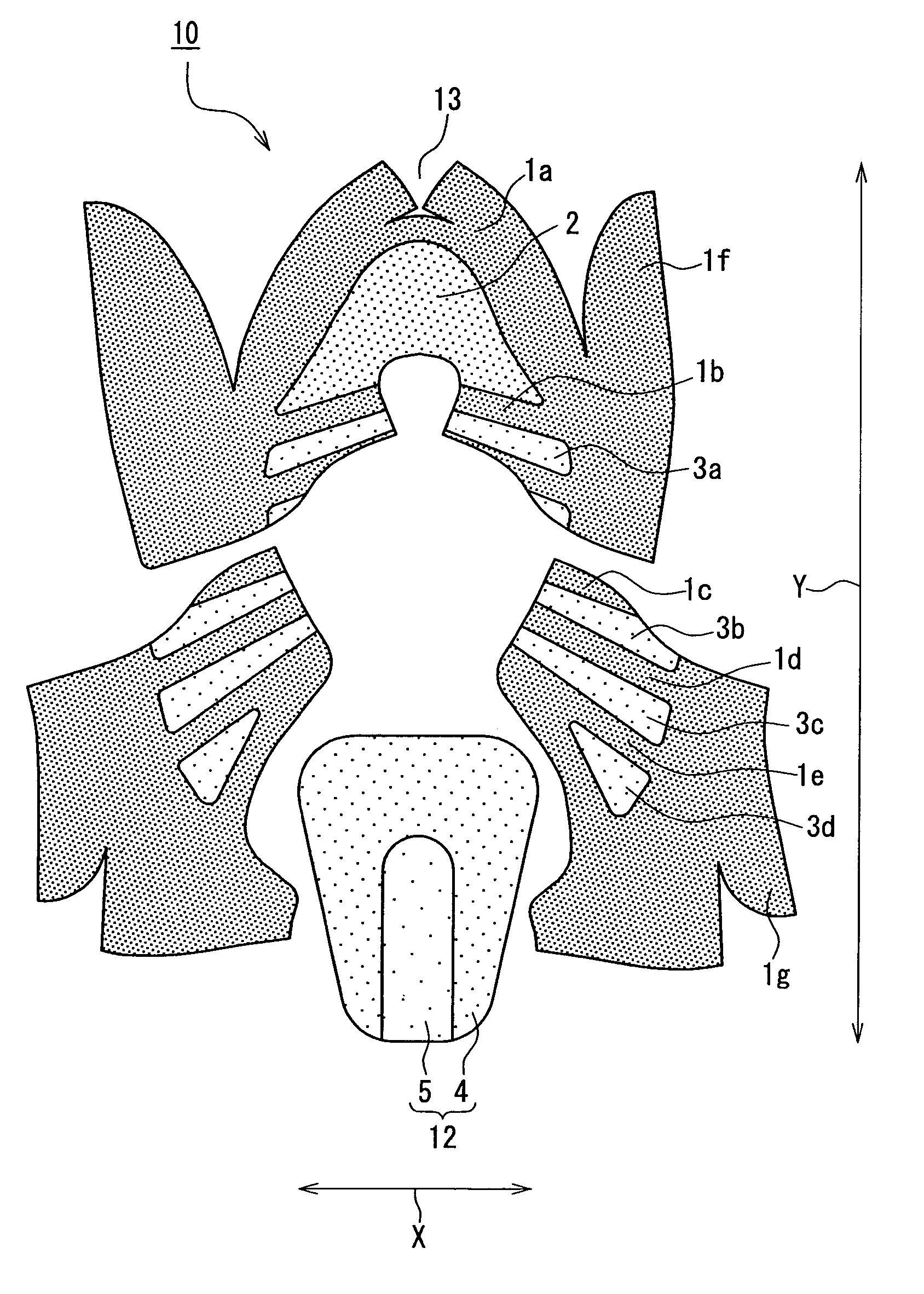

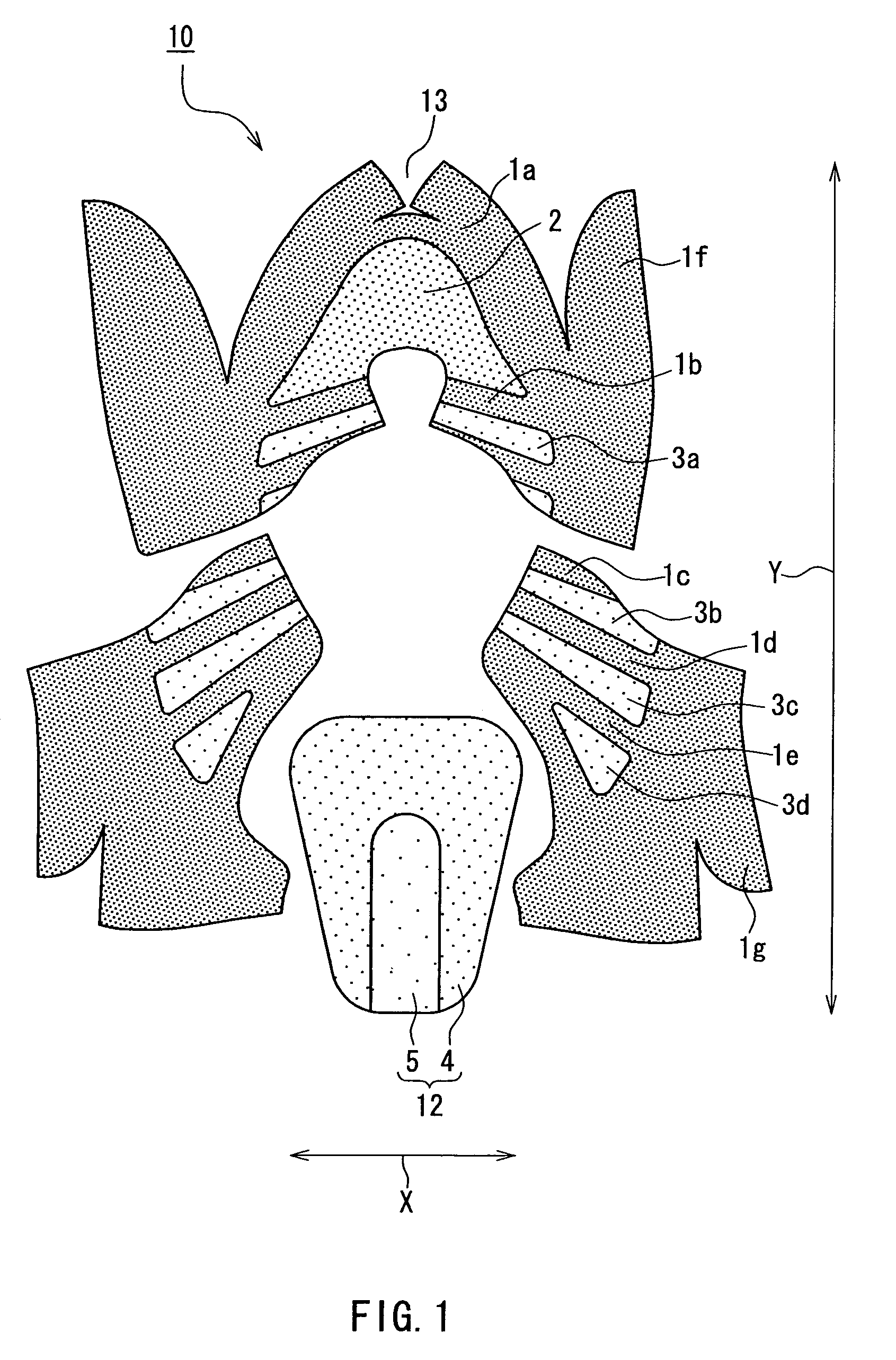

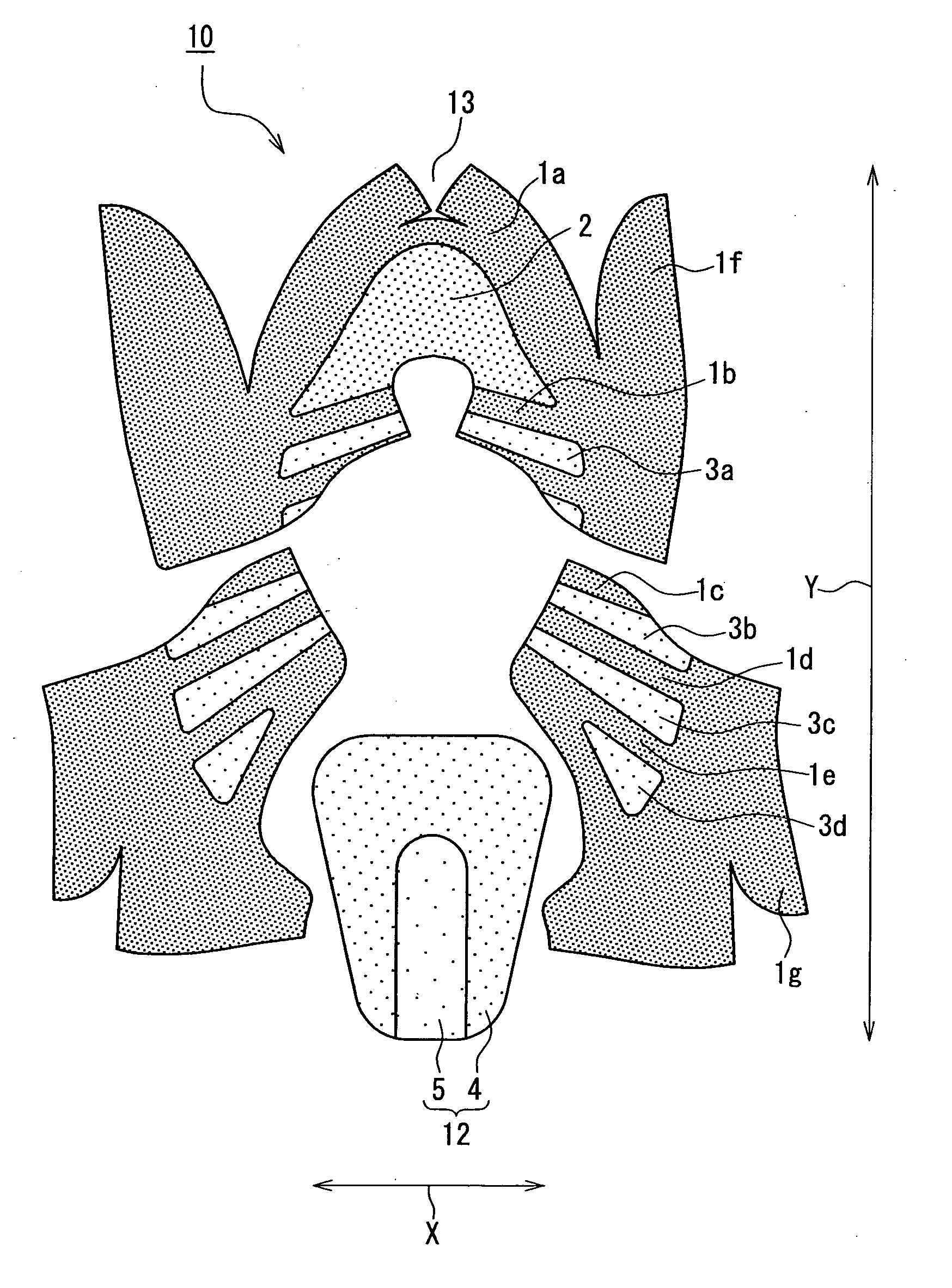

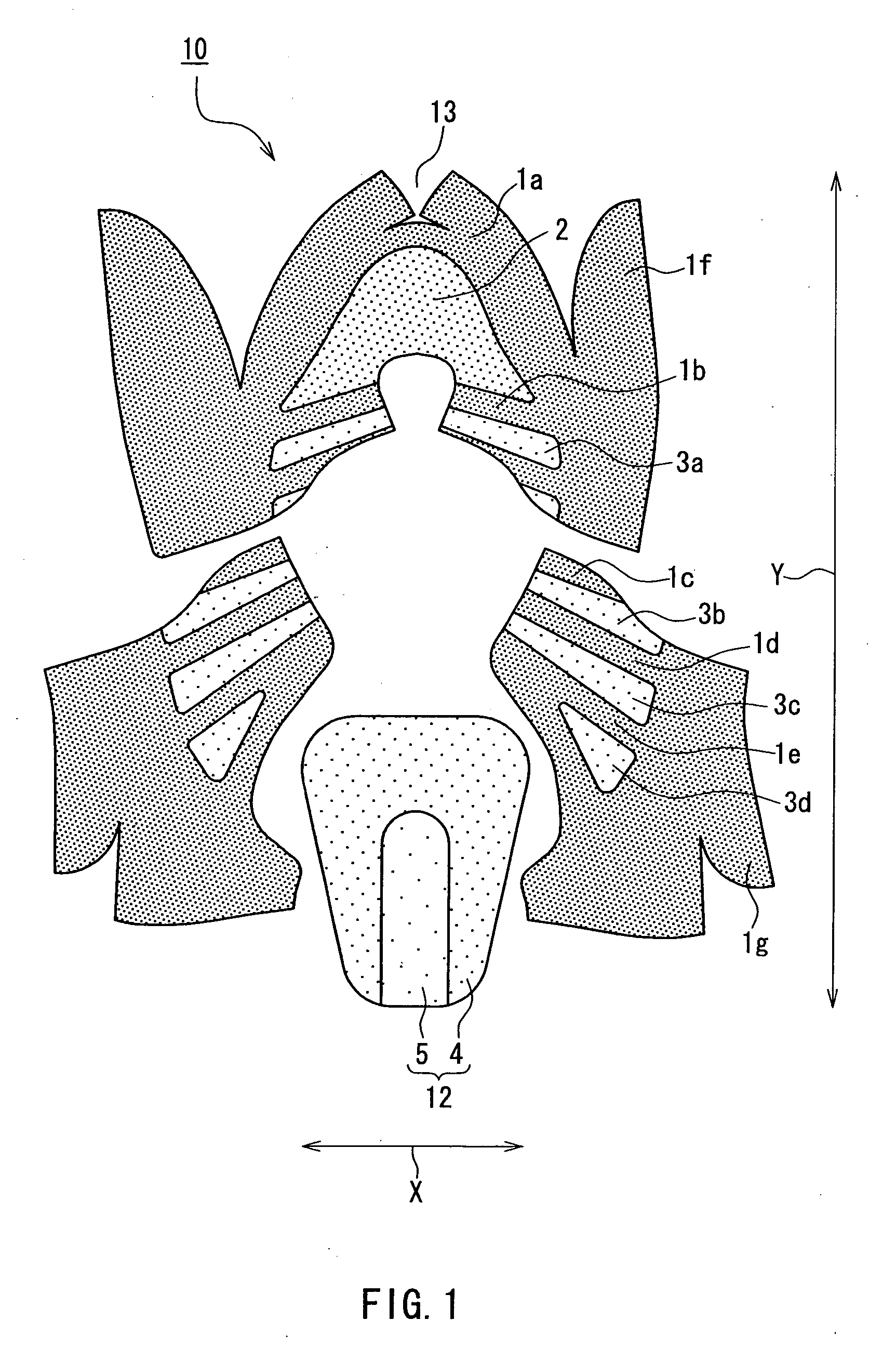

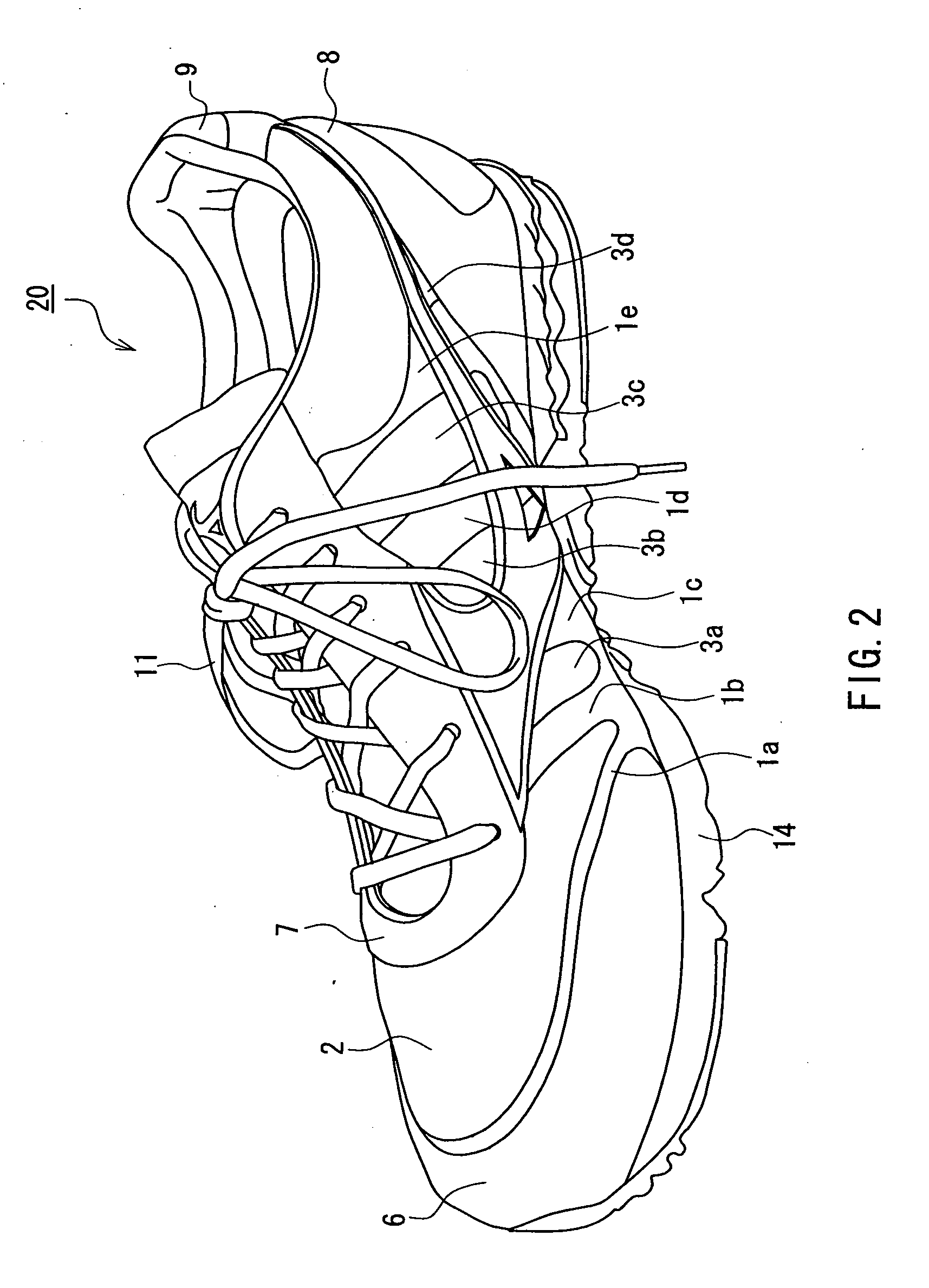

Light weight shoes

ActiveUS7051460B2Increased durabilityOrnamental textile articlesWarp knittingBursting strengthEngineering

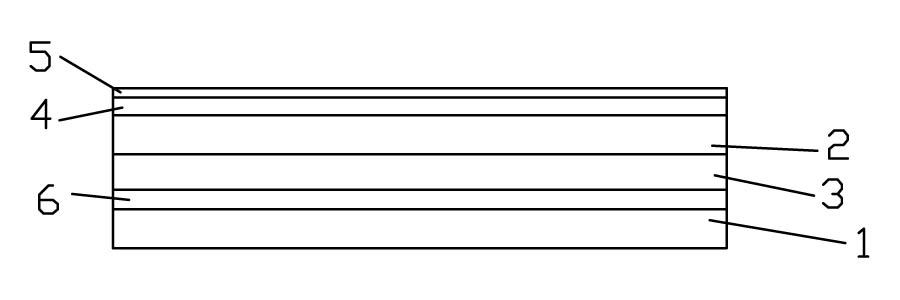

A shoe including an upper material using a double raschel warp knitted fabric is provided. The upper material includes a first surface having a non-mesh structure and a second surface having a non-mesh structure part (A) and mesh structure parts (B, C). The burst strengths burst strengths A, B and C of the parts (A, B and C) satisfy the relationship: A>B>C. The non-mesh structure part (A) is disposed in a part surrounding the tiptoe, a part connecting to a shoe sole and disposed in both sides of the foot for example, in a stripe. The mesh structure part (B) is disposed in the vicinity of the surface of the toe and the mesh structure part (C) is disposed in the both sides of the foot for example, in a stripe. Thus, a shoe having lightweight, air permeability and durability and a double raschel knitted fabric used for the shoe are provided.

