Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4165 results about "Sodium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium oxide is a chemical compound with the formula Na₂O. It is used in ceramics and glasses, though not in a raw form. It is the base anhydride of sodium hydroxide, so when water is added to sodium oxide NaOH is produced.

Ultrastable Y-type RE molecular sieve active component and its prepn process

InactiveCN1506161AReasonable matching activityIncreased hydrogen transfer activityMolecular sieve catalystsMolecular sieveActive component

The active component of ultrastable Y-type RE molecular sieve is composite modified Y-zeolite containing RE oxide 8-25 wt%, P 0.1-3.0 wt% and sodium oxide 0.3-2.5 wt%, and with degree of crystallization 30-55 % and unit cell parameter 2.455-2.477 nm. It is prepared with Y-zeolite as material and through the steps of exchange with RE and the first roasting to obtain RE-Na Y-zeolite; reaction with RE, reaction with P-containing compound, and the second roasting. The ultrastable Y-type RE molecular sieve is used as the active component of cracking catalyst and has the obvious effect of lowering olefin content in gasoline and the features of resulting in moderate coke yield and high diesel oil yield. The preparation process is simple and high in the utilization of the modifying elements.

Owner:PETROCHINA CO LTD

Hydrocracking catalyst and preparation method thereof

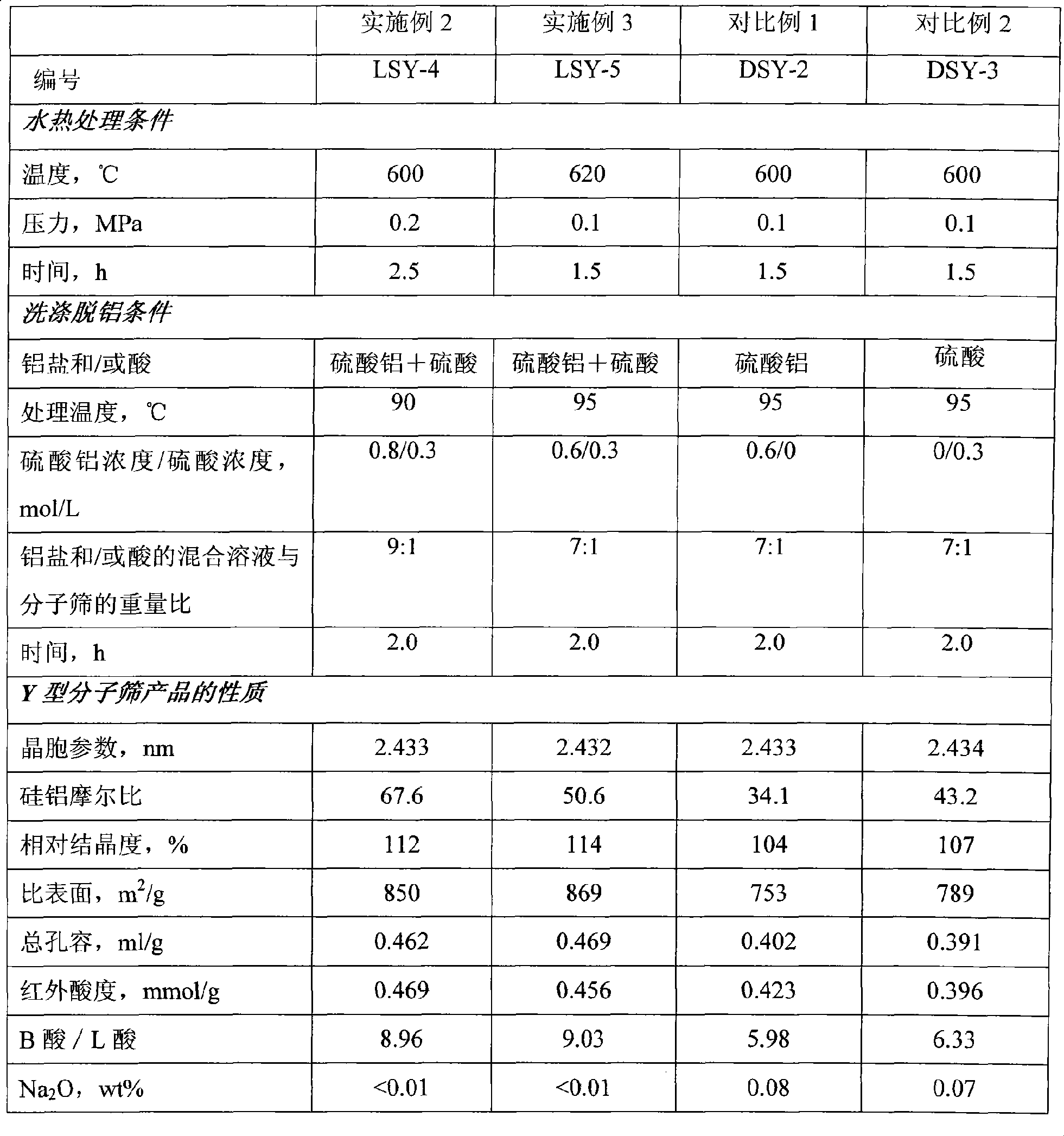

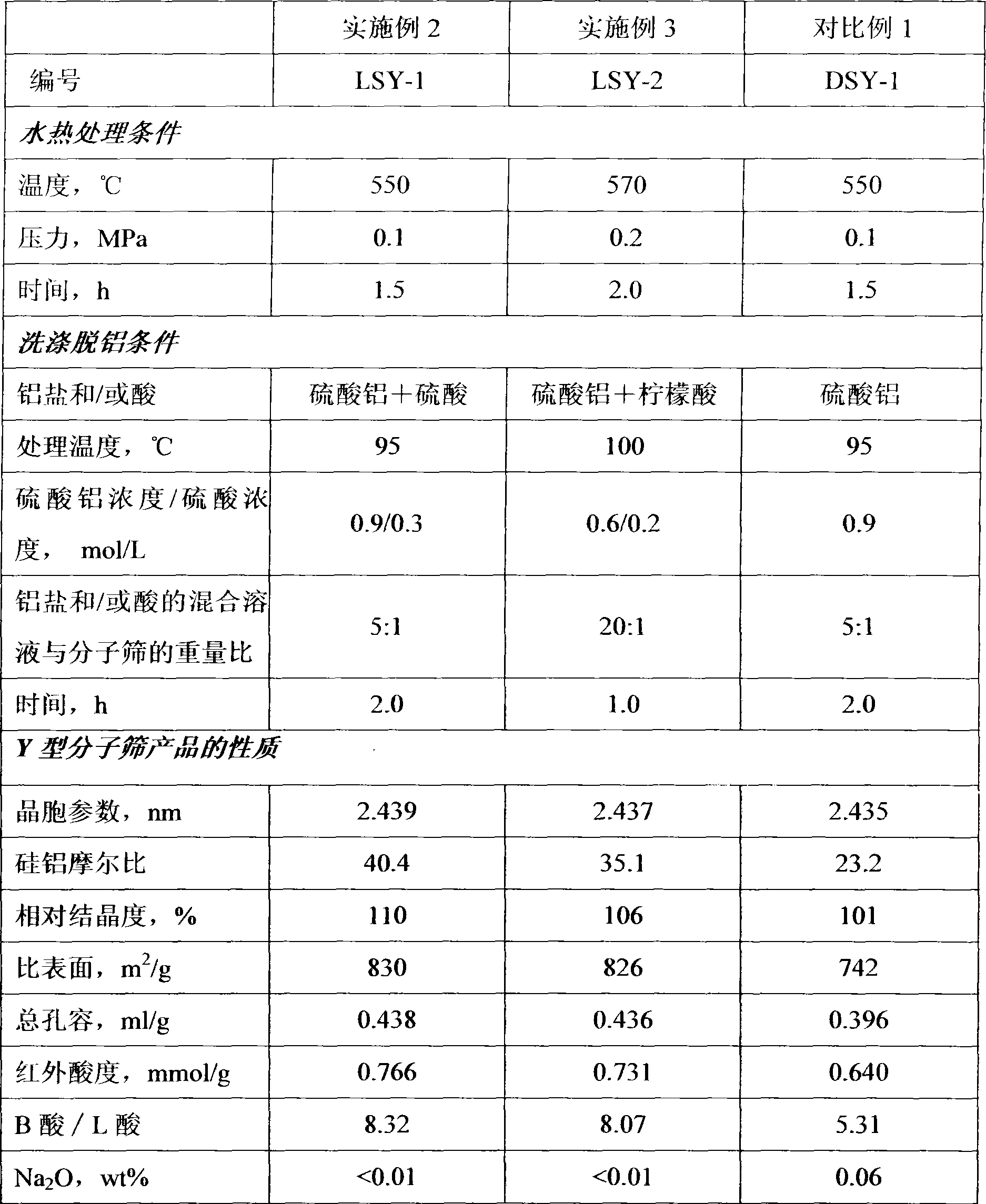

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Method for preparing cellulose composite aerogel

The invention belongs to the field of fine chemical materials, and more particularly relates to a method for preparing cellulose composite aerogel. The method is mainly characterized by taking a carbon material as a modifying agent, and comprises the following main processes of: firstly dissolving cellulose in a sodium hydroxide / thiourea aqueous solution, a sodium hydroxide / urea aqueous solution or other solvents to prepare a cellulose solution with a certain concentration, adding a carbon nanotube (CNT), graphene oxide (GOS), reduced graphene oxide (rGO) and other modifying agents, standing for carrying out gelation, carrying out solvent exchange on the obtained gel, and drying the composite gel to obtain the cellulose composite aerogel. The preparation technique provided by the invention has a simple process and convenience for operation, and can obviously shorten the time of forming the gel from the solution; and the prepared composite aerogel has higher compressive strength and modulus as well as good heat stability, and has wide application prospects in the biomedical, biological sensing and detecting and other fields.

Owner:FUDAN UNIV

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

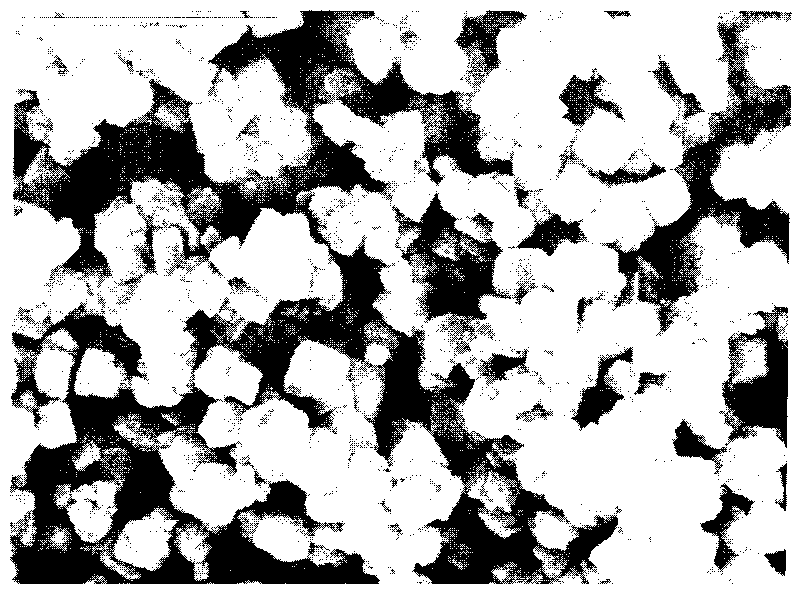

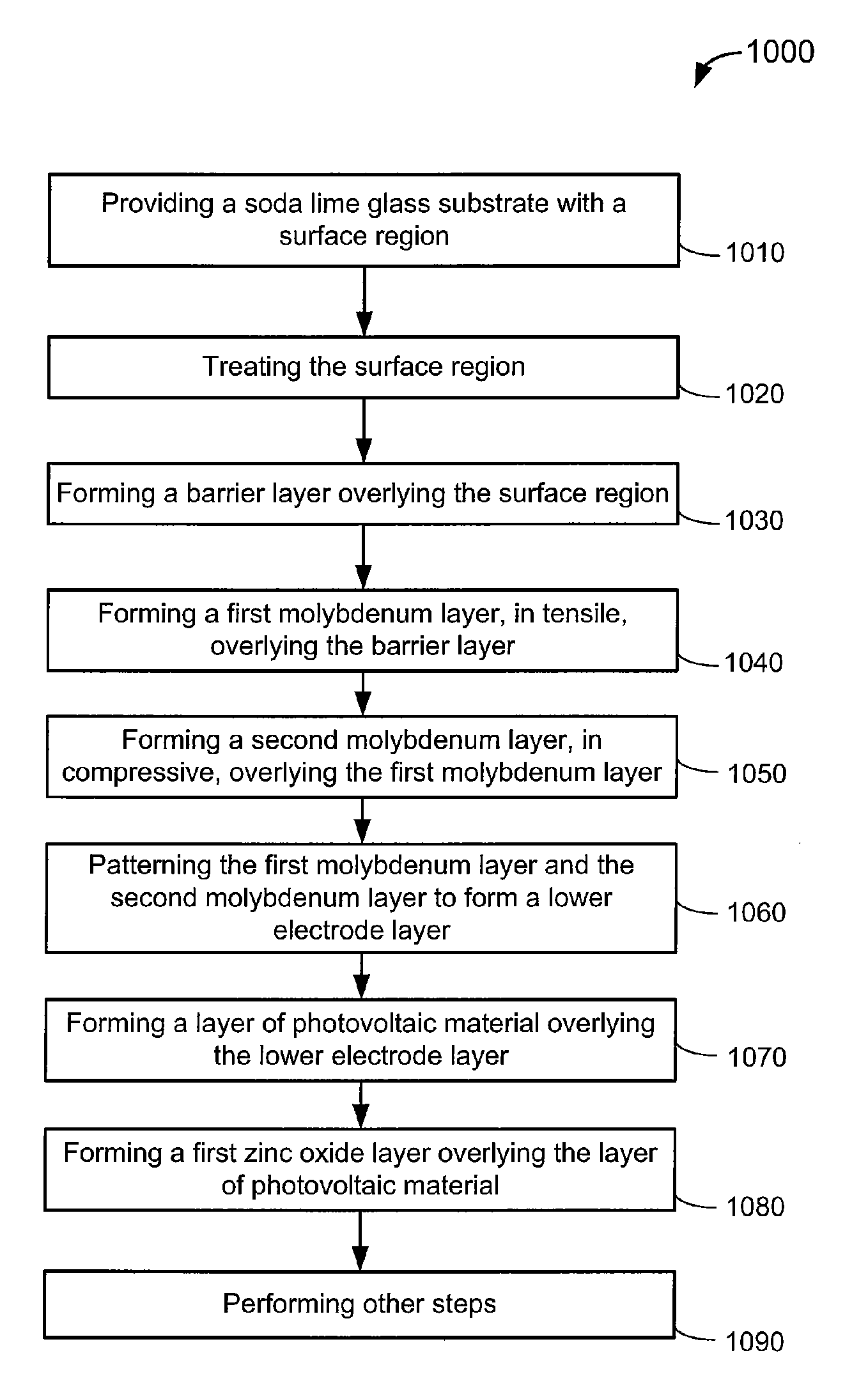

InactiveUS20100258179A1Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptoelectronicsSpecies barrier

A method for fabricating a thin film solar cell includes providing a soda lime glass substrate comprising a surface region and a concentration of sodium oxide of greater than about 10 wt % and treating the surface region with one or more cleaning process, using a deionized water rinse, to remove surface contaminants having a particles size of greater than three microns. The method also includes forming a barrier layer overlying the surface region, forming a first molybdenum layer in tensile configuration overlying the barrier layer, and forming a second molybdenum layer in compressive configuration using a second process overlying the first molybdenum layer. Additionally, the method includes patterning the first molybdenum layer and the second molybdenum layer to form a lower electrode layer and forming a layer of photovoltaic material overlying the lower electrode layer. Moreover, the method includes forming a first zinc oxide layer overlying the layer of photovoltaic materials.

