Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3932 results about "Vacuum furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum furnace is a type of furnace in which the product in the furnace is surrounded by a vacuum during processing. The absence of air or other gases prevents oxidation, heat loss from the product through convection, and removes a source of contamination. This enables the furnace to heat materials (typically metals and ceramics) to temperatures as high as 3,000 °C (5,432 °F) with select materials. Maximum furnace temperatures and vacuum levels depend on melting points and vapor pressures of heated materials. Vacuum furnaces are used to carry out processes such as annealing, brazing, sintering and heat treatment with high consistency and low contamination.

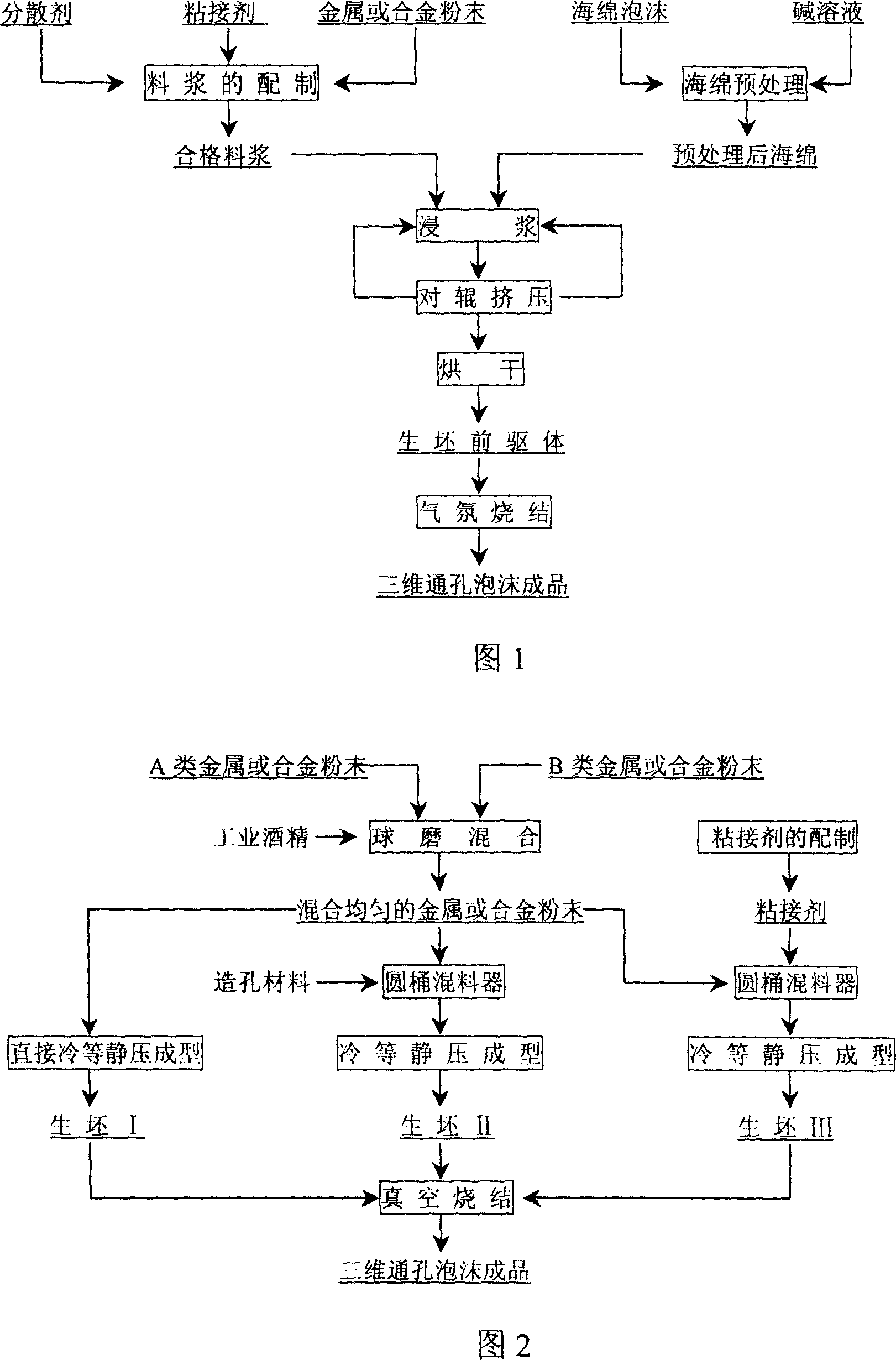

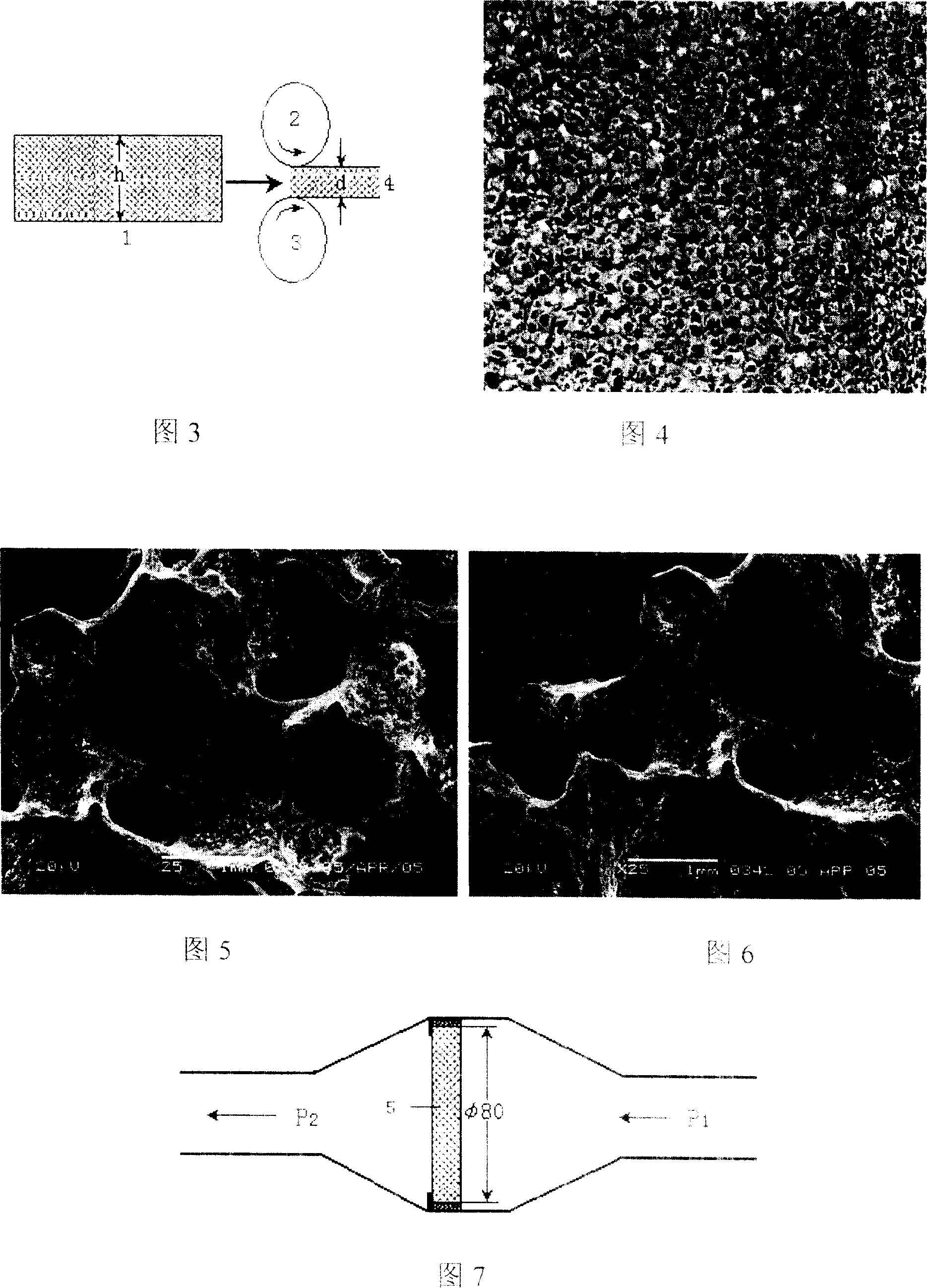

Three-dimensional through-hole or part-hole interconnecting porous metal foam and its preparing method

The invention relates to a multi-hole foamed metal material and the manufacturing method. It includes the following steps: equally dispersing metal or alloy powder that has the particle diameter at 1-100um into solution contains adhesive agent to make slime, pouring the slime into through-hole polyurethane sponge foam, after taking drying and sintering, the material would be gained. It also could be make by the method of directly isostatic cool pressing one or more metal or alloy powder, isostatic cool pressing after mixing with pore forming material or isostatic cool pressing after mixing with adhesive agent solution to gain green pressing that would be sintered in vacuum furnace to make the material. The invention could be used to process vehicle tail gas and could also be used to filter the smoke form thermal power station or metallurgical furnace.

