Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1350 results about "Wet strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wet strength of paper and paperboard is a measure of how well the web of fibers holding the paper together can resist a force of rupture when the paper is wet. Wet strength is routinely expressed as the ratio of wet to dry tensile force at break.

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

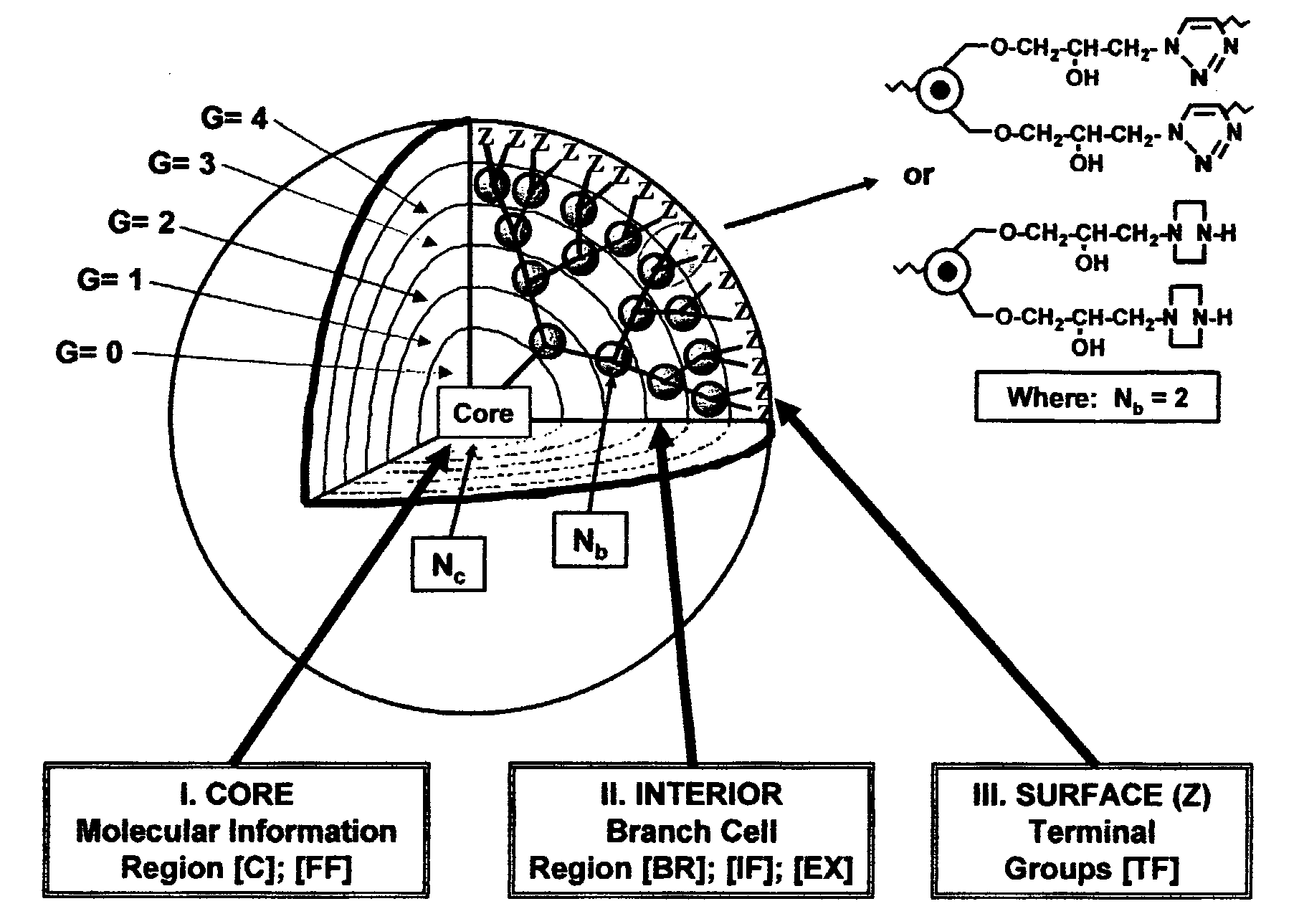

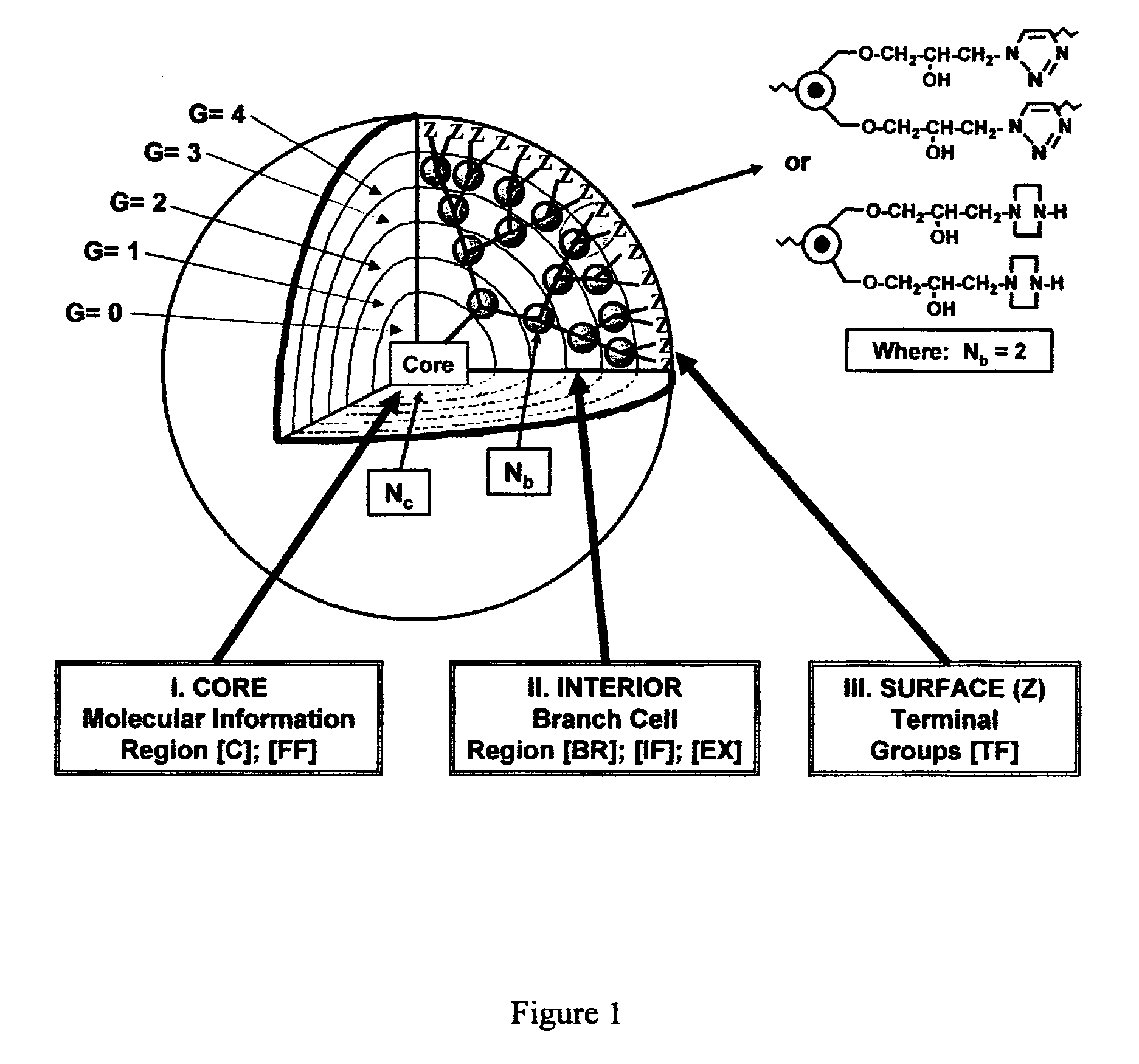

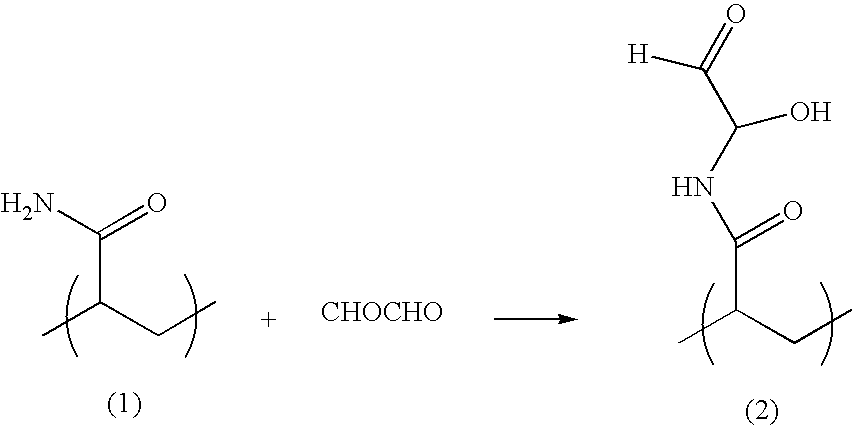

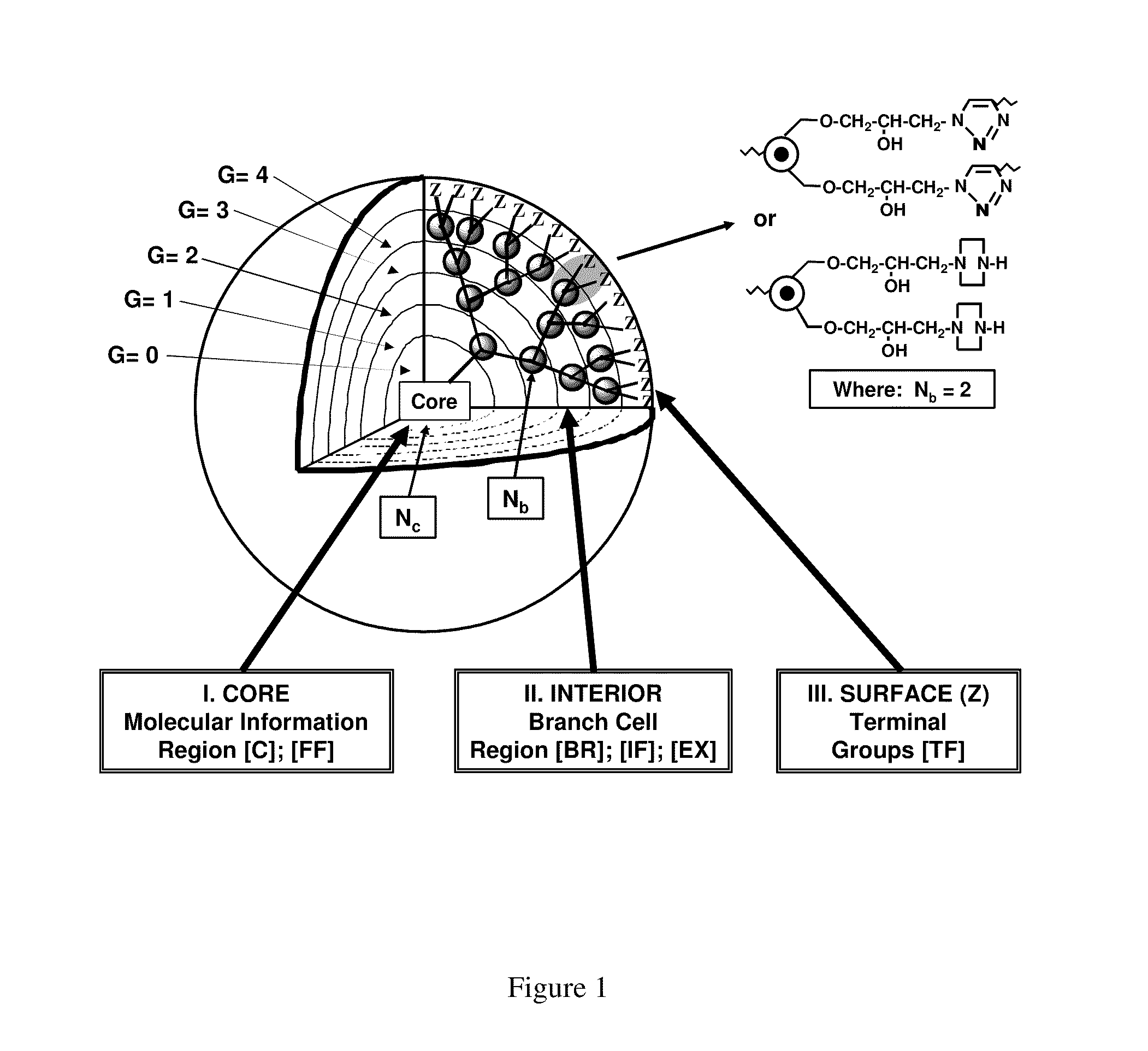

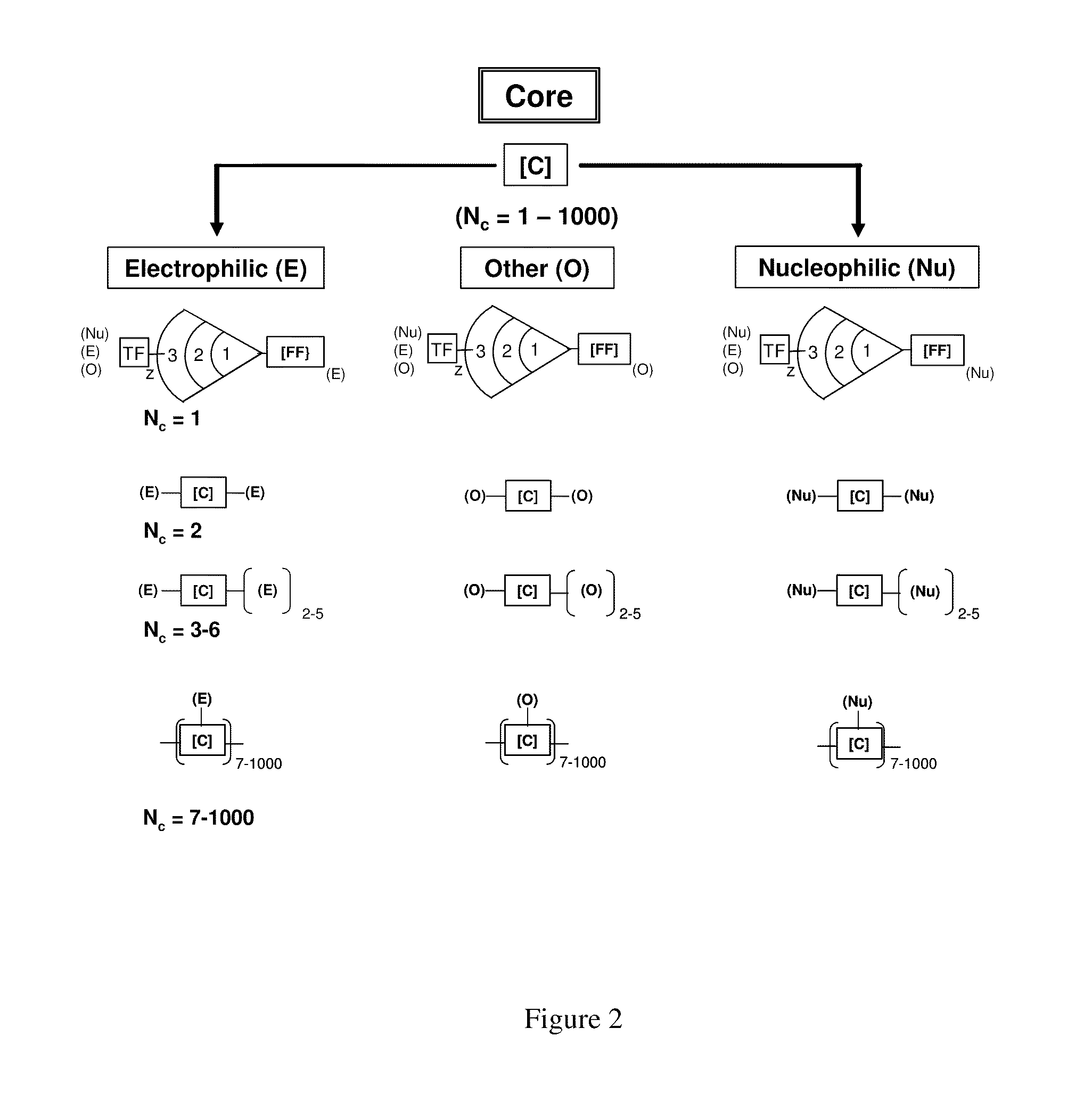

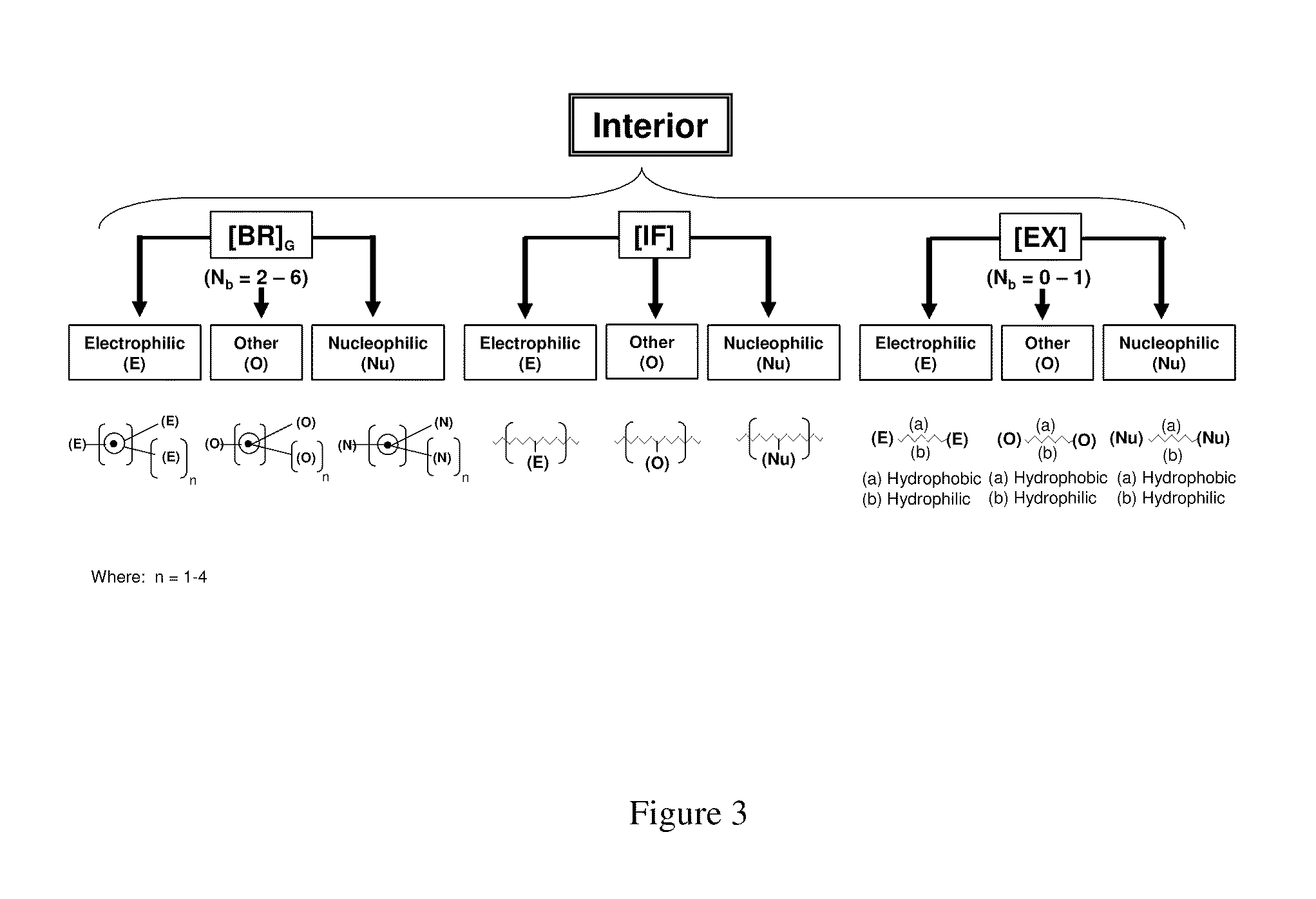

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Soft tissue having temporary wet strength

Disclosed is a soft, low density paper product made using papermaking fibers and a cationic temporary wet strength resin. Such paper products have a density less than about 0.6 grams per cubic centimeter, a basis weight is between about 10 and about 65 grams per square meter, a dry strength less than about 500 grams per inch (197 grams per centimeter), a ratio of an initial wet strength to the dry strength greater than about 0.15:1, and a ratio of a thirty minute wet strength to the initial wet strength less than about 0.4. Methods for producing such paper products are also disclosed. The paper products may be produced either as homogeneous structures or as multi-layered structures and may be either creped or uncreped.

