Ultrasonic surface rolling process nanoparticlization method and apparatus

A nanometerization and ultrasonic technology, applied in the field of metal surface treatment, can solve the problems of easy wear of the working head, low life, and the improvement of the service life can not meet the practical requirements of long-term continuous work, so as to improve the comprehensive mechanical properties and improve the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

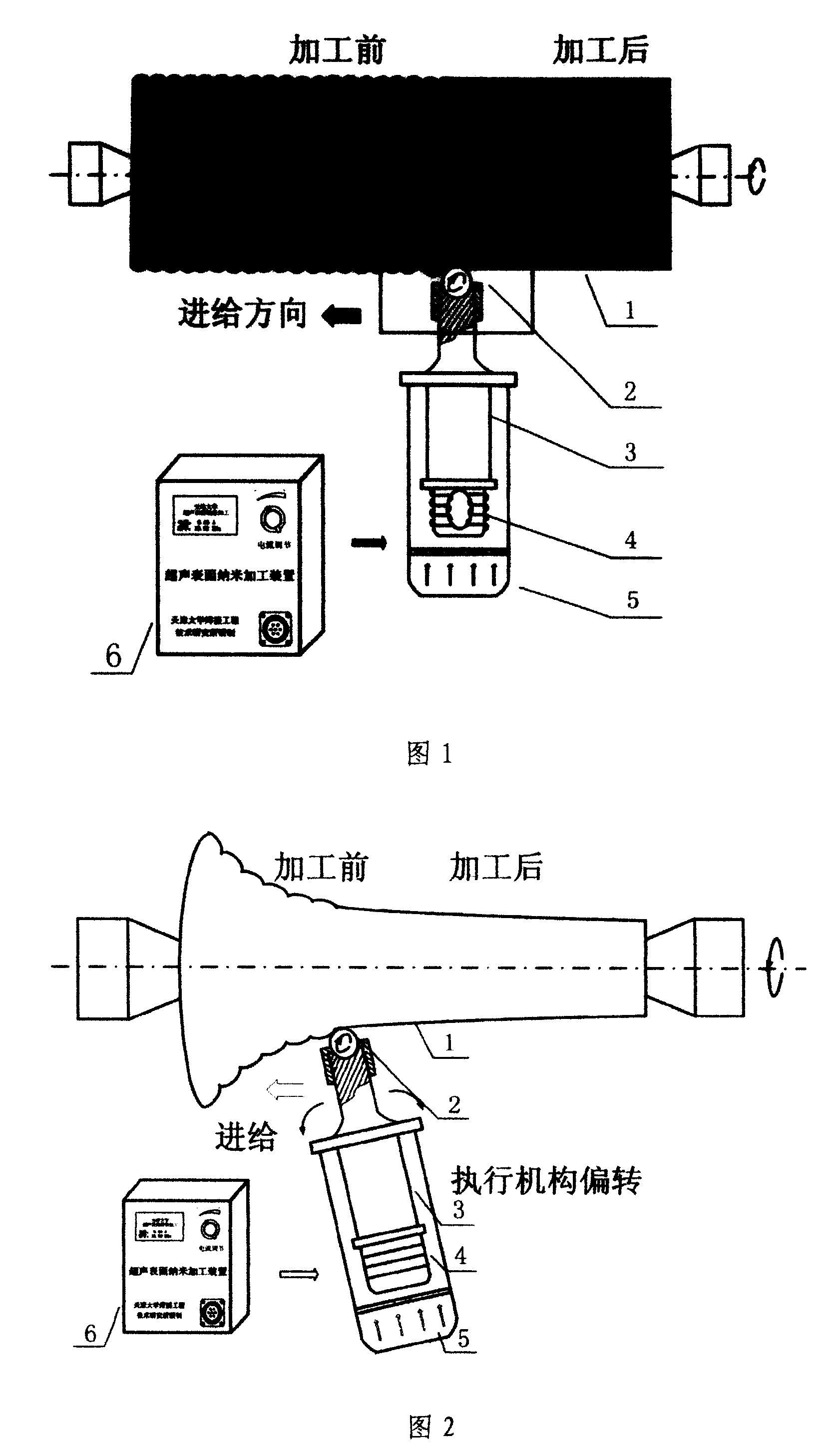

[0039] The quenched and tempered 40Cr shaft with a diameter of 60mm is surface-treated by ultrasonic surface rolling nano-processing method. The main technical parameters are as follows:

[0040] The spindle speed of the machine tool is 255r / min; the feed rate of the working head of the impact gun is 0.07mm / r; the static pressure is 400N; the processing is 15 times; the emulsified coolant is used as the lubricant; the working head is made of hard alloy material, and the spherical radius is 5mm; The ultrasonic amplitude at the output of the working head is 10 microns.

