Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Raise Strength Index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

Production process of ABS valve body material for cars

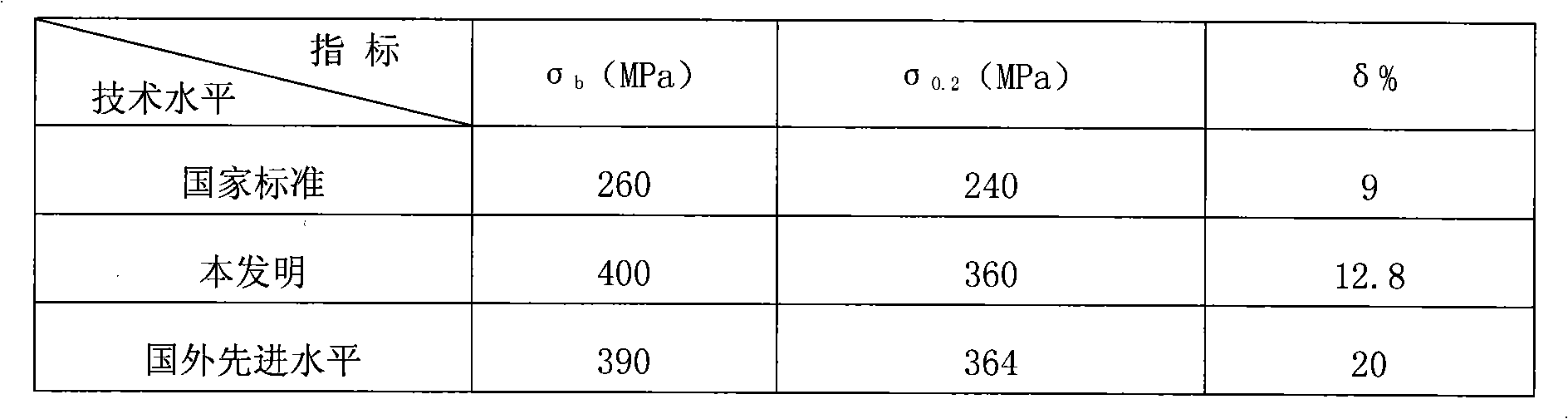

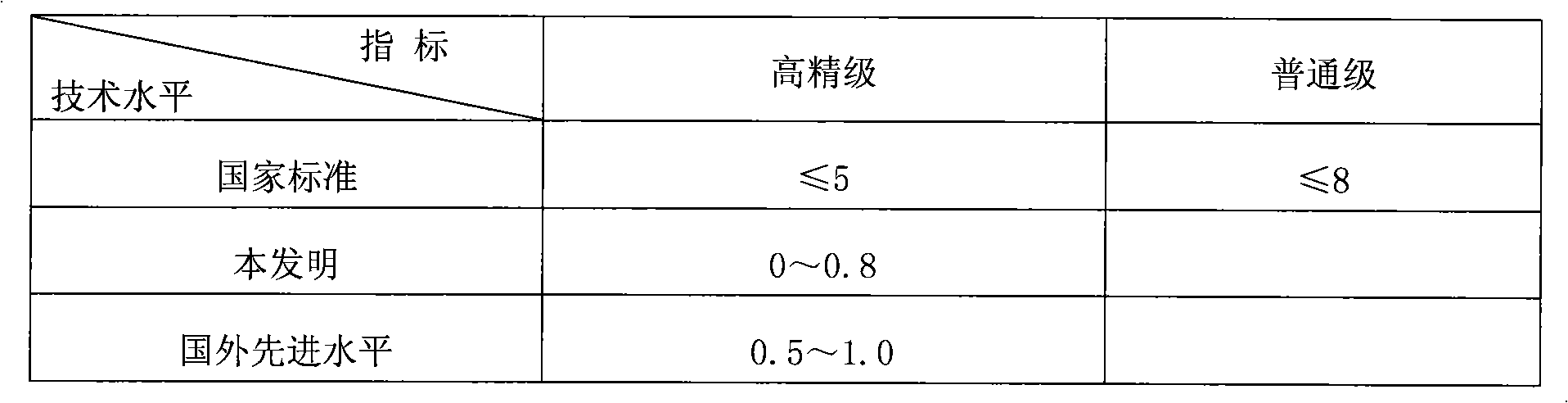

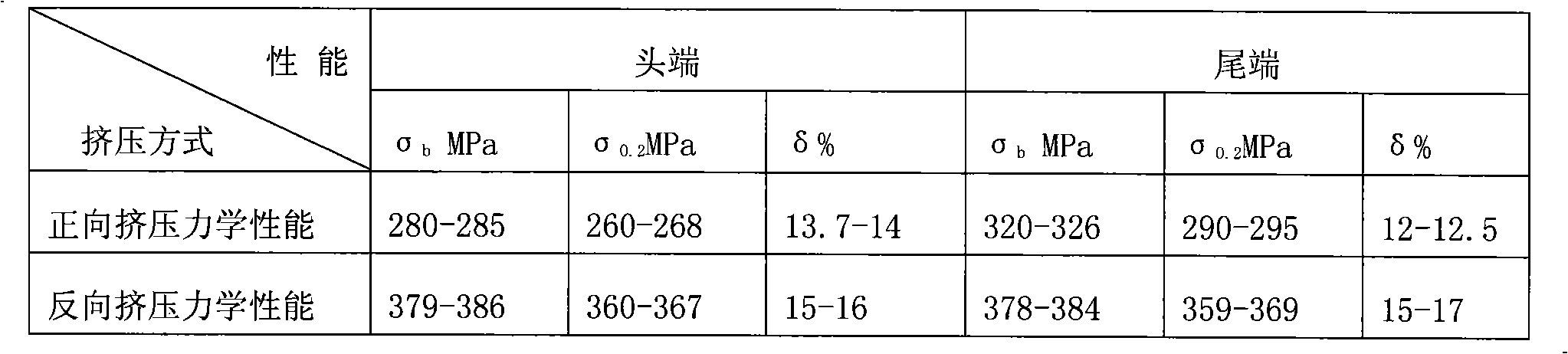

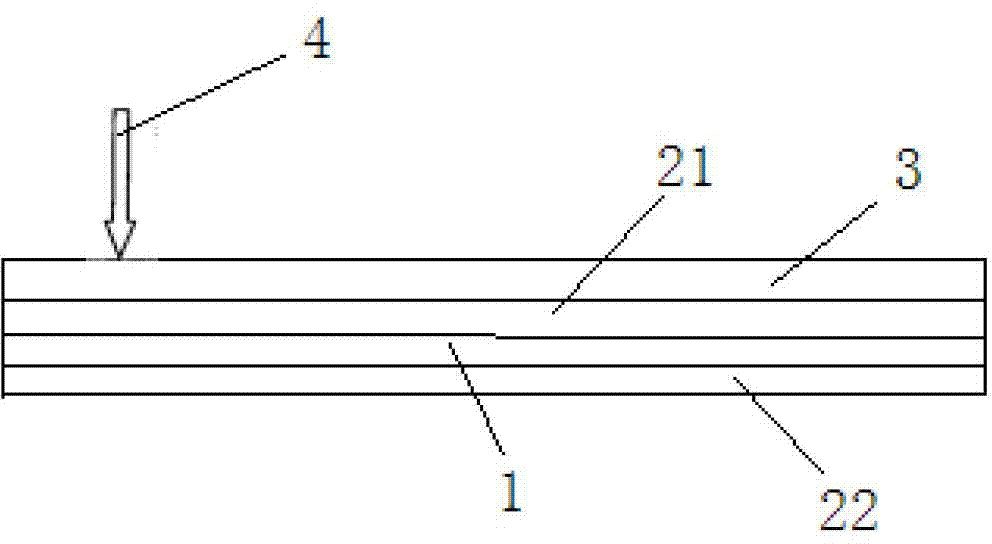

The invention provides a production process of the automobile ABS valve body material, which includes the following steps: preparing raw materials, melting, refining and standing, filtering and casting, homogenizing, ingot processing, ingot heating, indirect extruding, on-line water quenching, stretch rolling, artificial aging and finished product inspecting. By adopting the optimized alloy component in combination with indirect extrusion technology and on-line heat treatment technology, particularly the indirect extrusion technology, the inventive production process achieves the high uniformity of material structure, head-and-tail measures and mechanical property, thereby solving the problems of 6061 alloy coarse grain zone and mechanical property, increasing the production yield index, reducing the energy consumption of unit product, obtaining the material of which the mechanical property, metallographic structure, dimensional precision and the surface quality reach the advanced level of foreign similar products, achieving the import substitution of the material and laying the foundation of automobile localization.

Owner:西北铝业有限责任公司

High strength weldable ageing hardening steel and its production method

A weldable high-strength steel hardened by ageing contains proportionally C, Si, Mn, P, S, Nb, Mo, Ni, Ti, Cu, Cr and Fe. Its preparing process includes smelting, desulfurizing, top blowing, converting, vacuum treating, casting and rolling. Its advantages are excellent mechanical performance and low-temp toughness, and high resistance to atmosphere and seawater corrosion and fatigue.

Owner:武钢集团有限公司

High-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and preparation method thereof

ActiveCN103170183AHigh filtration precisionHigh operabilityFibre typesSynthetic resin layered productsFiberEngineering

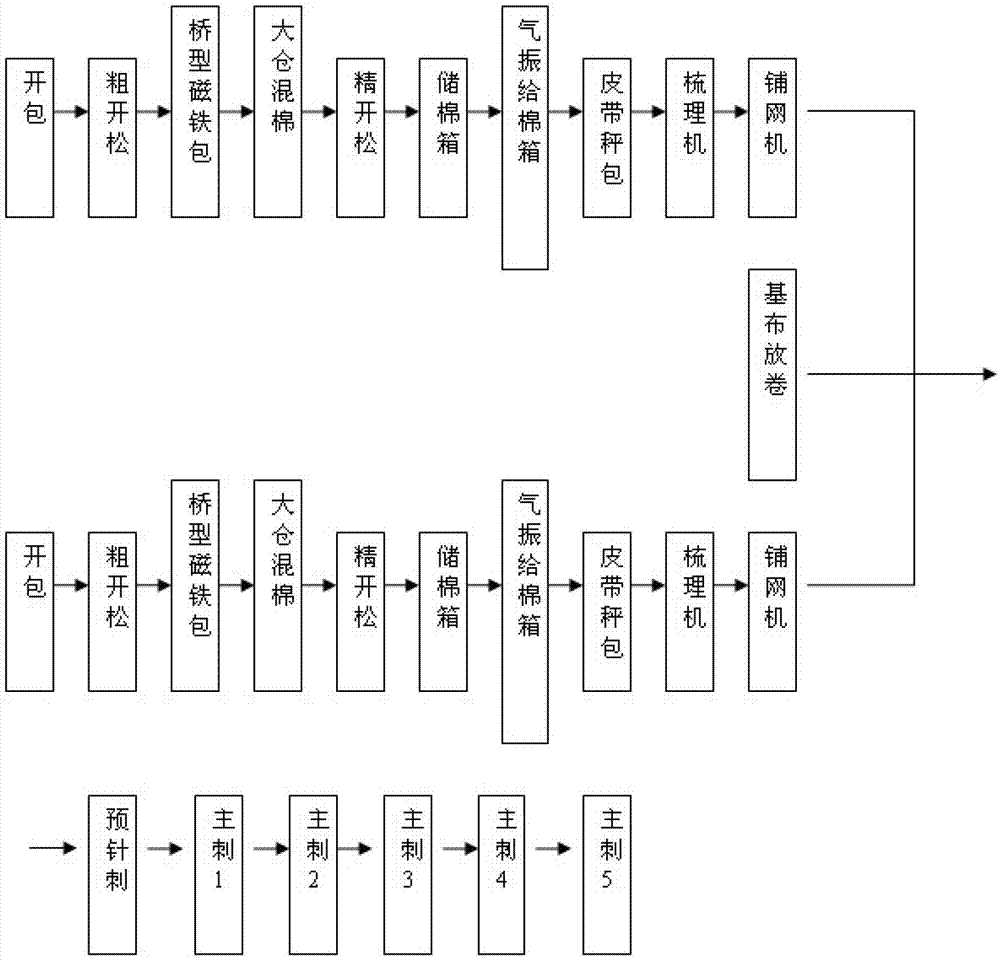

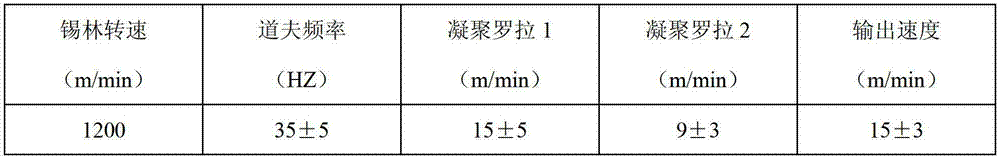

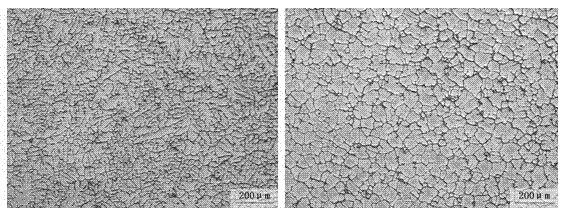

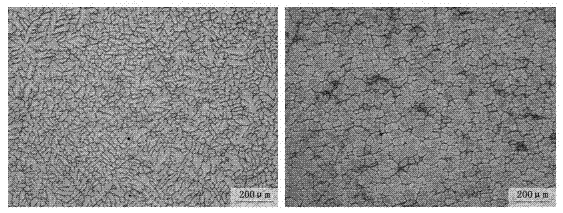

The invention provides a high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and a preparation method thereof. The filter material disclosed by the invention is formed by compounding a PTFE (Polytetrafluoroethylene) high-compactness microporous membrane layer and a punched felt in sequence from top to bottom. The punched felt is formed by compounding a first polysulfonamide fiber surface layer, a high-intensity low-stretchability base cloth layer and a second polysulfonamide fiber surface layer in sequence from top to bottom. The preparation method comprises steps of: preparation of the punched felt, high-temperature thermoforming, singeing and pressing treatment, full-saturation immersion treatment, predrying, baking curing, and high-temperature high-pressure coating with the PTFE high-compactness microporous membrane. The high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material has high intensity and low stretchability, longitude and latitude strengths are both larger than 3000N / 50mm; the longitude and latitude elongations at break are both smaller than 10%; and the filter material can resist a high temperature grade of 250 DEG C and has high corrosion resistance, good oxidization resistance, smooth surface, high deashing efficiency and wide application range.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

