Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2302results about "Domestic footwear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

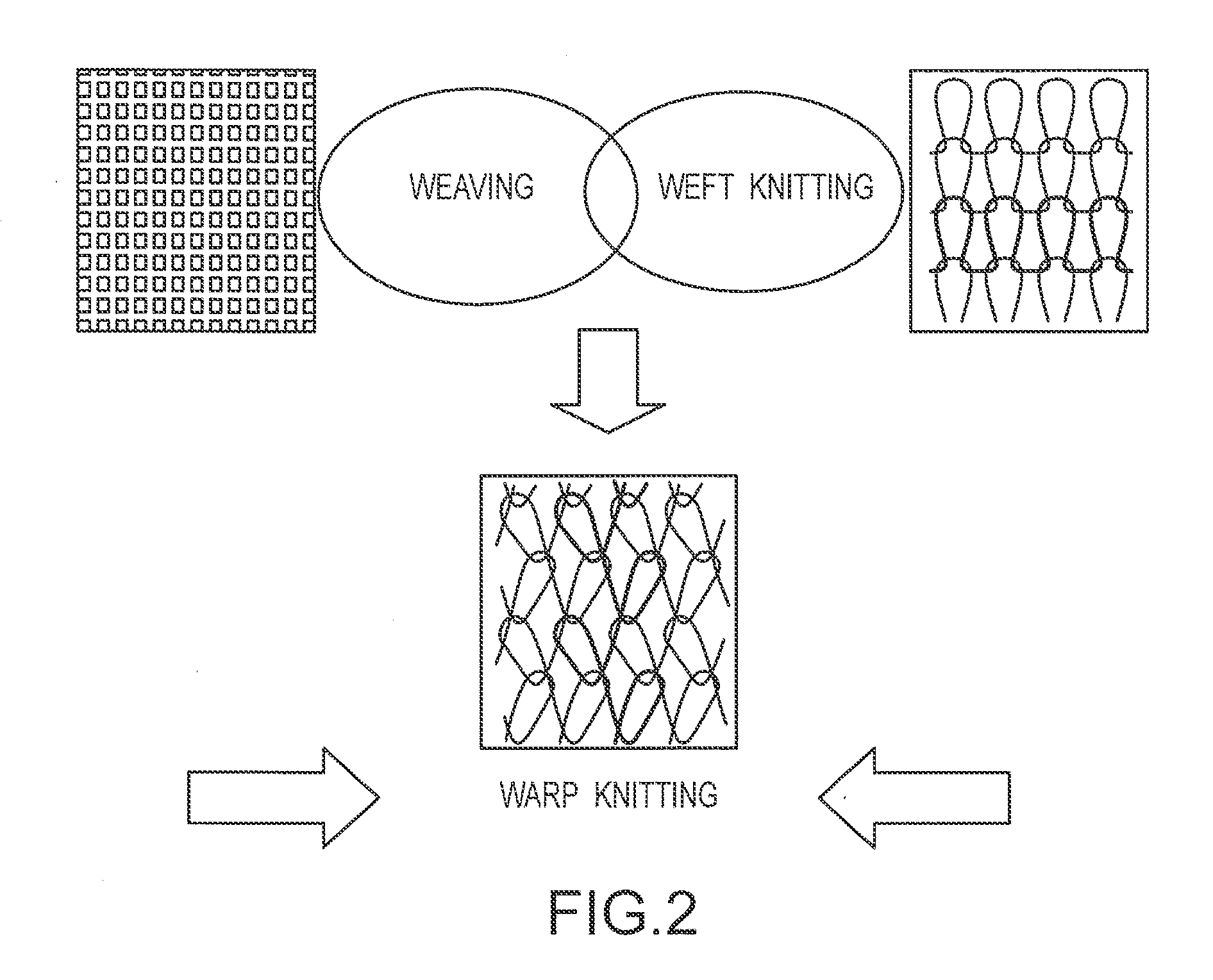

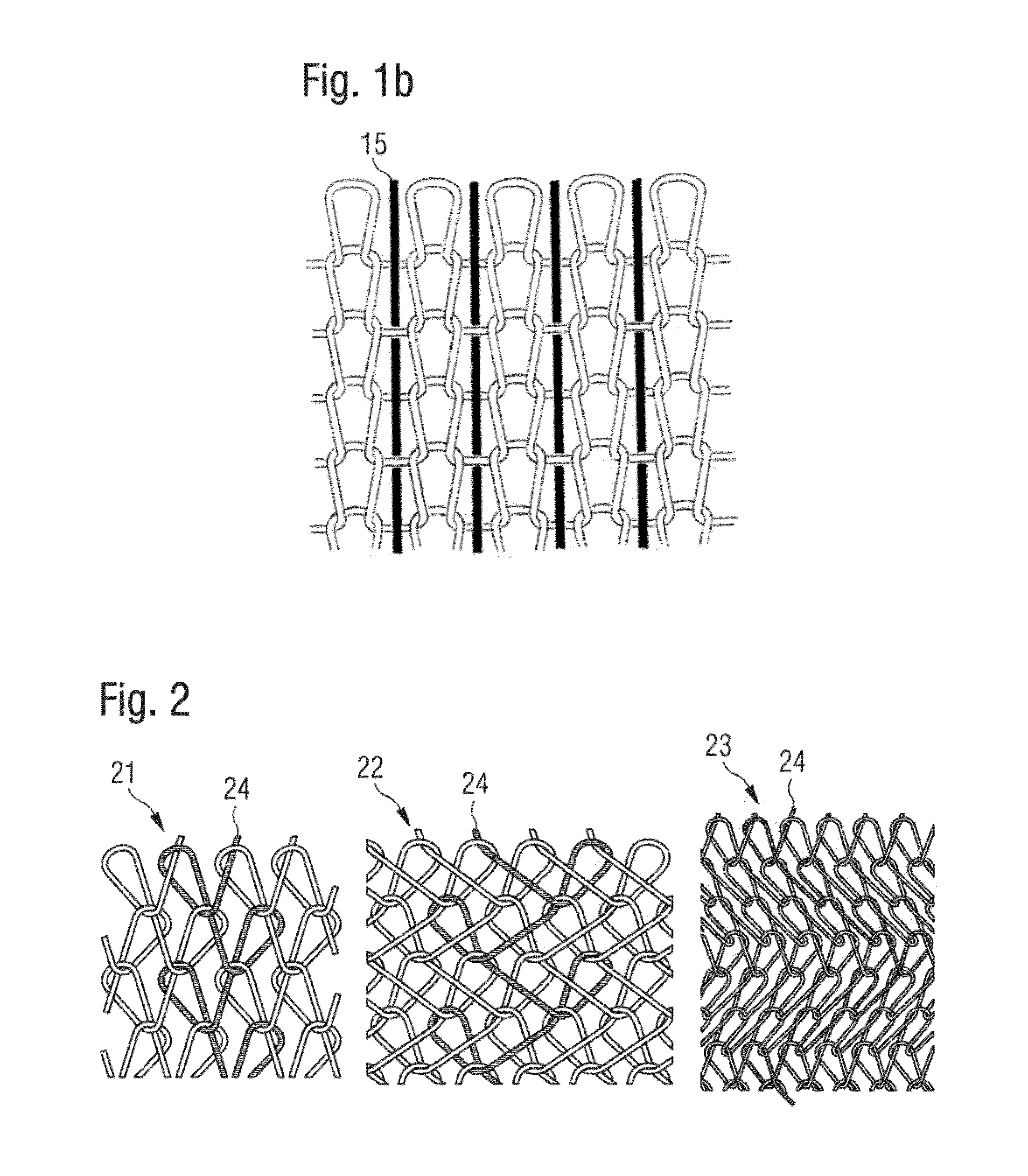

Seamless upper for footwear and method for making the same

InactiveUS20120255201A1Ease and efficiency of productionShorten assembly timeShoemaking devicesLastingInterior spaceEngineering

Owner:DASHAMERICA INC D B A PEARL IZUMI USA

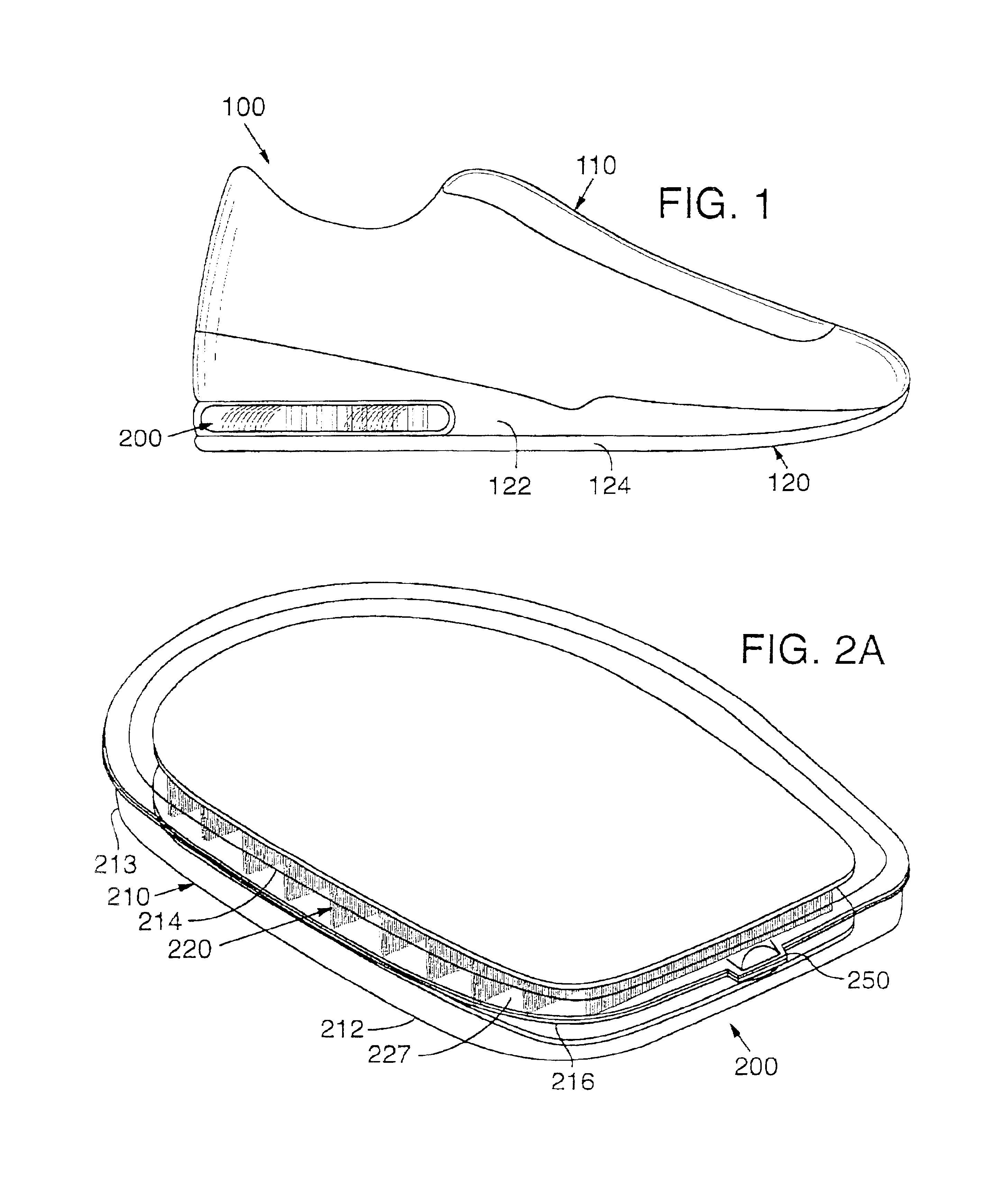

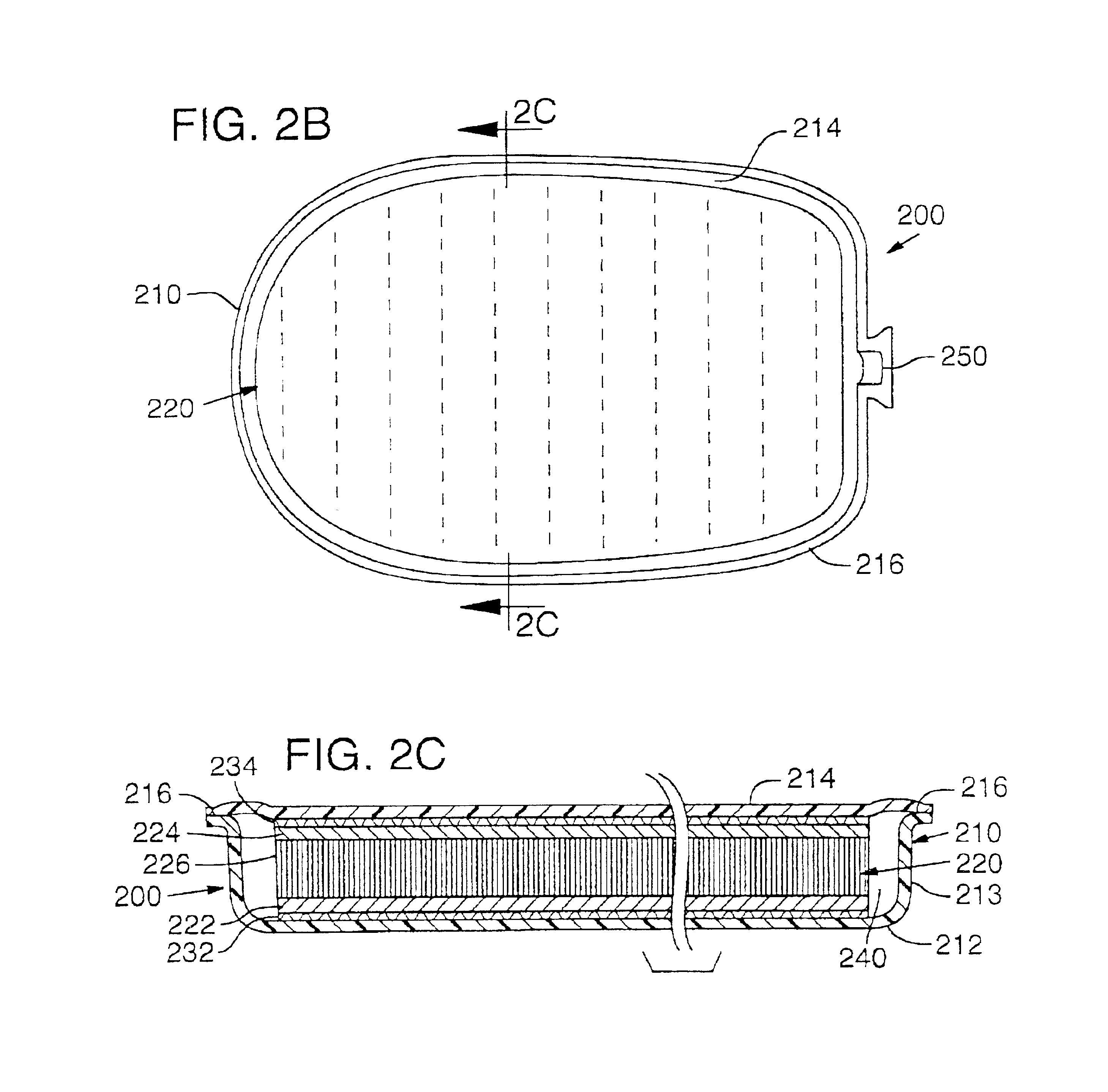

Fluid-filled bladder incorporating a foam tensile member

Owner:NIKE INC

Shoe sole component and shoe sole component construction method

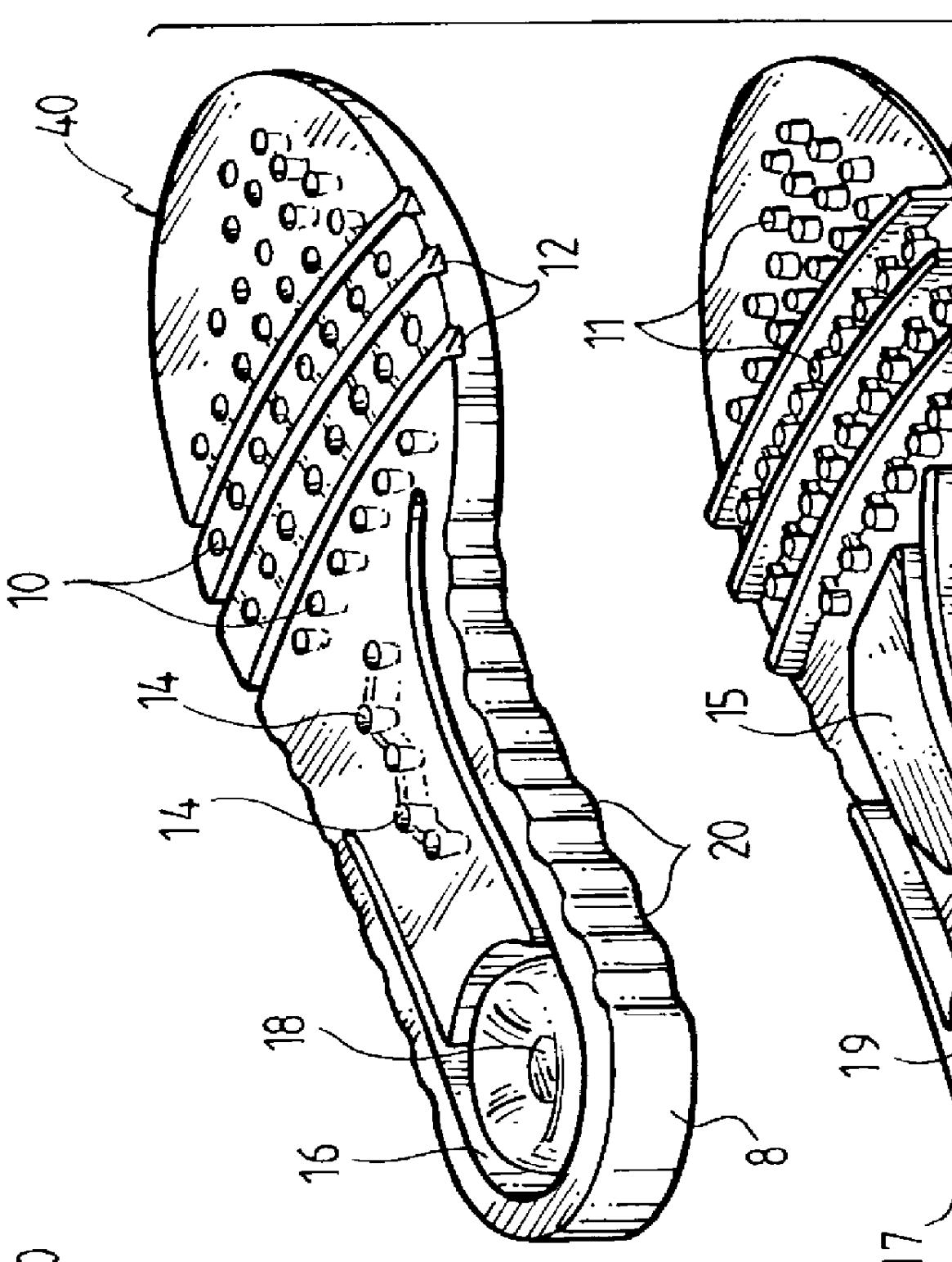

A high polymer resin material is configured into a shoe sole component having a plurality of inwardly extending indentations in one or both of the top and bottom members of the component. The indentations extend into the interval between the members and adjacent to the opposite member to provide support members for the sole component. The sole component can be constructed by molding upper and lower sole component halves wherein the molds are configured to provide indentations in the top and bottom members. The upper and lower sole component halves are then joined to complete the sole component.

Owner:LIESENFELD MARY C +1

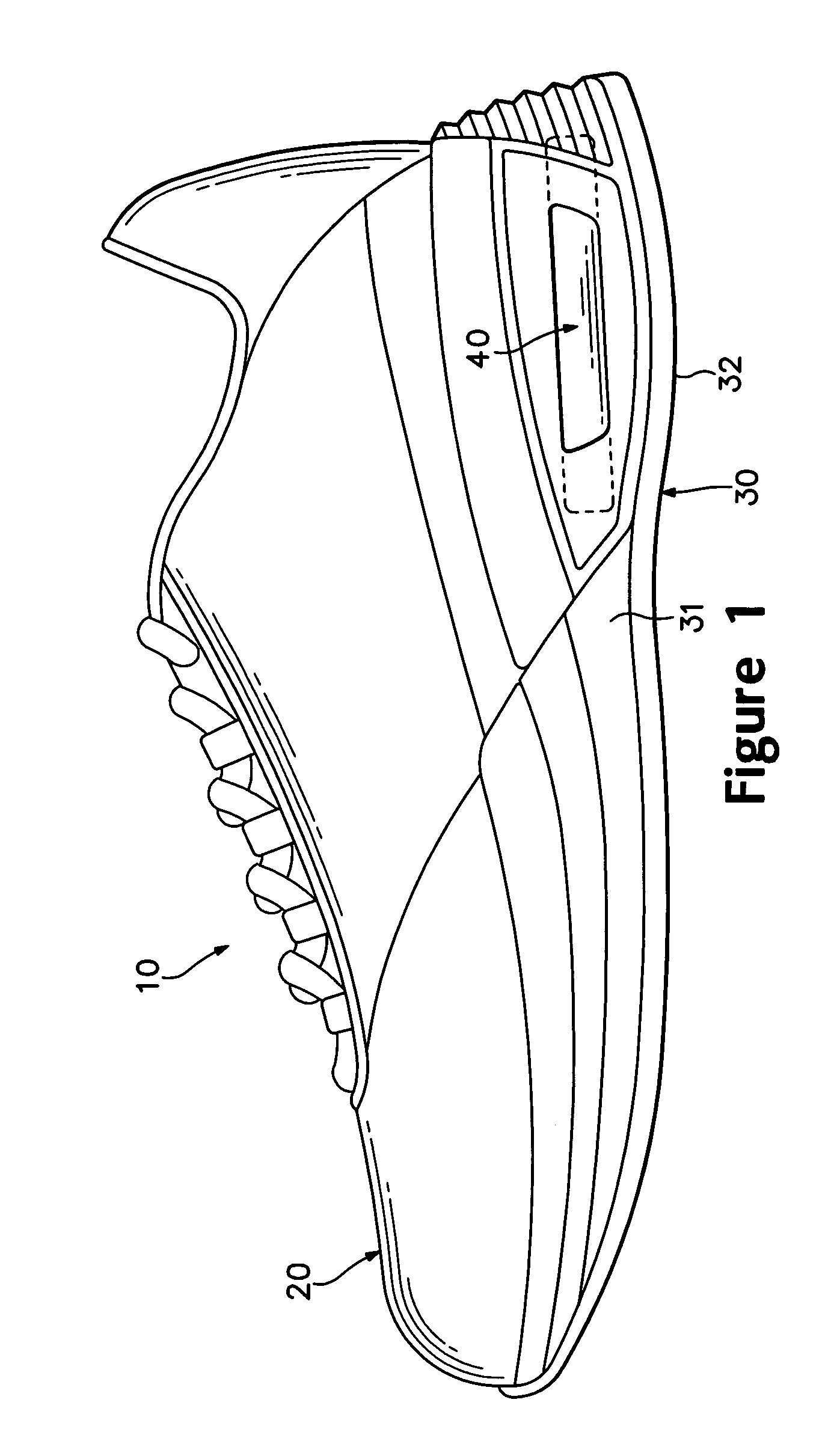

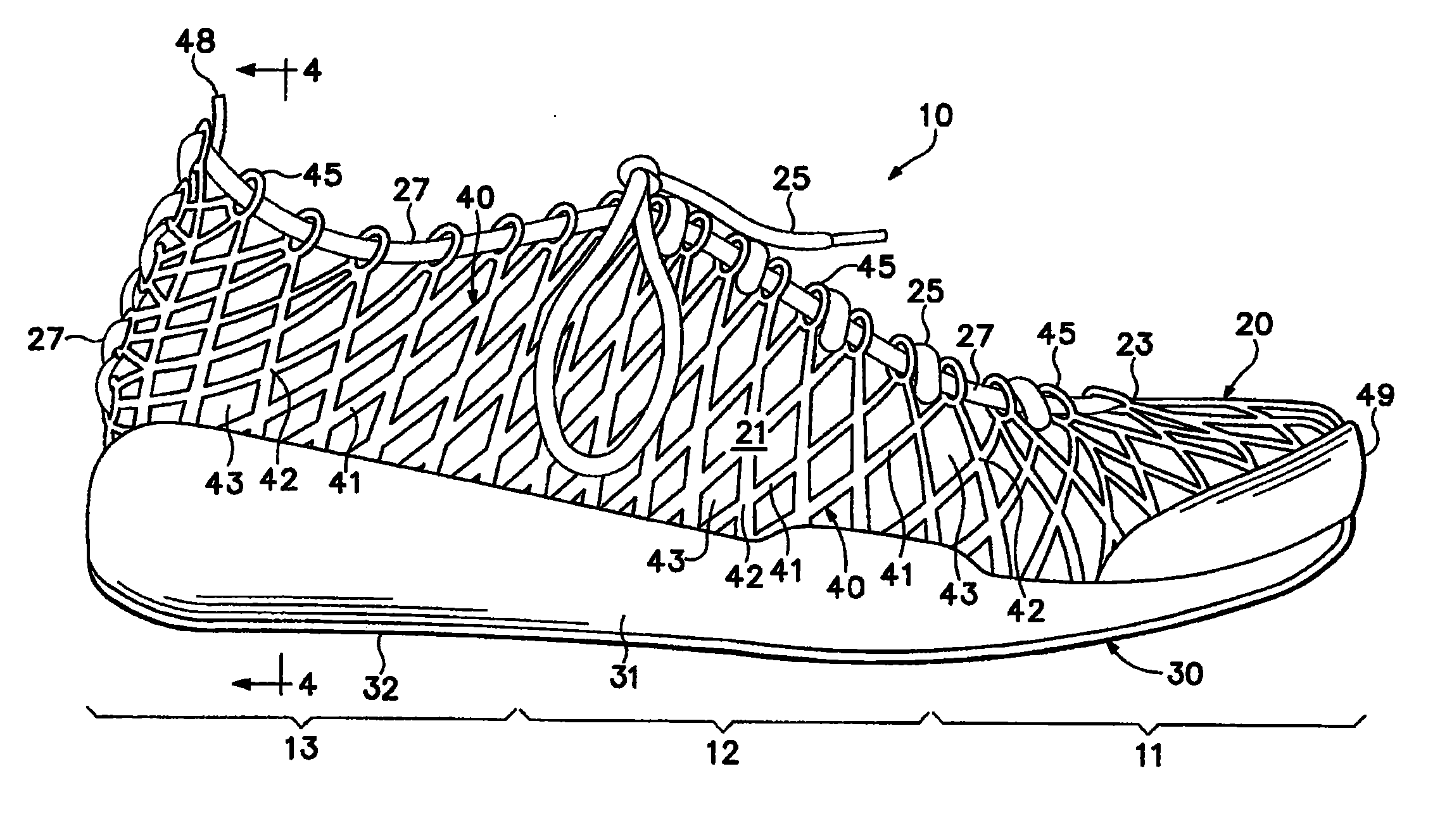

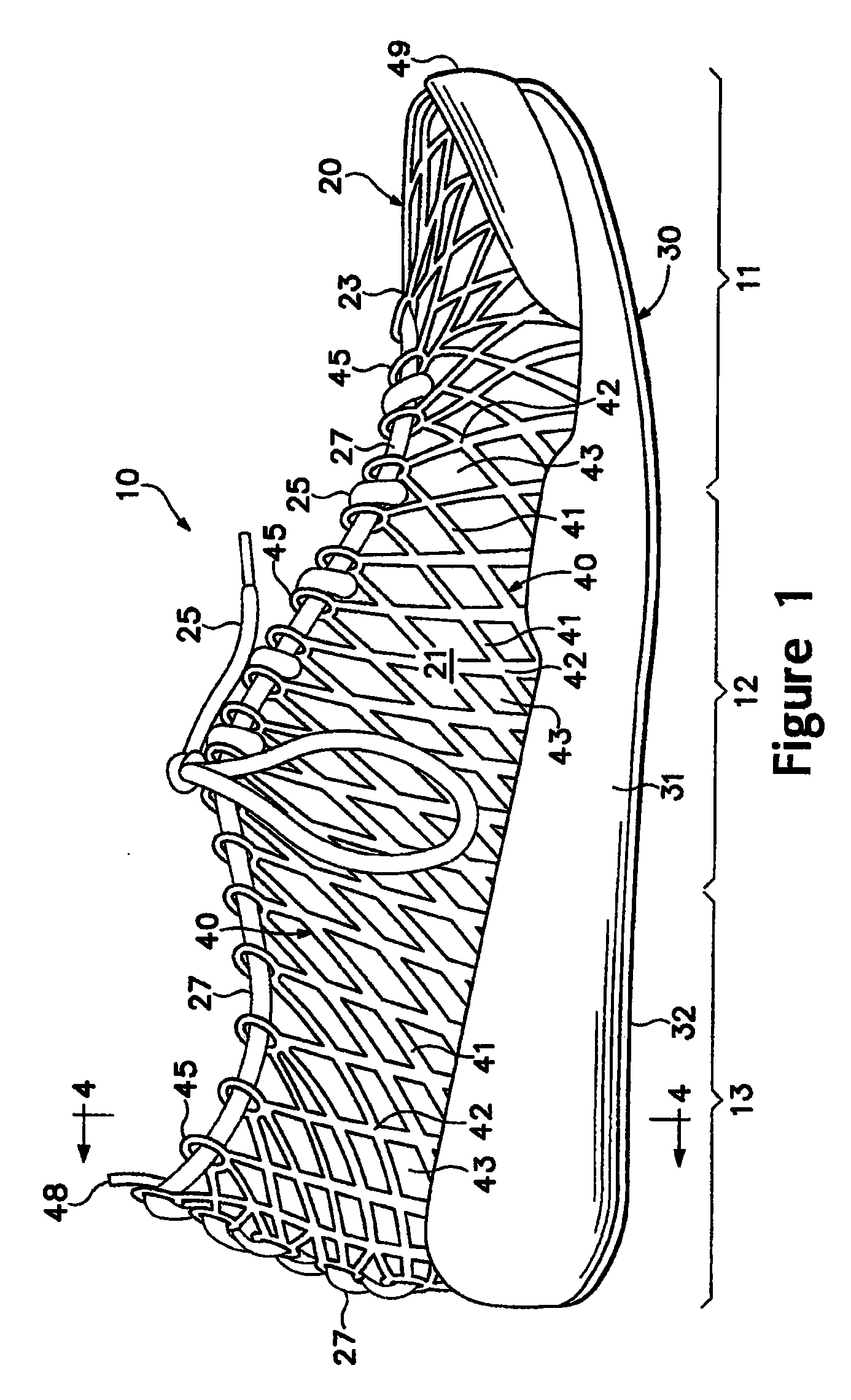

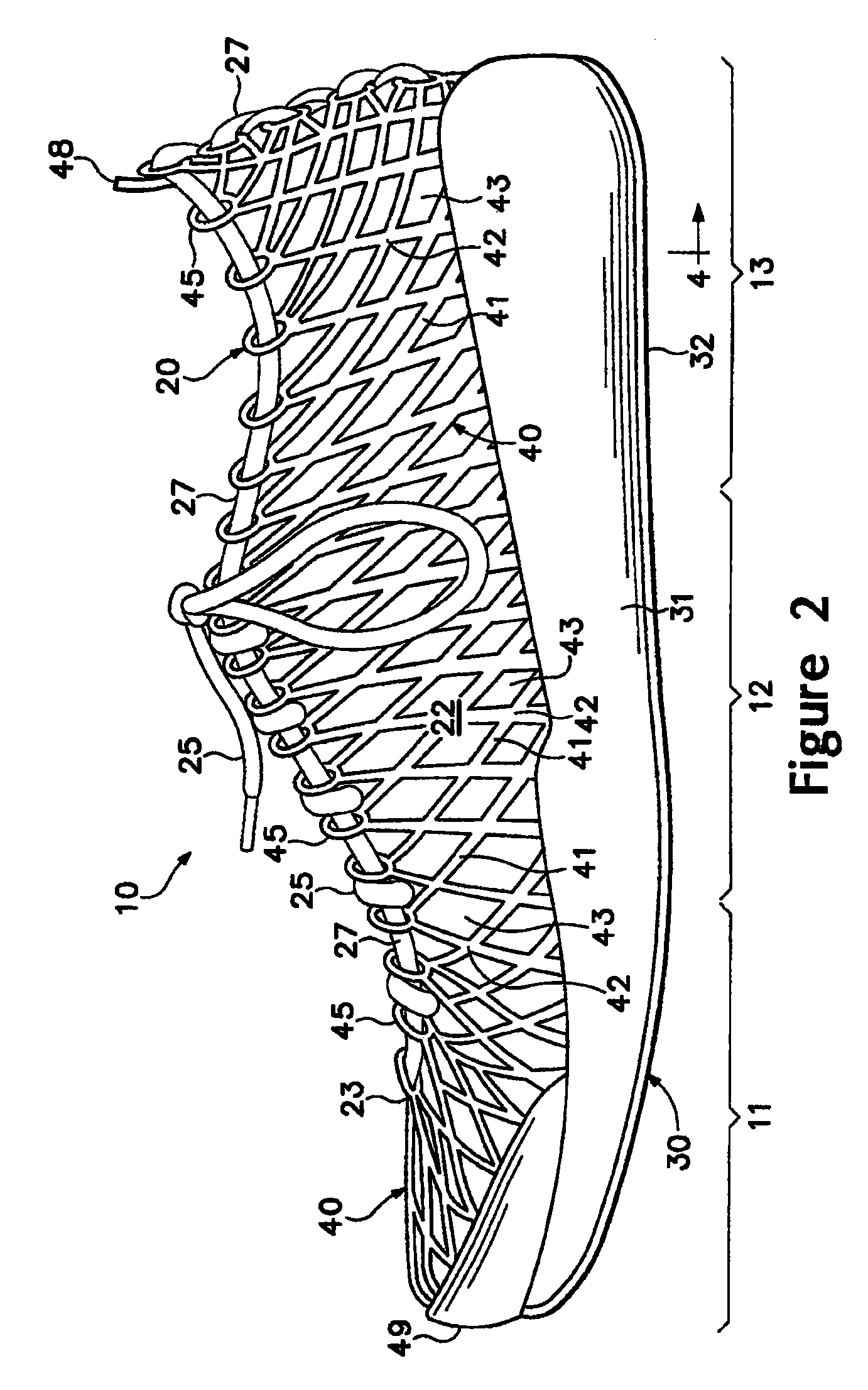

Article of footwear having an upper with a matrix layer

Articles of footwear, including athletic footwear, include one or more of: (a) a sole structure; (b) an upper having lateral and medial side elements engaged with the sole structure, the upper made from a polymer matrix structure that extends through at least a heel region; (c) a size adjustment mechanism located at the heel region; (d) a heel tongue element located adjacent the size adjustment mechanism; (e) a shoe securing mechanism; (f) an instep tongue member; and / or (g) a bootie member located at least partially within the foot-receiving chamber. Methods of manufacturing such articles of footwear also are disclosed.

Owner:NIKE INC

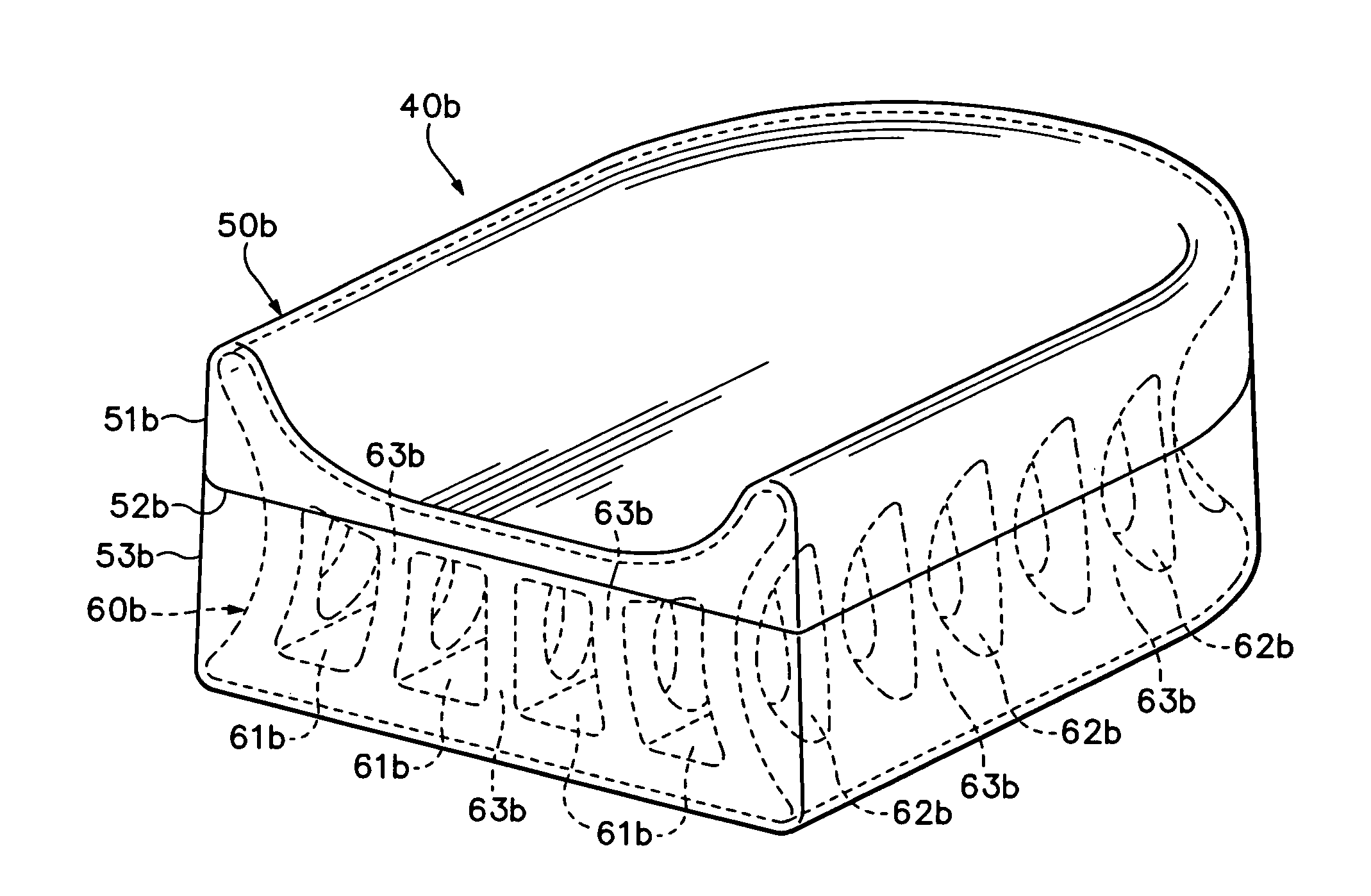

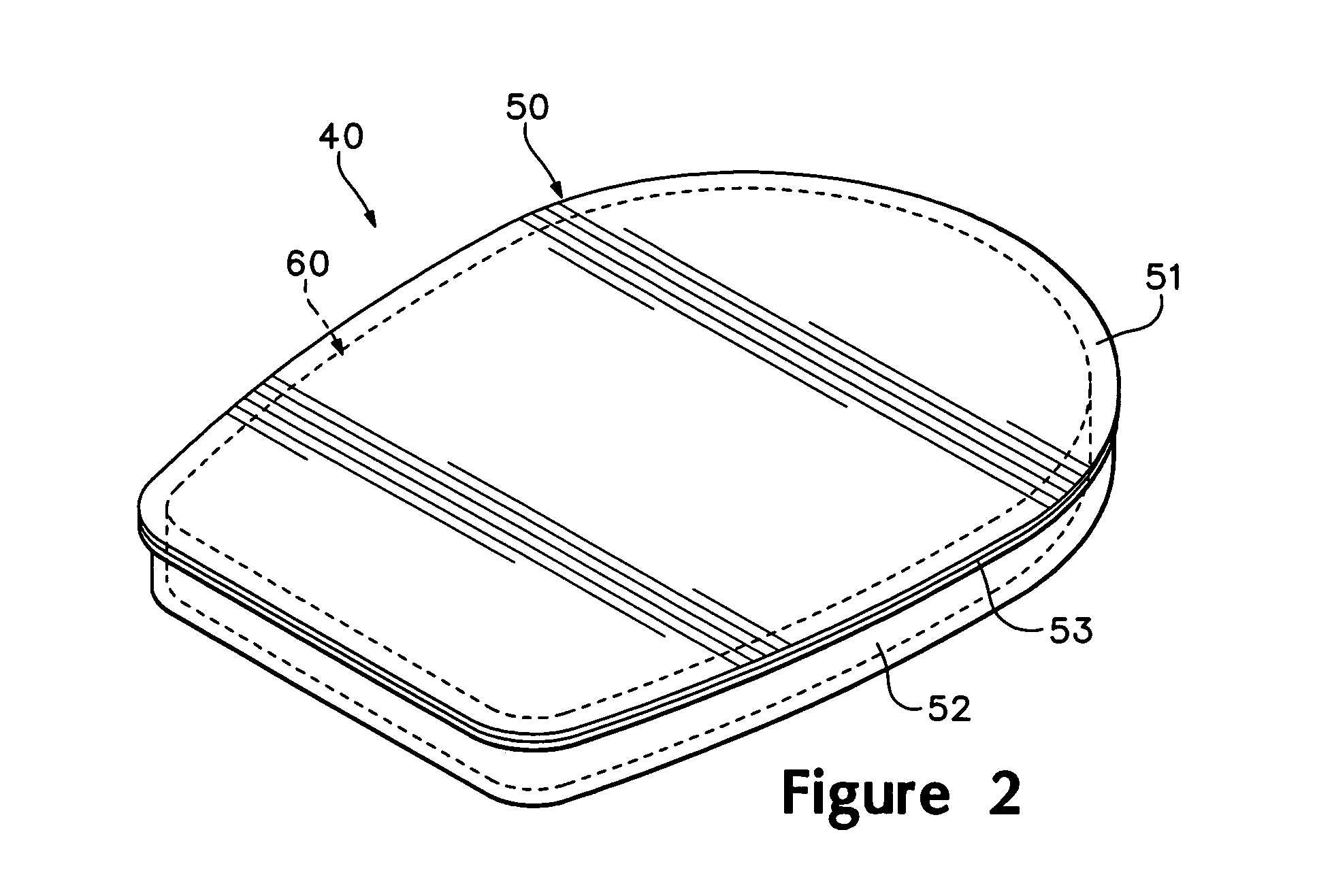

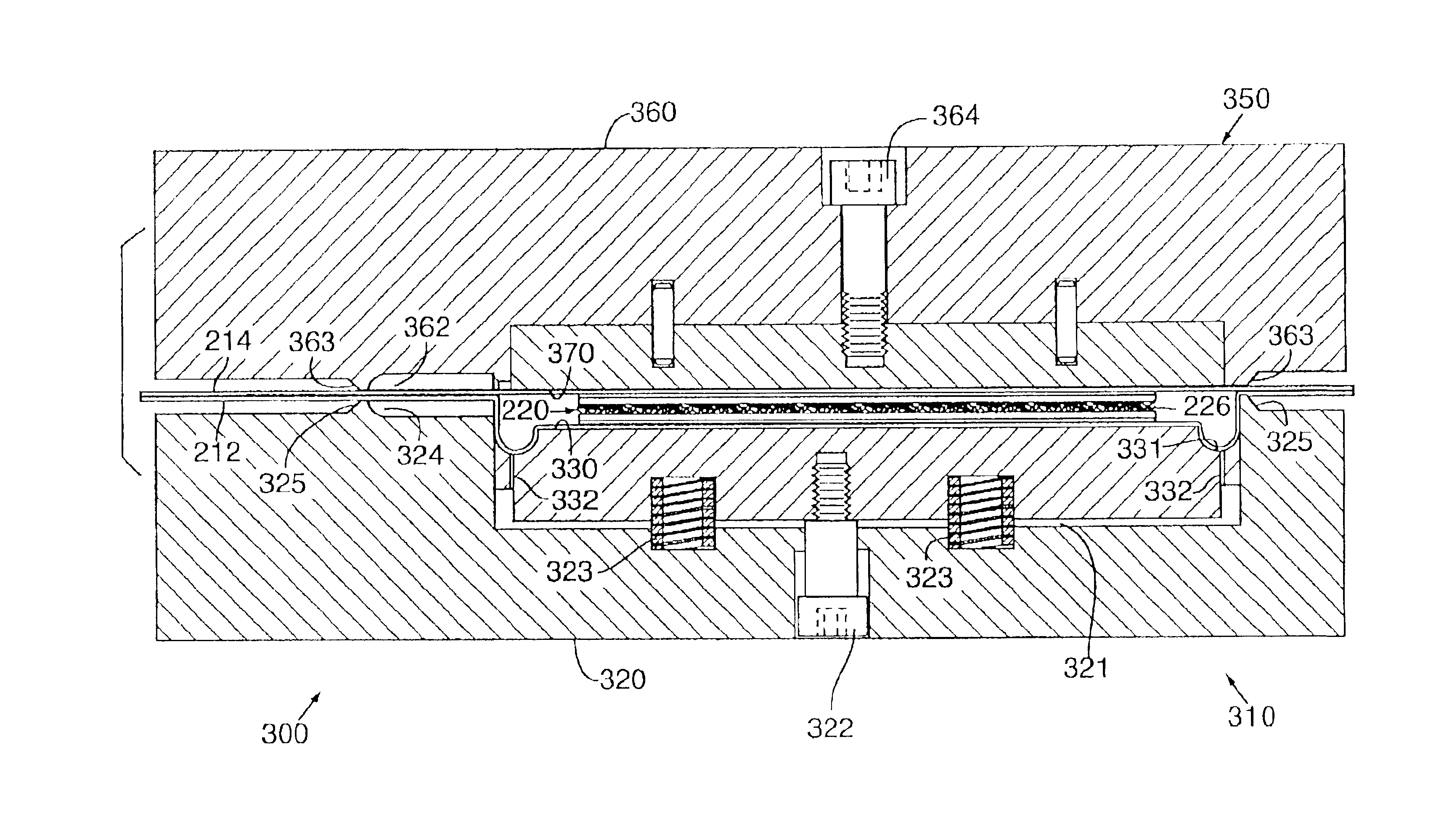

Method of thermoforming a bladder structure

InactiveUS6837951B2Increase awarenessImprove efficiencySolesOrnamental textile articlesBladder structureThermal contact

A method for thermoforming a resilient, fluid-filled bladder structure with thermal contact molding is disclosed. The bladder includes two sheets of thermoplastic material that are separated by at least one core formed of two spaced outer layers connected together by a plurality of connecting members. The bladder is formed by bonding the sheets to the core, bonding the sheets to each other around the periphery of the core and forming a sidewall between the sheets in a single mold. A fluid is then inserted into the space bounded by the peripheral bond and the two sheets such that the connecting members are extended.