Owner:THE PROCTER & GAMBLE COMPANY

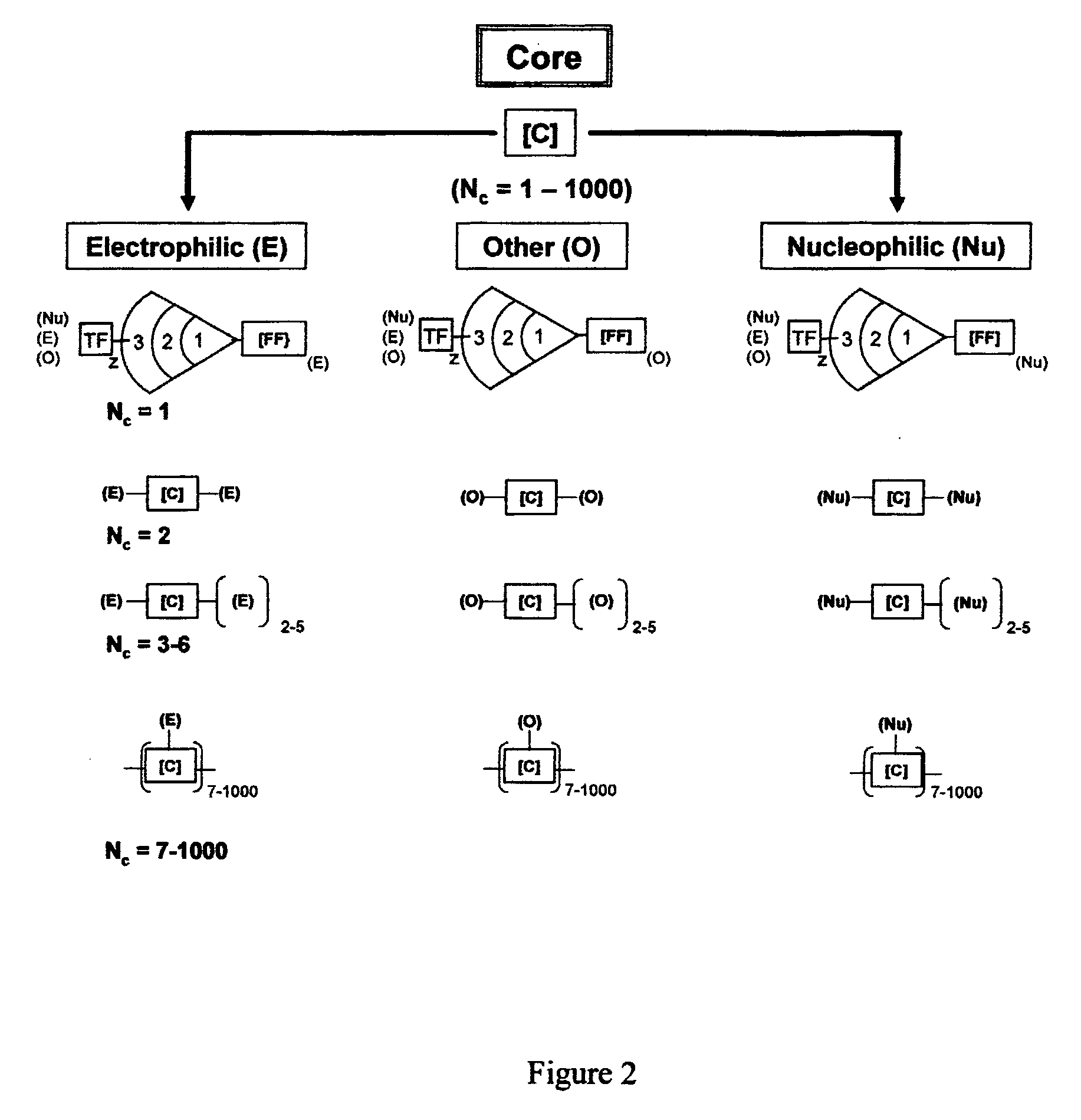

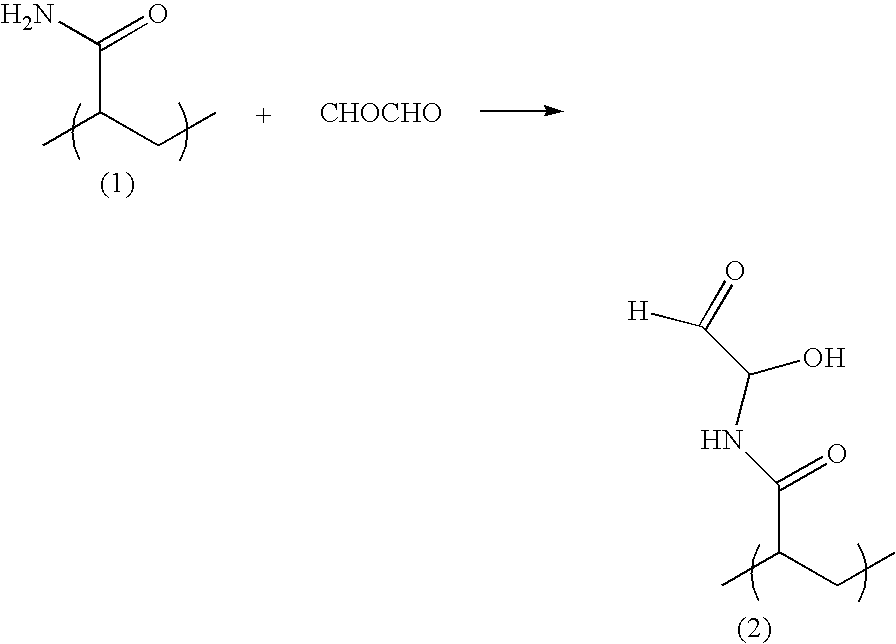

Blends of glyoxalated polyacrylamides and paper strengthening agents

Compositions comprising a blend of two or more paper strengthening agents have improved stability compared with previously known paper strengthening agents. One component is a polymeric paper strengthening agent, preferably a wet strengthening agent. The other component is a stabilized polyacrylamide prepared by (1) reacting a first portion of glyoxal with a polyacrylamide having pendant amide groups to form a first reaction mixture comprising polyacrylamide; (2) adding an acid to the first reaction mixture to form a second reaction mixture having a reduced pH and comprising the polyacrylamide; and (3) adding a second portion of glyoxal to the second reaction mixture to form the stabilized polyacrylamide. If desired, an aldehyde scavenger can be included in one or more of step (1), step (2), step (3), or the stabilized polyacrylamide. Such compositions can be used to enhance the strength of paper, particularly the wet strength of paper.

