Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

297 results about "Rail profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

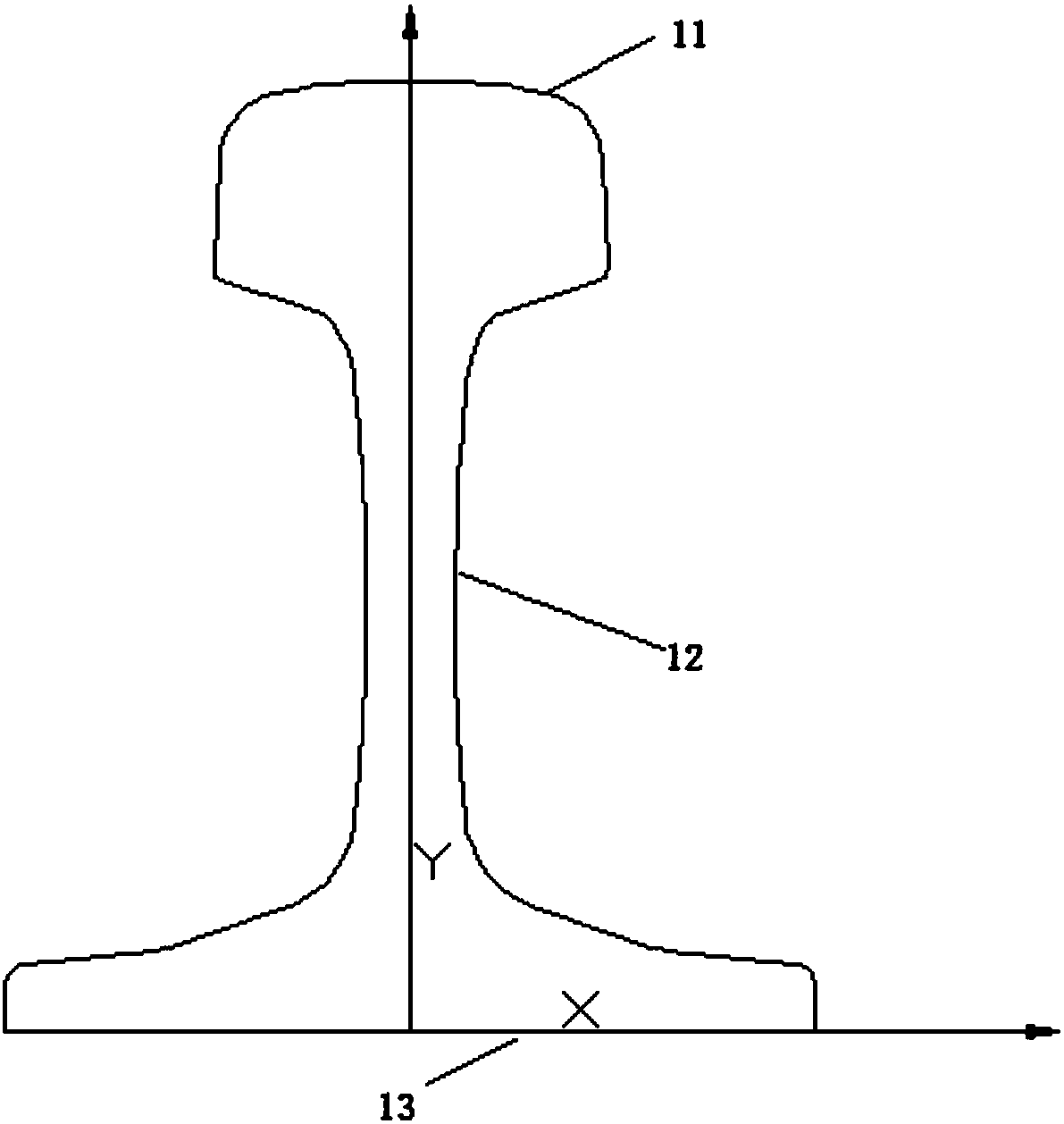

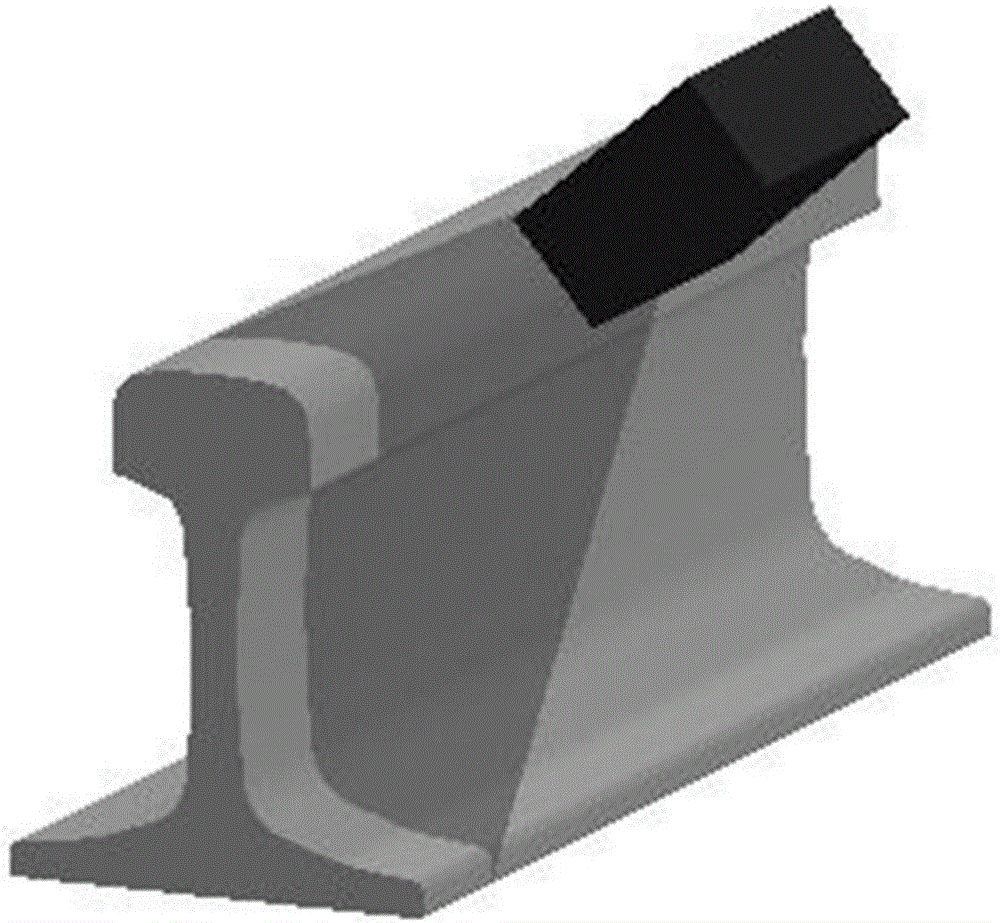

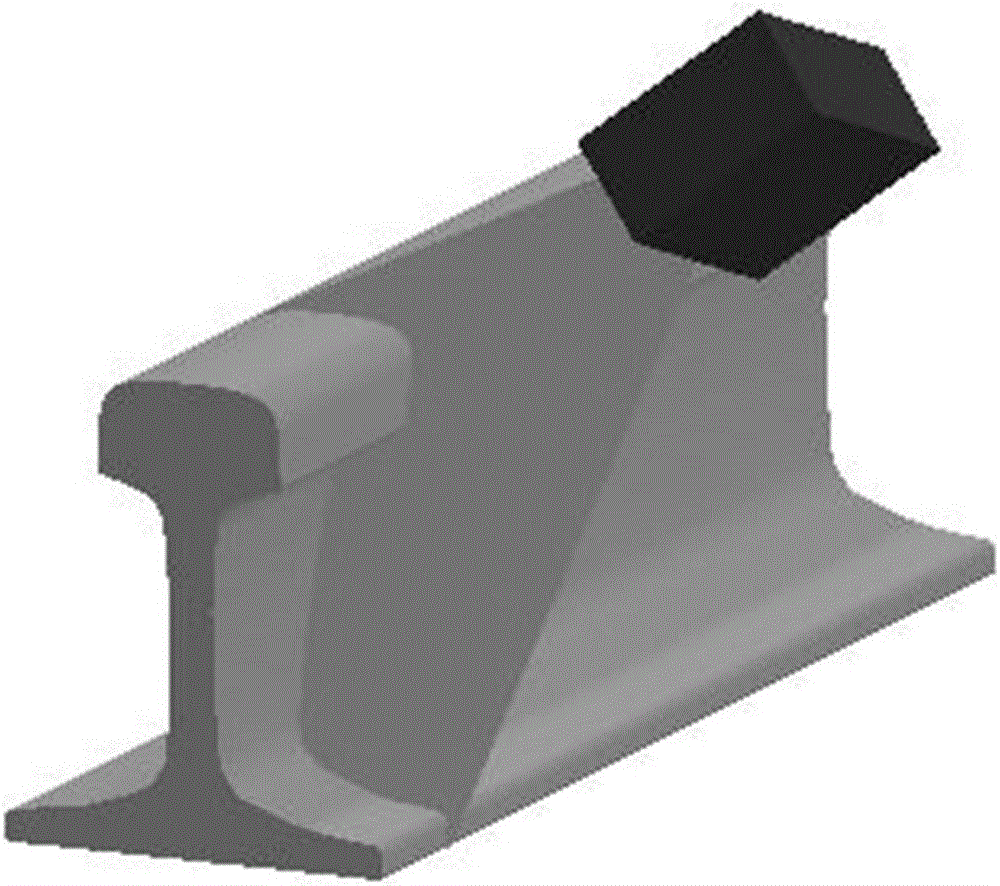

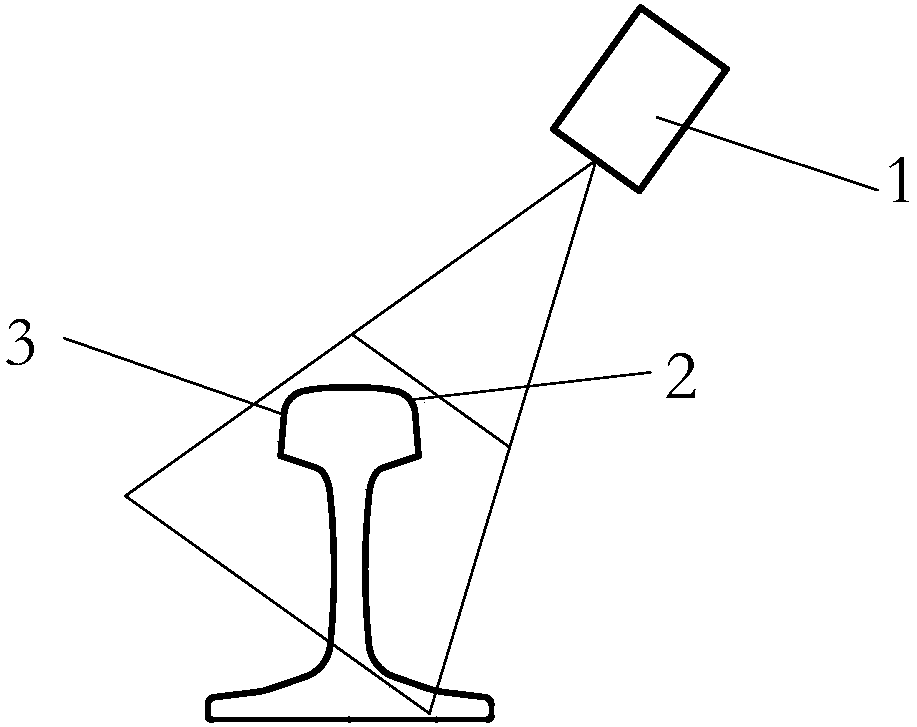

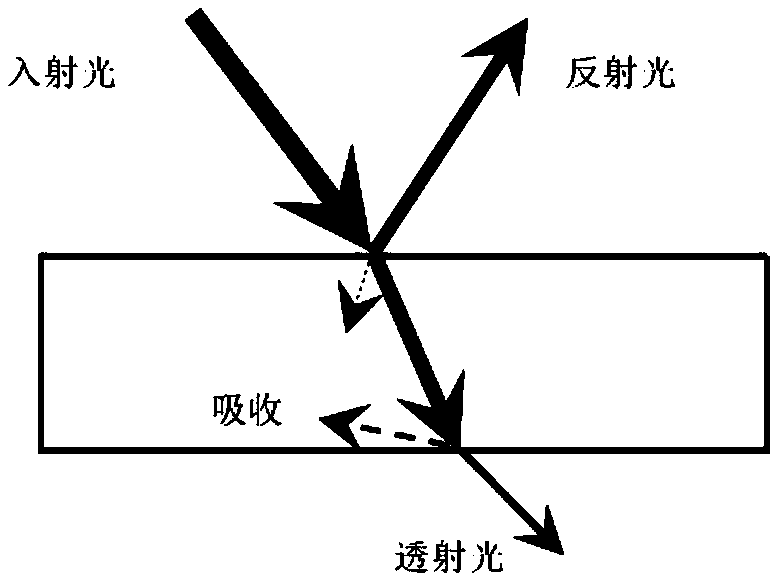

The rail profile is the cross sectional shape of a railway rail, perpendicular to its length. Early rails were made of wood, cast iron or wrought iron. All modern rails are hot rolled steel with a cross section (profile) approximate to an I-beam, but asymmetric about a horizontal axis (however see grooved rail below). The head is profiled to resist wear and to give a good ride, and the foot profiled to suit the fixing system.

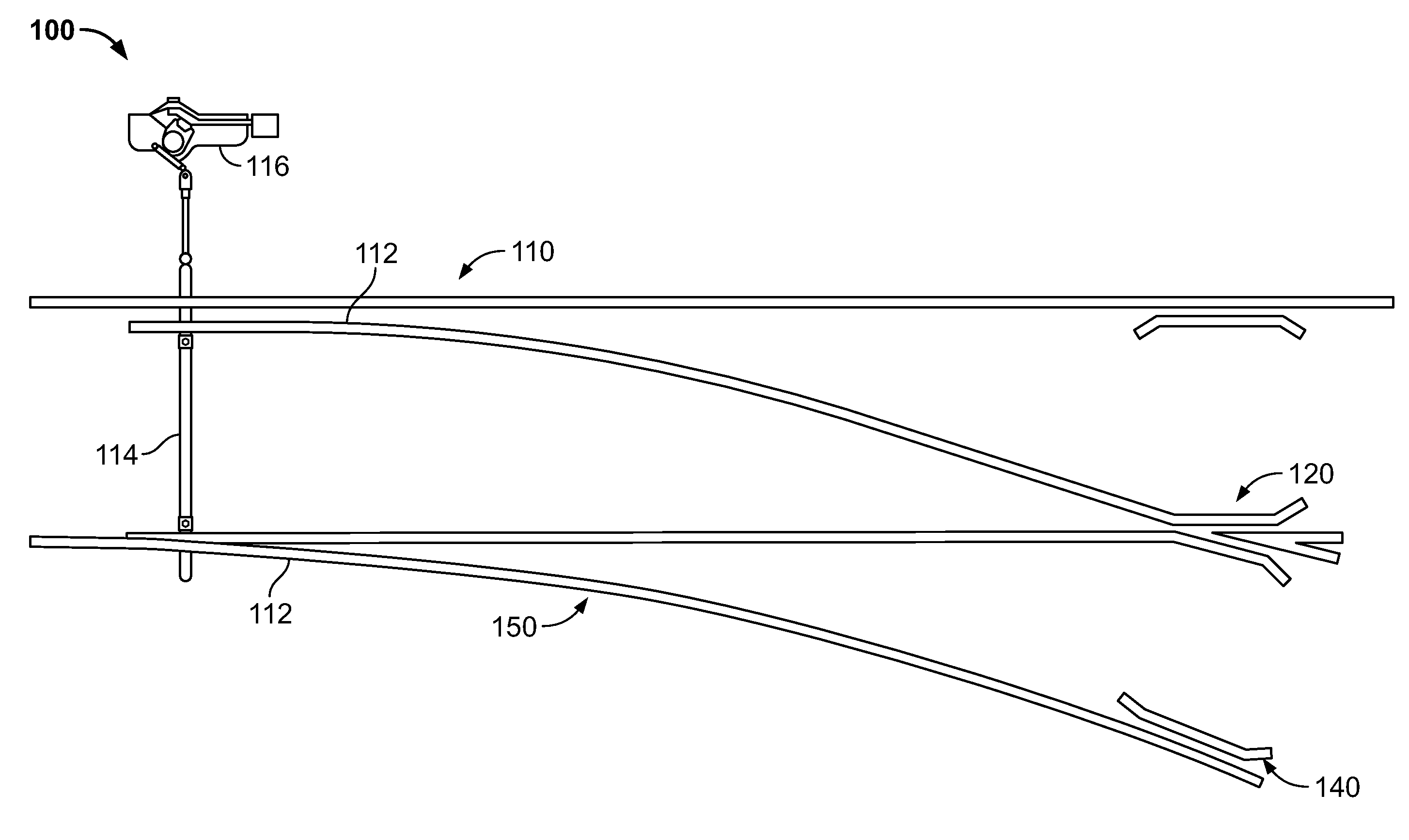

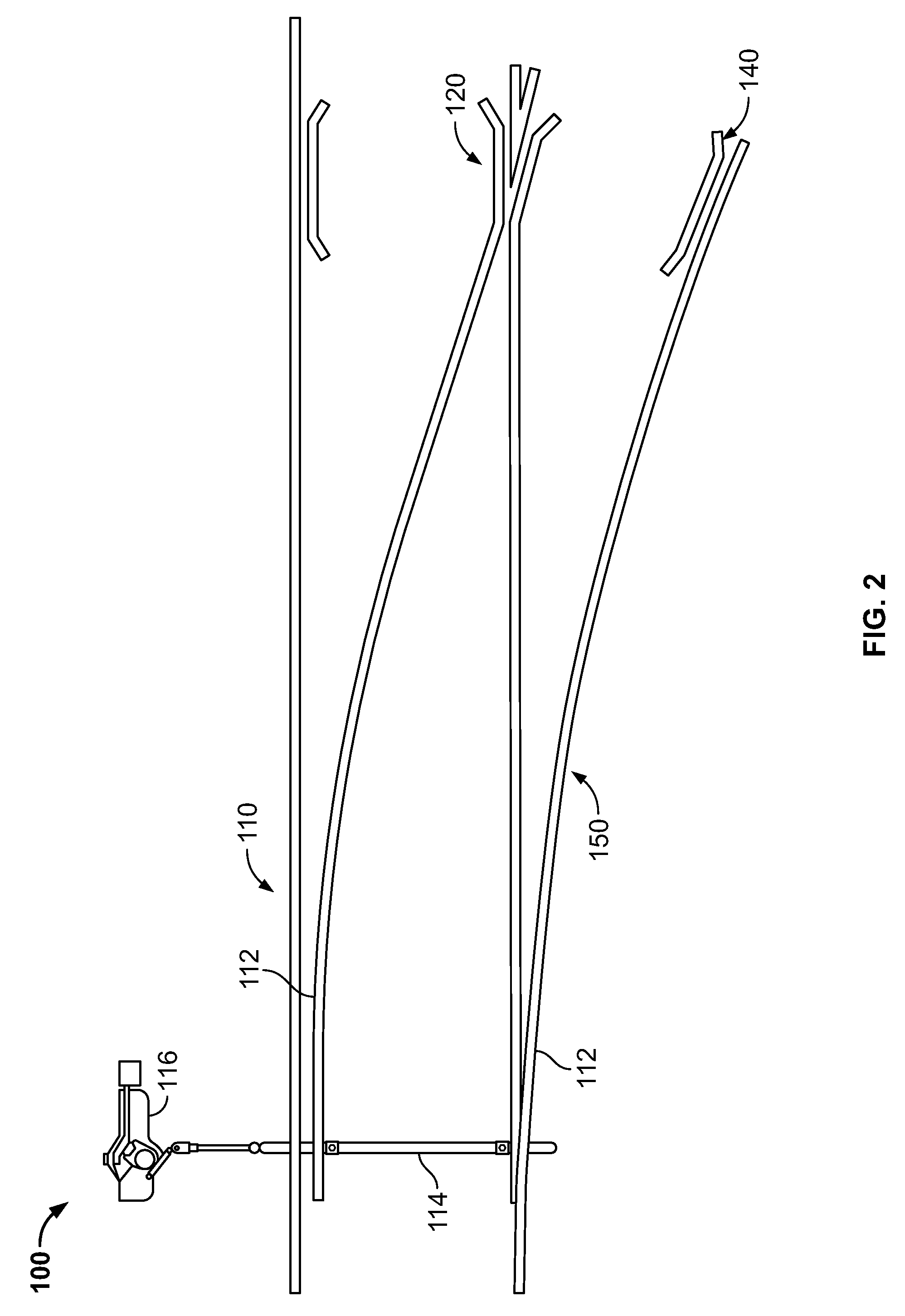

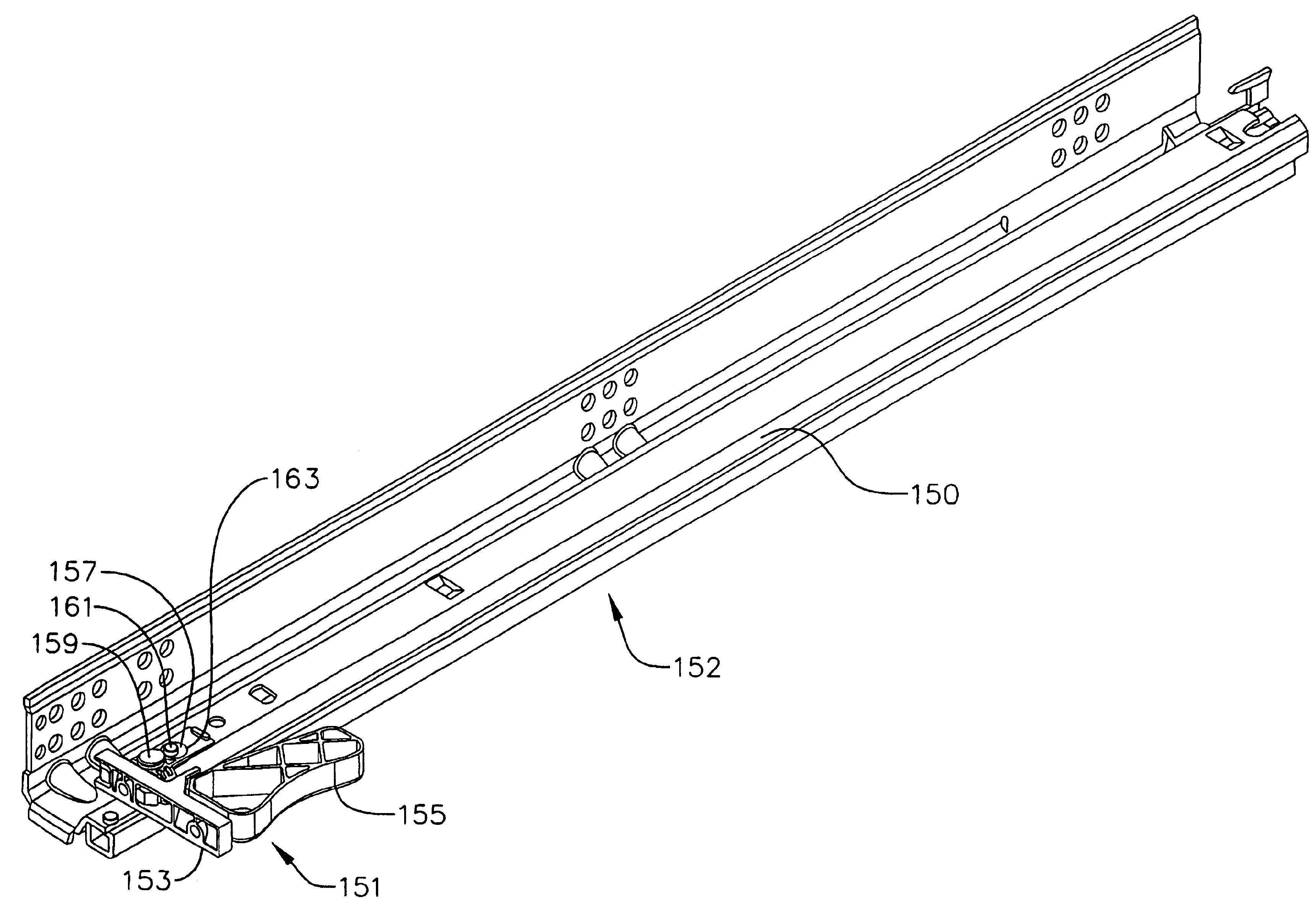

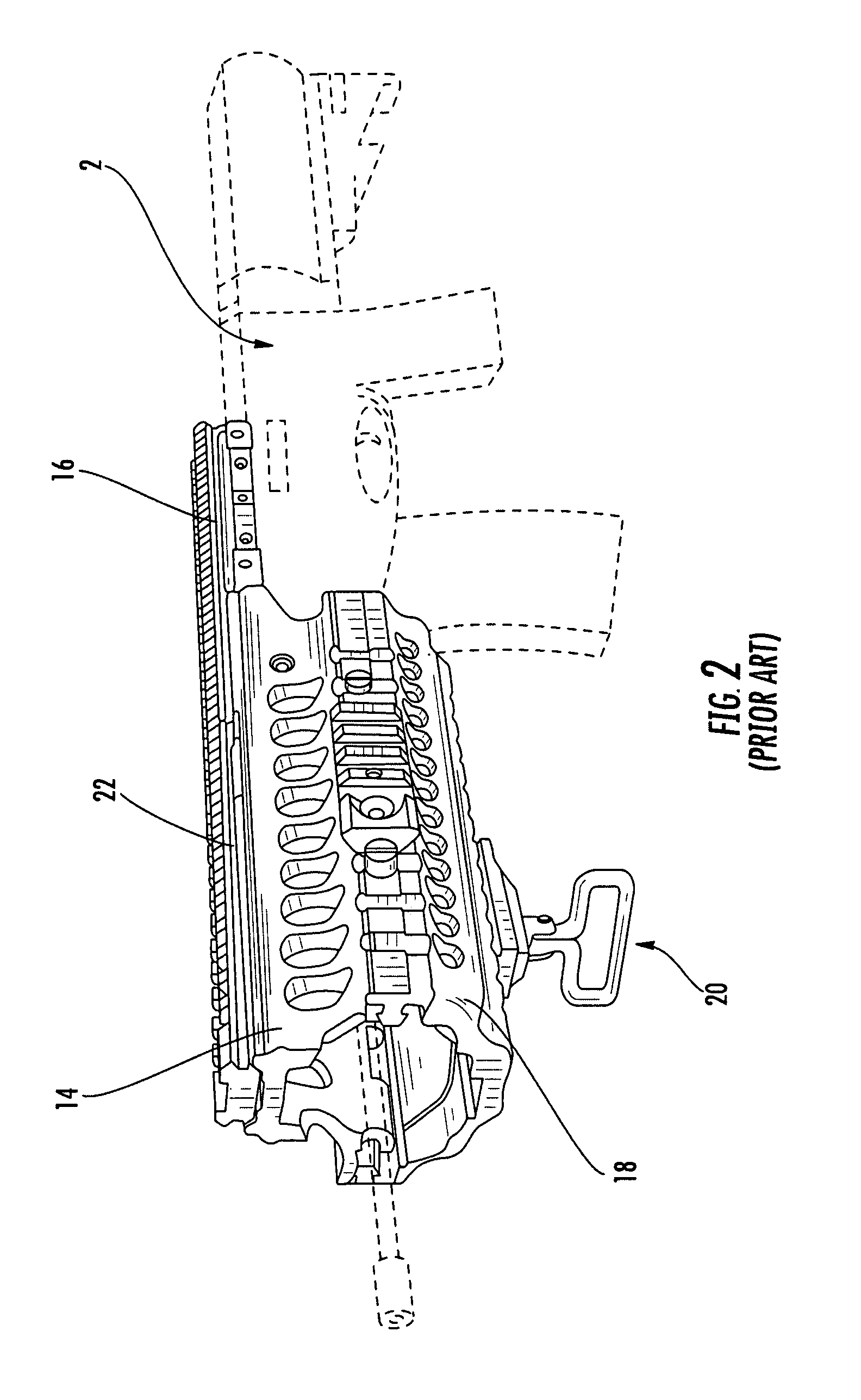

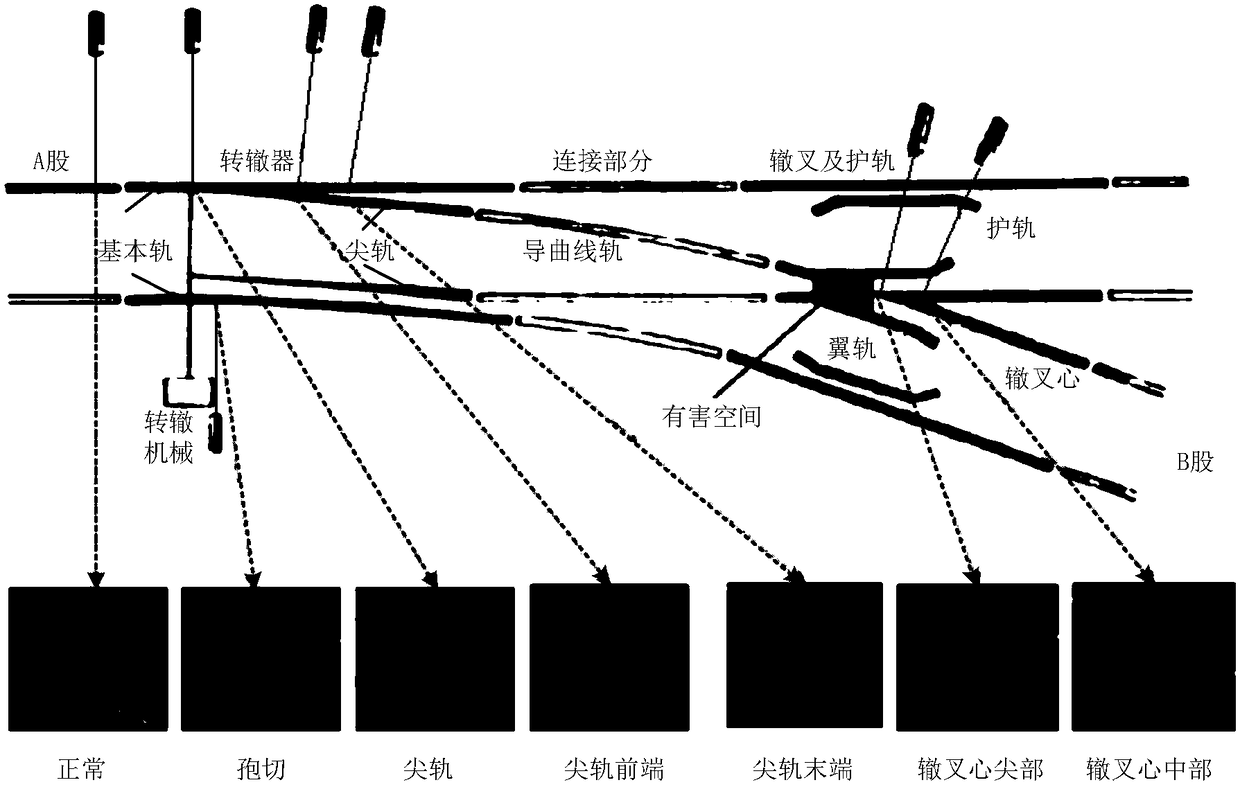

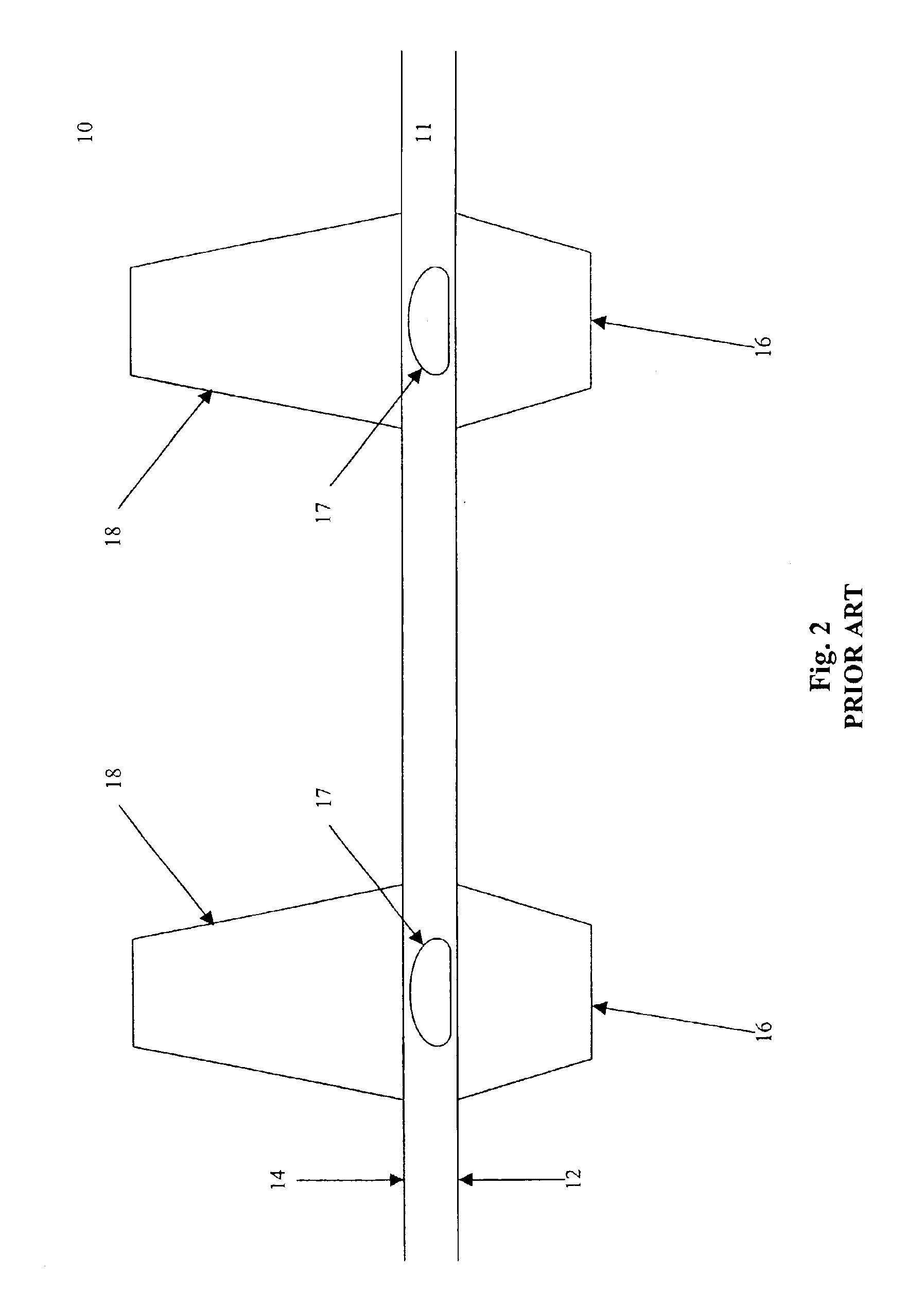

Automated turnout inspection

ActiveUS20110064273A1Enhancing turnout inspection approachReduce dependenceCharacter and pattern recognitionRailway signalling and safetyRail profileDerailment

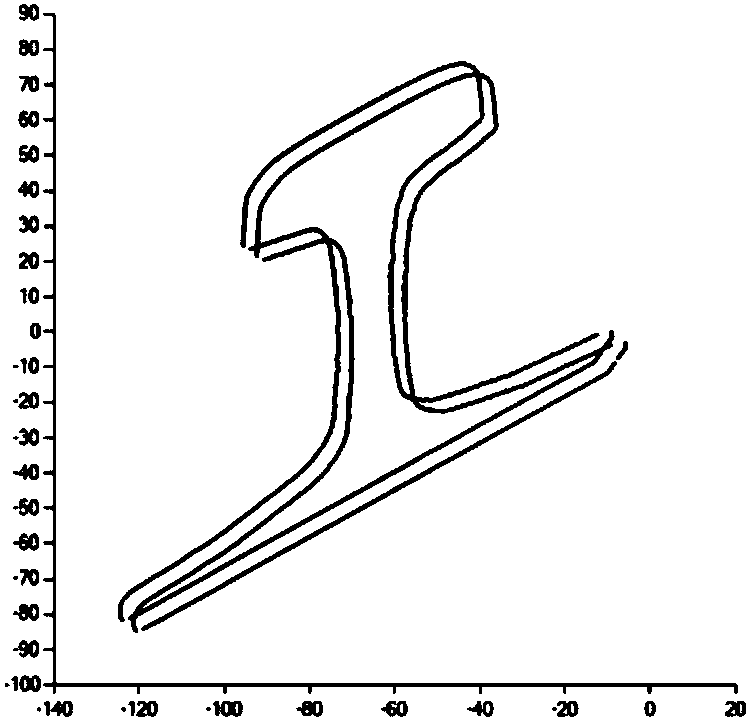

A method of inspecting a turnout of a track includes the steps of: capturing images of the components of the turnout; converting each image into a set of coordinates that traces the transverse cross-section of a rail profile; analyzing the rail profile to determine if the rail profile is a profile of arunning rail portion or a component. Upon determination that the image represents a component, taking measurements of the rail profile and applying virtual gauges to the rail profile to check for potentially dangerous conditions of the component; and generating a summary of each cross-section of the rail profile of the component indicating problem areas. The method is used for identifying certain classes of switch or turnout rail conditions which can lead to derailments, and for enhancing the turnout inspection approach currently used. The use of this method as an integrated part of the rail profile monitoring program will reduce reliance on field measurements and will also allow more frequent, comprehensive, and convenient analysis of turnout condition.