Owner:NIKE INC

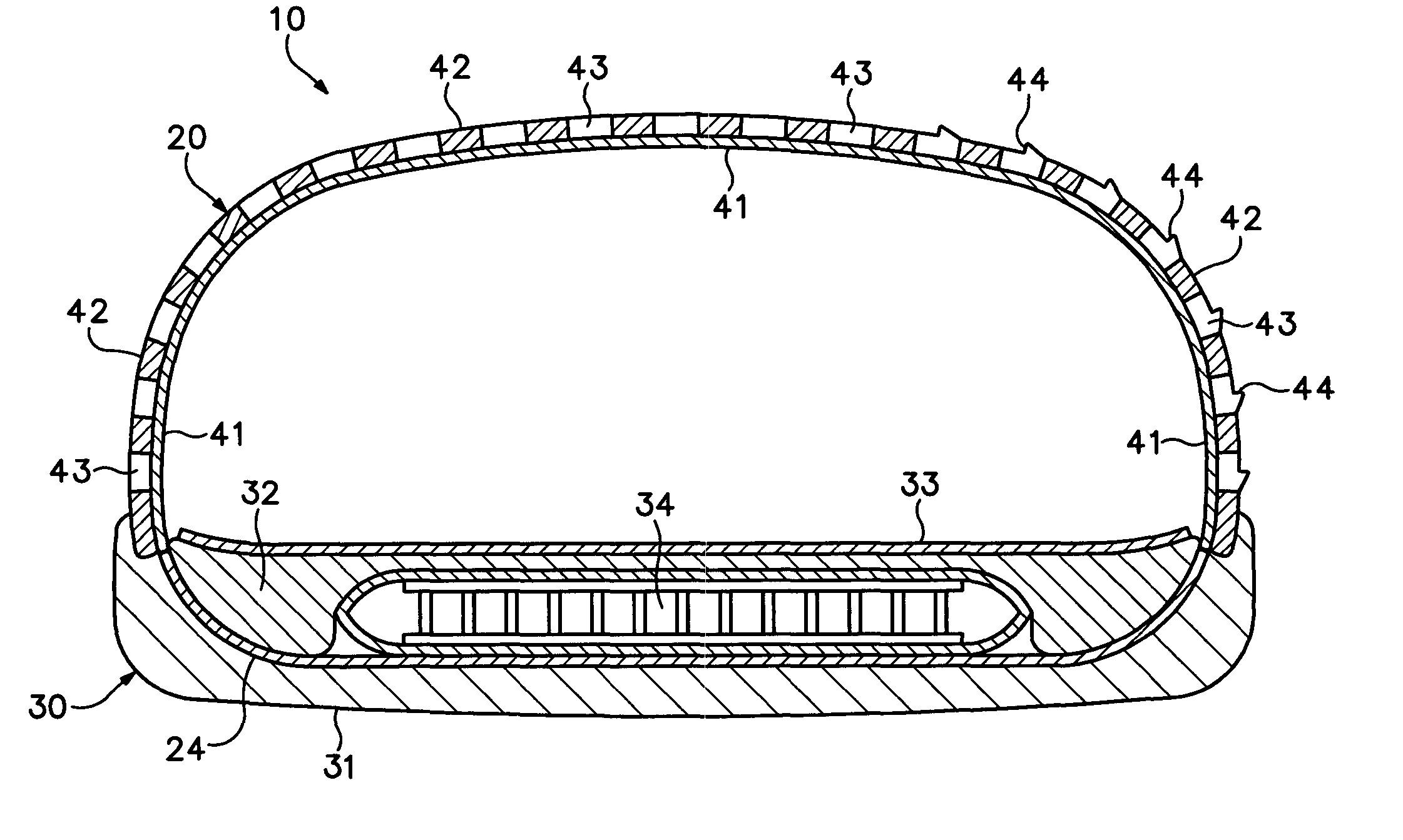

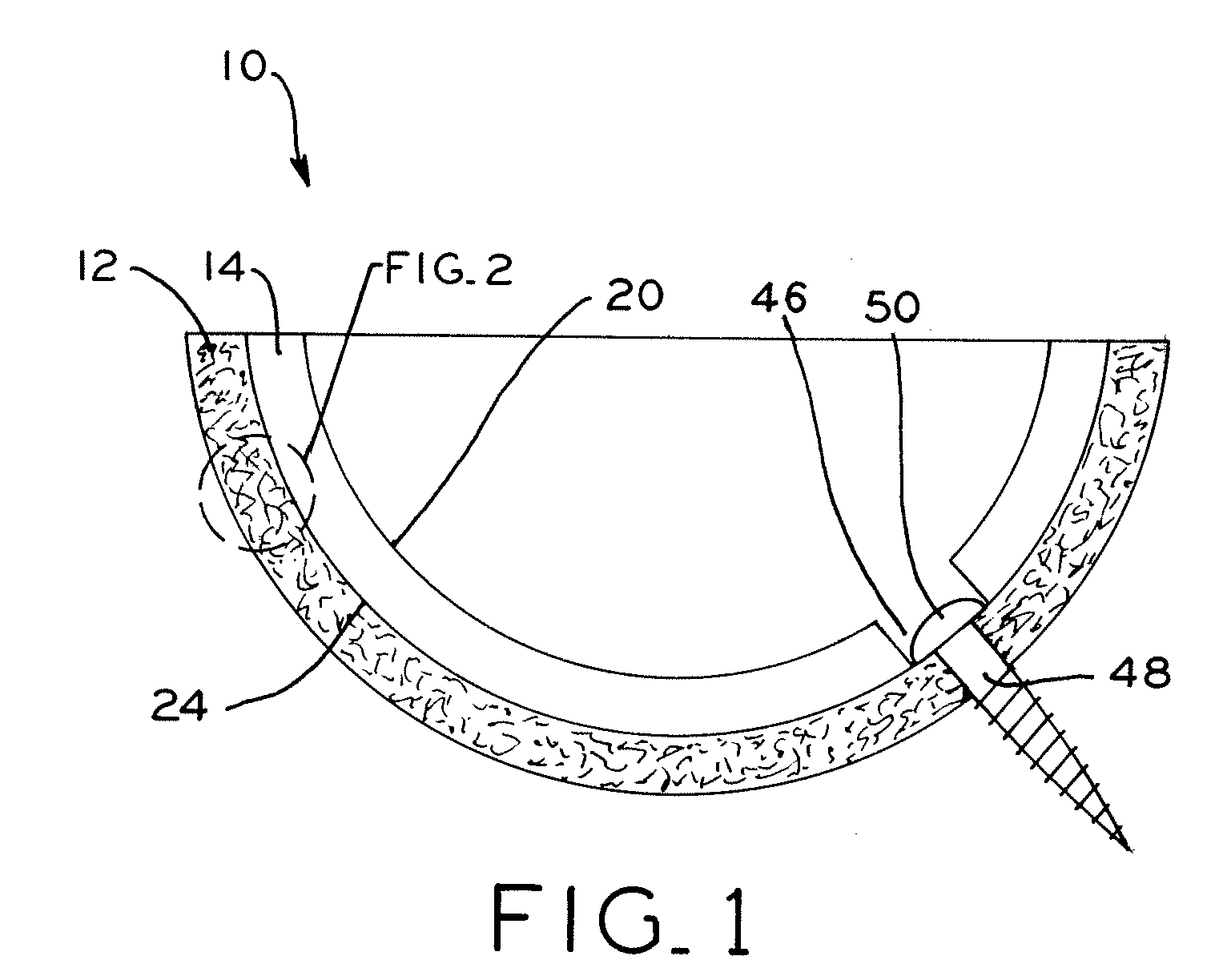

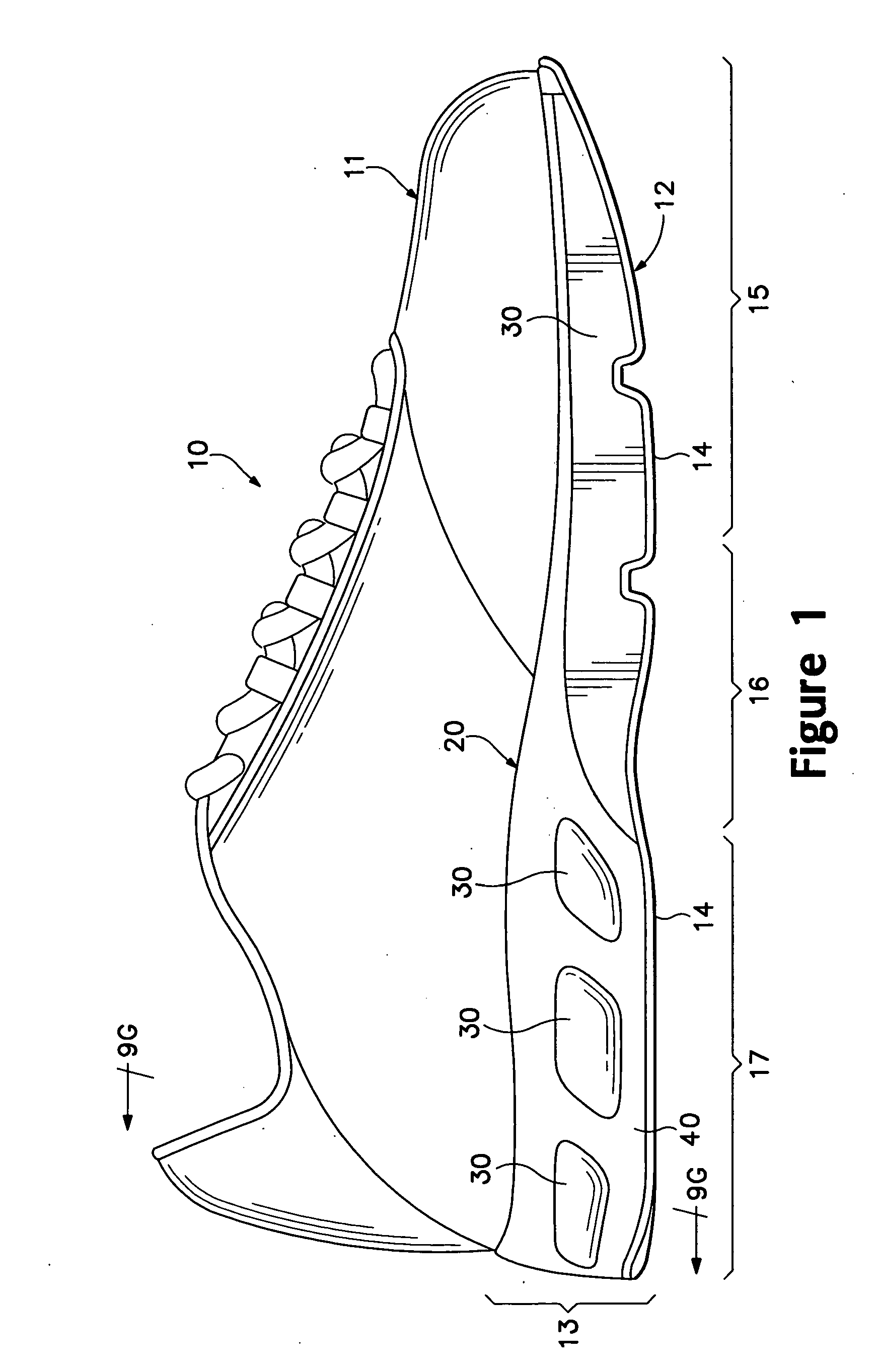

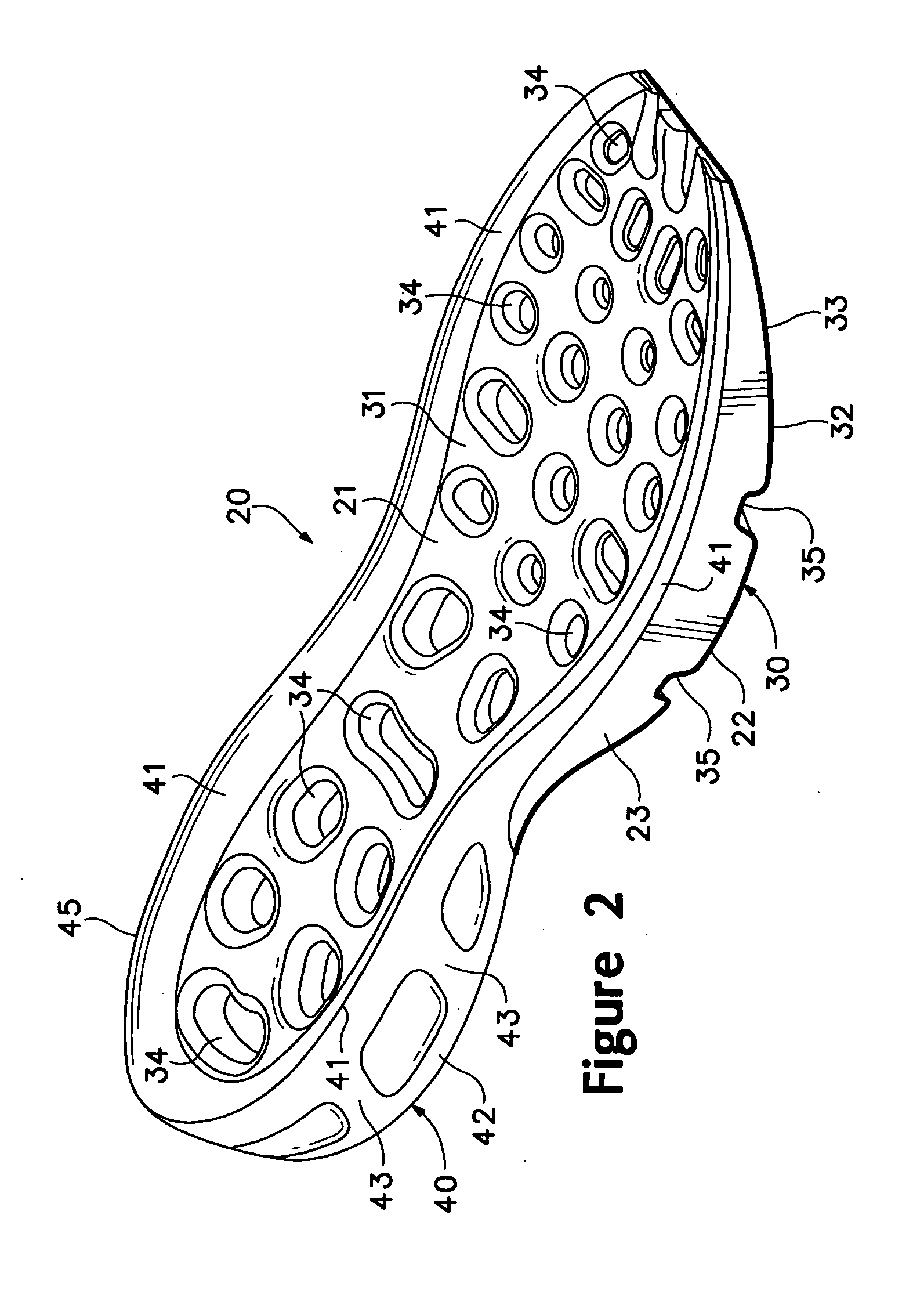

Article of footwear having a fluid-filled bladder with a reinforcing structure

A sole component and a method of manufacturing the sole component are disclosed. In general, the sole component includes a fluid-filled bladder and a reinforcing structure extending around the bladder. The reinforcing structure is bonded to the exterior of the bladder, and may be recessed into the bladder. In some embodiments, the reinforcing structure extends along the side surfaces of the bladder and between upper and lower surfaces of bladder. In manufacturing the sole component, the reinforcing structure may be located within a mold, and the polymer material forming the bladder may be bonded to the reinforcing structure during the molding process.

