Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

991 results about "Vacuum forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers. Normally draft angles are present in the design of the mold (a recommended minimum of 3°) to ease removal of the formed plastic part from the mold.

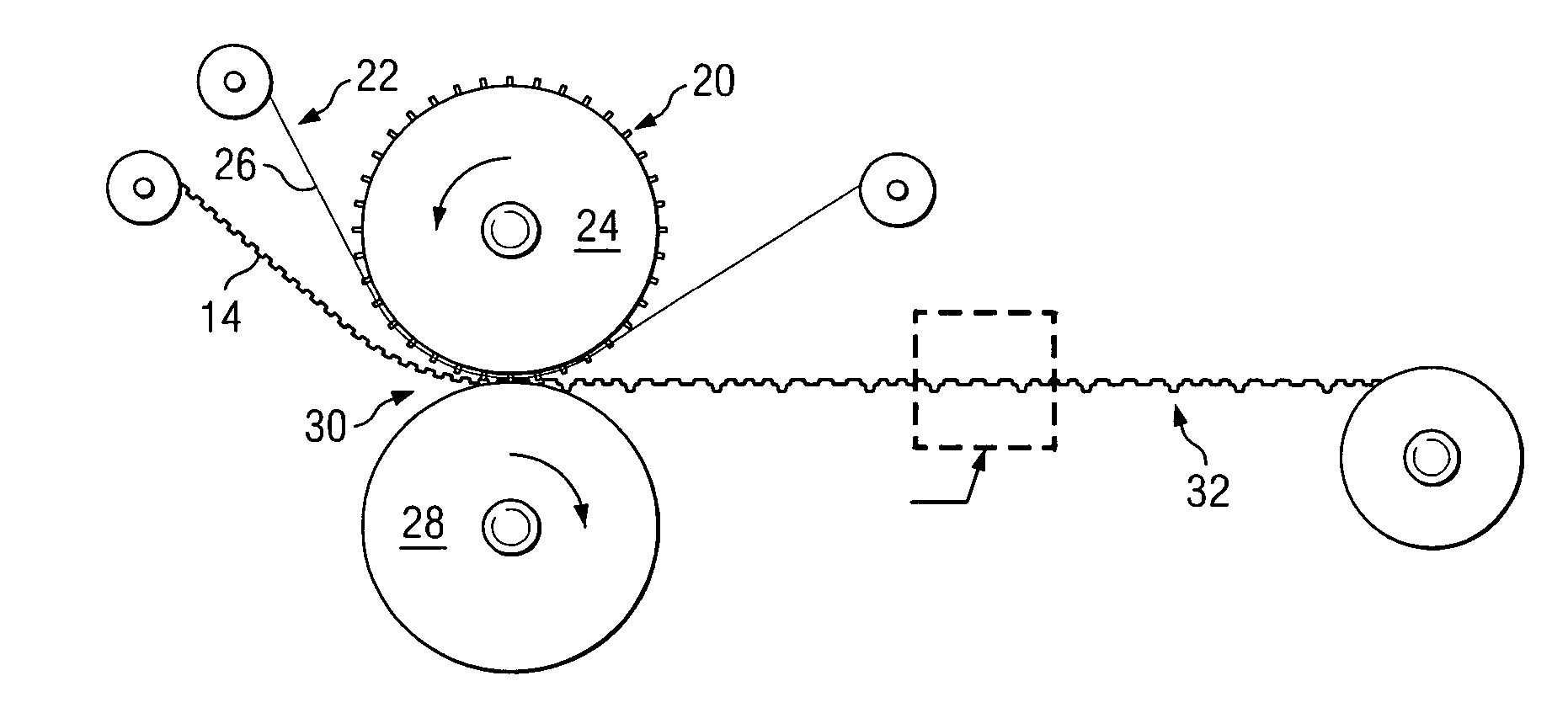

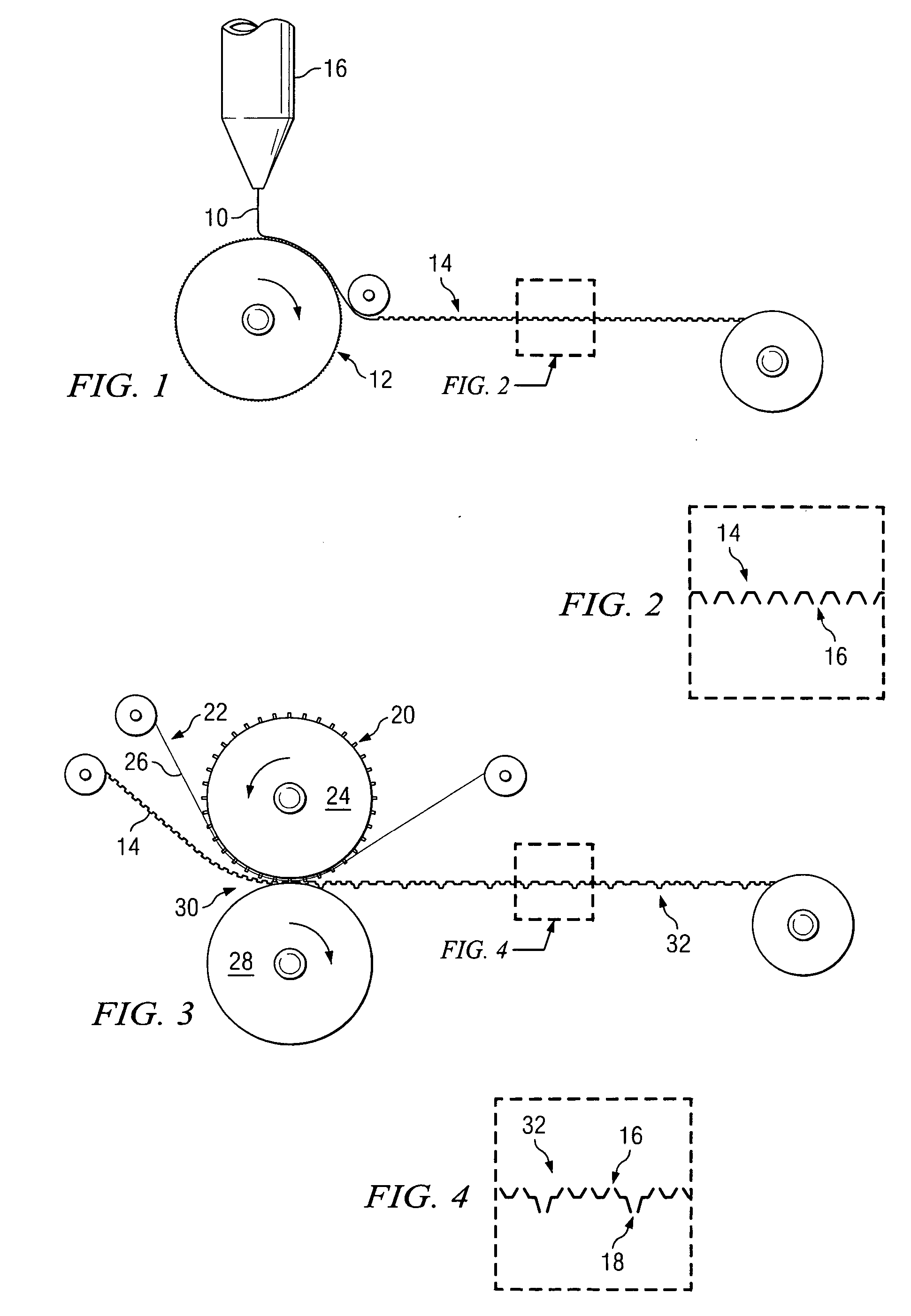

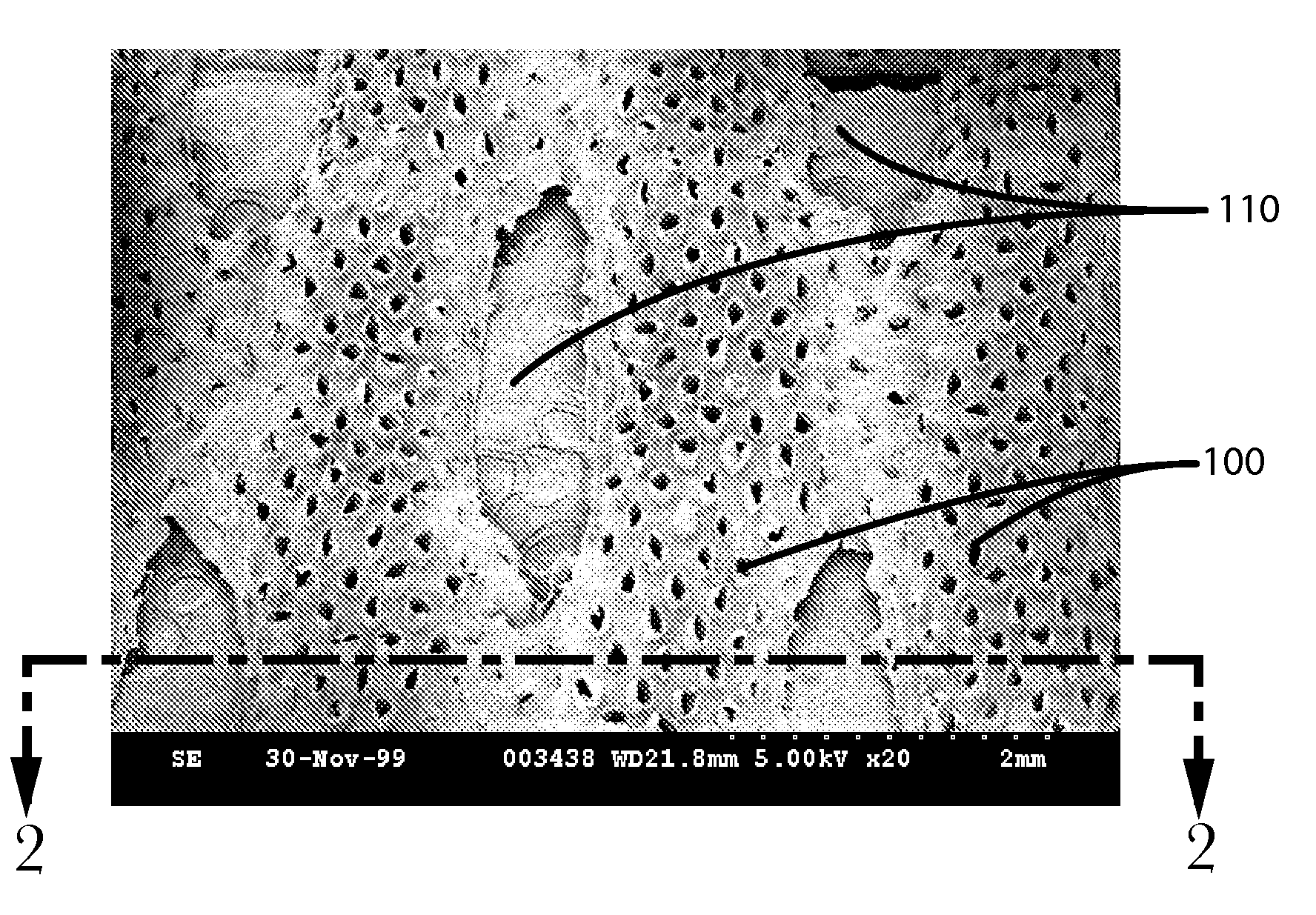

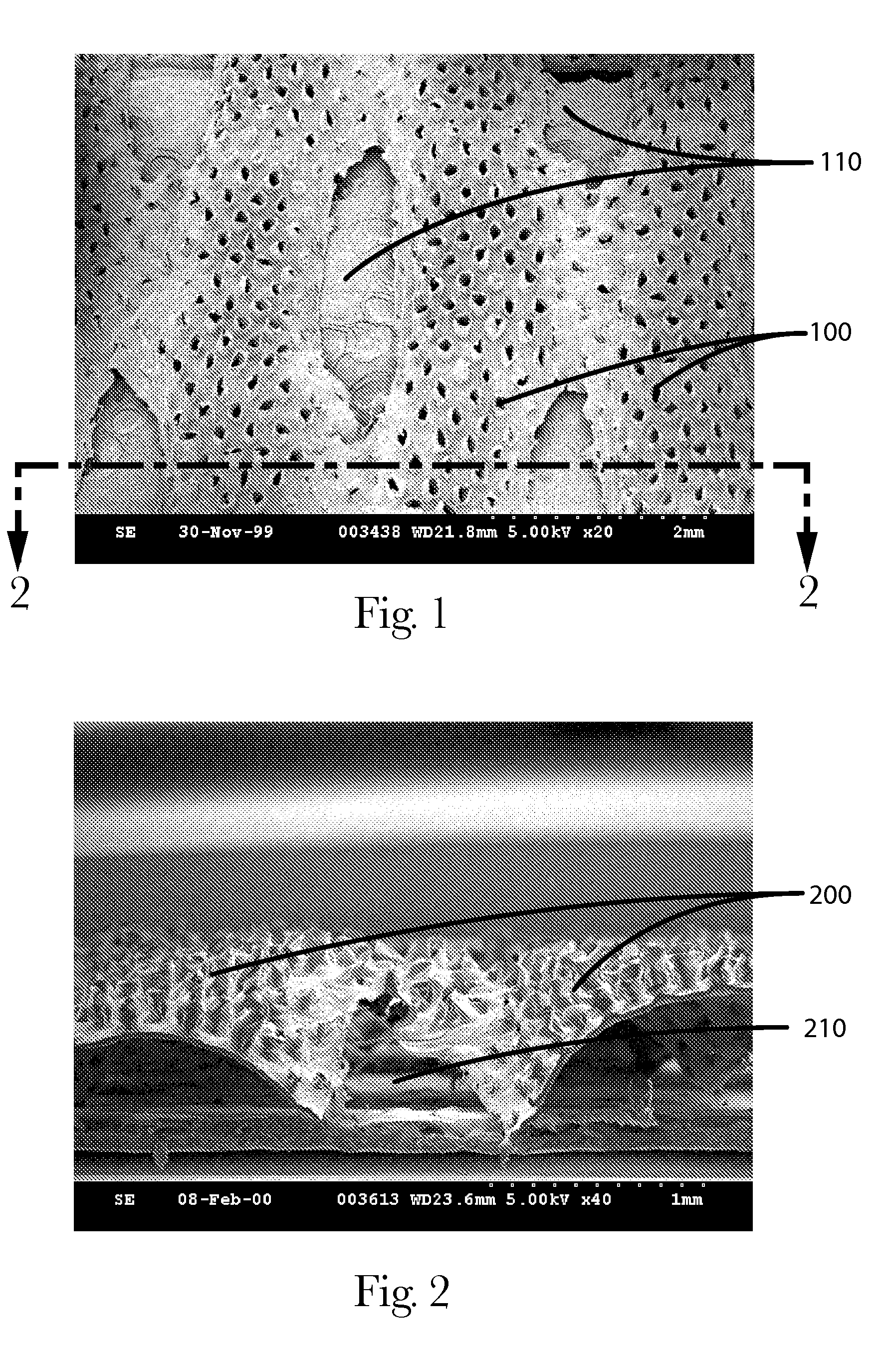

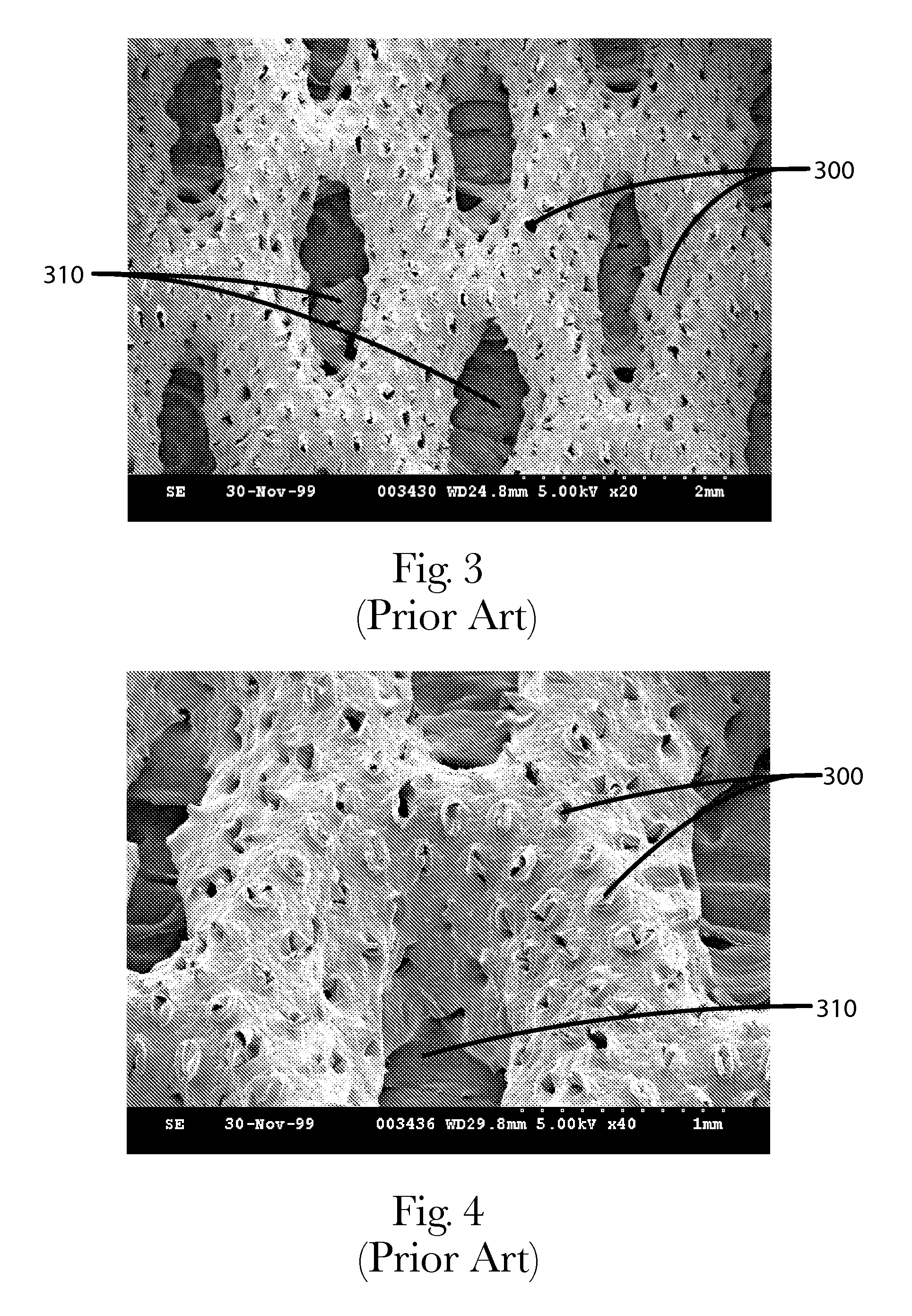

Apertured material for use in absorbent articles and method of making the same

Owner:TREDEGAR FILM PROD CORP

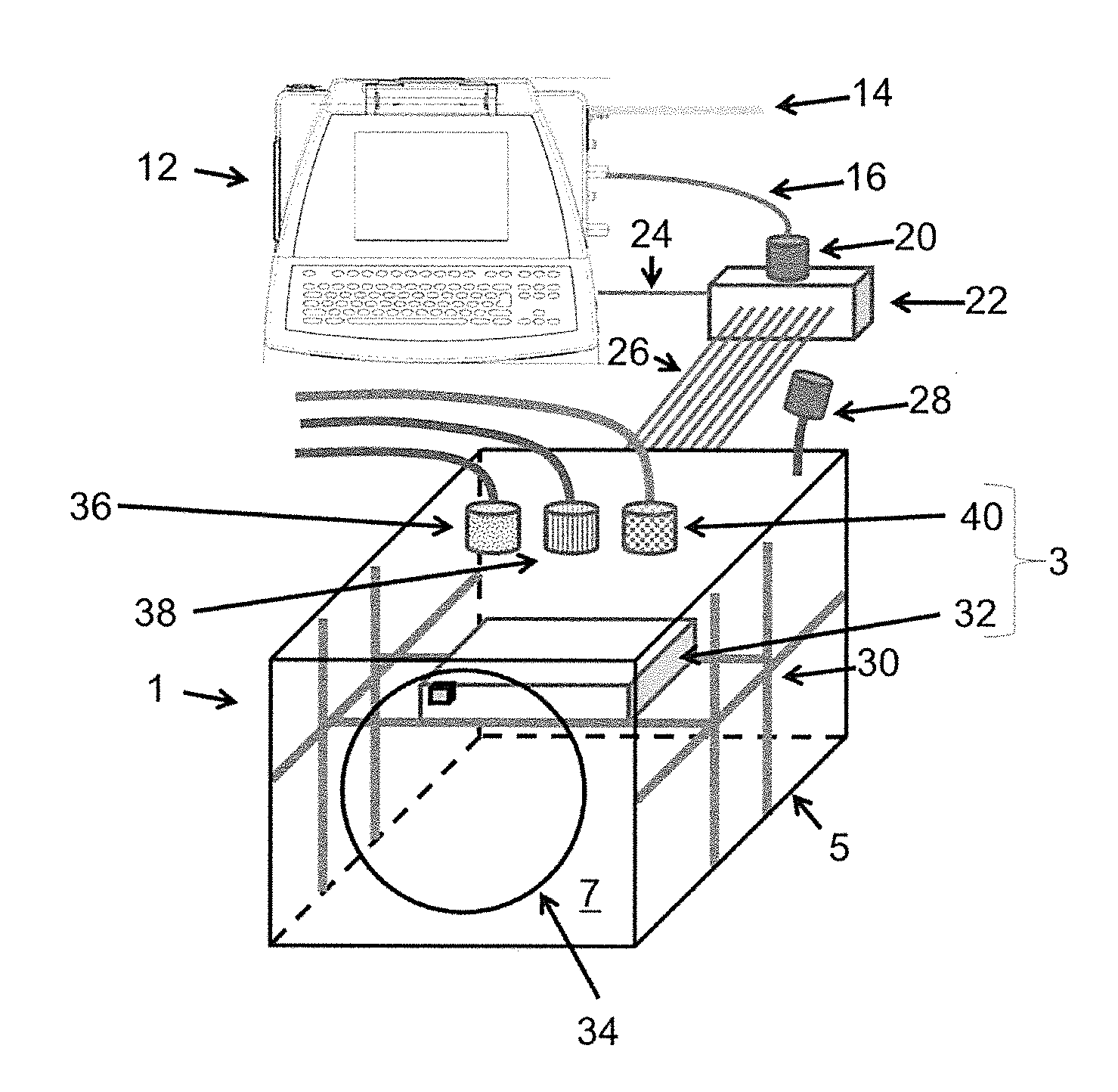

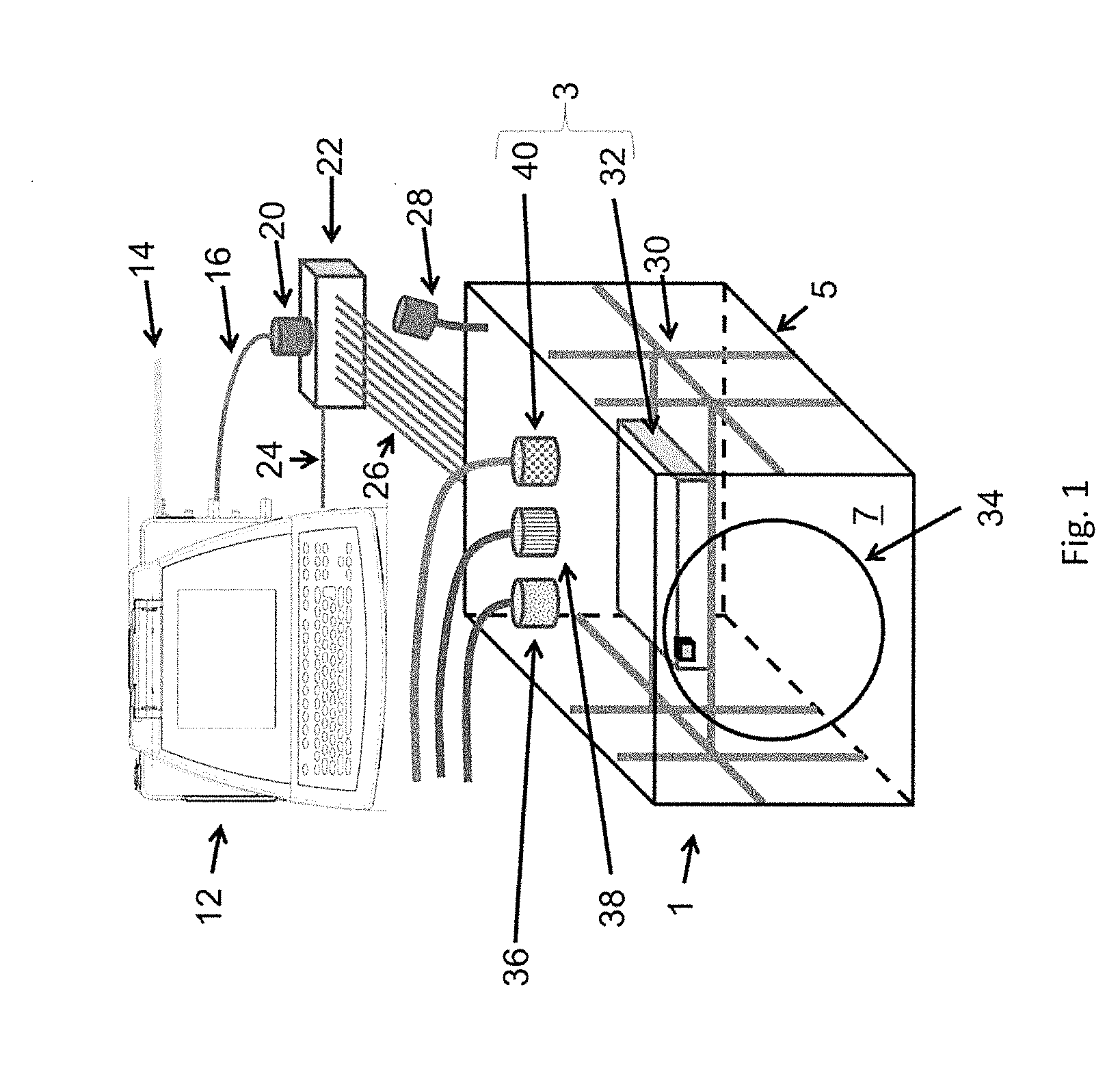

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

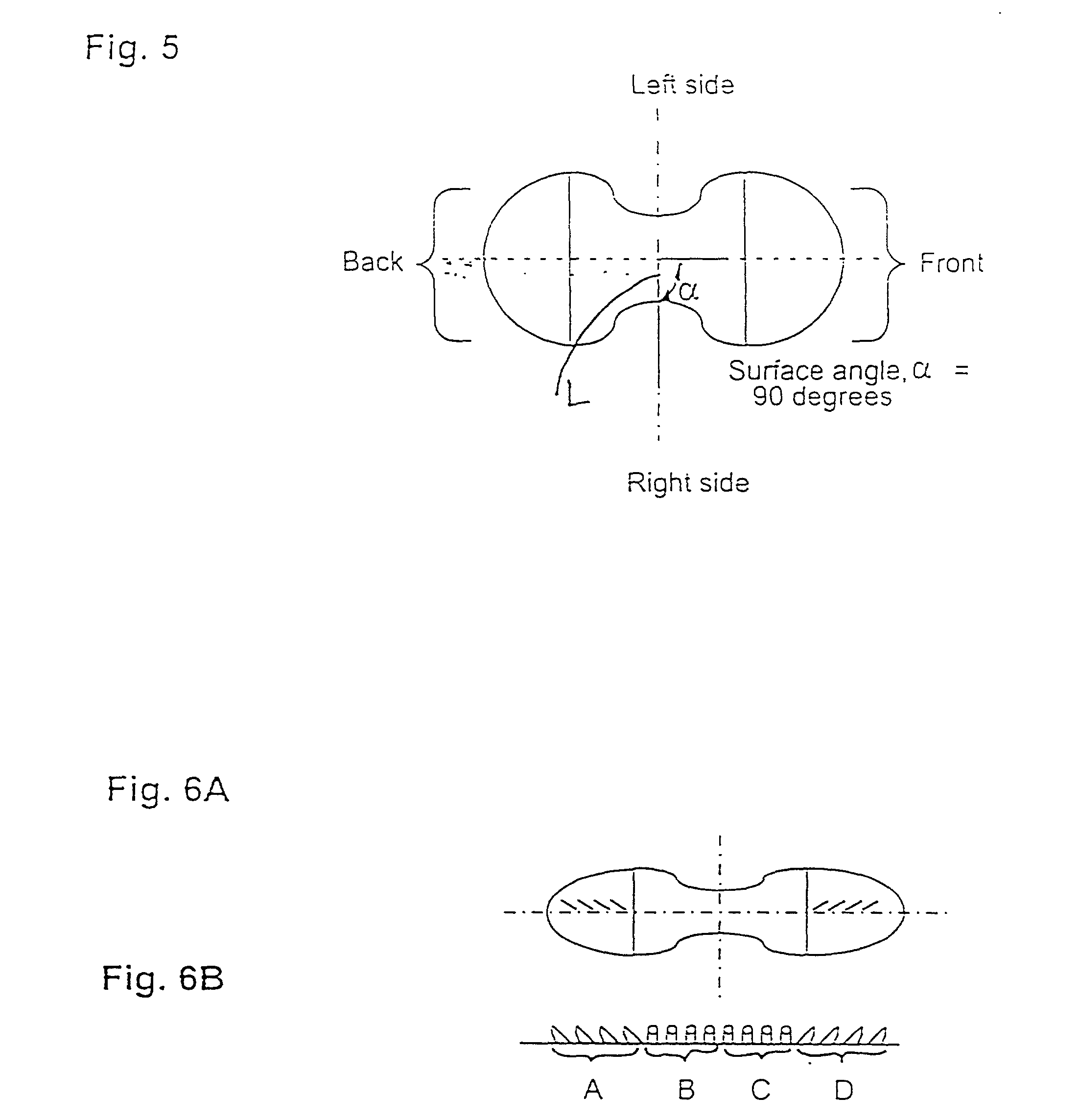

Absorbent article with a response surface

InactiveUS20020133132A1Improve the immunitySimple structureLayered productsSanitary towelsHydroformingBody fluid

A breathable absorbent article has at least one of a topsheet, an absorbent core, an optional distribution layer or a backsheet that comprises at least one to layer of a resilient, three dimensional liquid impervious polymeric film having apertures. The apertures form capillaries which are disposed at multiple directions, and / or have different diameters and lengths to create a response surface that is proportional to the pressure applied by the user's body, volume distribution of bodily fluid discharged by the user, the location of the discharge with respect to the position of the article, or a combination thereof, while the article is in use. The polymeric film can be formed by various processes, for example, vacuum forming or hydroforming methods.