Owner:MIZUNO CORPORATION

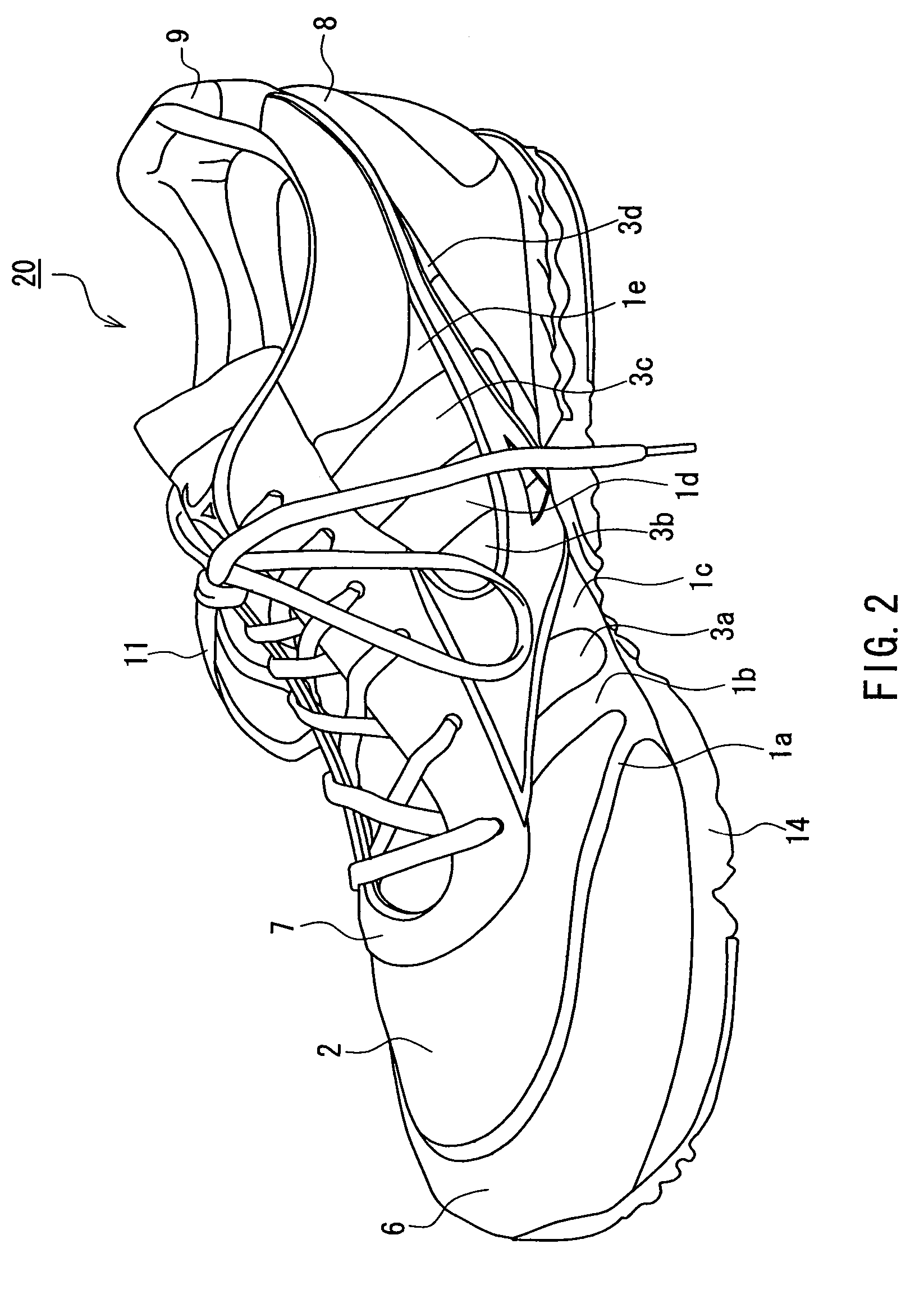

Water-absorbing agent and production process therefor, and water-absorbent structure

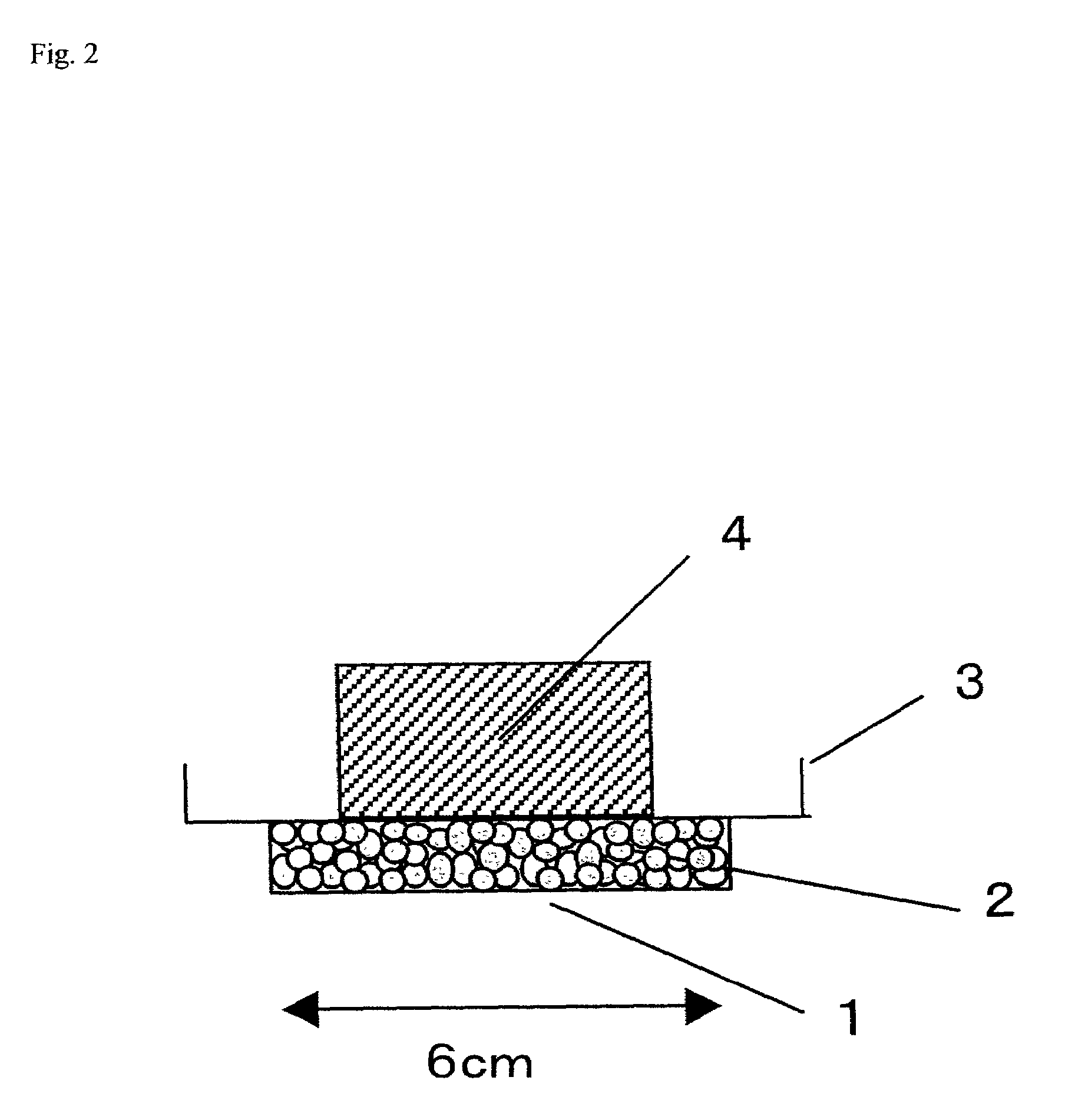

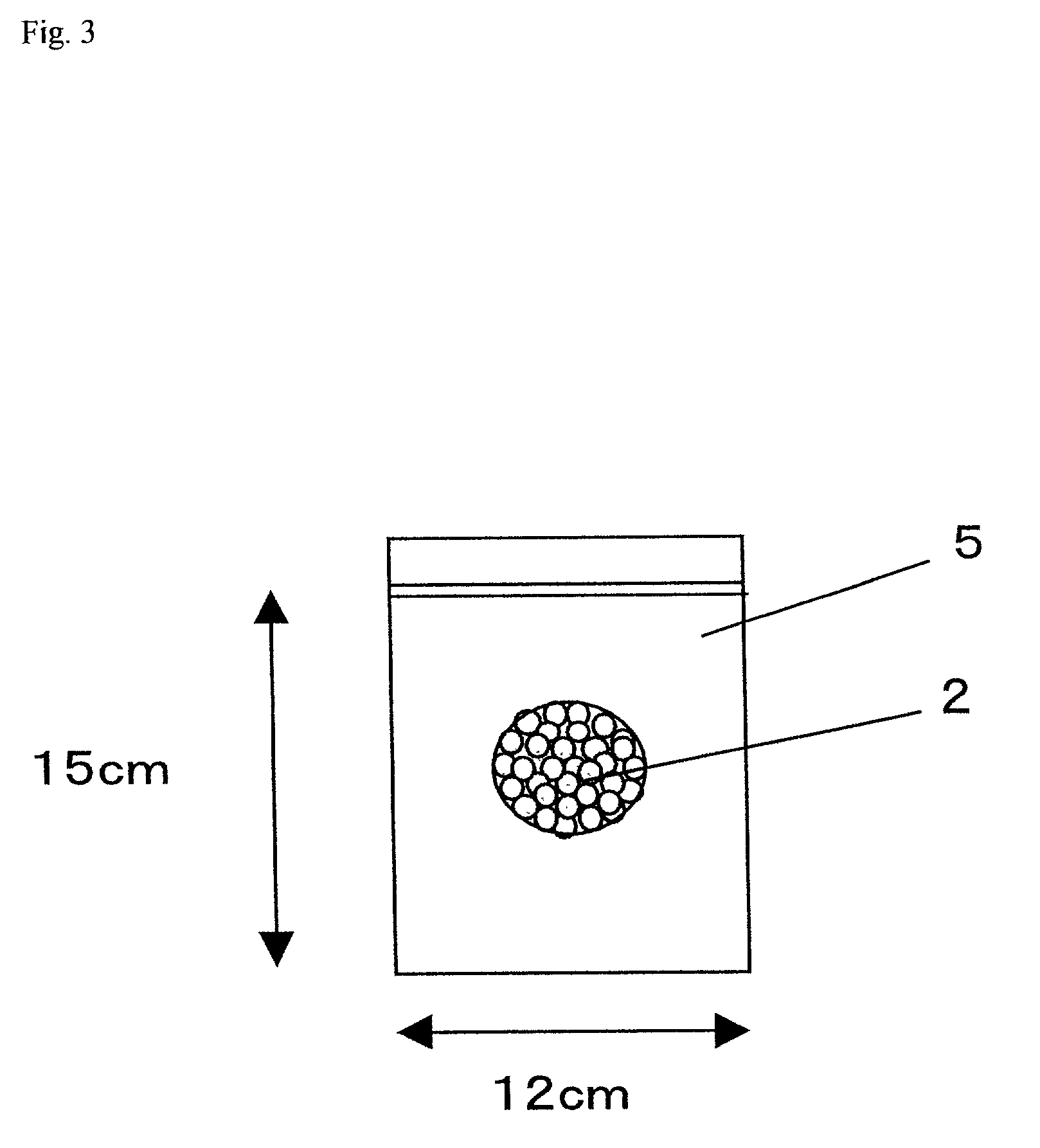

InactiveUS7098284B2Promote absorptionMaintain good propertiesOther chemical processesAbsorbent padsBursting strengthAbsorption capacity

The present invention provides: a novel water-absorbing agent, which exhibits an excellent absorption capacity under a load (AAP), gel layer liquid permeation rate under a load (FRUP), saline flow conductivity (SFC), and shape-maintaining property and ball burst strength (BBS) of a swollen water-absorbing agent aggregate, and excellent persistency of these effects for a long time. The water-absorbing agent, which comprises a polymer obtained by a process including the steps of polymerizing and then crosslinking a monomer including acrylic acid and / or a salt thereof, with the water-absorbing agent being characterized by: (1) exhibiting a free swelling capacity of not less than 23 g / g (GV), a gel deformation of not more than 12.5 cm under a short-time load (0.5 hrPT), and a gel deformation deterioration of not more than 3.5 cm under a load with the passage of time (ΔPT); (2) exhibiting a free swelling capacity of not less than 23 g / g (GV), a ball burst strength of not less than 80 gf (BBS), and a deterioration of ball burst strength of not more than 40% (DBBS); or (3) exhibiting a free swelling capacity of not less than 23 g / g (GV), an absorption capacity of not less than 20 g / g under a load of 4.9 kPa (AAP), and a gel deformation of not more than 12.5 cm under a load (16 hrPT).

