Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232 results about "Static strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Static Strength is your ability to hold a pose without movement (concentric and eccentric contractions). Static Strength is often measured by Isometric Exercises. The most common example of static strength is holding the PLANK pose: The average college student is able to hold this for about 1min 30sec -1:46.

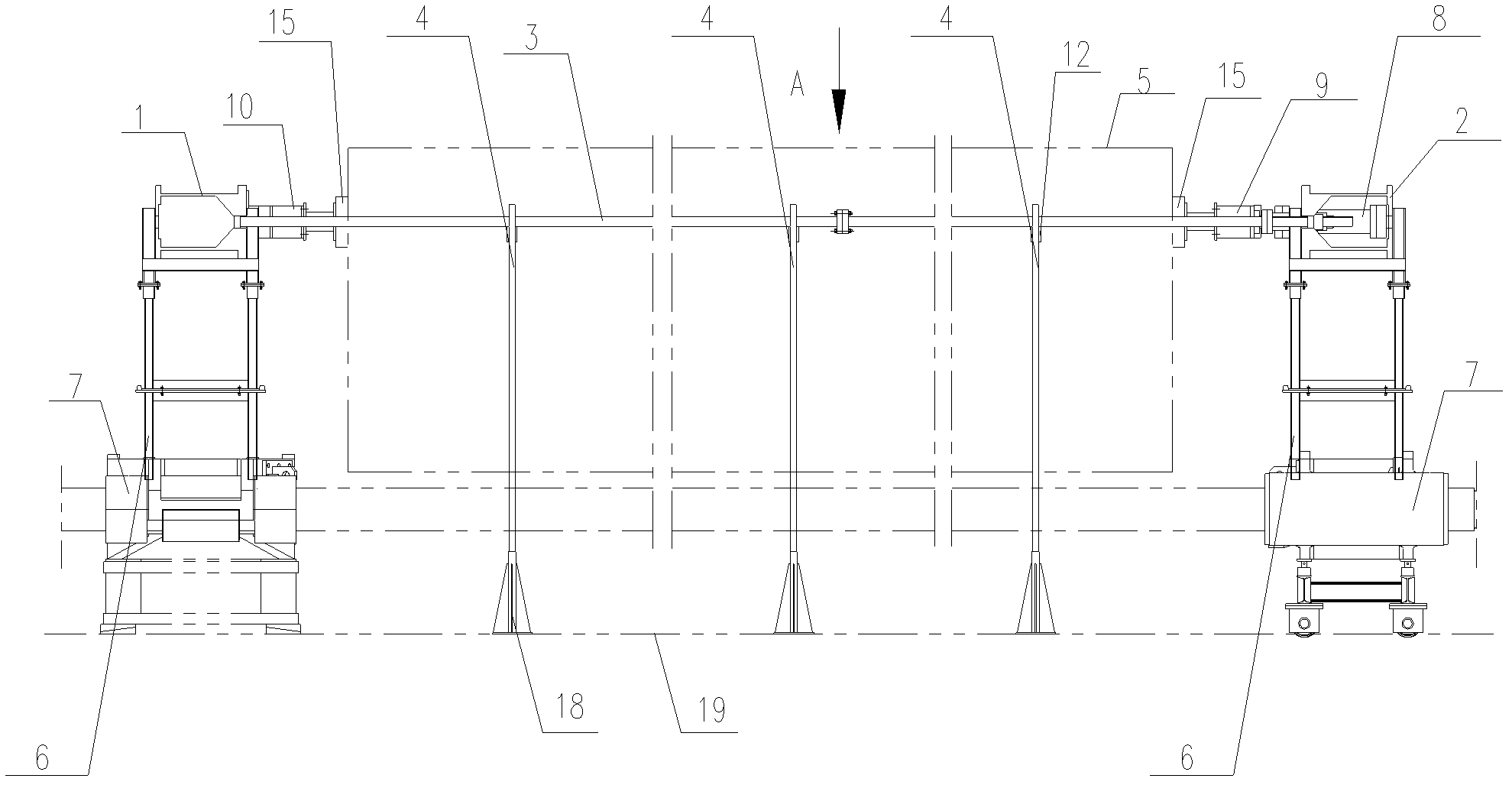

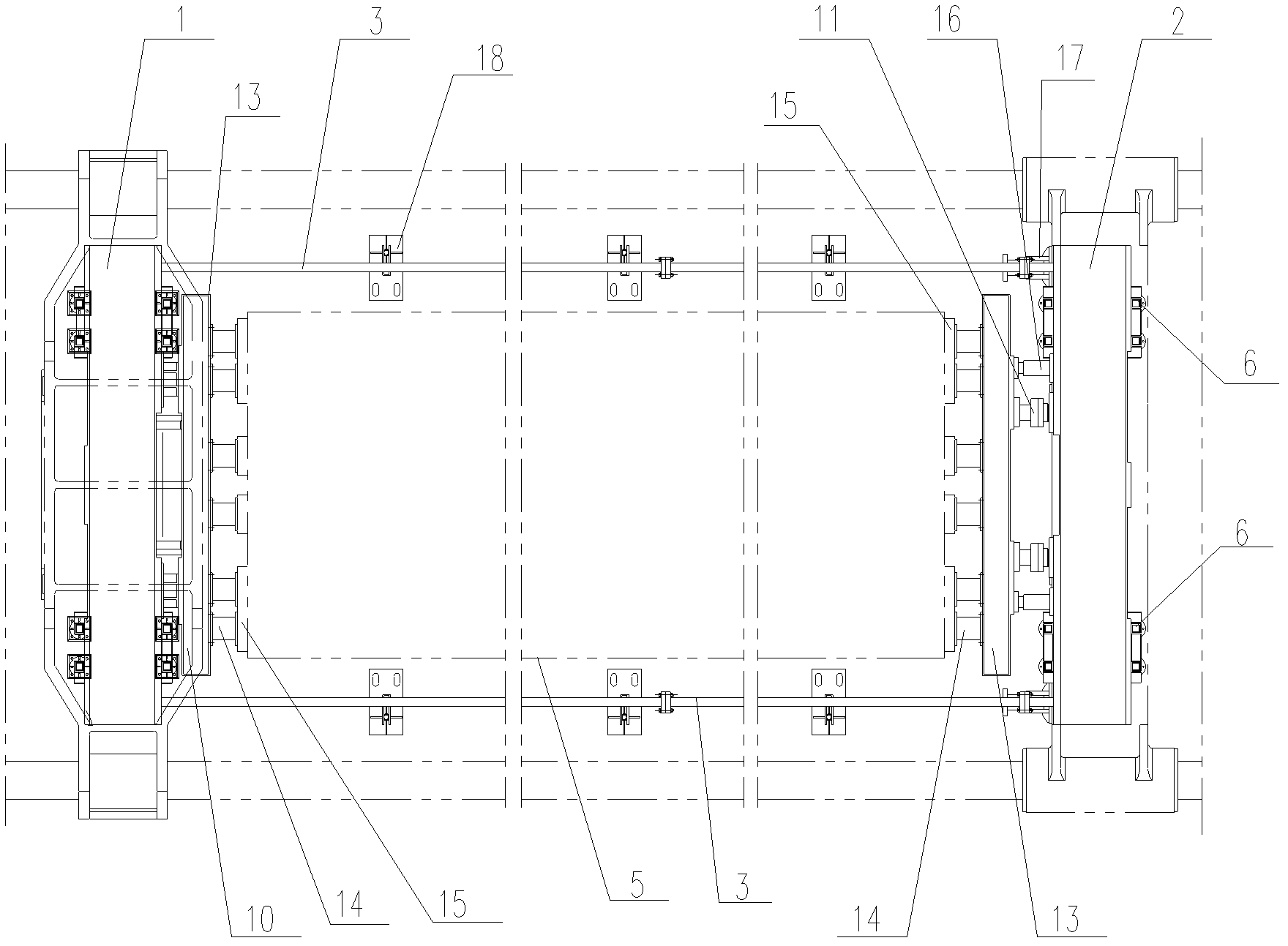

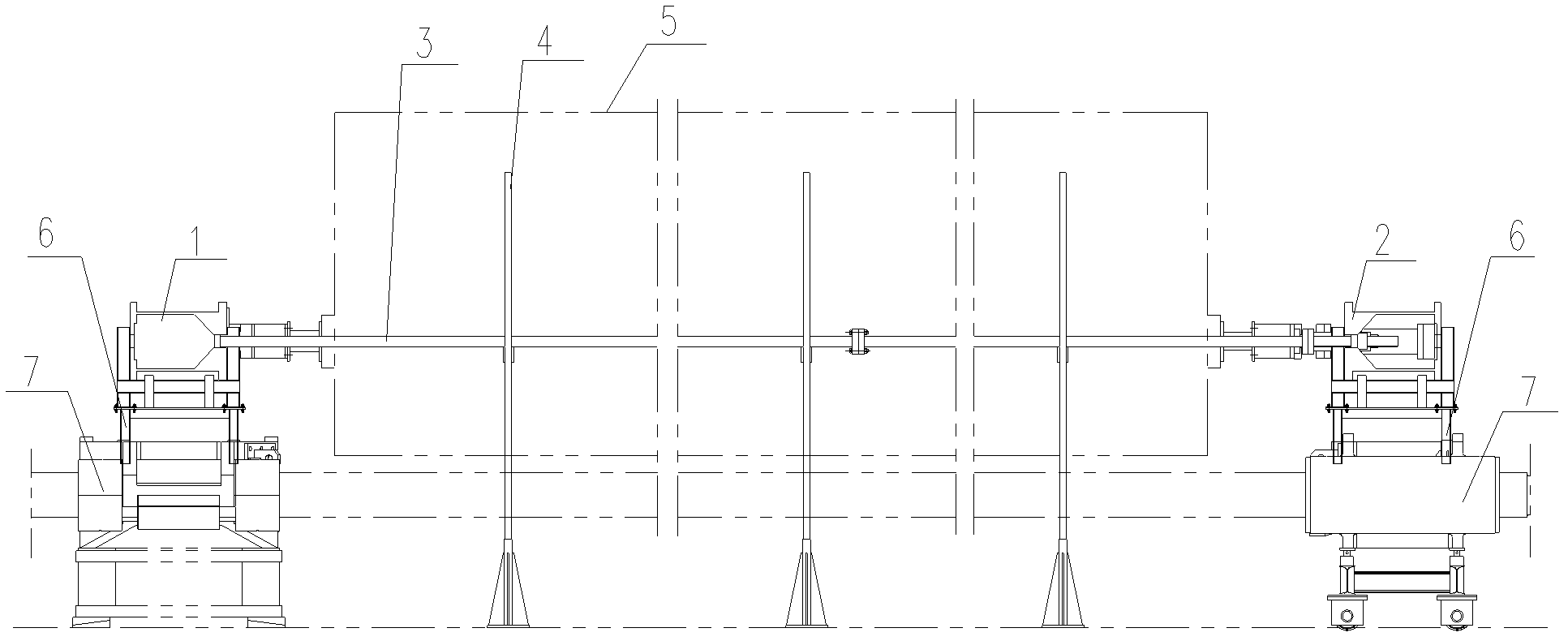

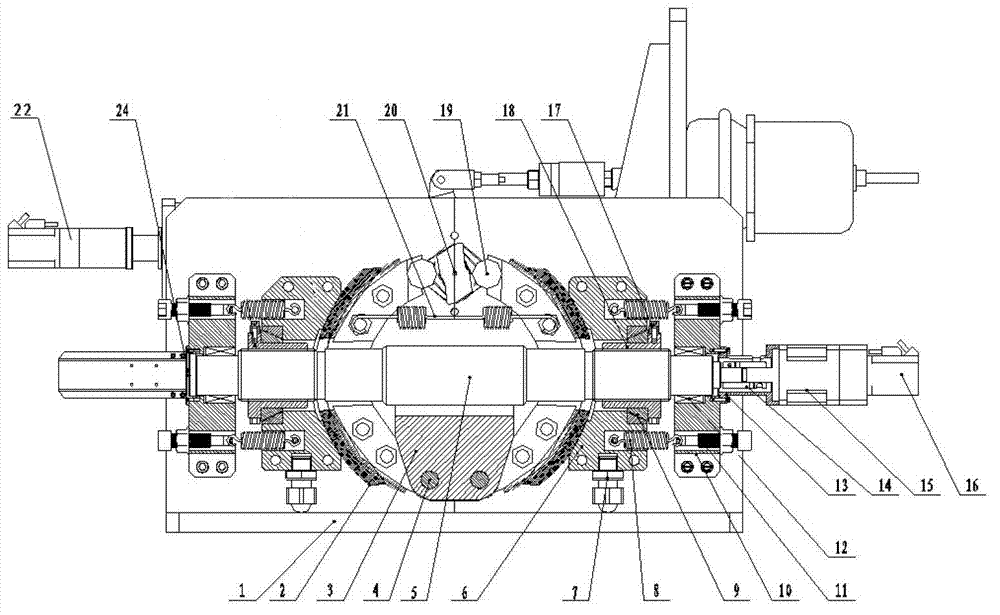

Static strength test method of large vane used for wind power and electrical power and test system thereof

InactiveCN101634604AEasy to moveHuge savingsMachine part testingMaterial strength using tensile/compressive forcesShape changeData information

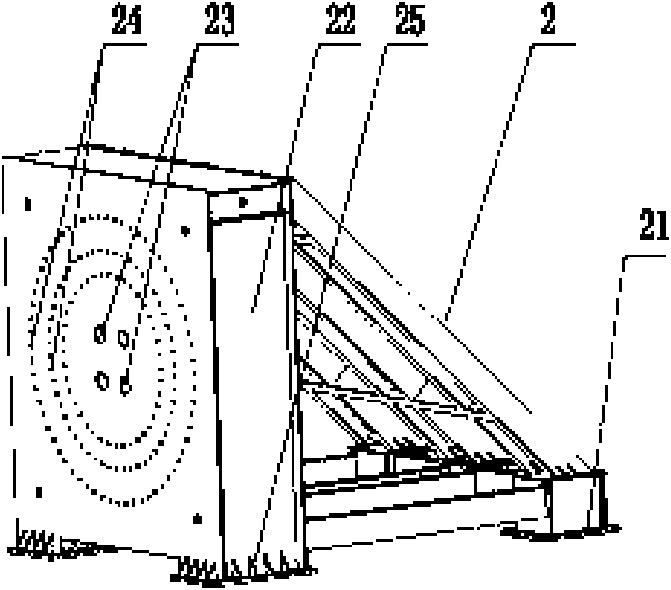

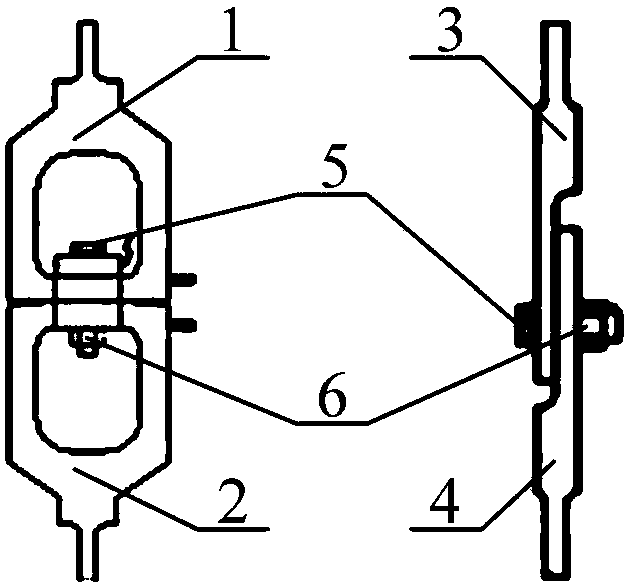

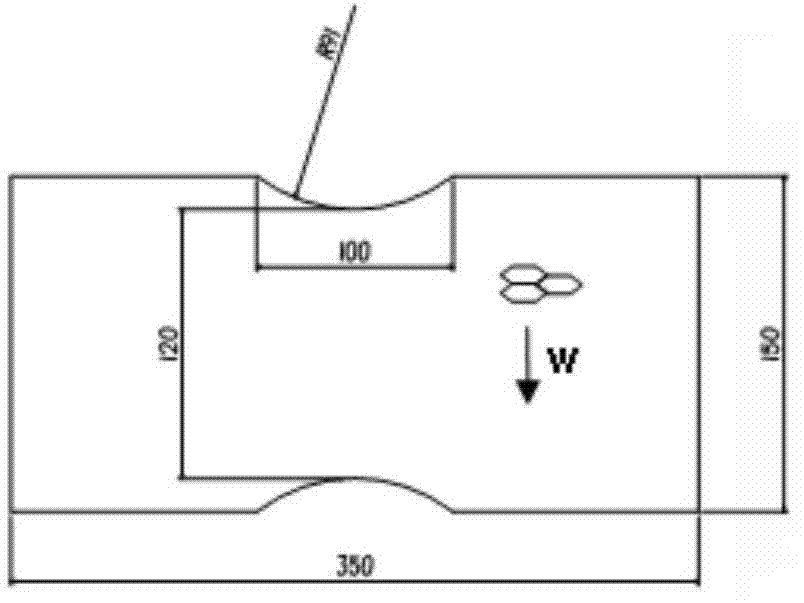

The invention discloses a static strength test method of a large vane used for wind power and electrical power and a test system thereof. The test method comprises the following steps: keeping the vane flat, fixing one end of the root of the vane through a fix support of the test system, vertically loading the vane with a crane, wherein the loading mode is as follows: single point loading through the crane is converted into multi-point loading through a load distributing beam; and then, transmitting the multi-point loading to the vane through a vane loading clamp. The lifting point of the crane, the load distributing beam and the vane loading clamp are connected together through slings provided with load sensors, a strain piece and a displacement sensor are arranged on the vane, and stress, shape change and displacement data information respectively collected from the loading process are used for determining whether the static strength of the vane meets the requirements of design or not. The test method of the invention has the advantages of low area limit, low test cost, convenient process operation and accurate test result; and the test system of the invention has the advantages of simple manufacturing, convenient assemble, low cost and long service life.

Owner:NAT UNIV OF DEFENSE TECH +1

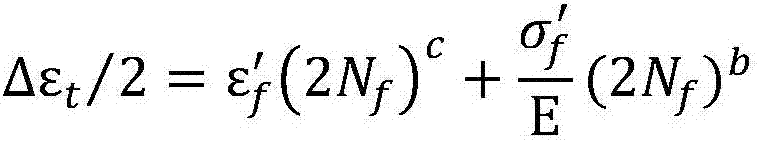

Turbine disc-based low-cycle fatigue crack propagation life prediction method

InactiveCN106644783AExtended Life SatisfactionMaterial strength using repeated/pulsating forcesElasticity measurementStress intensity factorScanning electron microscope

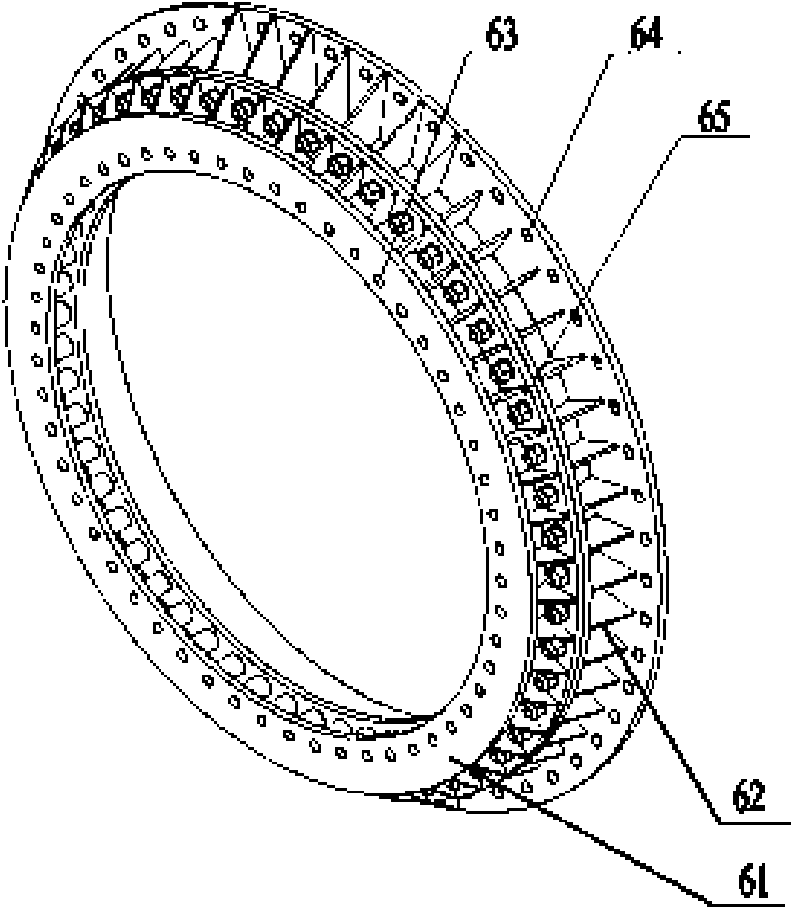

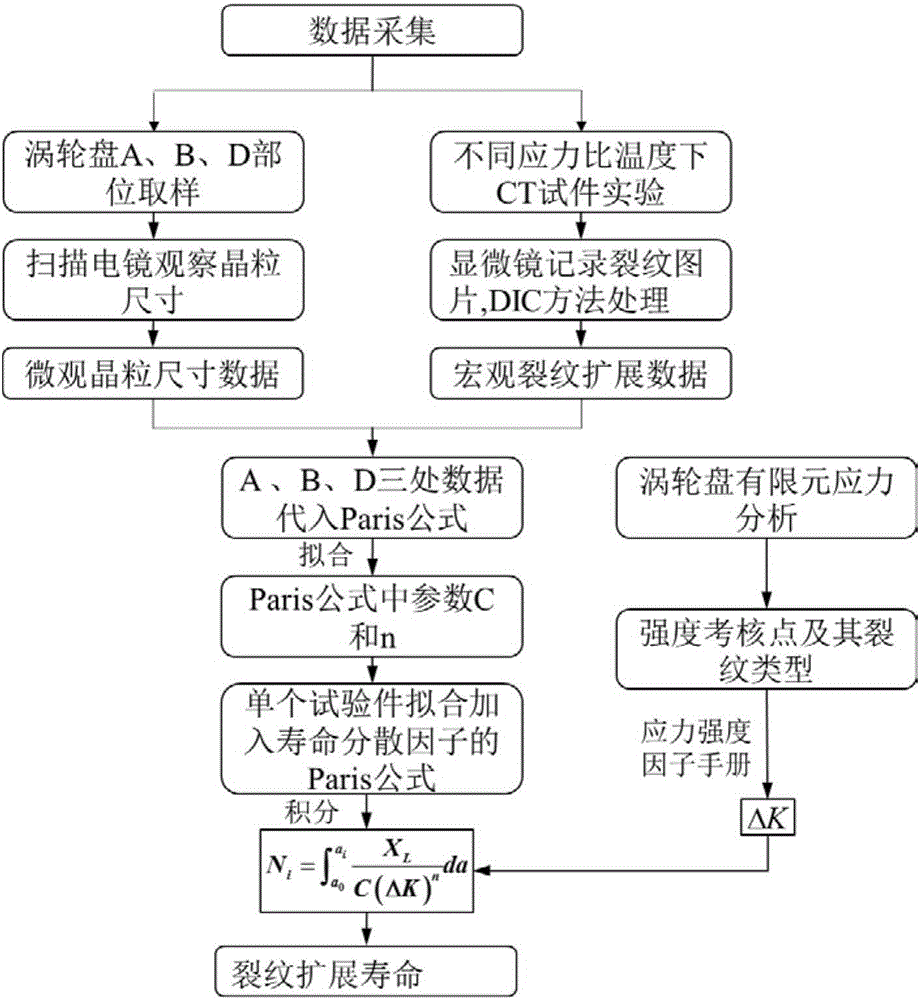

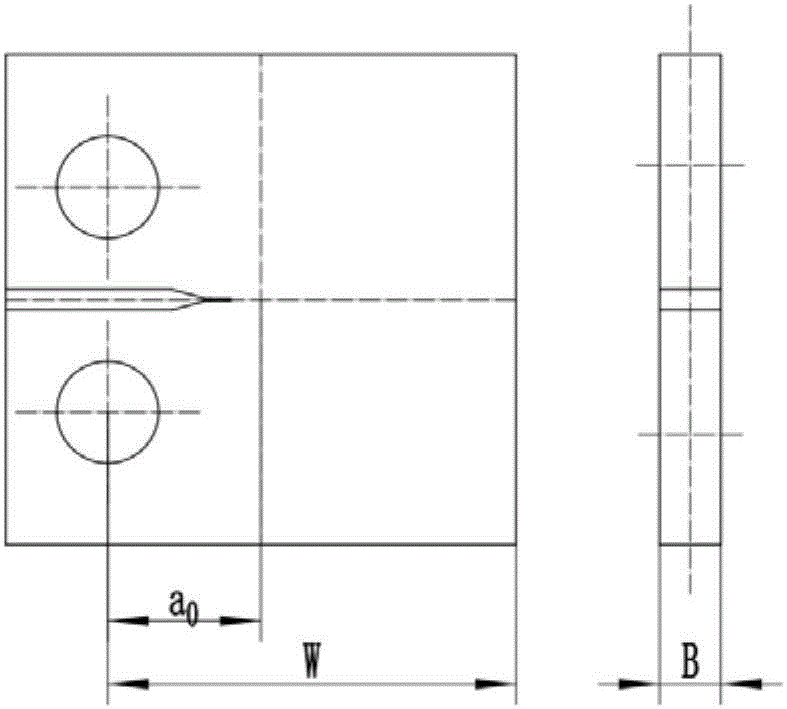

The invention relates to a turbine disc-based low-cycle fatigue crack propagation life prediction method, comprising the following steps: (1) collecting micro-data of different sampling positions of a turbine disc by using a scanning electron microscope, and obtaining a distribution rule; (2) designing a low-cycle fatigue test for the different positions, and collecting macro-data; (3) according to the data collected in steps (1) and (2), obtaining the distribution of a life scattering factor and a Paris formula considering the life dispersibility of the different sampling positions of the turbine disc; (4) performing static strength analysis to obtain a dangerous point position stress intensity factor deltaK, integrating by using the life scattering factor and the Paris formula considering the life dispersibility, which are obtained in step (3), then acquiring the relationship between crack propagation life and crack length, and giving the crack propagation life according to the crack length.

