Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

766results about "Fibre treatment to obtain bast fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making bamboo fiber

InactiveCN1621580ASolve the problem of excessive lignin contentHigh strengthWood working apparatusMechanical fibre separationCardingToughness

The present invention is preparation process of bamboo fiber, including coarse bamboo fiber, refined bamboo fiber and spinnable bamboo fiber. The coarse bamboo fiber is prepared through cutting bamboo, separating bamboo fiber, steaming inside the No. 1 softening liquid and enzyme fermentation; the refined bamboo fiber is prepared through steaming inside the No. 2 softening liquid, enzyme fermentation, rinsing and bleaching, acid treatment, and oil soaking and drying; and the spinnable bamboo fiber is prepared through emulsifying, initial carding, combing and drawing. The bamboo fiber has lignin content lower than 5 %, and has the features of being natural and green, high in strength, high toughness, high brightness and high elasticity.

Owner:临安力源竹纤维技术开发有限公司

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Preparation method of ko-hemp

The invention relates to a preparation method of ko-hemp, which comprises the following steps: pueraria lobata is collected after leaves fall down in the end of fall and prepared into the ko-hemp through stewing, immersion, rolling, kneading, brushing and drying. The prepared ko-hemp is pure white, glossy and soft and has good toughness, thereby being used as materials of mattresses, seat cushions, wall papers and pillows.

Owner:汪盛明

Water-disintegratable sheet and manufacturing method thereof

InactiveUS7241711B2Good wettingImprove dry strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

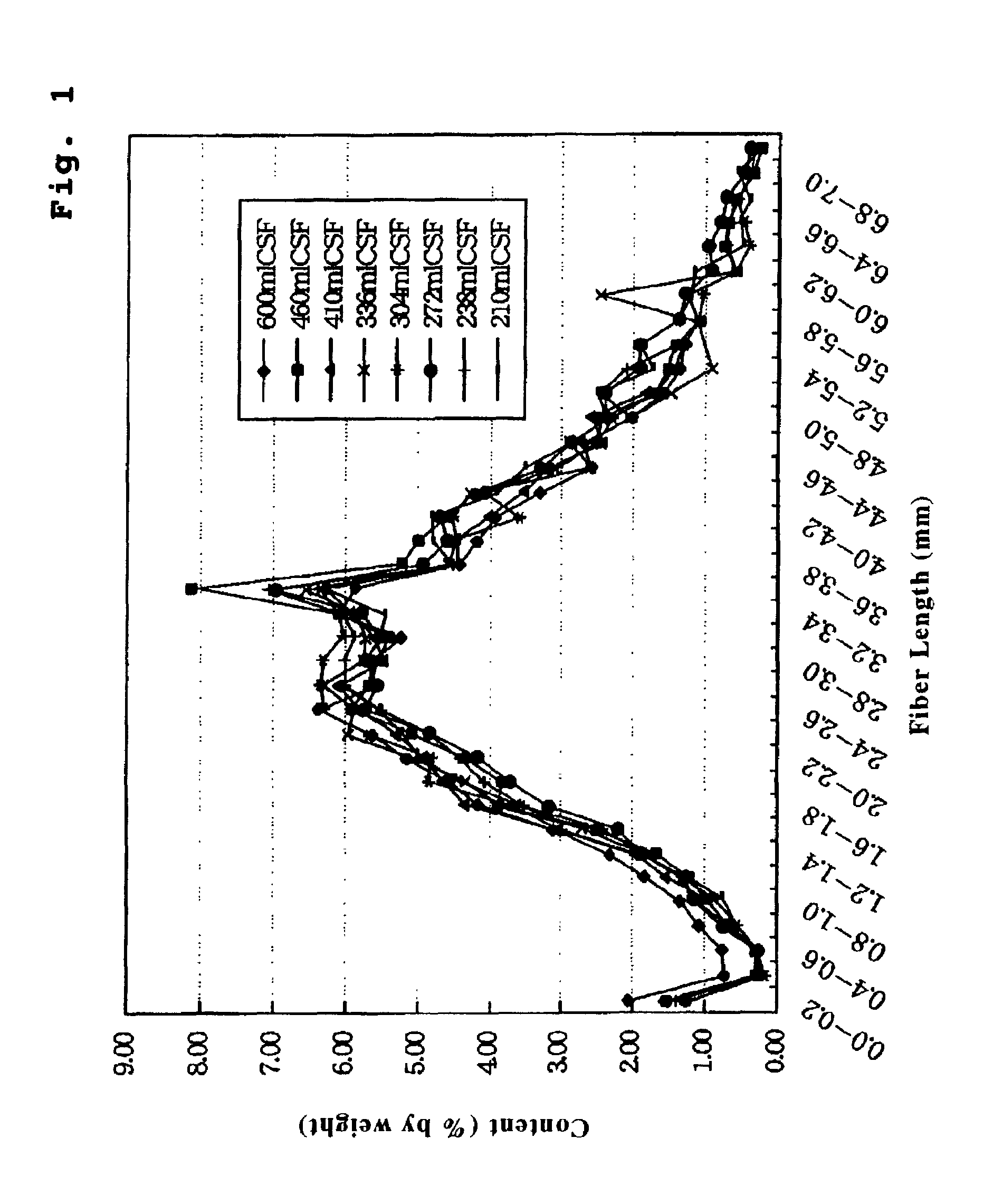

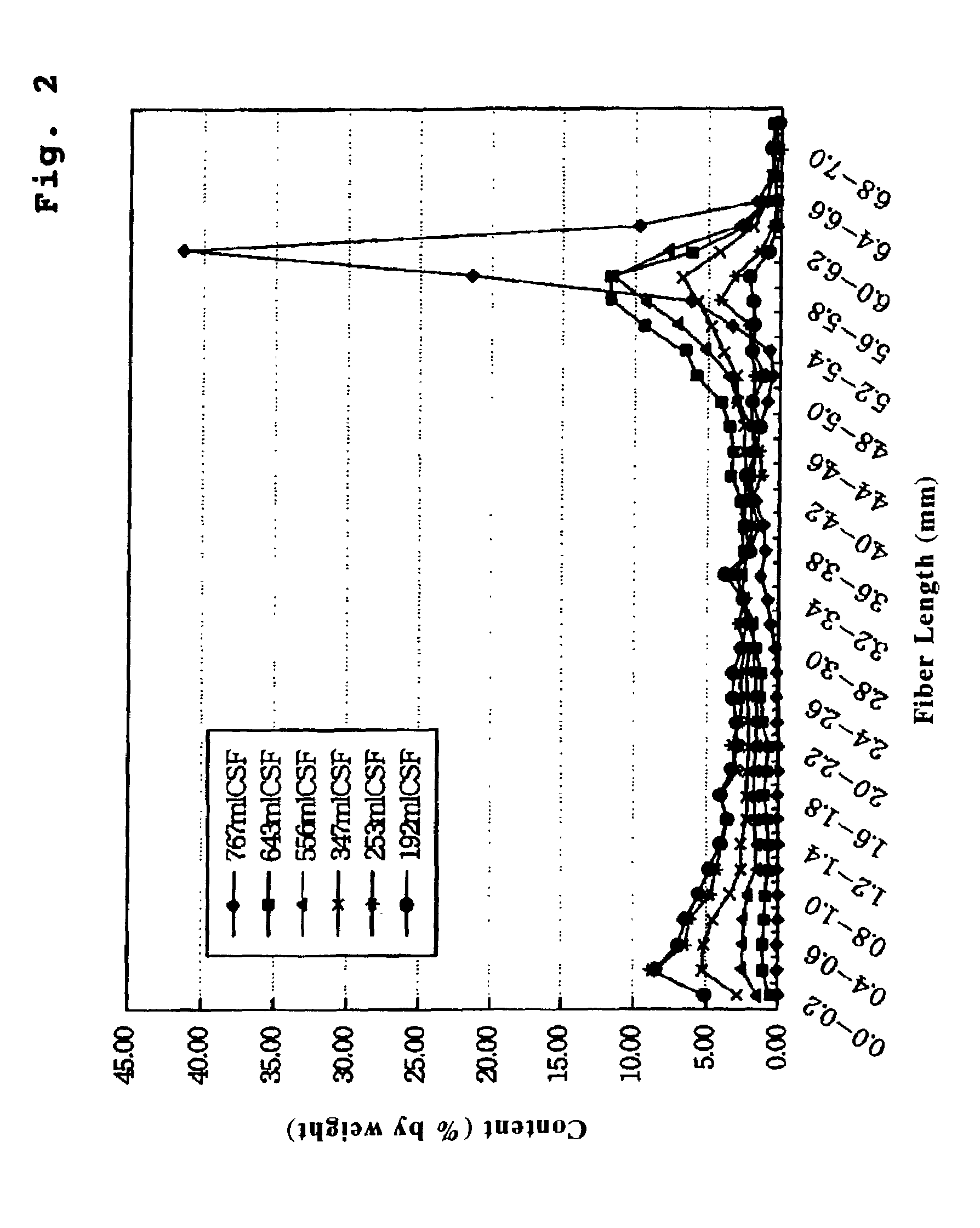

Disclosed is a water disintegratable sheet of which fibers are hydroentangled about each other. The water disintegratable sheet includes: at least one kind of primary fibers having a fiber length of at most 10 millimeter; and bast / leaf fibers having a Canadian Standard freeness value of at most 600 milliliter and a fiber length of at most 10 millimeter.

Owner:UNI CHARM CORP

Water-disintegratable sheet and manufacturing method thereof

InactiveUS7250382B2Reduce manufacturing costImprove balanceNon-fibrous pulp additionNatural cellulose pulp/paperFiberSheet material