Owner:HARSCO CORP

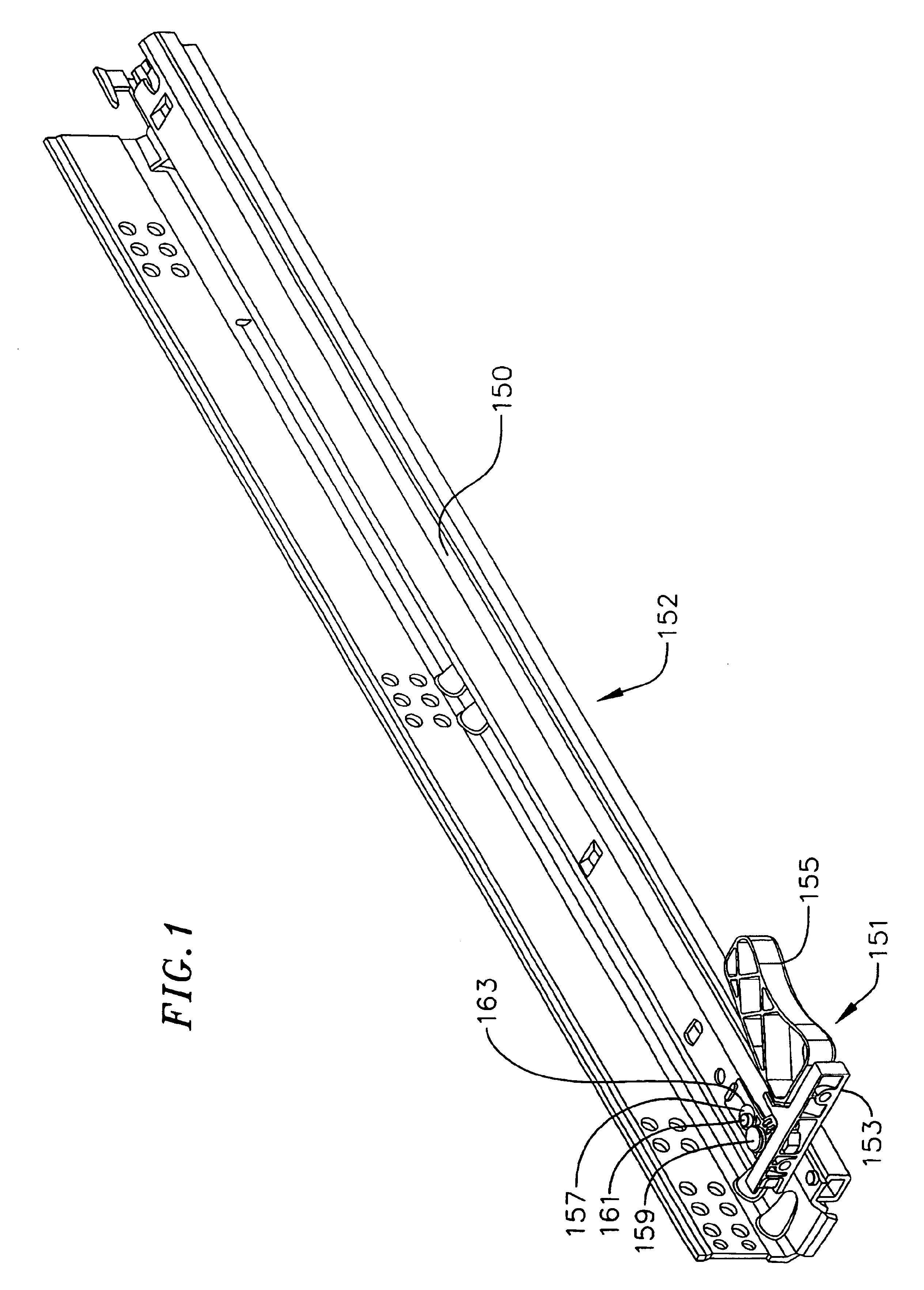

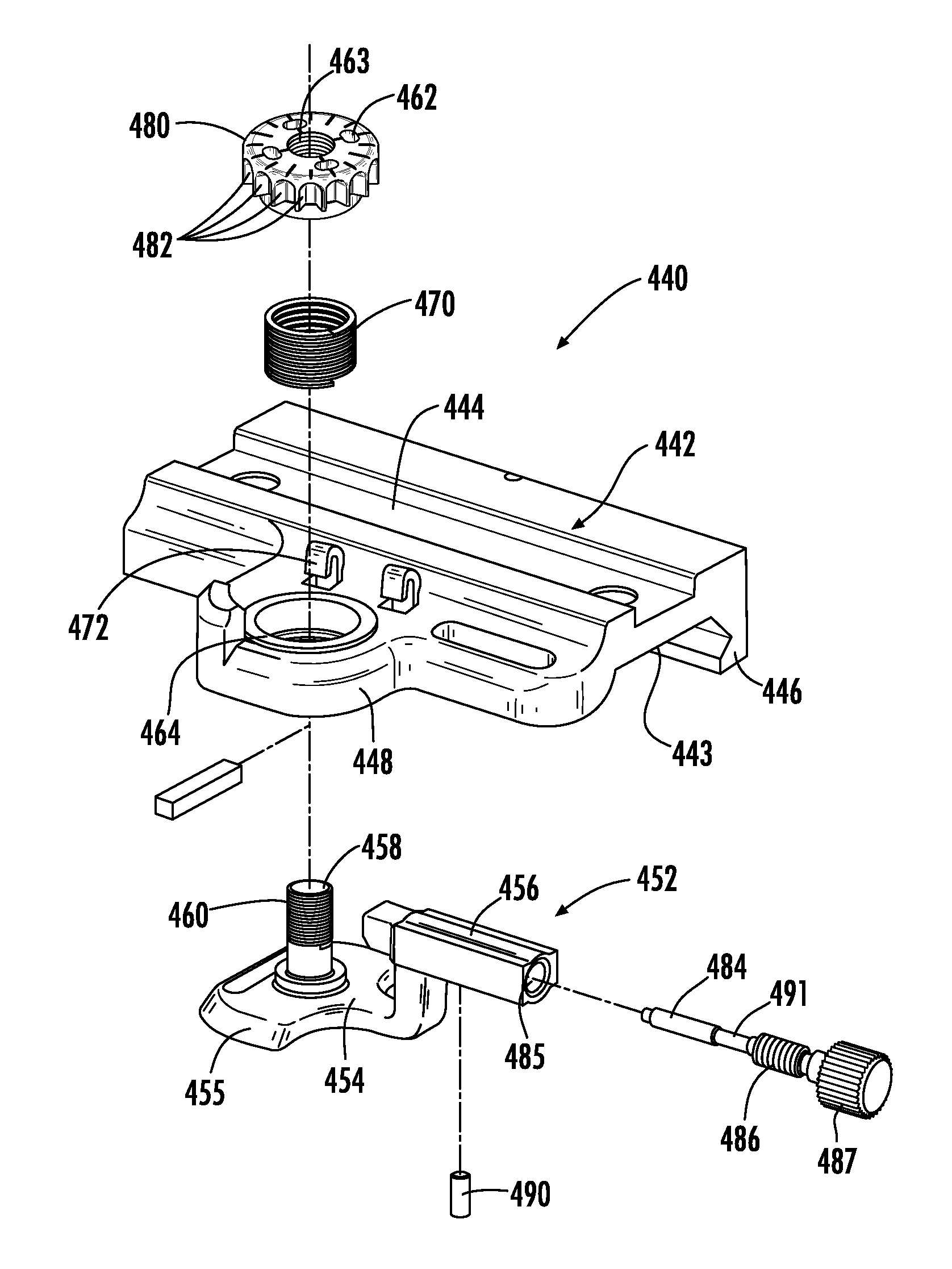

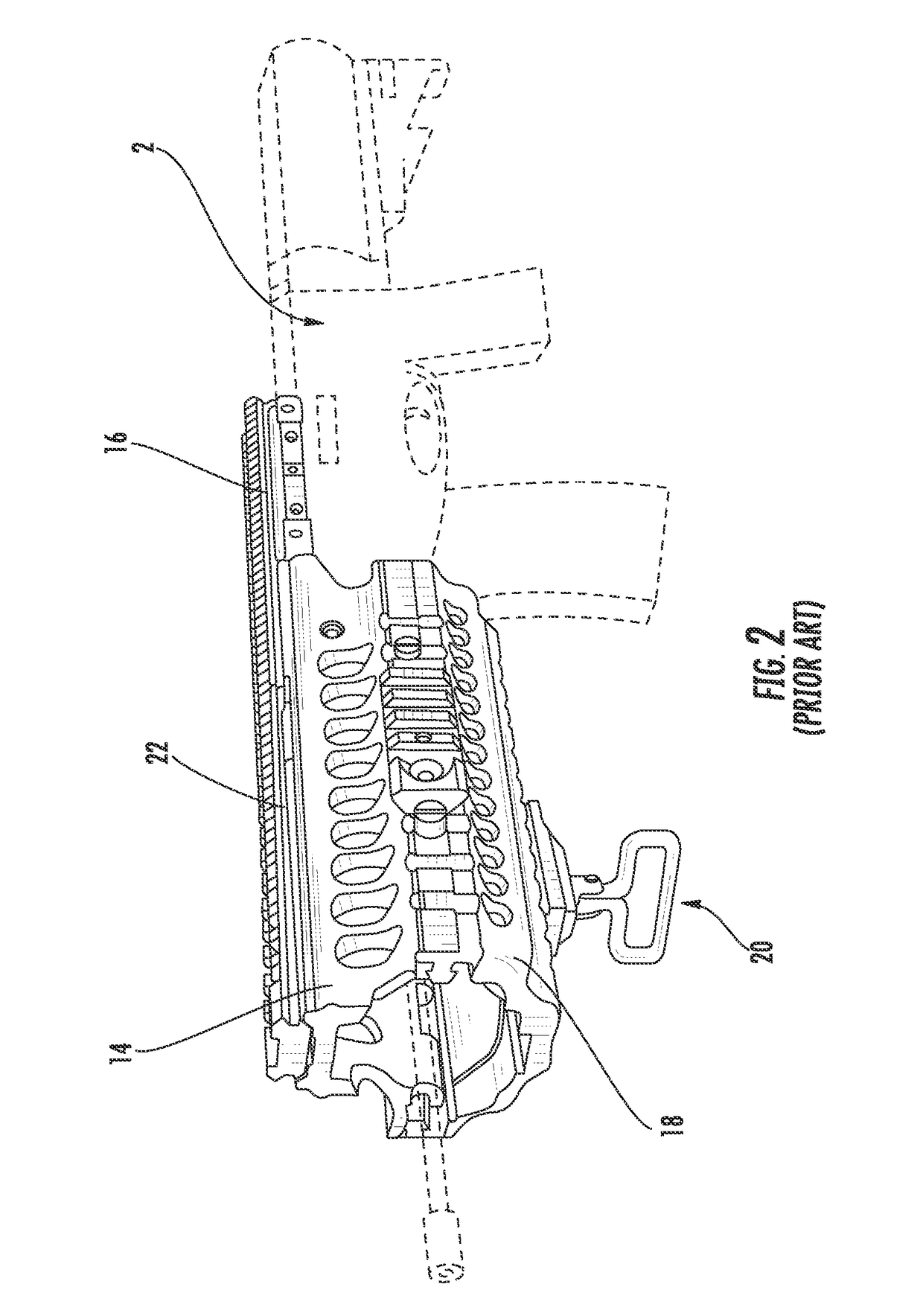

Drawer slide adjustment mechanism

Owner:STANDARD PURISHIJIYAN

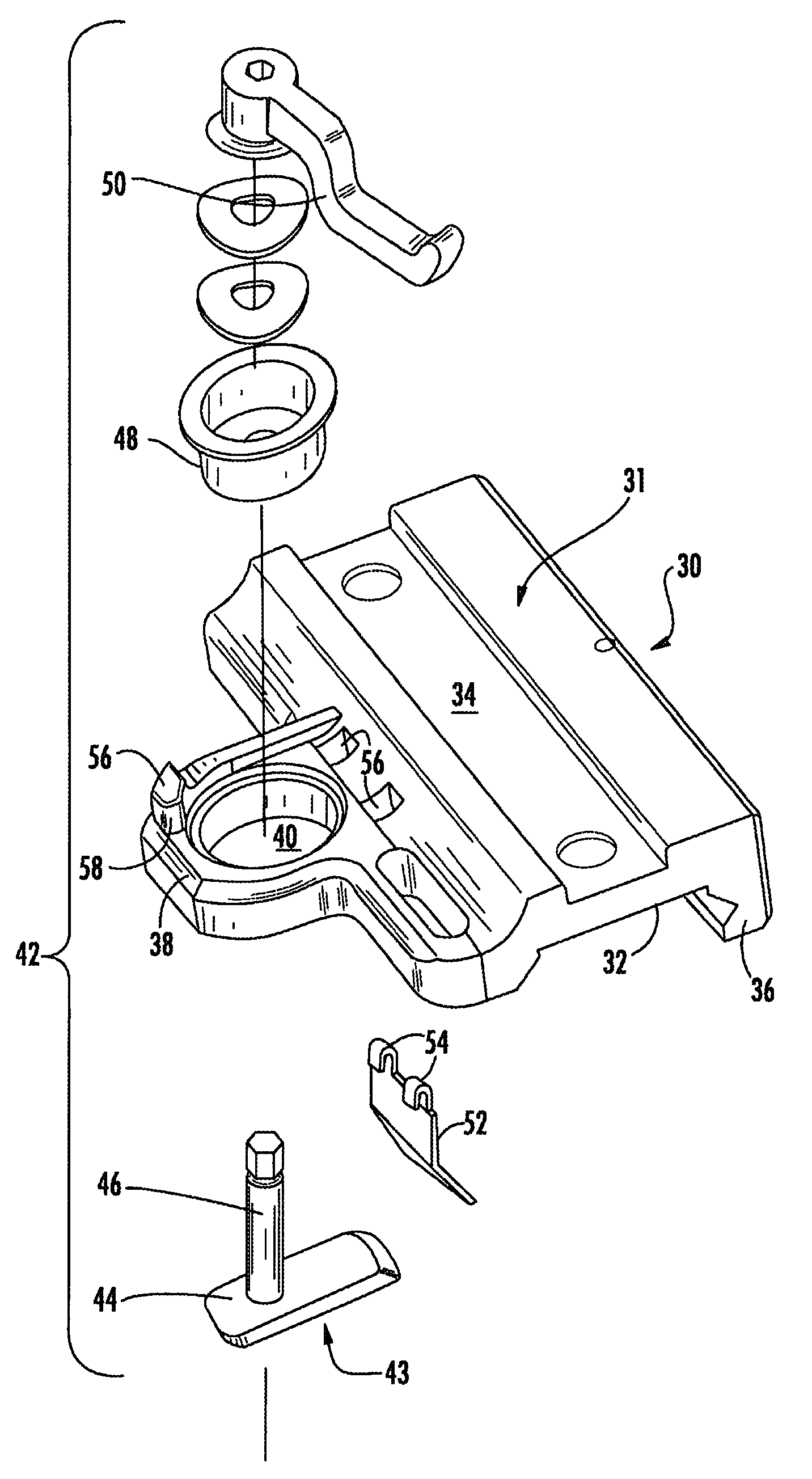

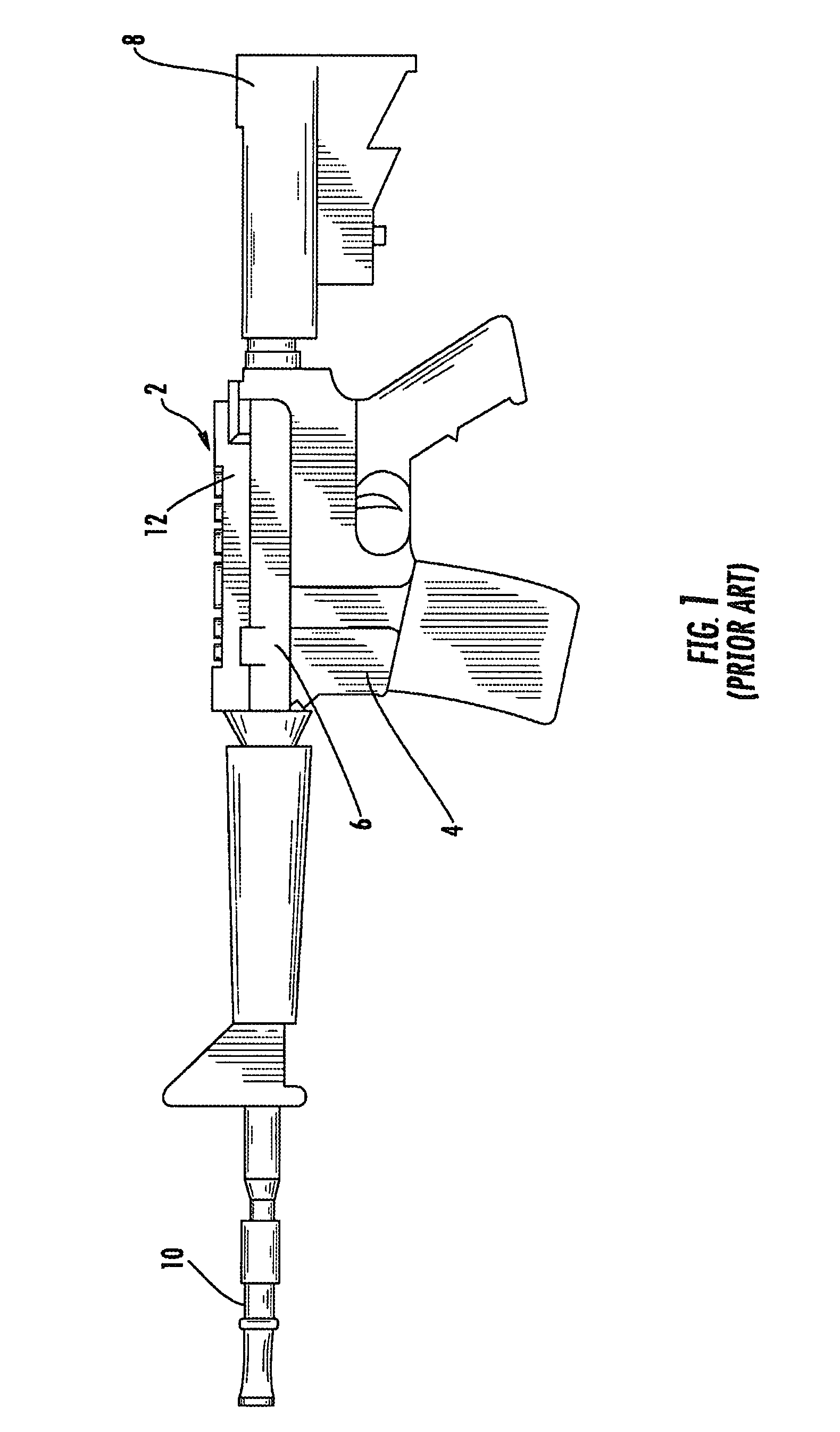

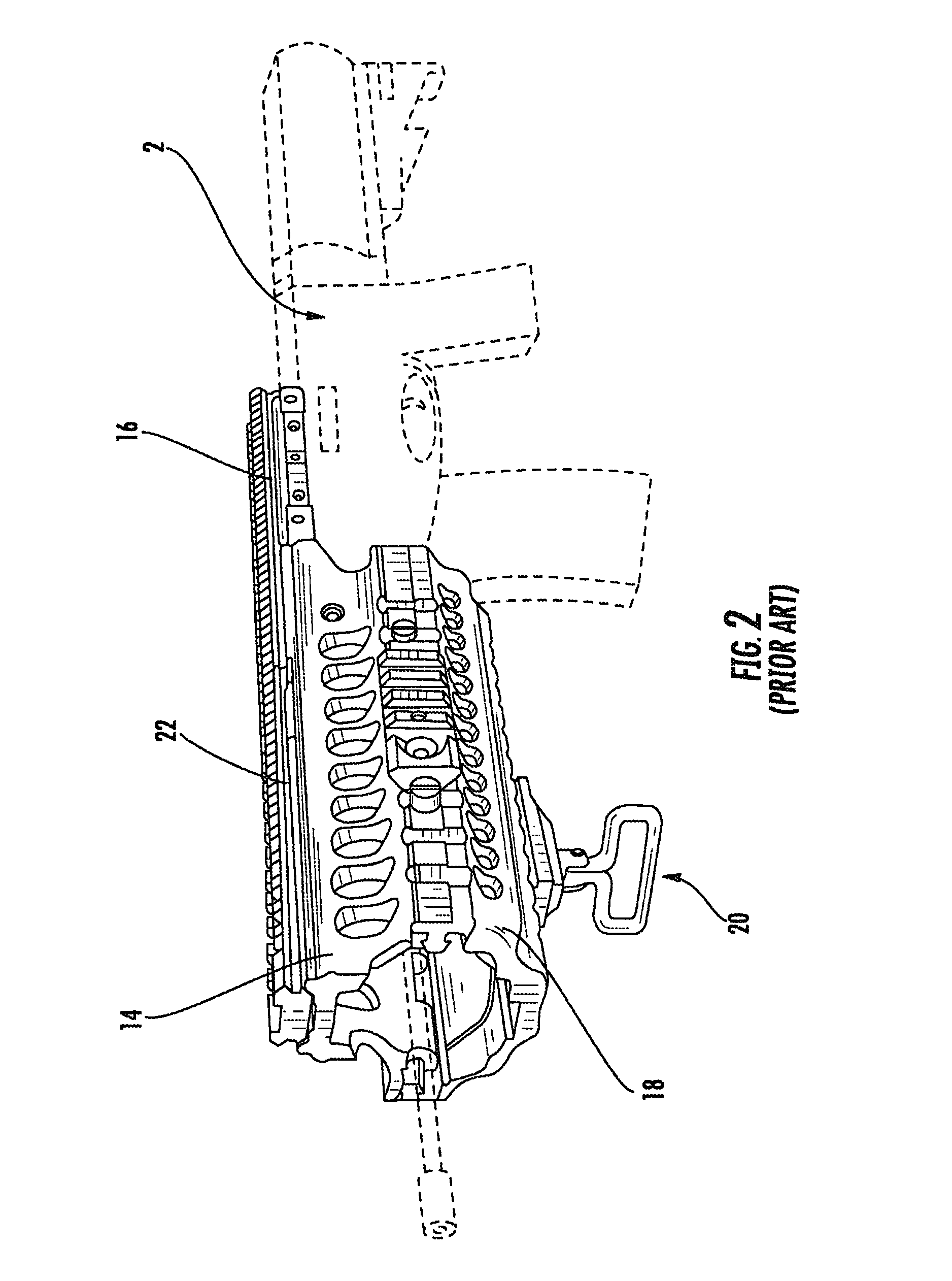

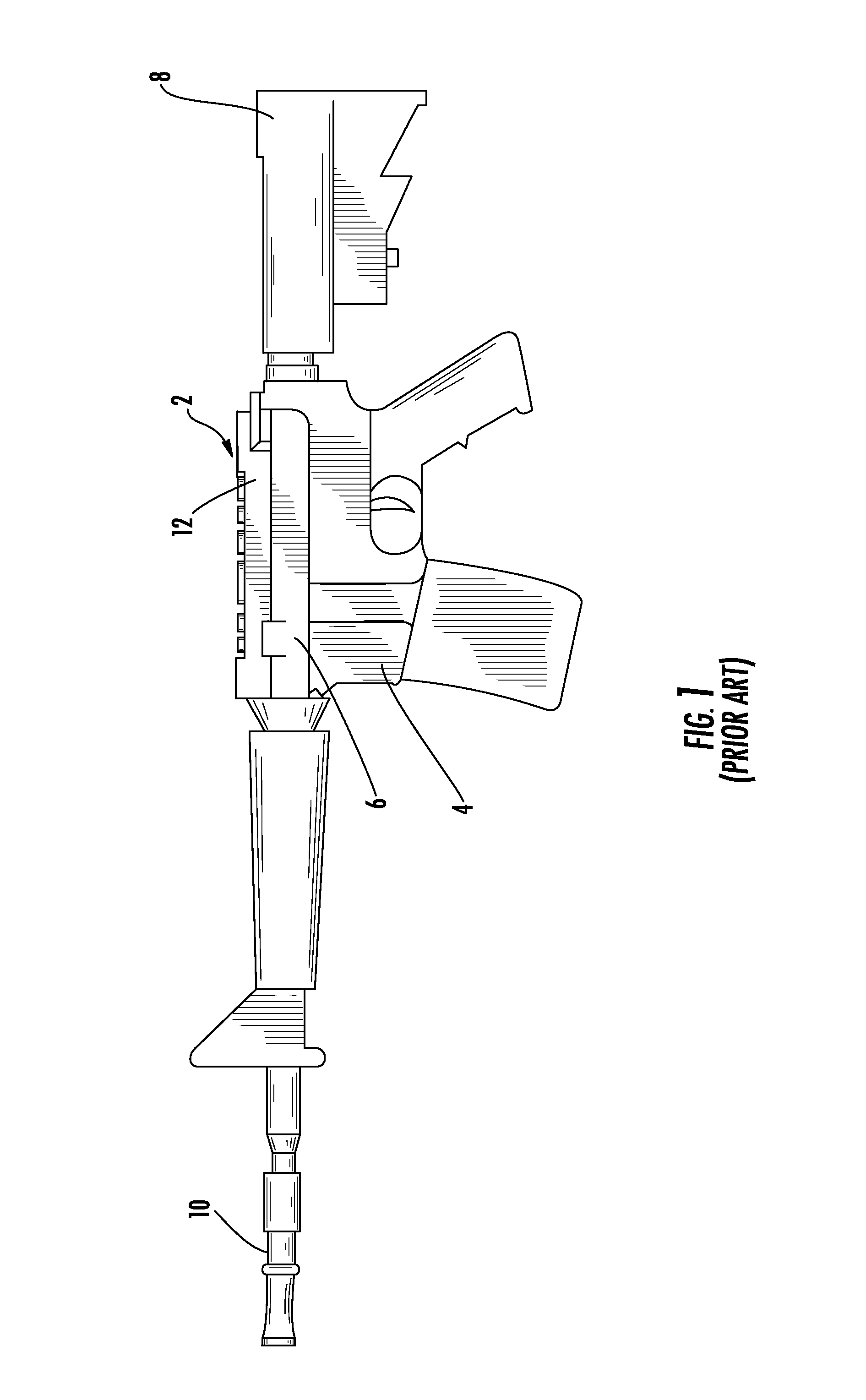

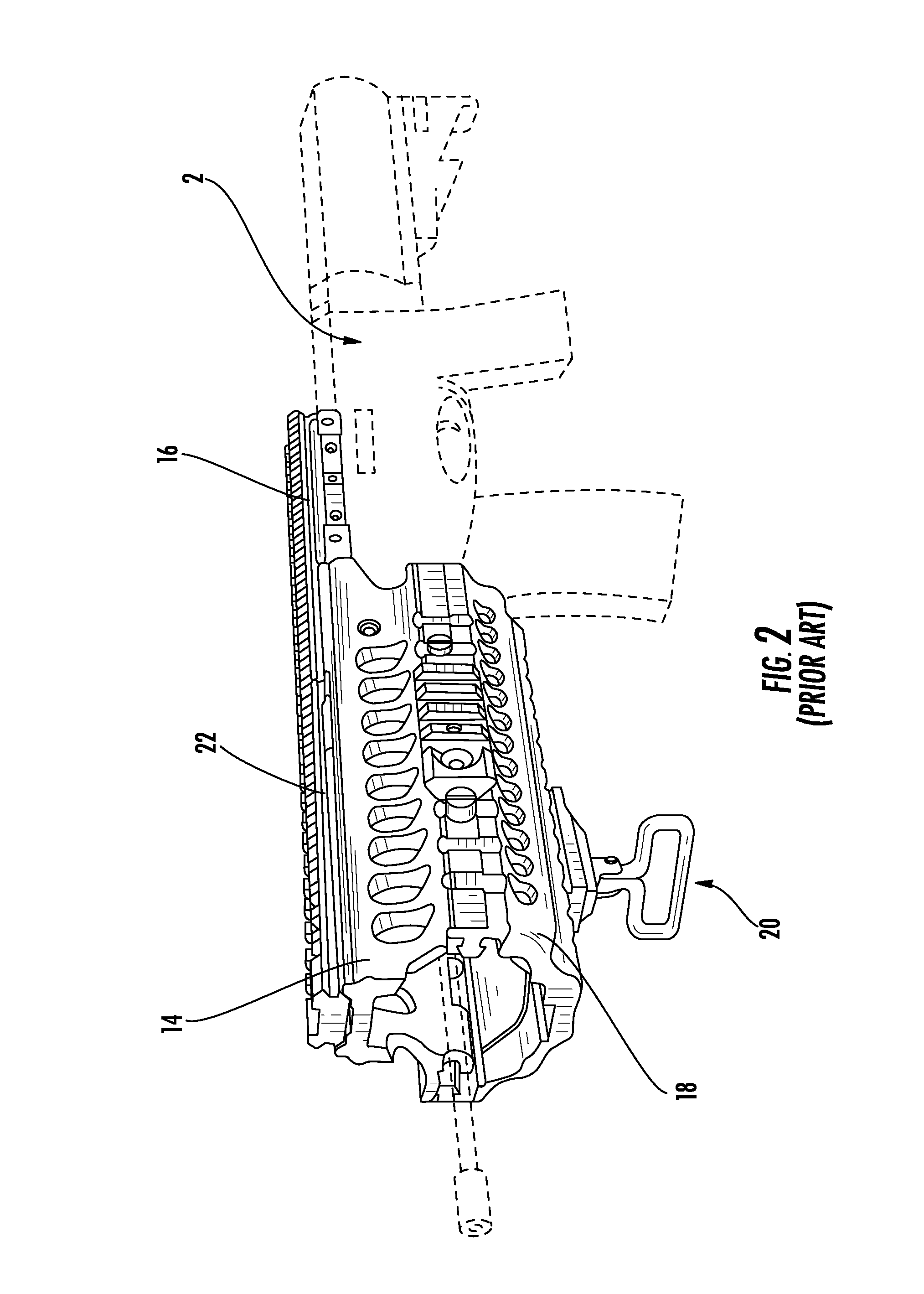

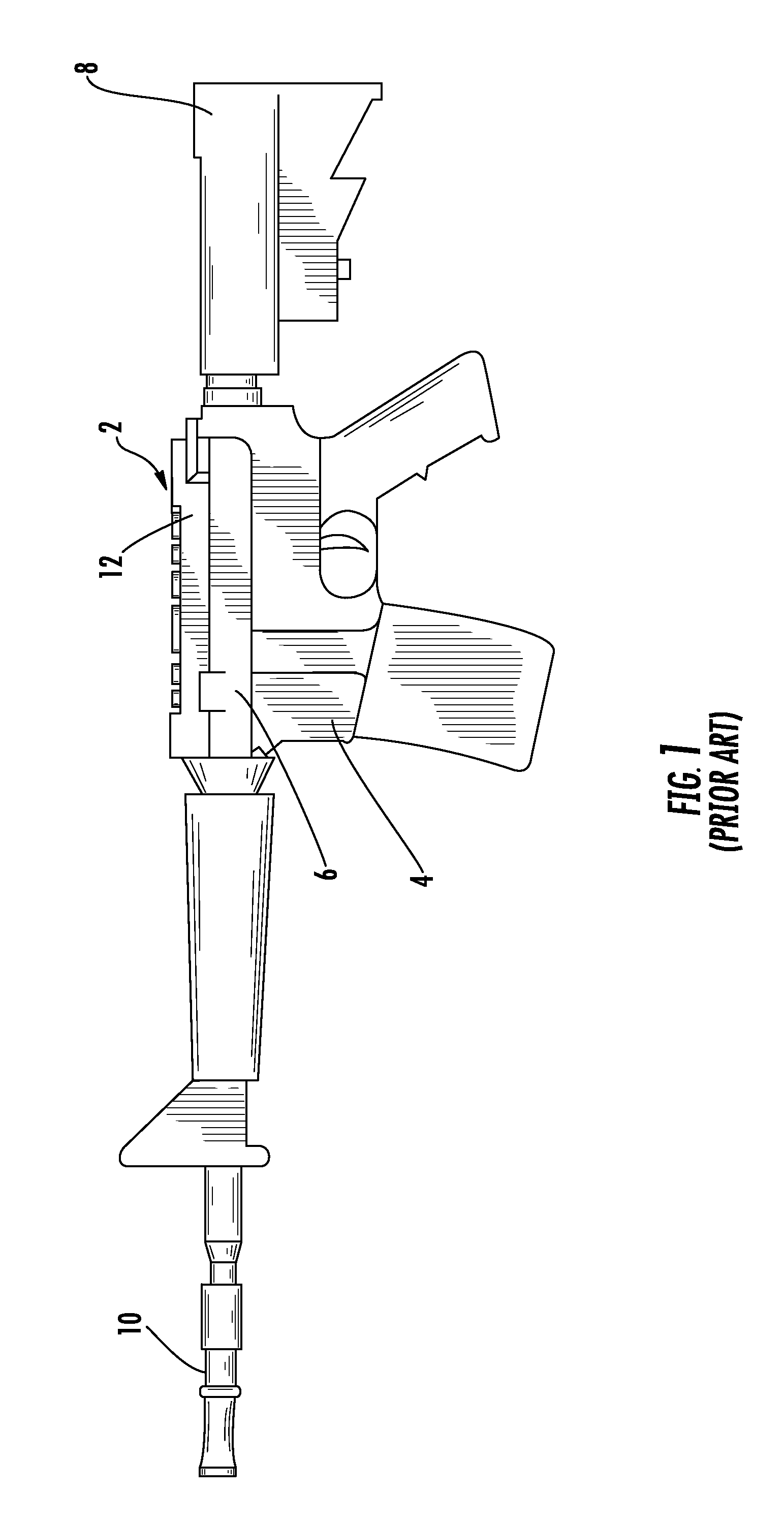

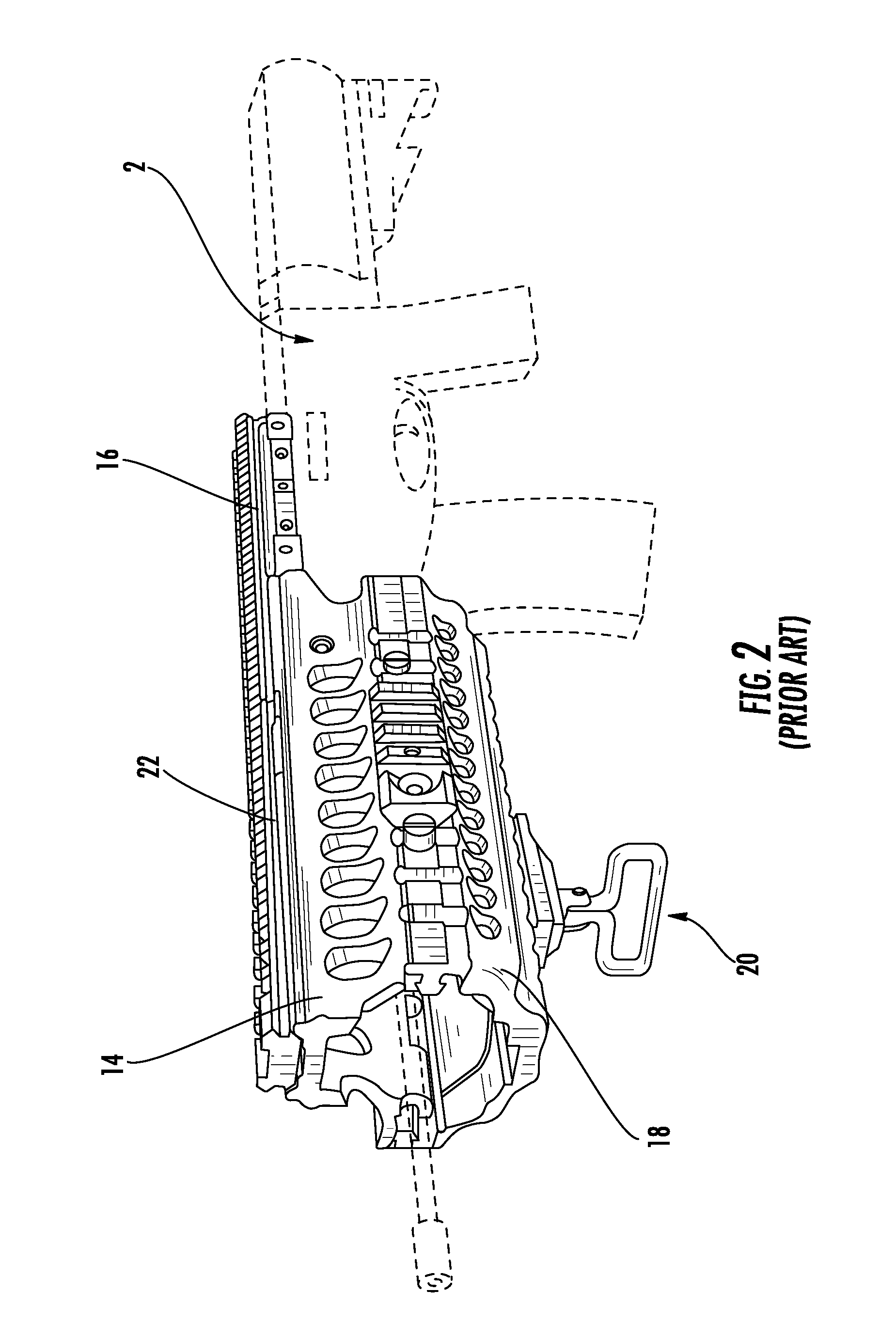

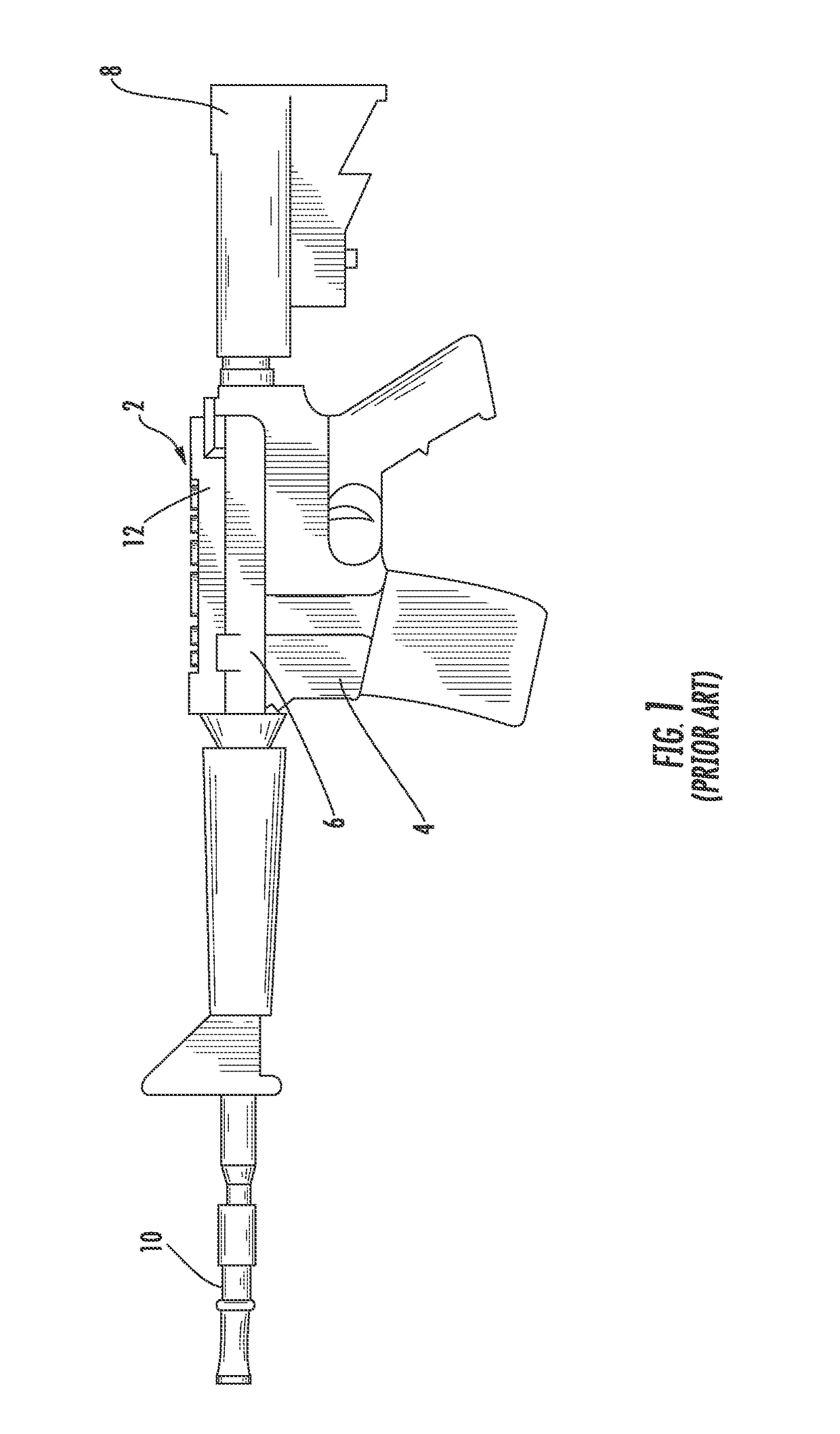

Mounting assembly with positive stop for actuator arm

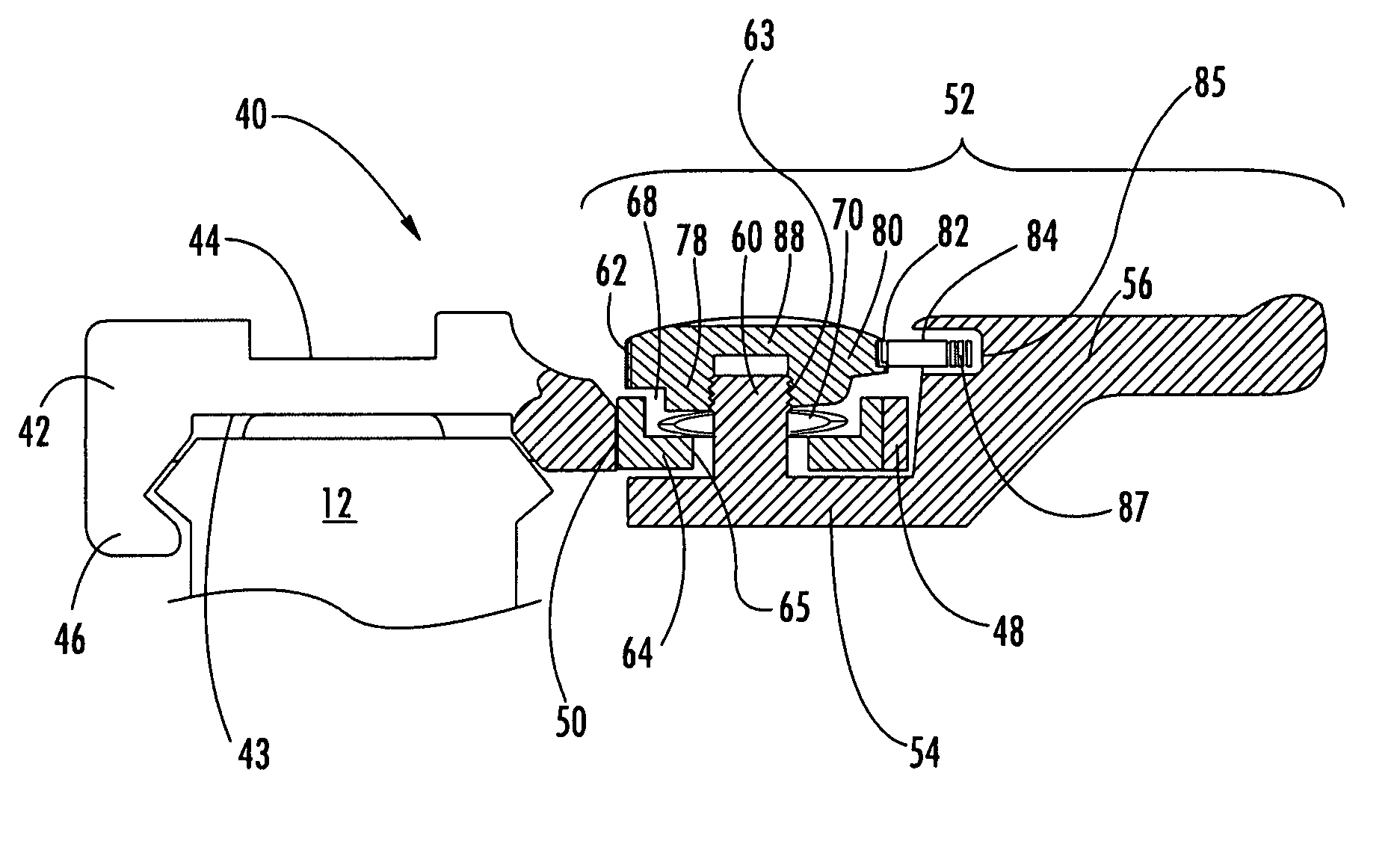

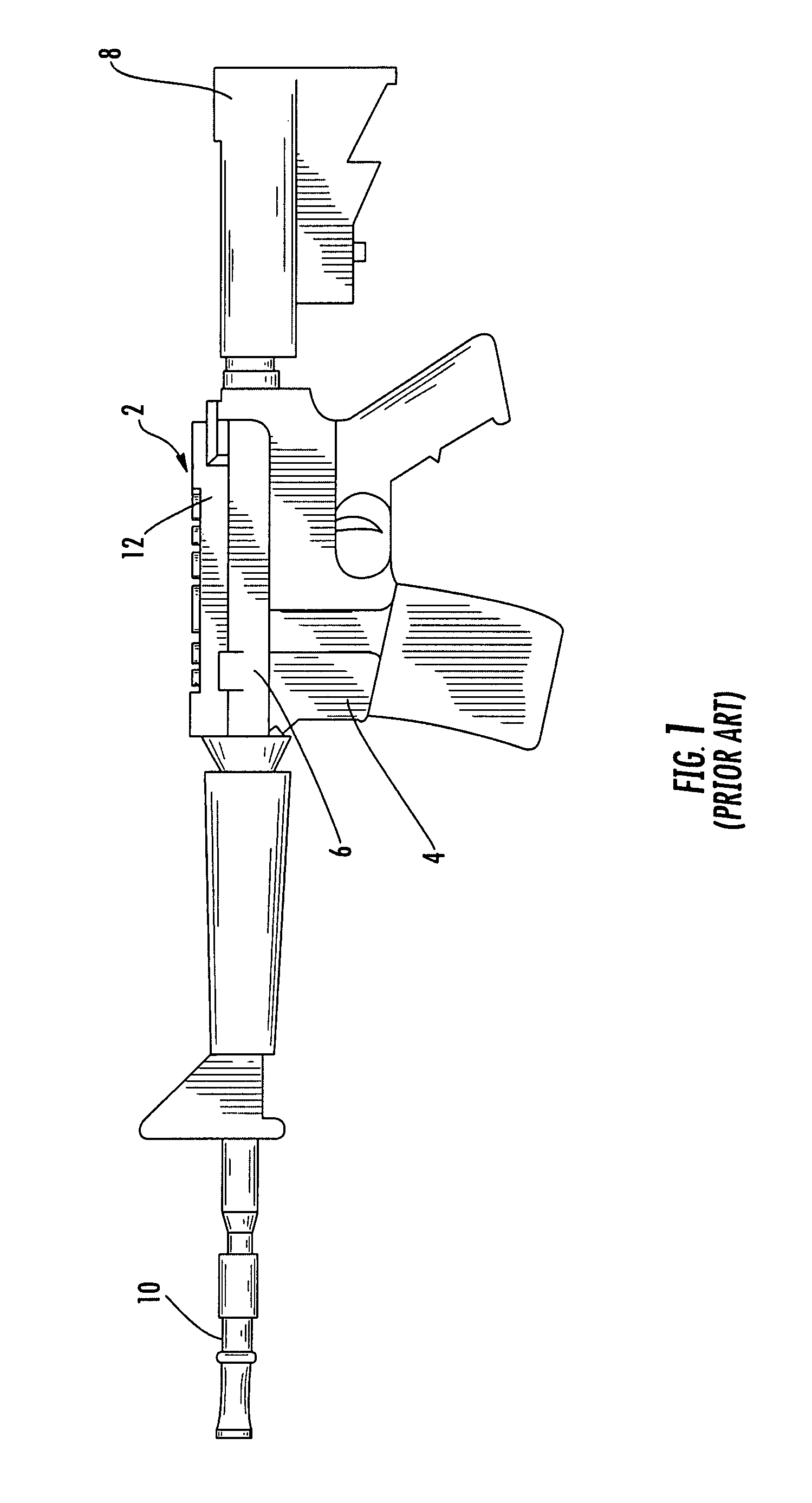

