Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

738 results about "Rotational molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotational Molding (BrE moulding) involves a heated hollow mold which is filled with a charge or shot weight of material. It is then slowly rotated (usually around two perpendicular axes), causing the softened material to disperse and stick to the walls of the mold. In order to maintain even thickness throughout the part, the mold continues to rotate at all times during the heating phase and to avoid sagging or deformation also during the cooling phase. The process was applied to plastics in the 1950s but in the early years was little used because it was a slow process restricted to a small number of plastics. Over time, improvements in process control and developments with plastic powders have resulted in a significant increase in usage.

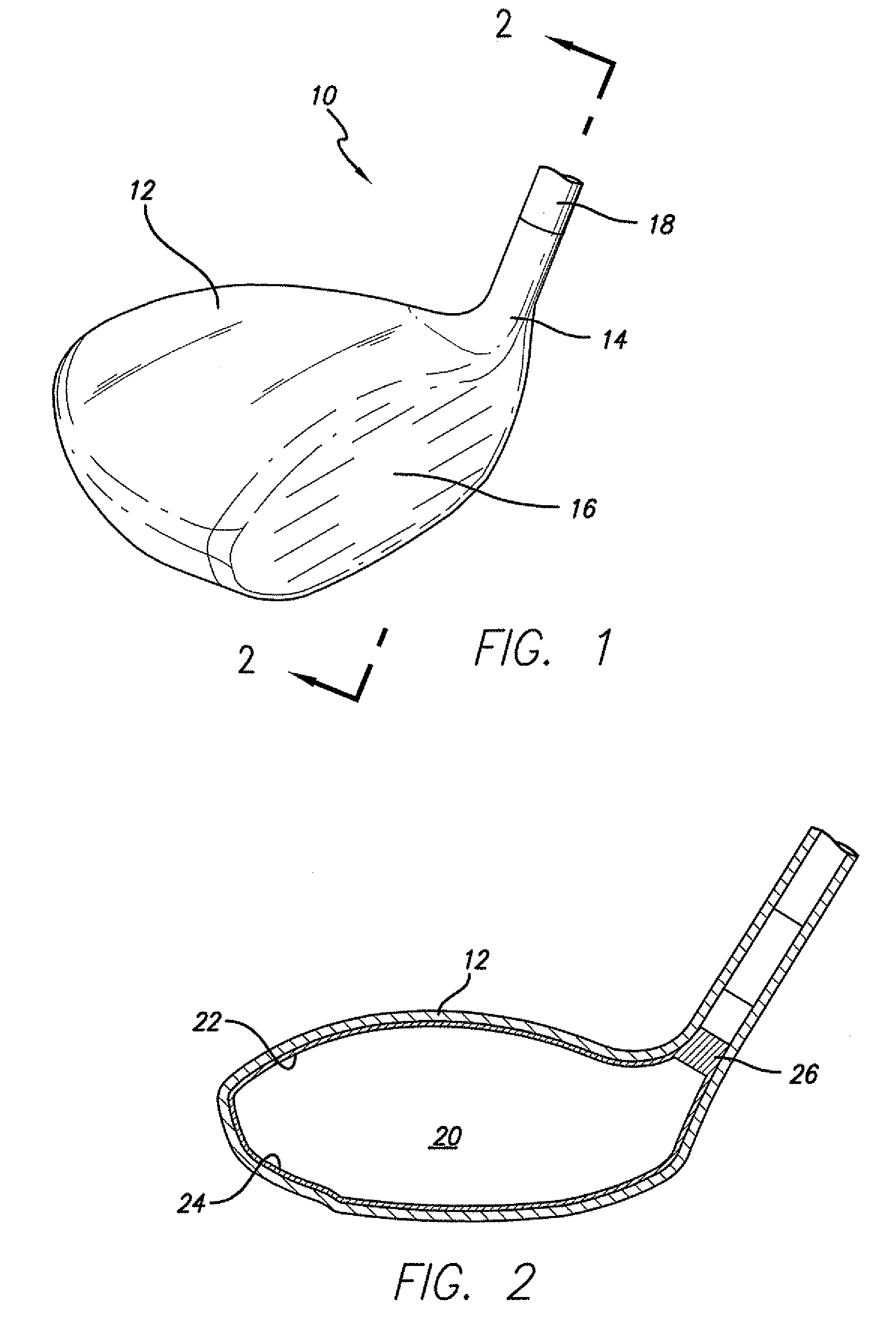

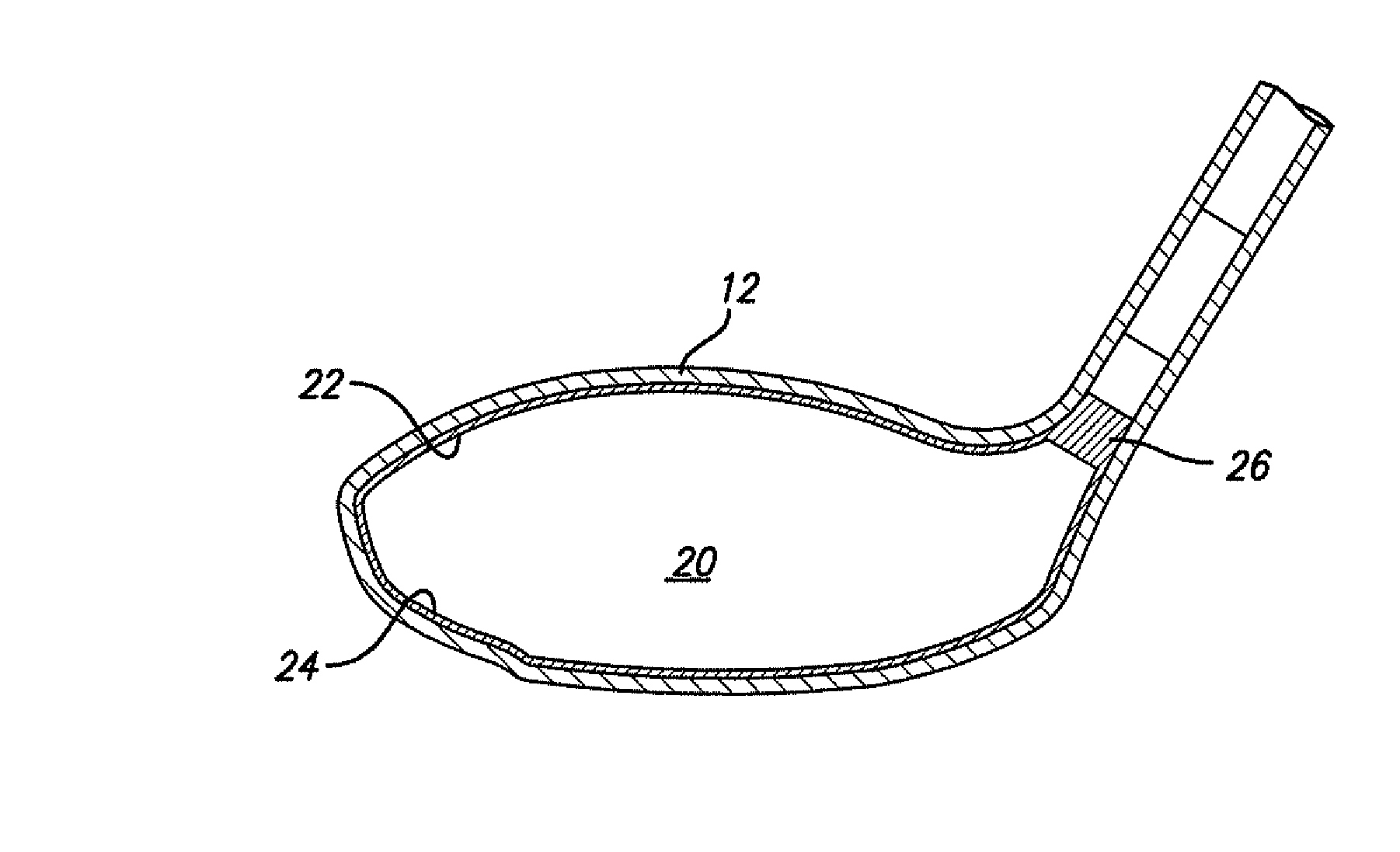

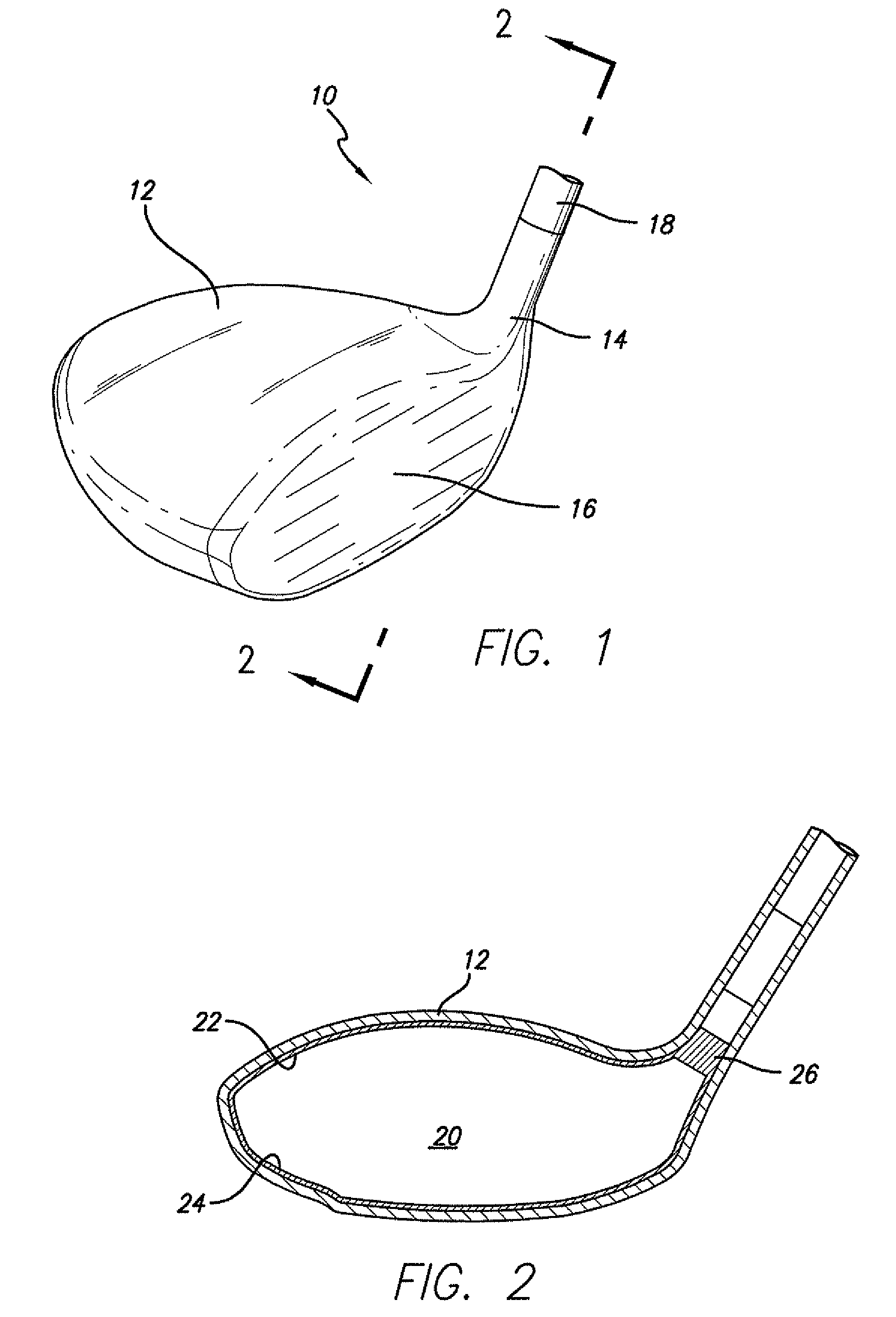

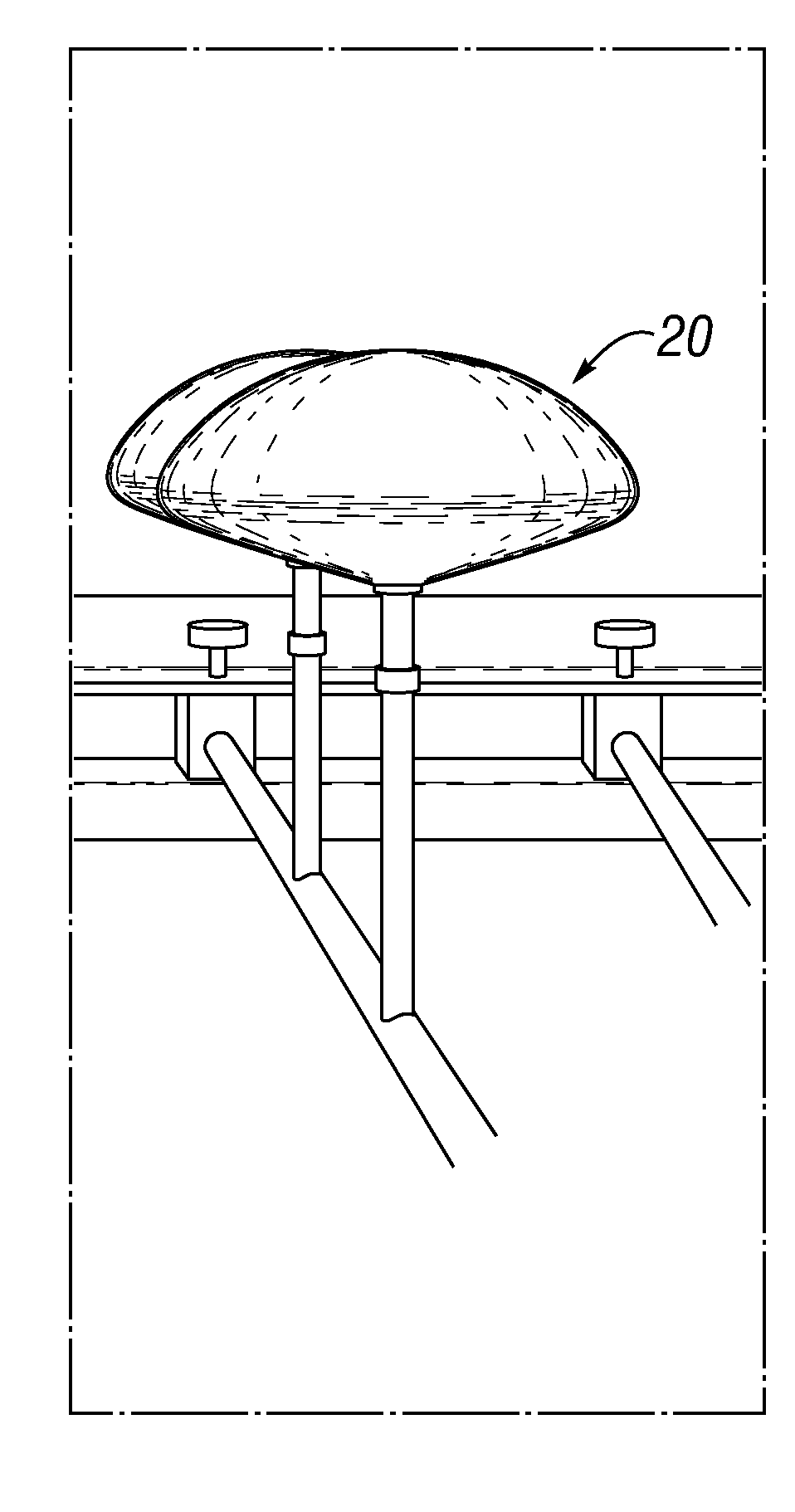

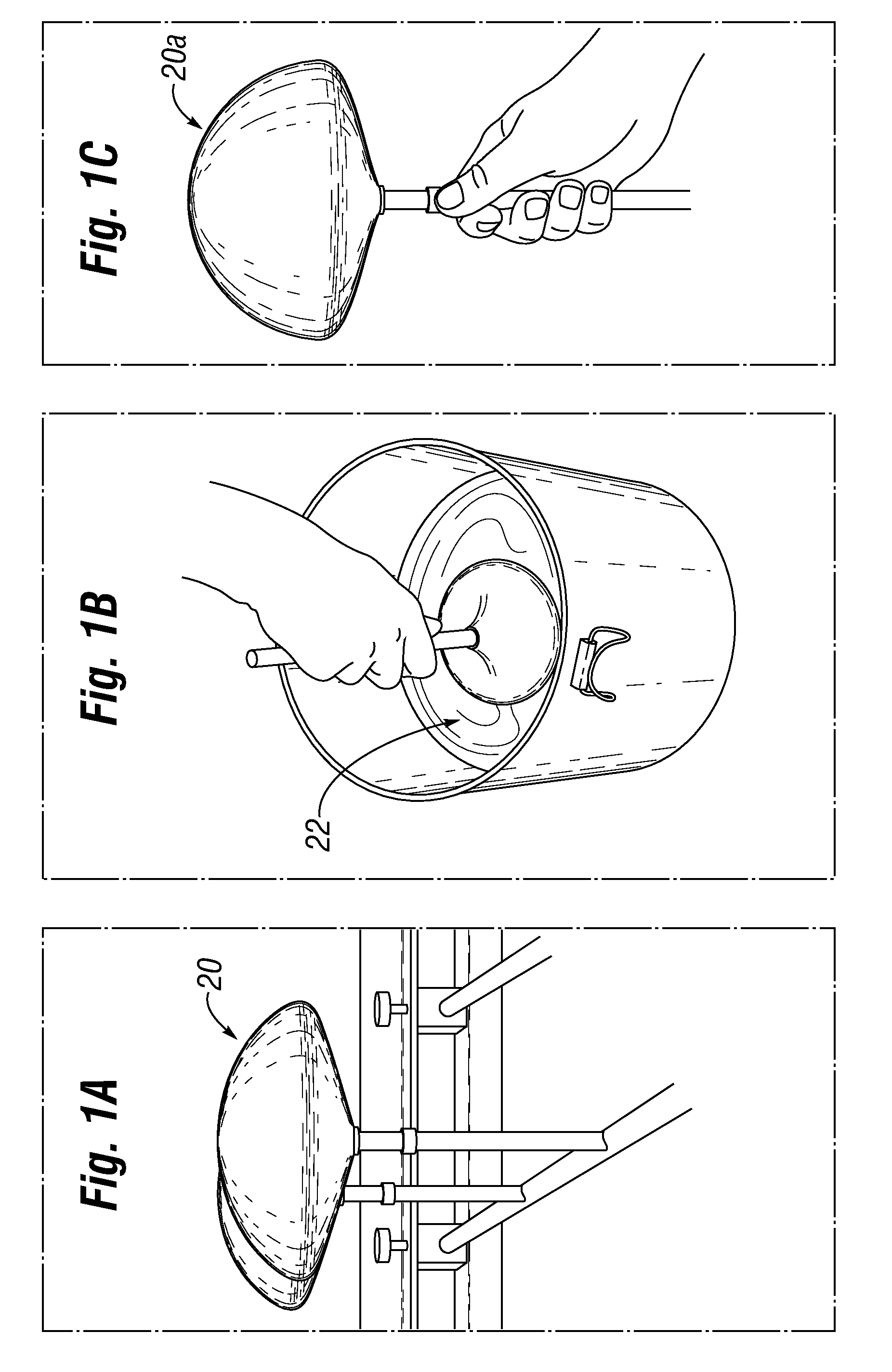

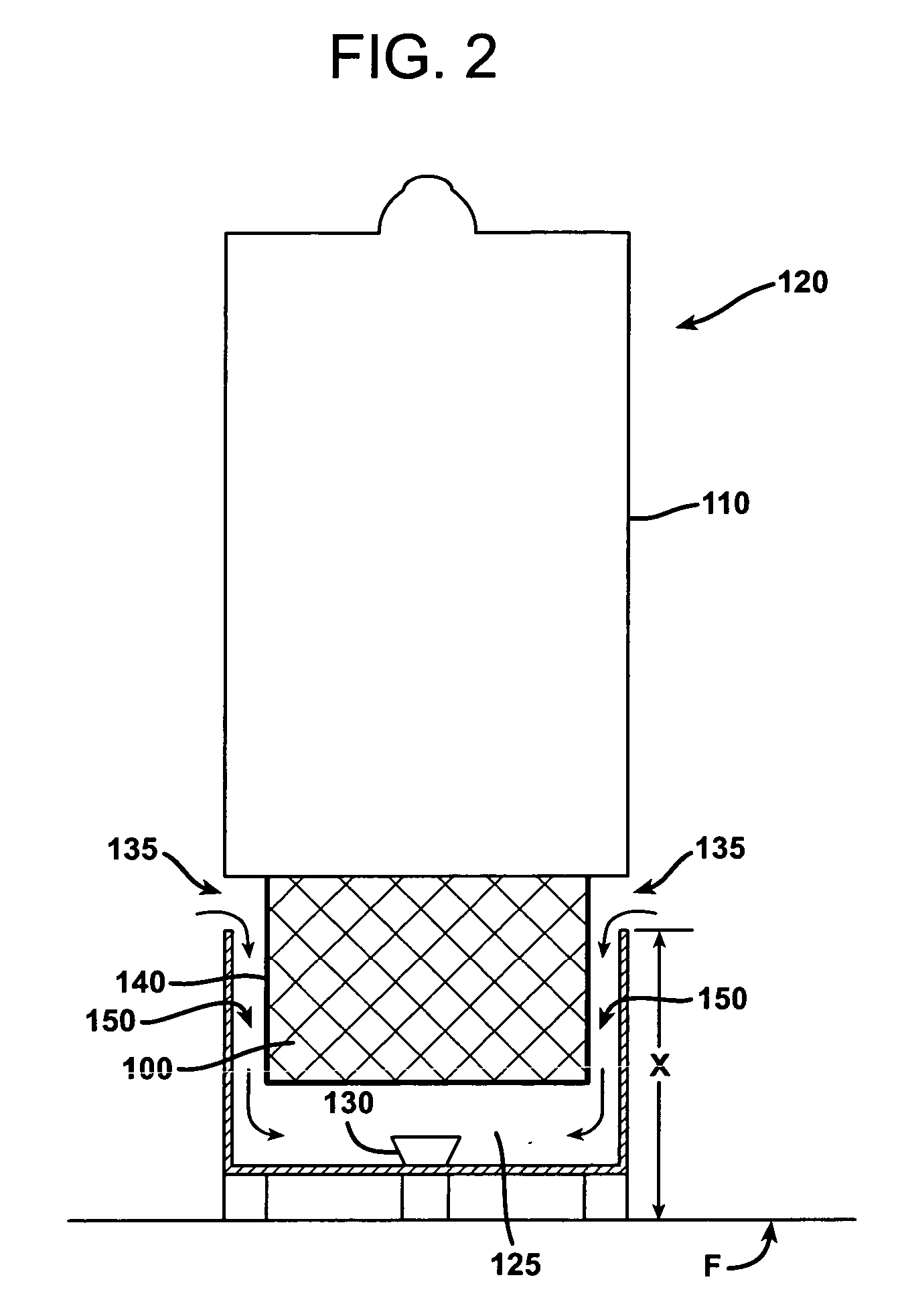

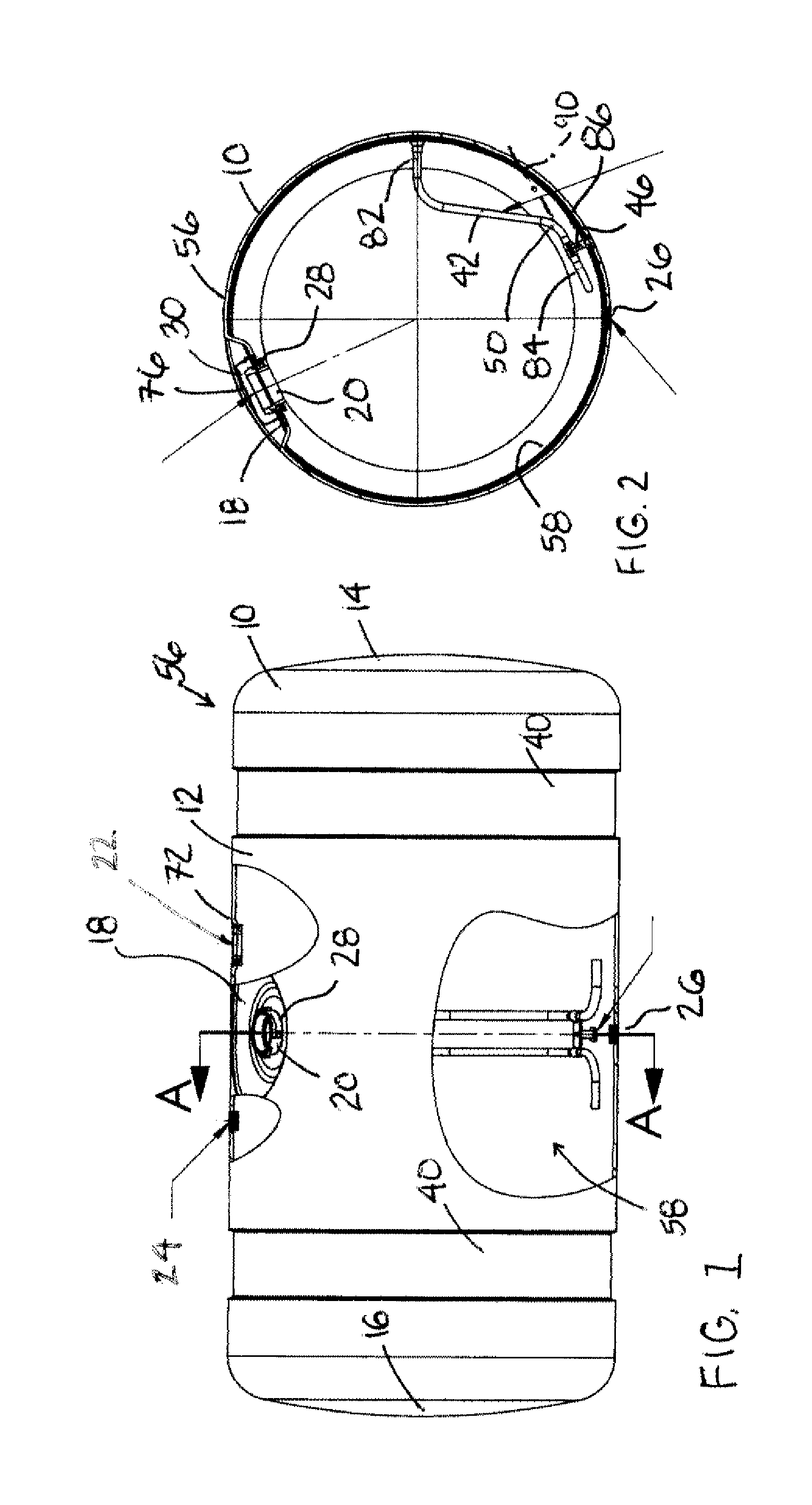

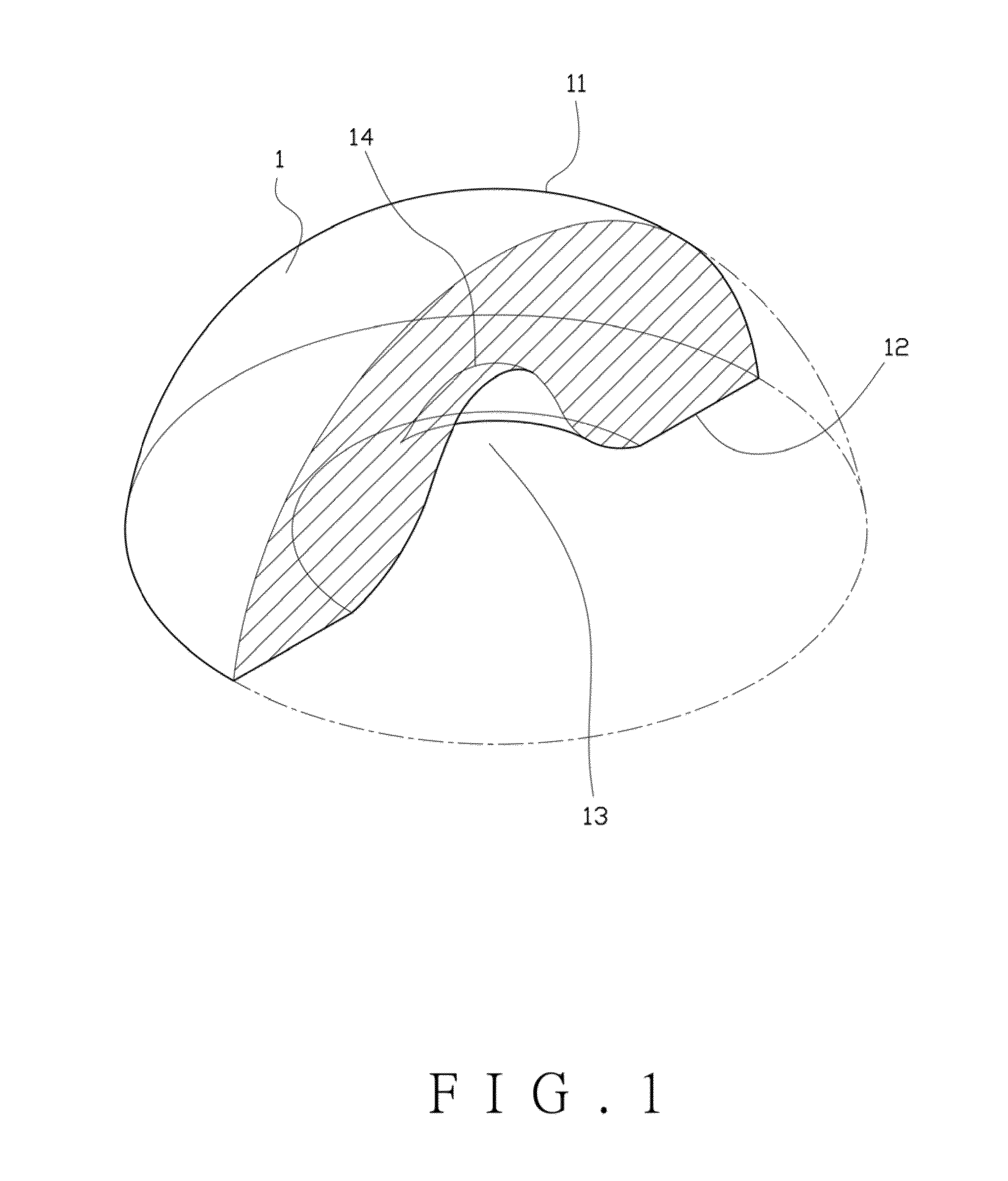

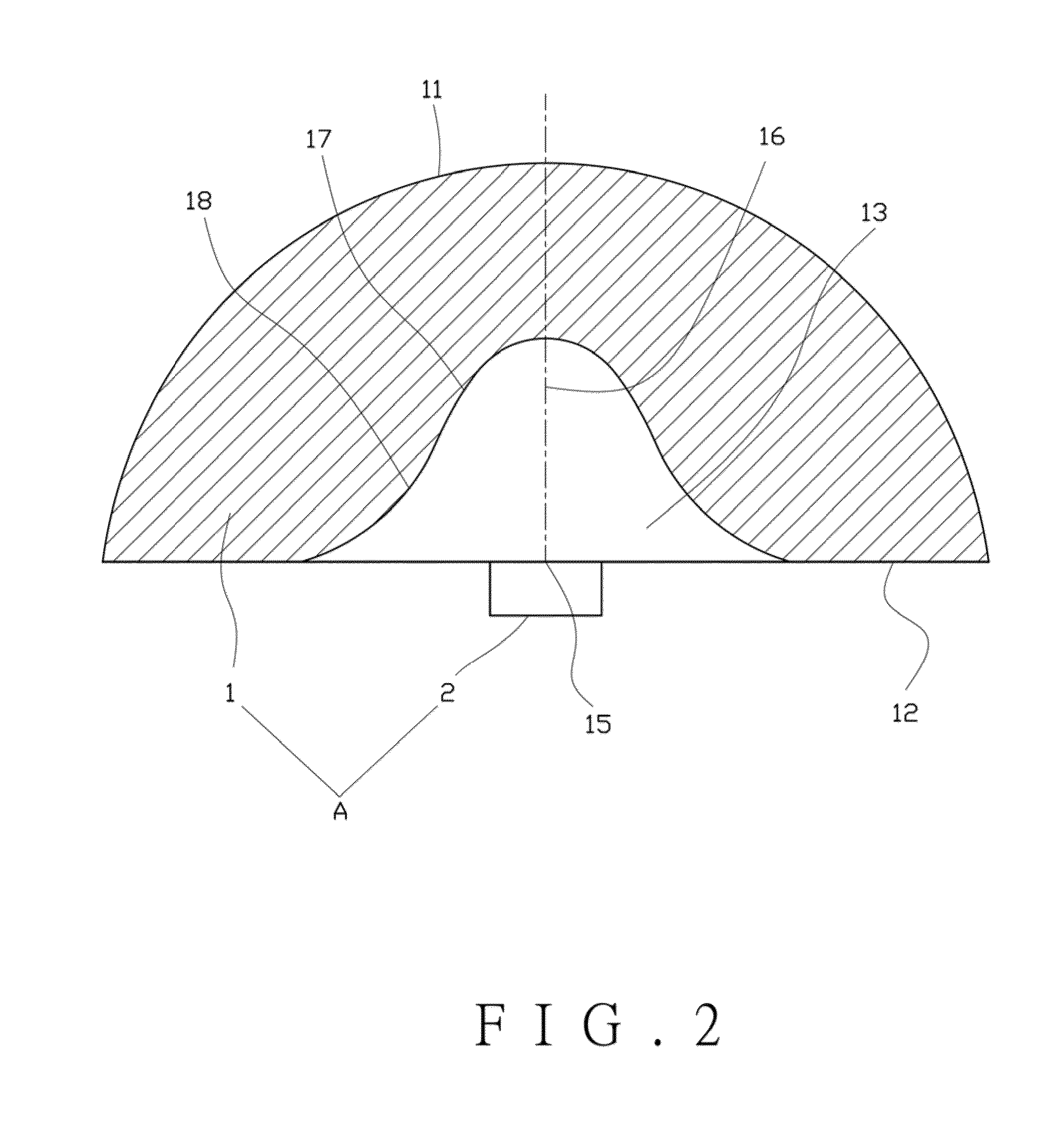

Golf club having a hollow pressurized metal head

ActiveUS20080188322A1Avoid passingPrevent escapeFilling using counterpressureMetal rolling stand detailsShell moldingPlastic materials

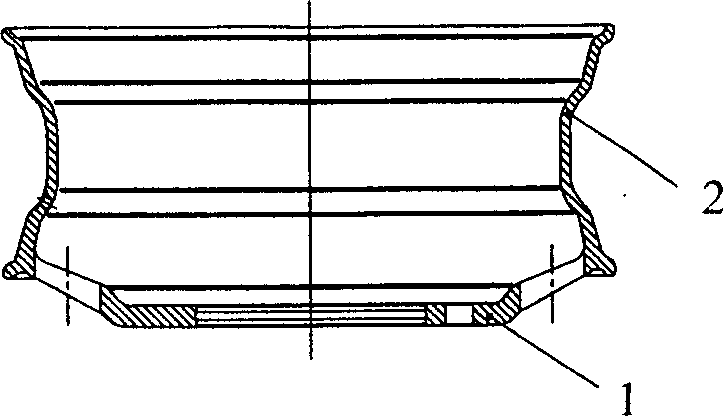

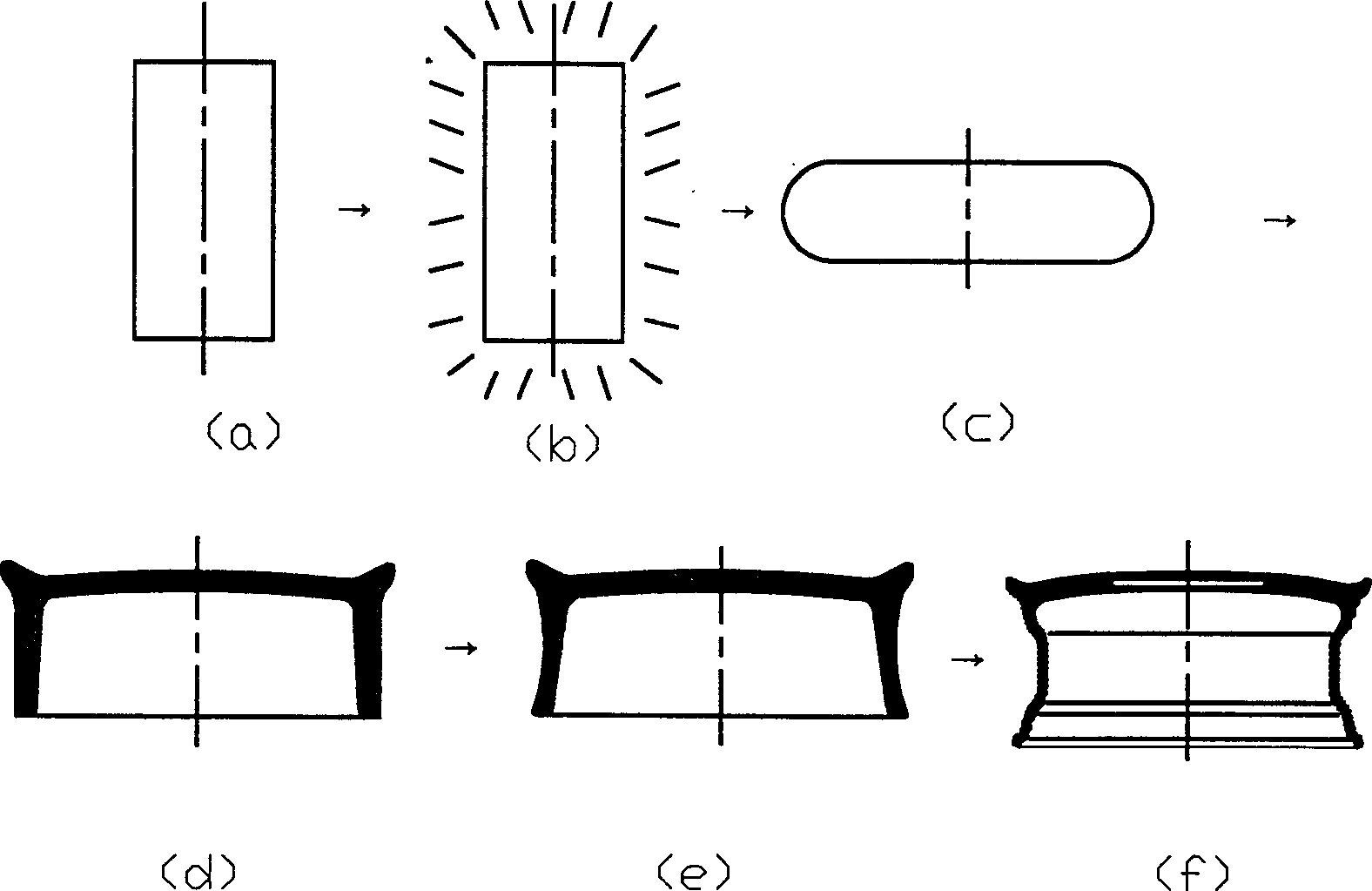

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

Golf club having a hollow pressurized metal head

ActiveUS8663026B2Prevent escapeMetal rolling stand detailsPackaging under special atmospheric conditionsPlastic materialsEngineering