Owner:ECOLAB USA INC

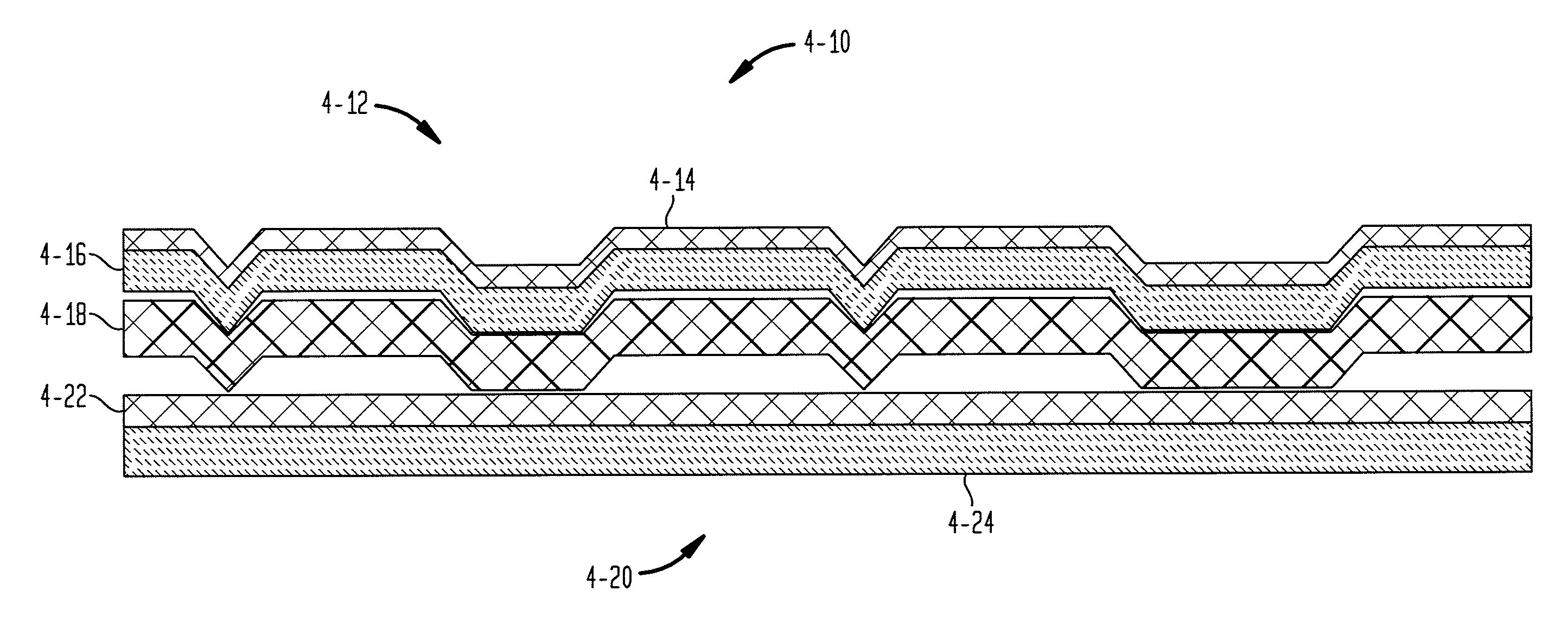

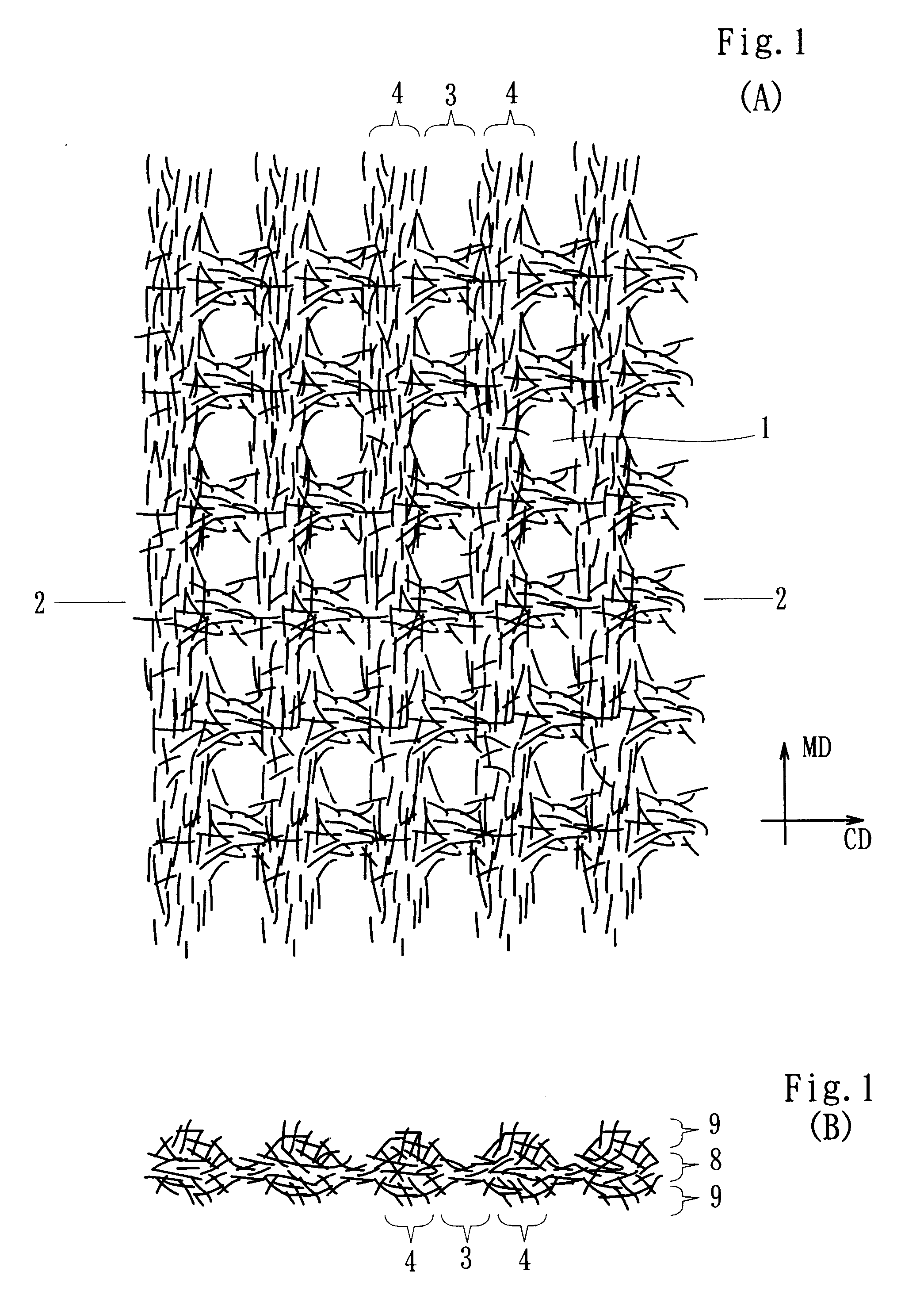

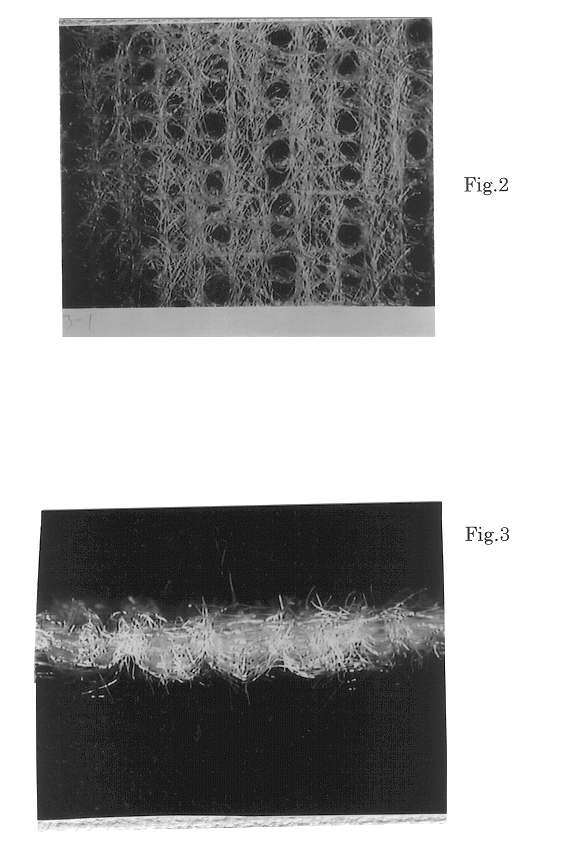

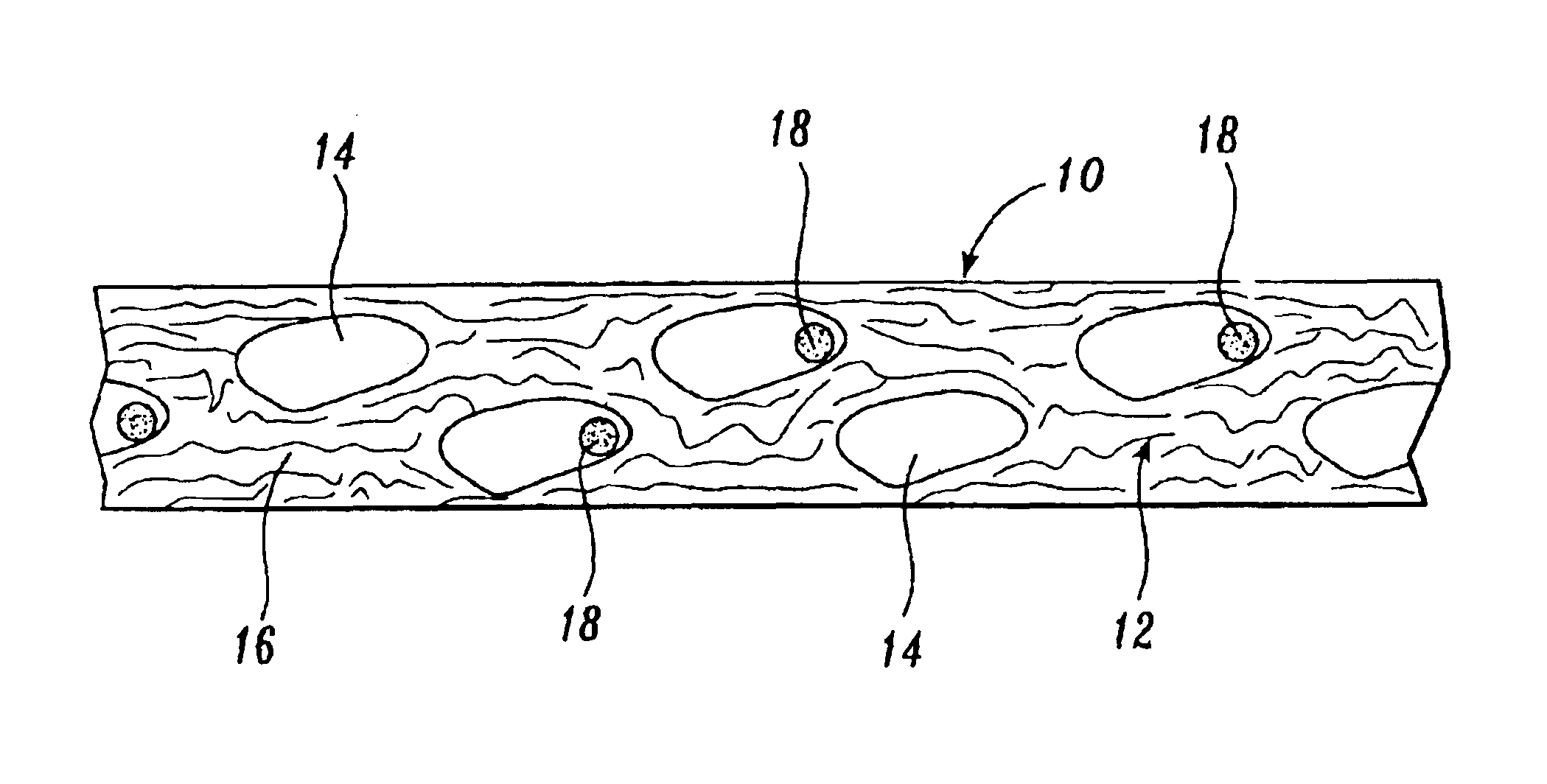

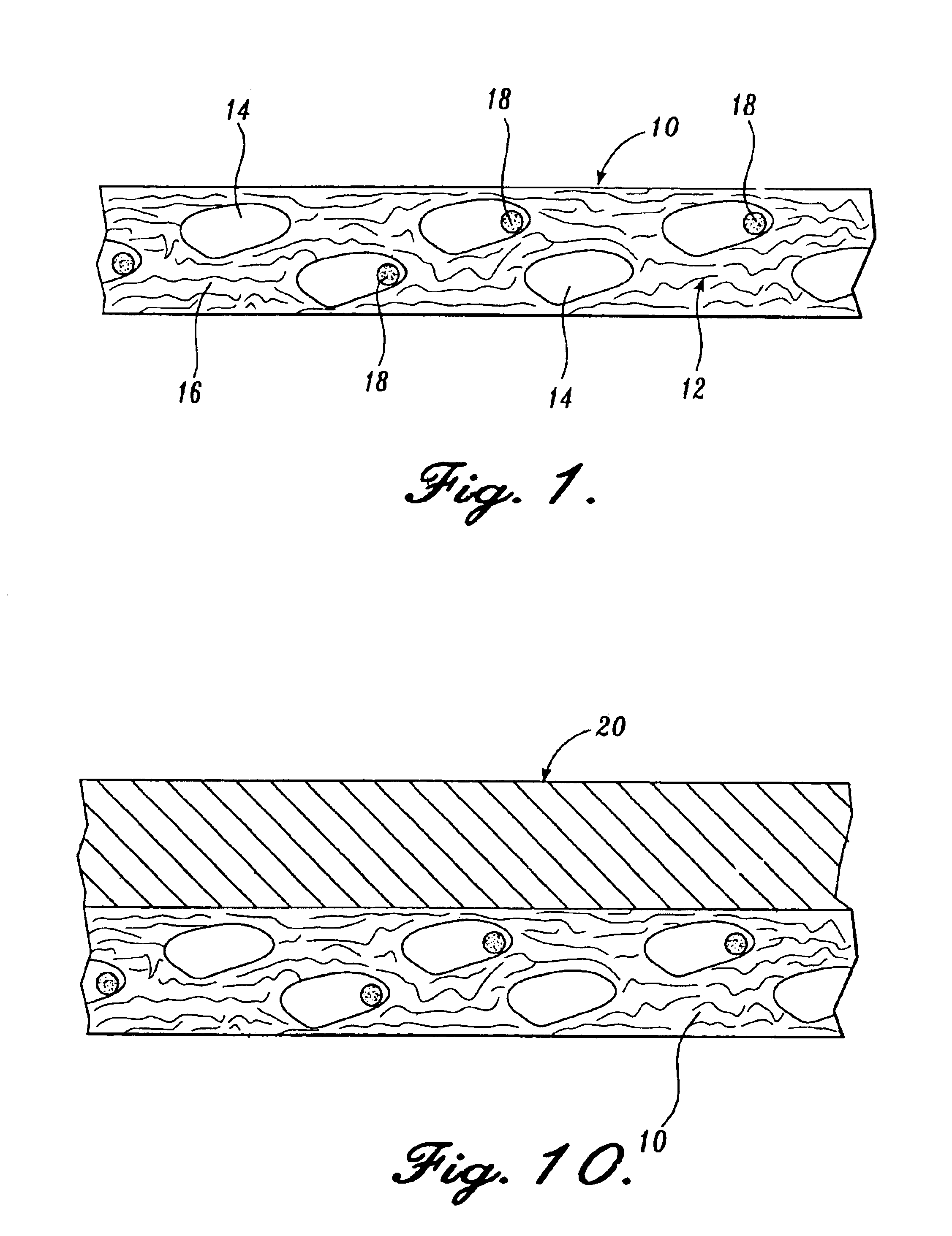

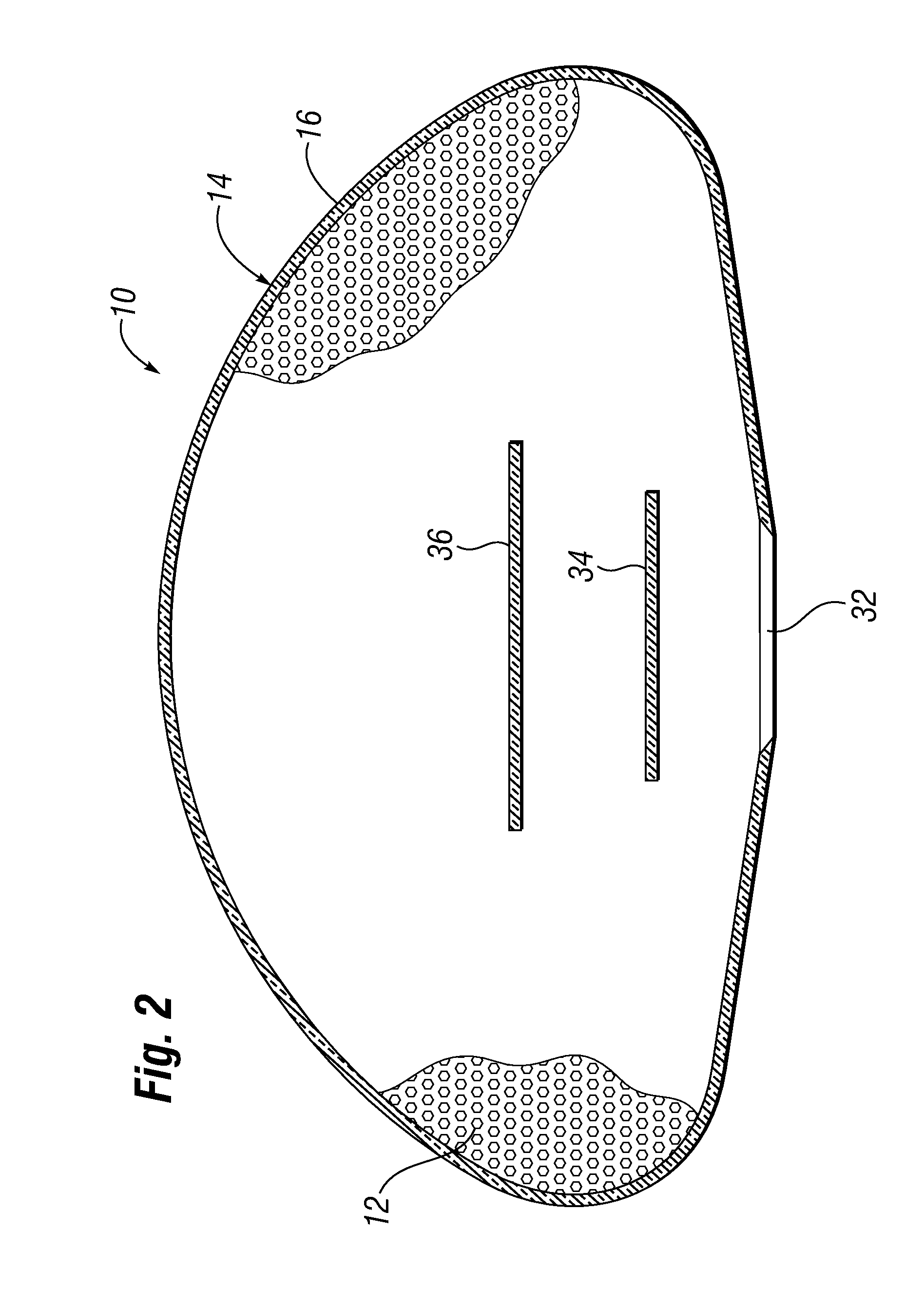

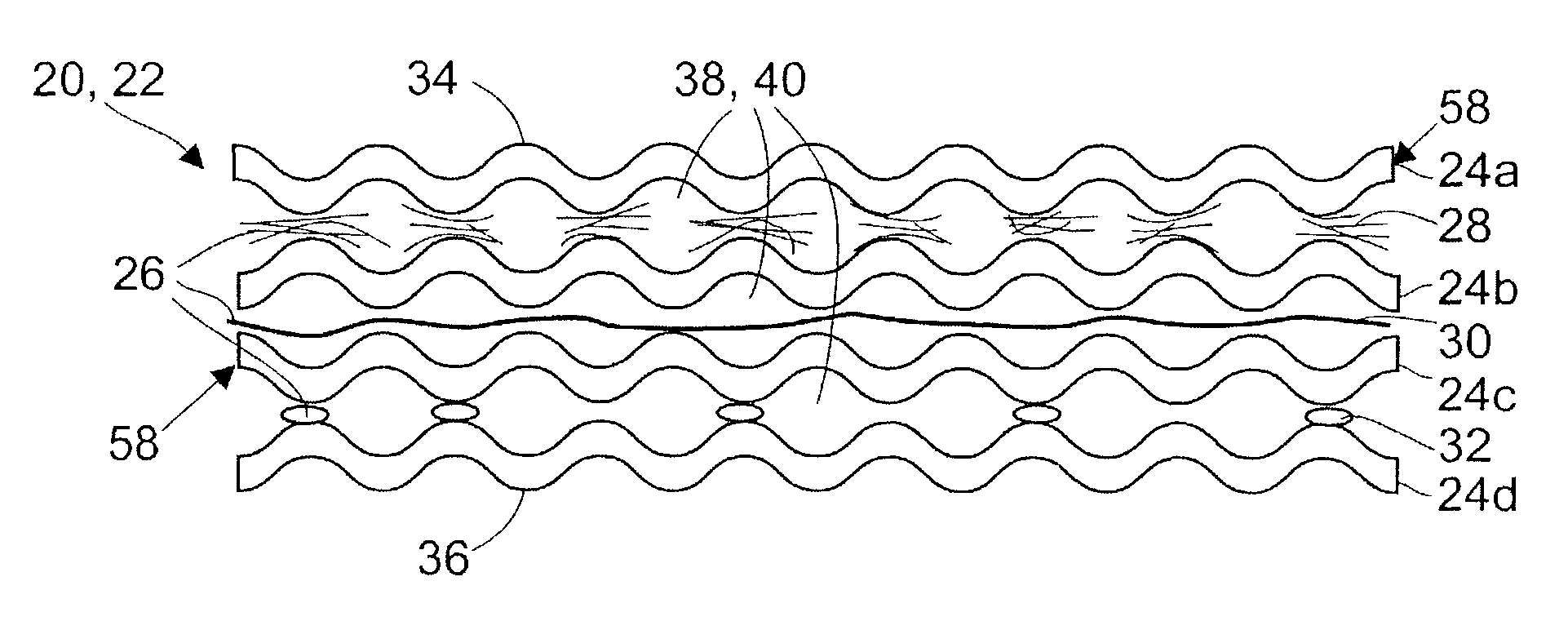

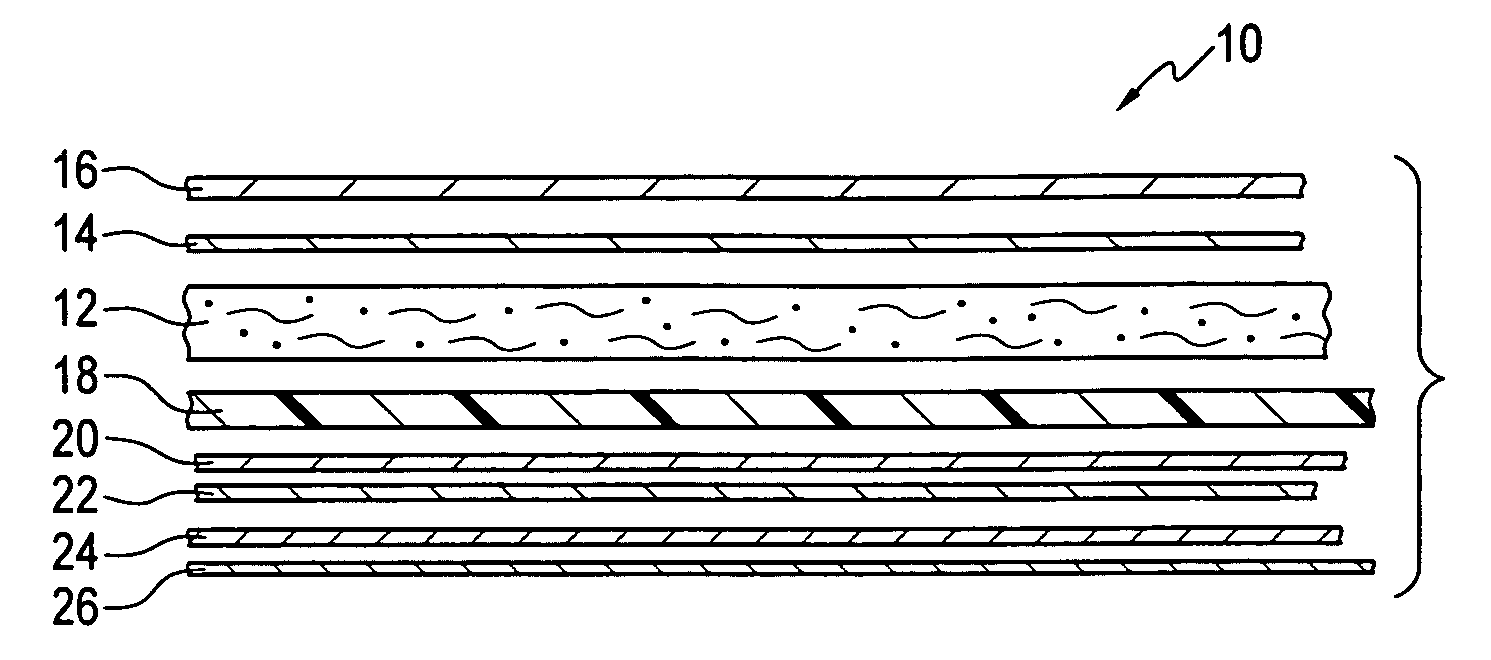

Reticulated absorbent composite

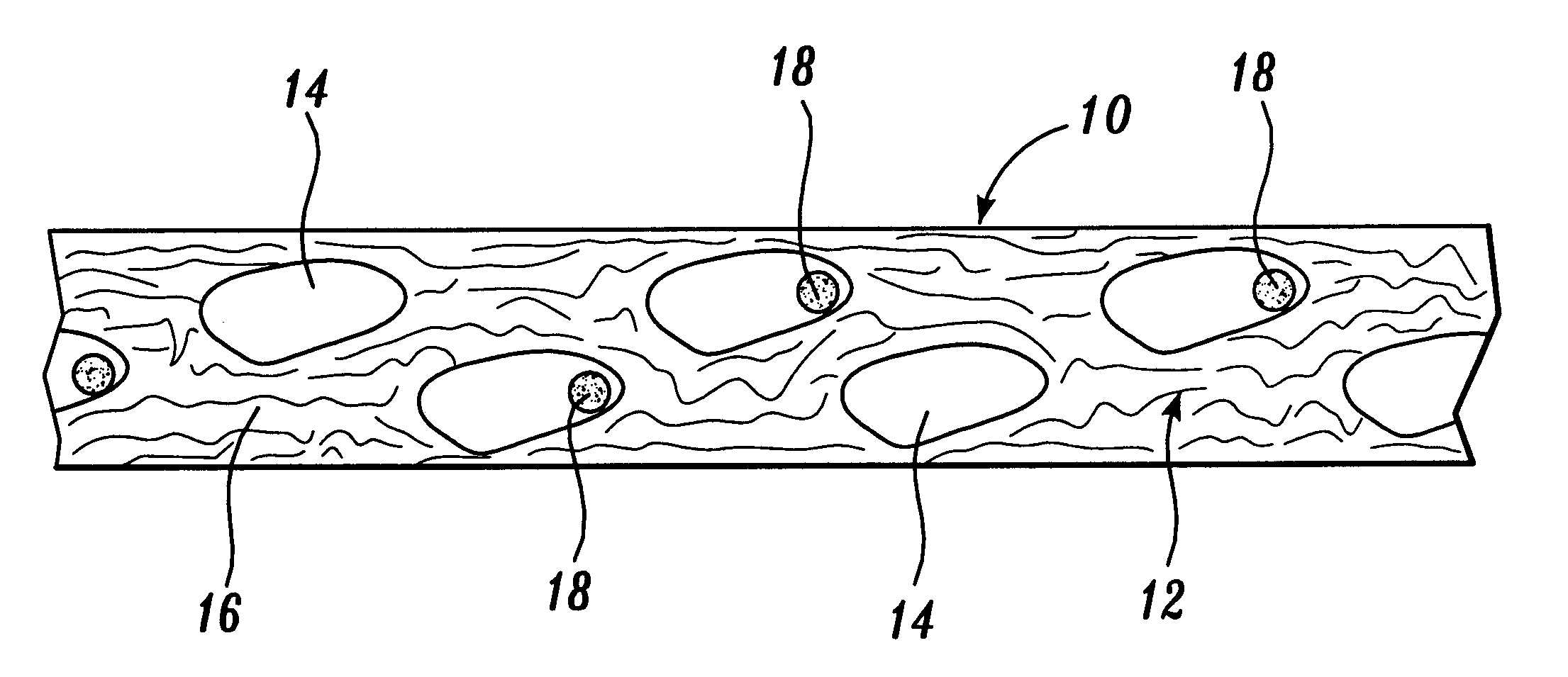

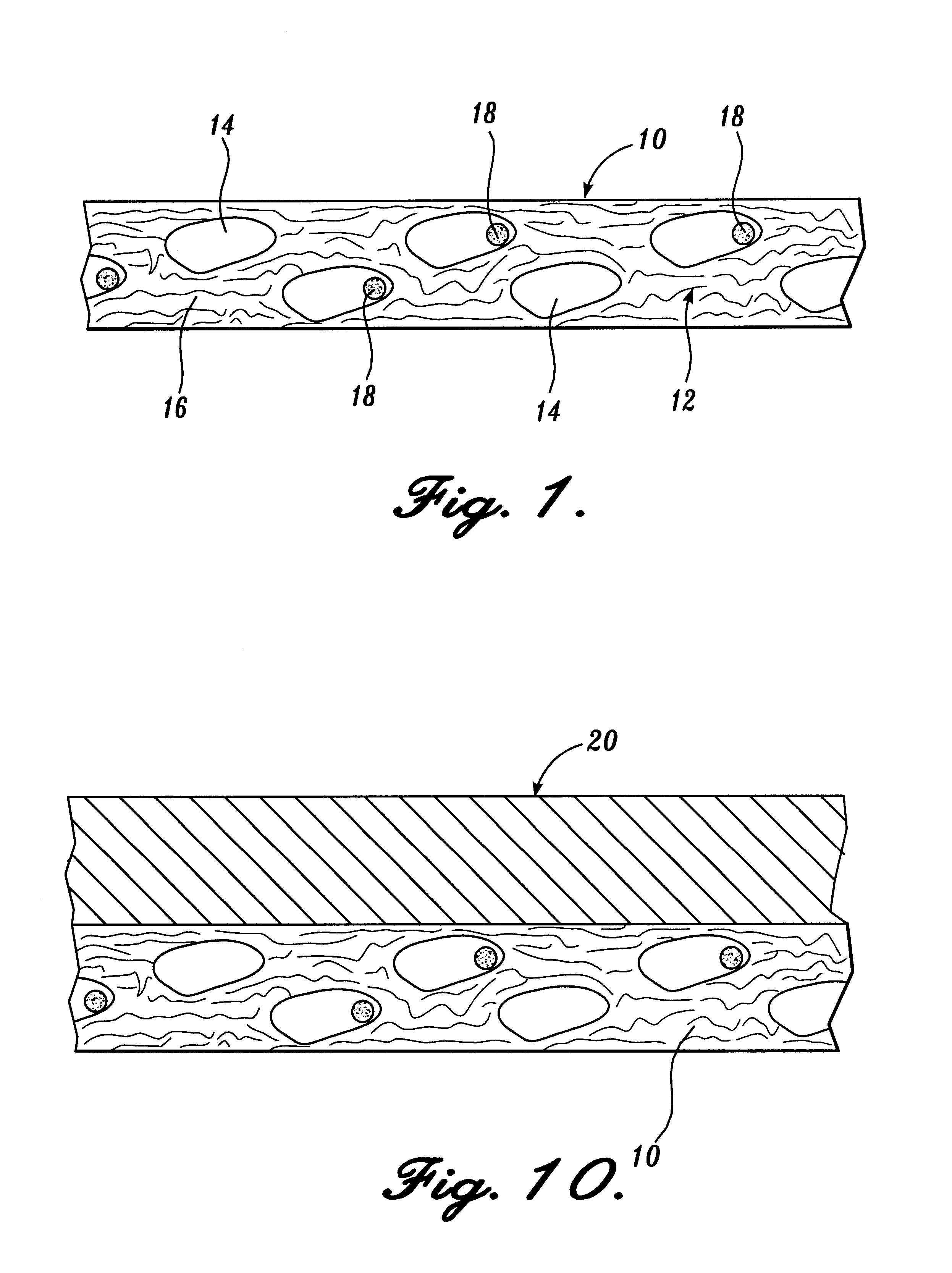

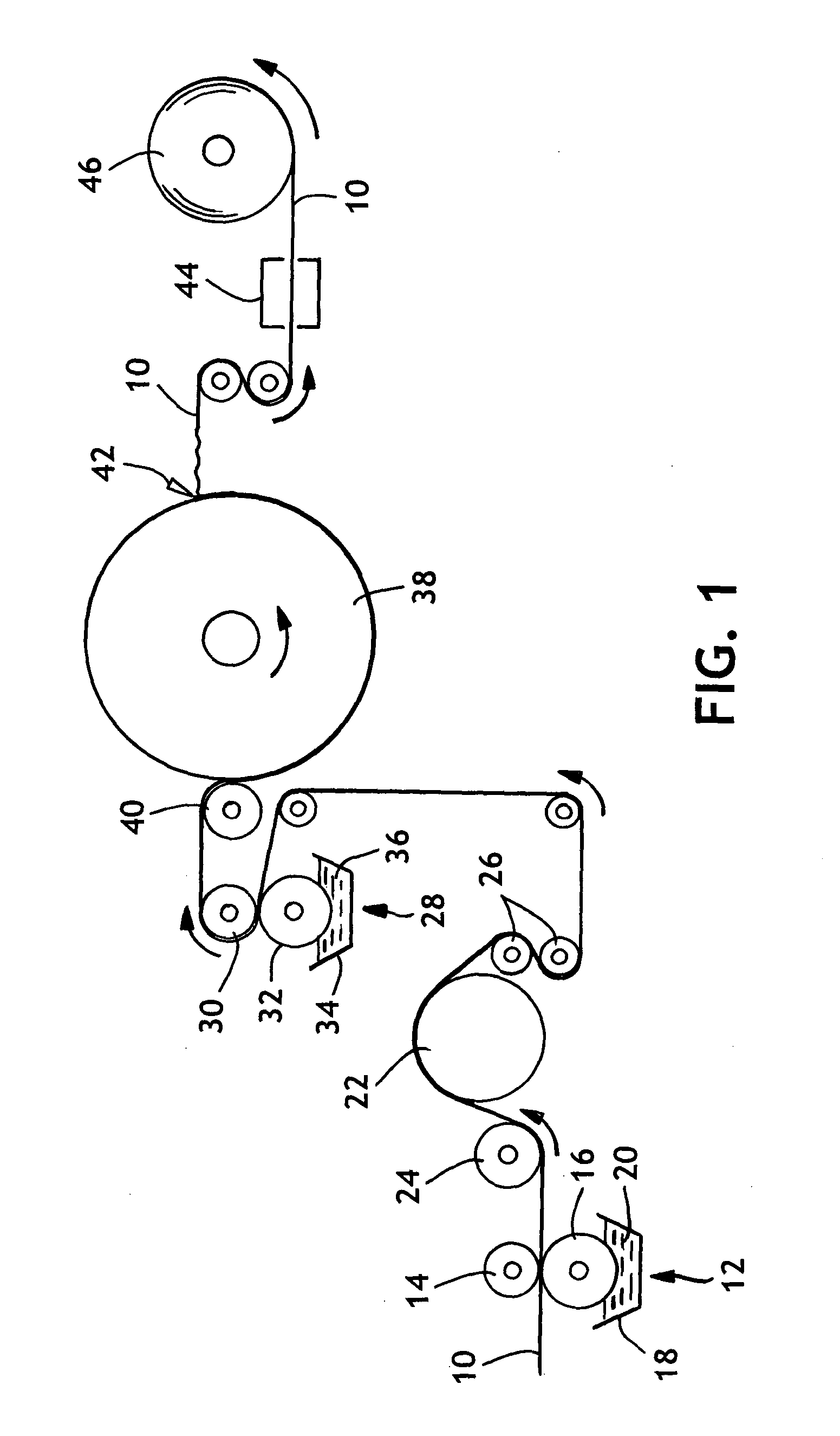

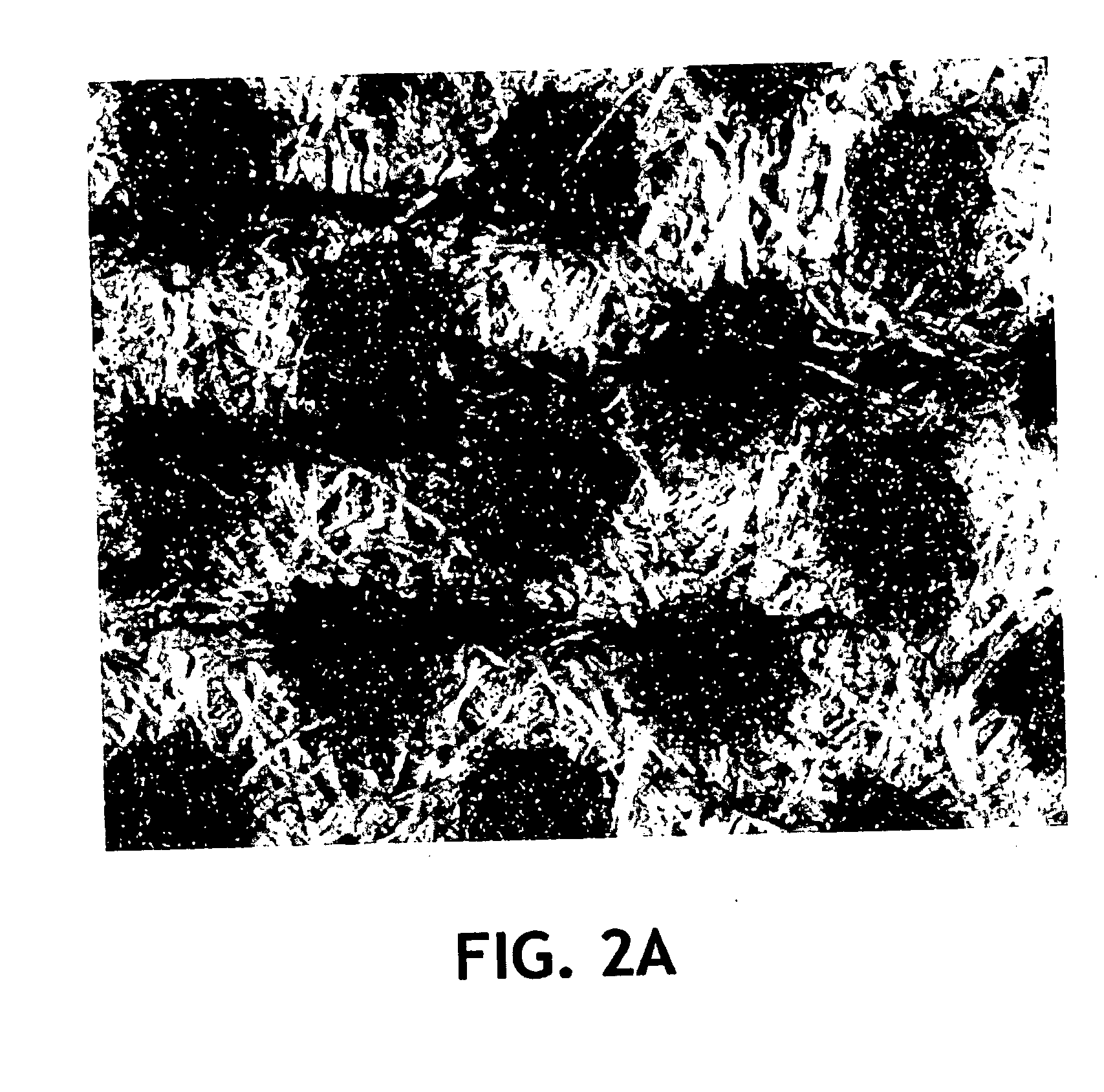

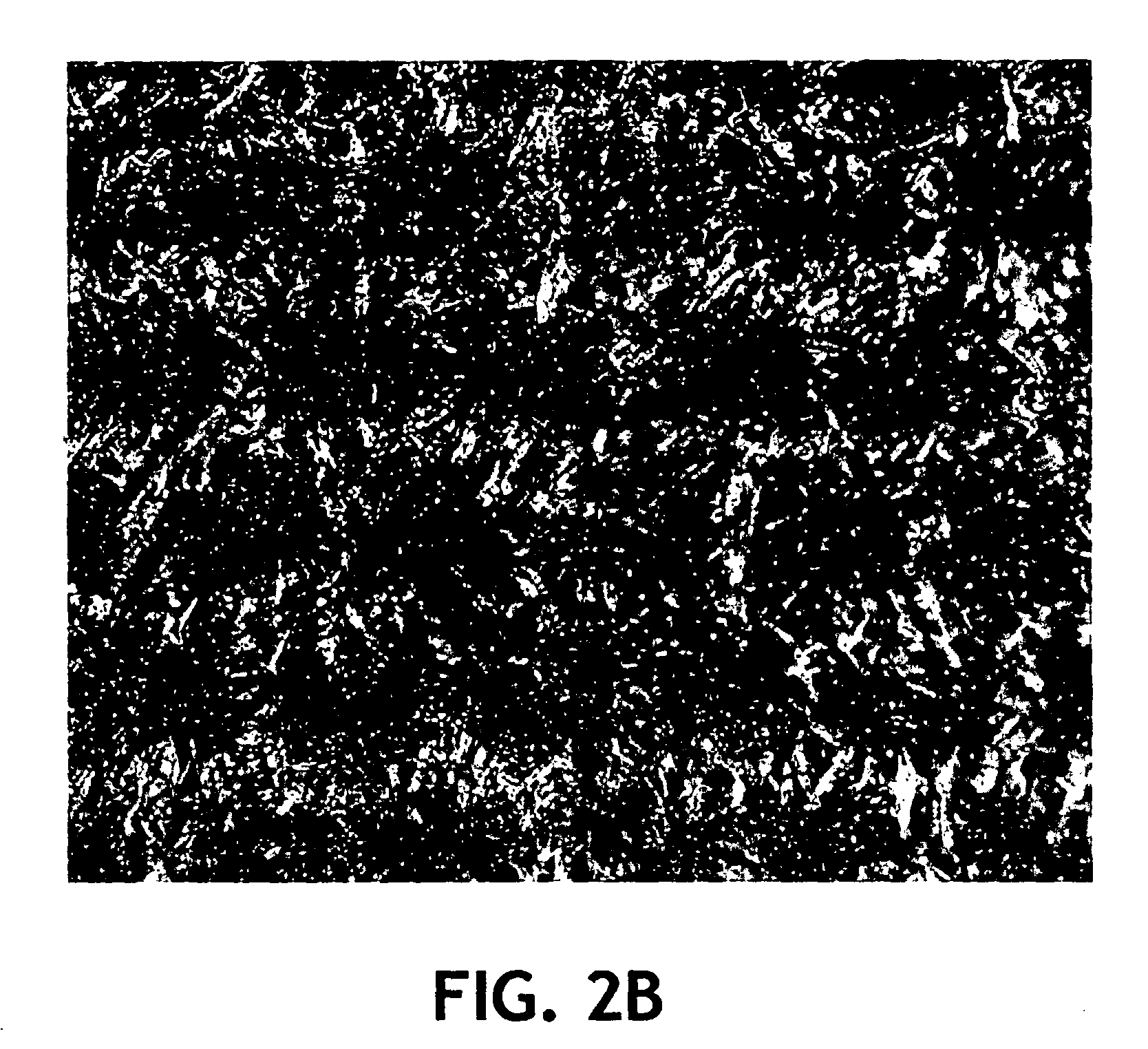

InactiveUS6969781B2Promote absorptionImprove acquisitionLayered productsBaby linensElastic fibresFiber

An absorbent composite (10) having a fibrous matrix that includes absorbent material is disclosed. The fibrous matrix defines voids (14) and passages between the voids, which are distributed throughout the composite. Absorbent material (18) is located within some of the voids (14). Absorbent material located in these voids is expandable into the void. In a preferred embodiment, the composite's fibrous matrix includes resilient and matrix fibers (16). The composite optionally includes a wet strength agent.