Owner:TREDEGAR FILM PROD CORP

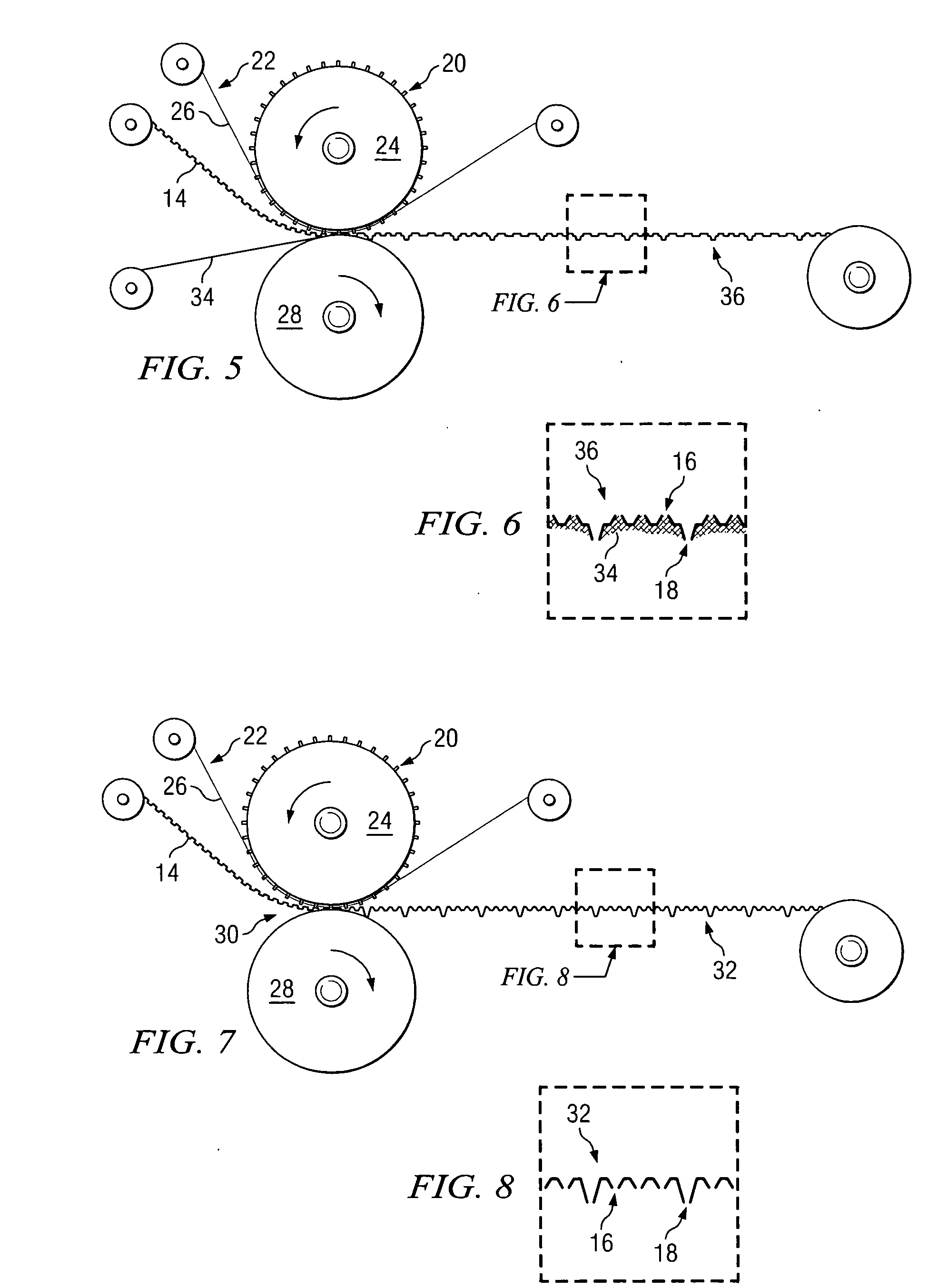

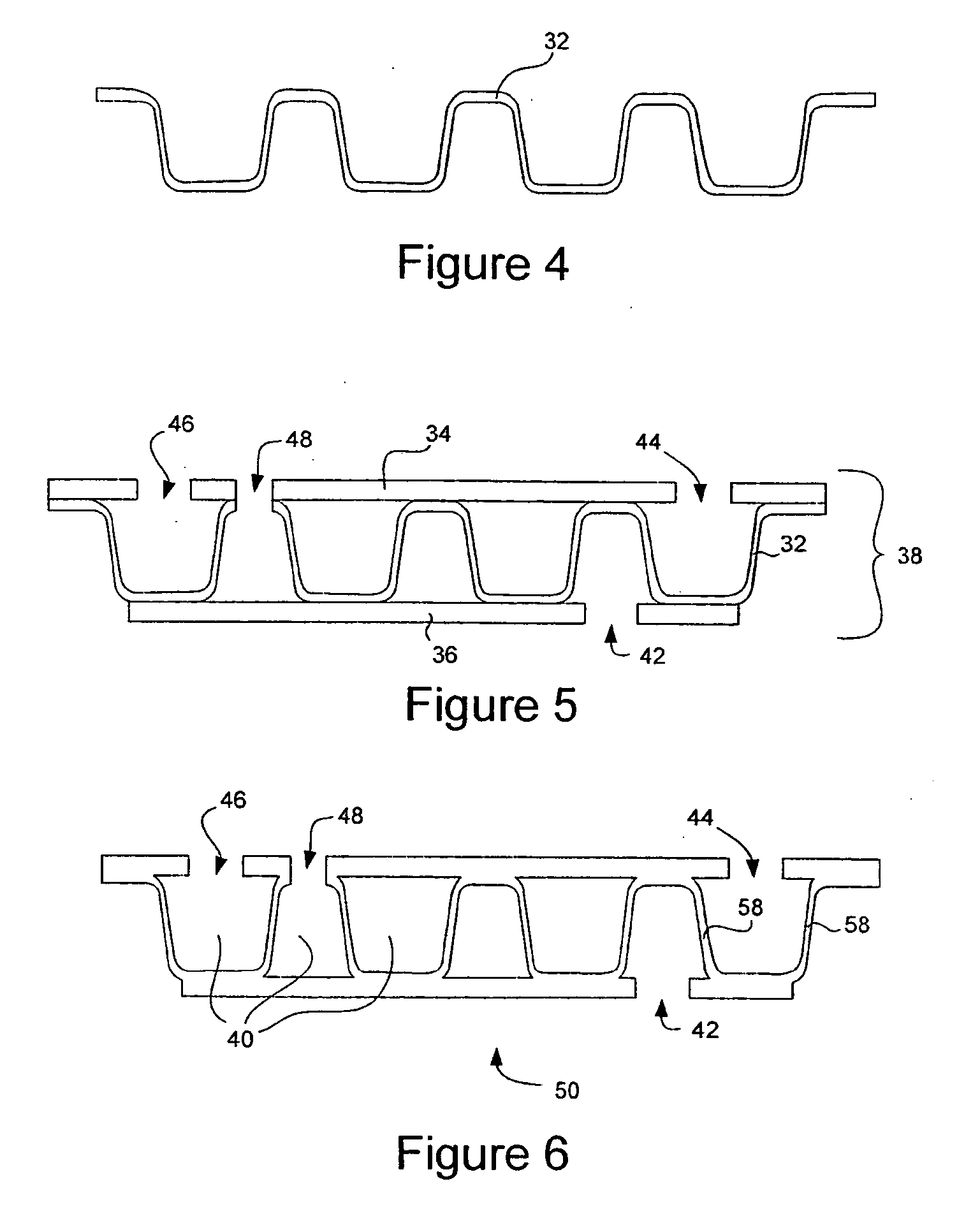

Apertured polymeric film webs and absorbent articles using such webs

A method for making an apertured polymeric film web, the method comprising the steps of:a. providing a polymeric film web;b. providing a first process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, flocking, ultrasonics, printed hair, brushing, and combinations thereof;c. providing a second process, different from the first process, the second process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, ultrasonics, stretch rupturing, hydrocutting, hydrosonics, slitting, ring-rolling, and combinations thereof;d. forming three dimensional surface structures in the polymeric film web by the first process; ande. forming fluid transport apertures in the polymeric film web by the second process.

Owner:THE PROCTER & GAMBLE COMPANY

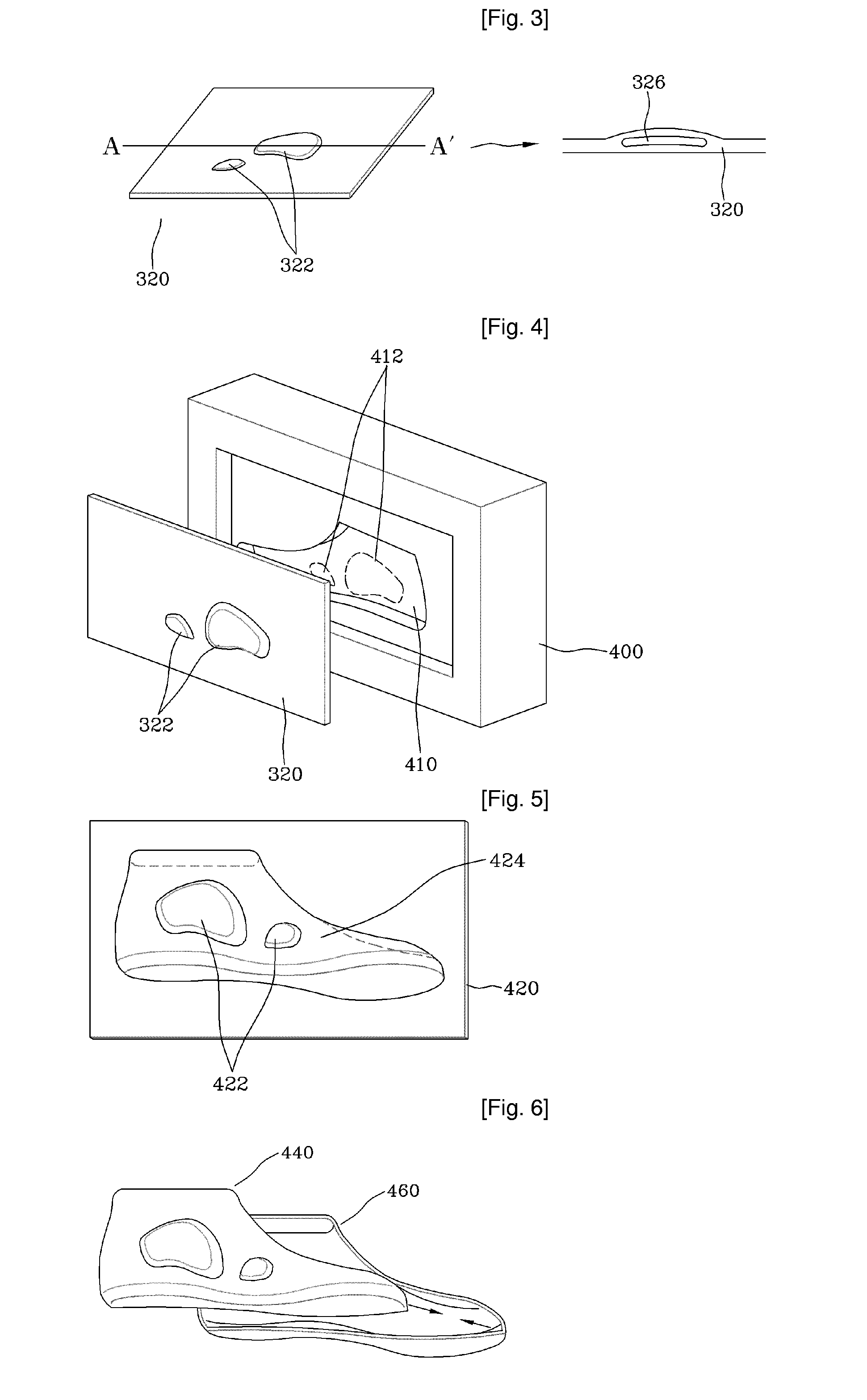

Method for forming footwear structures using thermoforming

Footwear and footwear structures are provided as well as methods for forming composite components for footwear or footwear structures. In forming the structures, two material layers are overlaid such that the two material layers are in contact with one another. The two material layers are heated to a forming temperature and are then vacuum-formed together to form a composite material layer in a three-dimensional form of the footwear structure. A provided footwear structure includes an upper and a sole assembly attached to the upper. The sole assembly includes a first material layer made of a thermoplastic, and a second material layer attached to the first material layer. The first material layer includes a recessed area including a flat support portion, and is transparent or translucent. The second material layer includes a portion that is positioned on a surface of the recessed area, and a color of the second material layer indicates a location and / or a function of the second material layer.

