Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

408 results about "Particle Size Analyzer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The particle size measurement is typically achieved by means of devices called Particle Size Analyzers (PSA) which are based on different technologies, such as high definition image processing, analysis of Brownian motion, gravitational settling of the particle and light scattering (Rayleigh and Mie scattering) of the particles.

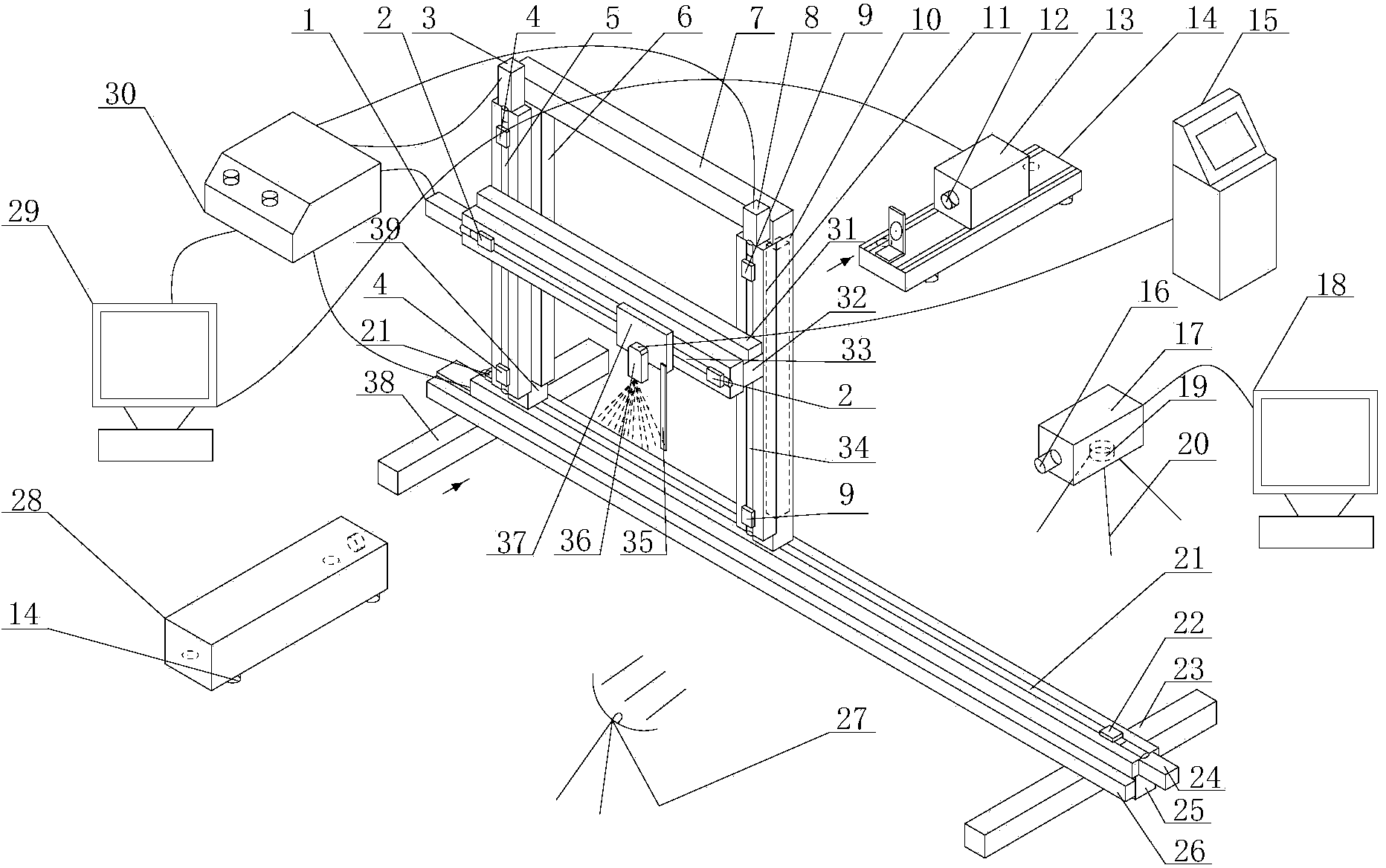

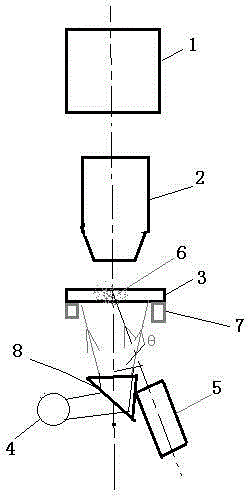

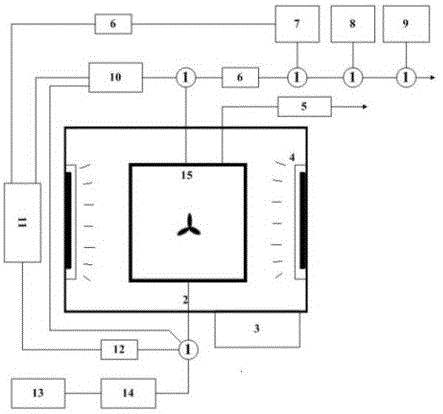

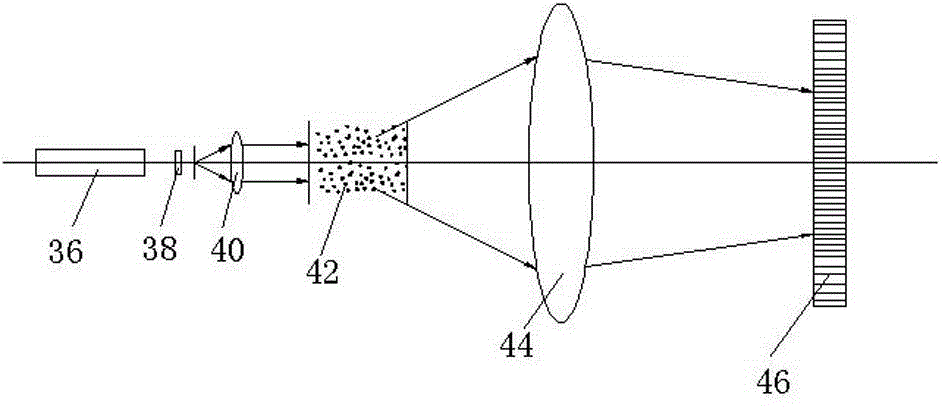

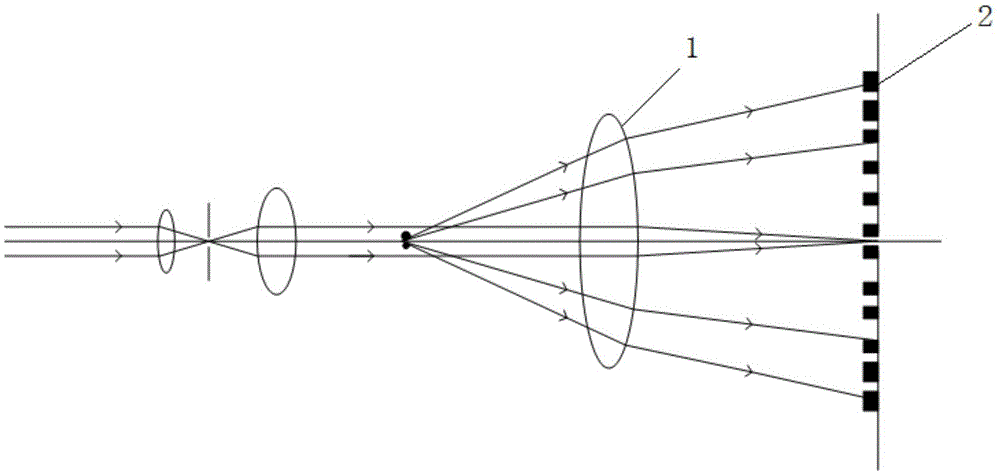

Spray characteristic parameter detection device and method

ActiveCN104181083AEasy to moveHigh degree of automationParticle size analysisControl systemEngineering

The invention discloses a spray characteristic parameter detection device and method. The spray characteristic parameter detection device comprises an integral support rack, a two-dimensional moving unit, a servo motor, a servo control unit, a spray control system, a pulse nozzle, a high-speed camera image acquisition system and a laser particle size analyzer system. On the basis of the device, the spray characteristic parameter detection method comprises the following steps: detecting an outline shape of spray, macroscopic two-dimensional distribution of spray and the flying speed of particles of spray by virtue of the high-speed camera image acquisition system; and detecting the particle size of spray with two-dimensional distribution in a spatial two-dimensional plane travel range by a two-dimensional precise servo driving system based on a laser particle size analyzer according to the outline and the macroscopic two-dimensional distribution of spray on the basis of a spray image acquisition result.

Owner:TIANJIN UNIV OF COMMERCE

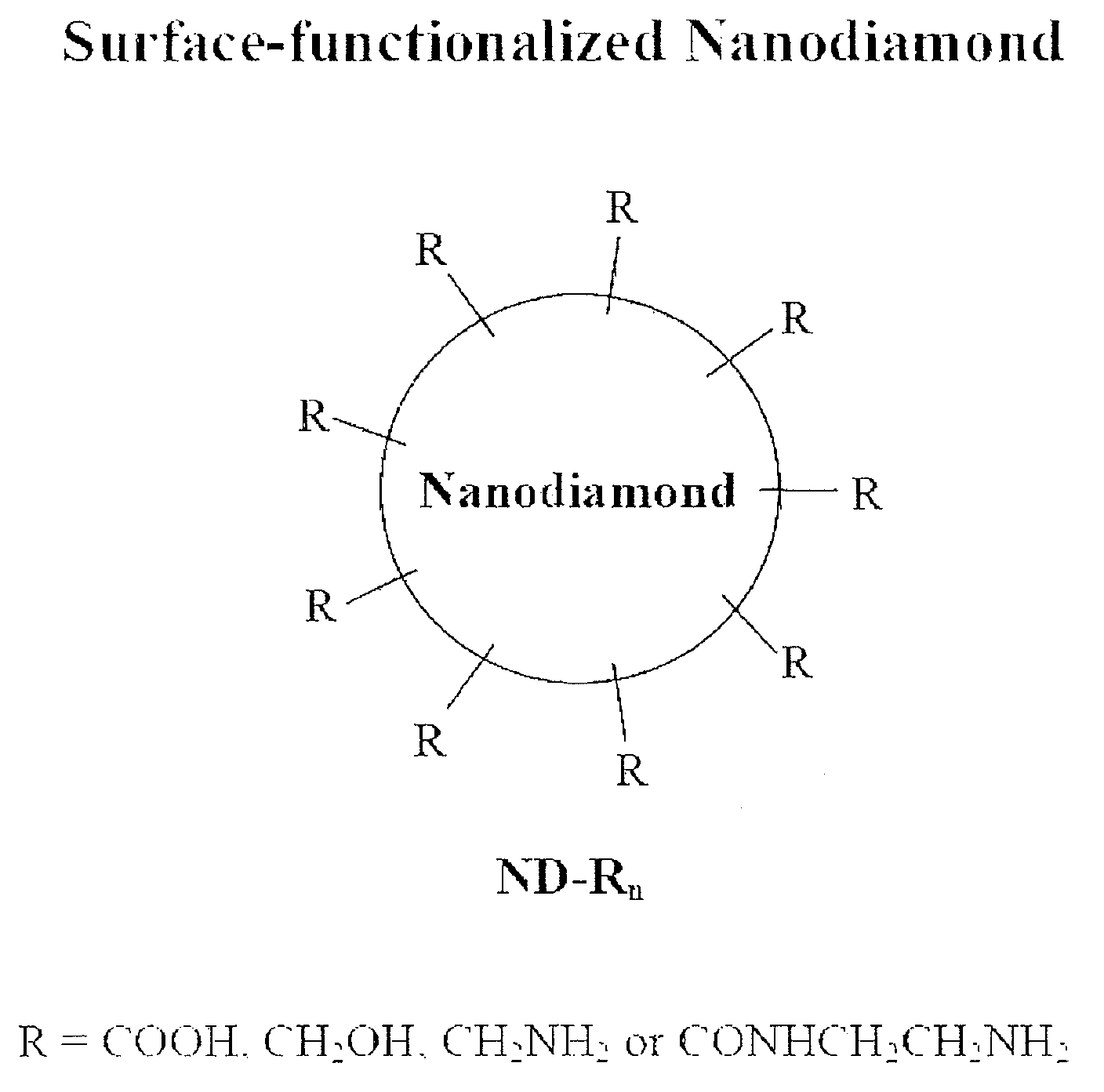

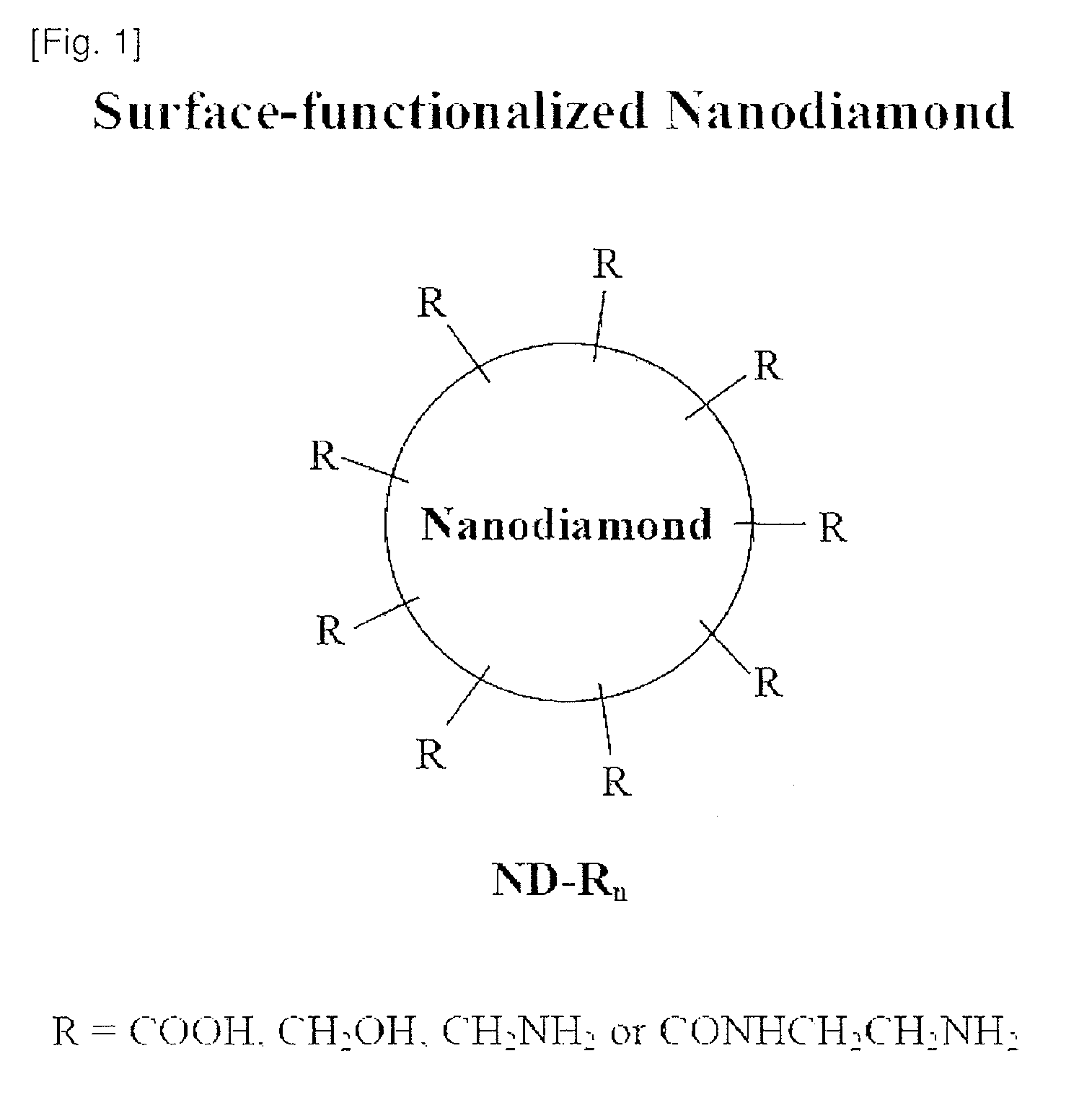

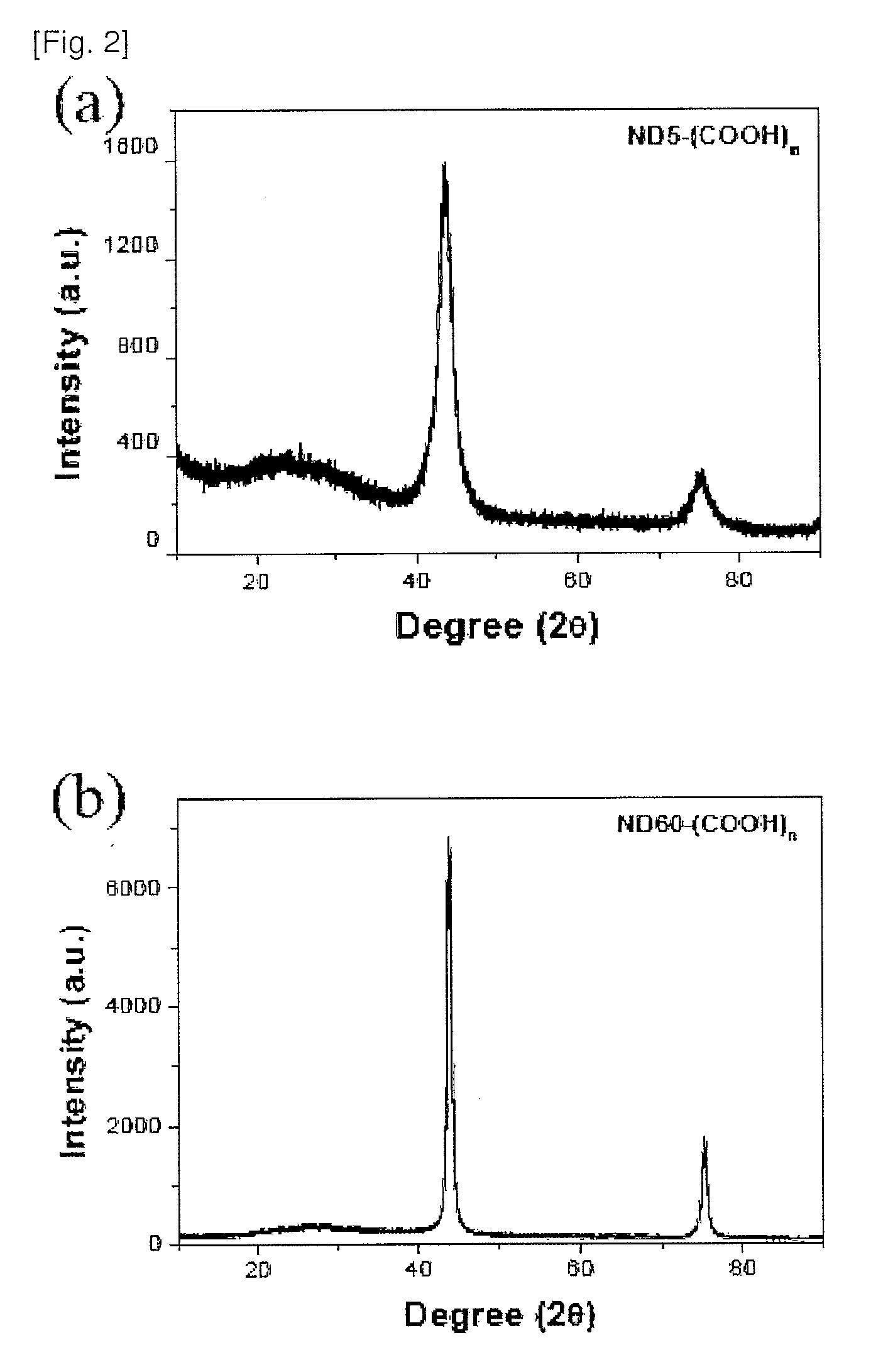

Nanodiamond compounds synthesized by surface functionalization

InactiveUS20100298600A1Improve solubilityMaterial nanotechnologyOxygen-containing compound preparationSolubilityStrong acids

Disclosed herein is a method for chemically attaching carboxyl, alcohol, amine or amide groups to the surface of nanodiamond (ND) in a liquid phase. Also disclosed herein are a functional ND compound obtained by the method and use thereof. The method includes treating synthetic ND with a size of 1 nm-1OO nm with sonication and a strong acid to provide ND-(COOH)n. The ND-(COOH)n compound is used as a starting material to provide ND compounds having alcohol, amine or amide groups attached to the surfaces thereof. The surface-functionalized ND compounds are characterized by using an X-ray diffractometer, FTIR, AFM, particle size analyzer and zeta sizer. The ND compounds show functionalities as well as high solubility to provide stable ND solutions in a liquid phase. Therefore, the ND compounds may be used as diamond coating agents. The powder of the ND compounds may be used as materials for producing composites of polymers, plastics, synthetic fibers, ceramics, etc., or as additives for toothpaste, shampoos, soap and cosmetic compositions.

Owner:NANODIAMOND

Miniaturized ultrafine particle sizer and monitor

InactiveUS8044350B2Material analysis using wave/particle radiationParticle separator tubesParticle Size AnalyzerParticle-size distribution