Owner:BEIHANG UNIV

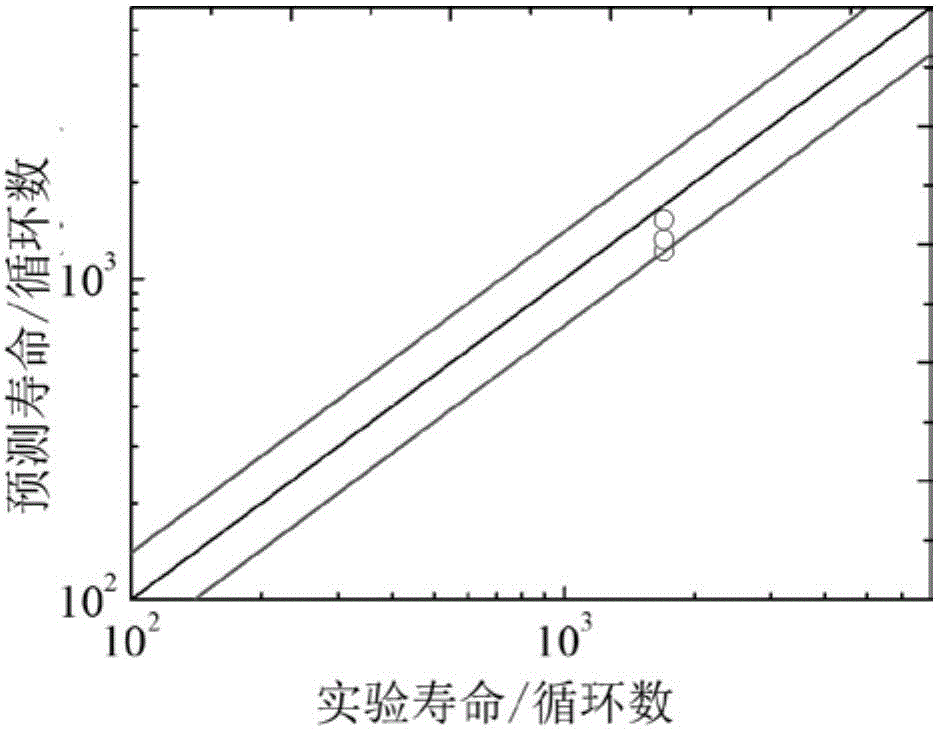

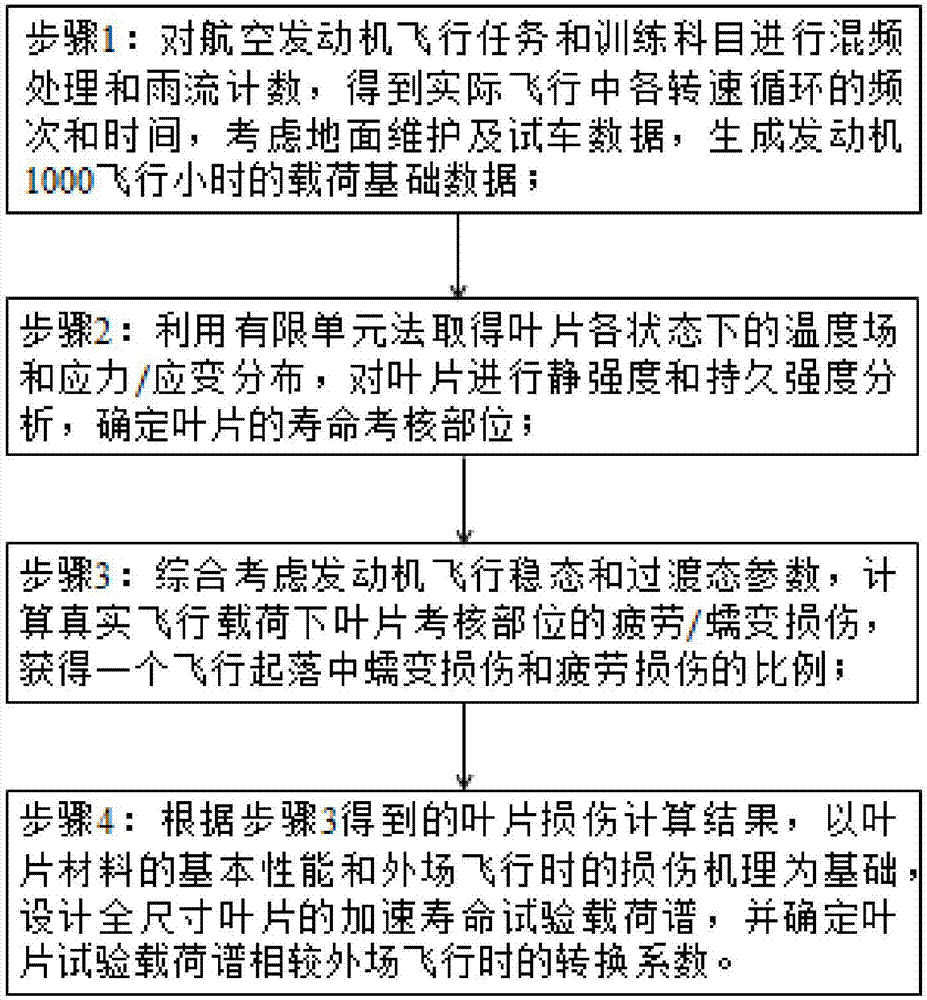

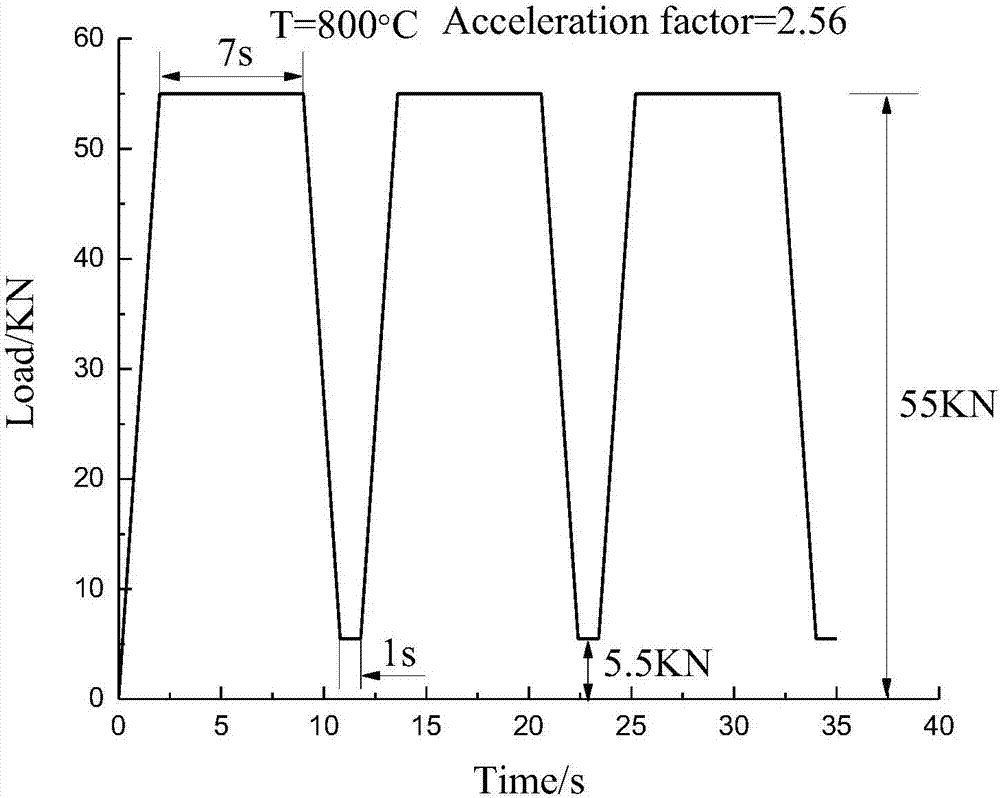

Turbine rotor blade accelerated life test load design method taking regard of flight damage

PendingCN107247002ADamage reasonably characterizedLife assessmentMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageAviation

The invention relates to a turbine rotor blade accelerated life test load design method taking regard of flight damage. The method includes: 1) conducting frequency mixing treatment and rain flow counting on aeroengine flight missions and training subjects to acquire the frequency and time of each rotation speed cycle in actual flight, thus obtaining the load basic data of an engine within certain flight hours; 2) acquiring the temperature field and stress strain distribution of the blade under all states by finite element method, analyzing the blade static strength and endurance, and determining a lifetime testing part of the blade; 3) calculating the fatigue damage and creep damage of the blade testing part under a true flight load to acquire a ratio of creep damage and fatigue damage during rise and fall of a flight; and 4) designing a accelerated life test load spectrum of a full-size blade, and determining a conversion coefficient of the blade test load spectrum relative to out-field flight. The method provided by the invention can be used for acquiring the technical life of the blade and studying the remaining life of the blade, and saves time and economic cost for the fatigue-creep lifetime test of the blade.

Owner:BEIHANG UNIV

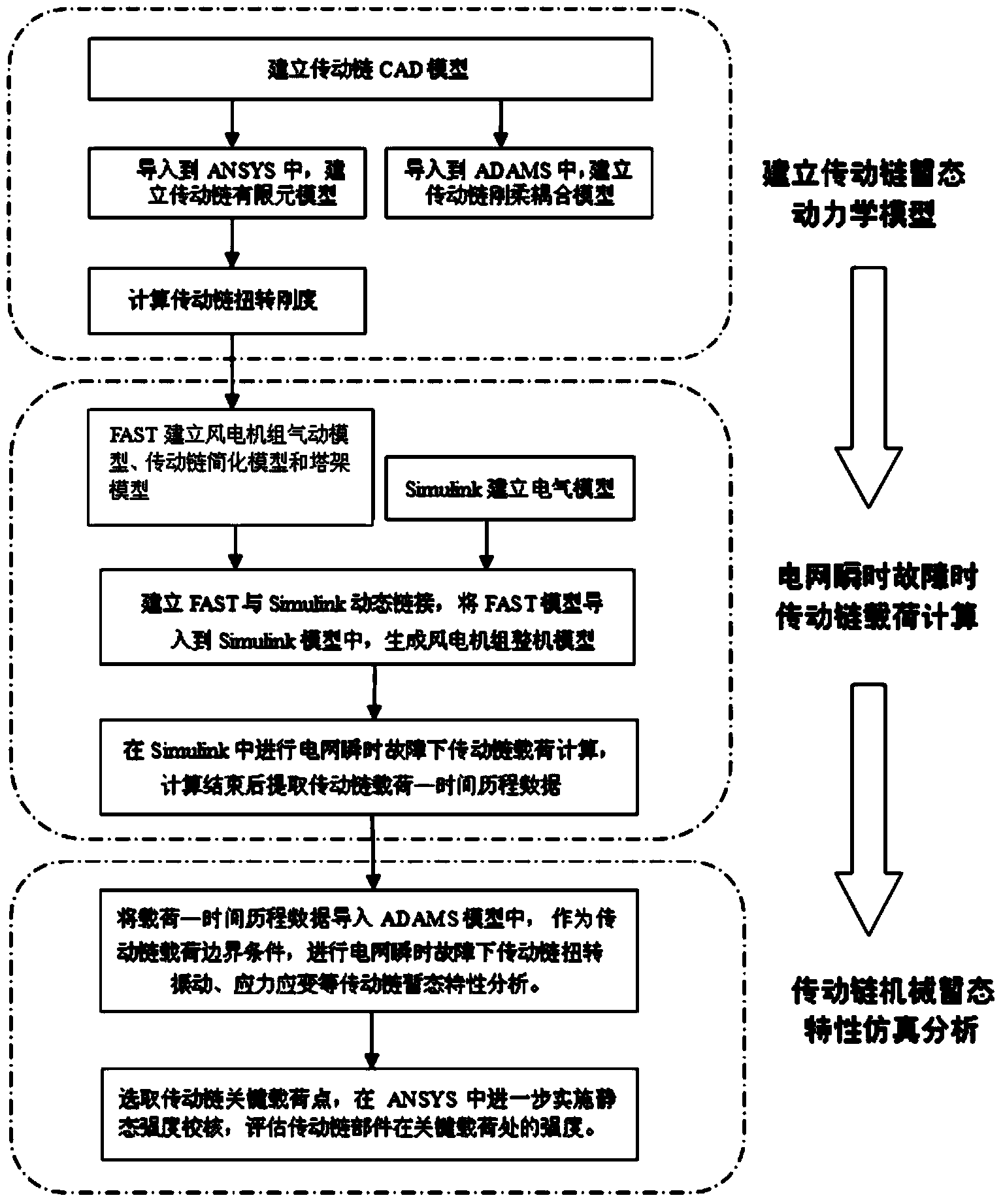

Modeling and simulating method for mechanical transient characteristics of transmission chain of wind generating set

ActiveCN103745070AOvercoming the disadvantages of mechanical transient characteristicsAnalyzing Mechanical Transient EffectsSpecial data processing applicationsInformation technology support systemElement modelSimulation

The invention discloses a modeling and simulating method for mechanical transient characteristics of a transmission chain of a wind generating set. The method comprises the following steps: (1) building a three-dimensional model of the transmission chain of the wind generating set; (2) importing the three-dimensional model of the transmission chain into ANSYS and ADAMS, and building a finite element model and a rigid-flexible coupling model of the transmission chain, wherein the rigid-flexible coupling model considers the flexibility of a main shaft, a planet carrier, a transmission shaft and an output shaft; (3) building a wind generating set model, calculating a transmission chain load when a power grid has a transient fault, and simulating the power grid fault through a voltage sag generator, wherein a torque-time history of the transmission chain is extracted after calculation; (4) loading the torque-time history of the transmission chain into an ADAMS model to serve as the load boundary condition for simulating the mechanical transient characteristics of the transmission chain, performing simulation analysis on the mechanical transient characteristics such as the torque vibration response and stress of the transmission chain when the power grid has the transient fault in ADAMS, and checking and evaluating the mechanical transient characteristics of the transmission chain; (5) selecting a key load point of the transmission chain and performing static strength check analysis in ANSYS.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

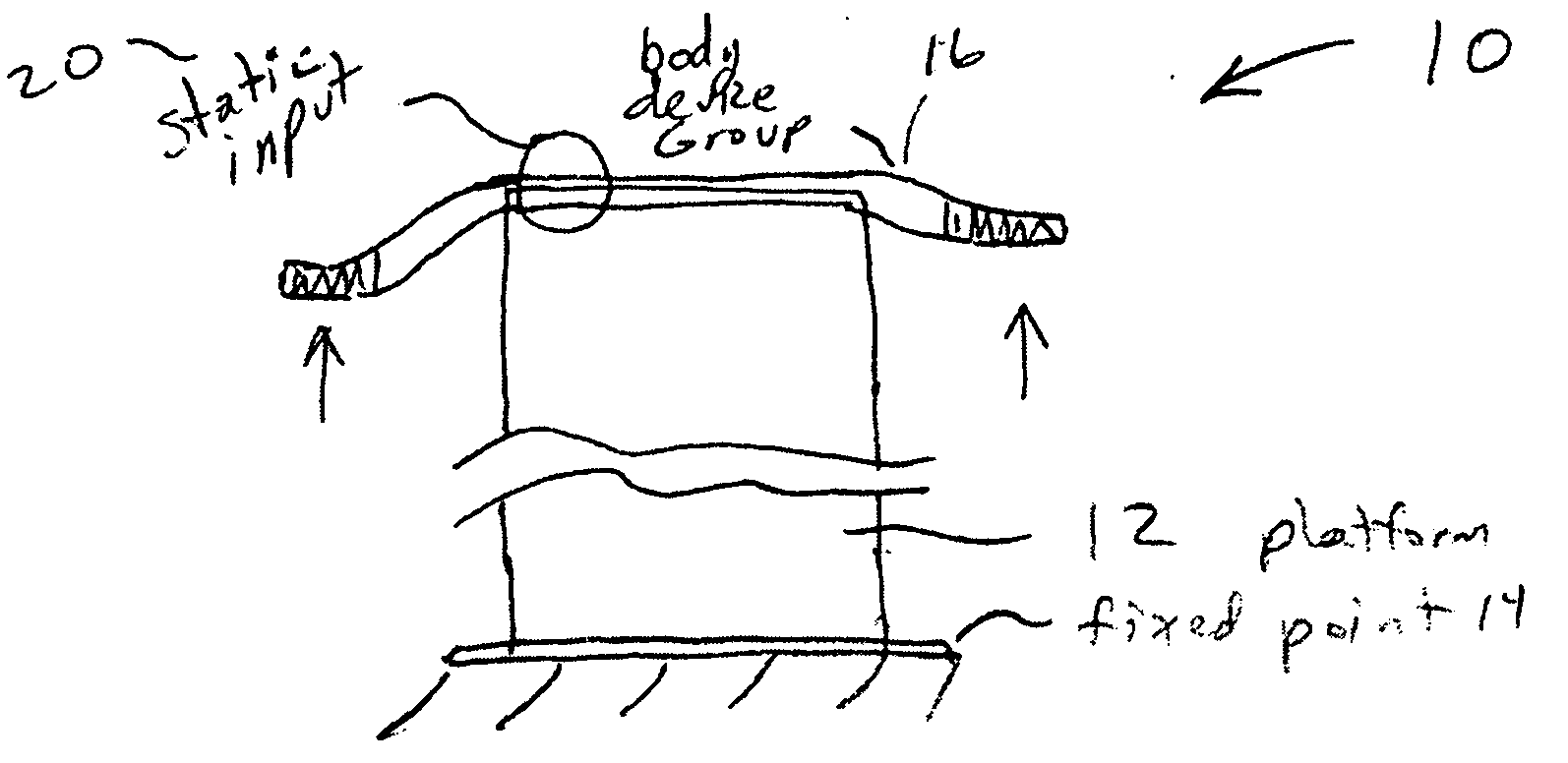

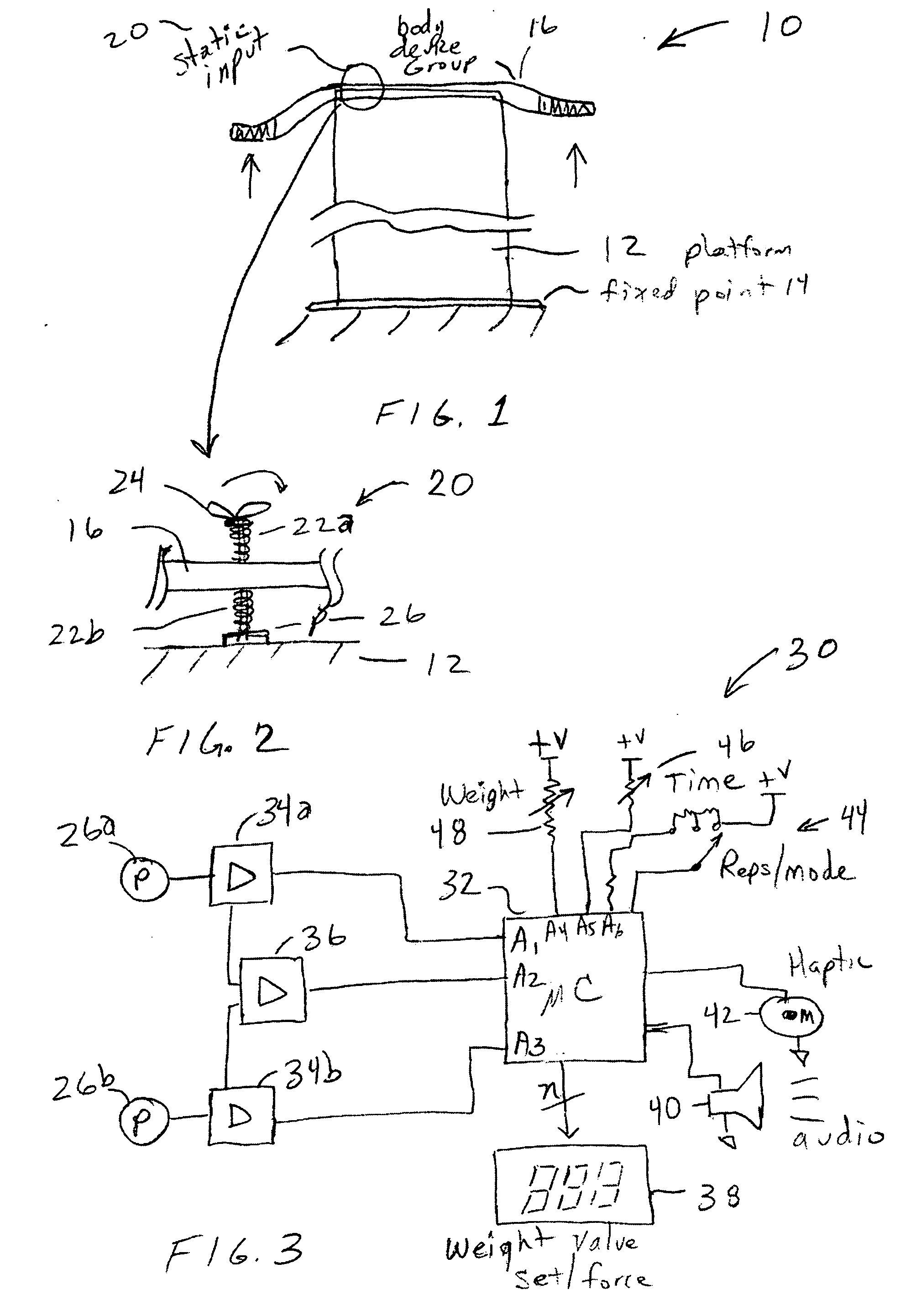

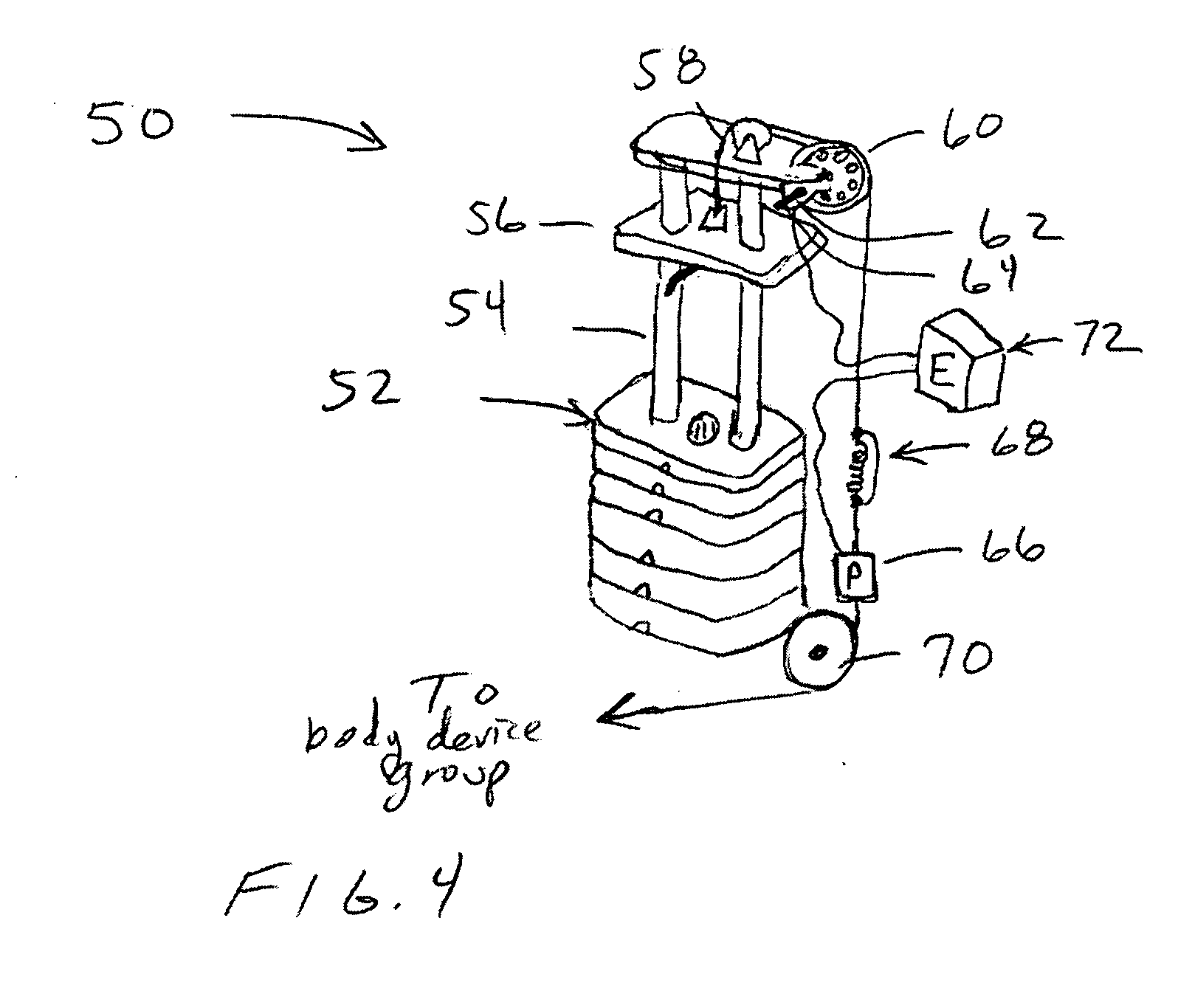

Apparatus and method for static resistance training

A system and method for performing static strength training. The system provides tactile feedback as well as directing the user in the proper application of sufficient and balanced force.

