Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205results about How to "Wide particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epitaxial Structures, Methods of Forming the Same, and Devices Including the Same

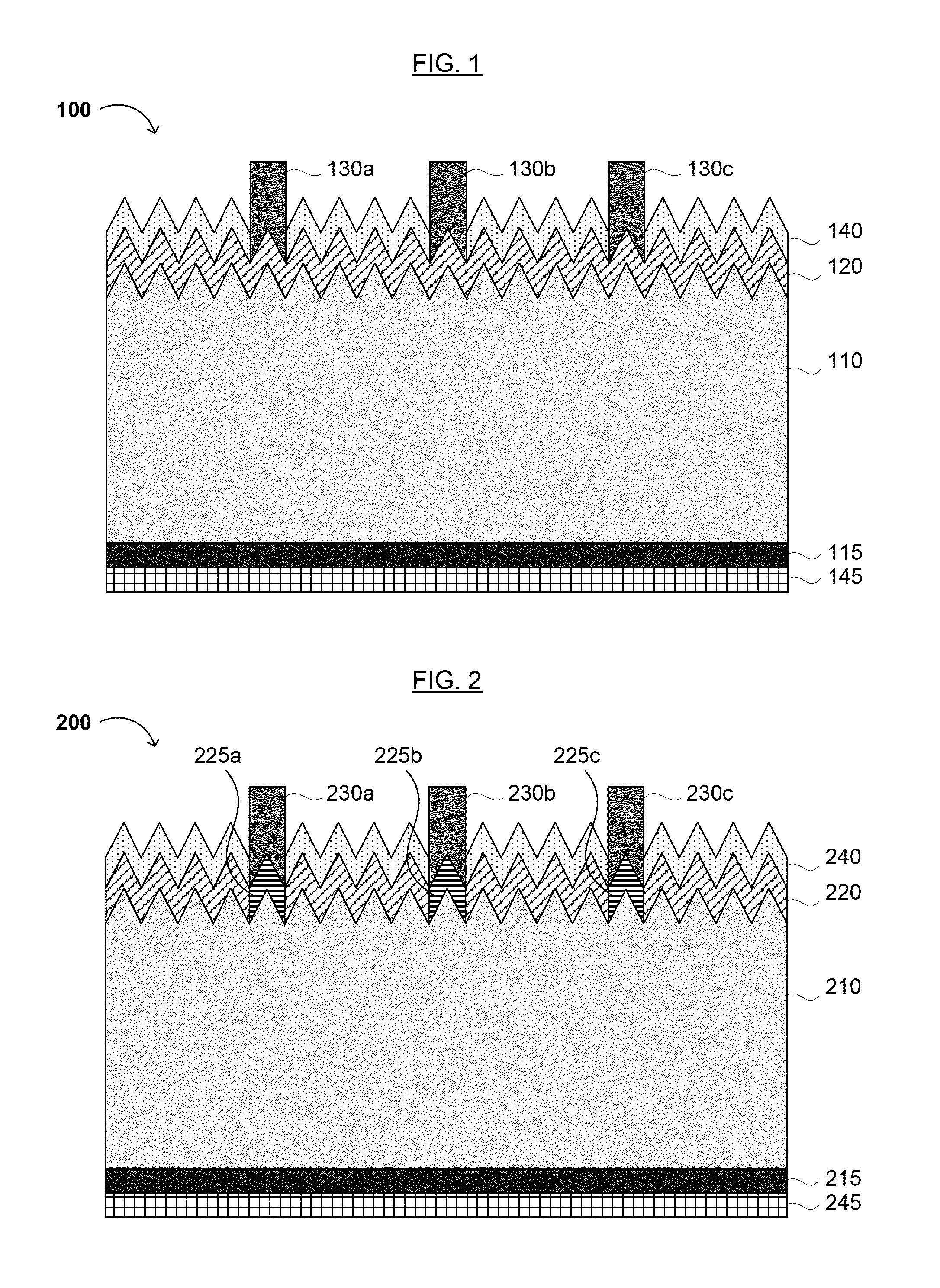

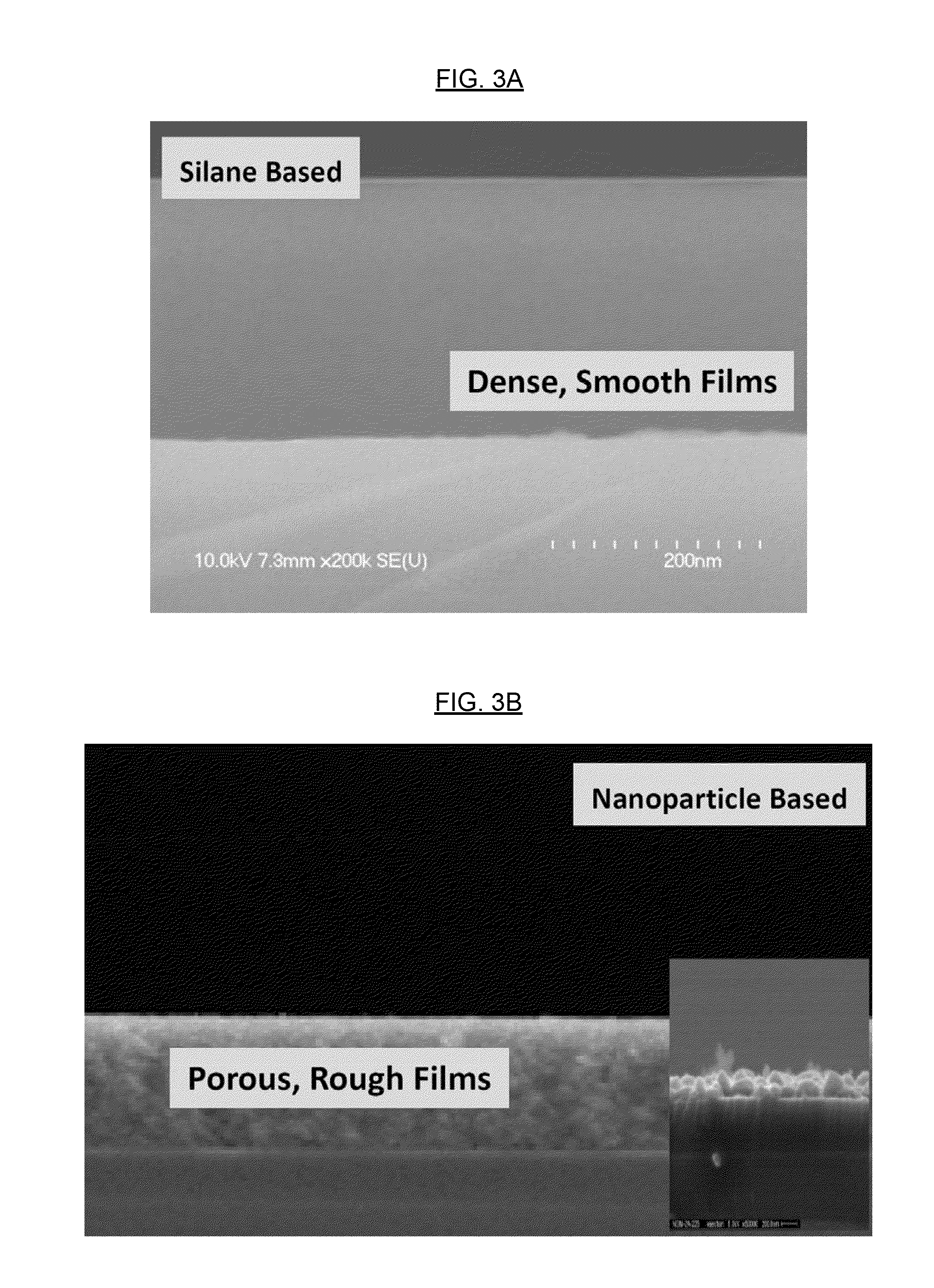

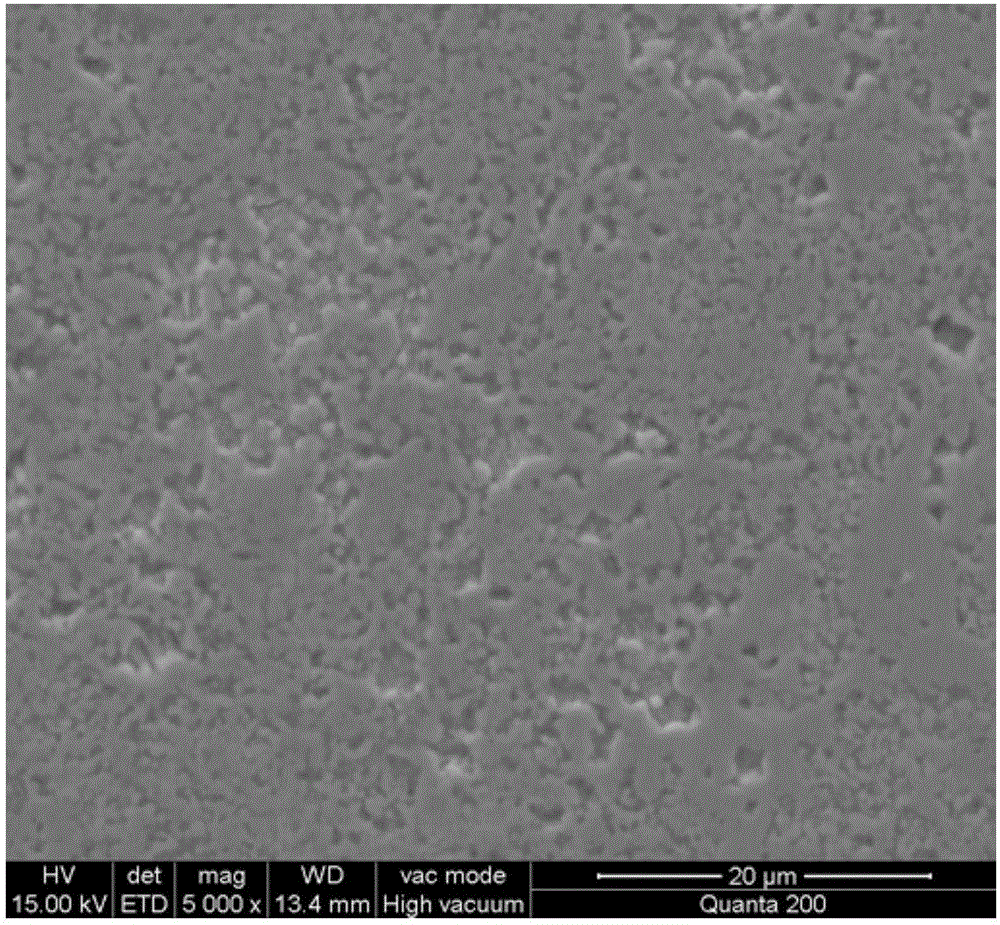

ActiveUS20110240997A1Wide particle size distributionSintering property becomes poorFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsSubstrate surface

Epitaxial structures, methods of making epitaxial structures, and devices incorporating such epitaxial structures are disclosed. The methods and the structures employ a liquid-phase Group IVA semiconductor element precursor ink (e.g., including a cyclo- and / or polysilane) and have a relatively good film quality (e.g., texture, density and / or purity). The Group IVA semiconductor element precursor ink forms an epitaxial film or feature when deposited on a (poly)crystalline substrate surface and heated sufficiently for the Group IVA semiconductor precursor film or feature to adopt the (poly)crystalline structure of the substrate surface. Devices incorporating a selective emitter that includes the present epitaxial structure may exhibit improved power conversion efficiency relative to a device having a selective emitter made without such a structure due to the improved film quality and / or the perfect interface formed in regions between the epitaxial film and contacts formed on the film.

Owner:ENSURGE MICROPOWER ASA

Toner coagulant processes

InactiveUS6416920B1Improve productivityQuality improvementOrganic dyesDevelopersPolymer scienceSilicon oxide

Owner:XEROX CORP

Aggregation processes

InactiveUS6309787B1Simple and economical processExcellent colorantDevelopersMiniemulsionPolymer chemistry

A process comprising aggregating a colorant encapsulated polymer particle containing a colorant with colorant particles and wherein said colorant encapsulated latex is generated by a miniemulsion polymerization.