Owner:CENT SOUTH UNIV

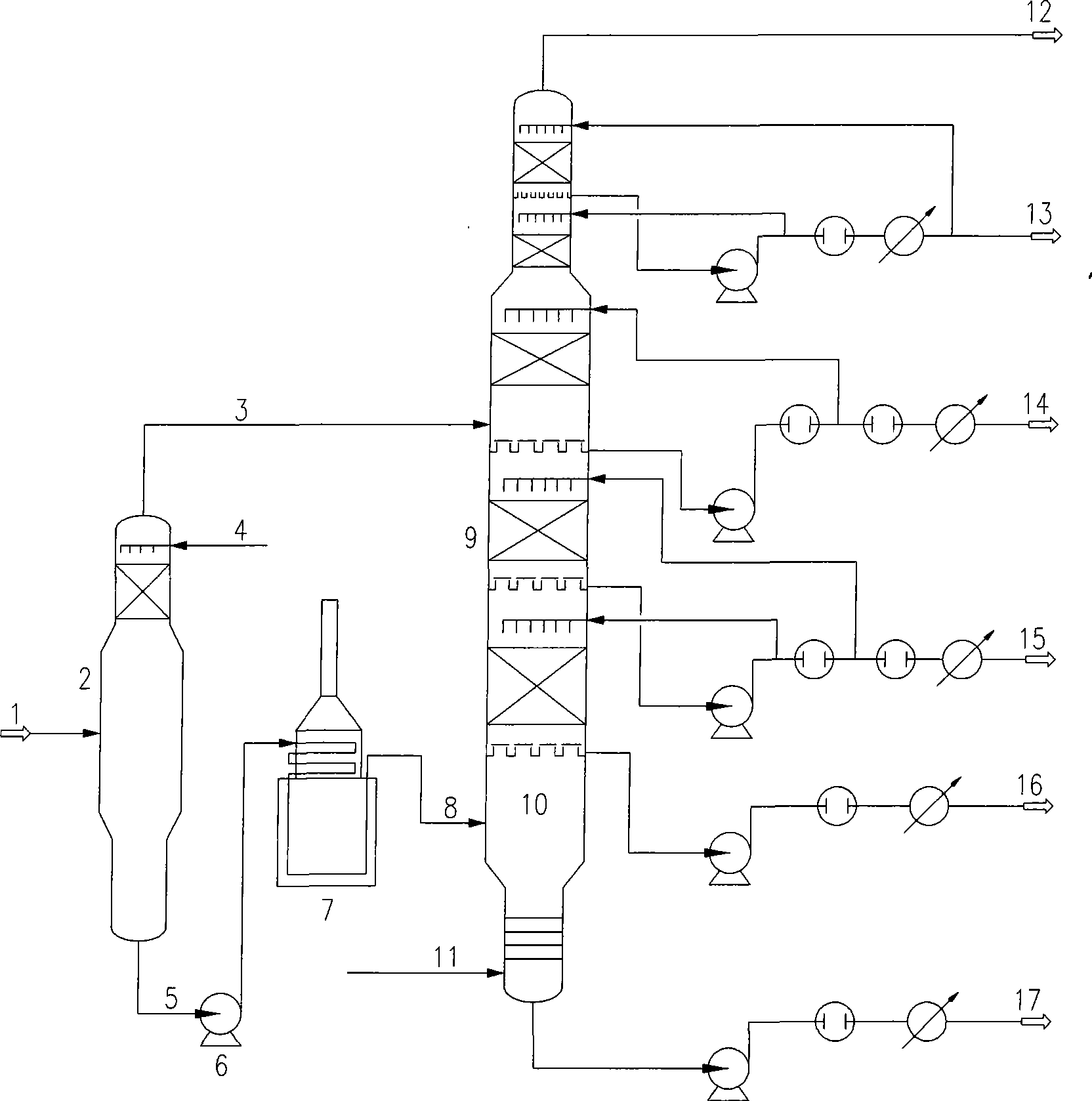

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

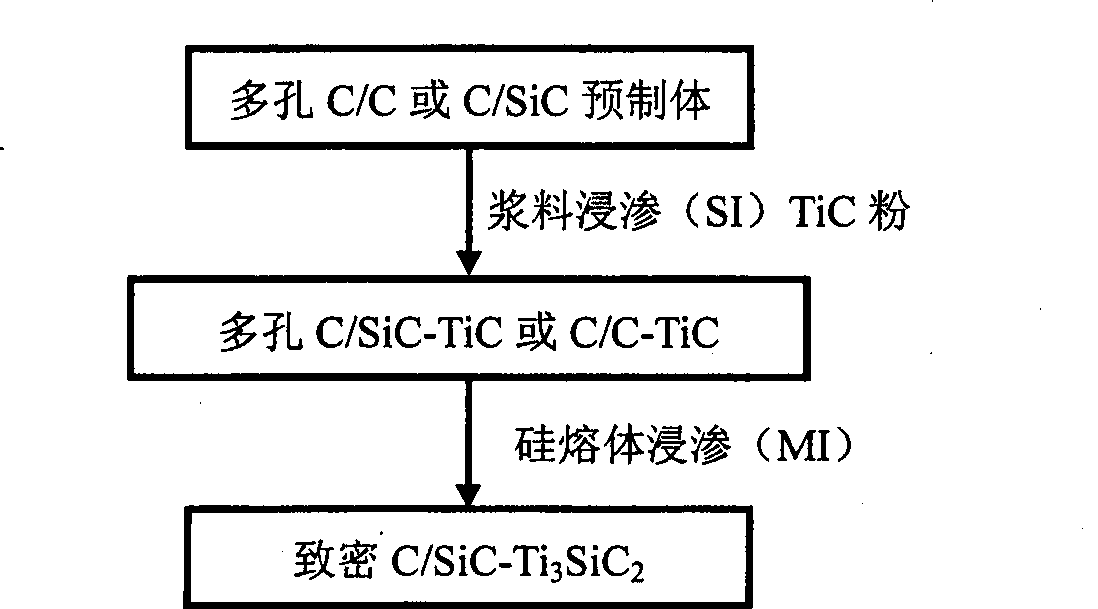

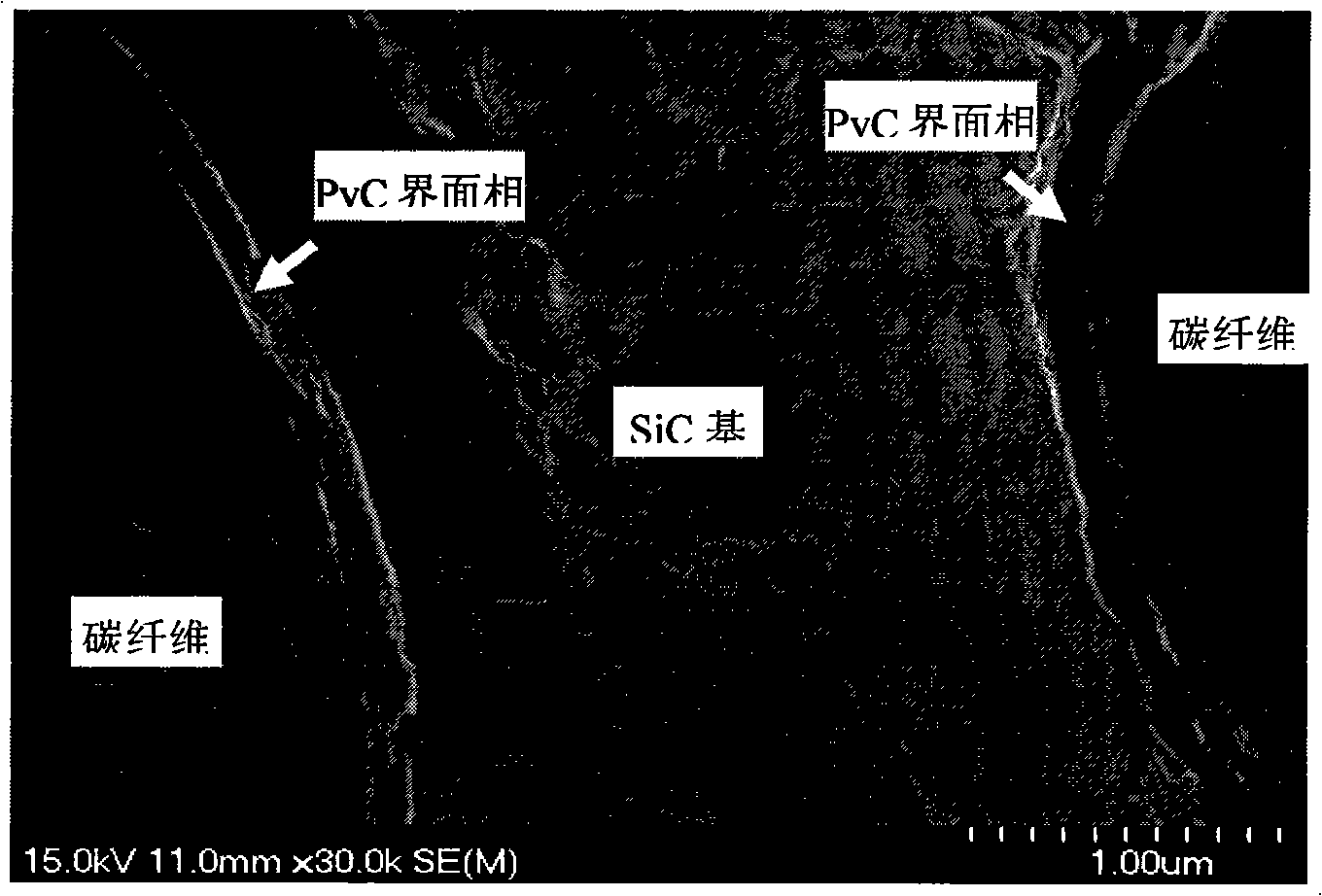

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

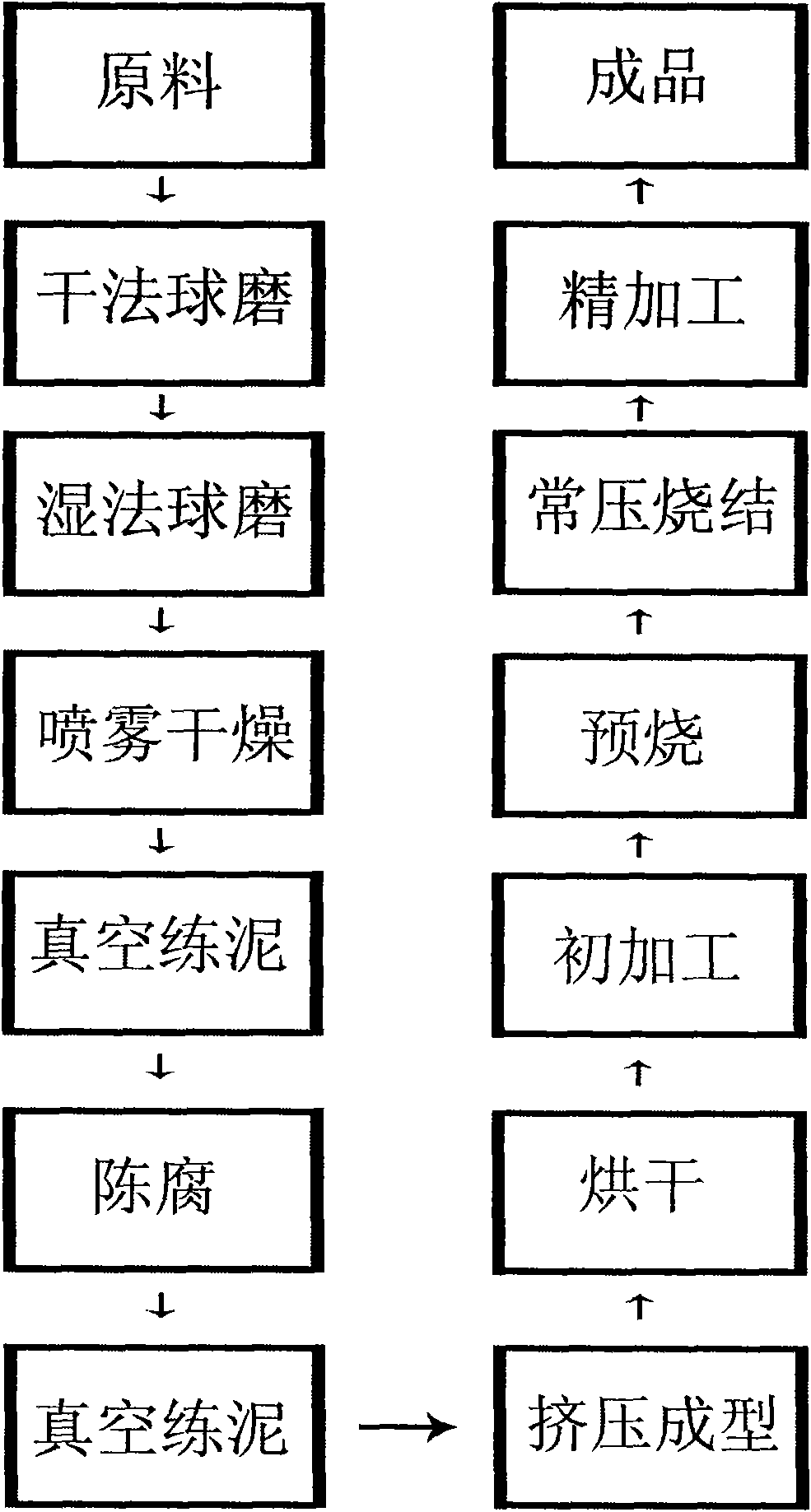

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

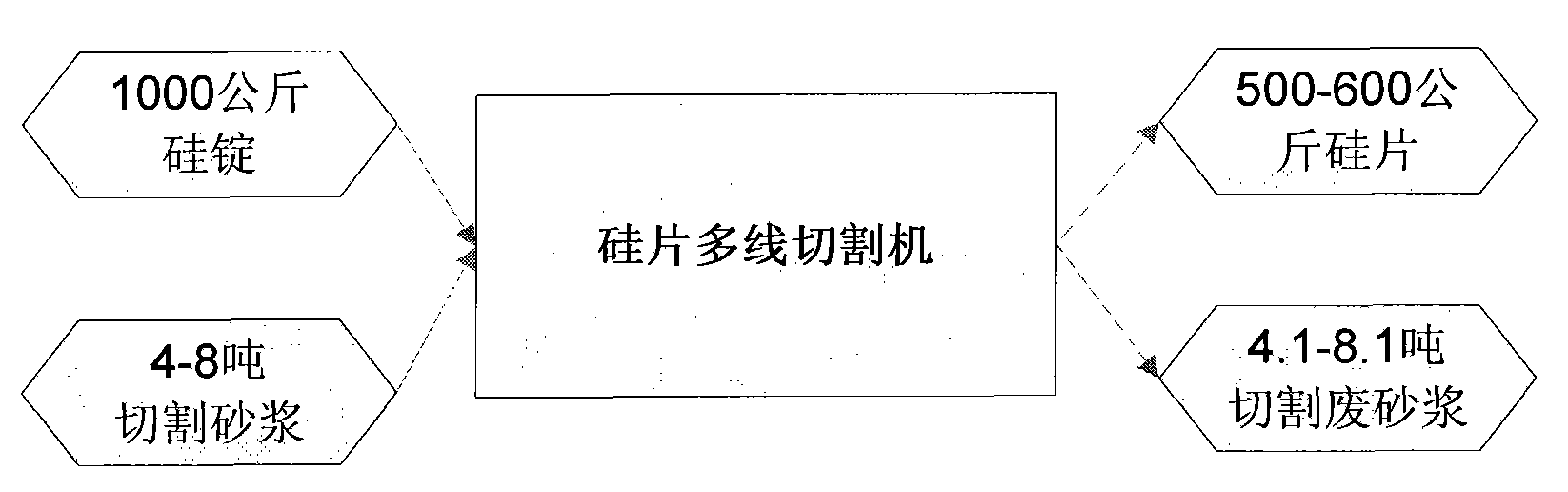

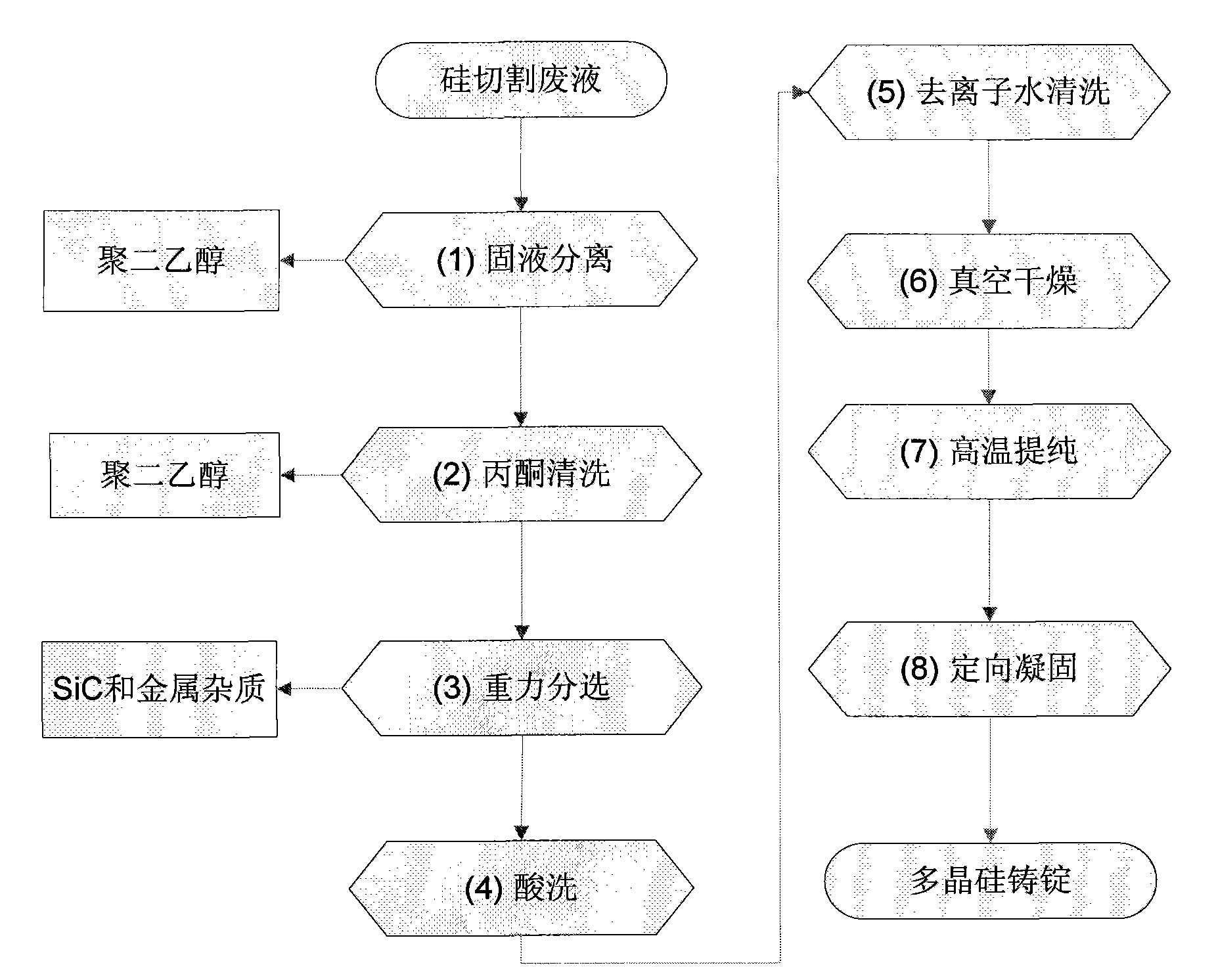

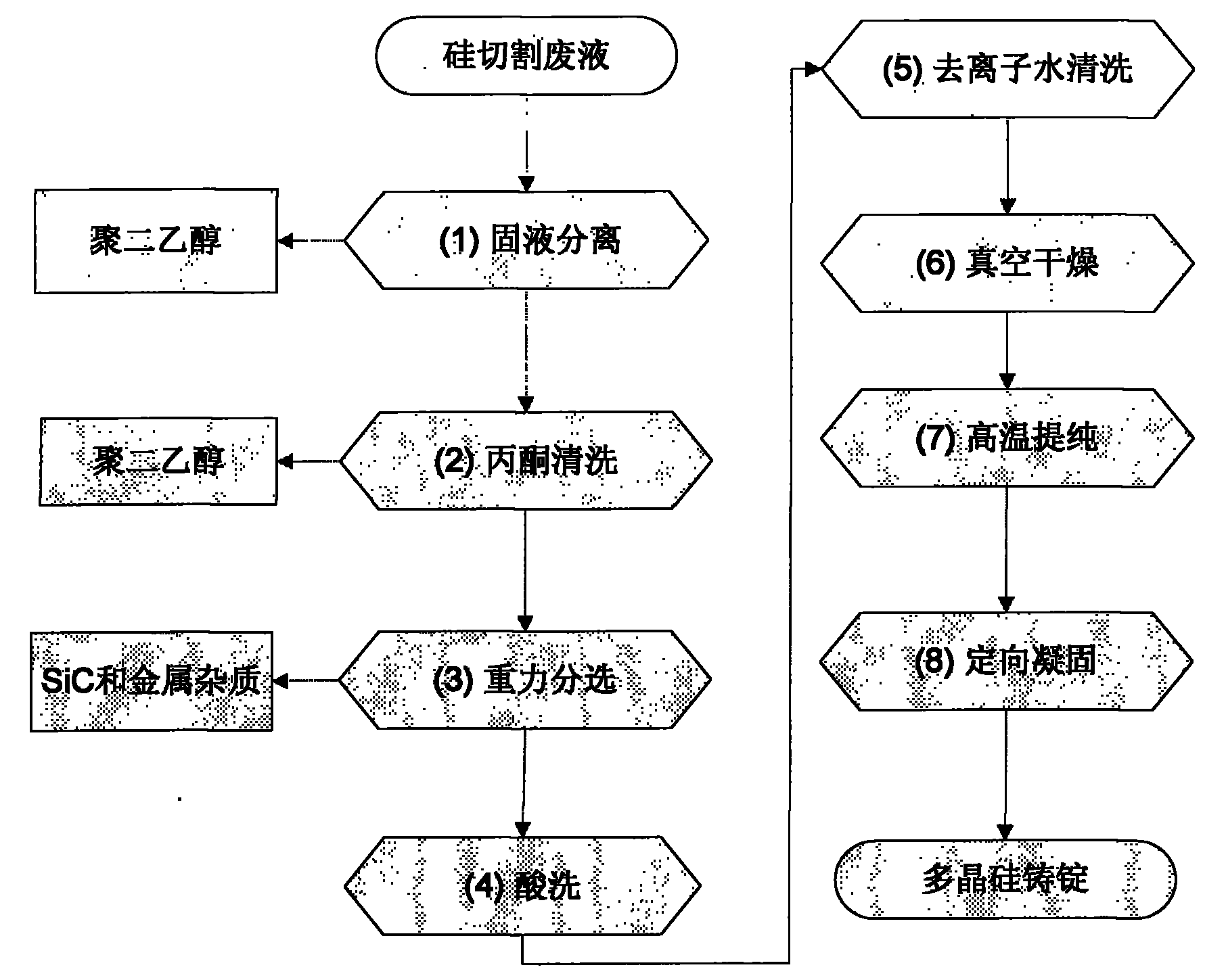

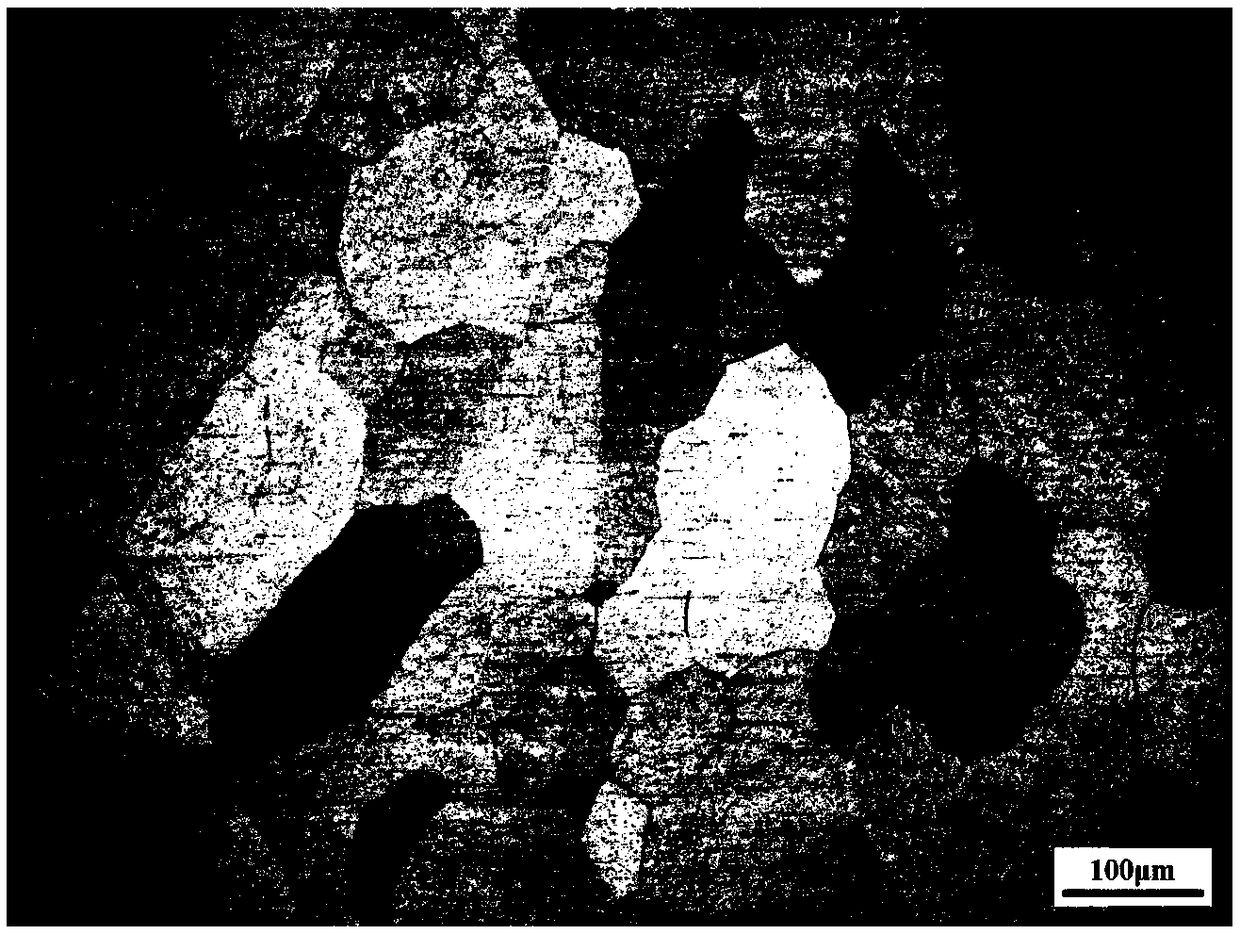

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

Process for manufacturing low-silicon low-carbon deep punching/drawing steel

ActiveCN101343677ARelaxation of sulfur content requirementsReduce manufacturing costManufacturing convertersProcess efficiency improvementExtensibilitySlag

The invention discloses a production method of low-silicon and low-carbon deep punching / drawing steel, bottom-blowing argon is performed in the whole process of converter smelting, and a single slag / double slag technique is adopted to pour out the dephosphorized slag, high-basicity slag is produced in later period, the dualistic basicity of final slag R is more than 3.5, the terminal temperature of molten steel is 1620 DEG C to 1650 DEG C, and tapping ( P ) is less than 0.012 percent. The molten steel is refined by adopting low-silicon and low-carbon high-basicity reductive slag in a LF furnace refining station, thus to manufacture reductive slag for desulphurisation, and the ( Al ) in the molten steel is less than 0.005 percent. The molten steel refined by the LF furnace is vacuum-treated by a RH vacuum furnace, the carbon and the silicon in the molten steel is circularly removed, the molten steel is continuously casted into a casting blank through a CSP sheet bar conticaster, the casting blank is sent into CSP sheet bar heat continuous rolling mill and rolled into a coiled sheet after being heated in a roller hearth soaking furnace, a hot rolled coiled sheet is coldrolled into cold rolled coiled sheet through a cold tandem mill or a single mill after being acidwashed, and leveled through a leveling machine after being annealed by a cover furnace, and a leveling divided coil is stretched and divided. The production method has the advantages that the production cost of the working procedure is saved, the consumption of the refractory consumption of the converter is reduced, the equipment investment is saved, the process of the production technique is steady and smooth, the n value of the cold rolled plate is bigger than 0.23, the r value thereof is bigger than 2.1, and the deep punching performance and the extensibility are good.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

