Blast furnace burden particle size monitoring system and distributed data on-line analysis method

A monitoring system and analysis method technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of inability to meet modern large-scale production, low efficiency, cumbersome and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

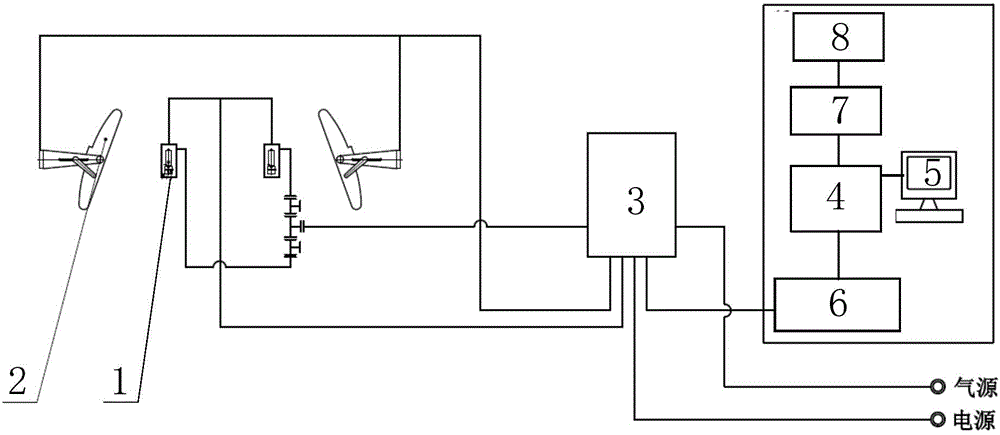

[0068] like figure 1 As shown, the blast furnace charge particle size monitoring system is set on-site imaging equipment 1, lighting source 2, on-site control box 3, and industrial computer 4, display device 5, indoor control box 6, signal converter 7 and Sound and light alarm device 8.

