High-temperature grain inhibitor for ceramic pigment, ceramic pigment and preparation method

A technology of grain inhibitors and ceramic pigments, which is applied in the field of ceramic pigments and its preparation, high-temperature grain inhibitors of ceramic pigments, can solve the problems of ceramic inks failing to meet the required standards, weakening of color development, and no color development, etc., to achieve Excellent color development properties, the effect of increasing color strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below through specific description and examples.

[0025] In order to solve the problem that the coloring power of ceramic pigments is greatly weakened after ultrafine treatment, a new high-temperature grain inhibitor is provided, which can well control the ceramic pigments during the preparation process of ceramic pigments. The growth of crystal grains enables ceramic pigments to maintain their original chroma well after nanoscale grinding treatment, and at the same time, the particle size distribution can be kept in a relatively narrow particle size range, so as to achieve the goal of ceramic ink preparation industry. The requirements for color materials are standard, and it can effectively save grinding time, save the loss of ceramic pigment grinding media and production costs.

[0026] Specifically, t...

Embodiment 1

[0046] Example 1 (blue material)

[0047] Mix 10kg of magnesium oxide, 40kg of chromium carbide, 40kg of industrial starch and 10kg of nano white carbon black evenly to obtain a high temperature grain inhibitor.

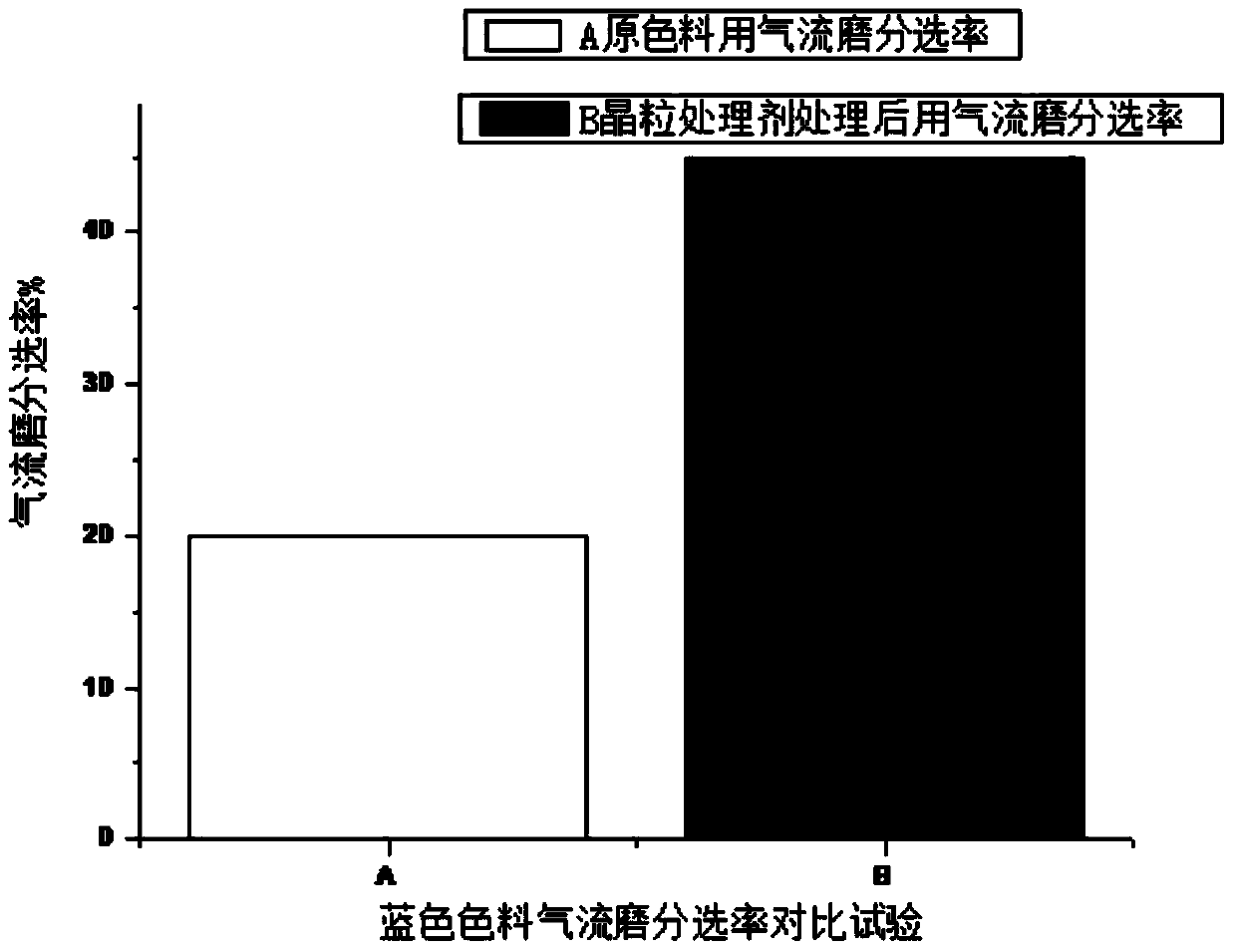

[0048]Mix the raw materials of the blue color material according to the original formula, and mix the high-temperature grain inhibitor with the blue color material evenly, wherein the high-temperature grain inhibitor accounts for 5% of the weight of the blue color material, and then heat Calcined at high temperature for 5 hours, cooled, and pulverized to an average size of 2.5 microns by jet mill to obtain a blue pigment for ceramic ink. The pigments for ceramic inks that were fired after being treated with high-temperature grain inhibitors, and the pigments prepared from the original color formulation without grain inhibitors were used as a control, and the jet mill sorting rate and chromaticity were compared and analyzed , the specific results are shown in Table 1...

