Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

A technology for cutting waste sand and polyethylene glycol, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high content and affect the conversion efficiency of photovoltaic cells, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

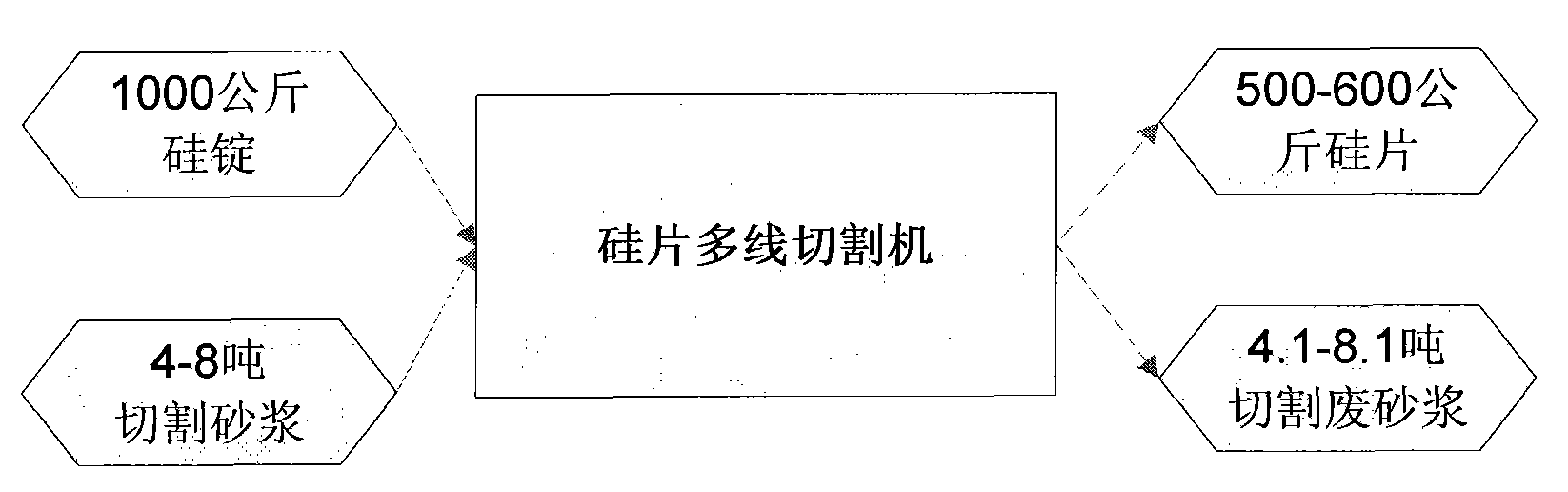

[0027] The composition of waste mortar for wire cutting of solar silicon wafers is as follows: liquid polyethylene glycol accounts for 50% by weight, silicon carbide powder accounts for 42% by weight, silicon chips account for about 6.5% by weight, and metal chips account for about 1.5% by weight.