Owner:CM MFG

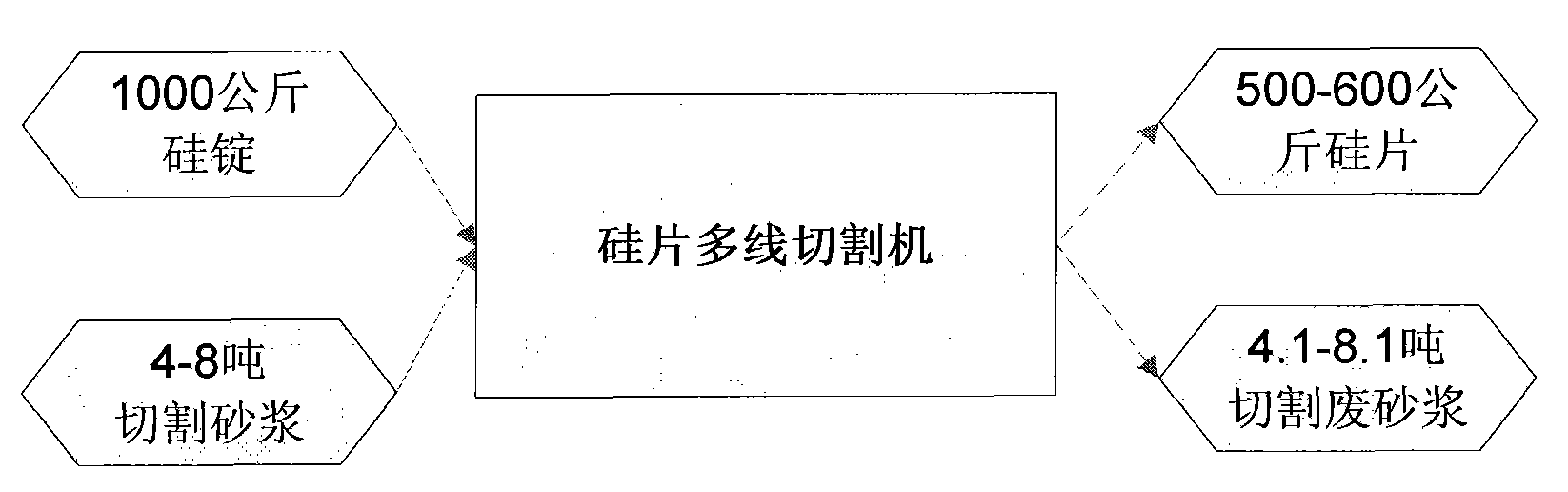

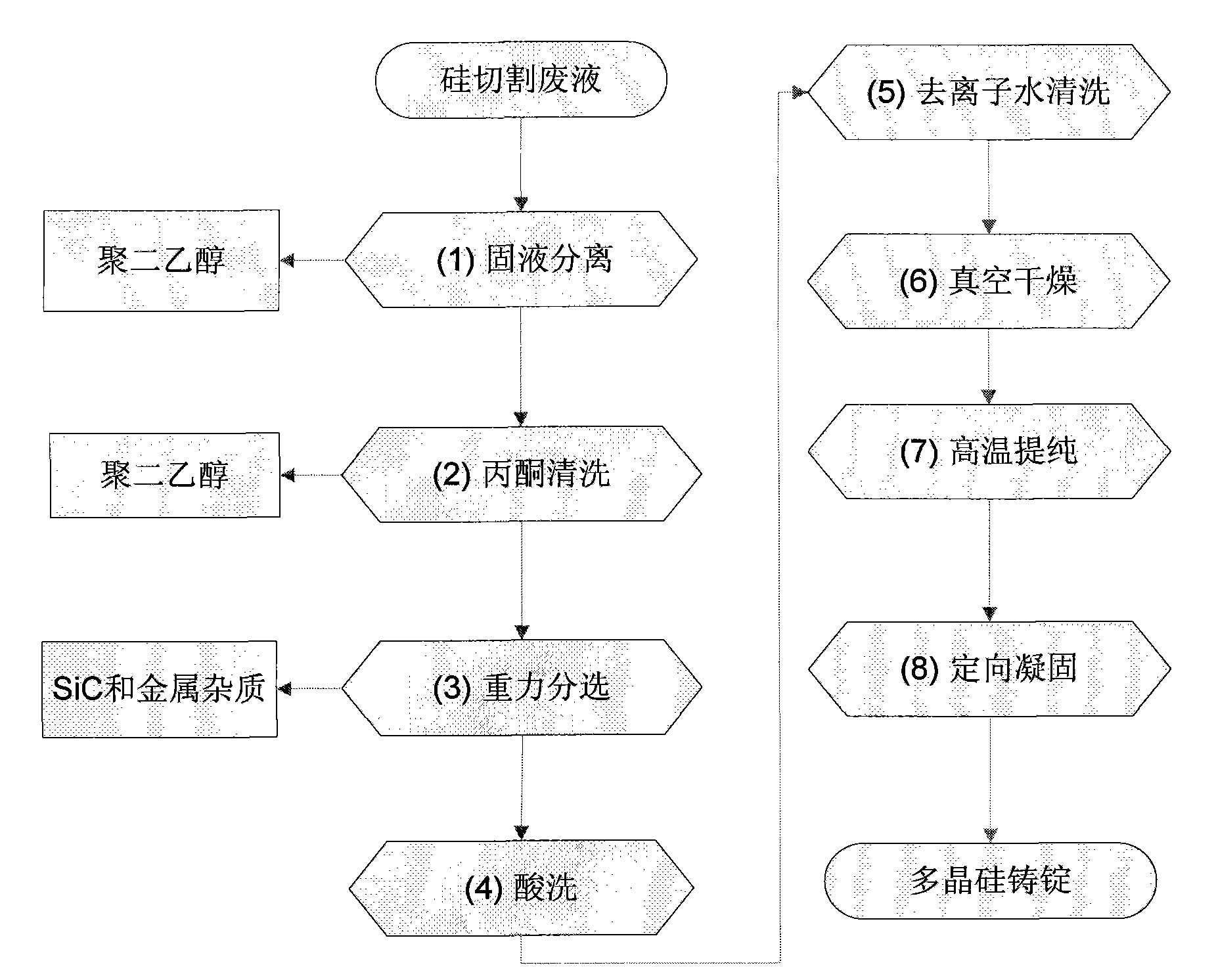

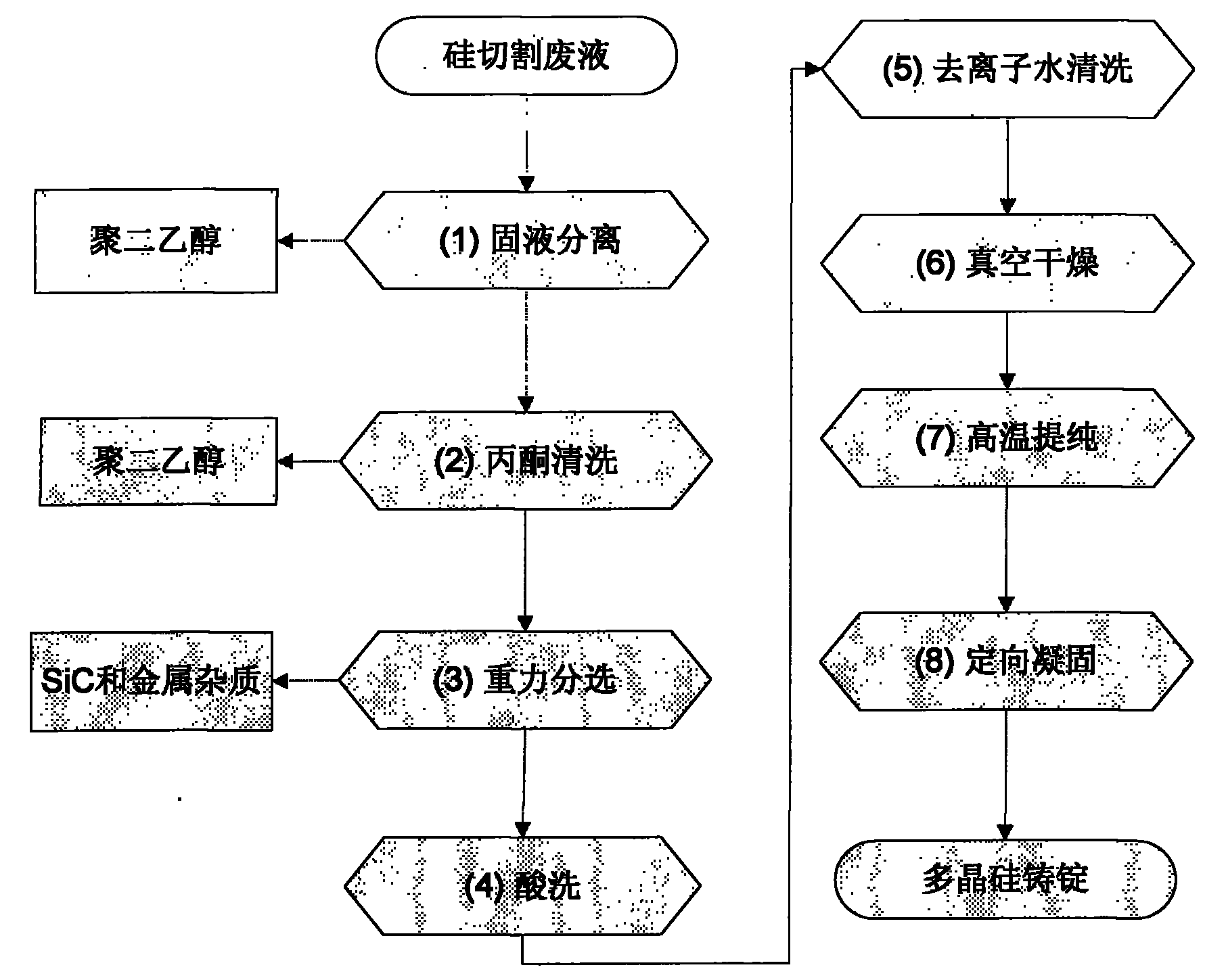

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Catalyst of catalyzing, cracking for reducing sulfur content in gasoline and preparation process thereof

InactiveCN1597850AGood dispersionGood hydrothermal stabilityCatalytic crackingMolecular sieveIn situ crystallization

The invention is a catalytic cracking catalyst to reduce sulfur content of gasoline and its preparing method, synthesis gama-type molecular sieve by kaoline in-situ crystallization and making exchange sodium reduction or / and rare-earth ion exchange processing to prepare it, and its characteristic: the weight percent of sodium oxide contained in it is less than 0.75%, the ratio of zeolite to silica-alumina is above 4.5, and it adds one or several of the sourish metal elements: Cu, Zn, Fe, Al, Ni, Zr, Sn, Ga, Ti and V in weight percent of 0.1-10%. It has good zeolite dispersivity and excellent hydrothermal stability, good catalytic cracking property, and excellent function of reducing sulfur content of gasoline. It can be used by mixing with routine FCC catalyst and also be singly applied in the catalytic cracking process course.