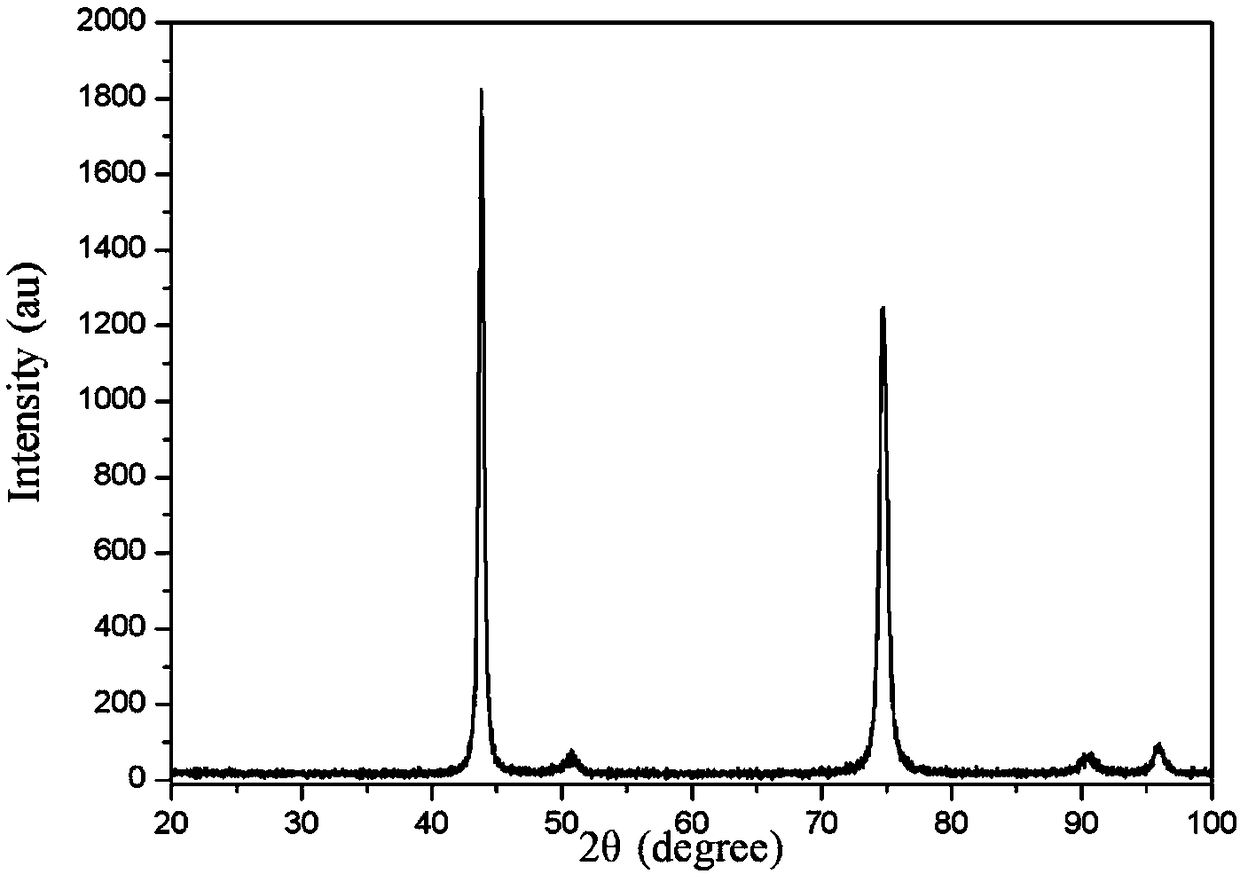

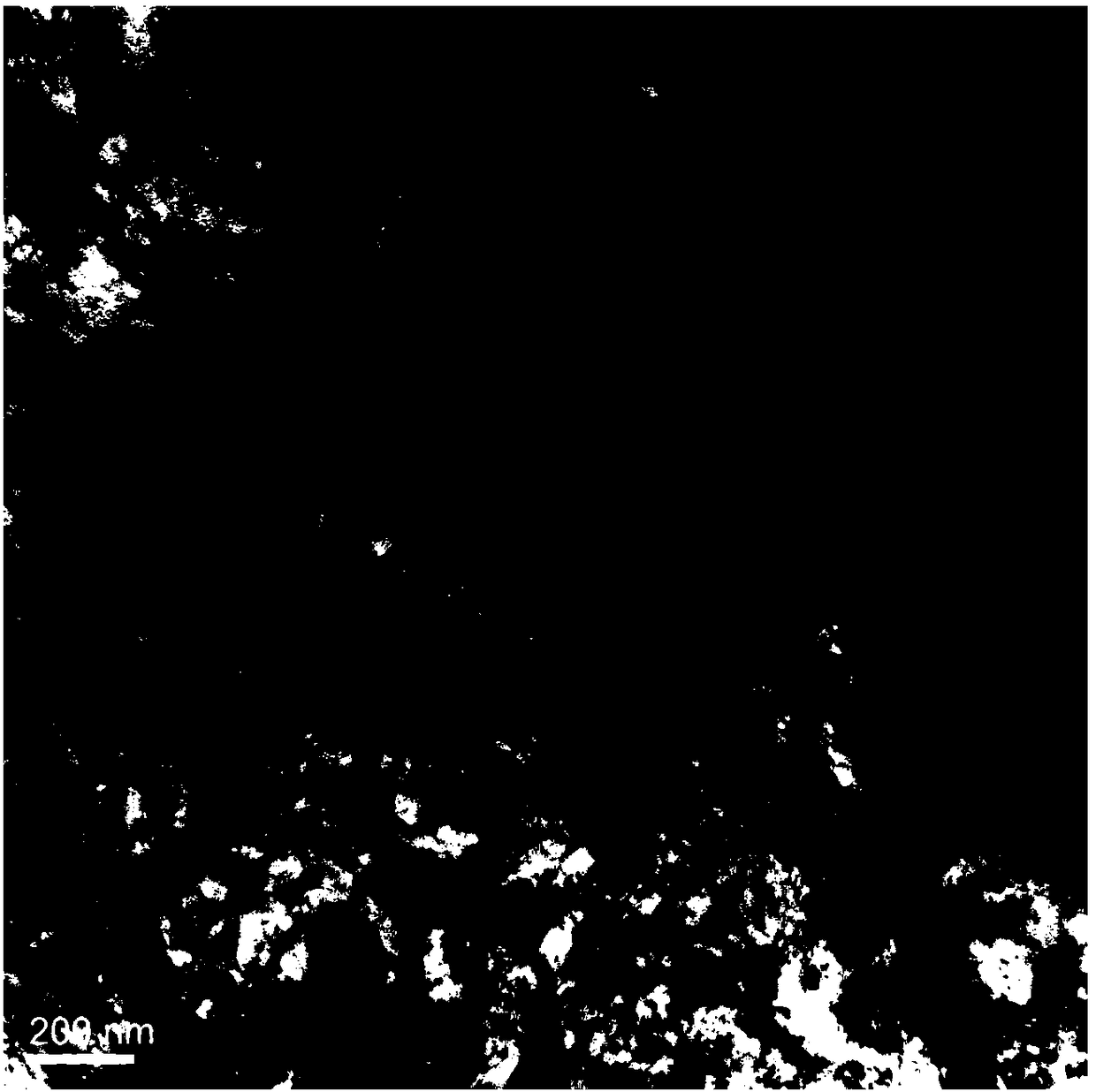

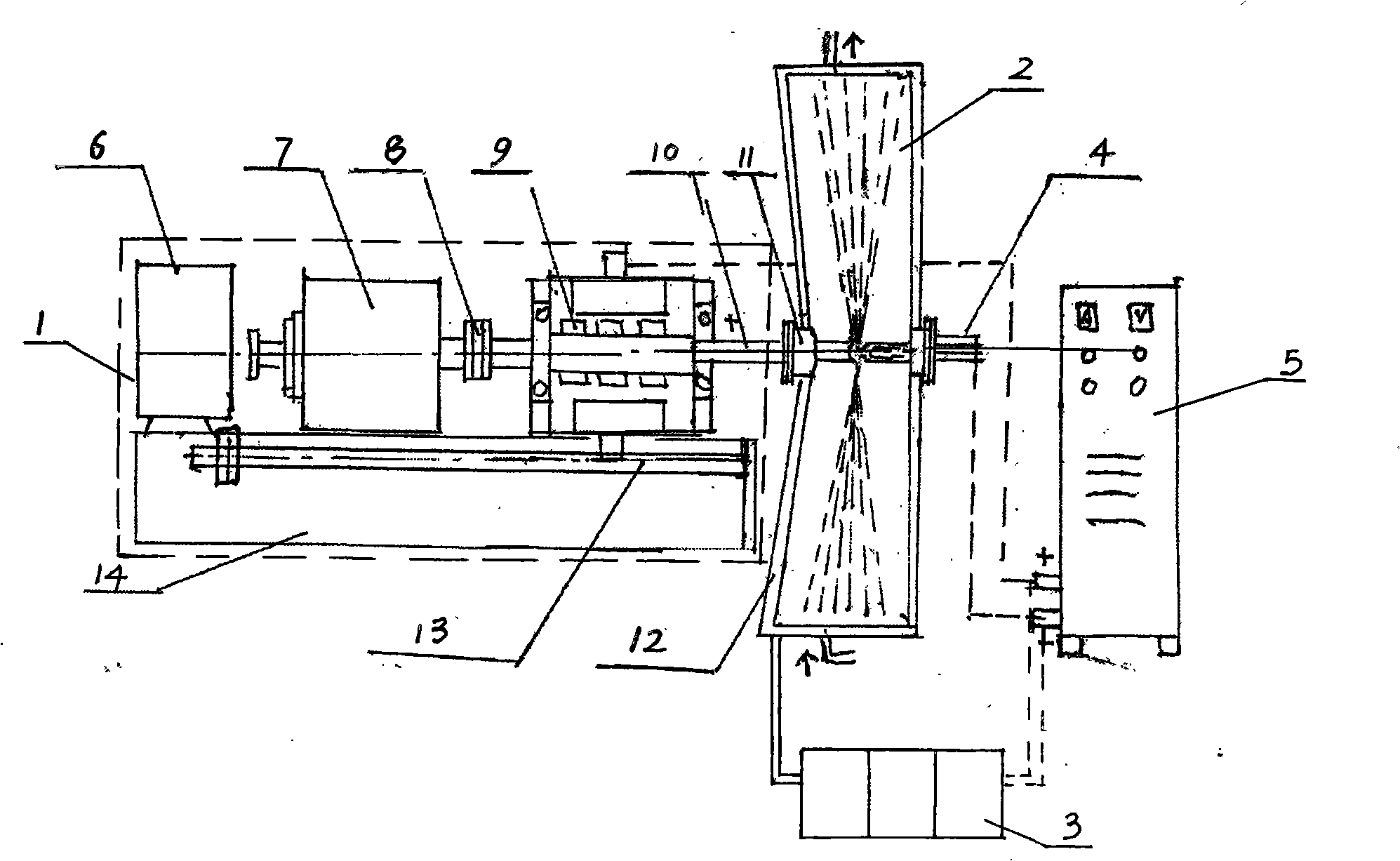

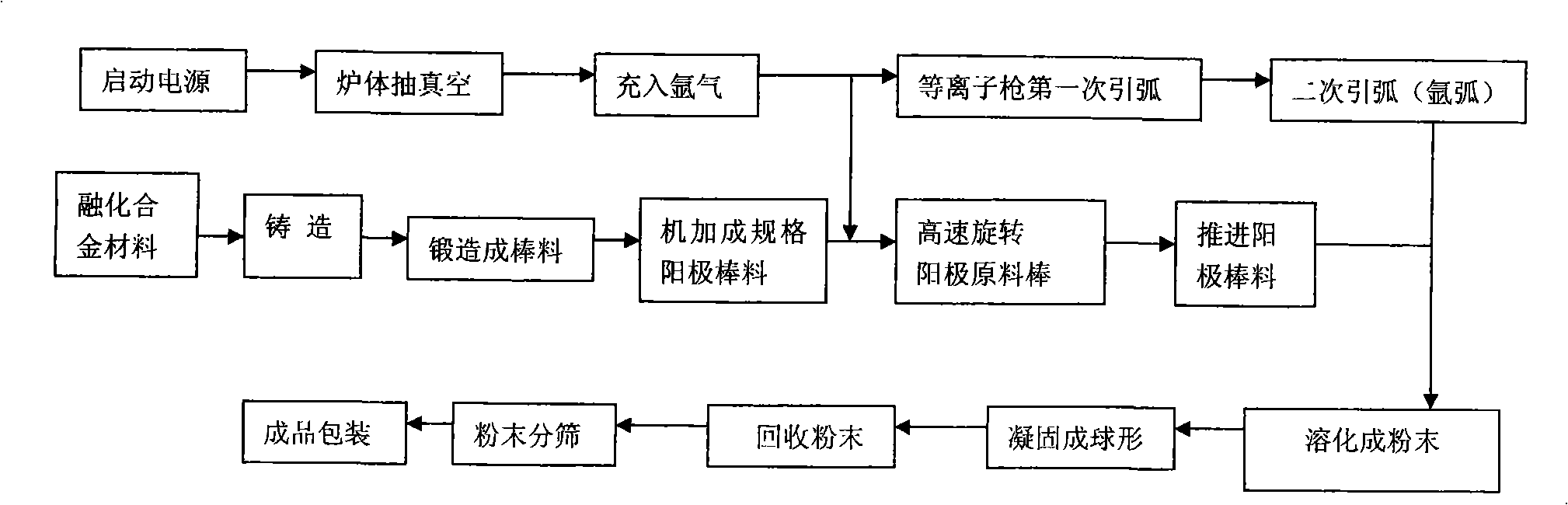

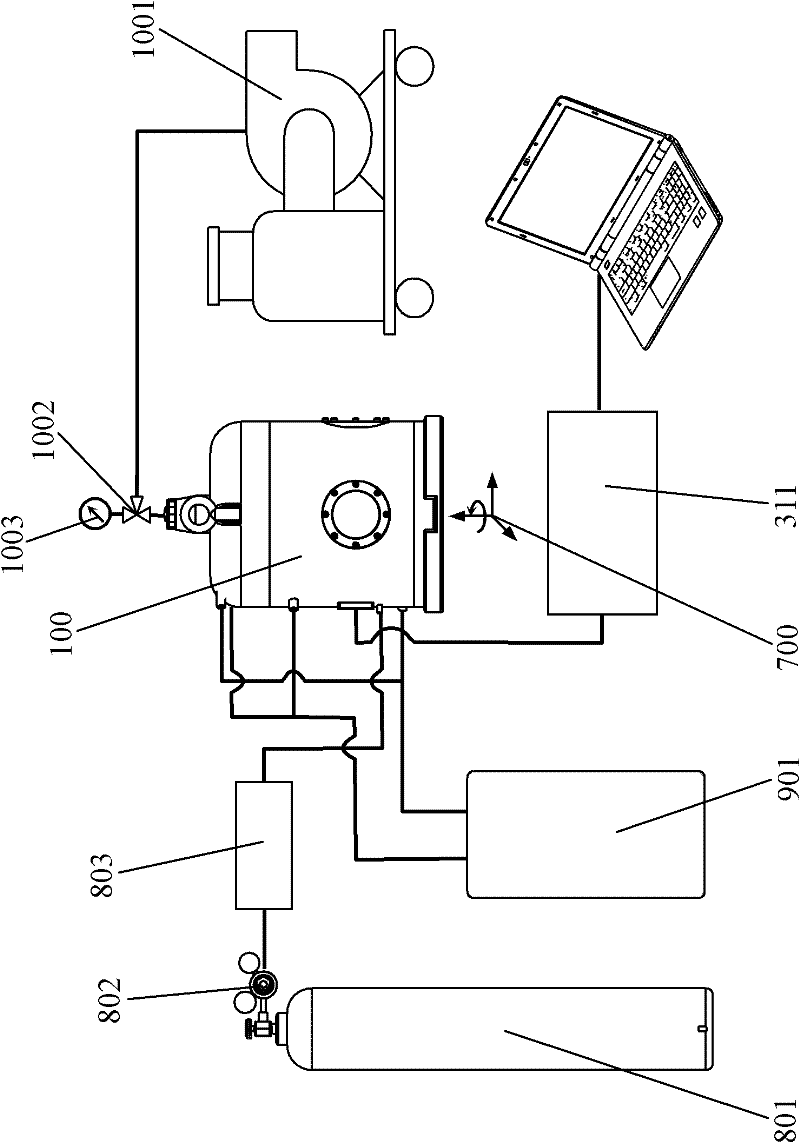

Plasma rotating electrode milling machine group and technique

The invention relates to a plasma rotary electrode powder milling set and a process thereof, relating to the technical field of powder metallurgy. The milling set comprises a rotating feeding mechanism, a vacuum furnace, a vacuum unit, a plasma gun device and an electrical source. The rotating feeding mechanism is arranged at the exterior of one side of the vacuum furnace; the plasma gun device is arranged at the interior of the other side of the vacuum furnace; the vacuum unit is communicated with the vacuum furnace through a ventilation pipe, wherein, the vacuum furnace body has a double-decker sandwich structure, and cooling circulating water is injected into the sandwich structure; a receiving mechanism is arranged at the bottom part of the vacuum furnace, wherein, the receiving mechanism comprises two cut-off valves connected in series. The process includes the following steps: metal is processed into electrode bars; low-voltage heavy current is applied to the electrode bars to melt the electrode bars in a highly vacuumized melting chamber through the high temperature produced by the cathode arc of the plasma gun, and to eject the molten metal instantly by the strong centrifugal force produced through the high-speed rotation of the electrode bars to produce fine metal powders. The invention is characterized in that the yield of perfect spherical metal powders is up to 97 percent, and the powders are free from the contamination of any microelement.

Owner:张建利

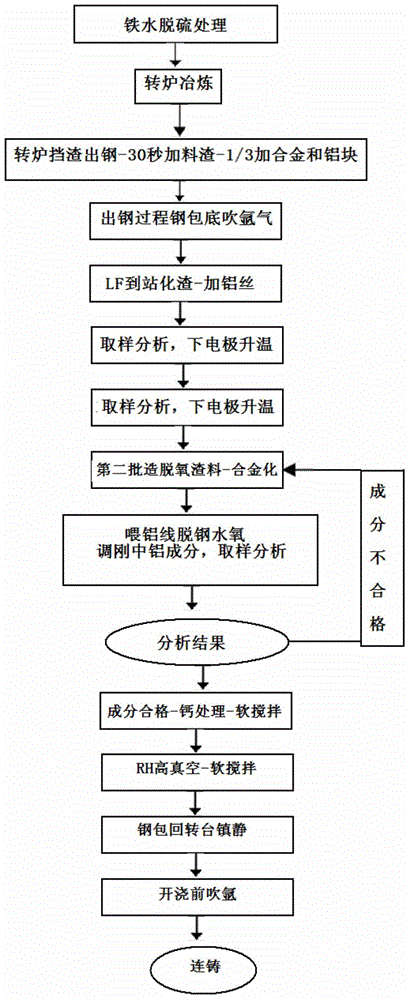

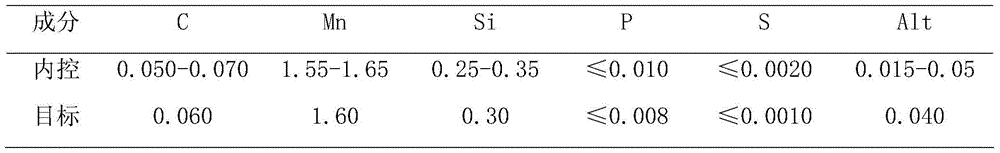

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

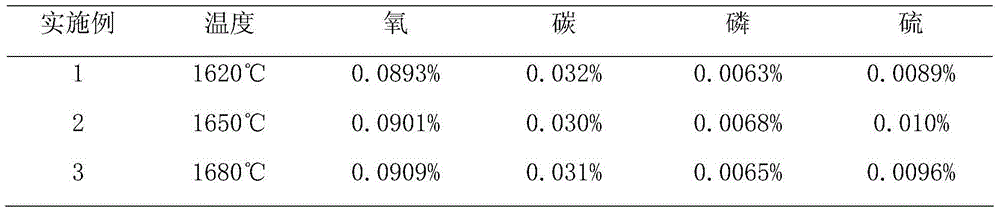

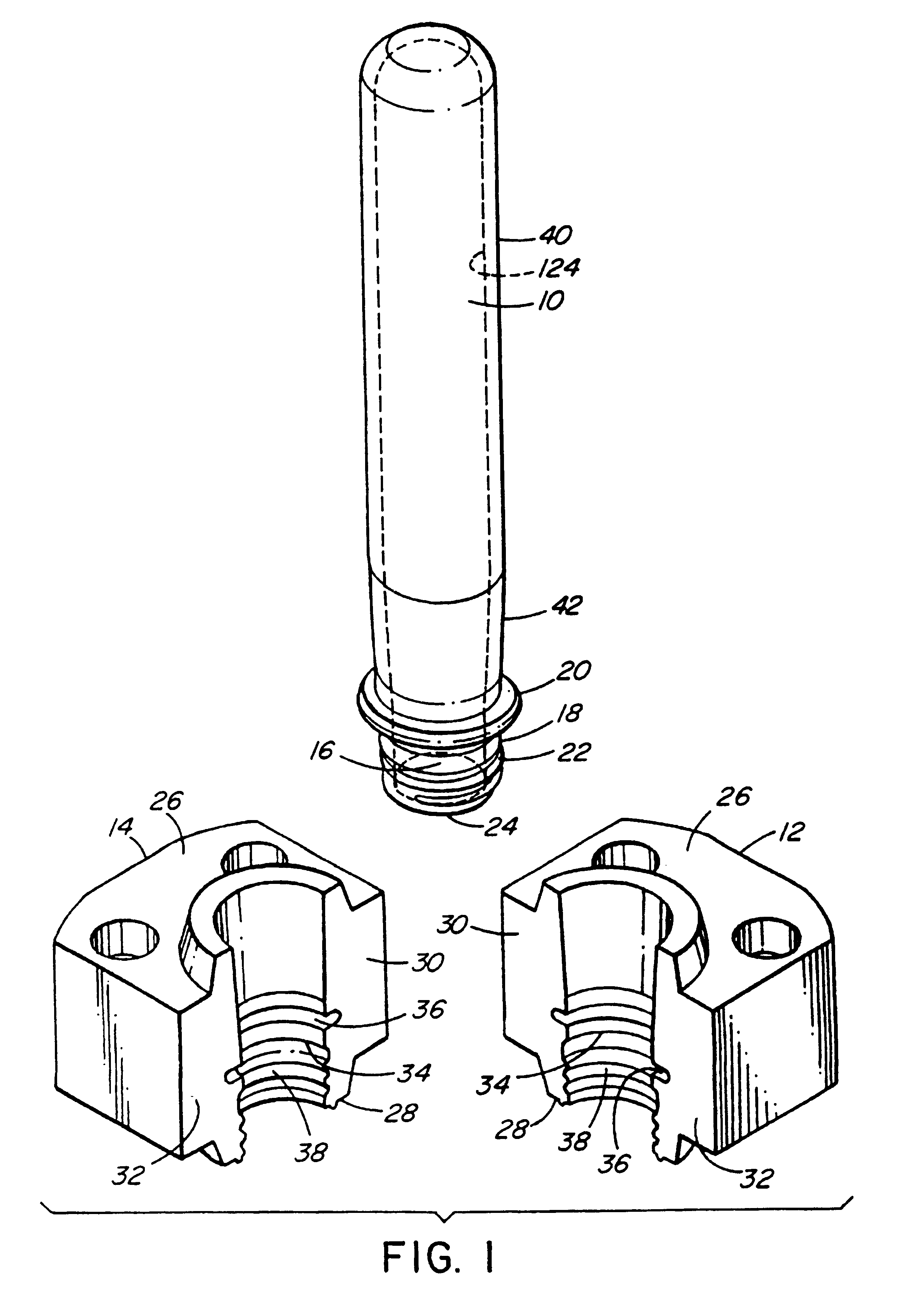

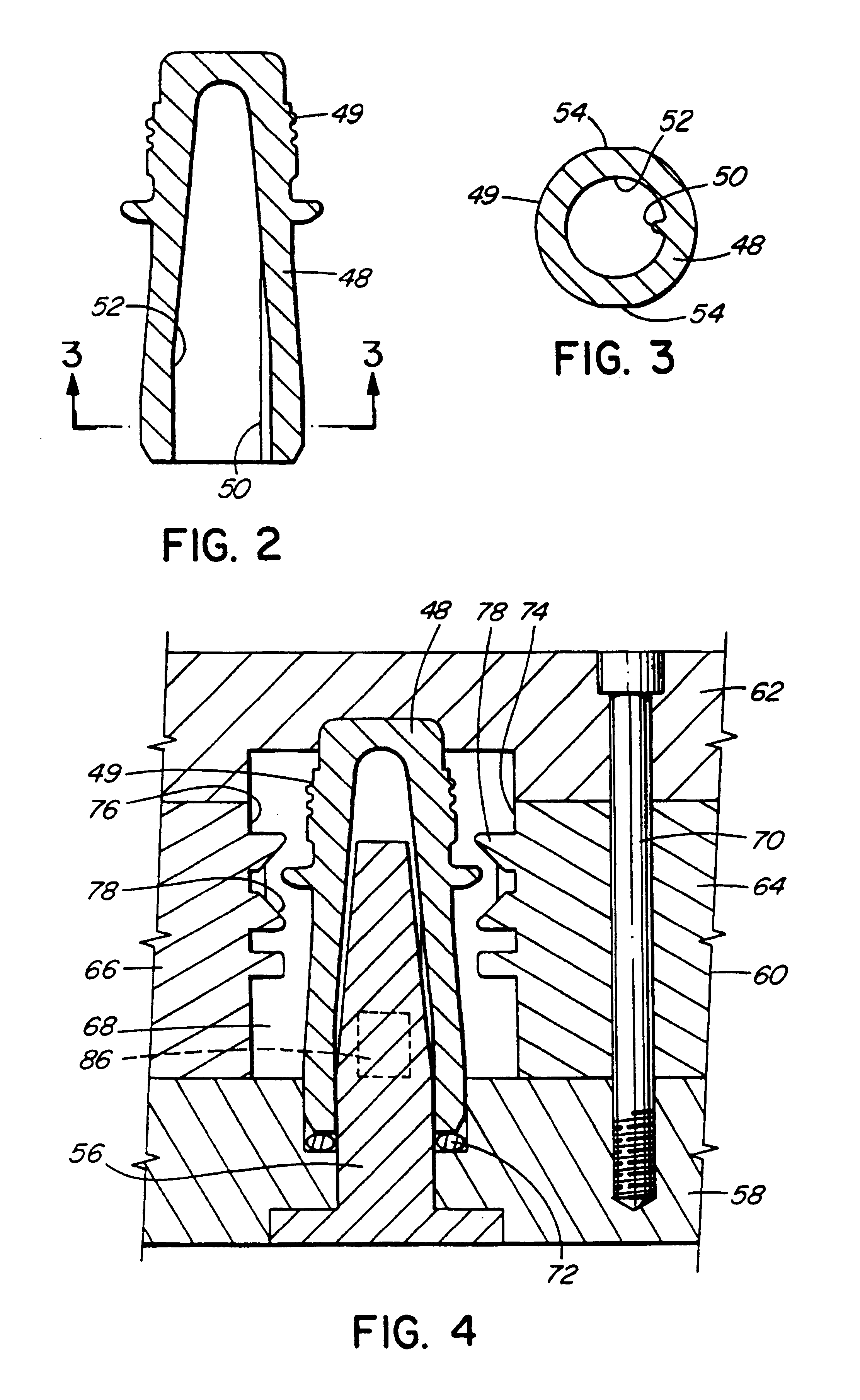

Method of making injection molding cooled thread split inserts

InactiveUSRE38396E1Metal rolling stand detailsFood shapingInvestment castingInjection molding machine

A method of making pairs of thread splits inserts used to injection mold bottle preforms. Machining a hollow outer part of the pair of thread split inserts with an opening therethrough and outer portions of two cooling conduits extending from the opening therethrough to respective inlets and outlets. Making an inner part of the pair of thread split inserts by injection molding a ceramic core with the required shape and investment casting the inner part around the ceramic core. The outer surface of the inner part having grooves to partially form inner portions of the two cooling fluid conduits. Then machining the cast inner part to fit in the opening through the outer part. Mounting the outer part around the inner part with the inner and outer portions of the two cooling fluid conduits aligned. Applying brazing material between the inner and outer parts and heating them in a vacuum furnace to integrally braze them together. Finally, cutting the integral inner and outer parts in half to form the pair of thread split inserts with each of the thread split inserts having one of the cooling fluid conduits therein.