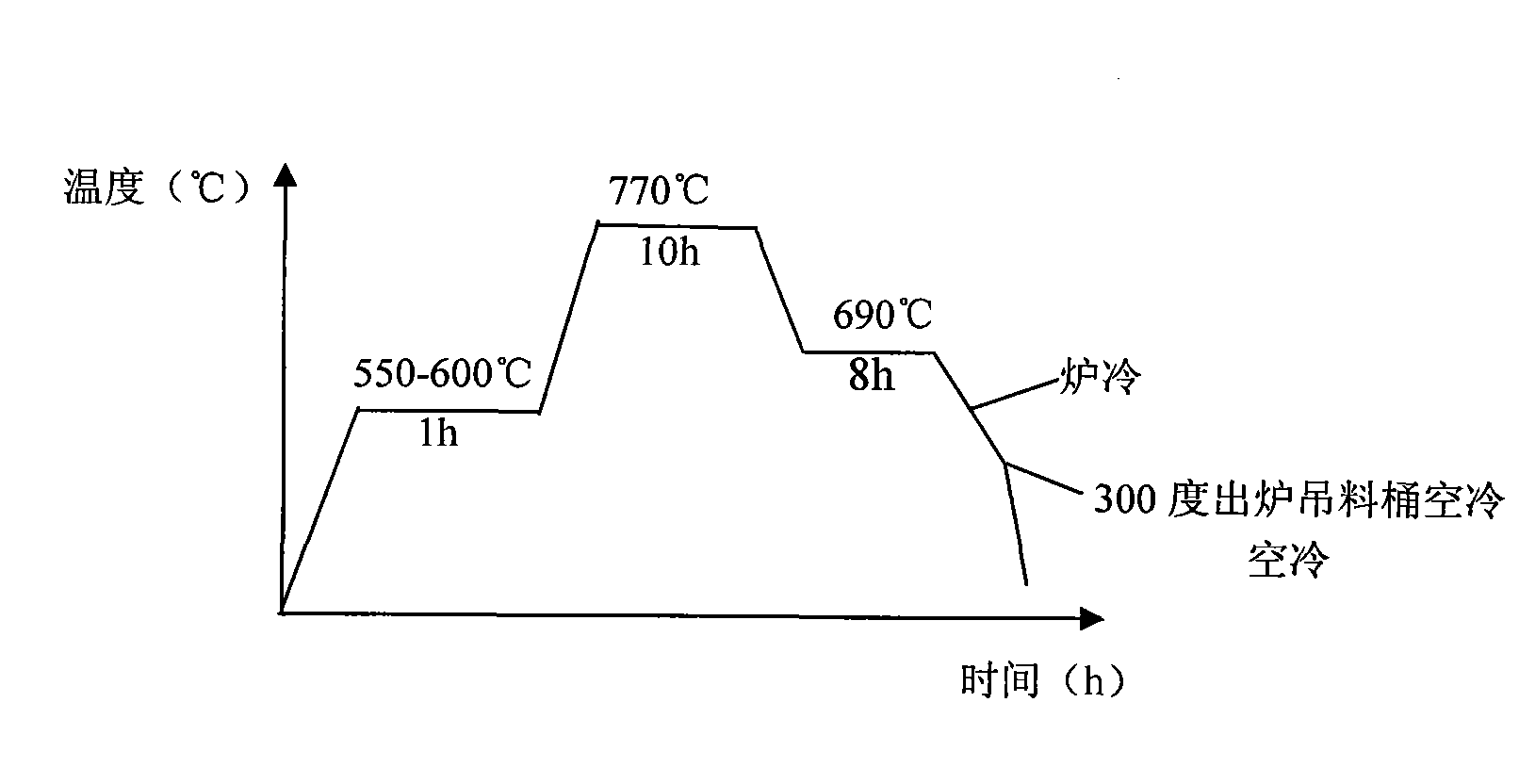

Wrought magnesium alloy with high intensity and method for preparing its extruded material

ActiveCN102392165AImprove surface qualityRaise Strength IndexExtrusion diesLubricationMetallic materials

The invention belongs to the metal material technical field and the metallurgy technical field, and concretely relates to a wrought magnesium alloy with high intensity and a method for preparing an extruded material. The wrought magnesium alloy with high intensity is a Mg-Zn-(Cu or Ni)-RE-based magnesium alloy, which comprises the following ingredients by mass percentage: 2.0%-6.0% of Zn, 1.5%-6.0% of Cu or Ni, 0.1%-0.5% of Y, Nd, Gd, Ce or MM, 0-0.8% of Zr and the balance of Mg, wherein the content of impurity Fe is less than 0.005% and the density is (1.84-1.86) *10<3>kg / m<3>. The method ischaracterized in that a magnesium alloy ingot blank is semi-continuous casted by using low frequency electromagnetic oil lubrication, then performed reverse temperature extrusion and T5 heat treatment to obtain the extruded material of the wrought magnesium alloy with high intensity. The density of the extruded material of the Mg-Zn-(Cu or Ni)-RE-based magnesium alloy is (1.84-1.86) *10<3>kg / m<3>, the room temperature tensile mechanical properties after T5 heat treatment is carried out are that: the tensile strength is 390-420MPa, the yield strength ratio is greater than 0.96, the elongation percentage is greater than 7%.

Owner:NORTHEASTERN UNIV

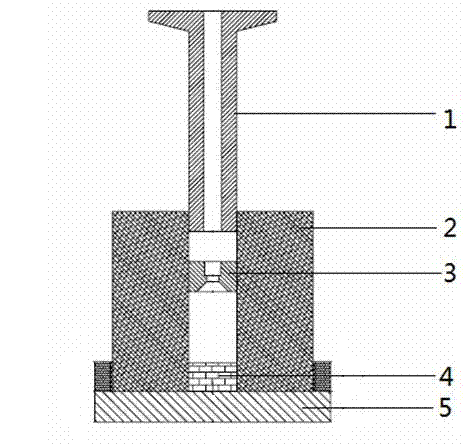

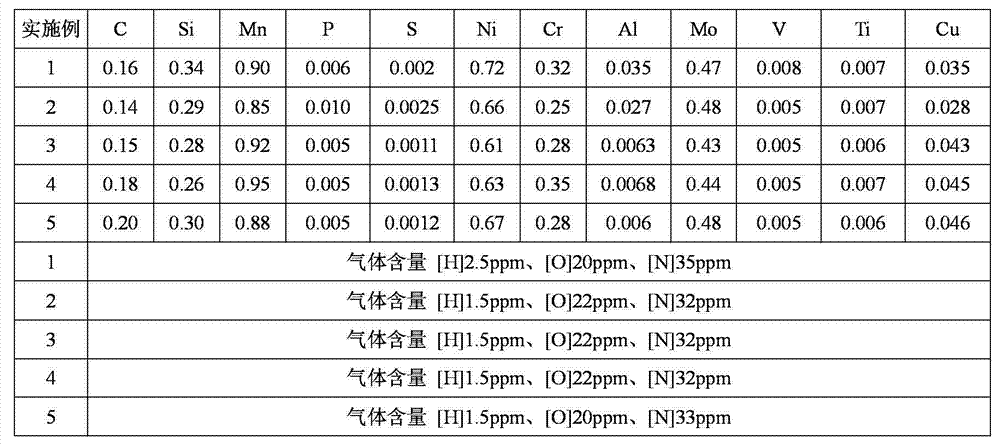

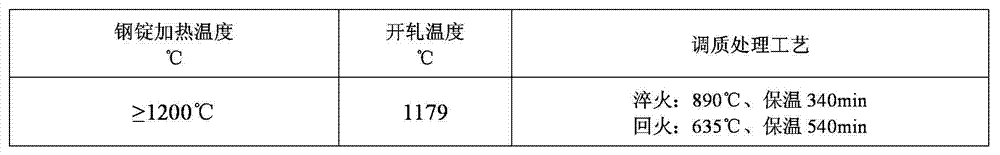

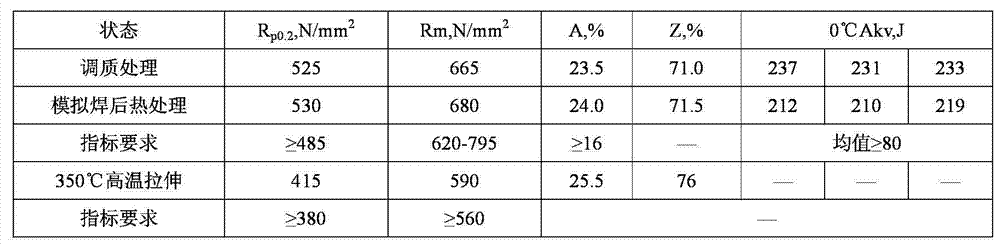

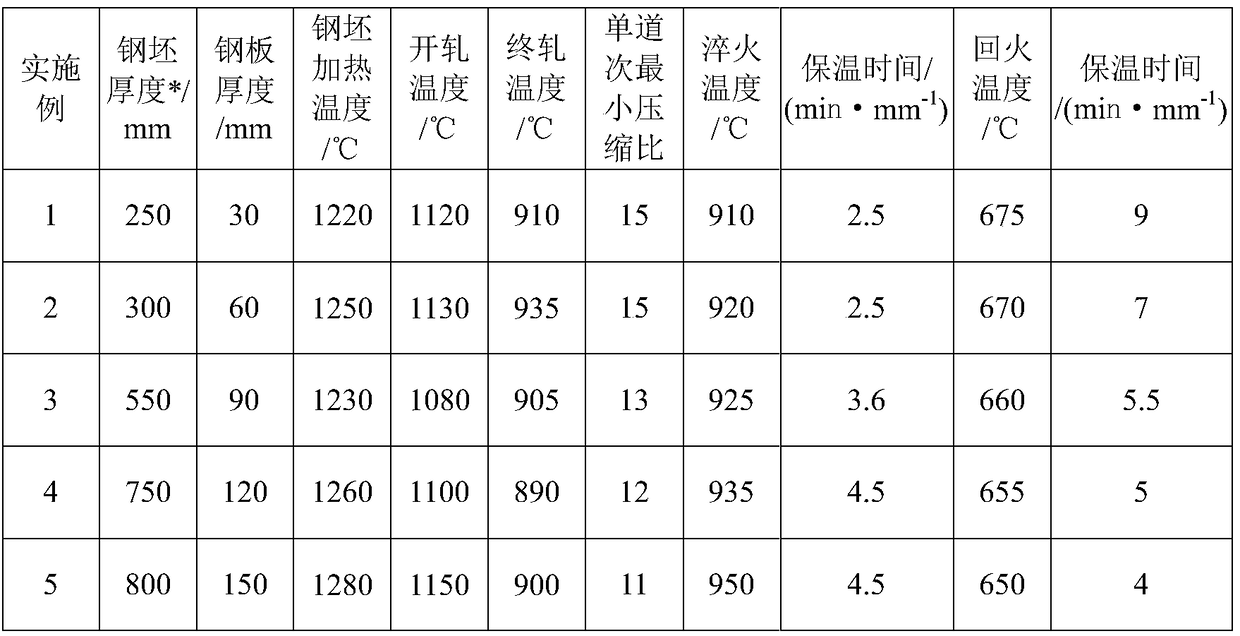

Steel used for voltage stabilizer of pressurized water reactor power station and manufacture method of steel

The invention provides steel used for a voltage stabilizer of a pressurized water reactor power station and a manufacture method of the steel. The steel comprises the following components: 0.10 to 0.25% of C, 0.15 to 0.35% of Si, 0.80 to 0.95% of Mn, not greater than 0.010% of P, not greater than 0.010% of S, 0.50 to 0.80% of Ni, 0.20 to 0.60% of Cr, 0.005 to 0.040% of Al, 0.40 to 0.70% of Mo, 0.005 to 0.01% of V, 0.005 to 0.01% of Ti, not greater than 0.10% of Cu, and the balance of Fe. The method comprises the following steps of: 1) smelting, namely, performing continuous casting on a 70mm steel plate through a converter, and performing die casing on the steel plate of not being less than 70mm; 2) rolling, namely, heating a continuously-casted steel billet to reach the temperature of 1,150 to 1,250 DEG C; controlling the temperature of final rolling in a recrystallization area to not less than 1,000 DEG C; controlling the temperature of rolling in a non-recrystallization area to 830 to 880 DEG C; controlling the total rolling reduction to more than 70%; heating a die-casted steel ingot in a chamber furnace, wherein the temperature in heating is not less than 1,200 DEG C, and the temperature in rolling starting is not less than 1,050 DEG C; and 3) hardening and tempering, namely, quenching at temperature of 850 to 930 DEG C, and maintaining the temperature for 2 to 4min / mm; tempering at 630 to 680 DEG C, and maintaining the temperature for 4 to 10min / mm. The steel product can meet various index requirements.

