Ultrasonic particle size analyzer

A particle size analysis and ultrasonic technology, applied in particle size analysis, particle and sedimentation analysis, analysis of materials, etc., can solve the problems of ultrasonic hardware not taking advantage of ultrasonic non-destructive detection, impossible to obtain particle size distribution, lack and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

[0033] The ultrasonic particle size analyzer described in this embodiment includes a hardware part and a software part, wherein:

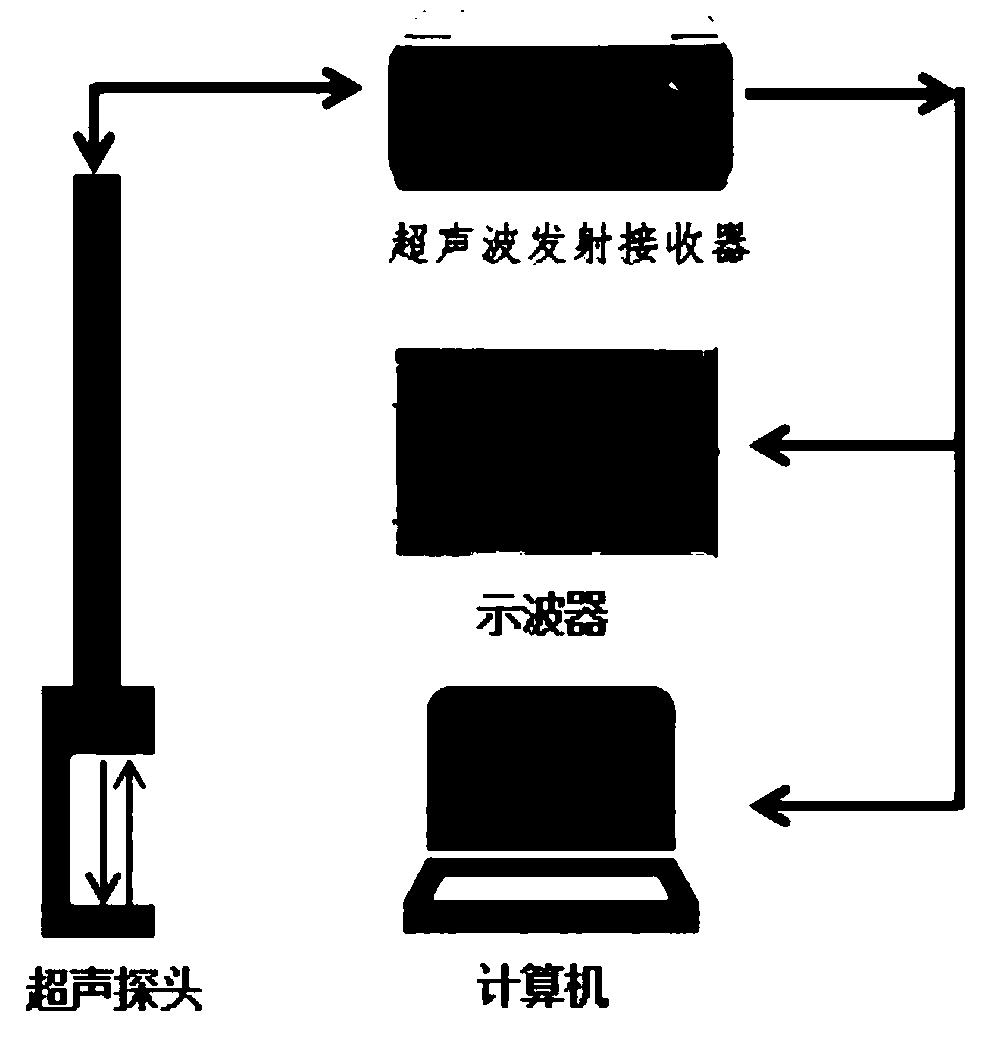

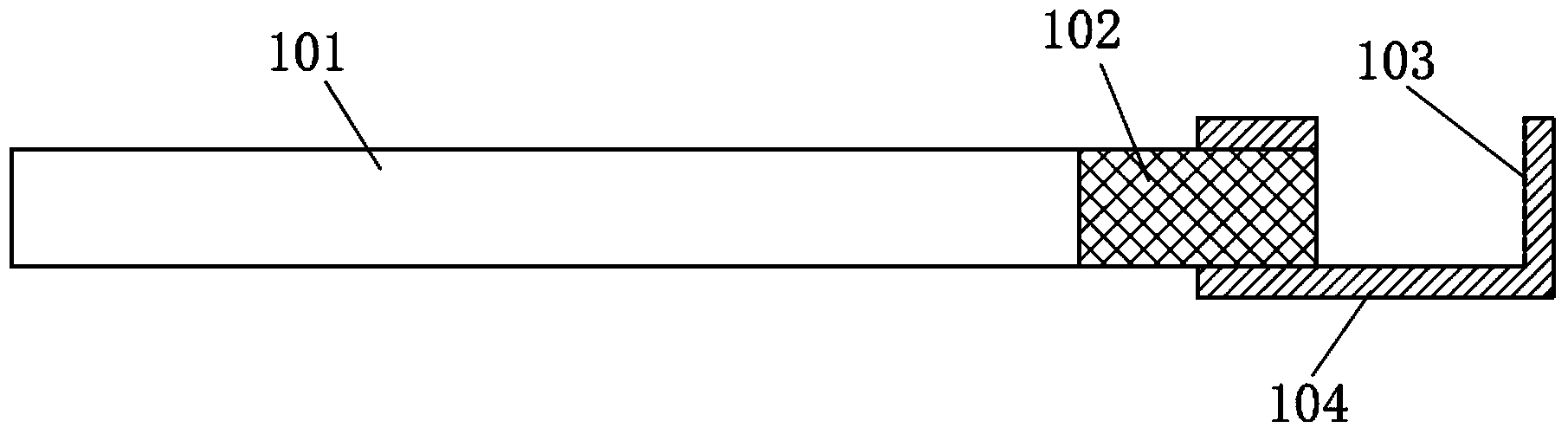

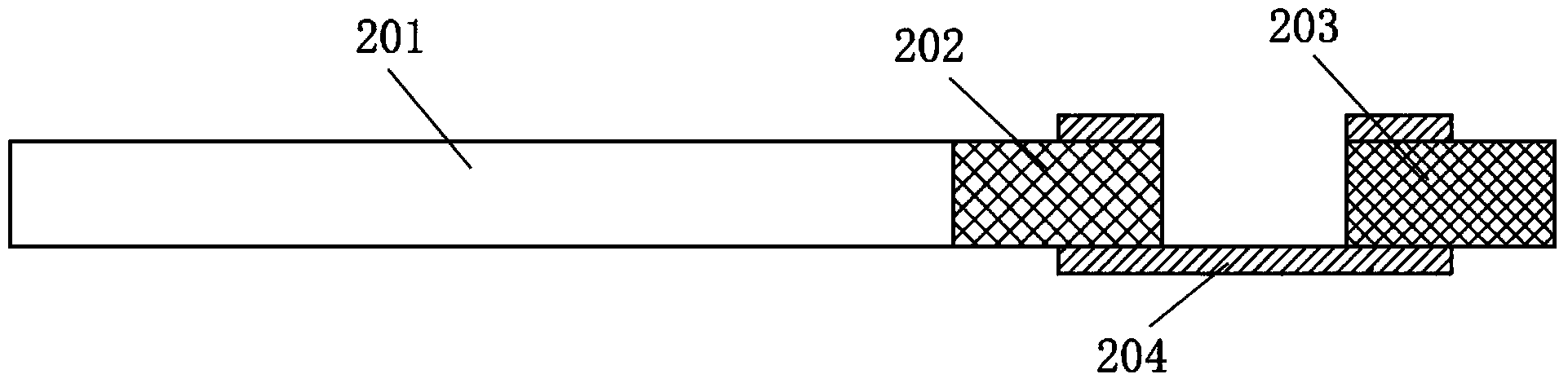

[0034] Such as figure 1 As shown, the hardware part includes an ultrasonic transmitter receiver and an ultrasonic detection device that are independent of each other, as well as an oscilloscope for real-time monitoring of the transmitted and received ultrasonic signals and a computer for data processing. The ultrasonic detection device adopts reflection mode or In transmission mode, it can be immersed in the sample for measurement or directly added to the existing pipeline for measurement.

[0035] When working, the ultrasonic transmitter receiver first sends out a high-frequency (1MHz-100MHz) ultrasonic signal, which propagates in the suspension through the ultrasonic detection device, changes its intensity after encountering particles, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com