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

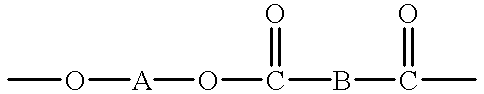

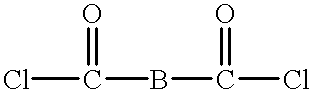

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

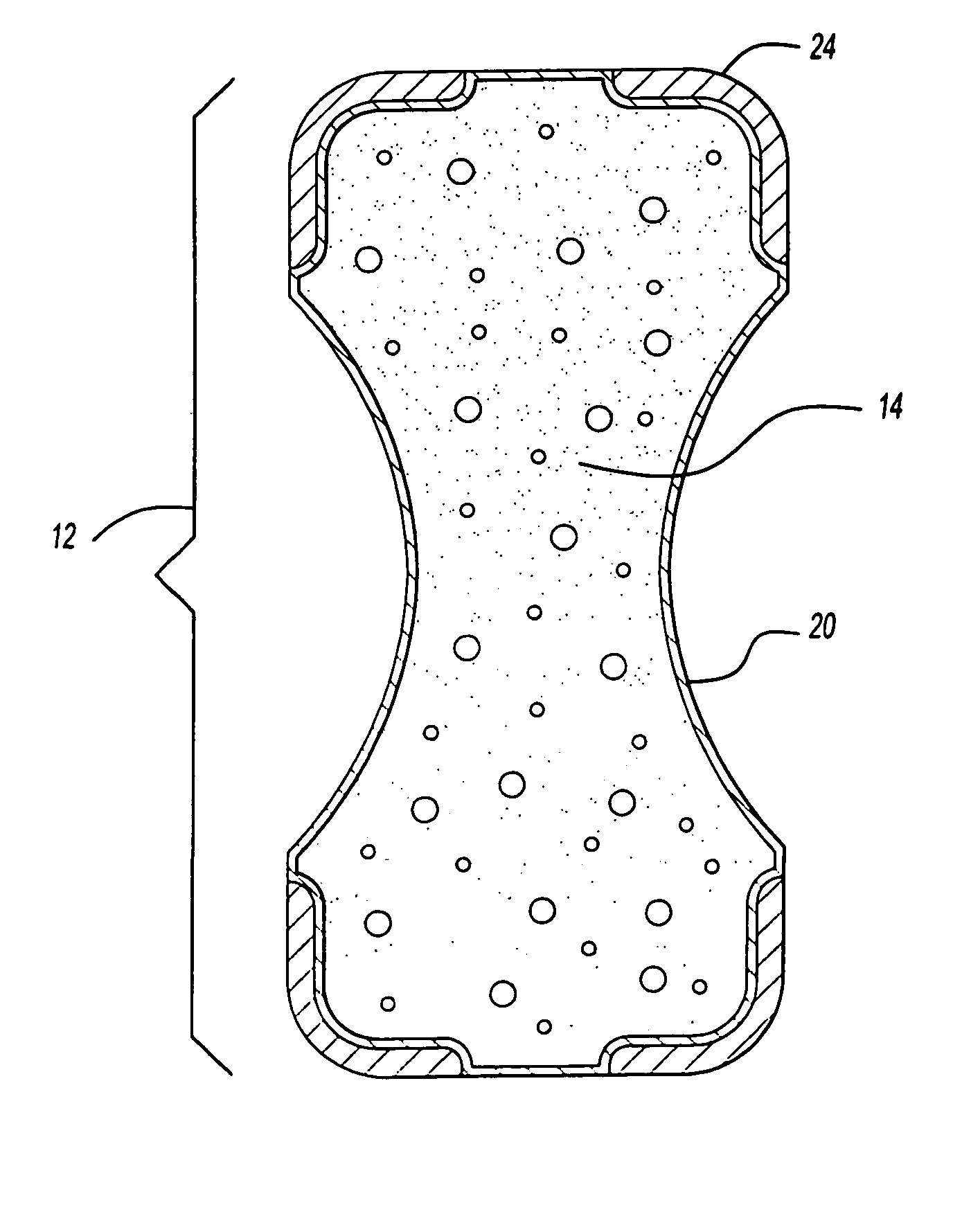

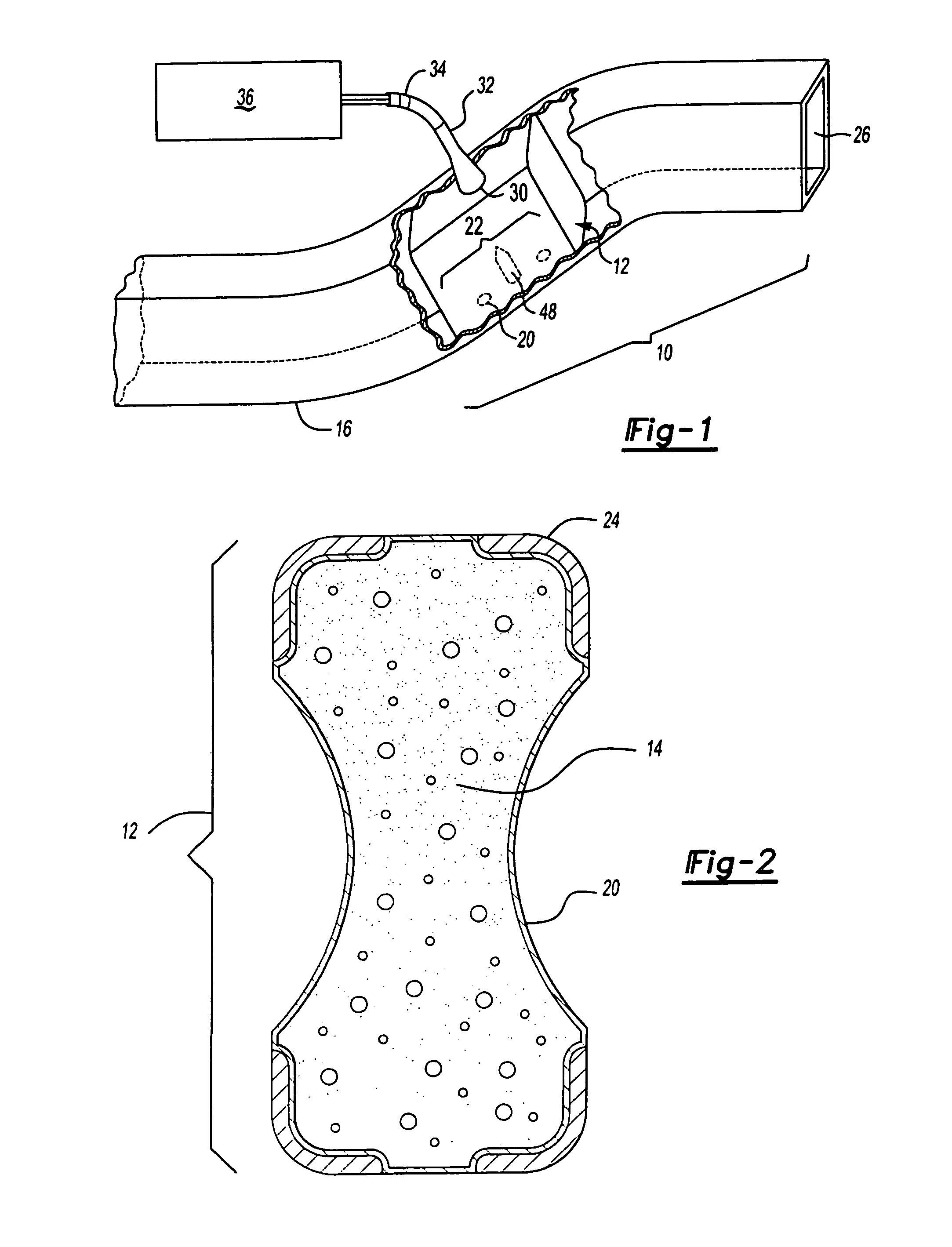

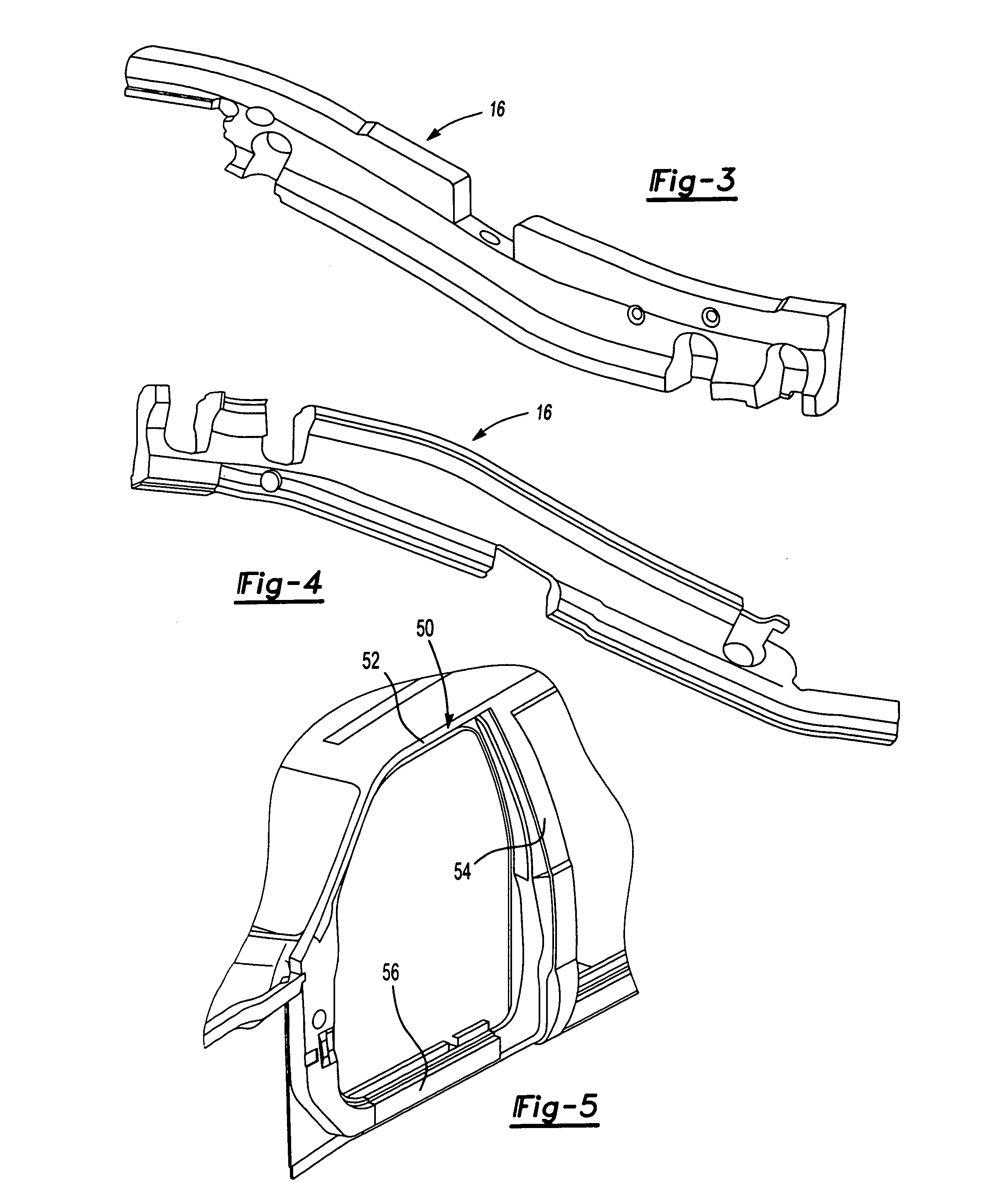

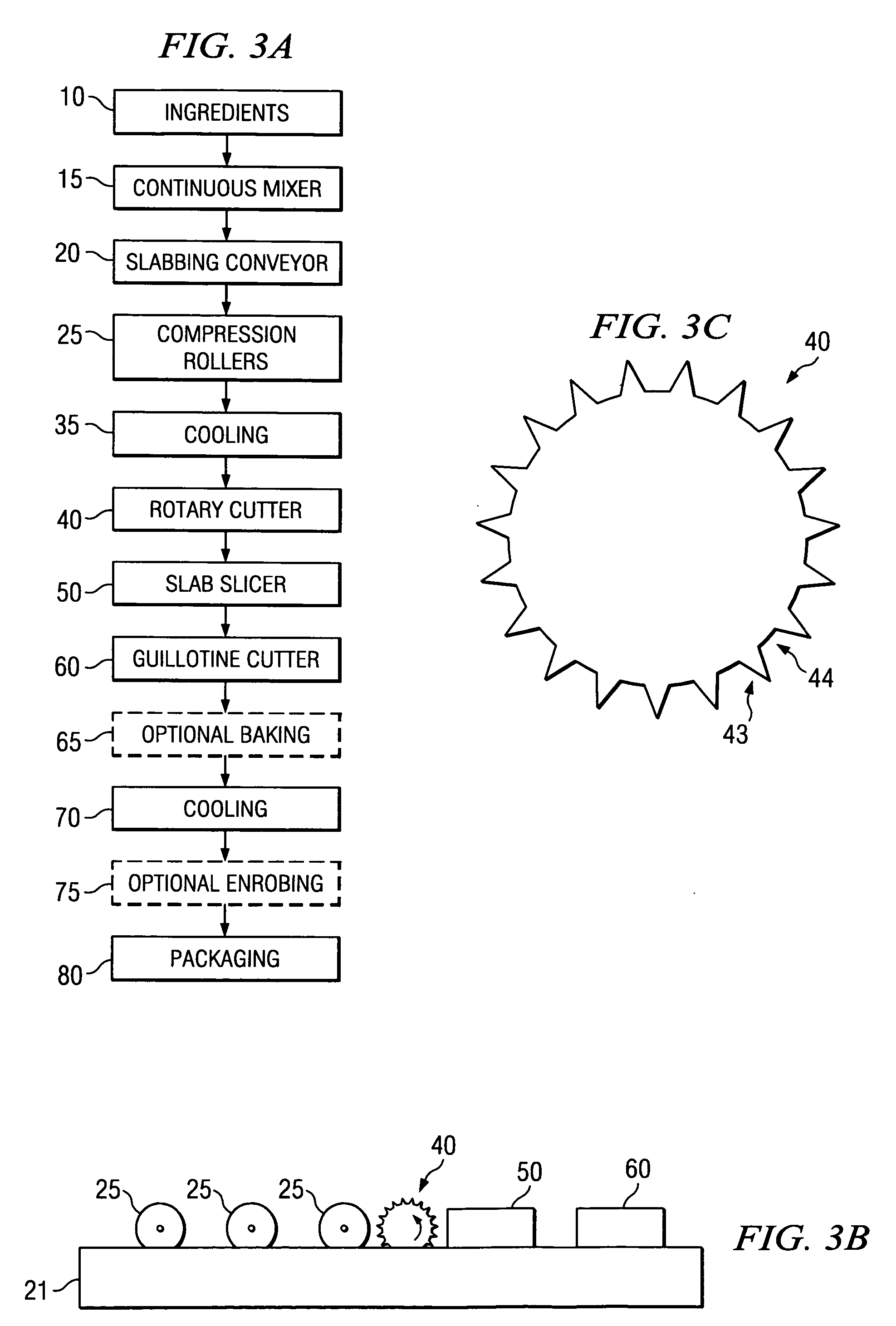

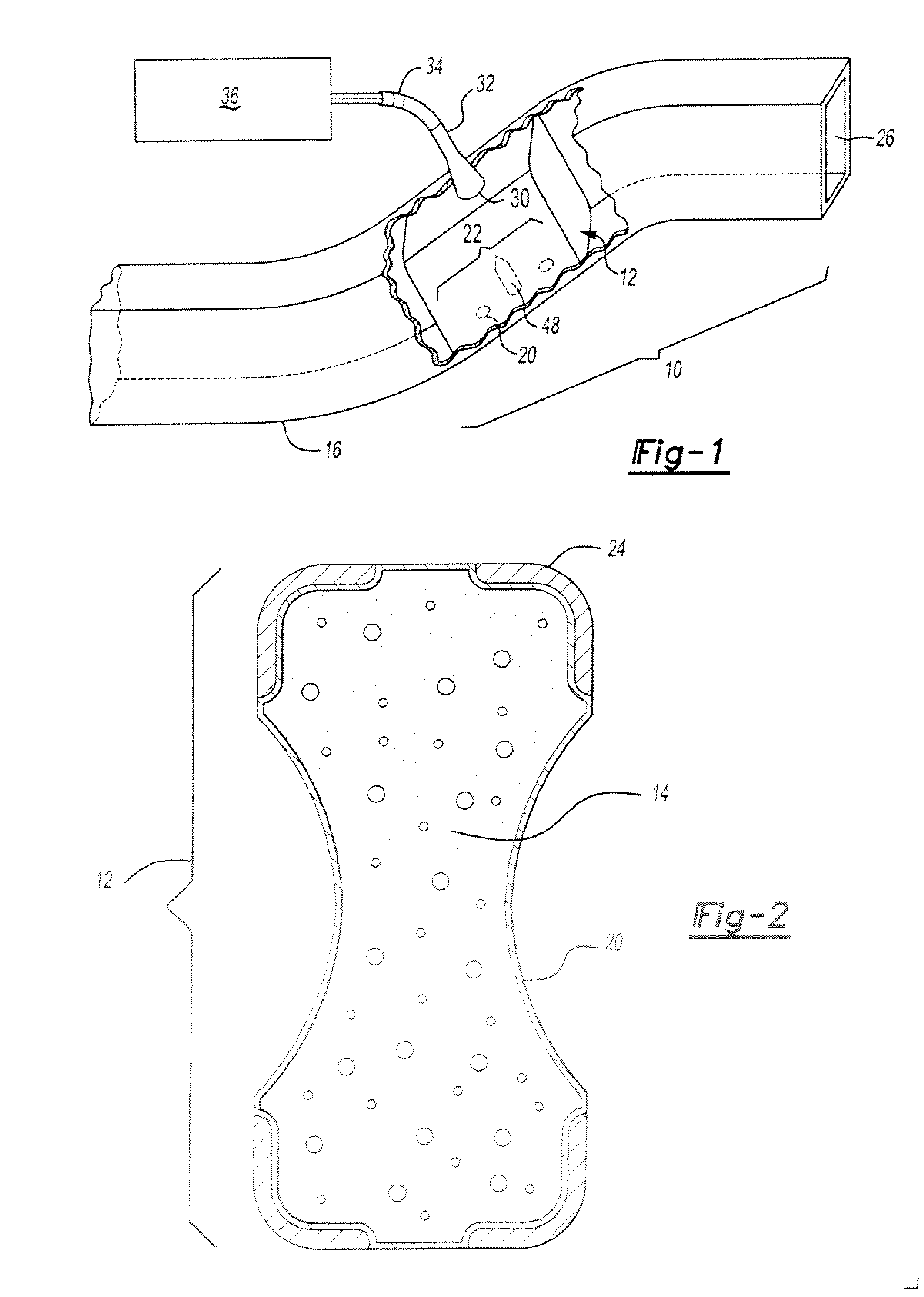

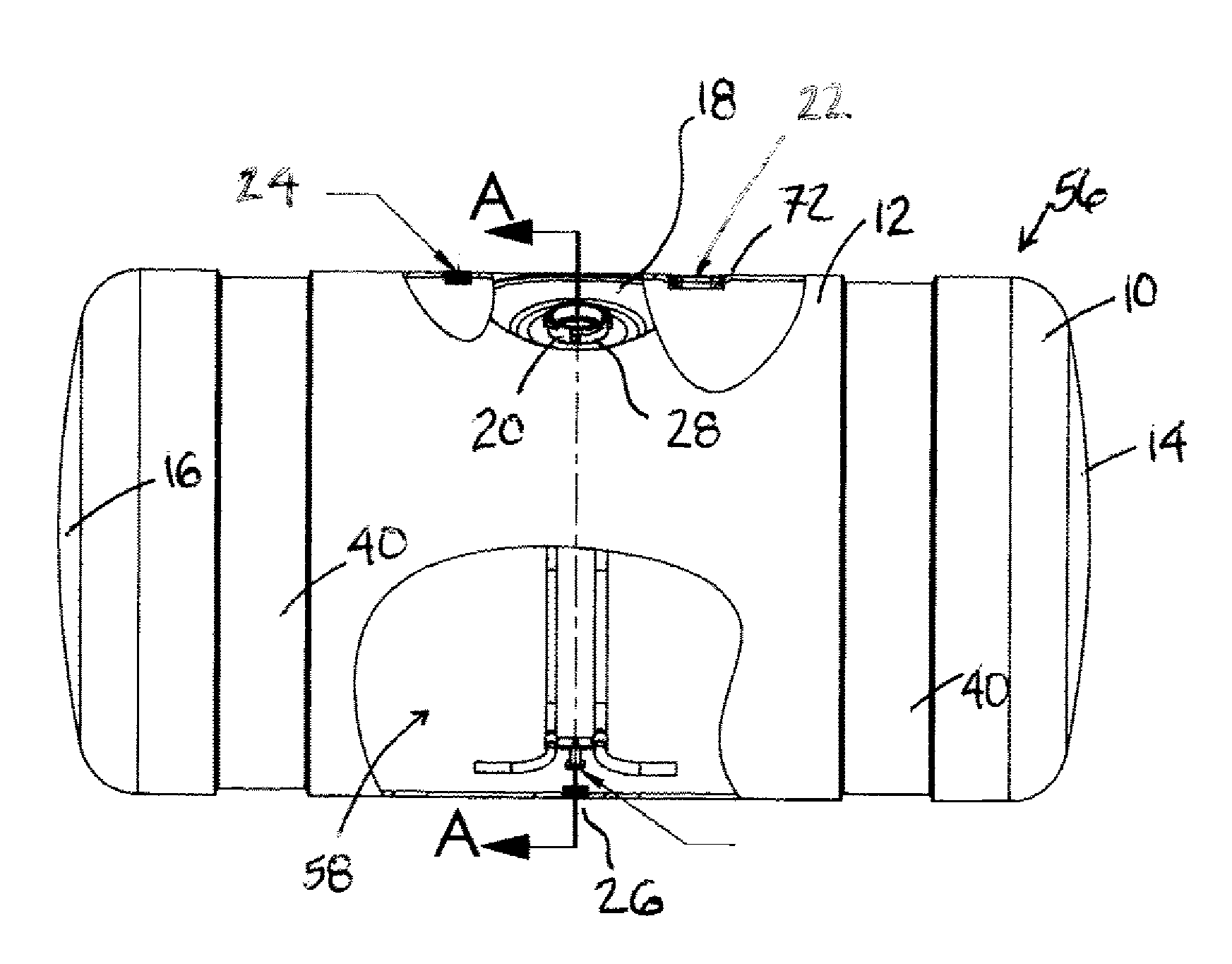

Reinforcement system utilizing a hollow carrier

ActiveUS7077460B2Reduce healthReduce cleanlinessVehicle seatsSynthetic resin layered productsBlow moldingShell molding

A system and method for reinforcing at least a portion of a structural member, including at least one hollow carrier, having an exterior shell and an interior portion, which substantially conforms to the dimensions and geometry of the structural member being reinforced; and a lightweight, low density material for filling the interior portion of one or more of the carriers. The material filling one or more of the carriers of the present invention can be a reinforcement material, self-curing material, or a heat activated expandable material. The carrier can be produced by blow molding or rotational molding and has an adhesive material disposed along at least a portion of the exterior shell used to place, adhere, and affix the carrier to a targeted portion of the structural member selected to be structurally reinforced.