Owner:MOLD MASTERS 2007

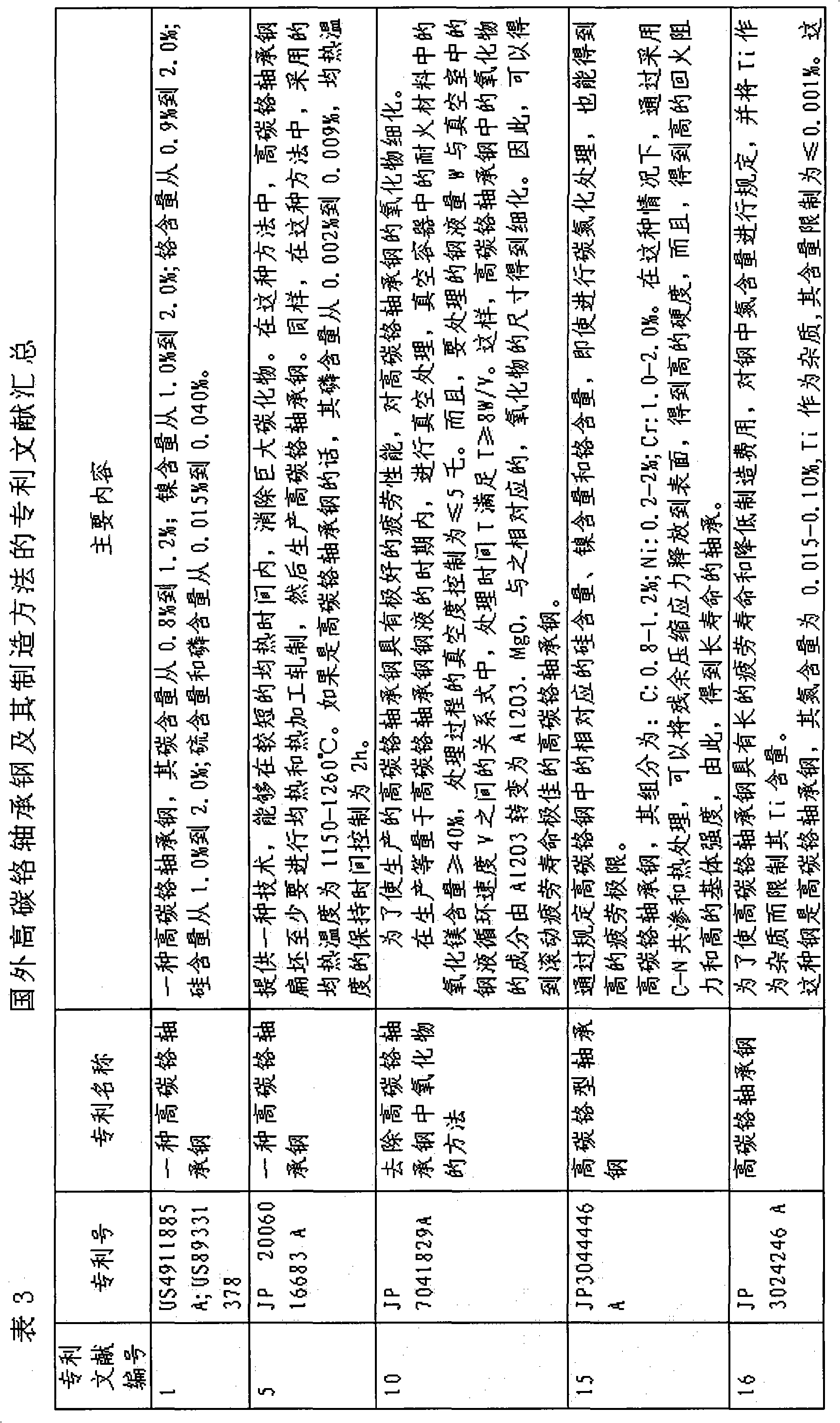

Production of clean high carbon chromic bearing steel

A method for manufacturing high-cleaning and high carbon complex bearing steel includes: 1) choosing charging mixture 2) first steel making molten steel by is greater than or equal to 30ton electric furnace a. smelting furnace burden b. running out foaming slag and adding lime c. alloying when steel tapping with 92% tap and >90% level 3) refining molten steel by steel ladle furnace a. cleaning steel ladle and furnace cleaning b. through bottom blowing argon mixing with 60 min, earlier stage argon blowing intensity 0.4Mpa and later stage 0.3Mpa, material adding amount is less than or equal to 8Kg / ton steel c. precipitating and deoxidizing by two-stage aluminum feeding method, adding crystallized silicon powder, fluorite(content of calcium is greater than or equal to 98%) into slag face, and dispersing deoxidizing 4) vacuum furnace treating a. bottom blowing argon 0.3Mpa, 25min, vacuum content is less than or equal to 140Pa b. bottom blowing argon mixing 15min, 0.1Mpa without materials after treating 5) molten steel mould casting under inactive gas a. ingot moulding temperature 70deg.C, runner brick coating b. pouring speed 5.1ton steel / min of ingot body and mouth. It achieves high yield.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

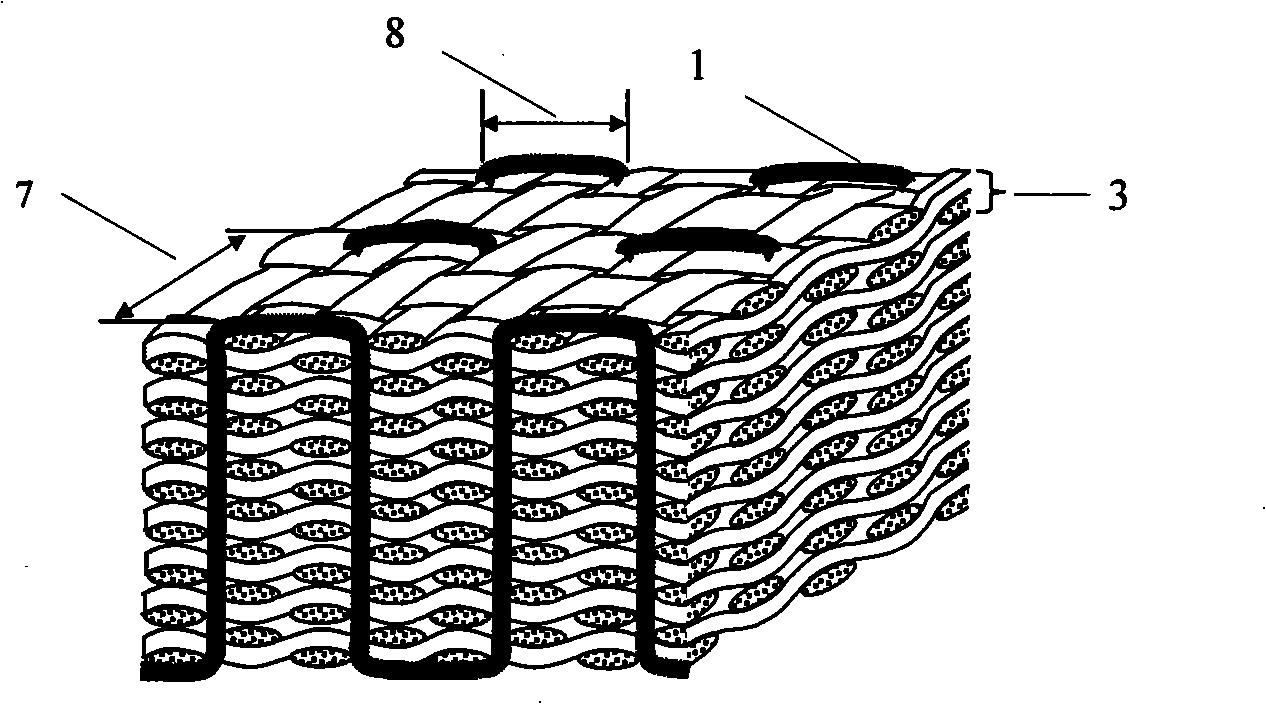

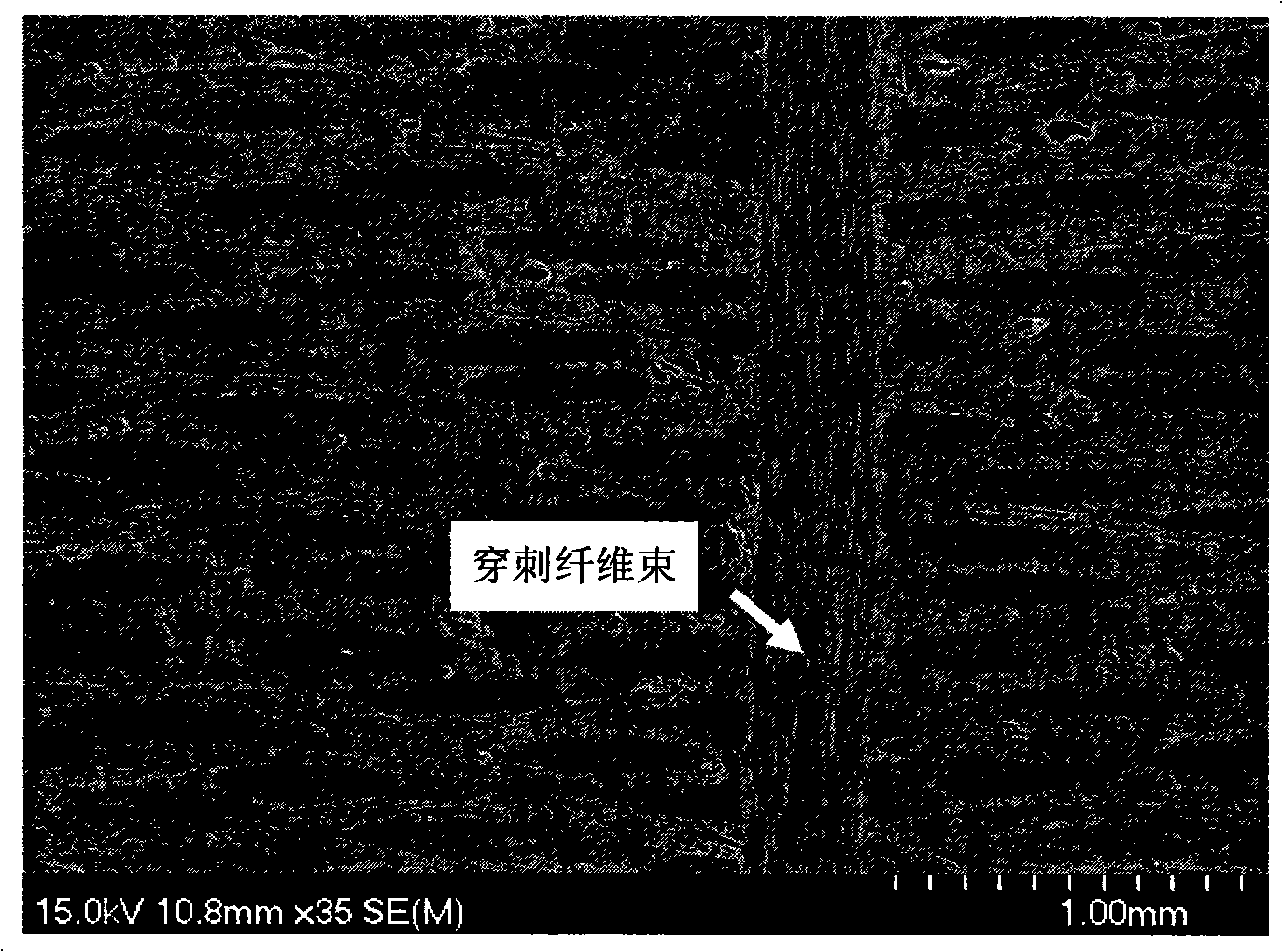

Process for preparing carbon/silicon carbide composite material

ActiveCN101337825AIncreased interlaminar shear strengthHigh tensile strengthInterlaminar shearPyrolytic carbon

The invention discloses a preparation method for a carbon / carborundum composite material. Firstly, carbon fibre is woven into single-layer plain cloth; a plurality of layers of the plain cloth are superposed, and are punctured and stitched with carbon fiber, thus forming a prefabricated carbon fiber body. The prefabricated carbon fiber body is arranged in a vacuum furnace and boiled off as well as pretreated; subsequently, pyrolytic carbon deposits, thus getting the C / C composite material; the multihole C / C composite material is heated; a SiC basal body is impregnated in the treated C / C composite material by adopting the CVI method, thus getting the C / SiC composite material. As the C / SiC composite material is prepared by puncturing and stitching the prefabricated carbon fiber body in combination of the CVI method. The interlaminar shear strength of the C-SiC composite material at 1200 DEG C is increased to 36 to 49MPa from 22 to 24MPa of the prior art; the tensile strength is increased to 275 to 345MPa from 220 to 300MPa of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

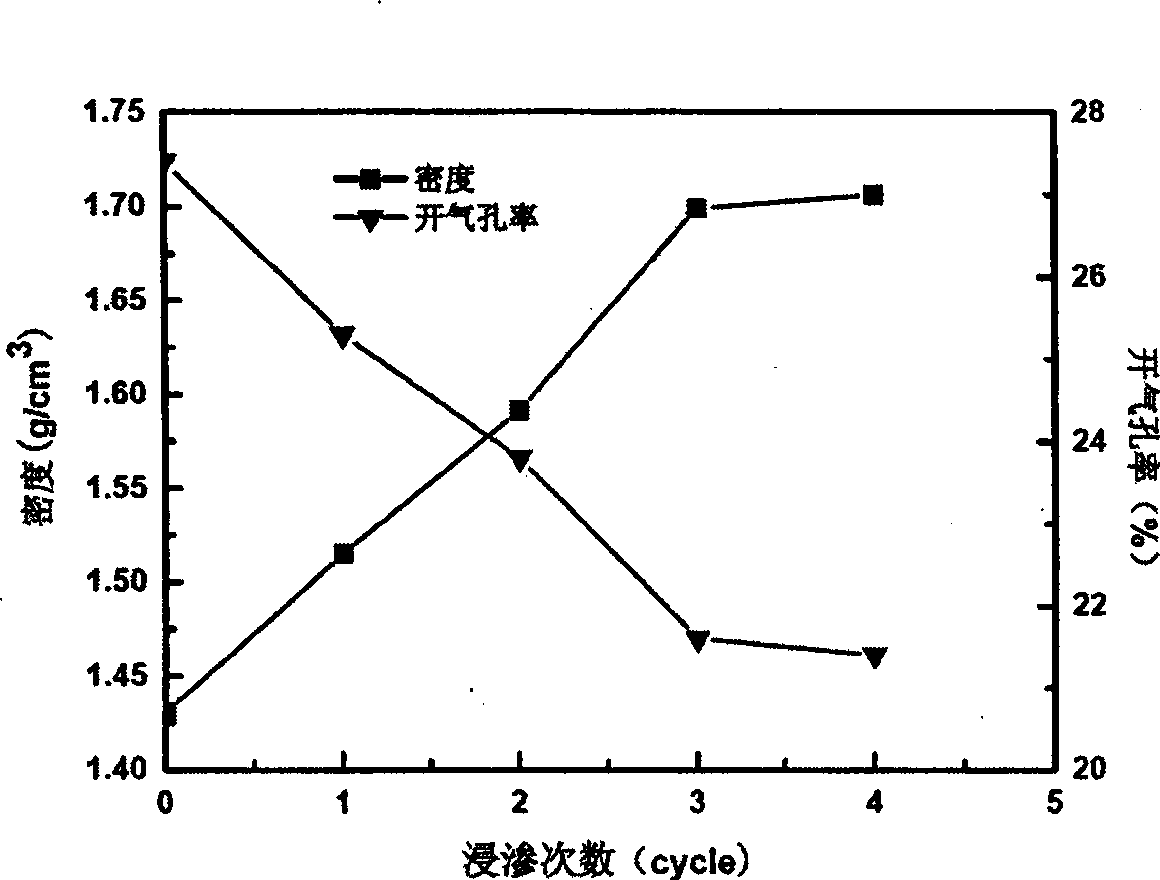

Preparation method of silicon carbide fiber reinforced silicon carbide composite material

