Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about "Eyelets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

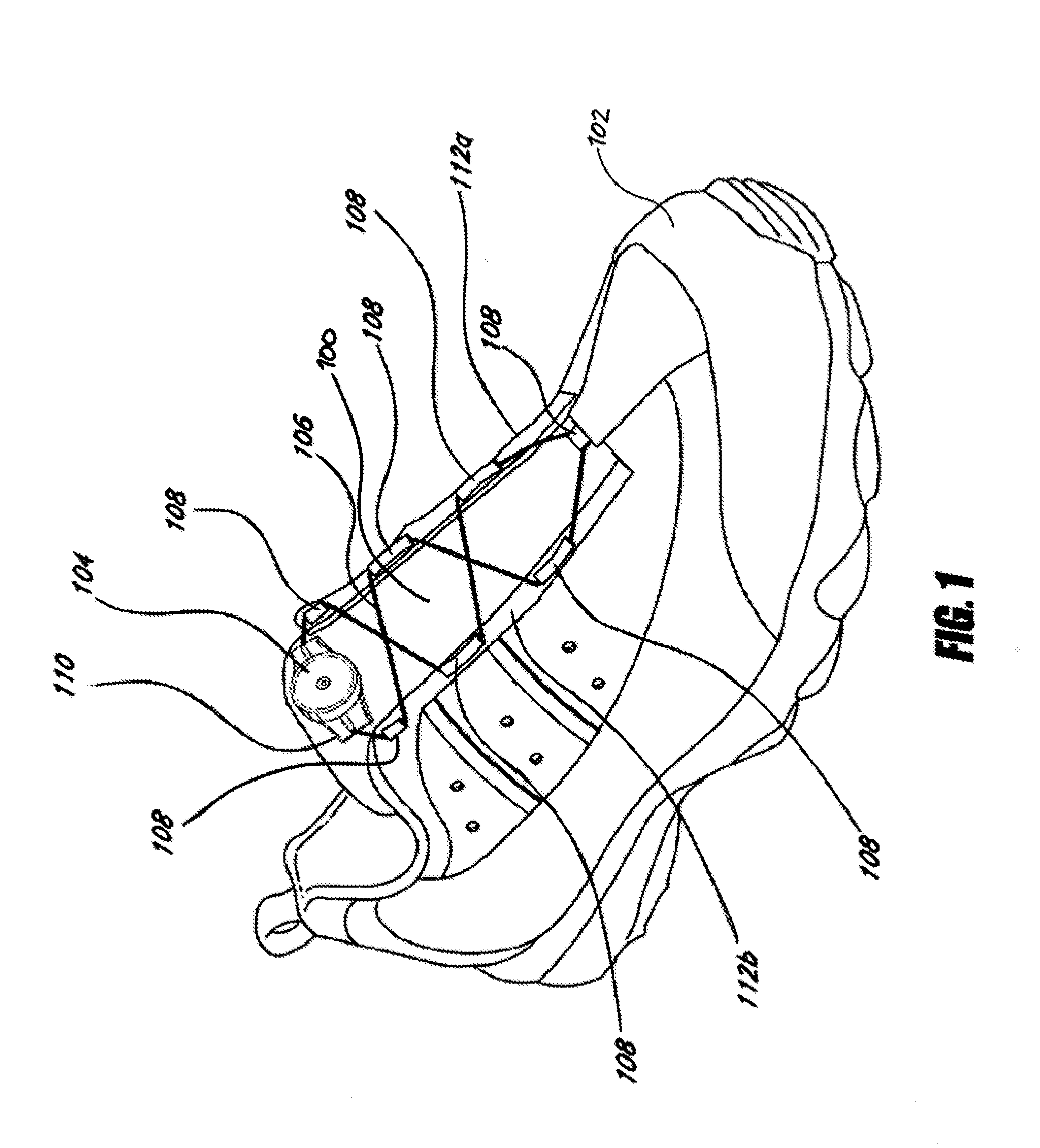

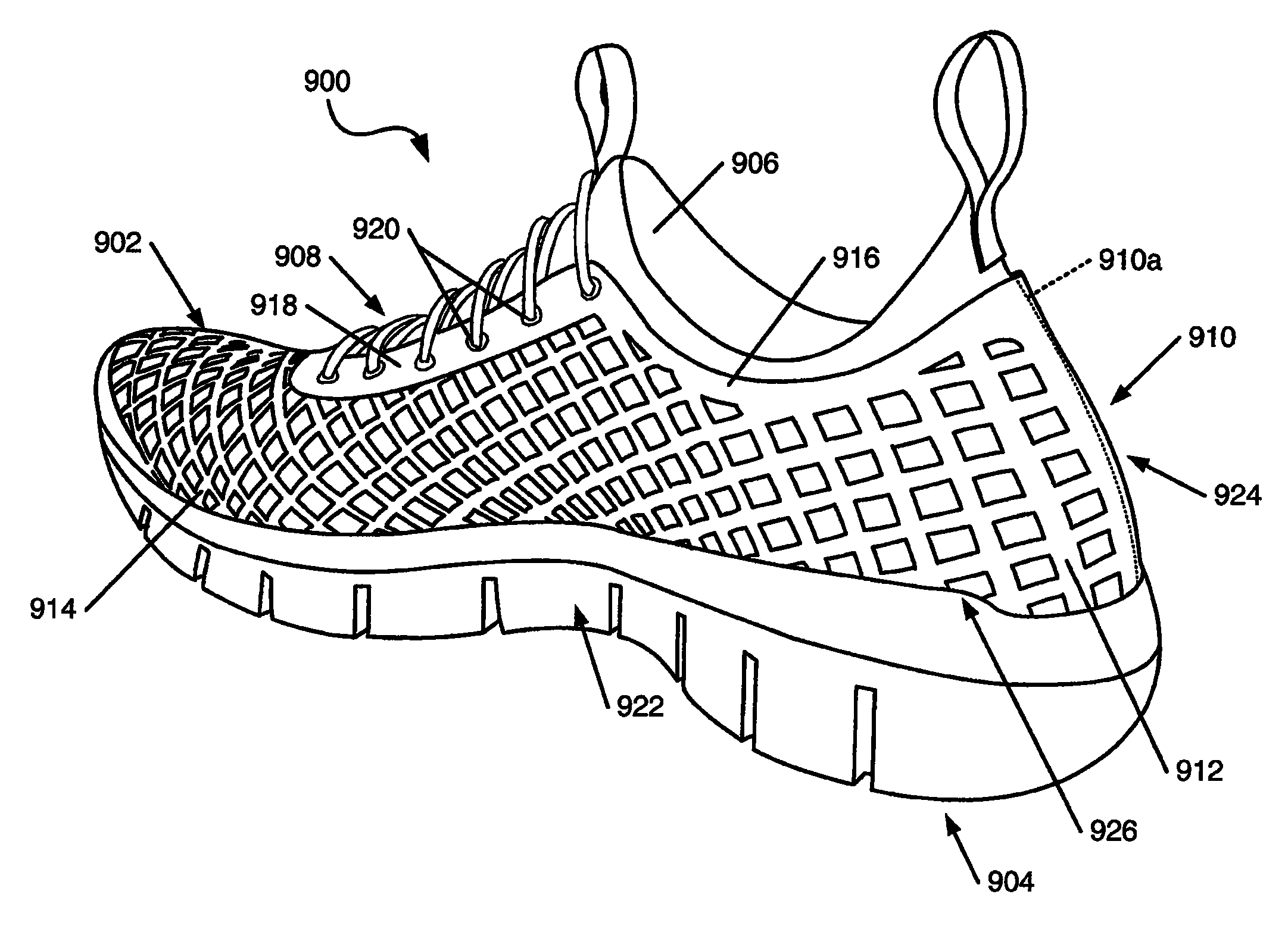

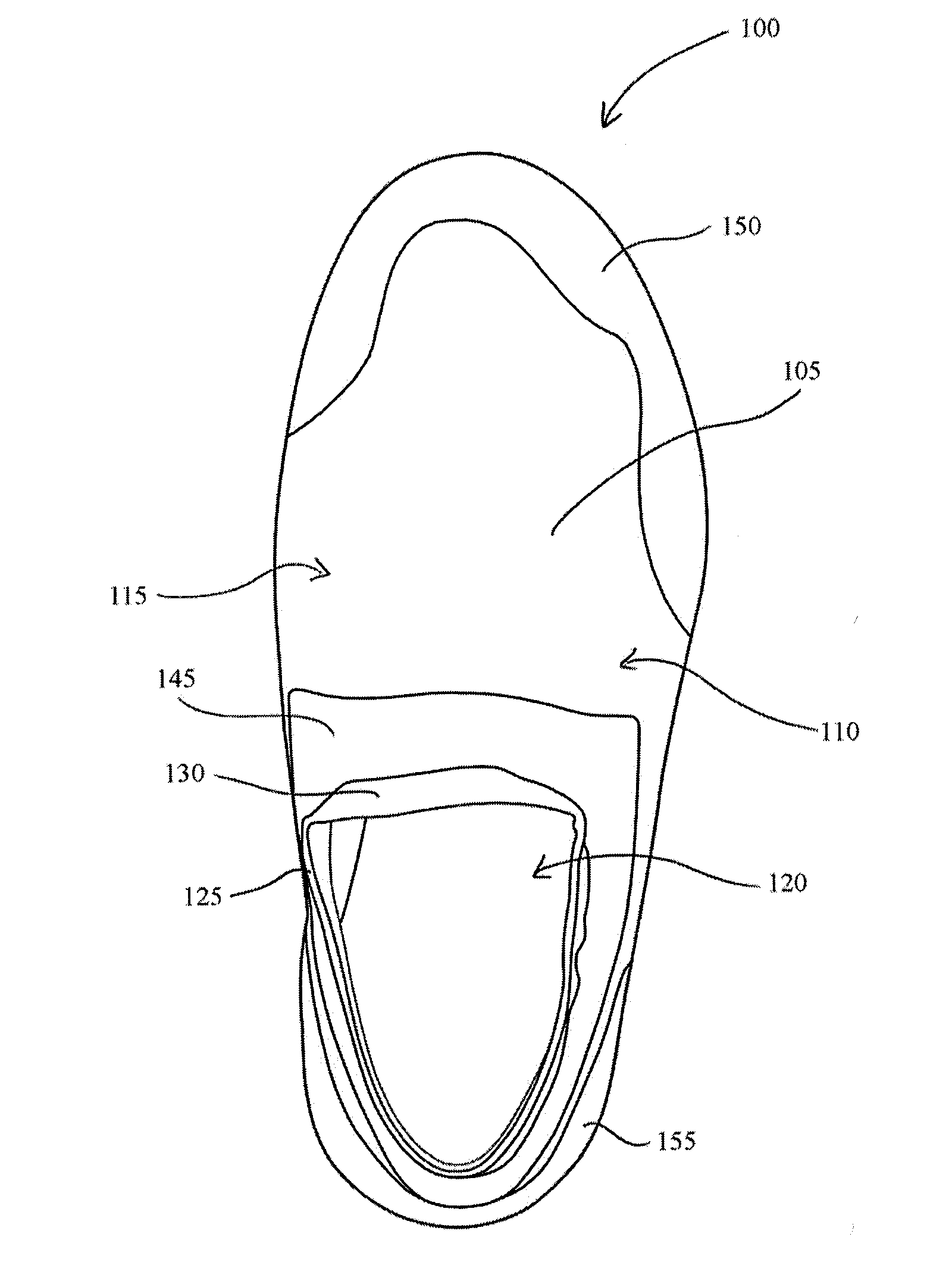

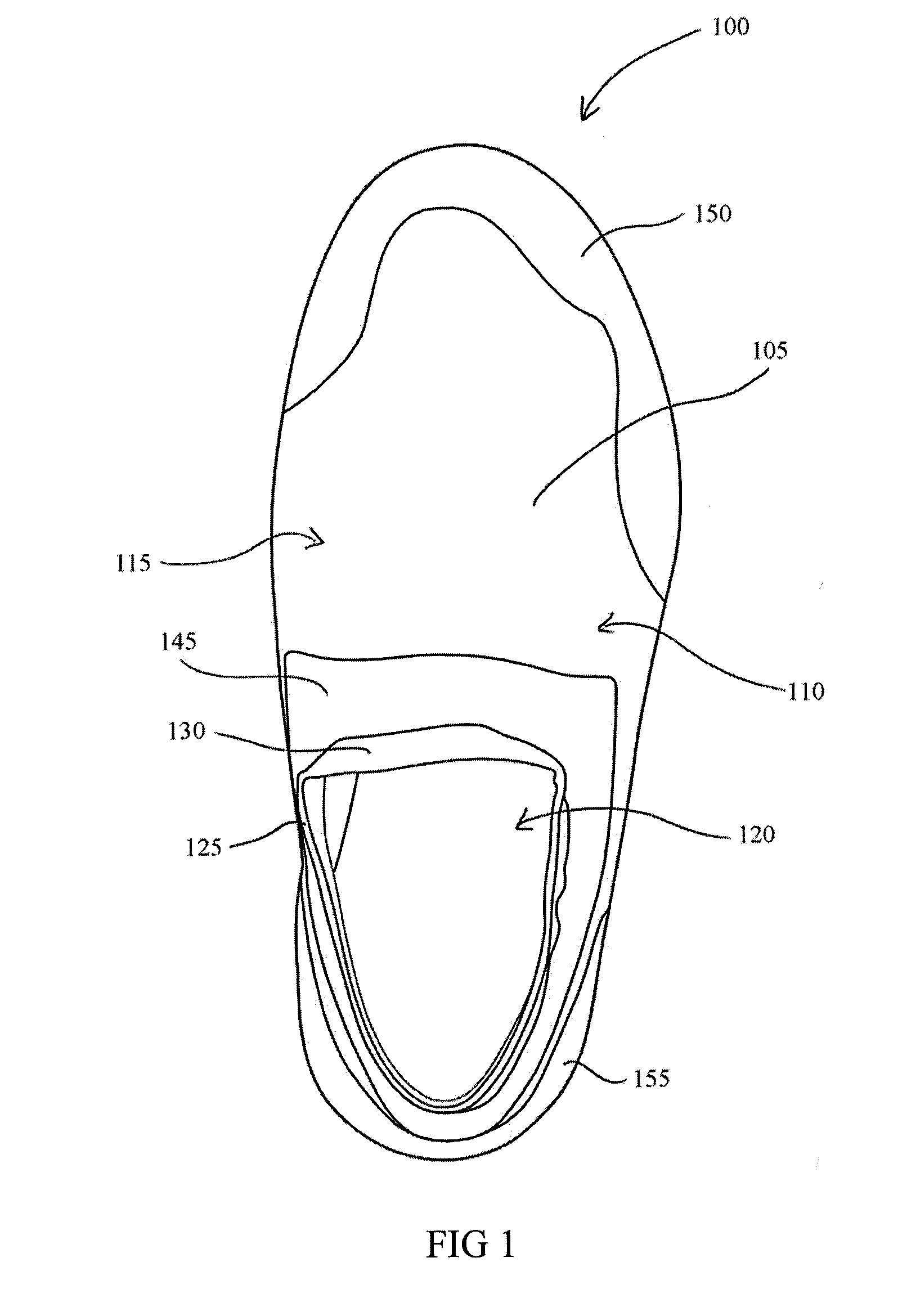

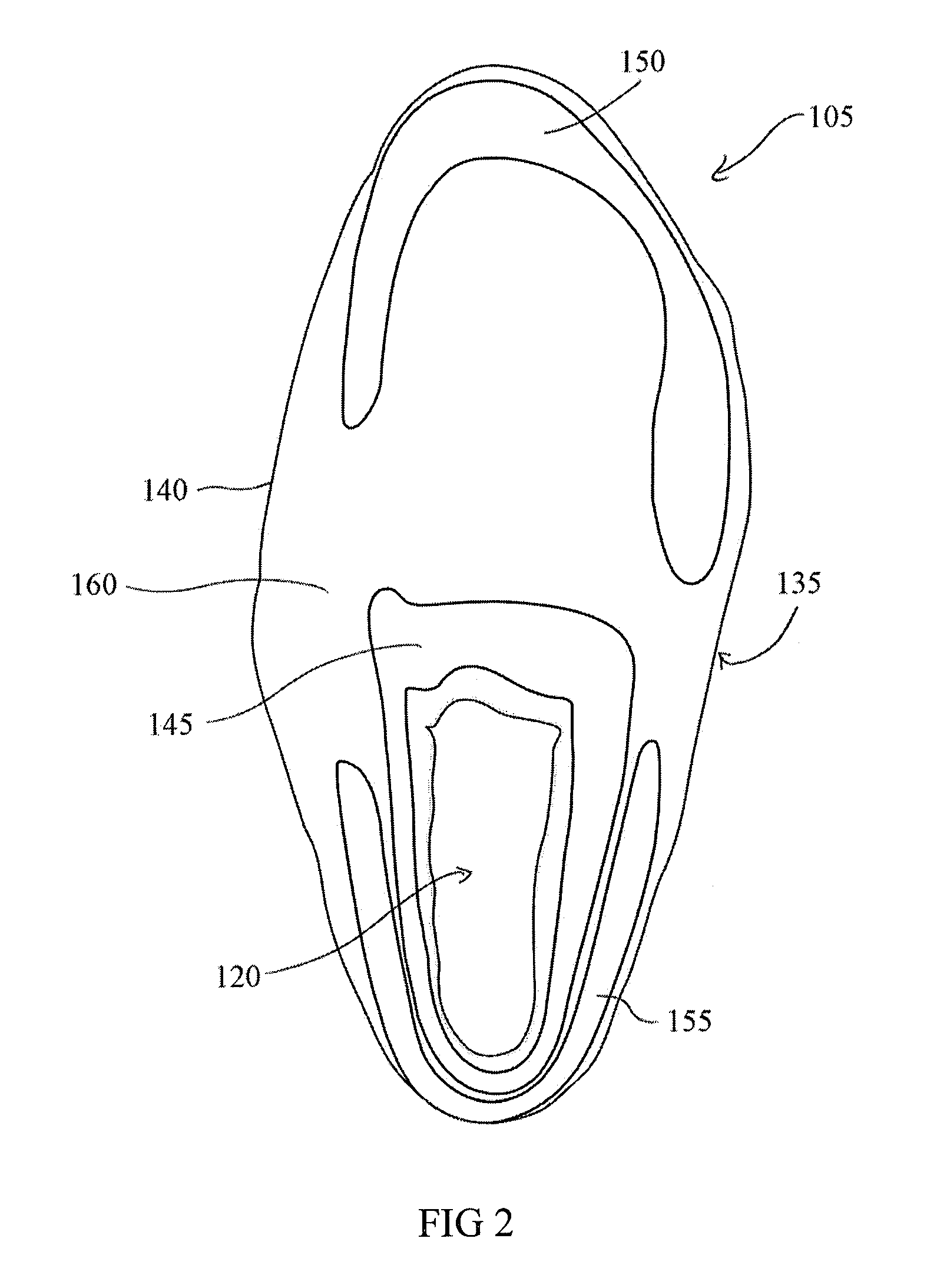

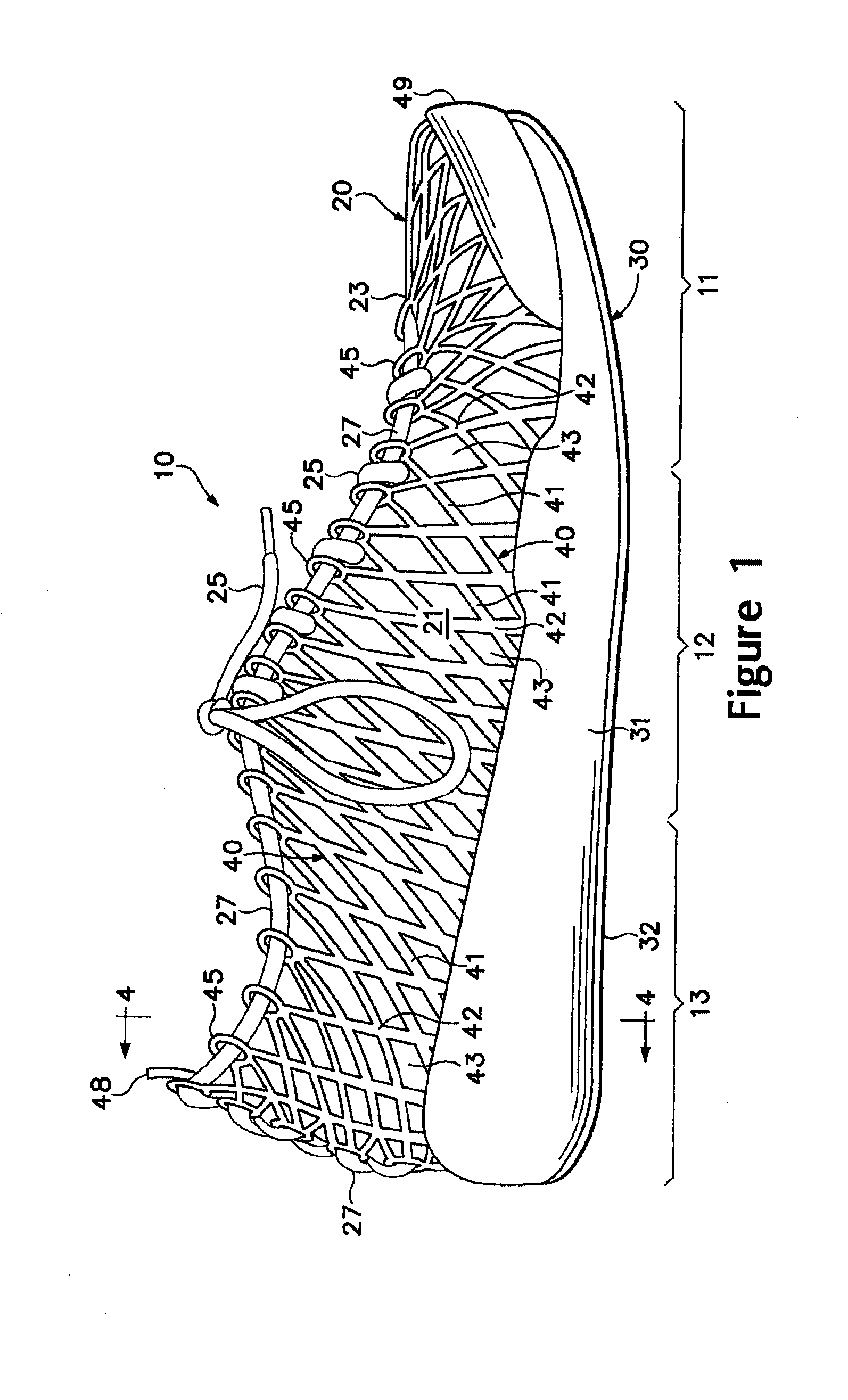

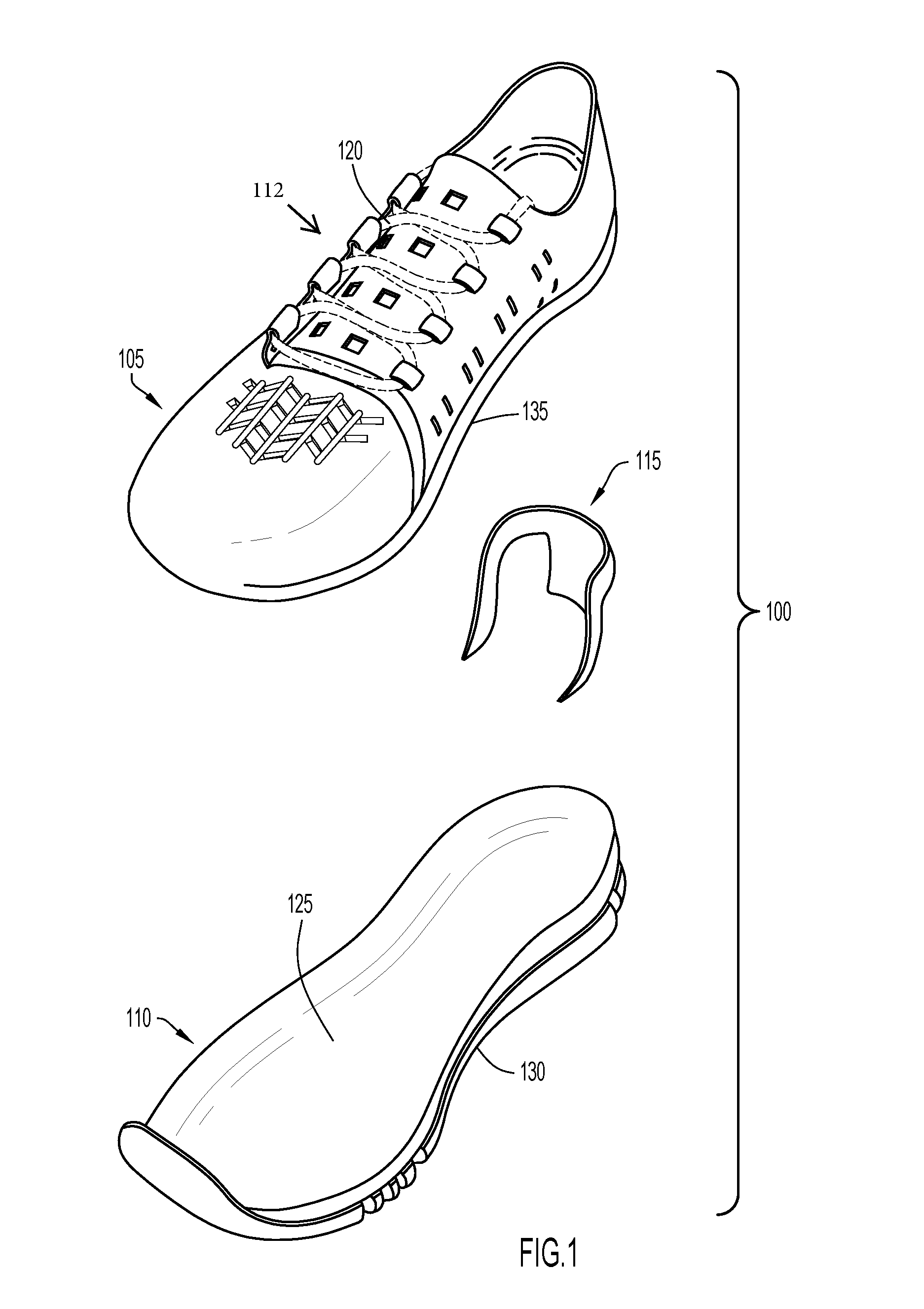

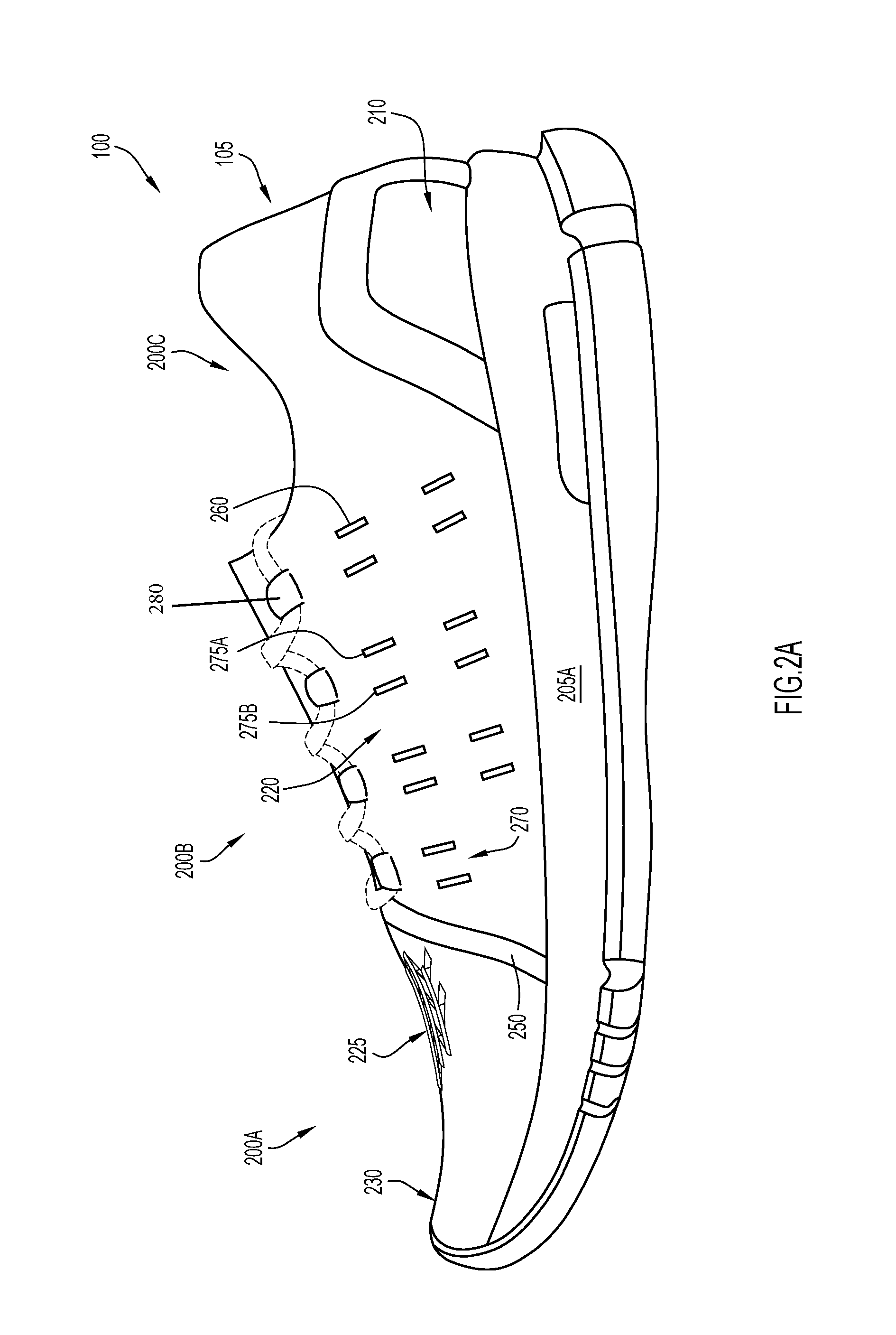

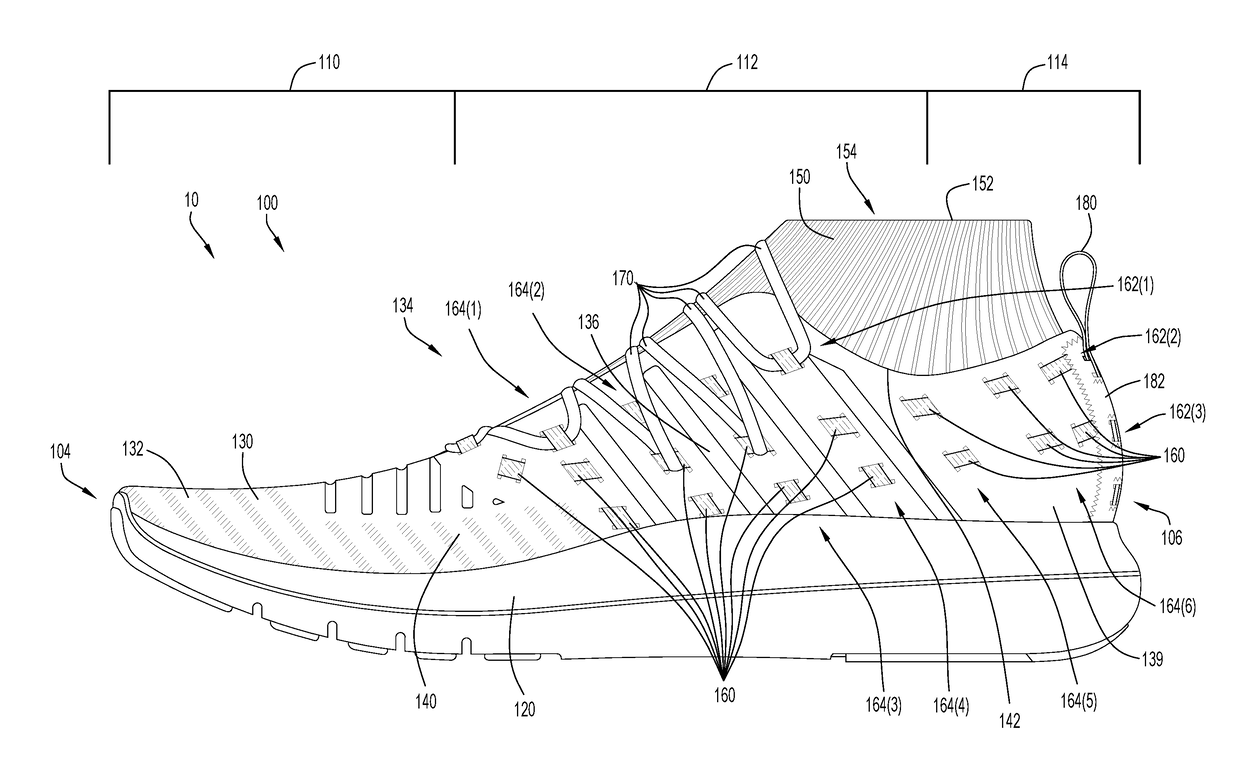

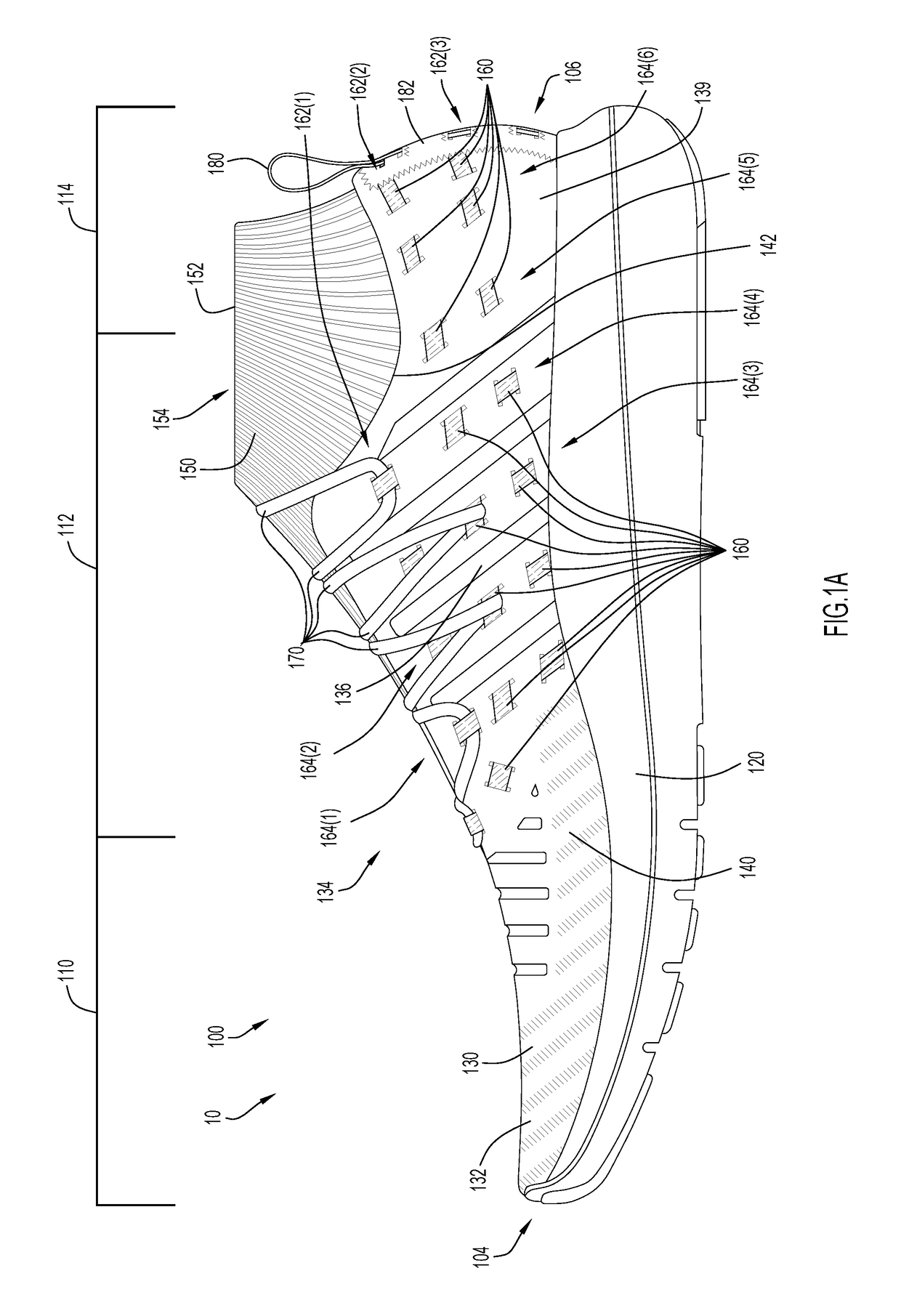

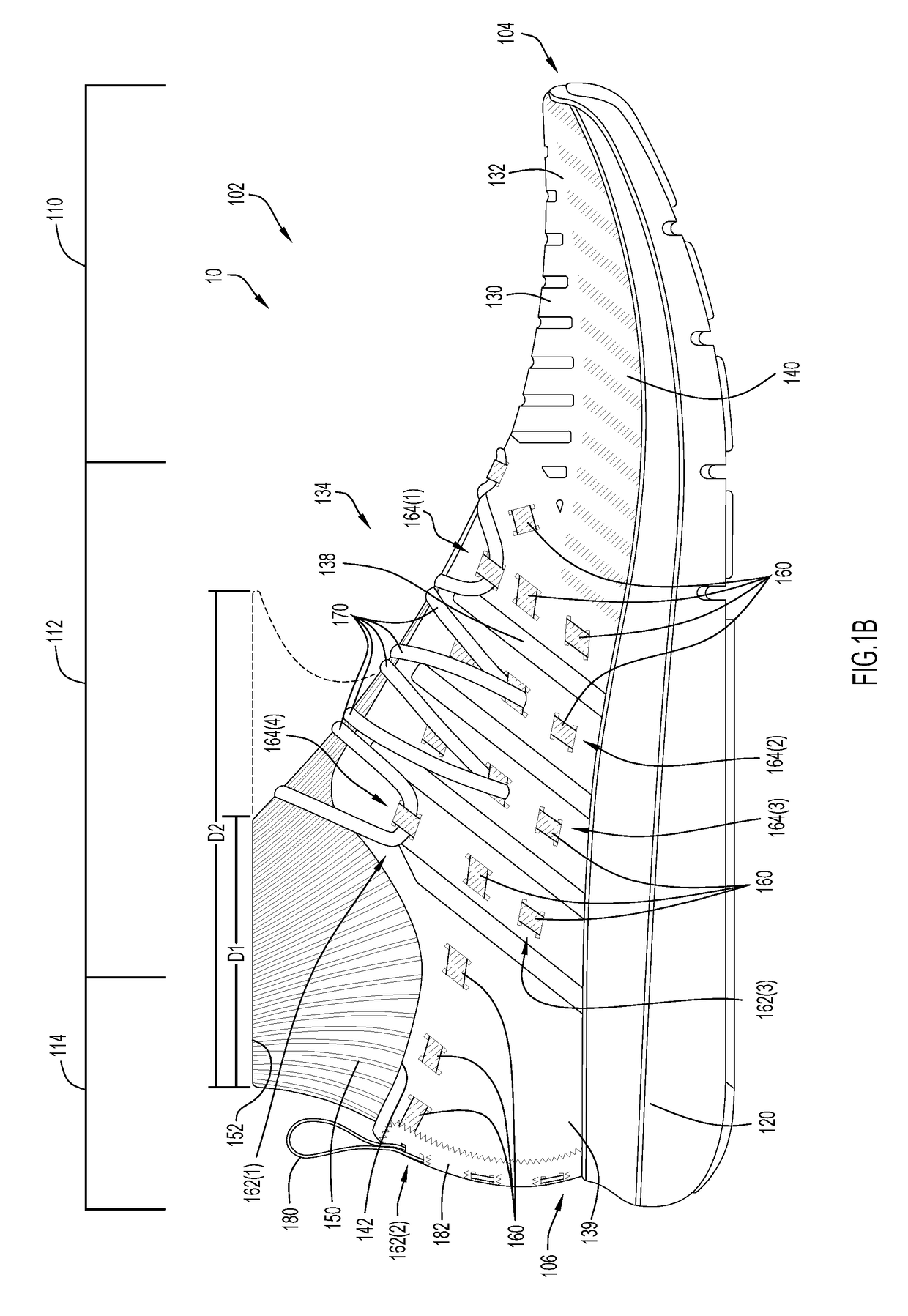

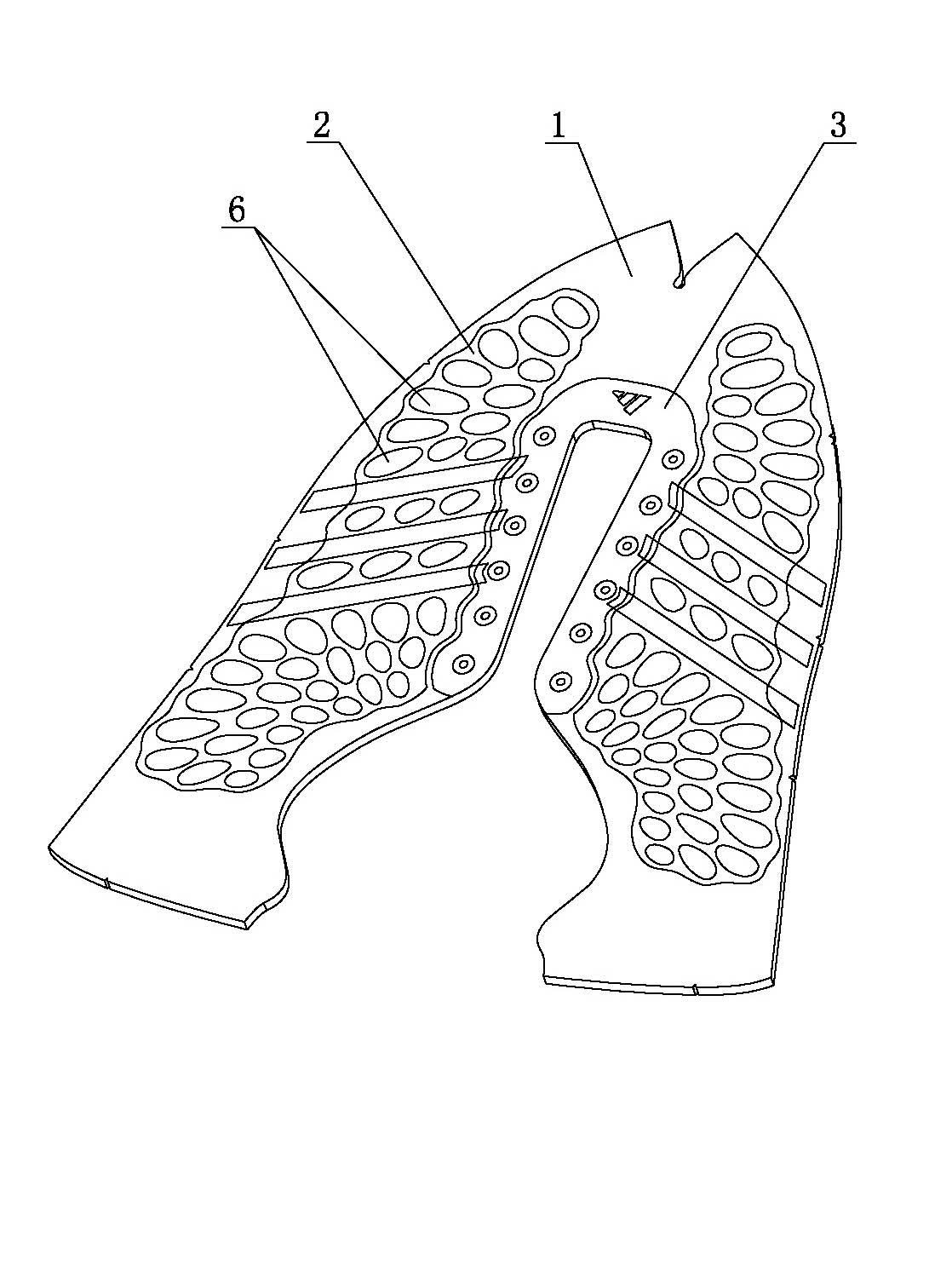

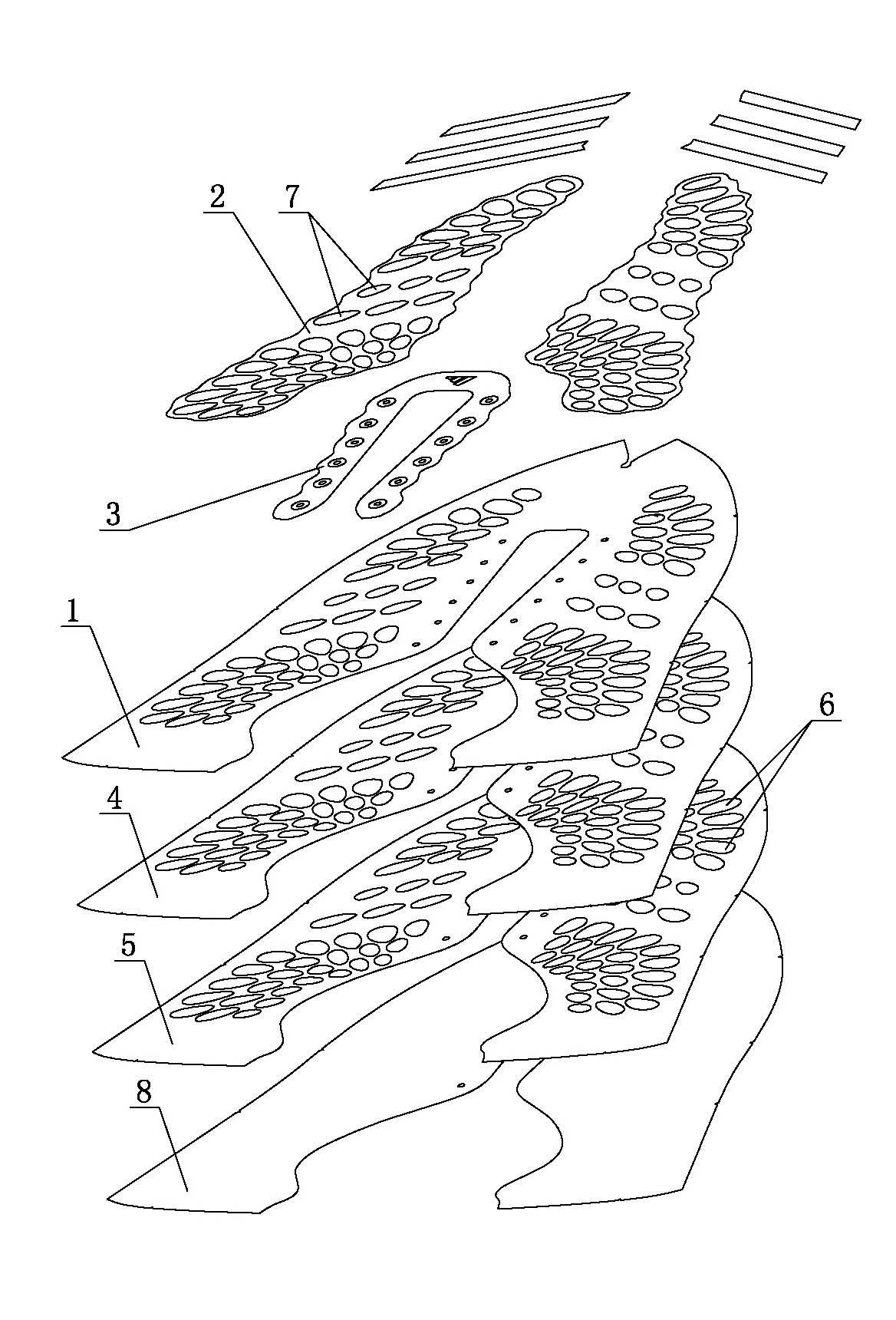

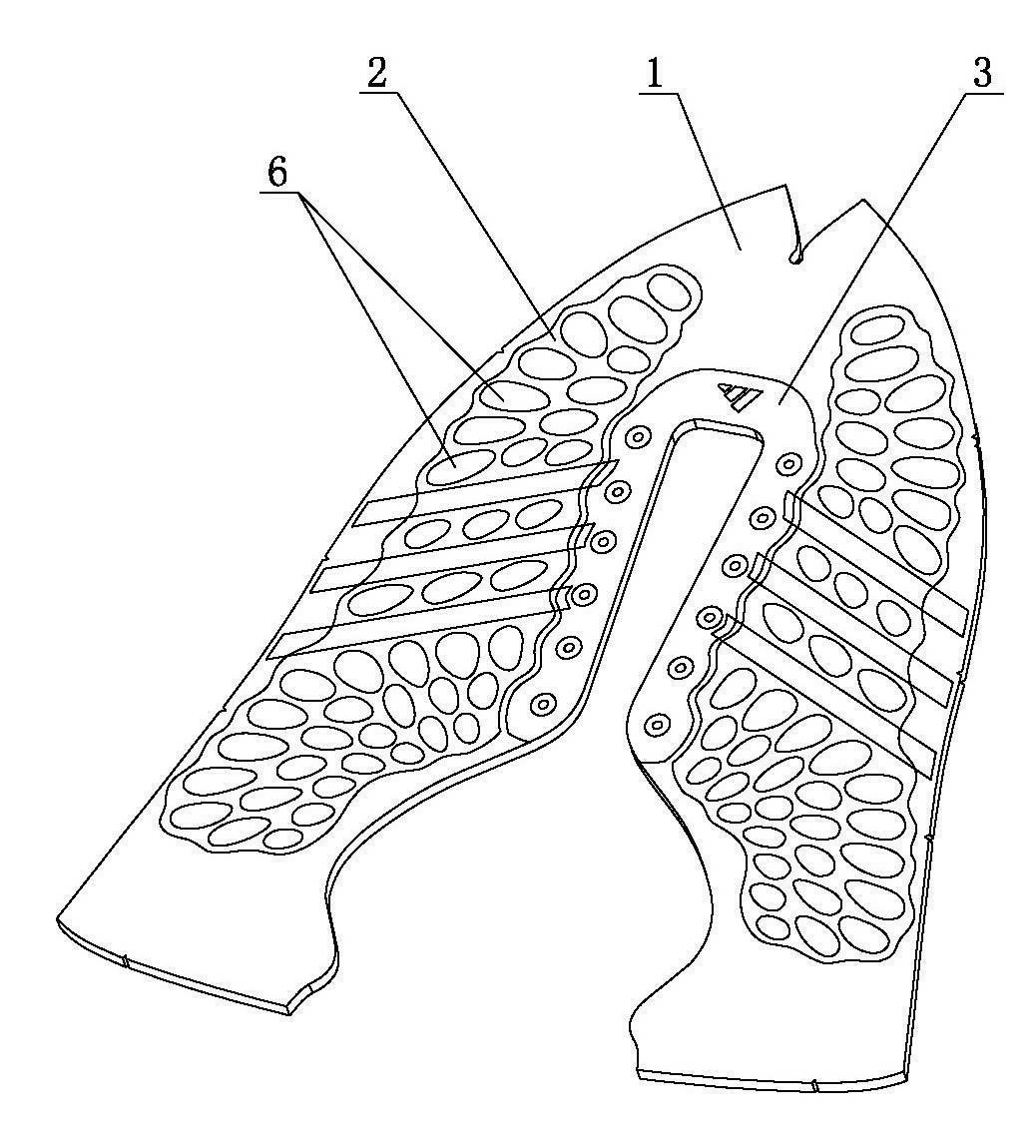

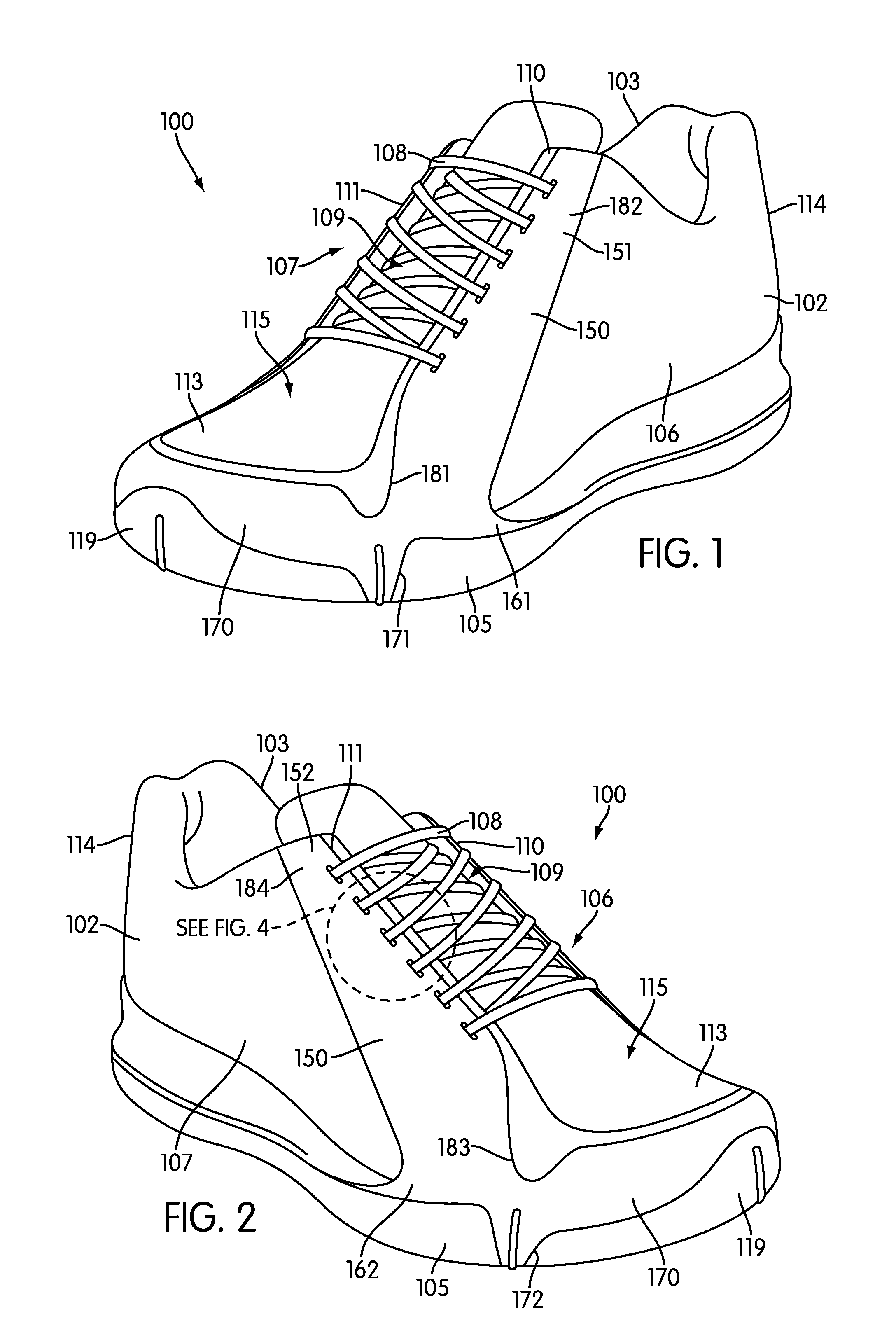