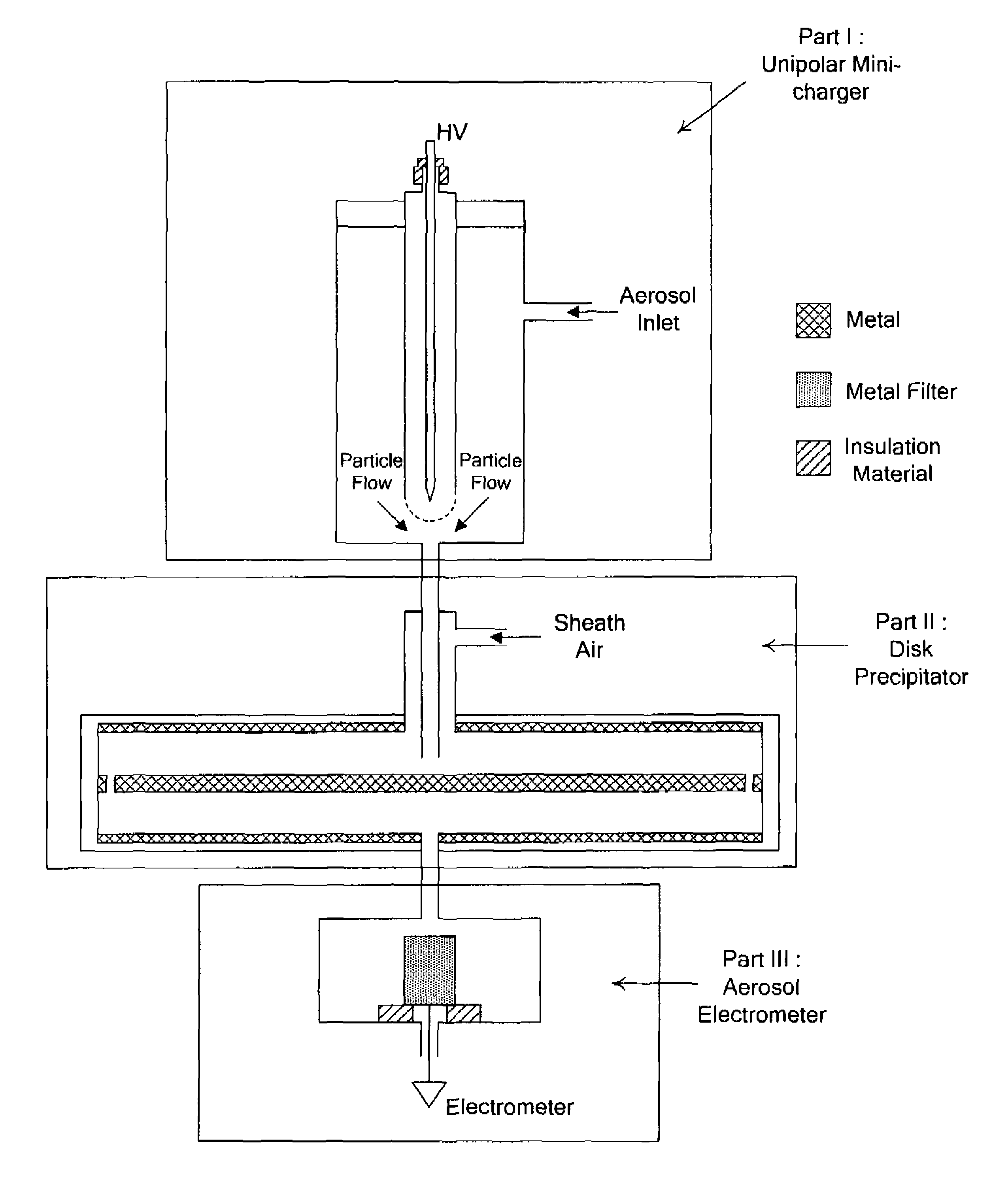

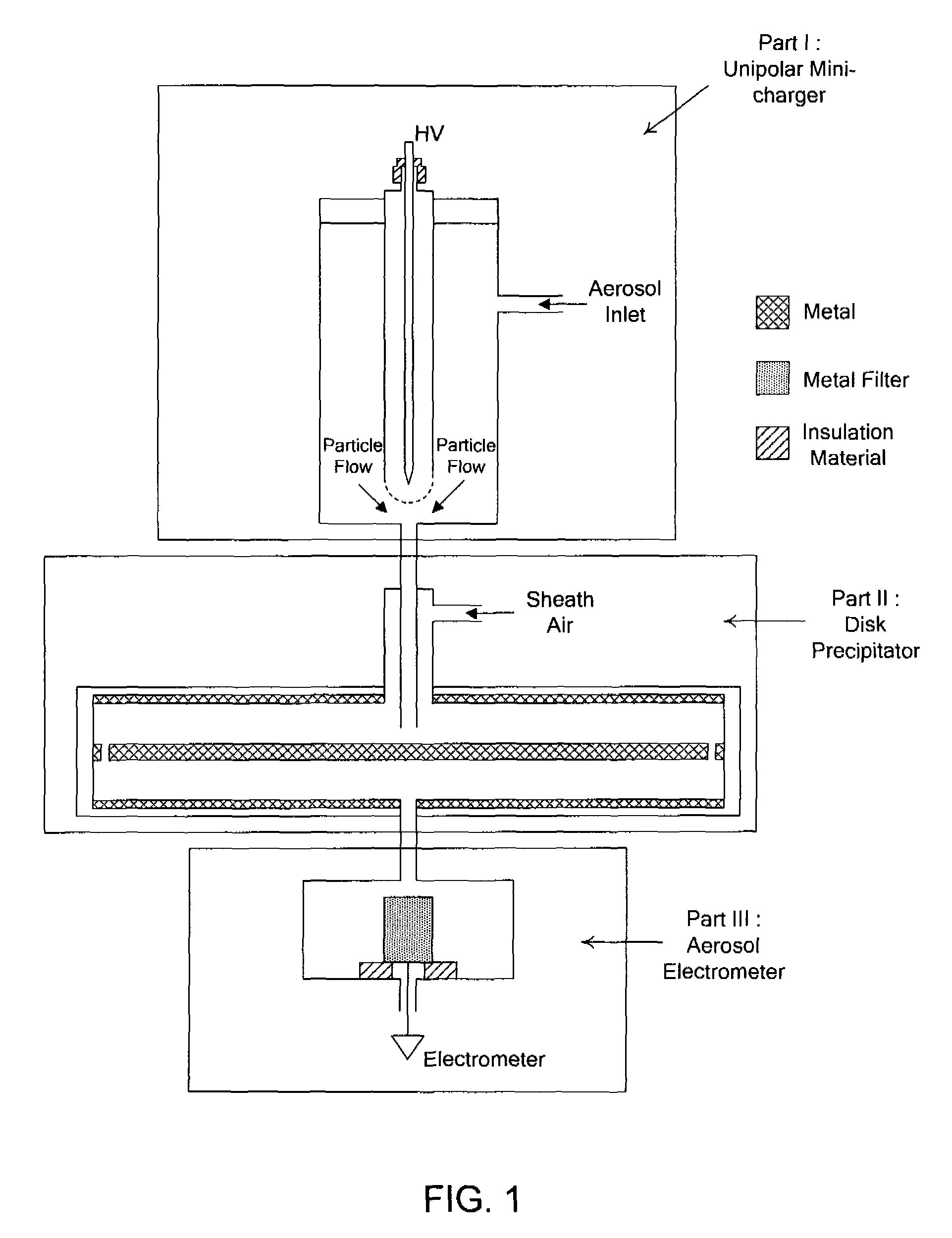

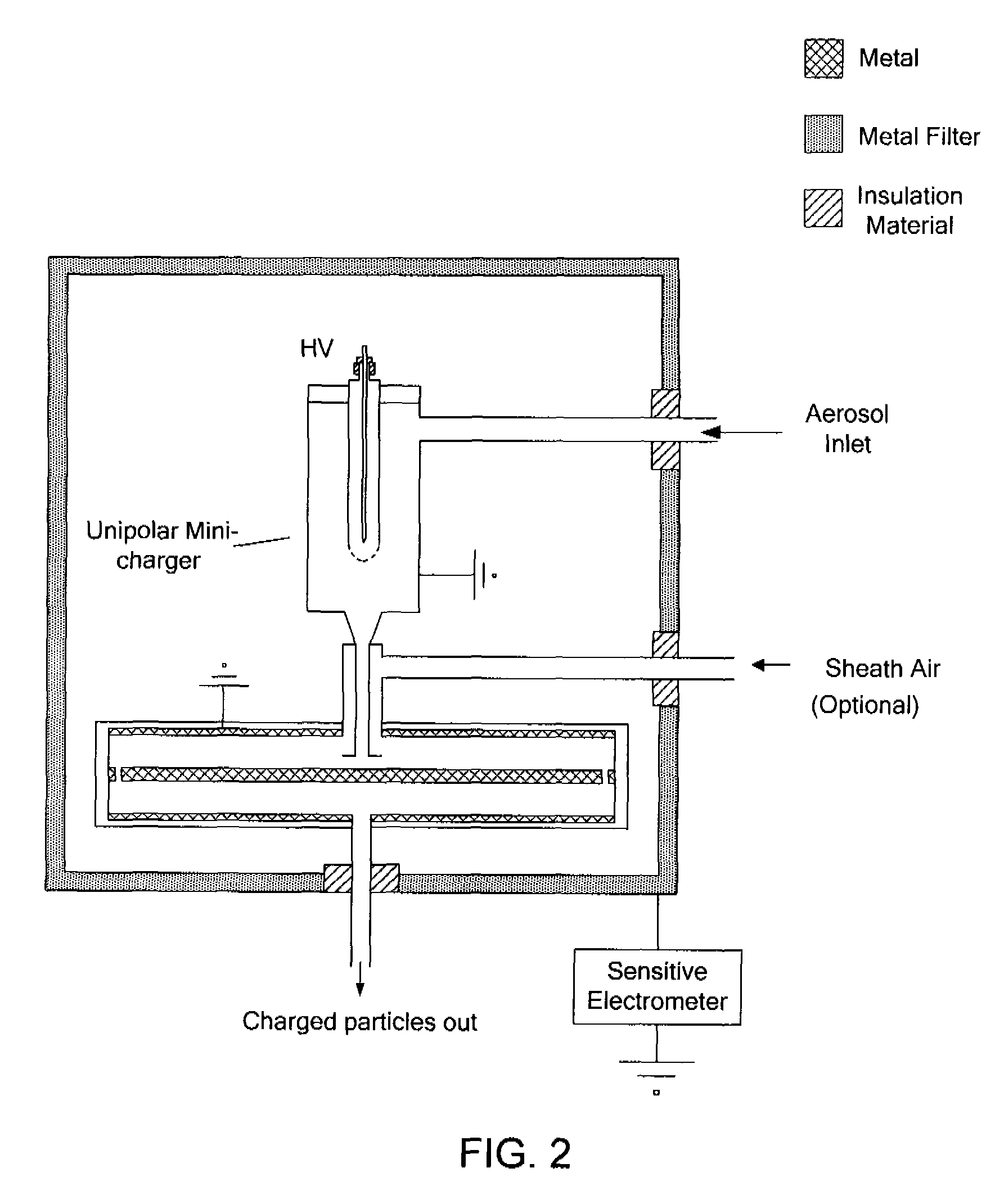

An apparatus for measuring particle size distribution includes a charging device and a precipitator. The charging device includes a corona that generates charged ions in response to a first applied voltage, and a charger body that generates a low energy electrical field in response to a second applied voltage in order to channel the charged ions out of the charging device. The corona tip and the charger body are arranged relative to each other to direct a flow of particles through the low energy electrical field in a direction parallel to a direction in which the charged ions are channeled out of the charging device. The precipitator receives the plurality of particles from the charging device, and includes a disk having a top surface and an opposite bottom surface, wherein a predetermined voltage is applied to the top surface and the bottom surface to precipitate the plurality of particles.

Owner:WASHINGTON UNIV IN SAINT LOUIS +1

Particle size analyzer

InactiveCN104089858AMeet the measurement requirementsEasy to carryParticle size analysisBrownian excursionDynamic light scattering

The invention discloses a particle size analyzer which is characterized in that a microscope objective is arranged below an area array sensor; a sample tank is arranged on the focusing plane of the microscope objective; two light sources, namely a transmission light source and a scattering light source are arranged below the sample tank; when micron-grade particles are measured, the transmission light source emits illumination light to illuminate particle samples to be detected, particle images are amplified by the microscope objective to be imaged on an image plane, and image signals obtained after receiving of the images by the area array sensor are transmitted to a computer to be processed to obtain particle size distribution; when nano particles are measured, the transmission light source is turned off while the scattering light source is turned on, laser emitted by the transmission light source is irradiated to nano particle samples, dynamic light scattering signals generated by Brownian movement of the nano particles are received by the area array sensor through the microscope objective, and the obtained signals are transmitted to the computer to be processed to obtain the particle size distribution. According to the particle size analyzer, the particles with the size range from nanometers to hundreds of microns can be measured by only one image sensor, so as to meet the requirements of wide-range particle measurement.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

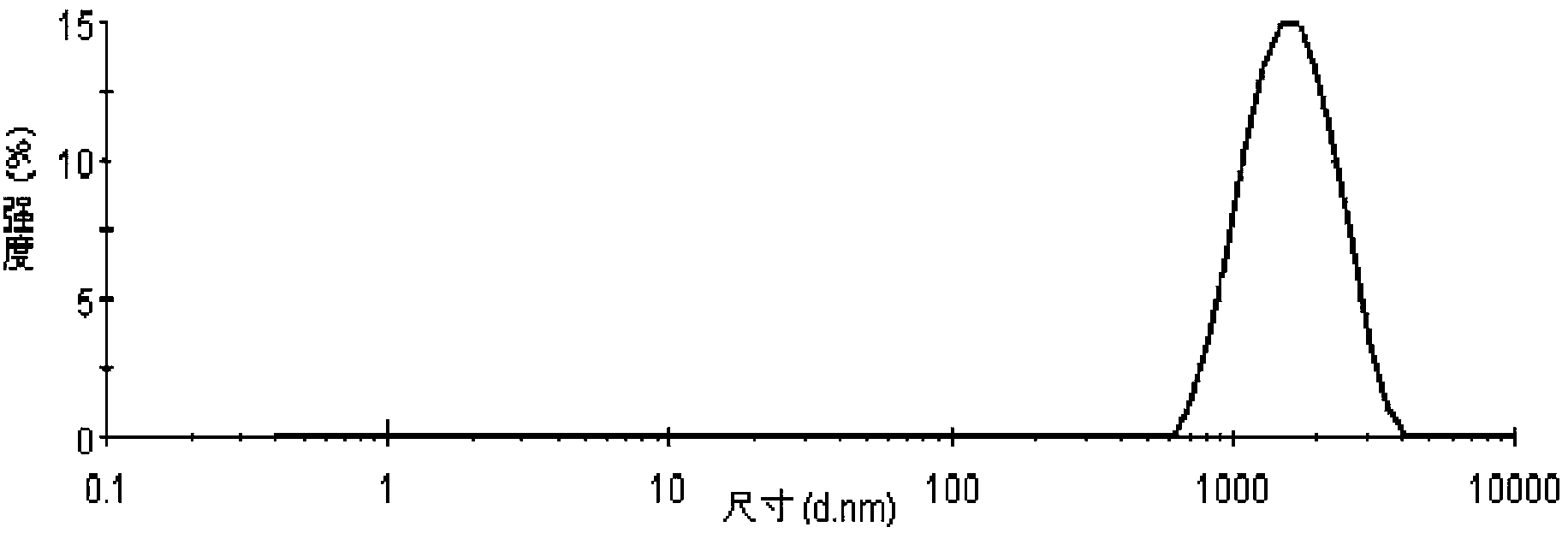

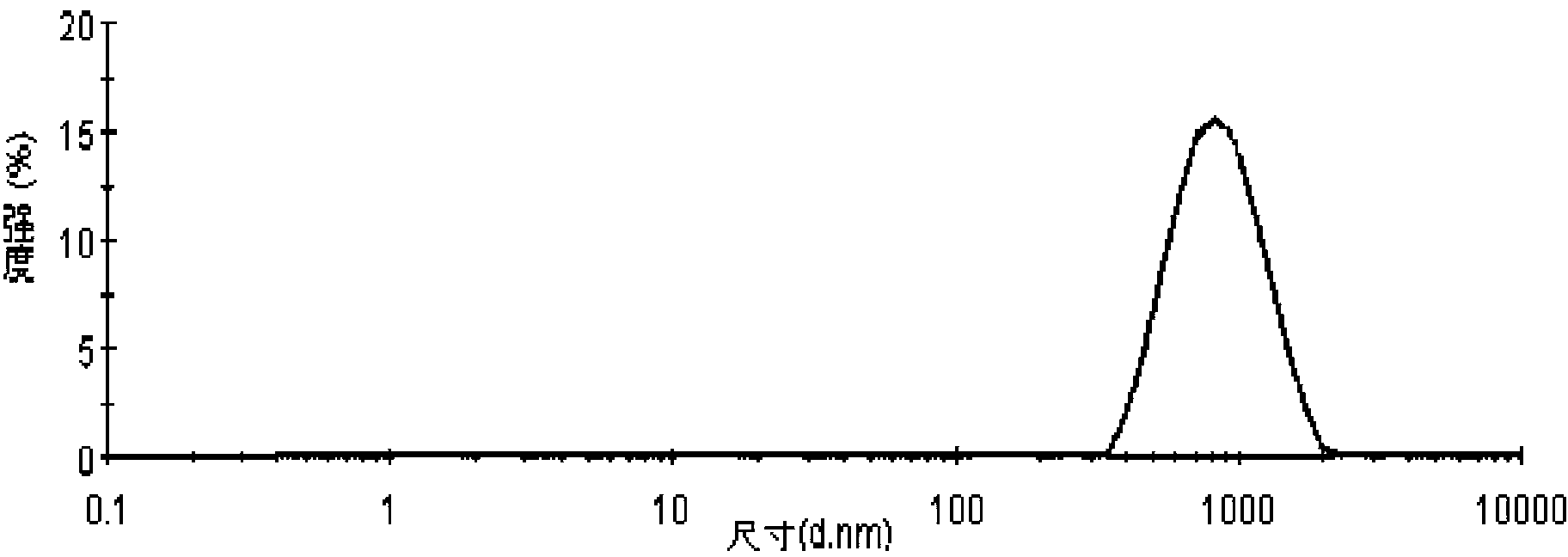

Powder average particle size determination method

The invention discloses a powder average particle size determination method. According to the method, 0.02-0.1g of powder to be measured is weighed and placed into a 50mL beaker; a dispersing agent and deionized water are mixed into a dispersing agent solution with a concentration of 15-25g / L. 2-5 drops of the prepared dispersing agent solution is dropped into the beaker; stirring, wetting, and dispersing are carried out by using a glass rod; 10-20mL of deionized water is added into the beaker; the solution is subjected to ultrasonic dispersing, such that a white suspension liquid is obtained; 1.5-3mL of the white suspension liquid is dropped into a quartz cuvette; and the cuvette is placed into a laser particle size analyzer, such that pearl powder particle size distribution diagram is determined, and an average particle size is calculated. The method provided by the invention can be used for determining average particle sizes of pearl powder, shell powder, and the like. The determination method provided by the invention has the advantages of high testing speed, good repeatability, high accuracy, simple operation, and the like.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

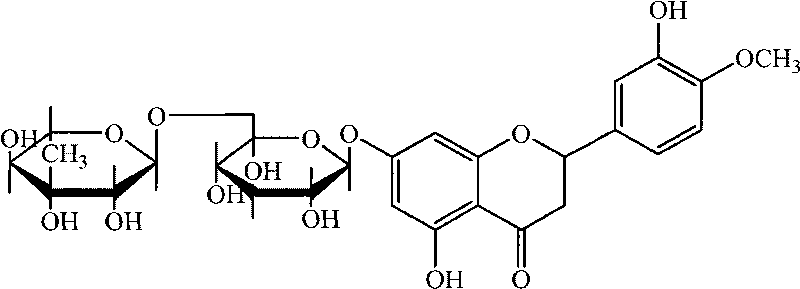

Method for extracting hesperidin from tangerine peel

ActiveCN101747394AReduce the impactGood choiceSugar derivativesSugar derivatives preparationDipotassium hydrogen phosphateSodium bicarbonate

The invention discloses a method for extracting hesperidin from tangerine peel. The method comprises: mixing tangerine peel with a solid-phase alkali reagent, wherein the tangerine peel is tangerine peel powder which is ground to have a powder particle size analysis result D90 between 10 and 200 mu m; adding water, stirring, centrifuging and taking supernatant; adding acid to regulate pH between 2.0 and 6.0; standing and then filtering the obtained product; drying a filter cake; and obtaining hesperidin. The solid-phase alkali reagent is one or arbitrary mixture of more than two of sodium hydroxide, aluminum hydroxide, calcium hydroxide, potassium hydroxide, sodium bicarbonate, potassium bicarbonate, sodium carbonate, potassium carbonate, calcium carbonate, sodium silicate, disodium hydrogen phosphate or dipotassium hydrogen phosphate. By adopting a mechanochemical technique to extract and separate the hesperidin, the method has the advantages of high extraction rate, high product purity, simple process, environment-friendly property, low cost and short production cycle, and is an extraction-separation route with broad industrialization prospects.

Owner:ZHEJIANG UNIV OF TECH

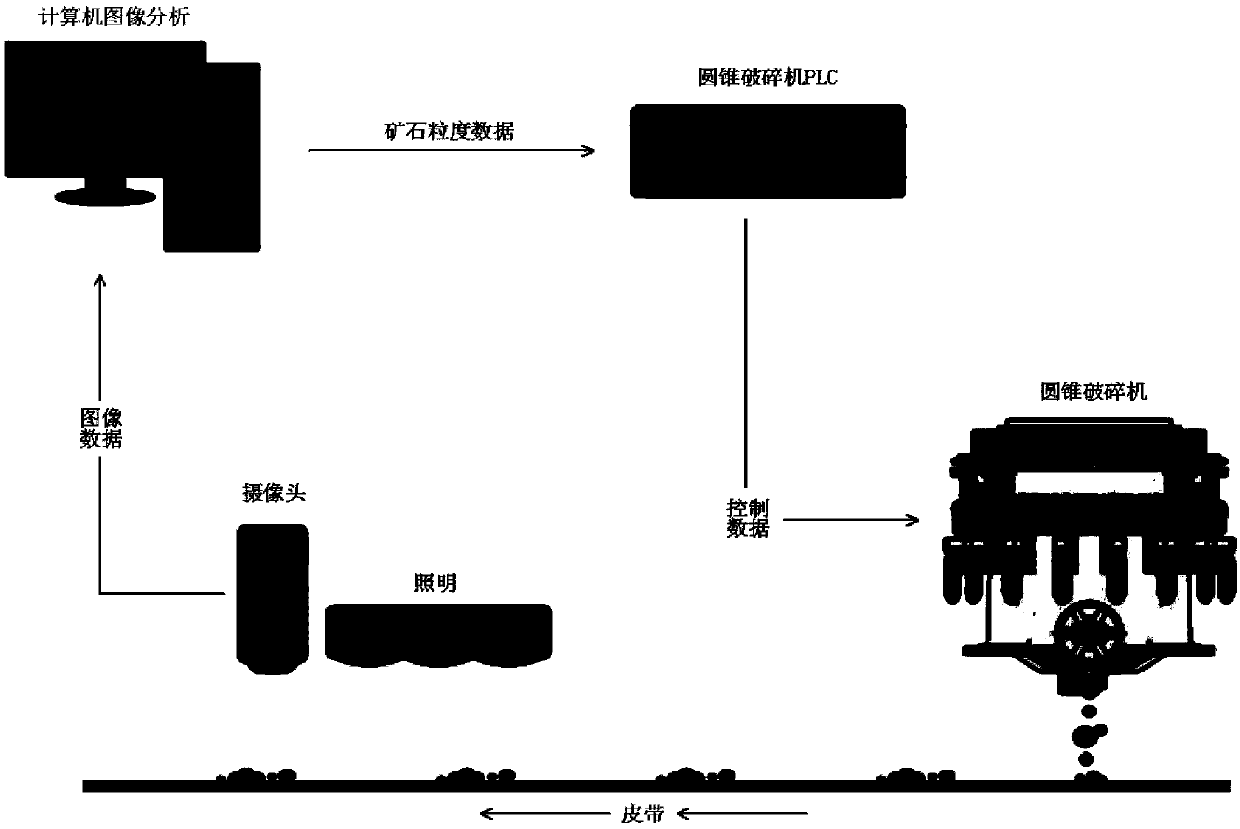

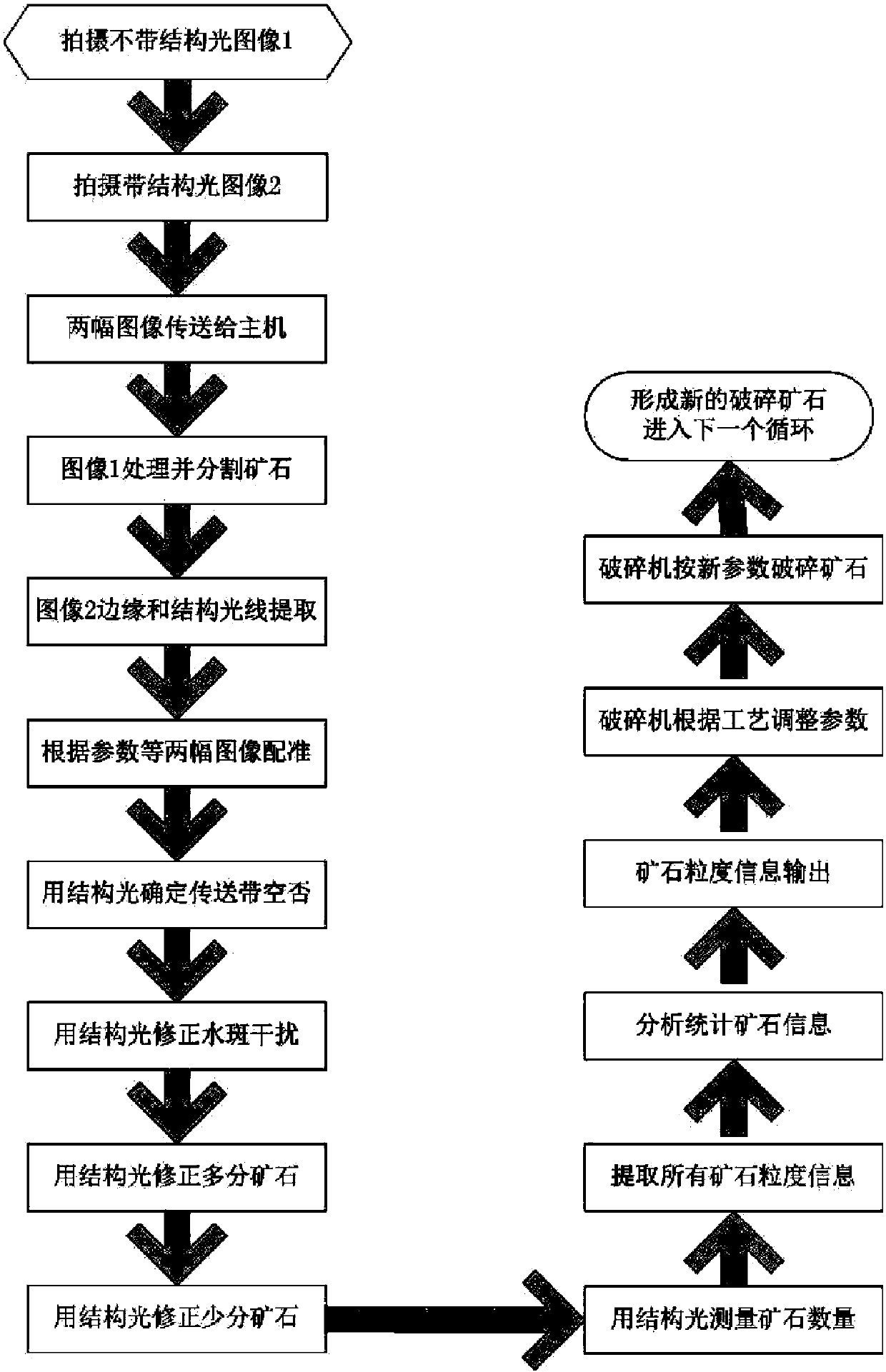

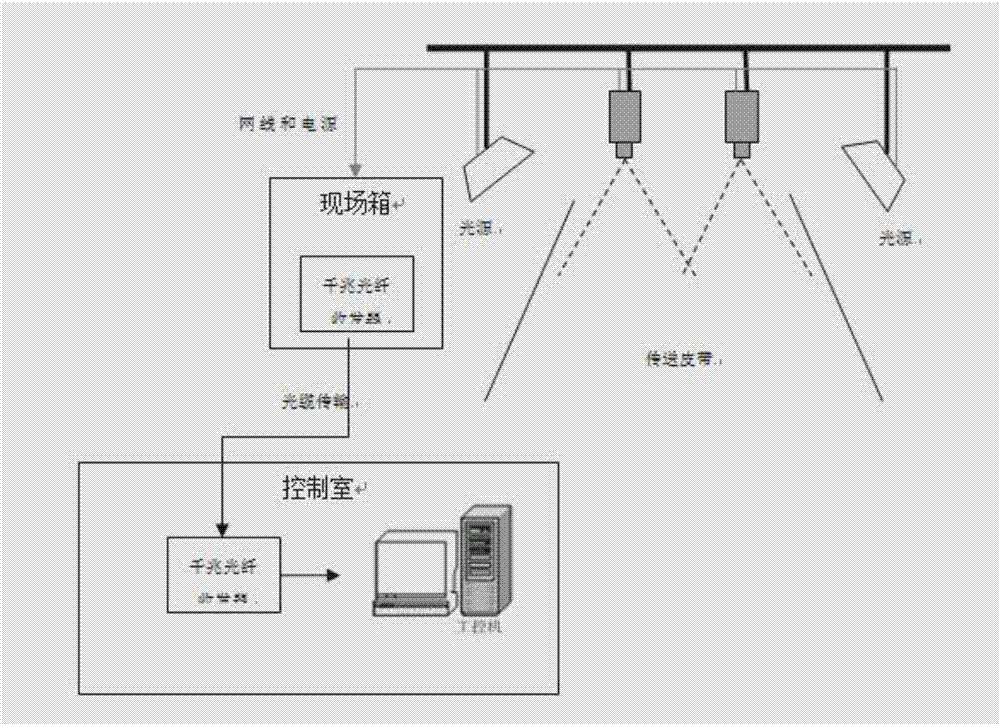

Smarter-vision-based high-performance ore granularity visual inspection system

InactiveCN107894379ASolve the problem of inaccurate detection and analysisImprove analytical accuracyParticle size analysisGrain treatmentsGranularityVision based

The invention relates to a smarter-vision-based high-performance ore granularity visual inspection system. Detection steps are as follows: a high-speed and high-definition camera is installed above anore conveyor belt; an ordinary image and an image with structured light of broken ore on the ore conveyor belt can be taken by the camera; information of the ordinary image and the image with the structured light is transmitted to a system host for detection, ore particles are cut, ore granularity information is extracted for statistics and analysis, and the ore granularity information is outputted to a main controller of an ore crusher; the main controller adjusts various control parameters of the ore crusher according to the requirements of the production process, and the ore crusher operates according to new control parameters; after the ore crusher operates according to the new control parameters, the broken ore again appears in the image of the camera, and the closed-loop control ofthe ore crusher is realized. The smarter-vision-based high-performance ore granularity visual inspection system can effectively solve the problems that an ordinary camera can only collect two-dimensional image information, and an ore particle size analyzer cannot distinguish an damaged or water-stained empty conveyor belt from a conveyor belt scattered with the ore, so that the ore granularity information detection and analysis are inaccurate.