Owner:ANGANG STEEL CO LTD

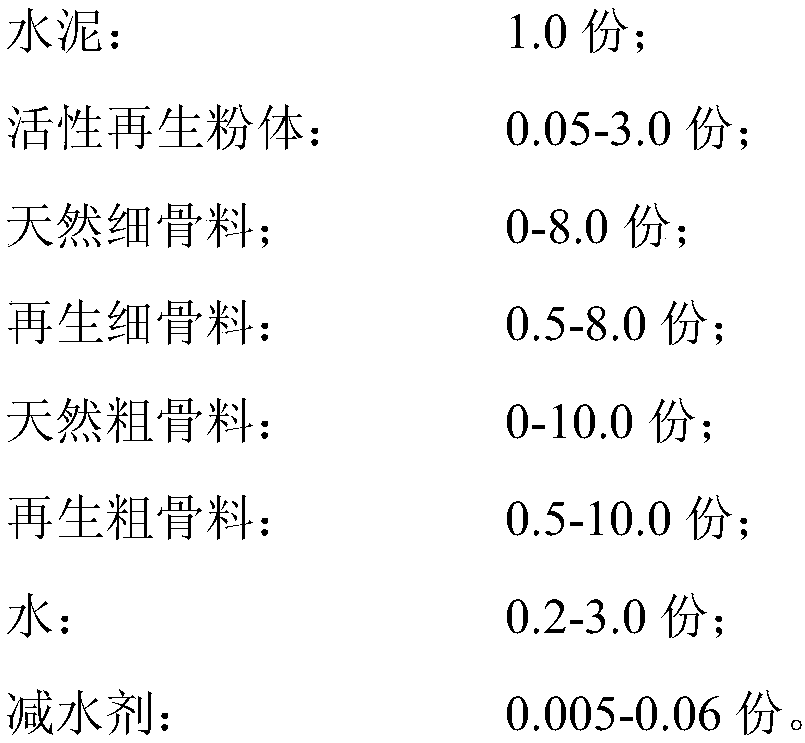

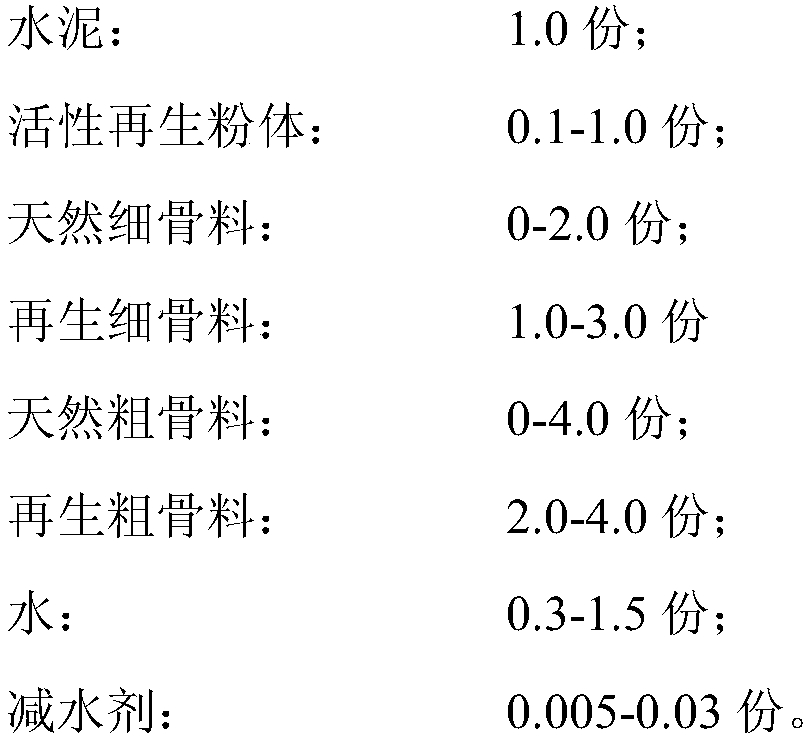

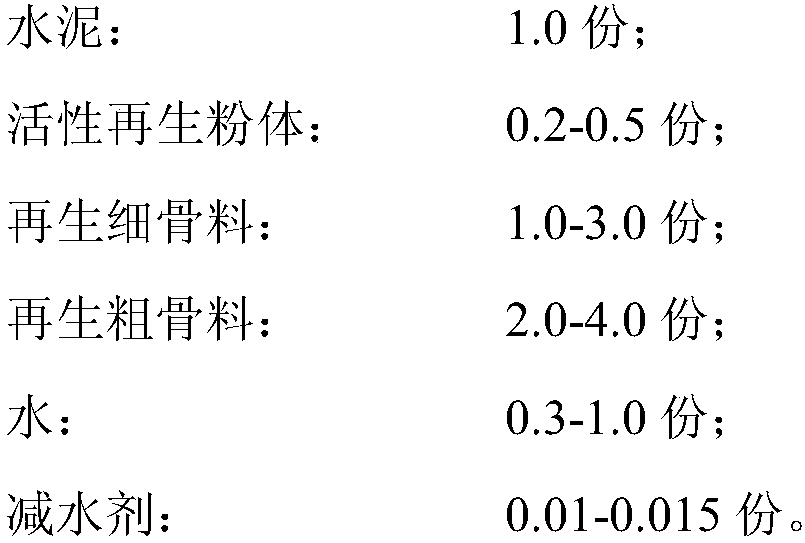

Regenerated concrete block material and production method thereof

InactiveCN108558303AImprove resource utilizationReduce manufacturing costSolid waste managementCement productionSocial benefitsHydration reaction

The invention provides a formula for preparing a regenerated concrete block material by using high activity regenerated powder and a regenerated aggregate. The invention further provides a productionmethod of the regenerated concrete block material based on a system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate'. The regenerated concrete block material prepared byusing the system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate' has excellent mechanical strength, the strength level range is 5-50 MPa, and the requirements of the concrete block material strength under different working conditions are met. The invention provides a novel developing route for the resource recycling of construction wastes. The performance of the regenerated powder is similar to the performance of mineral admixture such as fly ash and the like, the activity is higher, secondary hydration reaction of a cement-based material can be promoted to relieve the current situation of insufficient supplying of mineral admixture such as fly ash and the like, and the regenerated concrete block material has higher economic benefit and social benefit.

Owner:TONGJI UNIV

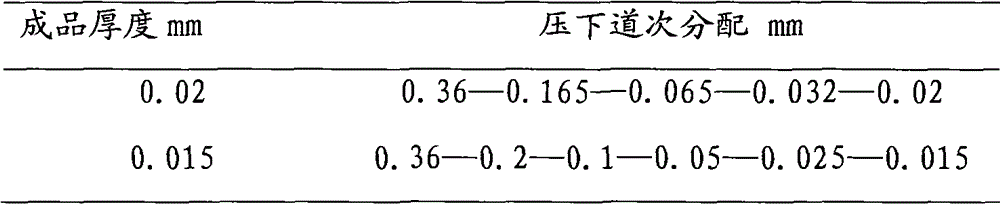

Process for producing battery aluminium foil

ActiveCN102744255AIncrease work hardeningImprove uniformityMetal rolling arrangementsElectrical batteryAlclad

The invention discloses a process for producing a battery aluminium foil. The process comprises the following steps of: (1), carrying out casting and rolling production by selecting 1070 alloyed scrap of which the scrap ratio is not more than 35%, and the rest of pure aluminium ingot to obtain a casting-rolling blank; (2), coldly rolling the casting-rolling blank to obtain an aluminium alloy belt material; (3), carrying out heat preservation on the aluminium alloy belt material at 500-560 DEG C for 8.5-9.5 hours, and intermediately annealing at 400-440 DEG C for 1.5-2.5 hours, wherein the thickness of the aluminium alloy belt material during intermediate annealing is 1.8 millimeters; and (4), rolling the intermediately annealed aluminium alloy belt material into a product with the thickness of a finished product. According to the process, the total processing rate after the intermediate annealing is increased; the work-hardening capacity of the material is enhanced; and therefore, the intensity index of the product is increased; in addition, because the annealing and temperature-increasing time is prolonged, the uniformity of the internal organization of the material is beneficial to being increased; and the process is relatively beneficial to processing of subsequent processes and the stability of the product quality.

Owner:NORTH CHINA ALUMINUM +1

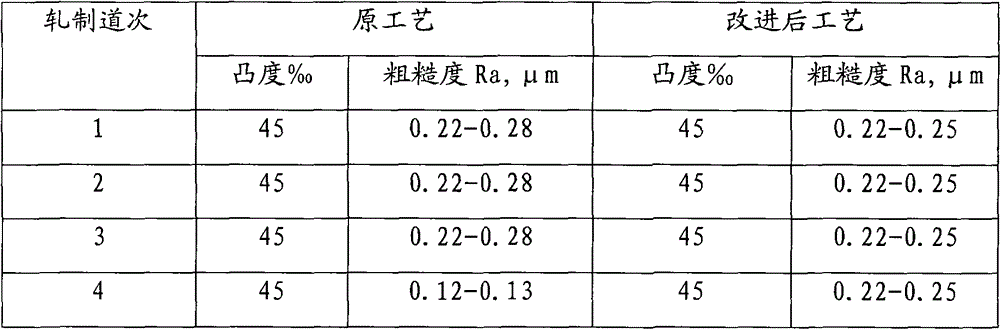

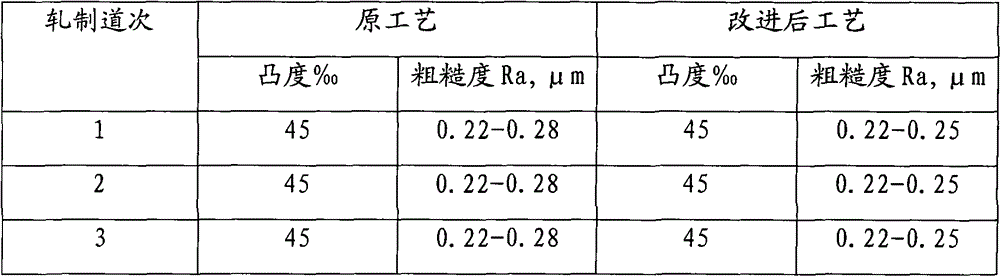

Method for producing 500 Mpa high strengh threaded reinforced bar

InactiveCN1792484AHigh strengthRaise Strength IndexTemperature control deviceWork treatment devicesHigh intensityWater cooling

A method for manufacturing the high-strength (500 MPa) threaded reinforcing bar includes such steps as providing 20MnSi steel bullet at 880-950 deg.C, cogging, middle rolling, pre-cooling by passing through water curtain, final rolling, cooling by passing through water curtain, and air cooling to release heat from its core for self tempering.

Owner:双菱钢铁集团控股有限公司

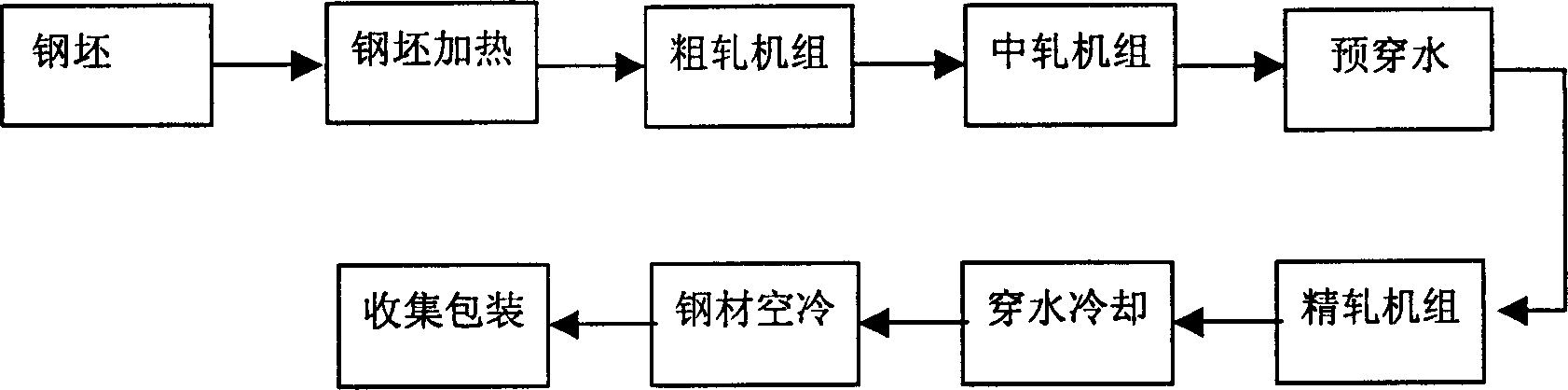

Steel for pressure bearing boundary part of steam generator in nuclear power plant and manufacturing method of steel

The invention discloses steel for a pressure bearing boundary part of a steam generator in a nuclear power plant and a manufacturing method of the steel. The steel comprises 0.15% to 0.22% of C, 0.10%to 0.30% of Si, 0.55% to 0.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30% to 0.60% of Ni, 0.70% to 1.10% of Cr, 0.80% to 1.50% of Mo, 0.020% to 0.040% of Al, 0.010% to 0.030% of Nb, 0.0005% to 0.002% of B, less than or equal to 0.05% of Cu and the balance of Fe and unavoidable impurities. A converter-continuous casting process is adopted when the thicknessof a steel plate is less than 80mm, wherein the heating temperature is 1180-1250 DEG C, the rolling starting temperature is greater than or equal to 1100 DEG C, and the rolling finishing temperature is greater than or equal to 900 DEG C; an electric furnace-die casting process is adopted when the thickness of the steel plate is greater than or equal to 80mm, wherein the heating temperature is greater than or equal to 1200 DEG C, the rolling starting temperature is greater than or equal to 1050 DEG C, and the rolling finishing temperature is greater than or equal to 850 DEG C; quenching and tempering treatment are performed on the steel plate after rolling; and the produced steel plate of 30-150mm has good high temperature performance and strong strength-toughness matching.

Owner:ANGANG STEEL CO LTD

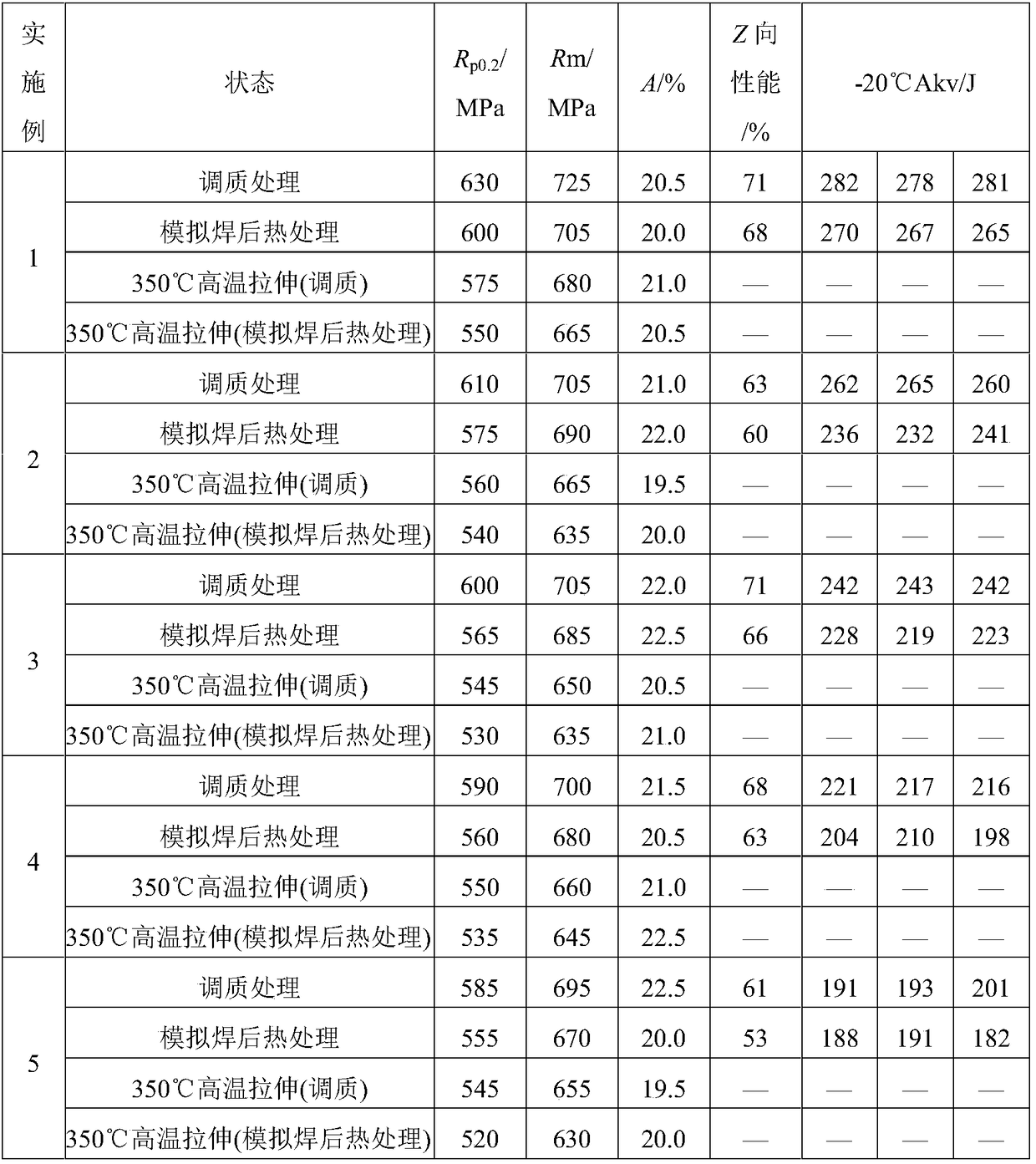

Pulp, pulp manufacturing method, body paper and papermaking method

InactiveCN102817282AImprove adsorption capacityComprehensive adsorptionInorganic compound additionRetention agents additionPapermakingFiber size

A pulp manufacturing method includes the steps of: filtering pulp with a screen of 80-200 meshes, and collecting short fiber size filtrate and filtered long fiber size, wherein the length of the short fiber in the short fiber size filtrate is smaller than or equal to 180 microns, and the length of the long fiber in the filtered long fiber size is larger than 180 microns; concentrating the short fiber size to enable the concentration of the short fiber size be 1%-10%; filling filler and retention aid in the concentrated short fiber size filtrate to form short fiber size; and mixing the short fiber size with the filtrated long fiber size to obtain the pulp, wherein 60% quality content of filler is absorbed on the surface of the short fiber. By means of the manufacturing method, retention rate of paper filler is improved, and simultaneously various strength indexes of paper are improved. The invention further provides the pulp, a papermaking method and body paper.