Owner:NAT INST FOR STRATEGIC TECH ACQUISITIONS & COMMLIZATION

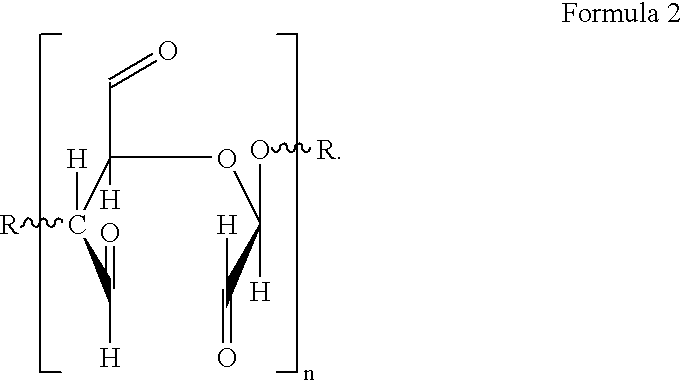

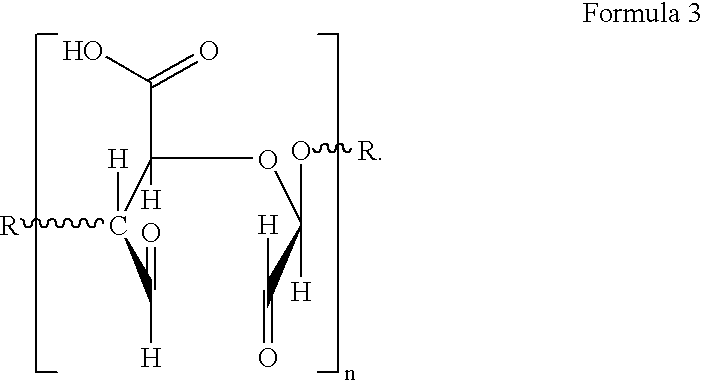

Oxidized polymeric carbohydrates and products made thereof

The present invention relates to a polysaccharide having functional groups, wherein said groups are aldehyde groups formed at positions C2 and / or C3 as well as at position C6 of the anhydroglucose units of the polysaccharide chain. Preferably the polysaccharide is a cellulosic fibrous material whose primary and secondary hydroxyl groups of the cellulose are oxidized into aldehyde groups at least in part by means of TEMPO oxidation and periodate oxidation.The invention also concerns a paper or nonwoven comprising the above polysaccharide. According to the invention a relative wet strength of more than 10% can be achieved.

Owner:SCA HYGIENE PROD AB

High Softness, High Durability Bath Tissues With Temporary Wet Strength

ActiveUS20130029105A1Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

Owner:GPCP IP HLDG LLC

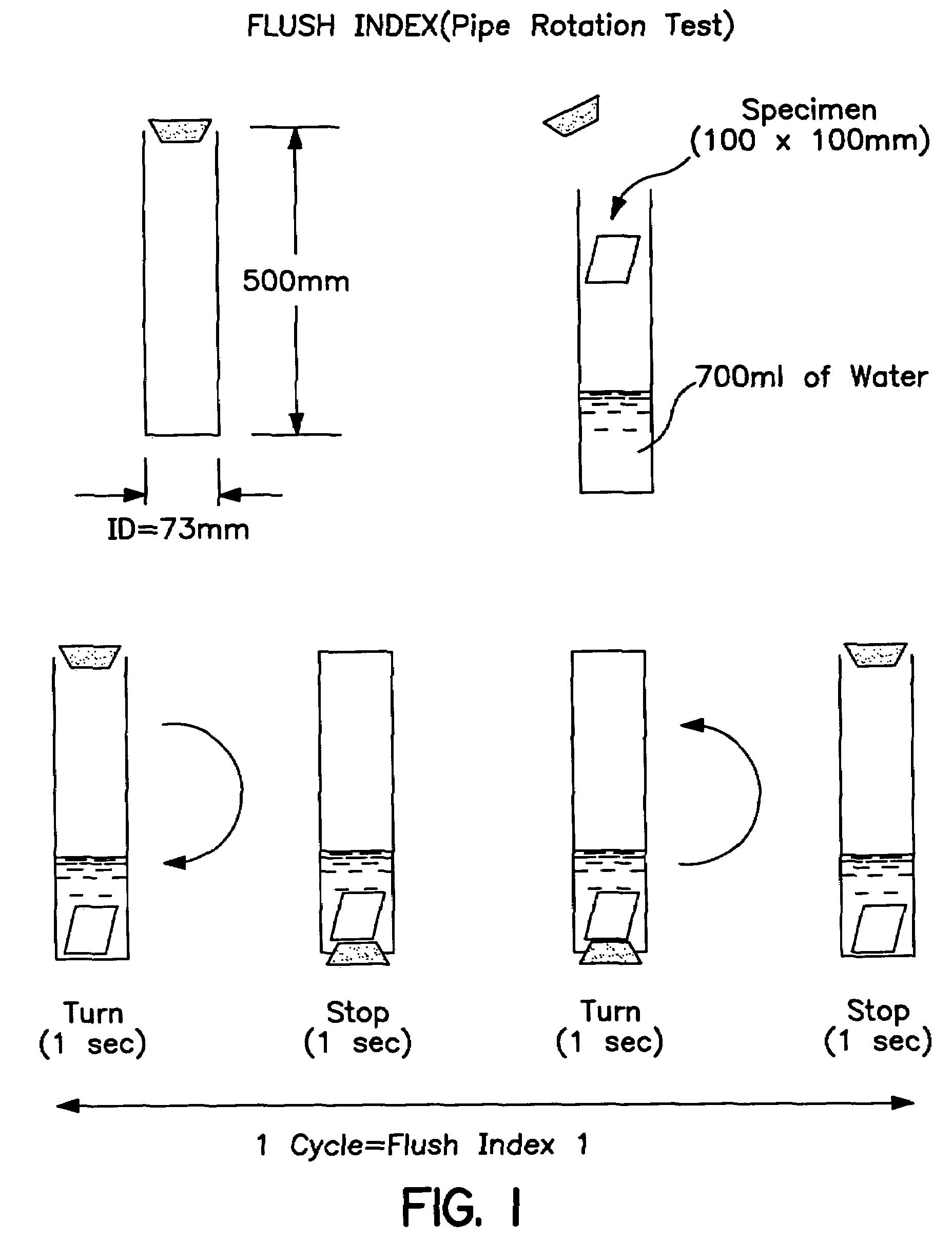

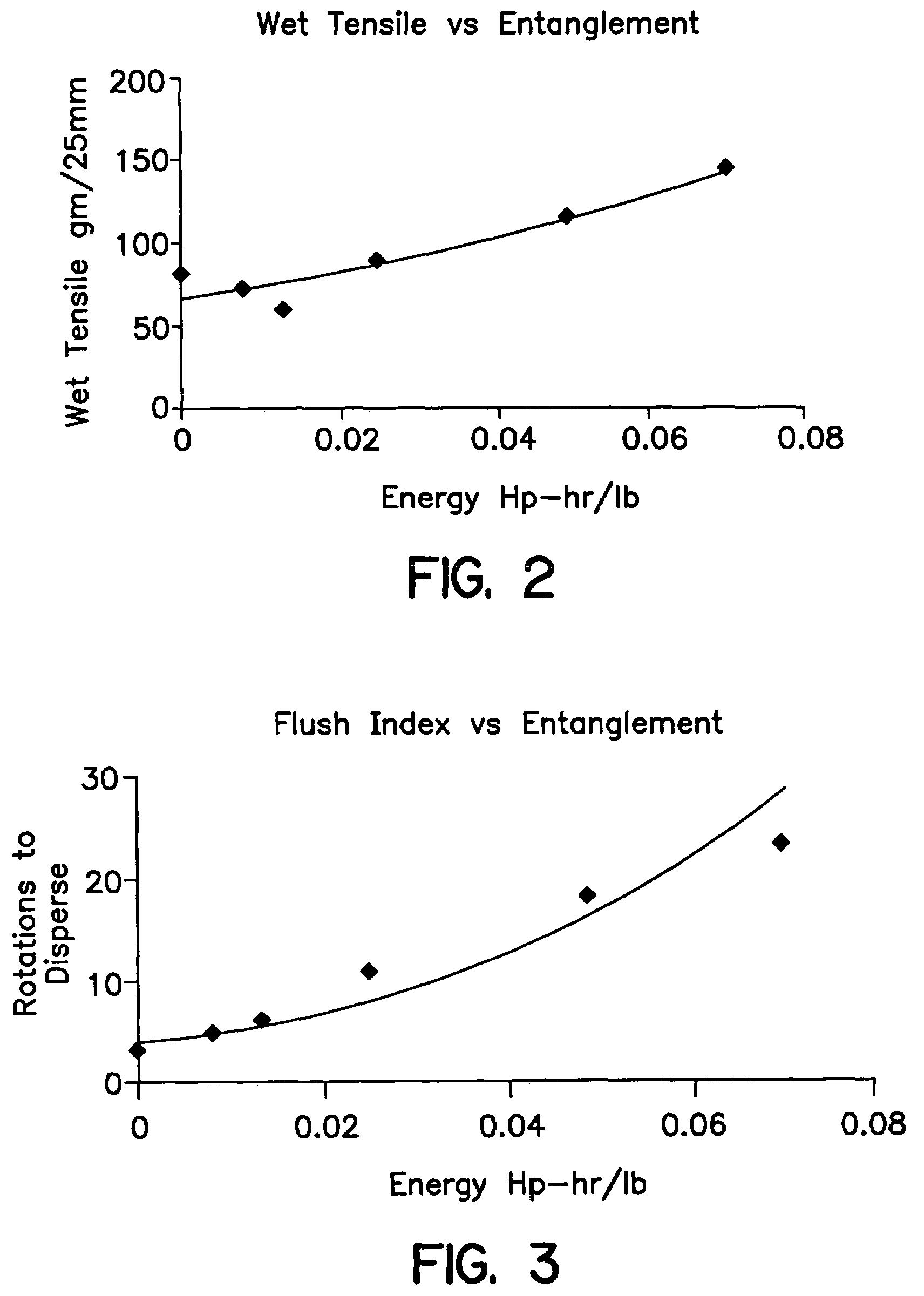

Method of manufacturing a water disintegratable non-woven fabric and the water disintegratable non-woven fabric

InactiveUS6451718B1Improve wiping effectNon-fibrous pulp additionSynthetic resin layered productsFiberCarboxymethyl cellulose

A water disintegratable non-woven fabric having excellent water disintegratability and high wet strength can be obtained by a step of forming a fiber web from fibers having a fiber length of 10 mm or less, a step of applying a water jet treatment to the fiber web to obtain a fiber sheet having wet strength of less than 100 g / 25 mm in MD and CD, the wet strength being defined by tensile strength at break of the fiber sheet, as measured by using a tensilon tester with a chuck distance of 100 mm, at a tensile speed of 100 mm / min to the fiber sheet which is cut into 25 mm width and 150 mm length and impregnated with water in an amount 2.5 times the weight of the fiber sheet, and a step of adding at least one binder selected from the group consisting of carboxymethyl cellulose, alkylcellulose, polyvinyl alcohol and modified polyvinyl alcohol to the fiber sheet. The water disintegratable non-woven fabric is sufficiently bulky and has an excellent wiping effect.

Owner:UNI CHARM CORP

Moisture resistant container

A sheet of cellulose based material having enhanced strength, particularly the dry strength, substantially unaffected repulpability is disclosed. The sheet of cellulose based materials generally includes a first cellulose based material connected with a second cellulose base material element. The first cellulose based material is formed by separating a portion of the fiber from a furnish, treating the separated portion with a cationic wet strength resin which is allowed to bond to the fiber. The treated fiber is them mixed with the untreated balance of the fiber at some point before the paper machine. The fiber that is separated may be secondary fiber, virgin fiber or combinations thereof. The second cellulose base material element is substantially free from any treatment. The second cellulose base material element may be include substantially all untreated fibers.

Owner:INT PAPER CO

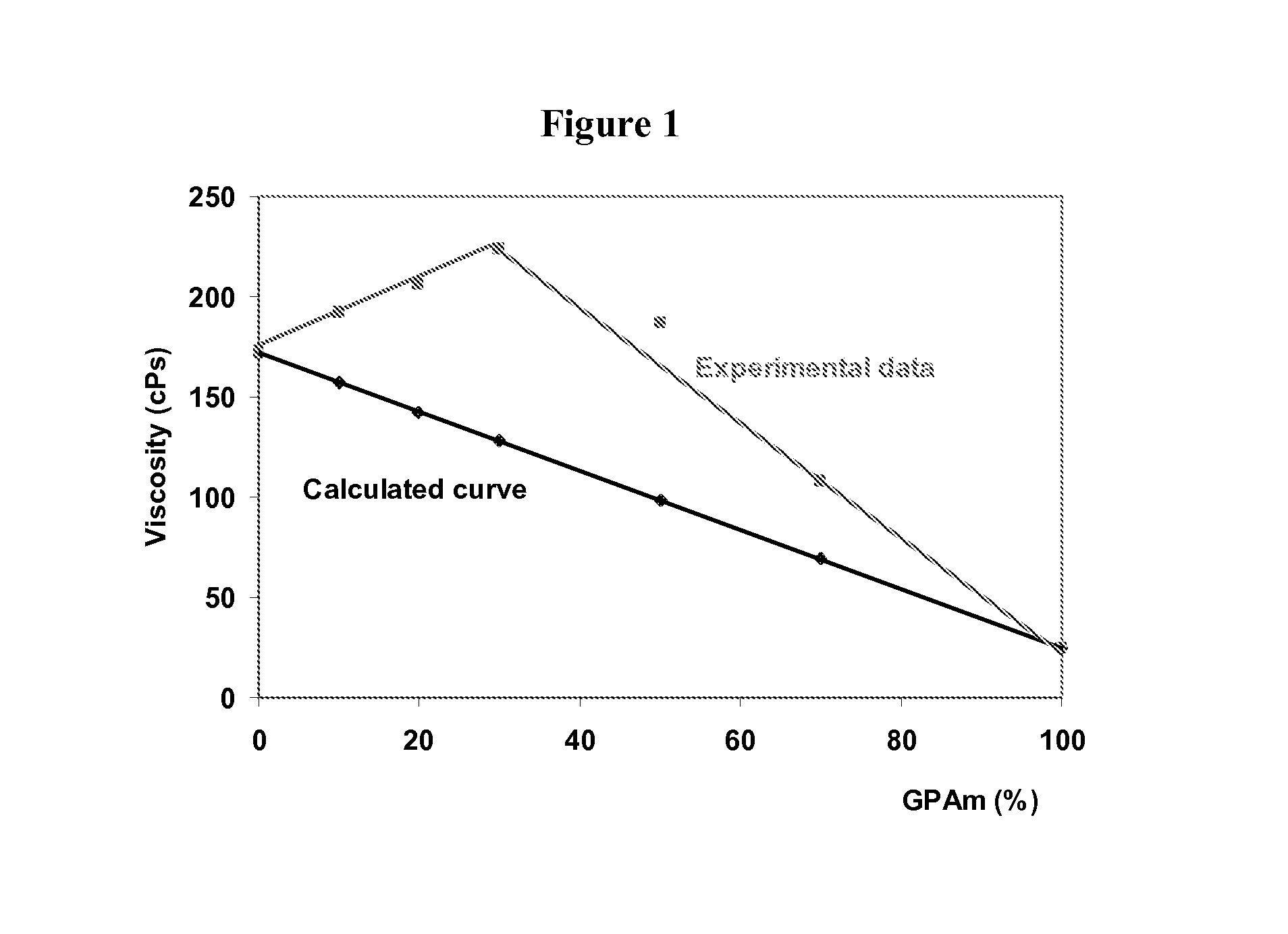

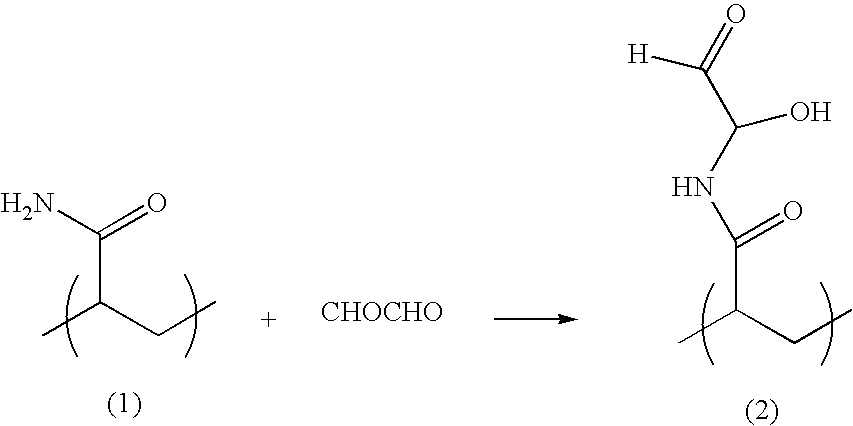

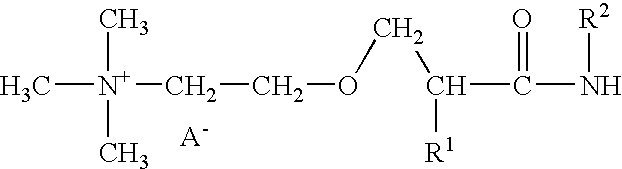

High Solids Glyoxalated Polyacrylamide

ActiveUS20080308242A1High solids glyoxalatedHigh strengthNatural cellulose pulp/paperSpecial paperPapermakingWet strength

Storage-stable glyoxalated polyacrylamide polymers and high solids aqueous compositions formulated with them are described. These glyoxalated polyacrylamide compositions can be used as additives for papermaking, providing paper with good dry and temporary wet strength, and increasing papermaking de-watering rates.

Owner:BUCKMAN LAB INT INC

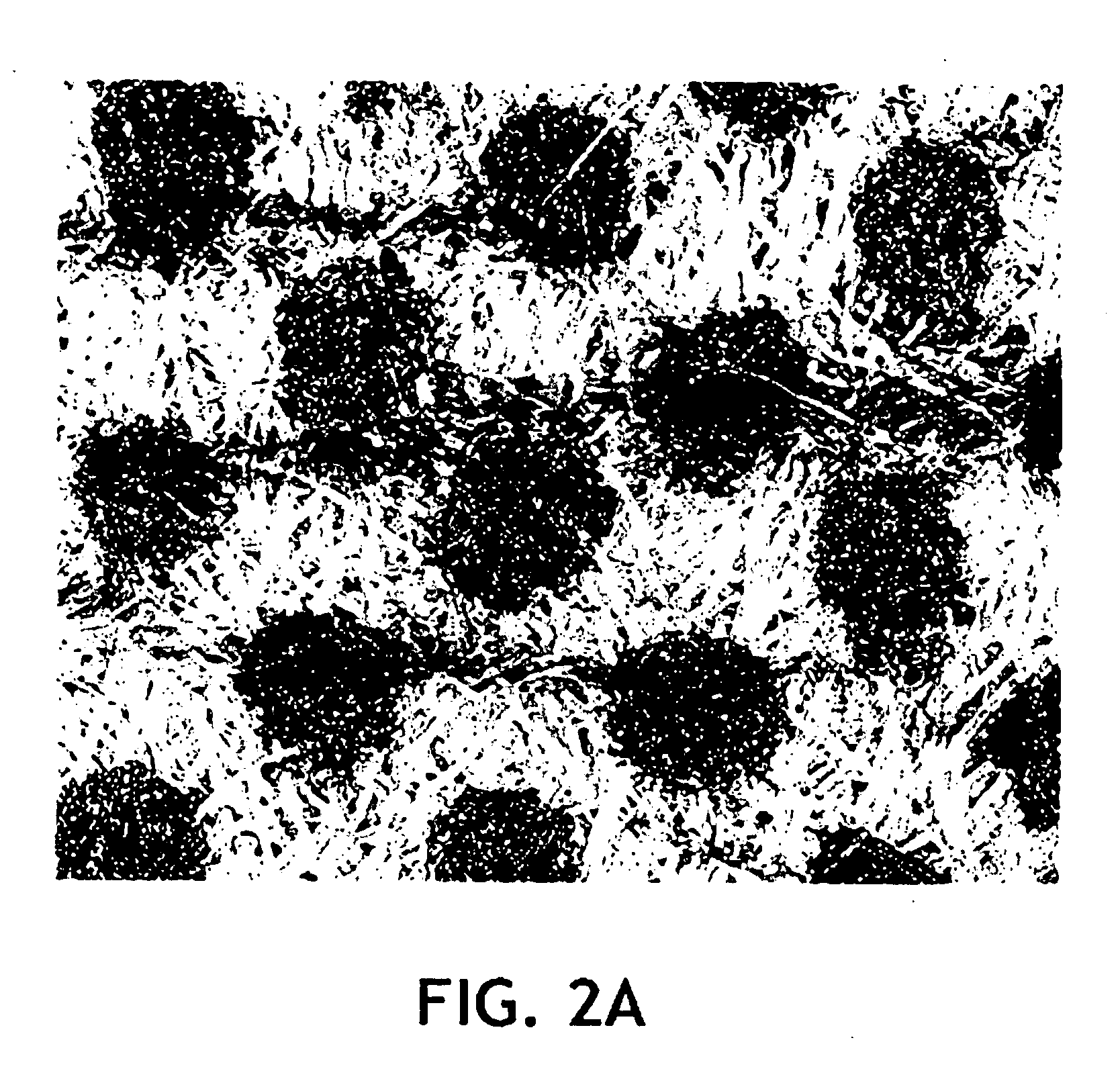

Reticulated absorbent composite

InactiveUS6962645B2Promote absorptionImprove acquisitionCellulosic pulp after-treatmentNon-fibrous pulp additionElastic fibresFiber

An absorbent composite (10) having a fibrous matrix that includes absorbent material is disclosed. The fibrous matrix defines voids (14) and passages between the voids, which are distributed throughout the composite. Absorbent material (18) is located within some of the voids (14). Absorbent material located in these voids is expandable into the void. In a preferred embodiment, the composite's fibrous matrix includes resilient and matrix fibers (16). The composite optionally includes a wet strength agent.