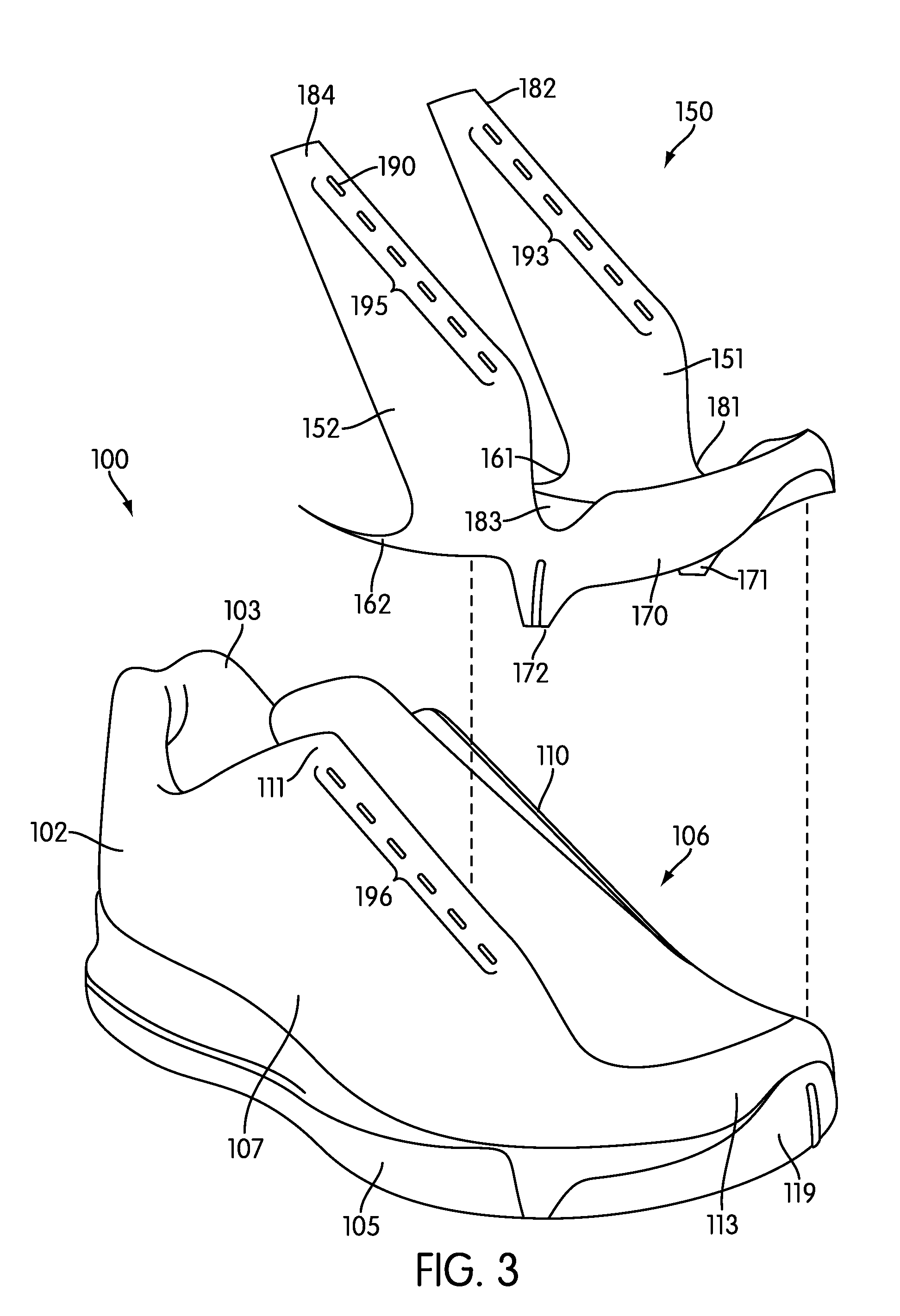

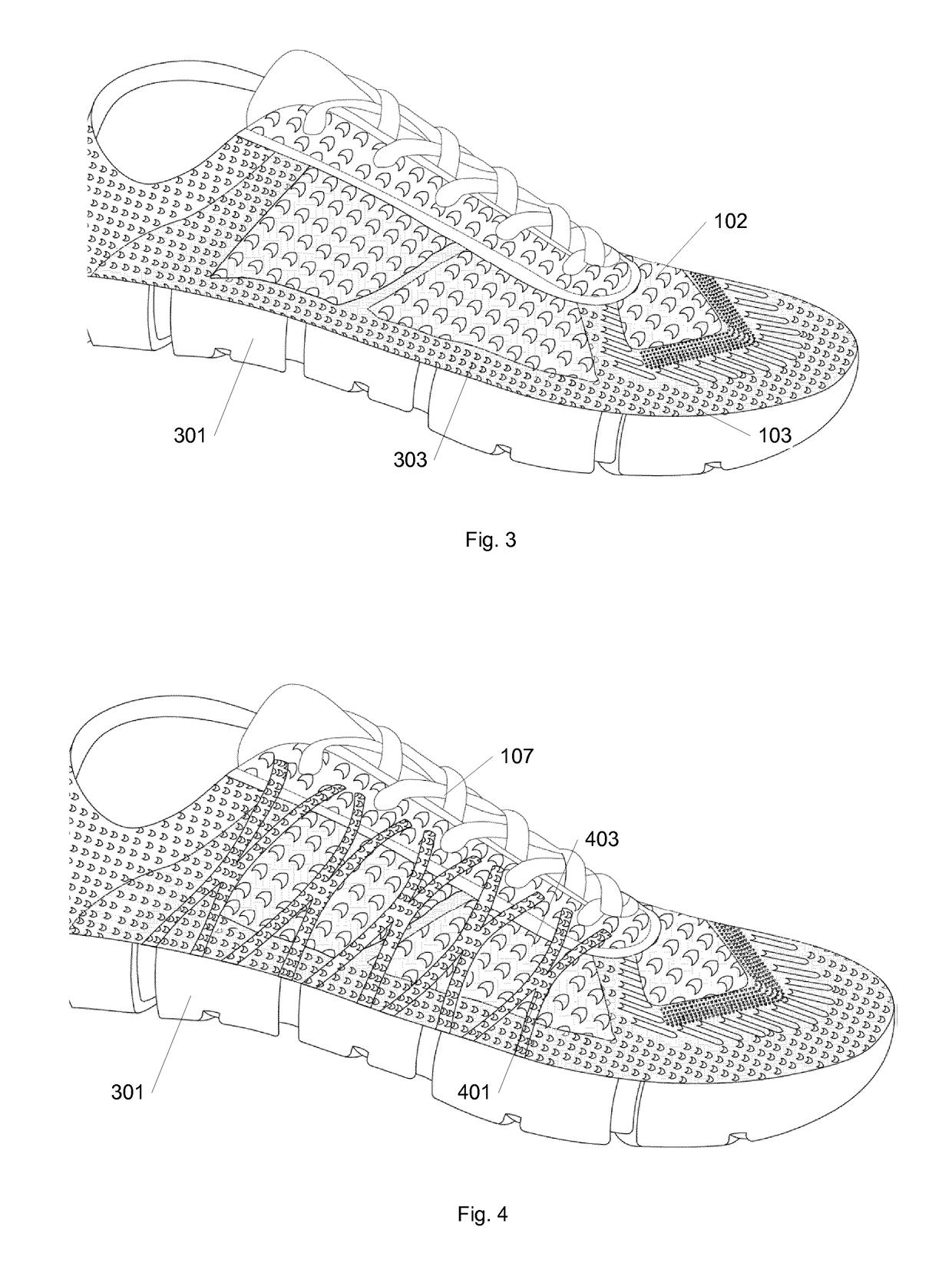

Article of footwear having an upper with a matrix layer

Articles of footwear, including athletic footwear, include one or more of: (a) a sole structure; (b) an upper having lateral and medial side elements engaged with the sole structure, the upper made from a polymer matrix structure that extends through at least a heel region; (c) a size adjustment mechanism located at the heel region; (d) a heel tongue element located adjacent the size adjustment mechanism; (e) a shoe securing mechanism; (f) an instep tongue member; and / or (g) a bootie member located at least partially within the foot-receiving chamber. Methods of manufacturing such articles of footwear also are disclosed.