Owner:NIPPON SHOKUBAI CO LTD

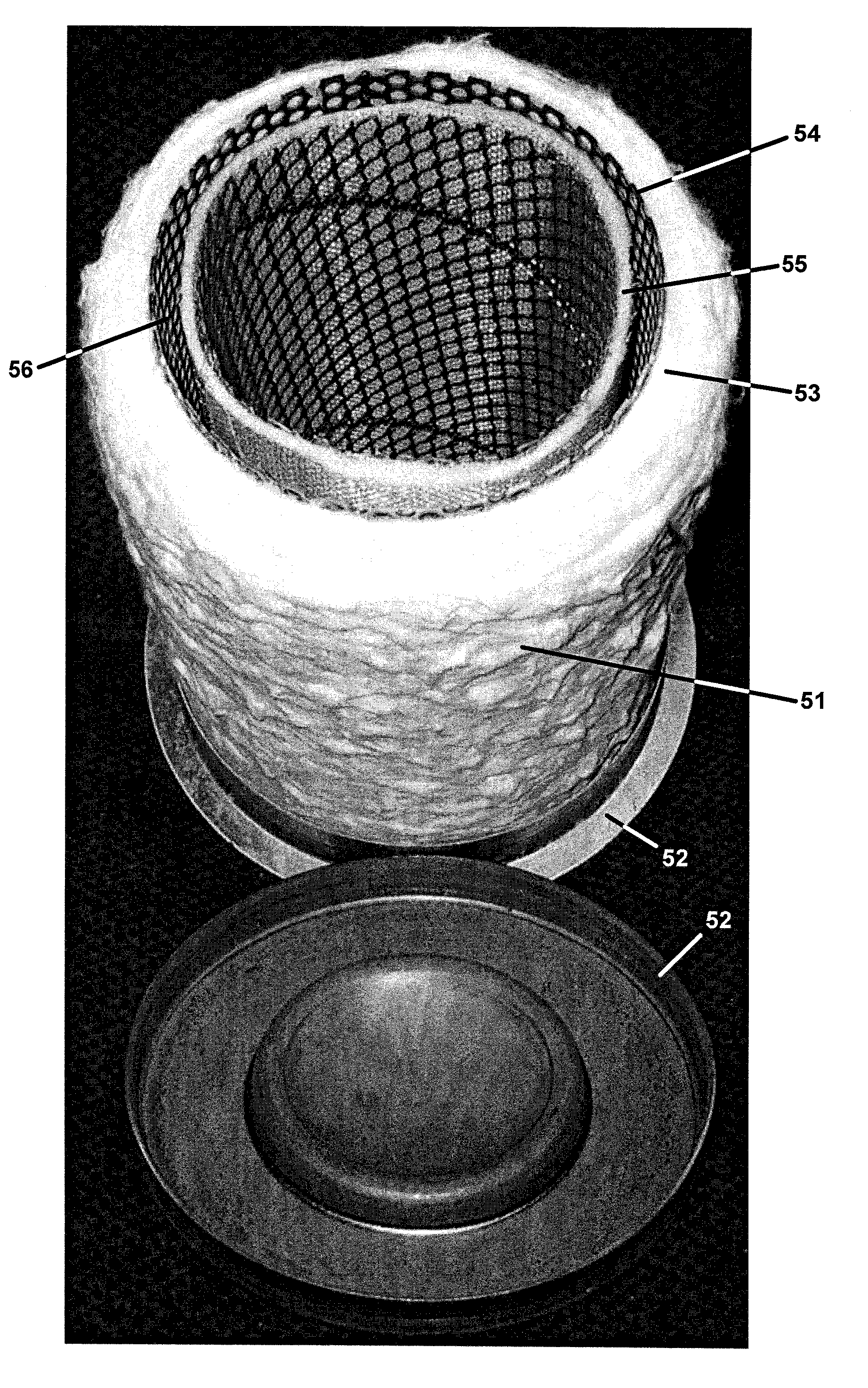

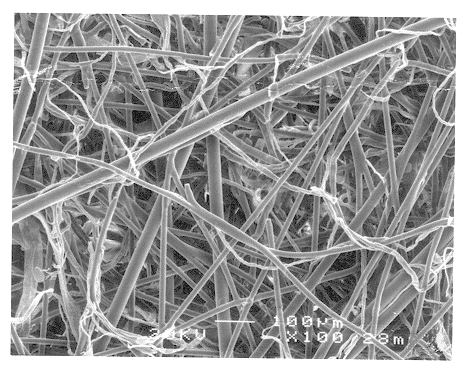

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

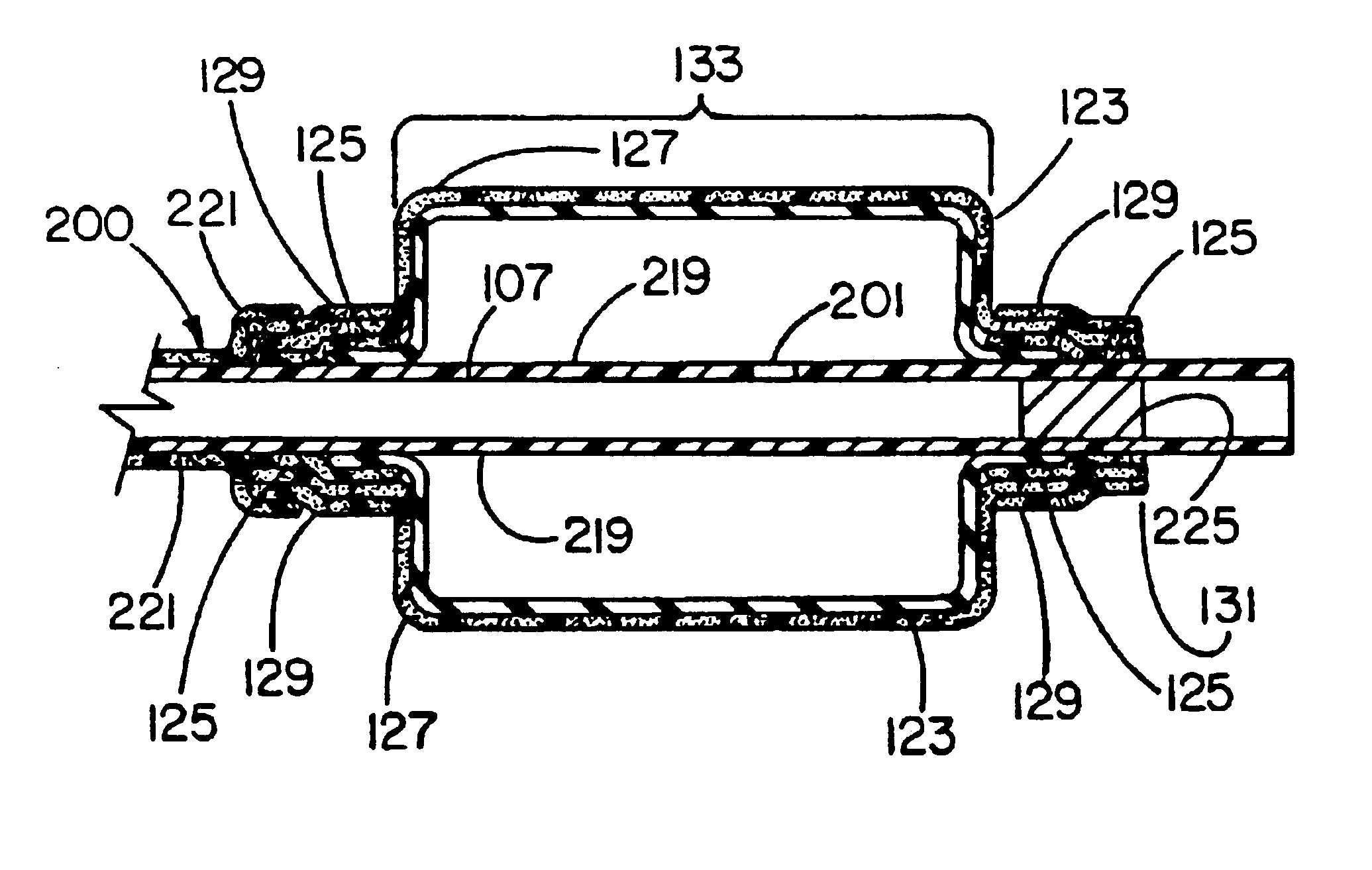

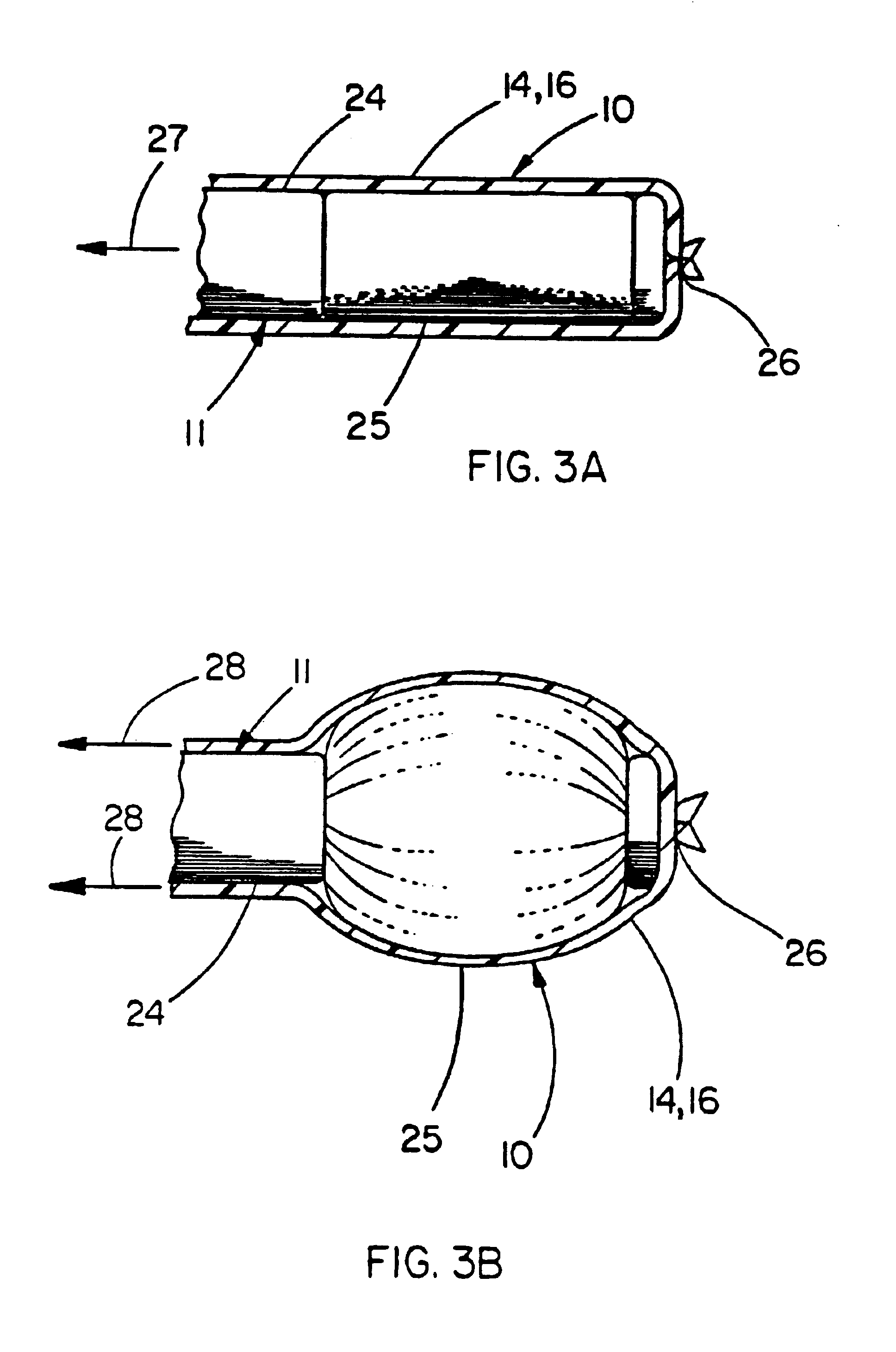

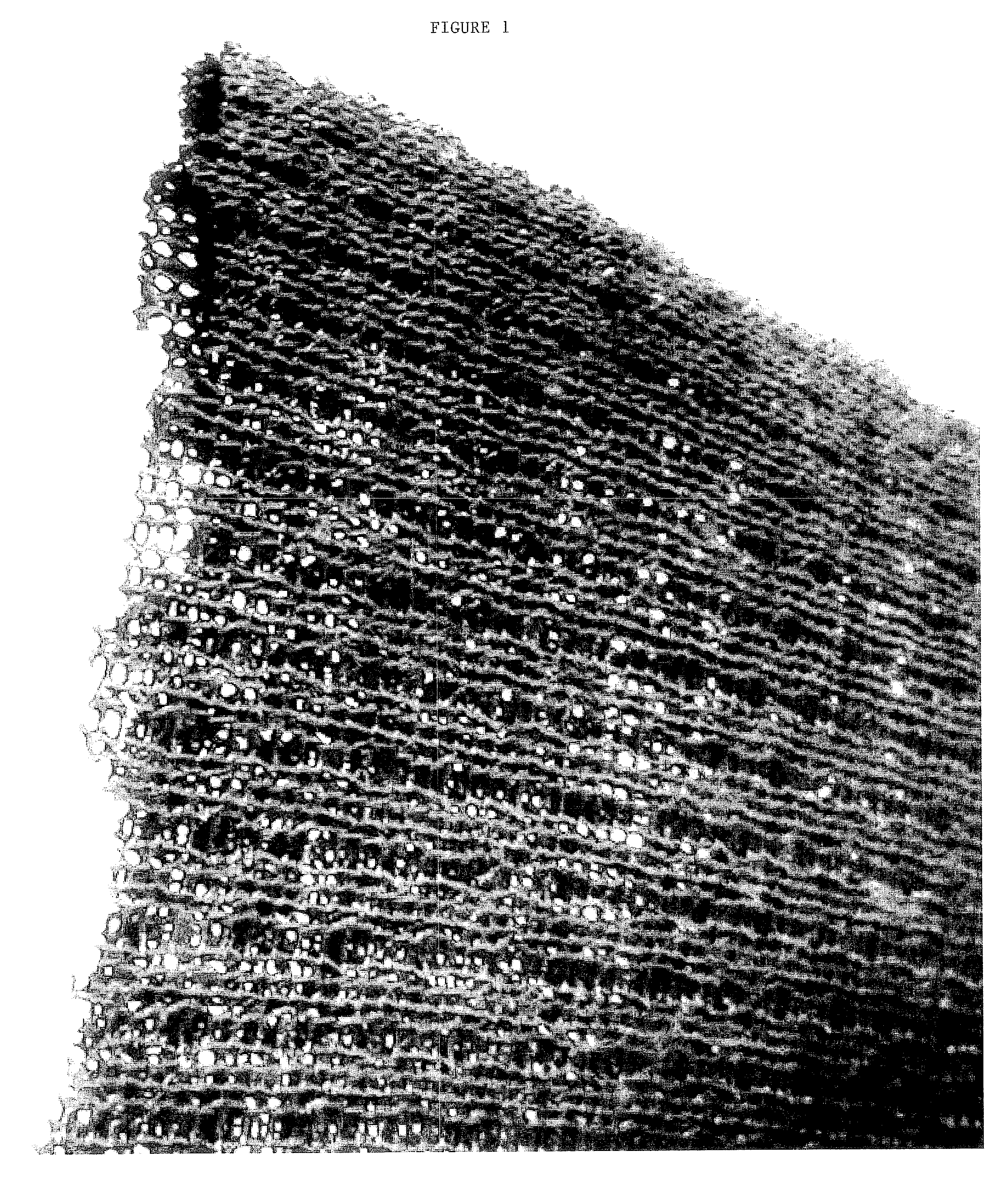

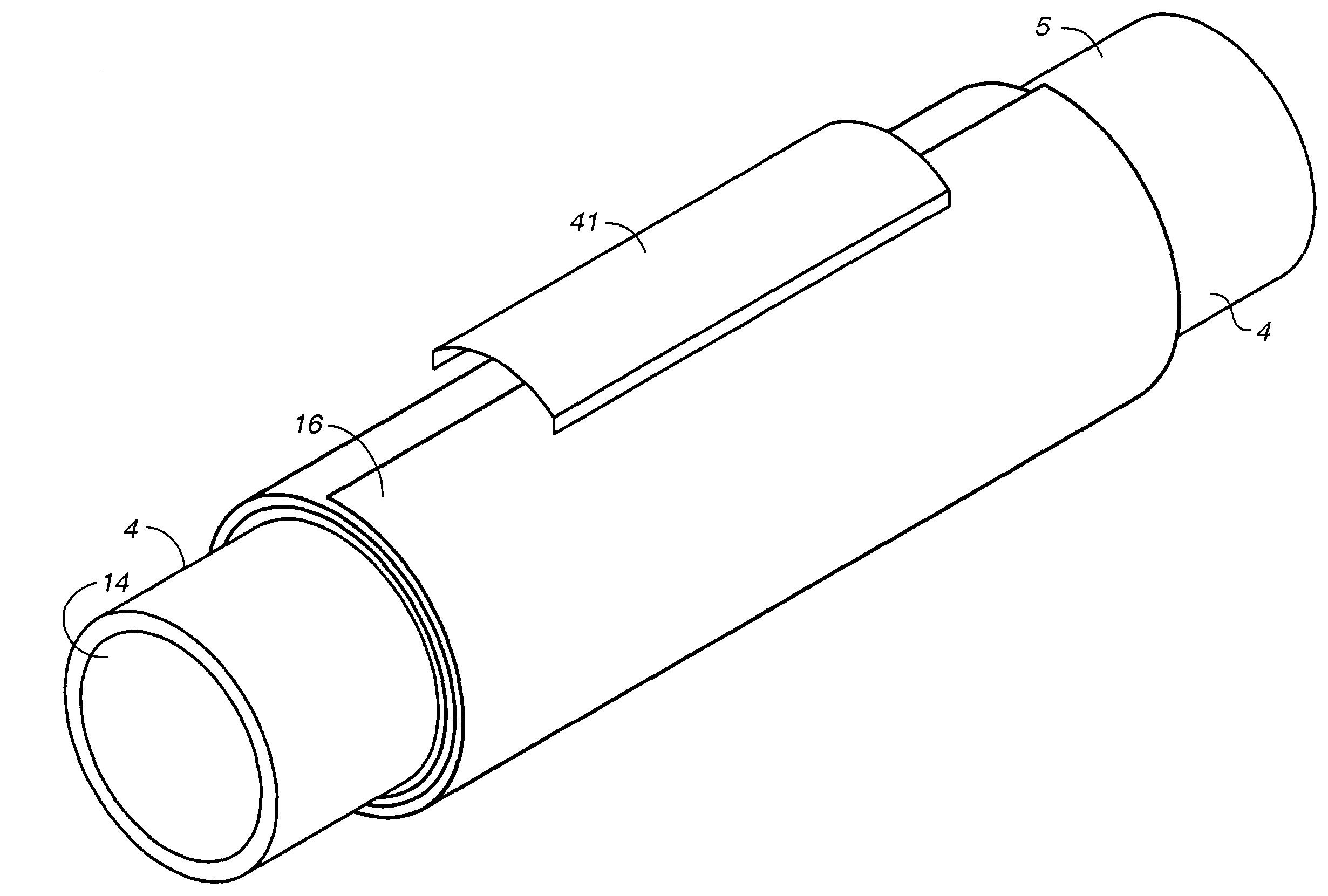

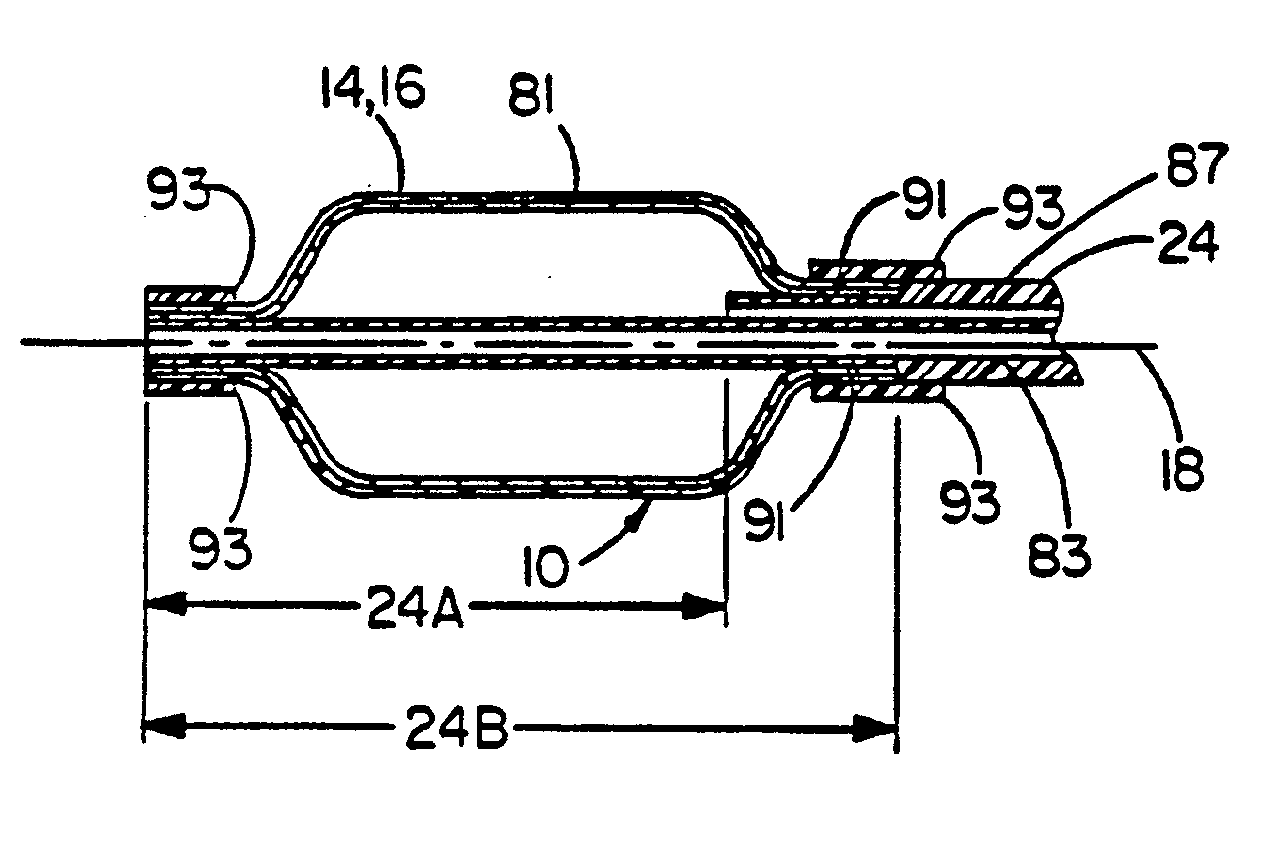

Balloon catheter device

InactiveUS6923827B2Bursting strengthAid in insertion and withdrawalStentsBalloon catheterAngioplasty balloonBursting strength

Balloon catheters having the strength and maximum inflated diameter characteristics of an angioplasty balloon and having the recovery characteristics during deflation of an elastic embolectomy balloon. The balloon catheter can be made in very small sizes and has a lubricious and chemically inert outer surface. The balloon catheter is easy to navigate through tortuous passageways, is capable of rapid inflation and deflation and has high burst strengths. Balloon covers having these same characteristics are also described for use with conventional embolectomy balloons or angioplasty balloons.

Owner:WL GORE & ASSOC INC

Formed filter element

InactiveUS20090050578A1Improve featuresLower overall pressure dropSemi-permeable membranesDispersed particle filtrationBursting strengthFiber

A filter medium for use in filtering a mobile fluid made from at least a bicomponent fiber. Other fibers, particles, or other materials can also be entrained in the filter medium. The filter medium has a substantial thickness compared to filters of the prior art. The fiber length and diameter dimensions are selected to obtain desired filter characteristics including thickness, basis weight, pore size, filtration efficiency, pressure drop, burst strength, and manufacturing efficiency. Further, a multilayer filter medium can be provided with ease. Each layer can have a different composition, pore size, basis weight, and so forth, thus providing the ability to build multiple functionality into the filter media of the invention.

Owner:DONALDSON CO INC

Light weight shoes

ActiveUS20050081402A1Increased durabilityOrnamental textile articlesWarp knittingBursting strengthEngineering

A shoe including an upper material using a double raschel warp knitted fabric is provided. The upper material includes a first surface having a non-mesh structure and a second surface having a non-mesh structure part (A) and mesh structure parts (B, C). The burst strengths burst strengths A, B and C of the parts (A, B and C) satisfy the relationship: A>B>C. The non-mesh structure part (A) is disposed in a part surrounding the tiptoe, a part connecting to a shoe sole and disposed in both sides of the foot for example, in a stripe. The mesh structure part (B) is disposed in the vicinity of the surface of the toe and the mesh structure part (C) is disposed in the both sides of the foot for example, in a stripe. Thus, a shoe having lightweight, air permeability and durability and a double raschel knitted fabric used for the shoe are provided.