Embodiment 2

[0051] Embodiment 2 (brown pigment)

[0052] Mix 65kg of magnesium carbonate, 20kg of calcium carbide, 10kg of maltose and 5kg of nano white carbon black evenly to obtain a high temperature grain inhibitor.

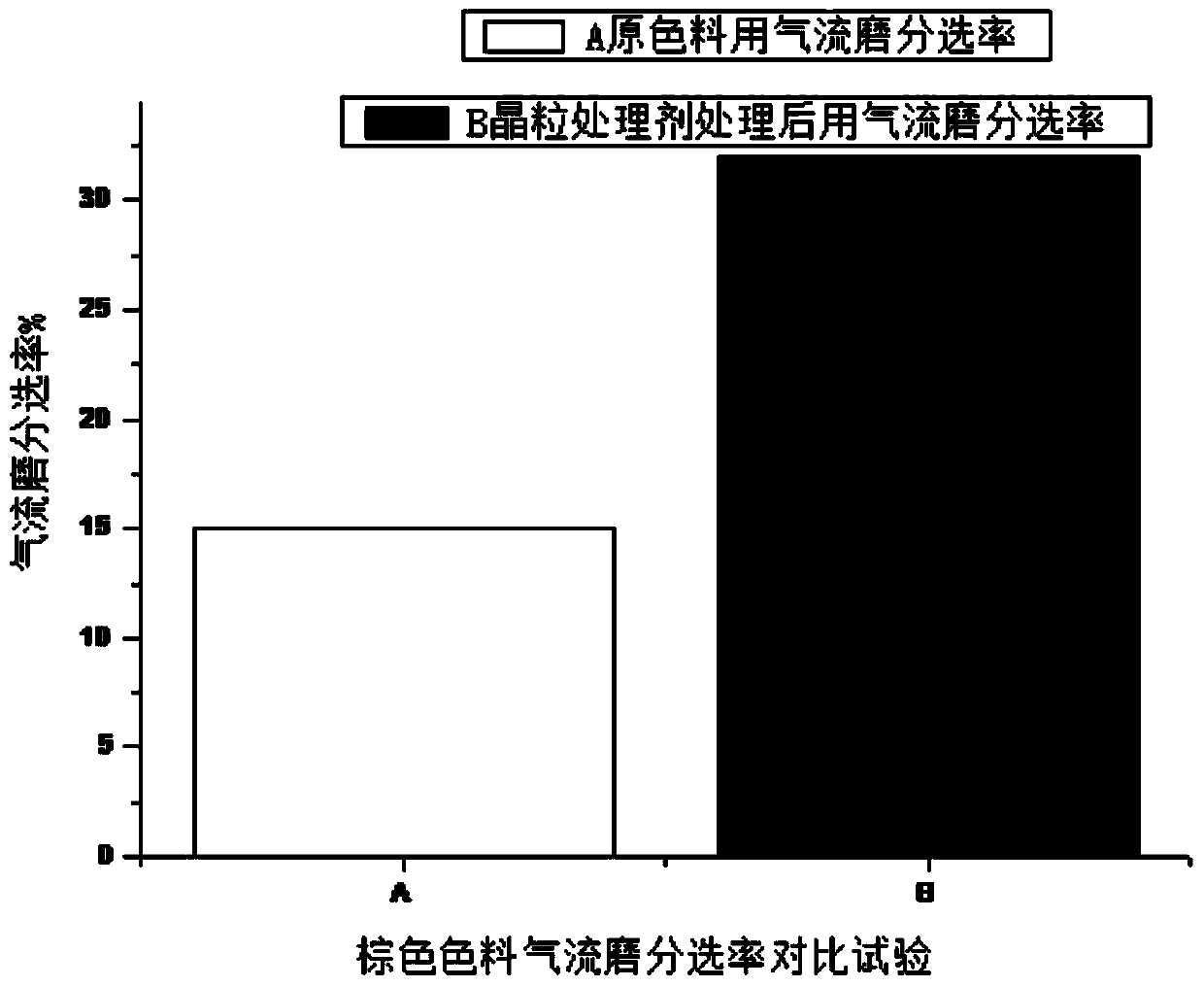

[0053] Mix the brown color material raw materials according to the original formula, and mix the high-temperature grain inhibitor and the brown color material raw material evenly, wherein the high-temperature grain inhibitor accounts for 10% of the weight of the brown color material raw material, and then Calcined at high temperature for 5 hours, cooled, and pulverized to an average size of 2.5 microns by jet mill to obtain a brown pigment for ceramic ink. The pigments for ceramic inks that were fired after being treated with high-temperature grain inhibitors, and the pigments prepared from the original color formulation without grain inhibitors were used as a control, and the jet mill sorting rate and chromaticity were compared and analyzed , the specific results are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com