Owner:UNI CHARM CORP

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

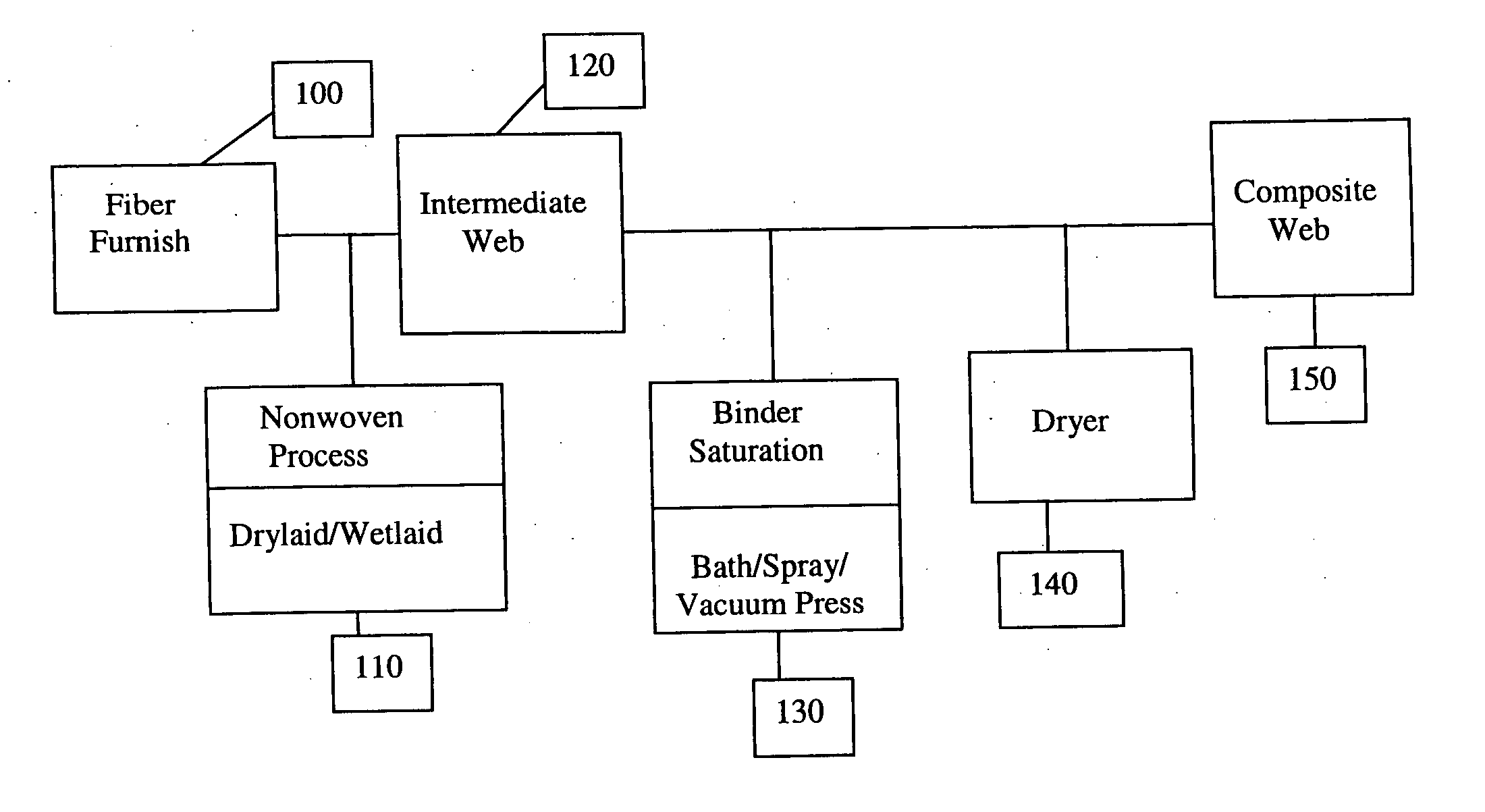

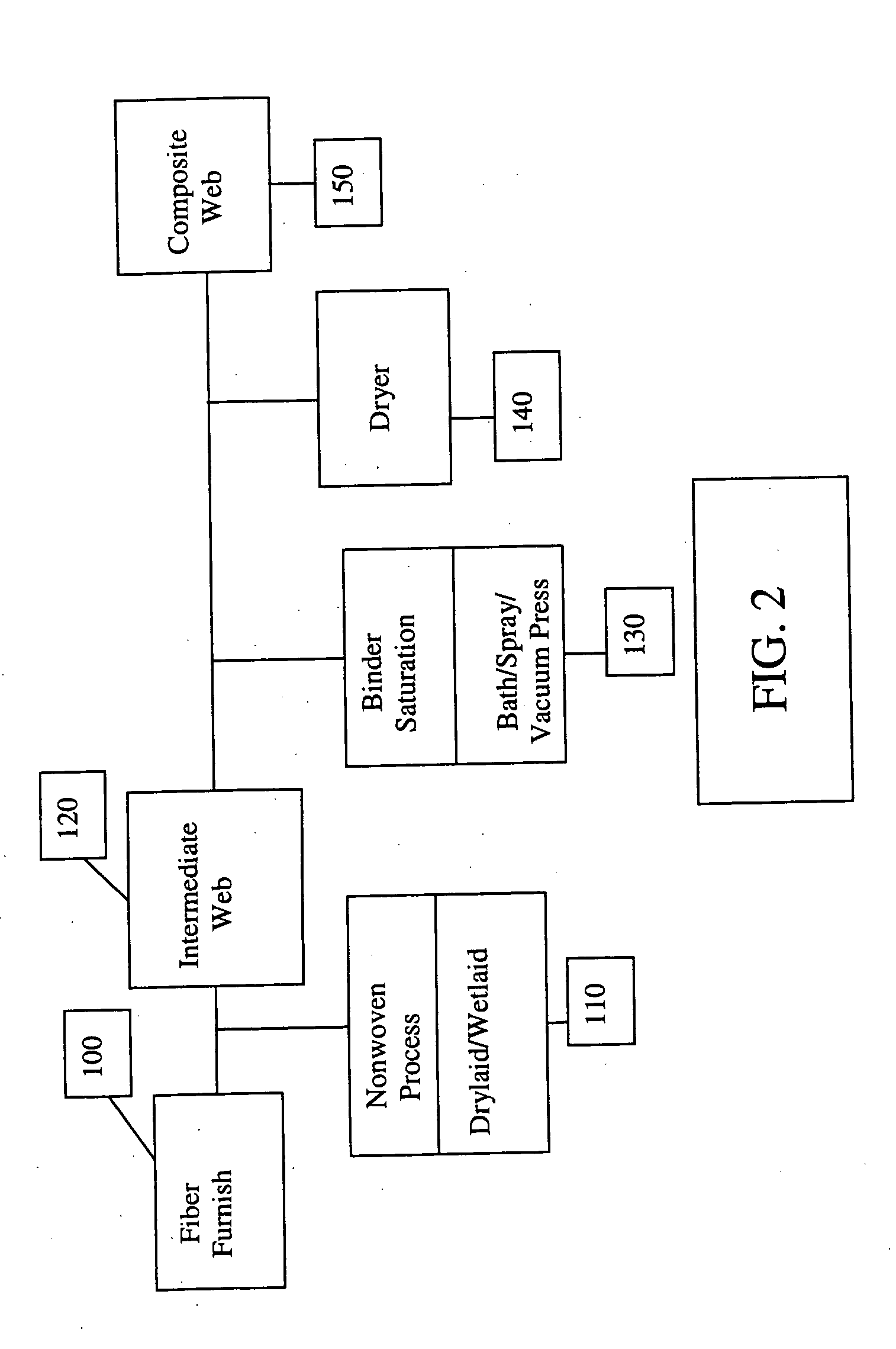

Composite web and process for manufacture from post-industrial scrap

A composite web and process for manufacture from post-industrial scrap wherein the fibers are pre-opened and cut to an average fiber length of about 4 mm. A scrap fiber component and a cellulosic component of such fibers are blended into a fiber furnish. The scrap fiber component includes at least 15% synthetic fibers and may include a blend of natural fibers, high melting point synthetic fibers, and low melting point synthetic fibers. The cellulosic component may include post-industrial cotton fibers which may be refined before blending with the scrap fiber component. The fiber furnish is processed into an intermediate web such as by a drylaid or a wetlaid nonwoven process. The intermediate web is saturated with a latex binding agent and pressed and / or dried to form a composite web capable of further processing into molded or formed consumer or industrial products. The process is capable of producing a high basis weight composite web.

Owner:SSI TECH INC

Method of preparing fiber for weave by peroxide degumming method

InactiveCN1924120APractical degummingPractical methodFibre treatment to obtain bast fibreHydrogenRamie

This invention relates to one fabric fiber method for oxidation glue removing, which uses ramie plant oxidation as oxidation agent and forms glue removing process liquid composed of chelant, hydrogen bonding destroy agent, anti-deposition agent, lignin removal agent and water under certain temperature for removing glue and bleaching. This invention can integrate glue removing and bleaching into one process for simplifying process.