Owner:RAST RODGER H

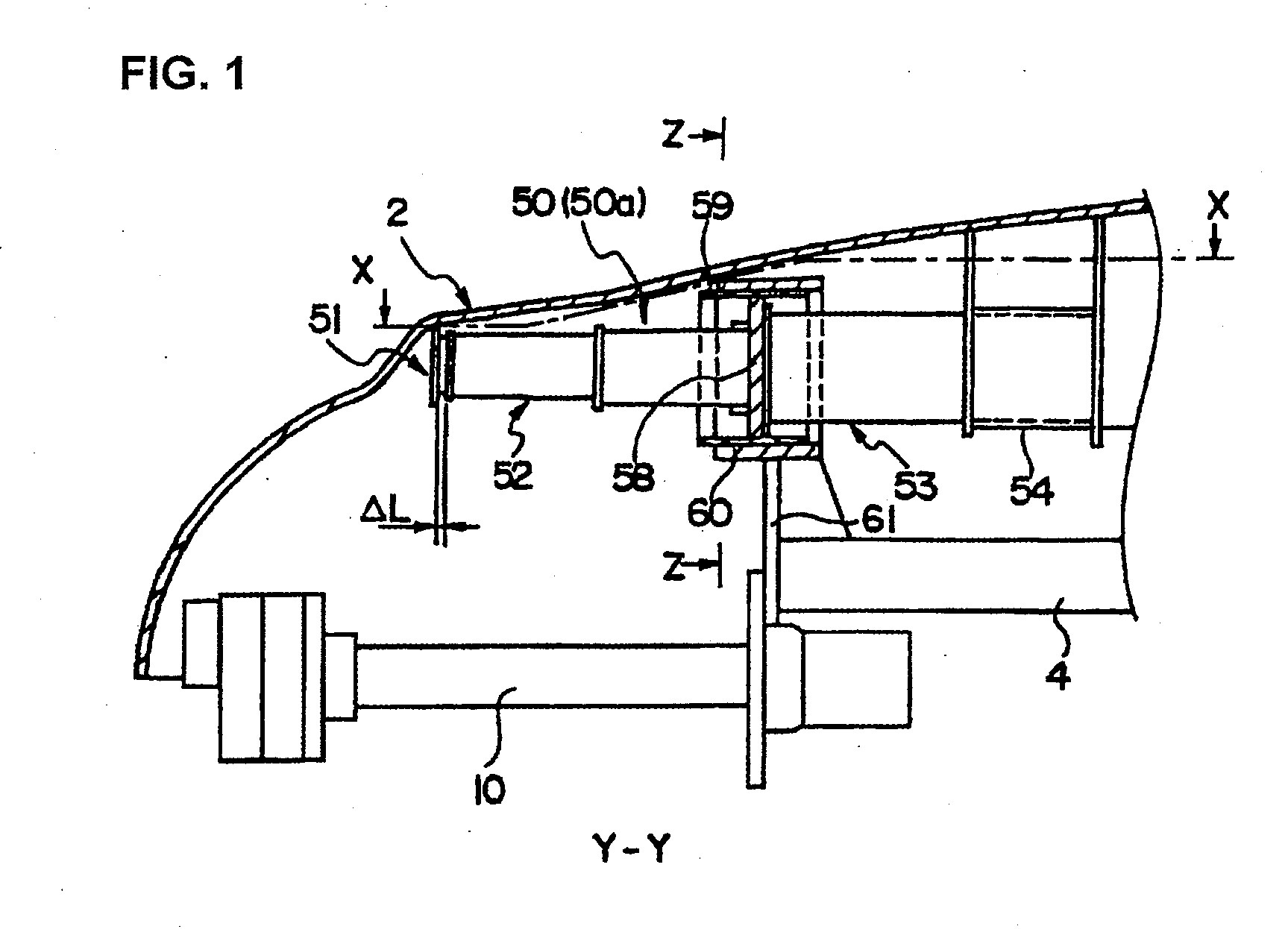

Collision energy absorbing apparatus and railway vehicle equipped with the same

Provided is a collision energy absorbing apparatus capable of mitigating loads to the car body proper, passengers and the like by adding a structure combining a prescribed static strength and collision energy absorption performance to an energy absorbing body of the collision energy absorbing apparatus. In a limited inner space of a car body, a cover 80 that covers energy absorbing bodies 51, 52 combines a prescribed static strength and collision energy absorption performance. The cover 80 prevents irregularities, such as the breakage of cylindrical bodies of aluminum alloy, i.e., the energy absorbing bodies 51, 52 in each of the stages of transportation, storage, assembling and the like of the collision energy absorbing apparatus 50. The cover 80 having static strength fulfills the role of withstanding a prescribed static load and in the event of a collision against an obstacle, the cover 80 is broken earliest and reduces a peak load of crush, with the result that part of the collision energy is used in the breakage of the cover 80. As a result of this, the cover 80 can contribute to the absorption and mitigation of the collision energy.

Owner:HITACHI LTD

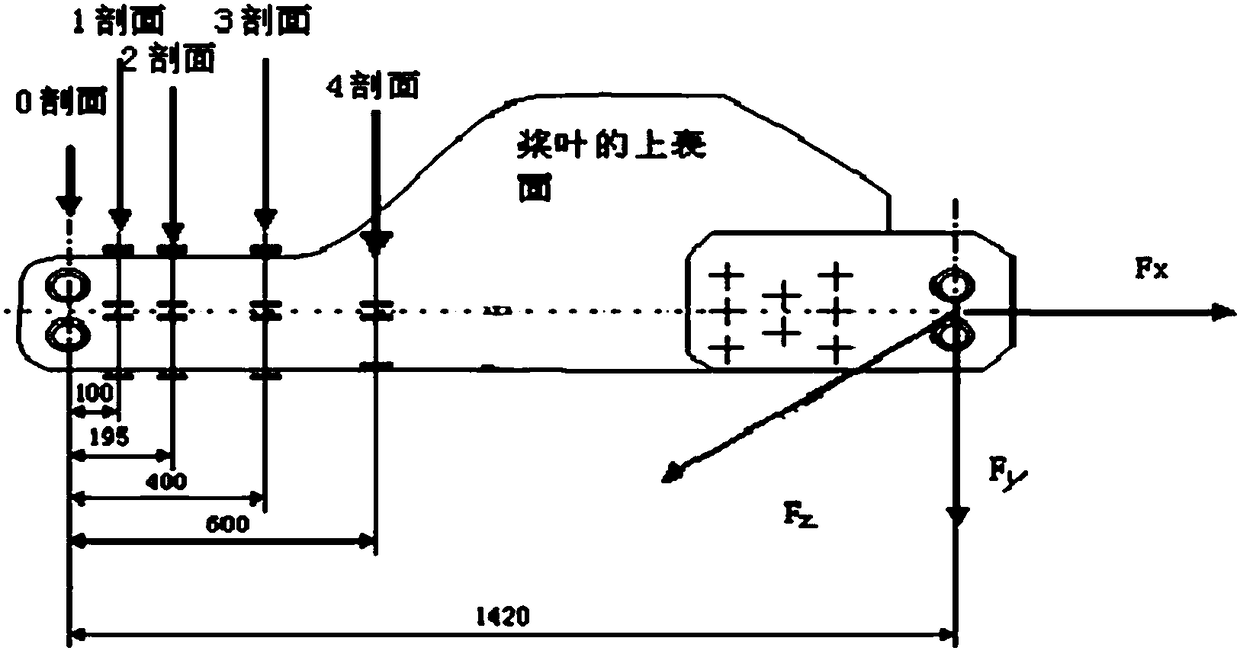

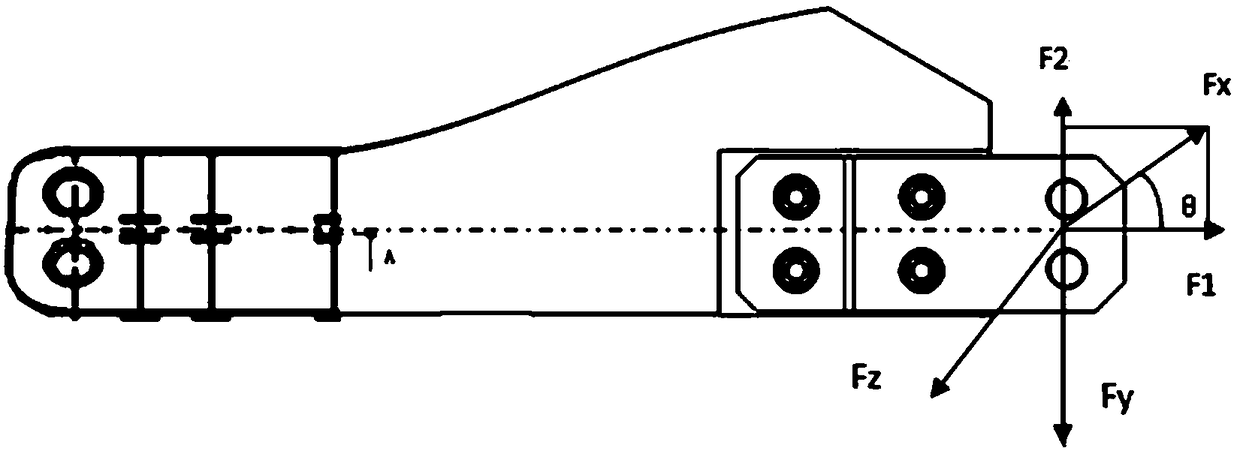

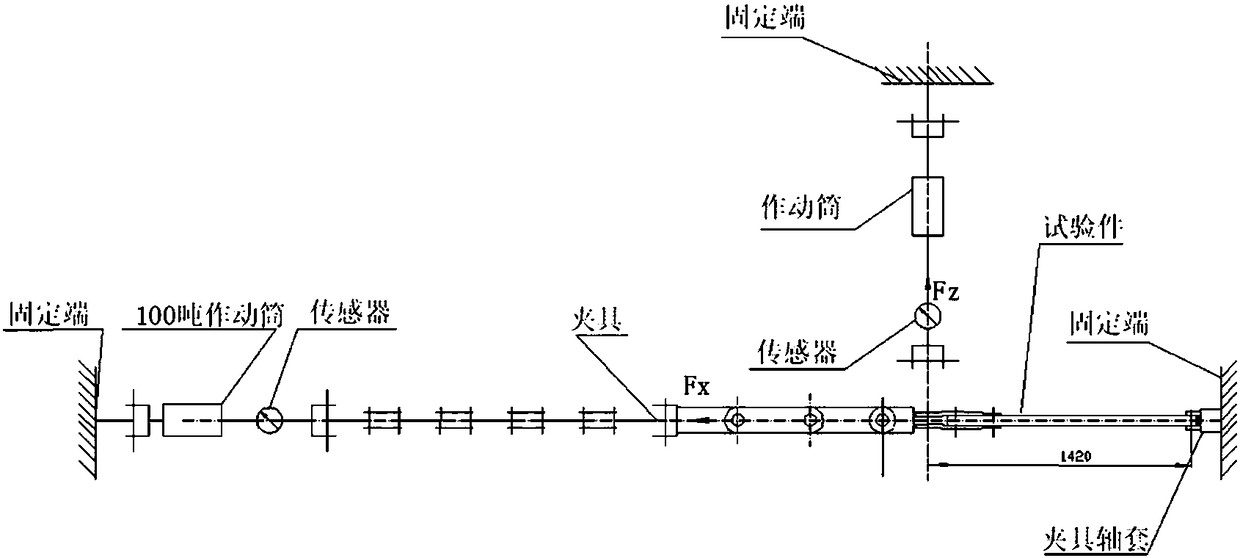

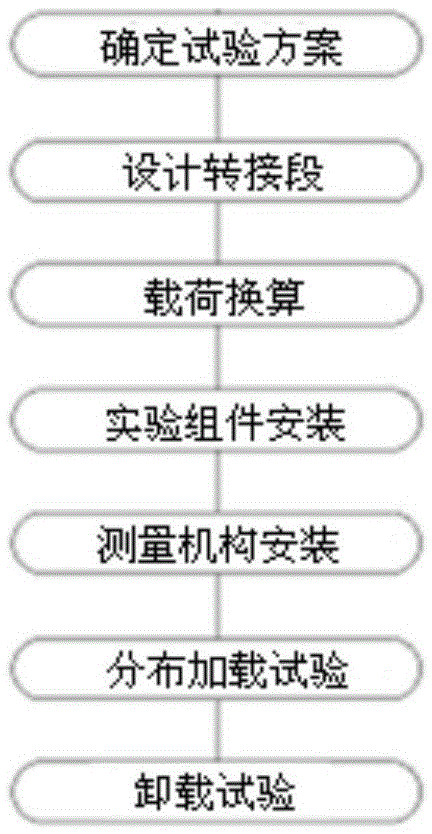

Method for testing static strength of helicopter blade

InactiveCN108120592ASolve the situationSolving Consistency IssuesMachine part testingEngineeringCentrifugal force

The invention provides a method for testing static strength of a helicopter blade, wherein the method belongs to the field of helicopter blade static strength testing. The method comprises the steps of obtaining a waving and swinging calibration equation according to a direct proportion relation between a stress and a bending moment; determining a testing section; determining a plurality of wavingand swinging loads according to a preset waving and shaking bending moment and the testing section; determining each waving and swinging strain value which corresponds with the waving and shaking load; connecting a blade loading end with actuators in a centrifugal force direction, a waving direction and a swinging direction through loading joints, and applying multiple grades of load to the blade. The strain value in the invention reflects a real load bearing condition of the blade on the condition of the corresponding load. The method effectively settles a problem of difference between an actual load bearing condition and applied force load in each direction at the loading end of an actuator. The method can be widely applied to subsequent static strength testing for different types of blades.

Owner:CHINA HELICOPTER RES & DEV INST

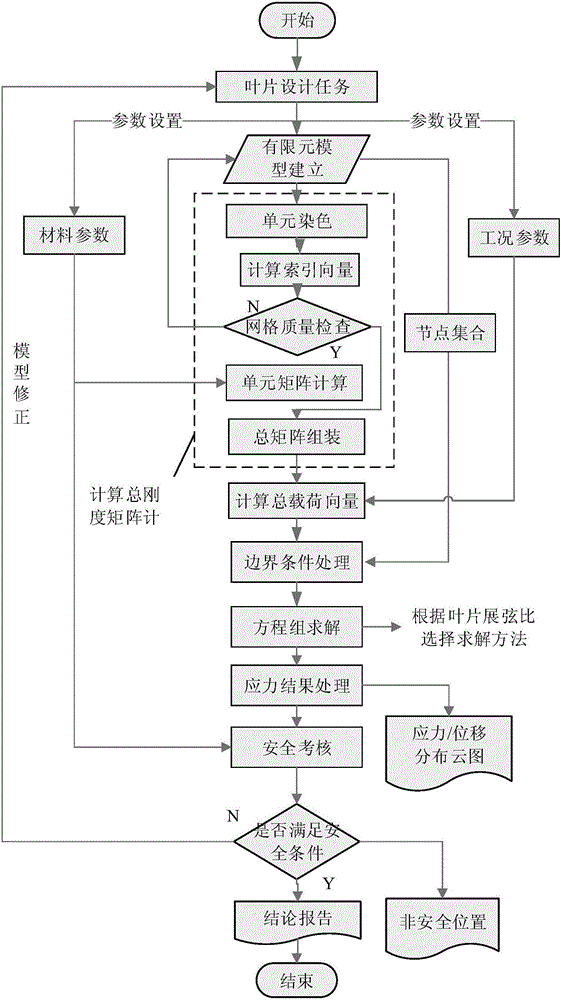

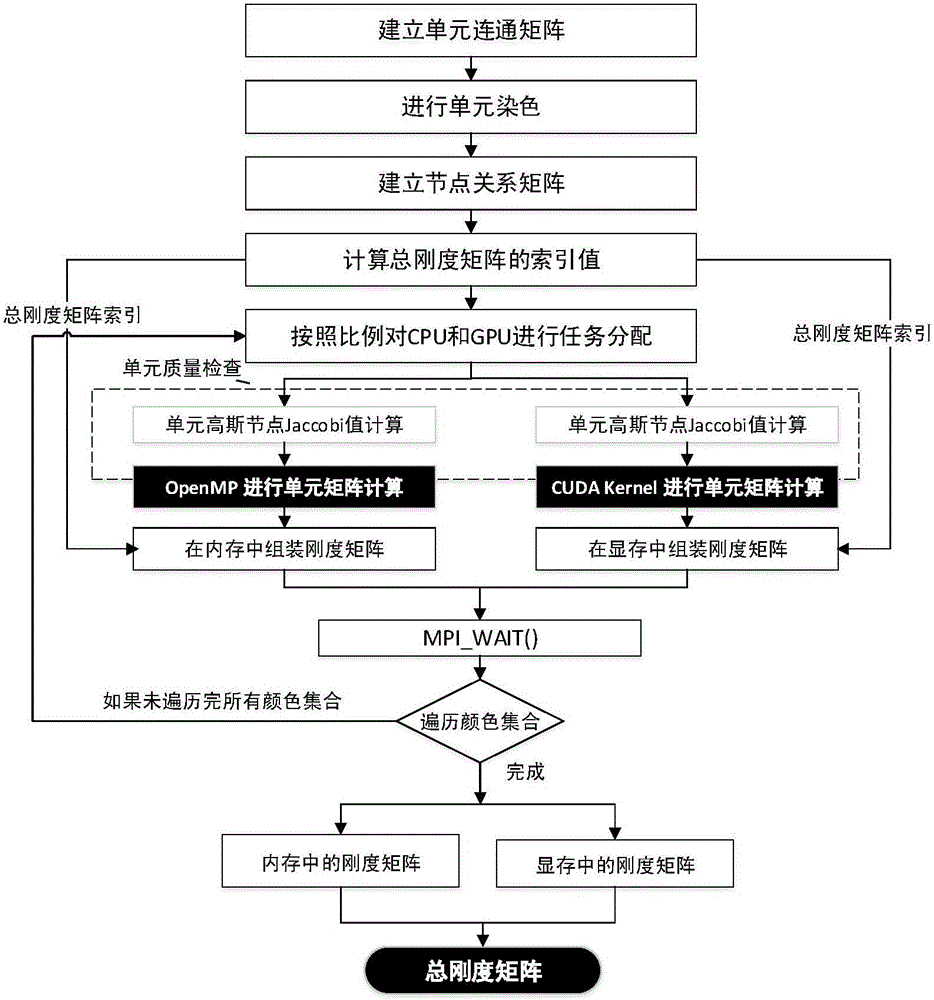

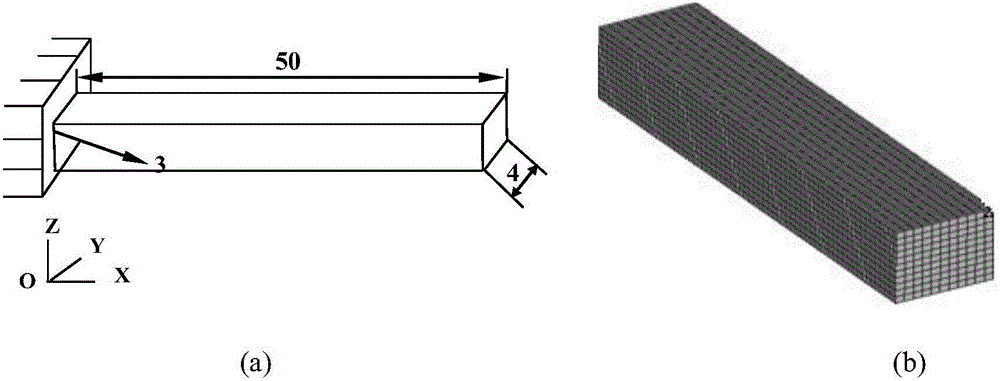

Method for analyzing static strength characteristics of turbomachinery blade based on CPU+GPU heterogeneous parallel computing

ActiveCN106570204AShorten the design cycleAccurate static strength characteristic analysis resultsGeometric CADDesign optimisation/simulationElement modelParallel algorithm

The invention discloses a method for analyzing static strength characteristics of a turbomachinery blade based on CPU+GPU heterogeneous parallel computing. The method comprises the following steps of firstly, establishing a finite element model, computing the total stiffness matrix of the model, then, computing the centrifugal load vector and the pneumatic load vector of the turbomachinery blade, performing displacement constraint and coupling of a node, and correcting the total stiffness matrix; and then, solving an equation set formed by the total stiffness matrix and the load vector in parallel by using CPU+GPU, obtaining a node displacement vector, then, computing the principal strain and the VonMises equivalent stress, drawing a distribution cloud picture, and finally, performing safety check. By means of the method disclosed by the invention, for static strength analysis and design of the turbomachinery blade, project planners can perform operation conveniently; simultaneously, due to an adopted CPU+GPU parallel algorithm, the computing speed of a finite element method can be effectively increased; an accurate and rapid blade static strength characteristic analysis result is provided for design of the turbomachinery blade; and the design period of the turbomachinery blade is greatly shortened.

Owner:XI AN JIAOTONG UNIV

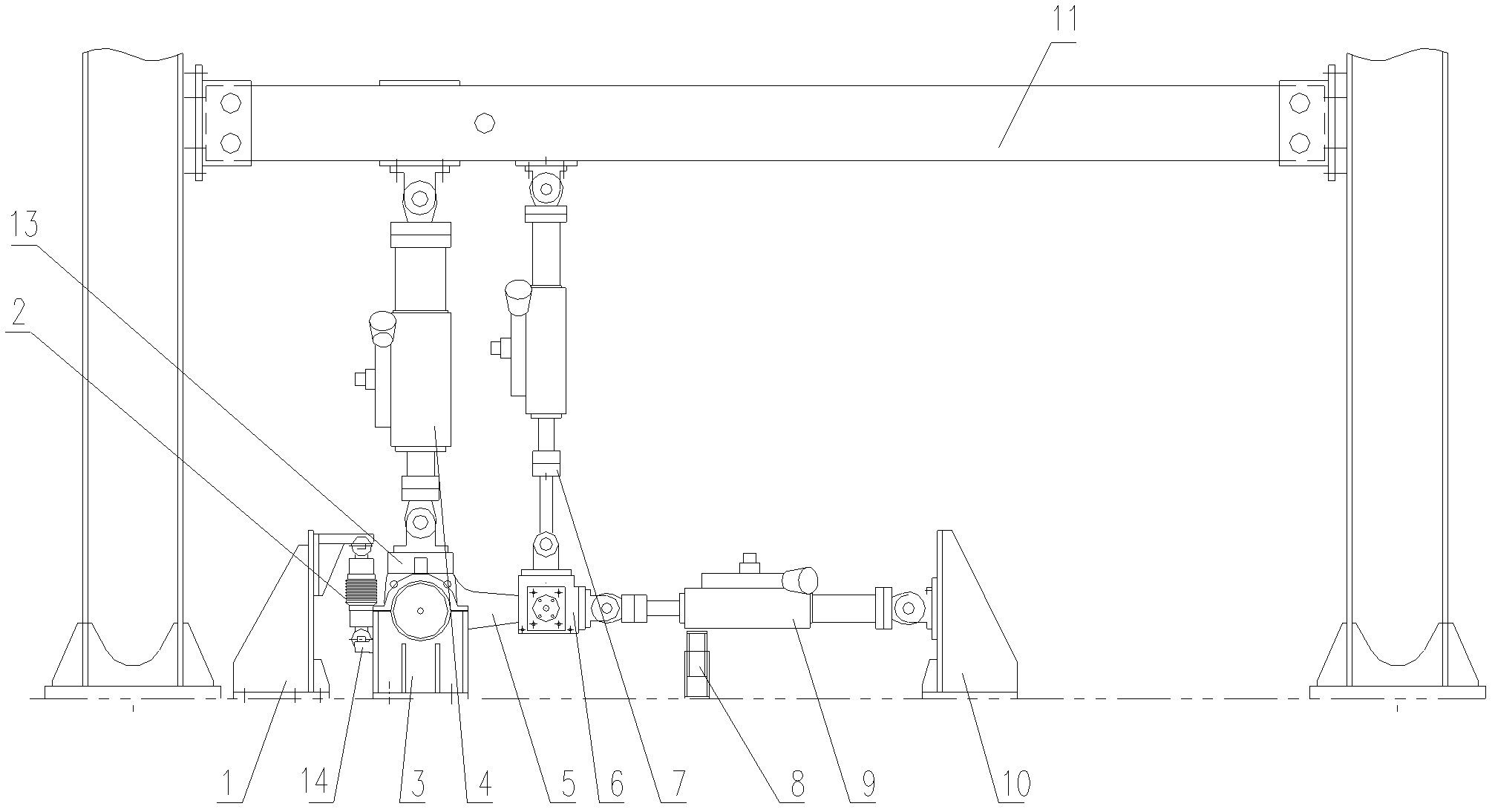

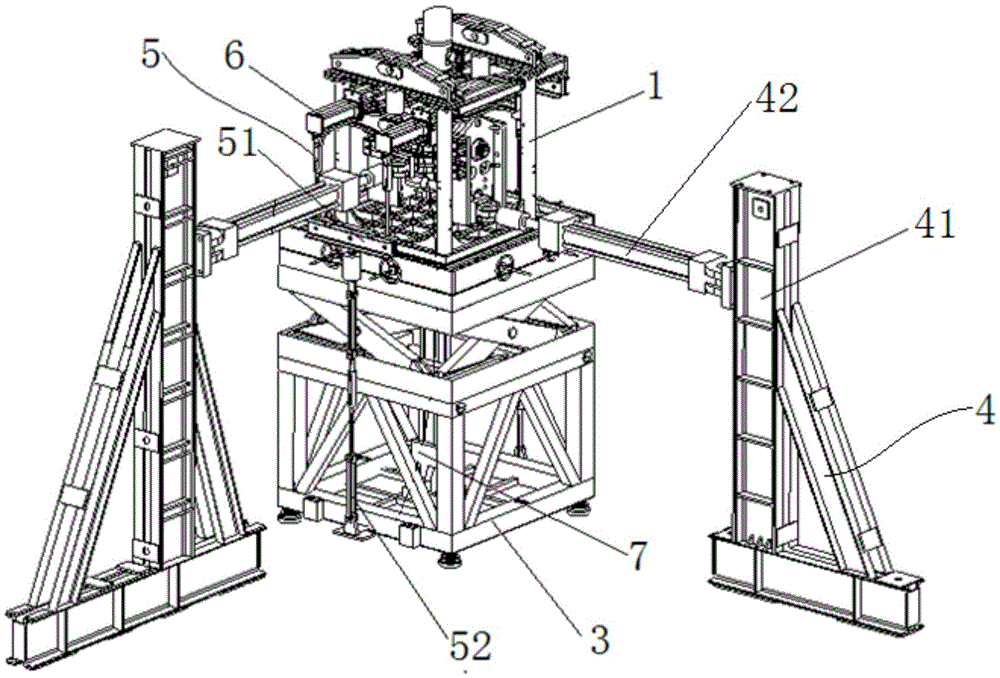

Loading device and method for car body strength test bed end wall

ActiveCN103105303ASimulation is accurateImprove accuracyRailway vehicle testingEngineeringStatic strength

The invention relates to a loading device and method for a car body strength test bed end wall. Longitudinal compression loading is exerted to the end walls on two sides of a tested car body simultaneously so as to simulate static strength testing conditions closest to actual use conditions accurately. The car body strength test bed end wall loading device comprises an end wall beam and an end wall loading beam, wherein the end wall beam and the end wall loading beam are respectively installed through a vertical support and a vertical beam installing seat. The end wall beam is used for fixing and clamping the end walls of the tested car body through a second conveying device, and the end wall loading beam is used for clamping and fixing the end walls of the tested car body through a first conveying device correspondingly. A loading oil cylinder is arranged on the end wall loading beam, the front end of the loading oil cylinder is fixedly connected with the first conveying device, and the end wall beam is fixedly connected with the second conveying device. A pressure sensor is arranged at the front end of the loading oil cylinder, the other end of the pressure sensor is fixedly connected with the first conveying device, and the pressure sensor is connected with a test bed control unit.