ActiveUS7493721B2Prevent rotationEasy to installCartridge extractorsSighting devicesRail profileActuator

Owner:SWAN RICHARD E

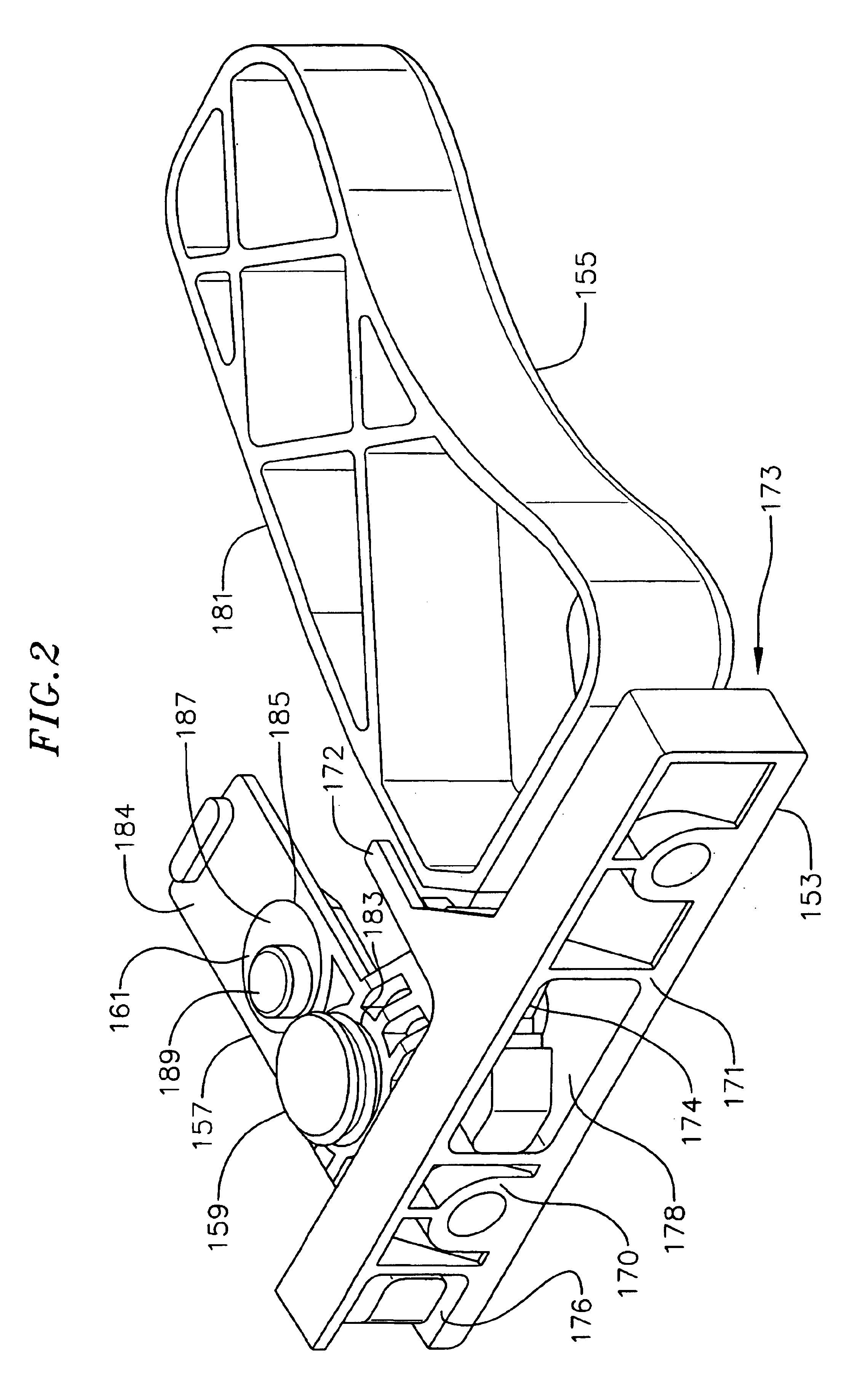

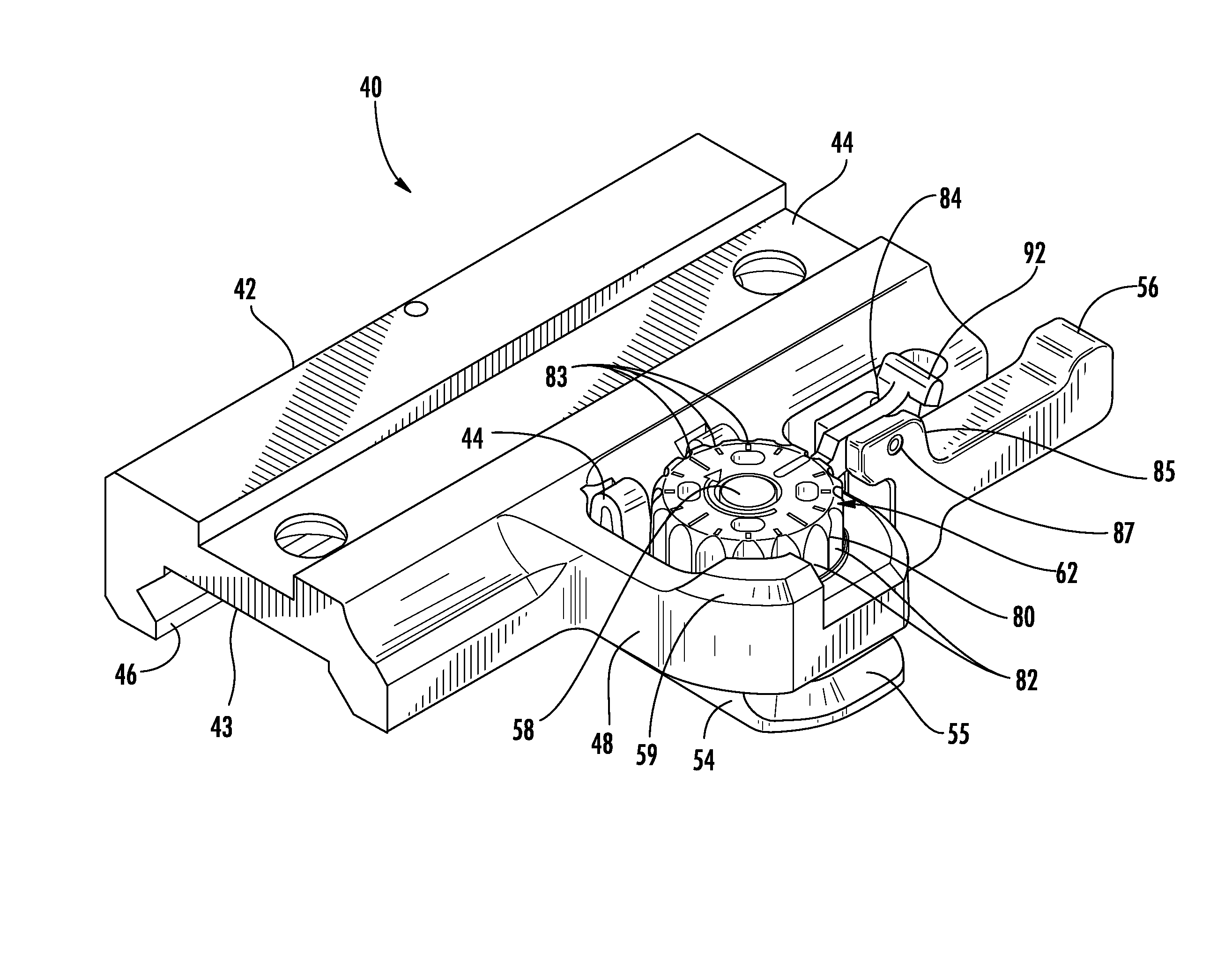

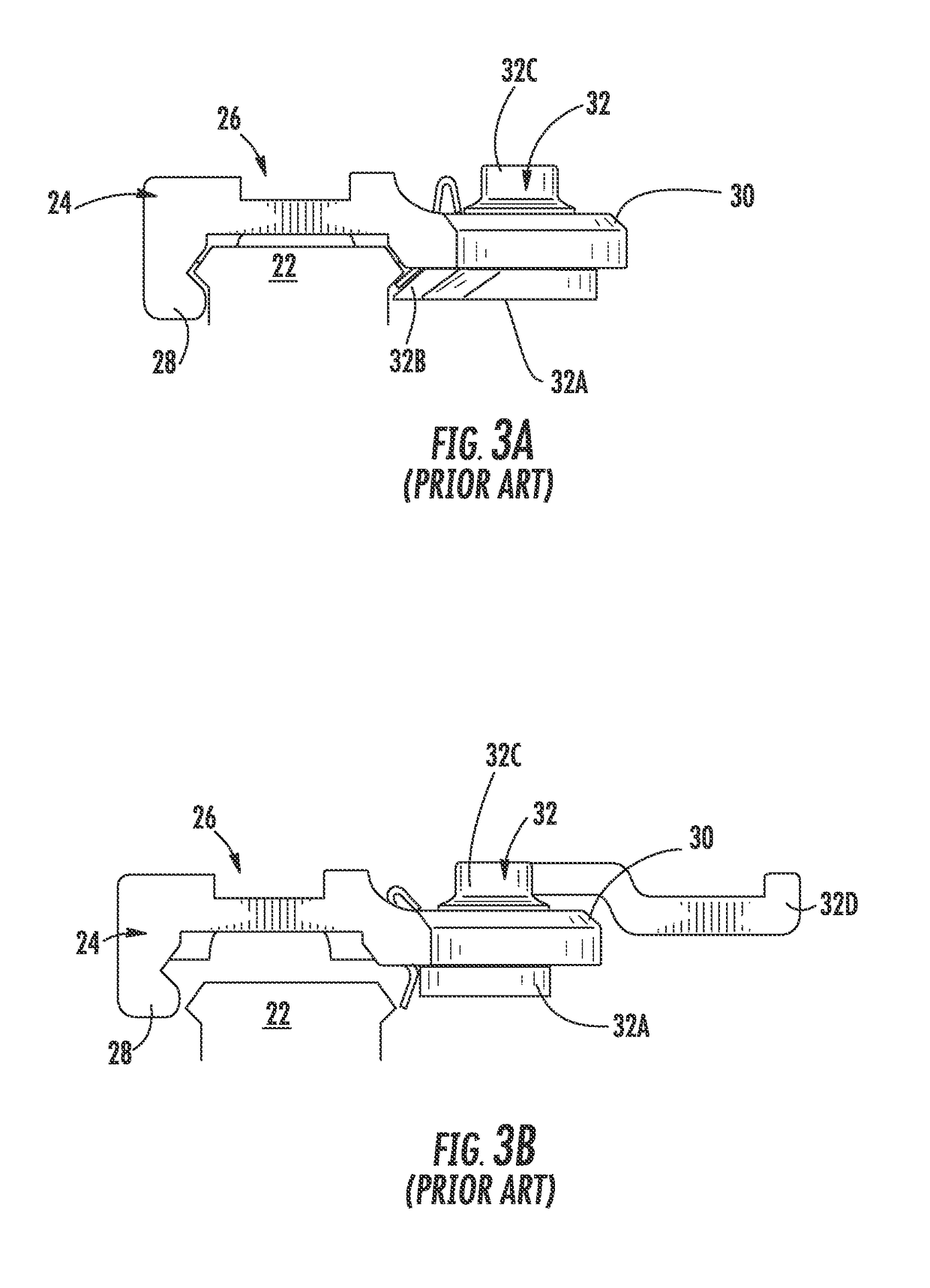

Mounting assembly with adjustable spring tension and pivoting lock lever

InactiveUS8112933B1Easy to installControl tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of a clamping assembly is adjustable. The mounting assembly includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly. A lock lever connected to the actuator arm selectively locks the position of the retention nut on the threaded shaft.