Owner:DONGHUA UNIV

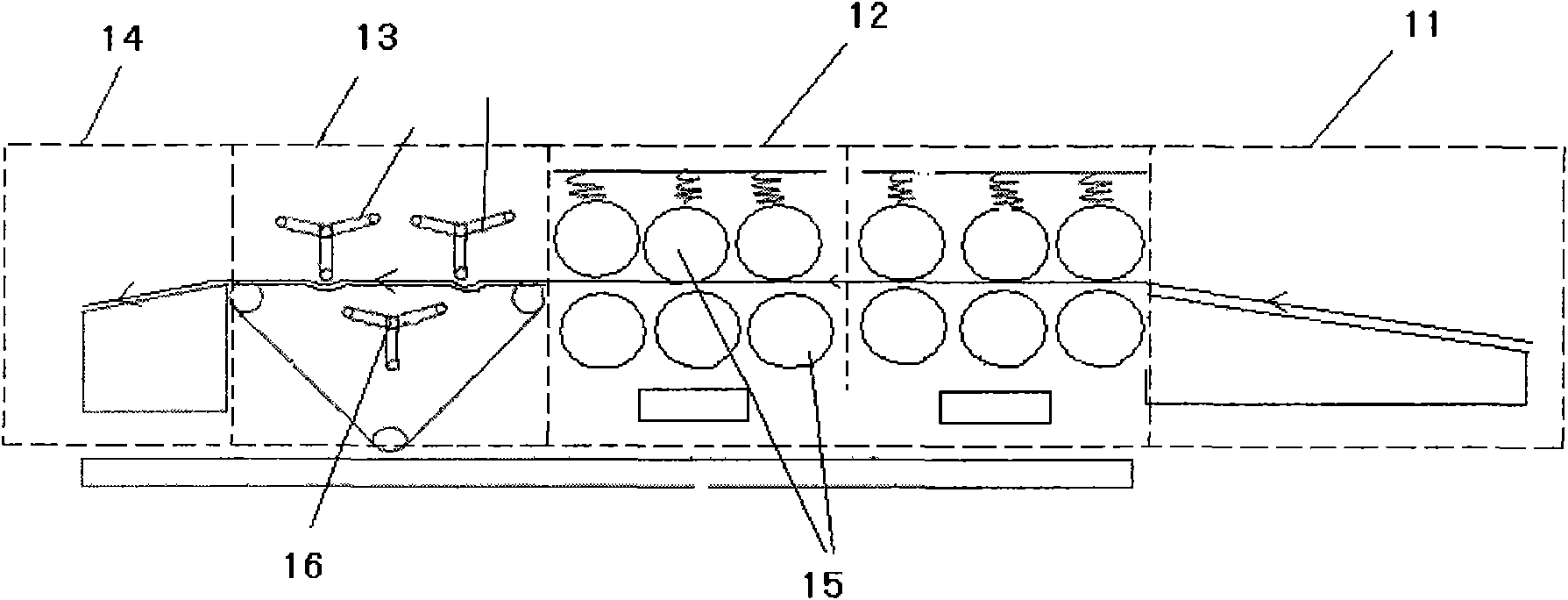

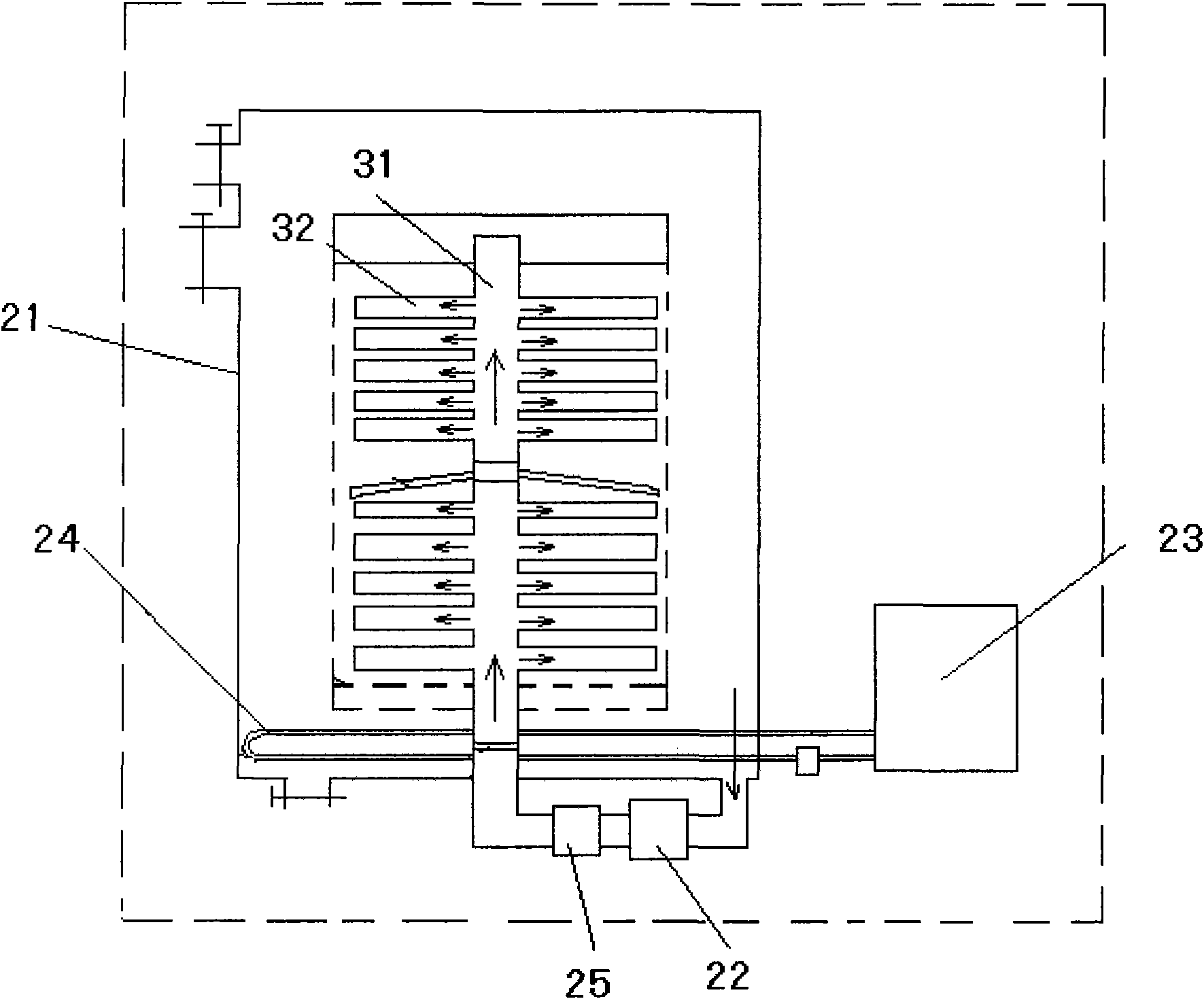

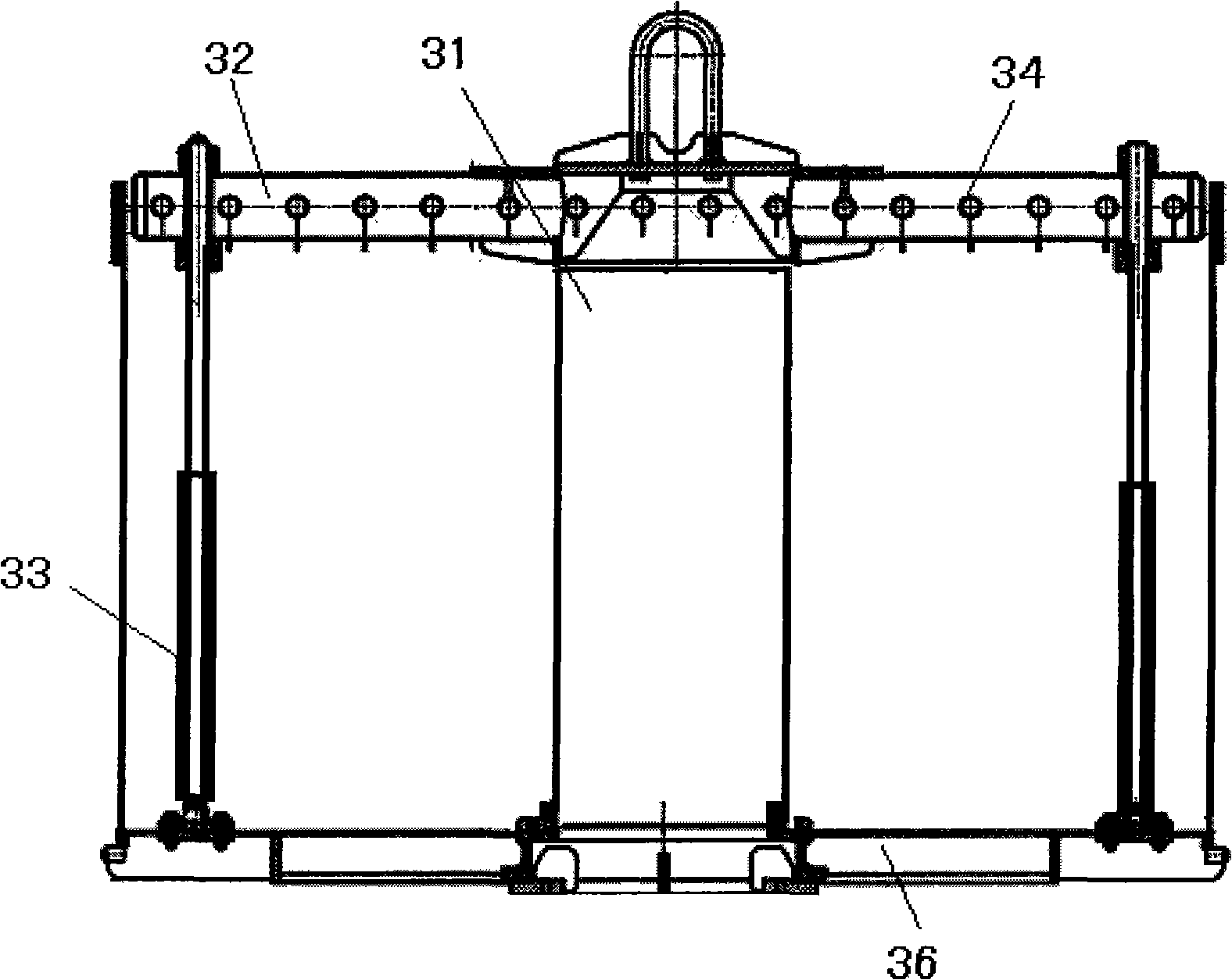

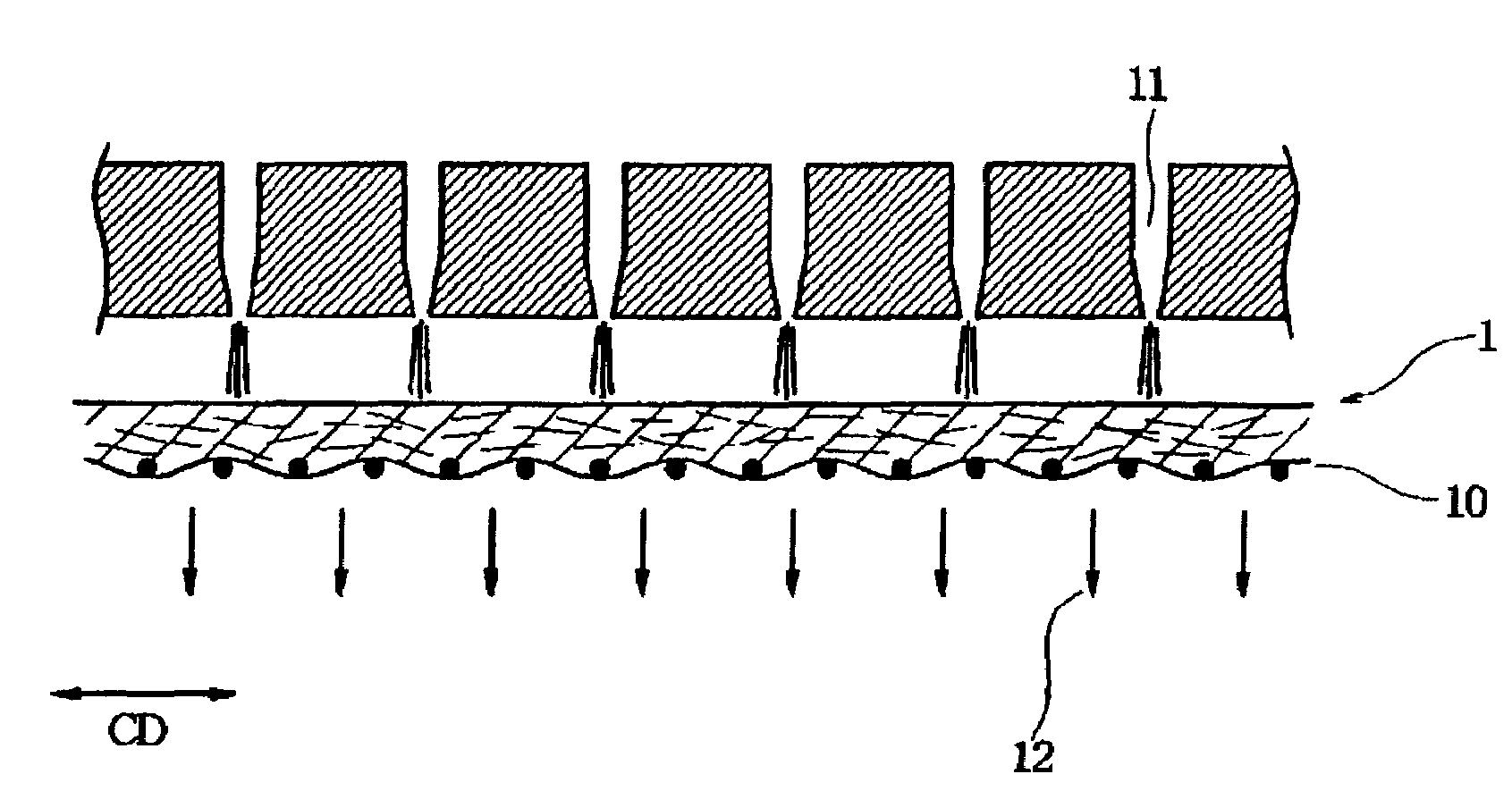

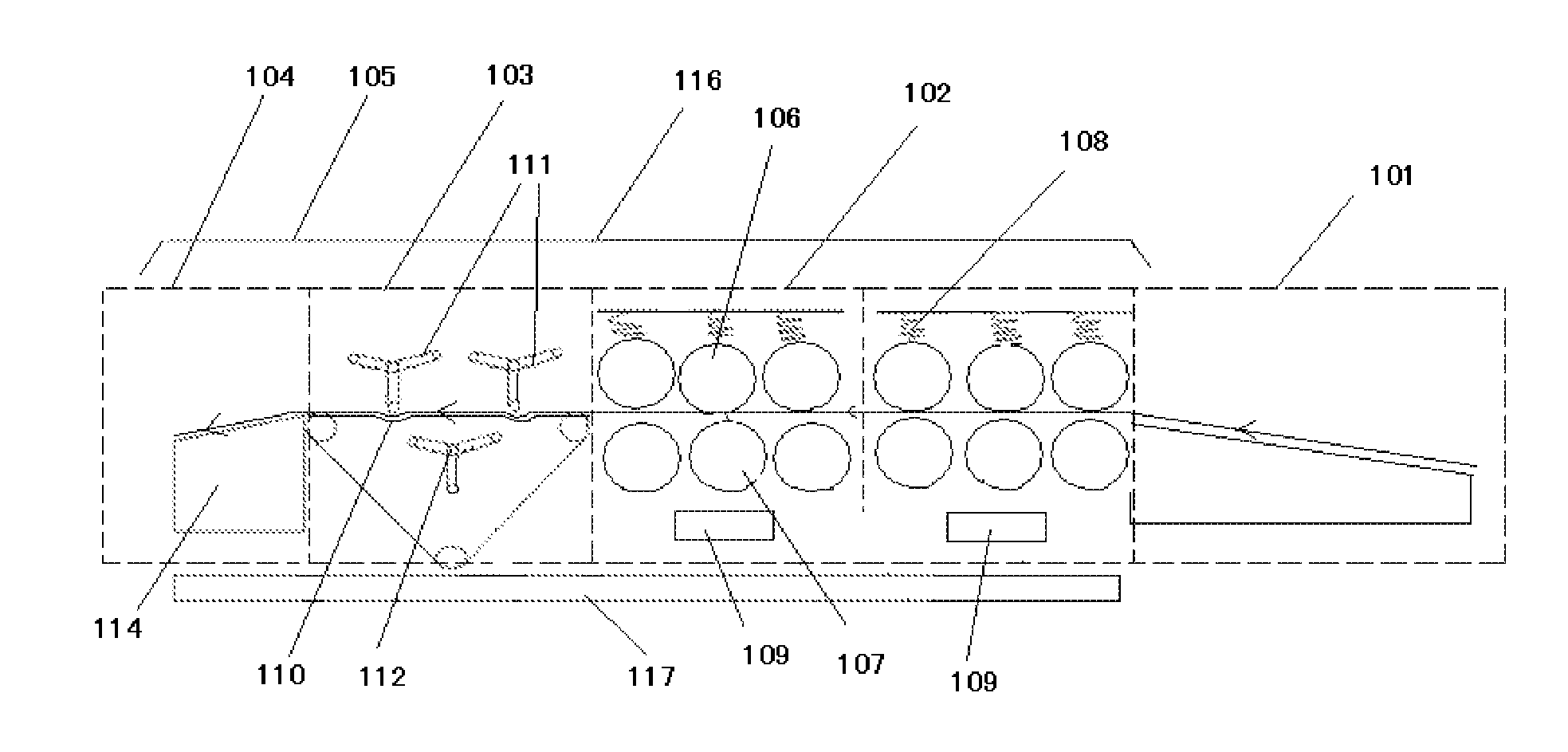

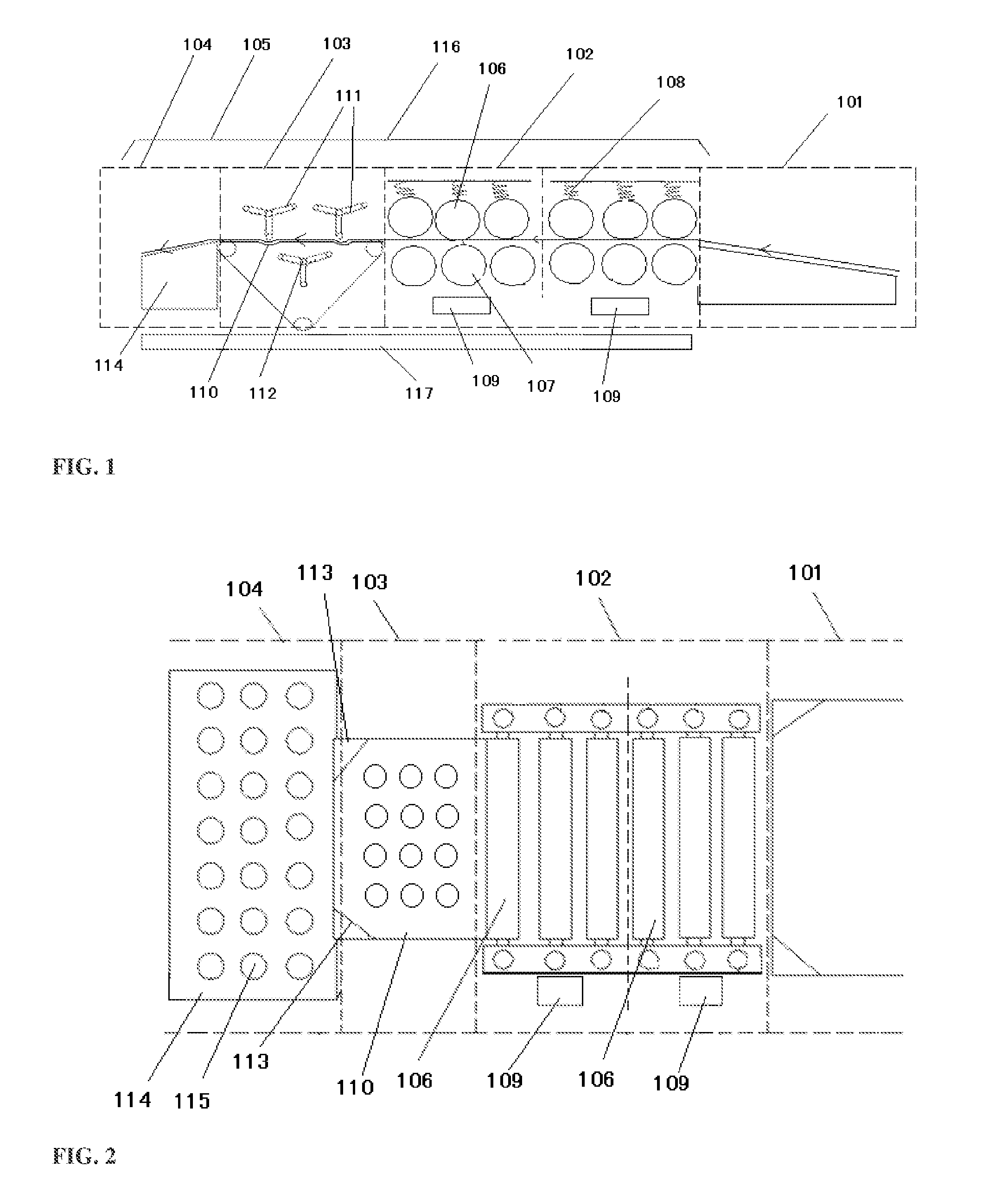