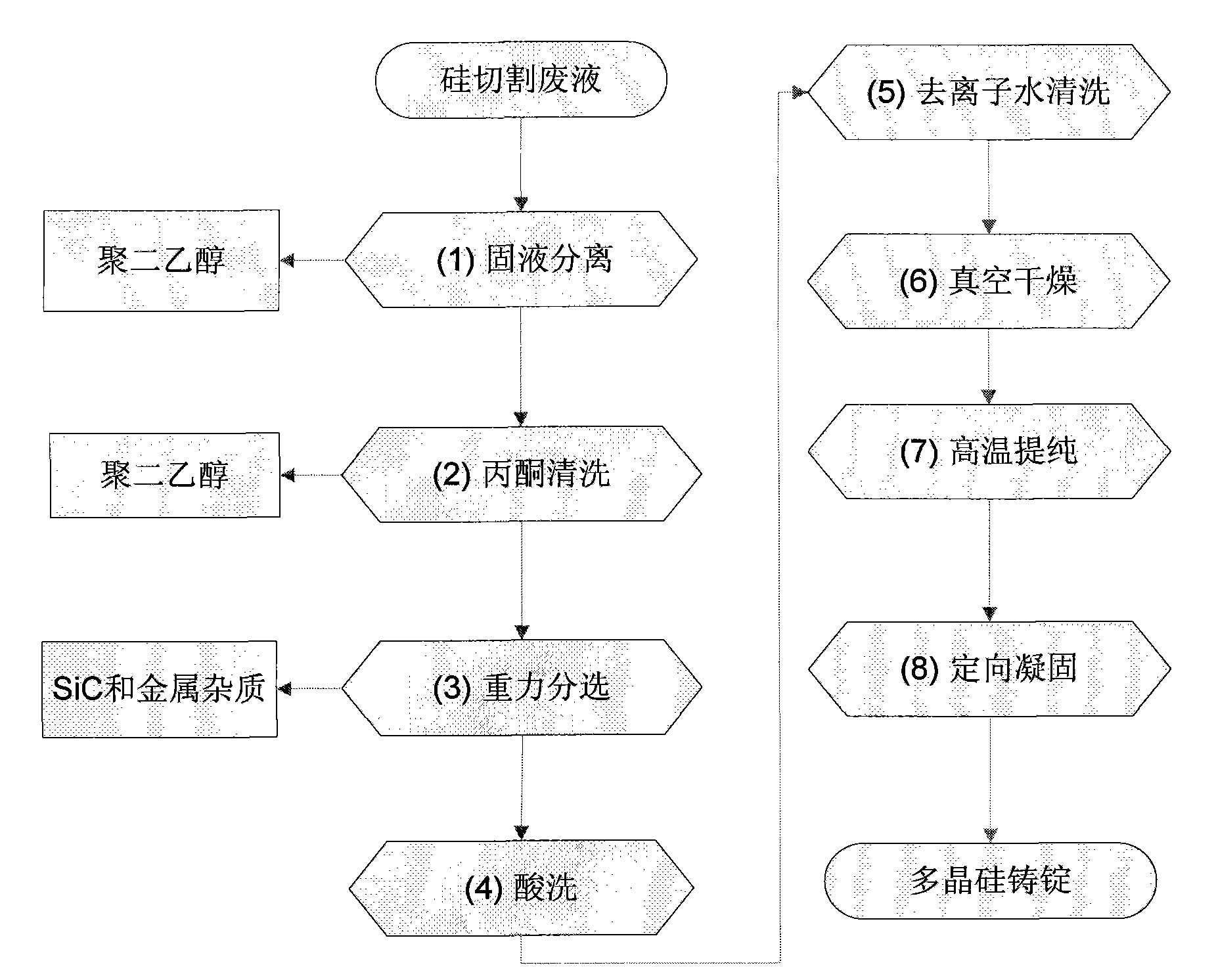

[0028] Take 100 kg of waste cutting mortar, and first carry out solid-liquid separation of the waste mortar through a plate and frame filter press, separate out 44 kg of liquid polyethylene glycol, and obtain 56 kg of sediment. After soaking and cleaning 56 kg of the obtained precipitate with acetone, 54 kg of the precipitate was obtained by centrifugation; the precipitate was washed with deionized water and dried to obtain 49 kg of powder, namely silicon powder, silicon carbide micropowder and metal particles mixed powder. The obtained mixed powder is dispersed by the jet mill and put into the container, and the density is 2.5g / cm 3 In the tribromomethane alcohol heavy liquid, us...