Owner:SWAN RICHARD E

Mounting assembly with adjustable spring tension

ActiveUS7757422B1Easy to installControl spring tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that a retention nut, which is locked relative to the clamping assembly, controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

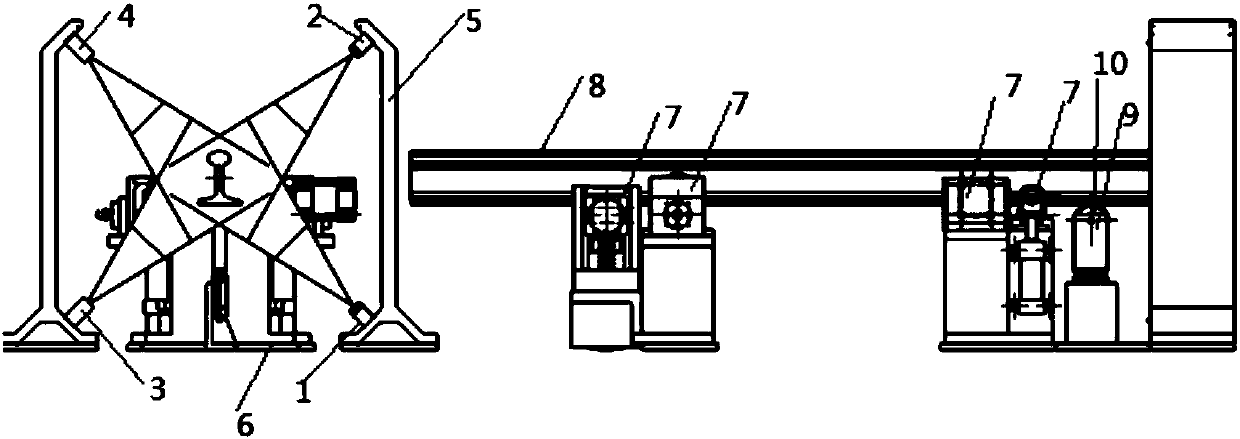

Method and device for detecting defect of surface of steel rail based on data processing

InactiveCN107632022AReduce vibrationExtend your lifeOptical rangefindersOptically investigating flaws/contaminationRail profileTriangulation

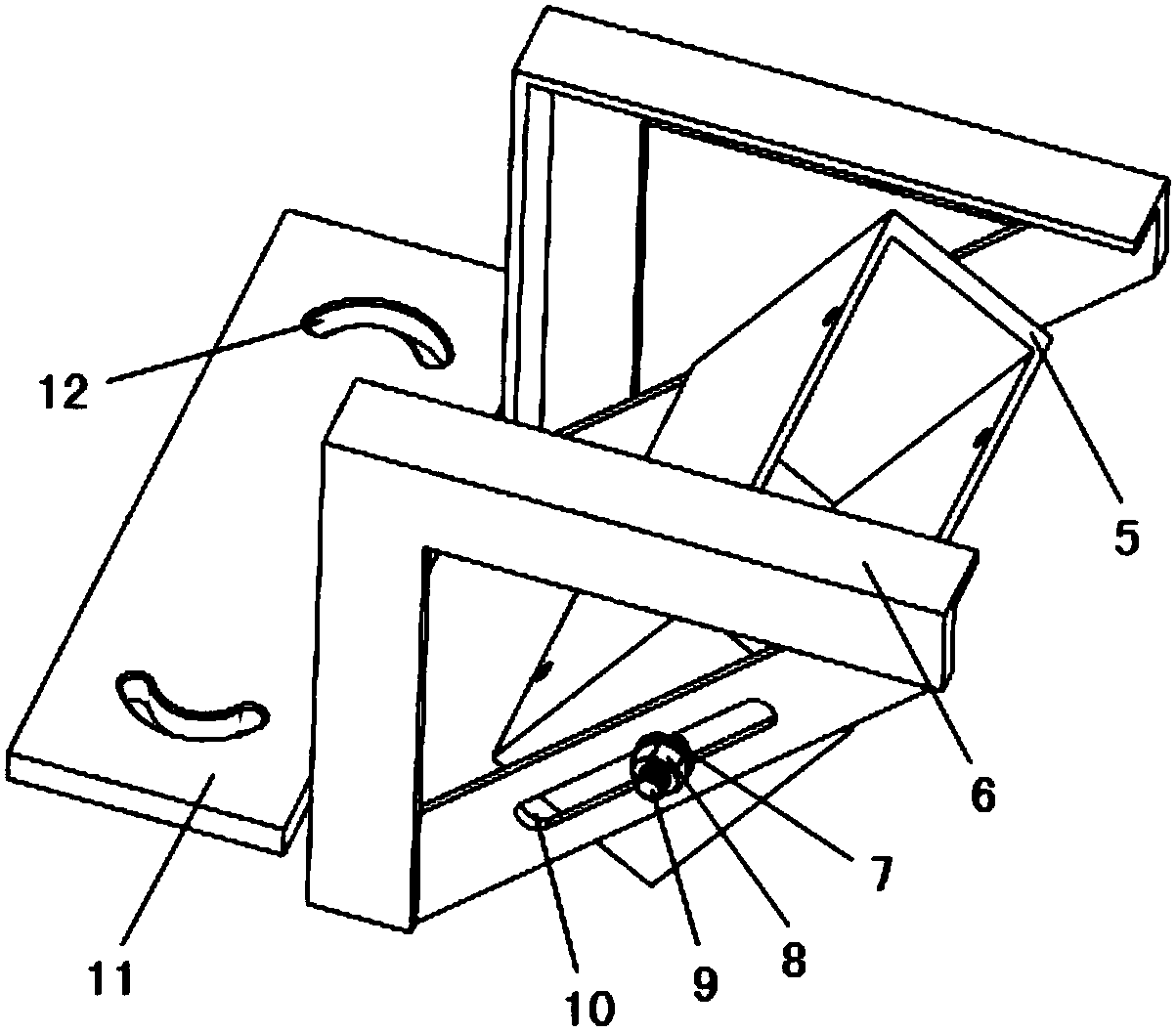

The invention relates to a method and device for detecting a defect of the surface of a steel rail based on data processing. The device comprises four sensors, a sensor bracket (5), a base (6), a railtransport roller (7), the steel rail (8), an encoder bracket (9) and an encoder (10); the four sensors are respectively arranged on four inner corners of the sensor bracket, the Z axes of all the sensors form a 45 degree included angle with the horizontal direction and are intersected at one point; the rail transport roller is fixed on the base and is used for supporting and transporting the steel rail. The method adopts the triangulation distance measurement principle of a linear laser, four line structured light laser sensors are used for collecting steel rail cross section profile data, and the steel rail profile data collected by all the sensors are subjected to coordinate conversion: rotation, translation, graphics splicing, and obtaining of the data splicing calibration value of allthe sensors. The method and devic can significantly improve the production efficiency, reduce the manual participation degree, and reduce the detection leakage rate and the misjudgment rate.

Owner:WUHAN UNIV OF TECH

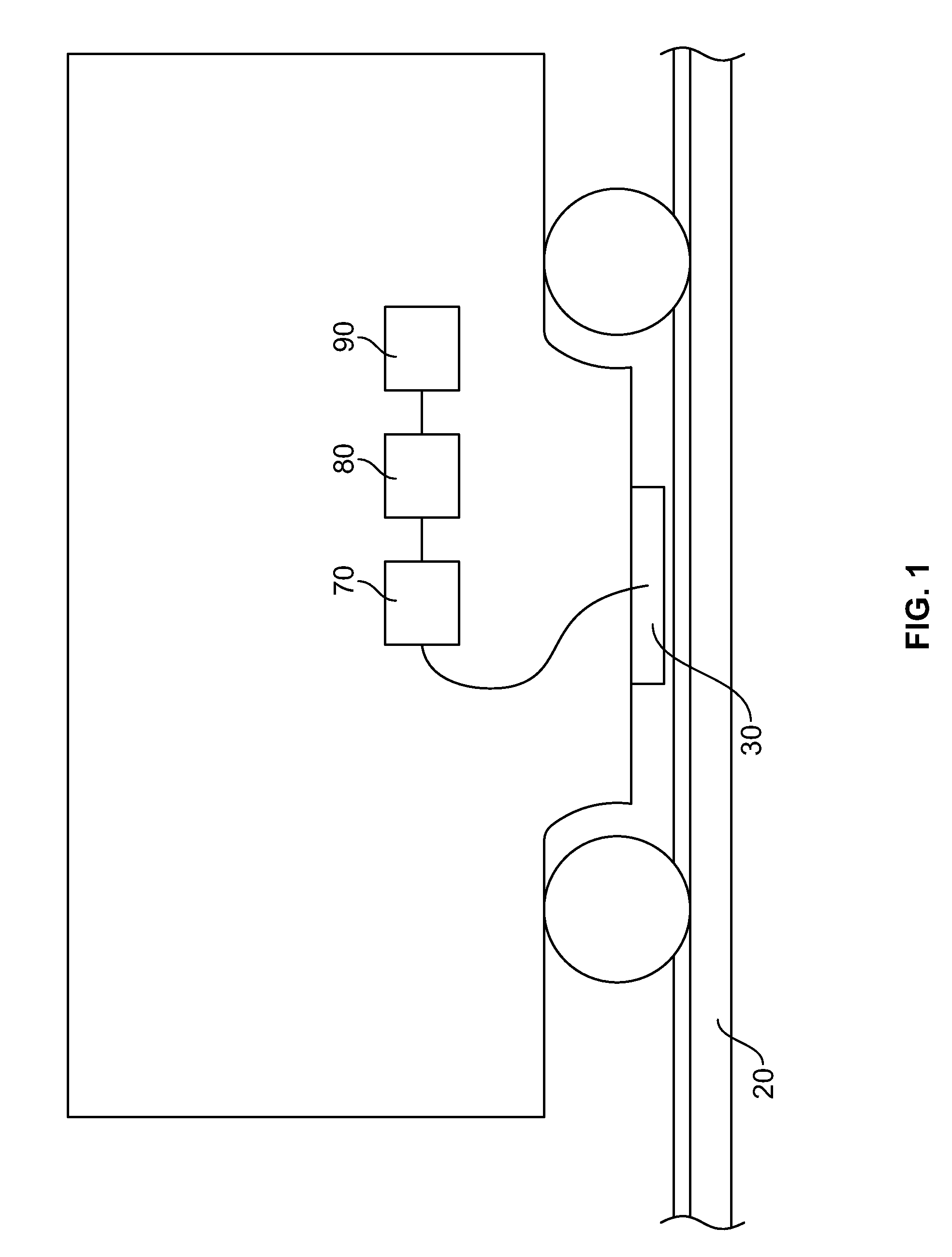

System for inspecting rail with phased array ultrasonics

InactiveUS20160304104A1Make up for deficienciesCompensation effectAnalysing solids using sonic/ultrasonic/infrasonic wavesSignalling indicators on vehicleRail profileEngineering

A system for inspecting railroad rail using phased array ultrasonic technology measures the time of flight of ultrasonic signals at locations across the rail head to determine the wear profile of the rail. The rail wear profile is then used to adjust the focal laws of the phased array ultrasonic probes to dynamically compensate for changes in the rail profile as the inspection vehicle moves along the rails.

Owner:TRANSPORTATION TECH CENT

Automated turnout inspection

ActiveUS8345948B2Reduce dependenceFrequent and comprehensive and convenient analysisCharacter and pattern recognitionRailway signalling and safetyRail profileDerailment

A method of inspecting a turnout of a track includes the steps of: capturing images of the components of the turnout; converting each image into a set of coordinates that traces the transverse cross-section of a rail profile; analyzing the rail profile to determine if the rail profile is a profile of arunning rail portion or a component. Upon determination that the image represents a component, taking measurements of the rail profile and applying virtual gauges to the rail profile to check for potentially dangerous conditions of the component; and generating a summary of each cross-section of the rail profile of the component indicating problem areas. The method is used for identifying certain classes of switch or turnout rail conditions which can lead to derailments, and for enhancing the turnout inspection approach currently used. The use of this method as an integrated part of the rail profile monitoring program will reduce reliance on field measurements and will also allow more frequent, comprehensive, and convenient analysis of turnout condition.

Owner:HARSCO CORP

Mounting assembly with adjustable spring tension

InactiveUS7757423B1Prevents over tighteningPrevents loosening of the nut once installedSighting devicesRod connectionsRail profileActuator

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

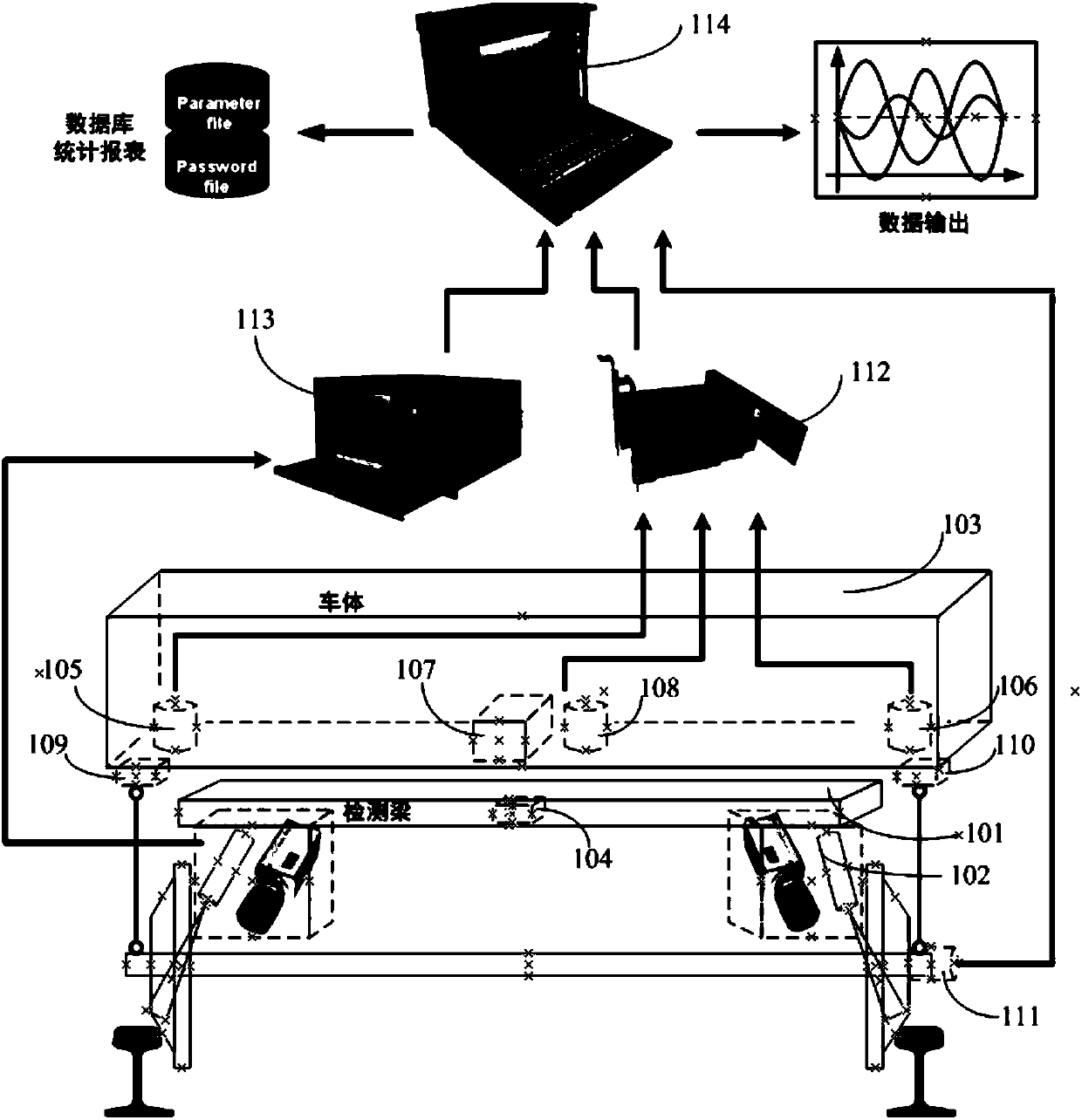

Train rail detection system and method

ActiveCN108032868ADoes not affect operationsSave complex work for retrofittingRailway auxillary equipmentRailway profile gaugesRail profileEngineering

The invention provides a train rail detection system and method and relates to the technical field of rail detection. An embedded computer device in the system sends sampling pulse signals to an inertia component and a laser photographing component; the laser photographing component shoots steel rail profile images and sends the steel rail profile images to the embedded computer device; the inertia component measures attitude parameters of a detection beam relative to steel rails and sends the attitude parameters to the embedded computer device; the embedded computer device determines transverse displacement data and vertical displacement data of the detection beam relative to the steel rails according to the steel rail profile images; calculation is conducted according to the transverse displacement data, vertical displacement data and the attitude parameters, and unsmooth geometric parameters of the train rails are determined; overrunning judgment is conducted according to the unsmooth geometric parameters, overrunning judgment data are obtained, and waveform data of the unsmooth geometric parameters are generated; and the overrunning judgment data and the waveform data are sentto a ground data processing center device.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Mounting assembly with adjustable spring tension

InactiveUS7905045B1Easy to installControl spring tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

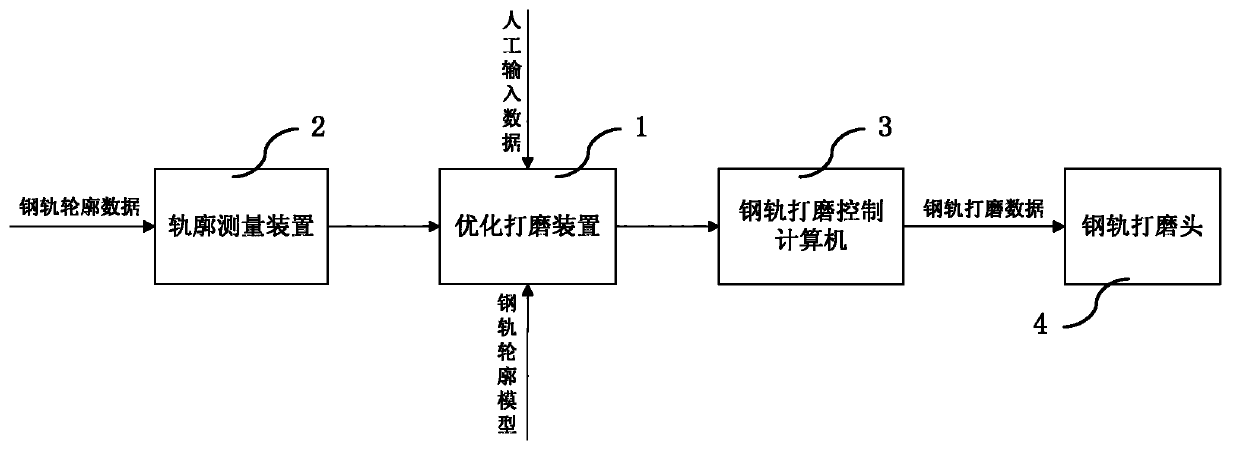

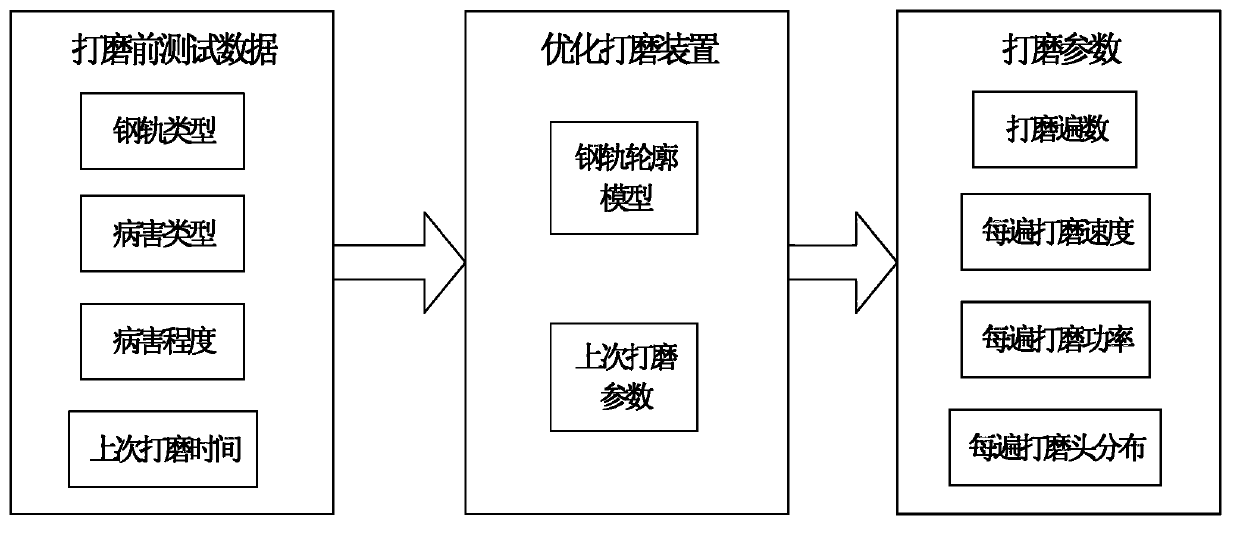

Optimized grinding method for rail grinding wagon

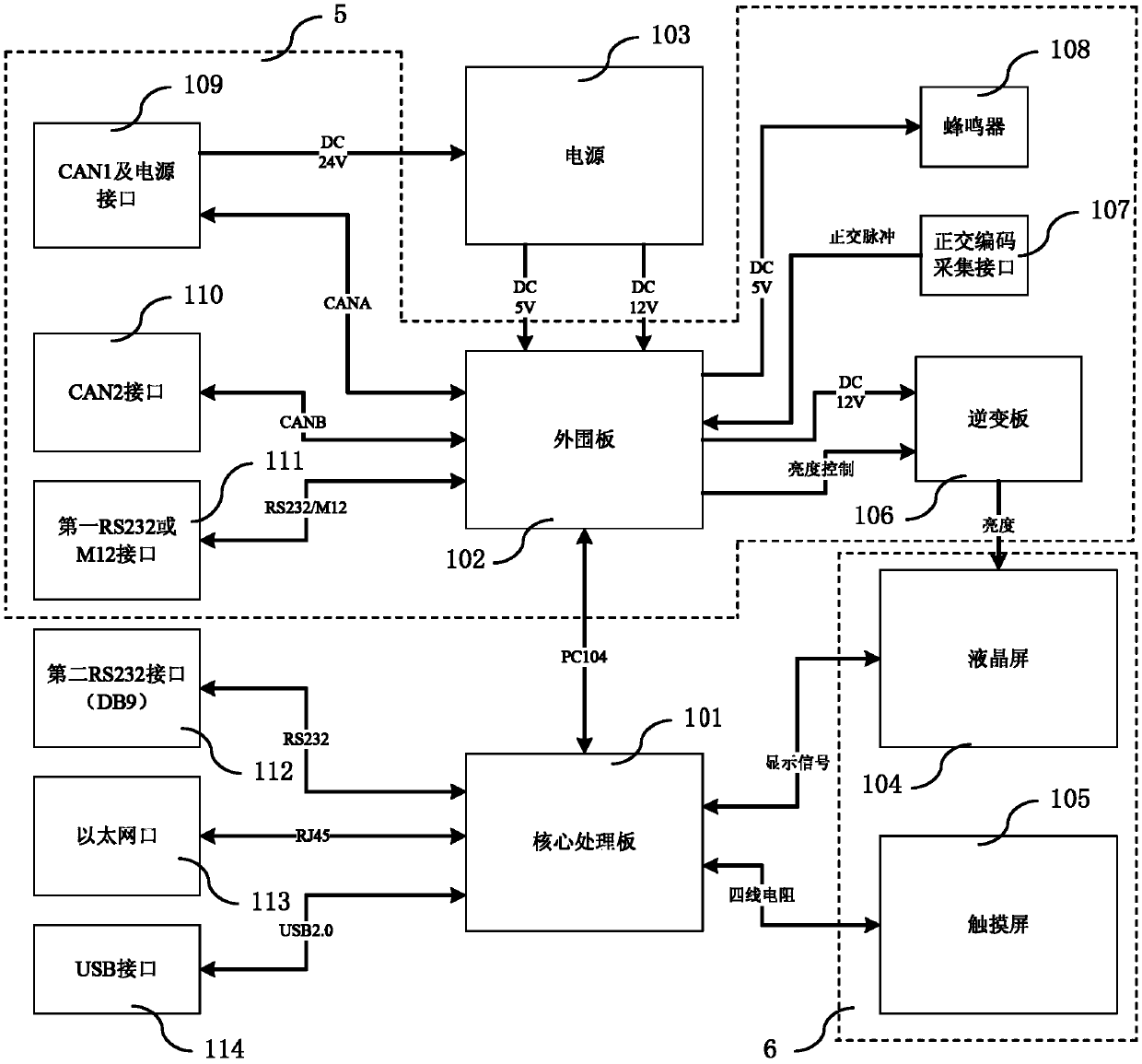

The invention discloses an optimized grinding method for a rail grinding wagon. A profile measurement device measures rail profile information, and a touch screen records the acquired information comprising the rail profile information in an interactive mode. A core processing board comprises a rail profile model; the core processing board receives the rail profile measurement data, and the rail profile measurement data and the rail profile model are compared to form rail grinding parameters. Meanwhile, the core processing board stores the rail grinding parameters to form recording for subsequent operation reference, the rail grinding parameters are output in a bus mode or a screen display mode or a dump mode, and finally, a rail grinding control computer outputs the rail grinding data to a rail grinding head according to the rail grinding parameters. The technical problems that the measured data only can be taken as guide data to participate in the rail grinding operation, accurate operation cannot be performed, the working efficiency is lowered and a unified executive standard does not exist for the determination of an operating mode of the grinding wagon and the grinding frequency in the prior art are solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +2

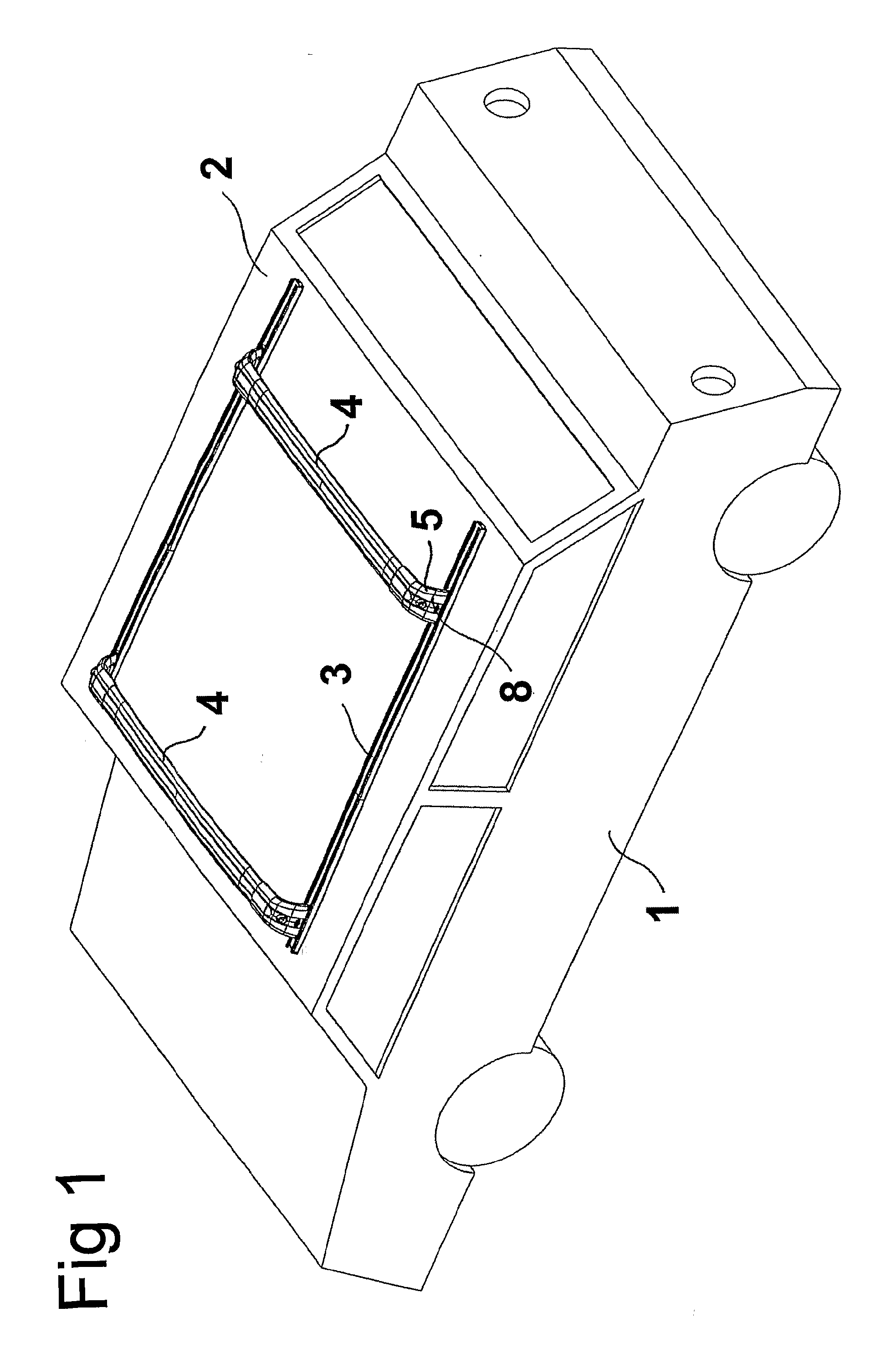

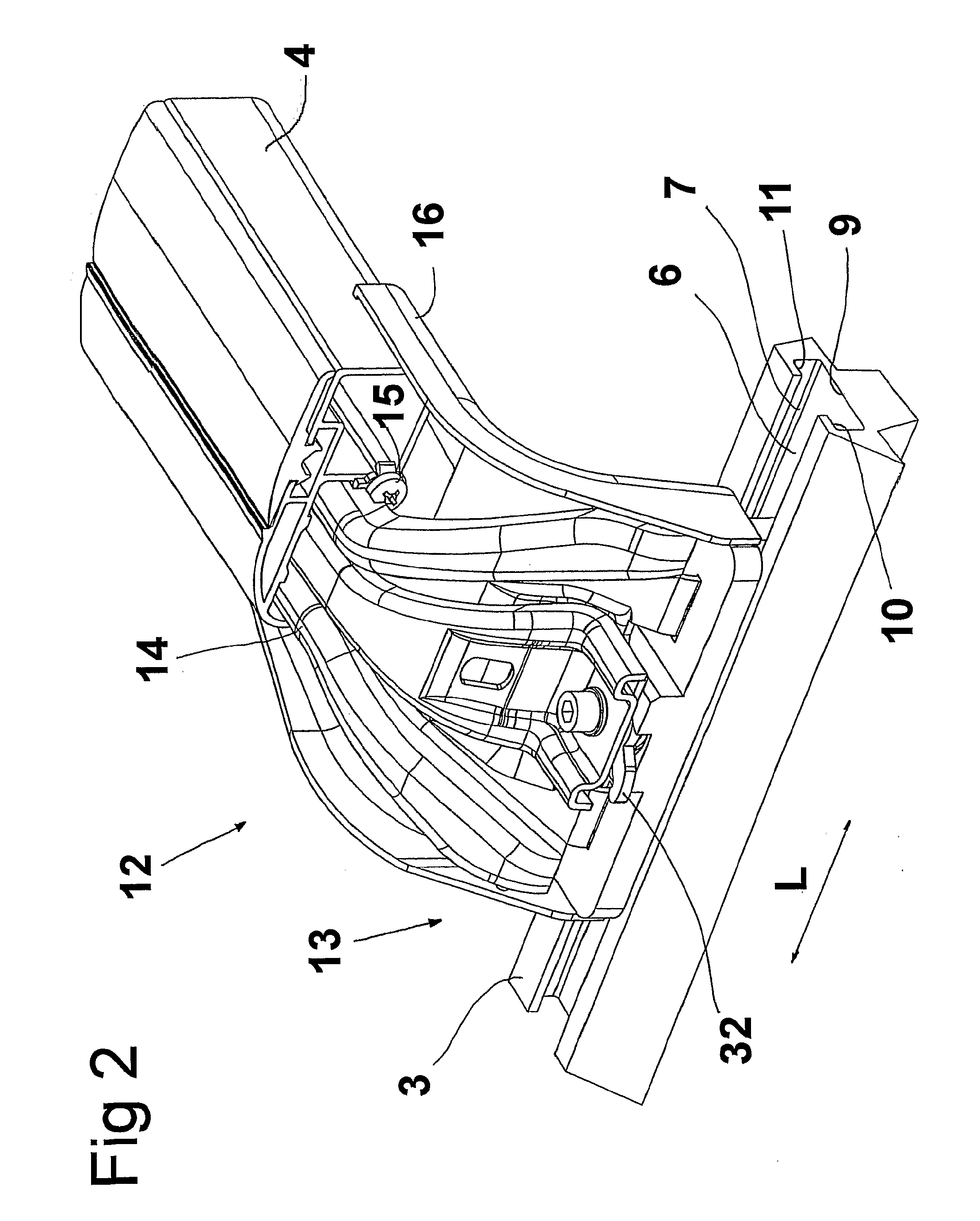

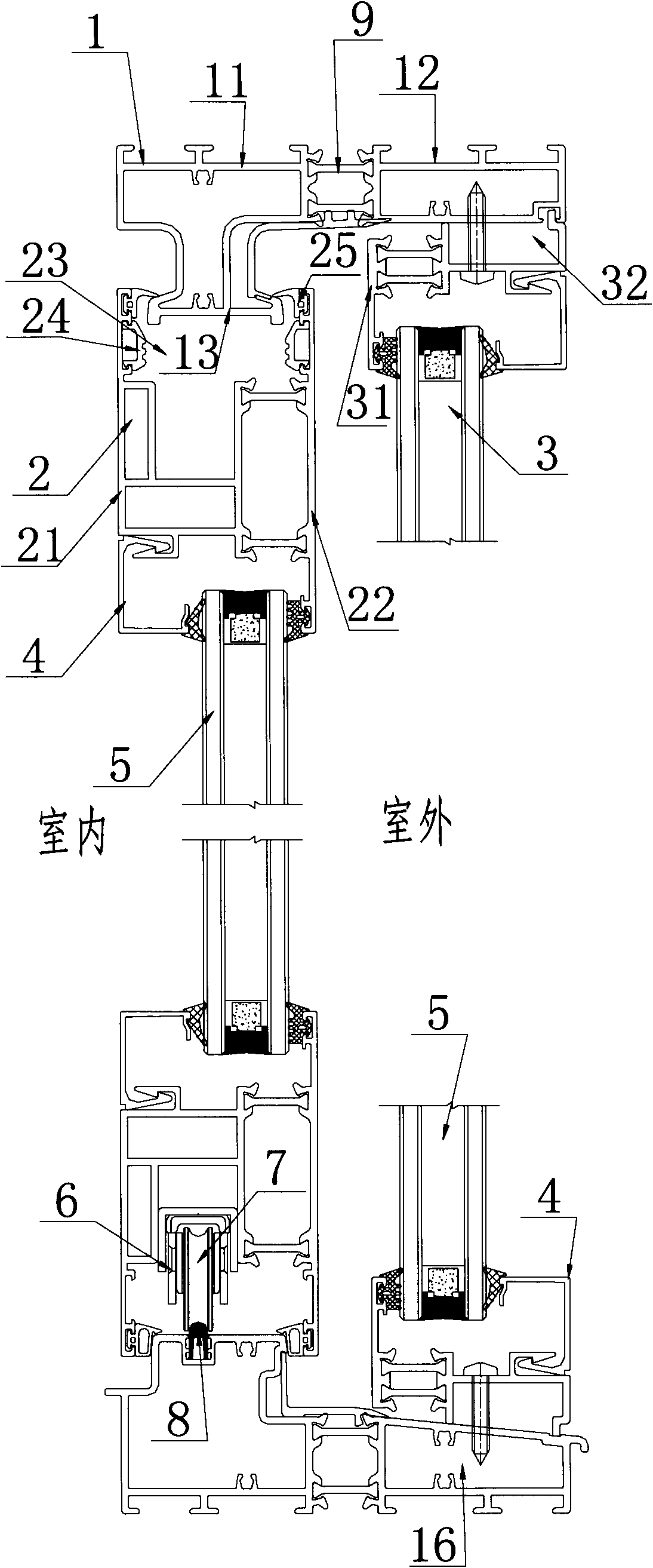

Sliding Door

InactiveUS20110067313A1Inexpensive to purchaseMaintain integrityBuilding braking devicesMan-operated mechanismRail profileEngineering

A sliding door with a door leaf, which is suspended from two carriages and displaceably guided along a roller rail profile, which is disposed at a wall or at a ceiling, the sliding door having at least one closing device, which is suitable to displace the decelerated door leaf into a closed position. The at least one carriage has a carrier, at or in which the closing device is disposed.