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

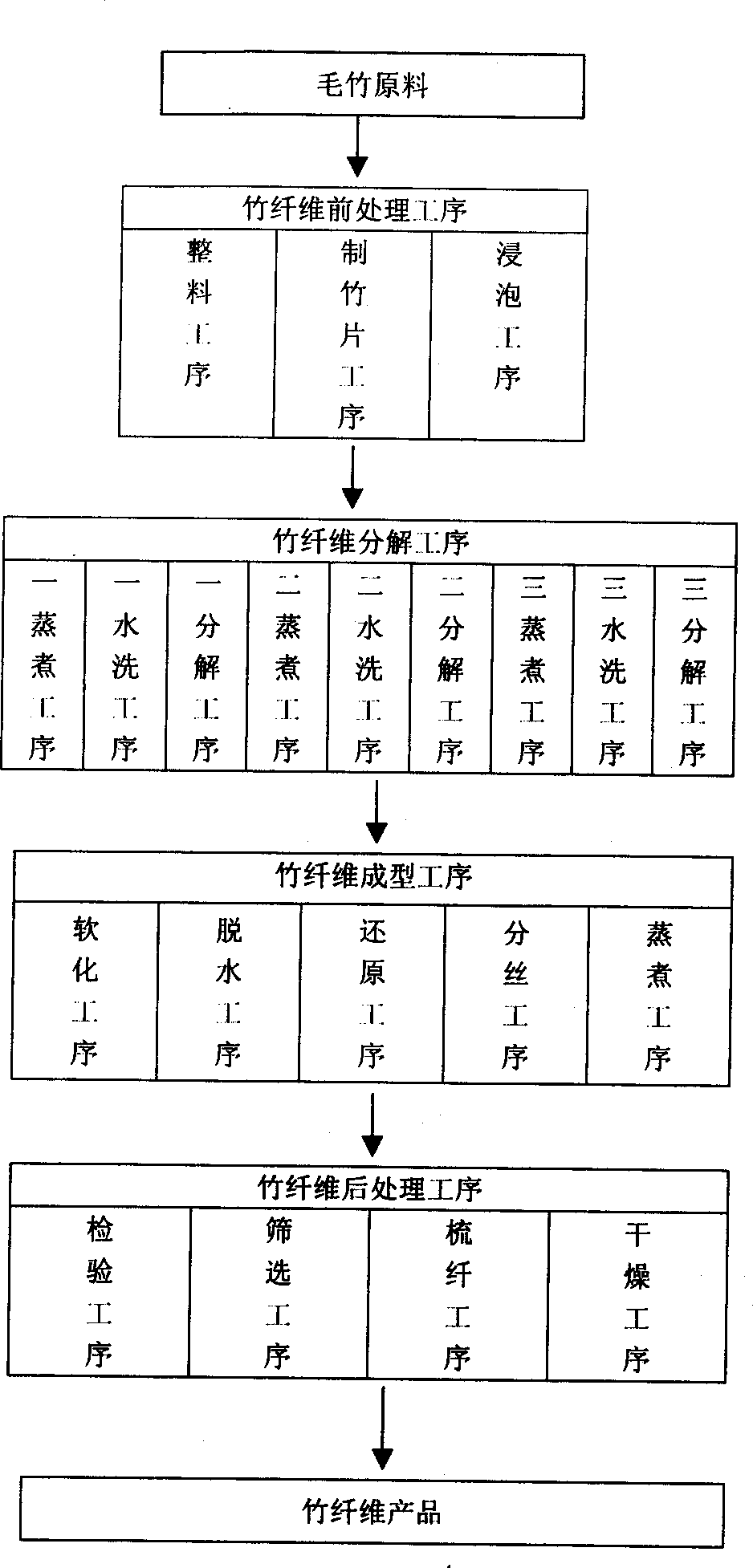

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS7481843B2Good bulkinessEasy crimpingBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