The invention discloses a preparation method of a silicon carbide fiber reinforced silicon carbide composite material. The preparation method comprises the following steps of preparing a SiC fiber knitted piece, placing the SiC fiber knitted piece into a vacuum furnace to carry out chemical vapor deposition through adopting methane or propylene as feed gas and a pressure difference method to deposit a carbon coating on the surface of the SiC fiber knitted piece, carrying out a vacuum impregnation process on the SiC fiber knitted piece deposited with the carbon coating through adopting a liquid SiC ceramic precursor as impregnation liquid, putting the impregnated SiC fiber knitted piece into a mold, carrying out thermal molding crosslinking in a dynamic nitrogen atmosphere, putting the crosslinked SiC fiber knitted piece into a cracking furnace to carry out high temperature cracking in a dynamic nitrogen atmosphere, repeating a vacuum impregnation-thermal molding crosslinking-high temperature cracking cycle so as to finish preparation until the weight increment of a sample obtained after the vacuum impregnation-thermal molding crosslinking-high temperature cracking cycle is less than 1% of the weight increment of the sample obtained after the previous cycle. The preparation method has the advantages of short period, low cost, low pollution and toxic effects, etc.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing extra-coarse grained carbide alloy

The invention discloses a method for preparing an extra-coarse grained carbide alloy. The method is characterized by comprising the following steps of: pre-mixing extra-coarse tungsten carbide powder having a grinding Fisher particle size of over 6 mu m and cobalt powder; adding molding agents and pressing the mixture to form lumps; pre-sintering the lumps in a degumming furnace having ammonia decomposition gas therein; placing the obtained product, the tungsten carbide powder and the cobalt powder into a ball mill for smashing and wet grinding to prepare a mixture containing 6 to 13 percent cobalt; adding molding agents into the mixture, and pressing to obtain the finished product; after degumming the finished product, sintering the finished product at the high temperature by using a pressurized sintering furnace; and thermally treating the sintered product by using a double-chamber high-pressure gas cooling vacuum furnace, wherein 87 to 94 parts of tungsten carbide, 6 to 13 parts of carbide powder and 0.5 to 2.5 parts of molding agent are pre-mixed. The method avoids the dispersing or grading sieving, and cobalt coating of the tungsten carbide; moreover, the prepared carbide alloy has good compactness, high strength and impact resistance, simple production process and no environment pollution.

Owner:SHANDONG CEMENTED CARBIDE

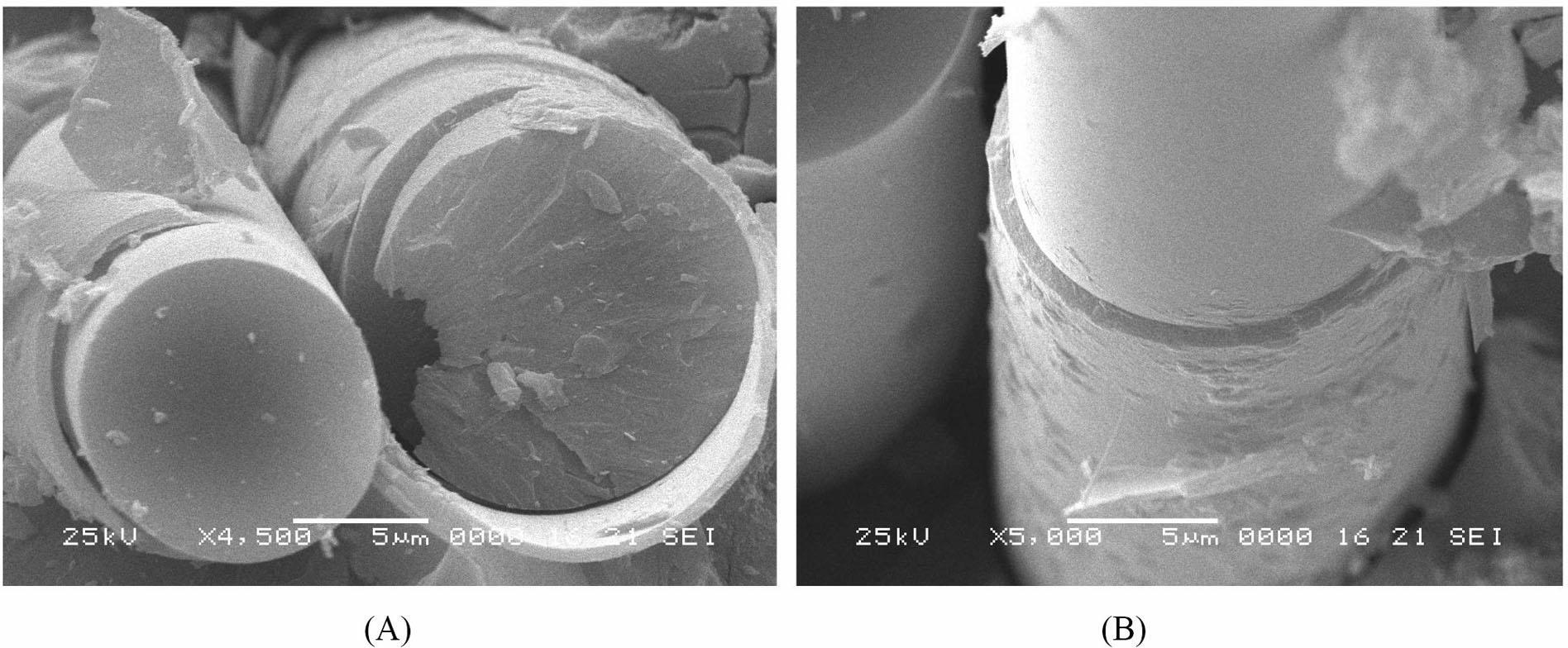

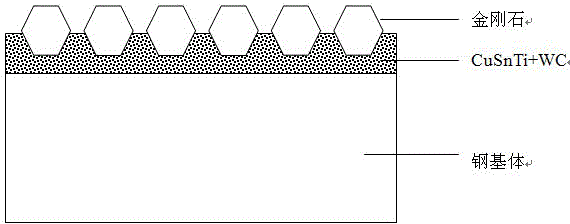

Manufacturing method of single-layer brazing diamond grinding wheel

InactiveCN103817610ALow costImprove wear resistanceAbrasion apparatusGrinding devicesChemical reactionFiller metal

The invention discloses a manufacturing method of a single-layer brazing diamond grinding wheel. The manufacturing method includes steps of preparing a base body of the diamond grinding wheel by a machining method, deoiling and descaling; utilizing mixture of Cu powder, Sn powder, TiH2 powder and WC (wolfram carbide) powder as brazing filler metal of the diamond grinding wheel, and mechanically blending uniformly; sequentially arranging the base body, the brazing filler metal and diamond grains of the diamond grinding wheel to manufacture a tool forming blank; placing the tool forming blank into a vacuum furnace, subjecting the brazing filler metal and the diamond grains to chemical reaction by means of brazing process, cooling to the room temperature along with the furnace, and discharging. Cost for raw materials can be reduced to some extent and oxidation pollution can be avoided by utilizing TiH2 as a Ti source, wear resistance and heat resistance of the brazing filler metal can be improved by adding the superfine WC powder into the Cu powder, the Sn powder and the TiH2 powder, graphitization of diamond can be reduced, thereby heat damage of the diamond can be reduced, and the diamond grinding tool can sufficiently give into play.

Owner:ZHONGYUAN ENGINEERING COLLEGE

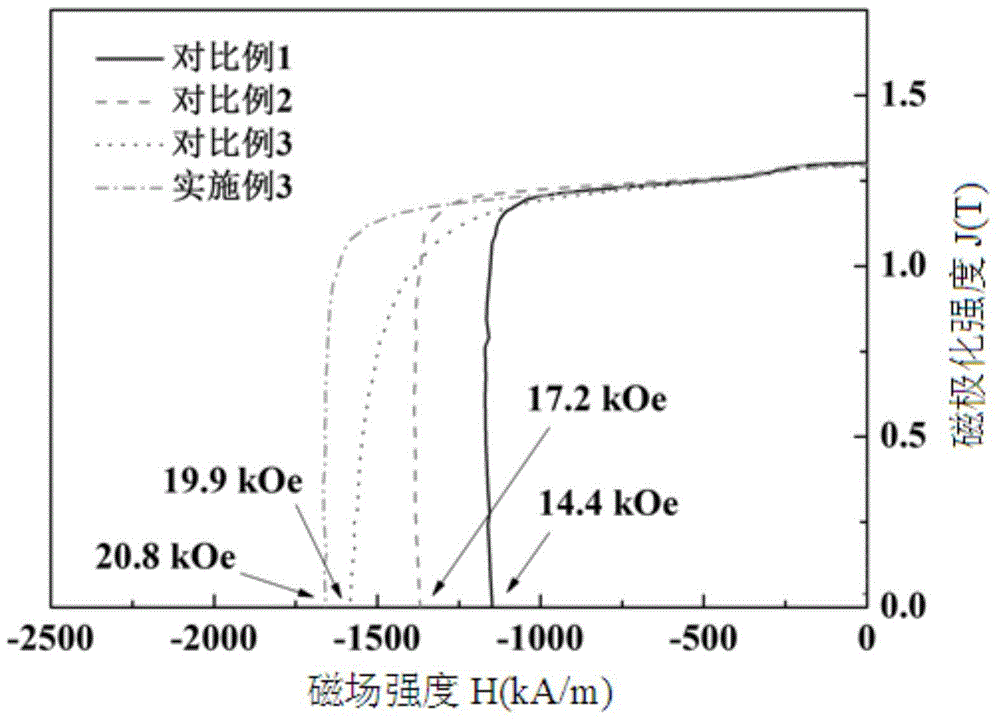

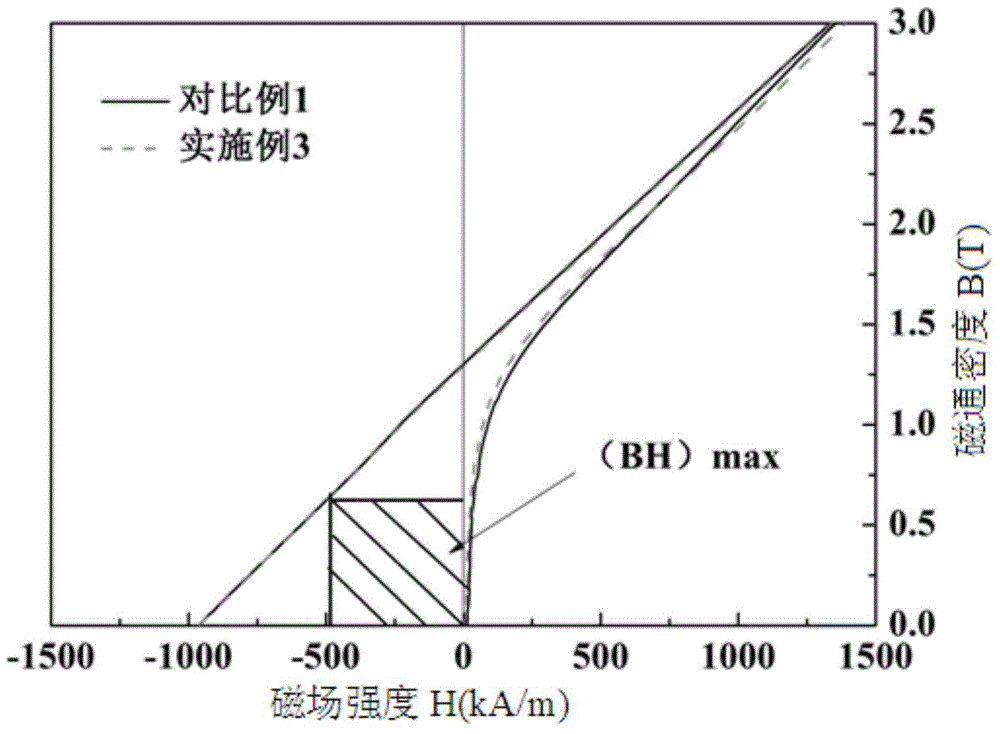

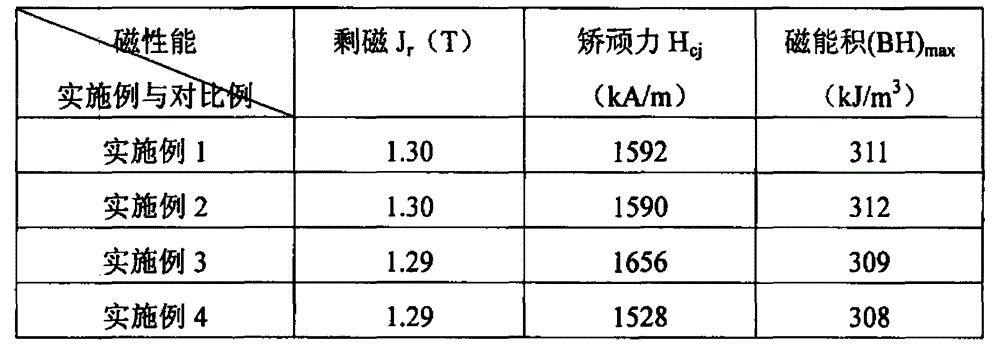

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

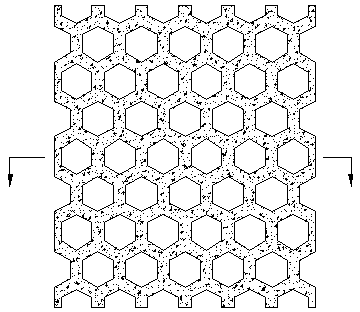

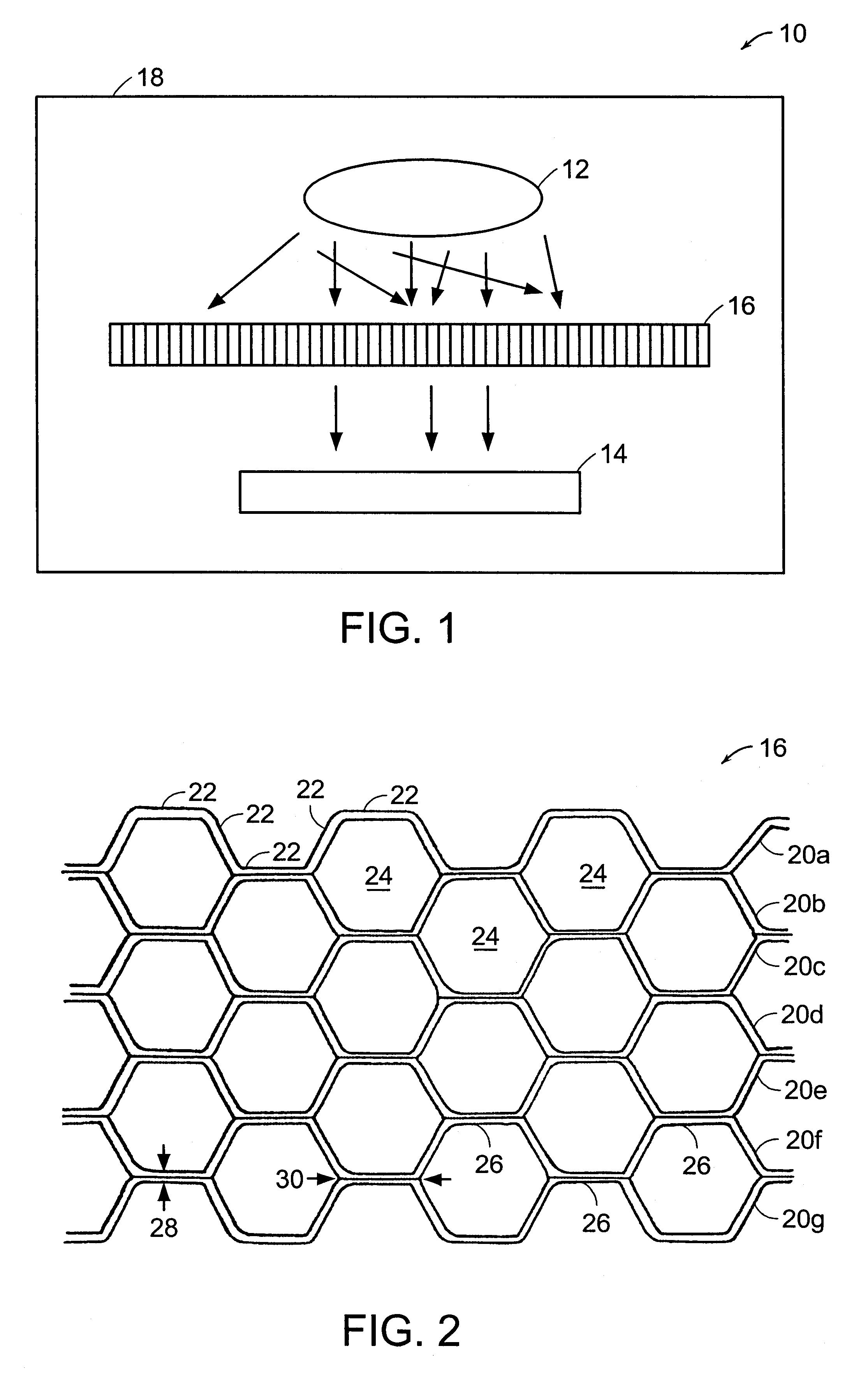

Brazed honeycomb collimator

A collimator filter for a physical vapor deposition apparatus useful for coating semiconductor wafers includes a plurality of corrugated ribbons attached at abutting double-walled nodes by resistance spot welding. The nodes are sealed by application of a braze material to diverging wall portions of the nodes by extrusion or spraying, followed by heating in a vacuum furnace. Alternatively, the nodes may be sealed by application of a braze material foil to a top and a bottom surface of the collimator followed by heating in the vacuum furnace. By sealing the nodes, a significant reduction may be achieved in outgassing and generation of particulate contaminants.