Owner:DORMAKABA DEUT GMBH

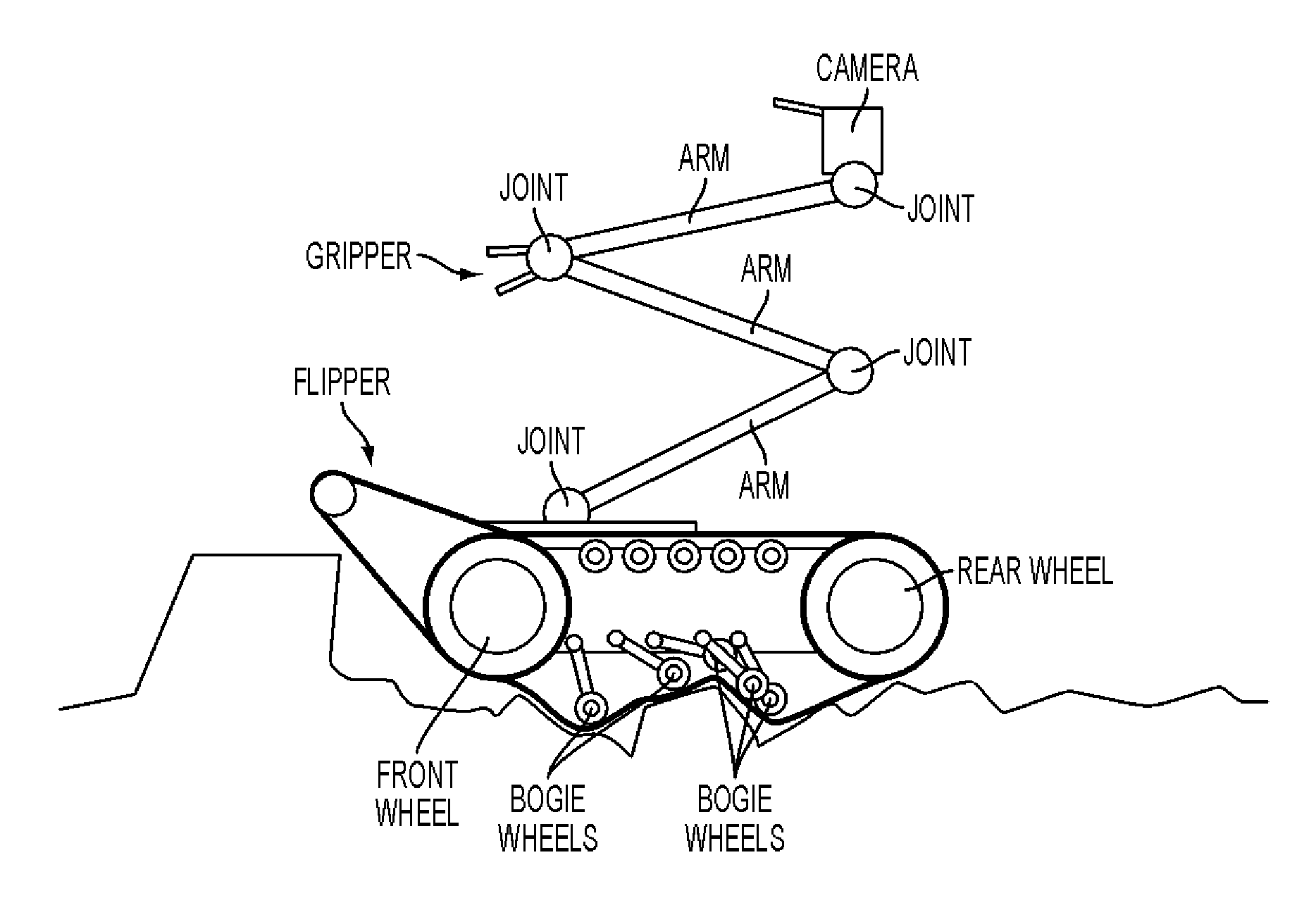

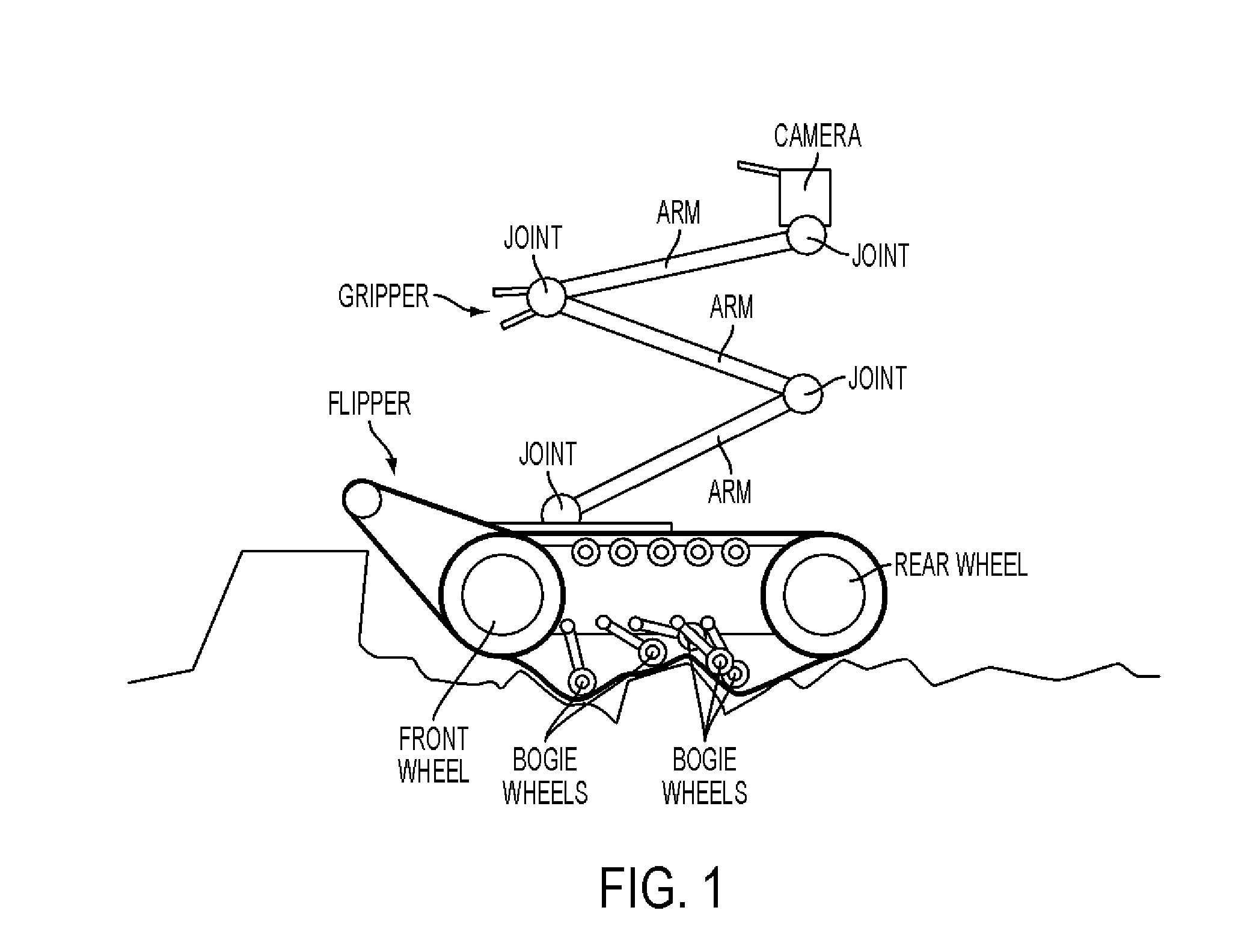

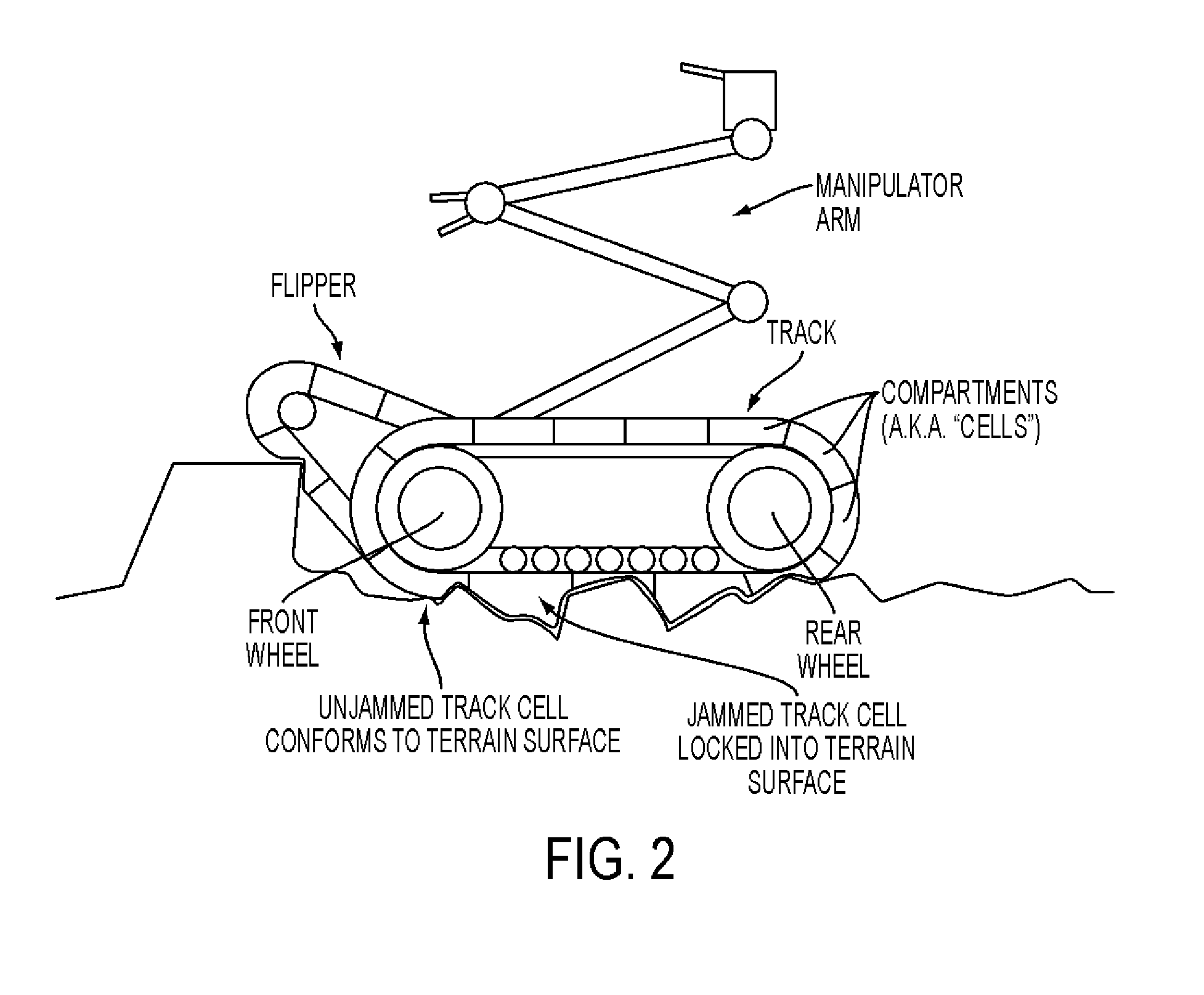

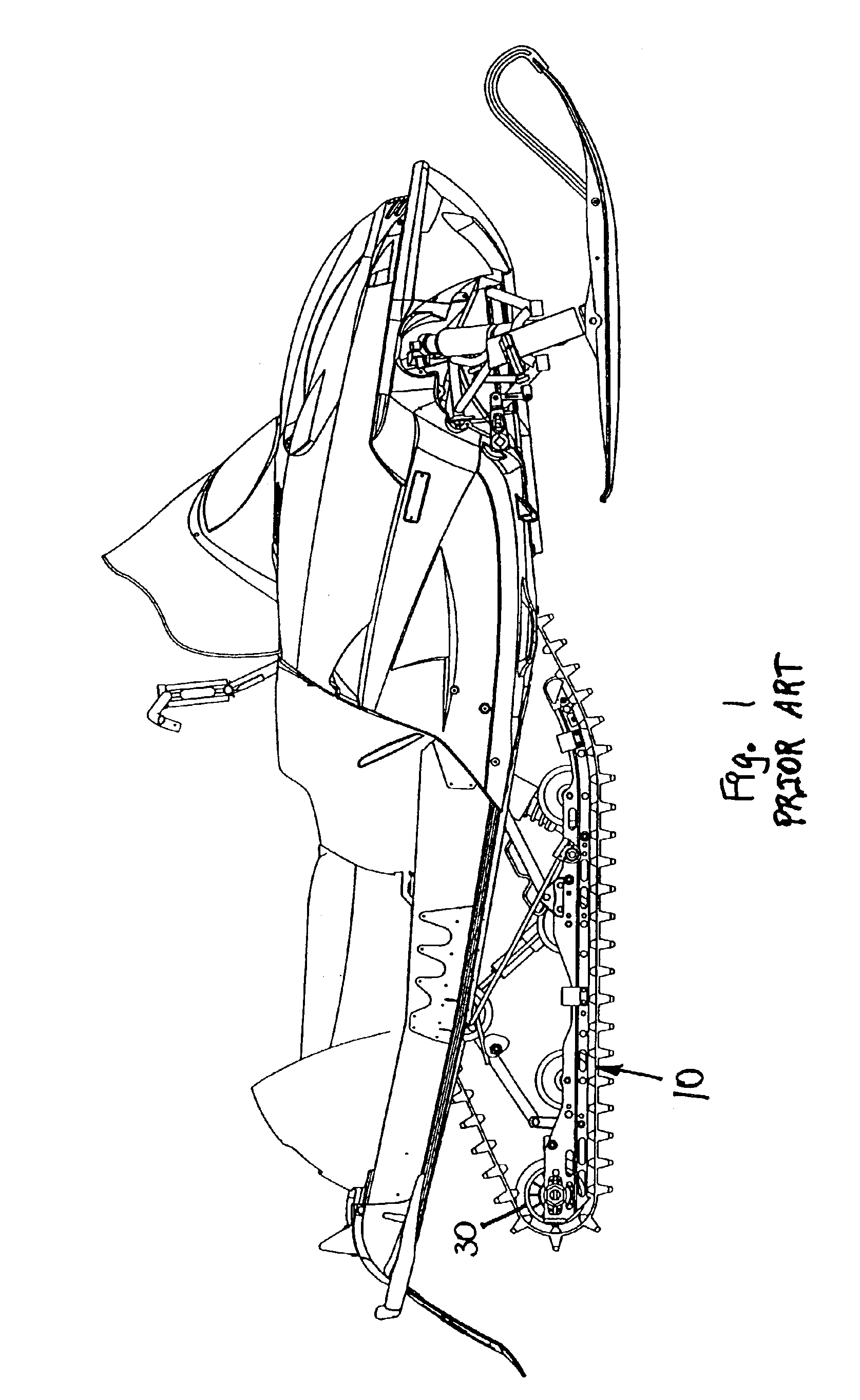

Biologically inspired compliant locomotion for remote vehicles

InactiveUS20110301785A1Smooth connectionDigital data processing detailsResilient suspensionsTerrainGround contact

A method for providing a uniform ground contact pressure when operating a tracked remote vehicle comprises: sensing the terrain below the remote vehicle using a series of proximity sensors that are configured to measure a distance from an underside of a chassis of the remote vehicle to the terrain directly beside a track of the remote vehicle; monitoring, mapping, and classifying an upcoming terrain; and adapting the remote vehicle's track profile, flipper position, arm position, and center of balance based on the upcoming terrain.

Owner:IROBOT CORP

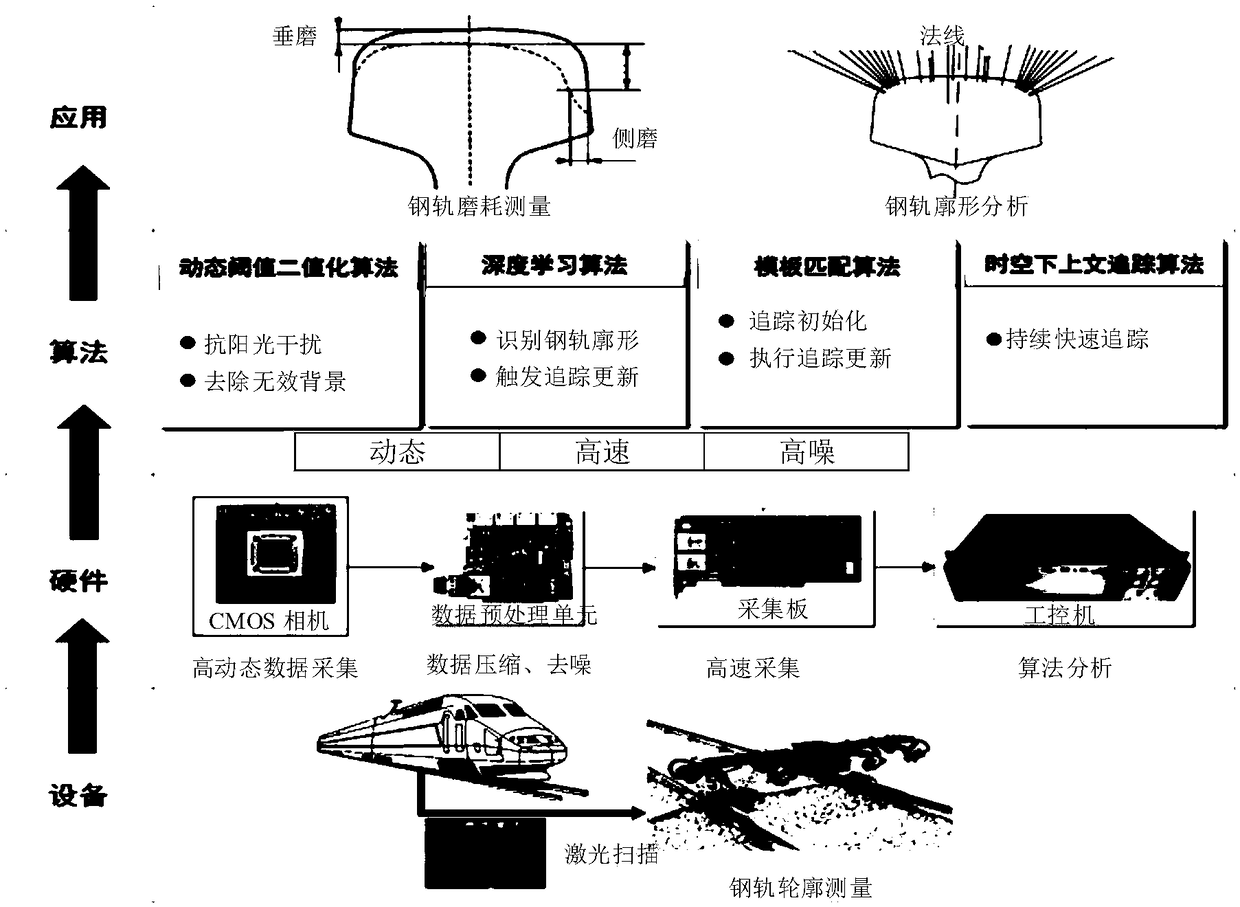

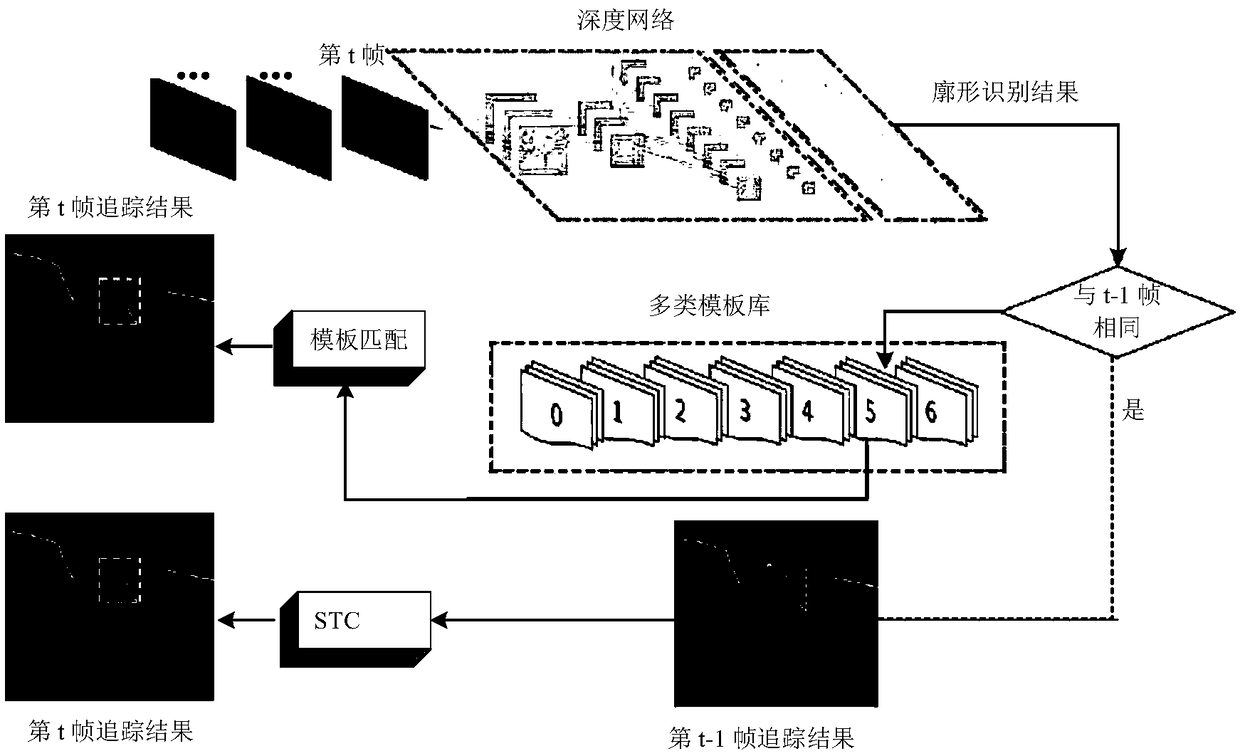

Tracking method, tracking system, and tracking device for rail profile

The invention discloses a tracking method, a tracking system, and a tracking device for rail profile. The method comprises: obtaining at least one frame of rail profile image, wherein each frame of the rail profile image is an image obtained by fusing images in multiple directions of the collected rail according to a frame in the process of measuring the rail profile by using the structured light;identifying the light strip type of the laser stripe in each frame of the rail profile image based on the deep learning profile identification model; tracking the position of the target stripe in therail profile image of the current frame based on the spatiotemporal context visual tracking algorithm in a case that the light strip type of the laser stripe in the rail profile image of the currentframe is the same as the previous frame; or tracking the position of the target stripe in the ail profile image of the current frame based on the template matching algorithm in a case that the light strip type of the laser stripe in the rail profile image of the current frame is different from the previous frame. According to the tracking method, the tracking system, and the tracking device for rail profile, the technical effect of the real-time detection of the rail profile under the high-speed dynamic driving environment is realized.

Owner:RAILWAY INFRASTRUCTURE TESTING RES INST CHINA ACAD OF RAILWAY SCI +2

Guardrail

ActiveUS20090302288A1Good energy dissipationPasturing equipmentRoadway safety arrangementsRail profileEngineering

An impact slider assembly for a guardrail which includes: a slider mechanism attached to a first rail and second rail which substantially conforms with a rail profile; and an integral means for attachment to the first rail, wherein the slider mechanism gathers telescoping rails whilst substantially maintaining the strength of the rails in a fully re-directing manner.