Embodiment 2

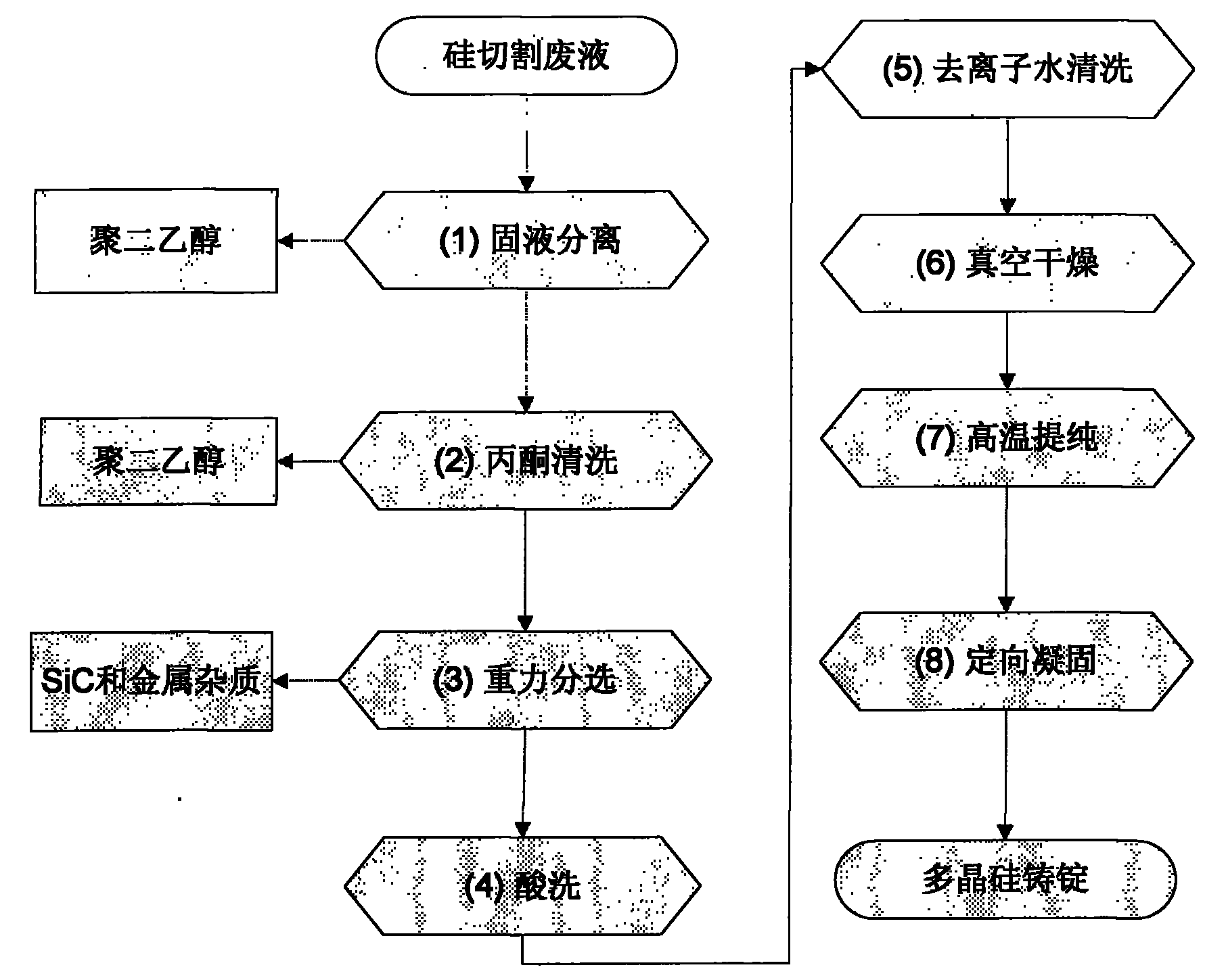

[0032] The composition of waste mortar for wire cutting of solar silicon wafers is as follows: liquid polyethylene glycol accounts for 50% by weight, silicon carbide powder accounts for 42% by weight, silicon chips account for about 6.5% by weight, and metal chips account for about 1.5% by weight.

[0033] Take 100 kg of waste cutting mortar, first dilute the waste mortar and water with a ratio of 1:5 and then carry out solid-liquid separation on a hydrocyclone, and separate to obtain 56 kg of sediment and 264 kg of liquid polyethylene glycol aqueous solution. The liquid polyethylene glycol aqueous solution was heated to 100°C, and the water was evaporated to obtain 43kg polyethylene glycol.

[0034] Put 56kg of sediment into the container, soak it with acetone to remove oil and residual polyethylene glycol, and then centrifuge to obtain 53kg of sediment; wash the sediment with deionized water and dry to obtain 48kg of silicon powder, carbonization Mixed powder of silicon micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com