Owner:NIKE INC

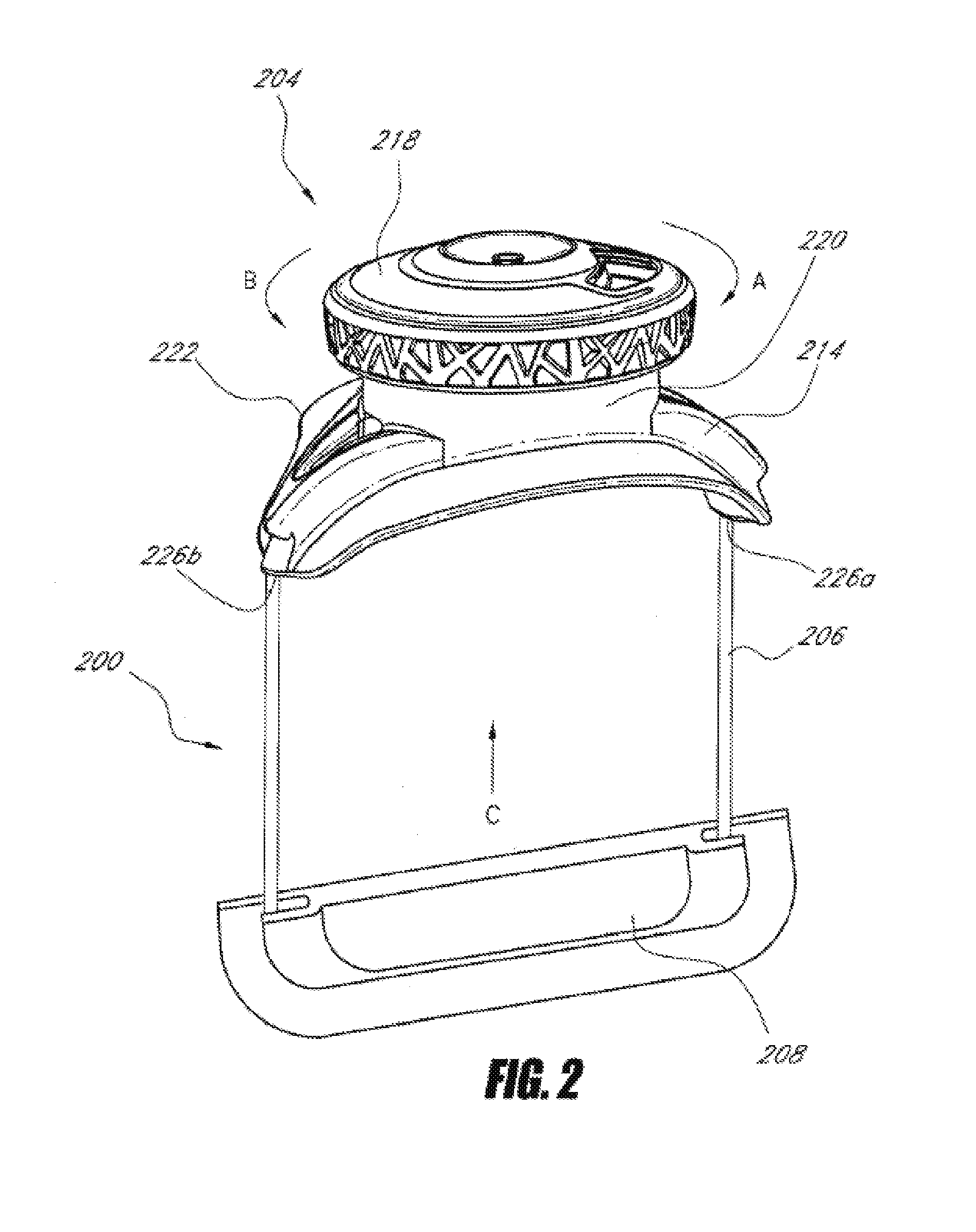

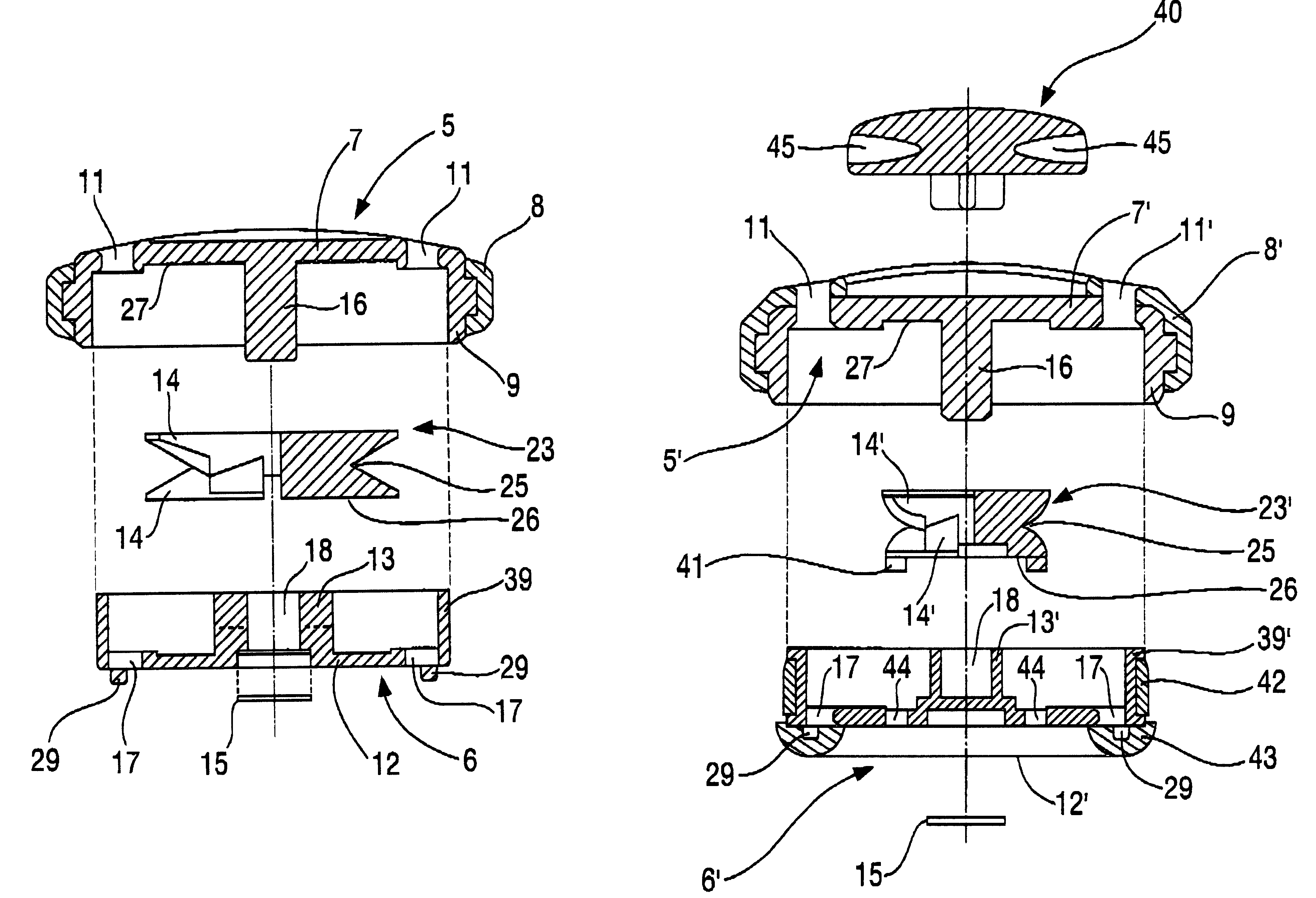

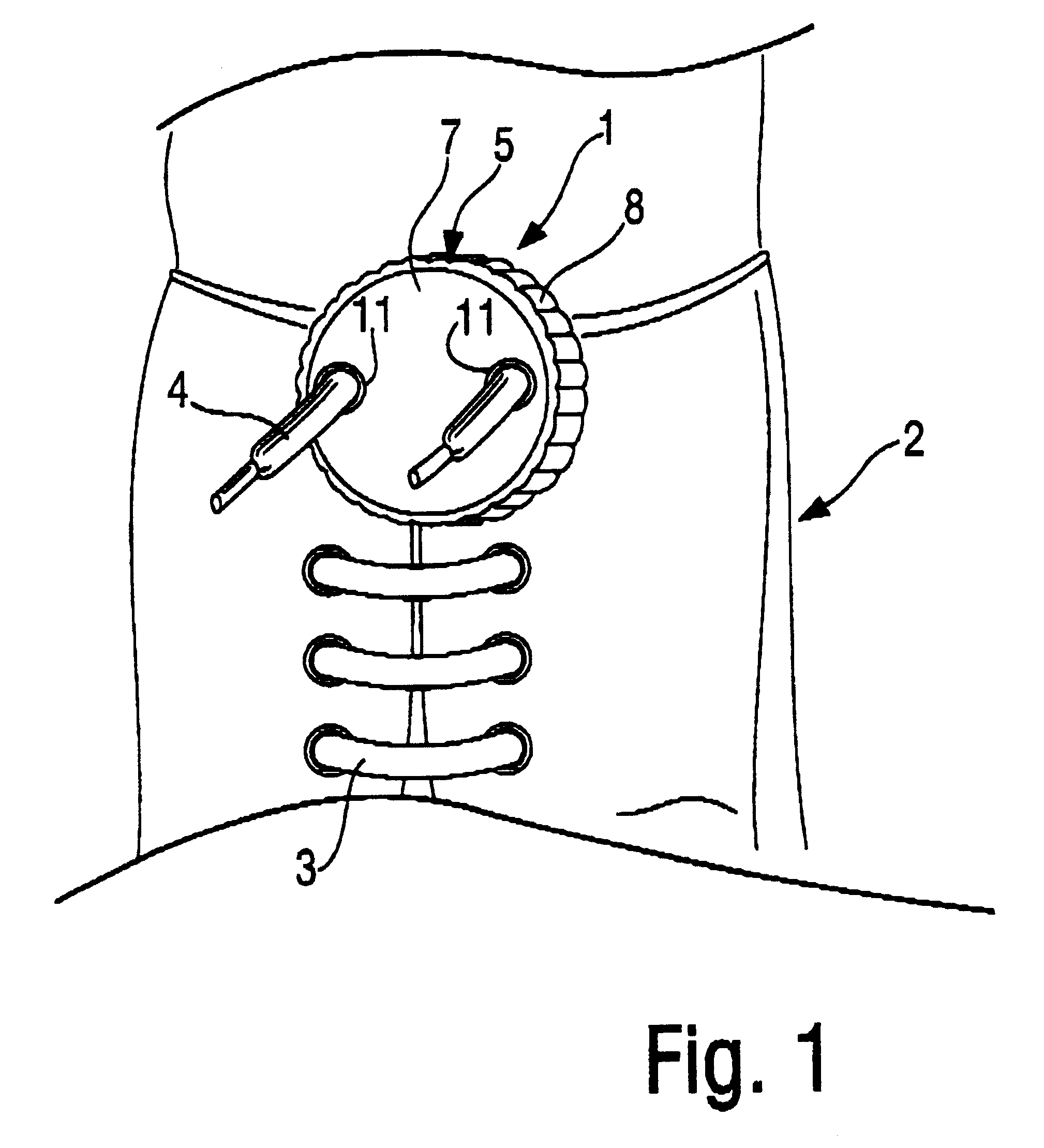

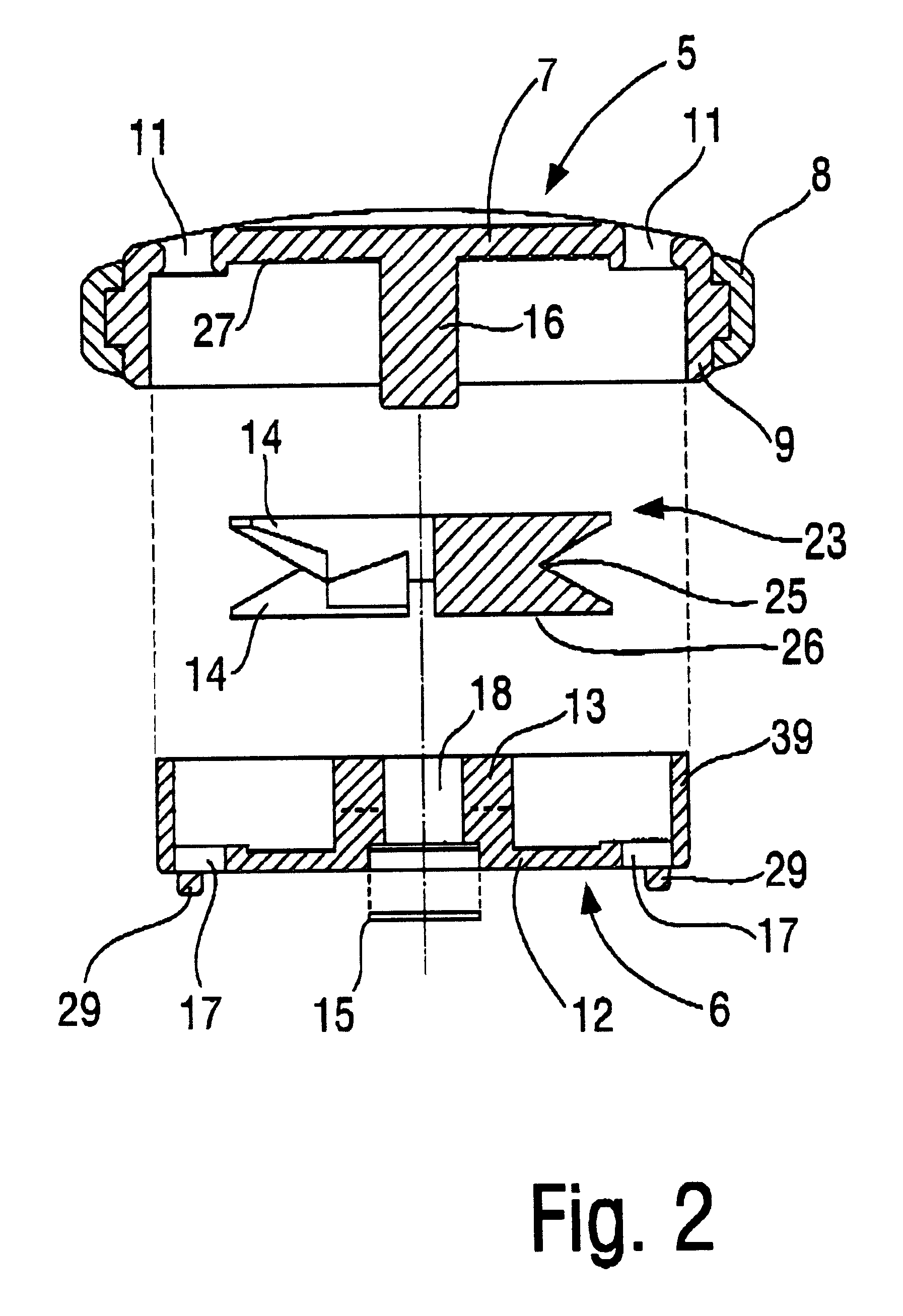

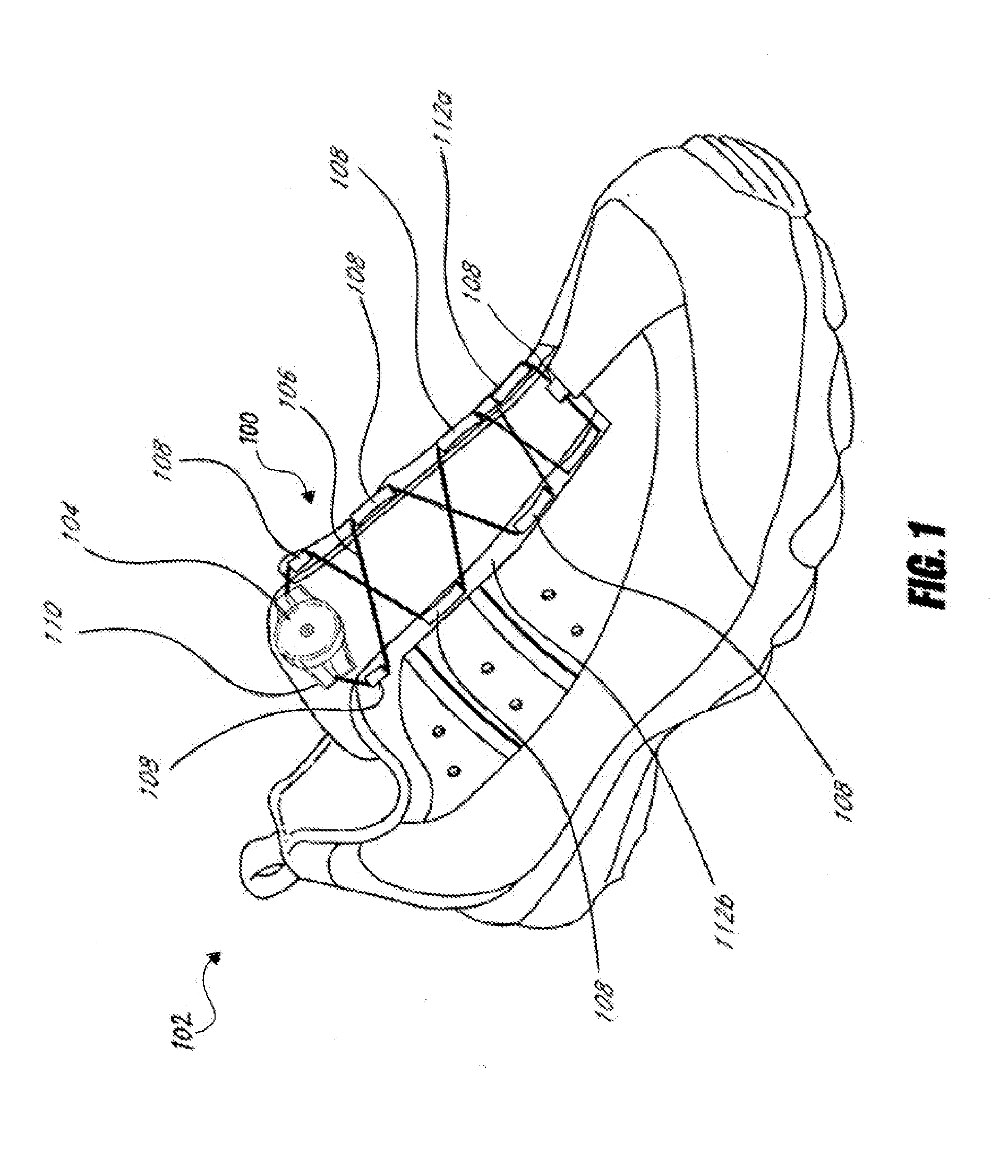

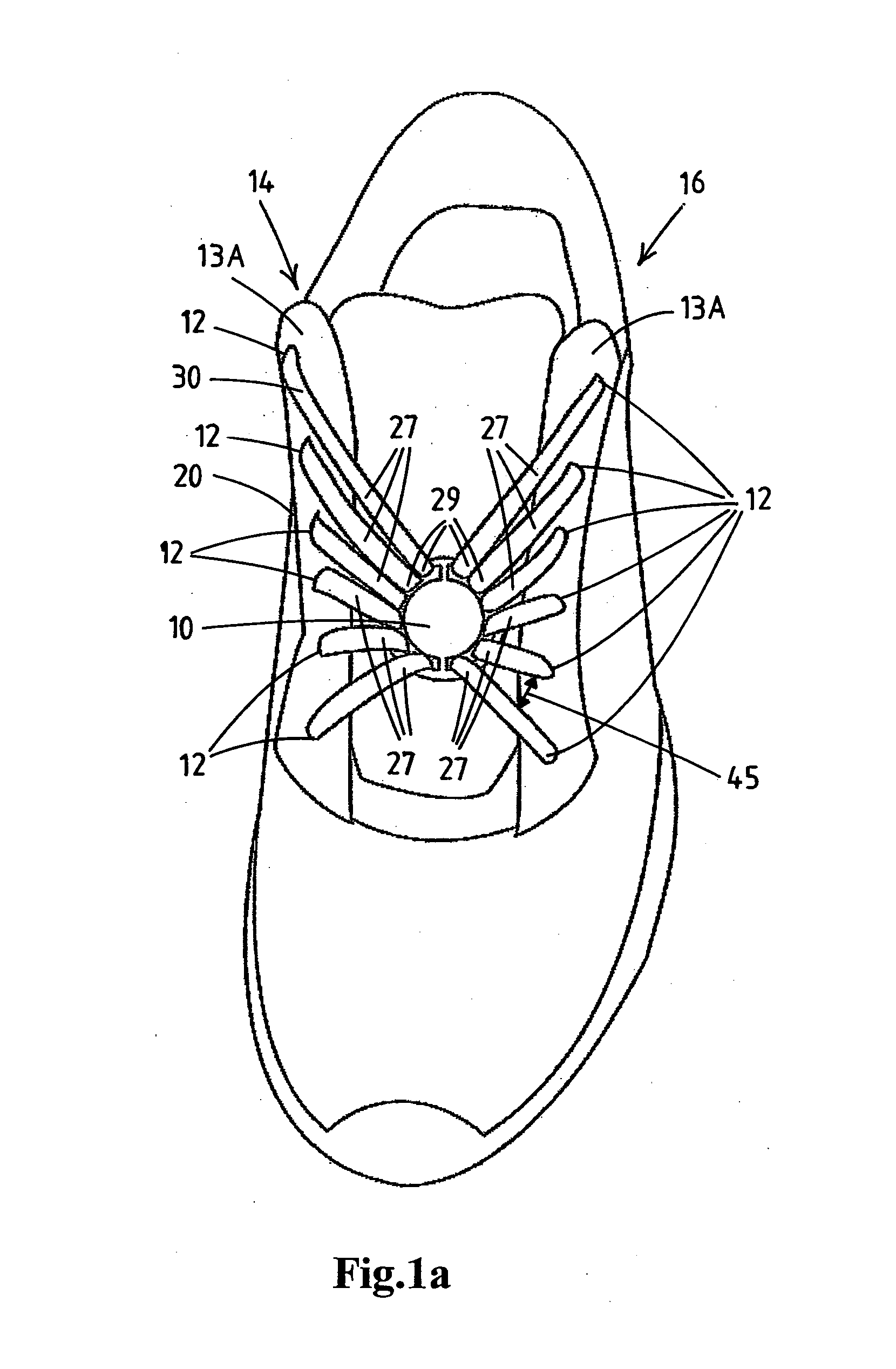

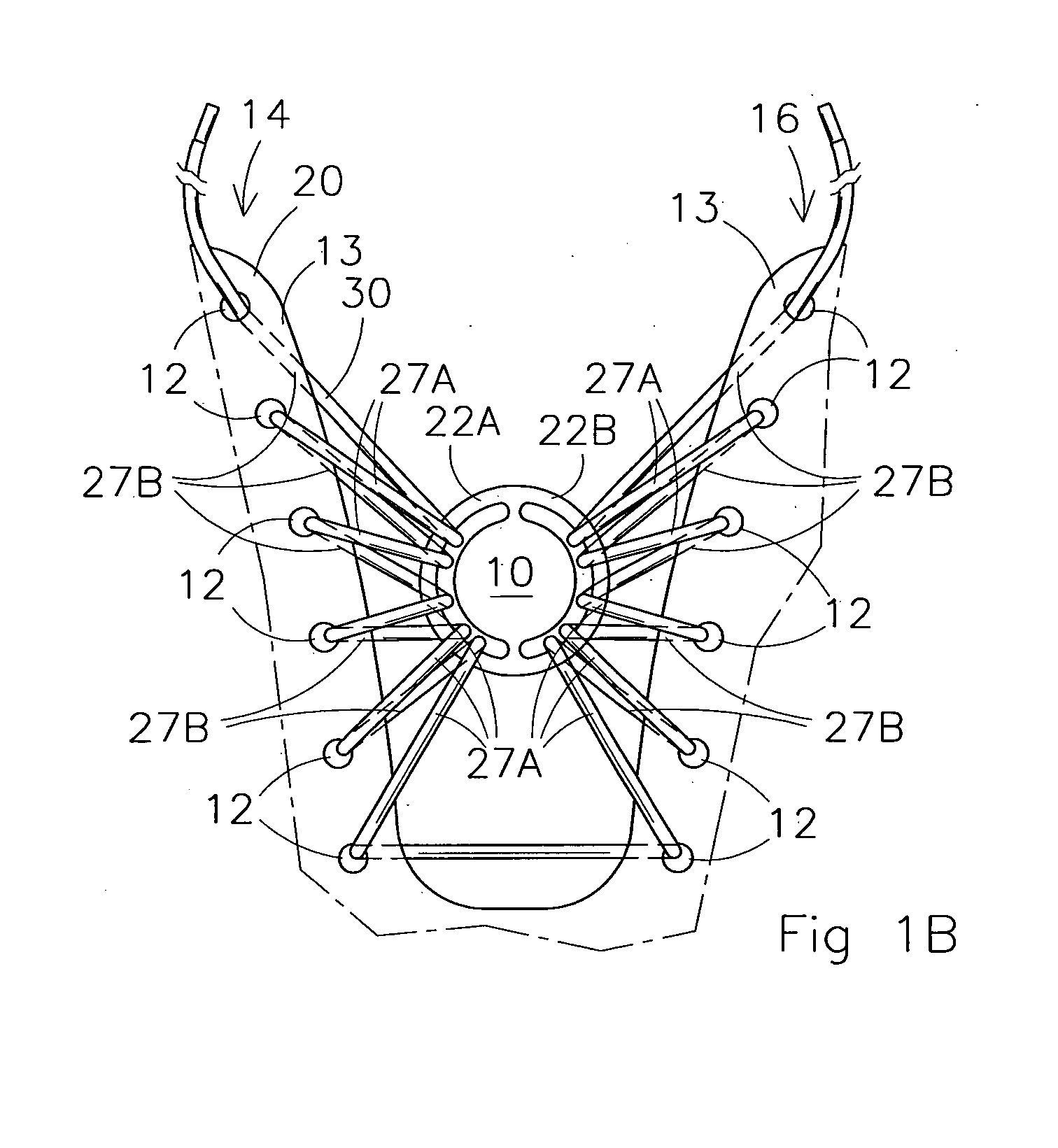

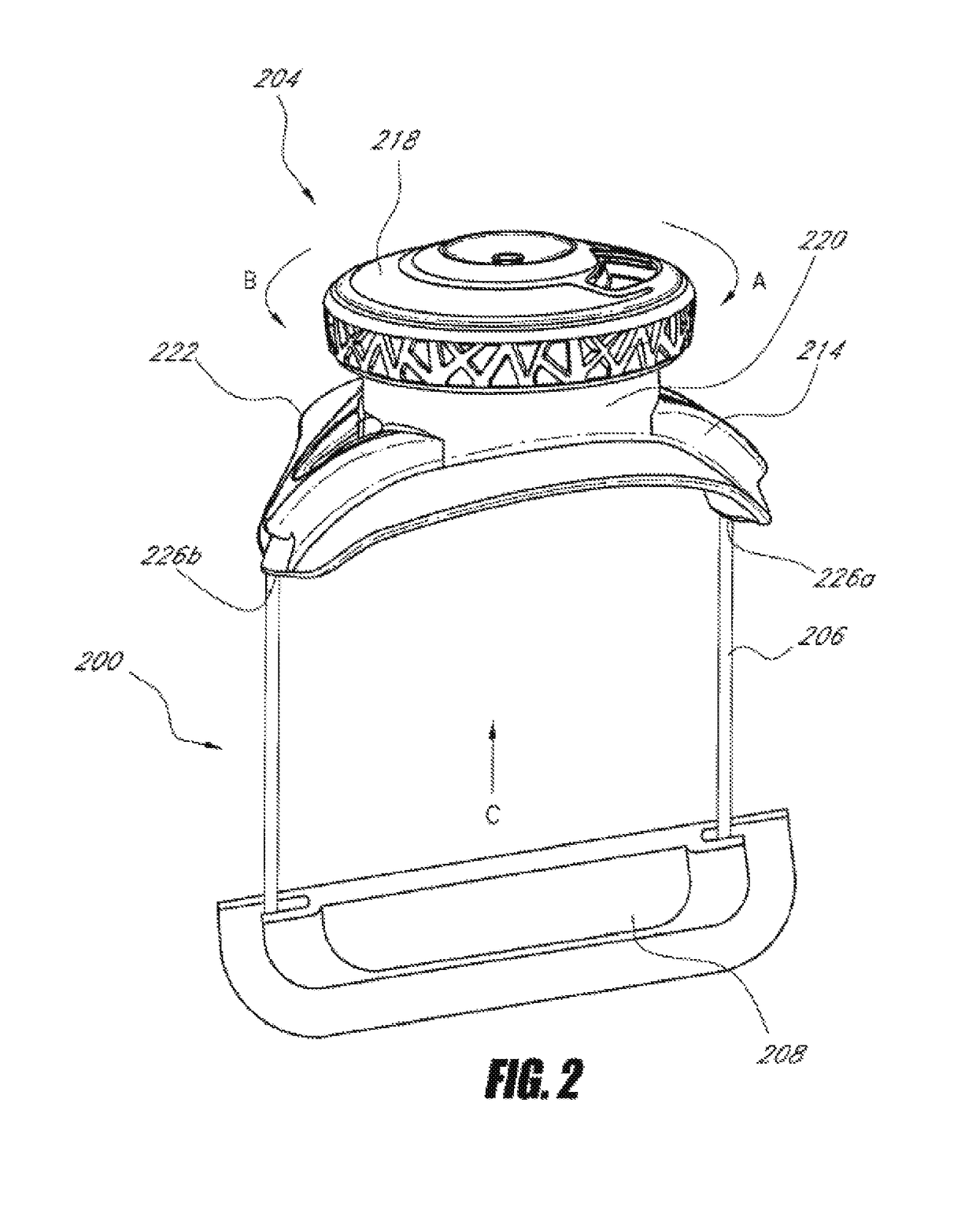

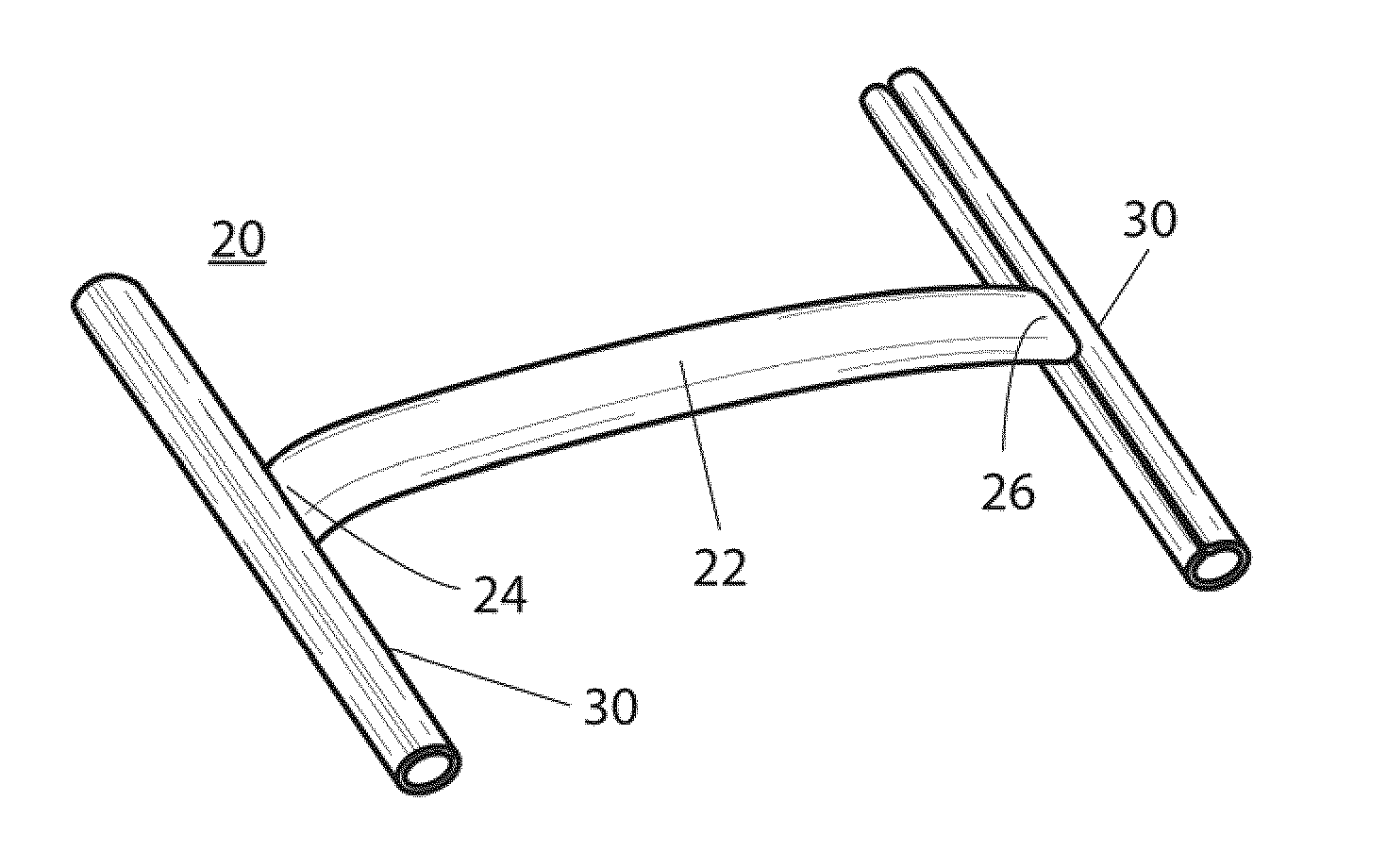

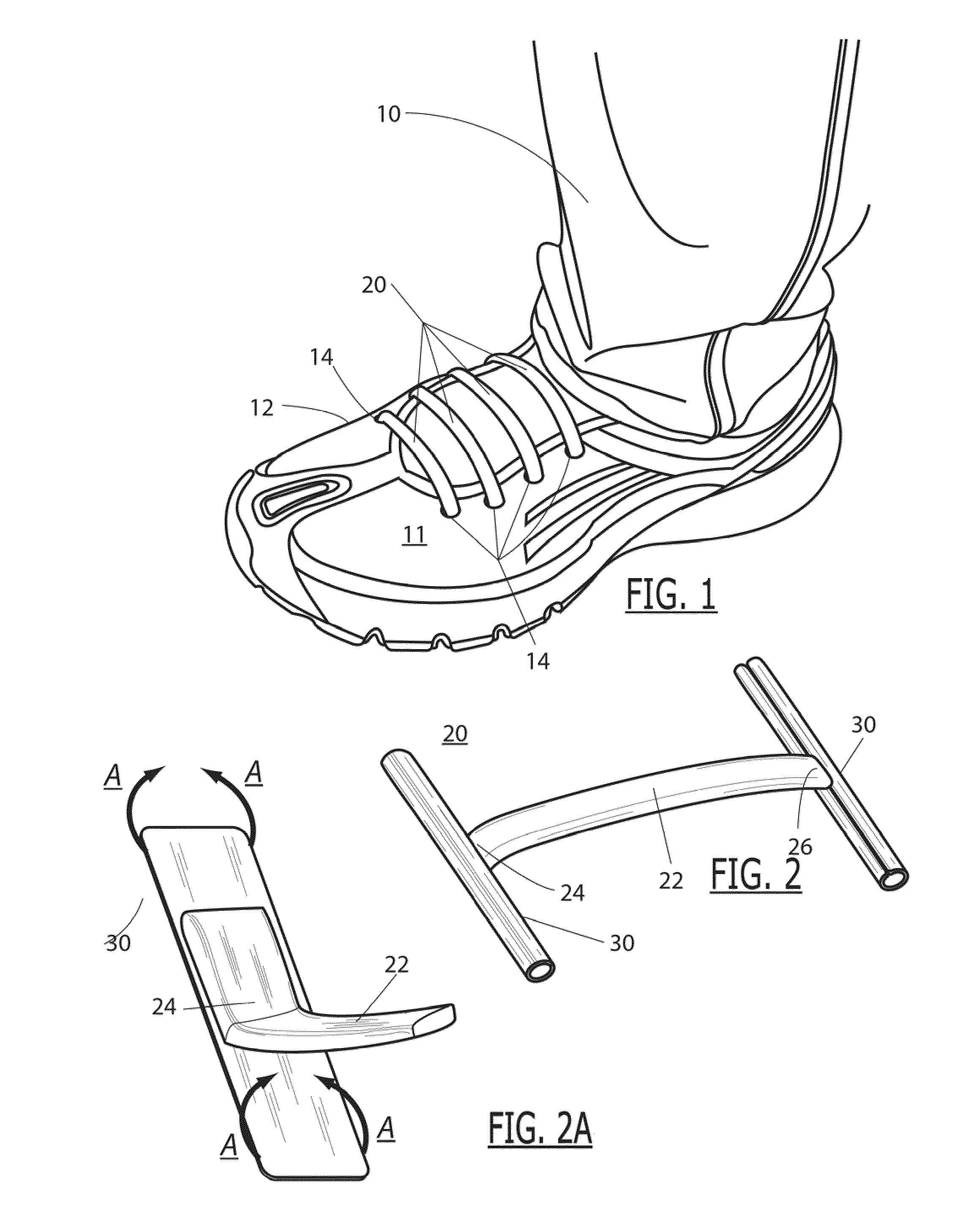

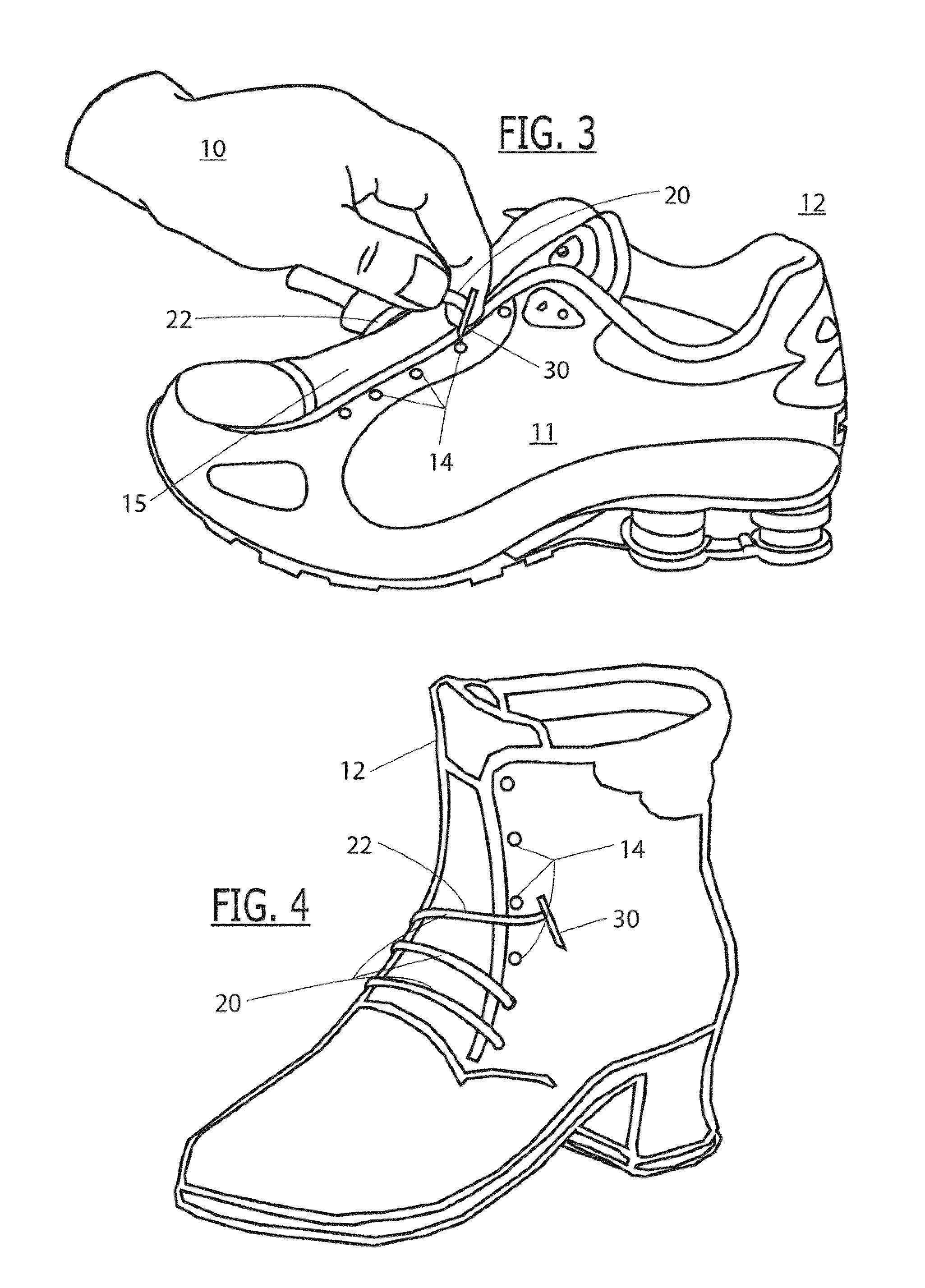

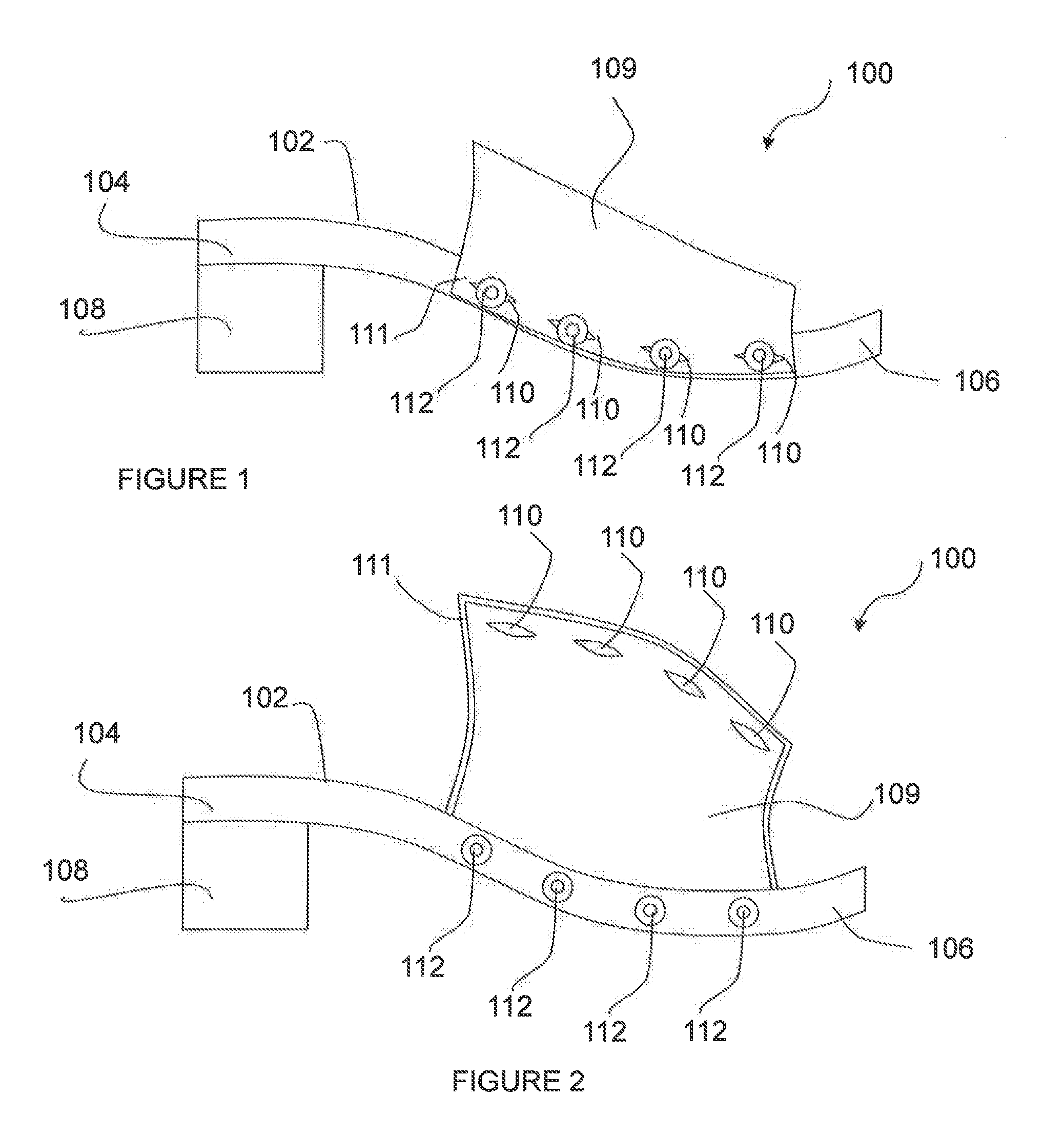

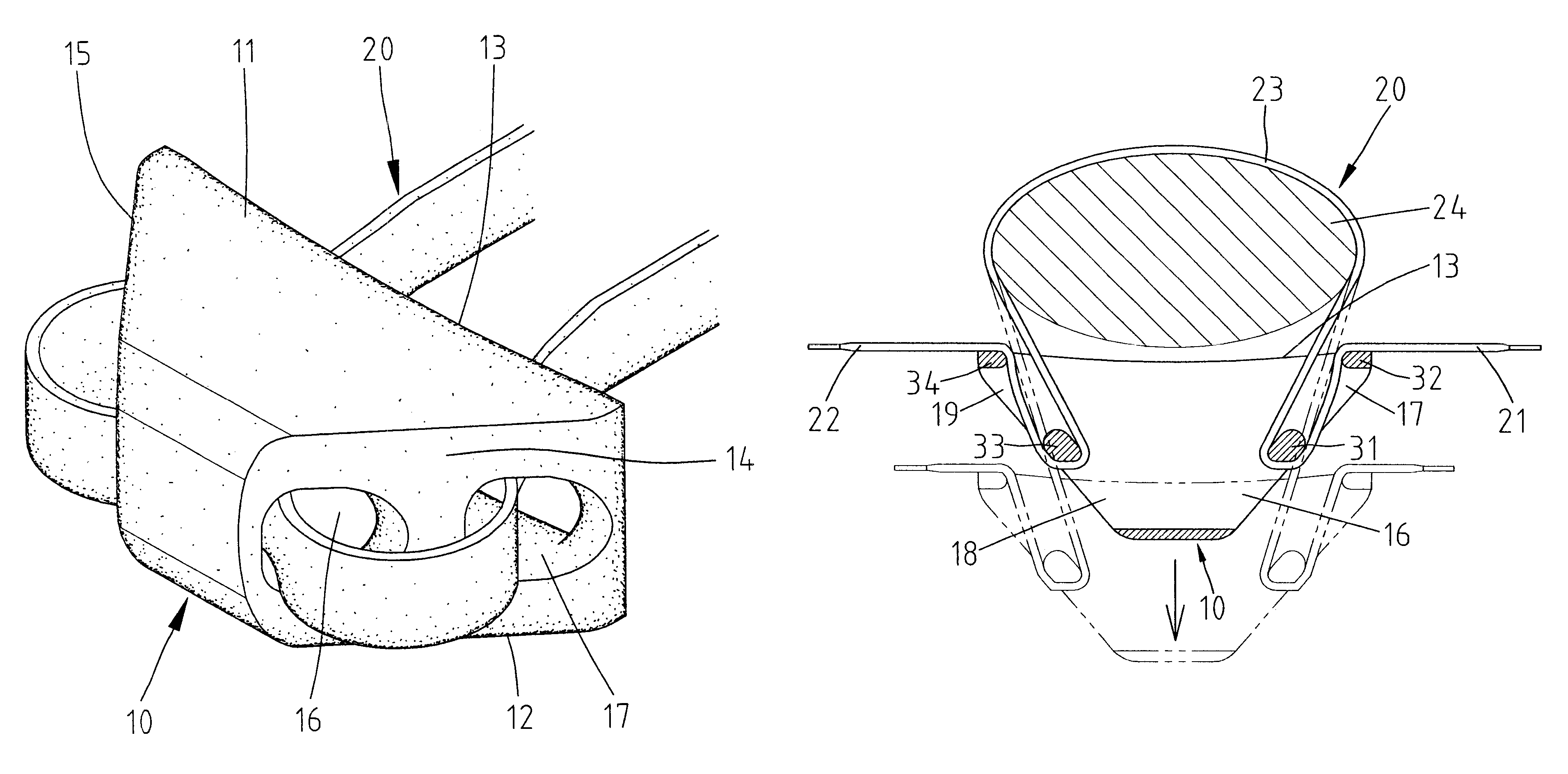

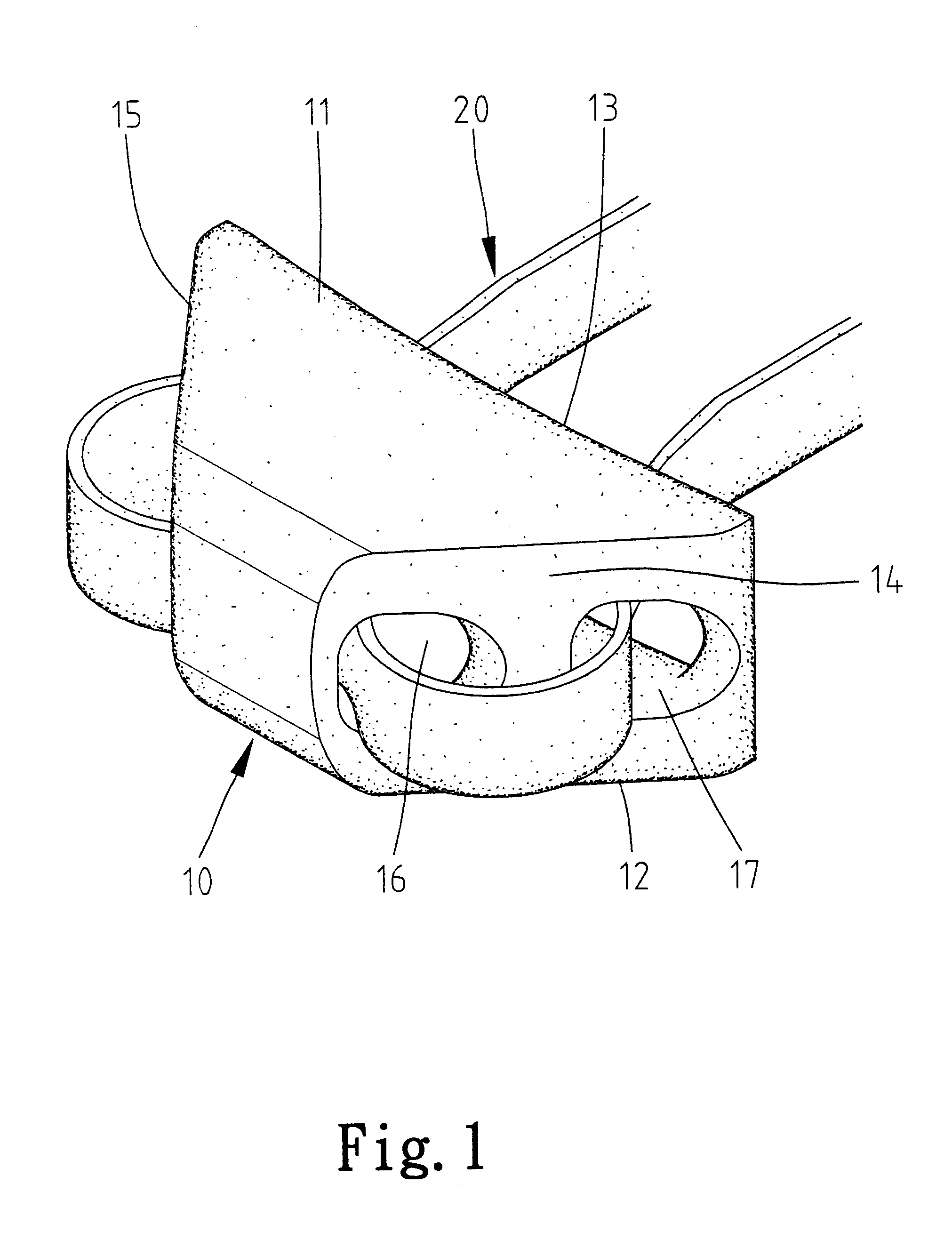

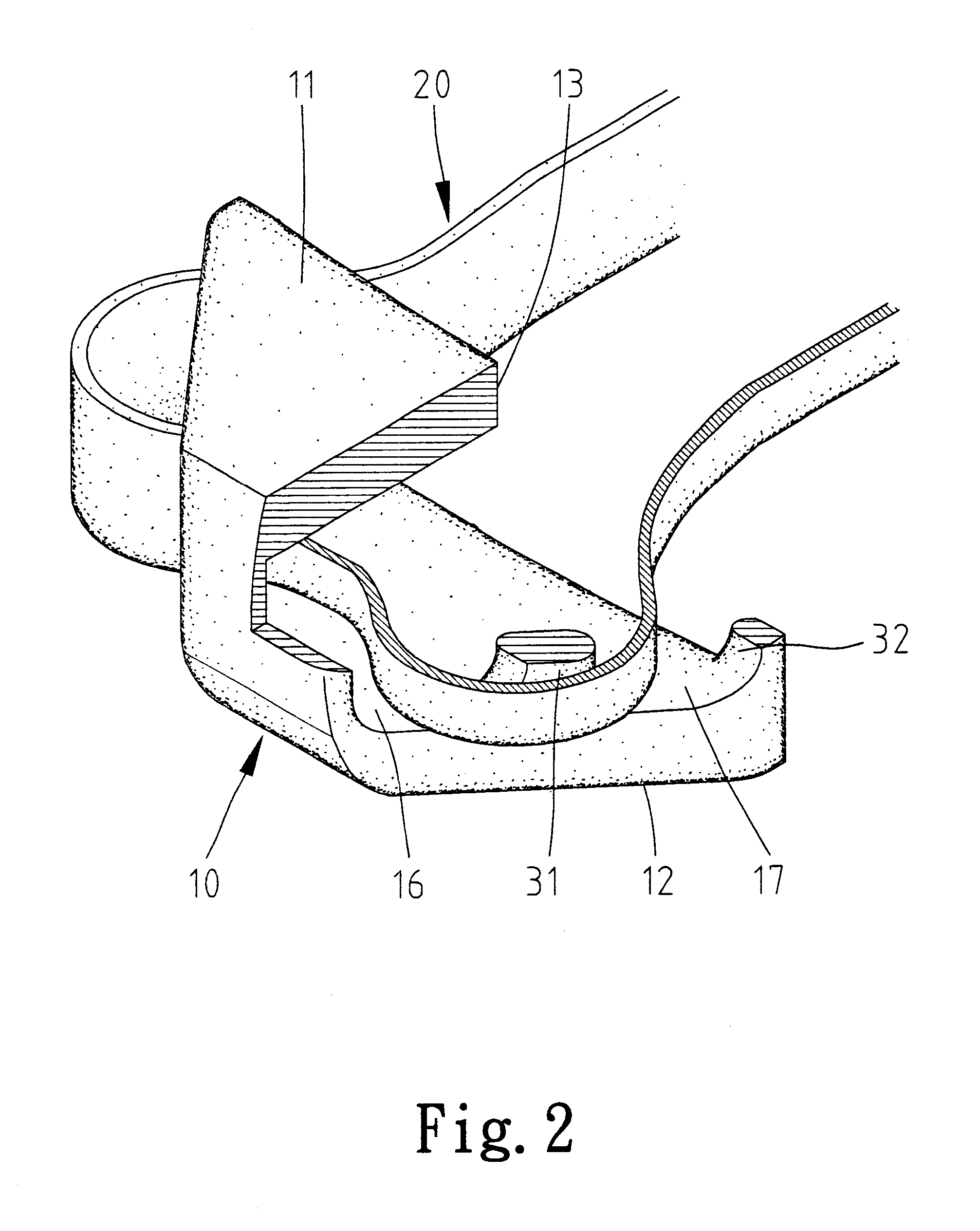

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

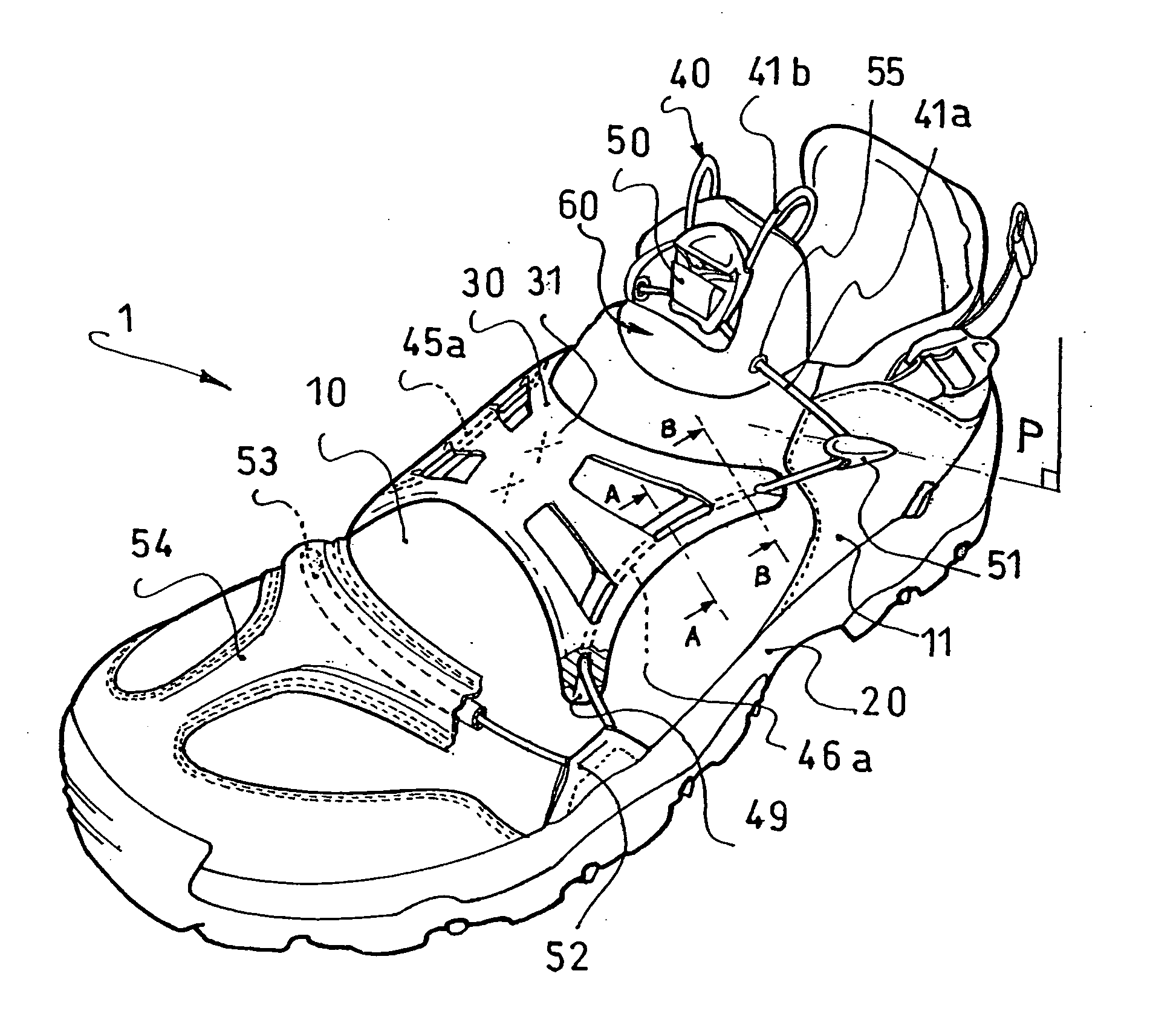

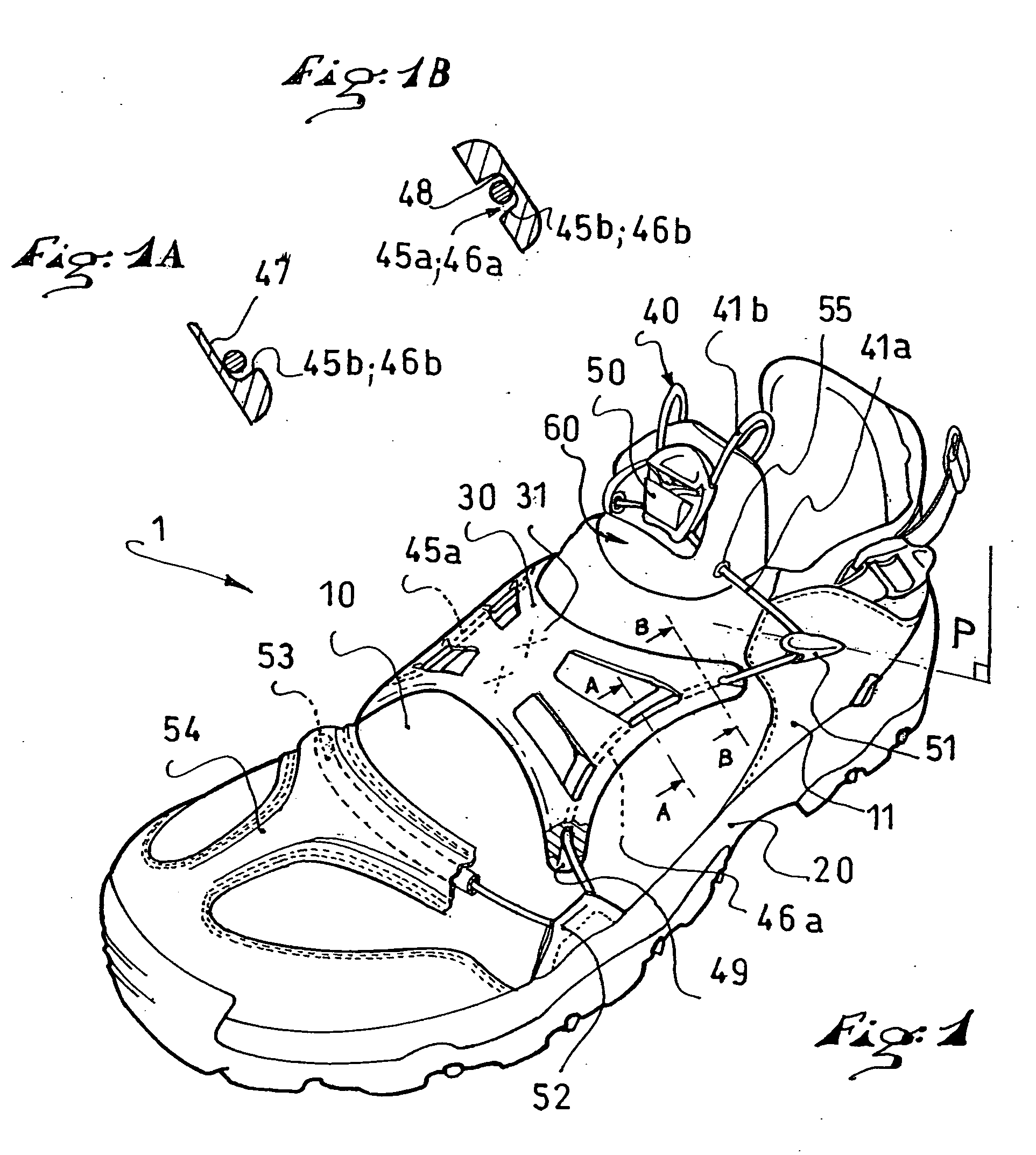

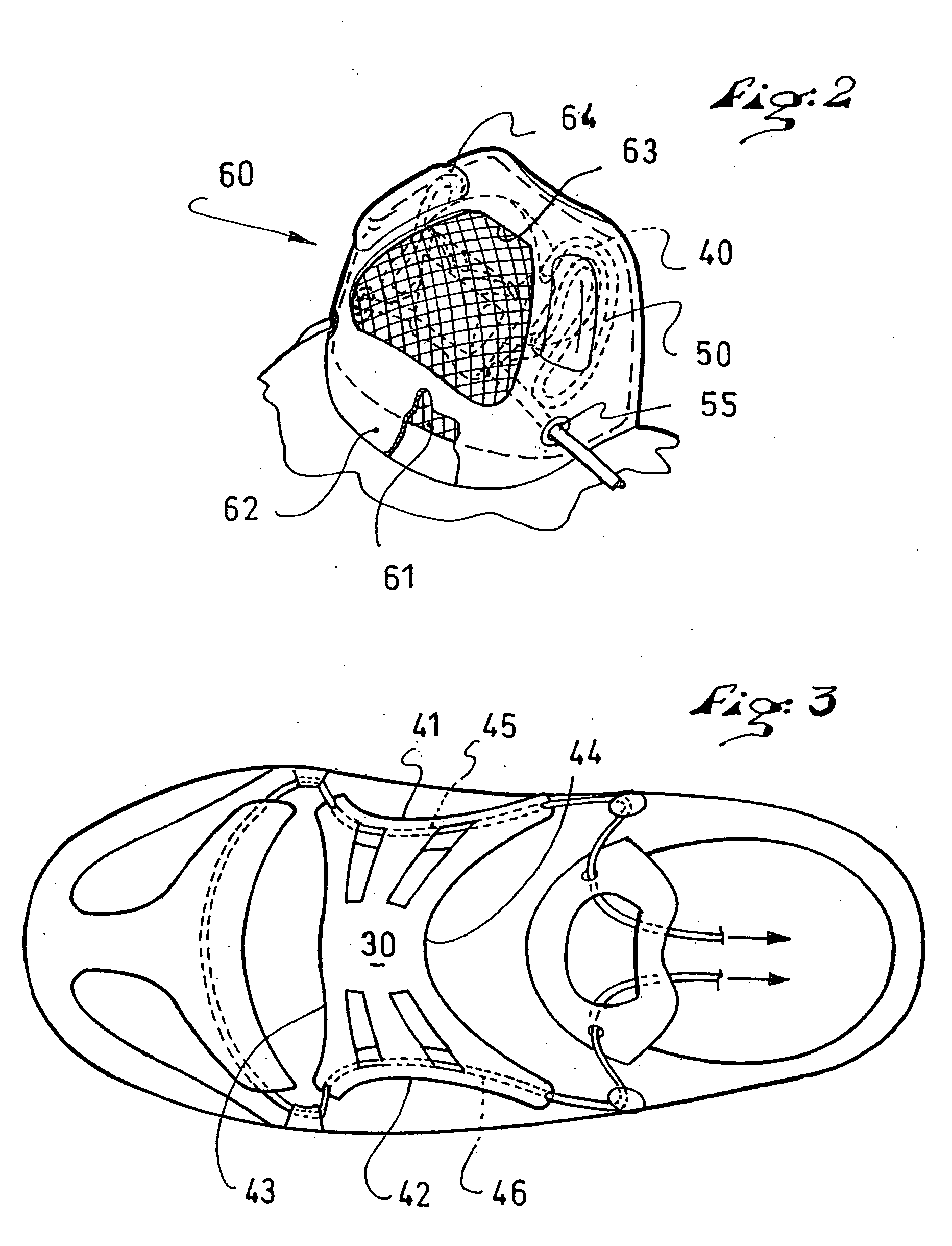

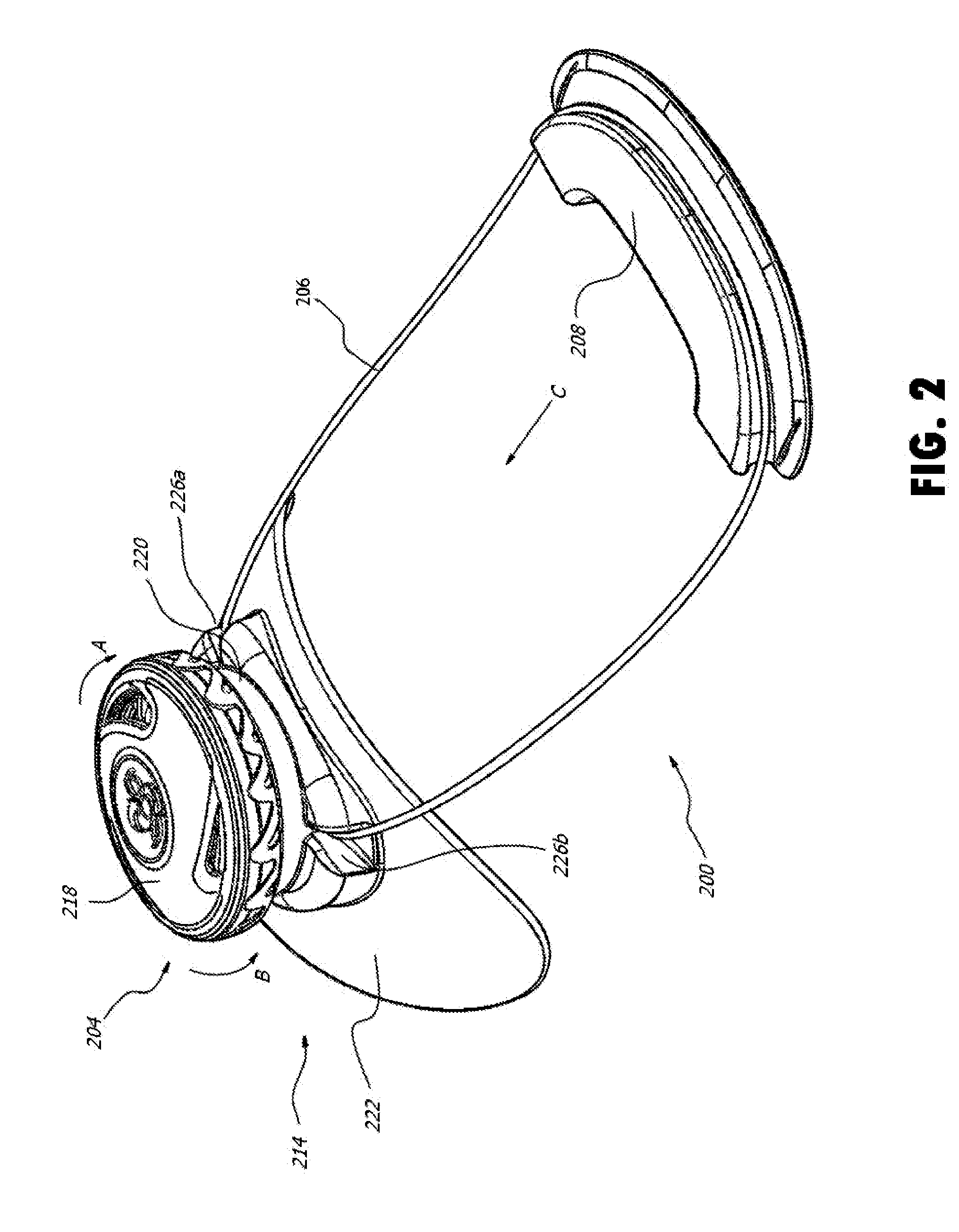

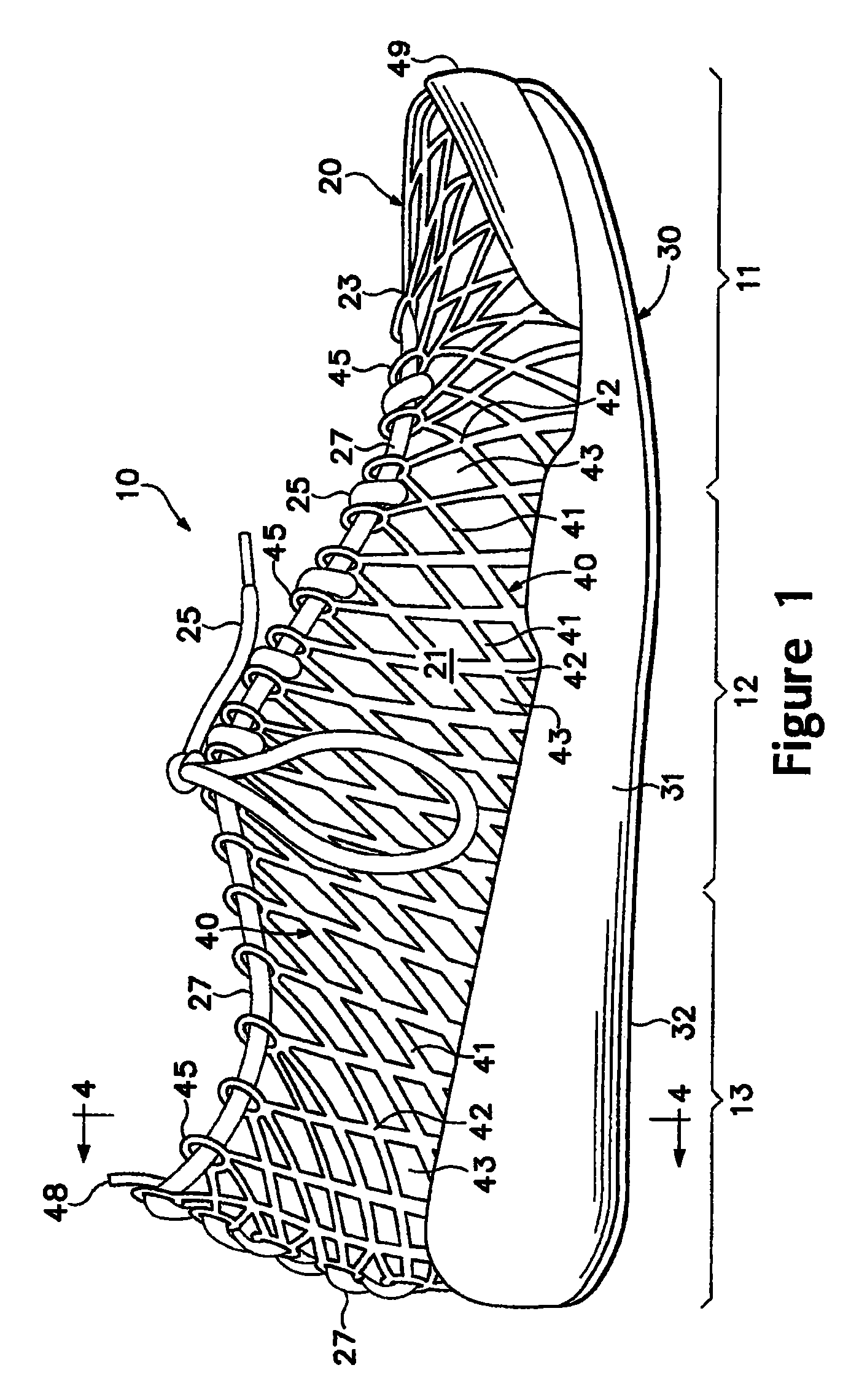

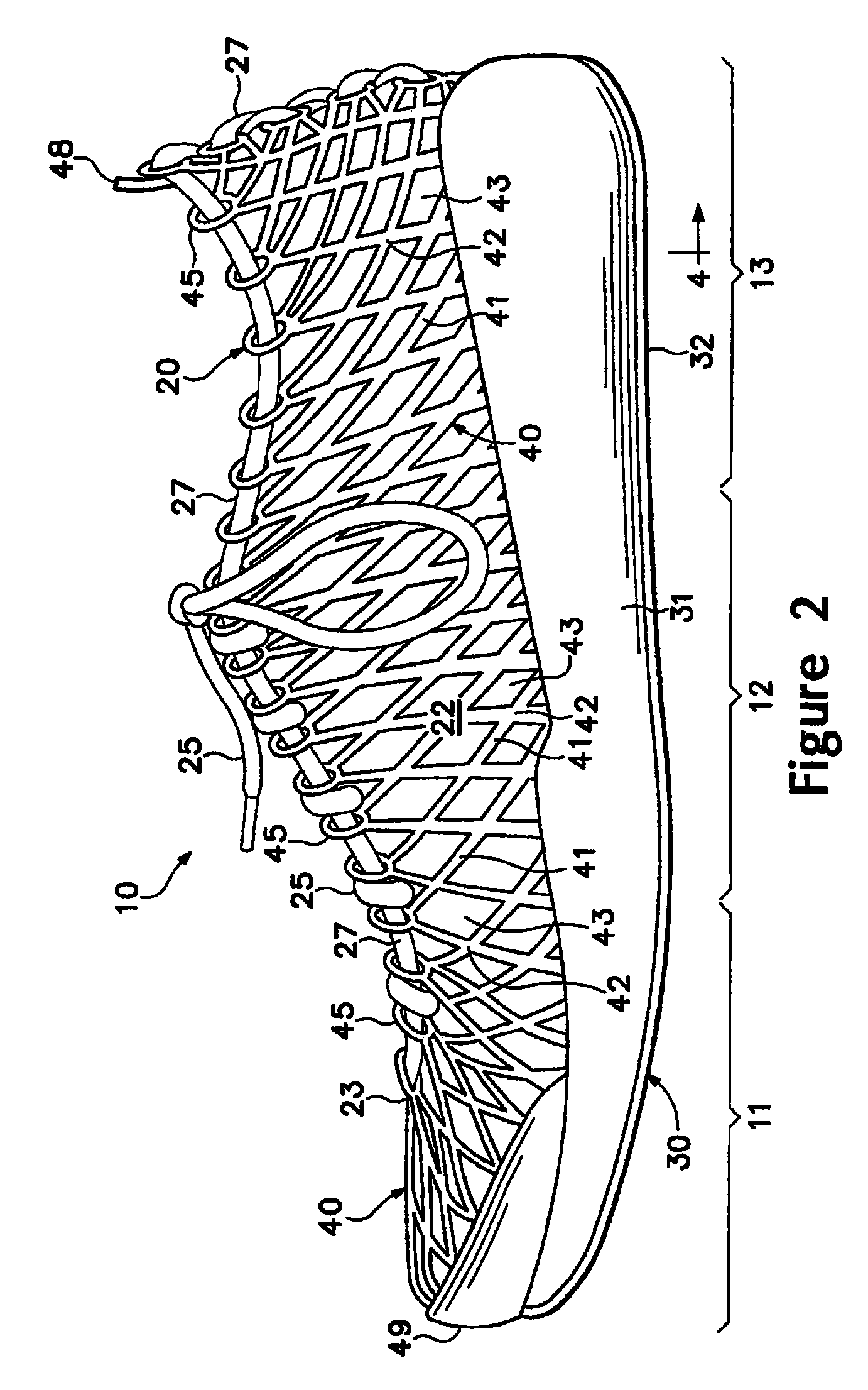

Article of footwear and lacing system therefor

InactiveUS20060000116A1Increase contactQuick and ergonomic tighteningEyeletsShoe lace fasteningsShoe lacesMechanical engineering

An article of footwear having an upper, a sole, and a tightening system, the tightening system having a tightening plate arranged in the area of the instep zone of the article of footwear, the tightening plate having on each medial and lateral side, respectively, at least one channel for the passage of a tightening cord / lace, the sole and / or the upper having on each medial and lateral side, respectively, at least one guide arranged in the vicinity of the sole and adapted to the passage of the tightening cord / lace, the tightening cord / lace having at least one strand running along an alternating path between each guide and channel of the upper / sole and tightening plate, respectively, a blocking mechanism being associated with each strand of the cord / lace, the tightening plate being displaceable at least vertically in relation to the sole by traction on the cord / lace.

Owner:SALOMON SA

Device for immobilizing the ends shoe laces

InactiveUS6502286B1Simple and wear-protectedProtection wearEyeletsRopes and cables for vehicles/pulleyShoe lacesMechanical engineering

Owner:DUBBERKE MARKUS

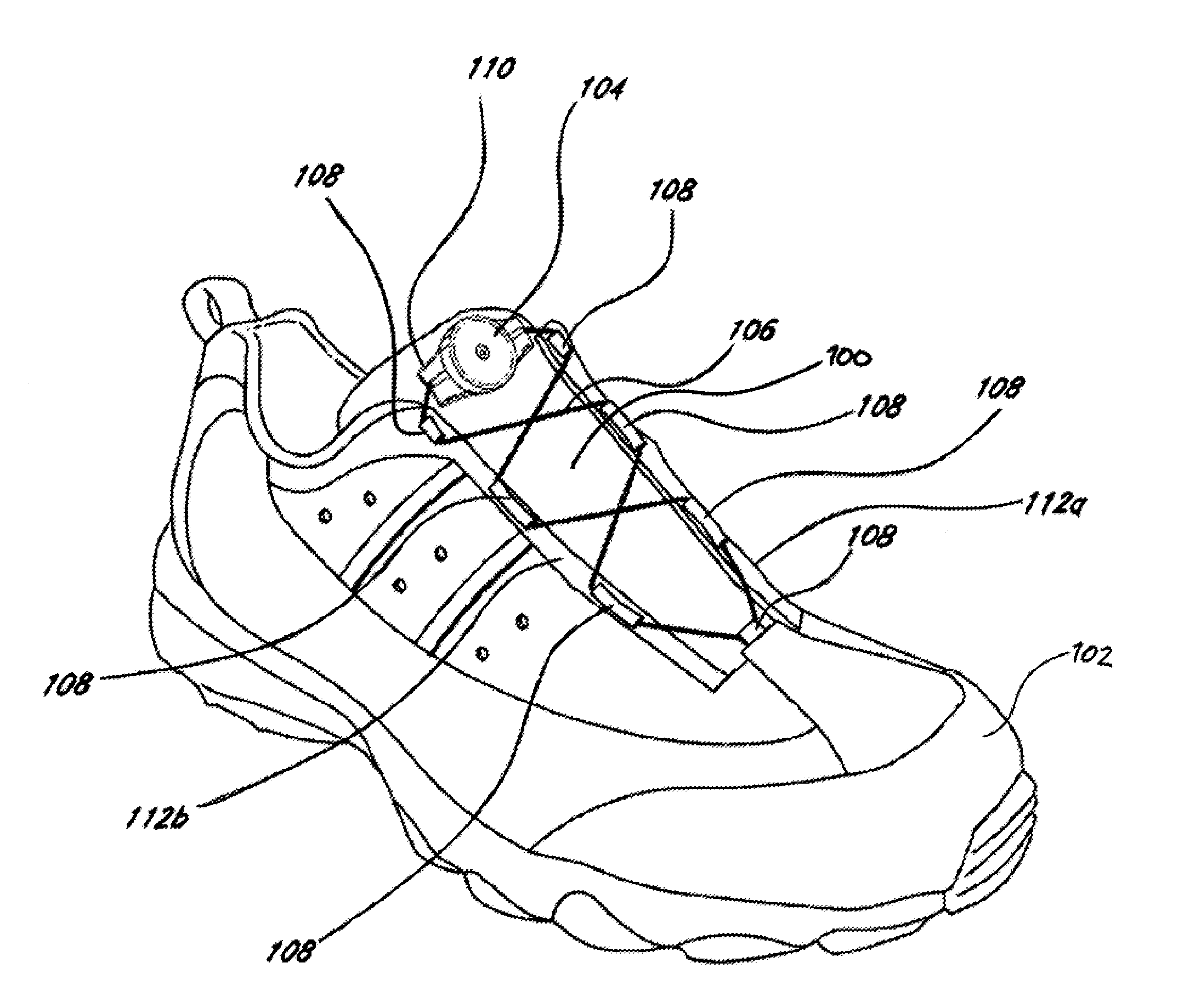

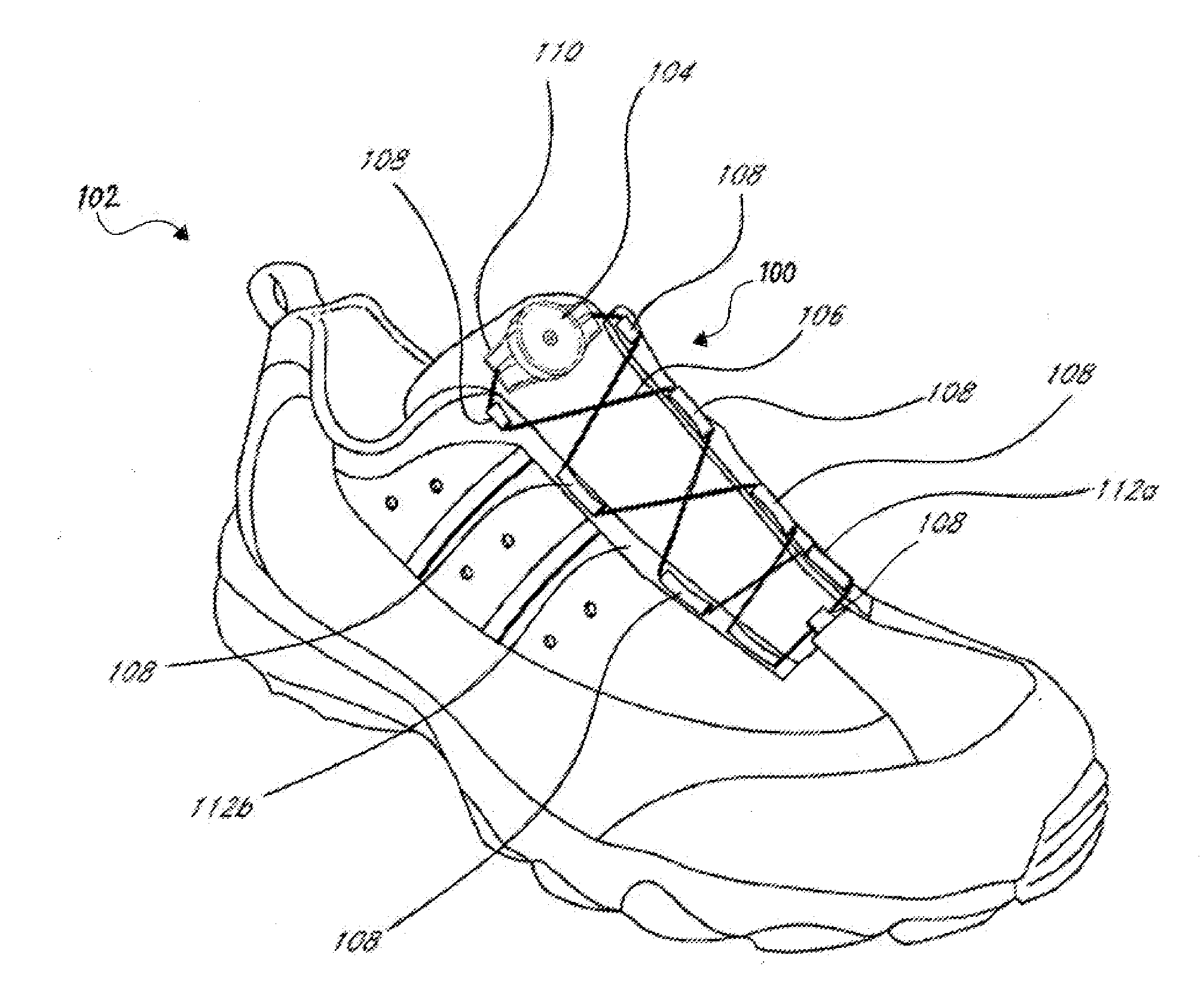

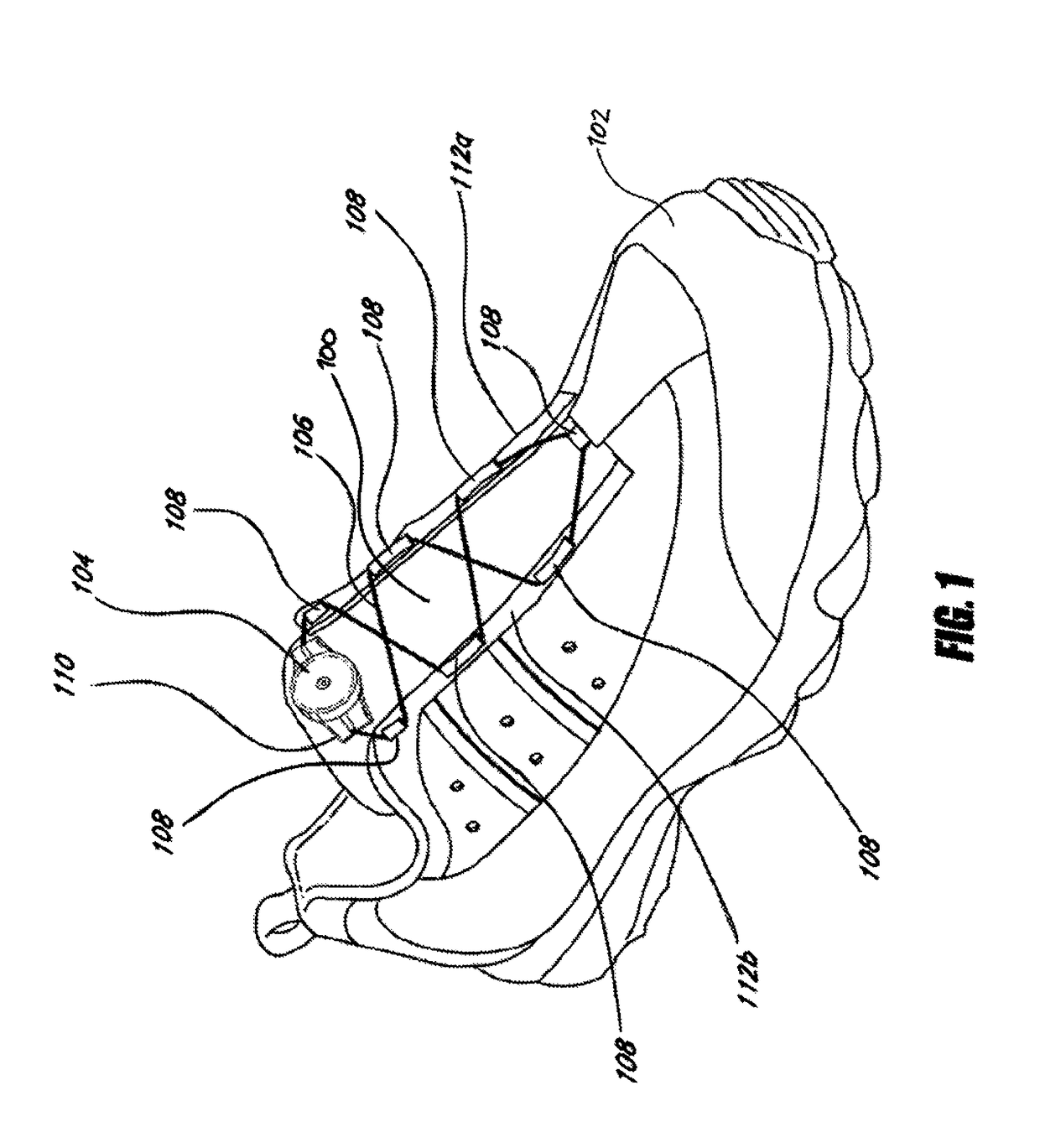