Owner:NIKE INC

Compression molded footwear and methods of manufacture

Owner:THE TIMBERLAND COMPANY

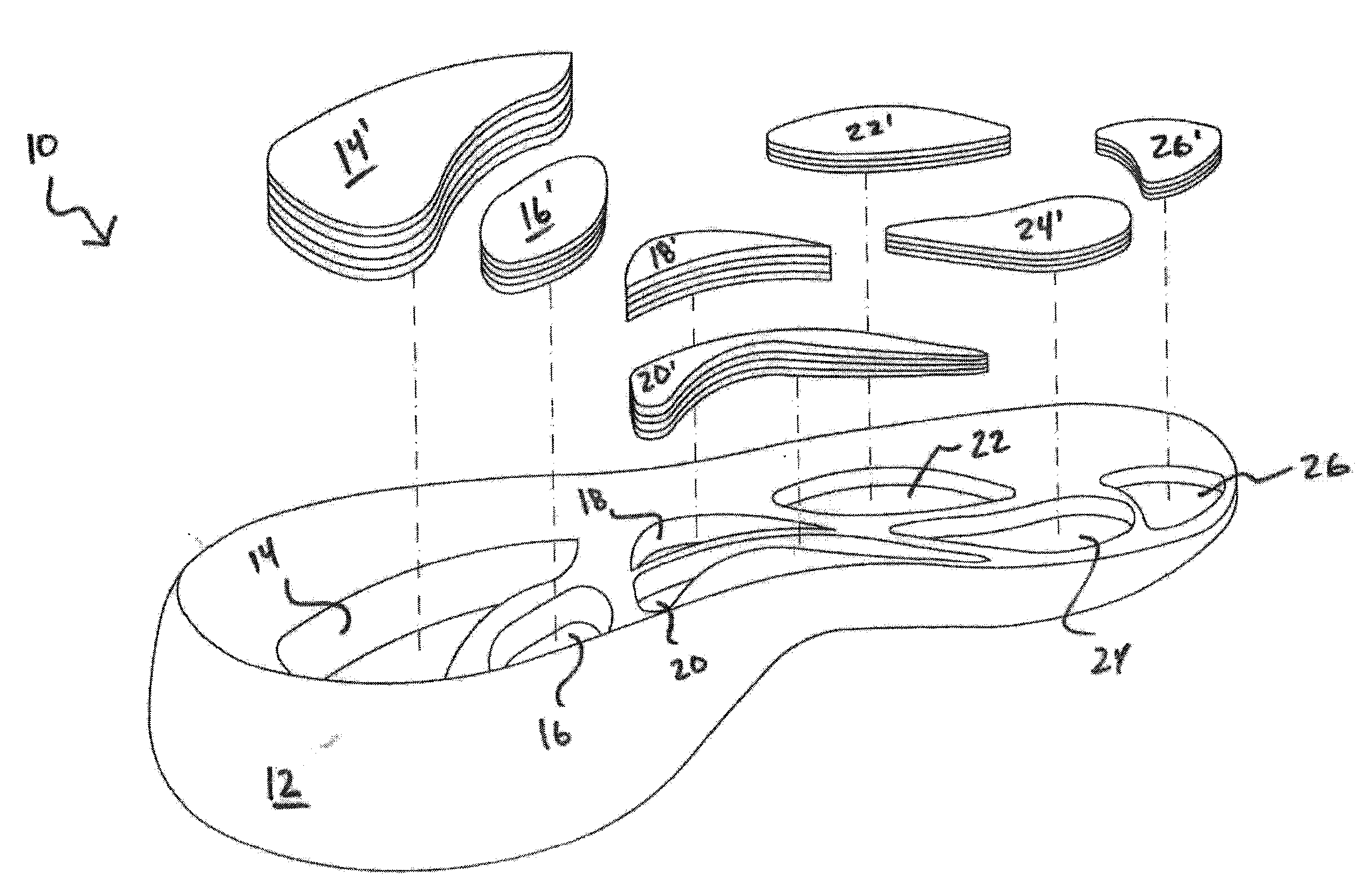

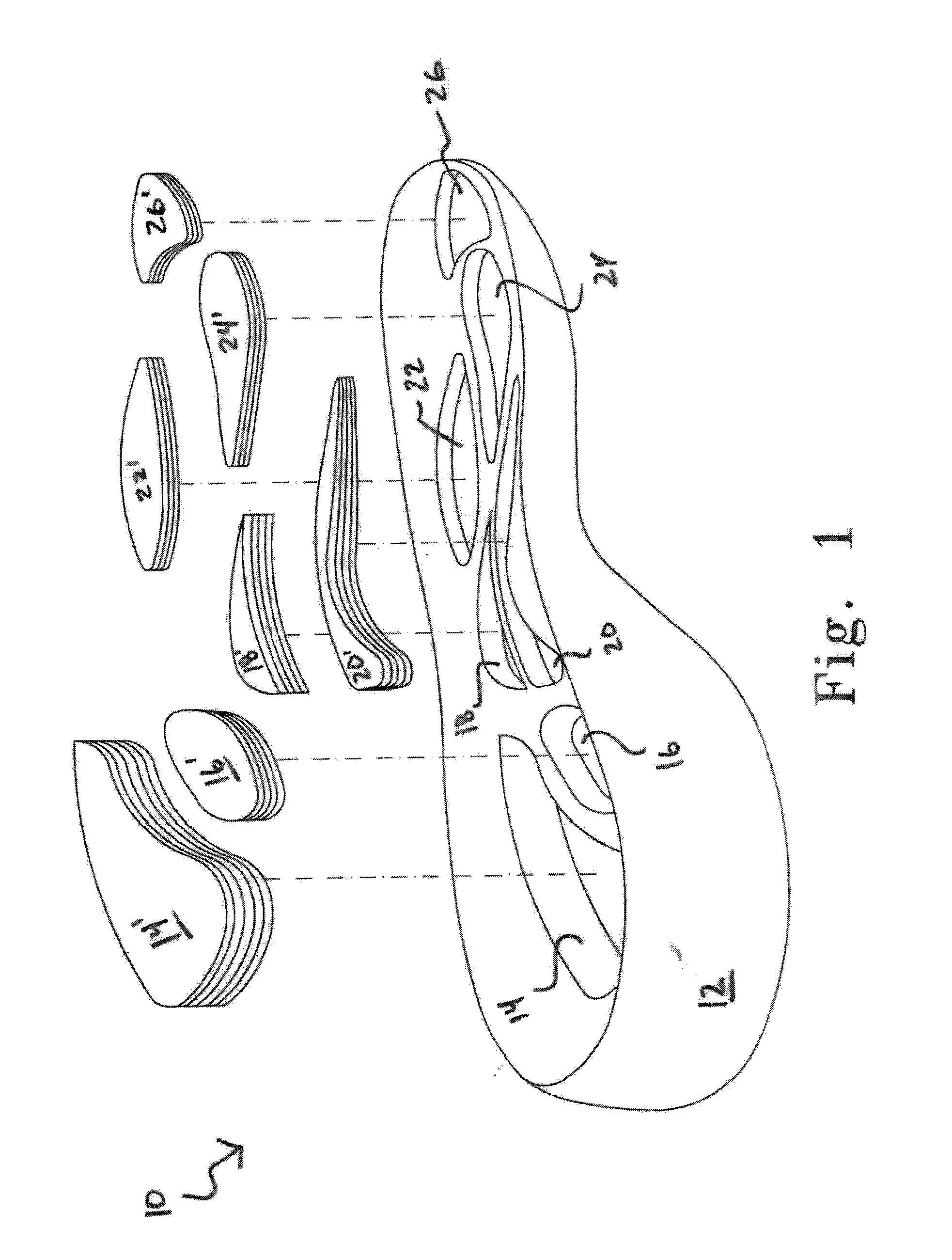

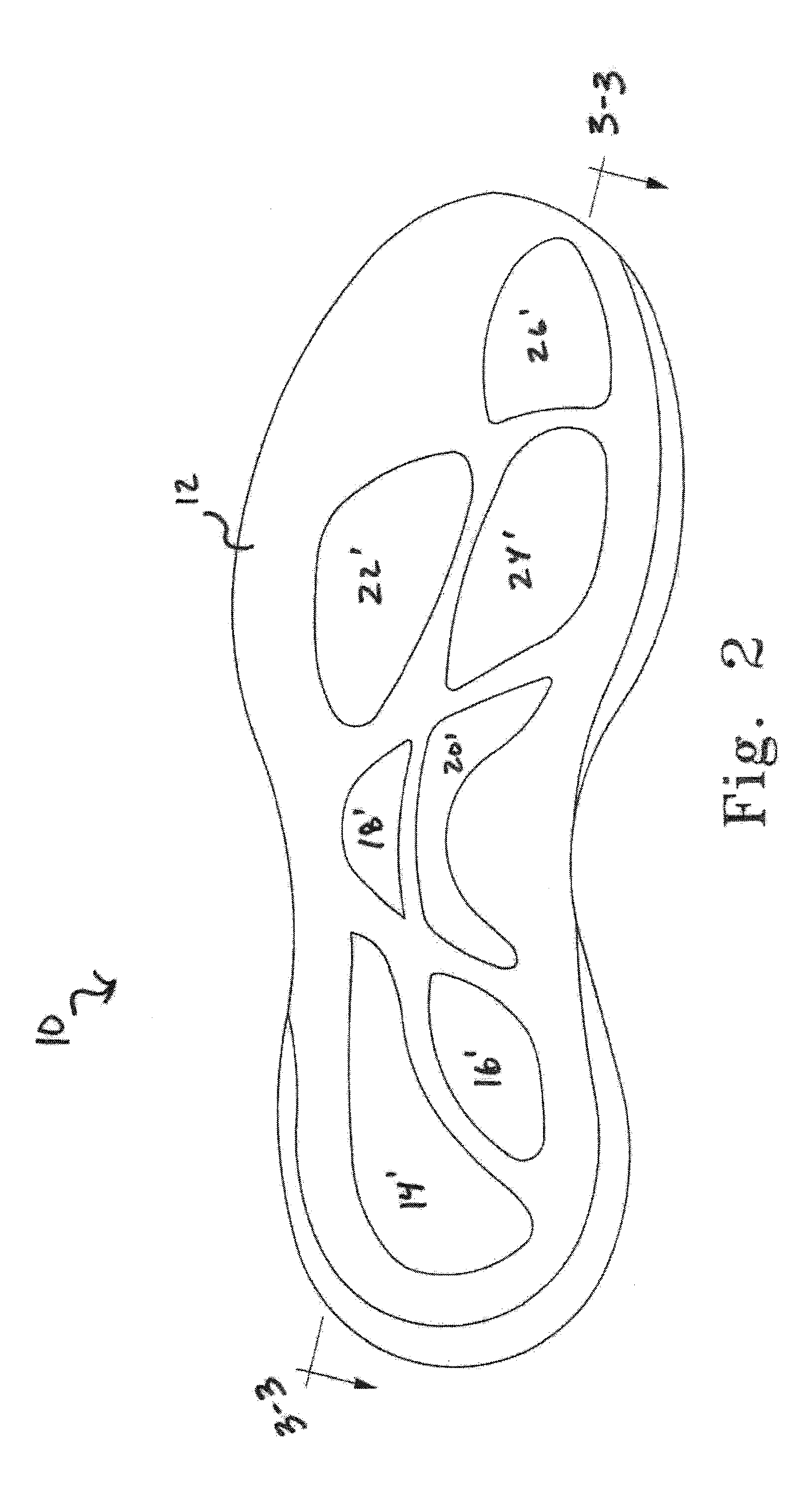

Customized footwear and methods for manufacturing

Owner:NXTMILE

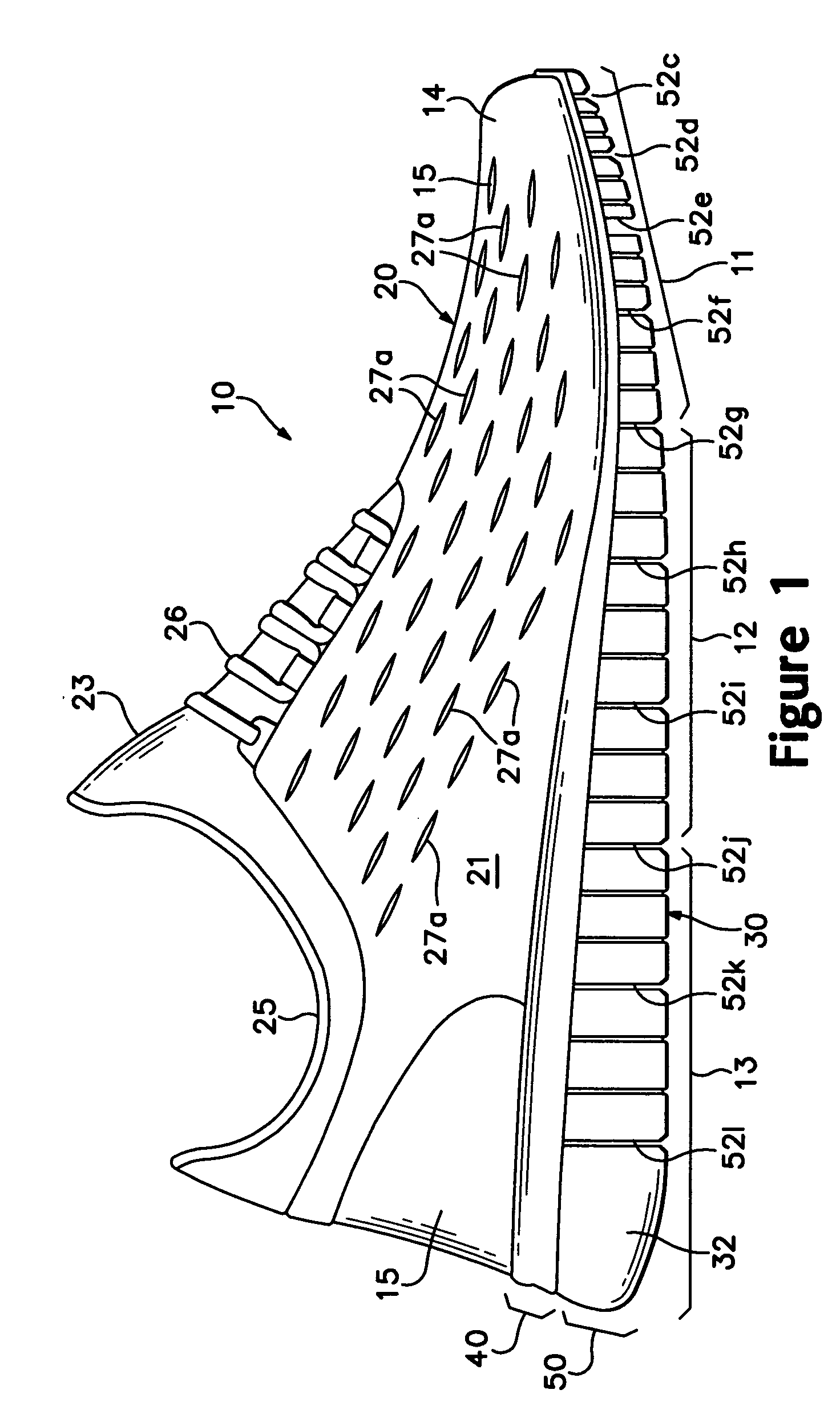

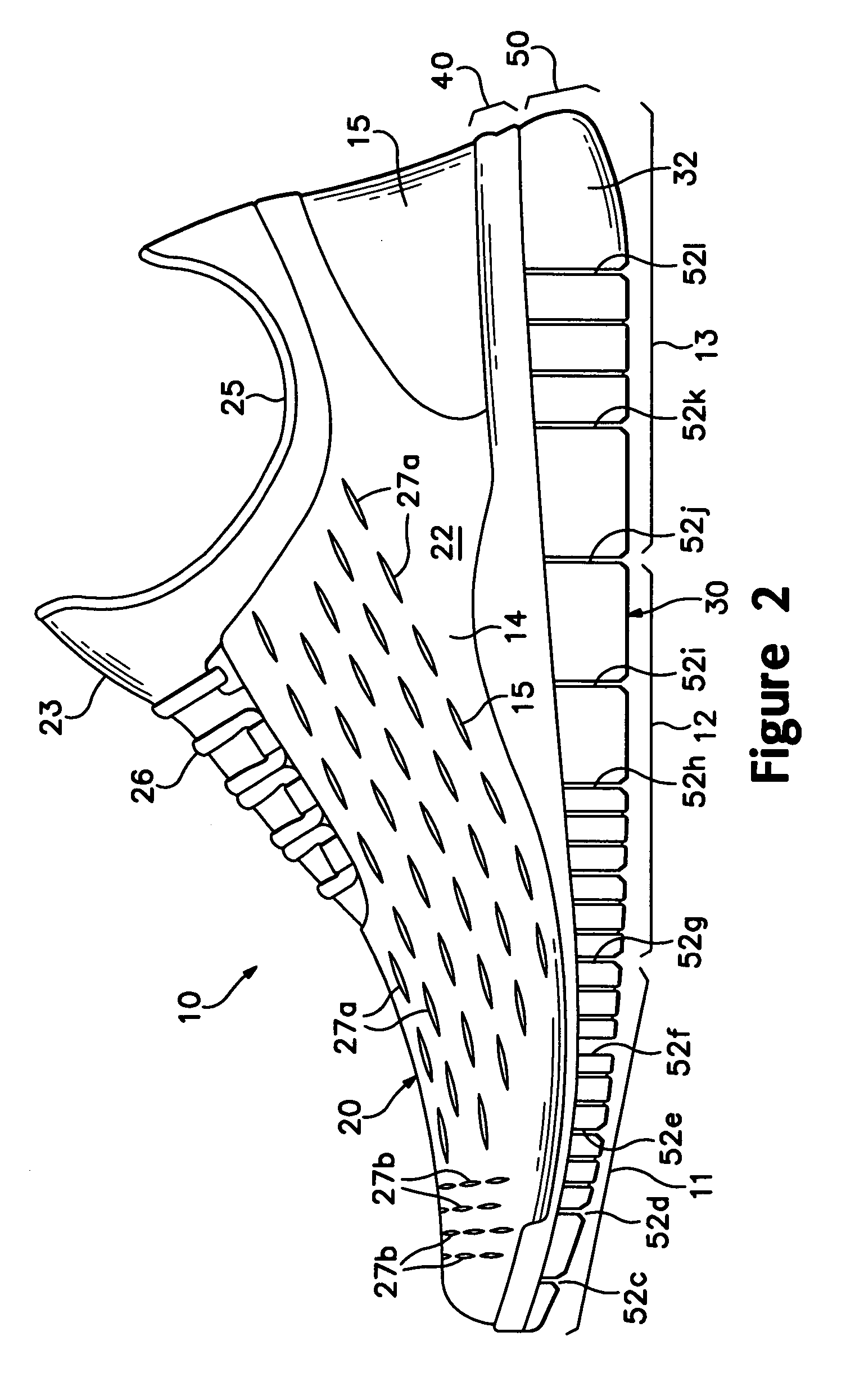

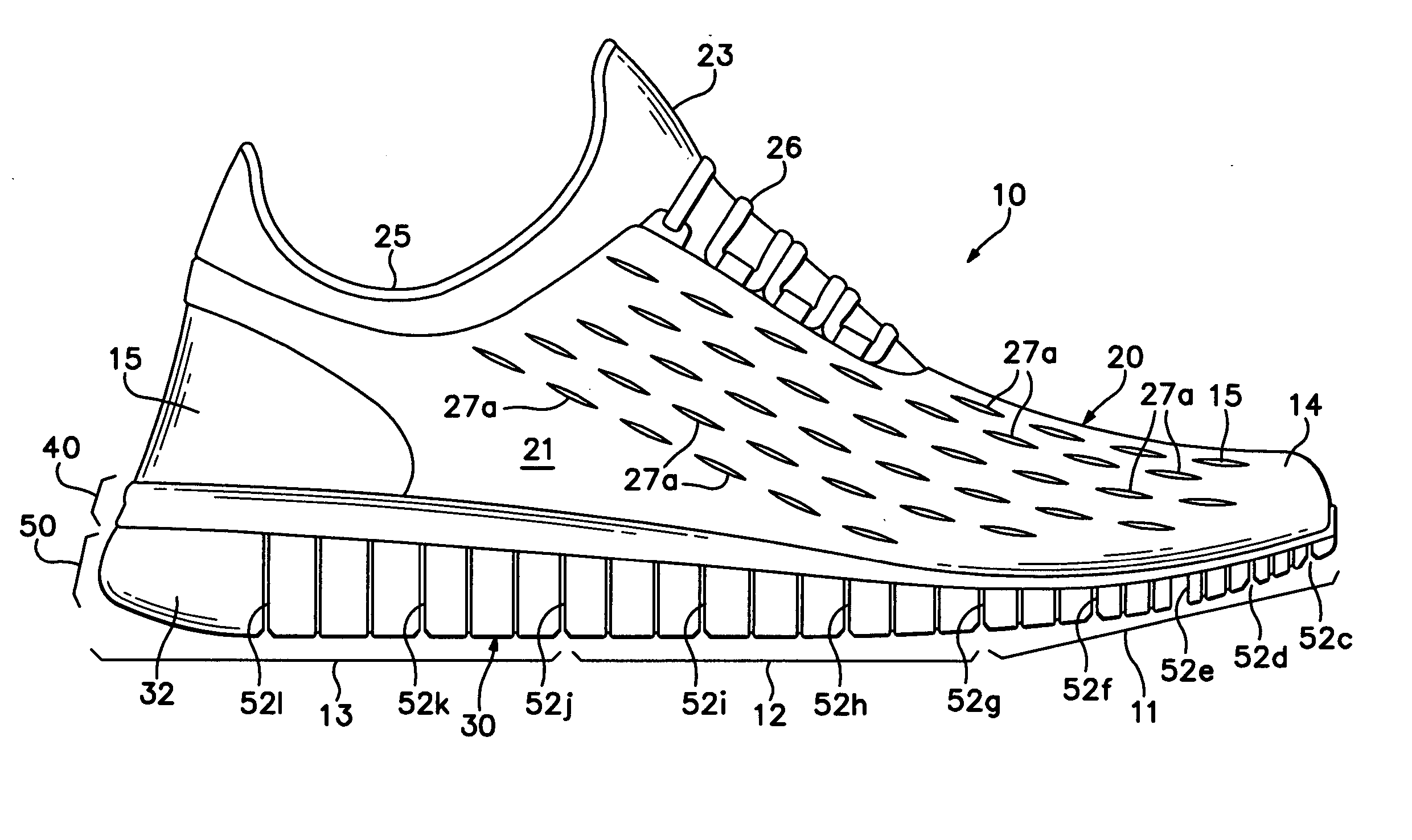

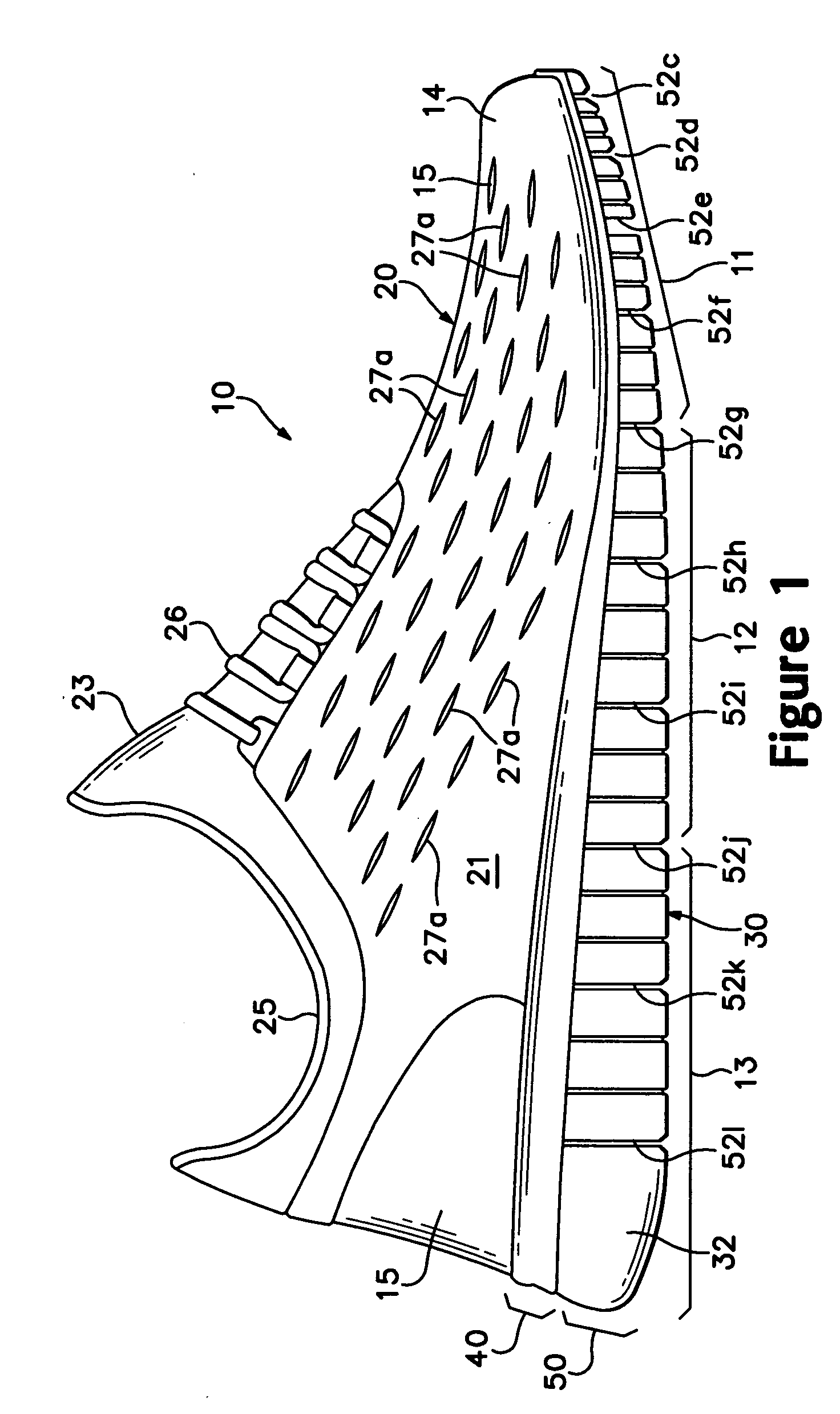

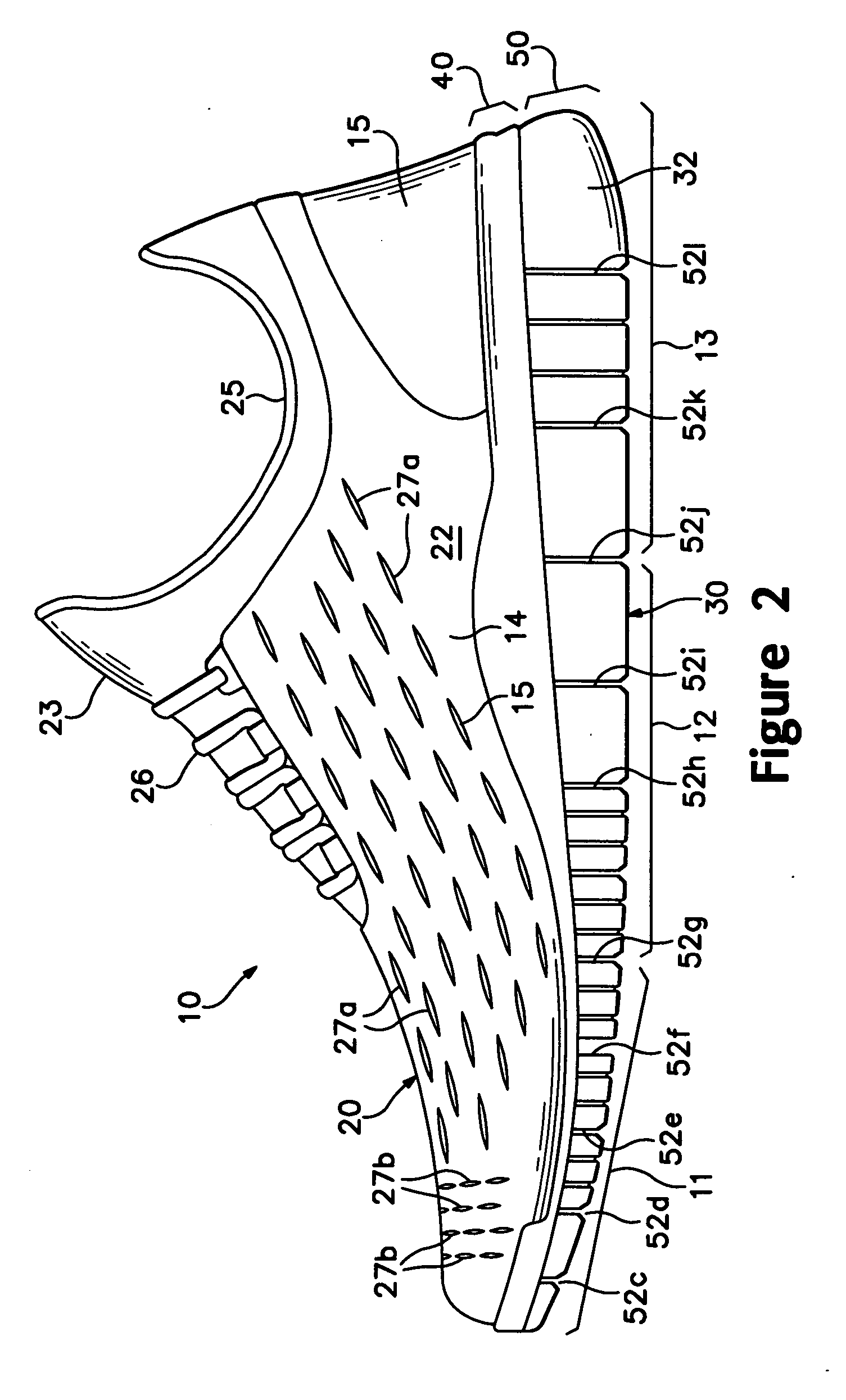

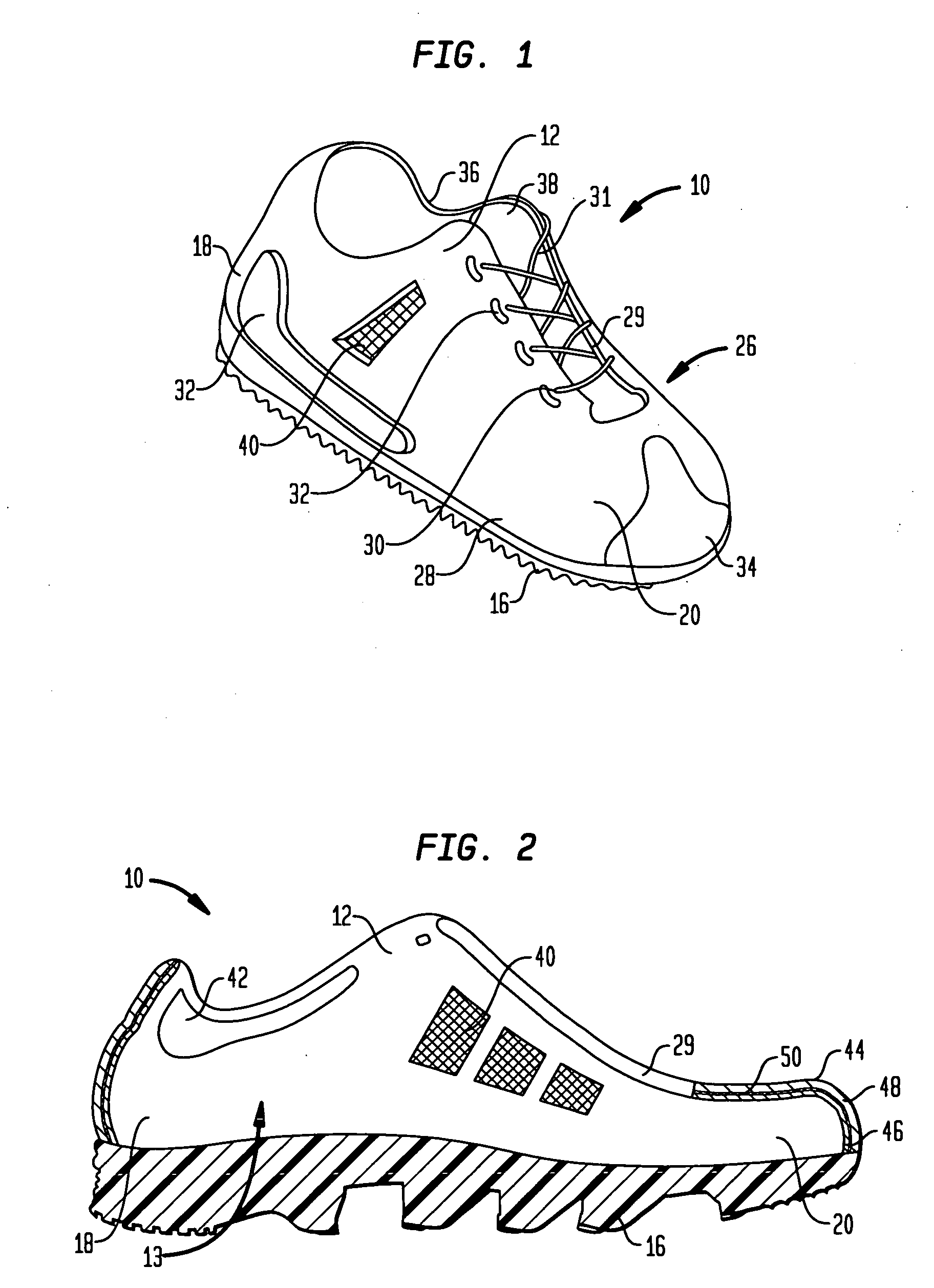

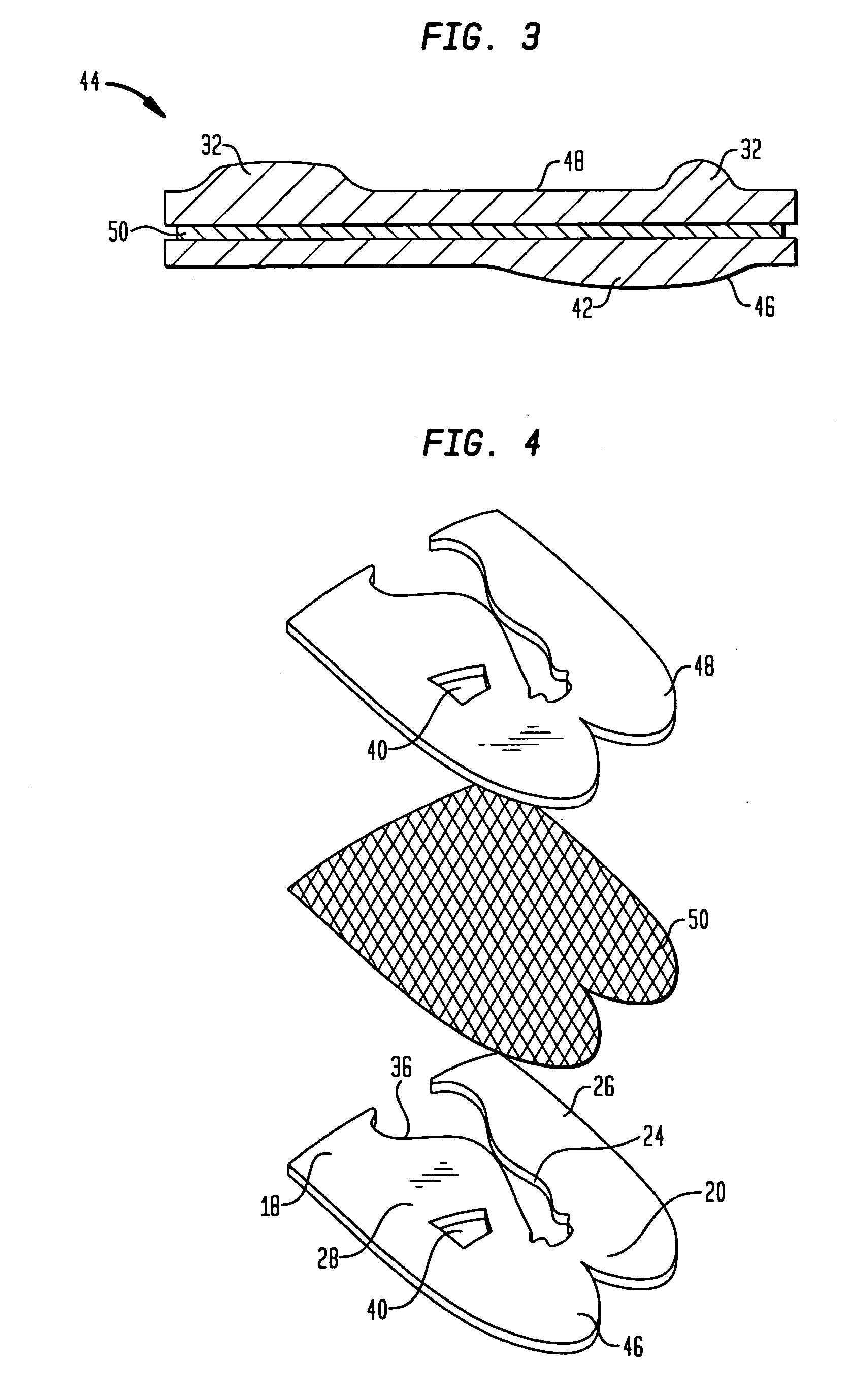

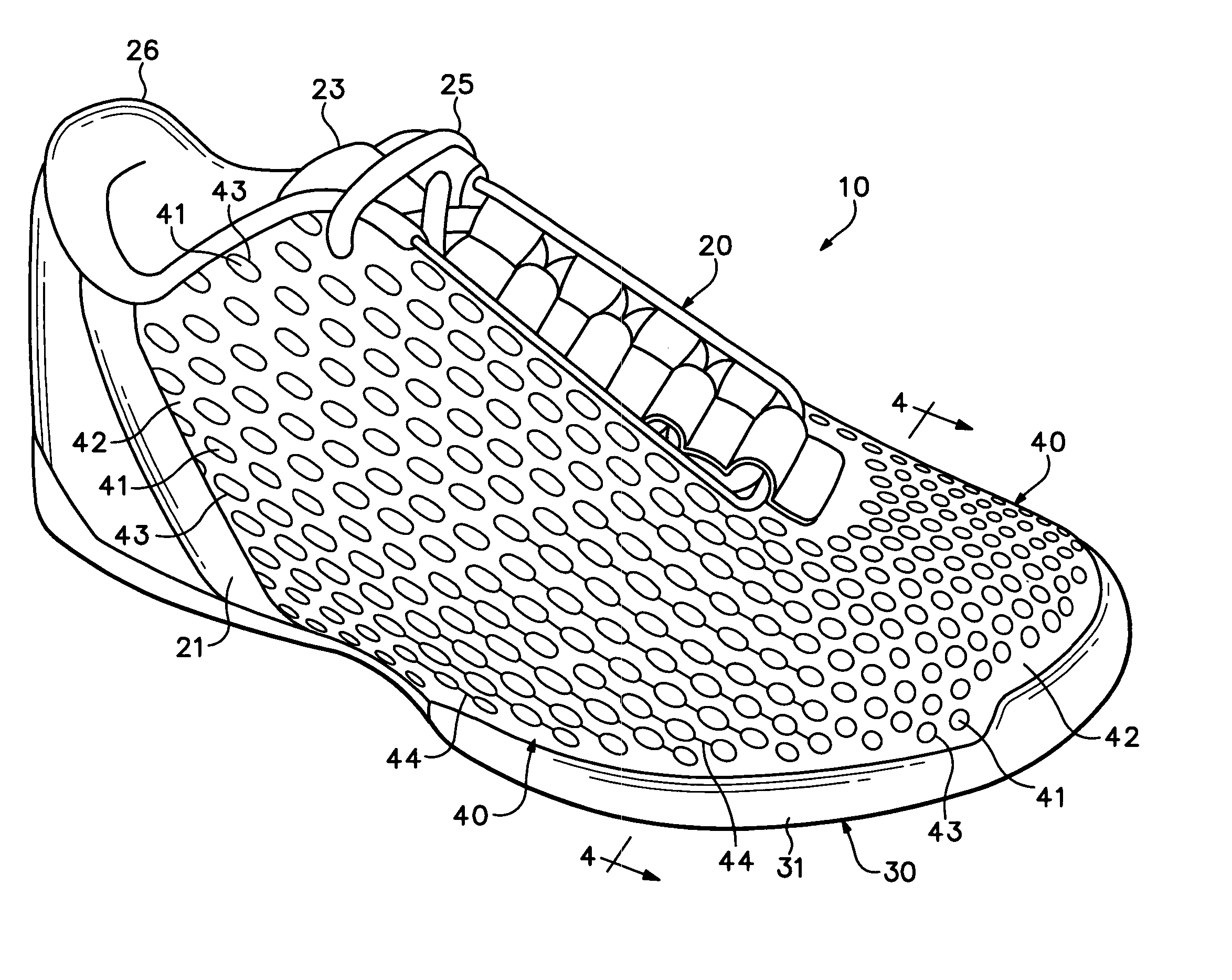

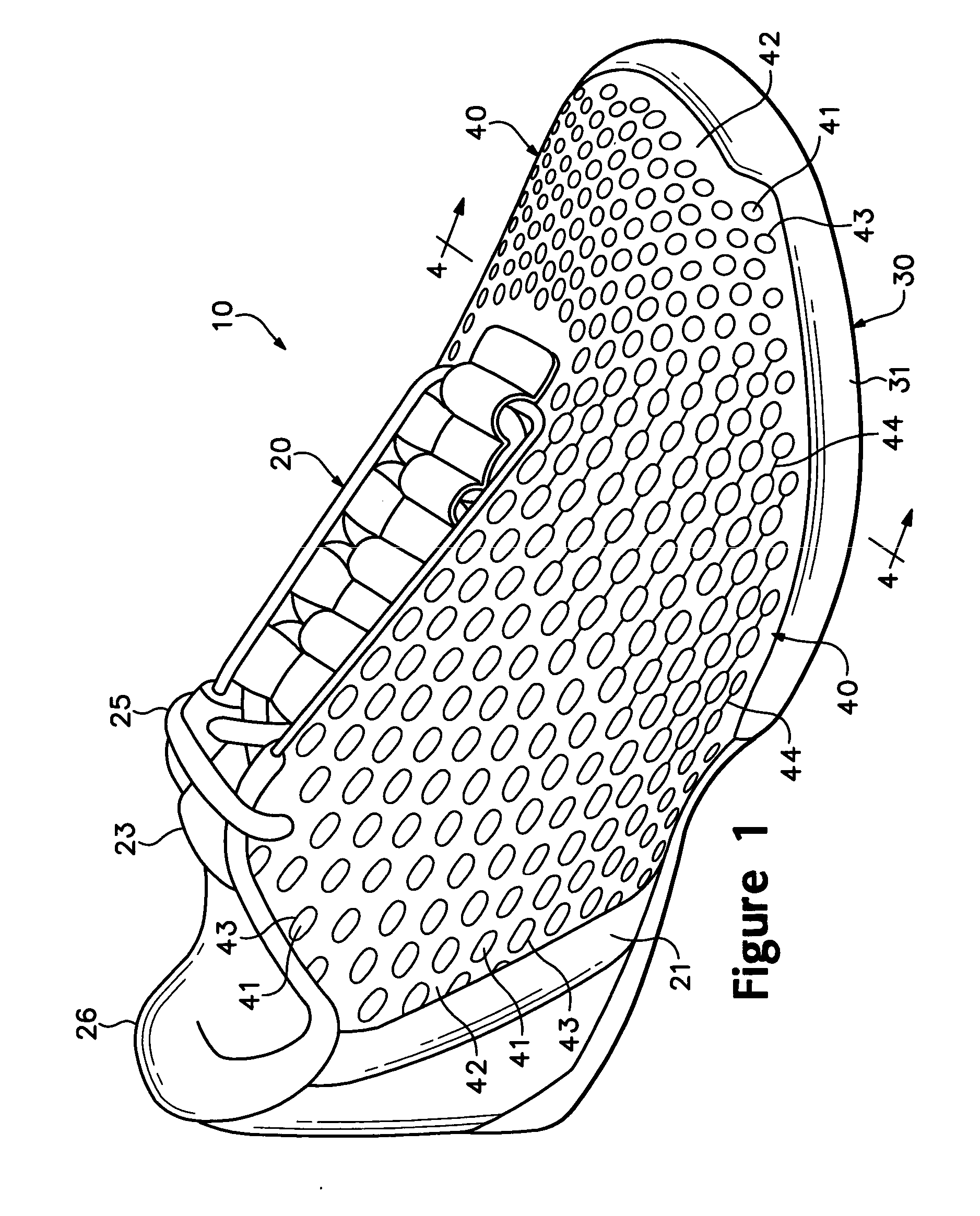

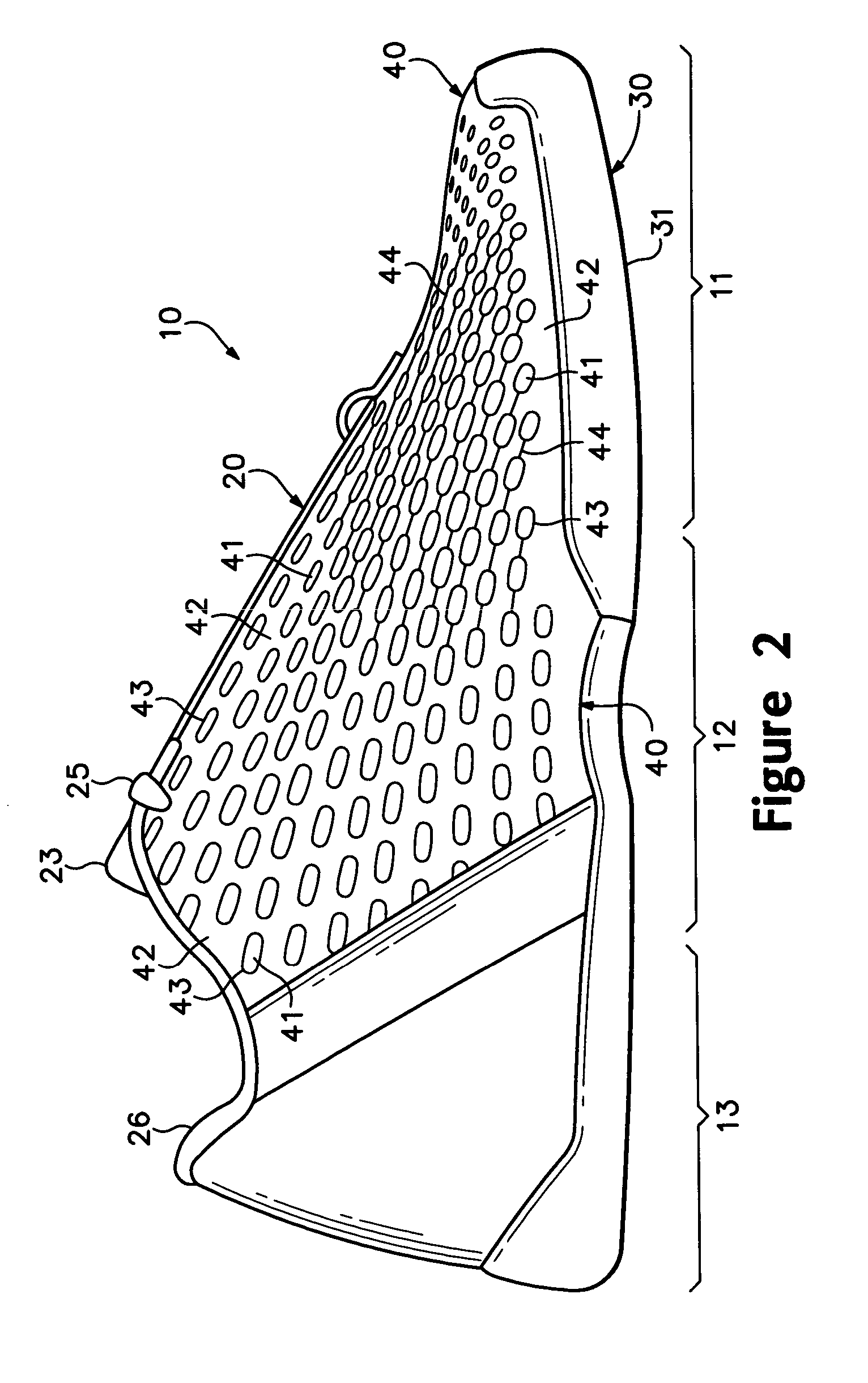

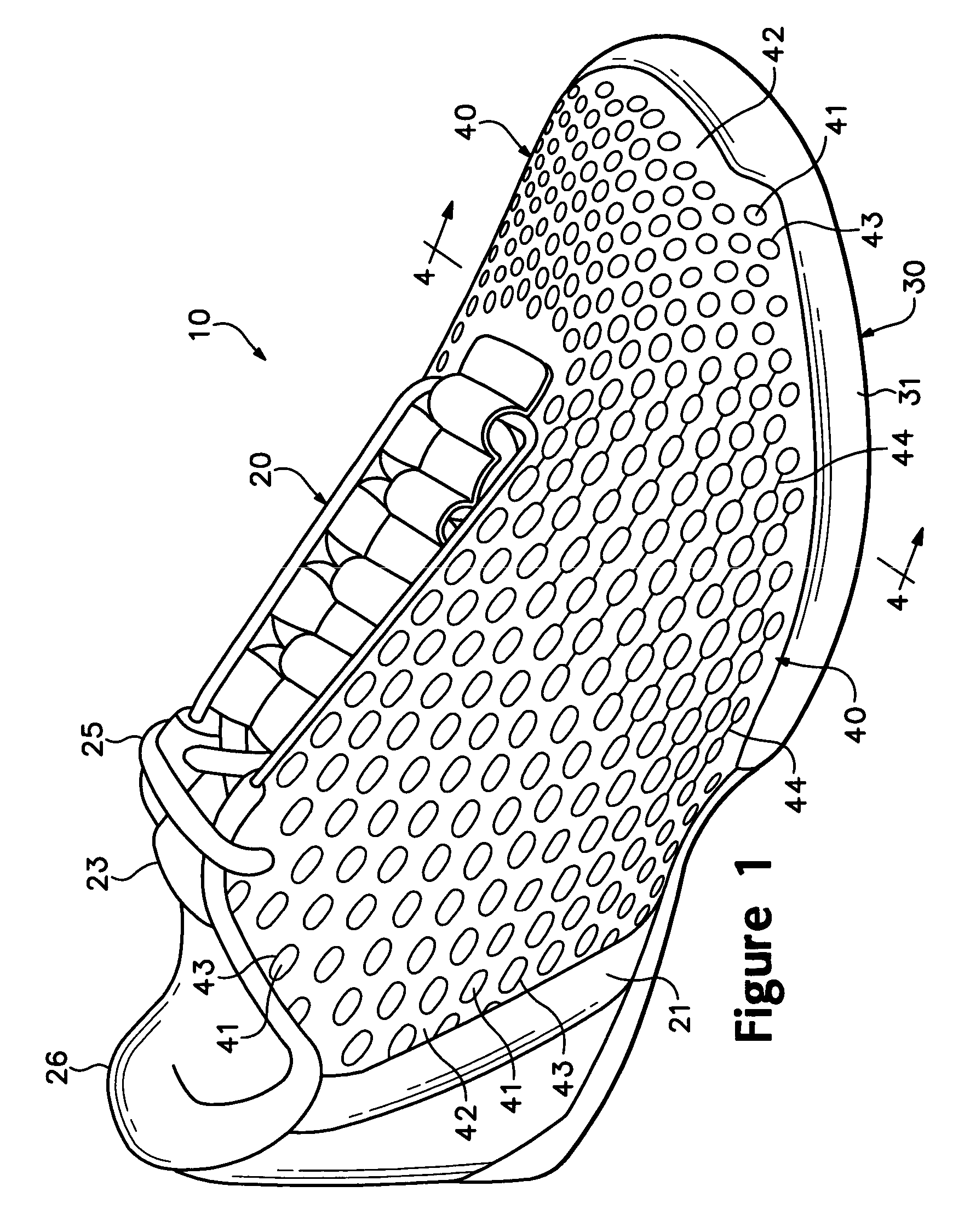

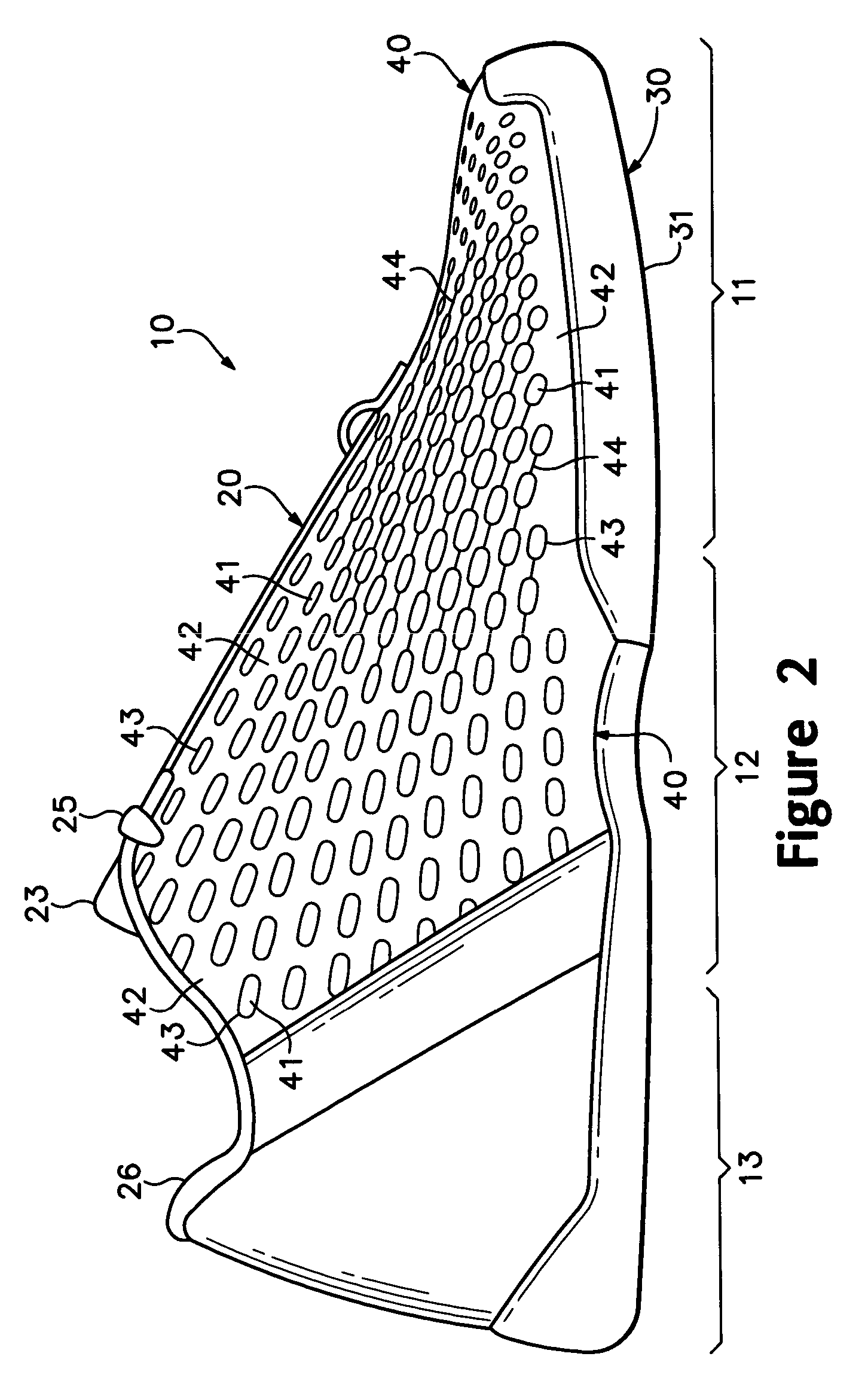

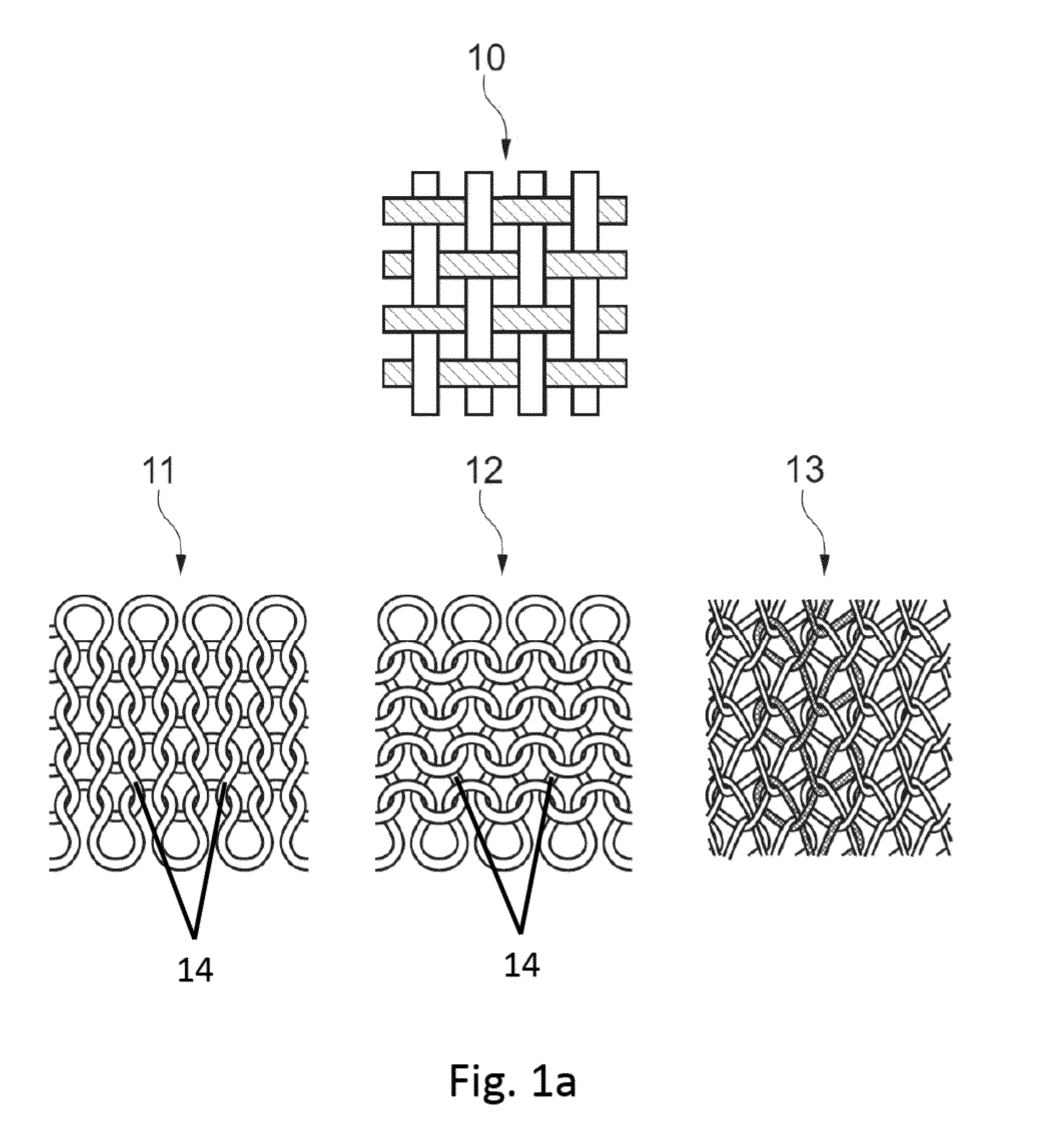

Article of footwear having an upper with a polymer layer

A article of footwear having an upper and a sole structure secured to the upper. At least a portion of the upper includes a substrate layer and a polymer layer. The substrate layer is formed of an air-permeable material, and may be a textile or mesh material. The polymer layer defines a plurality of apertures that expose portions of the substrate layer, and the polymer layer is formed of a polymer material that infiltrates the substrate layer and is thereby secured to the substrate layer. A method of forming the material for the upper includes casting a polymer resin to form the polymer layer.

Owner:NIKE INC

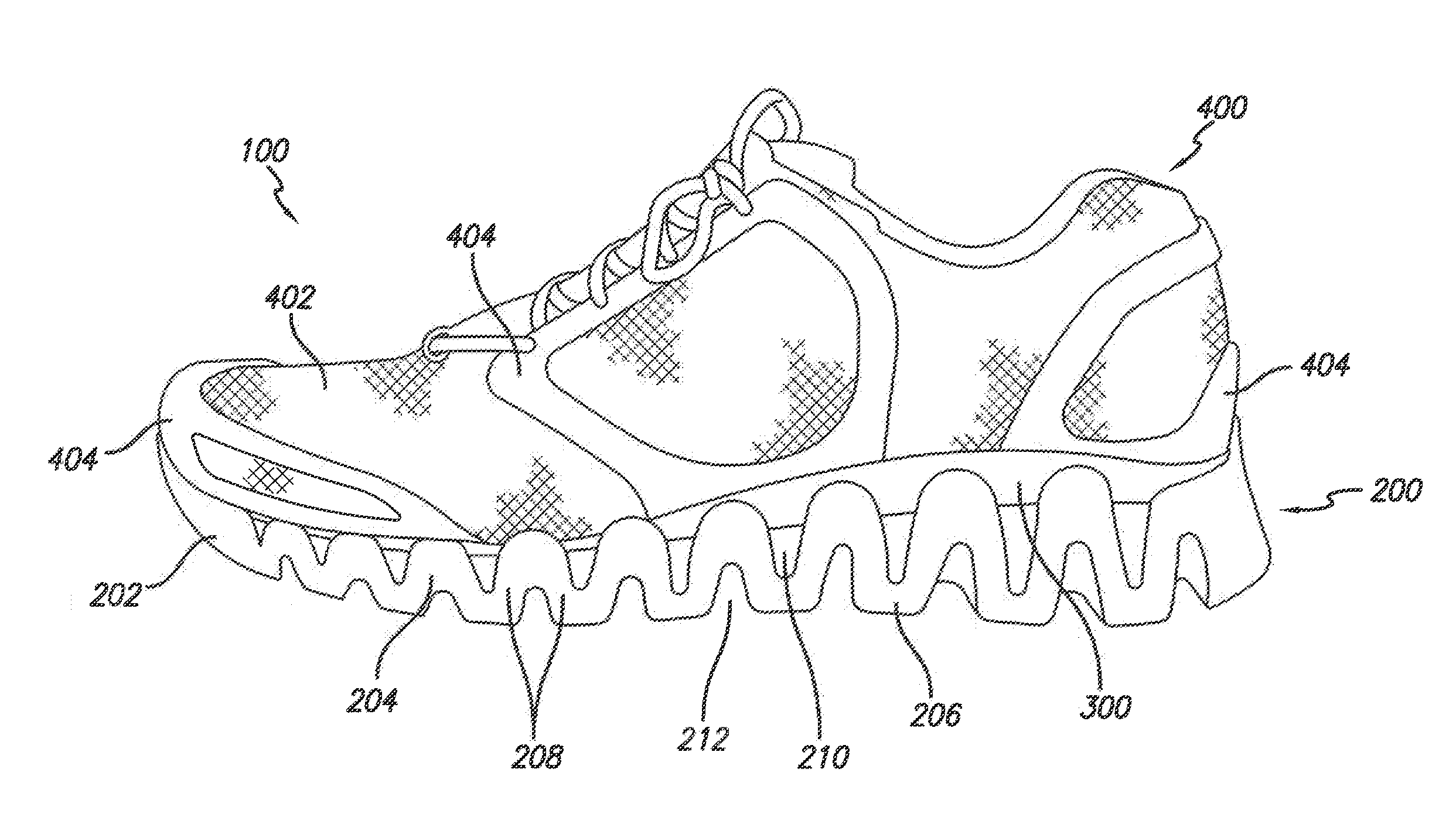

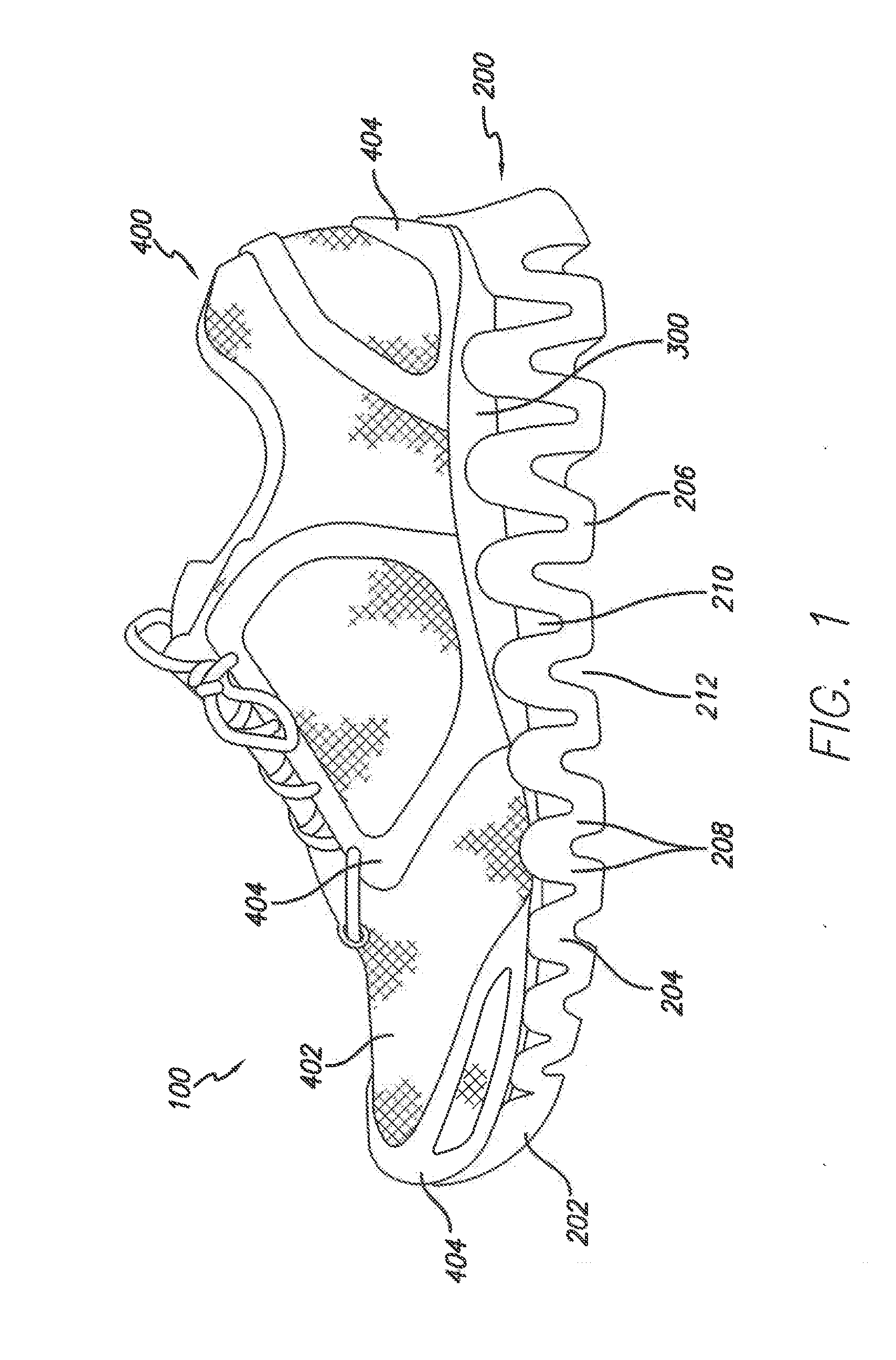

Article Of Footwear And Methods Of Making Same

An article of footwear with an undulating sole provides cushioning and support to an article of footwear. The sole has an undulating shape that may be substantially similar to a sine wave with a series of alternating peaks and troughs.