Owner:PETROCHINA CO LTD

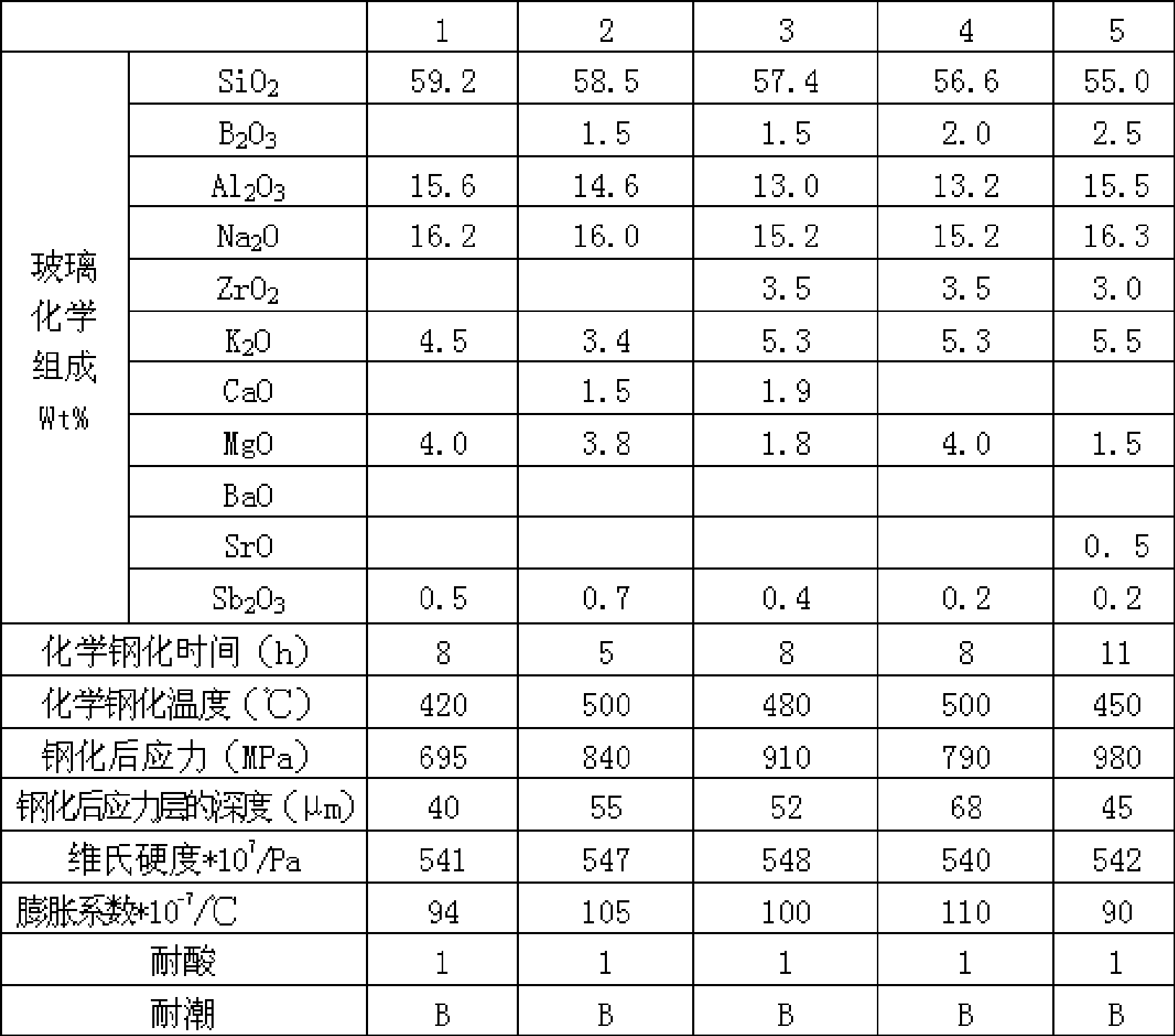

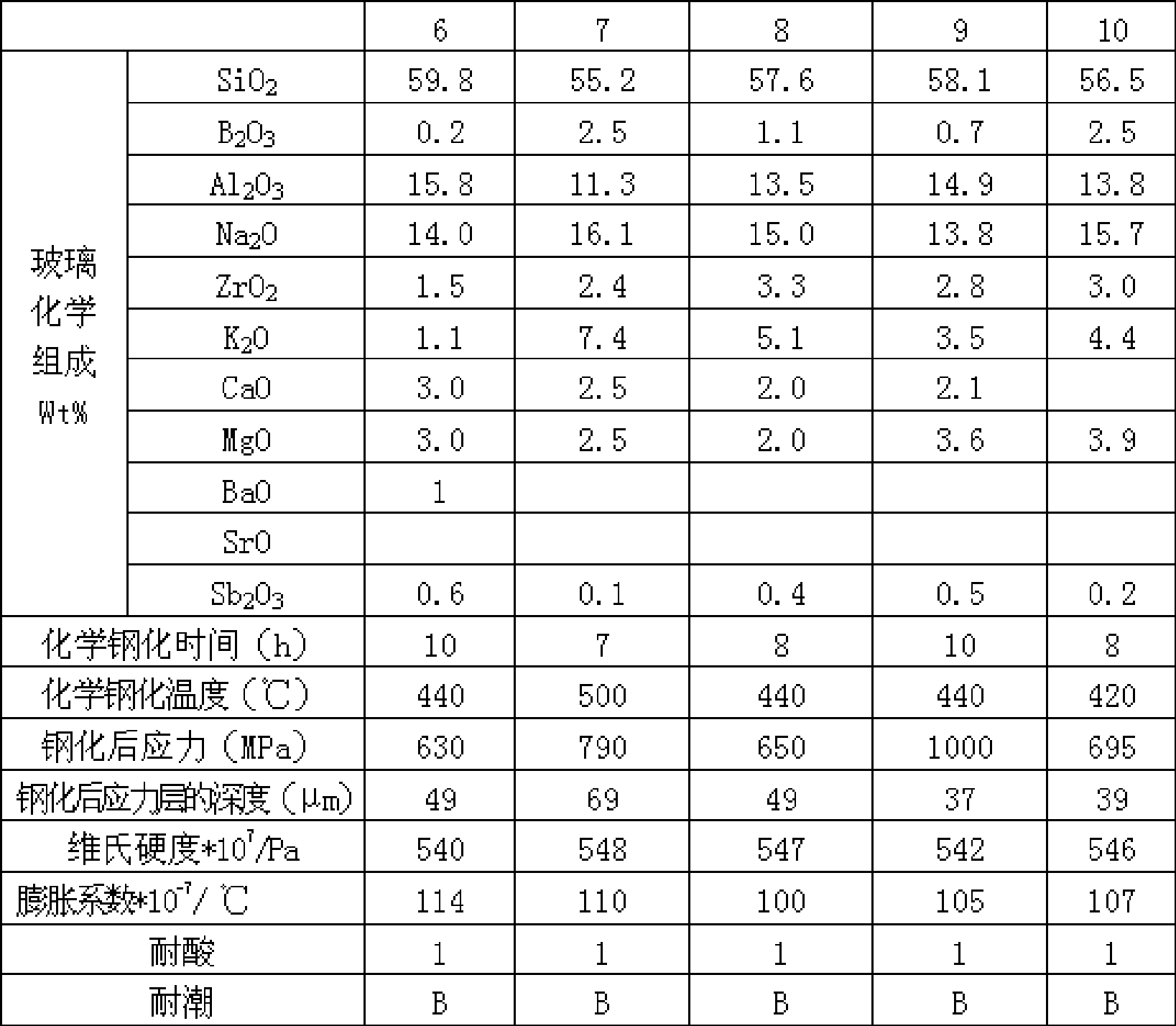

Glass suitable for chemically tempering and chemical tempered glass

ActiveCN101508524AReduce manufacturing difficultyLower melting temperatureGlass tempering apparatusThin material handlingProtective glassesIon exchange

The invention provides silica-alumina-sodium oxide glass which is suitable for a low-temperature ion exchange process and is easy to melt. The glass is suitable for chemical tempering, and comprises the following compositions in percentage by weight: 55 to 60 percent of SiO2, 0.1 to 2.5 percent of B2O3, 11 to 16 percent of Al2O3, 14 to 17 percent of Na2O, 1 to 8 percent of K2O, 0 to 8 percent of ZrO, 0 to 5 percent of CaO, 0 to 5 percent of MgO, and 0 to 1 percent of Sb2O3. The invention, by reasonably setting the compositions, reduces the manufacturing difficulty of the glass, obviously reduces the melting temperature of the glass, and is favorable for reducing energy consumption and improving the rate of finished products of products; and under the conditions that the tempering temperature of the glass is between 380 and 500 DEG C and the tempering time is between 4 and 12 hours, the surface compressive stress of the glass can reach between 610 and 1,100MPa, the depth of a stress layer can reach between 31 and 80 mu m, and the glass is strengthened and has good shock resistance. The glass has higher wear resistance, and is suitable for protective glass materials of high-grade electronic display products such as mobile phones, PDA and the like.

Owner:CDGM OPTICAL GLASS

Catalytic cracking co-catalyst for producing diesel oil and its preparing method

InactiveCN1683474AReasonable hole structureReasonable strengthCatalytic crackingIn situ crystallizationSodium oxide

The catalytic cracking co-catalyst for increasing diesel oil yield is prepared through roasting kaolin at over 900 deg.c for in-situ crystallization. The co-catalyst contains type-Y zeolite in 5-20 wt%, as well as magnesia 0.5-3 wt%, RE oxide 0.5-5 wt%, and sodium oxide less than 0.6 wt%, and the zeolite has Si / Al ratio of 4.0-6.0. Adding certain amount of the catalytic cracking co-catalyst without altering the main catalyst in the oil refining apparatus can raise diesel oil yield of FCC catalyzed apparatus, improve product distribution, raise available catalyst utilization, and improve the activity stability of the catalyst system and heavy metal resistance.

Owner:PETROCHINA CO LTD

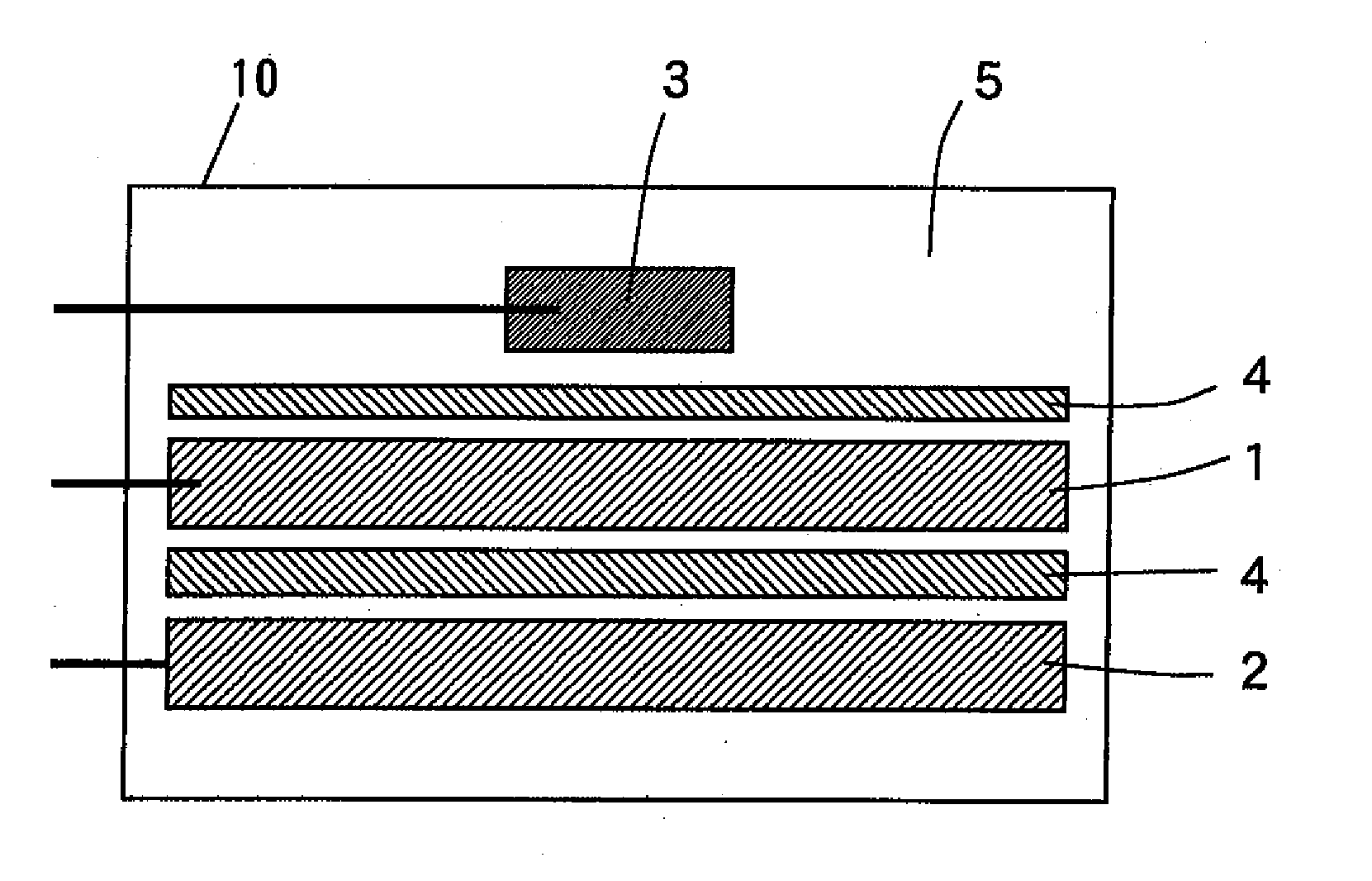

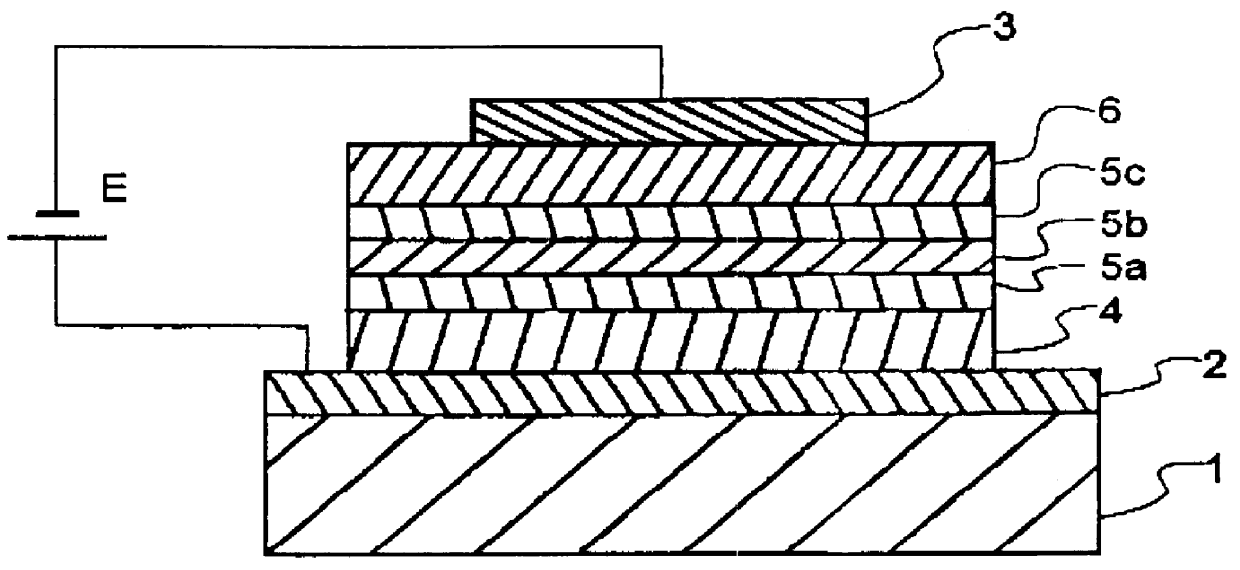

Organic electroluminescent device having a conjugated polymer and an inorganic insulative electron injecting and transporting layer

InactiveUS6404126B1Improve efficiencyLong lastingDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An organic electroluminescent device having high efficiency, a long life time, and low cost, includes a substrate, a hole injecting electrode and an electron injecting electrode formed on the substrate, an organic material-containing organic layer between the electrodes, and an inorganic insulative electron injecting and transporting layer between the light emitting layer and the electron injecting electrode. The organic layer includes a light emitting layer containing a conjugated polymer, and the inorganic insulative electron injecting and transporting layer comprises three components. The first component is at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, and cesium oxide. The second component is at least one of strontium oxide, magnesium oxide, and calcium oxide. The third component consists of silicon oxide, germanium oxide, or mixtures thereof.

Owner:TDK CORPARATION

Preferred materials for pigmented ink jet ink

InactiveUS6866379B2Measurement apparatus componentsDuplicating/marking methodsAddition polymerLithium hydroxide

An ink jet ink composition including from 40.0 to 99.0% by weight of water; from 0.1 to 20.0% by weight of a pigment dispersed with an oleoyl methyl taurine salt dispersant from 0 to 70.0% by weight of a water miscible co-solvent; and from 0.1 to 20.0% by weight of a water-reducible addition polymer; wherein the weight average molecular weight of the polymer is from 2,000 to 100,000; the acid number is from 50 to 400; and the acid group on the polymer is neutralized by an alkaline metal hydroxide such as lithium hydroxide, sodium hydroxide potassium hydroxide, or a mixture thereof; and wherein all weight percentages are based on the total weight of the ink composition. An ink jet printing method is also disclosed.