Owner:POLYWORKS

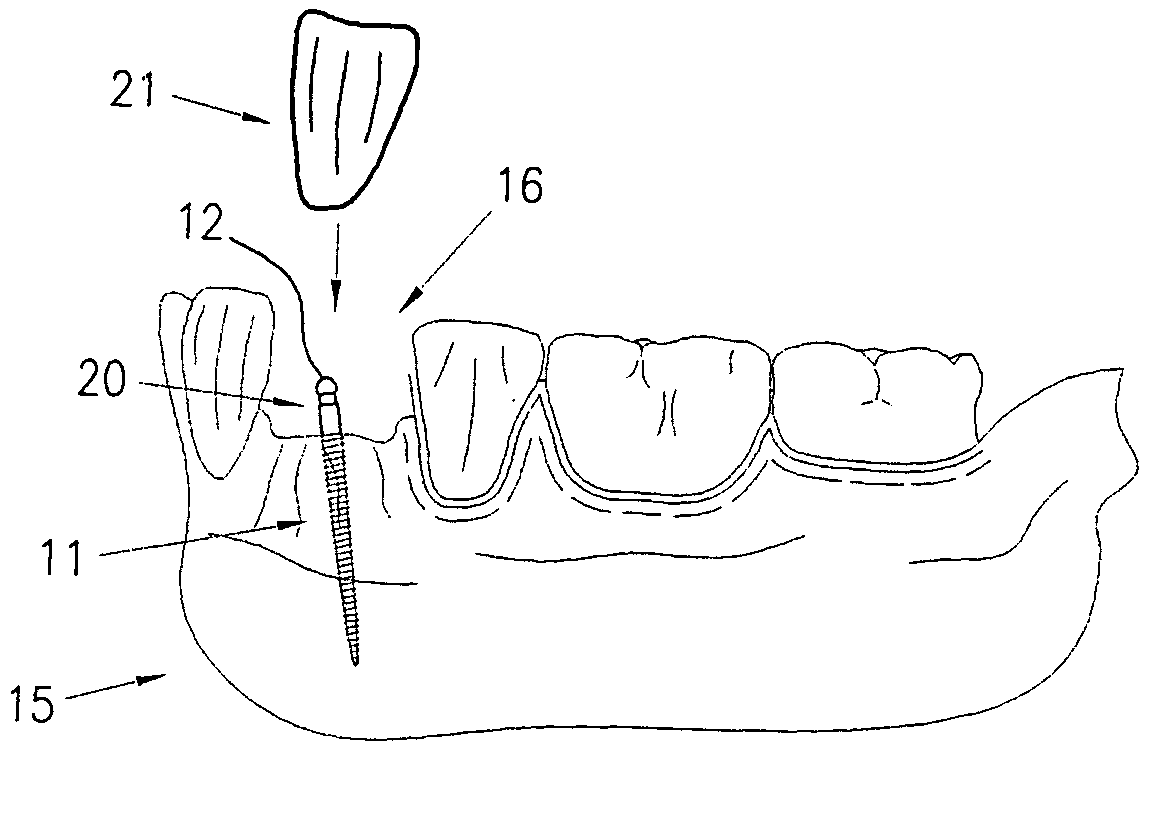

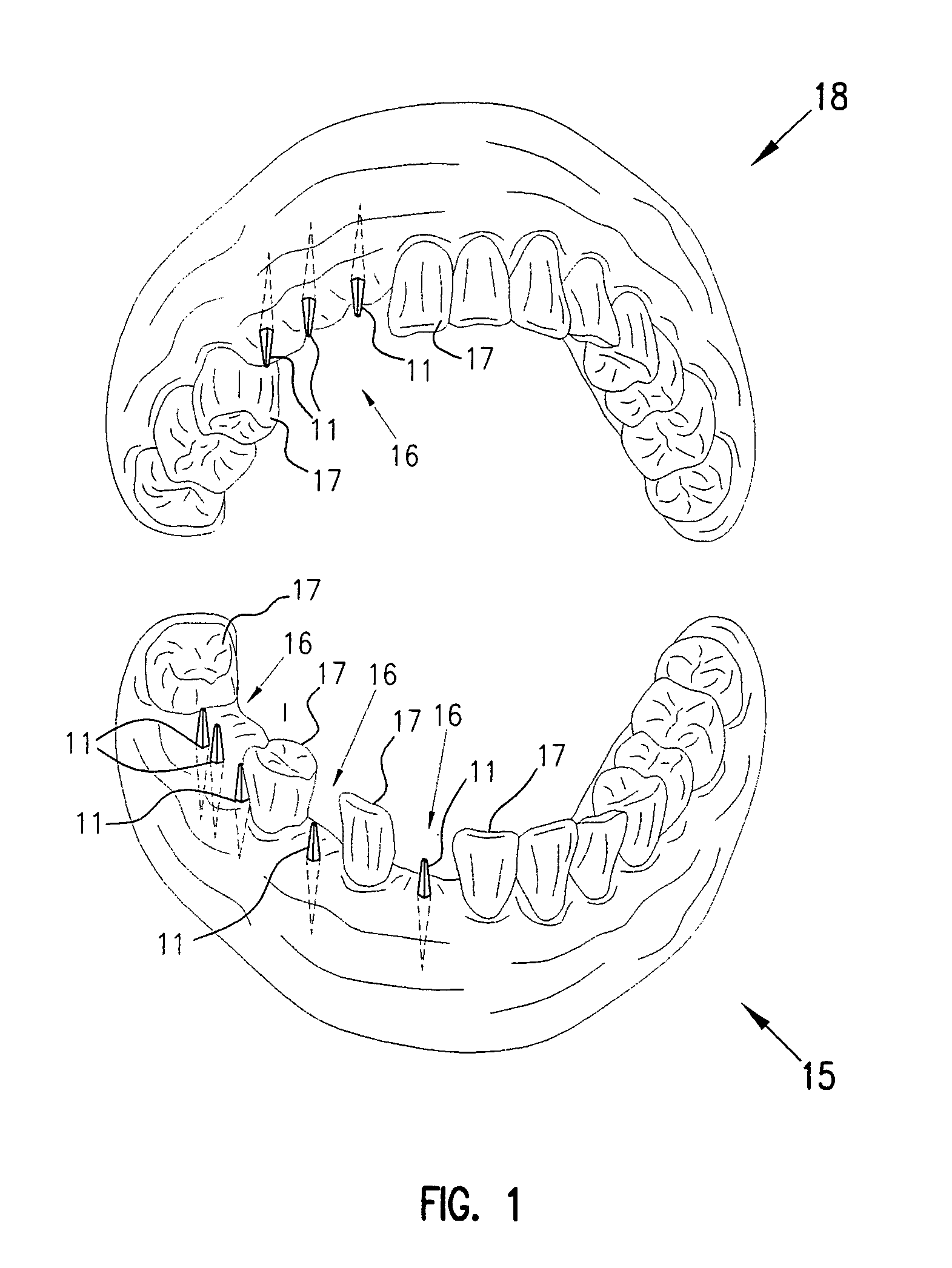

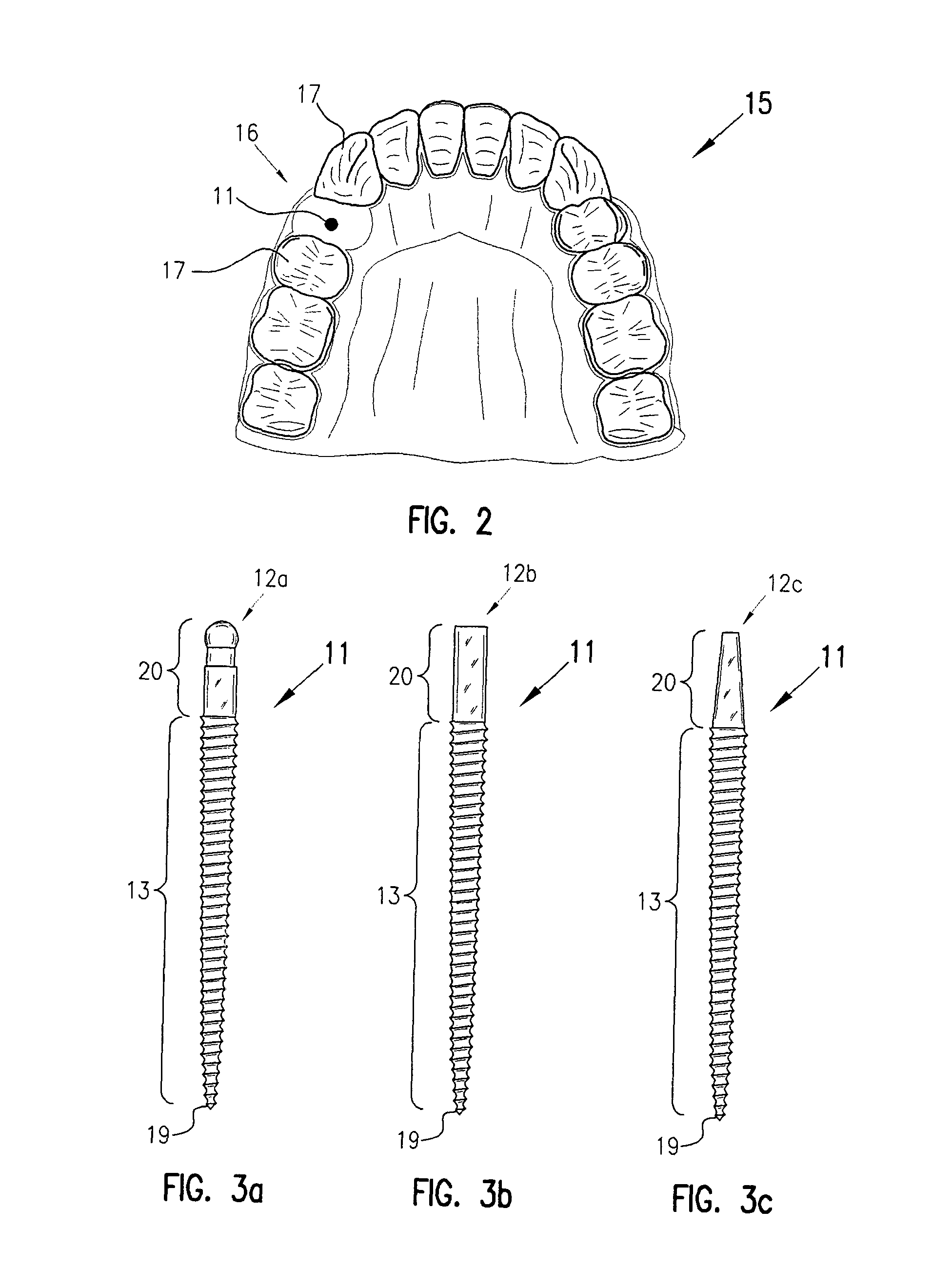

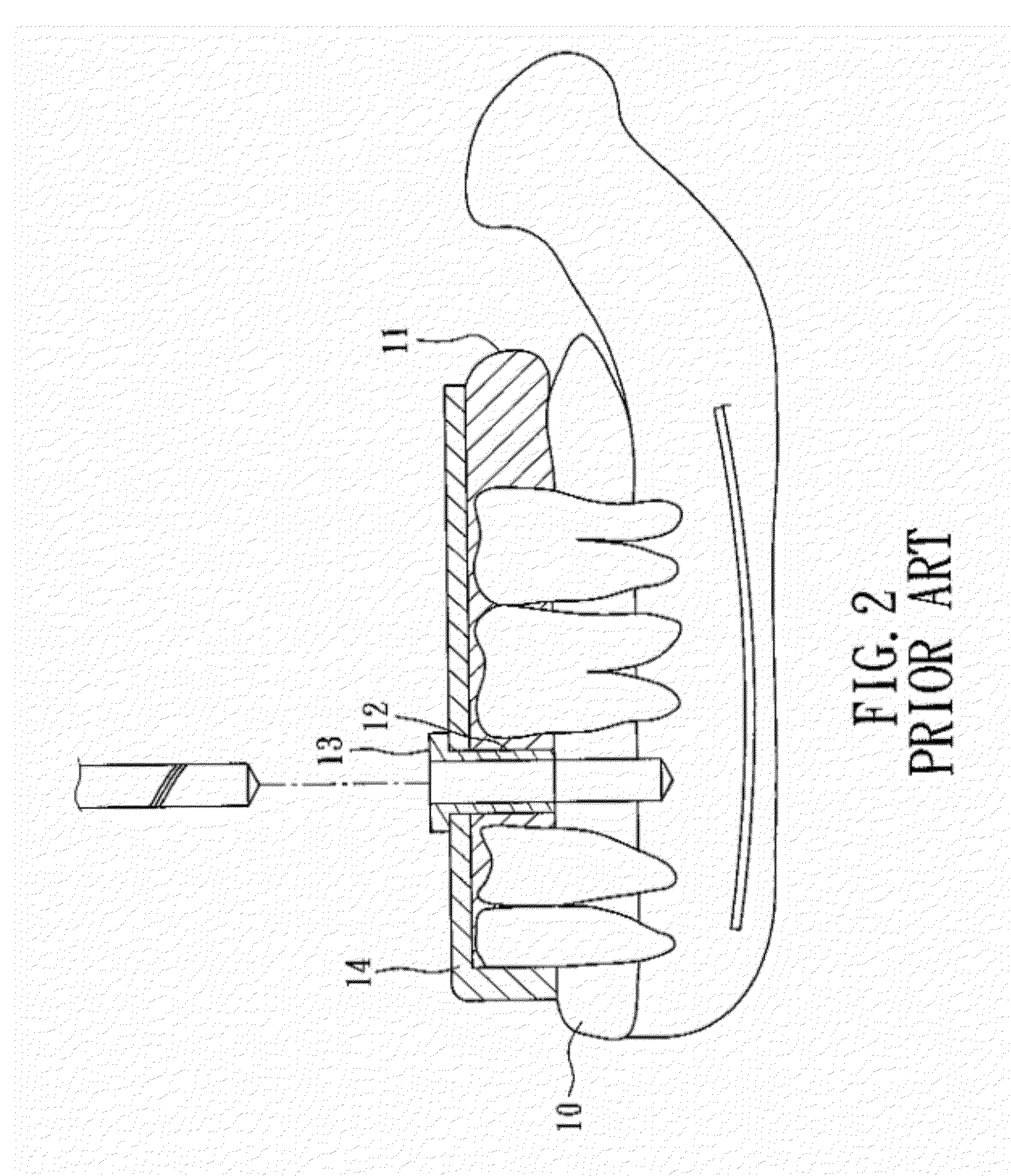

System of dental restoration of single stage dental implants and loading with a preformed crown restoration

The present invention is prosthetic tooth replacement including a dental crown portion and a joining portion adapted to fixedly attach to a dental implant. Further, present invention also comprises the combination of a prosthetic tooth replacement and a dental implant. Additionally, the present includes a method for making an oral surgical guide stint by vacuum forming a thermoplastic material over a model of an implant target area. Finally, the present invention includes a method of inserting the combination of the prosthetic tooth replacement and implant into the jaw of a patient.

Owner:SHATKIN TODD E

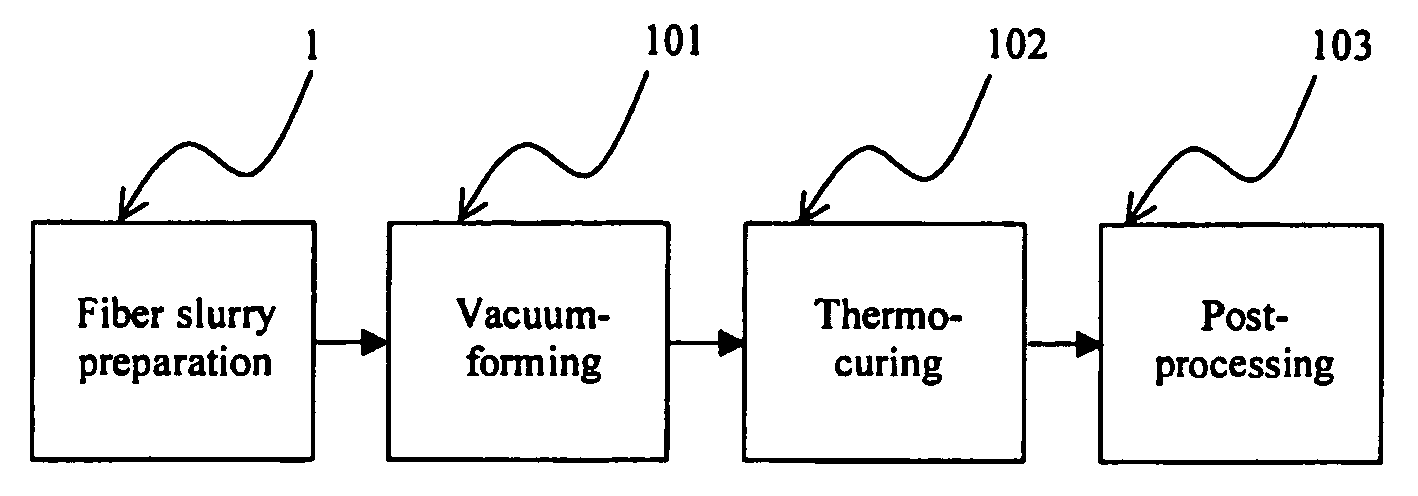

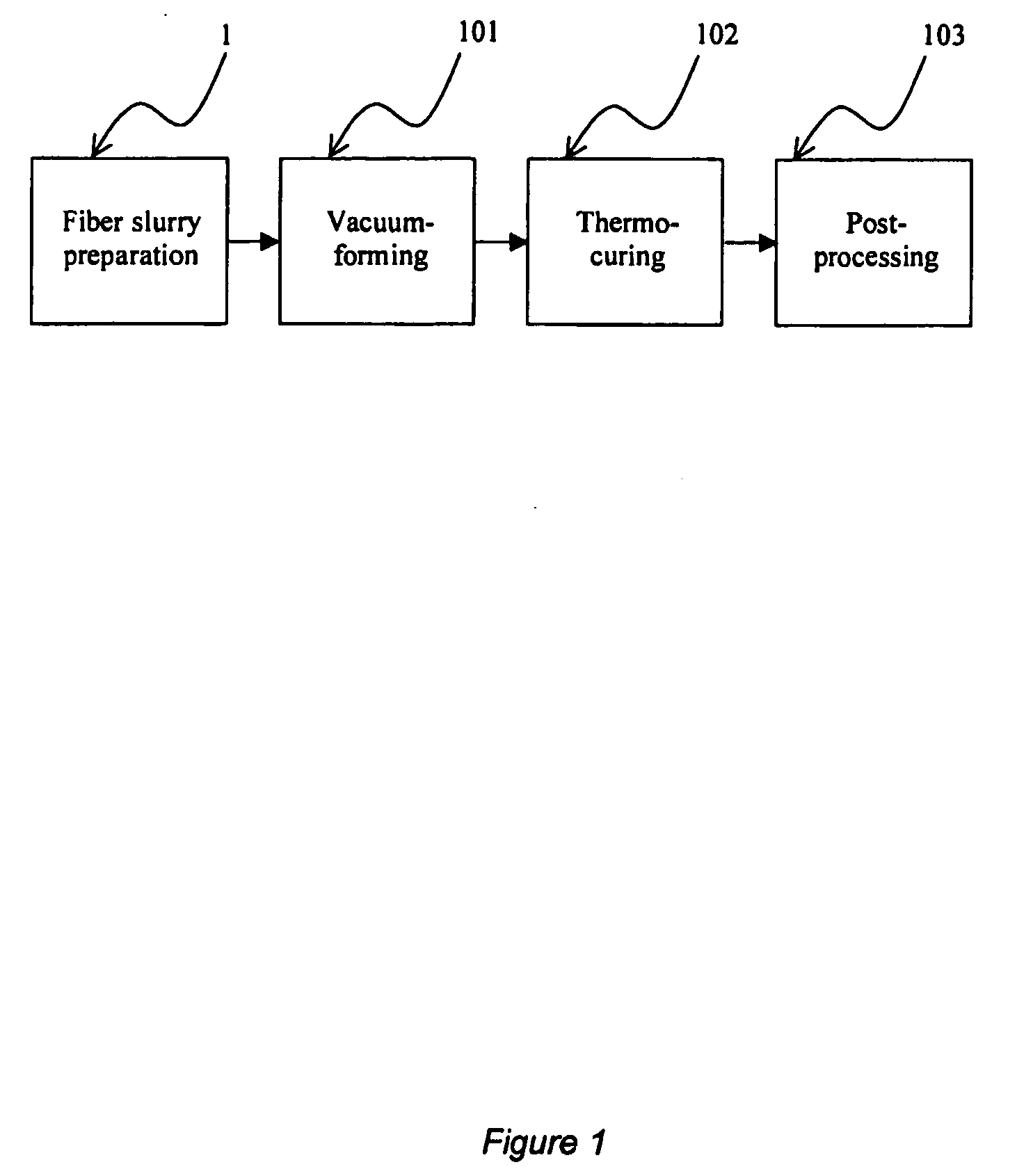

Molded fiber manufacturing

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

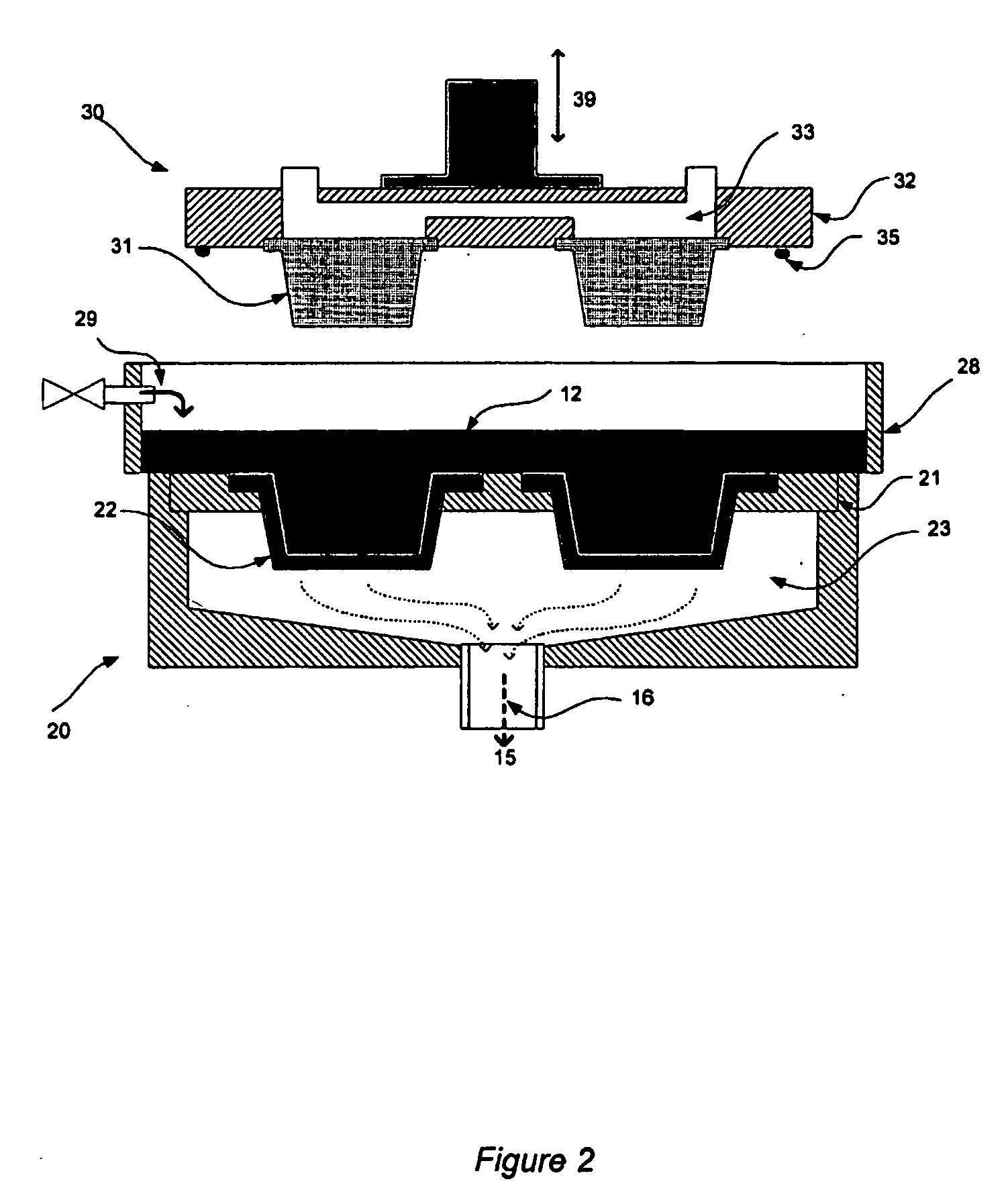

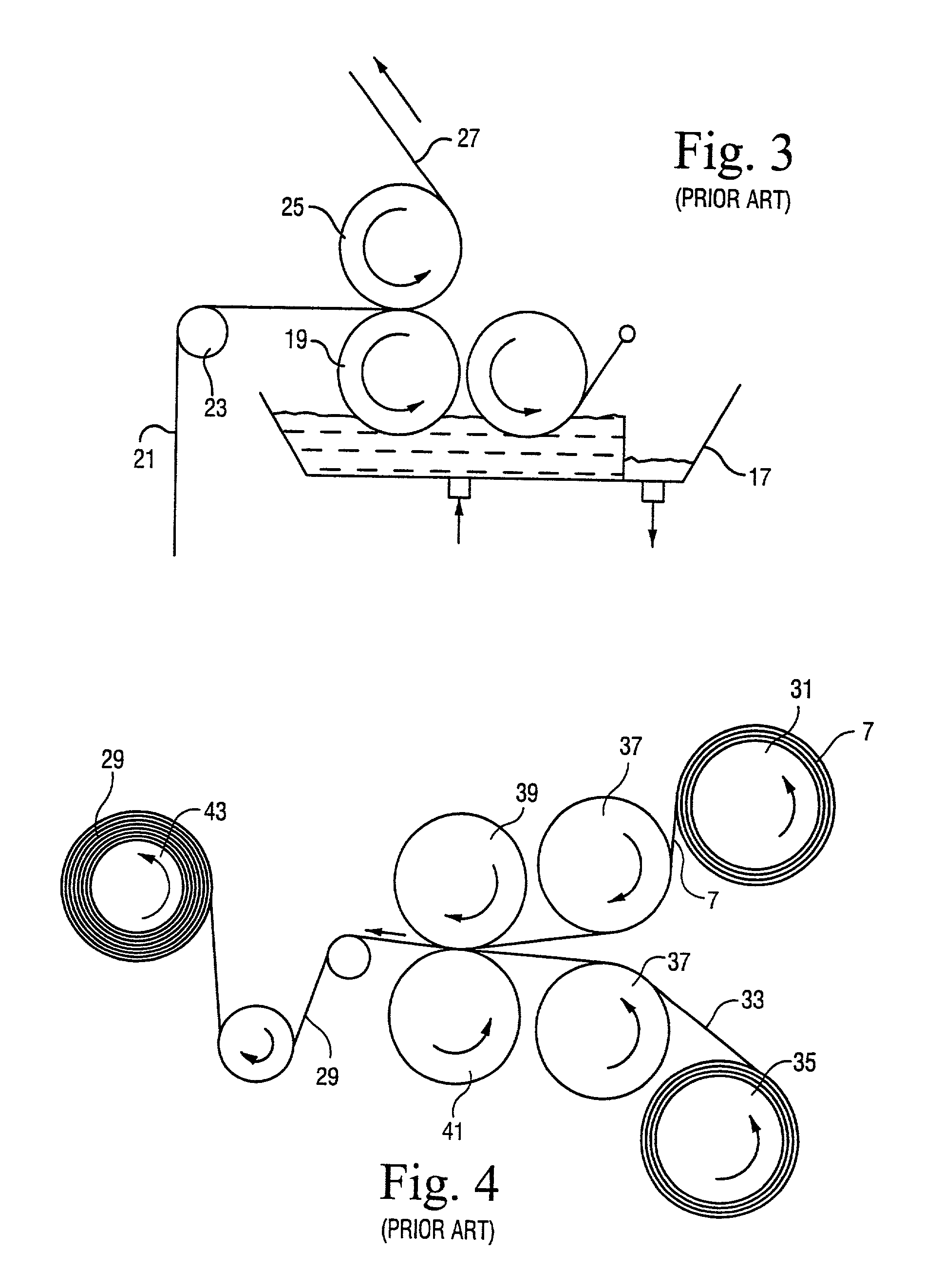

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

Polyester film

ActiveUS20070009750A1Poor producibilityHigh production costFlexible coversWrappersPolyesterIngested food

[Problems] The present invention provides a-polyester-film superior in heat resistance, chemical resistance, insulation property and thermal dimensional stability, and suitable for application to fields associated with boiling or retort treatment, which require tenacity, pinhole resistance, bending resistance, bag breakage resistance on dropping, impact resistance and the like, fields requiring thermoforming or vacuum forming, and various uses such as packaging bags for water-containing food, pharmaceutical products and the like. [Solving Means] The polyester film characteristically shows an initial elastic modulus in at least one direction of 2.5-10 GPa, an impact strength of 40-10000 J / mm, a thermal shrinkage in at least one direction at 150° C. of −0.5% to 6%, a haze of 0.001% to 7%, and an absolute value of the difference in the thermal shrinkage between the longitudinal direction and the transverse direction of not more than 1.1%.