Owner:NAT INST FOR STRATEGIC TECH ACQUISITIONS & COMMLIZATION

Dendritic polymers with enhanced amplification and interior functionality

ActiveUS7985424B2Increase productionSimple materialPowder deliveryCosmetic preparationsCross-linkChemical reaction

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Absorbent sheet prepared with papermaking fiber and synthetic fiber exhibiting improved wet strength

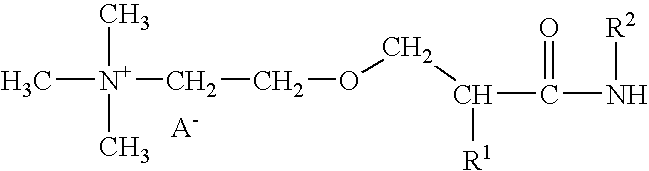

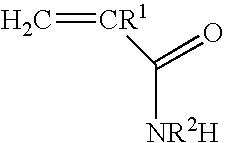

ActiveUS20090308551A1Increase wet/dry tensile ratioNatural cellulose pulp/paperPaper after-treatmentWet strengthCopolymer

A wet-laid absorbent sheet includes a mixture of pulp-derived papermaking fibers and synthetic polymer fibers, a strength agent selected from carboxymethylcellulose and anionic starch as well as an epihalohydrin / amine functional wet strength resin. Also included is an anionic olefin copolymer resin effective to increase the wet / dry tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