Owner:MIZUNO CORPORATION

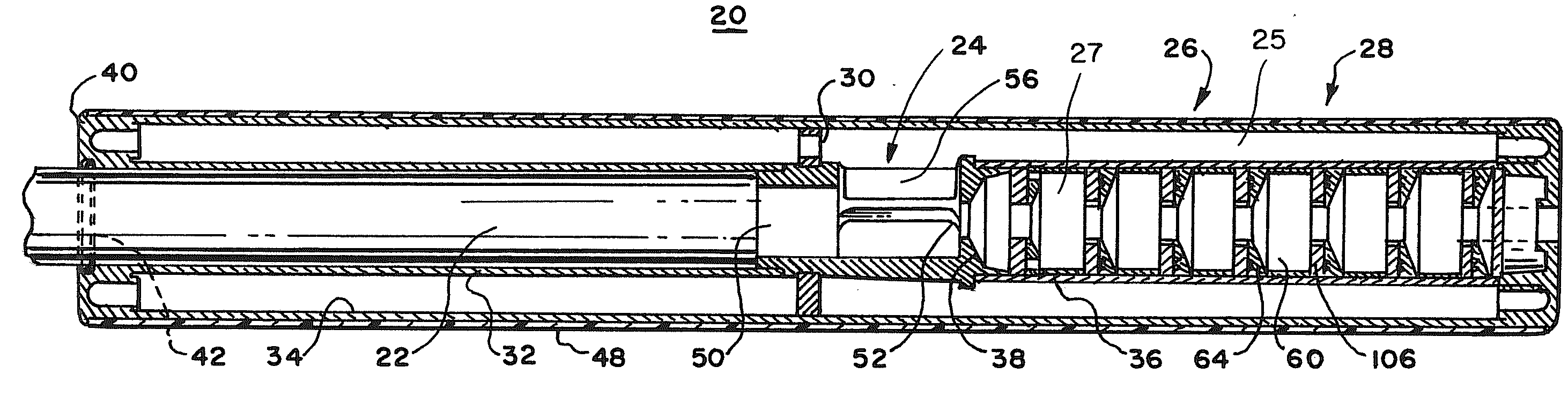

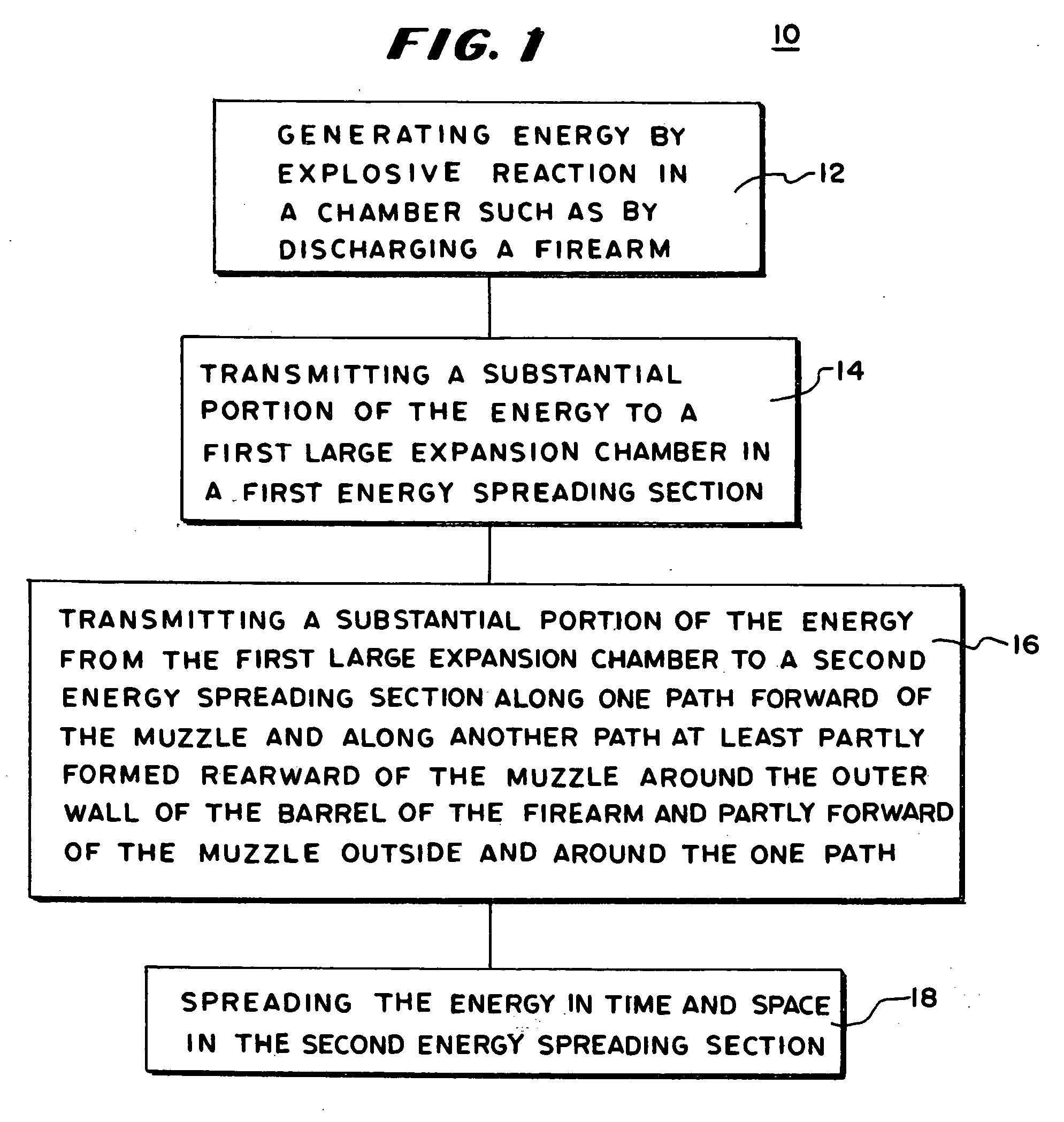

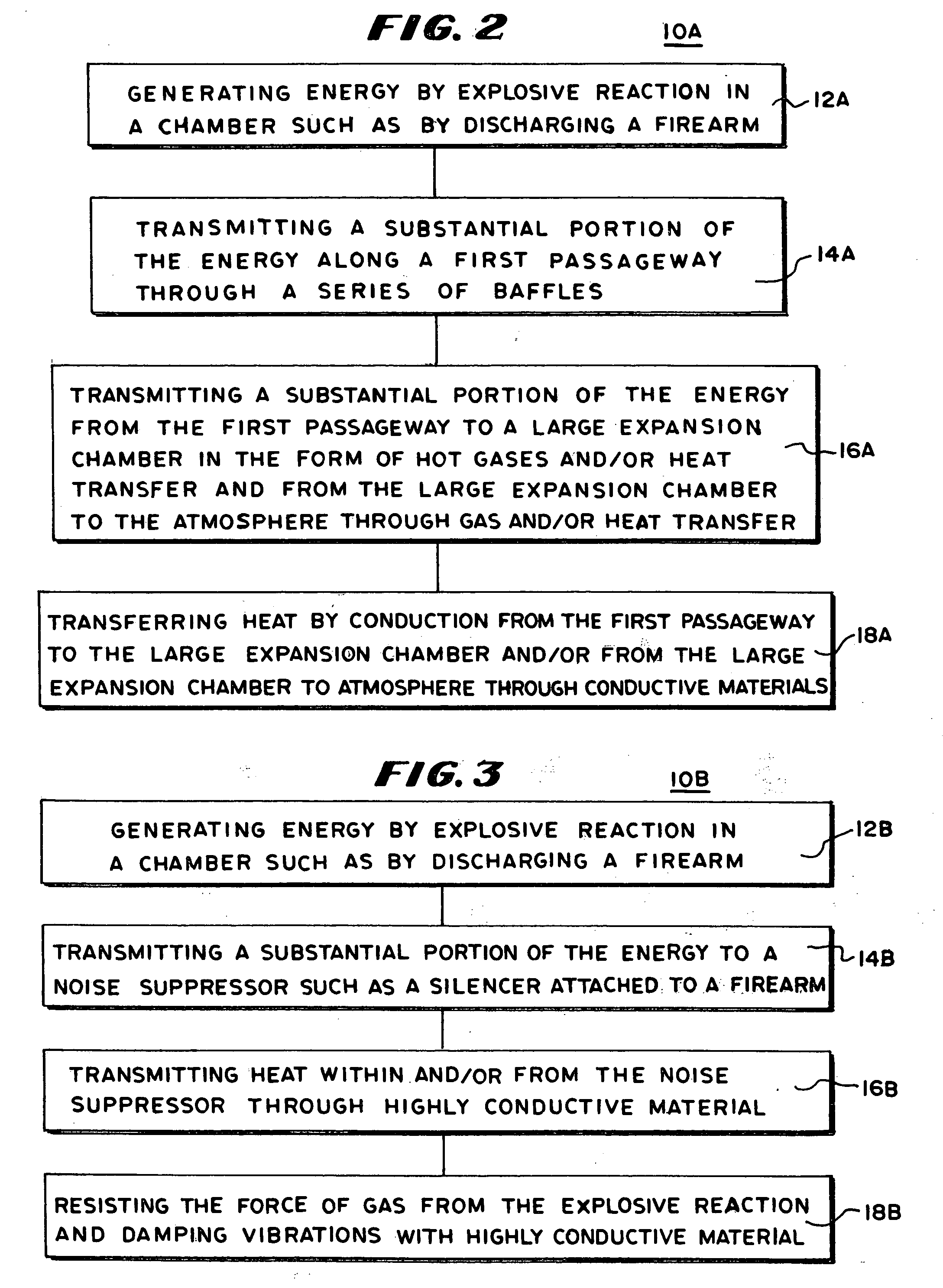

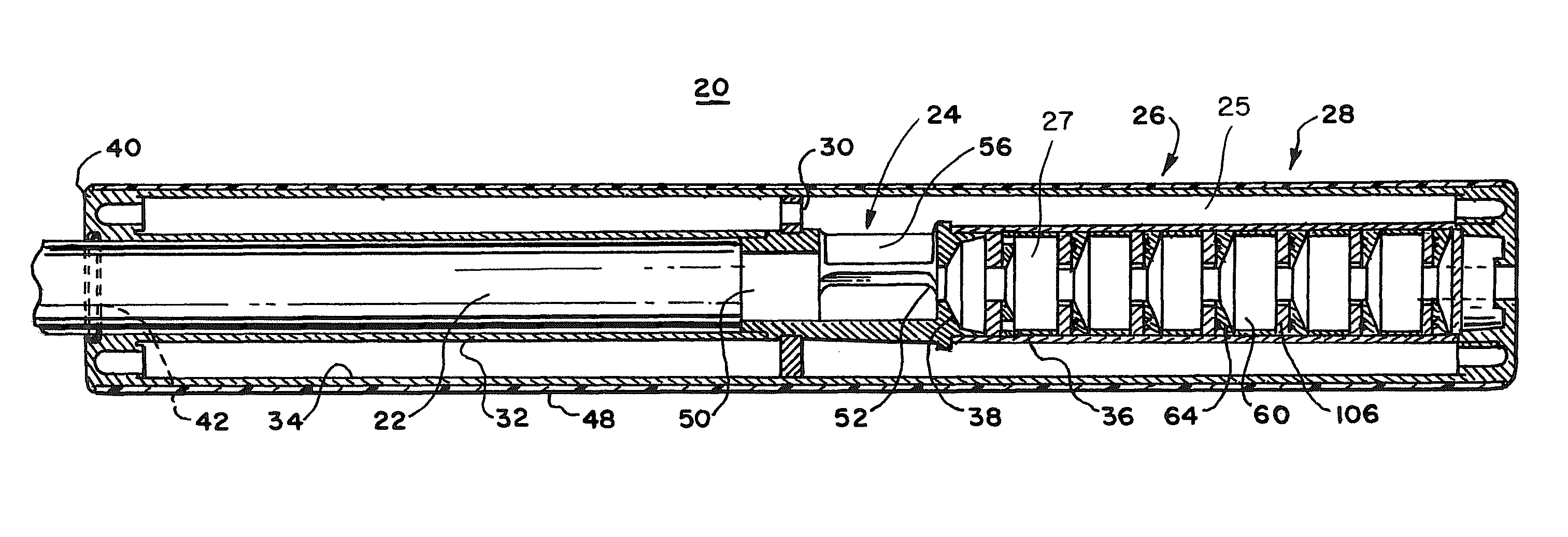

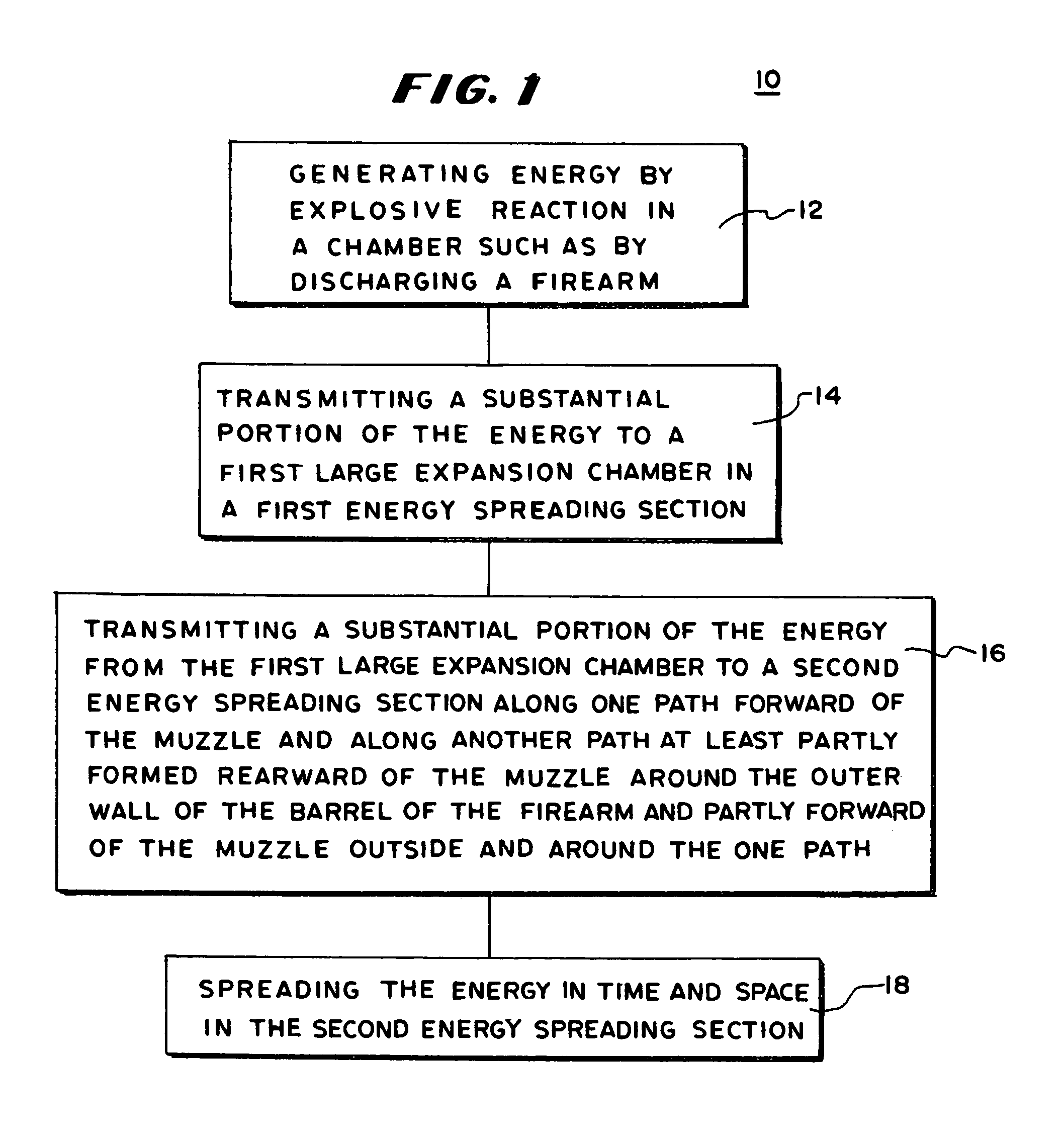

Energy suppressors

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

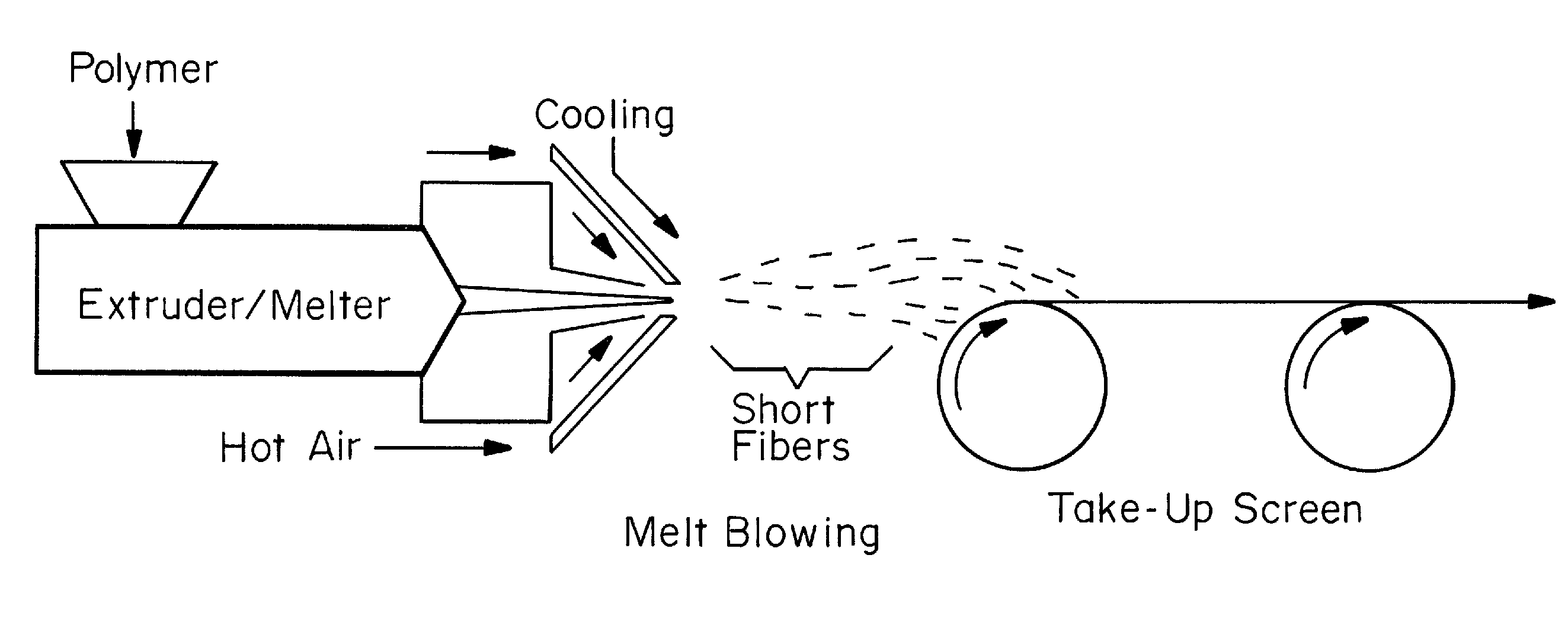

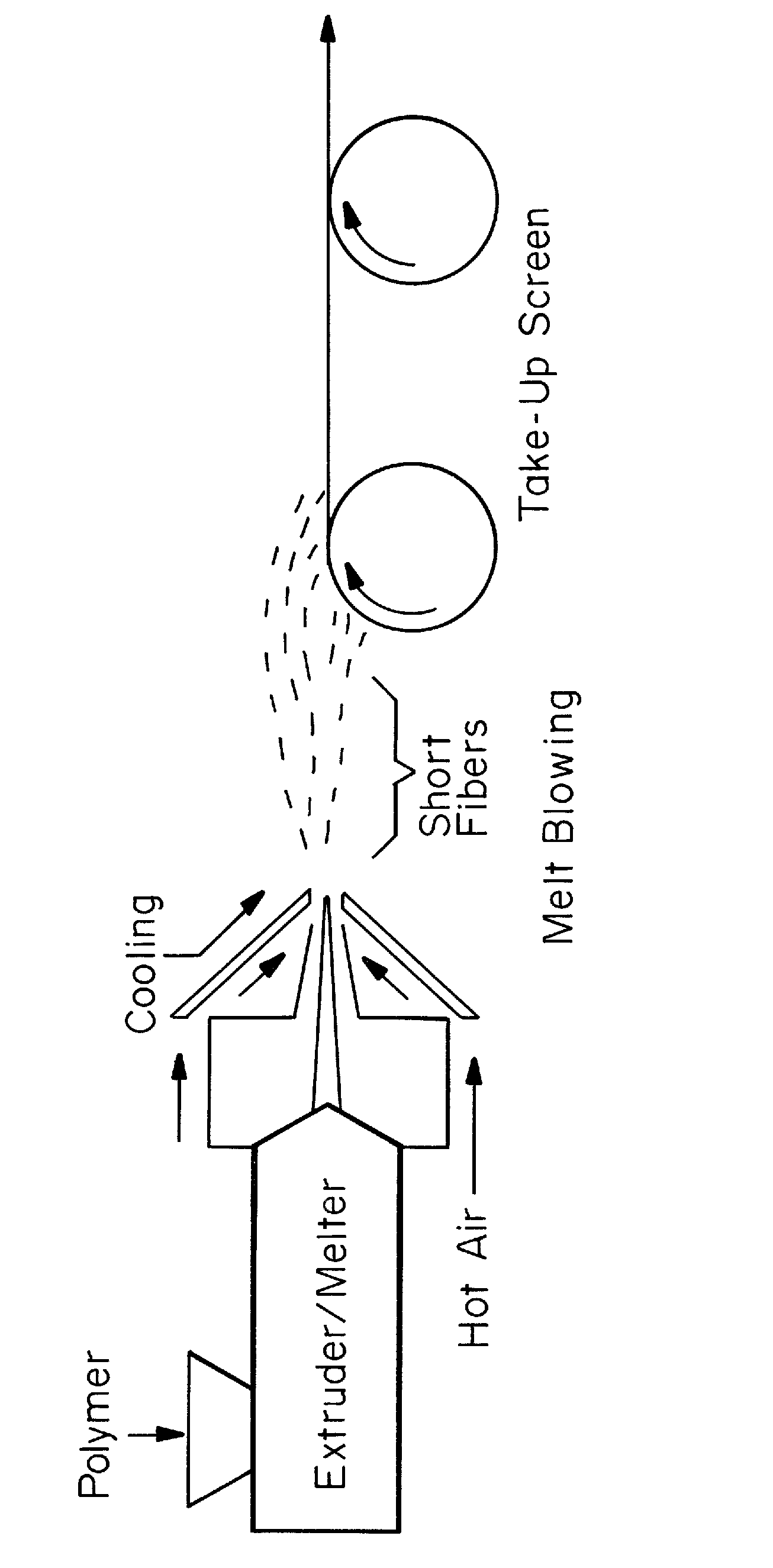

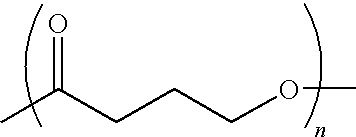

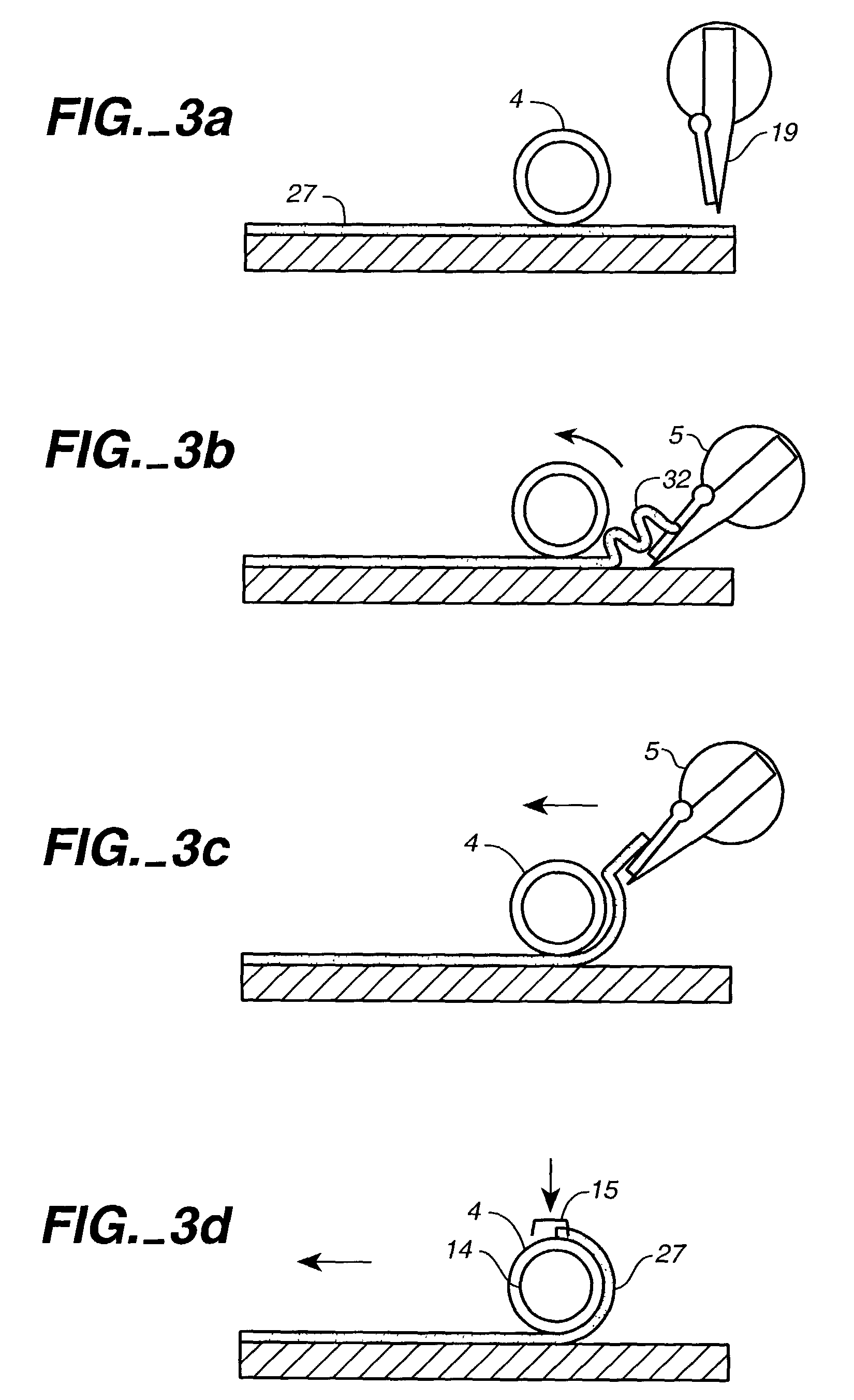

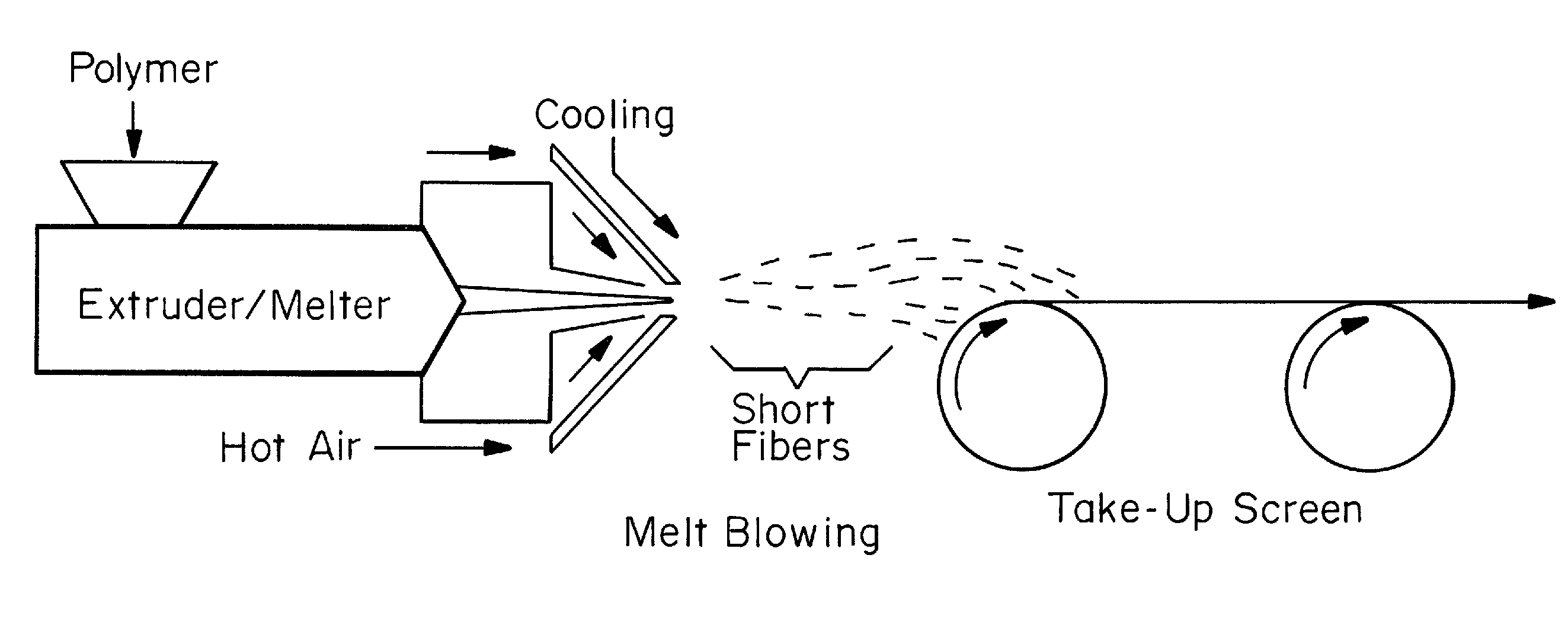

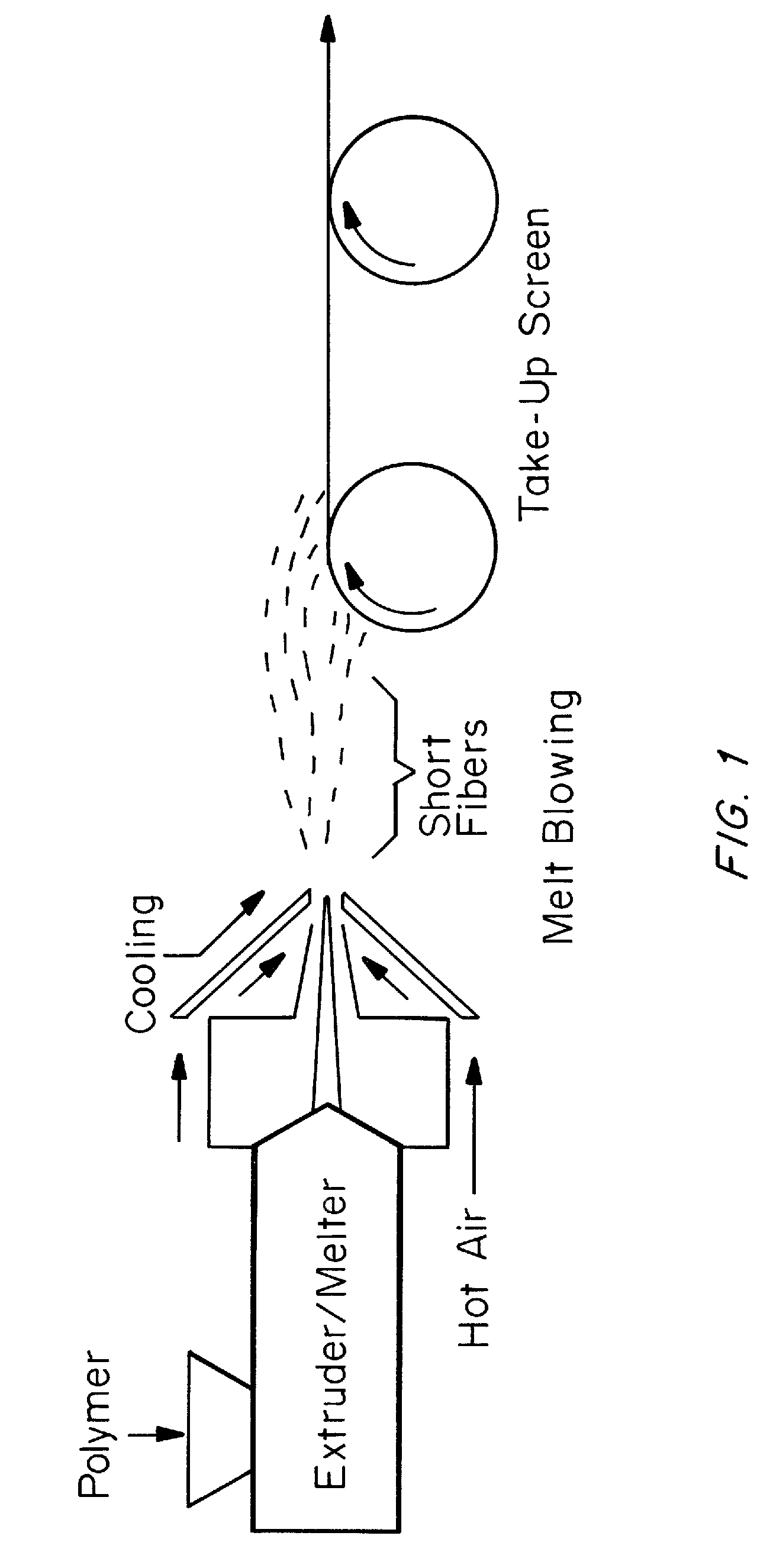

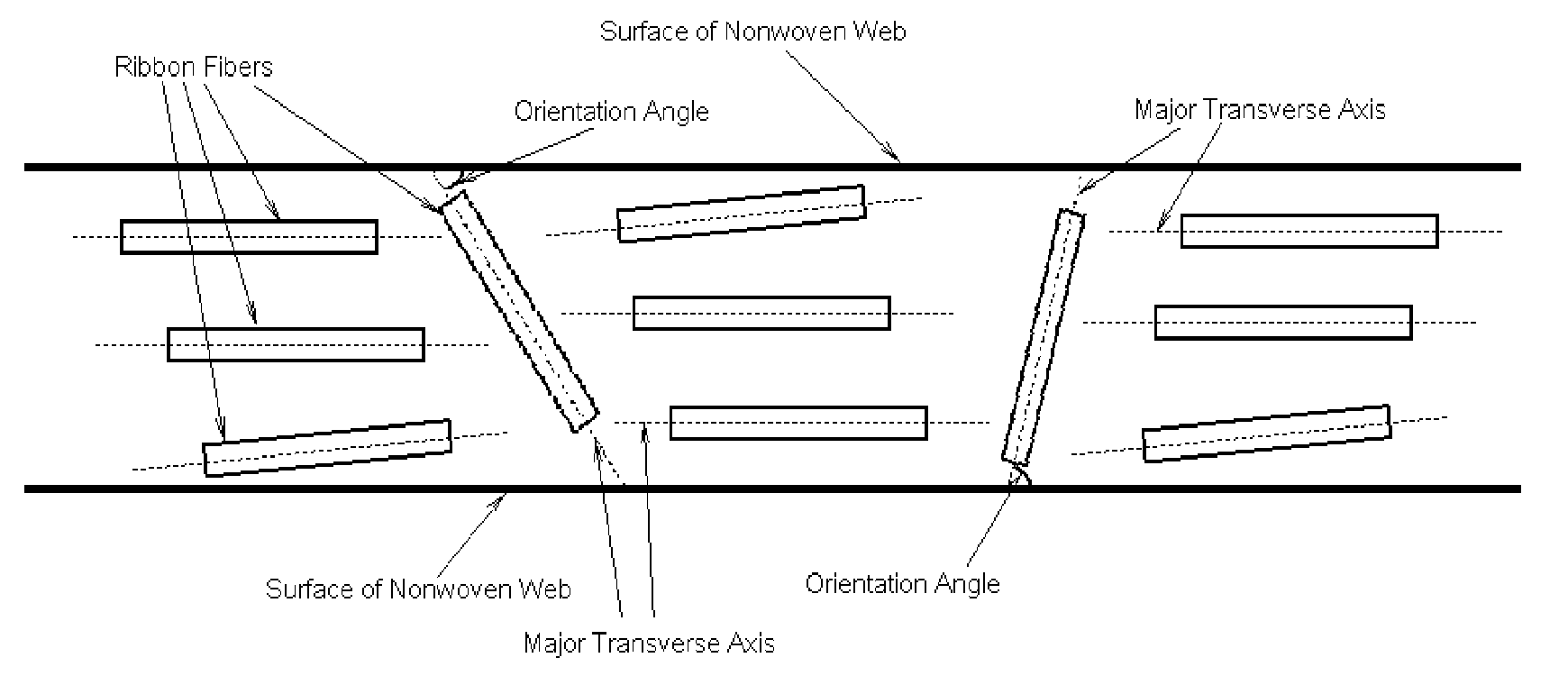

Medical devices containing melt-blown non-wovens of poly-4-hydroxybutyrate and copolymers thereof

Continuous processing methods for making absorbable polymeric non-wovens with one or more of the following properties: high burst strength, fine fibers of average diameter from 1 μm to 50 μm, and thickness from 10 μm to 50 mm, have been developed. Improved fiber cohesion is made possible by allowing the fibers of the non-woven to initially remain molten during web collection. In the preferred embodiment, the polymer is a polyhydroxyalkanoate, and in the most preferred embodiment, the polymer comprises 4-hydroxybutyrate. A particularly preferred embodiment is a non-woven of poly-4-hydroxybutyrate or copolymer thereof, wherein the non-woven has a burst strength greater than 0.1 Kgf, wherein the non-woven is derived by a continuous melt-blown process. The non-wovens can be used for a variety of purposes including fabrication of medical devices.

Owner:TEPHA INC

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN1864828AAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

The invention discloses a method for preparing intensified netted hollow fiber membrane, belonging to technology for preparing hollow fiber membrane. The process comprises: taking polyvinylidene fluoride as membrane material, N,N-dimethyl formamide as disslovant, polyvinyl pyrrolidon as additive, preparing membrane liquid according to a certain proportion among them; textiling hollow fiber membrane under certain temperature, pressure and dragging speed; braiding net with synthetic fiber out of hollow fiber membrane, putting intensified hollow fiber membrane sequentially through membrane producing liquid and coagulating bath; coating and congealing under certain temperature, pressure and dragging speed, and getting final product. The invention is characterized in that there is no clogging, the flow resistance is small, stretching intensity amounts to 10-50 MPa, bursting strength is 0.5-1 MPa, and the process is continous and easy for industrialization.

