Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159 results about "Particle size measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

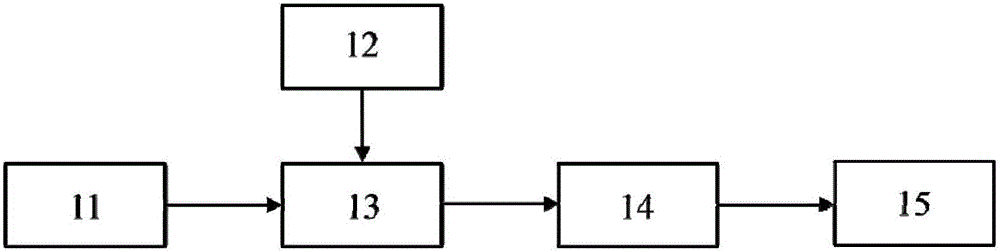

Measurement method for particle size

InactiveCN102252944ALarge sample volumeFast measurementParticle size analysisManufacturing technologyParticle size measurement

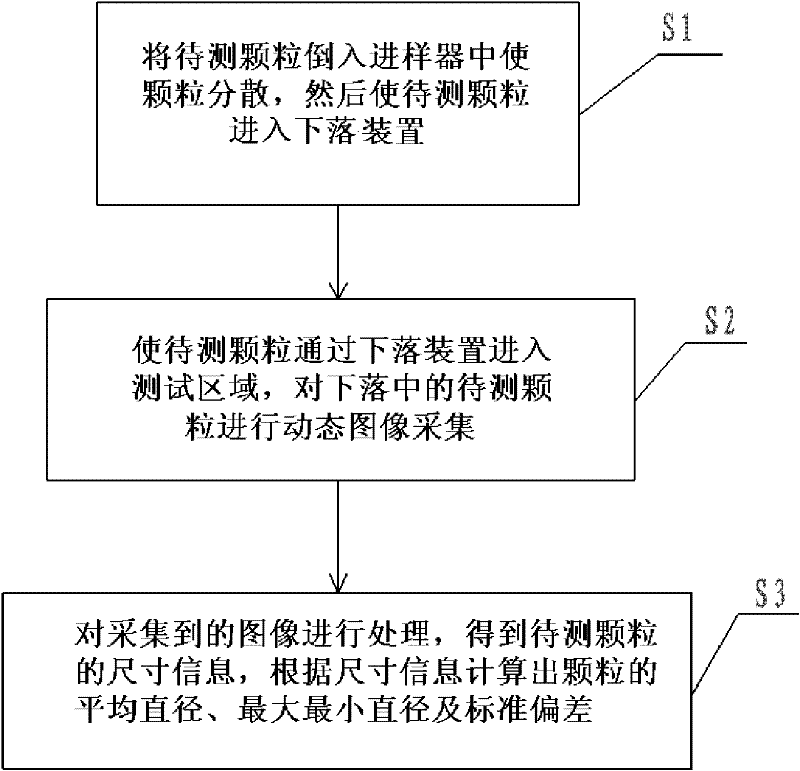

The invention discloses a measurement method for particle size, and relates to the technical field of high temperature gas cooled reactor fuel element preparing. The method comprises the following steps that: S1, particles requiring measurements are poured into a sample injector to be dispersed, then the particles requiring measurements enter a falling apparatus; S2, the particles requiring measurements enter a test area through the falling apparatus, followed by carrying out dynamic image acquisition for the particles during falling; S3, the acquired images are processed to obtain the size information of the particles requiring measurements. With adopting the method provided by the present invention to carry out the particle size measuring, the size information of different angles of the particles or the powders can be obtained through regulating image acquisition frequencies and carrying out repetitive measurements, such that the amount of the measured samples is large, and the measurement speed is quick. In addition, because the scope of the screen conditions is set to remove influence due to dust, the powders having no single dispersion state and the particles having no single dispersion state, the measurement accuracy is high.

Owner:TSINGHUA UNIV

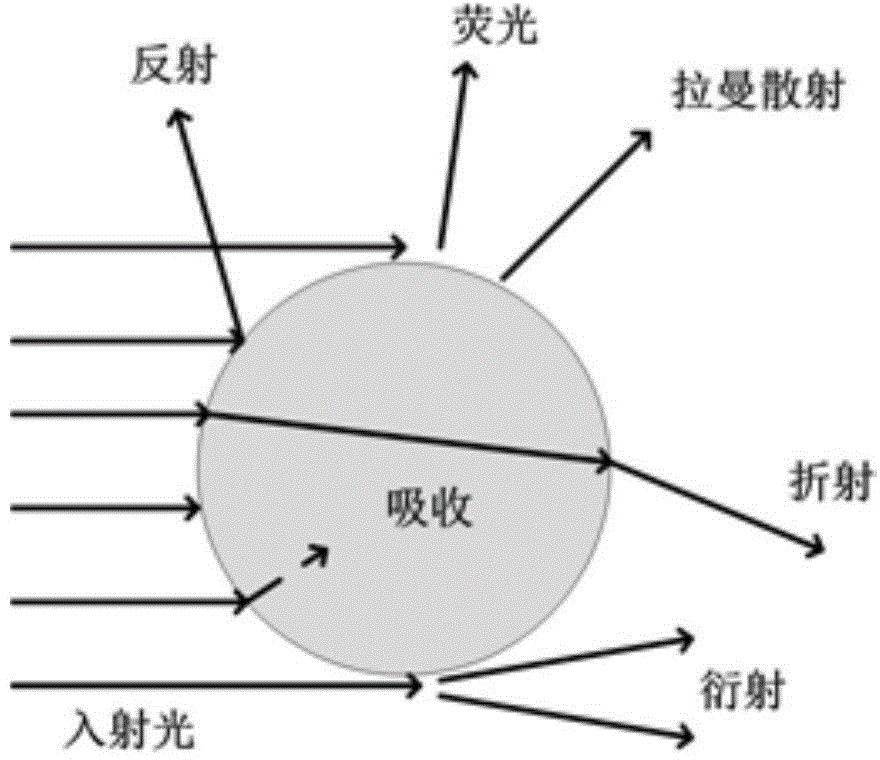

A real-time dual-wavelength optical aerosol particle size measuring device

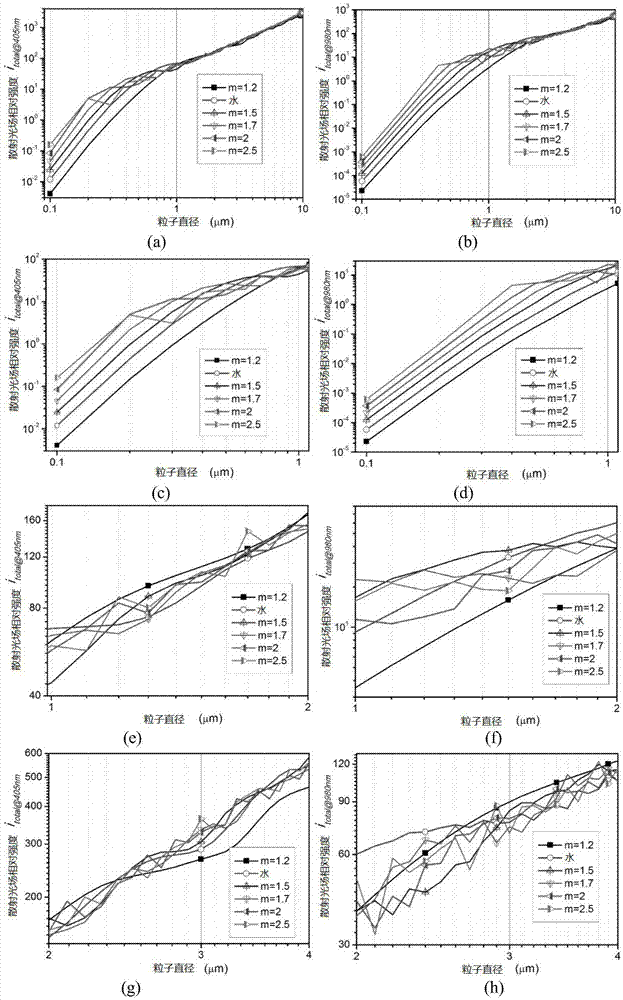

ActiveCN104764680AImprove particle size detection accuracyPrecise inversionParticle size analysisParticle size measurementRefractive index

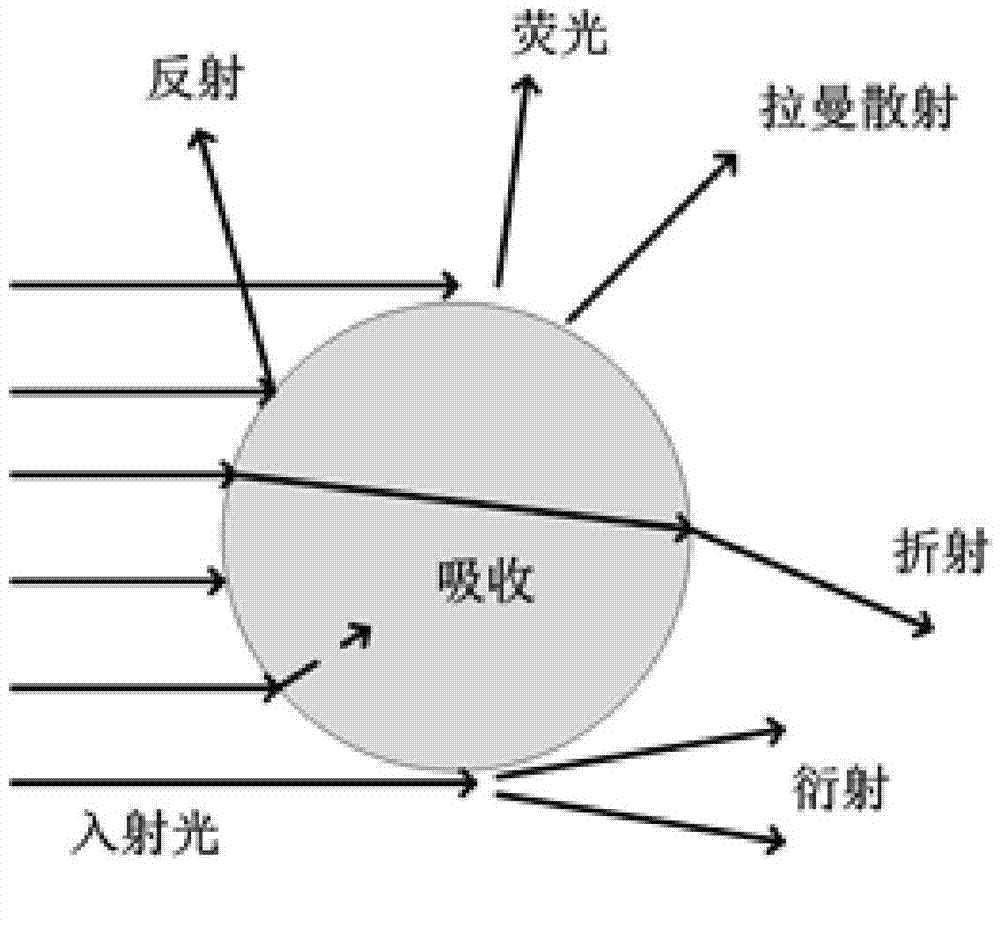

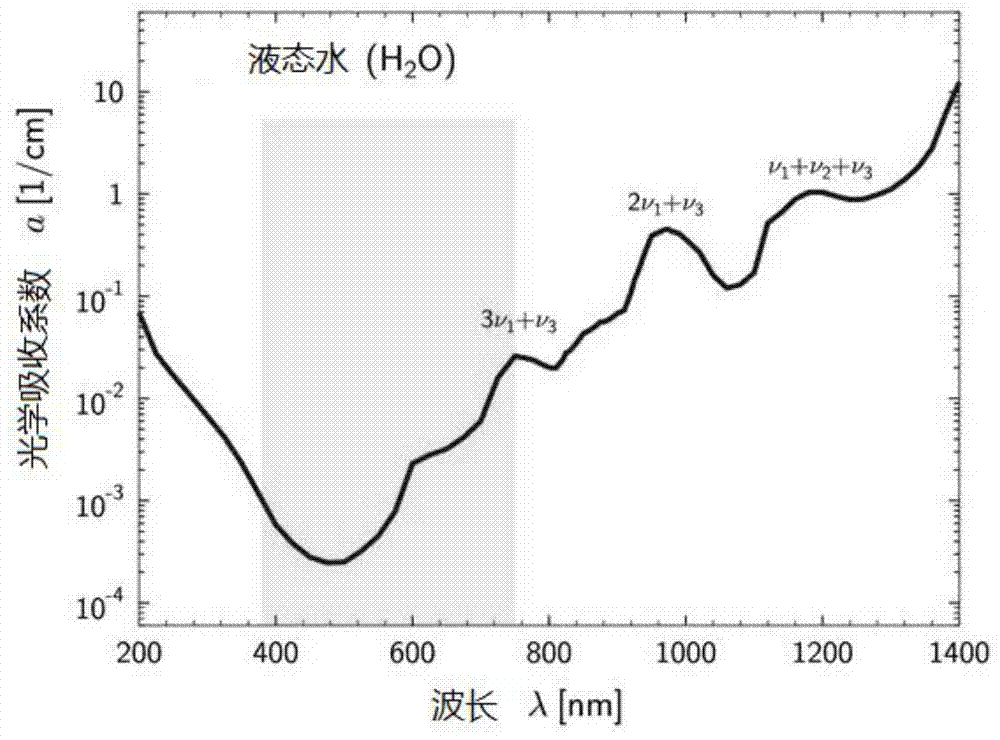

A real-time dual-wavelength optical aerosol particle size measuring device is disclosed. The device comprises a single-particle focusing gas path, two light intensity detecting units, two optical field distribution detecting units, a scattering cavity, a microcomputer control unit and a power supply system. The device reduces influences of the particle refractive index, environment humidity, and other conditions on measurement of the particle optical-equivalent grain size by a light scattering method, and can improve particle size measurement sensitivity and accuracy. The particle refractive index is calculated by adopting a front side scattering optical field distribution detecting unit, thus improving particle size measurement accuracy. The device can be combined with other aerosol particle measuring techniques to improve measurement accuracy.

Owner:上海镭慎光电科技有限公司 +1

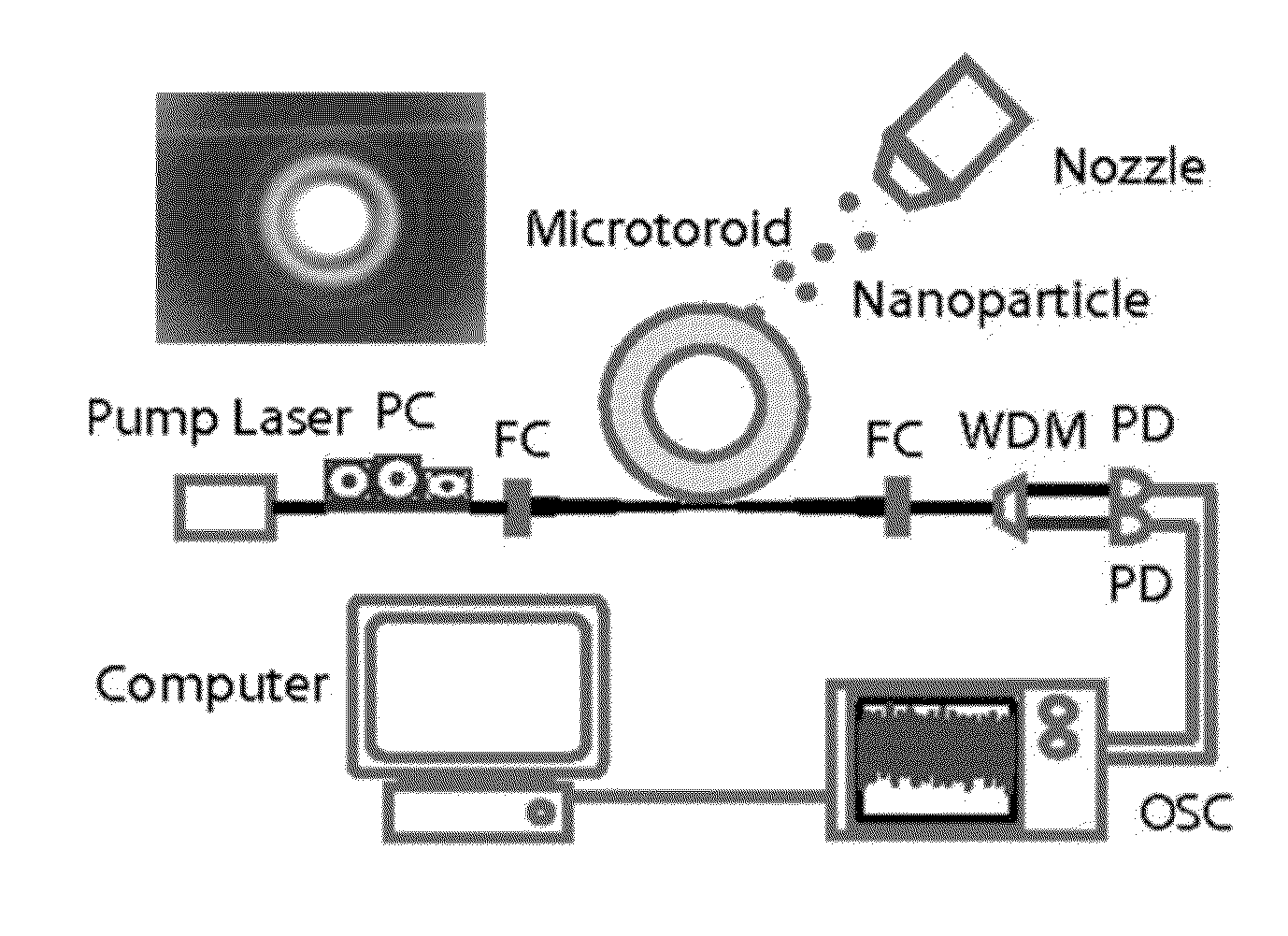

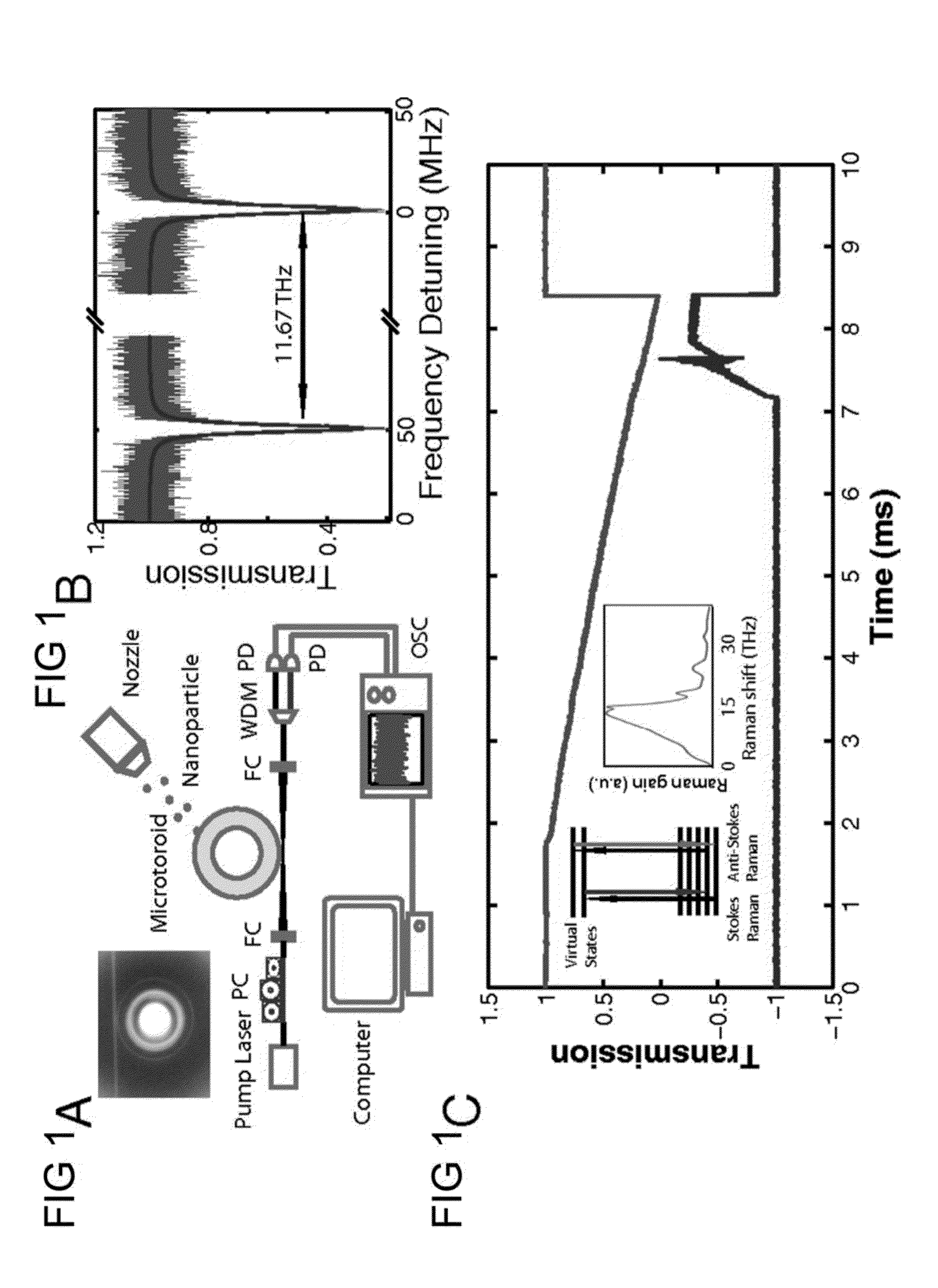

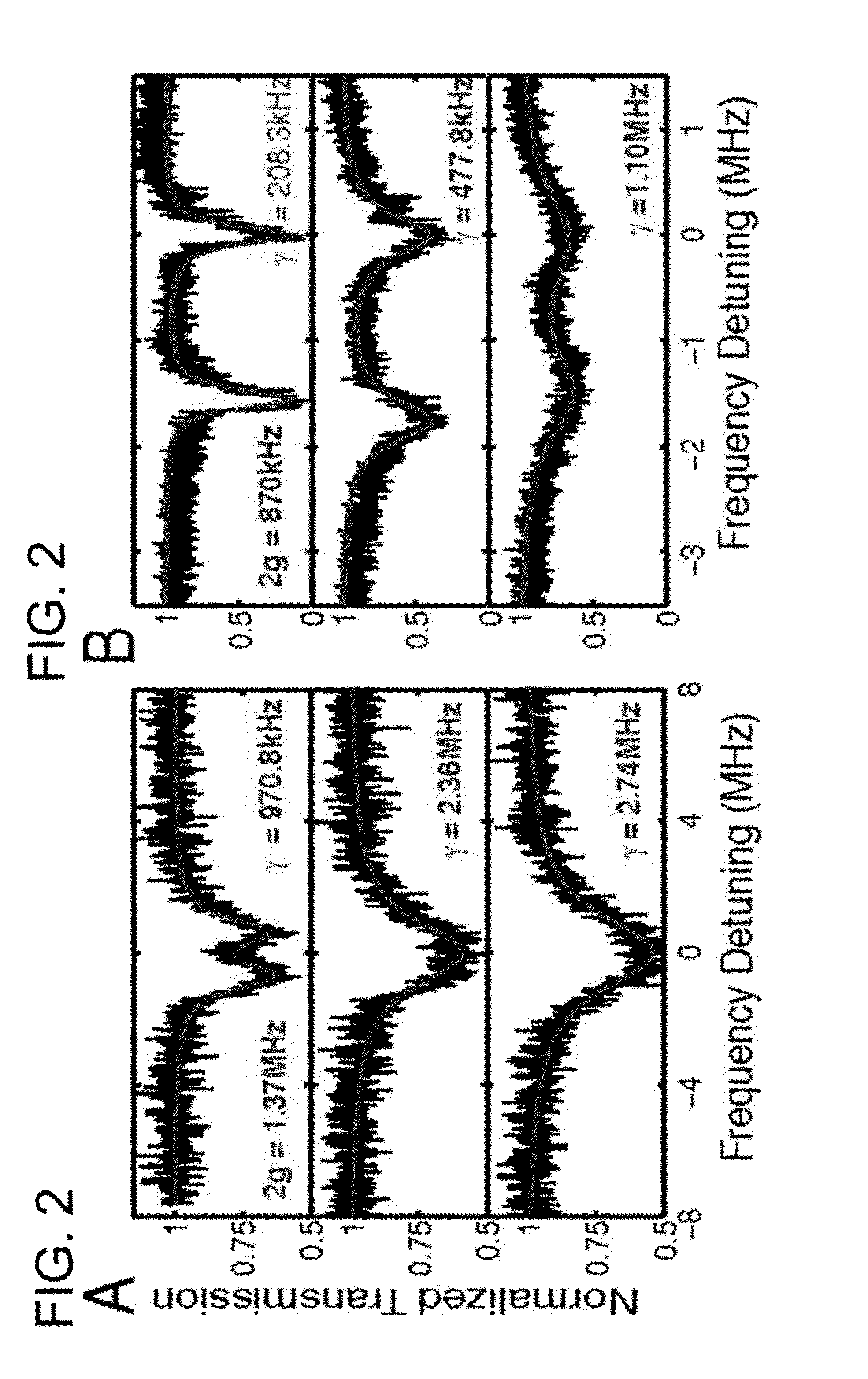

Detection of nano-scale particles with a self-referenced and self-heterodyned raman micro-laser

InactiveUS20150285728A1Maintain biocompatibilityEasy to useNanotechRadiation pyrometryWhispering galleryParticle size measurement

A system and method for is a micro-laser based nano-scale object detection system and method using frequency shift and / or mode splitting techniques. The system and method can provide highly sensitive detection of nanoparticles with a self-referenced and self-heterodyned whispering-gallery Raman micro-laser. The system and method also provides for nano-particle size measurement.