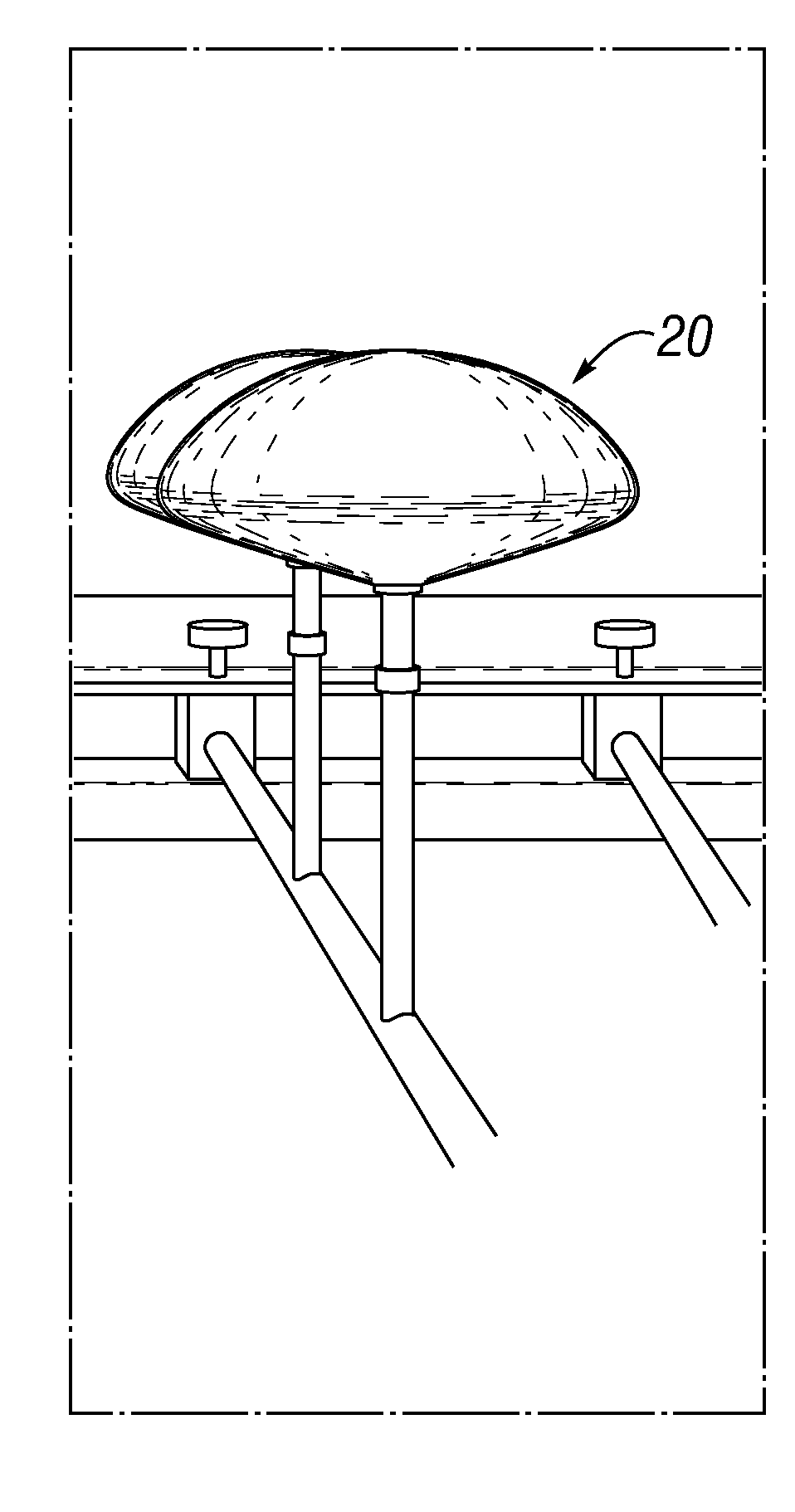

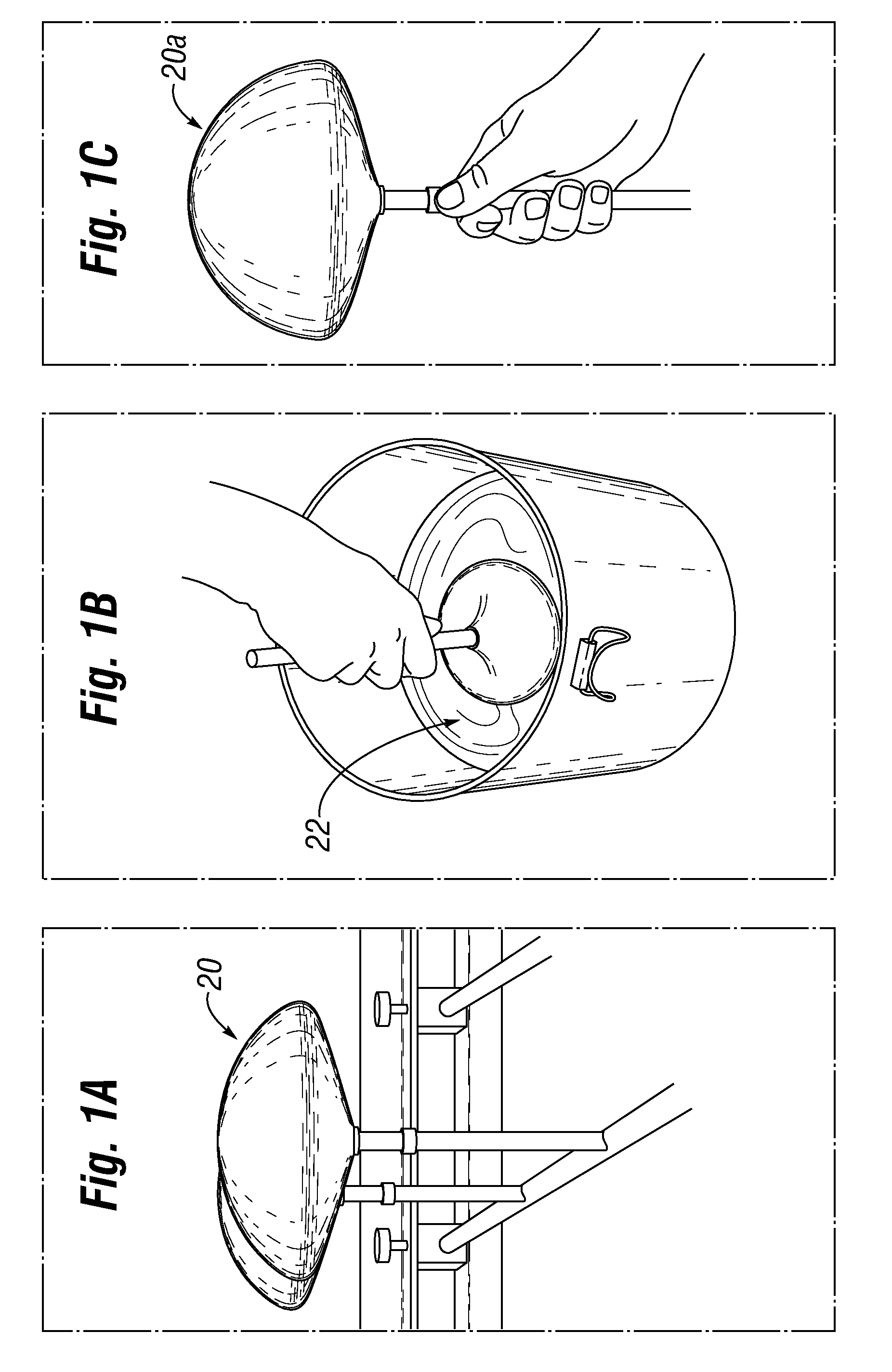

All-barrier elastomeric gel-filled breast prosthesis

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

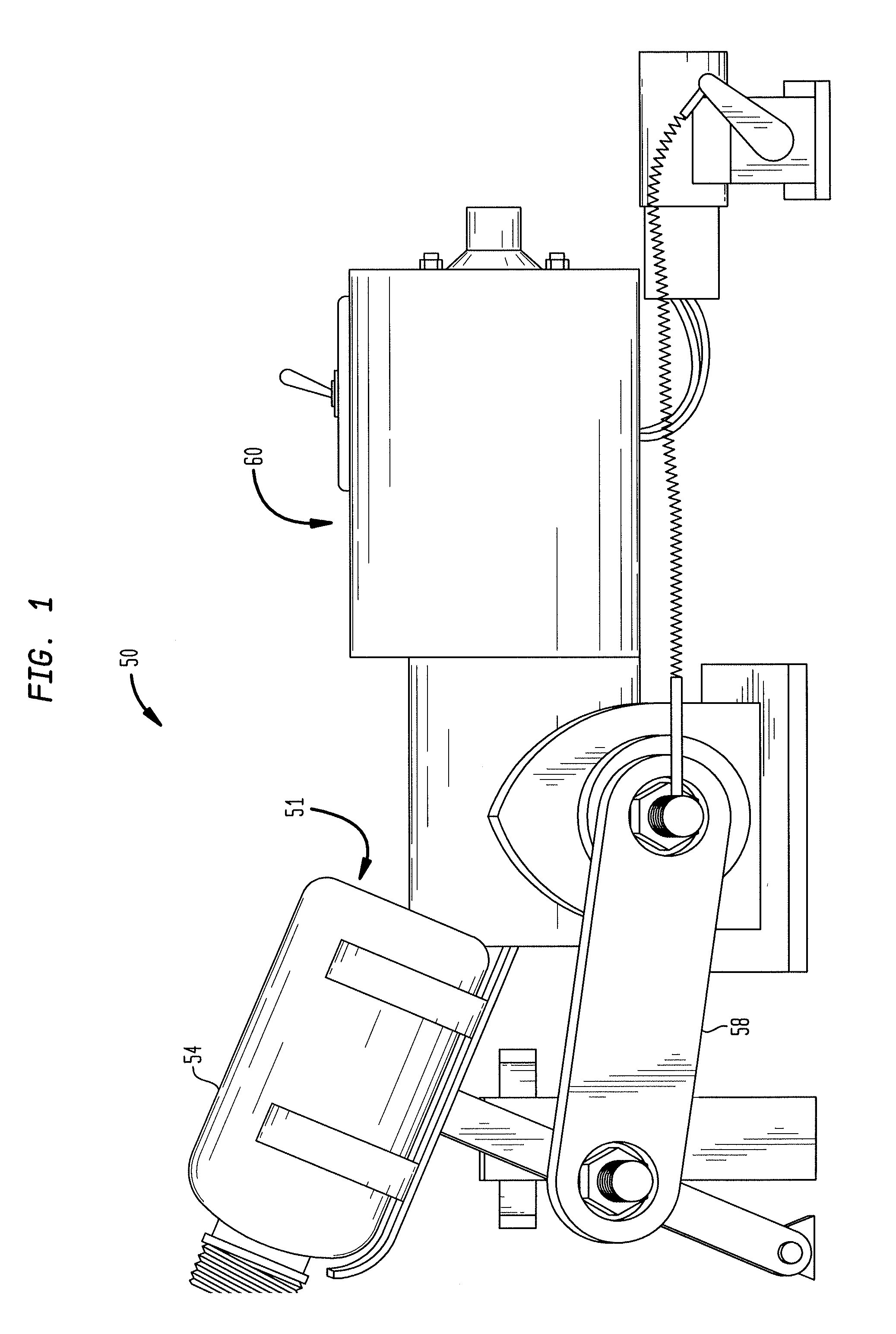

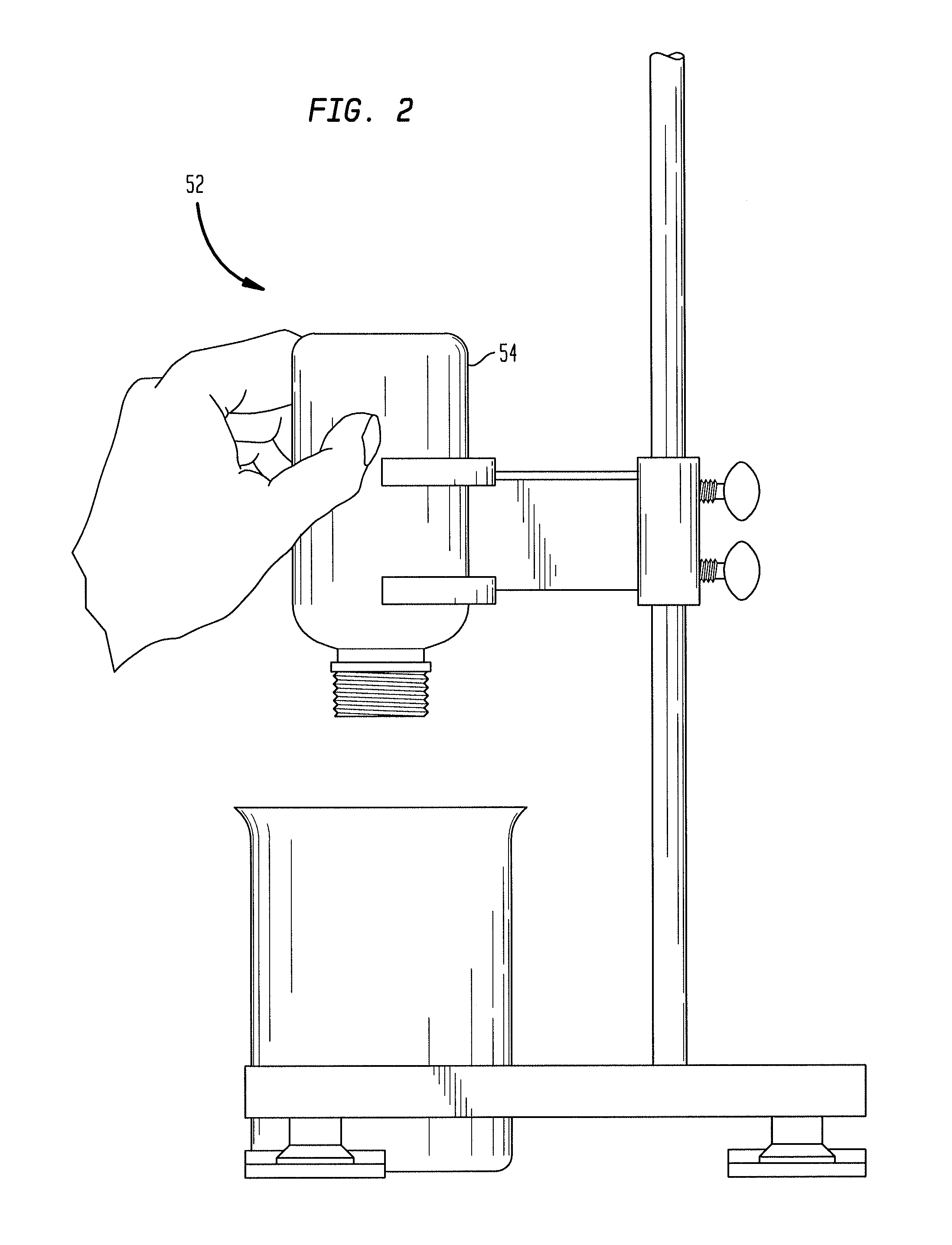

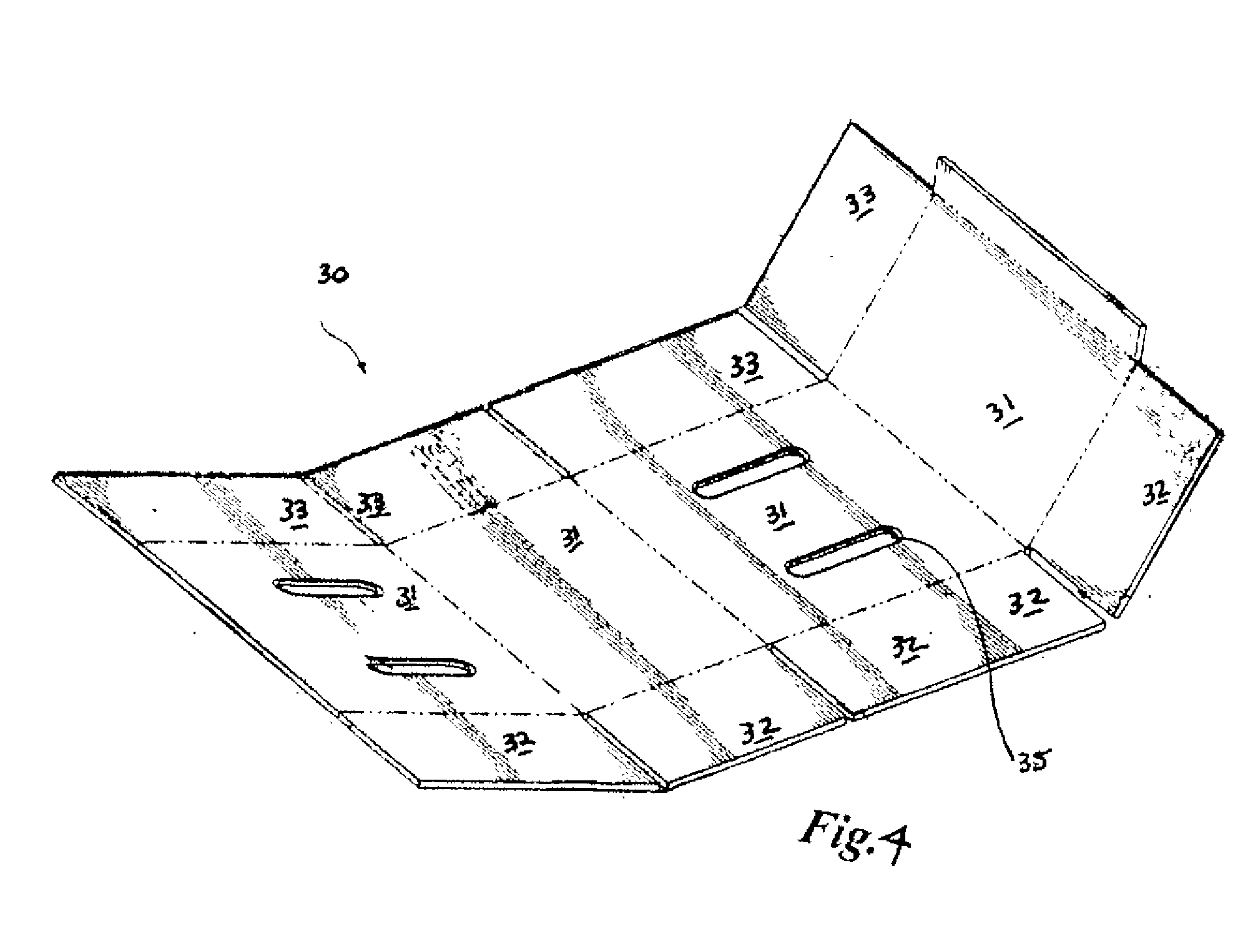

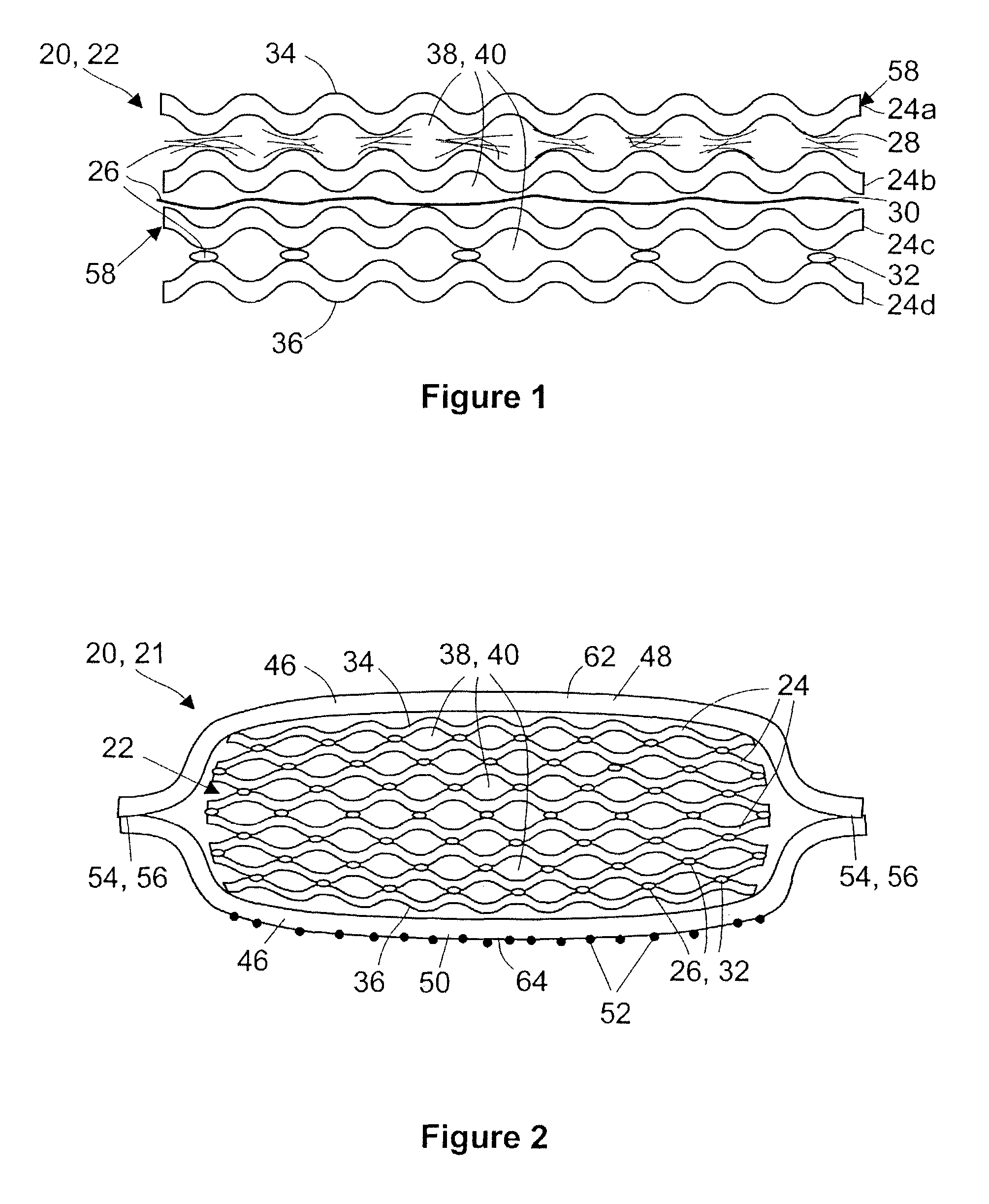

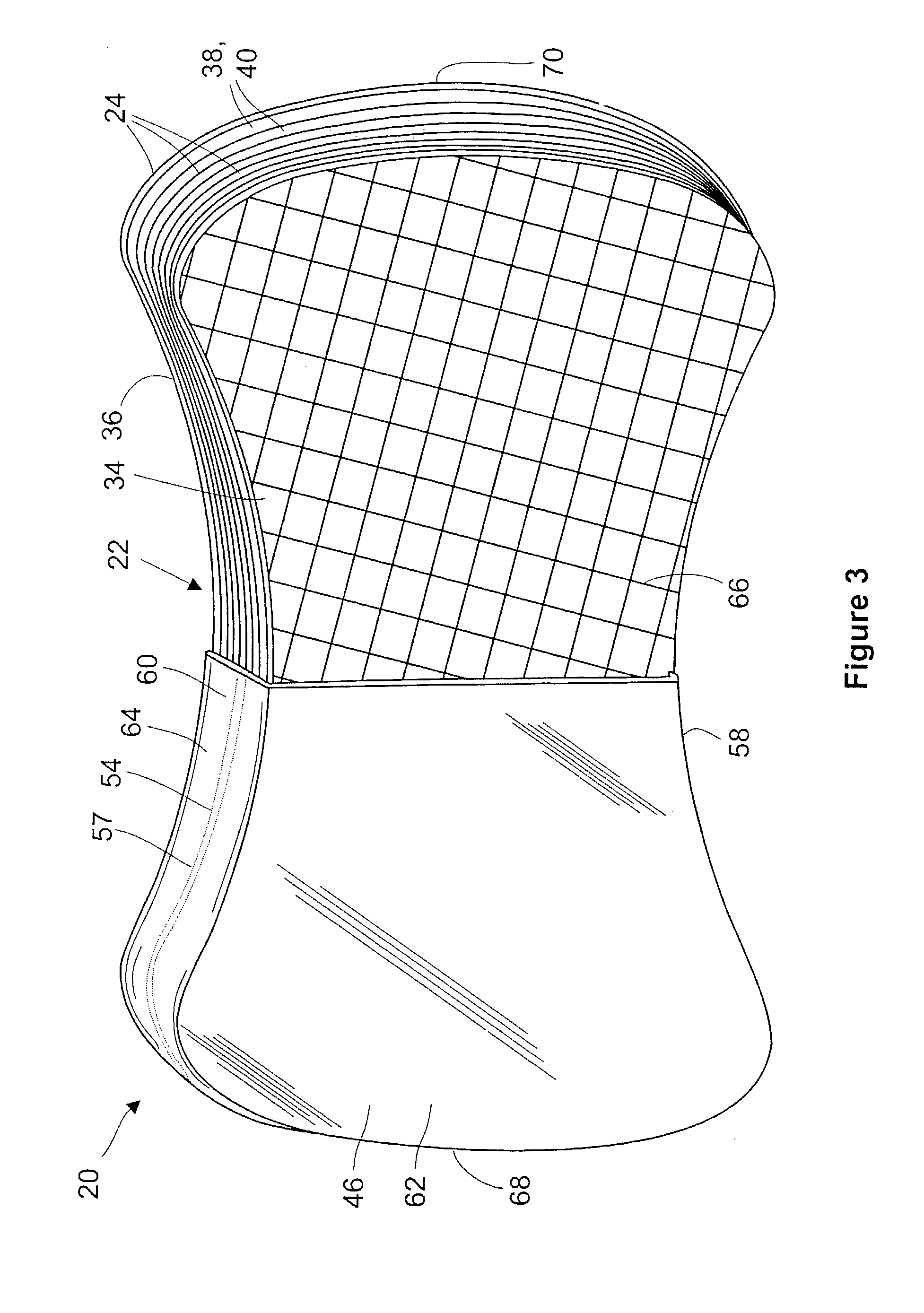

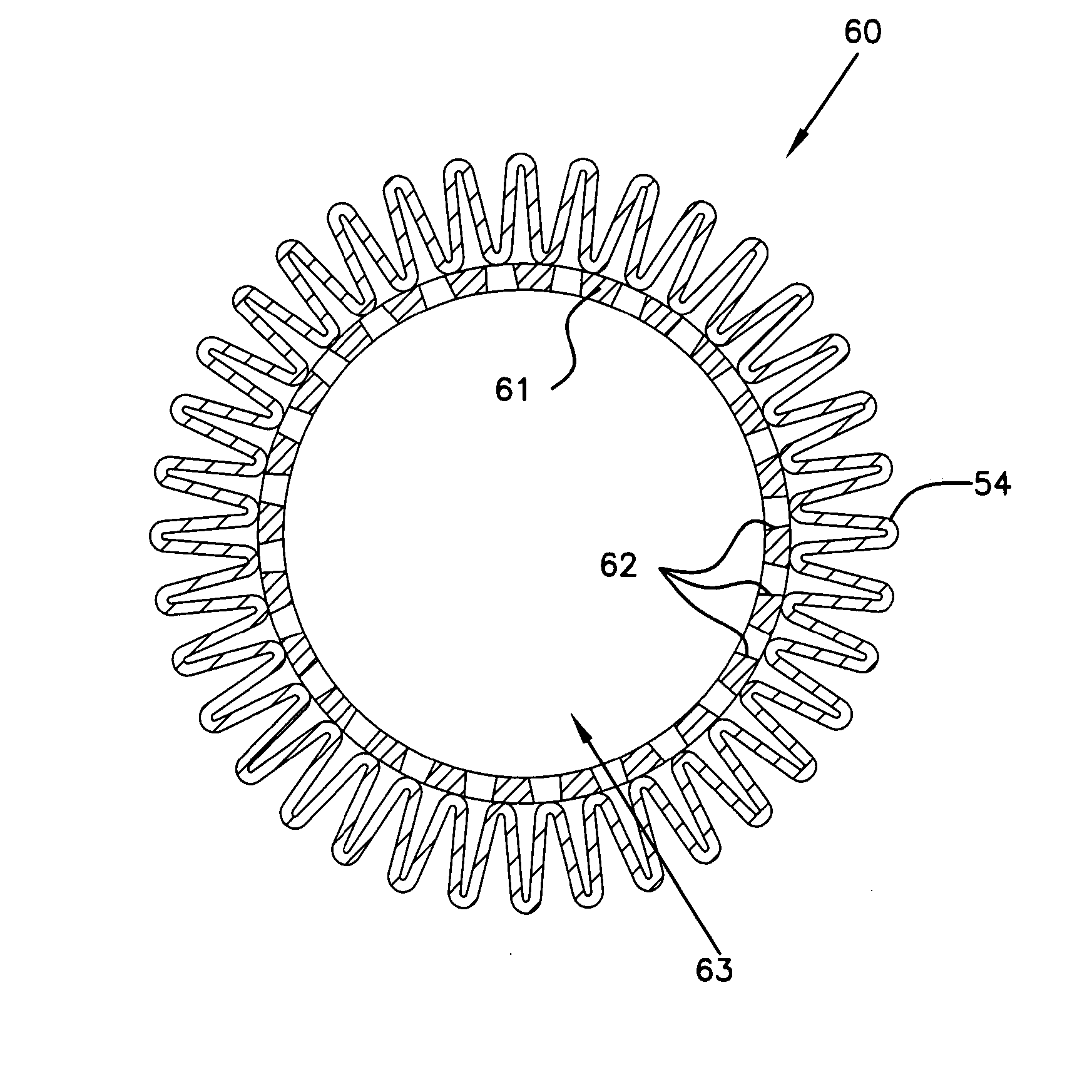

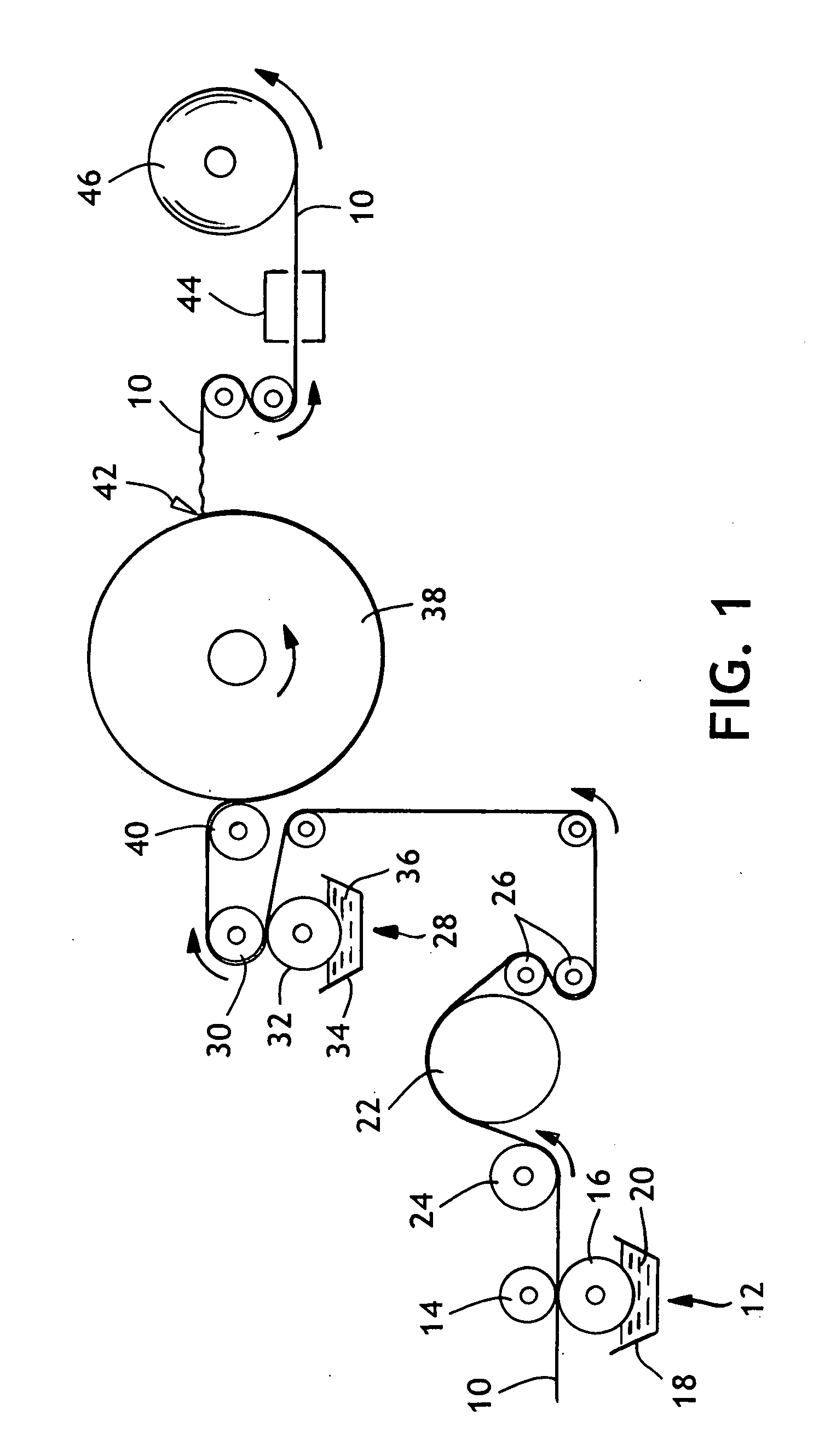

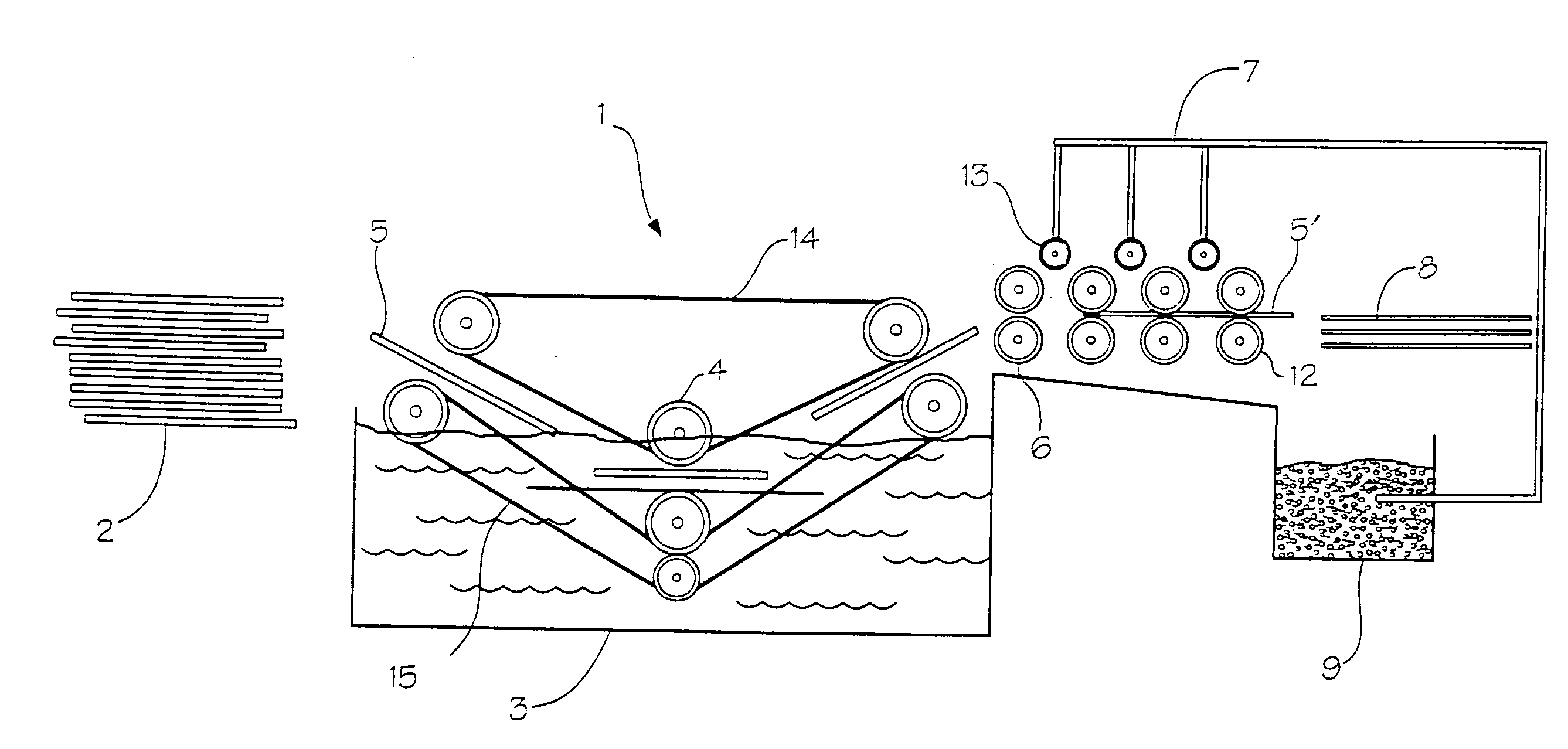

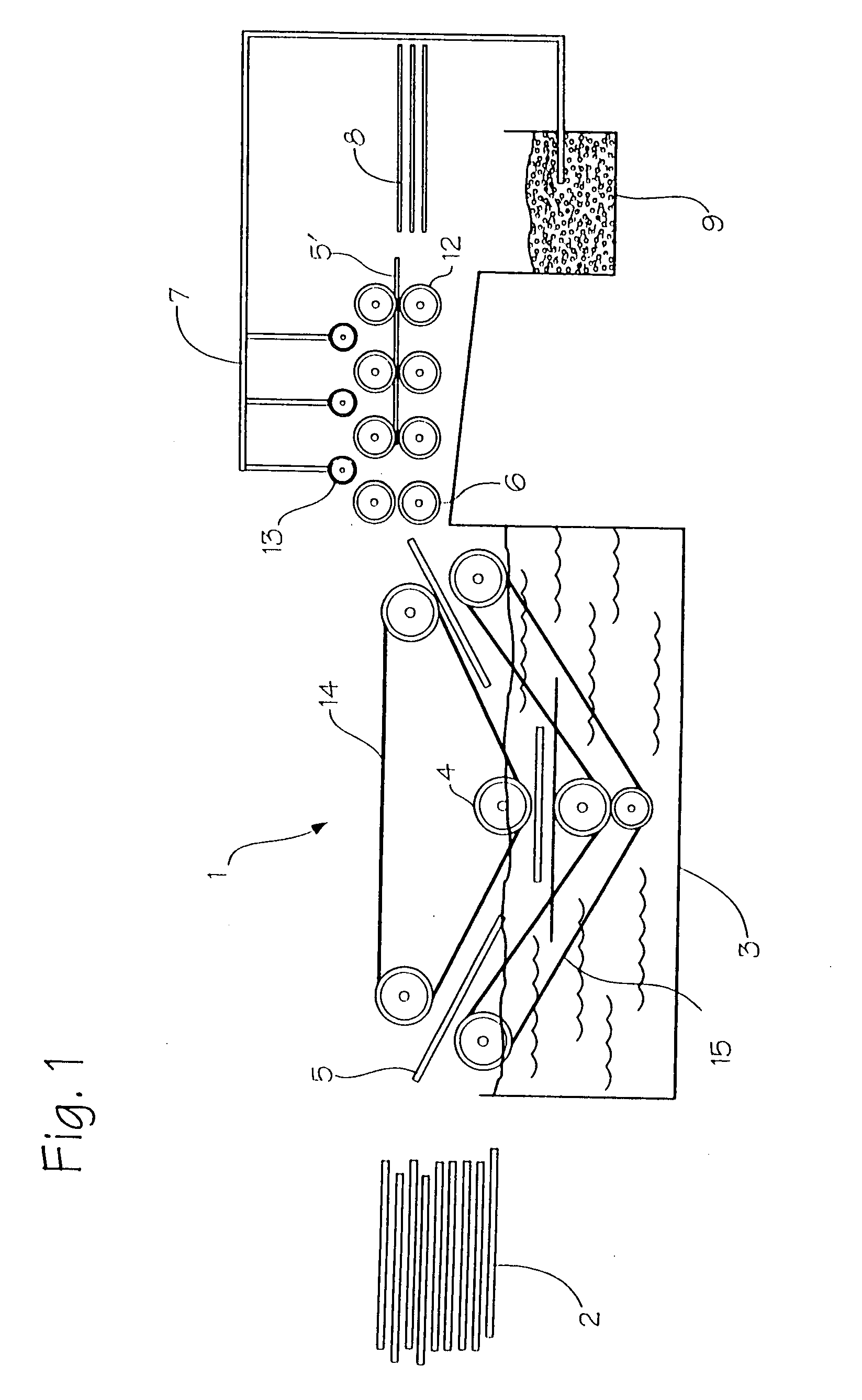

Sponge-like pad comprising paper layers and method of manufacture

InactiveUS7799968B2Significant valueHigh fluid capacityCarpet cleanersFloor cleanersFiberPulp and paper industry

A sponge-like pad used for cleaning and other wiping and polishing applications is disclosed. The sponge-like pad is made from a plurality of textured paper webs attached together at selected locations. The paper web can be, for instance, a highly textured throughdried paper web containing high-yield fibers and a wet strength agent. In one embodiment, the stacked plies can be contained within a cover material that is liquid pervious. The sponge-like product of the present invention can be used alone or it can be incorporated into a cleaning tool, such as a mop.

Owner:KIMBERLY-CLARK WORLDWIDE INC

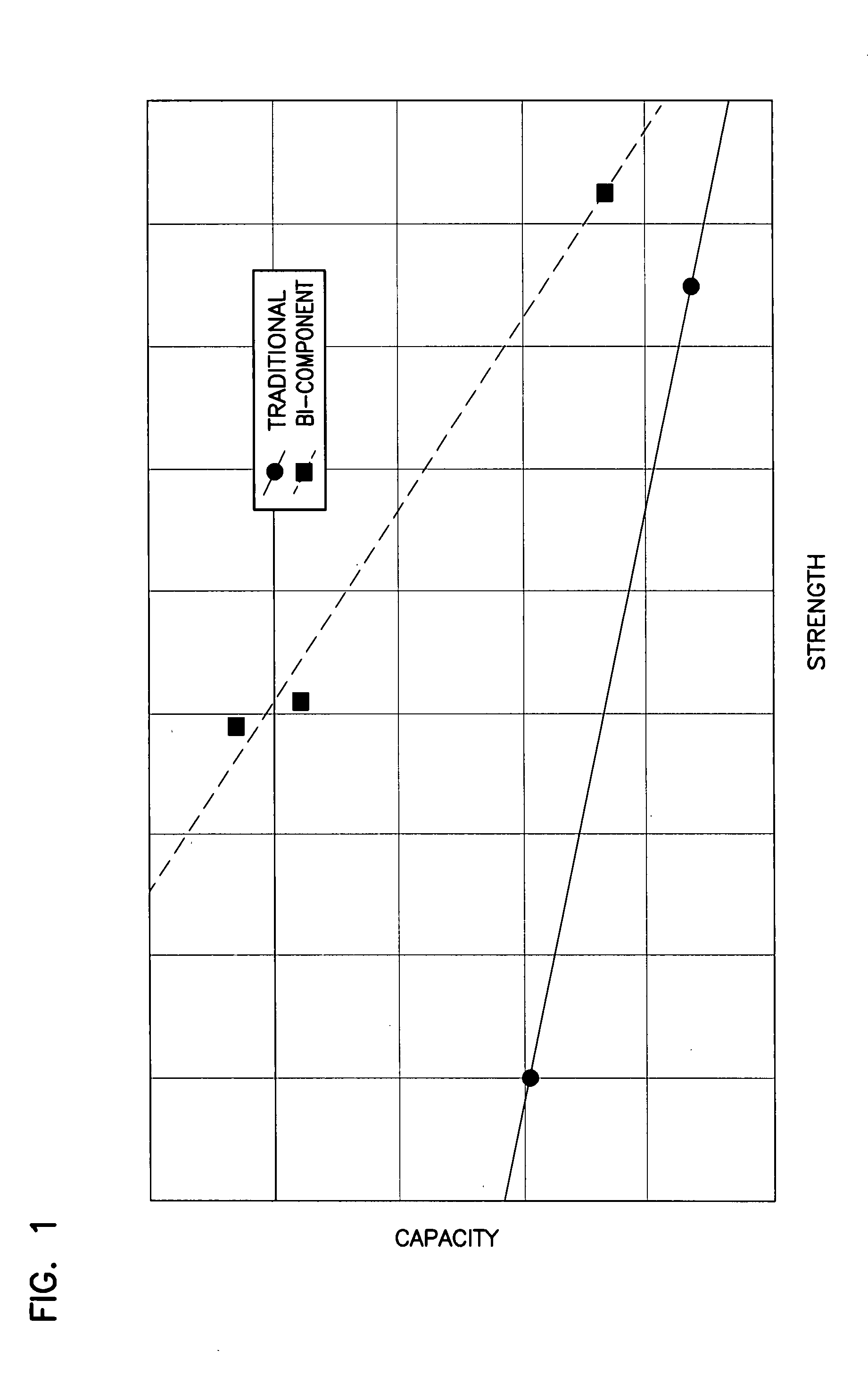

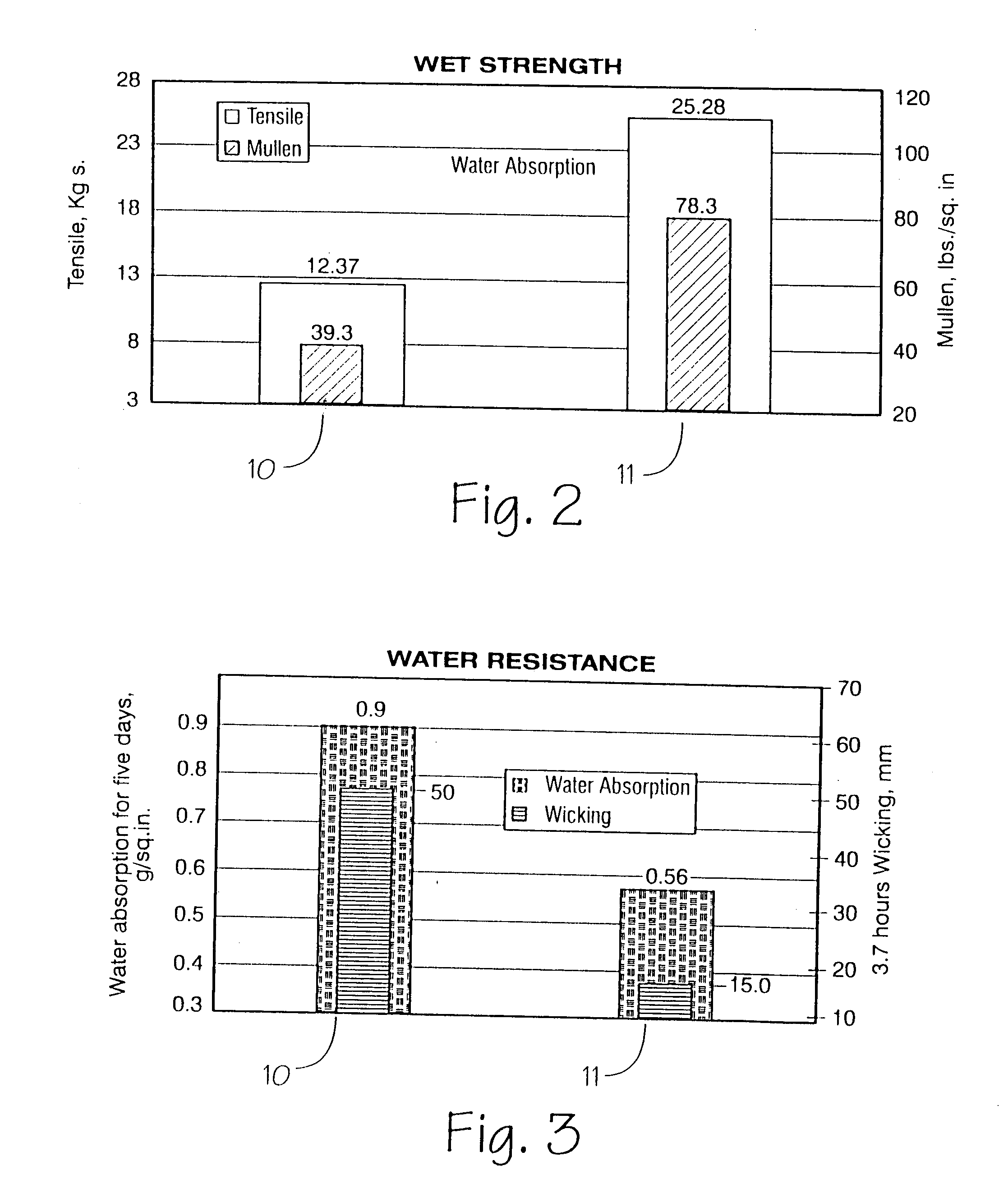

High strength, high capacity filter media and structure

ActiveUS20080073296A1Large capacitySubstantial permeabilitySemi-permeable membranesWater/sewage treatmentParticulatesFilter media

In the filtration of fluid materials, the removal of particulate from the moving stream requires substantial pressure to maintain flow and substantial capacity for removing particulate. The filters of the invention are rugged, high wet strength materials having a basis weight, permeability and efficiency suitable to obtain substantial reduction in particulate loading from liquid streams without plugging or mechanical failure. In particular, the filters of the invention permit the removal of substantial proportions of particulate from non-aqueous streams including lubricant oils, hydraulic fluids and other contaminated streams.