Owner:EASTMAN KODAK CO

Method for preparing activated carbon material with humic acid as raw material and application of activated carbon material

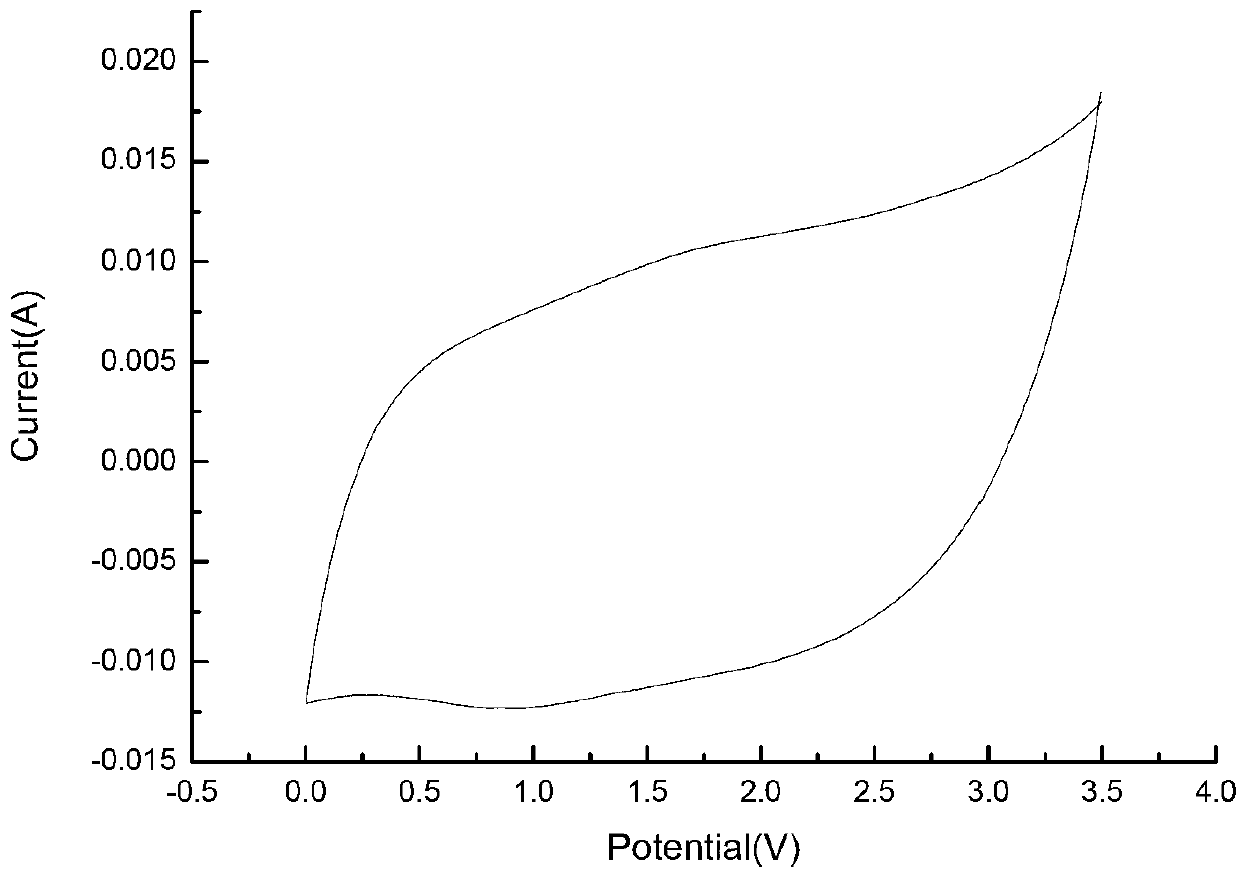

InactiveCN103641117ALarge reservesLarge specific surface areaCarbon compoundsOther chemical processesCapacitancePotassium hydroxide

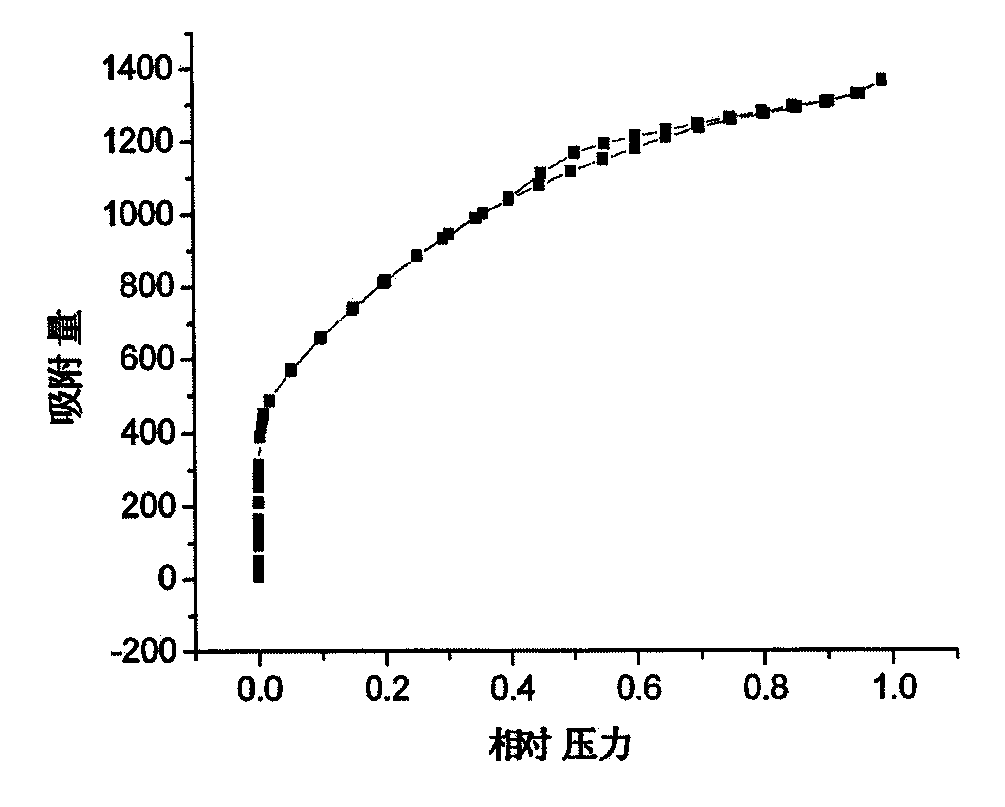

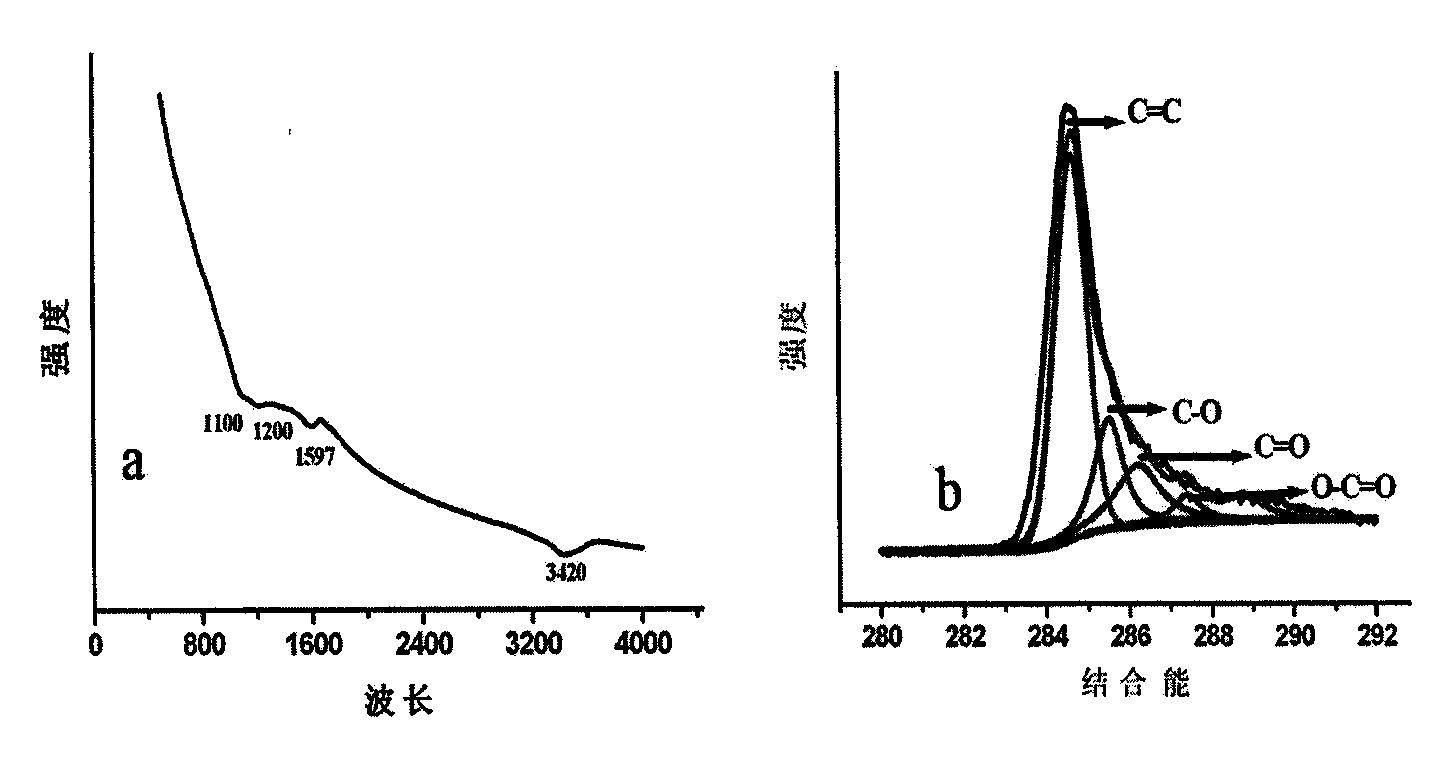

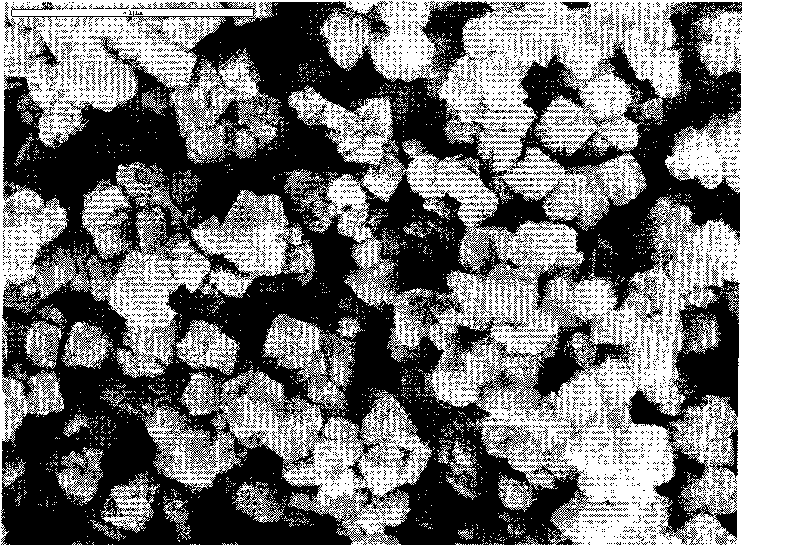

The invention relates to a method for preparing activated carbon with humic acid as a raw material and an application of the activated carbon. The method comprises the steps of mixing industrial humic acid with an activating agent which is potassium hydroxide, sodium hydroxide, zinc chloride, potassium carbonate or phosphoric acid uniformly to react under inert atmosphere protection for 1-5 hours; then cooling the product, washing the product in an acid solution until the pH value is 6-7 and drying the product, thus obtaining the activated carbon. The method is convenient to operate, is relatively low in energy consumption and is suitable for large-scale industrial production. The humic acid porous activated carbon material obtained by the method has a rich porous structure and a relatively big specific surface area, is used for preparing water purifiers or electrode materials of supercapacitors, and has methylene blue dye adsorption value of 600mg / g. Besides, the humic acid porous activated carbon material is used as the electrode material of a supercapacitor to assemble a high-performance supercapacitor. The specific capacitance of the activated carbon single electrode is 351Fg<-1>. Various test results show that the activated carbon is microporous-mesoporous composite carbon and has specific surface area of about 3200m<2> / g, the pore size distribution of the activated carbon is 1-5nm, and the pore volume of the activated carbon is about 2cm<3> / g.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

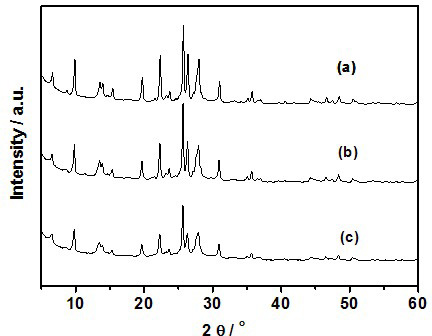

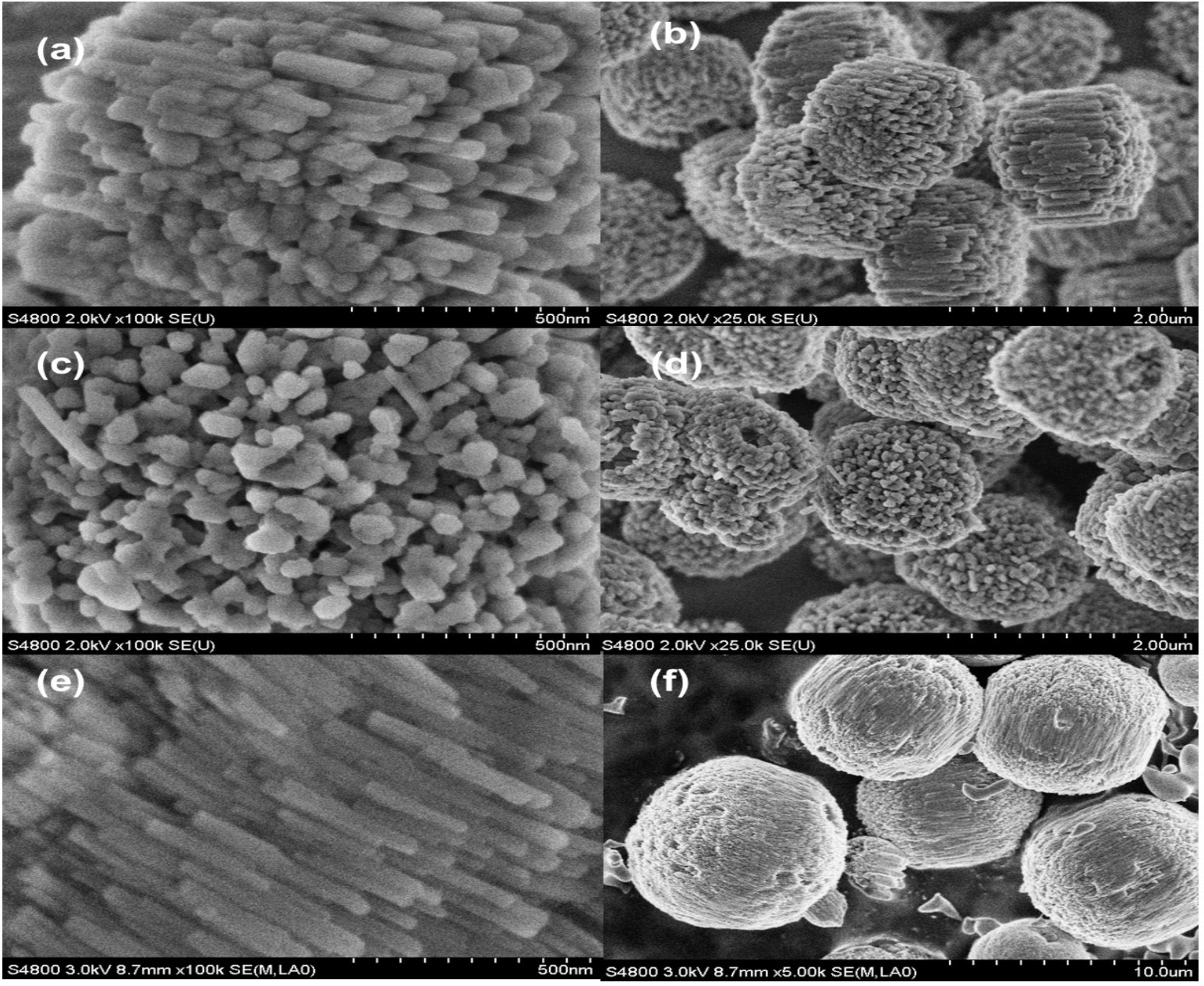

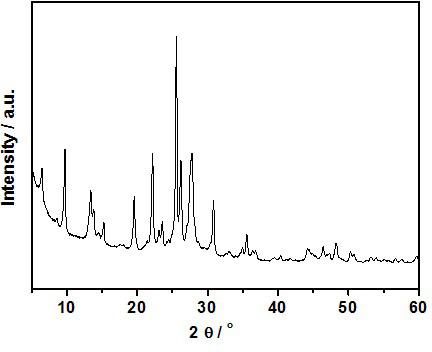

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

InactiveUS8217261B2Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationBarrier methodWater rinsing