Owner:GOLD EAST PAPER JIANGSU

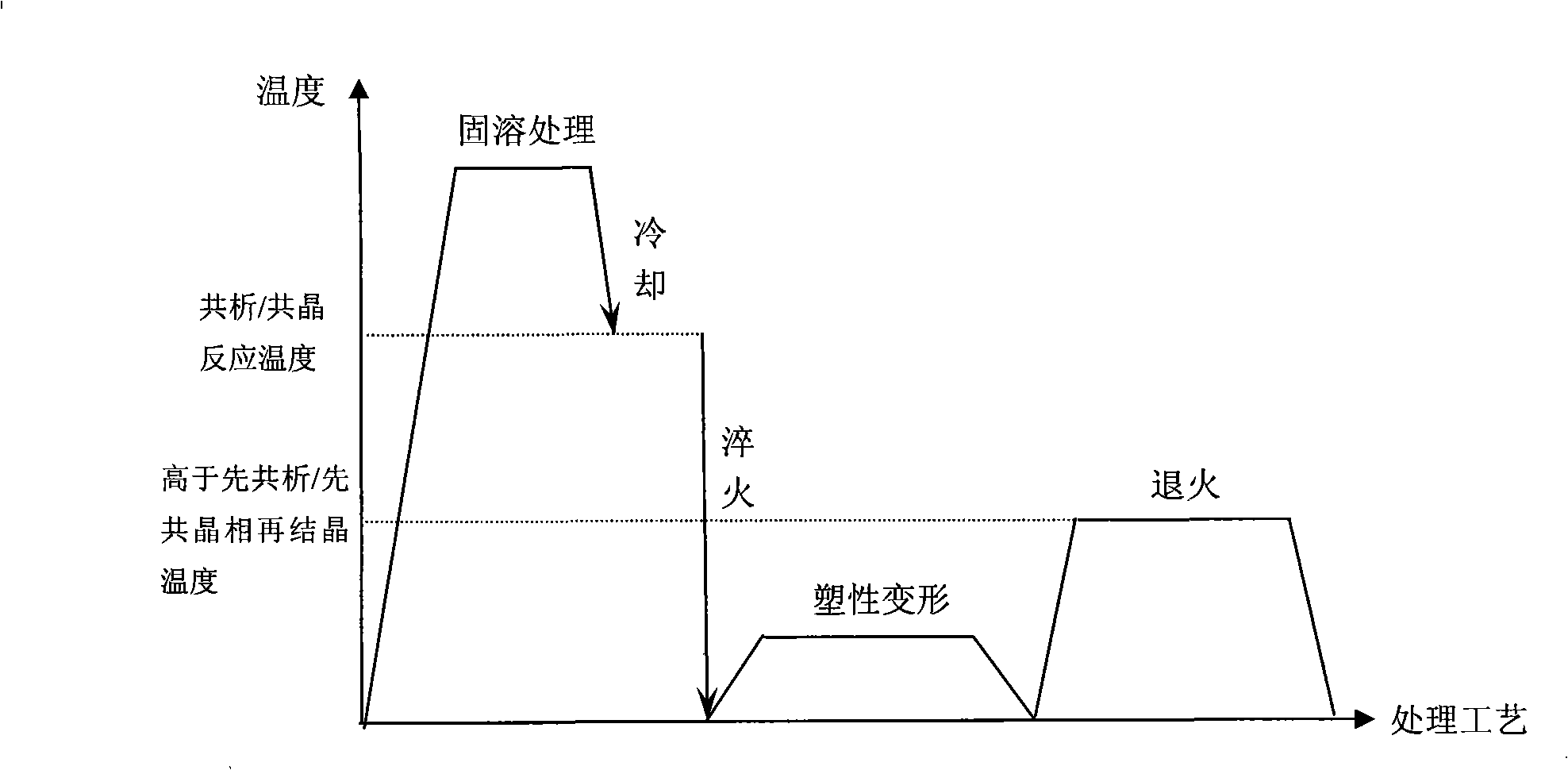

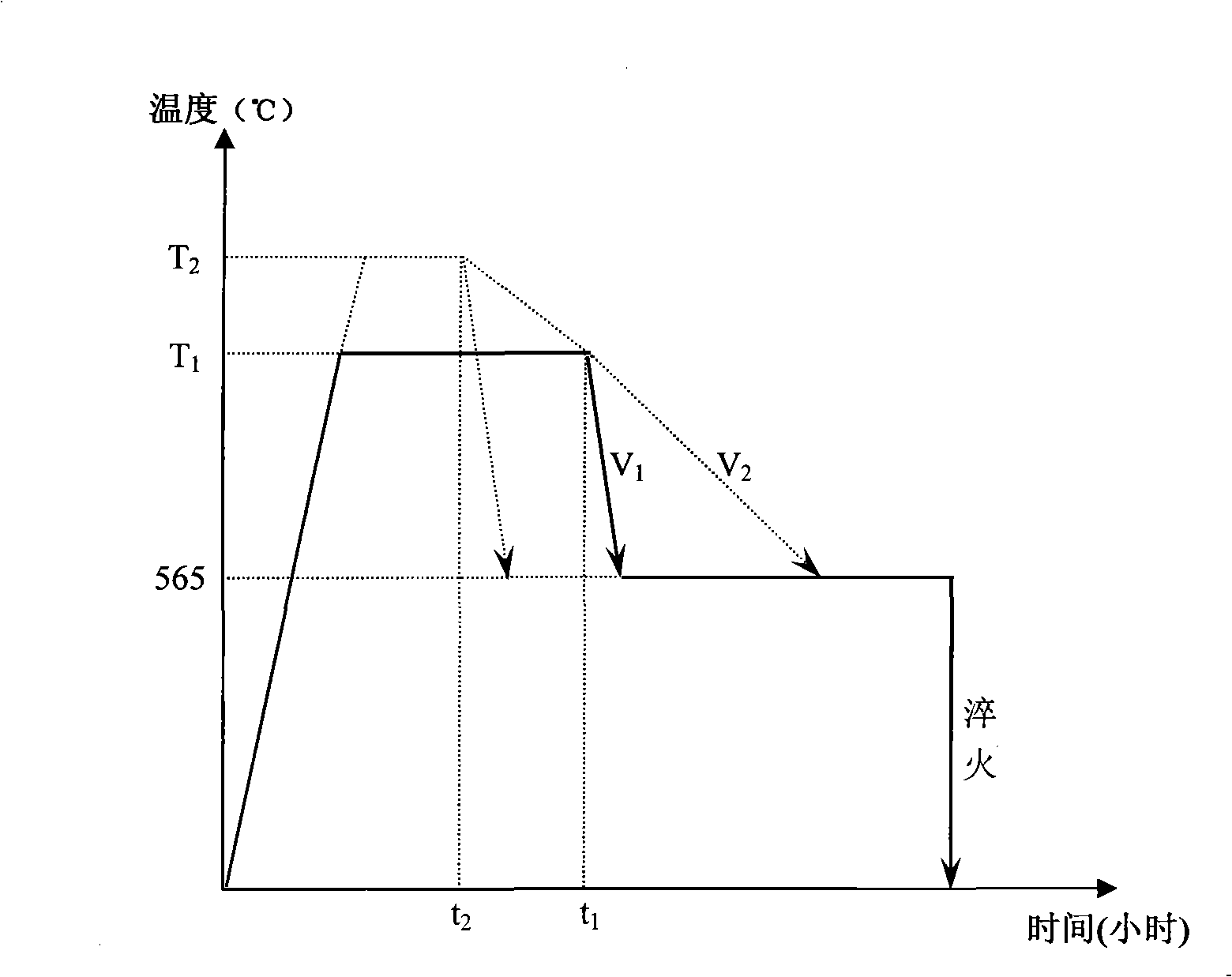

Preparation of crystal grain size controllable bimodal distribution block superfine/nanocrystalline alloy

The invention discloses a method for preparing a block superfine / nanocrystal alloy with controllable grain size and bimodal distribution. The method comprises the following steps: firstly, a biphase eutectoid or eutectic is selected and calculated according to a phase diagram combined with a lever rule, and the proportion of a primary eutectoid phase or a primary eutectic phase is quantitively controlled through reasonable selection of alloy compositions; secondly, after the alloy compositions are selected, alloy compositions undergo solution heat treatment and then are cooled, and the size of the primary eutectoid phase or the primary eutectic phase is controlled; thirdly, the alloy structure is thinned through violent plastic deformation or general plastic deformation, and then complete superfine crystal or nanocrystal alloy is obtained; and fourthly, the alloy obtained undergoes short-time annealing under the condition that the temperature is higher than the recrystallization temperature of the primary eutectoid phase or the primary eutectic phase, and then the block superfine / nanocrystal alloy with the controllable grain size and the bimodal distribution structure is obtained. The method realizes controllable grain size and bimodal distribution in the eutectoid or eutectic alloy, quantitively and precisely controls the proportion and the distribution of microcrystals, adopts the technological combinations of design of the alloy compositions, solid phase-transition treatment, plastic deformation and annealing for the first time, and is simple and easy to realize.

Owner:NANJING UNIV OF SCI & TECH

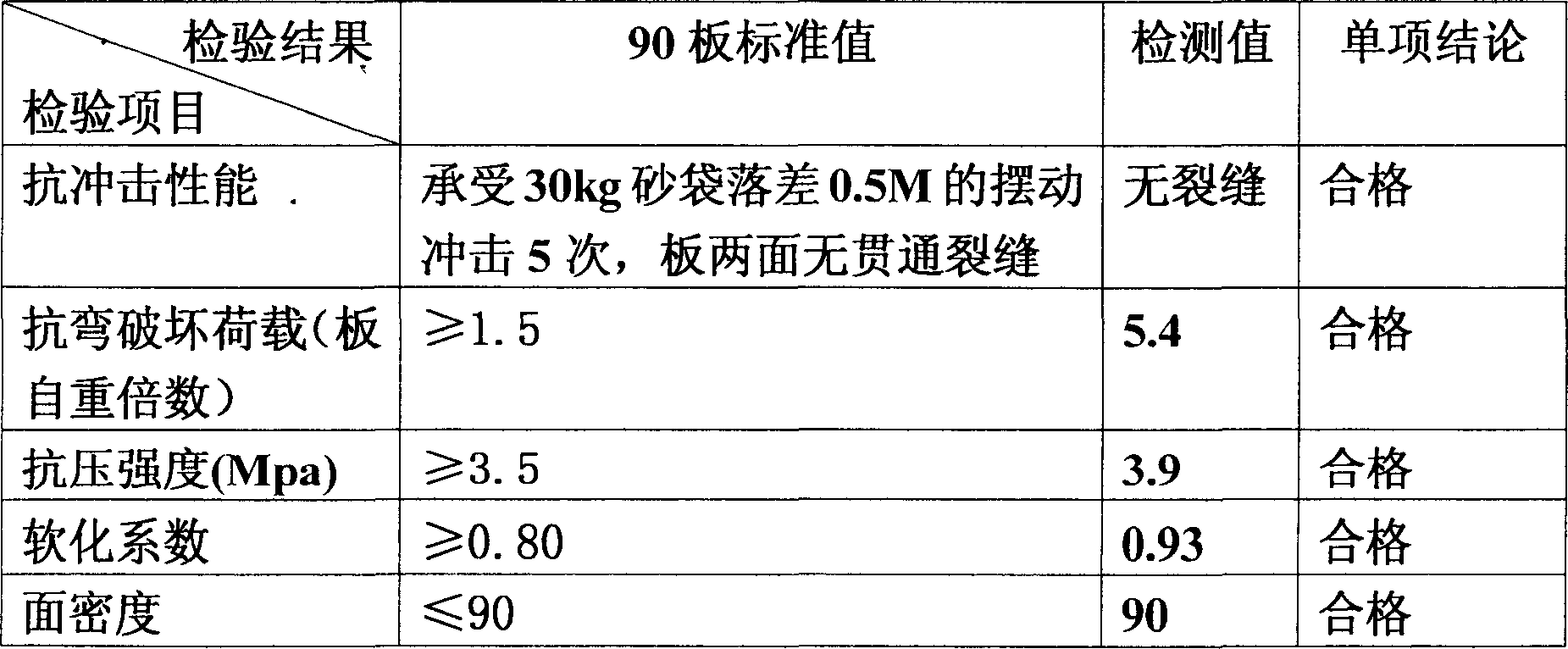

Light heat insulating sound proofing wall partition board and its production method

InactiveCN1785887ALight in massHigh strengthCeramic shaping apparatusSurface strengthMaterials science

The present invention relates to a light heat-insulating sound-proof partition wall board and its production method. It is made up by using cement, light asbestos wool, light stone granules and polypropylene fibre through a certain production process. Besides, said invention also provides the concrete steps of said production process.

