Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

523 results about "Ultrasonic horn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum (commonly between 15 and 100 kHz). The device is necessary because the amplitudes provided by the transducers themselves are insufficient for most practical applications of power ultrasound. Another function of the ultrasonic horn is to efficiently transfer the acoustic energy from the ultrasonic transducer into the treated media, which may be solid (for example, in ultrasonic welding, ultrasonic cutting or ultrasonic soldering) or liquid (for example, in ultrasonic homogenization, sonochemistry, milling, emulsification, spraying or cell disruption). Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.

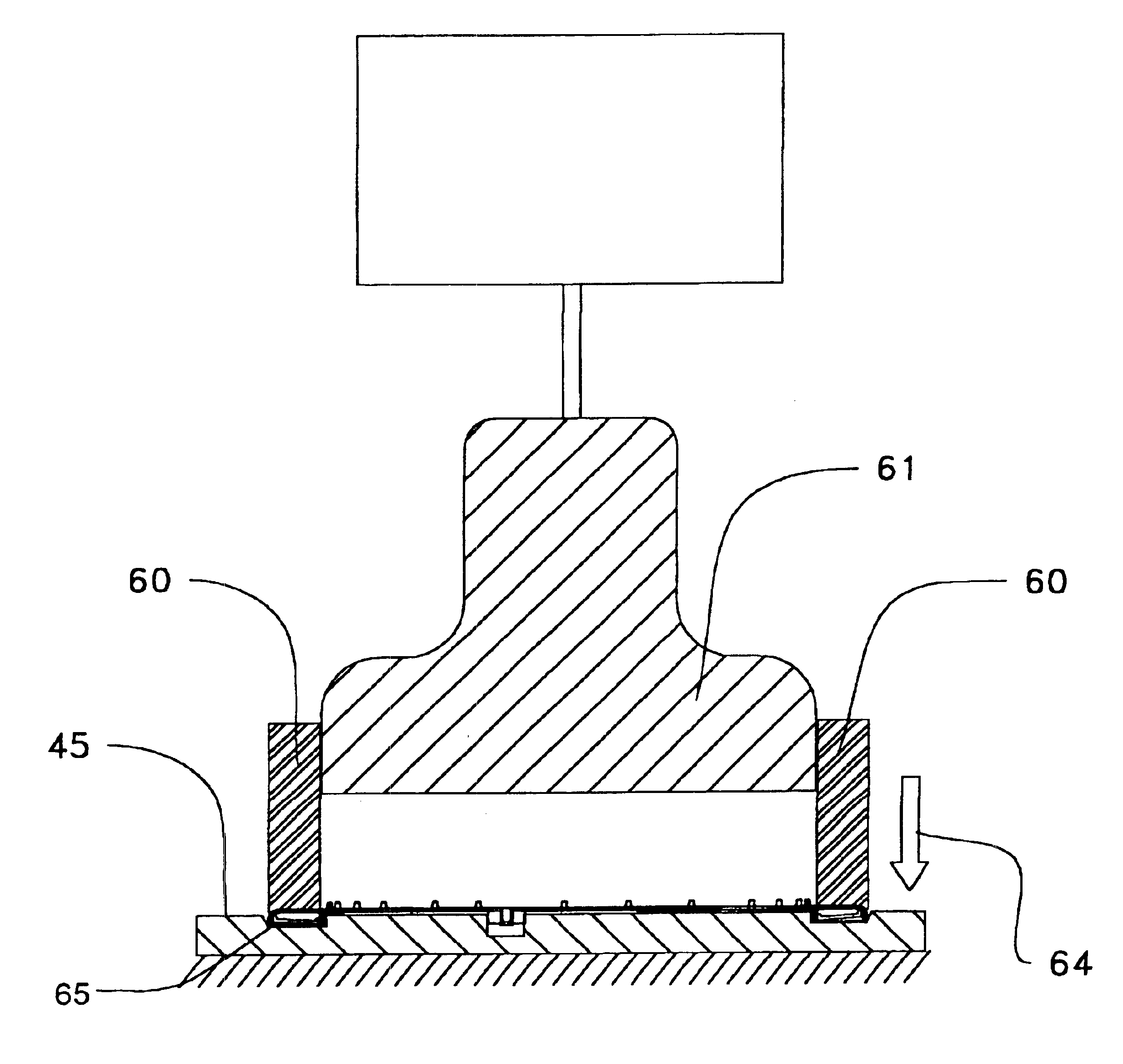

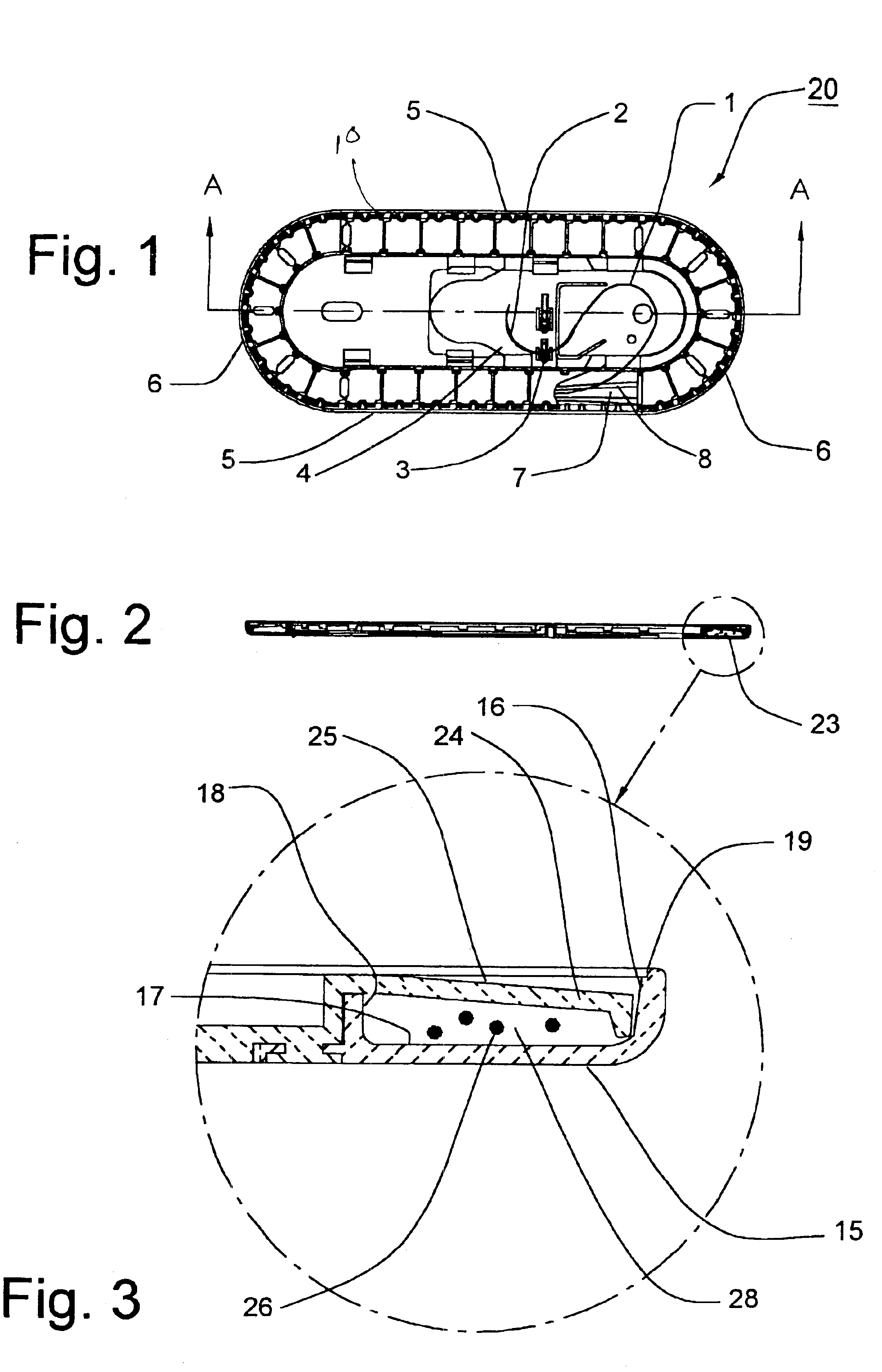

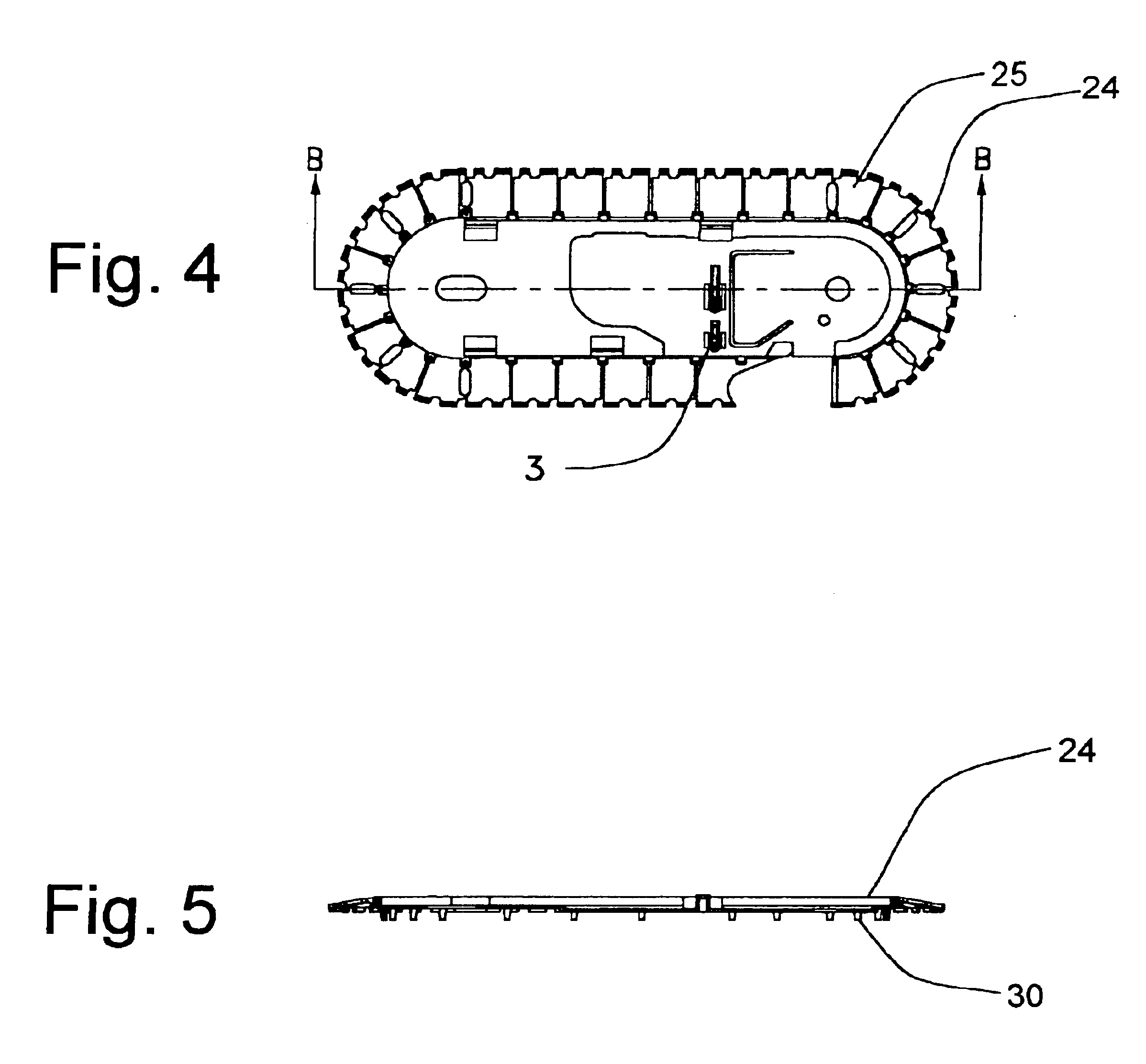

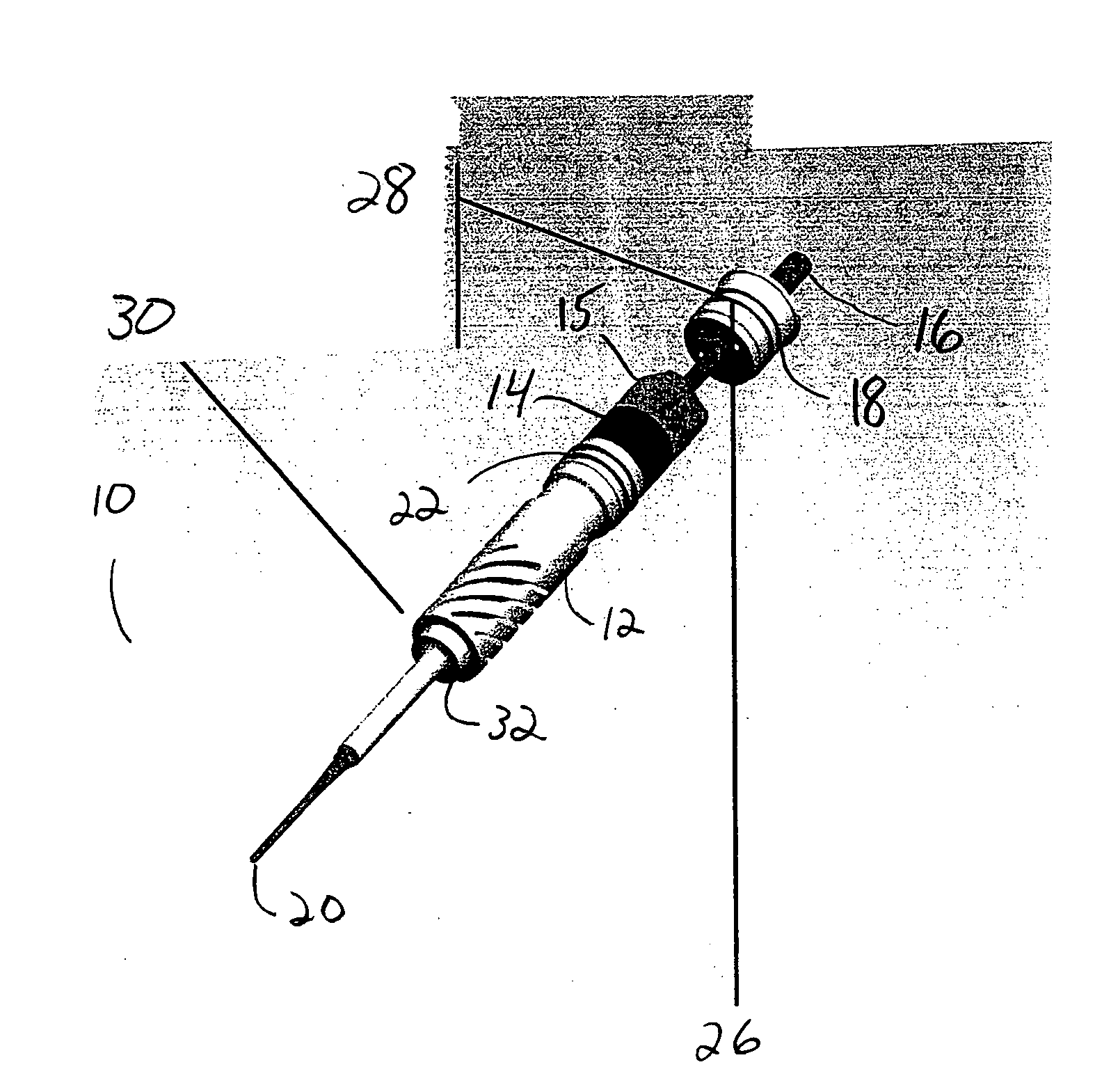

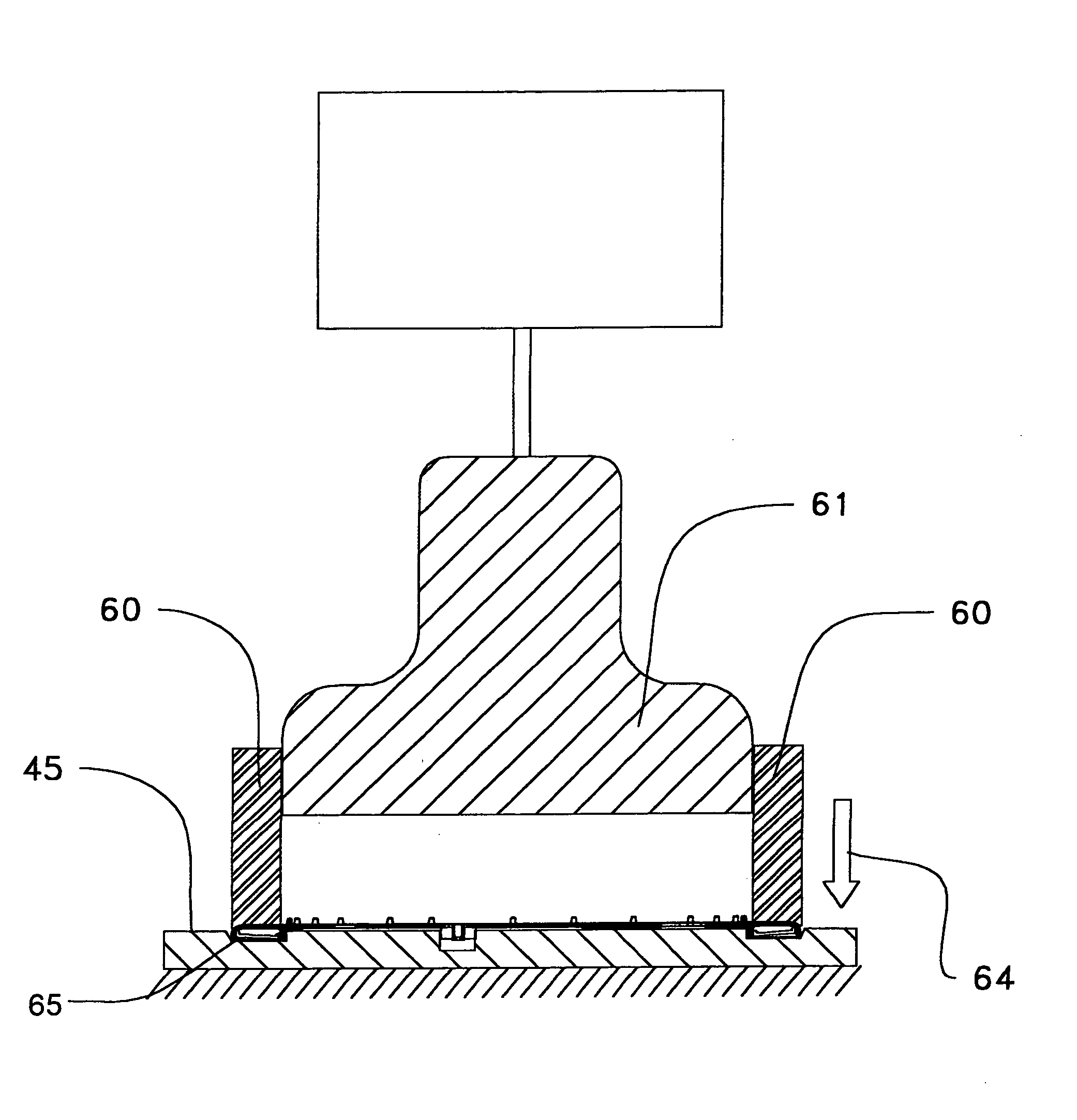

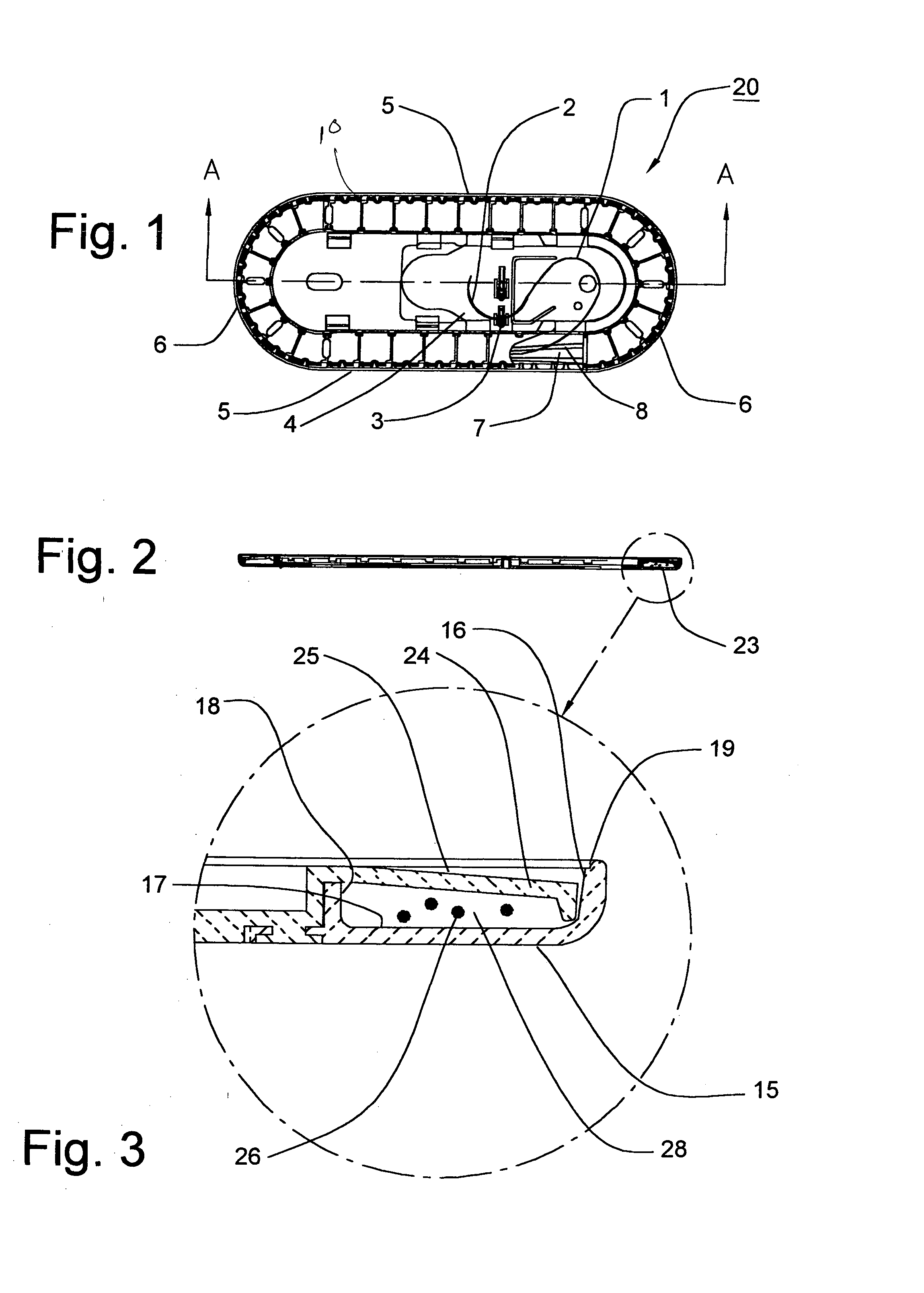

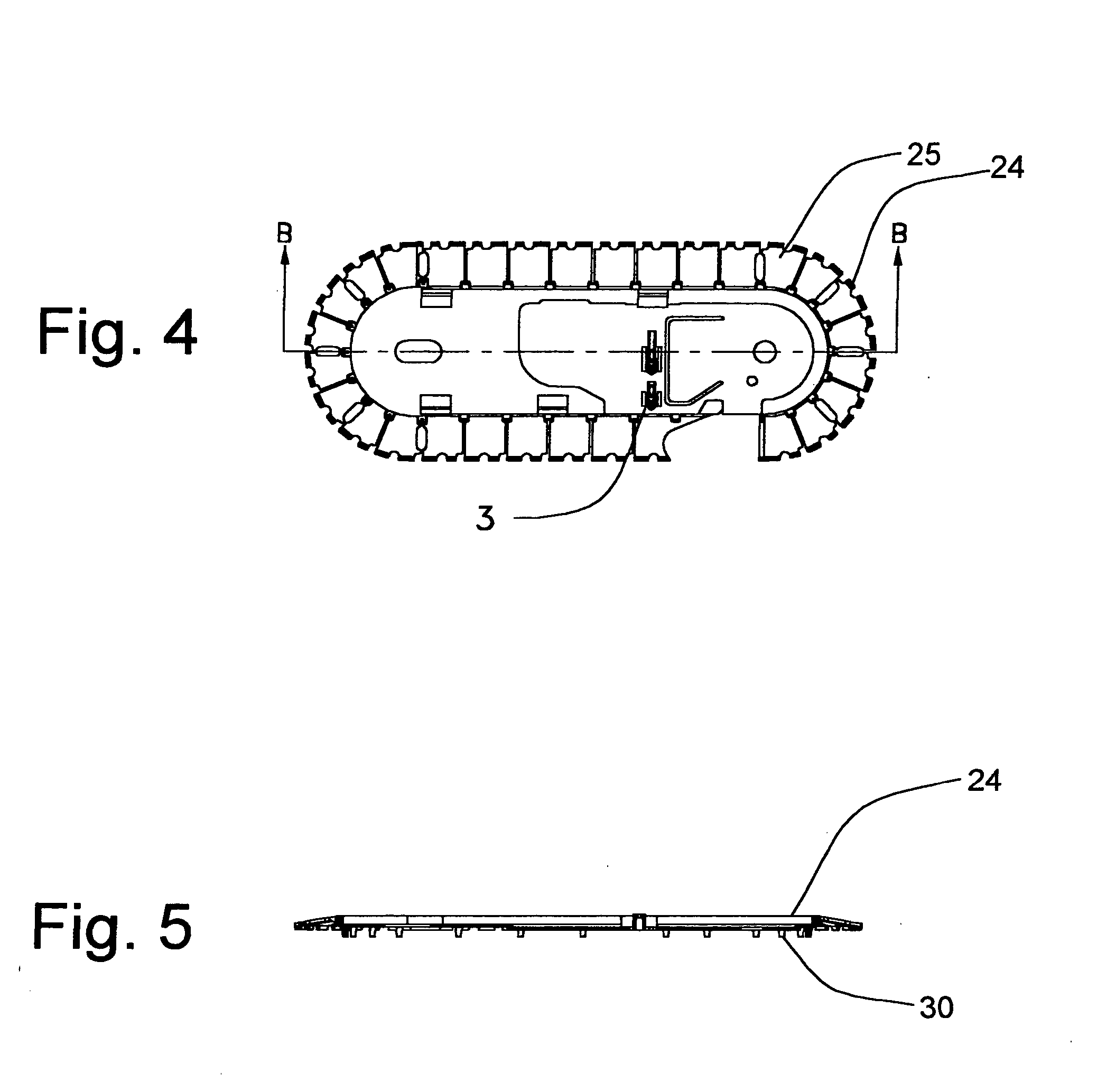

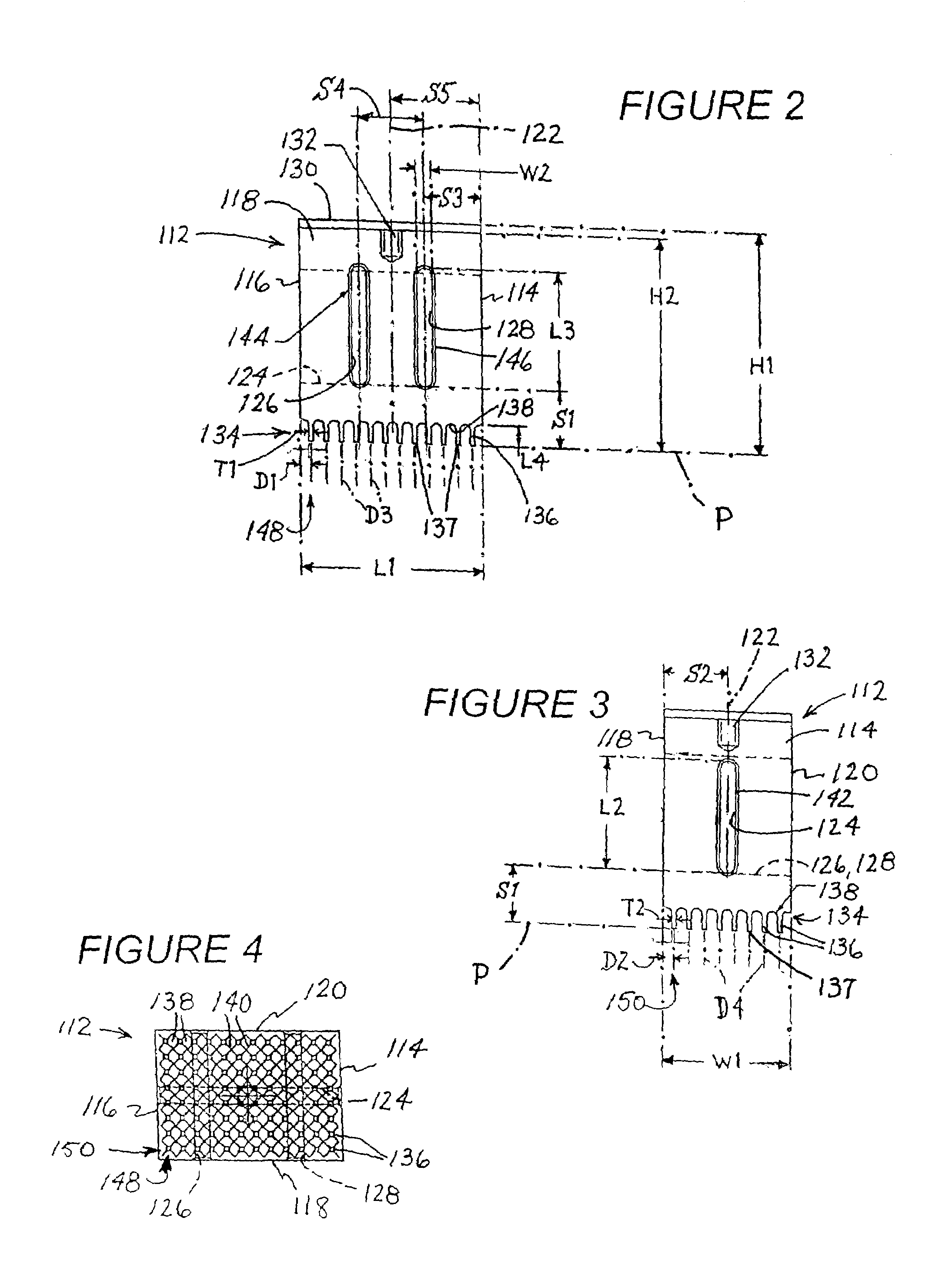

Method for assembling a package for sutures

InactiveUS6915623B2Not slowing downReduce manufacturing costSuture equipmentsSurgical needlesCounterboreUltrasonic generator