Owner:WASHINGTON UNIV IN SAINT LOUIS

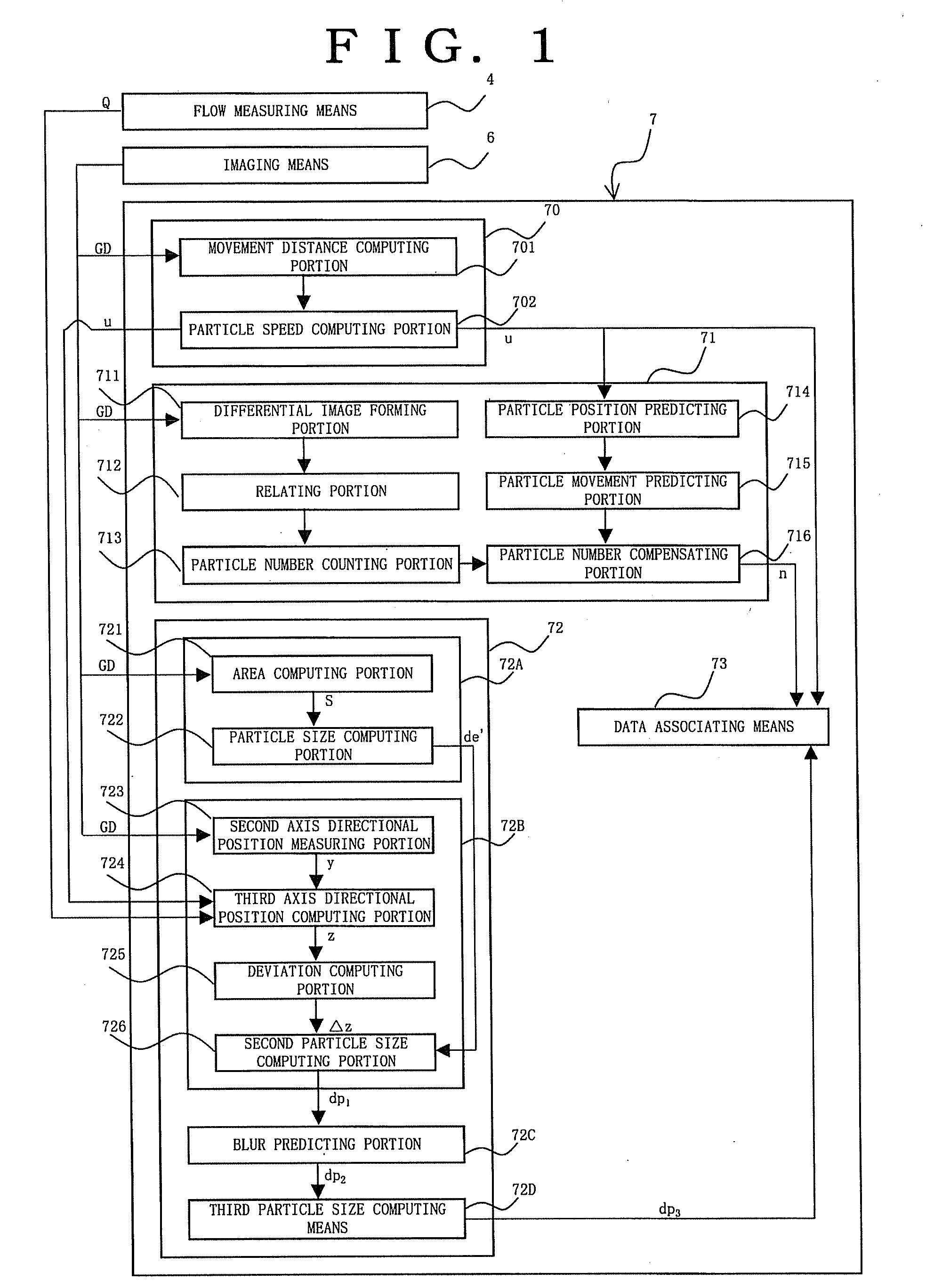

Particle measuring device and particle size measure device

InactiveUS20100110177A1Investigating moving fluids/granular solidsScattering properties measurementsParticle flowMeasurement device

Owner:KOWA CO LTD

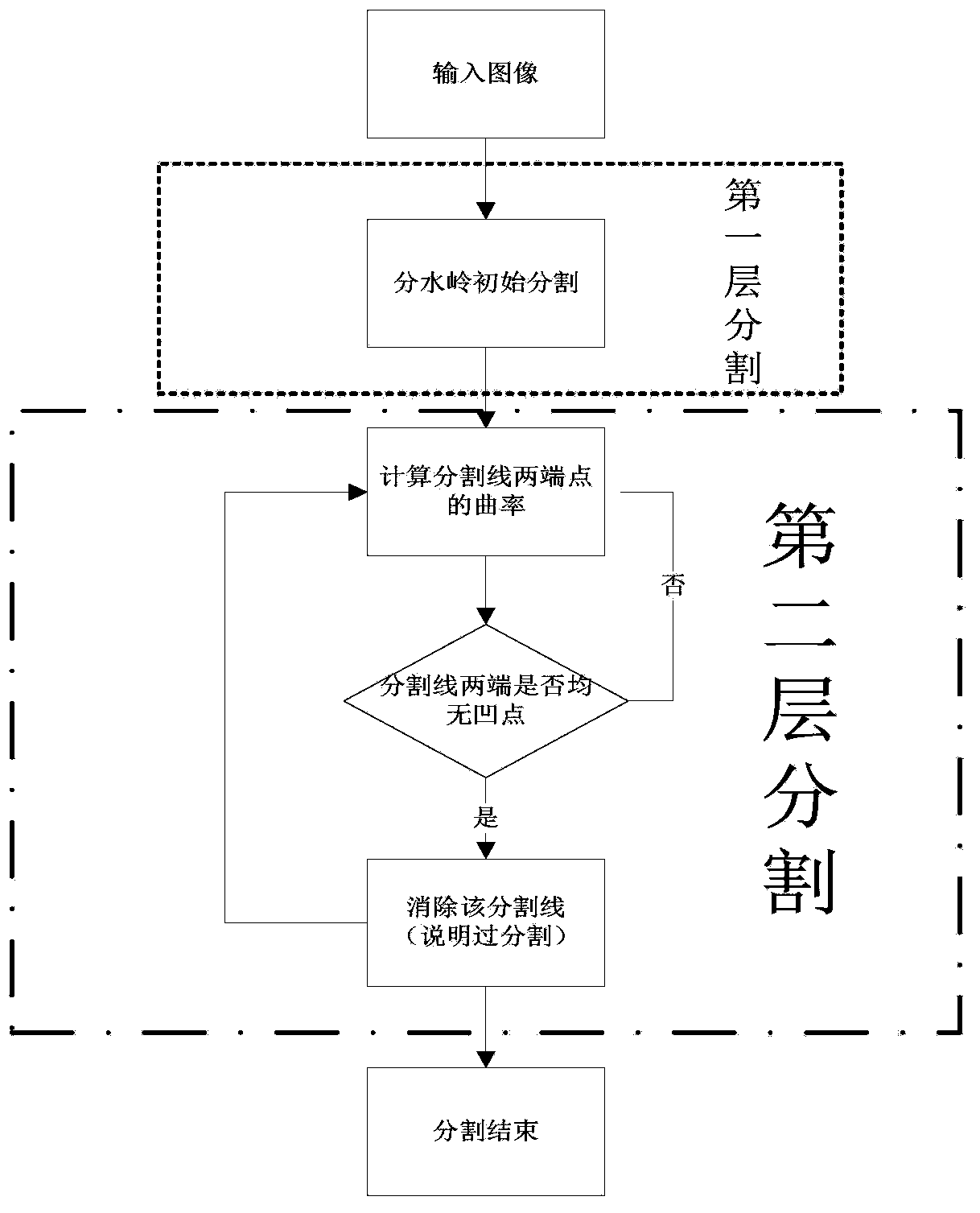

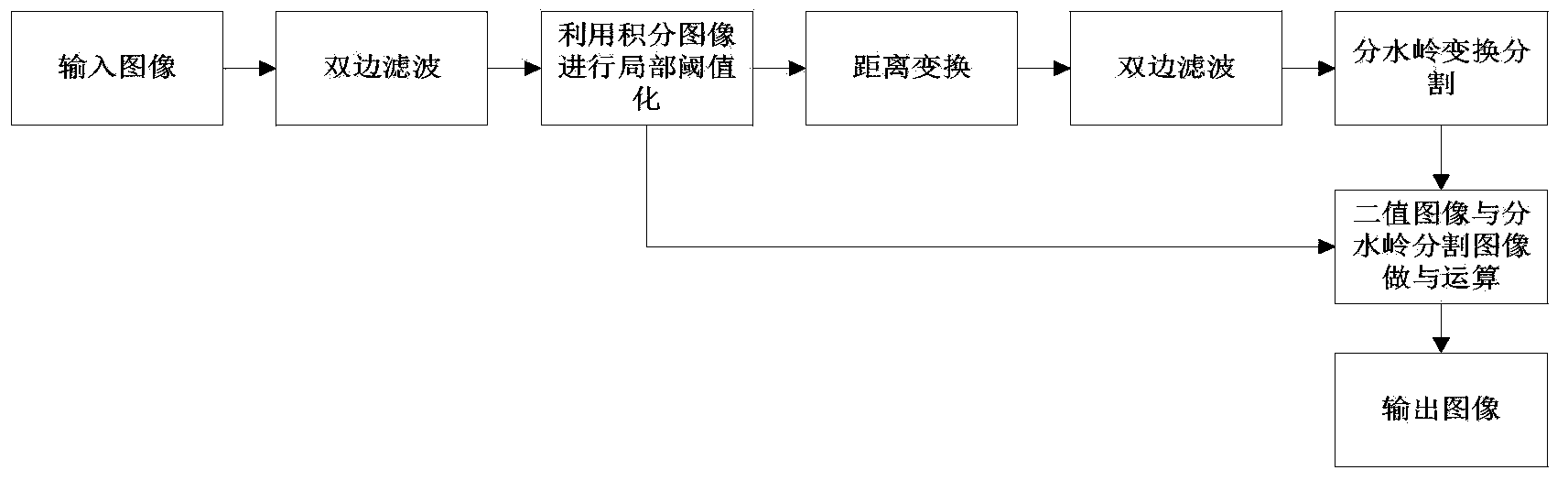

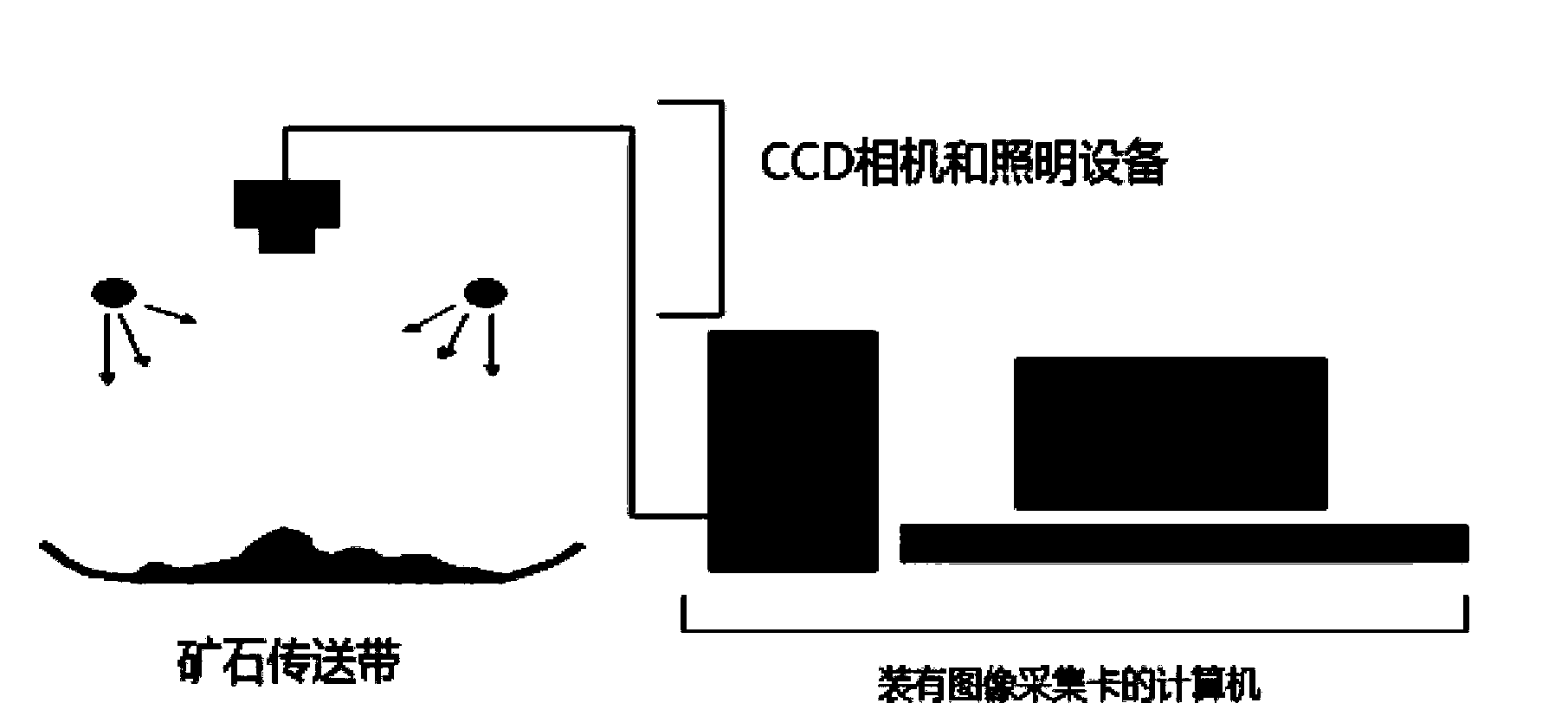

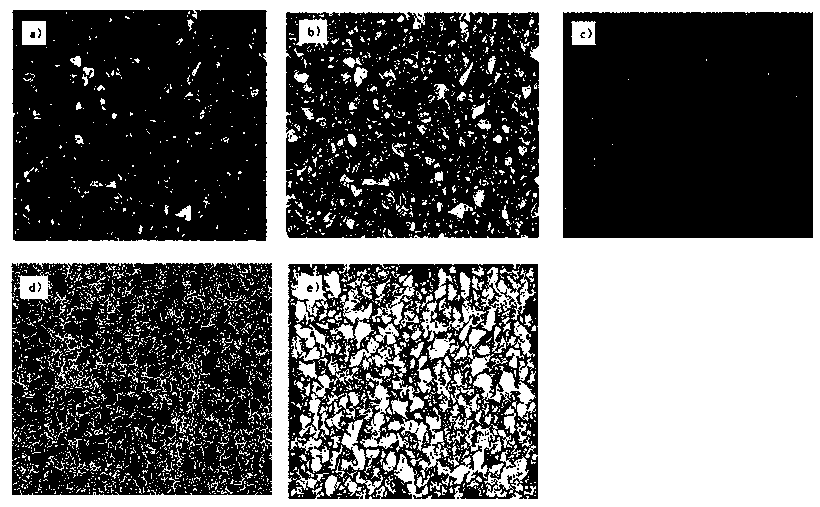

Ore particle size image segmentation method combining multi-feature and multi-level

InactiveCN103413290AResolve blurSolve the noiseImage enhancementImage analysisSplit linesParticle size measurement

The invention discloses an ore particle size image segmentation method combining multi-feature and multi-level. In the segmentation method, bilateral filtering and local self-adaptive thresholding based on an integral image are first carried out for an image. Then, filtering and distance transformation are carried out for a binary image. Finally, after watershed transformation, the image and a binary image are overlaid to obtain a first layer segmentation. After the first layer segmentation, by use of a characteristic that adhesion of two ores leads to the presence of pits, a proposed circular template method is used for detecting all the initially segmented segment lines. If two sides of a segment line are provided with pits, the segment line is retained; and the incorrect segment line is removed otherwise. By use of the brightness and shape feature of the ore image for double-deck segmentation, an ideal result is obtained and therefore higher reliability is provided for subsequent particle size measurements. The ore particle size image segmentation method combining multi-feature and multi-level has the advantages of wide application range, good real-time, high precision, easy installation and low cost.

Owner:BEIJING UNIV OF TECH +1

Particle-size measuring instrument

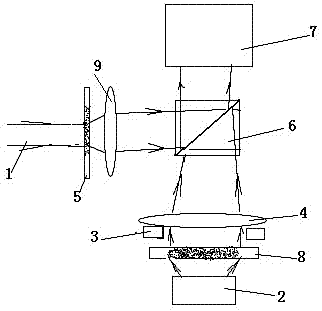

InactiveCN102207443AExpand the upper and lower limits of particle size measurementMeet the requirements of wide range particle size distribution measurementParticle size analysisLower limitMeasuring instrument

The invention discloses a particle-size measuring instrument. A laser light source, chromatic light illuminating light sources, a micro-objective lens, a semi-transparent and semi-reflecting mirror, an area array digital camera or a video camera, sample cells and a lens are combined into two light-path structures; in one light-path structure, light emitted from the first chromatic light illuminating light source irradiates on a sample in the first sample cell, an image magnified by the micro-objective lens is reflected to the area array digital camera or the video camera through the semi-transparent and semi-reflecting mirror; and in the other light-path structure, light emitted from the laser light source irradiates on a sample in the second sample cell, an image magnified by the micro-objective lens is reflected to the area array digital camera or the video camera through the semi-transparent and semi-reflecting mirror. The invention has the beneficial effects that various measuringmethods are integrated by utilizing the same digital camera, the upper and the lower limits for particle-size measurement of the particle-size measuring instrument are broadened by using a simple structure, so that the measurement range based on the particle-size measuring instrument disclosed by the invention can be from nanometer order to several-hundred micron order to meet the requirements for measurement of wide-range particle size distribution, and topography parameters of particles can be given by way of an image method.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