Owner:TOYO TOYOBO CO LTD

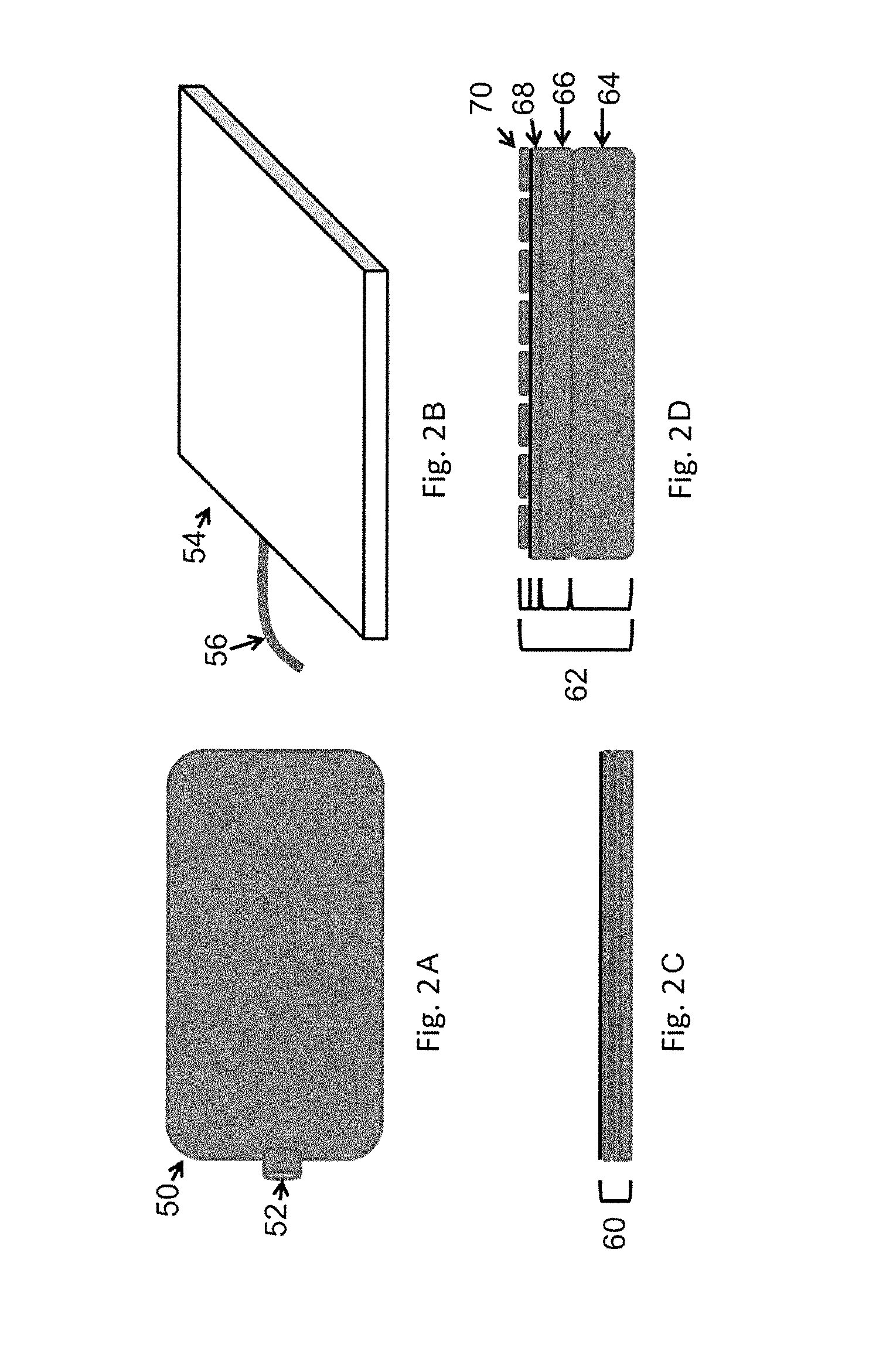

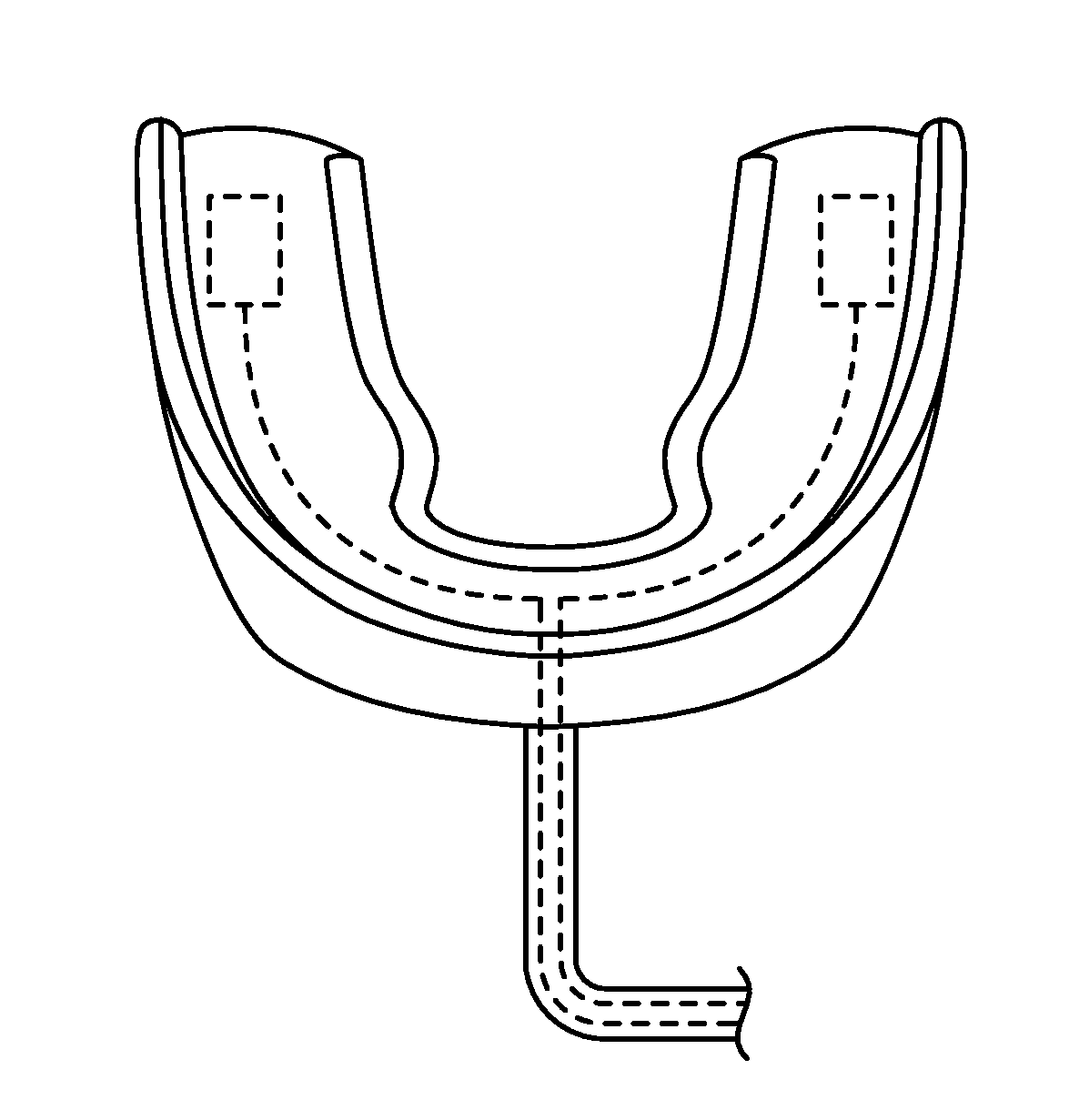

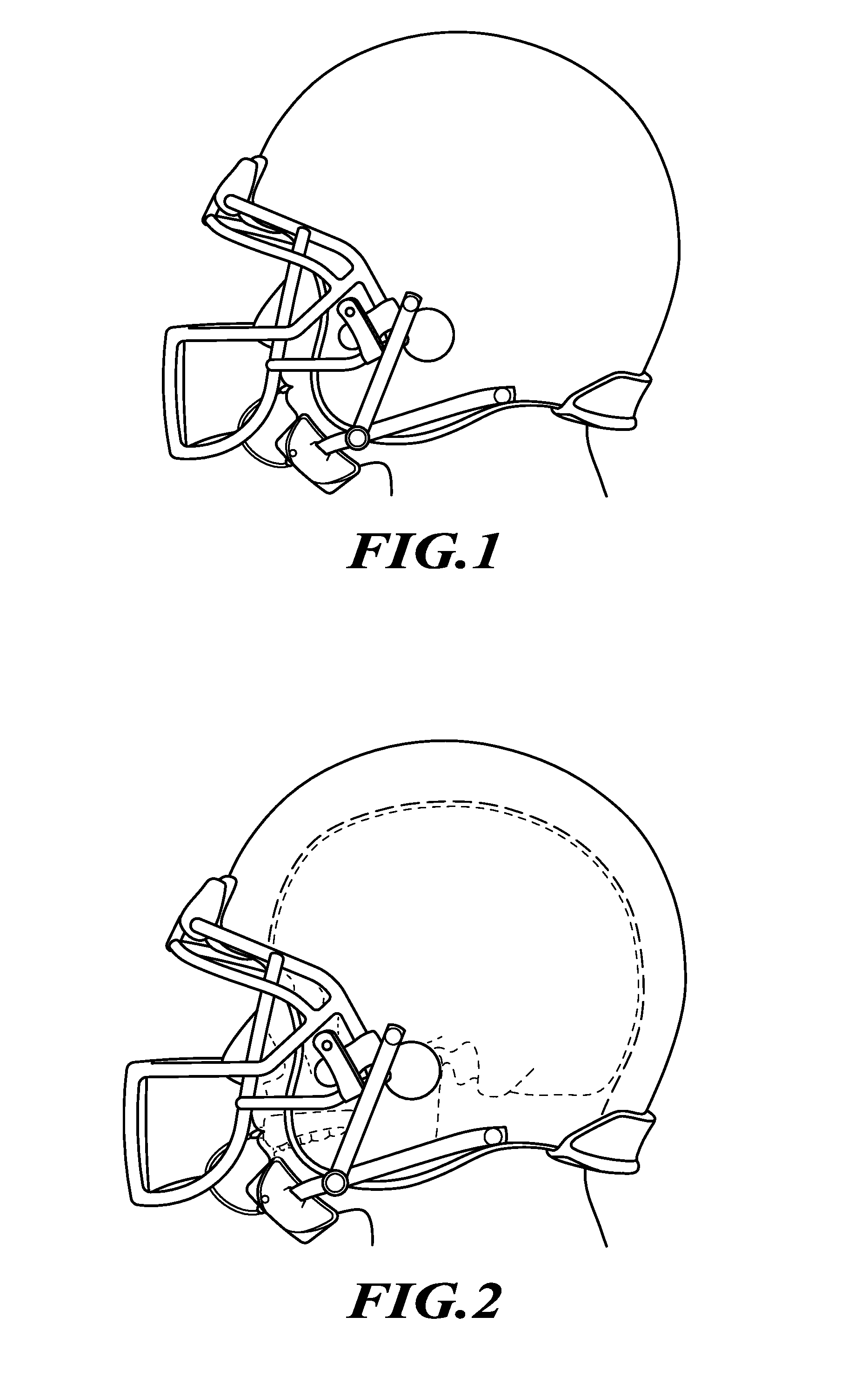

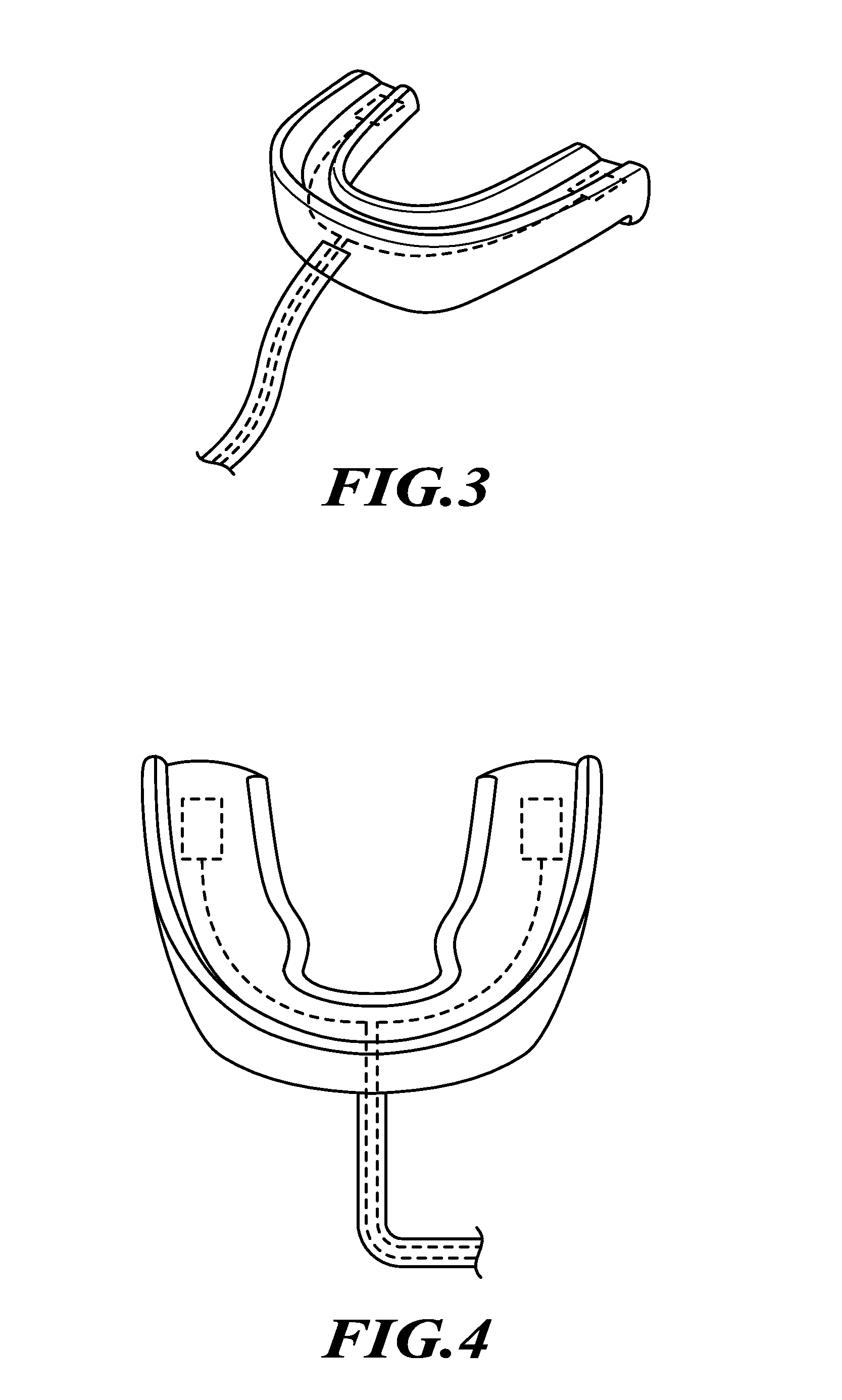

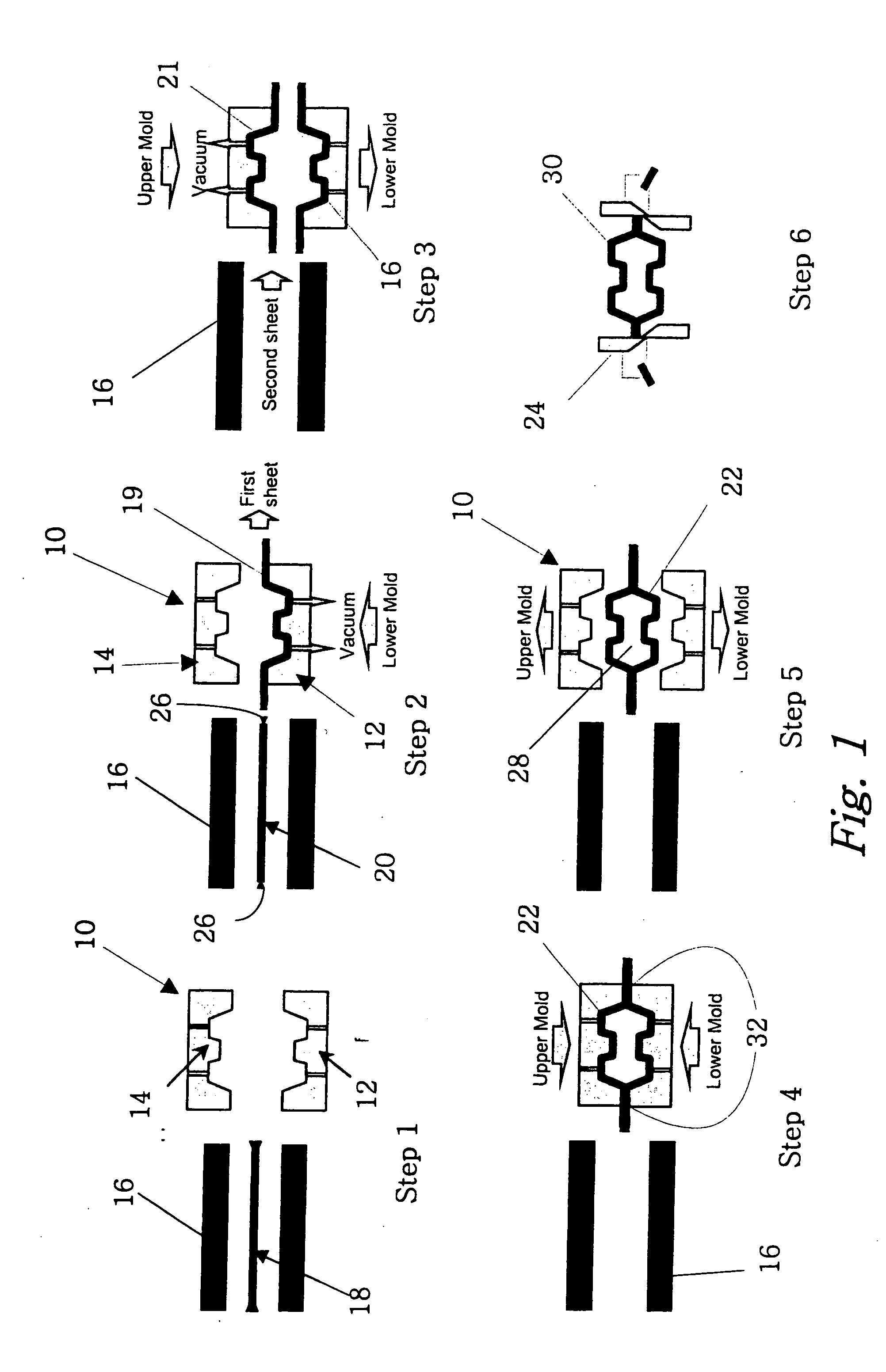

Mouth guard formation methods

A method for producing a mouth guard having an encapsulated sensor module. The method includes vacuum forming a first sheet of thermoplastic material using a mold to produce a first mouth guard layer, attaching a sensor module to the first mouth guard layer with a hot melt adhesive, vacuum forming a second sheet of thermoplastic material over the sensor module to produce a second mouth guard layer, storing a default threshold level in the sensor module, and calibrating the sensor module to account for sensor alignment. In an example embodiment, the first and second layers are formed such that they define an open area that allows a user's tongue to touch their upper palate after the mouth guard has been inserted and such that the layers define a channel for accepting a plurality of teeth, including the incisors of a user.

Owner:PREVENT BIOMETRICS INC

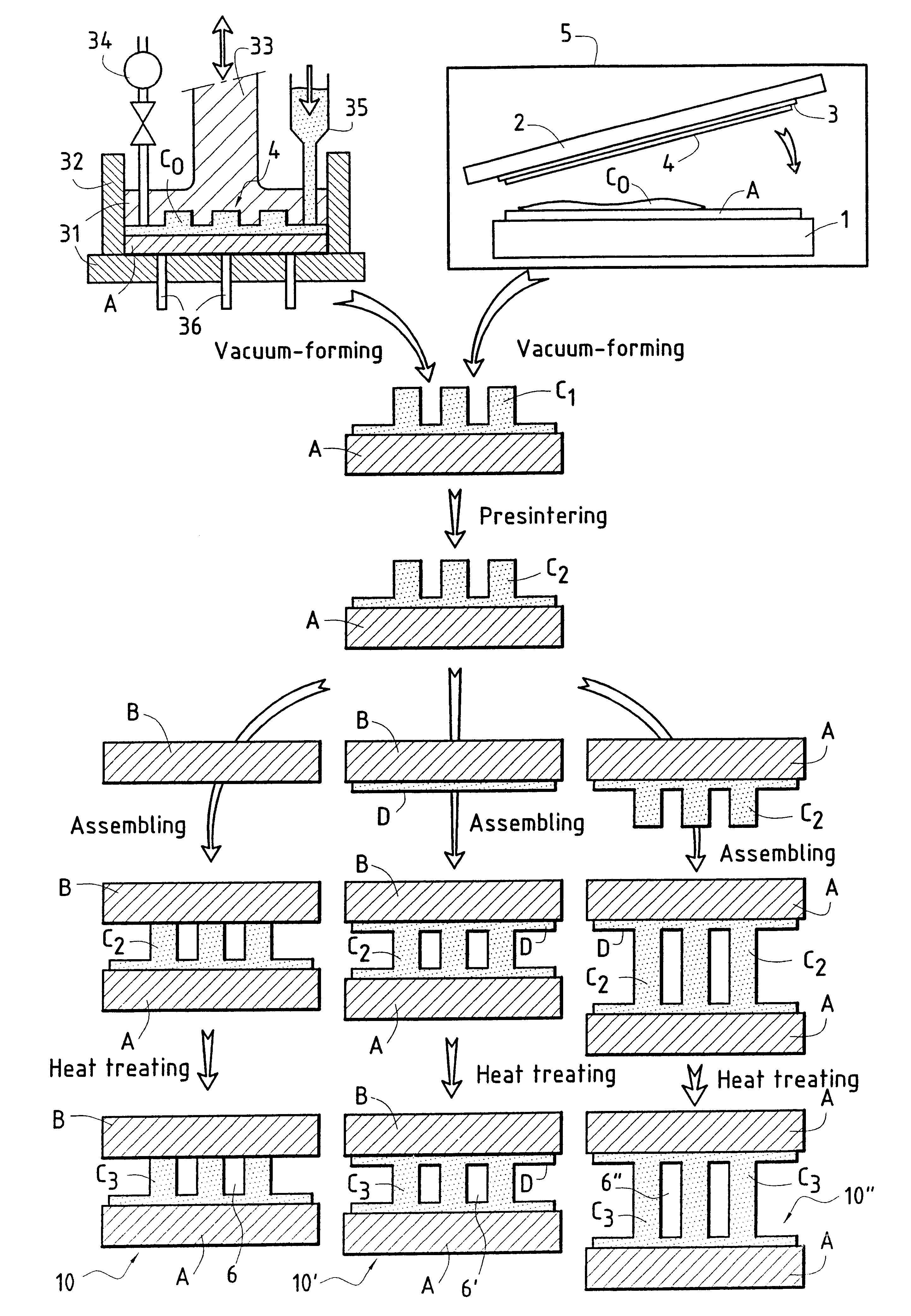

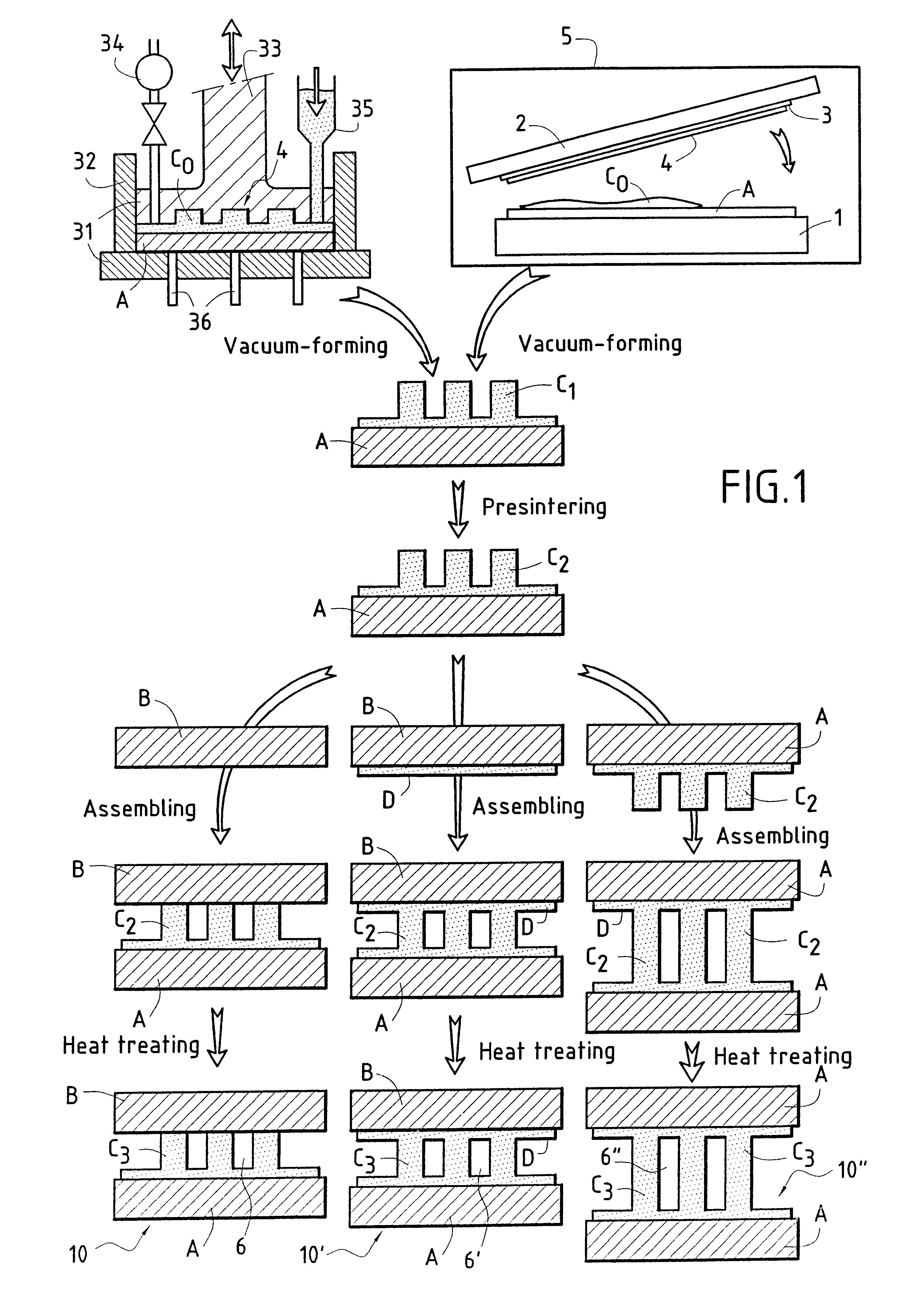

Microfluidic device and manufacture thereof

InactiveUS6595232B2Low cost productionHigh yieldVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsEngineeringGlass-ceramic

The present invention relates to microfluidic devices and to their method of manufacture. The microfluidic devices are original by their specific structure (of sandwich type) and by the materials from which they are made (mainly glasses, glass ceramics, ceramics), and also by their specific method of manufacture, which is based on a vacuum-forming operation. The microfluidic device includes a first assembly including a microstructure and a first substrate, wherein the microstructure is constructed and arranged on the substrate under vacuum. A second assembly includes a second substrate positioned on the microstructure after the first assembly is presintered and adhered thereto by heat treatment to form a one-piece microstructure defining at least one recess between the first and second substrates.

Owner:CORNING INC

Custom 3-D Milled Object with Vacuum-Molded 2-D Printout Created from a 3-D Camera

A 3D copy of a 3D subject is made by combining a 3D custom milled shape and a 2D printed 2D image sheet molded to the contours of the 3D custom milled shape. A 3D camera captures 3D details of the 3D subject and also captures a multi-color 2D image of the 3D subject. The 3D camera outputs a geometry file to a CNC milling machine that cuts a milling blank to make a custom milled shape. The 3D camera also outputs a 2D image file to a personal computer that prints the 2D image onto a plastic sheet. The custom milled shape is placed as a mold on a vacuum-forming machine. The plastic sheet is aligned to the custom milled shape and heat and vacuum pressure applied. The 2D image is molded into the 3D shape of the custom milled shape.