Owner:XEROX CORP

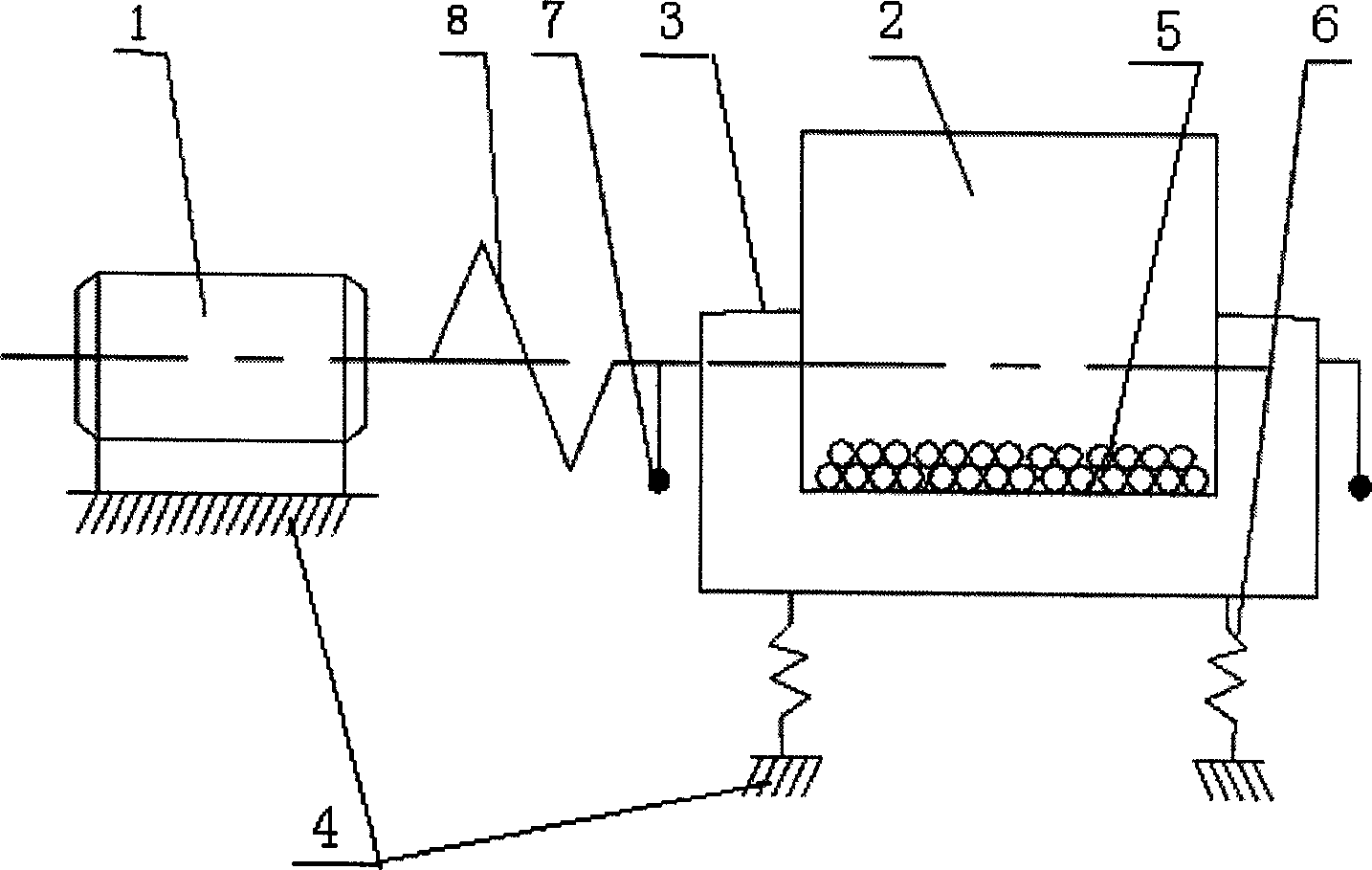

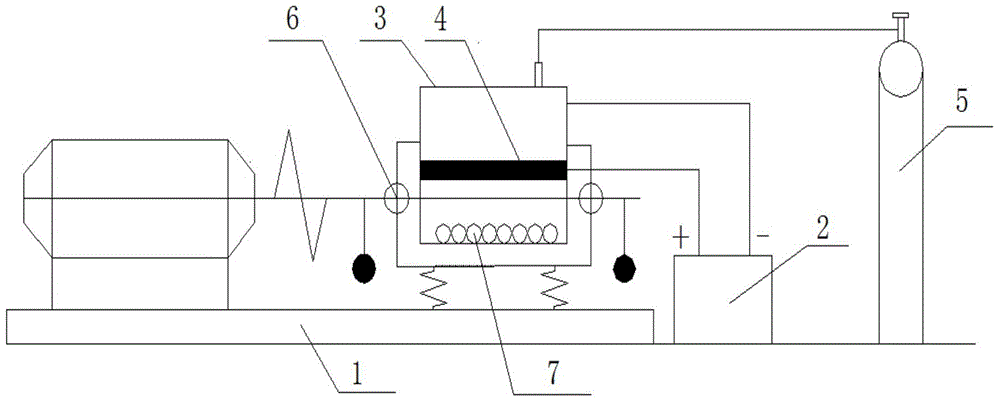

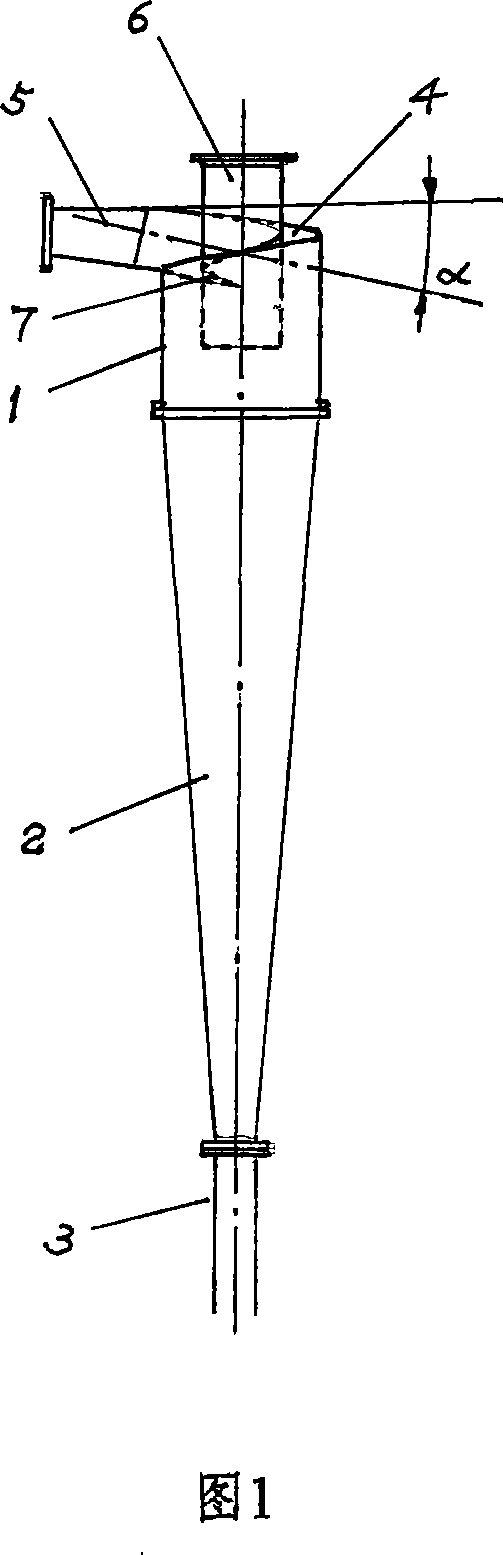

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

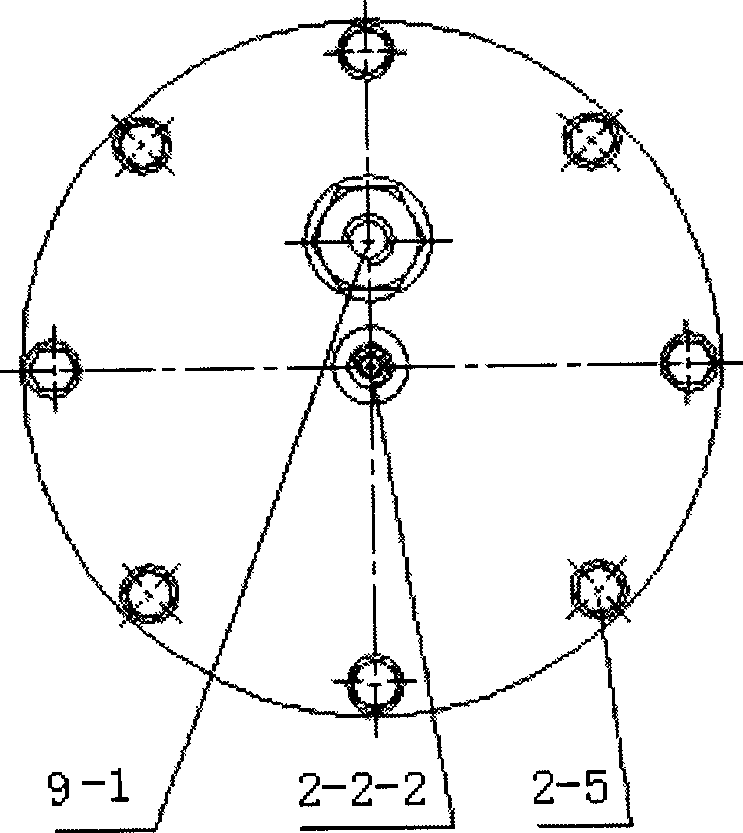

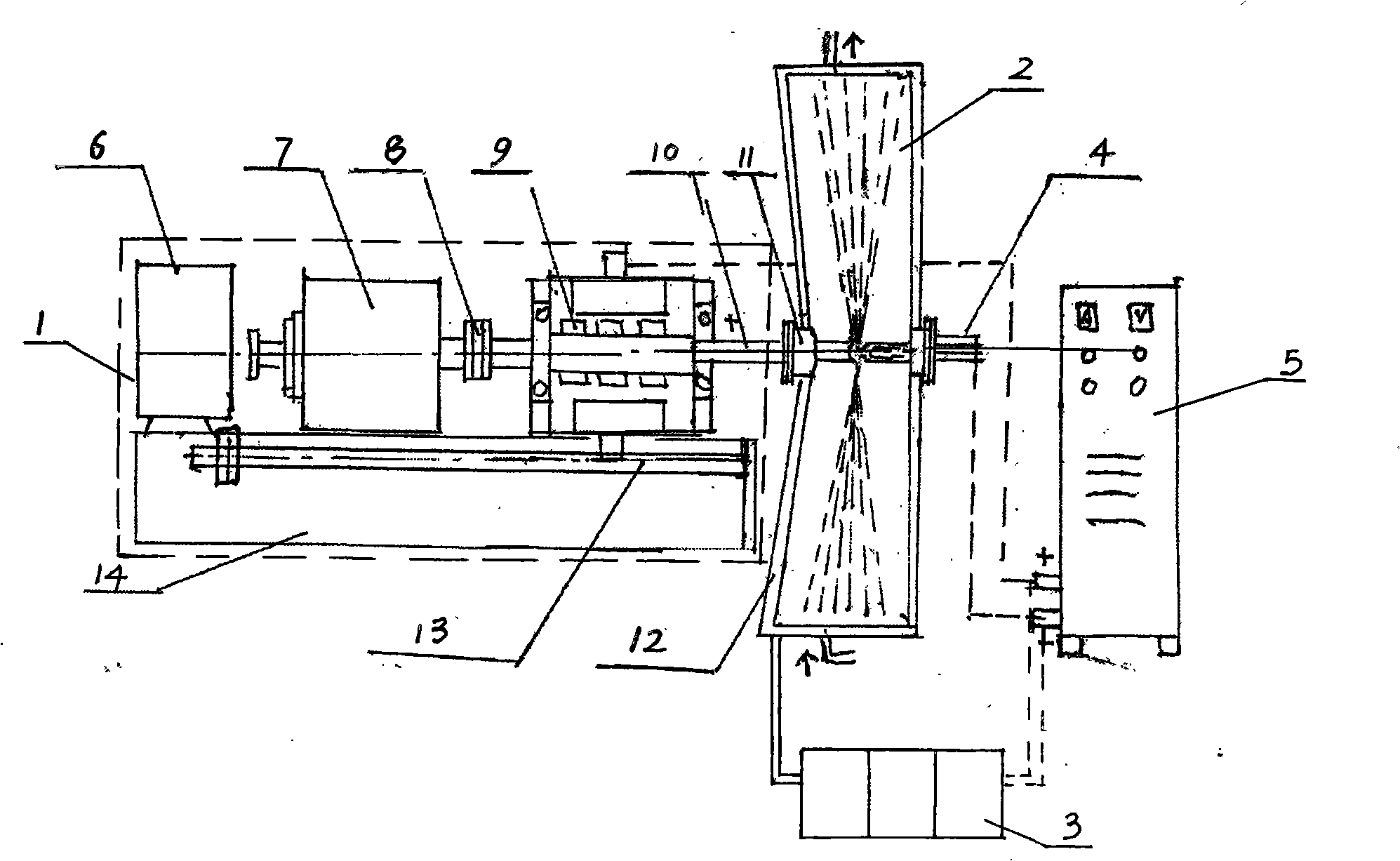

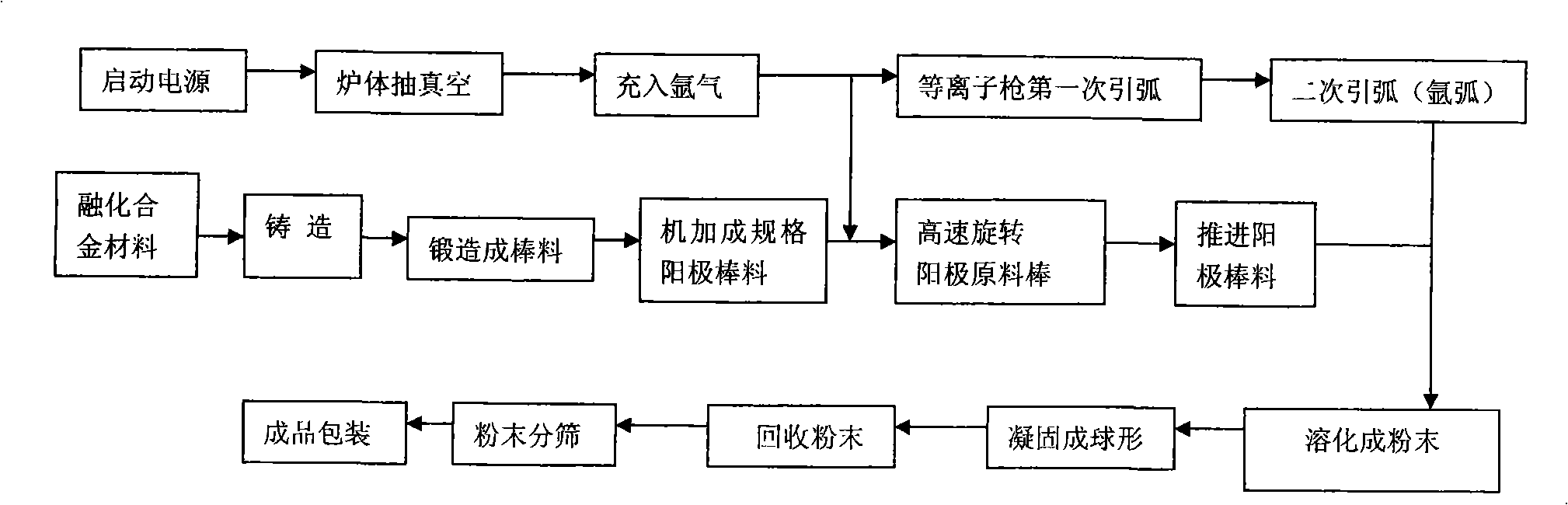

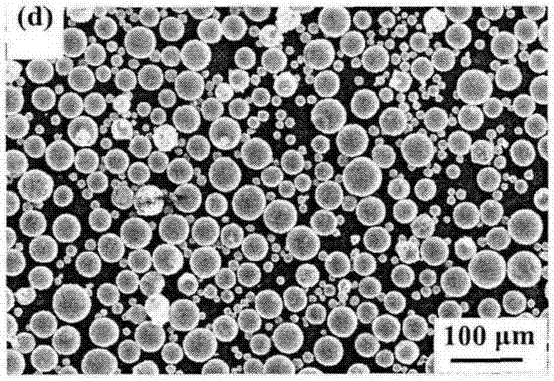

Plasma rotating electrode milling machine group and technique

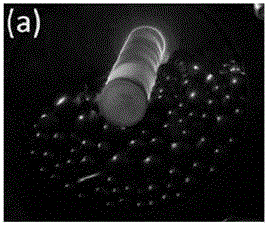

The invention relates to a plasma rotary electrode powder milling set and a process thereof, relating to the technical field of powder metallurgy. The milling set comprises a rotating feeding mechanism, a vacuum furnace, a vacuum unit, a plasma gun device and an electrical source. The rotating feeding mechanism is arranged at the exterior of one side of the vacuum furnace; the plasma gun device is arranged at the interior of the other side of the vacuum furnace; the vacuum unit is communicated with the vacuum furnace through a ventilation pipe, wherein, the vacuum furnace body has a double-decker sandwich structure, and cooling circulating water is injected into the sandwich structure; a receiving mechanism is arranged at the bottom part of the vacuum furnace, wherein, the receiving mechanism comprises two cut-off valves connected in series. The process includes the following steps: metal is processed into electrode bars; low-voltage heavy current is applied to the electrode bars to melt the electrode bars in a highly vacuumized melting chamber through the high temperature produced by the cathode arc of the plasma gun, and to eject the molten metal instantly by the strong centrifugal force produced through the high-speed rotation of the electrode bars to produce fine metal powders. The invention is characterized in that the yield of perfect spherical metal powders is up to 97 percent, and the powders are free from the contamination of any microelement.

