Method for preparing submicron polycrystalline diamond abrasive with narrow particle size distribution

A polycrystalline diamond, sub-micron technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as workpiece scratches and unfavorable processing, and achieve the effects of short production cycle, enlarged production scale, and regular particle shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

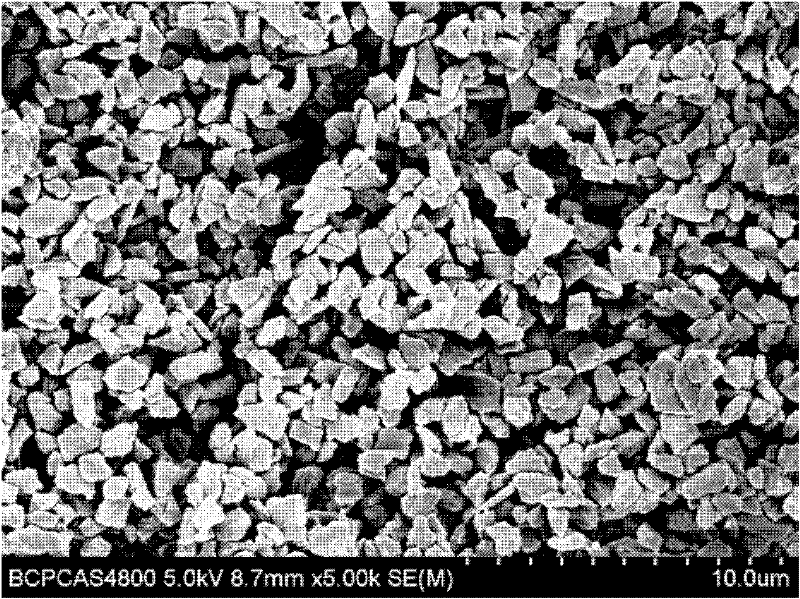

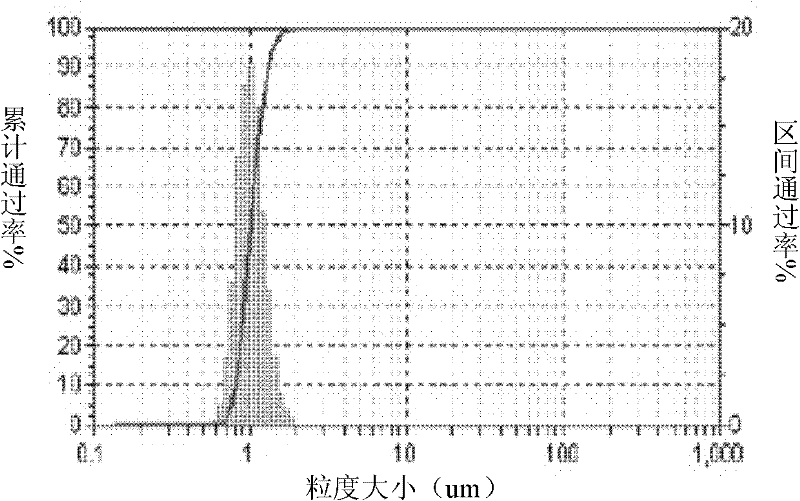

[0035] Take 2 kg of semi-finished unshaped unclassified polycrystalline diamond micropowder with an original particle size of um and disperse it in 10 kg of pure water. Add 10 ml of concentrated ammonia water and 10 g of sodium hexametaphosphate, and stir and disperse for 30 minutes. Add the dispersed slurry into the planetary ball mill tank, add 16kg of 5mm steel balls, start the ball mill to start shaping, and run for 12h at 400rpm. Discharging drying, pickling to remove metal impurities, cleaning to PH=6. The pickled and purified diamond is ultrasonically dispersed in pure water at a concentration of 1% to 10%, and centrifuged at 800 rpm for 10 minutes for centrifugal classification. The lower part is taken and the particle size is tested with the laser particle size analyzer MICROTRAC S35OO. The particle size distribution diagram is shown figure 1 . The morphology of the particles was tested with a scanning electron microscope, and the results are as follows figure 2 . I...

Embodiment 2

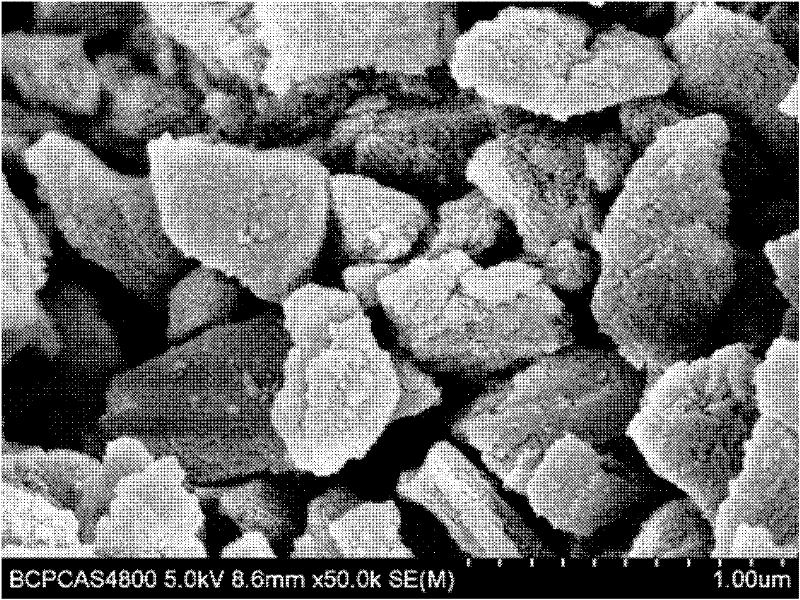

[0037] Take 15 kg of semi-finished unshaped and unclassified polycrystalline diamond powder with an original particle size of um and disperse it in 60 kg of pure water, add 100 ml of triethanolamine, and stir and disperse for 30 min. Add 10kg of steel balls with a diameter of 2mm into the main cavity of the ultra-fine mill, add the dispersed slurry into the barrel, start the ultra-fine mill to begin crushing and shaping, and run at 800 rpm for 8 hours. Discharging drying, pickling to remove metal impurities, cleaning to PH=6. The pickled and purified diamond is ultrasonically dispersed in pure water at a concentration of 1% to 10%, centrifuged at a centrifugal speed of 800 rpm for 10 minutes, and the upper material is taken. Then the top material is centrifuged and classified at a centrifugal speed of 2000 rpm for 30 minutes, and the bottom material is taken. Use the laser particle size analyzer MICROTRAC S35OO to test its particle size, see the particle size distribution diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com