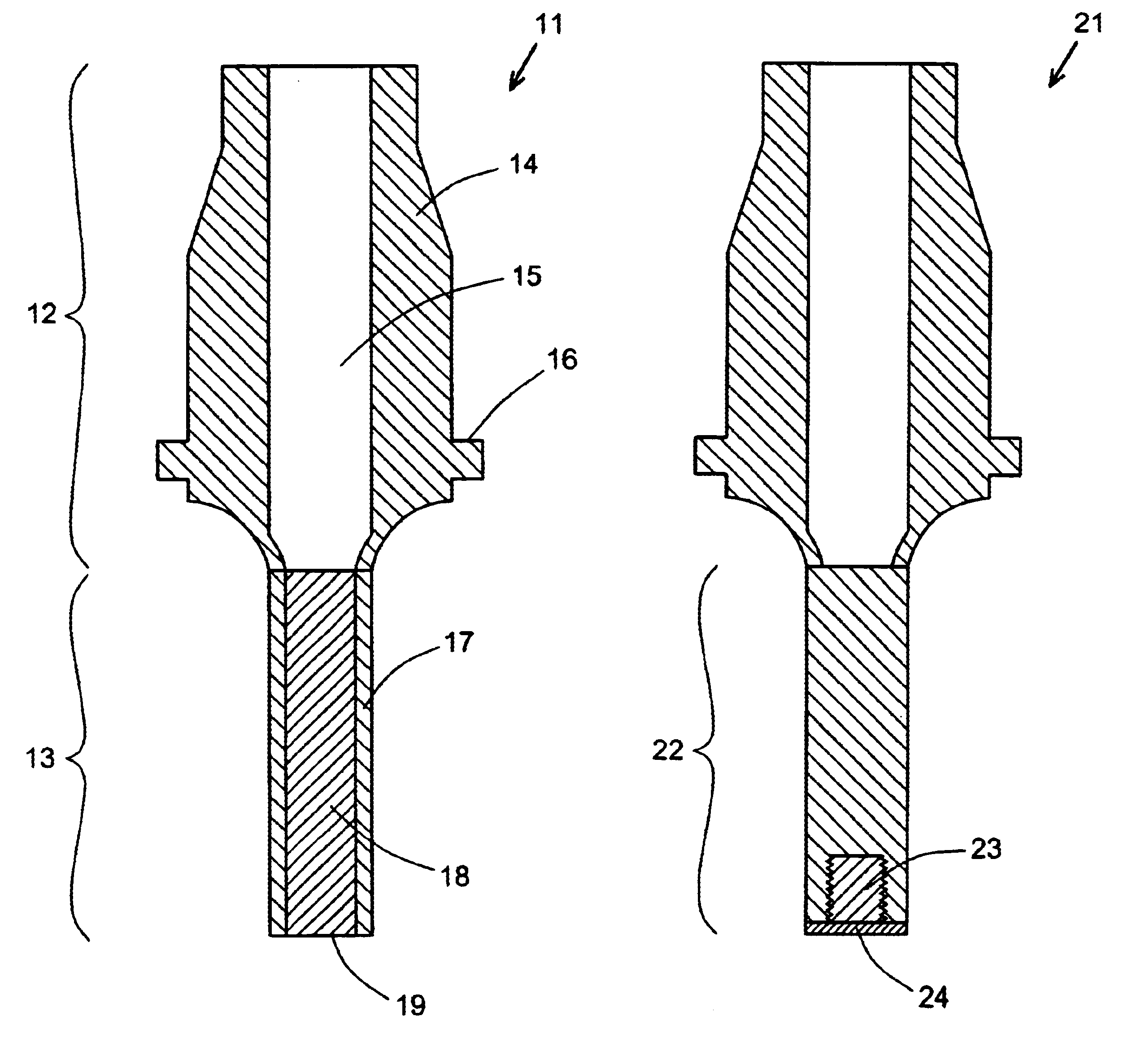

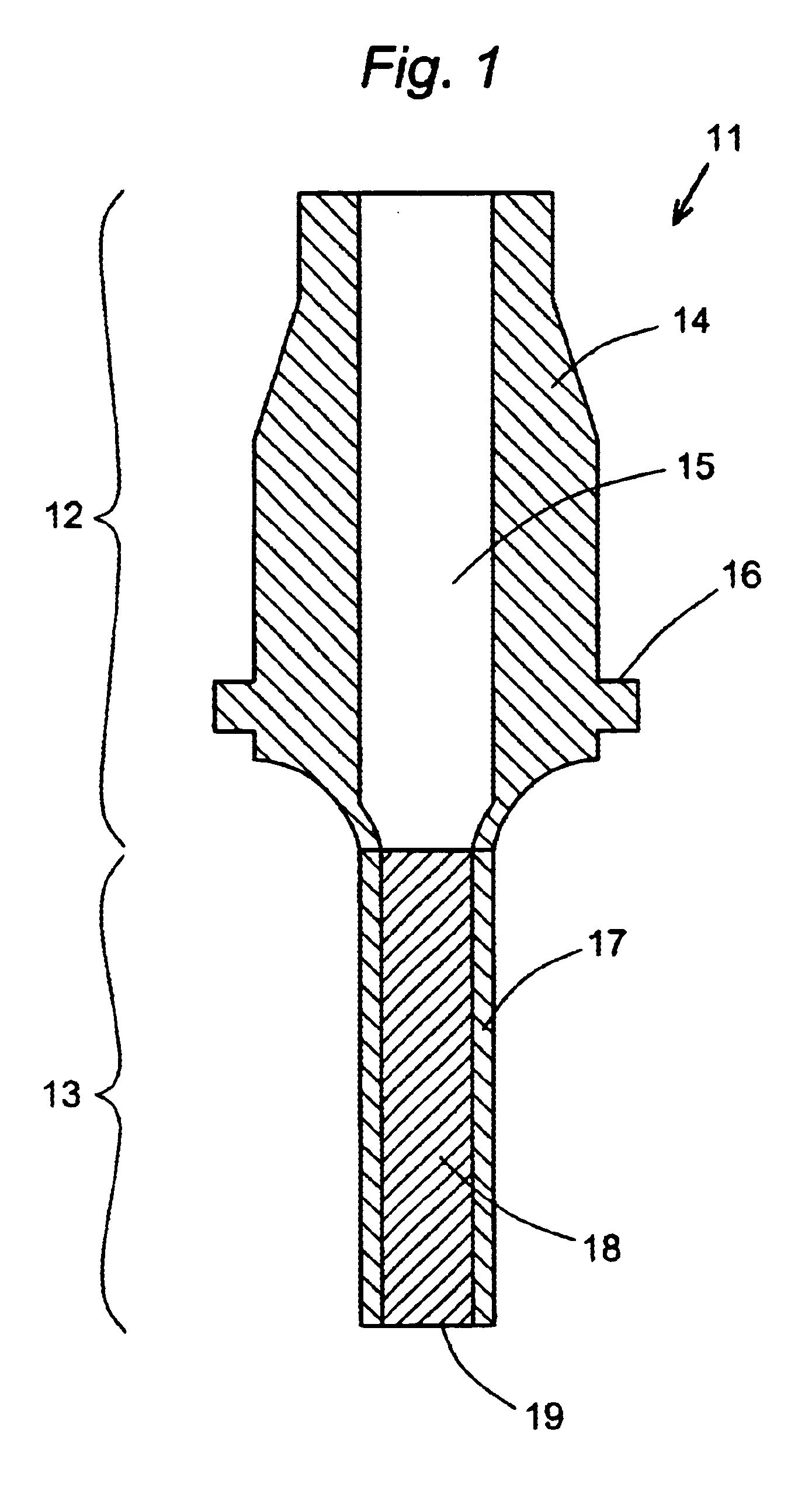

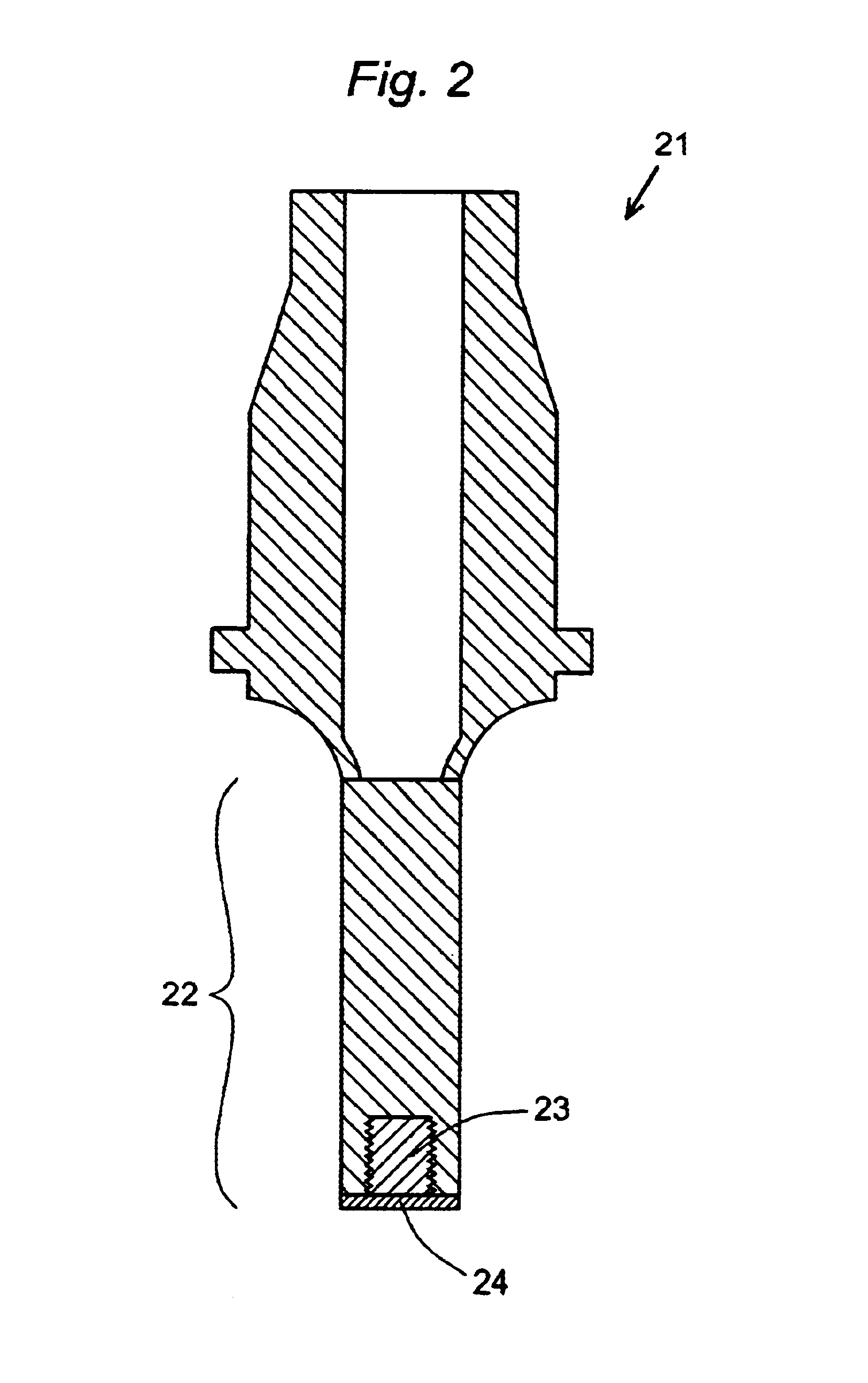

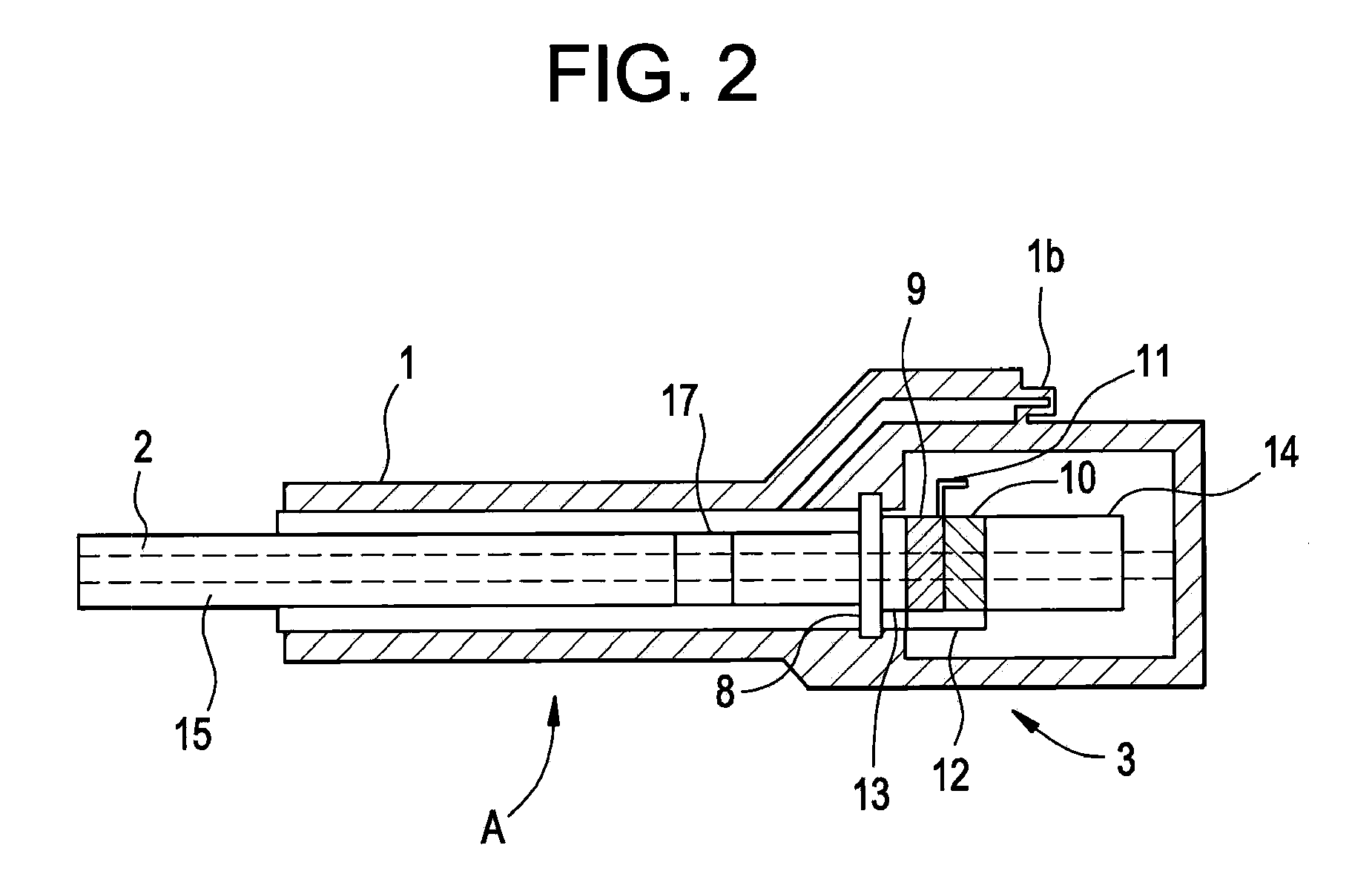

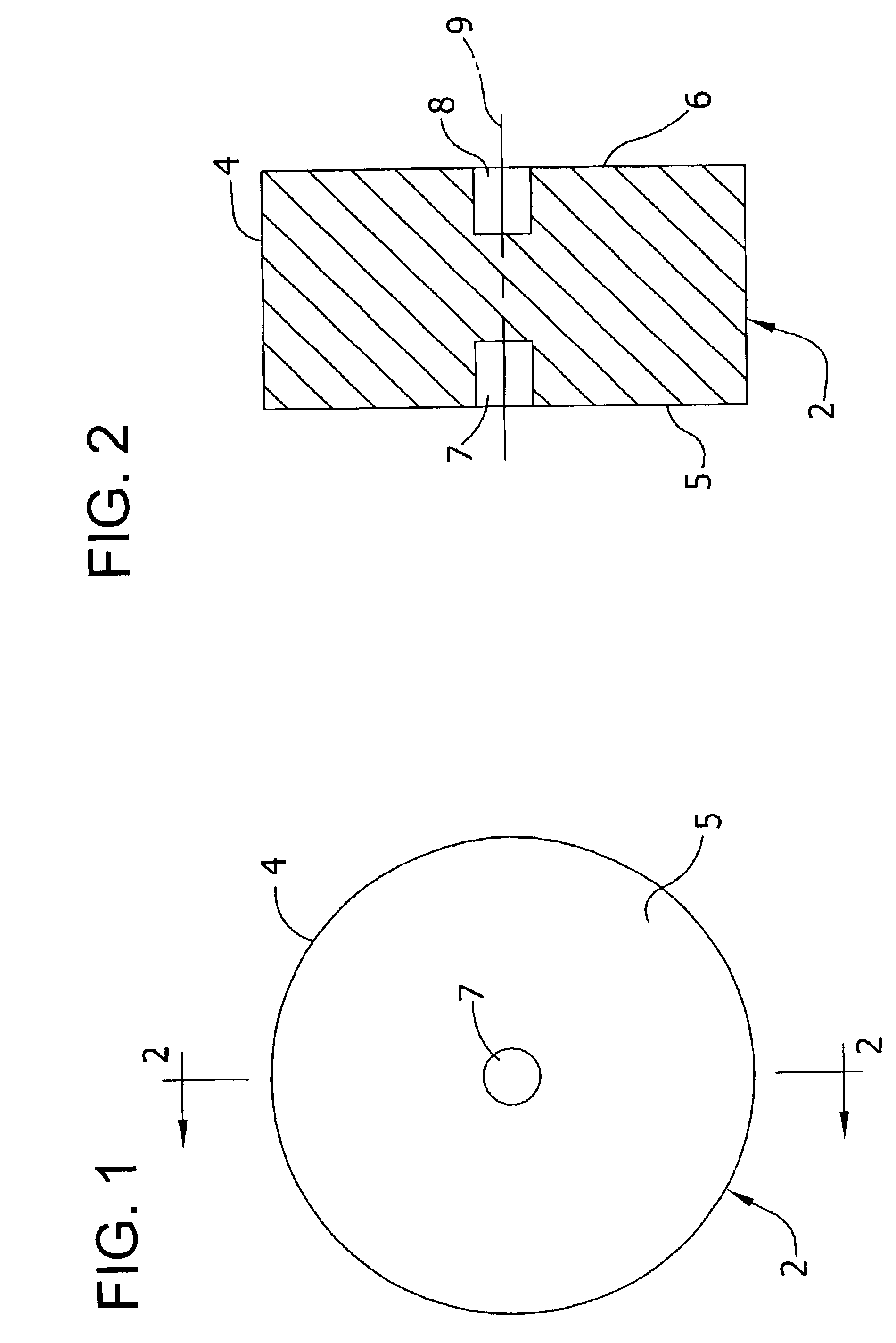

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity. The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

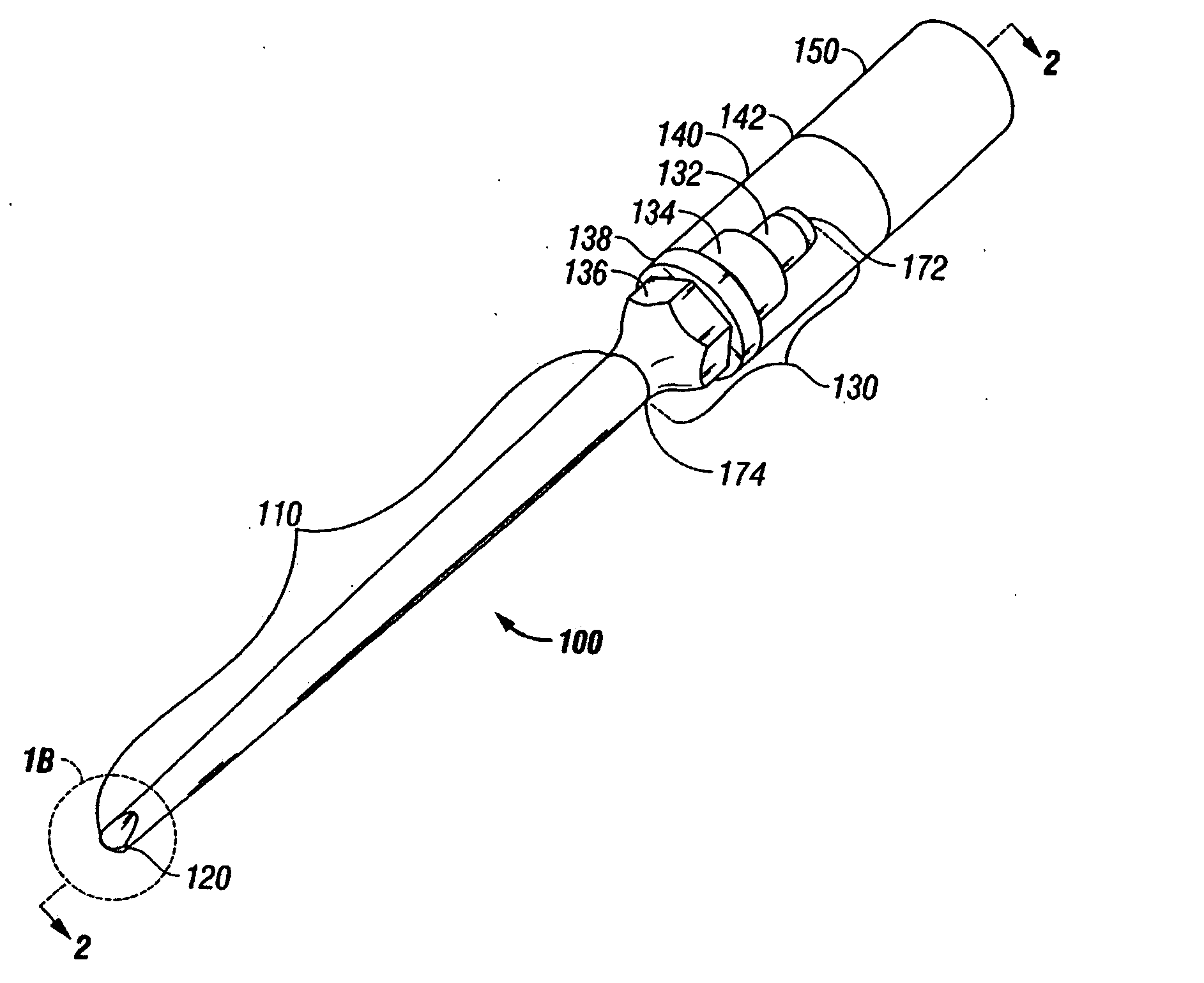

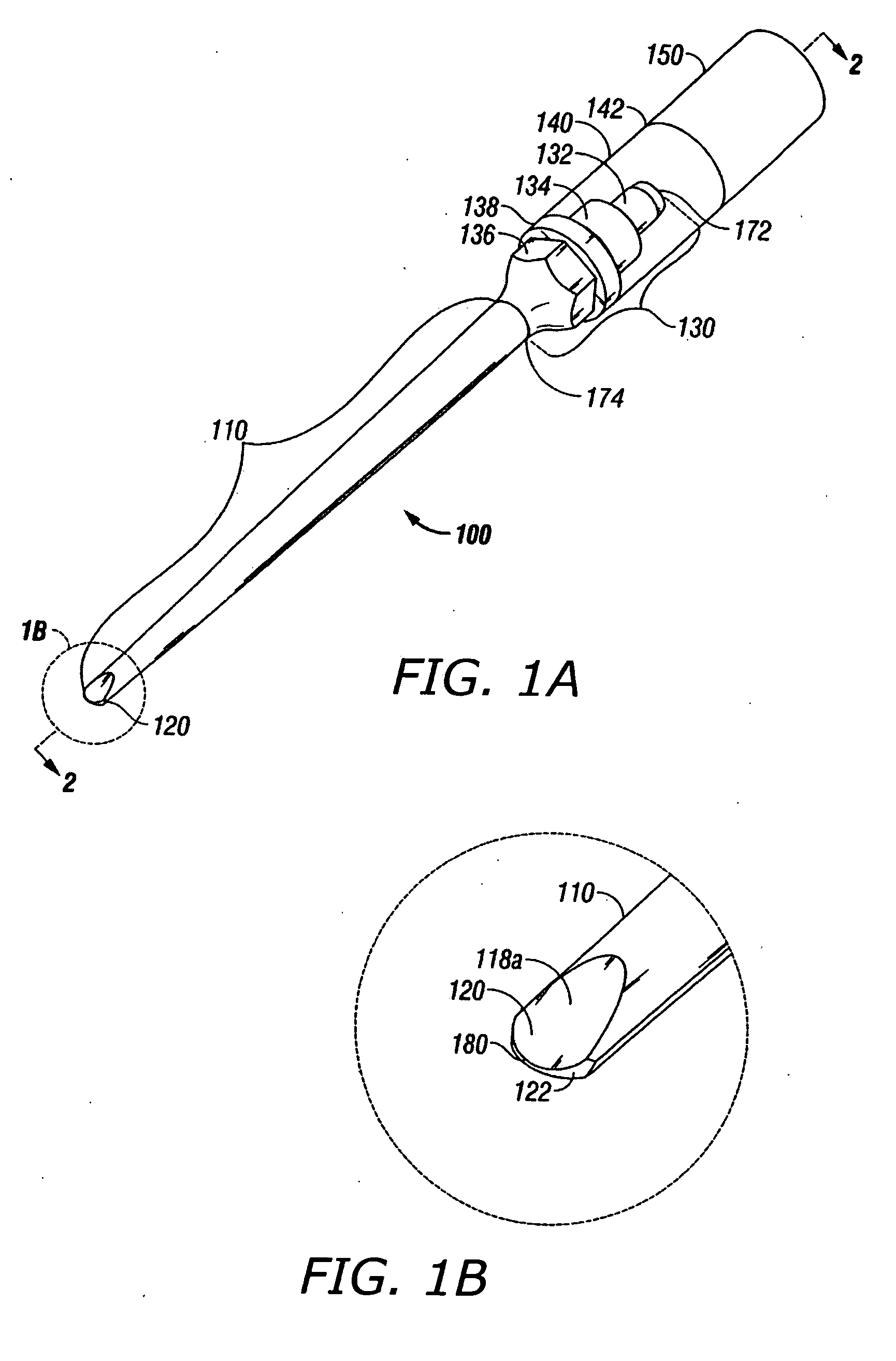

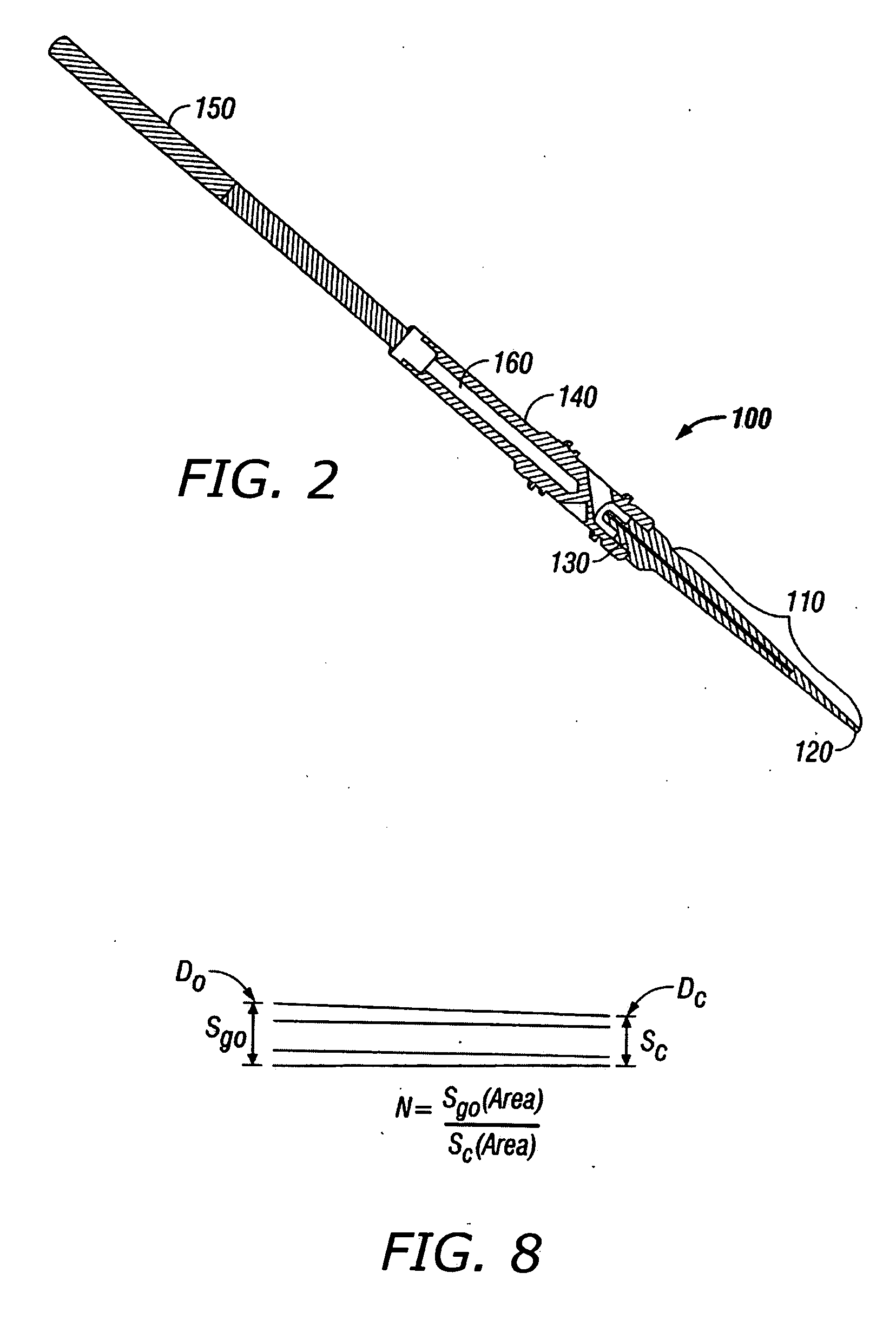

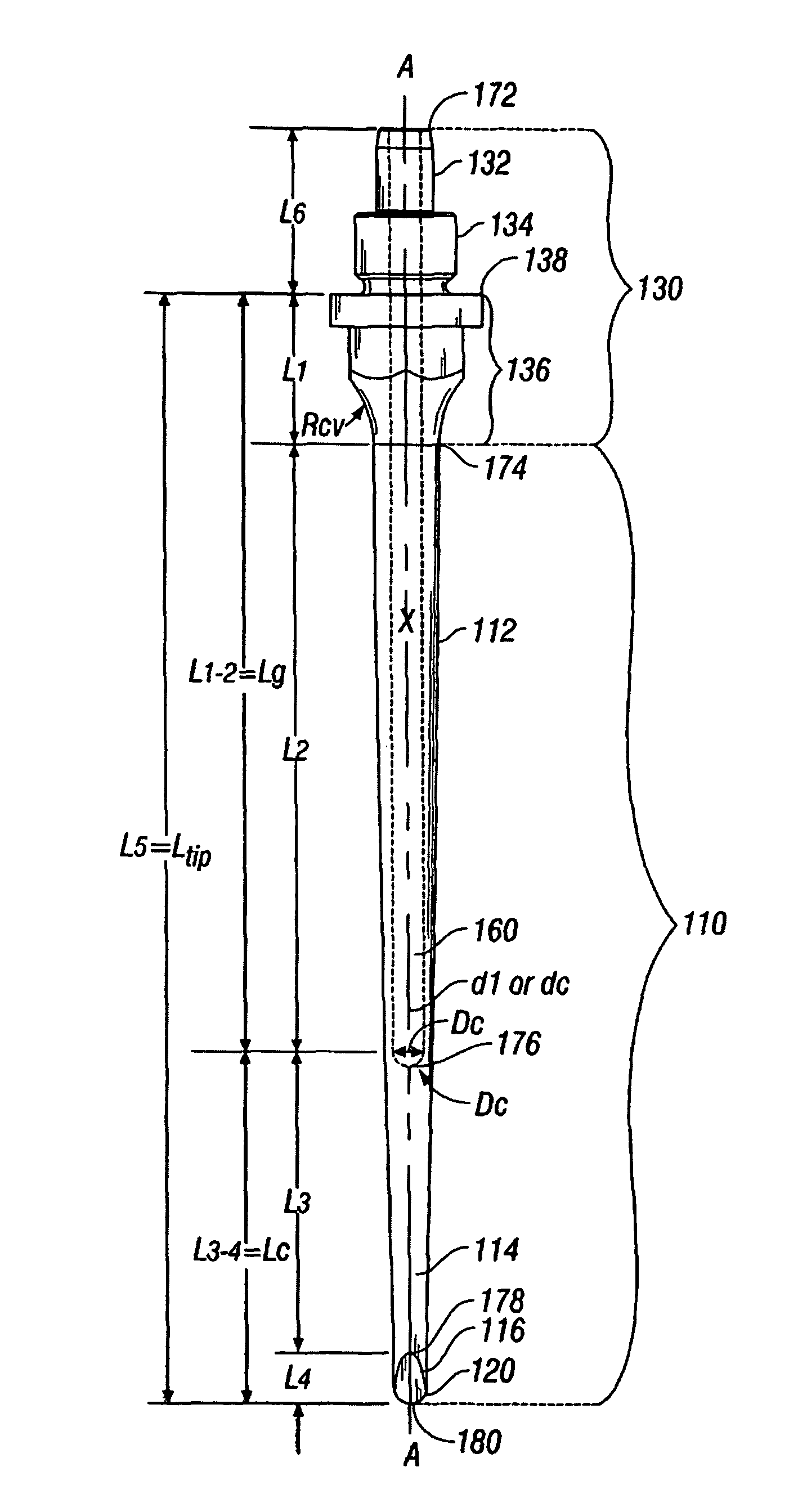

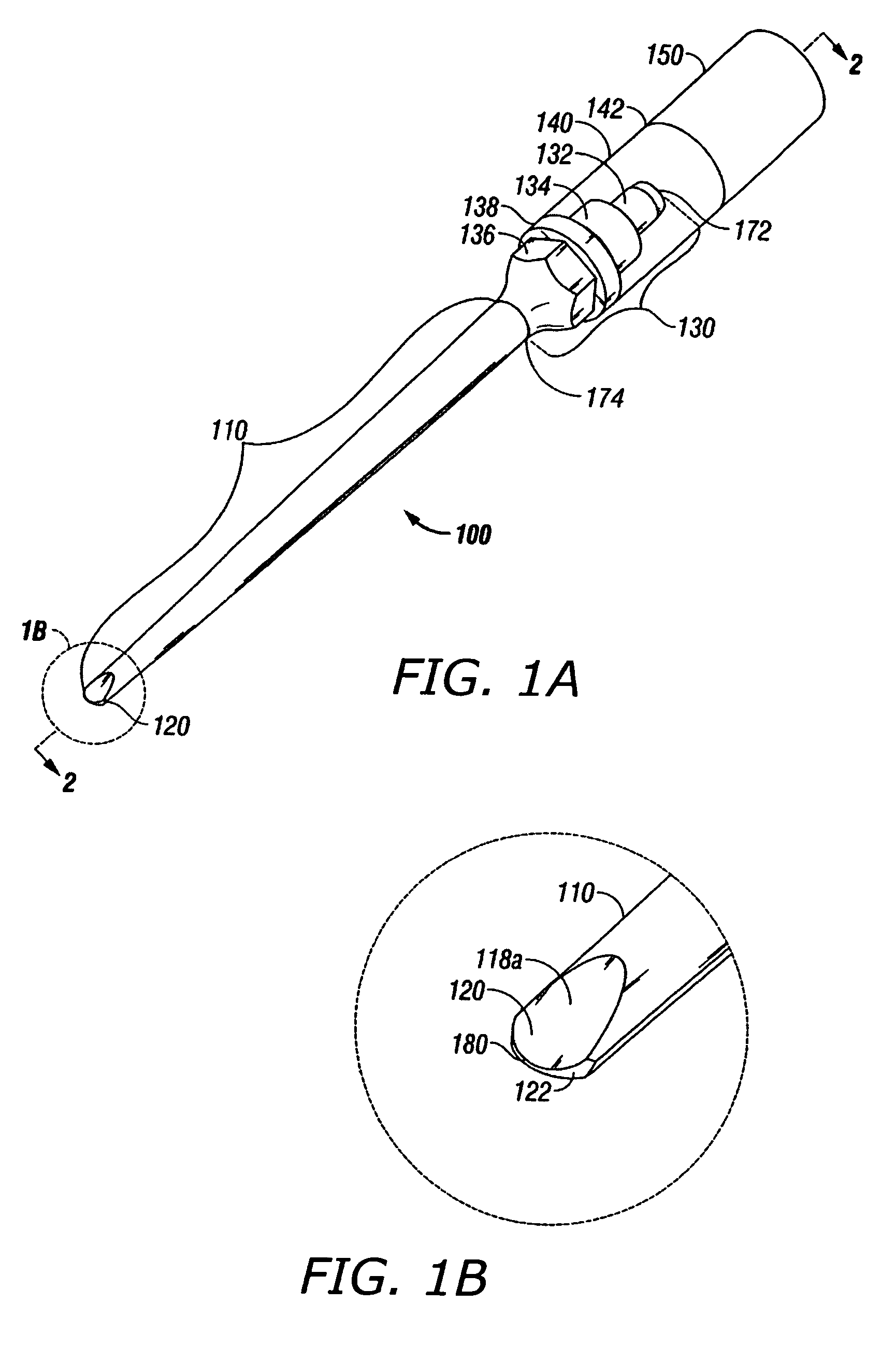

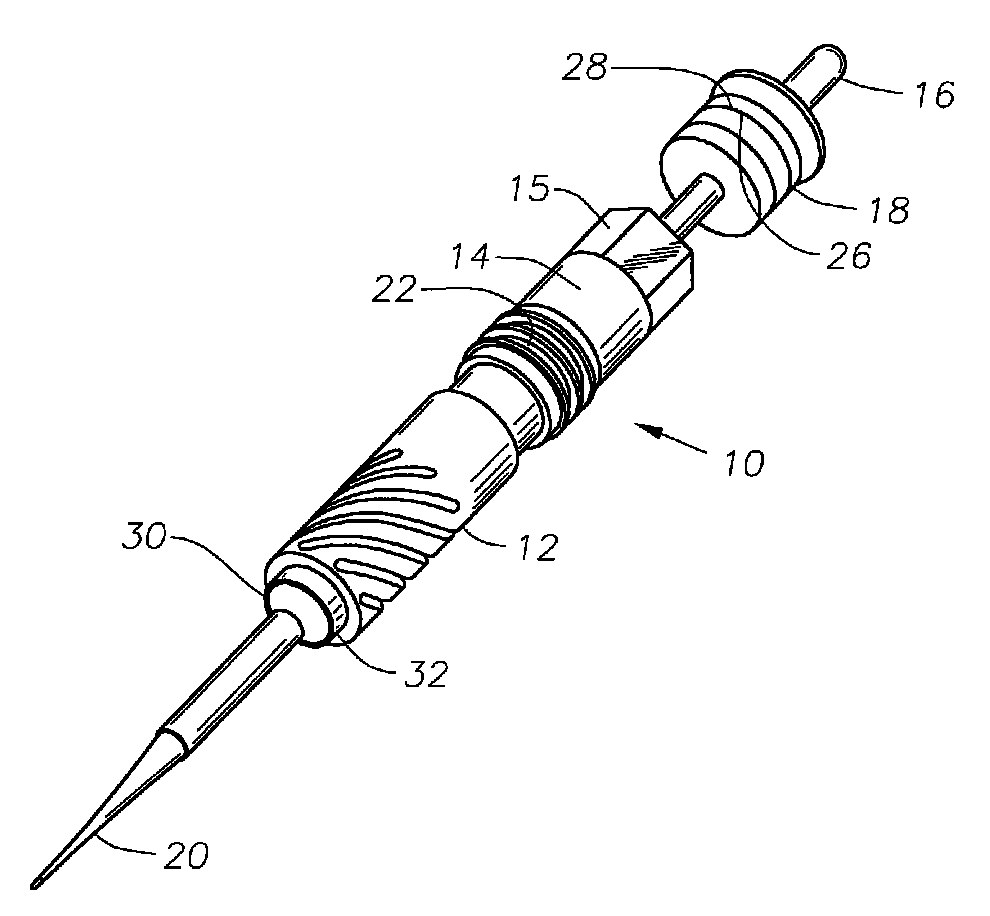

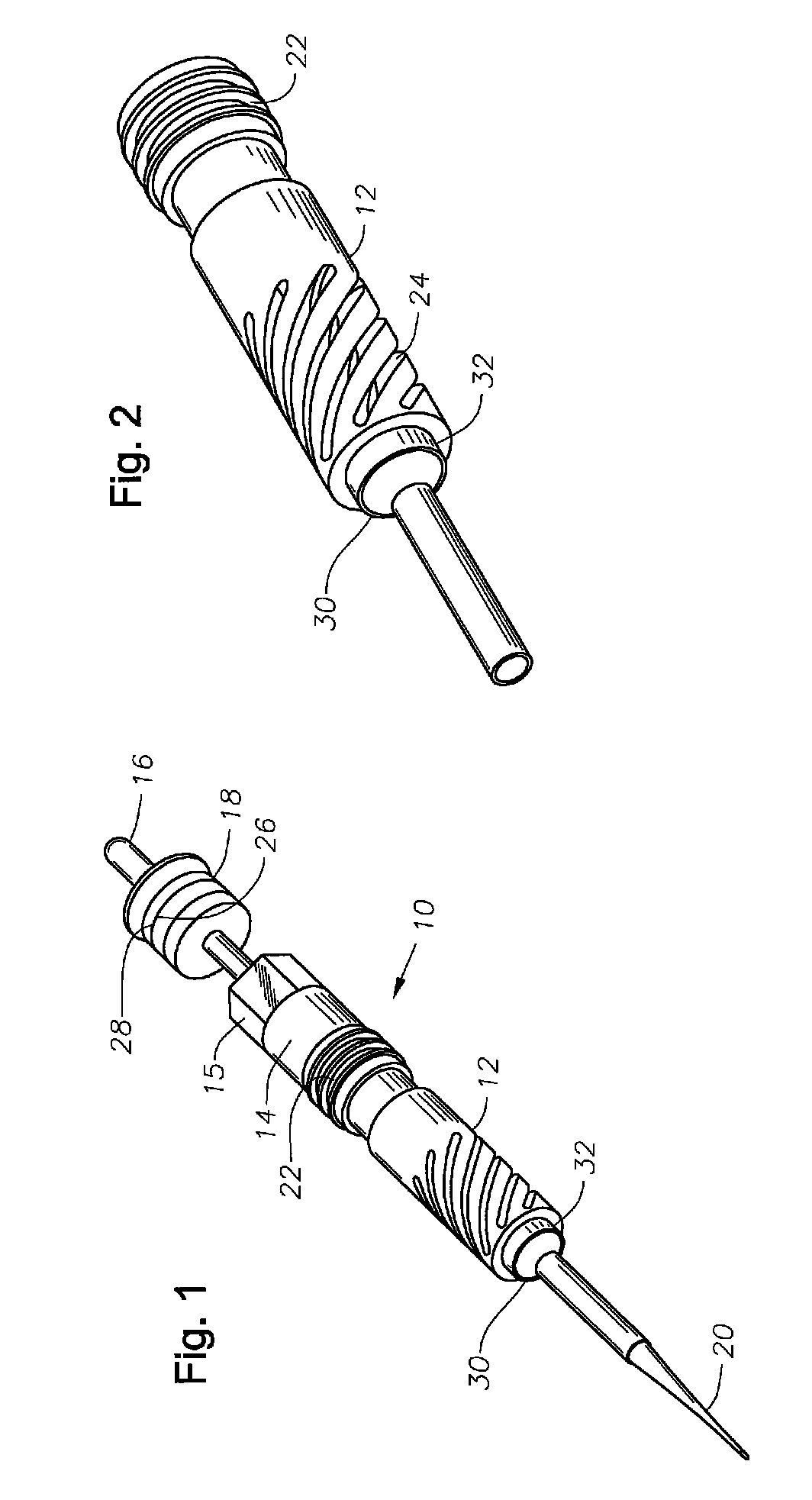

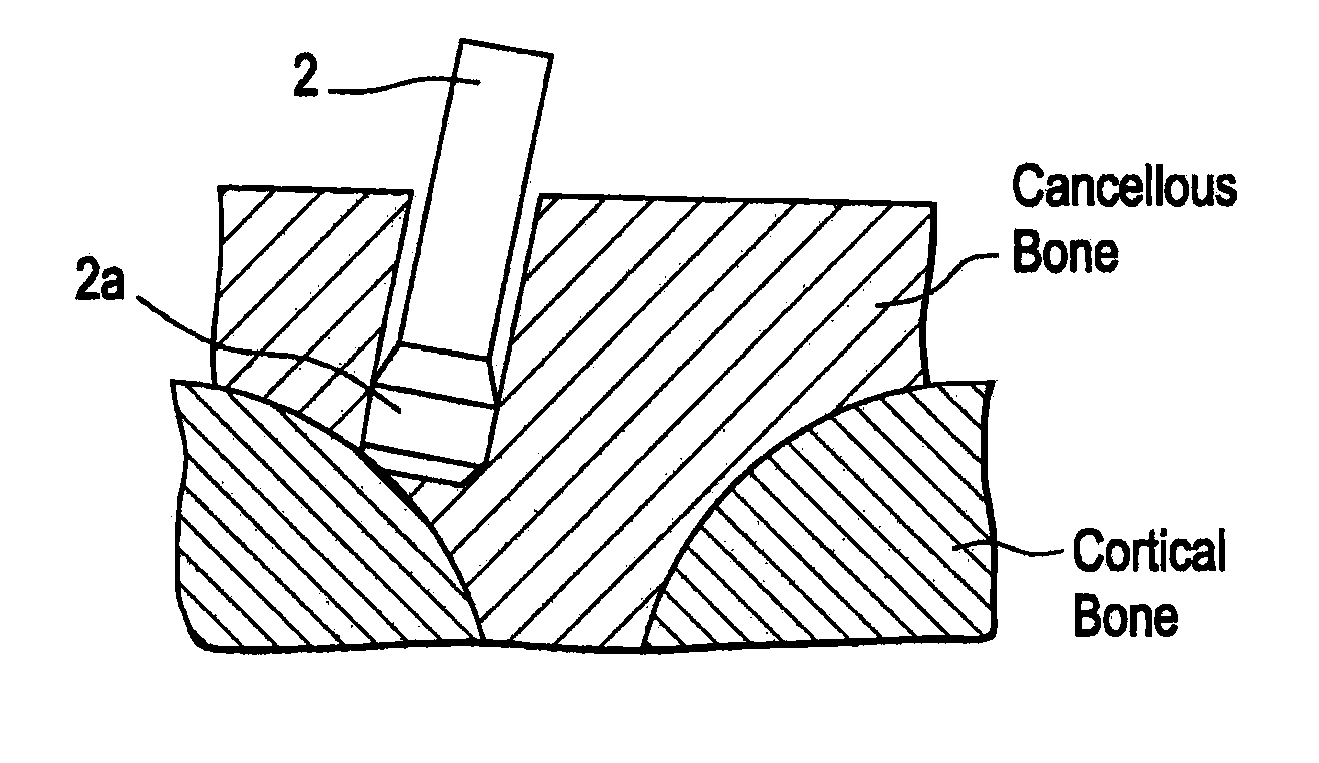

Ultrasonic horn for removal of hard tissue

ActiveUS20060235306A1Reduce the amplitudeMinimal reflectionUltrasonic/sonic/infrasonic diagnosticsSurgeryChiselSurgical department

Ultrasonic horns configured for use with a surgical ultrasonic handpiece including a resonator are described. The ultrasonic horns include an elongated member having a longitudinal internal channel extending partially therethrough. Disposed on the distal end of the elongated member is a chisel and awl shaped tip configured for cutting and / or abrading hard tissue, for example bone.

Owner:INTEGRA LIFESCI IRELAND

Ultrasonic horn for removal of hard tissue

ActiveUS8092475B2Minimal reflectionLimit transmitted soundUltrasonic/sonic/infrasonic diagnosticsSurgeryHard tissueBiomedical engineering

Ultrasonic horns configured for use with a surgical ultrasonic handpiece including a resonator are described. The ultrasonic horns include an elongated member having a longitudinal internal channel extending partially therethrough. Disposed on the distal end of the elongated member is a chisel and awl shaped tip configured for cutting and / or abrading hard tissue, for example bone.