Owner:杨立峰

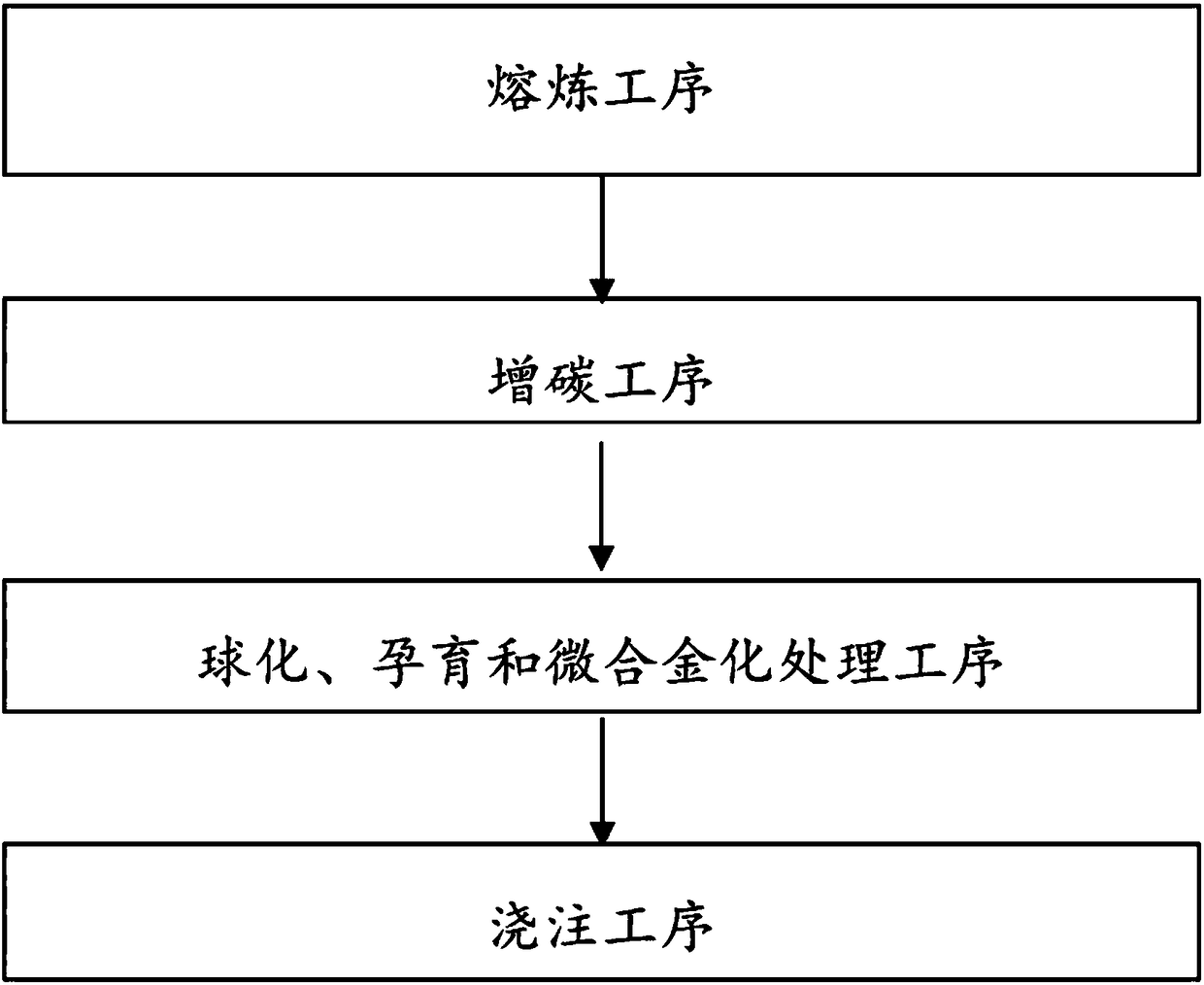

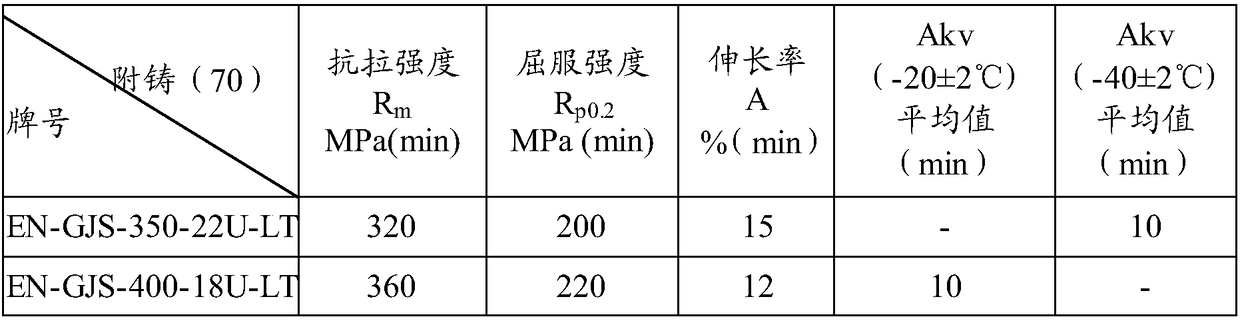

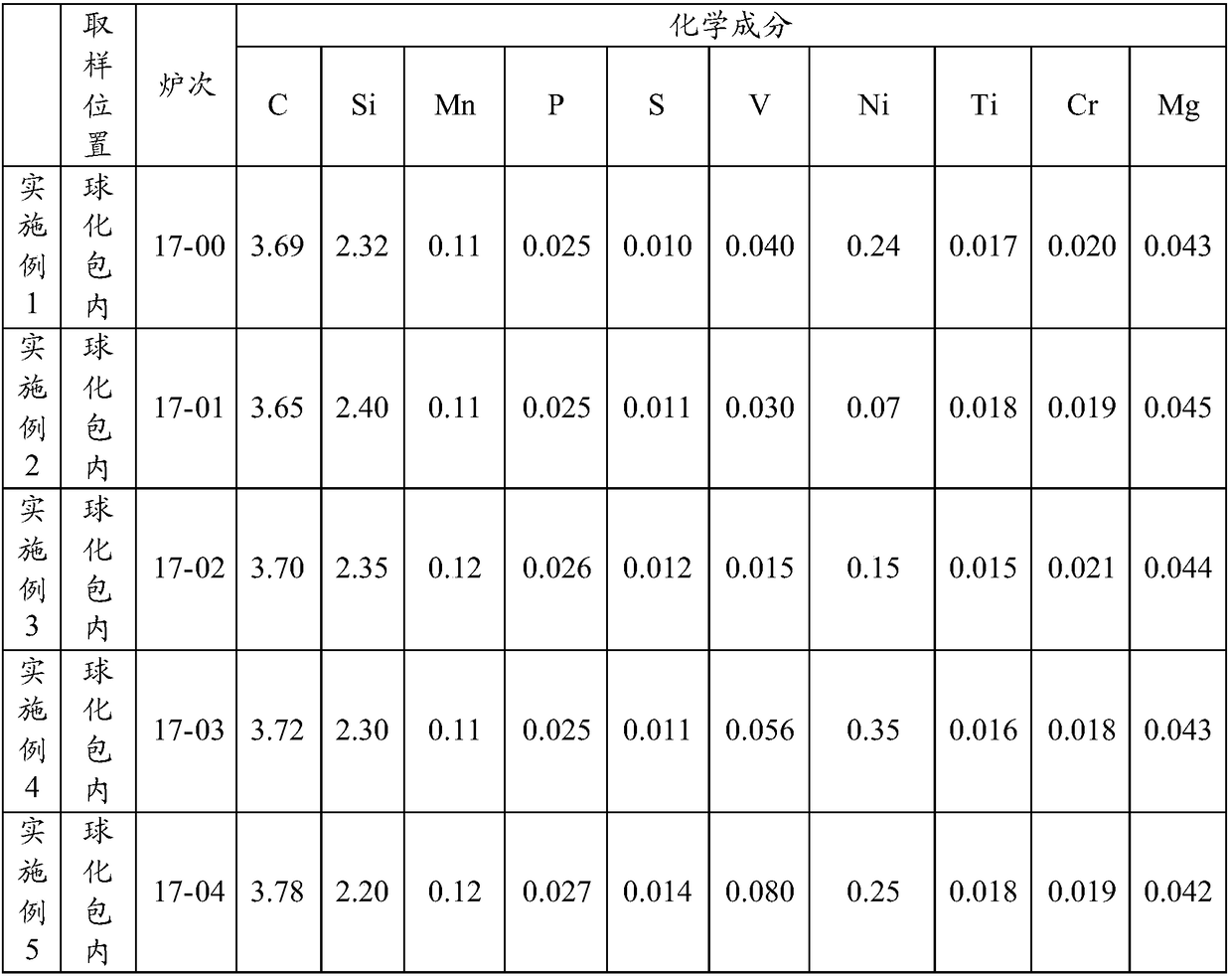

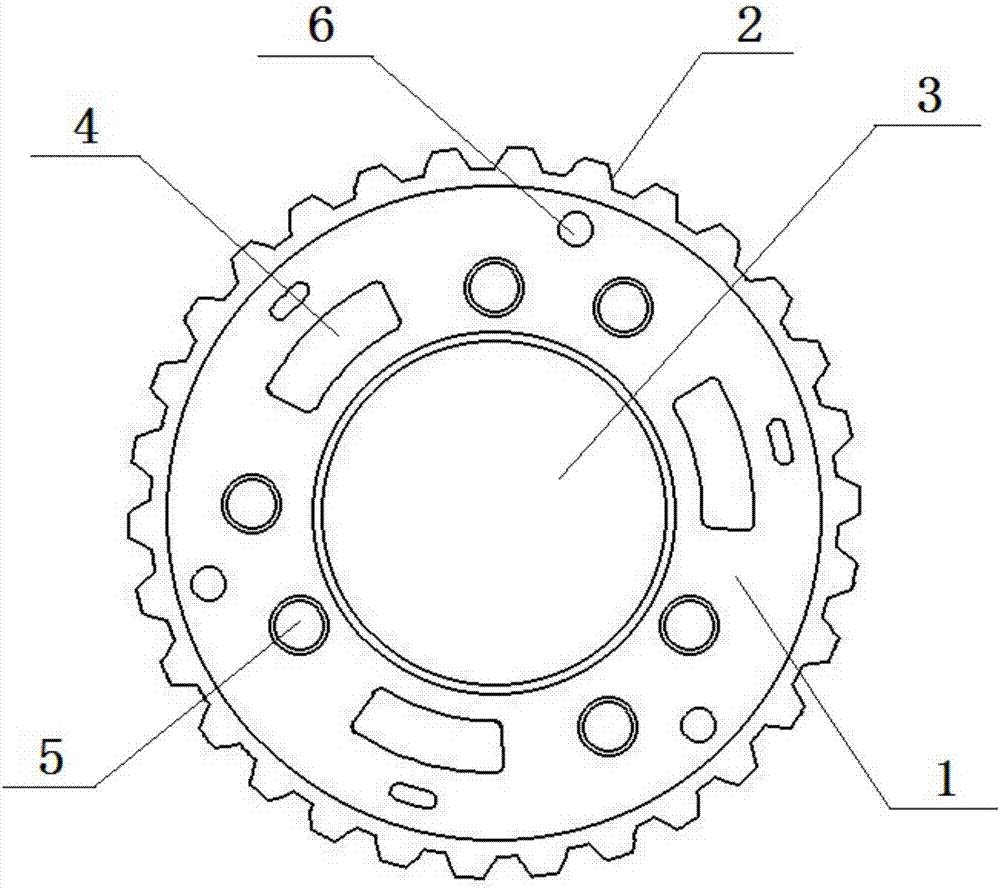

Ultra high strength low temperature ductile iron casting for wind turbine generator and manufacturing method thereof

InactiveCN108300930ARaise Strength IndexAchieve lightweight designProcess efficiency improvementChemical compositionDuctile iron

The invention discloses an ultra high strength low temperature ductile iron casting for a wind turbine generator and a manufacturing method thereof. The ductile iron casting comprises, by weight, 3.6-3.8% of C, 2.1-2.5% of Si, no more than 0.15% of Mn, no more than 0.027% of P, 0.008-0.014% of S, 0.01-0.10% of V, 0.05-0.40% of Ni, no more than 0.020% of Ti, no more than 0.025% of Cr, 0.035-0.045%of Mg residual, and the balance Fe and unavoidable impurities. The tensile strength of the ductile iron casting Rm is larger than or equal to 400MPa, the yield strength Rp0.2 is larger than or equal to 260MPa and the impact energy alpha k is larger than or equal to 10J at minus 20 DEG C. The proportional relationship of the chemical composition of the ductile iron casting is determined according to CE, Rm and / or alpha k. The ultra high strength low temperature ductile iron casting for the wind turbine generator greatly improves the strength index under the situation of ensuring the low temperature impact energy at minus 20 DEG C.

Owner:XINJIANG GOLDWIND SCI & TECH +1

Manufacturing process for bearing plate of planetary carrier of automobile CVT automatic transmission

ActiveCN107186450AThe technical route of the manufacturing process is reasonableImprove tooth surface strengthGearing detailsAutomatic transmissionGraphite

The invention discloses a manufacturing process for a bearing plate of a planetary carrier of an automobile CVT automatic transmission. The manufacturing process comprises the following steps: (1) blanking; (2) blank making before warm forging; (3) shot blasting; (4), warm forging and extrusion forming: heating a blank to 210+ / -20 DEG C, coating graphite, then continuing to heat to 820-860 DEG C, firstly upsetting and extruding and then performing backward extrusion forming to form a round plate and forming a metal ring vertically extending to one side on the edge of the circumference of the round plate, and then punching a central hole of the round plate; (5) residual heat annealing; (6) blank making and shot blasting after the warm forging; (7) lubricating treatment; (8) outer tooth forming by cold forging extrusion: placing the lubricated blank into a female die, and performing cold extrusion to form an outer gear ring; and (9) nitriding, wherein an effective oxide layer on the surface has a depth of 0.007-0.3mm. The manufacturing process is reasonable in technical route, metal flows are not cut off, a tooth surface strength of the product is high, raw materials are saved, and the production efficiency is high.