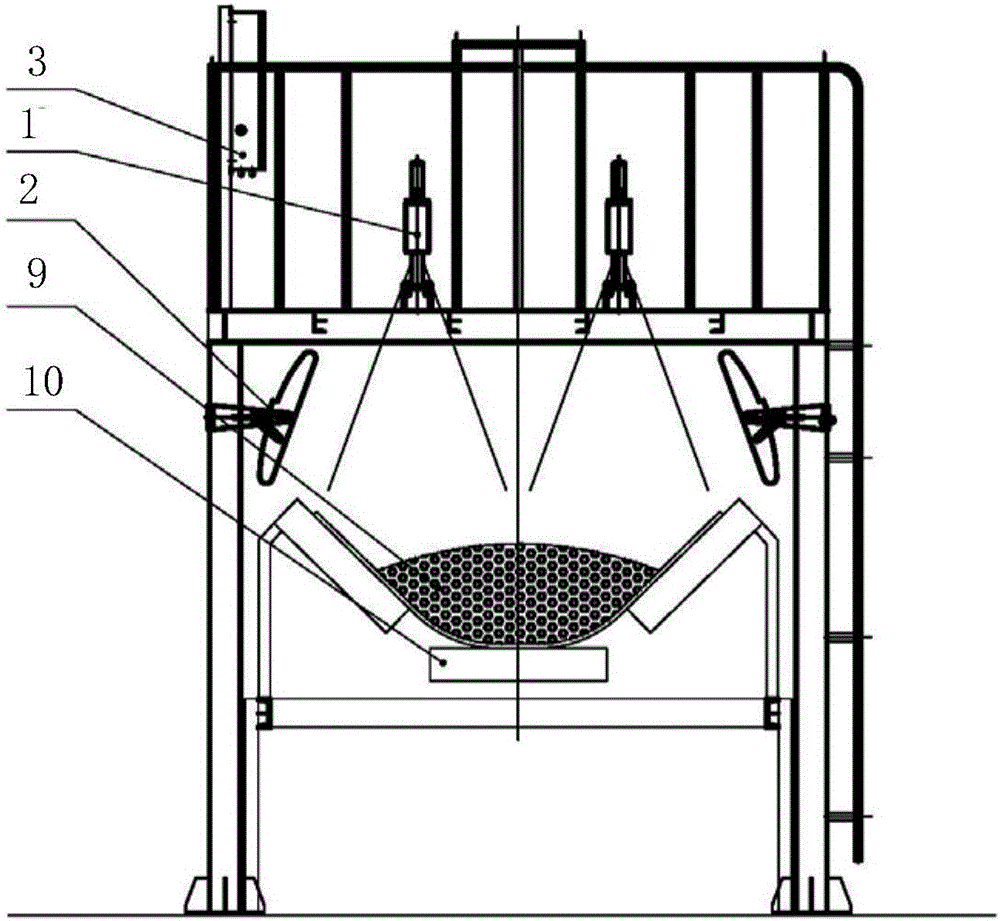

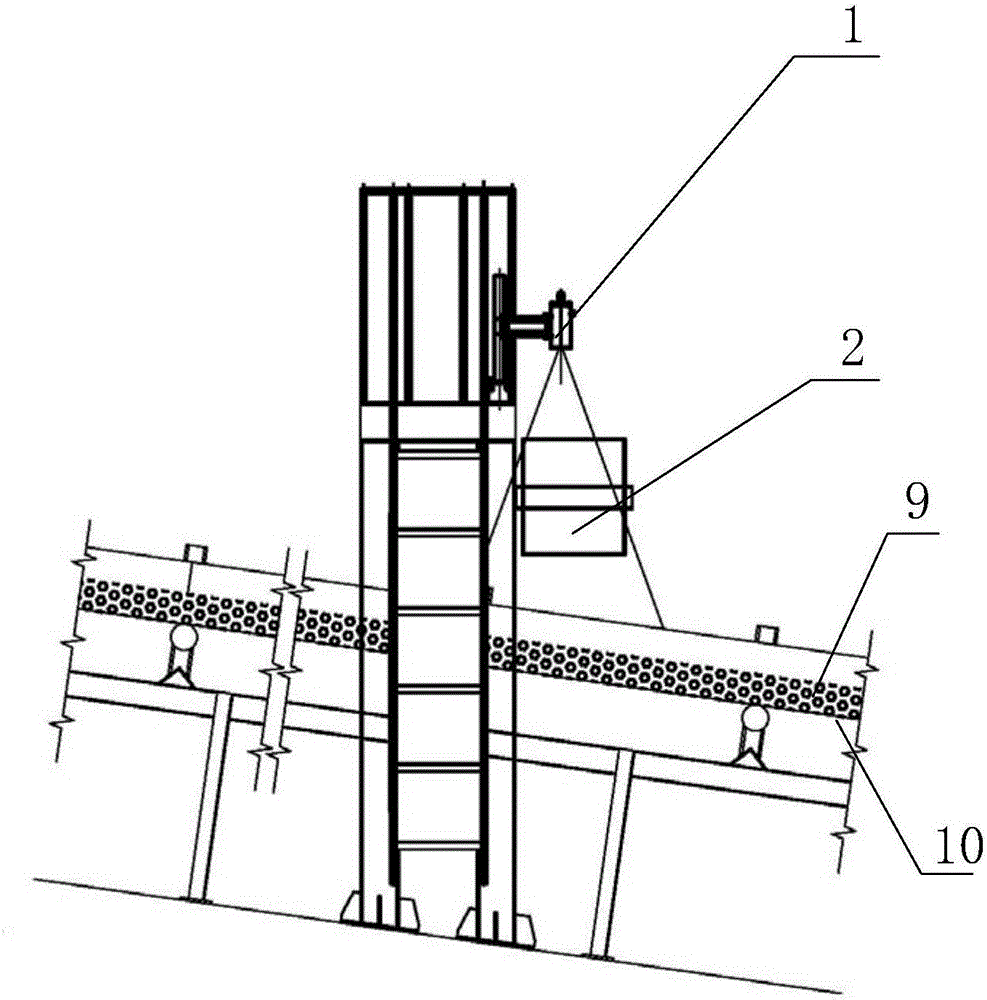

[0069] like Figure 2~3 As shown, the imaging device 1 and the lighting source 2 are arranged above the blast furnace charge conveying equipment; the blast furnace charge is transported to the blast furnace furnace by a conveyor belt, the imaging device 1 is arranged directly above the conveyor belt, and the lighting source 2 is below the imaging device. Set opposite to each other at 0.4m, the inclination angle is 45°, that is, the luminous angle is 45°; specifically, the lighting source 2 is HQ-SD-W400F floodlight, which satisfies the luminous flux of 40000±5% LM, and the color temperature is 5500 ~ 6000K requirements.

[0070] Since the width of the conveyor belt is 1.6m, the imaging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com