Owner:INTEGRA LIFESCI IRELAND

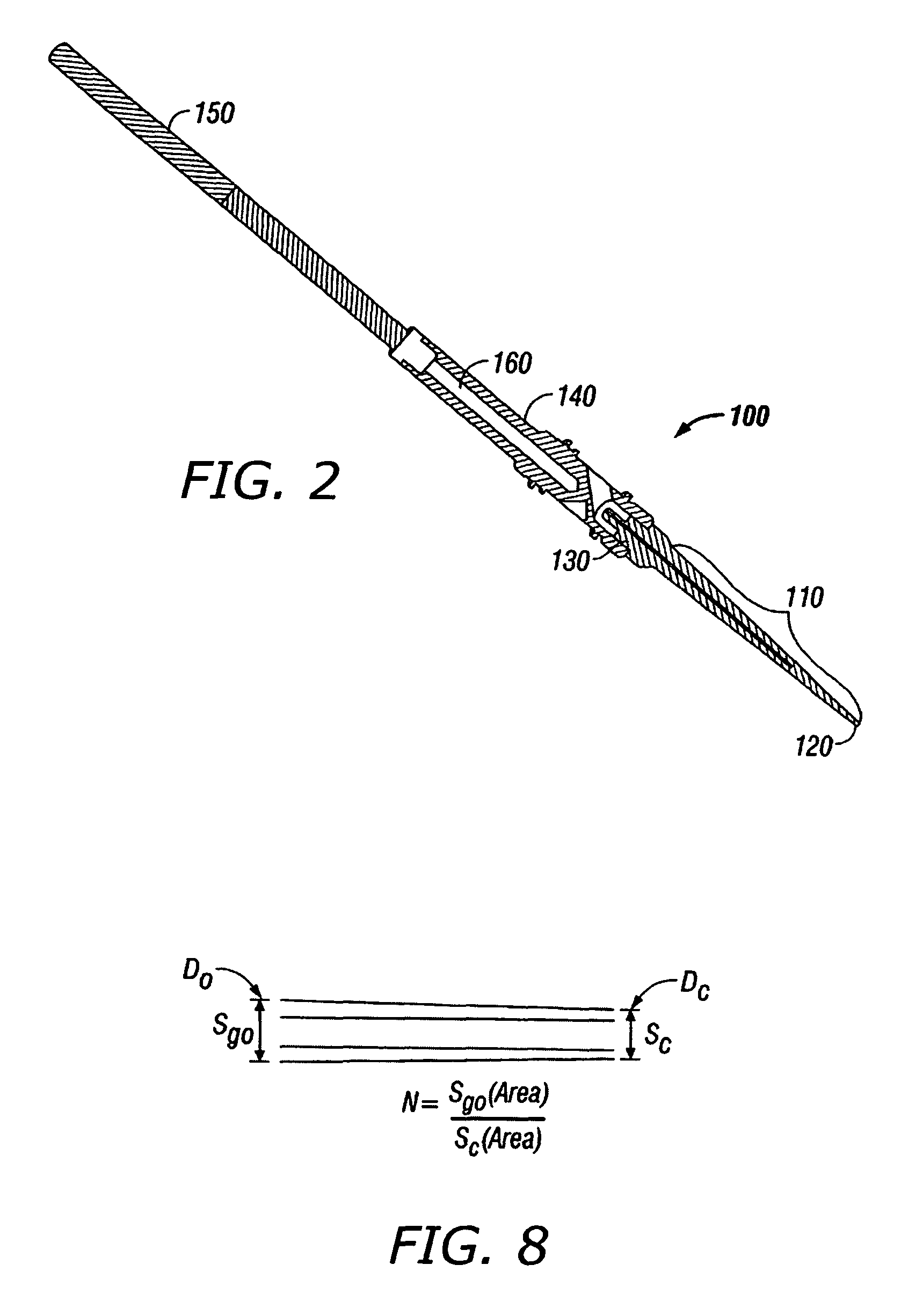

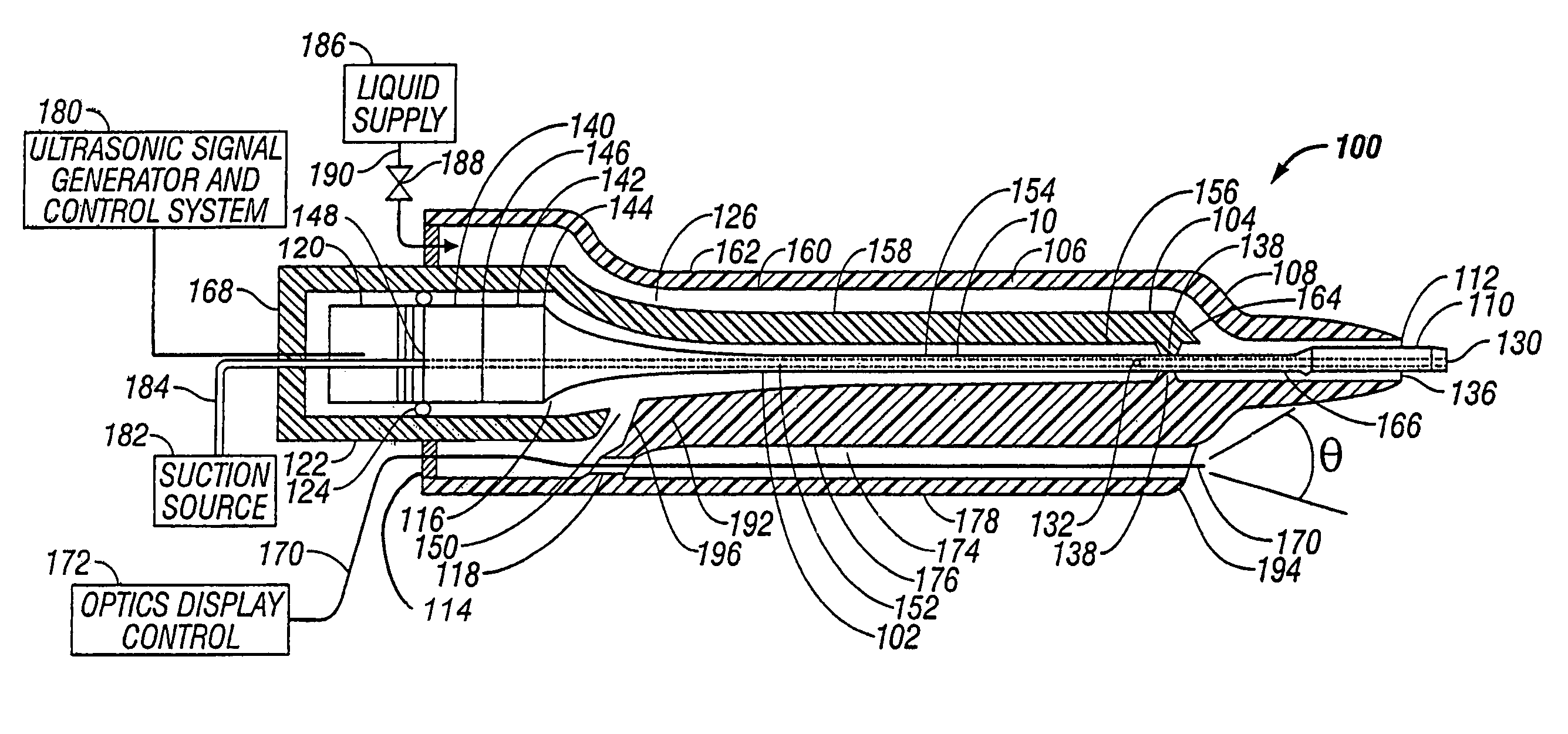

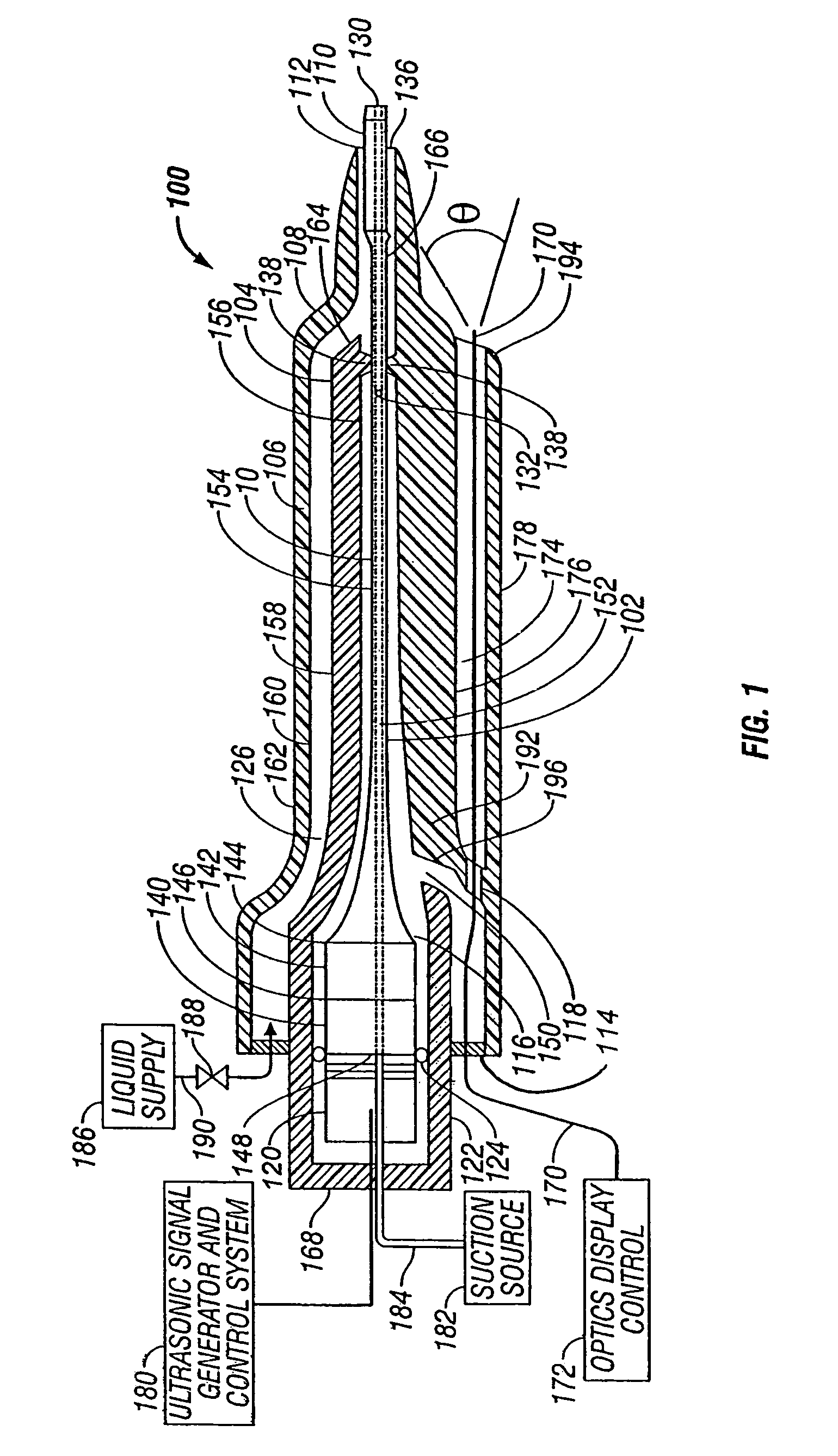

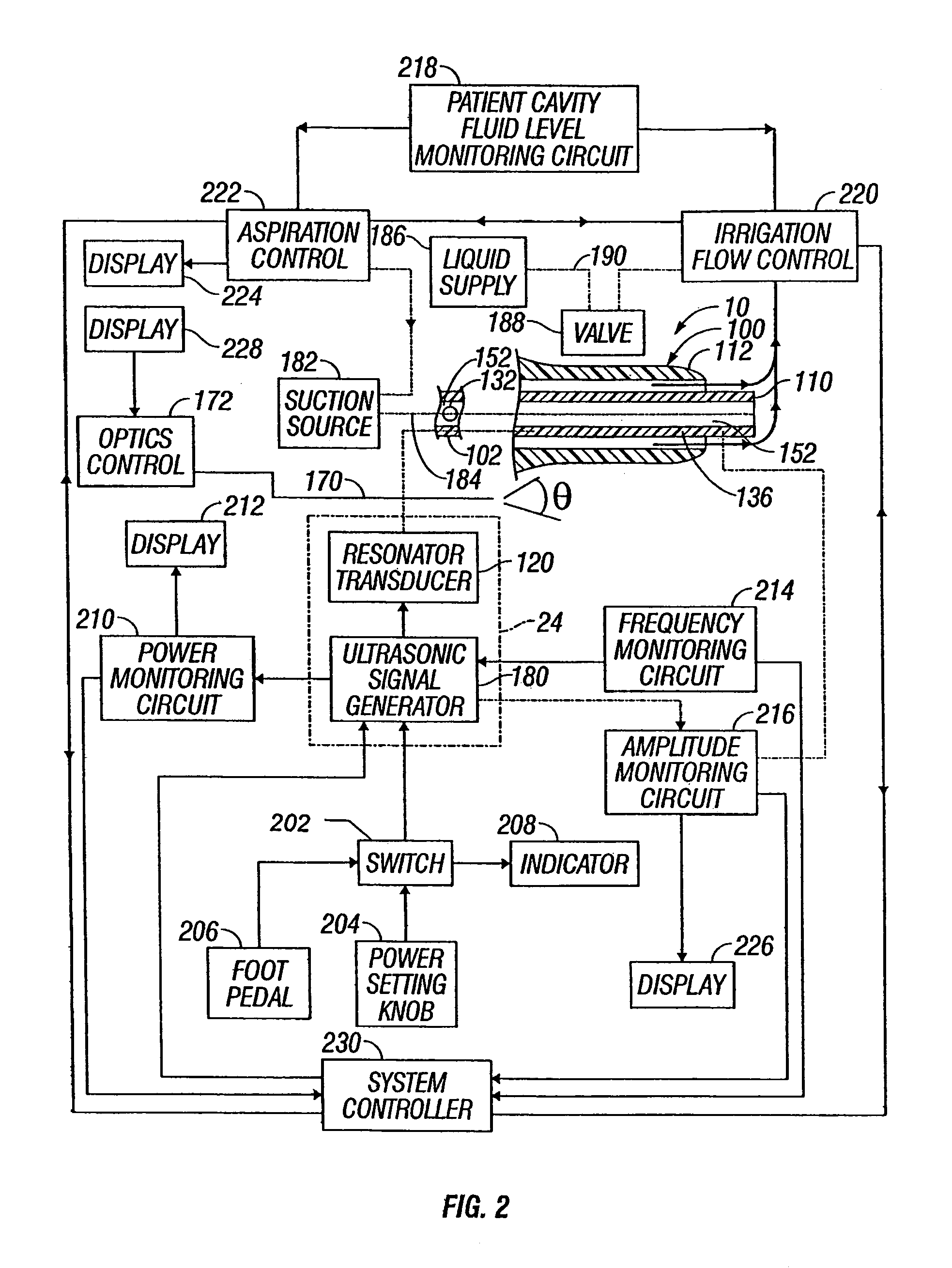

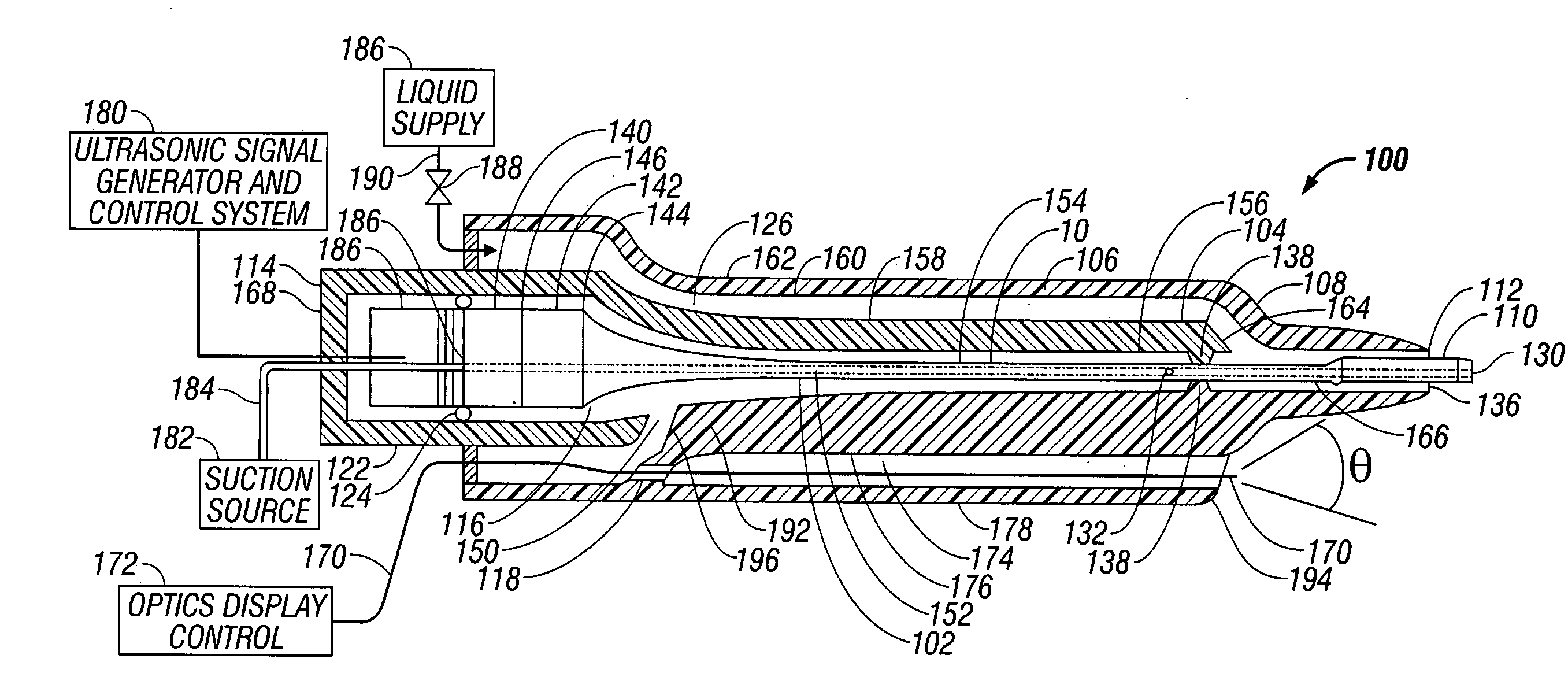

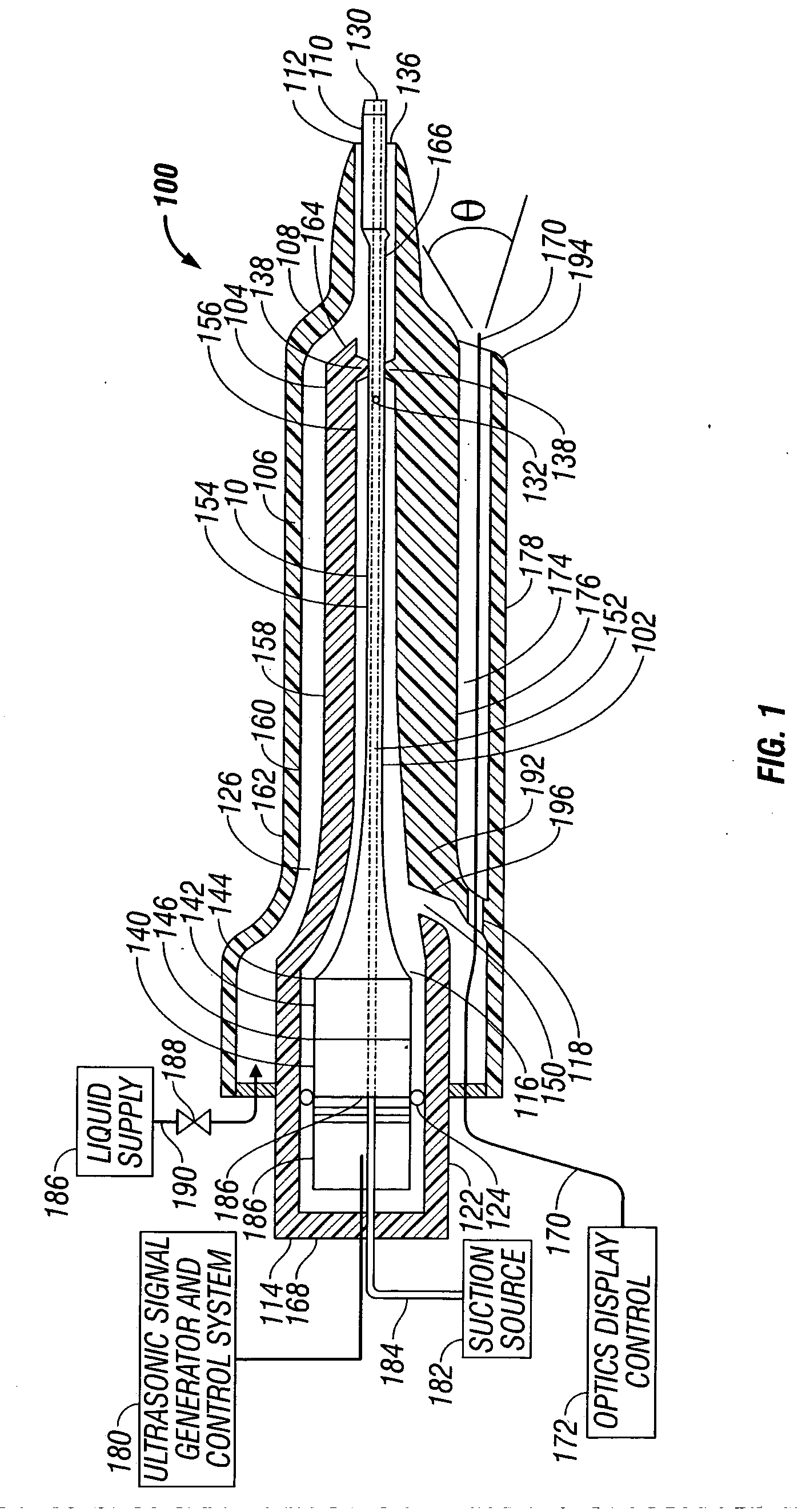

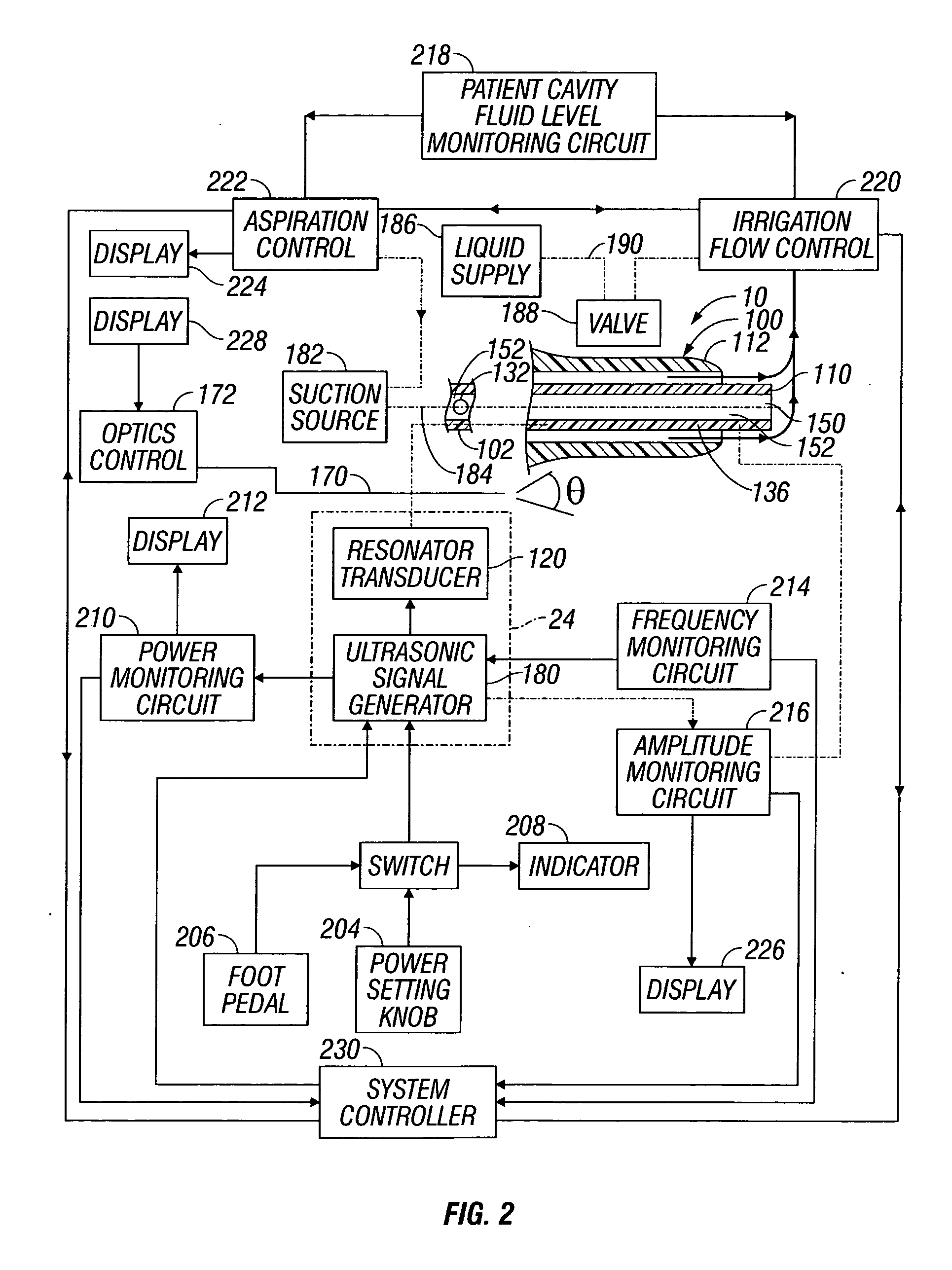

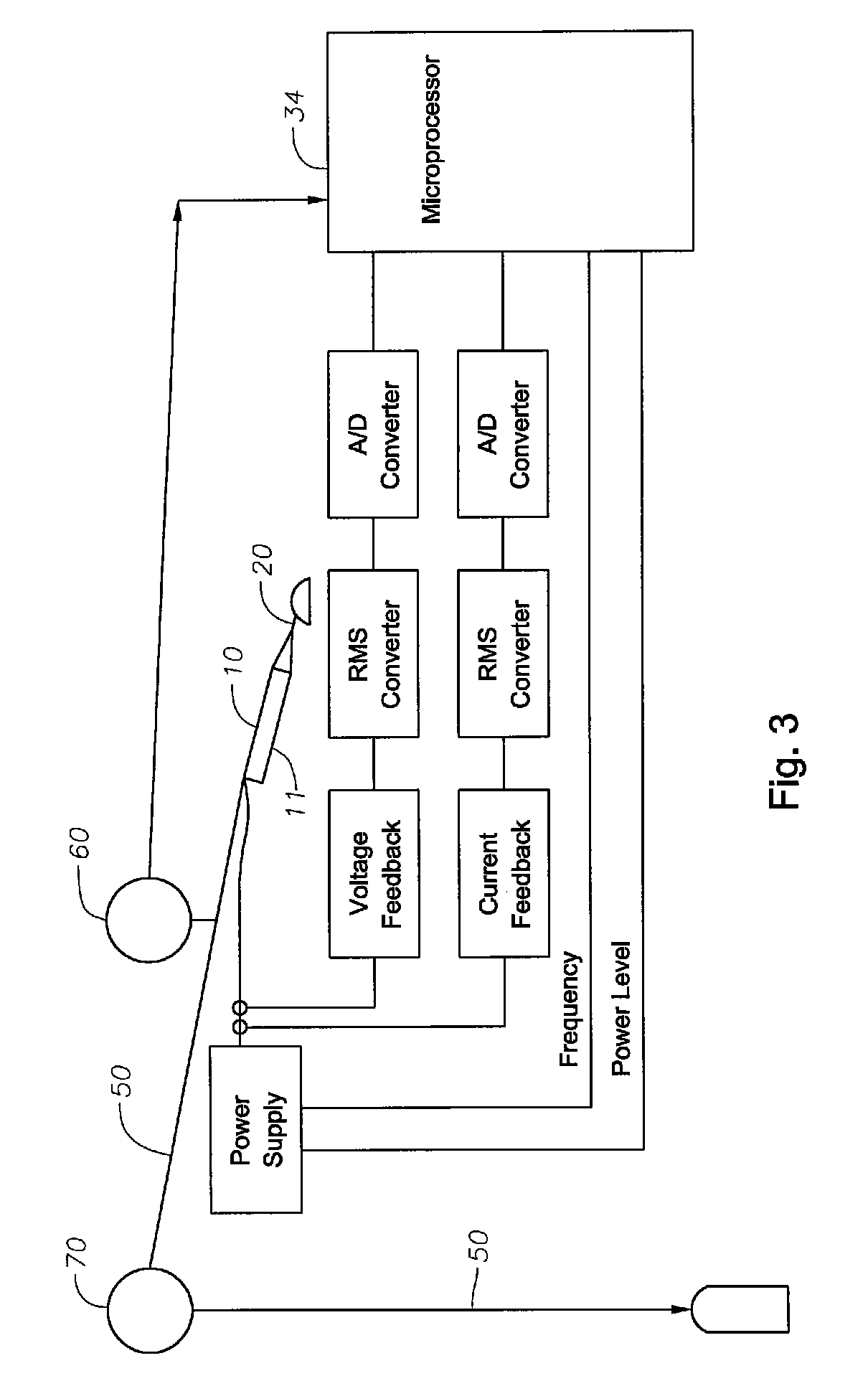

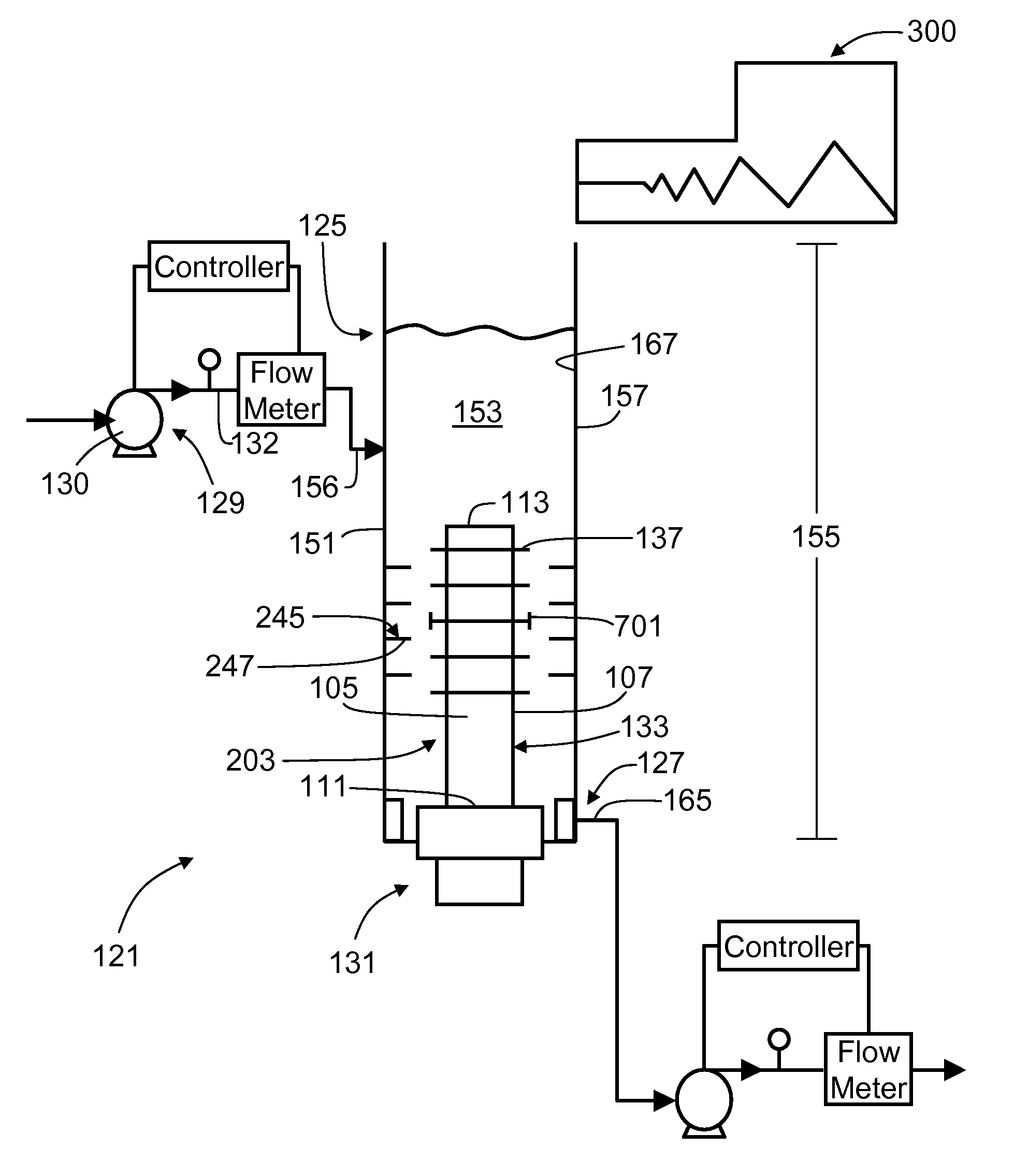

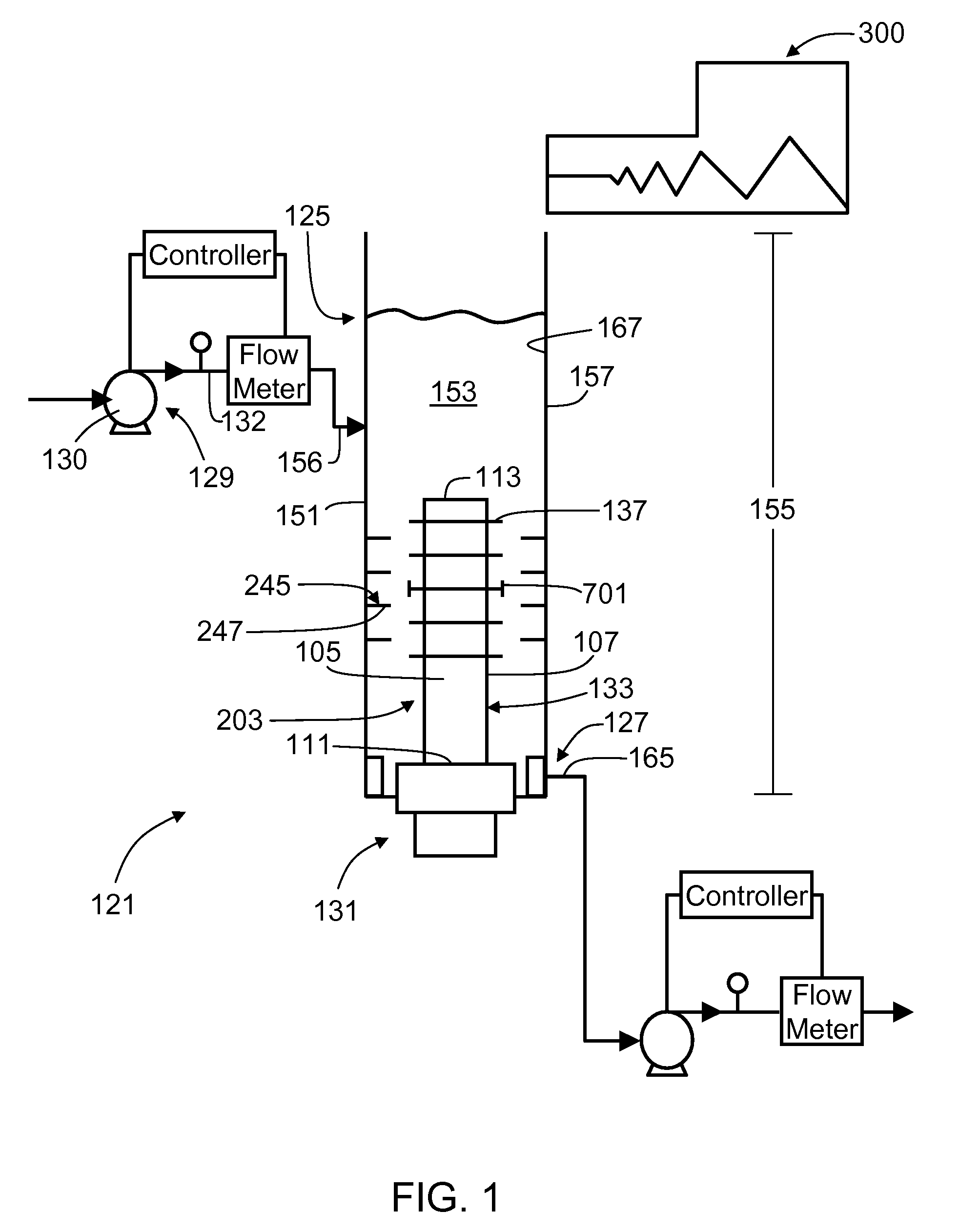

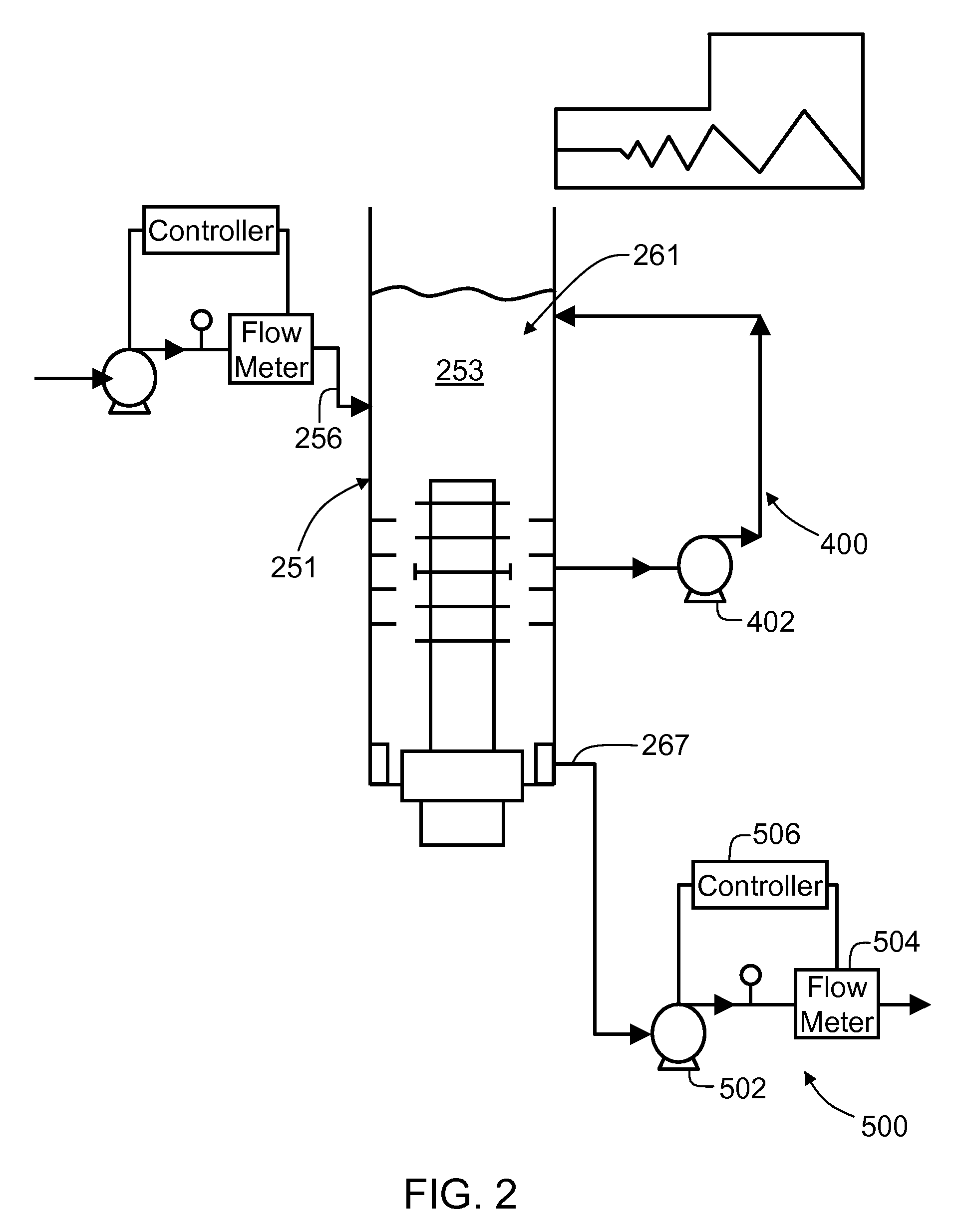

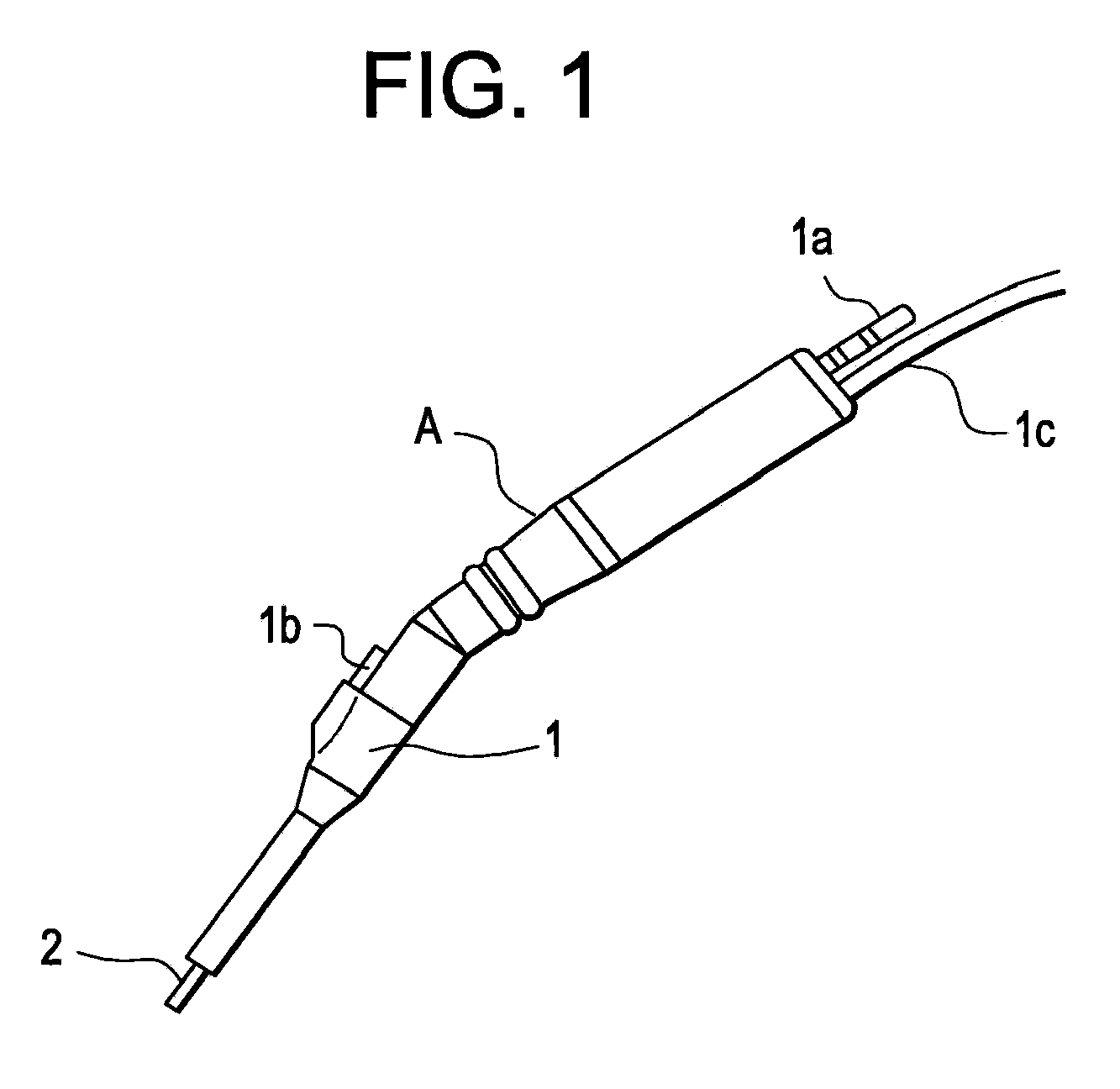

Endoscopic ultrasonic surgical aspirator for use in fluid filled cavities

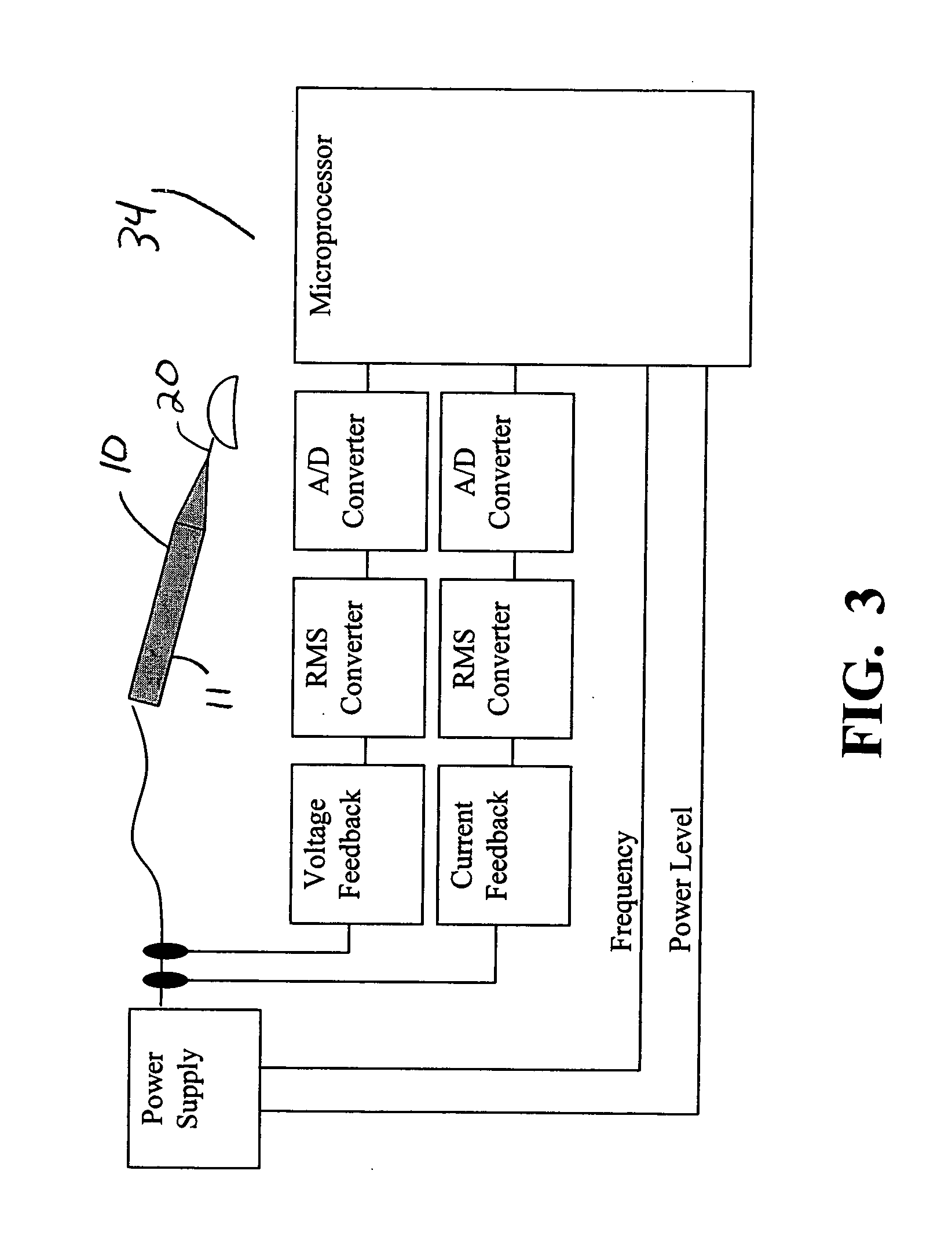

ActiveUS7871392B2Minimize damping vibrationVibration minimizationDiagnosticsSurgeryControl powerMedicine

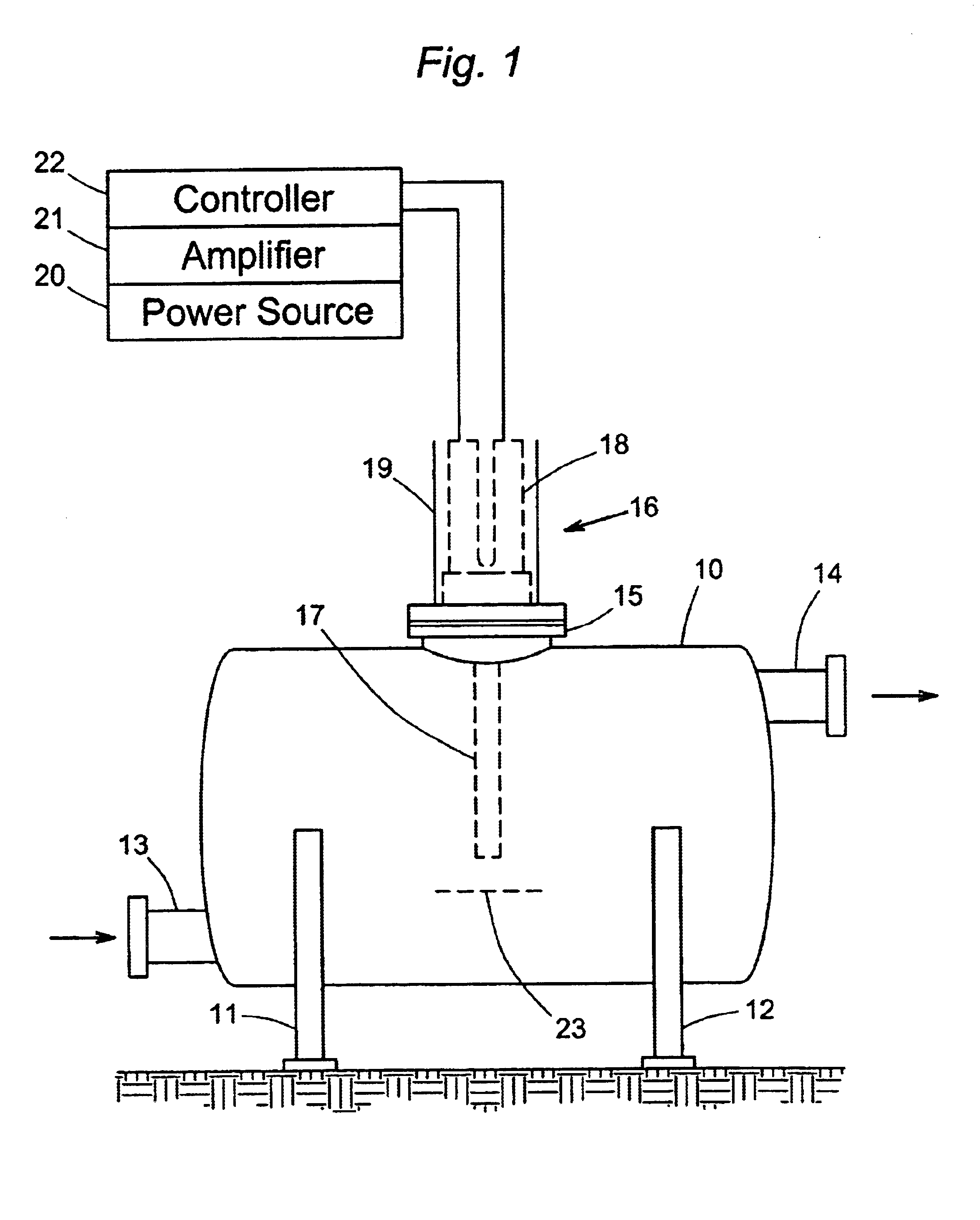

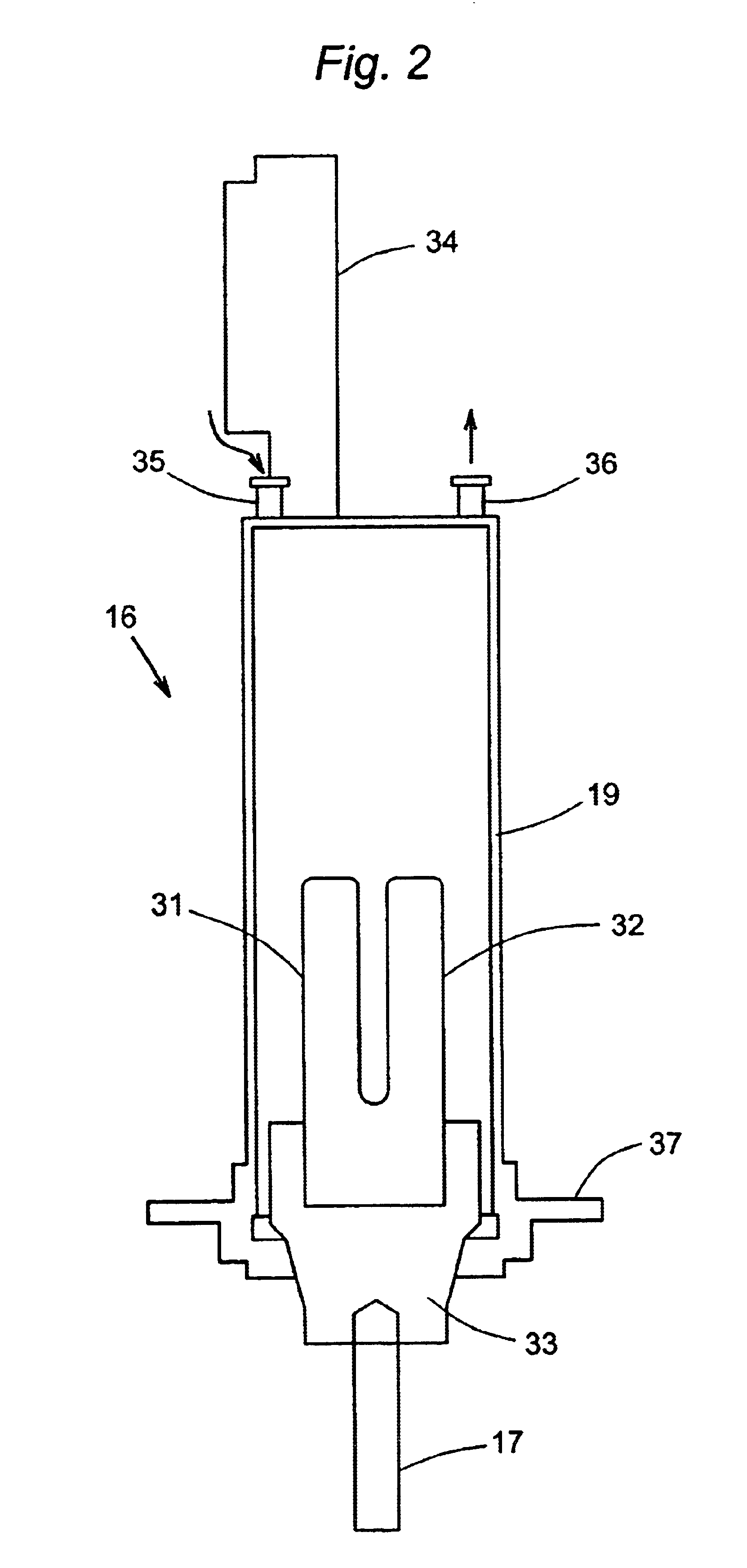

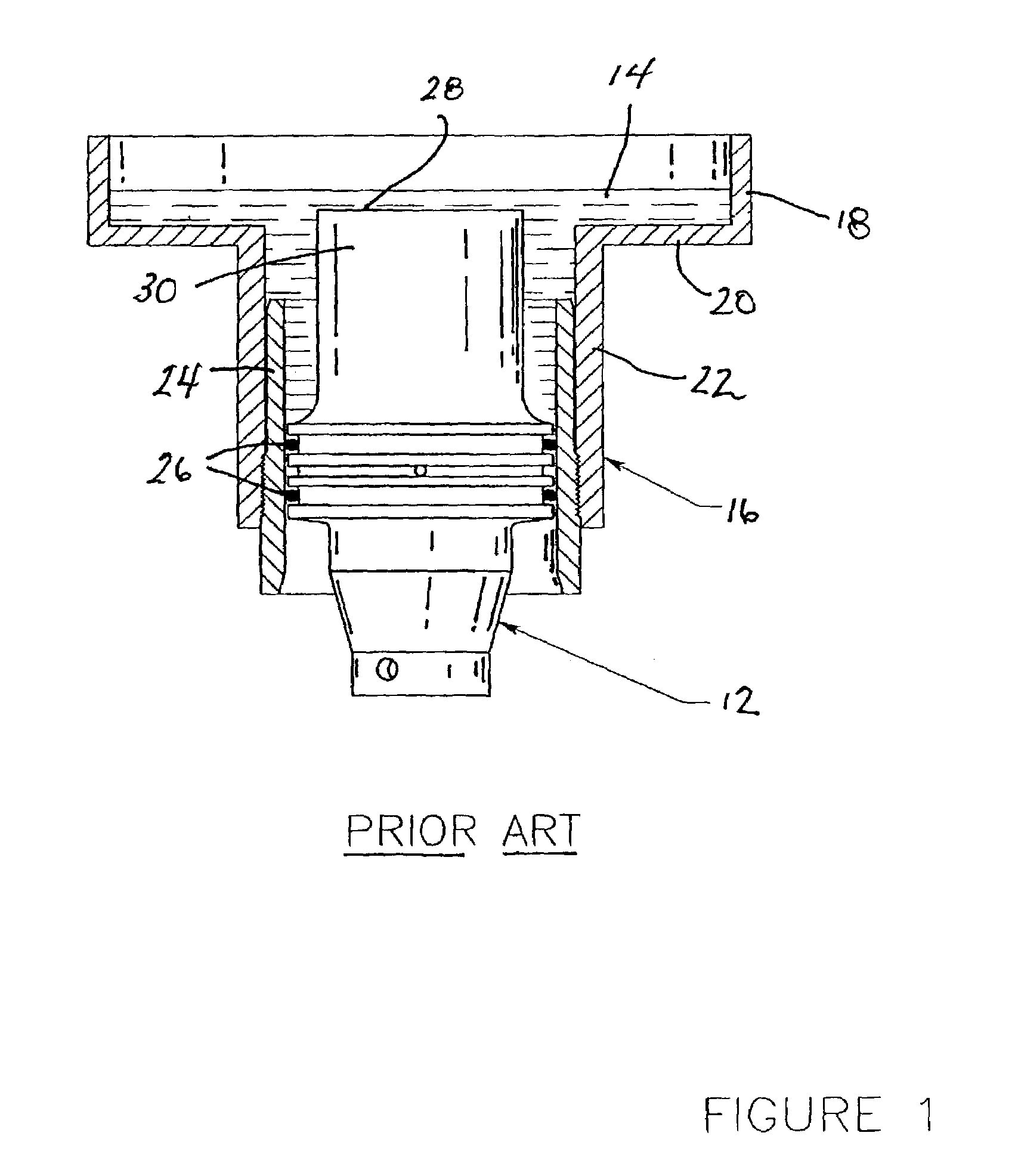

An ultrasonic horn assembly is configured so that irrigating fluid can be supplied only to a vibrating tip portion of the ultrasonic horn and so that suction aspiration can occur through a portion of the ultrasonic horn not in contact with the irrigating fluid. Controllers supplying irrigation fluid during a surgical procedure and controlling suction aspiration via monitoring of fluid level in the patient cavity are operatively coupled one to another to coordinate control of the fluid level in the patient cavity. Circuitry controlling power, frequency and amplitude of the tip of the ultrasonic horn occurring as a result of operation of a source of ultrasonic signal generating power controls either or both the supply of irrigation fluid and the suction aspiration so as to minimize damping of vibration of the tip of the ultrasonic horn. An optical viewing element is provided to view the tip of the ultrasonic horn.

Owner:INTEGRA LIFESCI IRELAND

Endoscopic ultrasonic surgical aspirator for use in fluid filled cavities

ActiveUS20070162050A1Minimize damping vibrationVibration minimizationDiagnosticsSurgeryControl powerMedicine

An ultrasonic horn assembly is configured so that irrigating fluid can be supplied only to a vibrating tip portion of the ultrasonic horn and so that suction aspiration can occur through a portion of the ultrasonic horn not in contact with the irrigating fluid. Controllers supplying irrigation fluid during a surgical procedure and controlling suction aspiration via monitoring of fluid level in the patient cavity are operatively coupled one to another to coordinate control of the fluid level in the patient cavity. Circuitry controlling power, frequency and amplitude of the tip of the ultrasonic horn occurring as a result of operation of a source of ultrasonic signal generating power controls either or both the supply of irrigation fluid and the suction aspiration so as to minimize damping of vibration of the tip of the ultrasonic horn. An optical viewing element is provided to view the tip of the ultrasonic horn.