Owner:CM MFG

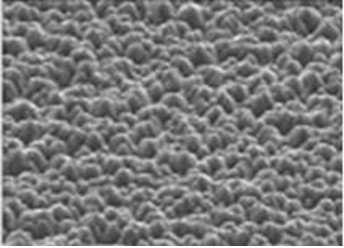

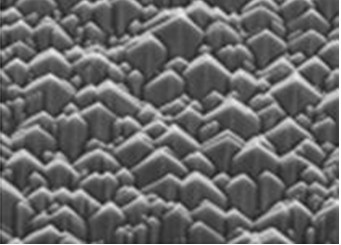

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

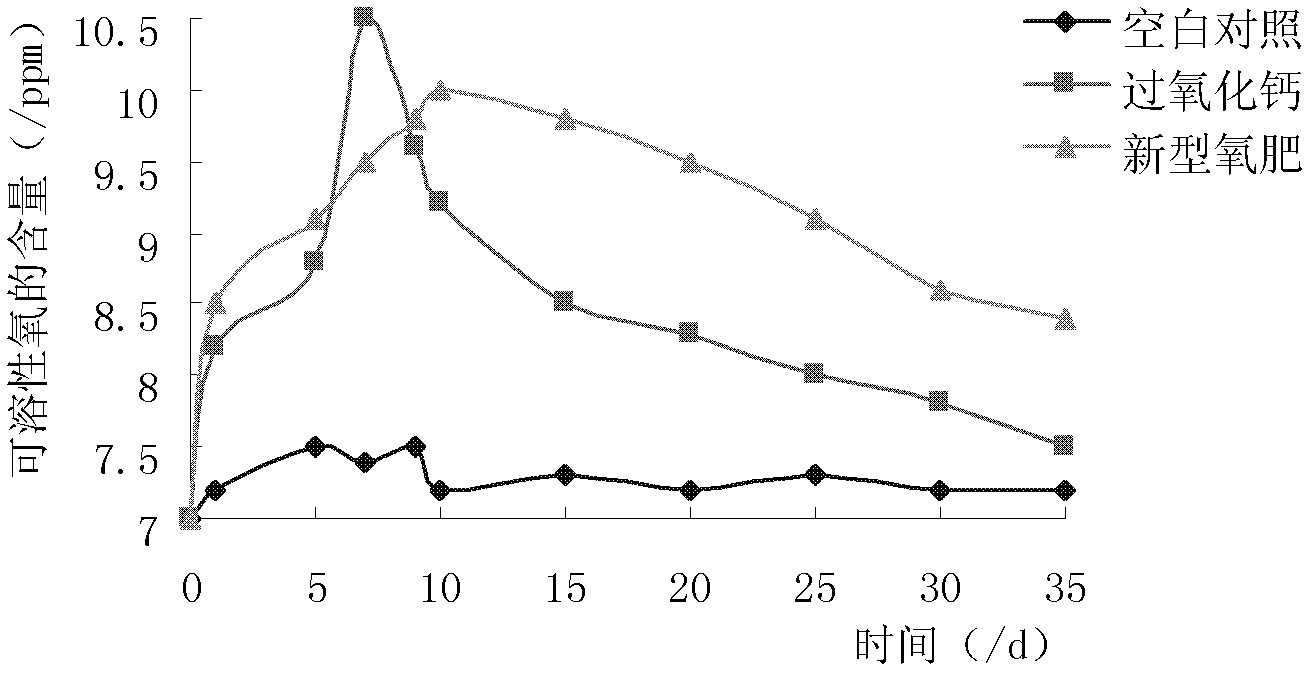

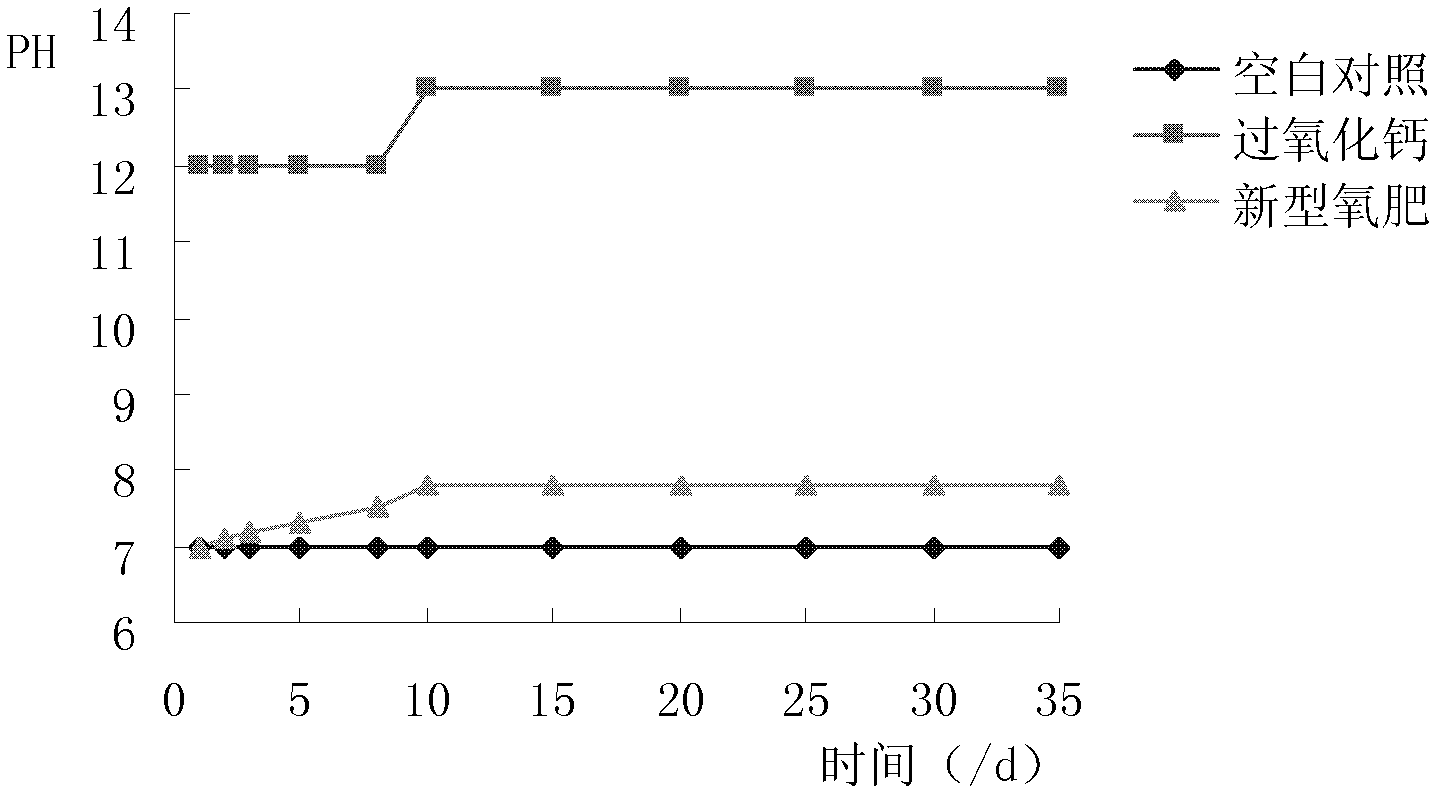

Oxygen fertilizer and preparation and application methods thereof

InactiveCN102584466ALift deathReduce economic costsFertilizer mixturesOxygen preparationSodium oxideChemistry

The invention discloses a novel oxygen fertilizer and preparation and application methods of the oxygen fertilizer. Mixtures of one or more of calcium peroxide, sodium peroxide and magnesium peroxide act as a core; nano chitosan doped with sodium alginate as the binding agent serves as a wrapping membrane; and the outer layer of the wrapping membrane is further wrapped by paraffin as a conditioner, so that a slow-release oxygen fertilizer is prepared. The oxygen fertilizer contains 70-75% of the core by weight, 20-25% of the wrapping membrane by weight, and 3-10% of the conditioner by weight and the particle diameter of the oxygen fertilizer particles is 3-10mm. The novel oxygen fertilizer prepared by the preparation method disclosed by the invention can supply oxygen to waterlogged plants for a long time and is convenient and simple to apply, simple in production process and environment-friendly, and saves time and labor and can be used widely.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method for mordenite with high Si/Al ratio and small crystal particle

ActiveCN102602957ANovel Crystal MorphologyIncrease surface areaNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsFiltration

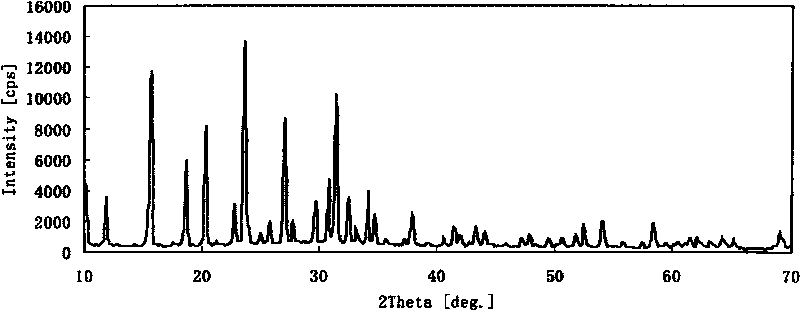

The invention discloses a preparation method for mordenite with a high Si / Al ratio and a small crystal particle, which comprises the following steps of: firstly, dissolving an Al source in sodium oxide solution; after an Si source is added, stirring and dispersing for certain time at room temperature and under strong magnetic force; mixing the Al source solution and the Si source solution which are evenly dispersed into glue at the room temperature; adding inorganic lamellar precursors, such as lamellar zeolite molecular sieves, lamellar silicate and the like to serve as seed crystal; after mixture is stirred and mixed evenly at the room temperature and under the strong magnetic force, transferring into a reaction crystallization kettle; at the temperature of 150-170DEG C, carrying out crystallization reaction for 0.5-3 days; and obtaining a solid product after common suction filtration, washing and drying. The synthesis method disclosed by the invention has the characteristics that expensive organic amine template is not used as structure-directing agent, and instead, the easily-obtained inorganic lamellar precursors with abundant source and low price are used as the seed crystal to directly synthesize a mordenite molecular sieve with the high Si / Al ratio. The prepared nanometer mordenite molecular sieve has the advantages of high degree of crystallinity and purity, controllable particle size and morphology, low cost and small environment pollution, and is convenient for industrially producing on a large scale.

Owner:EAST CHINA NORMAL UNIV

High-toughness enamel glaze

InactiveCN108658462AImprove toughnessOvercome the defect of porcelain crackLithium oxideSilicon dioxide

The invention discloses high-toughness enamel glaze. The enamel glaze is prepared from the following components in parts by weight: 40-50 parts of silicon dioxide, 15-25 parts of titanium dioxide, 5-15 parts of potassium oxide, 10-20 parts of sodium oxide, 1-5 parts of lithium oxide, 2-4 parts of calcium fluoride, 6-12 parts of vanadium pentoxide, 1-3 parts of tungsten carbide and 5-10 parts of aluminum oxide and zirconium dioxide. According to the enamel glaze, by means of the composition, the toughness of the enamel glaze can be greatly improved, meanwhile, the defect that ceramic cracks arecaused due to collision can be overcome, and therefore, the enamel glaze has a wide application prospect.

Owner:沙冰娟

Hollow glass microballoons and production method thereof

InactiveCN101638295AGood chemical stabilityIncrease Young's modulusGlass shaping apparatusSilicon dioxideQuenching

The invention relates to hollow glass microballoons and a production method thereof. The hollow glass microballoons are characterized by comprising the following raw materials in portion by weight: 75to 80 portions of silicon dioxide, 7 to 15 portions of boron oxide, 1 to 4 portions of aluminium oxide, 0.5 to 1.5 portions of calcium oxide, 0.8 to 1.2 portions of magnesium oxide, 5 to 6 portions of sodium oxide, 0.0 to 0.3 portion of sulfur trioxide and 0 to 0.05 portion of ferric oxide. The production method of the hollow glass microballoons comprises the following steps: compounding, melting, water quenching, drying, crushing, grading, hollow balling, collection and air separation, and is characterized in that the hollow balling comprises the following steps: ejecting a glass raw material, gas and combustion-supporting gas upwards from the bottom of a balling furnace for combustion, and cooling the glass microballoons upwards by a cooling device after melting under the action of a draft fan. The hollow glass microballoons have the advantages of good surface tension, high compression strength and chemical stability. The production method can better ensure material balling, and hassimple process, less equipment and good effect as much as possible.