Owner:TSENG TAN

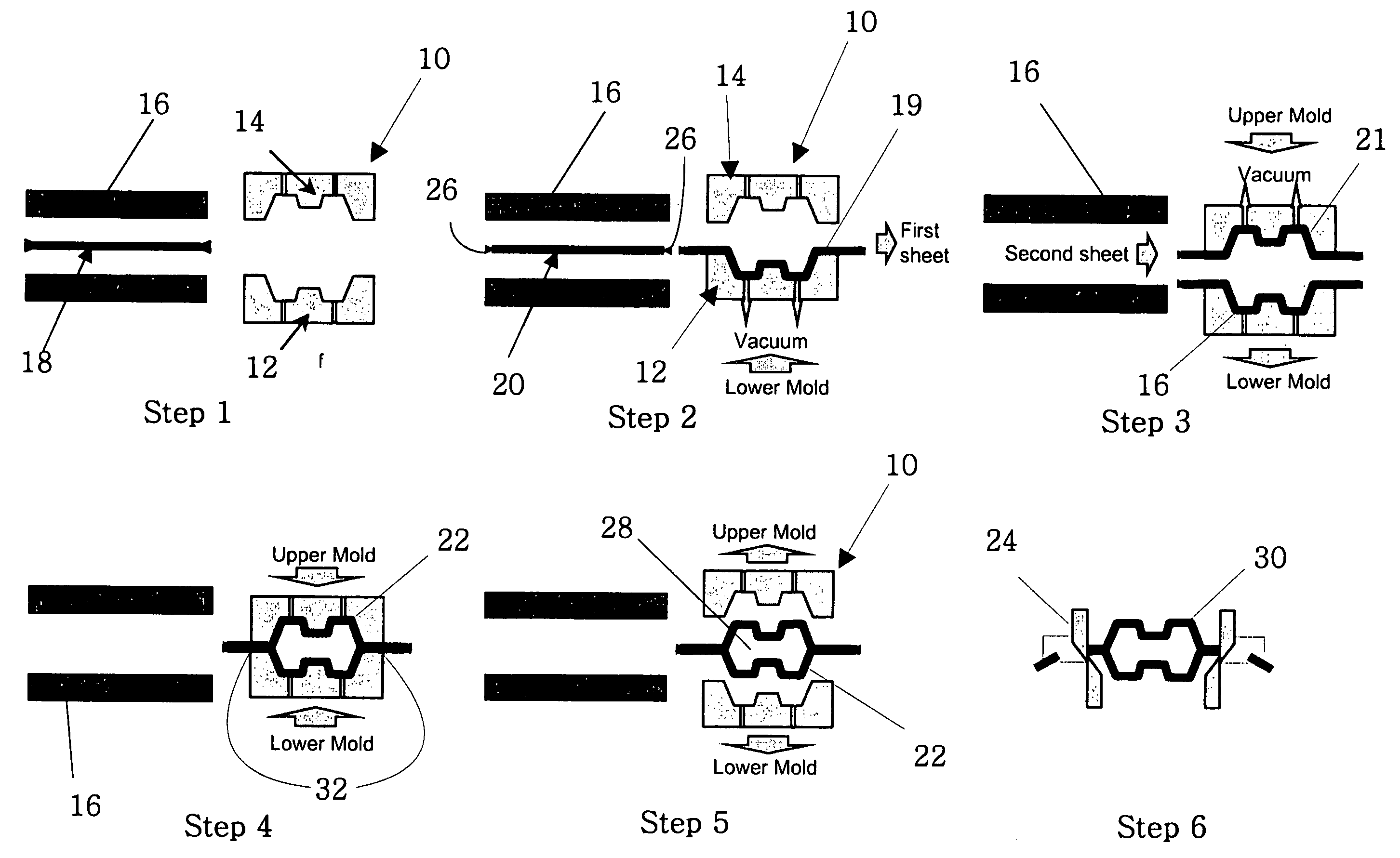

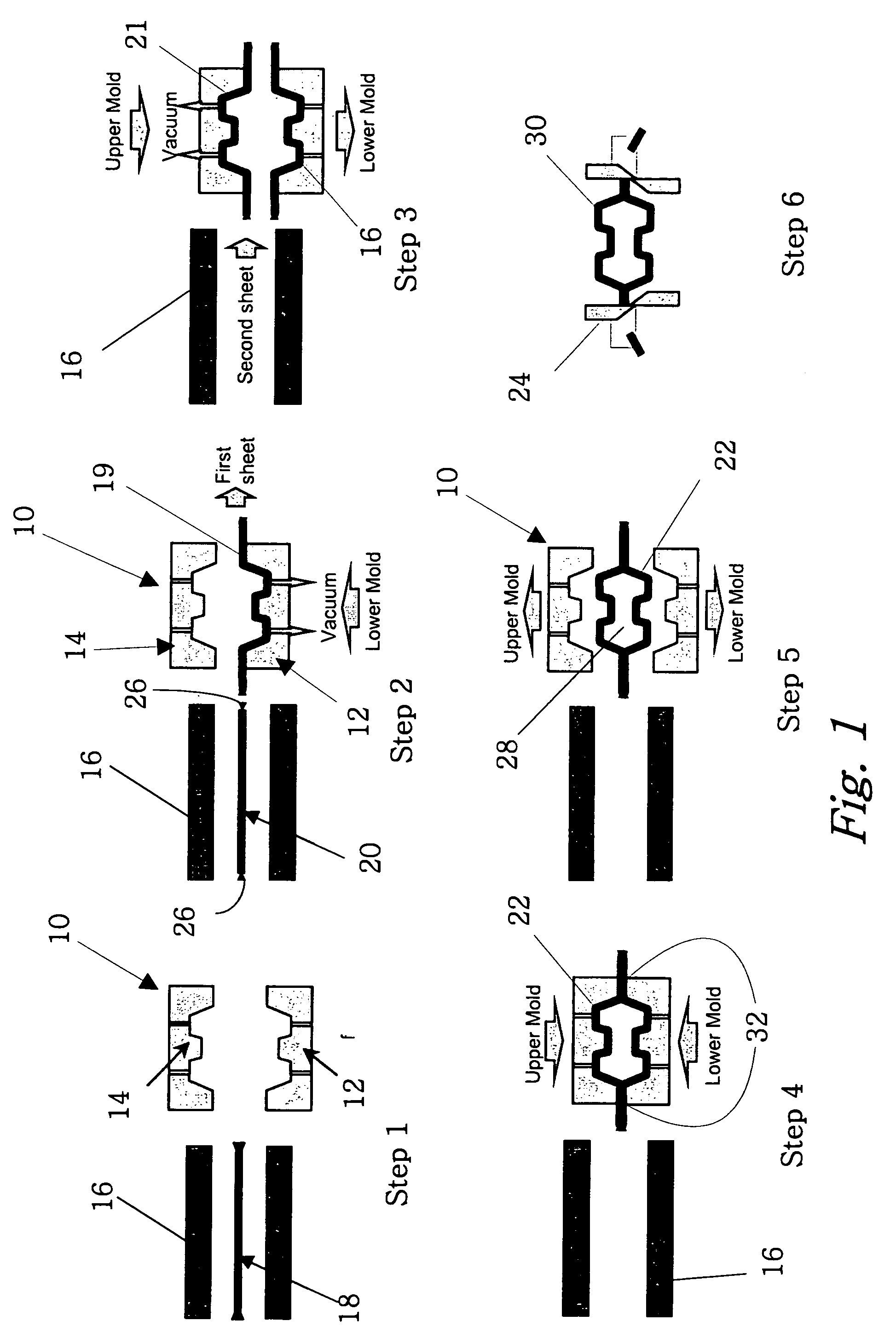

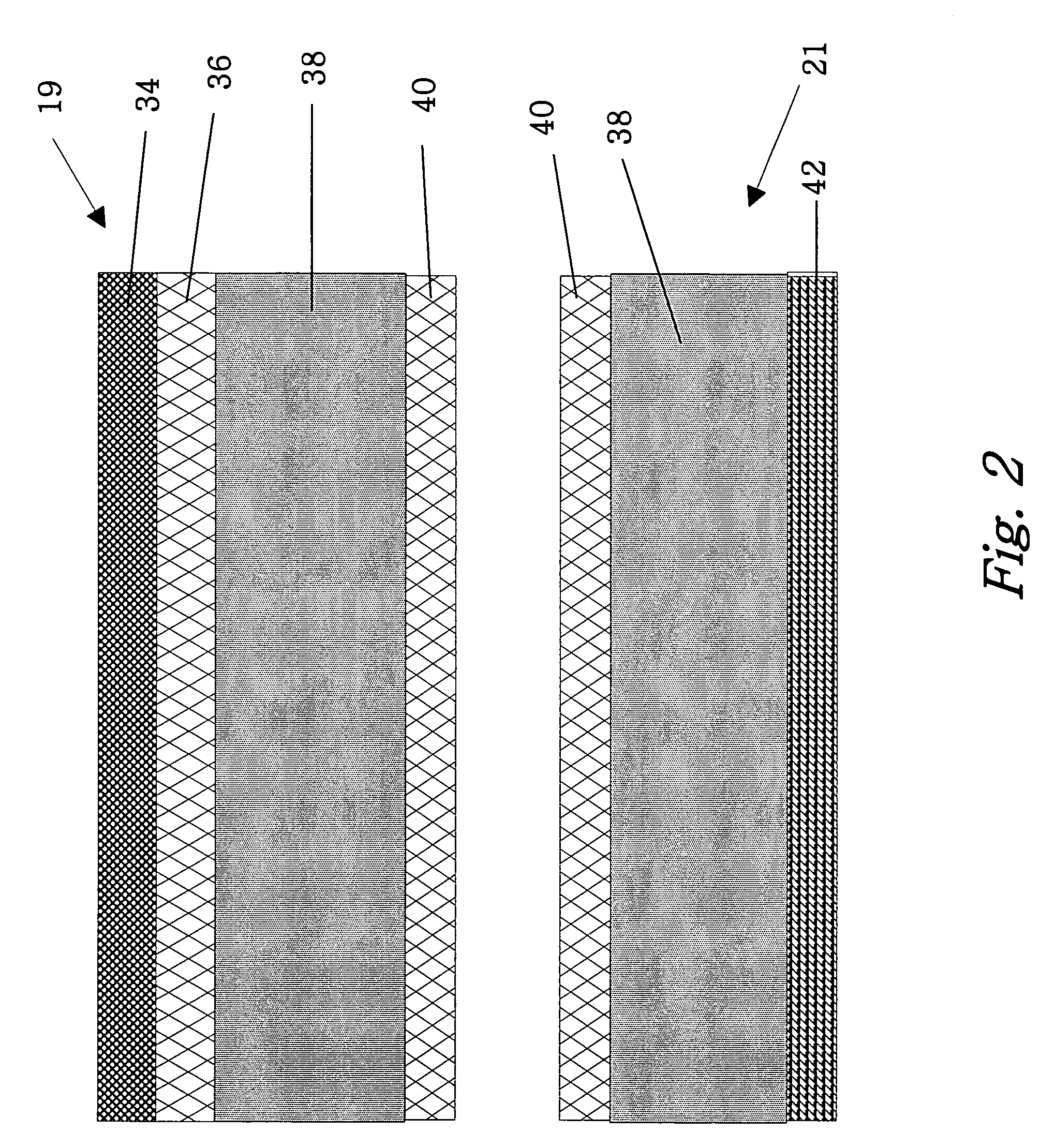

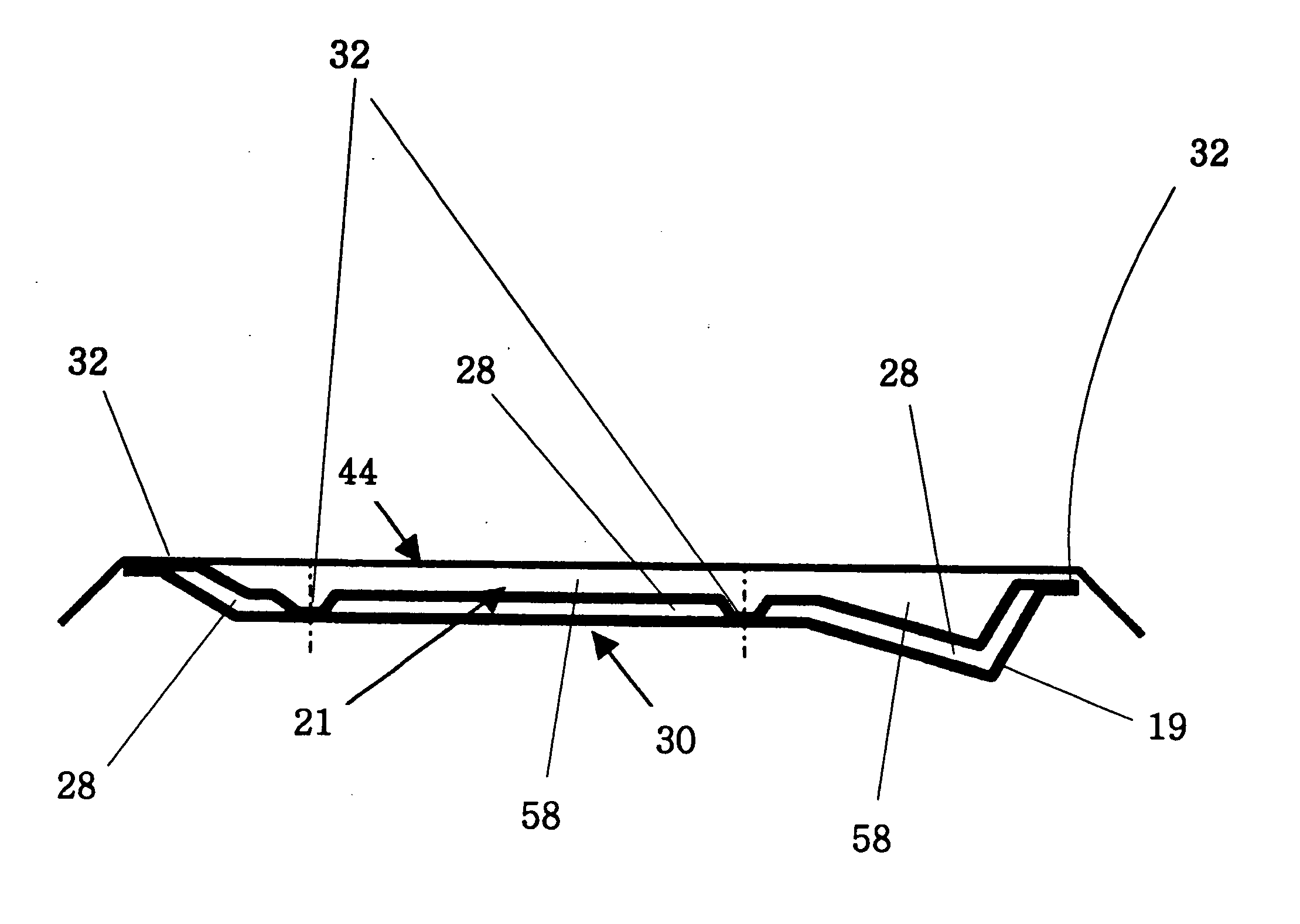

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

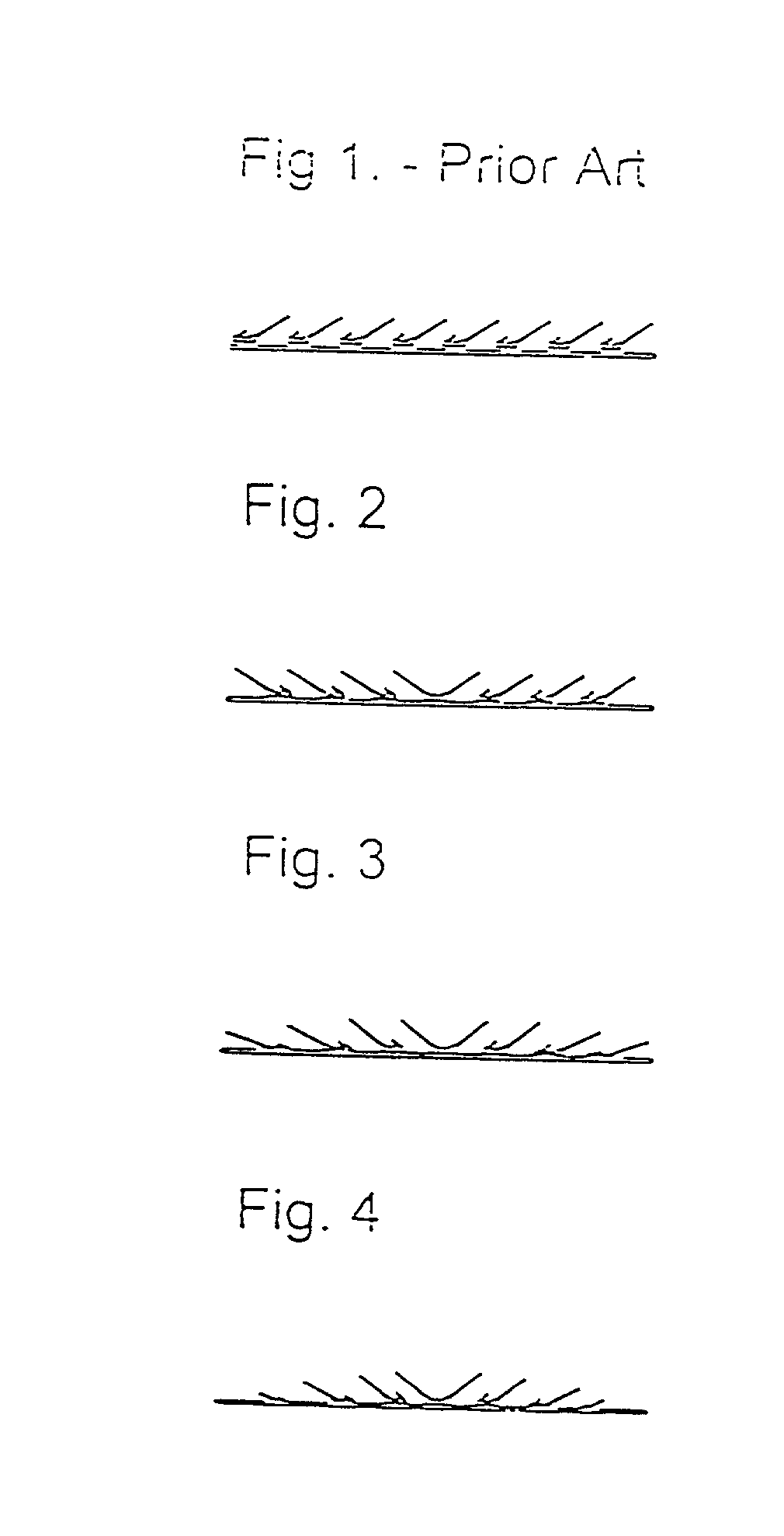

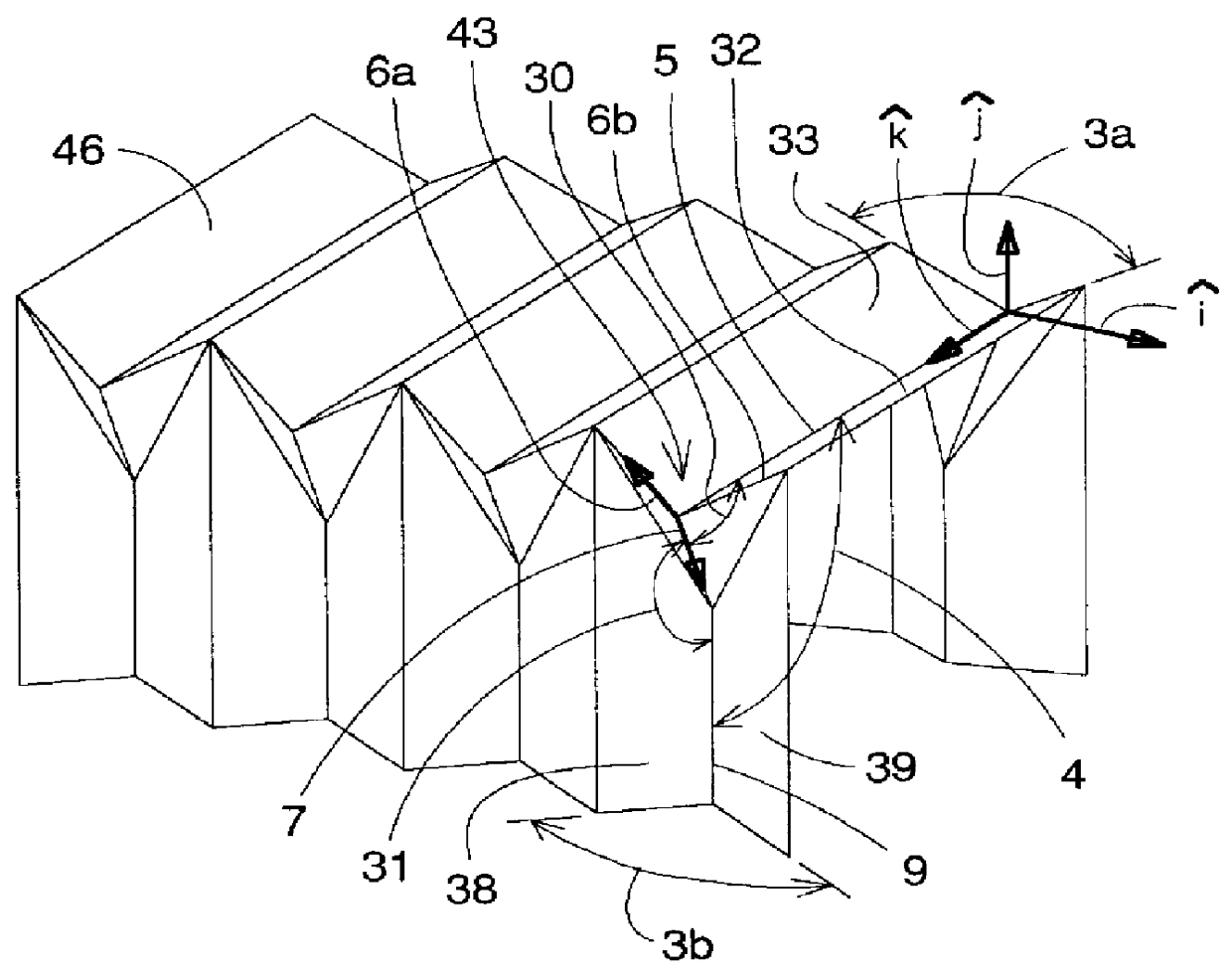

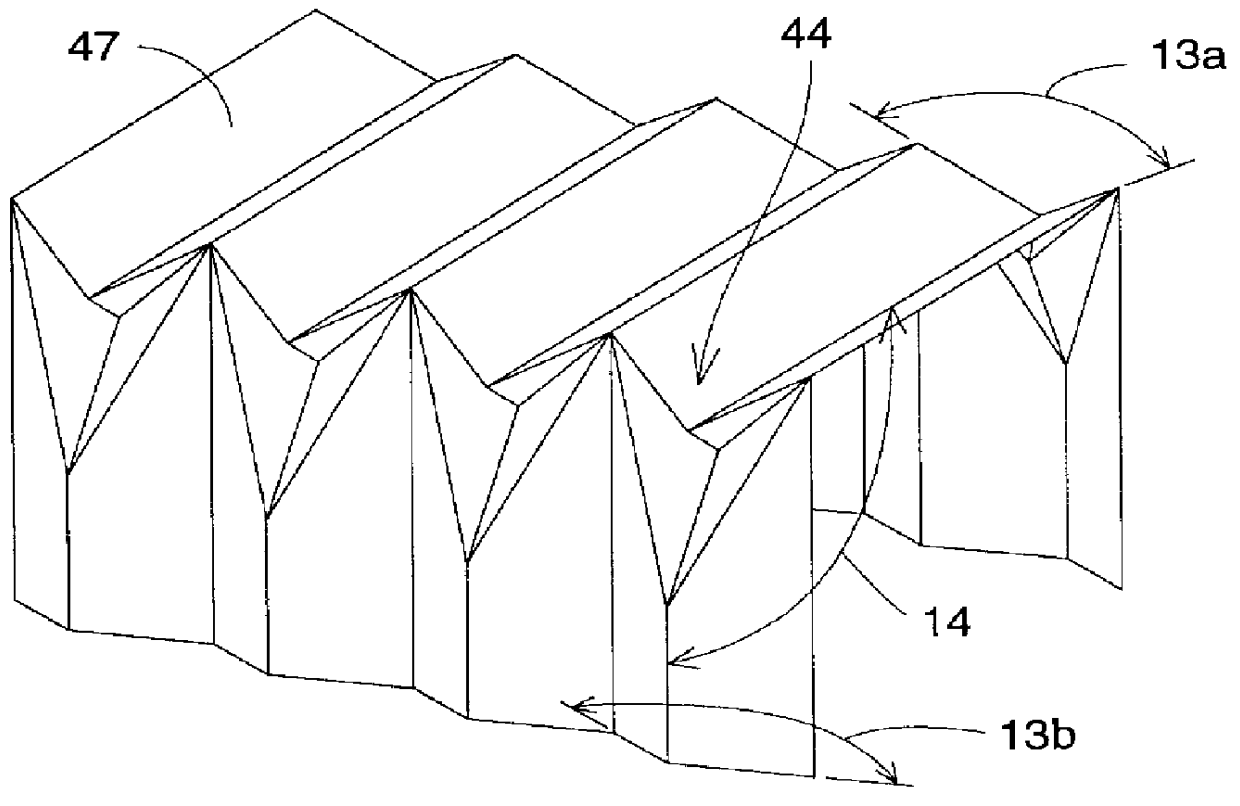

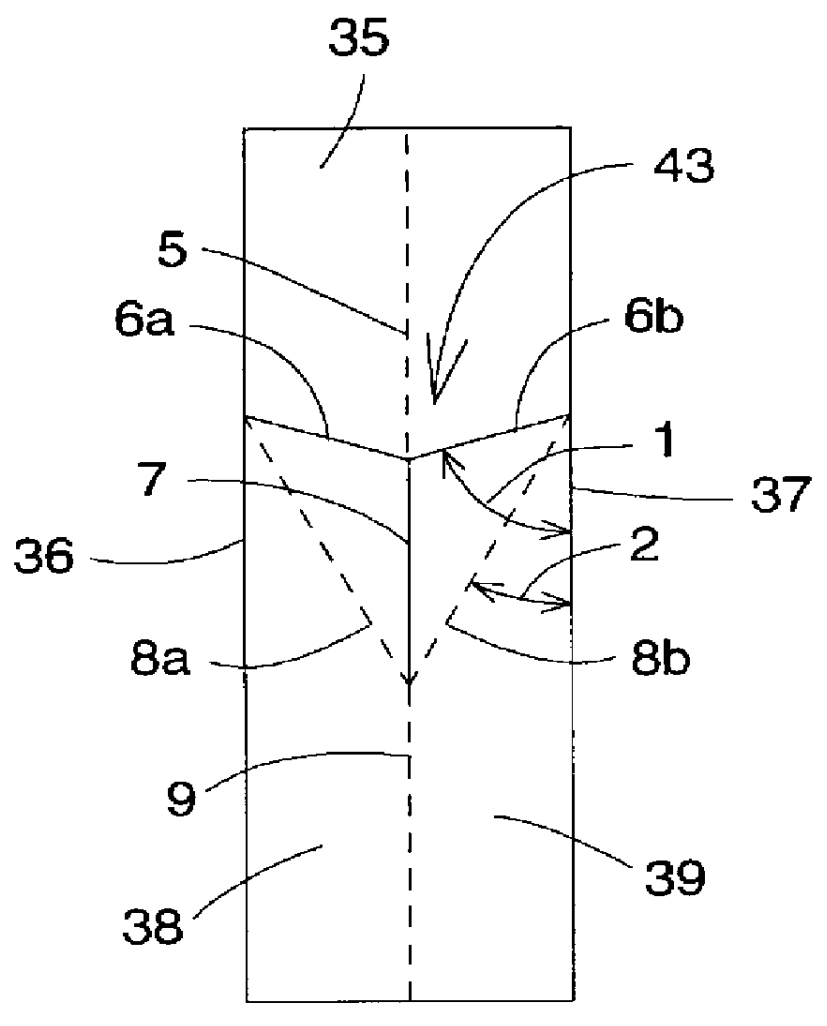

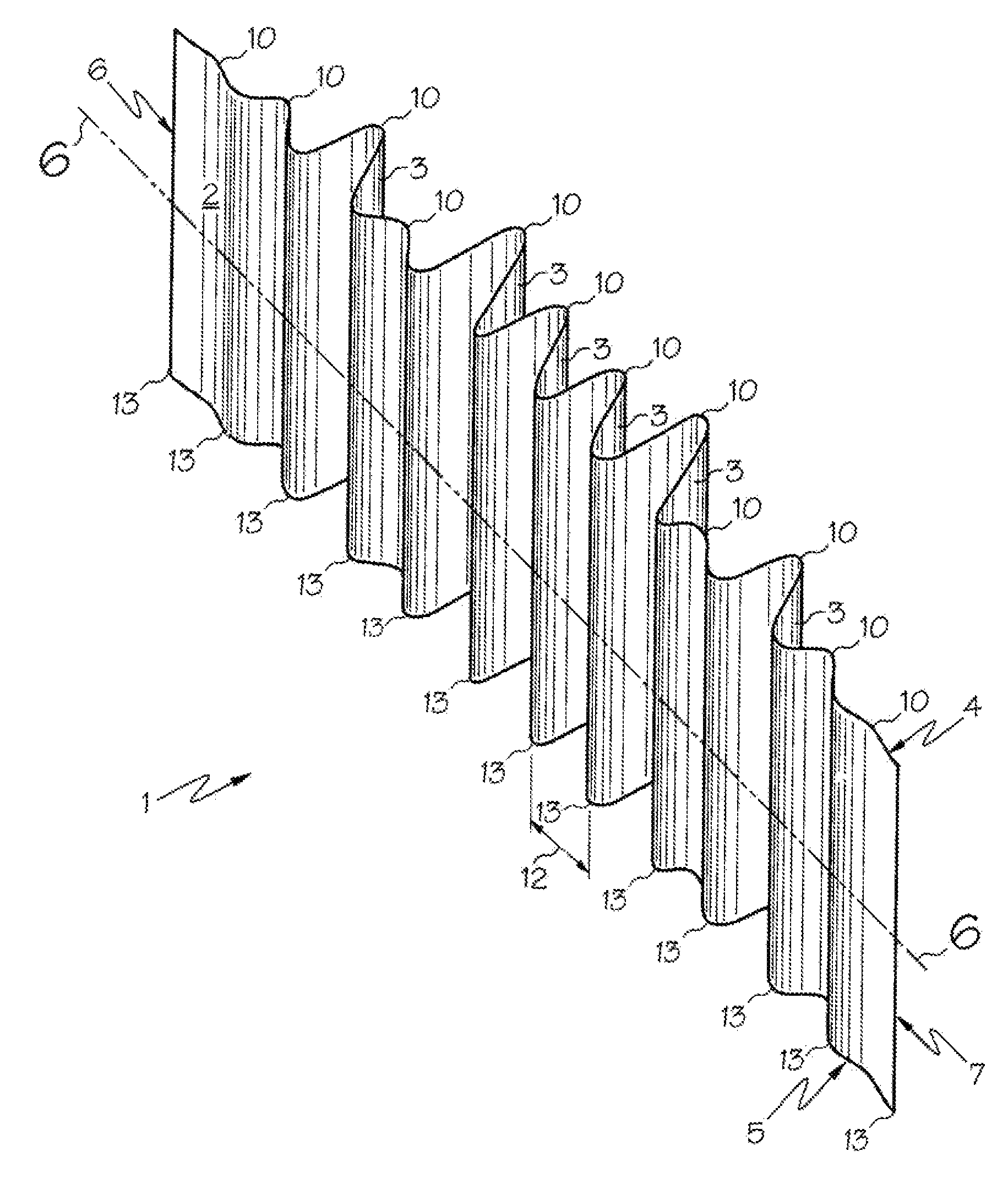

Mathematically optimized family of ultra low distortion bellow fold patterns

An improved mathematically modeled family of bellow fold patterns, useful for making bellows from stiff but foldable materials, which forms a corner of a bellow consisting of a series of several single inversion fold patterns, each having a characteristic design angle which is mathematically computed to provide a desired initial wall angle for the bellow and to minimize wall tilting over a predetermined extension angle range, thereby allowing low cost bellows to be made which can extend long distances while using a minimal amount of stiff but foldable material. In addition, each characteristic design angle can be computed to provide exactly zero tilting of the bellow walls at one or more non-zero extension lengths specified by a designer, thus allowing, unlike all other prior art folds, a structurally stiff, long extending bellow to be formed in an extended state using fast production techniques such as vacuum forming, blow molding or injection molding, while also allowing the bellow to be free of distortion in the compressed state.