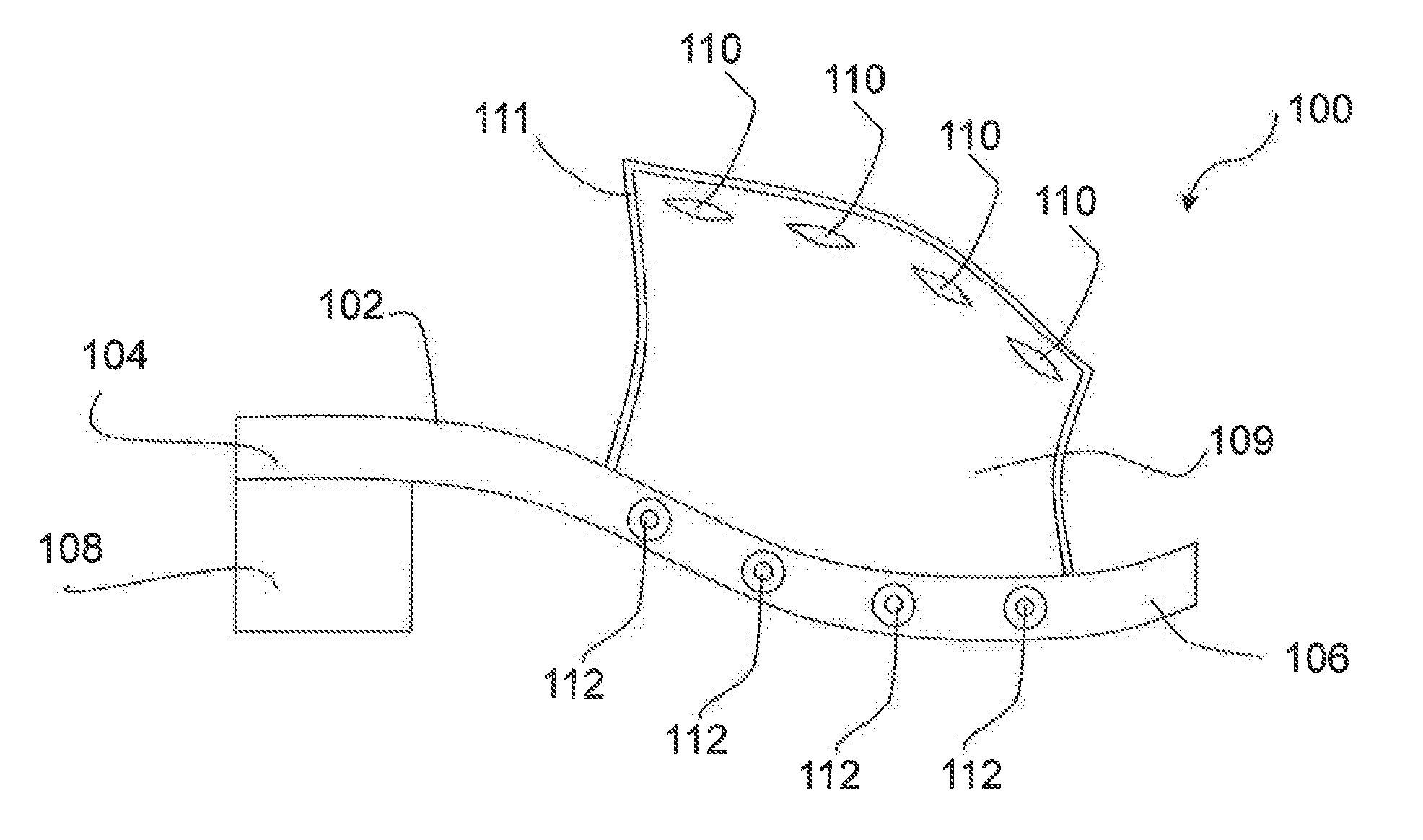

Methods and devices for retrofitting footwear to include a reel based closure system

ActiveUS20140290016A1Help positioningStabilize the elongate panel memberEyeletsLastingCouplingEngineering

According to one embodiment, a removable tightening device is described. The tensioning mechanism is removably coupleable with an article without damaging the article so that upon removal, the coupling of the tensioning mechanism with the article is unrecognizable or not readily detectable. The tensioning mechanism is operable with a tension member to maintain a tension of the tension member and thereby maintain a tightness of the article. The tension member is guided along a path about the article, via one or more guide members, and is tensionable, via the tensioning mechanism, to tighten the article.

Owner:BOA TECHNOLOGY

Ornamental attachment for footwear

InactiveUS20110162236A1Simple and cost-effectiveFirmly connectedEyeletsShoe lace fasteningsShoe lacesBiomedical engineering

Owner:FRANS VOSKUIL +1

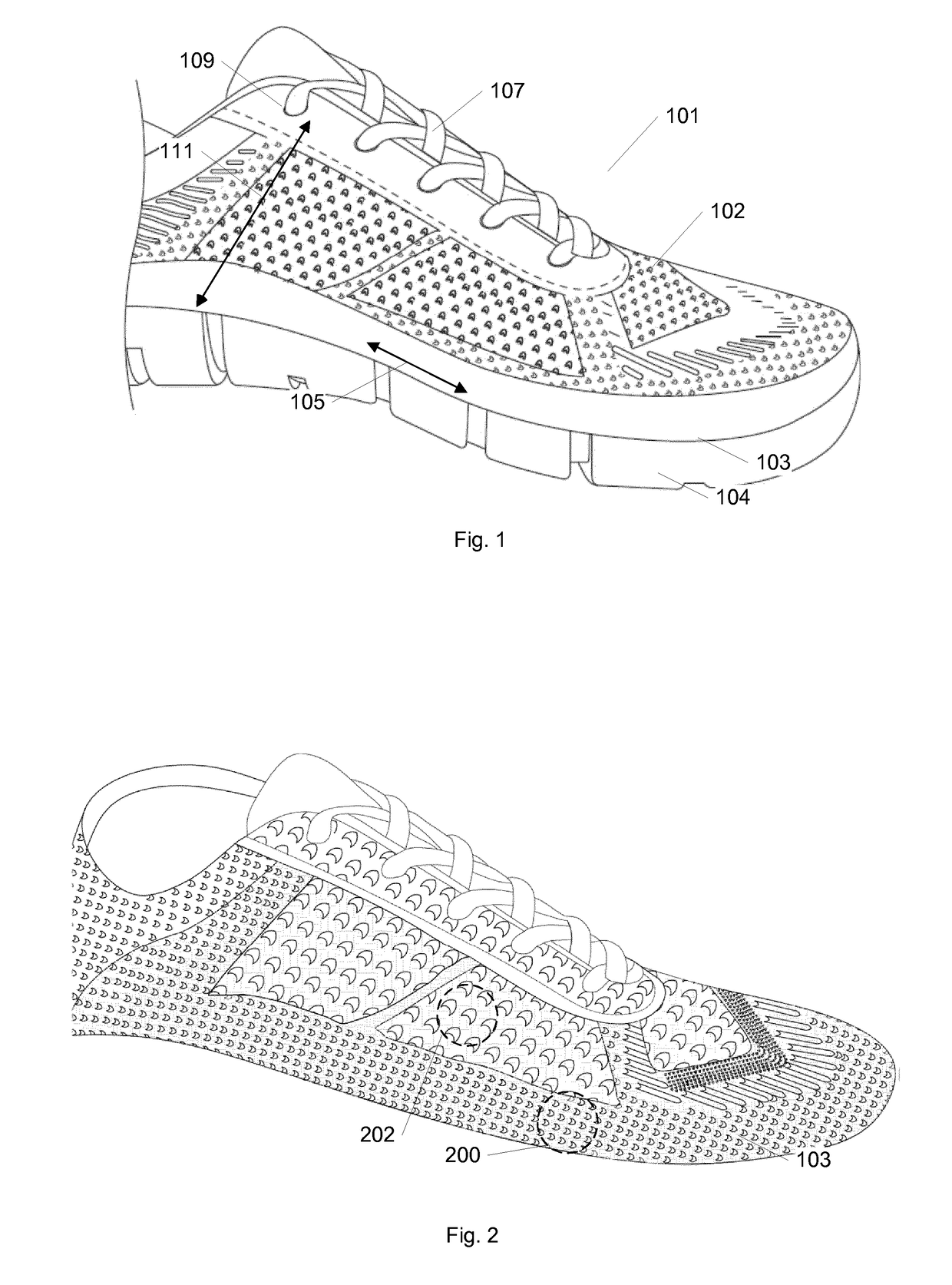

Article of footwear having an upper with a matrix layer

Articles of footwear, including athletic footwear, include one or more of: (a) a sole structure; (b) an upper having lateral and medial side elements engaged with the sole structure, the upper made from a polymer matrix structure that extends through at least a heel region; (c) a size adjustment mechanism located at the heel region; (d) a heel tongue element located adjacent the size adjustment mechanism; (e) a shoe securing mechanism; (f) an instep tongue member; and / or (g) a bootie member located at least partially within the foot-receiving chamber. Methods of manufacturing such articles of footwear also are disclosed.

Owner:NIKE INC

Article of footwear

InactiveUS20130047471A1Improve buffering effectImprove reinforcementEyeletsShoemaking devicesEngineering

The present disclosure provides an article of footwear including: a footwear upper formed of one or more pieces, each piece comprising one or more layers; and a footwear lower attached to the footwear upper to provide a sole supporting member to the article of footwear; wherein the one or more pieces used to form the footwear upper are molded into a three dimensional configuration. Also provided is a method for forming the same and an inner lining for an article of footwear.