Owner:CRRC QINGDAO SIFANG CO LTD

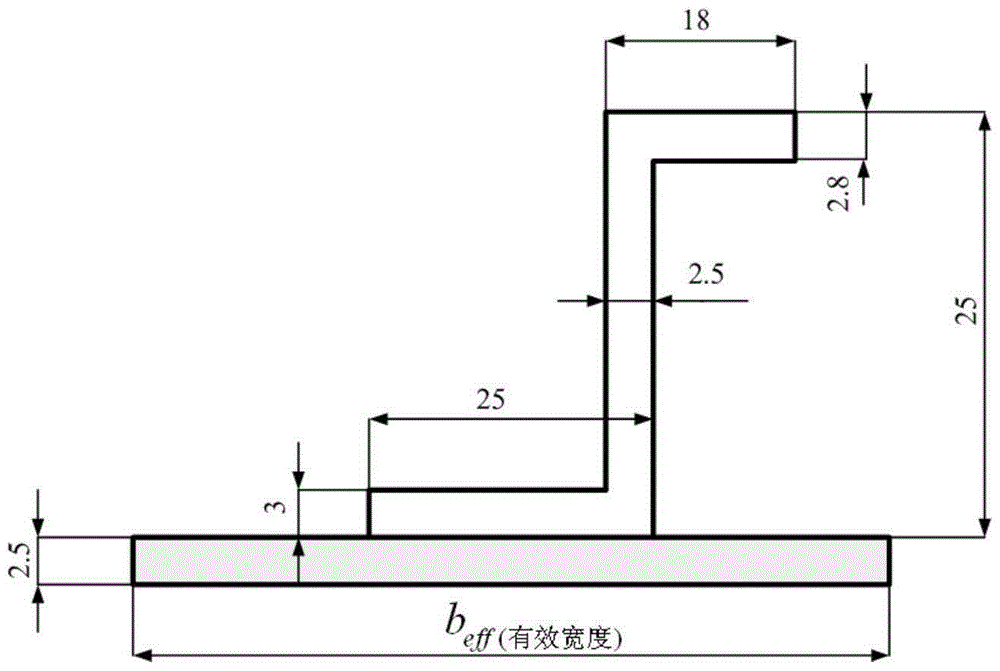

Integrated optimization method of static strength, rigidity, stability of wallboard structure

The invention discloses an integrated optimization method of static strength, rigidity, stability of a wallboard structure. In an optimization design process, apart from conventional static strength and rigidity, an integrated stability determination coefficient of the wallboard structure is introduced as a constraint condition, i.e., in an iteration process, automatic calculation and determination are performed on multiple instability modes including wallboard rib compression stability, pressing damage strength, compression stability of a skin diaphragm structure, cutting stability, integrated wallboard stability and the like, minimization of the total weight of the structure is taken as an object, dimension parameters of the wallboard structure are optimized, under the condition that the static strength, the rigidity and the integrated stability performance of the wallboard structure after the optimization satisfy design requirements, the weight of the structure is the lightest, recalculation on various stability of the structure after conventional engineering design and optimization is avoided, the problems of increased calculation cost and design change risks which are caused by using a conventional method are solved, and the design efficiency is substantially improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

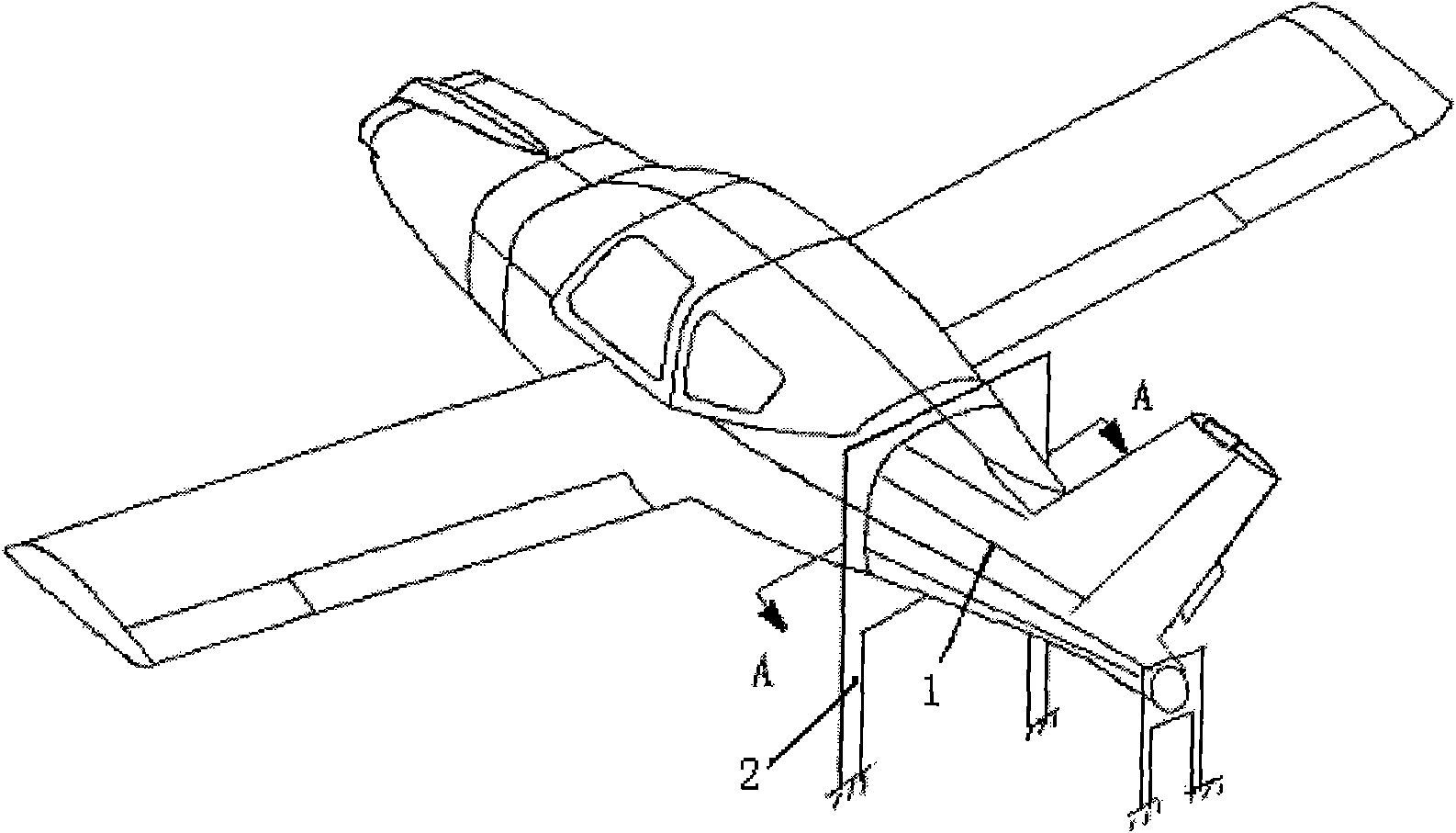

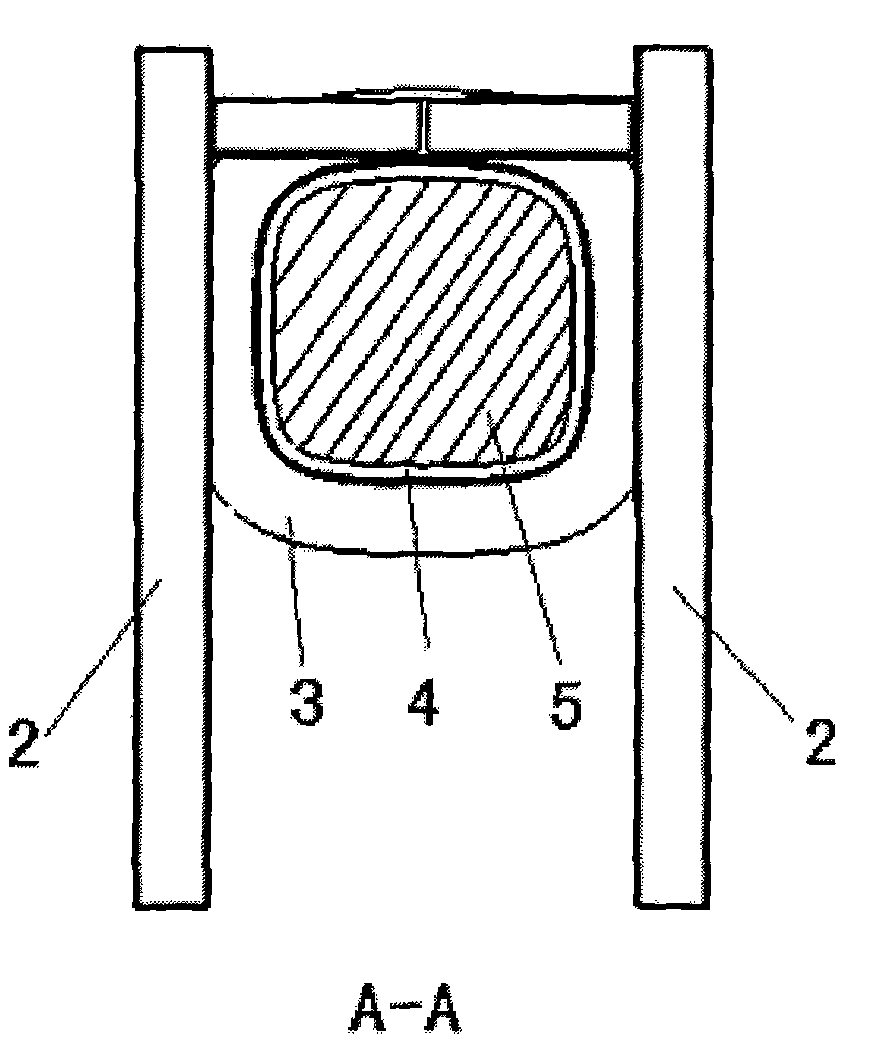

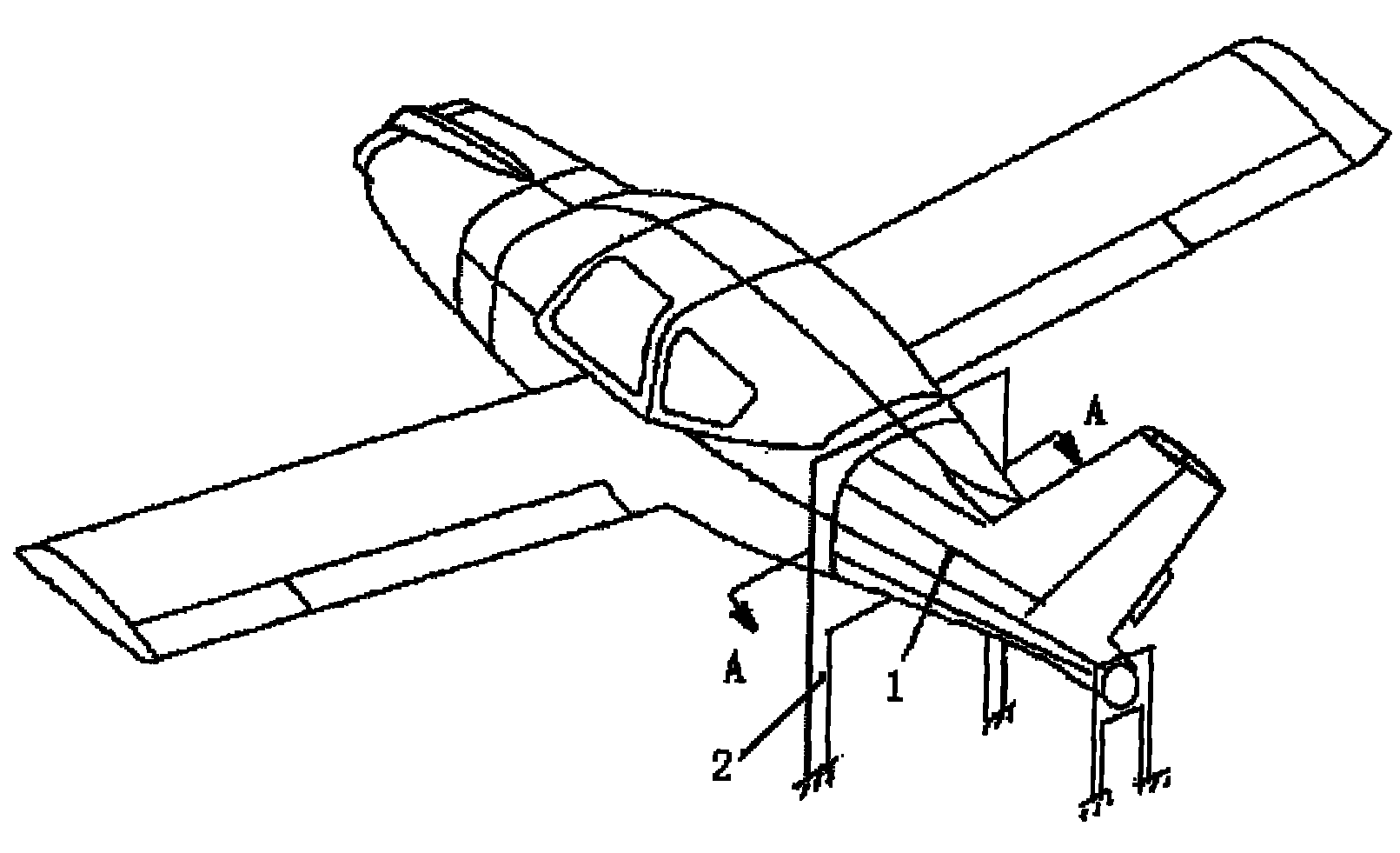

Method for supporting static test for light-aircraft fore fuselages

ActiveCN101788397AEasy to operateHigh precisionStructural/machines measurementAircraft components testingStatic strengthUltimate tensile strength

The invention relates to an aircraft supporting-fixing method in static strength test, in particular to an aircraft-supporting method in static strength test for fore fuselages. The method for supporting static test for light-aircraft fore fuselages comprises that: a straight frame of an aircraft rear fuselage is provided with two clamp hoops; the clamp hoops and the fuselage are tightly clamped; each clamp hoop is connected with two upright columns arranged on two sides of the fuselage; the width of a clamp-hoop edge strip is not greater than that of a fuselage edge strip where the clamp-hoop edge strip is arranged; one clamp hoop is arranged on the fuselage straight frame between aircraft wings and an aircraft horizontal tail, and the other clamp hoop is arranged at the aircraft tail end after the aircraft horizontal tail is detached; a longitudinal part is arranged on the fuselage between the two clamp hoops; and the longitudinal part is a long truss on the fuselage. The method for supporting static test for light-aircraft fore fuselages has the advantage of effectively solving the problem of supporting the whole fore fuselage of a light aircraft in static strength test, along with simple operation, little influence on test results, high precision, low cost and great practical application value.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

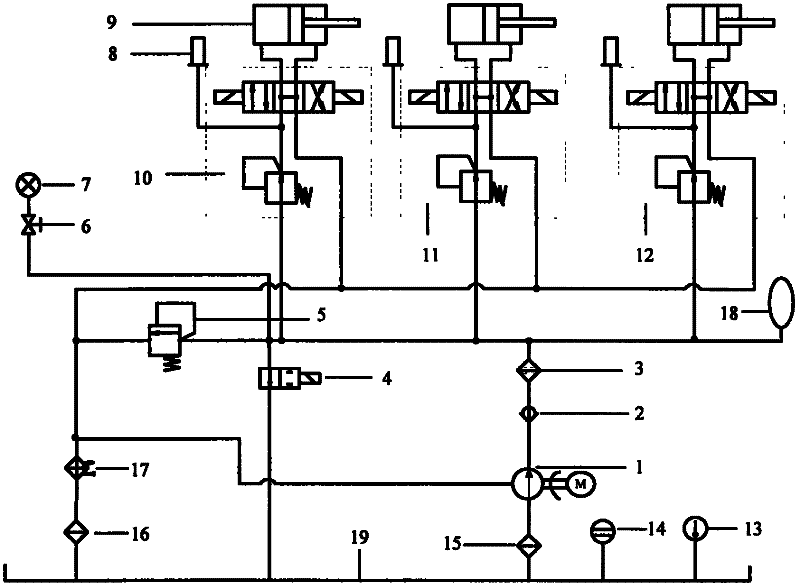

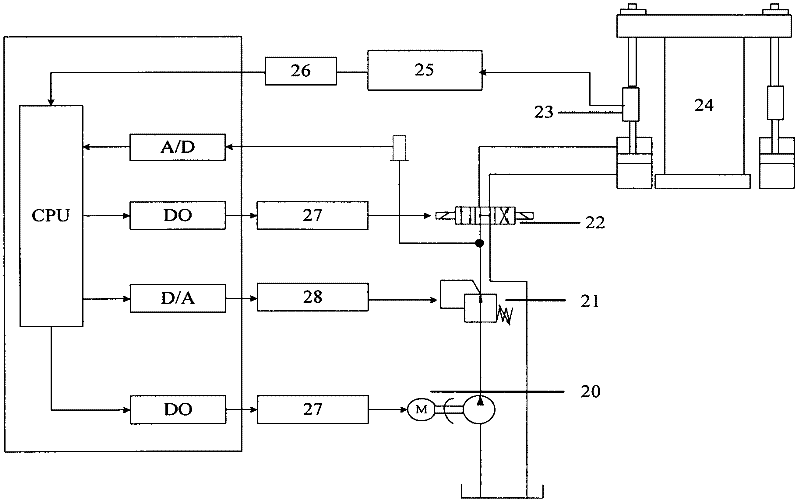

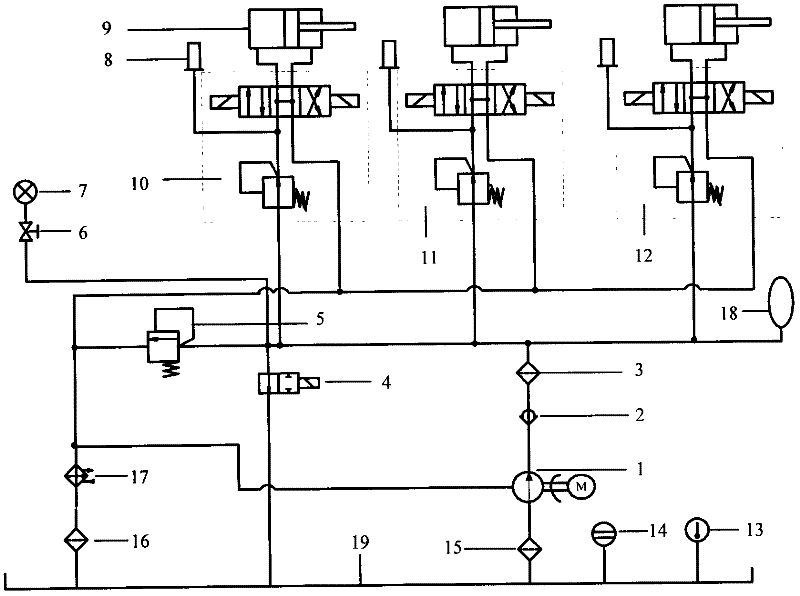

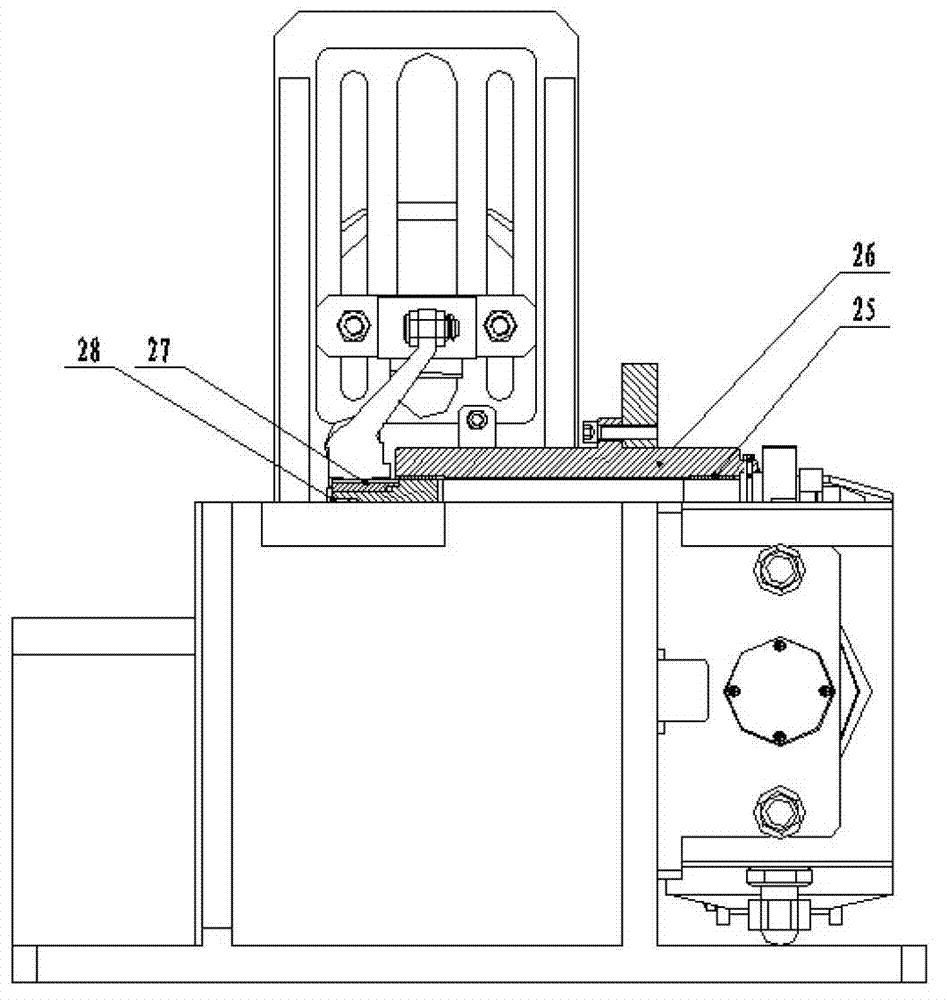

Test device for comprehensive test of occupant restraint system

InactiveCN102323153ASimple structureLow costMaterial strength using tensile/compressive forcesShock testingHydraulic pumpData acquisition

The invention discloses a test device for a comprehensive test of an occupant restraint system. The device can carry out a seat assembly static strength test, a strength test for a backrest and its adjusting equipment, a headrest performance test and an automobile safety belt fixed point strength test according to the requirements of laws and regulations. The test device mainly comprises three modules, i.e. a test bench, a hydraulic system and a measurement and control system. The test bench consists of a main test bench, a seat fixation platform, a safety belt fixation column and a headrest impact test bench that function as load bearing parts during an experiment; the hydraulic system consists of a motor, a hydraulic pump, hydraulic control valves and a hydraulic cylinder etc. that serve as power output parts during an experiment; the measurement and control system includes a host computer, a data collection card, sensors and LabVIEW engineering software that serve as parts for datacontrol and recording during an experiment. The device of the invention has the characteristics of simple structure, low cost, convenient operation and multiple test functions etc.