Owner:沈阳聚德视频技术有限公司

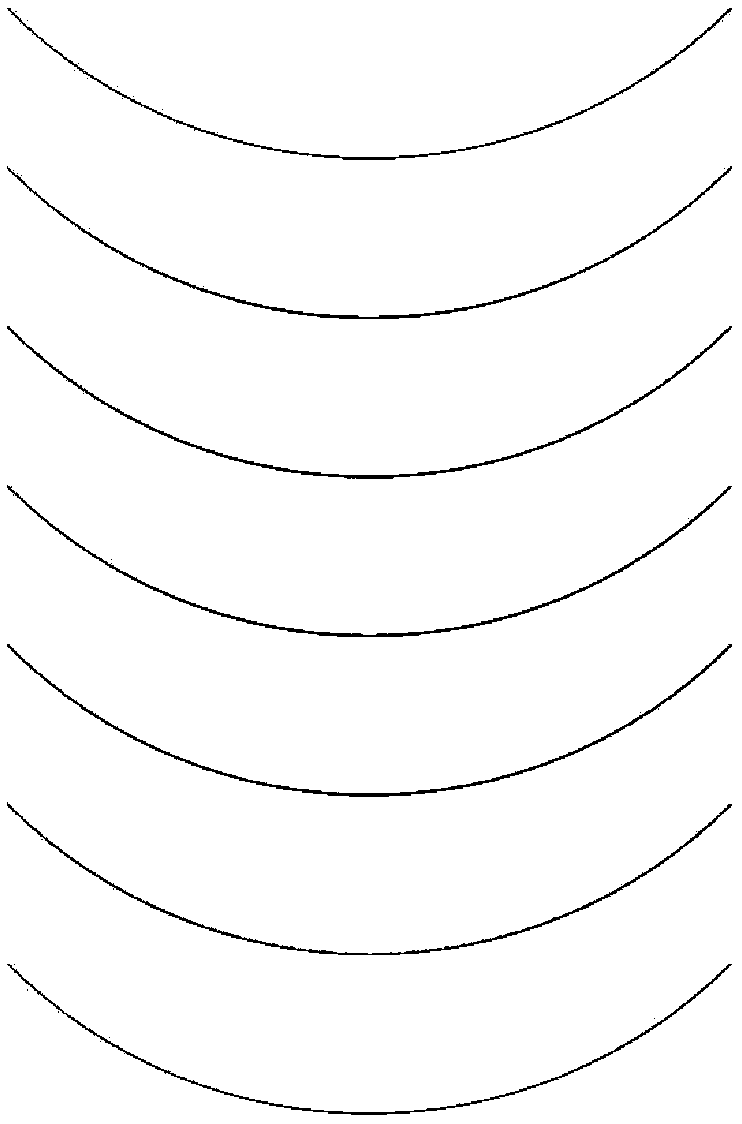

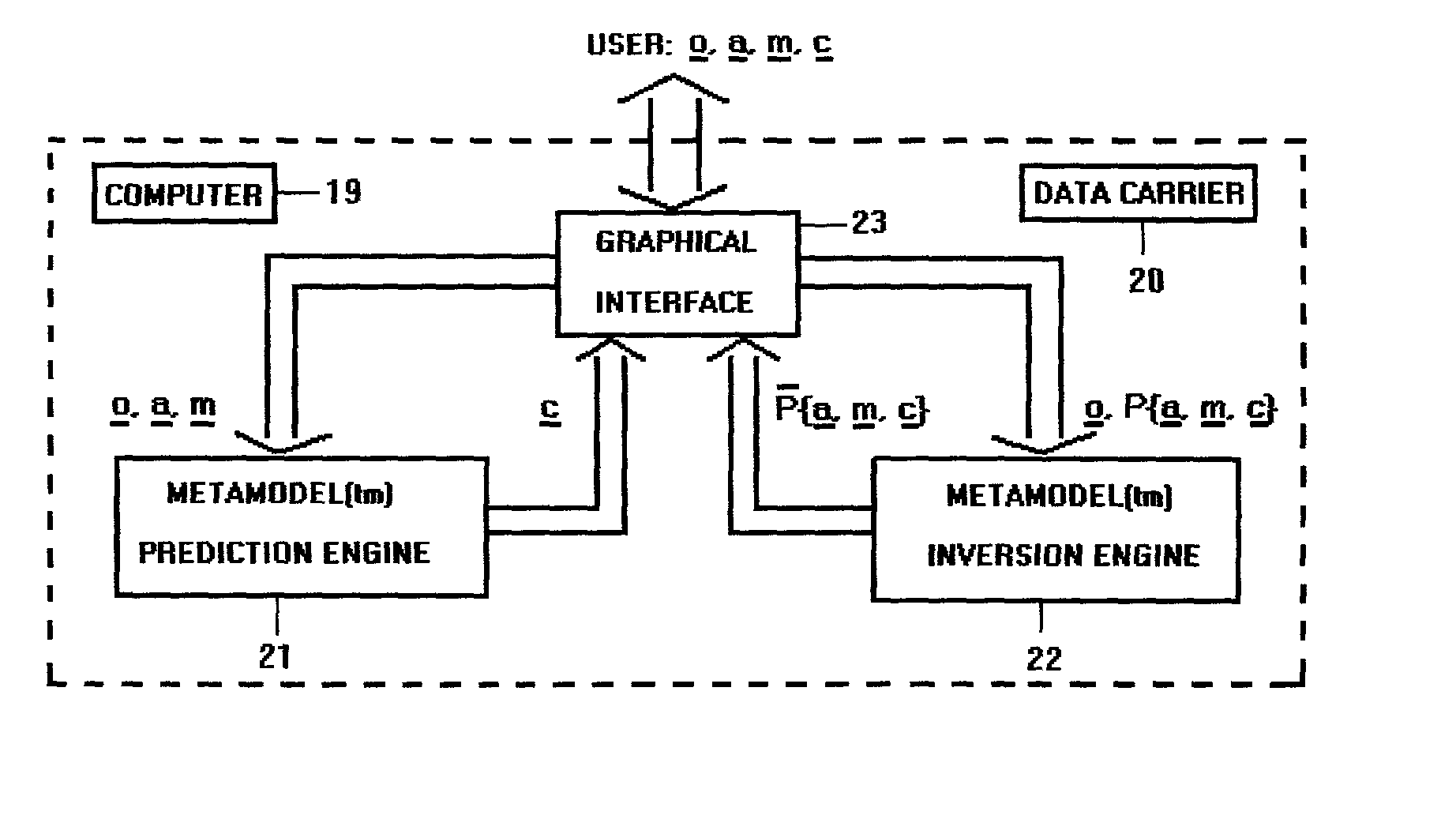

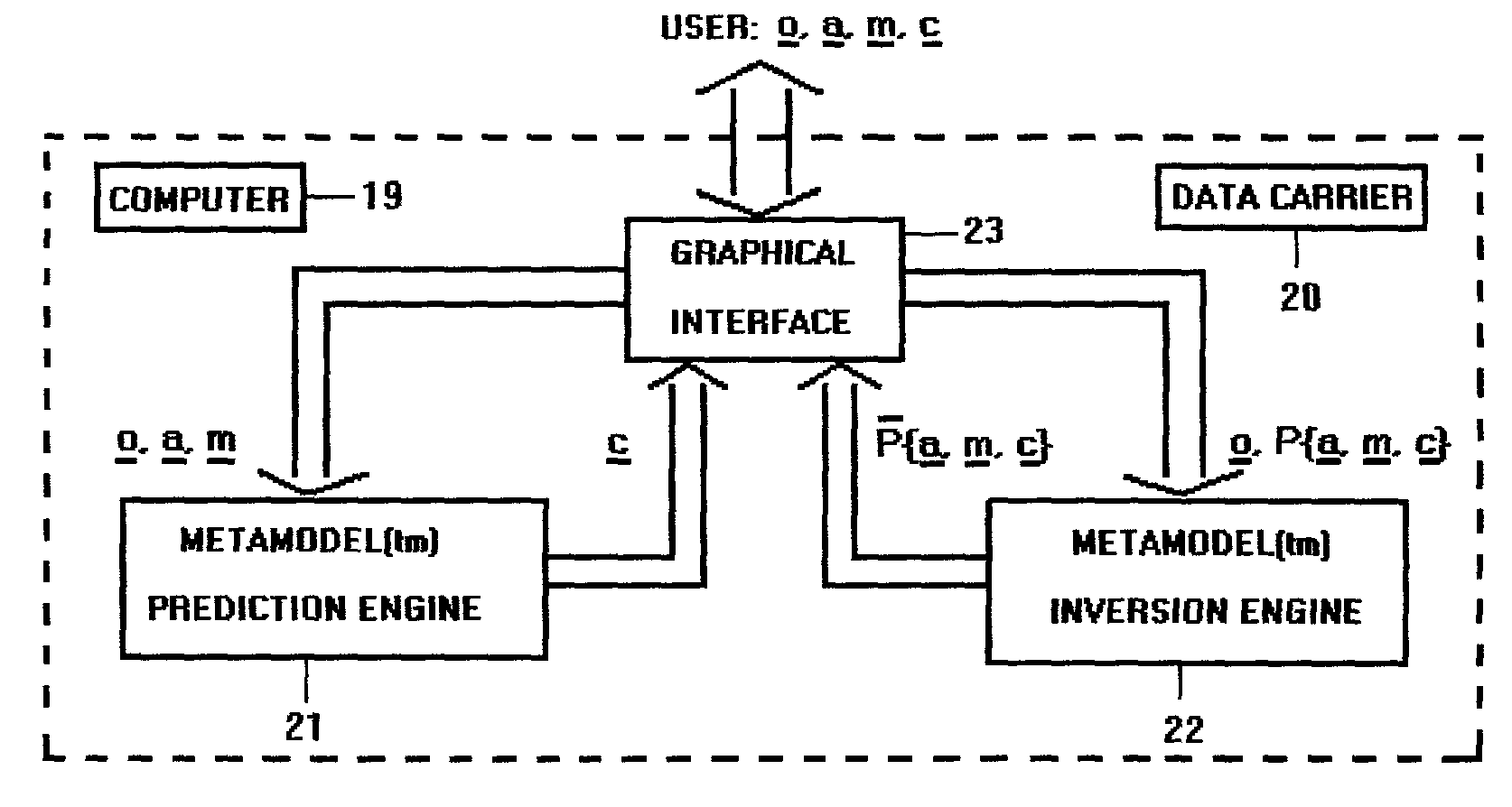

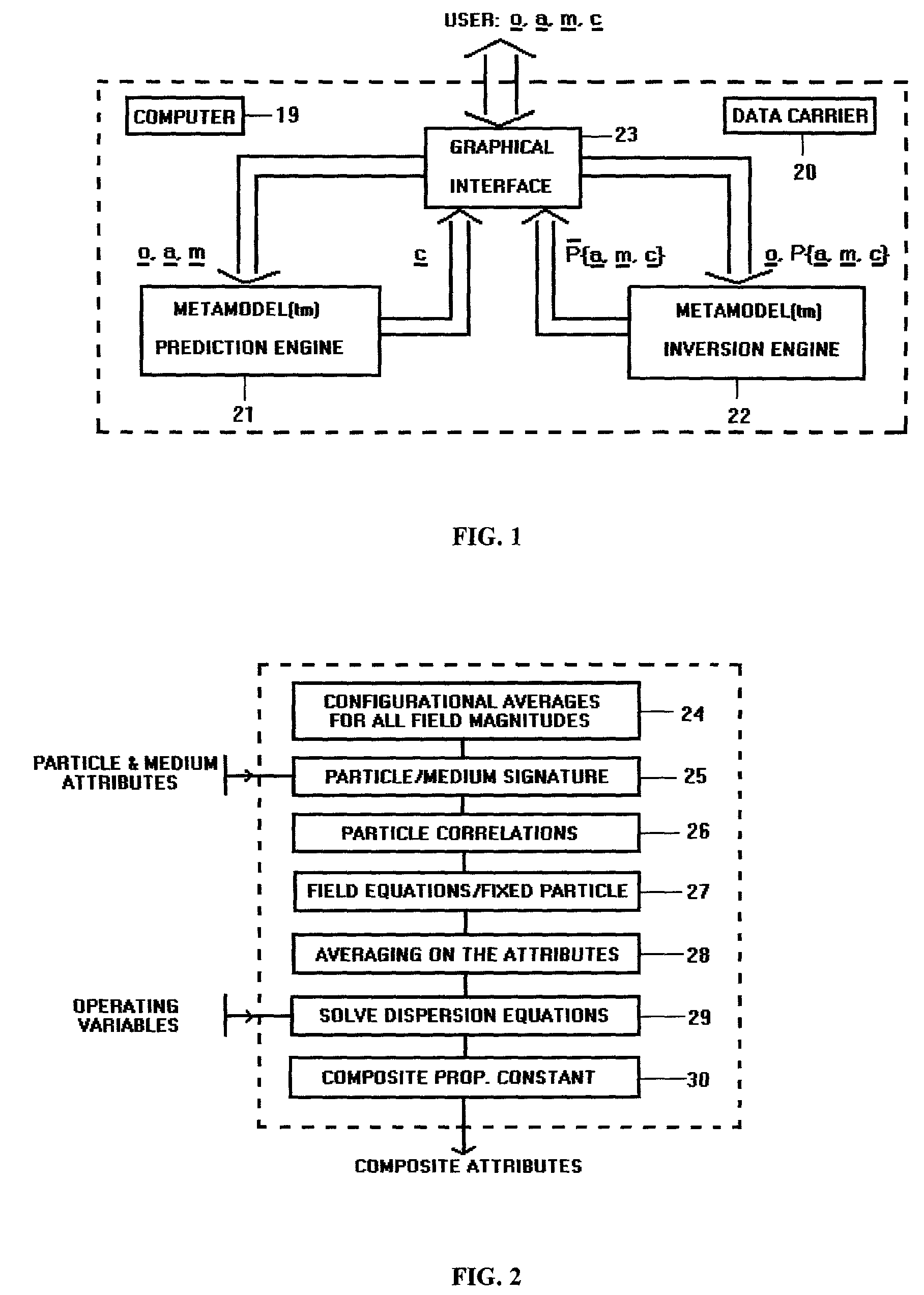

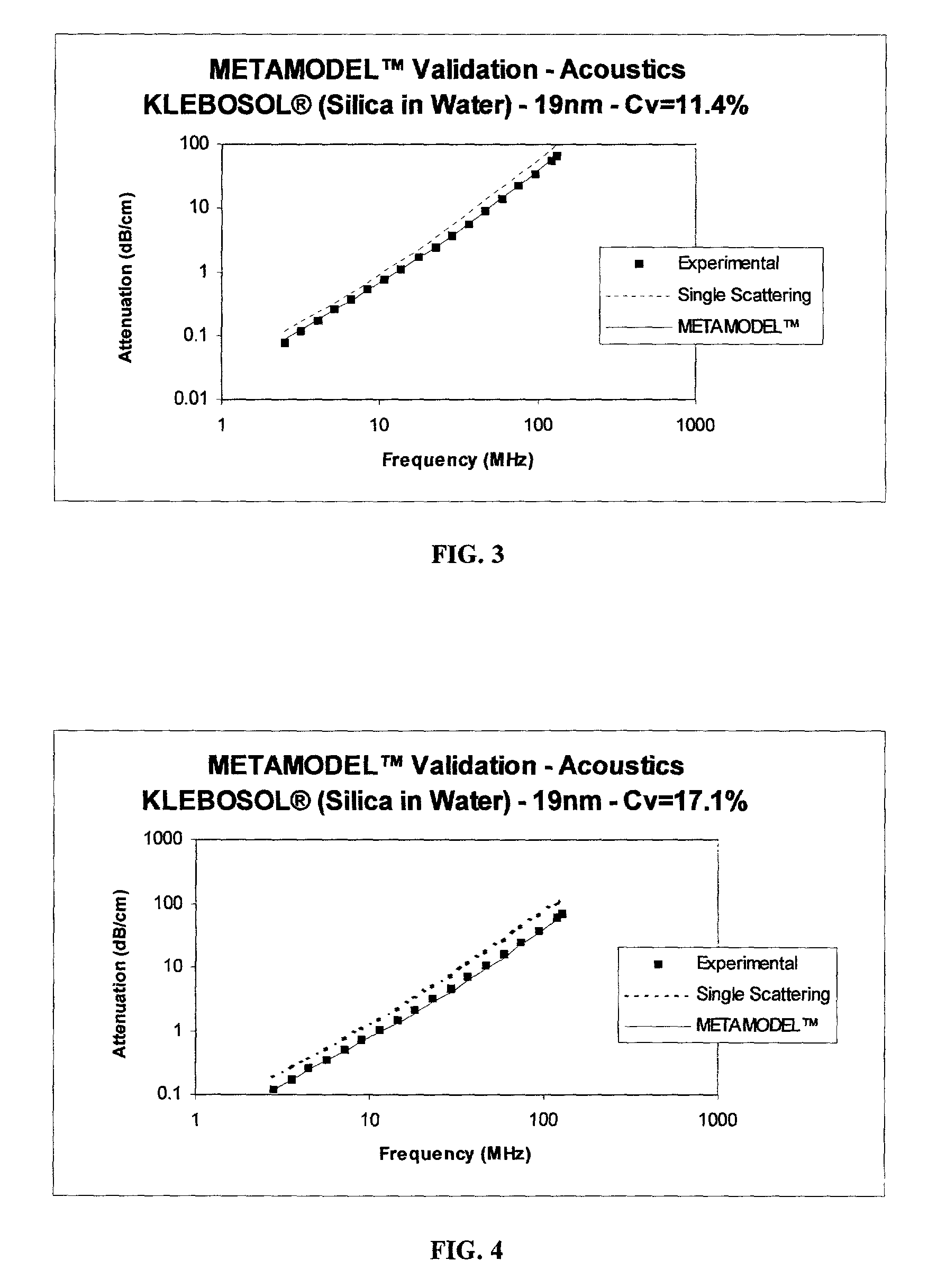

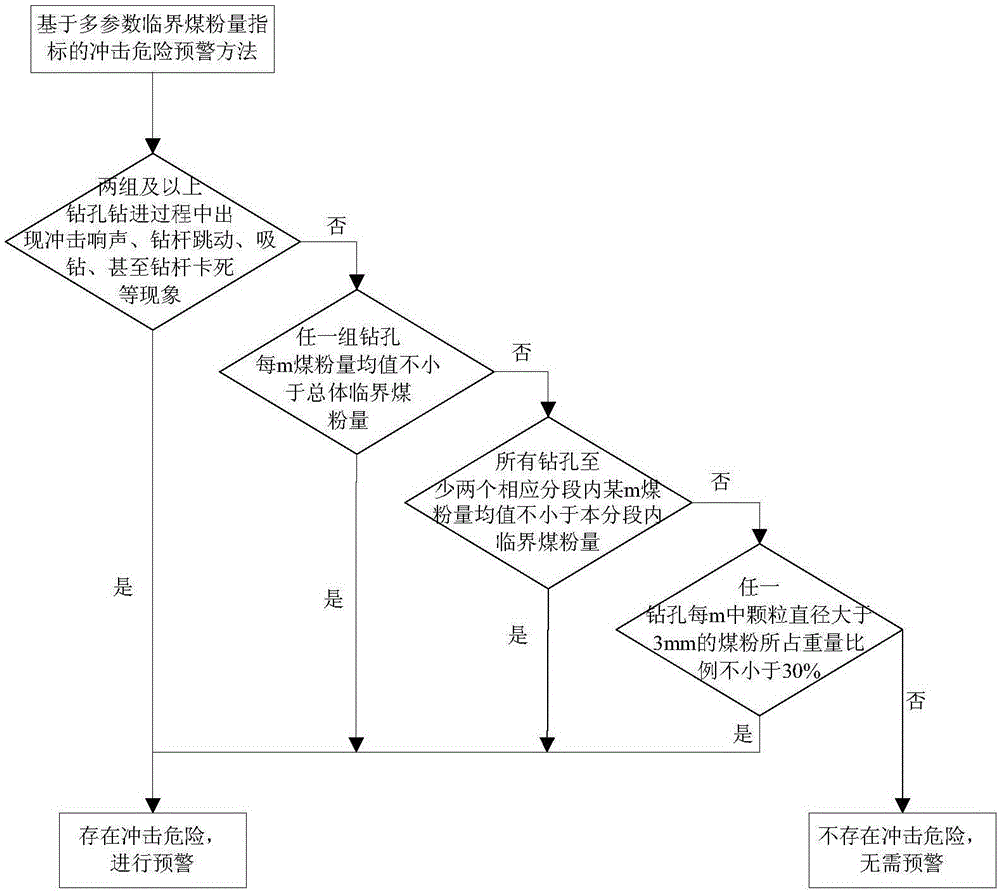

Fundamental method and its hardware implementation for the generic prediction and analysis of multiple scattering of waves in particulate composites

InactiveUS20030167156A1Computation using non-contact making devicesScattering properties measurementsReal systemsFluid phase