Owner:张建利

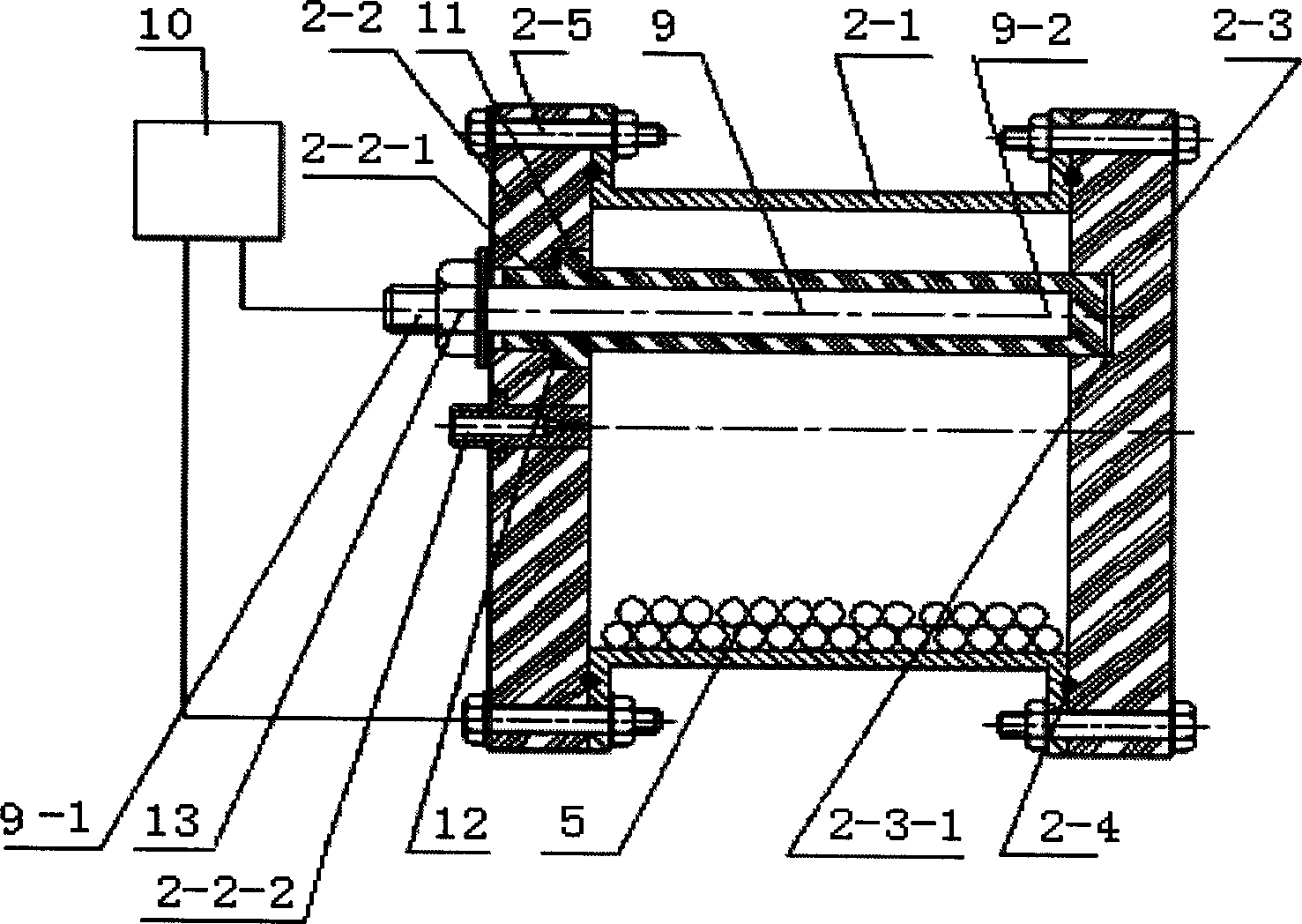

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

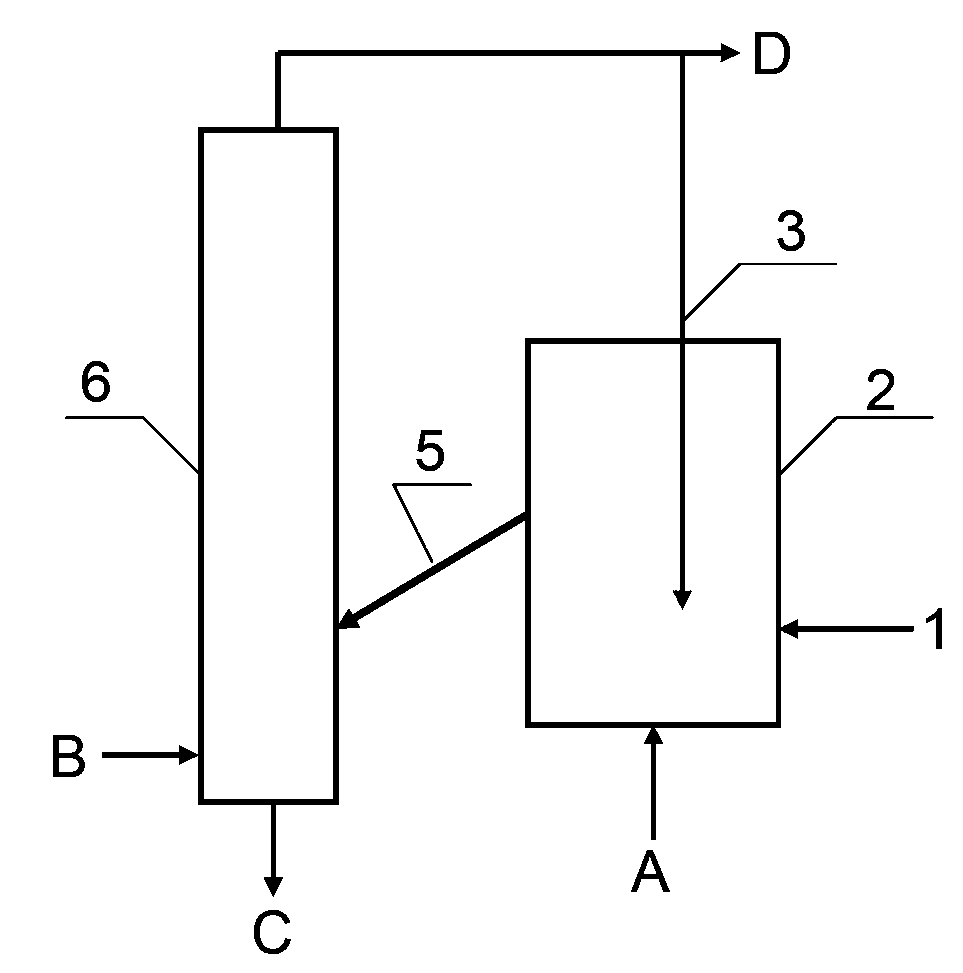

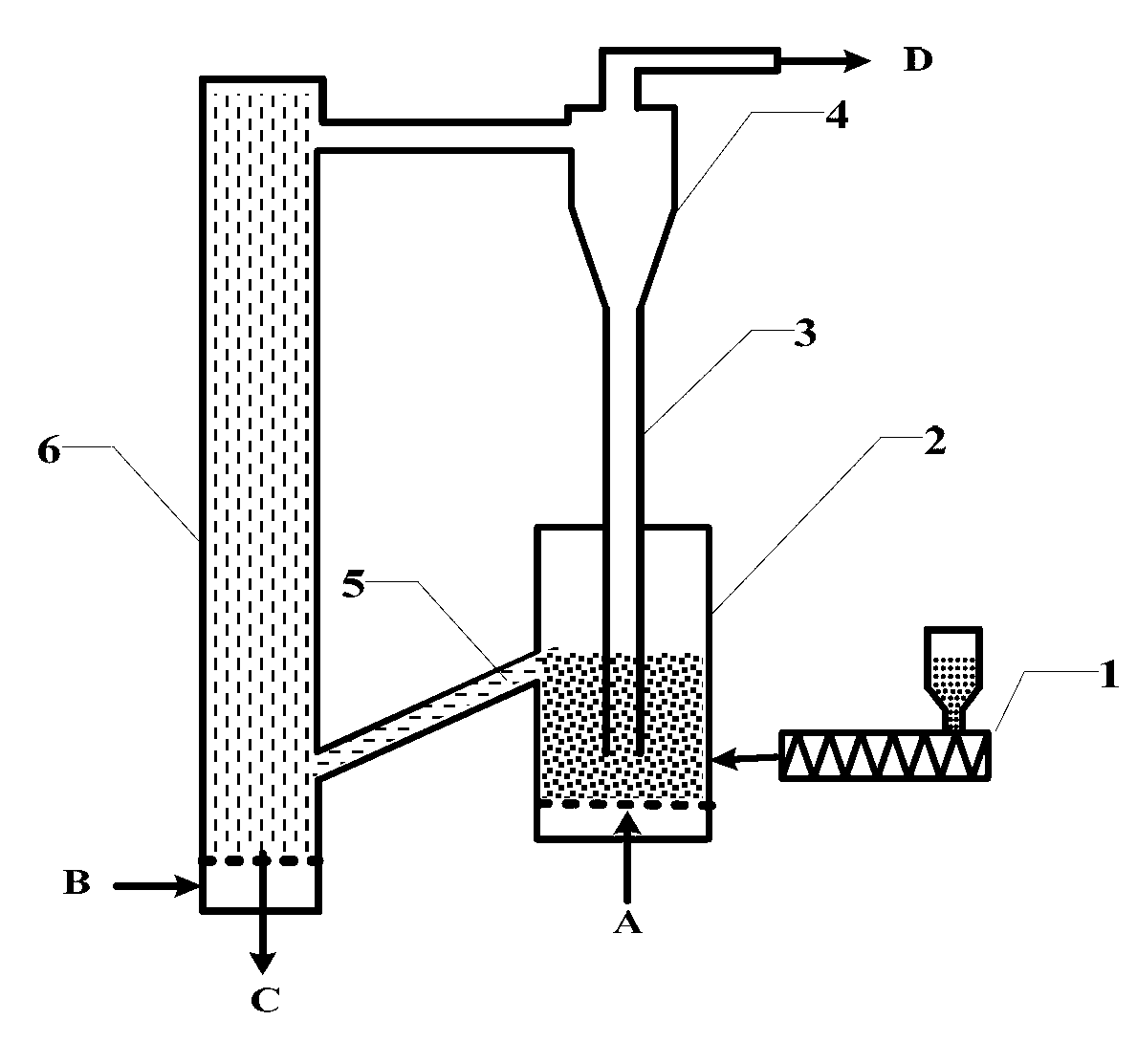

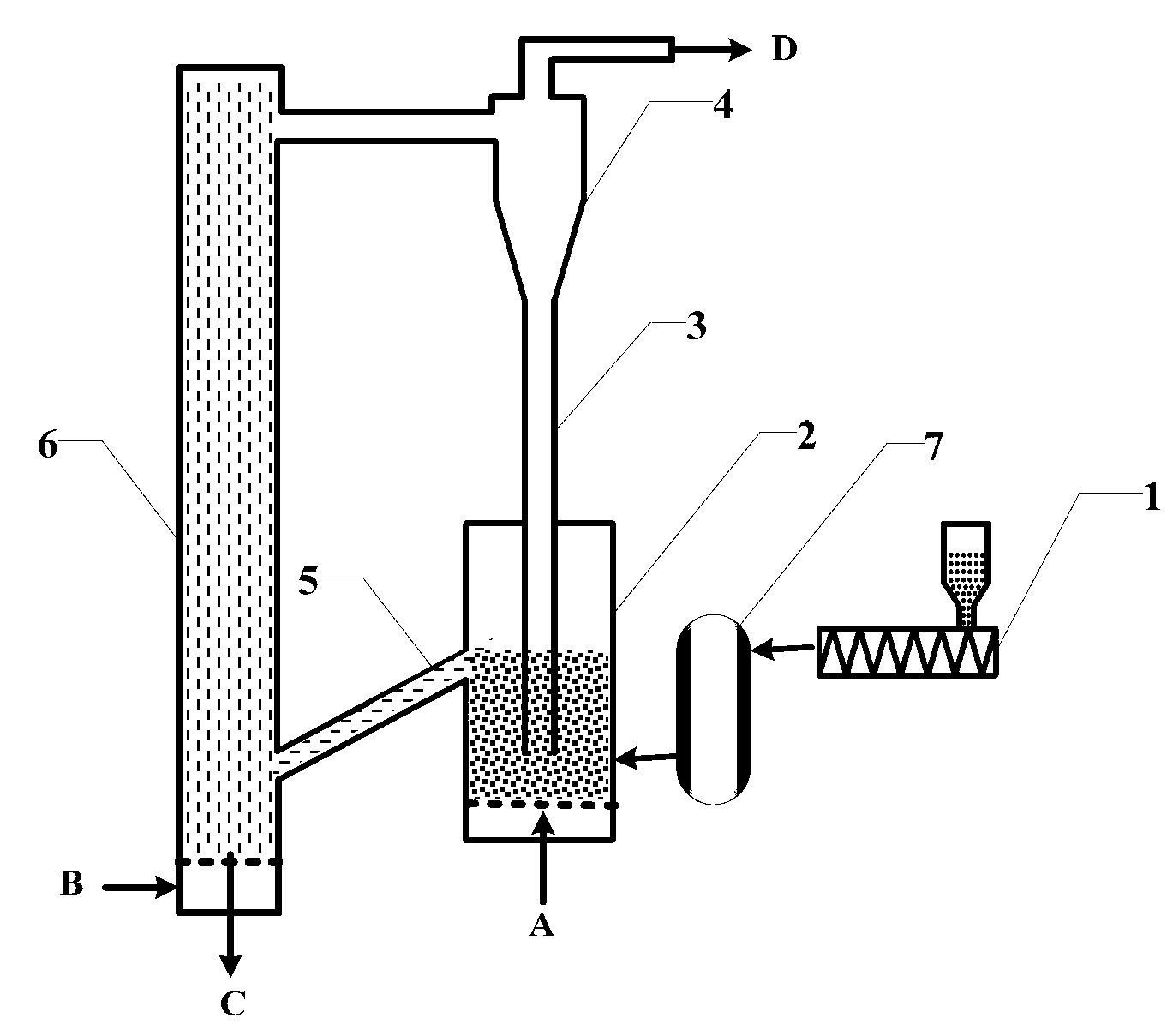

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-solid content waterborne polyurethane emulsion with particle size polydispersity and preparation method thereof

The invention relates to a high-solid content waterborne polyurethane emulsion with particle size polydispersity and a preparation method thereof, belonging to the technical field of high polymer materials. The preparation method comprises the following steps of: preparing a polyurethane prepolymer, diluting the synthesized polyurethane prepolymer by adding a solvent, then dividing the diluted polyurethane prepolymer into a plurality of portions, respectively adding different doses of sulfonate hydrophilic chain extender to the different portions of polyurethane prepolymer for remixing, dispersing the mixtures to deionized water, carrying out secondary chain extension and removing the solvent from the emulsion in vacuum, thus obtaining the waterborne polyurethane emulsion with the solid content being higher than or equal to 50%. The preparation method has the advantages that a catalyst is not needed, the production time is short, and the process is simple and easy to control. The prepared waterborne polyurethane emulsion is relatively wide in particle size distribution and relatively low in viscosity and can be applied to the fields of environment-friendly coatings, adhesives and the like.

Owner:SOUTH CHINA UNIV OF TECH

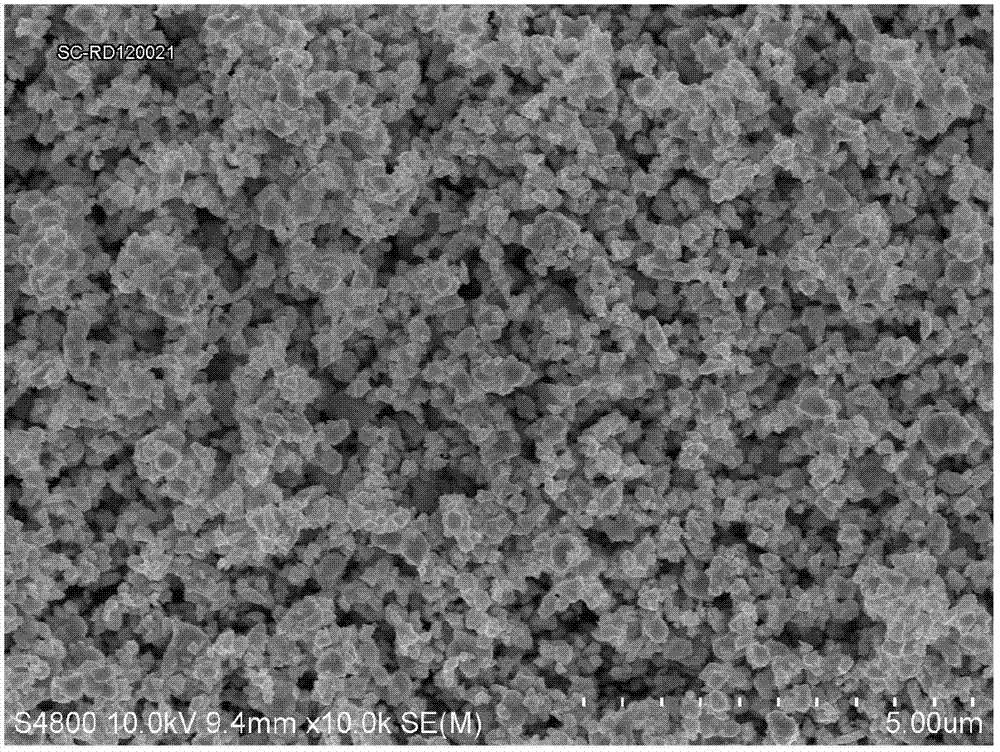

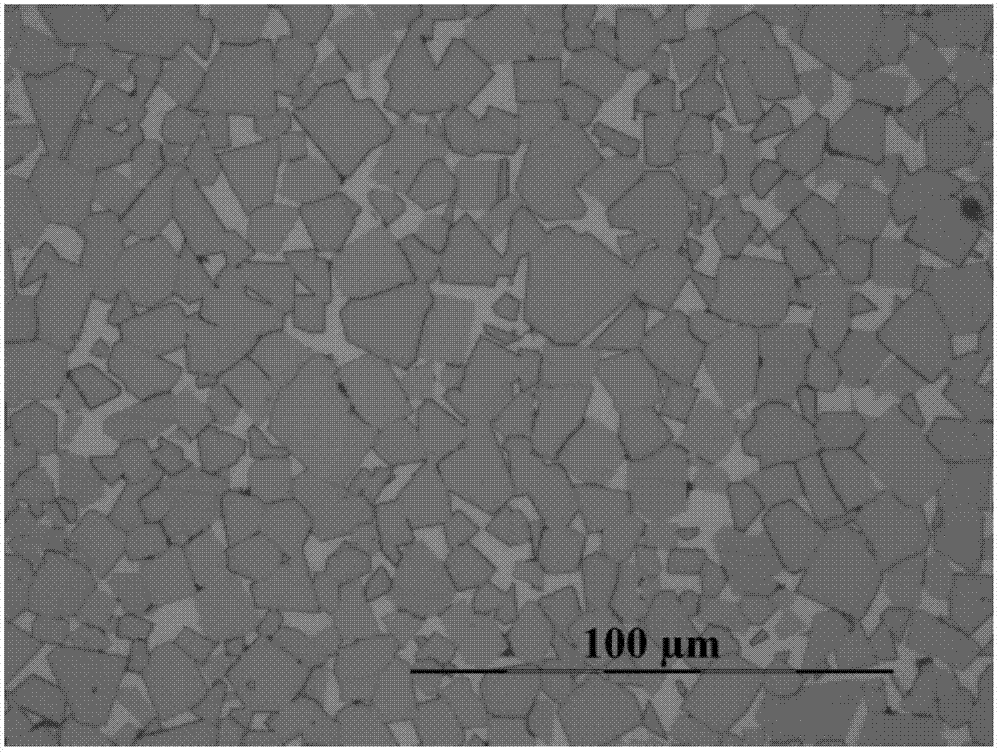

Preparation method for super coarse crystal WC-Co hard alloy

The invention discloses a preparation method for a super coarse crystal WC-Co hard alloy. According to the preparation method, a proper amount of fine tungsten carbide powder is added into a raw material, and the super coarse crystal WC-Co hard alloy is prepared by proper ball milling and sintering processes, so that the super coarse crystal hard alloy with the grain size of 6.0 to 14.0 microns can be prepared successfully. The preparation method has the characteristics that the process is simple, the process is easy to control, the production cost is low, and the WC grain size distribution in the alloy product is uniform.

Owner:XIAMEN TUNGSTEN +1

Paraffinic hydrocarbon aromatization catalyst and its preparation method

InactiveCN1830558AHigh surface energyImprove surface activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonMolecular sieveDiffusion resistance

A catalyst for aromatizing paraffin is a non-noble metal modified nano-class zeolite molecular sieve, which is composed of MFI-type zeolite molecular sieve as carrier and the Zn and Ga as active component. It has high catalytic activity, selectivity and stability. Its preparing process is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

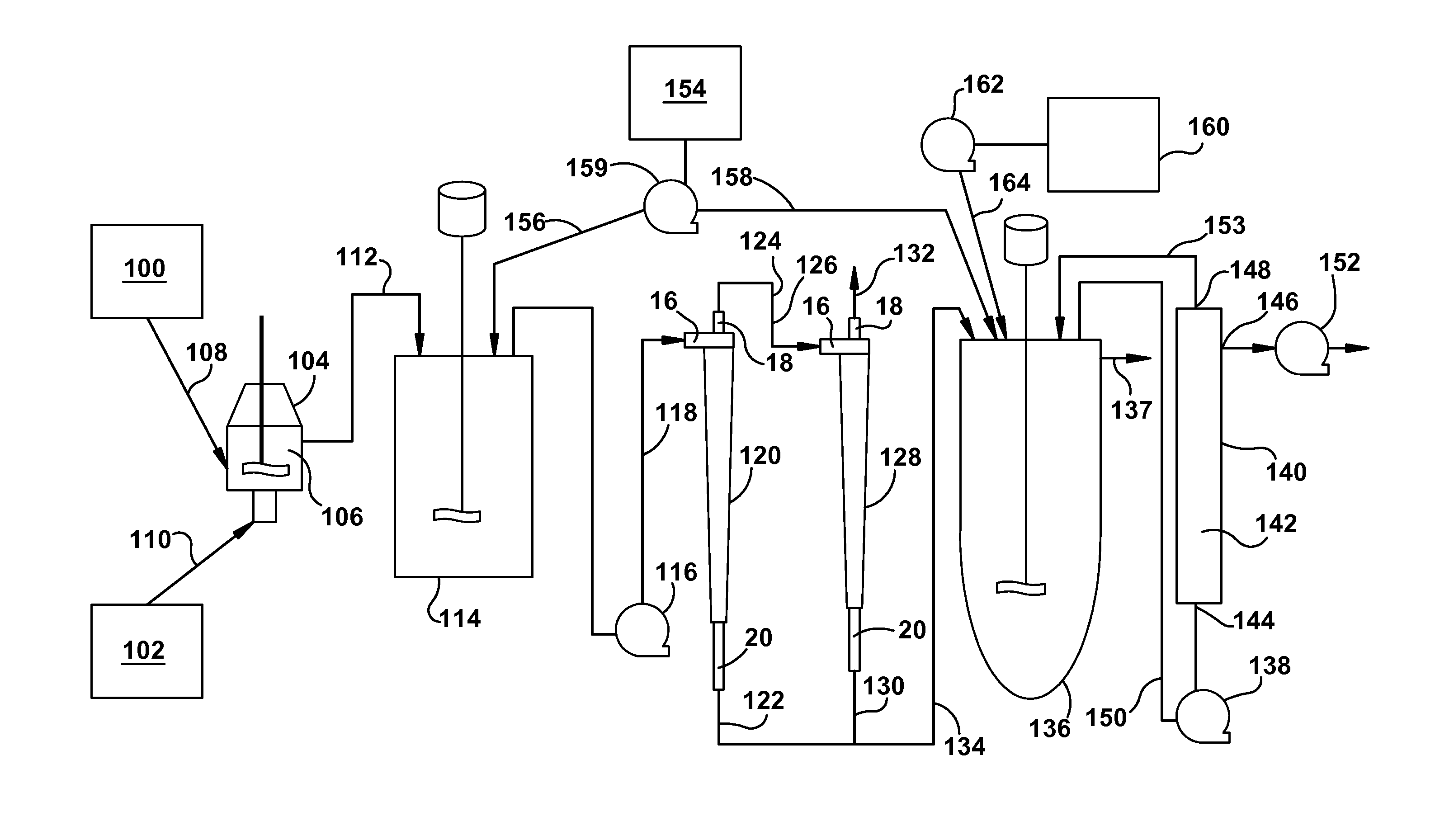

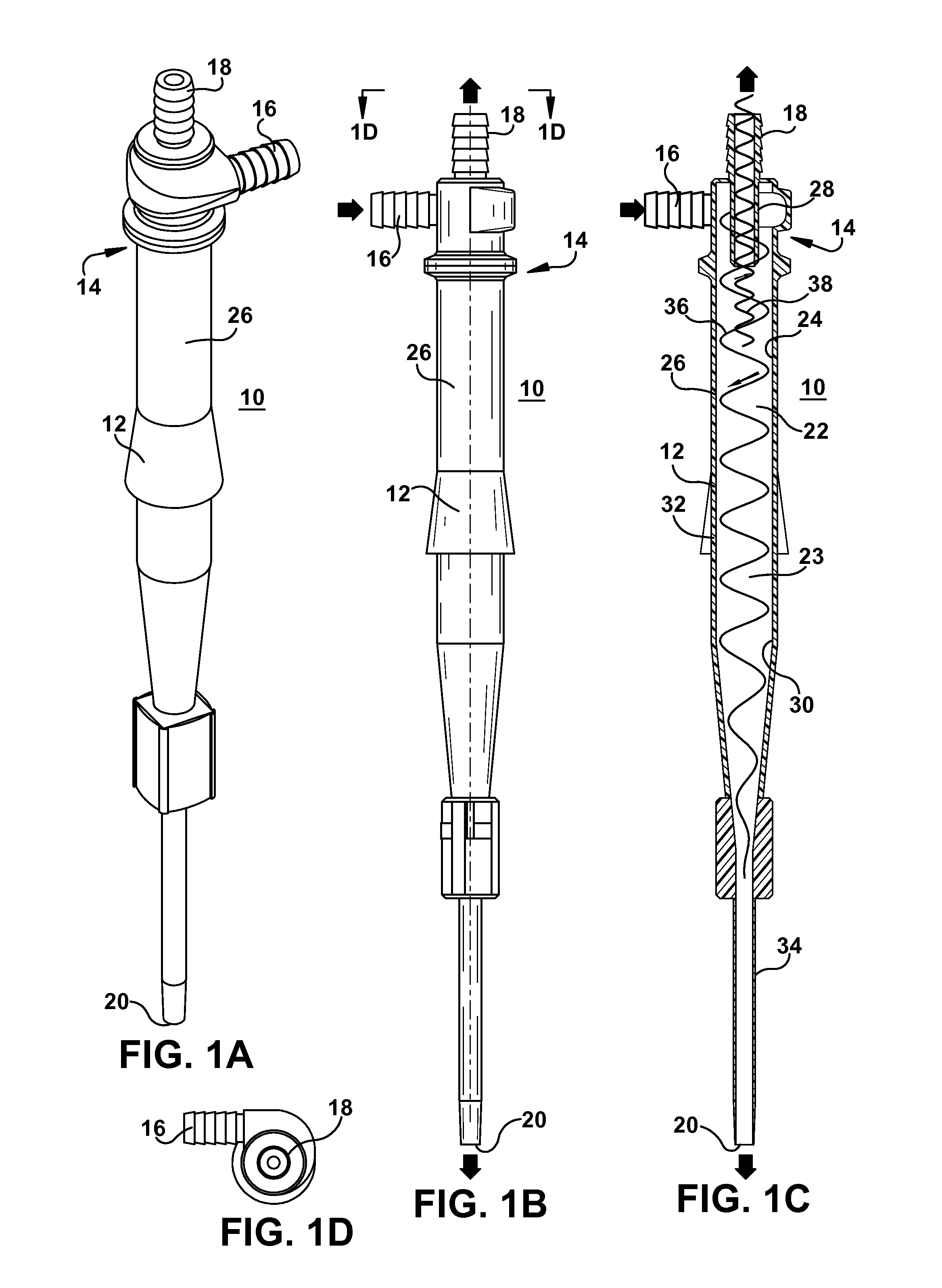

Manufacture of microspheres using a hydrocyclone

ActiveUS20120205293A1Faster rateLarge volume rapidlyAntibacterial agentsSievingActive agentEngineering

This disclosure features a system for processing microspheres. A vessel contains a suspension of solidified microspheres comprising polymer and an active agent. A hydrocyclone has a fluid inlet, a first fluid outlet and a second fluid outlet. The fluid inlet is in fluid communication with the vessel and receives the suspension. The second fluid outlet contains a flow of the suspension having concentrated microspheres. The first fluid outlet contains a flow of a relatively large amount of liquid compared to the flow from the second fluid outlet. Also featured is a method of processing the microspheres using the hydrocyclone.