Owner:REEBOK

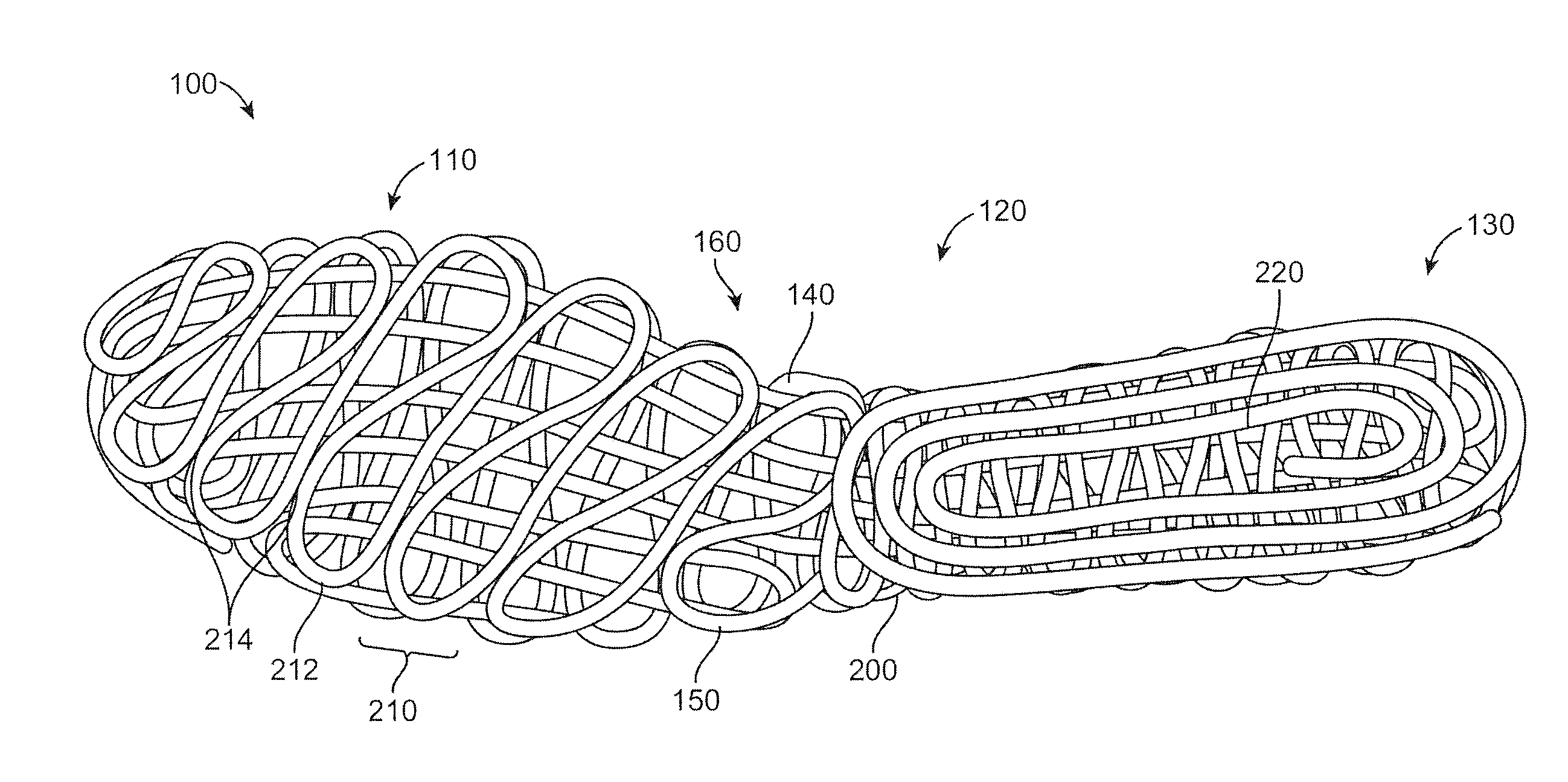

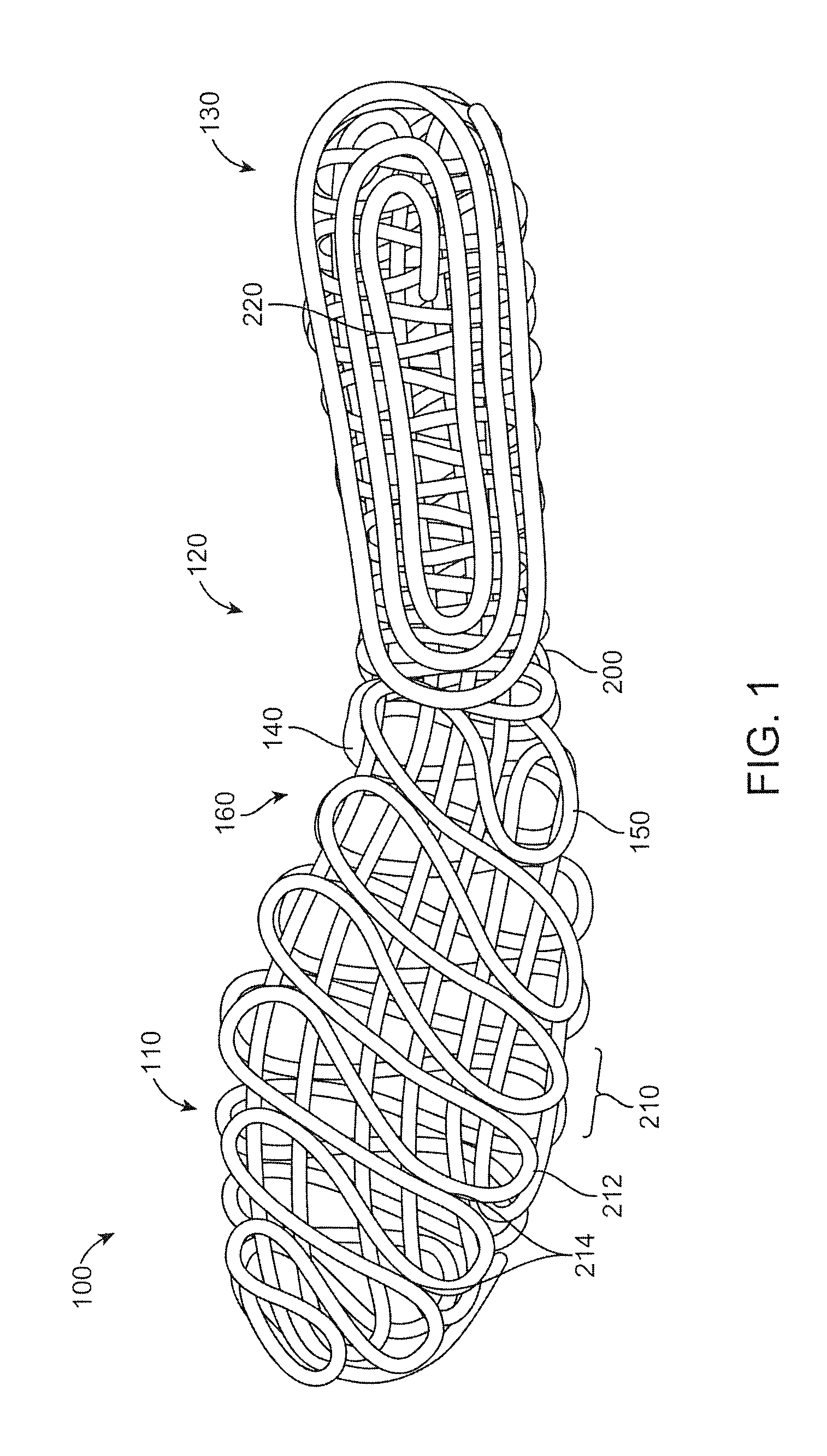

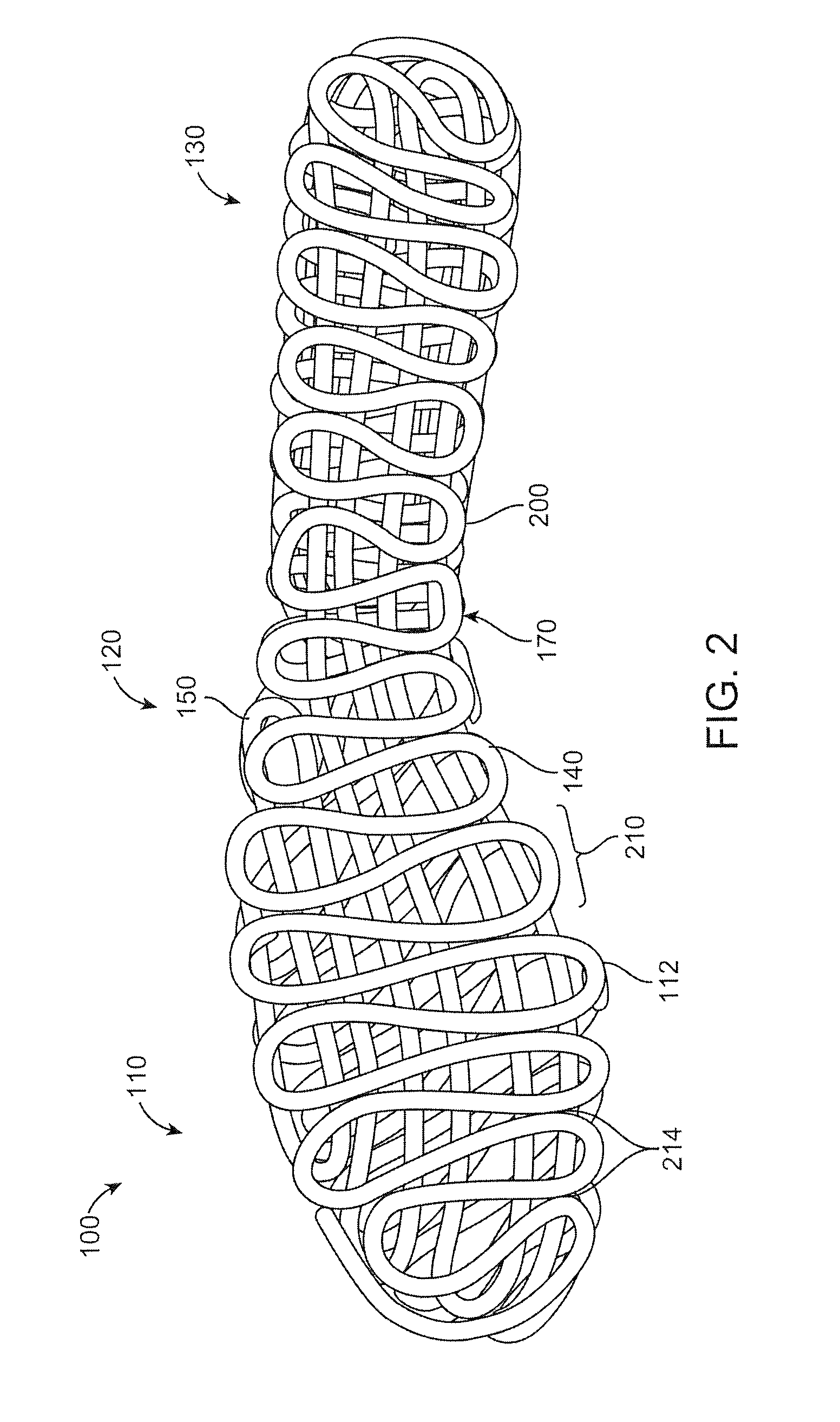

Article Of Footwear With Extruded Components

The disclosed embodiments relate to portions of an article of footwear formed from an extruded member. In certain embodiments, a sole or portion of a sole can be formed from one or more extruded members. In certain embodiments, the extruded member can be a single, continuous piece of solid material. In certain embodiments, a sole for an article of footwear can be fashioned from an extruded member formed in a controlled geometric pattern. In certain embodiments, the sole can include one or more layers.