Owner:REGINA MIRACLE INTERNATIONAL (GROUP) LIMITED

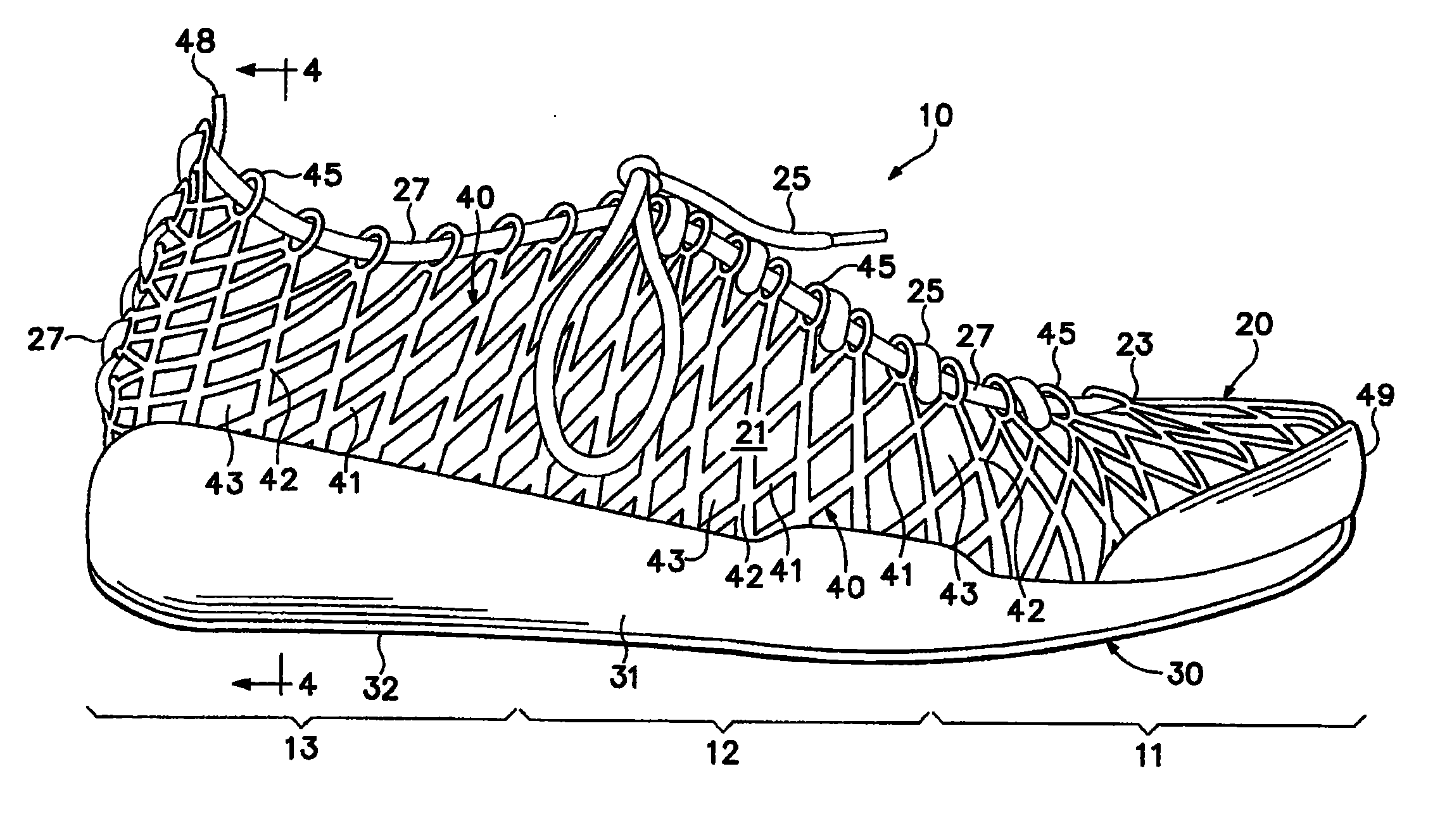

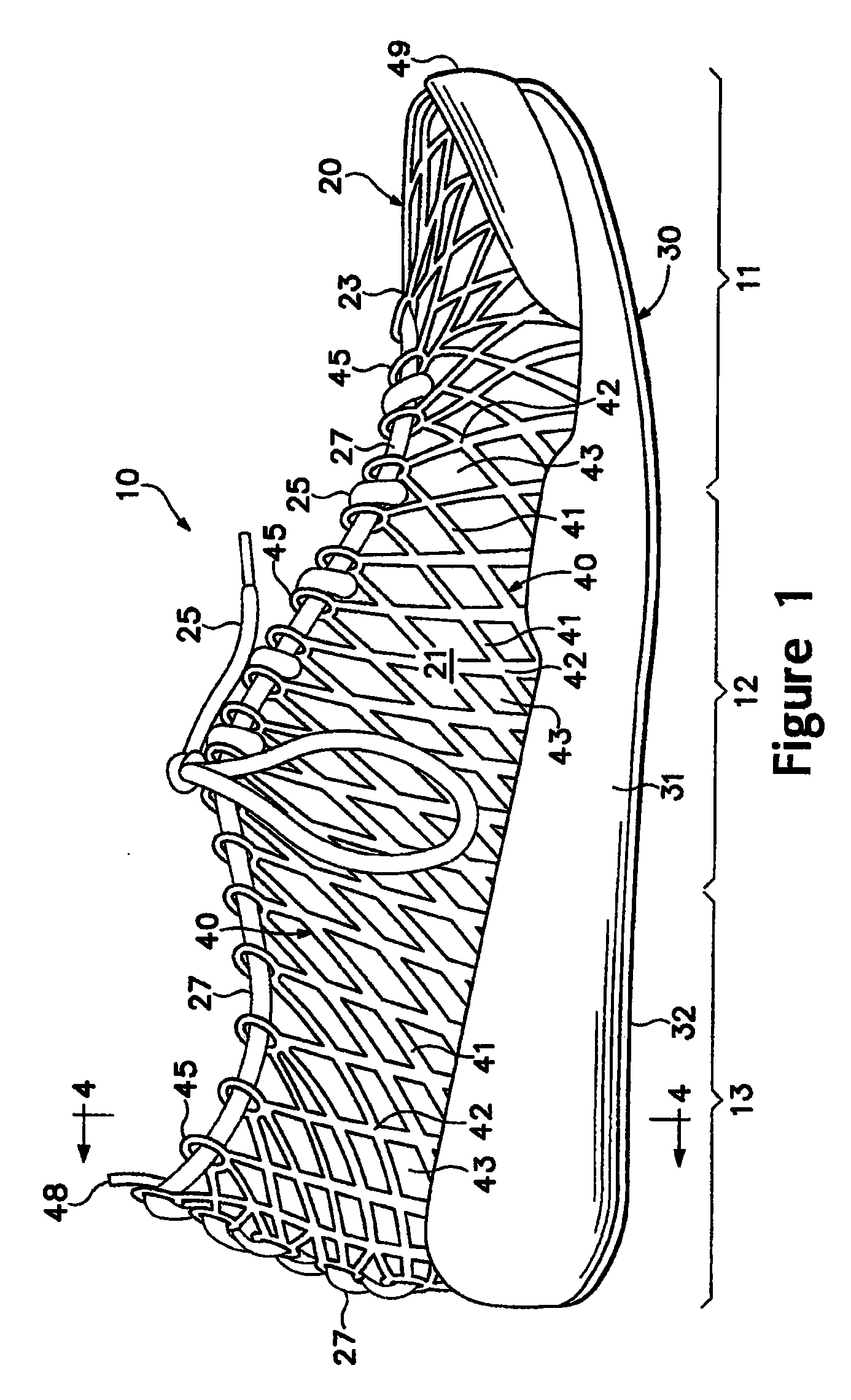

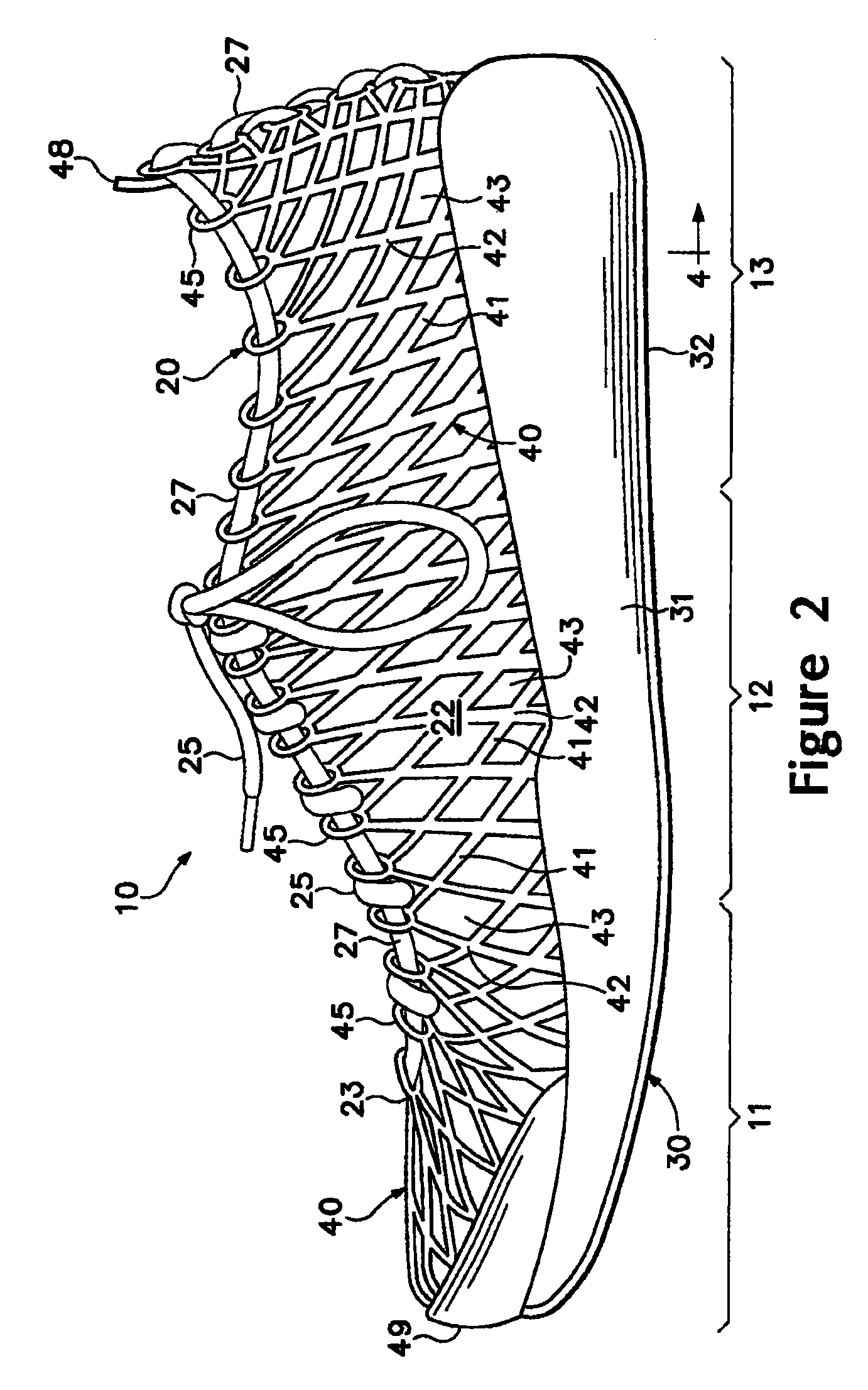

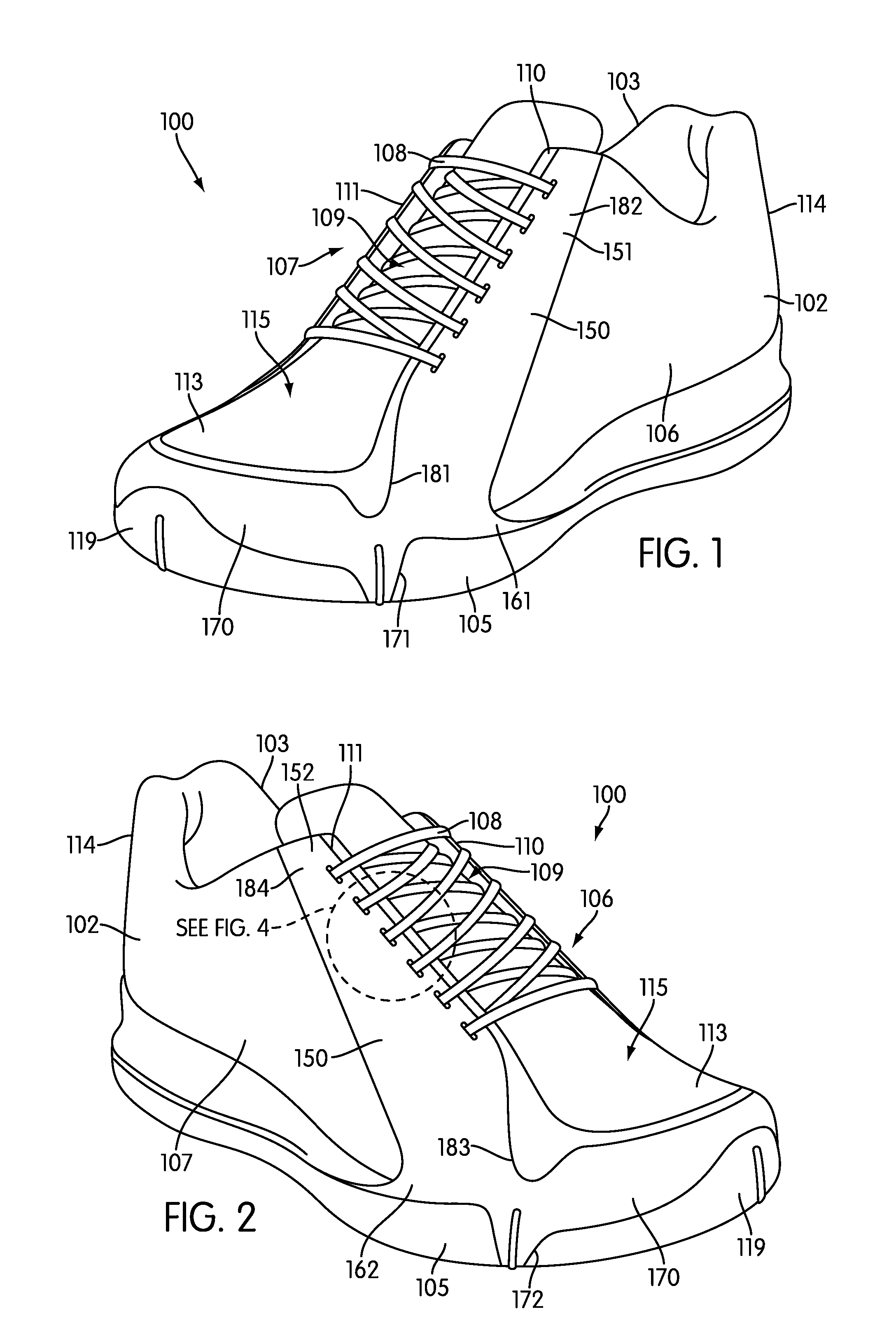

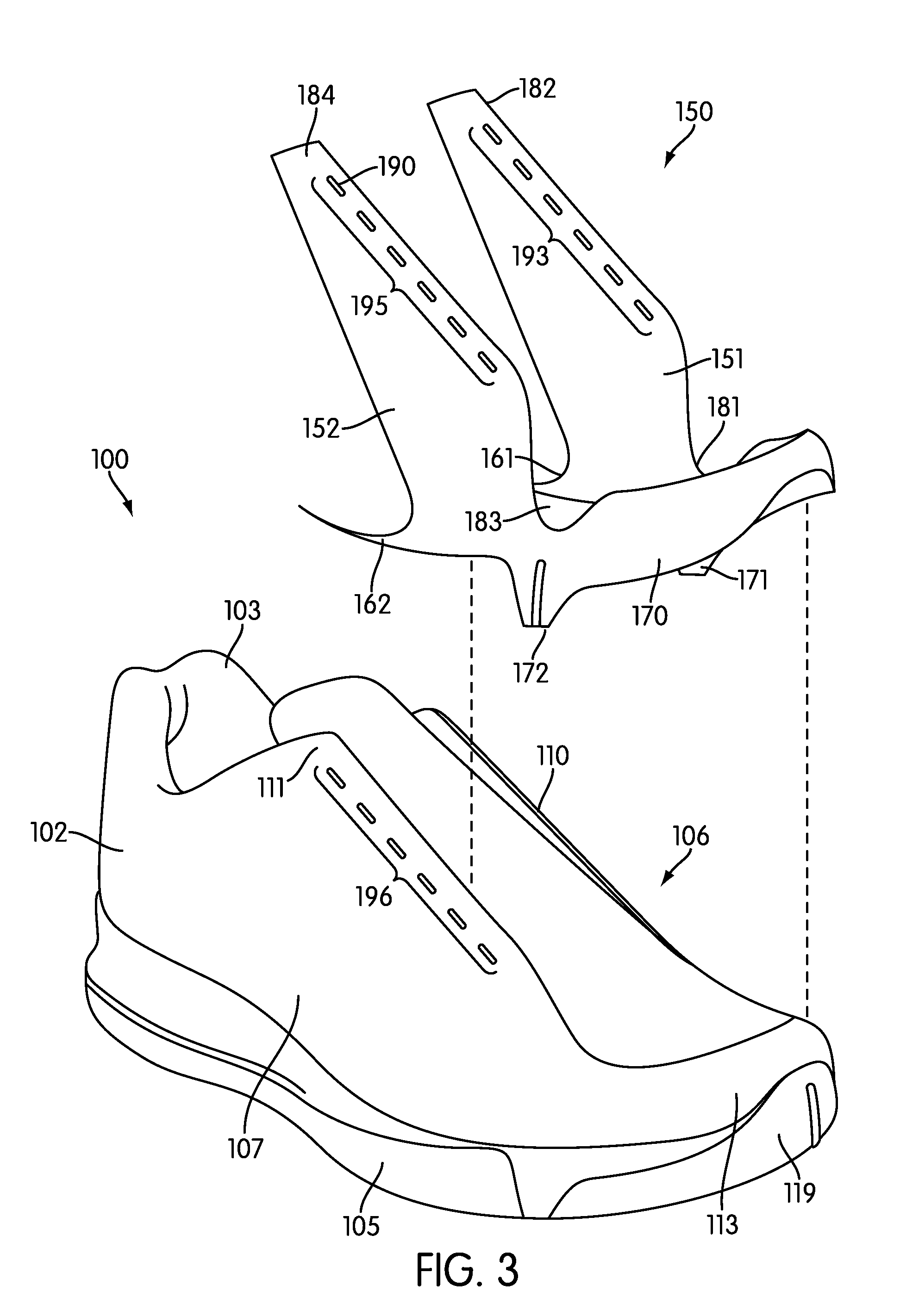

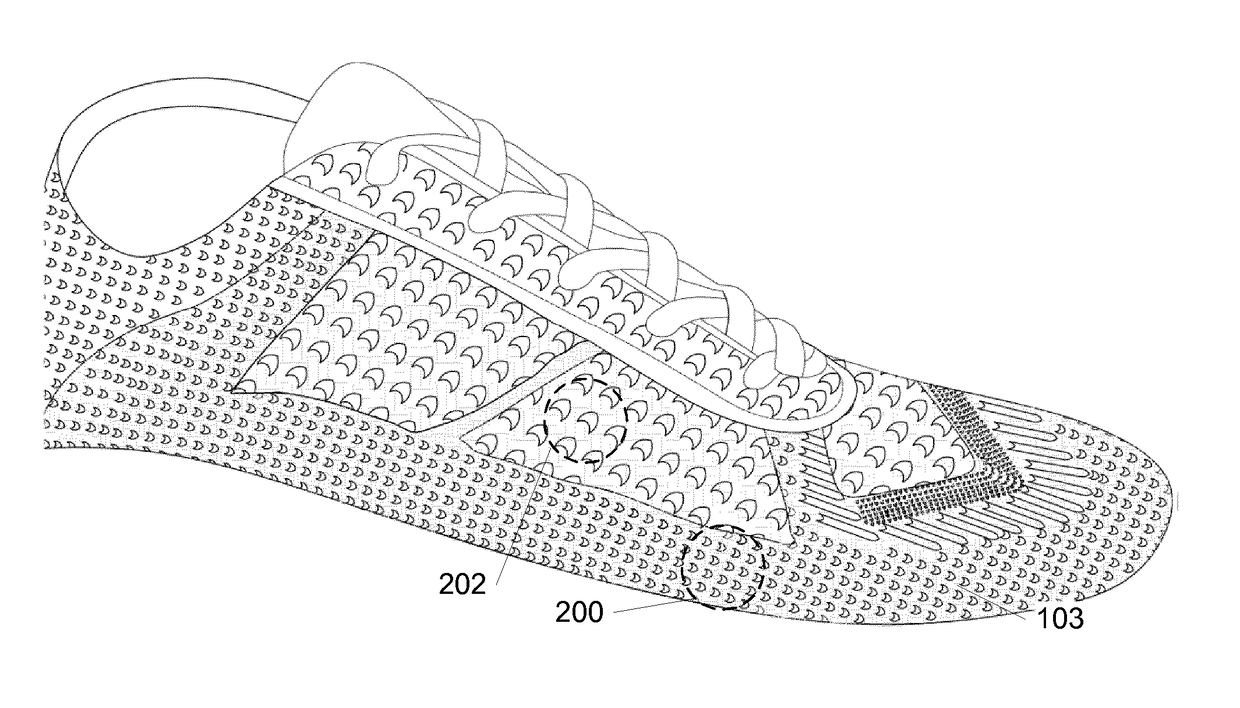

Article of Footwear Having an Upper with a Matrix Layer

Articles of footwear, including athletic footwear, include one or more of: (a) a sole structure; (b) an upper having lateral and medial side elements engaged with the sole structure, the upper made from a polymer matrix structure that extends through at least a heel region; (c) a size adjustment mechanism located at the heel region; (d) a heel tongue element located adjacent the size adjustment mechanism; (e) a shoe securing mechanism; (f) an instep tongue member; and / or (g) a bootie member located at least partially within the foot-receiving chamber. Methods of manufacturing such articles of footwear also are disclosed.

Owner:NIKE INC

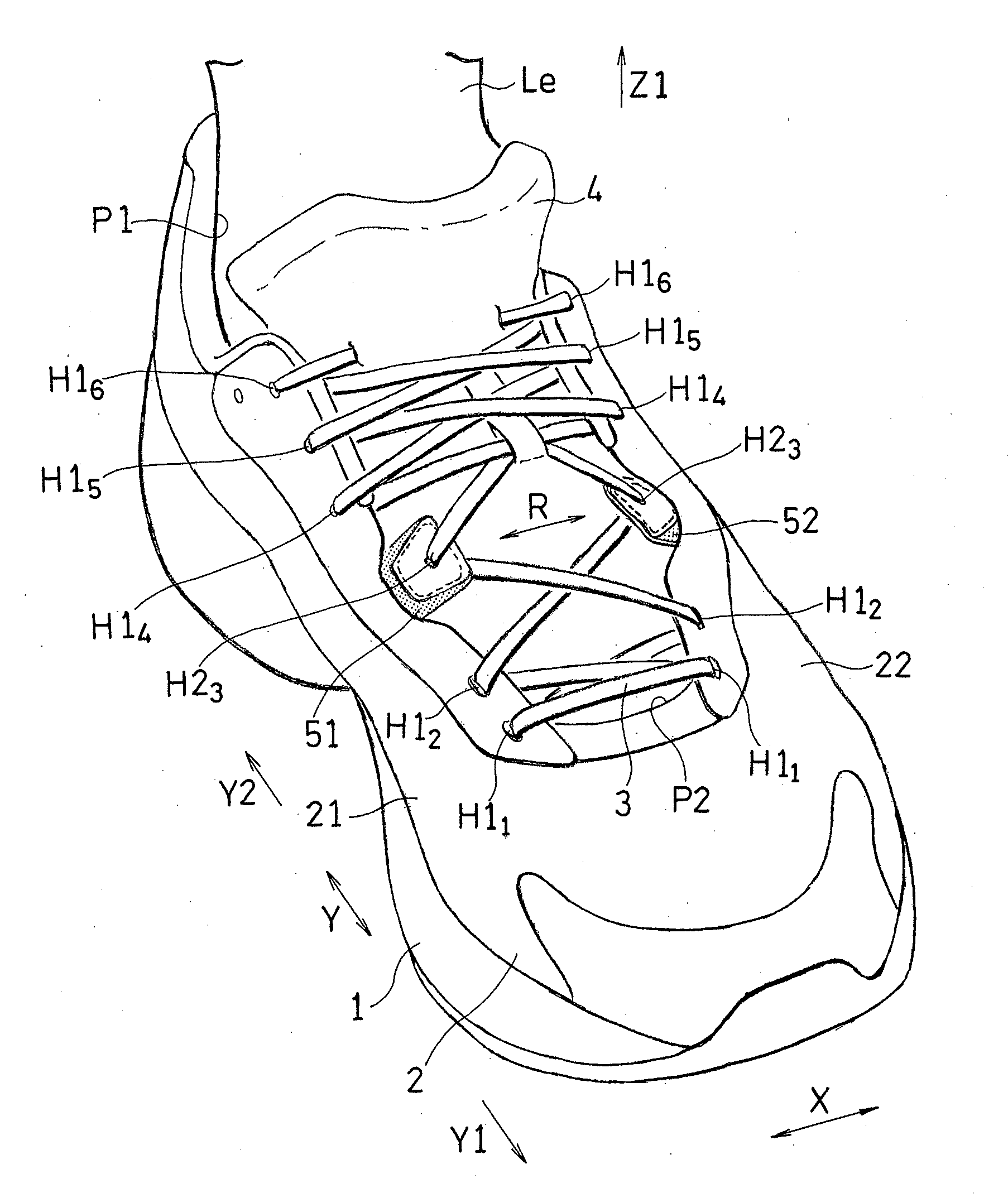

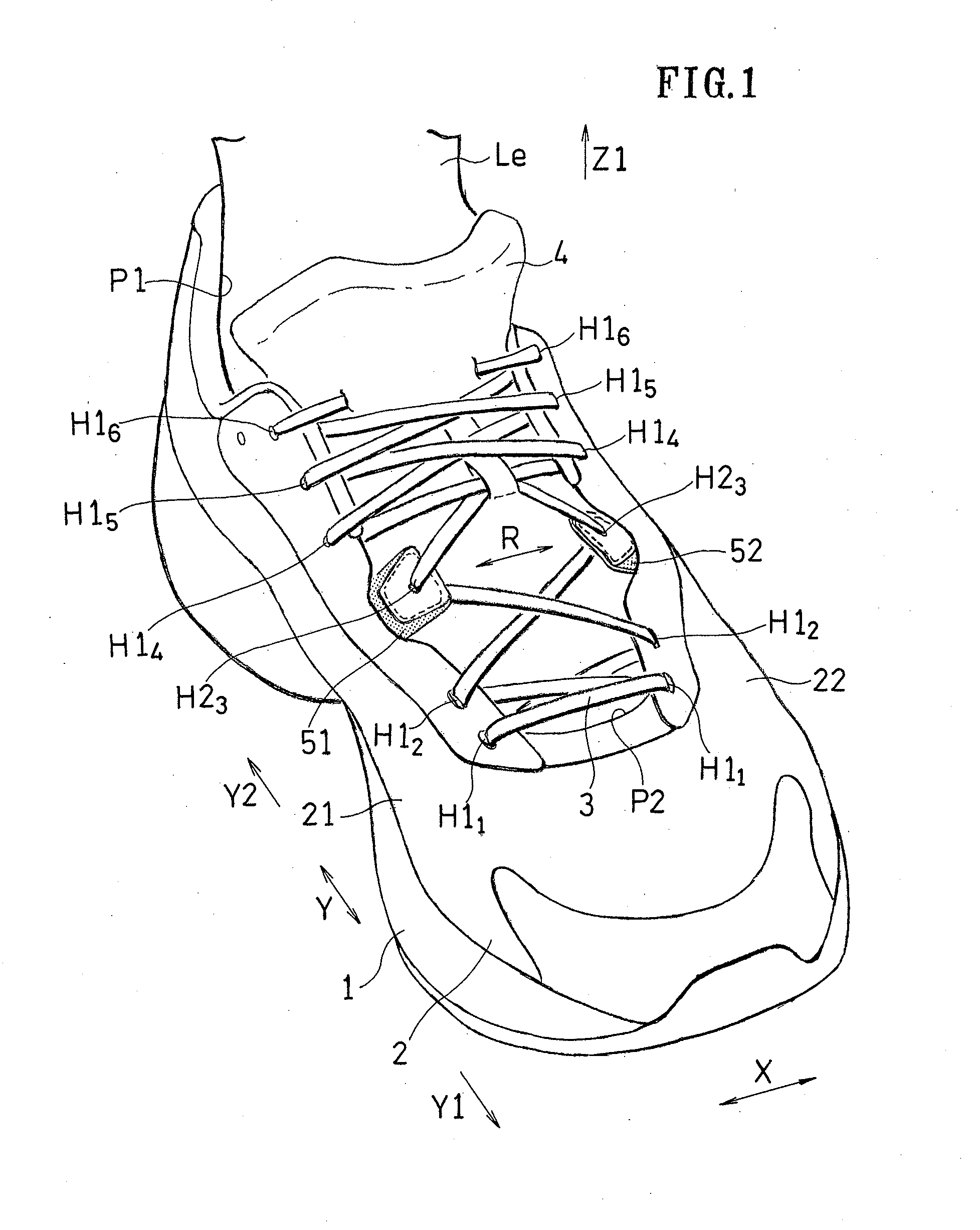

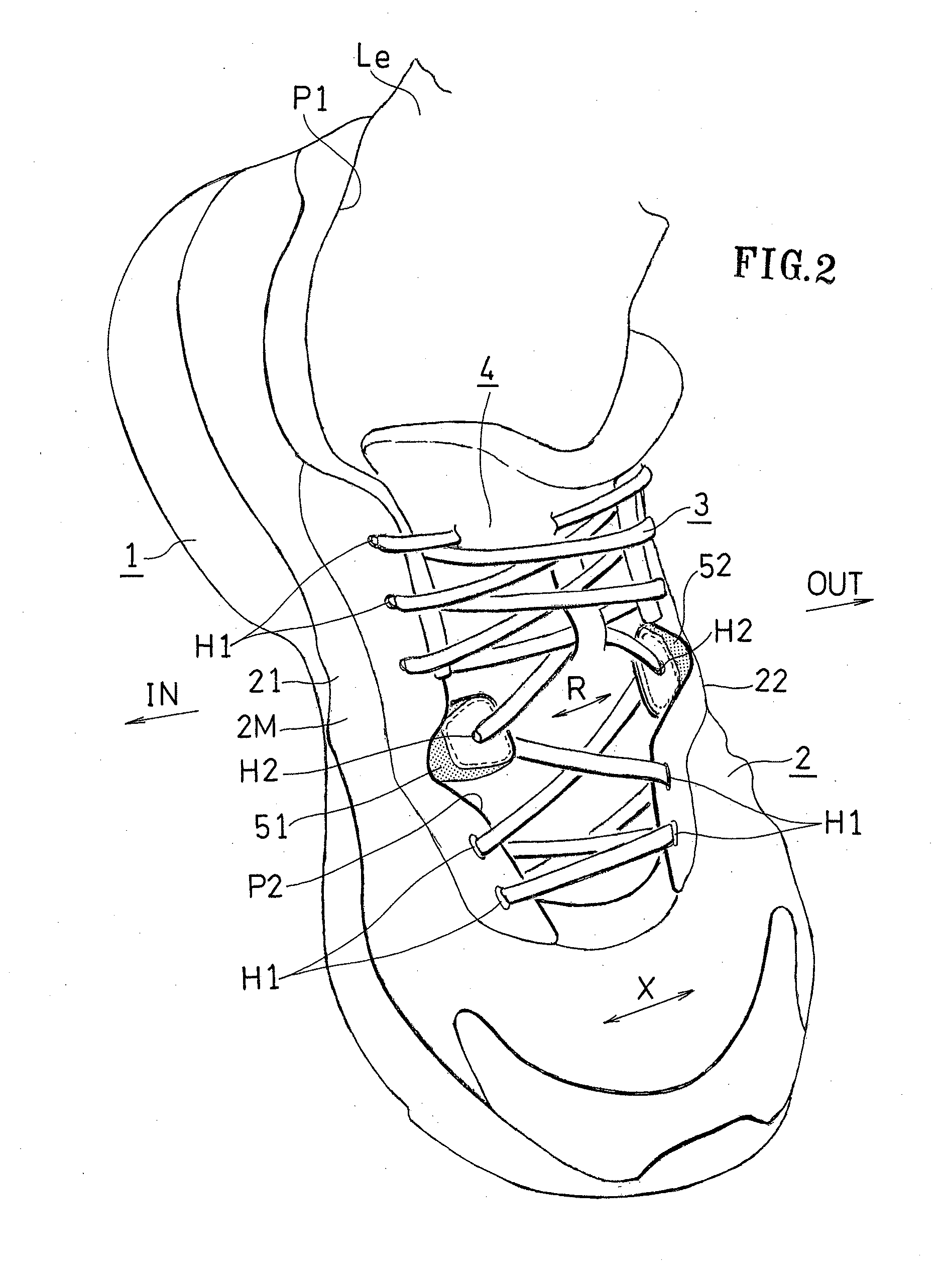

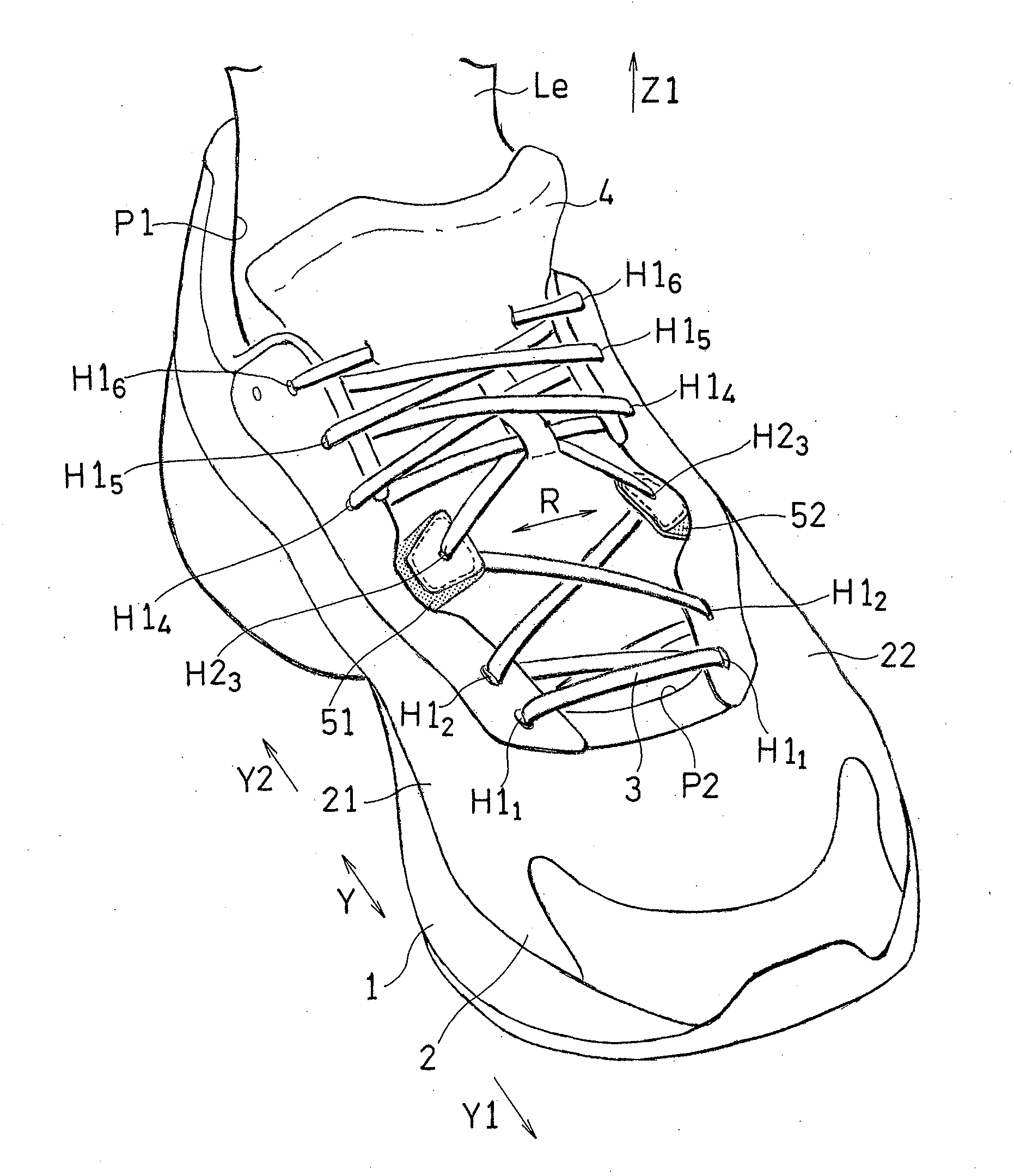

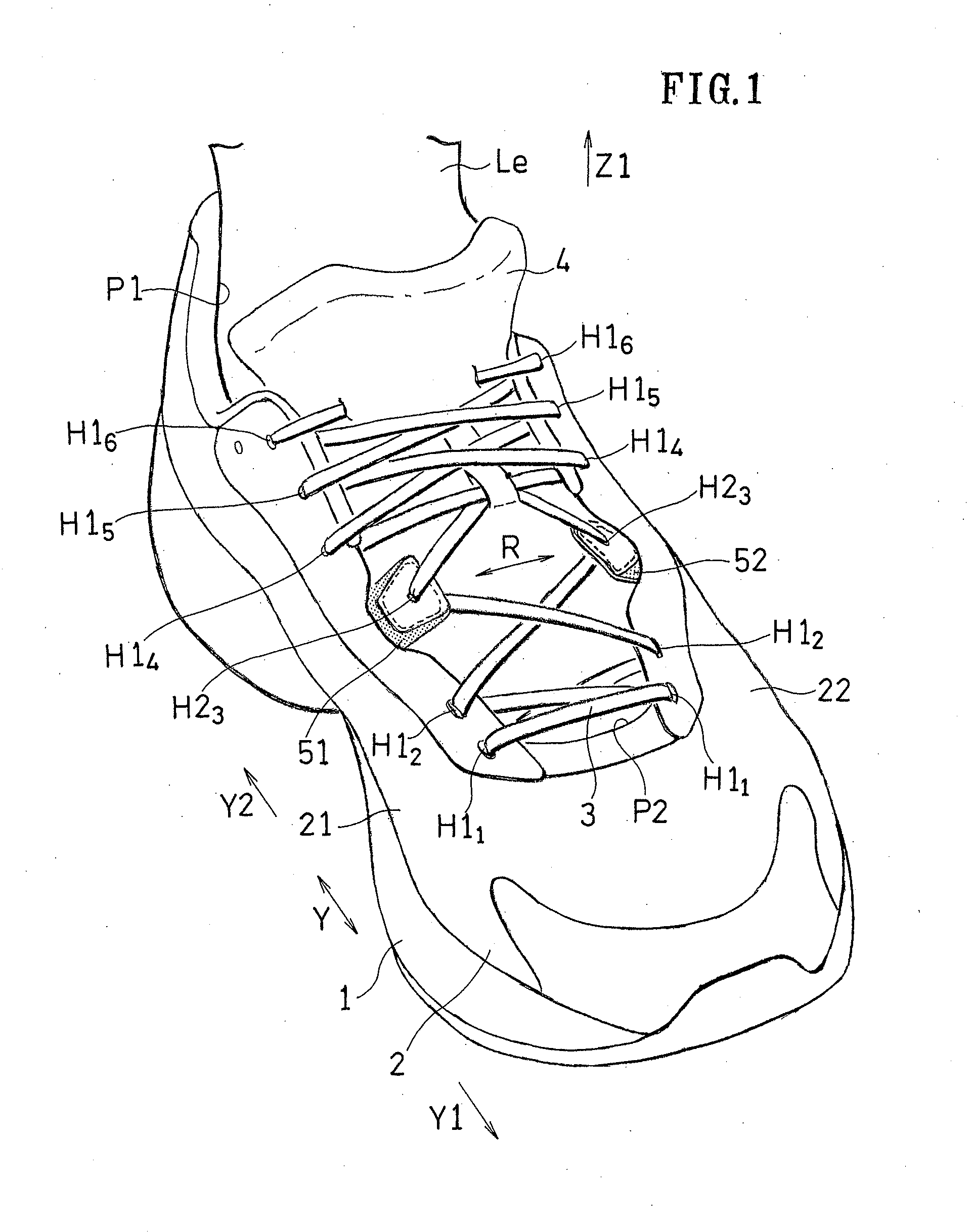

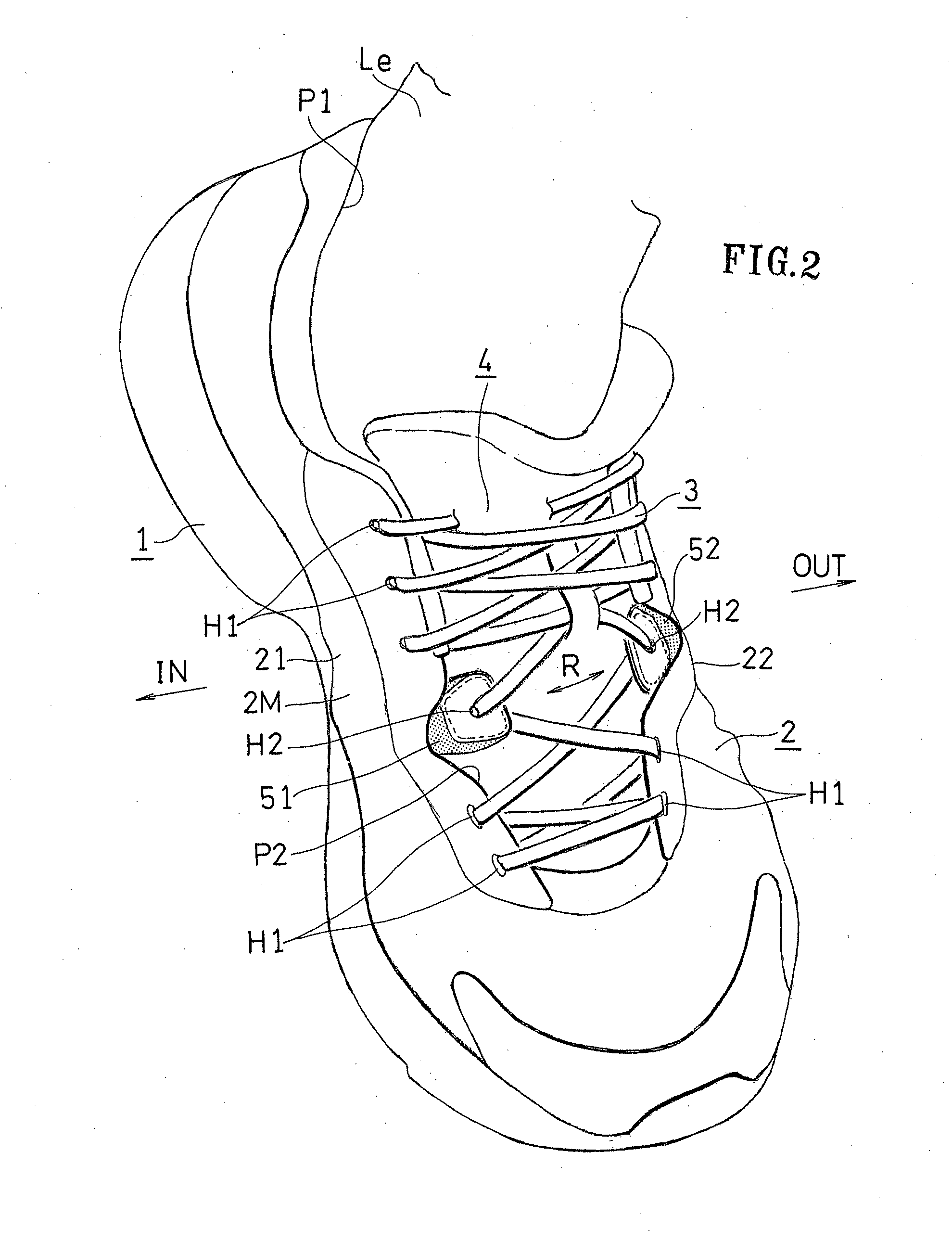

Shoe having lace fitting structure

A shoe having a sole, an upper including a first opening and a second opening, and shoelace means, the upper including: a first side edge portion having a plurality of first eyelets; a second side edge portion arranged between the plurality of first eyelets and having one or more second eyelets which the shoelace means engages with; a movable portion for allowing the second eyelet to move with respect to the first eyelets both in a transverse direction across the second opening and a diagonal front-back direction that is perpendicular to the transverse direction and is extending along the instep; and a main portion covering a medial side surface, a lateral side surface, a toe, the instep and a back surface of a foot, the main portion including the first side edge portion and excluding the second side edge portion and the movable portion; the second eyelet is relatively displaced via the movable portion with respect to the main portion both in the transverse direction and the diagonal front-back direction in response to a change in a direction of a resultant force between a first tensile force and a second tensile force acting upon the second side edge portion from a V-shaped portion of the shoelace means engaging with the second eyelet while transitioning from a flat-footed position to a heel-raised position.

