Hemp fiber and preparation method thereof

A technology of hemp fiber and fineness, which is applied in the directions of fiber processing, plant fiber, fiber cleaning, etc., can solve the problems of coarse hemp fiber fineness and coarse yarn fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

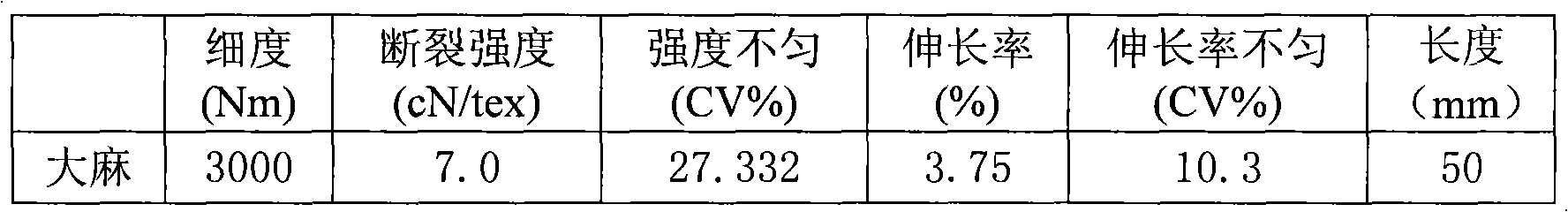

Embodiment 1

[0074] The hemp husk is put into the oxidizing solution, 10 kilograms of water per kilogram of hemp husk (that is, the bath ratio is 1: 10), hydrogen peroxide (according to pure hydrogen peroxide) in the oxidizing solution 2 o 2 Calculation) content is 8g / L, sodium silicate content is 4g / L, urea content is 2g / L, JFC content is 2g / L. Raise the temperature of the oxidizing solution from normal temperature to 90°C at a constant speed, and control the heating time at 30 minutes. After the temperature reaches the temperature, let the oxidizing solution keep warm for 1.5 hours; the oxidized hemp skin is washed with water and then put into the alkali boiling solution. The hydrogen in the alkali boiling solution The content of sodium oxide is 6g / L, the content of sodium silicate is 2g / L, the content of urea is 2g / L, the content of penetrant JFC is 2g / L, the bath ratio is 1:10 (10 kg of water per kg of marijuana), and the temperature is raised to 100°C in 35 minutes. And keep warm for...

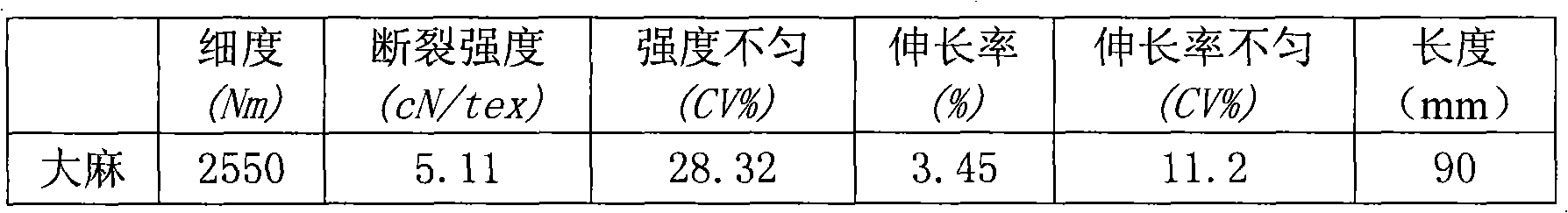

Embodiment 2

[0078] The hemp husk is put into the oxidizing solution, 10 kilograms of water per kilogram of hemp husk (that is, the bath ratio is 1: 10), hydrogen peroxide (according to pure hydrogen peroxide) in the oxidizing solution 2 o 2 Calculation) content is 8g / L, sodium silicate content is 4g / L, urea content is 2g / L, JFC content is 2g / L. Raise the temperature of the oxidizing solution from normal temperature to 90°C at a constant speed, and control the heating time at 30 minutes. After the temperature reaches the temperature, let the oxidizing solution keep warm for 1.5 hours; the oxidized hemp skin is washed with water and then put into the alkali boiling solution. The hydrogen in the alkali boiling solution The content of sodium oxide is 6g / L, the content of sodium silicate is 2g / L, the content of urea is 2g / L, the content of penetrant is 2g / L, the bath ratio is 1:10 (10 kg of water per kg of marijuana), the temperature is raised to 100°C in 35 minutes, and the temperature is kep...

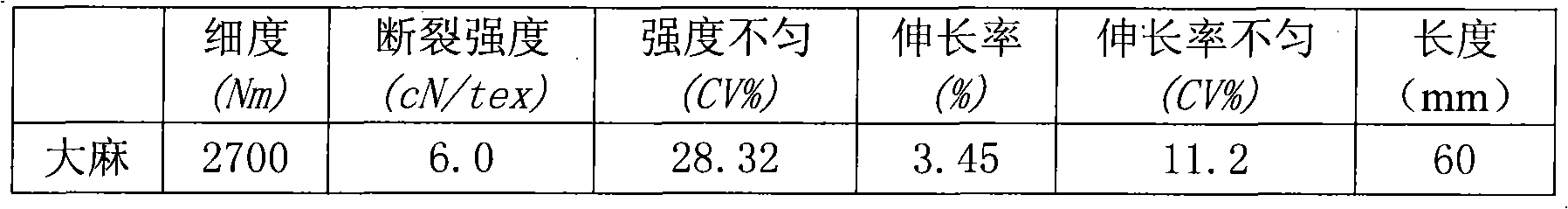

Embodiment 3

[0082] Concrete operation is with embodiment 1,2, and concrete reagent consumption and operation parameter are as follows:

[0083] Oxidation: hydrogen peroxide (according to pure H 2 o 2 Calculate) 7g / L, potassium silicate 2g / L, urea 3g / L, JFC 4g / L. The temperature is 70°C, the heating time is 34min, the heat preservation is 1.5h, and the bath ratio is 1:10;

[0084] Soda cooking: Potassium hydroxide 3g / L, potassium silicate 2g / L, urea 2g / L, penetrant JFC 3g / L, bath ratio 1:10, temperature 100°C, heating time 35min, heat preservation 4h;

[0085] Post-treatment: leavening agent (leaving agent BK-100 mixed with urea at 2:1) 4g / L, bath ratio 1:10, temperature 60°C, time 30min;

[0086] Oil supply: white oil 15g, potassium hydroxide 6g, detergent 7g, water 8kg, temperature 80°C, keep warm for 1h;

[0087] Oil humidification: 20g tea oil, 6g potassium hydroxide, 7g detergent, 90g water;

[0088] Stacking: temperature 37℃, time 37h;

[0089] Mechanical opening: the cotton fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com