Owner:KANE NATHAN R

Apertured polymeric film webs and absorbent articles using such webs

Owner:PROCTER & GAMBLE CO

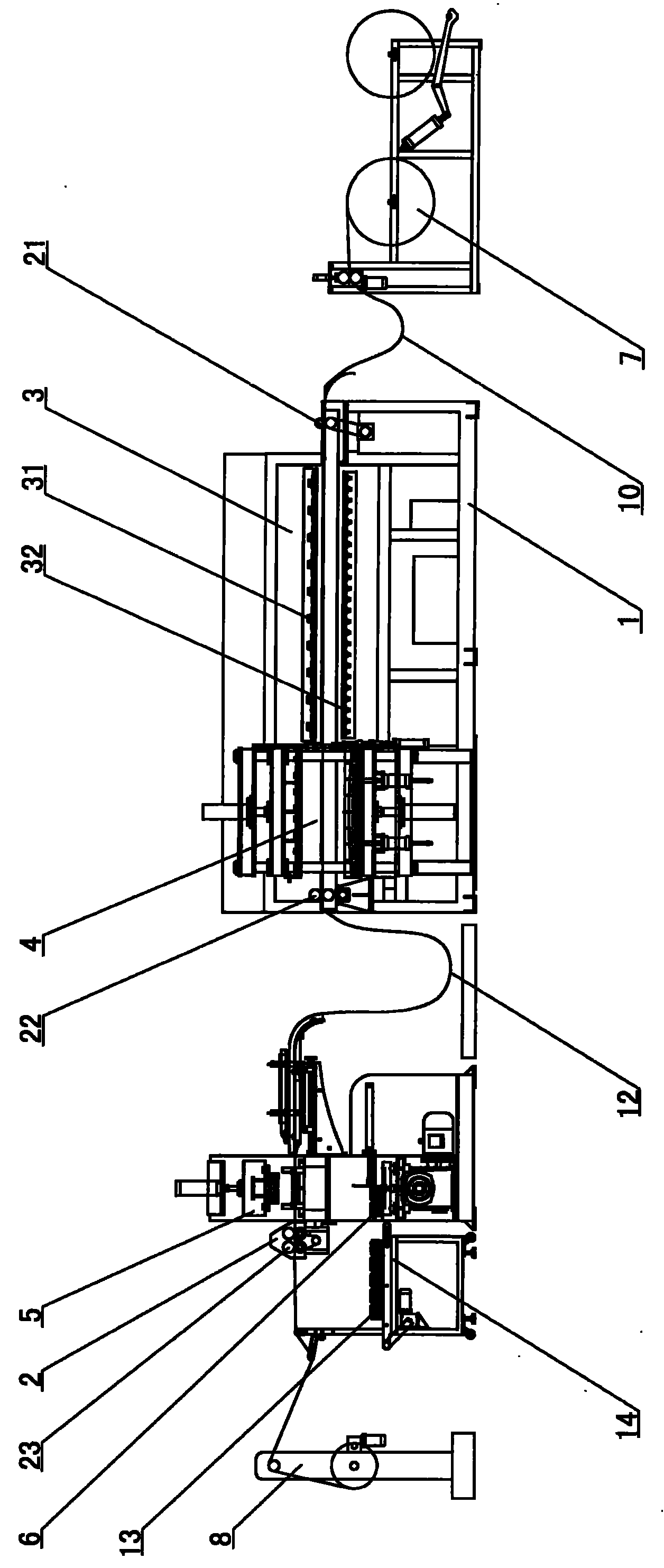

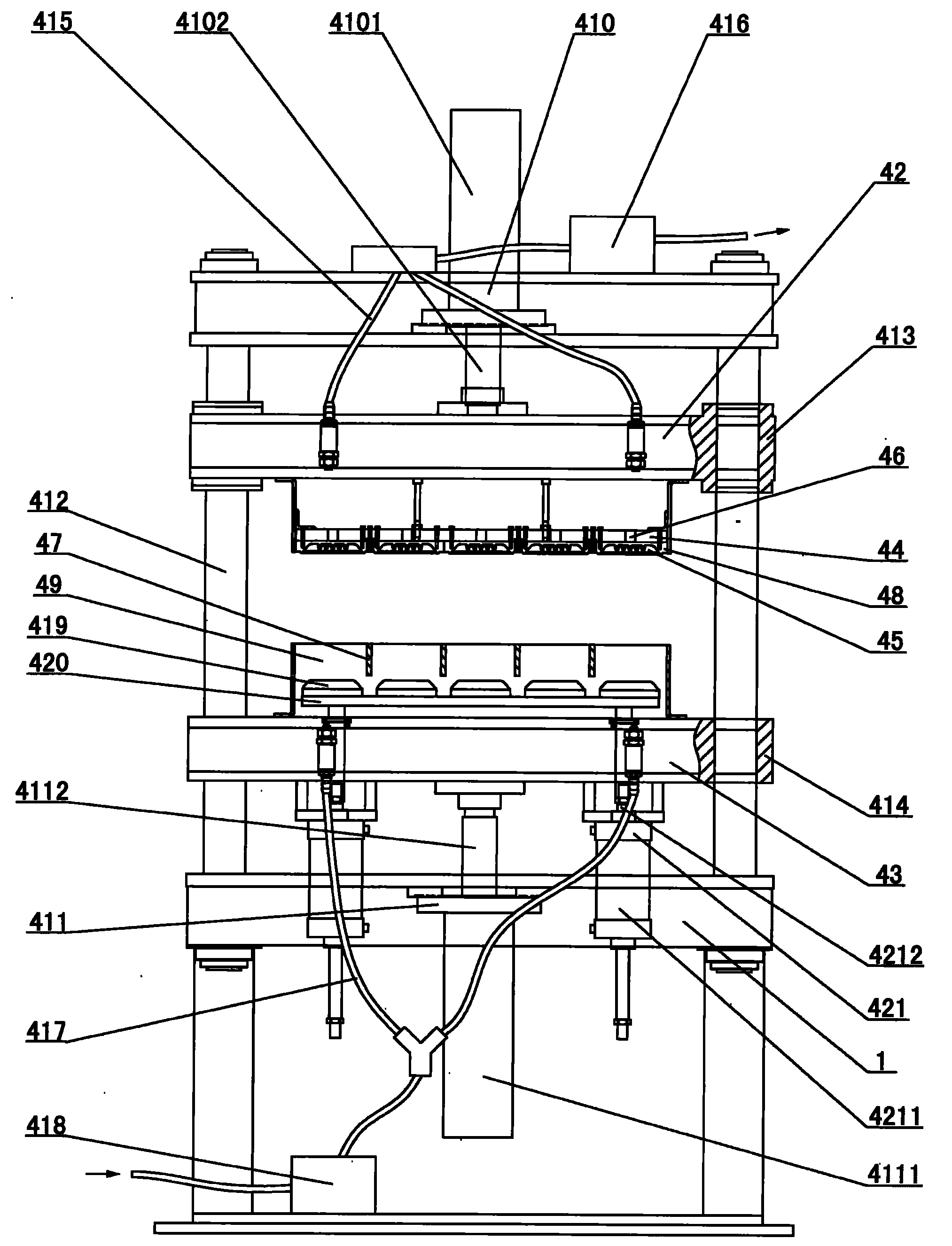

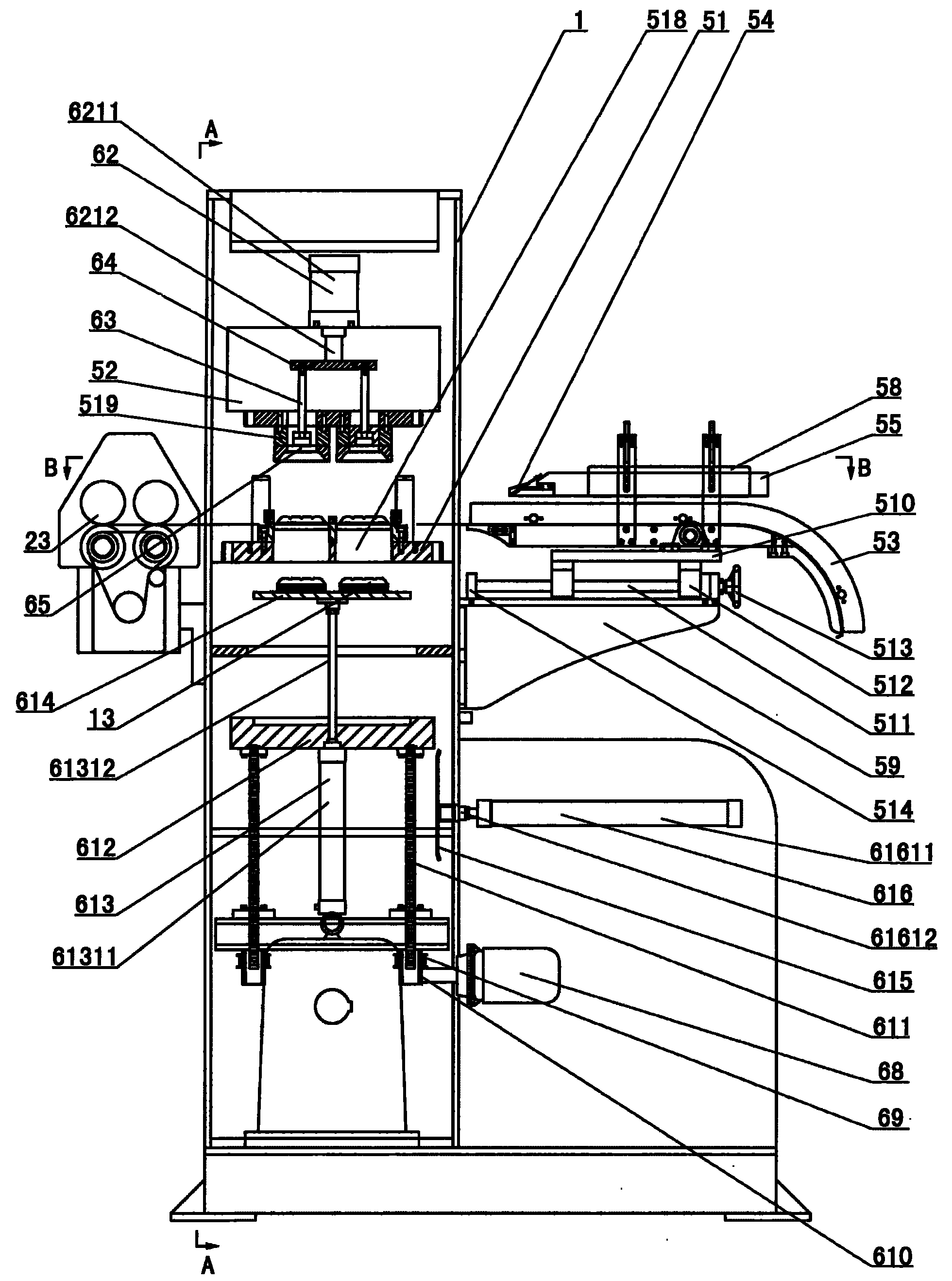

All-in-one machine for vacuum forming, molding and punching

InactiveCN101774273AAvoid lateral displacementAccurate horizontal positionMetal working apparatusTrappingPlastic film

The invention relates to an all-in-one machine for vacuum forming, molding and punching, comprising a rack, a material traction device, a heating device, a forming unit, a punching device and a control device; wherein a top die platform and a bottom die platform of the forming device are provided with moulding moulds which are thereupon provided with a convex part or a concave part for forming a light trapping bump on plastic sheets; the punching device comprises a punching shear mechanism, a guide rail which moves frontwards and backwards and a photocell eye for detecting the light trapping bump; the guide rail is arranged in the front of the punching shear mechanism, the photocell eye is arranged in the front of the punching shear mechanism and is connected with a corresponding input terminal corresponding to the control device.In the invention, when forming is carried out, the light trap bump can be formed on the plastic sheet, the flaky plastic products can be prevented from transversely displacing by the guide of the guide rail, the photocell eye can be used to detect the light trap bump and the control device can be used to lead the material traction device to convey the flaky plastic products to preset distance, so that the longitudinal position of the plastic products is accurate when the plastic products enter the punching shear mechanism and the flaky plastic products can accurately arrive at the preset position of the punching mechanism.

Owner:广东金兴机械股份有限公司

High thermal efficiency glass microfluidic channels and method for forming the same

InactiveUS20050241815A1Improve surface propertiesExcellent chemical durabilityLaboratory glasswaresGlass reforming apparatusMicrofluidic channelGlass-ceramic

A microfluidic device includes a formed sheet of glass or glass ceramic material formed to have one or more first micro channels on a first surface thereof and one or more second micro channels on a second surface opposite the first. The second channels are complementary to the first channels and the first channels are substantially closed by a first sheet of glass or glass ceramic material bonded to the first surface of the formed sheet. The second channels may be substantially closed by a second sheet of a glass or glass ceramic material bonded to the second surface. The first and second sheets may also be formed sheets. The device may be formed by vacuum-forming the formed sheet against a single surface mold, then bonding a plate to one or both sides of the formed sheet.

Owner:CORNING INC

Method of making a colored automotive trim product

InactiveUS7005103B2Eliminate needEasy constructionMechanical working/deformationTurning machine accessoriesShell moldingMultiple layer

An automotive trim product is made as follows. A single or multiple layer sheet is extruded so as to include at least one color pigmented and / or metallized layer therein. The sheet is then thermoformed into a three-dimensionally shaped preform via vacuum forming or the like. The preform is placed into a cavity of an injection molding apparatus and heated semi-molten material is injected thereinto. The semi-molten material bonds to the preform in the cavity. After cycling, the molding apparatus ejects a final automotive trim part. Optionally, some processing (e.g. trimming) may be performed following ejection.

Owner:GUARDIAN AUTOMOTIVE TRIM

Method of making a surgical template used for a computer-guided dental implant surgery

InactiveUS8135492B2Data efficientImprove efficiencyImpression capsMechanical/radiation/invasive therapiesDentistrySurgical template

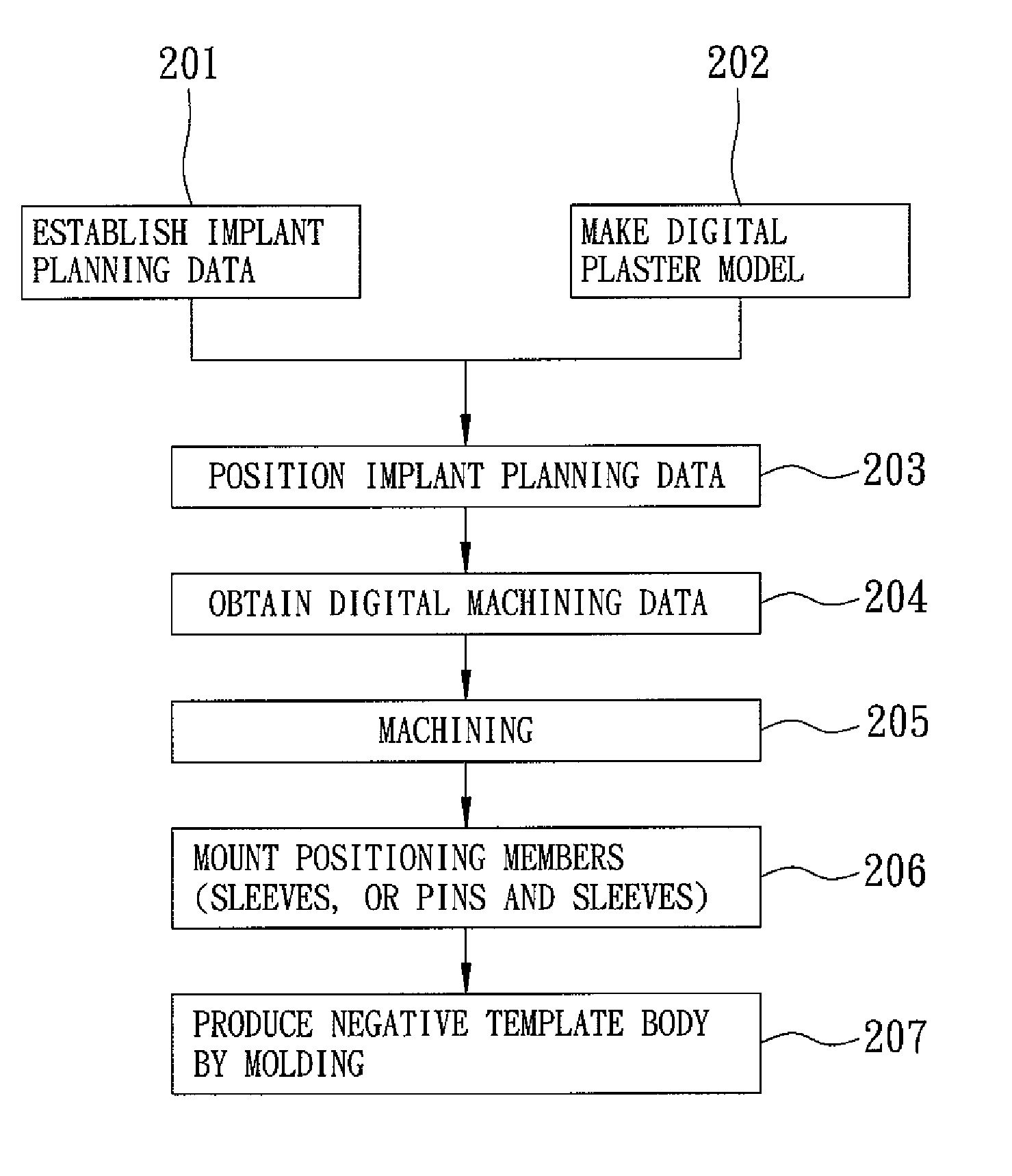

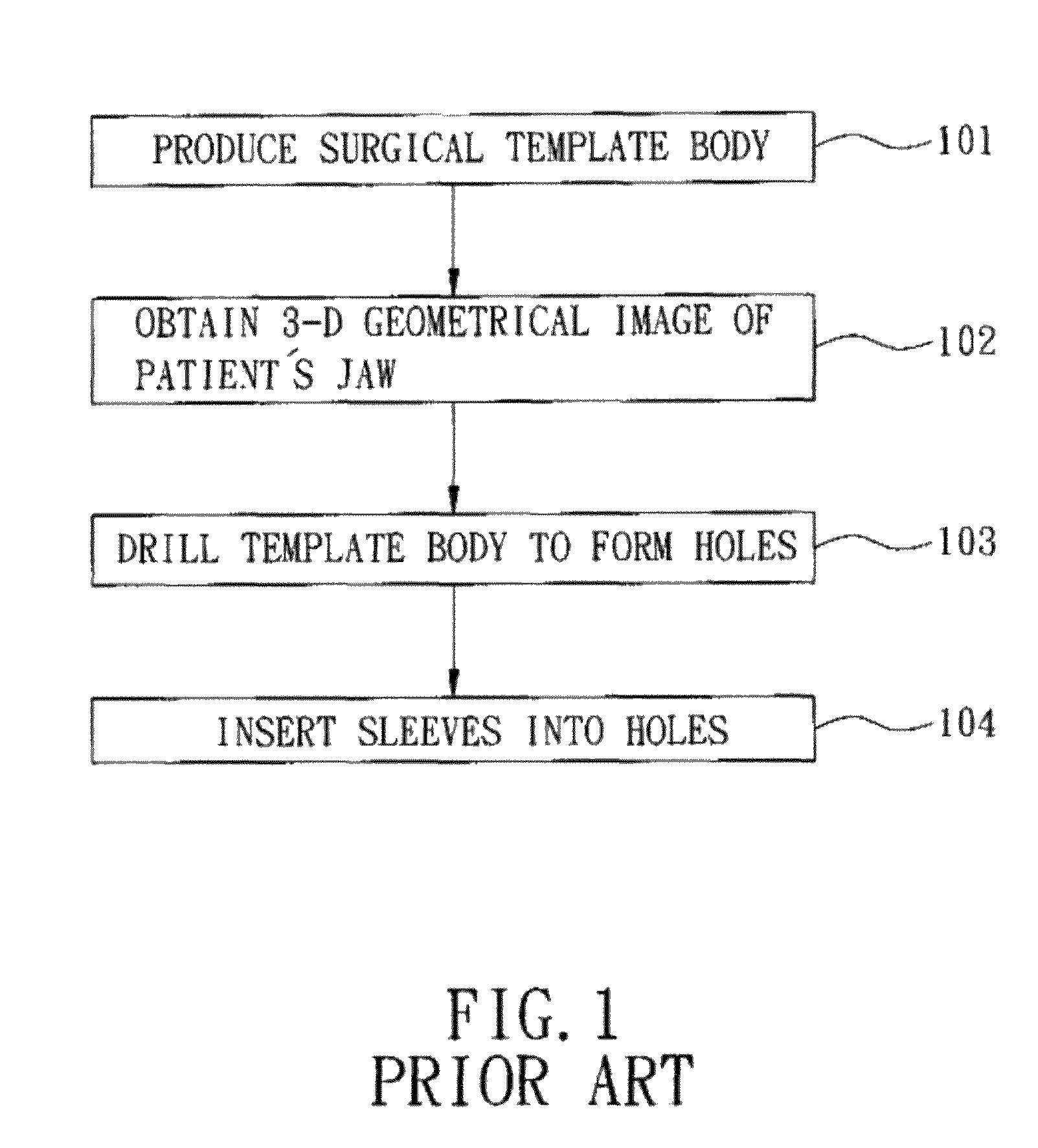

A method of making a surgical template used for a computer-guided dental implant surgery includes the steps of: establishing implant planning data of a patient's jaw, producing a digital plaster model of the patient's jaw, allowing the digital plaster model to have the implant planning data, integrating the digital plaster model with the implant planning data to obtain a digital machining data, holding and machining a modeling block at a machining position according to the digital machining data to form a solid jaw model corresponding to the patient's jaw and having teeth, gums, and at least one implant-position indicating structure, mounting a positioning member at the implant-position indicating structure, and producing a negative template body from an assembly of the solid jaw model and the positioning member with a thermoplastic dental material by a molding process or a vacuum forming process.

Owner:POU BIOTECH

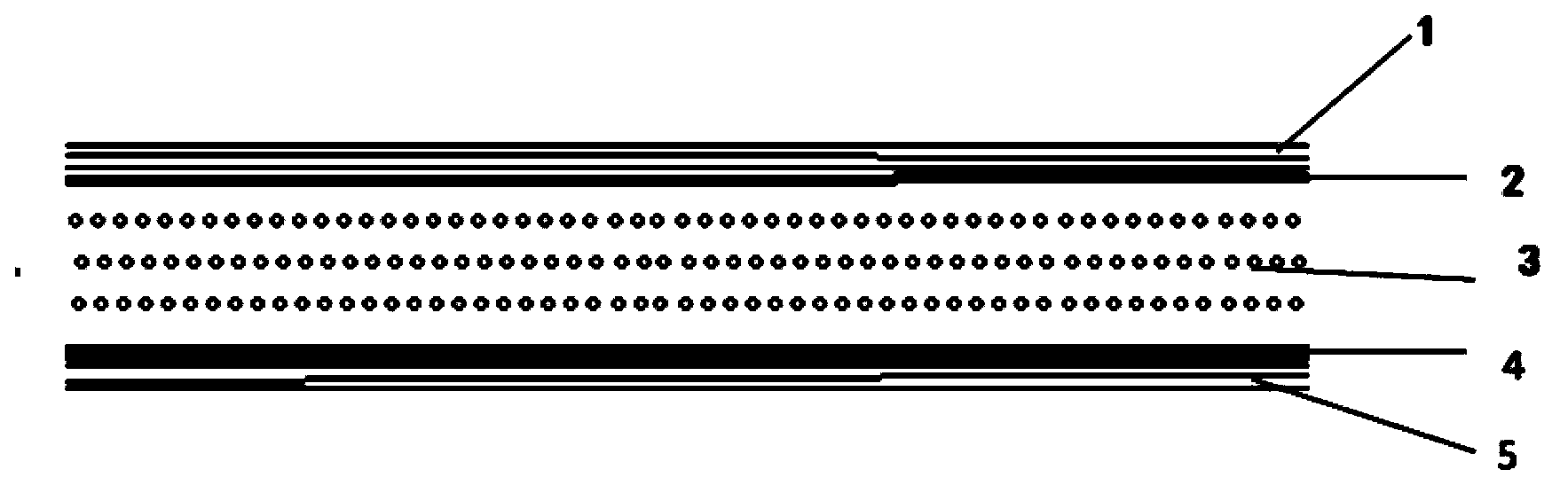

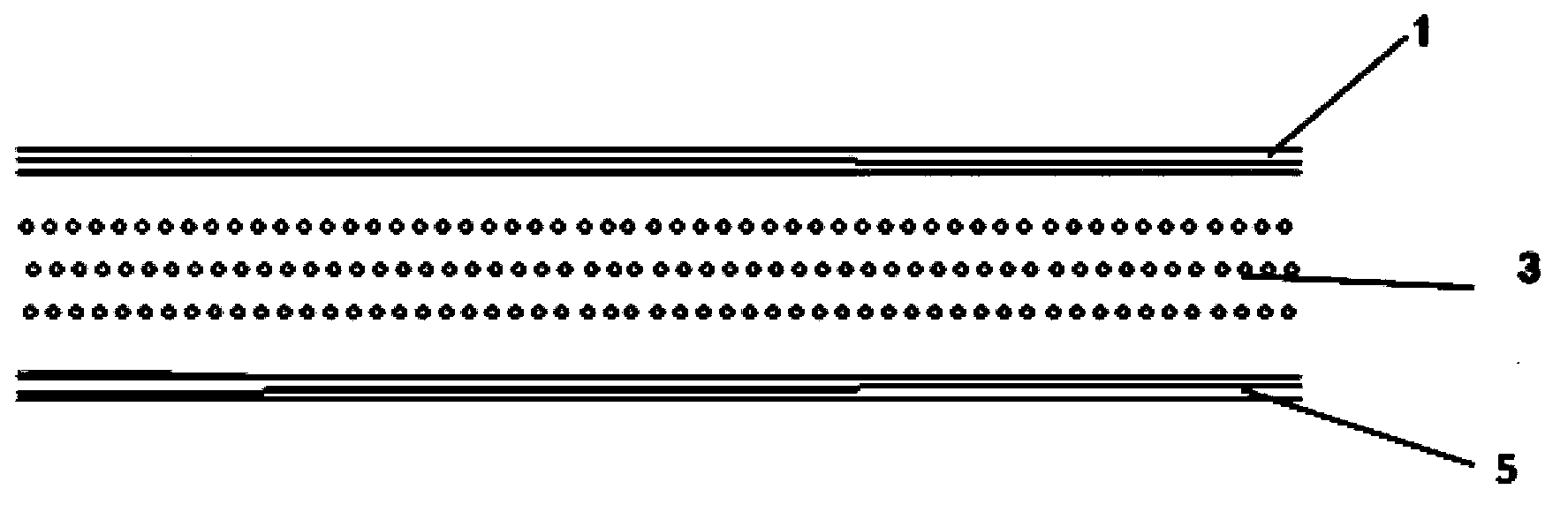

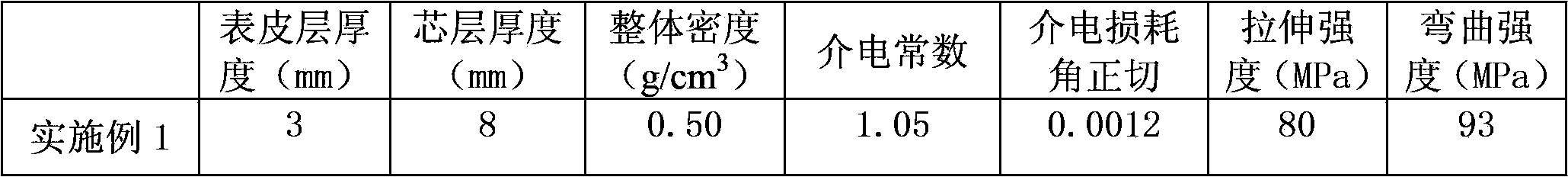

Wave-transmitting core clamping material of antenna cover and manufacturing method and application thereof

ActiveCN103660410AHigh mechanical strengthIncreased protectionSynthetic resin layered productsLaminationUltimate tensile strengthThermoplastic composites

The invention belongs to the technical field of materials, and relates to a wave-transmitting core clamping material and a manufacturing method and application thereof. The wave-transmitting core clamping material comprises an upper skin layer, a core layer and a lower skin layer, wherein the upper skin layer and the lower skin layer are bonded on the two sides of the core layer, respectively; the upper skin layer and the lower skin layer are made of a fiber-reinforced thermoplastic composite material or a laminated material of the fiber-reinforced thermoplastic composite material and a transition material. The prepared wave-transmitting core clamping material provided by the invention has the characteristics that the quality is light, the intensity is high, the wave-transmitting property is good, the adaptive temperature range is wide, and the core clamping material is manufactured to be in different shapes through different manners of hot pressing, vacuum forming and the like so as to meet the requirement on the shape of an antenna cover.

