Mechanical structure crack expansion rate and crack expansion life span predication method

A technology of crack growth life and crack growth rate, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve problems such as time-consuming and laborious, increasing product development costs and cycles, and inability to establish a relationship with crack growth rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

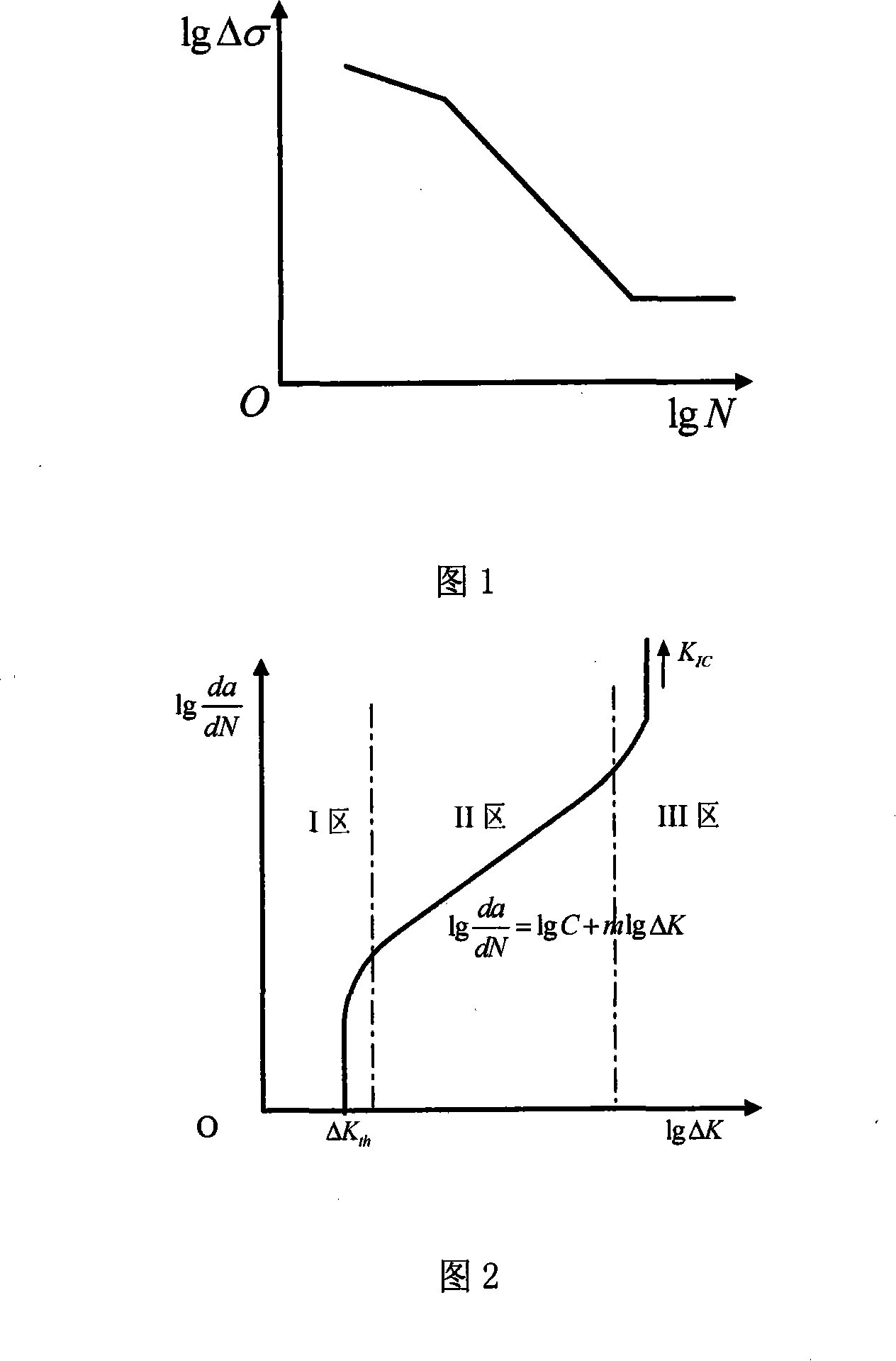

[0029] The linear portion of the curve in Figure 1 can generally be expressed as

[0030] C 1 =Δσ m N f (1)

[0031] where C 1 , m is a material constant, which can be determined through tests or mechanical design manuals; Δσ represents the stress level of the structure, N f Indicates the structural fatigue life.