Owner:HUNAN UNIV

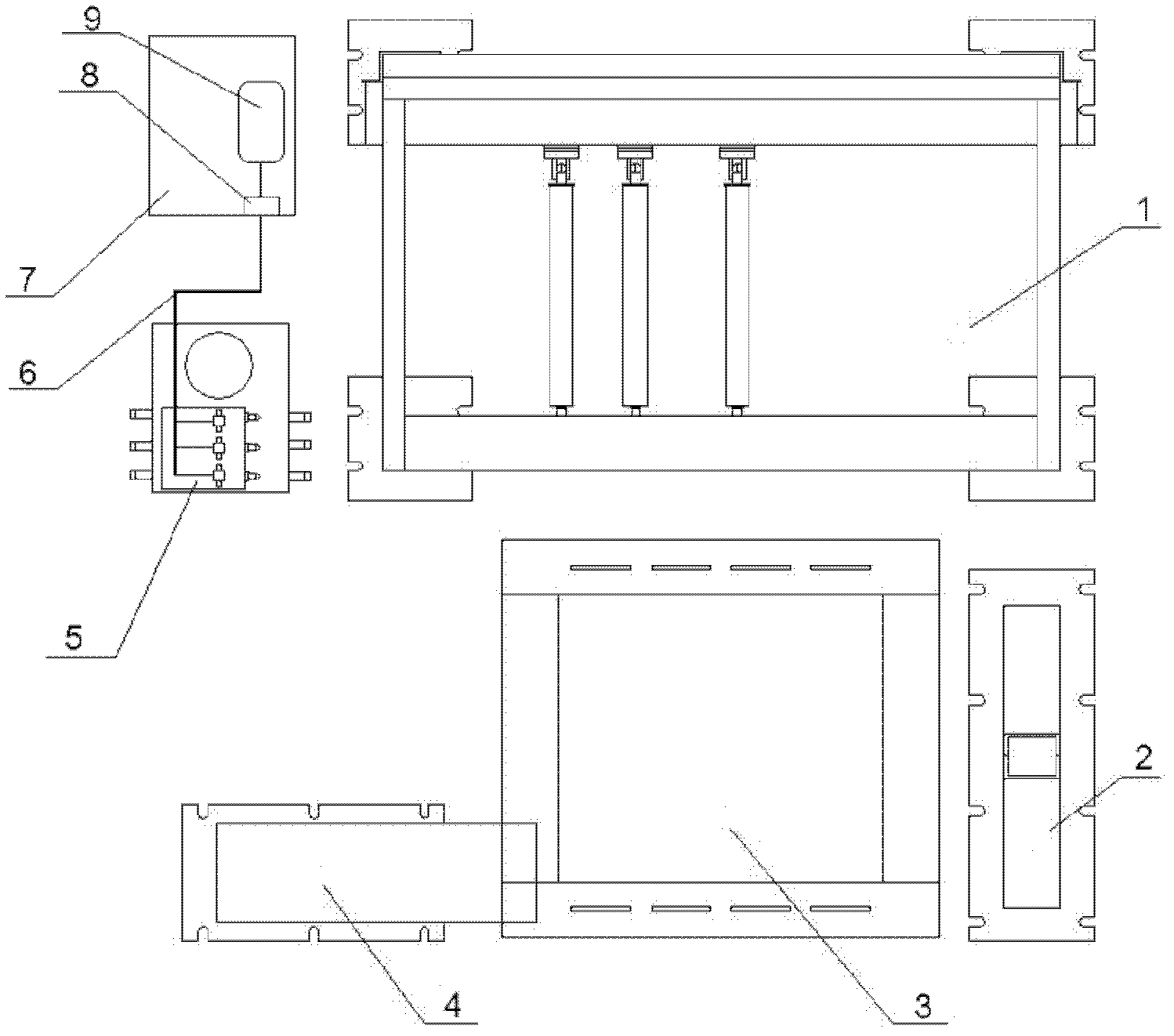

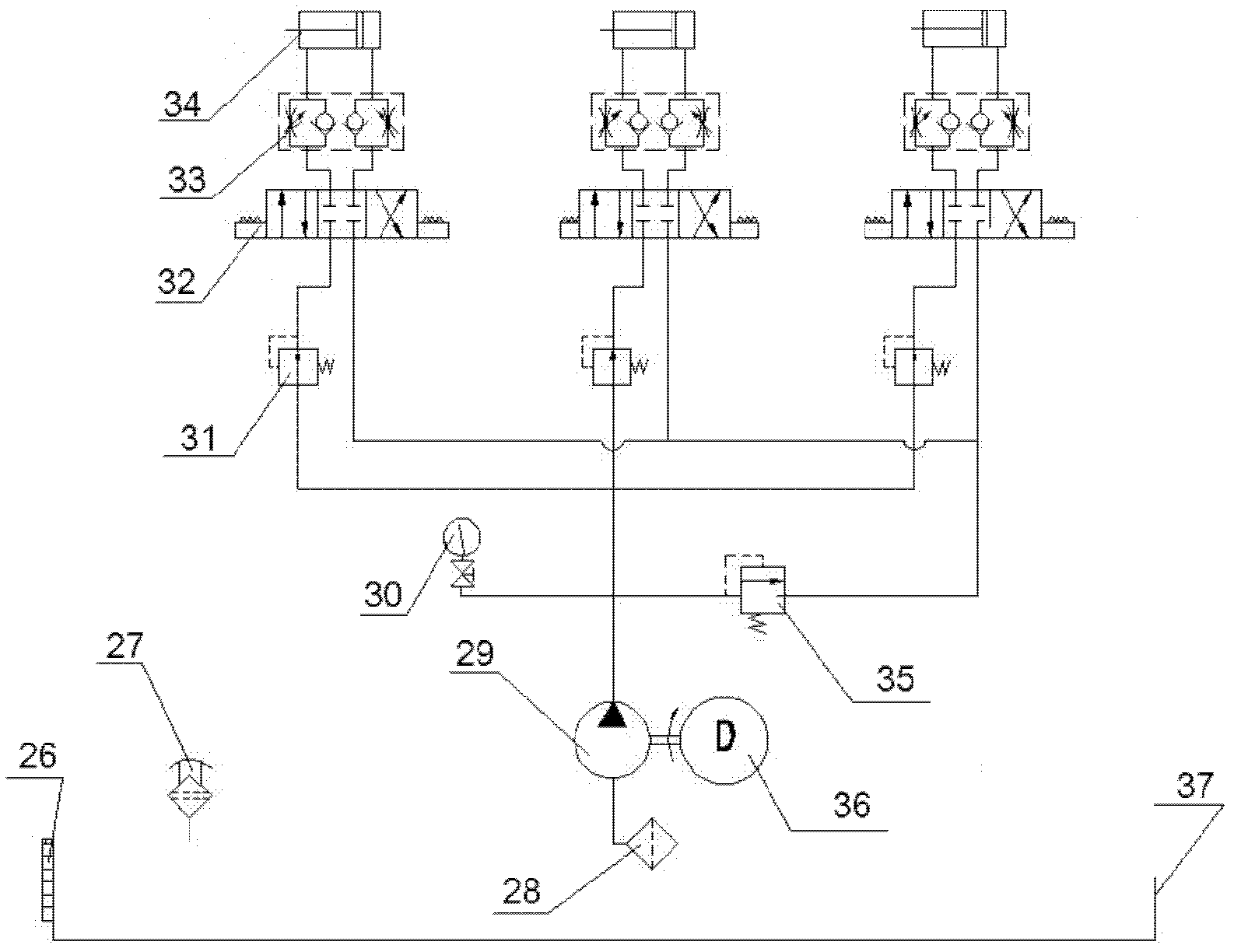

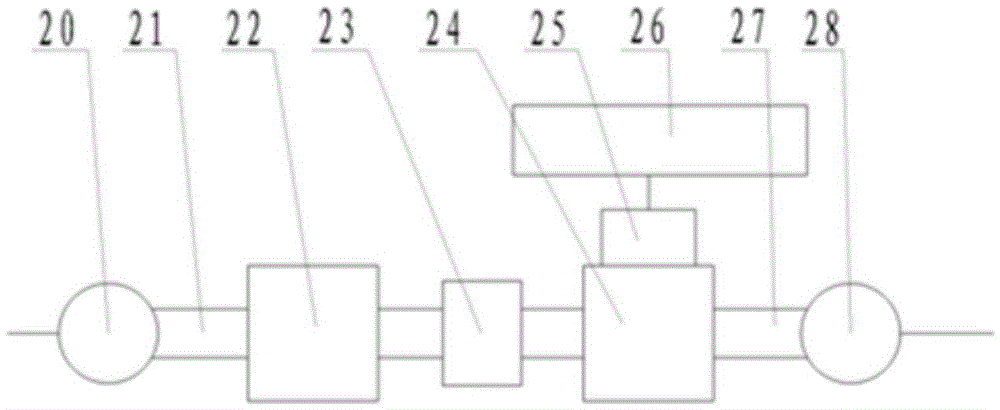

Combined loading system for static strength tests of solid motors

ActiveCN102435490AEnsure safetyEasy to detectEngine testingStrength propertiesCommunication interfaceEngineering

The invention relates to a combined loading system for static strength tests of solid motors. The combined loading system is characterized by comprising a hydraulic energy part and a control part, wherein the hydraulic energy part comprises a plunger pump, a motor, an oil way block, an energy accumulator, a filter, a proportional overflow valve, a proportional reducing valve, a reversing valve, acooler and an actuating cylinder; and the control part comprises an alternating current motor, a force sensor, a communication interface, a digital quantity output driving circuit, an analog quantityoutput driving circuit and a central processing unit (CPU). The combined loading system for the static strength tests of the solid motors is suitable for the static strength tests of various solid motors, and solves the technical problems that the coordination control accuracy is low, safety factors of the tests are not considered fully and the like in the traditional hydraulic loading system.

Owner:中国航天科技集团公司第四研究院四0一所

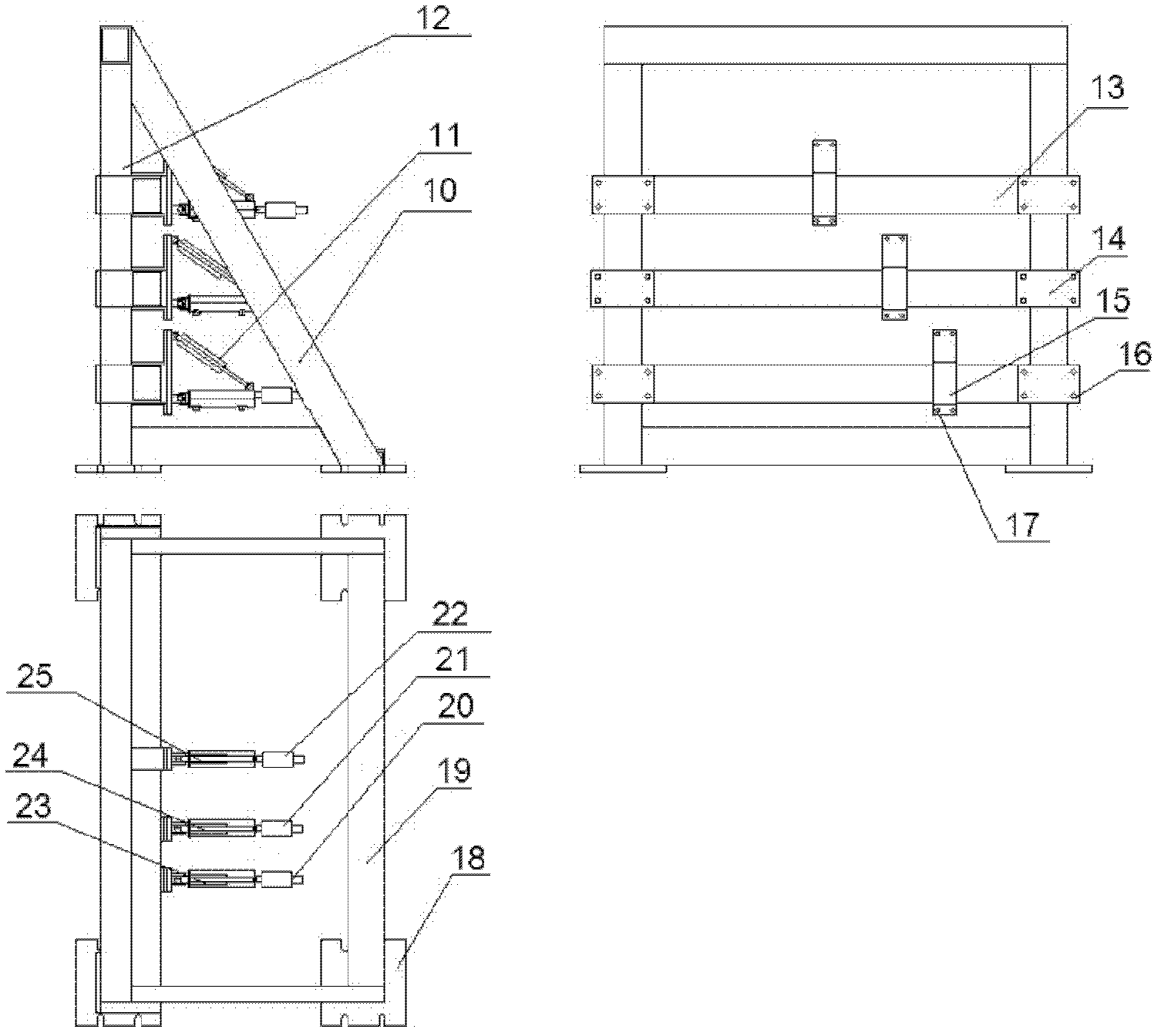

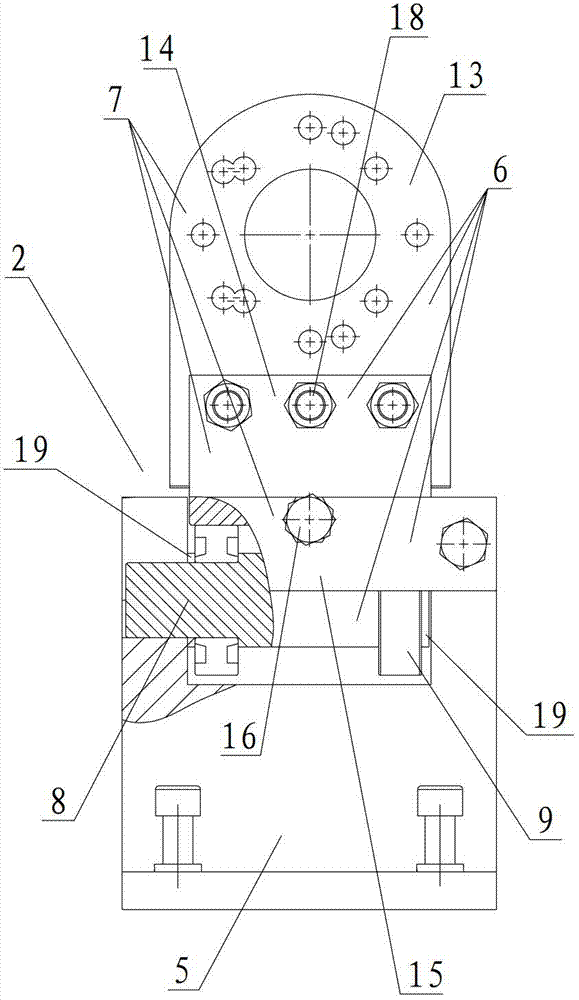

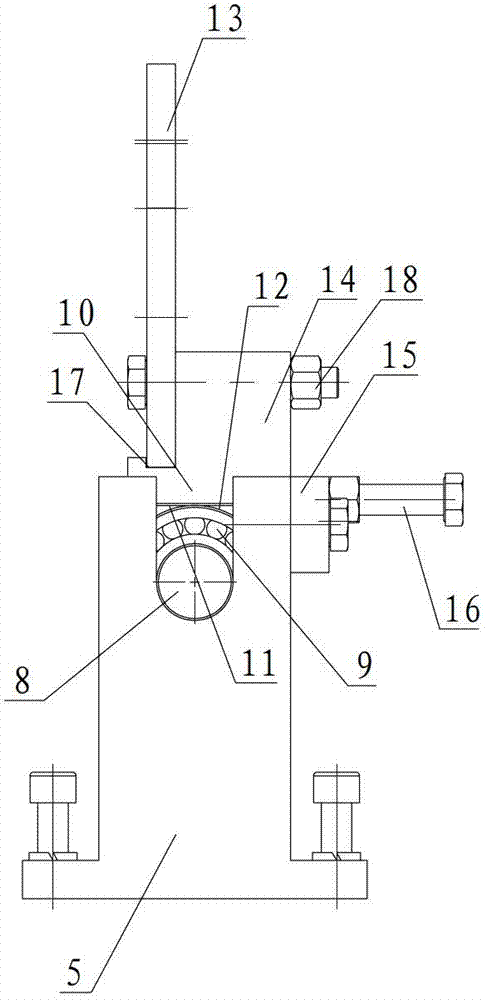

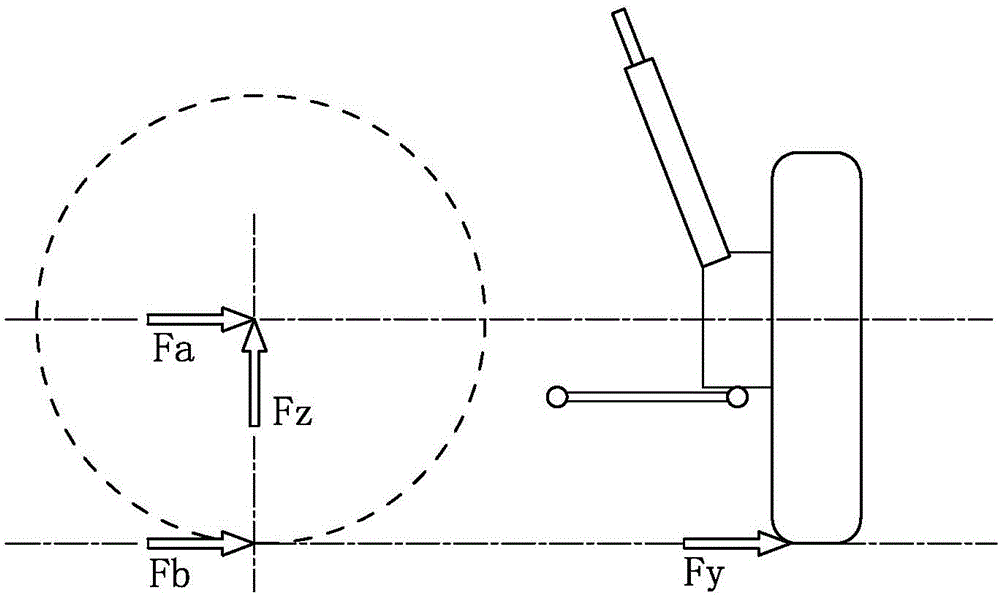

Static strength and fatigue test device for tumbler type shaft housing as well as its method

InactiveCN103175748AAccurate forceAccurate lifeMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesTest specificationStatic strength

The invention discloses a static strength and fatigue test device for a tumbler type shaft housing as well as its method. A static strength and fatigue test is implemented independently for the tumbler type shaft housing by taking an equivalent load converted from a line spectrum load, so that the test specifications and flows of loads in a plurality of directions are standardized to obtain a real and accurate shaft housing strength and fatigue test results and further assist in the improvement and optimization of the structure and stress design of the shaft housing. The test device for a static strength and fatigue test method of the tumbler type shaft housing comprises a loading beam and a shaft housing seat. A shaft housing body of the tumbler type shaft housing is fixed on the shaft housing seat. A shaft housing spring seat on the top of the tumbler type shaft housing is connected with a first vertical actuating cylinder. A second vertical actuating cylinder, a transverse actuating cylinder and a longitudinal actuating cylinder are connected to an elastic joint of the tumbler type shaft housing respectively.

Owner:CRRC QINGDAO SIFANG CO LTD

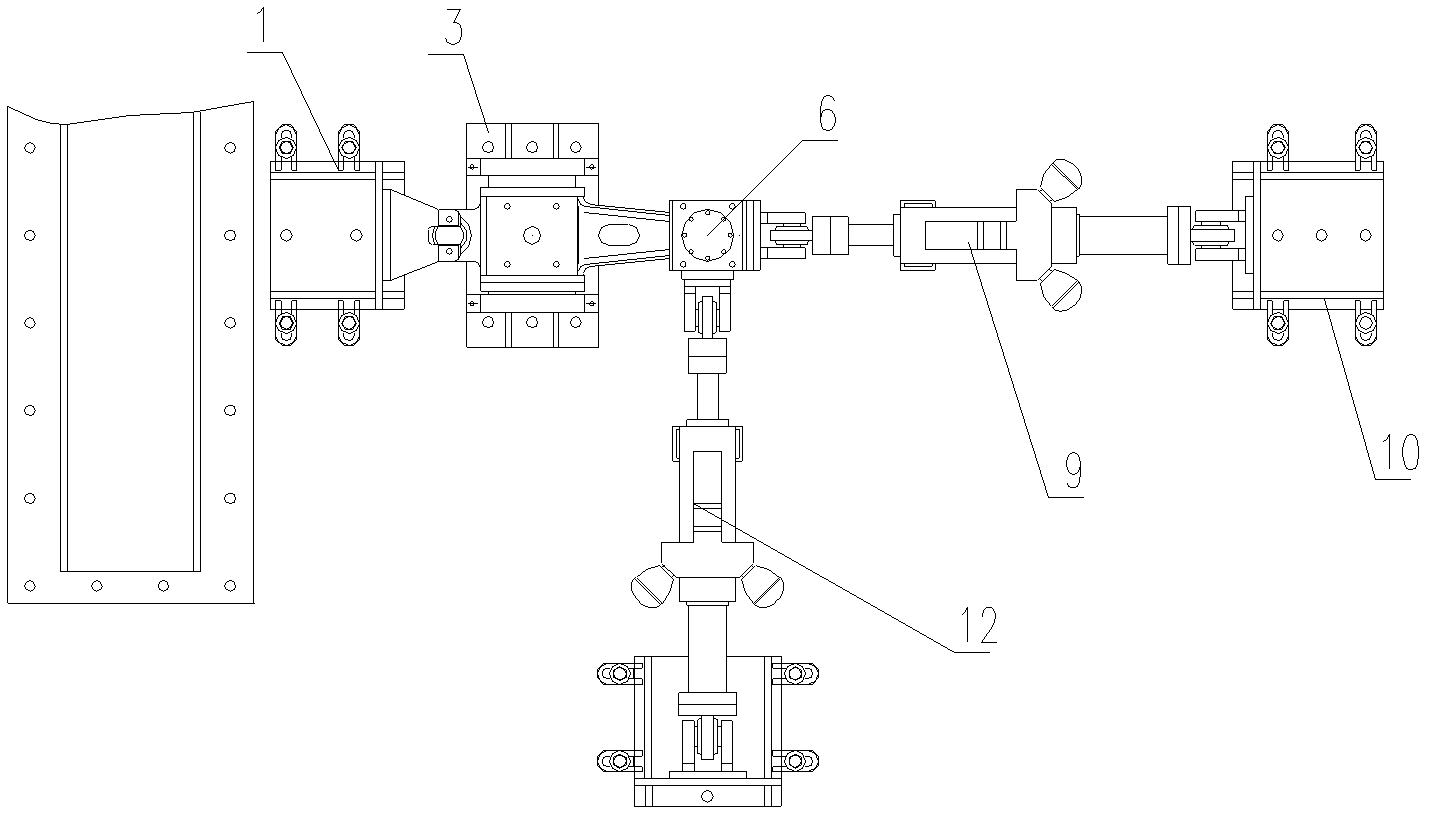

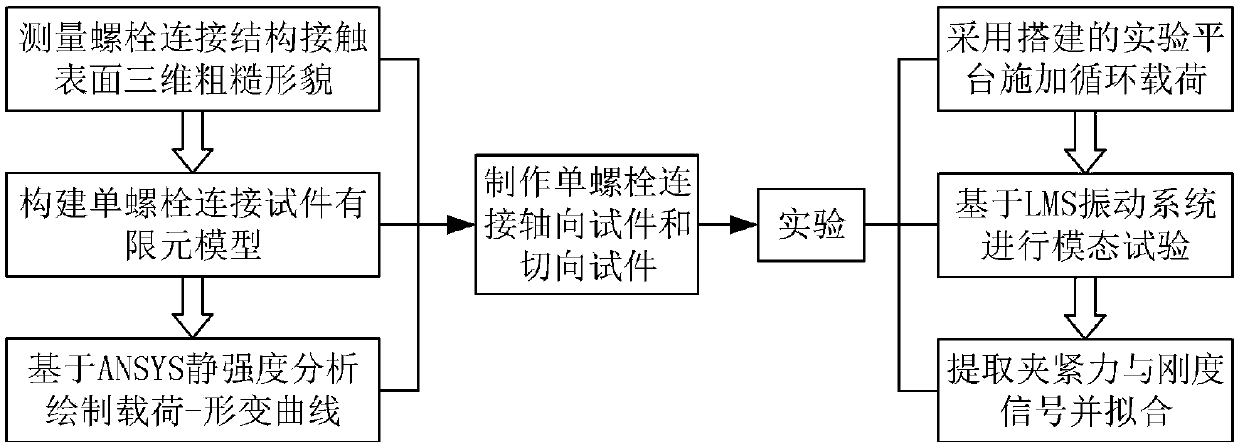

Experimental method for characterizing relaxation characteristics of bolted joint structure

ActiveCN108388696ASolve the problem of high costAvoid safety hazardsMachine part testingDesign optimisation/simulationElement modelExperimental methods

The present invention discloses an experimental method for characterizing relaxation characteristics of a bolted joint structure. The method comprises: constructing a finite element model of a singlebolted joint test piece based on the obtained three-dimensional rough shape of the contact surface of the bolted joint structure; performing static strength analysis on the single bolted jointed testpiece by using ANSYS software, and drawing the deformation curve of the single bolted jointed test piece under load conditions; making a single bolted joint axial test piece and a tangential test piece to analyze the influence law of the axial external load and the outward shear load on the relaxation characteristics of the bolted joint structure; establishing an experiment platform, and through the cyclic load control software, applying a cyclic load with a certain frequency on the single-bolt test piece clamped on the fatigue testing machine; performing the modal test on the single bolted joint test piece by using the LMS vibration system at the same time interval; and extracting a clamp force signal output by a pressure sensor and a stiffness signal in the modal test, and fitting the curve for the clamp force signal and the stiffness signal for comparison. The method disclosed by the present invention provides technical support for the relaxation determination and refastening of thejoint bolts of the key precise complicated components.