Owner:VALMONT HIGHWAY TECH

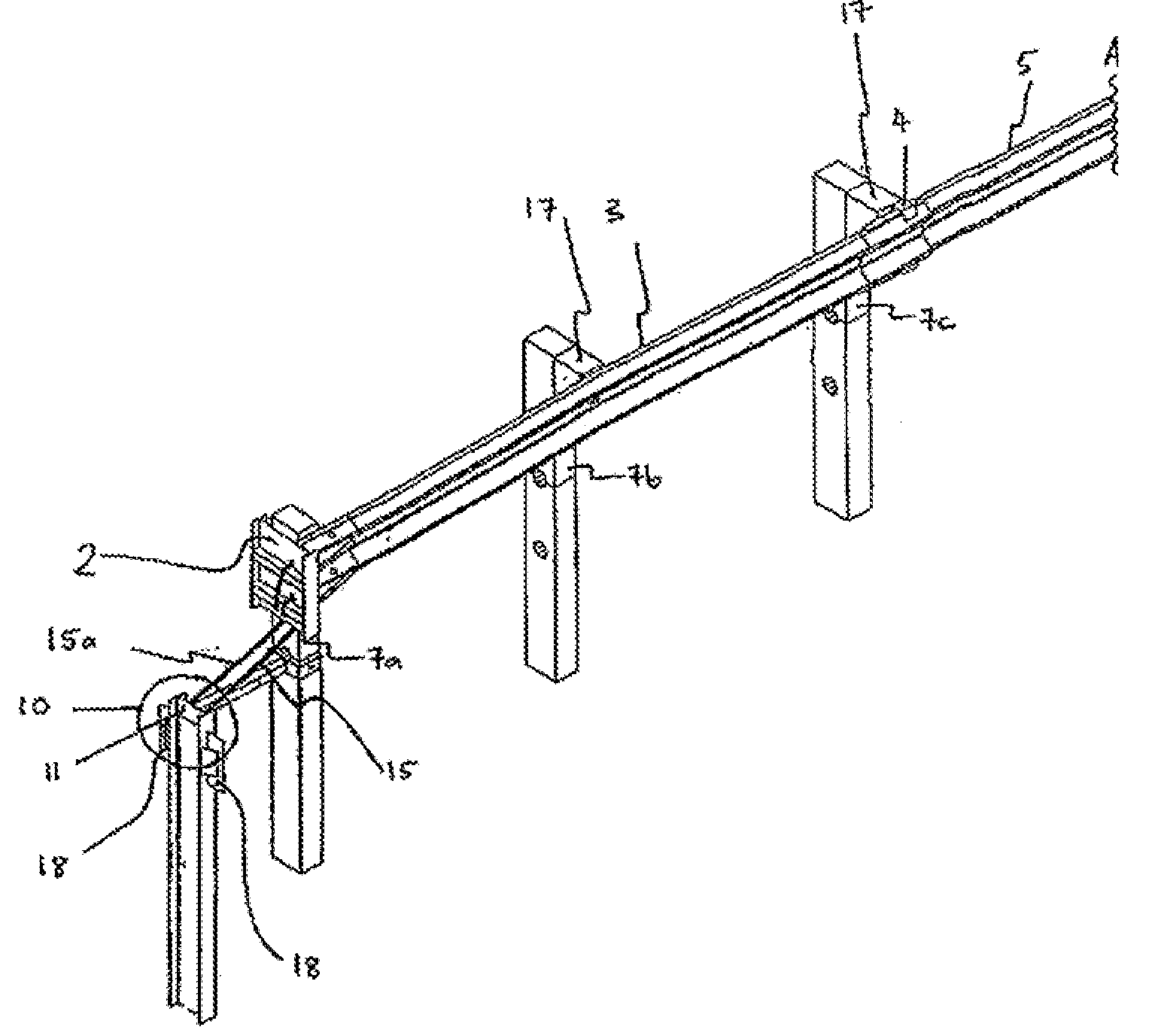

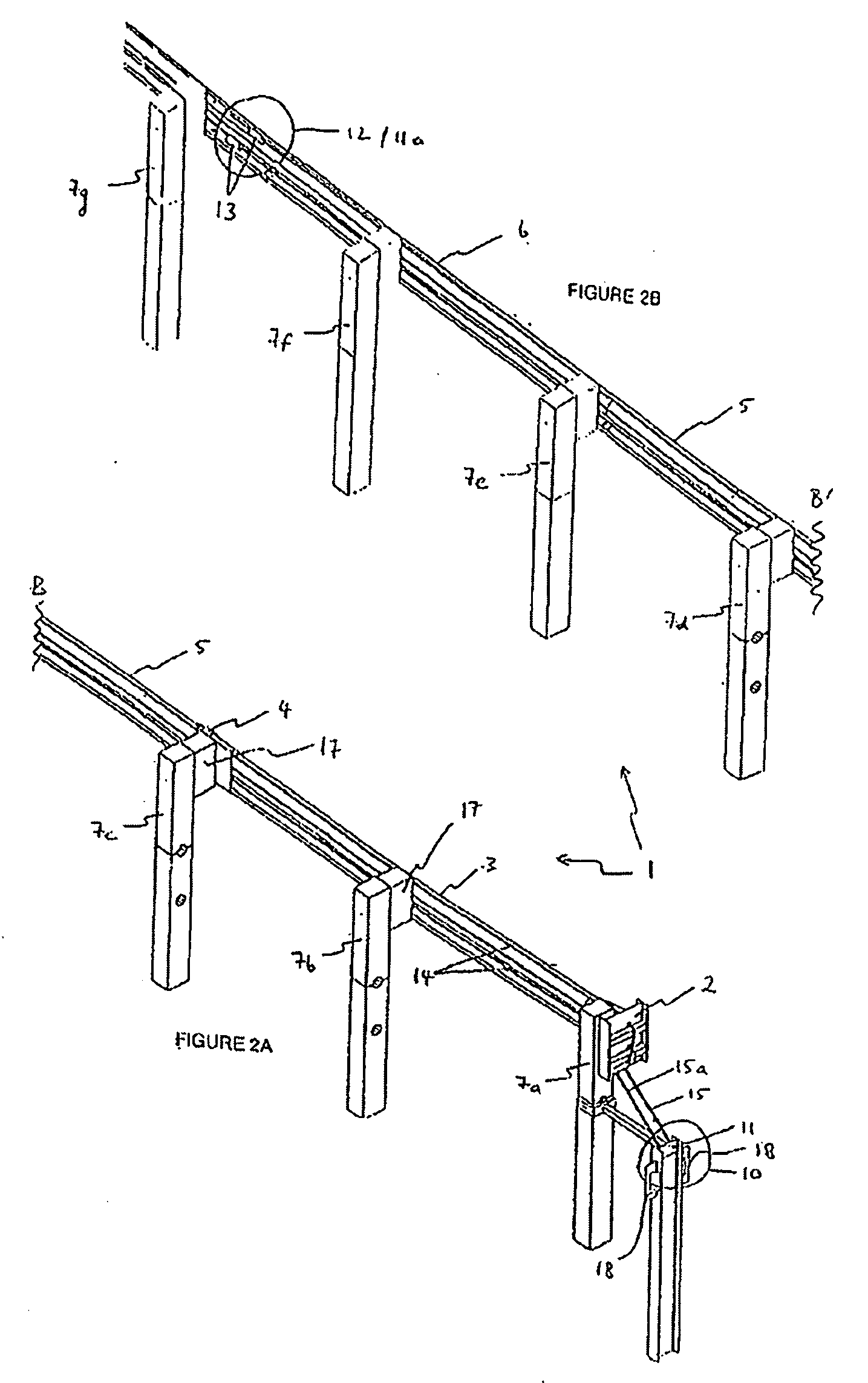

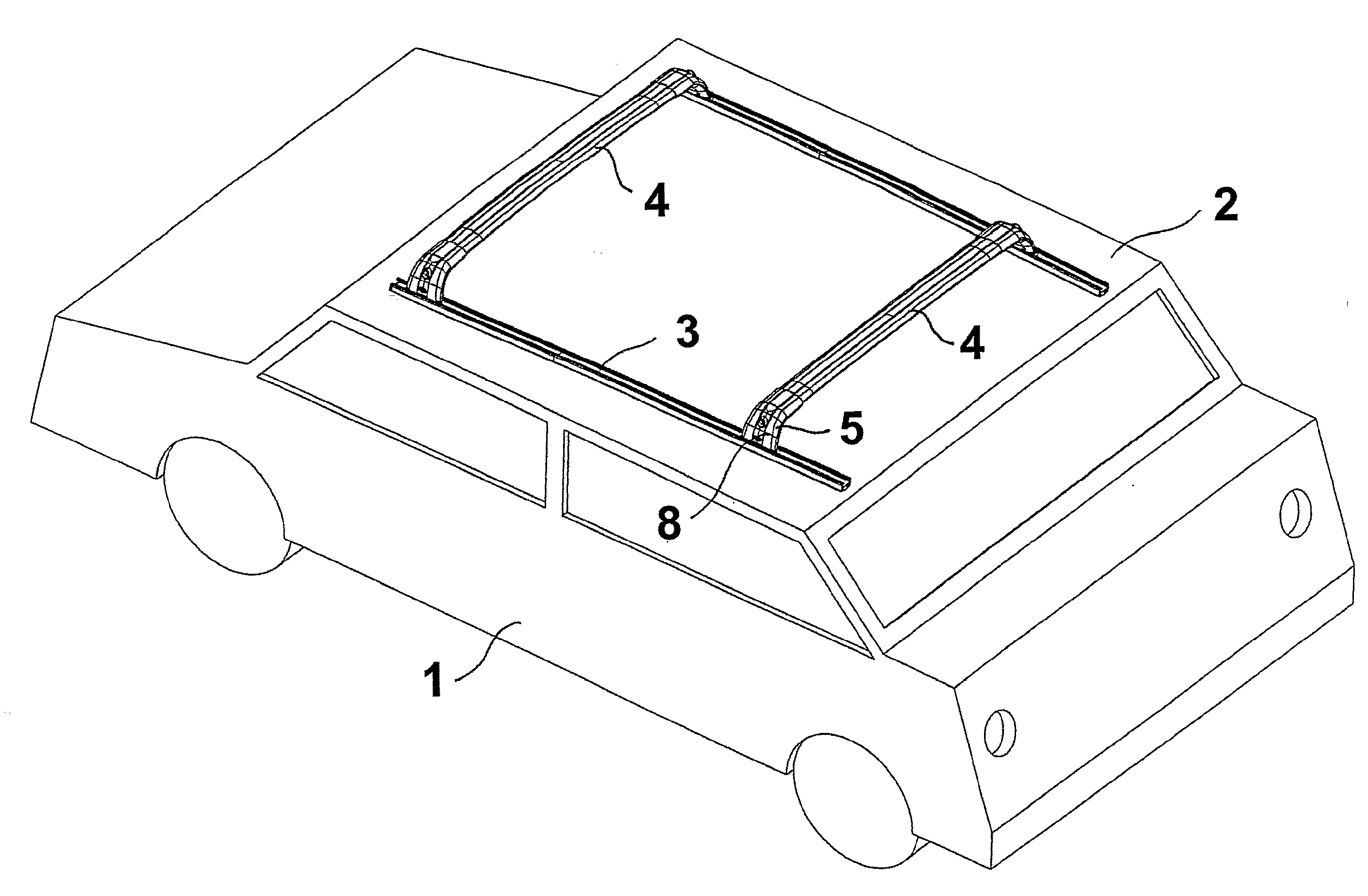

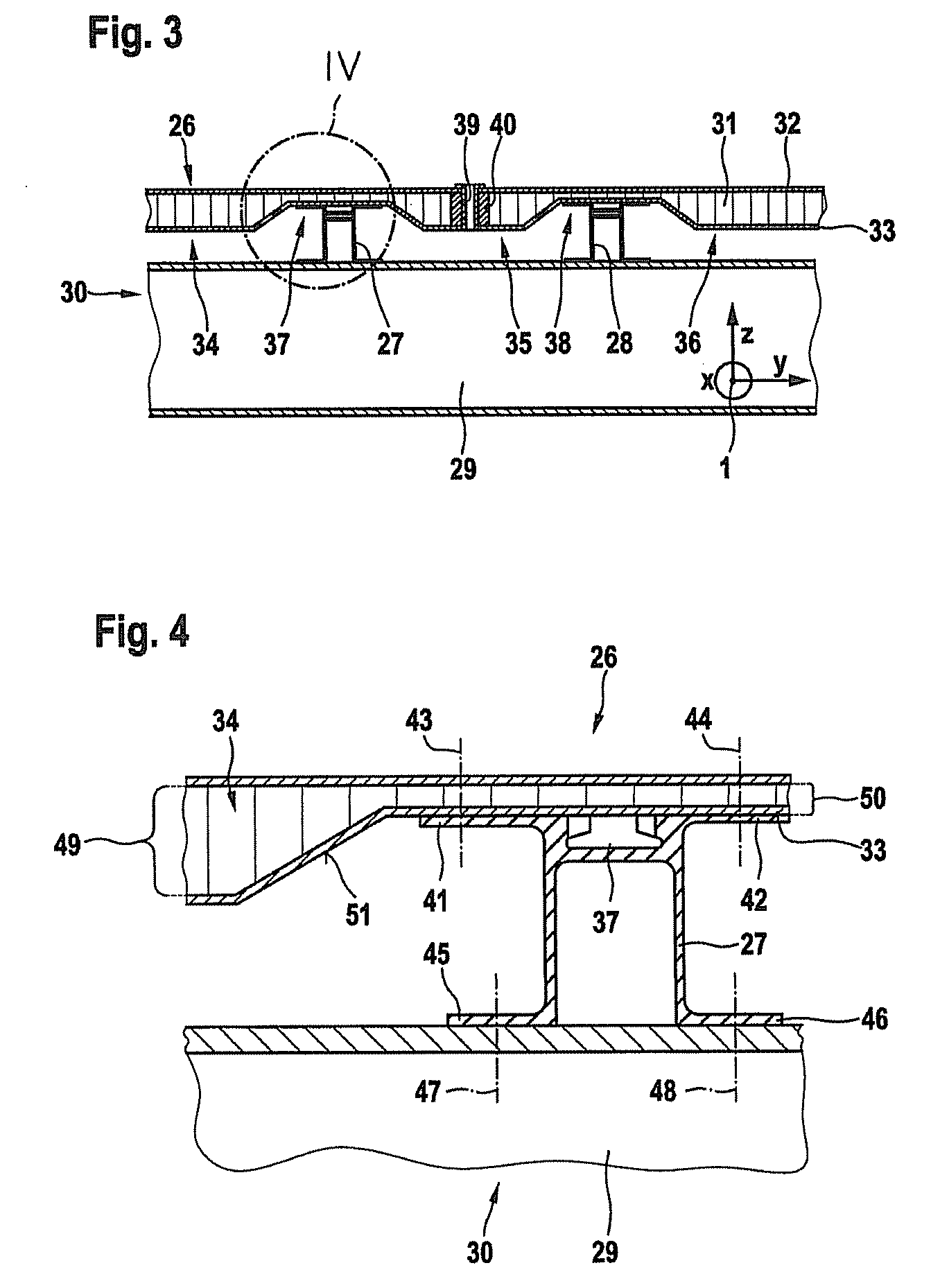

Load carrier foot

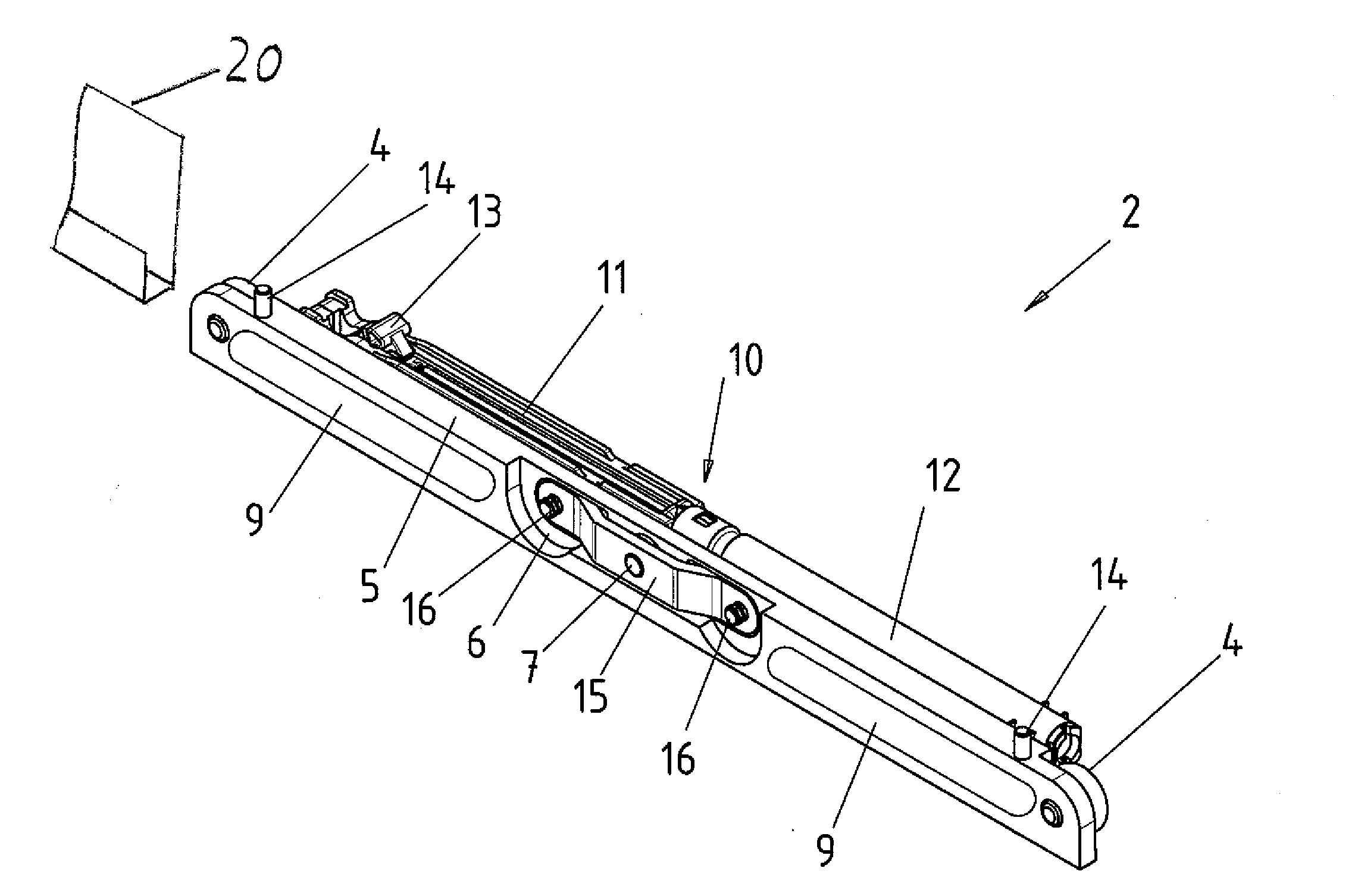

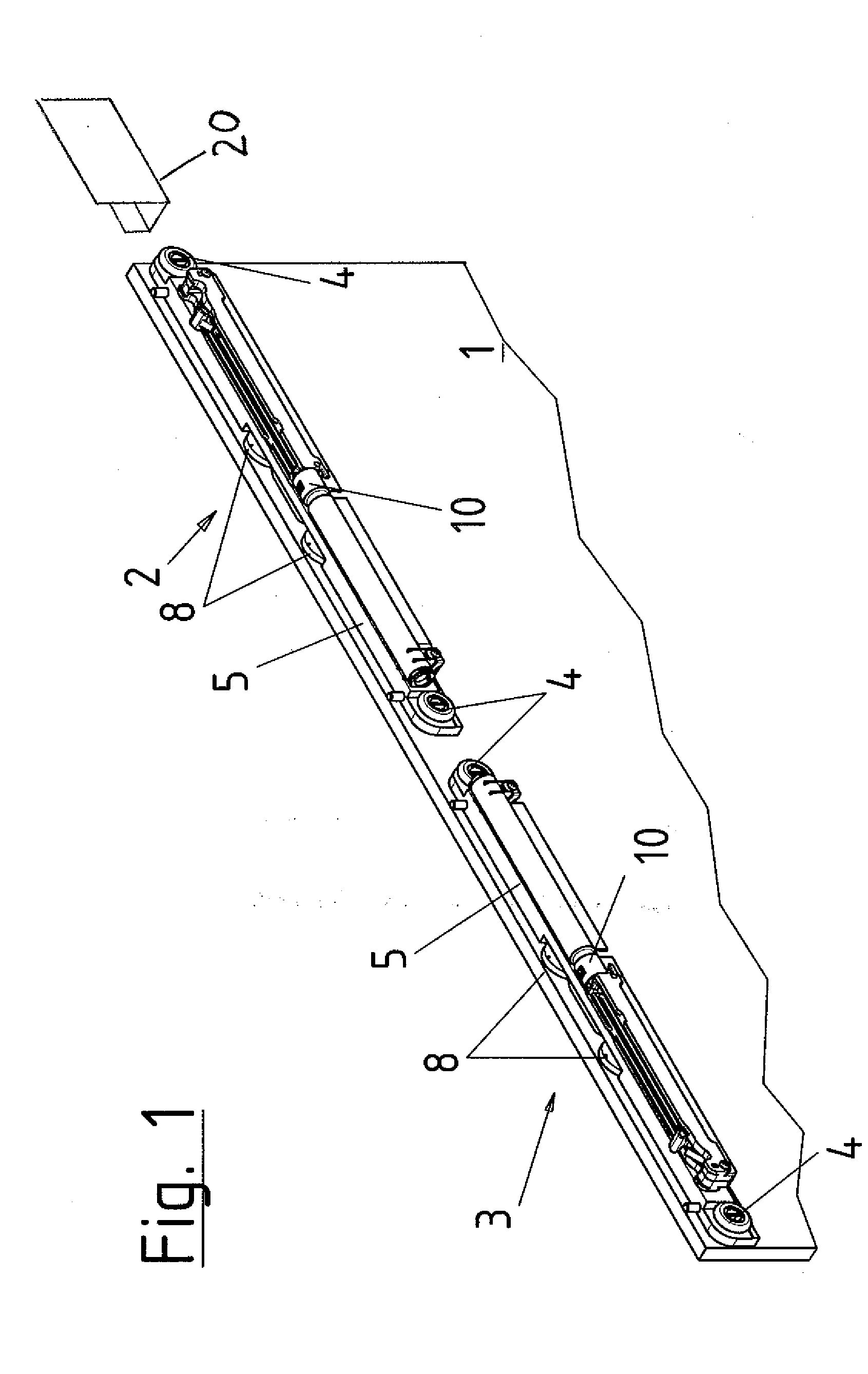

Load carrier foot (5) for connecting a load carrier bar (4) to an, at a vehicle connected, elongated rail profile (3), having in the longitudinal direction (L) of the rail an extended cavity (6), with an upwards turned opening (7), in which the width (B) of the cavity across the longitudinal direction of the rail exceeding the width (b) of the opening, whereby the cavity on each side of the opening having walls (10, 11), which are directed essentially downwards against the bottom (9) of the cavity, whereby the load carrier foot having a base part (13), which extends through the opening towards the bottom of the cavity. A fastening device (29), which by means of a clamping device (51) is moved upwards to clamping contact with the downwards directed walls (10, 11) when the base part being secured to the rail profile. A connection means (25,30) is firmly connected with the locking device (29) and turnable connected to the base part (13), and an elastic body (24) is located between the base part and the connection means, which turns the connection means and the locking device to a position in which the locking device being located transverse relative the longitudinal direction of the rail profile when the base part is mounted to the cavity, and in which position the locking device certainly will be in contact with the downwards directed walls (10, 11) when the locking device being clamped against the walls by the clamping device (51).

Owner:THULE SWEDEN AB

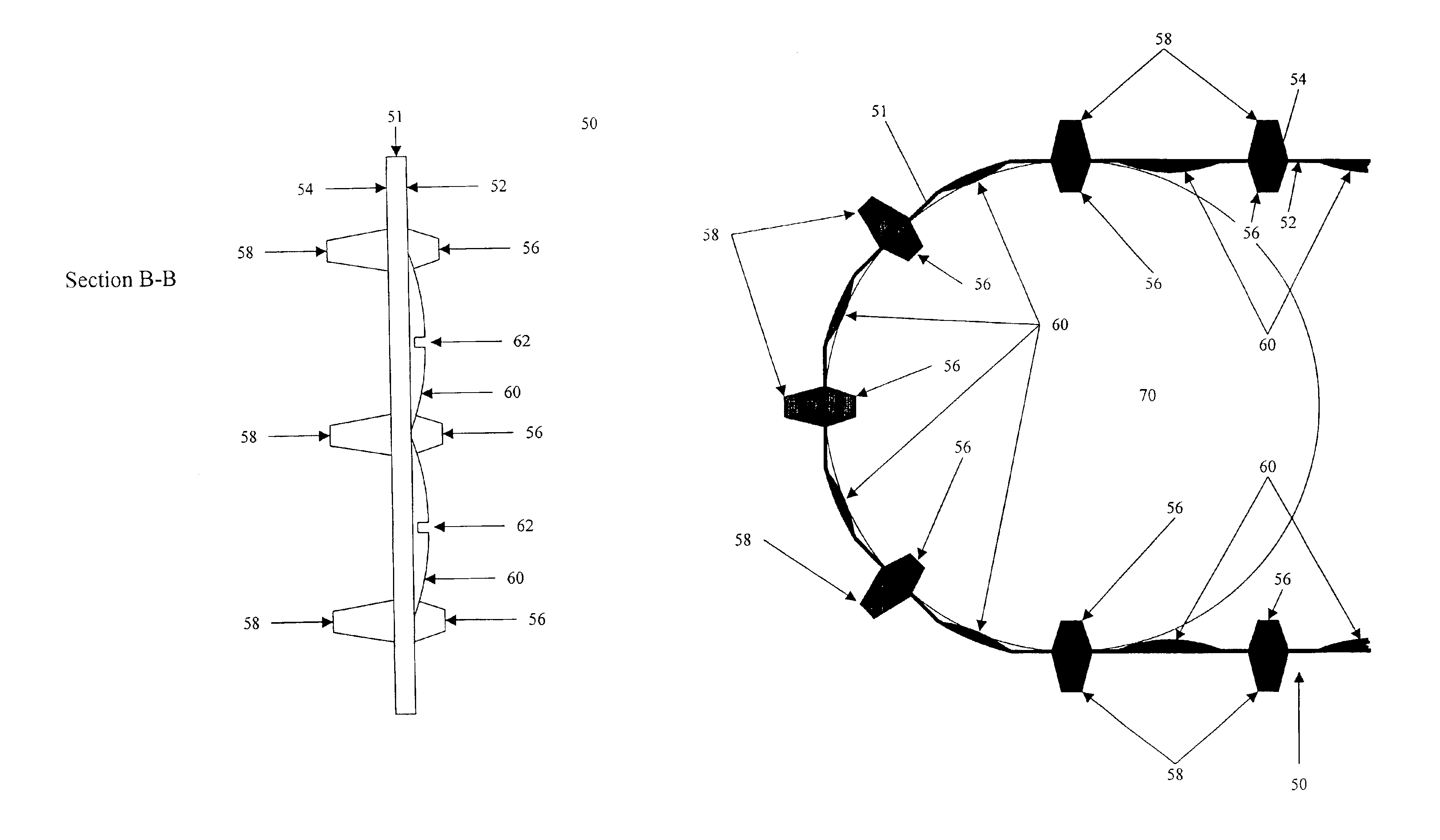

Low noise track profile

A track for a tracked vehicle, consisting of a track substrate. Terrain lugs are distributed about the circumference the track substrate on its outer surface. Drive profiles, each consisting of at least one drive lug arranged across the width of the track substrate, are distributed about the circumference of the track substrate on its inner surface. The drive profiles may consist of at least two drive lugs spaced apart across the width of the track substrate. Projections are distributed on the inner surface of the track substrate, arranged so as to engage a wheel in a track system that includes the track. The projections are disposed circumferentially between two drive profiles, and may also be disposed laterally between two drive lugs. The projections have a height such that the noise generated when the track moves in a track system is less than the noise generated when a track without such projections moves in a track system. A noise reduction of at least 6 to 8 dB is achievable. The projections may be from at least 3% to at least 7% of the radius of a wheel in the track system.

Owner:ARCTIC CAT

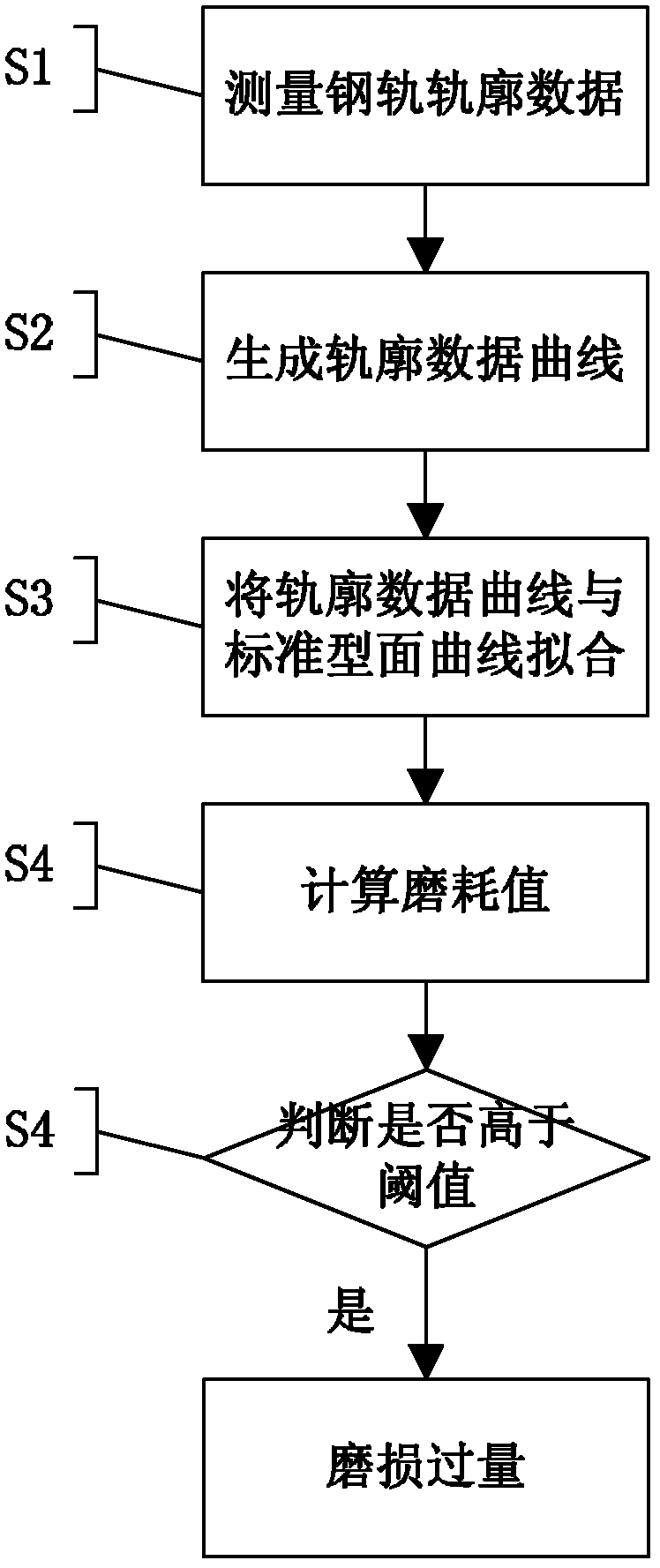

Rail outline detection method based on abrasion value

InactiveCN103171589AImprove accuracyRailway auxillary equipmentRailway profile gaugesRail profileComputer science

The invention relates to a rail outline detection method based on an abrasion value. The rail outline detection method comprises the following steps of (1) using a rail profile gauge to measure rail outline data; (2) using the rail profile gauge to send the rail outline data to a data processing device; (3) using the data processing device to receive the rail outline data and conduct data processing to obtain the abrasion value of a rail outline; and (4) making a comparison on the abrasion value obtained in the step (3) and a setting threshold value, and judging that the rail outline is excessively worn when the abrasion value is higher than the threshold value. Compared with the prior art, the rail outline detection method enables imitative effects of the rail outline data and a standard profile curve to be good and improves accuracy of calculation of the abrasion value.

Owner:TONGJI UNIV

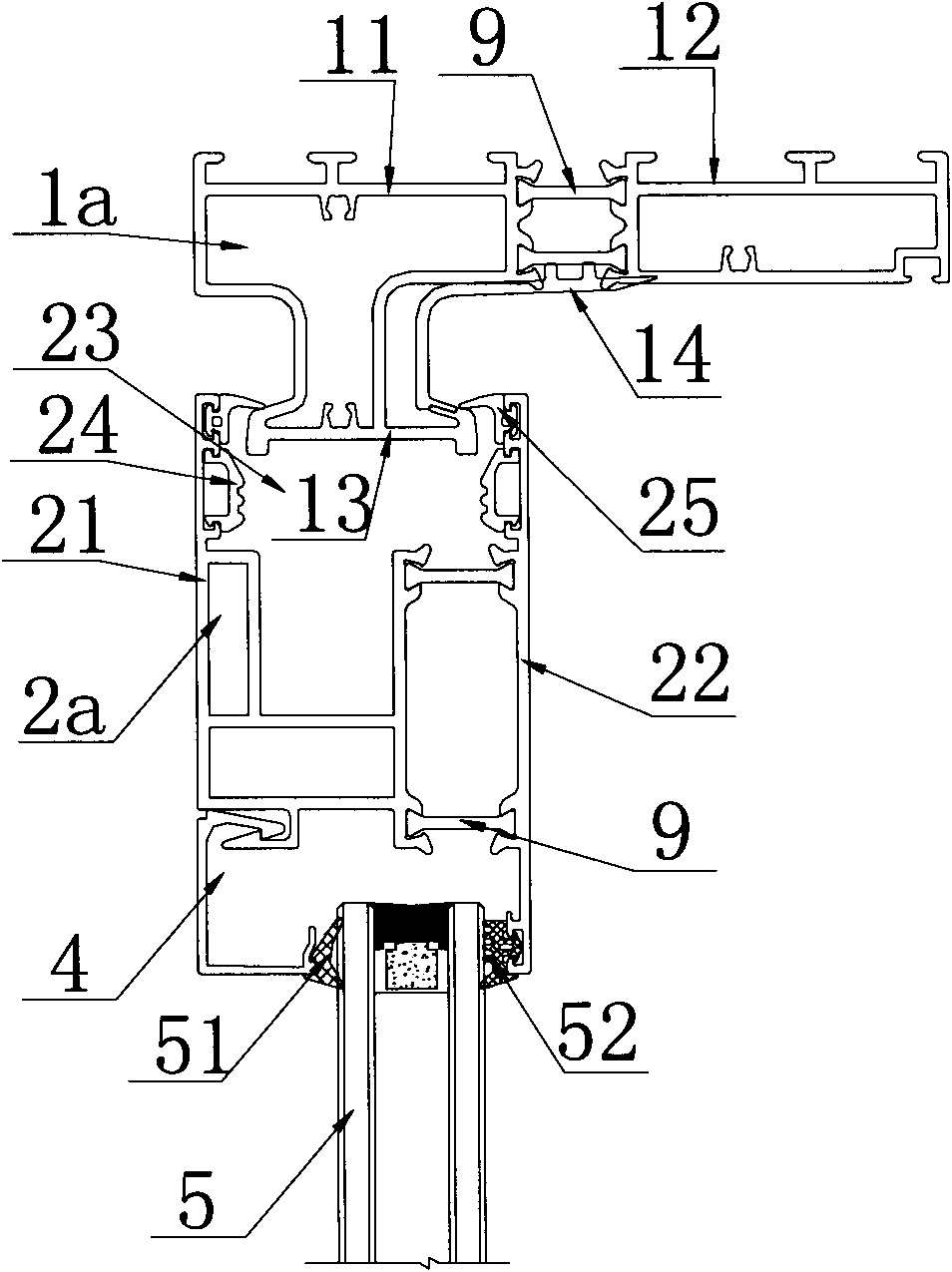

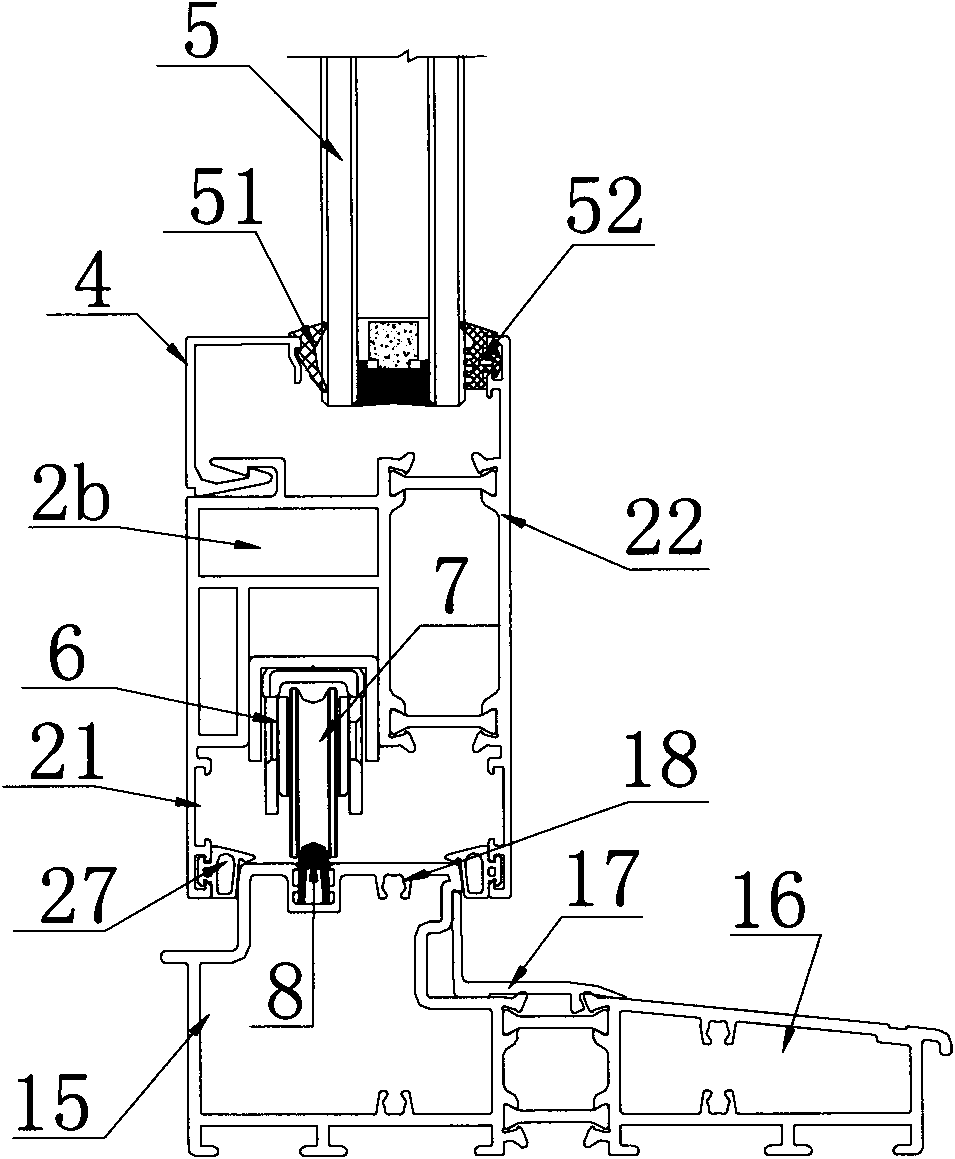

Aluminum alloy lifting sliding energy-saving door system

ActiveCN101899937AExtended service lifeClever useSealing arrangementsWing arrangementsRail profileEngineering

The invention relates to a sliding energy-saving door system, in particular to an aluminum alloy lifting sliding energy-saving door system. The aluminum alloy lifting sliding energy-saving door system is characterized in that: an upper rim and a lower rim of the energy-saving door system consist of a guide rail profile and a rim profile respectively; a door leaf is provided with a mounting port, the upper guide rail profile is provided with a raised rib which is movably arranged in the mounting port, and a leaf sealing rubber strip seals a gap between the raised rib and the mounting port; a pulley is arranged in the mounting port of the lower door leaf, the lower guide rail profile is provided with a raised rib which is provided with a slide rail, the pulley is arranged on the slide rail, and a leaf upper port sealing rubber strip is arranged between the raised rib and the mounting port; the mounting port of the left door leaf is provided with a leaf sealing plate and sealed; and a lock hardware is arranged in the mounting port of the right door leaf, and a sealing rubber strip gap is formed between the right rim and the mounting port. The aluminum alloy lifting sliding energy-saving door system has the characteristics of compact and skilful structure, stability, sealing property, better pressure resistance, sound insulation, heat preservation, energy conservation, luxury, high grade and more convenient manufacture, installation and use.

