Small-particle-diameter praseodymium zirconium yellow ceramic pigment and preparation method thereof

The technology of a ceramic colorant and praseodymium zirconium yellow is applied in the field of praseodymium zirconium yellow ceramic colorant and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

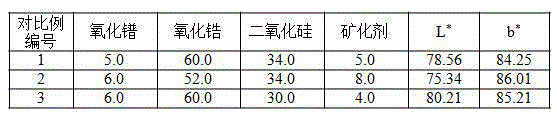

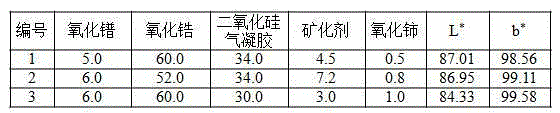

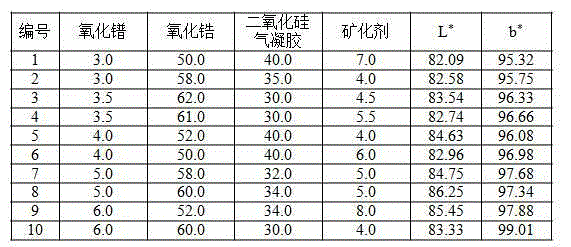

Examples

preparation example Construction

[0033] The preparation method of praseodymium zirconium yellow ceramic pigment is as follows:

[0034] Step 1, pulverizing and grinding praseodymia, zirconia, silica airgel and mineralizer raw materials to a particle size of 1 μm, drying and mixing uniformly;

[0035] Step 2: Place the mixed raw materials in a sagger for calcination. The calcination temperature is 1000°C. The heating time is controlled at 3 hours. After the temperature rises to the calcination temperature, keep it warm for 2 hours. Take out the sagger to obtain the praseodymium-zirconium yellow ceramic pigment. burnt products;

[0036] Step 3: Grind the calcined product in Step 2 evenly, wash with deionized water for 3 times, and dry to obtain the required praseodymium-zirconium yellow ceramic pigment.

[0037] Judgment method of the color intensity of the pigment: Add 6% of the prepared praseodymium-zirconium yellow material to the transparent base glaze to make a colored glaze, and then glaze it on the blank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com