Owner:TIANJIN UNIV

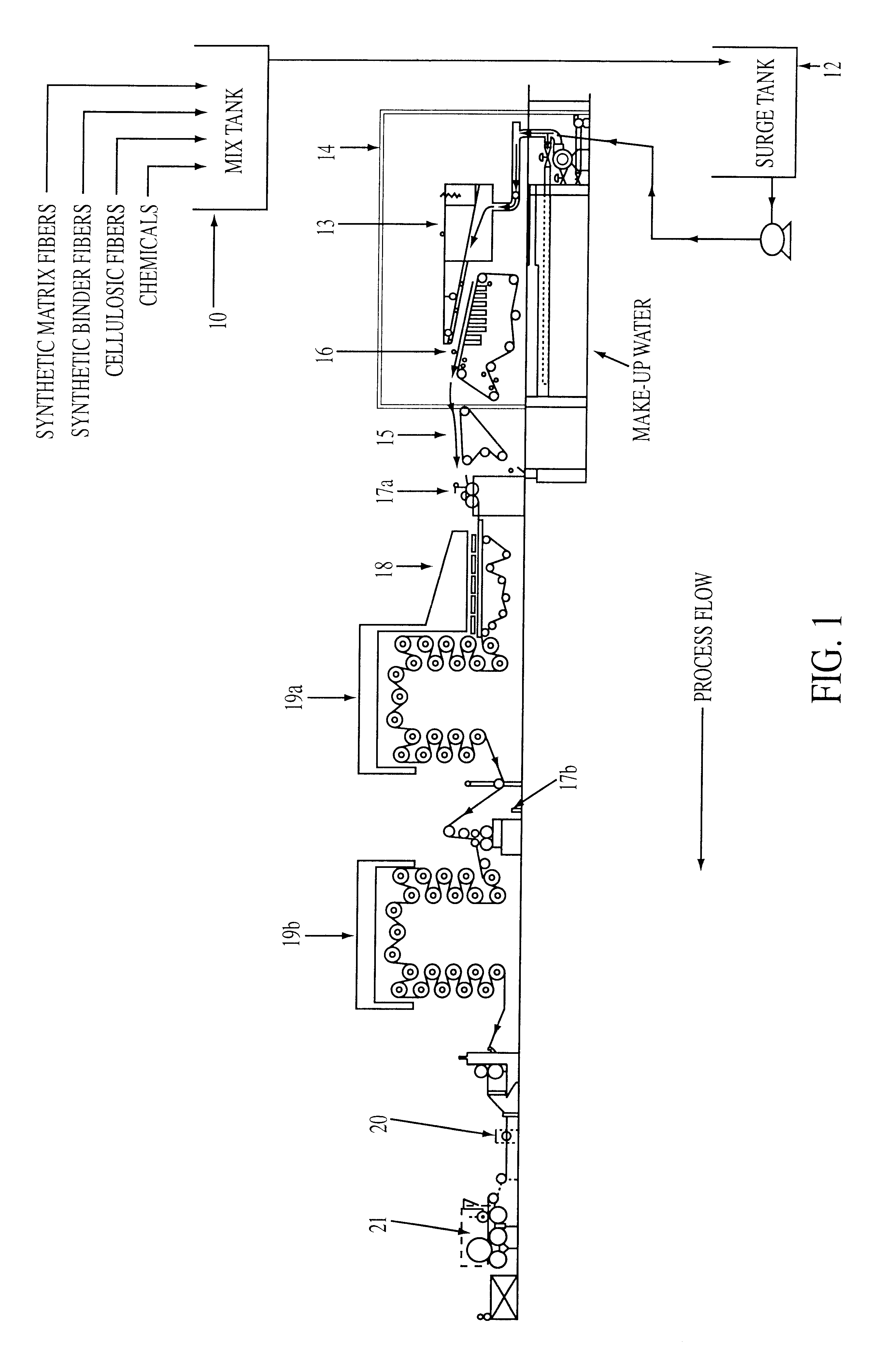

High efficiency thermally bonded wet laid milk filter

InactiveUS6352947B1Increase flow rateImprove filtering effectSynthetic resin layered productsPaper/cardboardFiberBursting strength

A filtration fabric which is composed of 15.0 to 100.0% binder fiber, 0.0 to 85.0% pulp portion, 0.0% to 15.0% latex binder or other stiffening agent. A filter media made of the fabric has an improved flow rate averaging no more than 21 seconds, while maintaining an average sediment retention of 70% and minimum wet burst strength of about 40 psi to about 50 psi, preferably about 50 psi.

Owner:AHLSTROM MOUNT HOLLY SPRINGS

Method of construction for density screening outer transport walls

InactiveUS6033564AThin and inexpensiveReduced toleranceRotary centrifugesCeramic shaping apparatusBursting strengthDynamic balance

A method for combining three different means of constructing the concentric layers of the outer collecting wall for industrial size centrifuges, whereby treating the inward-facing elements of easily cast or stamped materials using processes such as Physical Vapor Deposition, Chemical Vapor Deposition or metal plating, transforms them into an innermost member with superior hardness and durability, and whereby said wear surface member or deposited layer is physically supported by a middle composite layer made up of one or more investment castings designed to optimally transfer centrifugally-induced compression loads from the innermost wear surface toward the outer surface of the composite wall, such castings being of ceramic, metals or other materials, and whereby the outer surface of said composite wall is comprised of a filament-wound hoop strength reinforcement layer, using aramid, graphic, carbon or such fibers mixed and embedded in resin, such that all highly desirable characteristics for a centrifuge outer, heavies-collecting wall are provided, including interior hardness and wear abrasion, incompressibility and intrinsic dynamic balance, and substantially higher hoop or bursting strength, than can be attained through any metal-crafted centrifuge outer wall, and, model for model, for substantially lower design and fabrication costs.

Owner:BERKELEY F FULLER

Sulfopolyester binders

Owner:EASTMAN CHEM CO

Energy suppressors

ActiveUS7789008B2Good noise suppression characteristicsReduce the amplitudeWeapon componentsBursting strengthFiber