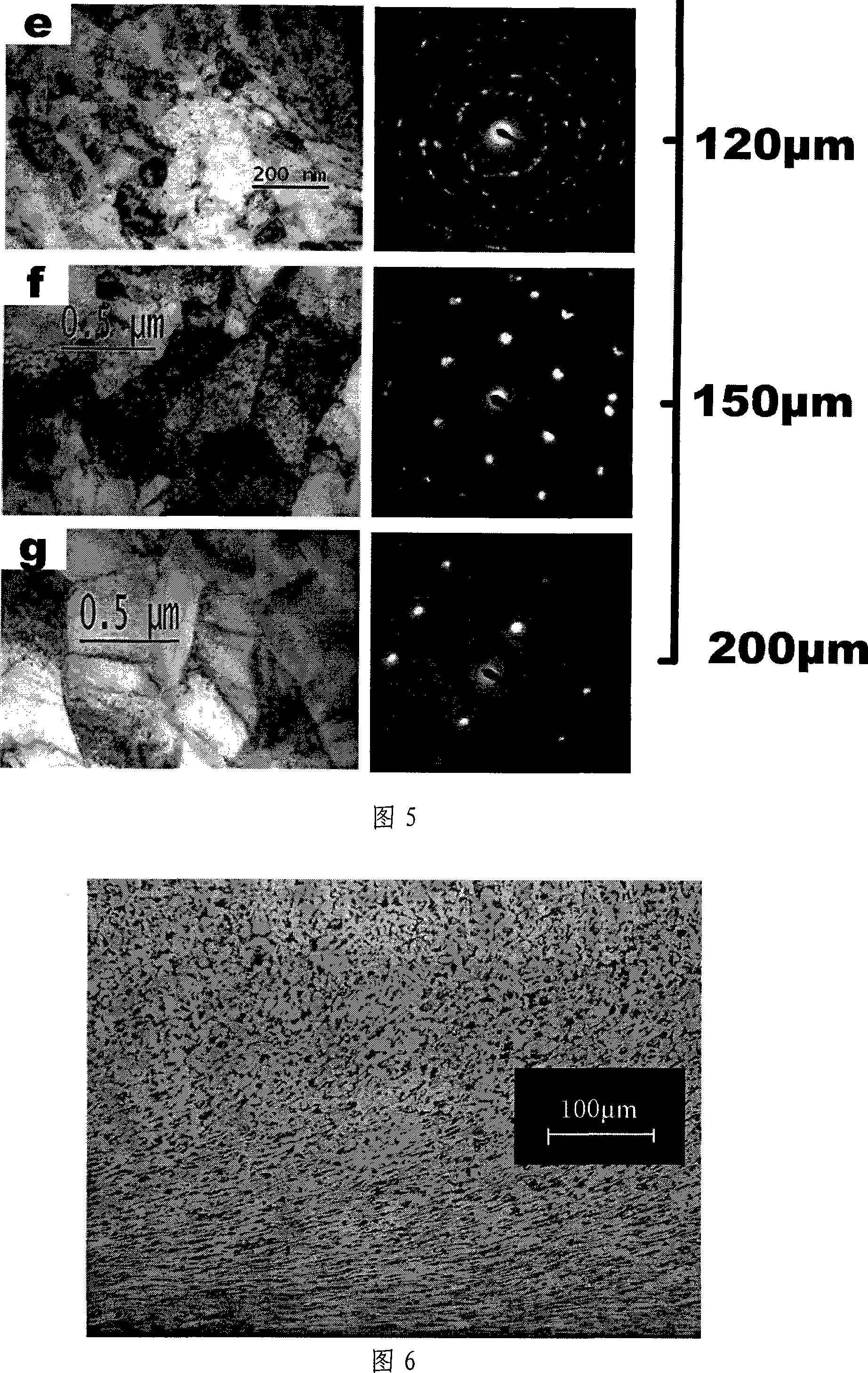

[0041] Experimental results: As shown in Figures 4 to 6, an amorphous nanocrystalline layer of nearly 100 microns was formed on the surface of the sample after USRP processing. The grains on the outermost surface are equiaxed, with an average grain size of about 3-7nm, which is about 2000 times finer than the original grain size (about 10μm); the hardness of the treated sample increases significantly, compared w...