Owner:ASICS CORP

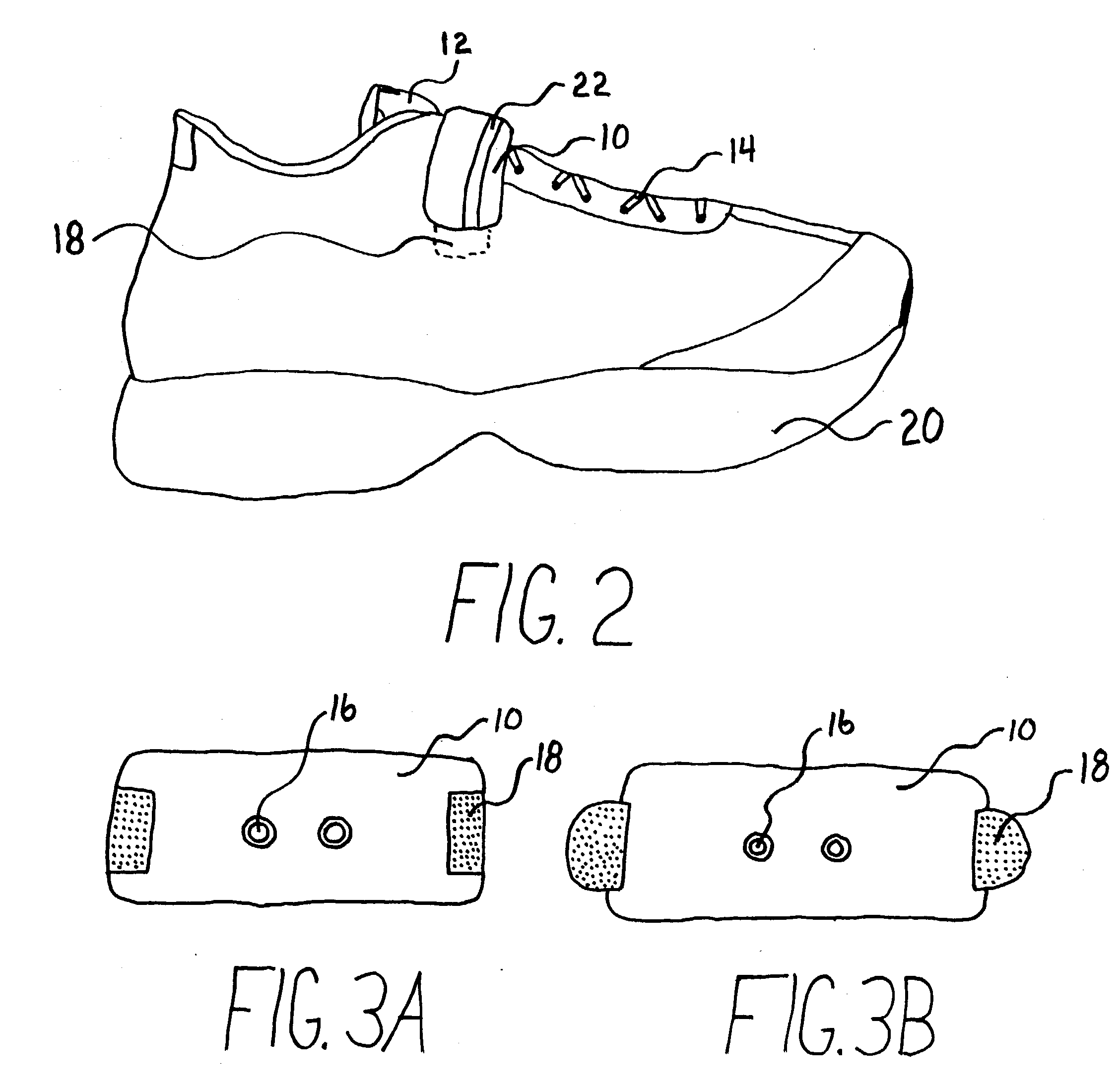

Shoe tongue positioner

An assembly for use in connection with lace-type shoes to secure the tongues of such shoes in a stationary position, and to provide a base or foundation for mounting of ornamental displays on the upper surface of shoe tongues. A rigid upper member having one or more bores is attached to the upper surface of a shoe tongue using tacks which are pushed through the shoe tongue and received within such bores. Shoelaces are wrapped around the rigid upper member and thereafter secured. The rigid upper member provides a base or foundation for attaching easily interchangeable ornamental designs.

Owner:BAR OREN

Guides and components for closure systems and methods therefor

ActiveUS9700101B2Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

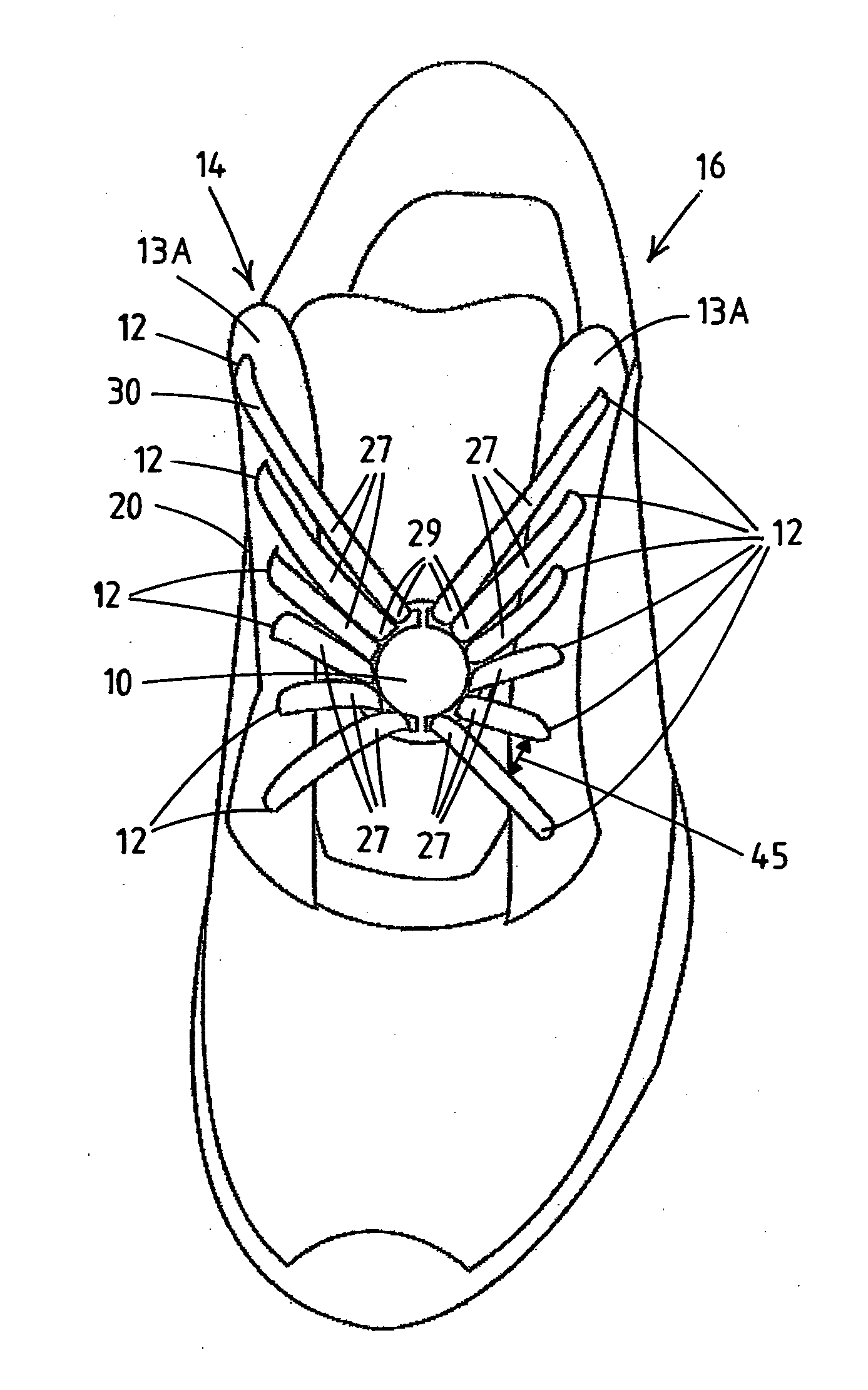

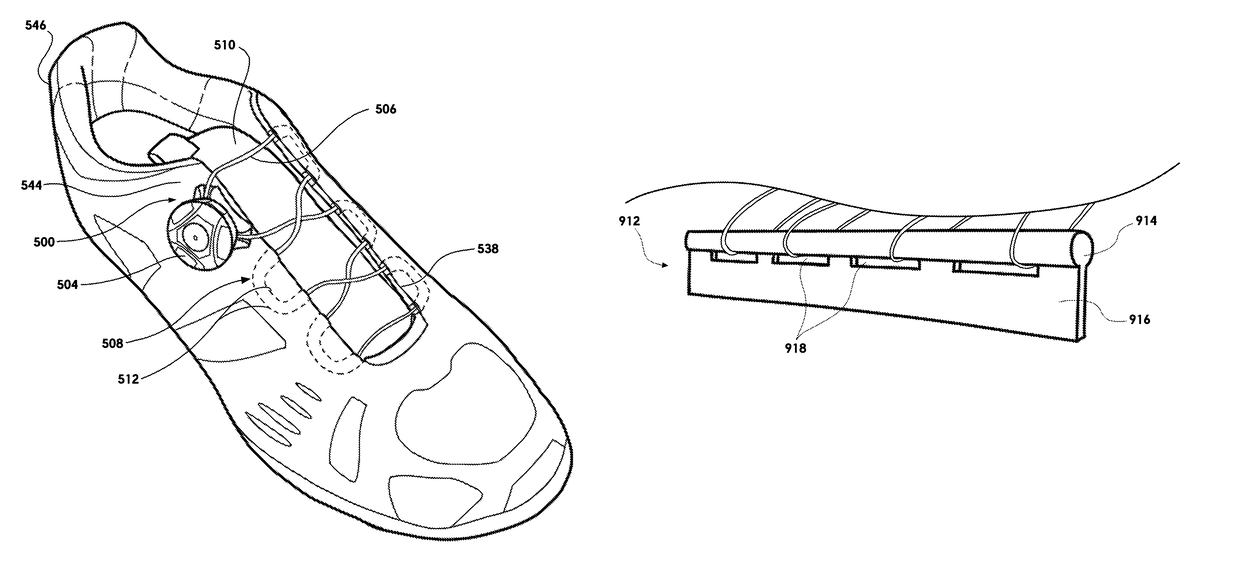

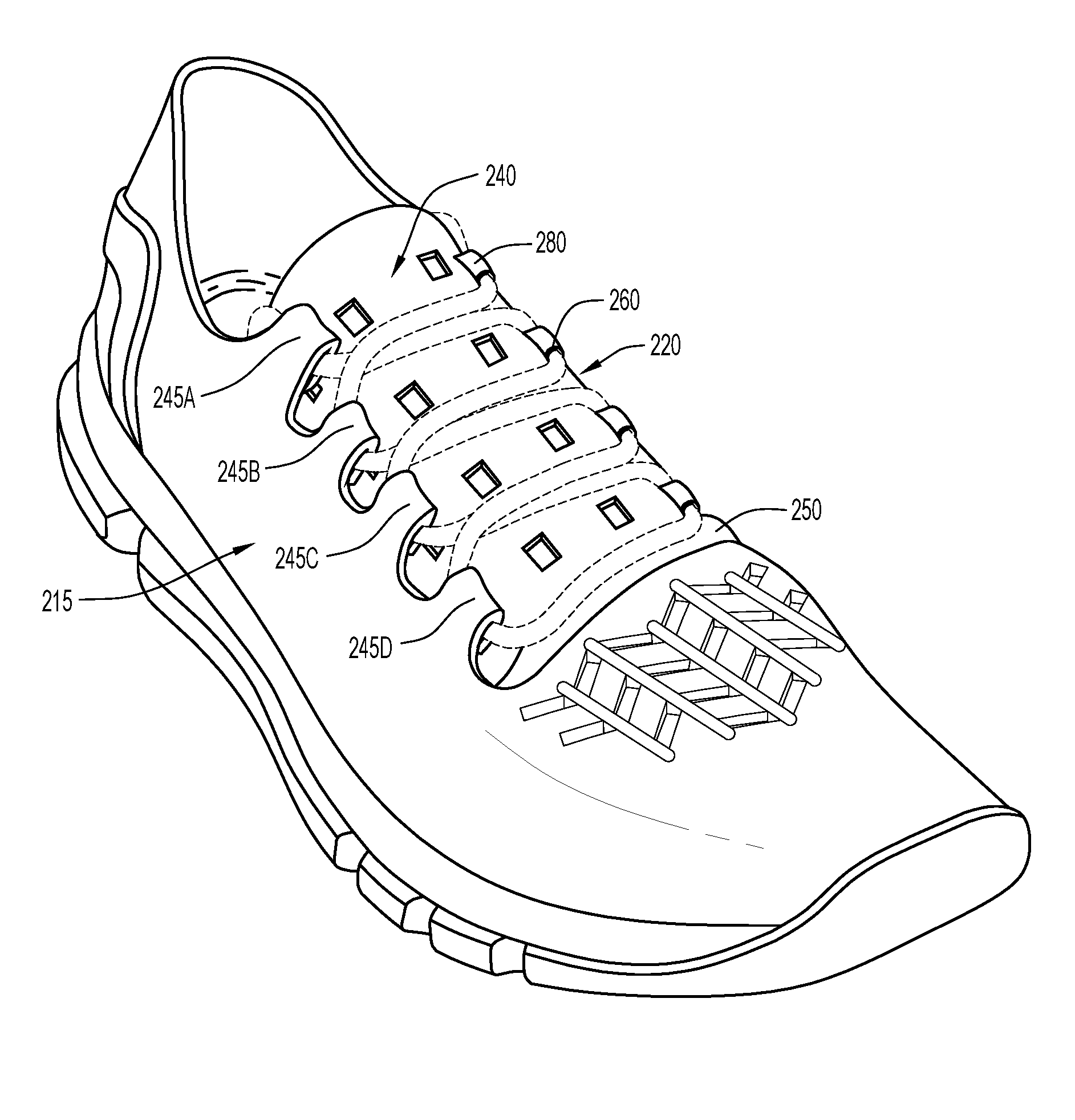

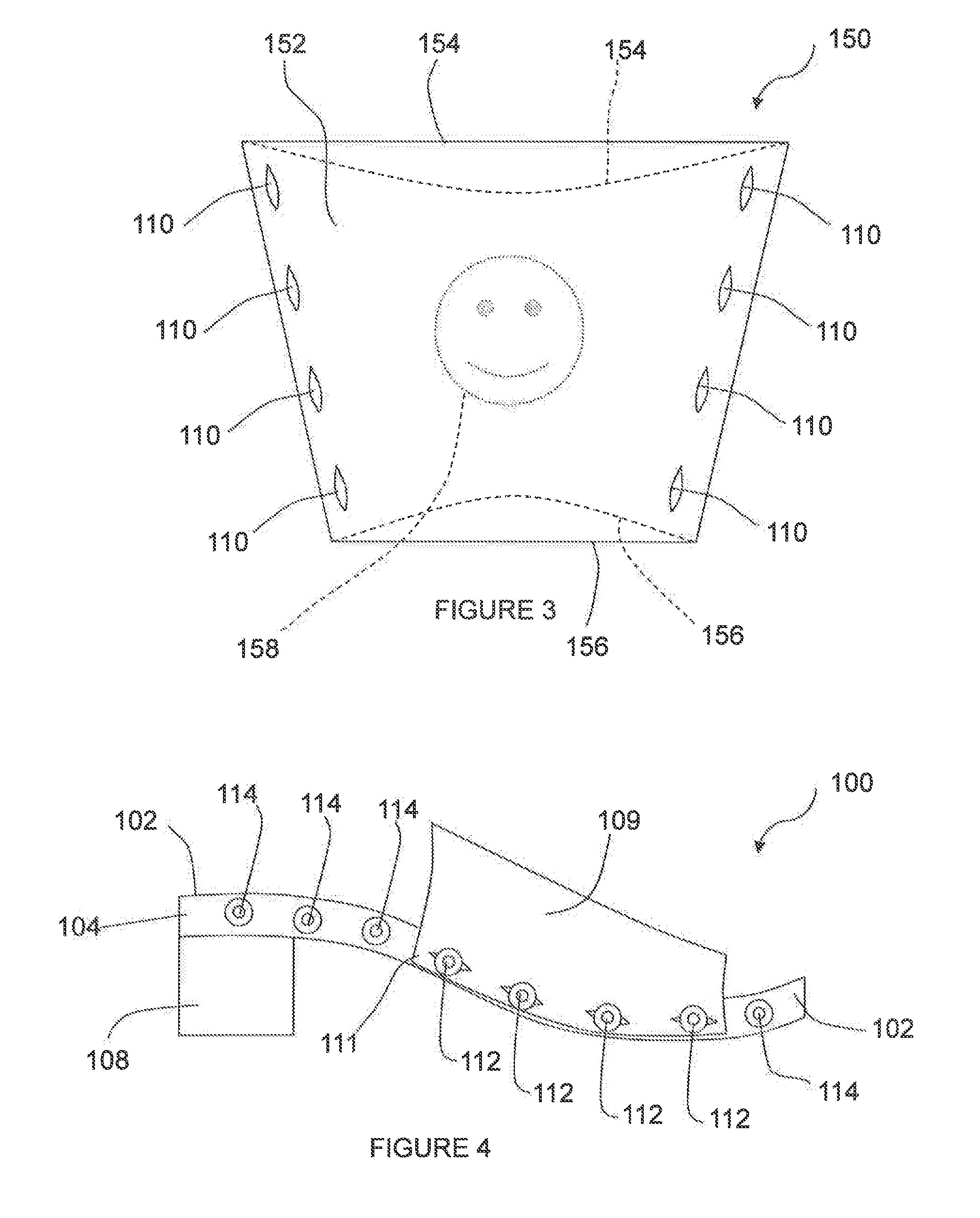

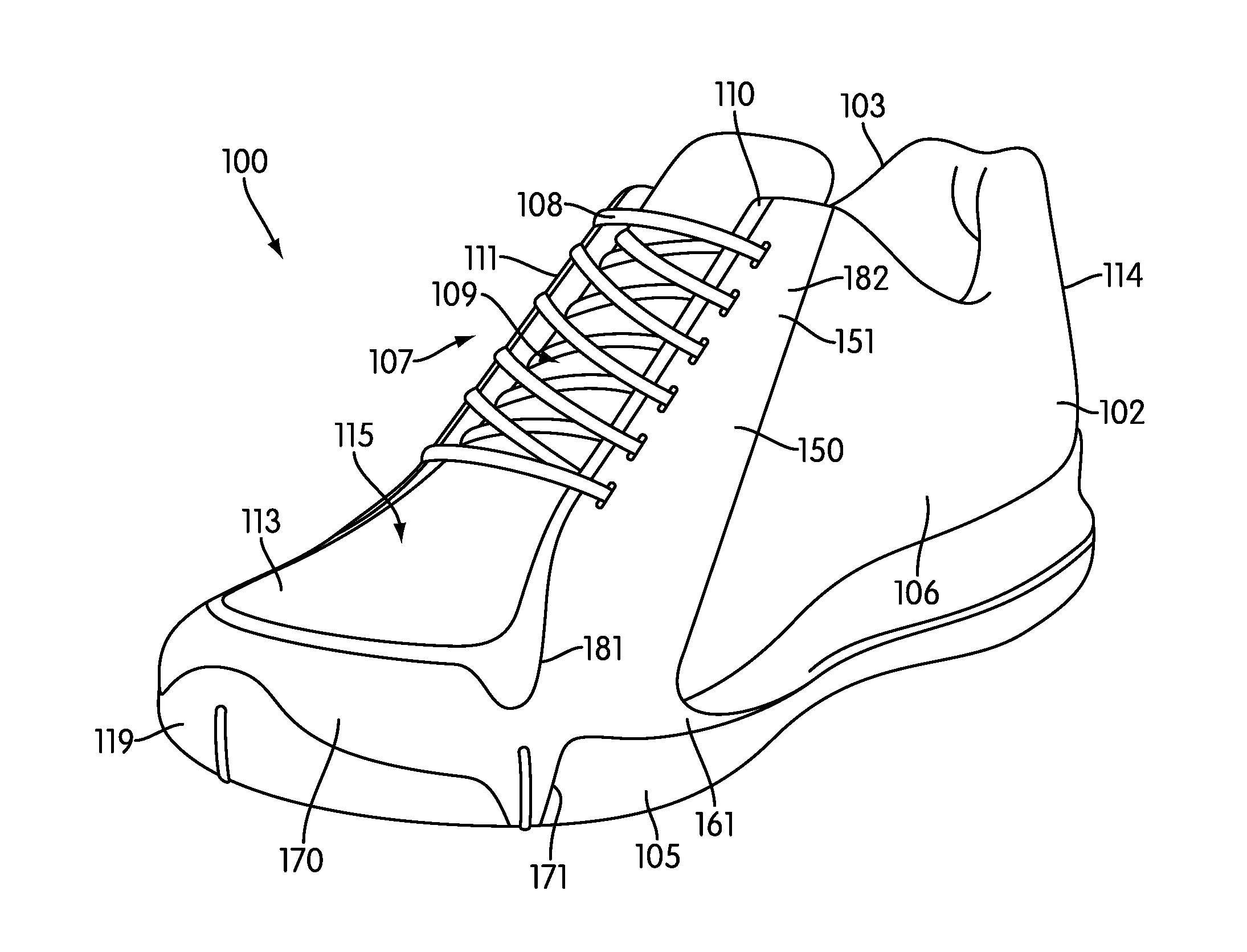

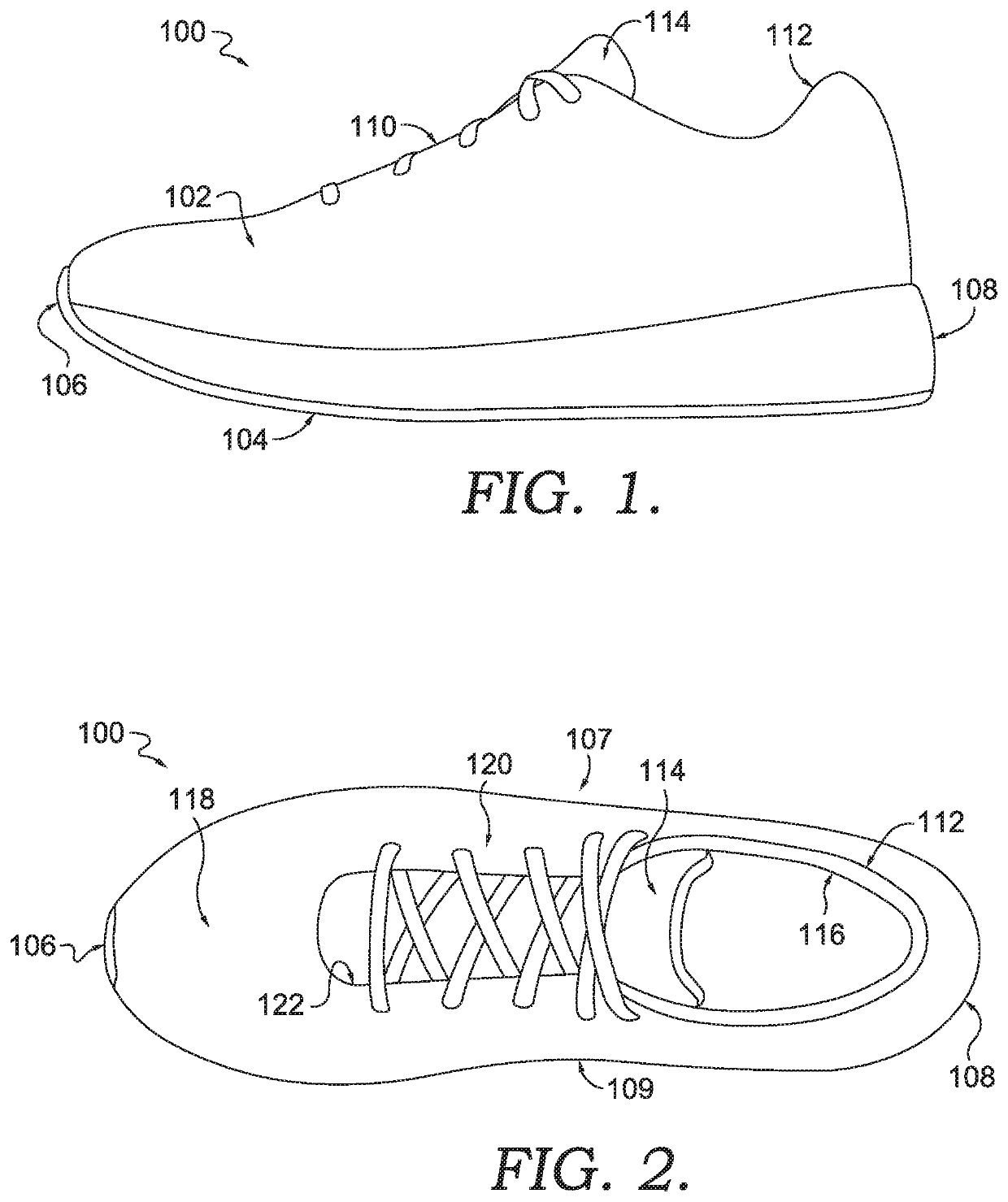

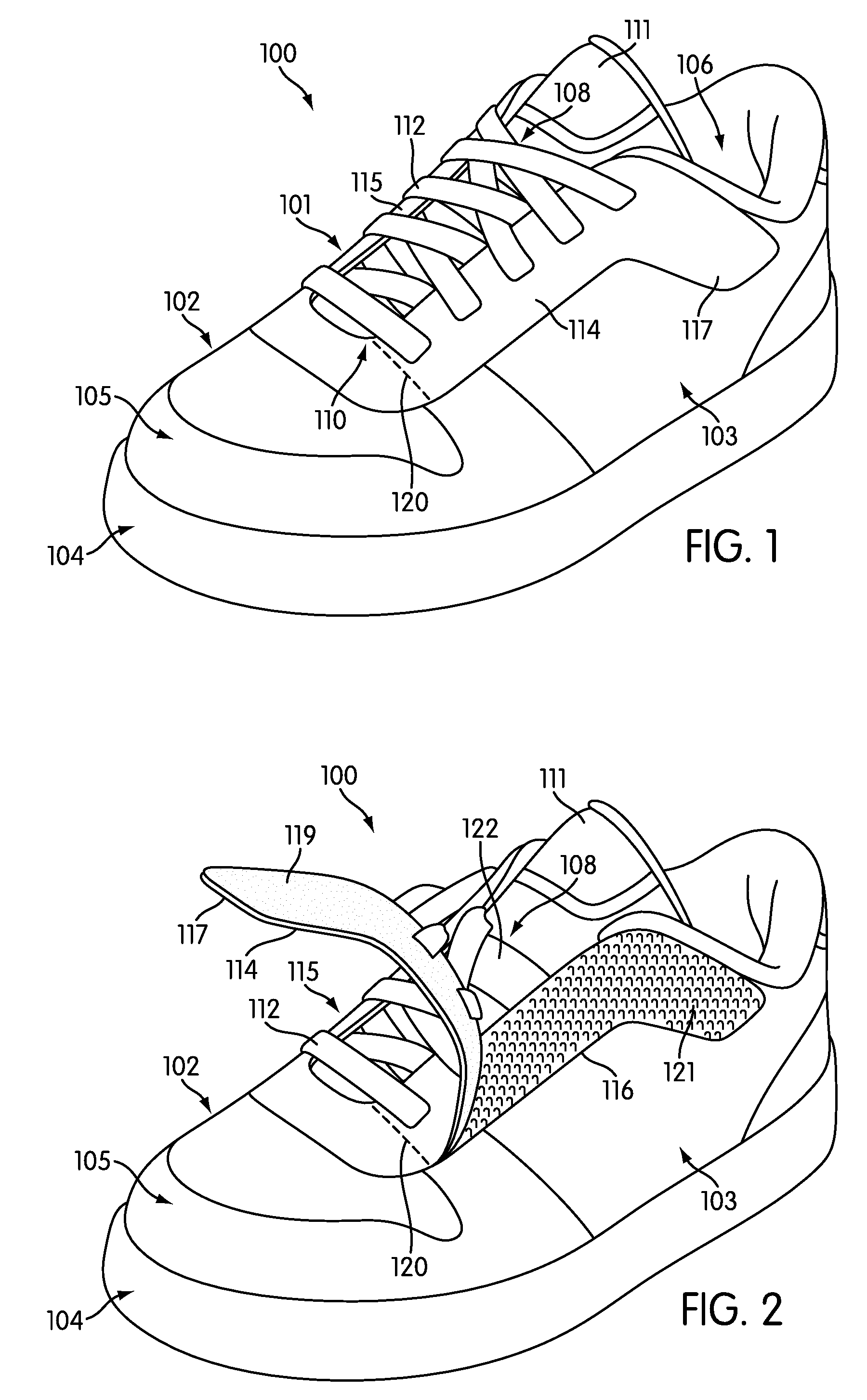

Footwear Including an Adaptable and Adjustable Lacing System

An article of footwear includes an upper and an adjustable lacing system. The adjustable lacing system includes a plurality of fastener engaging elements located at the medial and lateral sides of the upper, where at least one of the medial side and the lateral side includes sets of fastener engaging elements. Each set of fastener engaging elements is distanced from another set in a direction transverse a lengthwise direction of the upper, and the fastener engaging elements are configured to engage with and retain a fastener structure that extends between the medial and lateral sides of the upper such that the fastener structure can be selectively engaged with different sets of fastener engaging elements to adjust a fit of the upper around a width of the foot disposed within the cavity.

Owner:UNDER ARMOUR

Slip on athleisure shoe

Owner:CONVERSE

Shoelace replacement system and method

InactiveUS20100325849A1Easily or casually withdrawn from the eyeletEasy to openEyeletsShoe lace fasteningsEngineering

Owner:CLAYTON JULIAN

Shoes with interchangeable and inter-zippable tops

A shoe with reversible and moveable tops is presented and includes fasteners, such as snaps or zippers, positioned all around the base of the shoe in order for the top half of the shoe to be changed. The tops are made of various materials and different styles, There can be full-covered footwear, sandal-type or any type of strapped shoe for women or men. Alternative embodiments comprise a sole, an upper, a leg shaft, a leg shaft extension, and a finishing collar that may be combined to create a distinctive shoe. The leg shaft and the leg shaft extension may have laces or vertical zippers to provide a better fit for the user. The finishing collar, leg shaft, and leg shaft extension are configured to provide a protective layer between zippers and a user's skin.

Owner:STILLWAGON ELIZABETH

Slip on athleisure shoe

Owner:CONVERSE

Fastener for lace

A fastener for lace includes an upper plate, a lower plate and first, second, third and fourth rods extending between the upper and lower plates. The upper and lower plates both include a front edge, a rear edge, a first lateral edge and a second lateral edge. The first and second rods extend between the first lateral edge of the upper plate and the first lateral edge of the lower plate. The third and fourth rods extend between the second lateral edge of the upper plate and the second lateral edge of the lower plate. A first length of lace is wound about the first rod and directed past the second rod. A second length of lace is wound about the third rod and directed past the fourth rod.

Owner:LIN WEN CHI

Article of footwear with arch wrap

An article of footwear with an arch wrap is disclosed. The arch wrap is configured to provide support to a midfoot. The arch wrap can include a plurality of eyelets that are configured to receive a lace of a lacing system of the upper.

Owner:NIKE INC

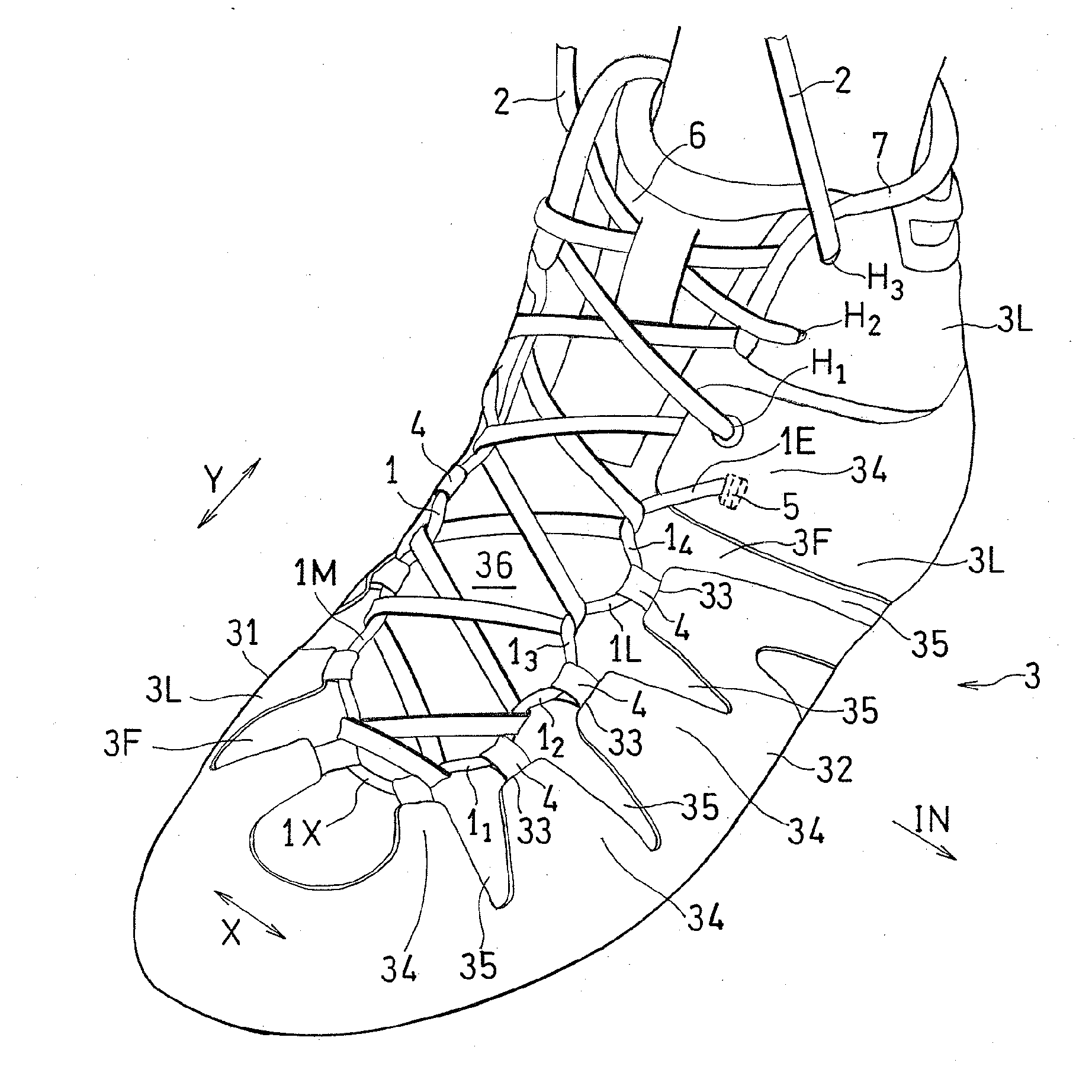

Lace Fitting Structure

ActiveUS20150026937A1Uniform pressureAvoiding local tighteningEyeletsShoe lace fasteningsMedial sideLittle toes

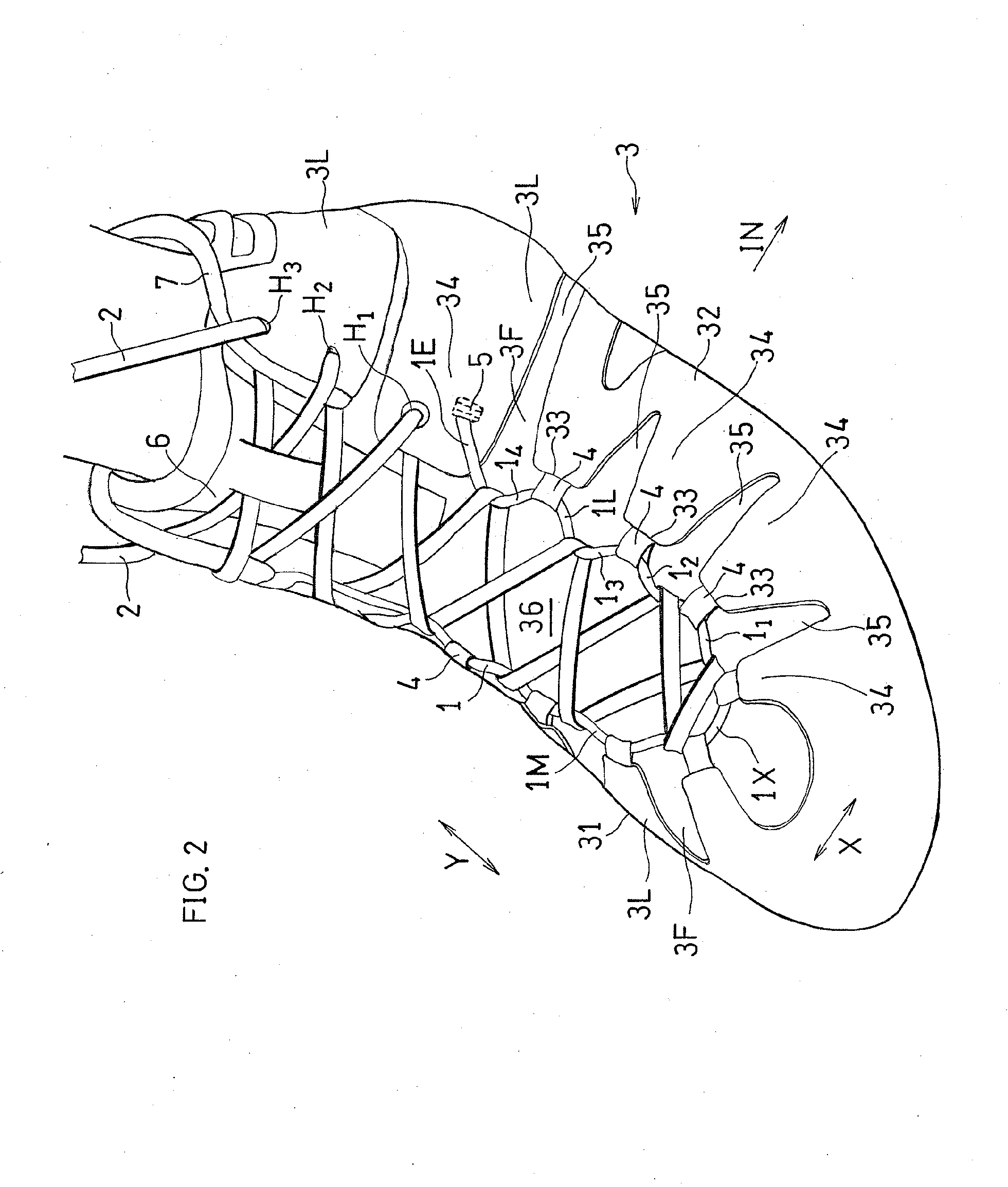

A lace fitting structure for fitting an upper 3 wrapping around an instep of a foot to the instep, the structure including: a medial side portion 31 covering the instep and a medial side surface of a big toe; a lateral side portion 32 covering the instep and a lateral side surface of a little toe; first shoelace means 1 placed to extend in a longitudinal direction Y of the foot and engaged with the medial side portion 31 and the lateral side portion 32 along central edge portions 33 of the medial side portion 31 and the lateral side portion 32; placement means for placing a portion of the first shoelace means 1 so that the first shoelace means 1 is exposed in a plurality of exposed areas 1i, which are separated from one another in the longitudinal direction Y; and second shoelace means 2 engaging, in a transverse direction X of the foot, with the first shoelace means 1 in the plurality of exposed areas 1i so as to bring the medial side portion 31 and the lateral side portion 32 closer to each other, wherein a length L of the exposed areas 1i in the longitudinal direction Y is greater than a thickness and a width of the second shoelace means 2.