Owner:OAKWOOD LAB LLC

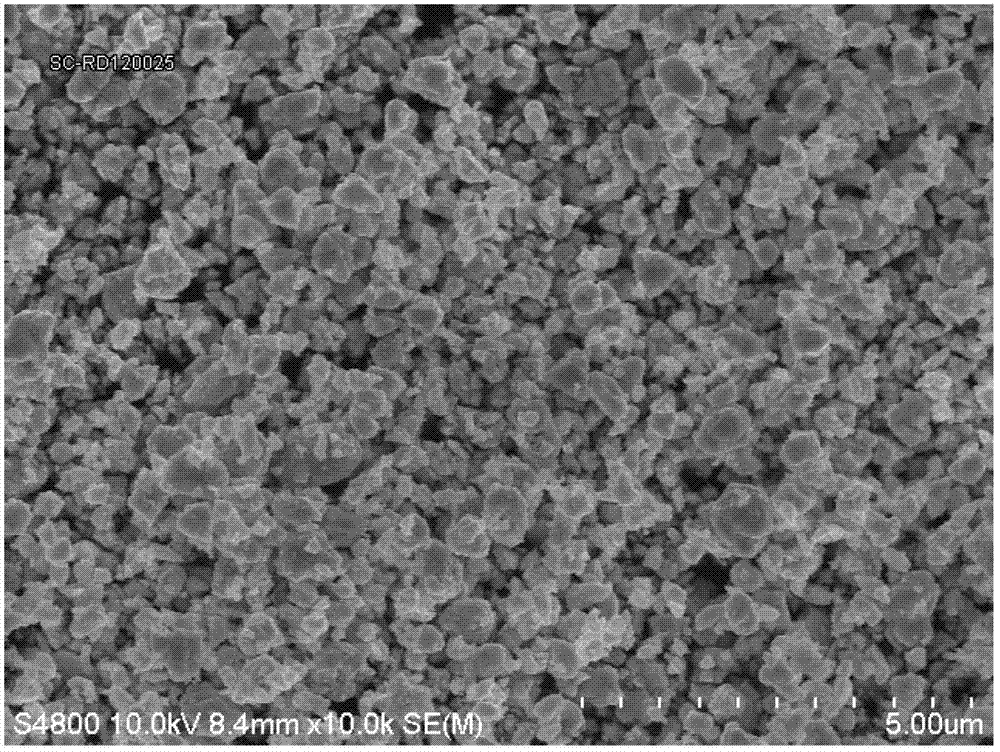

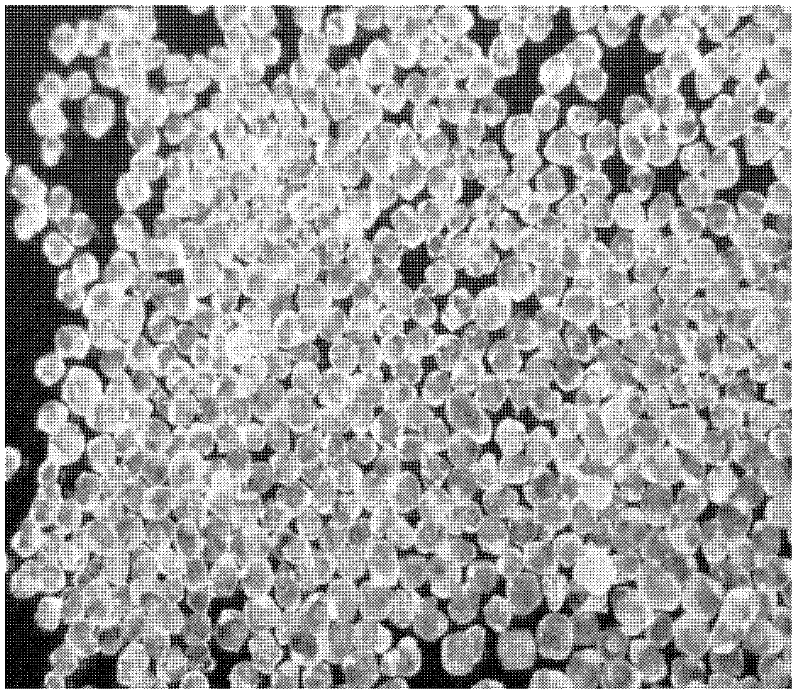

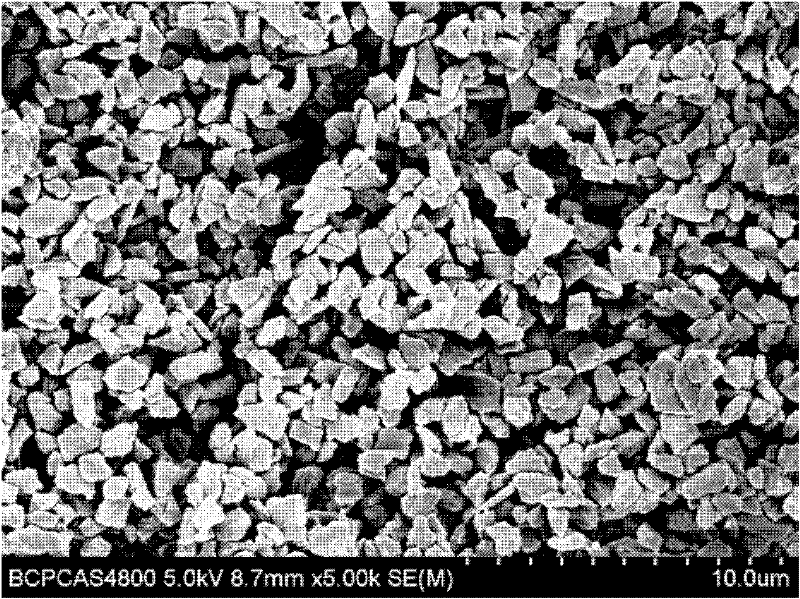

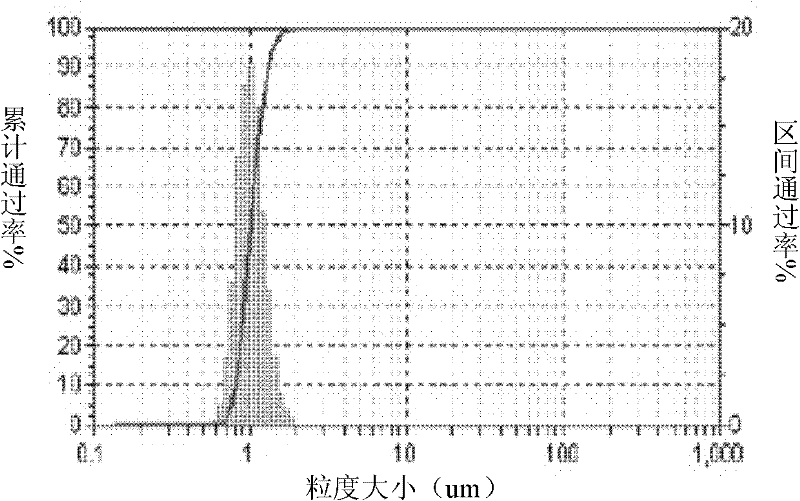

Precursor nickel-cobalt-manganese hydroxide of ternary material used for lithium batteries and preparing method thereof

ActiveCN104201368AIncrease compaction densityImprove thermal stabilityCell electrodesSecondary cellsManganeseDischarge rate

The invention relates to a precursor nickel-cobalt-manganese hydroxide of a ternary material used for lithium batteries and a preparing method thereof. The nickel-cobalt-manganese hydroxide is characterized in that: the general chemical formula of the nickel-cobalt-manganese hydroxide is NixCoyMnz(OH)2, wherein the sum of the x, the y and the z is 1, the x is less than 1 and more than 0, the y is less than 1 and more than 0 and the z is less than 1 and more than 0. The ternary material prepared from the nickel-cobalt-manganese hydroxide is high in compaction density, good in cyclic performance, high in thermal stability and low in self-discharge and has good comprehensive performance. The preparing method introduces a single-kettle batch production mode into a continuous production mode. A product with wide particle size distribution and more small particles is prepared by continuous production. Based on the product of the continuous production, batch production is utilized, the production process is free of generation of new small particles, only original small particles grow to be more compact, other larger particles grow at the same time, and the finished product is still wide in particle size distribution.

Owner:宁夏中色金辉新能源有限公司

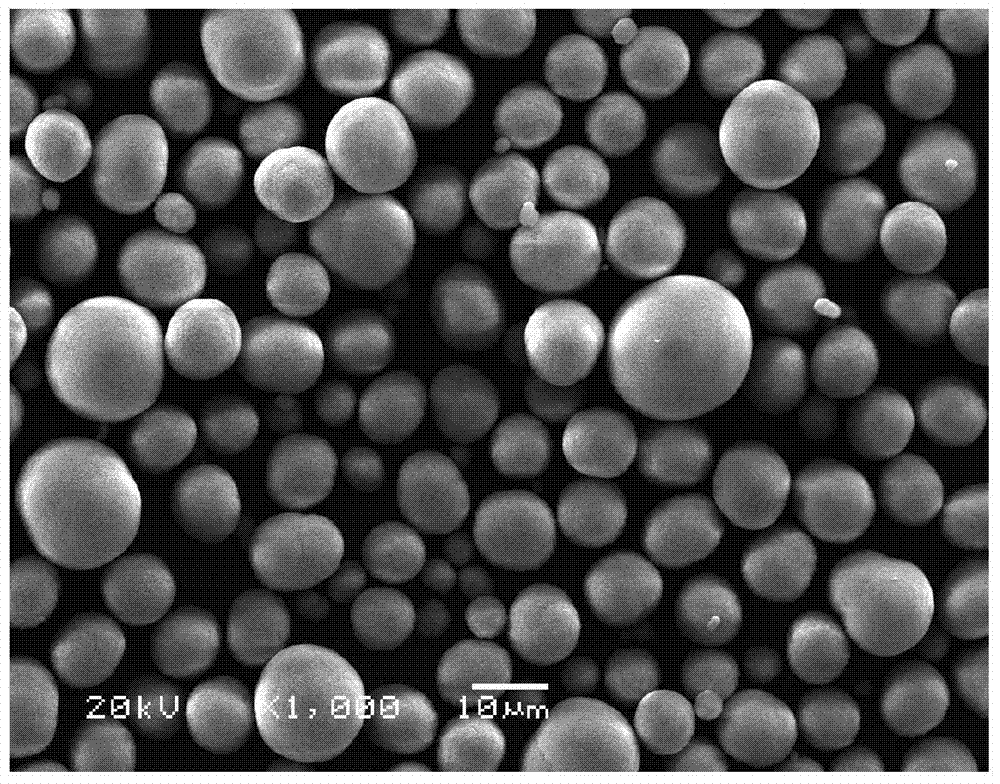

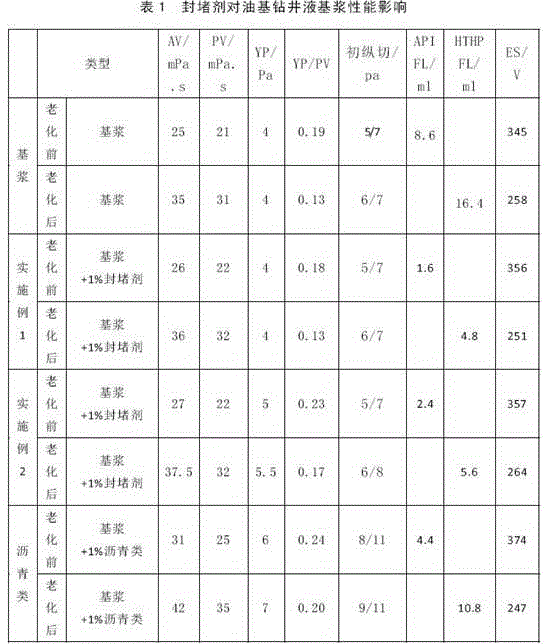

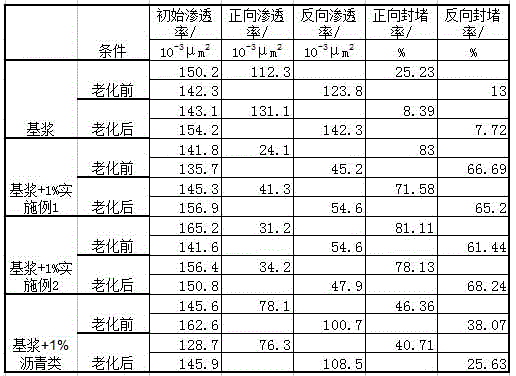

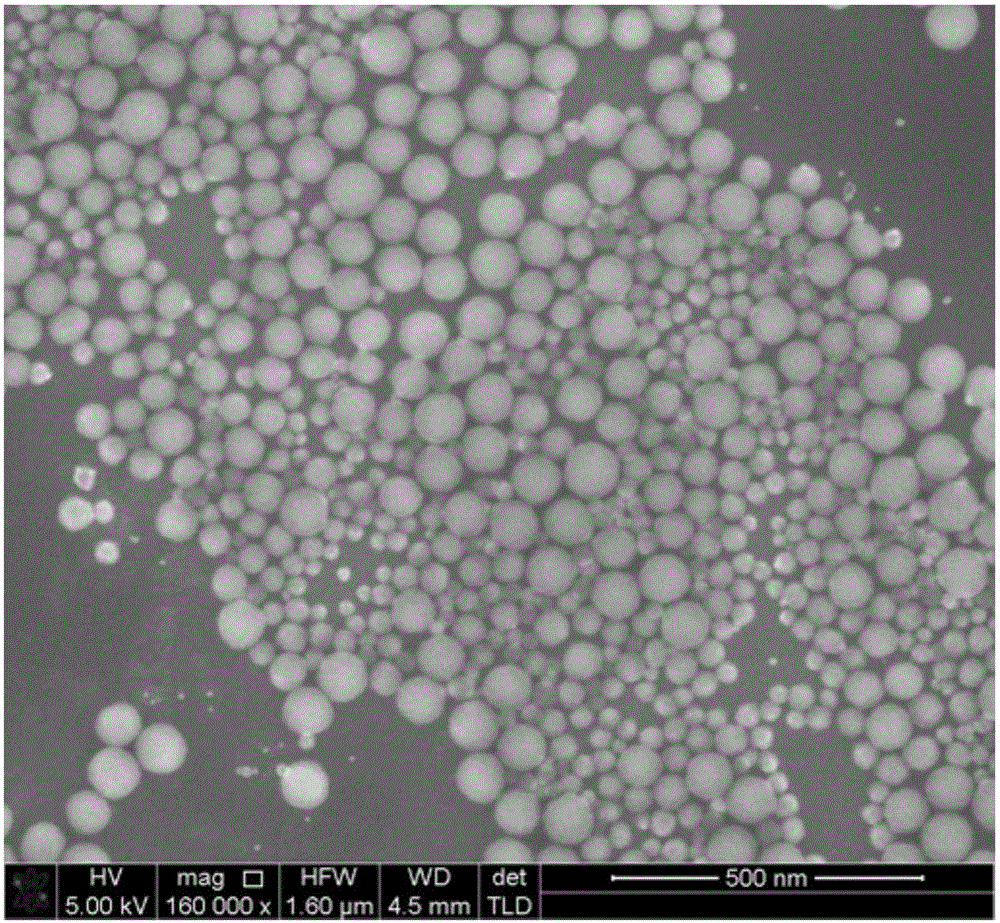

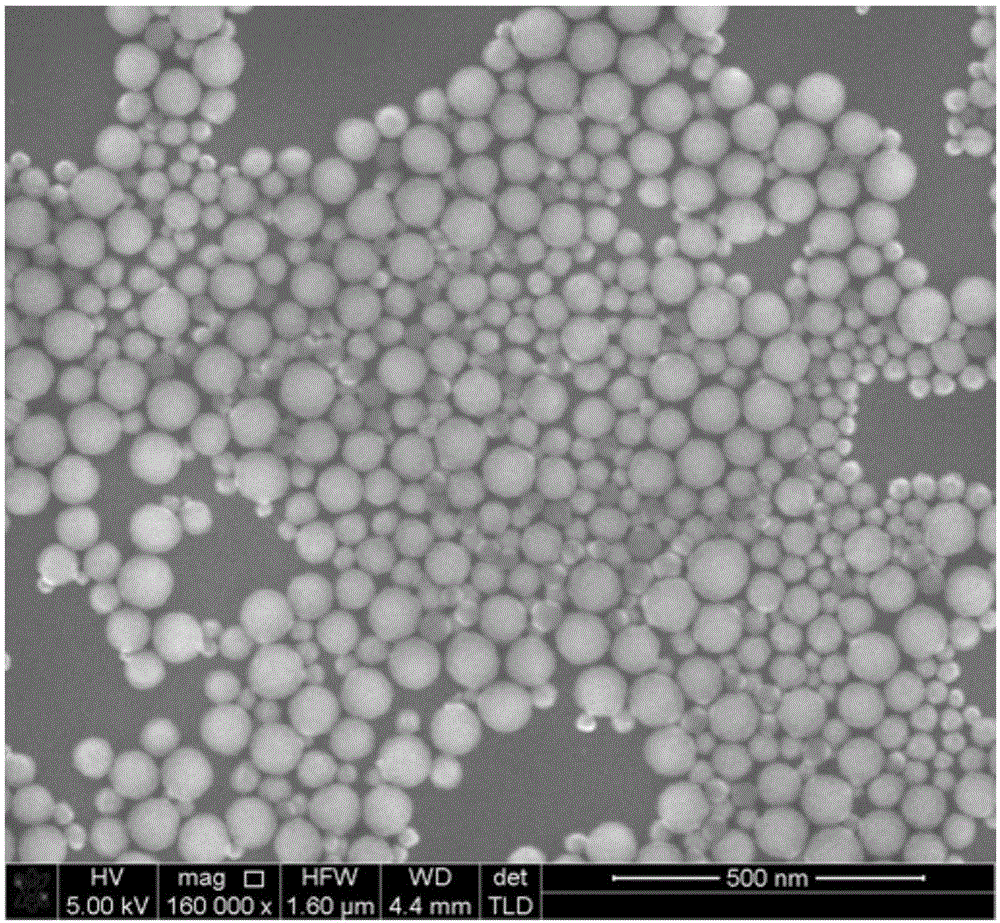

Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

ActiveCN105462568AHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

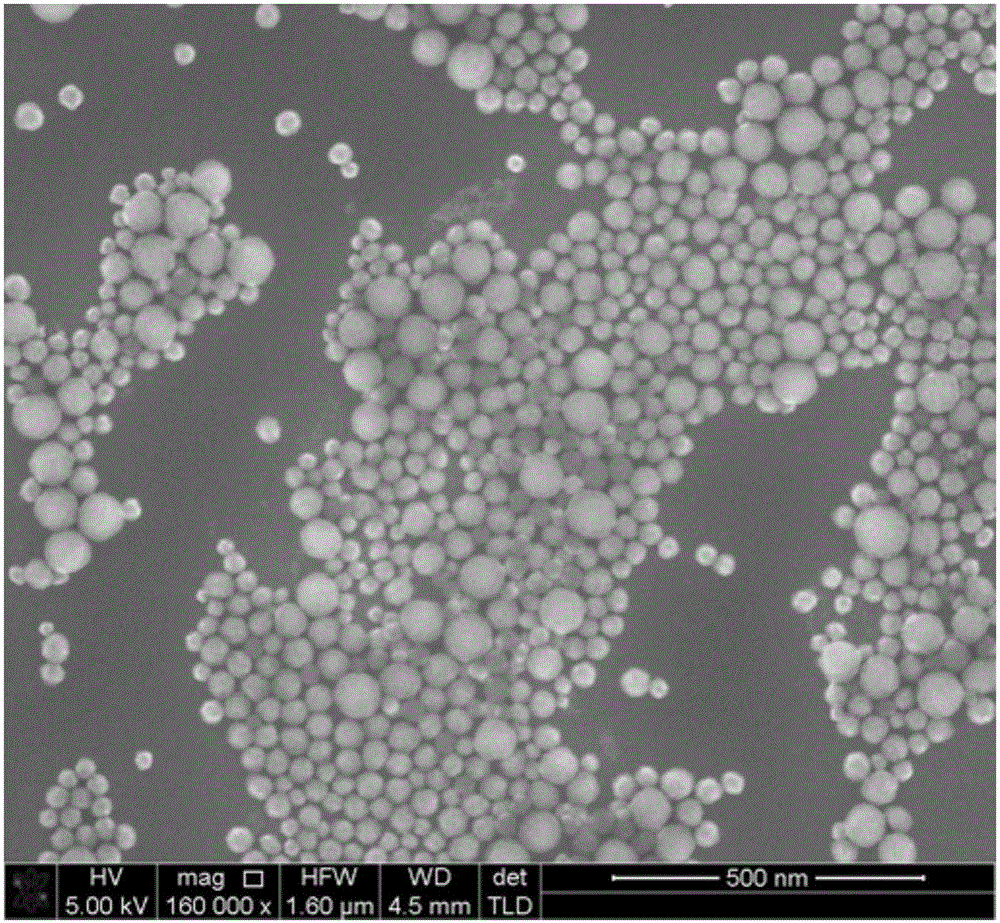

Polydisperse large-particle-size silica sol and preparing method thereof

ActiveCN106044786AWide particle size distributionImprove polishing efficiencyMaterial nanotechnologySilicaSilicic acidReaction system

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

Method for producing anhydrous citric acid crystal

InactiveCN102391103AUniform particle sizeWide particle size distributionCarboxylic compound separation/purificationNucleationSupersaturation

The invention provides a method for producing an anhydrous citric acid crystal. The method comprises the following steps of: concentrating citric acid solution until the degree of supersaturation is between 1.02 and 1.15 at temperature of above 36.6 DEG C, and adding an anhydrous citric acid seed crystal. In the method for producing the anhydrous citric acid crystal, the anhydrous citric acid seed crystal is added within the range of between 1.02 and 1.15 of the degree of supersaturation of the citric acid solution, the content of the anhydrous citric acid crystal in a mixture of the citric acid solution and the anhydrous citric acid crystal in the crystallization process is controlled to be between 20 and 50 weight percent, so that nucleation caused by crystal explosion during the earlier stage of crystallization and nonuniformity of crystal granules due to less crystal nucleus yield in the crystallization process are avoided, the number of the crystal granules is controlled stably and effectively, and thus the production of the anhydrous citric acid crystal is controllable, and the method is easy and convenient to operate. The anhydrous citric acid crystal produced according to the method is uniform in size distribution and attractive in appearance of products.