Owner:ZEPHYROS INC

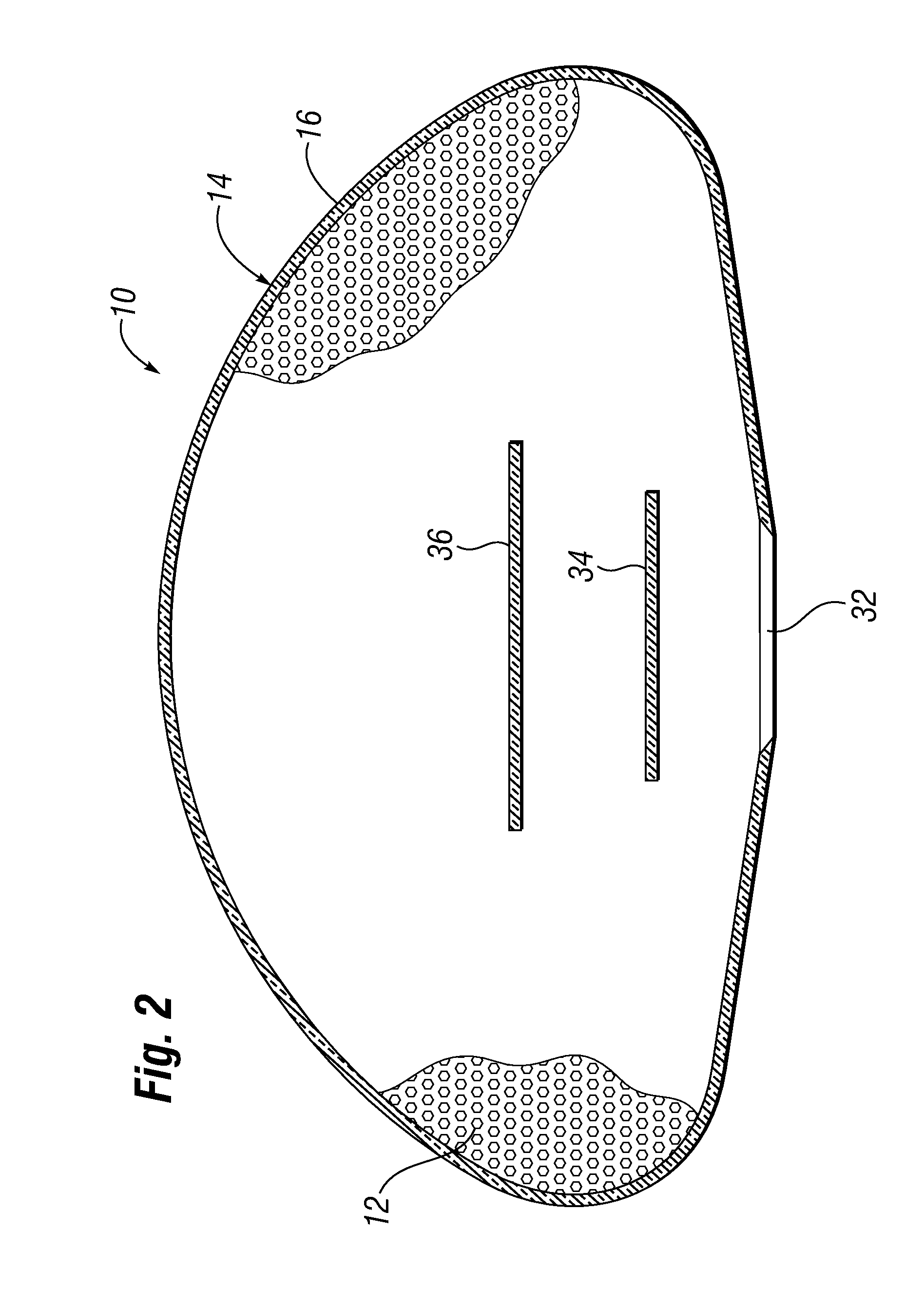

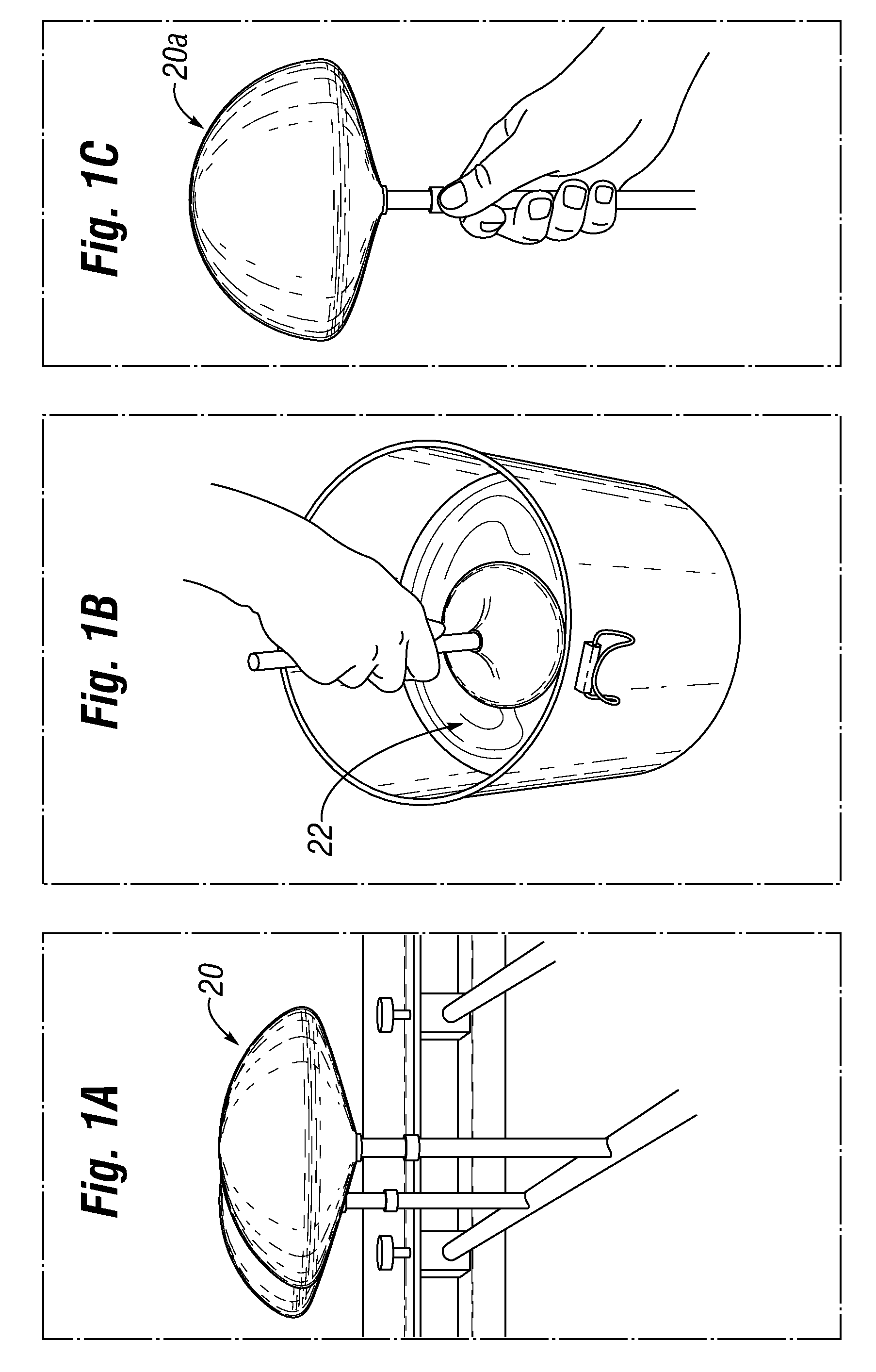

All-barrier elastomeric gel-filled breast prosthesis

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

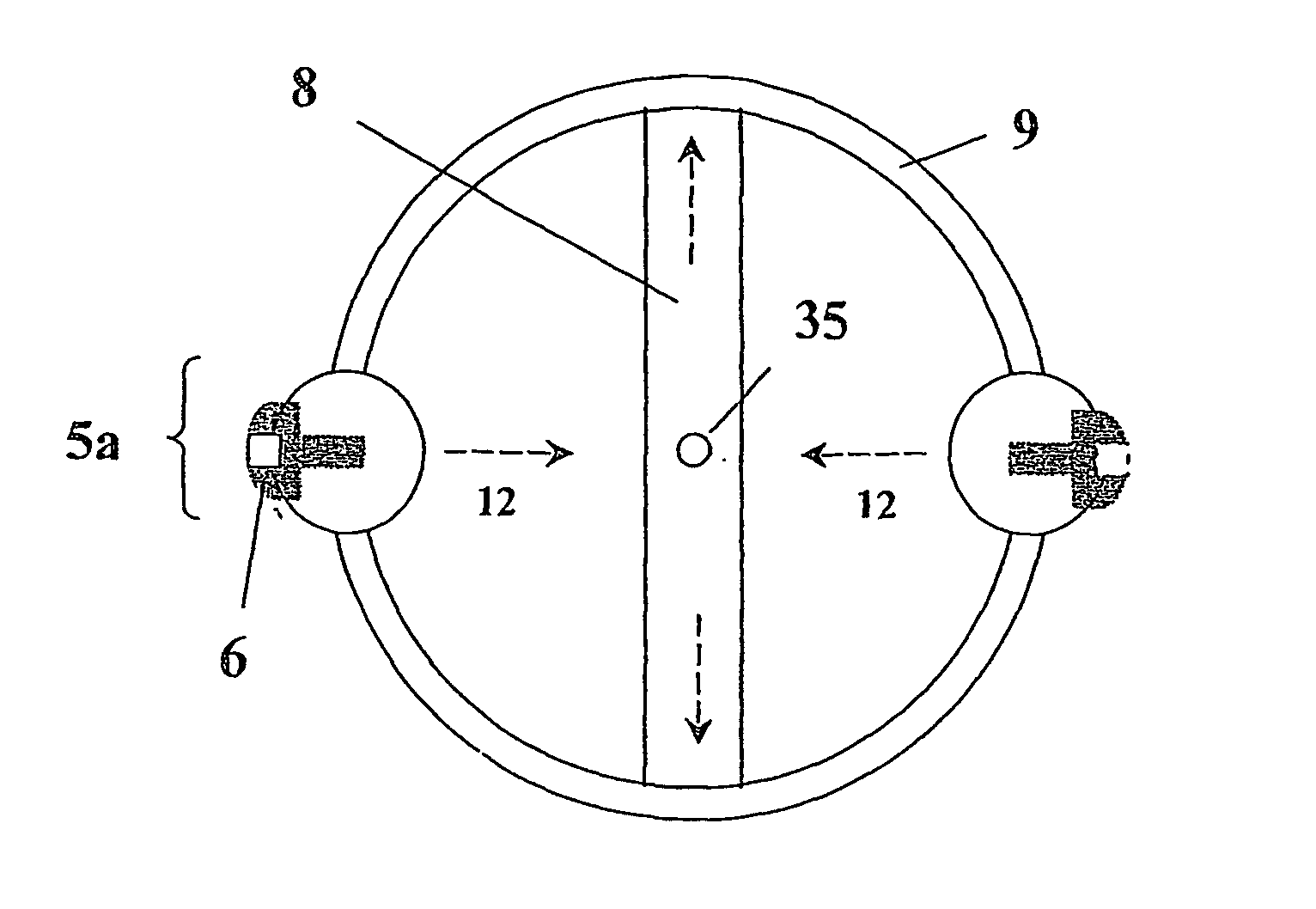

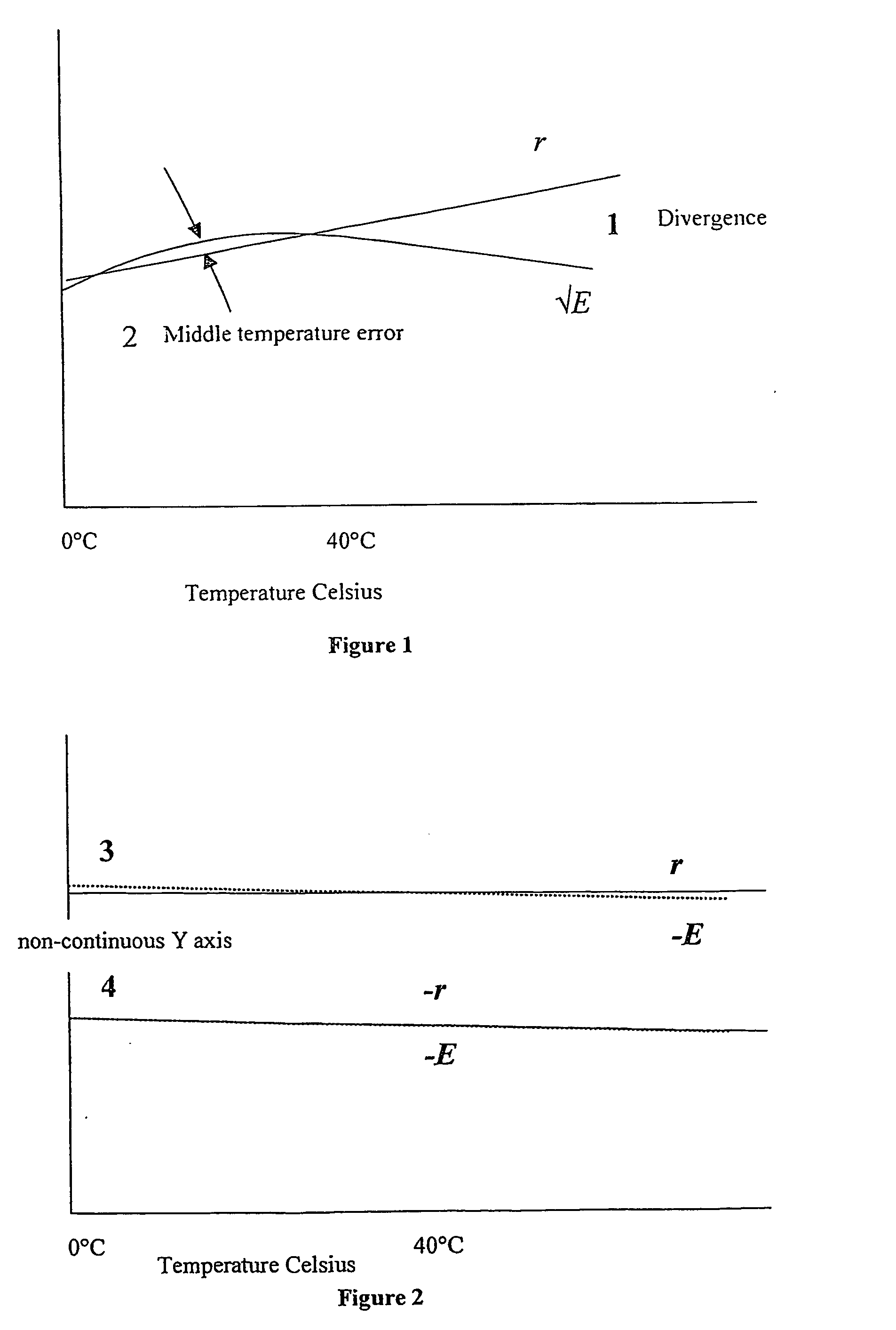

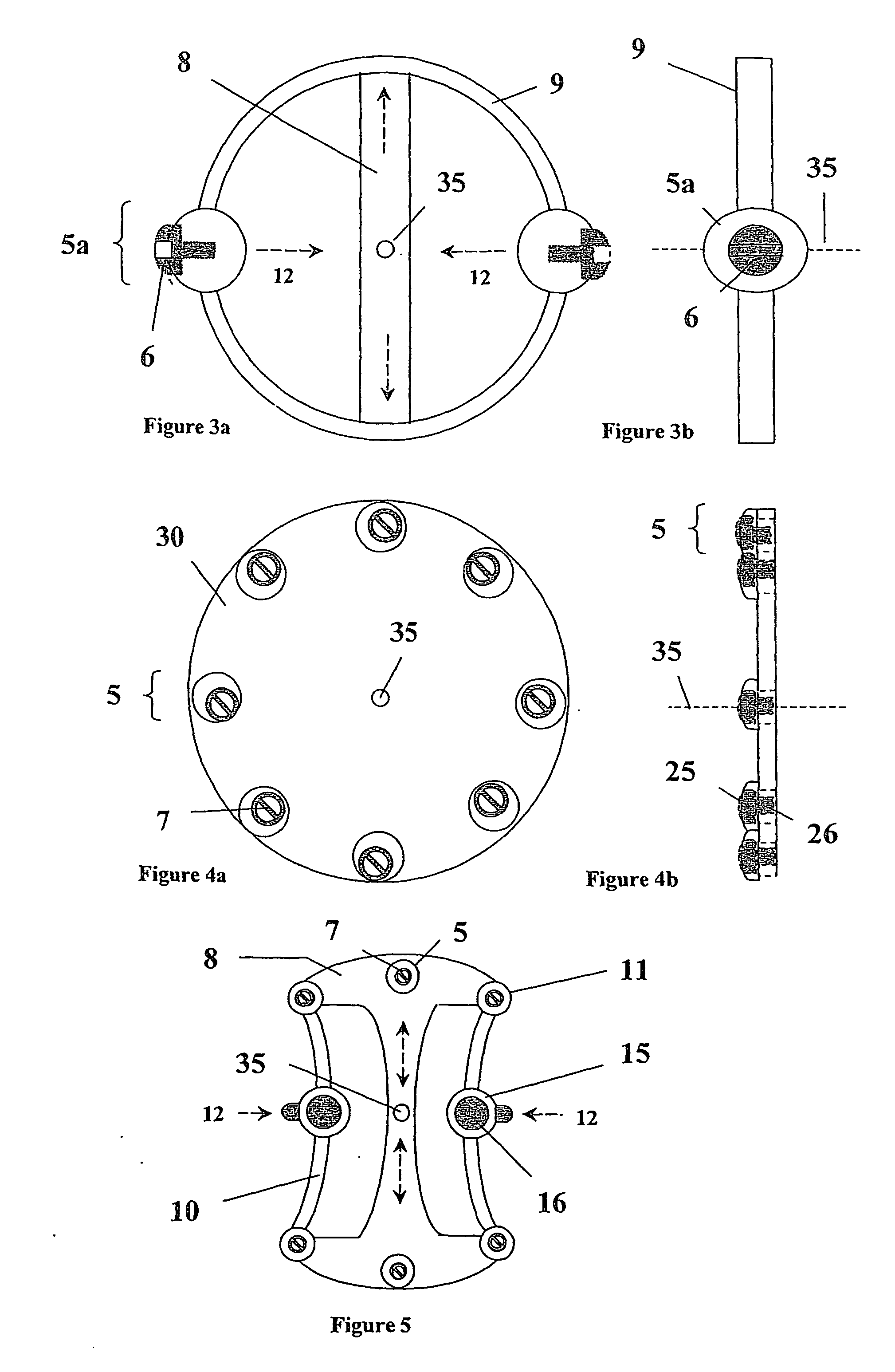

Balance wheel, balance spring and other components and assemblies for a mechanical oscillator system and methods of manufacture

The application discloses a method of making a balance spring (100) from continuous fibres or ceramic by winding them around a cylindrical former (90), interspaced with a releasing agent (110). Also disclosed is a method of making a balance spring, preferably of a ceramic material (60), by applying it to a rotating former (70) mandrel or plate and subsequently heat treating. Balance wheels (30) having a moment of inertia which decreases with a rise in temperature due to a special arrangement of components (8, 9, 10) having different coefficients of thermal expansion are also disclosed. A mechanical oscillator system comprising a non-magnetic ceramic or continuous fibre balance spring (50) and a non-magnetic balance wheel (30) formed of a material having a coefficient of thermal expansion of less than 6×10−6K−1 and having a plurality of non-magnetic poising or timing appendages (5) is also disclosed.

Owner:CARBONTIME

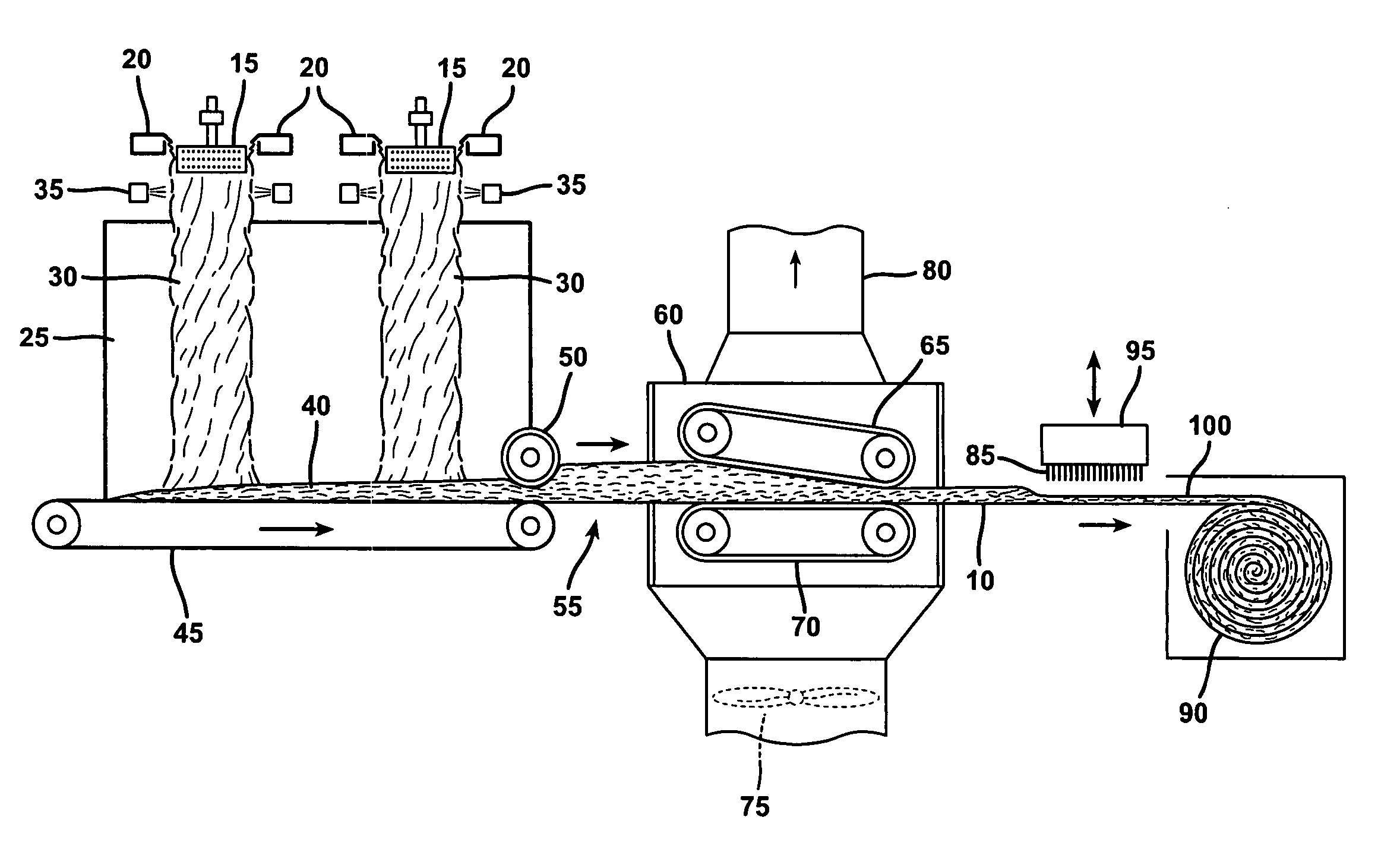

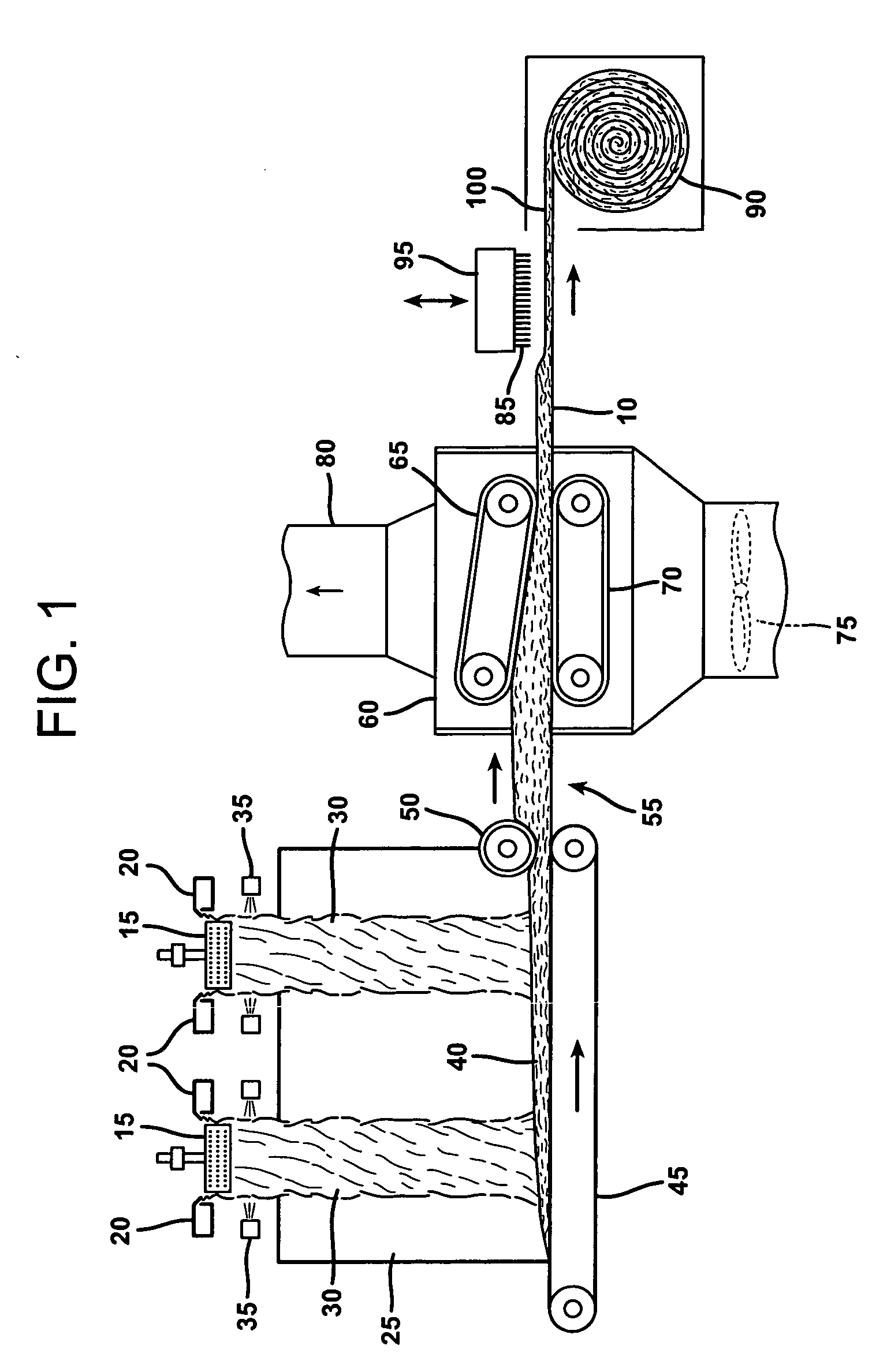

Thin rotary-fiberized glass insulation and process for producing same

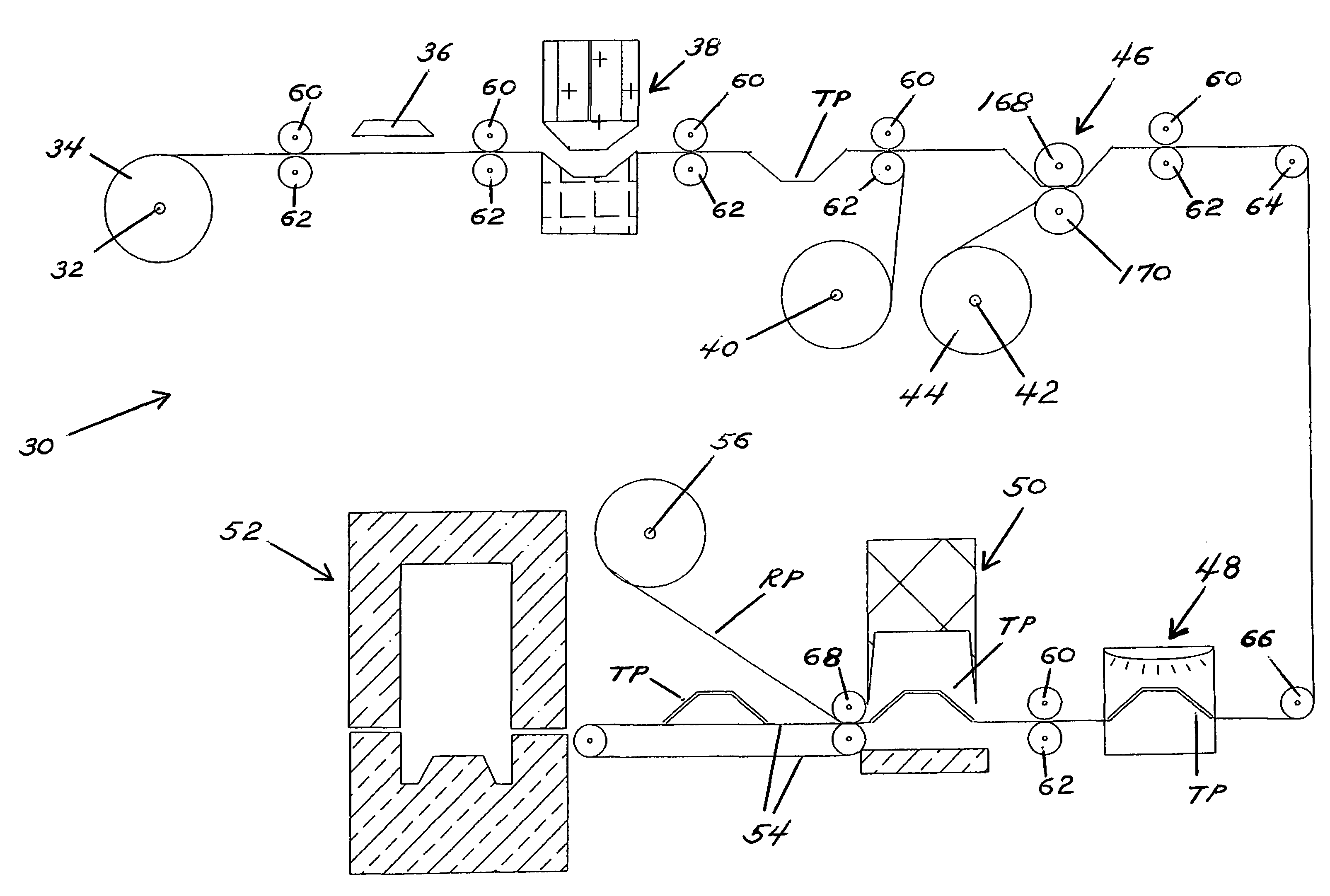

InactiveUS20070014995A1Shorten the timeSoft touchGlass making apparatusThermal insulationGlass fiberFiber

A rotary fiberglass needled glass insulation product is provided. The formation of the needled insulation product may be conducted in a continuous in-line process in which the fibers are rotary formed, a binder is sprayed onto the hot fibers, the fibers are collected onto a conveyor and formed into a fiberglass pack, the fiberglass pack is passed through the oven, and the cured insulation blanket is passed through the needling apparatus. The needled insulation product may have a thickness of less than about 0.75 inches. The reduction in thickness and increased density caused by the needling process permits the production of lower thickness and higher density final insulation products. Thin insulation products made in accordance with the present invention can be manufactured using current manufacturing lines, thereby saving time and money. The needled insulation product may be utilized in household appliances, water heaters, and HVAC equipment.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Rotational molding wear-resistant polyolefin resin and preparation method thereof

InactiveCN101735505AImprove wear resistanceImprove friction and wear propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding wear-resistant polyolefin resin and a preparation method thereof. In the rotational molding wear-resistant polyolefin resin, raw materials commonly used in the rotational molding process, namely linear low-density polyethylene, high-density polyethylene or polypropylene is taken as a matrix material; and by adding components of an inorganic filler, ultrahigh molecular weight polyethylene and a lubricant, the wear resistance of the matrix resin is improved. The rotational molding wear-resistant polyolefin resin consists of the following components in percentage by mass: 70 to 80 percent of matrix resin, 10 to 15 percent of inorganic filler subjected to surface treatment, 4 to 13 percent of ultrahigh molecular weight polyethylene and 1.5 to 2 percent of lubricant, wherein the matrix resin is the linear low-density polyethylene, the high-density polyethylene or the polypropylene; and a range of a melt flow rate of the matrix resin is between 2g / 10min and 15g / 10min.