Owner:浙江安贝格系统门窗科技有限公司

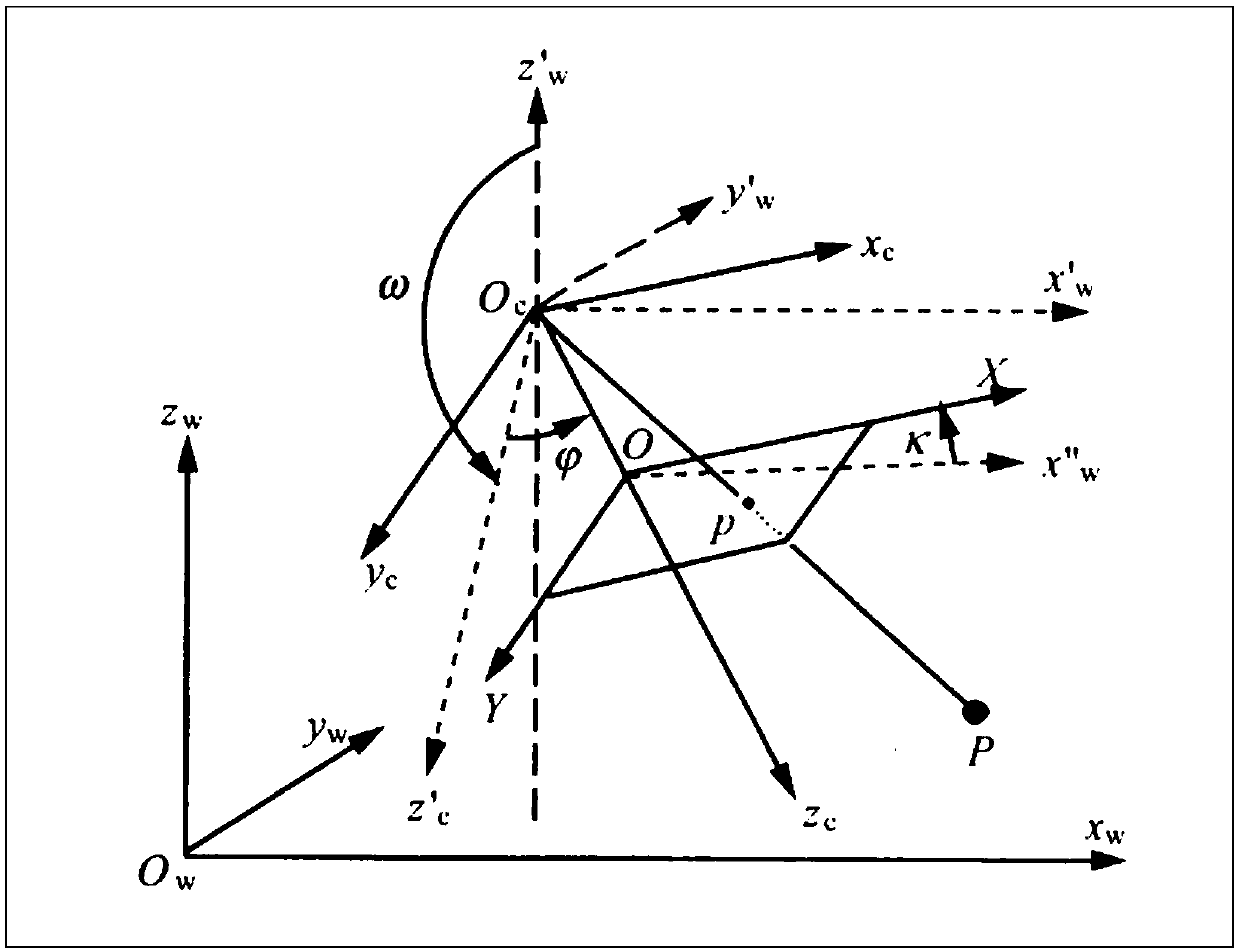

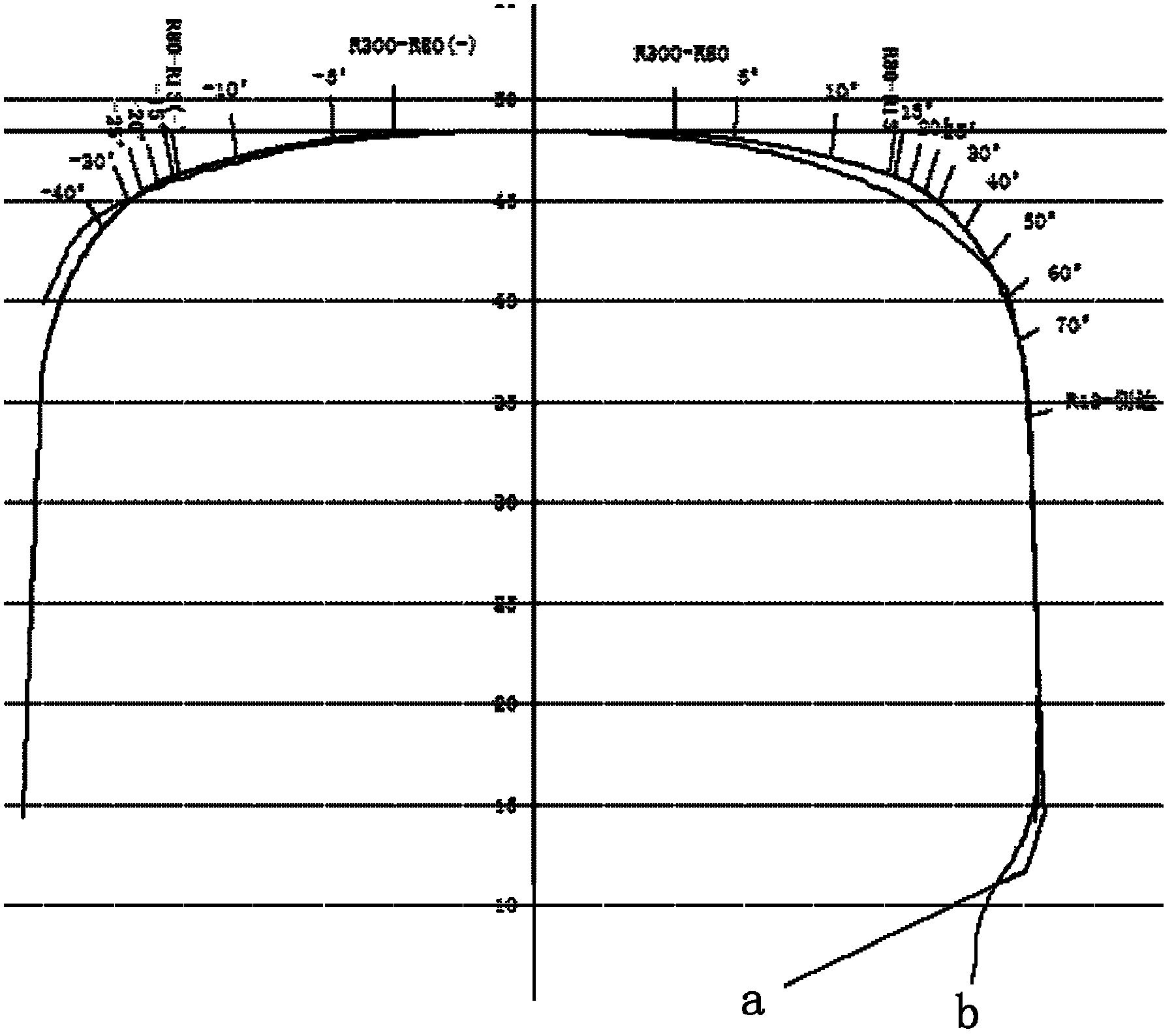

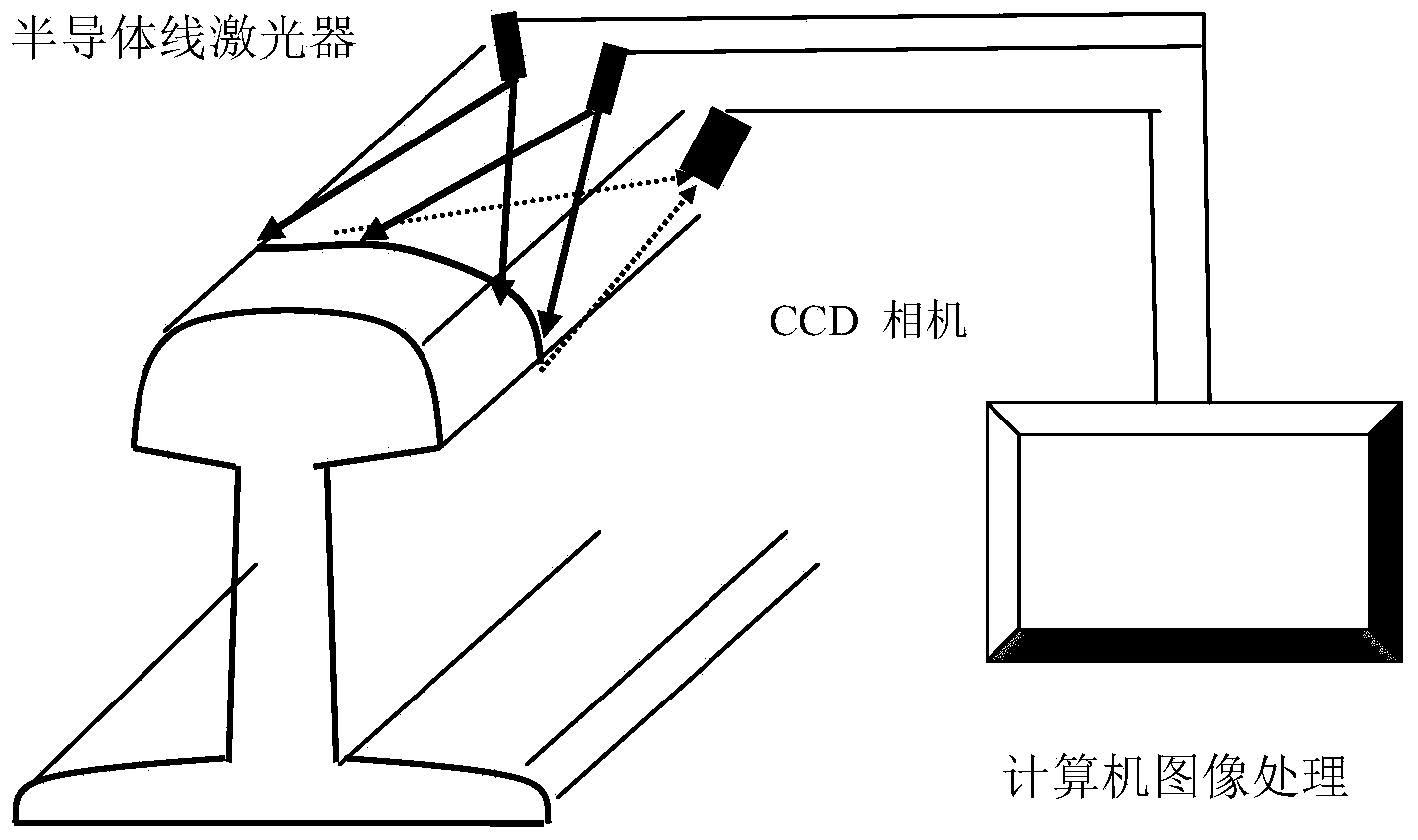

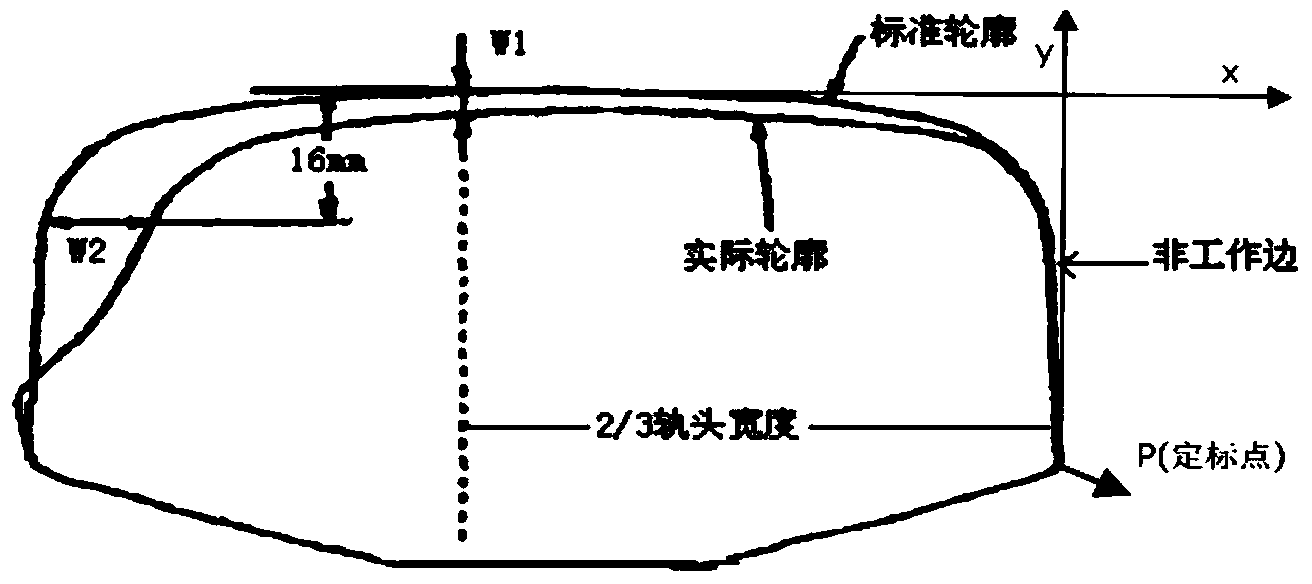

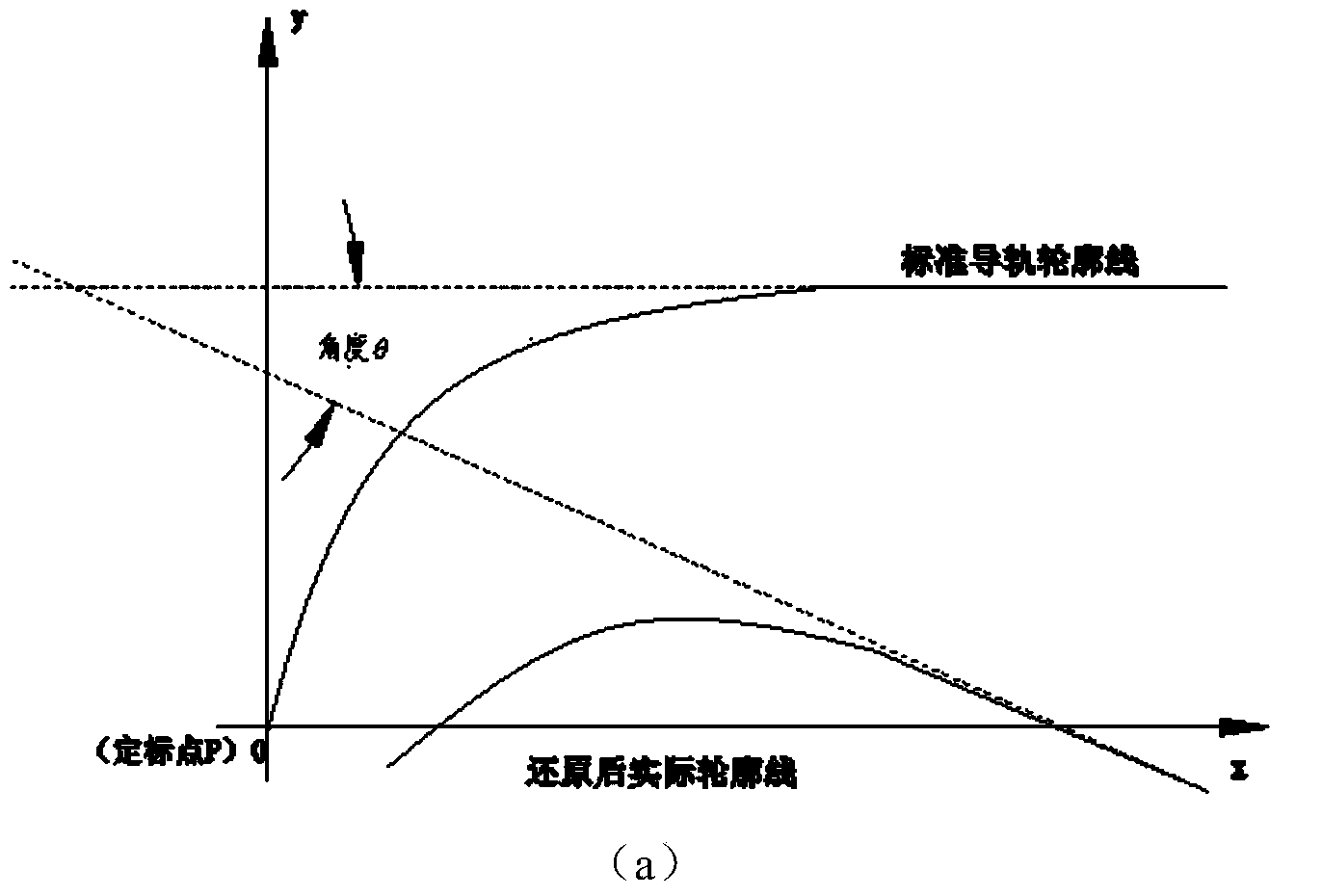

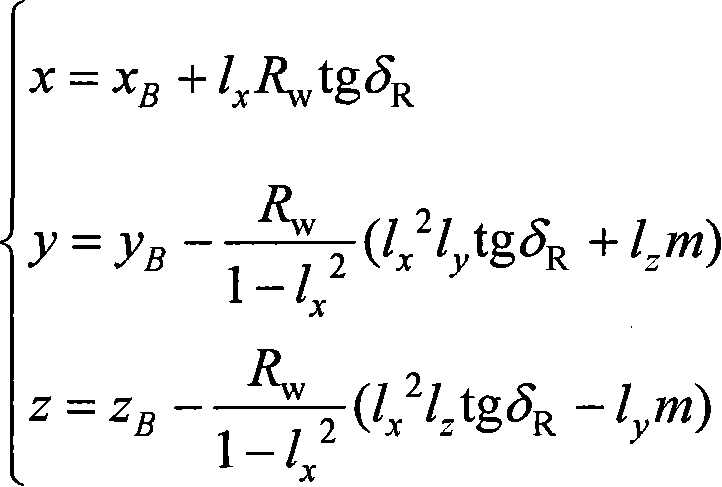

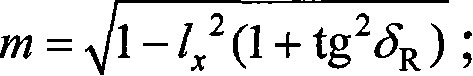

Contour registration method used in train guide rail contour measurement based on machine vision

InactiveCN104296682AThe registration result is accurateEasy to observeUsing optical meansRail profileMachine vision

The invention discloses a contour registration method used in train guide rail contour measurement based on machine vision. Contour measurement comprises the first step of collecting steel rail images, the second step of obtaining a single-pixel curved line of a steel rail profile through computer processing, the third step of carrying out calibration restoring and the fourth step of carrying out contour registration. The contour registration method comprises the steps of enabling an actual contour line and a standard contour line to be unified in a coordinate system and utilizing asymptotic lines of the two contour lines to obtain an included angle between the actual contour line and the standard contour line, rotating the actual contour line and enabling the asymptotic lines of the two contour lines to be paralleled, and horizontally moving the actual contour line and enabling ends of the actual contour line to be coincident with ends of the standard contour line. According to the contour registration method, the actual contour line and the standard contour line are unified into the coordinate system and the actual contour line is processed, the asymptotic lines of the actual contour line and the standard contour line are paralleled and coincide at ends, and therefore the registration result is accurate, observation and calculation are carried out conveniently and reliable abrasion loss data can be achieved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

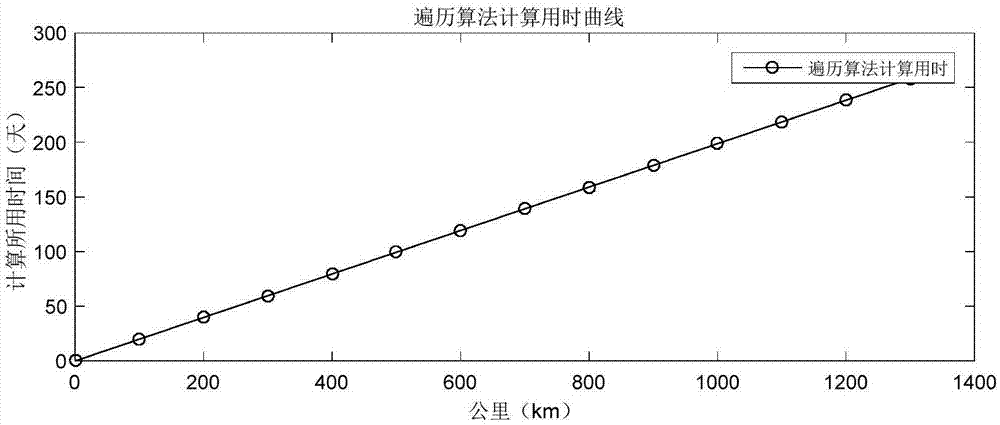

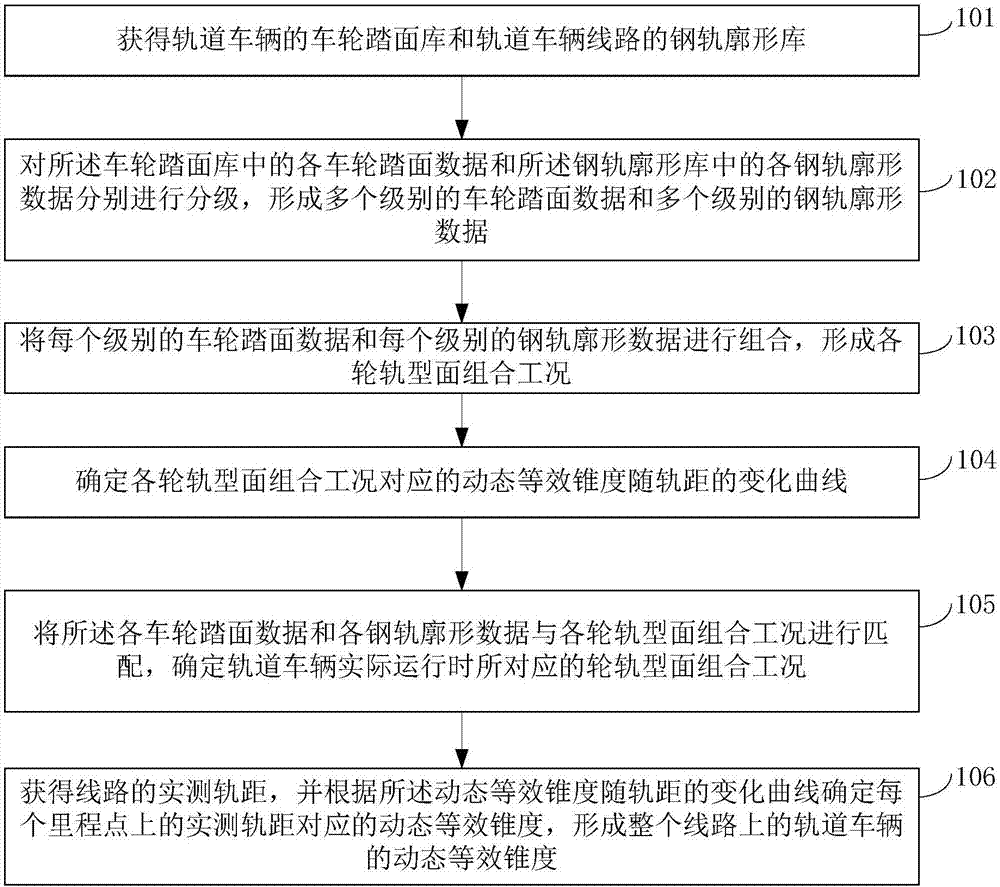

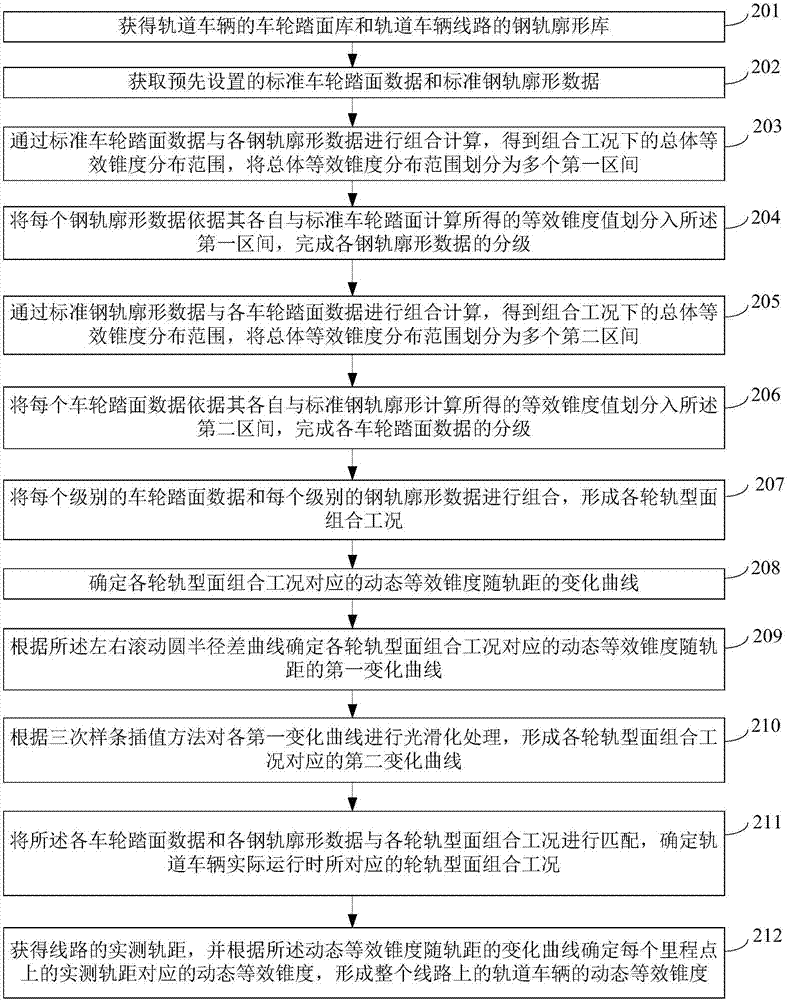

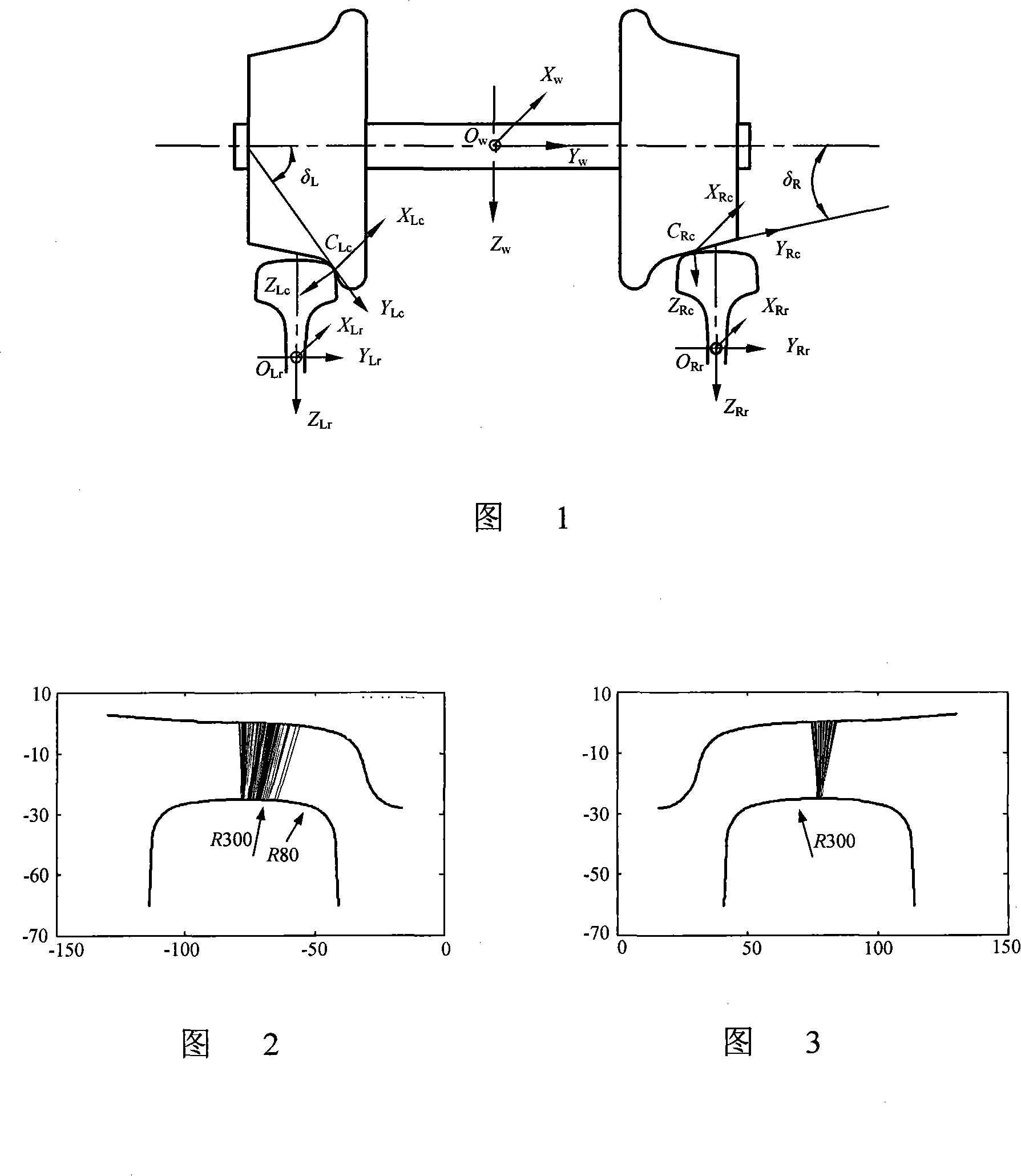

Method and device for determining dynamic equivalent conicity of railway vehicle

InactiveCN107391911ASimple calculationSpecial data processing applicationsInformaticsRail profileEngineering

The invention provides a method and device for determining the dynamic equivalent conicity of a railway vehicle, and relates to the technical field of railway vehicle routes. The method comprises the steps that tread data of each wheel in a wheel tread library and profile data of each steel rail in a steel rail profile library are classified and combined respectively, and various wheel-rail molded surface combined working conditions are formed; the change curve of the equivalent conicity corresponding to the wheel-rail molded surface combined working conditions along with the gauge is determined; the tread data of each wheel and the profile data of each steel rail are matched with the wheel-rail molded surface combined working conditions, and the wheel-rail molded surface combined working conditions corresponding to actual operation of the railway vehicle are determined; the actually measured gauge of a route is obtained, the dynamic equivalent conicity corresponding to the actually measured rail gauge on each mileage point is determined according to the change curve of the dynamic equivalent conicity along with the gauge, and the dynamic equivalent conicity of the railway vehicle on the whole route is formed.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

Calibration method for steel rail profile measured by adopting laser displacement technology

InactiveCN106643545AImprove fine-tuning efficiencyGuaranteed real-timeUsing optical meansRailway auxillary equipmentFeature vectorContour segmentation

The invention discloses a calibration method for the steel rail profile measured by adopting a laser displacement technology. The calibration method comprises the steps of segmenting the steel rail profile, and calculating an index value; acquiring absolute affine invariants; acquiring a local affine non-deformation description feature vector set in an offline state and a local affine non-deformation description feature vector set in an operating state, matching feature vectors and acquiring a matching point set; calculating a transformation relational expression of profile data in the offline state and a transformation relational expression of profile data in the operating state; acquiring an affine transmission matrix; acquiring an affine transmission matrix set for each pair of matching points and completing data processing; and performing calibration on the steel rail profile according to the affine transmission matrix, the translation amount and the profile data transformation relational expressions. The invention innovatively proposes a new method for extracting, describing and matching the steel rail profile local affine invariants, puts forwards a quick iterative closest point algorithm to precisely adjust affine transformation parameters, and solves a problem of profile deformation in steel rail profile measurement performed by adopting the laser displacement technology, so that accurate correction is performed on the steel rail profile. In addition, the method is high in calculation speed and high in accuracy.