Owner:INNOVENT

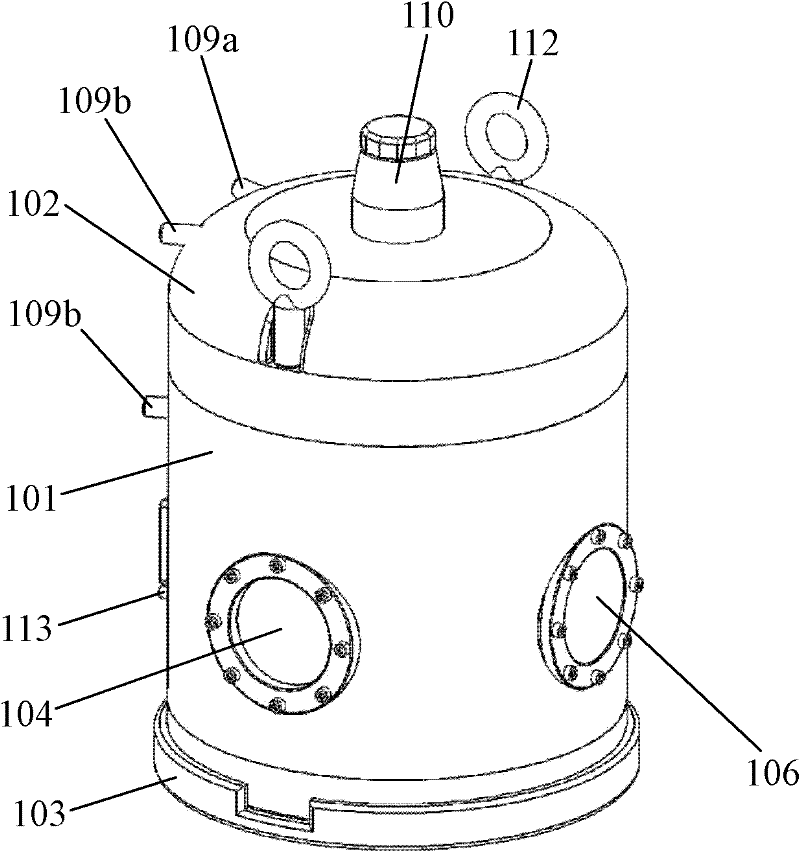

High-temperature fused salt synchrotron radiation in-situ research device

InactiveCN102590253AEliminate phenomena that introduce artifactsExpand the detection angleMaterial analysis using wave/particle radiationFluorescenceIonization chamber

The invention discloses a high-temperature synchrotron radiation in-situ research device. The high-temperature fused salt synchrotron radiation in-situ research device comprises a fused salt test tube, a vacuum furnace, a heating device, a first ionization chamber, a second ionization chamber or a charge coupled device (CCD) detector and an external fluorescence detector, wherein a cavity is formed in the vacuum furnace; an incident window, a transmission window and a fluorescence window are arranged on the furnace wall of the vacuum furnace; the incident window and the transmission window are arranged coaxially and collinearly; the axial line of the fluorescence window is vertical to that of the incident window and / or the transmission window; the heating device is arranged in the cavity of the vacuum furnace and is used for heating the fused salt test tube arranged in the heating device; an incident hole, a transmission hole and a fluorescence hole corresponding to the incident window, the transmission window and the fluorescence window respectively are formed on the heating device; the first ionization chamber corresponding to the incident window is arranged outside the vacuum furnace; the second ionization chamber or the CCD detector corresponding to the transmission window is arranged outside the vacuum furnace; and the external fluorescence detector corresponding to the fluorescence window is arranged outside the vacuum furnace.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

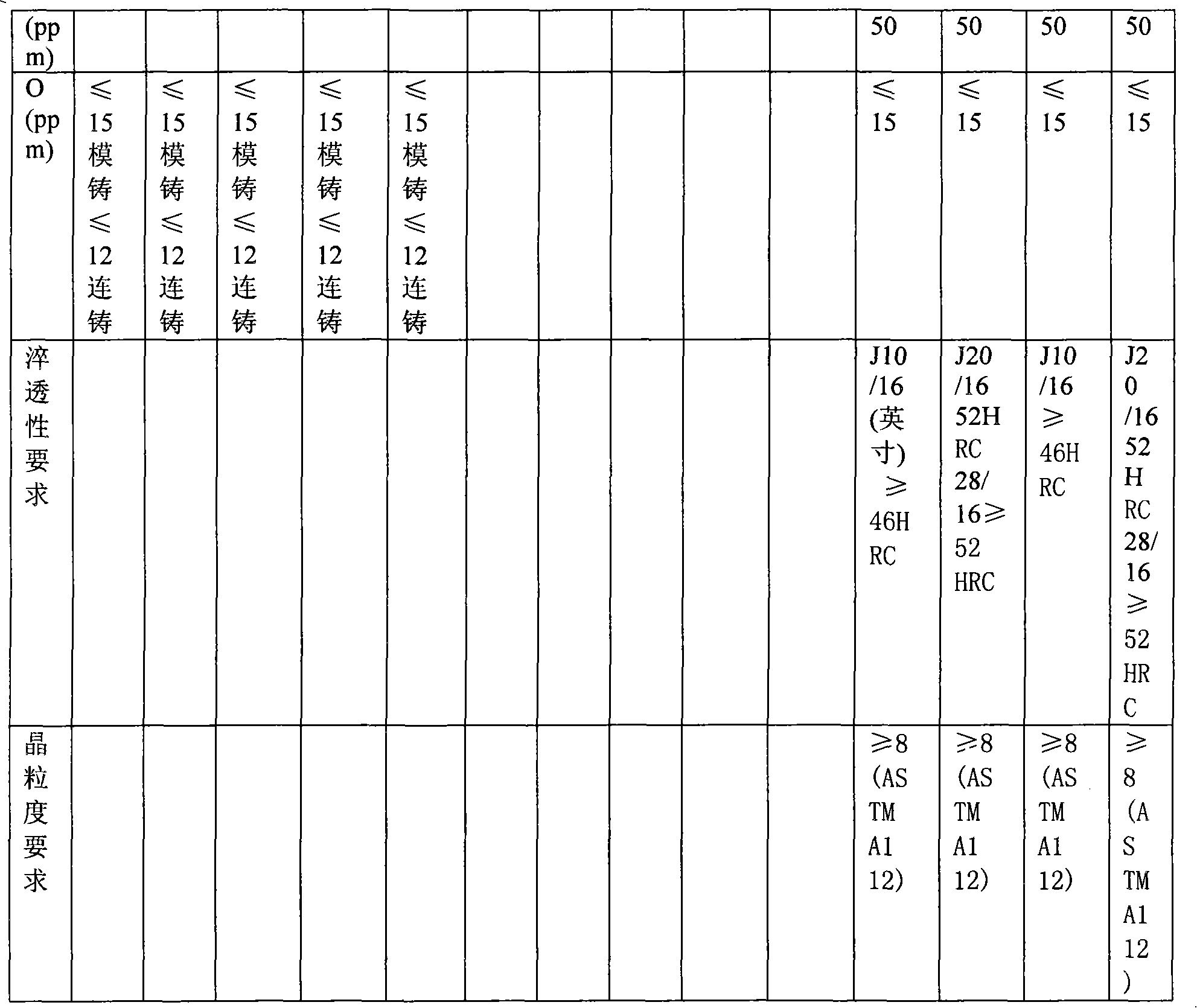

High-carbon-chromium bearing steel and manufacture method thereof

The invention discloses high-carbon-chromium bearing steel and a manufacture method thereof. The high-carbon-chromium bearing steel comprises the following chemical compositions by weight percentage: C: 0.90-1.05; Cr: 0.90-1.20; Mn: 0.90-1.25; Si: 0.45-0.75; Al: 0.02-0.04; oxygen is less than or equal to 0.0007; phosphorus is less than or equal to 0.010; sulfur is less than or equal to 0.005; titanium is less than or equal to 0.0025; copper is less than or equal to 0.15; nickel is less than or equal to 0.10; nitrogen is less than orequal to 0.0070; and the balance of unavoidable impurities and Fe. The manufacture method comprises the following steps: smelting in an electric furnace, refining in a ladle arc furnace, degassing in a vacuum furnace, pouring steel liquid into steel ingots, heating steel ingots in a heating furnace, rolling the steel ingots into square billets by a rolling mill, heating the steel ingots in a heating furnace and rolling the steel ingots into round steel by a rolling mill. Compared with the prior art, the invention has high hardenability, high crystal grain size of more than 8 grade, high commonality in technology and wide application.

Owner:BAOSHAN IRON & STEEL CO LTD

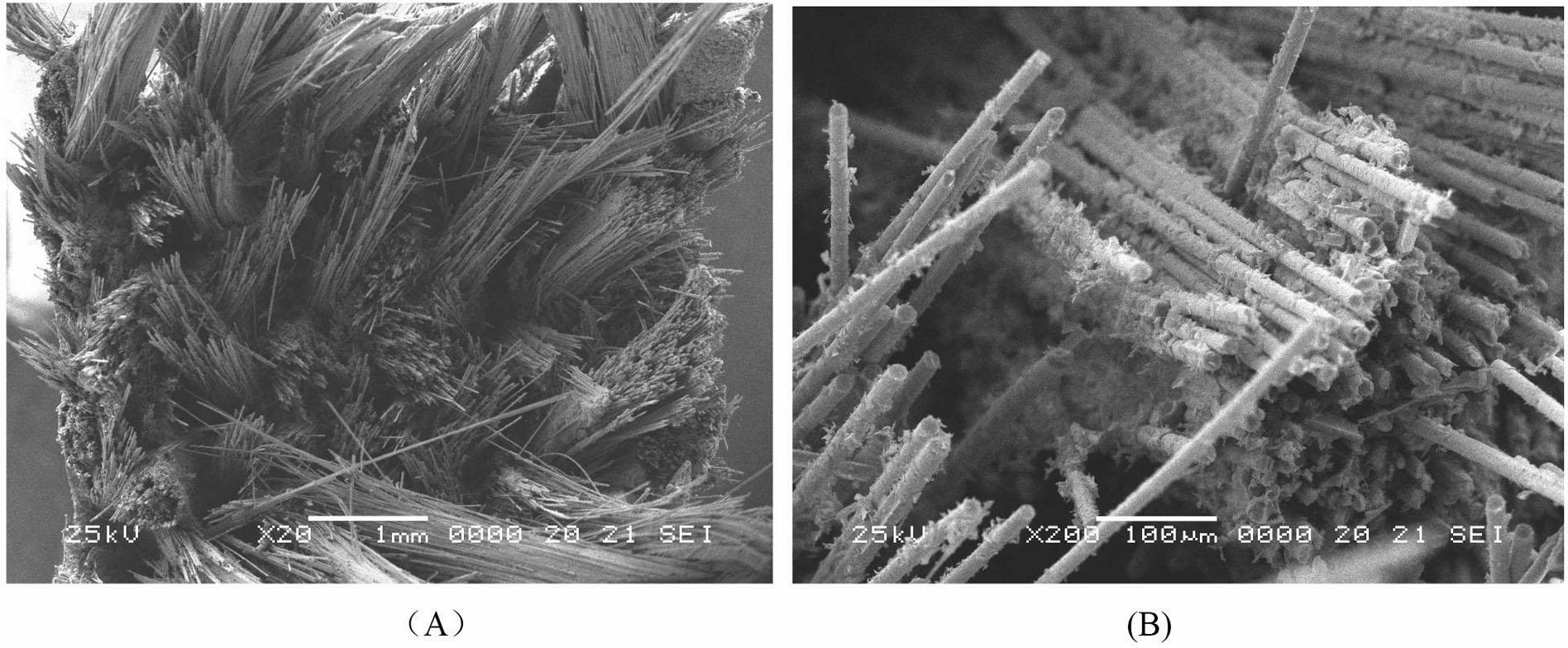

Charcoal/pottery brake lining manufacturing method for industrial brake

InactiveCN101493126AReduce processing intensityIncrease coefficient of frictionFriction liningGas phaseLow density

The invention discloses a method for manufacturing carbon / ceramic braking linings used in an industrial brake, which comprises the following steps: carbon fiber performs are prepared by a needle method; low-density C / C composite material is prepared by a chemical gas permeation method after the carbon fiber performs are treated in high temperature; the C / C composite material is treated in high temperature, machined and then the molten silicon infiltration is carried out on the C / C material in a high temperature vacuum furnace; Sic is formed by the Si and C reaction to prepare C / C-SiC baking material; and finally after the C / C-SiC baking material is machined, the C / C-SiC baking material is riveted with the steel backing by a rivet in a cold way to prepare the needed C / C-SiC baking material used in an industrial brake. The carbon / ceramic braking lining manufactured by the method has higher mechanical property and excellent frictional wear performance and is used in the industrial brake.

Owner:CENT SOUTH UNIV

High-toughness cadmium-free silver solder and preparation method thereof

ActiveCN101693325AImprove wettabilityHigh temperature toughnessWelding/cutting media/materialsSoldering mediaIntermediate frequencyManganese

The invention relates to a high-toughness cadmium-free silver solder and a preparation method thereof. The solder comprises the following materials by weight percent: 22-58 percent of Ag, 15-35 percent of Cu, 13-38 percent of Zn, 4-8 percent of Mn, 1.5-5 percent of Ni, 0.8-3 percent of Co, 0.01-0.45 percent of B, 0-1.5 percent of V, 0-1.5 percent of Nb, 0.005-0.9 percent of Ce, 0.005-0.9 percent of La and 0-0.5 percent of Sr. The preparation method comprises the following steps of smelting the metal with high-melting point and partial copper into a preliminary alloy A, smelting oxidized metal and partial copper in a vacuum furnace into a preliminary alloy B, smelting silver and the remained copper in an intermediate-frequency furnace and then adding the preliminary alloy A, adding metals of manganese and zinc and then adding the preliminary alloy B after complete fusion, fusing completely again and standing for 60 minutes, and casting to form a silver alloy ingot, performing even annealing and scaling on the alloy ingot, extruding the alloy into a stripe shape or a bar shape by an isothermal extrusion method, and then rolling into a band or drawing and reducing to a filament.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Method for preparing light highly-conductive hot carbon nano composite material

ActiveCN101250059AImprove high temperature thermal conductivitySimple preparation processHeat-exchange elementsFiberCarbon fibers

The invention relates to a preparation method of light carbon nanometer composite material with high thermal conductivity, belonging to the technical field of carbon nanometer material, which comprises selecting raw materials that uses carbon nano-tubes / carbon fibers as carbon raw material and uses high-carbon organic solution as stuff, mixing and solidifying that mixes and solidifies the carbon nano-carbon organic solution / carbon fiber with the high carbon organic solution, and graphitizing that sinters the material in a vaccum furnace under the protection of inertia gas or hydrogen gas at high temperature. Compared with the prior art, the invention uses carbon nano-tube / carbon fiber as raw material and has the characters of simple preparation, low energy consumption and low cost, and improves the high-temperature thermal conductivity of carbon nano-tube / carbon fiber with confirmed light weight and high strength, thereby reducing the product weight and obtaining better plasticity, thermal conductivity and thermal stability, with simple operation and better product repeatability.