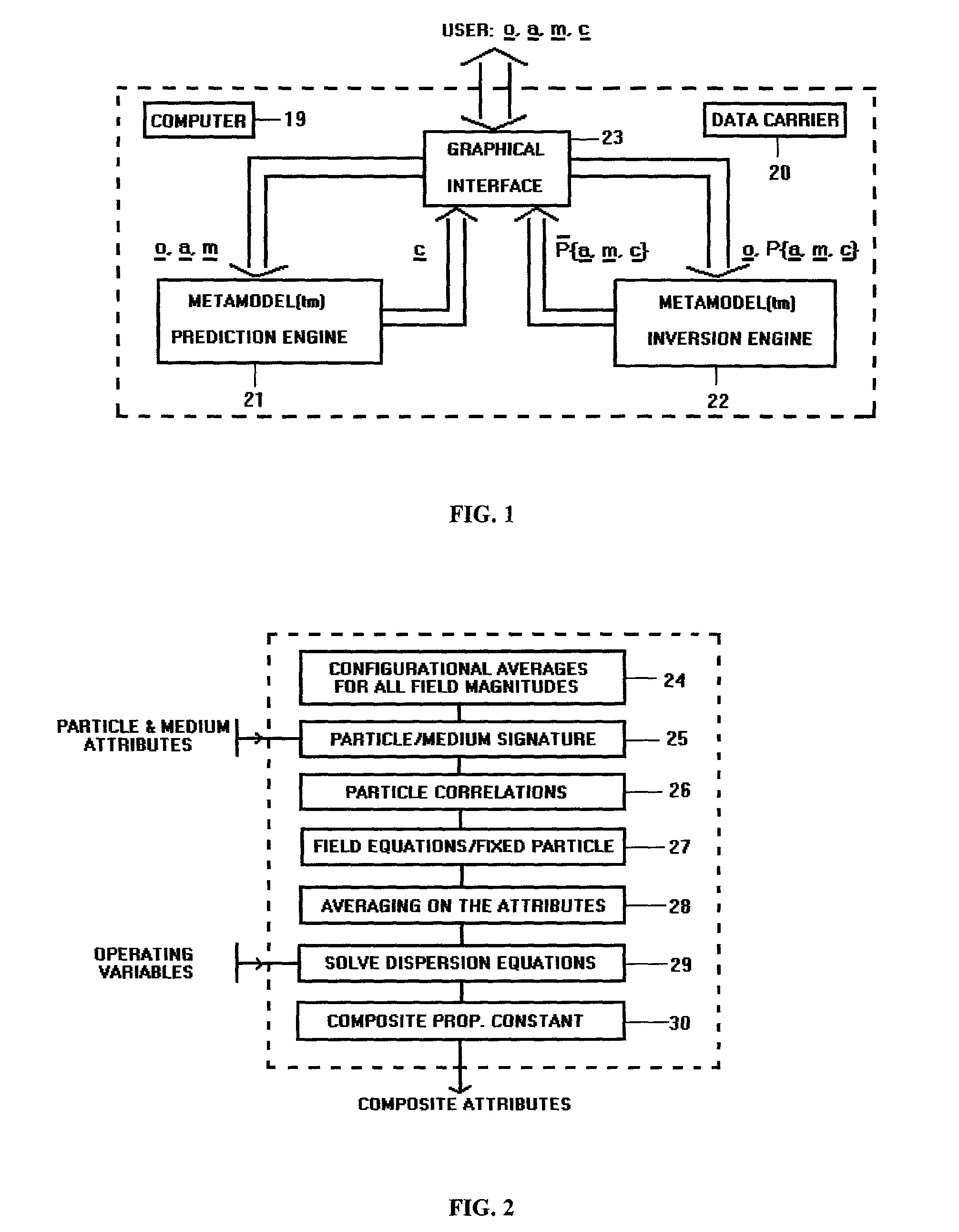

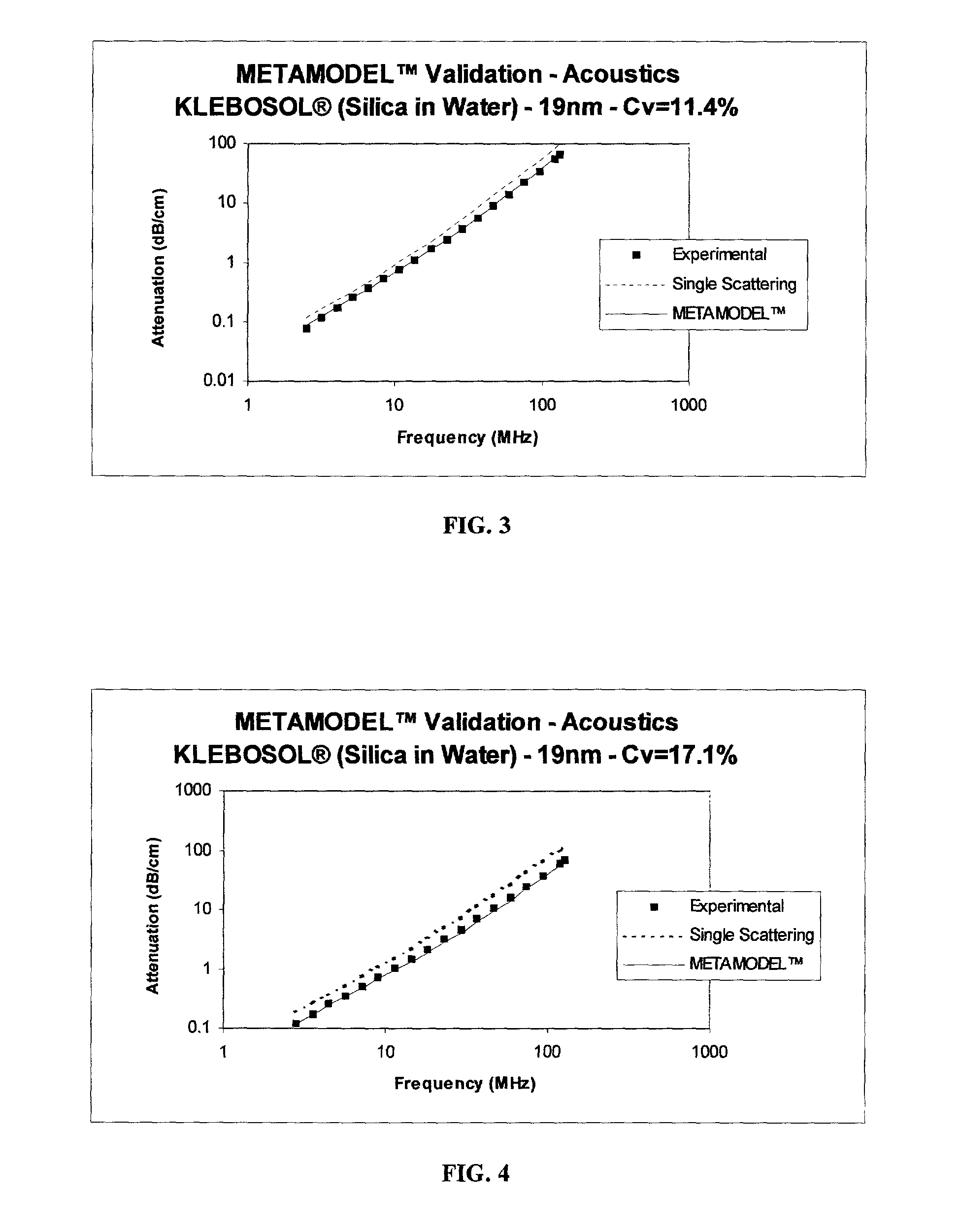

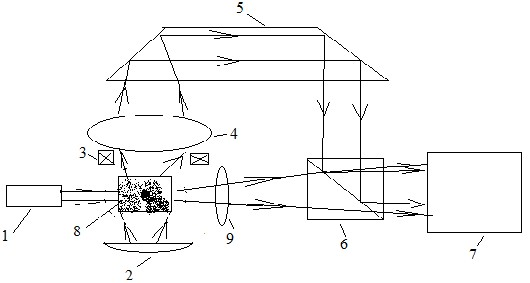

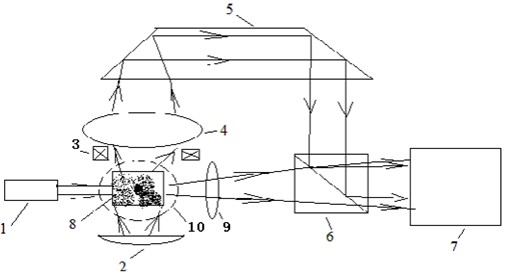

This invention relates to a method and apparatus for the fundamental prediction, analysis, and parametric studies of the interaction of multiply scattered waves of any nature (acoustic, electromagnetic, elastic) with particulate composites (solid or fluid particulate phases included in a solid or fluid phase). It comprises of: a) a Prediction Engine 21 to predict the composite physical attributes from those of the constituent phases, b) an Inversion Engine 22 to estimate a subset of the attributes of the constituent phases and composite from the rest of those attributes, and c) an ergonomic Graphical Interface 23 to allow the user to easily set up complex simulation experiments to assist in parametric studies, analysis, and synthesis of real systems in which waves of any nature interact with composites. The Prediction Engine 22 is suitable for integration into existing acoustic or optical particle size analyzers to thereby extending substantially their concentration ranges.

Owner:FELIX ALBA CONSULTANTS

Multi-method combined particle size analyzer

InactiveCN102095672AExpand the upper and lower limits of particle size measurementMeet the requirements of wide range particle size distribution measurementParticle size analysisLower limitMulti method

The invention discloses a multi-method combined particle size analyzer which is characterized in that a laser source, a non-monochromatic lighting source, a microobjective, a Dove prism or two 90-degree turning prisms or total reflection mirrors, a half transparent and half reflecting mirror, an array digital camera or a video camera, a sample cell and a lens form two light path structures, wherein one light path irradiates samples in the sample cell from the non-monochromatic lighting source, and an image magnified by the microobjective is transmitted to the array digital camera through the Dove prism and the half transparent and half reflecting mirror; and the other light path irradiates the samples in the sample cell from the laser lighting source, and the image magnified by the lens is transmitted to the array digital camera through the half transparent and half reflecting mirror. The multi-method combined particle size analyzer has the benefits of combining multiple measuring methods together by using one digital camera, expanding the upper limit and the lower limit of the particle size analyzer by using a simple structure, enabling the measurement range of the particle size analyzer to be from nanometer to hundreds of microns, meeting the requirement of wide-range size distribution measurement, and being capable of giving morphology parameters of particles by using the image method simultaneously.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

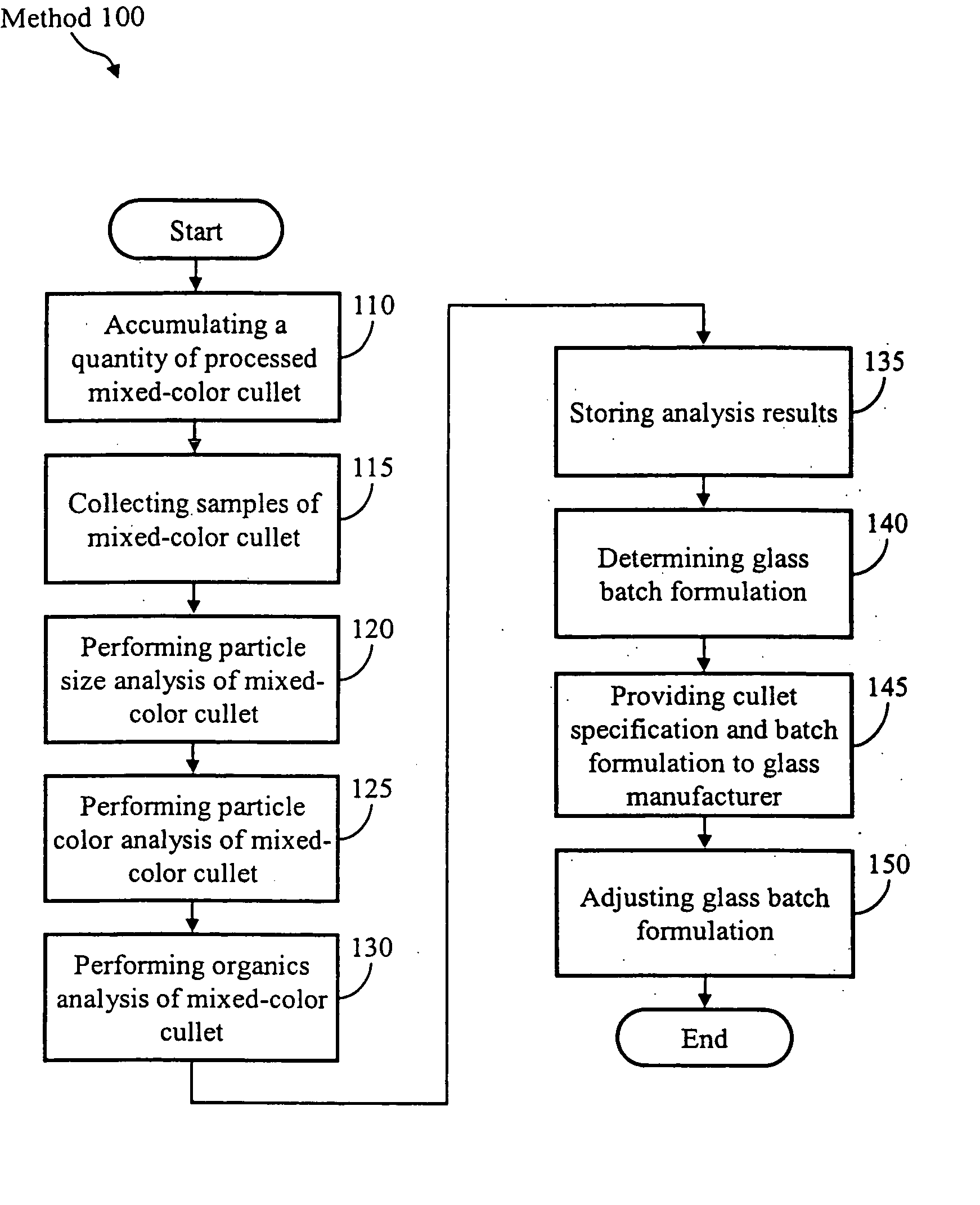

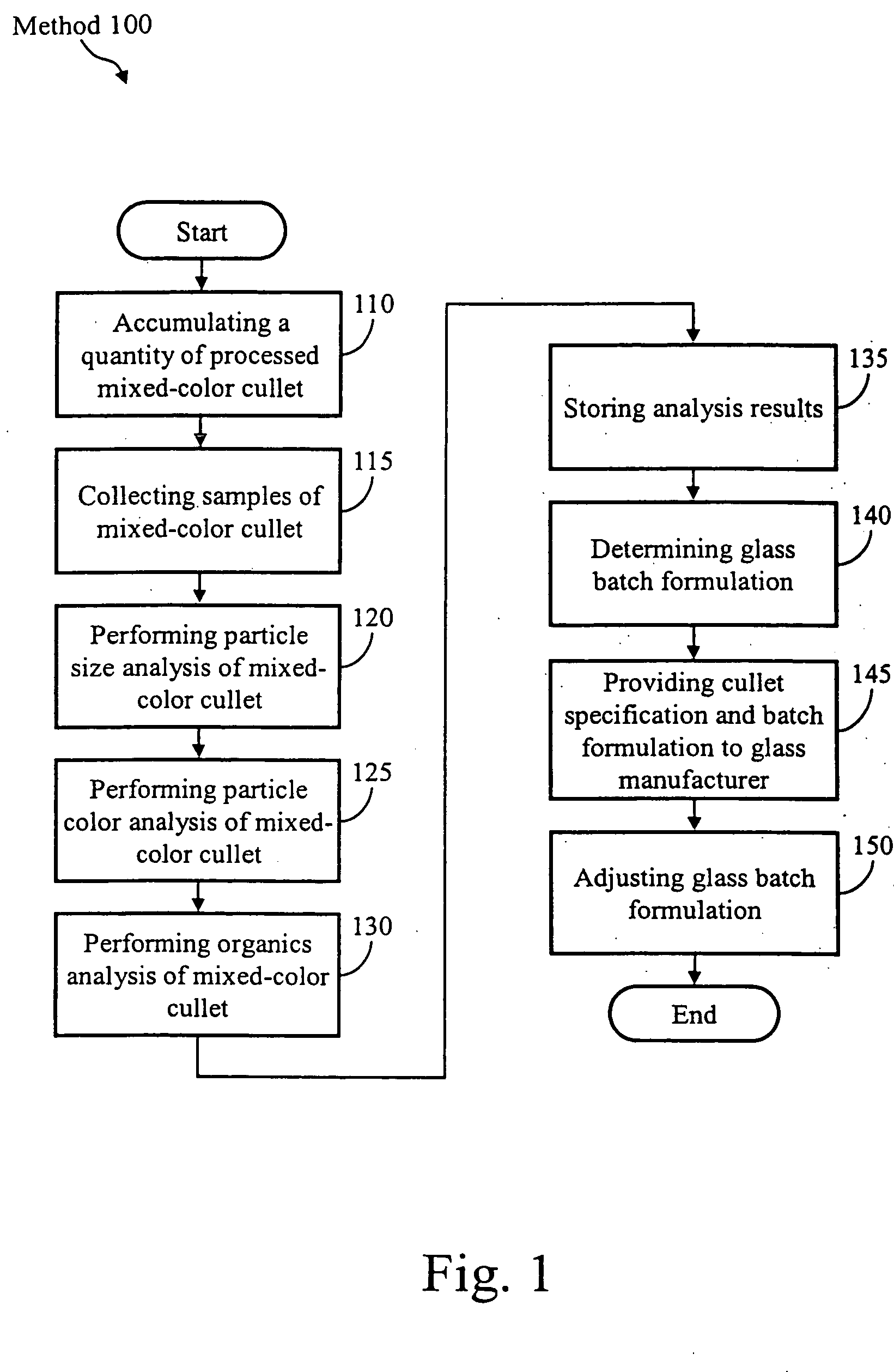

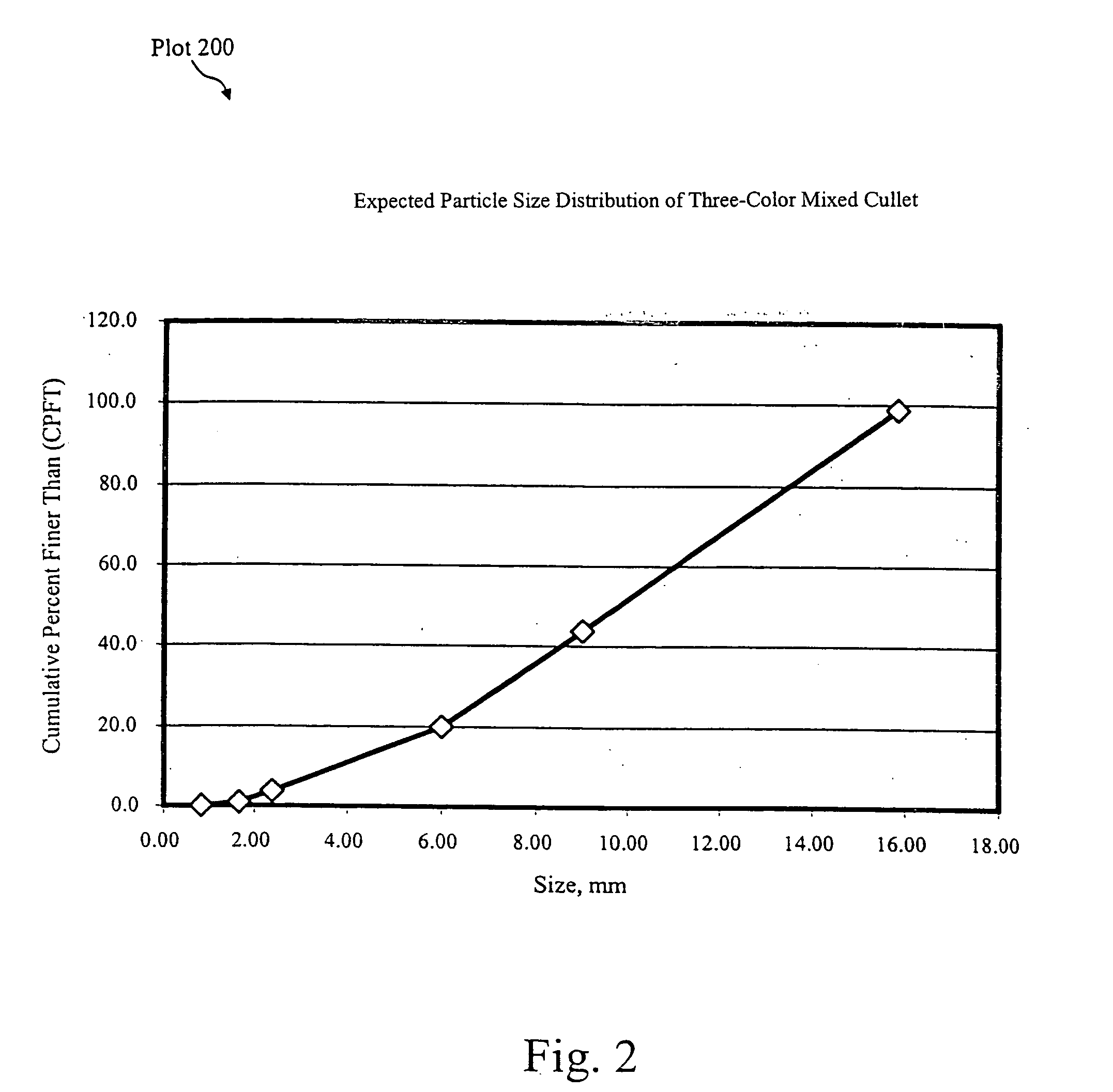

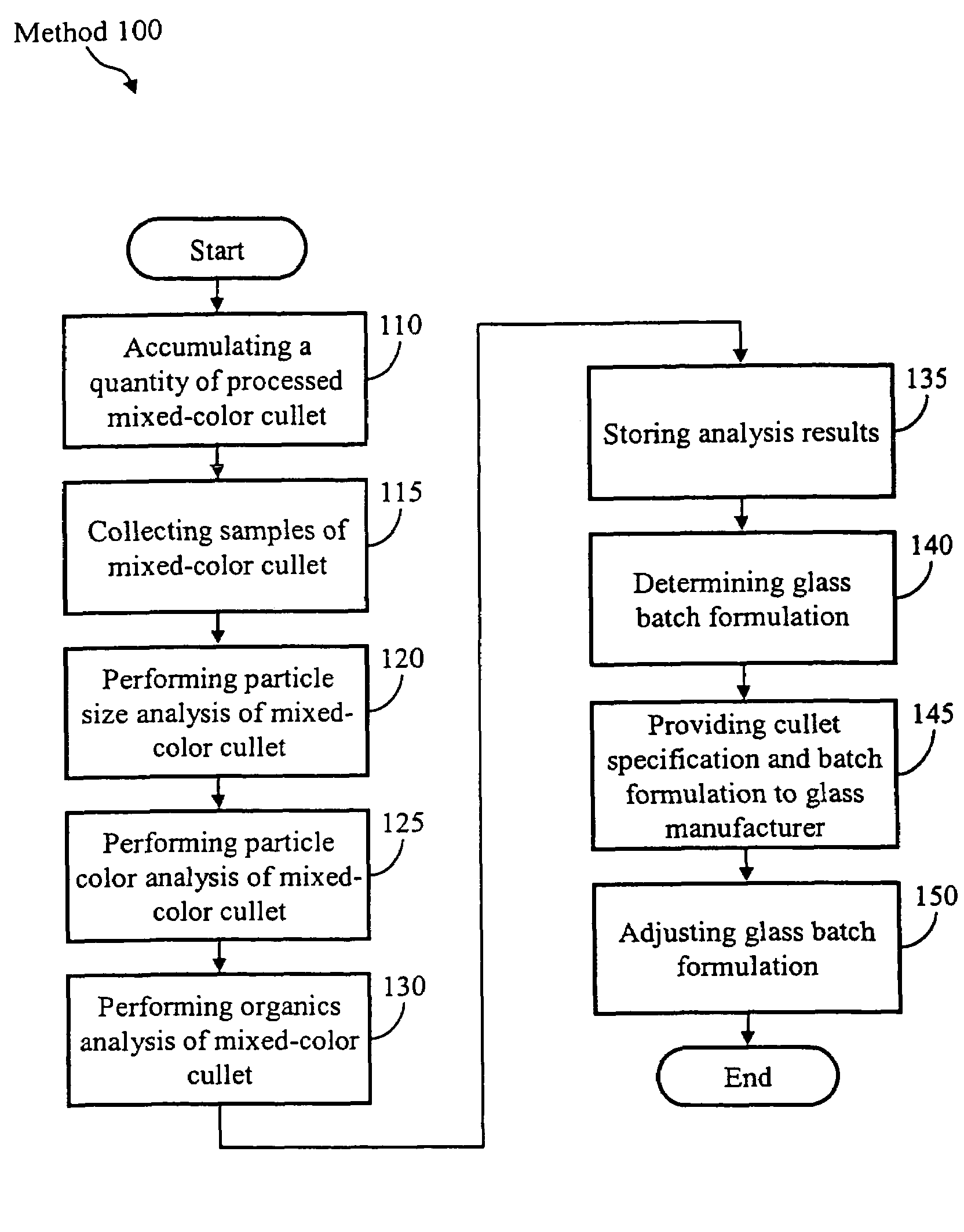

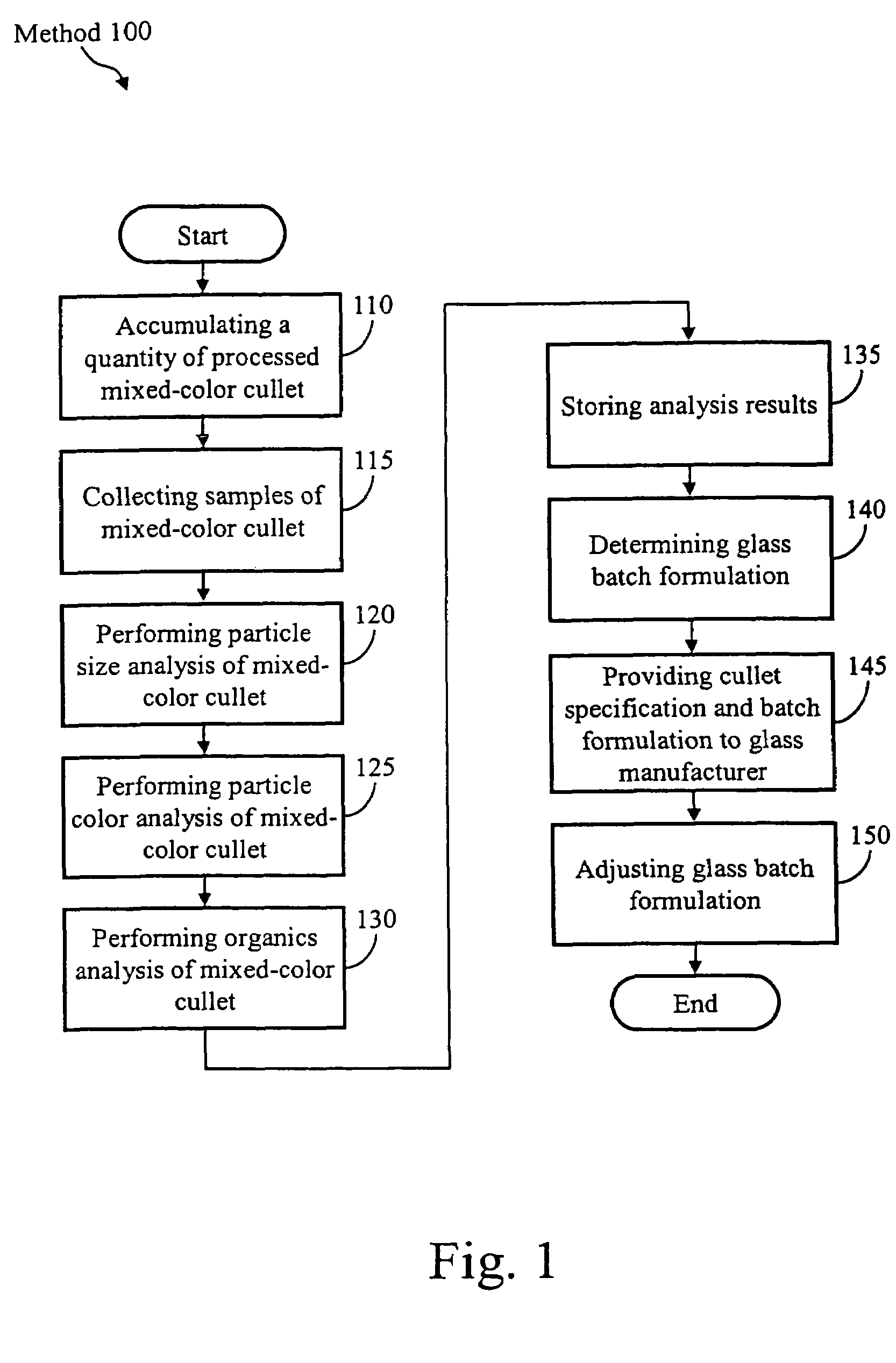

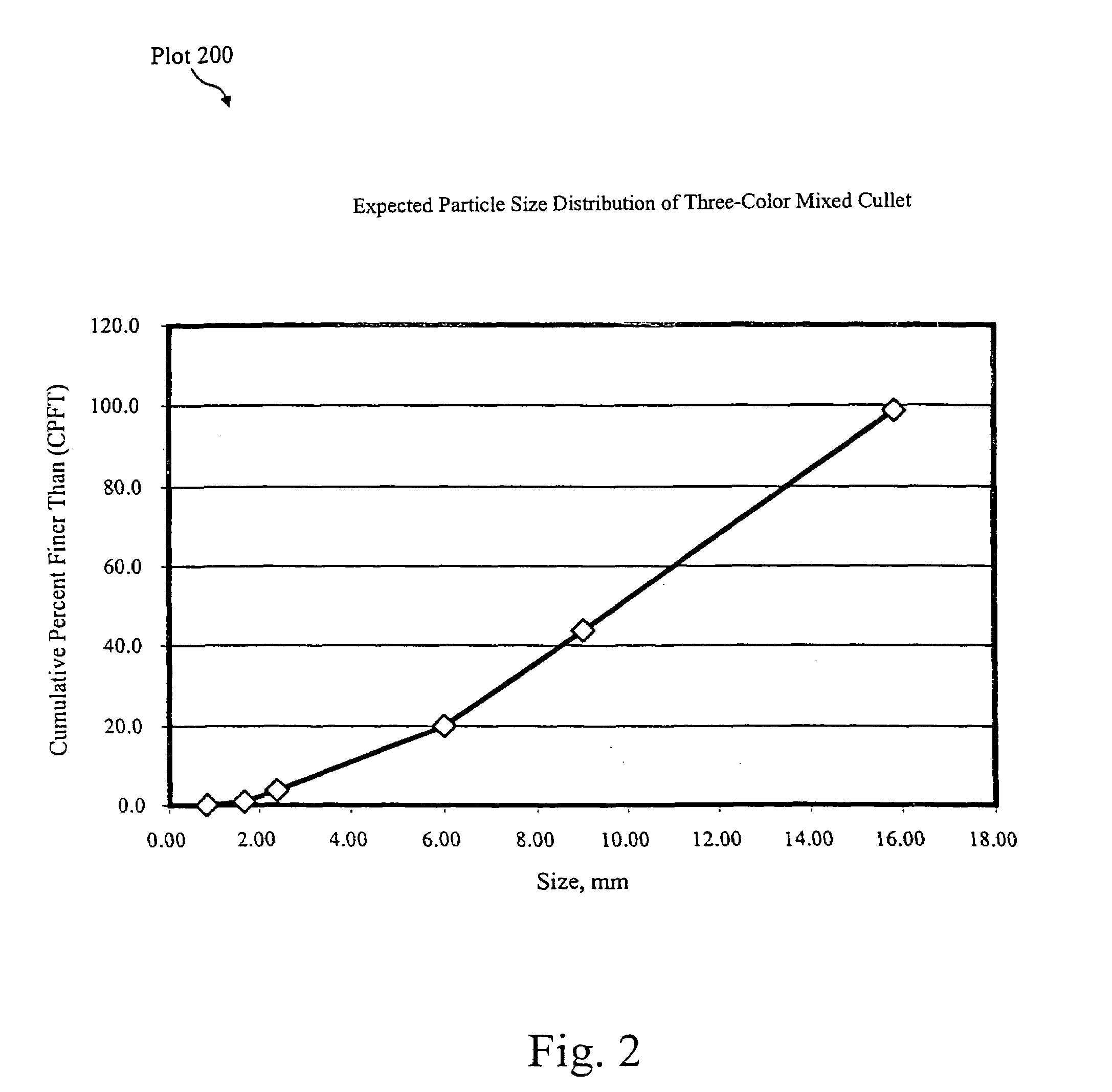

Method of analyzing mixed-color cullet to facilitate its use in glass manufacture

A method of determining the constituents and impurities in mixed-color cullet to facilitate use of mixed-color cullet in glass manufacture is provided. A glass batch formulation is adjusted based on the measured characteristics of supplied mixed-color cullet. More specifically, certain preferred aspects of the present invention include the steps of providing quantity of mixed-color cullet, collecting at least one sample of the mixed-color cullet, performing, either singularly or in combination, particle size analysis, particle color analysis, or organics analysis of the mixed-color cullet, optionally storing the analysis results, determining a glass batch formulation, providing the cullet specification and the batch formulation to a glass manufacturer, and adjusting glass batch formulation based on the cullet specification to ensure consistent glass quality.