Owner:INTEGRA LIFESCI IRELAND

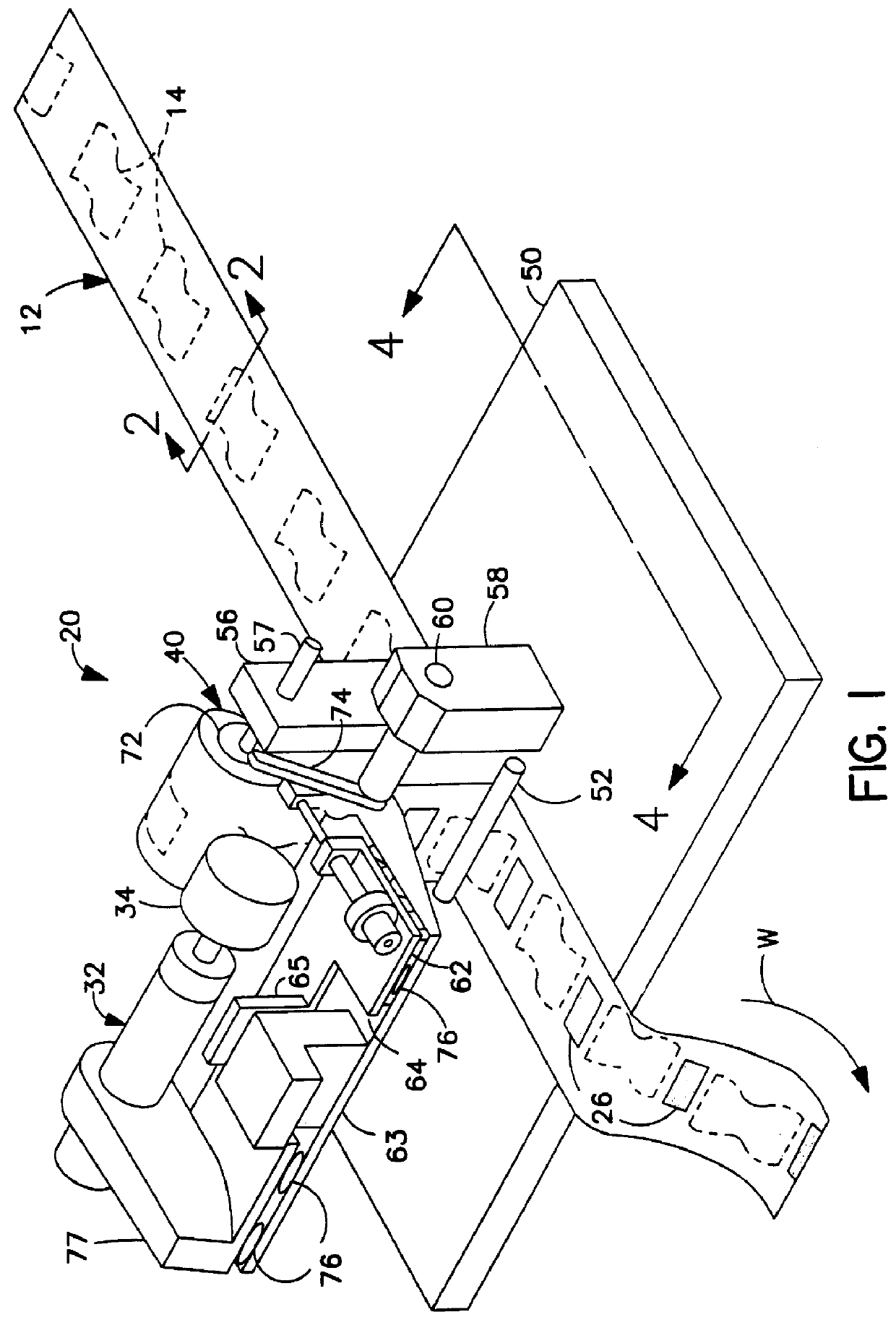

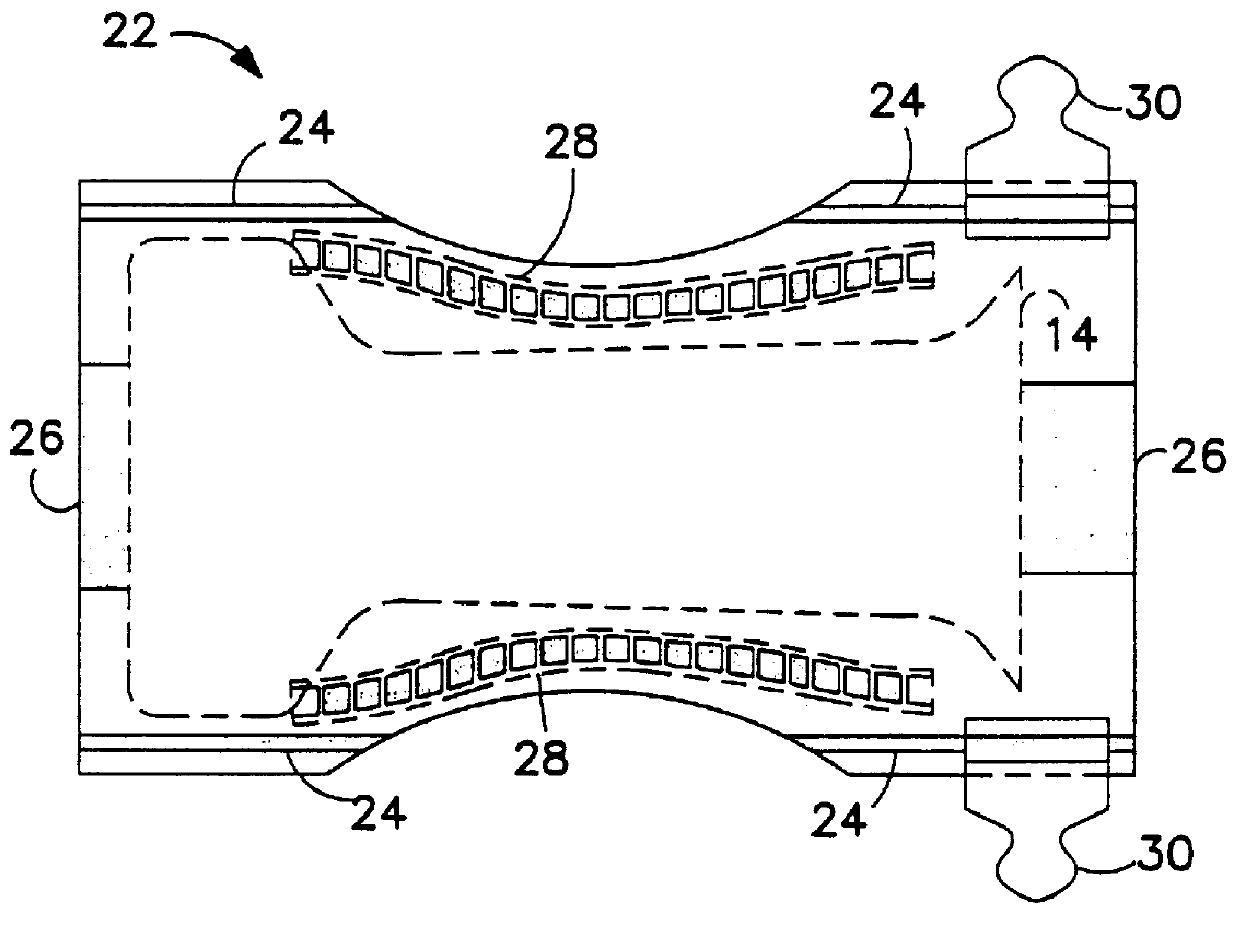

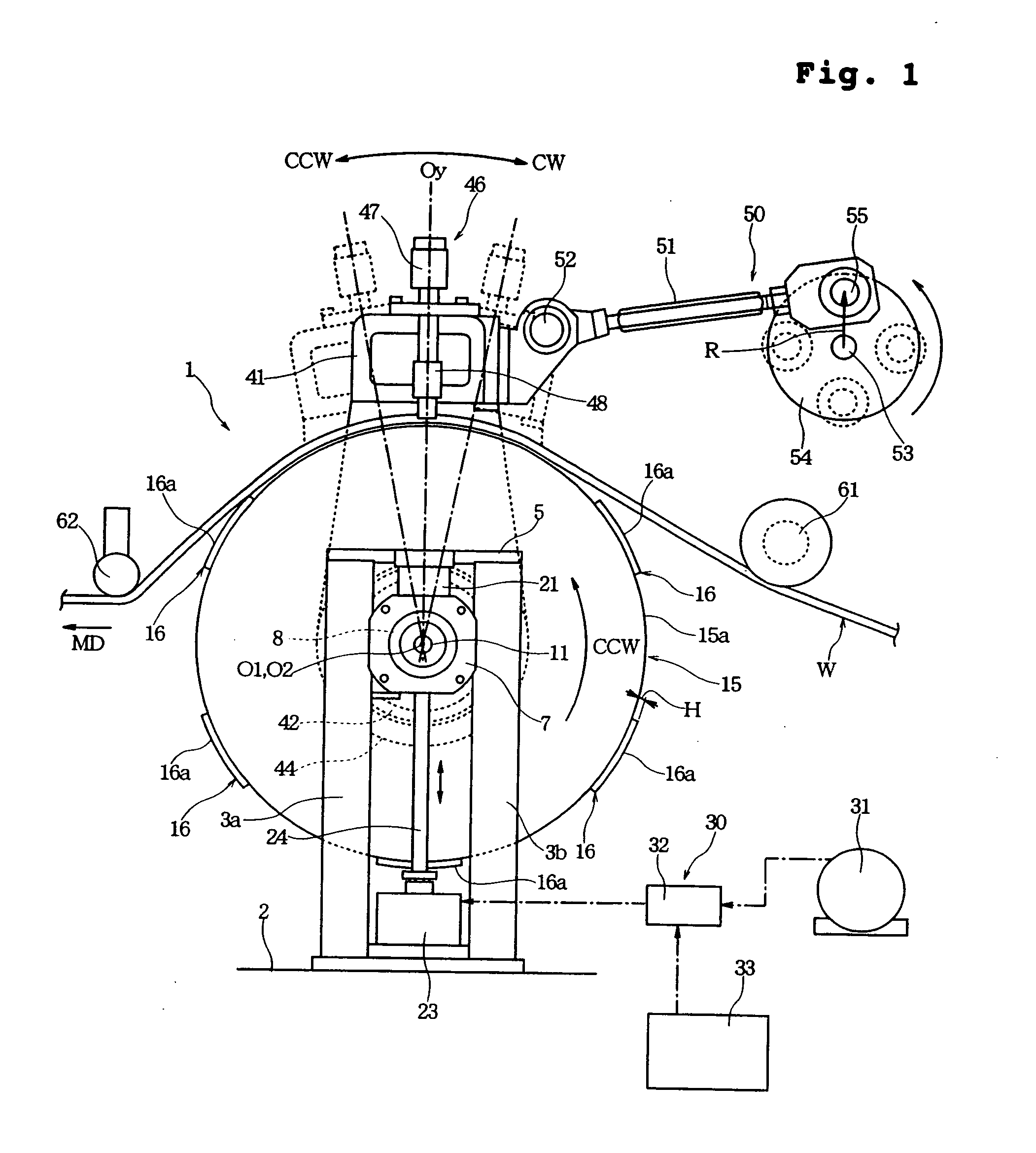

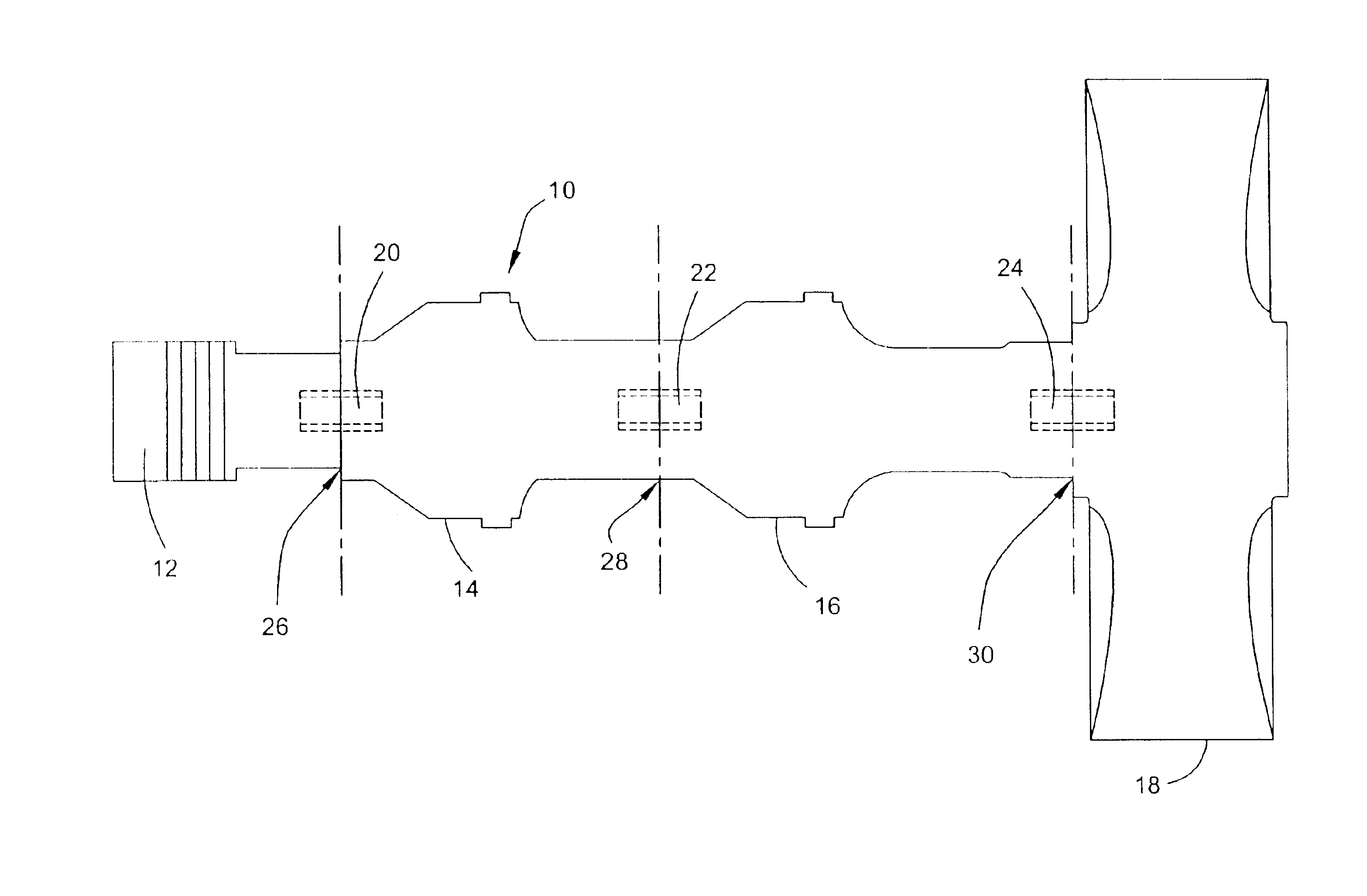

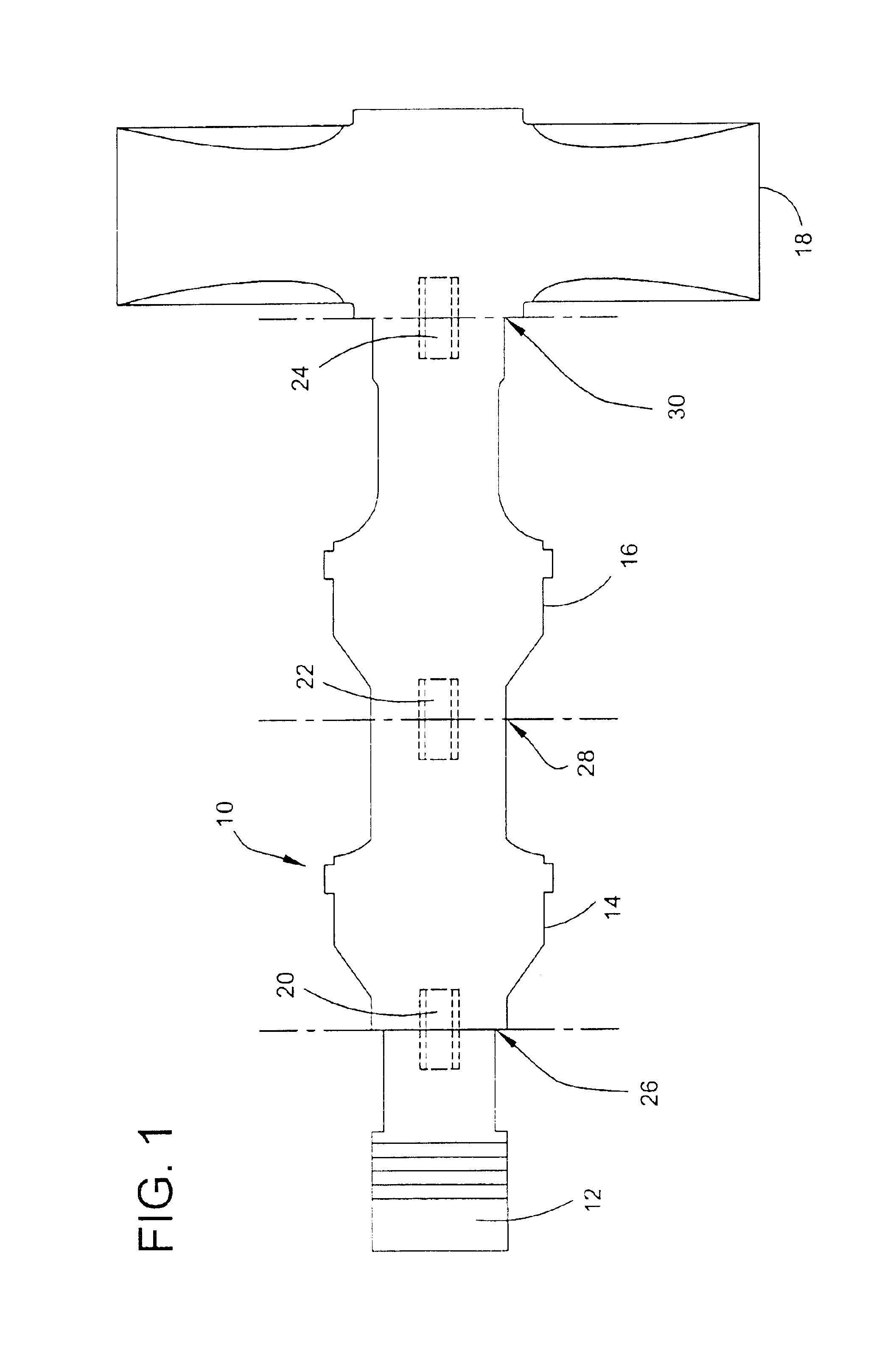

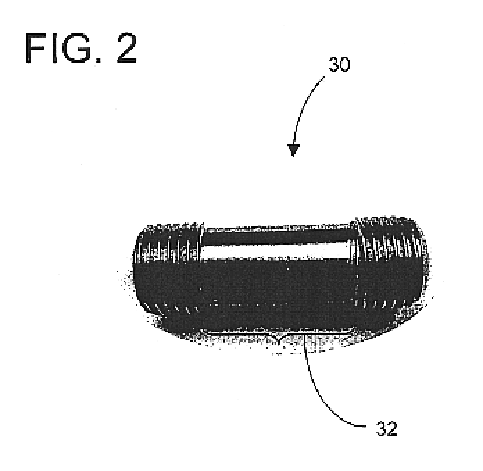

Methods and apparatus for intermittent rotary ultrasonic bonding system

InactiveUS6123792AAvoids deleterious bounceExtended service lifeLaminationLamination apparatusFiberSurface velocity

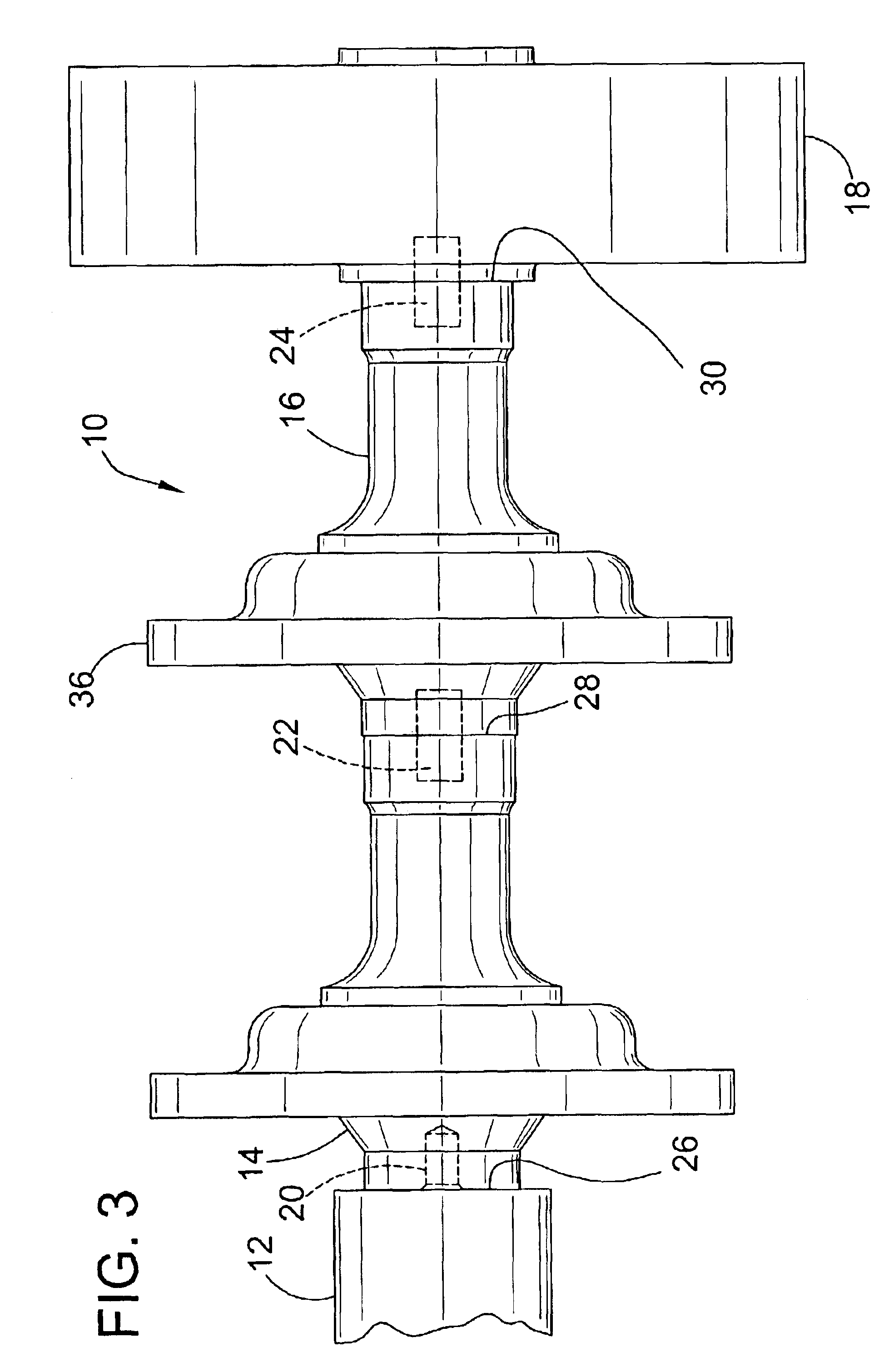

This invention relates to apparatus and methods for intermittently bonding a substrate web in fabricating a blank subassembly for an absorbent article. The invention comprises ultrasonic bonding apparatus including an anvil roll, a substrate web thereon, and at least one rotary ultrasonic horn. The substrate web can comprise at least first and second layers of material. The rotary ultrasonic horn, in combination with the anvil roll, ultrasonically bonds intermittent segments of the first and second layers of the substrate web to each other. Such intermittent bonds can comprise end seals for the absorbent articles. The ultrasonic horn and anvil roll are periodically separated from each other to provide the intermittent bonding of the substrate web. An actuator apparatus periodically moves the anvil roll and ultrasonic horn from engaging contact with each other preventing bond formation. The actuator apparatus can include a cam mechanism moving one of the anvil roll and ultrasonic horn from engaging contact with the other during rotation of the rotary ultrasonic horn. The cam mechanism can create a physical gap between the ultrasonic horn and the anvil roll. The cam mechanism moves either the ultrasonic horn and the anvil roll toward the other of the ultrasonic horn and anvil roll at a velocity of no more than about 80 millimeters / second to prevent bounce or impact loading when the horn and anvil roll are in engaging contact. The anvil roll comprises a substrate-receiving surface generally moving the substrate web through the nip at a surface speed of at least 300 meters per minute. The ultrasonic system generally creates bonds between the first and second layers of the substrate web at least about 600 times per minute.