Owner:ASICS CORP

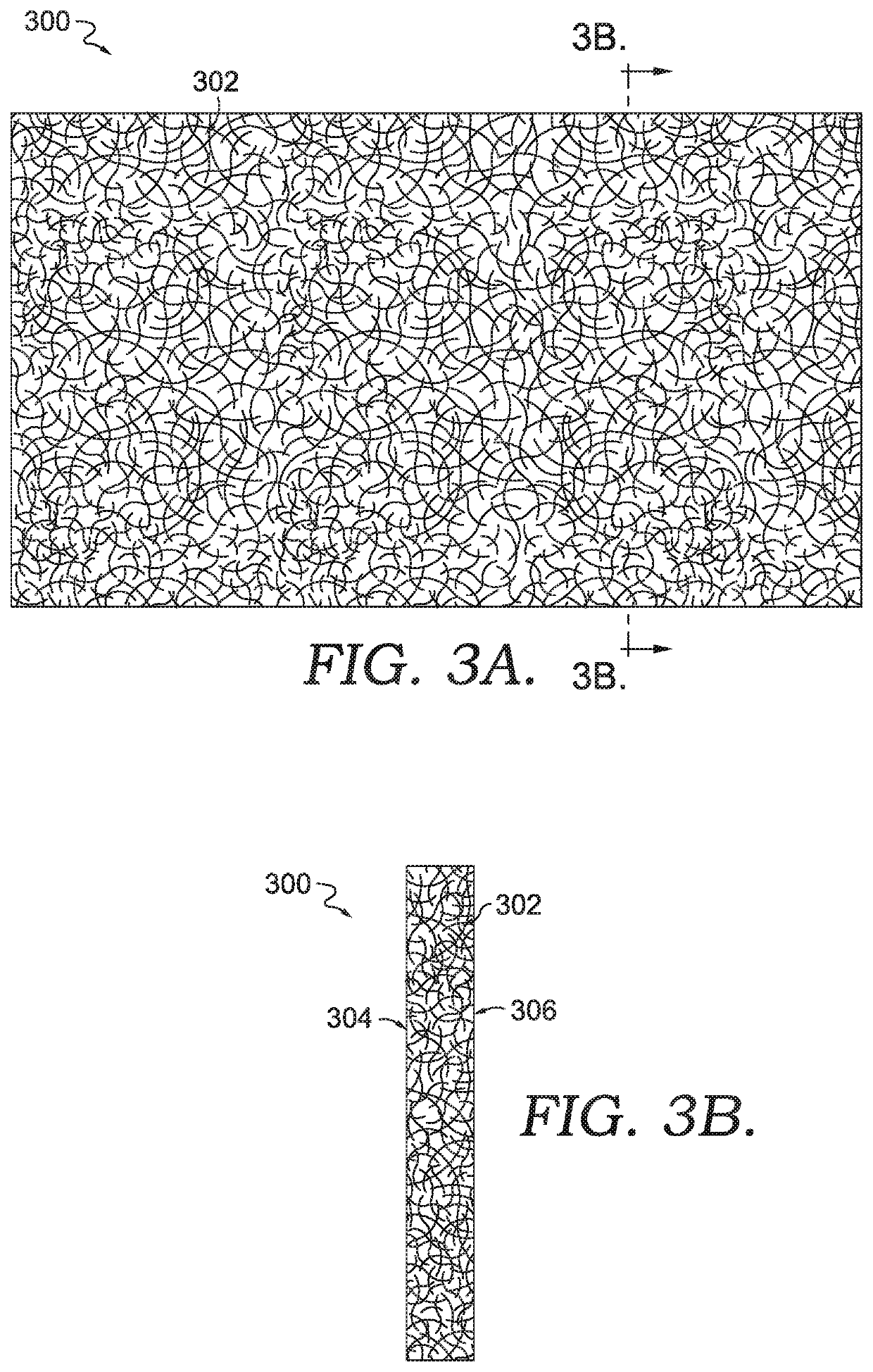

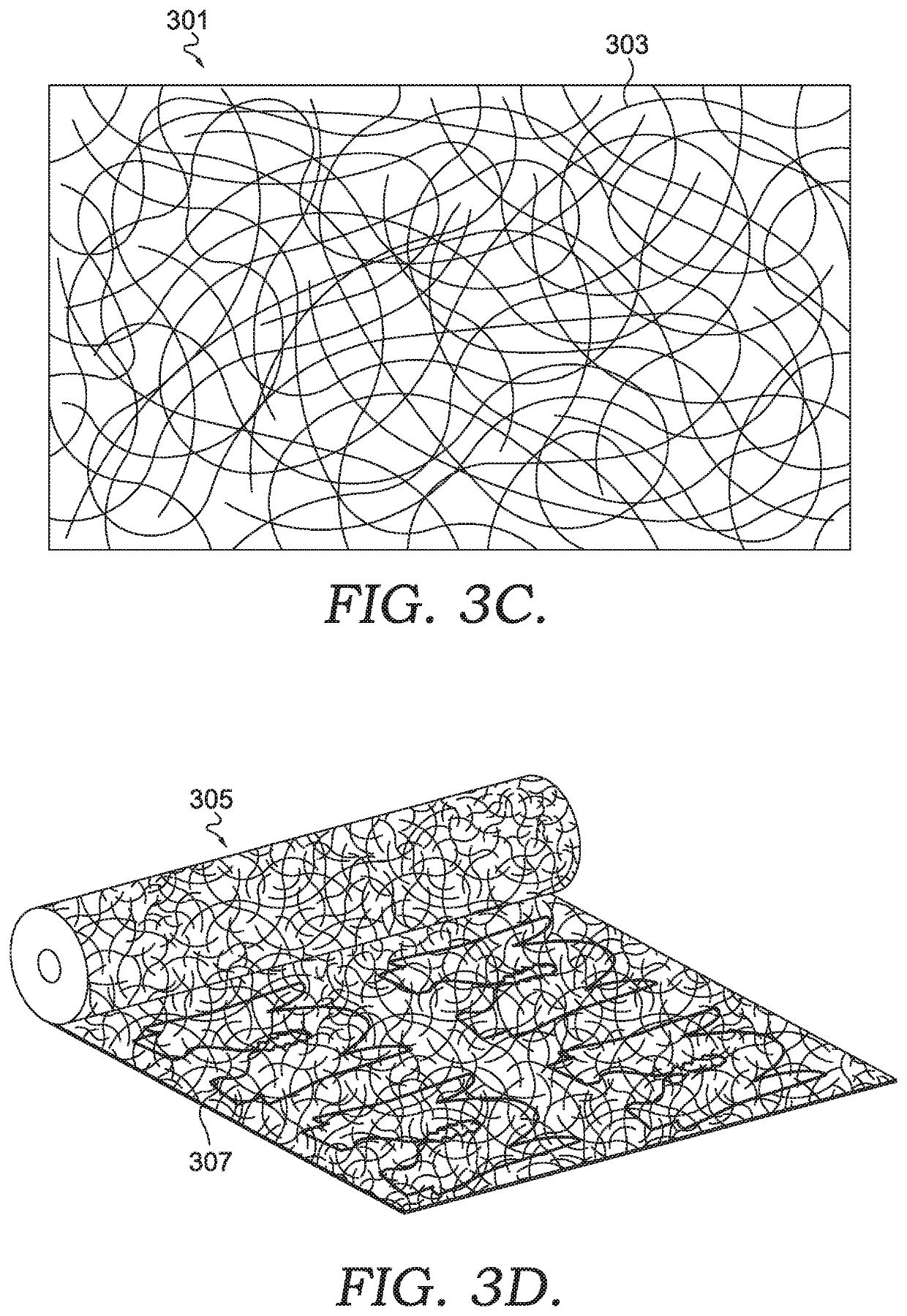

Fiber-Bound Engineered Materials Formed Using Engineered Scrims

A fiber bound engineered material is provided that imparts an intended characteristic at an intended relative location. A fiber layer is entangled with additional fibers in a manner to create a non-uniform engineered material. The lack of uniformity of a fiber bound engineered material may be accomplished through manipulation of the fibers and / or through fiber binding a scrim. The fiber layer binds with additional fibers through entanglement such that a mechanical connection between the entangled fibers is provided. This entanglement allows the fibers to bind without supplemental adhesives, interlacing, or connections. Variations in the fibers and / or inclusion of scrim materials prior to entanglement allows for an intended characteristic (e.g., a functional characteristic) at an intended relative location (e.g., a position determined by an article to be formed therefrom).

Owner:NIKE INC

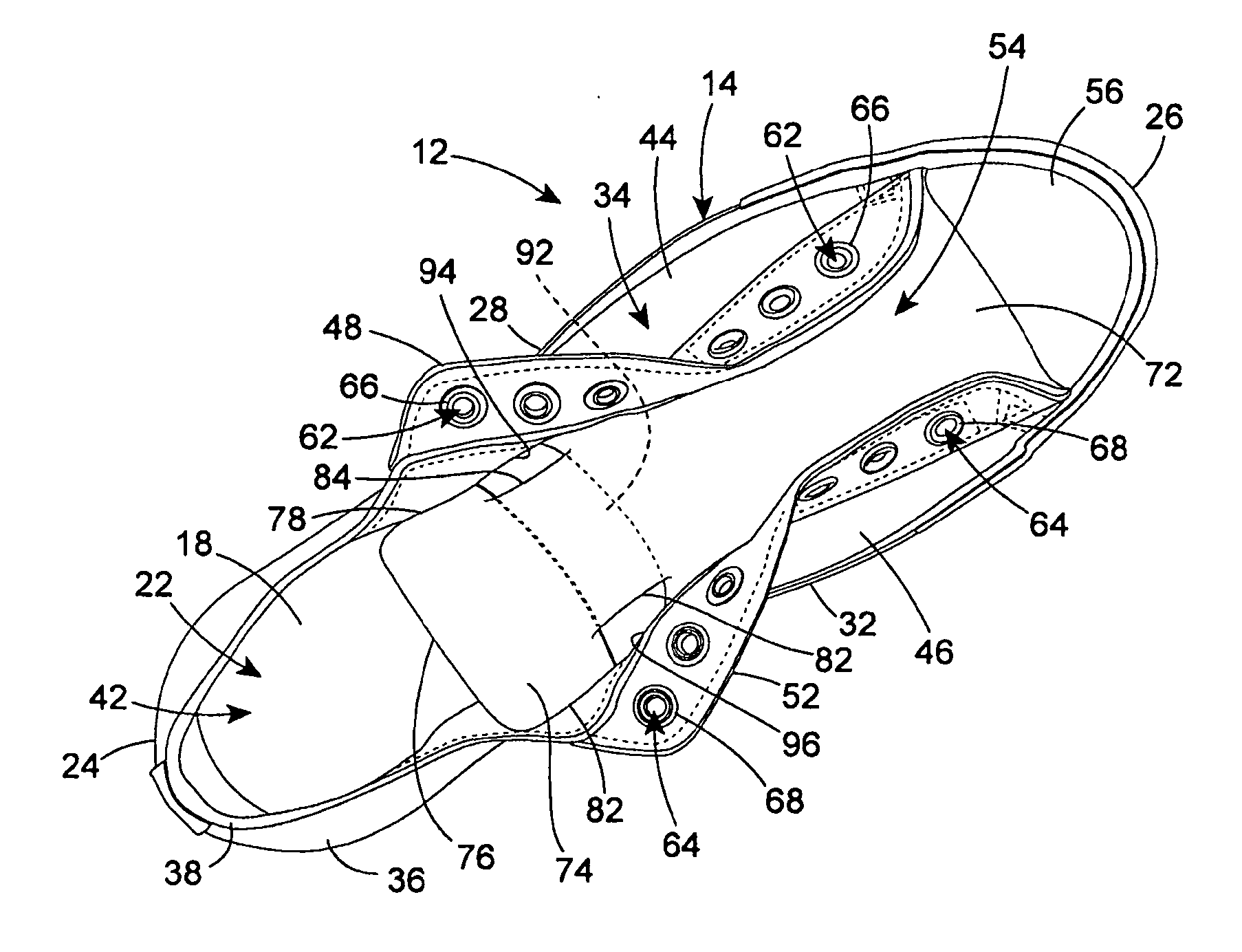

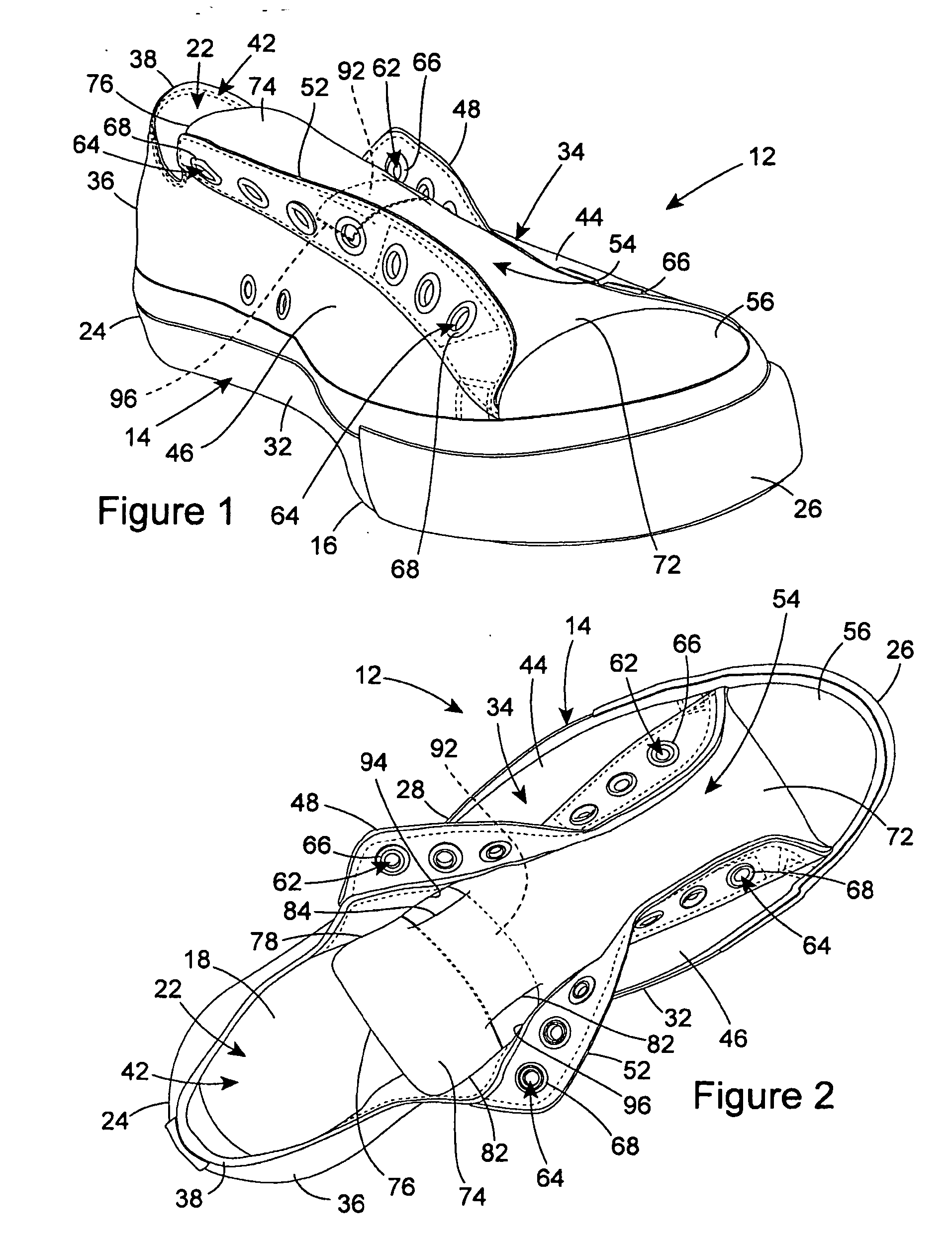

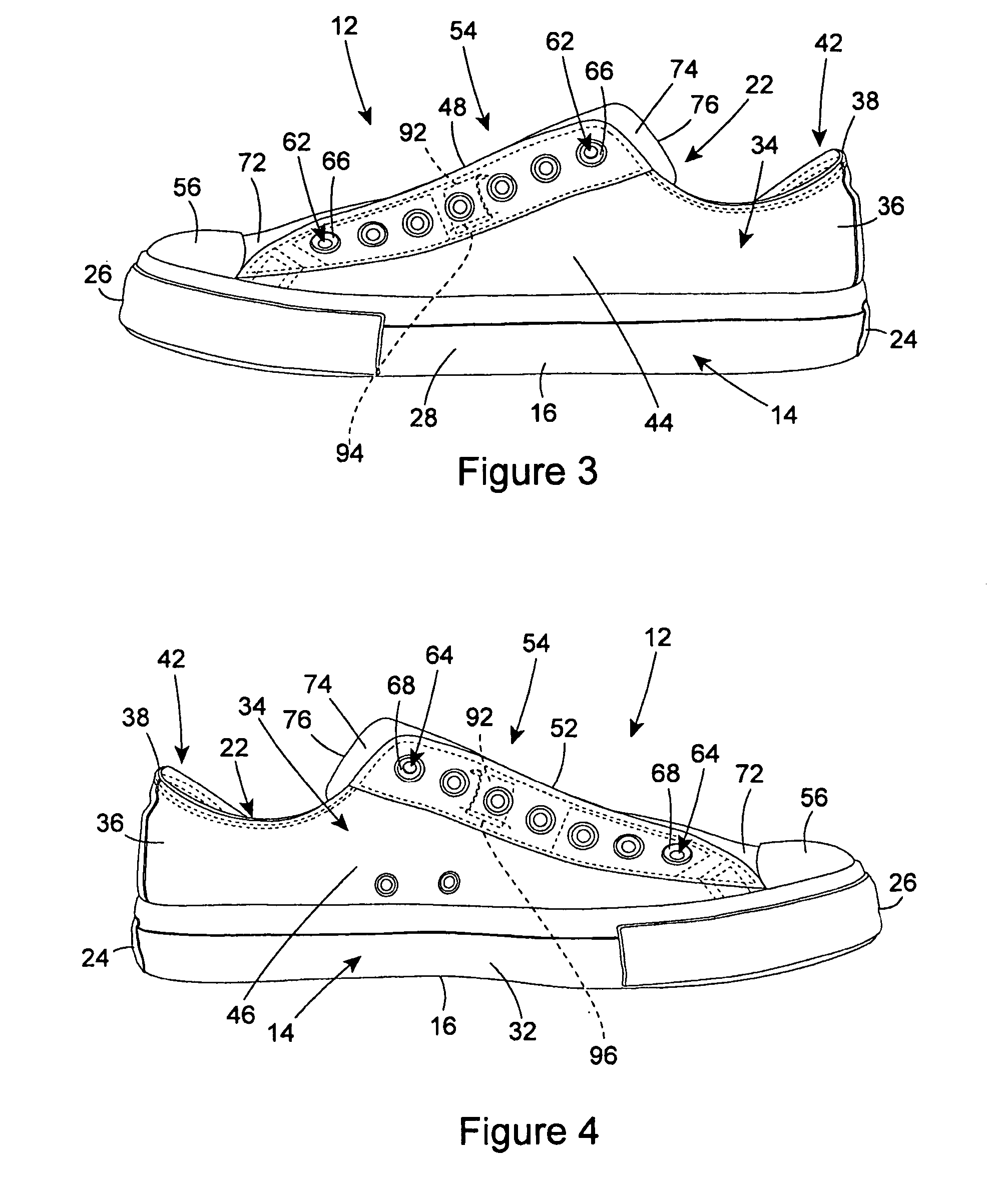

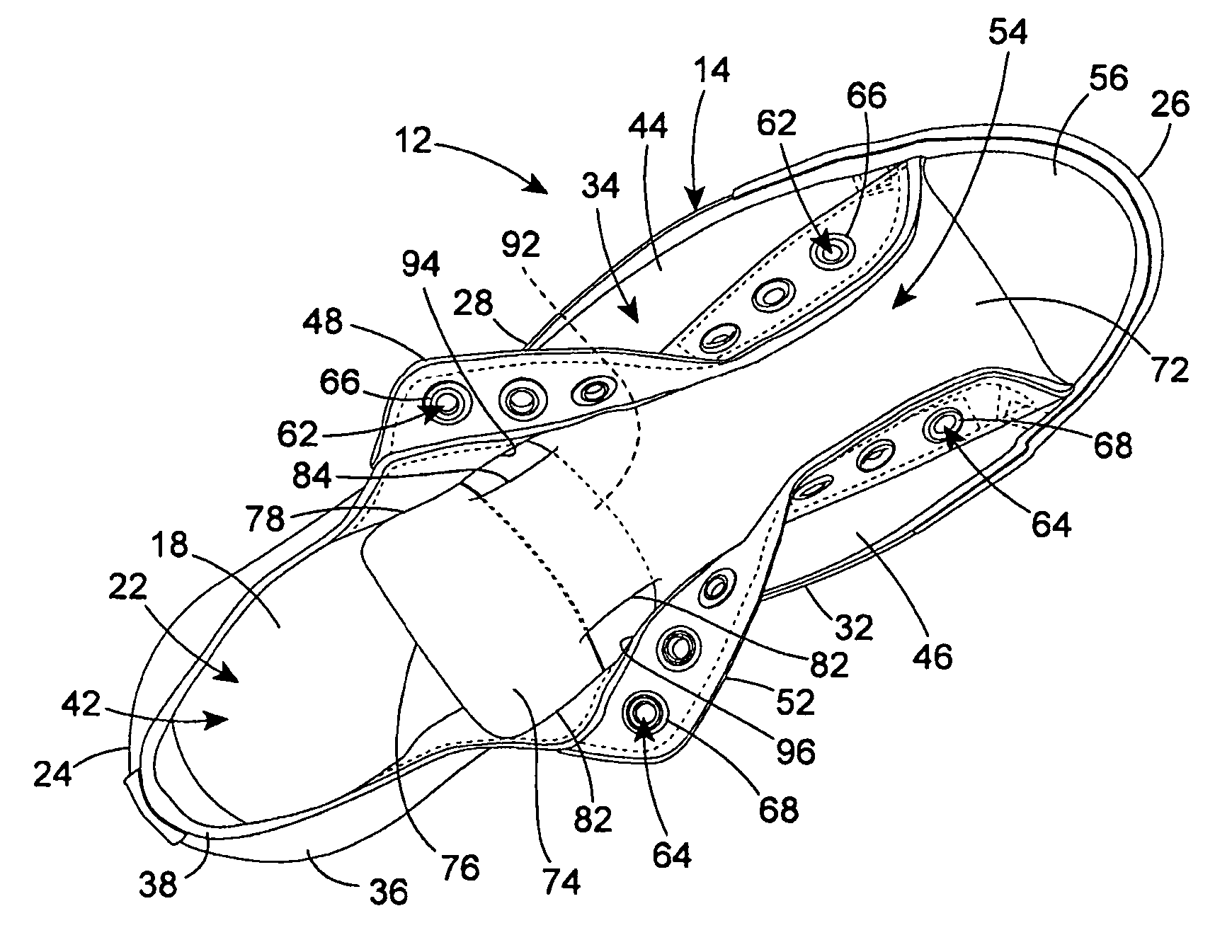

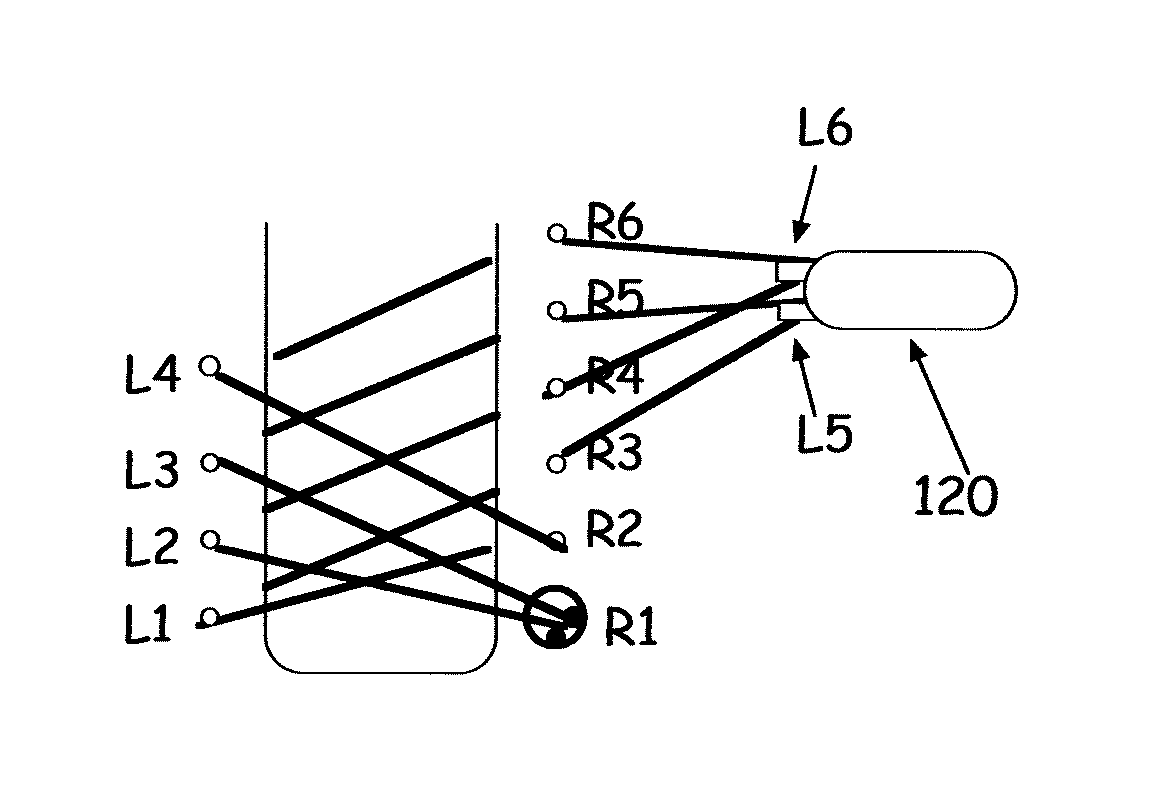

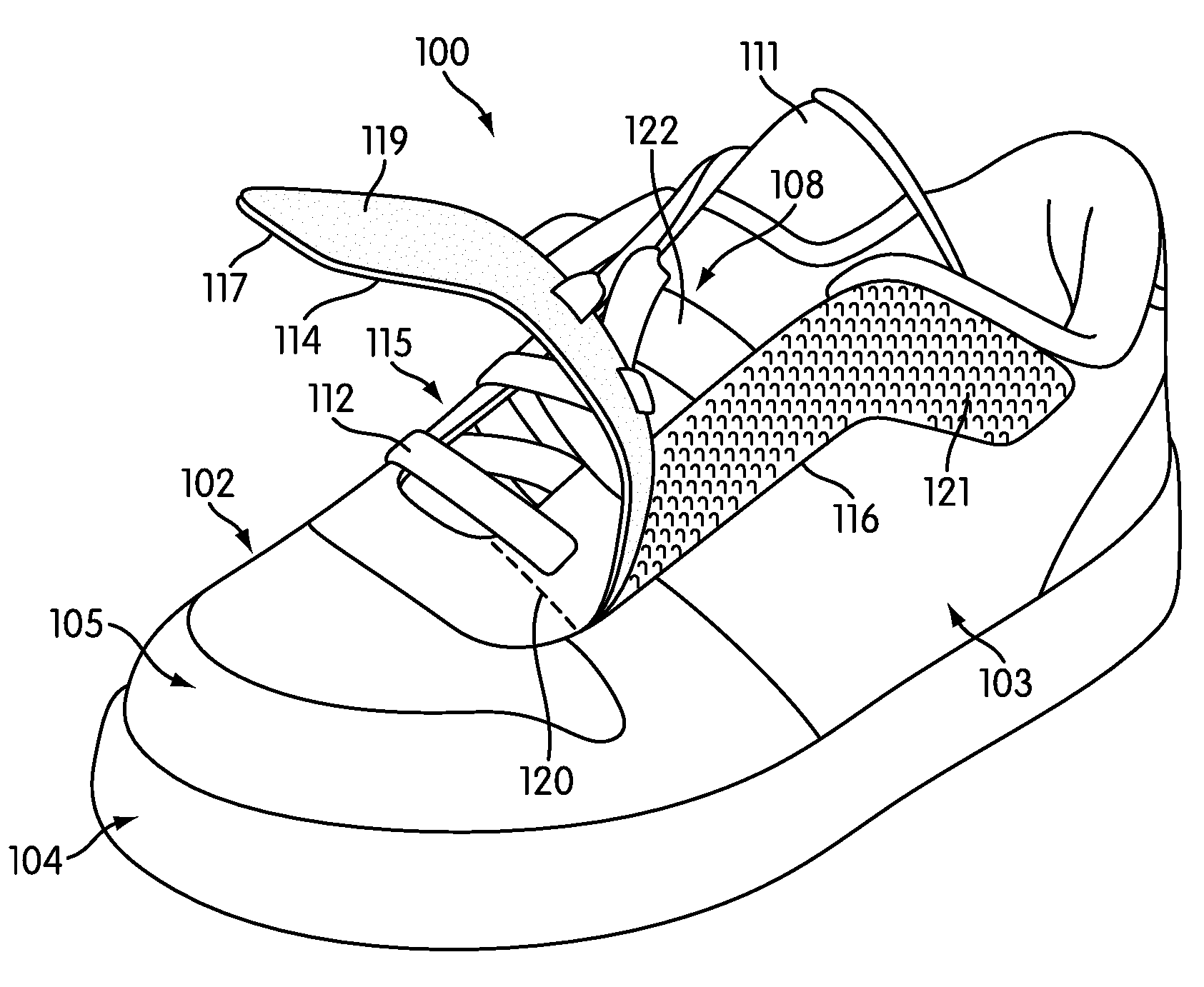

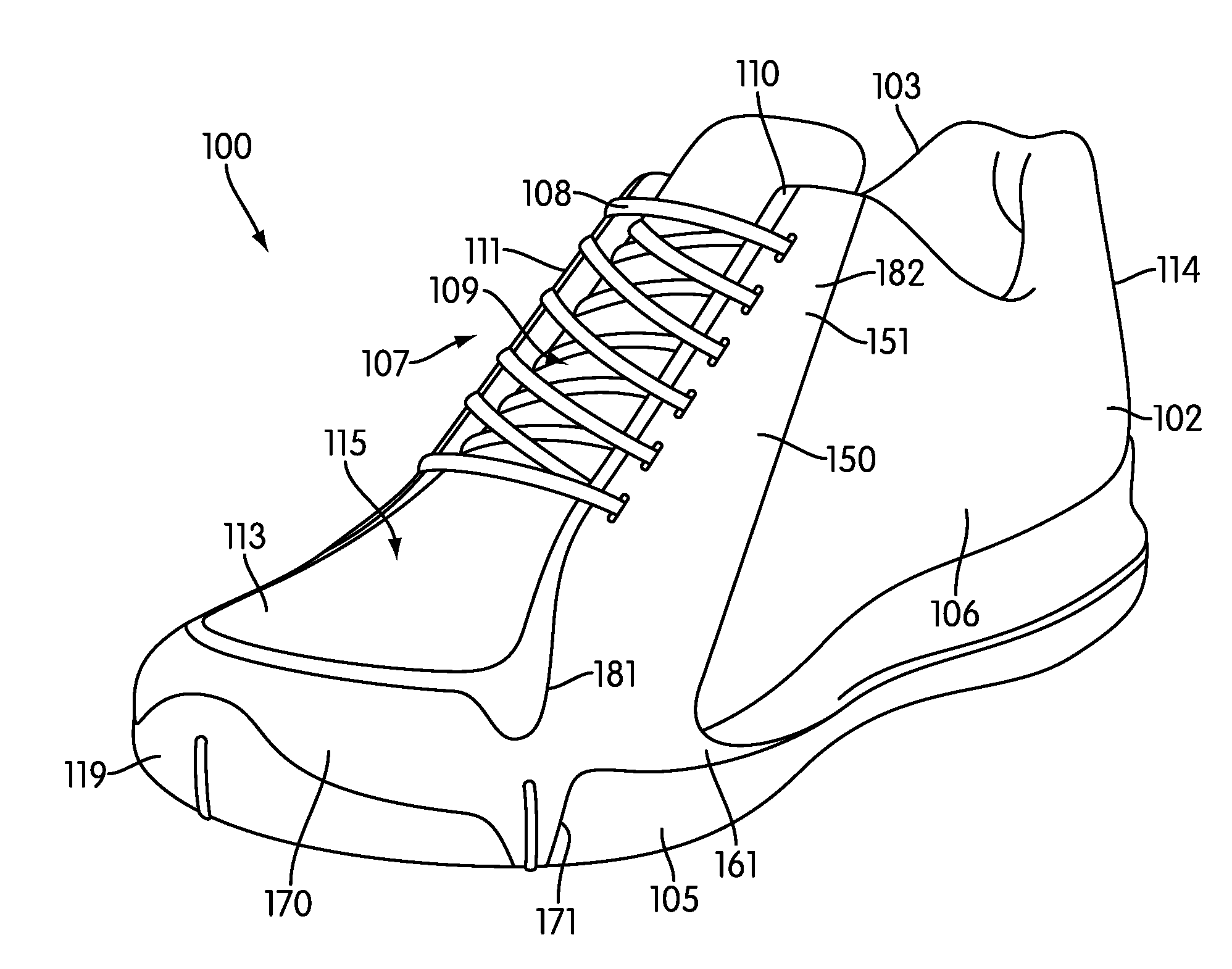

Article of footwear with reconfigurable fastening system

An article of footwear includes a sole, an upper, and a reconfigurable fastening system. The upper is coupled to the sole and includes medial and lateral quarters. Disposed on the medial and lateral quarters are a plurality of eyelets. Each of the eyelets includes a pair of openings disposed in the upper. The plurality of eyelets further includes at least one elongate member threaded through the pair of openings of each eyelet. The elongate member includes a series of first, or unexposed, portions that are disposed on an inner surface of the upper, and a series of second, or exposed, portions that are disposed on the outer surface of the upper. As fastener or lacing may be selectively threaded through an eyelet of the plurality of eyelets, where the fastener may be threaded between the second portion of the elongate member and the outer surface of the upper.

Owner:UNDER ARMOUR

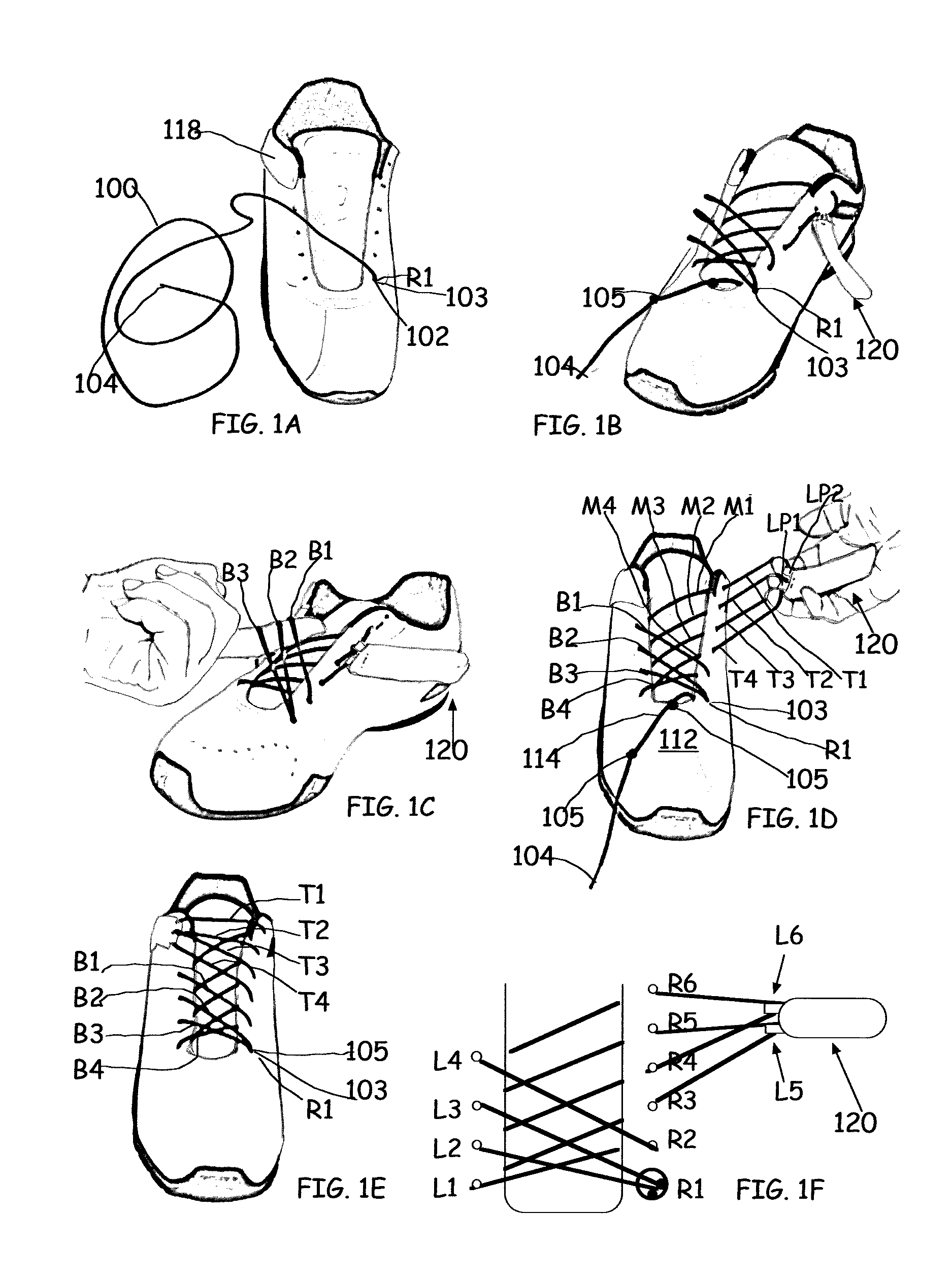

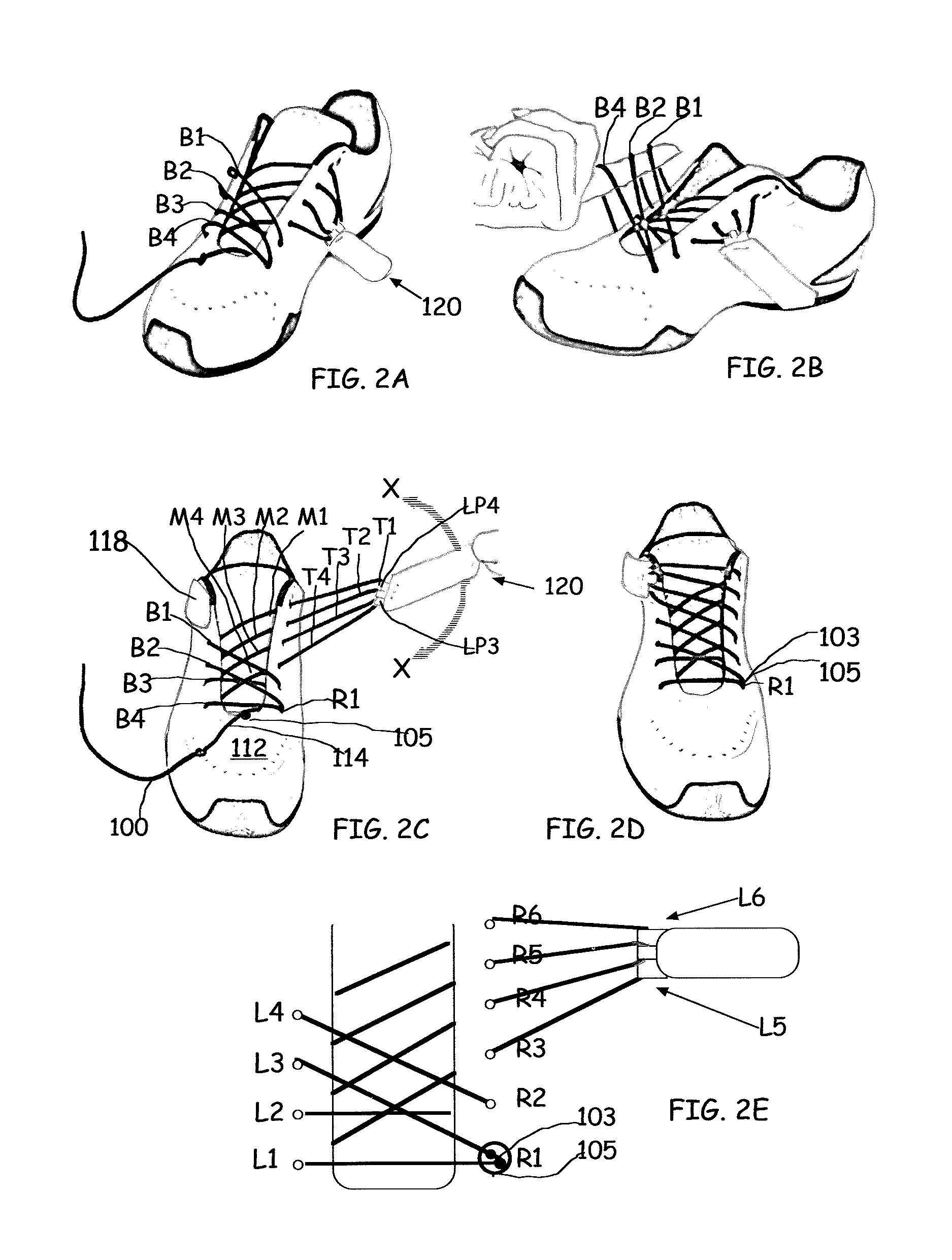

Dually adjustable, anchored, parallel lacing technology

A lacing system having multiple anchor types, i.e., interior anchors, end anchors, and dynamically adjustable anchors, that, in combination with parallel lacing technology, provide instant and reliable fastening for shoes, boots, and other articles of manufacture. The lace is threaded and anchored so that, a single arcuate pull on the movable fastener(s) causes the multiple lace segments to move through the eyelets of the shoe, and align in unison, so that the entire shoe opening contracts (or opens wide) simultaneously. The fastener(s) can be hook and loop, ratchet buckles, adjustable buckles, or cord locks. The laces are replaceable. The adjustable opening is customizable for different width feet providing “gross” adjustment. The fastener provides “fine” adjustment. Methods and diagrams are disclosed for threading, anchoring, and customizing the lacing, as well as for indicating that the lacing is correct.