Owner:CULCHROME LLC

Method and device for studying mechanism that secondary organic aerosol is produced by photo-oxidation transformation of fuel coal

ActiveCN105606758AAccurate captureSimple and fast operationChemical analysis using combustionMaterial analysis by electric/magnetic meansProton-transfer-reaction mass spectrometrySpectrometer

The invention discloses a method for studying a mechanism that secondary organic aerosol is produced by photo-oxidation transformation of fuel coal. The method comprises the steps: subjecting raw coal to chemical component and particle size analysis via a single particle aerosol mass spectrometer according to the principle of laser ablation; detecting chemical component and particle size distributions of volatile organic matters and particulate matters in fuel coal by using proton transfer reaction mass spectrometry and single particle aerosol mass spectrometry; by using a smog box system, inspecting parameters such as chemical components and particle size of gas and particulate matters in the fuel coal in a photochemical reaction within different combustion times, and their variation trends, analyzing intermediate state data, and comparing data of a static coal erosion experiment and a static coal combustion experiment to obtain the mechanism that secondary organic aerosol is produced by photo-oxidation transformation of fuel coal. The invention also discloses a device. It is possible to simulate transformation processes of the fuel coal in different atmospheric environments, accurately capture intermediate state products of the fuel coal and quantify the effects of coal combustion and post-combustion photo-oxidation.

Owner:SHANGHAI UNIV

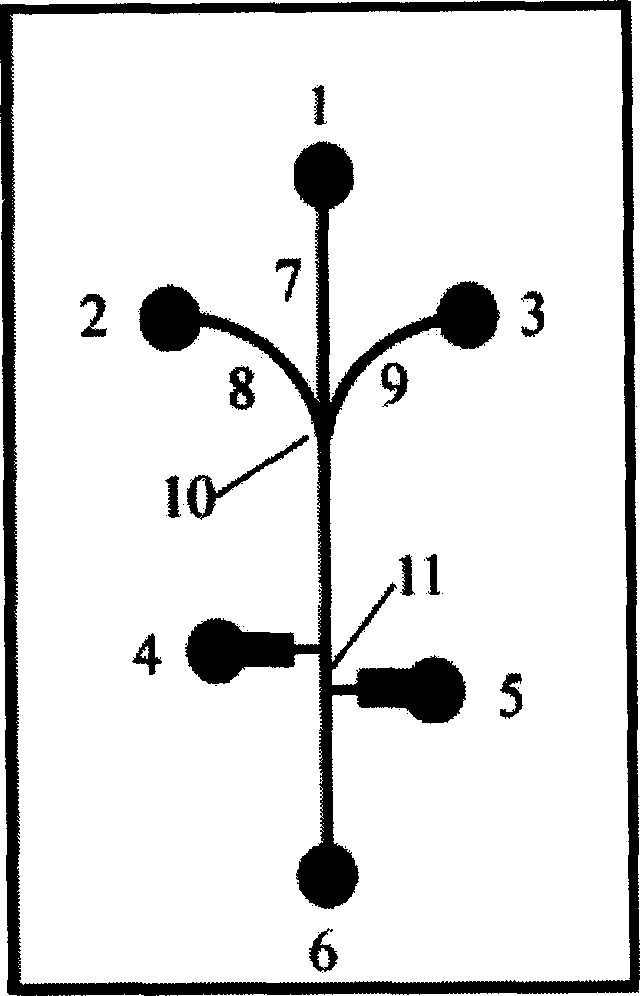

Particle analyzing chip with microflow control of single-cell algae

InactiveCN1712927AMiniaturizationAchieve integrationIndividual particle analysisField analysisParticle Size Analyzer

A mini-flow control chip of mono-cell alga size analysis is prepared by having substrate and cover-plate in symmetric structure, setting psi form liquid flow system formed by intermediate sample channel and sheath channel as well as setting double T form detection channel on both of substrate and cover-plate, setting electrode at two sides of detection channel with constant current for obtaining potential difference to change pulse signal when cell passes through detection channel, then calculating size and number of cell as per pulse frequency and intensity .

Owner:OCEAN UNIV OF CHINA

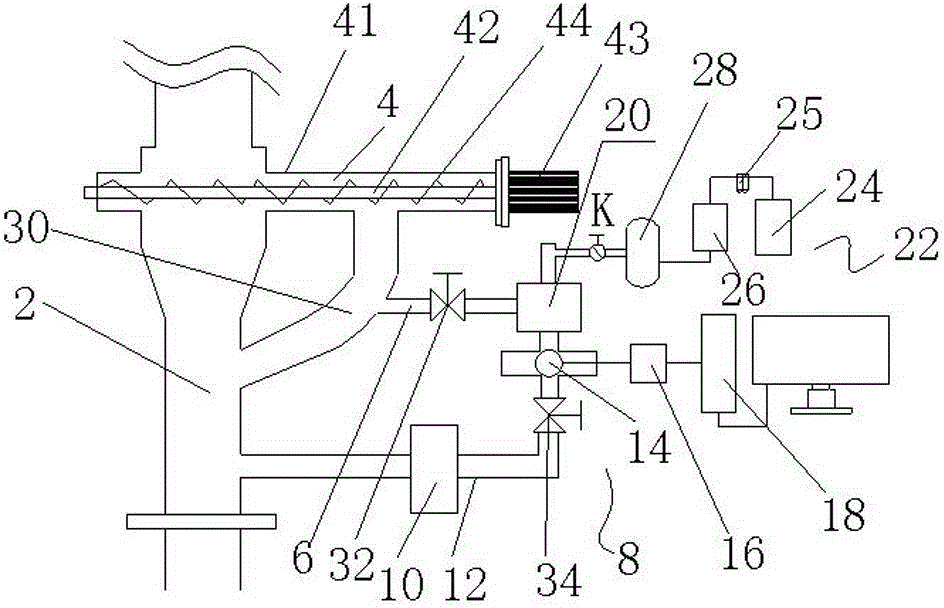

On-line cement particle size detection method and one-line cement particle size device

InactiveCN104614293AQuality improvementImprove stabilityParticle size analysisElectrical connectionLaser beams

The invention provides an on-line cement particle size detection method. The on-line cement particle size detection method is characterized in that a laser particle size analyzer is arranged in a material conveying chute of a cement grinding powder selector, a signal control box and a analyzer host are arranged to be in electrical connection with the laser particle size analyzer, cement samples in the shape of single particles are blown into a detection window of the laser particle size analyzer, when laser beams emitted by the laser particle size analyzer encounter cement particles in a propagation process, a part of light deviates from an original propagation direction and is scattered to form a scattering angle, a signal representing the size of the scattering angle and the intensity of scattered light which is output by the laser particle size analyzer is converted into an electrical signal by the signal control box and the electric signal is output to the analyzer host, and the particle size and size distribution of cement can be seen in the analyzer host. The on-line cement particle size detection method provided by the invention has the characteristics of rapid and accurate detection, and wide range; and a device provided by the invention can be used for improving the quality and particle size stability of cement after being used, and reducing the waste of energy consumption caused by quality fluctuation.

Owner:XIANGSHUI ZHONGLIAN CEMENT CO LTD

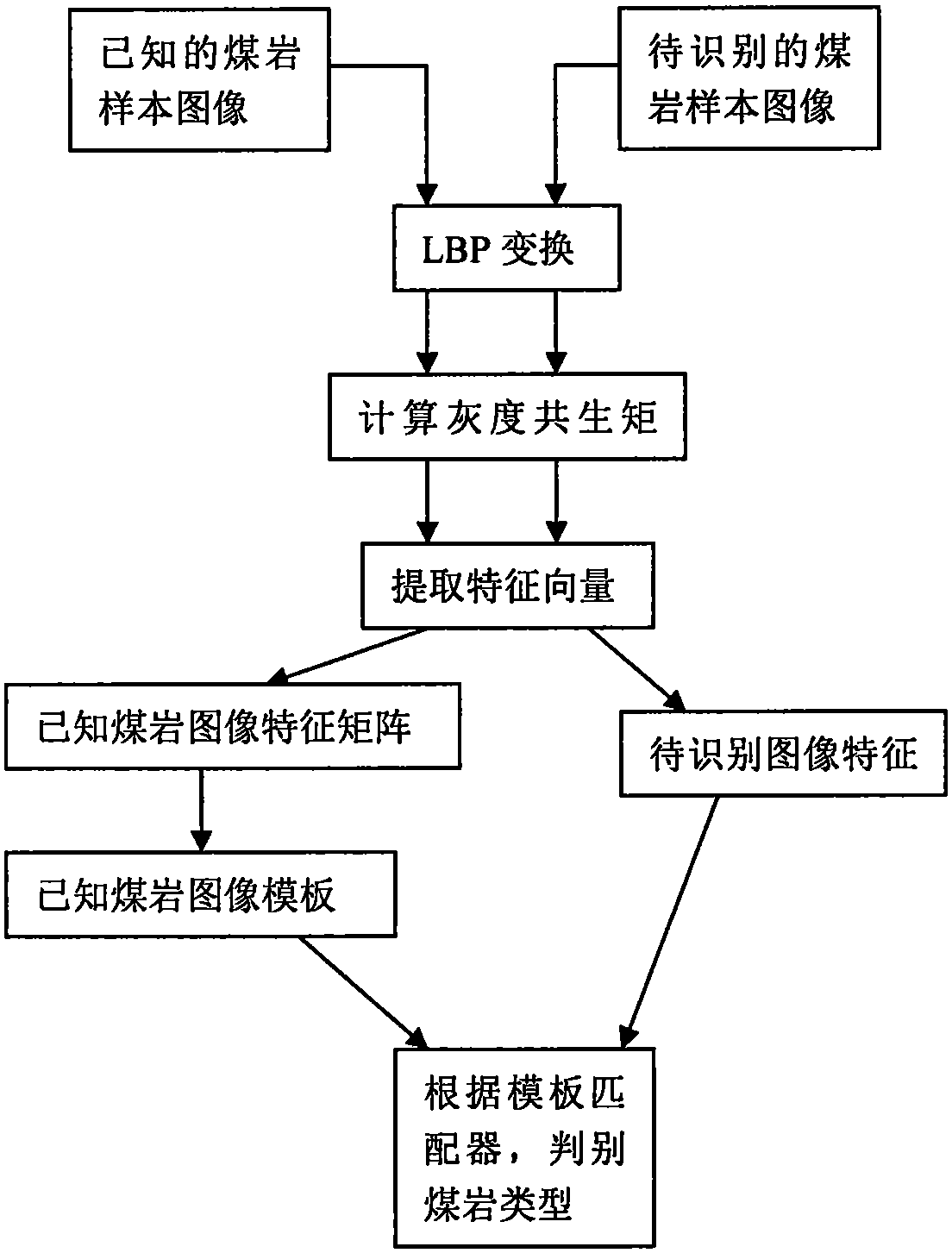

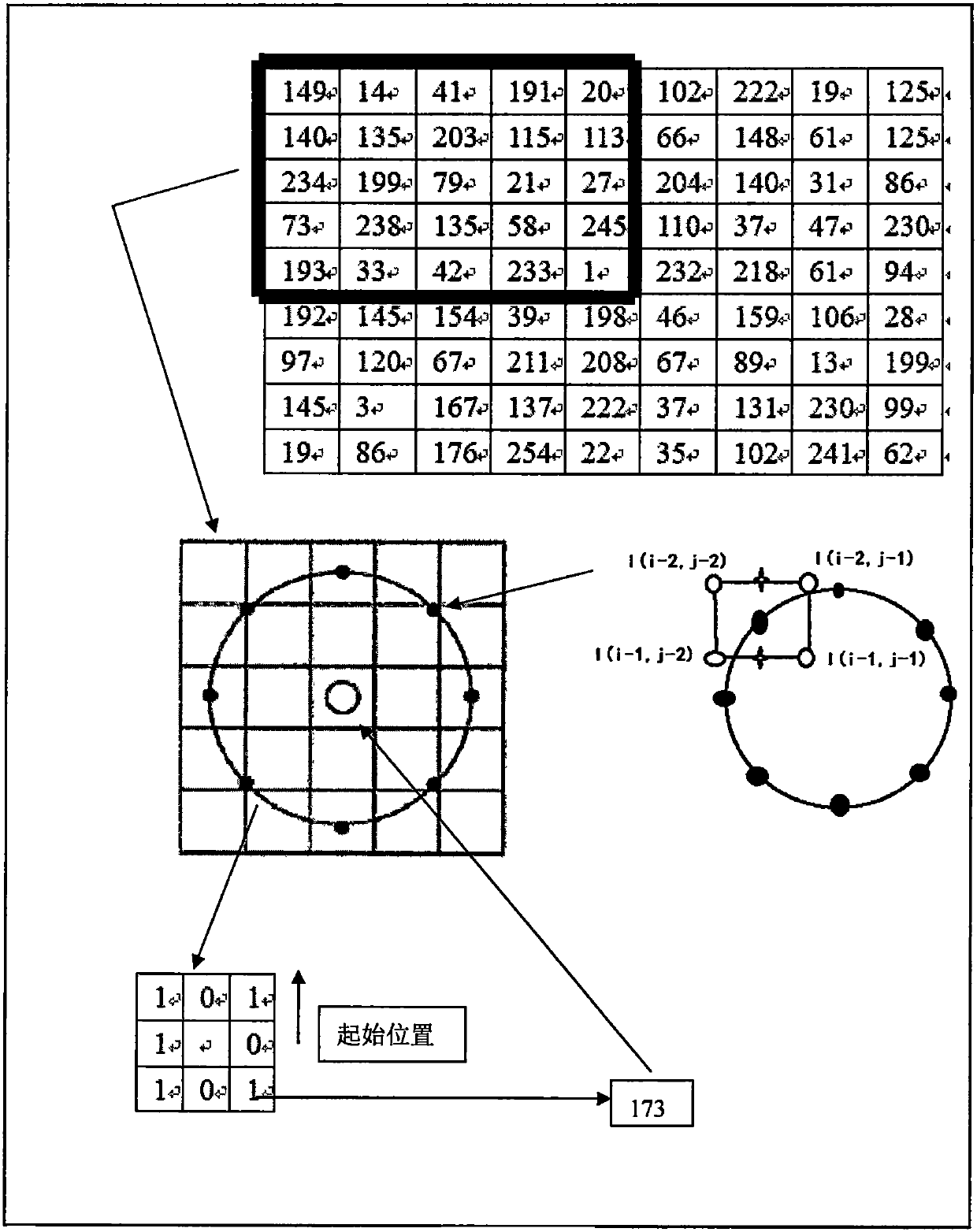

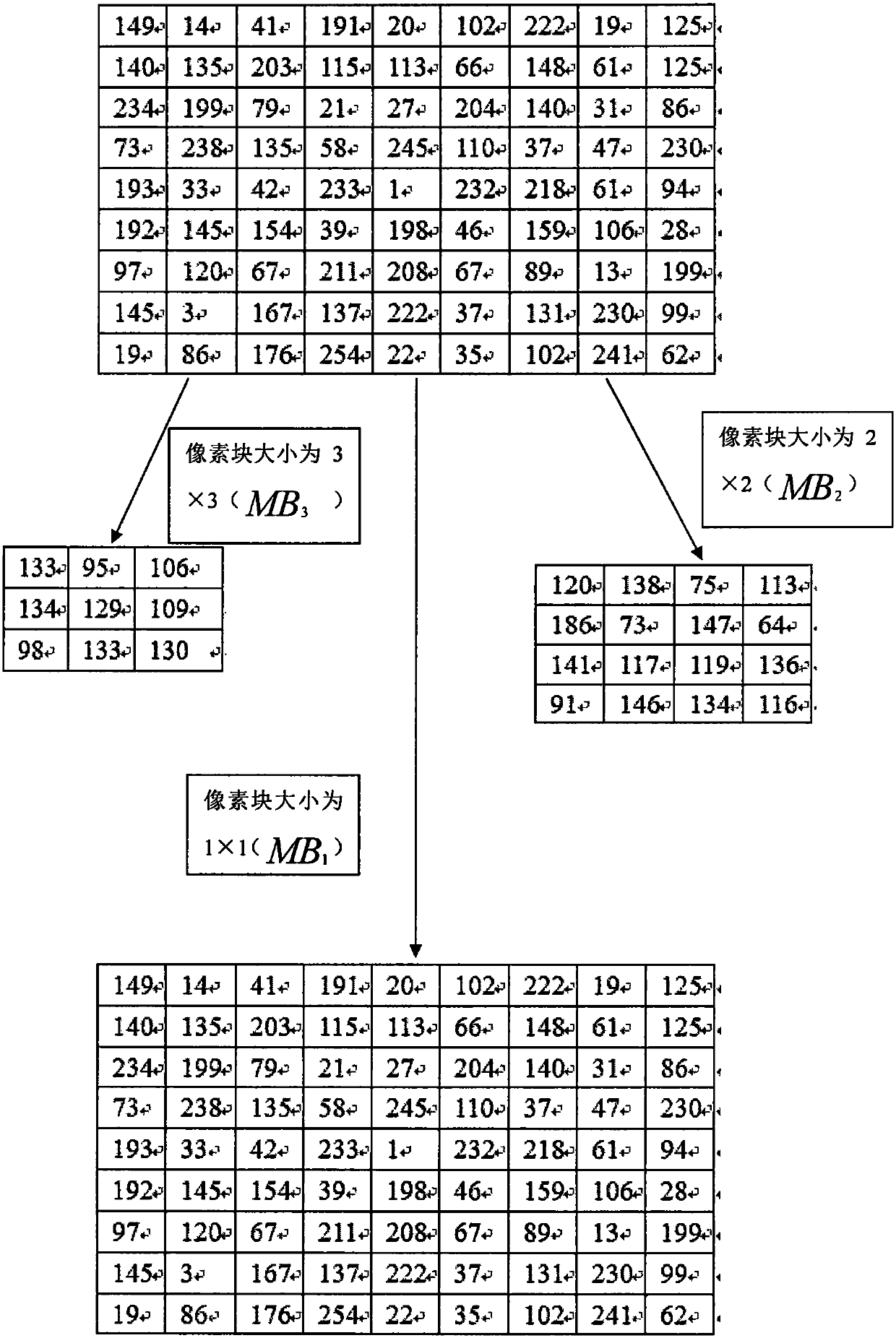

Coal-rock identification method based on image LBP

InactiveCN105184300AIncrease the amount of calculationImprove real-time performanceCharacter and pattern recognitionTemplate matchingFeature vector

The invention discloses a coal-rock identification method based on image LBP. The method comprises the following steps: carrying out different observation and particle size analysis conversion on images to obtain LBP response images of the sample images; carrying out co-occurrence matrix calculation on the LBP response images to obtain gray-level co-occurrence matrixs of the LBP response images respectively; extracting characteristic values of the gray-level co-occurrence matrixs of the LBP response images respectively, and forming feature vectors; forming a characteristic matrix of the images according to the obtained feature vectors of the gray-level co-occurrence matrixs of the LBP response images; and on the basis of the template matching technique, comparing the image to be identified with each template, and the template, of which the matching degree is the highest, being the template of the image to be identified. The method is low in influence of illumination factor, good in stability and high in recognition rate.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method of analyzing mixed-color cullet to facilitate its use in glass manufacture

Owner:CULCHROME LLC

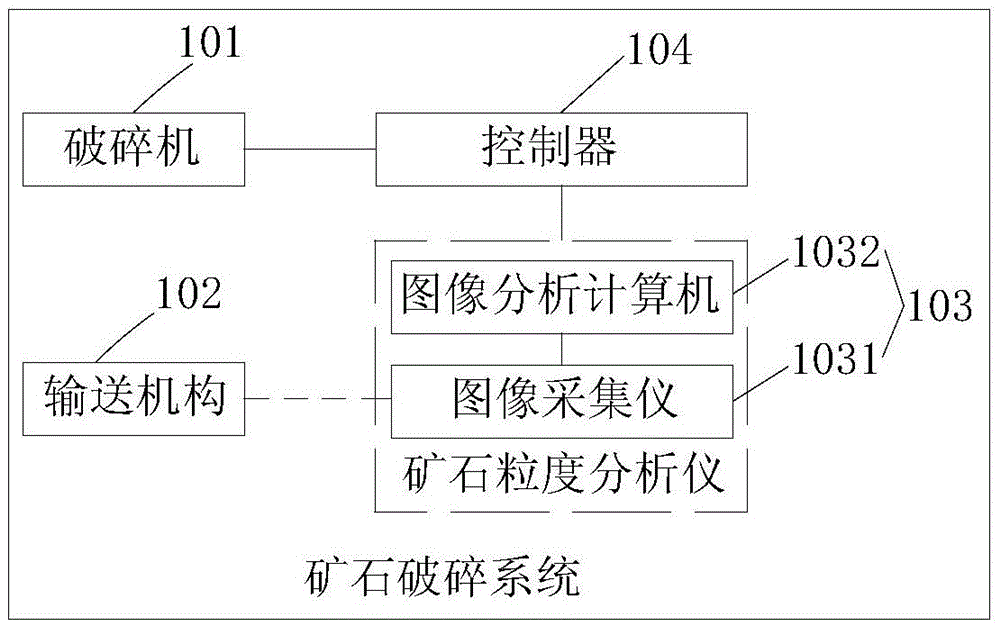

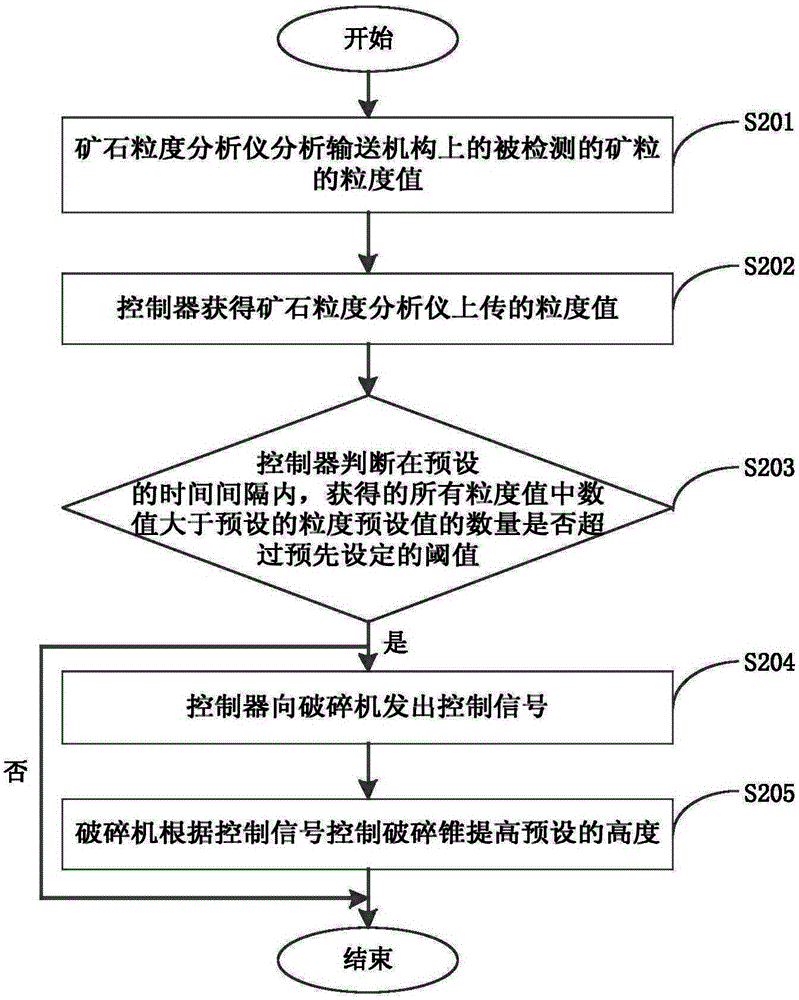

Ore crushing system and control method of crusher

InactiveCN105478220AReduce processing costsRealize intelligent controlGrain treatmentsControl signalEngineering

The embodiment of the invention provides an ore crushing system and a control method of a crusher, and relates to the technical field of ore machining. The ore crushing system comprises the crusher, a conveying mechanism, an ore particle size analyzer and a controller. The controller is electrically connected with the crusher and the ore particle size analyzer. The ore particle size analyzer is used for analyzing particle size values of detected ore particles on the conveying mechanism. The controller is used for judging whether the number of the values, larger than the preset particle size value, of all the particle size values which are acquired within preset time intervals and uploaded by the ore particle size analyzer exceeds a preset threshold value or not, and if the judgment result shows that the number of the values exceeds the preset threshold value, a control signal is sent to the crusher, and the crusher controls a crushing cone to increase the preset height according to the control signal. According to the ore crushing system and the control method of the crusher, the size of an ore discharging opening of the crusher can be effectively controlled, the ore particles discharged by the ore discharging opening can meet the later machining requirement, manpower resources are saved, and the machining cost in the ore machining process is reduced.