Owner:DUKANE IAS LLC

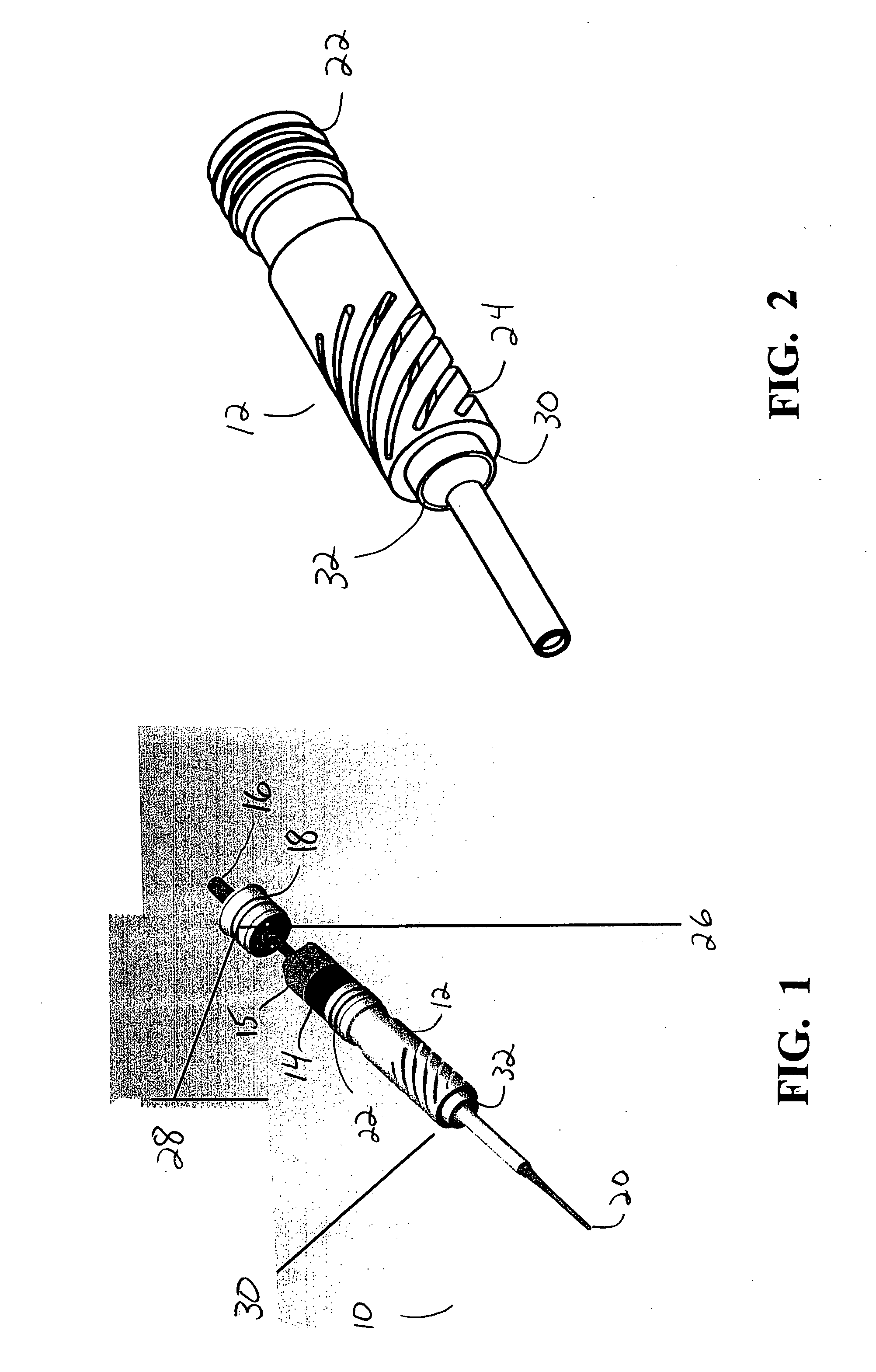

Ultrasound handpiece

A handpiece having at least one set of piezoelectric elements polarized to produce longitudinal motion when excited at the relevant resonant frequency. The piezoelectric crystals are connected to an ultrasonic horn to which a cutting tip is attached. The horn and / or the cutting tip contains a plurality of diagonal slits or grooves. The slits or grooves produce optimized torsional movement in the cutting tip when the piezoelectric crystals are excited at a second resonant frequency.

Owner:ALCON INC

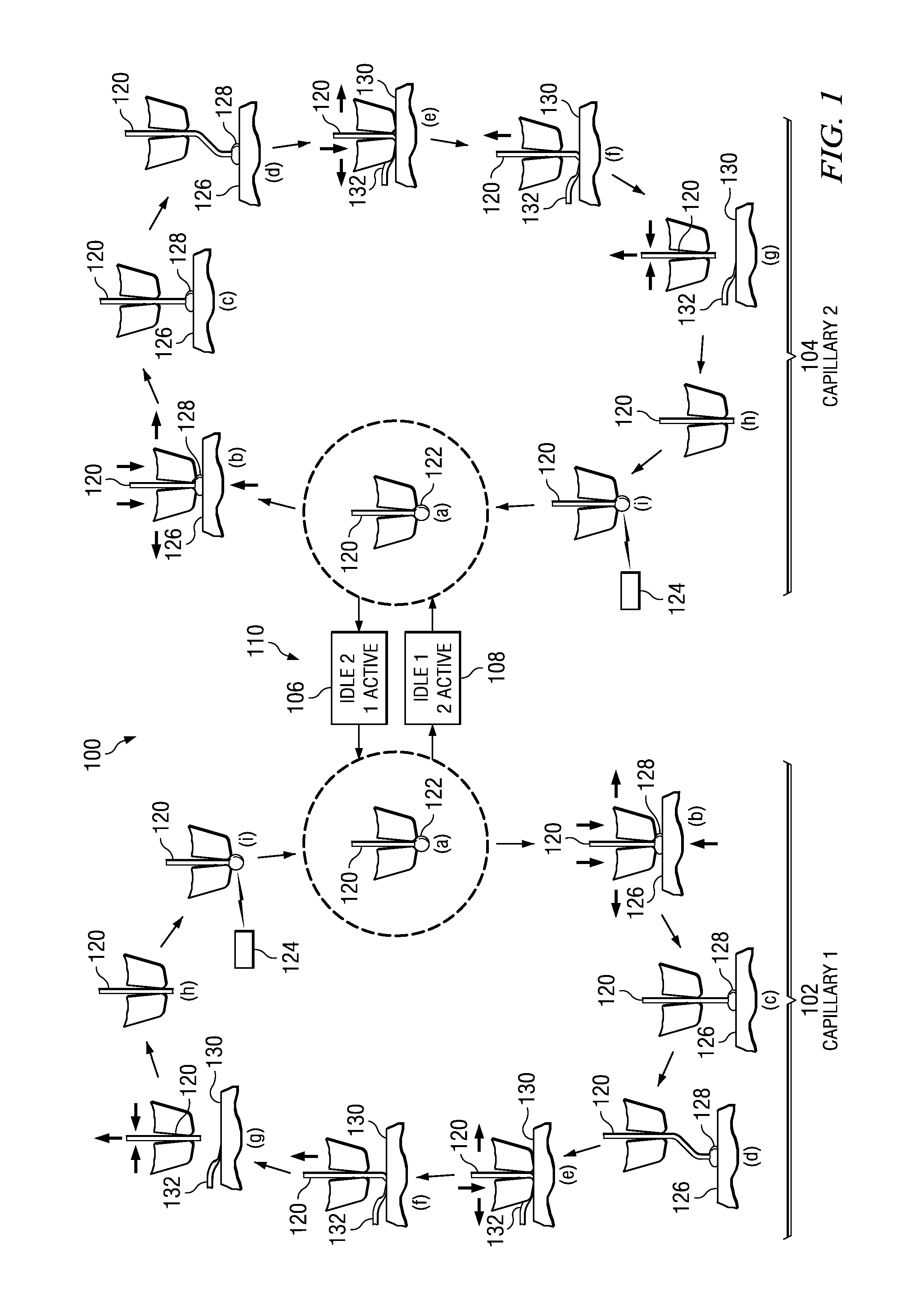

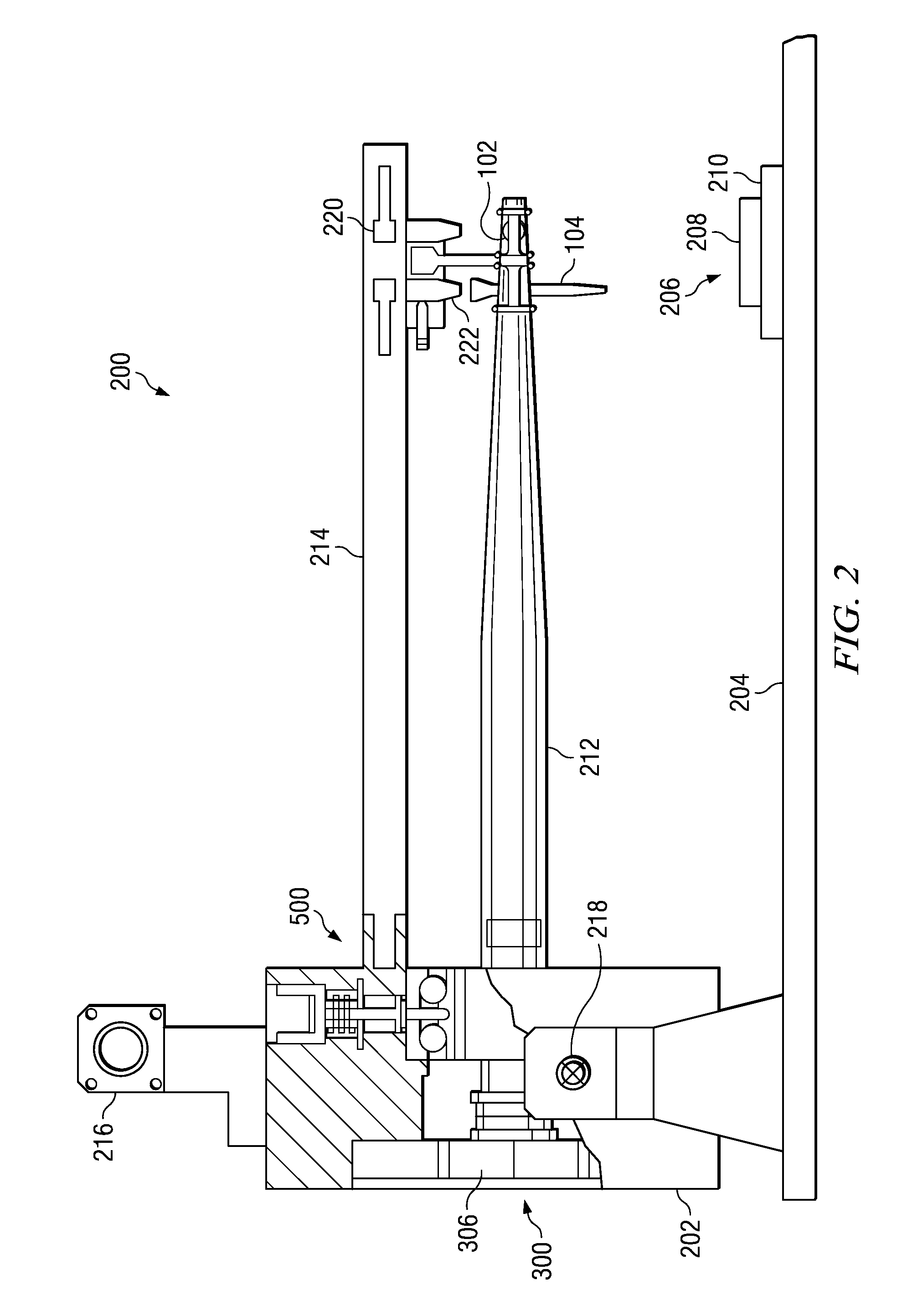

Dual Capillary IC Wirebonding

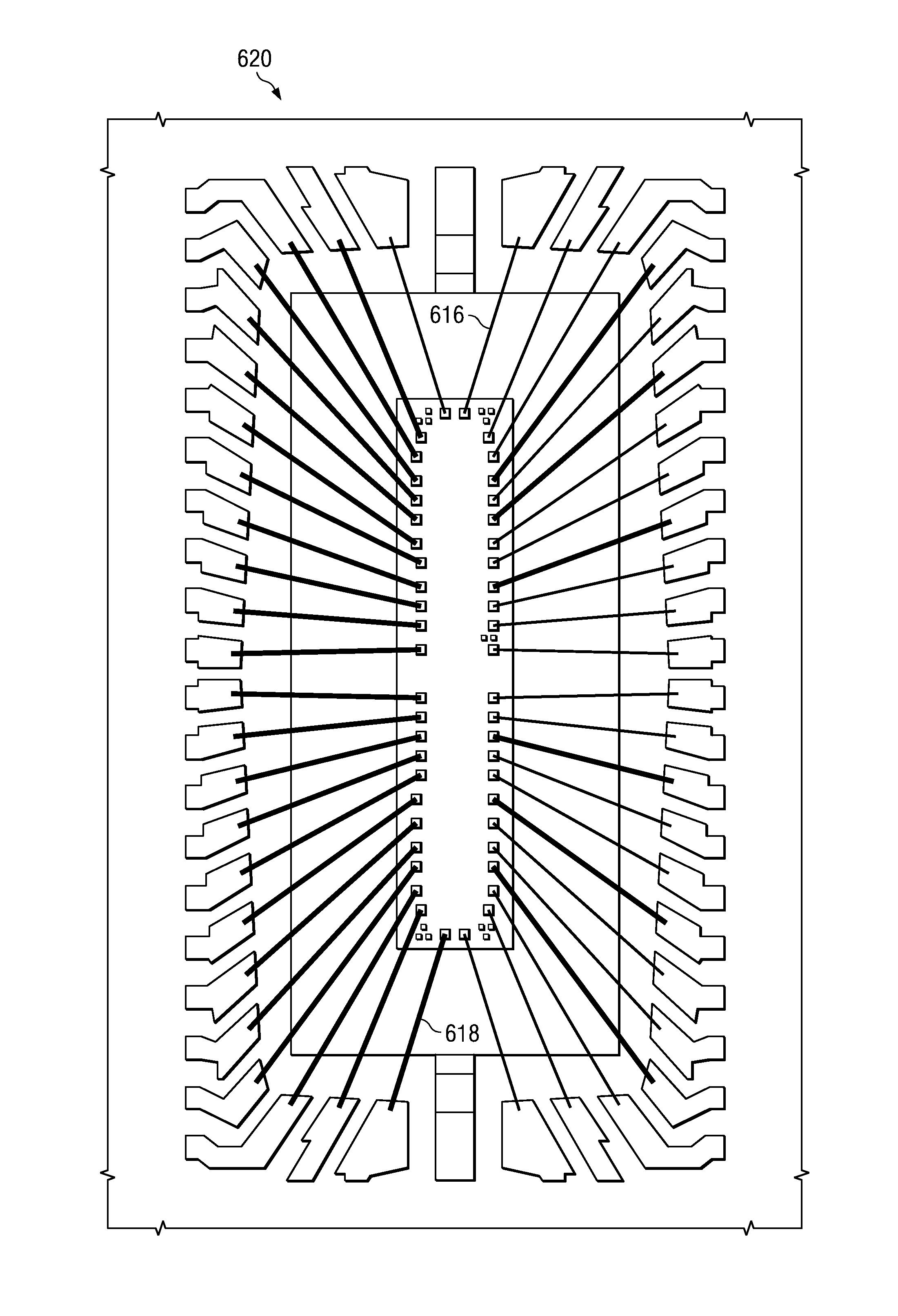

ActiveUS20110272449A1Add equipmentImprove processing throughputSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

The invention discloses apparatus and methods for the formation of bond wires in integrated circuit assemblies by attaching two separate wires using a dual capillary bond head. The separate wires are preferably non-identical, for example, being of different gauges and / or material composition. According to a preferred embodiment of the invention, dual capillary bond head apparatus includes a rotatable ultrasonic horn with a pair of capillaries for selectably dispensing separate strands of bond wire and for forming bonds on bond targets. According to another aspect of the invention, a method is provided for dual capillary IC wirebonding including steps for using two dual capillary bond heads for contemporaneously attaching non-identical bond wires to selected bond targets on one or more IC package assemblies.

Owner:TEXAS INSTR INC

Method of Operating an Ultrasound Handpiece

A method employing a handpiece having at least one set of piezoelectric elements polarized to produce longitudinal motion when excited at the relevant resonant frequency. The piezoelectric crystals are connected to an ultrasonic horn to which a cutting tip is attached. The horn and / or the cutting tip contains a plurality of diagonal slits or grooves. The slits or grooves produce optimized torsional movement in the cutting tip when the piezoelectric crystals are excited at a second resonant frequency. When in torsional mode, material may clog the cutting tip. The present method includes the step of providing a pulse of longitudinal movement of the tip when clogging is detected.

Owner:ALCON INC

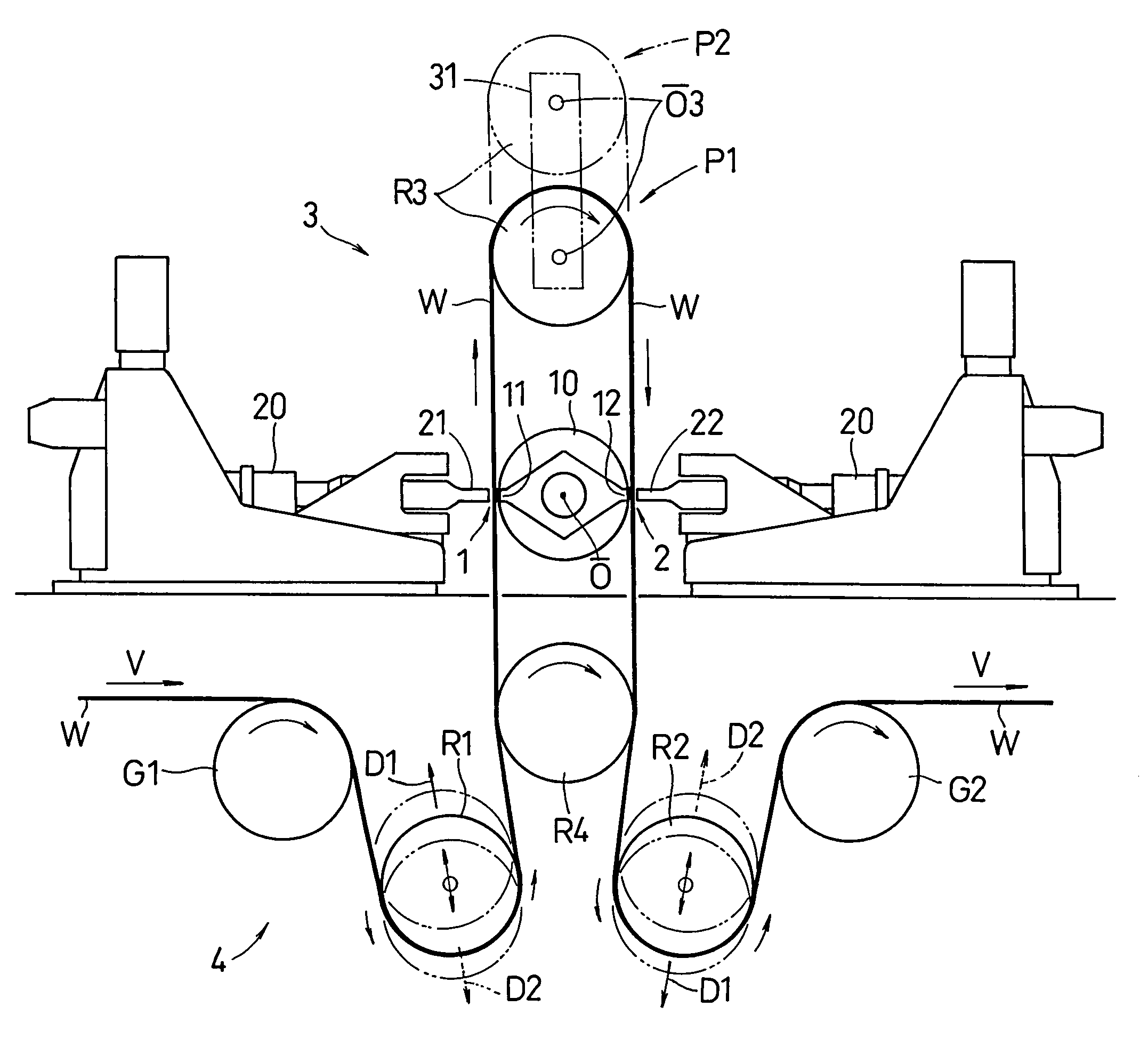

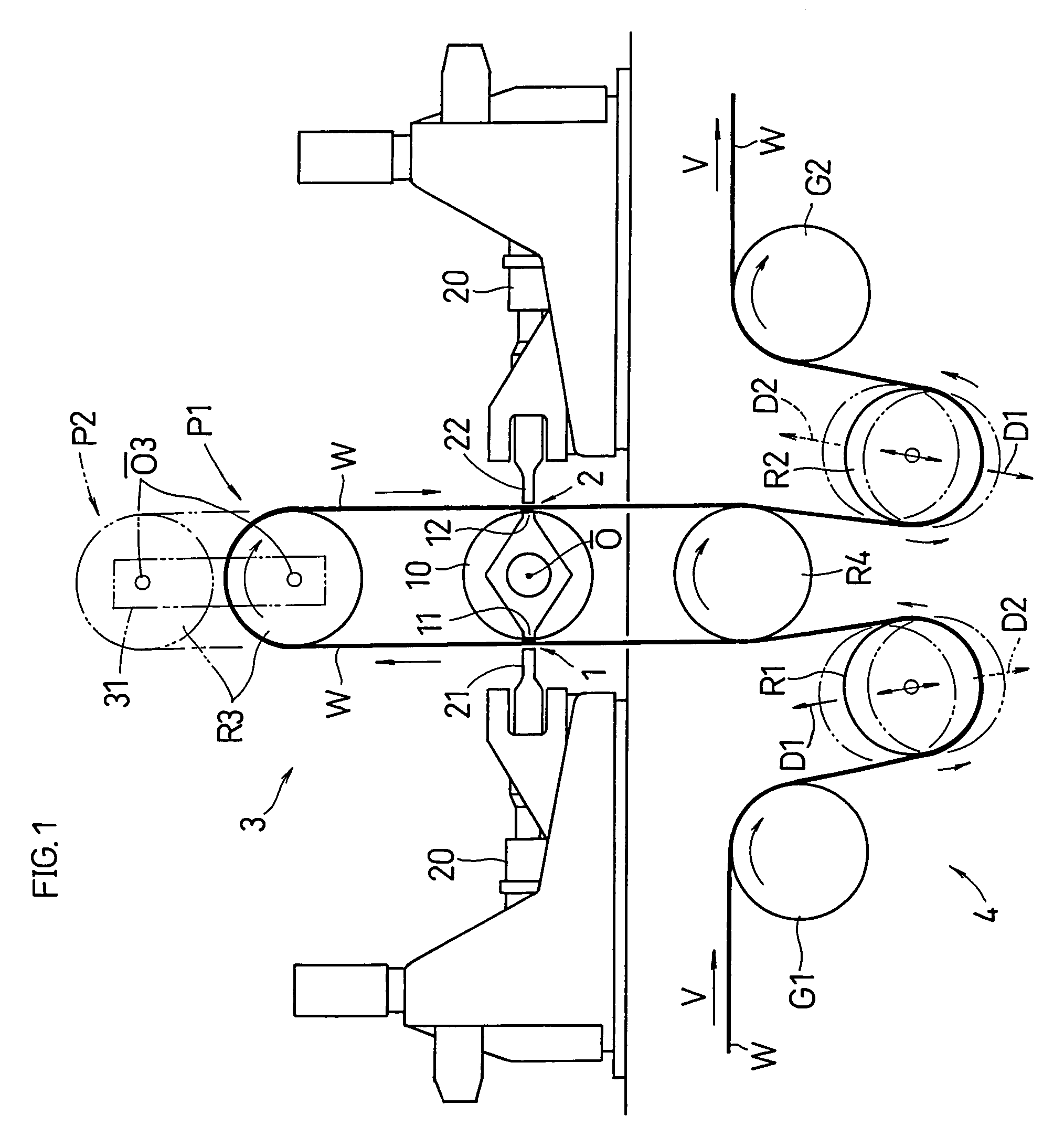

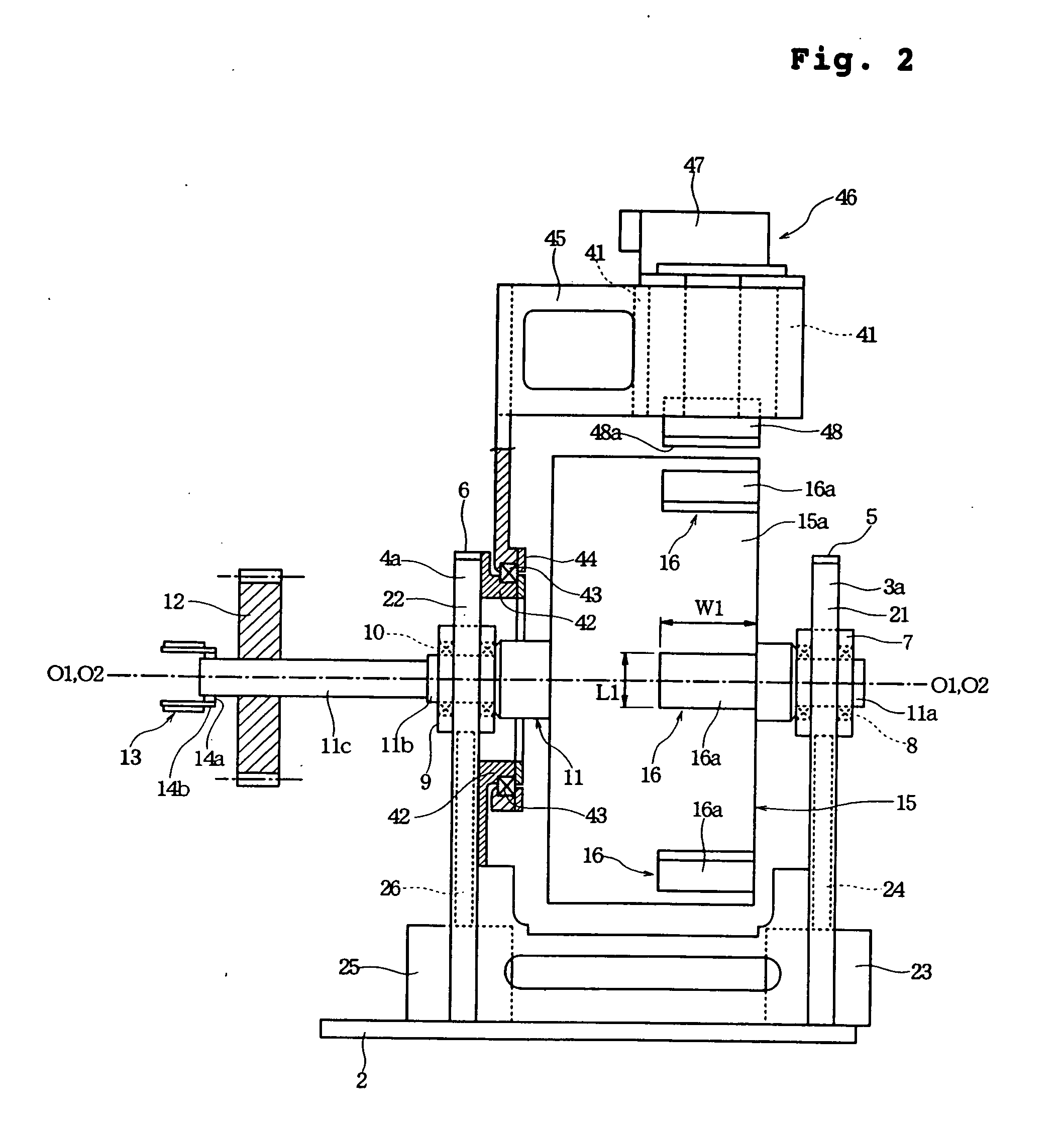

Web welding system

ActiveUS7449084B2Durability is impairedImprove accuracyLaminationLamination apparatusEngineeringWelding

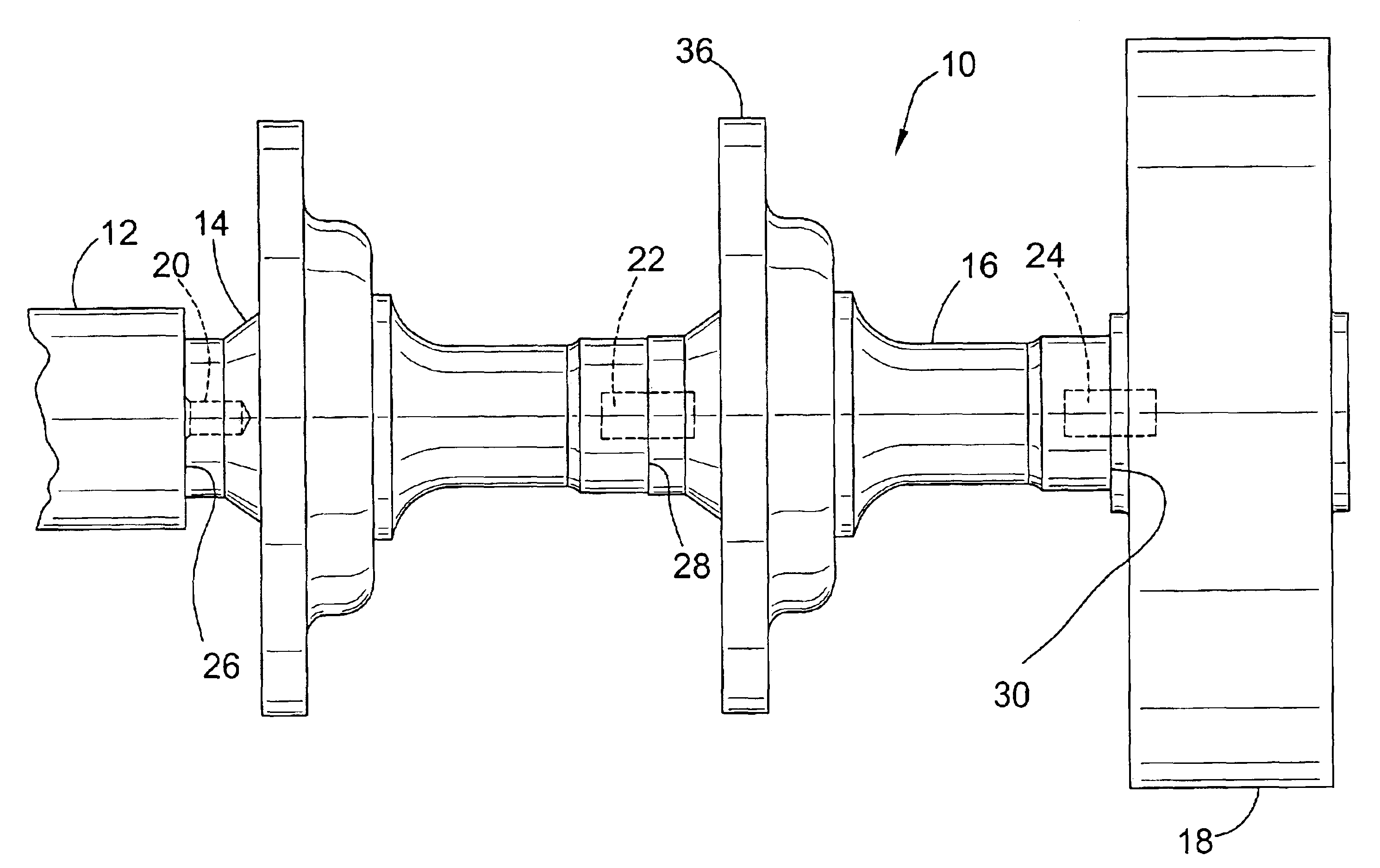

An object of the present invention is to provide a welding system wherein the positional accuracy of welding and the quality of welding are improved. The present welding system includes an ultrasonic welder for welding a plurality of webs W together while carrying the webs W. The ultrasonic welder includes: an anvil roller 10 including a pair of anvils 11, 12; a first ultrasonic horn 21 and a second ultrasonic horn 22 that apply vibration energy to the webs W in cooperation with the pair of anvils 11, 12. The pair of anvils 11, 12 are provided symmetrically with each other with respect to an axis line O of the anvils roller 10. The first and second ultrasonic horns 21, 22 apply the vibration energy to the webs W simultaneously while each of the anvils 11, 12 faces the first or second ultrasonic horn 21, 22.