Owner:上海吒吒新材料科技有限公司

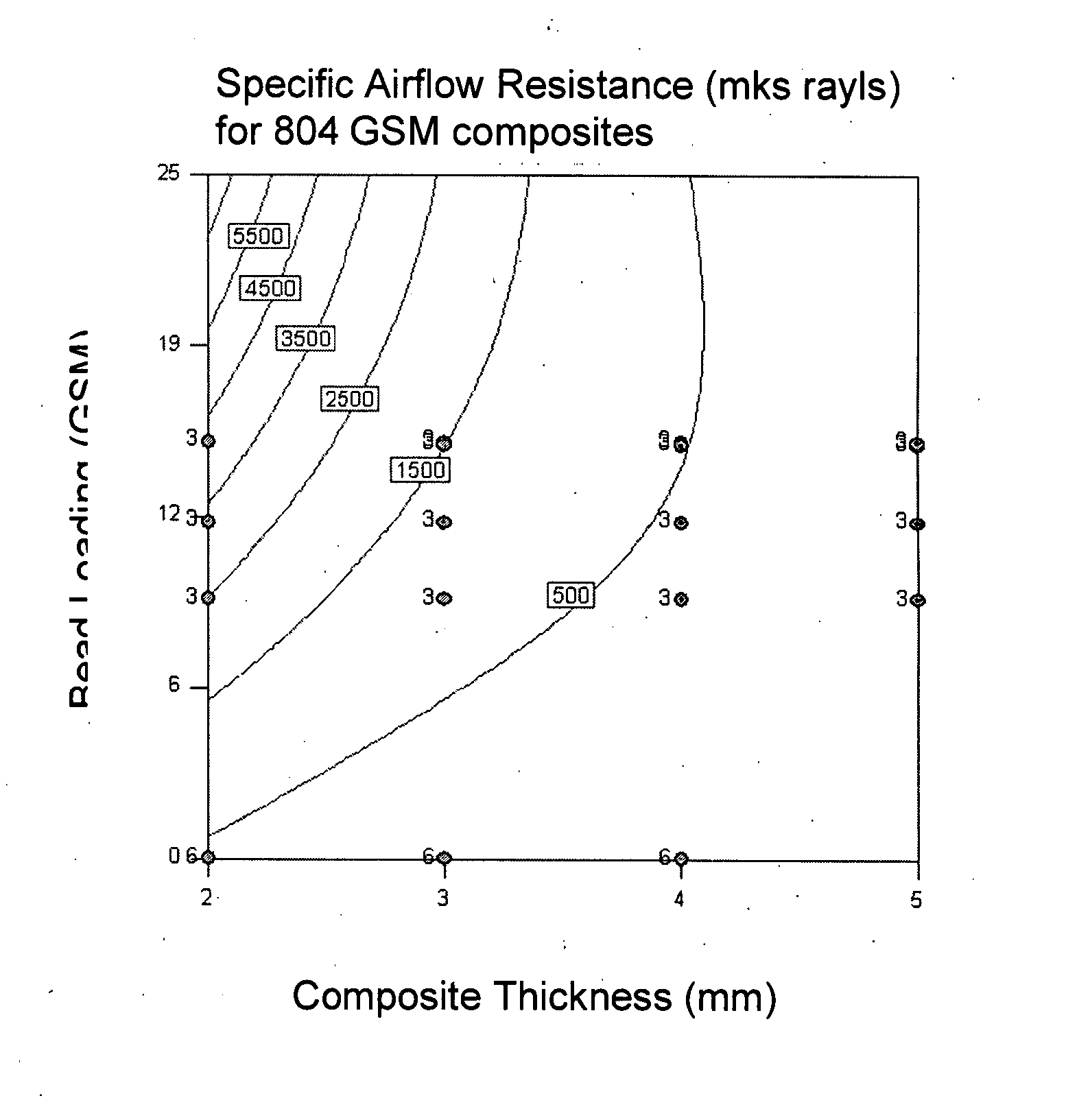

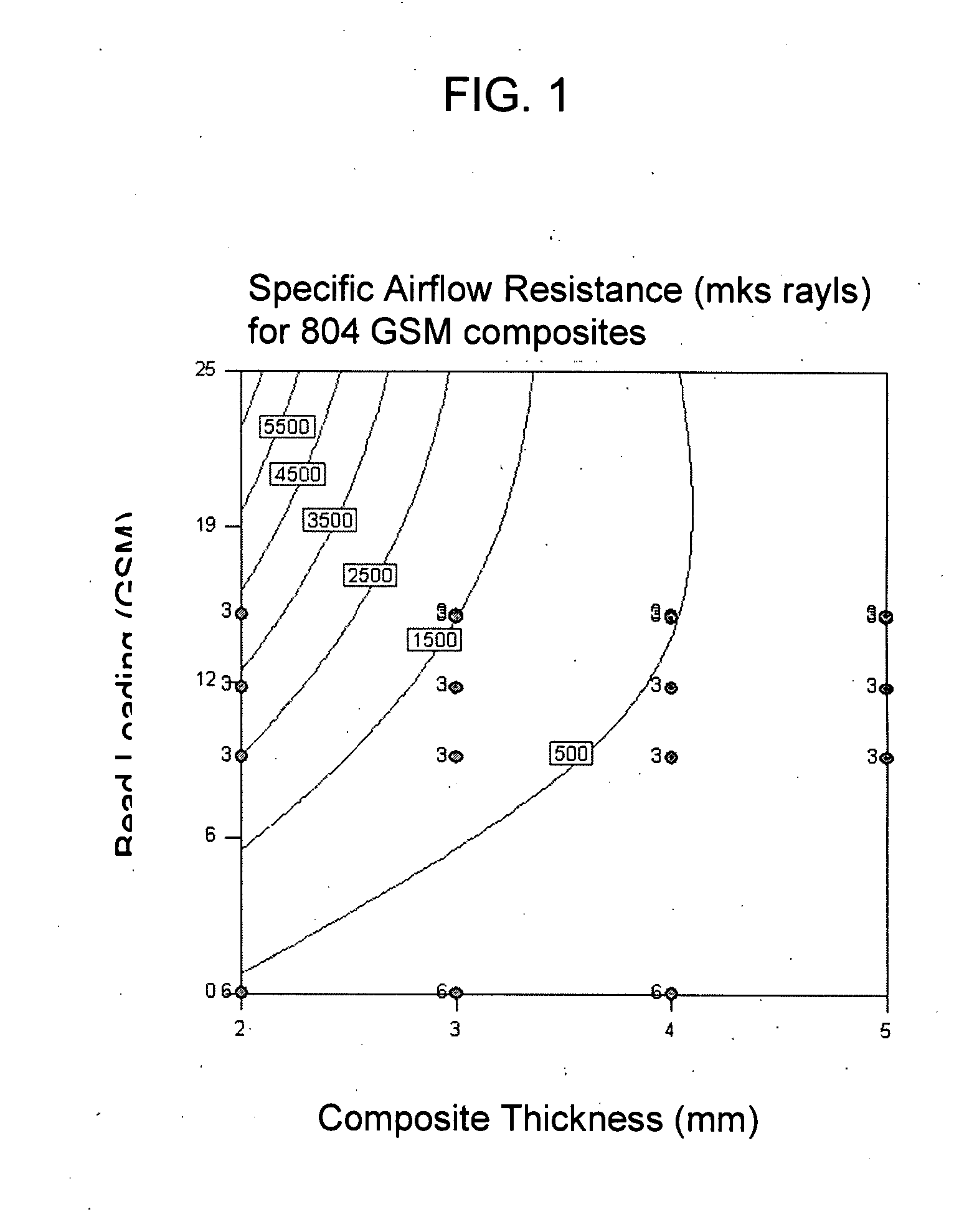

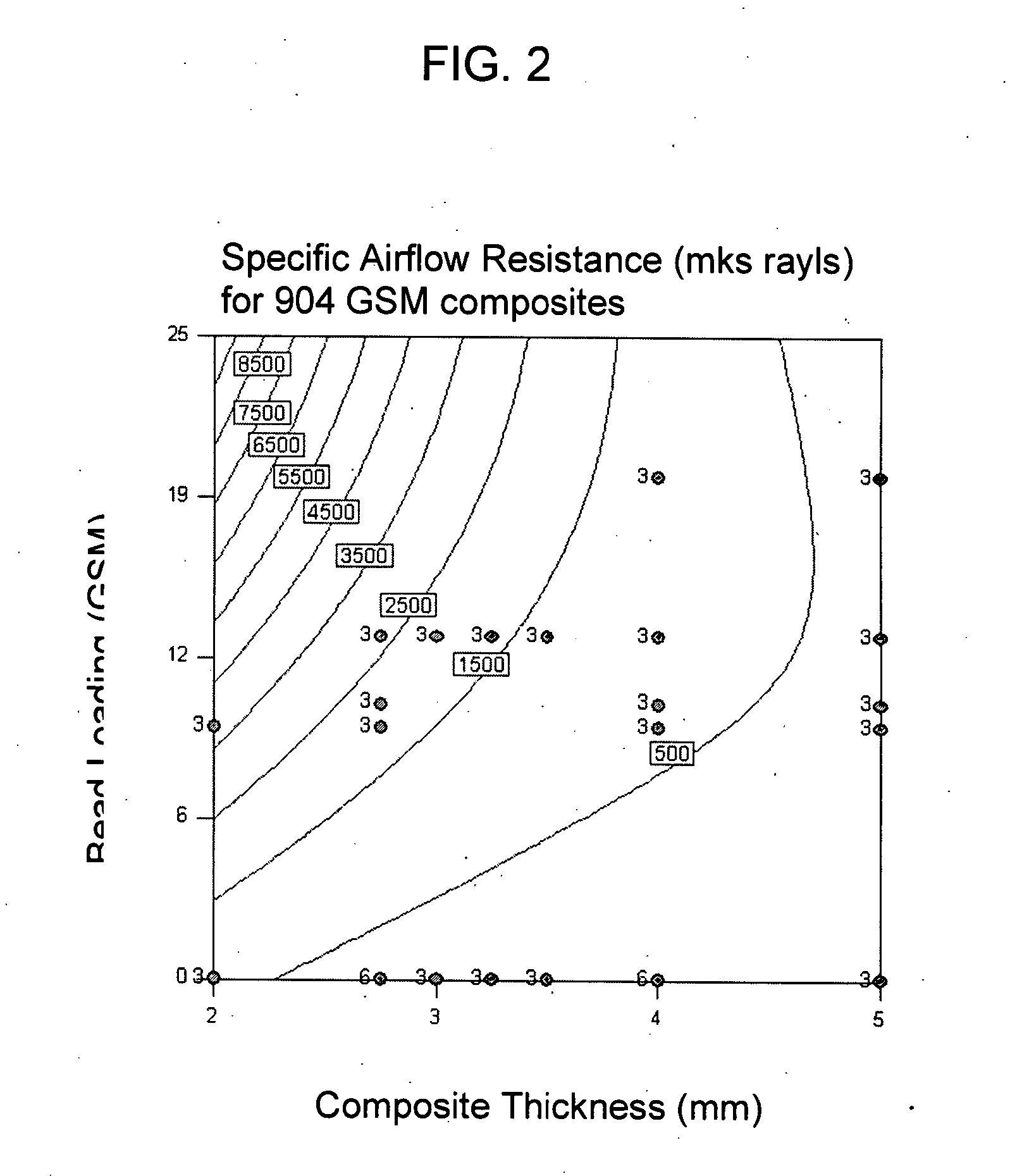

Enhanced sound absorption in thermoplastic composites

InactiveUS20080008869A1Good sound-absorbing propertiesEnhanced sound absorption characteristicNatural cellulose pulp/paperSynthetic resin layered productsMetal formingMicrosphere

A moldable composite sheet having enhanced sound absorption characteristics and attenuation of transmitted sound intensities. In one aspect, the composite sheet may be a porous fiber-reinforced thermoplastic comprising discontinuous reinforcing fibers, expandable polymeric beads such as microspheres, and, optionally, one or more thermoplastic skins. Generally, the composite sheet may have a void content or porosity from greater than 0% to about 95% by volume of the sheet, an areal weight between about 400 g / m2 to about 4000 g / m2 (gsm), a fiber content from about 20% to about 80% by weight, and an expandable polymeric bead content from greater than 0 gsm to about 25 gsm. The composite sheet can be molded via low pressure processes, such as thermoforming, match metal molding on stops, vacuum forming and pressure forming, to produce durable automotive interior trim parts and construction articles having enhanced sound absorption capabilities in addition to other beneficial characteristics.

Owner:AZDEL INC

Data entry terminal having flexible, transparent front cover

InactiveUS20060186001A1Interface is not particularly fastFit tightlyTravelling carriersHoldersAdhesivePolyvinyl chloride

A durable, clear, protective cover for a device having a touch screen, keypad, or other user interface. The cover protects the device without interfering with the ability to use the device. The protective cover is constructed by vacuum-forming a thin sheet of transparent polyurethane or polyvinyl chloride (PVC) on the front and at least a portion of the sides of a mold made of the target device. Accordingly, the protective cover made from a single piece of material will have the topography matching the device, which facilitates in the continued usability of the device when the protective cover is disposed on the device. Furthermore, the protective cover fits securely on the device such that no adhesives or other mechanisms are required to secure the protective cover onto the device, nor are any tools required to install or remove the protective cover.

Owner:INTERMEC IP

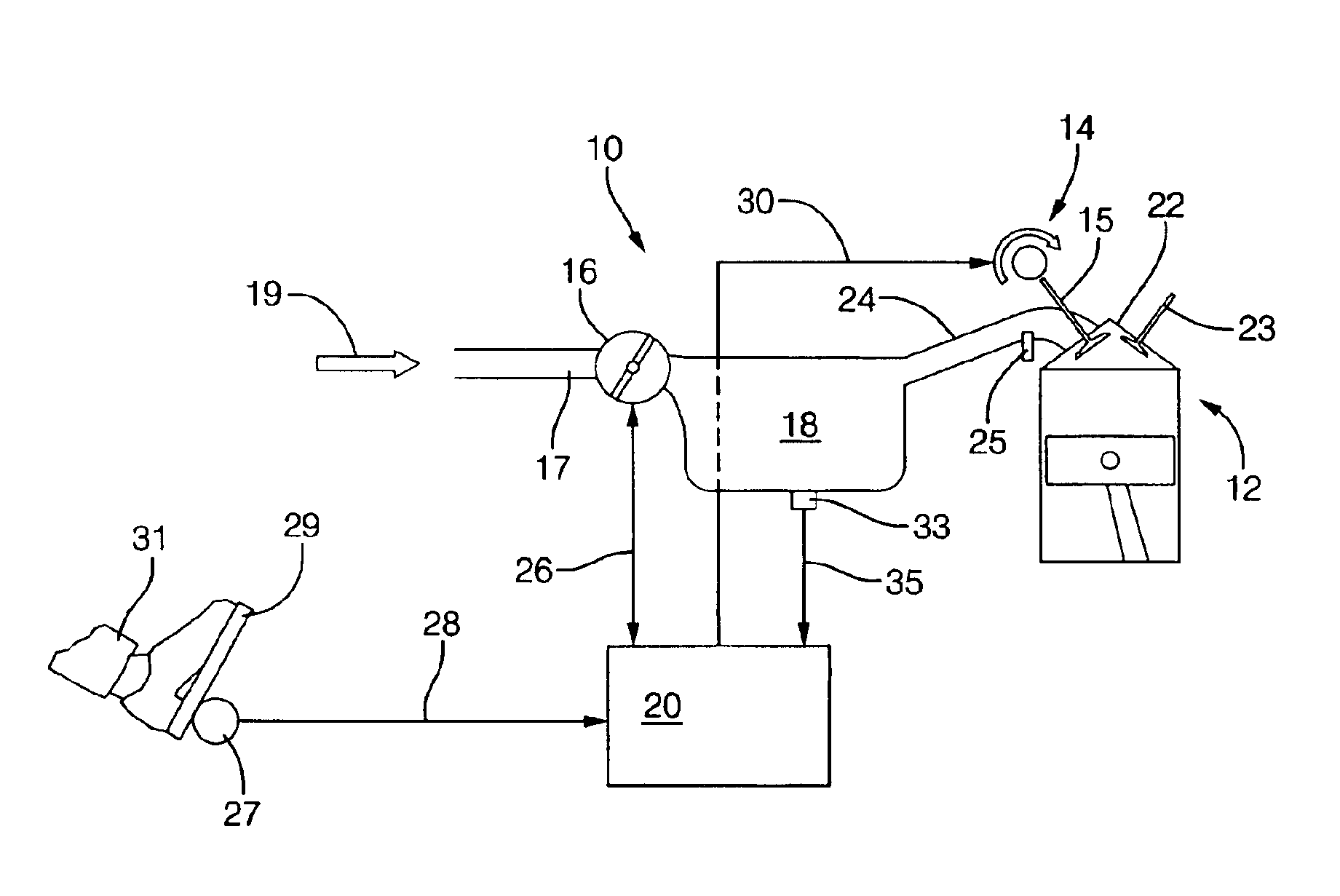

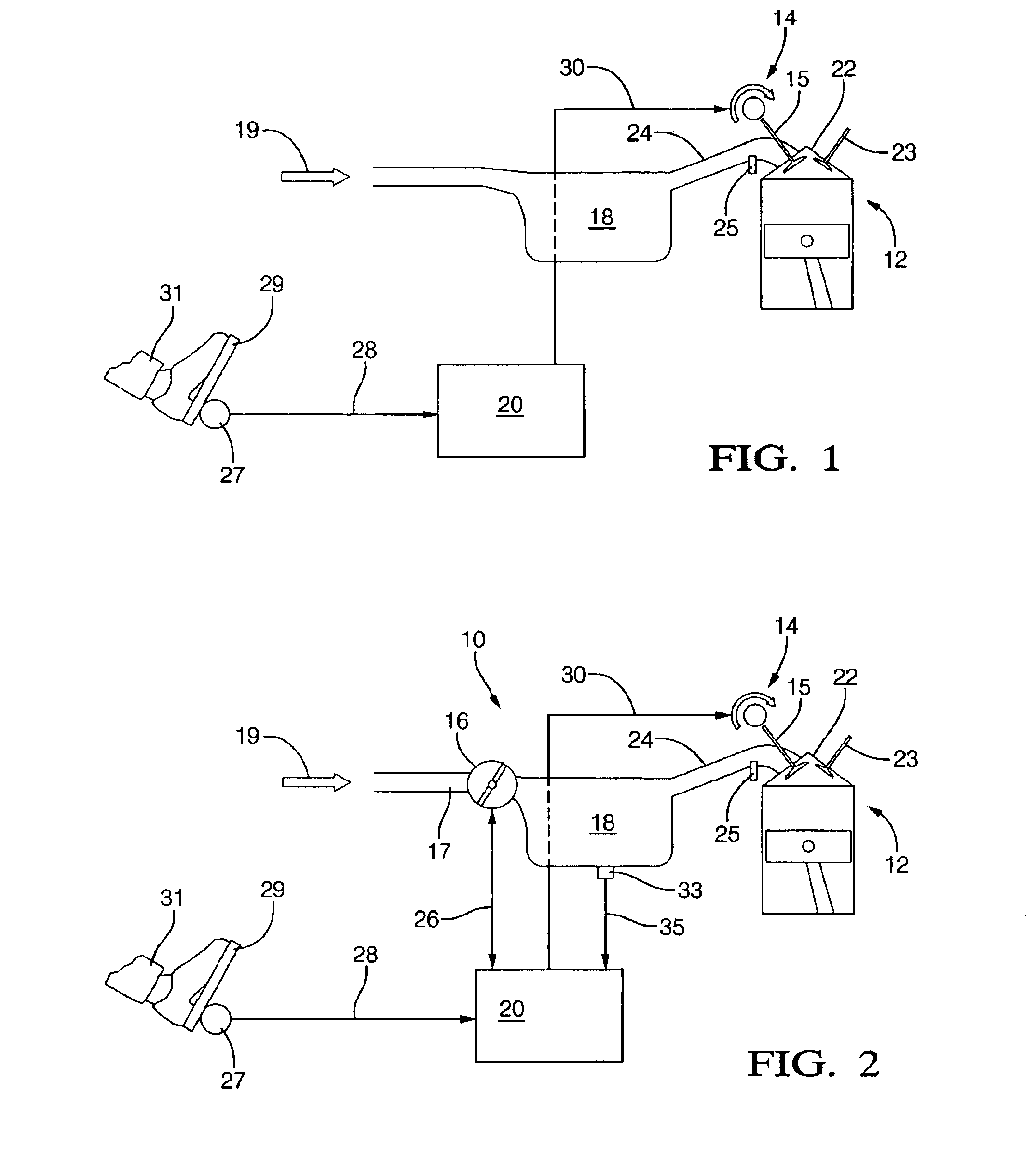

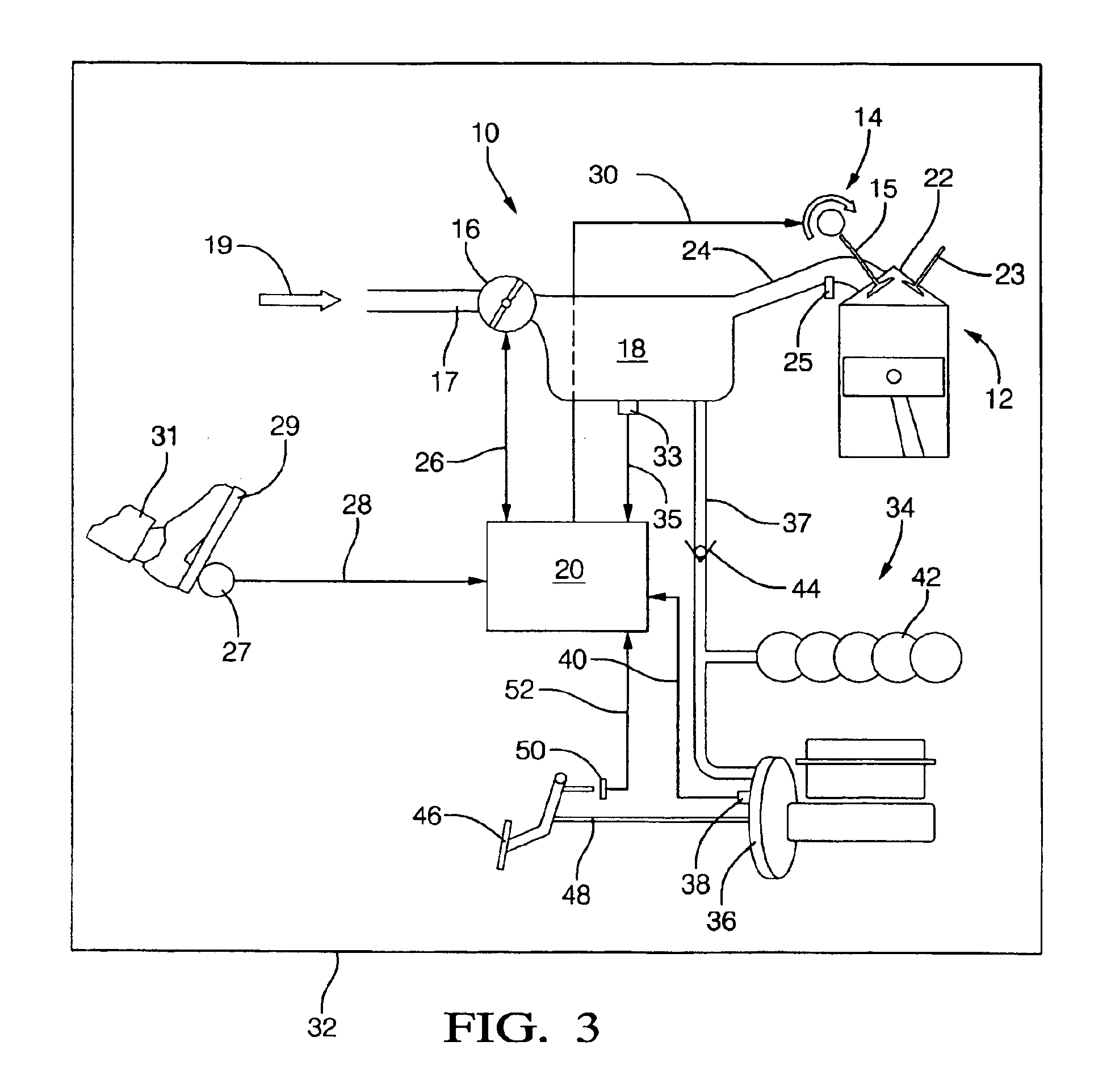

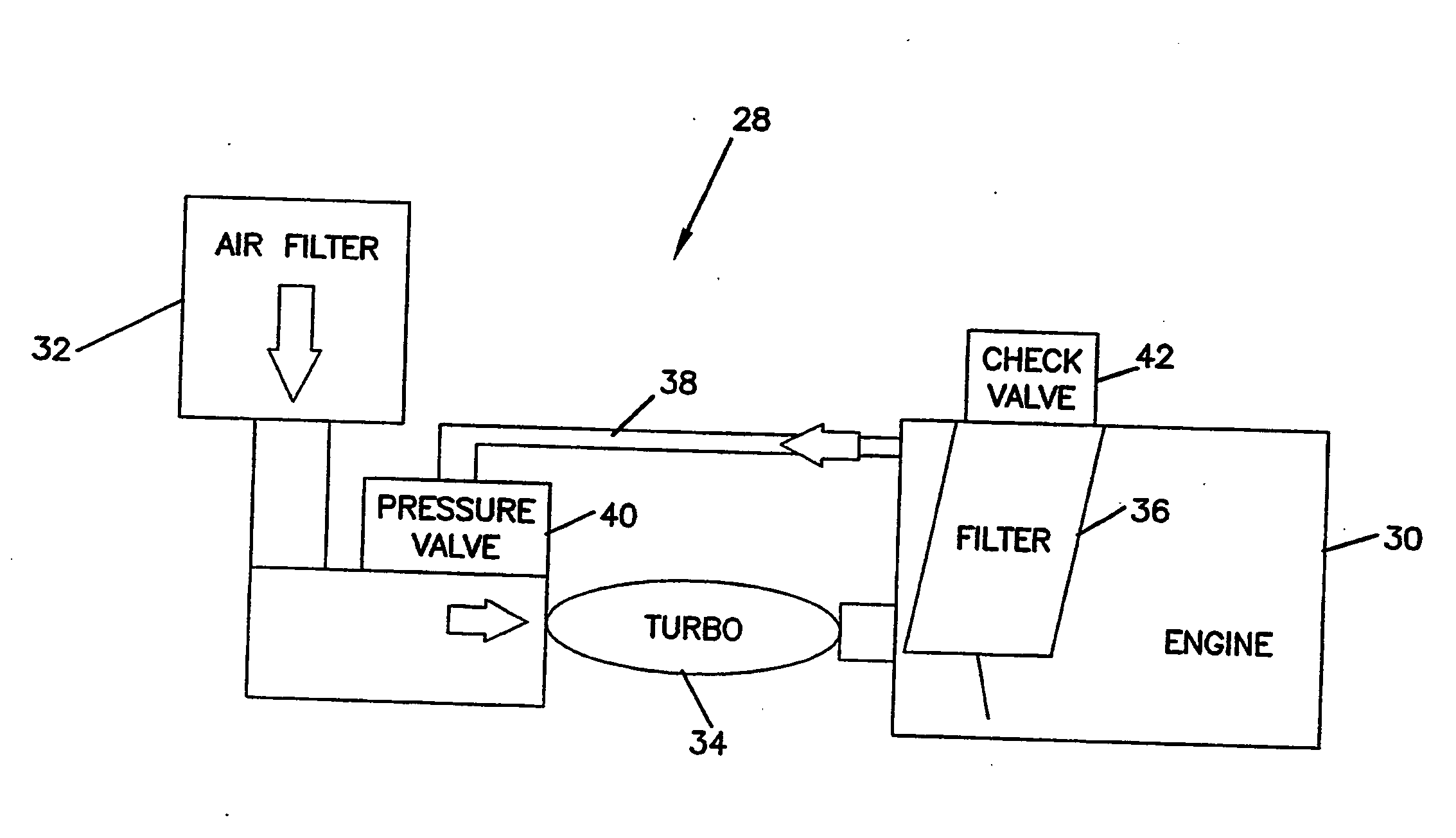

Vacuum system for engine with variable valve lift

InactiveUS6863048B2Improve fuel economyElectrical controlInternal combustion piston enginesVariable valve timingInlet valve

A vacuum system for an engine with variable valve lift includes a controllable vacuum-forming valve at the entrance to the intake manifold and a programmable engine control module (ECM) to increase vacuum as desired within the manifold by modulating the valve as needed to optimize fuel economy. To provide vacuum brake assist, a brake booster diaphragm is connected conventionally to the manifold and a vacuum storage tank and check valve are disposed between the booster diaphragm and the manifold. During periods of vehicle deceleration, when engine load is low, the ECM may switch the VVL-controlled intake valves to a higher lift to increase the pumping capacity of the engine, while simultaneously partially closing the vacuum-forming valve to create vacuum in the intake manifold, the brake booster, and the vacuum storage tank at little or no expense to engine performance.