Owner:DONALDSON CO INC

Low odor binders curable at room temperature

InactiveUS20050045294A1Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an epoxy-reactive polymer, such as a carboxyl-functional polymer, and an epoxy-functional polymer. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

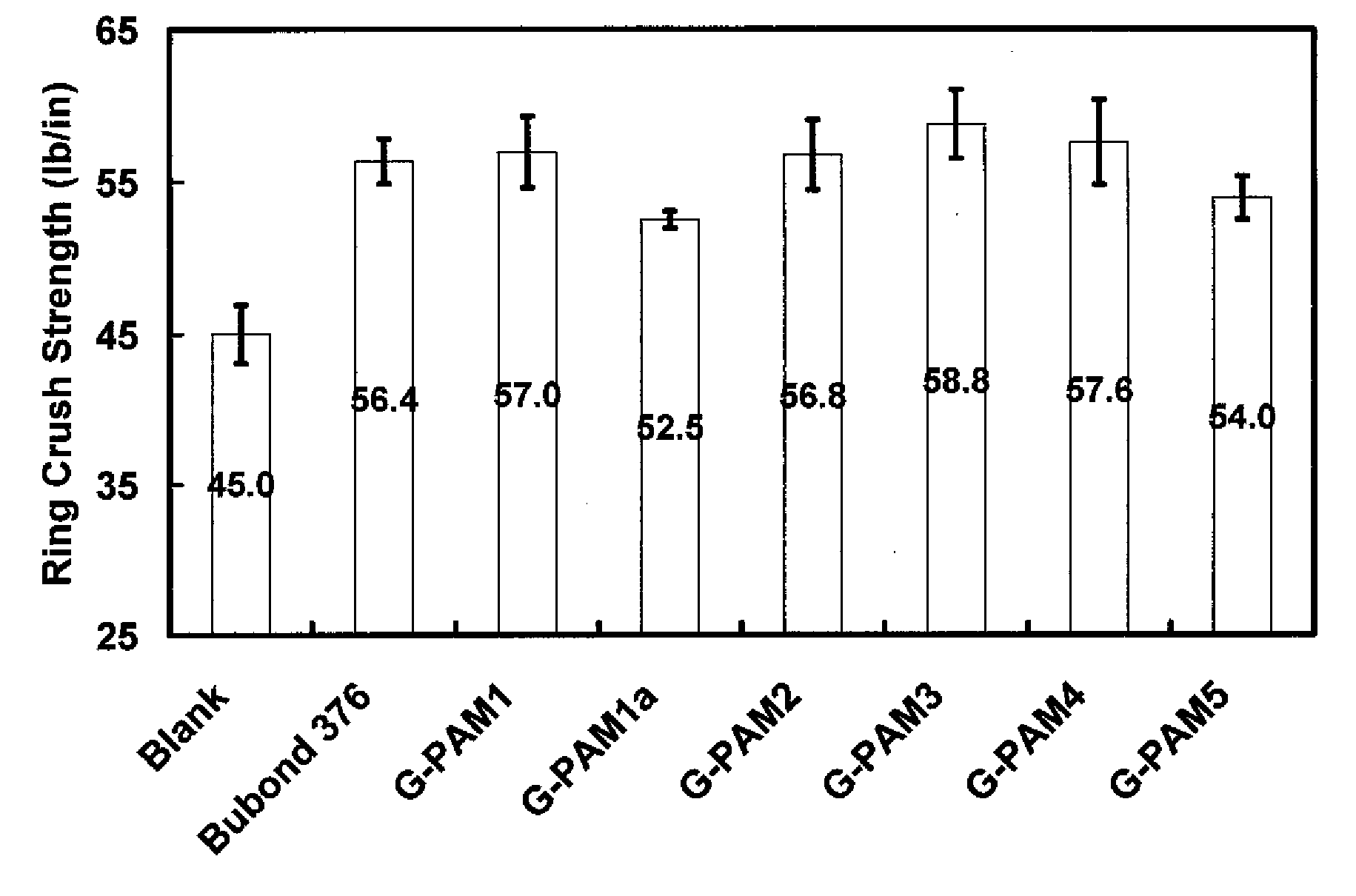

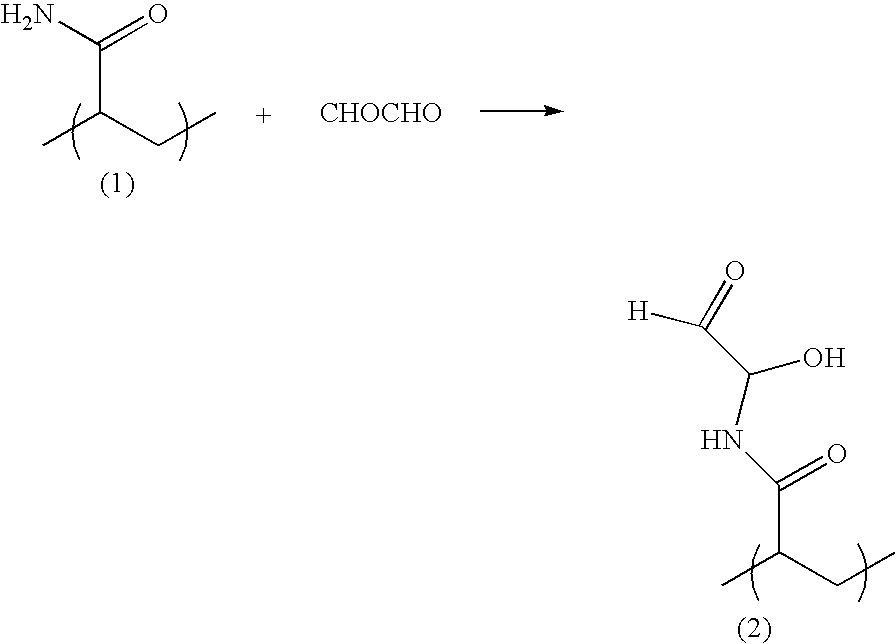

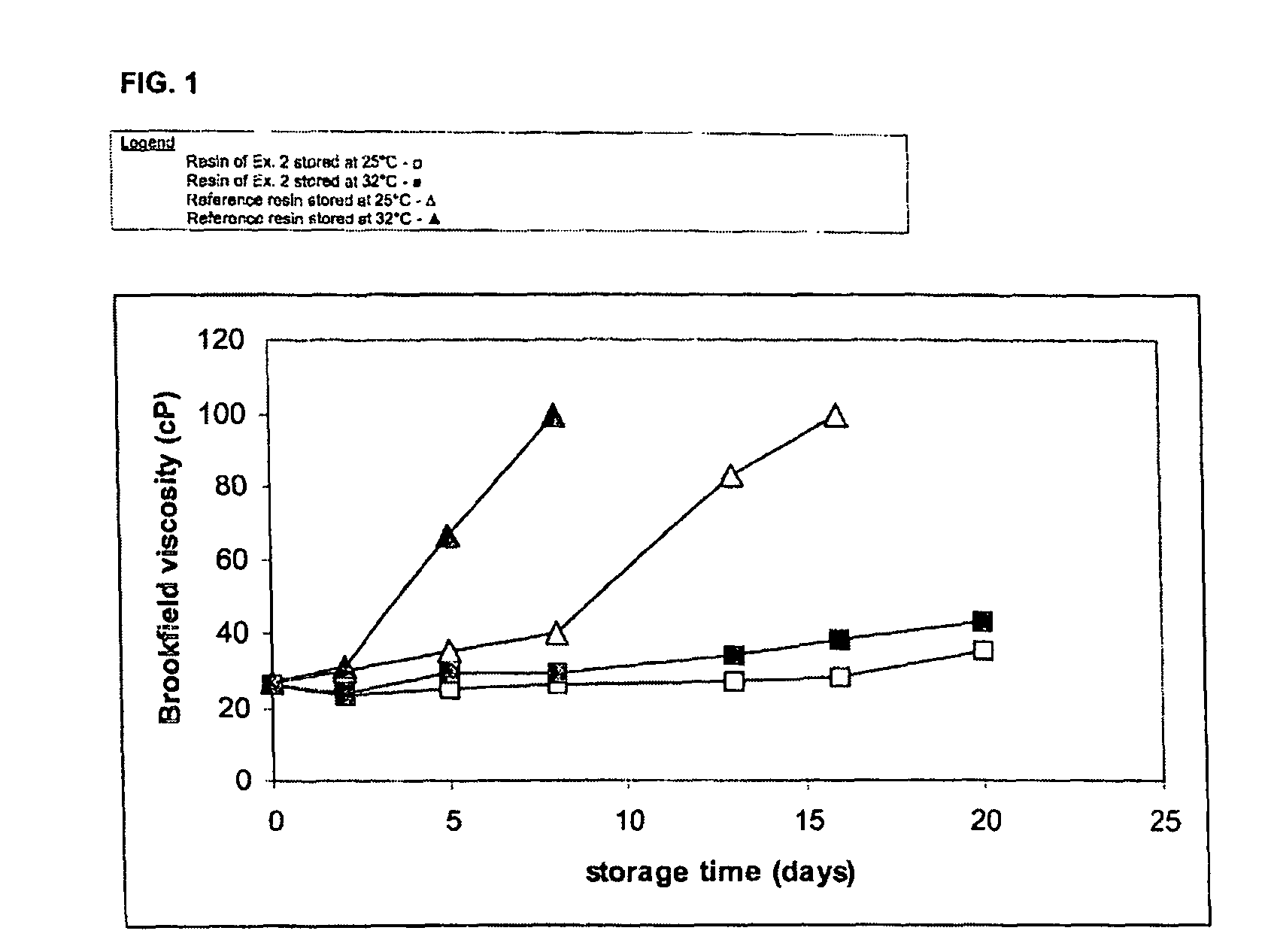

Blends of glyoxalated polyacrylamides and paper strengthening agents

ActiveUS20060037727A1Improve stabilityReadily break down during repulpingNatural cellulose pulp/paperSpecial paperWet strengthGlyoxal synthesis

Compositions comprising a blend of two or more paper strengthening agents have improved stability compared with previously known paper strengthening agents. One component is a polymeric paper strengthening agent, preferably a wet strengthening agent. The other component is a stabilized glyoxalated polyacrylamide prepared by (1) reacting a first portion of glyoxal with a polyacrylamide having pendant amide groups to form a first reaction mixture comprising glyoxalated polyacrylamide; (2) adding an acid to the first reaction mixture to form a second reaction mixture having a reduced pH and comprising the glyoxalated polyacrylamide; and (3) adding a second portion of glyoxal to the second reaction mixture to form the stabilized glyoxalated polyacrylamide. If desired, an aldehyde scavenger can be included in one or more of step (1), step (2), step (3), or the stabilized glyoxalated polyacrylamide. Such compositions can be used to enhance the strength of paper, particularly the wet strength of paper.

Owner:ECOLAB USA INC

Low odor binders curable at room temperature

InactiveUS20050045295A1Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an epoxy-reactive polymer, such as a carboxyl-functional polymer, and an epoxy-functional polymer. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Blends of glyoxalated polyacrylamides and paper strengthening agents

Compositions comprising a blend of two or more paper strengthening agents have improved stability compared with previously known paper strengthening agents. One component is a polymeric paper strengthening agent, preferably a wet strengthening agent. The other component is a stabilized polyacrylamide prepared by (1) reacting a first portion of glyoxal with a polyacrylamide having pendant amide groups to form a first reaction mixture comprising polyacrylamide; (2) adding an acid to the first reaction mixture to form a second reaction mixture having a reduced pH and comprising the polyacrylamide; and (3) adding a second portion of glyoxal to the second reaction mixture to form the stabilized polyacrylamide. If desired, an aldehyde scavenger can be included in one or more of step (1), step (2), step (3), or the stabilized polyacrylamide. Such compositions can be used to enhance the strength of paper, particularly the wet strength of paper.

Owner:ECOLAB USA INC

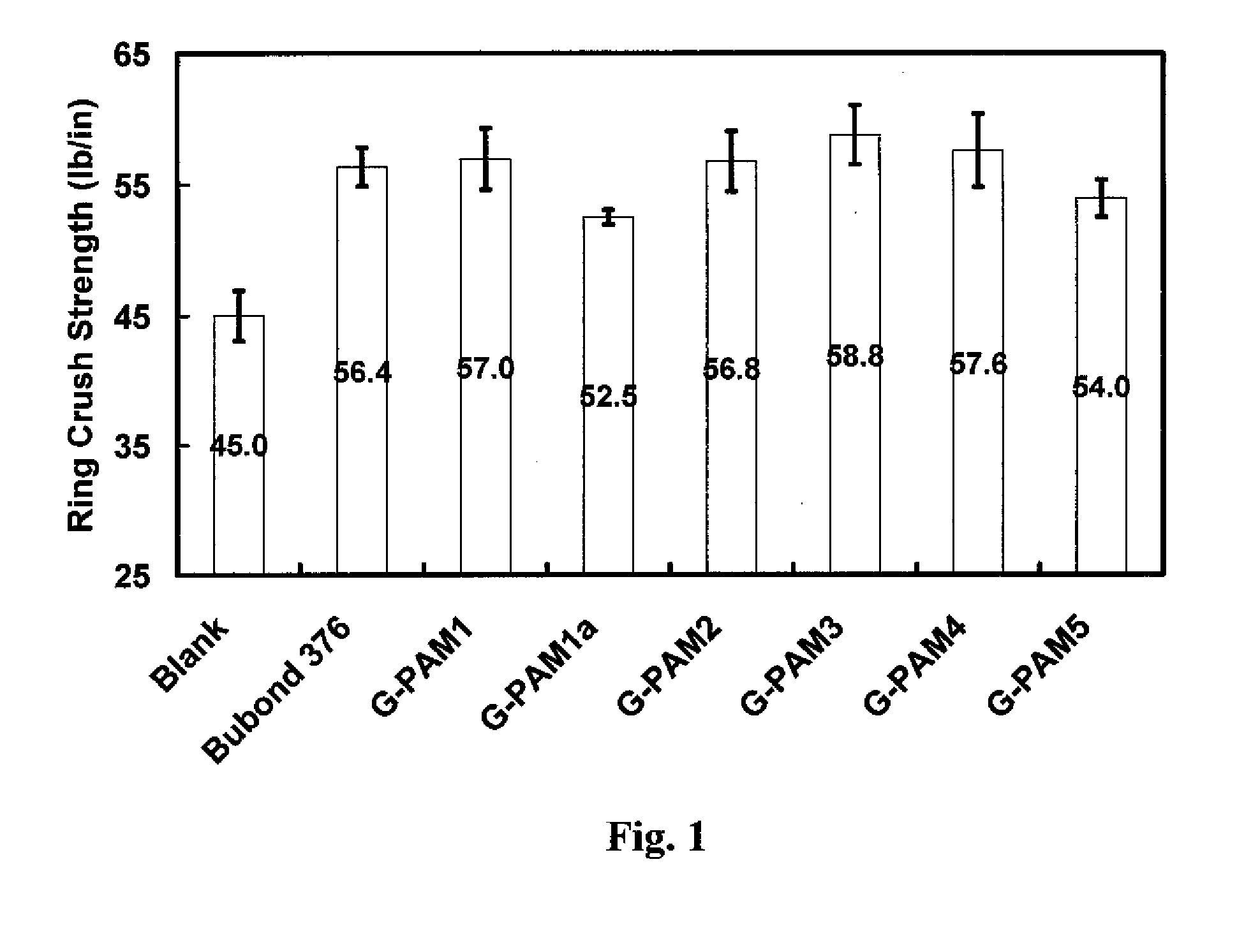

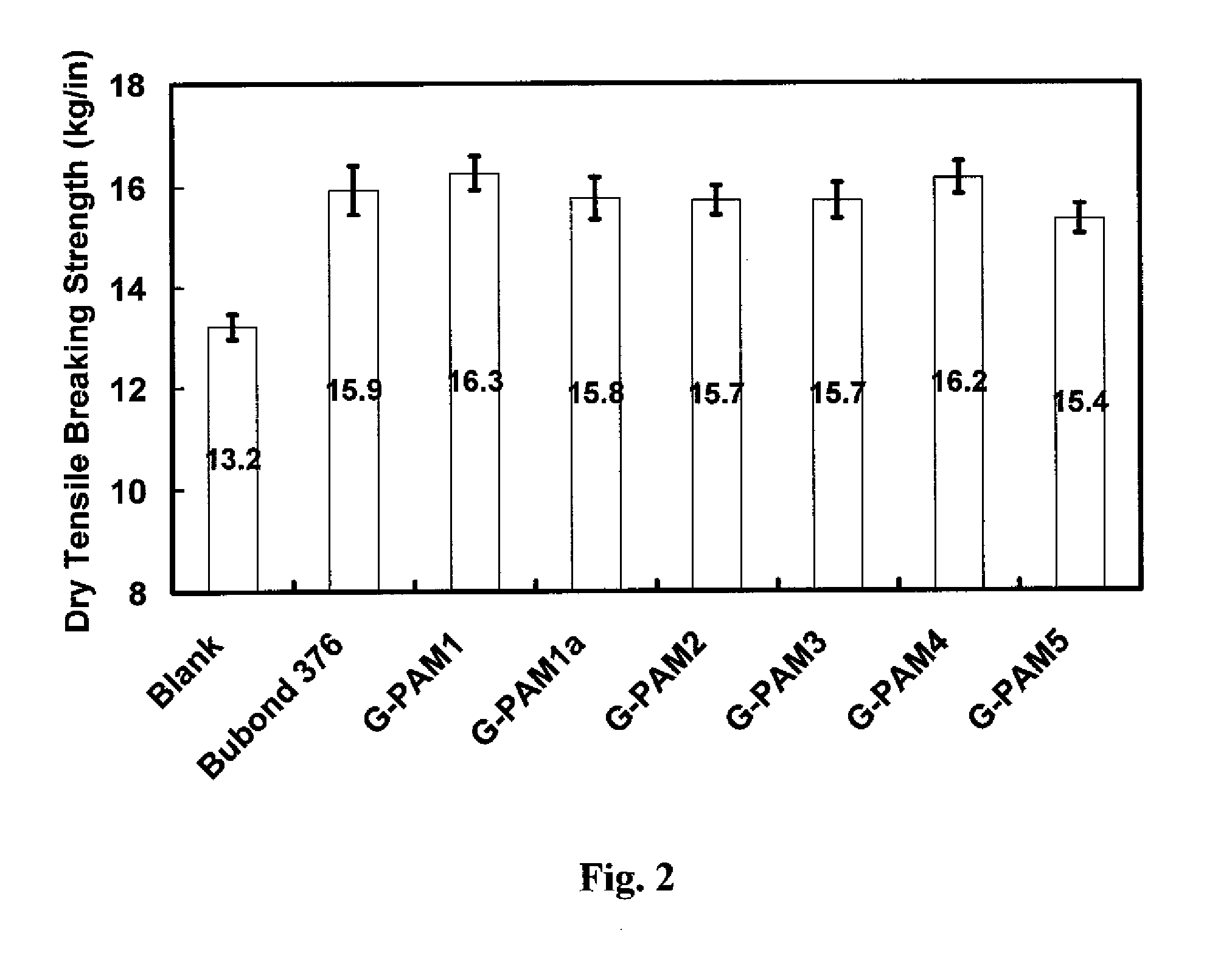

Method for increasing the advantages of strength aids in the production of paper and paperboard