Owner:REEBOK

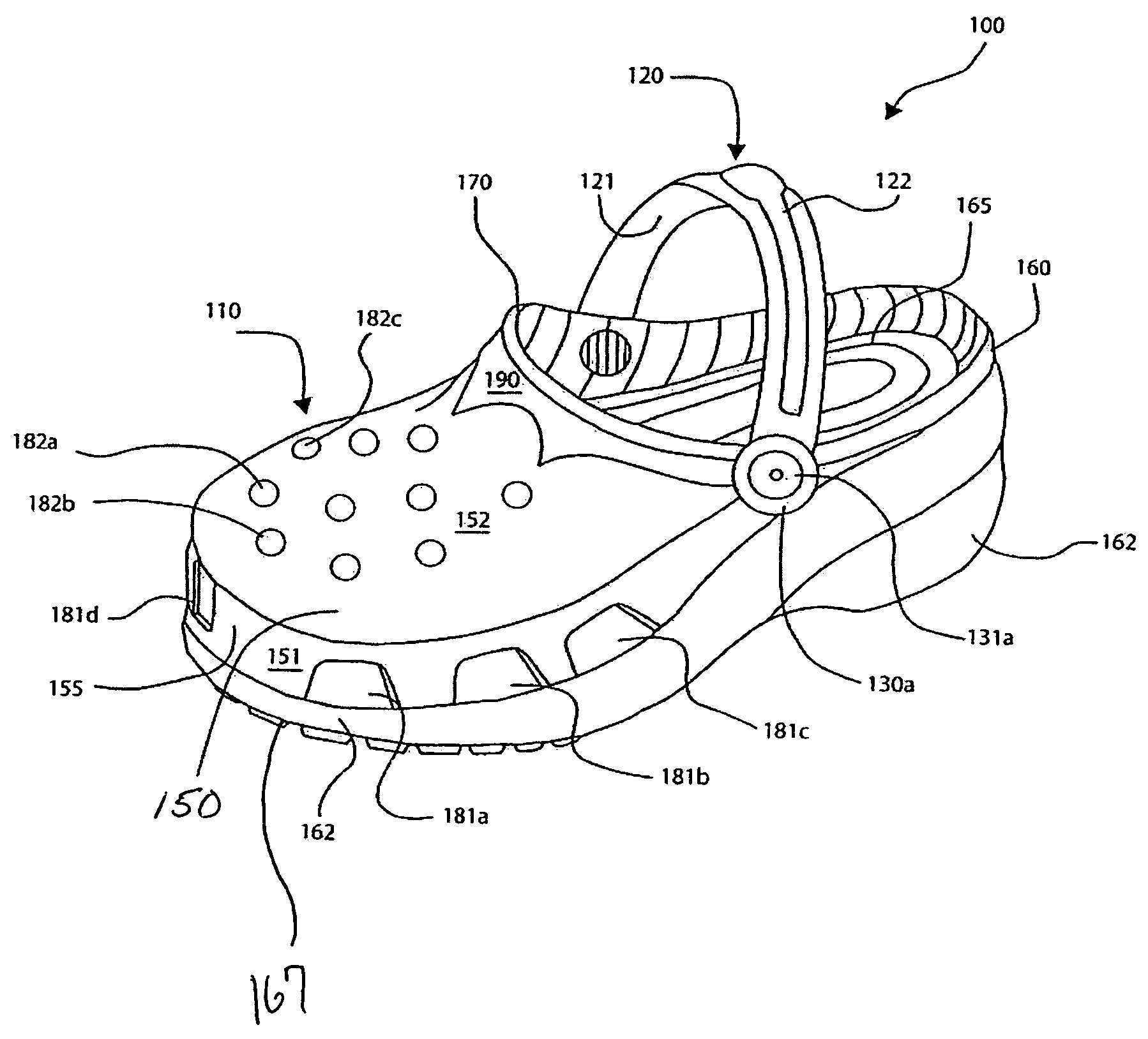

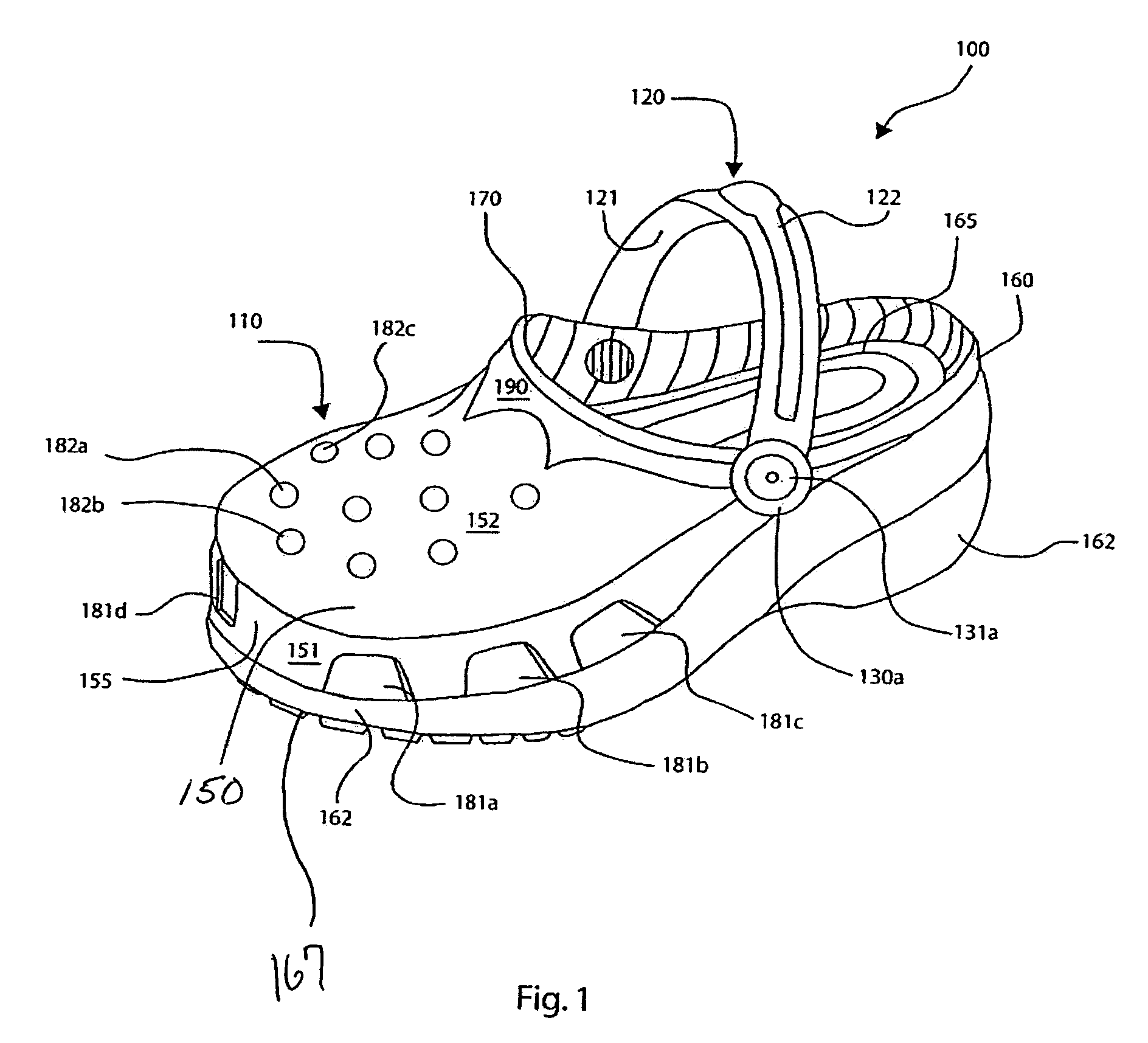

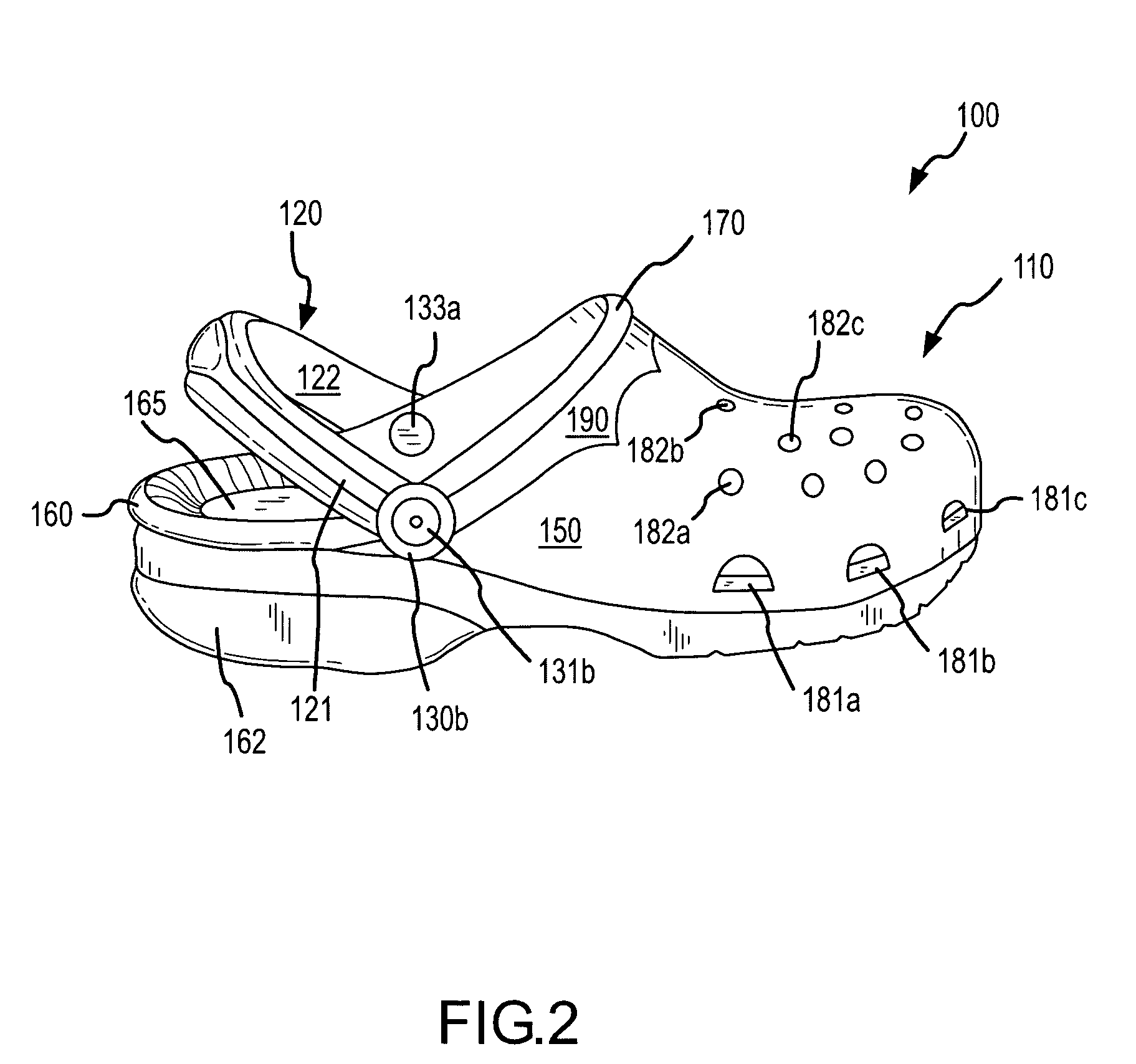

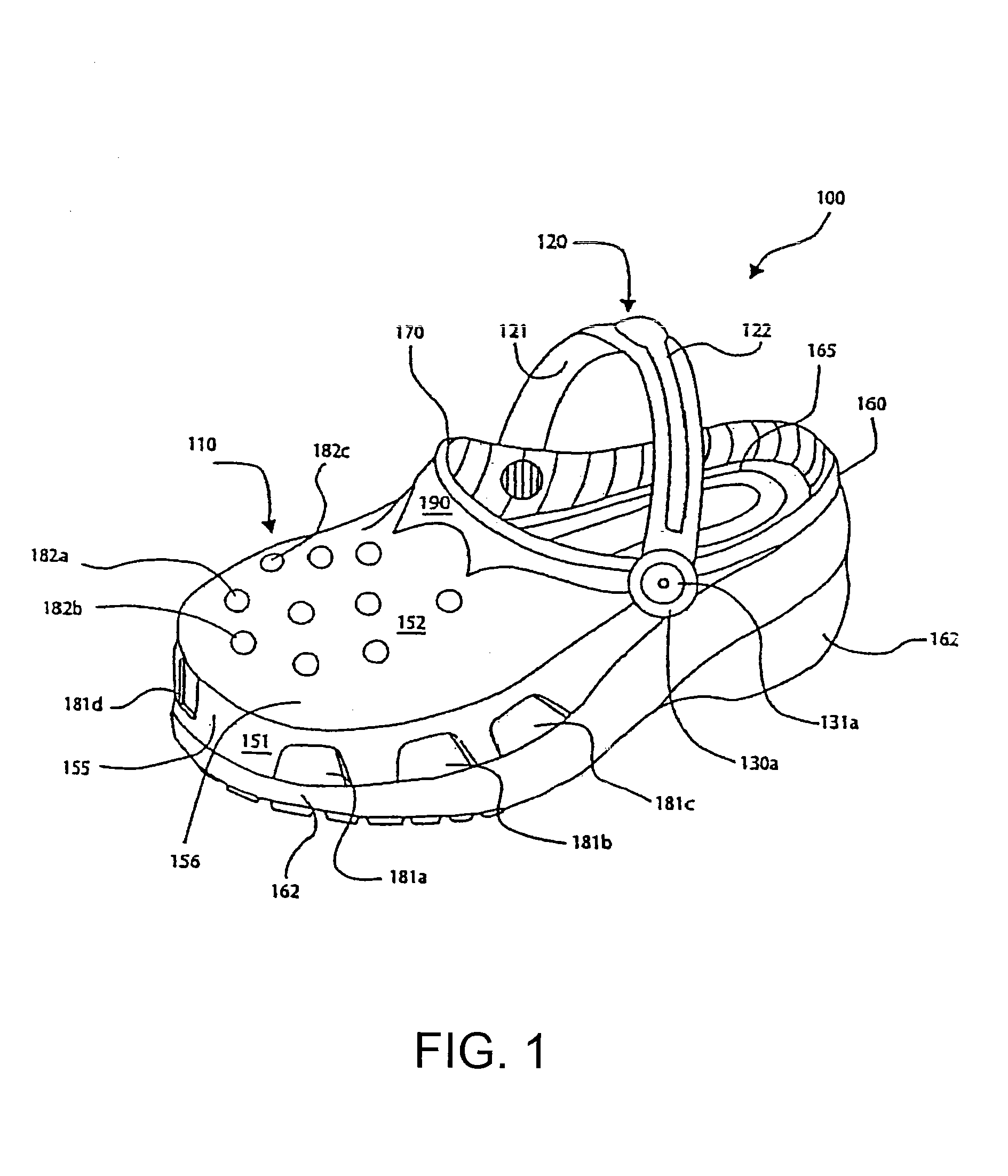

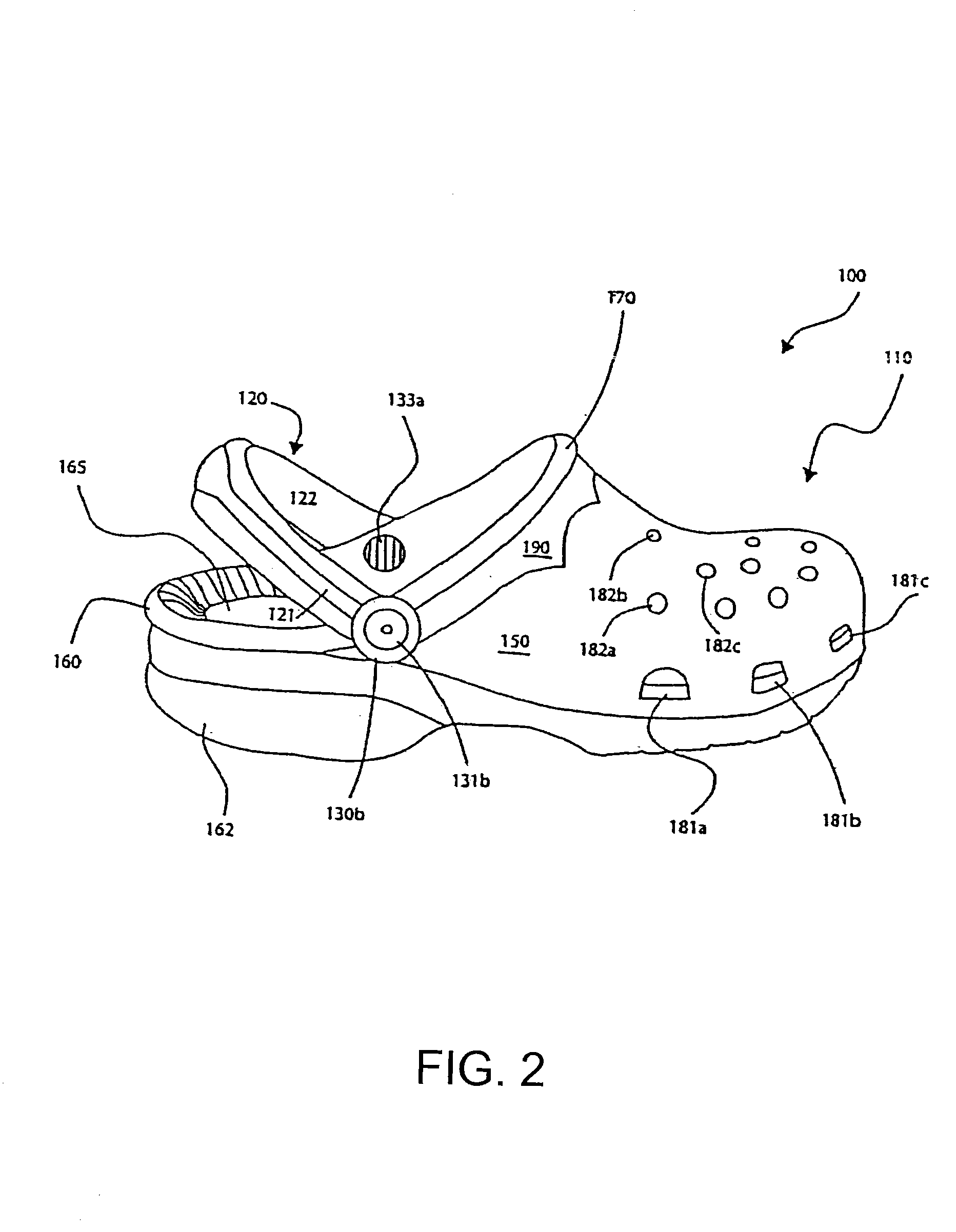

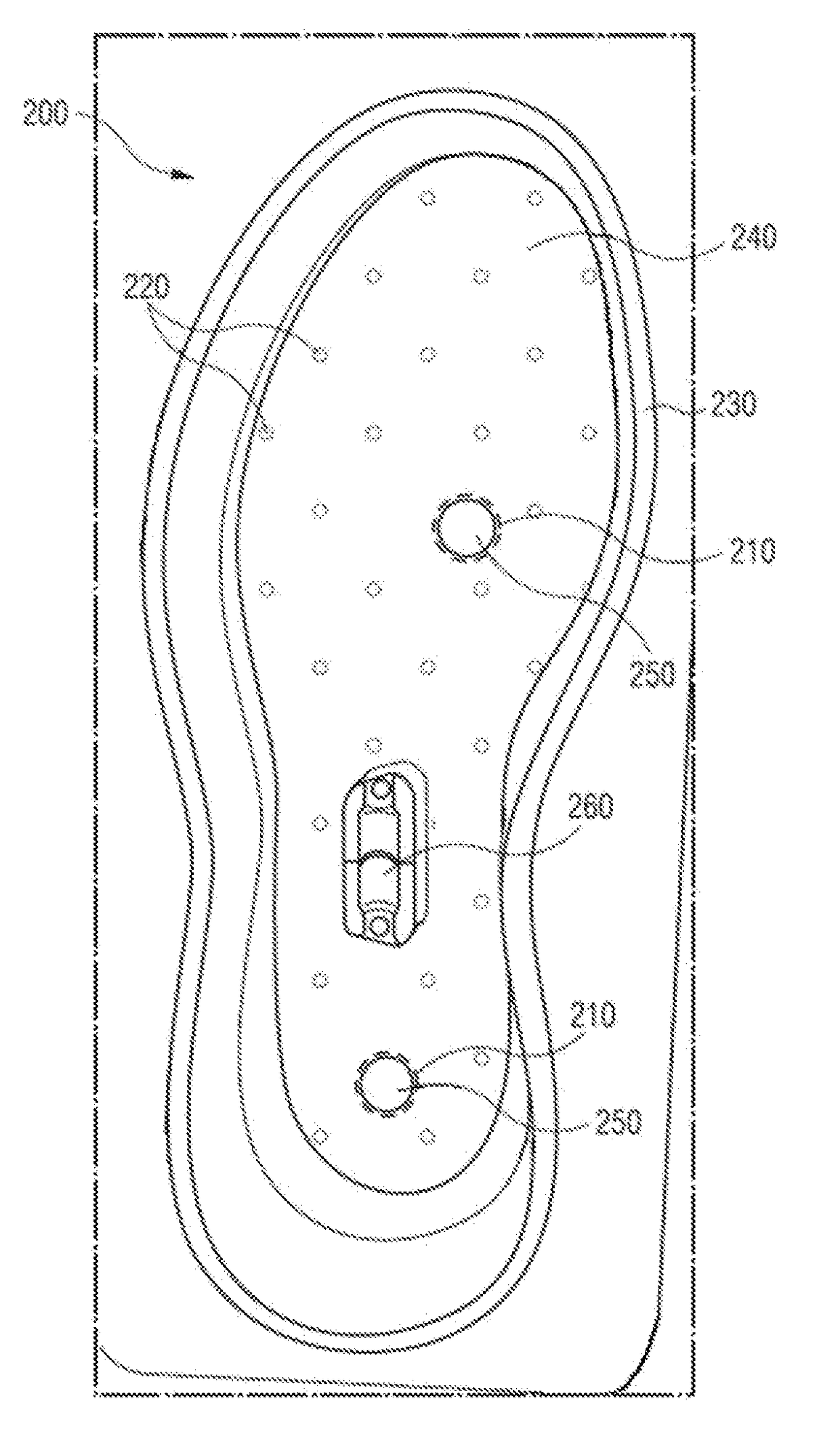

Breathable footwear pieces

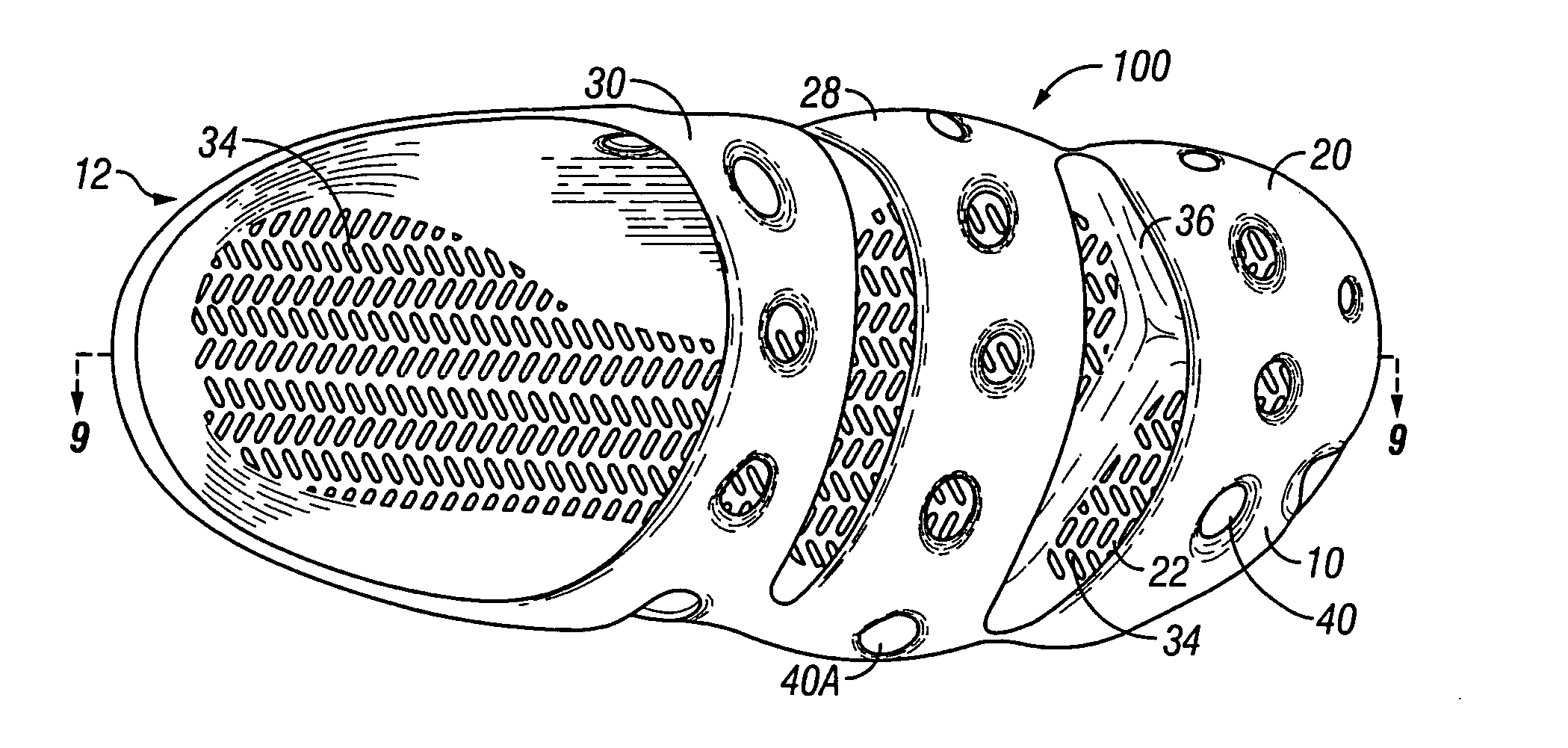

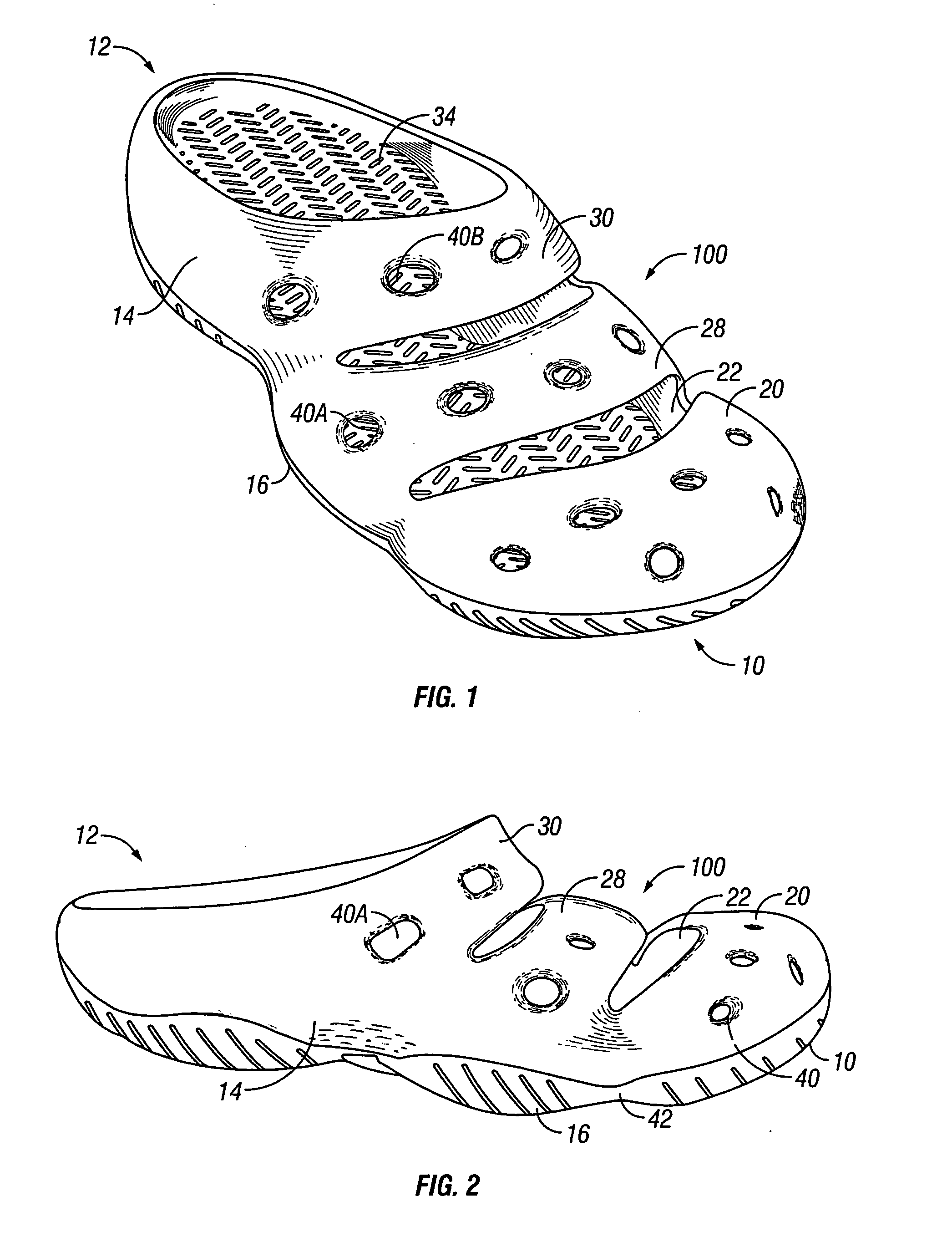

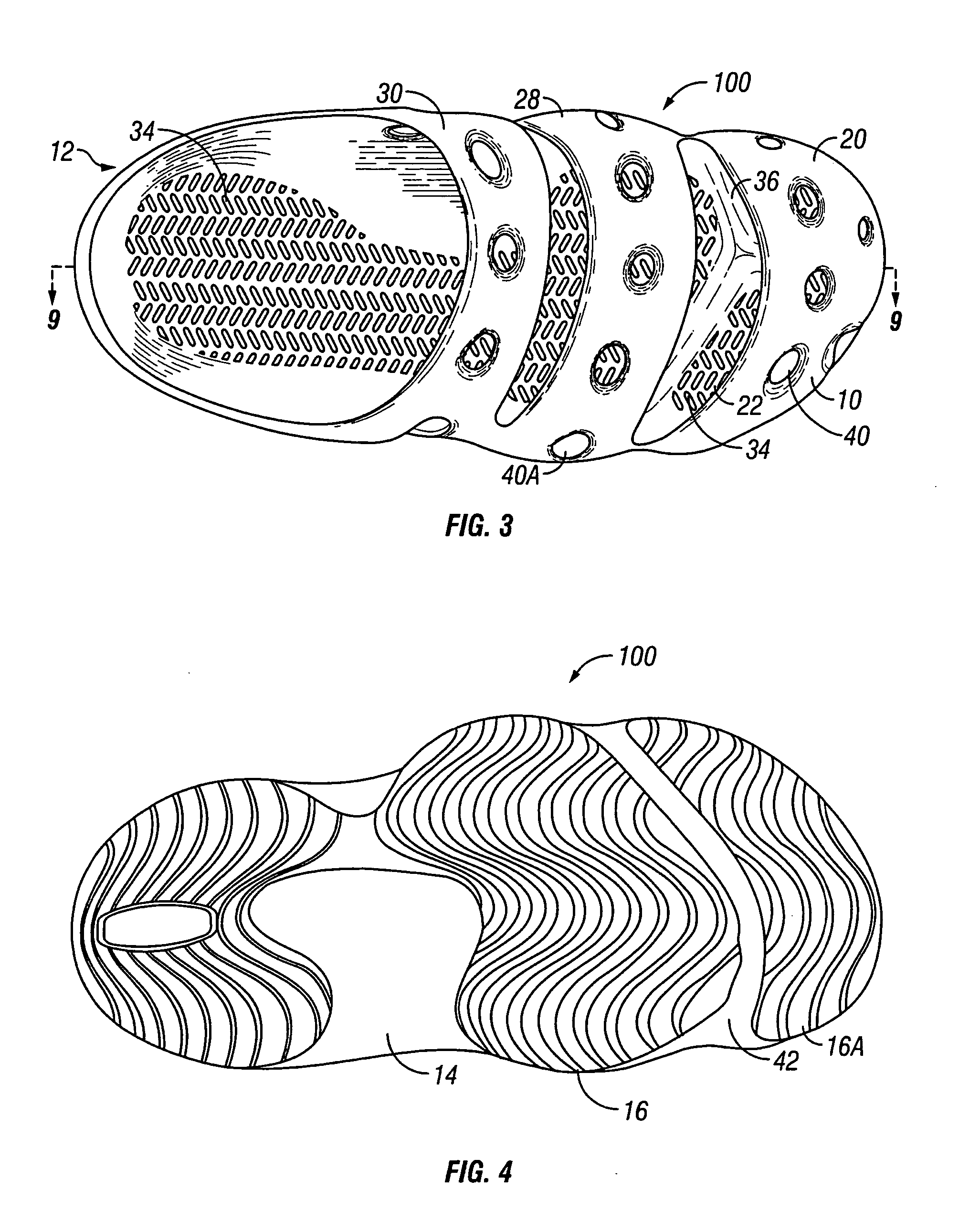

ActiveUS6993858B2Improve ventilationAvoid exposureDomestic footwearFasteningsElectrical conductorEngineering

Among other things, the present invention provides various footwear pieces, and methods for manufacturing such pieces. In various cases, the footwear pieces are molded from a lofting material. Further, in various cases, the footwear pieces include one or more ventilators formed in the footwear piece that are surrounded by liquid conductors capable of channeling liquid spilled on the surface of the footwear pieces away from a foot within the footwear pieces.

Owner:CROCS INC

Footwear having an enclosed and articulated toe

ActiveUS20050060914A1Increase flexibilityInexpensively formedSolesDomestic footwearMechanical engineeringEngineering

Articles of footwear having an enclosed articulated toe portion, including a molded midsole with an integrally-molded toe cap shaped to receive a foot therein and to enclose the toes of the foot. The toe cap terminates at a position adjacent to the base of the toes of the foot. The articles additionally include an outsole affixed to the bottom of the midsole and an upper which in some embodiments is co-molded with the midsole and toe cap.

Owner:KEEN INC

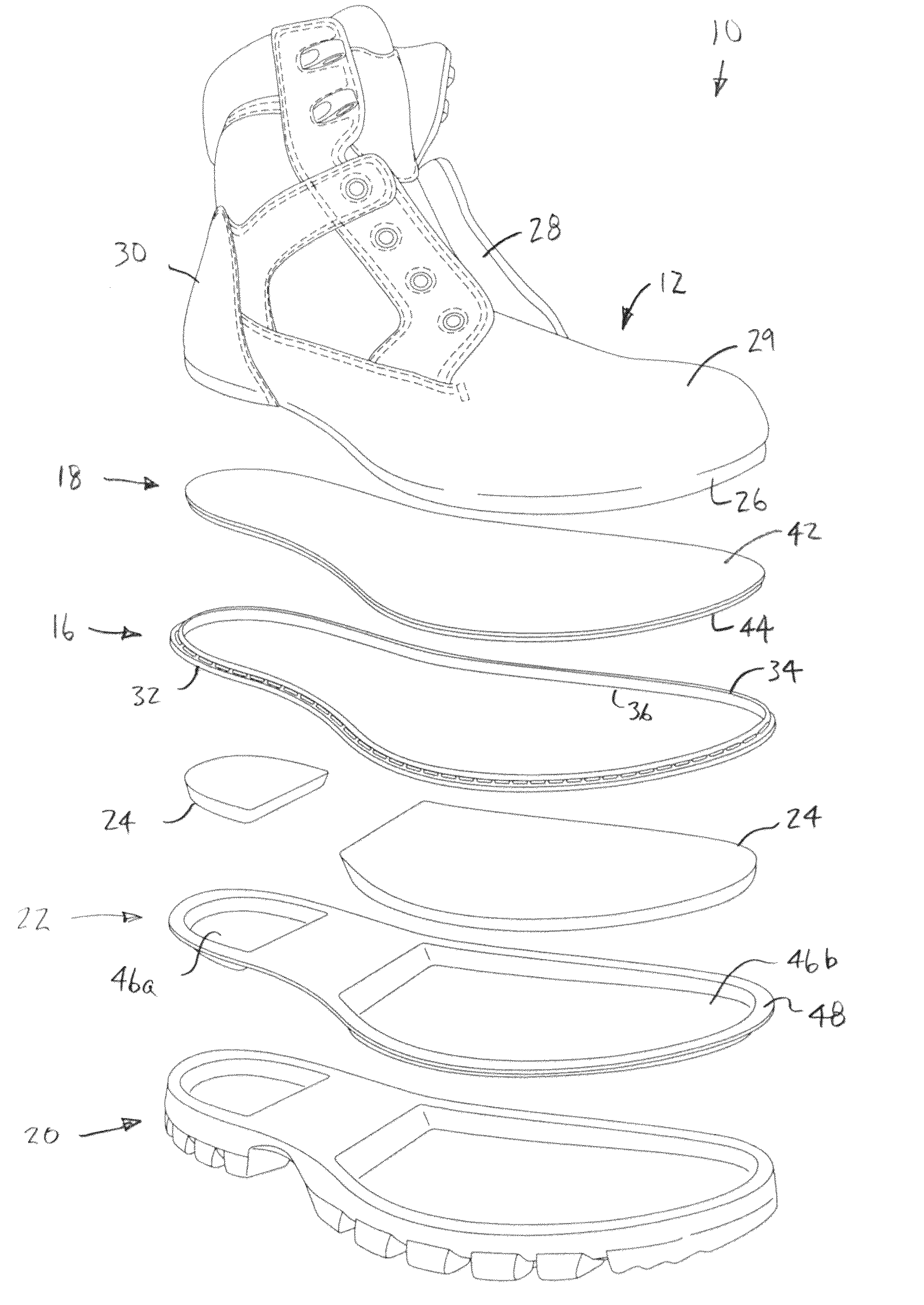

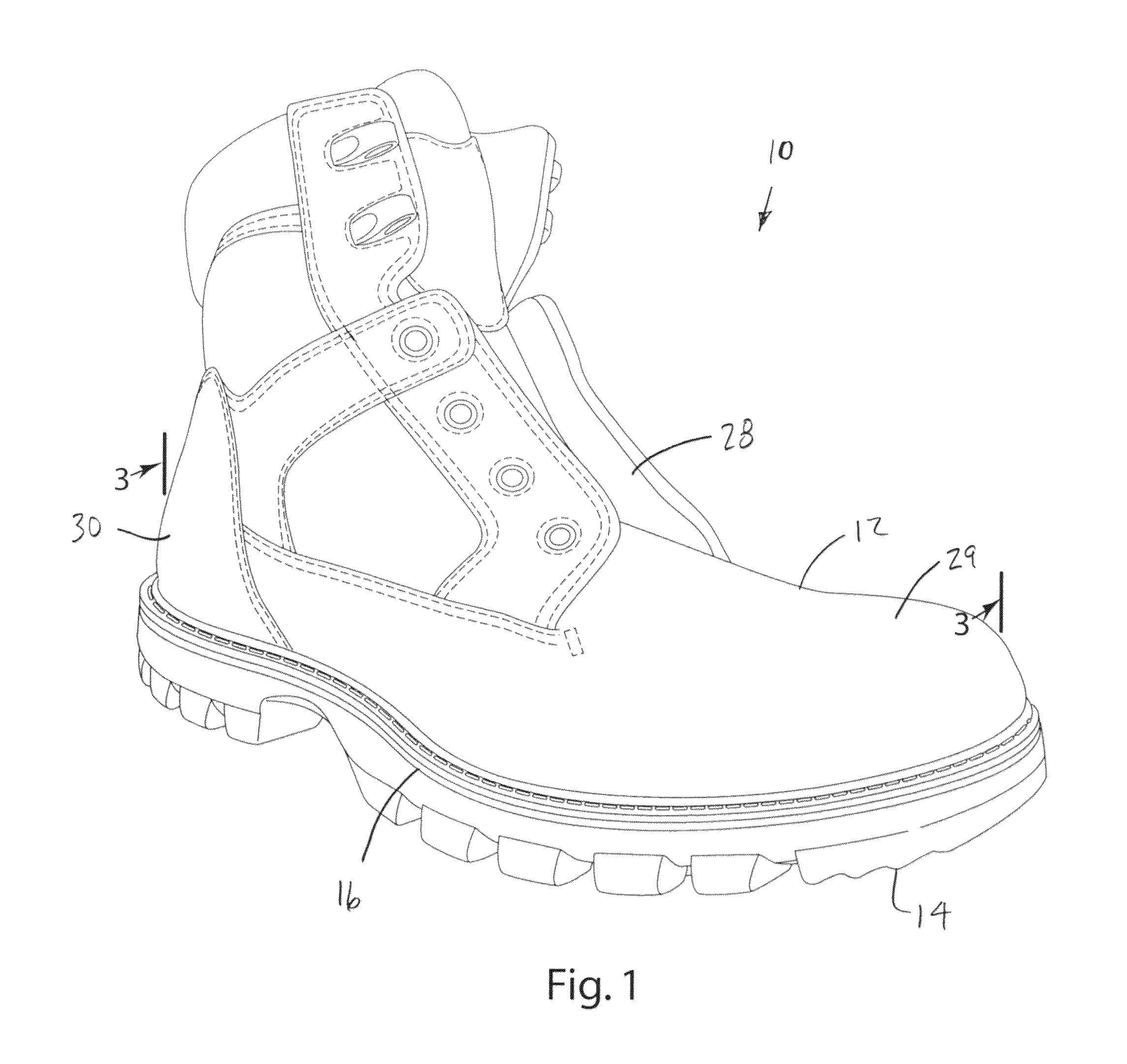

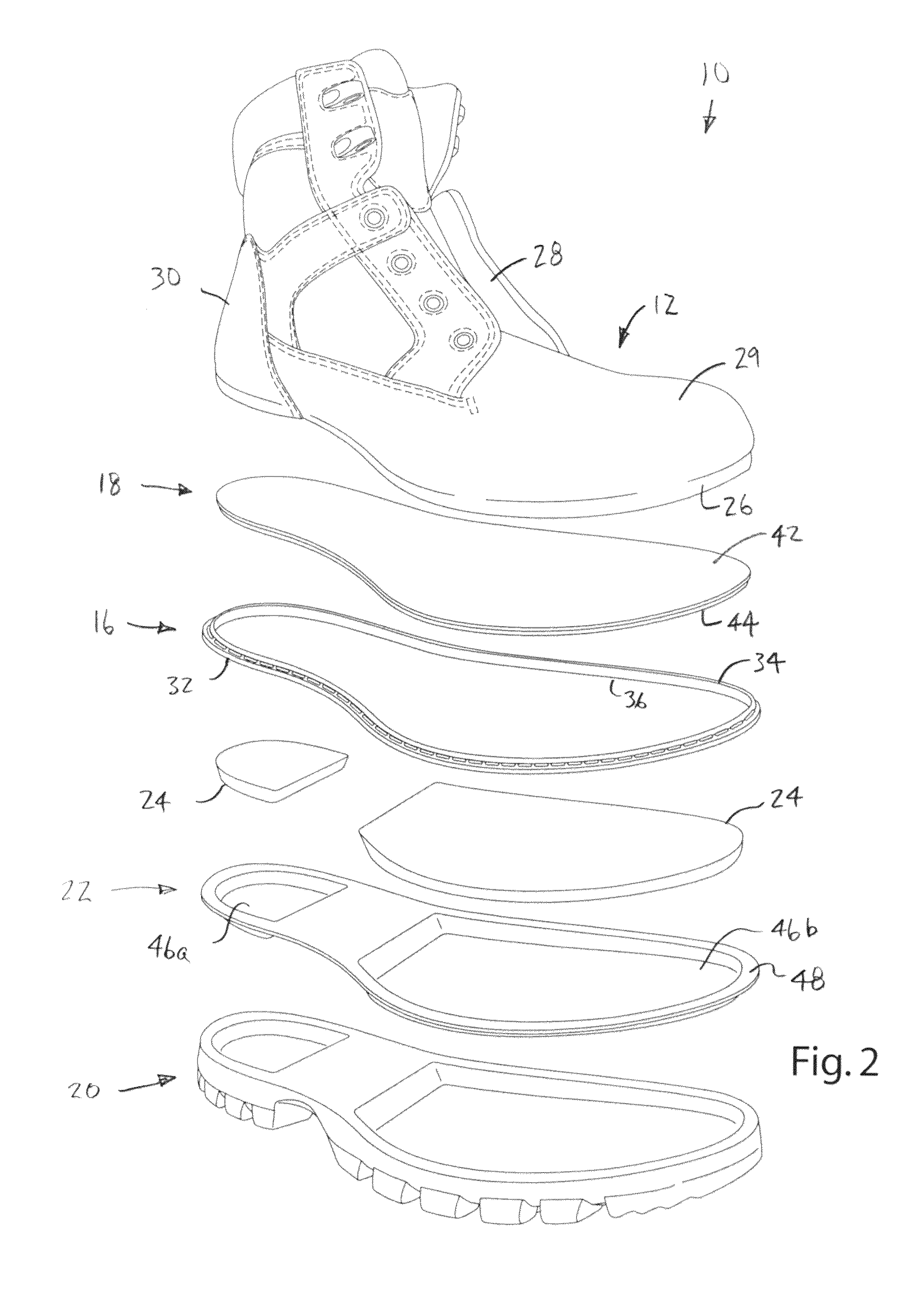

Footwear construction

A welted footwear construction with a direct-attach outsole and an internal tray containing a low density cushioning material. The welt may be secured to the upper and insole by one line of stitching and to the tray by a second line of stitching. The tray may include separate heel and forefoot cavities, each containing a low density cushioning material. The tray may be manufactured from thermoplastic urethane (“TPU”) and may contain low-density polyurethane (“PU”). The low-density PU may be molded in place within the cavities in the tray. The outsole may be directly attached to the undersurface of the tray, and may be manufactured from high-density PU.

Owner:WOLVERINE OUTDOORS

Article of footwear having an upper with a polymer layer

A article of footwear having an upper and a sole structure secured to the upper. At least a portion of the upper includes a substrate layer and a polymer layer. The substrate layer is formed of an air-permeable material, and may be a textile or mesh material. The polymer layer defines a plurality of apertures that expose portions of the substrate layer, and the polymer layer is formed of a polymer material that infiltrates the substrate layer and is thereby secured to the substrate layer. A method of forming the material for the upper includes casting a polymer resin to form the polymer layer.

Owner:NIKE INC

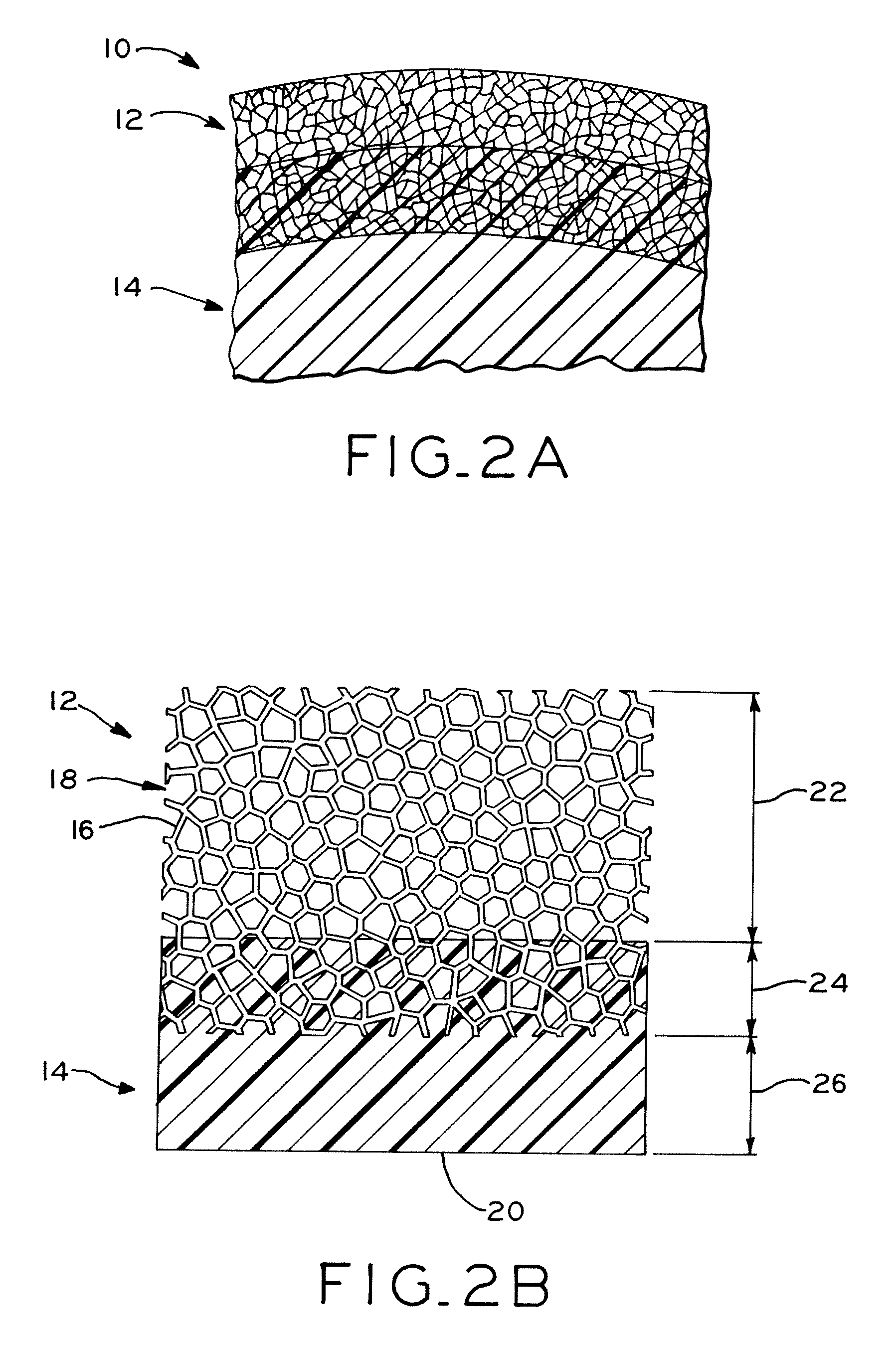

Orthopedic component of low stiffness

ActiveUS20090192610A1Component can be removedReduce the impactBone implantSynthetic resin layered productsAcetabular linerPlastic surgery

An orthopedic component having multiple layers that are selected to provide an overall modulus that is substantially lower than the modulus of known orthopedic components to more closely approximate the modulus of the bone into which the orthopedic component is implanted. In one exemplary embodiment, the orthopedic component is an acetabular shell. For example, the acetabular shell may include an outer layer configured for securement to the natural acetabulum of a patient and an inner layer configured to receive an acetabular liner. The head of a femoral prosthesis articulates against the acetabular liner to replicate the function of a natural hip joint. Alternatively, the inner layer of the acetabular shell may act as an integral acetabular liner against which the head of the femoral prosthesis articulates.