Owner:DELPHI TECH INC

Combination acoustic diffuser and absorber and method of production thereof

The present invention relates to a combination acoustic diffuser and absorber and method of production thereof. The diffuser has an acoustically reflective surface that may be made by the vacuum forming of pliable sheet material in conformity with a shaped template and the subsequent fixing of the resulting shape of said material, and which surface includes a plurality of wells, the depths of which wells may be determined by number theory sequences. The absorber may include one or more tunable Helmholtz resonators which may be attached to the rear face of the diffusing surface. The combination acoustic diffuser and absorber may be optimized in its function and construction for use in a typical residential application. A kit may also be provided that comprises a diffuser, absorbers, mounting hardware, and assembly and adjustment instructions.

Owner:GUDIM WILLIAM ORLIN

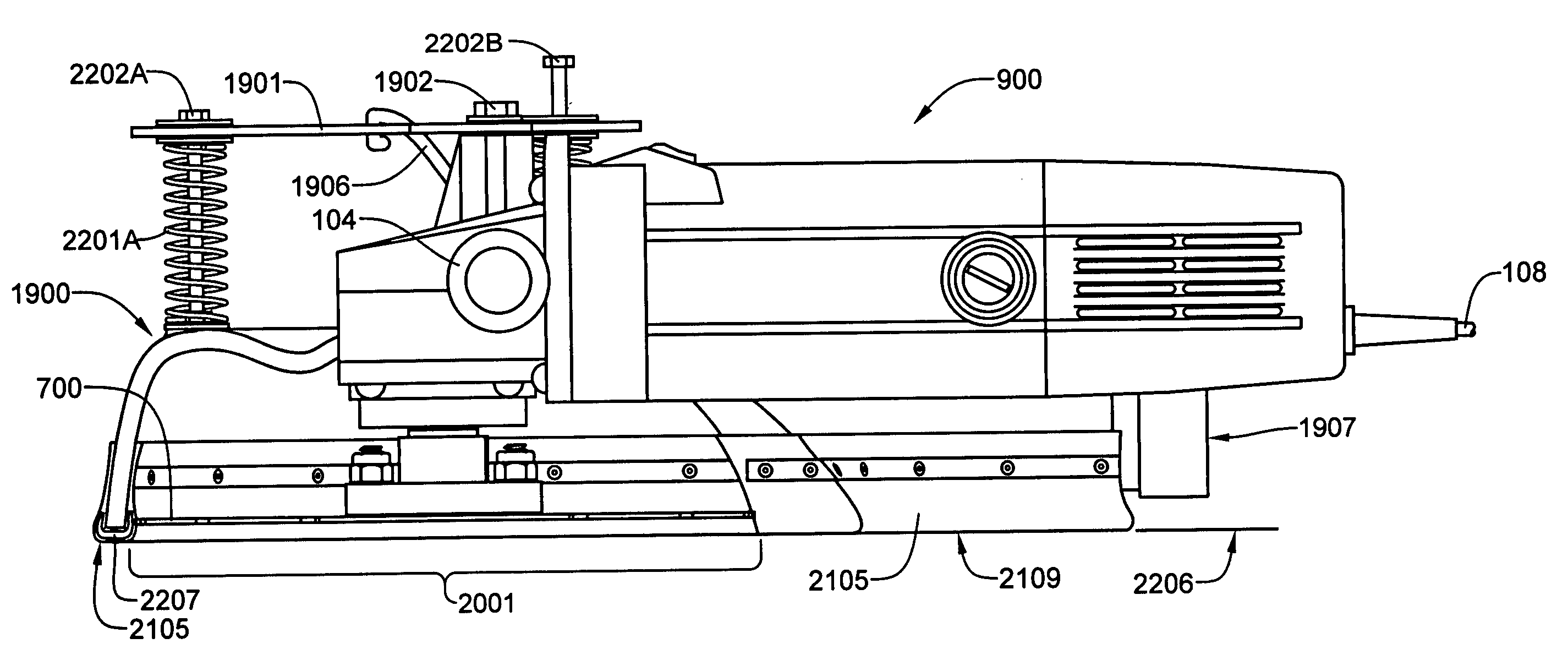

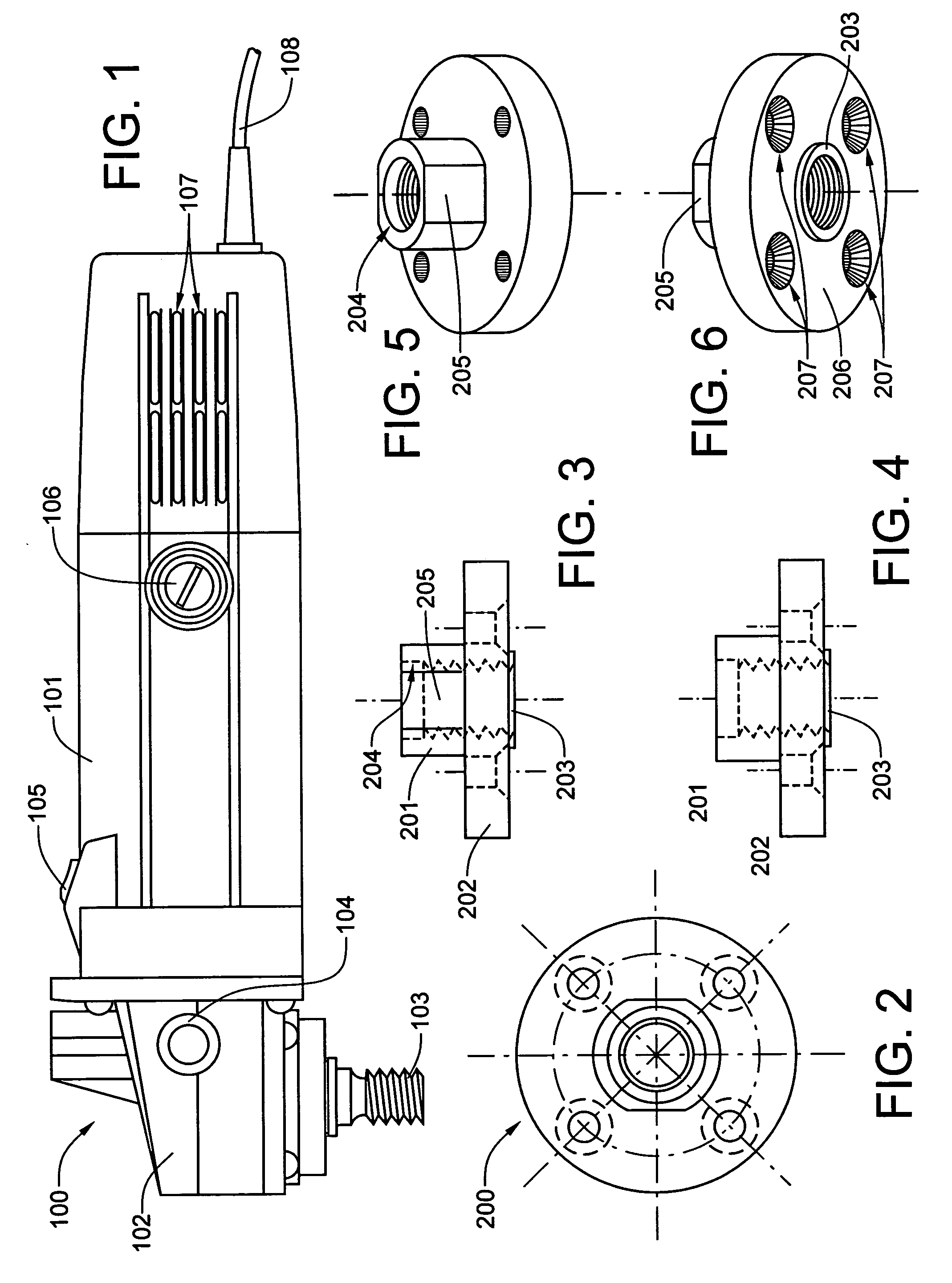

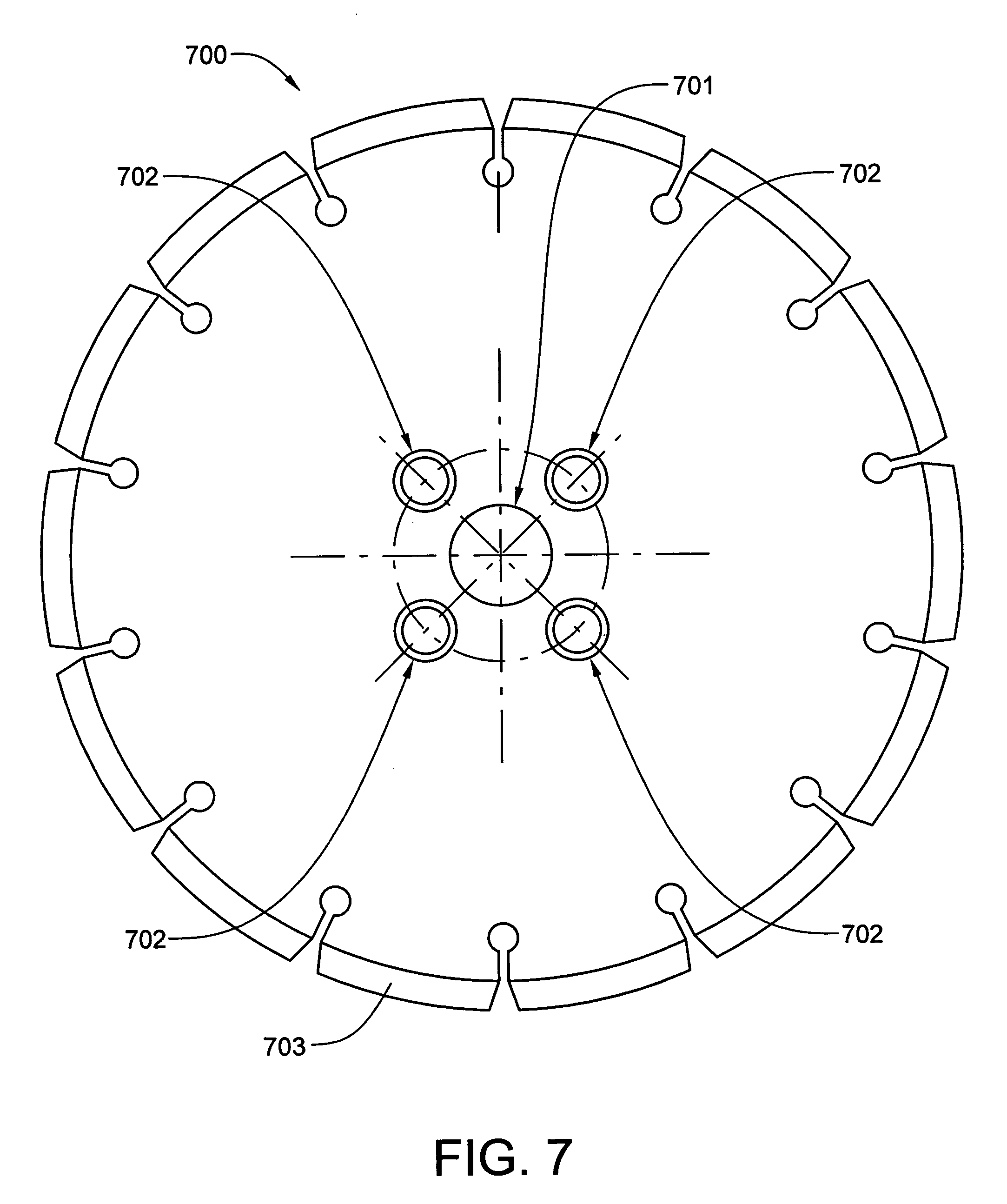

Handheld flush-cutting concrete saw having a dust abatement vacuum hood

A dust abatement vacuum hood, provided for a flush-cutting concrete saw, includes a rigid shell that is preferably either vacuum formed or injection molded from a tough polymeric material that may be reinforced with structural fibers. Alternatively, the vacuum hood may be stamped or cast from a durable metal. The vacuum hood is equipped with a vacuum port to which one end of a vacuum hose may be attached. The opposite end of the vacuum hose is attached to a vacuum cleaner system. The vacuum hood has a spring-mounted attachment bracket that can be bolted directly to the concrete saw. As the blade of the concrete saw rotates, pulverized concrete is discharged into a chamber opening of the vacuum hood. Internally, the vacuum hood is shaped so that the pulverized concrete is directed toward the vacuum port, from where it is directed to the vacuum cleaner system.

Owner:PRECISION CONCRETE CUTTING

Aerosol separator

An arrangement separating a hydrophobic liquid phase from gaseous stream, for crankcase ventilation arrangements as described. The arrangement includes a media stage comprising media formed from a vacuum forming process and including at least 50%, by weight, bi-component fiber therein. Useable media formulations and arrangements are described. Also described are techniques for assembly and use.

Owner:DONALDSON CO INC

Manufacturing Method of Three-Dimensional Cross-Linked Foam for Uppers of Shoes

The present invention provides a manufacturing method of three-dimensional cross-linked foam for uppers of shoes, comprising: preparing a plurality of foaming materials in a planar or three-dimensional shape with a cross-linked foaming suppressed; forming at least one interfacing pattern on at least one foaming material to prevent physical and chemical interactions between the foaming materials, the interfacing pattern formed of at least one interfacing material; cross-linked foaming of the foaming material having the interfacing pattern thereon to obtain a cross-linked foam in a planar shape, the cross-linked foam having at least one inner cavity structure therein; and vacuum molding the planar cross-linked foam in a vacuum molding die to obtain a cross-linked foam having a shape corresponding to a last, the planar cross-linked foam disposed in a cavity of the vacuum molding die, the cavity having a shape corresponding to the last.

Owner:PARK LTD

Door of refrigerator

InactiveCN1896657ALess quantityPrevent leakageDomestic cooling apparatusLighting and heating apparatusEngineeringVacuum forming

This invention relates to fridge door. The fridge door gasket of fridge outer door is made from ABS material plates and vacuum forming. The sealing components, which prevent the foaming liquid constituting the heat-insulating layer from leaking, are filled between the outer door and fridge door gasket. The sealing component includes the positioning part positioning in the positioning groove on the outer door; and the clinging part, which firmly attaches to the inner side of fridge door gasket. The positioning part is set with the fixing groove that can insert into the outer door. Several concave-convex parts are formed at anterior surface of the clinging part. This invention can reduce the material using and prevent foaming liquid leaking.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Vacuum forming technique for sandwich structure piece of composite material of fiberglass-reinforced plastics

ActiveCN1915650AFlat surfaceNo stratificationSynthetic resin layered productsGlass fiberOptoelectronics

A composite glass fiber reinforced plastics material with sandwich structure is composed of an external layer made of glass fiber reinforced plastics and coated by water-proof resin, an internal layer made of glass fiber reinforced plastics, and a core layer with cellular structure or made of foam plastics. Its vacuum forming technology includes such steps as respectively preparing mould, external layer, internal layer and core layer, molding, and vacuum solidifying.

Owner:上海之合玻璃钢有限公司

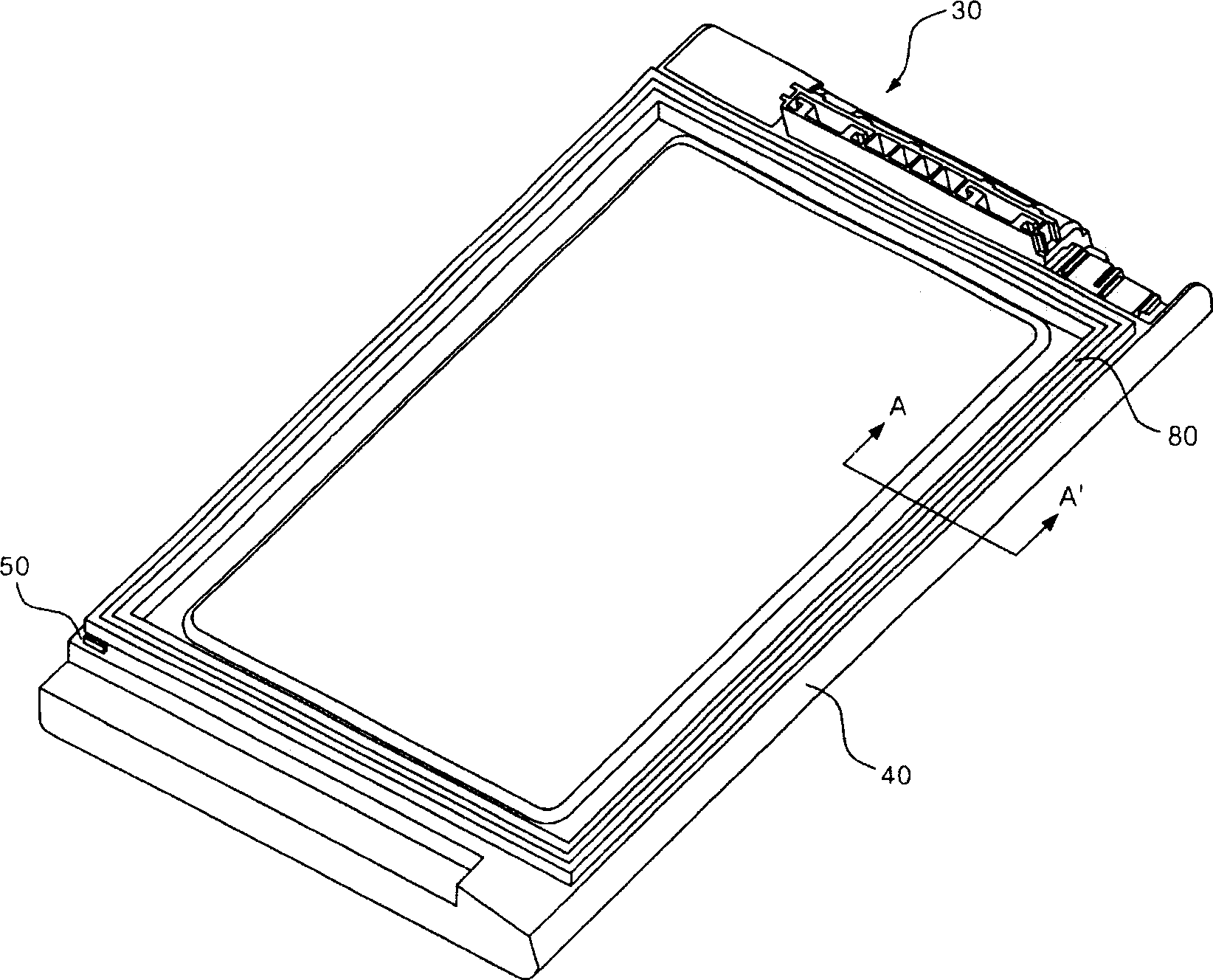

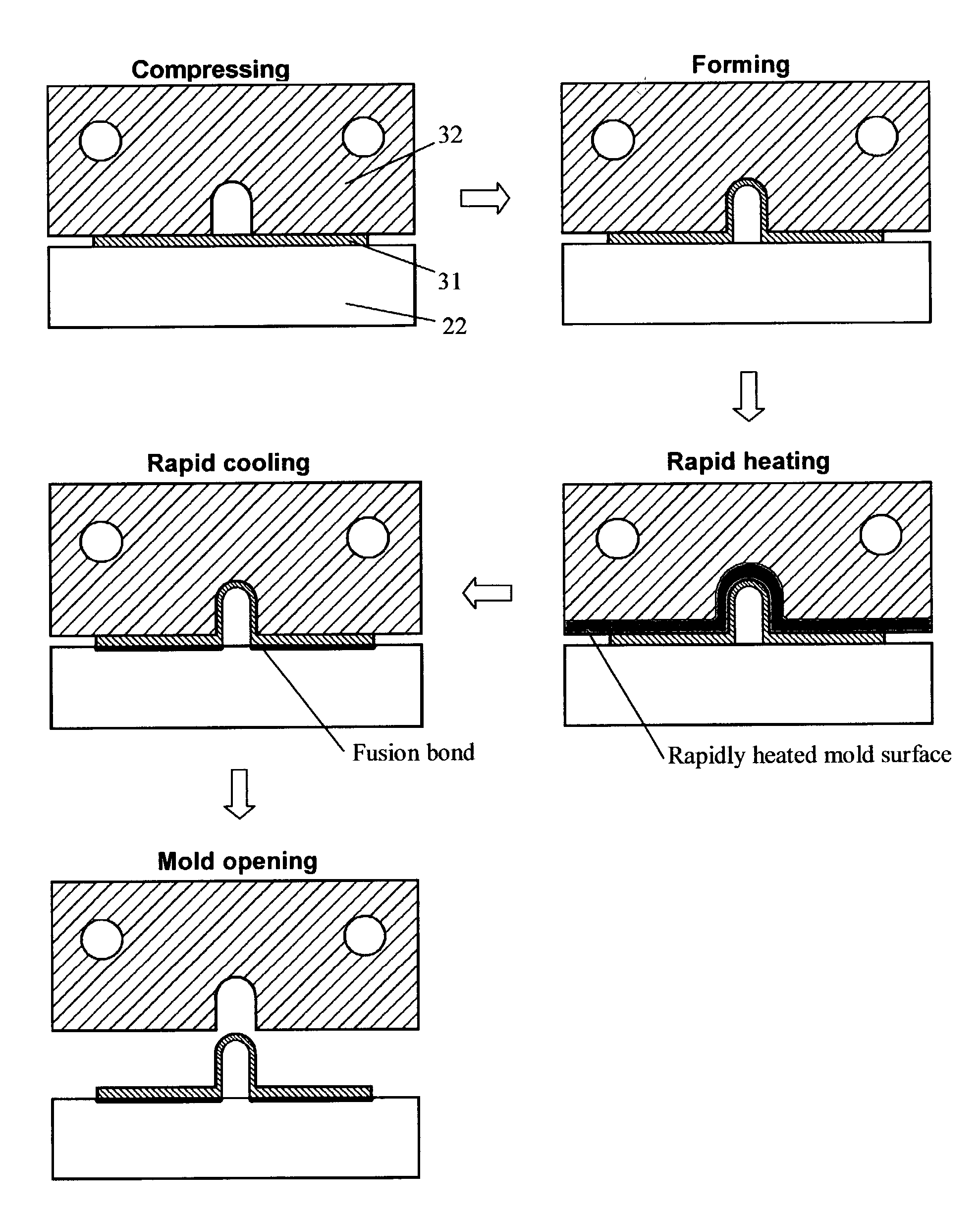

Microchannel fabrication

InactiveUS20040046290A1Volume/mass flow by thermal effectsFixed microstructural devicesBlow moldingEconomic production

A design of microchannels and a method for economic production of such microchannels. The new microchannel design comprises a thin thermoplastic film and a relatively thick substrate to form microchannels in-between. The microchannels are displaced on the film side. The method for fabricating such microchannels is a hybrid process combining compression, and blowing or vacuum forming to form microchannels between the film and the substrate. During the process, the film is placed on the top of the substrate. A mold or die with to-be-replicated microchannels clamps the film against the substrate. Either blow molding or vacuum forming is then carried out to deform the film and replicate the microchannels. Rapid heatable and coolable molds are preferred to soften the film and form bonds between the film and the substrate while short cycle time is maintained.

Owner:KIM BYUNG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com