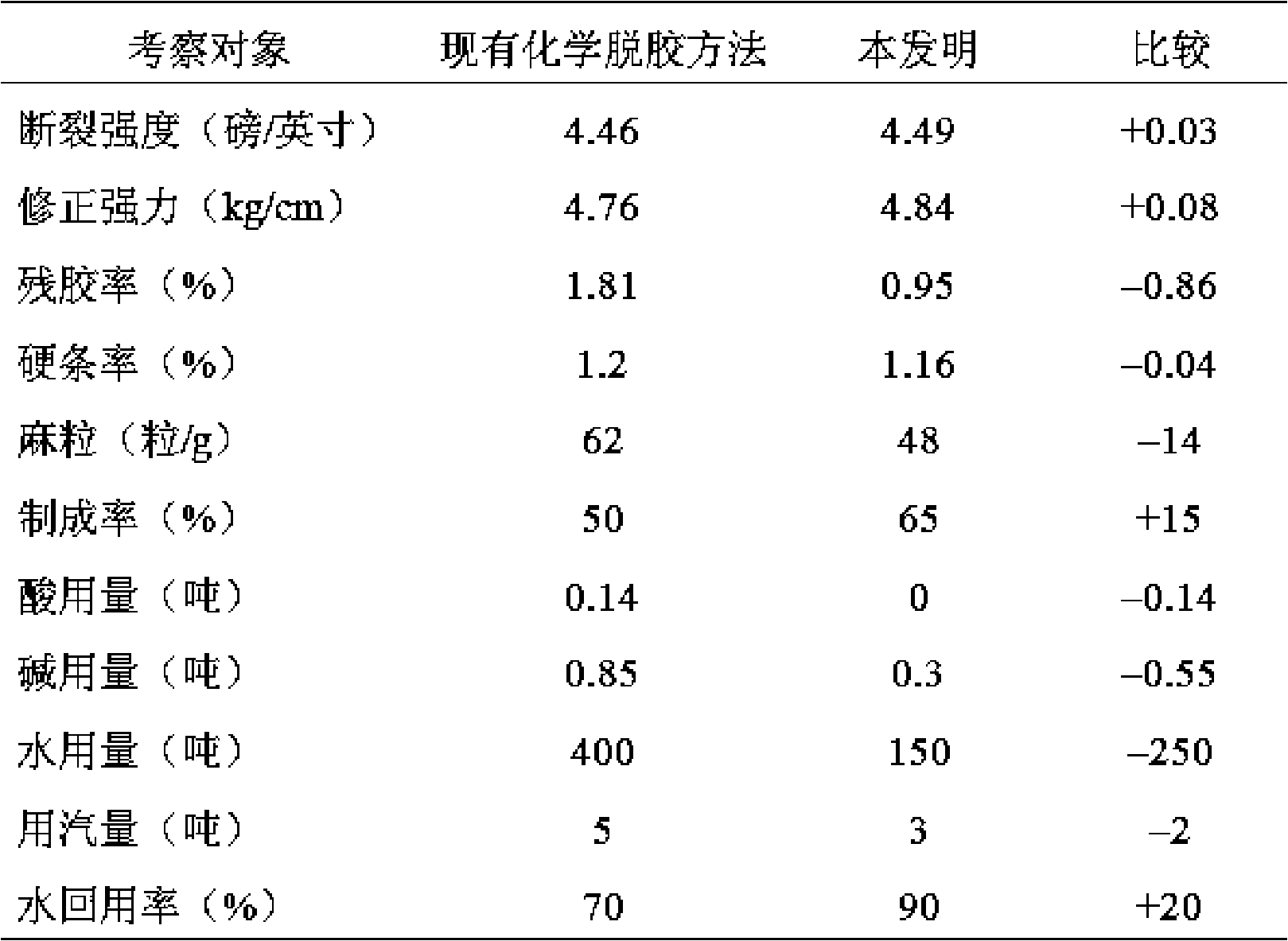

Manufacturing method of ramie based on sectioned circulation

ActiveCN101624727AGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Degumming technology of mulberry bark

InactiveCN101638811AImprove production rateAvoid damageVegetable materialBacteriological rettingFiberCellulase