Owner:ZIMMER INC

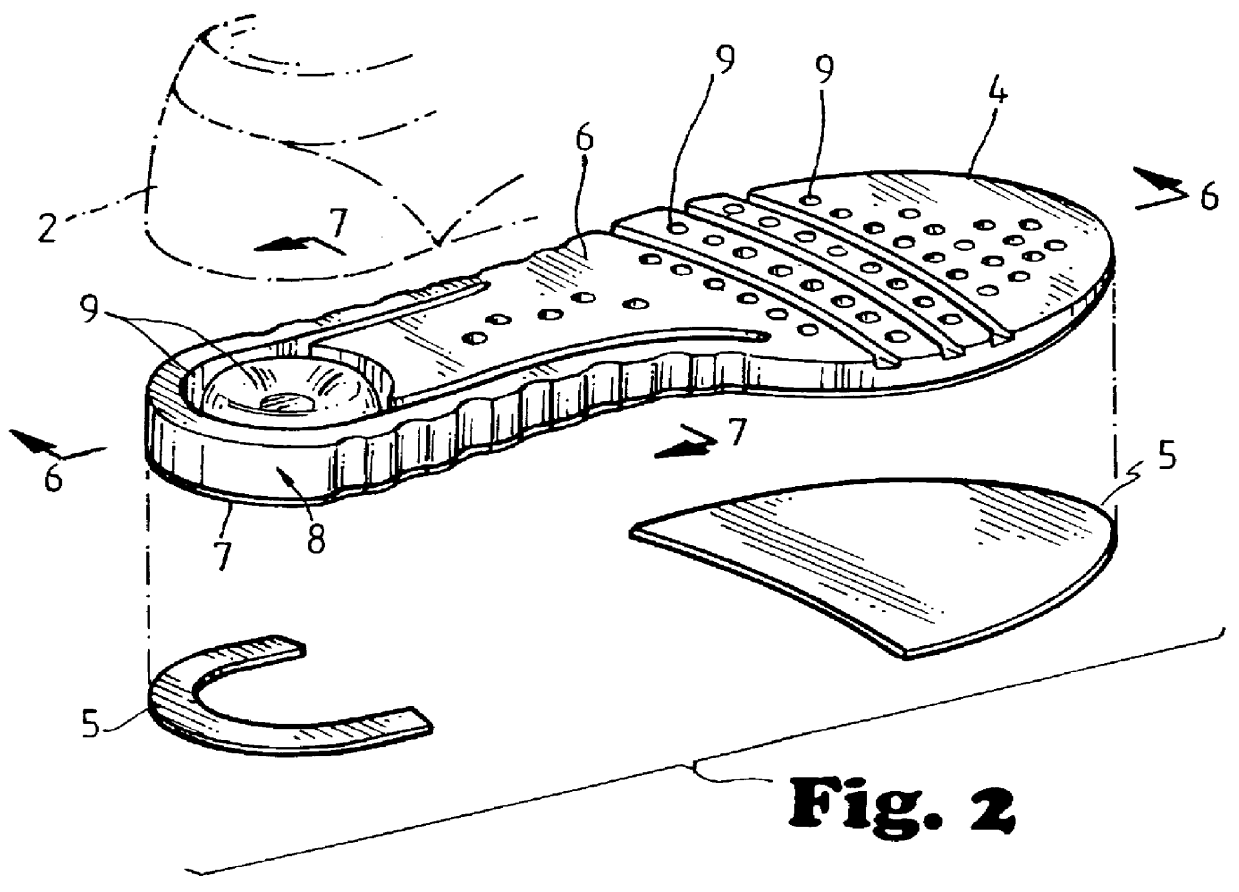

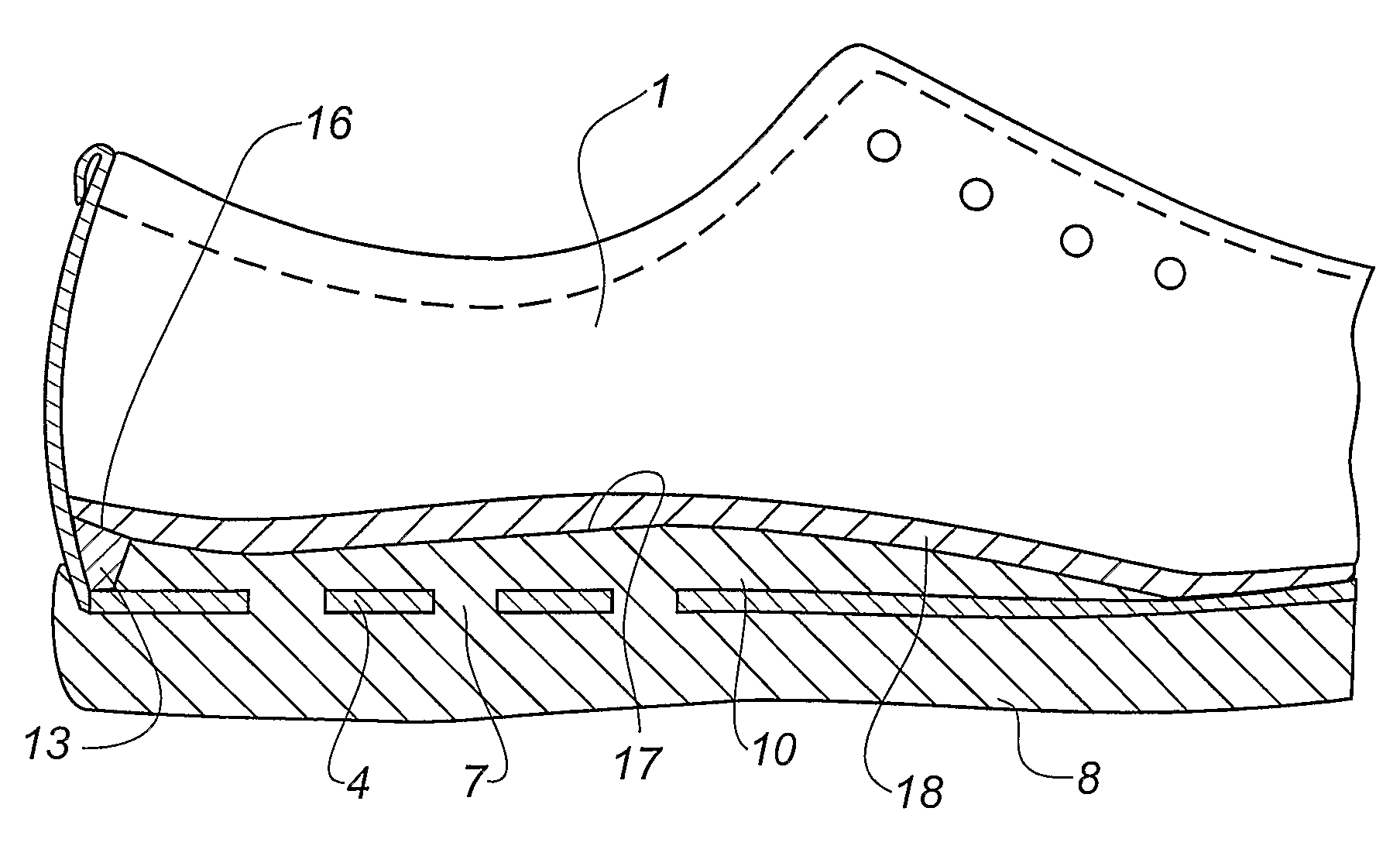

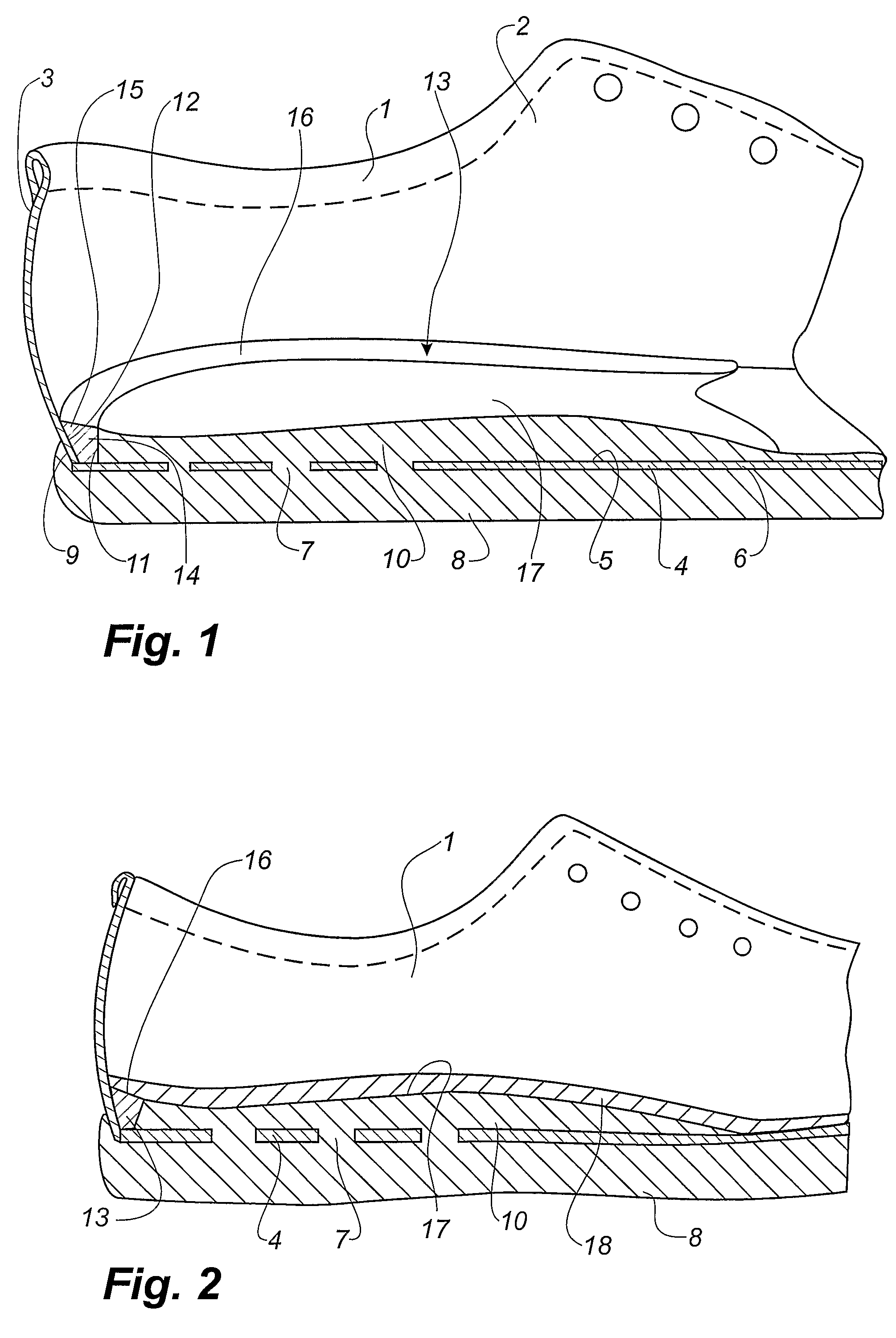

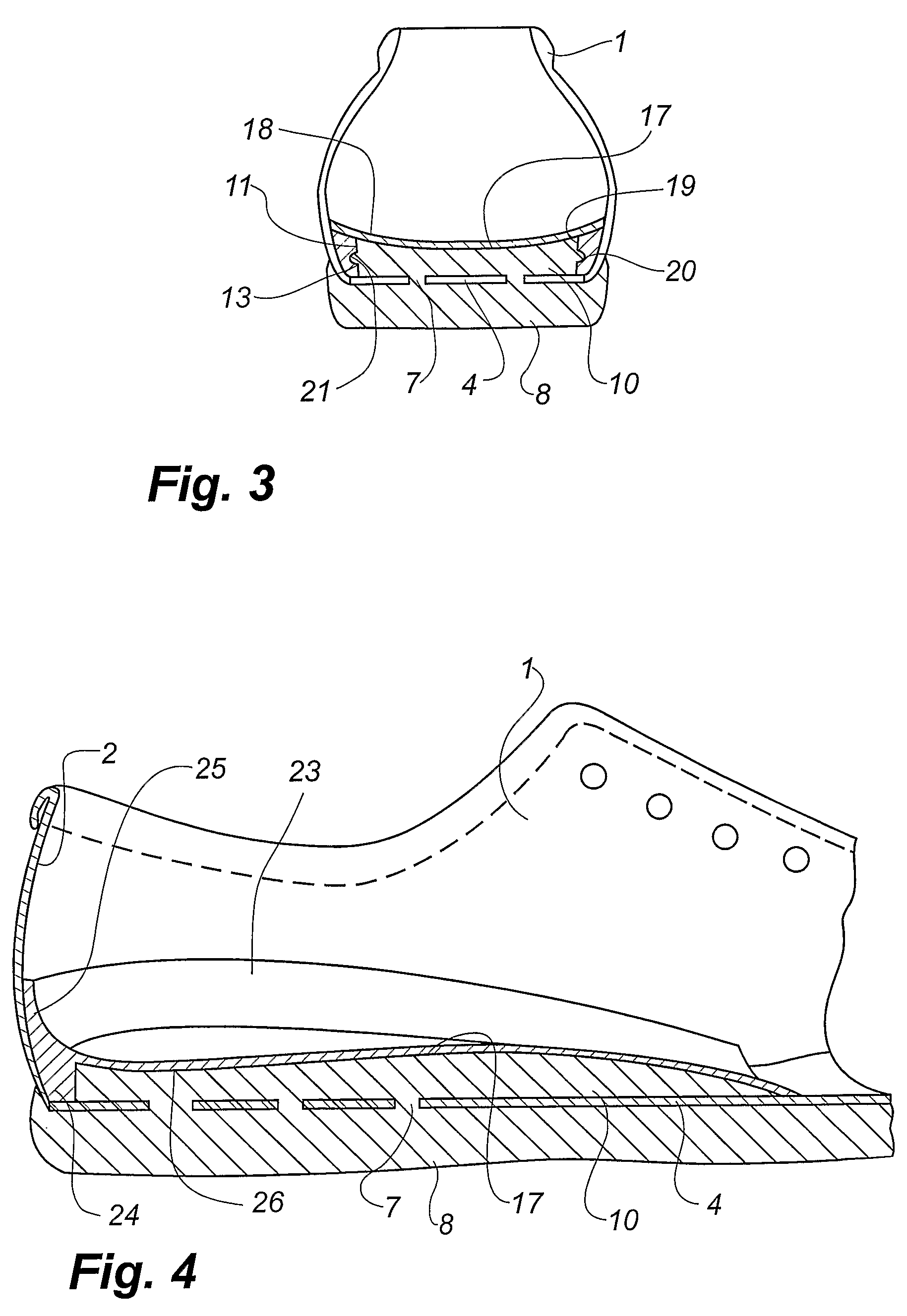

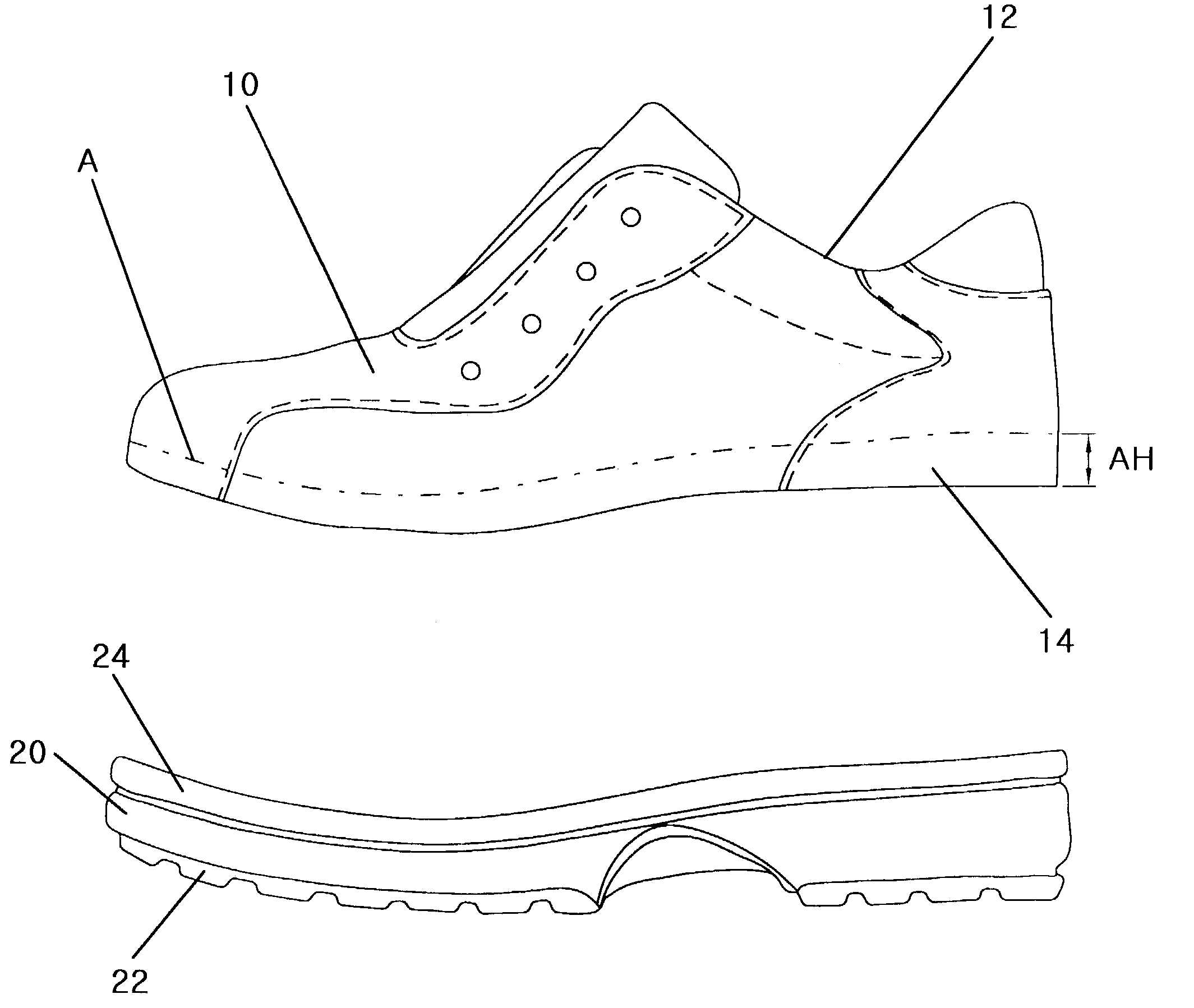

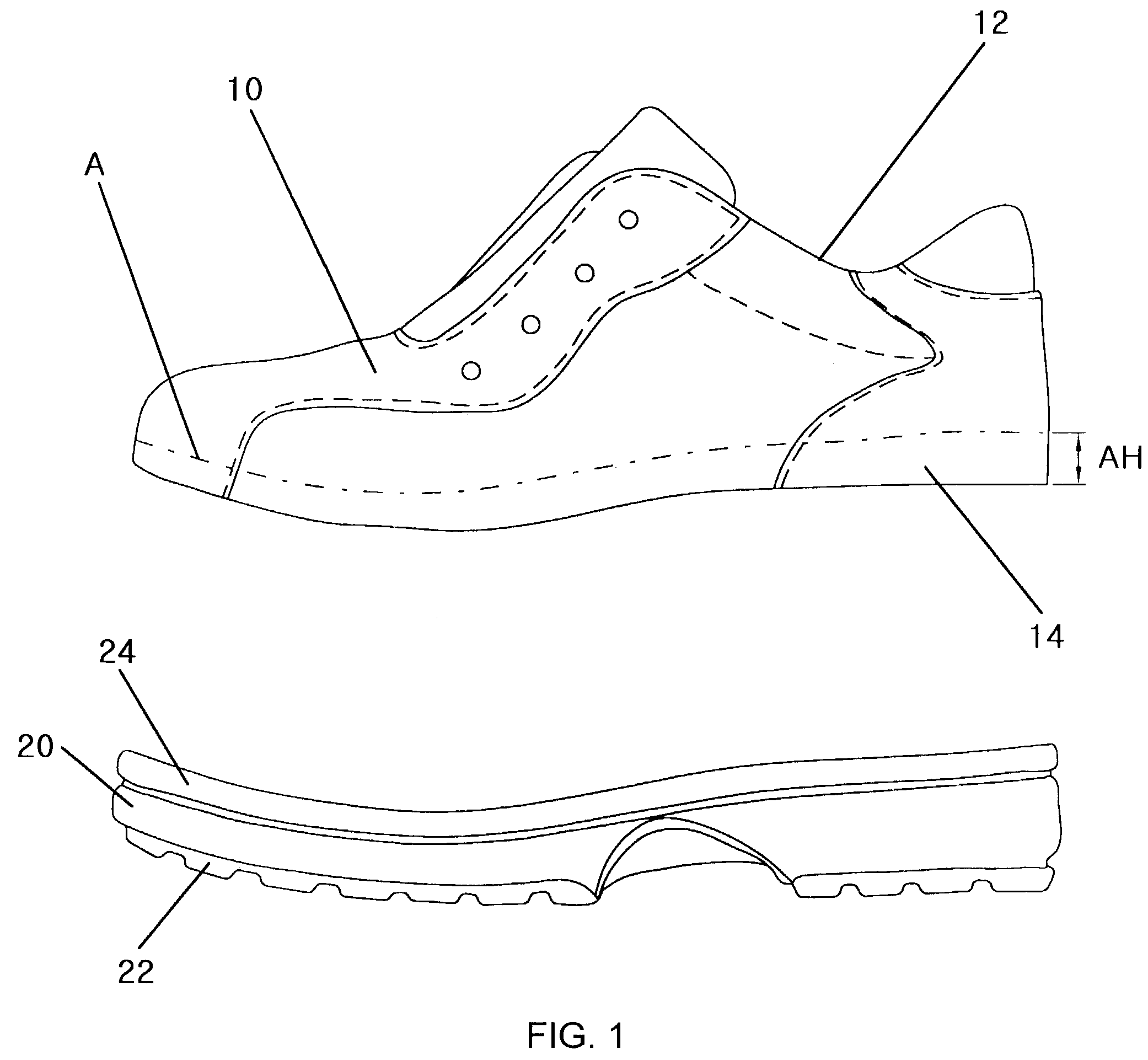

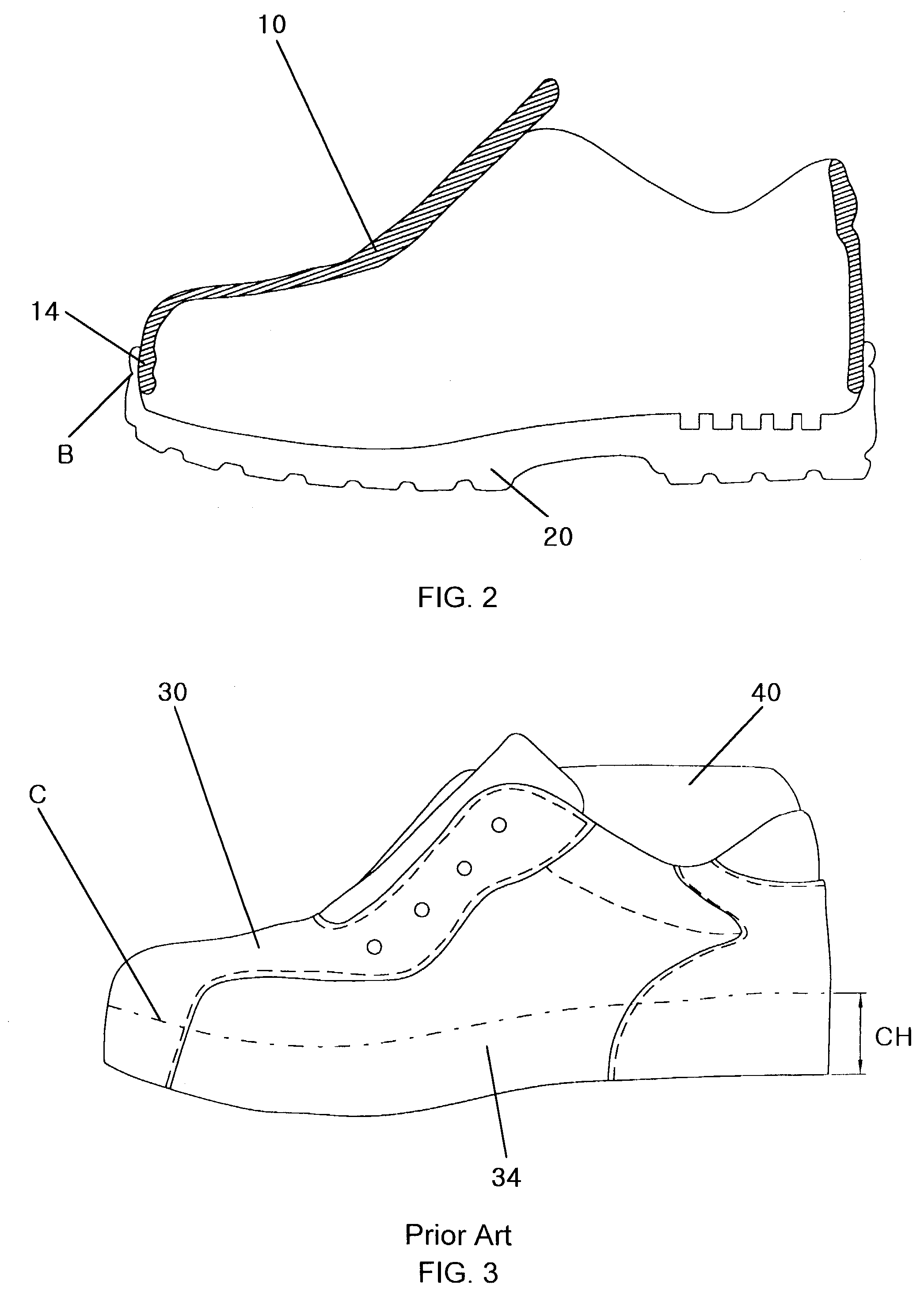

Shoe and a method of making shoes

InactiveUS7743530B2Reduce manufacturing costHigh densityLastingSolesPlastic materialsInjected material

A method of making a shoe, said shoe having an interior sole (10) and an outsole (8) being integrally moulded onto an upper (1) with an insole (4), comprising the following steps: providing of a last (30) having a wedge-shaped recess (32) is its heel area, said recess being defined by a projecting rib (33), providing an upper (1) with an insole (4) on the last (30), said insole (4) being provided with a hole (7) in the heel area, arranging the lower part of the last provided with the upper (1) and the insole (4) in a mould (34), injecting a plastic material into a closed mould cavity formed by the last and the mould, allowing the injected material to harden, whereby the rib (32) of the last (30) forms a corresponding groove (12) between the interior sole (10) and the inner face of the upper (1), removing the upper (1) with the moulded-on soles (8, 10) from the last (30), providing a separately formed insert (13) of a shape substantially corresponding to the shape of the groove (12) and placing the insert in the groove (12).

Owner:ECCO SKO

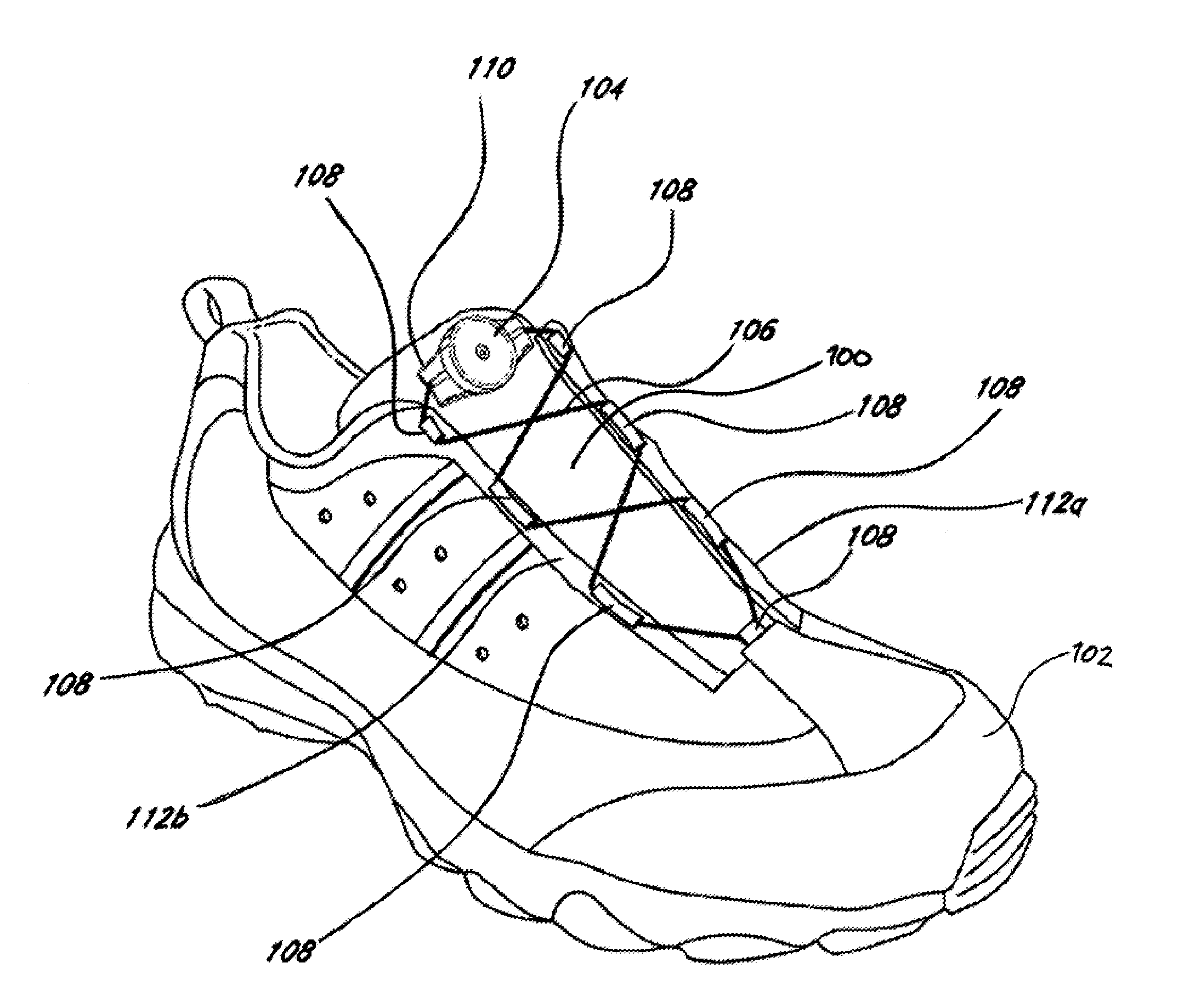

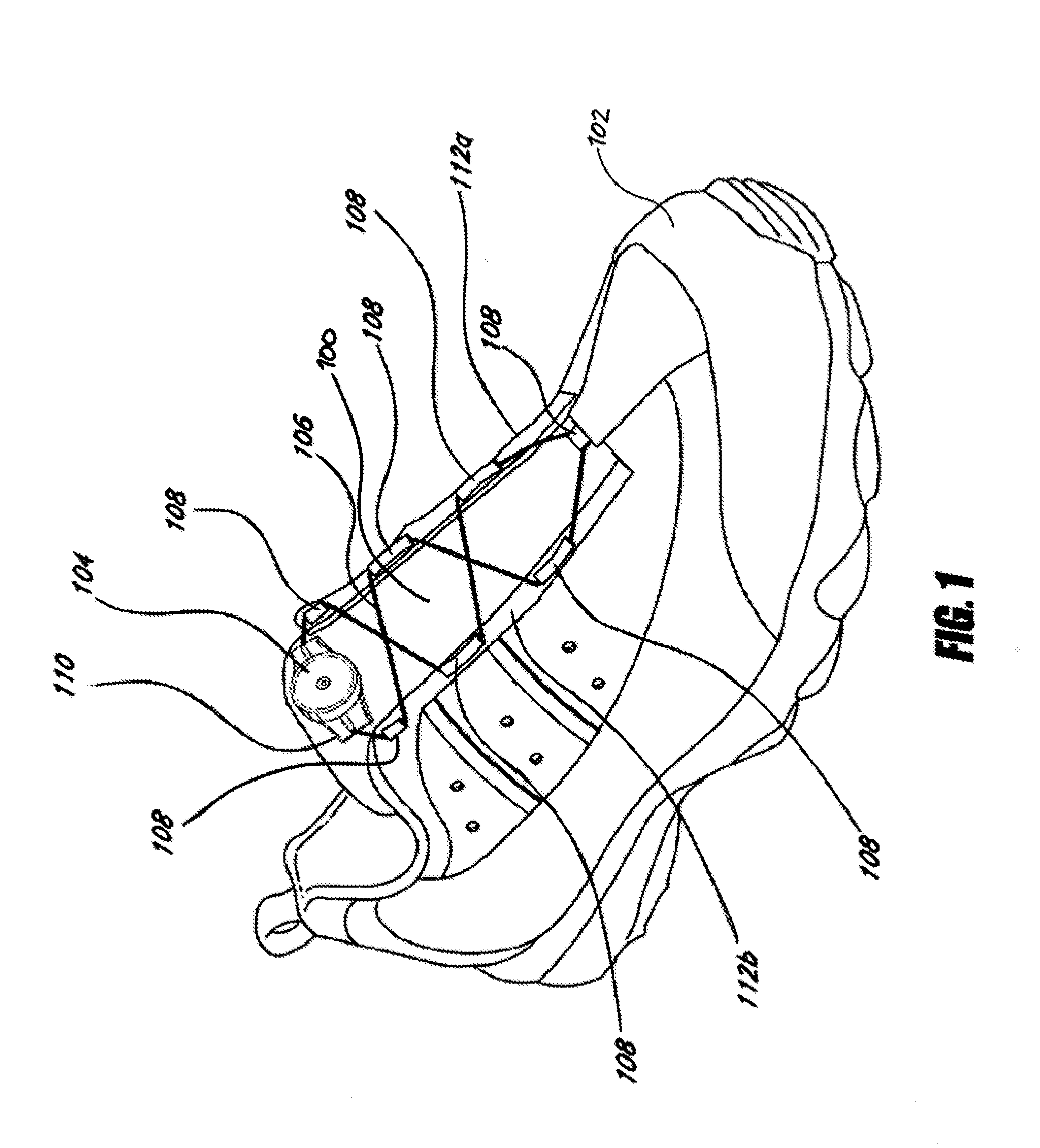

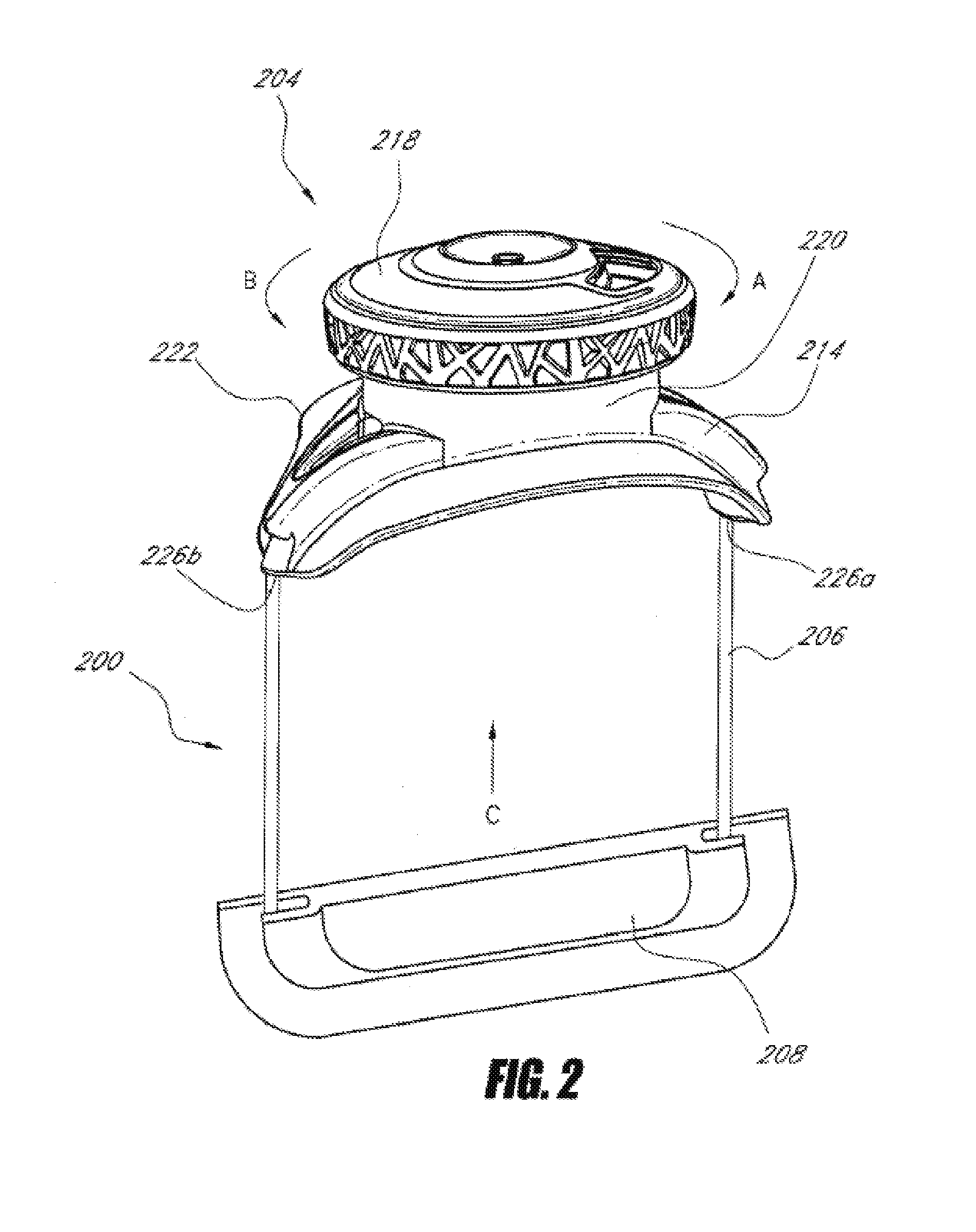

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

Method for manufacturing shoes and shoes manufactured by the method

InactiveUS6978557B2Reduce the amount requiredShorten the timeSolesDomestic footwearMolding machineEngineering

A method for manufacturing shoes is provided. The method includes preparing an upper and an outsole, applying an adhesive agent to the outer surface of an upper seal portion and the inner surface of an outsole seal portion, stitching together the outer surface of the upper seal portion and inner surface of the outsole seal portion, activating the adhesive agent by applying heat to the stitched seal portions, and molding the upper and the outsole by using a molding machine. Therefore, since the amount of the upper can be reduced and a separate insole is not necessary, the total weight of the shoes can also be reduced. The flexibility of shoes can also be enhanced.

Owner:JUNG IN LEE

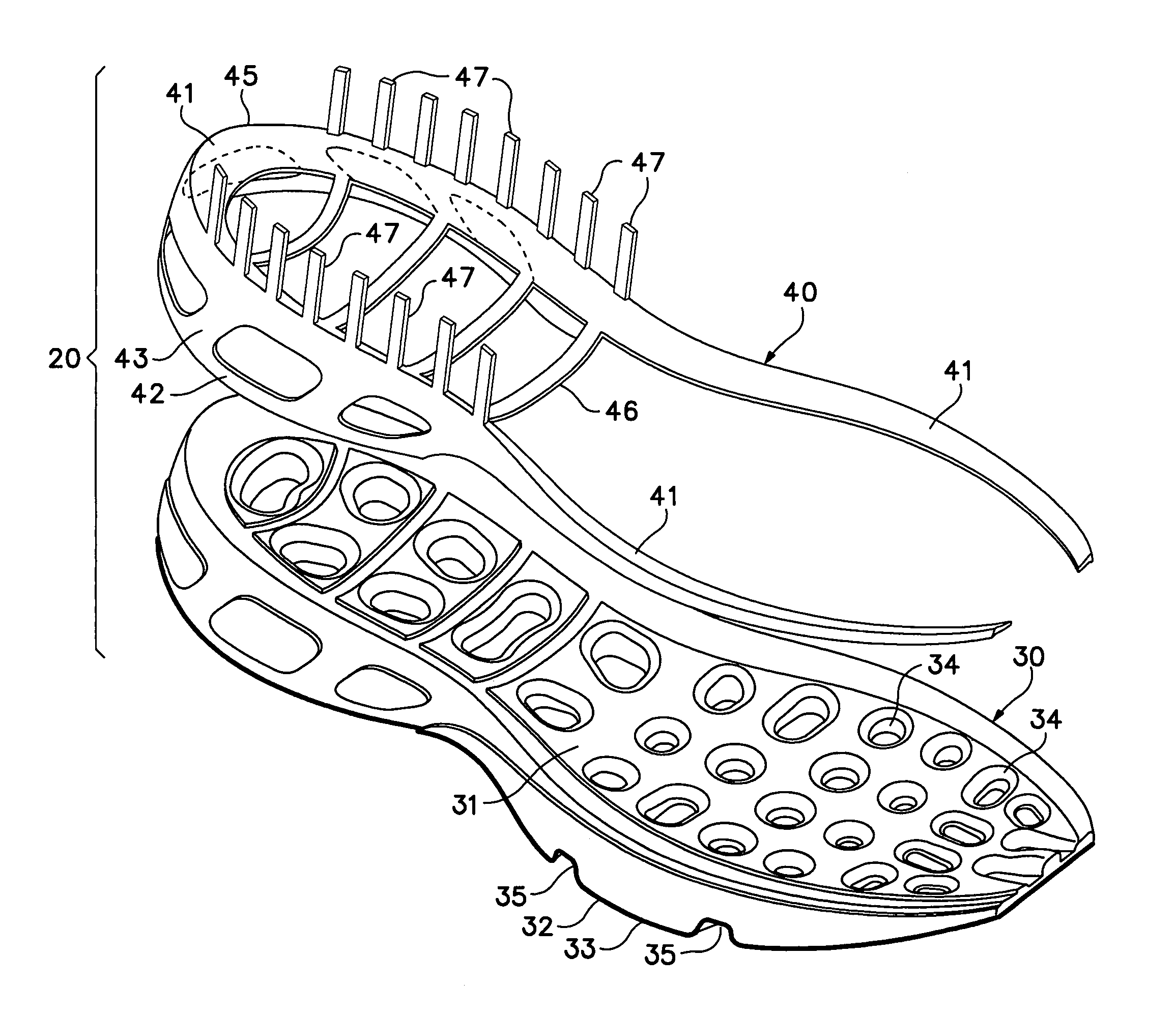

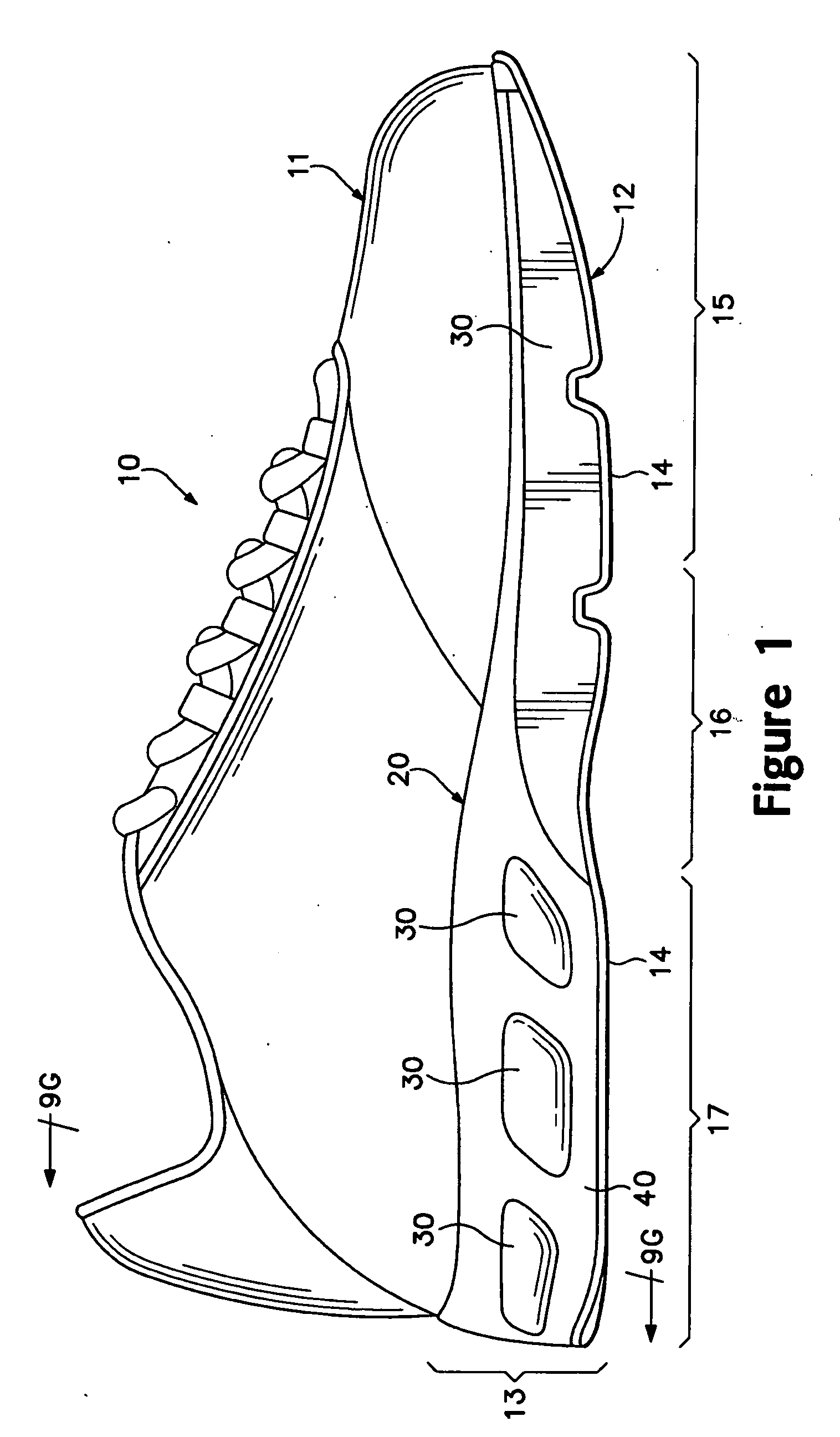

Footwear with a sole structure incorporating a lobed fluid-filled chamber

A fluid-filled chamber for an article of footwear and a method for manufacturing the chamber are disclosed. The chamber may be incorporated into a sole structure of the footwear and includes a central area and a plurality of lobes extending outward from the central area. The lobes are in fluid communication with the central area and are formed from a first surface, a second surface, and a sidewall. The sidewall joins with the first surface with the second surface to seal the fluid within the chamber, but no internal connections are generally utilized to join interior portions of the first surface with interior portions of the second surface. The fluid within the chamber may be air at a pressure that is approximately equal to an ambient pressure.