Owner:BEIJING UNIV OF TECH

Epoxy resin composition, prepreg, and fiber-reinforced composite material

ActiveCN101679609AHigh elastic modulusImprove heat resistanceSynthetic resin layered productsRodsHigh stiffnessHeat resistance

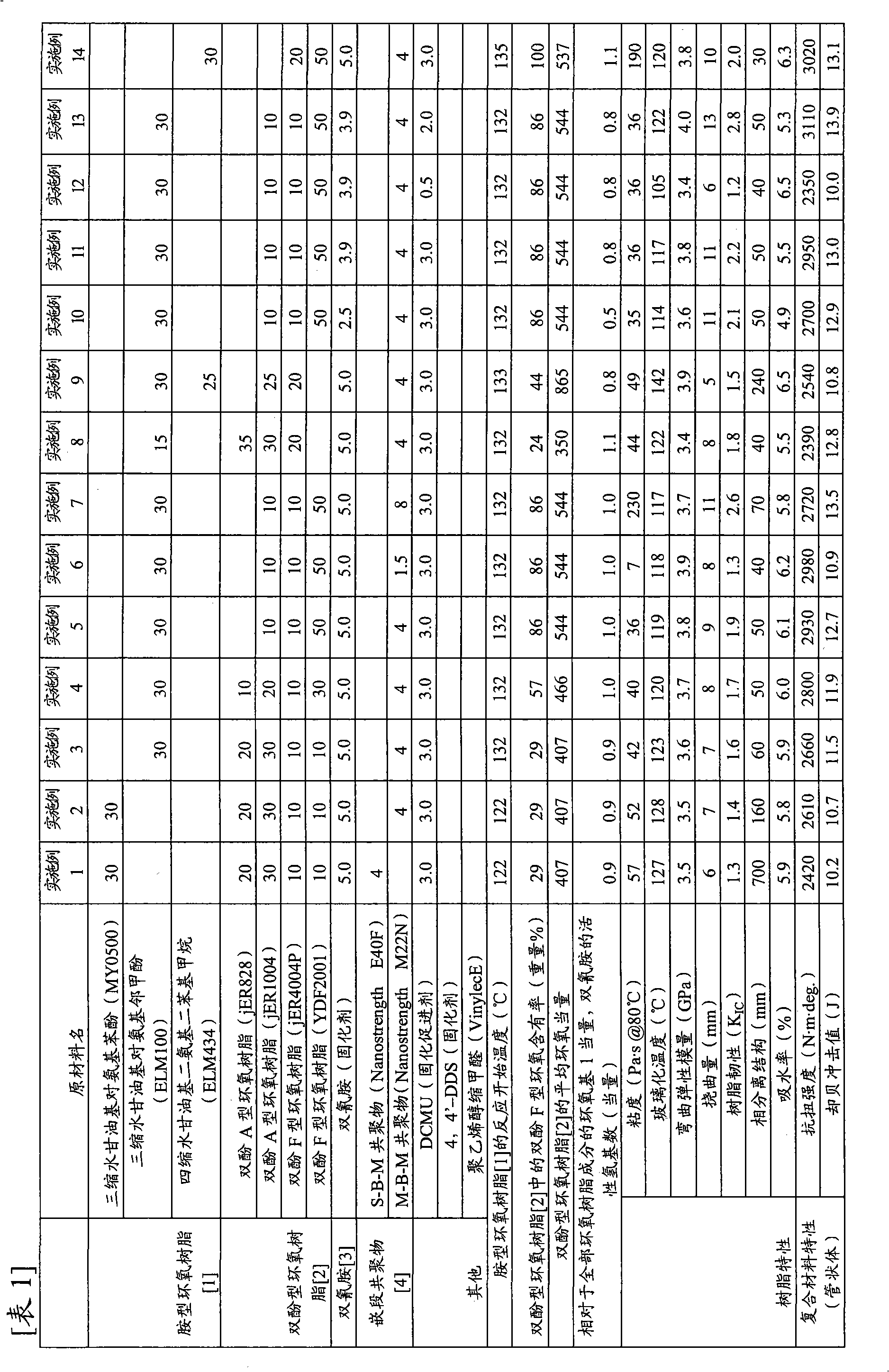

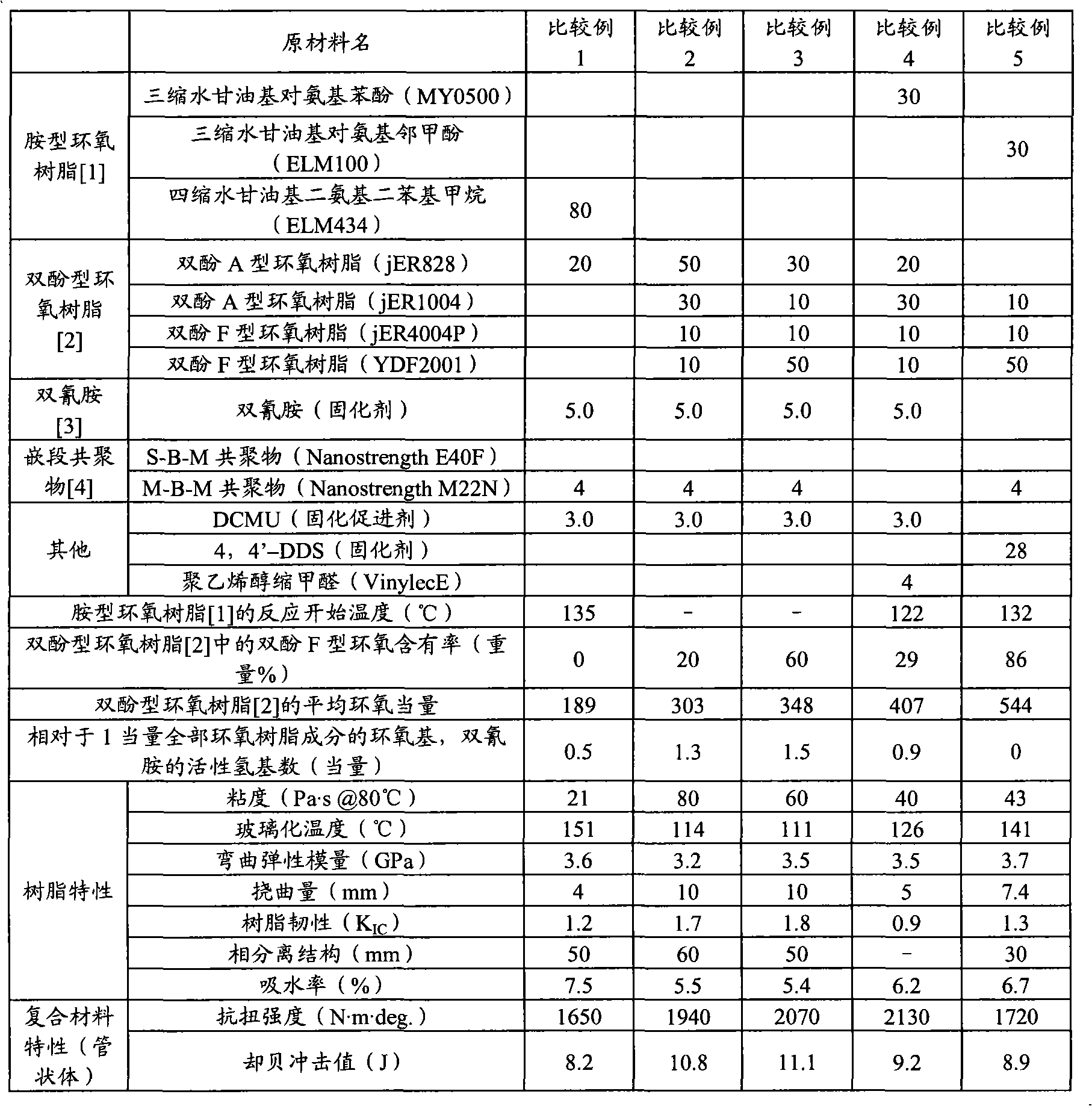

Disclosed are: a fiber-reinforced composite material having both of excellent static strength properties and excellent impact resistance; and an epoxy resin composition for producing the fiber-reinforced composite material, specifically an epoxy resin composition which enables to produce a cured product having a high elastic modulus, high heat resistance, a high plastic deformation ability and high stiffness. Specifically disclosed are: an epoxy resin composition comprising the following components ¢A! to ¢D!; a prepreg produced by impregnating a fiber base material with the epoxy resin composition; a fiber-reinforced composite material produced by curing the prepreg; and a tubular article produced from the fiber-reinforced composite material. ¢A!: an amine-type epoxy resin: 10 to 60 partsby weight; ¢B!: a bisphenol-type epoxy resin: 40 to 90 parts by weight; ¢C!: dicyandiamide or a derivative thereof: 1 to 10 parts by weight; and ¢D!: at least one block copolymer selected from the group consisting of S-B-M, B-M and M-B-M: 1 to 10 parts by weight.

Owner:TORAY IND INC

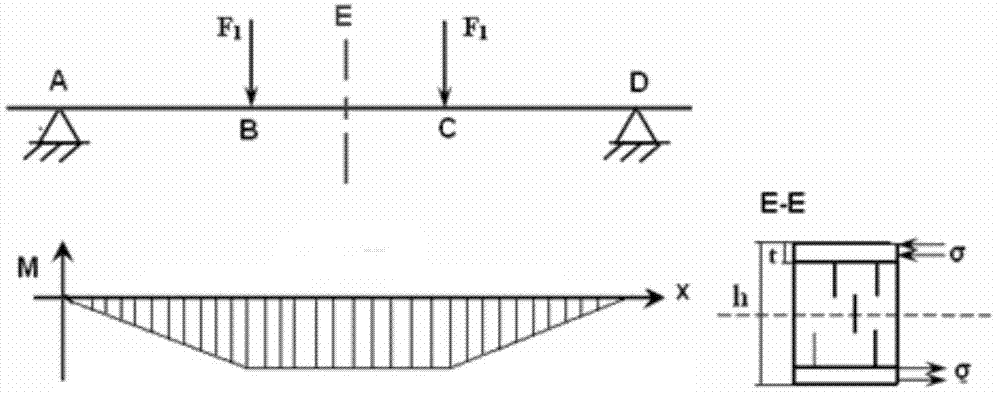

Bending test device for semi-floating drive axle, and test method of same

ActiveCN103196754AImprove practicalityImprove effectivenessVehicle testingMaterial strength using steady bending forcesCar manufacturingStatic strength

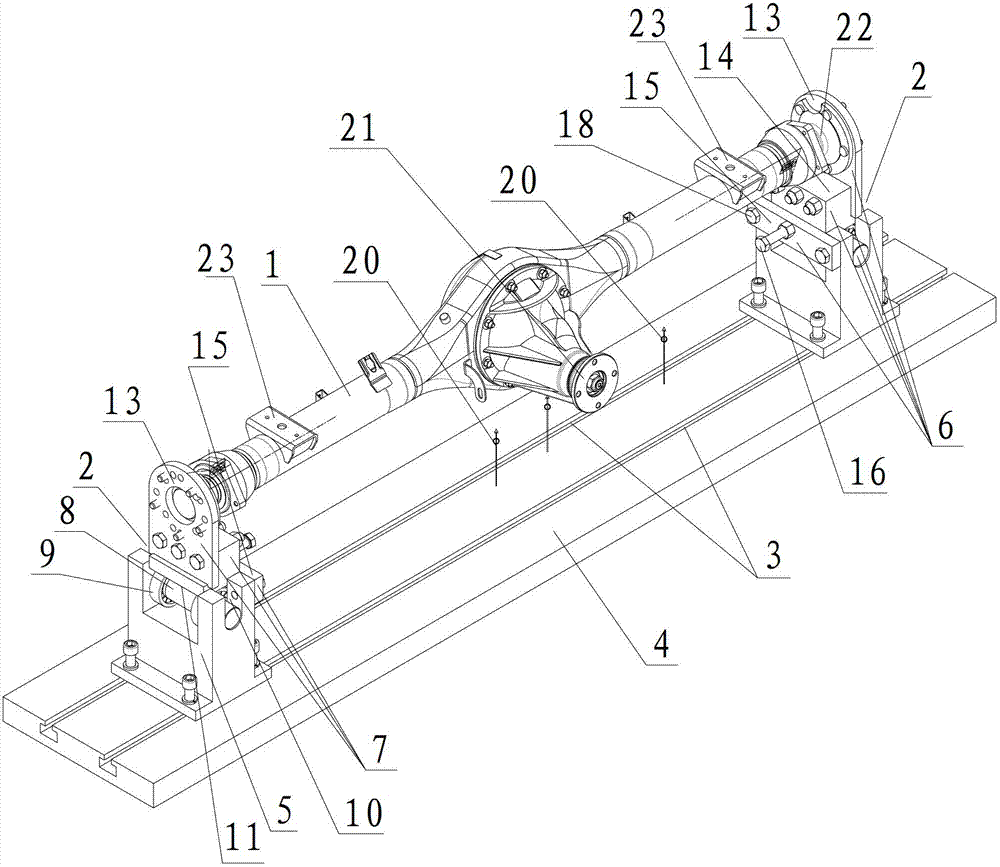

The invention discloses a bending test device for a semi-floating drive axle, and a method for performing the bending test on the semi-floating drive axle by the bending test device, belonging to the technical field of automobile manufacturing. A bending test device for the semi-floating drive axle, which can meet the stressing features of the semi-floating drive axle in the semi-floating drive axle bending test, and a method for performing bending test on the semi-floating drive axle by the test device, are provided. A wheel simulator is arranged on the chassis of each support frame for test of a support frame group; when the vertical bending rigid test, the vertical bending static strength test and the vertical bending fatigue test of the semi-floating drive axle are performed, after the semi-floating drive axle sample is connected with the wheel simulators, a workbench for test is supported by the chassis, and a test support counter force identical to the actual service condition is applied on the semi-floating drive axle through the wheel simulators.

Owner:SICHUAN JIANAN IND

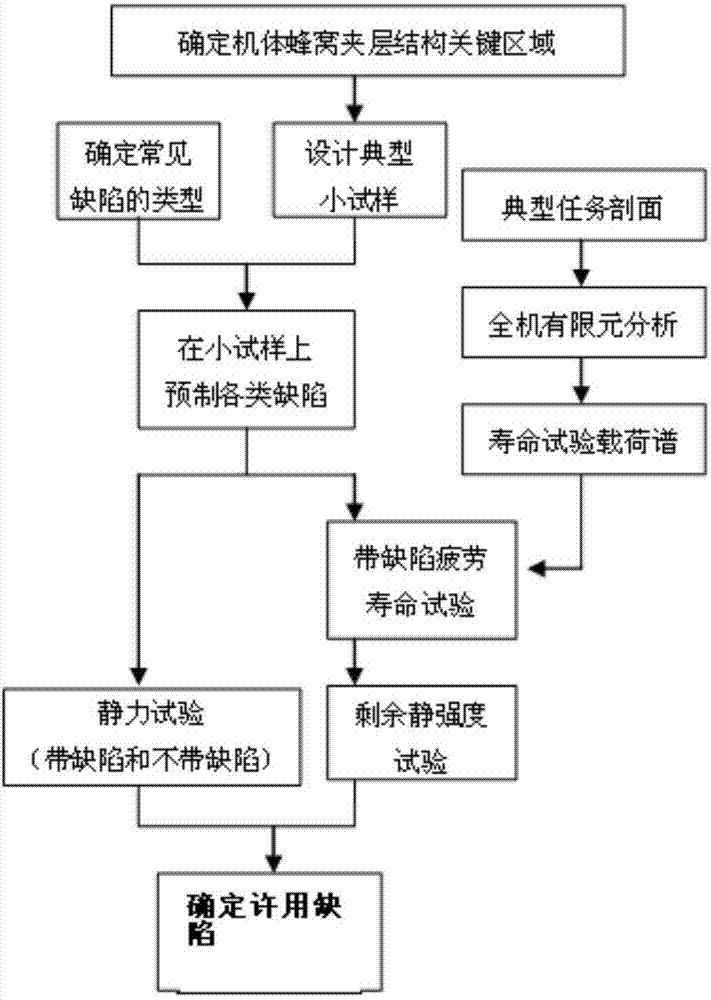

Method for determining allowable defect of honeycomb sandwich layer of helicopter

InactiveCN104778372AReduce manufacturing costReduce the risk of structural defectsSpecial data processing applicationsComparative testResidual strength

The invention discloses a method for determining allowable defects of a honeycomb sandwich layer of a helicopter, belongs to the technical field of structural fatigue design of helicopters and particularly relates to a method for determining honeycomb sandwich layer structure defects of a helicopter body with defects. By prearranging internal and external defects on a honeycomb sandwich layer test piece and determining the rationality of defect parameters by adopting static strength, fatigue and remaining strength comparative tests under real load-bearing environments, bases are provided for the design and handling of such manufacturing deviations, the manufacturing and using costs of the honeycomb sandwich layer structure can be decreased and the risk in use of the defective structure is reduced.

Owner:CHINA HELICOPTER RES & DEV INST

Safety mountaineering rope and manufacturing method therefor

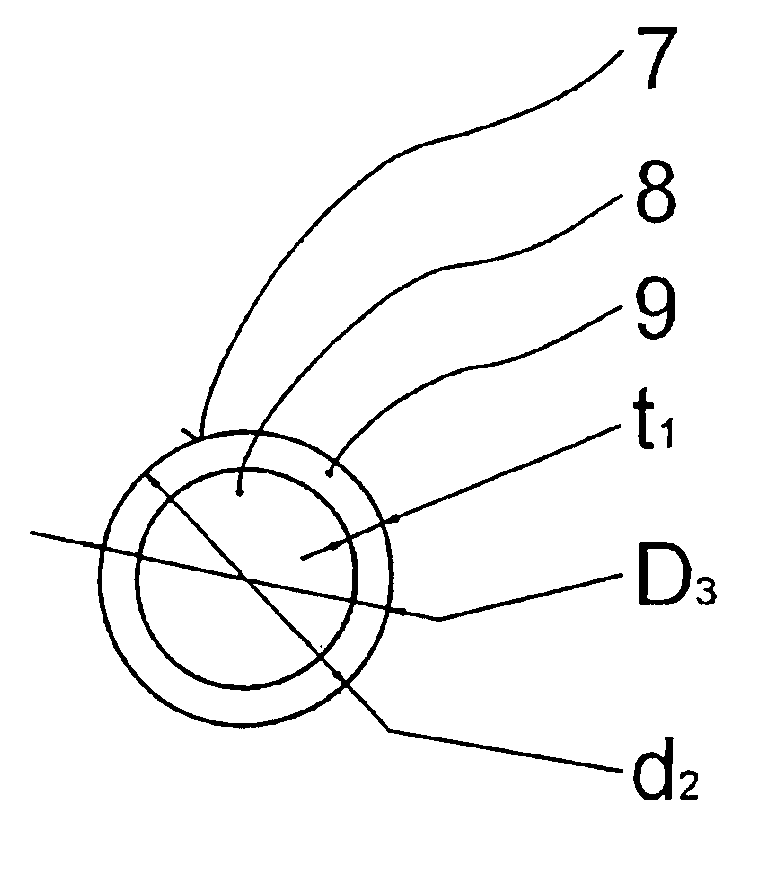

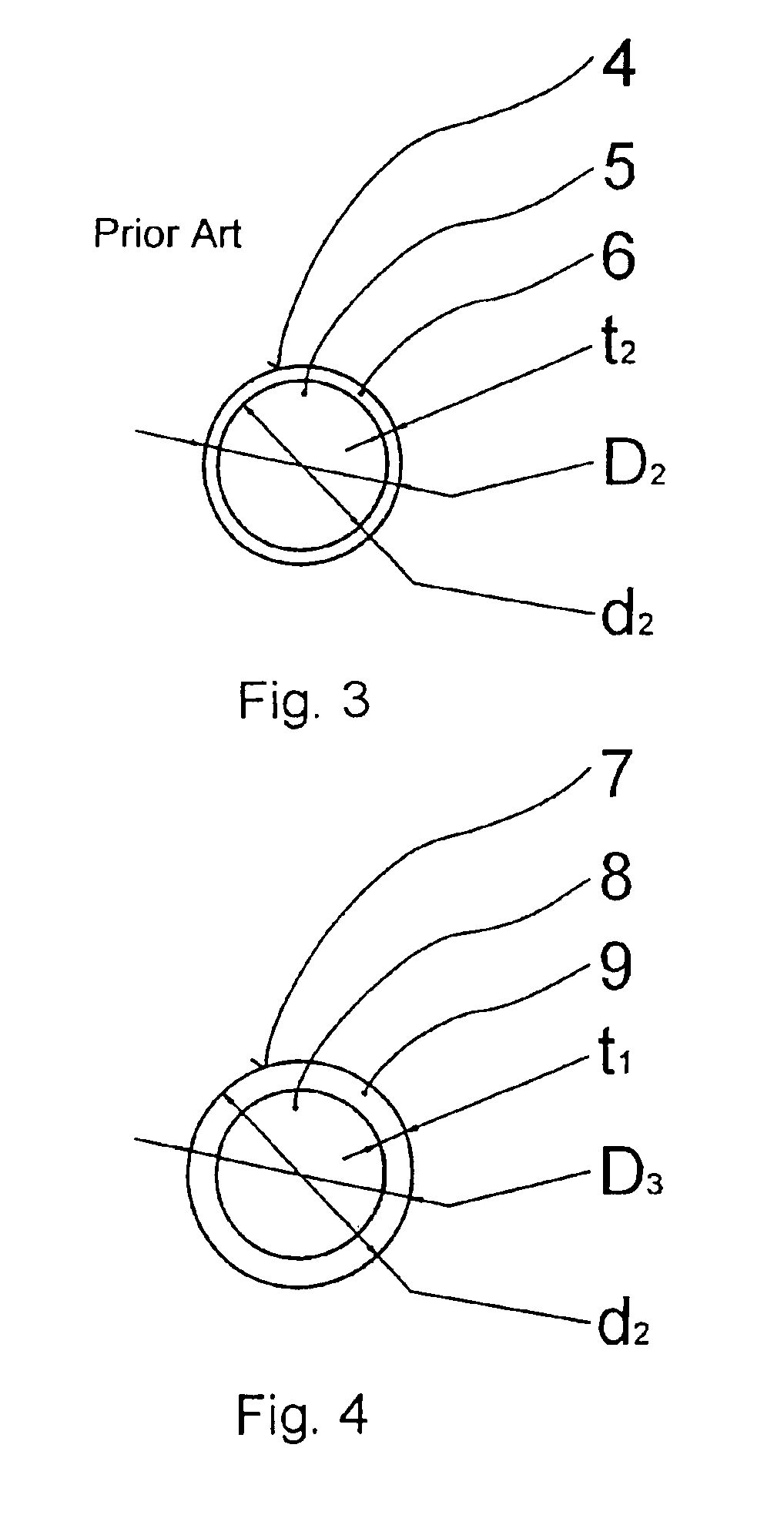

A mountaineering rope (7) with the diameter 10.1 mm to 10.8 mm characterized in that the core (8) made from such number of yarns being necessary for achieving required static strength and resistance to dynamic stress. A braiding (9) around the core (8) is made using a circular braiding machine with 44 carrier, and from yarn having linear density 1500 dtex to 6000 dtex on each carrier.

Owner:SINGING ROCK

Tester for testing multifunctional vane

InactiveCN101539478AImprove support strengthStable center of gravityMachine part testingMaterial strength using tensile/compressive forcesAbove groundReinforced concrete

The invention discloses a tester for testing a multifunctional vane, which comprises a test bed, a tester for testing static strength and a tester for testing fatigue, wherein the bed body of the test bed is cast by reinforced concrete; the part of the test bed below ground takes the shape of a ladder; and the front end of the part of the test bed above ground is provided with a vane connecting disc fixed by a fixing part. The vane connecting disc and the bed body corresponding to the vane connecting disc are internally provided with a plurality of blind holes which are internally provided with bolt sleeves embedded with the vane connecting disc. The bolt sleeves are fixed by extension reinforcing rods fixed in the bed body. In addition, a test pit is positioned on the ground on which the front end of the bed body of the test bed is arranged; and the test pit is a slope with one end away from the bed body extending below ground. The invention has the advantages of solid structure, strong holding power and long service life. The tester has firm structure, strong supporting force and long service life, and is suitable for installation test of various vanes with different sizes, available for tests of different indexes for vanes. The tester is accurate in test, very convenient in use and wide in application range. In addition, the tester has the advantages of reducing disassembly and assembly of the vane for testing the performance index thereof, saving the testing time and cost, and reducing the damage to the vane.

Owner:中能风电设备有限公司

Aircraft static strength test loading device

ActiveCN105606357AUnconstrained horizontal load deformationImplement vertical supportMachine part testingRolling resistanceVertical load

The invention discloses an aircraft static strength test loading device, and relates to the technical field of aircraft test. The aircraft static strength test loading device comprises an upper frame, a ball plate, a lifting platform and a horizontal restraint device, wherein the upper frame is used for connecting virtual wheels of an undercarriage; the ball plate comprises balls and a clamping plate, the clamping plate is provided with a plurality of ball grooves, the balls are arranged in the ball grooves, and the spherical surfaces of the balls protrude two opposite sides of the clamping plate in the thickness direction; the lifting platform is used for adjusting the height position of the upper frame; the horizontal restraint device is used for connecting the virtual wheels of the undercarriage and applying a horizontal restraint; the upper frame is installed on the lifting platform, and the ball plate is arranged between the upper frame and the installation surface of the lifting platform. The aircraft static strength test loading device has the advantages that the device is provided with the ball plate, and the balls are arranged on the ball plate to provide low rolling frictional resistance, so that the undercarriage is horizontally loaded and deformed without being restrained while a vertical load is applied.

Owner:CHINA AIRPLANT STRENGTH RES INST

Epoxy resin composition, prepreg, fiber-reinforced composite material

ActiveUS20100209642A1Improve plastic deformation abilityImprove heat resistanceSynthetic resin layered productsRodsHeat resistanceFiber-reinforced composite

It is an object of the present invention to improve drawbacks in conventional technology and provide a fiber-reinforced composite material having both an excellent static strength property and impact resistance, and an epoxy resin composition for obtaining the fiber-reinforced composite material. More particularly, it is the object of the present invention to provide the epoxy resin composition that gives a cured material having a high elastic modulus, a high heat resistance, a high plastic deformation capacity and a high toughness.The epoxy resin composition containing following [A] to [D], a prepreg obtained by impregnating a fiber substrate with the epoxy resin composition, a fiber-reinforced composite material obtained by curing the prepreg and a tubular body thereof.[A] 10 to 60 parts by weight of an amine type epoxy resin,[B] 40 to 90 parts by weight of a bisphenol-type epoxy resin,[C] 1 to 10 parts by weight of dicyandiamide or a derivative thereof, and[D] 1 to 10 parts by weight of at least one block copolymer selected from the group consisting of S-B-M, B-M and M-B-M.