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

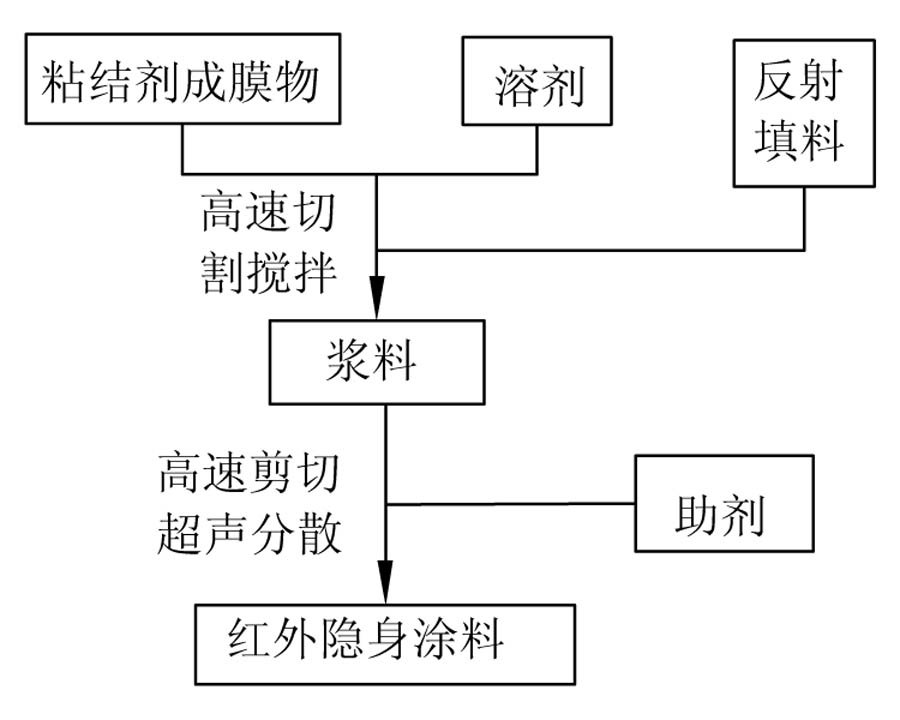

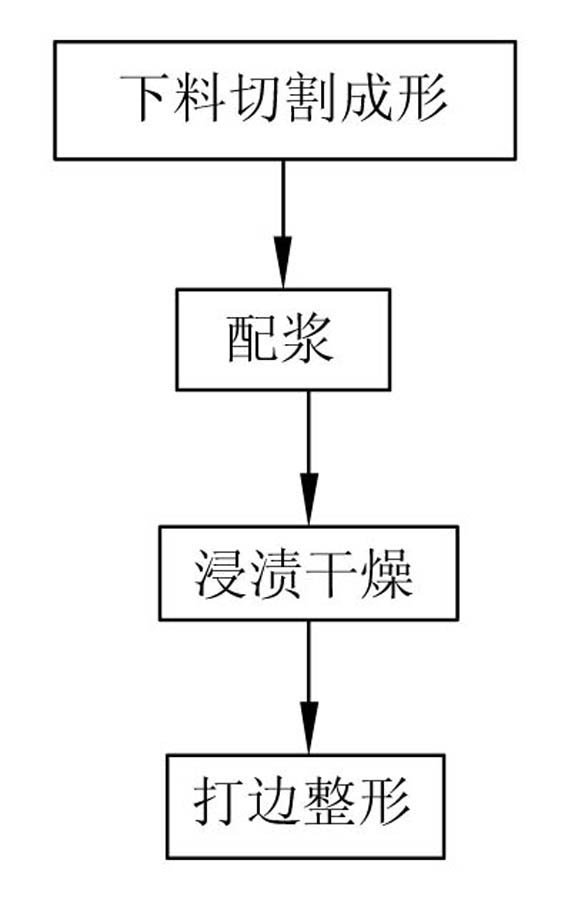

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

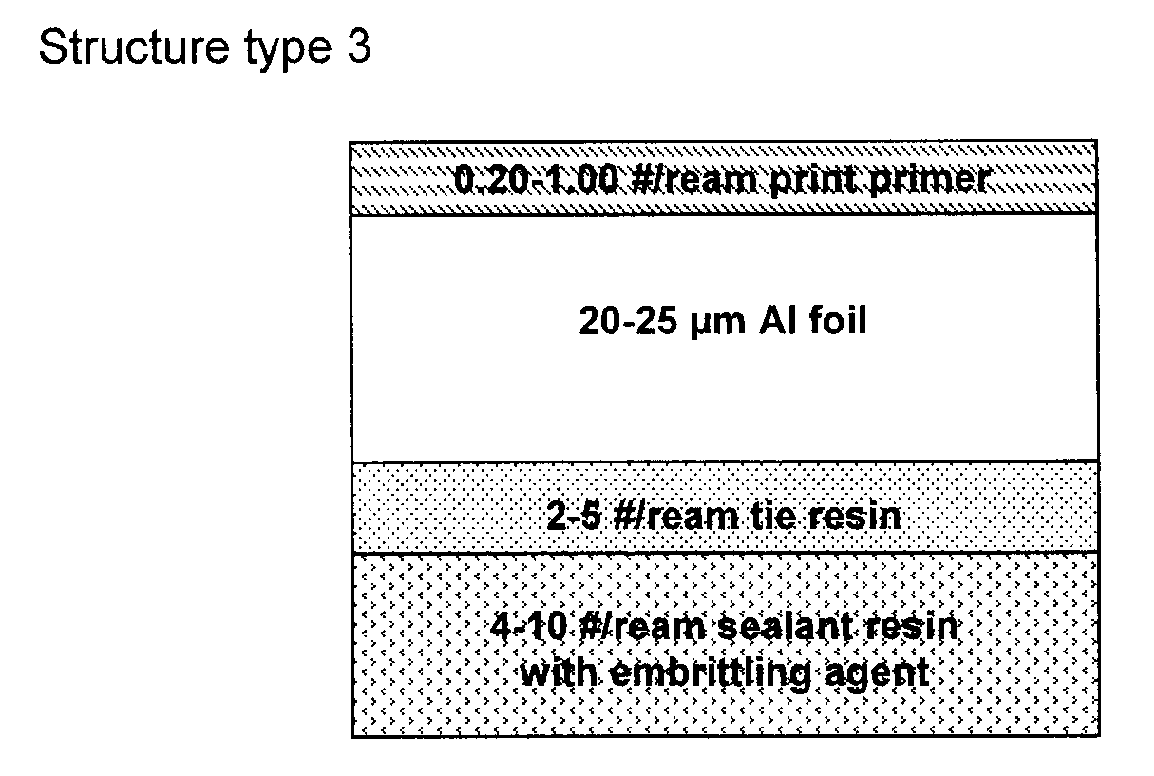

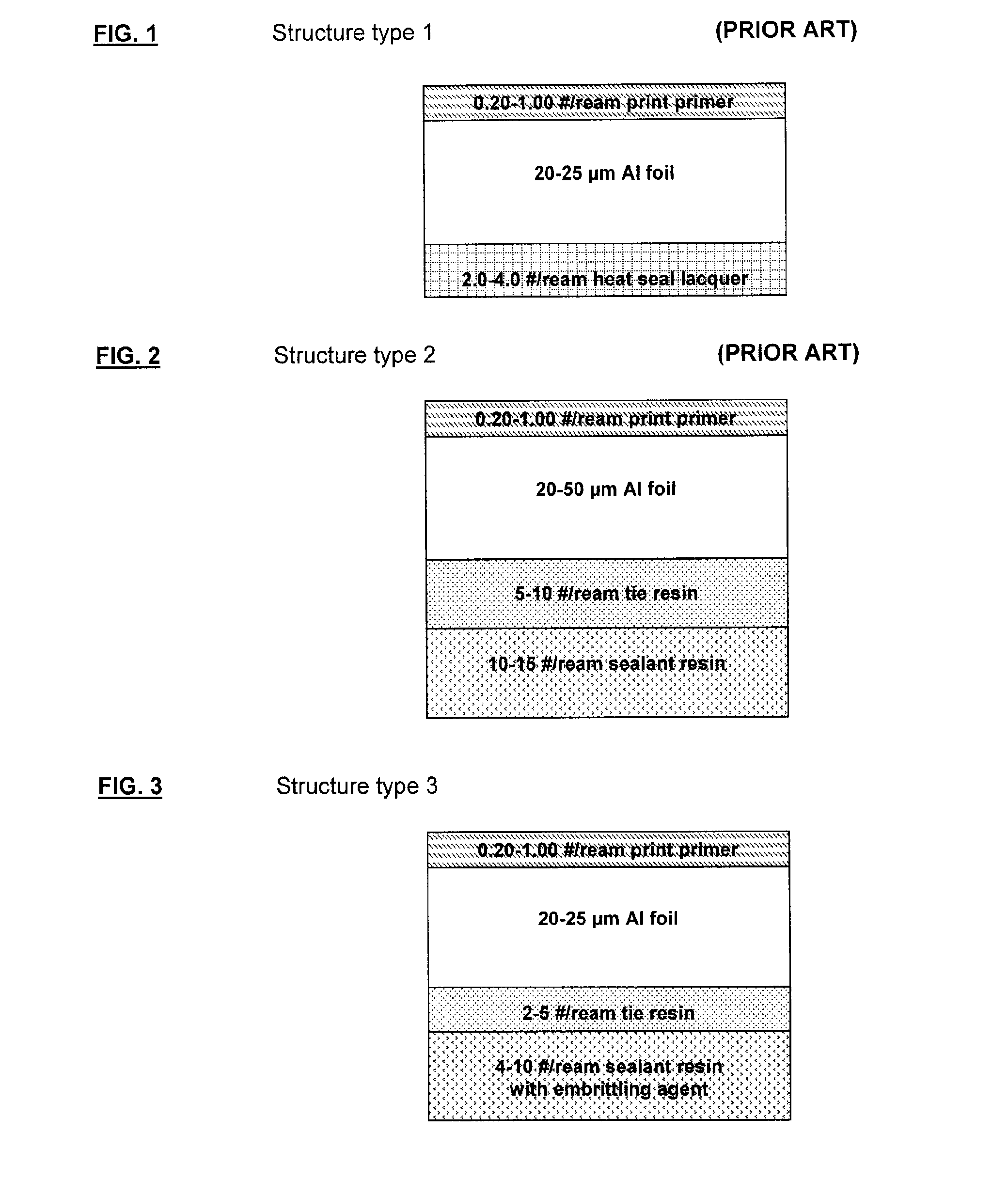

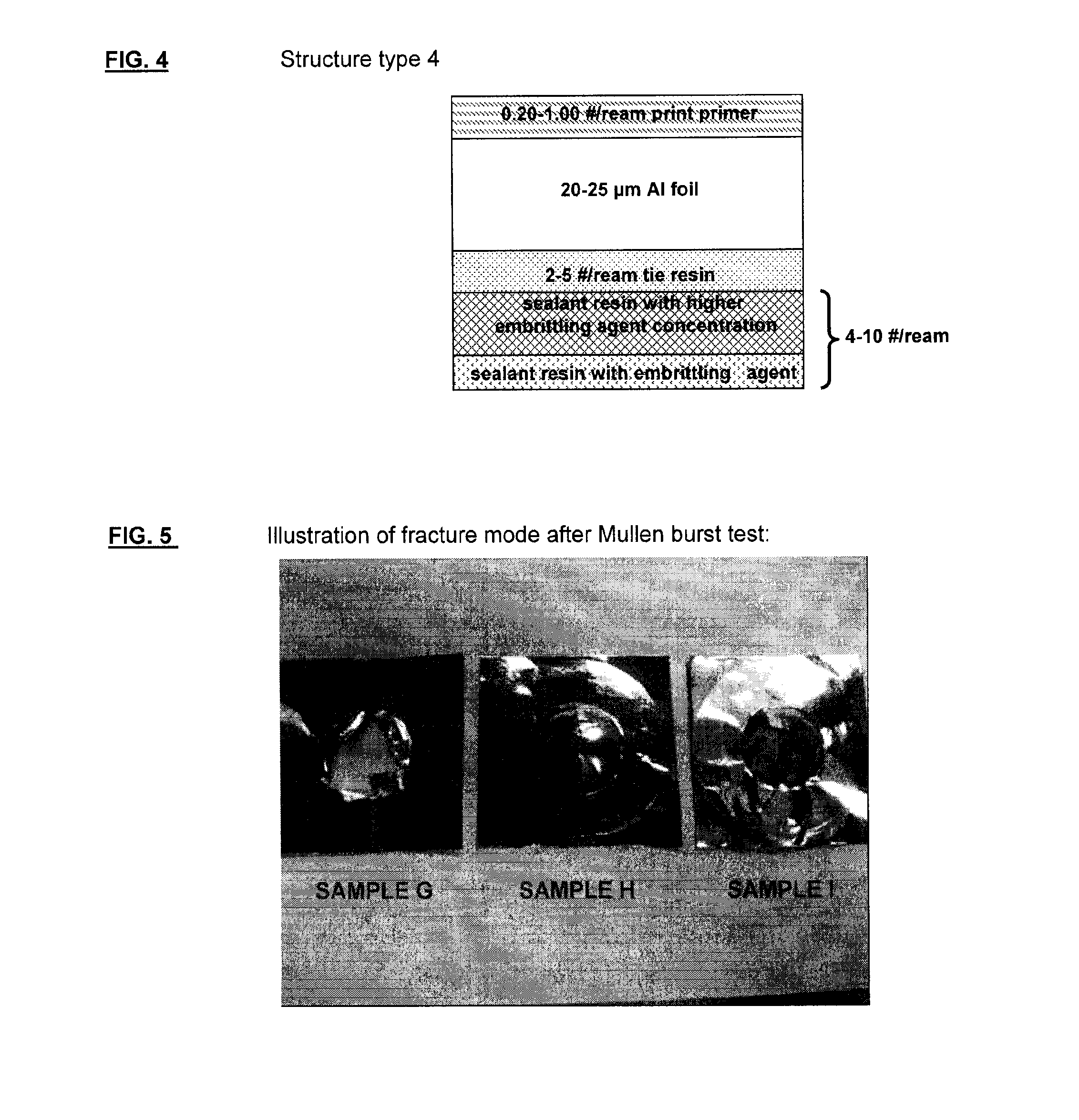

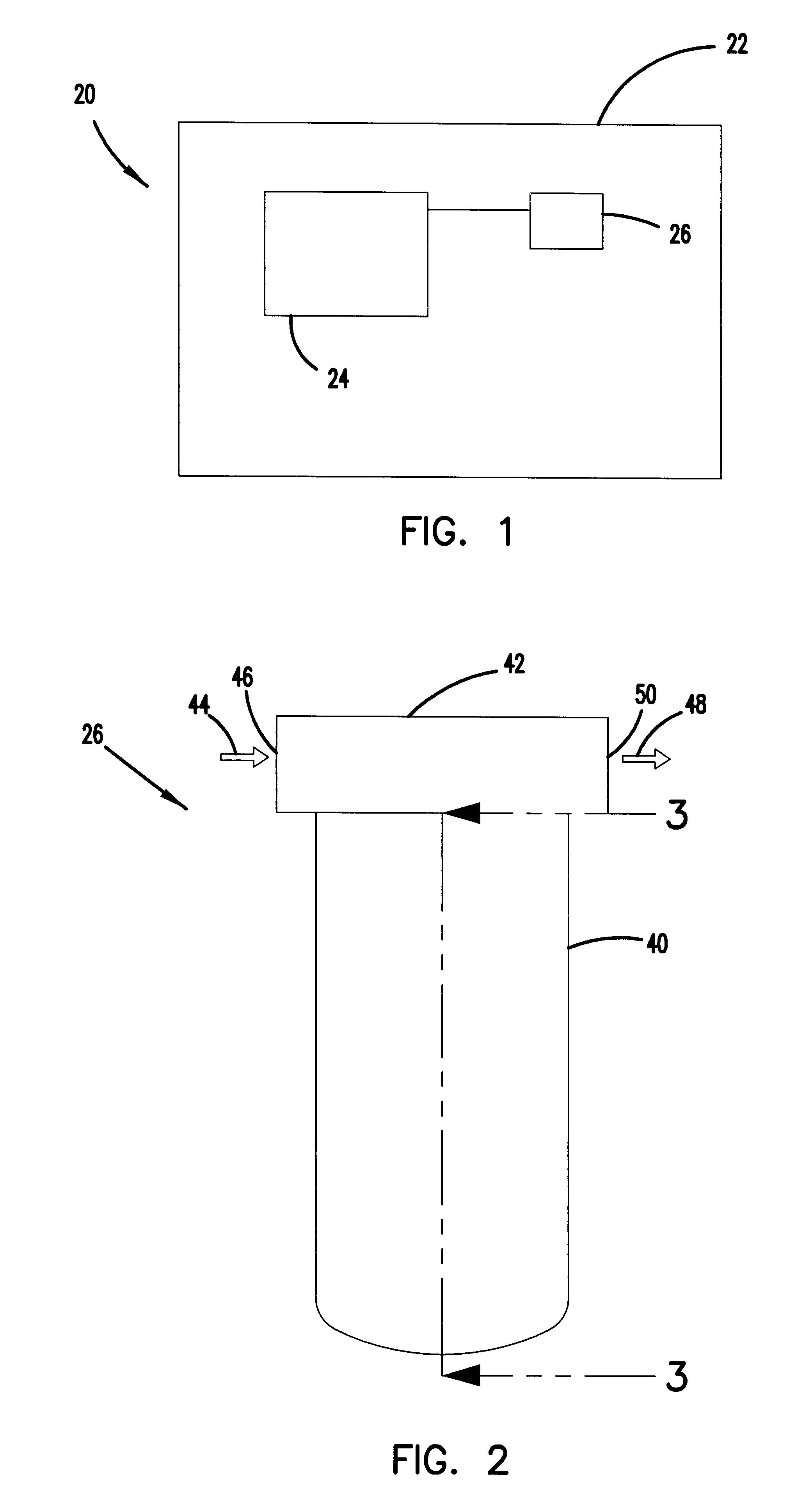

Extrusion-Coated Lidding Foil For Push-Through Blister Packaging

InactiveUS20110005961A1Small article dispensingContainer/bottle contructionBursting strengthGram-force

An extrusion-coated lidding foil for blister packaging particularly suitable for push-through pharmaceutical and food blister packaging. The lidding foil includes a foil layer on which one or more tie layer and one or more sealant layer, one or both of which include an embrittling agent mixed therein, are extrusion coated resulting in a lidding foil having push-through ability. The push-through ability of the lidding foil is characterized by a Mullen burst strength of about 10 psi to about 30 psi and an MD tear strength of about 30 to about 100 grams-force.

Owner:WINPAK HEAT SEAL PACKAGING

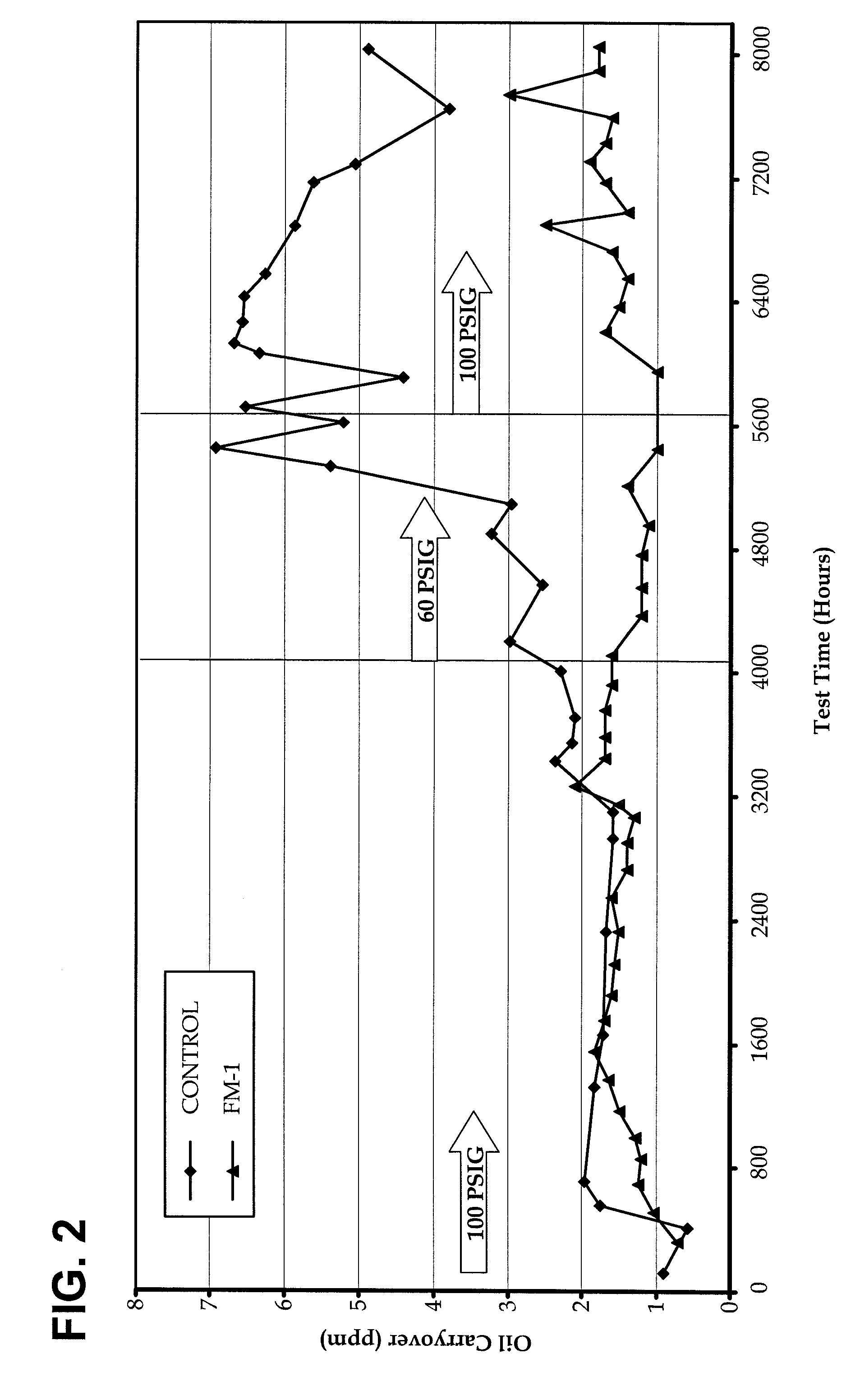

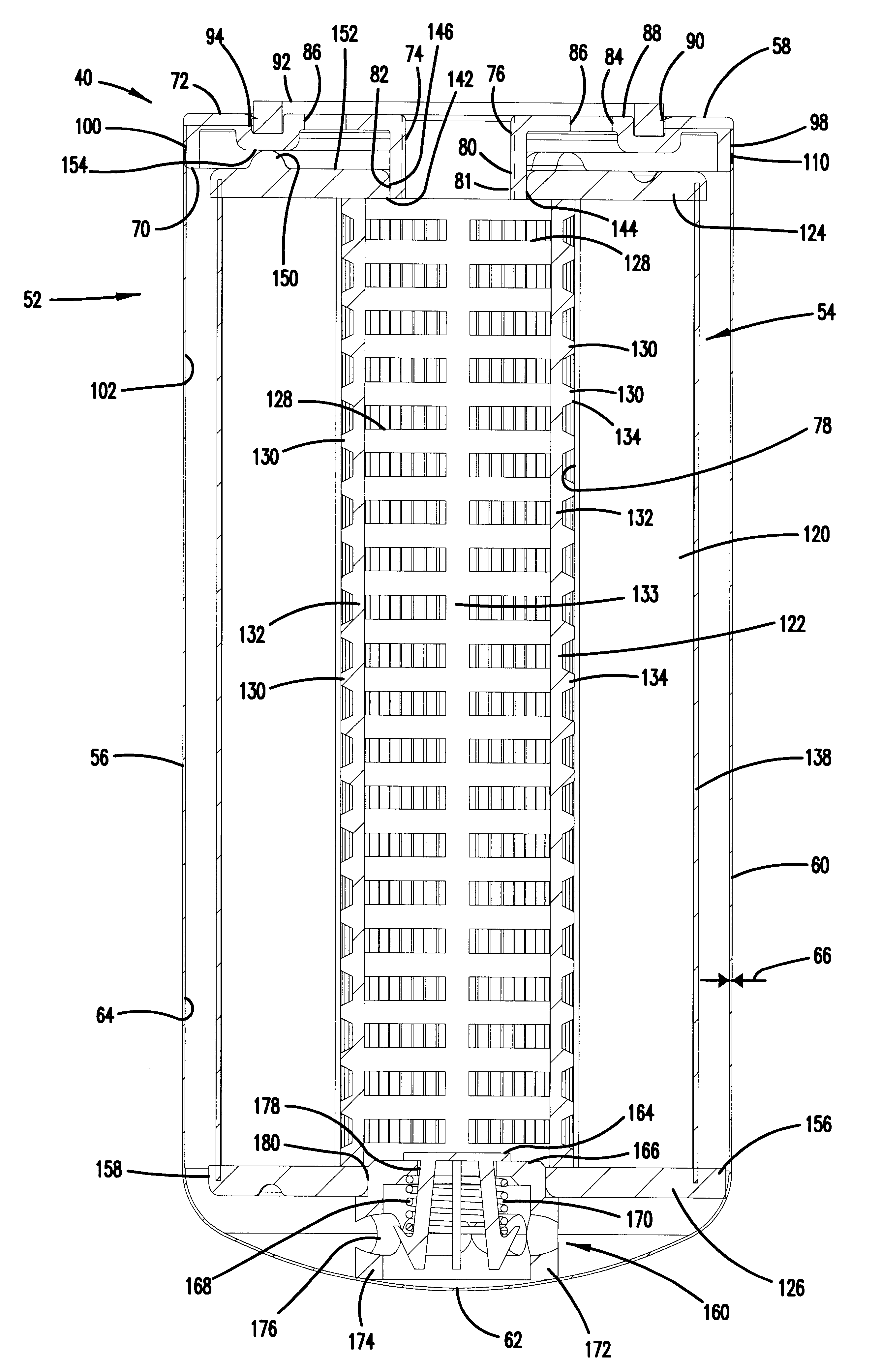

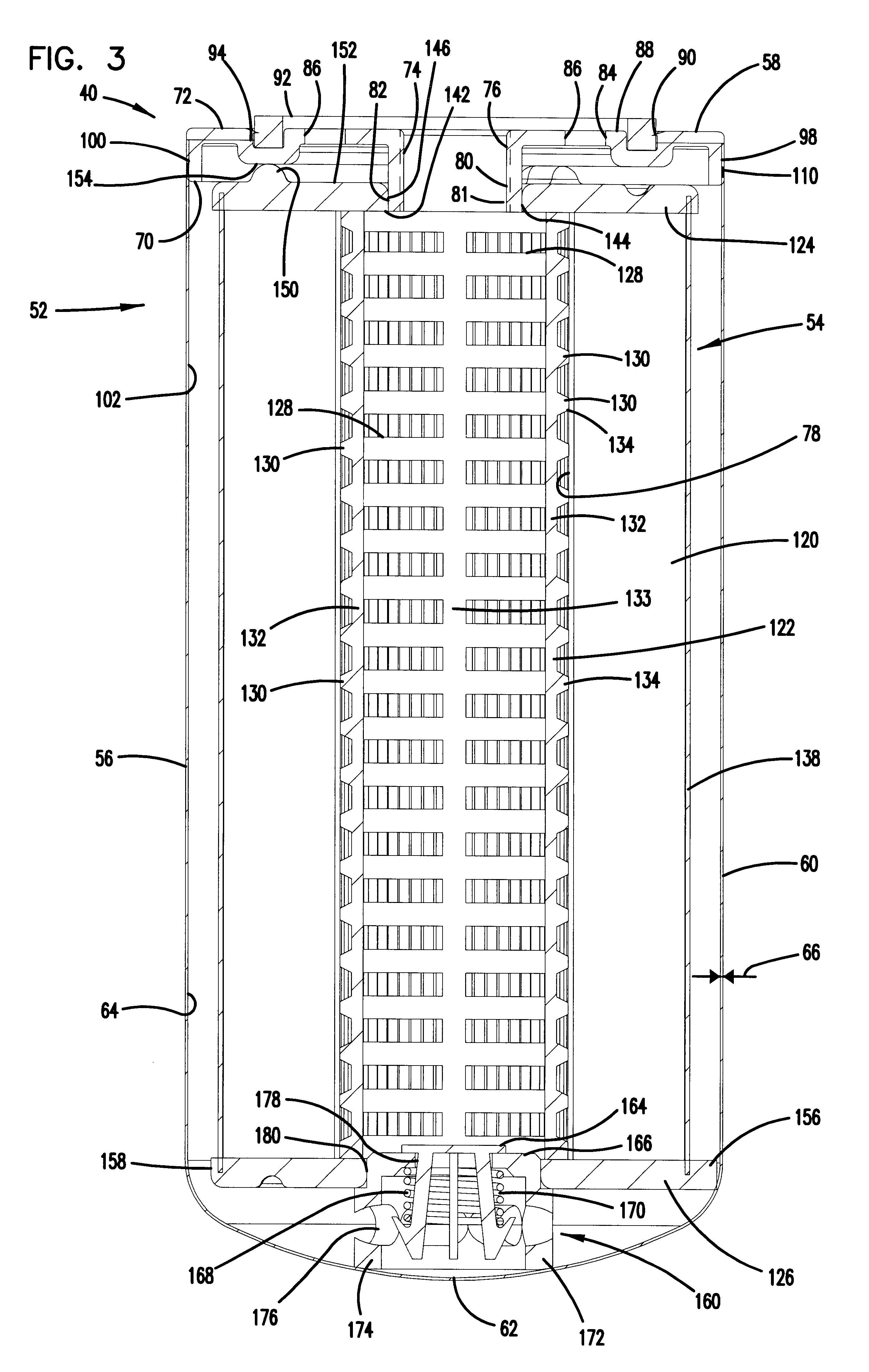

Liquid filter construction and methods

Owner:DONALDSON CO INC +1

Knit fabrics and base layer garments made therefrom with improved thermal protective properties

ActiveUS20090019624A1Effective thermal protective characteristicHigh tensile strengthChemical protectionHeat protectionFiberYarn

Knit fabrics and military apparel such as T-shirts made therefrom are disclosed. The fabrics are constructed from blended yarns made from an intimate combination of nylon and cotton staple fibers. Such fabrics comprise a weight ratio of cotton to nylon which ranges from about 55:45 to about 85:15, and these fabrics also have a weight ranging from about 3 to about 8 oz / yd2. Knit fabrics of this type possess a desirable combination of good thermal protective properties, provided the specified high level of staple fiber blend uniformity is achieved, along with very useful abrasion resistance, bursting strength and drying time characteristics.