Owner:YANCHENG INST OF IND TECH

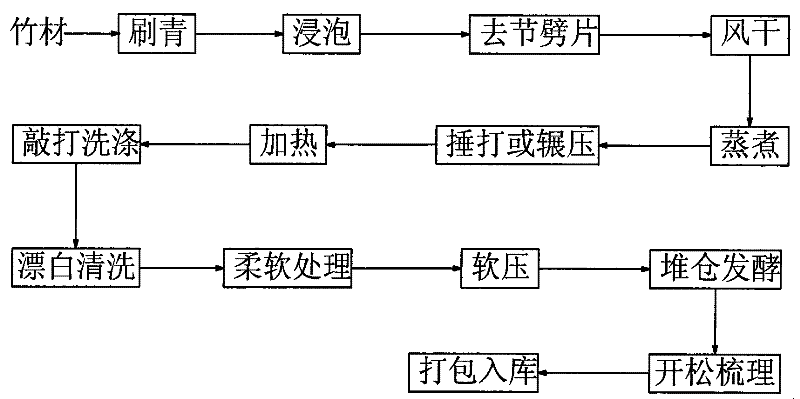

Solvent method for biologically preparing bamboo fiber

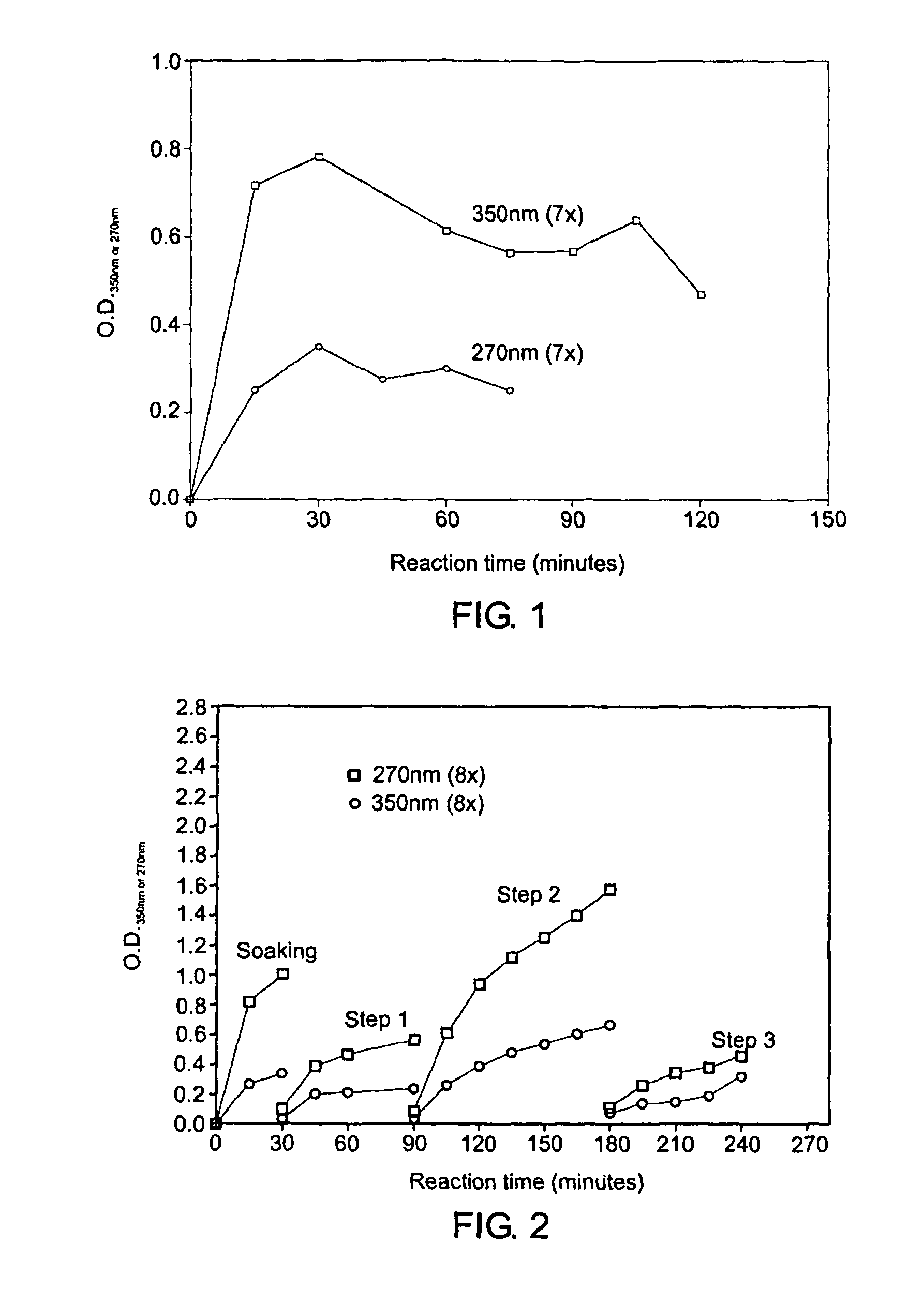

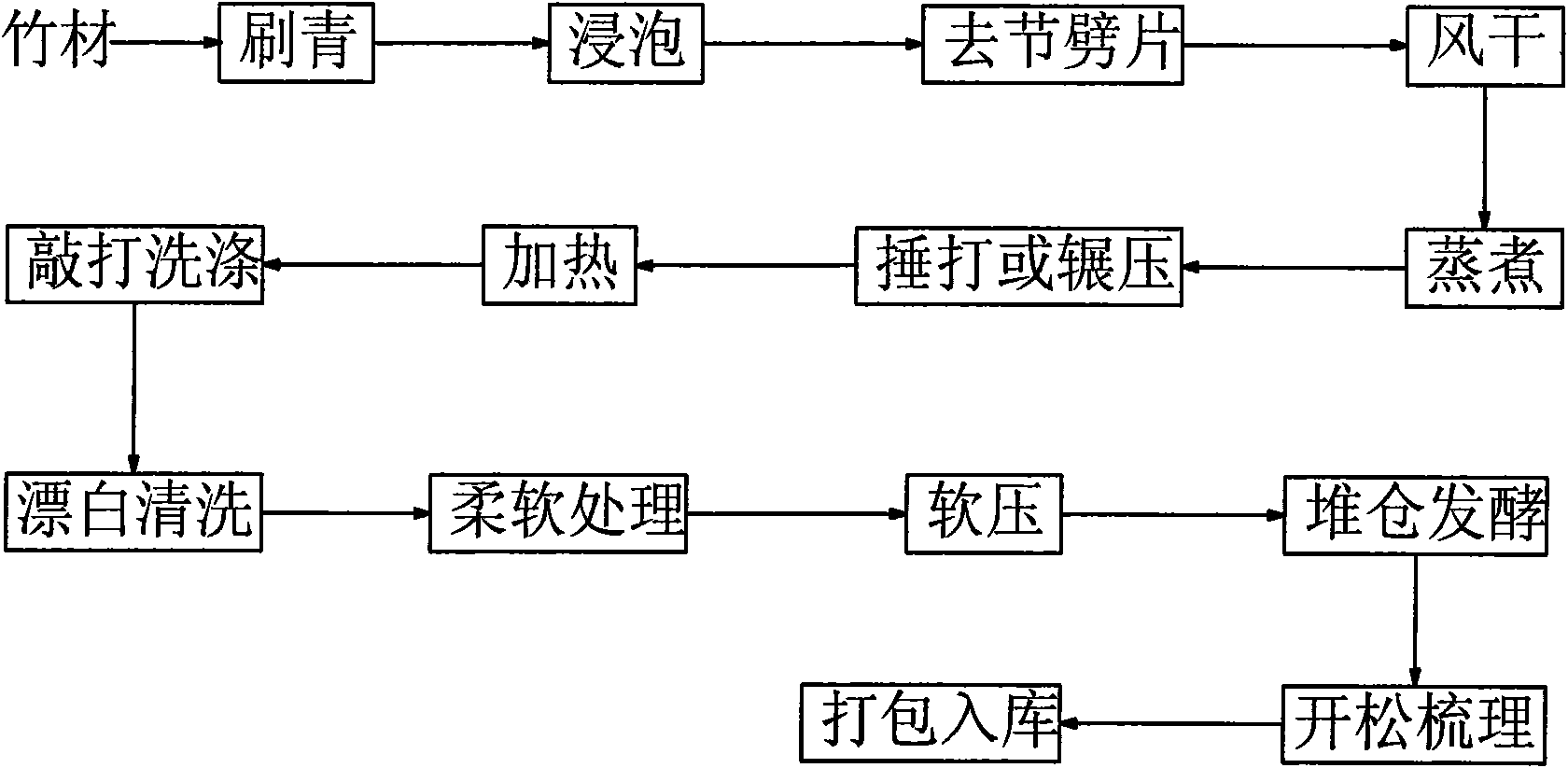

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Cotton stalk peel fiber cleaning and deguming method

InactiveCN101008108AQuality improvementReduce concentrationFibre treatment to obtain bast fibrePulp and paper industryHigh pressure

The invention discloses a method for cleaning and degumming cotton stalk bark fiber, combining flash explosion, high pressure and high pressure. The inventive method comprises that: washing cotton stalk bark in water, drying, flash explosion, washing in hot water, washing in water, degumming with high pressure and high temperature, washing in water, feeding oil to soften, removing oil, drying and ultra drying cotton stalk bark fiber. The invention first utilizes flash explosion technique to degrade part of semi-cellulose and lignin, utilizes high-temperature high-pressure technique to treat cotton stalk bark deeply in order to remove the lignin and semi-cellulose and obtain white soft cotton stalk bark fiber. Since the cotton stalk bark fiber is similar to prior estopa fiber, it has high lignin content and high strength; since the inventive method uses flash explosion and high-pressure high-temperature low-alkali technique, it can effectively remove lignin and reduce fiber strength to effectively degum, without pollution.

Owner:ZHEJIANG SCI-TECH UNIV

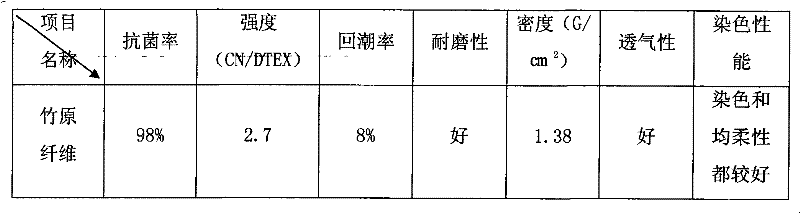

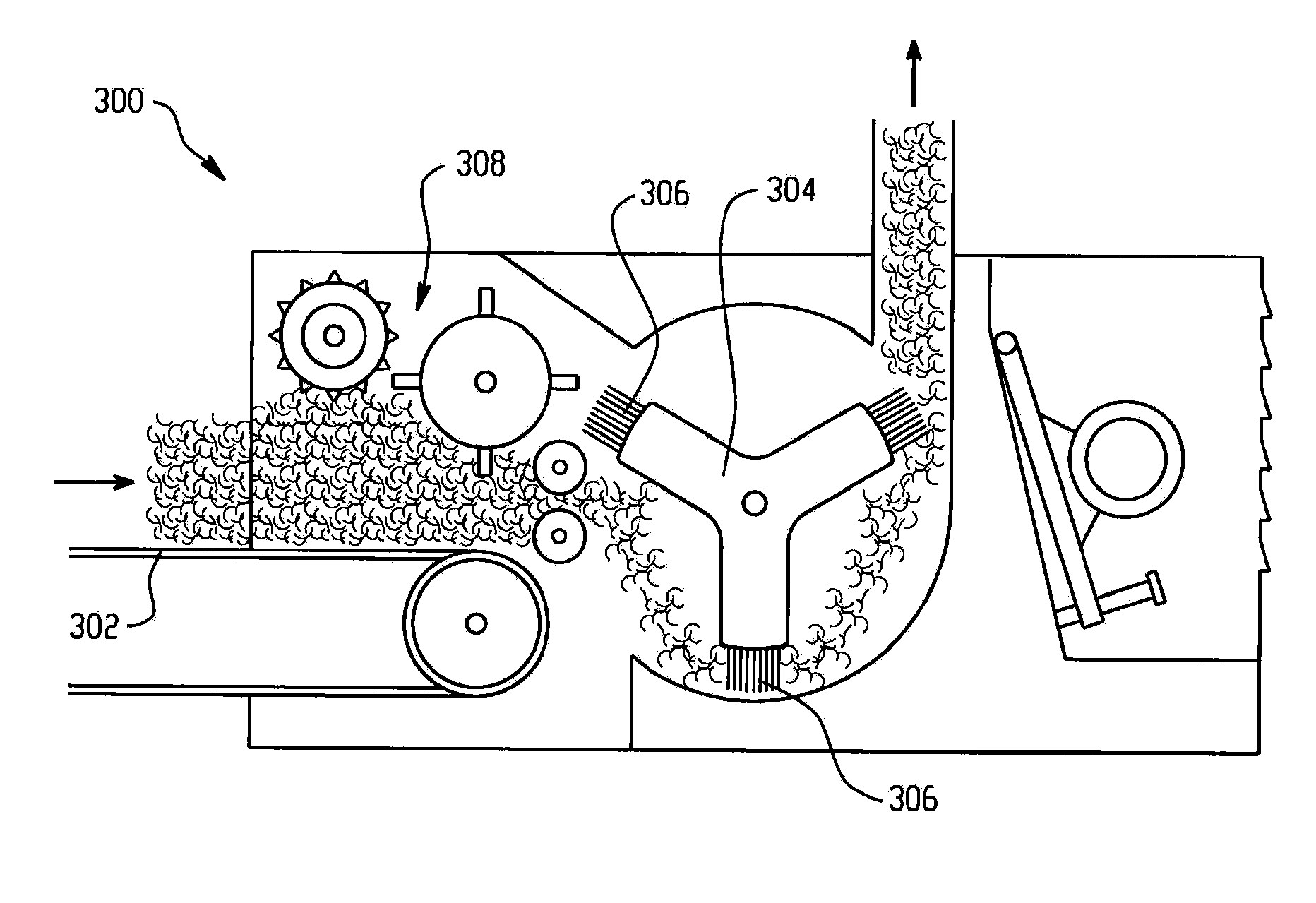

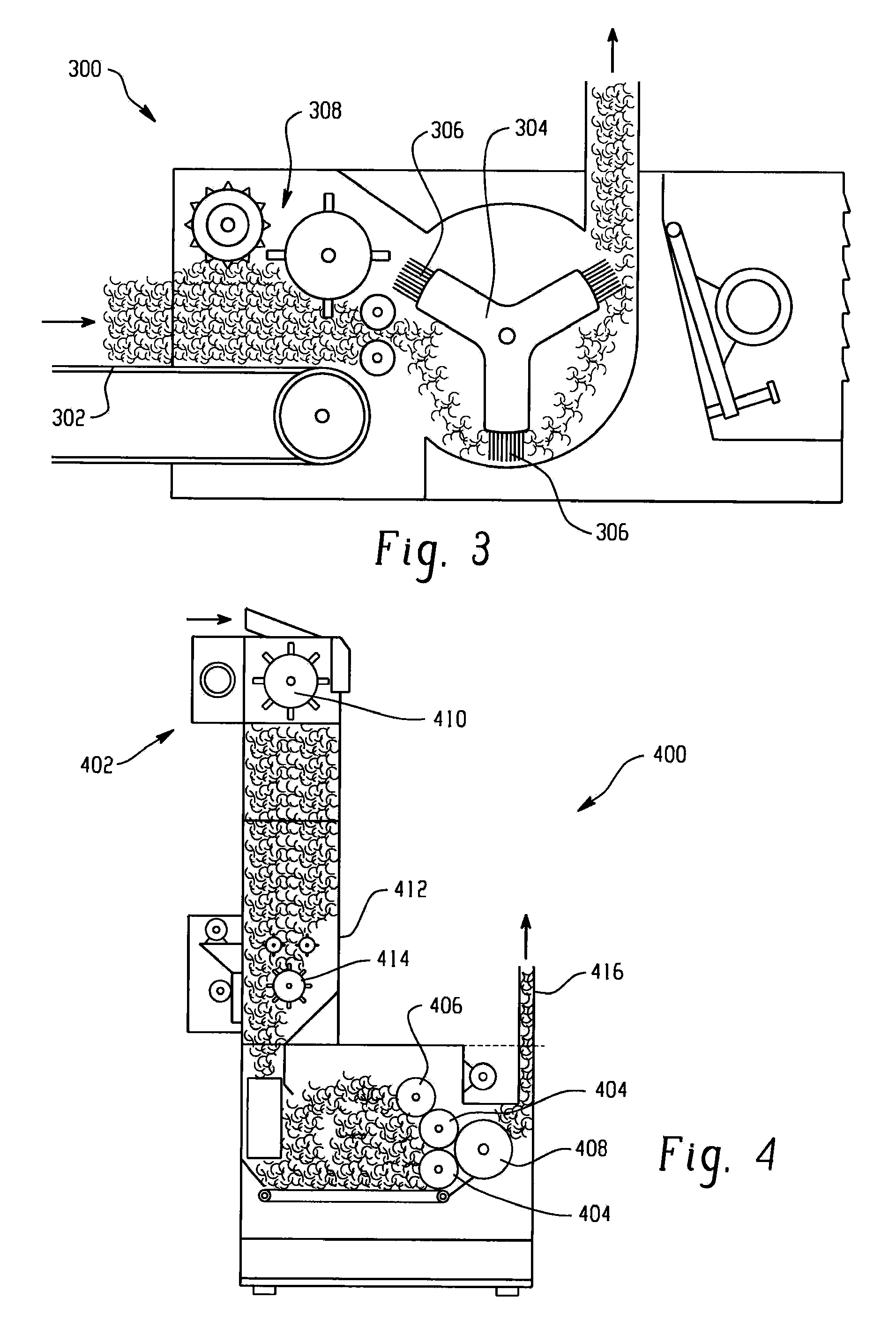

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

Bamboo viscose fibre and its preparing method

InactiveCN1458306ARetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

Hemp fiber degumming boiling-off additive, preparing method and application thereof

InactiveCN101550607AConvenient lengthImprove finenessFibre treatment to obtain bast fibreWastewaterSURFACTANT BLEND

The present invention discloses a hemp fiber degumming boiling-off additive, a preparing method and the application thereof. The invention is characterized in that the additive is composed of two parts of organic surfactant and inorganic boiling-off additive. The additive I and the additive II are prepared through compounding the organic surfactant and inorganic boiling-off additive. Furthermore the additive I and the additive II are applied for the chemical degumming of raw hemp ramie. When the additive I and the additive II according to the invention are applied to the industrial process of chemical boiling-off degumming, not only are the xylogen content and residual adhesive rate reduced, but also the degumming effect is increased. Furthermore the boiling-off time is shortened. The dosage of NaOH and the discharge amount of polluted wastewater are reduced. Additionally, the adding of the additive according to the invention increases the whiteness and plasticity of degummed ramie. The hemp fiber degumming boiling-off additive has excellent application value.