Owner:CHINA GOLD INNER MONGOLIA MINING

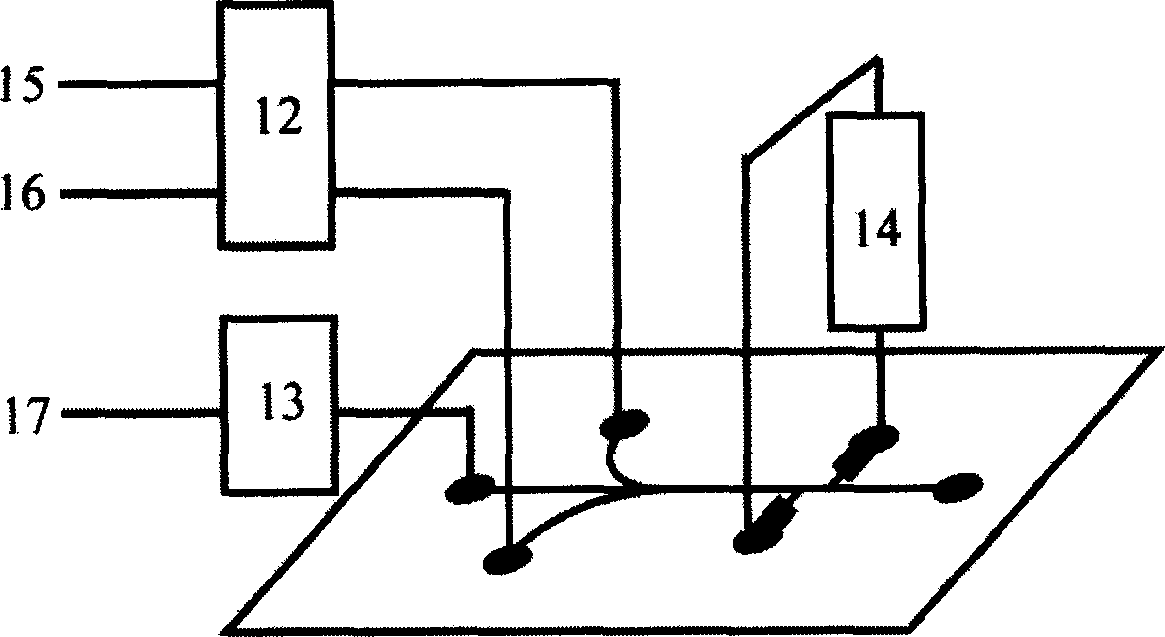

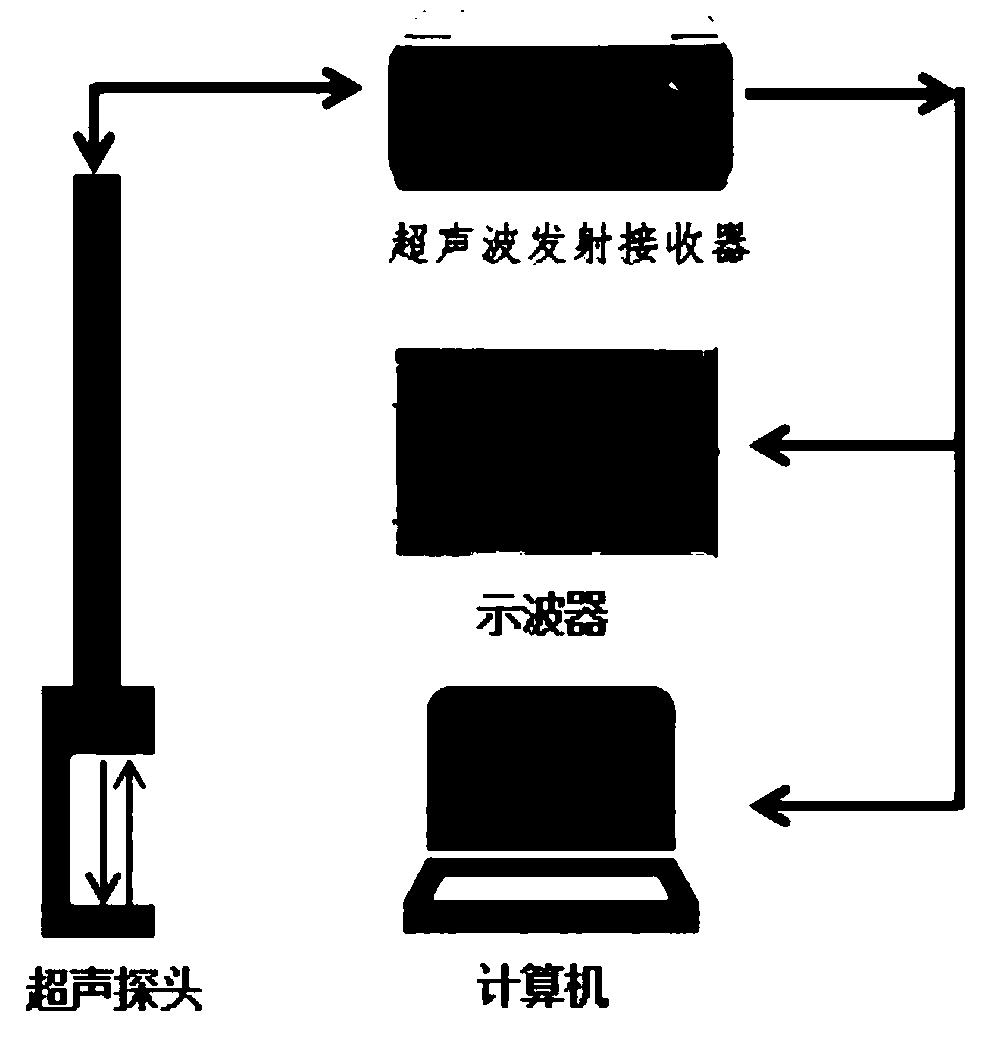

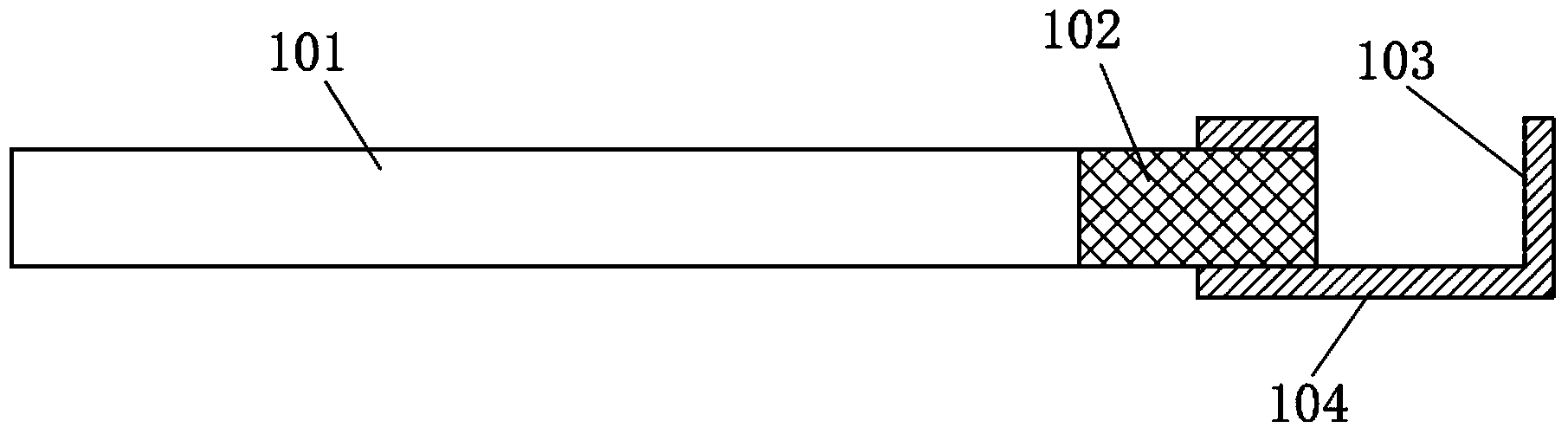

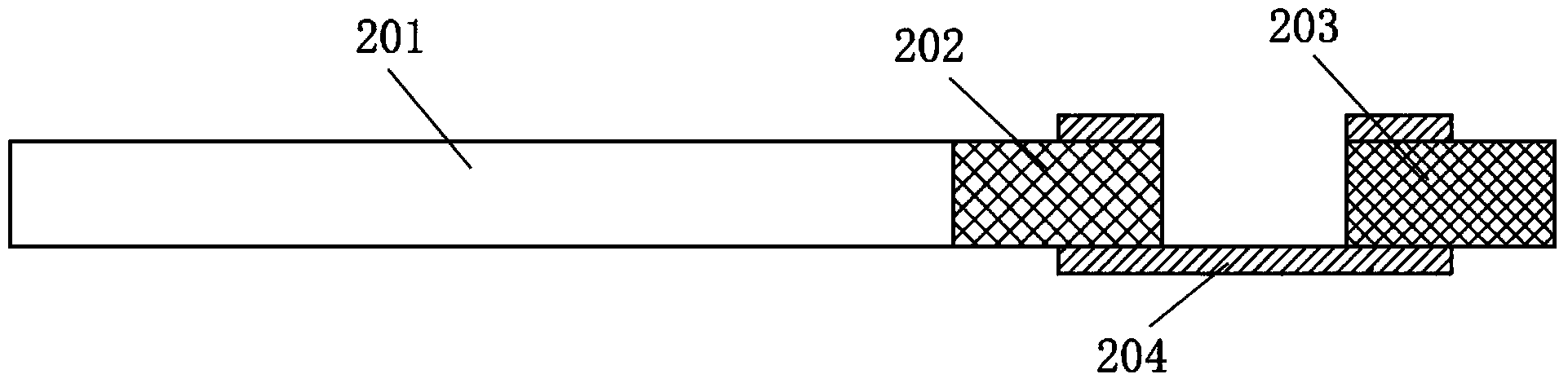

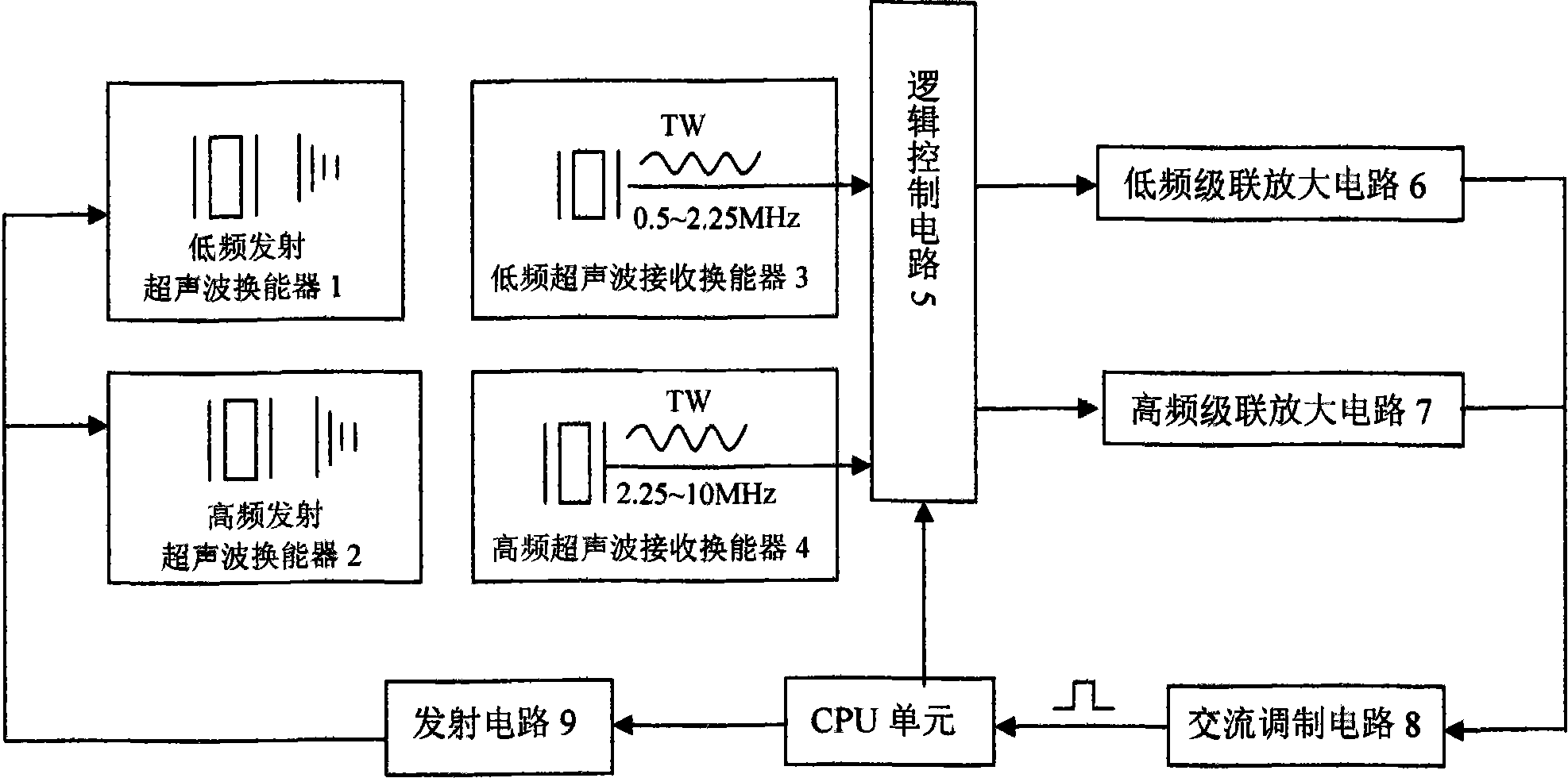

Ultrasonic particle size analyzer

InactiveCN104075968ANo need to diluteMaterial analysis using sonic/ultrasonic/infrasonic wavesParticle size analysisHigh concentrationSonification

The invention discloses an ultrasonic particle size analyzer, which comprises a hardware part and a software part, wherein the hardware part comprises an ultrasonic wave transmitting and receiving device and ultrasonic detection devices which are independent mutually, as well as an oscilloscope and a computer; the software part comprises a plurality of ultrasonic models, five global optimization algorithms and an expert consultation mode. An ultrasonic pulse signal is generated by the ultrasonic transmitting and receiving device, the ultrasonic waves are transmitted to suspension liquid through different ultrasonic detection devices, the amplitudes of the ultrasonic waves are attenuated after the ultrasonic waves are interacted with particles in the suspension liquid, and at different frequencies, the attenuation of the amplitudes is different according to the sizes and volume fractions of particles; particle size distribution and volume fractions of required particles can be obtained after the collected attenuation signal is processed through the computer. The ultrasonic particle size analyzer provided by the invention can perform nondestructive measurement, is rapid, reliable, and particularly suitable for high-concentration non-transparent samples, and samples are not required to be diluted.

Owner:PHARMAVISION QINGDAO INTELLIGENT TECH LTD

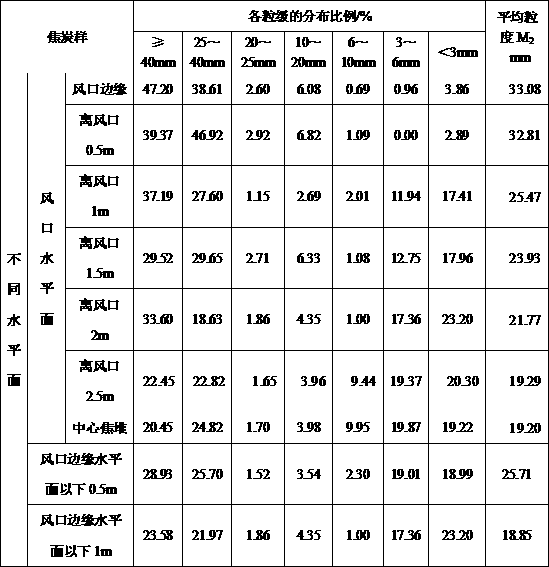

Method for evaluating coke degradation degree in blast furnace

ActiveCN108676944AReflect degraded behaviorAccurate guidanceBlast furnace detailsProcess efficiency improvementCombustionSlag

The invention provides a method for evaluating the coke degradation degree in a blast furnace. The method comprises the following steps that particle size analysis is carried out on coke entering theblast furnace on the previous day before damping down; when the blast furnace damps down, coke samples are taken; stemming in the coke is removed, and iron particles are taken out by a magnet for thefirst time; the particle size is graded; the coke which is taken out from each grade of coke is put into a muffle furnace for combustion correspondingly; after the coke is taken out, residual iron slags are taken out again by using the magnet; the iron slags are weighed; the weight percentage Xi of the residual iron slags taken out for each grade accounting for the coke of the same grade in the muffle furnace is calculated correspondingly; the net coke net weight Bi in the furnace with each particle size grade is calculated; the percentage Ci of the coke for each grade in the furnace accounting for the total weight of the coke is calculated; the average particle size M2 is calculated; the difference value M is calculated; the M is used for representing the degradation degree of the coke inthe blast furnace; and the shape and the size of a tuyere convolution zone are judged, and whether the coal gas distribution in the blast furnace is reasonable or not is analyzed so as to adaptivelyadjust the air inlet area and the air inlet speed of the blast furnace.

Owner:武汉钢铁有限公司

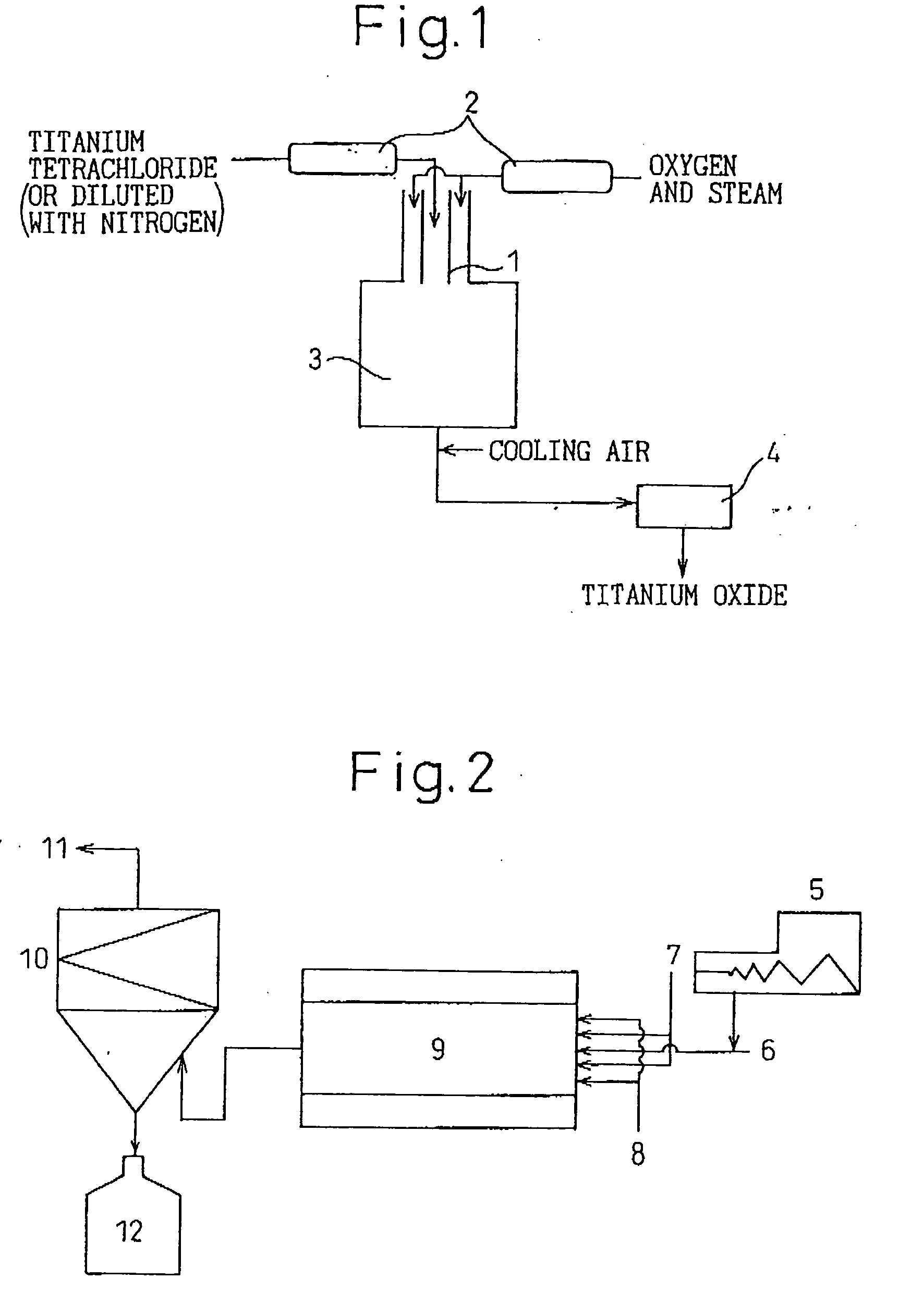

High purity titanium oxide and production process thereof

InactiveUS20060074173A1Good dispersionEasy to supervisePigmenting treatmentCosmetic preparationsGas phaseCombustible gas

A titanium dioxide characterized by having an average particle size of 5 to 200 μm as measured through laser particle size analysis; having a purity of at least 99.5 mass % as reduced to TiO2; and having an Fe content of 20 mass ppm or less, an Ni content of 20 mass ppm or less, a Cr content of 20 mass ppm or less, an Al content of 20 mass ppm or less, a Zr content of 20 mass ppm or less, an Si content of 40 mass ppm or less, a Cl content of 0.05 mass % or less, and an S content of 50 mass ppm or less. The titanium dioxide is produced by a process comprising bringing titanium dioxide serving as a raw material into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, to thereby yield spherical titanium dioxide, characterized in that said raw material titanium dioxide has been produced through a vapor-phase process in which titanium tetrachloride is oxidized with an oxidative gas at high temperature.