Owner:KRENGEL ANNA

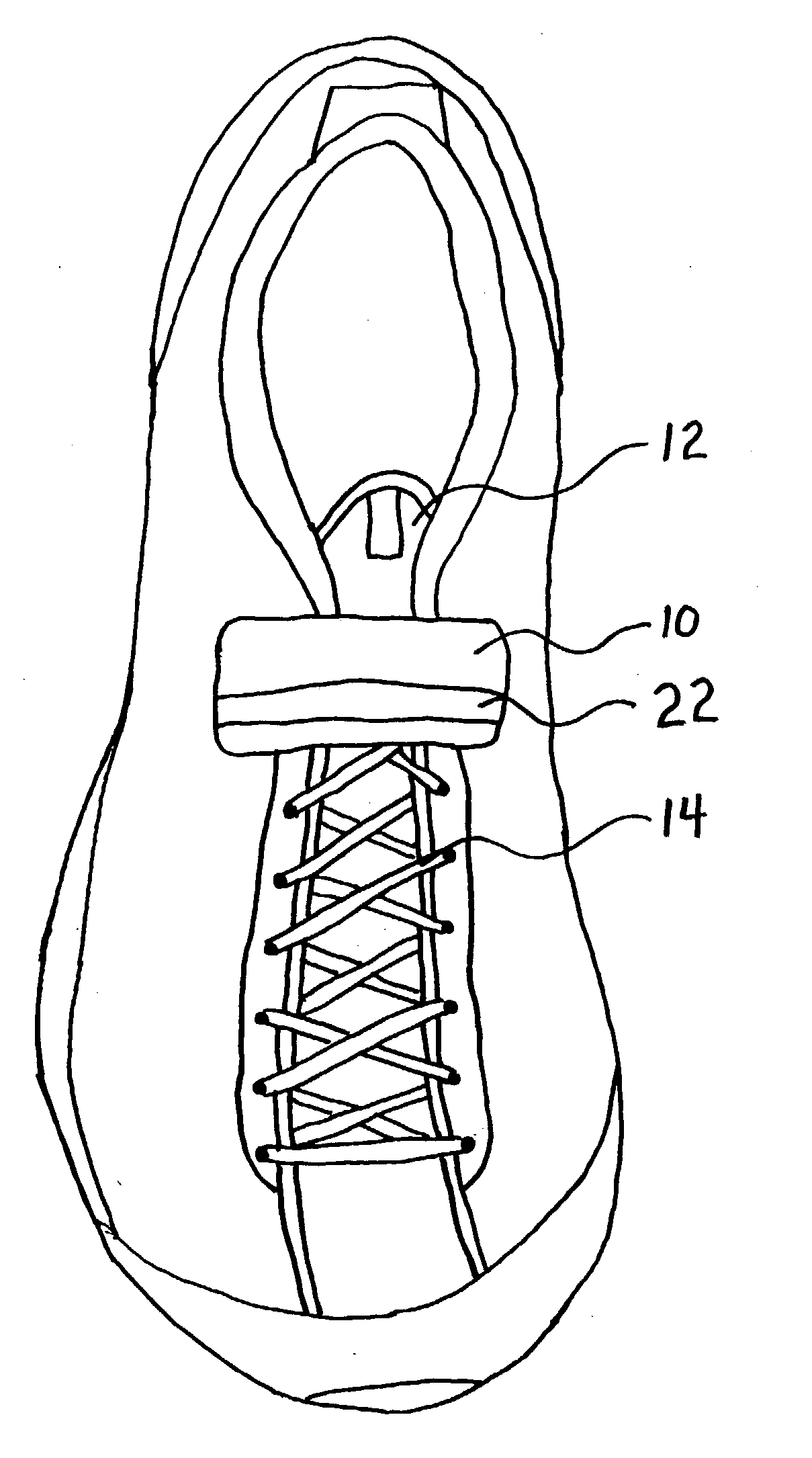

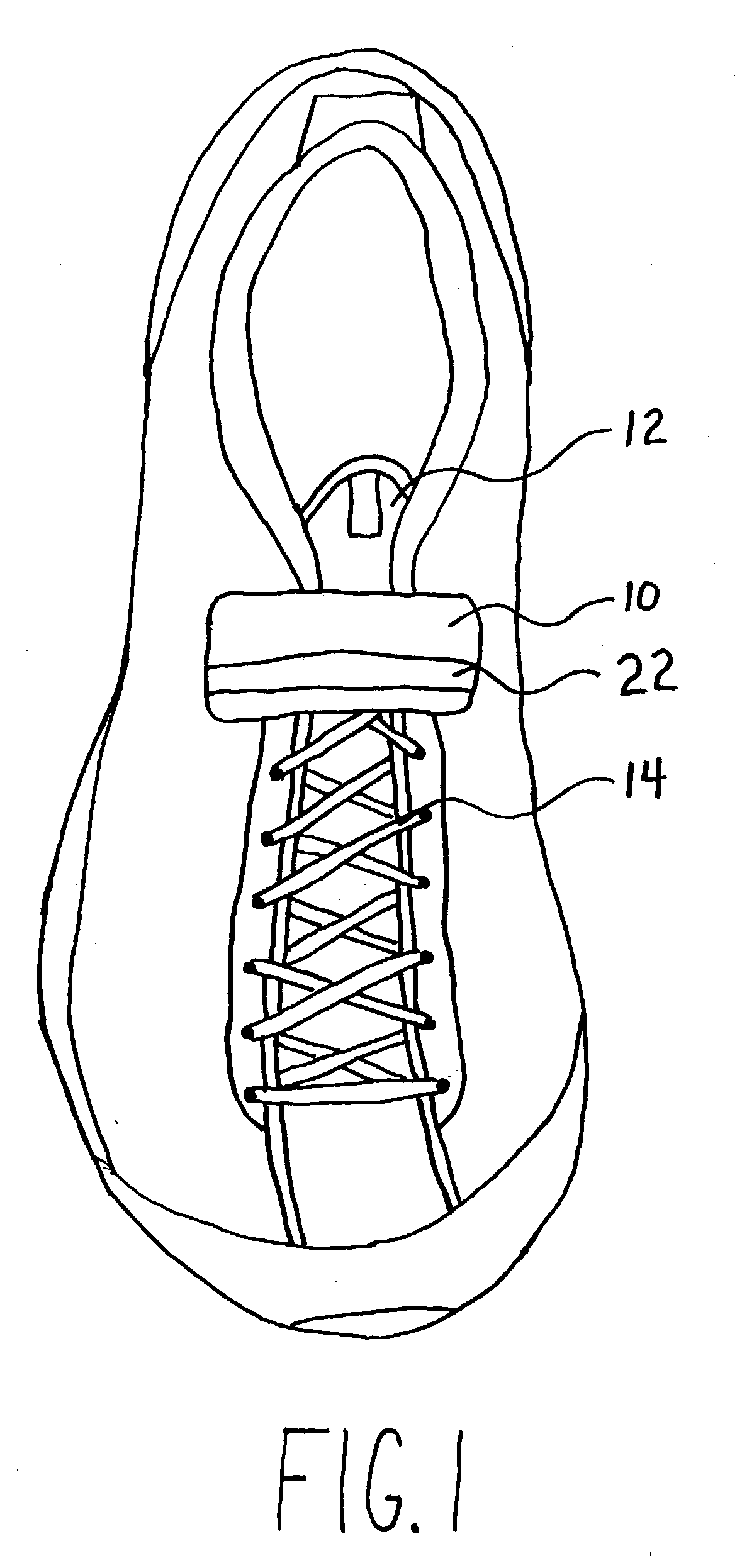

Pouch for concealing and containing shoelaces

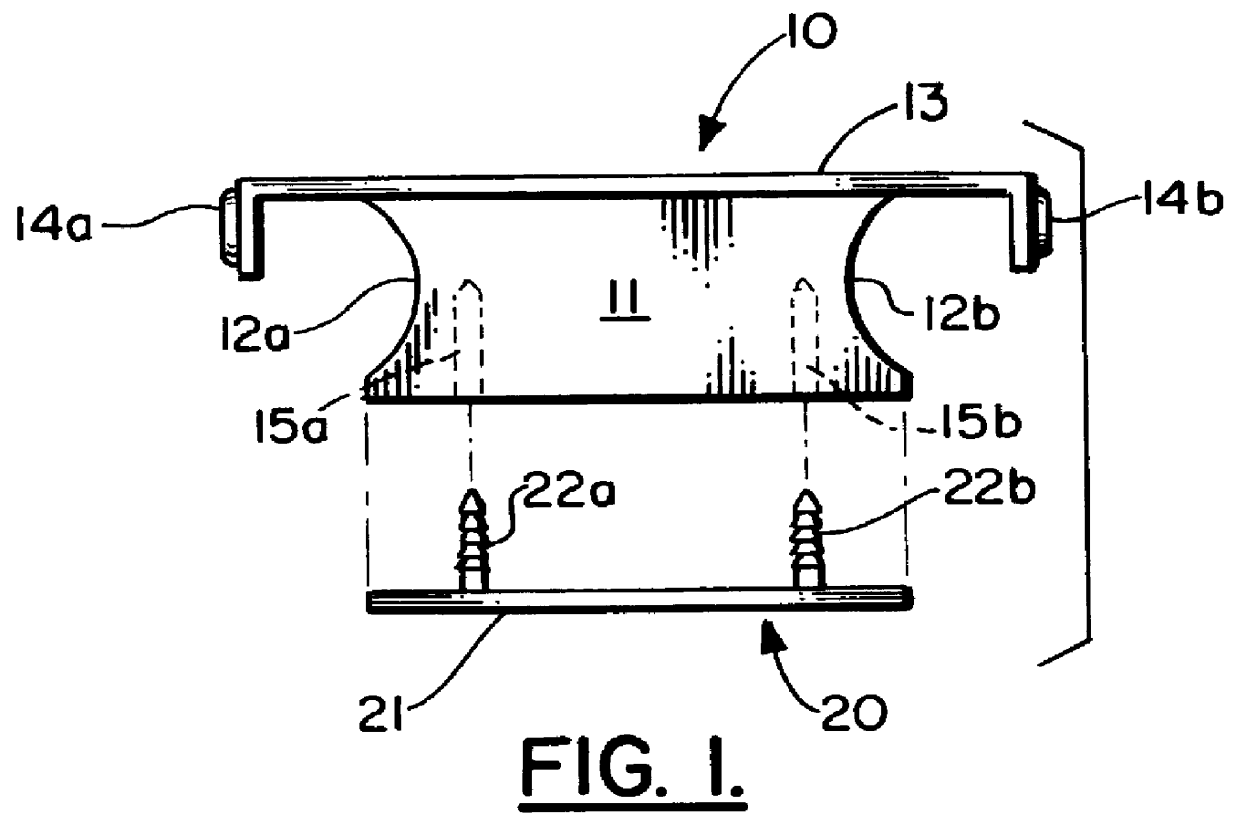

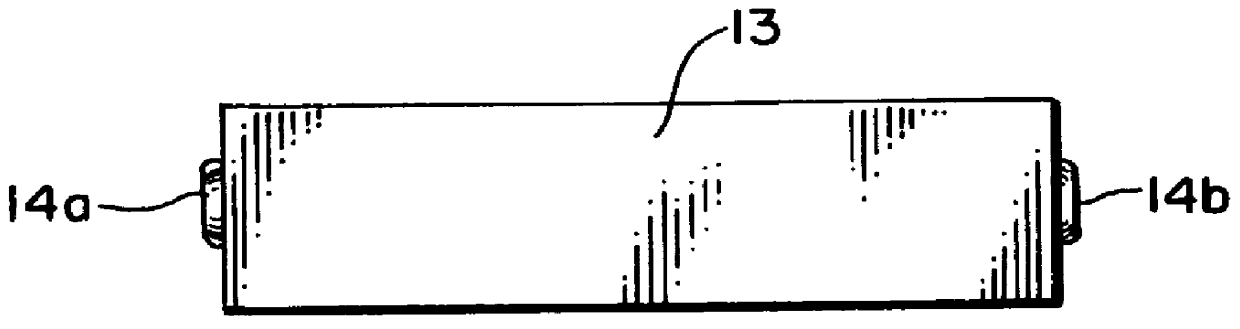

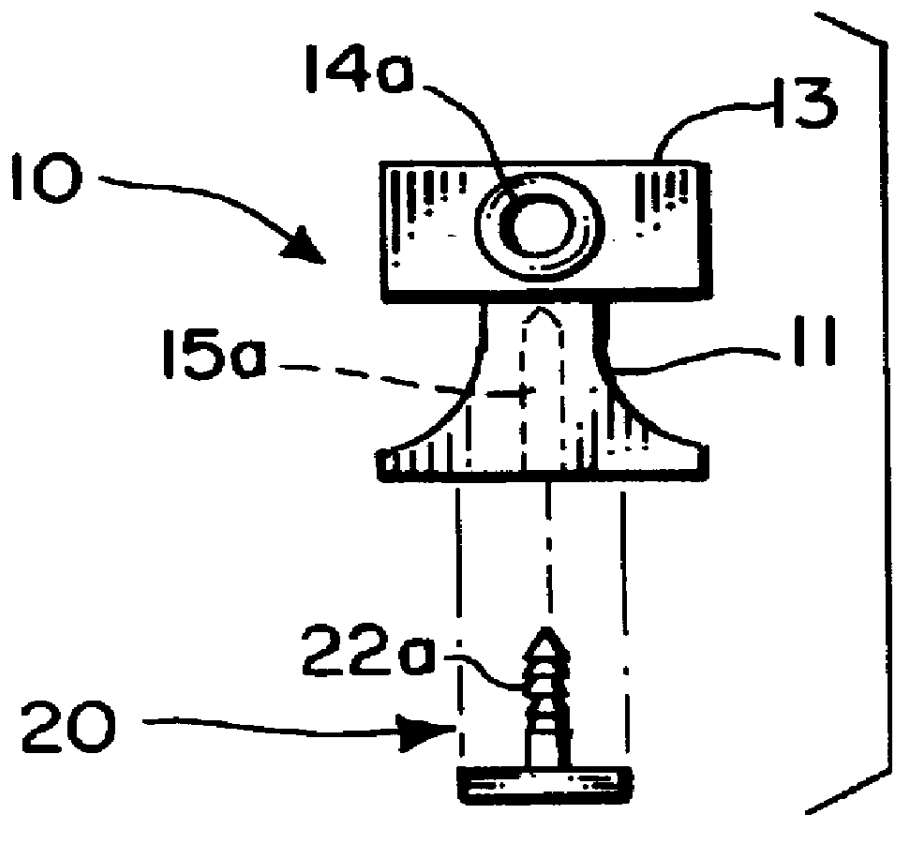

A shoe with improved lacing means includes a shoe, shoe laces (14) and a hook and loop element pouch (10). On the underside, the side making contact with the shoe, are two openings (16) that are used to slide the shoelaces through. With the pouch (10) open, the shoelaces (14) are pushed through the holes (16), pulled firmly and then tied as usual. Place the tied shoelaces (14) down into the pouch (10). There is a hook and loop element strip (22) on the opening making it easy to close, while keeping laces (14) secure. The pouch (10) can be attached to the shoe by hook and loop element strips (18) on both the right and left underside of the pouch (10). The pouch (10) will keep the shoelaces (14) from loosening, snagging and untying.

Owner:JOHNSON JAY ALLEN

Article of footwear having removable eyelet portion

An article of footwear is configured so that a child or other wearer may easily insert his or her foot into the article of footwear without tying laces while maintaining the look of a laced article of footwear. A lateral portion of the eyelet region partially surrounding the vamp is removably attached to the upper, such as with a hook-and-loop system, to allow the width of the vamp to be manipulated. The medial portion of the eyelet region is fixedly attached to the upper so that the rubbing together of the medial sides of the feet to not unintentionally disengage the medial portion from the upper. The lateral portion of the eyelet region rotates on a hinge formed in the eyelet region. Laces are fixedly attached to the eyelet region. A gore strap is optionally provided for more secure wear.

Owner:NIKE INC

Sewing-free upper vamp and manufacture method thereof

InactiveCN102150976AEasy to processReduce processing costsEyeletsShoemaking devicesHot meltTime cost

The invention relates to the technical field of an upper vamp, in particular to a sewing-free upper vamp and a manufacture method thereof. The sewing-free upper vamp comprises an upper vamp material, a decorative auxiliary material, a hot melt glue layer and a ventilating layer, wherein eyelet stays are arranged at the upper surface of the upper vamp material, the upper surface of the hot melt glue layer is adhered to the lower surface of the upper vamp material, and the lower surface of the hot melt glue layer is adhered to the ventilating layer. The manufacture method of the sewing-free upper vamp comprises the steps of cutting the upper vamp material into a set shape, coloring the decorative auxiliary material, adhering the decorative auxiliary material to the upper surface of the upper vamp material, coating a layer of hot melt glue film at the lower surface of the upper vamp material, sealing the ventilating layer at the lower surface of the upper vamp material, coating a layer of hot melt glue film at the upper surface of the upper vamp material, and pressing the eyelet stays at the upper surface of the upper vamp material. After the upper vamp and the method is used, a large number of labor cost and time cost caused by running a sewing machine are greatly reduced; and the upper vamp dose not need to be sewed by the sewing machine, so that the working procedures for manufacturing the upper vamp is greatly reduced, and the processing difficulty is reduced.

Owner:东莞中志鞋材有限公司

Article of Footwear with Arch Wrap

An article of footwear with an arch wrap is disclosed. The arch wrap is configured to provide support to a midfoot. The arch wrap can include a plurality of eyelets that are configured to receive a lace of a lacing system of the upper.

Owner:NIKE INC

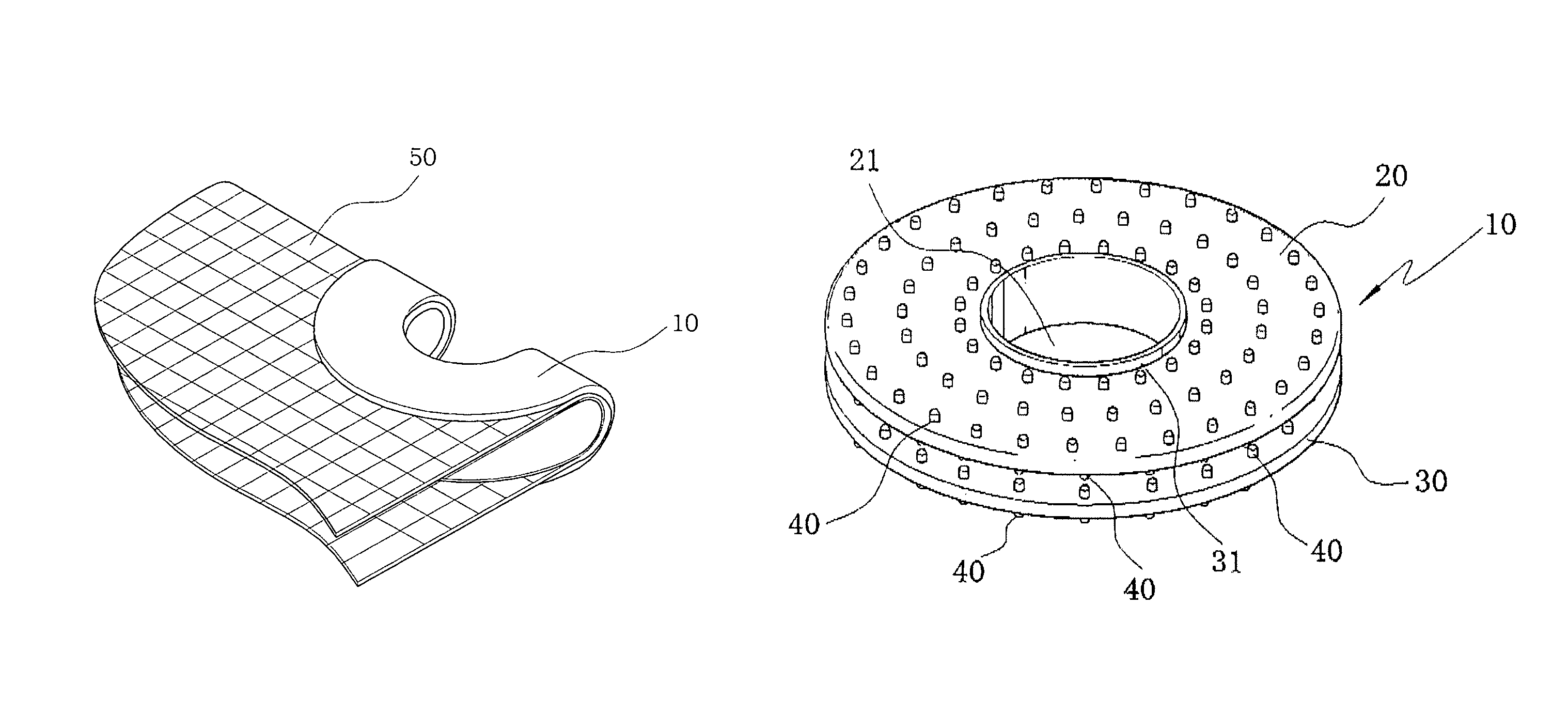

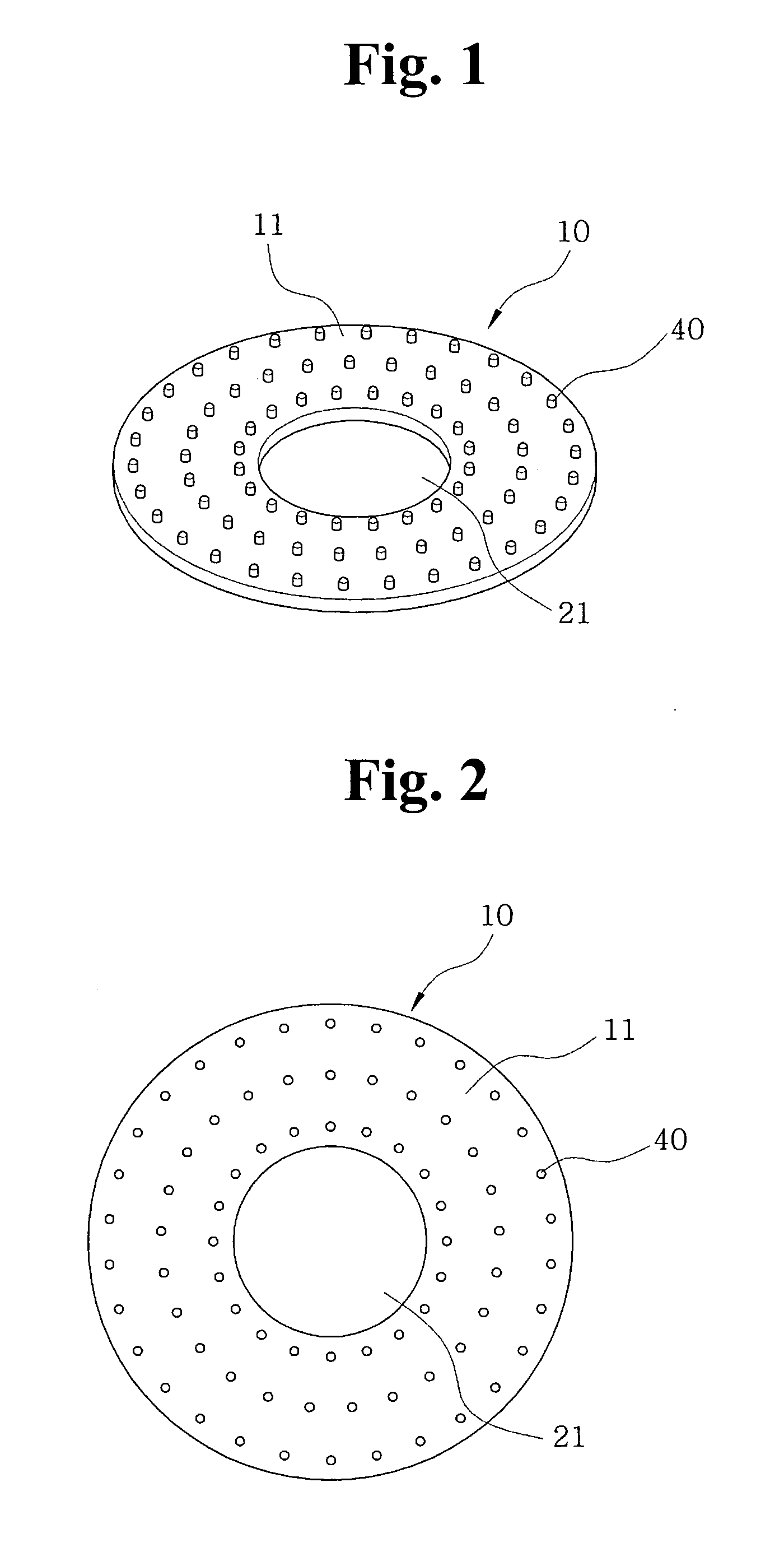

Manufacturing method for eyelet and structure thereof

The present invention discloses a method for manufacturing an eyelet for a tarpaulin, the eyelet having upper and lower eyelet bodies each provided with a plurality of fixing protrusions formed in a shape of concentric circles on one surface thereof in such a manner that the plurality of fixing protrusions formed on the upper eyelet body confront to the plurality of fixing protrusions formed on the lower eyelet body, the method comprising the following steps of: a step of positioning the upper and lower eyelet bodies by using a conveying means in such a manner as to place the tarpaulin there between; a step of punching a given position on the tarpaulin fabric by means of a punching machine with an integrally-formed ultrasonic horn; a step of conveying the upper and lower eyelet bodies to a position of the ultrasonic horn and fusing the upper and lower eyelet bodies to the tarpaulin through the compression of the ultrasonic horn; a step of fusing a protruded part extending upwardly from the circumference of a through-hole of the lower eyelet body by compression in the ultrasonic-fusing step to form an inner circumferential edge part; and a step of passing a rope through the through-hole of the eyelet mounted on the tarpaulin.

Owner:QINGDAO GYOHA & TECH PLASTICS

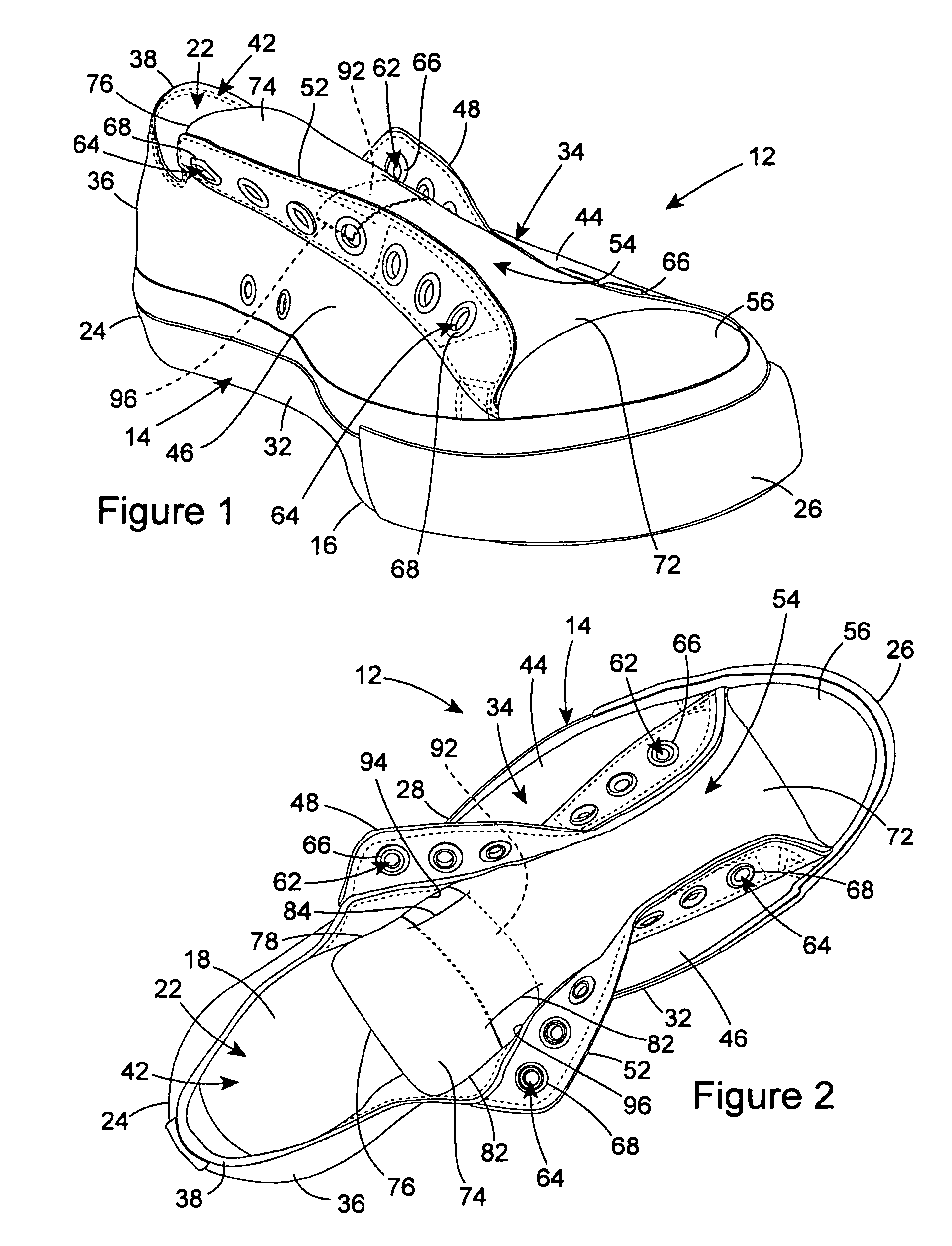

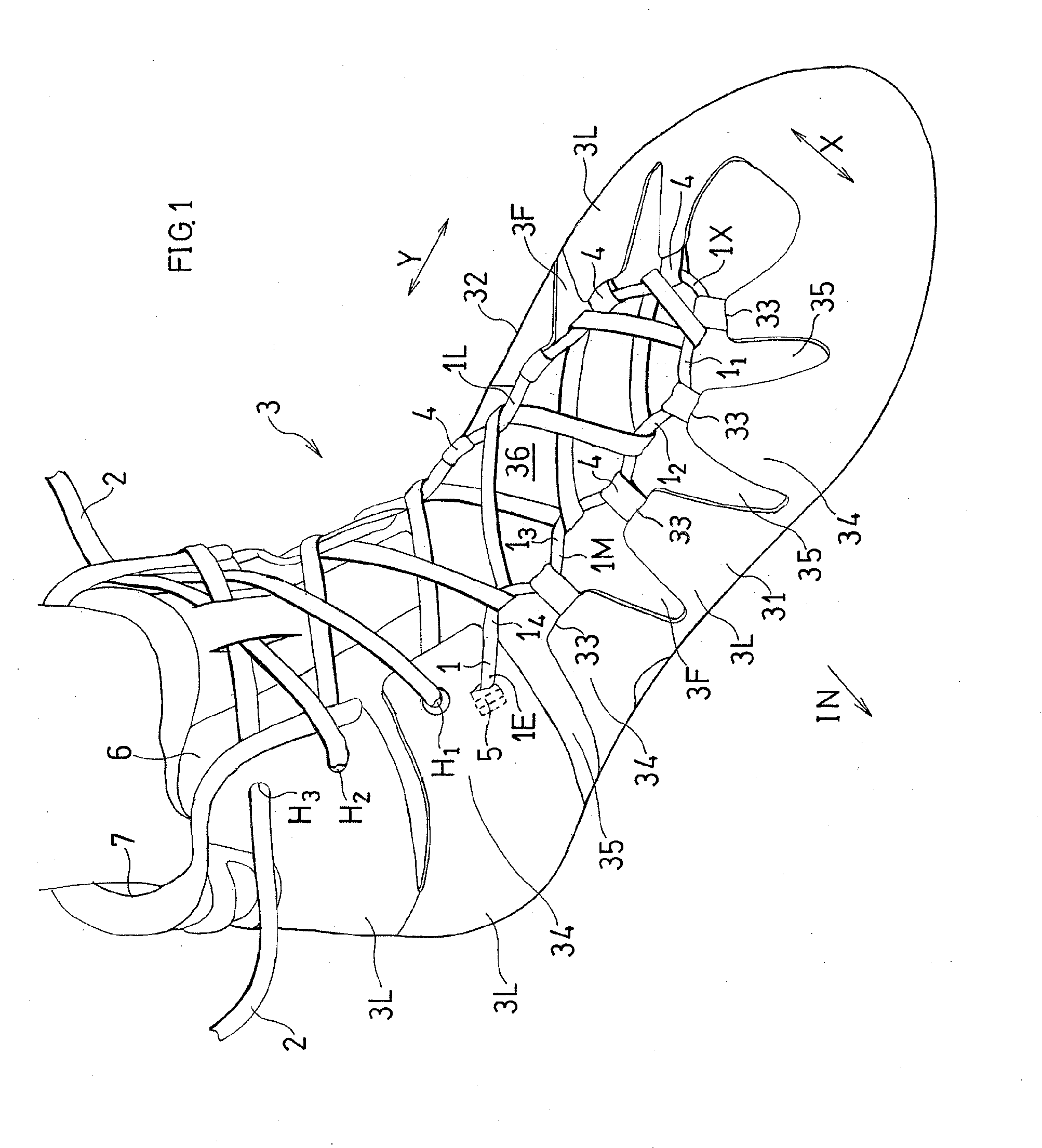

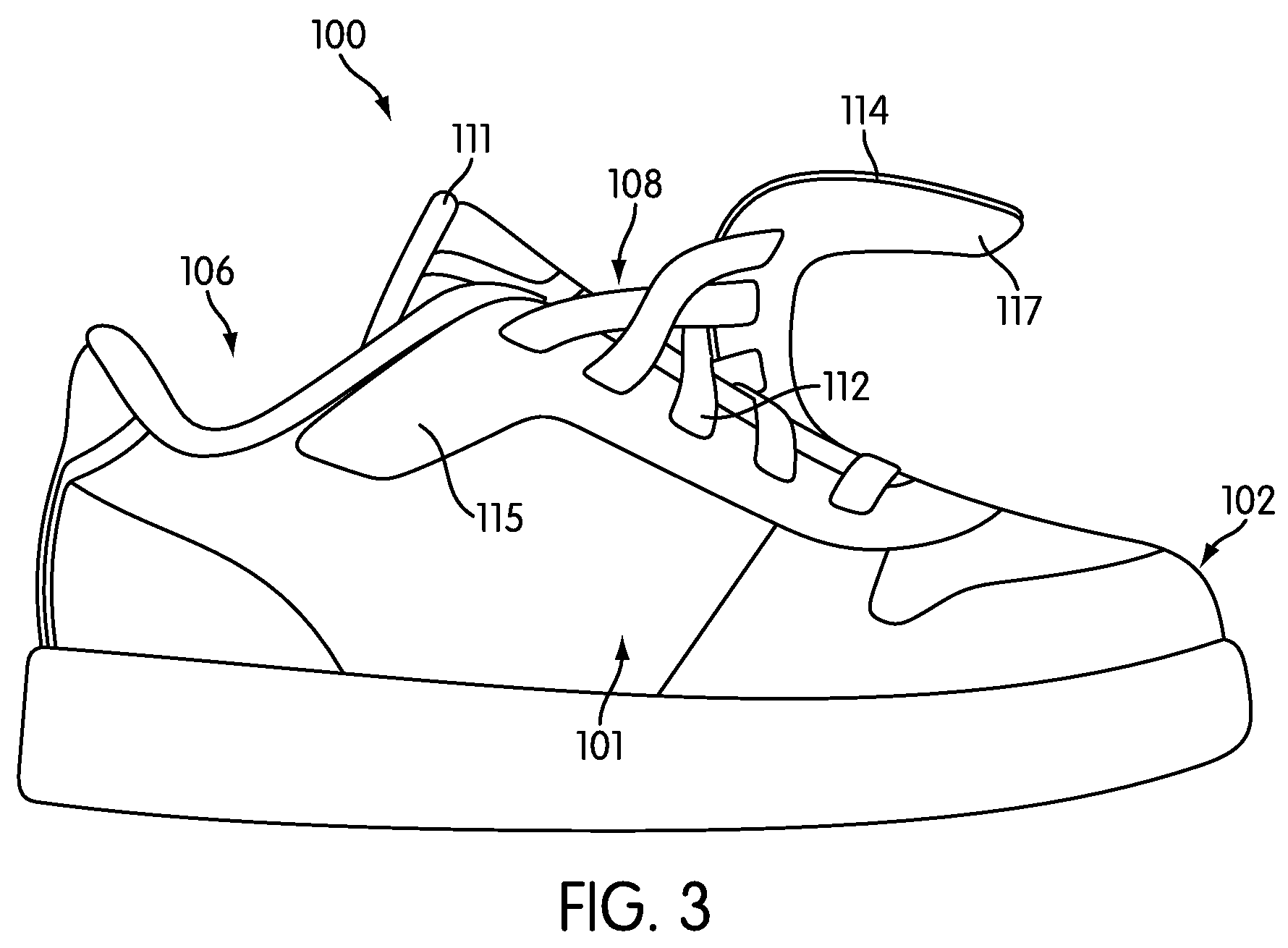

Shoe having lace fitting structure

ActiveUS20120131818A1Easily fits to footImprove fitness property of upperEyeletsShoe lace fasteningsMedial sideEngineering

A shoe including a sole 1 for absorbing an impact of landing, an upper 2 for wrapping around an instep, and shoelace means 3 for fitting the upper 2 to the instep, the upper 2 including: a main portion 2M covering a medial side surface, a lateral side surface, a toe, the instep and a back surface of a foot; a side edge portion having a plurality of first eyelets H1; a first side panel 51 covering the medial side surface of the foot; and a second side panel 52 covering the lateral side surface of the foot, wherein each side panel includes: a tip portion 53 having a second eyelet H2 which is provided at a tip of the side panel and which the shoelace means passes through and engages with; a bottom portion 54 attached to the main portion and / or the sole; and a middle portion 55 arranged between the tip portion and the bottom portion so as to allow the tip portion to move in the front-back direction of the foot with respect to the bottom portion, wherein with at least one of the side panels, the middle portion 55 can stretch and shrink to increase a length from the tip portion to the bottom portion.

Owner:ASICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com