Owner:TAIYUAN UNIV OF TECH +1

Method for preparing bamboo fiber from bamboo

InactiveCN1415790APromote growthWide variety of sourcesMechanical treatmentFibre treatment to obtain bast fibreFiberAcid washing

A process for preparing bamboo fibres from bamboo includes preparing raw material, softening, water washing, rolling, water washing, treating by urea and oxygen, water washing, boiling in alkali solution, water washing, bleaching by urea and oxygen, acid washing, dewatering, loosening and drying in air. The said bamboo fibres can be used to weave cold fabrics.

Owner:DONGHUA UNIV

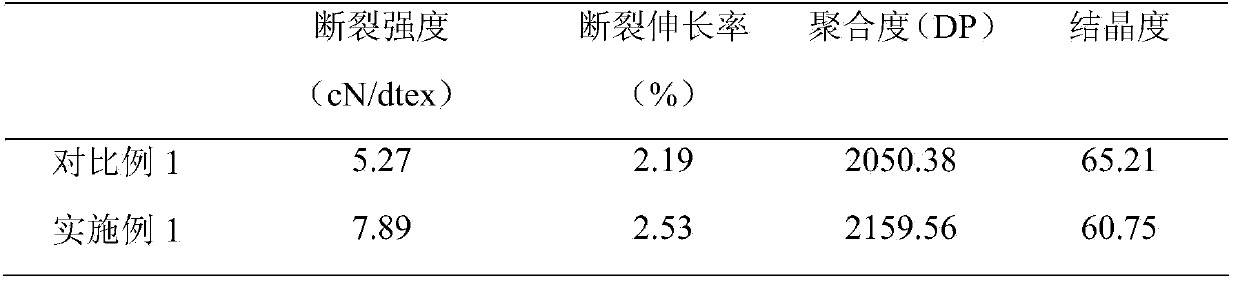

Method for enhancing property of ramie fiber through oxidative degumming

ActiveCN103993364AGood extensibilityHigh elongationFibre treatment to obtain bast fibreActive agentPhysical chemistry

The invention relates to a method for enhancing the property of a ramie fiber through oxidative degumming. The method comprises the following steps of mixing original ramie and a peroxide degumming solution according to mass ratio being 1 to 10, boiling for 40-60 minutes under the condition of 80-85 DEG C, wherein with respect to the weight percent of the original ramie, the peroxide degumming solution comprises the following components by weight percent: 1%-4% of sodium hydroxide, 3%-8% of peroxides, 0.5%-4% of quinones compounds, 1%-6% of a metal ion chelating agent, 2%-4% of a peroxide stabilizing agent, 2%-6% of a surface active agent and the balance being water; adding sodium hydroxide, boiling for 1-1.5 hours under the condition of 100 DEG C to obtain treated ramie; boiling the treated ramie and a reducing solution at 60-100 DEG C for 40-90 minutes, then applying oil, and drying. According to the method disclosed by the invention, needed degumming time is short and the efficiency is high and the bleaching and the degumming can be completed together; the prepared ramie fiber has good tensile property.

Owner:DONGHUA UNIV

Extraction of hemp fibers

InactiveUS8591701B2Improve efficiencyEfficient extractionDigestersPulping with organic solventsPectinaseCellulose

Owner:NAT RES COUNCIL OF CANADA

Process for increasing the charge on a lignocellulosic material

InactiveUS6187136B1Avoid reactionIncrease surface charge densityFungiPaper/cardboardCatalytic oxidationCellulose fiber

A process for production of a lignocellulosic material modified by conjugation thereto of a phenolic substance comprising a substituent which, in the conjugated form of the phenolic substance, is, or may become, negatively or positively charged, respectively, comprises: reacting a lignocellulosic fibre material and the phenolic substance with an oxidizing agent in the presence of an enzyme capable of catalyzing the oxidation of phenolic groups by the oxidizing agent; and reacting together the products of the reactions; with the proviso that the phenolic substance is not a phenolic polysaccharide. A strengthened lignocellulose-based product (e.g. a paper product) may be prepared by a procedure wherein a product produced in accordance with the latter process is treated with a strengthening agent having an ionic charge of sign opposite to that which is conferred on the modified lignocellulosic material by the charge-conferring substituent.

Owner:NOVOZYMES AS

Method for improving physical and mechanical properties of oxidation-degummed ramie

ActiveCN103215655AImprove applicabilityImprove performanceFibre treatment to obtain bast fibreFiberColloid

The invention provides a method for improving the physical and mechanical properties of oxidation-degummed ramie. The method comprises the following steps of: preparing a degumming solution by using caustic soda, an oxidant, a surfactant, a fiber expanding agent, an oxidant stabilizer and water; mixing raw ramie and the degumming solution, heating, and boiling off to sufficiently remove colloid; and then cooling, adding a reduction softener, maintaining the temperature, oiling and drying after washing with clear water, and opening and carding to obtain textile ramie fiber subjected to reduction modification. According to the method disclosed by the invention, the defects of the prior art are overcome; and the reduction softener is added to raffinate obtained after oxidation-degumming, oxycellulose produced in the degumming process is reduced and softened, so that the physical and mechanical properties, such as strength, length, elongation and softness of the fiber are improved, the working procedures are simplified, and pollution and environmental pressure are lightened.

Owner:DONGHUA UNIV

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743AHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Process for producing sisal fiber

InactiveCN101294309AImprove finenessGood flexibilityMechanical fibre separationFibre treatment to obtain bast fibreColloidHemicellulose

The method for preparing sisal fiber is characterized in that the method comprises the following steps: (1) scraping colloid in sisal leaf pulp by mechanical knocking or rolling, and removing partial lignin, hemicellulose and pectin therein; (2) pre-soaking fiber material in sulfuric solution at 30 to 80 DEG C for 1 to 3 h; (3) cleaning with circulating water to adjust pH value to 6.8 to 7.2; (4) adding the fiber material in a boiler with pressure of 0.1 to 0.2 MPa, and boiling with sodium hydroxide solution for 2 to 6 h; (5) cleaning with circulating water to adjust pH value to 6.8 to 7.2; and (6) post-treating to obtain sisal fiber. The method has the advantages that the fineness and the flexibility of sisal fiber prepared by the method are improved greatly in comparison with unprocessed crude sisal.

Owner:DONGHUA UNIV

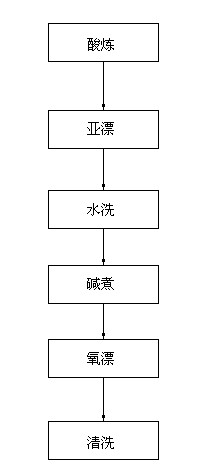

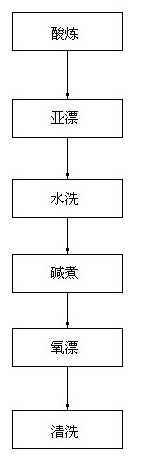

Short flax fiber degumming and bleaching process

ActiveCN102409414AImprove finenessIncrease bleachingFibre treatment to obtain bast fibreYarnPolymer science

The invention discloses a short flax fiber degumming and bleaching process. The process is characterized by taking short flax fibers as the processed objects and comprises the following steps in sequence: washing, alkali boiling, oxygen bleaching and cleaning. The process is mainly characterized by also comprising the steps of acid washing and sodium chlorite bleaching in sequence before the step of short flax fiber washing. The process has the following beneficial effects: not only does the process have good degumming and bleaching effects, but also the short flax fibers are characterized in that the short flax fibers can be used for spinning medium / high count yarns; and a simple and effective way is provided for utilization of the short flax spun fibers.

Owner:TUNGGA LINENANDCOTTON CO LTD

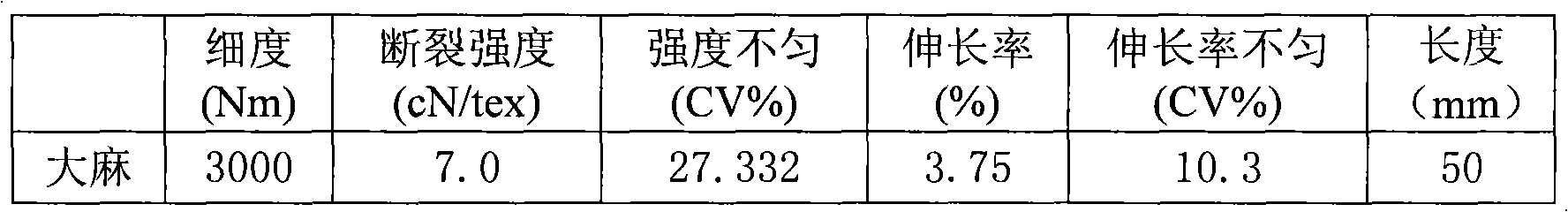

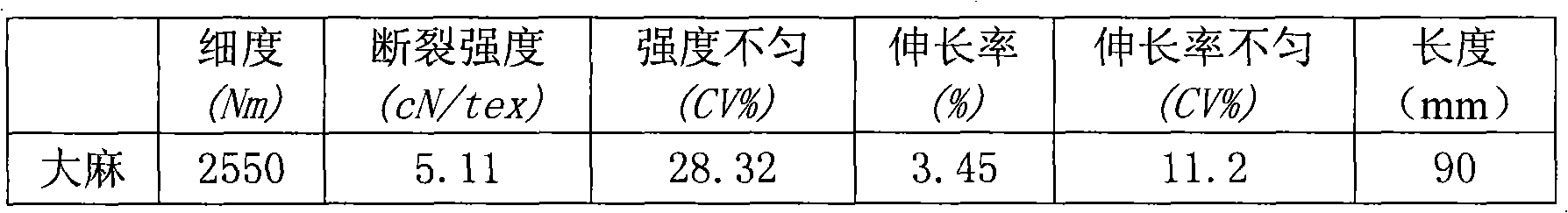

Hemp fiber and preparation method thereof

ActiveCN101831715AShorten the timeReduce processFibre cleaning/openingCarding machinesHempcreteSoftening