Owner:CHINA TRIUMPH INT ENG +1

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

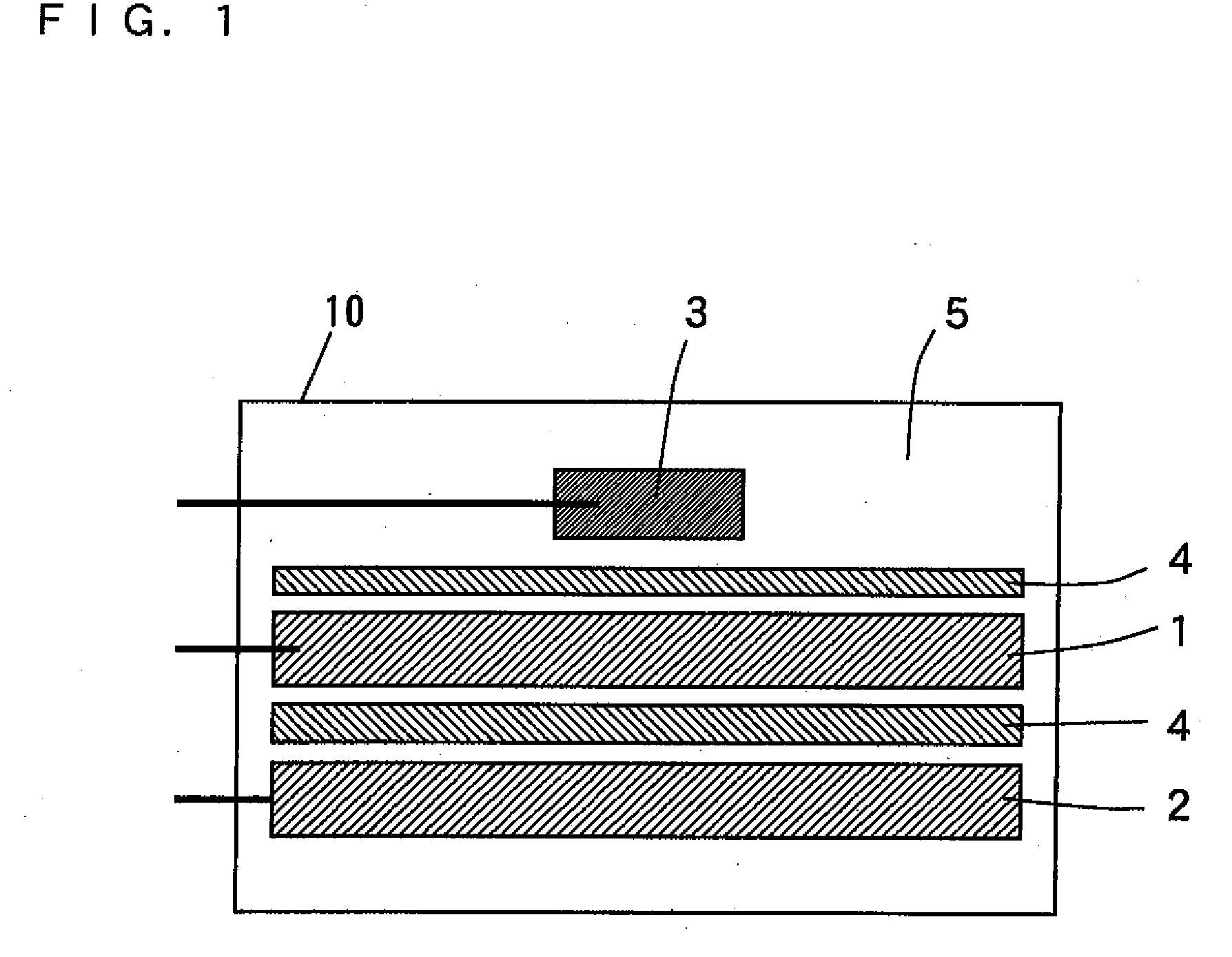

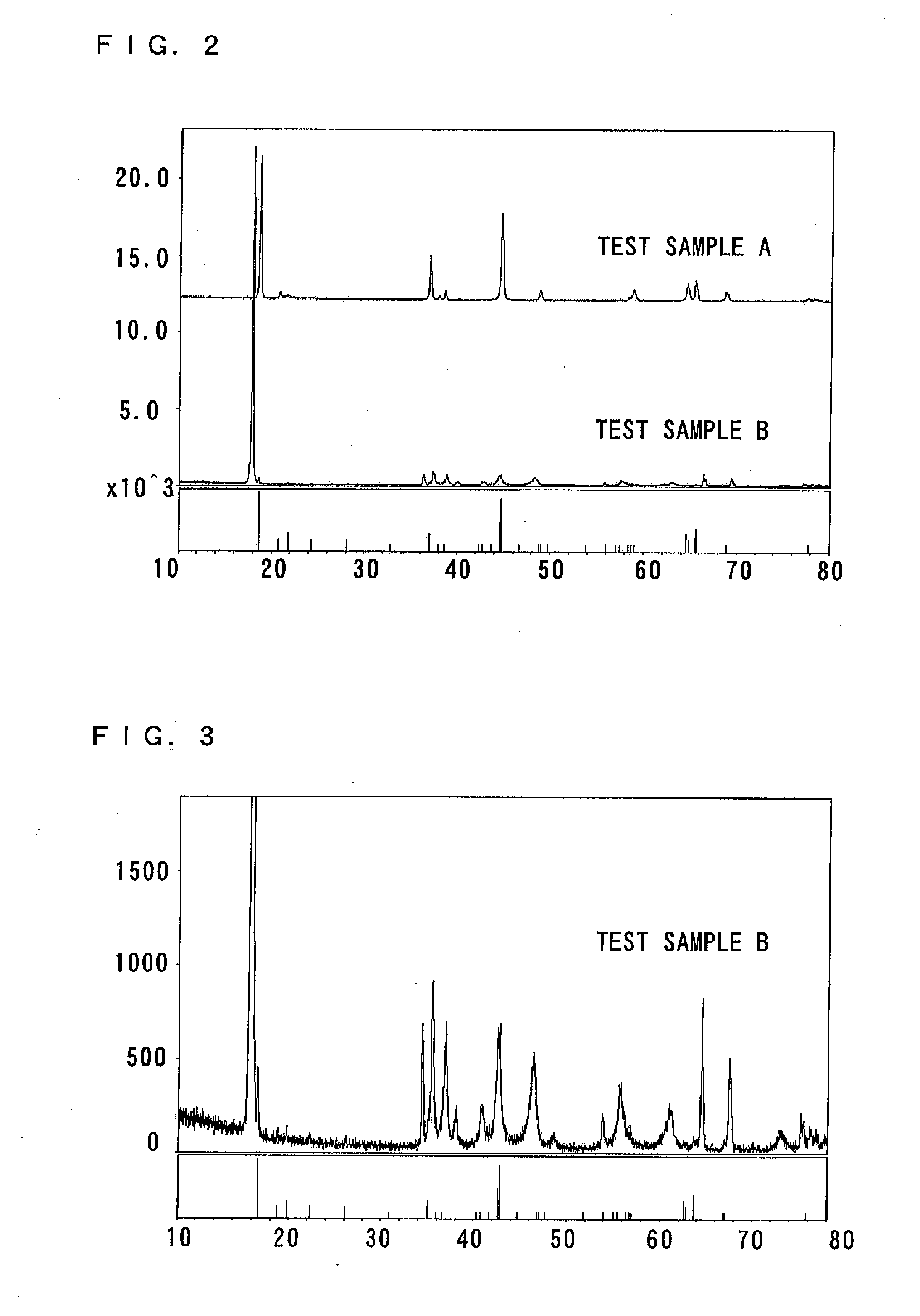

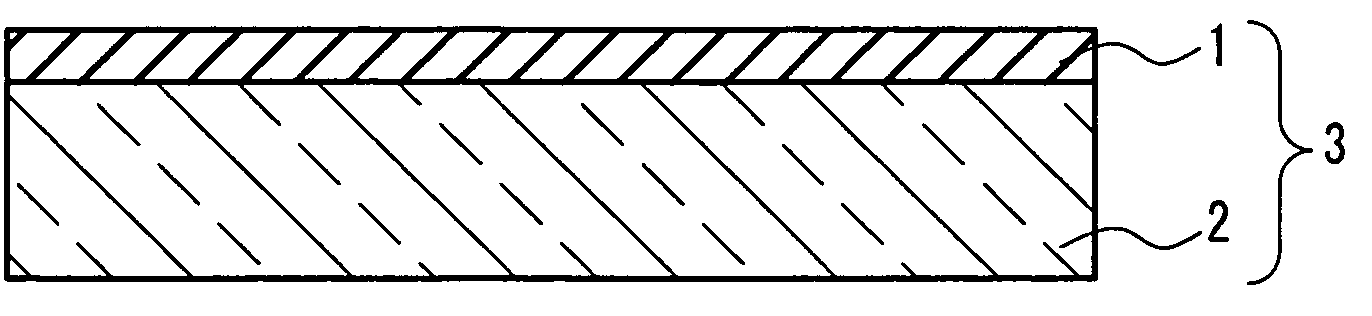

Nonaqueous electrolyte secondary battery and method of manufacturing the same

ActiveUS20100104944A1Large capacityCharge-discharge efficiency can be improvedElectrode manufacturing processesFinal product manufactureLithium metalIon exchange

A mixed positive electrode active material is used. The mixed positive electrode active material is obtained by mixing a layered oxide whose initial charge-discharge efficiency when lithium metal is used for a counter electrode is less than 100% (hereinafter referred to as a first layered oxide) and a layered oxide whose initial charge-discharge efficiency is 100% or more (hereinafter referred to as a second layered oxide). Examples of the first layered oxide include Li1+aMnxCoyNizO2. A sodium oxide such as LiANaBMnXCoYNiZO2 other than a layered compound from which lithium is previously extracted by acid treatment or the like can be used as the second layered oxide whose initial charge-discharge efficiency is 100% or more. A layered oxide obtained by replacing (ion exchange) sodium in the foregoing LiANaBMnXCoYNiZO2 with lithium can be also used as the second layered oxide.