Owner:江苏威鹰机械有限公司

Micro-alloying high-strength fork steel

ActiveCN101117684AImprove hardenabilityMeet the hardenability requirements of quenchingChemical compositionHigh intensity

The present invention discloses a microalloyed high-intensity steel used for pallet porks with a weight percentage of chemical compositions as follows: C 0.28-0.37 percent, Si 0.15-0.45 percent, Mn 1.20-1.60 percent, Cr0.25-0.65 percent, S less than or equal to 0.030 percent, P less than or equal to 0.030 percent, Ti 0.015-0.100 percent, B 0.005-0.0040 percent and the remainder is Fe. The chemical compositions still contains Ni less than or equal to 3.0 percent, V less than or equal to 0.5 percent, Nb less than or equal to 0.5 percent, Cu less than or equal to 0.5 percent and Mo less than or equal to 0.5 percent. The invention adopts the microalloyed B and Ti to improve the hardenability of the material notably, to meet the hardenability requirement of the monolithic quenching of big workpieces and promote the comprehensive mechanical property of the material greatly, so compared with the alloyed Mo steel material of the same hardenability, the precious metal Mo can be saved by 20 percent or more per ton, and the cost of the steel can be reduced by approximately 1000 yuan per ton.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

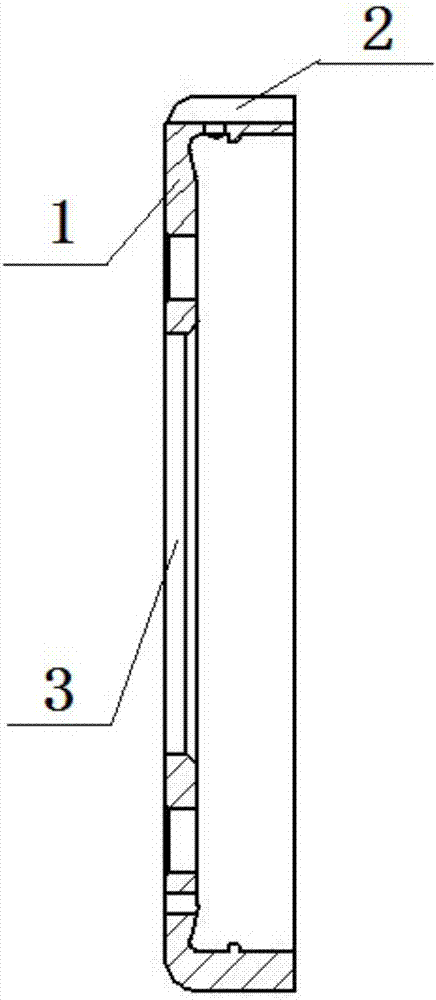

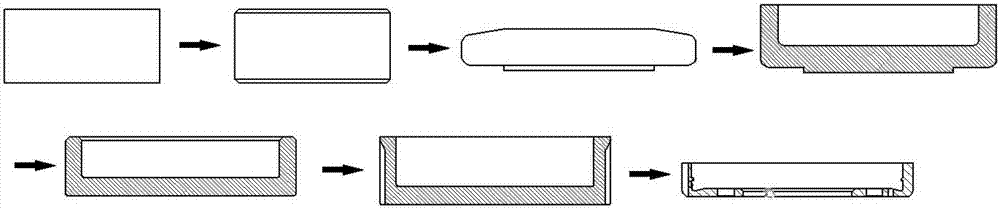

Manufacturing process of stator

InactiveCN101630883AMake up for deficienciesIncrease productivityManufacturing stator/rotor bodiesNumerical controlNitrogen

The invention relates to a manufacturing process of a stator, which comprises the following steps: (1) blanking: adopting a numerical control band sawing machine to carry out blanking with a verticality being smaller than or equal to 0.3; (2) annealing: adopting a well type vacuum annealing furnace to vacuumize and fill nitrogen for protection and annealing with an oxidation and decarbonization jersey knit being smaller than or equal to 0.1 and material hardness HB of 113-120 after the annealing; (3) blank preparing: adopting an ordinary C6130 lathe to prepare a blank by controlling a height error within 0.3; (4) lubrication process; (5) hole extruding: adopting an ordinary 4000KN oil press to extrude with extruding force P of 280T, an extruding hole diameter phi of 39+ / -0.05 and an extruding depth of 70+ / -0.5mm by reserving 5-6mm at the bottom of the hole after extruding with hole wall roughness of 1.6; and (6) gear extruding: adopting a 4000KN oil press to extrude with the extruding force P of 300T, gear accuracy of + / -0.03 and an extruding depth of 80+ / -0.5mm.

Owner:镇江中虎弹簧有限公司

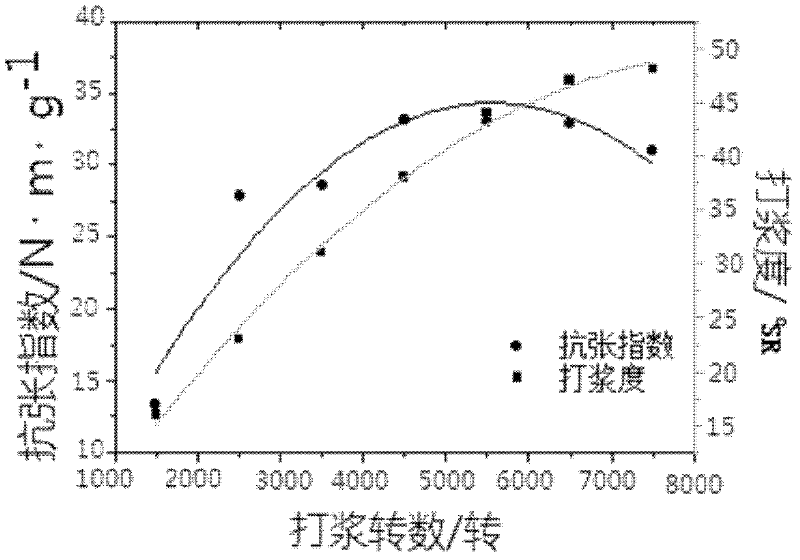

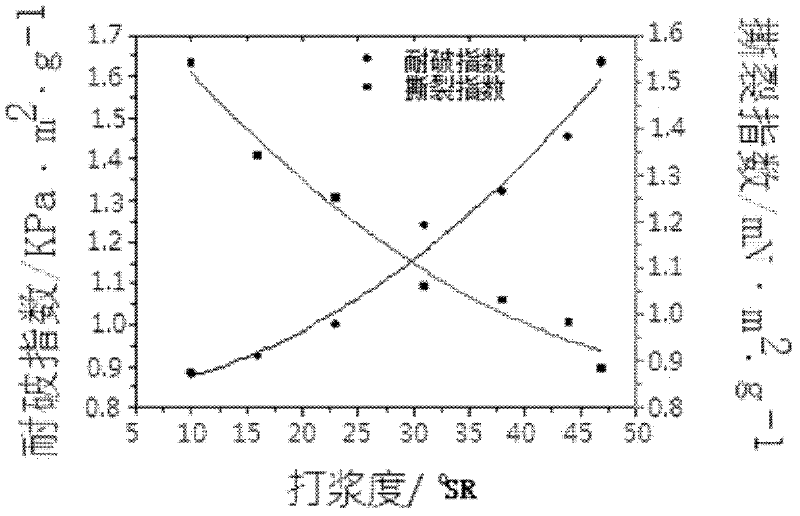

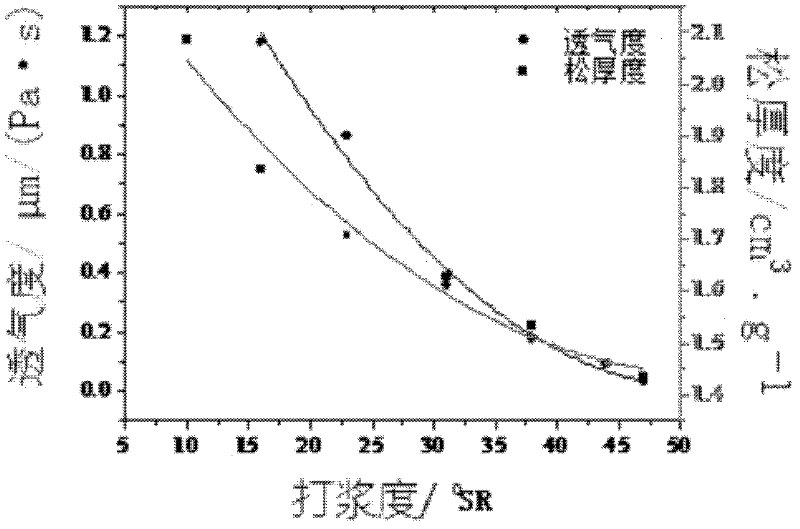

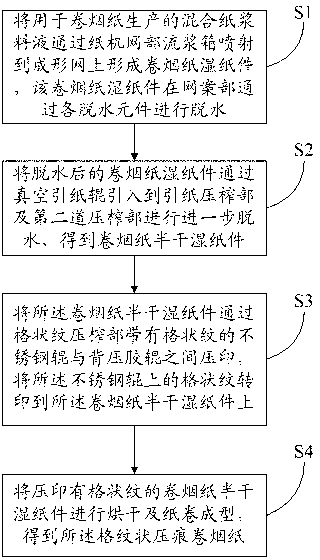

Preparation method of tobacco sheet paper base by cabo

ActiveCN102640980AOptimization of beating processAccurately reflect the actual lengthTobacco preparationFiberPaper based

The invention discloses a preparation method of tobacco sheet paper base by cabo. The tobacco sheet paper base is prepapred by taking the cabo as raw material and adopting a paper making method. The preparation method comprises the steps of dipping the cabo, grinding, beating, making sheet and drying the cabo. The beating concentration is 10%, the gap between a beating roller and a beating room is 0.2mm, and the beating pressure is 3.33N / mm; and the beating revolution is 1500-2500, and the bearing degree is 20-30 degrees SR. According to the preparation method, the optimal process condition of the beating steps is determined, the technical scheme for the comprehensive performances that the tobacco sheet paper base is prepared by utilizing the cabo again is optimized, the proper design and technical conditions of the beating degree of the cabo is determined, the excellent fiber shape and the excellent physical performance of pulp are obtained, the tensile indexes, tearing indexes, bulk, air permeability and burst indexes of the paper base product are proper, and the good quality of the tobacco which is prepared again can be ensured.

Owner:CHINA TOBACCO GUANGDONG IND +1

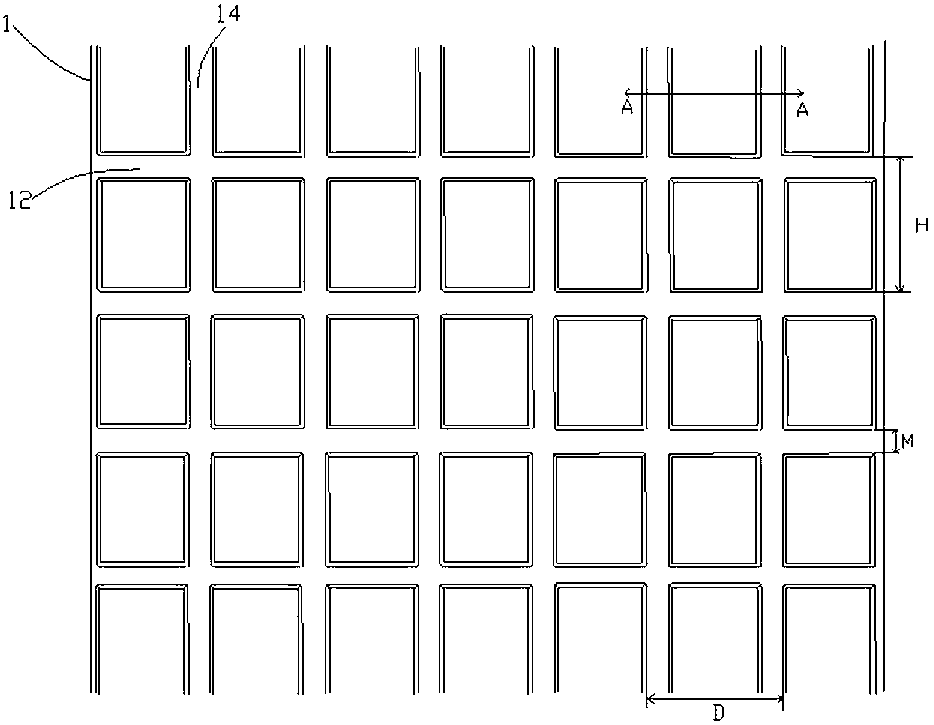

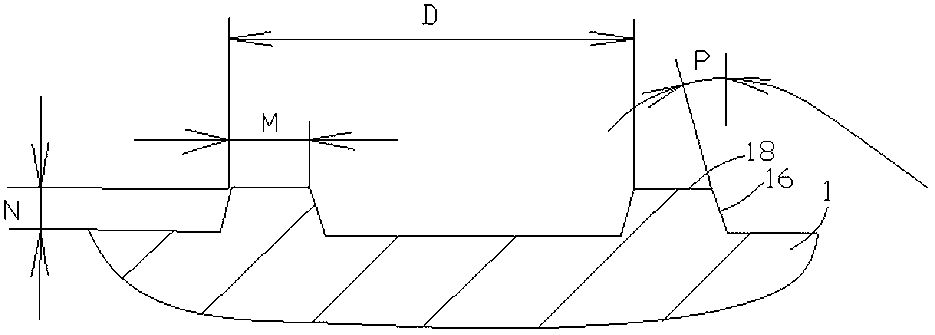

Cigarette paper with lattice fringes and production method thereof

ActiveCN103255681AImprove noveltyOptimize internal stress structureSpecial paperPaper after-treatmentPaper sheetSmoke paper

The invention provides a piece of cigarette paper with lattice fringes and a production method thereof. The cigarette paper with lattice fringes comprises a paper body, wherein a plurality of first direction pressing marks and second direction pressing marks which are intersected are pressed on the paper body through a lattice fringe stainless steel roller and a back pressure roller. According to the cigarette paper with lattice fringes and the production method thereof provided by the invention, the plurality of first direction pressing marks and the second direction pressing marks are pressed through the lattice fringe stainless steel roller and the back pressure roller to form the cigarette paper with the pressing marks of the lattice fringes, so that the novelty of the appearance of the cigarette paper is increased, the internal stress structure of the cigarette paper is optimized, and the strength index of the cigarette paper is improved.