Owner:TORAY IND INC

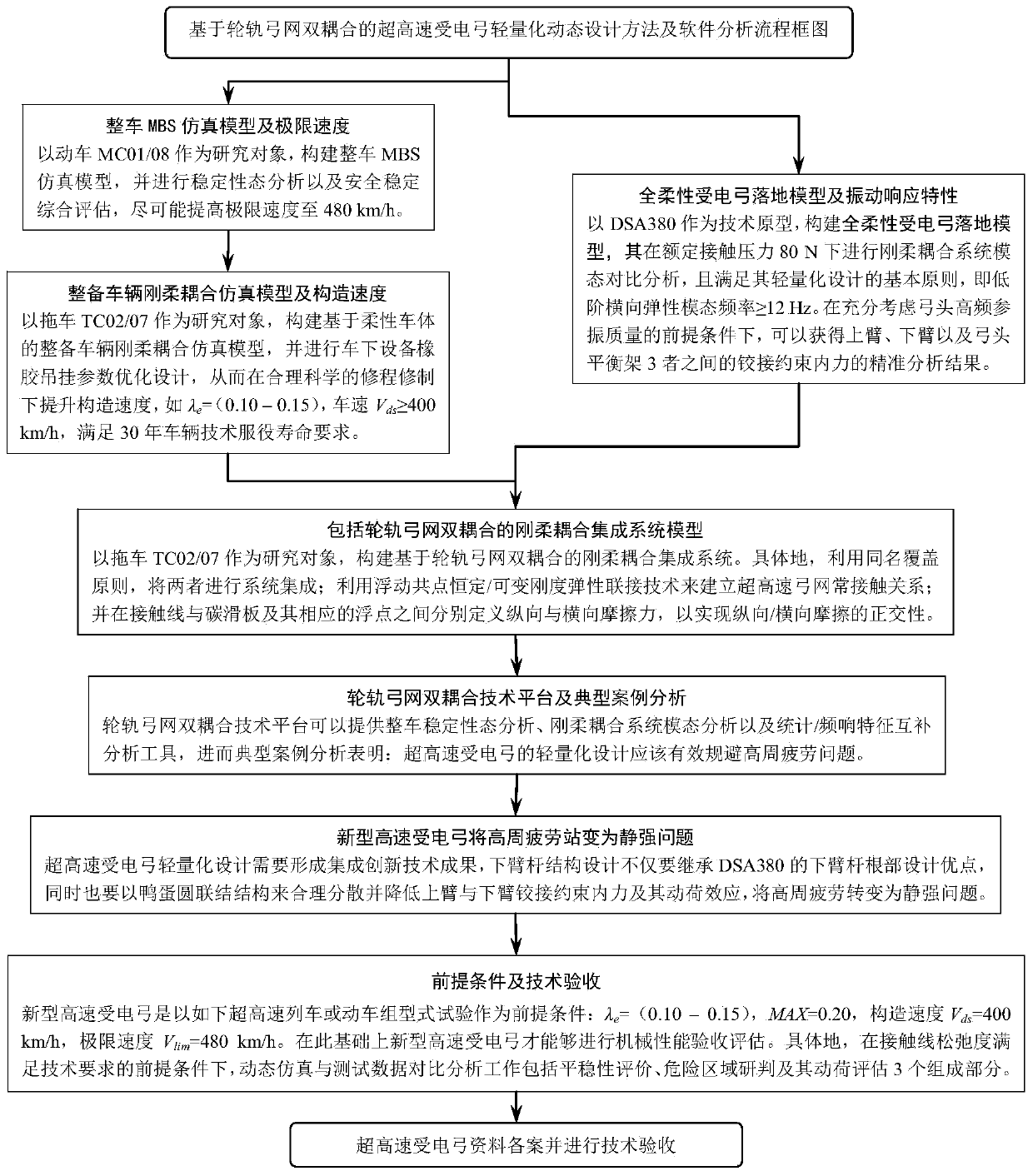

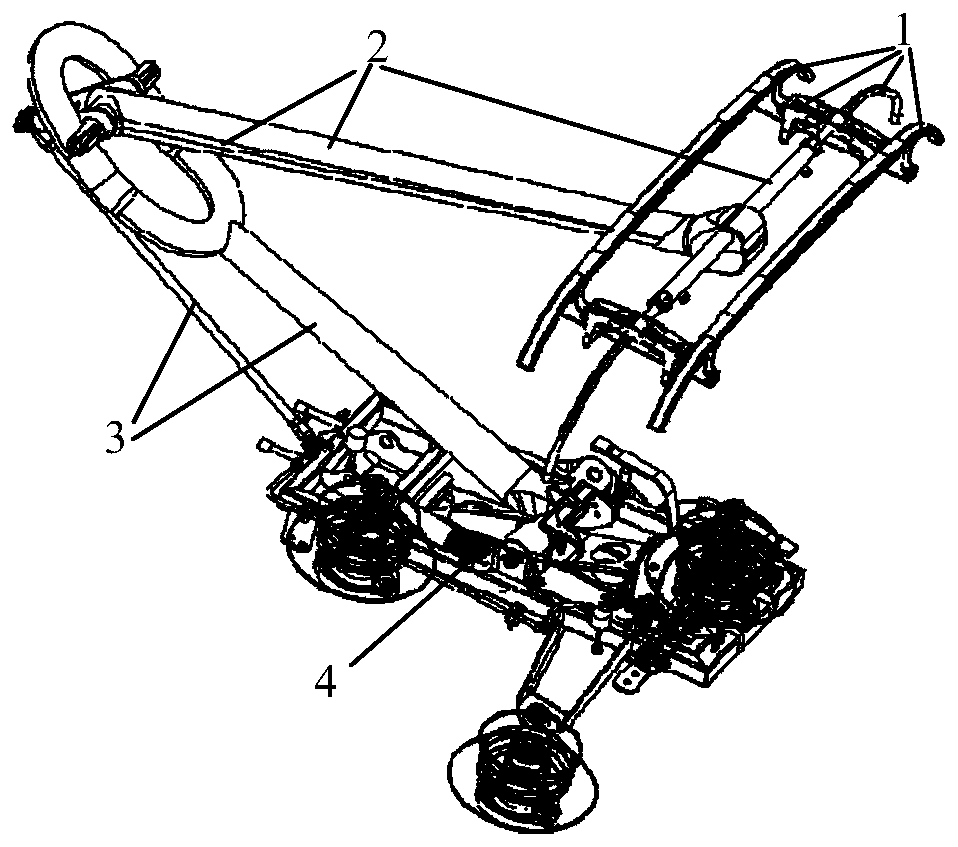

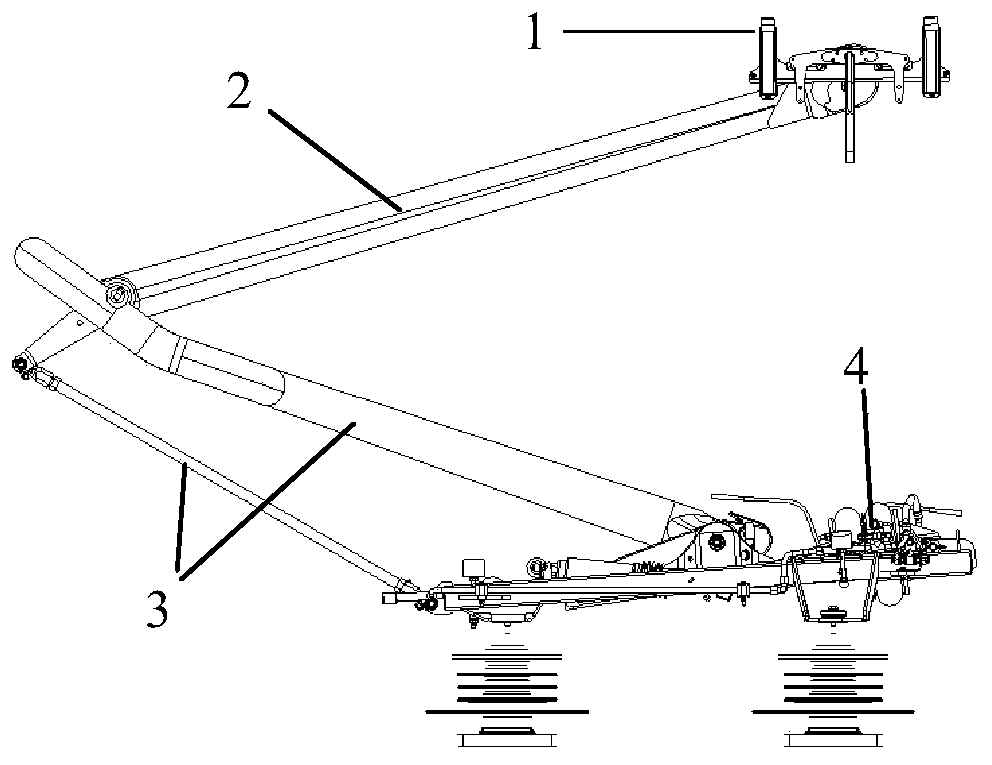

Novel high speed pantograph and lightweight dynamic design method thereof

InactiveCN110126625AReduce contact dynamicsAvoid implicating sports relationshipsGeometric CADDesign optimisation/simulationBogieRail profile

The invention discloses a novel high speed pantograph and lightweight dynamic design method thereof. Optimization of bogie parameters is led according to a root locus diagram, the dynamic action of the contact rail of an abrasion wheel is lowered, under the condition of uniform / normative wheel rail profile matching, the limiting speed is improved up to 480 km / h; through optimal design of rubber suspension parameters of equipment under a vehicle, the transverse vibration mass of hostling flexible vehicle body is decreased, and under reasonable and scientific repair program and repair system, the construction speed is increased up to 400 km / h. In order to better count input stimulus formed by high speed pantograph net contact, a fully flexible pantograph landing model and a hostling vehiclerigid flexible coupling simulation model are systematically integrated to construct a wheel rail pantograph net double coupling simulation technology platform. According to complex constraint and accurate analyze of internal force, analysis of a typical case indicates that a novel lightweight design form is needed by an ultra-high speed pantograph, namely the hinging constraint force between an upper arm and a lower arm and the dynamic load effect are reasonably dispersed and reduced through a duck-egg-shaped joint structure, and thus high cycle fatigue is transformed to a static strength problem.

Owner:DALIAN JIAOTONG UNIVERSITY

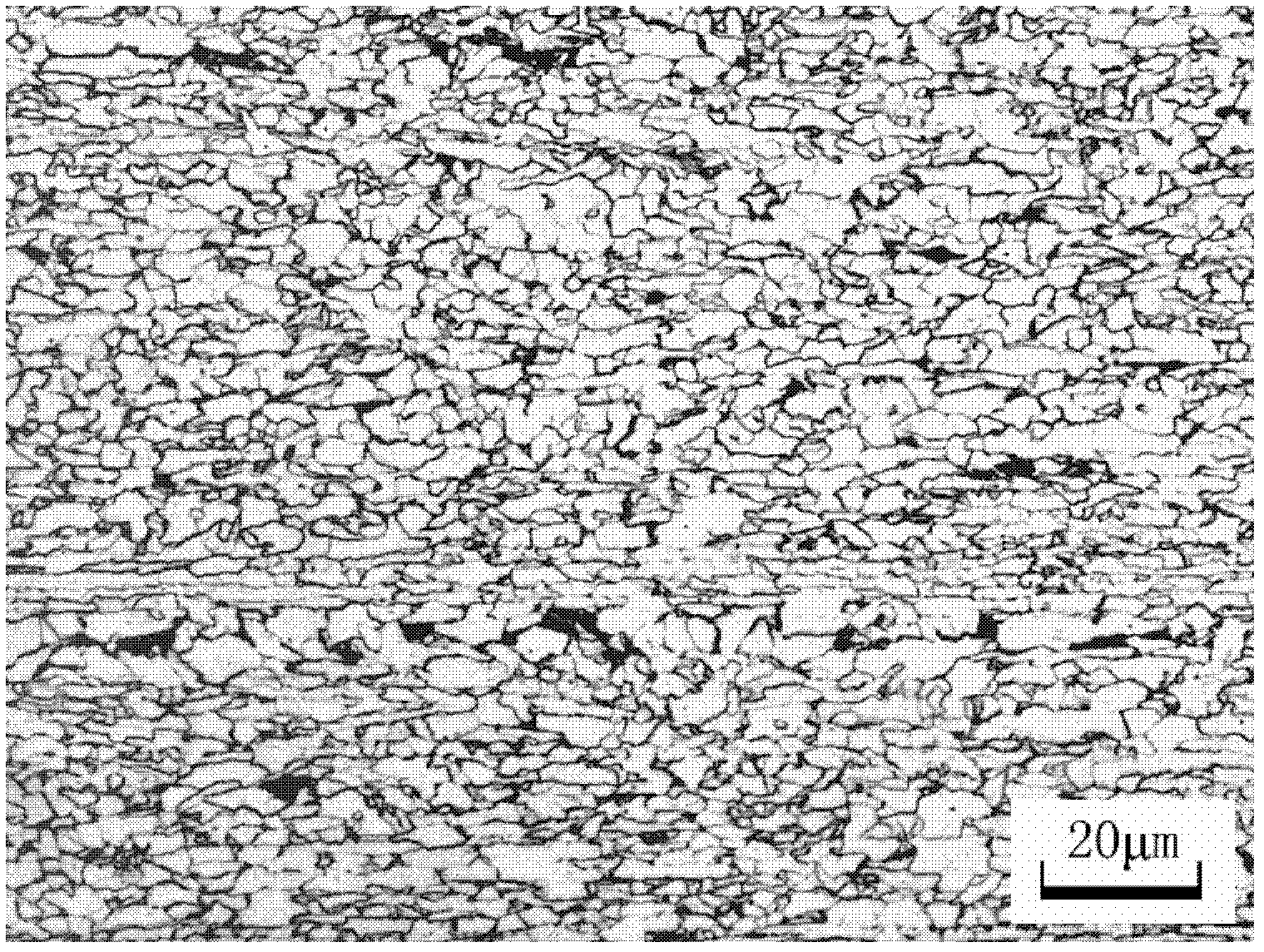

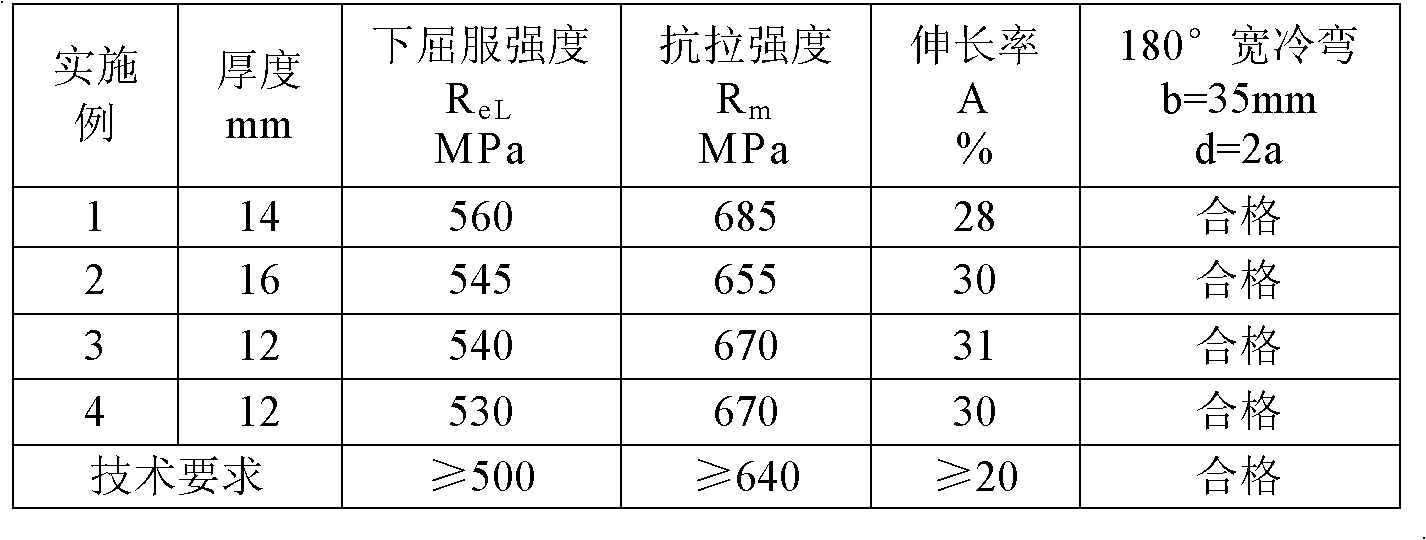

Steel for 13-dwt vehicle axle housing and production method thereof

The invention relates to steel for 13-dwt vehicle axle housing and a production method thereof. The steel comprises the following chemical components by weight: 0.04%-0.08% of C, 0.10%-0.60% of Si, 1.3%-1.45% of Mn, not more than 0.025% of P, not more than 0.08% of S, 0.01%-0.06% of Al, 0.04%-0.06% of Nb, 0.03%-0.05% of Ti, and the balance of Fe and inevitable impurities; The preparation method comprises the following steps: converter smelting; vacuum treatment; continuous casting; casting blank heating; rough rolling; finish rolling by a 7 frame; cooling with laminar flow; coiling. Because of the low carbon content of the steel of the invention, the steel has excellent stamping performance and welding performance, has a stable dimension after cold forming, and completely meets the requirements for manufacturing and application of 13-dwt vehicle axle housing. Through bench tests of the manufactured 13-dwt vehicle axle housing assembly, the product has excellent vertical bending fatigue life, vertical bending rigidity, and vertical bending static strength, and completely meets the requirements of users.

Owner:武汉钢铁有限公司

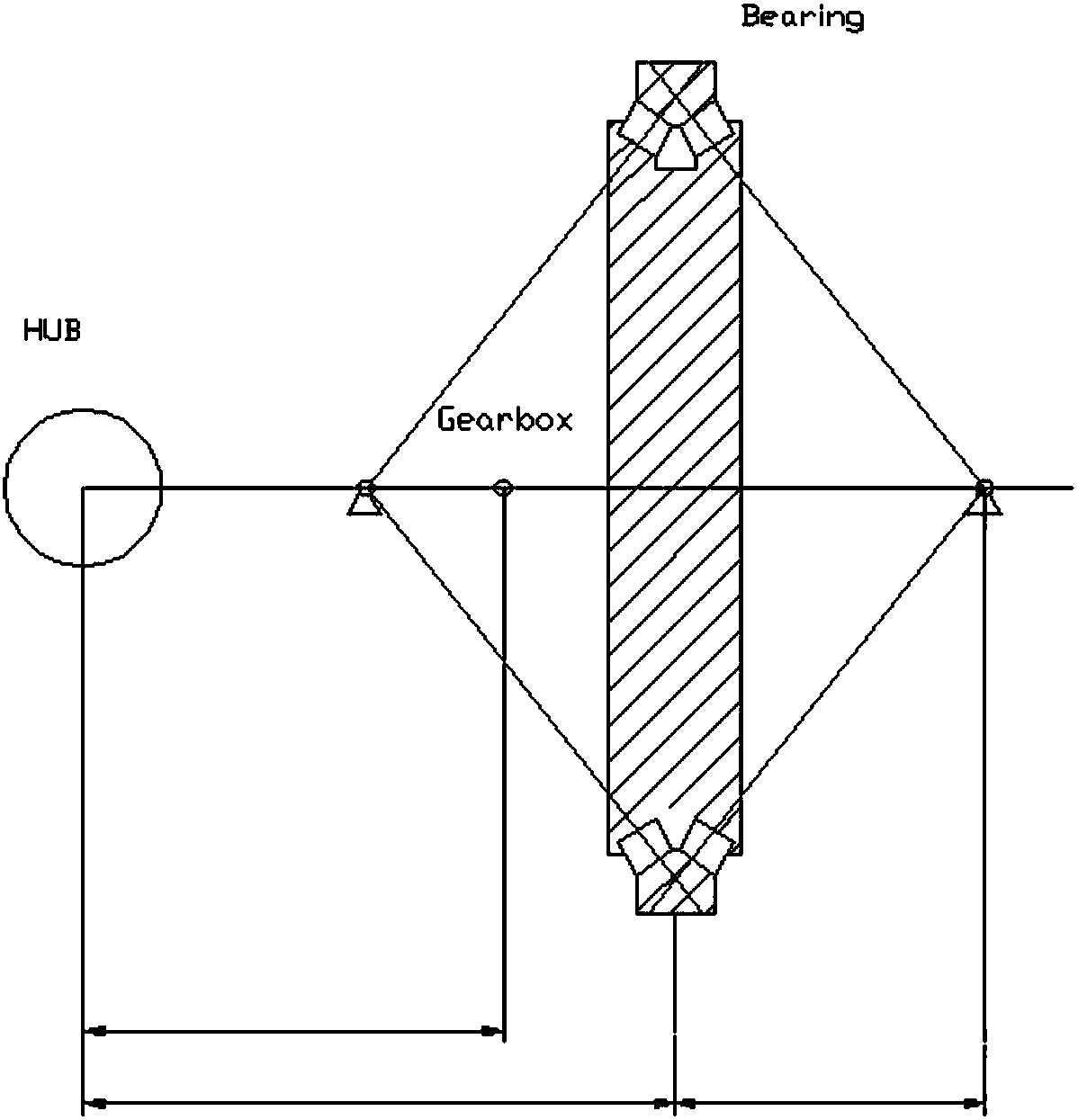

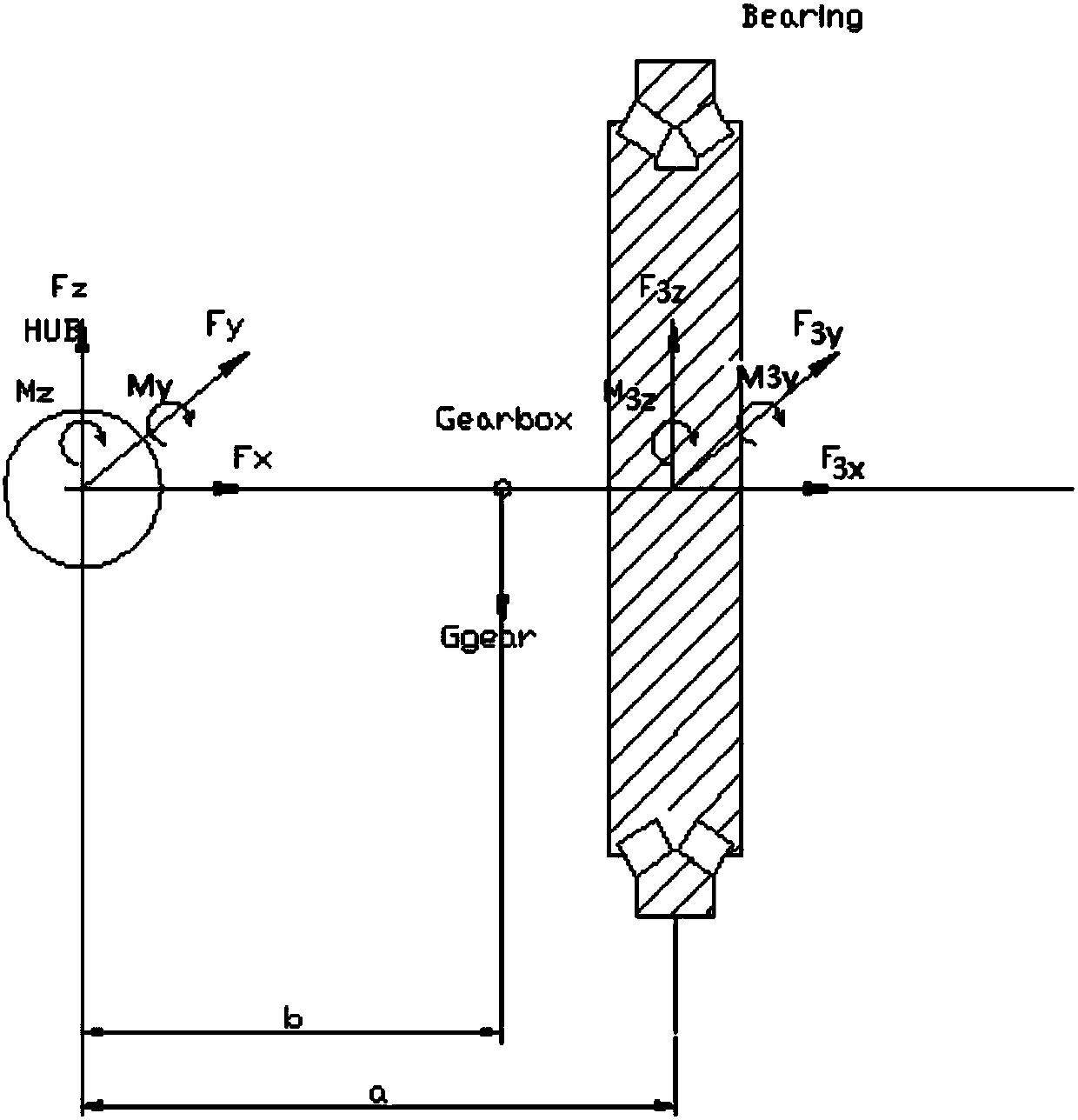

Checking tool for bearing raceways of main shafts

ActiveCN107729597AFull controlShorten the design cycleBearing componentsDesign optimisation/simulationWind drivenDesign cycle

The invention discloses a checking tool for bearing raceways of main shafts. The tool can be used for directly conducting equivalence treatment on time sequence load and LDD load spectrums, each working condition is equivalent to one group of loads, the equivalent loads are loads at the centers of hubs and can be further transmitted to the centers of bearings through a balance relation, and the tool is divided into two modules including the checking module for double-row spherical roller bearing raceways and a checking module for double-row tapered roller bearing raceways according to a bearing structure form; firstly, the static strength safety factors and contact stress of the bearing raceways are solved according to a method provided in ISO76-2006 standards, secondly, the basic rating service life and corrected rating service life of the bearing raceways are solved according to ISO281-2007 standards, and finally, the reference service life of the bearings is solved according to ISO16281-2008 standards. By means of the tool, the starting design cycle of a complete machine can be very effectively shortened, the tool better serves to the design, certification and evaluation of a wind-driven generator, the reliability of the design of a wind-driven generator set is improved, and the cost is saved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

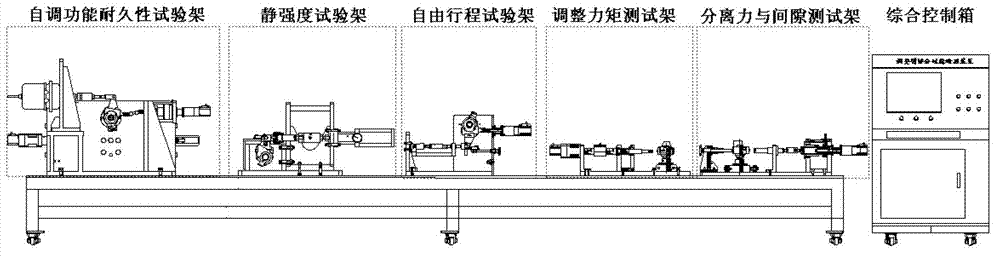

Detection assembly line used for comprehensive performance testing of adjusting arm