Owner:HUNAN UNIV +1

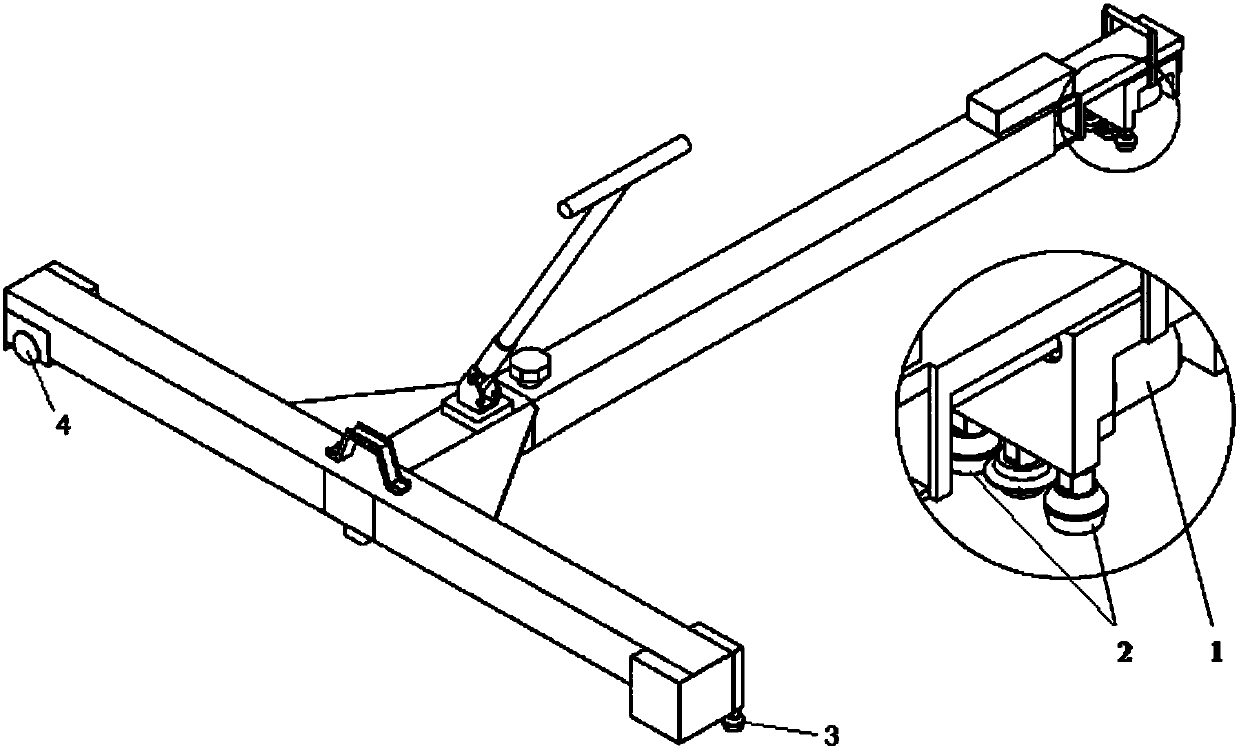

Two-dimensional laser dynamic detection device and method of steel rail profiles and corrugations

ActiveCN107839714AFast measurementRealize continuous measurementUsing optical meansRailway auxillary equipmentRail profileEngineering

The invention discloses a two-dimensional laser dynamic detection device and method of steel rail profiles and corrugations. A two-dimensional laser displacement sensor is adopted to collect steel rail profile initial-data, and fixed on a walking trolley through an adjustable bracket. The walking trolley is composed of a T-shaped structural component, a walking wheel, a positioning wheel and a guide wheel, and mainly used for carrying the two-dimensional laser displacement sensor and achieving longitudinal movements along a steel rail. A coder coaxially connected with the walking wheel of thewalking trolley is used for recording the walking position of the walking trolley. Then, a series of analytical processing is conducted on the steel rail profile initial-data collected by the two-dimensional laser displacement sensor so as to complete profile deviation calculation of the steel rail profiles and corrugation analysis. The detection device can not only conduct steel rail profile dynamic-continuous-detection on a specified interval, but also conduct static detection on the steel rail profile of a specified position, and has the advantages of complete detection functions, high efficiency and the like.

Owner:CENT SOUTH UNIV

Method for measuring steel rail appearance geometric dimension and surface quality and device thereof

InactiveCN104897052AAchieve sizeImprove integrityOptically investigating flaws/contaminationUsing optical meansRail profileEngineering

The invention relates to a method for measuring steel rail appearance geometric dimension and surface quality and a device thereof. Three sets of laser devices, a total of eight two-dimensional laser sensors, are adopted to acquire steel rail cross section contour data, data fusion is performed by computer software, all cross sections are spliced and the three-dimensional contour of a steel rail is acquired. Each cross section contour of the steel rail is automatically analyzed, the appearance geometric dimension of the steel rail is detected, steel rail surface quality is detected and detection results are uploaded to a welded rail production and management system so that automatic rail distribution and steel rail information recording can be realized. The detection results are displayed in real time, and three-dimensional contour pictures of surface quality with defects are recorded. The detection results are displayed in real time, and real-time sound-light alarm is performed when the detection results exceed standard values. The steel rail appearance geometric dimension and surface quality can be effectively detected by the method so that utilization rate of the steel rail can be greatly enhanced and safety hidden trouble in subsequent use can be reduced.

Owner:WUHAN HANNING TECH

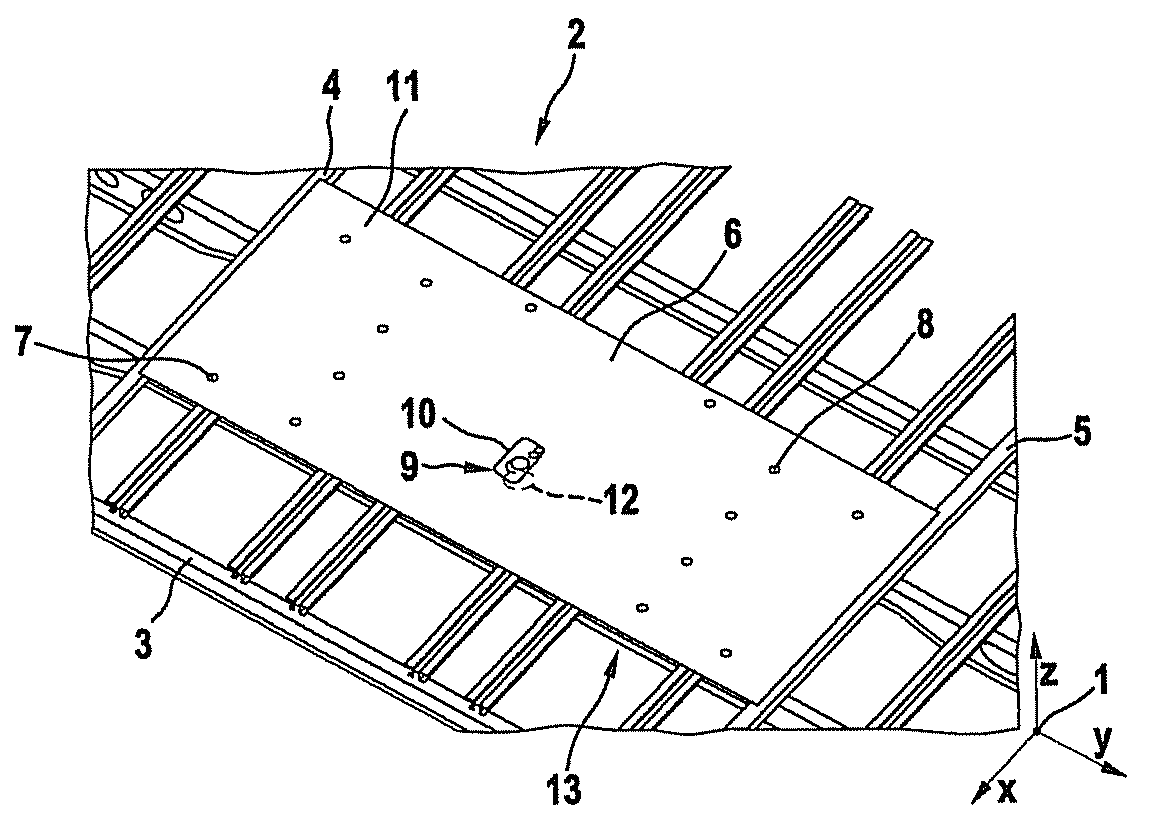

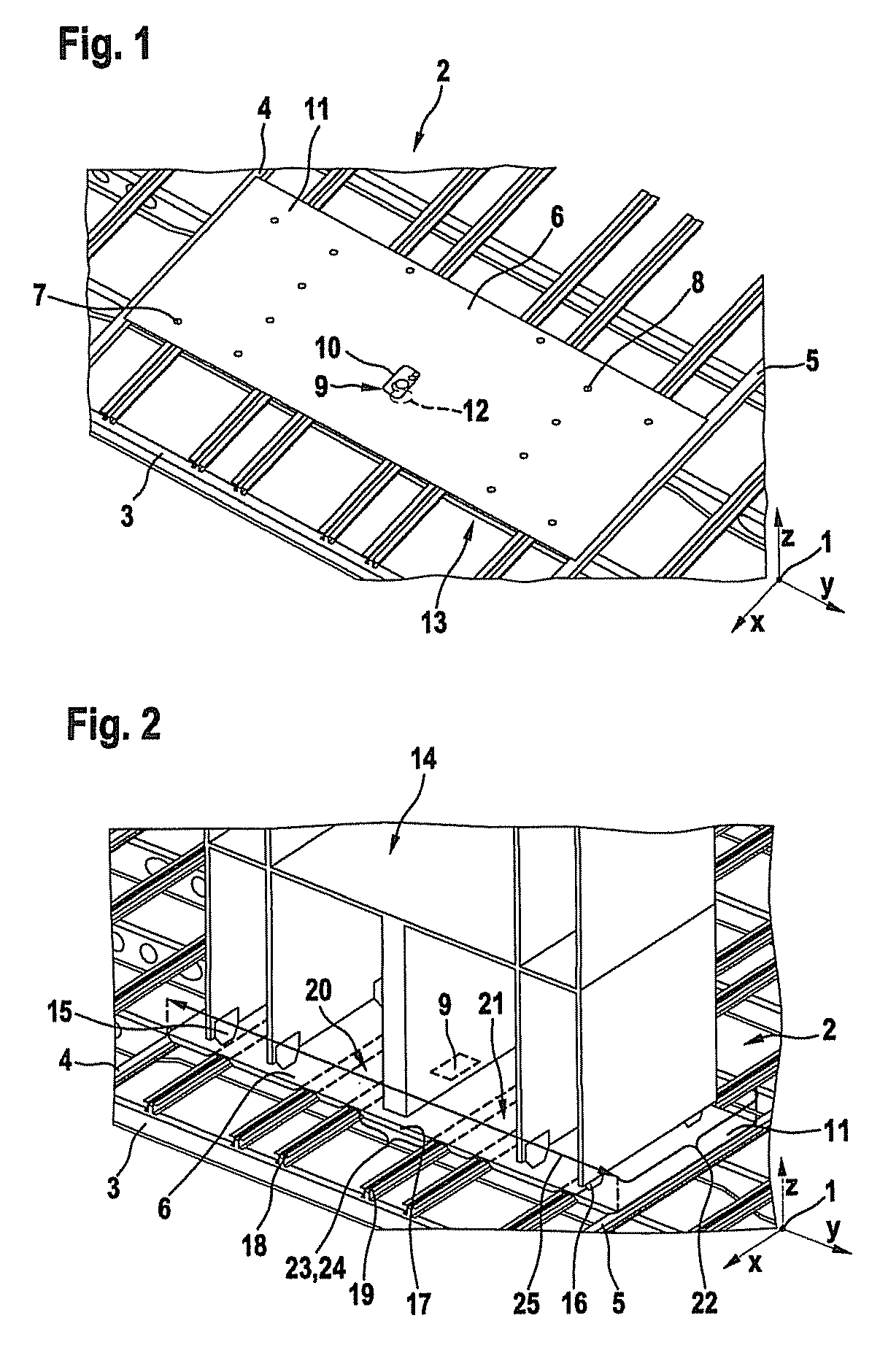

Floor plate for covering a floor framework in an aircraft

ActiveUS20090166472A1Simple and especially positionally flexibleInstallation effort is requiredBuilding componentsFuselagesRail profileOn board

The invention relates to a floor plate for bearing upon a floor framework in an aircraft. The floor framework is formed with a multiplicity of transverse beams which are arranged like a truss, and a multiplicity of longitudinal profiles, especially seat rail profiles, which extend transversely to the transverse beam. At least one sub-assembly, for example a kitchen module and / or a sanitary cell, can be fastened on the floor plate. The floor plate bears upon at least four longitudinal profiles and has at least one connecting point, especially an insert, for fastening of the sub-assembly. In addition, at least one system port is provided for the tool-less, pluggable connecting of the sub-assembly to any on-board systems of the aircraft, especially to electrical systems, to feed-air systems, to exhaust air systems, to fresh-water systems or to waste-water systems.

Owner:AIRBUS OPERATIONS GMBH

A method and a device for extract that center of a laser stripe of a rail profile unde a dynamic driving environment

ActiveCN109389639AImprove robustnessAvoid matching problemsImage analysisNeural learning methodsRail profileGray level

A method and device for extract laser stripe cent of rail contour under dynamic driving environment A laser stripe image of a rail profile to be extracted is input to a depth learning network structure segmentation model, and the light stripe image is segmented into a plurality of sub-region images accord to the gray level characteristics and the gradient direction characteristics of the light stripe; Determining the normal principal direction of each sub-region based on the gradient histogram of the light stripe; Each sub-region corresponds to a normal principal direction; According to the main normal direction of each sub-region, constructing the corresponding direction template for each sub-region. According to the direction template, the sub-pixel coordinates of the center of the lightstrip in each sub-region are determined. According to the sub-pixel coordinates of the center of the light strip in each sub-region, the sub-pixel coordinates of the center of the laser stripe of therail contour in the dynamic driving environment are extracted. The technical scheme improves the efficiency, accuracy and robustness of the laser stripe center extraction under the dynamic driving environment.

Owner:RAILWAY INFRASTRUCTURE TESTING RES INST CHINA ACAD OF RAILWAY SCI +2

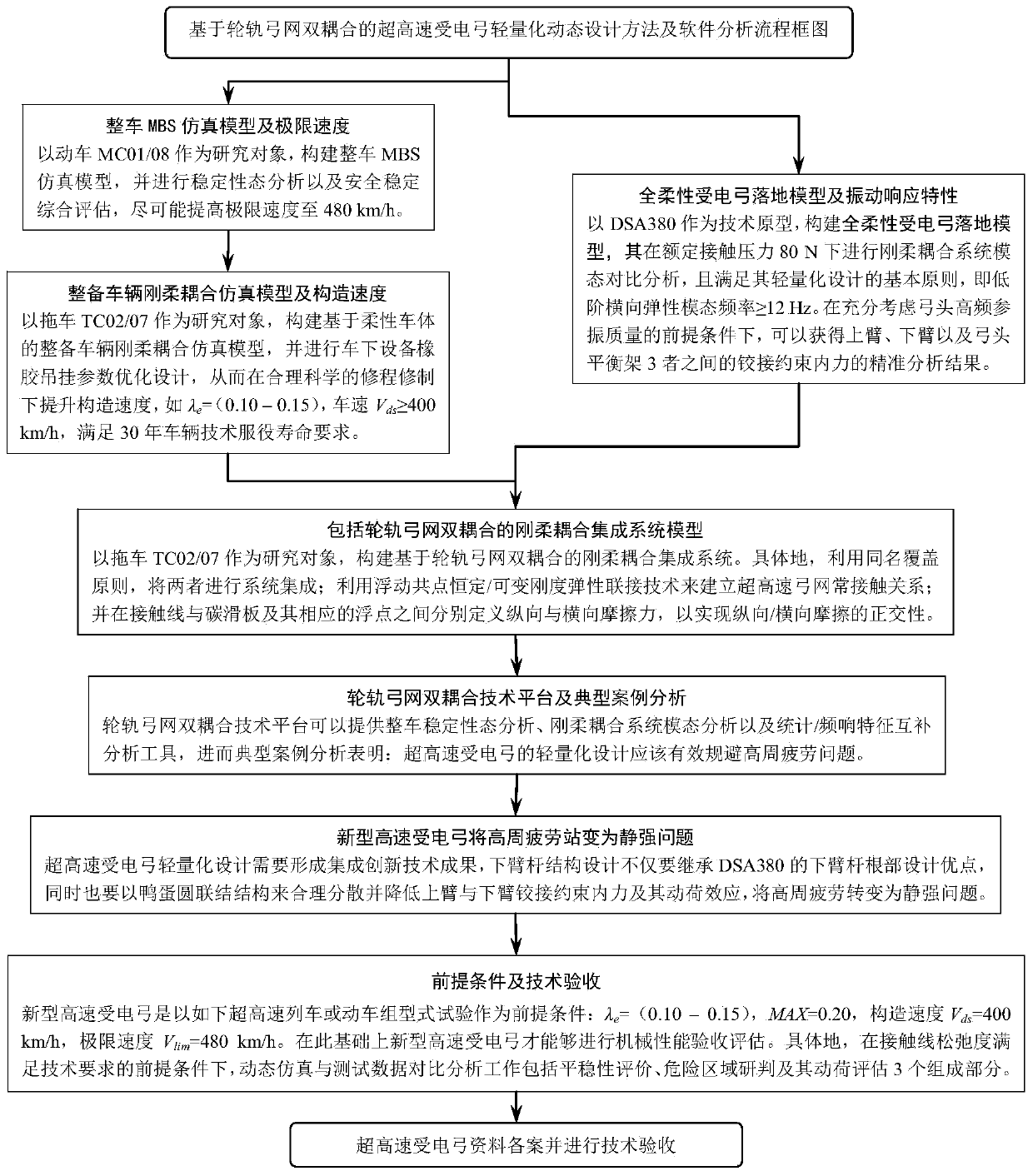

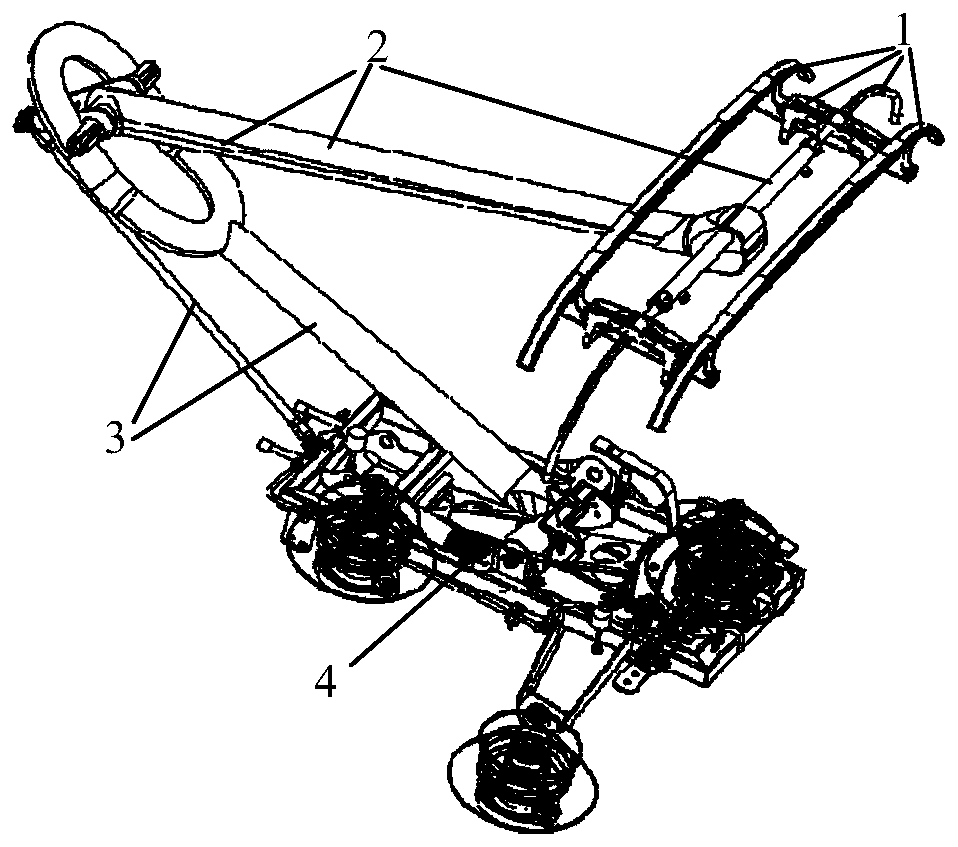

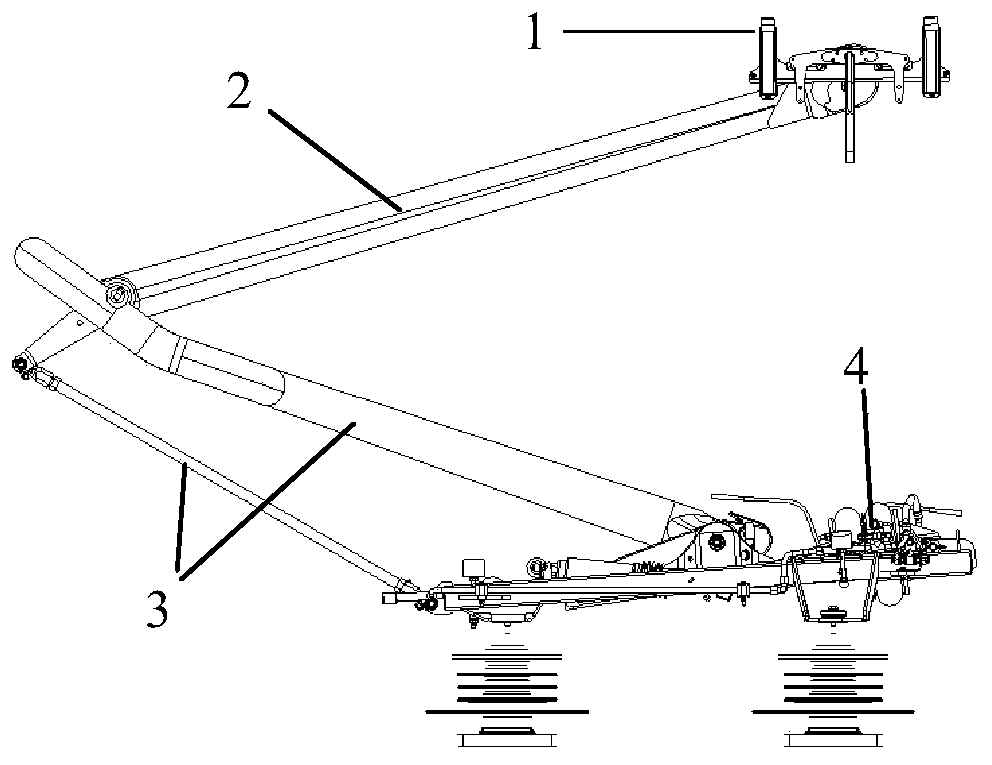

Novel high speed pantograph and lightweight dynamic design method thereof

InactiveCN110126625AReduce contact dynamicsAvoid implicating sports relationshipsGeometric CADDesign optimisation/simulationBogieRail profile

The invention discloses a novel high speed pantograph and lightweight dynamic design method thereof. Optimization of bogie parameters is led according to a root locus diagram, the dynamic action of the contact rail of an abrasion wheel is lowered, under the condition of uniform / normative wheel rail profile matching, the limiting speed is improved up to 480 km / h; through optimal design of rubber suspension parameters of equipment under a vehicle, the transverse vibration mass of hostling flexible vehicle body is decreased, and under reasonable and scientific repair program and repair system, the construction speed is increased up to 400 km / h. In order to better count input stimulus formed by high speed pantograph net contact, a fully flexible pantograph landing model and a hostling vehiclerigid flexible coupling simulation model are systematically integrated to construct a wheel rail pantograph net double coupling simulation technology platform. According to complex constraint and accurate analyze of internal force, analysis of a typical case indicates that a novel lightweight design form is needed by an ultra-high speed pantograph, namely the hinging constraint force between an upper arm and a lower arm and the dynamic load effect are reasonably dispersed and reduced through a duck-egg-shaped joint structure, and thus high cycle fatigue is transformed to a static strength problem.

Owner:DALIAN JIAOTONG UNIVERSITY

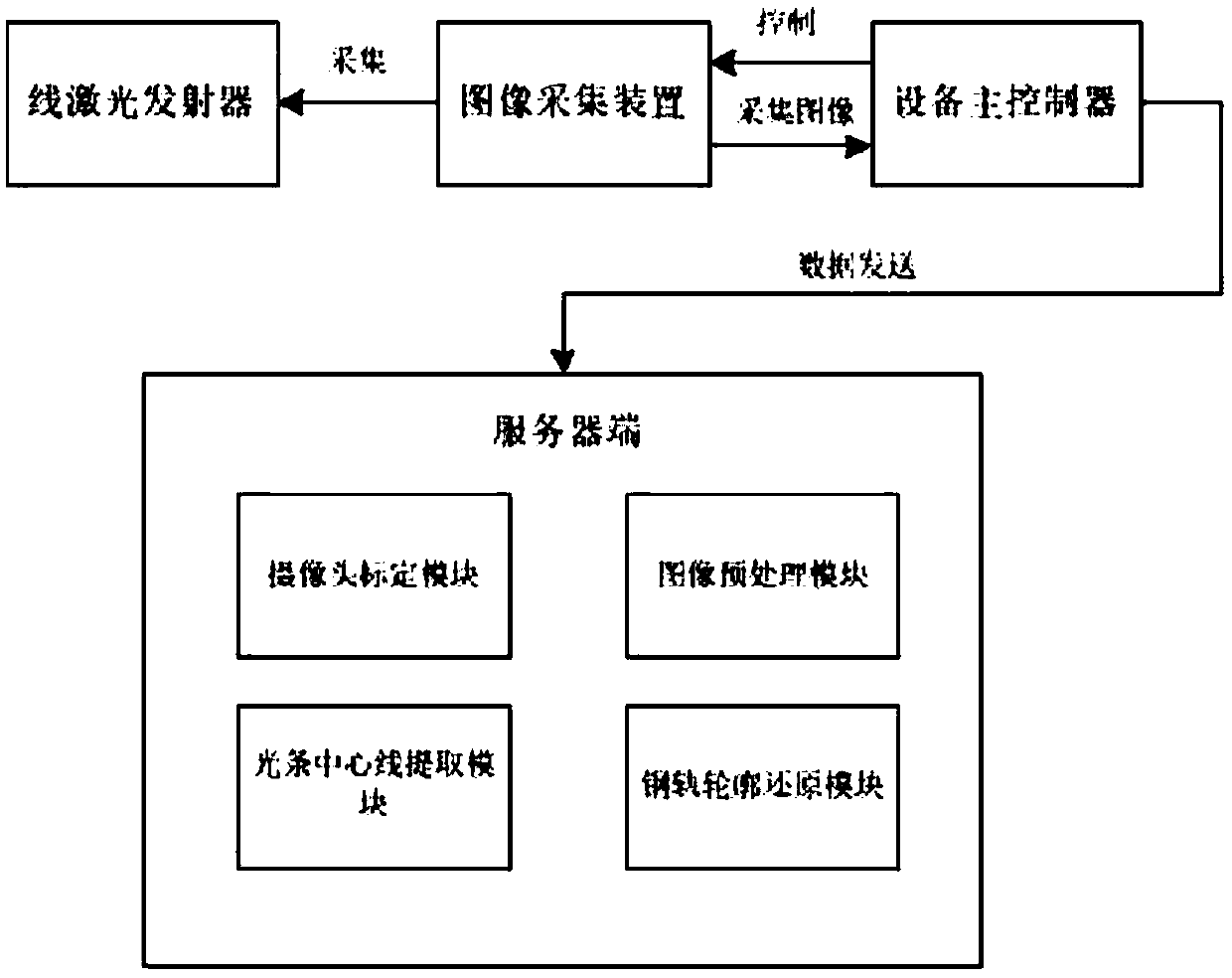

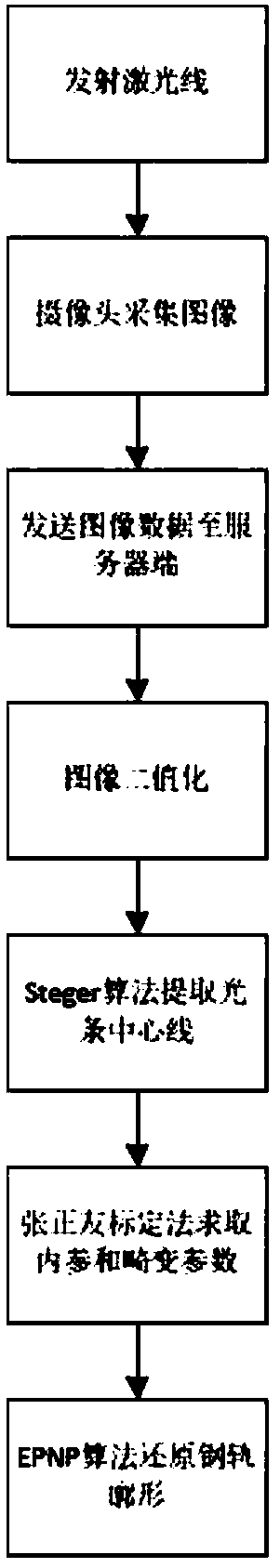

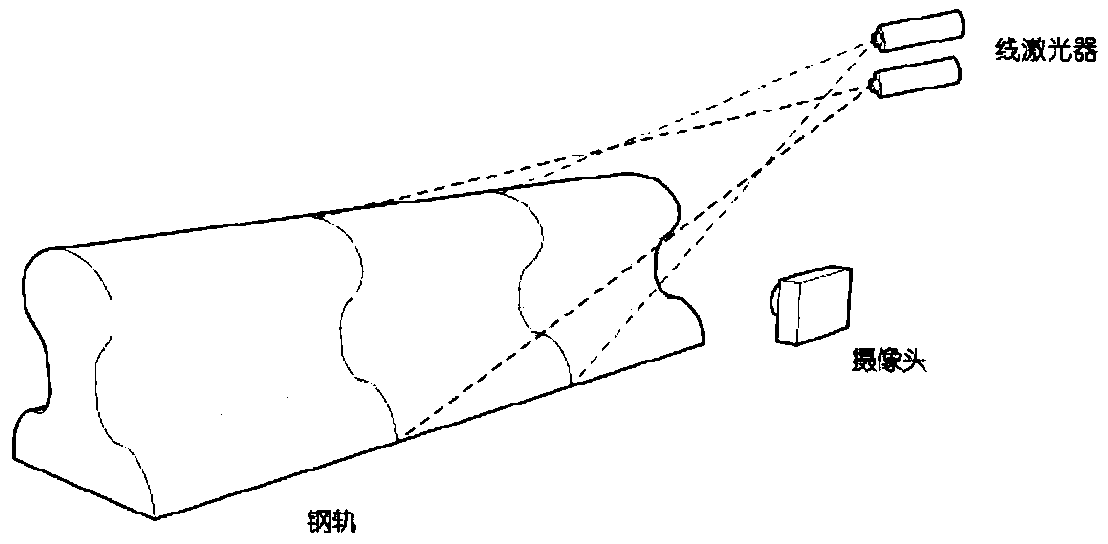

A rail profile detection method and system based on EPNP

PendingCN108986082ASolve the accuracy problemHigh precisionImage enhancementImage analysisLaser transmitterRail profile

The invention discloses a rail profile detection method and system based on EPNP. The system comprises: a line laser emitter, which is used for emitting laser lines to the rail to be detected to formlaser light strips, wherein the laser light strips correspond to the outer edge of the cross section of the rail; an image acquisition device for acquiring an image of a rail with a laser beam attached to a surface through a camera; a main controller of the equipment, which is used for sending the rail image data collected by the image collecting device to the server end.; and a server end, whichis used for receiving the image data sent by the main controller of the equipment, extracting the centerline of the light stripe in the image, obtaining the rail profile, and calculating the rail weardegree. The invention solves the problems of long time consumption and low precision of a conventional rail profile detection method, and has the advantages of low time complexity and high precision.

Owner:WUHAN UNIV OF TECH

Method for describing railway wheeltrack spacing dynamic connecting state

InactiveCN101117127AReal contact stateUnified dynamic analysis basisRailway auxillary equipmentRailway profile gaugesRail profileEngineering

A method describes the railway wheel track space dynamic contact state and the steps are as follows: a) generating the wheel and track surface according to discrete data points of the wheel and the steel rail profile; b) according to the preset running speed, working out the vibration displacement of wheel pairs and the steel rail at every moment and finding out the wheel space trace at corresponding moment through rail-track coupled system dynamics computing method; c) calculating the vertical distance between wheel space trace points and the steel rail and finding out left and right side wheel track contact points; d) marking left and right side wheel track contact points at every moment, and connecting the points on left and right side wheels and the points on the steel rail, that is to say, describing the railway wheel track space dynamic contact state. The method shows the complex railway wheel track space dynamic contact state in a visual, simple and more actual way, realizes the study and analysis on the railway wheel track dynamic contact geometrical relation, provides reference for the optimum design and manufacture of the wheel tread and the steel rail profile, and has great technical application value.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com