Owner:NIKE INC

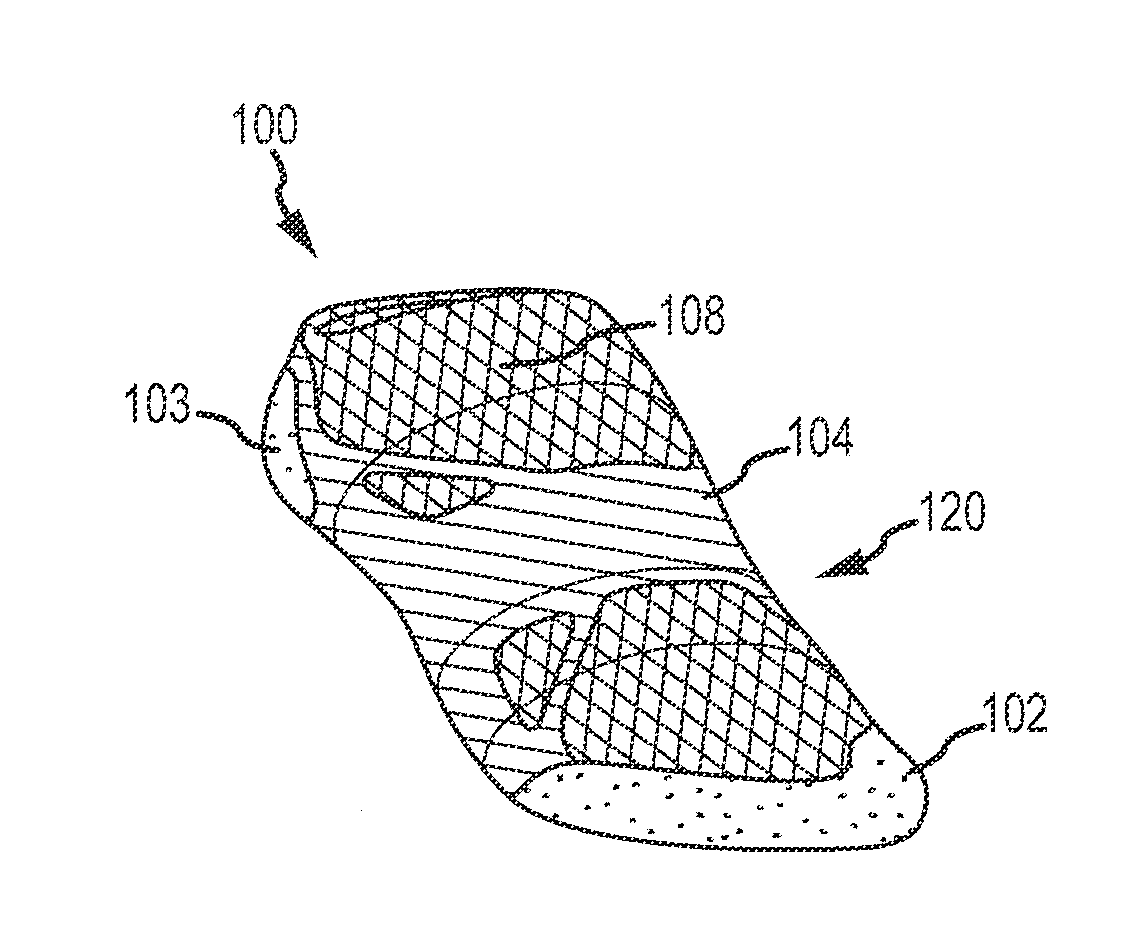

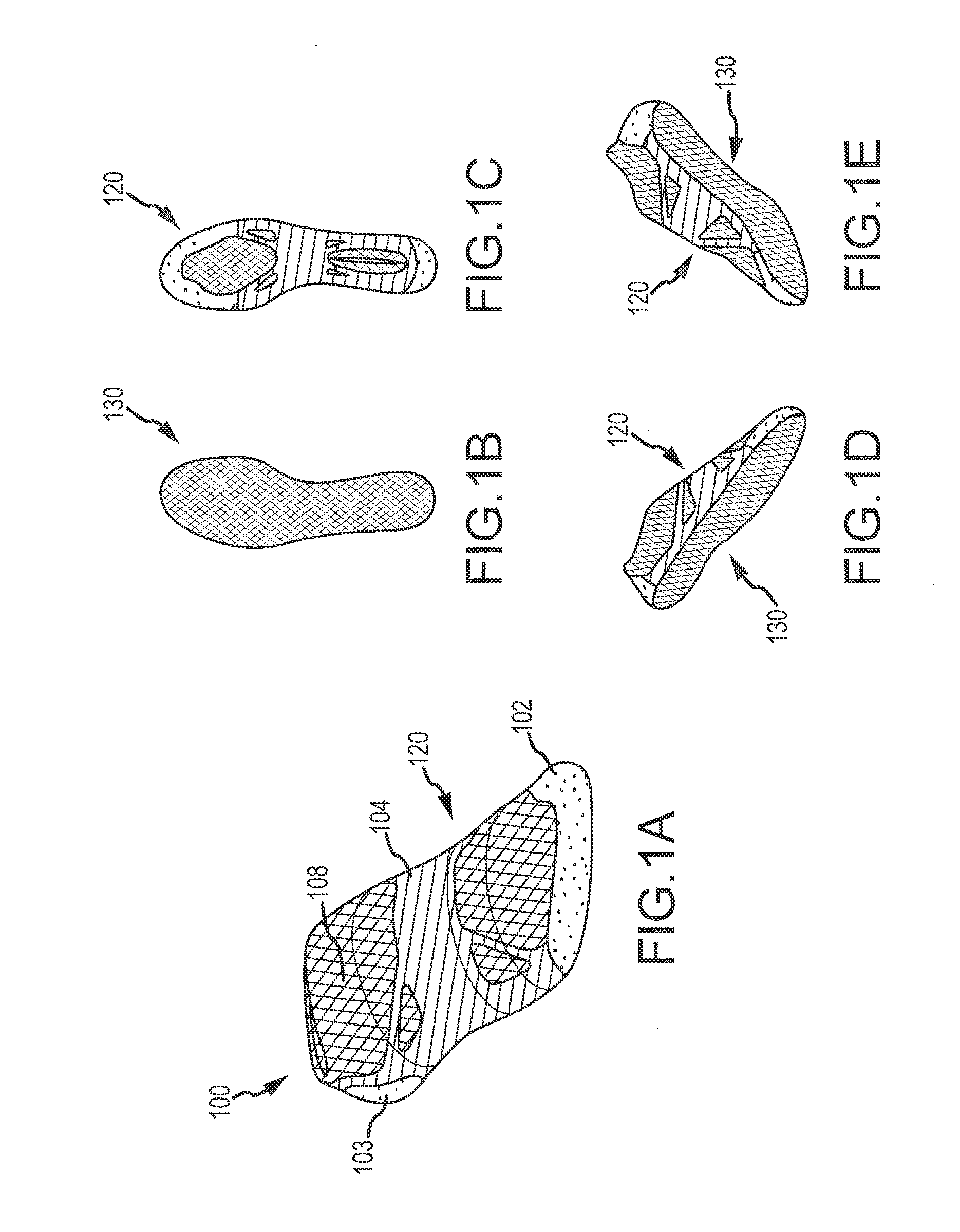

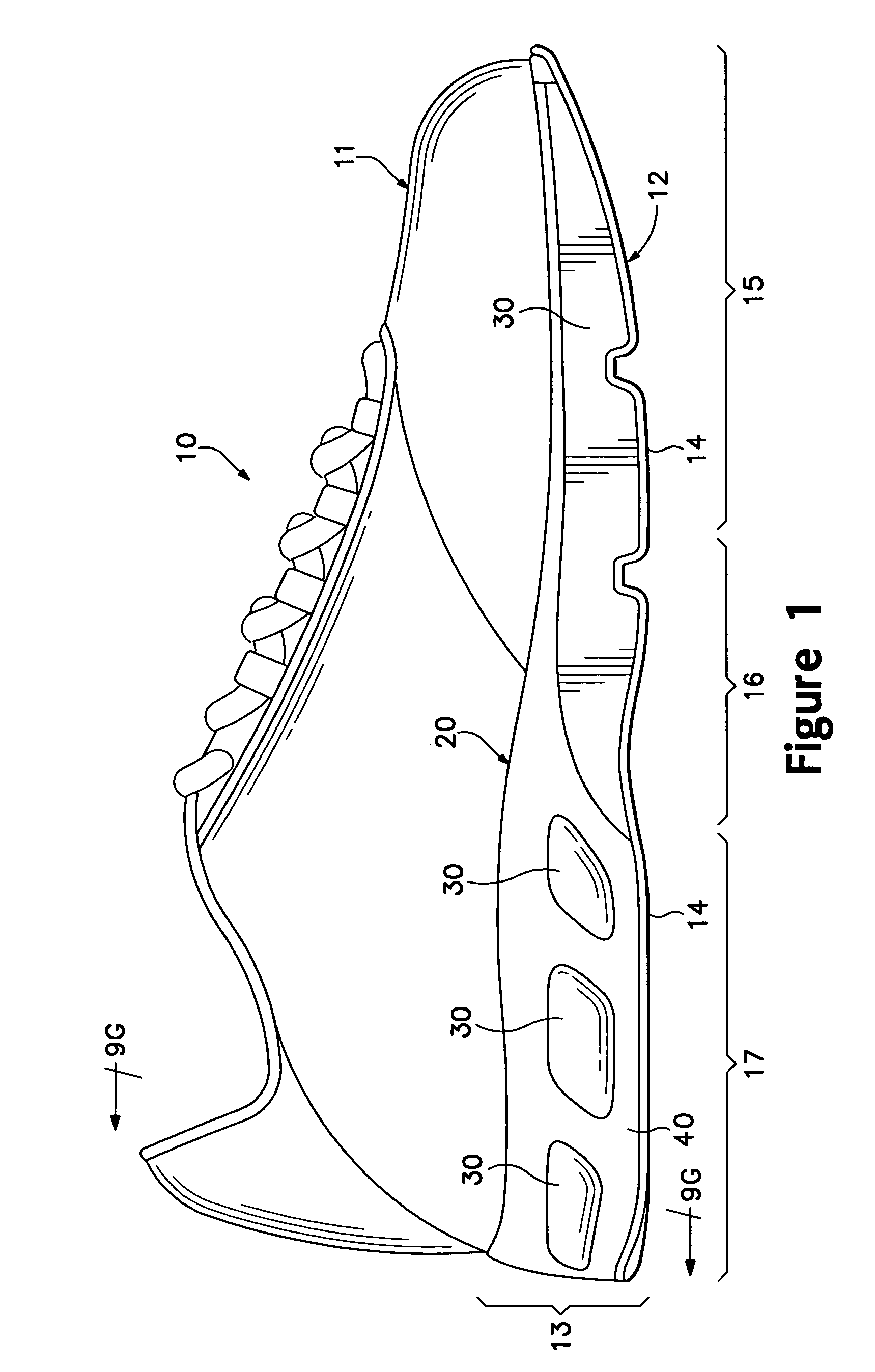

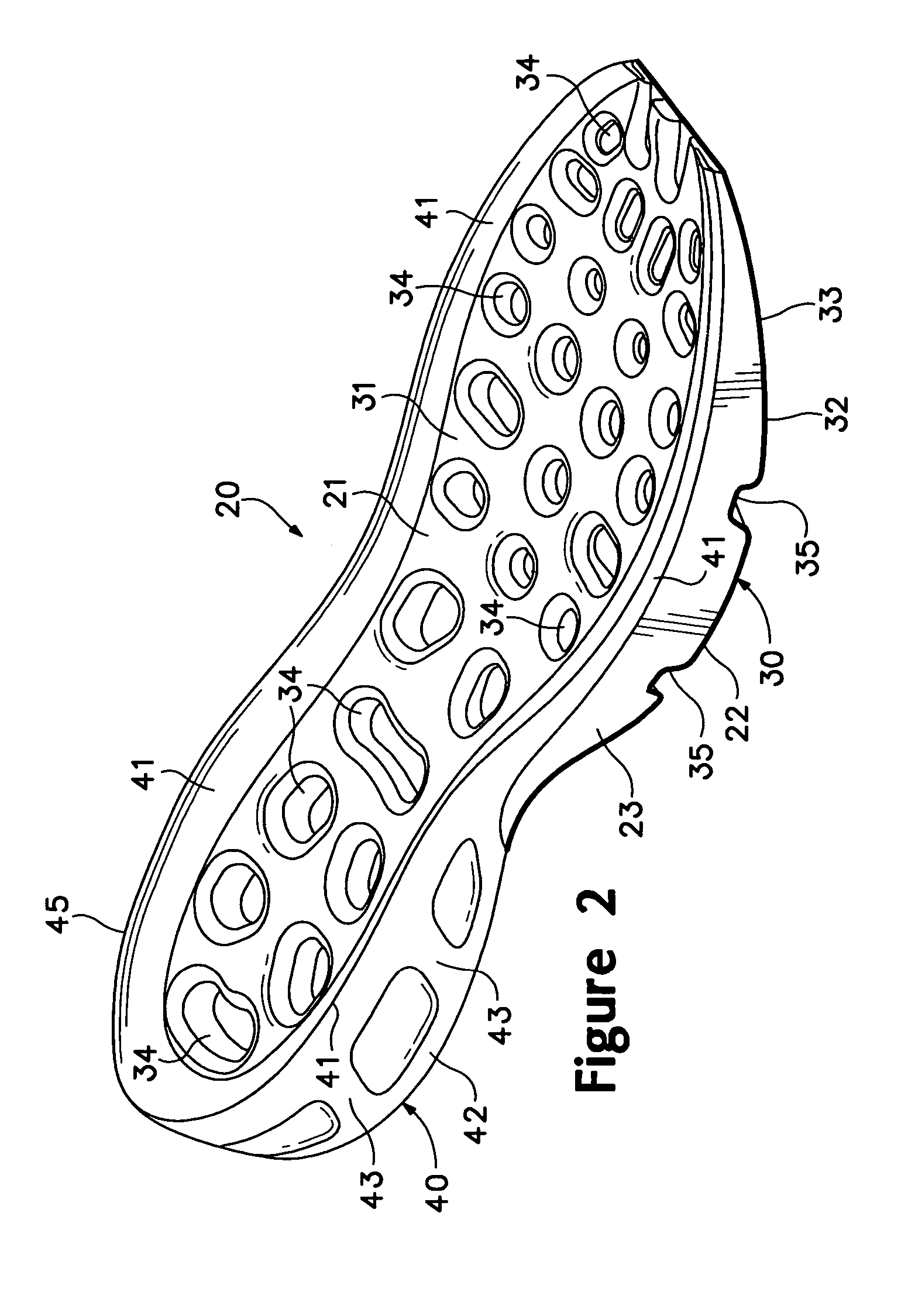

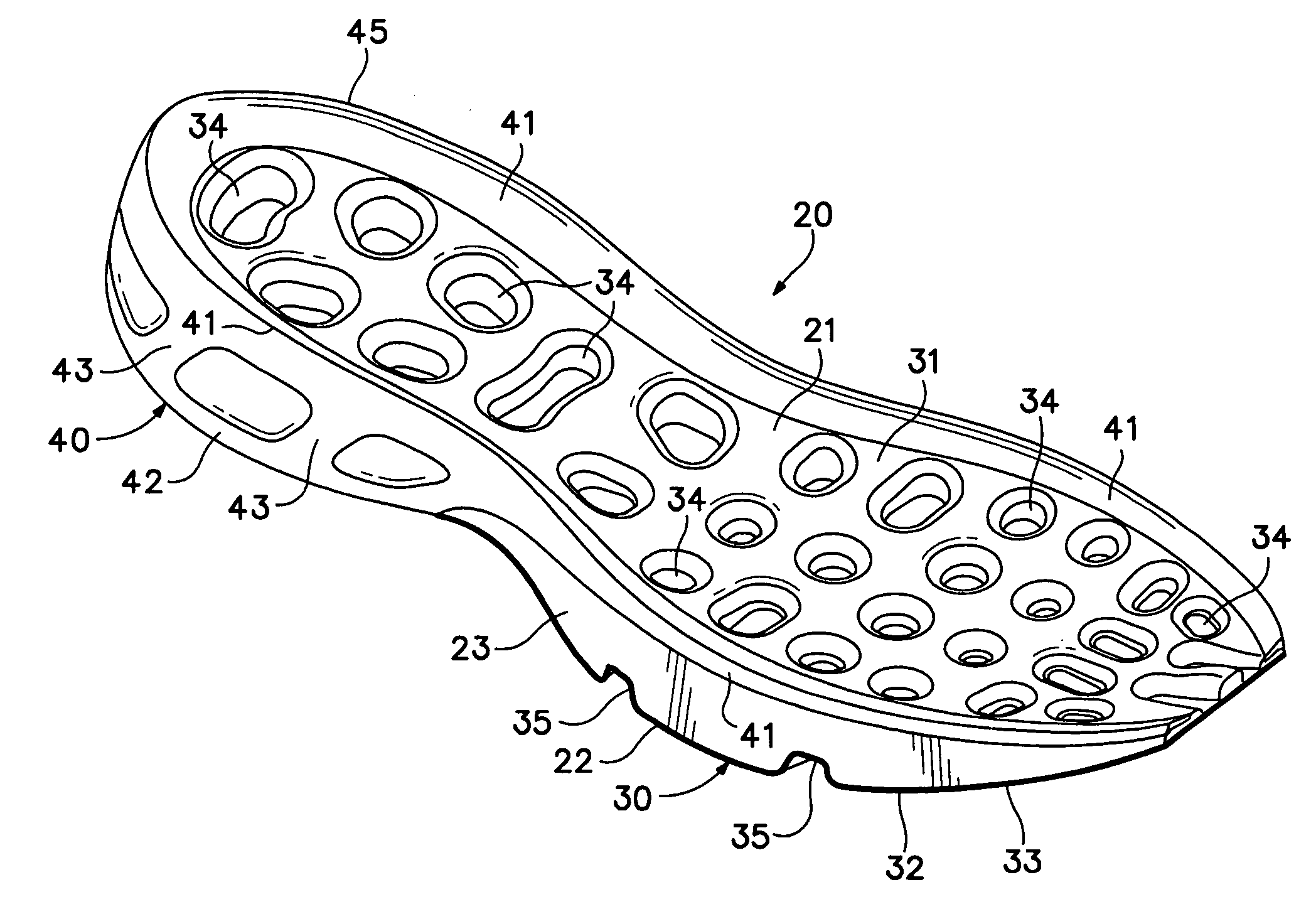

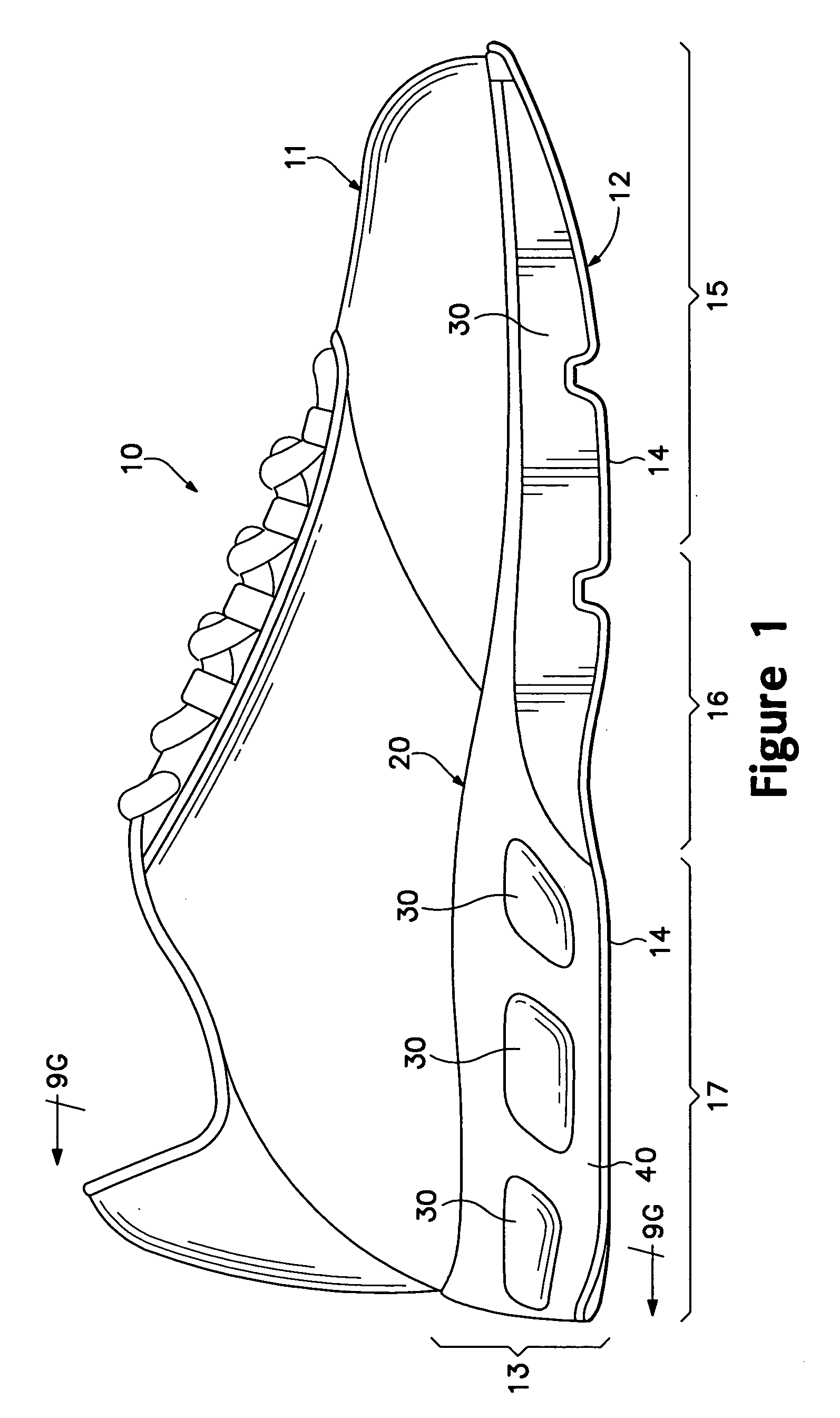

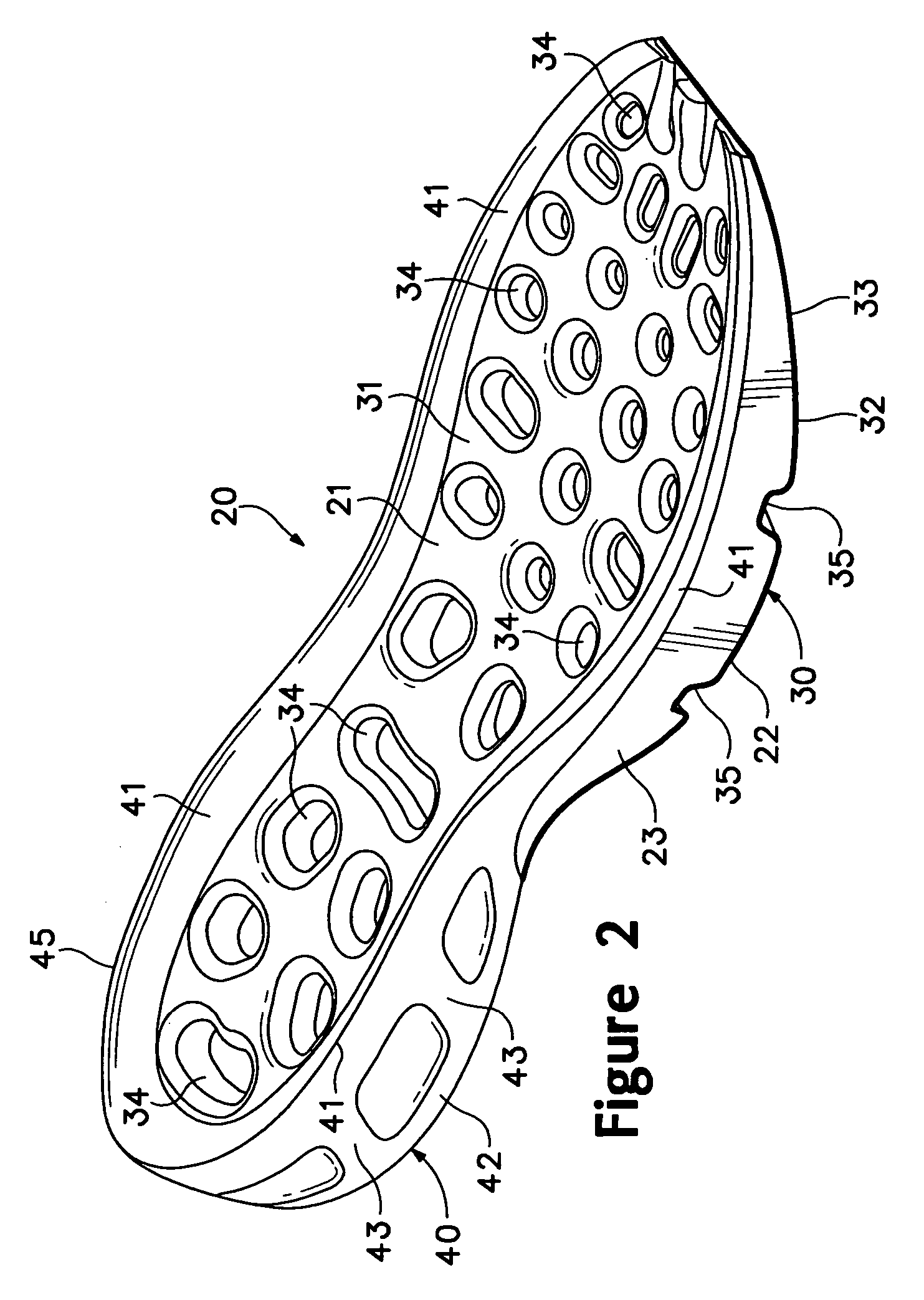

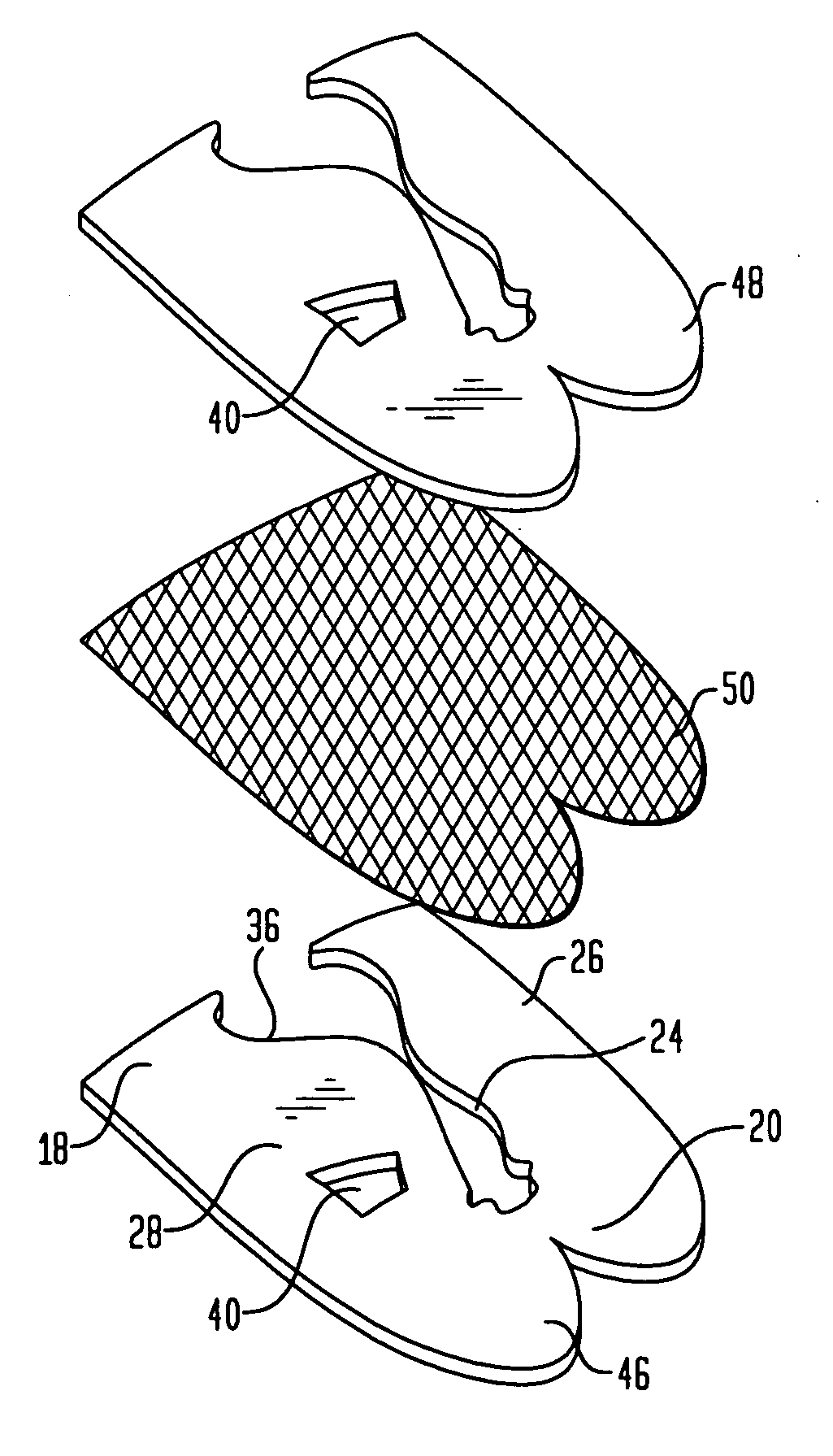

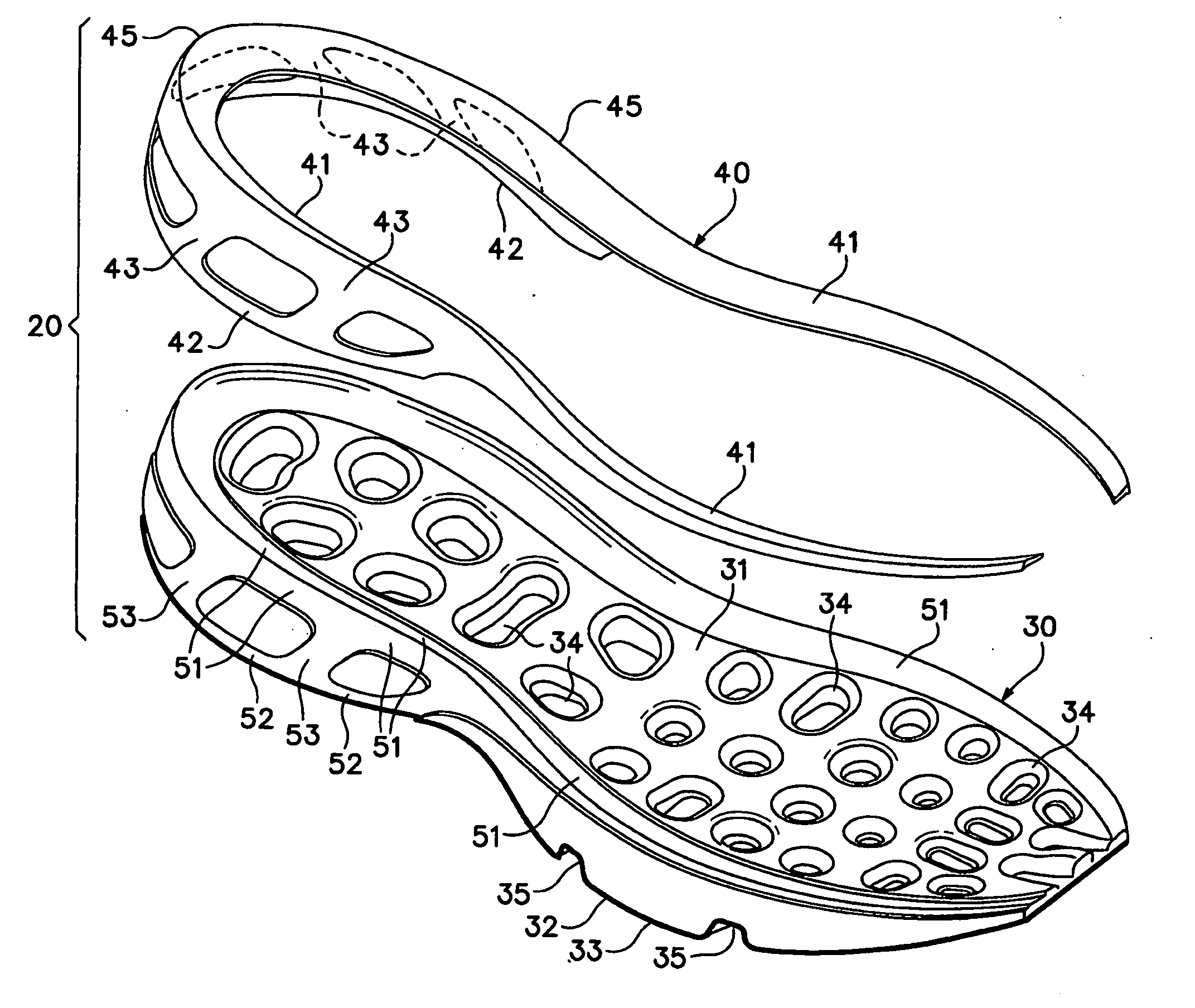

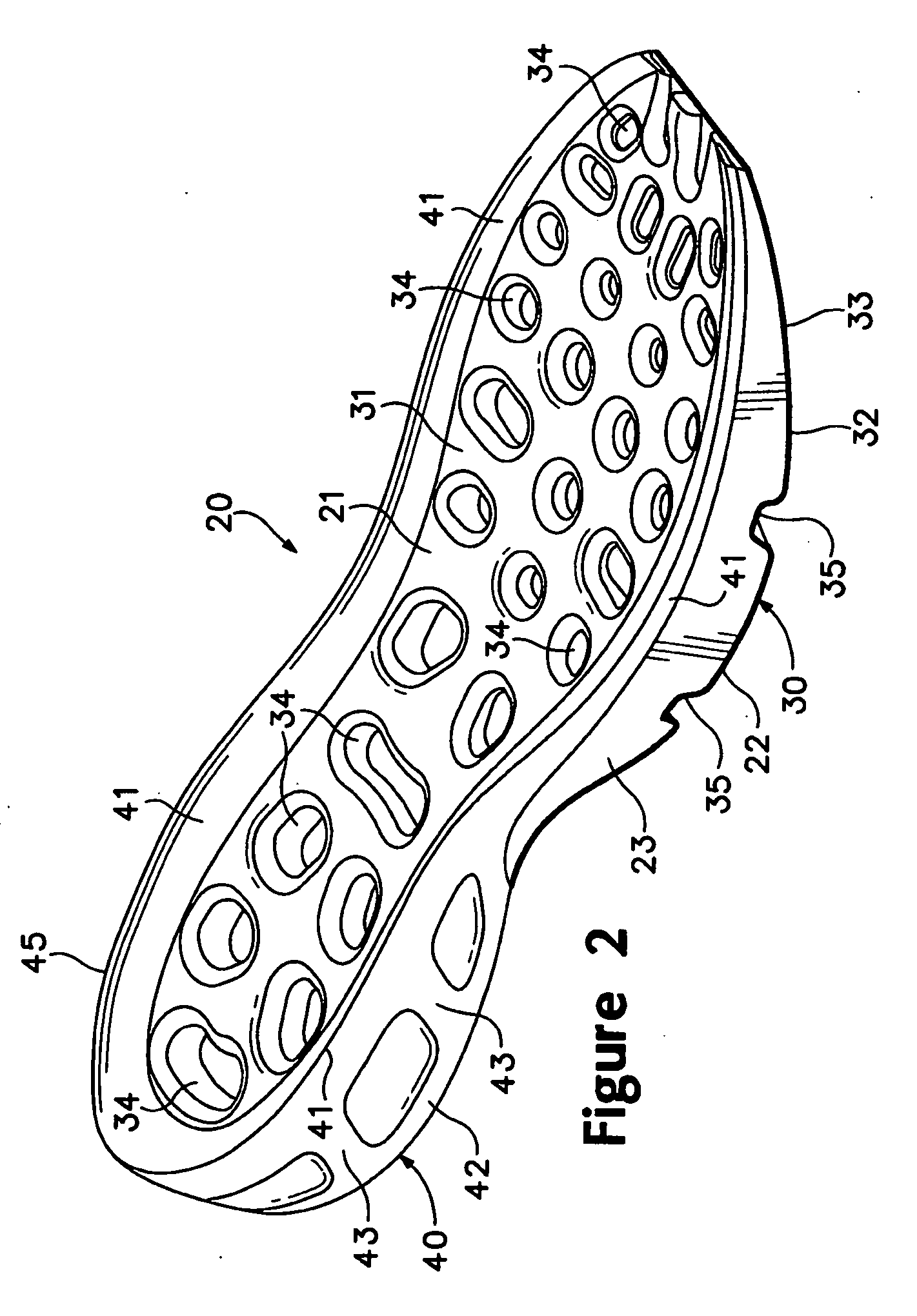

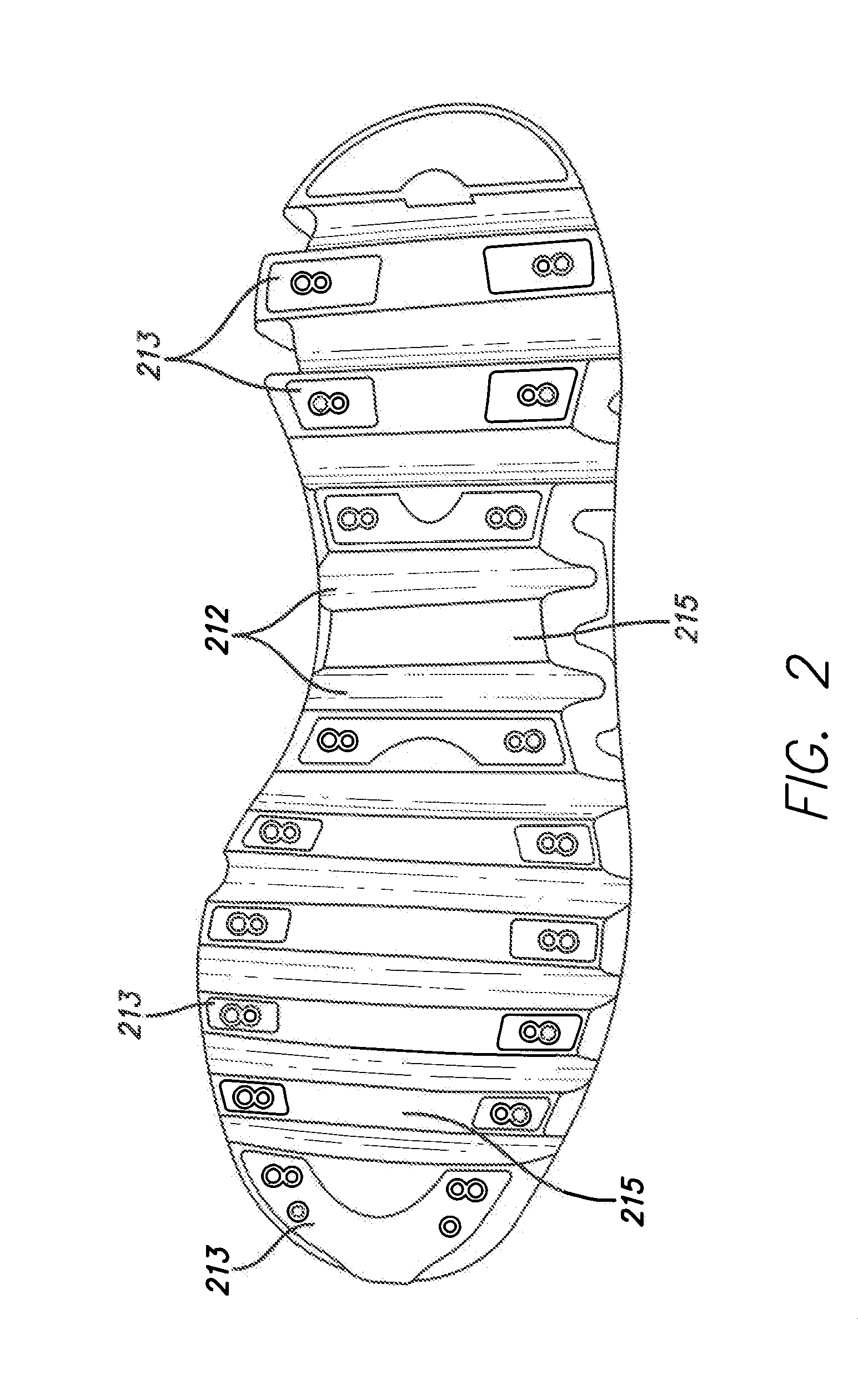

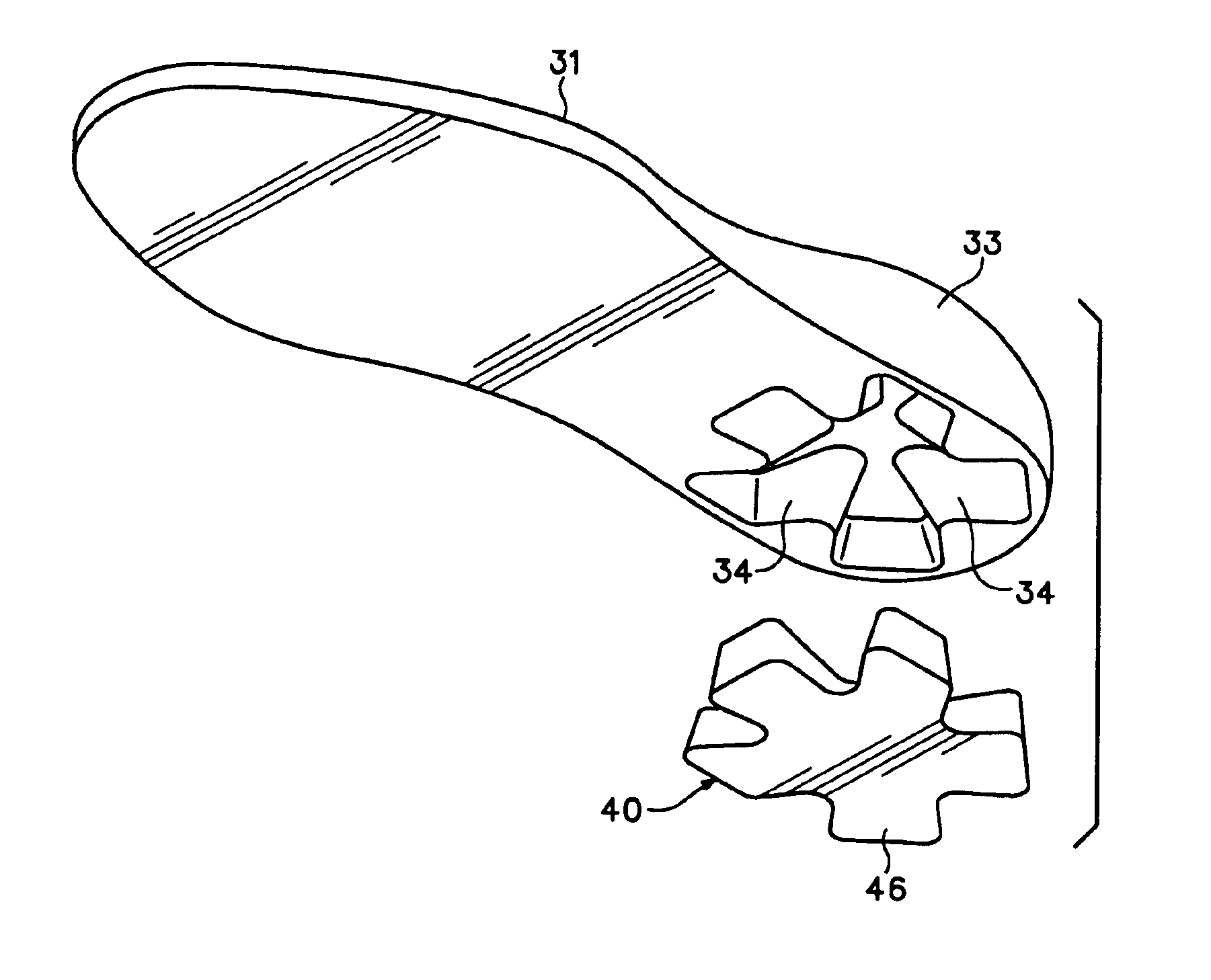

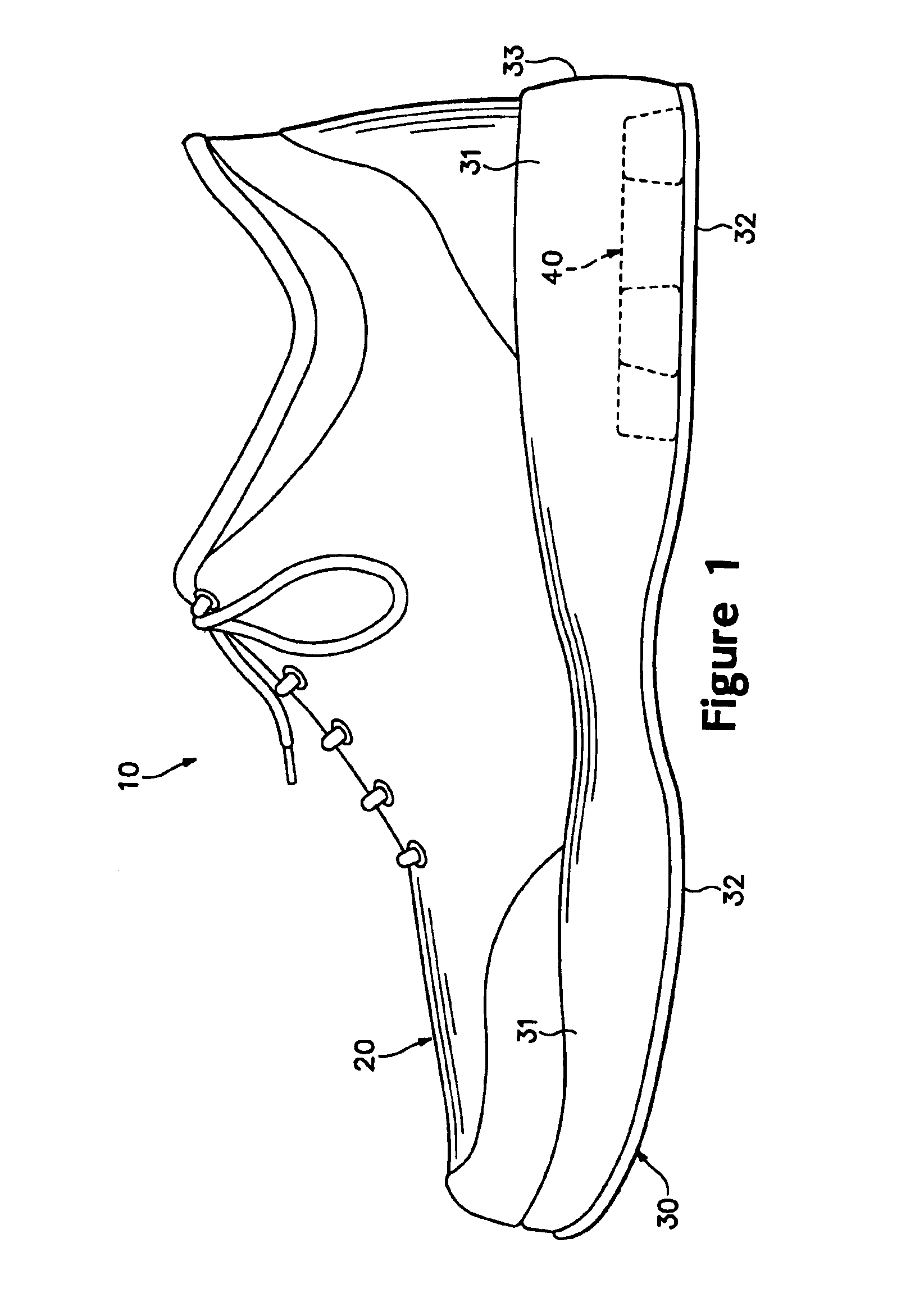

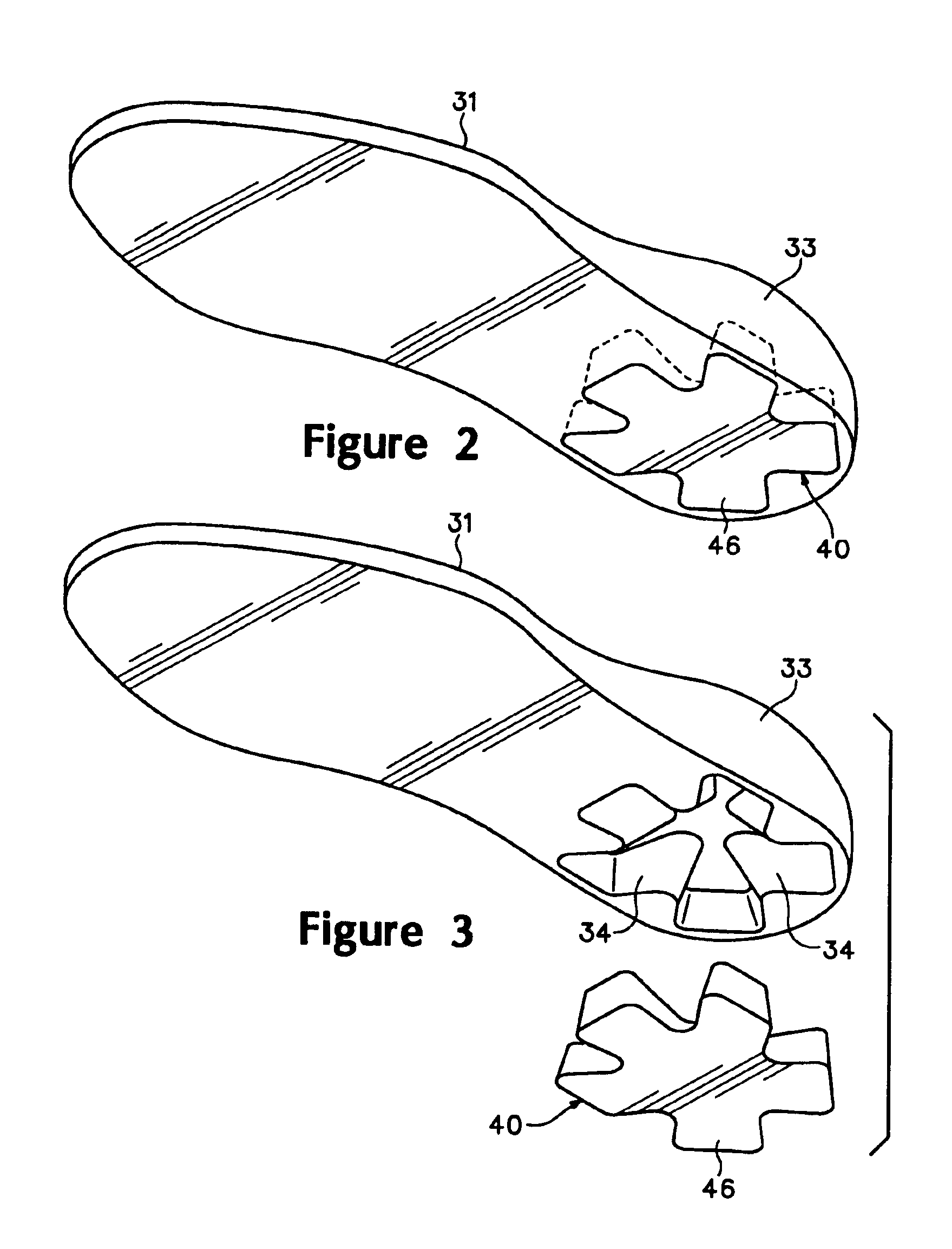

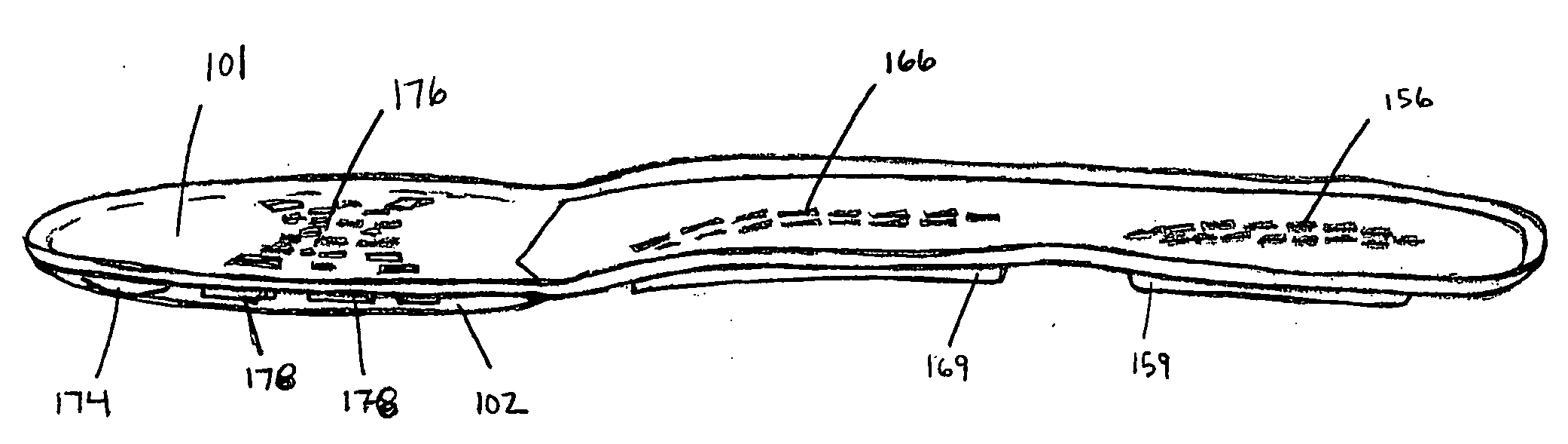

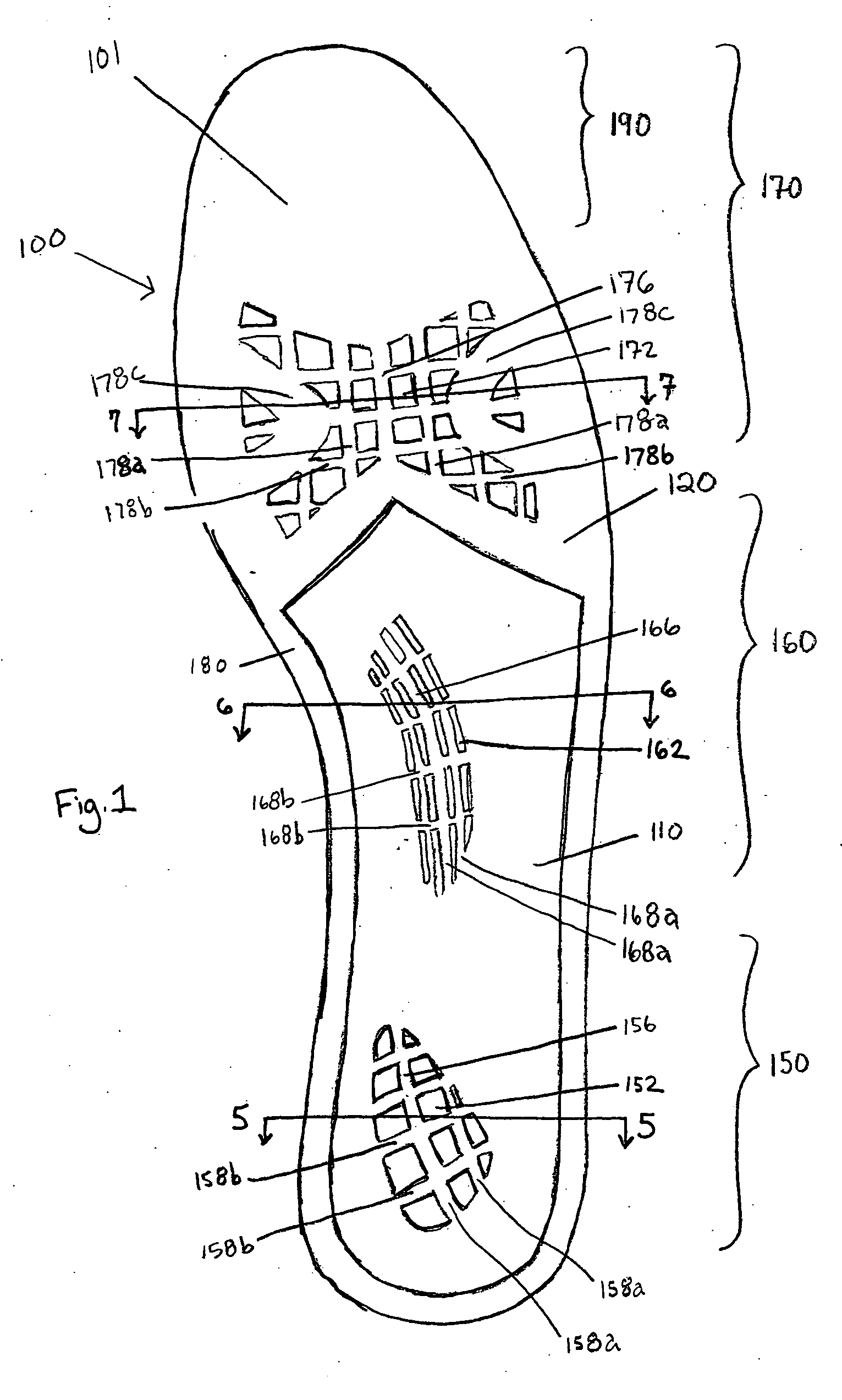

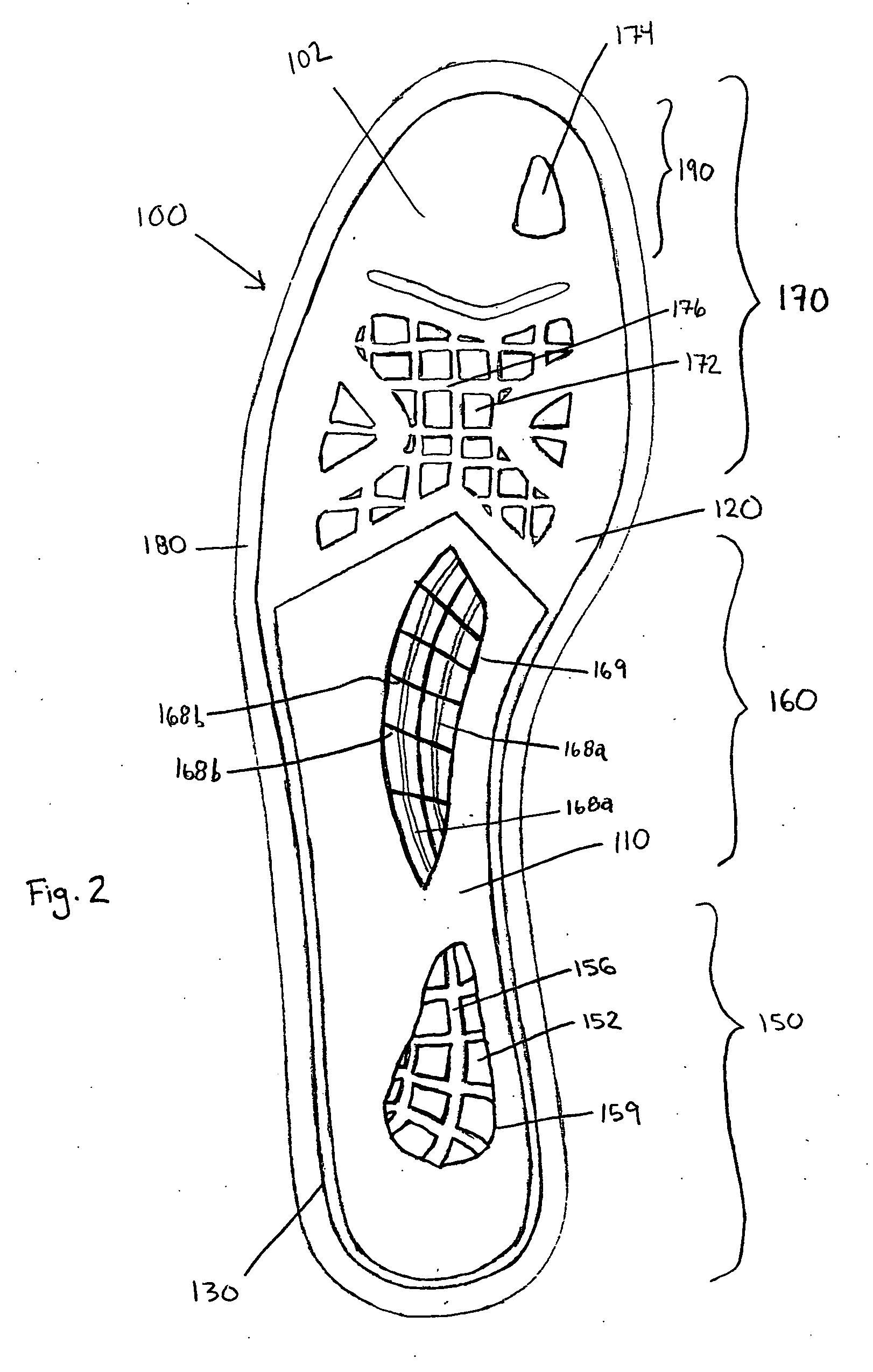

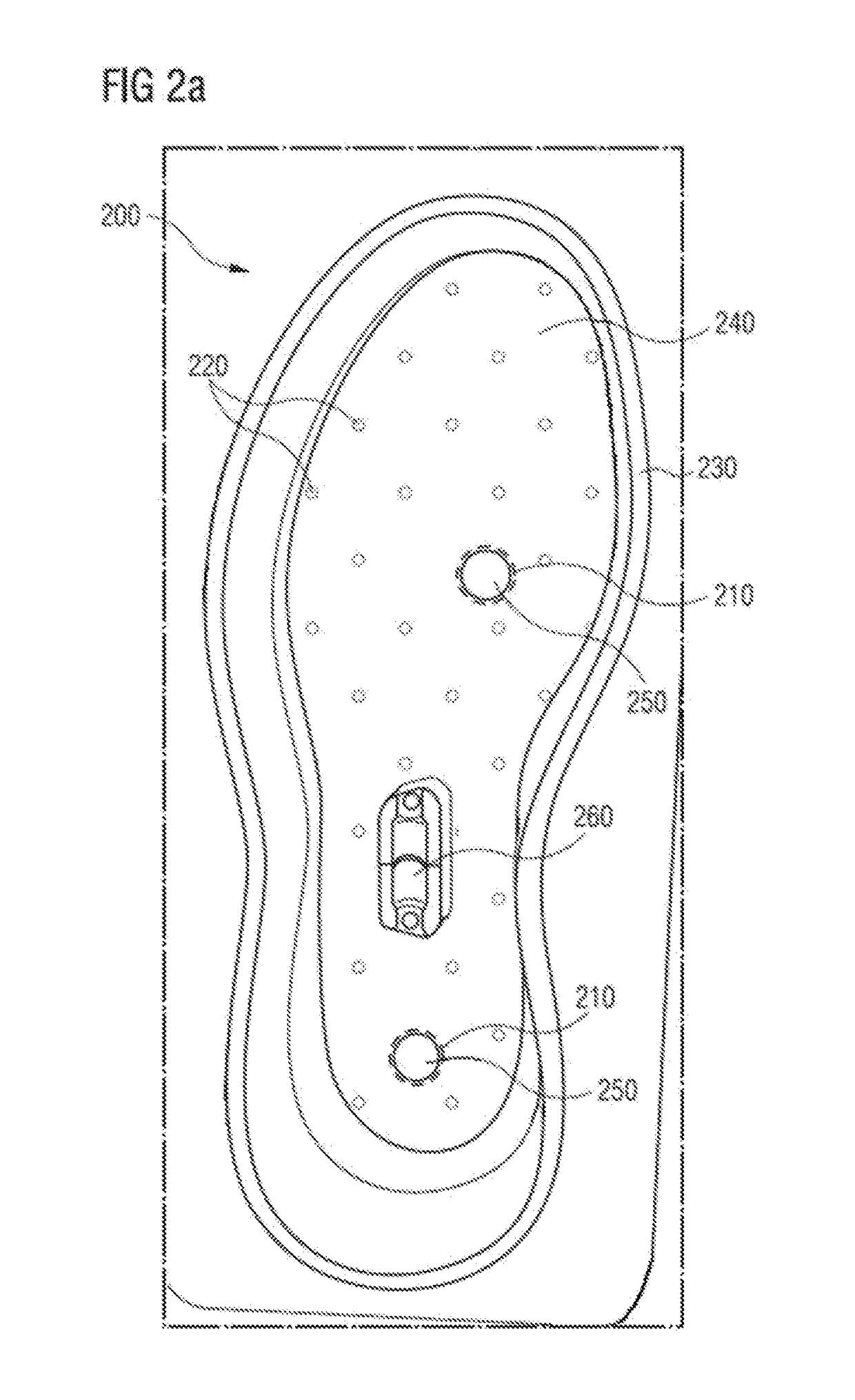

Grid midsole insert

A midsole insert for use with a shoe is provided. The midsole insert includes a heel portion, a midfoot portion, and a forefoot portion, and a plurality of grid systems located on the midsole insert, where each grid system includes a plurality of openings cut into the midsole insert forming a lattice pattern. The plurality of grids may be located on at least one of the heel portion, the midfoot portion, and the forefoot portion, constructed to provide energy return features. The midsole may further be constructed and arranged to attach directly to an upper during a manufacturing step, to secure the shape of the upper on a last. By attaching directly to the upper, the midsole insert eliminates the need for a stroble board, which is typically used to secure the upper to the last. By eliminating the stroble board, the present invention places the midsole insert and the energy return grid system closer to the foot, which maximizes reaction time and performance. The midsole insert may be formed of at least two materials having different hardnesses, such that the heel portion has a greater hardness than the forefoot portion.

Owner:SAUCONY

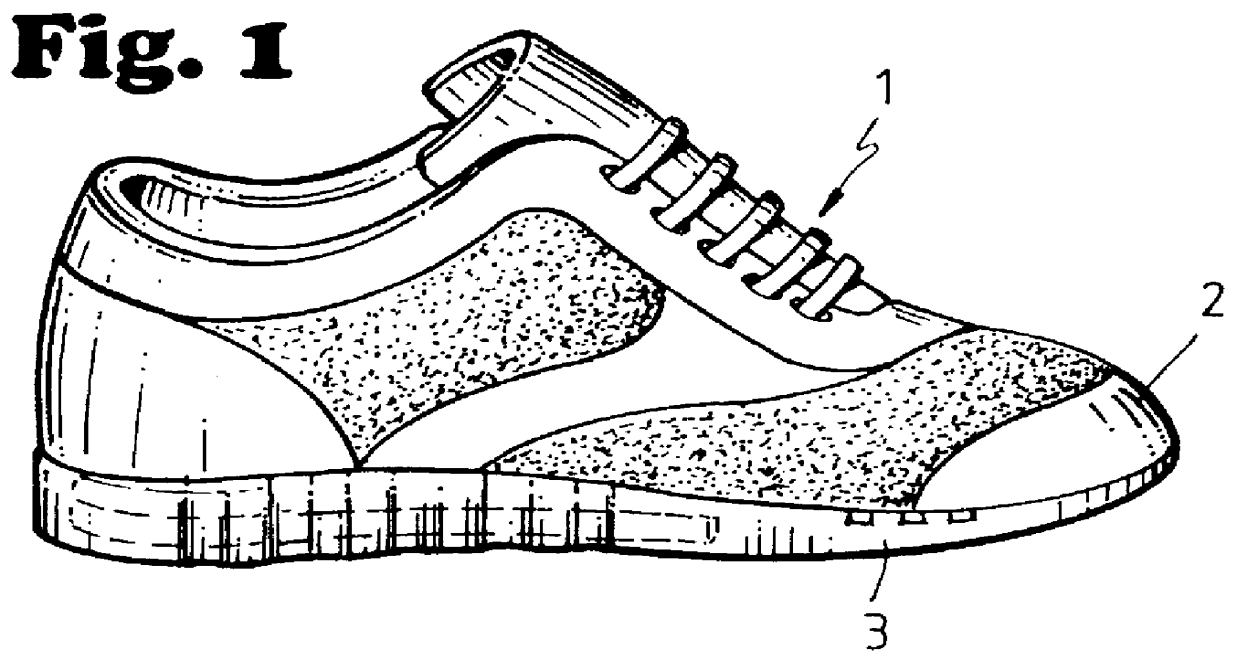

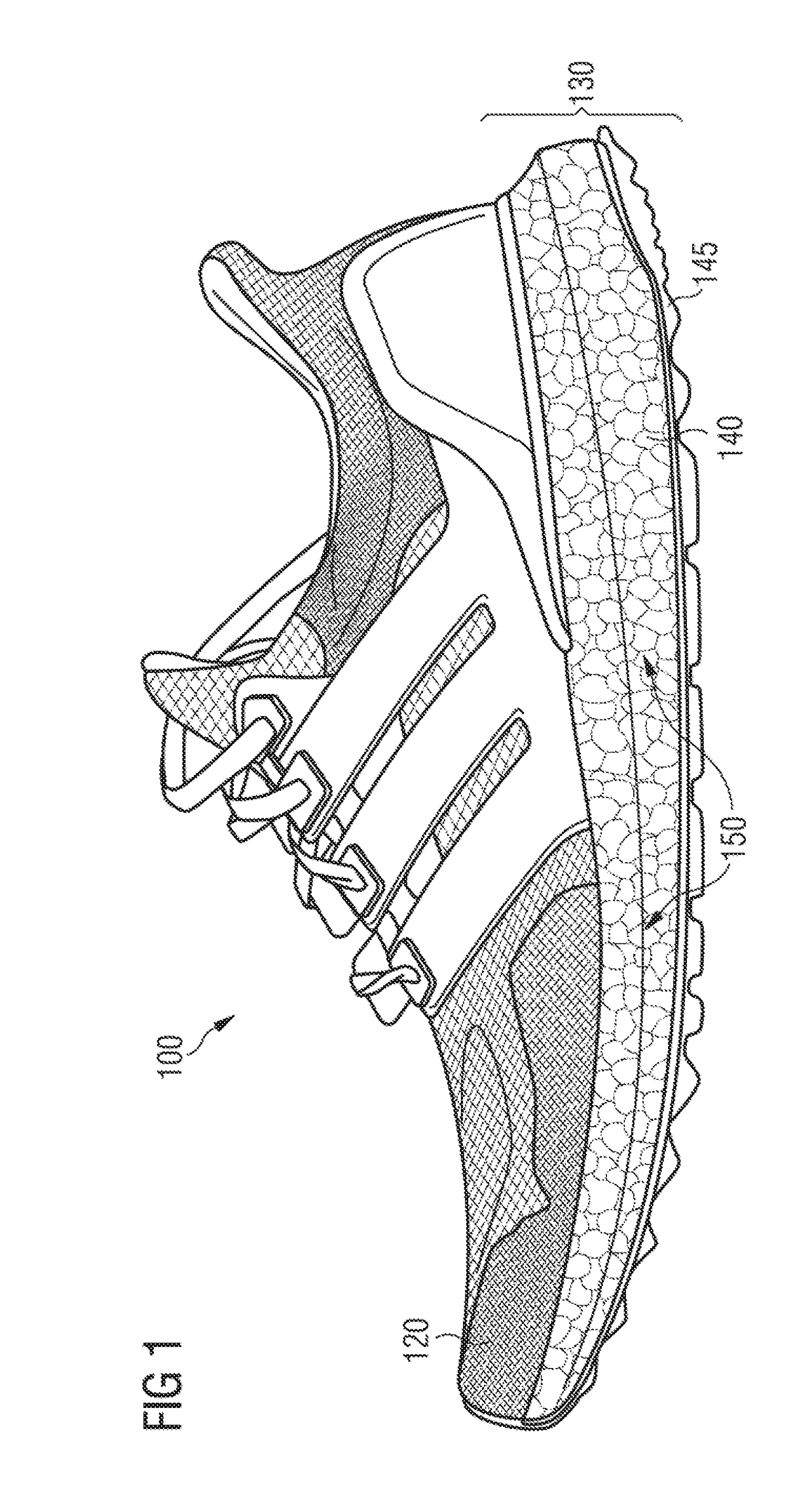

Shoe

Owner:ADIDAS

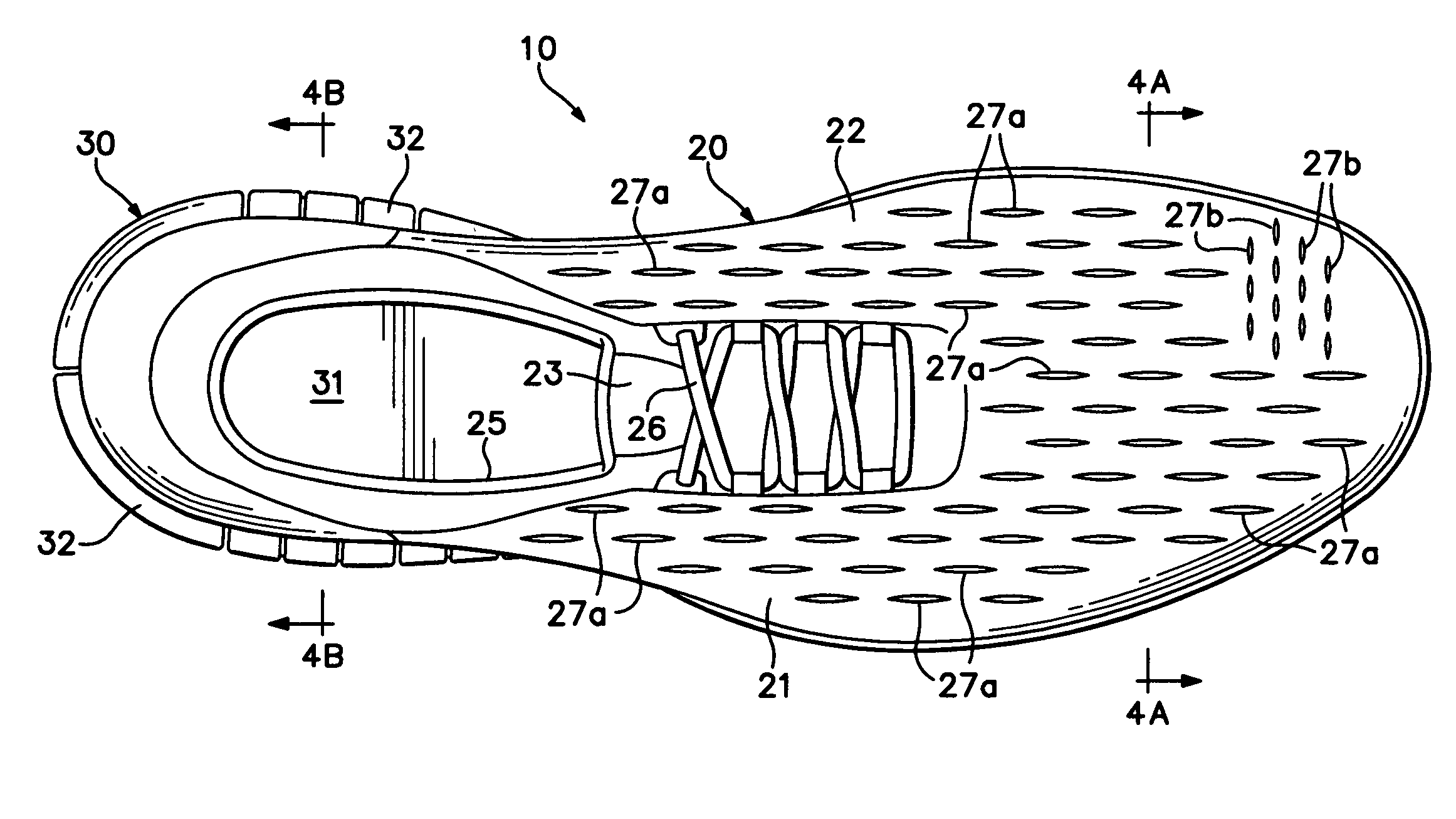

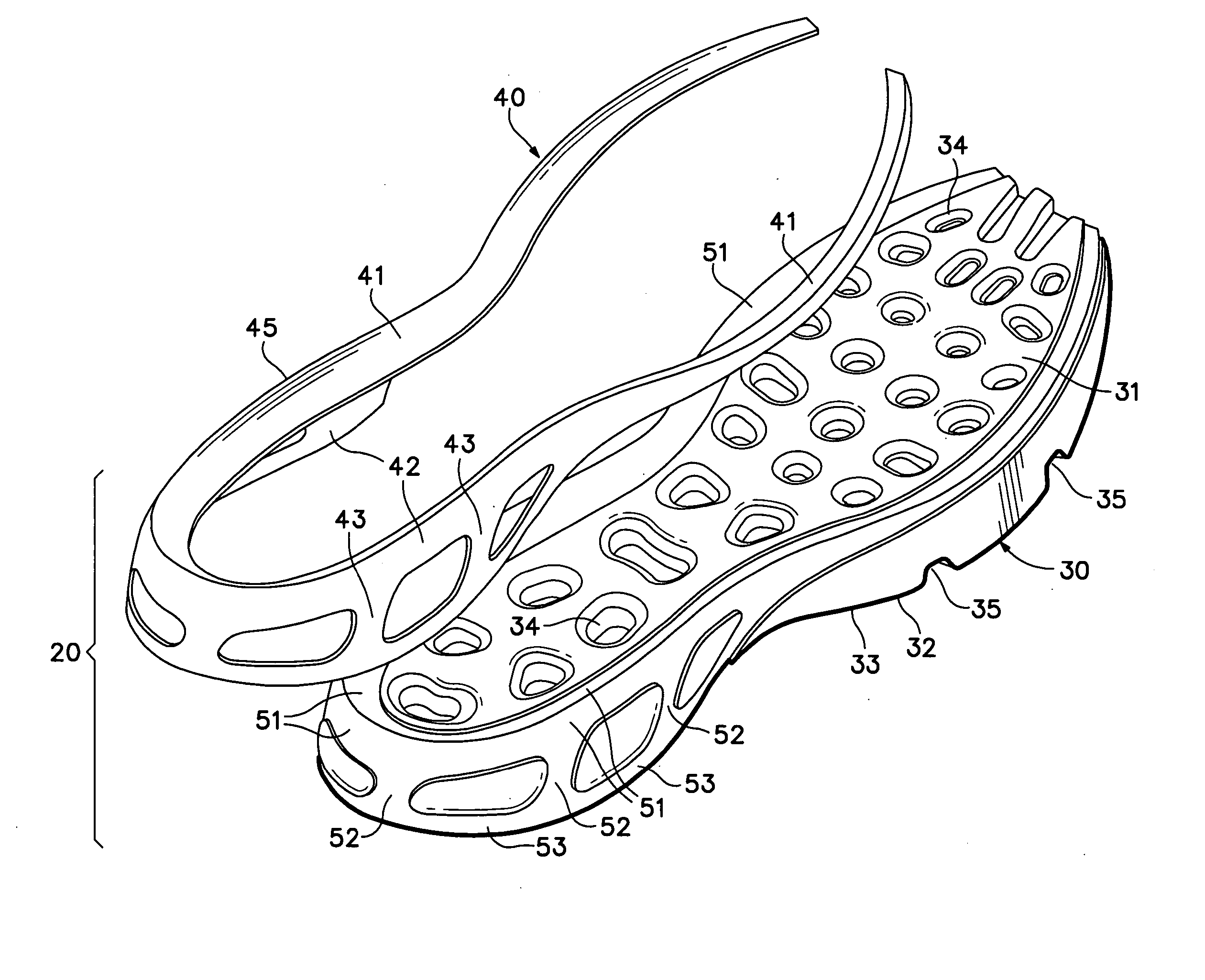

Article of footwear having a fluid-filled bladder with a reinforcing structure