Owner:COFCO BIOTECHNOLOGY CO LTD

Alpha type cyclone separator

InactiveCN101116844AAvoid double hoistingGood drainageReversed direction vortexHigh concentrationCyclone

An alpha type cyclone separator which belongs to the isolation technique comprises a straight bowl body, a conical bowl body, an ash exhausting pipe, a coping, a liquid inlet, and a liquid outlet. The utility model is of small conical angle and long conical body structure, and the angle between the axes of the liquid inlet and the horizontal direction is of alpha. The coping is a spiral lamina with an obliquity of alpha, and an air inlet and the straight bowl boy, as well as the coping are tangent according to the obliquity alpha of the coping. The alpha is from 5 DEG C to 25 DEG C, and a second class or a second and third circumfluent cyclone separator also can be connected in series. The separating efficiency of the alpha type cyclone separator is obviously superior to a traditional hydrocyclones, and the alpha type cyclone separator is of low pressure drop, small amplification effect, high separation definition, and obvious energy saving effect. The pressure drop is about 70 percent that of traditional hydrocyclones, therefore, the utility model can satisfy the separating demand of high concentration, widely distributed granularity of solid particles, highly required technical process, and great difficulty for classification. The cyclone separator can be widely popularized and applied in chemical engineering, petroleum, metallurgy, medicine, and environmental protection field.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of precision casting fused quartz powder and quartz powder produced by same

ActiveCN103130405AHigh purityWide particle size distributionSilicaGlass shaping apparatusZirconImpurity

The invention relates to a preparation method of precision casting fused quartz powder and quartz powder produced by the method. The preparation method comprises the following steps of: smashing, sieving, purifying, fusing by an electric furnace, smashing, dry type ball-milling and sieve for a quartz raw material to obtain a product. An ultrasonic field is introduced in the scouring purifying and washing process of quartz, so that the content of impurities in powder is effectively reduced, and the step time is greatly shortened and the production efficiency is improved. Full grain fused quartz powder required is directly obtained by optimizing ball-milling process parameters and adopting a unique feeding mode, so that the grain composition step in conventional method is reduced. The method is simple in technical process, short in period, low in energy consumption and low in cost, and is beneficial for large-scale batch production. The fused quartz powder produced is high in purity, wide in grain distribution, free from graduation, mellow and full on surface of grains and good in rheological property of paint, and can be better applied to the field of investment casting and can partially or completely replace expensive shell material zircon power, so that the production cost of precision casting is effectively reduced.

Owner:LIANYUNGANG RISTAR ELECTRONICS MATERIALS

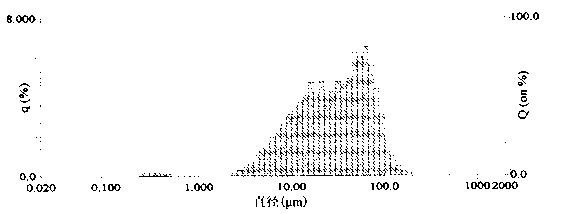

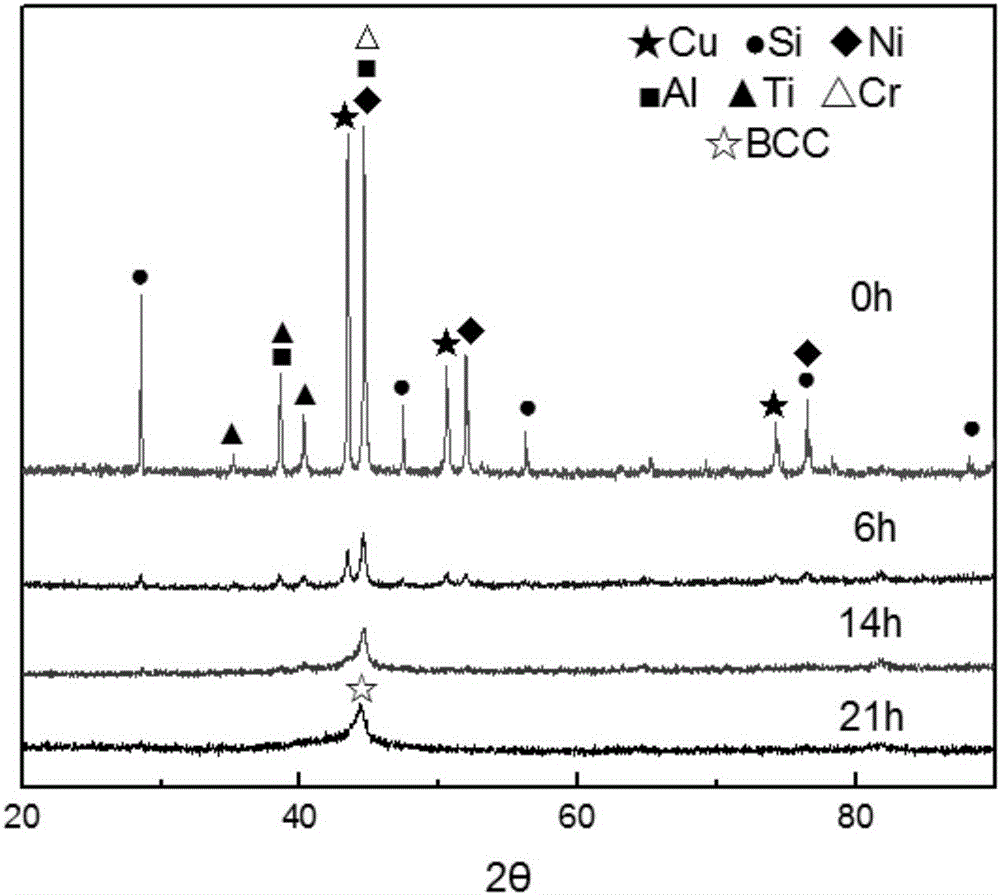

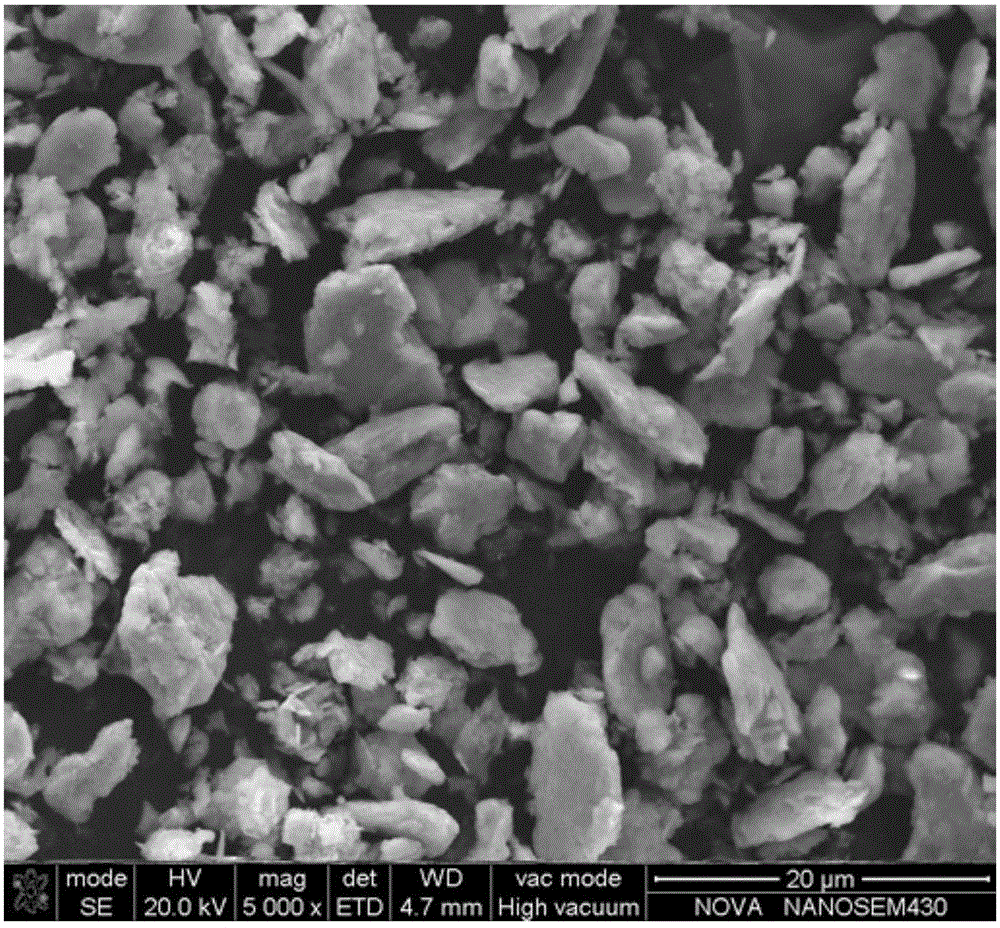

Low-density and high-entropy alloy material and preparation method thereof

Owner:GUANGDONG XINGFA ALUMINUM +1

Water-swelling rubber composite material, and preparation method and application thereof

InactiveCN103570985AImprove mechanical propertiesHigh expansion ratioDrilling compositionPolyethylene glycolAccelerant

The invention discloses a water-swelling rubber composite material. The rubber composite material is formed from the following components in parts by weight: 100 parts of rubber, 30-100 parts of super adsorbent resin, 2-10 parts of metal ion sealing agent, 0.5-2.5 parts of solid softening agent, 0.5-3.5 parts of coloring agent, 1-7 parts of anti-aging agent, 1-7 parts of accelerant, 1-8 parts of zinc oxide, 5-45 parts of reinforcing agent, 5-20 parts of plasticizer, 0.1-2.6 parts of vulcanizing agent, and 5-45 parts of mixture of PEG (polyethylene glycol) and MDI (diphenylmethane diisocyanate) at a molar ratio of 1:1. The invention further provides a preparation of the rubber composite material, in particular provides an application of the rubber composite material as superfine rubber swelling particles in a large pore path or high-permeability belt of a reservoir deep strata for profile control and water shutoff of an oil-water well.