Owner:云南红塔蓝鹰纸业有限公司 +1

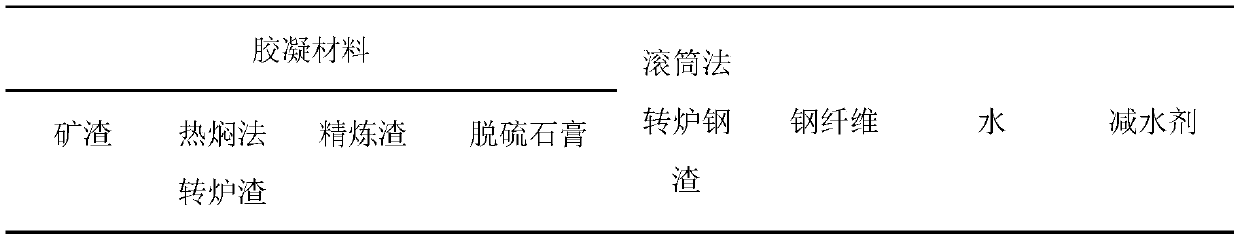

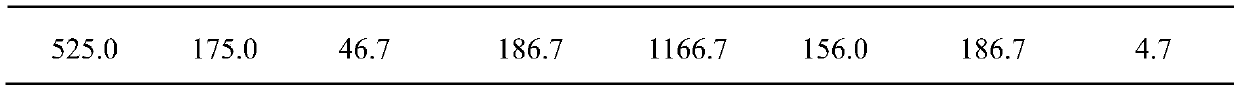

Steel fiber reinforced ultra-high-performance concrete synergistically prepared by multiple solid waste and preparation method of steel fiber reinforced ultra-high performance concrete

The invention provides a steel fiber reinforced ultra-high-performance concrete synergistically prepared by multiple solid waste and a preparation method of the steel fiber reinforced ultra-high performance concrete, and belongs to the technical field of solid waste resource utilization. The steel fiber reinforced ultra-high-performance concrete is prepared from the components in percentage by weight: 35%-50% of a binding material, 35%-50% of an aggregate, 0%-3% of a water reducing agent, 5%-8% of a steel fiber and 7%-9% of water, during preparation, firstly slag, heat stewing converter slag,refining slag and industrial by-product gypsum are separately ground or ground in a mixed mode, and the binding material is prepared through even mixing; and then after the binding material, the skeletal material, the water reducing agent, the steel fiber and the water are stirred evenly in percentage by mass, casting molding is conducted and maintenance is conducted, and the steel fiber reinforced ultra-high-performance concrete synergistically prepared by the multi-solid waste is obtained. According to the steel fiber reinforced ultra-high-performance concrete and the preparation method, theultra-high-performance concrete with compressive strength of 100 MPa to 160 MPa and flexural strength of 35 MPa to 45 MPa in 28 days under the standard curing condition is prepared, the utilization rate of the solid waste in the ultra-high-performance concrete is increased significantly, the cost is lowered, and obvious environmental and economic benefits are achieved.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

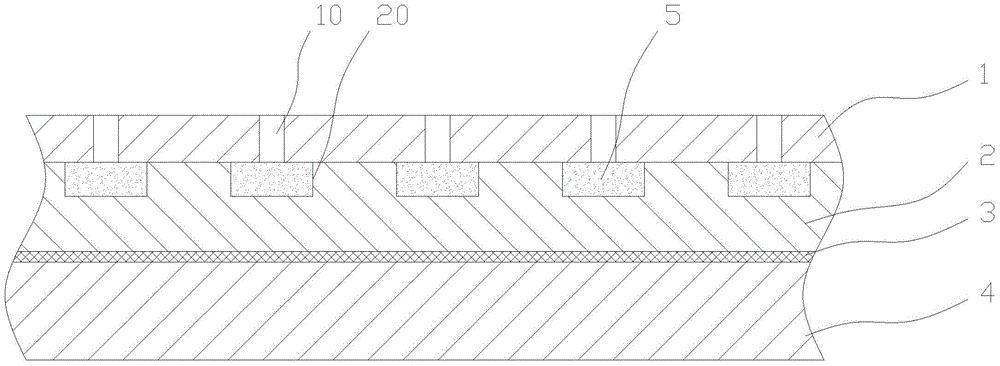

Automobile decorating plate

InactiveCN104417447ARaise Strength IndexEffective clamping actionLayered productsSuperstructure subunitsMetal meshNon toxicity

The invention provides an automobile decorating plate having the advantages of simple structure, good usage effect, high water absorption, non-toxicity and no pollution. The automobile decorating plate comprises a leather layer, a mixed material layer I, a metal mesh and a mixed material layer II; a plurality of penetrating holes are formed on the leather layer; a plurality of containing slots are formed on the end surface of the mixed material layer I toward the leather layer; the penetrating holes are concentric to the containing slots and the inner diameters of the penetrating holes are less than that of the containing slots; and coumarin is filled in the containing slots. Various strength indicators of the automobile decorating plate can be improved effectively by the metal mesh arranged additionally. In addition, the penetrating holes match with the containing slots of the mixed material layer I so as to give out the flavor of the coumarin and effectively clamp the coumarin.

Owner:扬州顺祥汽车内饰材料有限公司

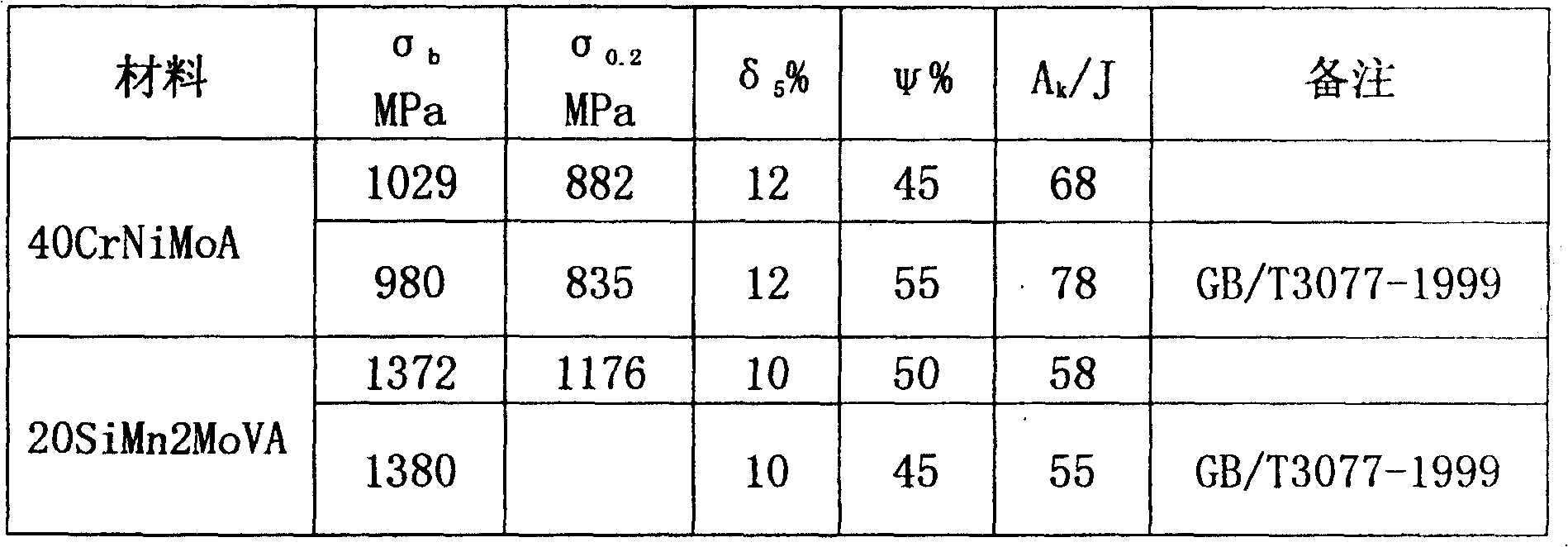

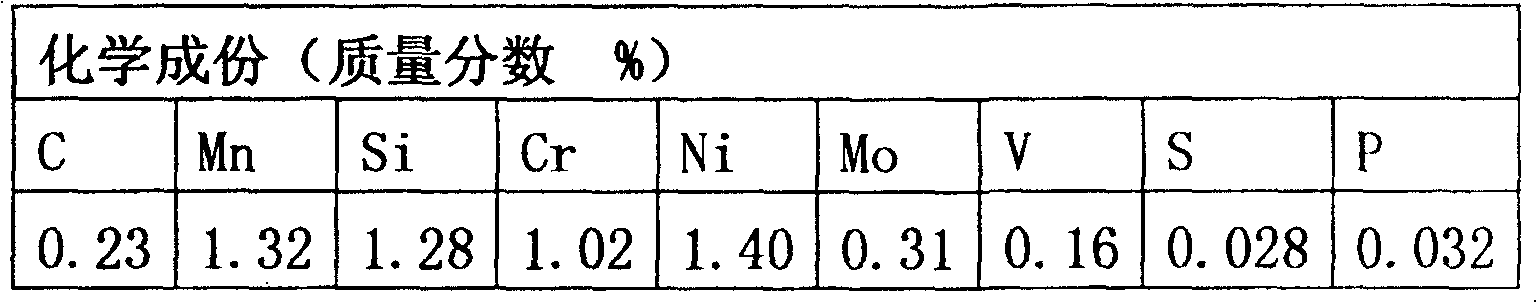

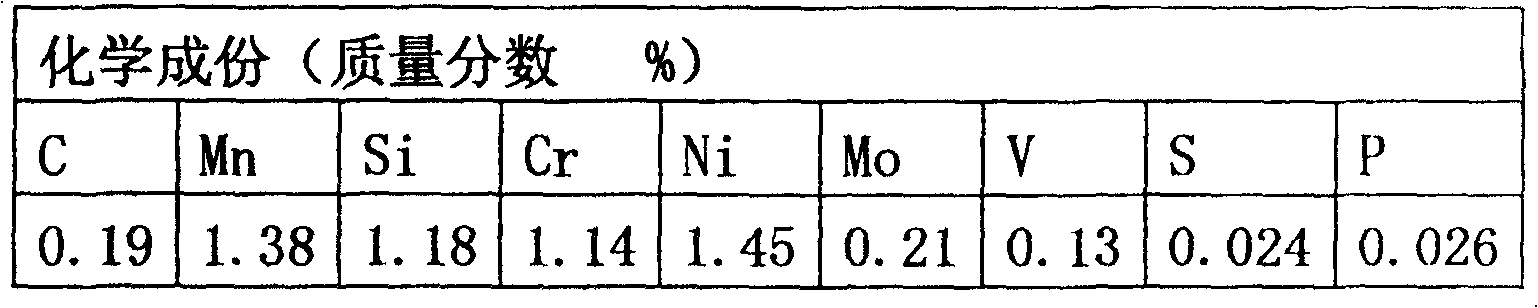

Low-temperature high-strength, high-toughness steel and preparing method therefor

InactiveCN100453683CHigh strengthGuaranteed toughnessHeat treatment process controlTemperingMechanical equipment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

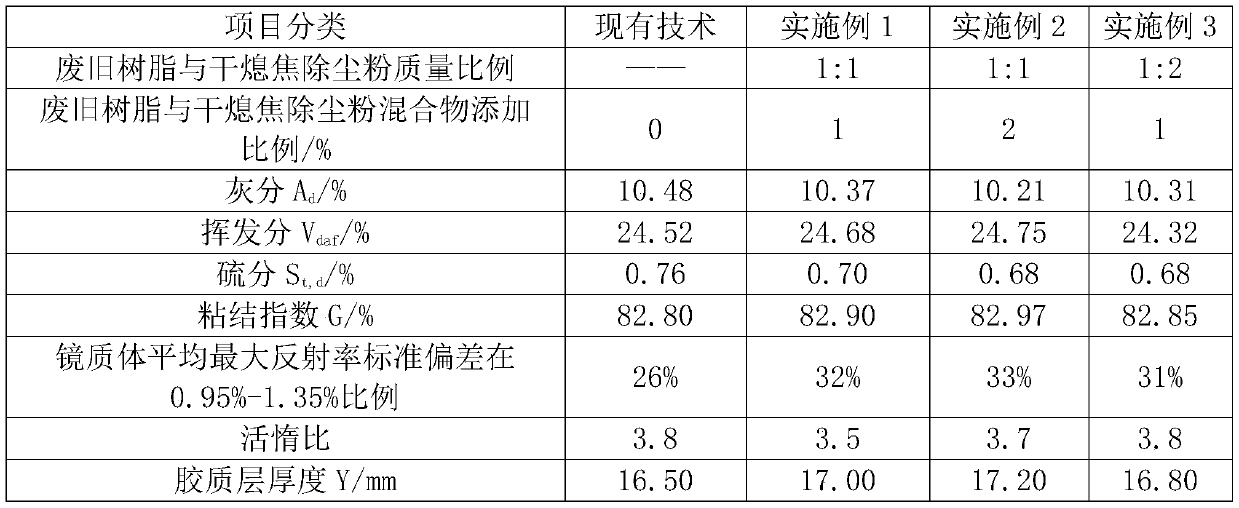

Method for preparing metallurgical coke

ActiveCN110819364AImprove quality indicatorsMeeting ever-increasing demandsProductsReagentsDusting powdersCoke oven

The invention relates to a method for preparing metallurgical coke. The method comprises the following steps: 1) taking blended coal, waste resin and dry quenching dedusting powder as raw materials; 2) intensively recovering the waste resin, and grinding the waste resin to make the particle size less than 3 mm; 3) fully mixing the waste resin with the dry quenching dedusting powder according to amass ratio of 1:1 to 1:5, and carrying out matching pelletizing to make the ball diameter be 1-3 cm; 4) respectively crushing and mixing various coal types in the blended coal, wherein the mass proportion of the average maximum reflectivity, in the interval range of 1.05-1.35%, of vitrinite in the blended coal is not lower than 45%; and 5) mixing the mixed balls of the waste resin and the dry quenching powder with the blended coal, and coking the obtained mixture in a coke oven, wherein the bending mass percentage of the mixed balls is 1-3%. The method achieves recycling of carbon-containing solid wastes of iron and steel enterprises, realizes complete recycling of the waste resin according to the characteristics of low dust, low sulfur and high iron of the waste resin, and achieves the effect of effectively improving the quality index of the coke through reasonable blending of the waste resin in a coal blending coking scheme.

Owner:ANGANG STEEL CO LTD

Production process of fine denier viscose staple fiber

InactiveCN103305939ARaise Strength IndexPromote rapid formationFilament manufactureStretch-spinning methodsCellulosePolymer science

The invention relates to a production process of fine denier viscose staple fiber, and belongs to the technical field of production of the viscose staple fiber. In the spinning step, a formed silk is guided and drafted by a silk guiding device and a drafting device; and in the silk guiding and drafting process, the total drafting rate is controlled at 130-160%, wherein the spinneret drafting rate is controlled at 60-80%, the air drafting rate is controlled at 25-40% and the plastic drafting rate is controlled at 5-12%. Through selection of the total drafting rate and various drafting rate allocations, in the spinning forming process and in the plastic state, neat arrangement of cellulose macromolecules of the fine denier staple viscose fiber is facilitated, rapid and high-quality formation of a crystalline area in the fiber is facilitated, and thus the fine denier viscose staple fiber is ensured to reach a higher strength index.