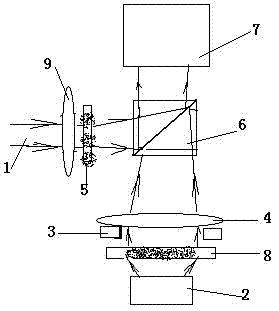

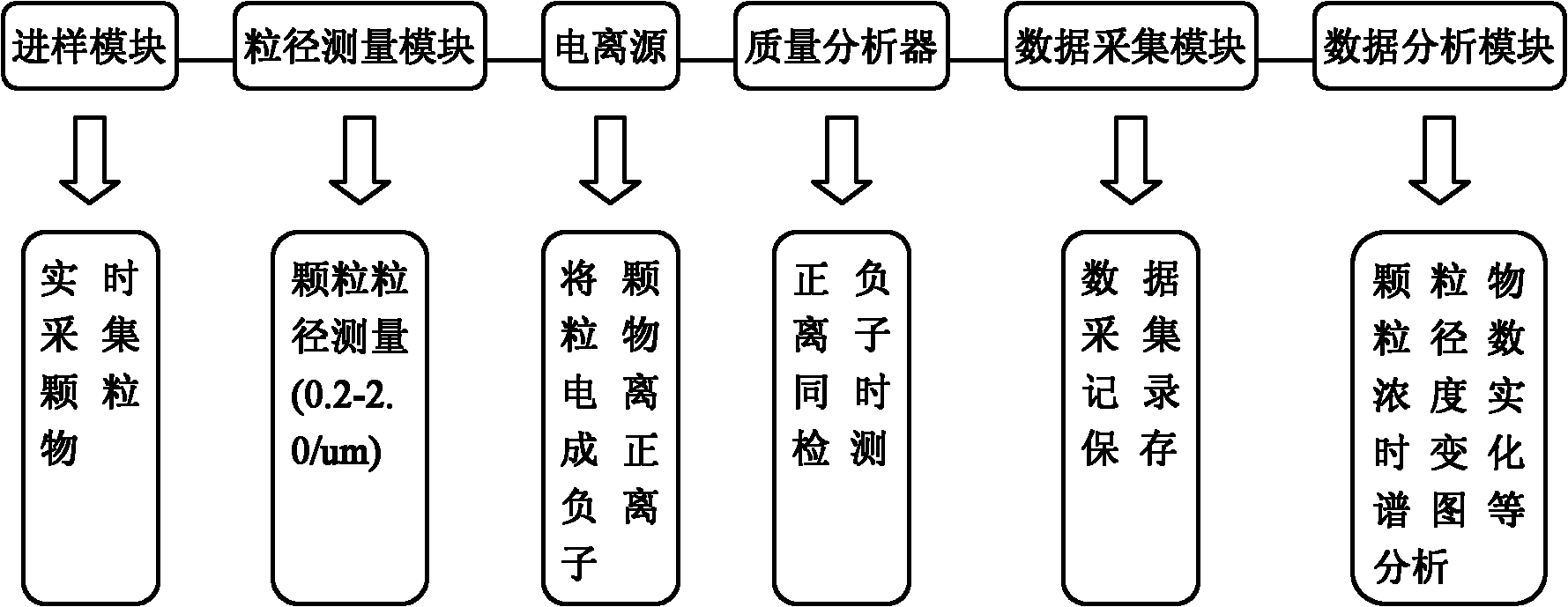

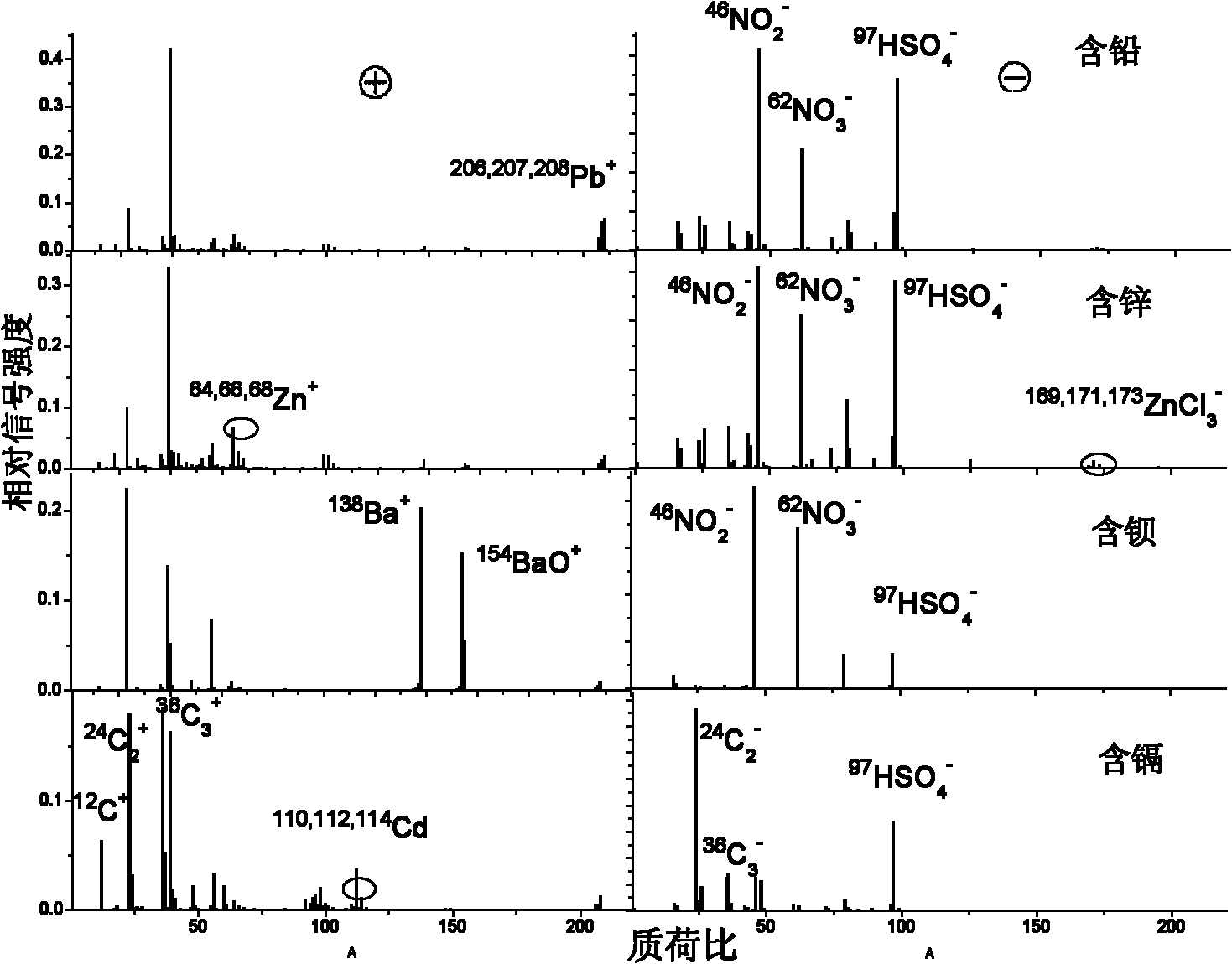

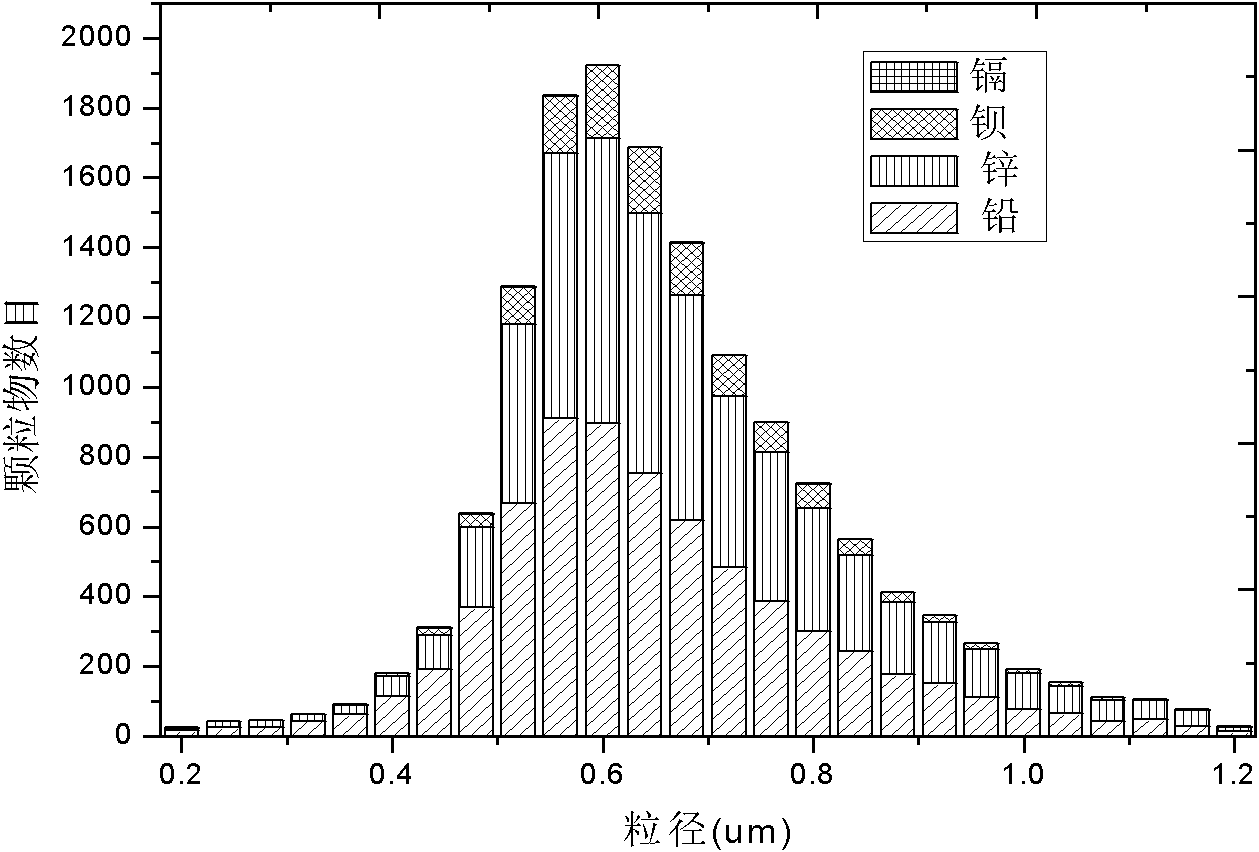

Method and device for detecting indoor heavy metal pollution by single particle aerosol mass spectrometry

InactiveCN102262039AAvoid Analytical ErrorsReal-time online collectionMaterial analysis by electric/magnetic meansParticle size analysisReal time analysisPolystyrene bead

The invention discloses a method and device for detecting indoor heavy metal pollution by single-particle aerosol mass spectrometry. The method is as follows: firstly, a polystyrene ball is used to perform a particle size calibration experiment on the instrument, and then a standard solution of known metal ions is used Carry out the mass number correction experiment. After the calibration is completed, use SPAMS to collect indoor atmospheric aerosols in different areas and heights in real time, and then use SPAMS to analyze and collect various parameters and status information of heavy metal particles in the samples in real time. The SPAMS in the device includes a sequentially connected sampling module, a particle size measurement module, an ionization source module, a mass analyzer module, a data acquisition module and a data analysis module. The invention can quickly, sensitively, accurately and real-time online detect the particle number concentration, particle size distribution, mass spectrum characteristics, mixing state, etc. of indoor heavy metal particles, and judge its possible source.

Owner:SHANGHAI UNIV +1

Device for detecting shapes of single aerosol particles in real time

ActiveCN104807738AReduce distractionsAvoid pollutionIndividual particle analysisLower limitAutomatic control

The invention discloses a device for detecting shapes of single aerosol particles in real time. The device comprises a single particle focusing gas path, a scattering cavity, a power supply system, two positioning trigger units, a scattering pattern detection unit and a microcomputer control processing unit. On the basis of characteristics of forward and lateral scattered light fields of the particles and in combination of related information of particle size measurement, the device judges the shapes of the particles, the detectable lower limit of particle size is increased, and the accuracy in actual application is high; with the adoption of the scattering cavity design, the structure is simpler, the stability is high, and assembling and debugging of optical systems are easy; in combination of the single particle aerodynamics focusing gas path technology as well as automatic control of the microcomputer control system, the single aerosol particles are detected in real time.

Owner:上海镭慎光电科技有限公司

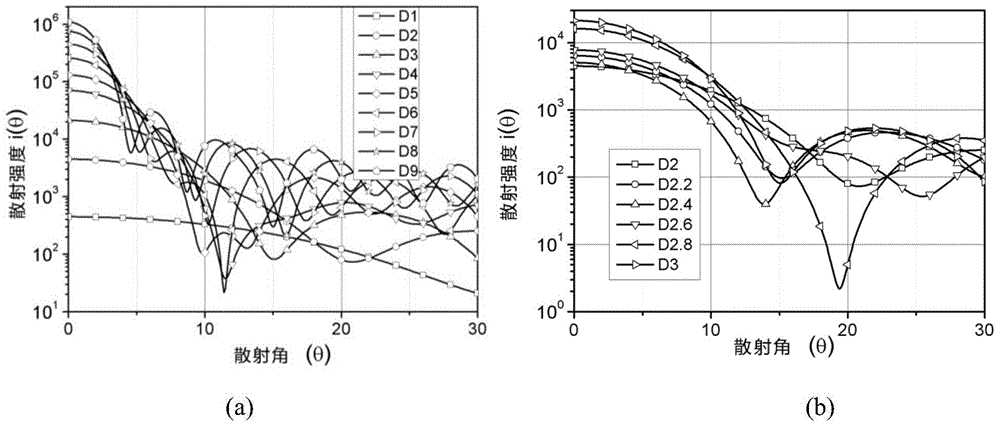

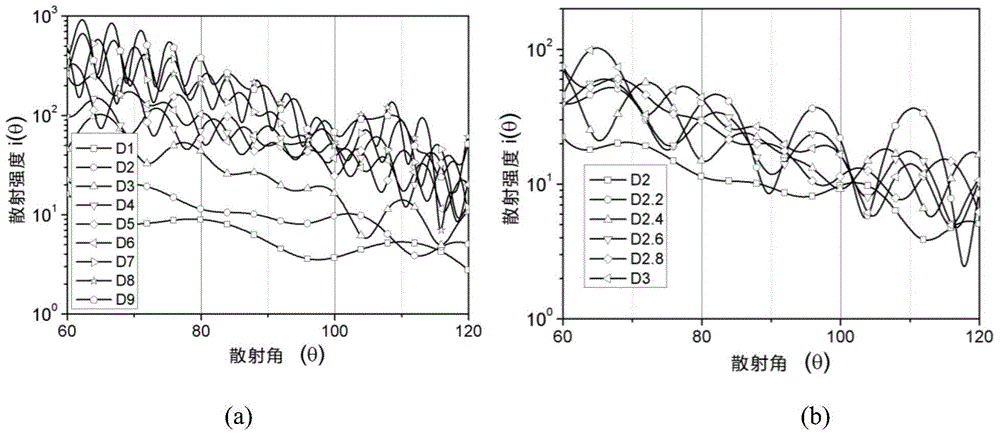

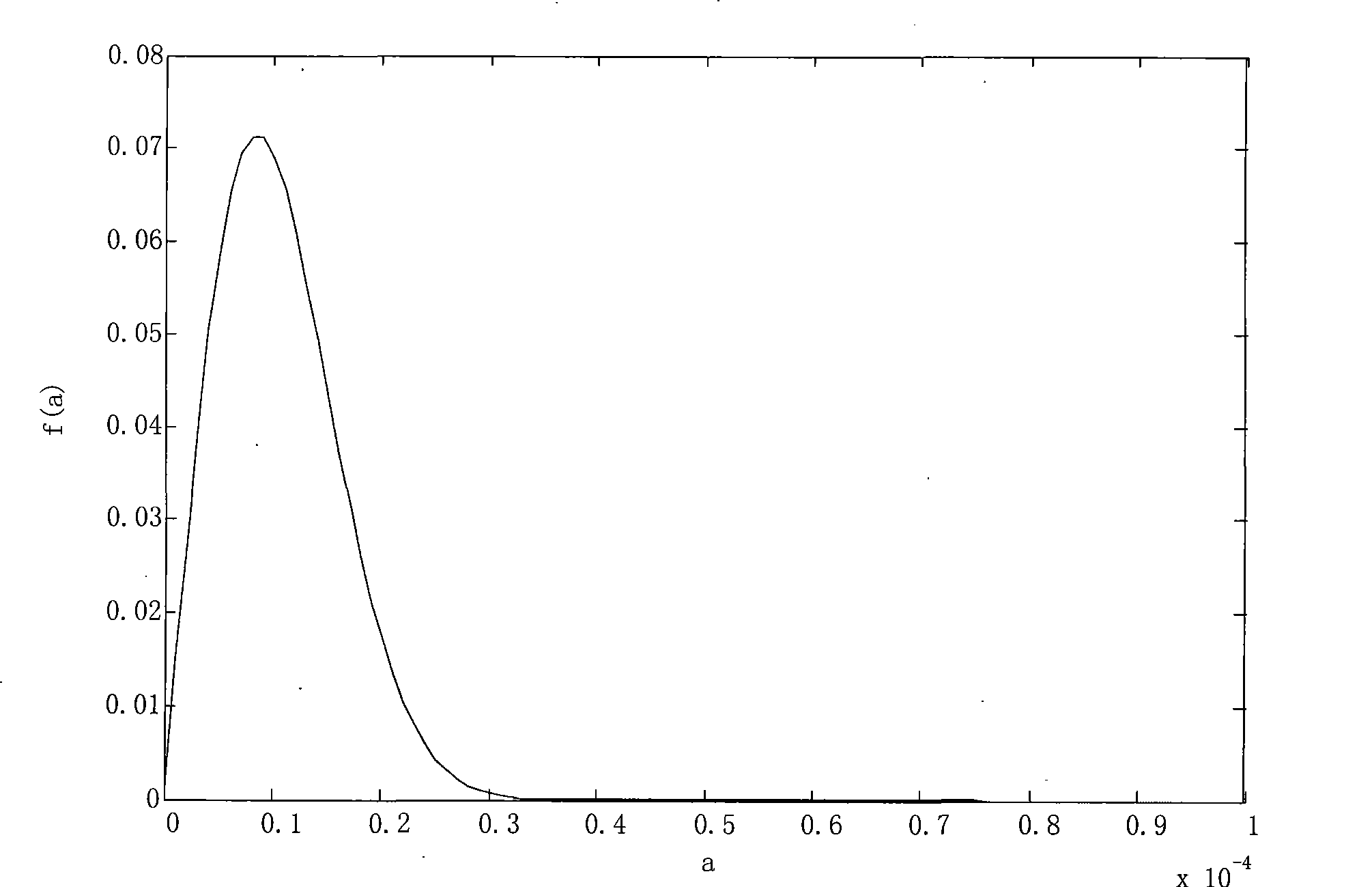

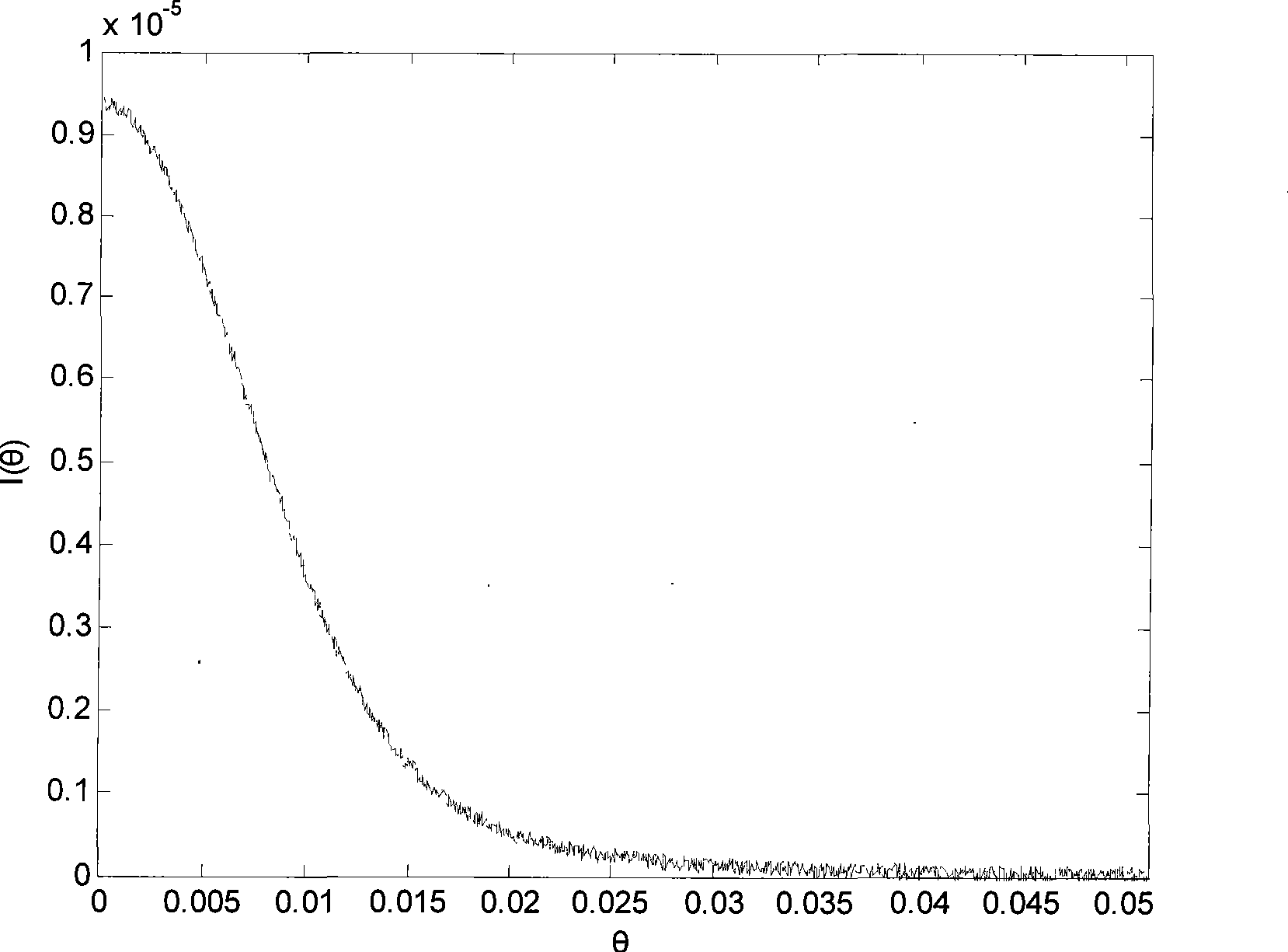

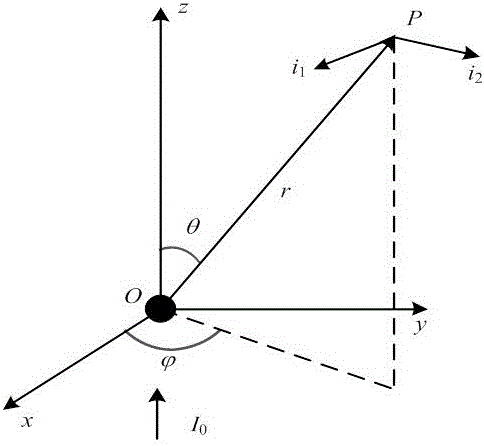

Integral inverse-calculation method for grain diameter measurement

ActiveCN101430268AReduce shockParticle size analysisComplex mathematical operationsLow-pass filterParticle size measurement

The invention relates to a particle size measurement integral inversion arithmetic which is characterized by comprising the steps as follows: (1) particle group diffraction light distribution I(theta) with the particle size parameter distribution of f(x) is obtained by measuring; (2) an inversion expression of a double-integral form is obtained by analytic solutions of Hankel transform and Scholmilch equation; (3) the equation obtained in step (2) is carried out discretization treatment by a Gauss interpolation method; and (4) Gauss interpolation coefficient and interpolation node are substituted in a formula after the discretization treatment in step (3) to obtain the particle size distribution f(x). The integral inversion arithmetic is adopted, and internal integral is equal to a lowpass, thereby reducing the influence of noise on a measurement signal; and the new arithmetic only contains one Bessel function, so that the oscillation is reduced obviously.

Owner:安徽欧泰祺智慧水务科技有限公司

Blast furnace burden particle size monitoring system and distributed data on-line analysis method

The invention discloses a blast furnace burden particle size monitoring system and a particle size distributed data on-line analysis method. Imaging equipment of the system comprises at least one industrial video camera. Lighting sources are obliquely arranged downwards in the opposite directions at the positions lower than the imaging equipment by 0.4-0.5m so that low-angle lighting can be realized. The luminous flux is 40000+ / -5%LM, the color temperature is 5500-6000K, and accordingly field images can be collected clearly. By matching the particle size distributed data on-line analysis method, the images collected at site are sequentially subjected to denoising, balancing, smoothing, reinforcement, sharpening, self-adaption threshold value binaryzation and corrosion and dilation operation, so that the particle size and lump number information of the burden fed into a blast furnace is obtained. The monitoring system is adopted to be matched with the image analysis method so that particle size measurement can be realized, and the accuracy and speed are high. The particle size and lump number information and other information are automatically acquired in an online mode in real time, the varieties of materials are matched automatically, and manpower and material resources are effectively reduced.

Owner:天津市三特电子有限公司

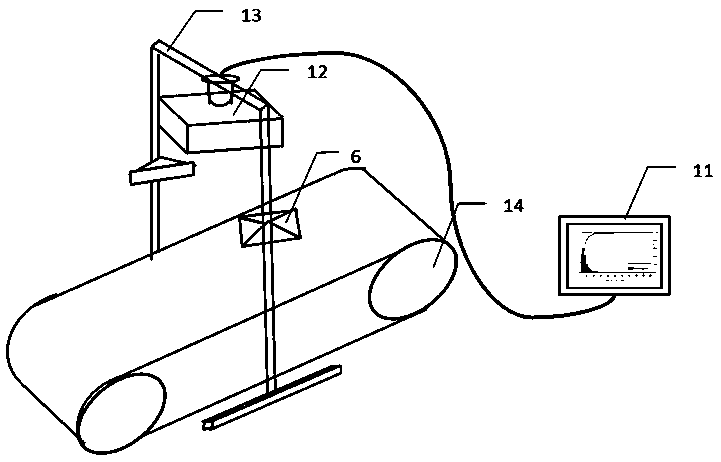

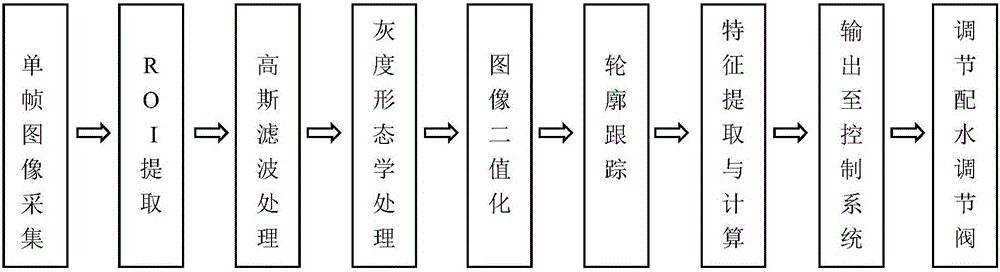

A machine vision-based material granularity on-line detection method

ActiveCN109598715ARealize the designEliminate Particle Size Measurement ErrorsImage enhancementImage analysisVisual technologyMachine vision

The invention relates to the technical field of machine vision. The machine vision based material particle size online detection method comprises the steps that image information of material particleson a conveying belt is collected through a camera, distance information of the material particles on the conveying belt is collected through a distance measuring module, and a particle size distribution diagram of materials is obtained by conducting image analysis on the collected image information through a computer. According to the method, a particle segmentation algorithm based on convex hullanalysis is adopted, whether particles are under-segmented particles or not is judged by detecting the convexity rate of the particles, the under-segmented particles are subjected to secondary segmentation, sticky particles in an image are distinguished, and therefore algorithm design of real-time on-line detection of particle size distribution of materials on a conveying belt is achieved. A distance measuring module is further added, and measured distance values are substituted into a pixel calibration algorithm to eliminate particle size measurement errors caused by thickness changes of materials on a belt.