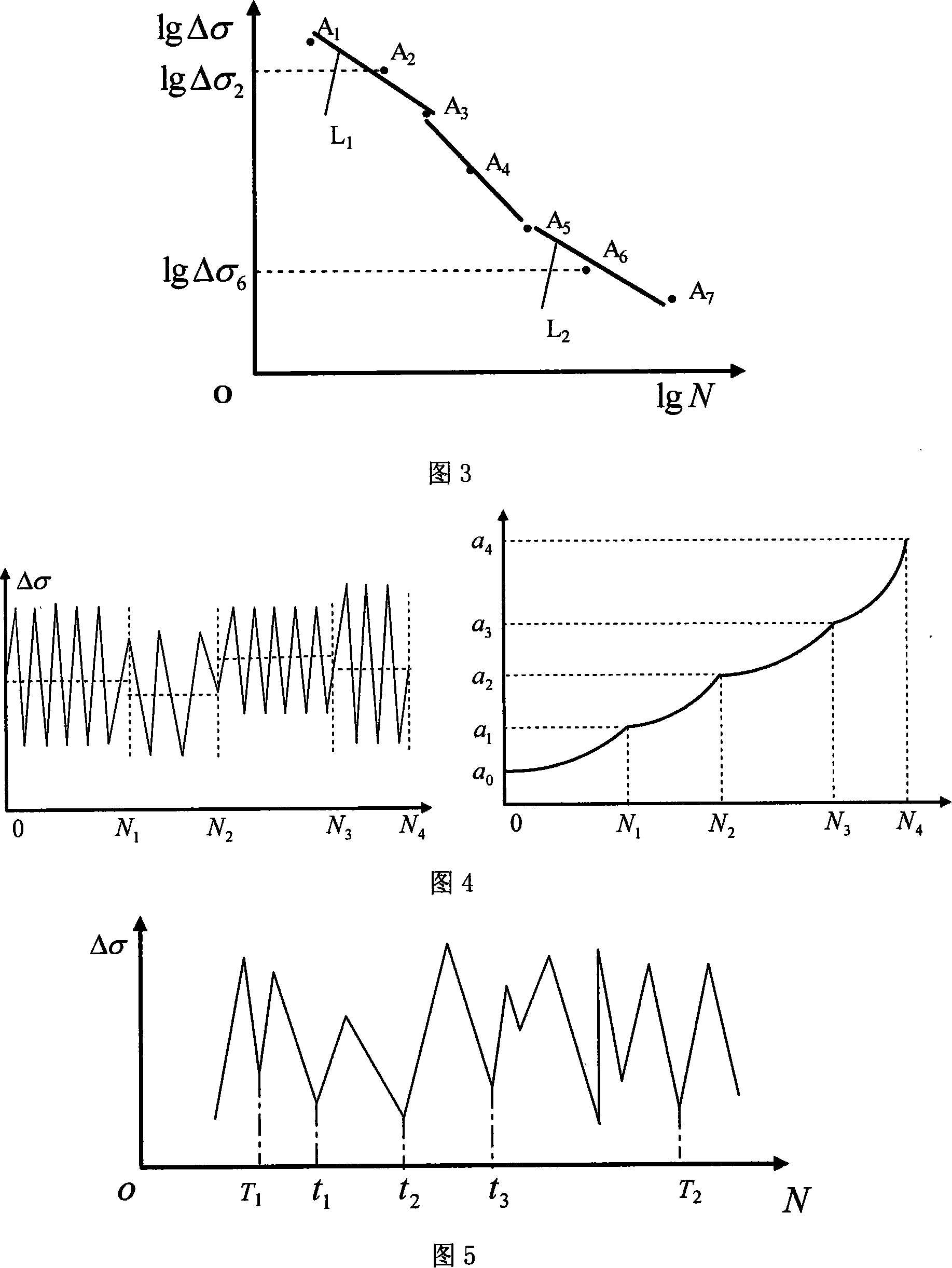

[0032] The linear portion of the curve in Figure 2 can generally be expressed as

[0033] da dN = C [ β ( a ) Δσ πa ] n - - - ( 2 )

[0034] In the formula, C and n are material constants, which are generally determined through experiments; a and N represent the crack length and the number of load cycles respectively; Ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com