Owner:SANYO ELECTRIC CO LTD

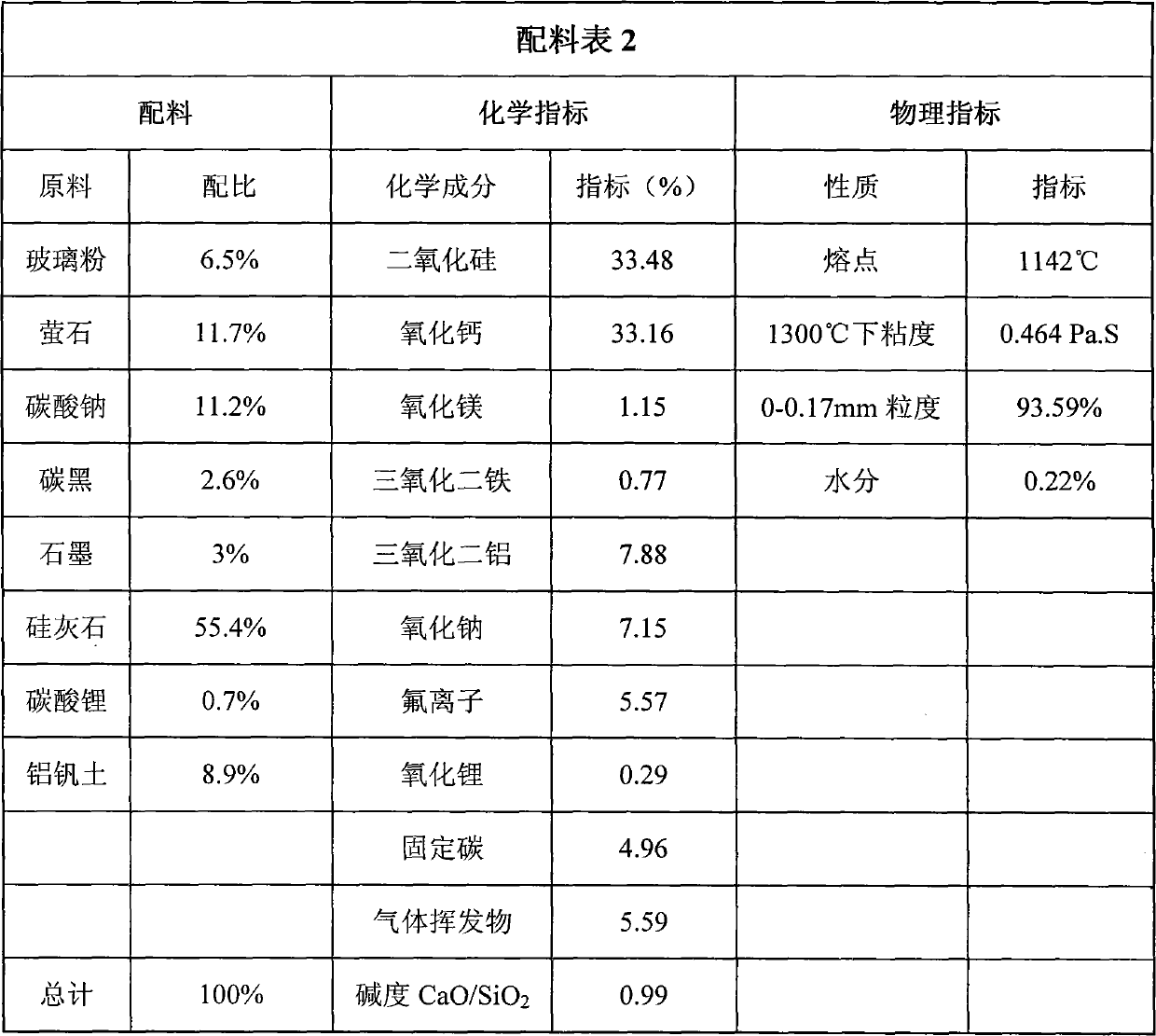

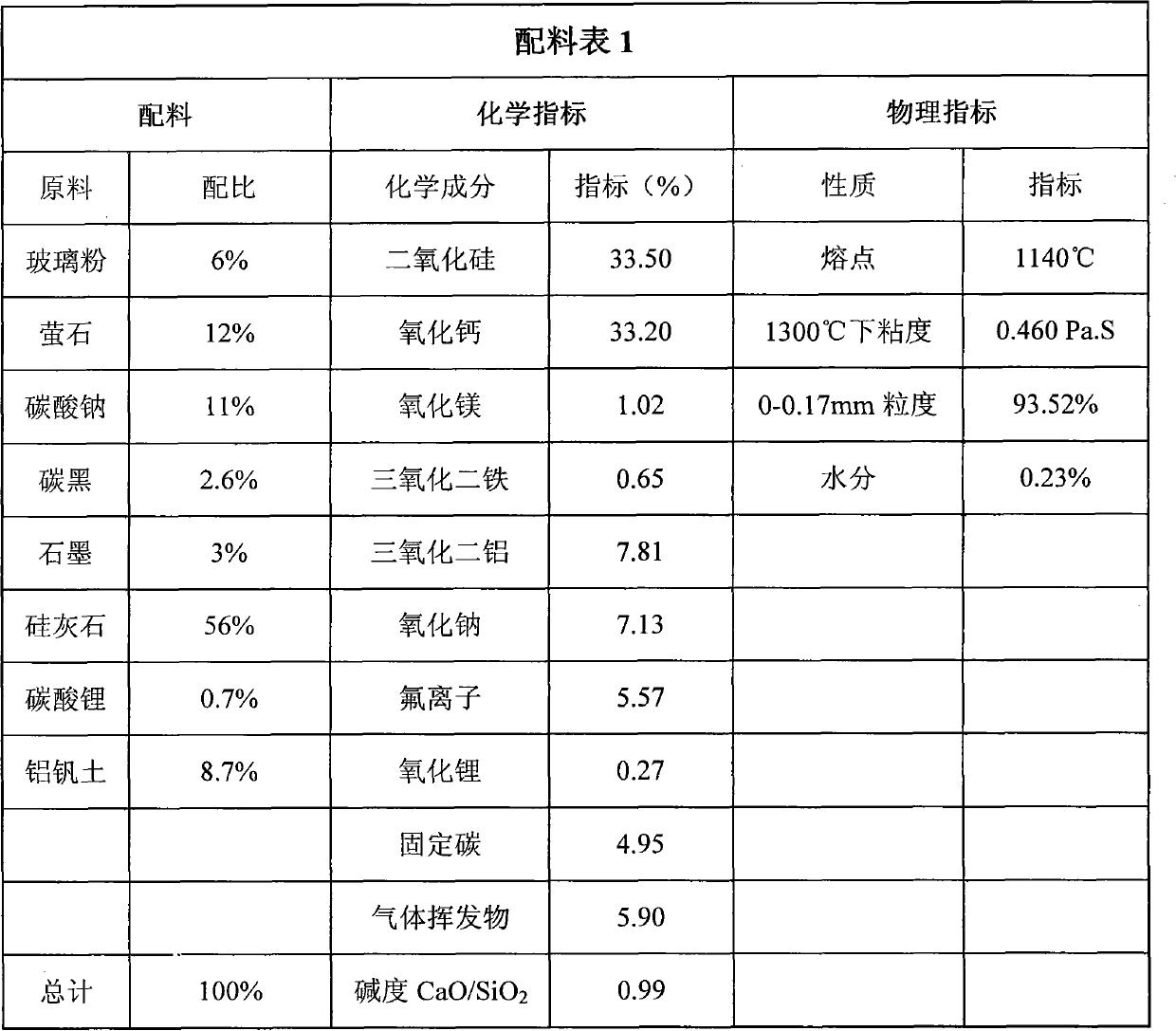

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

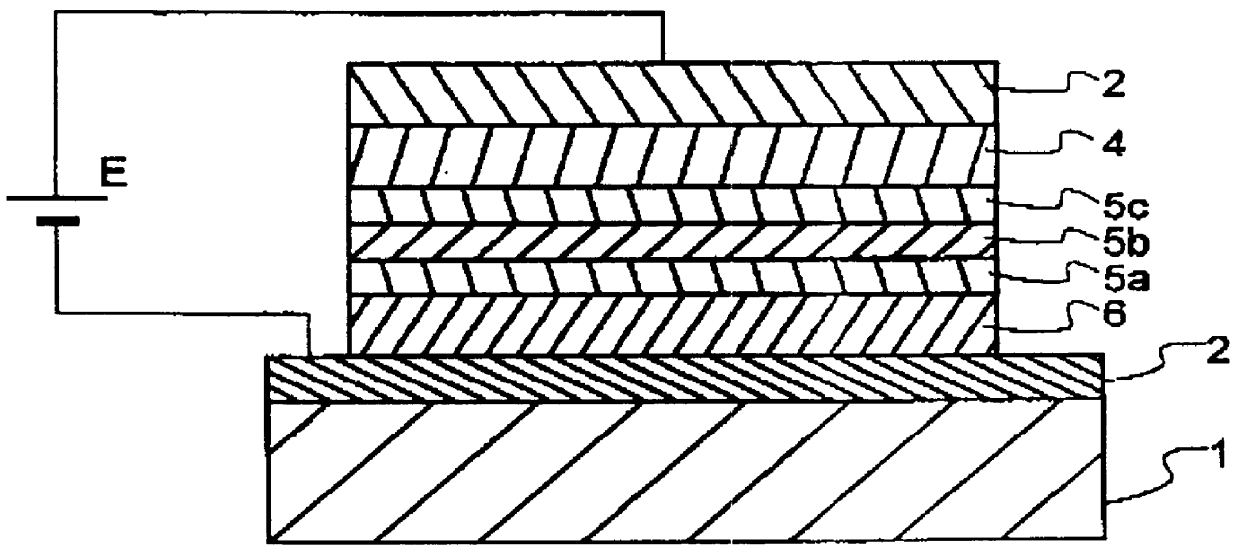

Organic electroluminescent device

InactiveUS6166488AImprove stabilityProlong lifeDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which is resistant to a deterioration of an inorganic-organic interface, has performance equivalent or superior to that of a prior art device comprising hole and electron injecting and transporting layers using an organic substance, possesses an extended life, weather resistance and high stability, and is inexpensive. This object is accomplished by the provision of an organic EL device which comprises a substrate, a hole injecting electrode and a cathode formed on the substrate, and an organic substance-containing light emitting layer located at least between these electrodes, wherein an inorganic insulating electron injecting and transporting layer is located between the light emitting layer and the cathode, and an inorganic insulating hole injecting and transporting layer is located between the light emitting layer and the hole injecting electrode. The inorganic insulating electron injecting and transporting layer comprises as a main component one or two or more oxides selected from the group consisting of strontium oxide, magnesium oxide, calcium oxide, lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, and the inorganic insulating hole injecting and transporting layer comprises as a main component an oxide of silicon and / or an oxide of germanium. The main component has an average composition represented by (Si1-xGex) Oy where 0< / =x< / =1, and 1.7< / =y< / =1.99. The light emitting layer comprises a layer made up of a host substance on a side thereof contiguous to the inorganic insulating electron injecting and transporting layer and / or the inorganic insulating hole injecting and transporting layer. A layer containing a dopant in addition to the host substance is located on the side of the light emitting layer that faces away from the layer made up of the host substance or between them.