Owner:山西镭谱光电科技有限公司

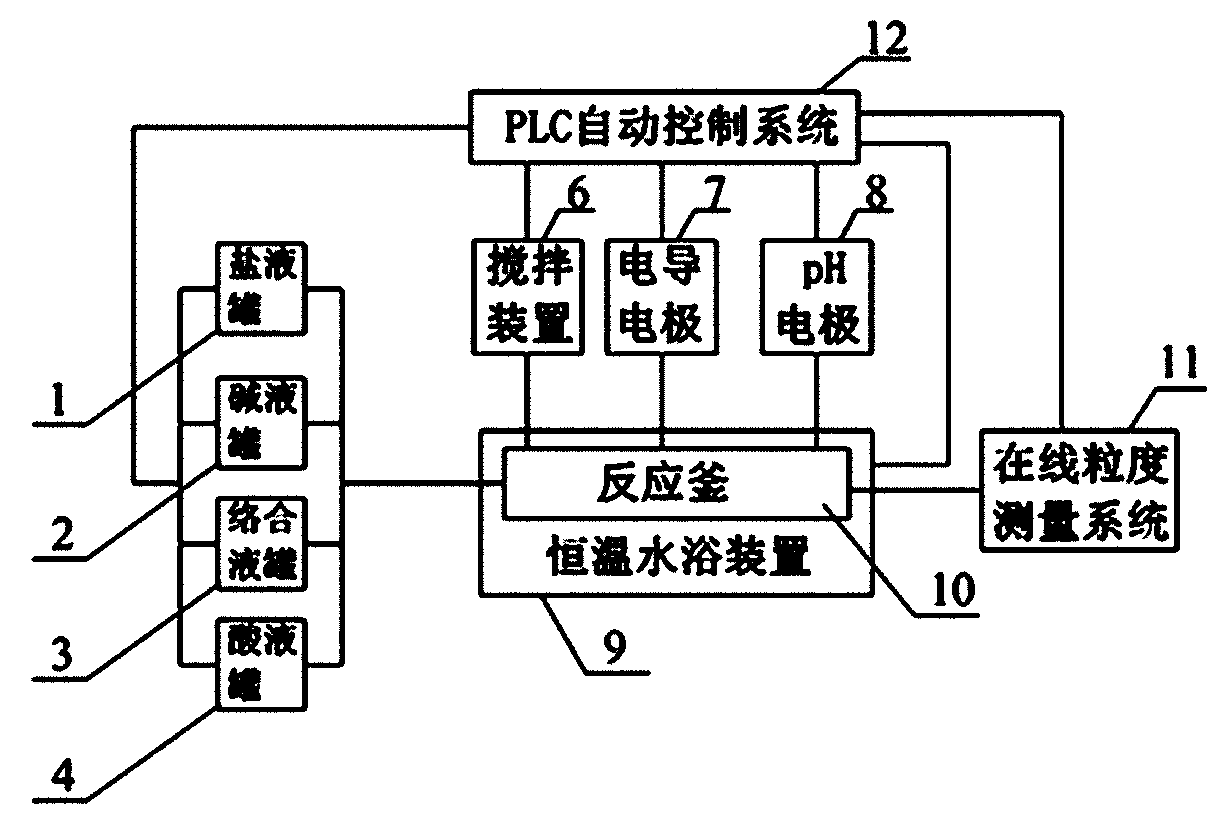

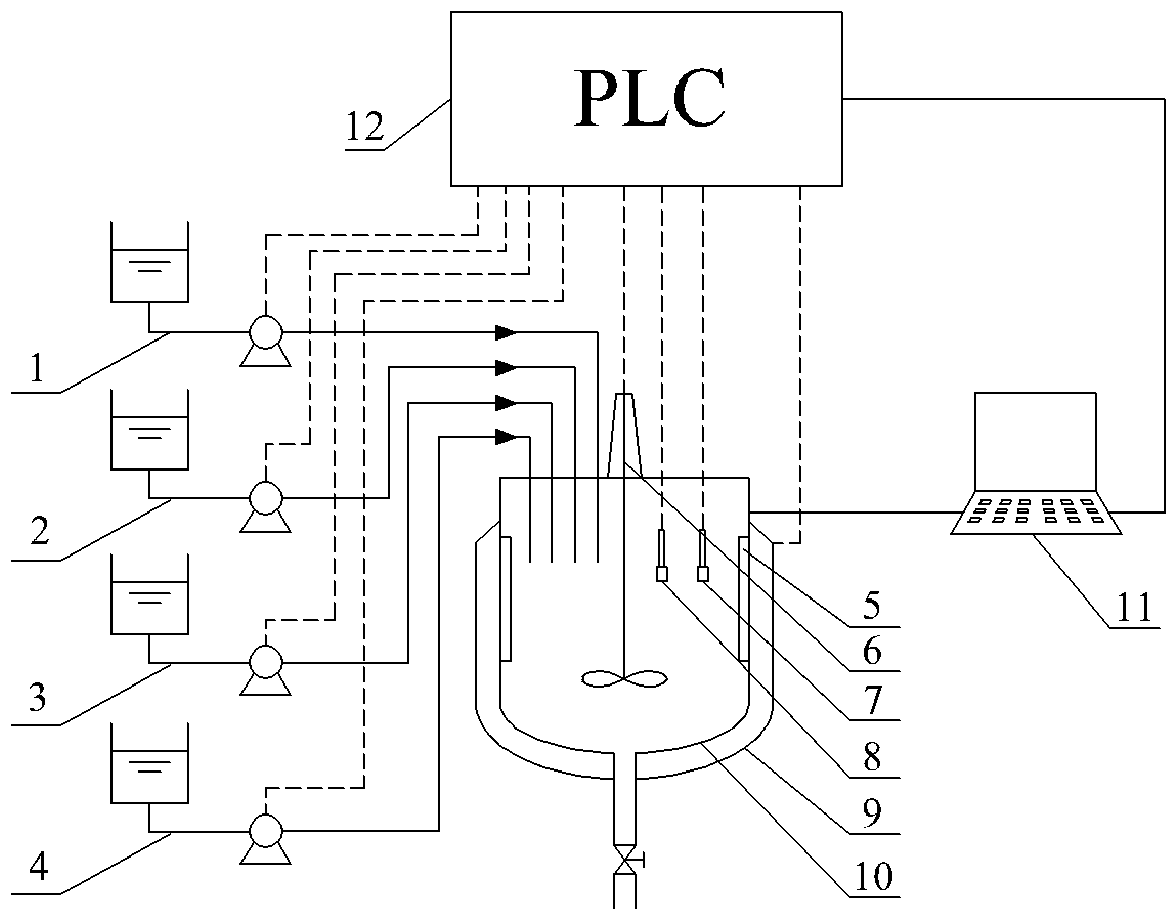

Efficient and intelligent reaction crystallization device

InactiveCN107855088AQuality assuranceGood lookingProcess control/regulationSolution crystallizationWater bathsAutomatic control

The invention discloses a device capable of controlling reaction crystallization process efficiently, intelligently and accurately. The device comprises a main device reaction kettle, a constant temperature water bath device is mounted on the outer side of the main device, a feeding device is mounted on the upper portion of the main device, a stirring device, a pH electrode and a conducting electrode are mounted on the upper portion of the main device; the constant temperature water bath device, the feeding device, the stirring device, the pH electrode, the conducting electrode and the like are connected with a programmable logic controller PLC automatic control system to realize automatic intelligent control, simultaneously particle sizes of the products are in real-time monitored by a on-line particle size measurement system. The device is simple and clear in whole structure, fully automatic measurement, feedback and control during the reaction crystallization process are realized, manual operating cost and manual operating errors are reduced to make the reaction crystallization process perform in a setting reaction condition all the time, accordingly quality and stability of thedesired products are guaranteed.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

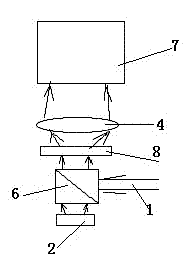

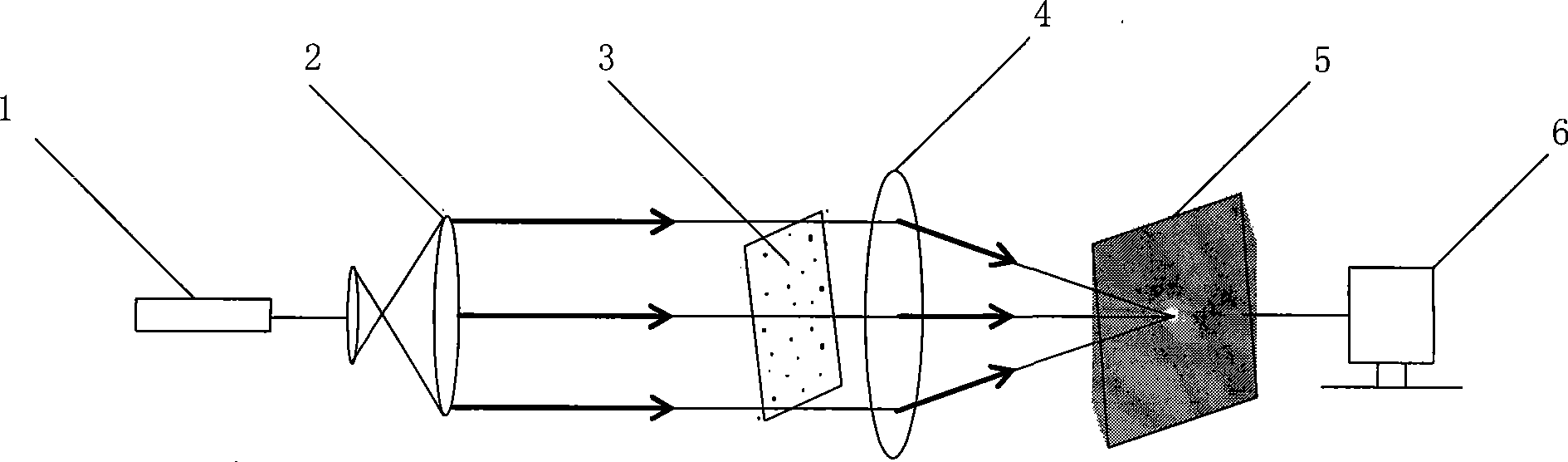

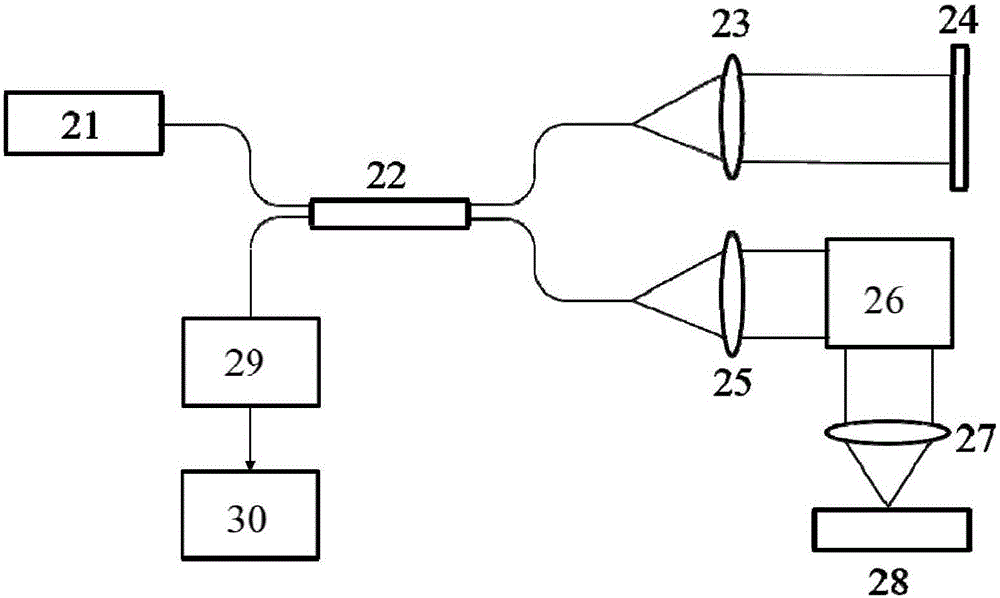

Nano-particle size measurement device and method

ActiveCN104568683AEasy to handleReduced measurement timeParticle size analysisCorrelation coefficientParticle size measurement

The invention discloses a nano-particle size measurement device and method. The device consists of a laser source, a sample cell, lenses, an area array photosensitive device and a computer, wherein laser beams emitted by the laser source irradiate nanoparticles in the sample cell after being converged, dynamic light scattering signals are generated by the particles performing Brownian movement in the sample cell under the irradiation of incident laser, and are converged after passing through the second lens, the area array photosensitive device arranged on the focal plane of the lens performs recording at a time interval of Deltatau to obtain two dynamic light scattering signal images of movement of the nanoparticles, and transmits the images to the computer, and the computer calculates a correlation coefficient of the two images by adopting a correlation algorithm, and determines the particle size of the nanoparticles according to the correlation coefficient. The device and the method have the benefits that measurement time is greatly shortened, and can reach the microsecond level, a data processing process is simple and low in time consumption, and the total measurement time can be millisecond or microsecond time.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

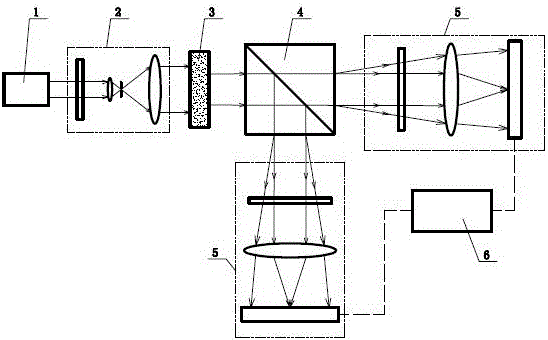

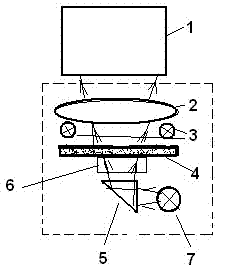

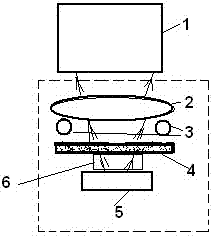

Optical detection method and optical detection system for particle morphology

PendingCN106248532AAvoid overlappingRapid refactoringUsing optical meansMaterial analysisMicro imagingParticle size measurement

The present invention discloses an optical detection method and an optical detection system for particle morphology. The method comprises: dispersing particle samples, obtaining the position information of the particles in a three-dimensional space by combining a low coherence interferometry measurement method and a microscopic imaging method, and extracting the morphological information of the analyzed particle, wherein the distribution positions of the dispersed particles along the optical axis direction are determined by using the low coherence interferometry measurement method, and the distribution positions of the dispersed particles in the plane perpendicular to the optical axis are obtained by using the microscopic imaging method. The system comprises a particle dispersing device, a low-coherence interferometry and microscopic imaging combined imaging measurement device, and a processor. According to the present invention, the operation is simple and effective, the distribution position information of the particles in the three-dimensional space can be provided, the overlapping effect of the particles with different depths in the two-dimensional image based on the image microscopic particle size measurement can be avoided, the particle measurement error is substantially reduced, and the method and the system can be used for the high precision particle morphology measurement in industrial production and scientific research.

Owner:ZHEJIANG UNIV

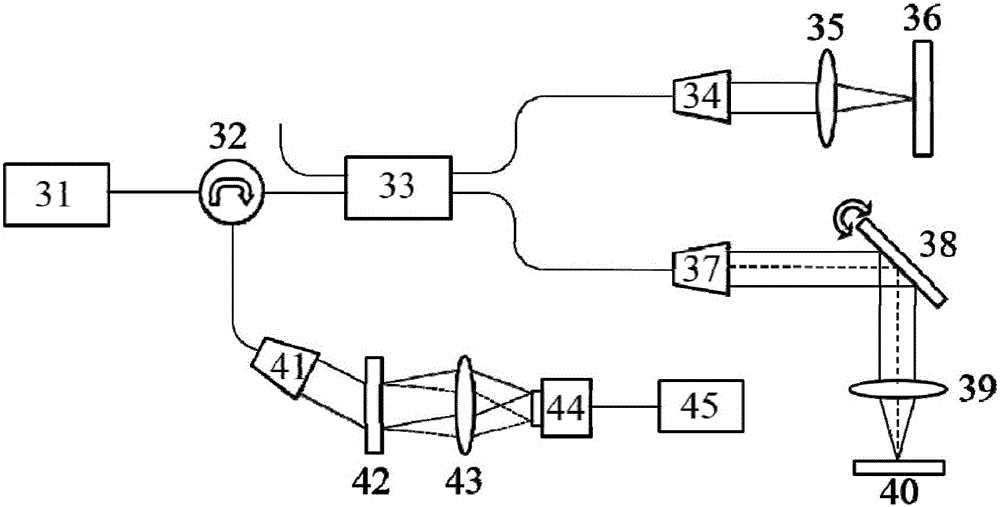

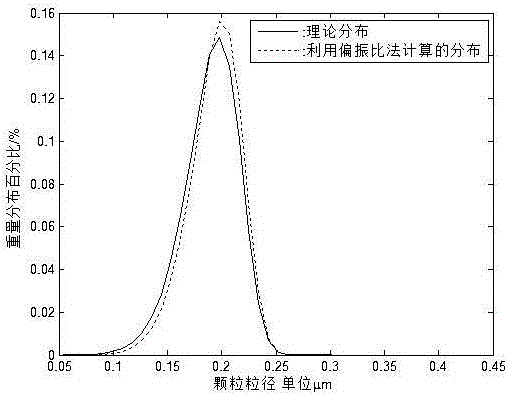

Particle size detecting device and method

InactiveCN105891066AImprove Particle Size Measurement ReliabilityReduce manufacturing costParticle size analysisChemical physicsParticle size measurement

The invention provides a particle size detecting device and method and relates to the technical field of tests. The device comprises a light source, a modulation unit, a sample cell, a light splitting prism, screening and converting units and a calculation unit, wherein the screening and converting units screen out scattered light components parallel with and perpendicular to a scattering surface and convert the scattered light components into light energy data, inversion calculation is performed, and particle size distribution information is solved. The particle size detecting device solves technical problems that particle size detecting devices in the prior art are complex in structure, inconvenient to operate and high in use cost. The particle size detecting device and method have the beneficial effects as follows: particle size inversion is performed according to the ratio of the two scattered light components, thus effects of air and scattered particles in a light path are effectively reduced, and the particle size measurement reliability is improved; the device is simple and reasonable in structure, low in manufacturing cost, simple to operate, convenient to carry and suitable for online detection.