Embodiment 2

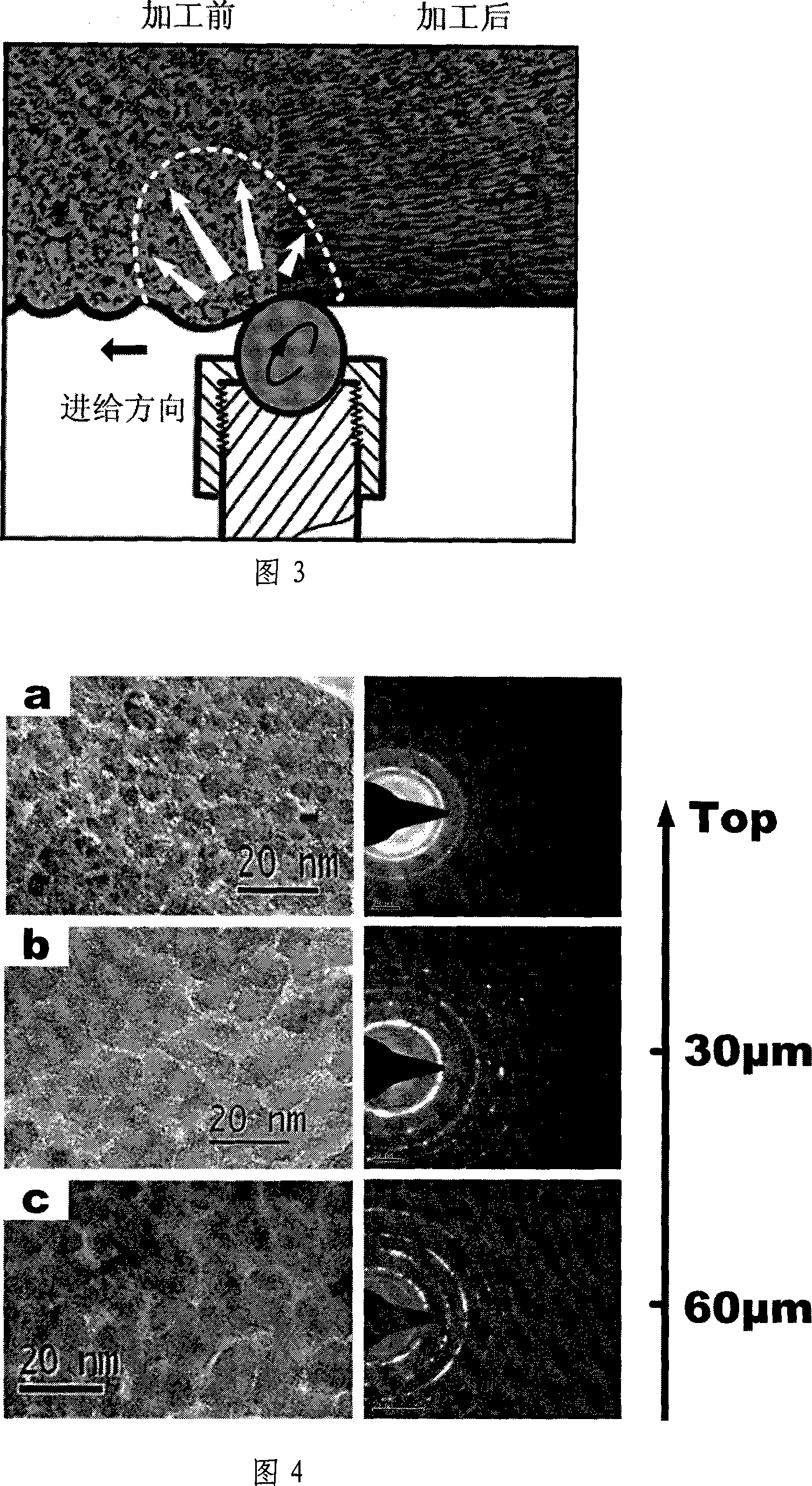

[0043] The R-arc workpiece of 45 steel, as shown in Figure 2, is surface treated by ultrasonic surface rolling nano-processing method. The main technical parameters are as follows:

[0044] The spindle speed of the machine tool is 225r / min; the axial feed of the working head of the impact gun is 0.07mm / r, the longitudinal feed of the R arc is 0.01mm / r, the fixture deflection is 30°; the static pressure is 150N; The emulsified cooling liquid is used as the lubricating liquid; the working head is made of hard alloy material, and the spherical radius is 5mm; the ultrasonic amplitude at the output end of the working head is 10 microns.

[0045] Experimental results: the grains on the outermost surface are equiaxed, with an average grain size of about 7nm, as shown in Figures 7 and 8; the surface roughness is Ra 0.11.

Embodiment 3

[0047] The ZLD201A cast aluminum shaft with a diameter of 60mm is surface treated by ultrasonic surface rolling nano-processing method. The main technical parameters are as follows:

[0048] The spindle speed of the machine tool is 405r / min; the feed rate of the working head of the impact gun is 0.25mm / r; the static pressure is 50N; the machining goes back and forth 3 times; the emulsified coolant is used as the lubricant; the working head is made of hard alloy material, and the spherical radius is 5mm; the ultrasonic amplitude at the output end of the working head is 10 microns.

[0049] Experimental results: the grains on the outermost surface are equiaxed, the average grain size is about 7nm, as shown in Figures 9 and 10, and the surface roughness Ra is 0.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com