Owner:江苏吉星管业科技有限公司

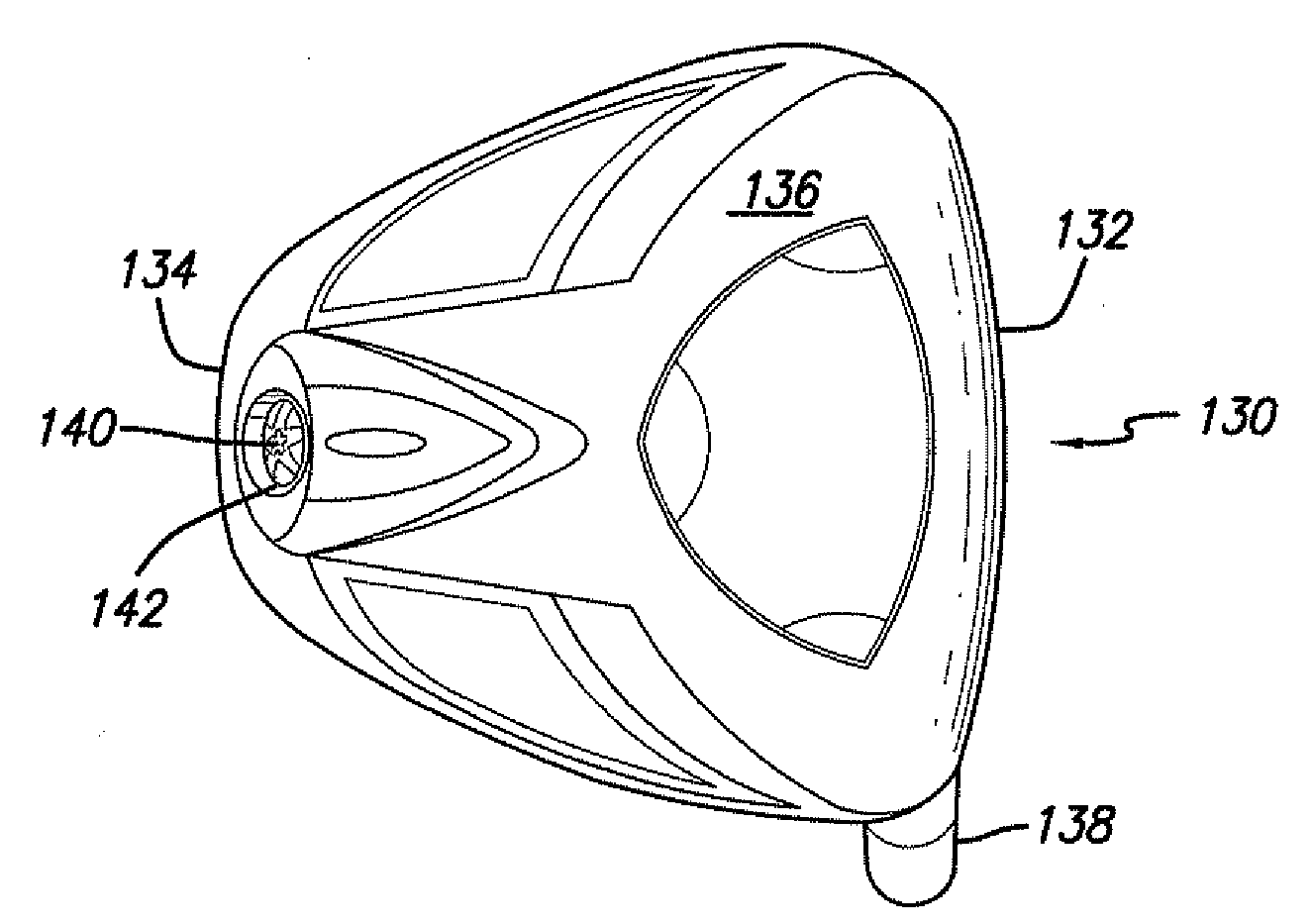

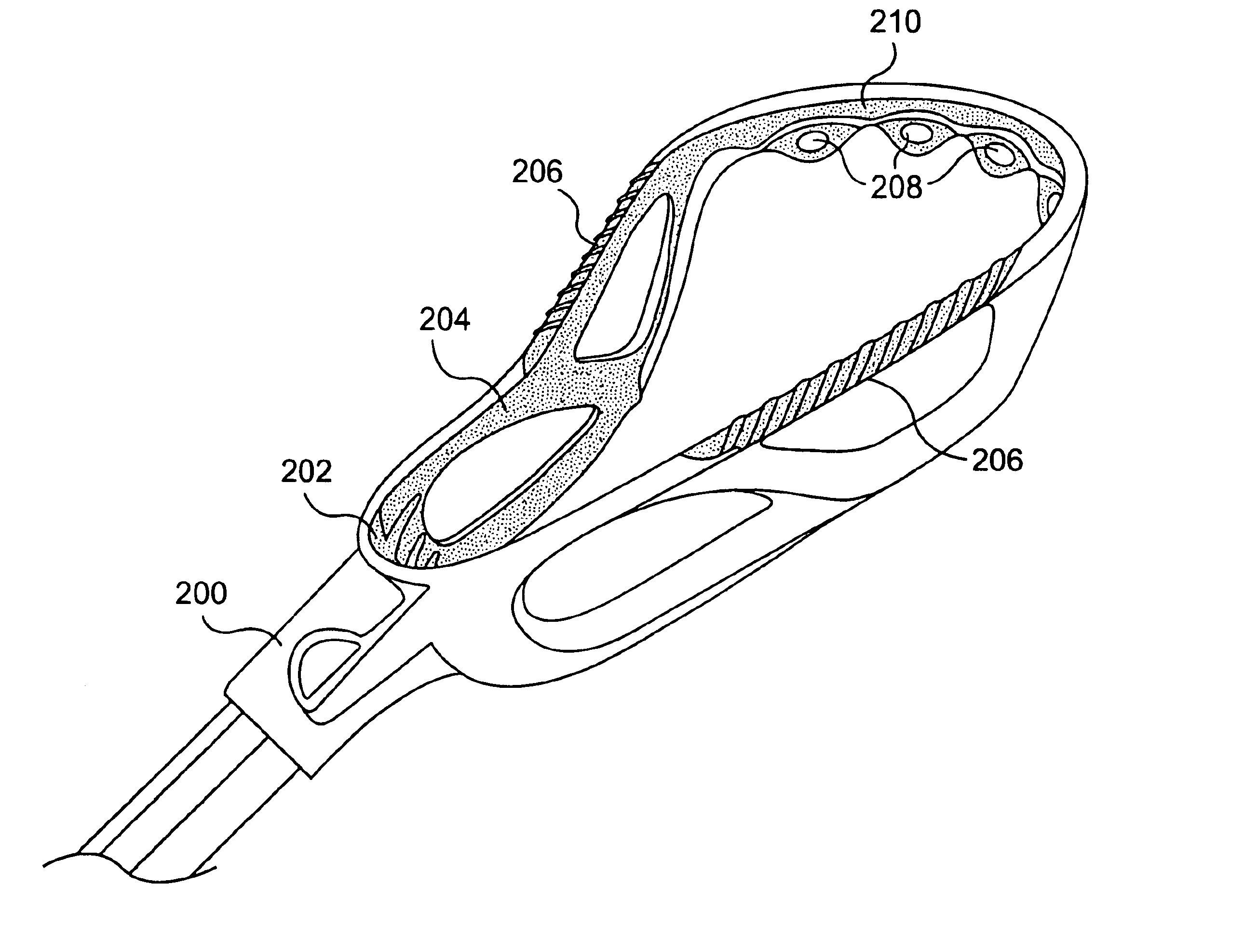

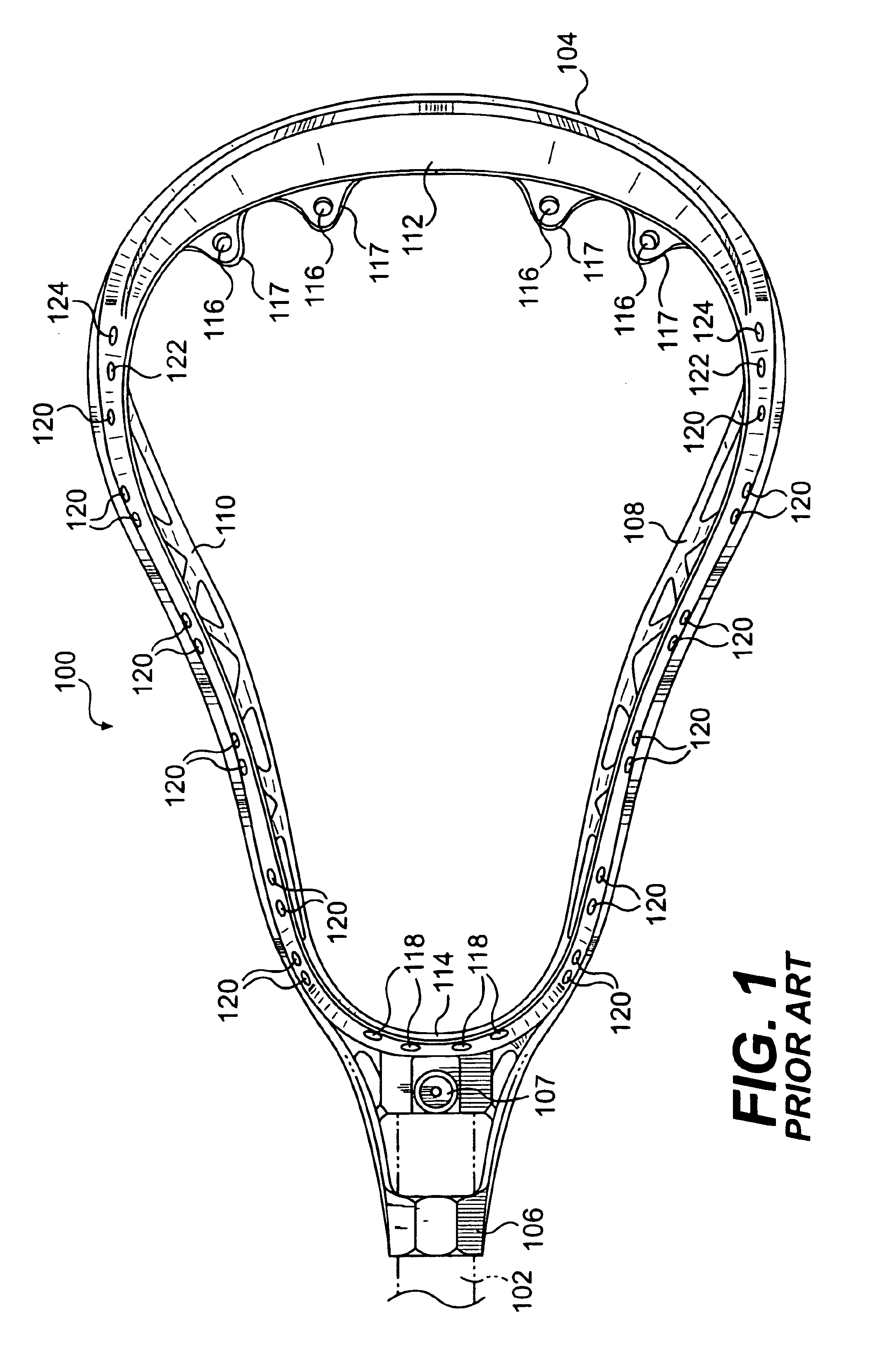

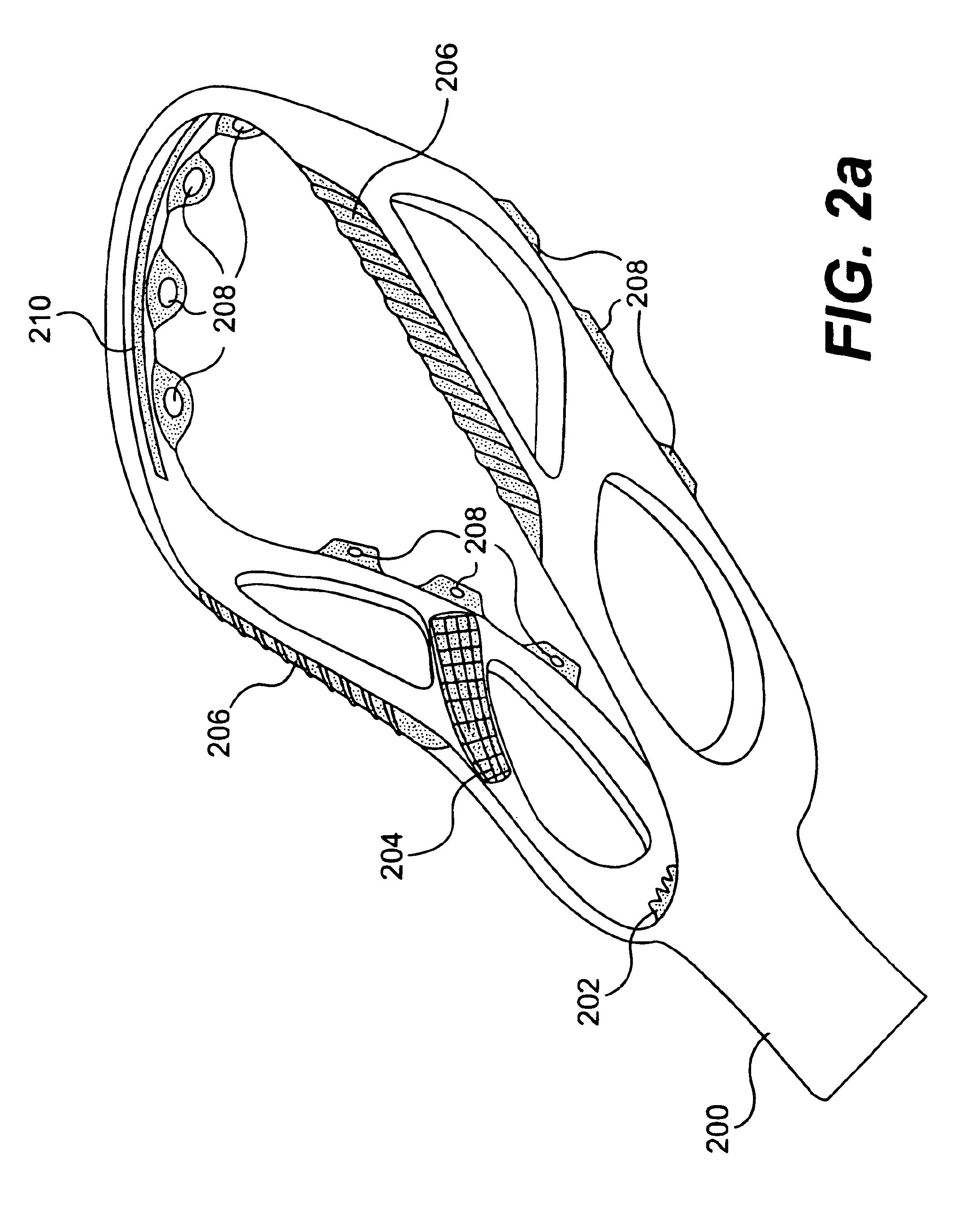

Multi-component lacrosse stick head

InactiveUS6910976B2Improve ball controlMinimize injuryThrow gamesBall sportsInterference fitSpherical form

A multi-component lacrosse stick head, made of at least two materials, including a base lacrosse head structure of one material and one or more overlays made of one or more other materials strategically located on the base structure. The base structure and overlays provide particular performance characteristics for the lacrosse head. An embodiment of the invention includes a base lacrosse head structure, and at least one of a ball stop overlay, a sidewall overlay, an edge overlay, a thread opening overlay, and a scoop overlay. The overlays are affixed to the base lacrosse head structure by, for example, insert molding, over molding, reaction injection molding, spray application, rotational molding, dual extrusion, casting, or an interference fit.

Owner:WM T BURNETT IP

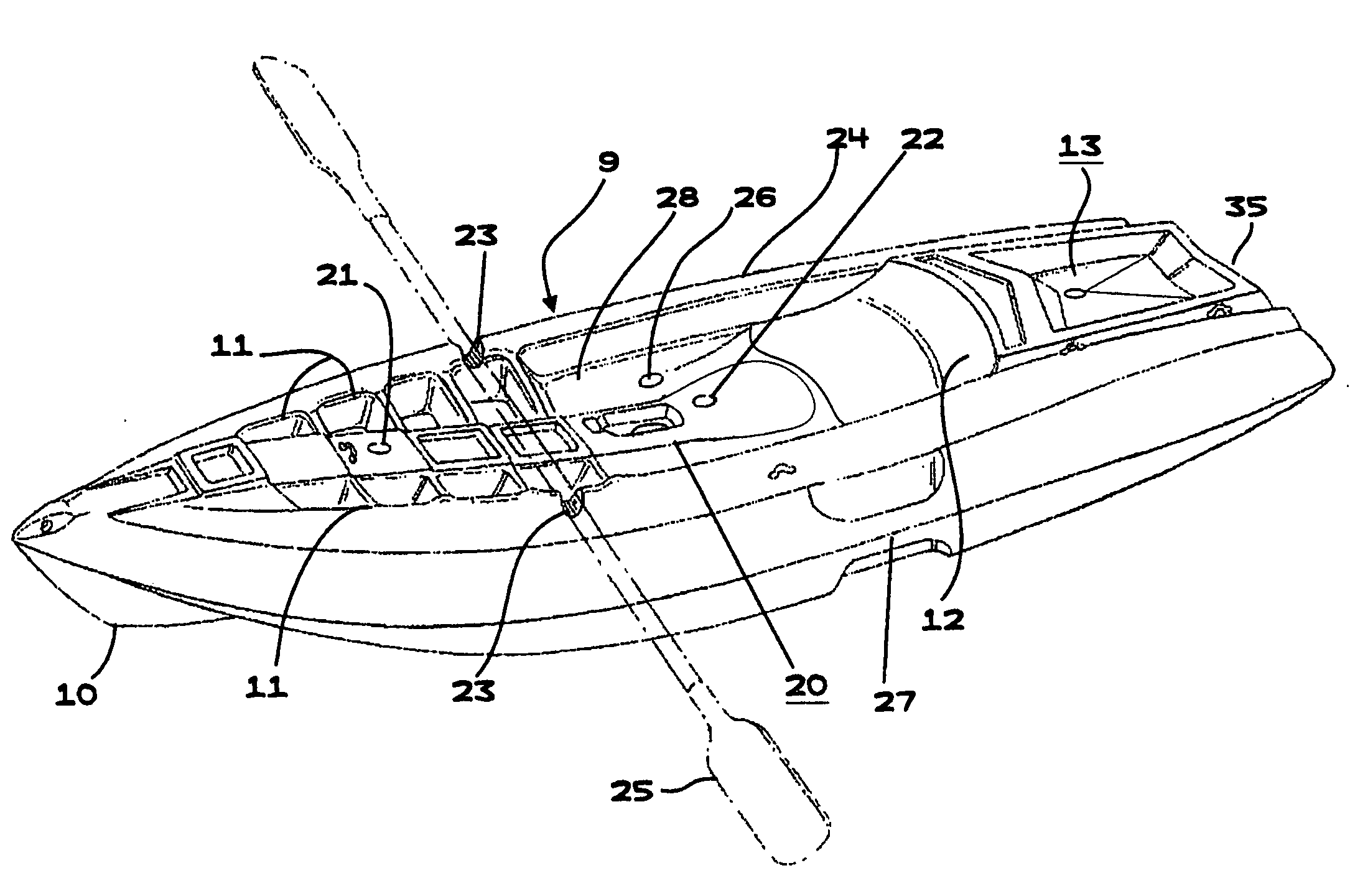

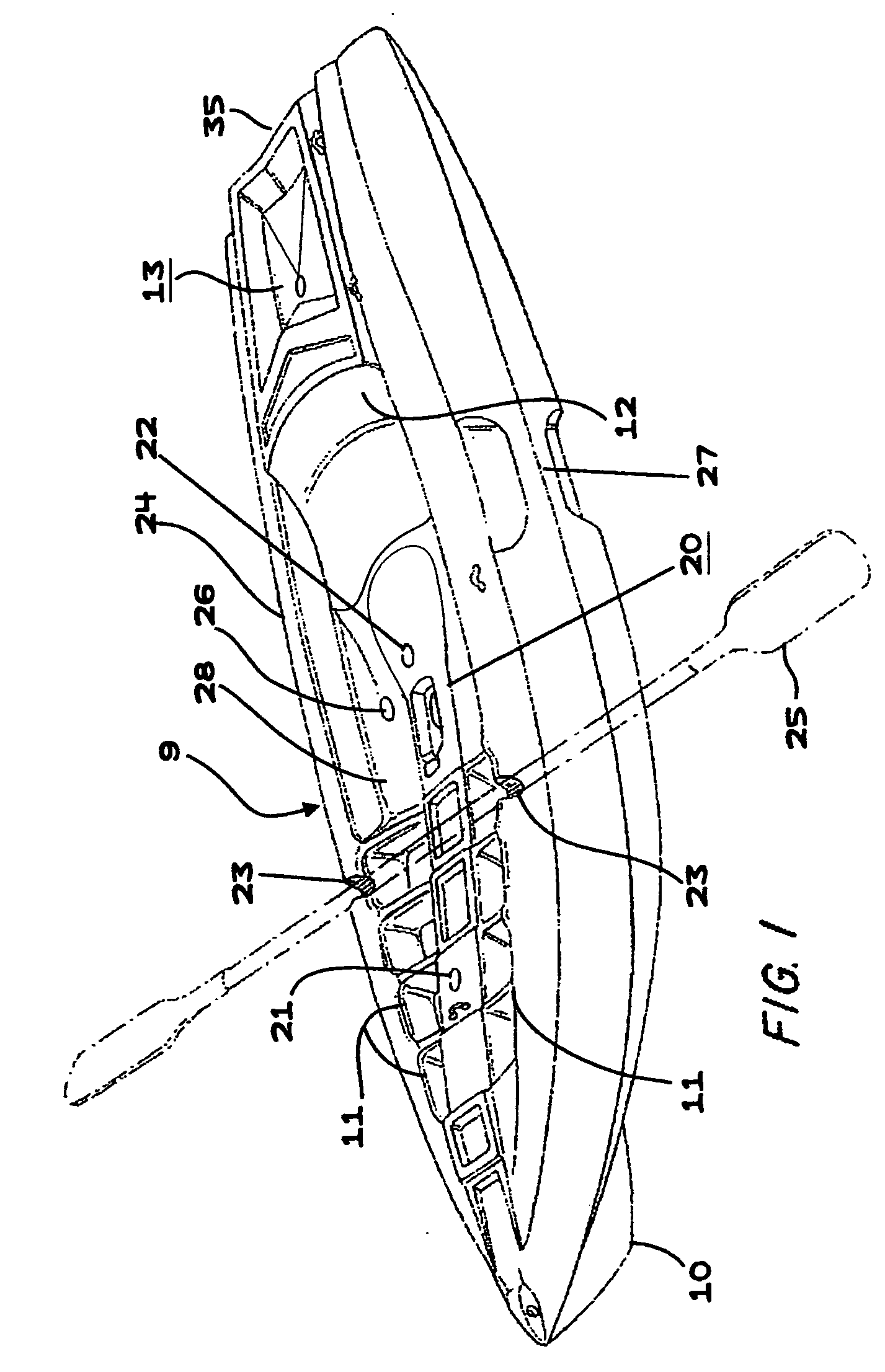

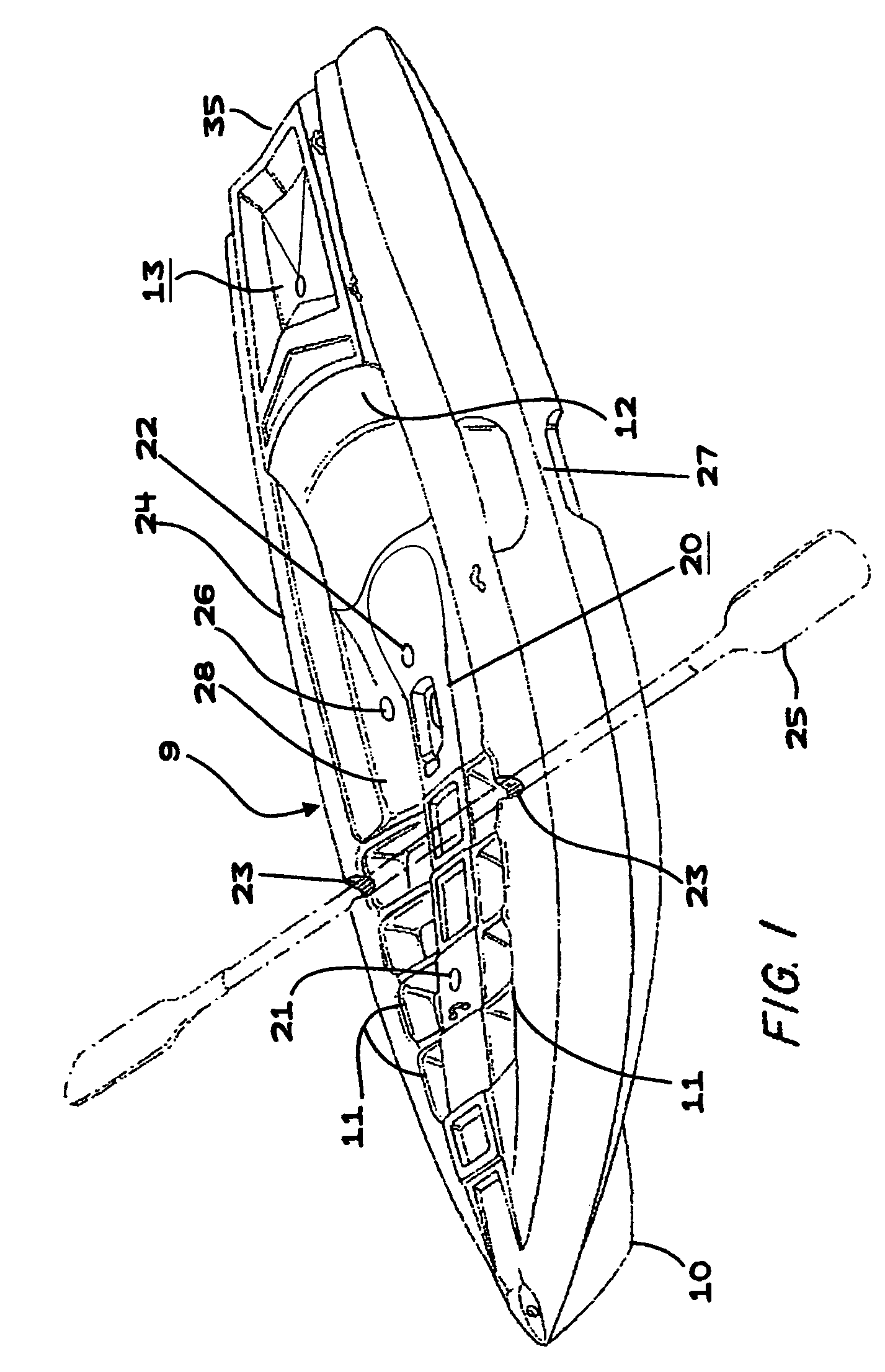

Multi-purpose, plastic molded, sit-on-top kayak

InactiveUS20060254495A1Stable and streamlined and controlled movementImproved kayak controlTravelling sacksPropulsion power plantsBlow moldingGlass fiber

A plastic molded, sit-on-top kayak of unique size and shape is disclosed with various components which provide multi-purpose usage. the kayak is especially useful for multi-purposes such as sailing kayak surfing, scuba diving, paddling, touring and electric motorized usage. The kayak has attachment points integrally molded that provide for these multi-purposes. An important component of the invention includes a removable backrest that additionally provides secure waterproof storage of the operator's personal items. The backrest can be easily removed and reattached securely in place when desired. The ability to easily remove a backrest or backpack option also enables a desirable compact capability for transportation and storage by a user. Additional benefits of this feature provide for a smaller profile for packaging and commercial transportation. The kayak as disclosed may be formed for the most part, typically by blow molding, rotational molding, injection molding, rim molding, fiberglass and thermoforming, and by using a wide variety of polymer materials that may be suitable.

Owner:LIFETIME PRODUCTS

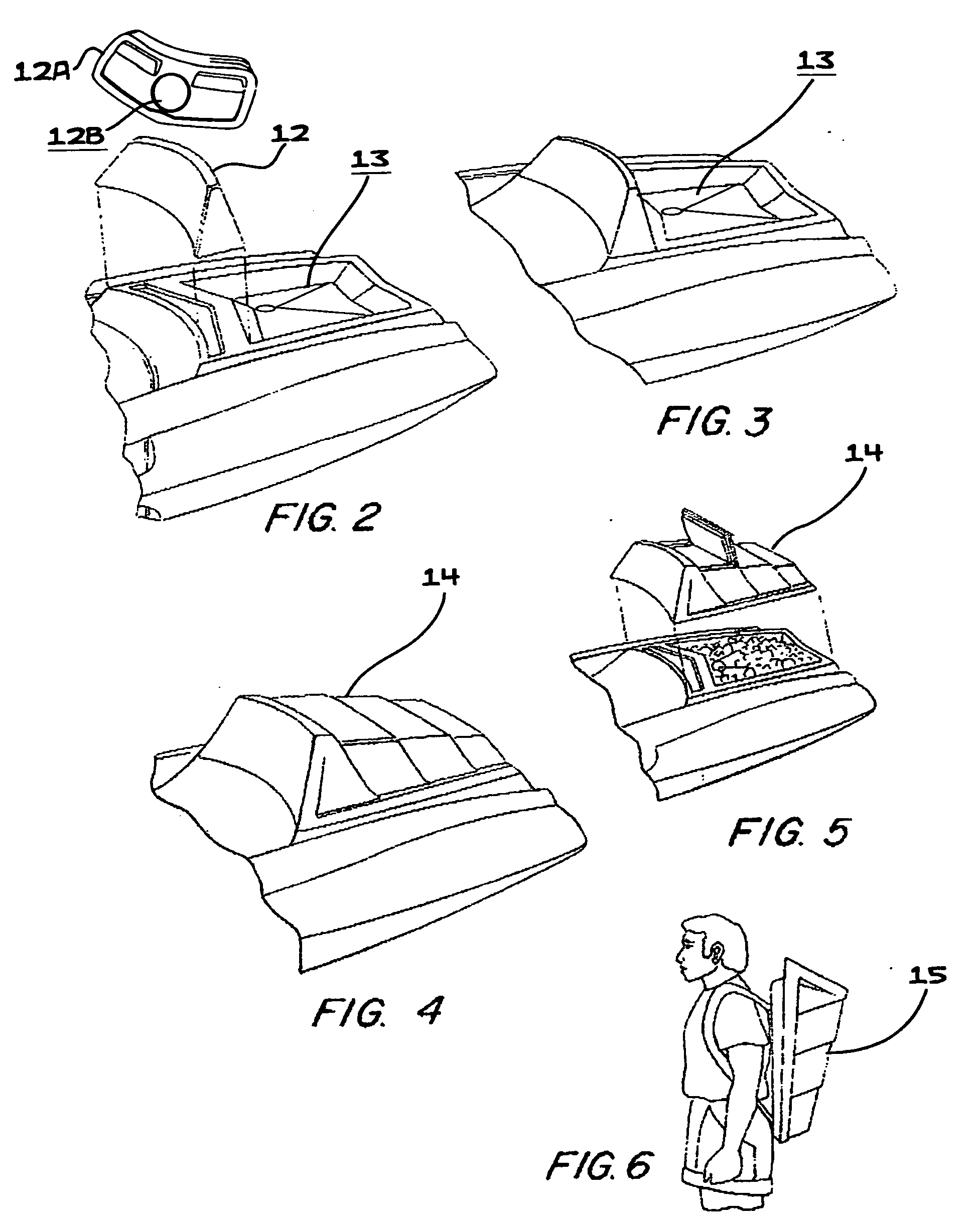

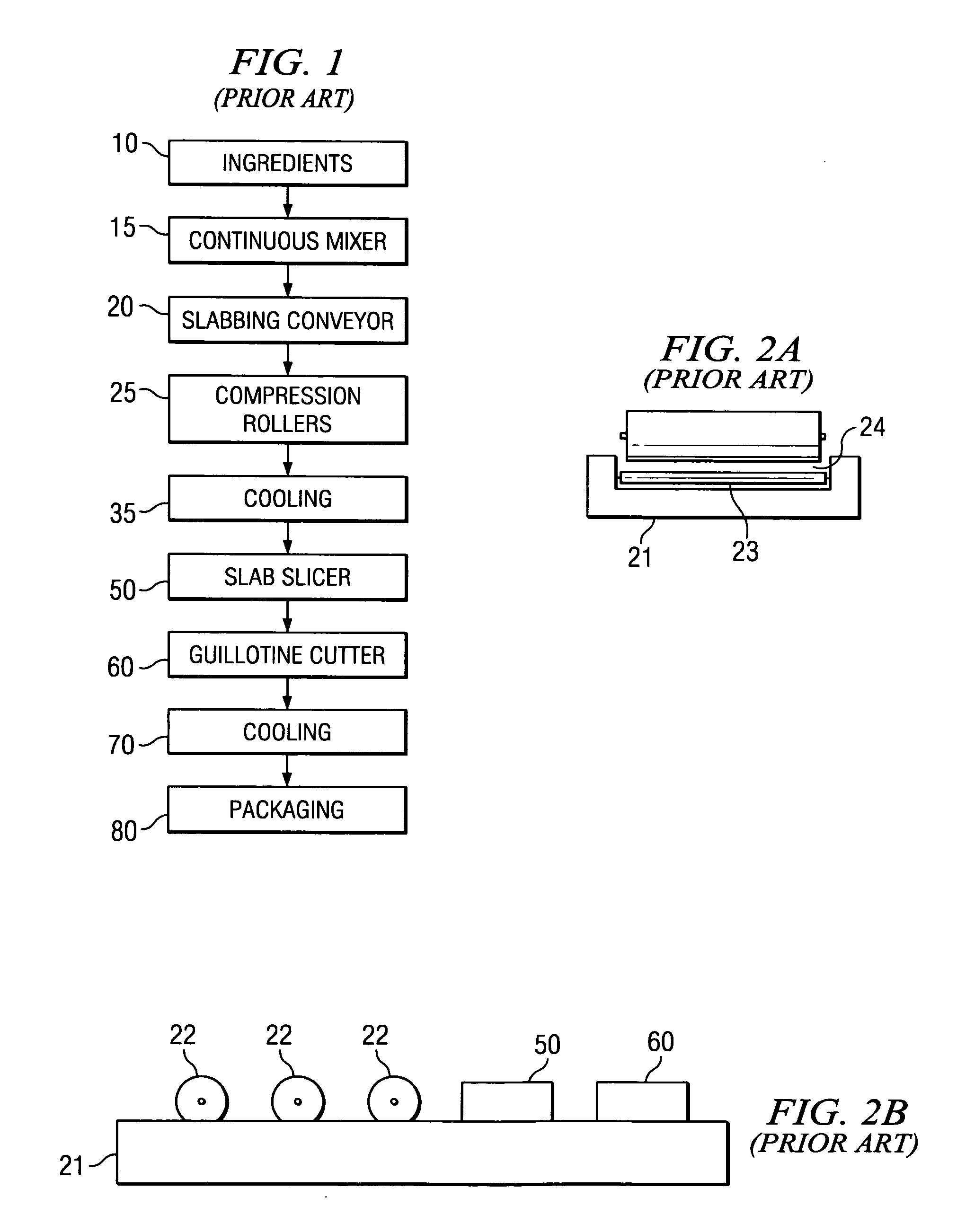

Method for making a cold formed segmented food product

A method for creating bite-sized or segmented pieces of a cold formed bar such as a granola bar. The invention is an improved process for manipulating and shaping granola without having the granola lose its characteristic texture. In one aspect, the invention adds a rotary cutter to a conventional slabbing operation. In one aspect, the invention uses a rotary molder to force granola into female molds where it can be shaped as desired.