Owner:CHINA JILIANG UNIV

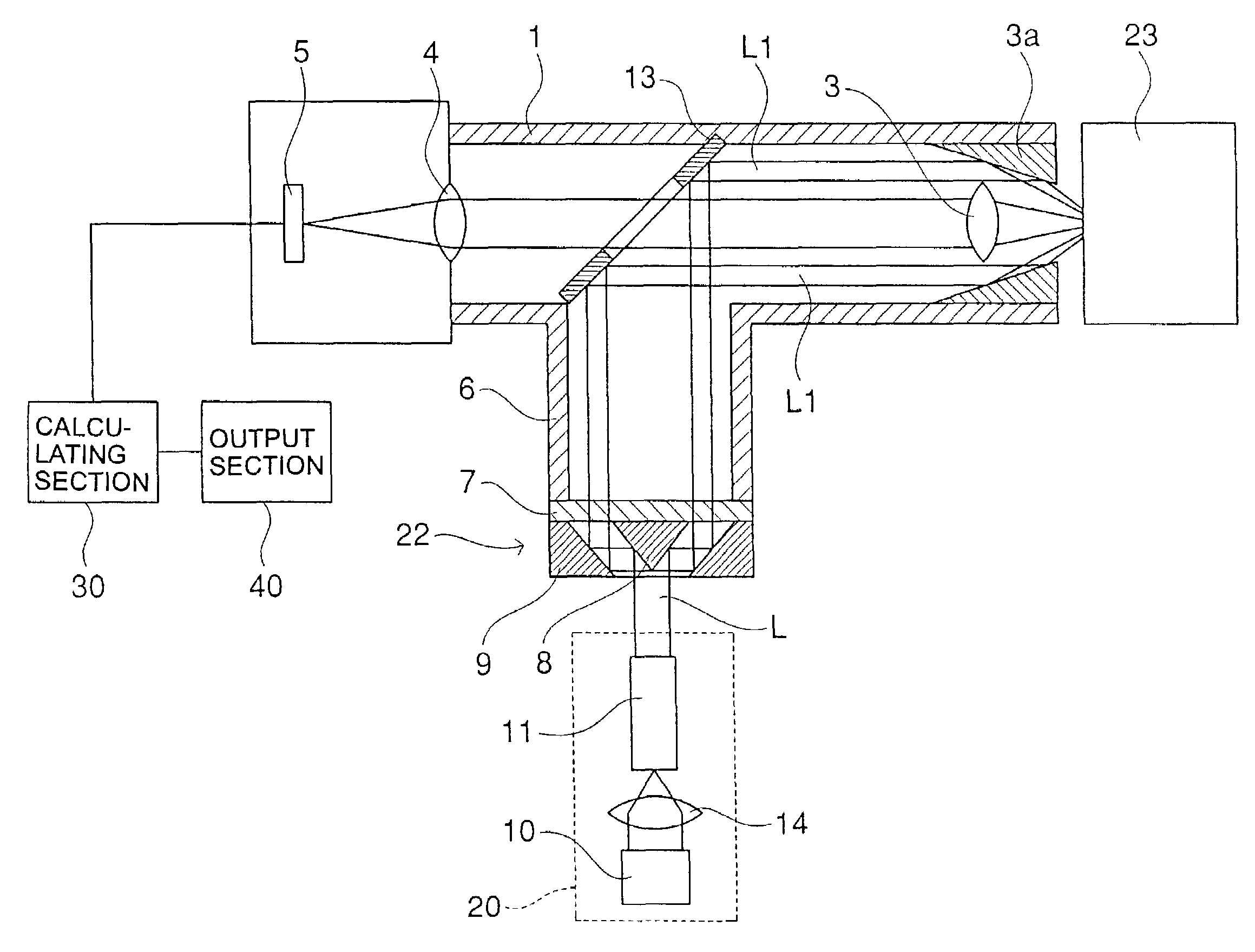

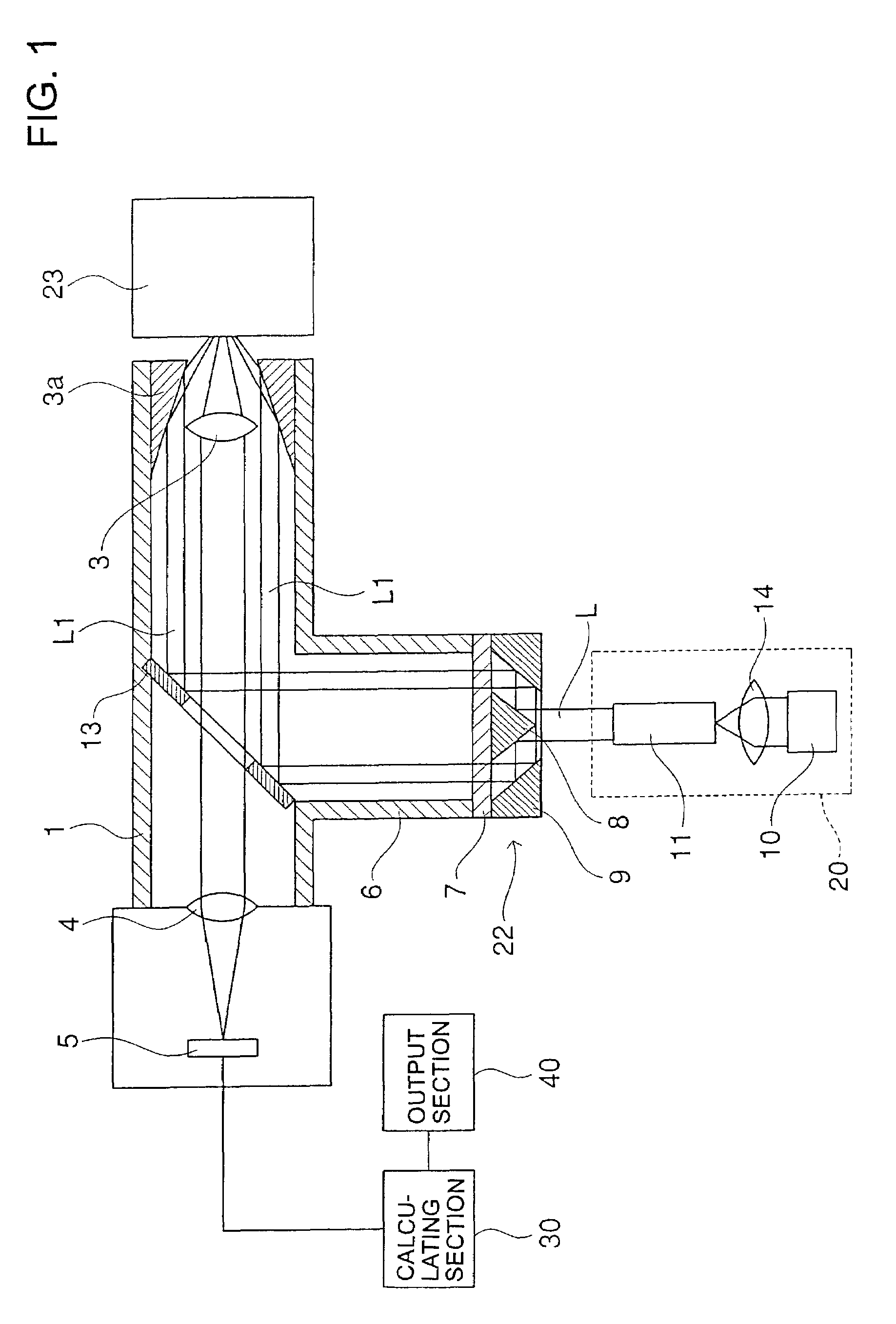

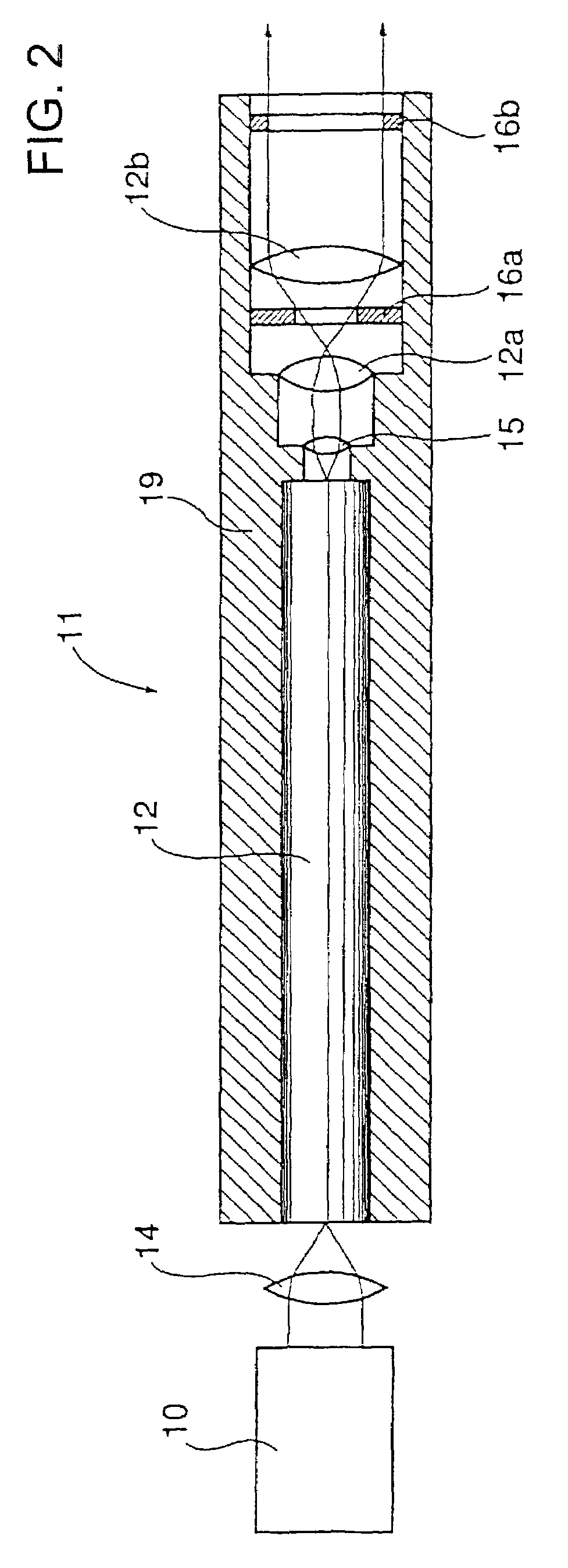

Apparatus and method for measuring particle size

InactiveUS6999171B2Easy to measureReduce coherenceParticle size analysisParticle size measurementLaser light

A particle size measuring apparatus includes a laser light source; a coherence reducing element for receiving laser light emitted by the laser light source, reducing coherence of the laser light and emitting the laser light whose coherence is reduced; a ring light forming section for converting the light emitted by the coherence reducing element into ring light; an internal reflection mirror for concentrating the ring light on a particle to be measured and illuminating the particle; an object lens for receiving scattered light from the illuminated particle inside the ring light; a photoreceptive element for receiving the scattered light through the object lens; and a calculating section for calculating a size of the particle from the intensity of the scattered light obtained by the photoreceptive element by using a monotone increasing function.

Owner:SYSMEX CORP

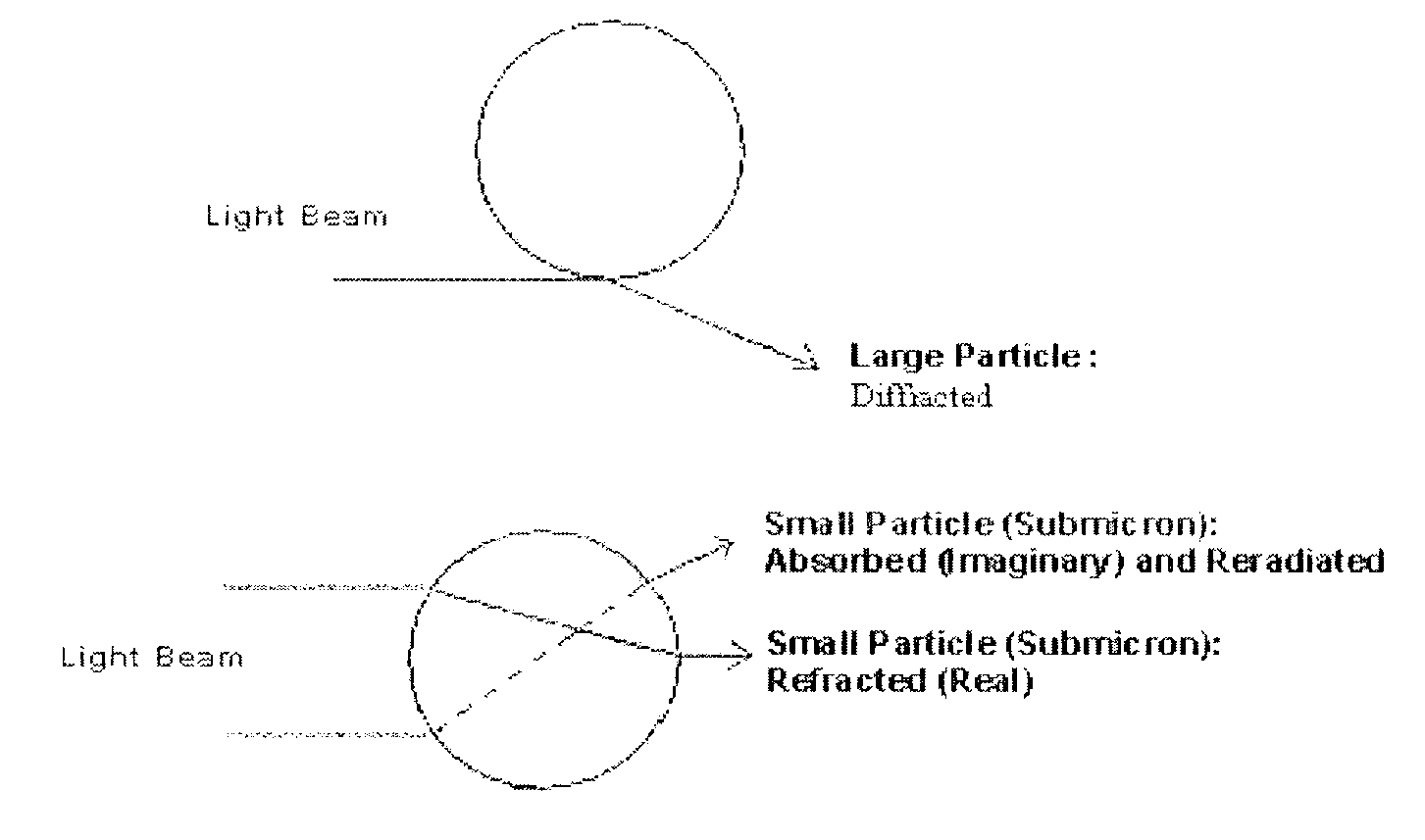

Method for measuring particle size distribution of a population of particles

InactiveUS7009169B2Investigating moving fluids/granular solidsScattering properties measurementsParticle size measurementRefractive index

The present invention provides for measuring a particle size distribution of a population of particles using a light scattering particle sizing instrument having a plurality of selectable imaginary component values of the refractive index. The particles each having a particle size and the process includes the steps of: (i) providing a population of the particles, wherein the particles have a refractive index; (ii) determining a real component of the refractive index of the particles using the Becke Line Method; (iii) determining an imaginary component of the refractive index of the particles; and (iv) determining the particle size distribution of the particles by the light scattering particle sizing instrument wherein the particle size distribution is determined using the real component of the refractive index measured in step (ii) and the imaginary component of the refractive index determined in step (iii).

Owner:BAXTER INT INC

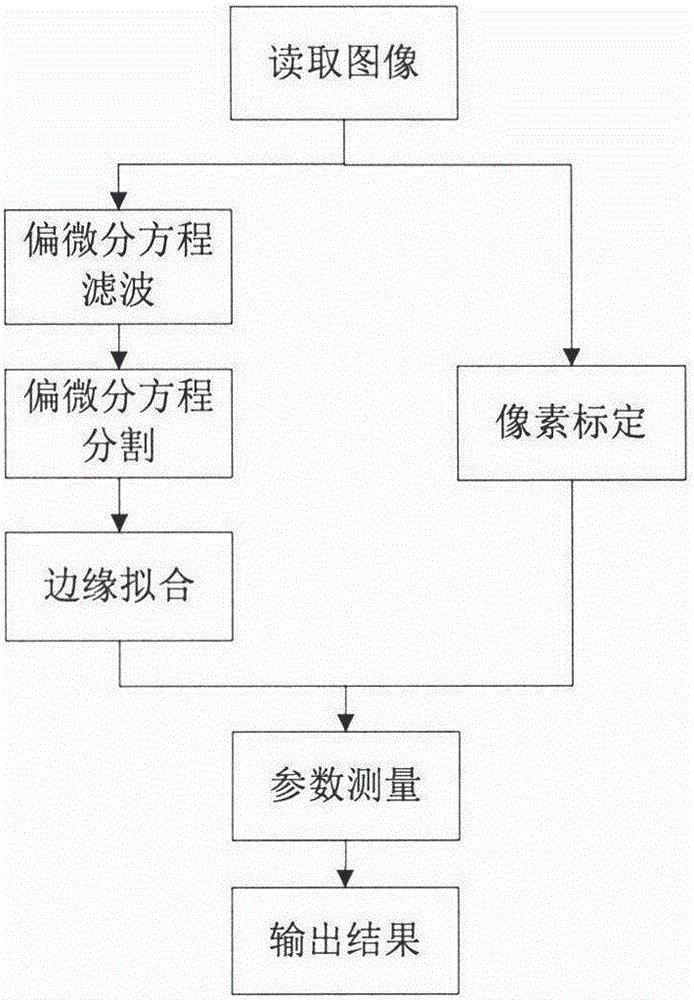

Partial differential equation-based nano-particle size measurement method

ActiveCN105931277AImprove efficiencyHigh precisionImage enhancementImage analysisParticle size measurementNanoparticle

The invention discloses a partial differential equation-based nano-particle size measurement method. The method includes the following steps that: 1) a nano-particle image I is inputted, pixel-level multiplication is performed on the filtering result of a mean curvature flow model and a PM model, so that a filtered image u can be obtained; 2) a region scalable fitting (RSF) model is adopted to segment the image u; 3) pixel calibration is carried out, the actual size of each pixel in the image can be obtained; 4) inadherent particles are selected out by means of the convexity (Cconv) of a target; and 5) least-square circle fitting is performed on the boundaries of the particles, so that the diameters of spherical nano-particles can be obtained, and the diameter rc of the internally tangent circle of the nano-particles, the diameter ri of the externally tangent circle of the nano-particles, and the sphericity of the nano-particles are obtained, wherein the sphericity of the nano-particles can be represented by an expression S=ri / rc. The method of the invention can be widely applied to the high-tech fields such as catalytic science, medical drugs, new materials, electric power industry and compound materials which require nano-particle size measurement technology.

Owner:思腾合力(天津)科技有限公司

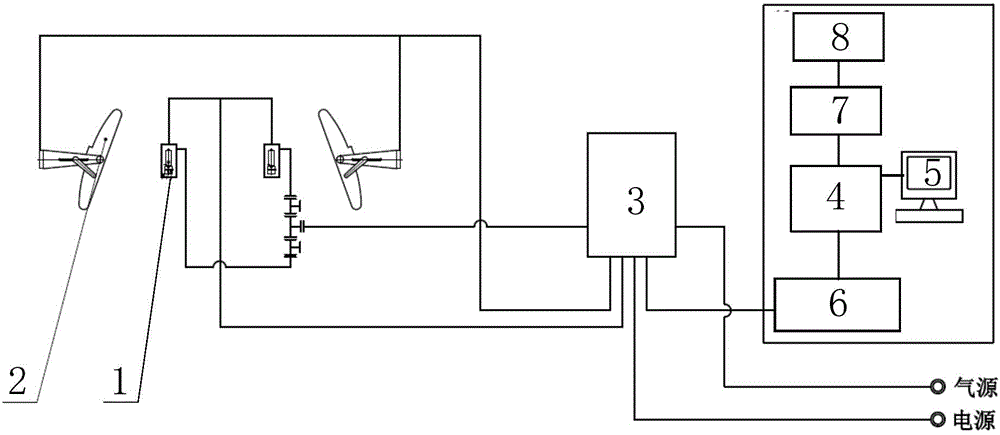

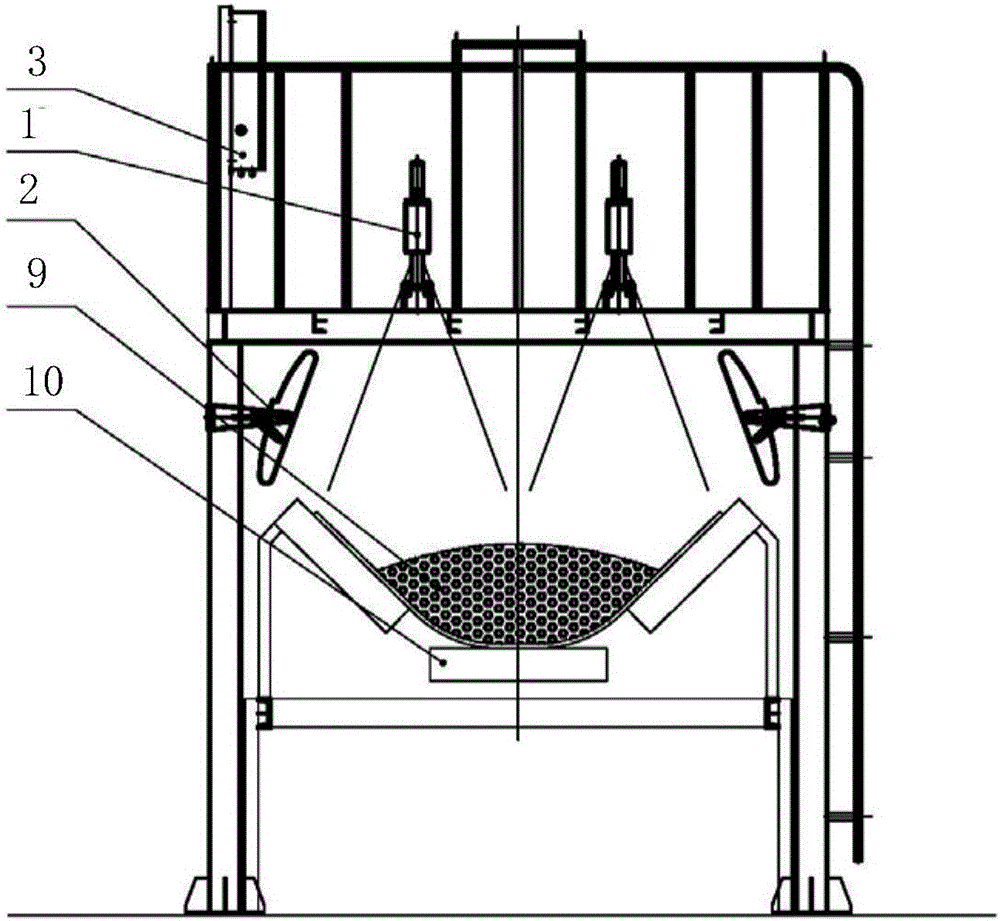

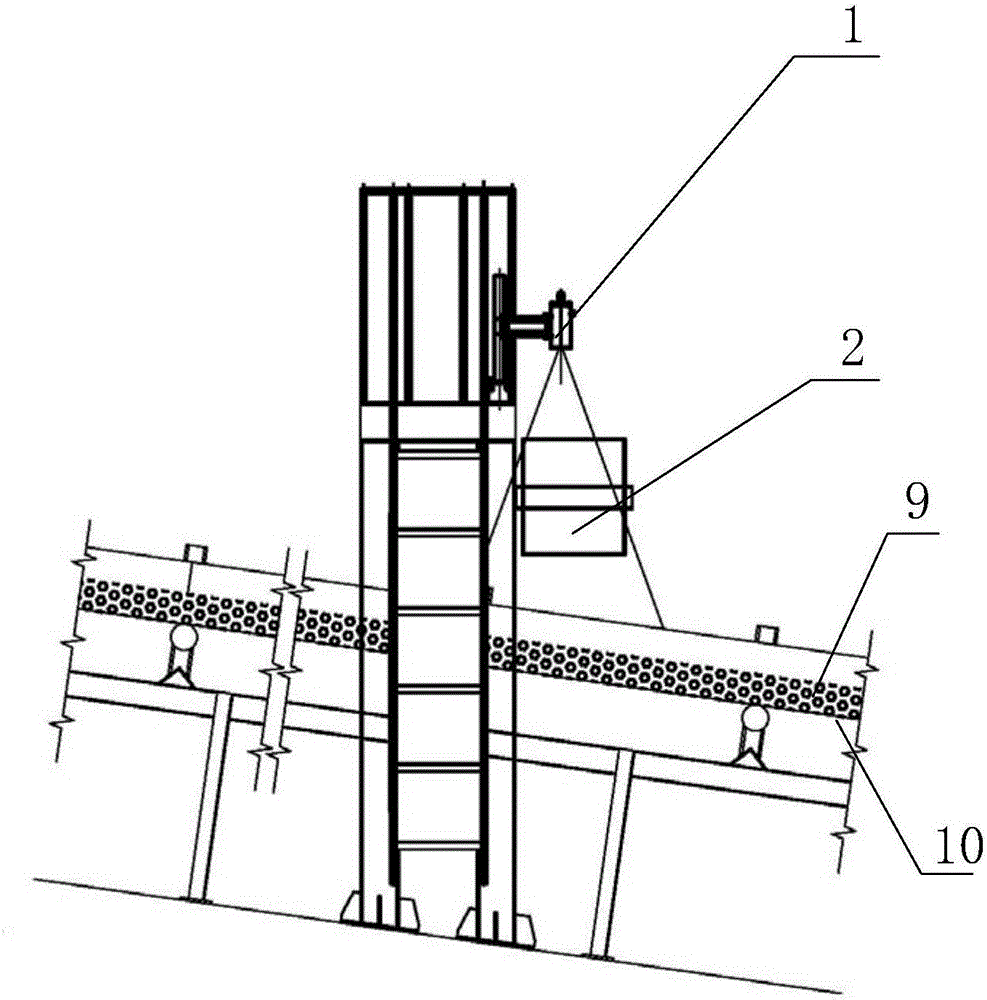

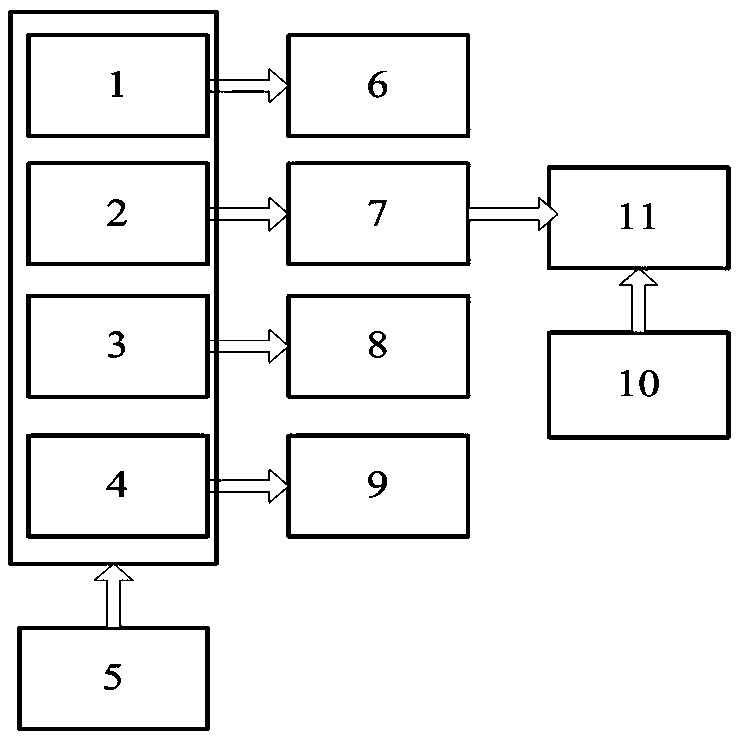

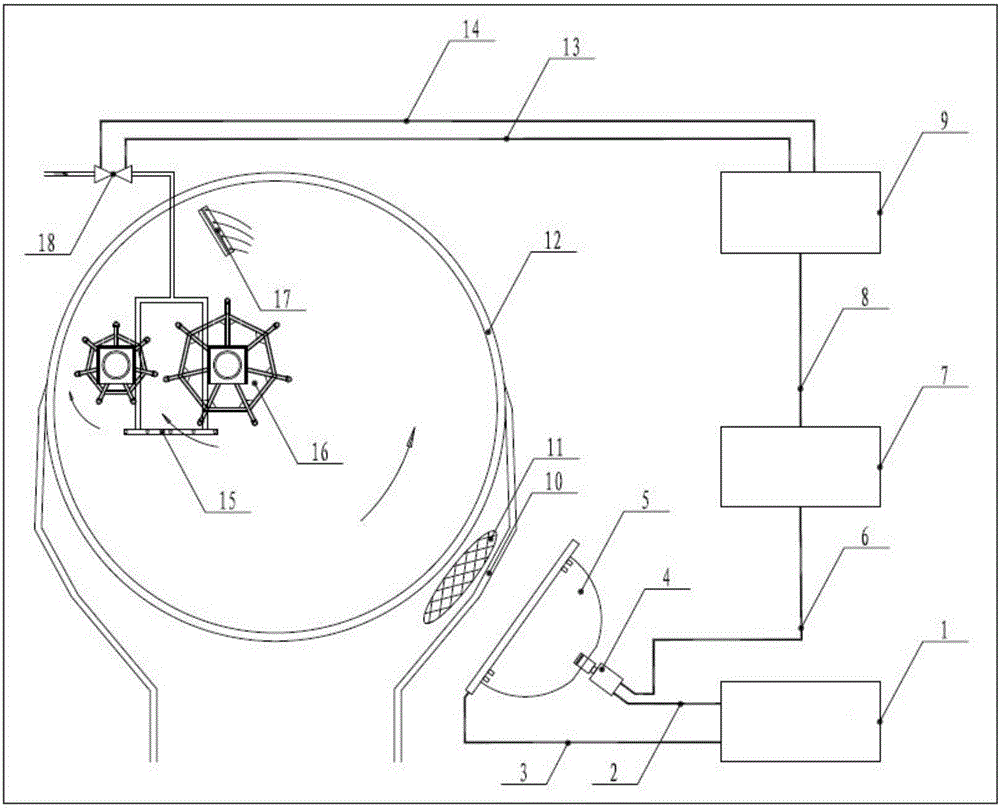

Submerged arc furnace smelting ferrochromium pellet particle size measurement device and method