Owner:CHINA PETROLEUM & CHEM CORP +1

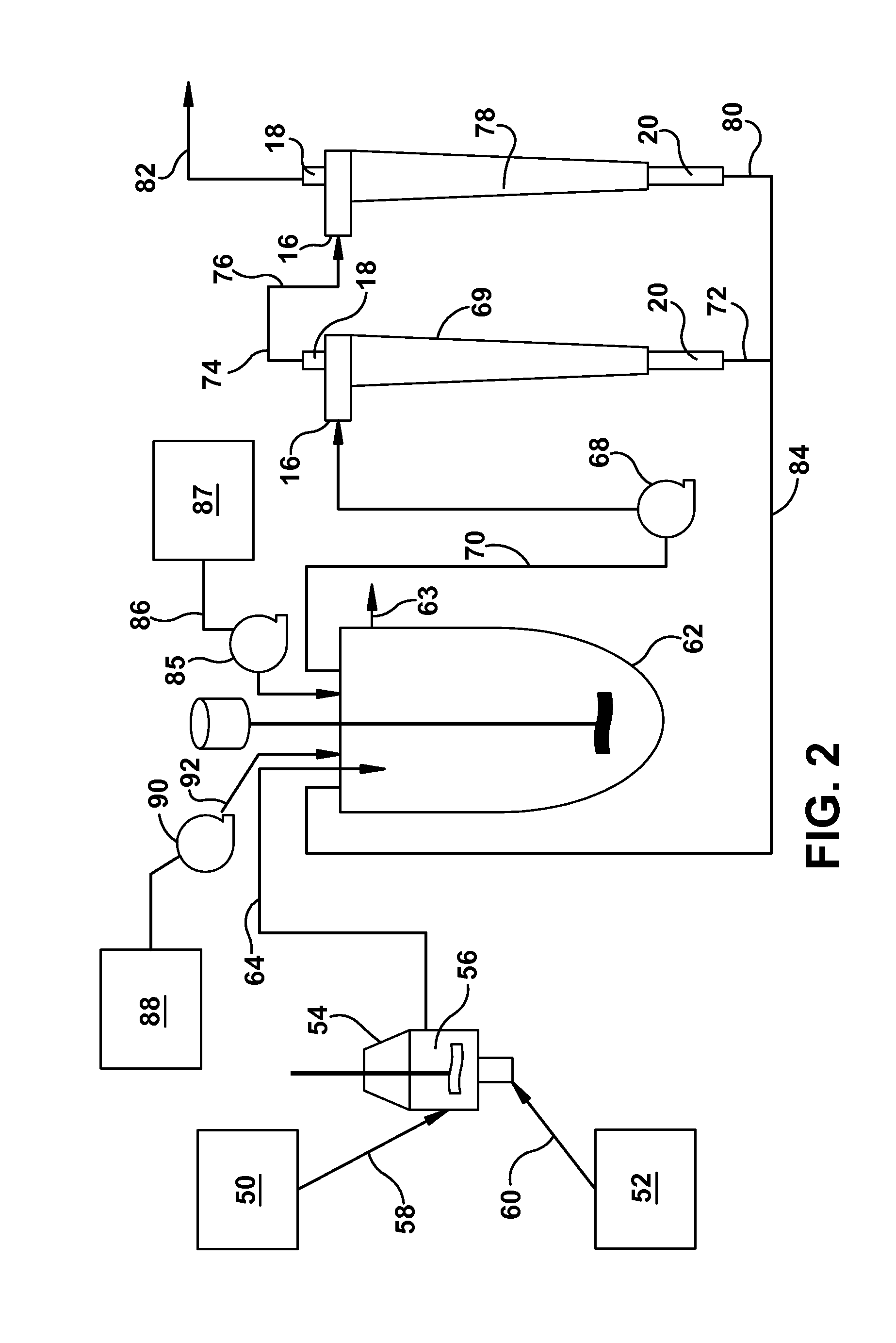

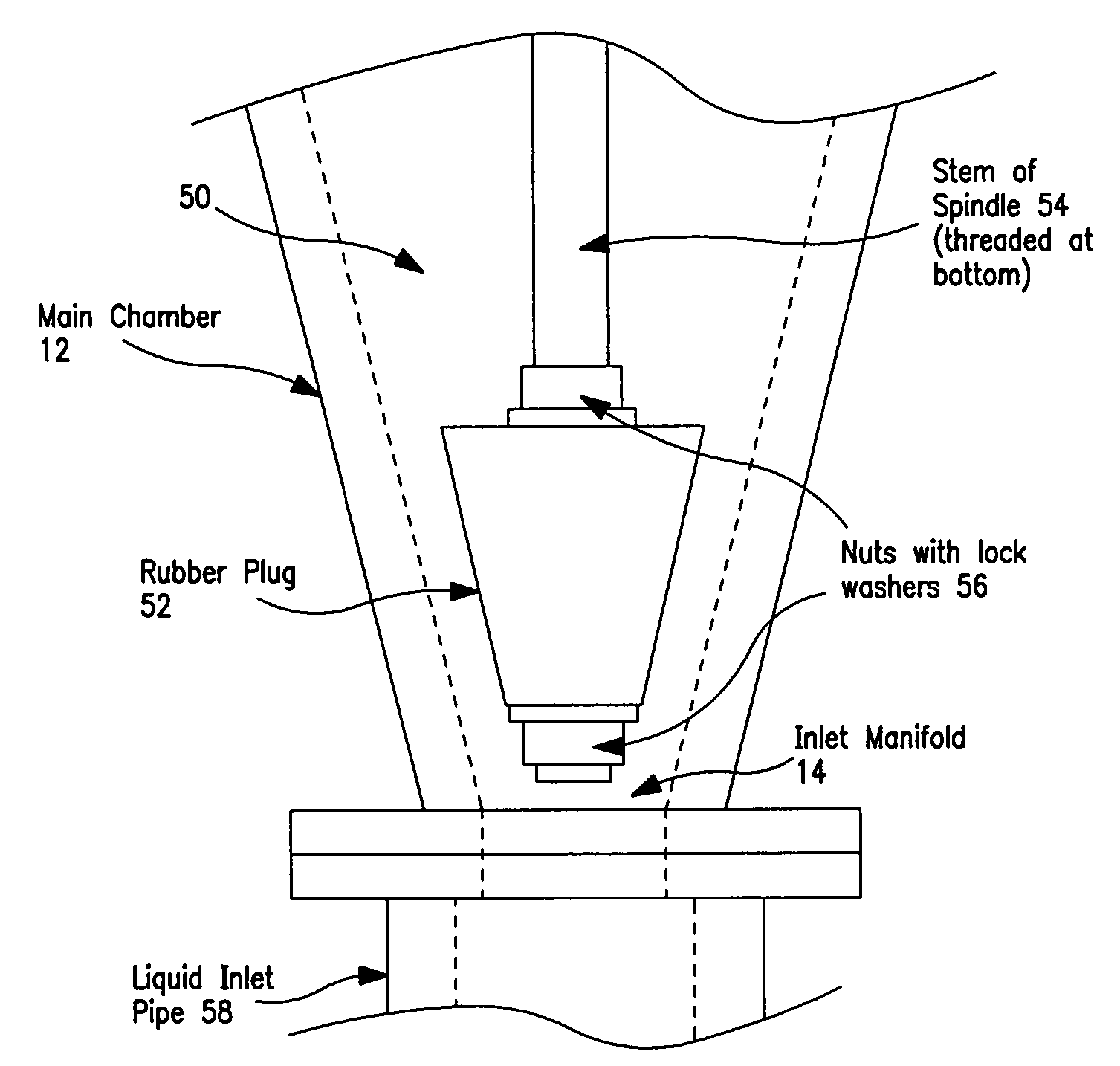

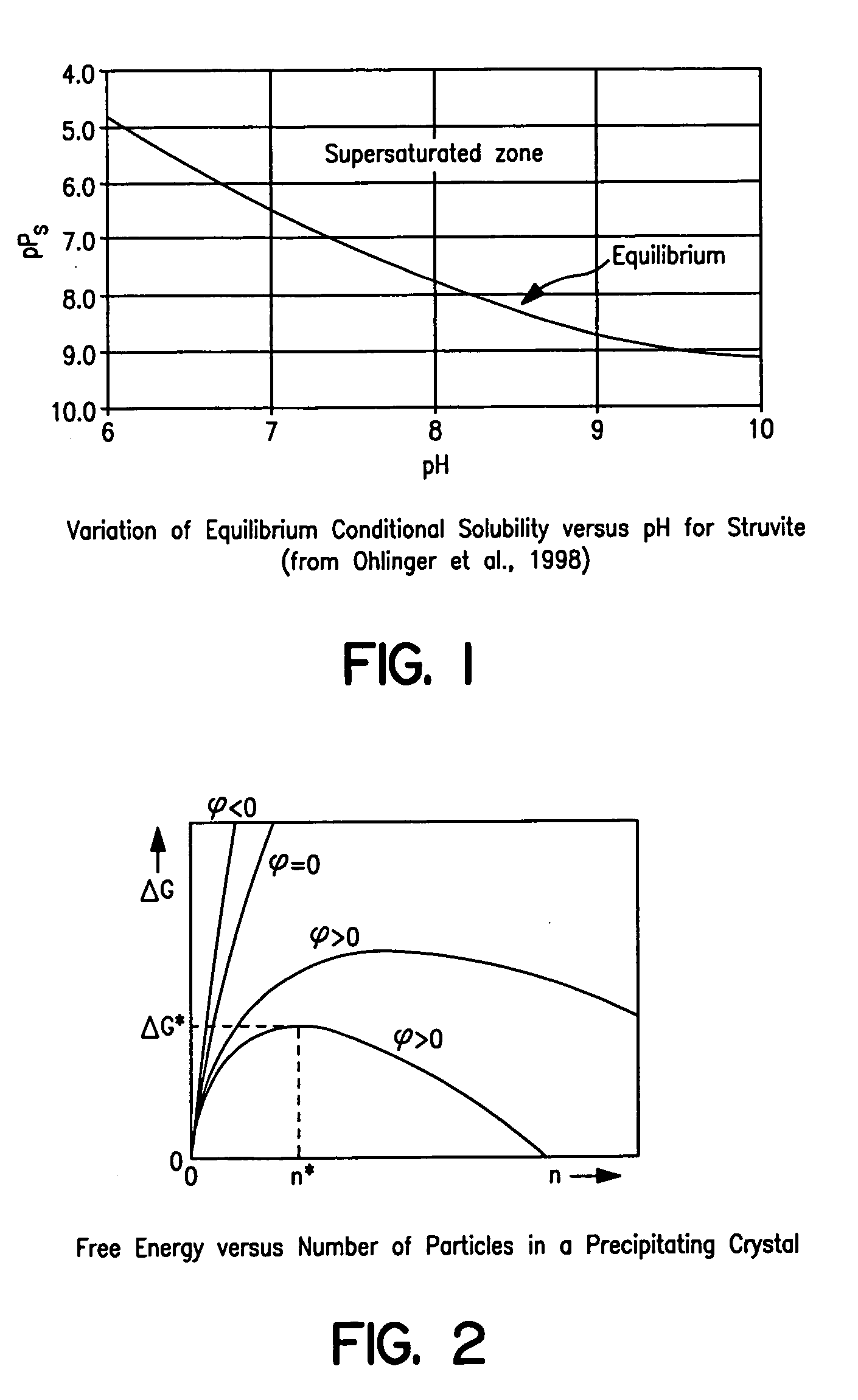

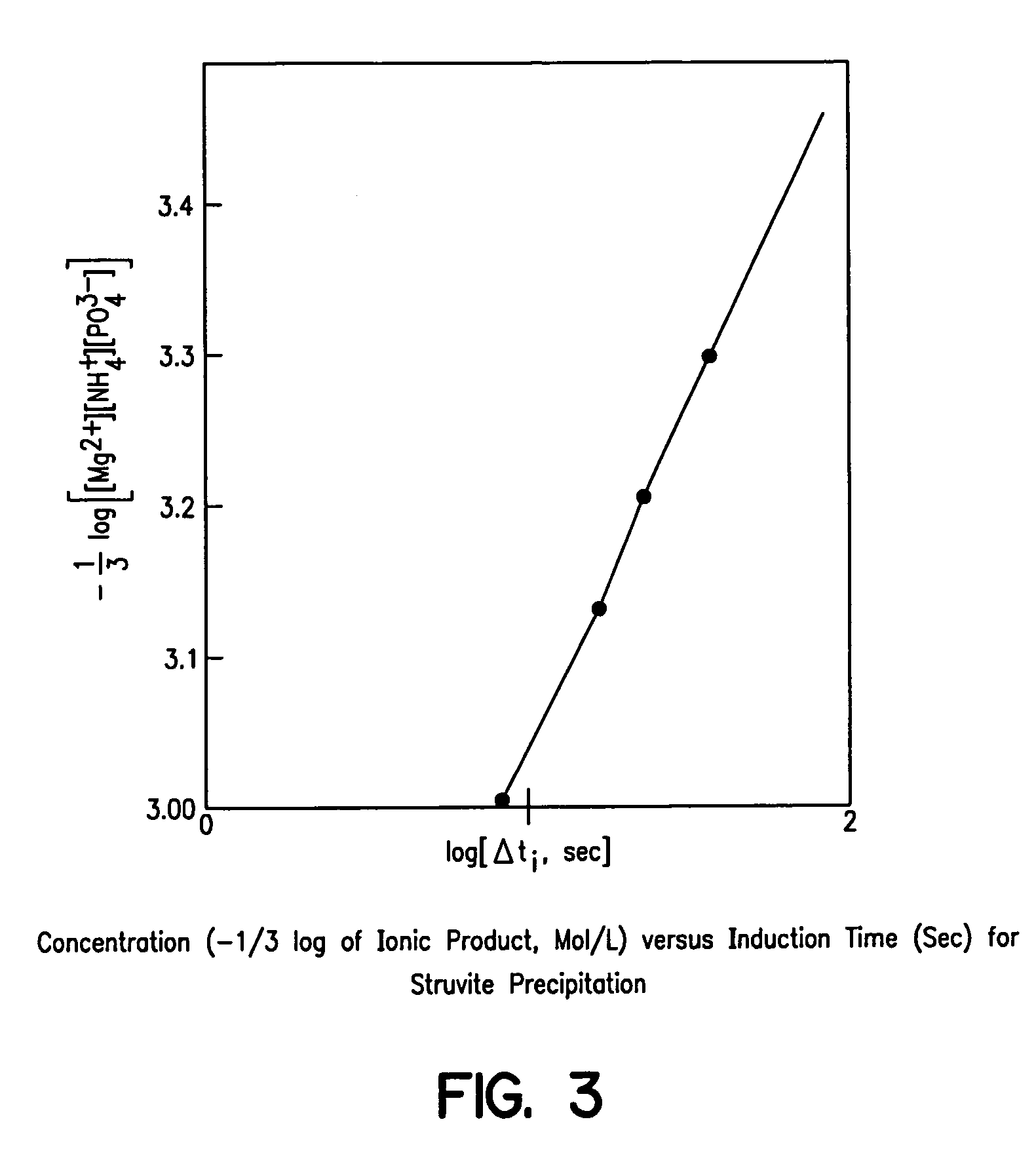

Apparatus and method for removing phosphorus from waste lagoon effluent

InactiveUS20060000782A1Reduce phosphorus contentWide particle size distributionWater contaminantsWaste water treatment from animal husbandryFluidized bedStruvite Crystals

Owner:NORTH CAROLINA STATE UNIV

Pre-coating film and preparation method thereof

ActiveCN103740291AWide particle size distributionHigh transparencyFilm/foil adhesivesSynthetic resin layered productsEmulsionPolymer science

The invention discloses a pre-coating film which comprises a base material layer, a polishing anti-bonding layer arranged on the first surface of the base material layer, and a pre-coating layer arranged on the second surface of the base material layer. The invention further discloses a preparation method of the pre-coating film. Because a high-solid-content polydispersion particle size styrene-acryli emulsion obtained by adopting a special polymerization process as the pre-coating film, the pre-coating film has good bonding force, excellent bonding strength for printing materials produced by various printing technologies, especially a digital printing technology, and embossing processes such as laminated embossing and rolling can be realized very well. Meanwhile, because modified glycidoxypropyltrimethoxy silane is used as a polishing anti-bonding layer, the pre-coating film has the advantages of strong universality, high color saturation, high brightness, high level and smooth degree, high flatness and the like, and meets the requirement of lamination of increasingly varied printing materials.

Owner:上海奇想青晨新材料科技股份有限公司

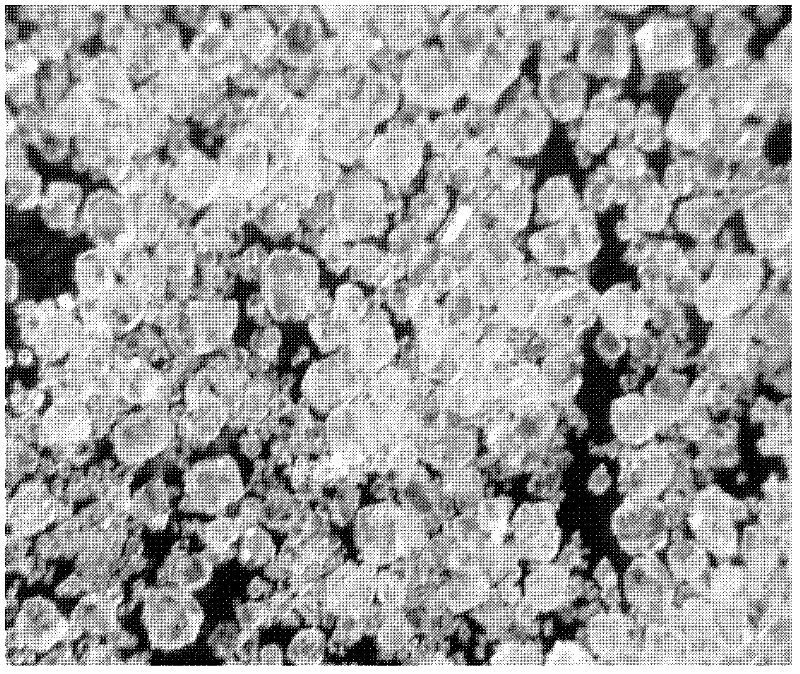

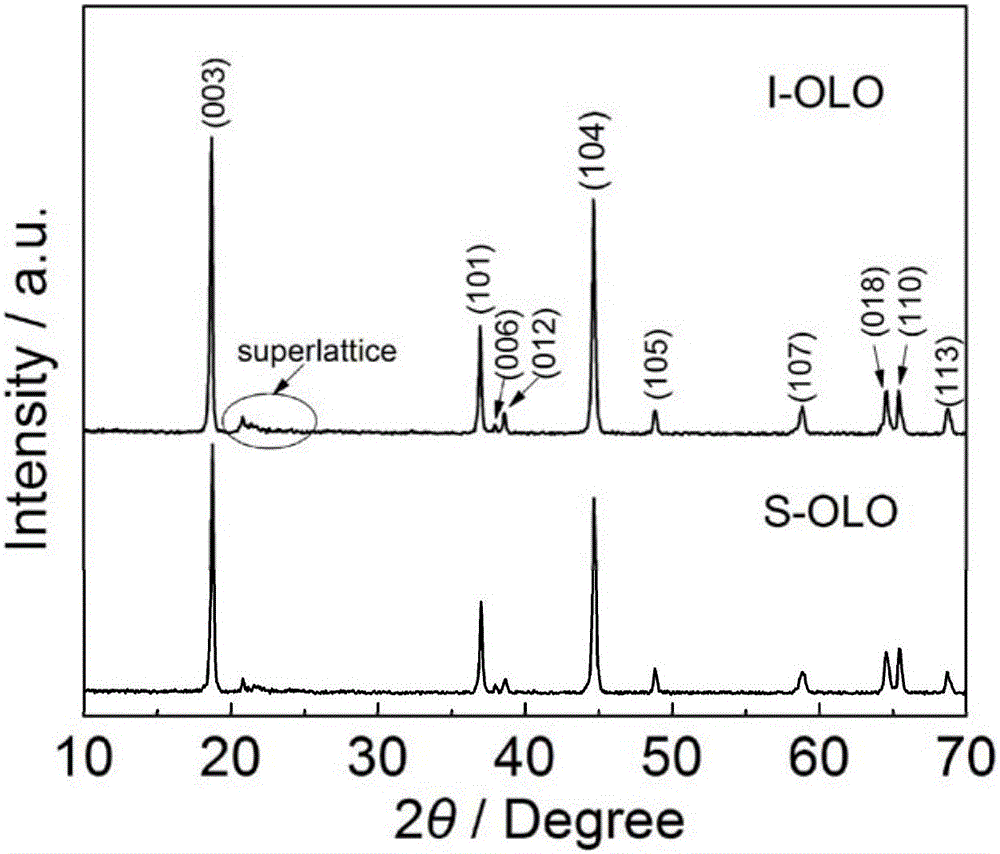

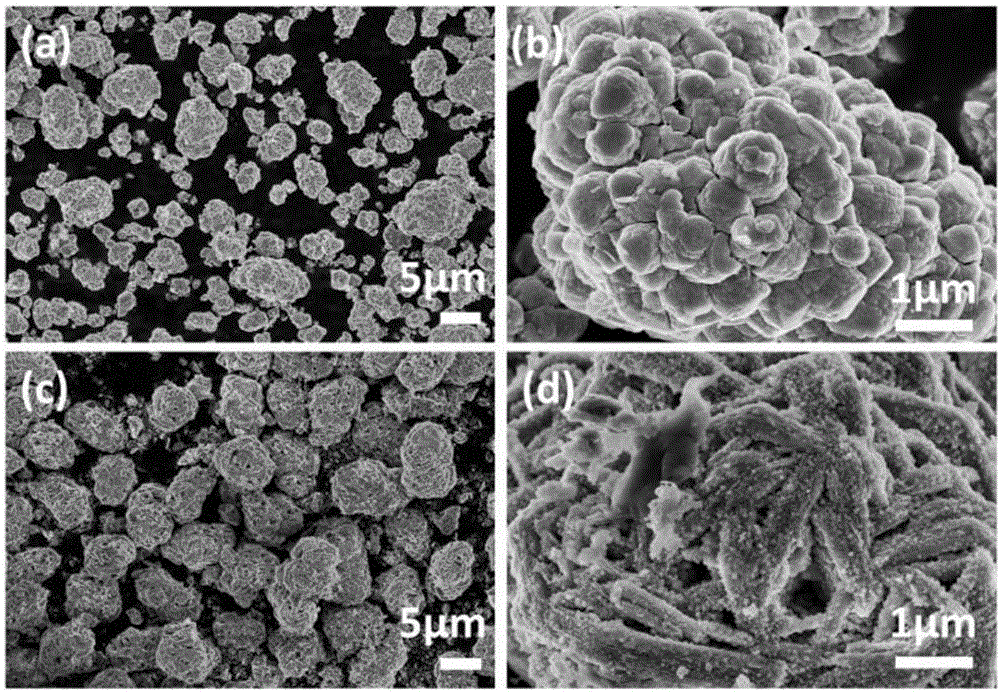

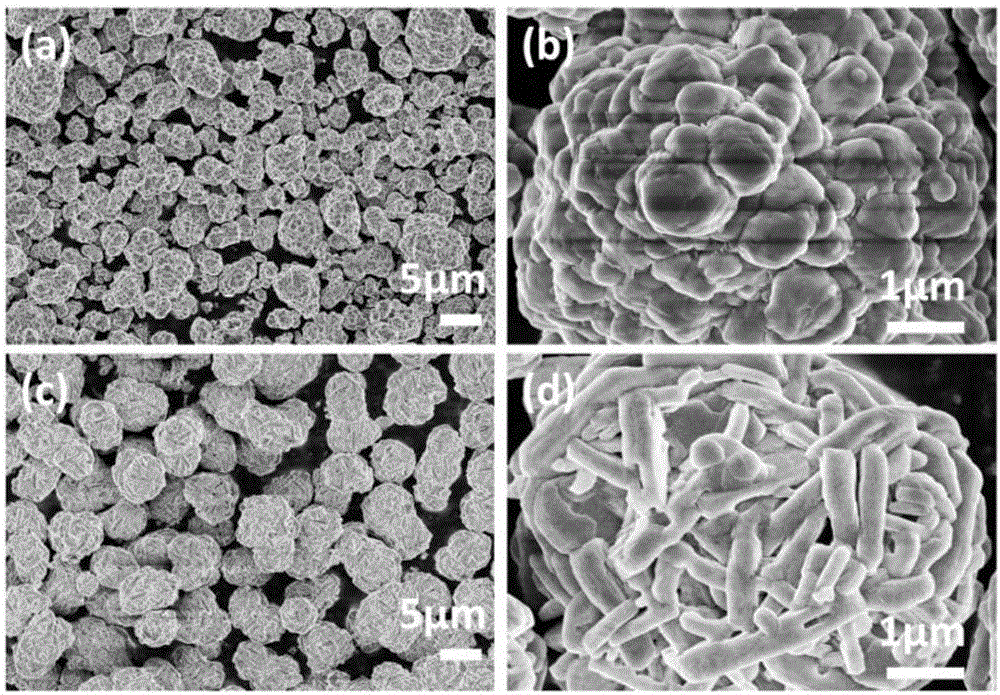

High-tap-density lithium-rich manganese-based positive electrode material and preparation method therefor

ActiveCN106129360ASuitable for large scaleSuitable for productivityCell electrodesSecondary cellsPhysical chemistryManganese

The invention discloses a high-tap-density lithium-rich manganese-based positive electrode material and a preparation method therefor. The positive electrode material is prepared by two steps of precursor preparing, and mixing and calcining. The positive electrode material has relatively high tap density and relatively excellent electrochemical performance; according to the preparation method for the positive electrode material, nitrogen atmosphere protection and ammonium hydroxide which can be used as a complexing agent are not required; instead, the secondary particle precursor which comprises micron-level sphere-like primary particles and has relatively wide particle size distribution is prepared by a coprecipitation method directly; and then the secondary particle precursor and a lithium-containing compound are mixed and calcined to obtain the positive electrode material. The lithium-rich manganese-based positive electrode material is simple and reliable in preparation method and process, and suitable for large-scale and commercial production.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Method for preparing submicron polycrystalline diamond abrasive with narrow particle size distribution

ActiveCN102250582AWide particle size distributionNarrow particle size distributionOther chemical processesMicrometerGranularity

The invention relates to a method for preparing submicron polycrystalline diamond abrasive with narrow particle size distribution, which comprises the following steps: (1) preparing pulp; (2) reshaping; and (3) centrifugally grading. In the invention, a submicron diamond product can be prepared by reshaping polycrystalline diamond powder of a particle size of 0.5 to 10 micrometer in a planet mill, superfine mill or supersonic pneumatic mill and grading in a high-speed centrifugal machine, wherein the particle sizes of the product may be 0.125 micrometer, 0.25 micrometer, 0.5 micrometer, 0.75 micrometer, 1 micrometer and 1.5 micrometers. The performance of the product is represented by the narrow particle size distribution of the product and regular particle shape. The product of the method is very suitable for fine polishing of sapphire, precision ceramics, optical crystals and metal molds; and after a sapphire wafer for an LED substrate is polished by the 0.5-micrometer diamond prepared by the method, the surface roughness of the sapphire wafer is 2.81 nanometers. The method is short in production period and is convenient for enlarging production scale.