Owner:FRITO LAY NORTH AMERICA INC

Molding of Thermoplastic Polyesters

InactiveUS20070224377A1Improve clarityIncrease flexibilityLayered productsBottlesPolyesterPolymer science

Disclosed are processes for rotational molding of thermoplastic polyesters and for hollow articles produced therefrom. The thermoplastic polyesters have a crystallization half time of at least 10 minutes and an inherent viscosity of 0.55 to 0.70 dL / g. Additional thermoplastic polymers may be used to produce multilayered articles.

Owner:EASTMAN CHEM CO

High-impact high-stiffness polypropylene rotational molding material and preparation method thereof

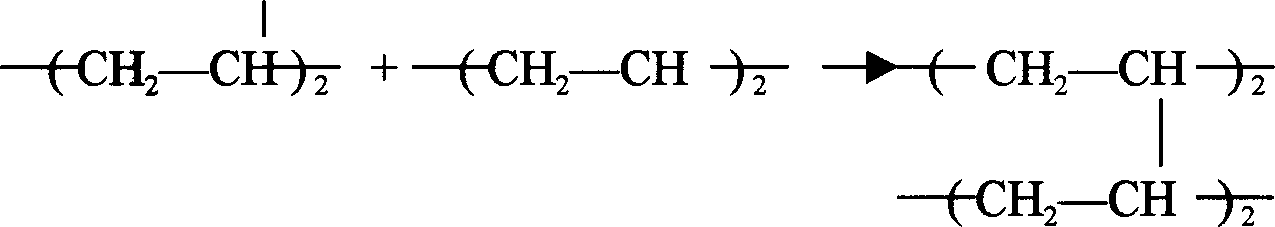

The invention relates to a high-impact high-stiffness polypropylene rotational molding material and a preparation method thereof. The rolling plastic rotational molding material comprises the following raw materials: by weight, 100 parts of polypropylene, 0-30 parts of polyethylene, 0-0.1 part of a crosslinking agent, 0-0.15 part of an auxiliary crosslinking agent, 1-10 parts of an elastomer, 0.1-0.5 part of an antioxidant, 0-10 parts of a nano filler, 0.1-0.5 part of a dispersing lubricant and 0-0.4 part of a surface treatment agent. According to the invention, the crosslinkable polyethylene is added in a polypropylene melt mixing process for melt curing to obtain the high-impact high-stiffness polypropylene modified rotational molding material with a semi interpenetrating network structure, and the high-impact high-stiffness polypropylene modified rotational molding material can meet the material requirements of vehicles and other different fields. The curing reaction of the polyethylene belongs to the in situ curing, the material has the unique semi interpenetrating network structure, different components are mutually bitten or buckled, the compatibility between the polyethylene and polypropylene resin can be improved, and the performance advantages of the both are full played.

Owner:天津市华鑫达投资有限公司

Rotational moulding

A method of producing a plastics article having solid skin and a foam core by a rotational moulding process, comprises charging a mold with a skin-forming component and substantially simultaneously with a foam core-forming component of bulk density greater than 0.5 g / cc, providing a first heating stage in which the mold is heated to a first temperature and is rotated for a first predetermined time to form a substantially impervious skin within the mold, and providing a second heating stage in which the mold is heated to a higher second temperature and is rotated for a second predetermined time to cause foaming of said foam core-forming component, thereby forming a foam core within said substantially impervious skin.

Owner:ROTEC CHEM

Reinforcement system utilizing a hollow carrier

InactiveUS20060267378A1Reduce healthReduce maintenanceVehicle seatsSuperstructure subunitsBlow moldingLow density

A system and method for reinforcing at least a portion of a structural member, including at least one hollow carrier, having an exterior shell and an interior portion, which substantially conforms to the dimensions and geometry of the structural member being reinforced; and a lightweight, low density material for filling the interior portion of one or more of the carriers. The material filling one or more of the carriers of the present invention can be a reinforcement material, self-curing material, or a heat activated expandable material. The carrier can be produced by blow molding or rotational molding and has an adhesive material disposed along at least a portion of the exterior shell used to place, adhere, and affix the carrier to a targeted portion of the structural member selected to be structurally reinforced.

Owner:ZEPHYROS INC

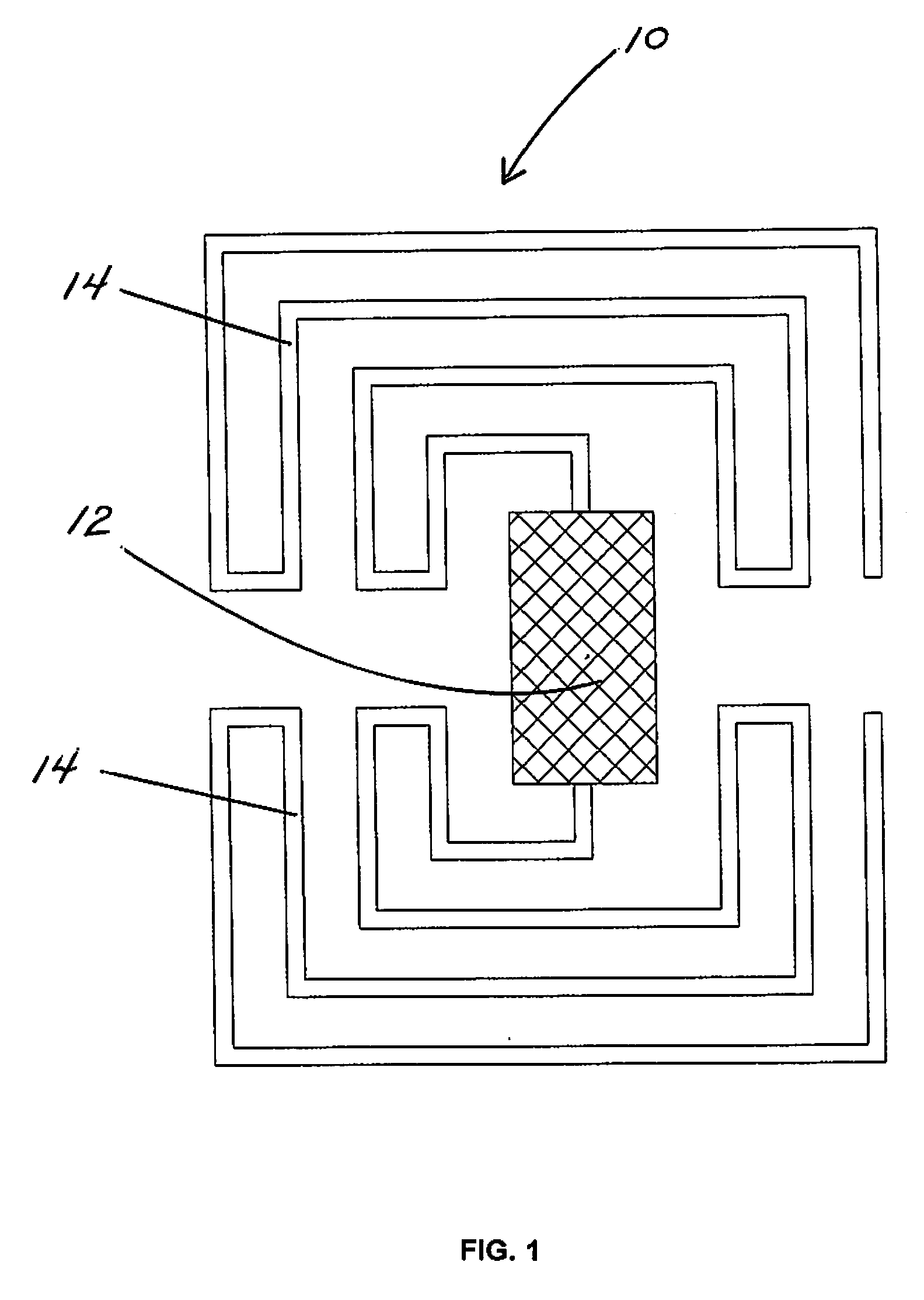

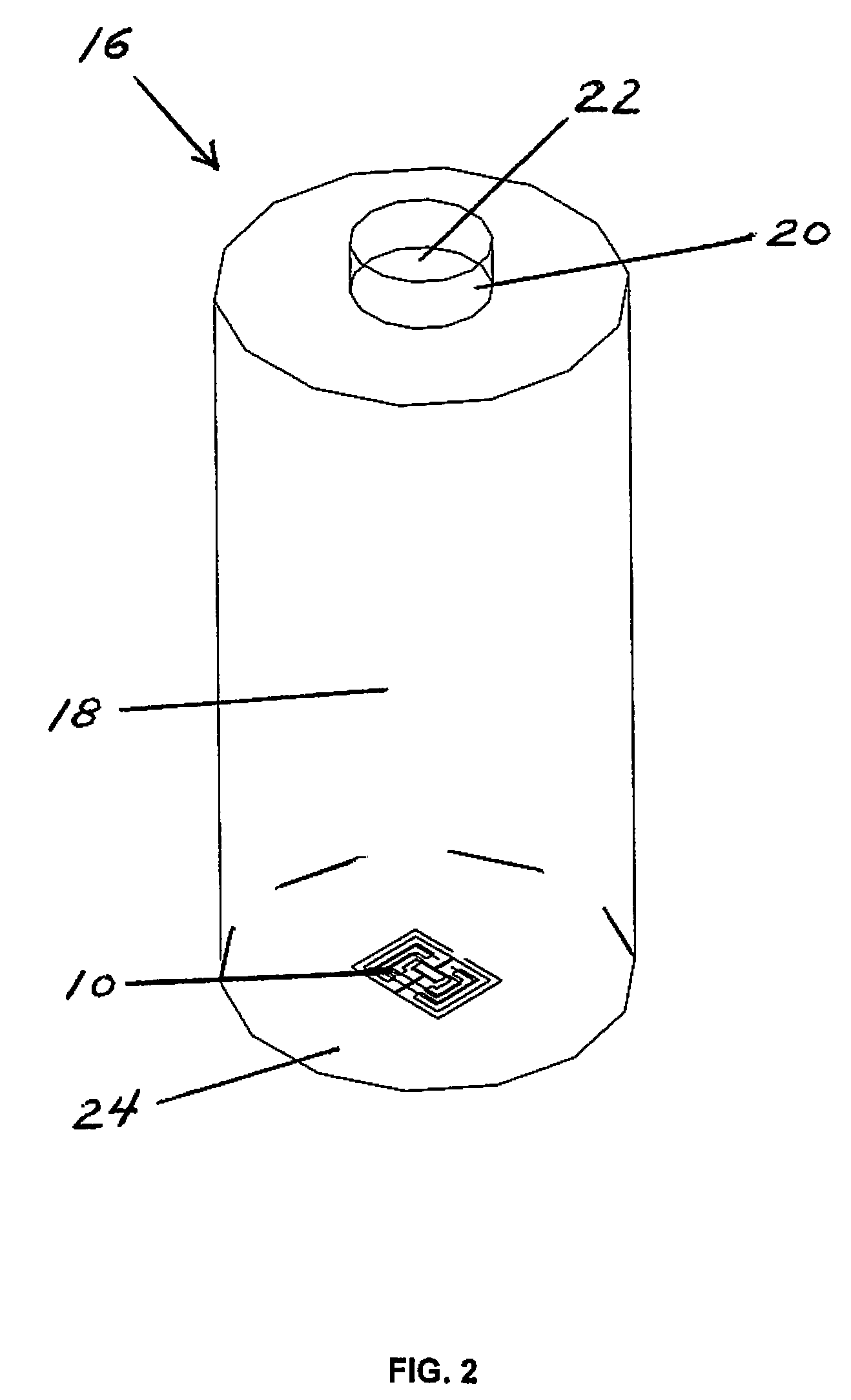

Method for molding an object containing a radio frequency identification tag

InactiveUS20110297306A1Simple processSimple manufacturing processLamination ancillary operationsSynthetic resin layered productsCompression moldingBlow molding

A method for applying a radio frequency identification tag to an object, e.g., a container, by means of an insert molding process or in-mold decorating process. Such a method can be utilized to simplify the manufacturing processes for applying a radio frequency identification tag to an object, e.g., a container. The molding process can be a conventional molding process, such as, for example, injection molding, blow molding, compression molding, transfer molding, and rotational molding. However, the conventional molding process is modified by inserting a radio frequency identification tag into the cavity of the mold prior to forming the molded article. The modified molding process results in a molded article having a radio frequency identification tag encapsulated by the polymeric material of the molded article.

Owner:ABBOTT LAB INC

All-barrier elastomeric gel-filled breast prosthesis

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

Toughened polymer compositions

Toughened thermoplastic compositions comprising a thermoplastic polymer toughened by the inclusion of a thermoplastic elastomer derived from a particulate rubber dynamically vulcanized in the presence of a matrix polymer. The toughened thermoplastic composition exhibits properties including toughness, improved impact resistance, and improved hardness. The compositions are utilized wherever toughened, high performance polymers are desired. A method for forming the toughened polymer compositions is also described. Processing methods, such as rotational molding, utilizing the toughened polymer compositions are described.

Owner:TEKNOR APEX

Forging and rotary extrusion forming process for aluminium alloy wheel

InactiveCN1827289AQuality improvementLight in massMetal-working apparatusMaterial consumptionRotational molding

The invention relates to a forging aluminum alloy wheel forging-rotational molding method, which combines the forging and rotational compressing techniques. In forging, molding part of spoke of wheel, and pre-molding the rim; then in rotational compressing, rotationally compressing the rim to complete the molding. Wherein, the rim is molded by forging, and the rim is mainly molded by rotational compression. The invention can combine the forging and rotational compression to express their advantages. And the inventive aluminum alloy wheel has better quality, high accuracy, less finish allowance, higher strength, and reduced material consumption.

Owner:JIAXING STONE WHEEL

Special cross-linked polyethylene material for rotational molding and preparing process thereof

InactiveCN1524899AImprove liquidityImprove permeabilityLinear low-density polyethyleneLow-density polyethylene

The invention relates to a crosslinked polyethylene single-purpose material for rotational moulding which comprises (by weight percent) linear low density polyethylene 70-90%, low density polyethylene 10-30%, cross linking agent 0.5-5%, anti-oxidant 0.1-1%. The invention also relates to the process for preparing the special-purpose material. The rotational moulding product prepared by the single-purpose material has good processing characteristics, fine impact strength, thermal creep resistance and low-temperature flexibility, good penetrability resistance and chemical environmental resistance.

Owner:PETROCHINA CO LTD

Molded fuel tank and method of manufacturing the same

One embodiment of a molded fuel tank includes a fuel tank molded from a synthetic material, such as a composite polymer. One embodiment may include molding a fuel tank with metal component fastening structures positioned within the fuel tank as it is molded. One embodiment may include molding a fuel tank and integral component fastening structures simultaneously from synthetic materials. One embodiment of a molded fuel tank may include a fuel tank formed by a rotational molding process.