Owner:SHOWA DENKO KK

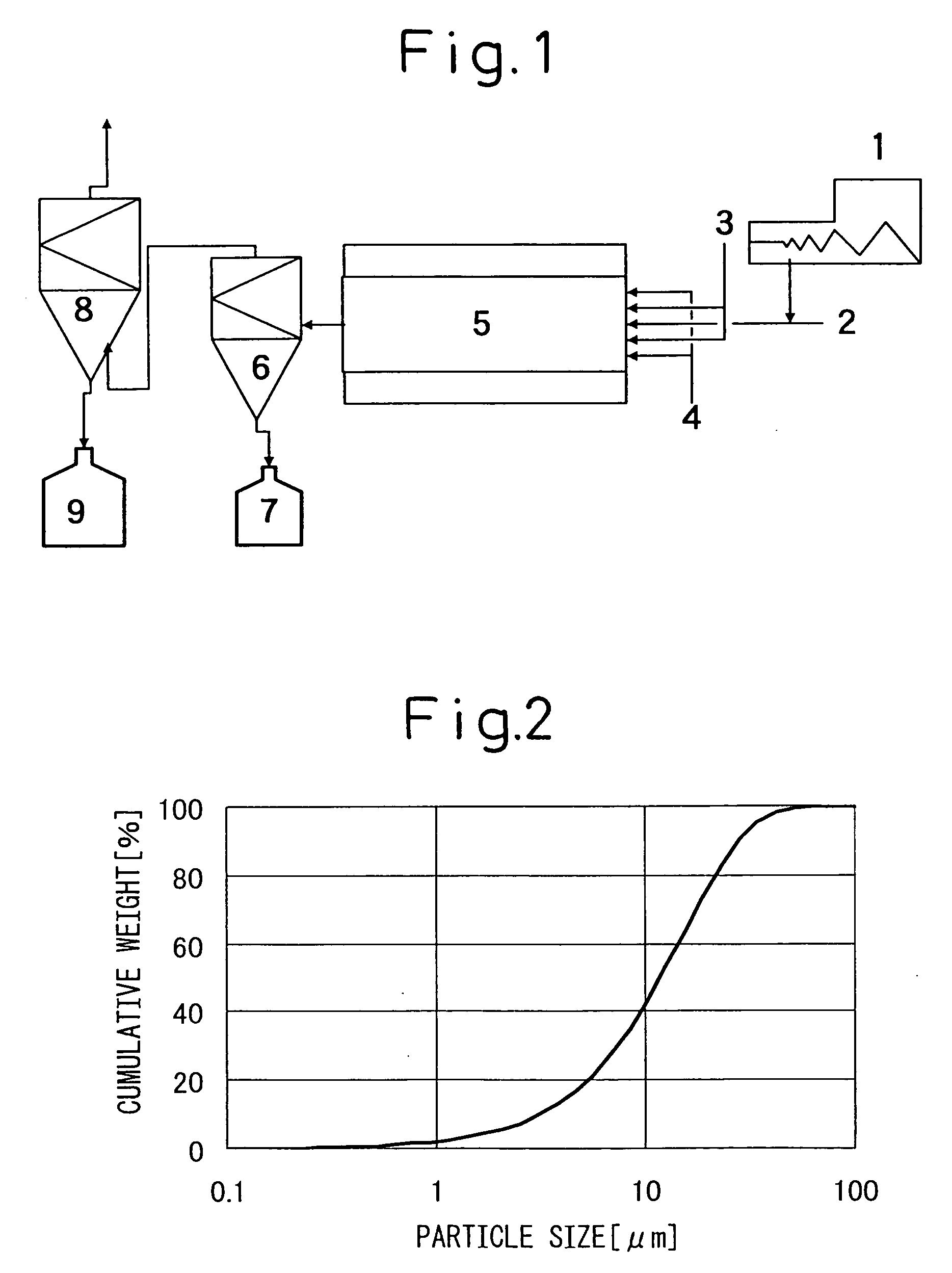

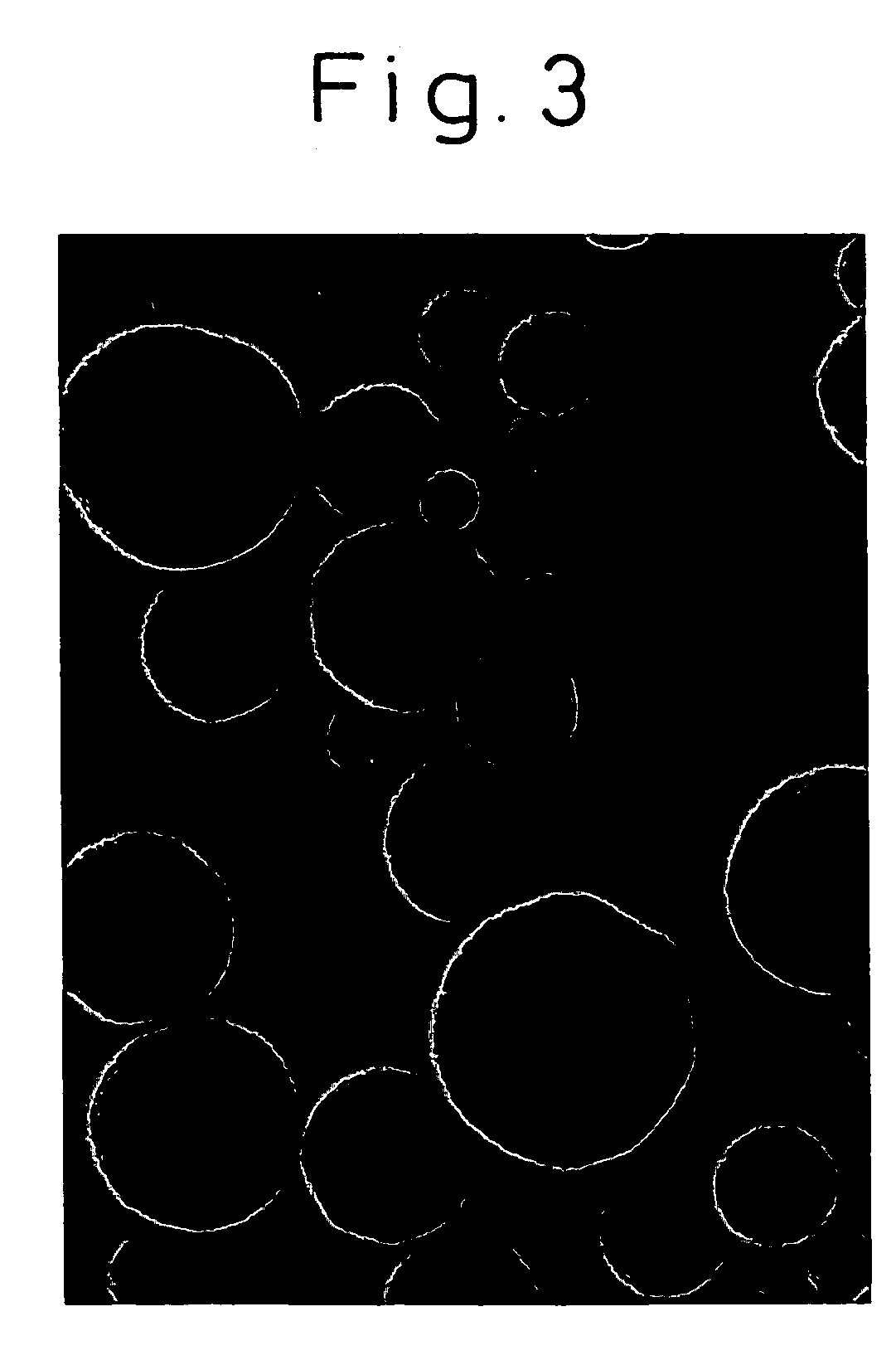

Surface modification method for inorganic oxide powder, powder produced by the method and use of the powder

InactiveUS20060127669A1Improvement ingredientsLow viscosityMaterial nanotechnologyInorganic pigment treatmentMetallurgyCombustible gas

A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, inorganic oxide powder A having an average particle size falling within a range of 0.5 to 200 μm as measured by means of laser diffraction / scattering particle size analysis and inorganic oxide powder B having a particle size calculated on the basis of its BET specific surface area of 100 nm or less, to thereby modifiy the surfaces of particles of the powder A by means of the particles of the powder B. A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, the inorganic oxide powder A; and bringing again the resultant powder into the high-temperature flame, to thereby modify the surfaces of particles of powder A.

Owner:SHOWA DENKO KK

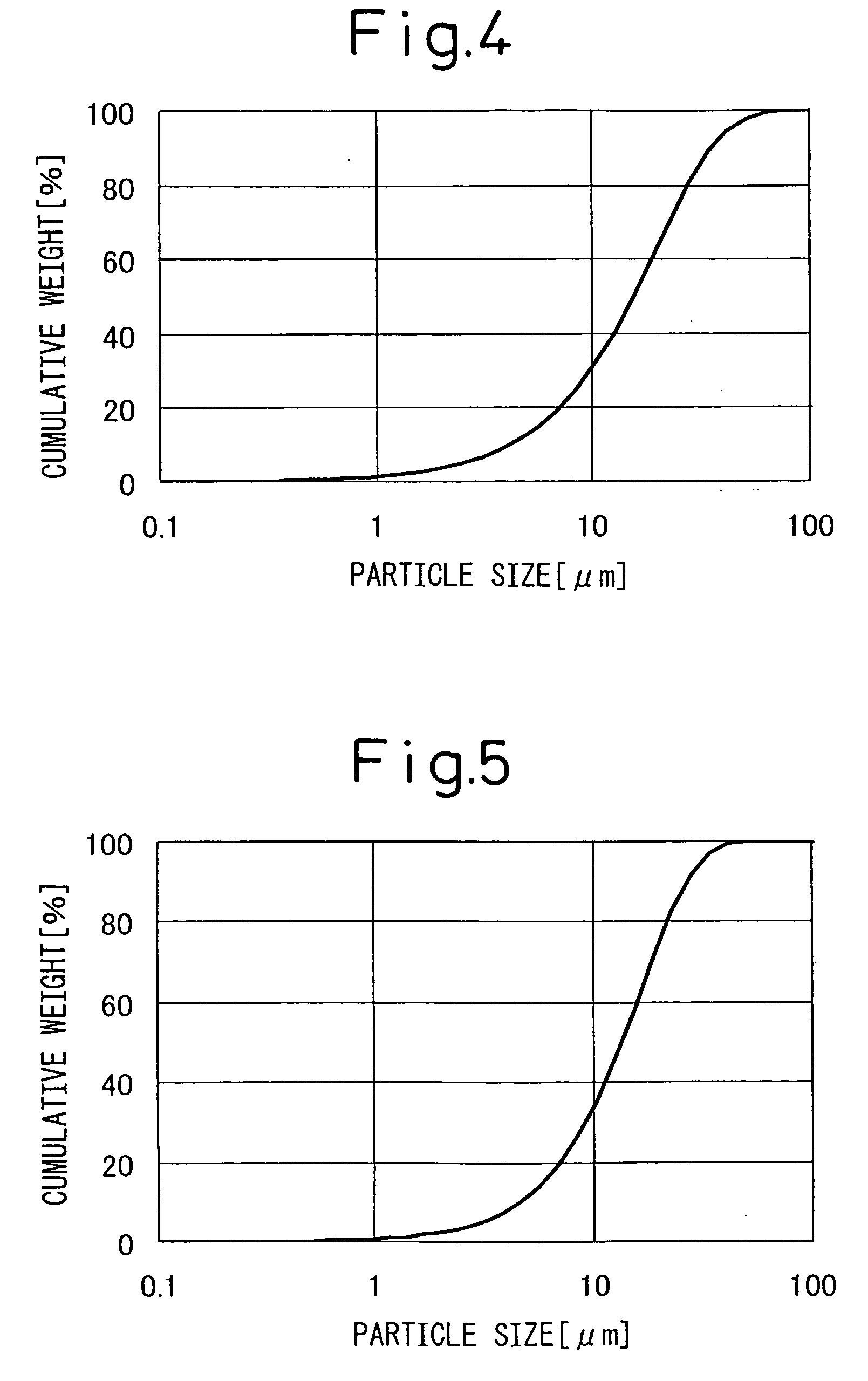

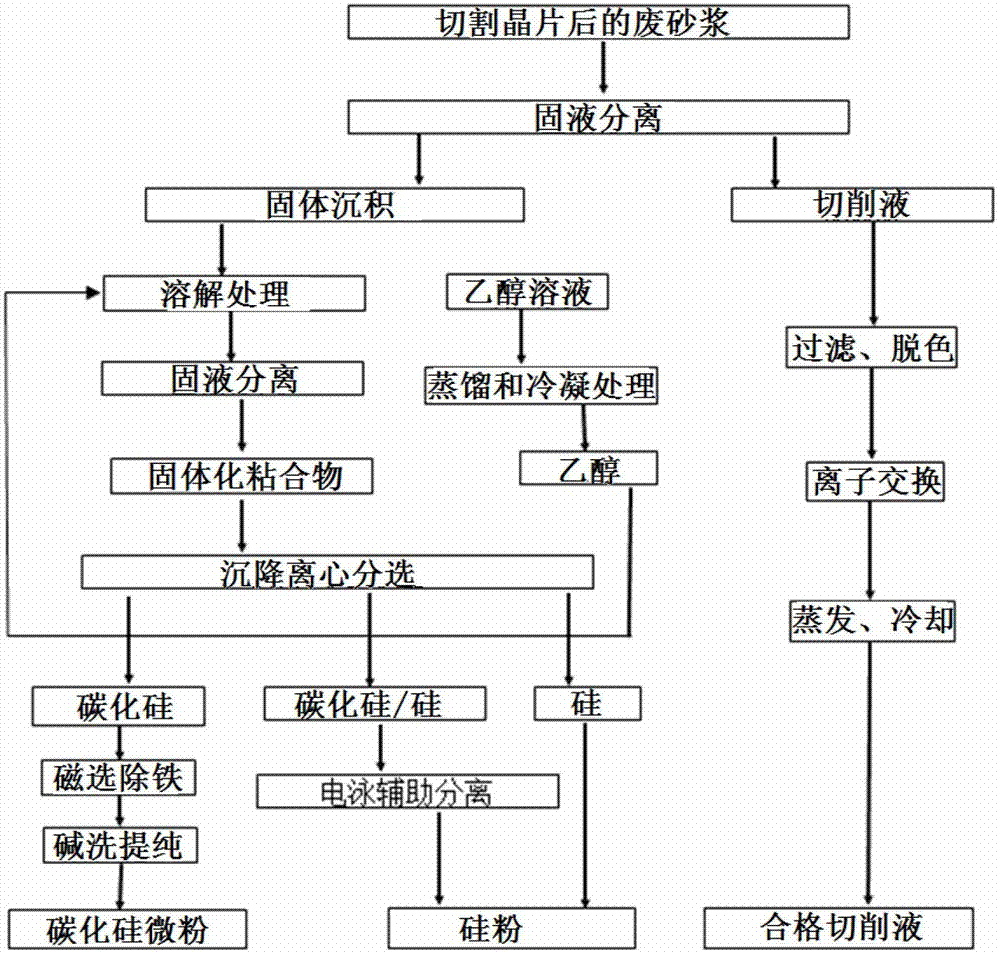

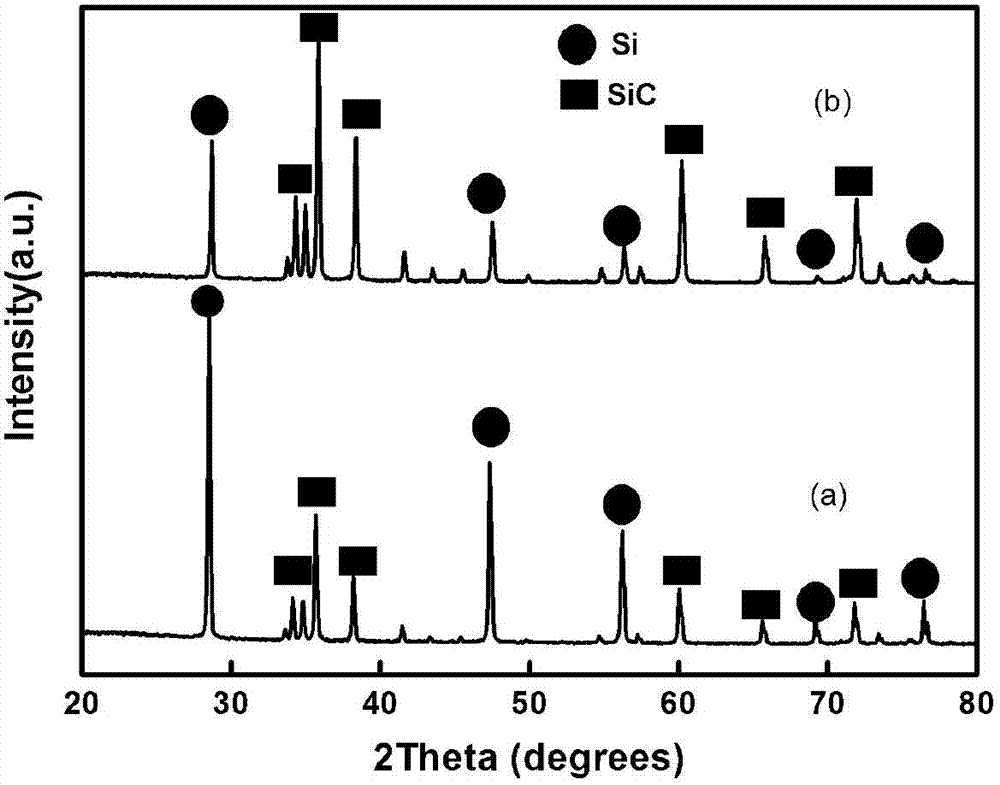

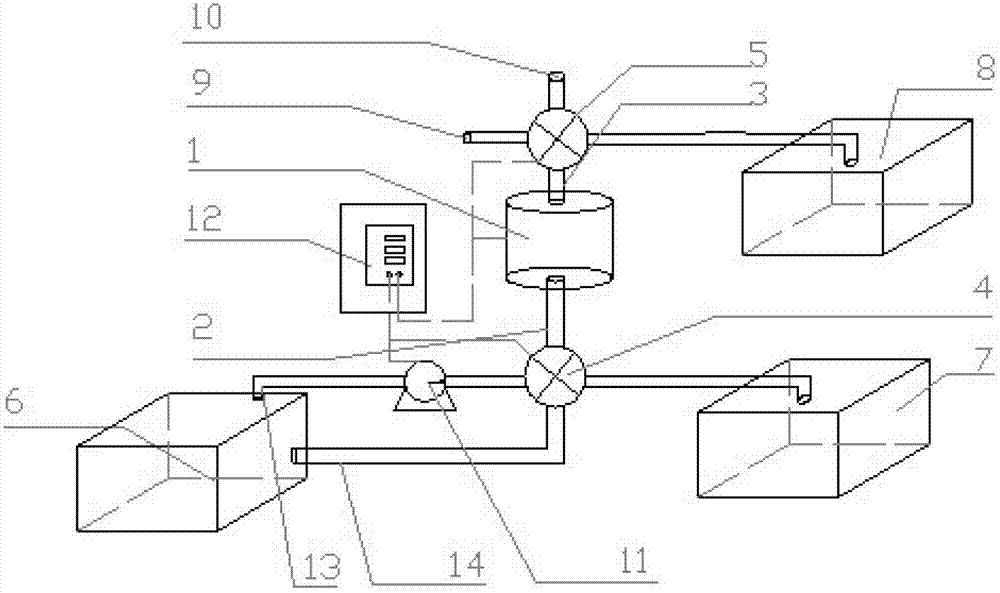

Method for separating cutting fluid, silicon carbide and silicon powder from wafer cutting mortar

InactiveCN102851110AAvoid pollutionImprove pollutionSilicon carbideSilicon compoundsSeparation technologyWafer dicing

The invention discloses a method for separating cutting fluid, silicon carbide and silicon powder from wafer cutting mortar. The method comprises the steps that: solid-liquid separation is carried out; solid obtained by separation is washed by using ethanol, and is then washed by using pure water; the solid is dried by centrifugation; Particle size composition and distribution state of silicon powder and silicon carbide / metal composition are determined by using a laser particle size analyzer; a mass ratio of the components is precisely determined by X-ray diffraction; the obtained data are converted into horizontal spiral sedimentation centrifuge sorting parameters; with the horizontal spiral sedimentation centrifuge, sand powder is primarily separated into coarse powder with main components of silicon carbide and iron, middle powder with main components of silicon carbide and silicon, and fined powder with a main component of silicon; the middle powder is added into an electrophoresis tank; the electrode in the electrophoresis tank is powered; under the action of an electric field, the silicon carbide powder is precipitated, and the silicon powder floats; the obtained silicon carbide powder and the coarse powder is subjected to alkali washing and iron-removing magnetic separation; and the obtained material is washed by using water, and is dried by centrifugation. The method provided by the invention is innovative than an ultrafine particle separation technology in waste mortar processing in prior arts. With the method, an existing pollution problem can be comprehensively treated and solved.

Owner:JIANGSU TAYAL PHOTOVOLTAIC AUXILIARY MATERIAL

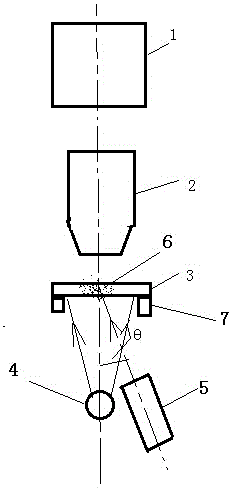

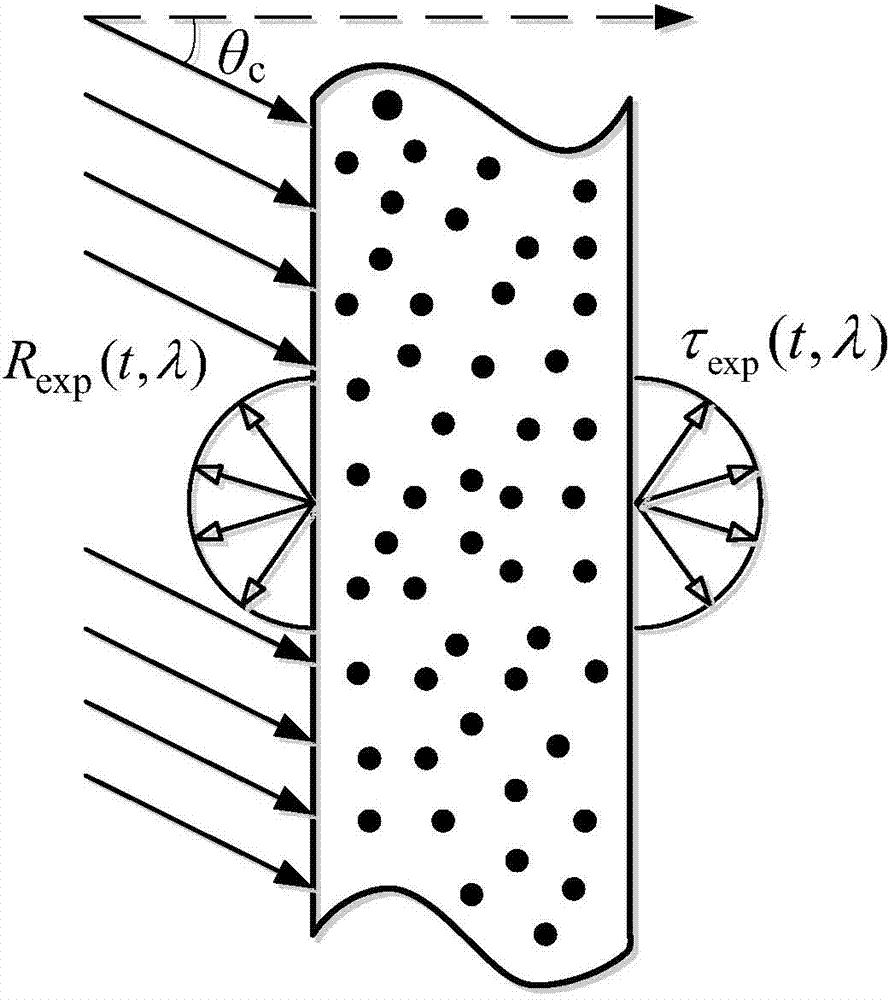

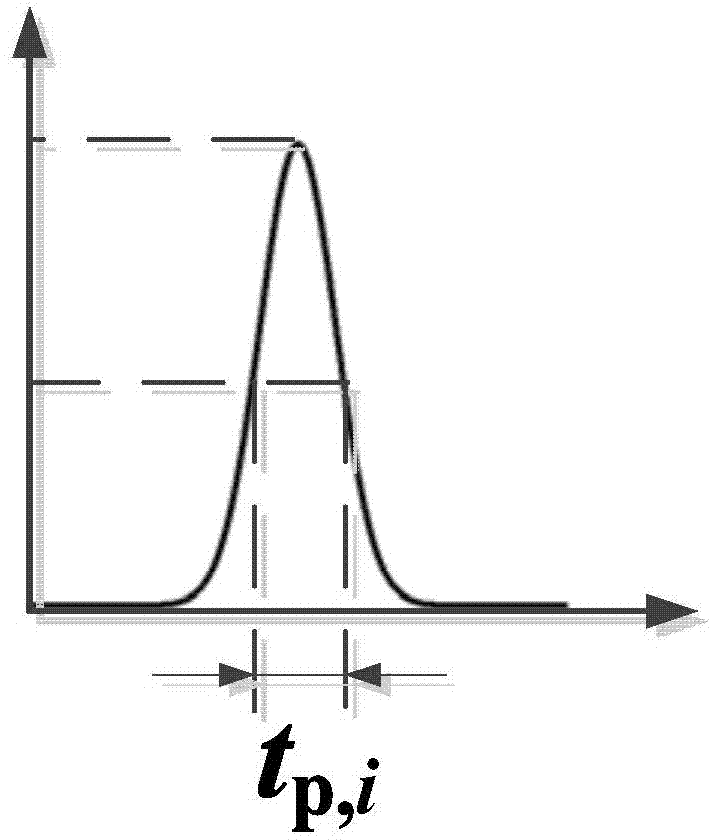

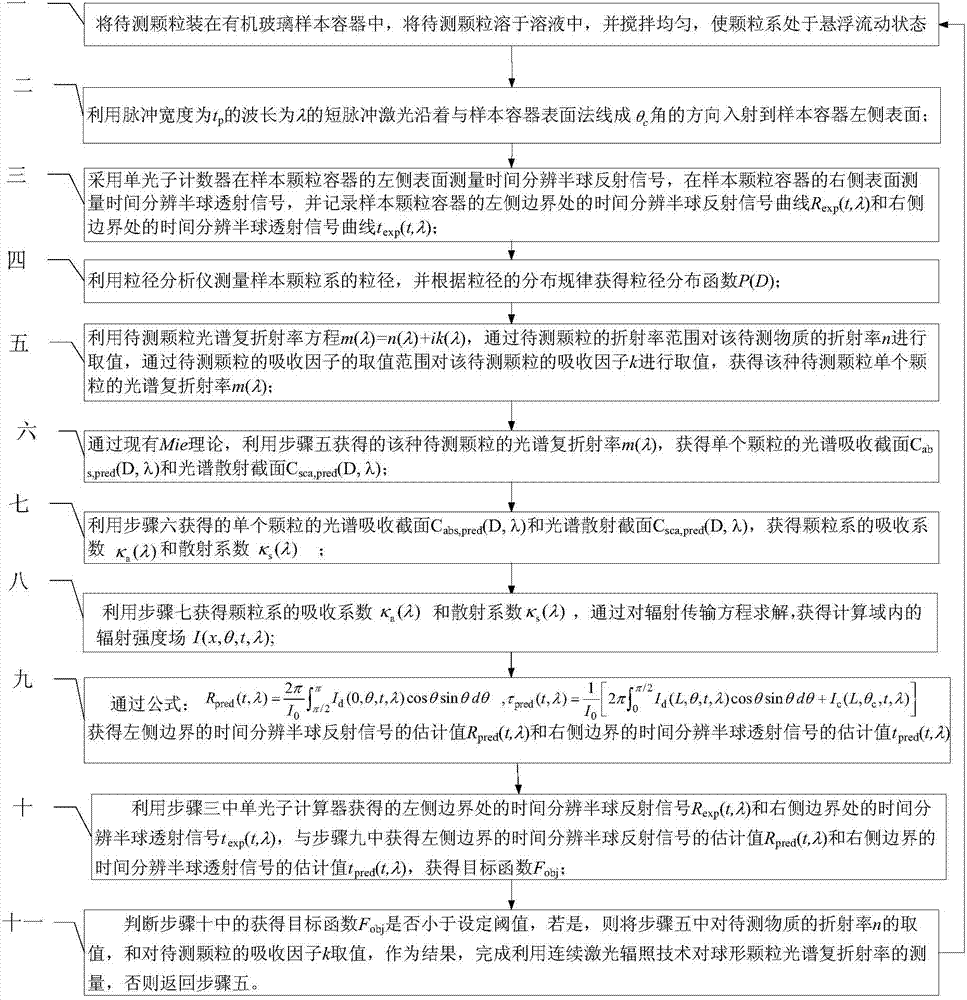

Spherical particle spectrum complex refractive index measurement method based on short pulse laser transmitted and reflected signals

ActiveCN103487356AEasy to measureThe inversion result is accurateParticle size analysisOptical propertyRefractive index

Belonging to the technical field of particle optical property measuring, the invention provides a spherical particle spectrum complex refractive index measurement method based on short pulse laser transmitted and reflected signals, and solves the problems of complex measuring process and low accuracy still existing in current spherical particle spectrum complex refractive index measurement methods. The method disclosed in the invention uses short pulse laser to irradiate a uniform spherical particle system, measures the reflected signal and transmitted signal of the particle system, employs a particle size analyzer to measure the particle size distribution of the particle system, utilizes a Mie theoretical model and inversion of a particle swarm optimization algorithm to obtain the spectrum complex refractive index of particles. The method provided in the invention is suitable for measuring the spectrum complex refractive index of particles.