Owner:ZUIKO CORP

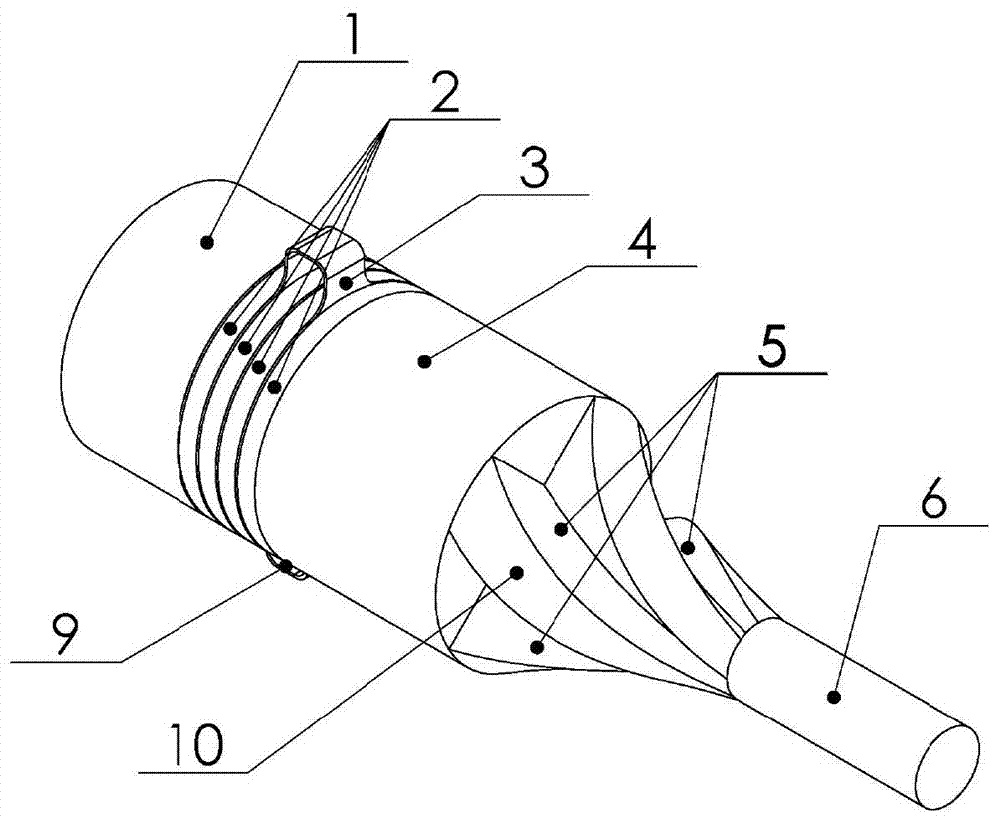

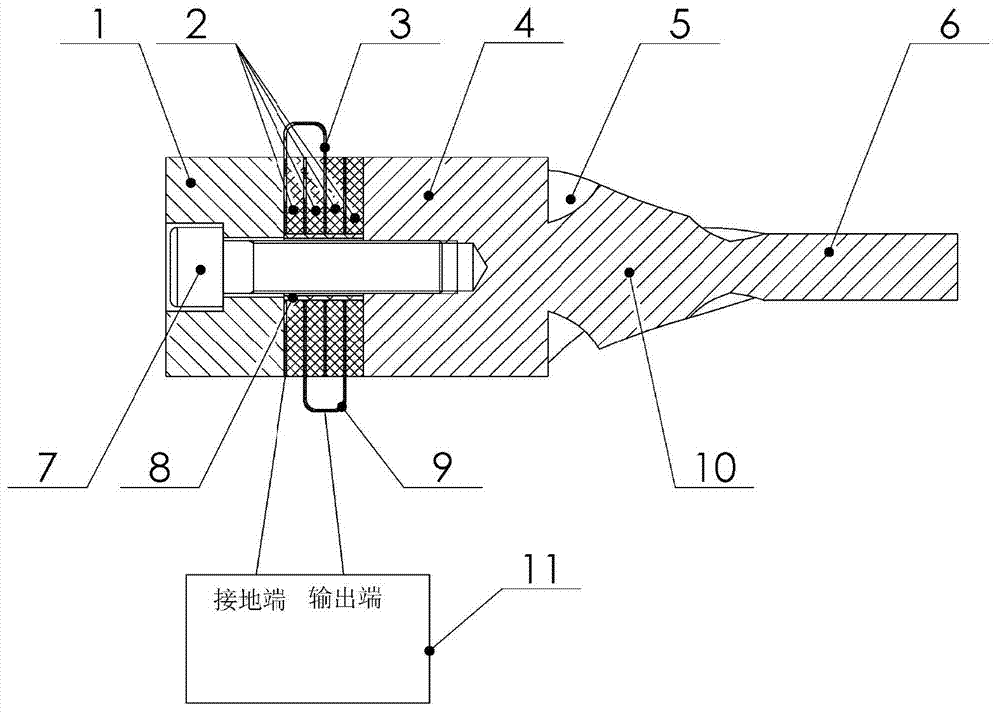

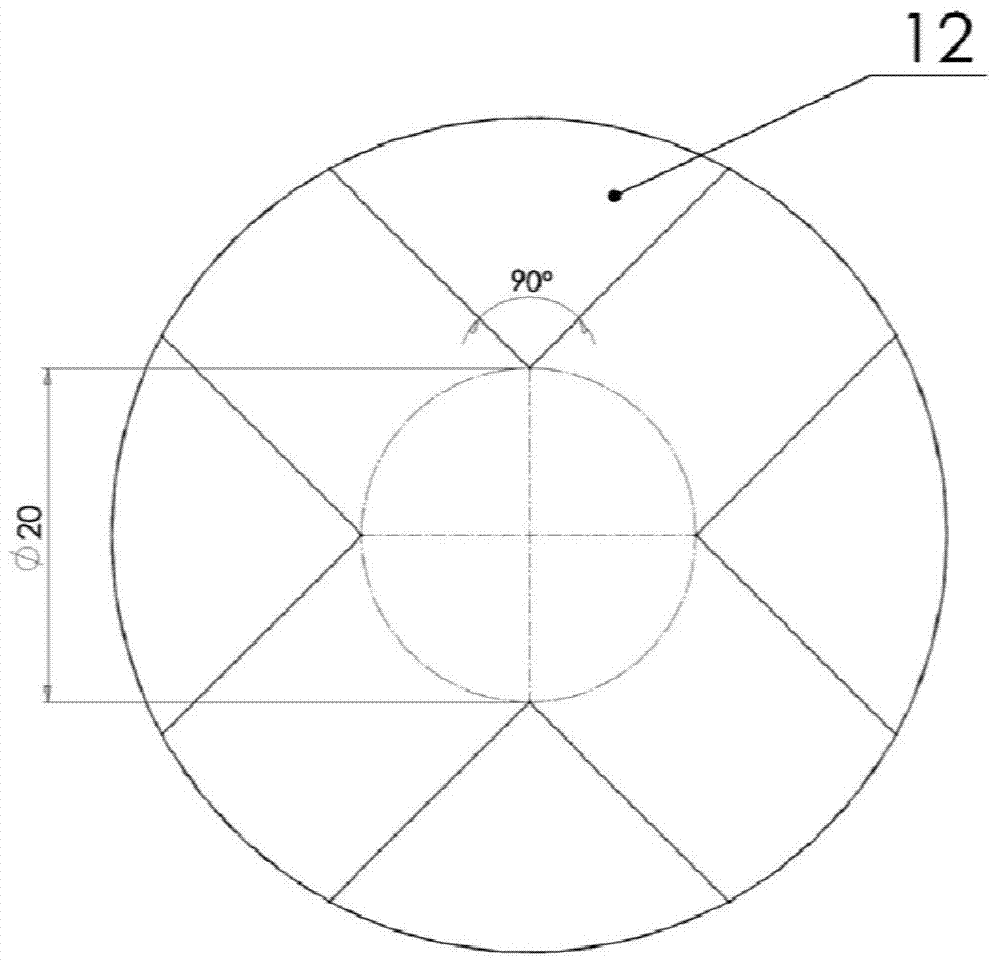

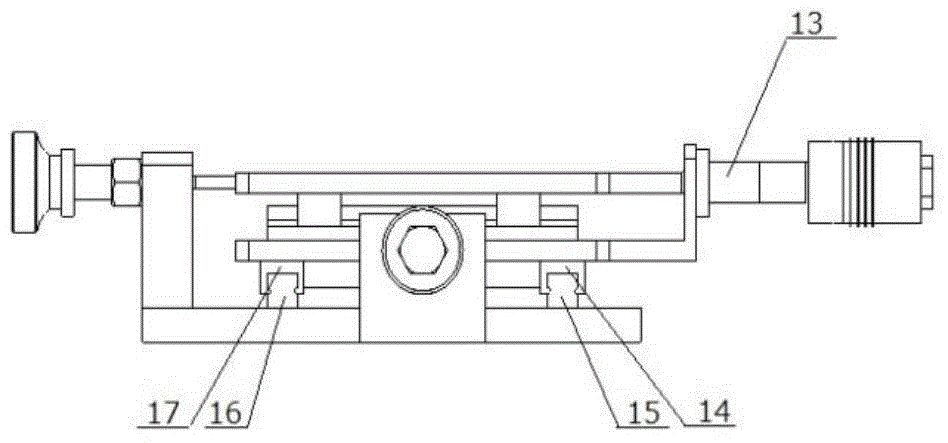

Longitudinal torsion composite supersonic vibration machining device

ActiveCN103920635ASimplify machining complexityLow costMechanical vibrations separationTransformerEngineering

The invention discloses a longitudinal torsion composite supersonic vibration machining device. The longitudinal torsion composite supersonic vibration machining device comprises a longitudinal supersonic vibration energy converter and an ultrasonic amplitude transformer arranged at the front end of the longitudinal supersonic vibration energy converter and integrally connected with the longitudinal supersonic vibration energy converter. The longitudinal supersonic vibration energy converter comprises a back cover plate, a piezoelectric ceramic piece, an electrode plate, a front cover plate, an insulating sleeve and a pre-tightening bolt for connecting the back cover plate, the piezoelectric ceramic piece, the electrode plate, the front cover plate and the insulating sleeve. The ultrasonic amplitude transformer comprises an amplitude transformer index section and an amplitude transformer cylindrical section, the amplitude transformer index section and the front cover plate are designed into a whole, the amplitude transformer cylindrical section is used for being connected with a machining tool, the surface of the amplitude transformer index section is provided with four same spiral grooves, part of longitudinal vibration generated by the longitudinal supersonic vibration energy converter can be converted into torsion vibration through the spiral grooves, and therefore the longitudinal torsion composite supersonic vibration can be generated one the end face of the amplitude transformer cylindrical section. The longitudinal torsion composite supersonic vibration machining device has the advantages of being simple in structure, large in torsion component, high in converting efficiency and the like.

Owner:BEIHANG UNIV

Method for assembling a package for sutures

InactiveUS20050034431A1Quick applicationReduce manufacturing costSuture equipmentsSurgical needlesEngineeringCounterbore

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

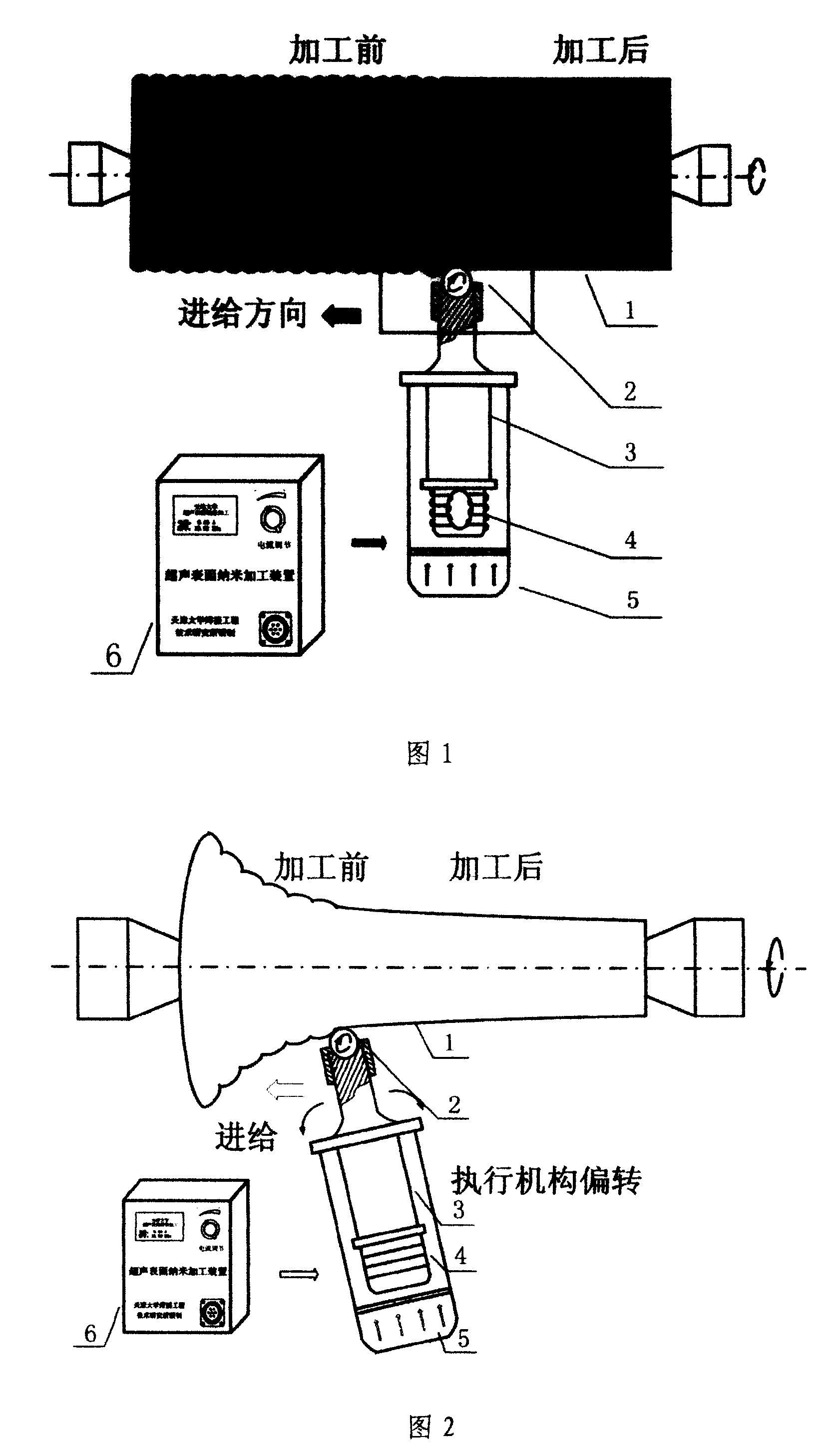

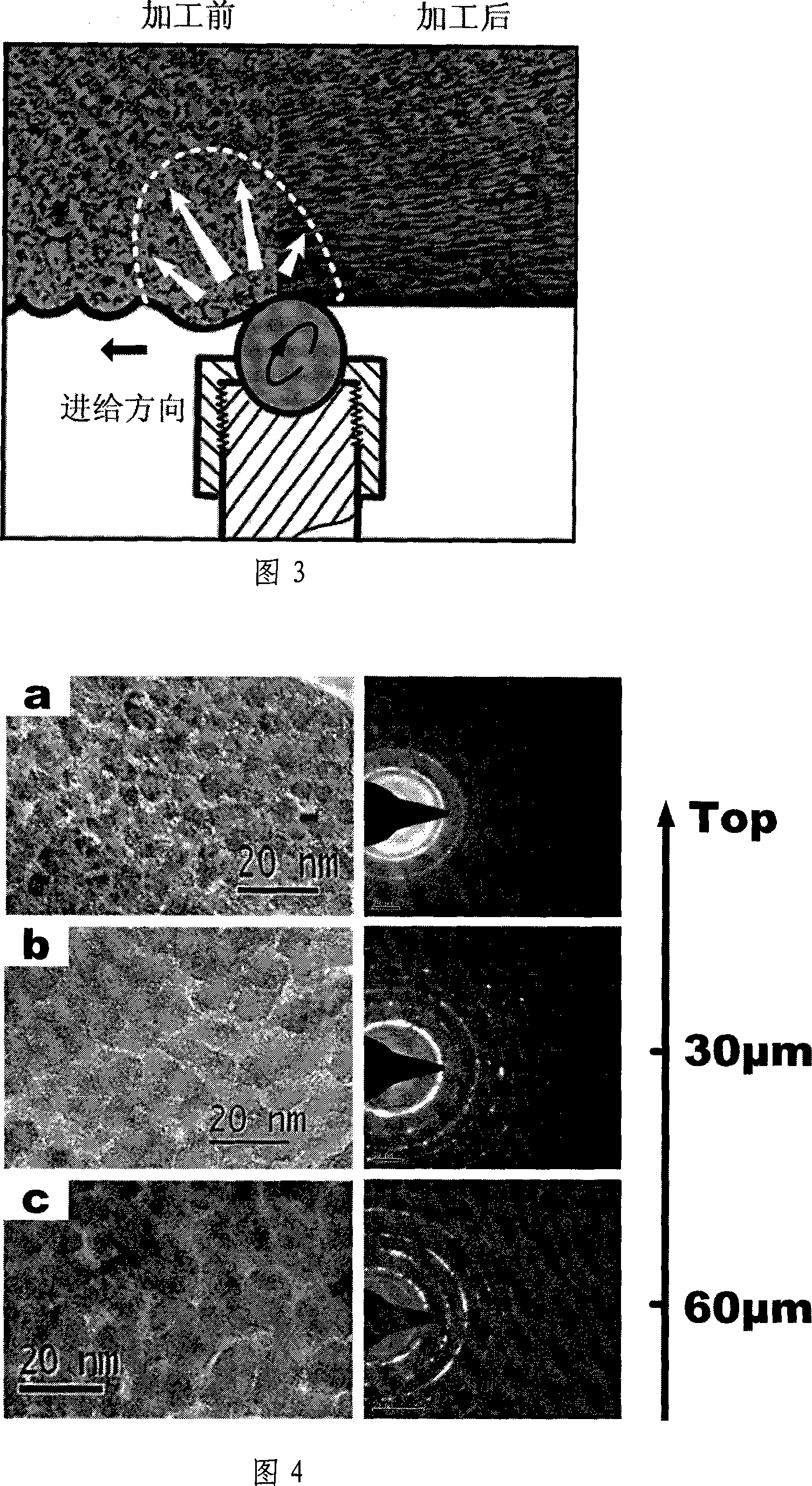

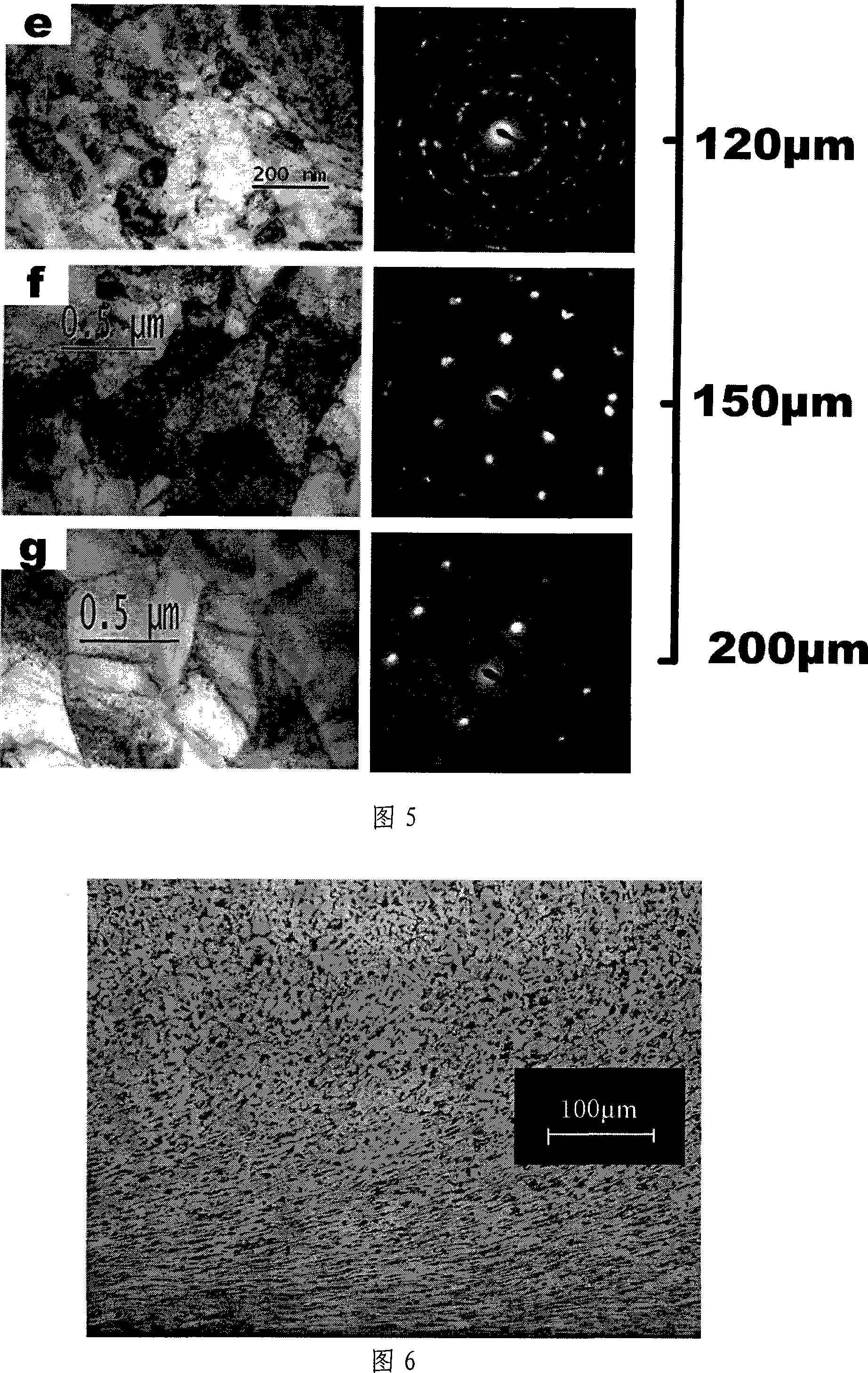

Ultrasonic surface rolling process nanoparticlization method and apparatus

The invention provides an ultrasonic surface rolling process nanostructure device and method, belonging to the mental surface process technical field, which comprises an ultrasonic generator and an executive mechanism. The executive mechanism consists of an ultrasonic transducer, an ultrasonic horn and an ultrasonic working joint, which is characterized in that the ultrasonic working joint is a rolling ball body. The method includes two steps: (1) the choice of the parameters is that the rotary speed of the Machine Tool Spindle is 200r to 700r per min; the axial direction feeding quantity of the working joint is 0.02mm to 0.1mm per r; the static pressure of the executive mechanism is 50N to 500N; the output terminal swing of the working joint is 5mm to 25 mm; (2) the reciprocating process is 2 times to 15 times. By adopting the device to carry out the nanostructure, the working life of the working joint can be prolonged and the crystal fineness of the same depth from the area closer to the surface is ensured to be more strict and even, thus obtaining the ideal surface finish. The surface can form noncrystalline nanometer crystal layer of about 100 mm depth.

Owner:TIANJIN UNIV

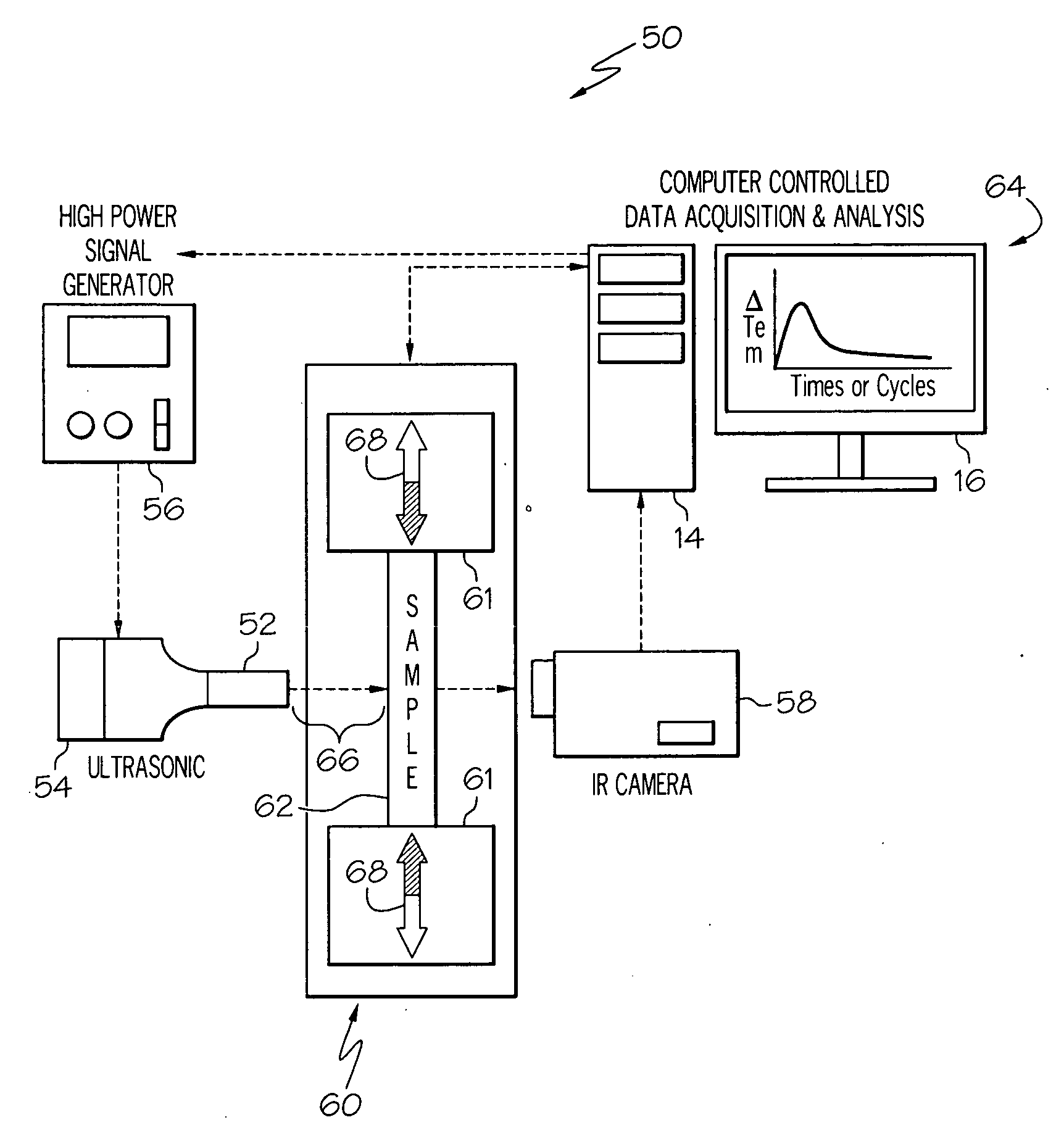

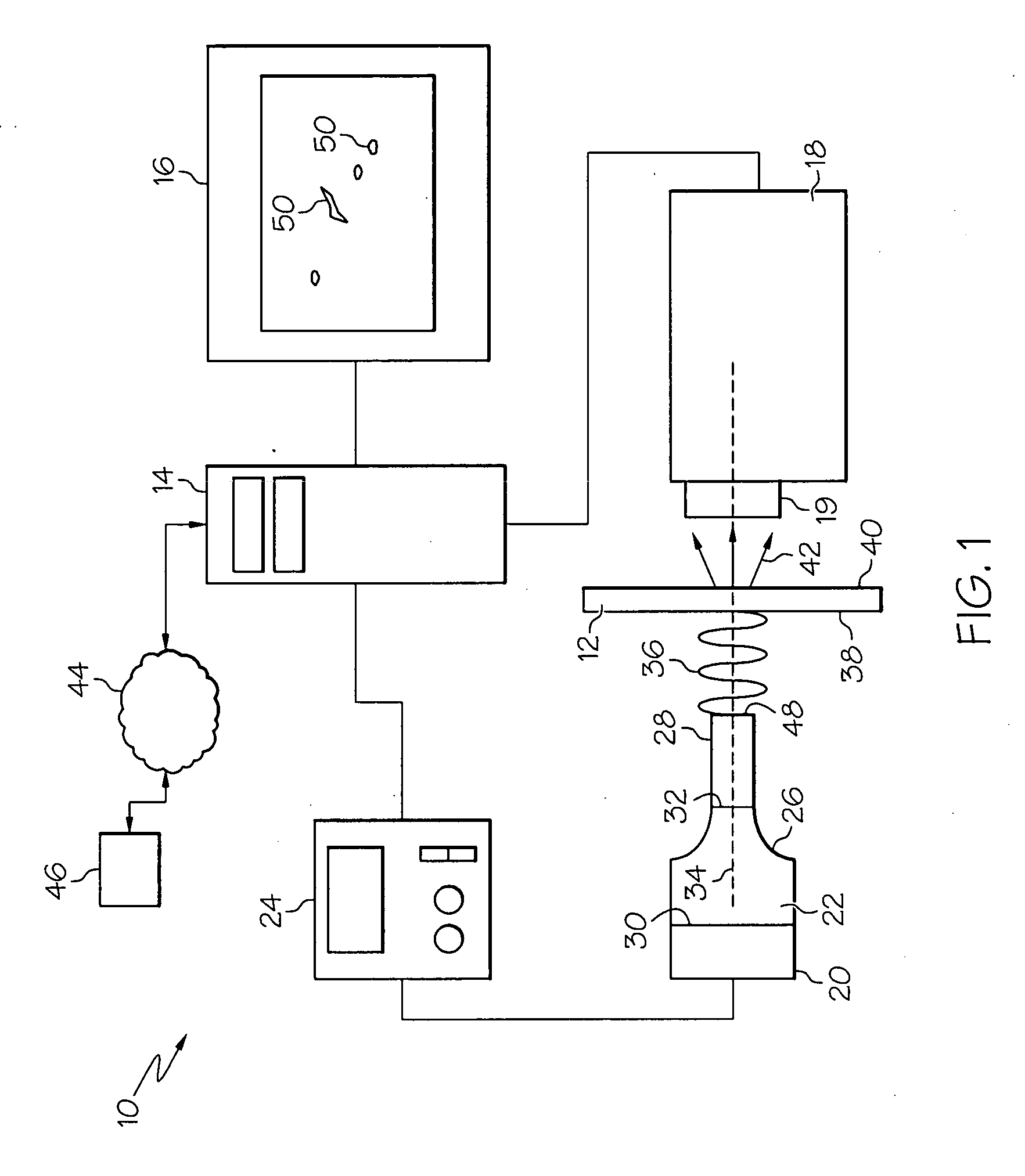

Non-contact acousto-thermal method and apparatus for detecting incipient damage in materials

InactiveUS20090000382A1Boost energy levelsAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial flaws investigationTime profileAcoustic wave

A non-contact acousto-thermal method and apparatus are provided for detection of incipient damage in materials. The apparatus utilizes an ultrasonic horn which receives an acoustic wave generated by an ultrasonic transducer energized by an RF pulse. The ultrasonic horn is placed at a distance from the sample to be tested with sufficient gap so that when excited, the face of the ultrasonic horn does not come into contact with the sample. An IR camera is placed at a distance from the opposite side of the sample. The acoustic wave is amplified by the ultrasonic horn, and the interaction between the sample and the acoustic wave produces changes in the temperature of the sample in the region of interaction during acoustic excitation such that the temperature of the material rapidly increases. The temperature-time profile is captured by the IR camera and may be analyzed by a data acquisition unit.

Owner:UNIV OF DAYTON

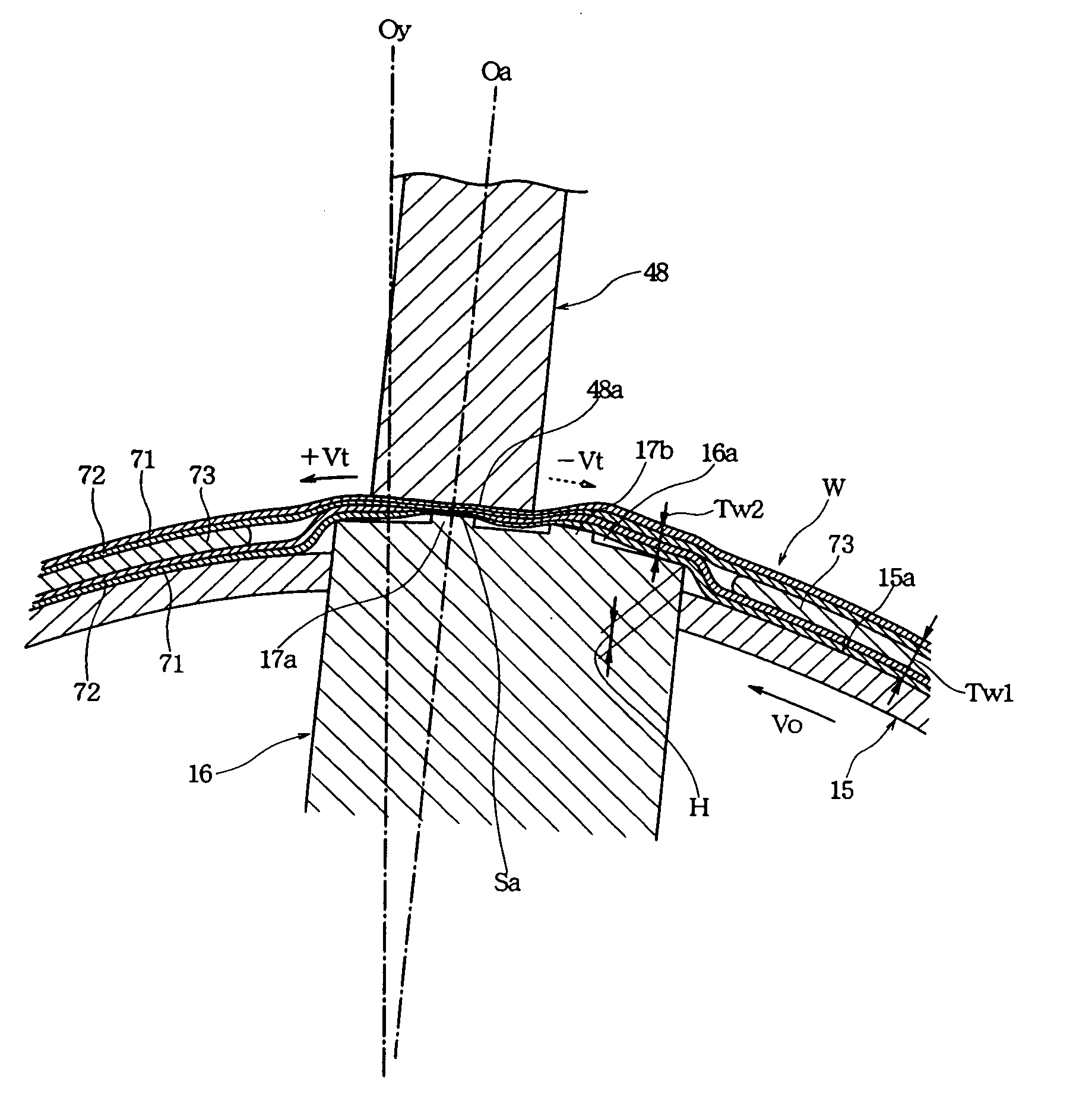

Sealing apparatus and sealing method using the sealing apparatus

ActiveUS20050145317A1Sufficient sealing energyHigh speed machiningLaminationLamination apparatusMechanical engineeringRelative velocity

Disclosed is a sealing apparatus including an anvil of a sealing abutment surface, which is driven to circulate with a constant peripheral velocity, and an ultrasonic horn of a sealing abutment surface, which is driven to reciprocate with varying velocities. Since the relative velocity of a soft workpiece moving along with the anvil against the sealing abutment surface of the ultrasonic horn can be made low, a sealing energy from the ultrasonic horn may be applied to the soft workpiece sufficiently long.