Owner:KEEFER NEAL +1

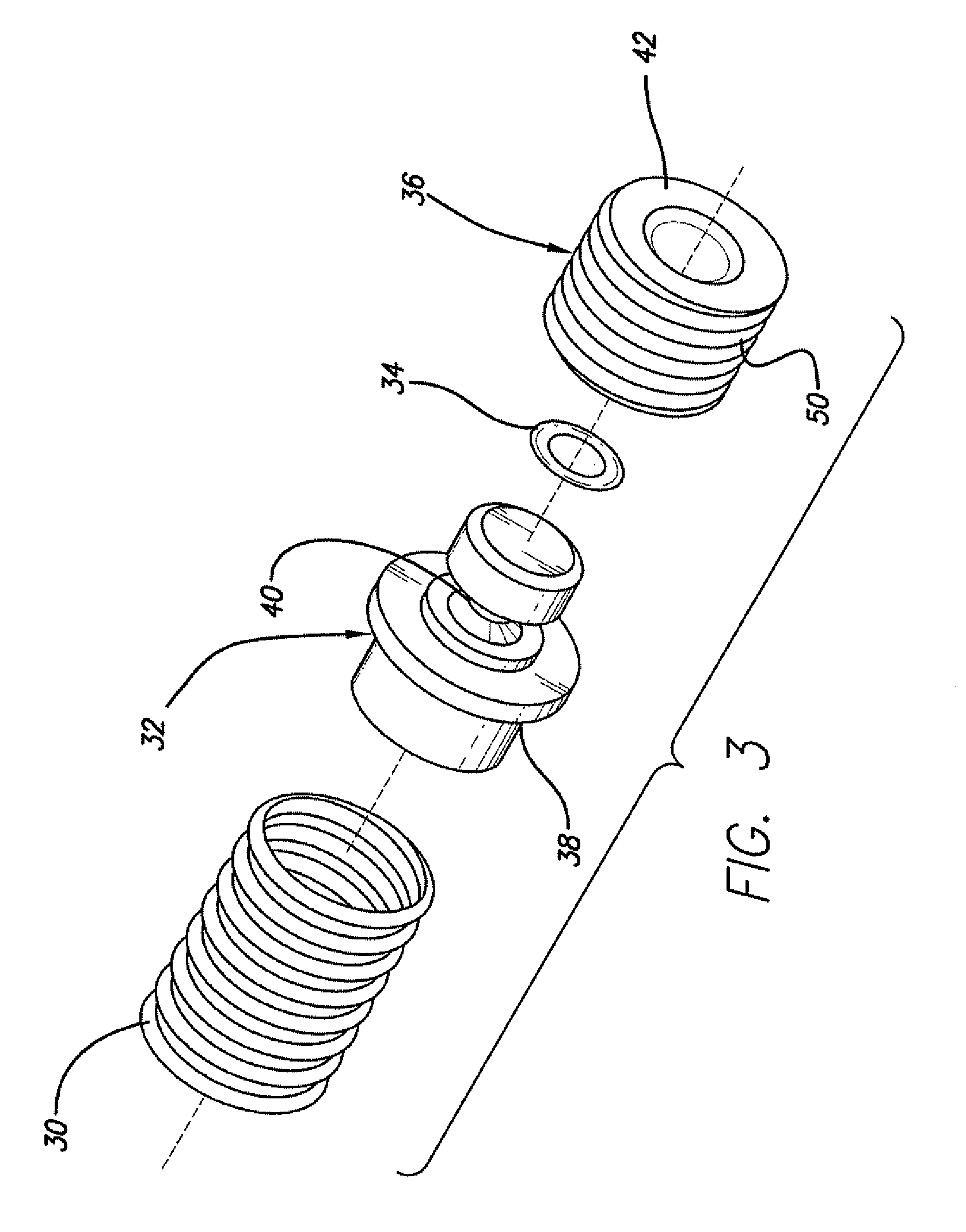

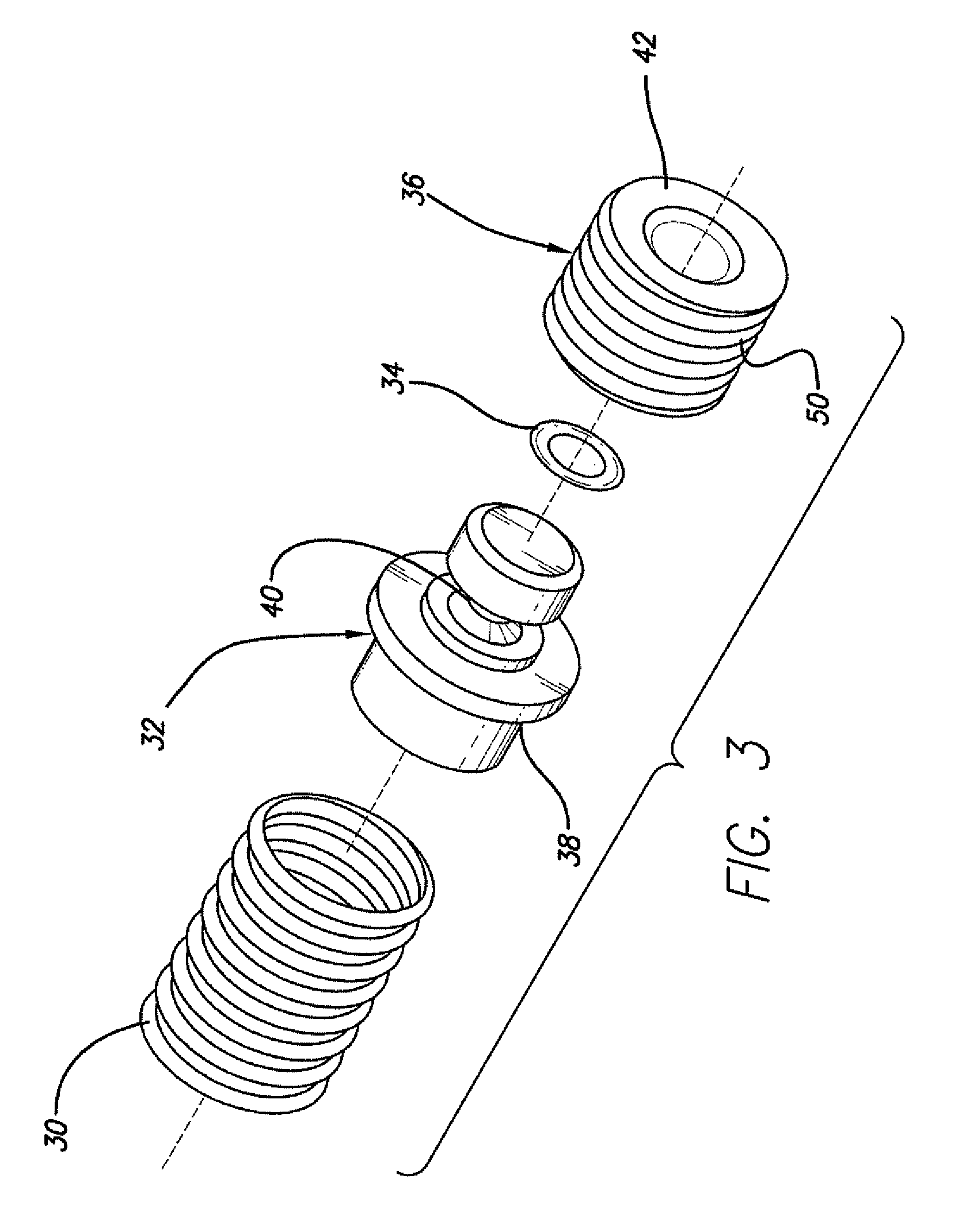

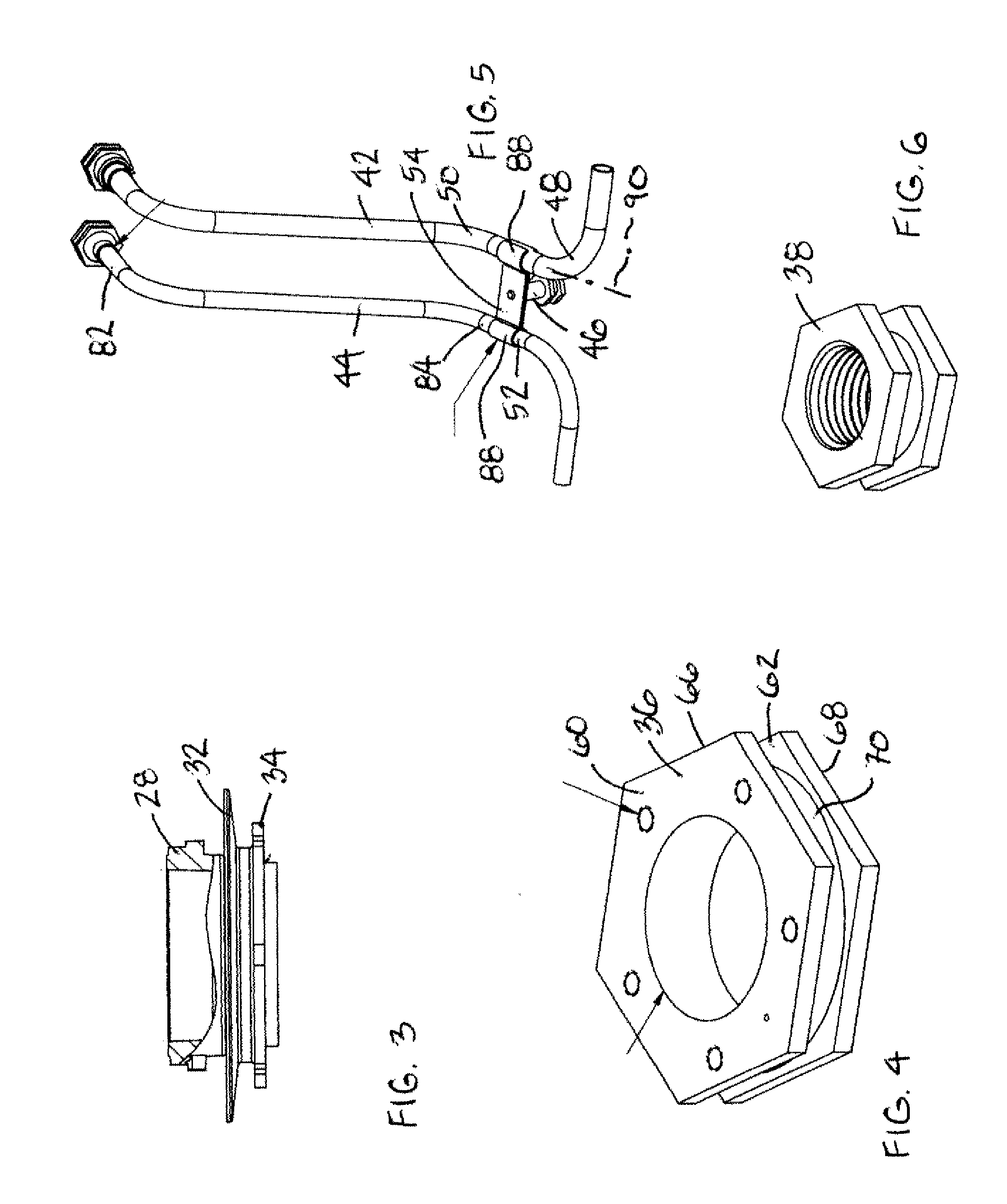

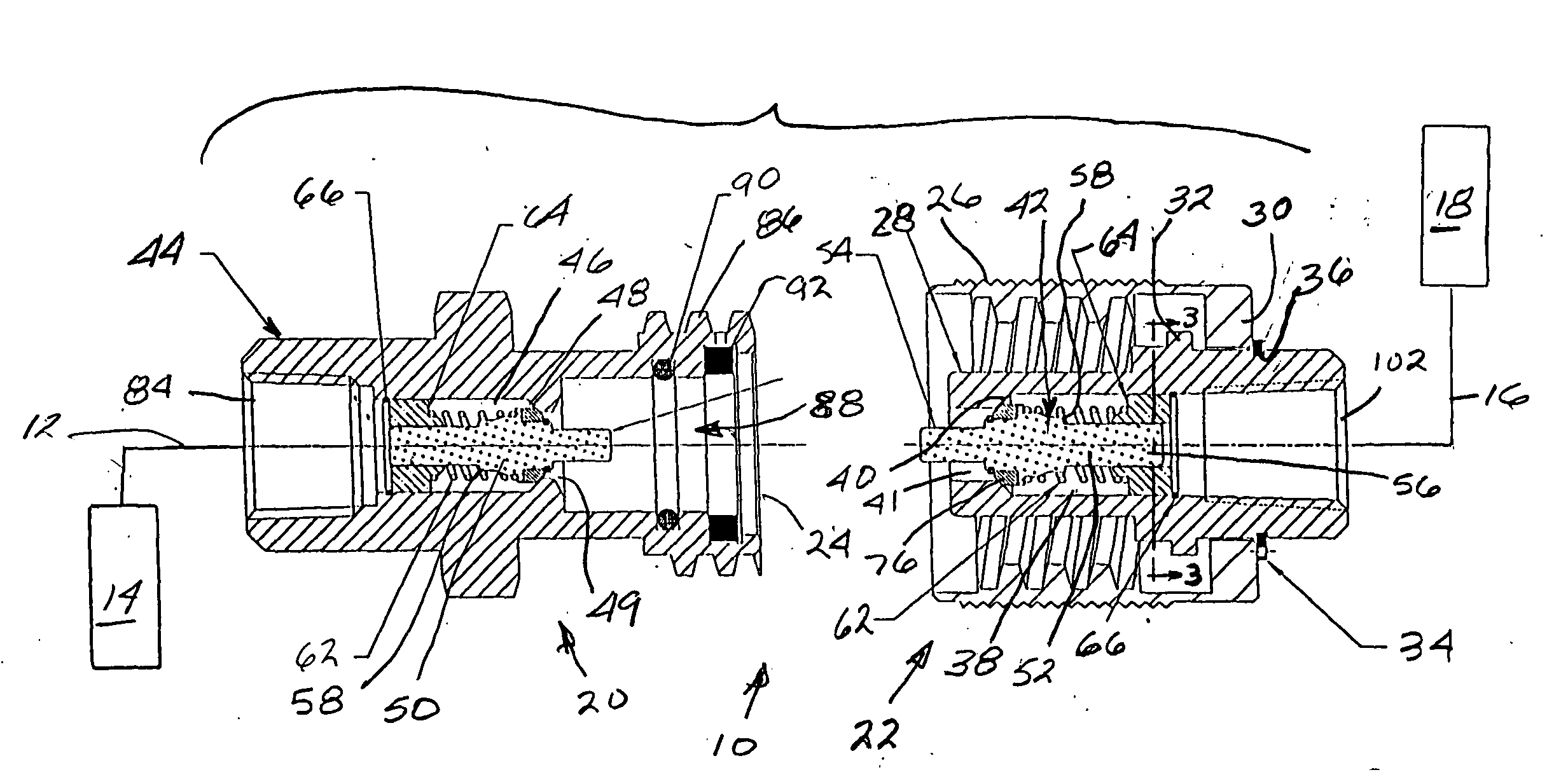

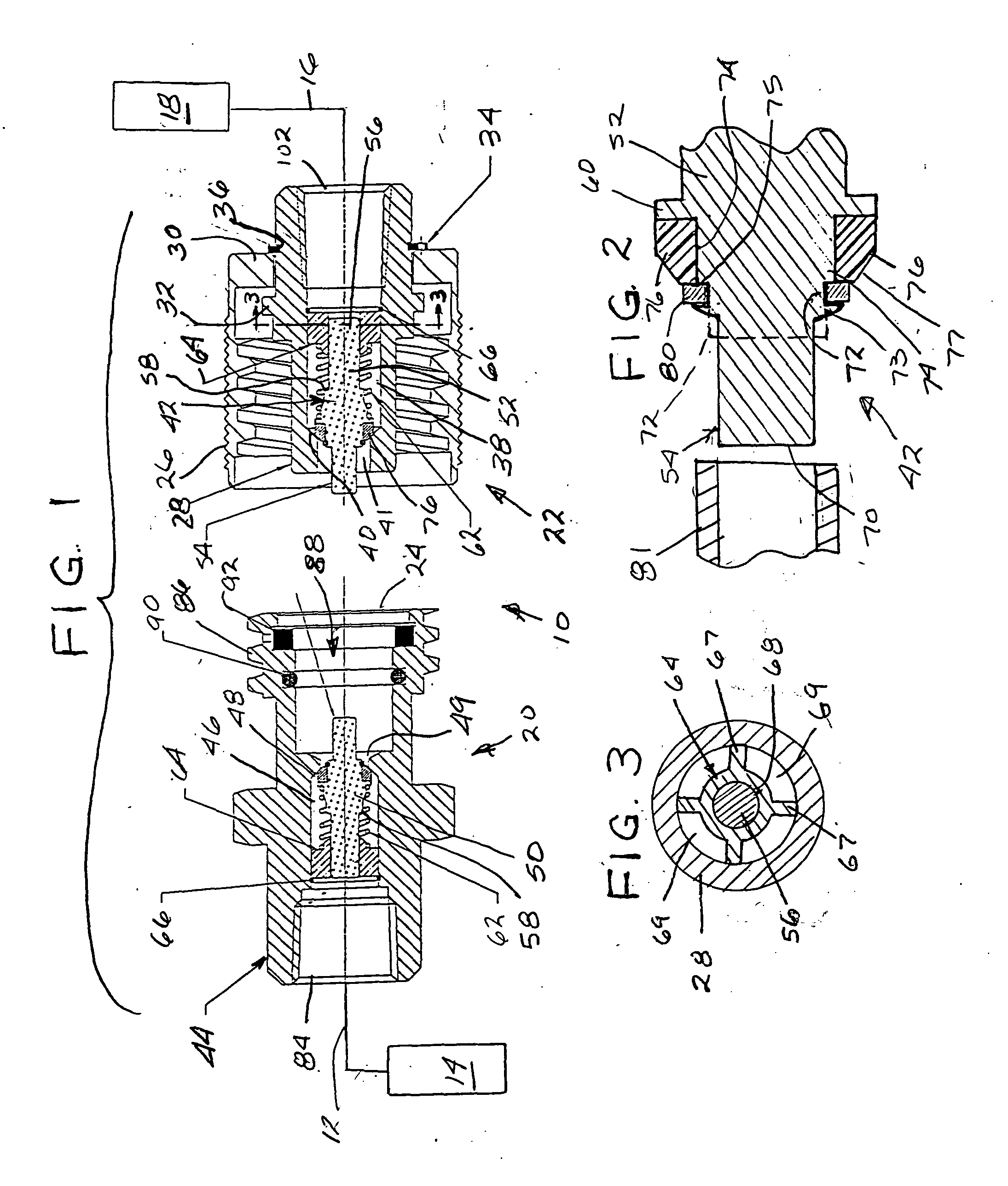

Pressurized gas coupling

InactiveUS20050001194A1Low costHuge savingsValve arrangementsJoints with fluid cut-off meansCouplingEngineering

A method for producing a valve holder assembly for an automatic gas shutoff valve in a pressurized gas coupling comprises mounting a compressible annular gasket on a cylindrical portion of the valve holder adjacent an enlarged flange that abuts an outer side of the gasket; mounting a retaining washer on the cylindrical portion adjacent an outer side of the gasket, the cylindrical portion extending outwardly past the retaining washer and terminating at a shoulder; and flaring the shoulder radially outwardly so as to form a retaining cap on an outer side of the retaining washer, thereby locking the gasket on the valve holder, by applying a rotary forming tool against the shoulder on the cylindrical portion. The coupling desirably includes shutoff valves in male and female components, with identical valve holder assemblies being used in both coupling components. A powdered metal guide can be used for a stem on the valve holder.

Owner:MARSHALL EXCELSIOR CO

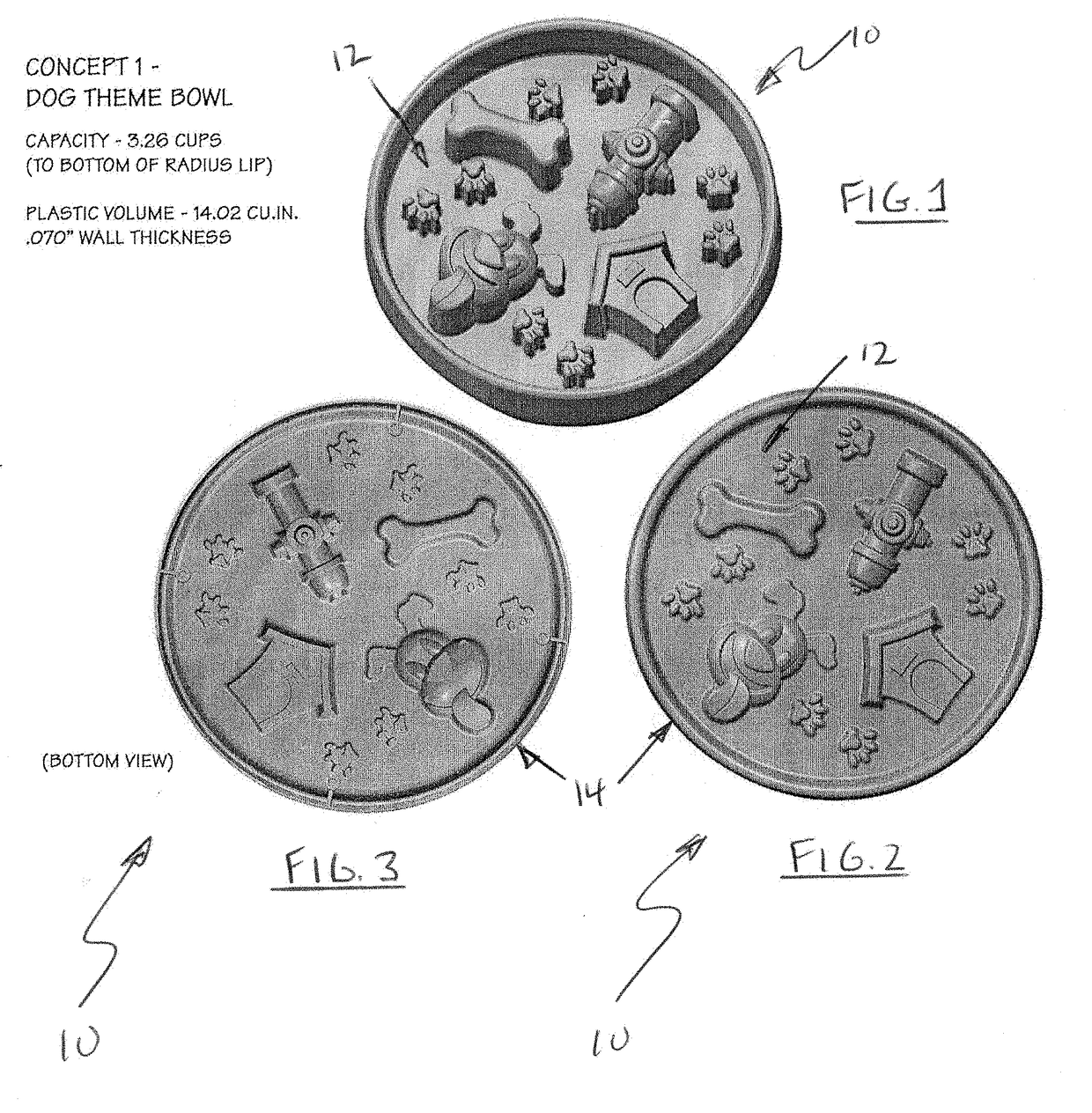

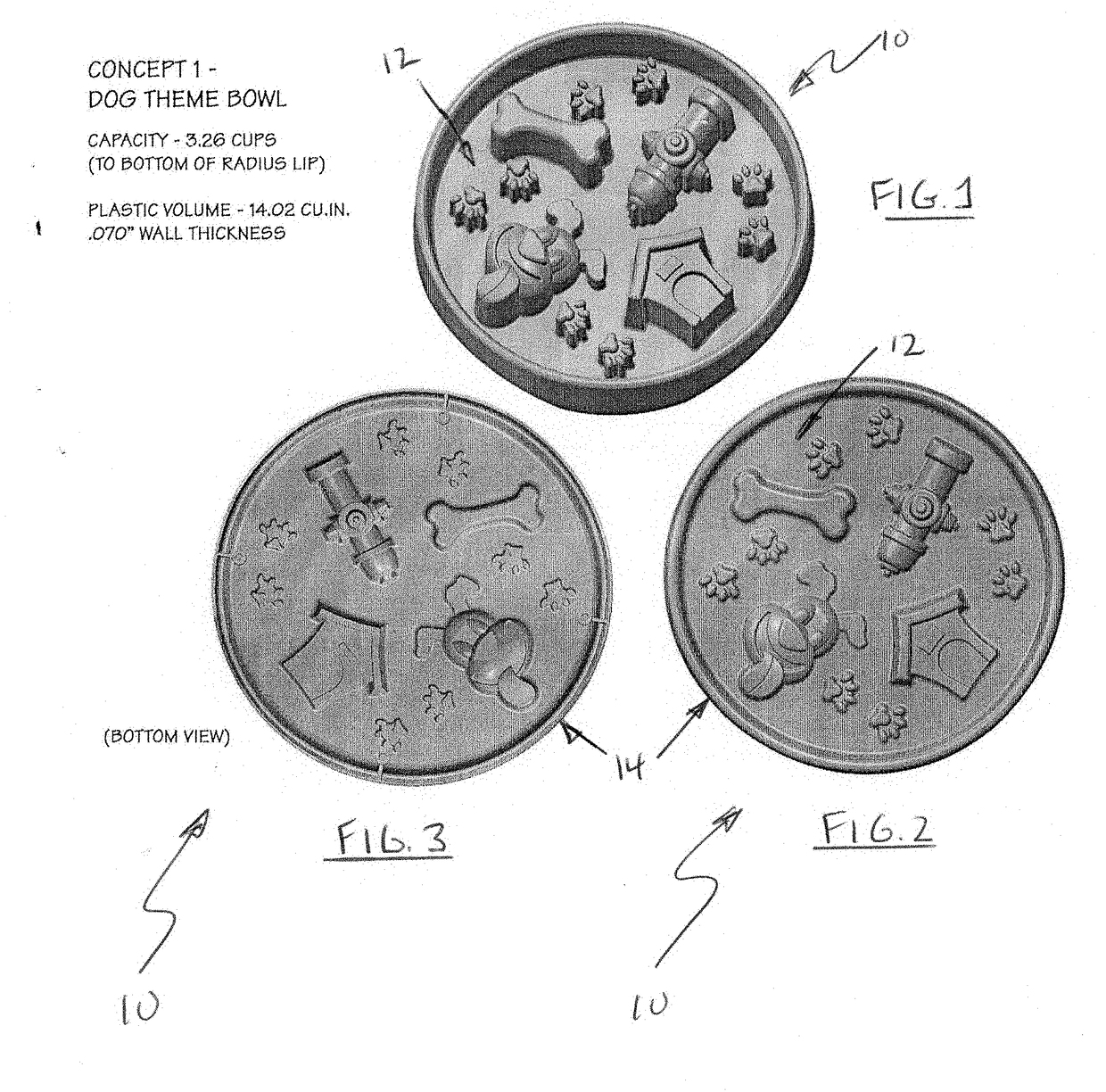

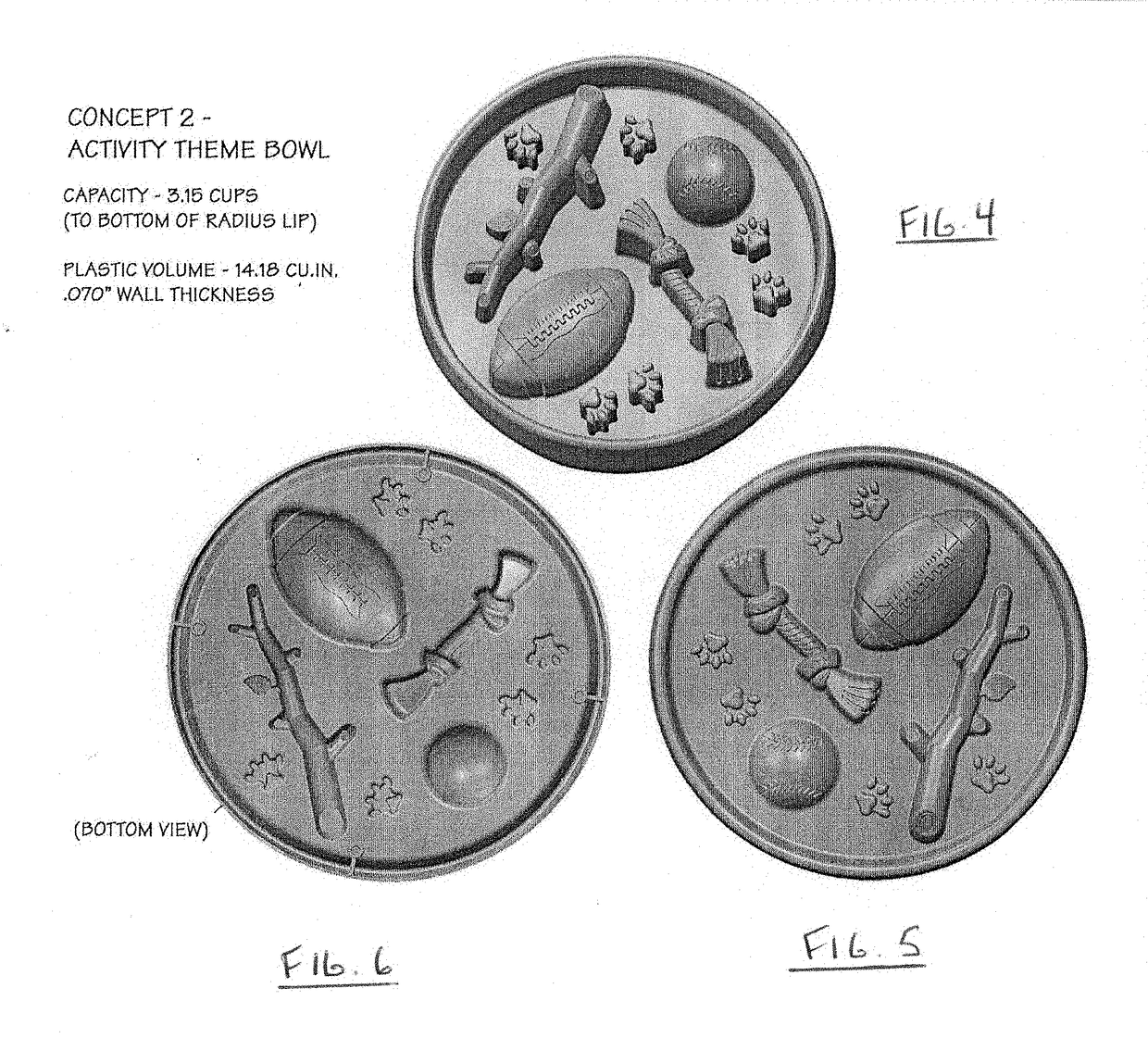

Metallized Plastic Pet Product

InactiveUS20180133991A1Not be readily and shapedMetallic coatingAnimal watering devicesAnimal feeding devicesBlow moldingSurface finish

A variety of pet related products are provided formed initially of plastic and finalized with a metallized surface finish. The pet product is molded using injection molding, rotational molding, vacuum forming, blow molding, compression molding, thermoforming or other plastic forming techniques that can provide a structure having a shape that cannot be readily or economically shaped by metal stamping or other conventional metalworking method. The semi finished plastic part is then subjected to a metallizing process in an individualized non-contiguous manner, where a thin metallic layer is deposited on at least one of the product surfaces. The resultant pet product item simulates the appearance metal, and may provide the durability, cleanability and the general antimicrobial nature resulting metal surfaces.

Owner:OUR PETS

Multi-purpose, plastic molded, sit-on-top kayak

InactiveUS7320291B2Increase buoyancyEasy to moveTravelling sacksPropulsion power plantsBlow moldingGlass fiber

A plastic molded, sit-on-top kayak of unique size and shape is disclosed with various components which provide multi-purpose usage. The kayak is especially useful for multi-purposes such as sailing kayak surfing, scuba diving, paddling, touring and electric motorized usage. The kayak has attachment points integrally molded that provide for these multi-purposes. An important component of the invention includes a removable backrest that additionally provides secure waterproof storage of the operator's personal items. The backrest can be easily removed and reattached securely in place when desired. The ability to easily remove a backrest or backpack option also enables a desirable compact capability for transportation and storage by a user. Additional benefits of this feature provide for a smaller profile for packaging and commercial transportation. The kayak as disclosed may be formed for the most part, typically by blow molding, rotational molding, injection molding, rim molding, fiberglass and thermoforming, and by using a wide variety of polymer materials that may be suitable.

Owner:LIFETIME PRODUCTS

Rotational molding grade cross-linked polyethylene wear-resistant composite and preparation method thereof

The invention discloses a rotational molding grade cross-linked polyethylene wear-resistant composite and a preparation method thereof. The rotational molding grade cross-linked polyethylene wear-resistant composite is prepared by the steps of mixing a base material, which is linear low-density polyethylene (granular or powdery) commonly used in a rotational molding process, with a cross-linking agent and an assistant cross-linking agent uniformly, absorbing for 80-120 minutes at 85 DEG C, and then adding ultra-high molecular weight polyethylene, an inorganic filler and other components for improving the wear resistance of the base. The rotational molding grade cross-linked polyethylene wear-resistant composite disclosed by the invention comprises the following components in percentage by weight: 76.7-79% of linear low-density polyethylene, 0.15-4% of cross-linking agent, 0.15-1% of antioxidant, 4-19% of ultra-high molecular weight polyethylene and 4-12% of inorganic filler subjected to surface treatment.