A sole component and a method of manufacturing the sole component are disclosed. In general, the sole component includes a fluid-filled bladder and a reinforcing structure extending around the bladder. The reinforcing structure is bonded to the exterior of the bladder, and may be recessed into the bladder. In some embodiments, the reinforcing structure extends along the side surfaces of the bladder and between upper and lower surfaces of bladder. In manufacturing the sole component, the reinforcing structure may be located within a mold, and the polymer material forming the bladder may be bonded to the reinforcing structure during the molding process.

Owner:NIKE INC

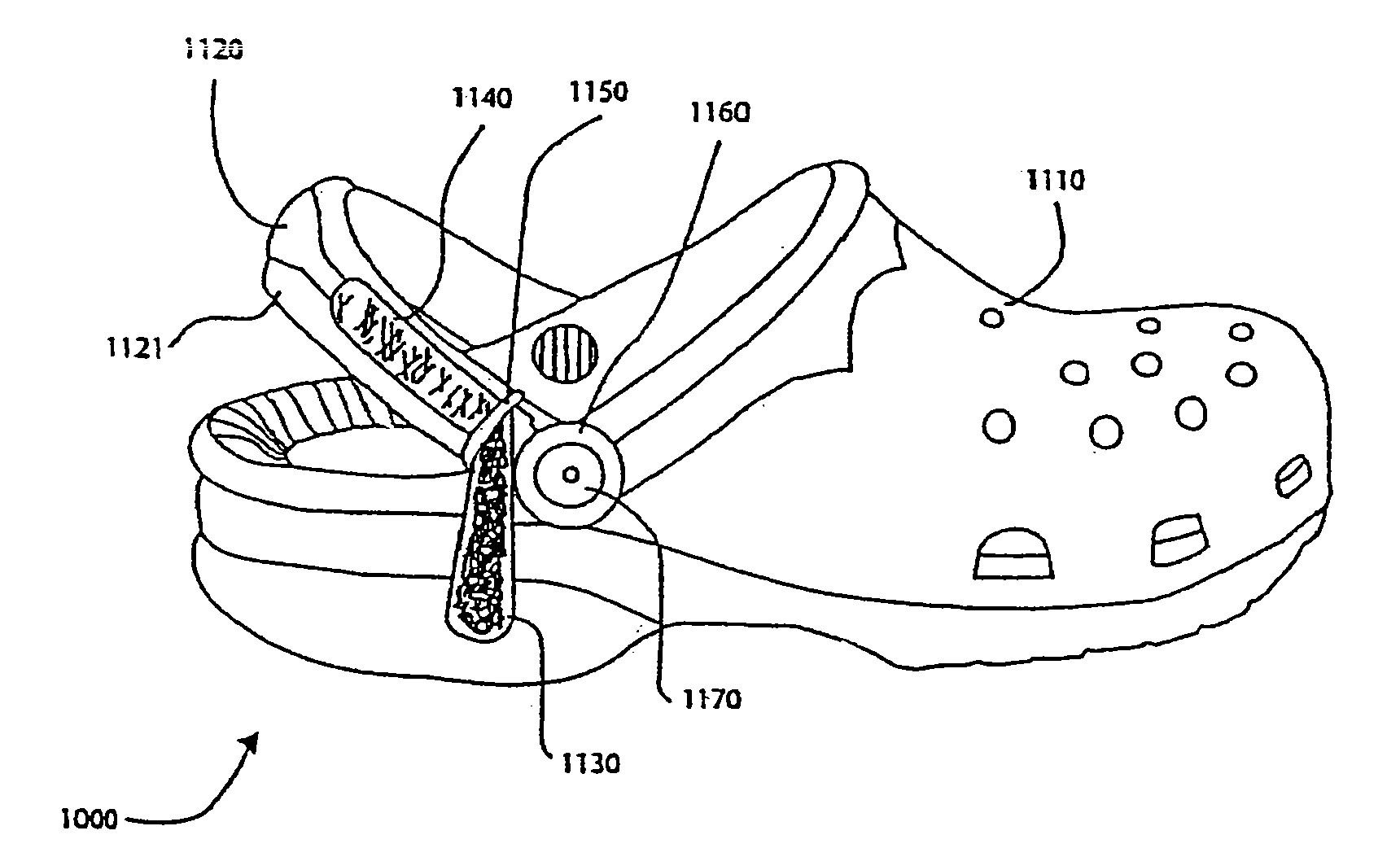

Footwear pieces

Owner:CROCS INC

Sole mold for manufacturing a sole

ActiveUS20170341325A1Reduce the total massReduce heating capacityAdditive manufacturing apparatusSolesLiquid mediumManufacturing engineering

A sole mold for manufacturing a sole from a plurality of particles includes at least one first opening for supplying the particles, and at least two second openings for supplying a gaseous and / or liquid medium to bond and / or fuse the particles together. At least a portion of the sole mold is manufactured by an additive manufacturing method.

Owner:ADIDAS

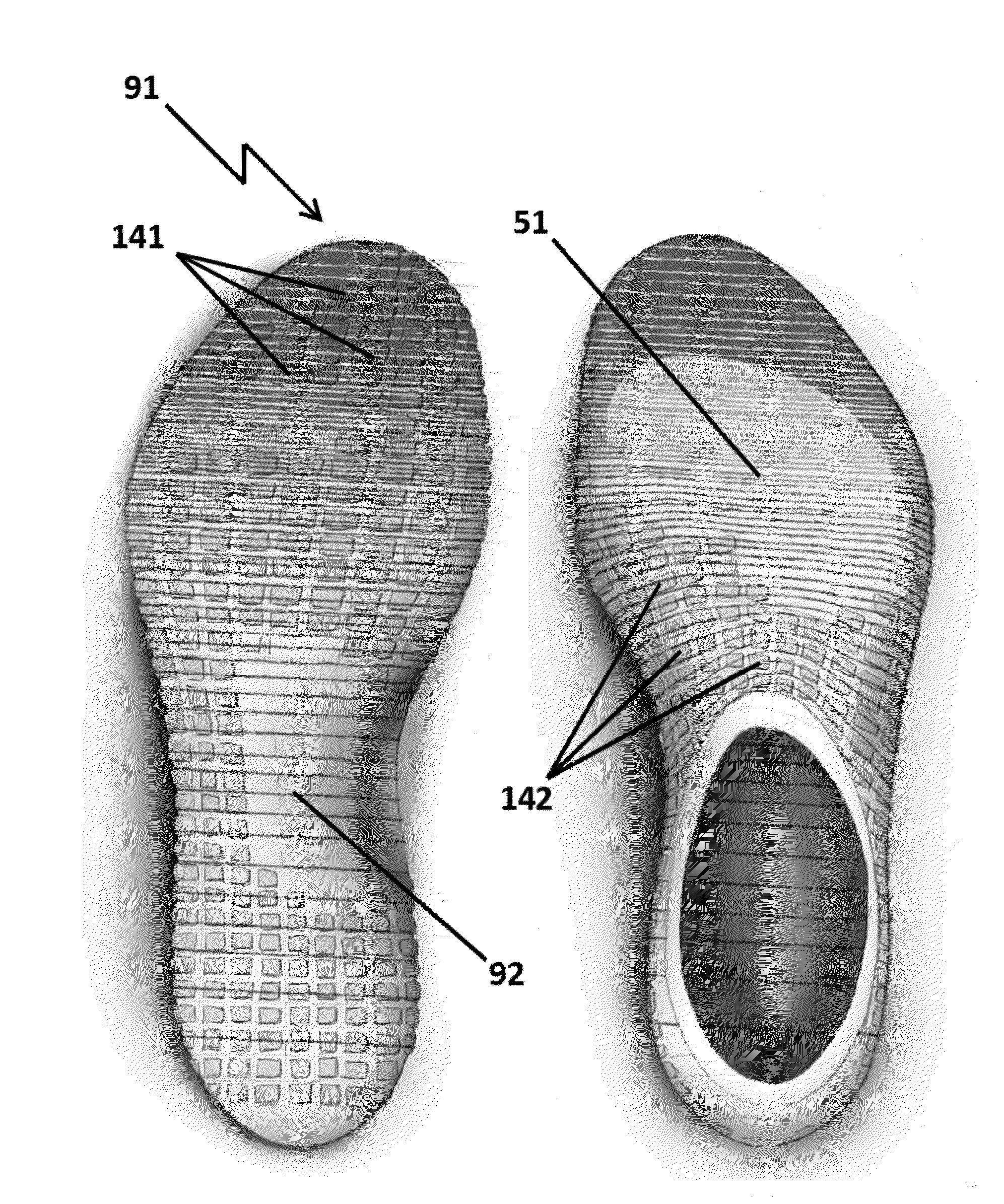

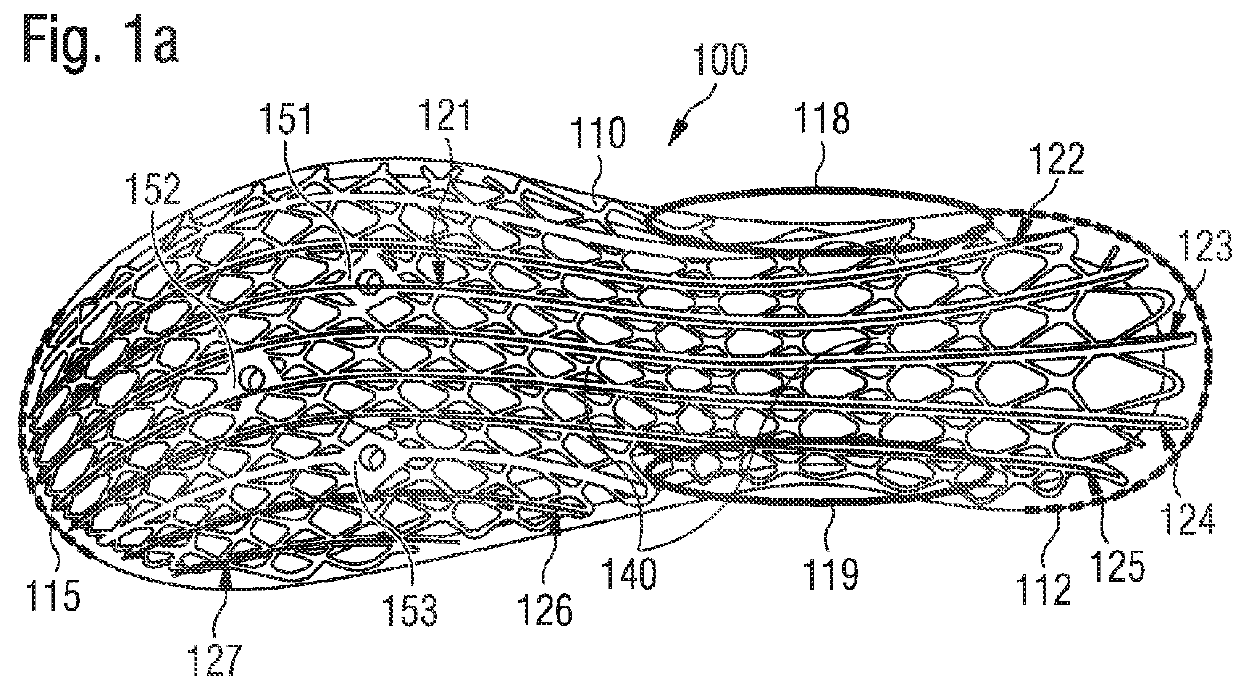

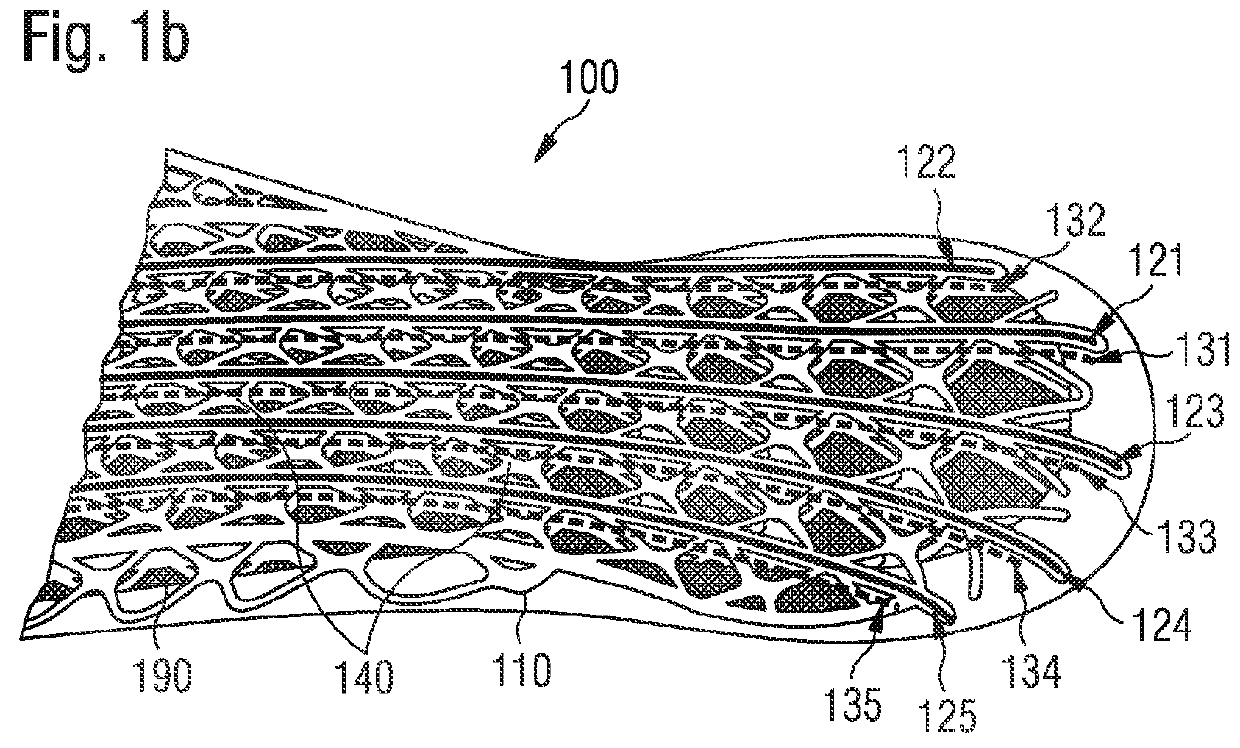

Additive Manufactured Metal Sports Performance Footwear Components

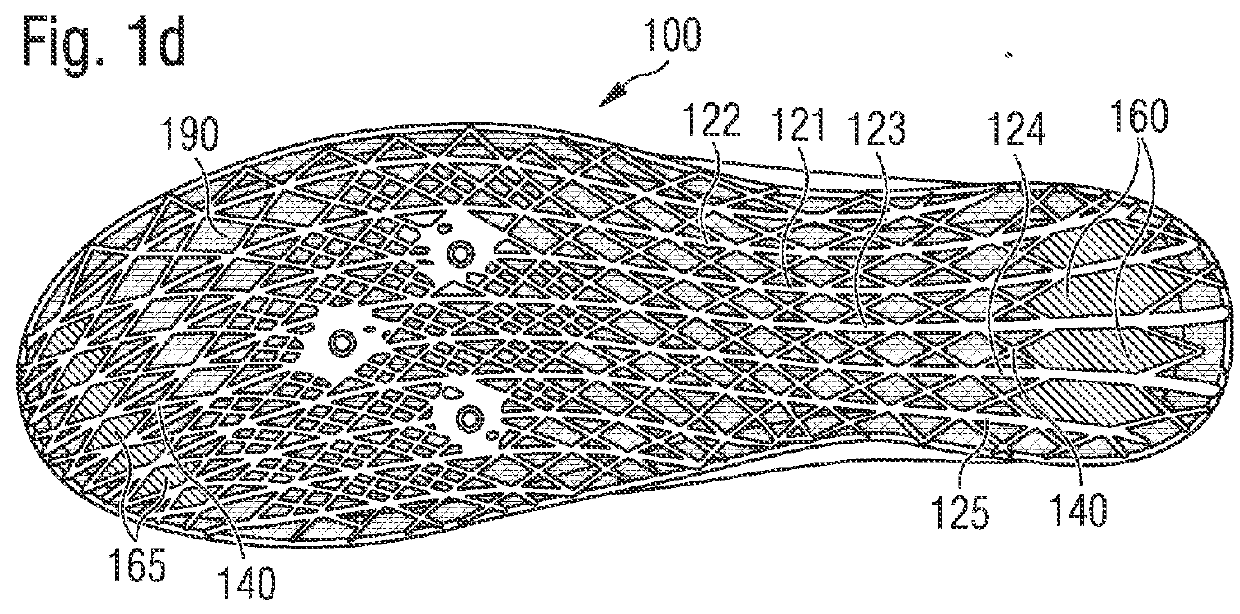

ActiveUS20160051009A1Wearing comfort without impairing the bending stiffness of the soleHigh tear strengthAdditive manufacturing apparatusLastingSports PerformancesMechanical engineering

The present invention relates to a sole (100; 200) for a shoe (300), in particular for a cycling shoe (300), comprising: (a.) a three-dimensionally shaped rim (110); and (b.) a plurality of first reinforcing struts (121-127; 221-222), wherein (c.) at least two (122-125; 221-222) of the plurality of first reinforcing struts (121-127; 221-222) extend from a heel region (112) of the rim (110) of the sole (100; 200) to a toe region (115) of the rim (110) of the sole (100; 200), and wherein (d.) the rim (110) of the sole (100; 200) and the plurality of first reinforcing struts (121-127; 221-222) are integrally manufactured as a single piece in an additive manufacturing process.

Owner:ADIDAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com