Owner:HARBIN INST OF TECH

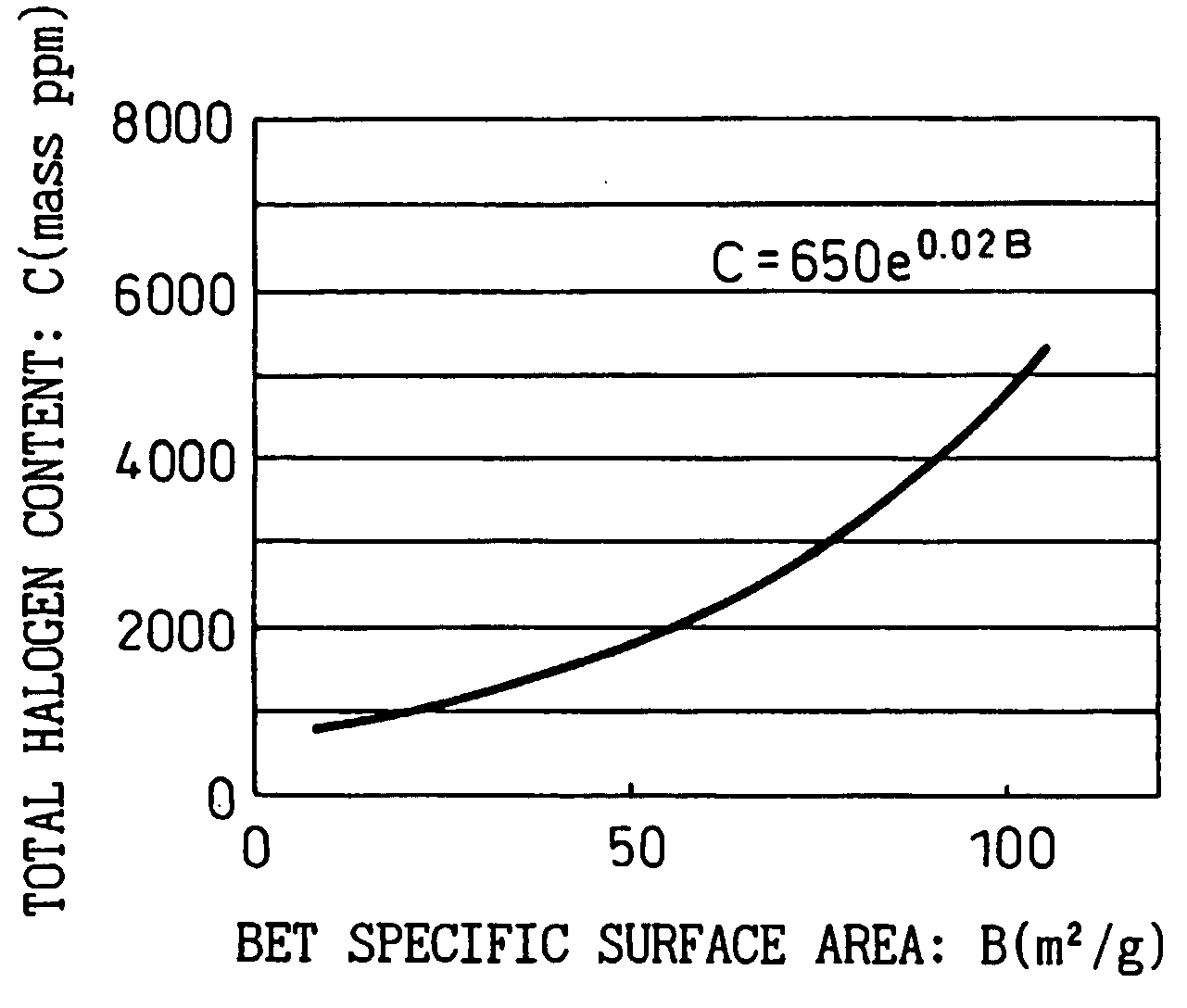

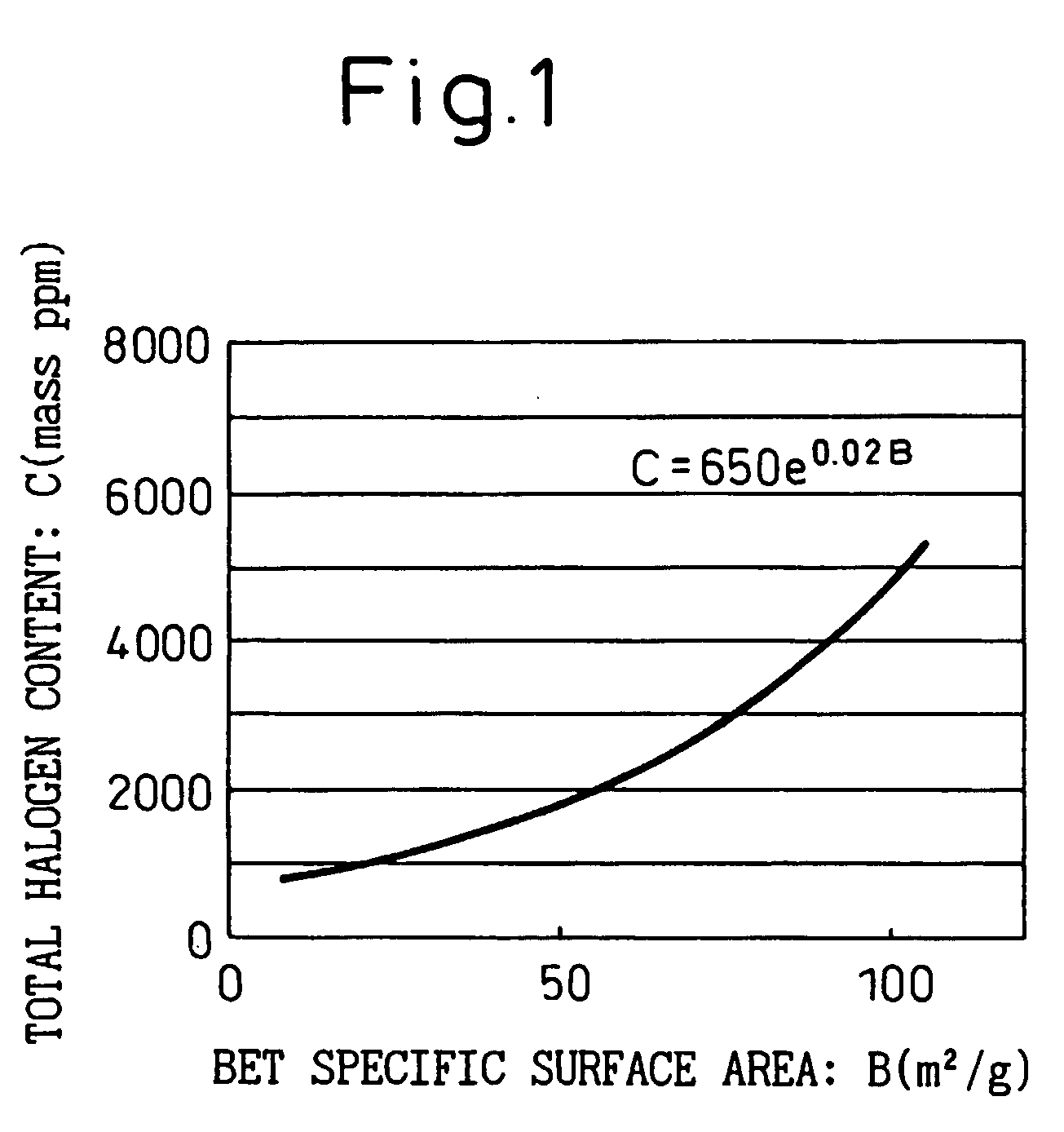

Ultrafine particulate titanium oxide with low chlorine and low rutile content, and production process thereof

InactiveUS20050076811A1Pigmenting treatmentCatalyst activation/preparationParticulatesTitanium oxide

An anatase-type ultrafine particulate titanium oxide process, which has low chlorine content compared with conventional titanium oxide having a BET specific surface area comparable to that of the ultrafine particulate titanium oxide. When the ultrafine particulate titanium oxide is subjected to dechlorination, the titanium oxide satisfies the relation between BET surface area (B) and chlorine content (C) represented by the aforementioned formula (2). The ultrafine particulate titanium oxide has a D90 of 2.5 (m or less as measured by means of laser diffraction particle size analysis. The present invention also provides a process for producing the ultrafine particulate titanium oxide.

Owner:SHOWA DENKO KK

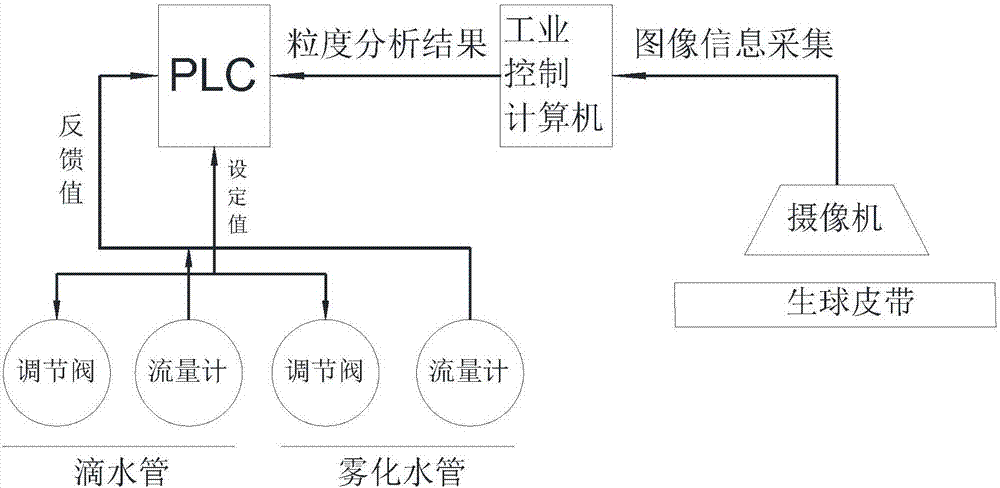

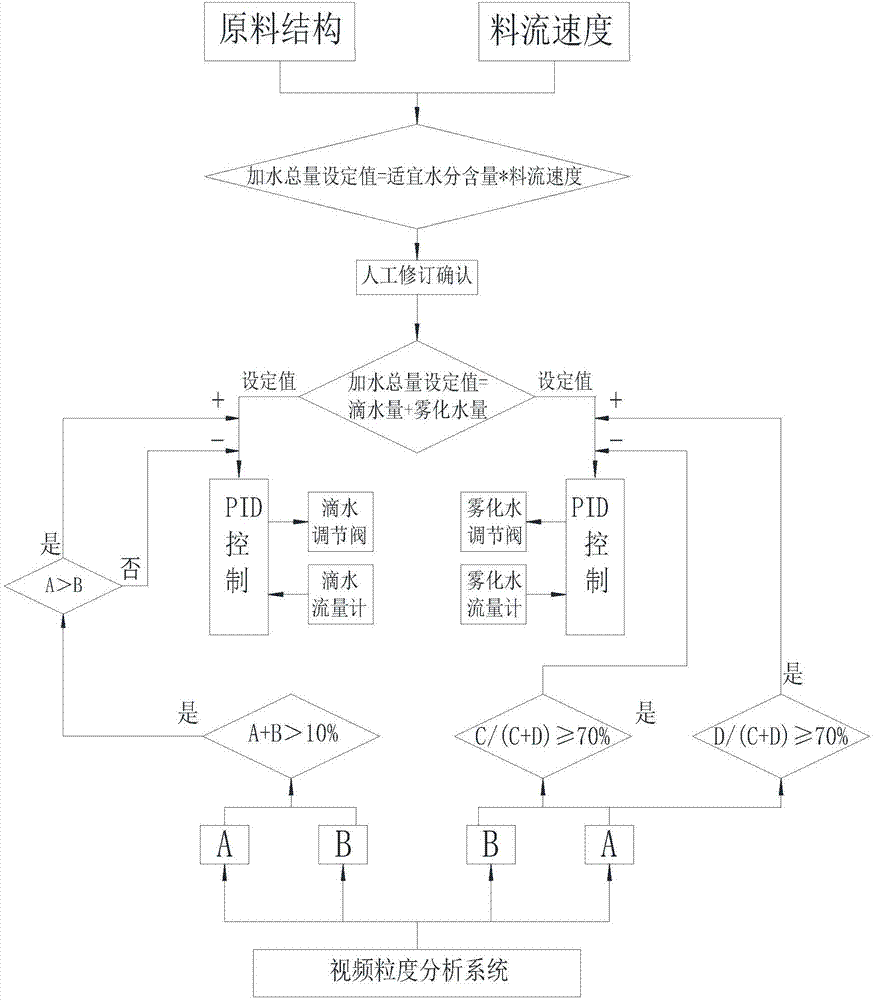

Automatic water adding control device and method for pelletizing pellets

InactiveCN107345271AImplement automatic settingsRealize regulationProgramme control in sequence/logic controllersProduction rateIron powder

The present invention relates to an automatic watering control device and method for pelletizing pellets, including a raw pellet belt, a video particle size analysis system, a drip pipe, and an atomizing tube. The video particle size analysis system includes a video camera and an industrial control computer. The video camera is installed on Above the raw ball belt, the camera is connected with the industrial control computer through the data transmission device, and the image signal is transmitted to the industrial control computer, and the industrial control computer is connected with the input end of the PLC. The present invention controls the whole process from the incoming iron powder, the ratio of additives to the granularity of green balls, not only can realize the automatic setting and adjustment of the total amount of water added; The water distribution is adjusted and controlled, which greatly improves the production rate of green pellets and reduces the energy consumption in the pellet roasting process.

Owner:SD STEEL RIZHAO CO LTD

Nano bamboo carbon powder and preparation method thereof

The invention discloses nanometer bamboo charcoal powder and a preparation method thereof. The method is characterized in that bamboo charcoal baked by an earth kiln is used, then a high-temperature electric box electric furnace is used for carbonization, the carbonization temperature is between 1,200 and 1,600 DEG C, the carbonization time is between 24 and 48 hours, carbide is crushed by a flat fluid jet mill into the particle size which is less than or equal to 1.5 um, and then the carbide, a coupling agent, an anion surfactant, a non-ionic interfacial agent-sodium polyacrylate salt used as a dispersant, a modified polysiloxane defoaming agent, and deionized water are mixed evenly and then are placed in a two-way rotary ball mill for grinding. The rotating speed of the ball mill is between 4,000 and 4,500r / m, and the grinding time is between 48 and 96 hours. A grinding mixture is diluted by the deionized water, is subjected to ultrasonic treatment, and is tested by a laser particle size analyzer (the measurement range is between 3 and 3,000 nm), the particle size and the particle size distribution are measured by a wet method, and the mixture is regarded not to reach the standard when the particle size is more than 300nm. Then the mixture continues to be ground in the ball mill until the average particle size of the mixture reaches 60 to 300 nm through the detection, and then is dried to obtain the nanometer bamboo charcoal powder.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

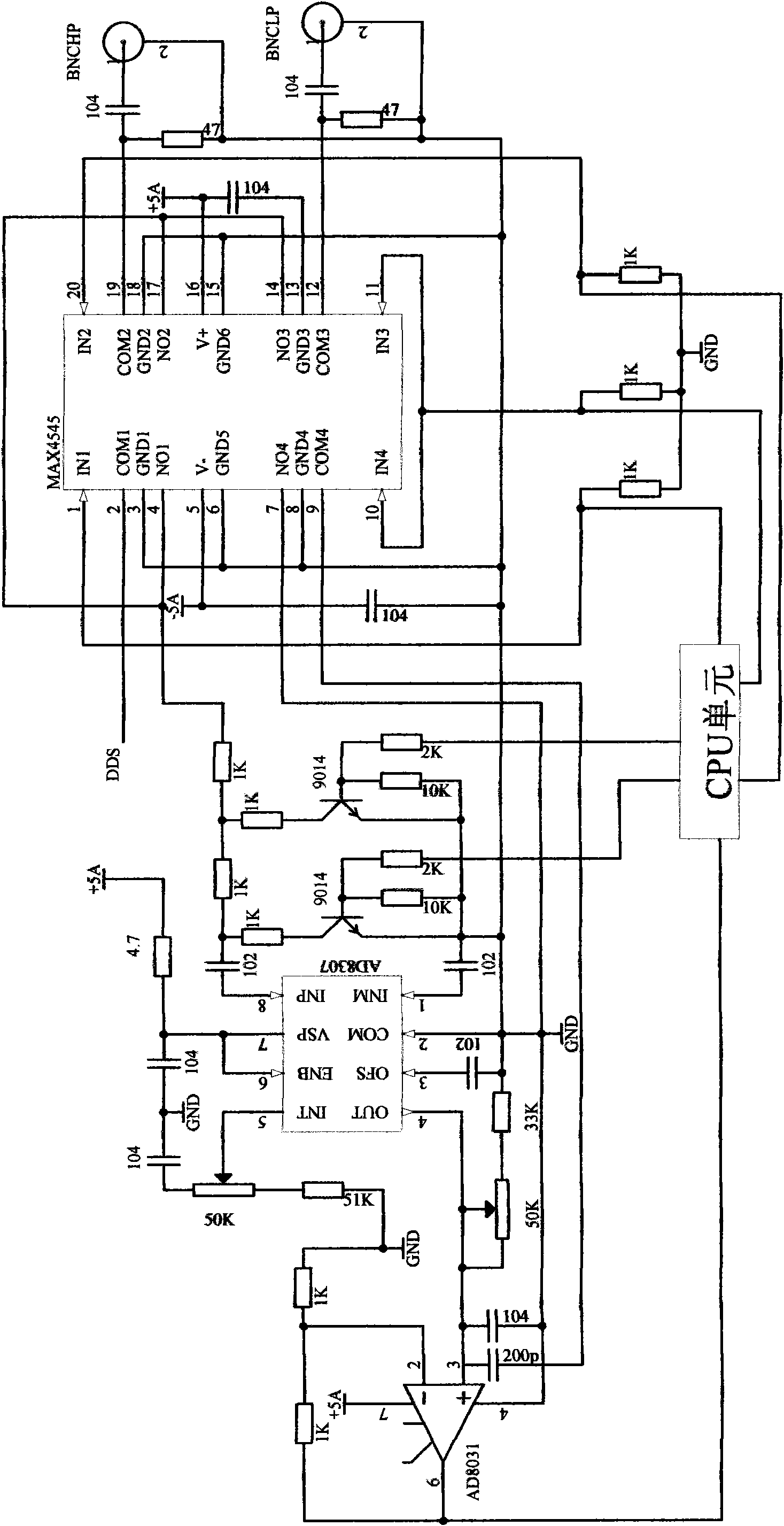

Dual-channel high-low-frequency ultrasonic attenuation signal detection device

InactiveCN101915719ALarge dynamic detection rangeParticle size analysisParticle suspension analysisSonificationUltrasonic attenuation

The invention relates to a dual-channel ultrasonic attenuation signal detection device. Ultrasonic attenuation signals received by two receiving ultrasonic transducers of the device are converted into DC signals capable of being collected by an A / D (Analog-to-Digital) converter through a logical control circuit, a cascade amplifying circuit and an AC modulation circuit. The ultrasonic attenuation signal detection accuracy of the device is not less than 0.1 dB, the ultrasonic attenuation signal detection capacity is in a dynamic range of 94 dB, and thus, the detection accuracy on pulp density and particle size for an ultrasonic online particle size analyzer is increased.

Owner:DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

Detection method for particle size distribution of insulator surface dirt

InactiveCN105588789AEasy to measureEasy to analyzeParticle size analysisElectron microscopeComputational physics

The invention discloses a detection method for particle size distribution of insulator surface dirt. The detection method comprises the following steps that the dirt amount of an insulator surface to be detected is judged; particle size distribution of the insulator surface dirt is measured with a laser particle size analyzer when it is judged that the dirt amount of the insulator surface is no less than a preset amount; an image of the insulator surface is shot with an electron microscope when it is judged that the dirt amount of the insulator surface is less than the preset amount; the image is analyzed to perform statistics on particle size distribution of the insulator surface dirt, and particle size distribution of the insulator surface dirt is measured. According to the detection method, defects of an existing laser particle size analyzer measurement method are overcome, and particle size distribution of the surface dirt of insulators in the regions with the lower pollution level, the shorter dirt accumulating period and the like can be measured and analyzed.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for evaluating insulation aging state of rubber-plastic cable

ActiveCN106199350AAccelerated agingImprove effectivenessTesting dielectric strengthMaterial strength using tensile/compressive forcesAnalysis dataX-ray

The invention discloses a method for evaluating an insulation aging state of a rubber-plastic cable. The method includes the steps of an aging accelerating step of allowing a large current to flow through an intact rubber-plastic cable under a constant temperature and humidity condition until the main insulation material in the rubber-plastic cable is broken down, letting the total time be T, taking N-1 time points at the same time interval within the total time T, recording the time points as t1, t2, ..., tn-1 sequentially, and letting t0=0 and tn=T; a comparison database establishing step of sampling the main insulation material in the rubber-plastic cable at various time points from t0-tn, conducting a scanning electron microscope test, a laser diffraction particle size analysis, a dielectric spectrum test, a fluorescence spectrum analysis and an X-ray diffraction analysis, a thermogravimetric analysis, an electric pulse test and a tensile test, and establishing the correspondence between the above test or analysis data and the various time points from t0-tn correspondence in a comparison database; and an evaluating step of determining the remaining life of the rubber-plastic cable according to the data of the main insulation material the rubber-plastics cable under test.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Fundamental method and its hardware implementation for the generic prediction and analysis of multiple scattering of waves in particulate composites

InactiveUS7257518B2Computation using non-contact making devicesScattering properties measurementsReal systemsFluid phase

This invention relates to a method and apparatus for the fundamental prediction, analysis, and parametric studies of the interaction of multiply scattered waves of any nature (acoustic, electromagnetic, elastic) with particulate composites (solid or fluid particulate phases included in a solid or fluid phase). It comprises of: a) a Prediction Engine 21 to predict the composite physical attributes from those of the constituent phases, b) an Inversion Engine 22 to estimate a subset of the attributes of the constituent phases and composite from the rest of those attributes, and c) an ergonomic Graphical Interface 23 to enable the user to easily set up complex simulation experiments for the analysis, and synthesis of real systems in which generic waves interact with composites. The Prediction Engine 22 is suitable for integration into existing acoustic or optical particle size analyzers to thereby extending their concentration ranges by at least two orders of magnitude.

Owner:FELIX ALBA CONSULTANTS

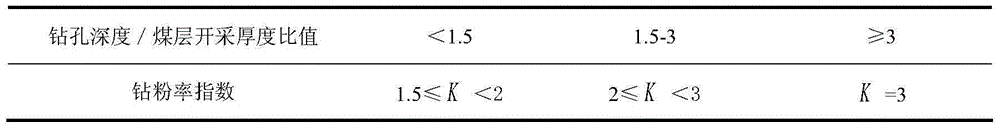

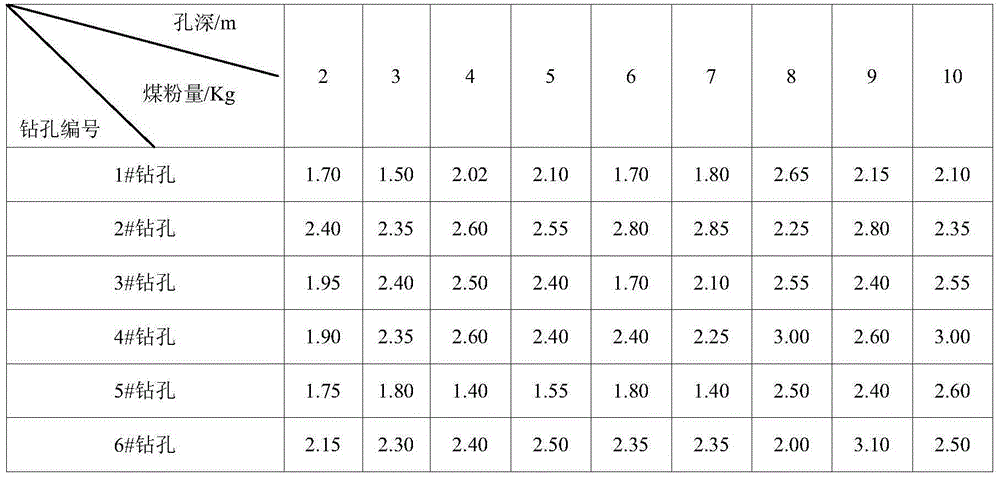

Impact risk warning method on basis of multi-parameter critical coal dust quantity indexes

InactiveCN105041306AThe impact risk warning flow chart is clearSimple on-site operationSpecial data processing applicationsBorehole/well accessoriesEngineeringParticle Size Analyzer

The invention discloses an impact risk warning method on the basis of multi-parameter critical coal dust quantity indexes. The impact risk warning method includes drilling 2-3 groups of drilled holes in to-be-warned working regions, recording the weight of drilled coal dust in each meter of each hole, counting the weight of the coal dust with the particle diameter larger than 3mm in each meter of each hole and counting weight proportion of the coal dust with the particle diameter larger than 3mm in each meter of each hole; analyzing coal dust quantity values obtained by means of recording and computing, comparing the coal dust quantity values to critical coal dust quantity values, and predicting whether impact risk warning needs to be carried out on the regions or not according to four warning decisions including dynamic phenomenon records, general critical coal dust quantity analysis, segmented critical coal dust quantity analysis on the drilled holes and coal dust particle size analysis. The impact risk warning method has the advantage that impact risks can be accurately and reliably warned by the aid of the step-by-step warning method.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com