Owner:江苏广鼎管业科技有限公司

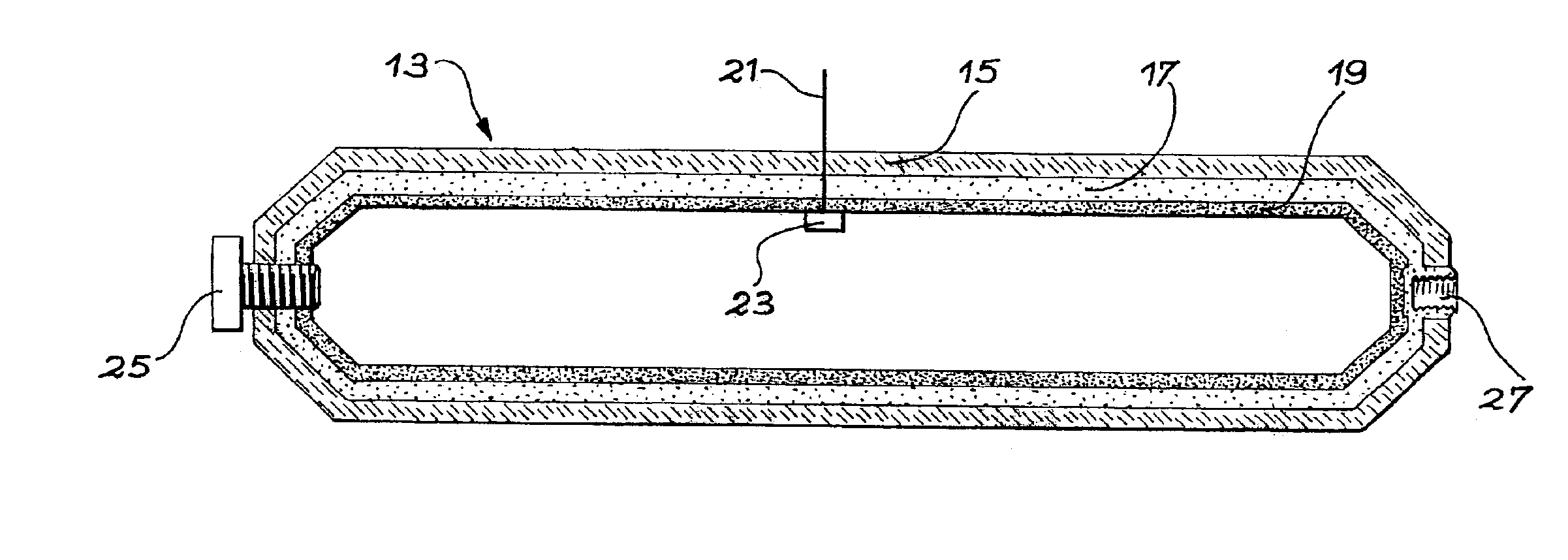

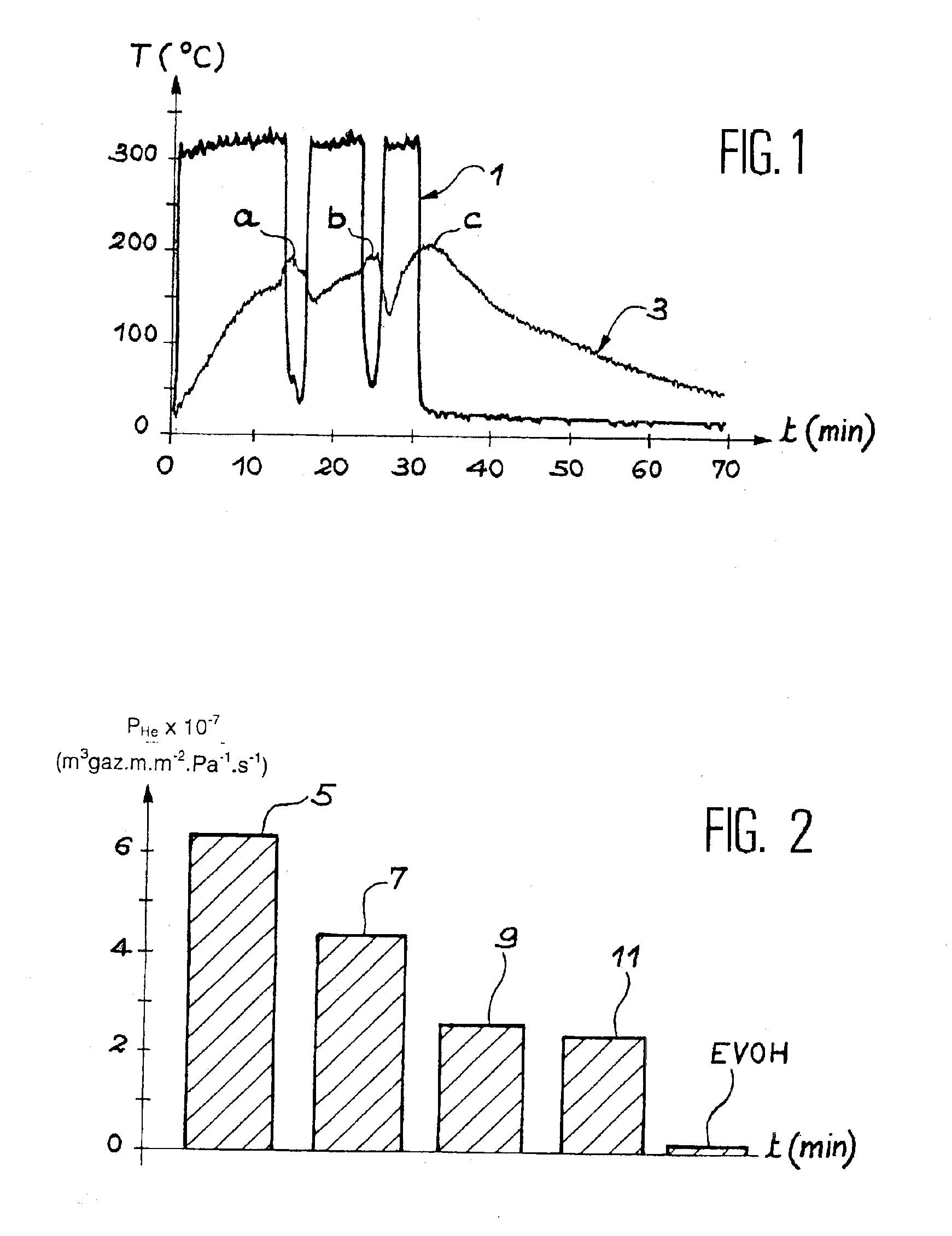

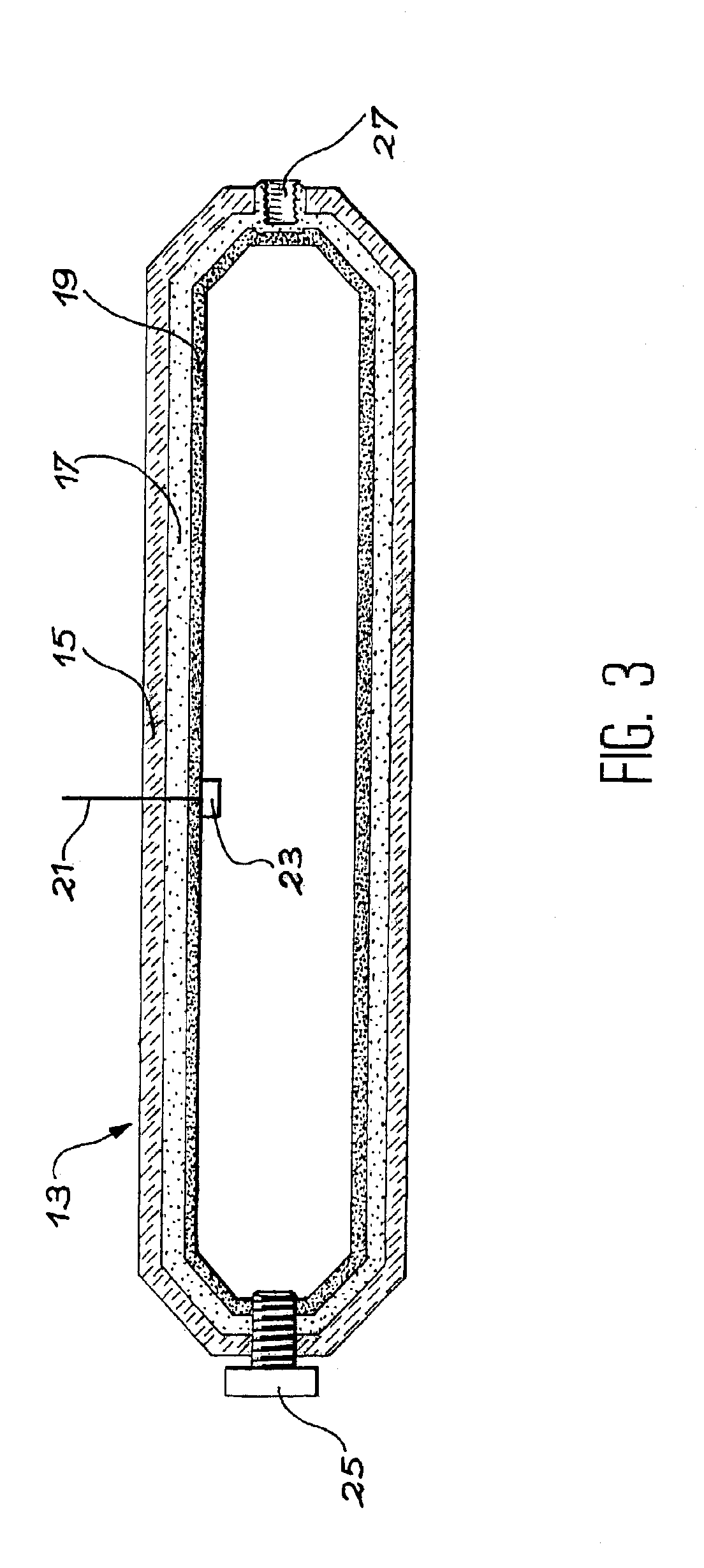

Multilayer thermoplastic structure for gas tank

A multi-layer thermoplastic structure that has at least one layer that is between 0.3 and 20 mm thick and is made of an ethylene-vinyl alcohol copolymer with a density of between 0.94 and 1.4, and a melt flow index of between 1.3 and 4.2 g / 10 minutes at a temperature between 170 and 240 degree C. The multi-layer thermoplastic structure is obtained by rotation moulding and is of particular benefit when functioning as a gas tank.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Optical lens, light-emitting diode optical component and light-emitting diode illumination lamp

InactiveUS20130083541A1Uniform areaUniform brightness distributionPoint-like light sourceGlobesSpherical shapedLight-emitting diode

The invention is related to an optical lens, a light-emitting diode optical component and a light-emitting diode illumination lamp. The optical lens formed as a semi-spherical shape includes an uplifting spherical surface and a bottom surface corresponding to the spherical surface, and the bottom surface includes an inward space concave to the spherical surface and formed with a free surface corresponding to the spherical surface. The free surface is axially-symmetrical formed as rotational molding with respect to an axis connected from the focus to a center point of the spherical surface, to form the free surface with a similar Gaussian distribution curve provided on a section vertically cut from the spherical surface to the bottom surface. A light-emitting diode is disposed below the focus of the optical lens. The special outline structure of the optical lens can provide a uniform luminance distribution on an illuminating area.

Owner:NAT APPLIED RES LAB

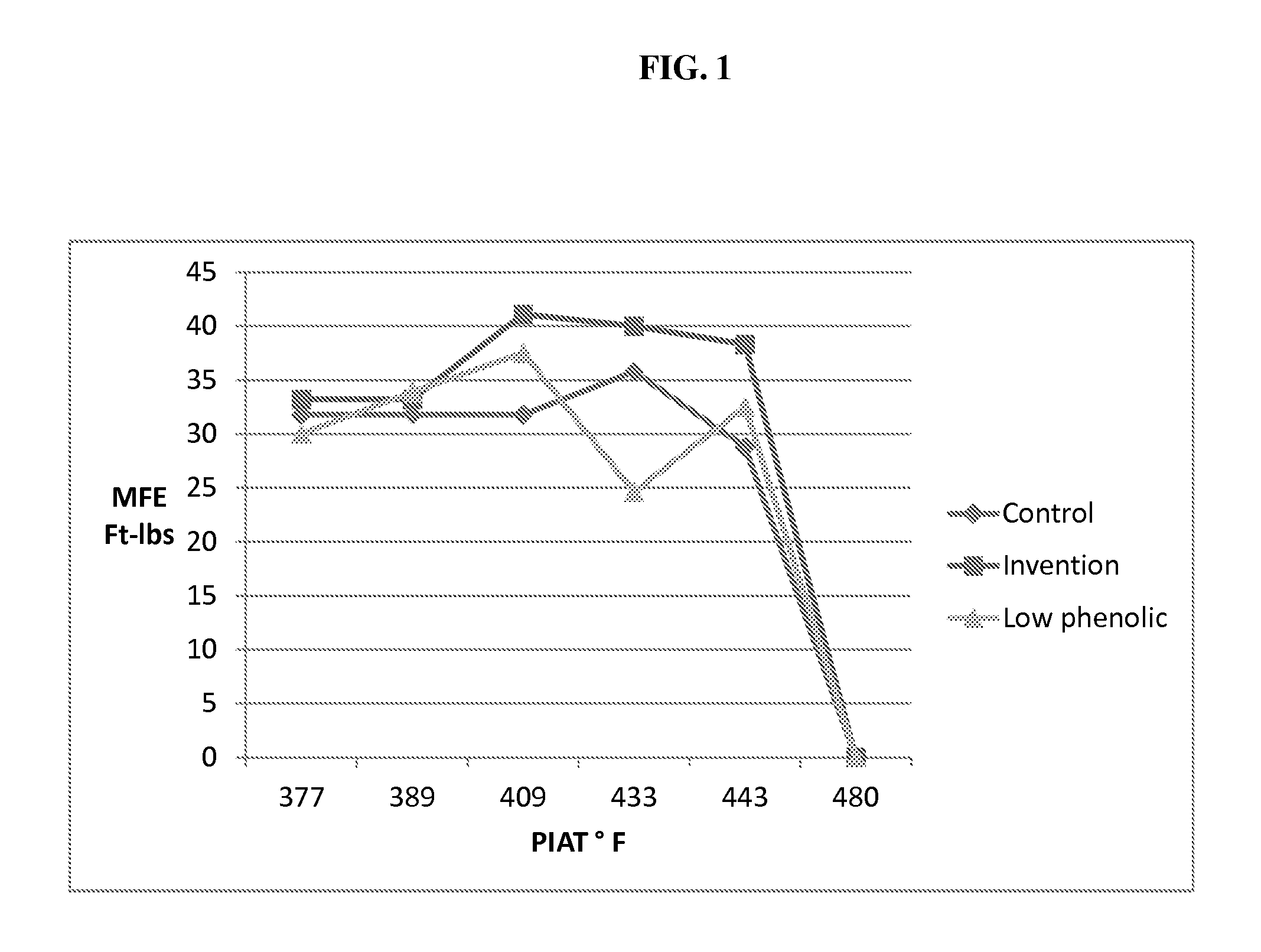

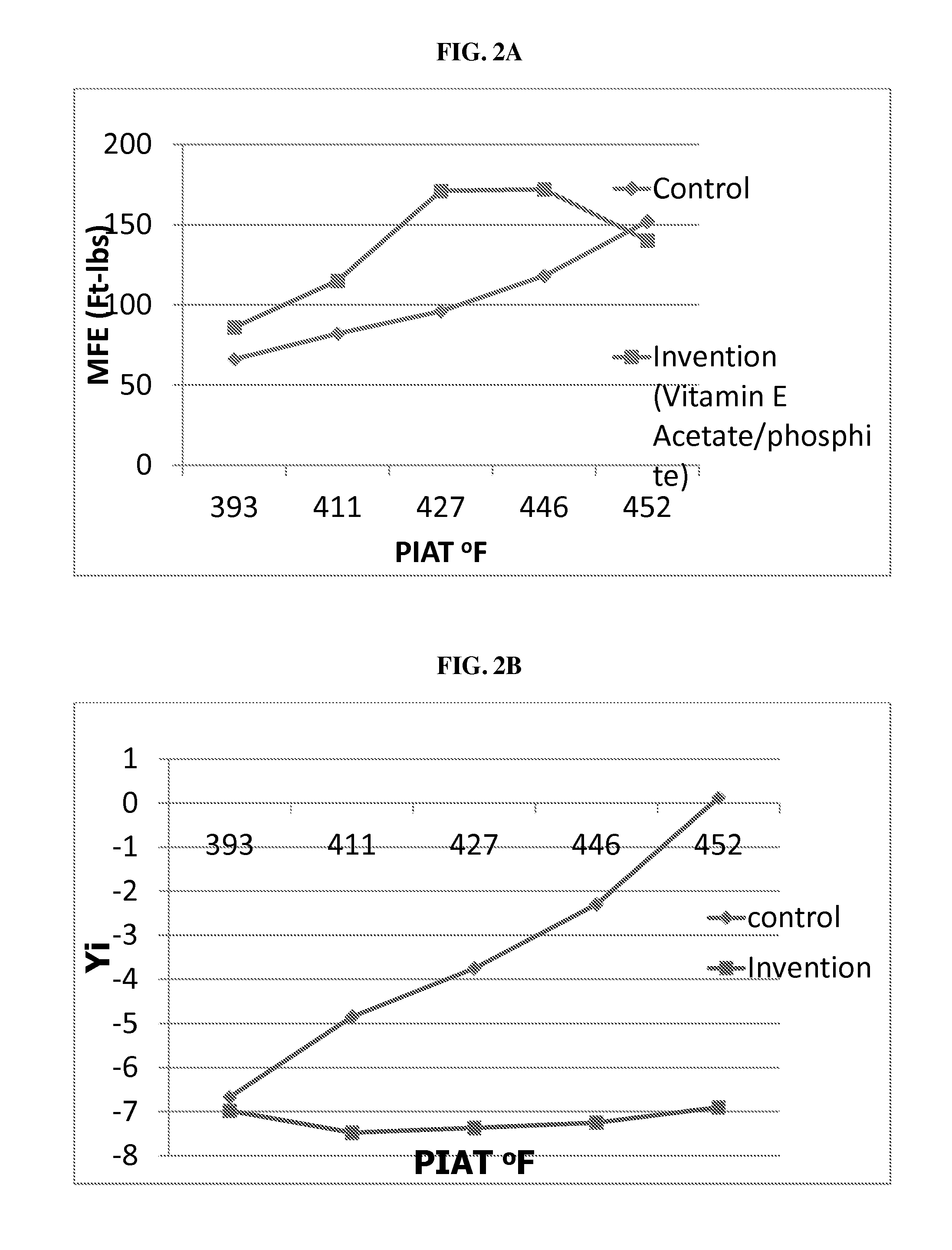

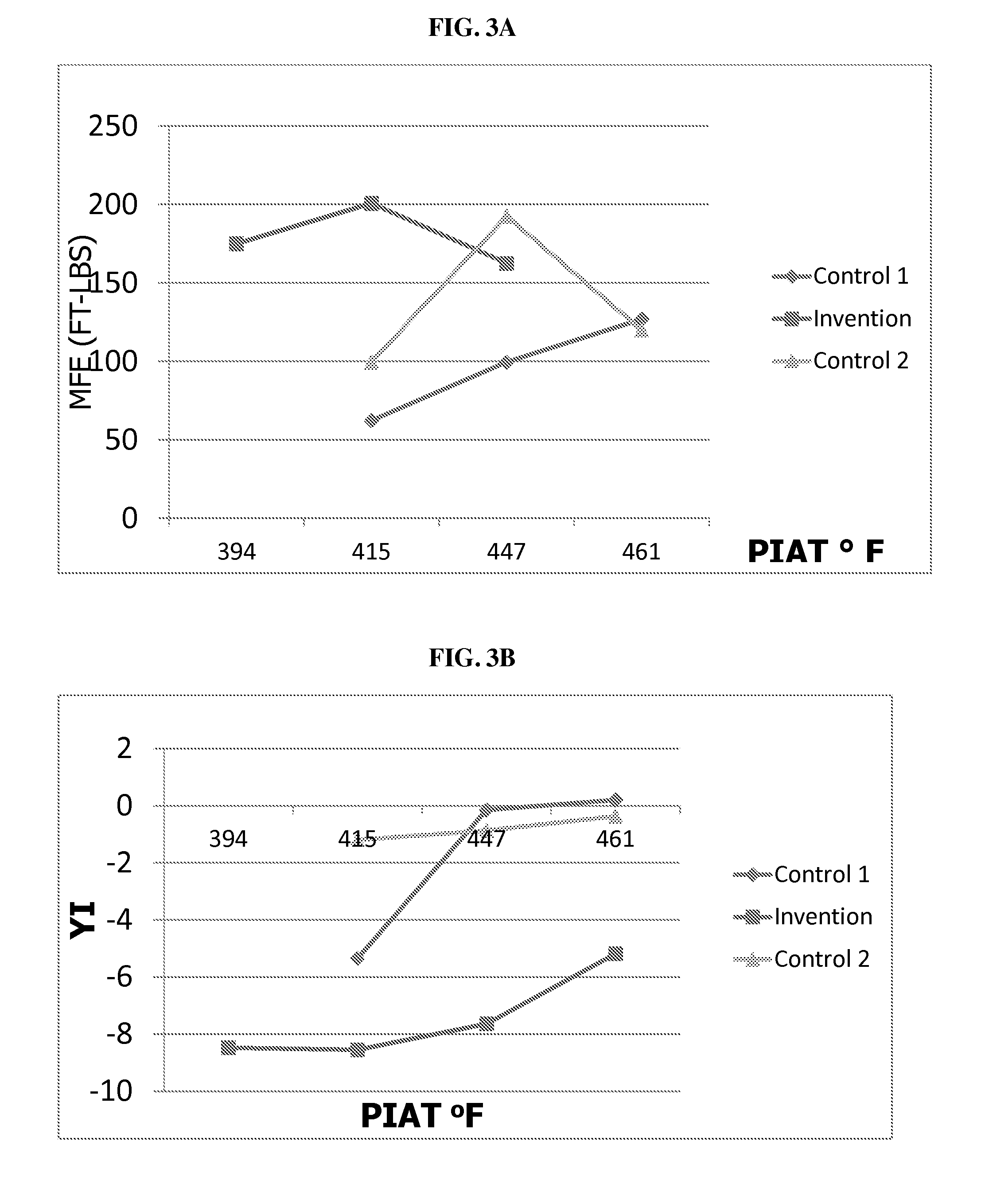

Processing additives and uses of same in rotational molding

ActiveUS20120146257A1Shorten cycle timeShorten the timeOrganic chemistryChemical industryShell moldingCycle time

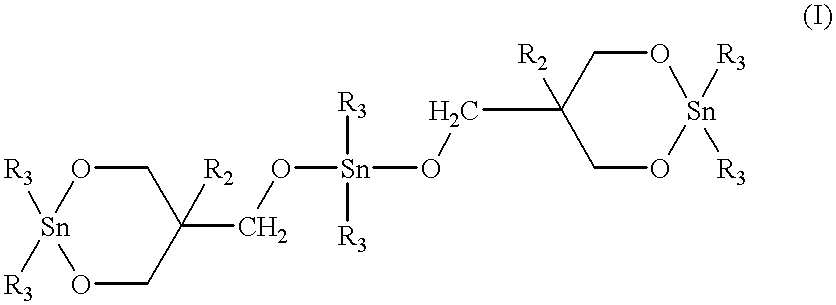

The cycle time of polymer compositions subjected to a rotomolding process is improved (i.e., reduced), while the processing window is simultaneously enlarged through the use of a polymer-stabilizing amount of a processing stabilizer system having at least one chroman-based compound according to Formula V:

Owner:CYTEC TECH CORP

Full-biodegradation ceratin fiber reinforced and fireproof modified polylactic acid material and preparation method thereof

The invention discloses a full-biodegradation ceratin fiber reinforced and fireproof modified polylactic acid material and a preparation method thereof. Polylactic acid is utilized as a basic resin material and combined with ceratin fibers, long-chain aliphatic-serie amide compound, bio-based ultraviolet stabilizer, natural oxidation inhibitor and impact modifier so as to realize reinforcement and fireproof modifying of the polylactic acid material. The modified polylactic acid material is applicable to mass production of various environment-friendly full-biodegradation plastic products or compounds with natural composite plant pigments to produce full-biodegradation ceratin fiber reinforced and fireproof modified polylactic acid plastic products capable of displaying colors. The requirements of processing performances of the preparation method of the modified polylactic acid material for foaming, extrusion molding, film blowing, blow molding, blister, injection molding, rotational molding and the like of sheets, plates, tubing, section bars or other plastic products can be completely met by universal equipment. The full-biodegradation ceratin fiber reinforced and fireproof modified polylactic acid material is a novel polylactic acid material which is high in performance, low in cost and capable of being subjected to complete biodegradation.

Owner:广州福原生物科技有限公司

Toughened polymer compositions

Toughened thermoplastic compositions comprising a thermoplastic polymer toughened by the inclusion of a thermoplastic elastomer derived from a particulate rubber dynamically vulcanized in the presence of a matrix polymer. The toughened thermoplastic composition exhibits properties including toughness, improved impact resistance, and improved hardness. The compositions are utilized wherever toughened, high performance polymers are desired. A method for forming the toughened polymer compositions is also described. Processing methods, such as rotational molding, utilizing the toughened polymer compositions are described.

Owner:TEKNOR APEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com