Owner:盘锦国瑞升科技有限公司

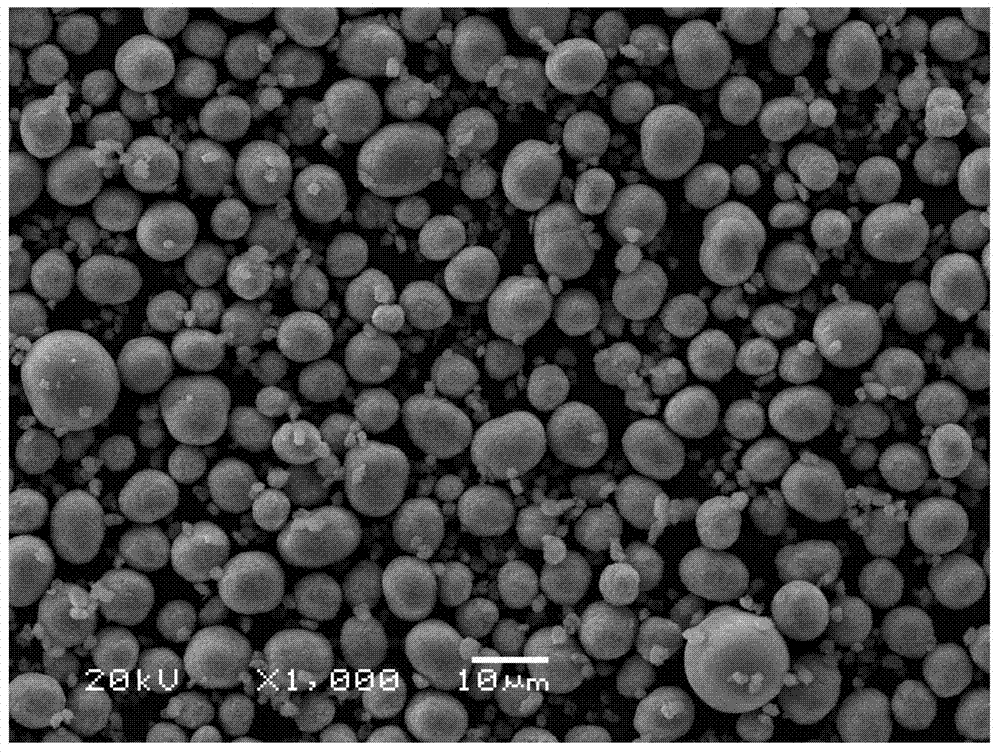

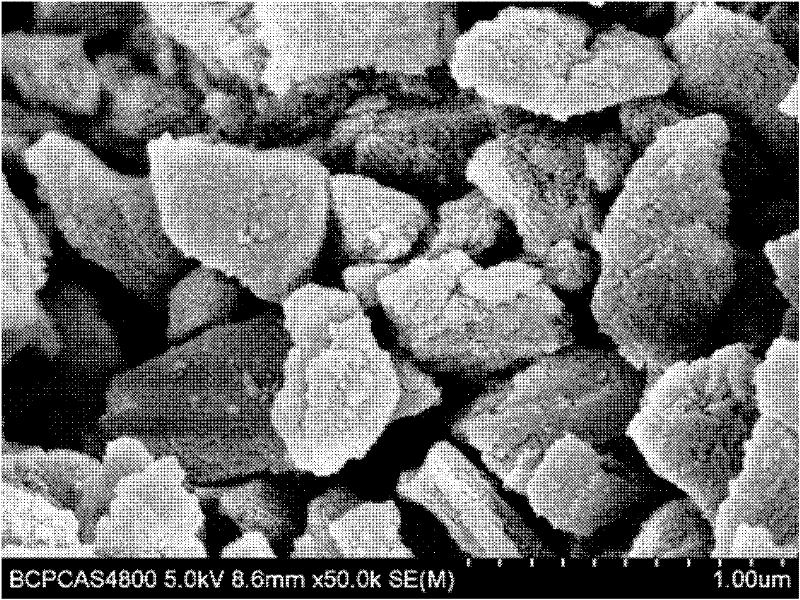

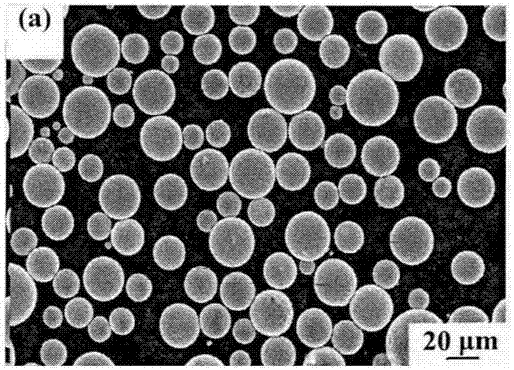

Preparation method and application of high-purity dense spherical molybdenum powder

ActiveCN107309434AHigh purityLow costAdditive manufacturing apparatusMolten spray coatingImpurityParticle-size distribution

The invention provides a preparation method and application of high-purity dense spherical molybdenum powder and belongs to the technical field of spherical metal powder material preparation. Conventional reduction molybdenum powder serves as the raw material, the particle size range of the granulated molybdenum powder is controlled actively by adjusting the granulation process, the molybdenum powder subjected to degumming, impurity removal and sintering is further screened, the particle size of the granulated molybdenum powder before plasma spheroidizing is effectively controlled, and it is beneficial to granularity control over the final granulated molybdenum powder. The particle size distribution of the molybdenum powder subjected to granulation and screening processing is narrow, vaporization and the burning loss of the molybdenum powder in the plasma spheroidizing process can be effectively lowered in cooperation with spherification process parameters, such as the input power, the powder feeding rate and the gas flow, it is beneficial to stability of the production process, and production efficiency and product quality are greatly improved; through introduction of hydrogen gas into the degumming, impurity removal and sintering processes of the molybdenum powder, the impurity content of the molybdenum powder before spherification is effectively lowered; and meanwhile, screening, spherification, cooling and collection of the molybdenum powder are all operated under the protection atmosphere of argon gas, and the oxygen content of a product is effectively lowered.

Owner:云航时代(重庆)科技有限公司

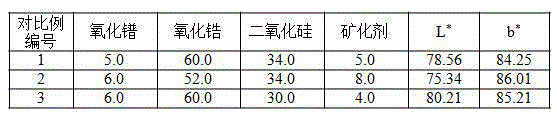

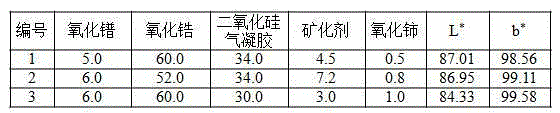

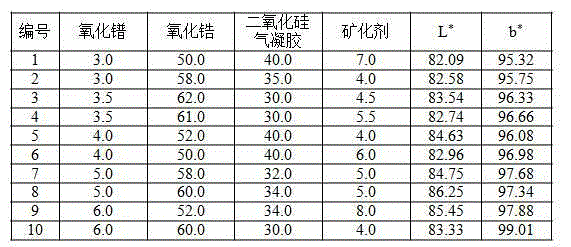

Small-particle-diameter praseodymium zirconium yellow ceramic pigment and preparation method thereof

The invention discloses a small-particle-diameter praseodymium zirconium yellow ceramic pigment which comprises the following components in percentage by weight: 3-6% of praseodymium oxide, 48-62% of zirconium oxide, 30-38% of silicon dioxide and 3-8% of a mineralizing agent, wherein the zirconium oxide selects the product which does not remove hafnium elements in the zirconium oxide production process, wherein the atom molar ratio of zirconium oxide to the hafnium elements is greater than 40:1; silicon dioxide selects silicon dioxide aerogel, wherein the BET specific surface area is 500-800 m<2> / g, the average particle diameter is 3-8 [mu]m, and the pore volume is 3-5. The praseodymium zirconium yellow pigment is small in particle diameter and relatively stable in structure, and is hard to damage in the ceramic ink preparation process. Meanwhile, the pigment is high in color strength in transparent glaze, and fine and smooth in color tone, and can be used as the high-grade ceramic pigment.

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

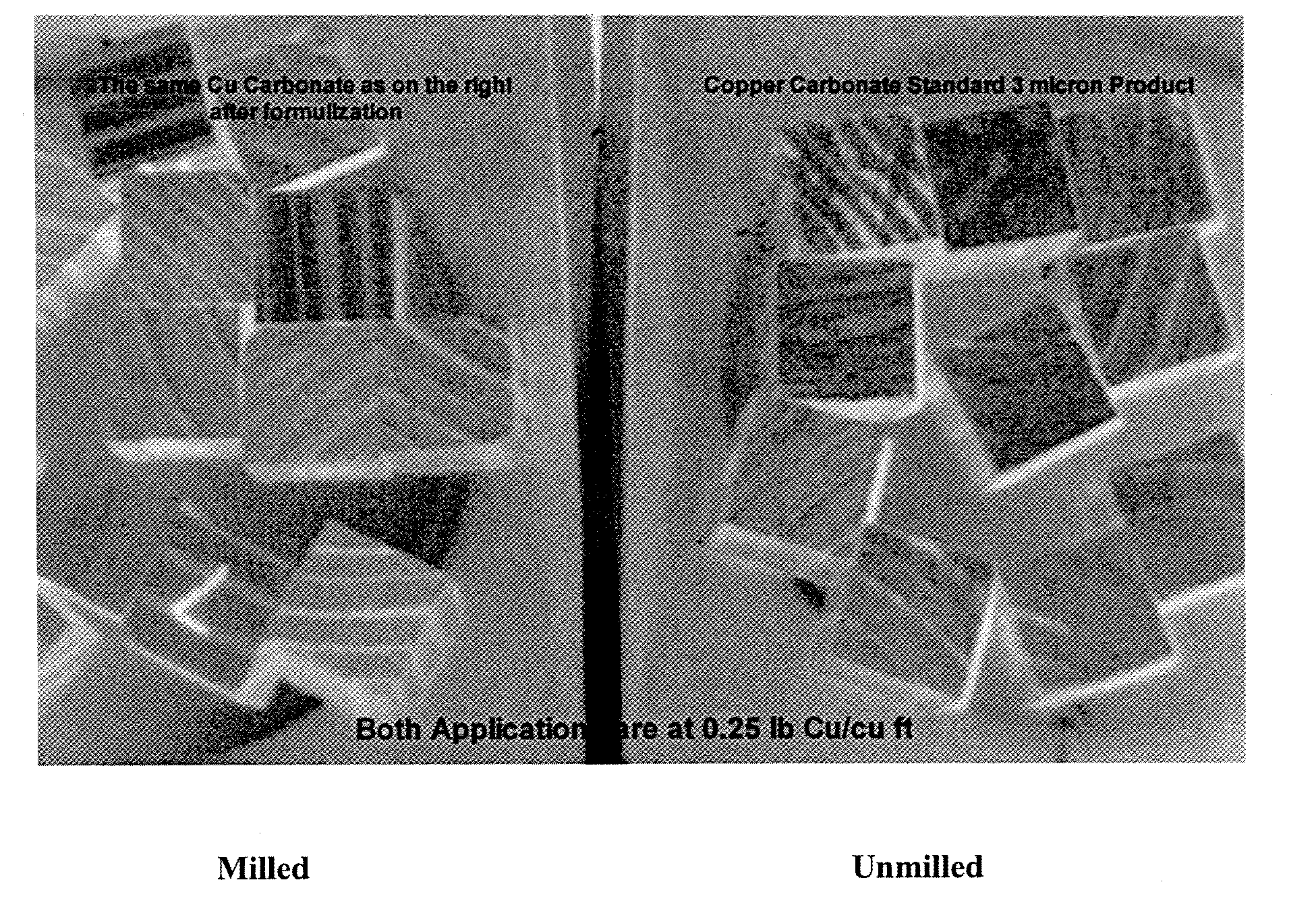

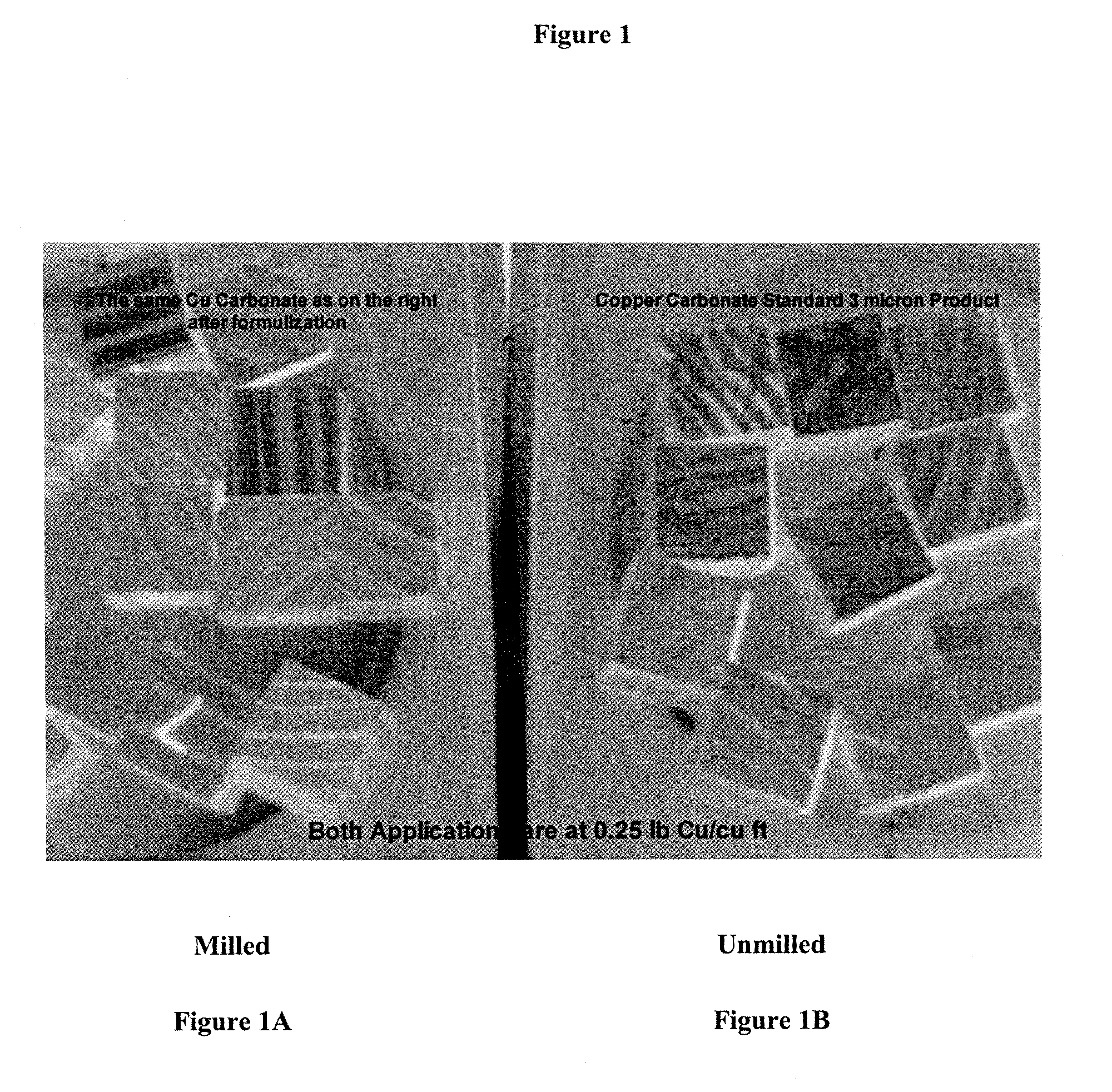

Particulate Wood Preservative and Method for Producing Same

ActiveUS20090123505A1Reduce the amount requiredWide particle size distributionBiocideLiquid surface applicatorsCopper nitrateTribasic copper sulfate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

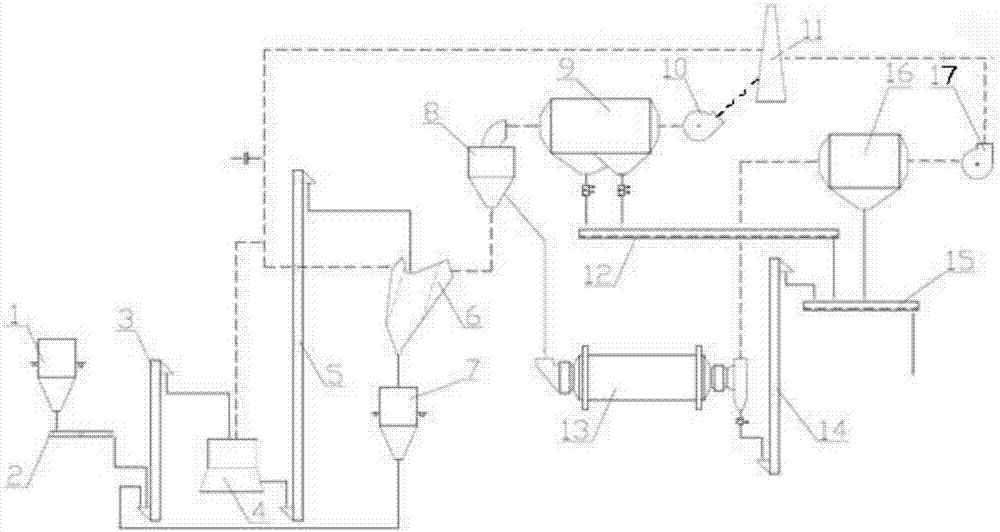

Built-out powder concentrator type vertical mill combined grinding system adopting non-metal grinding medium

PendingCN107350062AReduce adsorptionImprove grinding efficiencyCement productionGrain treatmentsBall millMetal

The invention relates to a built-out powder concentrator type vertical mill combined grinding system adopting a non-metal grinding medium. The built-out powder concentrator type vertical mill combined grinding system adopting the non-metal grinding medium is characterized by comprising a material distribution bin, a weighing scale, a feeding lifting machine, a vertical mill, a V-shaped powder concentrator feeding lifting machine, a V-shaped powder concentrator, a buffering bin, an efficient powder concentrator, a system dust collector, a system draught fan, a chimney, a first finished-product conveying chute, a ball mill, a mill tail lifting machine, a second finished-product conveying chute, a mill tail dust collector and a mill tail dust collection draught fan, wherein the material distribution bin, the weighing scale, the feeding lifting machine, the vertical mill, the V-shaped powder concentrator feeding lifting machine, the V-shaped powder concentrator, the buffering bin, the efficient powder concentrator, the system dust collector, the system draught fan, the chimney, the first finished-product conveying chute, the ball mill, the mill tail lifting machine, the second finished-product conveying chute, the mill tail dust collector and the mill tail dust collection draught fan are sequentially connected. The built-out powder concentrator type vertical mill combined grinding system adopting the non-metal grinding medium can stabilize operation of the vertical mill, adjust the cement grain size grading, relieve the ball coating phenomenon in the mill, improve the grinding efficiency in the mill, lower the noise of the ball mill in the operation process, reduce the pollution to finished products, reduce the unit power consumption and improve the performance of finished cement.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Matt waterborne polyurethane material and preparation method thereof

The invention discloses a matt waterborne polyurethane material and a preparation method and relates to the technical field of waterborne polyurethane materials. The matt waterborne polyurethane material has the solid content of 30%-40% and is prepared from raw materials in parts by weight as follows: 20-30 parts of diisocyanate, 40-50 parts of macromolecular polyols, 1.2-3 parts of a small-molecular chain extender, 1-2.5 parts of a small-molecular hydrophilic compound, 0.2-0.4 parts of a catalyst, 0.7-1.4 parts of an anionic emulsifier, 131-170 parts of deionized water, 0.7-2 parts of a neutralizer and 3-5 parts of a polyamine chain extender. The prepared matt waterborne polyurethane material does not require an additional matting agent, avoids the whitening and yellowing phenomena and issafe and environmentally friendly, and the emulsion performance is stable; the matt waterborne polyurethane material has excellent mechanical performance, friction resistance and water resistance, has matt performance and can be widely applied to waterborne coatings.