ActiveCN105973771ALow costSimple structureParticle size analysisIndustrial EthernetParticle size measurement

The invention discloses a submerged arc furnace smelting ferrochromium pellet particle size measurement device and method. The device comprises a pelletizing disc, a feeding belt for conveying materials to the pelletizing disc, a scraper system for stirring materials in the pelletizing disc, and an atomize-spraying device used for adding water into the pelletizing disc, and further comprises a site local control box, an area array industrial intelligent camera, a high-brightness LED shadowless dome light source, a PLC station and an industrial Ethernet switch. A detection area of a round projection area is arranged on a chute between the discharging end of the pelletizing disc and a discharging baffle, a water distribution regulating valve is arranged on a water supply pipeline of the atomize-spraying device, the high-brightness LED shadowless dome light source directly irradiates the detection area, and the area array industrial intelligent camera is installed right in the middle of the top end of the high-brightness LED shadowless dome light source. By the adoption of the technical scheme, the opening degree of the pneumatic water distribution regulating valve is controlled, the mathematic relation of water distribution and pallet size is established through online debugging and real-time monitoring, and then automatic identification and control are realized.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

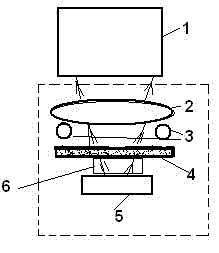

Image-method particle-size analyzer

InactiveCN102207444AEasy to disassemble and connectSmall sizeParticle size analysisUsing optical meansParticle size measurementGranularity

The invention discloses an image-method particle-size analyzer, which has the characteristics that a digital camera, a micro-objective lens, reflection light sources, a sample cell or a glass slide, a microspur adjusting supporter and a transmission light source are sequentially arranged on the particle-size analyzer from the top down, wherein the reflection light sources and the transmission light source all adopt light-emitting diodes; the sample cell or the glass slide is arranged on the microspur adjusting supporter; when measurement is performed, a clear image can be obtained by adjusting the microspur adjusting supporter; if the transmission light source is lighted and the reflection light sources are not lighted, the transmission method is used for measurement; if the reflection light sources are lighted and the transmission light source is not lighted, the reflection method is used for measurement; and the micro-objective lens, a light-emiting light source and the sample cell constitute an integral component, and the integral component can be conveniently detachably connected with the digital camera to constitute the image-method particle-size analyzer. The invention has the beneficial effects that the size of the image-method particle-size analyzer can be greatly reduced by adopting the structure, and a protable minitype image-method particle-size analyzer with wide particle-size measurement range is constituted.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

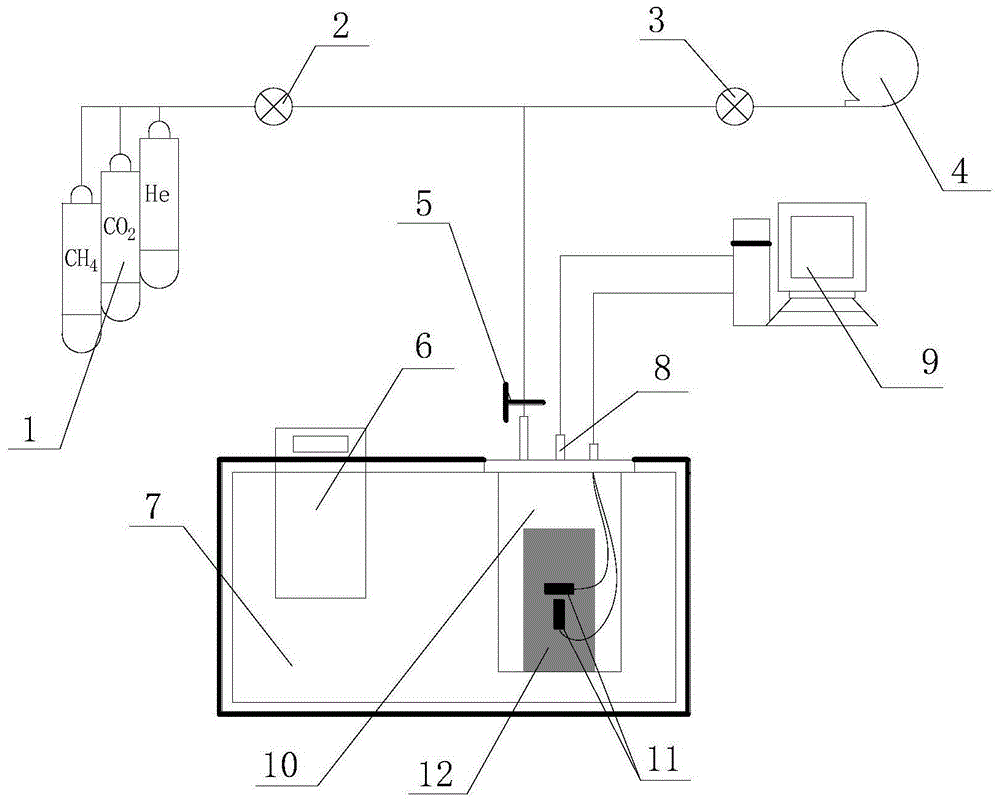

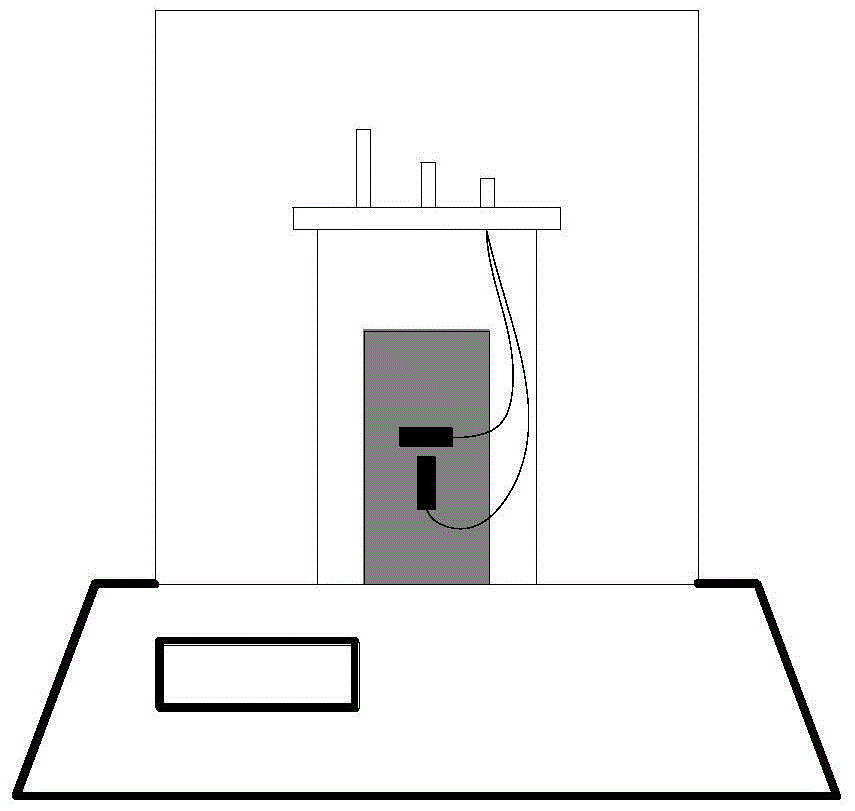

Test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and instrument

InactiveCN105043920AAvoiding Difficulties in High-Precision CalibrationImprove reliabilityStrength propertiesWeighing by absorbing componentAdsorption equilibriumParticle size measurement

Belonging to testing methods and instruments for rock mass constant temperature and rock mass strain, the invention relates to a test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and an instrument. According to the test method, rock mass constant temperature adsorption capacity is measured by an indirect gravitational method, at the same time, transverse and longitudinal strain gauges can be pasted to a side of a tested sample, the strain condition of the rock sample is monitored while the rock sample reaches adsorption equilibrium, thus being convenient to analyze the relation between rock mass adsorption and rock mass microscopic stress. A plurality of adsorption tanks are added, also adsorption test is carried out on rock samples in different particle size ranges at the same time, the rock mass sample particle size measurement range is wide, and the particle size test range covers 100micrometer-20mm. The test method calculates the sample adsorbing capacity by high precision balance weighing, which is different from the previous volumetric method for measurement of adsorbing capacity. The method can be used for determining the adsorbing capacity of rock to gas in laboratories, test enterprises and government departments. The test instrument is single, has few joints, enhances the system airtightness, and has the characteristics of simple operation, simple and reliable calculation method, and high accuracy.

Owner:CHINA UNIV OF MINING & TECH

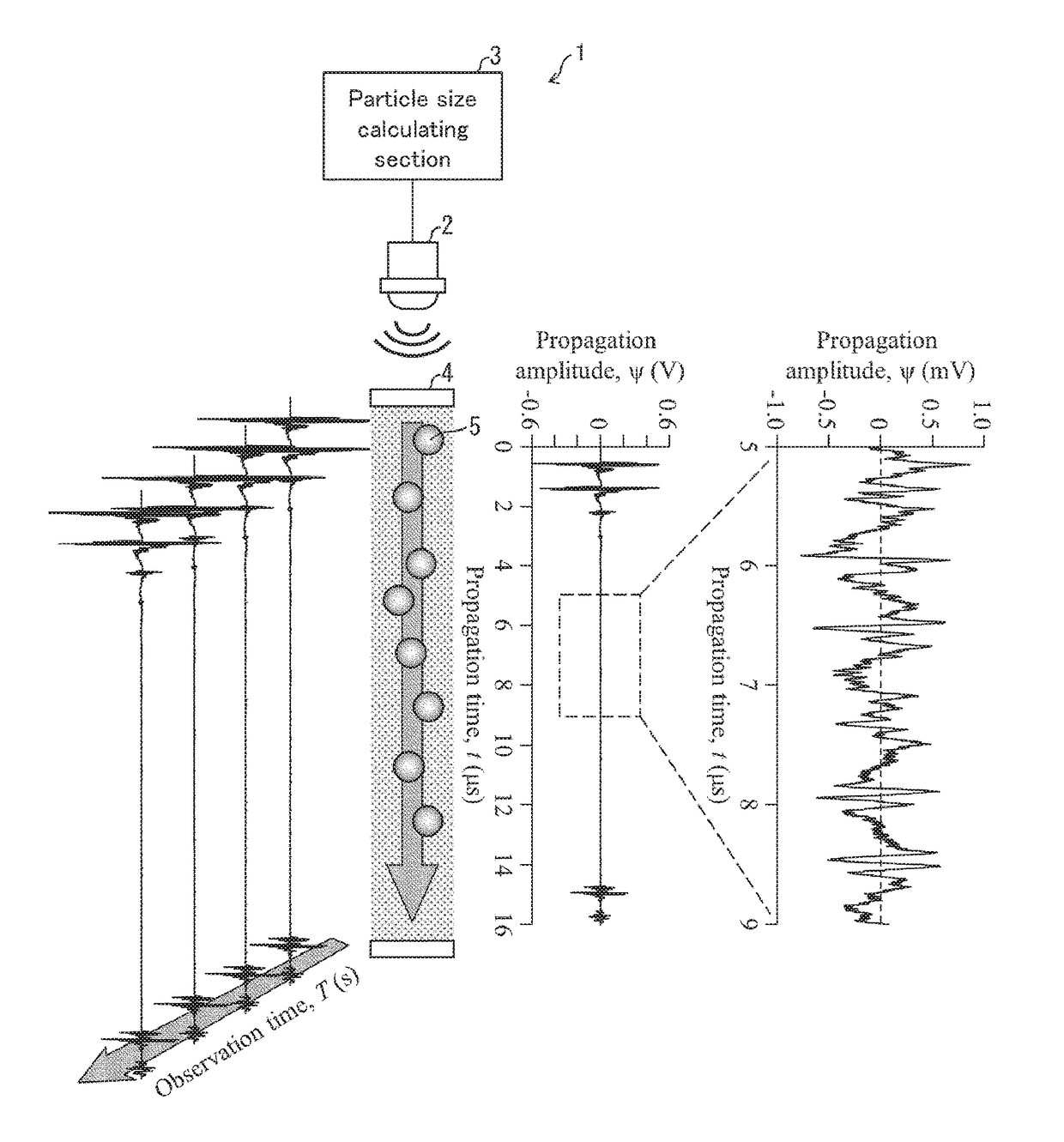

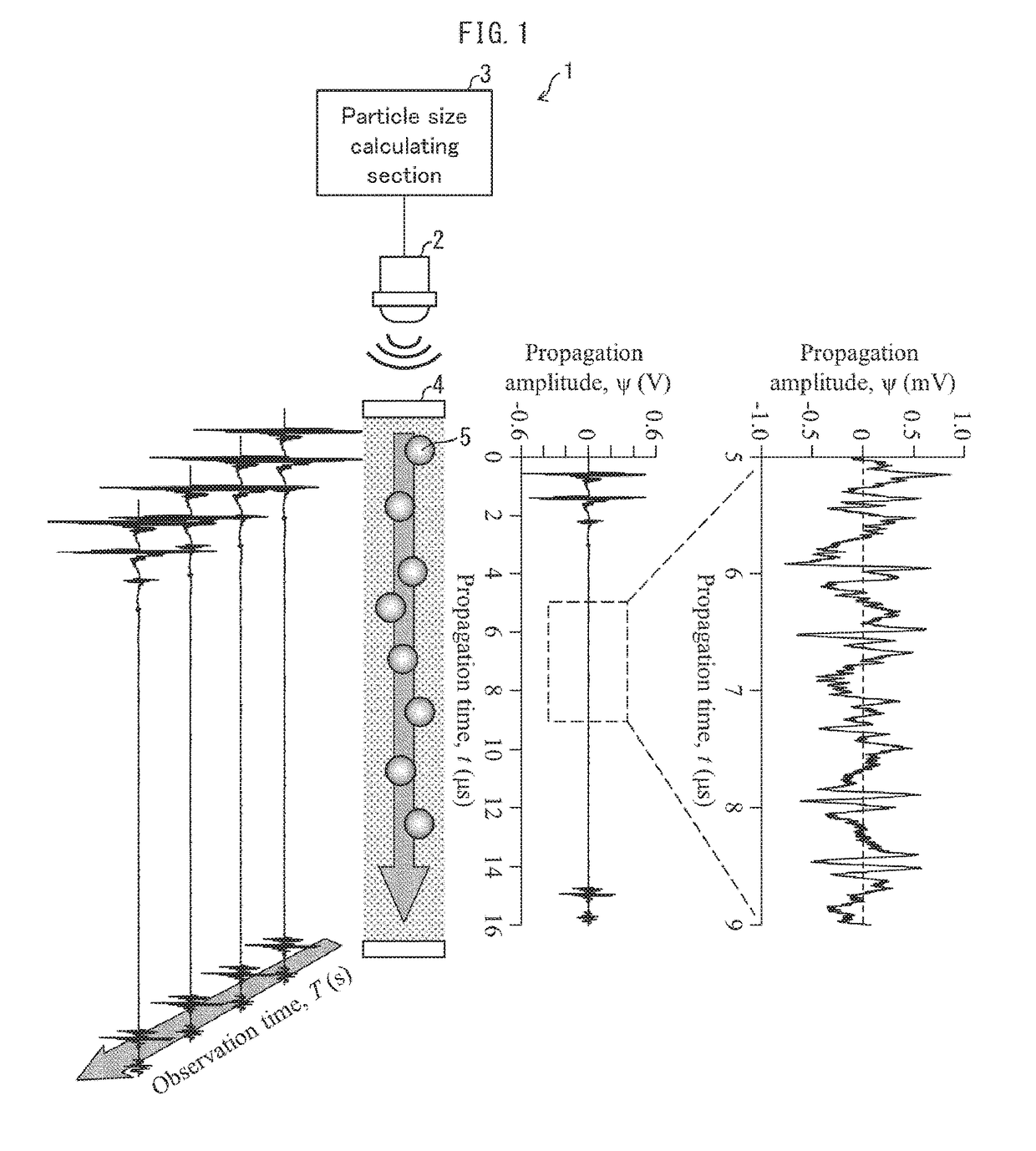

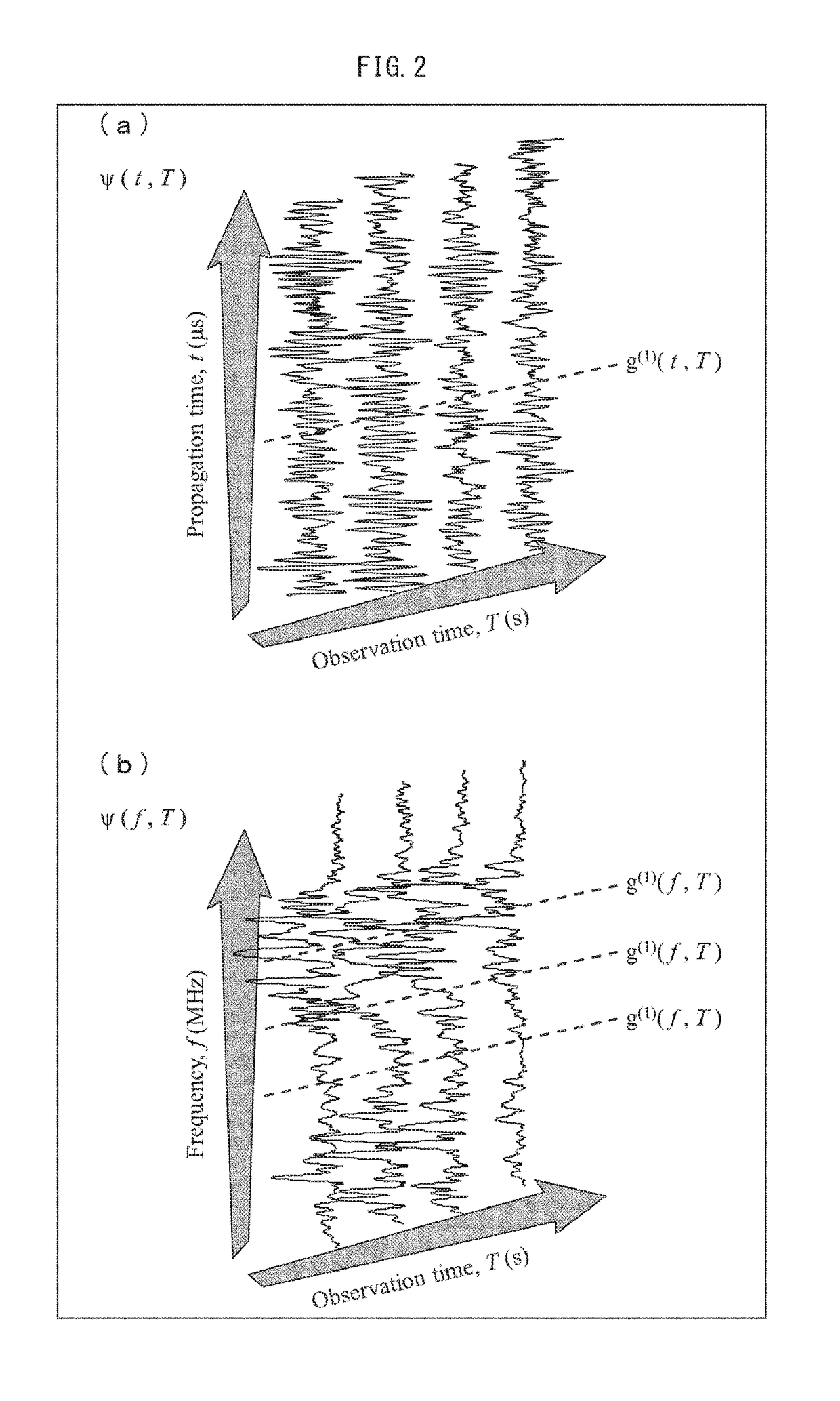

Ultrasonic particle size measurement device and ultrasonic measurement device

ActiveUS20180031464A1Move quicklyImprove accuracyProcessing detected response signalParticle size analysisParticle size measurementAcoustics

An ultrasonic particle size measurement device includes: a transducer for (i) receiving an ultrasonic pulse scattered after being emitted to a fine particle and (ii) generating a first scattering amplitude ψ; and a particle size calculating section for calculating a particle size of the fine particle by calculating an amplitude r and a phase θ in accordance with a real part and an imaginary part, respectively, of a second scattering amplitude ψ obtained by subjecting the first scattering amplitude ψ to a Fourier transform.

Owner:NAT UNIV KYOTO INST OF TECH

Blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition

InactiveCN110218824AControl diameterOvercome technical issues that cannot be measured in real timeCharacter and pattern recognitionParticle size analysisSlagParticle size measurement

The invention discloses a blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition. The detecting system comprises a control unit, a slag taking device and an image acquisition unit, wherein the slag taking device carries out sampling on slag particles obtained after the blast furnace slag is centrifuged and pelletized; the image acquisition unit collects the images of the slag particles; the control unit detects and analyzes the sizes of the slag particles according to the collected images to obtain the detecting data of the sizes ofthe slag particles; and the control unit is connected with the slag taking device and the image acquisition unit. According to the detecting system, the image acquisition unit is arranged to collectthe images of the slag particles, the data of the size of the slag particles is obtained after image analysis, the soft measurement method is adopted to solve the technical problem that the particlesof the blast furnace slag cannot be measured in real time due to high temperature, and the real-time performance and the precision of blast furnace slag centrifuging and pelletizing particle size measurement are improved. A blast furnace slag pelletizing device can be adjusted and controlled in real time according to the size data of the slag particles to control the particle diameter in real timeand ensure the heat recovery efficiency of mechanical centrifuging and pelletizing of liquid-state slag.