ActiveCN103115782ADurability gainReal-time monitoring of movementVehicle testingMotor driveSignal conditioning

The invention discloses a detection assembly line used for comprehensive performance testing of an adjusting arm. The detection assembly line is characterized in that a self-adjusting function durability testing frame, a static strength testing frame, a free stroke testing frame, an adjusting moment testing frame and a separating force and gap testing frame are sequentially fixed on a big supporting rack from left to right. The testing frames on the supporting seat are respectively used for detecting testing tasks of specified items of the adjusting arm. A comprehensive control cabinet is placed on the right side of the supporting seat, communicates with the same through a cable, comprises a PC (personal computer), a data collection system, a motor driving system, a signal conditioning system and other electric auxiliary systems, and is used for controlling the testing tasks of each testing frames, receiving testing data and judging whether performance parameters of the adjusting arm are qualified or not. The detection assembly line used for comprehensive performance testing of the adjusting arm is simple in structure and convenient to operate.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

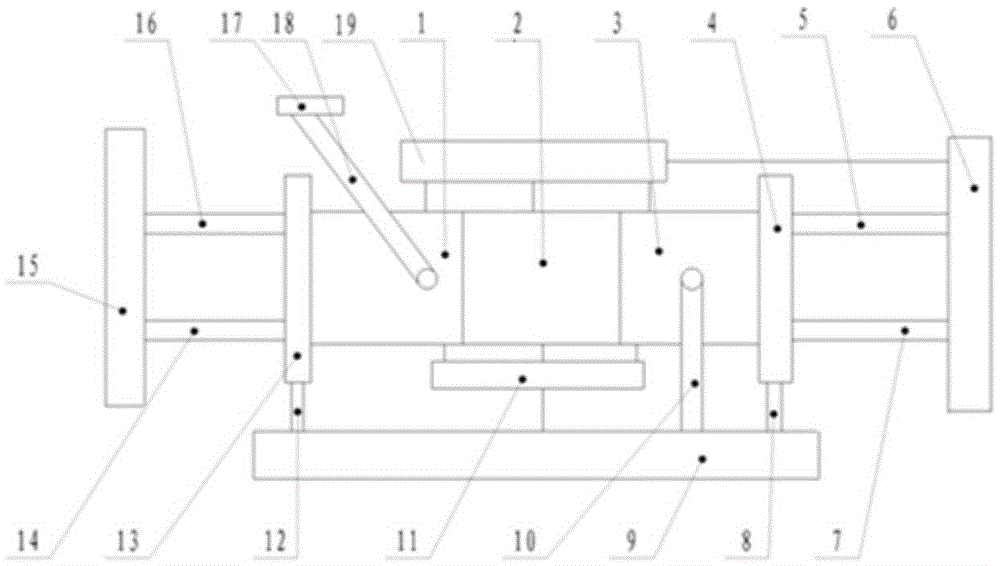

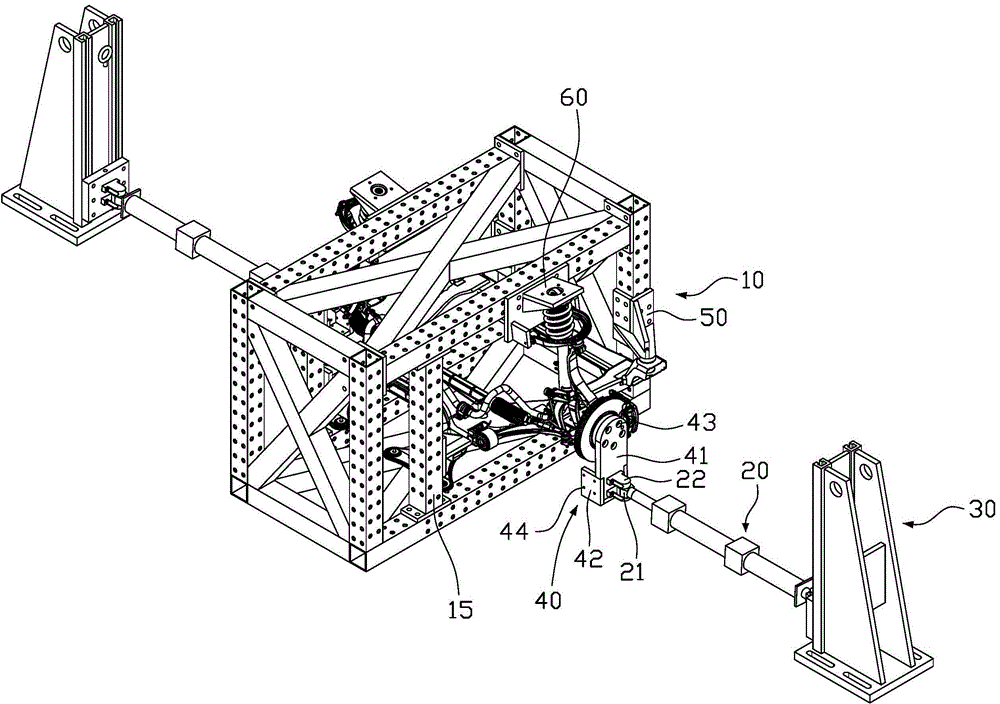

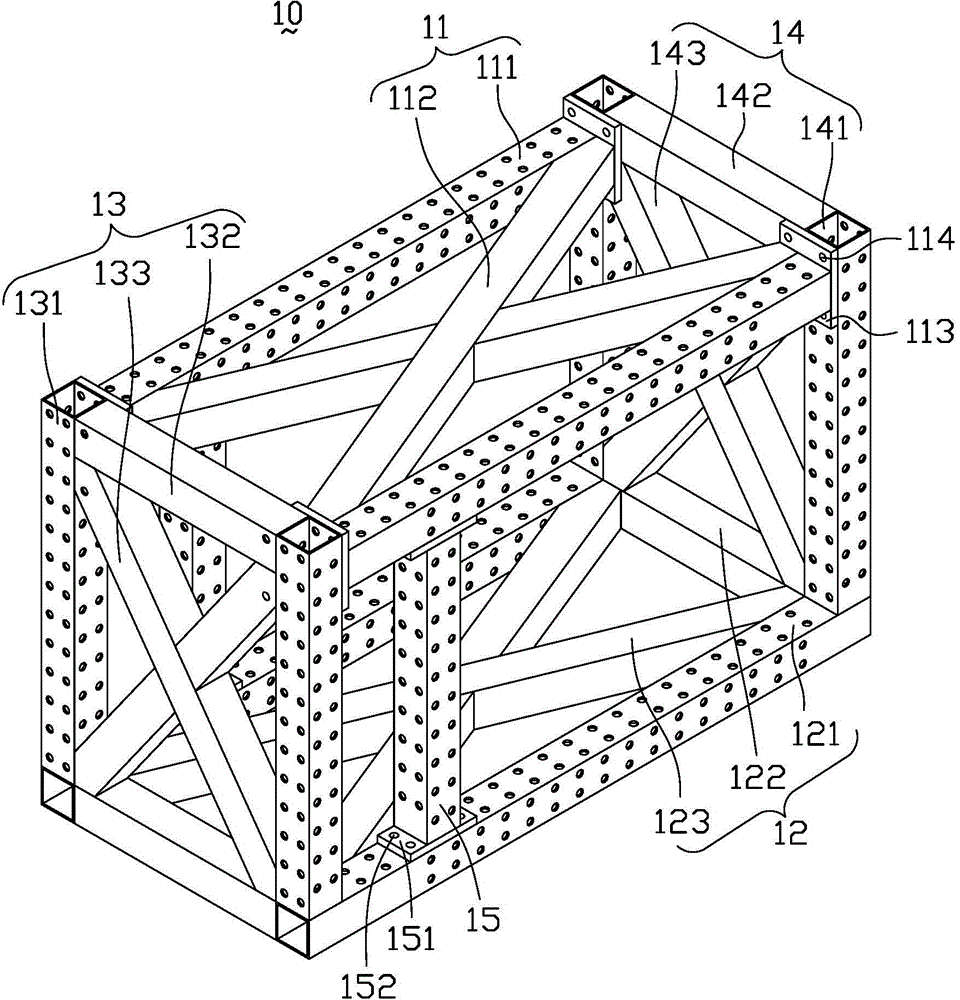

Aero-engine main force bearing component overall static strength assessment test system and method

The invention discloses an aero-engine main force bearing component overall static strength assessment test system and an aero-engine main force bearing component overall static strength assessment test method. The aero-engine main force bearing component overall static strength assessment test system comprises a plurality of loading assemblies and a measuring mechanism, wherein adapting sections at left and right ends of a test assembly are connected with test frameworks through the plurality of loading assemblies, upper and lower ends of the test assembly are fixed on the test frameworks, the lower part of the test assembly is connected with the lower test framework through the fourth loading assembly, and the measuring mechanism is arranged on the right test framework and is connected with the test assembly. The test method provided by the invention has clear and feasible test steps and detailed loading process, can truly simulate working states of an aero-engine main force bearing component, applies complex load on the integral aero-engine main force bearing component synchronously on a test device, and is suitable for carrying out static strength assessment tests on various types of aero-engine main force bearing components integrally.

Owner:AECC AVIATION POWER CO LTD

Automotive suspension intensity test bed

ActiveCN105403416AShorten the development cycleIncrease stiffnessVehicle suspension/damping testingVehicle frameEngineering

The invention discloses an automotive suspension intensity test bed, and the test bed comprises a frame, an actuator, a counter-force frame, and a wheel replacement part. Two opposite ends of the actuator are respectively connected with the counter-force frame and the wheel replacement part. The wheel replacement part is connected with the frame through an automobile suspension and a subframe. The frame is provided with an adjustment vertical column, and the subframe is fixed between the adjustment vertical column and the frame. The position of the adjustment vertical column on the frame can be adjusted in the first direction, and the positions of the subframe on the adjustment vertical column and the frame can be adjusted in the second direction. The wheel replacement part is provided with a plurality of installation surfaces in different directions, and the actuator is fixed on different installation surfaces under different testing demands. The test bed is suitable for different types of subframes in different sizes through adjusting the lateral position of the adjustment vertical column on the frame and / or the longitudinal position of the subframes on the adjustment vertical column and the frame, can select different installation surfaces of the wheel replacement part according to different testing demands, and achieves the testing of fatigue strength and static strength of different suspensions.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

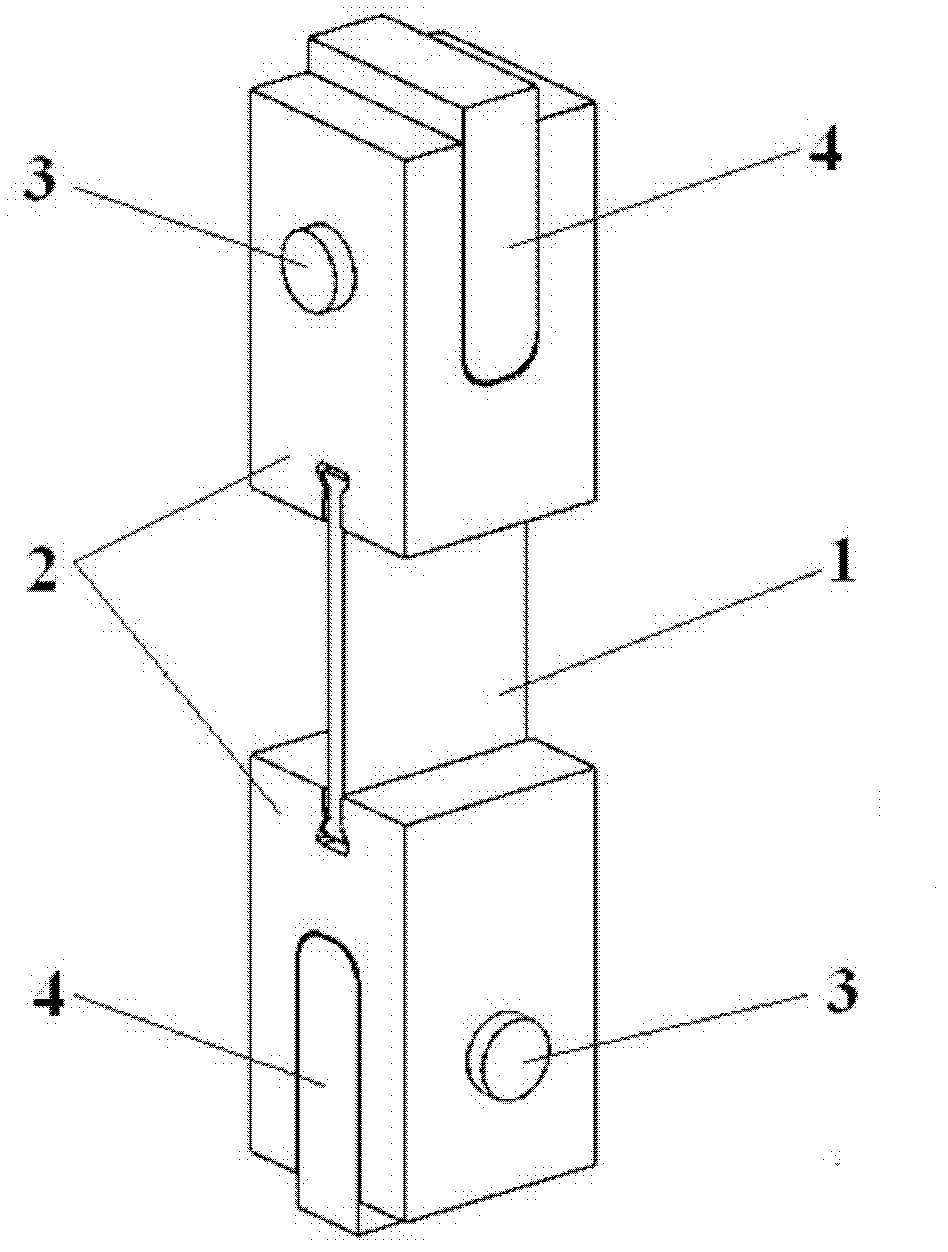

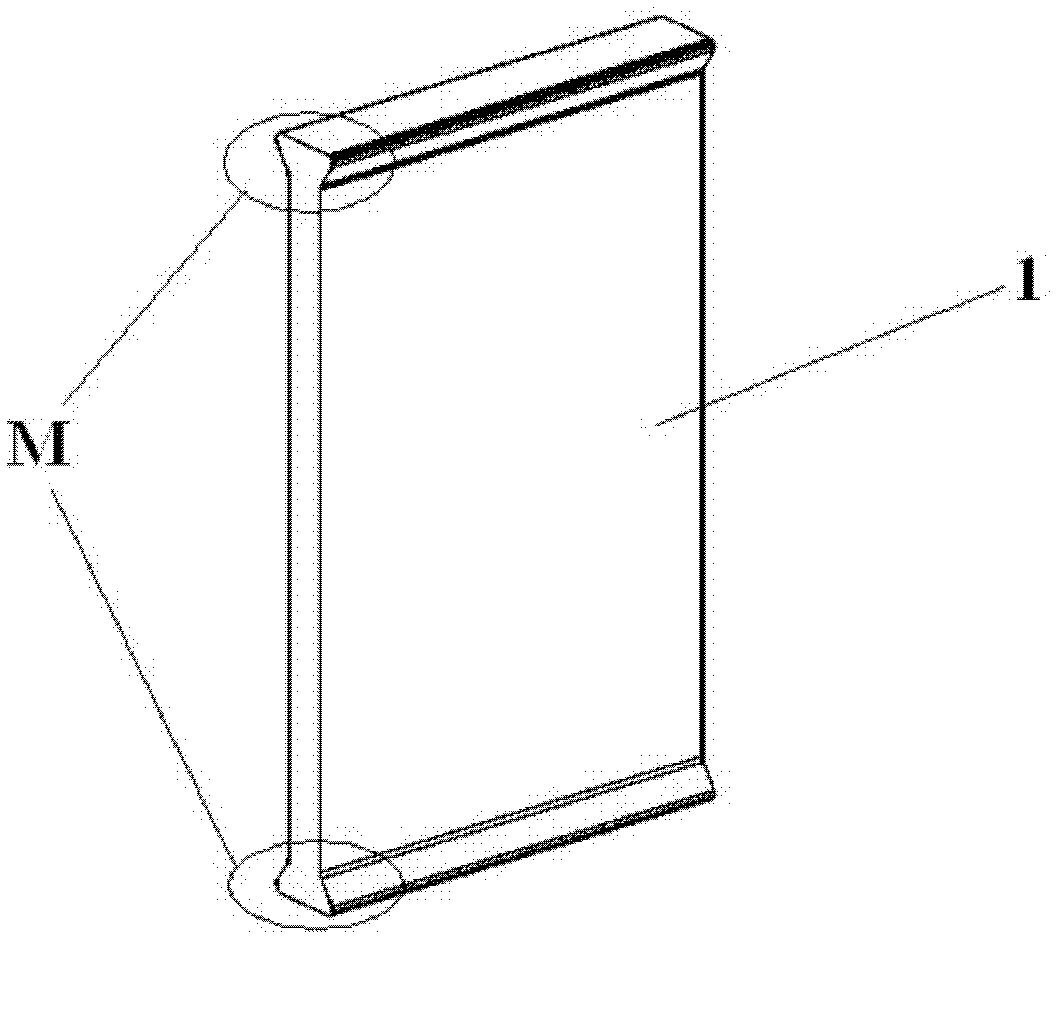

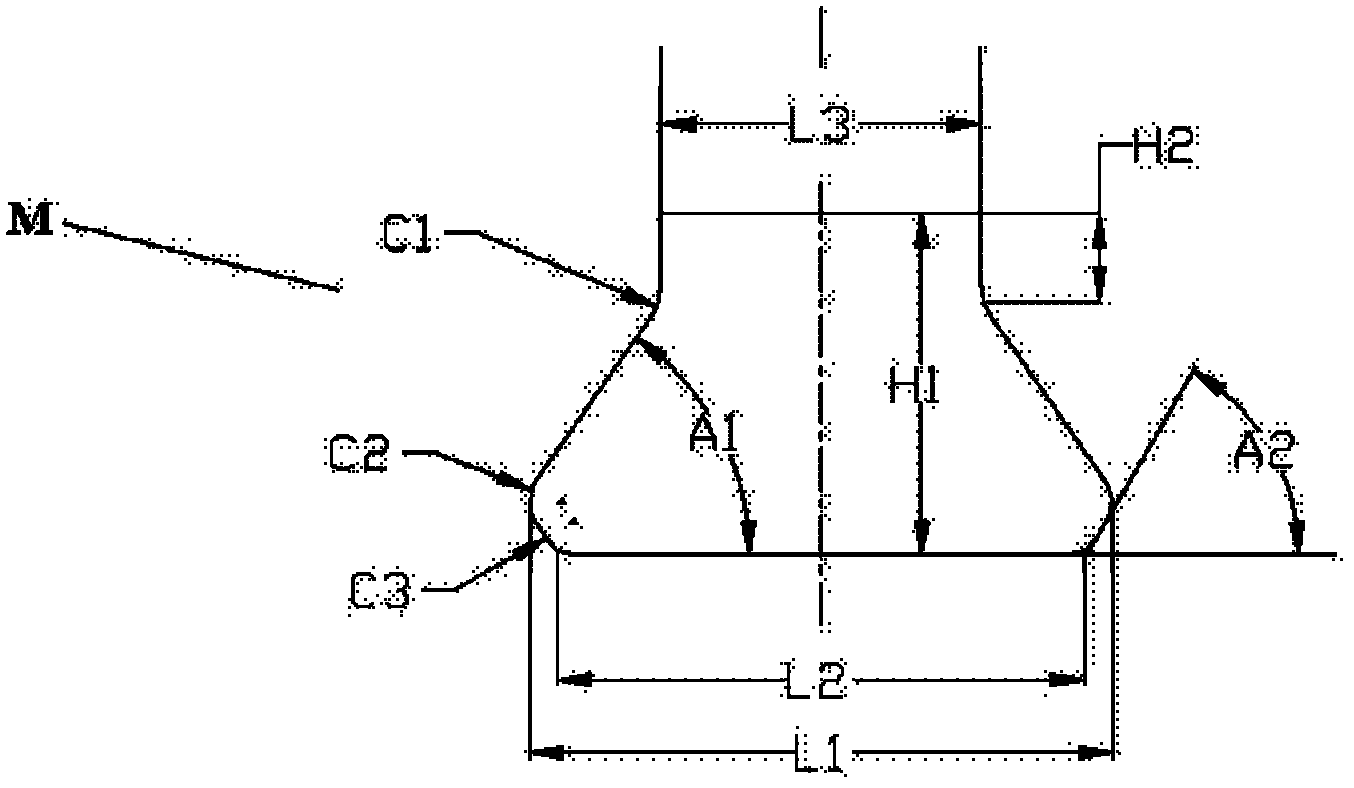

Double-head tenon joint tension test structure without additional bending moment

InactiveCN102607951AAvoid designReduce processing stepsMaterial strength using tensile/compressive forcesImpellerTest efficiency

The invention discloses a double-head tenon joint tension test structure without an additional bending moment. The test structure consists of a blade test piece (1), clamps (2), pins (3) and stress pieces (4). During test, tenons at two ends of the blade test piece (1) are clamped into mortises of the clamps (2), the clamps (2) are connected with the stress pieces (4) at two ends through the pins (3), and the two pins (3) are respectively vertical to the axis of the blade test piece (1) and mutually orthogonally distributed. The test structure is simple in structure and scientific in design, can be widely applied to tests on tensile static strength, fatigue, durability, creep deformation, vibration and the like of blades (containing tenons and mortises) in impeller machinery, and can be used for solving the problems of high design and machining difficulty of test clamps, generation of additional bending moment and low test efficiency in blade test. The test structure has the advantages of good practical value and good application prospect in the field of aerospace propulsion.

Owner:BEIHANG UNIV

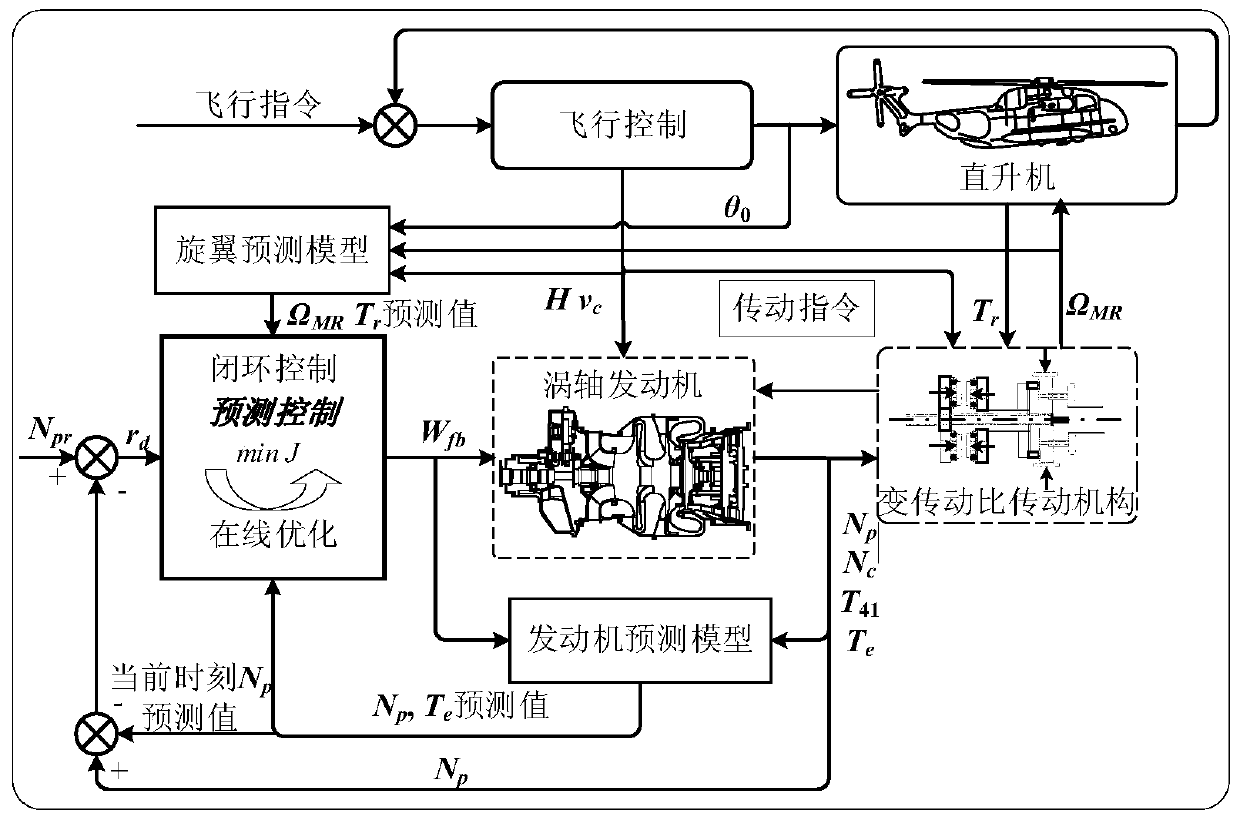

Variable rotor speed helicopter-vortex engine integrated control method and device

InactiveCN109896026AQuick Response ControlExtended service lifeAircraft power plantsSpecial data processing applicationsStatic strengthResponse control

The invention discloses a variable rotor speed helicopter-vortex engine integrated control method. The variable rotor speed helicopter-vortex engine integrated control method is characterized in thaton-line optimization of fuel flow rate of a turboshaft engine is carried out on the basis of comprehensive consideration of a speed control index and rotor dynamic characteristics of matching torque through a variable transmission ratio transmission mechanism; under the conditions of satisfying various restrictions such as compressor speed and engine static strength, speed overshoot and sag of a power turbine in the process of variable rotor speed can be significantly reduced, and not only is fast response control of the turboshaft engine realized, but also the service life of the engine is prolonged. Further disclosed is a variable rotor speed helicopter-vortex engine integrated control device. The variable rotor speed helicopter-vortex engine integrated control method and the device thereof have the advantages of significantly reducing the speed overshoot and sag of the power turbine in the process of the variable rotor speed under the conditions of satisfying the various restrictions such as compressor speed and engine static strength, realizing the fast response control of the turboshaft engine, and prolonging the service life of the engine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com