Owner:YIBIN GRACE +2

Method of regulating and controlling air volume of sintering machine by using main ventilation valve and rotating speed in combined mode

The invention provides a method of regulating and controlling the air volume of a sintering machine by using a main ventilation valve and the rotating speed in a combined mode, and belongs to the field of metallurgical production. The opening degree of an inlet baffle of a draught fan is regulated to 14%-65%, and the rotating speed of the draught fan is regulated to 700-1000rpm. By means of the method, the temperature of sintering flue gas can be effectively stabilized, the frequency of abnormal vibration, caused by the excess temperature of the flue gas, of a main ventilation draught fan is reduced, and threats to operation of a flue gas desulfurization and denitrification system caused by the excess temperature of the flue gas can be reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Refining processing method for apocynum venetum fiber

ActiveCN106319642AImprove qualityImprove degumming effectFibre treatment to obtain bast fibreElectricityApocynum venetum

The invention discloses a refining processing method for an apocynum venetum fiber. The method comprises the steps of infiltrating and activating apocynum venetum bast; performing steam explosion activating treatment; caking and putting into a cage; performing directional catalytic oxidizing; chemically degumming and post-processing. Organic amine is adopted for infiltrating and activating and steam explosion activating treatment is performed, and then a ferrite solution and an activating agent are adopted for performing directional catalytic oxidization on lignin and hemicellulose; through the organic combination of a series of technical methods, such as, infiltration and activation, steam explosion, degumming and directional catalytic oxidization, the production method provided by the invention has the characteristics of good degumming effect, excellent indexes including finish fineness, length, strength and the like of the acquired apocynum venetum fiber, high quality, excellent spinning property, and the like; the chemical consumption is low; the environment-friendly pressure is low; the technical control is simple; the consumption of the public works, such as water, electricity and gas, is low, the efficiency is high and the method is suitable for industrial production.

Owner:QINGDAO UNIV

Inorganic face lifting terrace material through natural flow

This invention relates to a self-leveling inorganic floor material. The material is composed of cement 50-100 wt. parts, sand 200-400 wt. parts, and heavy weight calcium carbonate 100-300 wt. parts. The material is also composed of tackiness agent 10-20 wt. %, polymer emulsion 10-30 wt. %, and water reducer 0.7 wt. %. The material can be used for retarding floors, and has such advantages as high adhesiveness, high water resistance, and good waterproof effect. The material can be manufactured into floors with different colors, and used in moisture environment.

Owner:SHANDONG ZERUI NEW MATERIAL TECH

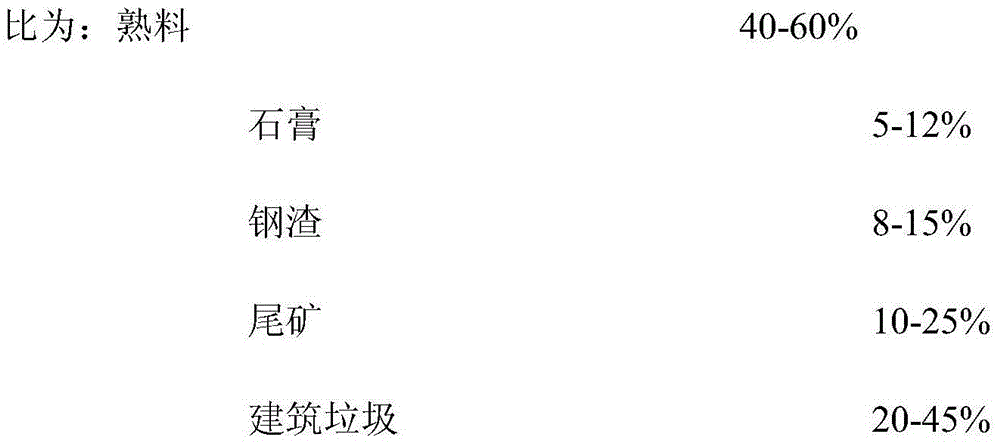

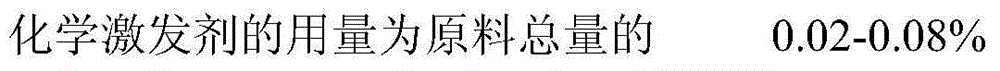

Silicate cement prepared from solid wastes and preparation method of silicate cement

The invention discloses silicate cement prepared from solid wastes and a preparation method of the silicate cement and belongs to the technical field of building materials. The silicate cement is prepared from the raw materials: clinkers, gypsum, slag, tailings and building wastes by adding a chemical excitant. The silicate cement is prepared from the following raw materials in percentage by weight: 40-60% of clinkers, 5-12% of gypsum, 8-15% of slag, 10-25% of tailings and 20-45% of building wastes, wherein the use level of the chemical excitant is 0.02-0.08% of the total weight of the raw materials; the slag is slag without metallic iron; the tailings are wastes left by exploiting a mine; the building wastes are building waste bricks or concrete plate blocks without metals or other impurities. The silicate cement disclosed by the invention is widely applied to concrete and cement products, relieves increasingly deficient clinker firing resources and reduces discharge of carbon dioxide of cement, thereby facilitating reduction of severe haze in atmosphere. primary resources are saved and replaced, so that the circular economy development is promoted and the pollution is reduced to protect the ecological environment. In the production process, further pollution on the environment is not generated.

Owner:XUZHOU YUXIN ENVIRONMENTAL PROTECTION BUILDING MATERIALS CO LTD +1

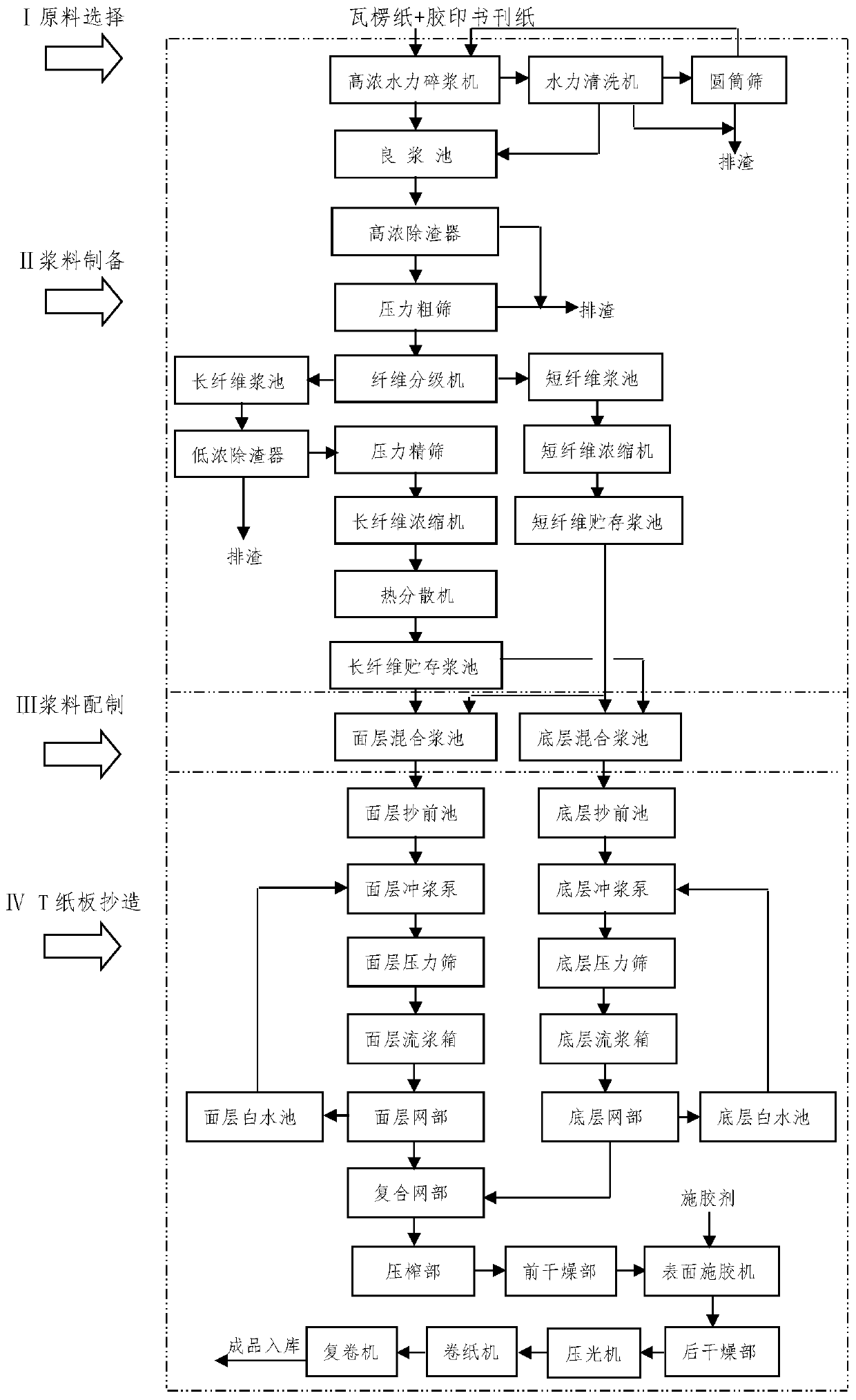

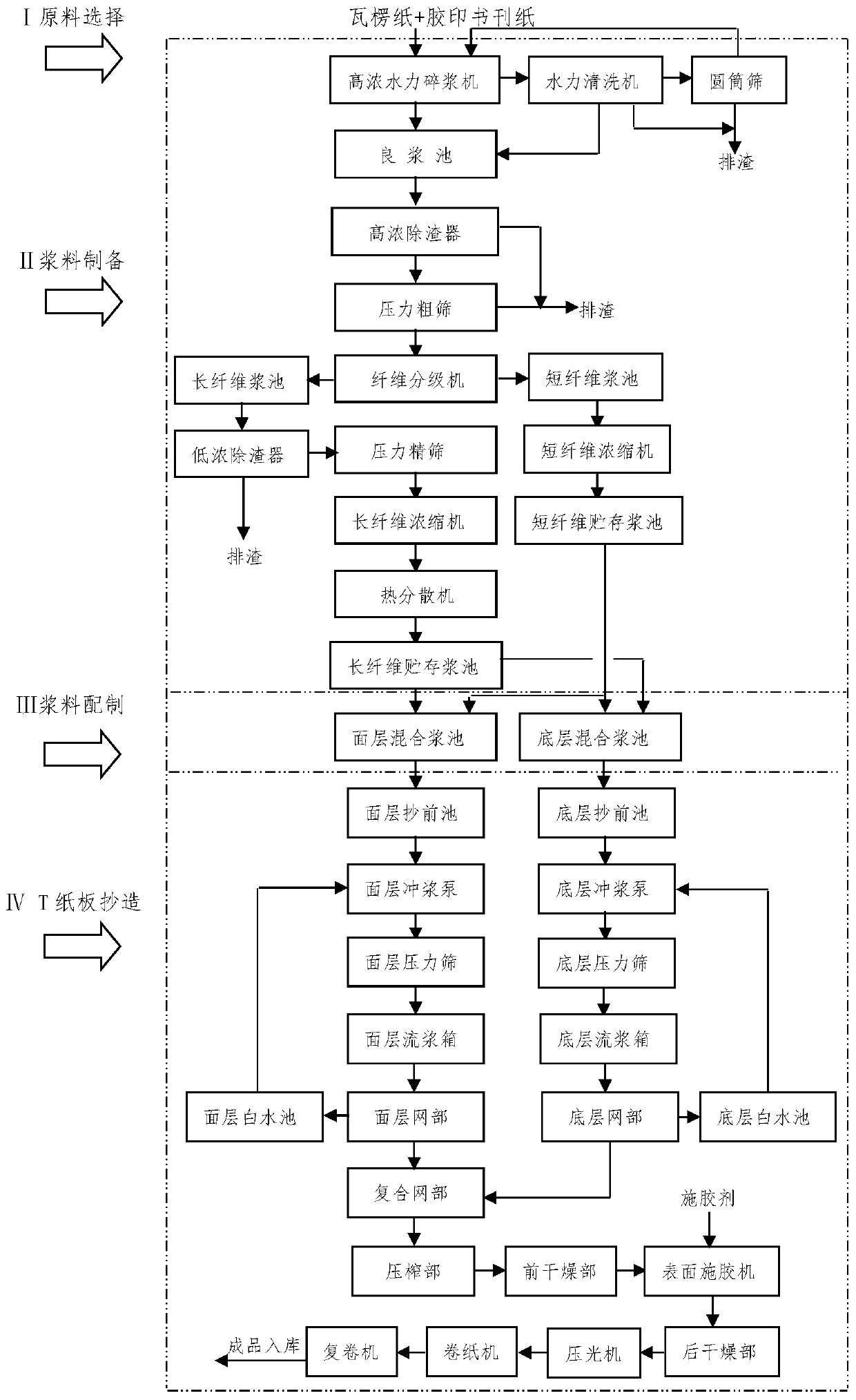

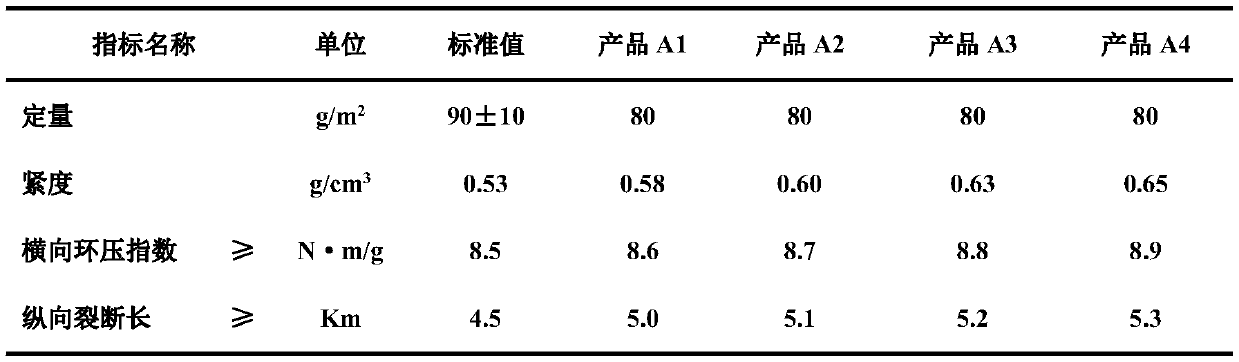

Preparation method for improving ring pressure strength of low-gram-weight T paper board

InactiveCN109837799AFair useHigh tensile strengthWater-repelling agents additionPaper/cardboardCardboardFiber

The invention discloses a preparation method for improving the ring pressure strength of a low-gram-weight T paper board, and the preparation method comprises the following four steps: (1) selecting raw materials, namely taking corrugated paper and offset printing periodical paper as raw materials; (2) preparing slurry, to be more specific, mixing the two raw materials obtained in the step (1) according to a ratio, carrying out crushing, impurity removal, fiber grading, heat dispersion and concentration treatment, and respectively storing long fiber slurry and short fiber slurry in respectiveslurry pools for later use; (3) preparing pulp, to be more specific, preparing surface layer pulp and bottom-layer pulp according to the proportions from the long fiber slurry and the short fiber slurry obtained in the step (2); and (4) making the T paper board, to be more specific, respectively allowing the surface layer pulp and the bottom-layer pulp obtained in the step (3) to pass through a fan pump and a pressure screen, then be conveyed to a surface layer and bottom layer pulp box pulp feeding total pipe for being loaded onto a net for forming, then enter a pressing part, a front and a rear drying part, surface sizing, a calender and the like for treatment after vacuum dewatering by a net part, and enter a winding machine, a rewinding machine and a packaging machine to obtain the low-gram-weight T paper board.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com