Owner:QINGDAO UNIV

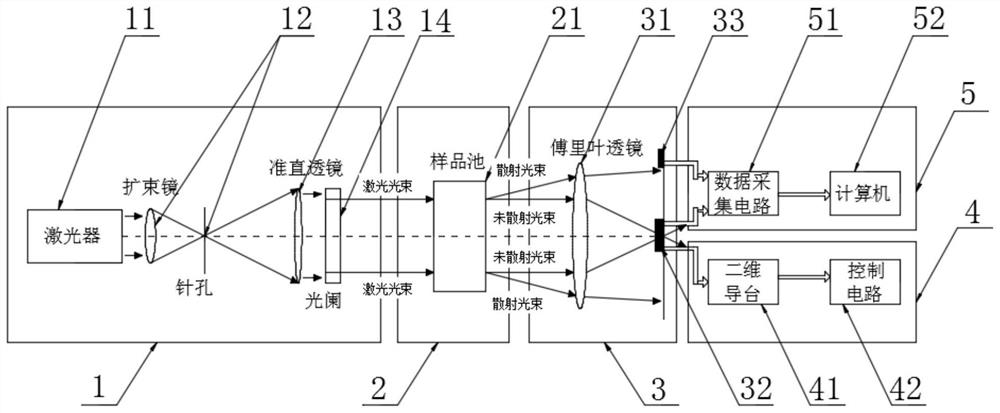

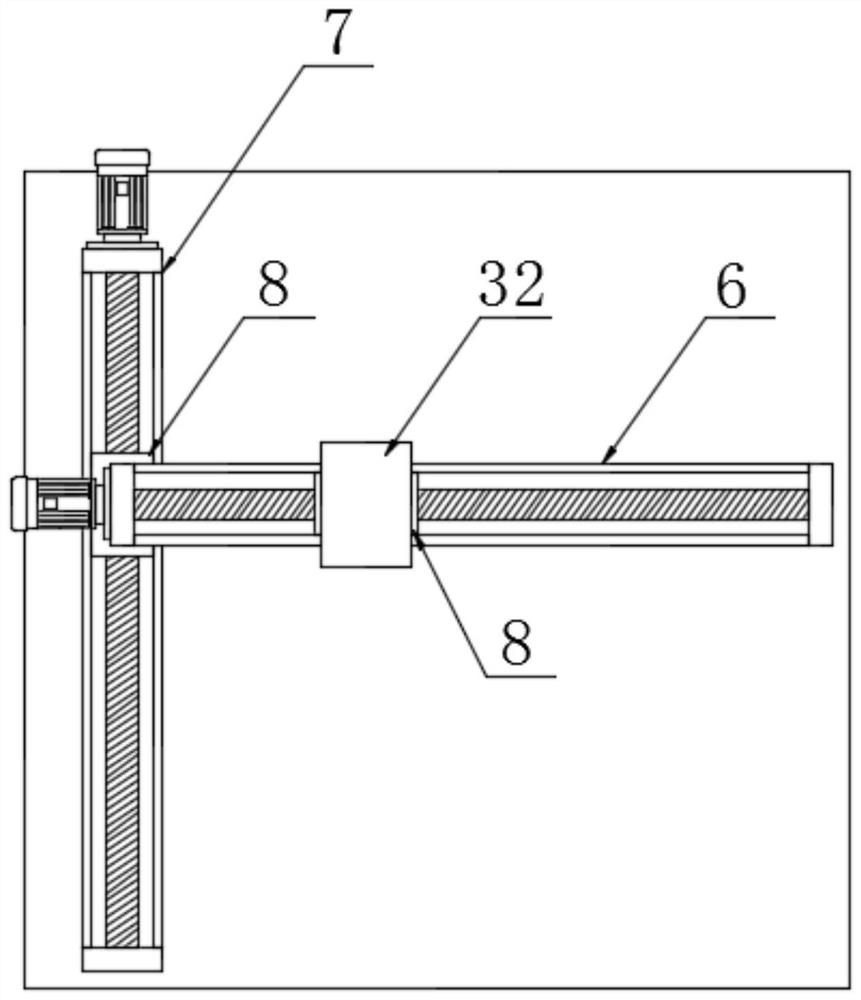

Particle granularity measuring equipment based on Mie scattering theory

PendingCN111650100AImprove accuracyHigh-resolutionScattering properties measurementsParticle size analysisImaging processingImage resolution

The invention discloses Particle granularity measuring equipment based on a Mie scattering theory, which particularly relates to the field of particle granularity measurement methods. The equipment comprises a parallel light generation module, a sample dispersion module, a light scattering acquisition module, an electric control two-dimensional guide table and a data processing module, wherein theparallel light generation module, the sample dispersion module and the light scattering acquisition module are distributed in a line from left to right. The area array CCD is used as a receiving device, anAiry disk image is obtained, the position information is extracted, image guide centering is realized, a centering correction parameter is solved, and the accuracy of a measurement result is improved; the position of the area array CCD is controlled by designing a two-dimensional guide table,a plurality of images at different positions are shot, an image splicing technology is utilized, a large-angle light scattering energy diagram is collected, an image processing method is utilized, scattering angles are dynamically divided, the resolution of granularity measurement is improved, a neural network principle is utilized, a traditional inversion algorithm is improved, and the accuracy, speed and reliability of the algorithm are improved.

Owner:EASTERN LIAONING UNIV

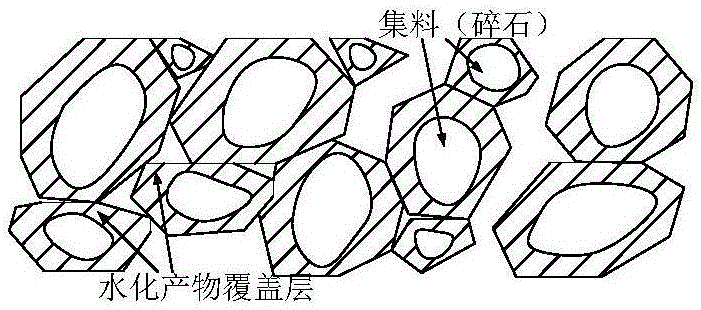

Pervious concrete aggregate particle size measurement method based on image processing

InactiveCN106596358ASmall sizeAccurate grading curveParticle size analysisImaging processingParticle size measurement

The invention discloses a pervious concrete aggregate particle size measurement method based on image processing. The method comprises the steps that a set quantity of pervious concrete aggregates are selected to be placed on white paper, a ruler with scales is placed, a square area is shot, and a digital photo is obtained; the digital photo is processed, and conversion of a pixel value and a millimeter distance value is completed; blackening and whitening processing is conducted; the particle size area of each particle is output, each aggregate particle is assumed as a circle, and the particle size is calculated; the particle sizes of all the aggregate particles in different shooting angles are averaged, and the initial particle size di0 of the i aggregate particle of pervious concrete is obtained; the aggregate volume expansion rate caused by a hydration product is calculated, the aggregate diameter enlarging rate is calculated through the aggregate volume expansion rate, the aggregate equivalent particle size is calculated through the aggregate diameter enlarging rate, correction on the initial particle size di0 of the i aggregate particle of the pervious concrete is completed, and the equivalent particle size Di of the i aggregate particle is obtained. The method has the advantages that operation is easy, processing is convenient, and a final result is stable and reliable.

Owner:SHANDONG UNIV

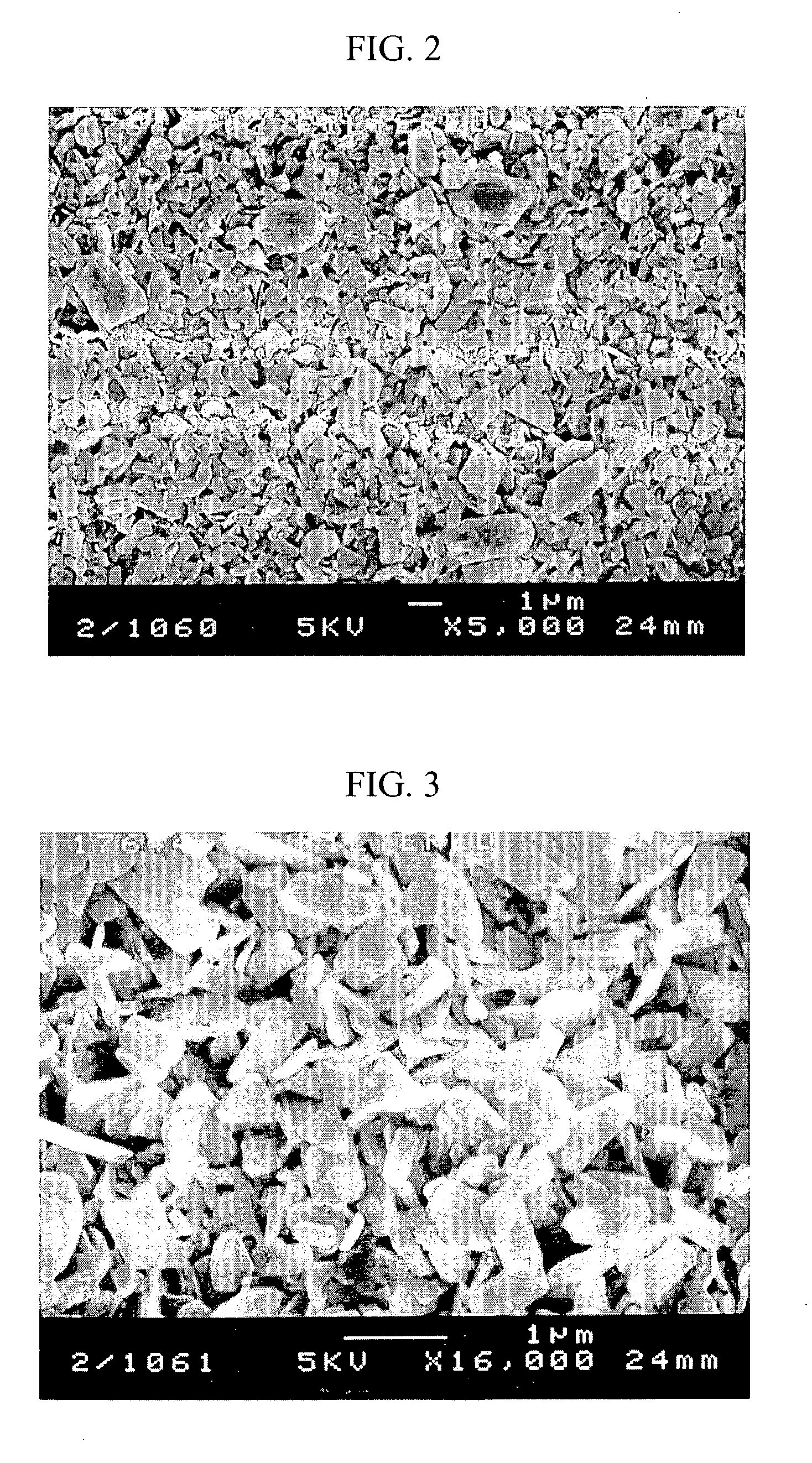

Low-temperature sinterable metal nanoparticle composition and electronic article formed using the composition

InactiveUS20110236709A1Quality improvementLow sintering propertyMaterial nanotechnologySimultaneous aerial operationsParticle size measurementElectron

[Object] A composition of a metal nanoparticle is provided in which reproducibility in a method of producing a metal film with excellent low-temperature sinterable properties is improved. An article using the metal nanoparticle composition is also provided.[Solving Means] A composition of a metal nanoparticle that has a secondary aggregation diameter (median diameter) of 2.0 μm or less as determined by disk centrifugal-type particle size measurement is used.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

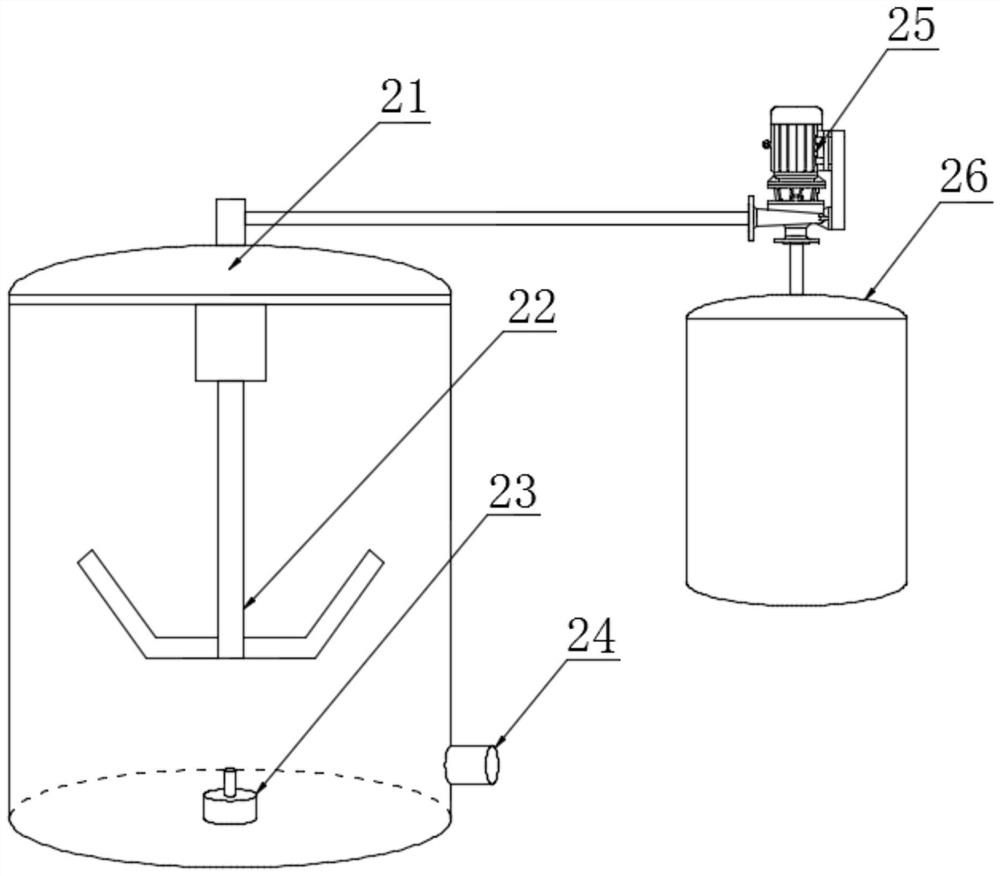

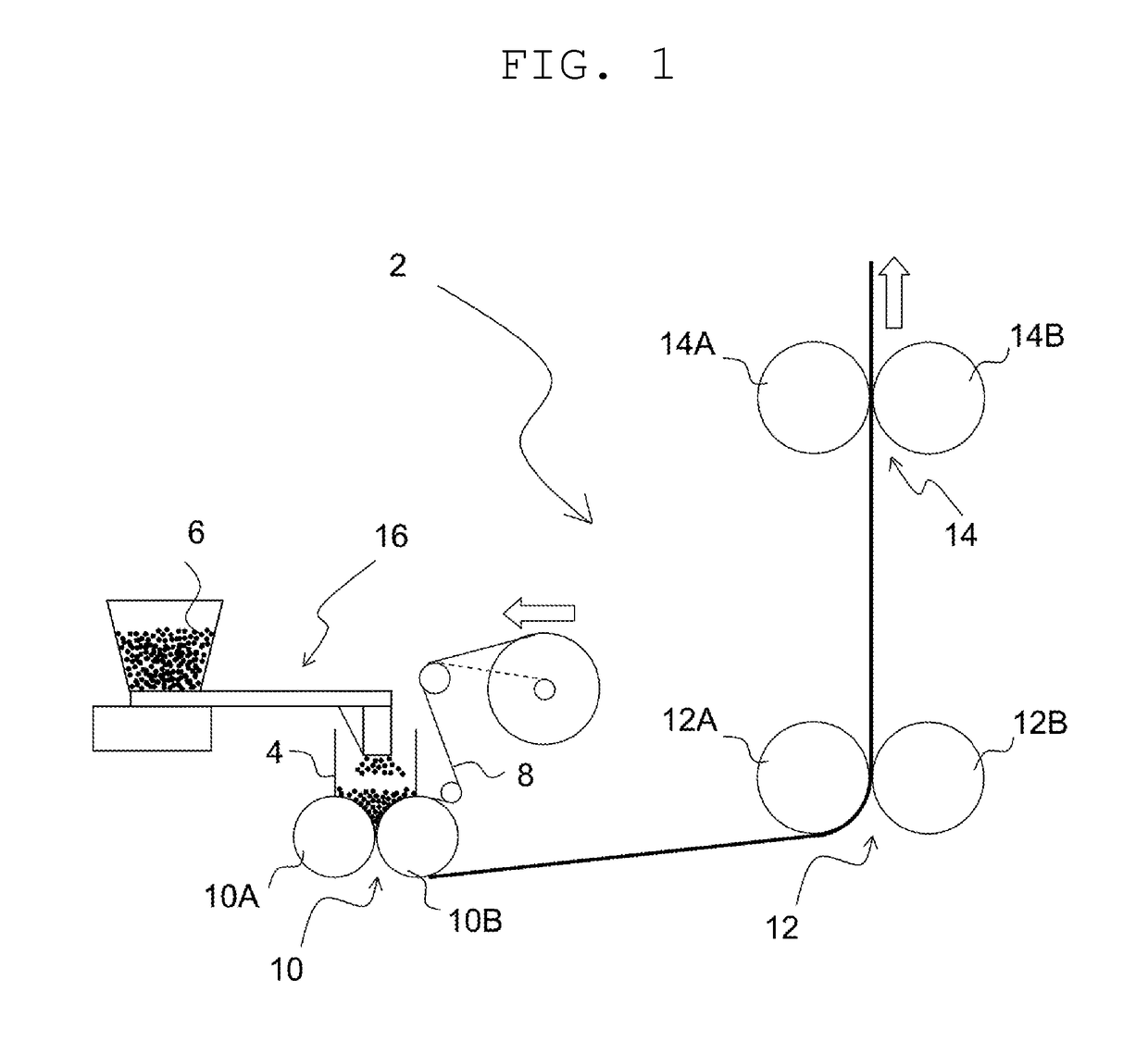

Automated recirculation system for large particle size analysis

InactiveUS20080285377A1Rotary stirring mixersPreparing sample for investigationParticle size measurementEngineering

The present invention relates to a wet-type recirculation system for particle size analysis of sample including coarse particles (hundreds to thousands μm). According to the wet-type recirculation system of the present invention, the mixture liquid is recirculated using not a single recirculation line but two recirculation lines between the mixer and the particle size analyzer and the recirculation lines are connected with the mixer at the upper inputting part side of the mixer to discharge the mixture liquid. Further, the rotatable baffle is attached to the inside of the mixer to generate vortex in a horizontal direction as well as a vertical direction within the reservoir of the mixer and the baffle is rotated by a pressure of the mixture liquid discharged from the two recirculation lines to form vortex. Consequently, the mixture liquid in which fine particles and coarse particles are uniformly mixed is provided to the particle size analyzer and thus reliable and accurate result of the particle size distribution measurement can be obtained when particle size measurement of sediment including from fine particles of several μm to coarse particles of thousands μm.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

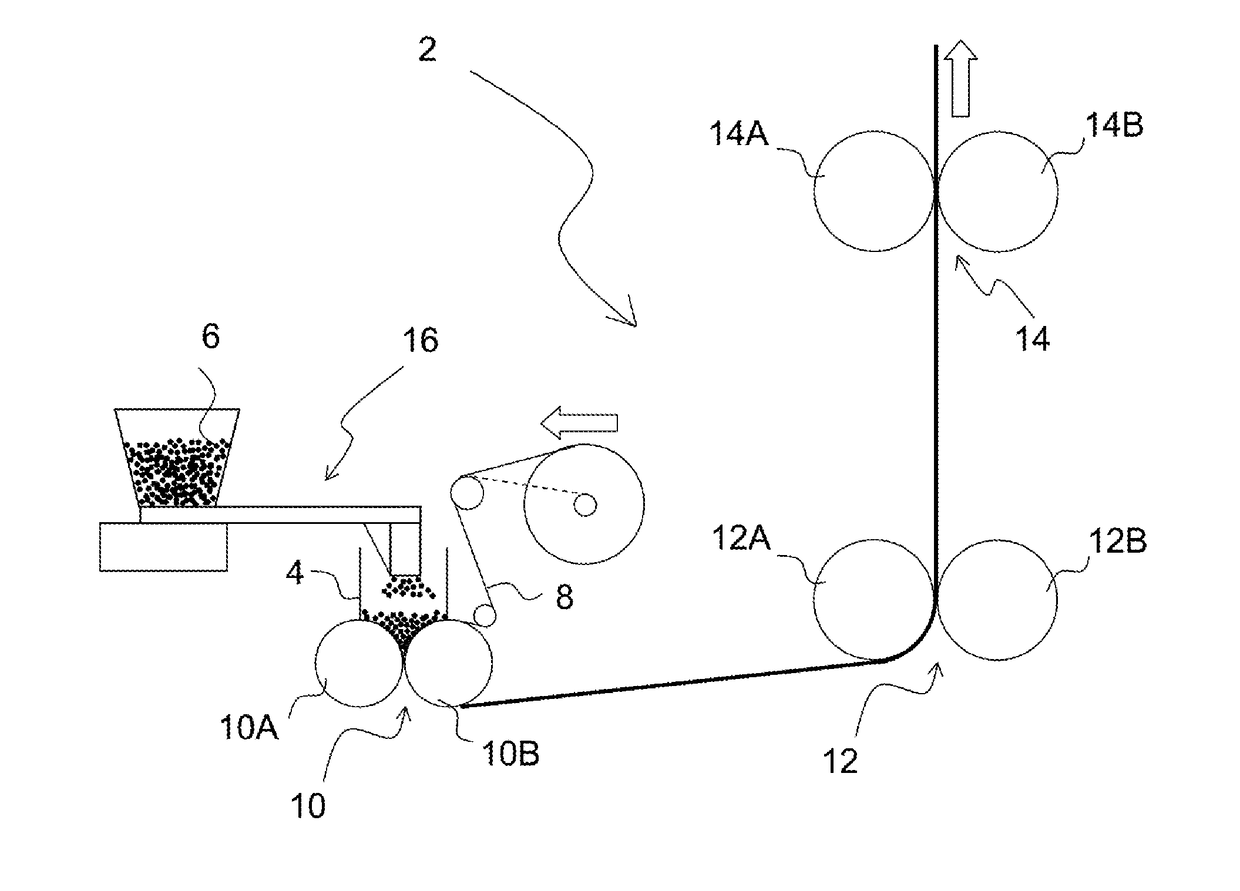

Composite particles for electrochemical device electrode, electrochemical device electrode, electrochemical device, method for manufacturing composite particles for electrochemical device electrode, and method for manufacturing electrochemical device electrode

InactiveUS20170104205A1High thickness accuracyLose weightElectrode rolling/calenderingFinal product manufactureParticle size measurementLaser light

An object of the present invention is to provide composite particles for an electrochemical device electrode capable of preparing an electrode having high thickness precision at a low basis weight, an electrochemical device electrode and an electrochemical device that use the composite particles for an electrochemical device electrode, and to provide a method for manufacturing the composite particles for an electrochemical device electrode, and a method for manufacturing the electrochemical device electrode.The present invention relates to composite particles for an electrochemical device electrode that are obtained by spray-drying a slurry containing an electrode active material and a binder resin, in which particles of 40 μm or less are 50% or less of an entire amount in a number-based particle size distribution obtained by particle size measurement using a laser light diffraction method and the cumulative 95% size (D95 size) is 300 μm or less in a volume-based particle size distribution.