The invention provides a hemp fiber with a fineness of 1,500-4,000 Nm and the strength of 4-10cN / dtex. The hemp fiber has higher fineness and strength and can be used for spinning by using a dry method and preparing various grades of textile products by blending with other fibers. The invention also provides a preparation method of the hemp fiber, comprising the following steps of: chemical degumming, aftertreatment, stamping, oil feeding, softening, oil feeding and humidification, stowing and mechanical opening, wherein the step of chemical degumming specifically comprises the following steps of: adding hydrogen peroxide, alkali metal silicates, urea and a penetrating agent to water and uniformly stirring; then adding hemp peels; heating up, preserving heat and washing by using clear water; adding alkali, the alkali metal silicates, urea and the penetrating agent to water and uniformly stirring; adding oxidized hemps; and heating up, preserving heat and washing by using clear water. The method can prepare hemp fibers with an extremely high fineness and has low environmental pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

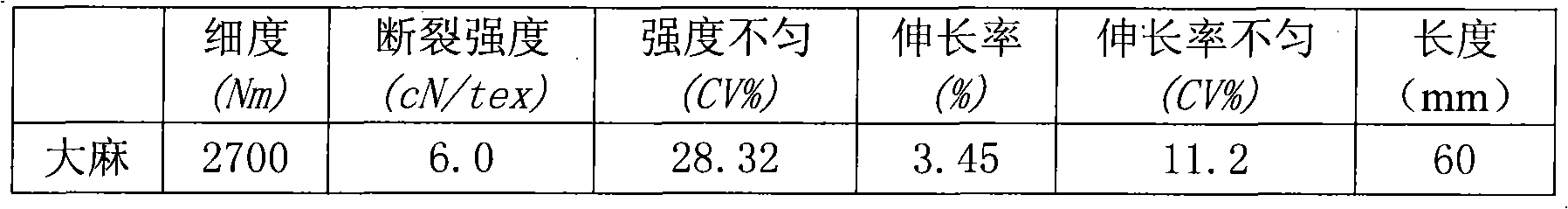

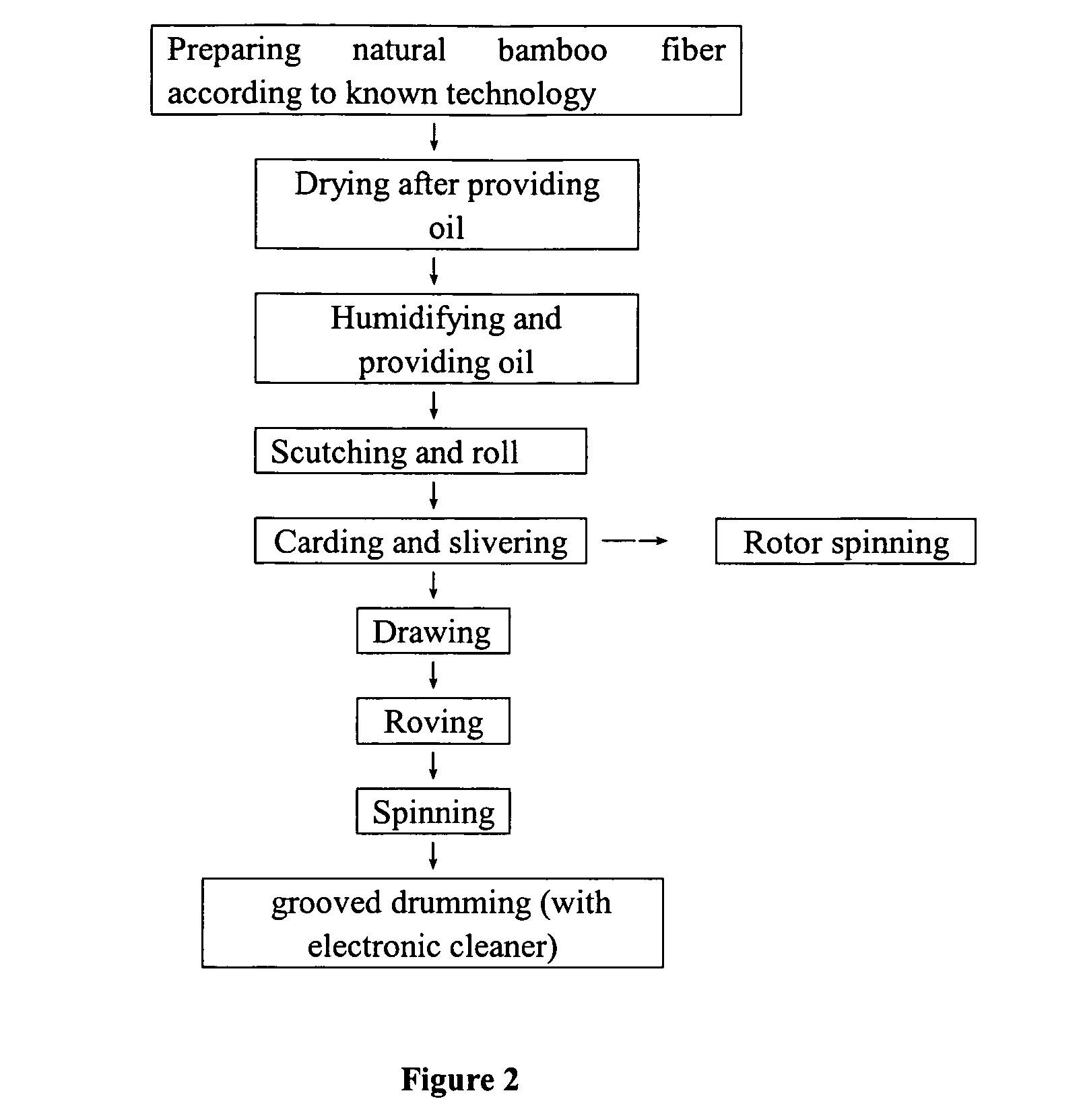

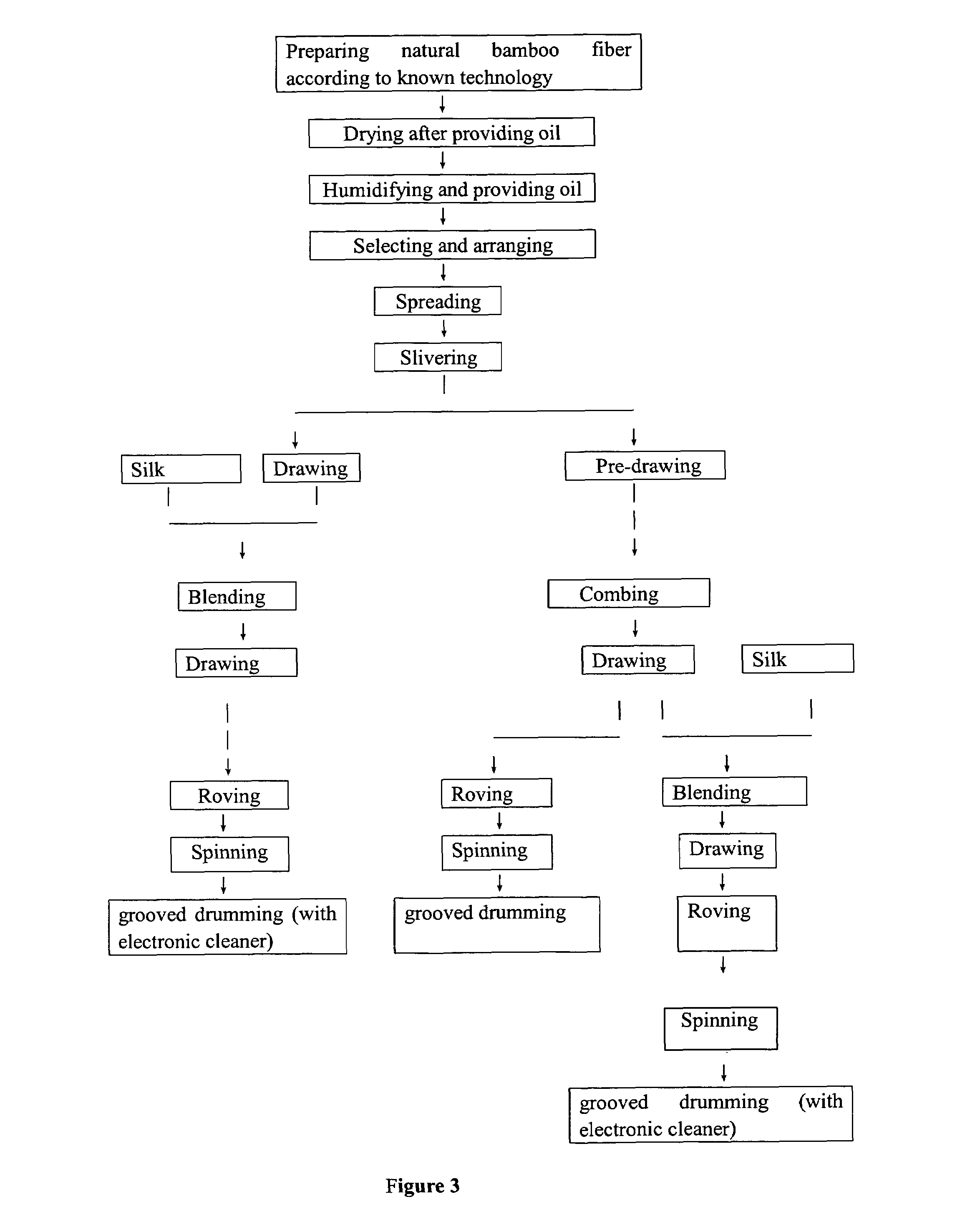

Yarn comprising bamboo fiber and the processing method thereof

ActiveUS7313906B2Avoid large quantitiesSmall tensionYarnFibre treatment to obtain bast fibreFiberYarn

Owner:ZHUZHOU CEDAR RAMIE INDAL

Enzymatic preparation of plant fibers

InactiveUS8603802B2Efficient and effective extractionReduce harmMicrobiological testing/measurementVegetable materialFiberAqueous solution

Owner:NAT RES COUNCIL OF CANADA

Degumming process for kudzu vine

InactiveCN103835006AReduce usageReduce hard bar rateFibre treatment to obtain bast fibreProcess chemistryEngineering

The invention provides a degumming process for a kudzu vine. Directed at the problems of a great usage amount of chemicals, a high fiber strength damage rate, severe environmental pollution and the like in conventional chemical degumming process, the invention provides a degumming method for the kudzu vine through low temperature refrigeration and vacuum technology. The process comprises the following steps: changing the interior structure of a raw kudzu vine by using low temperature vacuum technology so as to form considerable micropores, thereby increasing the surface area of a fiber; and then fully injecting dilute alkali lye and a low-concentration hydrogen peroxide solution into the interior of the fiber by using vacuum negative pressure technology so as to allow alkali lye and hydrogen peroxide to exert maximum efficacy. The process provided by the invention substantially reduces the usage amount of chemicals, shortens degumming flow and has a high gum and lignin removal rate and a low fiber damage rate.

Owner:姜著川

Popular searches

Liquid/gas/vapor treatment of definite length materials Textile treatment by spraying/projecting Liquid/gas/vapor fibres/slivers/rovings treatment Paper coating Record information storage Synthetic cellulose/non-cellulose material pulp/paper Pulp material addition processes Combination recording Synthetic resin layered products Woven fabrics

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com