Owner:上海纳晶科技有限公司

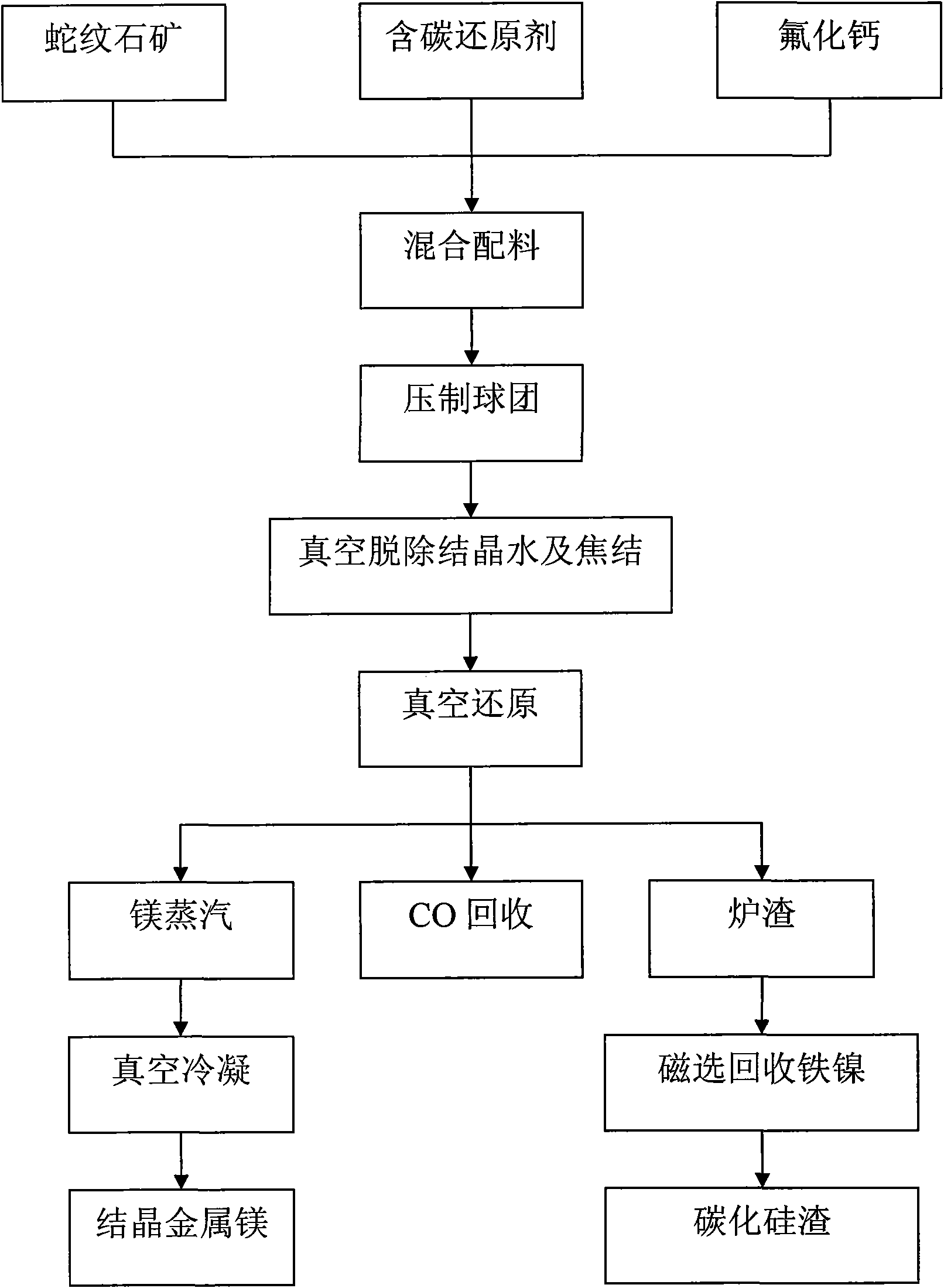

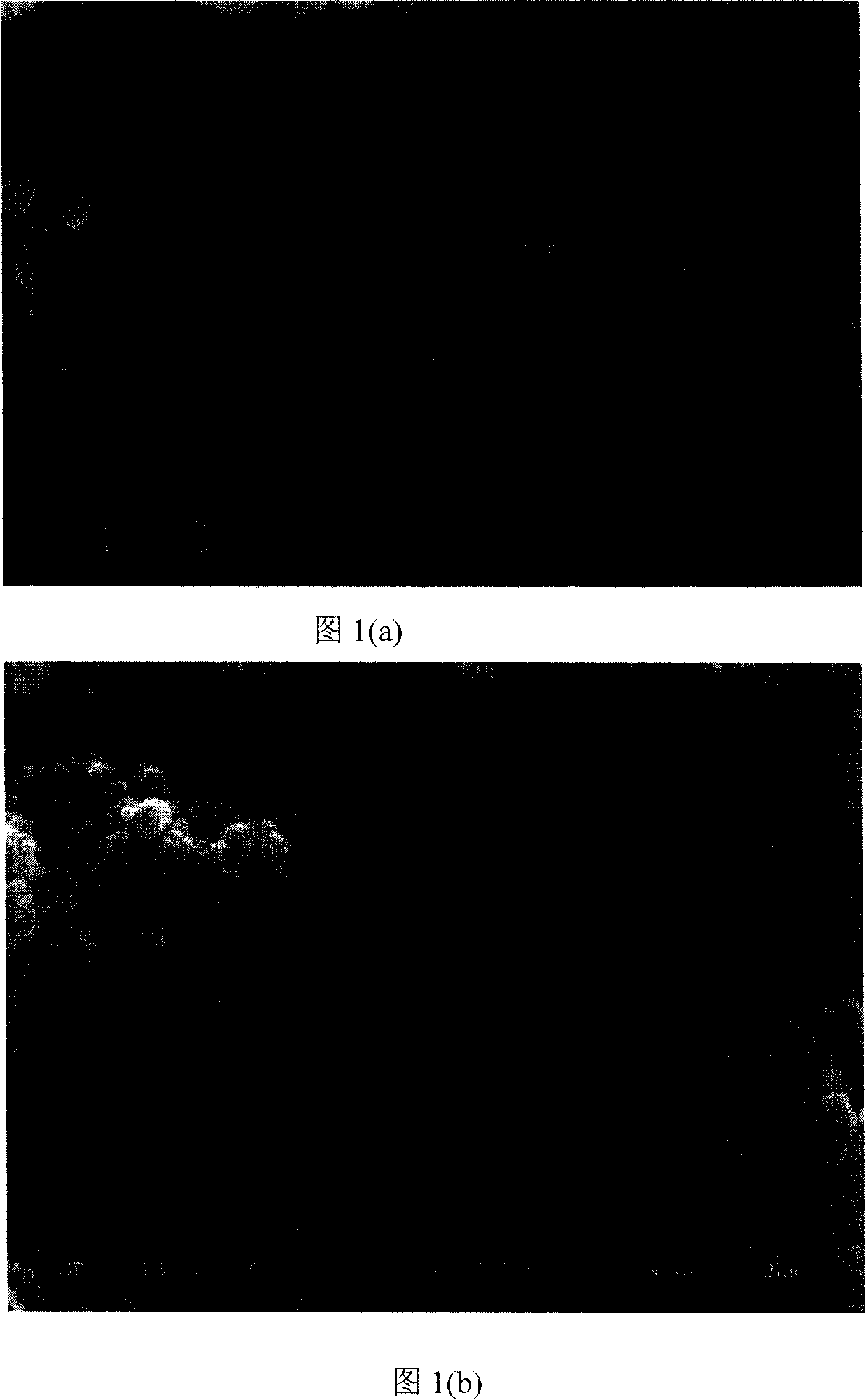

Method for preparing magnesium metal and by-product by vacuum carbothermic reduction with serpentine minerals

InactiveCN101560603AHigh in magnesiumNo need for calcination to remove carbonProcess efficiency improvementMagnetic separationSlagMassicot

The invention discloses a method for preparing a magnesium metal and a by-product by vacuum carbothermic reduction with serpentine minerals. The method comprises the following steps: using serpentine mineral powder as a raw material; adding a carbonaceous reducing agent which is 1 to 2 times of the theoretical quantity of carbon required for completely reducing magnesium silicate in the serpentine; adding a catalyst, and mixing the materials evenly to obtain a mixed raw material; pressing the mixed raw material into spherical or blocky ball agglomerations and drying the ball agglomerations; putting the dried ball agglomerations into a vacuum furnace, controlling the vacuum degree in the furnace to between 10 and 500 Pa, raising the temperature to between 500 and 700 DEG C, and keeping the temperature for 20 to 60 minutes to remove crystal water and clinker the materials; keeping the vacuum degree in the furnace, raising the temperature to between 1,200 and 1,500 DEG C, and reducing the magnesium silicate and oxides of metallic iron and nickel at a constant temperature for 30 to 60 minutes; and condensing magnesium vapor obtained from the reduction on a magnesium condenser into crystallized magnesium, recycling the metallic iron and the metallic nickel in the slag through magnetic separation, and preparing the slag after the magnetic separation into industrial silicon carbide through decarburization and purification.

Owner:北京华夏建龙矿业科技有限公司

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

Diffusion soldering method capable of making copper-aluminium joint binding strength high

InactiveCN1743118ASimple processing methodReduce manufacturing costWelding/cutting media/materialsSoldering mediaComposite plateCopper

A diffusion soldering method for making the jointing strength of copper-aluminium joint high is disclosed. Place the flaky Al-Si-Mg solder (after being removed oxide film from the surface) between the faces to be welded of the copper plate and the aluminium plate folded each other which are clamped by stainless steel plate and put into the vacuum furnace to conduct vacuum soldering. The craftwork parameter as follows: programming rate: 10-20 deg.C / min, when the temperature raises to 300-350 deg.C and 510-540 deg.C, keep the temperature 5min respectively, then continues to rise the temperature to 616-624 deg.C, and keep the temperature for 4-6 minutes. The invention realizes high reliability joining of copper and aluminum, good interface of composite plate, good sealing performance and smooth beauty joint part. The shear strength of the interface is 60Mpa and the tensile strength of the interface is more than 100Mpa.

Owner:北京中纺精业机电设备有限公司

Method for preparing inoxidzable coating at high-temperature on carbon/carbon composite material surface

The invention provides a preparation method of a high temperature oxidation-resistant coating on the surface of a carbon / carbon composite material. The preparation method comprises placing Si powder, C powder, and Al2O3 into an agate ball milling tank, adding distilled water, mixing and ball milling, taking out the mixed solution, and drying to form inner layer embedded powder; placing the treated C / C composite material into the powder in a graphite crucible; placing into a vertical type vacuum furnace with graphite being the heating body for preparing an undercoat; mixing the Si powder, Mo powder, W powder and C powder with absolute ethanol and silica sol to obtain slurry; and uniformly brush coating surface of the SiC inner layer of the C / C composite material I with the slurry, drying, and placing into an alumina crucible for preparing a top coating. The antioxidant protective time of the C / C composite material is increased from 100 hours in prior art to 200-252 hours in 1500 DEG C air using high temperature oxidation resistance of MoSi2 and WSi2 via combination of the undercoat and the top coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

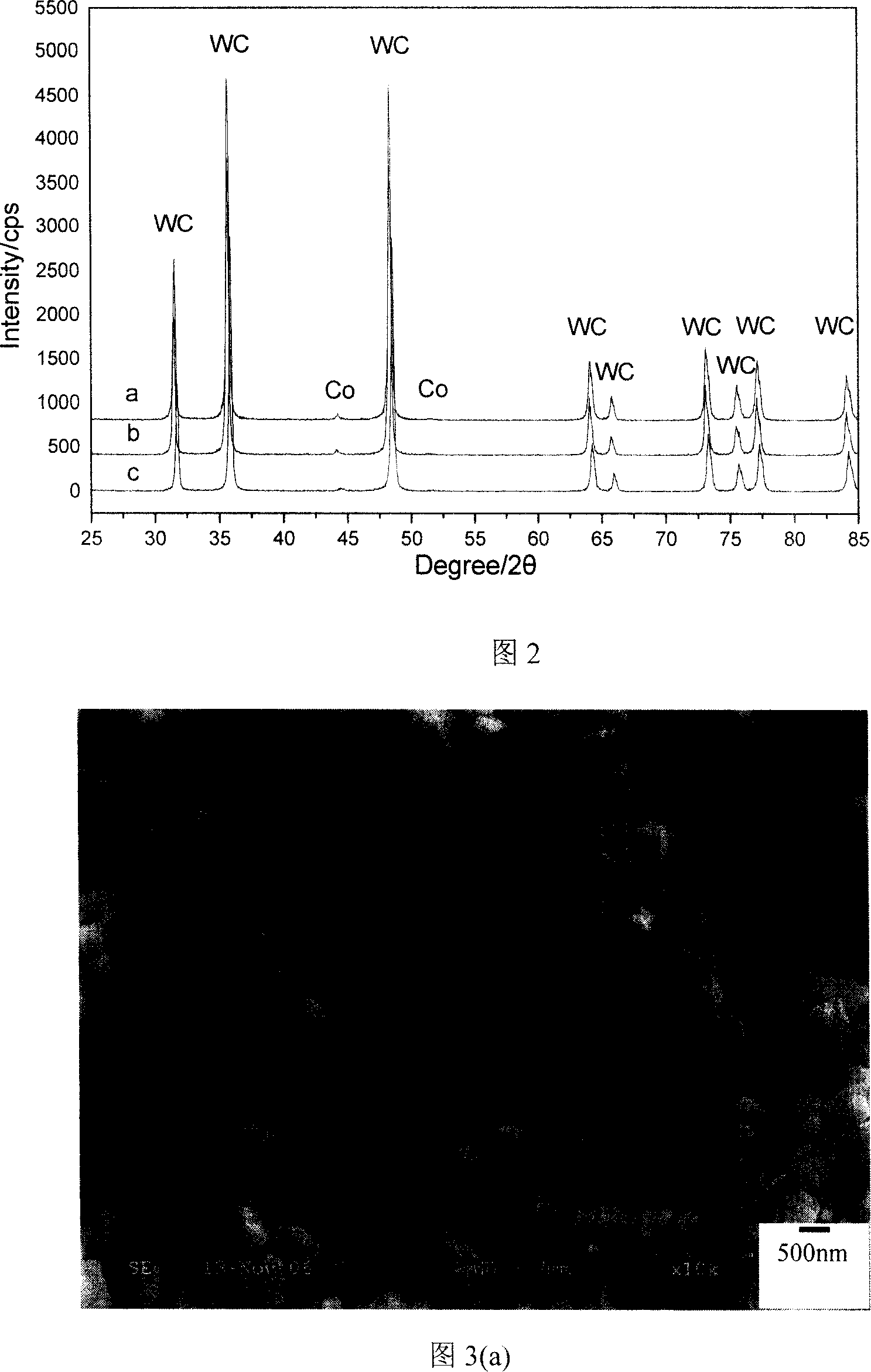

Simple fast preparing process of superfine WC-Co composite powder

The simple fast preparation process of superfine WC-Co composite powder belongs to the field of nanometer powder preparing technology. The preparation process includes the following steps: mixing WO2.9, Co3O4 and carbon black material in the required Co content; ball milling the mixture in a ball milling into superfine powder and cold pressing; heating in a vacuum furnace at vacuum condition to produce redox and carbonizing reaction at heating rate of 15-30 deg.c / min, reaction temperature 1050-1150 deg.c for 3-4 hr. The present invention has simple preparation path and short technological process, and obtains WC-Co composite powder of average particle size smaller than 400 nm.

Owner:BEIJING UNIV OF TECH

Method for preparing Al-base composite material

InactiveCN101058866APromote wettingImprove uniformityLiquid/solution decomposition chemical coatingVacuum furnaceAluminum matrix composites

The invention discloses a making method of aluminium-based composite material, which comprises the following steps: fusing the aluminium based alloy at 750 deg. c; adding the alloy into 0. 15-0. 35wt% CeO2 powder; stirring; alloying; insulating; adding reinforcer during insulating to stir; transmitting the material into vacuum furnace to degas; casting; making the aluminium based material; selecting carbon fiber as the base of reinforcer; metalizing the surface; setting the quantity of reinforcer as 3-5% as carbon fiber.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com