Owner:ZEON CORP

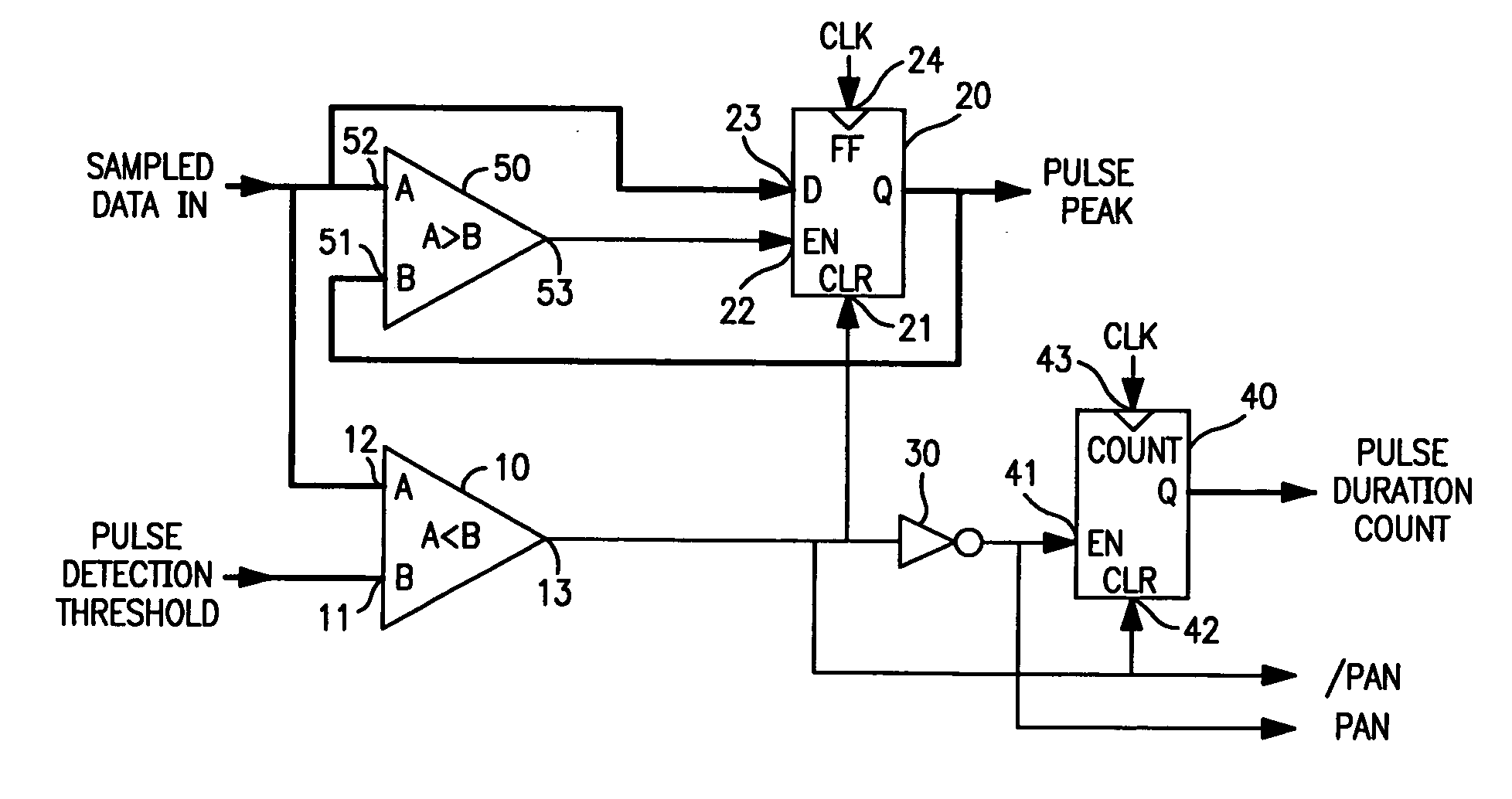

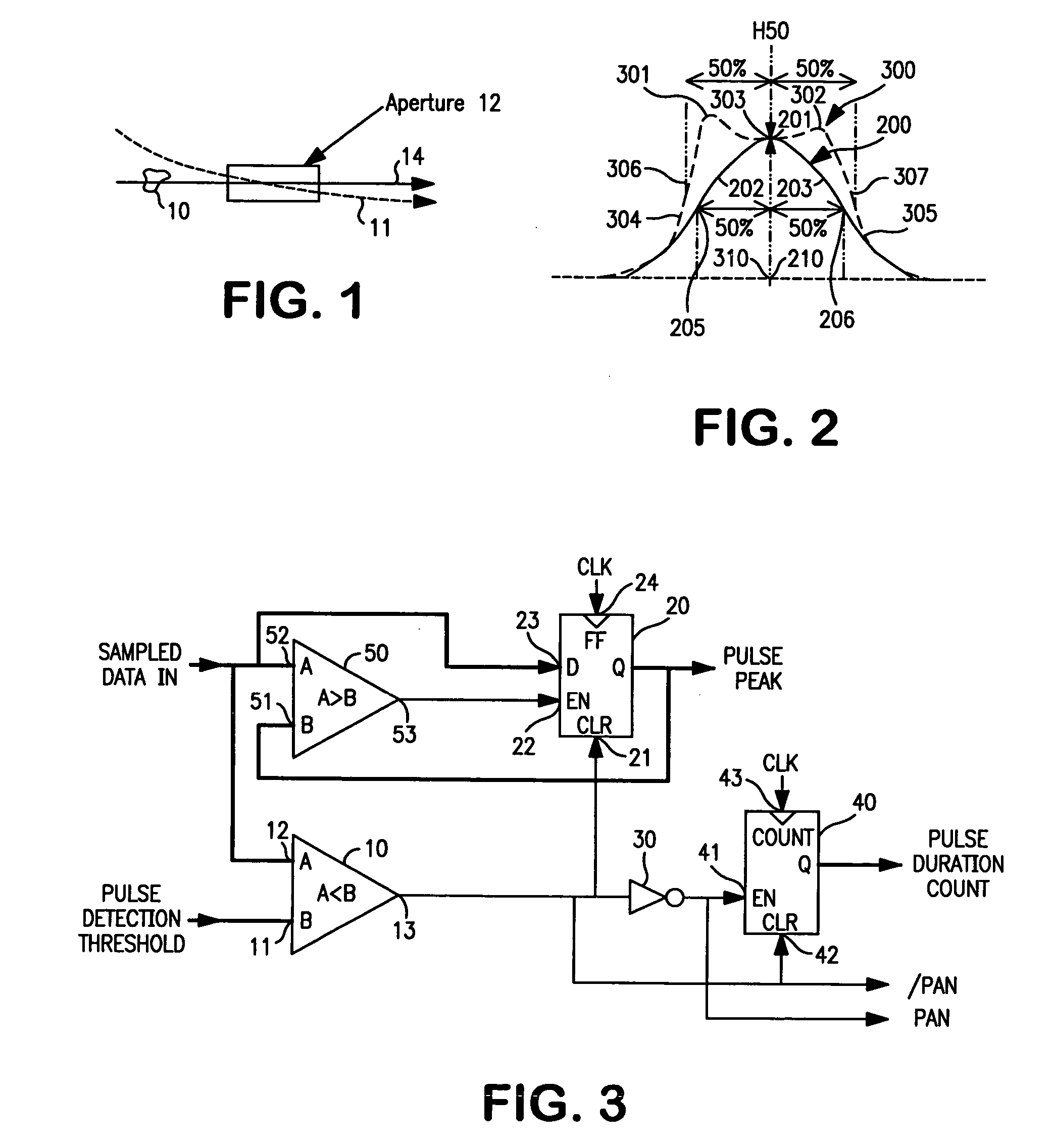

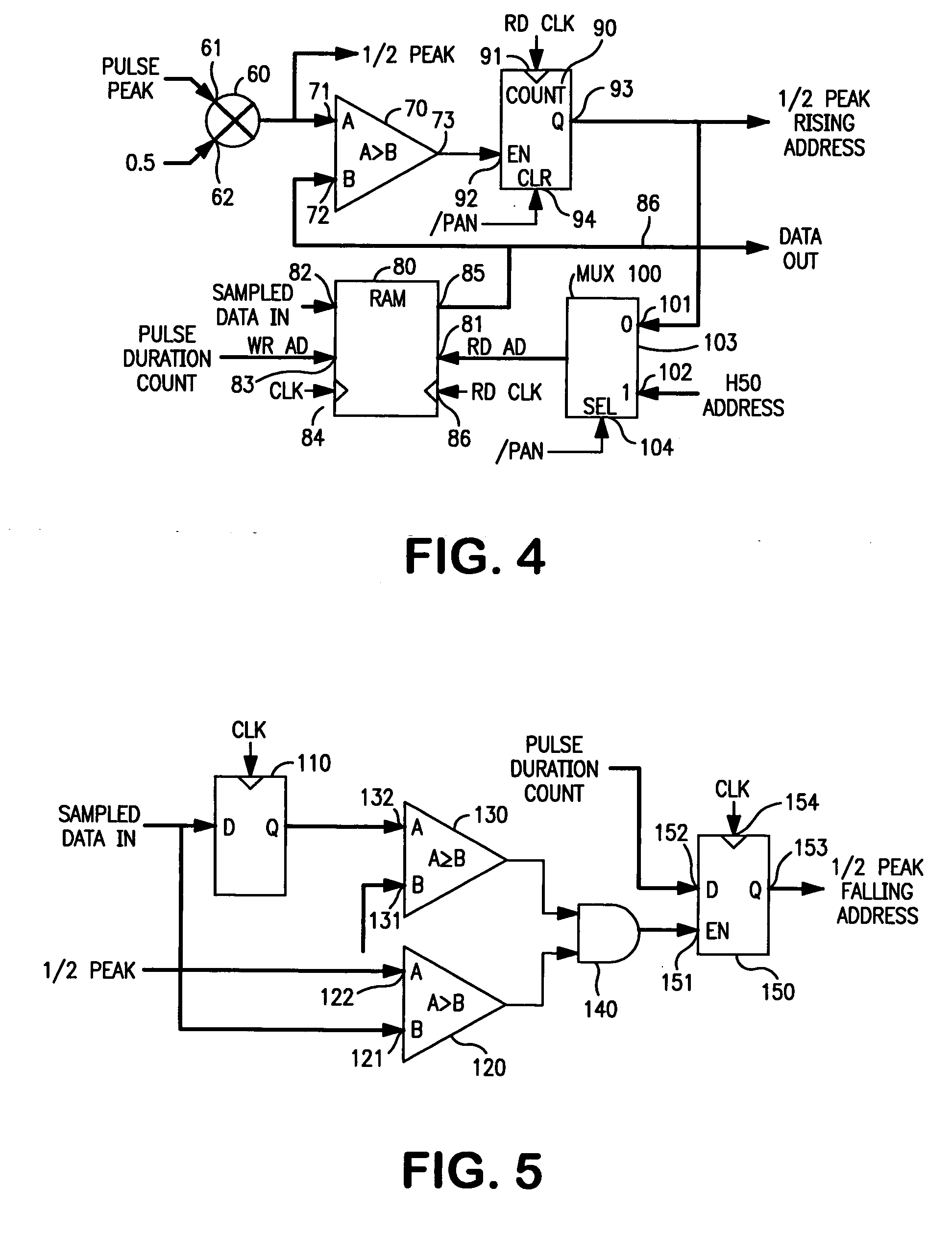

Method and apparatus for finding center amplitude of particle size-representative pulses produced by aperture based sizing system

ActiveUS20070047674A1Prevented from incrementingAmplitude-modulated carrier systemsElectrical measurementsMedicine.hematologyParticle size measurement

Pipelined digital processing circuitry for use with a particle size measurement system, such as that employed in automated hematology systems, measures the ‘center’ amplitude of a pulse produced by a particle or cell passing through a flow cell measurement aperture, such as the detection aperture of a Coulter Principle-based electronic particle analysis system. The circuitry of the invention processes successive pulse samples by means of a half-peak / half-width methodology that analyzes each pulse as its continuously sampled and temporarily stored in memory. Concurrent analysis of the data in memory during storage locates the pulse width at a prescribed percentage (e.g., 50%) of the peak amplitude of the pulse. This pulse width data is then processed to determine the pulse amplitude at the midpoint of the width of the pulse between its mid-peak values on rising edge and fall edge portions of the pulse.

Owner:BECKMAN COULTER INC

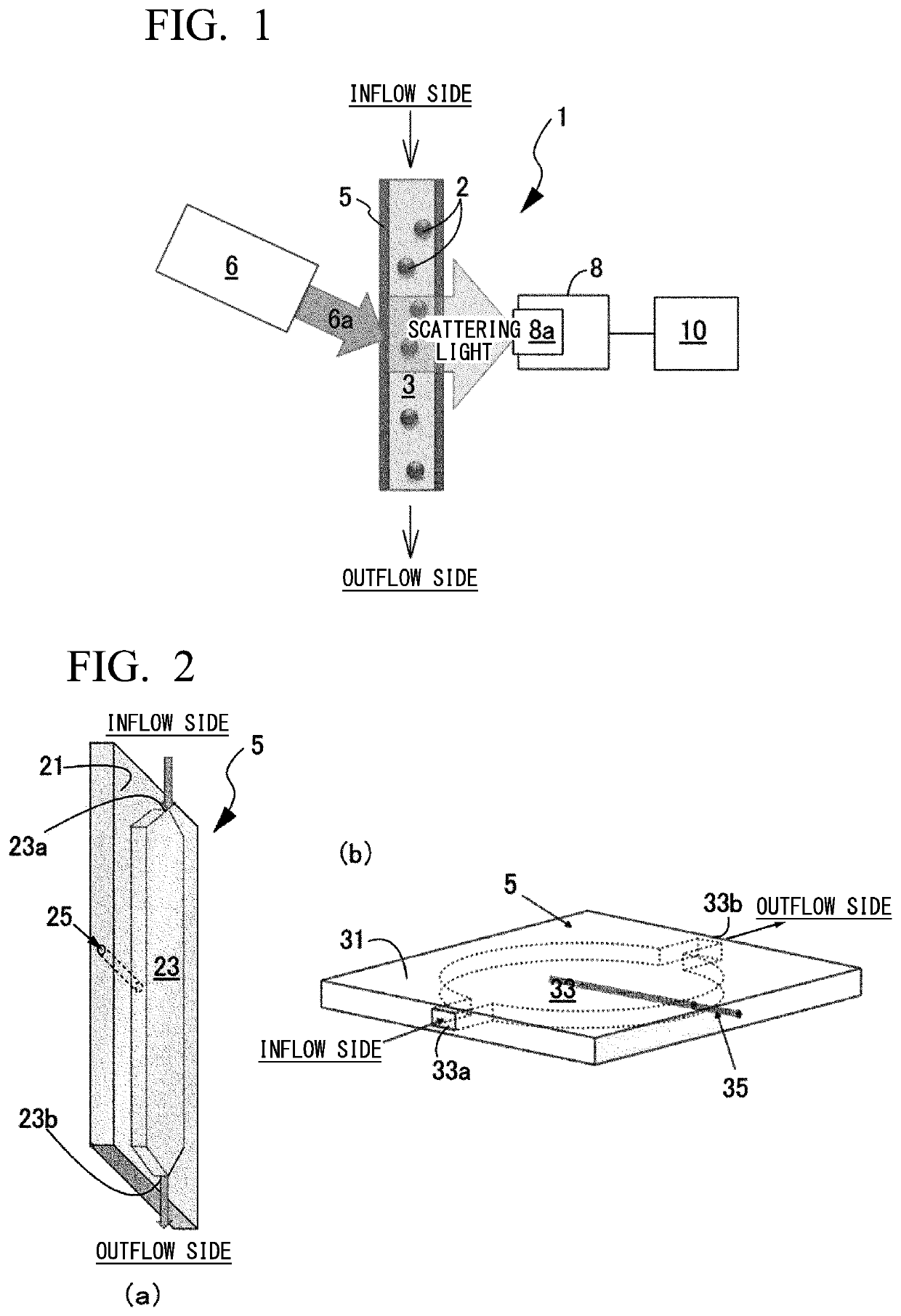

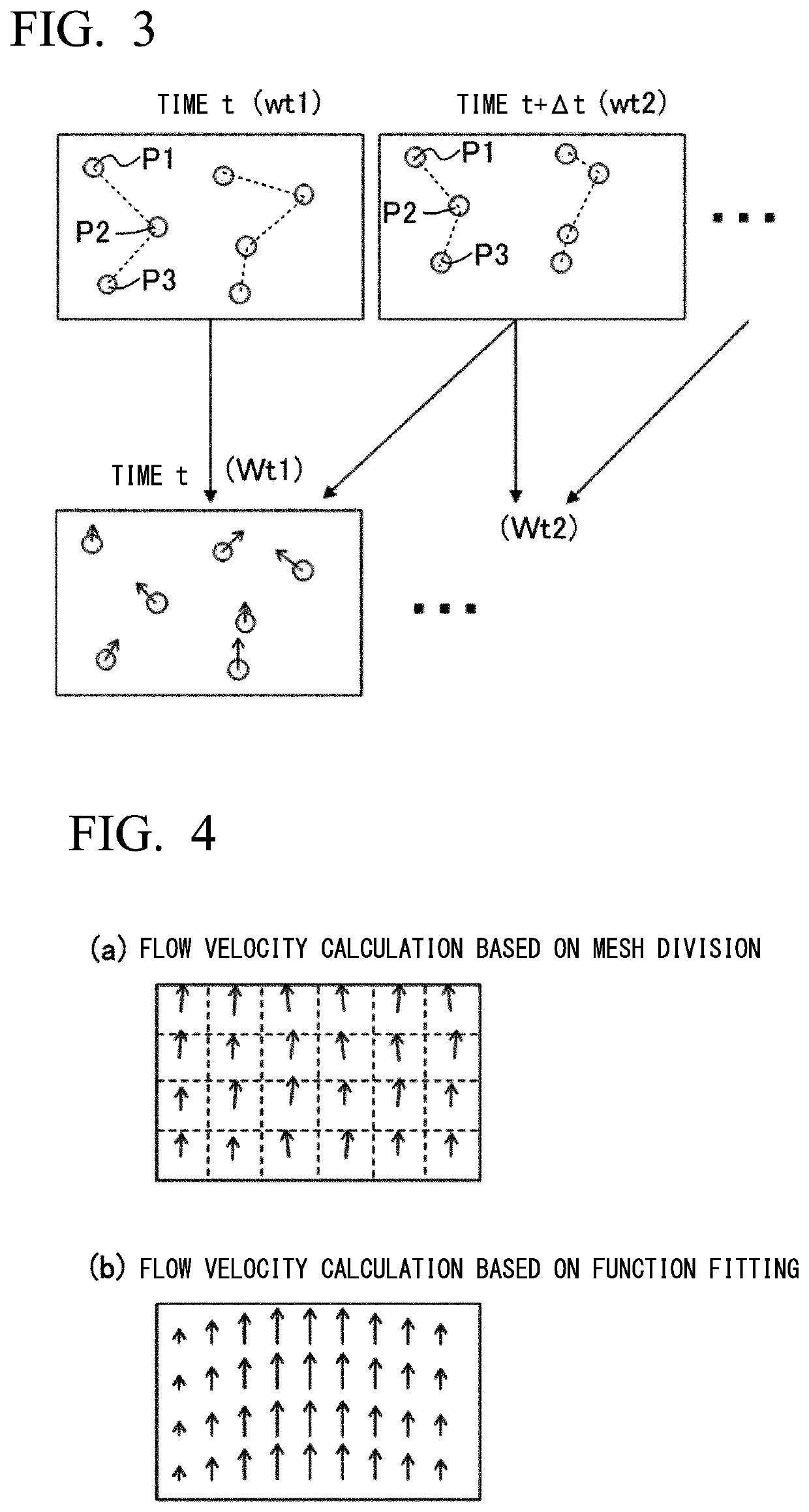

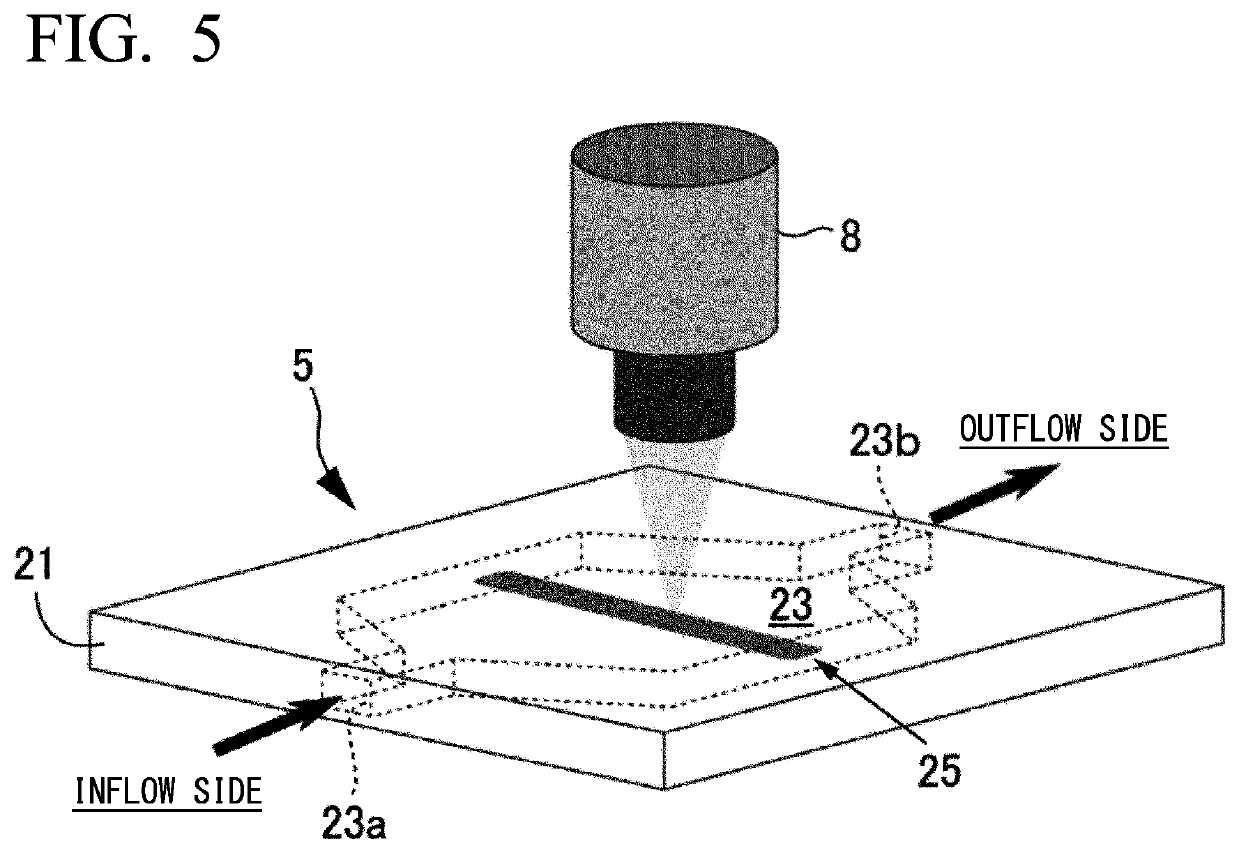

Flow velocity distribution measuring method and particle size measuring method

ActiveUS20200064169A1Increase the number densityReduce the amount of informationVolume/mass flow measurementParticle size analysisParticle size measurementLaser light

A measuring method enabling simple and accurate measurement of a flow velocity distribution in a flow field inside a flow passage of an optical cell and a particle size-measuring method using the measuring method are provided. In a device including a laser light irradiation unit irradiating laser light at a wavelength λ into the flow passage, a camera capturing an inside of the flow passage to which the laser light is irradiated, and an analysis unit obtaining a flow velocity distribution in the flow field from at least a plurality of images captured in a light exposure time τ at each predetermined time interval Δt, providing a tracer particle of a smaller size than the wavelength λ of the laser light into the flow passage and capturing a bright spot attributed to the light scattering from tracer particles by the camera, and obtaining the flow velocity distribution by the analysis unit by obtaining an amount of movement of each tracer particle from movement of the bright spot and correcting a Brownian motion component from a correlation between an average value of variations of the amount of movement and Brownian motion are performed. In addition, obtaining the particle size of a measurement target particle by obtaining a corrected displacement obtained by removing a movement component of the flow field caused by the flow velocity distribution from a displacement of the measurement target particle is performed.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com