Owner:安徽匠星联创新材料科技有限公司

Filter element

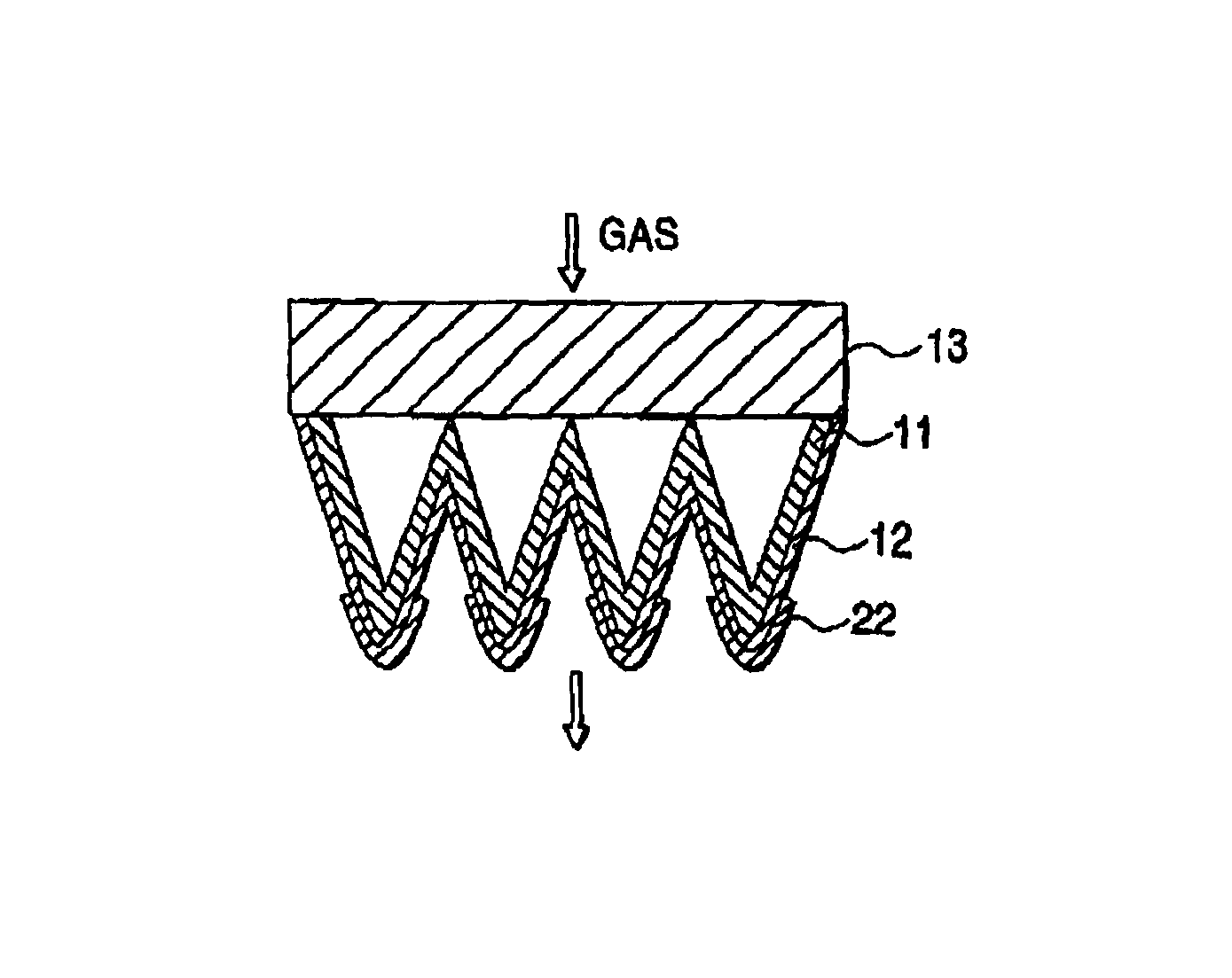

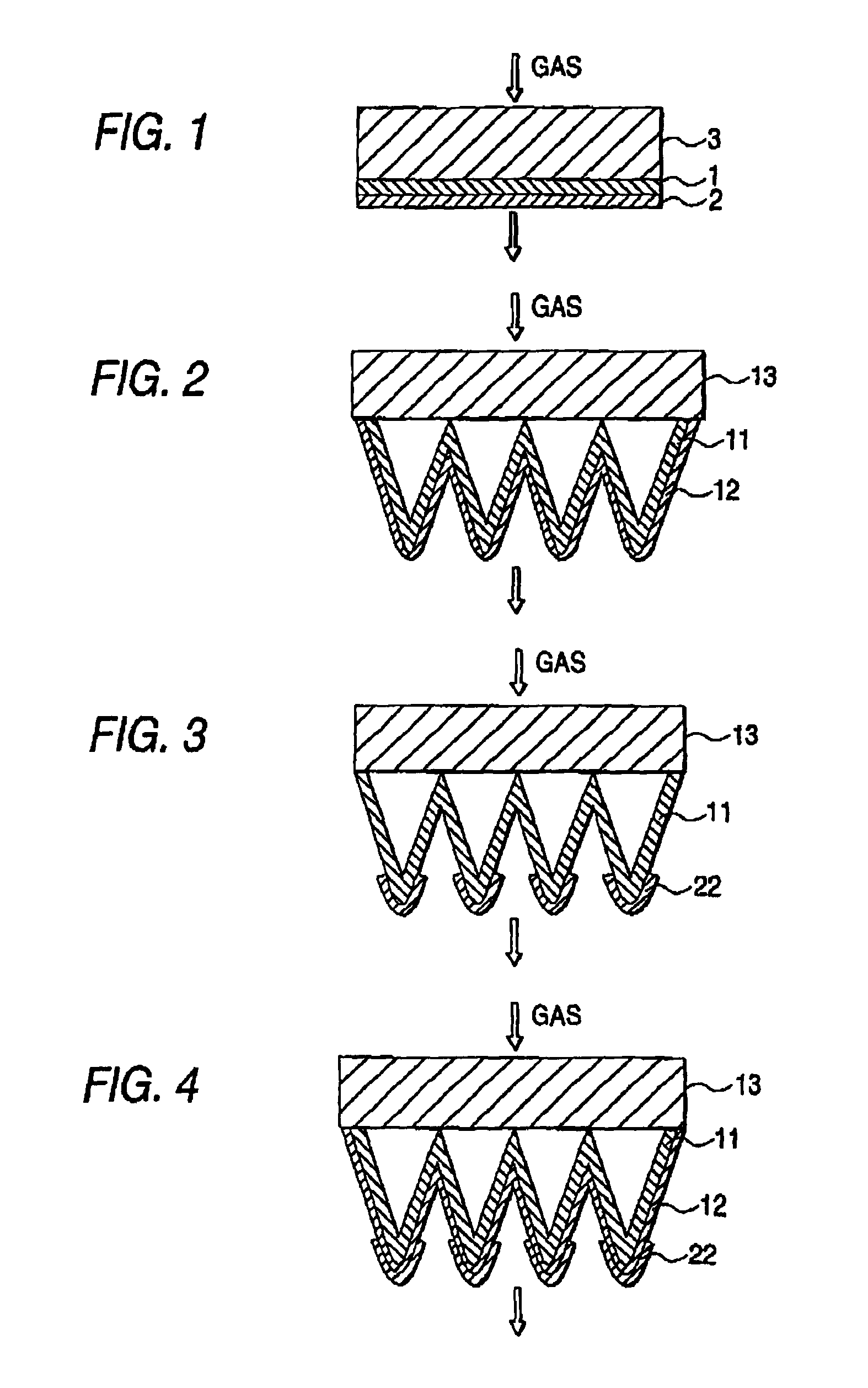

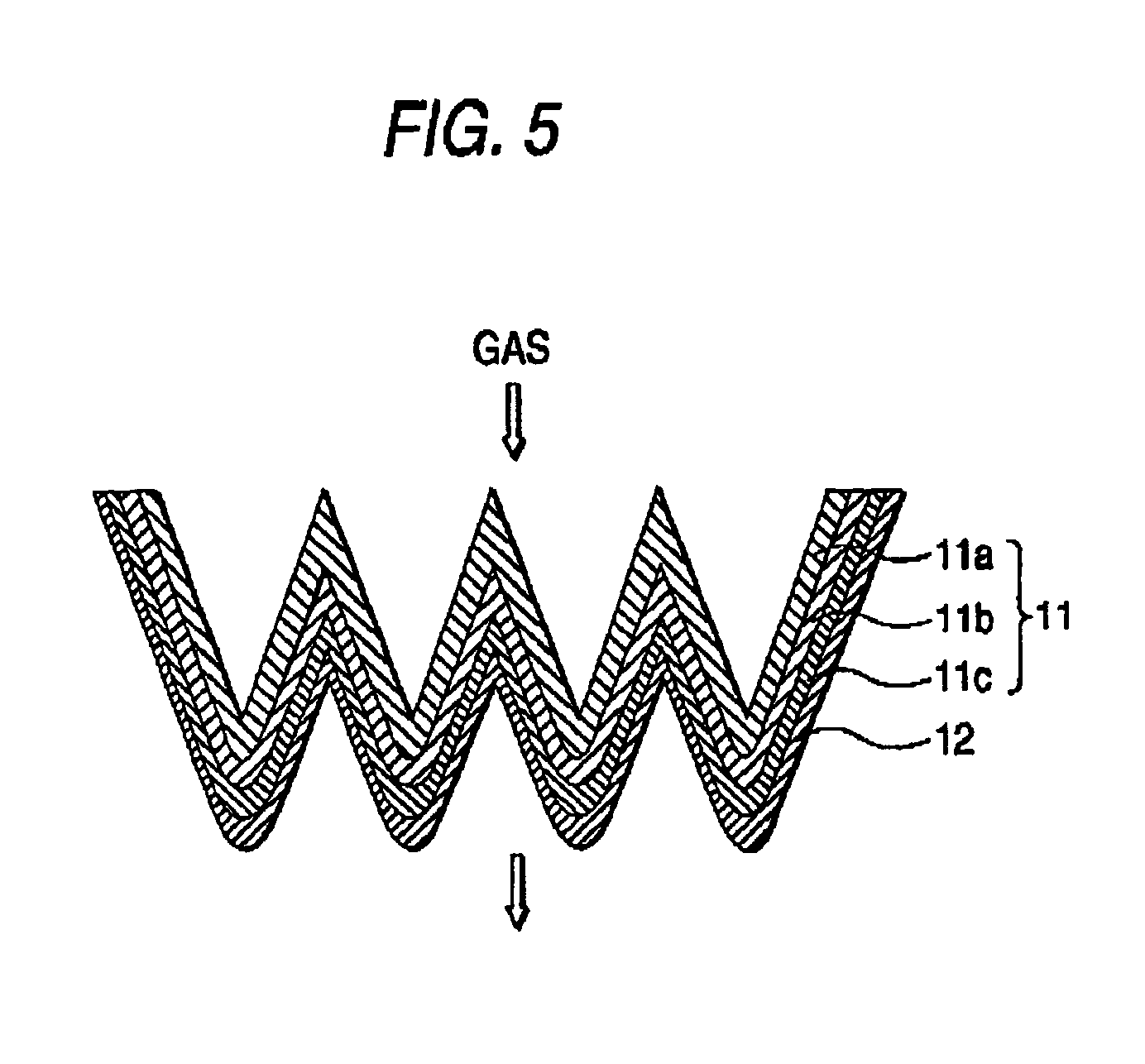

InactiveUS6926750B2Improve cleaning efficiencyExtended service lifeCombination devicesDispersed particle filtrationFolded structureRidge

A filter element comprises an oil-impregnated filtering member, and a transmission preventing layer formed on a downstream side of the filtering member, for restricting transmission of at least the carbon dusts from the oil-impregnated filtering member. The filtering member may be formed like a ridge-like-folded structure. The transmission preventing layer may be formed of a coating layer having a resistance against a viscous oil that is impregnated in the filtering member. This coating layer may be formed uniformly as a whole or the thickness or the content of the coating layer may be increased partially. A ventilation shutting-off member (filling layer) may be formed as the transmission preventing layer in the root portion areas of the ridge portions. The transmission preventing layer may comprise a resistant component that is insoluble in the oil that is impregnated in the filtering member.

Owner:HONDA MOTOR CO LTD +1

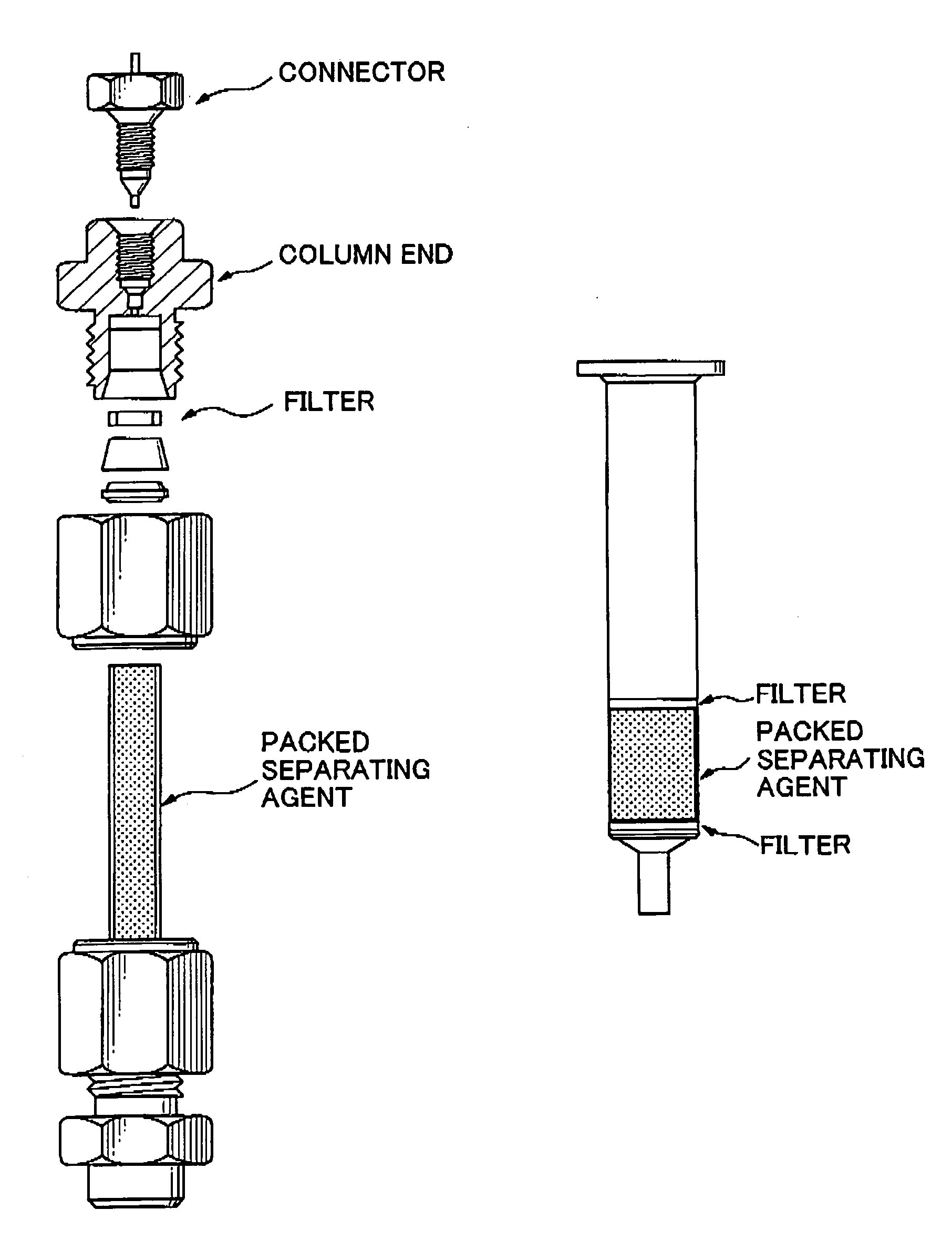

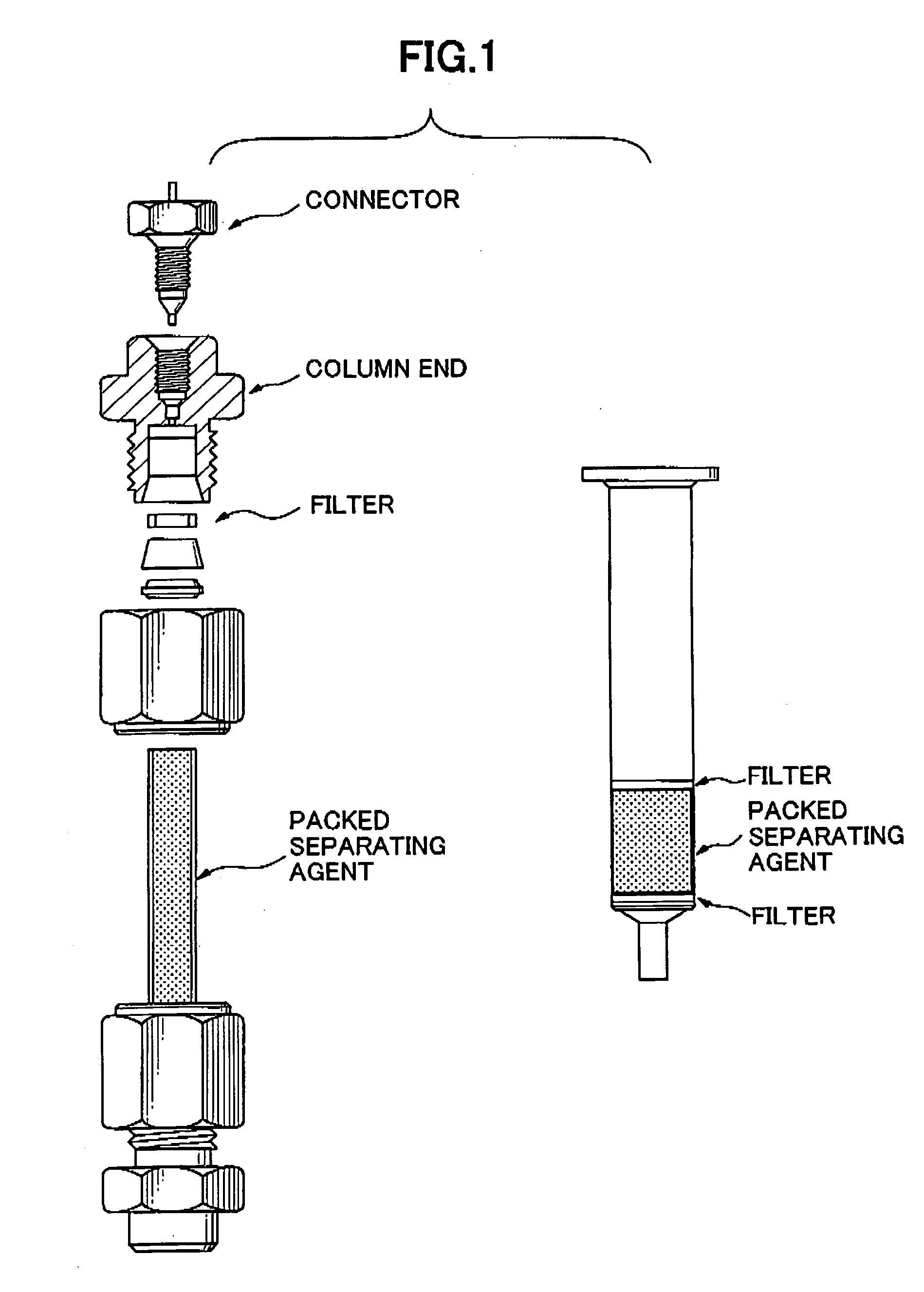

Separating agent for solid-phase extraction

ActiveUS20060043022A1Improve machinabilityIncrease productionIon-exchange process apparatusSamplingHydrophilic polymersHydrophobic polymer

The present invention relates to a separating agent for solid-phase extraction which comprises core particles of a base material; a hydrophilic polymer layer formed on the surface of the particles; and a hydrophobic polymer layer formed on the surface of the hydrophilic polymer layer. The separating agent can be used in a cartridge or a column for solid-phase extraction and the latter can in turn be used in a variety of methods such as a method for concentrating a subject to be separated; a method for removing impurities; a method for solid-phase extraction of an environmental, medicinal and / or biological samples; and a method for pre-treating a protein component-containing sample.

Owner:SHINWA CHEM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com