Owner:UNI CHARM CORP

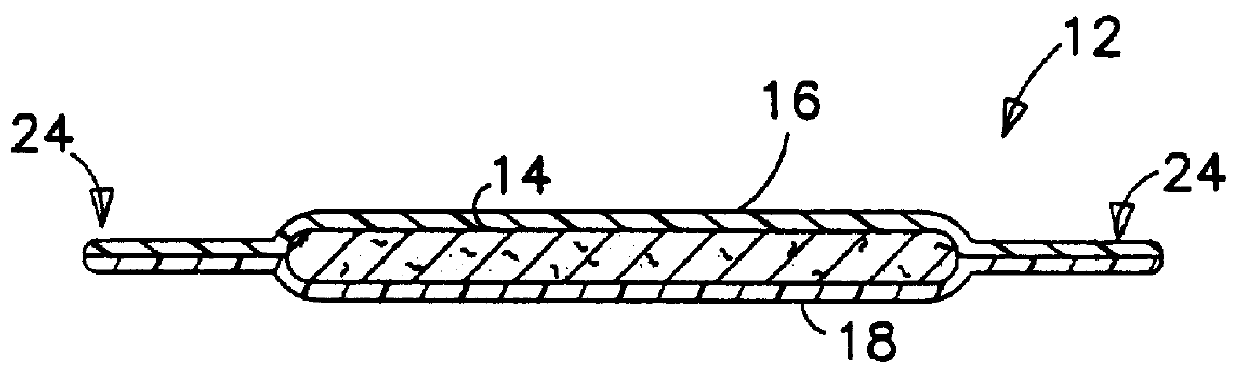

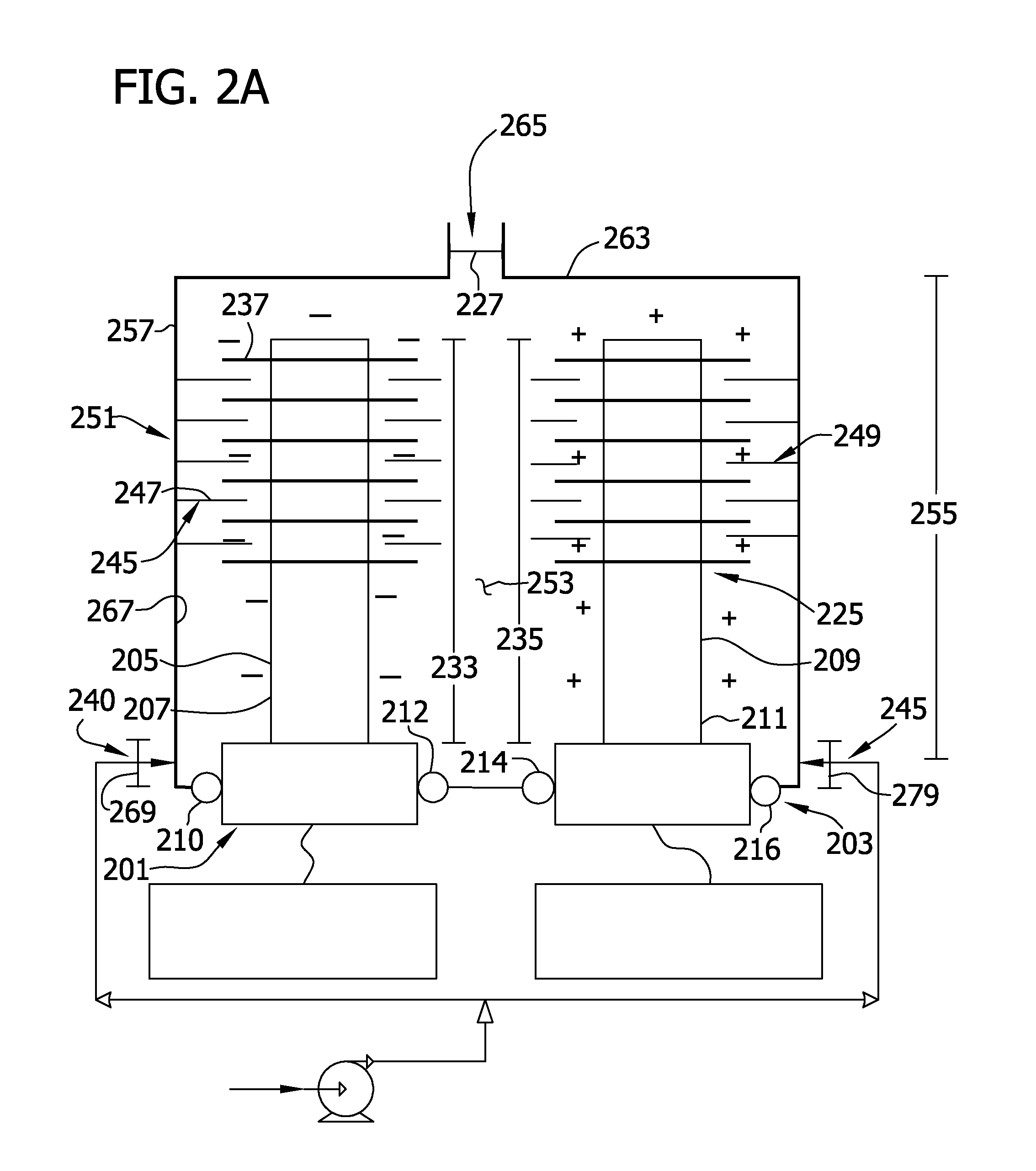

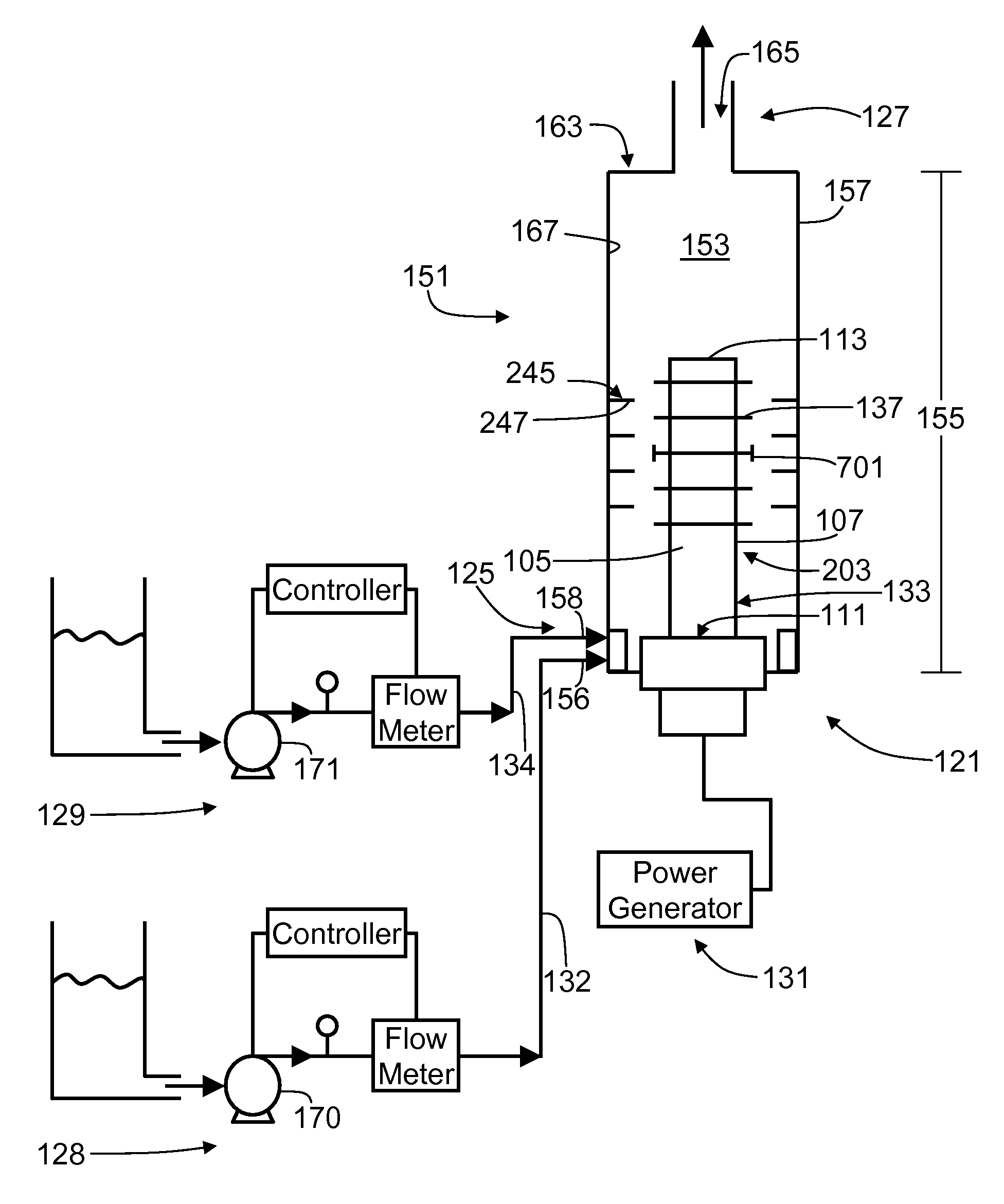

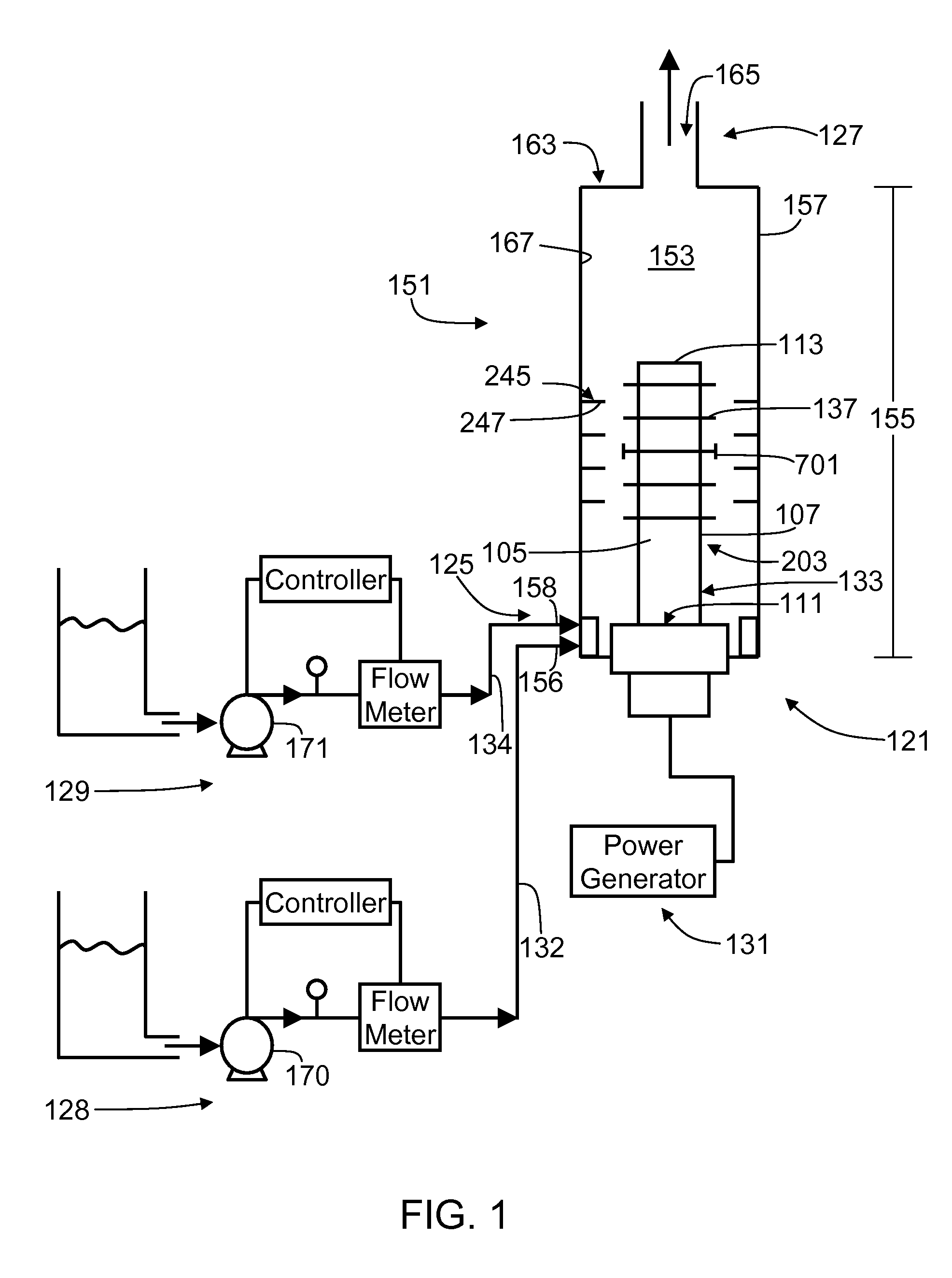

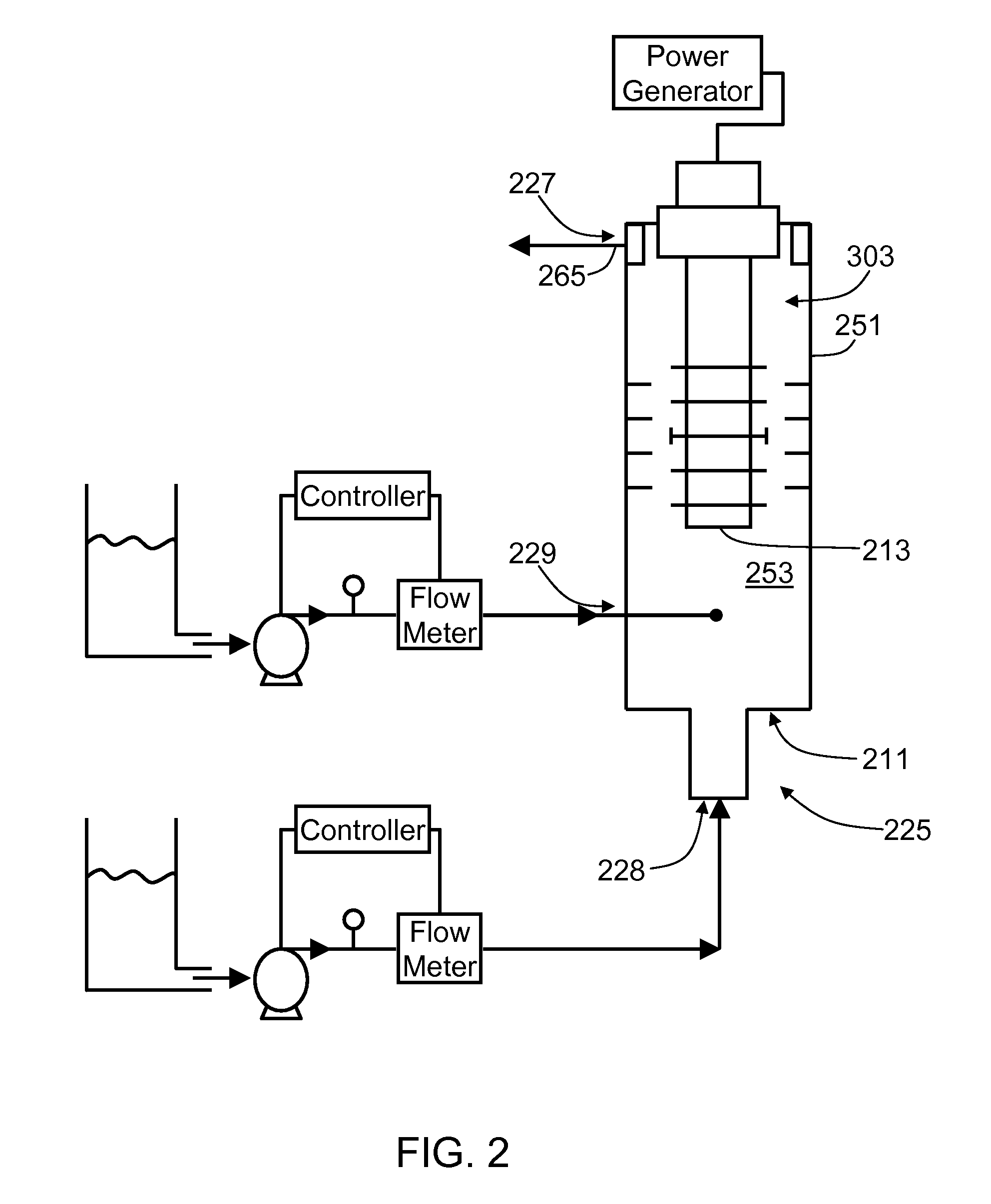

Ultrasonic treatment chamber for particle dispersion into formulations

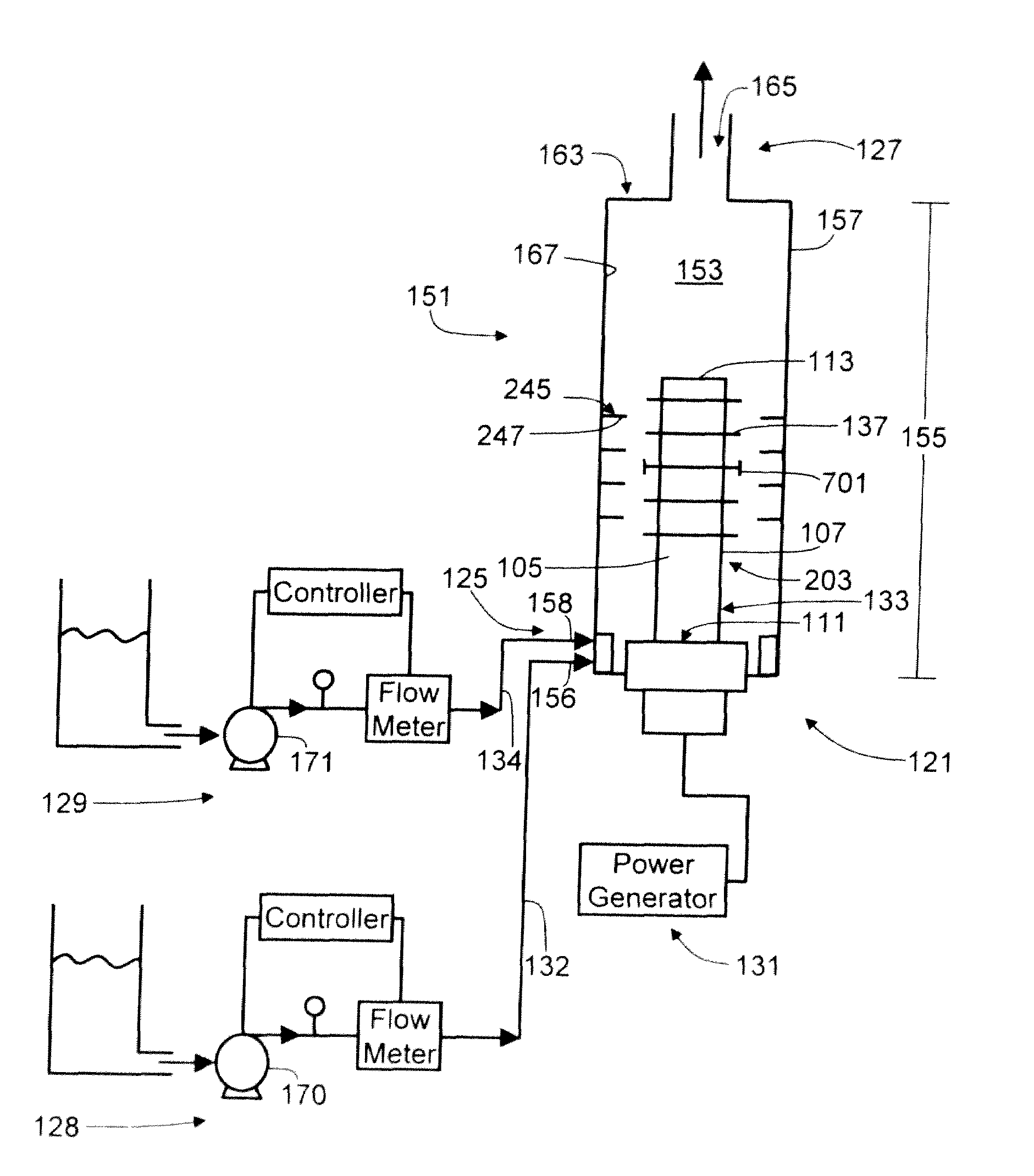

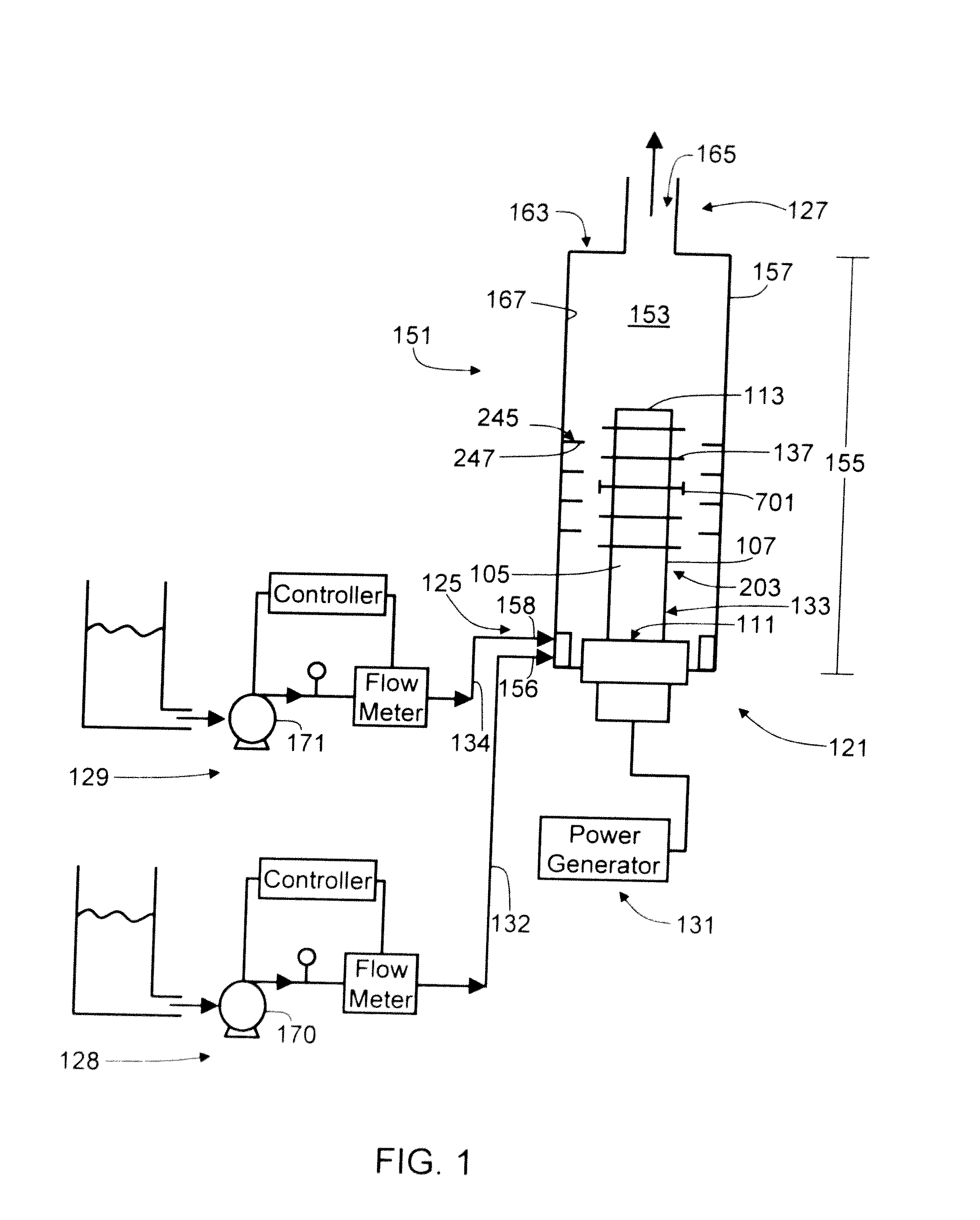

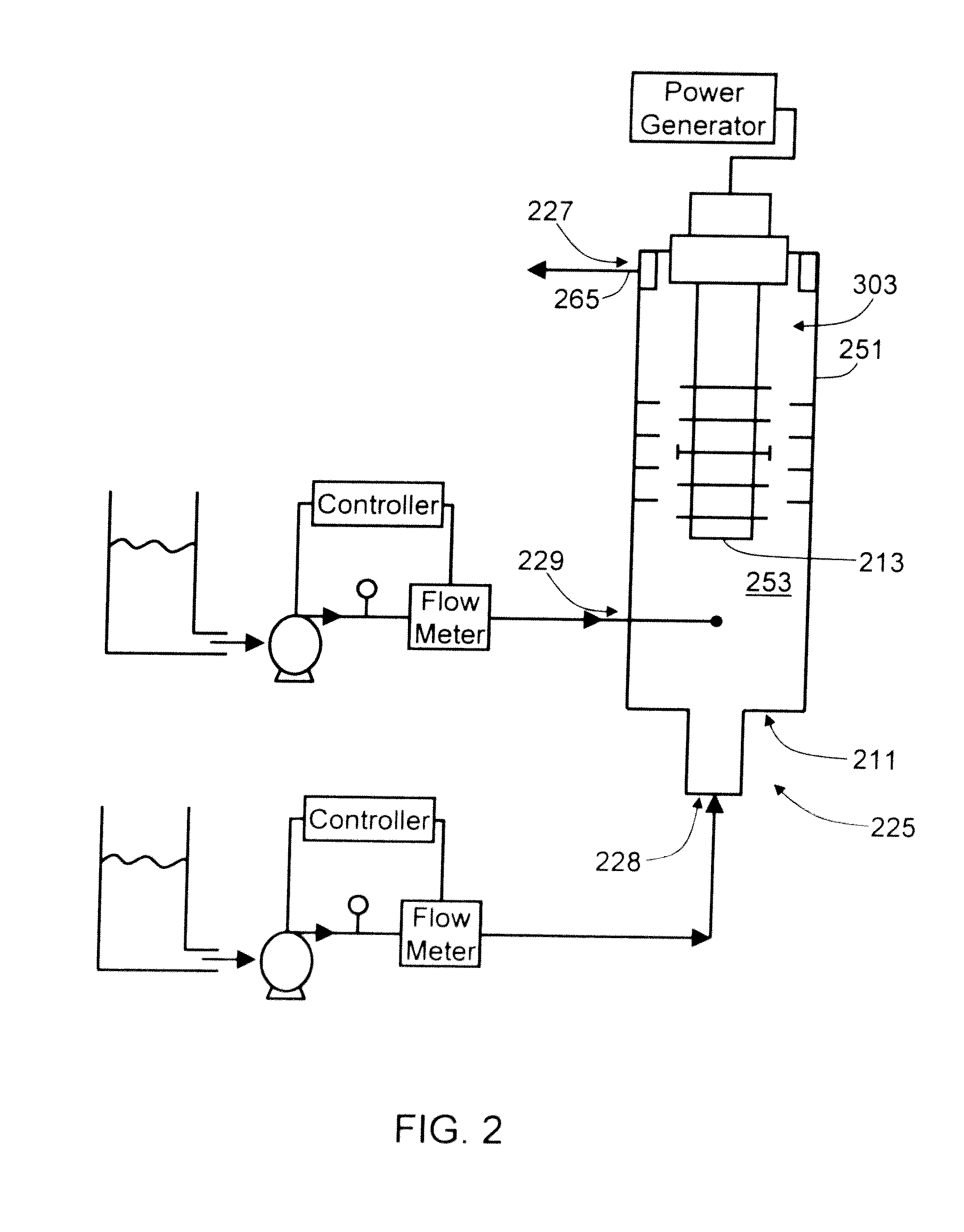

ActiveUS20090168591A1Shaking/oscillating/vibrating mixersFlow mixersUltrasonic cavitationDynamic motion

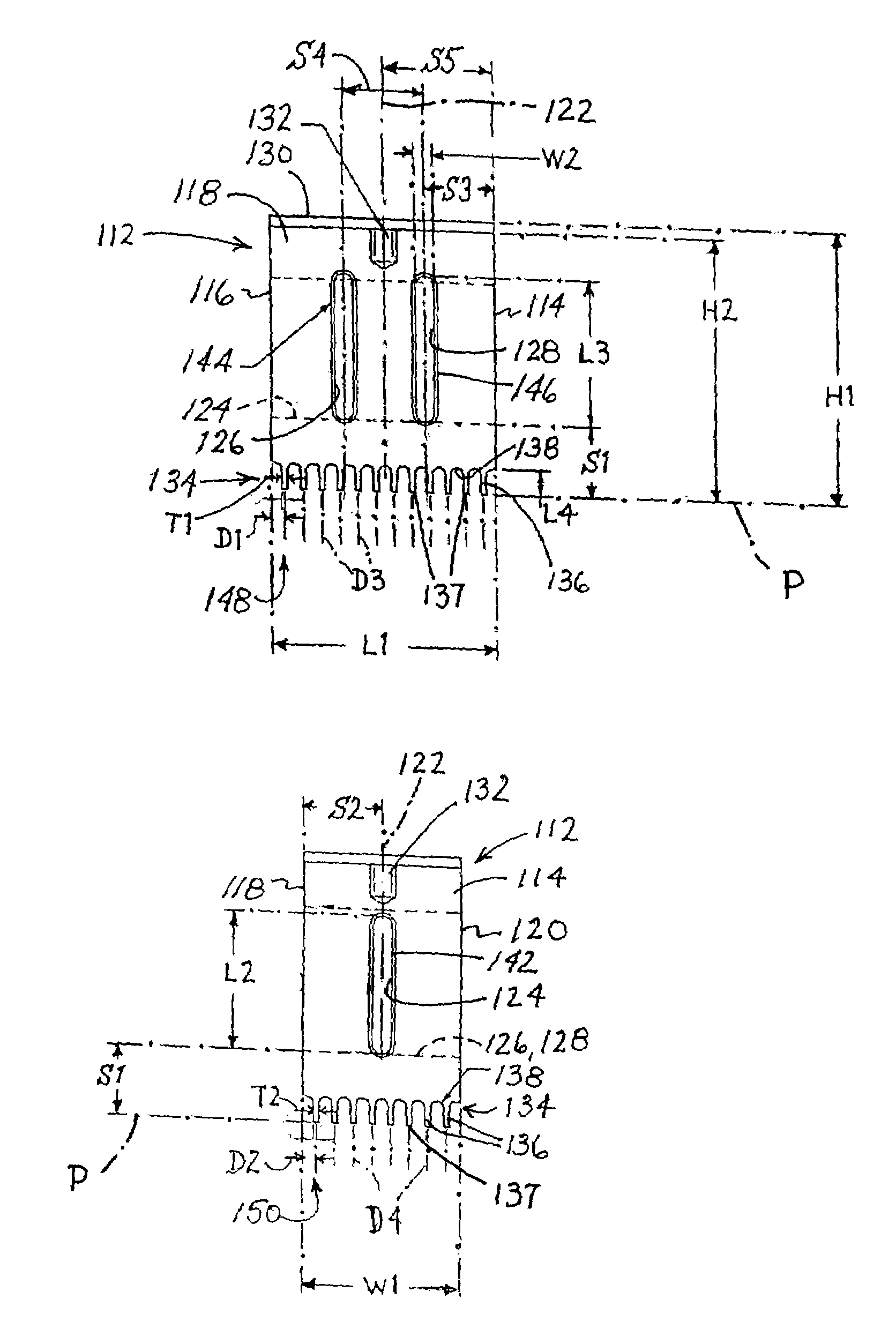

An ultrasonic mixing system having a particulate dispensing system to dispense particulates into a treatment chamber and the treatment chamber in which particulates can be mixed with one or more formulations is disclosed. Specifically, the treatment chamber has an elongate housing through which a formulation and particulates flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the formulation and particulates within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the formulation and particulates being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

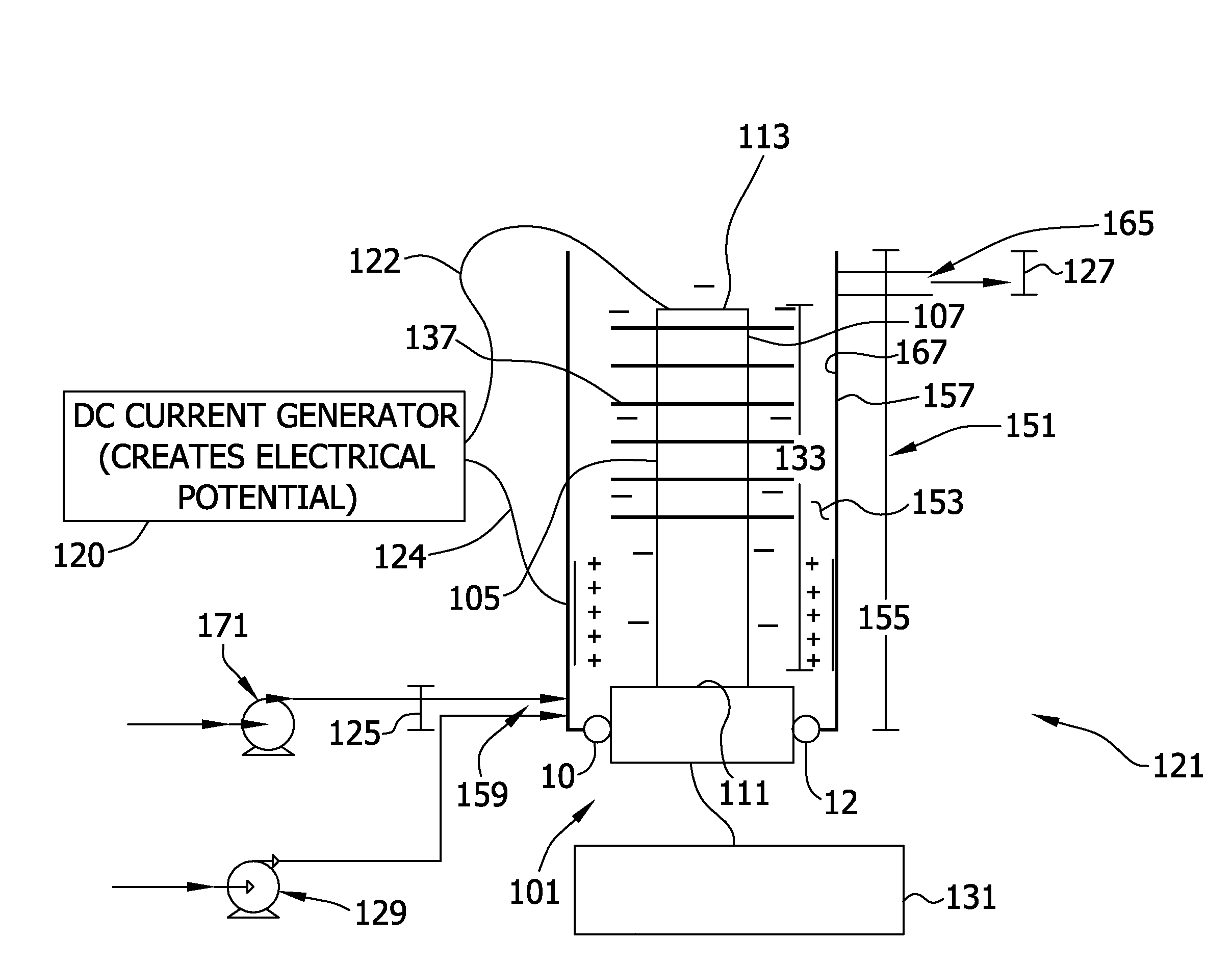

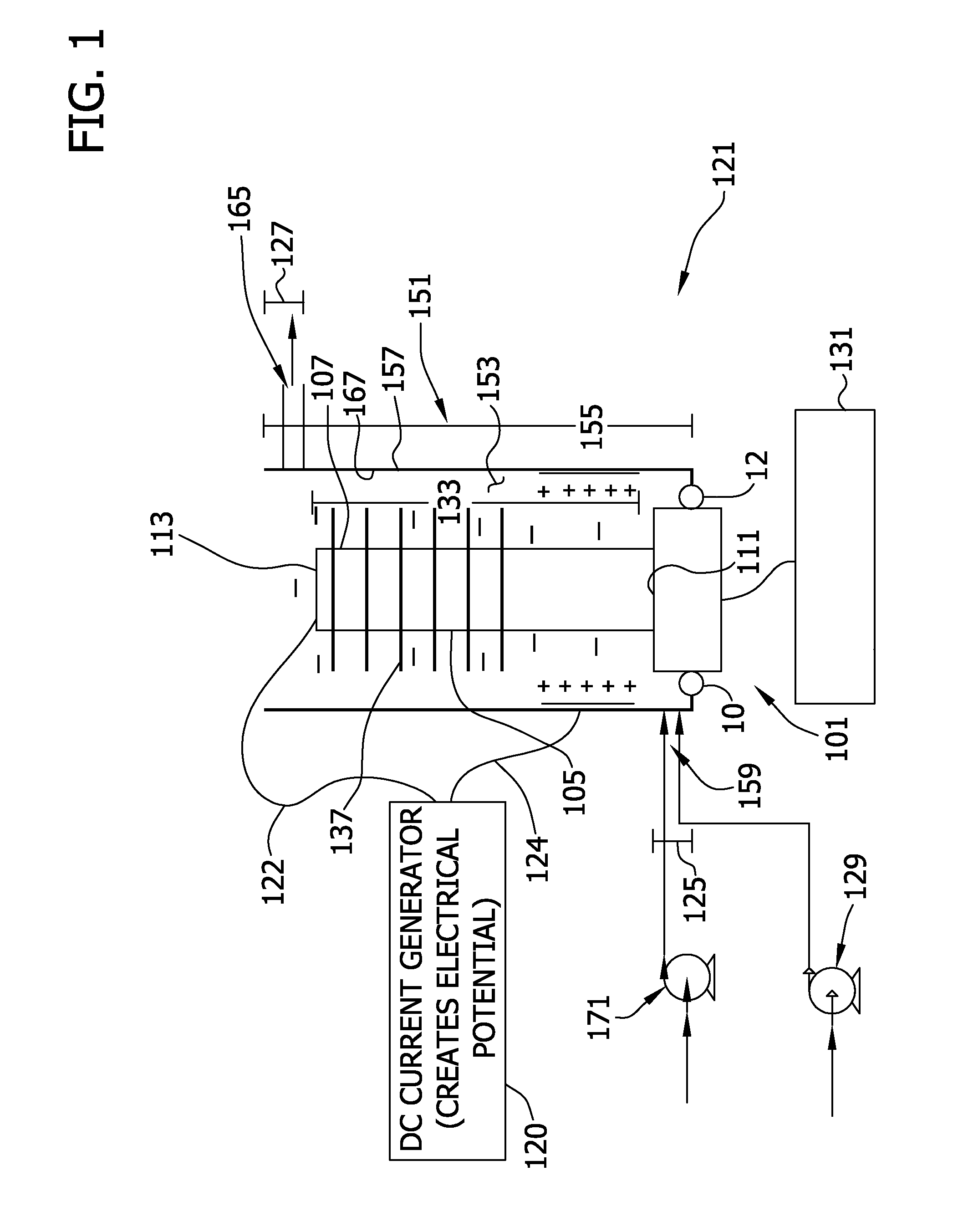

Ultrasonic treatment chamber having electrode properties

InactiveUS20090014377A1Electrolysis componentsSpecific water treatment objectivesElectrode potentialElectrolysis

A liquid treatment chamber having an elongate housing through which liquid flows longitudinally from an inlet port to an outlet port thereof is disclosed. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrode potential to ultrasonically energize and electrolyze liquid within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the liquid being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

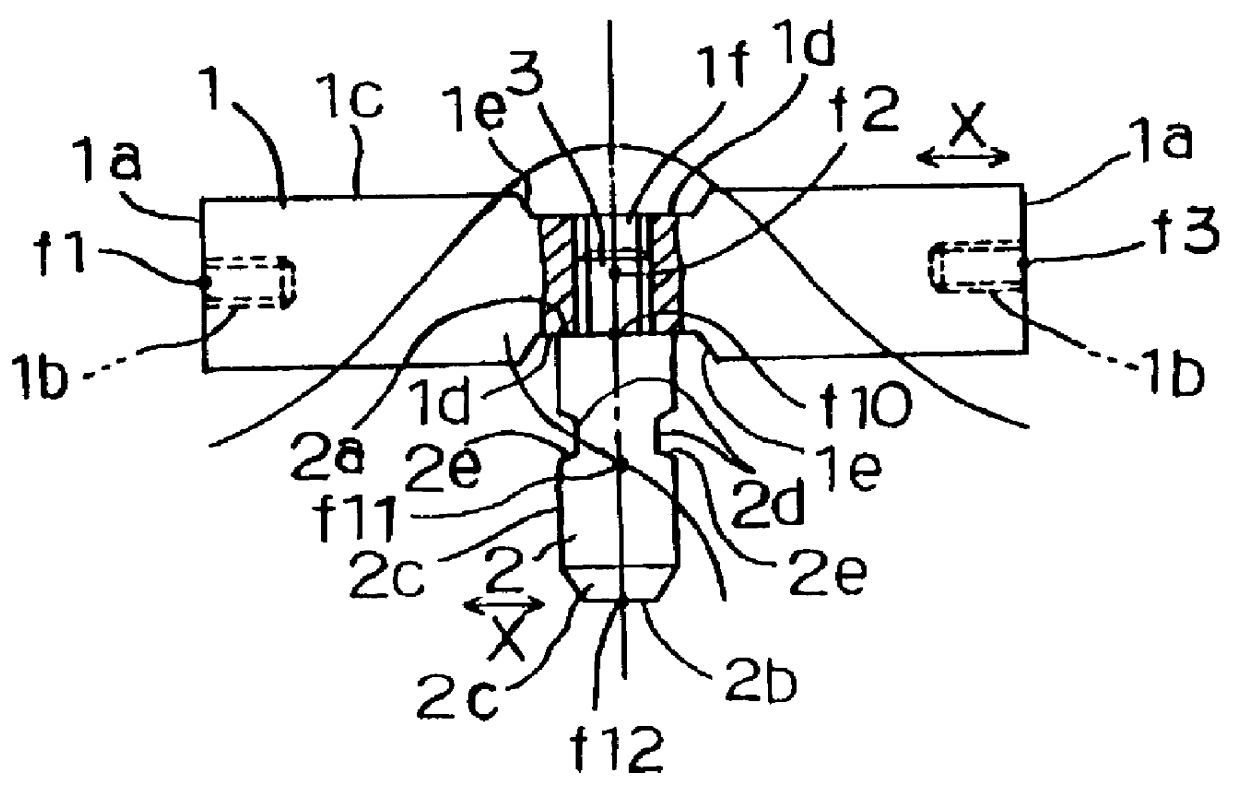

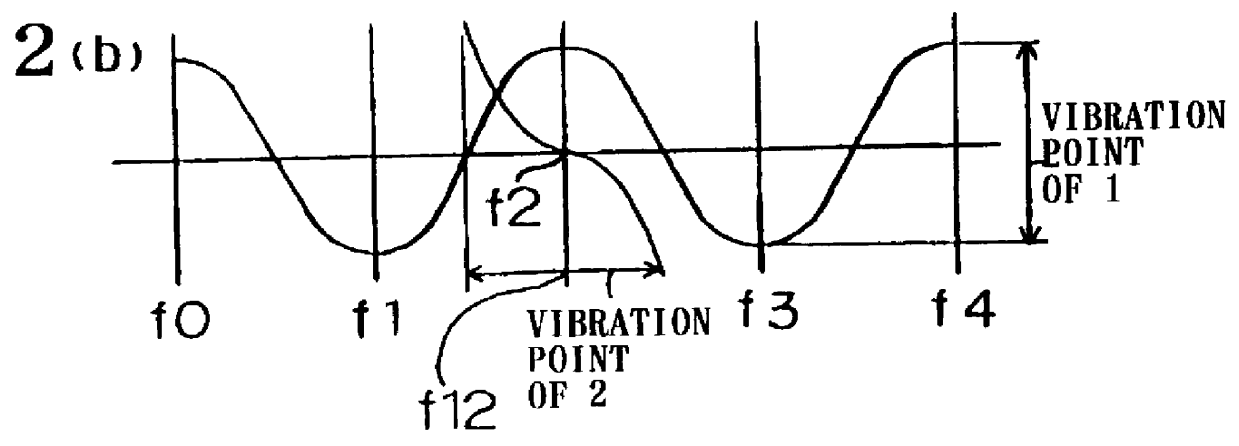

Ultrasonic vibration bonding resonator

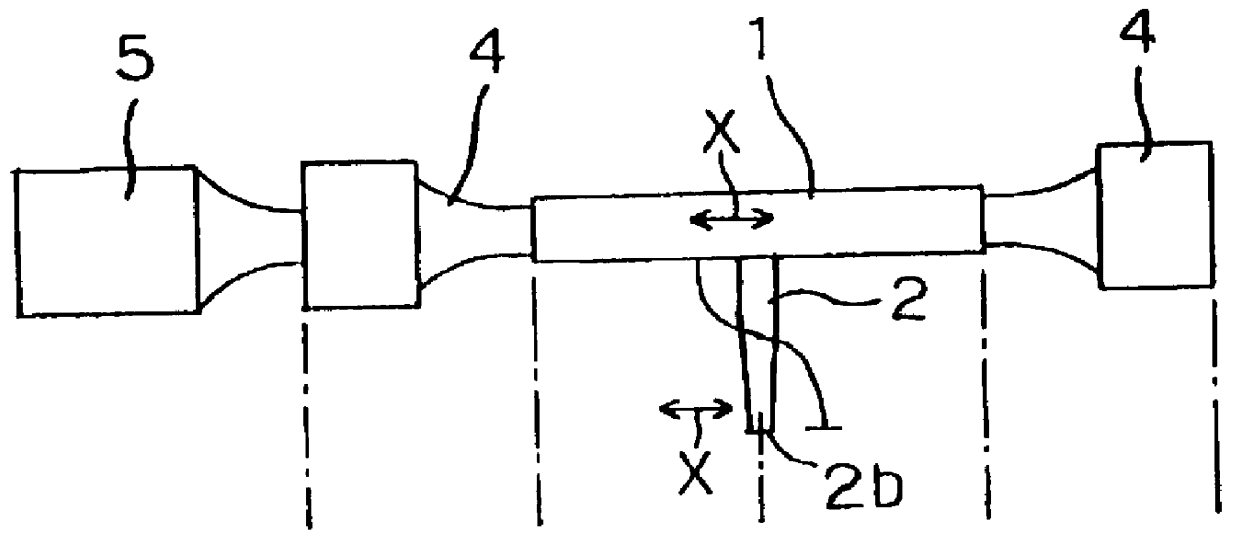

InactiveUS6109502APiezoelectric/electrostriction/magnetostriction machinesWelding/cutting auxillary devicesResonanceUltrasonic vibration

In order to realize effective and economical bonding operation even on workpiece whose inside is quite deep, a bonding tool, which has a length equivalent to a whole number of multiples of half the wavelength of the resonance frequency, is secured to an ultrasonic horn by a screw member which can advance or retreat in a direction perpendicular to the vibration direction indicated by an arrow X,thereby causing a front end surface of the bonding tool vibrate in the same direction as the vibration of the ultrasonic horn.