Owner:INV PERFORMANCE MATERIALS LLC

High-temperature resistant fiber filter paper for engine oil filter and preparation method of high-temperature resistant fiber filter paper

ActiveCN102912680AImprove high temperature resistanceImprove toughnessNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses high-temperature resistant fiber filter paper for an engine oil filter and a preparation method of the high-temperature resistant fiber filter paper. The high-temperature resistant fiber filter paper comprises, by weight, 60-70 parts of coniferous wood pulp, 20-30 parts of cotton pulp, 20-30 parts of modified polyimide fiber, 2-5 parts of kaoline, 1-3 parts of lithopone, 2-4 parts of silica gel, 1-2 parts of nanometer titania, 0.5-0.8 part of ammonium polyphosphate, 1-2 parts of modified acrylic emulsion, 2-4 parts of acetic styrene-acrylic emulsion, 0.5-1 part of stearic acid monoglyceride, 0.5-1 part of silane coupling agent KH590, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of urea resin. The high-temperature resistant fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the high-temperature resistant fiber filter paper can reach 99.97%.

Owner:ANHUI PHOENIX INT CO LTD

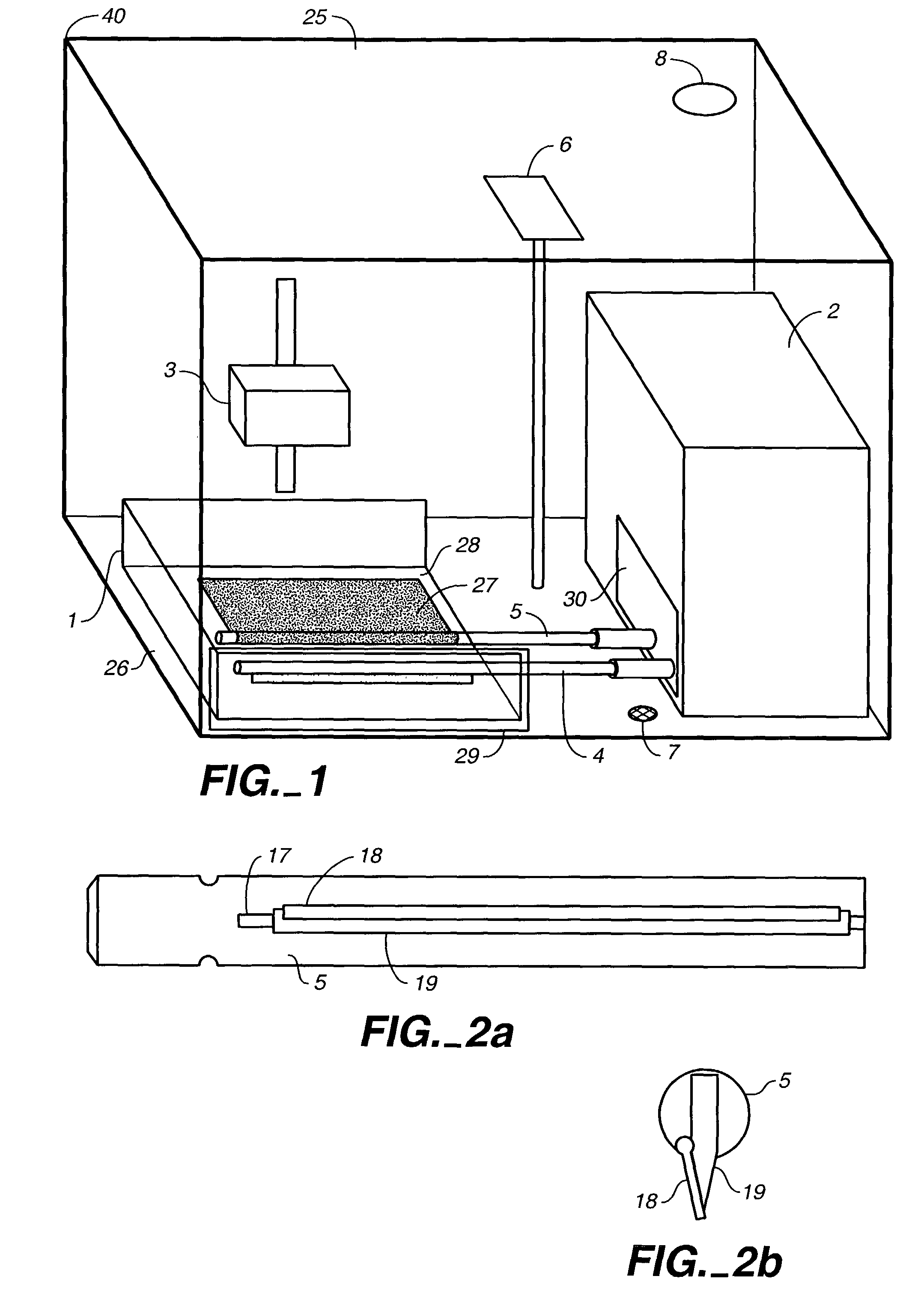

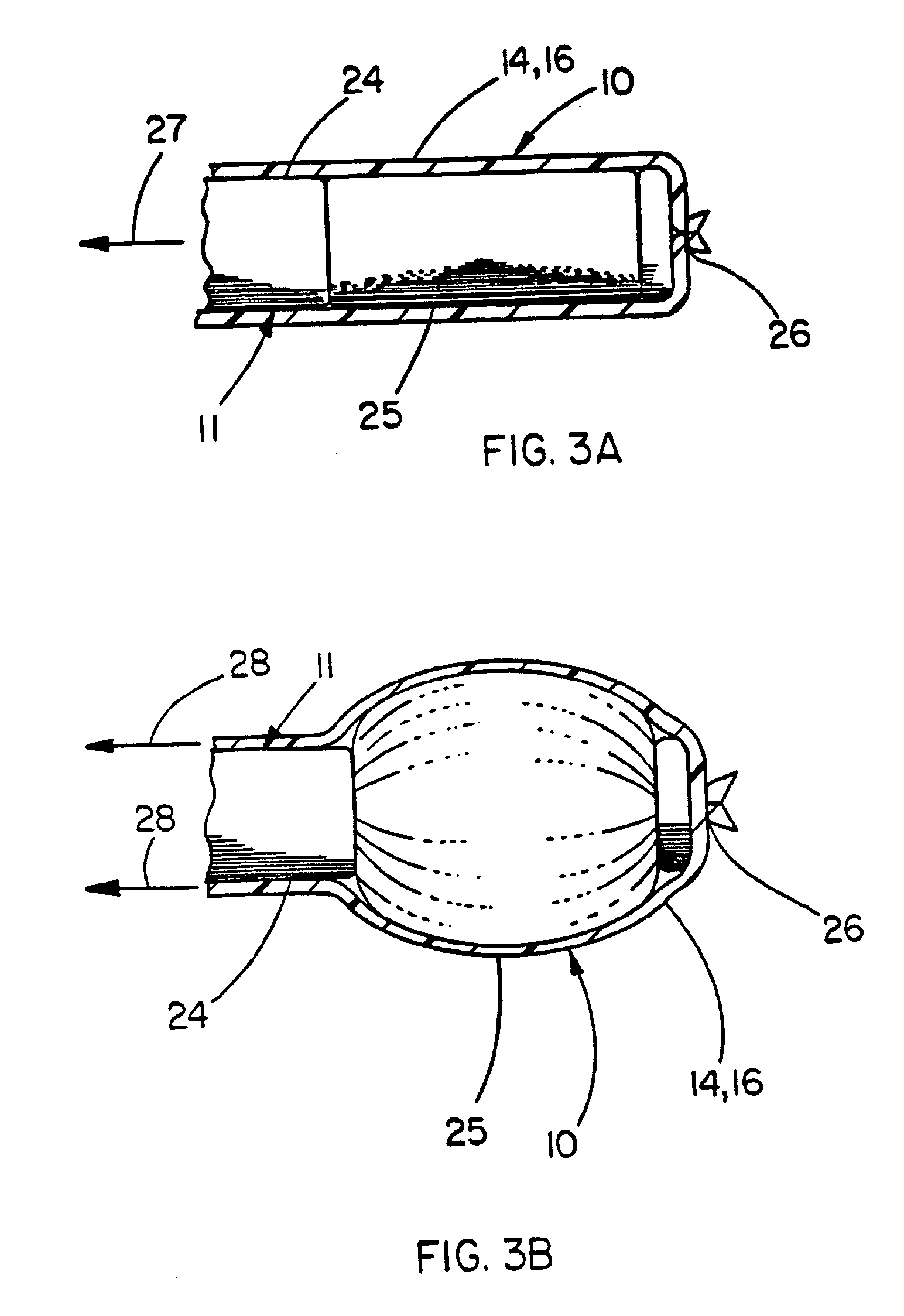

Tissue engineered blood vessels and apparatus for their manufacture

InactiveUS7112218B2Eliminate the problemBioreactor/fermenter combinationsBiological substance pretreatmentsBursting strengthFiber

The invention is a tissue engineered blood vessel (TEBV) made from a cultured fibroblast sheet rolled into a multilayer vessel which has sufficient burst strength to withstand physiological blood pressure without the inclusion of smooth muscle cells or synthetic scaffolding. The TEBV is made in a bioreactor having an enclosed chamber, a sheet growth module, a rollable mandrel, and a clamp for holding the sheet to the mandrel for rolling.

Owner:NIGHTINGALE INC

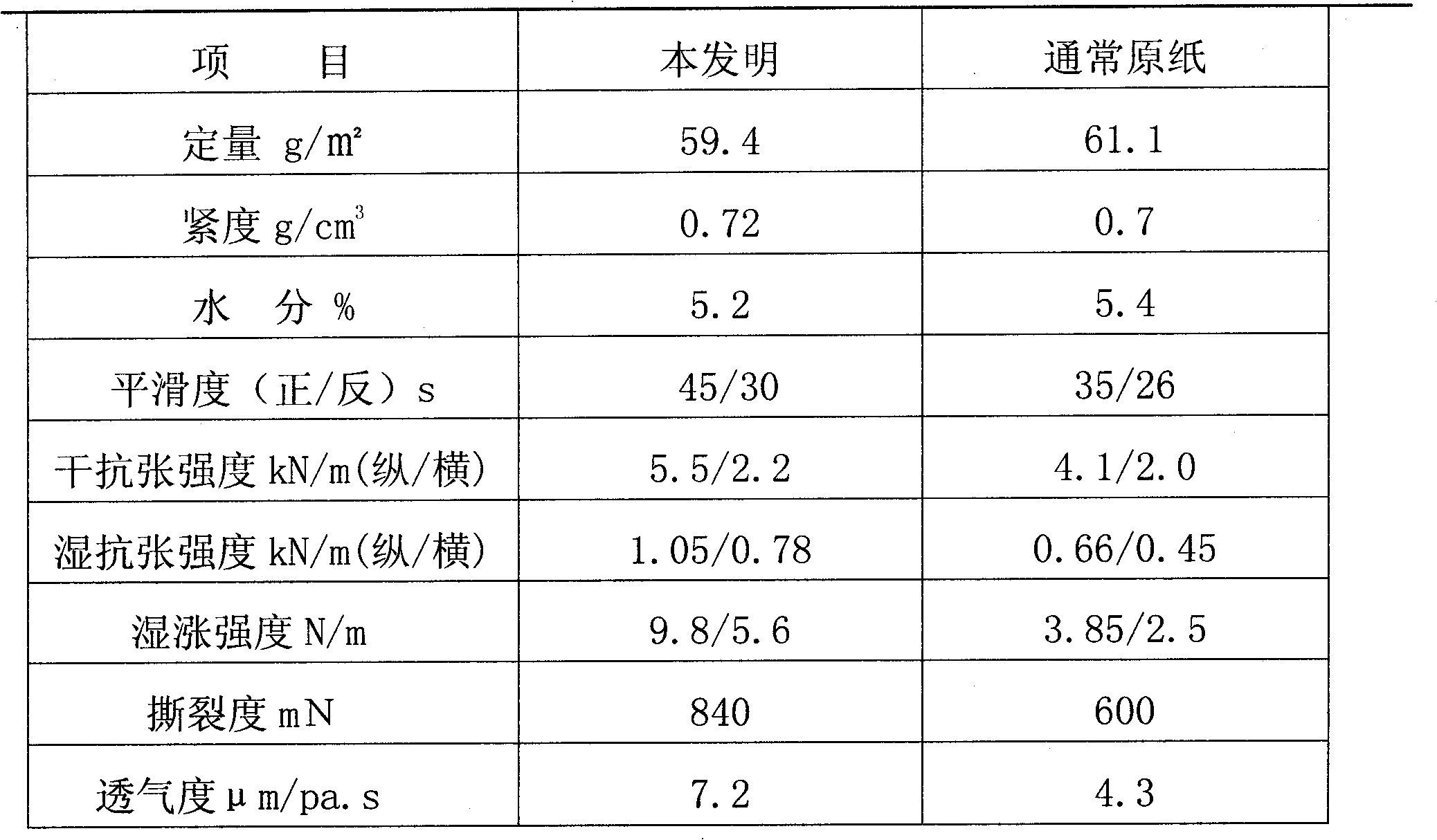

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

Dust filter bag including a highly porous backing material ply

InactiveUS20020083690A1Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

The invention relates to a dust filter bag having a highly porous backing material ply and to a method for producing the dust filter bag The dust filter bag comprises at least one filter material ply and at least one backing material ply, the backing material ply featuring an air permeability of at least 900 l / m2xs, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 N and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm2 and transversely better than 0.25 cN cm2, a basis weight of 30-80 g / m2 and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER

Solid dust suppressant

InactiveCN104817997AHigh bonding strengthGuaranteed moisture contentOther chemical processesBursting strengthMoisture absorption

A solid dust suppressant is prepared by mixing 40-90% of a water-soluble high molecular polymer, 5-40% of water-soluble high molecular glue, 0-25% of a moisture absorption humectant, 0.5-5% of a flexibilizer, 1-5% of an antiseptic and 3-10% of an osmotic agent, and has the characteristics of high film forming strength, low brightness and moderate viscosity. The viscosity (at 25DEG C), the pH value, the wind loss rate (under 30mm / s wind speed 5mins, %), the cured layer thickness, the film tensile strength, the film elongation at break and the material bursting strength of the solid dust suppressant are not lower than 8.0mPa.s, 6.0-7.0, not greater than 0.40, not lower than 11.25mm, greater than 11mpa, greater than 13% and greater than 0.05mpa respectively, and the solid dust suppressant realizes difficult brittle rupture after film formation, has a long effective dust suppression time and an ideal dust suppression effect.

Owner:INNER MONGOLIA BORAN TECH CO LTD

Process for preparing starch grafting acrylamide paper reinforcing agent

InactiveCN102617799AGood storage stabilitySmall molecular weightReinforcing agents additionPaper/cardboardBursting strengthEmulsion

The invention relates to a process for preparing a starch grafting acrylamide paper reinforcing agent, which includes the following steps of adding an oxidant and sodium hydroxidein into a starch emulsion for an oxidizing reaction at the temperature between 30 DEG C and 80 DEG C; adding a cationization reagent for a cationization reaction at the temperature between 30 DEG C and 90 DEG C; gelatinizing and cooling the obtained starches, utilizing acrylamide and cation monomers as mixed grafting monomers, adding initiating agents, performing a graft copolymerization reaction in the aqueous phase at the temperature between 40 DEG C and 80 DEG C, and obtaining a starch grafting copolymer. The starch grafting copolymer is a reinforcing agent capable of being used in improving the ring crush strength, the bursting strength, the stiffness and the like of papers.

Owner:GUANGDONG PAPER IND RES INST

Medical devices containing melt-blown non-wovens of poly-4-hydroxybutyrate and copolymers thereof

Continuous processing methods for making absorbable polymeric non-wovens with one or more of the following properties: high burst strength, fine fibers of average diameter from 1 μm to 50 μm, and thickness from 10 μm to 50 mm, have been developed. Improved fiber cohesion is made possible by allowing the fibers of the non-woven to initially remain molten during web collection. In the preferred embodiment, the polymer is a polyhydroxyalkanoate, and in the most preferred embodiment, the polymer comprises 4-hydroxybutyrate. A particularly preferred embodiment is a non-woven of poly-4-hydroxybutyrate or copolymer thereof, wherein the non-woven has a burst strength greater than 0.1 Kgf, wherein the non-woven is derived by a continuous melt-blown process. The non-wovens can be used for a variety of purposes including fabrication of medical devices.