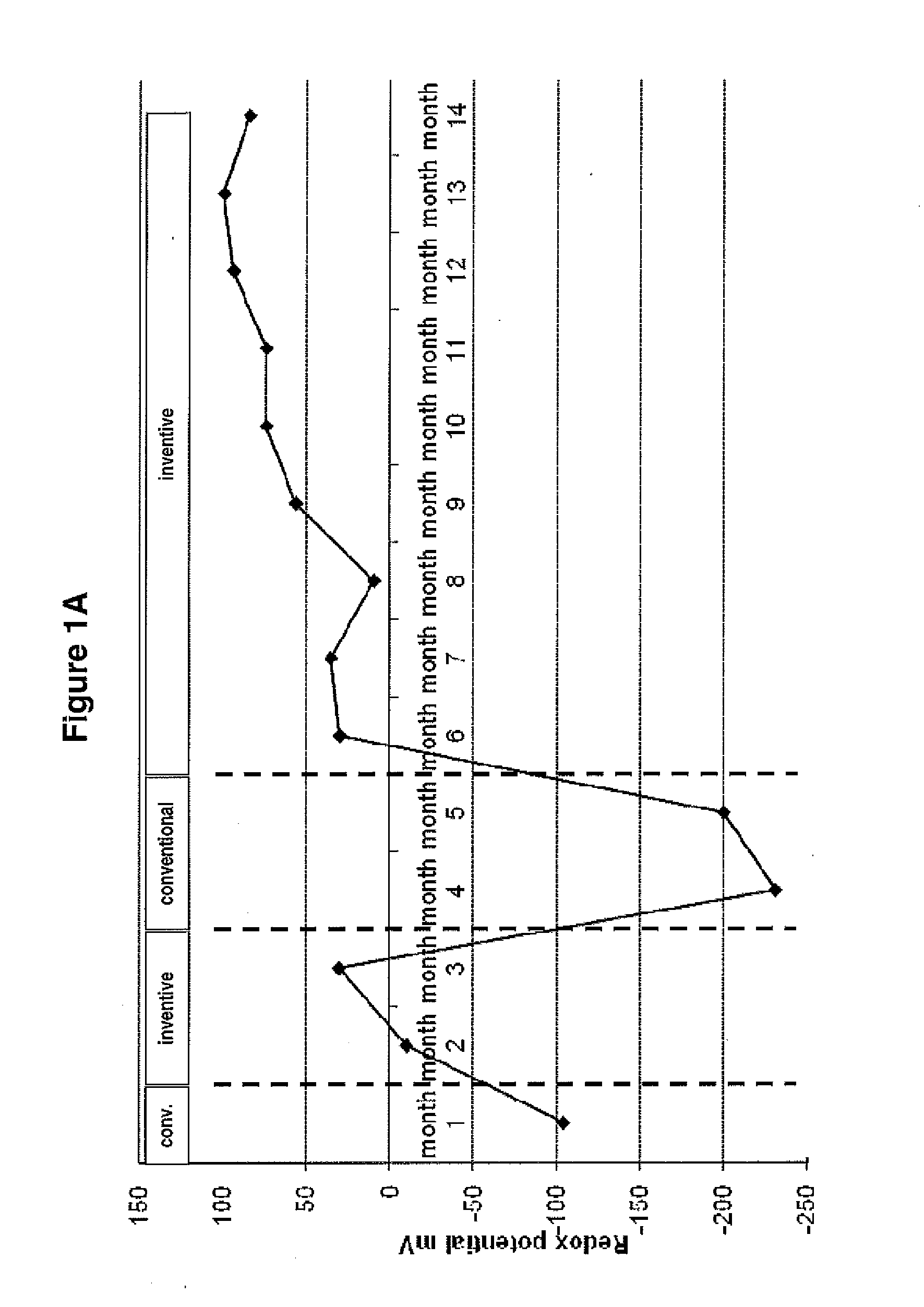

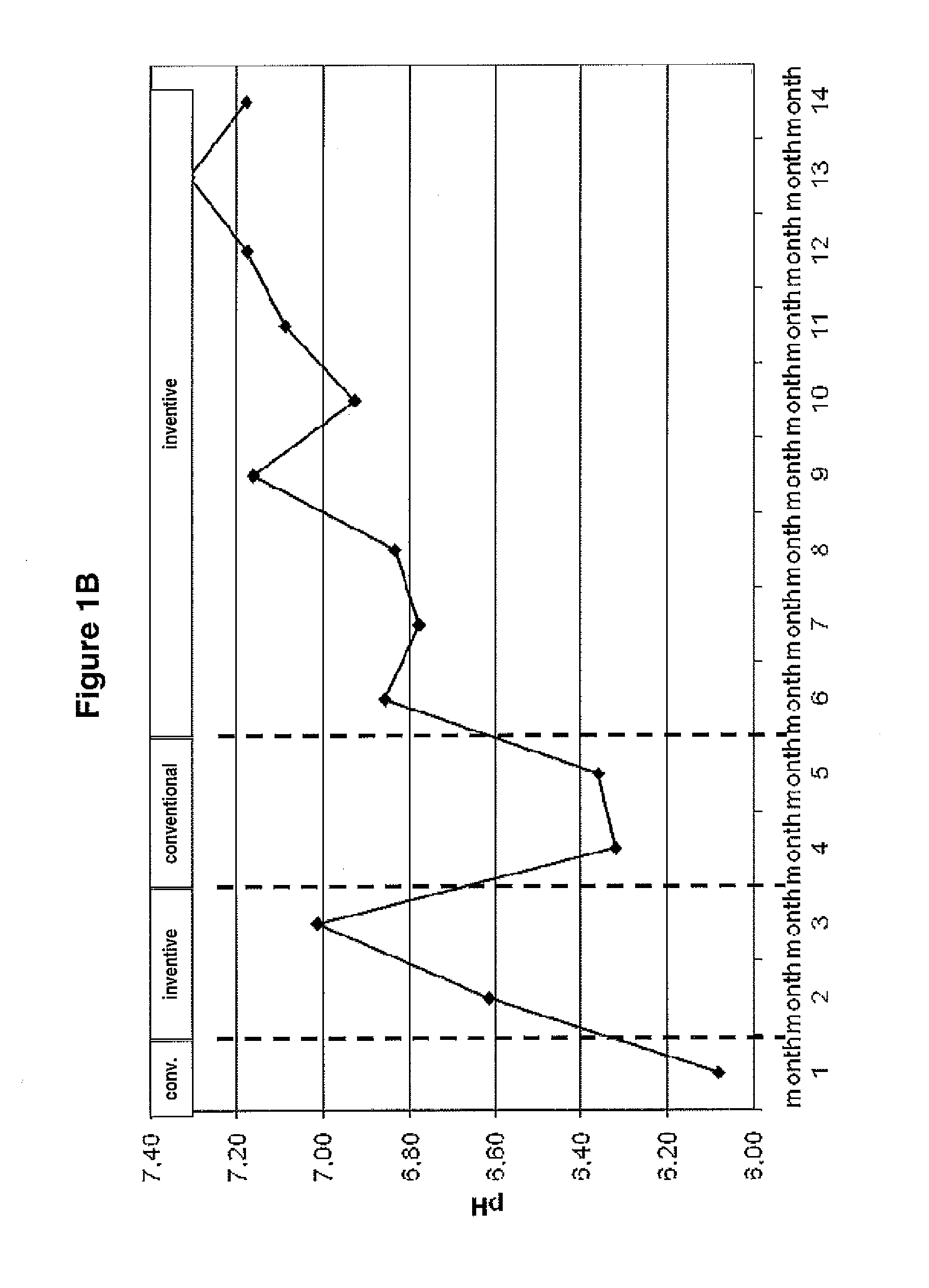

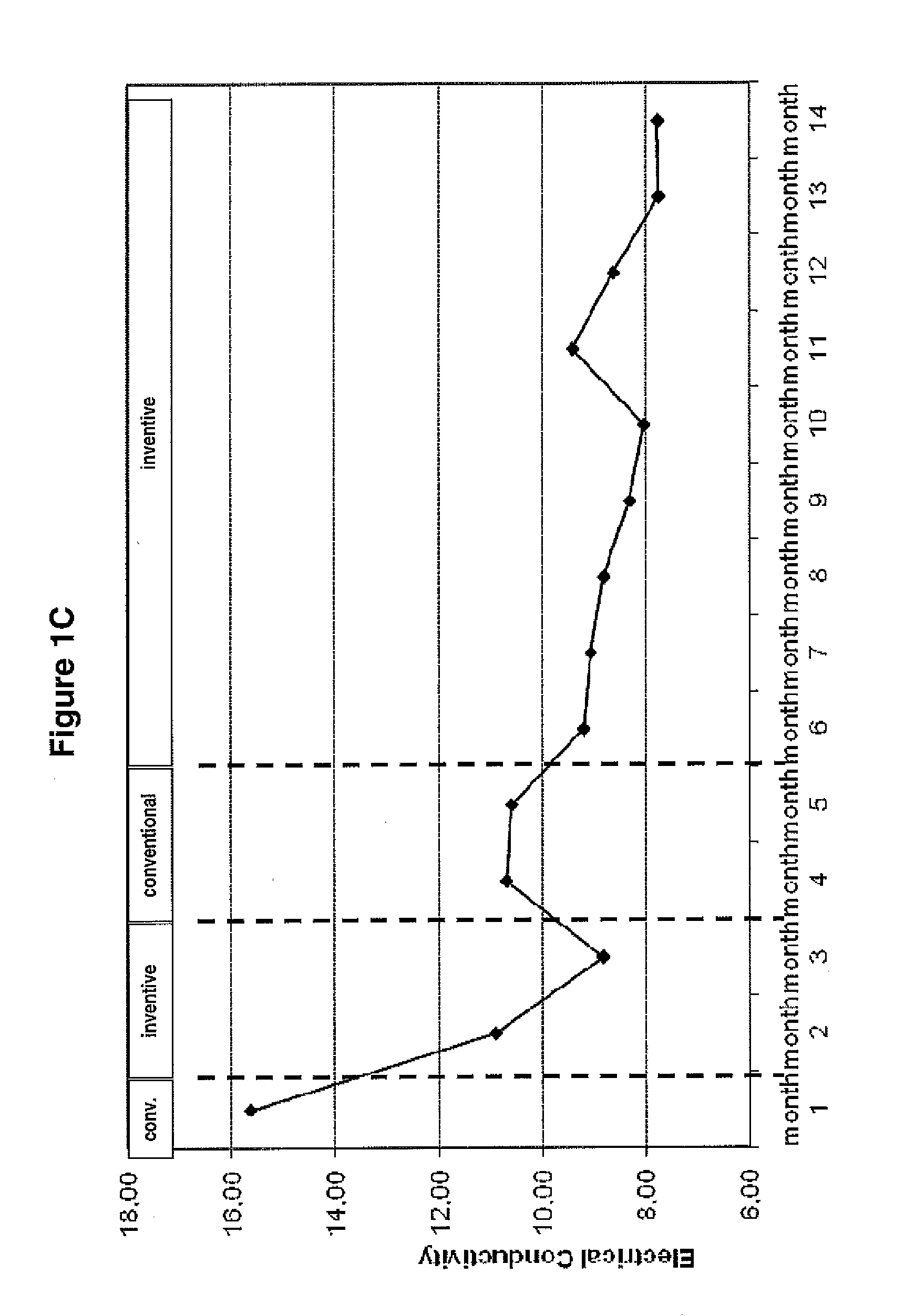

ActiveUS20140284011A1Prevent microbiological degradationReduce electrical conductivityNatural cellulose pulp/paperSpecial paperCellulosePaperboard

The invention relates to a method for manufacturing paper, paperboard or cardboard comprising the steps of(a) pulping an aqueous cellulosic material containing a starch;(b) preventing at least a portion of the starch from being microbially degraded by treating the aqueous cellulosic material containing the starch with one or more biocides; and(h) adding a dry and / or wet strength polymer to the cellulosic material.

Owner:SOLENIS TECH CAYMAN

Multi-layer, high barrier packaging materials

InactiveUS20070087212A1Provide moisture resistanceProvide anti-wicking propertySynthetic resin layered productsCellulosic plastic layered productsPaper basedEngineering

A multi-layer, high barrier packaging lid material is adapted for releasably sealing to a plurality of containers including a first container comprised of one polymer and a second container comprised of another polymer. The packaging lid material comprises a paper base with an internal wet strength agent and an anti-wicking agent and having interior and exterior surfaces. A polymer oxygen barrier layer is bonded on the interior surface of the base. A tie layer is on the barrier layer, and a seal-peel layer is on the tie layer. The seal-peel layer is comprised of a blend of a first polymer and a second polymer. When the lid material is heat sealed to a first container the first polymer in the seal-peel layer bonds with the first container while the second polymer in said seal-peel layer functions as a contaminant to provide easy peeling. When the lid material is heat sealed to a second container the second polymer in the seal-peel layer bonds with the second container while the first polymer in the seal-peel layer functions as a contaminant to provide easy peeling.

Owner:STORA ENSO NORTH AMERICA

Binders curable at room temperature with low blocking

ActiveUS20060014884A1Without imparting objectionable odorEasy to prepareNatural cellulose pulp/paperPaper after-treatmentRoom temperaturePaper towel

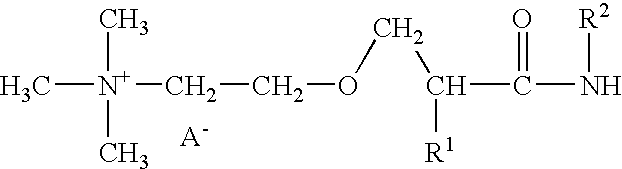

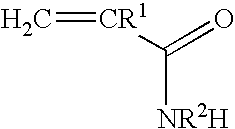

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an azetidinium-reactive polymer, such as a carboxyl-functional polymer, an azetidinium-functional polymer and, optionally, a component useful for reducing sheet-to-sheet adhesion (blocking) in the product. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

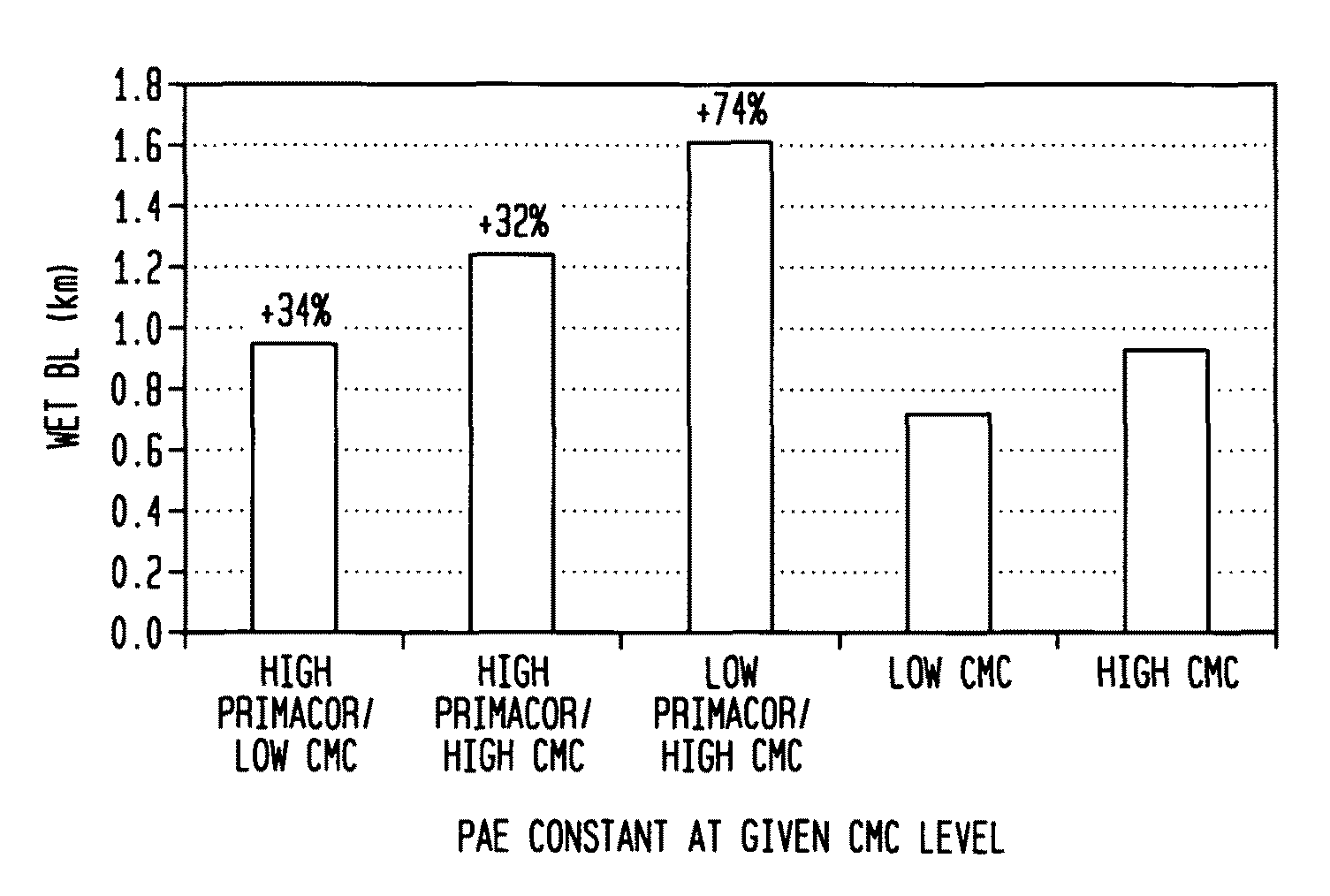

Polysaccharide aldehydes prepared by oxidation method and used as strength additives in papermaking

InactiveUS6872821B2Maximum effective aldehydeMinimal carboxylic acid contentSugar derivativesReinforcing agents additionAldehydeHydroxyl radical

Polysaccharide aldehydes are prepared using selective oxidation involving the use of nitroxyl radical mediated aqueous oxidation with a limited amount of oxidant and defined reaction conditions. These polysaccharide aldehyde derivatives having maximum effective aldehyde and minimal carboxylic acid levels making them especially useful as wet, temporary wet and dry strength additives for paper.

Owner:BRUNOB II BV

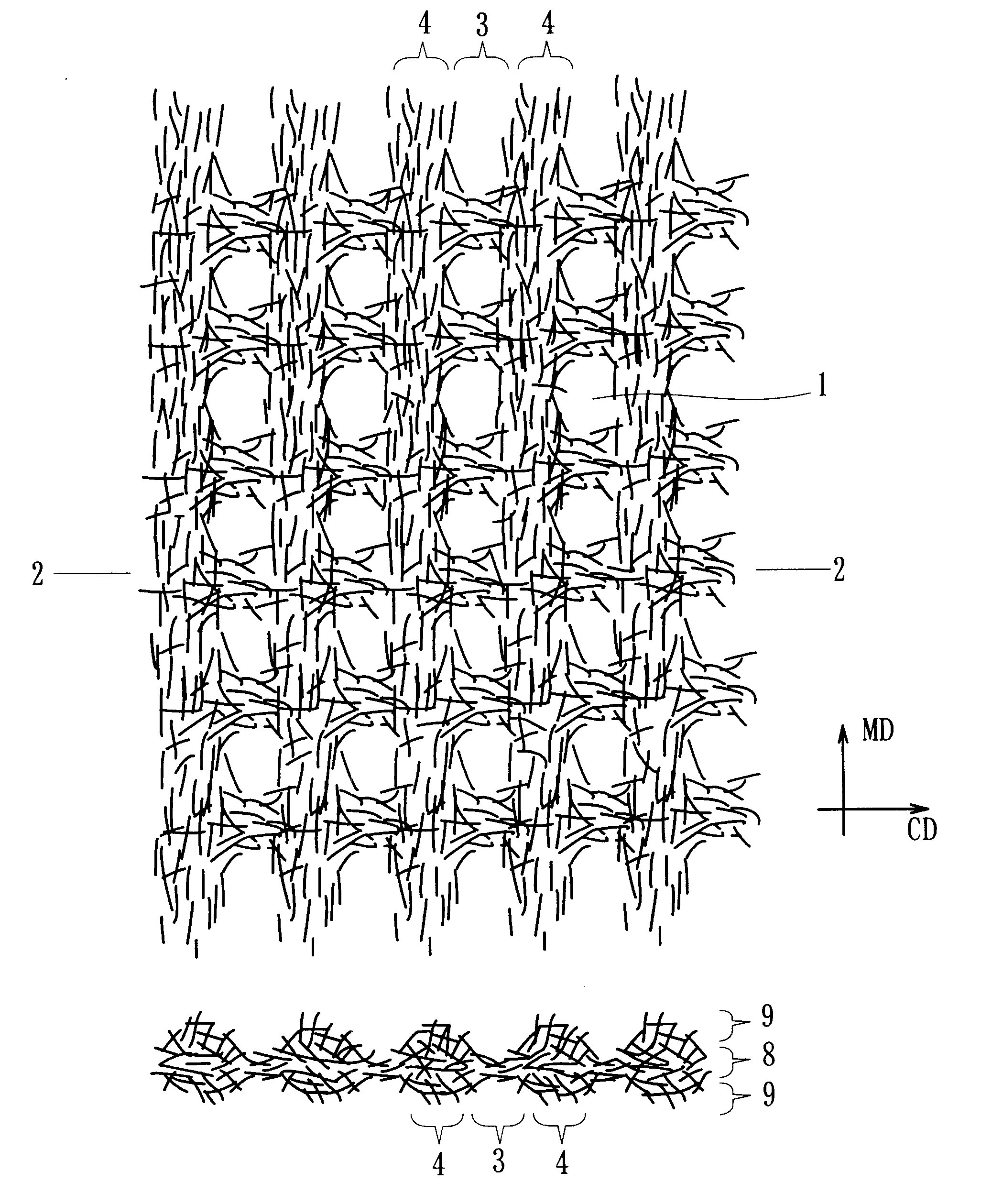

Disposable nonwoven wiping fabric and method of production

InactiveUS7732357B2Improve wet strengthImprove aestheticsCosmetic preparationsMake-upPolymer scienceCellulose fiber

Disclosed is a fibrous nonwoven web material and a method of manufacture thereof. The fibrous nonwoven web material includes natural cellulose fibers, manmade cellulose fibers and synthetic fibers. The manmade cellulose fibers are preferably high crystallinity cellulose fibers. The fibrous nonwoven web material has appreciable wet strength yet is capable of dispersing in most aqueous environments with only mild agitation. The fibrous nonwoven web material can be wet laid from an aqueous dispersion of fibers.

Owner:SUOMINEN CORP

Reactive cationic resins for use as dry and wet strength agents in sulfite ion-containing papermaking systems

This invention relates to resins useful for imparting strength to paper, the process of incorporating these resins into paper and the paper produced containing the resins. In particular the invention relates to resins useful for imparting dry-strength and wet-strength to paper under conditions of high sulfite ion concentrations.

Owner:SOLENIS TECH CAYMAN

Water disintegratable fibrous sheet

InactiveUS20120080155A1High strengthResistant to tearingNon-fibrous pulp additionSpecial paperPolymer scienceWet strength

To provide a water disintegratable fibrous sheet with high water disintegratability and wet strength, that can be used as a cleaning sheet. A prescribed water disintegratable fibrous sheet comprising 30-50% by mass of unbeaten pulp (a) with a beating degree of 700 cc or greater; 20-40% by mass of beaten pulp (b) with a beating degree of 400-700 cc; 15-45% by mass of regenerated cellulose (c) with a beating degree of 700 cc or greater; and 2-15% by mass of fibrillated purified cellulose (d) with a beating degree of 0-400 cc.

Owner:UNI CHARM CORP

Absorbent sheet prepared with papermaking fiber and synthetic fiber exhibiting improved wet strength

ActiveUS8066849B2Increase wet/dry tensile ratioNatural cellulose pulp/paperPaper after-treatmentWet strengthCopolymer

Owner:GPCP IP HLDG LLC

Moisture resistant, repulpable paper products and method of making same

InactiveUS20050123780A1Easily biodegradableEasy to recyclePaper coatingReinforcing agents additionParaffin waxParaffin oils

Hydrogenated triglycerides having melting points above 50° C. are substituted for paraffin as a coating material for the surface of paper products and the resulting paper products have improved wet strength and moisture resistance in addition to being repulpable thereby providing a distinct environmental advantage over paraffin coated products.

Owner:AKZO NOBEL CHEM INC

Blends of glyoxalated polyacrylamides and paper strengthening agents

ActiveUS7488403B2Improve stabilityReadily break down during repulpingNatural cellulose pulp/paperSpecial paperScavengerSide chain

Compositions comprising a blend of two or more paper strengthening agents have improved stability compared with previously known paper strengthening agents. One component is a polymeric paper strengthening agent, preferably a wet strengthening agent. The other component is a stabilized glyoxalated polyacrylamide prepared by (1) reacting a first portion of glyoxal with a polyacrylamide having pendant amide groups to form a first reaction mixture comprising glyoxalated polyacrylamide; (2) adding an acid to the first reaction mixture to form a second reaction mixture having a reduced pH and comprising the glyoxalated polyacrylamide; and (3) adding a second portion of glyoxal to the second reaction mixture to form the stabilized glyoxalated polyacrylamide. If desired, an aldehyde scavenger can be included in one or more of step (1), step (2), step (3), or the stabilized glyoxalated polyacrylamide. Such compositions can be used to enhance the strength of paper, particularly the wet strength of paper.

Owner:ECOLAB USA INC

Sulfopolyesters for paper strength and process

Sulfopolyester thermoplastic resins provide advantages in papermaking processes and in paper products including paperboard. Improvements in wet strength and dry strength of paper products are achieved by addition of sulfopolyester thermoplastic resins and cationic strength additives during the paper making process. The use of sulfopolyester thermoplastic resins in paper products also significantly enhances the repulpability of the paper.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com