Owner:ULTEX CORP

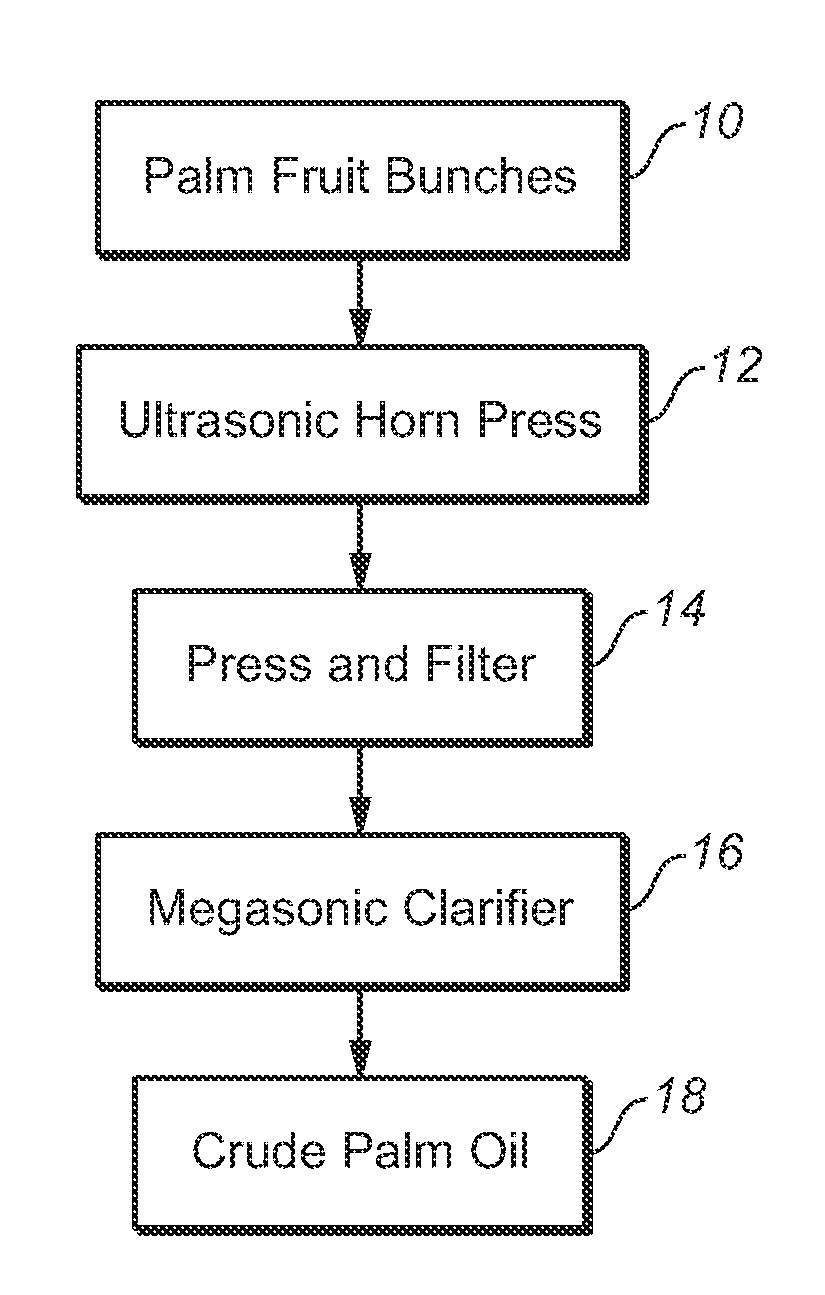

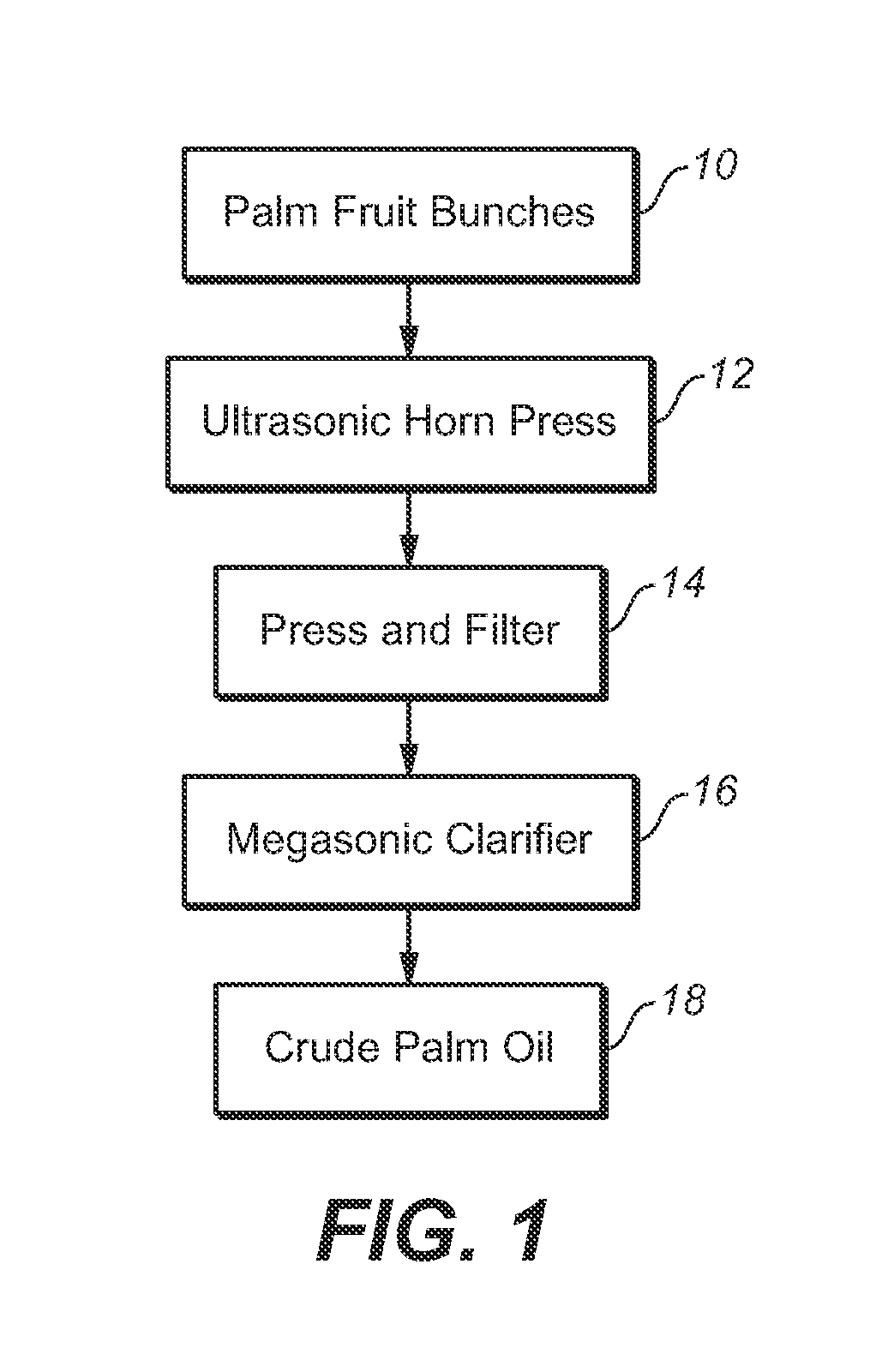

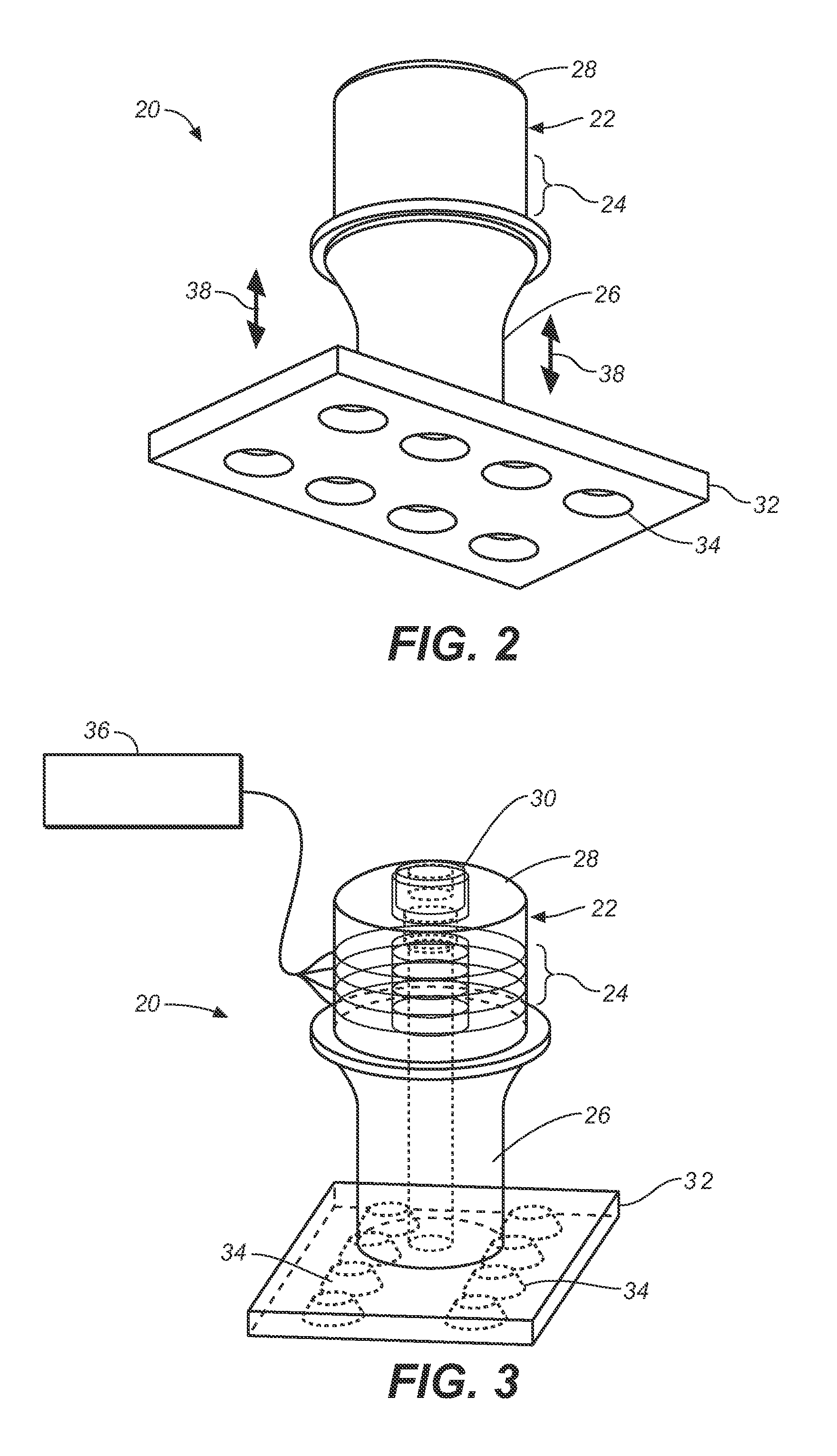

Ultrasonic and megasonic method for extracting palm oil

ActiveUS9388363B2Fatty-oils/fats productionCarboxylic compound separation/purificationPalm fruitUltrasonic vibration

A process for extracting palm oil includes an ultrasonic horn press and a megasonic clarifier. The ultrasonic horn press uses ultrasonic vibrations to rupture the palm fruit. After pressing and filtering the palm oil from the ultrasonic horn press, the megasonic clarifier applies megasonic vibrations to clarify the palm oil. The ultrasonic horn press and megasonic clarifier significantly reduce the use of water and minimizes pollution as compared to conventional processes.

Owner:MEGASONIC SWEEPING INC

Corrosion resistant ultrasonic horn

InactiveUS6652992B1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksTitaniumAqueous medium

Owner:TALISMAN CAPITAL TALON FUND

Ultrasonic treatment chamber for preparing emulsions

InactiveUS20090166177A1Shaking/oscillating/vibrating mixersCircuit elementsUltrasonic cavitationEmulsion

An ultrasonic mixing system having a treatment chamber in which at least two separate phases can be mixed to prepare an emulsion is disclosed. Specifically, at least one phase is a dispersed phase and one phase in a continuous phase. The treatment chamber has an elongate housing through which the phases flow longitudinally from a first inlet port and a second inlet port, respectively, to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the phases within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the phases being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ultrasonic horn with enlarged distal end portion

InactiveUS20100121197A1Avoid efficiencyUltrasonic/sonic/infrasonic diagnosticsSurgeryBiomedical engineeringUltrasound

An ultrasonic horn includes a main body portion and a distal end structure formed at a distal end of the main body portion, the ultrasonic horn being adapted to be used to cut living tissue. The largest outer diameter of a portion of the ultrasonic horn is in the distal end structure, the portion being inserted into the living tissue when the living tissue is cut.

Owner:STRYKER CORP

High-power ultrasound generator and use in chemical reactions

InactiveUS6897628B2Reaction be enhancedHigh yieldPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationChemical reactionEngineering

Ultrasound for use in promoting a chemical reaction is generated by an electromagnet formed from a pair of magnetostrictive prongs wound with coils that are oriented to produce an oscillating magnetostrictive force when an oscillating voltage is applied, in conjunction with a sensing electromagnet of magnetostrictive material that is arranged to receive the vibrations generated by the driving electromagnet and produce internal magnetic field changes due to the reverse magnetostrictive effect. These field changes generate voltages that are representative of the amplitude of the oscillating magnetostrictive force. The generated voltage is compared to a target value in a control circuit that adjusts the applied oscillating voltage accordingly. The oscillations in the prongs of the electromagnet are transmitted to an ultrasonic horn that is immersed in the reaction medium to provide direct contact with the reaction mixture.

Owner:NOKIA CORP +1

Ultrasonic horn with isotropic breathing characteristics

An ultrasonic horn having substantially uniformly isotropic radial expansion and contraction amplitude in all radial directions upon excitation. The horn has a microstructure characterized by isotropically random directional grain alignment. A method for manufacturing a horn.

Owner:DUKANE IAS LLC

Ultrasonic horn

InactiveUS7004282B2Minimal energyMechanical vibrations separationSupporting apparatusProximal pointUltrasonic vibration

An ultrasonic horn in accordance with the present invention comprises a horn body having a longitudinal transmission axis, a proximal end attachable at least indirectly to a source of ultrasonic vibrations, and a distal end with an active end face. The end face is provided with a plurality of fingers projecting parallel to one another and to the axis.

Owner:ISONIX LLC

Ultrasonic horn assembly stack component connector

InactiveUS6841921B2Reduced maintenance needsEfficient transferPiezoelectric/electrostriction/magnetostriction machinesLaminationBiomedical engineeringUltrasound

An ultrasonic horn assembly for applying ultrasonic energy at an operating location which assembly includes a connector between horn assembly components which provides uniform clamping pressure between transfer faces of the components.

Owner:DUKANE IAS LLC

Ultrasonic Treatment Chamber for Preparing Emulsions

ActiveUS20090262597A1Improve emulsion stabilityEasy to cleanShaking/oscillating/vibrating mixersTransportation and packagingEmulsionEngineering

An ultrasonic mixing system having a treatment chamber in which at least two separate phases can be mixed to prepare an emulsion is disclosed. The treatment chamber has an elongate housing through which the phases flow longitudinally from a first inlet port and a second inlet port, respectively, to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the phases within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other.

Owner:KIMBERLY-CLARK WORLDWIDE INC

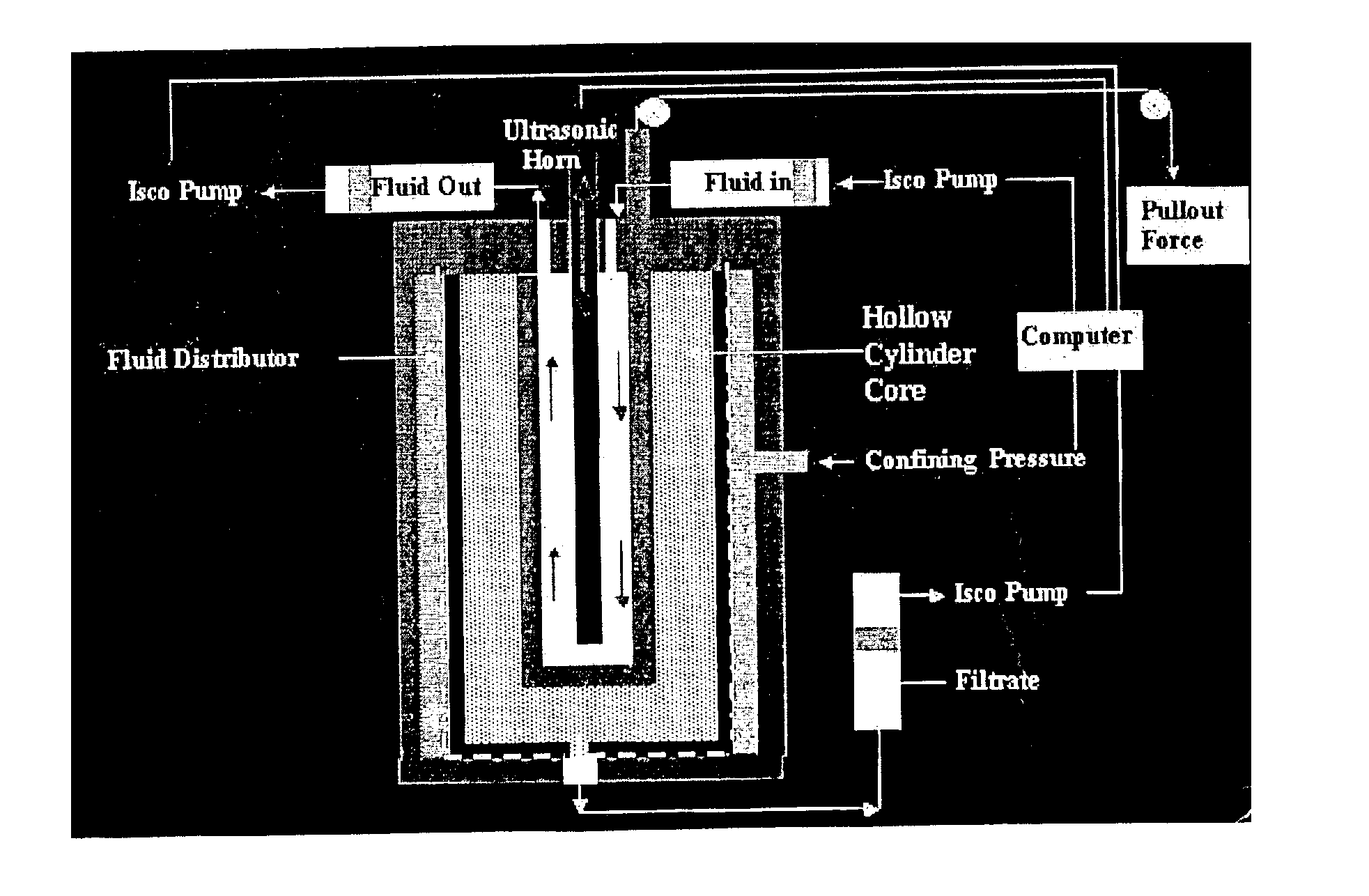

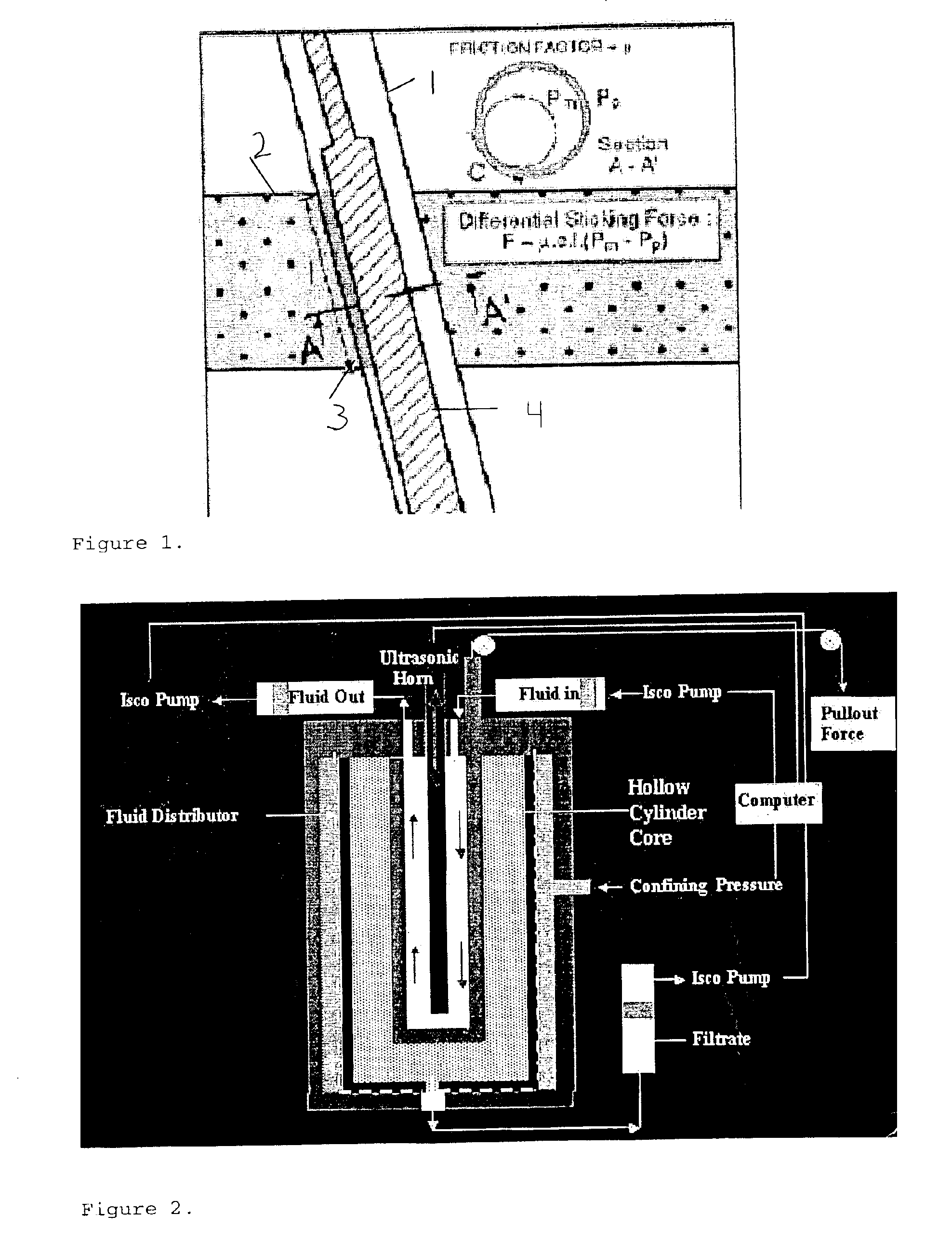

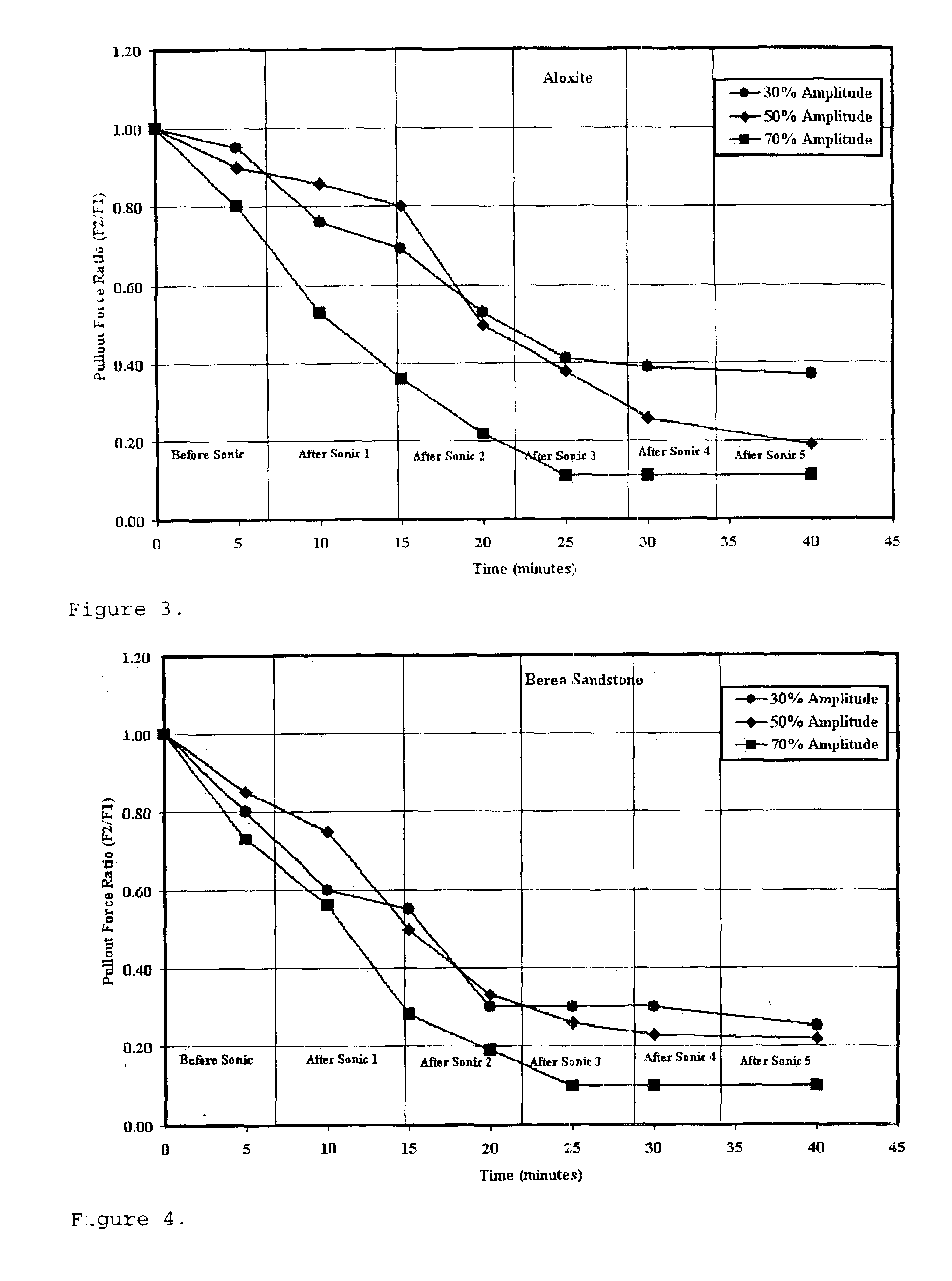

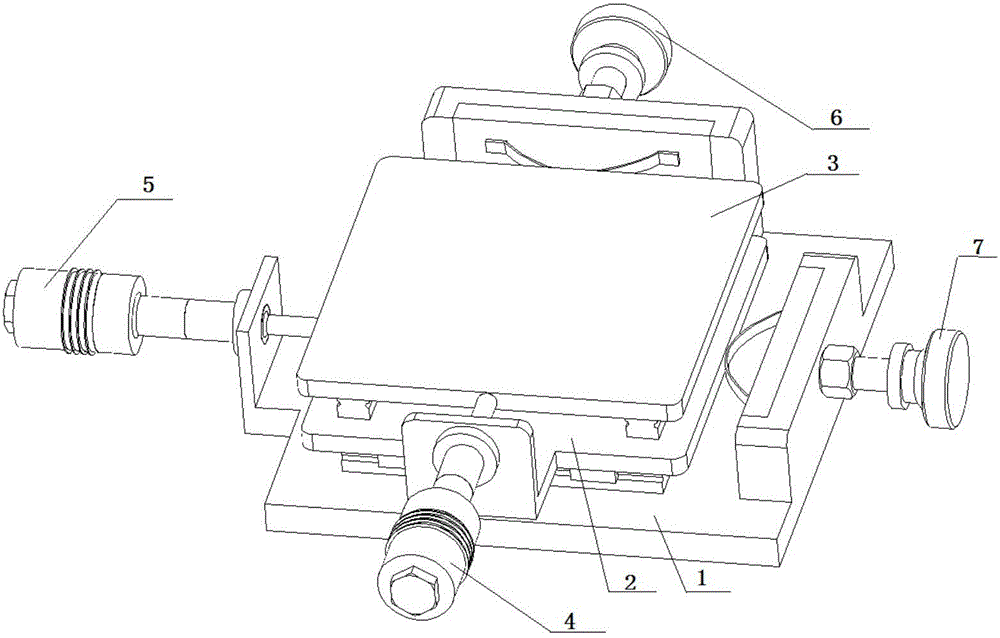

Method of freeing stuck drill pipe

InactiveUS6845818B2Reduce the amount requiredFluid removalSealing/packingPetroleum engineeringFilter cake

Disclosed is an auxiliary method for freeing a drill pipe stuck due to build up of filter cake, which provides a reduction in the amount of force required to free said pipe which comprises:a) Lowering an ultrasonic horn type device down the drill pipe to the point of contact between said drill pipe and mud filter cake;b) Producing ultrasonic energy at the point of contact until the contact area is sufficiently reduced such that substantially less force is required to free the pipe.

Owner:SHELL OIL CO

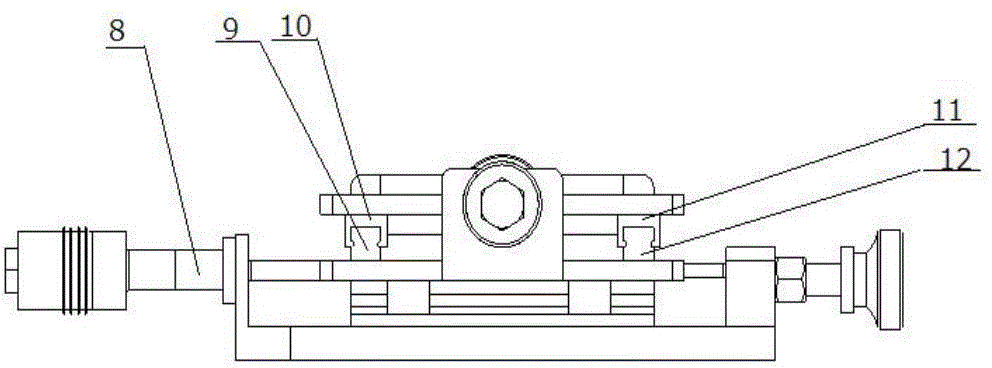

Two-dimensional ultrasound vibration platform

The invention discloses a two-dimensional ultrasound vibration platform and relates to the technical field of non-traditional machining. The two-dimensional ultrasound vibration platform aims at solving the problems that cutting force is large and a tool is worn badly when a common micro milling machine is used for machining hard and brittle materials. The two-dimensional ultrasound vibration platform comprises a bearing plate, an upper vibrating plate, a lower vibrating plate, linear moving guide rails, bow spring pieces, fine adjusting devices, an ultrasonic power supply, ultrasonic amplitude transformers and ultrasonic transducers. The bottom of the bearing plate is directly fixed to a platform of a machine tool through bolts. The lower vibrating plate is mounted on the bearing plate. The middle of one side of the upper vibrating plate and the middle of one side of the lower vibrating plate are each connected with a vibrator. The bow spring pieces are arranged in the middles of the other sides of the vibrating plates. The two ends of each bow spring piece are fixed to the output end of the corresponding fine adjusting device. The amplitude transformers and the transducers are connected through threads to form the vibrators. According to the two-dimensional ultrasound vibration platform, the vibrators produce ultrasonic vibration to drive the upper vibrating plate and the lower vibrating plate to vibrate, different motion tracks can be coupled out according to different demands, and the two-dimensional ultrasound vibration platform is high in transportability and suitable for being popularized in vibration milling or other vibration screening fields.

Owner:TIANJIN UNIV

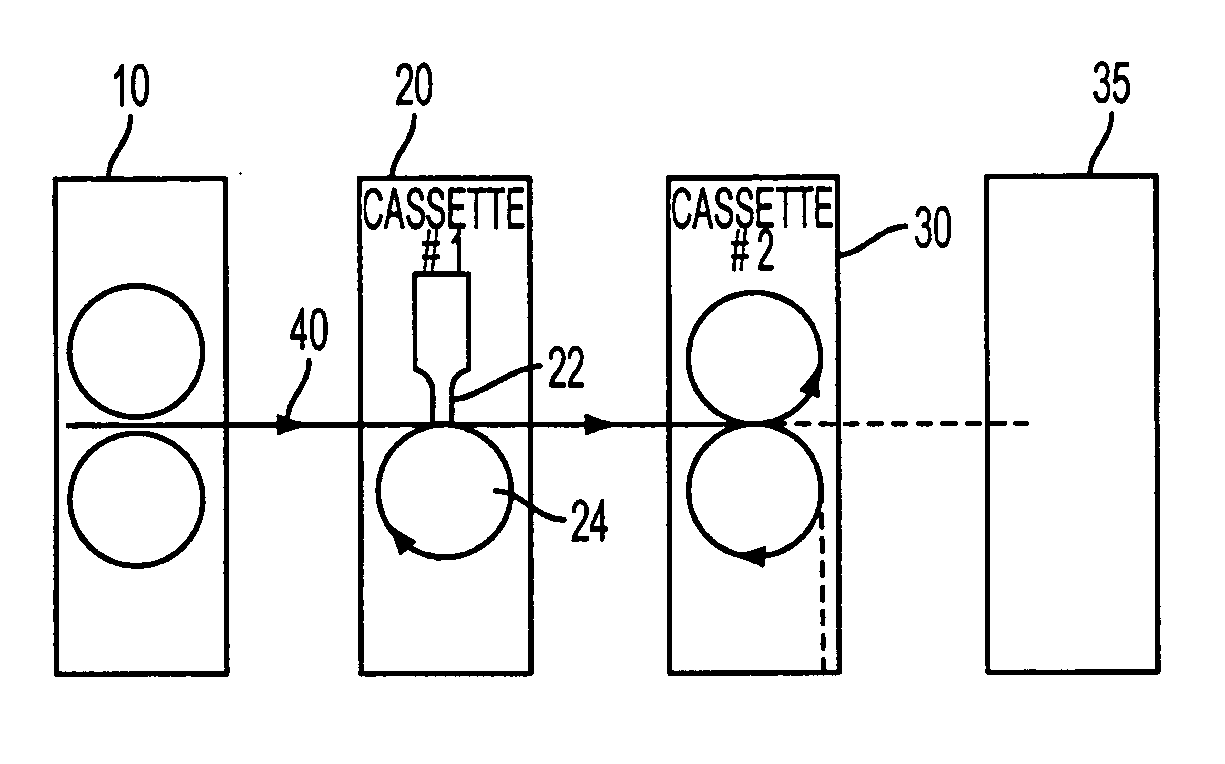

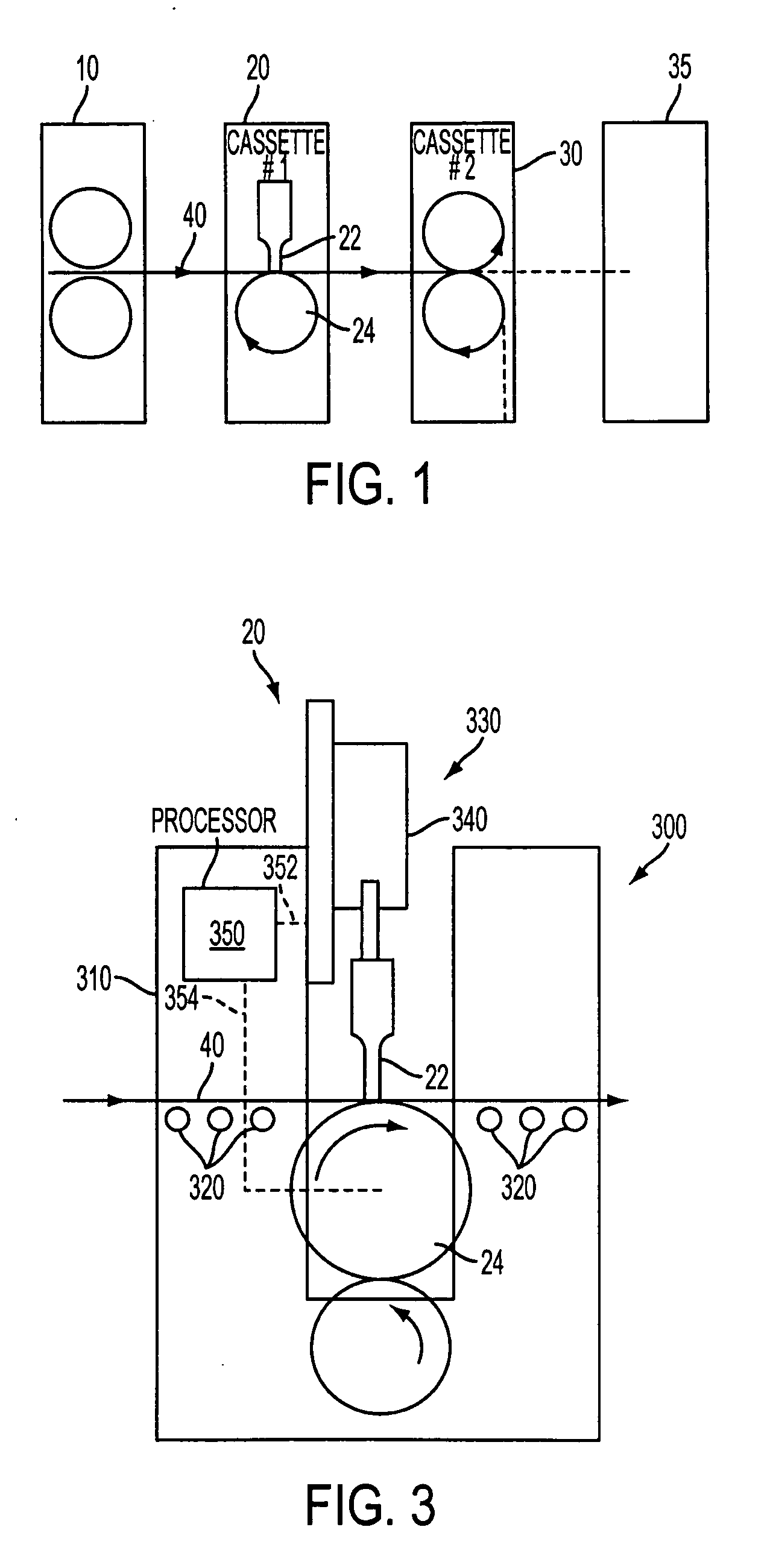

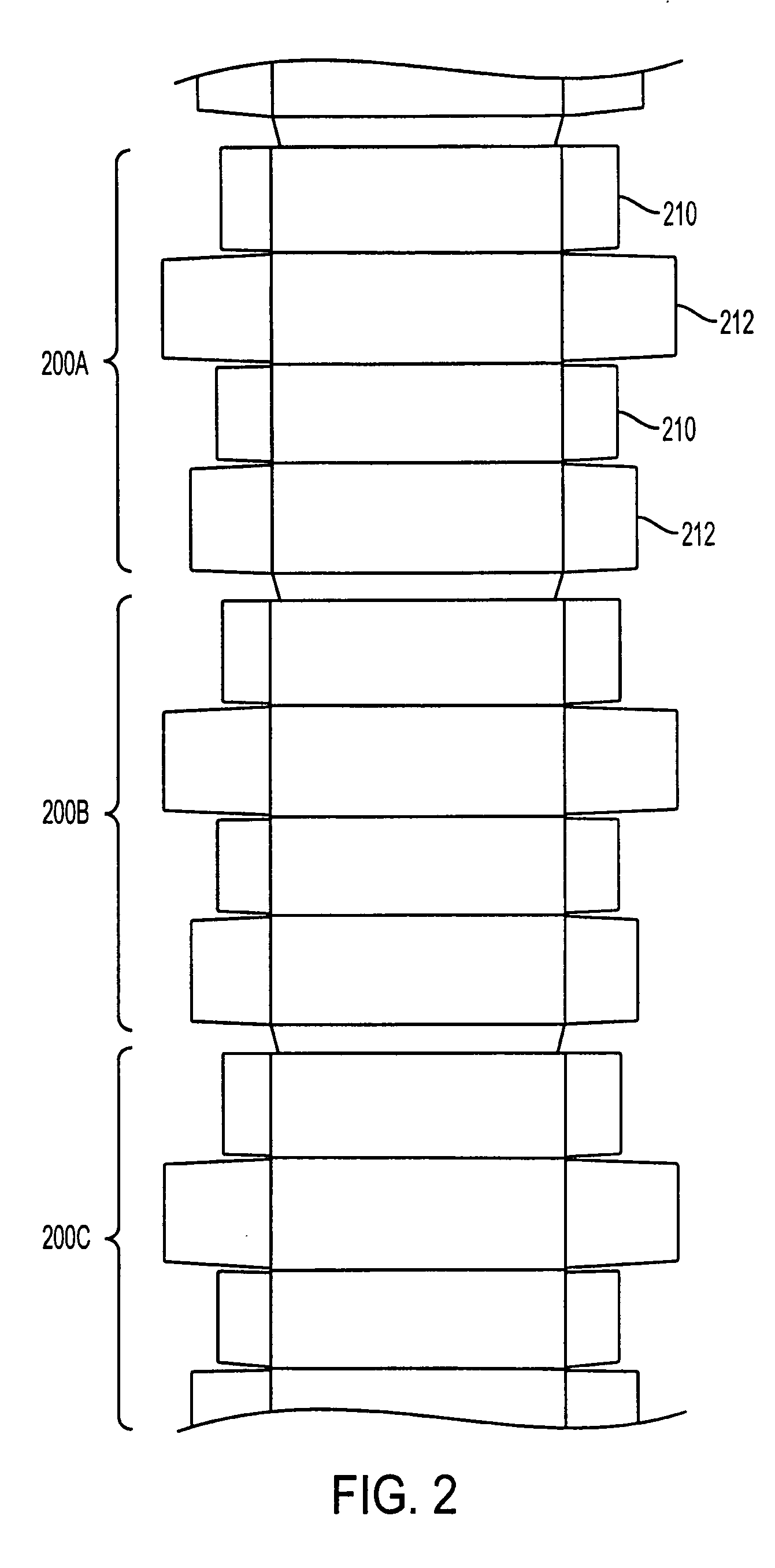

Ultrasonic scoring for a web

InactiveUS20070069428A1Reduce thicknessAvoid insufficient heatingMechanical working/deformationBoxes/cartons making machineryEnergy deviceLinearity

An apparatus, method, in-line press, and cassette for conditioning a substrate for subsequent processing, the apparatus comprising: an ultrasonic energy device with an ultrasonic horn having a contact surface; a rotatable cylinder having a raised profile with a linear or curvilinear pattern, the rotatable cylinder disposed adjacent the horn, but on an opposite side from the substrate; wherein the substrate is squeezed between the contact surface of the ultrasonic horn and the pattern on the rotatable cylinder to thereby apply heat and pressure during operation of the ultrasonic energy device to create a linear or curvilinear indentation in a surface of the substrate.

Owner:DELAWARE CAPITAL FORMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com