Owner:TDK CORPARATION

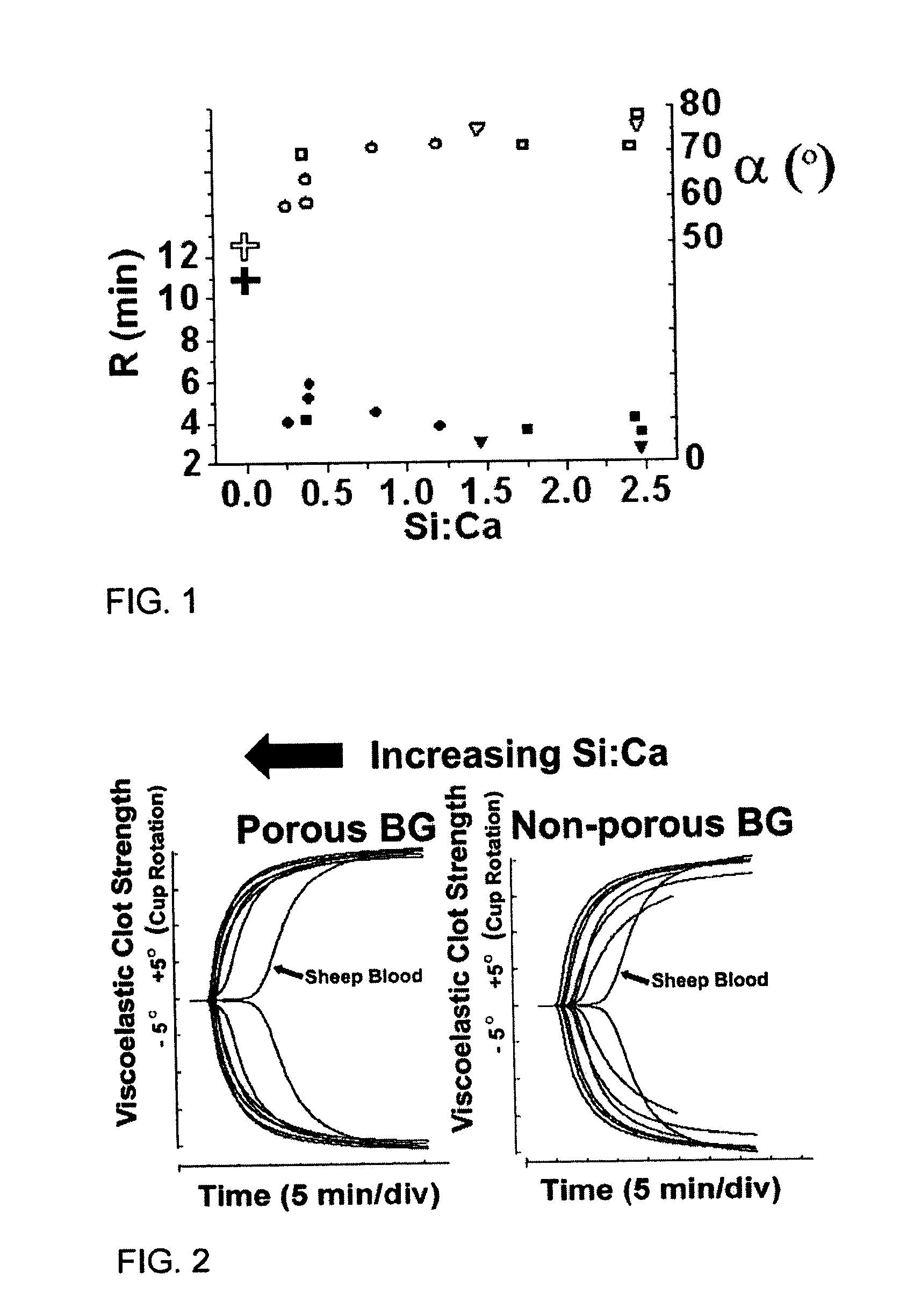

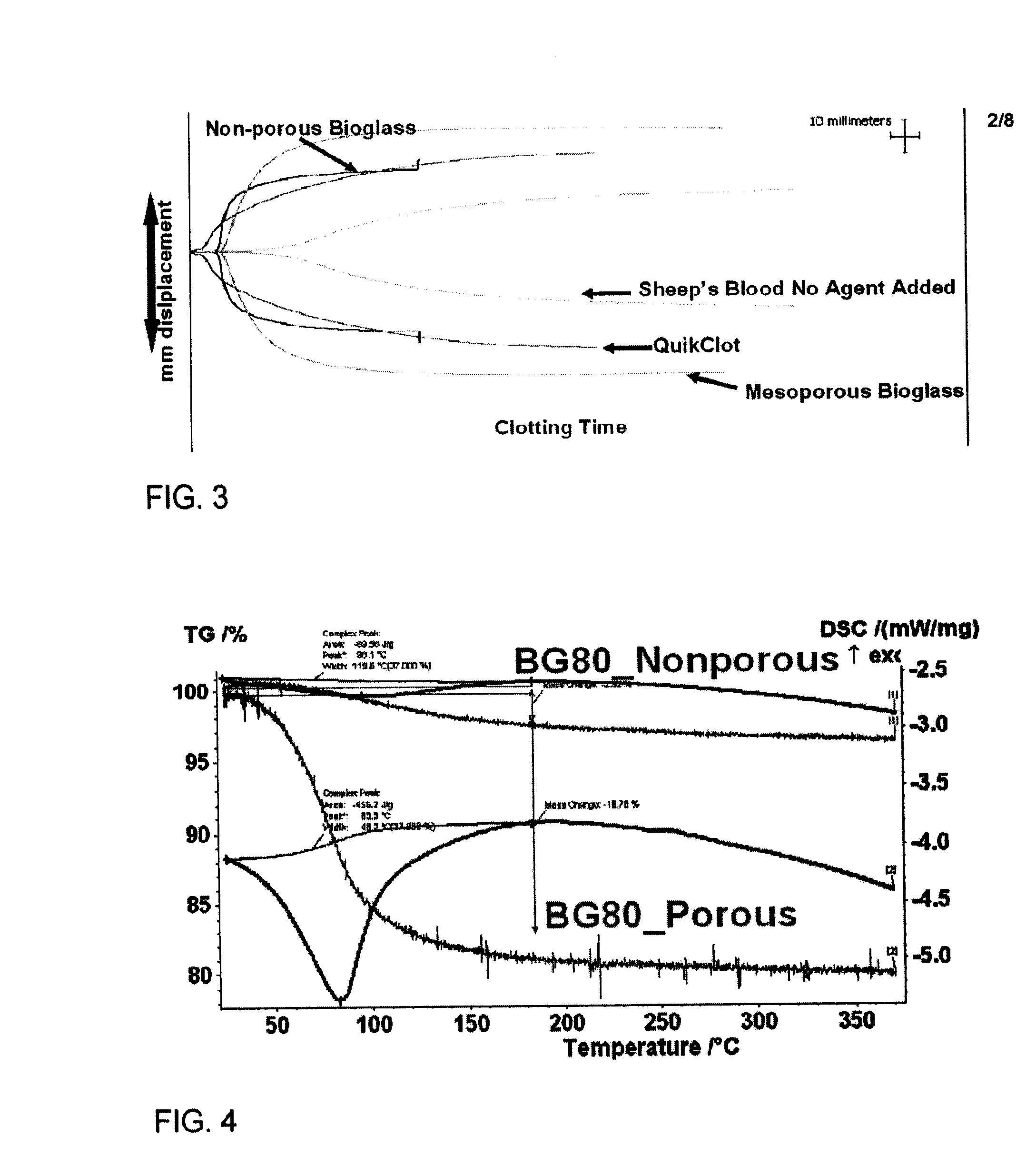

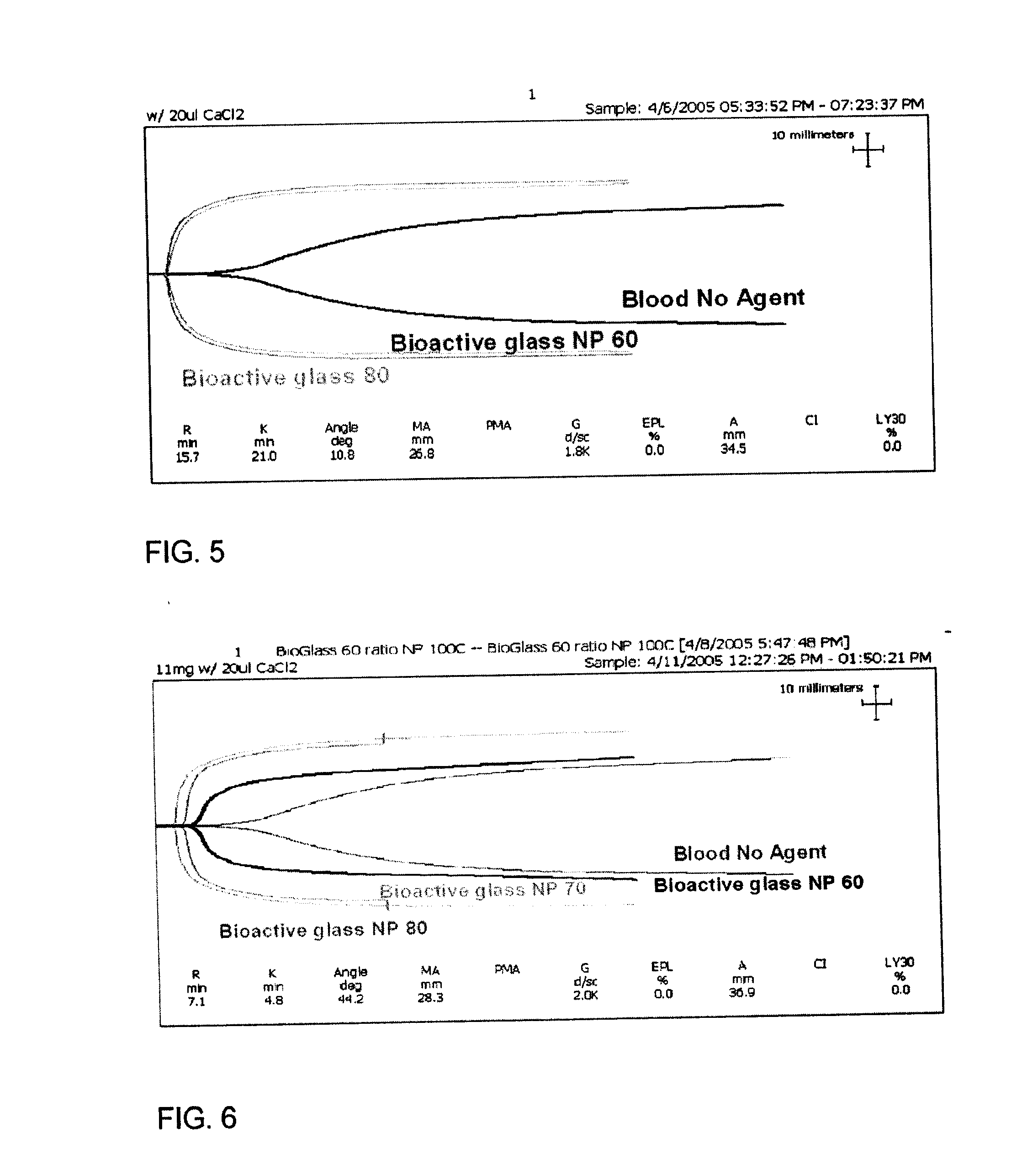

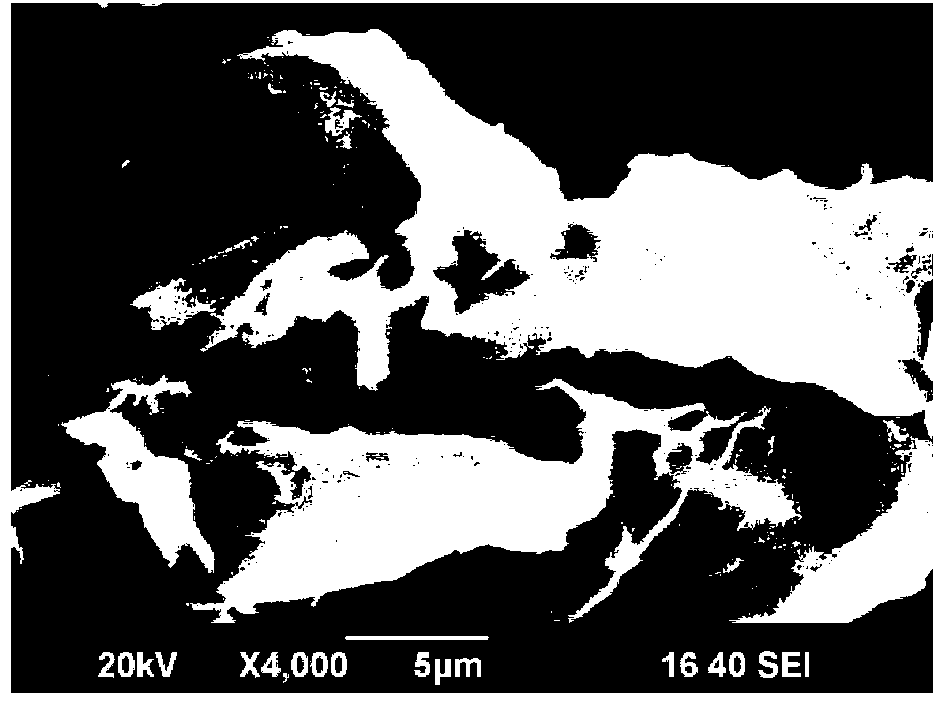

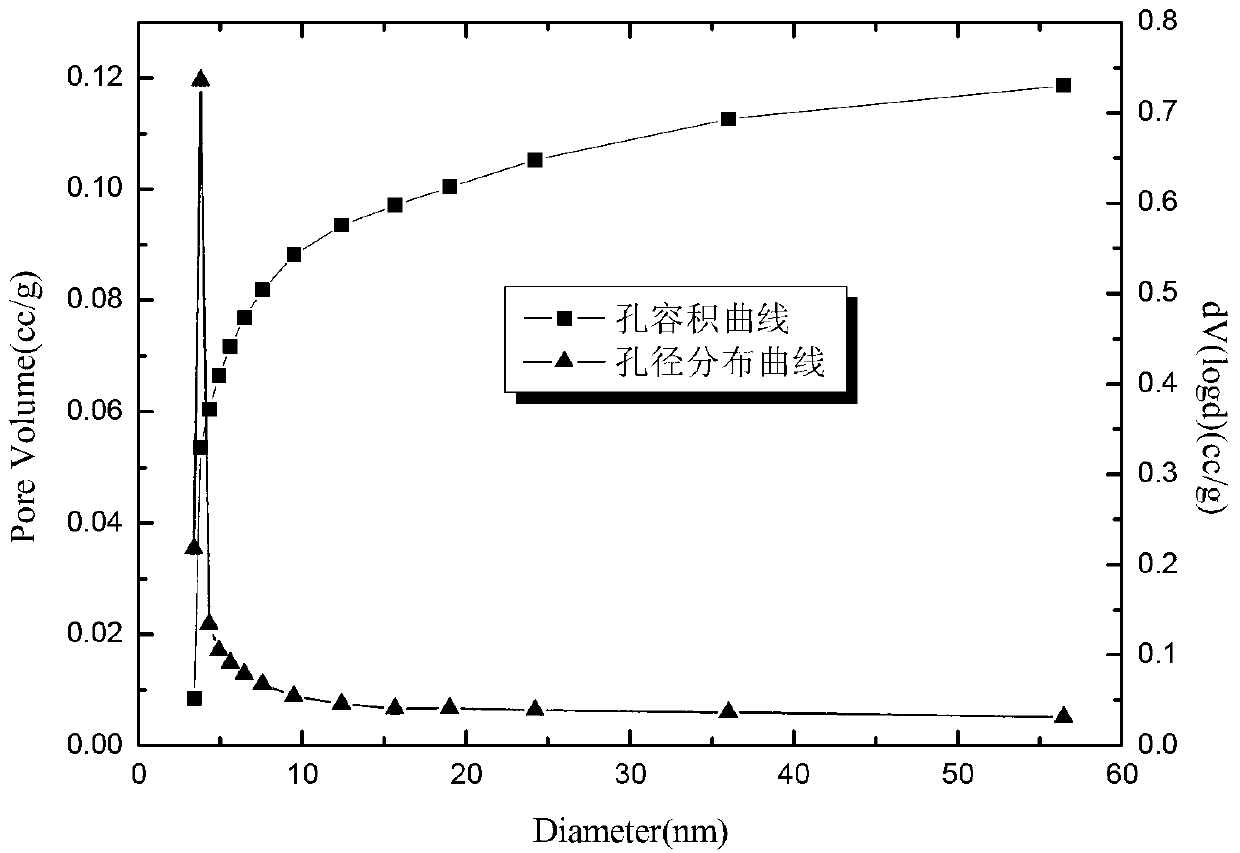

Oxides for Wound Healing and Body Repair

The invention provides a homogeneous composition comprising a hemostatically effective amount of a charged oxide, wherein the composition has an isoelectric point, as measured in calcium chloride, below 7.3 or above 7.4. Typically, the charged oxide is selected from the group consisting of silaceous oxides, titanium oxides, aluminum oxides, calcium oxides, zinc oxides, nickel oxides and iron oxides. In some embodiments, the composition further comprises a second oxide selected from the group consisting of calcium oxide, sodium oxide, magnesium oxide, zinc oxide, phosphorus oxide and alumina. In a typical embodiment of the invention, the charged oxide is silaceous oxide, the second oxide comprises calcium oxide and the ratio, by molar ratio, of silaceous oxide to calcium oxide is 0.25 to 15. Optionally, the composition further comprises phosphorous oxide. Also described are methods of making and using such compositions.

Owner:RGT UNIV OF CALIFORNIA

High specific surface area graphene with well-developed mesopores, and preparation method thereof

ActiveCN102992313AImprove permeabilityStrong intercalationGraphenePhosphoric acidPotassium hydroxide

The invention relates to a preparation method of high specific surface area graphene with well-developed mesopores. The method comprises the steps of mixing graphene oxide and an activating agent under a protective atmosphere; passing through an activating gas to active the mixture; and finally obtaining the high specific surface area graphene with the well-developed mesopores through processes of washing, filtering and drying. The activating agent is selected any one from potassium hydroxide, sodium hydroxide, phosphoric acid and zinc chloride or a combination of at least two of the above materials. The method is simple in equipment and low in cost, is safe and reliable, has small pollutions and high production efficiency, and is suitable for large-scale production. The obtained graphene has high specific surface area, and is more suitable for migration of electrolyte ions.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Polycarboxylic superplasticizer, synthesis method thereof and application method thereof

The invention discloses a synthesis method of a polycarboxylic superplasticizer. The raw materials for synthesis of the polycarboxylic superplasticizer are APEG of two types of molecular weight (respectively 500-1000 and 1600-2200), MPEGMA of two types of molecular weight (respectively 800-1400 and 2000-2500), maleic anhydride, acrylic acid, alkylphenol ethoxylate, hydrogen peroxide, ascorbic acid, ferrous sulfate, sodium persulfate, sodium hydroxide and deionized water. Since the APEG and MPEGMA of different types of molecular weight are simultaneously adopted as crossing branch chains, the invention not only has a high water-reducing rate, but also maintains good water-reducing rate, has good adaptability to sands and stones with high clay contents, and improves the strength of concrete, Compared with the prior art, the invention has the advantages that the raw materials of the product are easily available, the synthesis process can be easily controlled, the performance of the reaction product is stable, and the cost is reduced by 5-10 percent.

Owner:GUANGDONG REDWALL NEW MATERIALS

Solid solution composition of cerium zirconium compound oxide with high specific surface and method for preparing the same

ActiveCN1962051AHigh degree of crystallizationImprove product qualityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCeriumHigh pressure

The invention relates to a high-specific area cerium zirconium oxide solid compound and relative production, wherein said compound is Ce1-xZrxNazOw or Cex'Zrx'MyNazOw, while the natron sodium oxide content is 5ppm-1000ppm. And the production comprises (1), preparing the solution as A; (2), dissolving the alkali material into water to obtain B; (3), adding A into B, to obtain deposition suspension; (4), adding additive, as surface activator, polymer, etc, mixing and heating, and crystallizing at high pressure; (5), filtering, and washing the deposit; (6), washing and filtering, drying, baking to obtain the solid. The invention has high crystallization degree, small grain and uniform distribution.

Owner:GRIREM ADVANCED MATERIALS CO LTD

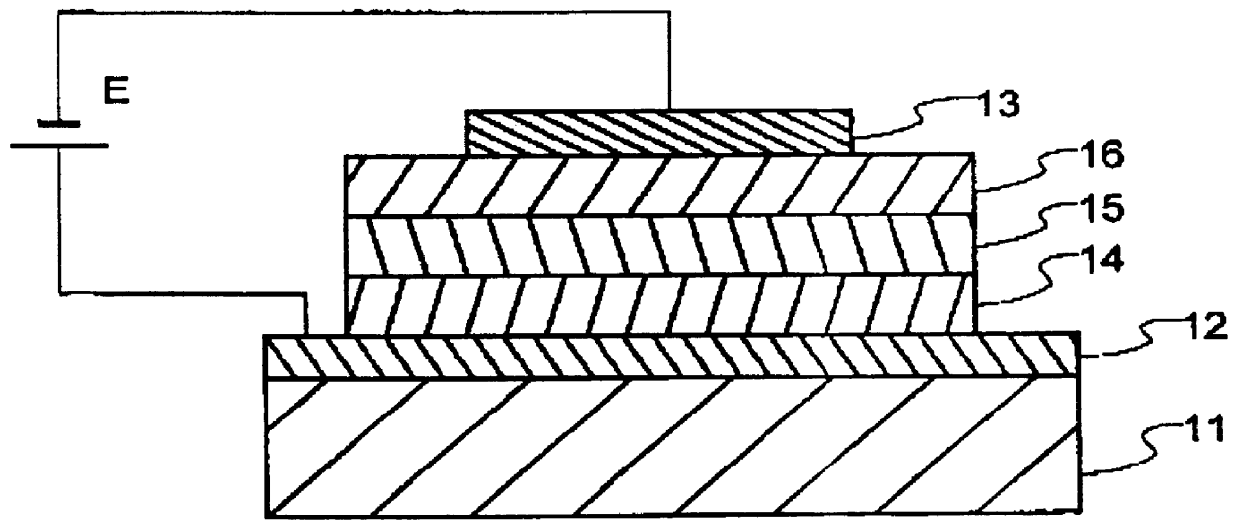

Organic luminescence device and its production method

InactiveUS20050122039A1Excellent gas barrier propertiesDischarge tube luminescnet screensLayered productsWater vaporOxygen

An organic luminescence device uses a substrate with a gas-barrier film in which a gas-barrier film containing an amorphous oxide and at least two kinds of oxides selected from the group consisting of boron oxide, phosphorus oxide, sodium oxide, potassium oxide, lead oxide, titanium oxide, magnesium oxide, and barium oxide is formed on a substrate. The selected two kinds of oxides are a combination of an oxide of an element having a large atomic radius and an oxide of an element having a small atomic radius. The substrate is made of glass or plastic. As a result, the organic luminescence device using a substrate excellent in gas-barrier capability to prevent the infiltration of oxygen, water vapor, etc. from outside is provided.

Owner:PANASONIC CORP

Paraffin dehydrogenation catalyst

ActiveUS7012038B2High activityRobust hydrothermal stabilityHydrocarbon by dehydrogenationCatalystsLithium oxideDehydrogenation

One aspect of the invention relates to a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide. The invention also relates to methods of making the dehydrogenation catalyst composite. Another aspect of the invention relates to method of dehydrogenating a dehydrogenatable hydrocarbon involving contacting the dehydrogenatable hydrocarbon with a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide to provide a dehydrogenated hydrocarbon, such as an olefin.

Owner:TEXAS PETROCHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com