Owner:TEPHA INC

Wet-Laid process to produce a bound nonwoven article

Owner:EASTMAN CHEM CO

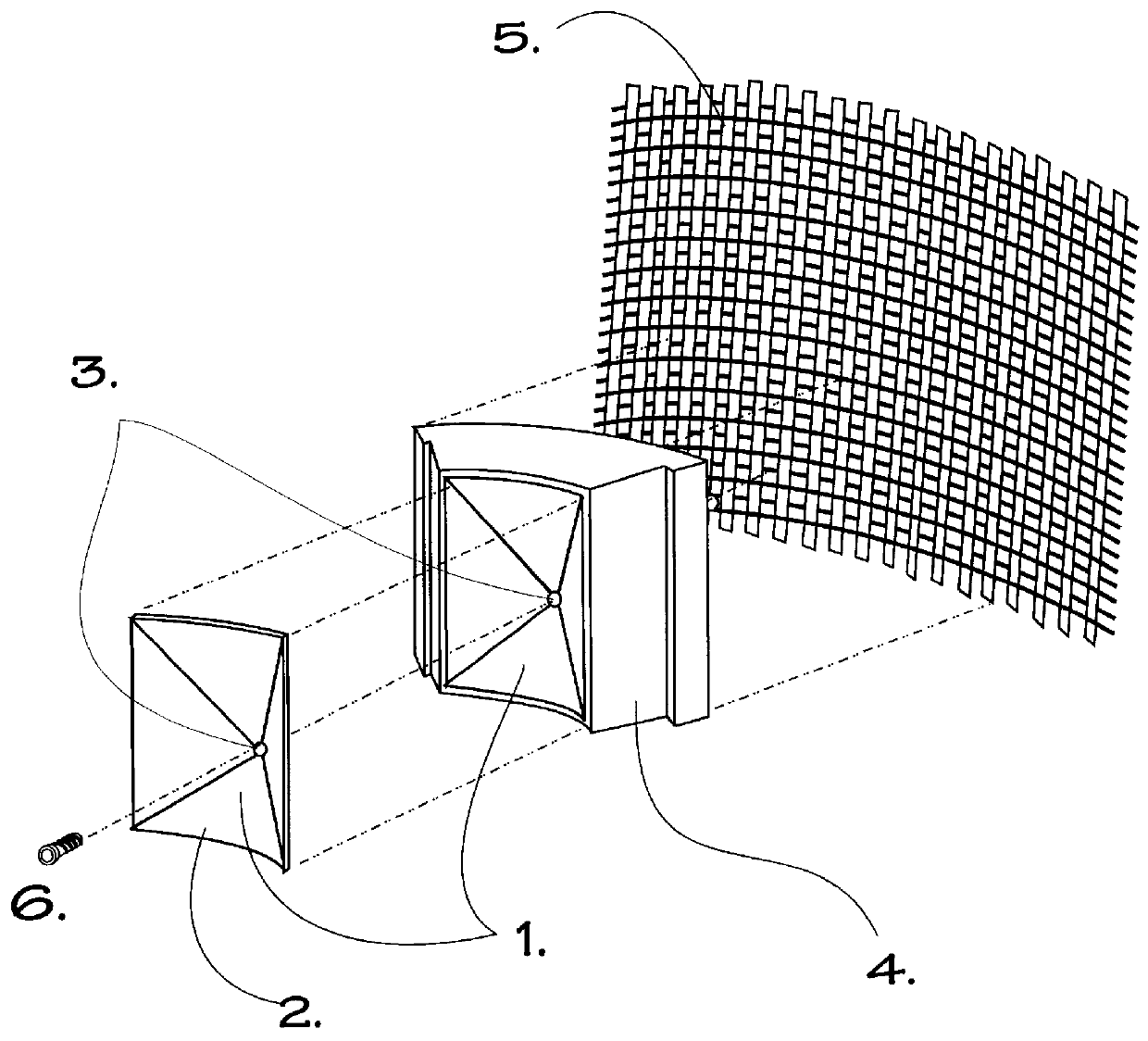

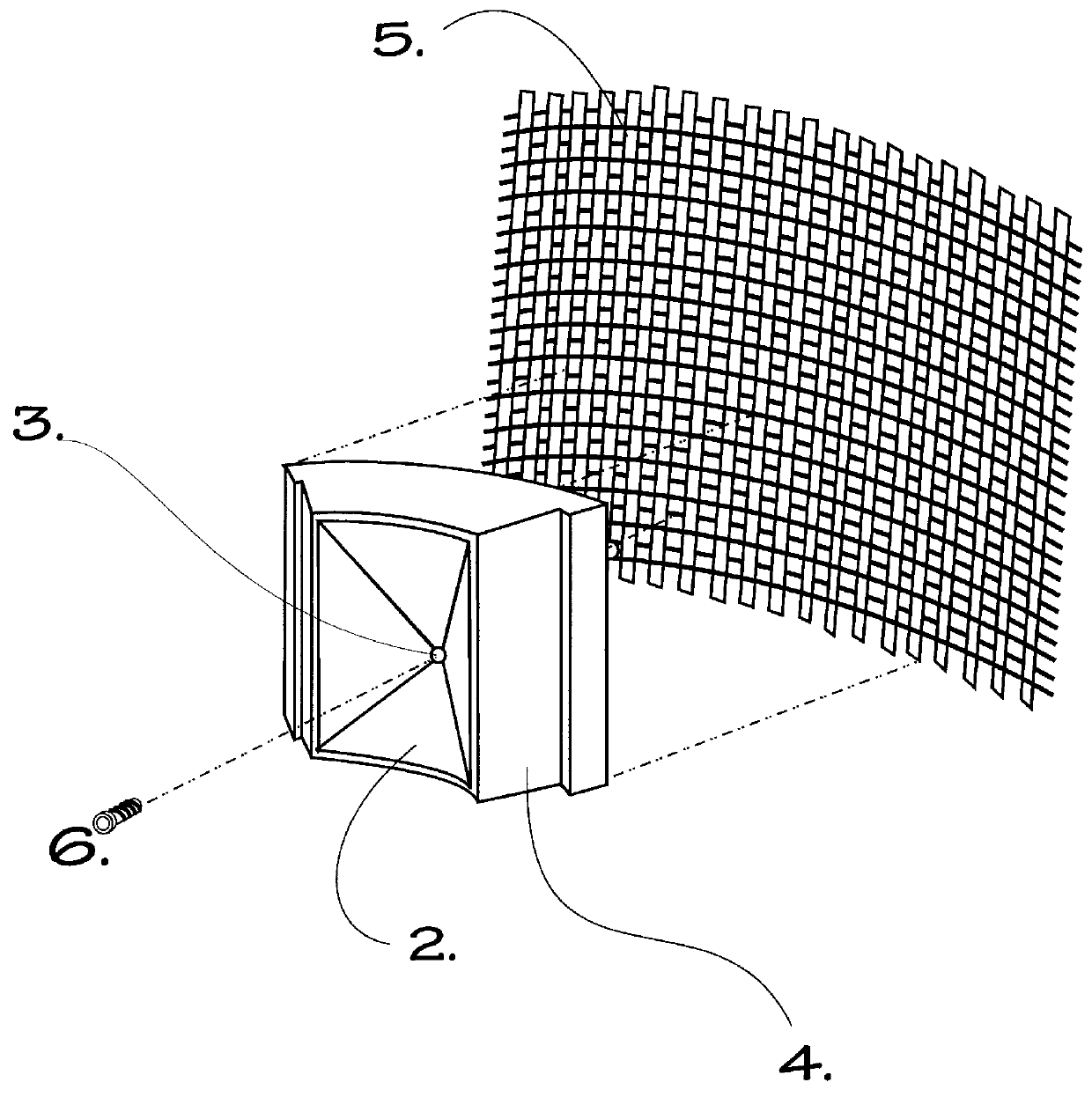

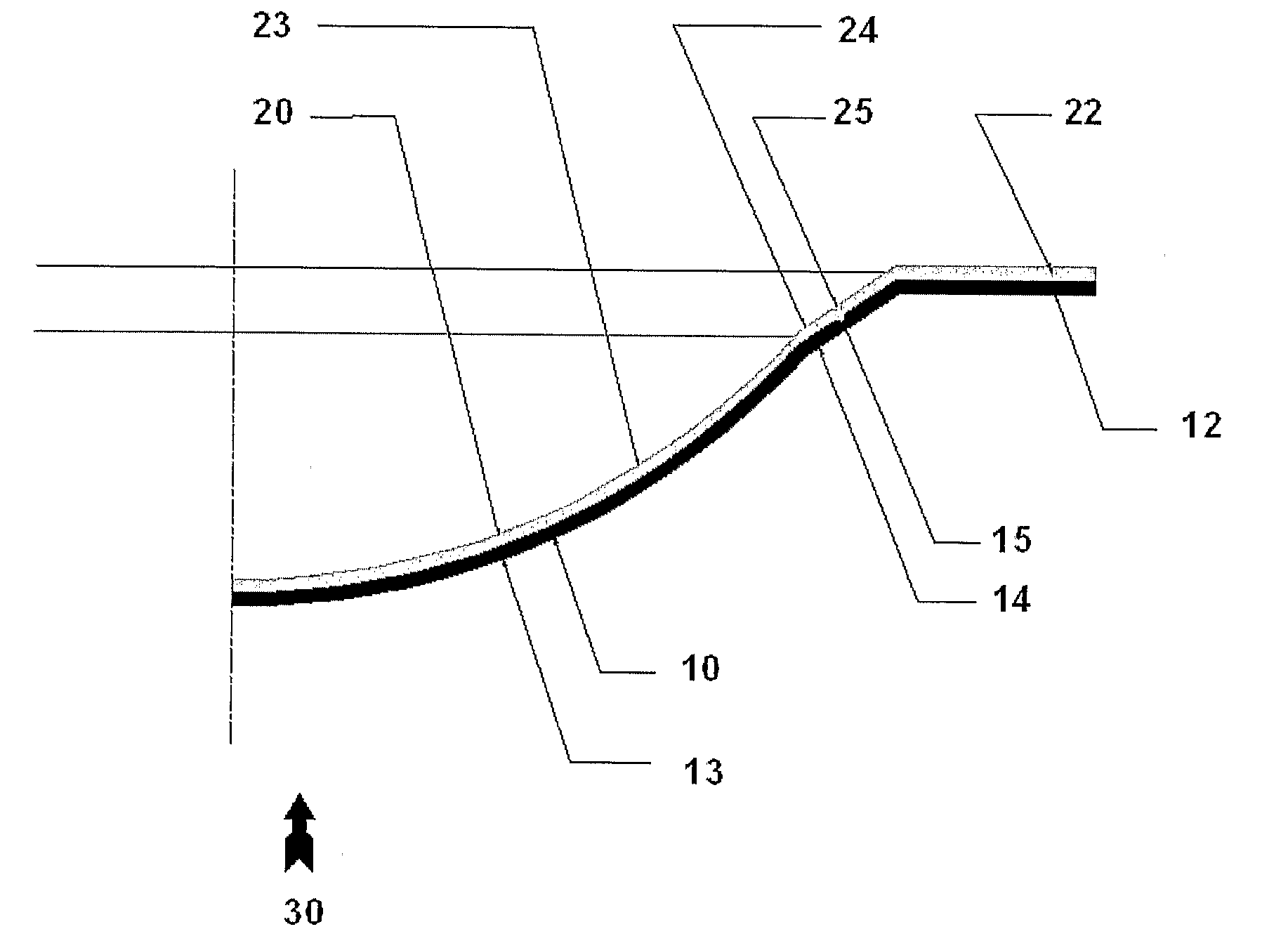

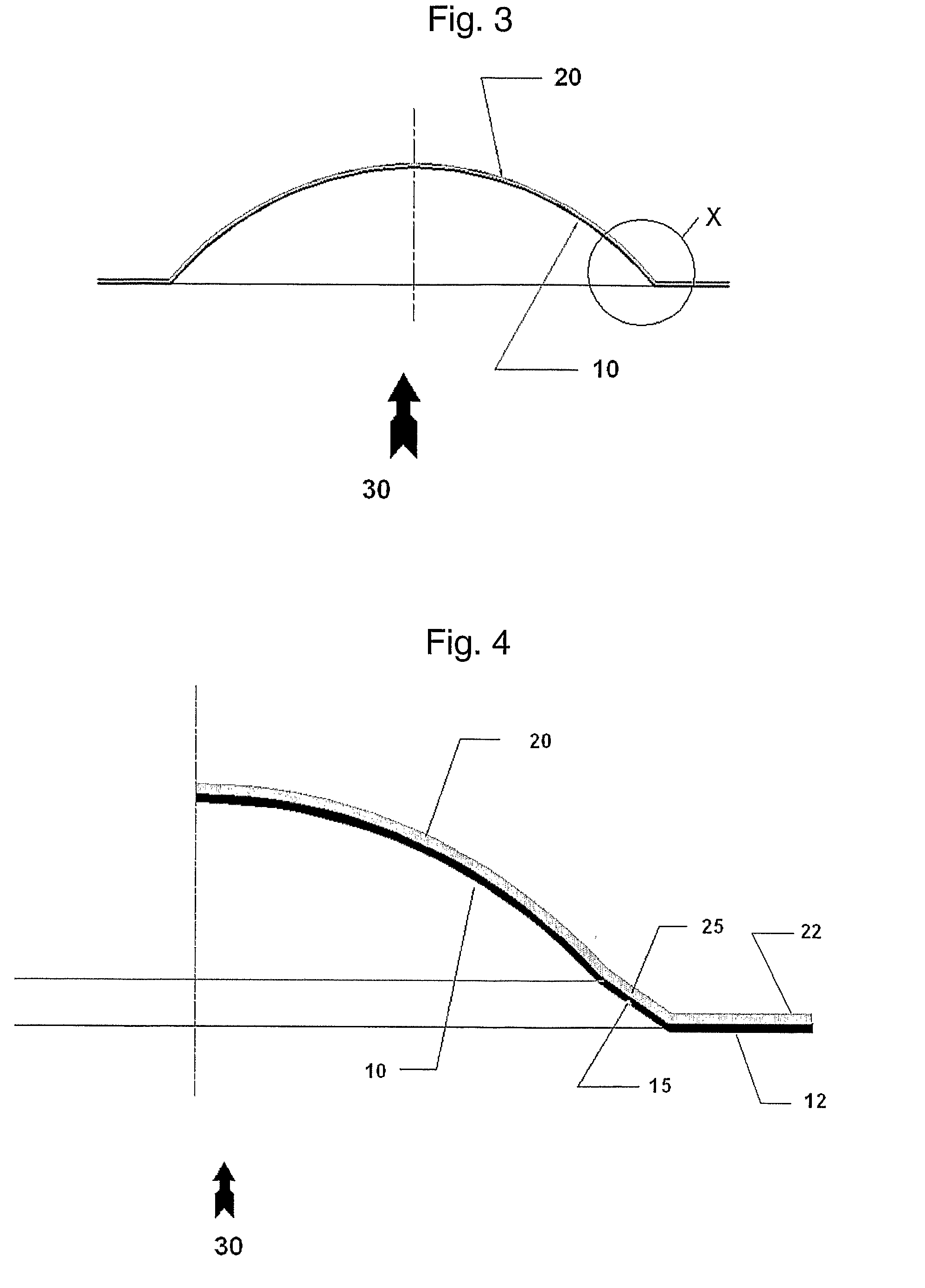

Bursting Disc Assembly

ActiveUS20080202595A1Easy to controlHigh strengthLarge containersEqualizing valvesBursting strengthDISC assembly

The bursting disc assembly has a primary bursting disc (10) and a secondary bursting disc (20) immediately behind and supporting the primary bursting disc. Each of the said discs (10,20) is made of metal and is gas impermeable, and the bursting strength of the assembly is derived from both of the bursting discs acting in combination. The primary and secondary bursting discs are in contact over the whole of the operating area of the disc, and are shaped together as a pair The materials of the two discs can be chosen suitably for their functions. The primary disc is for example corrosion-resistant.

Owner:ELFAB LTD

Balloon catheter device

InactiveUS20050273152A1Bursting strengthAid in insertion and withdrawalStentsBalloon catheterBursting strengthAngioplasty balloon

Balloon catheters having the strength and maximum inflated diameter characteristics of an angioplasty balloon and having the recovery characteristics during deflation of an elastic embolectomy balloon. The balloon catheter can be made in very small sizes and has a lubricious and chemically inert outer surface. The balloon catheter is easy to navigate through tortuous passageways, is capable of rapid inflation and deflation and has high burst strengths. Balloon covers having these same characteristics are also described for use with conventional embolectomy balloons or angioplasty balloons.

Owner:WL GORE & ASSOC INC

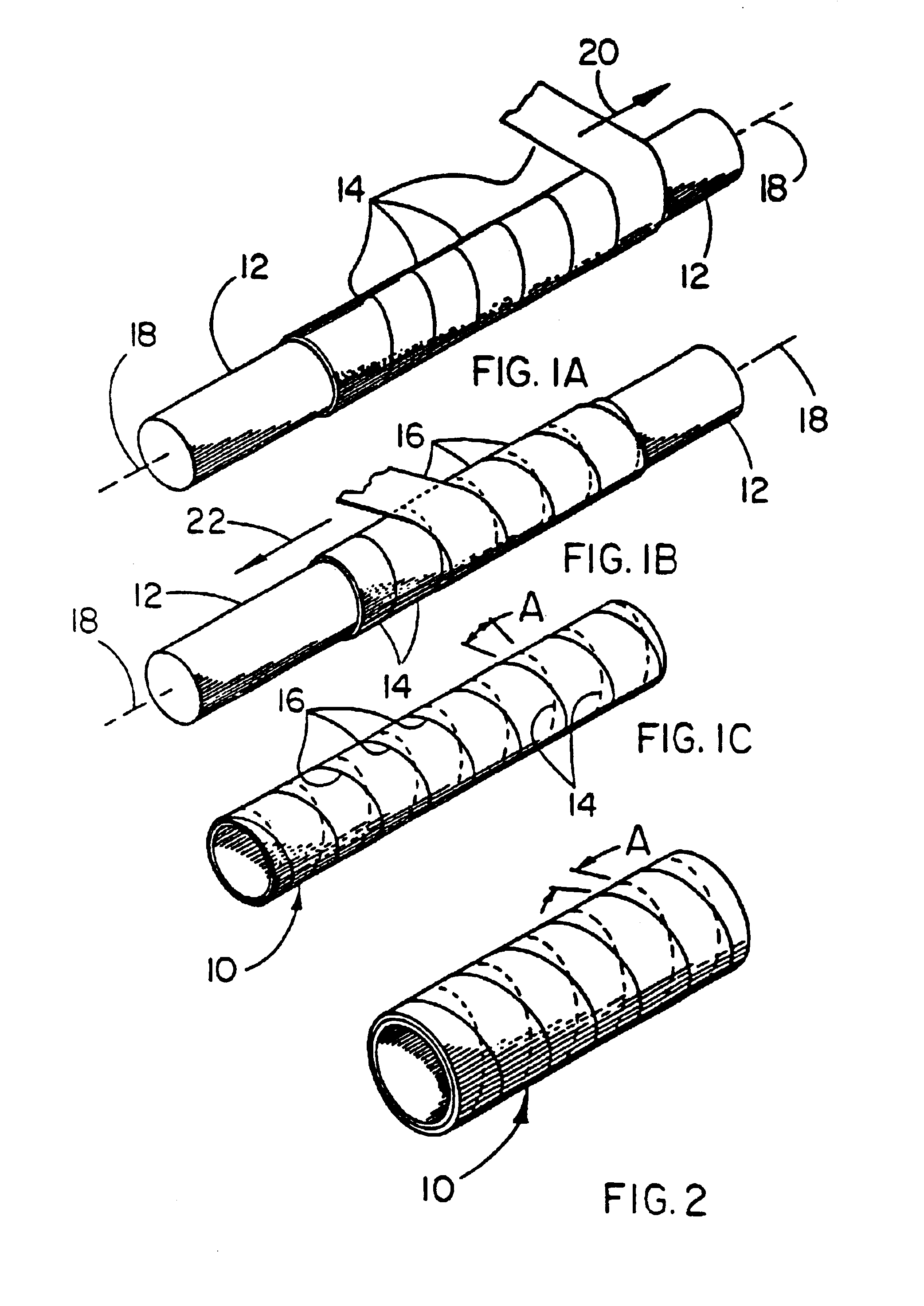

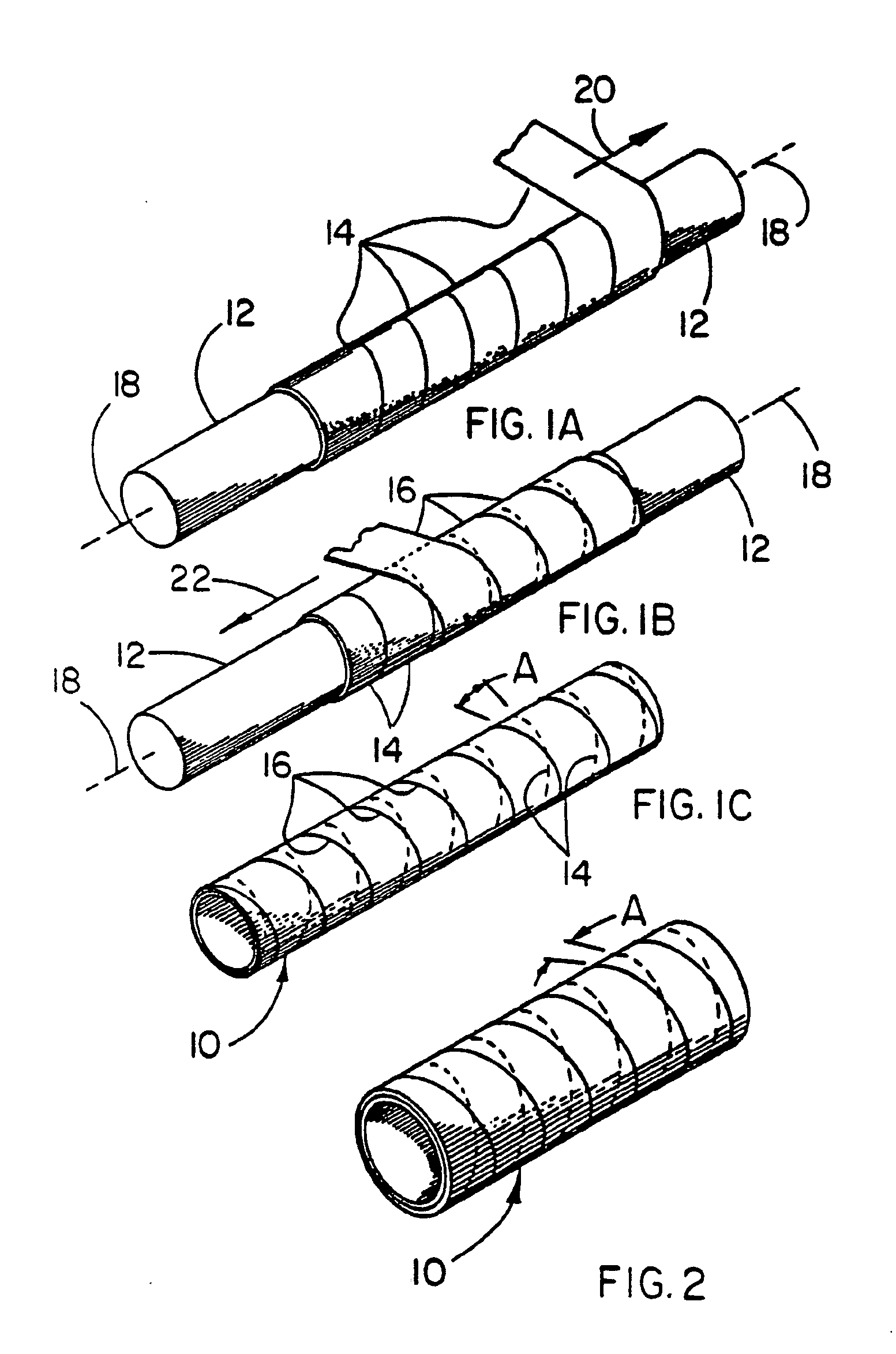

Reinforced plastic pipe

InactiveUS7600537B2Improve toughnessImprove burst strengthSynthetic resin layered productsCorrosion preventionBursting strengthPolyolefin

Plastic pipes, such as high density polyethylene plastic pipes, useful for distributing natural gas and which have improved impact resistance and burst strength. The plastic pipe has an inner and an outer surface, with the inner surface defining a channel for conveying natural gas and the like. A fabric overlies the outer surface, preferably in a helical wrap. The fabric is formed of high tenacity polyolefin fibers, preferably polyethylene and / or polypropylene fibers. The fabric provides the pipe with improved burst strength and impact resistance. The pipe can be used to transport natural gas under low pressure or higher pressures.

Owner:HONEYWELL INT INC

Reinforced plastic pipe

InactiveUS20070062595A1Adding to of cost of manufactureAdding to weightSynthetic resin layered productsCorrosion preventionBursting strengthPolyolefin

Plastic pipes, such as high density polyethylene plastic pipes, useful for distributing natural gas and which have improved impact resistance and burst strength. The plastic pipe has an inner and an outer surface, with the inner surface defining a channel for conveying natural gas and the like. A fabric overlies the outer surface, preferably in a helical wrap. The fabric is formed of high tenacity polyolefin fibers, preferably polyethylene and / or polypropylene fibers. The fabric provides the pipe with improved burst strength and impact resistance. The pipe can be used to transport natural gas under low pressure or higher pressures.

Owner:HONEYWELL INT INC

Production method for bactericidal packing paper

ActiveCN102154944AImprove breathabilityHigh strengthPaper coatingReinforcing agents additionBursting strengthCarboxymethyl cellulose

The invention discloses a production method for bactericidal packing paper, which comprises the following steps of: (1) preparation working procedure of applying glue solution to pulp; (2) preparation working procedure of applying glue solution to a surface; (3) working procedure of sizing agent repulping, selecting Southern pipes produced in America to make pulp, adding sodium carbonate and carboxymethyl cellulose into a repulping liquid; (4) working procedure of pulp matching, adding a wet strength agent; (5) working procedure of webbing and forming; (6) working procedure of applying glue solution to the surface, using modified tapicoa starch and polyvinyl alcohol for applying the glue solution to the surface; and (7) completion working procedure. The bactericidal packing paper has good air permeability, high surface strength, tearing resistance after disinfection and high bursting strength and can block bacterium invasion.

Owner:安徽华邦古楼新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com